SECTION 4B1 - DRIVELINE CONTROL SYSTEM

Service Precaution

Shift On The Fly System

Outline of Shift on The Fly System

Functions of Indicator Lamp

Diagnosis

Shift On The Fly Electrical Equipment

Axle Shaft Connection and Disconnection

Actuator Assembly

4WD Control Unit

4WD Control Unit Associated Parts

Removal

Installation

Shift On The Fly Controller

Shift On The Fly Controller and

Associated Parts

Removal

Installation

SERVICE PRECAUTION

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE

TO FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS

SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

SHIFT ON THE FLY SYSTEM

OUTLINE OF SHIFT ON THE FLY

SYSTEM

The Shift On the Fly system allows the driver to

electrica lly switch between 2 WD High and 4WD High a t

vehicle speeds up to 100km/h. Shifting between 4WD

High and 4WD Low is accomplished by moving the

transfer case lever with the vehicle stationary.

Manual or automatic lo cking hubs are not requir ed with

this system.

The SOF system controls the following operations:

1. Shifting the transfer front output gear (Connecting,

and disconnecting, the drive to the front propeller

shaft by a motor actuator).

2. Connecti ng fr ont wheels to, and di sc on necti ng them

from, the front axles by axle motor actuator.

3. Send a ‘4WD Engaged’ signal to the Electronic

Hydraulic Control Unit ( ABS Modulator)

4. Illuminate the 4WD Indicator on instrument panel.

5. Monitor system operation and provide a fault

indication to the driver if necessary.

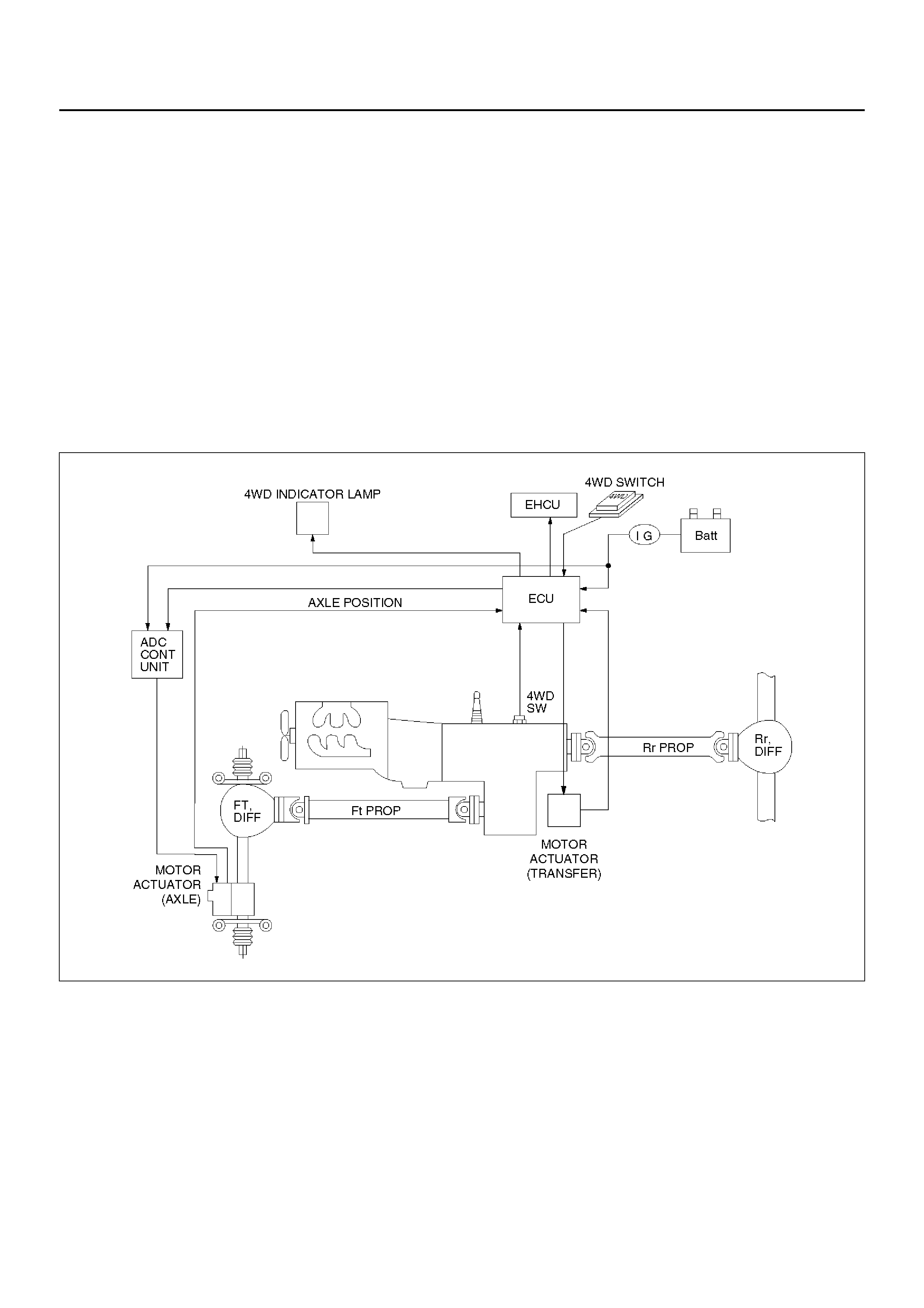

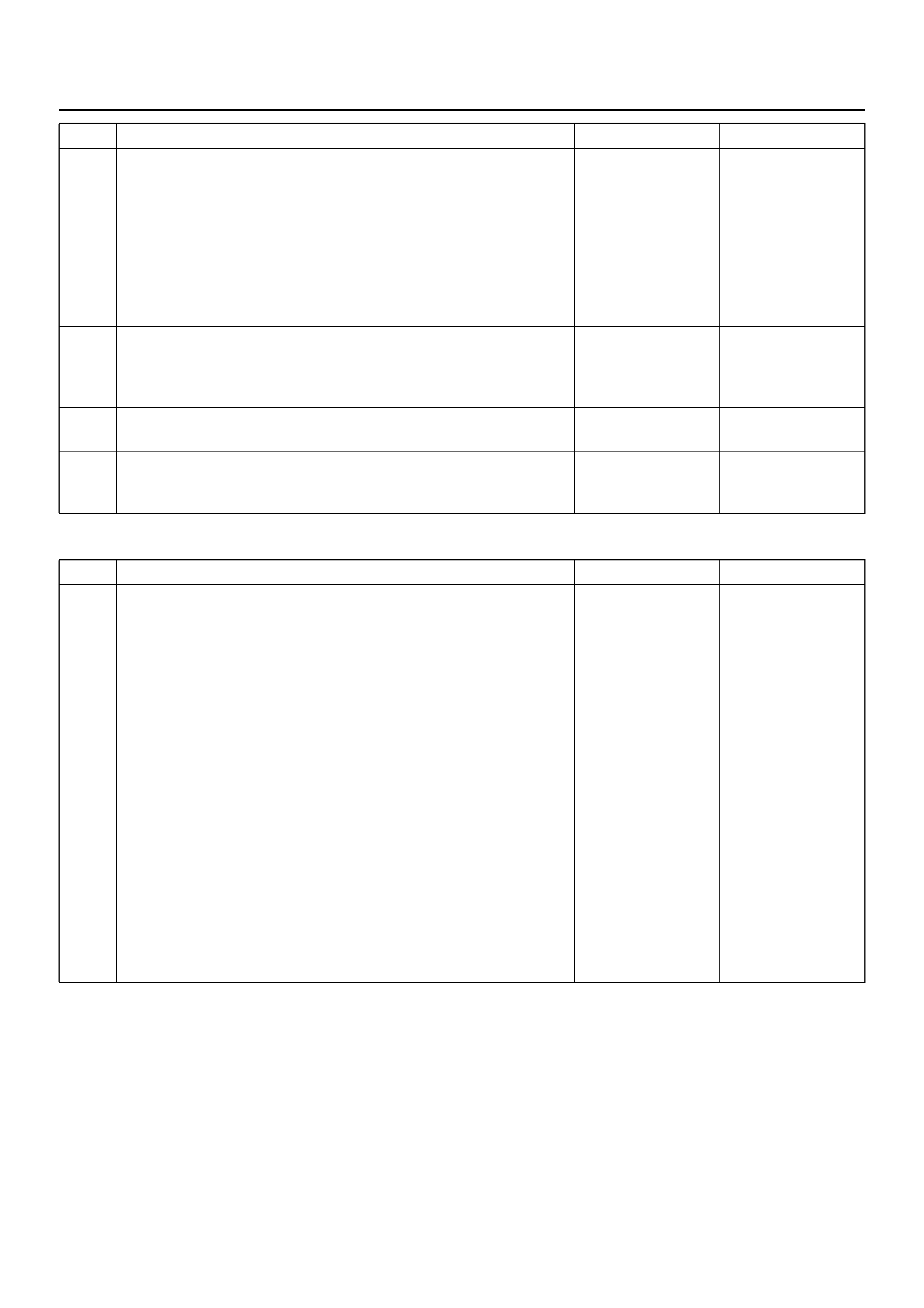

System Diagra ms

412RY00005

Normal Operation

The motor act uator, mou nted on the rear of th e transfer

rear case, is driven by a signal from the Instrument

Panel (IP) 4WD switch. The output signal of the transfer

position switch changes as the front output gear is

connected or disconnected from the front propeller

shaft. The Axle Disconnect Controller receives the the

signal from the transfer position switch and commands

the axle motor actuator to connect or disconnect the

front wheels to the front axles.

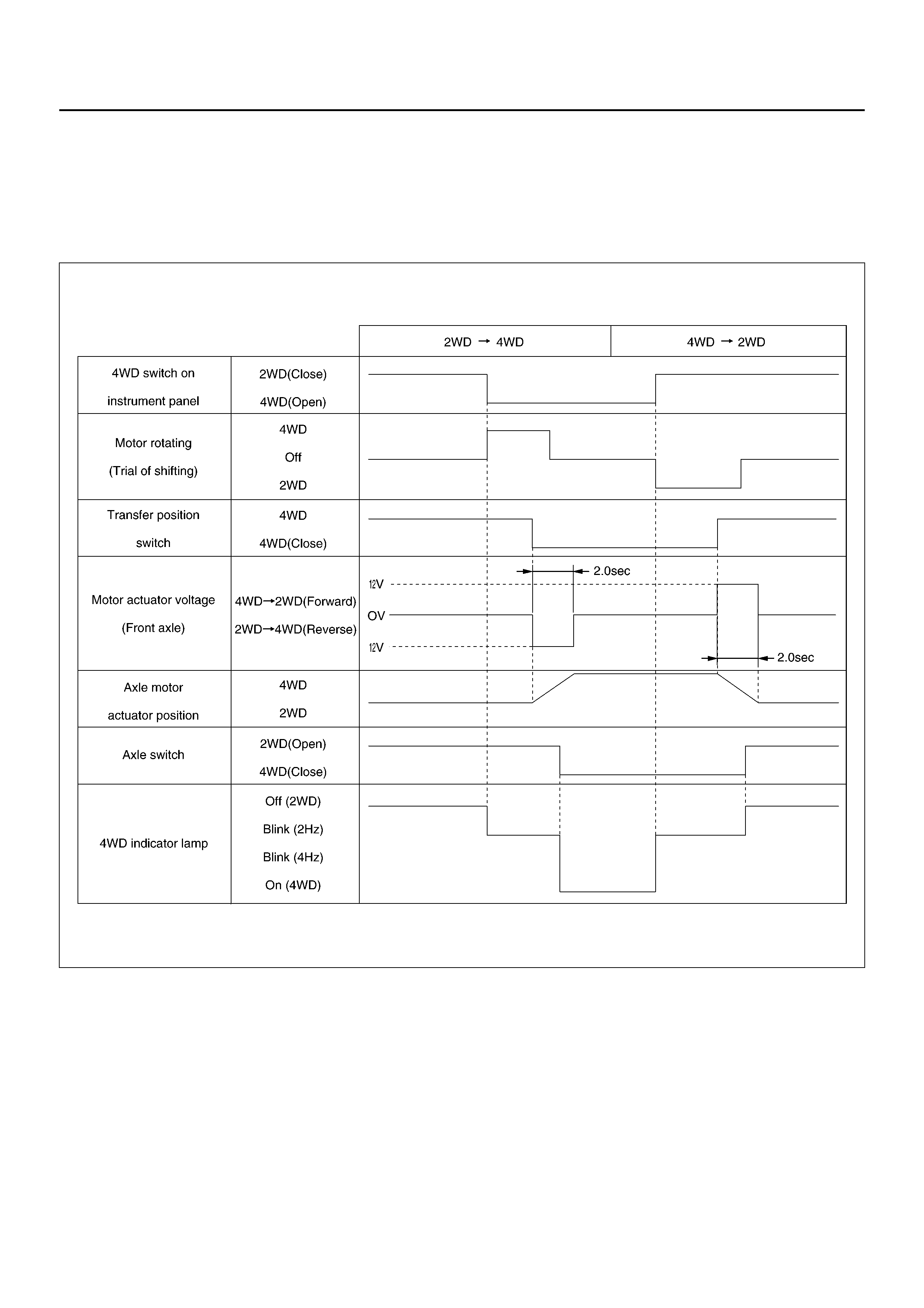

Time Chart of Shifting Under Normal Condition

F04R100004

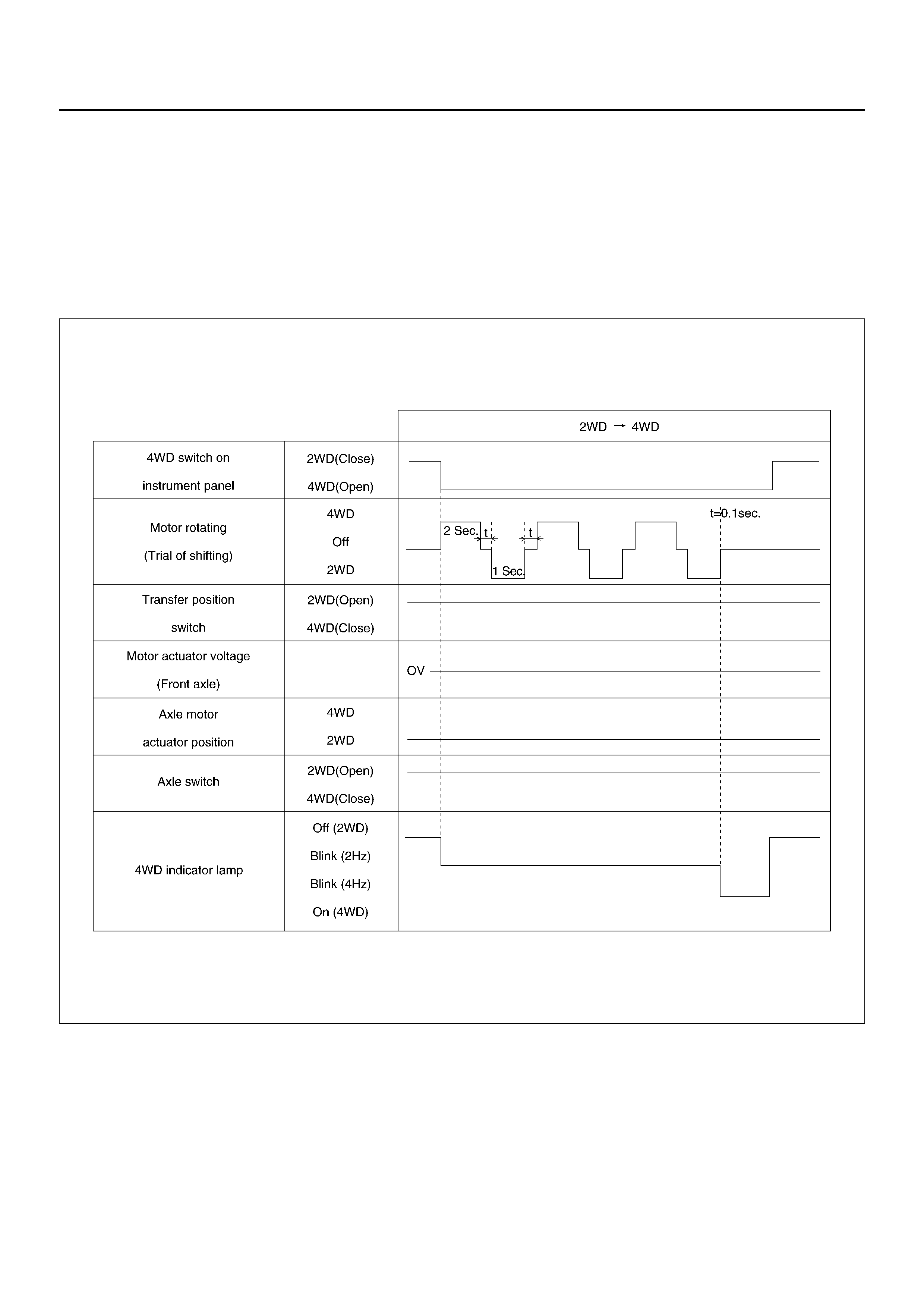

Retrial

The transfer motor actuator starts the transfer case gear

moving after a command is received from the Axle

Disconnect Controller. However, shifting may not occur

in severe cold wea ther or unde r high speed (>100 km/h)

conditions. When 2 seconds have passed since the

transfer gear shifting has commenced and the transfer

position switch does not activate (gear engagement is

not completed), the motor reverses its rotation for 1.2

secon ds and automa tically rep eats the operation aga in.

If after 3 attempts the transfer position switch does not

activate, the transfer motor actuator will be disabled and

the 4WD i ndicator lam p will blink 4 tim es per second to

alert the driver that the SOF operation has failed. The

lamp will continue to blink until the driver selects 2WD

mode.

Time Chart of Shifting Under Severe Conditions (retrial)

F04R100002

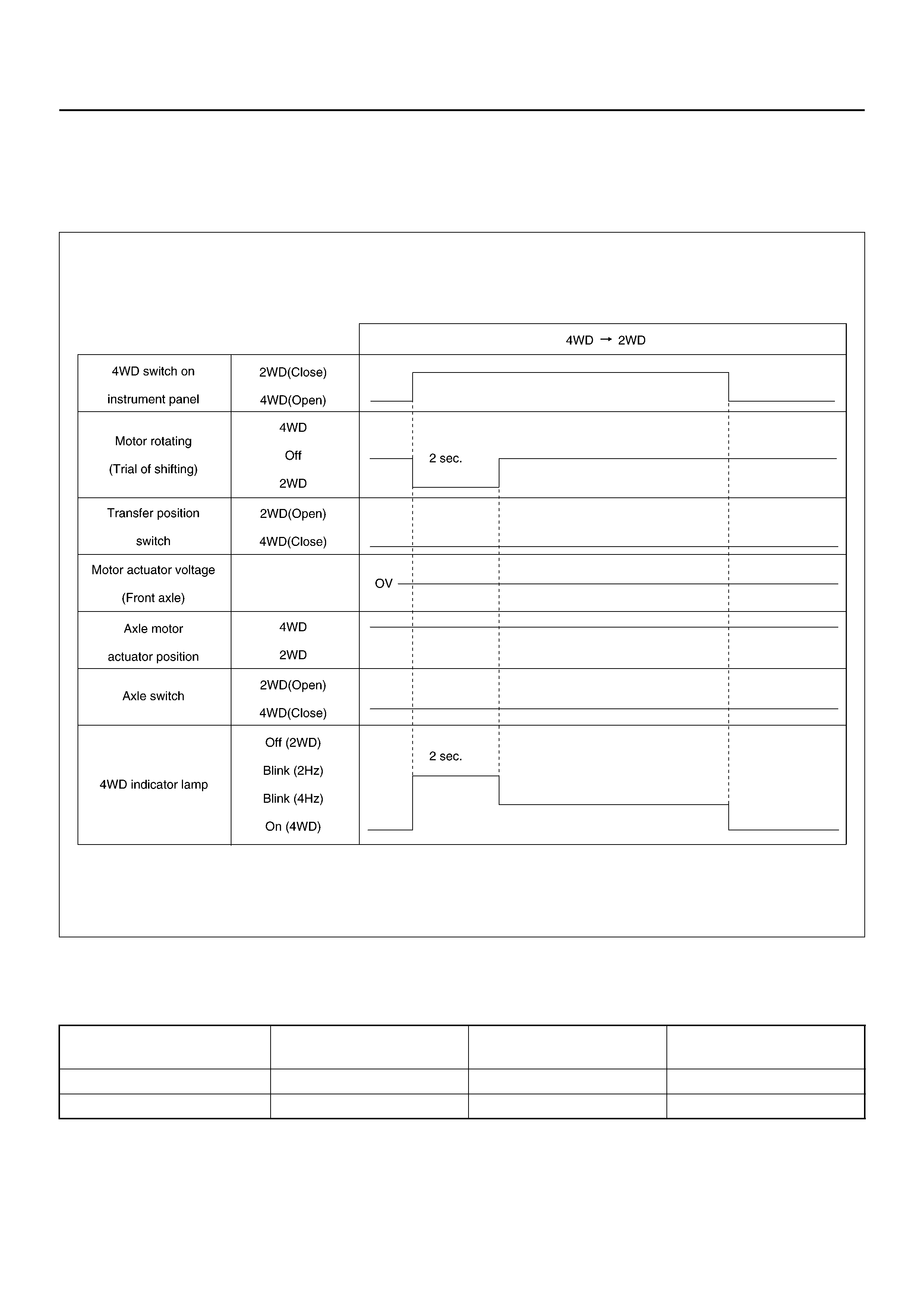

Wa rning at “4L" position : Shifti ng from 4WD to 2WD

while in “4L" mode is not possible. While in “4L" mode,

the transfer position switch cannot be deactivated.

Should the 4WD switch be pressed while in "4L", then

the 4WD i ndicator lam p will blink 4 tim es per second to

alert the driver of the incorrect operation and the 4WD

to 2WD mode will be cancelled.

Time Chart of Shifting from 4WD to 2WD at “4L" Condition

F04R100003

4WD out signal to the Electronic Hydraulic Control

Unit : The SOF Axle Disconnect Controller transmits a

4WD output signal to the Electronic Hydraulic Control

Unit (ABS Modulator). The frequency of signal

transmitted will depend on the drive range selected.

Based upon this signal, the calibration of the ABS

system will be varied to suit the selected driving mode.

4WD Output Sig nal

(Period) Vehicle Condition Transfer Case Position

switch Front Axle Switch

120 ms 2WD 2WD (Open) 2WD (Open)

240 ms 4WD 4WD (Close) 4WD (Close)

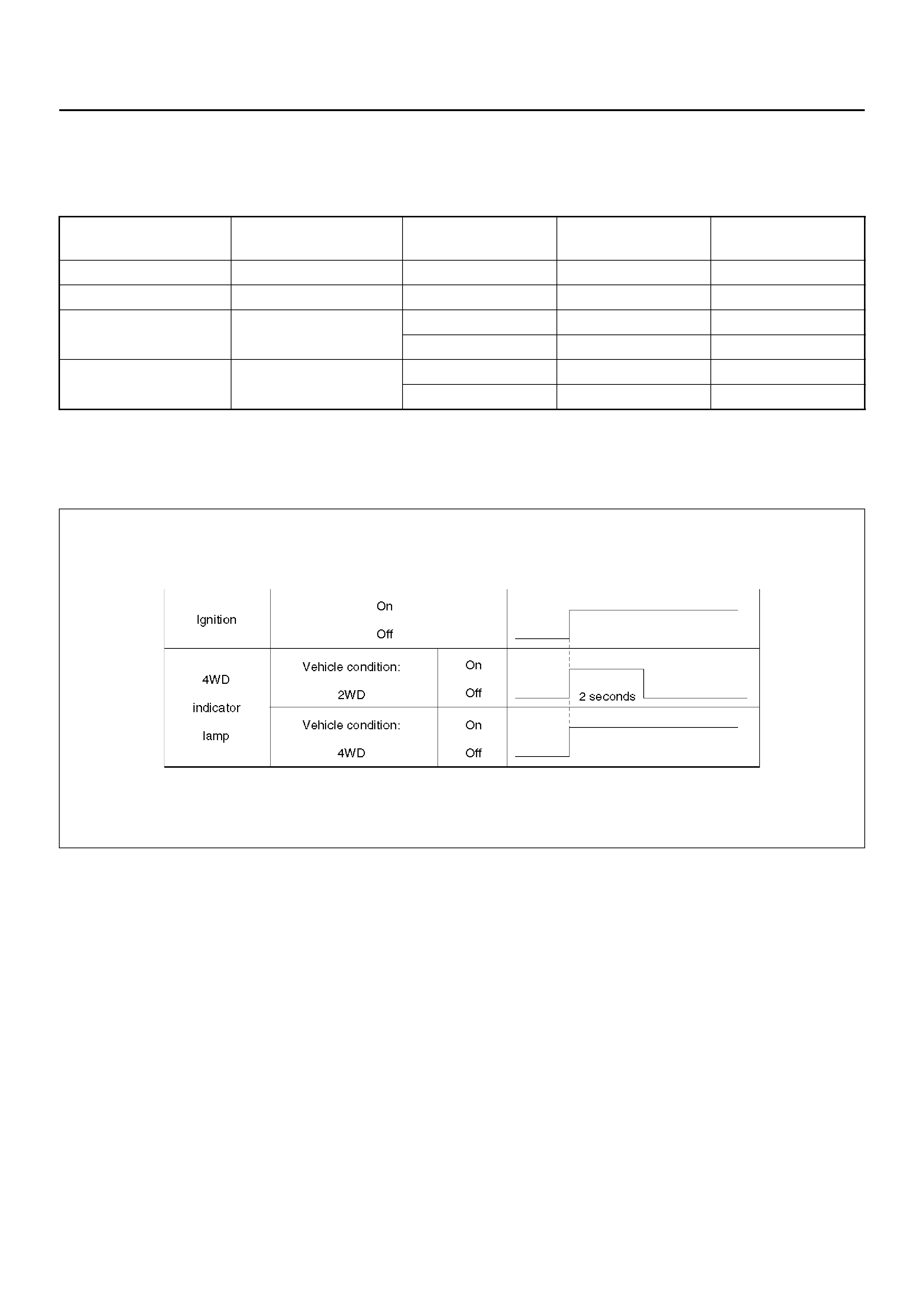

FUNCTIONS OF INDICATOR LAMP

Indication of vehicle condition :

Indicator lamp is controlled by the Axle Disconnect

Controller and indicates vehicle conditions as below.

Bulb check :The indicator lamp is illuminated for 2

seconds when the ignition is first turned on.

Time Chart of Bulb Checking

F04RW004

Retrials from 2WD to 4WD :Shifting from 2WD to 4WD

may not occur when in severe cold weather

conditions or under high speed conditions. Should this

occur, the 4WD indic ato r lamp will fla sh cont ino us ly at a

rate of 4 times per second until the driver disengages

the 4WD operation (see Retrial for more information).

Indicator Vehicle condition 4WD switch Transfer Position

Switch Front Axle Switch

Off 2WD Off (Close) 2WD (Open) 2WD (Open)

On 4WD On (Open) 4WD (Close) 4WD (Close)

Flash 2 times per

second (2Hz) Operating On (Open) 4WD (Close) 2WD (Open)

Off (Close) 2WD (Open) 4WD (Close)

Flash 4 times per

second (4Hz) Shift inoperative On (Open) 2WD (Open) 2WD (Open)

Off (Cl ose) 4WD (Close) 4WD (Close)

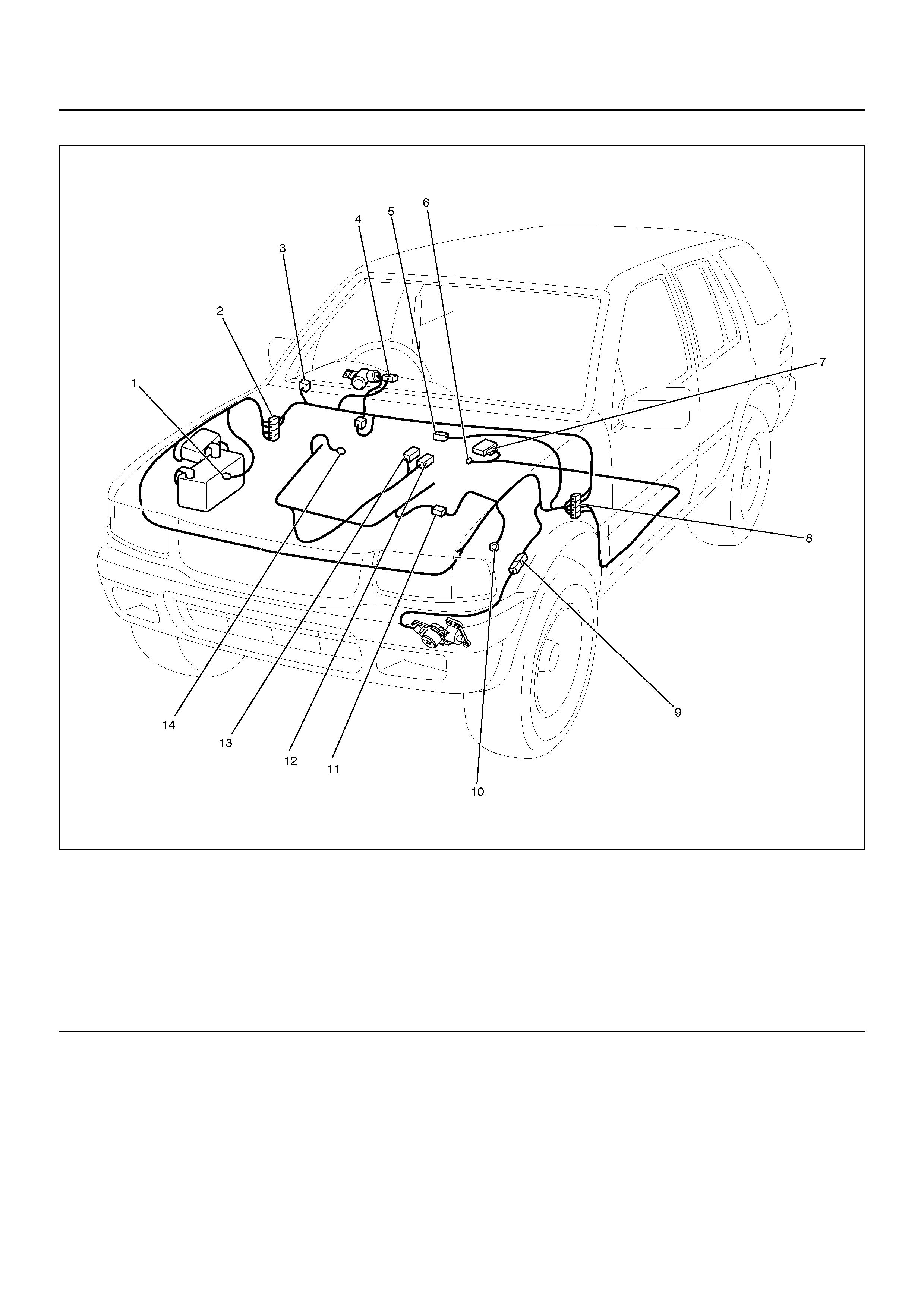

Parts Location

828R100003

EndOFCallout

Legend

(1) C–36

(2) H–18

(3) I–19

(4) I–1

(5) C–49

(6) B–8

(7) B–19

(8) H–15, H–17

(9) C–55

(10) C–16

(11) H–6

(12) E–60

(13) E–56, E–57

(14) E–30

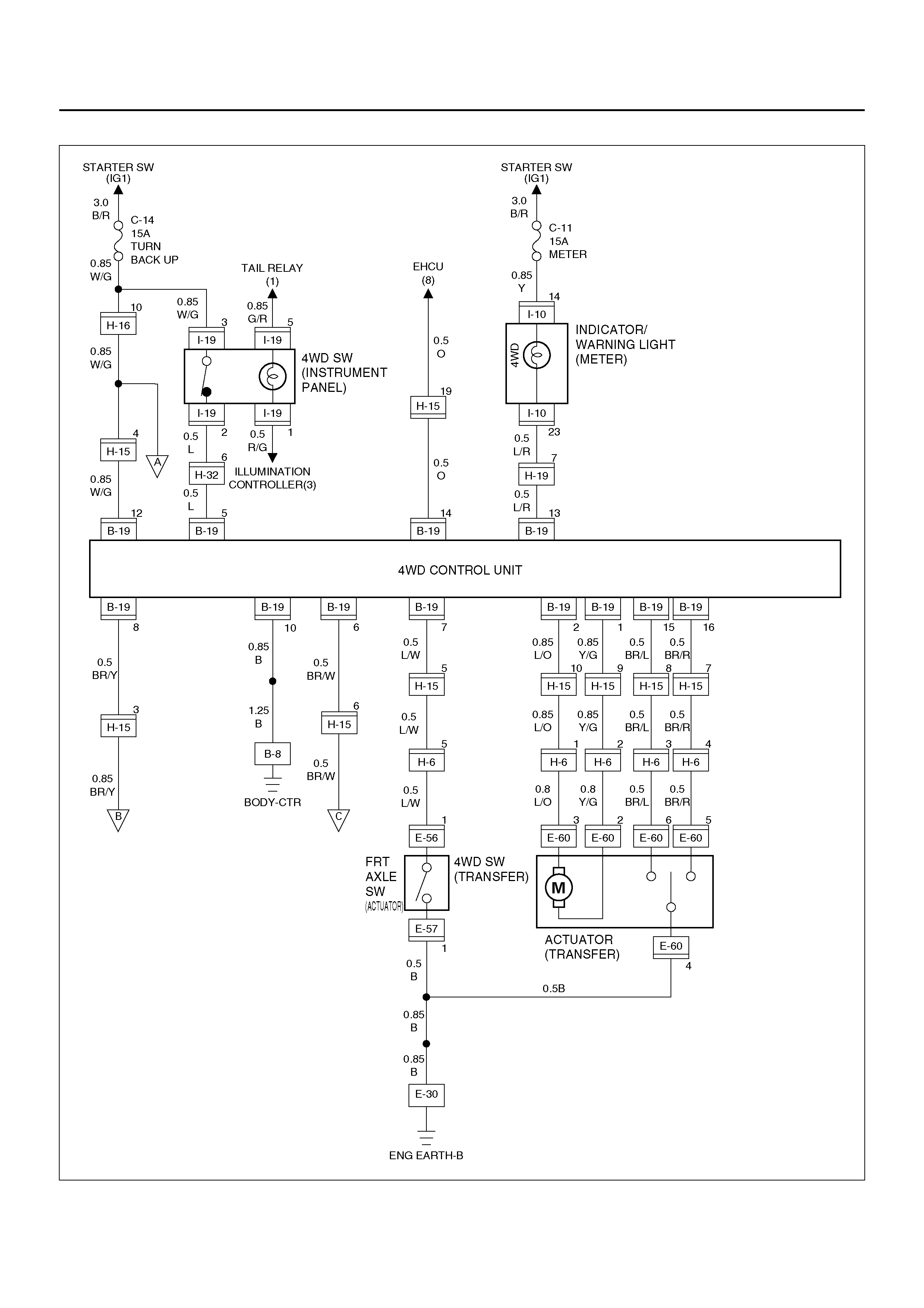

Wiring Diagram

D04R100026

D04R100027

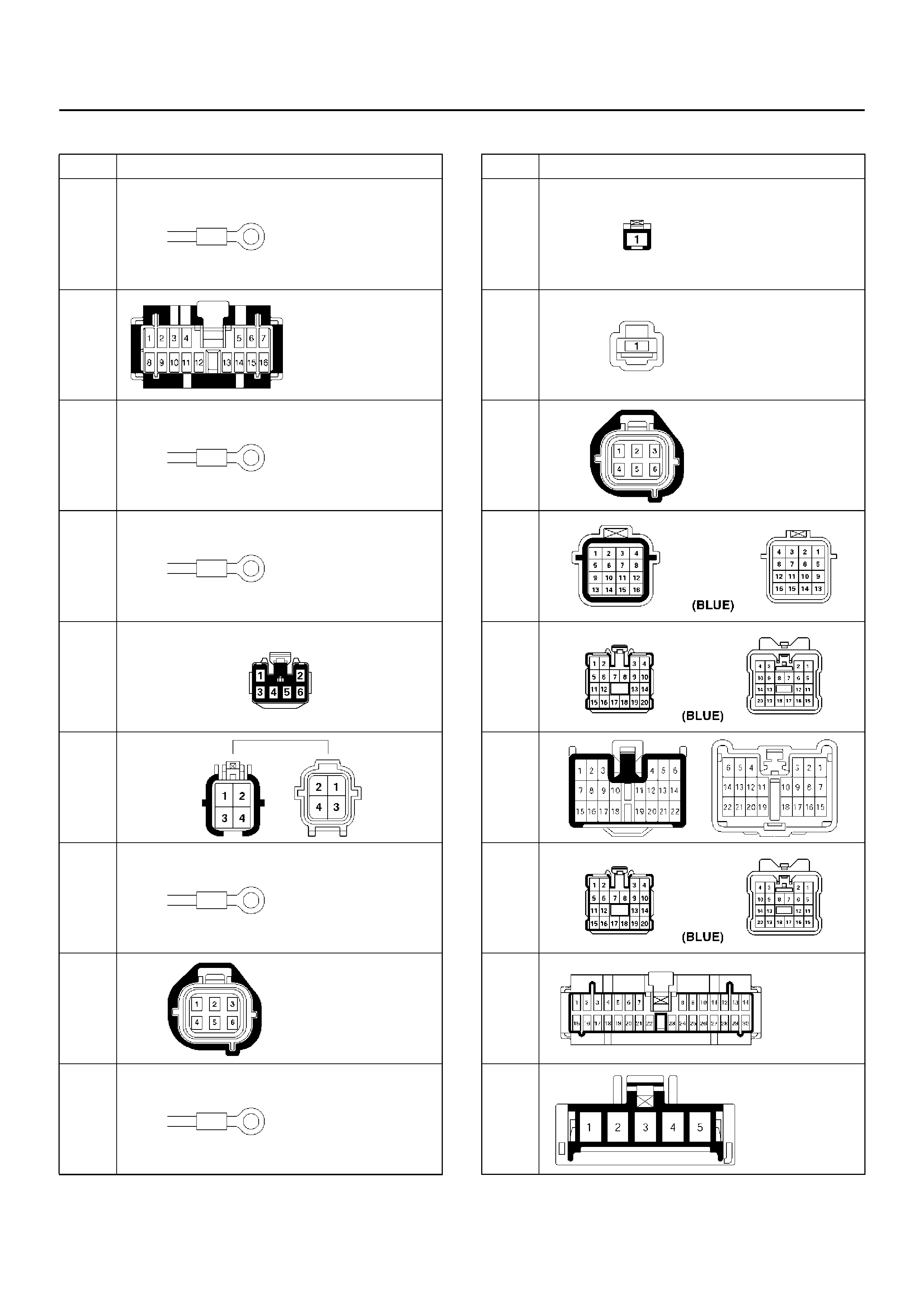

Connector List

No. Connector face

B-8

B-19

C-16

C-36

C-49

C-55

E-4

E-19

E-30

E-56

E-57

E-60

H-6

H-15

H-17

H-18

I-1

I-19

No. Connector face

DIAGNOSIS

Identifying the problem

When Switching from 2WD to 4WD

1. Flashing of the 4WD indicator changes from 2

times per second (2Hz) , to 4 times per second

(4Hz).

When a high synchronization load is encountered,

the motor actuator will make up to 3 attempts to shift

the tran sfer gear. The 4WD indicator lamp will flas h

at 2Hz whi le th e m oto r actuator attemp ts the s hift. If

after the 3rd att empt, the shift is not co mpleted, the

4WD indicator lamp will begin to flash at 4Hz and

the motor actuator will return to 2WD mode.

A high synchronization load occurs:

• At severe low temperatures.

• A high rotational difference in speed occurs

between the front wheels and the front axles

during cornering .

Solution 1: Attempt to select 4WD mode again at

a lower speed or when the vehicle is stationary.

2. The 4WD indicator continues flashing at 2Hz for

more than 11.5 seconds.

When there is rotational difference in speed

between the front wheels and axles, the front

wheels and the front axles may have difficulty

engaging. The flashing of the 4WD indicator lamp at

2Hz will indicate that the transfer case is shifting into

the 4WD mode. Shifting into 4WD mode is

impossible if a high rotational difference in speed

occurs between the front whe els and the front axles

during cornering, resulting in the indicator flashing

for an extended period.

Solution 2: If the vehicle is moving, drive the

vehicle straight while accelerating and

decelerating, and if the vehicle is at a stop,

move the vehicle forward an d backward fo r 2 to

3 met res.

When Switching from 4WD to 2WD

1. The 4WD indicator lamp continues to flash 2

times per second.

When switching from 4WD to 2WD, the 4WD

indicator lamp continues to flash until both shifting of

the transfer gear and disconnecting the front wheels

are completed. When drive line is subject to a high

torque load, the shifting transfer gear and

disconnecting of the front wheels are impossible.

In this case , remo val o f the torque load on t he d rive

line makes the shifting transfer gear and

disconnecting front wheels possible.

Solution 3: If the vehicle is moving, drive the

vehicle straight while accelerating and

decelerating, and if the vehicle is at a stop,

move the vehicle forward an d backward fo r 2 to

3 met res.

2. When the 4WD indicator lamp flash pattern changes

from 2Hz to 4Hz.

Check the position of the transfer lever. Is it in the

“4L" position? Shifting from 4WD to 2WD while at

“4L" will not occur.

Solution 4: Push the 4WD switch ON (to 4WD),

then shift the transfer lever to the “High"

position and then push the 4WD switch OFF (to

engage to 2WD).

Fault diagnosis based on the status of 4WD Indicator Lamp, 4WD Switch and T/F Change

Lever

A diagnostic flow chart is shown below. If after performing the diagnosis and a condition still exists, then there may be

a fault in the Axle Disconnect Controller. The Axle Disconnect Controller will need to be replaced and perform the

diagnostic flow chart again.

Fault on Switching from 2WD to 4WD

1. When the 4WD indicator lamp flash pattern changes from 2Hz to 4H z after perf orming “Solution 1."

The mo tor ac tua tor or th e tr ansfer case a ssem bly m ay be i nop erati ve . Rem ove an d be nc h te stth e m otor ac tu ator.

Make any necessary repairs and perform “Solution 1" again. Then disassemble and inspect the transfer case

assembly. Repair or replace as needed. If after the repairs, the condition still exists, then replace the Axle

Disco nne ct Control le r.

2. When the 4WD indicator lamp does not flash or light up when switching from 2WD to 4WD.

Step Action Yes No

1Is ignition turned on? Go to Step 2

Turn on the ignition

and trace this chart

from start.

2Does the 4WD indicator lamp light up during the two second

initialization after the ignition is turned on?

Go to Step 3

Failed indicator

lamp or

disconnected

harness wire.

Perform the

diagnostic chart

from step 1 after

repair or

replacement.

3Is the 4WD switch activated from 2WD to 4WD mode? Short-circuit

(body short) on

harness of the

4WD switch.

Inoperative

4WD switch

(stuck closed

condition).

T rac e this cha rt

fr om th e st ep 1

after repair or

replace. Push the 4WD

switch to 4WD.

3. When the 4WD Indicator lamp continues to flash after performing Solution 2.

Step Action Yes No

1 Check tire pressure and tire wear.

Were problems found? Correct the tire

pressure and

replace worn tires

then perform

“Solution 2." Go to Step 2

2Can the transfer lever be operated from High to 4L or vice versa?

Go to Step 3

If the motor

actuator

harnes s was

disconnected,

then repair and

repeat ste p 1.

If the motor

actuator is

inoperative,

replace the

motor actuator

and repeat step

1.

If the transfer

case was not

operating

correctly , repair

as neccessary

and repeat step

1.

3 Confirm that the transfer swit ch is operatin g correctly. Replace if

necessary. Go to Step 4 —

4 1. Disconnect the connector C–47.

2. Turn on the starter switch

3. Measure voltage between the connector C–47 terminals 4

and 3, when 4WD sw itch on instrum ent panel is swit ched on

2WD and 4WD position.in

Is the motor actuator voltage on the axle as “Time Chart of

Shifting Under Normal Condition" Refer to the page (4B–3). Go to Step 8 Go to Step 5

5 1. Inspect the wiring for poor electrical connections, open or

short to ground between the connector-terminal E56–1 and

B19–7, E57–1 and ground, C47–1 and B19–6, C47–2 and

ground, H1 8–1 and B1 9–1 2, B 19– 8 an d C49 –3, H17– 19 a nd

C49–3, C49–1 and C47–4, C49–2 and C47–3, and C49–6

and ground.

2. Repair the circuit.

Is the motor actuator voltage on the axle as in “Time Chart of

Shifting Under Normal Condition" Refer to the page (4B–3). Go to Step 8 Go to Step 6

6 Check the axle switch continuity between the connector C–47

termina ls 1 and 2.

Is the axle switch open or closed as in “Time Chart of Shifting

Under Normal Condition". Refer to the page (4B–3). Go to Step 8 Go to Step 7

7 Replace the axle motor actuator. Go to Step 8 —

8 Reconnect all components, ensure all components are properly

mounted.

Was this step finished Trace this chart

from the start. Go to Step 8

Fault on Switching from 4WD to 2WD

1. Indicator lamp on continuously.

2. When the indicator lamp continues to flash at

2Hz after performing Solution 3.

Step Action Yes No

1Does the indicator lamp turn off at ignition off? Go to Step 2 Short circuit of the

indicator harness.

2Is the 4WD switch on 2WD position? Disconnection on

the 4WD switch

harness or

breakdown of the

4WD switch in

open state. Trace

this chart from the

start after repair or

replace.

Turn the 4WD

switch to 2WD

position. Trace this

chart from the

start.

Step Action Yes No

1 Check the air pressure and wear on all tires.

Were problems found? Perform “Solution

3" after correcting

the tire air pressure

and replacing worn

tires. Go to Step 2

2Can the transfer lever be operated from High to 4L or vice versa? If the motor

actuator

harness was

disconnected,

then repair as

needed and

repeat step 1.

If the transfer

case was not

working

properly, then

repair as

needed and

repeat step 1.

If the motor

actuator is

inoperative,

then replace the

motor actuator

and repeat step

1. Go to Step 3

3 1. Disconnect the connector C–47.

2. Turn on the starter switch

3. Measure voltage between the connector C–47 terminals 4

and 3, when 4WD sw itch on instrum ent panel is swit ched on

2WD and 4WD position.

Is the motor actuator voltage on the axle as “Time Chart of

Shifting Under Normal Condition" aforementioned? Refer to the

page (4B–3). Go to Step 7 Go to Step 4

3. Indicator flash changes to 4Hz after Solution 4 is

carried out.

4 1. Inspect the wiring for poor electrical connections, open or

short to ground between the connector-terminal C47–1 and

B19–6, C47–2 and ground, H18–1 and B19–12, B19–8 and

C49–3, H17–19 and C49–3, C49–1 and C47–4, C49–2 and

C47–3, and C49–6 and gro und.

2. Repair the circuit.

Is the motor actuator voltage on the axle as “Time Chart of

Shifting Under Normal Condition" aforementioned? Refer to the

page (4B–3). Go to Step 7 Go to Step 5

5 Check the axle switch continuity between the connector C–47

termina ls 1 and 2.

Is the axle swi tch ope n or close as “Time Chart of Shifting Under

Normal Condition" aforementioned? Refer to the page (4B–3). Go to Step 7 Go to Step 6

6 Replace the axle motor actuator. Go to Step 7 —

7 Reconnect all components, ensure all components are properly

mounted.

Was this step finished Trace this chart

from the start. Go to Step 7

Step Action Yes No

Step Action Yes No

1Can the transfer lever be operated from High to 4L or vice versa? If the motor

actuator

harness was

disconnected,

then repair as

needed and

repeat step 1.

If the motor

actuator is

inoperative,

then replace the

motor actuator

and repeat step

1.

If the transfer

case was not

working

properly, then

repair as

needed and

repeat step 1.

Faults on the ECU.

Trace this chart

from the start after

replace.

SHIFT ON THE FLY ELECTRICAL EQUIPMENT

AXLE SHAFT CONNECTION AND DISCONNECTION

412RY00035

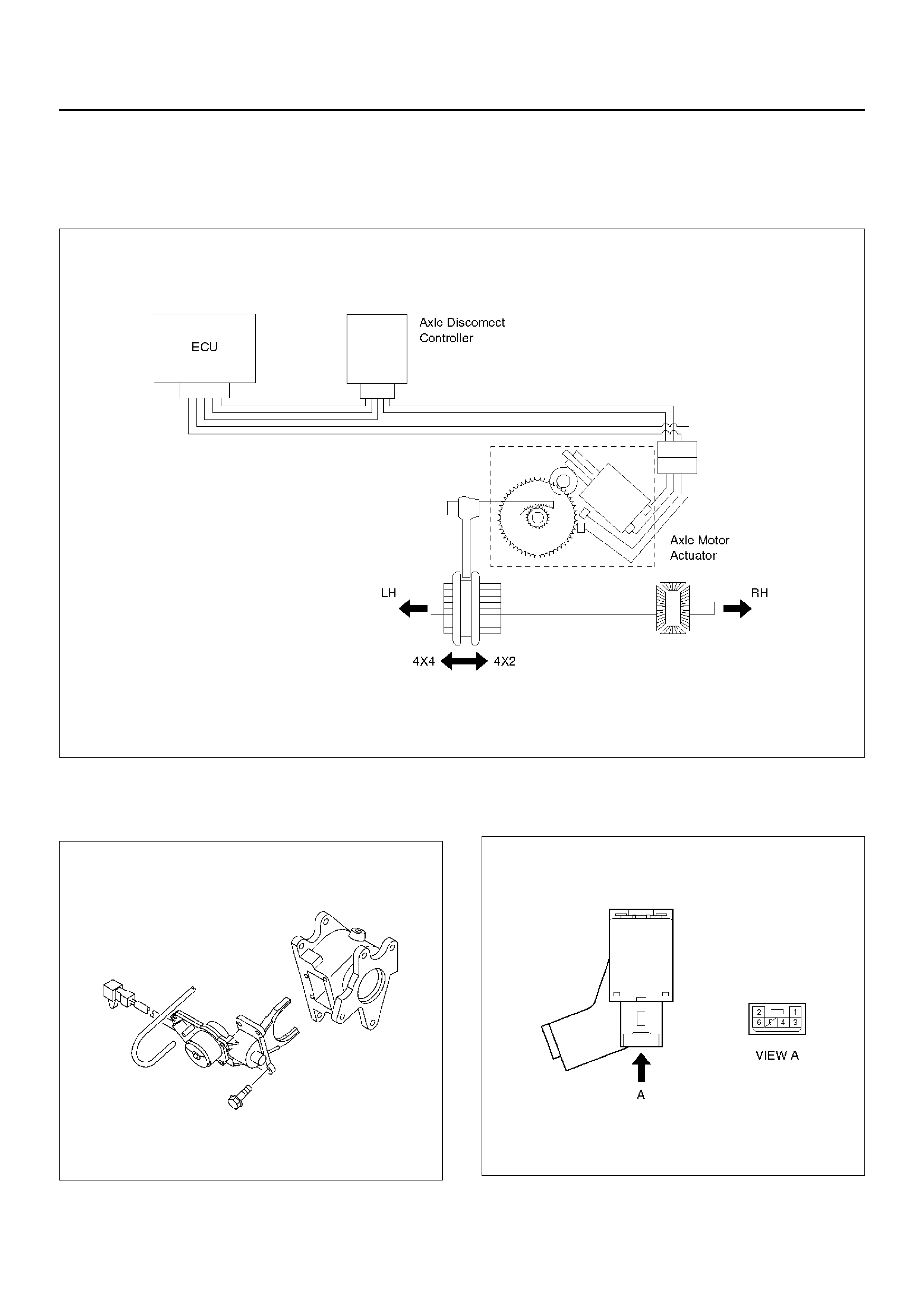

ACTUATOR ASSEMBLY

412RY00004

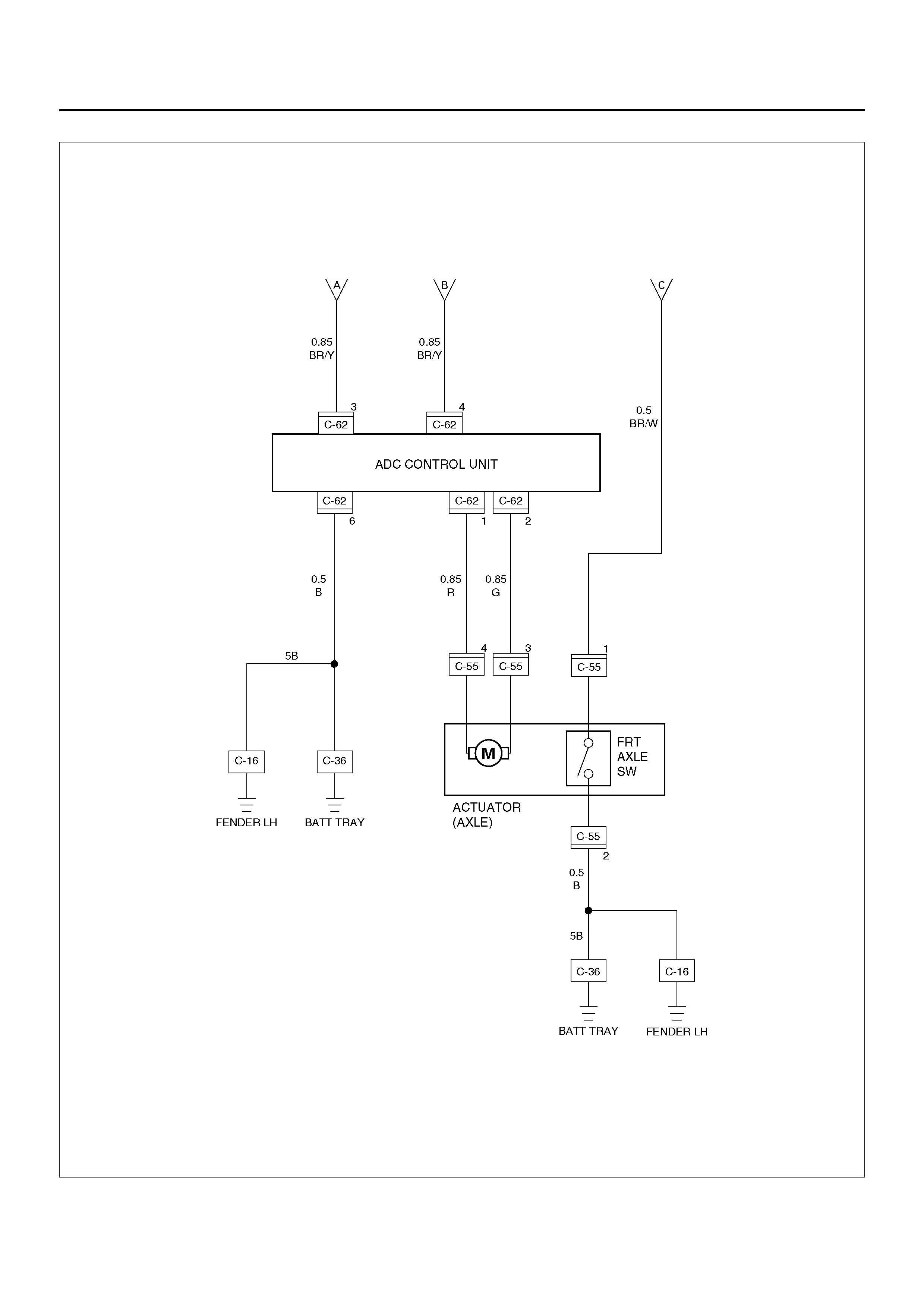

Axle Disconnect Controller

828RY00009

828RY00010

EndOFCallout

1. Connect 12V with terminal (3) and the ground with

the terminal (6).

2. Send the signal to the terminal (4)

2WD → 4WD less than 2.4V

4WD → 2WD more than 9.0V

3. Confirm the output signal from the terminals (1) &

(2) (2 seconds output)

4. If the trouble occurs afther above test, charge the

Axle Disconnect Controller to the new one.

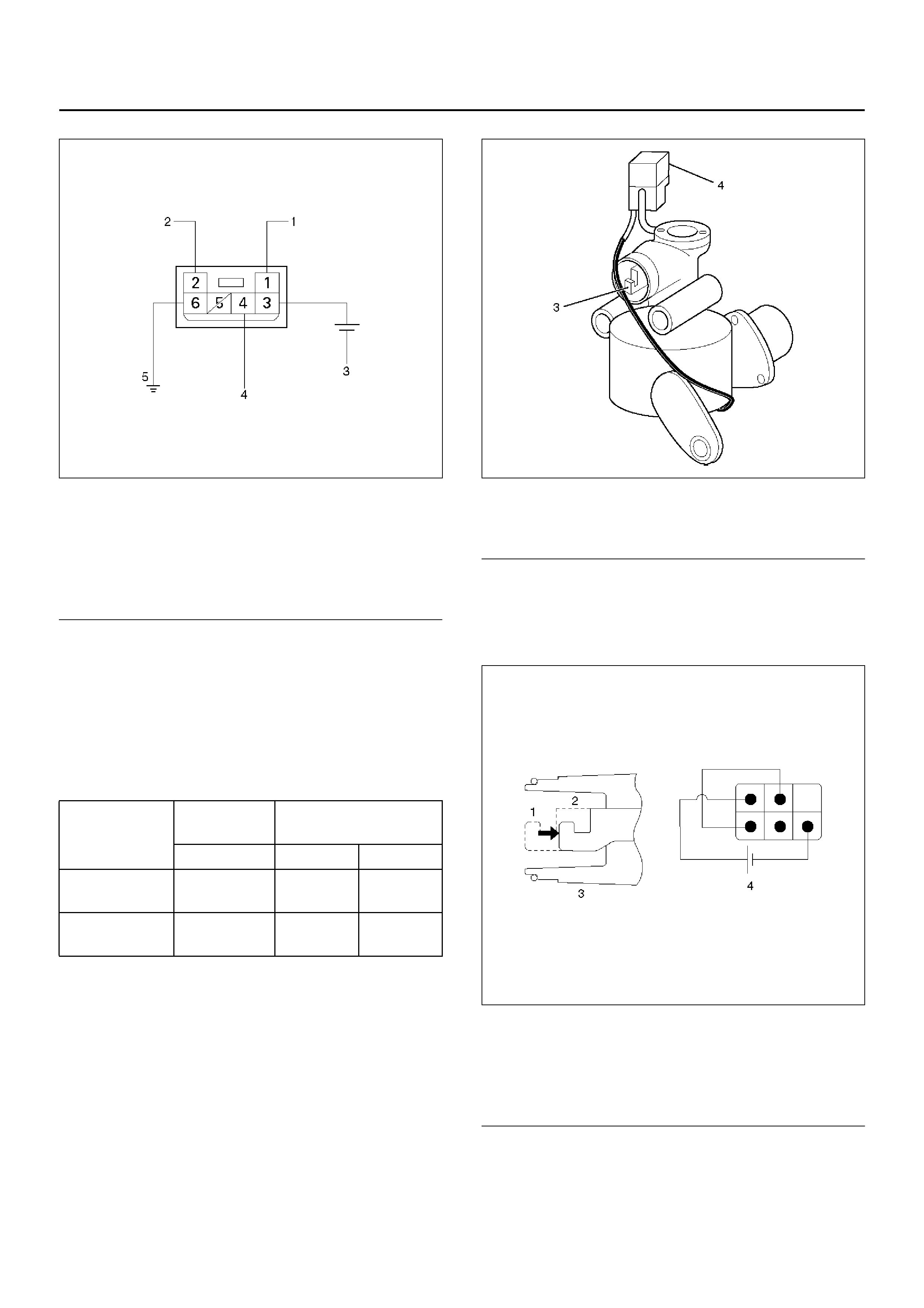

Motor Actuator Assembly (Tra nsfer)

Inspect the function of the motor actuator assembly as

follows:

1. Disassemble the motor actuator from transfer rear

case.

412RW037

EndOFCallout

2. Connect the terminals as shown in figure.

Shift rod of the motor actuator moves and stops

at 4WD position.

412RW038

EndOFCallout

Legend

(1) Output Signal

(2) Output Signal

(3) 12V

(4) Input Signa l

(5) GND

INPUT

SIGNAL OUTPUT SIGNAL (2

seconds)

412

2WD → 4WD Les s than

2.4V 0V 12V

4WD → 2WD More than

9.0V 12V 0V

Legend

(3) Shift Rod

(4) Connector

Legend

(1) 2WD

(2) 4WD

(3) Shift Rod

(4) Connector

3. Connect the terminals as shown in figure.

Shift rod of the motor actuator moves and stops

at 2WD position.

412RW039

EndOFCallout

4. If 2) and 3) fail, replace with a new motor actuator.

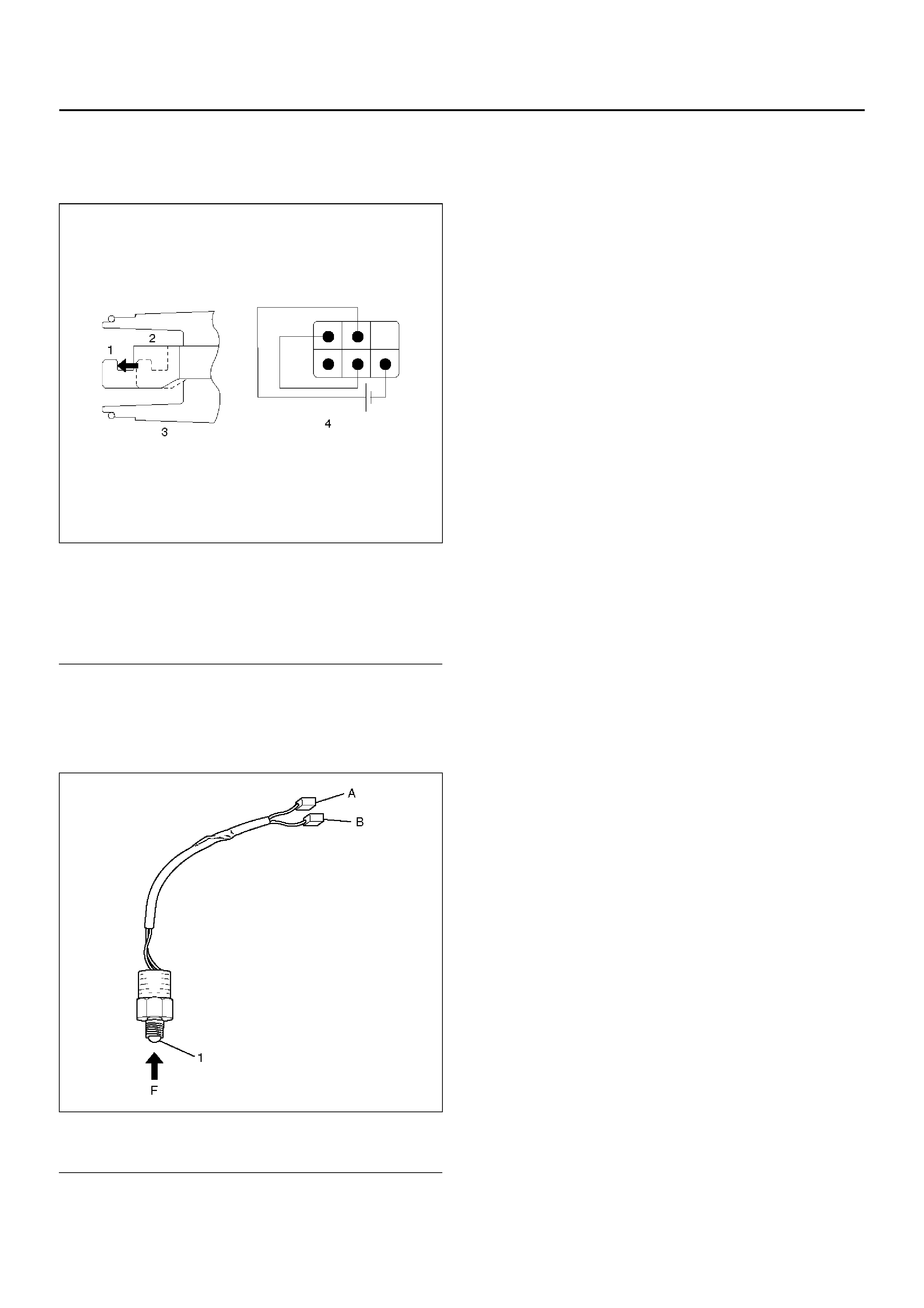

Tran sfer Position Switch

412RW040

EndOFCallout

1. With ball being free.

A–B : There is continuity.

2. With ball forced into the switch.

A–B : No continuity.

3. If 1) and 2) fail, replace with a new switch.

Legend

(1) 2WD

(2) 4WD

(3) Shift Rod

(4) Connector

Legend

(1) Ball

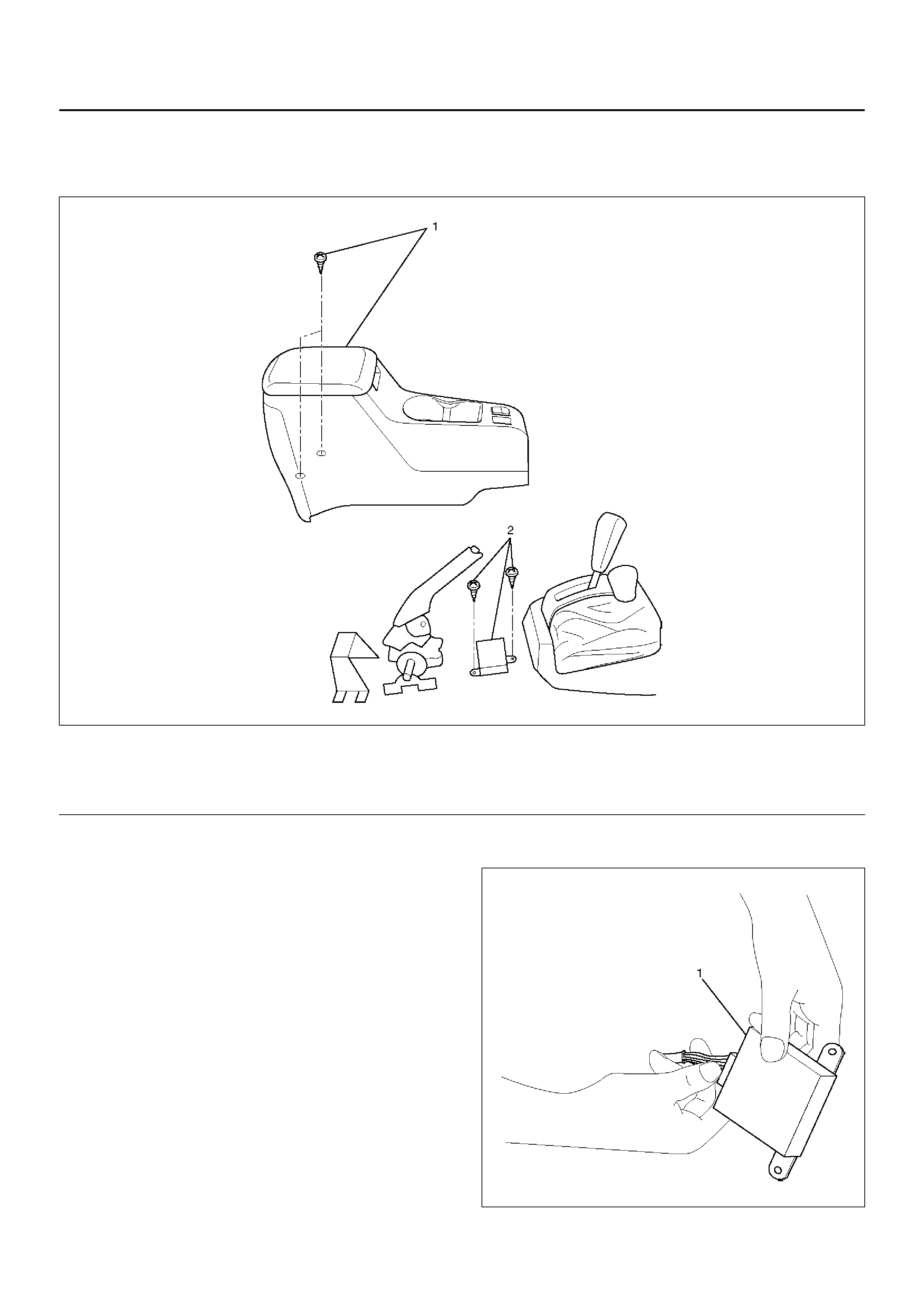

4WD CONTROL UNIT

4WD CONTROL UNIT ASSOCIATED PARTS

412RW042

EndOFCallout

REMOVAL

1. Remove center console assembly.

Refer to Interior Trim in Body and Accessories

section.

2. Remove two screws and harness connector (1)

from 4WD control unit.

412RW041

Legend

(1) Center Console Assembly (2) 4WD Control Unit

Legend

(1) Harness Connector

INSTALLATION

1. Connect harness connector, then install 4WD

contr ol uni t.

2. Install center console assembly.

SHIFT ON THE FLY CONTROLLER

SHIFT ON THE FLY CONTROLLER AND ASSOCIATED PARTS

828RY00003

EndOFCallout

REMOVAL

1. Disconnect the battery ground cable.

2. Remove the front console assembly.

Refer to Console in Body and Accessories section.

3. Disconnect the connector from the controller.

4. Remove the nut.

5. Remove the controller.

INSTALLATION

To install, follow the rem oval st eps in t he revers e orde r,

noting the following points.

Torque: Nut (1) 8 N·m (0.8 kg·m/69 Ib in)

Legend

(1)

(2) Nut

SOF Cont roll er (3) Connector