SECTION 4C - DRIVE SHAFT SYSTEM

Service Precaution

General Description

Diagnosis

Front Hub and Disc

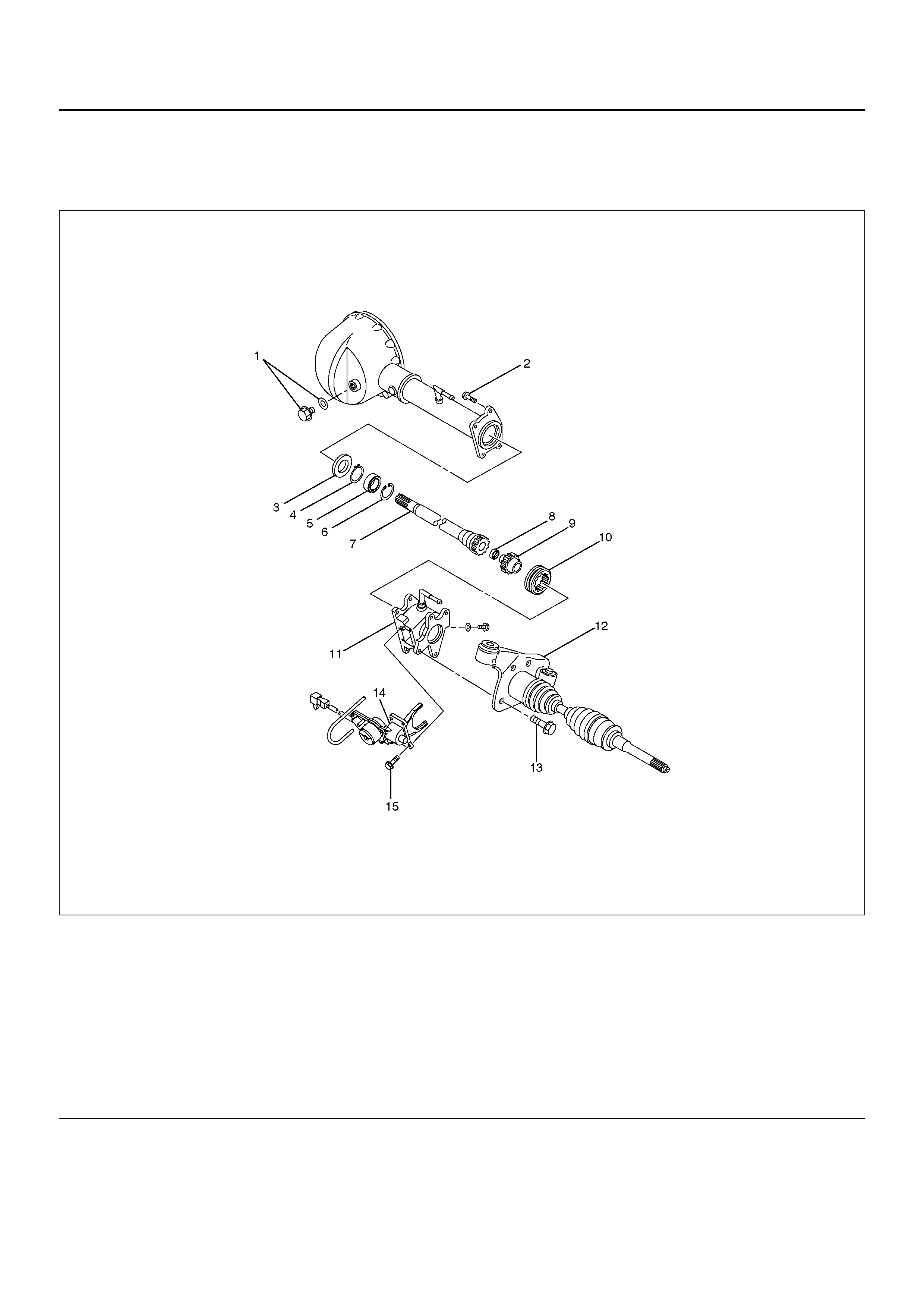

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Front Drive Shaft Joint

Front Drive Shaft Joints Replacement

Front Axle Drive Shaft

Front Axle Drive Shaft

and Associated Parts

Disassembly

Inspection And Repair

Bushing Replacement

Reassembly

Shift On The Fly System

Shift On The Fly System

and Associated Parts

Disassembly

Inspection And Repair

Reassembly

Main Data and Specifications

Special Tools

Propeller Shaft

General Description

Universal Joint

Diagnosis of Propeller Shaft

and Universal Joint

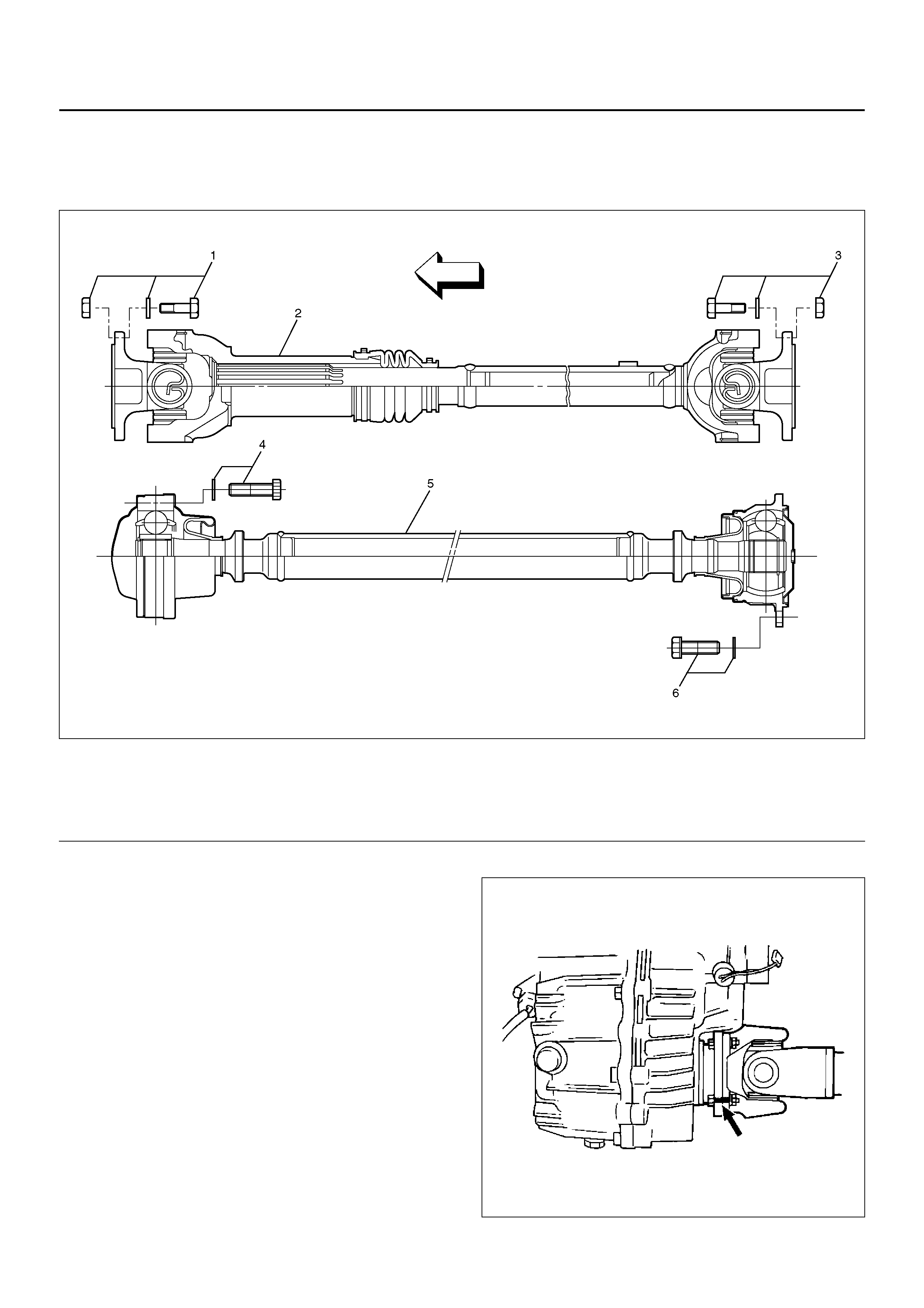

Front Propeller Shaft

Front Propeller Shaft

and Associated Parts

Removal

Installation

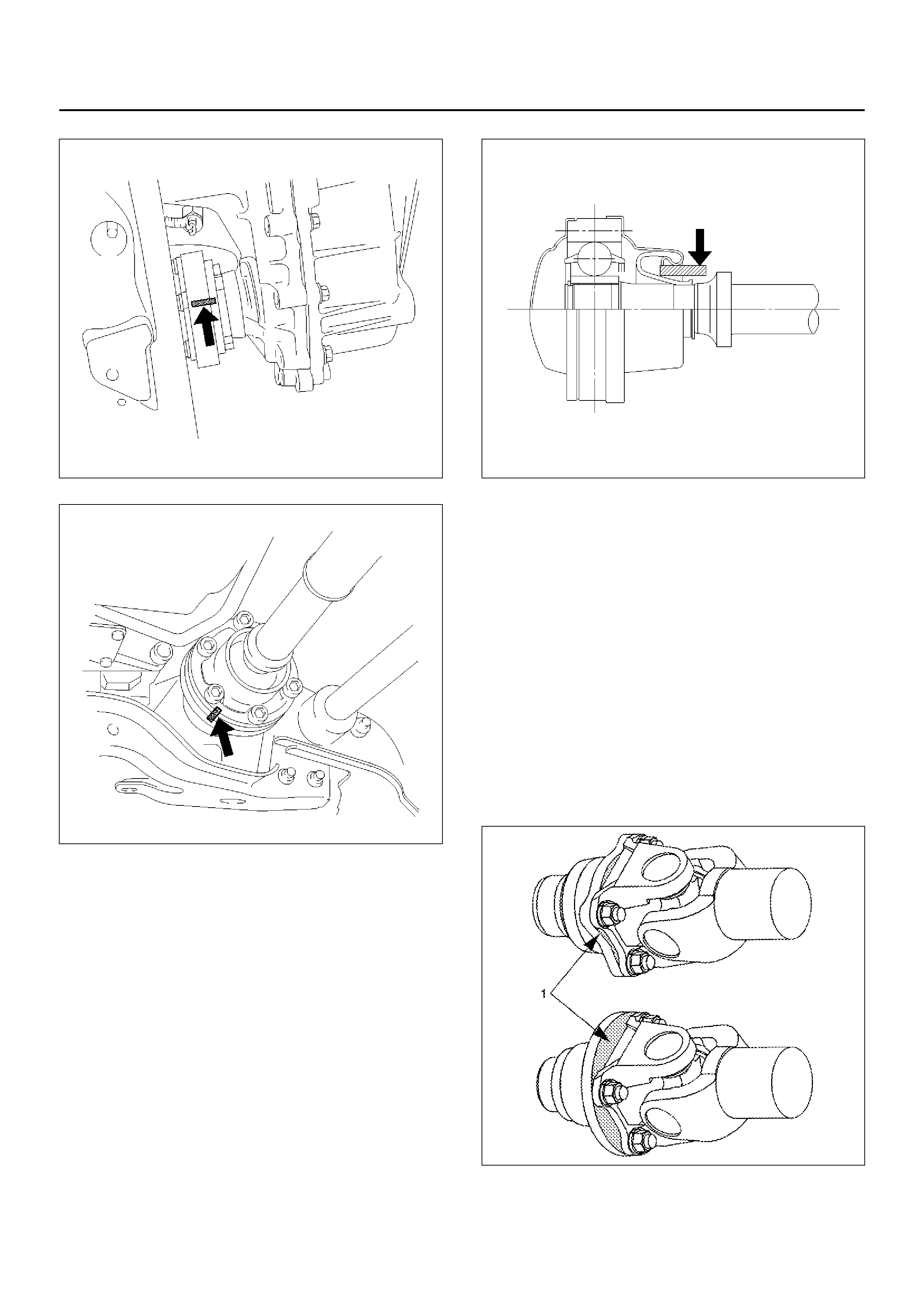

Slip Joint Disassembly

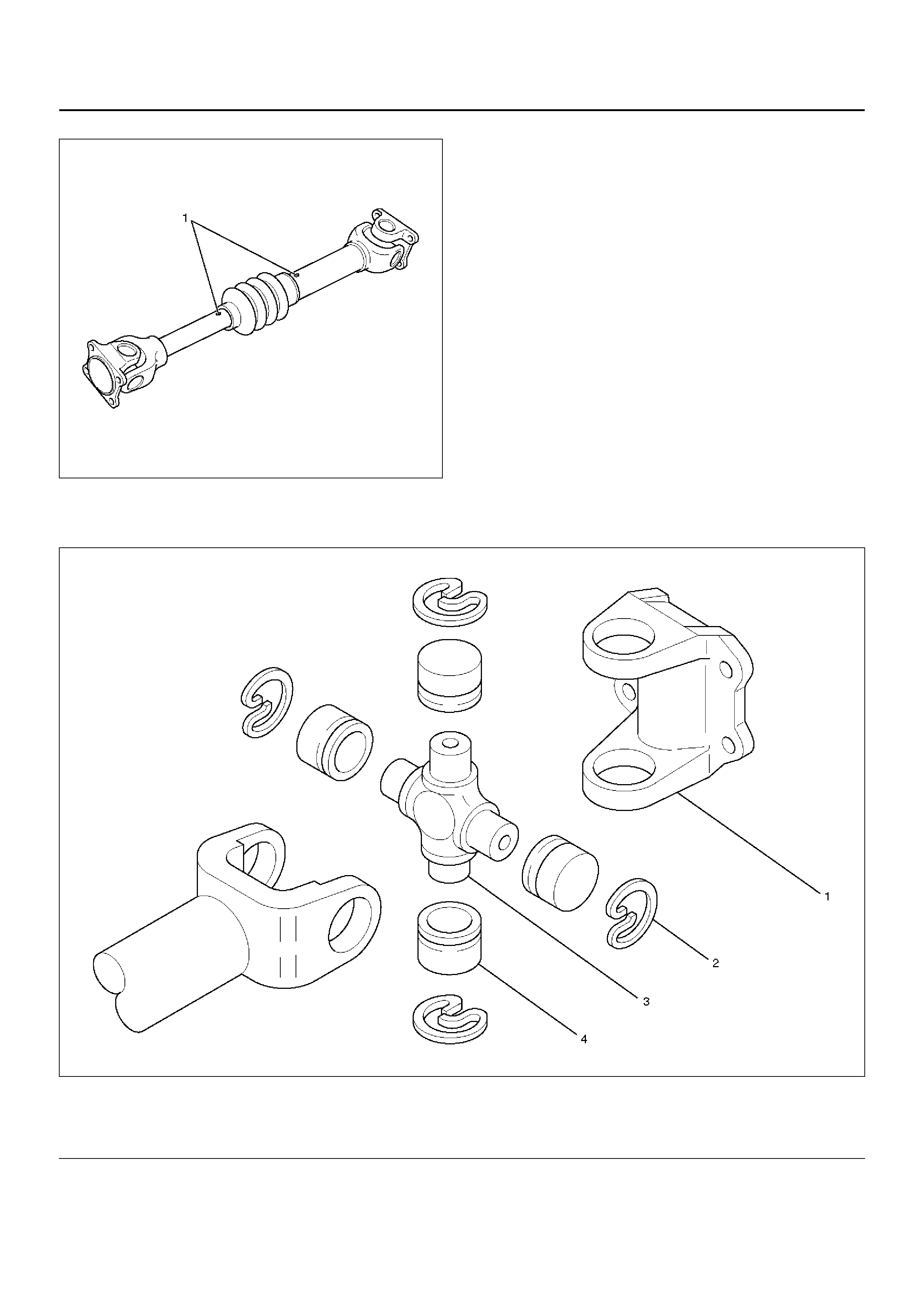

Universal Joint Disassembly

Inspection and Repair

Universal Joint Reassembly

Slip Joint Reassembly

Main Data and Specifications

Rear Propeller Shaft

Rear Propeller Shaft and Associated Parts

Removal

Installation

Slip Joint Disassembly

Universal Joint Disassembly

Inspection

Universal Joint Reassembly

Slip Joint Reassembly

Main Data and Specifications

SERVICE PRECAUTION

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM(SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE REFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFOMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED ,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally,such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener.

When you install fasteners, use the correct

tightening sequence and specification. Following

these instructions can help you avoid damage to

parts an d systems.

GENERAL DESCRIPTION

This Section contains essential removal, installation,

adjustment and maintenance procedures.

The front axle utilizes a central disconnect type front

axle/transfer case system.

The drive axles assemblies, consisting of inner and

outer constant velocity (CV) driveshaft joints connected

by an axle shaft.

For description of front propeller shaft and universal

joint, refer to Front Propeller Shaft in this section.

DIAGNOSIS

Condition Possible cause Correcti on

Oil Leak At Front Axle Worn or defective oil seal. Replace the oil seal.

Front axle housing cracked. Repair or replace.

Oil Leak At Pinion Shaft Too much gear oil. Correct the oil level.

Oil seal worn or defective. Replace the oil seal.

Pinion flange loose or damaged. Tighten or replace.

Noises In Front Axle Drive Shaft

Joint Broken or worn drive shaft joints and

bellows. Replace the drive shaft joints and

bellows.

“Clank" When Accelerating From

“Coast" Loose drive shaft joint to output

shaft bolts. Tighten.

Damaged inn er drive sha ft joi nt. Replac e.

Shudder or Vibration During

Acceleration Excessive drive shaft joint angle. Repair.

Worn or damaged drive shaft joints. Replace.

Sticking spider assembly (inner

drive shaft joint). Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint). Lubricate or replace.

Vibration At Highway Speeds Out of balance or out of round tyres. Balance or replace.

Front end out of alignment. Align.

Noises in Front Axle Insufficient gear oil. Replenish the gear oil.

Wrong or poor grade gear oil. Replace the gear oil.

Drive pinion to ring gear backlash

incorrect. Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear. Replace the ring gear , pinion gear or

side gear.

Pinion shaft bearing worn. Replace the pinion shaft bearing.

Wheel bearing worn. Replace the wheel bearing.

Differential bearing loose or worn. Tighten or replace.

W anders and Pulls Wheel bearing preload excessive Adjust the wheel bearing preload.

Incorrect front alignment. Adjust the front alignment.

Steering unit loose or worn. Tighten or replace.

tyre worn or improperly inflated. Adjust the inflation or replace.

Front or rear suspension parts loose

or broken. Tighten or replace.

Front Wheel Shimmy Wheel bearing worn or improperly

adjusted. Adjust or replace.

Incorrect front alignment. Adjust the front alignment.

Worn ball joint or bush. Replace the ball joint or bush.

Steering unit loose or worn. Tighten or replace.

tyre worn or improperly inflated. Replace or adjust the inflation.

Shock absorber worn. Replace the shock absorber.

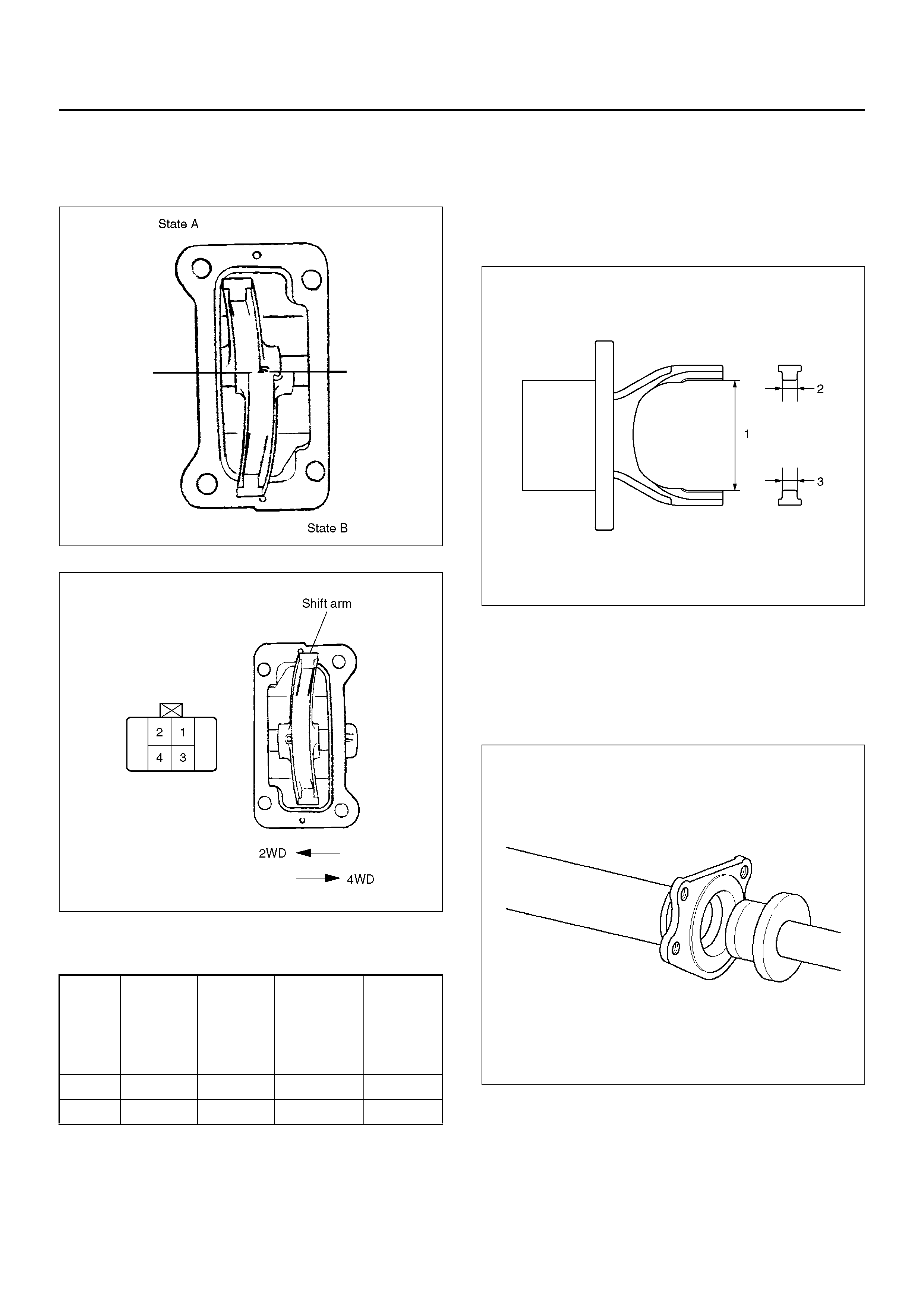

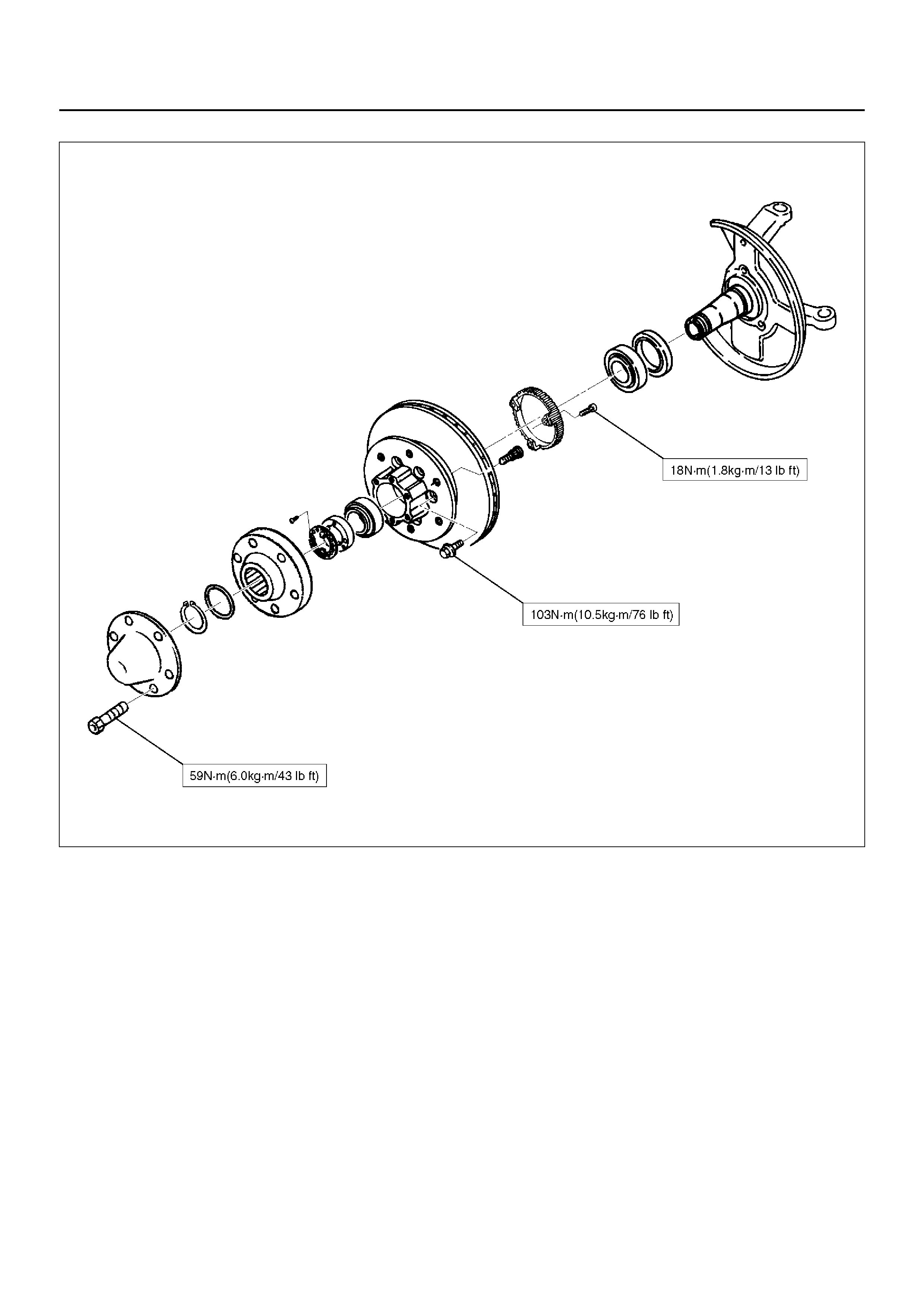

FRONT HUB AND DISC

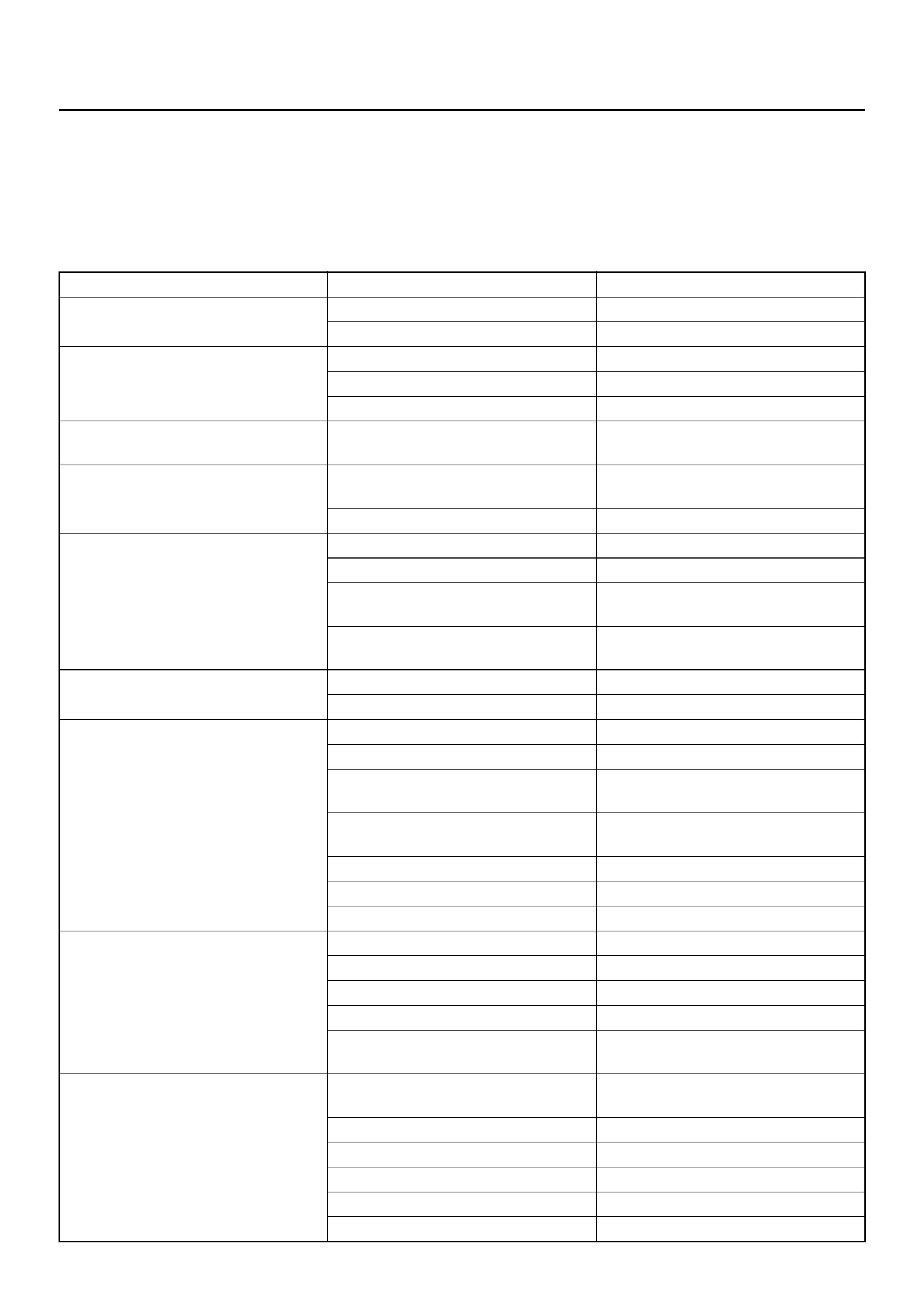

DISASSEMBLED VIEW

411RW001

Legend

EndOFCallout

DISASSEMBLY

1. Before disassembly, select the 2WD position with

the 4WD switch.

2. Jack up the front of vehicle and support frame with

jack stands.

3. Remove the disc brake caliper assembly and hang it

on the frame with wires. Refer to Disc Brakes in

Section 5C.

4. Remove Bolt.

5. Remove cap.

6. Remove snap ring and shim.

(1) Bolt

(2) Cap

(3) Snap Ring and Shim

(4) Hub Flange

(5) Lock Washer and Lock Screw

(6) Hub Nut

(7) Outer Bearing

(8) Bolt

(9) Hub and Disc Assembly

(10) Wheel Pin

(11) ABS Sensor Ring

(12) Inner Beari ng

(13) Oil Seal

7. Remove hub flange.

8. Remove lock washer and lock screw.

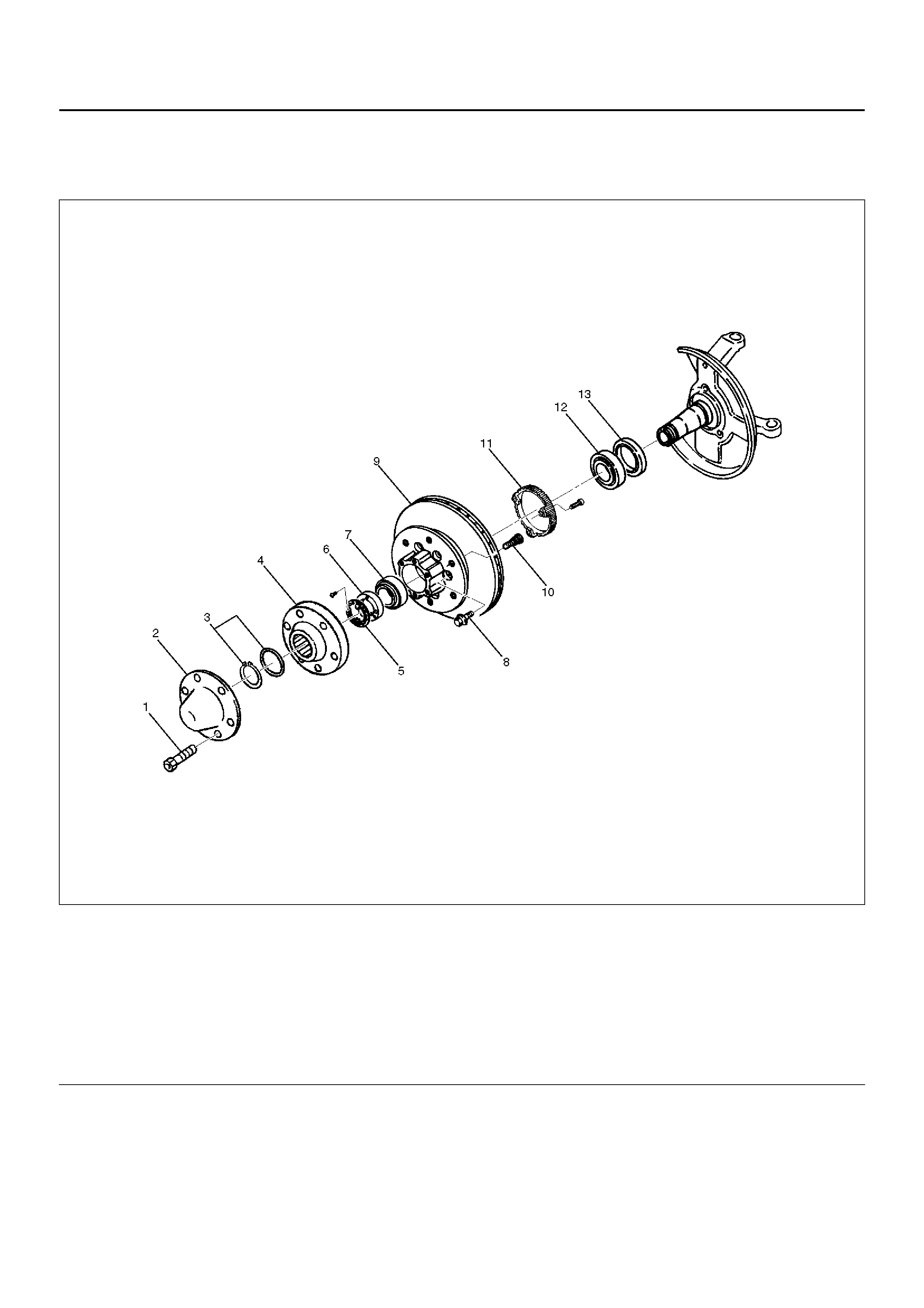

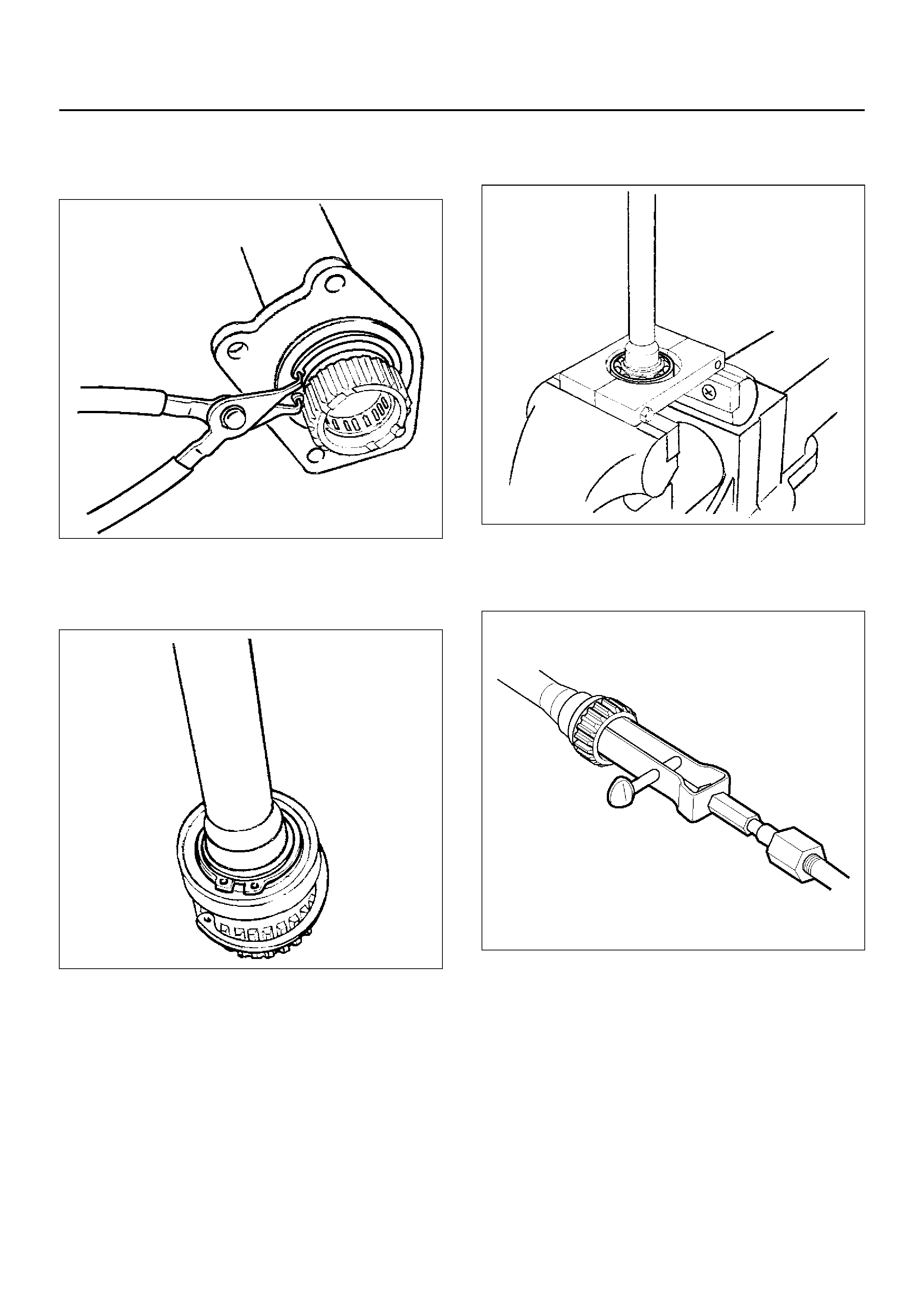

9. Use wrench 5–8840–2117–0, remove hub nut.

411RW005

10. Remove hub and disc assembly.

11. Remove ABS sensor ring.

12. Remove outer bearing.

13. Remove oil seal.

14. Remove inner bearing.

15. Remove bolt , if necessary, replace the wheel pin in

the following manner.

• Apply a scribe mark(1) to disc to hub.

• Clamp the hub and disc assembly in a vise, using

protective pads. Remove the 6 disc–to–hub

retaining bolts.

411RS003

• Place hub on a suitable work surface and remove

the studs by using a hammer.

411RS004

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

Check the following parts.

•Hub

• Hub bearing oil seal

• Knuckle spindle

•Disc

• Caliper

• Shift on the fly system parts (Cap, Hub flange, Shim,

Snap ring)

• ABS sensor ring

For inspection and servicing of disc caliper and related

parts, refer to Disc Brakes in Brake section.

REASSEMBLY

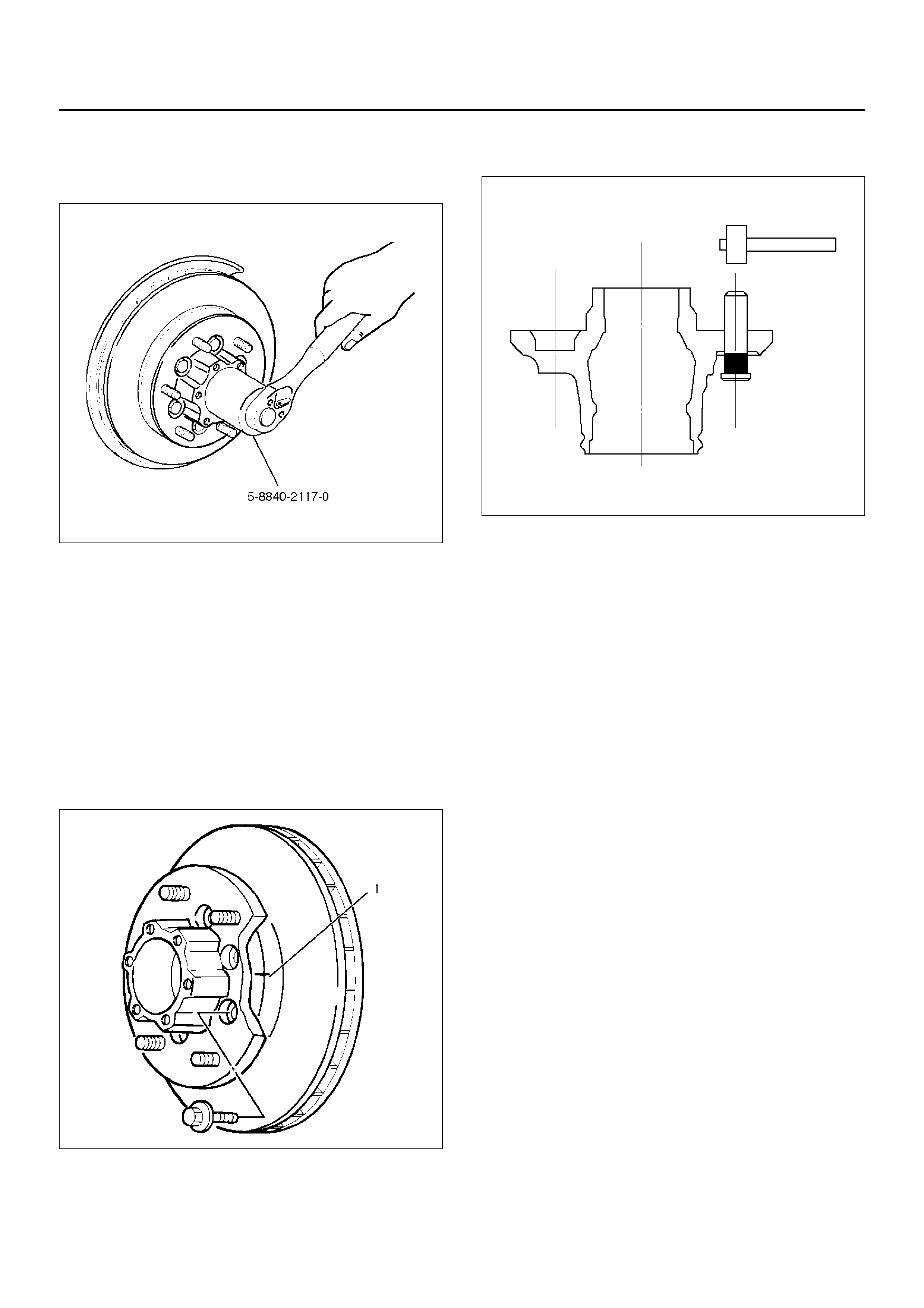

1. Install wheel pin.

• Place the hub on a wood workbench or a block of

wood approx. 100mm by 100mm to protect the

wheel stud ends and threads.

• Insert a wheel stud using a hammer .

Be sure the wheel stud is started squarely and

seats completely.

411RS005

2. Align scribe marks(1) and attach the hub to the disc,

then tighten the bolts to the specified torque.

Torque: 103N·m

411RS003

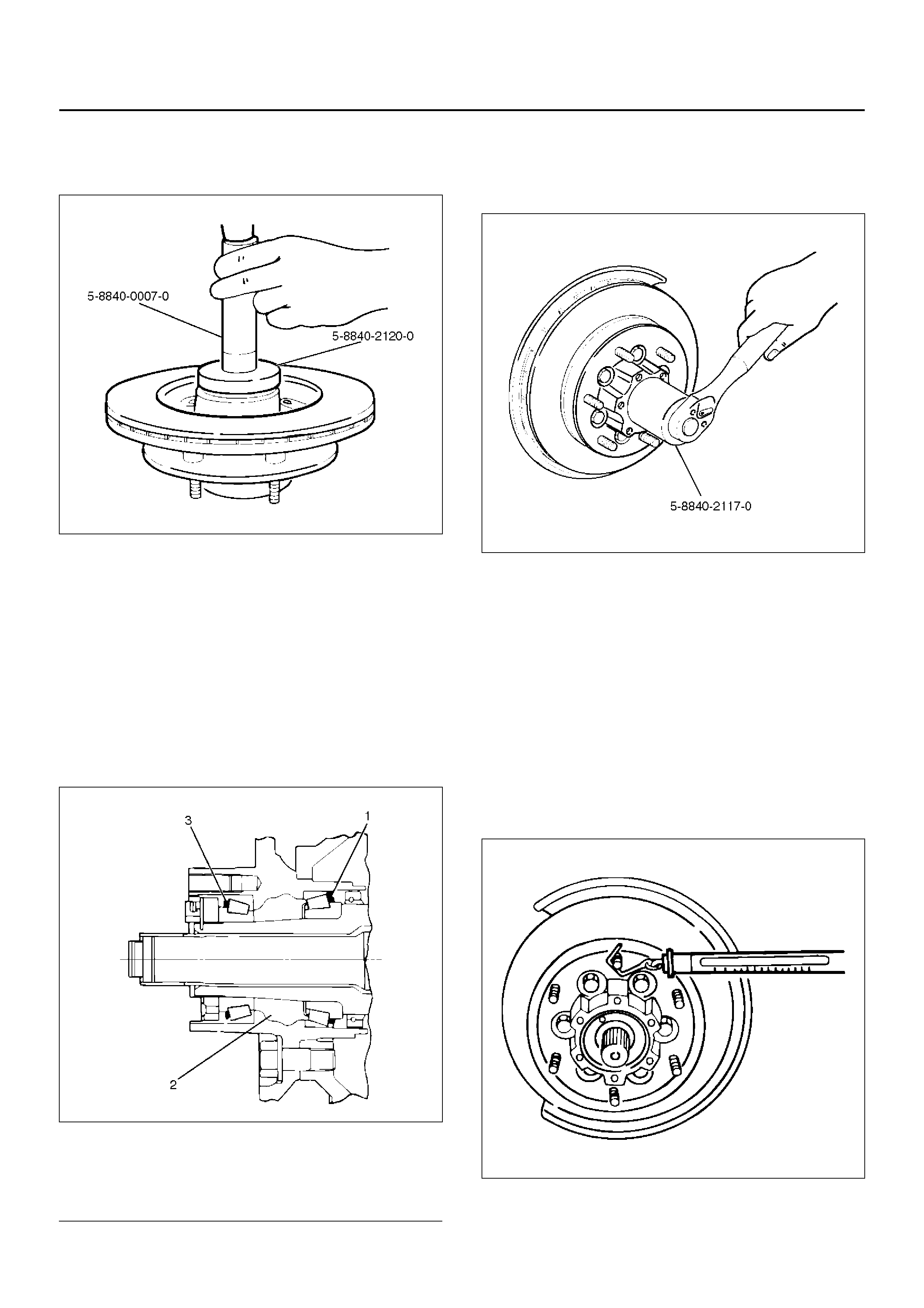

3. Use installer 5–8840–2119–0 and grip 5–8840–

0007–0, then install the inner bearing by driving it

into the hub.

411RW006

4. Use installer 5–8840–2118–0 and grip 5–8840–

0007–0 then install the outer bearing by driving it

into the hub.

411RW007

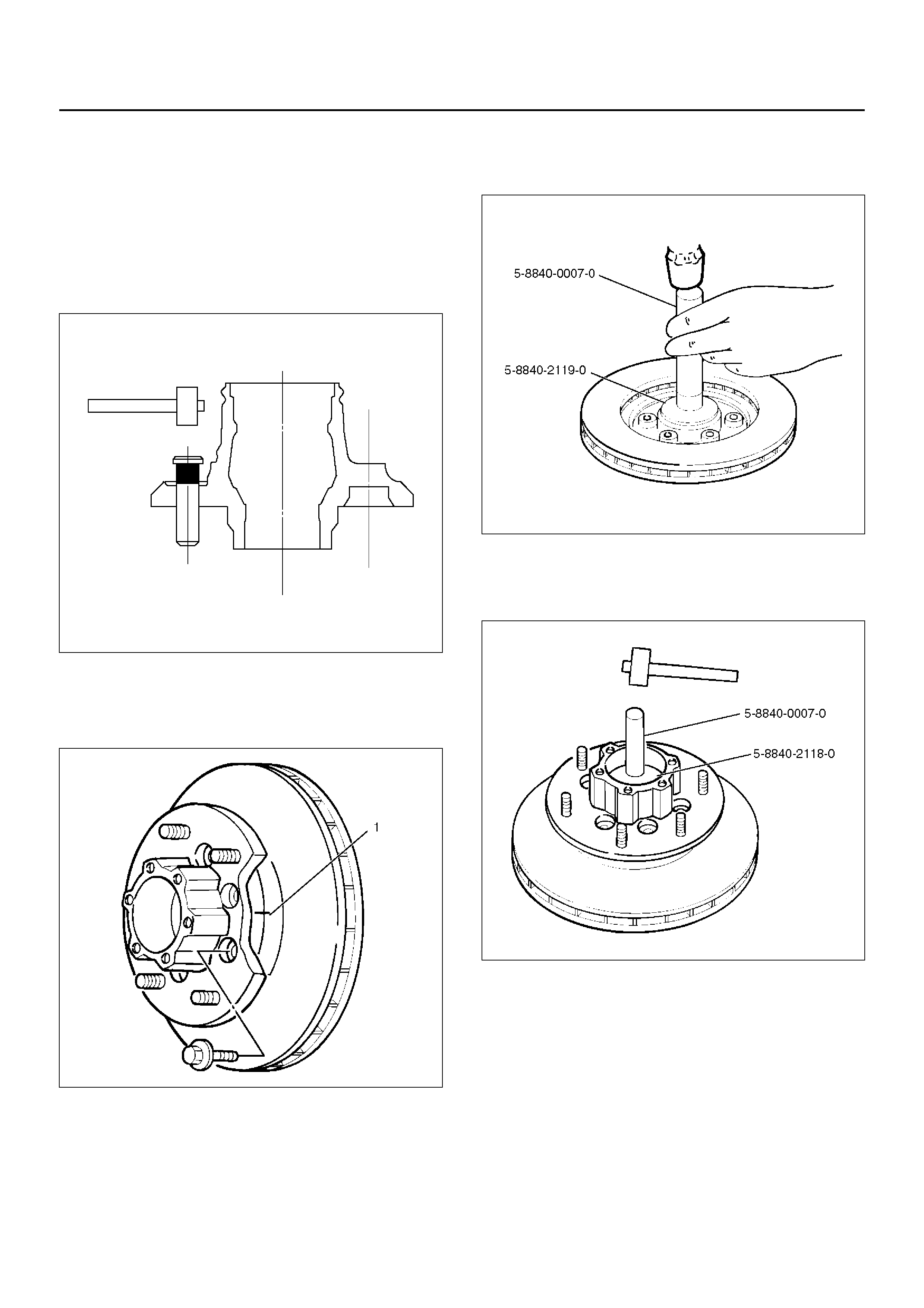

5. Apply grease (NLGI No.2 or equivalent) to the lip

portion, then install oil seal by using installer 5–

8840–2120–0 and grip 5–8840–0007–0.

411RW008

6. Install ABS sensor ring, then tighten the bolts to the

specified torque.

Torque: 1 8N·m

7. Install hub and disc assembly.

• Apply grease in the hub.

• Apply wheel bearing type grease NLGI No. 2 or

equivalent to the outer and inner bearing.

Grease Amount

Hub: 35g

Outer bearing: 10g

Inner bearing: 15g

411RS009

Legend

EndOFCallout

8. Install hub nut.

Turn to the place where there is a chamfer in the

tapped hole to the outer side, then attach the nut by

using front hub nut wrench 5–8840–2117–0.

411RW005

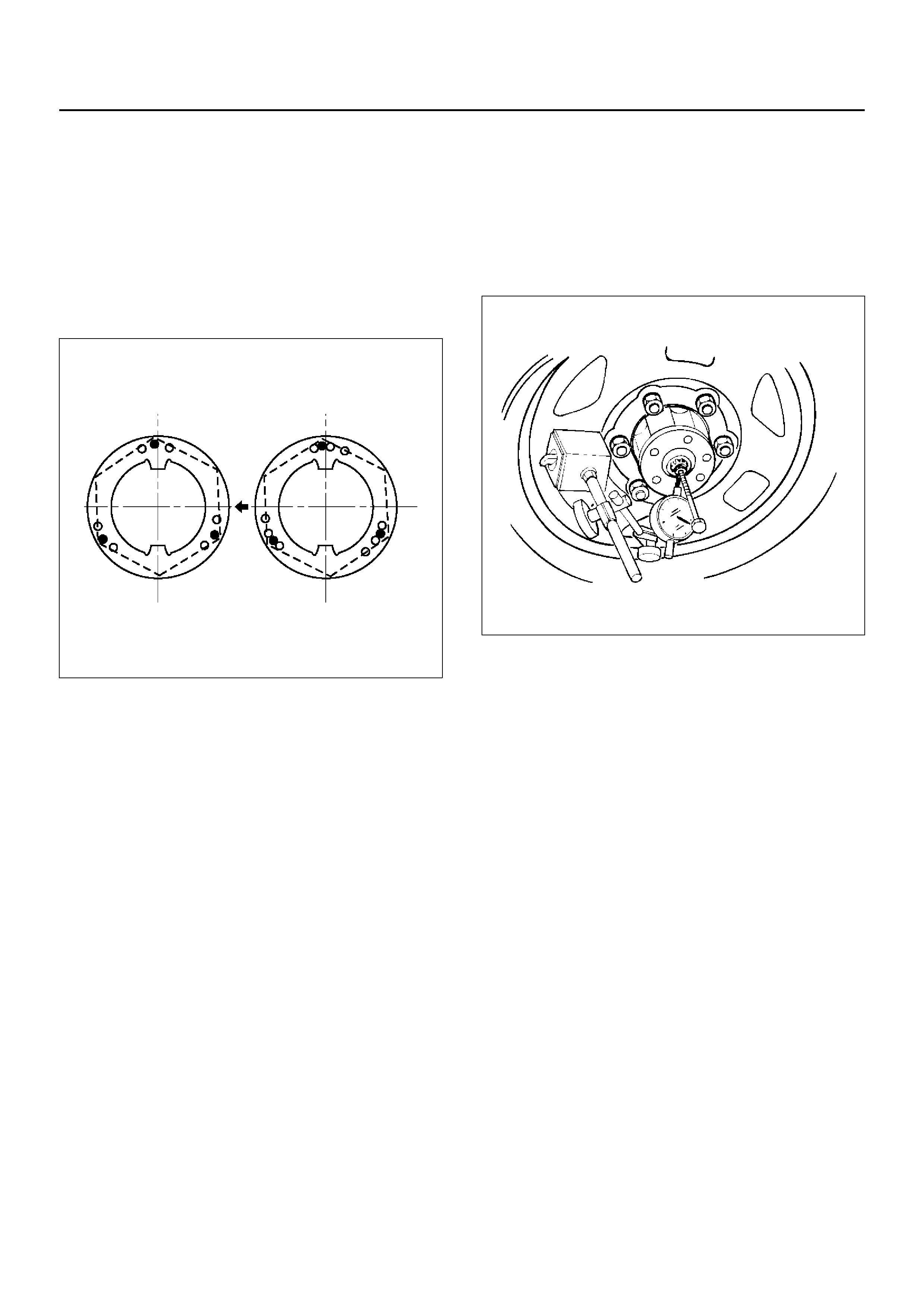

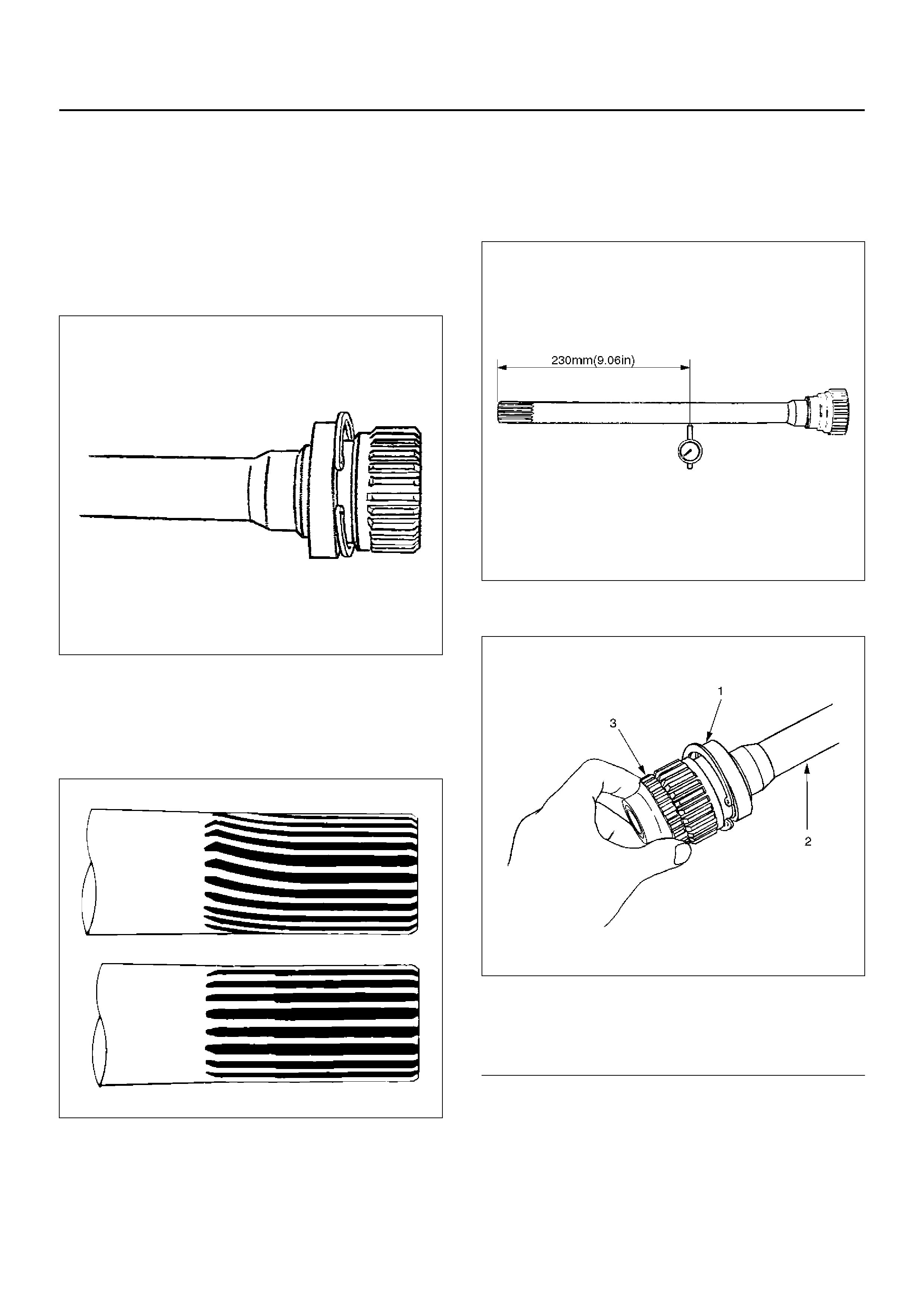

Preloa d Adjustmen t

1. T ighten the hub nut to 29 N·m , then fully loosen

the nut.

2. Tighten the hub nut to the value given below,

using a spring scale on the wheel pin.

New bearing and New oil seal

Bearing Prel oad: 20– 25N

Used bearing and New oil seal

Bearing Prel oad: 12– 18N

If the measured bearing preload is outside the

specifications, adjust it by loosening or tightening

the bearing nut.

411RS011

9. Install lock washer and lock screw in the following

manner.

(1) Inner Bearing

(2) Hub

(3) Outer Bearing

• Turn the side with larger diameter of the tapered

bore to the vehicle outer side, then attach the

washer.

• If the bolt holes in the lock plate are not aligned

with the corresponding holes in the nut, reverse

the lock plate.

• If the bolt holes are still out of alignment, turn in

the nut just enough to obtain alignment.

• Screw is to be fastened tightly so its head may

come lower than the surface of the washer.

411RS012

10. Apply adhesive (LOCTITE 515 or equivalent) to

both joining flange faces then install hub flange.

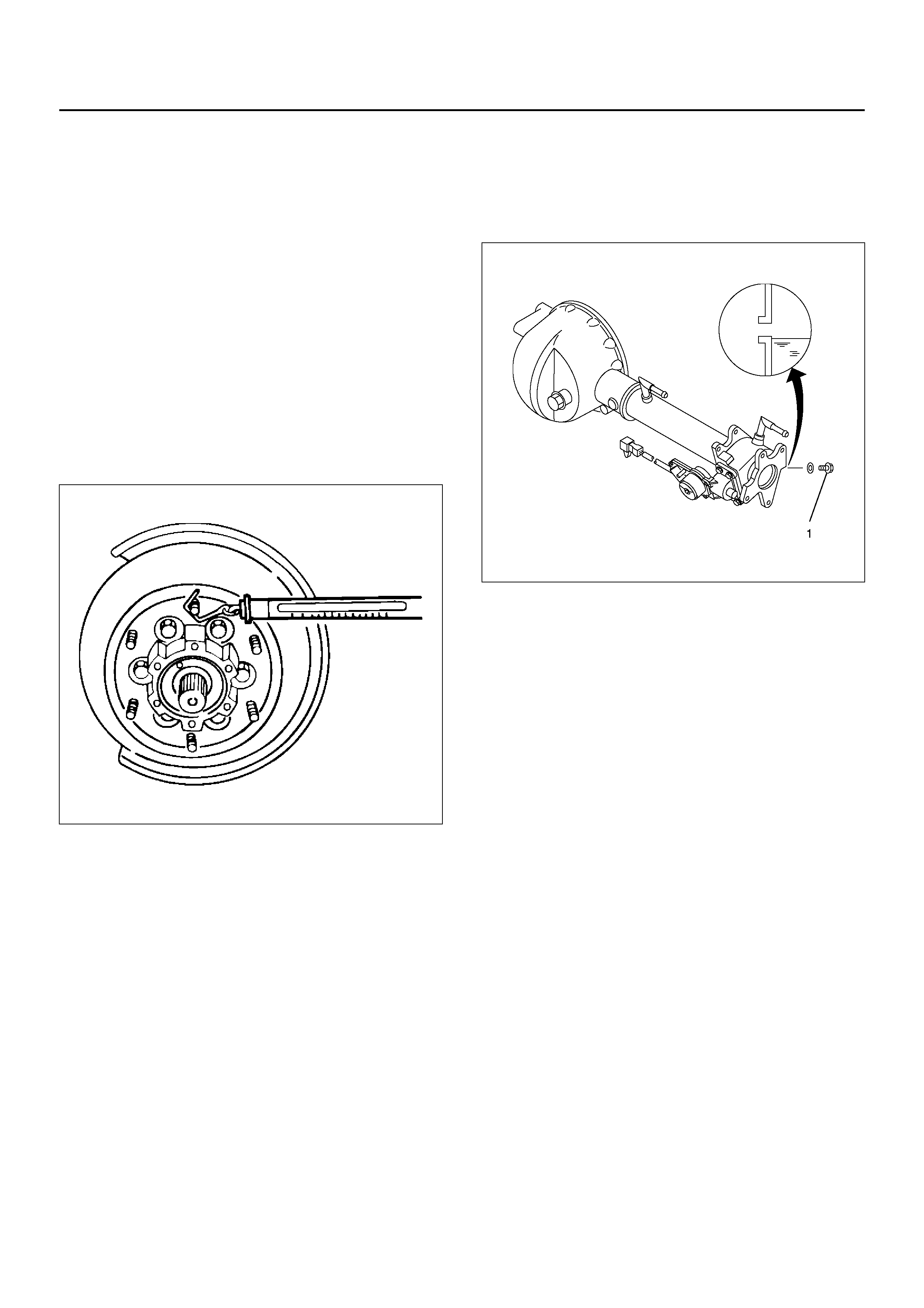

11. Install snap ring and shim.

• Adjust the clearance between the free wheeling

hub body and the sna p ring.

Clearance: 0mm–0.3mm

Shims Av ailable: 0.2mm, 0.3mm, 0.5mm, 1.0mm

411RW002

12. Install hub cap.

13. Tighten the bolts to the specified torque.

Torque: 59N·m

FRONT DRIVE SHAFT JOINT

FRONT DRIVE SHAFT JOINTS

REPLACEMENT

• Refer to Front Drive Axle Assembly Replacement in

this section, and refer to Front Hub and Disc

Overhaul in Suspension section.

Front Hub Bearing Preload Check

Check the hub bearing preload at the wheel stud.

New beari ng and New oil seal:

20 – 25N

Used bearing and New oil seal:

12 – 18N

411RS011

Inspection Of Shift On The Fly System Gear

Oil

412RY00008

1. Open filler plug and make sure that the oil up to the

plug port.

If the oil is short, replenish with gear oil GL–5 grade.

2. Tighten the filler plug to specified torque.

Torque:78N·m

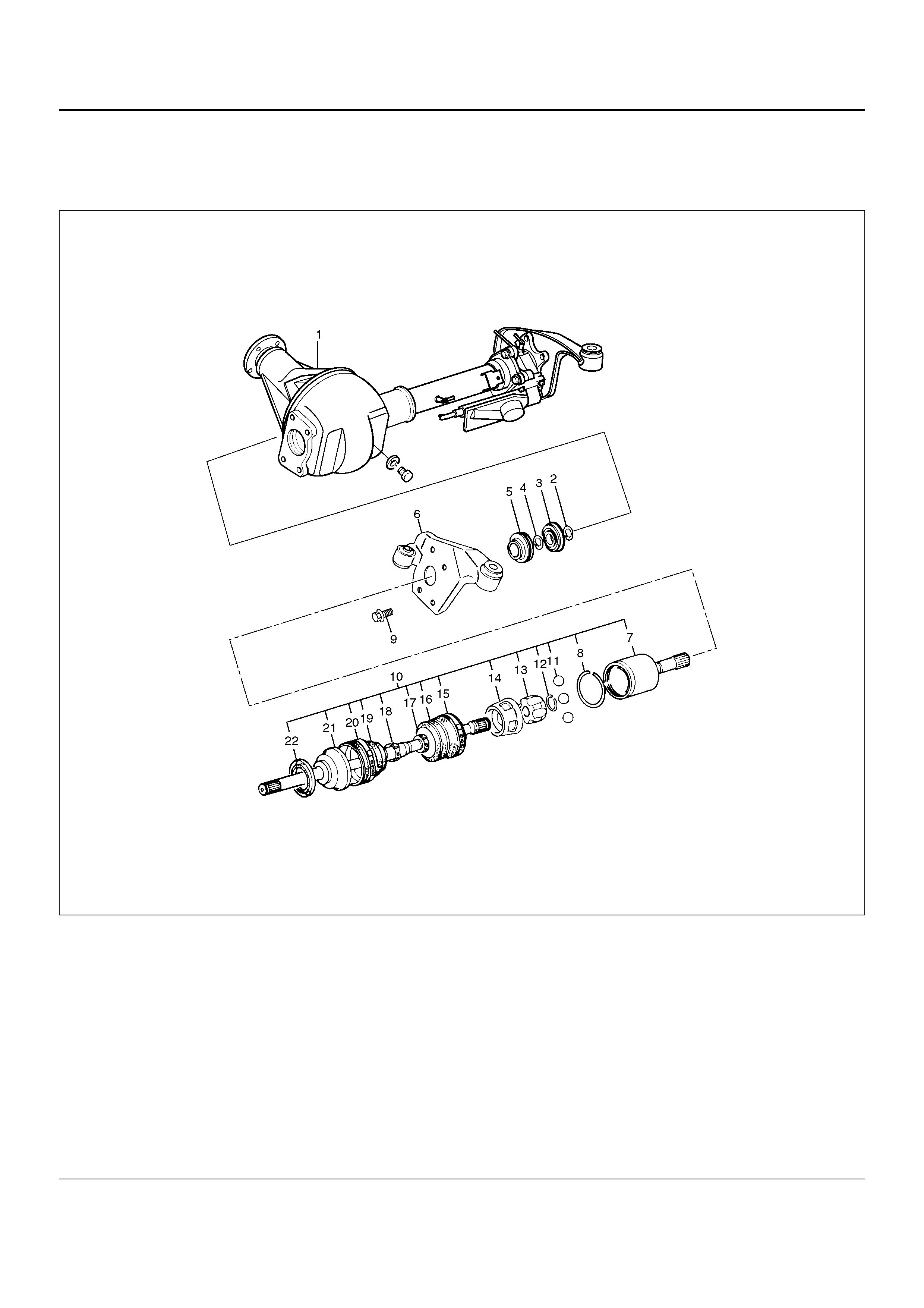

FRONT AXLE DRIVE SHAFT

FRONT AXLE DRIVE SHAFT AND ASSOCIATED PARTS

412R100004

Legend

EndOFCallout

(1) Axle Case and Differential

(2) Snap Ring

(3) Bearing

(4) Snap Ring

(5) Oil Seal

(6) Bracket

(7) DOJ Case

(8) Circlip

(9) Bolt

(10) Drive s haft Joint Assembly

(11) Ball

(12) Snap Ring

(13) Ball Retainer

(14) Ball Guide

(15) Band

(16) Bellows

(17) Band

(18) Band

(19) Bellows

(20) Band

(21) BJ Shaft

(22) Dust Seal

DISASSEMBLY

NOTE: For the left side, follow the same steps as right

side.

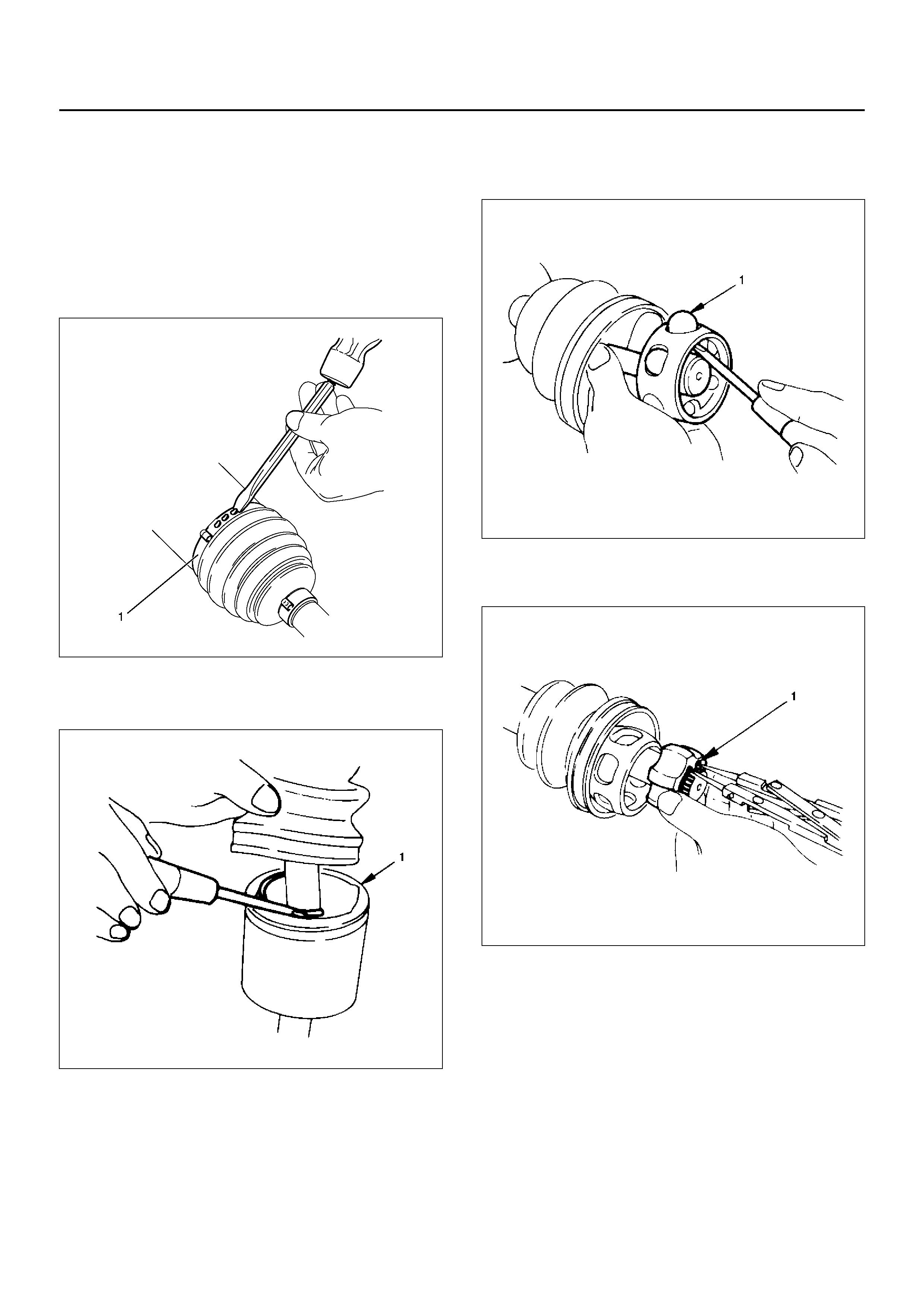

1. Use a hammer and chisel to remove the 3 pawls

(above the large and small boot bands on the DOJ

side).

CAUTION: Take care not to damage the bellows

during band removal.

412R100011

2. Remo ve ban d( 1).

3. Pry off circlip (1) with a screwdriver or equivalent.

412RS010

4. Remove drive shaft joint assembly.

5. Remove the six balls (1) with a screwdriver or

equivalent.

412RS012

6. Using snap ring pliers, remove the snap ring (1)

fastening the ball retainer to the center shaft.

412RS013

7. Remove ball retainer, ball guide and bellows.

8. Use a hammer and chisel to remove the 3 pawls

(above the large and small boot bands on the BJ

side).

CAUTION: Take care not to damage the bellows

during band removal.

412R100009

9. Remove band(1).

10. Remove bellows.

11. Remove dust seal from BJ.

12. Remove BJ shaft assembly.

13. Remove the mounting bracket fixing bolts, and then

remove DOJ case assembly from the axle case.

14. Remove snap ring and bearing.

15. Remove snap ring and oil seal.

16. Remove bracket.

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

Check the following parts.

1. Drive shaft joint assembly

2. DOJ case, ball, ball guide, ball retainer

3. Bellows

4. Bearing

5. Dust seal, oil seal

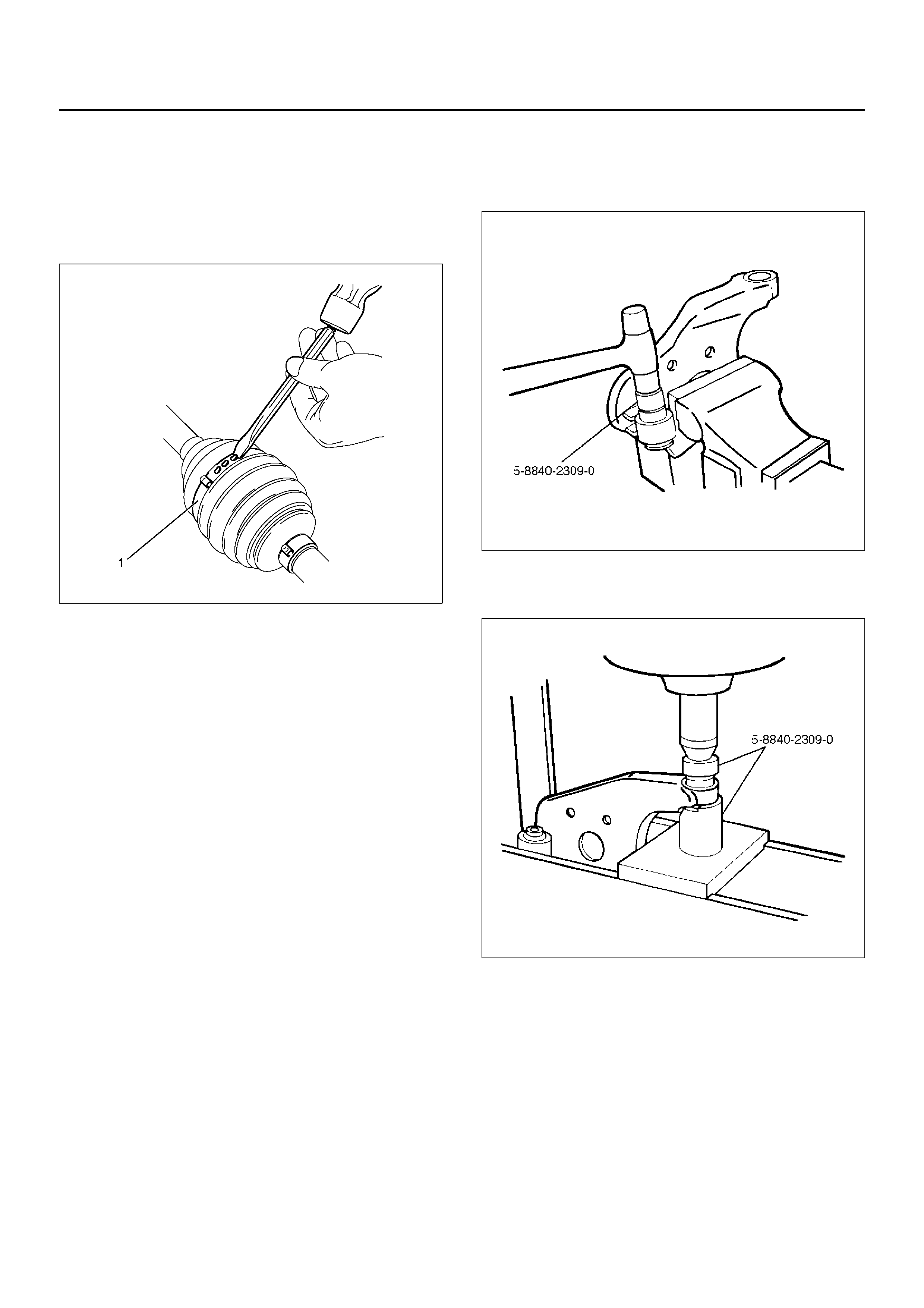

BUSHING REPLACEMENT

• Remove the bushings using a remover 5–8840–

2309–0 and hammer.

412RW051

• By using installer and base 5–8840–2309–0, press

fit the bushings into the bracket.

412RW052

REASSEMBLY

1. Install DOJ case to bracket.

2. Install oil seal and fix snap ring.

3. Install bearing and fix snap ring.

4. Install bracket to axle case. Tighten the bracket bolt

to the specified torque.

Torque:116N·m

5. Apply 150g of the specified grease in BJ.

6. Install dust seal for BJ.

7. Apply a thin coat of grease to the shaft for smooth

installation then install bellows.

CAUTION: During bellows assembly, be sure to

insert both ends of the bellows into the case and

shaft grooves.

412R100007

Legend

EndOFCallout

412R100013

Legend

EndOFCallout

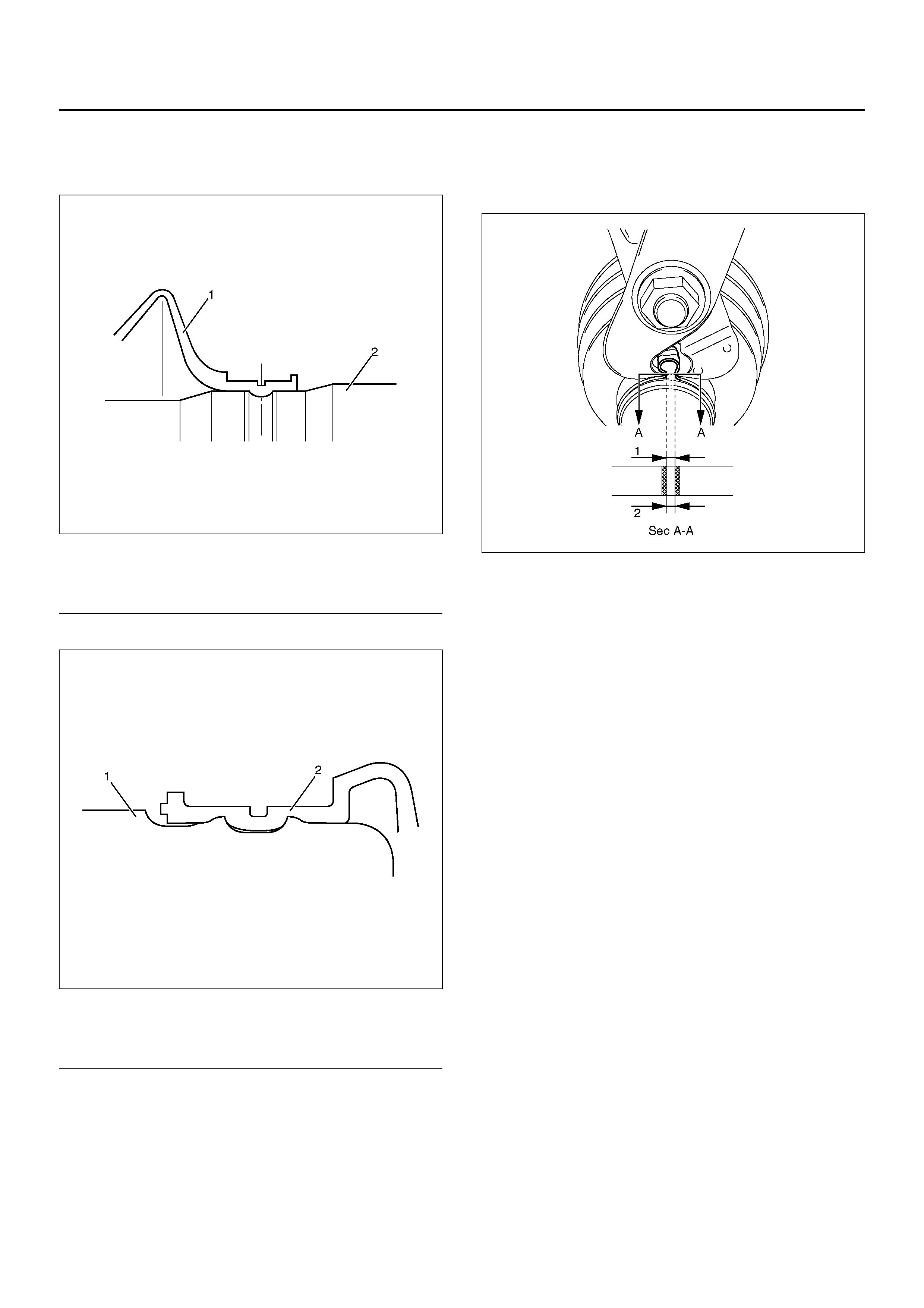

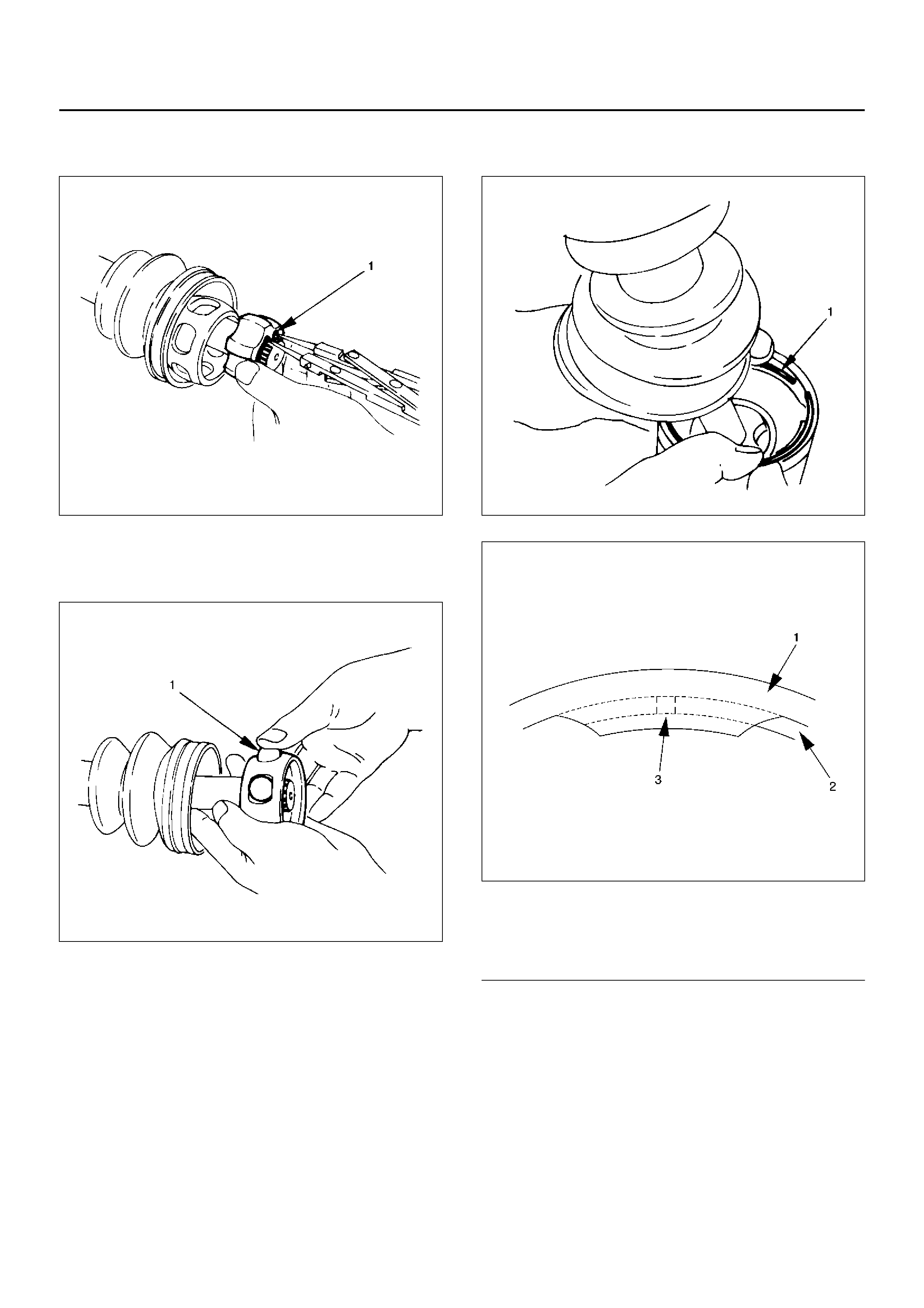

8. Install band. Note the setting direction. After

installati on , chec k Standard Caulk Mea sure .

Use the special tool pliers 5-8840-2745-0 to caulk

the bands to the specified value.

412R100012

Standard Caulk Measure

• Dimensions (1) & (2) = 1.2 - 4.0mm

• Max. variation between (1) & (2) = 0.4mm

9. Install another bellows and fix band.

10. Install the ball guide with the smaller diameter side

ahead onto the shaft.

11. Install ball retainer.

(1) Bellows

(2) Shaft

(1) DOJ Case

(2) Bellows

12. Using snap ring pliers, install the snap ring (1)

securing the ball retainer to the shaft.

412RS013

13. Align the track on the ball (1) retainer with the

window in the cage, and install the six balls into

position.

412RS018

14. Pack 150g of the specified grease in DOJ case,

then install drive shaft joint assembly. After

reassembly, move the DOJ longitudinally several

times to get to fit.

15. Install the circlip (1) so that open ends are

positioned away from the ball groove.

412RS019

412RS020

Legend

EndOFCallout

16. Install band. After installation, check that the bellows

is free from distortion.

(1) Outer Case

(2) Circlip

(3) Open Ends

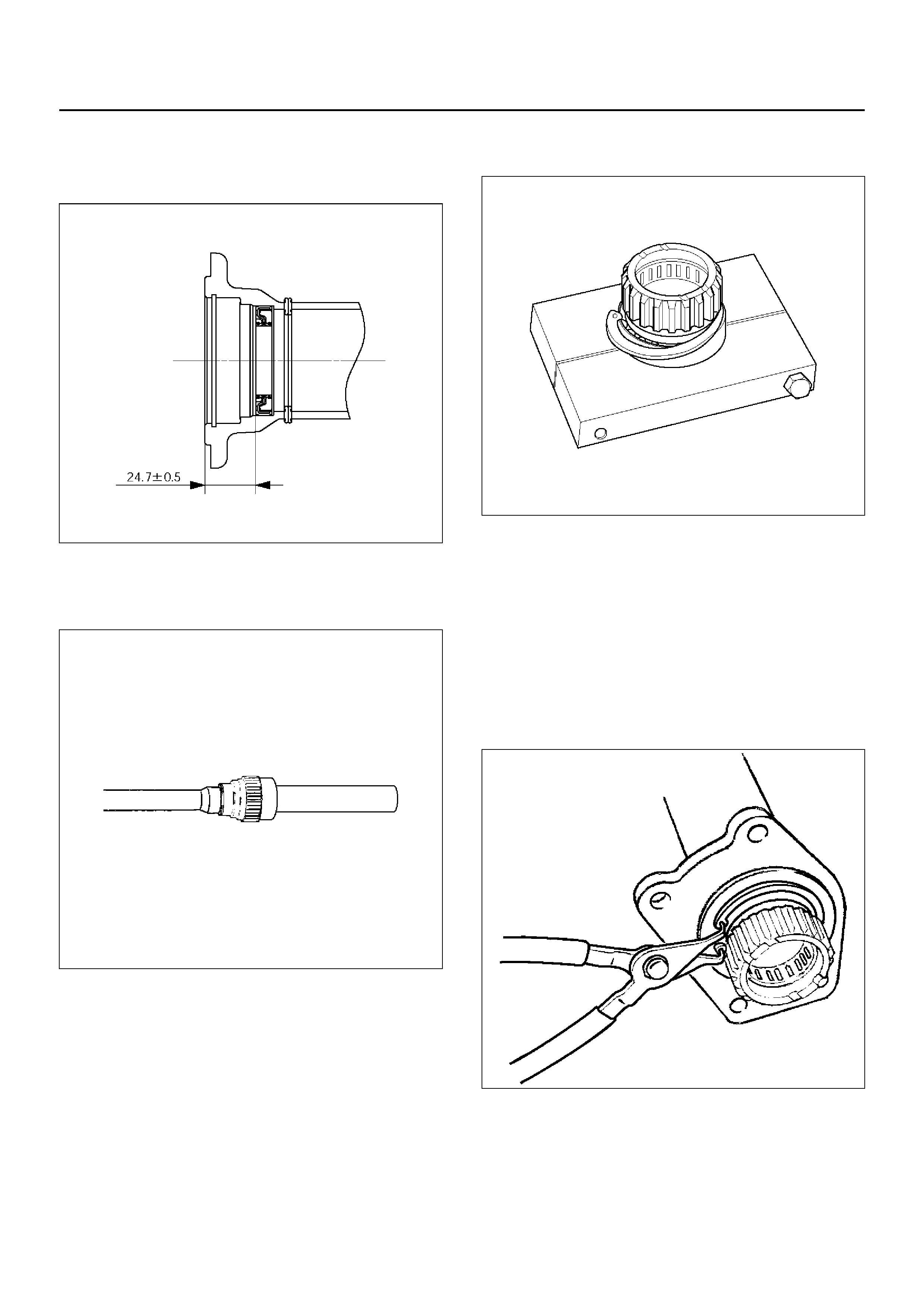

SHIFT ON THE FLY SYSTEM

SHIFT ON THE FLY SYSTEM AND ASSOCIATED PARTS

412RY00007

Legend

EndOFCallout

DISASSEMBLY

1. Remove filler plug and gasket, drain oil.

2. Loosen mounting bracket fitting bolts and remove

front axle drive shaft from front axle case.

3. Remove actuator assembly and draw out actuator

assembly.

4. Remove housing.

5. Remove sleeve.

(1) Filler Plug

(2) Bolt

(3) Oil Seal

(4) Snap Ring(External)

(5) Inner Shaft Bearing

(6) Snap Ring(Internal)

(7) Inner Shaft

(8) Needle Bearing

(9) Clutch Gear

(10) Sleeve

(11) Housing

(12) Front Axle Drive Shaft(LH side) with Bracket

(13) Bolt

(14) Actuator Assembly

(15) Bolt

6. Remo ve cl utc h gear.

7. Remove snap ring from front axle case by using

snap r ing pliers.

412RW017

8. Take out inner shaft from front axle case.

9. Remove snap ring from inner shaft by using snap

ring pliers.

412RW016

10. Remove inner shaft bearing.

NOTE: Be careful not to damage the shaft.

412RW015

11. Remove needle bearing from inner shaft by using a

remover 5–8840–0027–0 and sliding hammer

5–8840–0084–0.

412RS045

12. Remove oil seal from front axle case.

NOTE: Be careful not to damage the front axle case.

INSPECTION AND REPAIR

Inspect the removed parts. If there are abnormalities

such as wear and damage, take corrective action or

replace.

Visual Check

1. Check and see if the inner shaft has such

abnormalities as wear and damage.

412RW014

2. When inspecting the inner shaft, be sure to check

and see if its splined part is twisted, worn, or

cracked. If so, replace with a new shaft. In case

such an abnormality in its gear part (a slide with

sleeve), replace the shaft.

420RS008

Inner Shaft Run–Out

With both end centers supported, rotate the shaft slowly

and measure deflection with a dial gauge.

Limit:0.5mm

NOTE: Do not heat the shaft to correct its bend.

412RS026

Inner Shaft Bearing

412RW006

Legend

EndOFCallout

1. Inspect the state of inner shaft bearing. If any

abnormality such as smoothlessness is found,

replace with a new inner shaft bearing.

2. Insert a clutch gear and check the state of needle

bearing.

3. If there is an abnormality such as smoothlessness,

replace the needle bearing.

(1) Inner Shaft Bearing

(2) Inner Shaft

(3) Clutch Gear

Sleeve Condition

Check and see that there is not wear damage, or

cracking in the sleeve.

NOTE: Close inspection of the groove and inner gear

are required because those are important parts.

Sleeve Function

412RY00039

Operate the sleeve with the inner shaft combined with

the clutch gear and if smoothlessness is felt, replace the

sleeve.

NOTE: Gear oil should be applied to the contact

surface of gear.

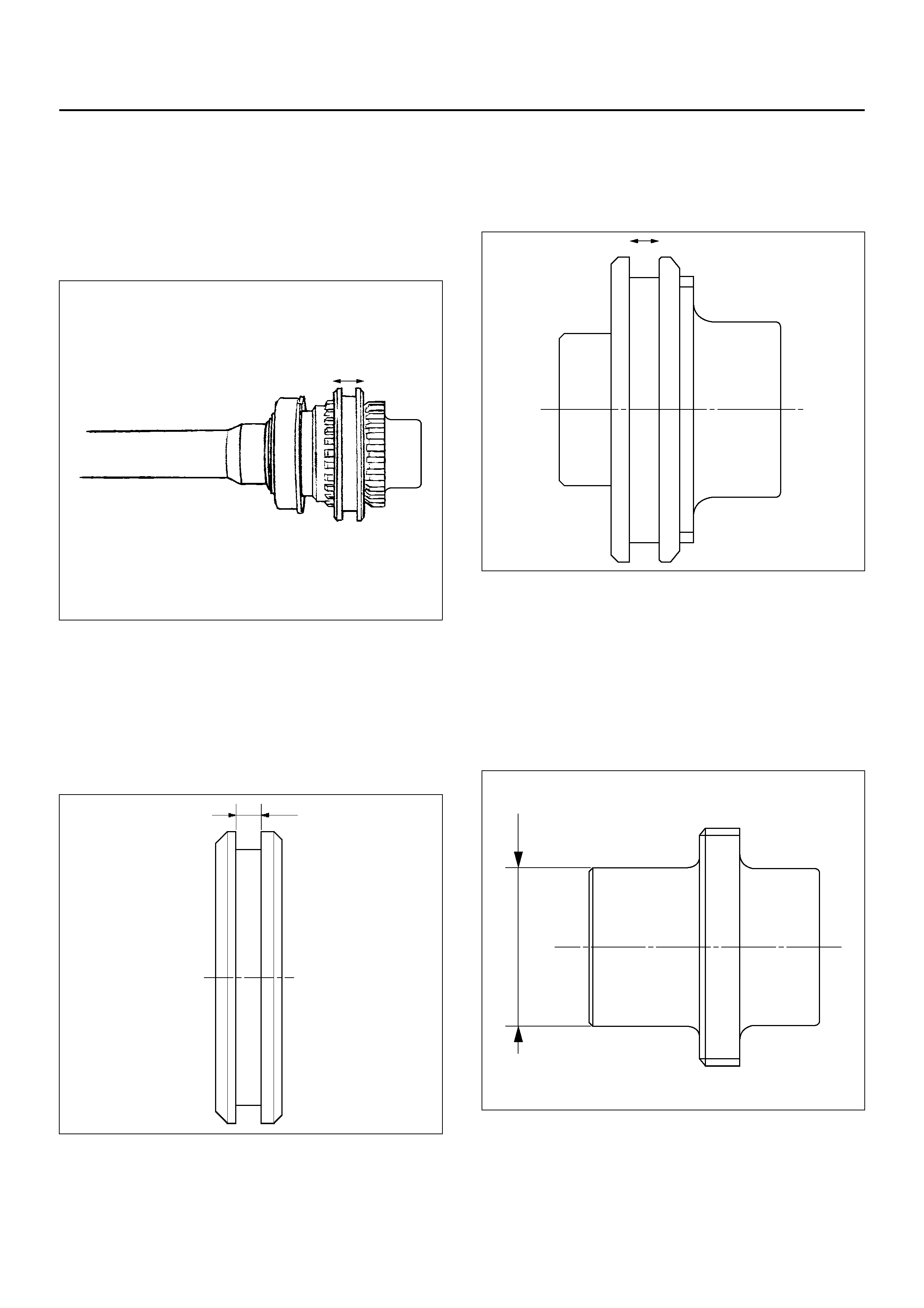

Check the width of sleeve center groove.

Limit:7.1mm

412RW022

Clutch Gear Condition

Check and see that there is not wear , damage, crack, or

any other abnormality in the clutch gear.

Clutch Gear Function

412RY00038

If there is an abnormality such as roughness when

operated in combination with sleeve, replace the clutch

gear.

NOTE: When inspecting, gear oil should be applied to

the contact surface of gear.

Clutch Gear Journal Diameter

Make sure of the size illustrated.

Limit:36.98mm

412RY00037

Actuator

Check and see that there is no damage, cracking, or

other abnormality.

Functional Check

412RY00041

412RY00009

To test the function of the actuator, connect an ohm

meter to terminals 1 & 2 and apply a 12 volt signal to

terminals 3 & 4 as shown in the table below.

If any fault is found, replace the actuator as an

assembly.

Dimensional Check

Measure illustrated sizes 1, 2, and 3.

Limit

1=64.1mm

2=6.7mm

3=6.7mm

412RY00010

REASSEMBLY

1. Install the new oil seal which has been immersed in

differential gear oil, by using an oil seal installer

5–8840–2407–0 and grip 5–8840–0007–0.

412RW034

State Terminal

3Terminal

4

Electric

circuit

between

terminal 1

& 2

Function

A +12V Ground OK 2WD

BGround+12V NONE 4WD

2. Check the oil seal installation position (from shaft

end to oil seal).

Depth:24.2–25.2mm

412RS052

3. Force a new needle bearing into inner shaft by

using a Installer 5–8840–2408–0 and grip

5–8840–0007–0.

412RS051

4. Place a new snap ring(internal) in inner shaft.

Force a new inner shaft bearing into the inner shaft.

412RS044

5. Install snap ring(external).

NOTE: Be careful not to damage the inner shaft.

6. Clean the housing contact surface of the front axle

case and insert inner shaft assembly into the front

axle case.

NOTE: Be careful not to damage seal.

7. Install snap ring internal in the groove of front axle

case.

NOTE: Be sure to install the snap ring properly.

412RW017

8. Apply differential gear oil to clutch gear, then install

clutch gear.

9. Apply differential gear oil to sleeve, then install

sleeve.

10. Clean contact surface with the front axle and

actuator mounting surface. Apply liquid gasket to

the contact surface on the front axle case, then

install in the housing.

412RW023

11. Tighten bolts to specified torque.

Torque:75N·m

12. Clean the actuator contact surface with the housing

then Install and tighten shift position switch to

specified torque.

Torque:39N·m

13. Apply liquid gasket to the contact surface on the

actuator side.

412RW012

14. Align shift arm with the groove of sleeve and install

the actuator.

15. Tighten bolts to specified torque.

Torque:9N·m

16. Install front axle drive shaft and mounting bracket.

Tighten fitting bolts to specified torque.

Torque:116N·m

17. Pour specified amount of differential gear oil to filler

plug.

Front Differential

Oil Capacity:1.4L

Actuator Housing

Oil Capacity:0.12L

18. Install filler plug through gasket and tighten to

specified torque.

Torque:78N·m

MAIN DATA AND SPECIFICATIONS

General Specifications

Torque Specifications

412R100003

Front drive axle oil capacity 1.25L (Differential)

0.12L(Actuator Housing:Shift on the fly)

Type of lubricant GL–5 (75W–90) Refer to chart in Section 0B

Axle shaft type Constant velocity joint (Birfield Joint type and Double Offset Joint)

E04RX012

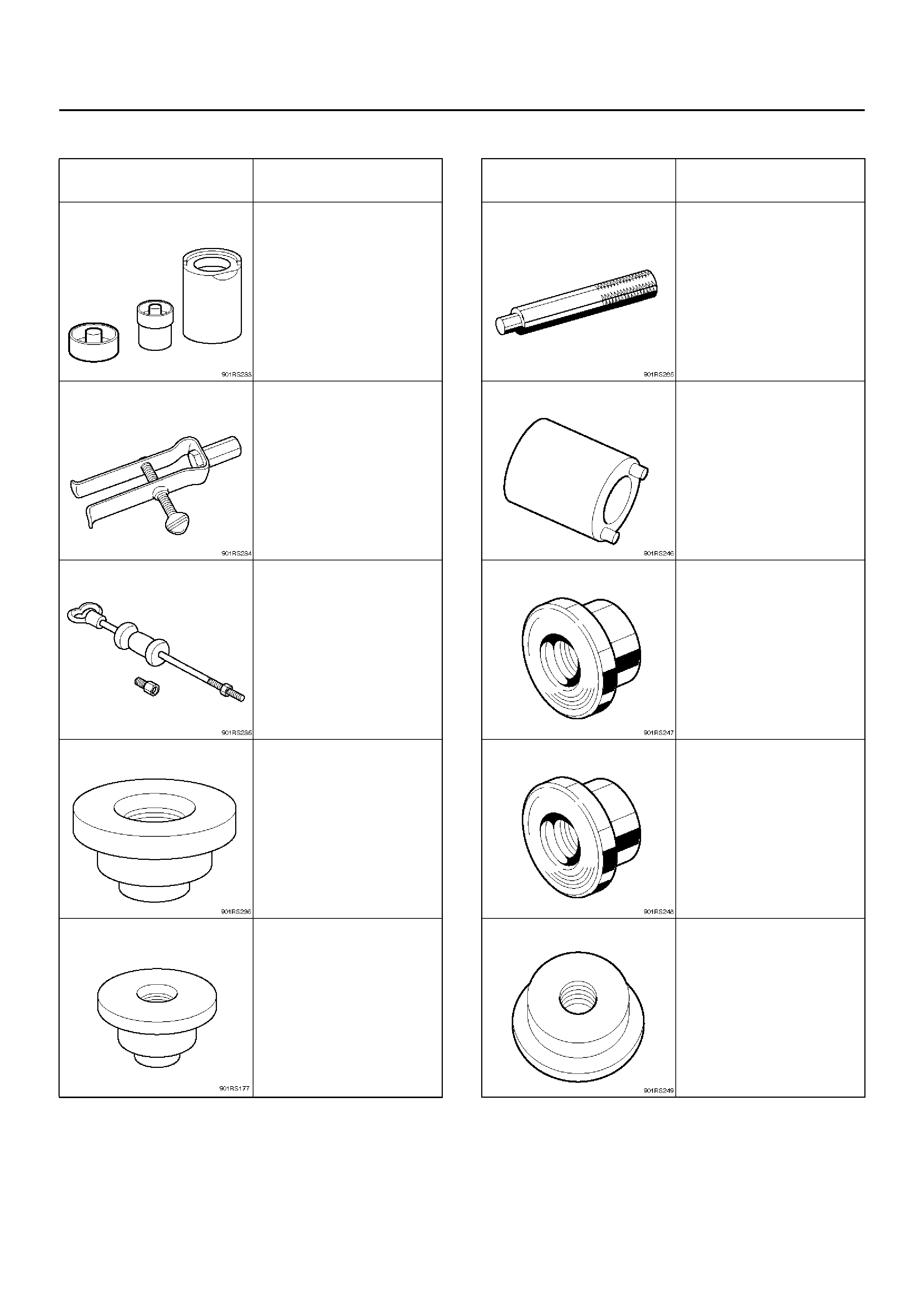

SPECIAL TOOLS

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–2309–0

(J–39378)

Remover and Installer;

Front Axle mount bushing

5–8840–0027–0

(J– 26941)

Remover; Bearing needle

5–8840–0084–0

(J–2619–01)

Hammer; Sliding

5–8840–2407–0

(J–41693)

Installer; Oil seal

5–8840–2408–0

(J–41694)

Installer; Bearing needle

5–8840–0007–0

(J–8092)

Grip

5–8840–2117–0

(J–36827)

Wrench; Hub nut

5–8840–2119–0

(J–36829)

Installer; Inner bearing

5–8840–2118–0

(J–36828)

Installer; Ou ter bearing

5–8840–2120–0

(J–36830)

Installer; Oil seal

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–2745–0

(J–35910)

Pliers; Band bellows,

drive sha ft

ILLUSTRATION TOOL NO.

TOOL NAME

PROPELLER SHAFT

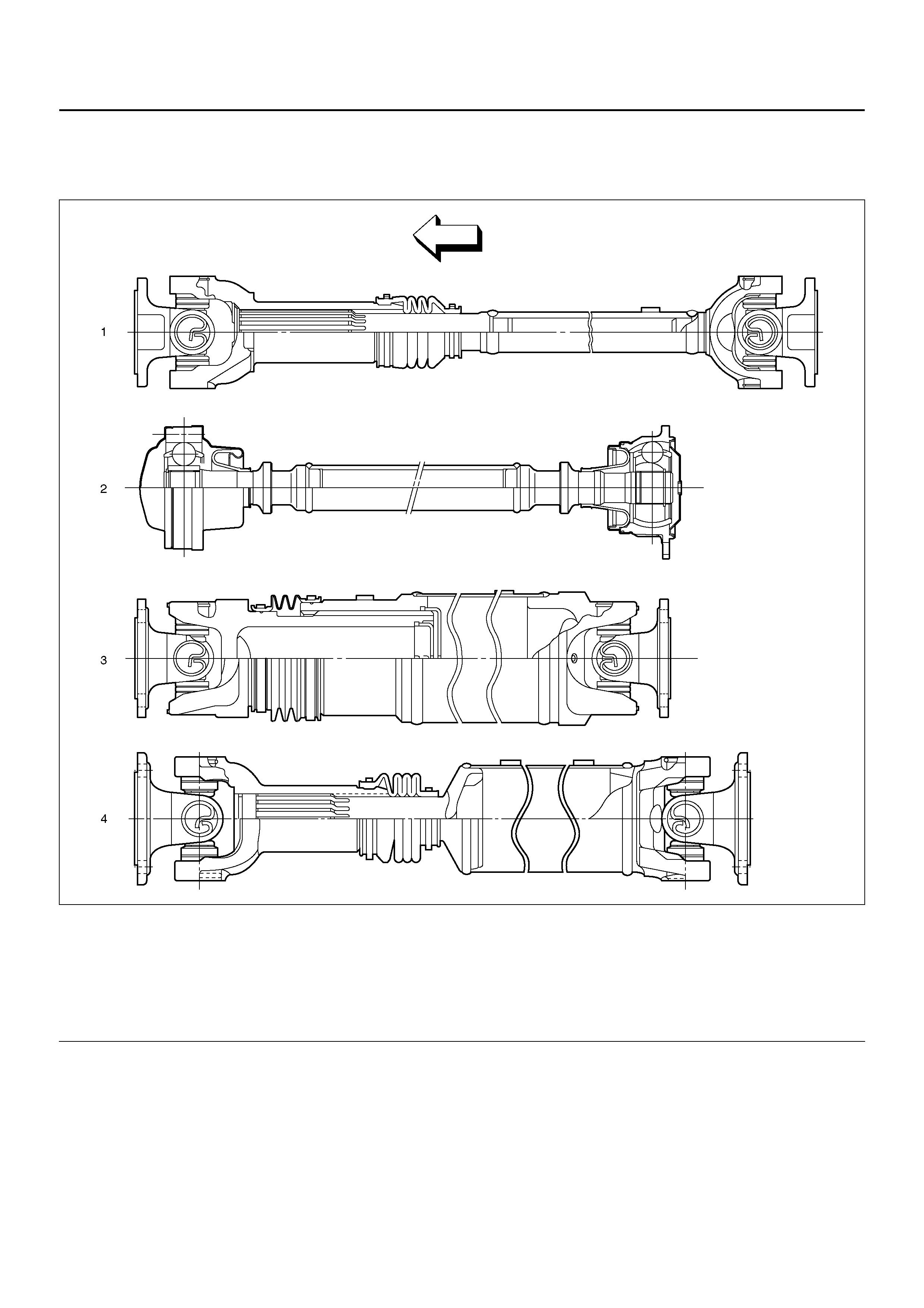

GENERAL DESCRIPTION

401R100003

Legend

EndOFCallout

(1) Front Propeller Shaft ( Manual Transfer Case)

(2) Front Propeller Shaft (TOD Transfer Case)

(3) Rear Propeller Shaft; Aluminum Tube (M/T)

(4) Rear Propeller Shaft;Steel Tube (A/T)

Torque is transmitted from the transmission to the axle

through propeller shaft and universal joint assembles.

All propeller shafts are the balanced tubular type. A

splined slip joint is provided in some drivelines.

• Since the propeller shaft is carefully balanced,

welding or any other modification are not permitted.

• Alignment marks should be applied to each propeller

shaft before removal.

• Be sure vehicle is stopped, engine is not running,

brake is secured and vehicle is secured to prevent

injury.

• Be careful not to grip the propeller shaft tube too

tightly in the vice as this will deform the tube.

Phasing

The propeller shaft is designed and built with the yoke

lugs (ears) in line with each other. This design phases

the joints, reducing the vibrations produced due to the

velocity fluctuations that can occur when rotating an out-

of-phase propeller shaft. The propeller shaft will absorb

vibrations from speeding up and slowing down each

time the universal joint goes around. This vibration

would be the same as a person snapping rope and

watching the "wave" reaction flow to the end. A

propeller shaft working in phase would be similar to two

persons snapping a rope at the same time, and

watching the "waves" meet and cancel each other out.

In comparison, this would be the same as the universal

joints on a propeller shaft. A total cancellation of

vibration produces a smooth flow of power in the

driveline. It is very important to apply a reference mark

to the propeller shaft before removal, to assure

installation alignment.

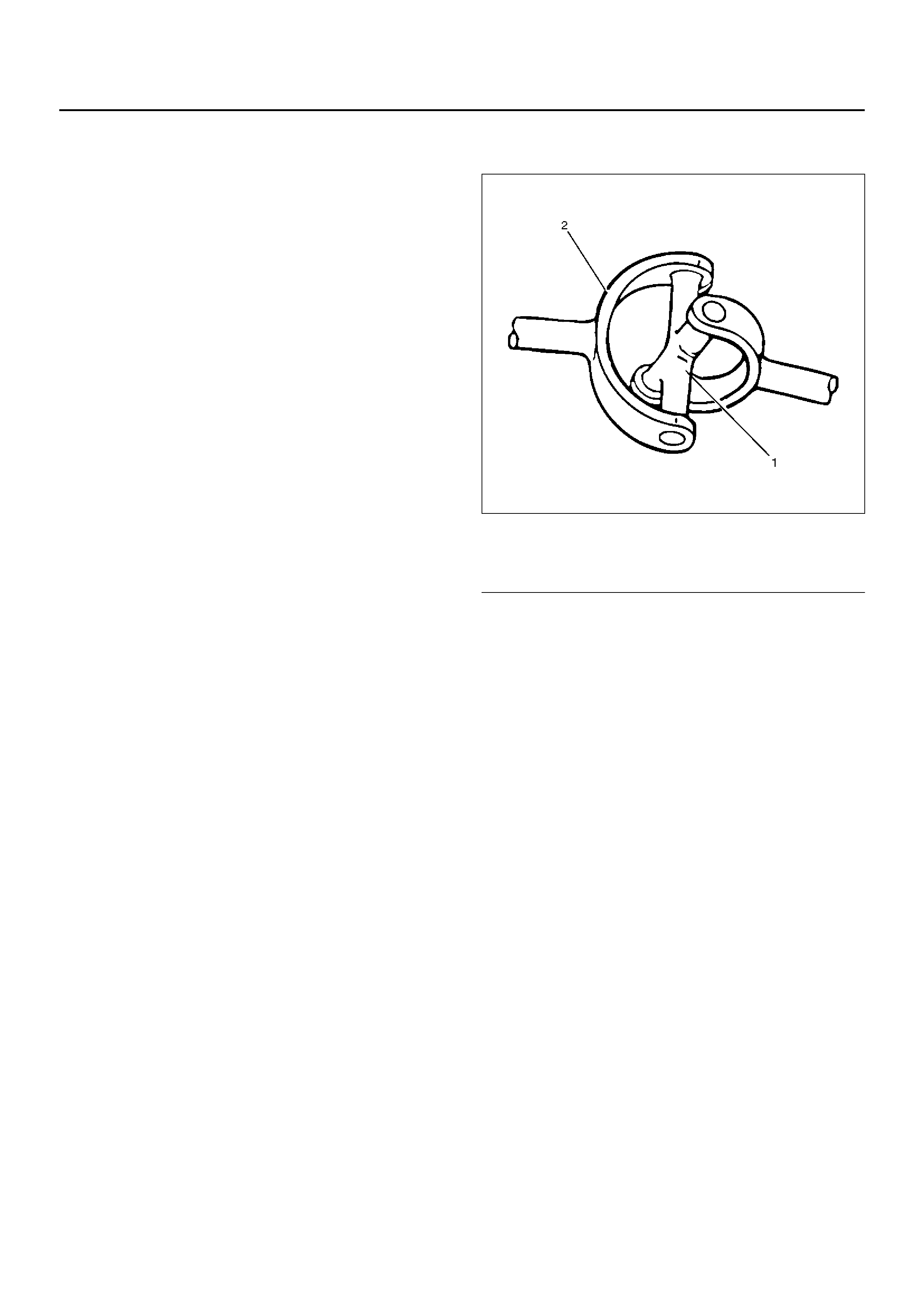

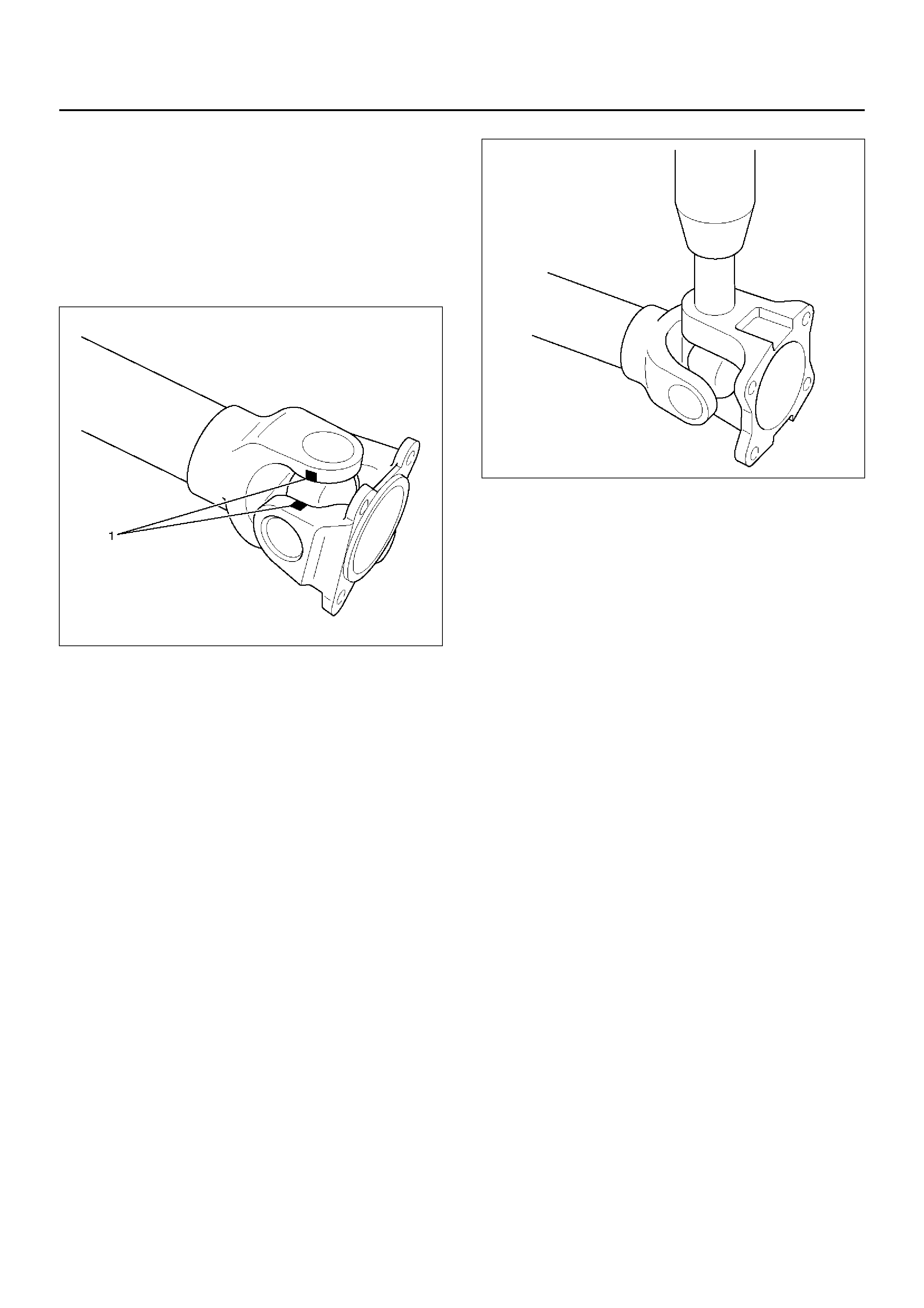

UNIVERSAL JOINT

401RW015

Legend

EndOFCallout

A universal joint consists of two Y-shaped yoke s

connected by a crossmember called a spider.

The spider is shaped like a cross. Universal joints are

designed to handle the effects of various loadings and

fron t or re ar axl e wi n dup du r i ng a cce l er at i on . Wi th i n t h e

desig ned ang le var i ations , the univ ers al joi nt wil l

operate efficiently and safely. When the design angle is

changed or exceeded the operationallife of the joint may

decrease.

The bearings used in universal joints are of the needle

roller type. The needle rollers are held in place on the

trunnions by round bearing cups. The bearing cups are

held in the yokes by snap rings.

(1) Spider

(2) Yoke

DIAGNOSIS OF PROPELLER SHAFT AND UNIVERSAL JOINT

Condition Possible cause Correcti on

Universal Joint Noise. Worn universal joint bearings. Replace.

Improper lubrication. Lubricate as directed.

Loose flange bolts. Tighten to specifications.

Ping, Snap, or Click in Drive Line

(Usually Heard on Initial Load after

the Transmission is in Forward or

Reve rse Ge ar )

Loose bushing bolts on the rear

springs or upper and lower control

arms.

Tighten the bolts to specified torque.

Loose or out-of-phase end yoke. Remove end yoke, turn 180 degrees

from its original position, lubricate

the splines and reinstall. Tighten the

bolts and pinion nut to specified

torque.

Knocking or Clanking Noise in the

Driveline when in High or Neutral

Gear at 16km/h

Worn or damaged universal joint Replace the universal joint.

Squeak Lack of lubricant. Lubricate joints and splines. Also

check for worn or brinelled parts.

Shudder on Acceleration (Low

Speed) Loose or missing bolts at the

flanges. Replace or tighten bolts to specified

torque.

Incorrectly set front joint angle. Install shim under the transmission

support mount to change the front

joint angle.

Worn universal joint. Replace.

Vibration Incorrect shaft runout. Replace.

Shaft out of balance. Adjust.

Transmission rear housing bushing,

transfer case housing bushing worn. Replace.

Yo ke sp li ne jam m ed . Replace.

Excessive Leak at the Front Spline

Yoke of Rear Propeller Shaft Rough surface on splined yoke;

burred nicked or worn. Replace the seal. Minor burrs can

be Smoothed by careful use of

crocus cloth or fine stone honing.

Replace the yoke if badly burred.

Defective transmission rear oil seal. Replace the transmission rear oil

seal and replenish the transmission

oil.

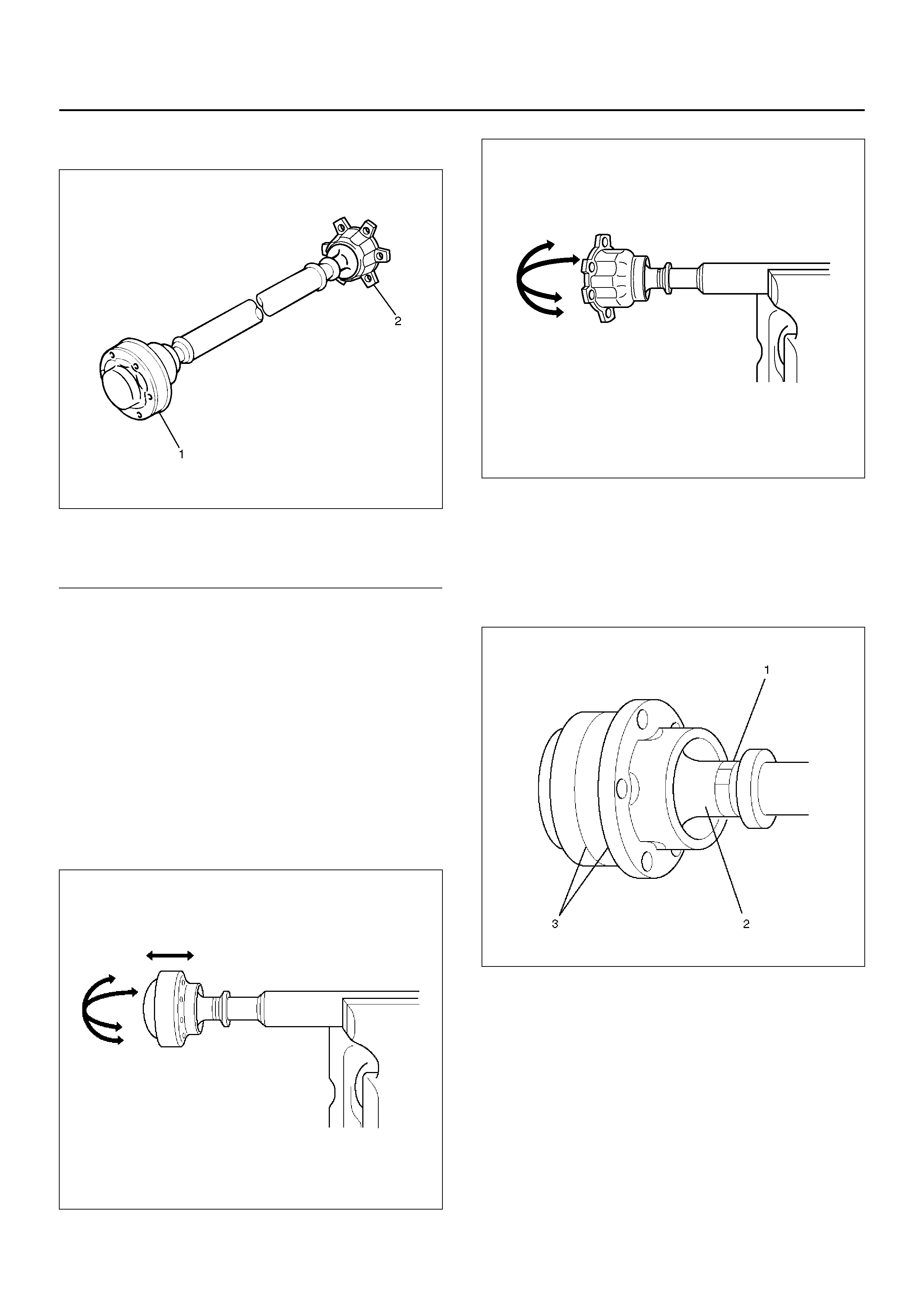

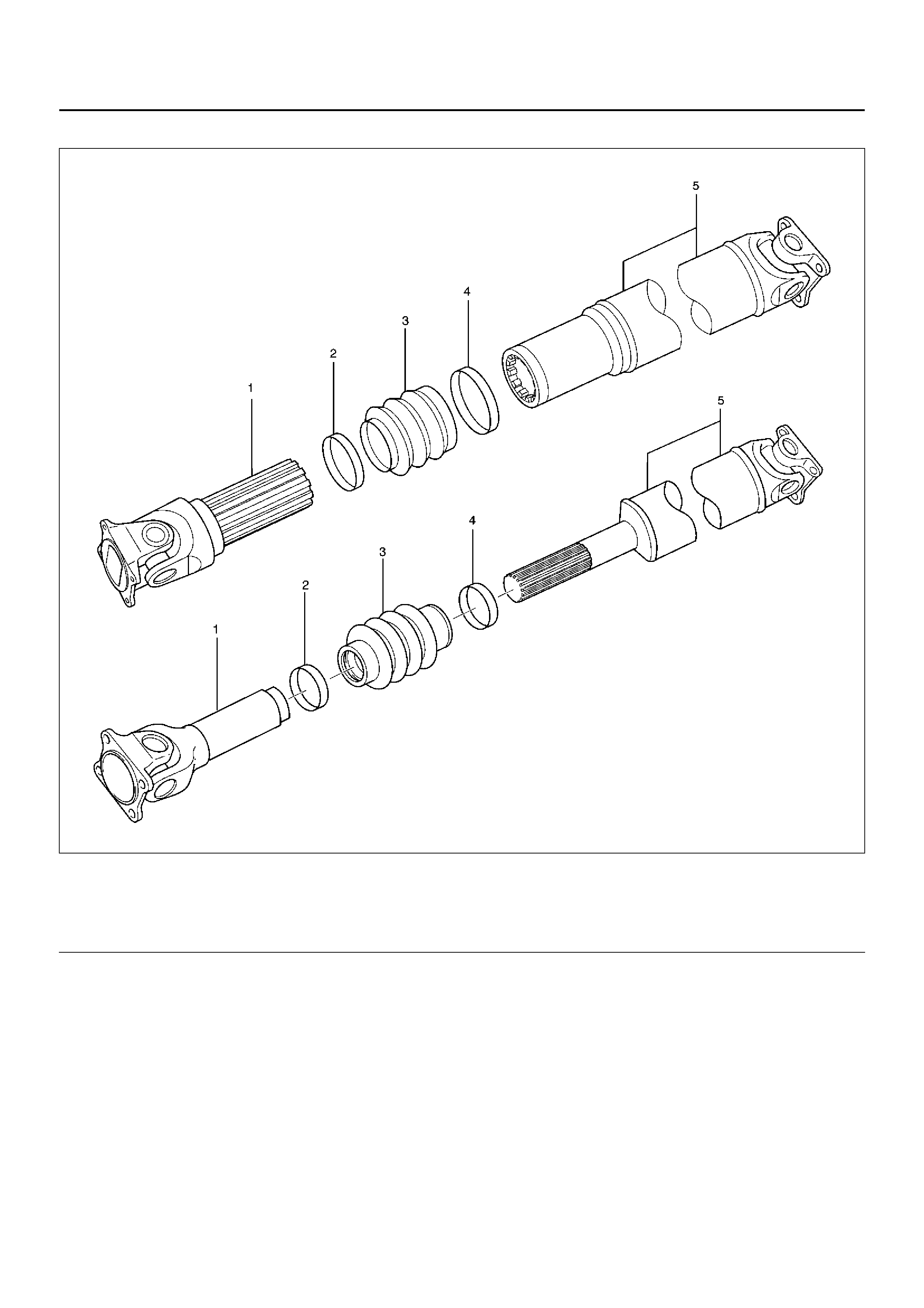

FRONT PROPELLER SHAFT

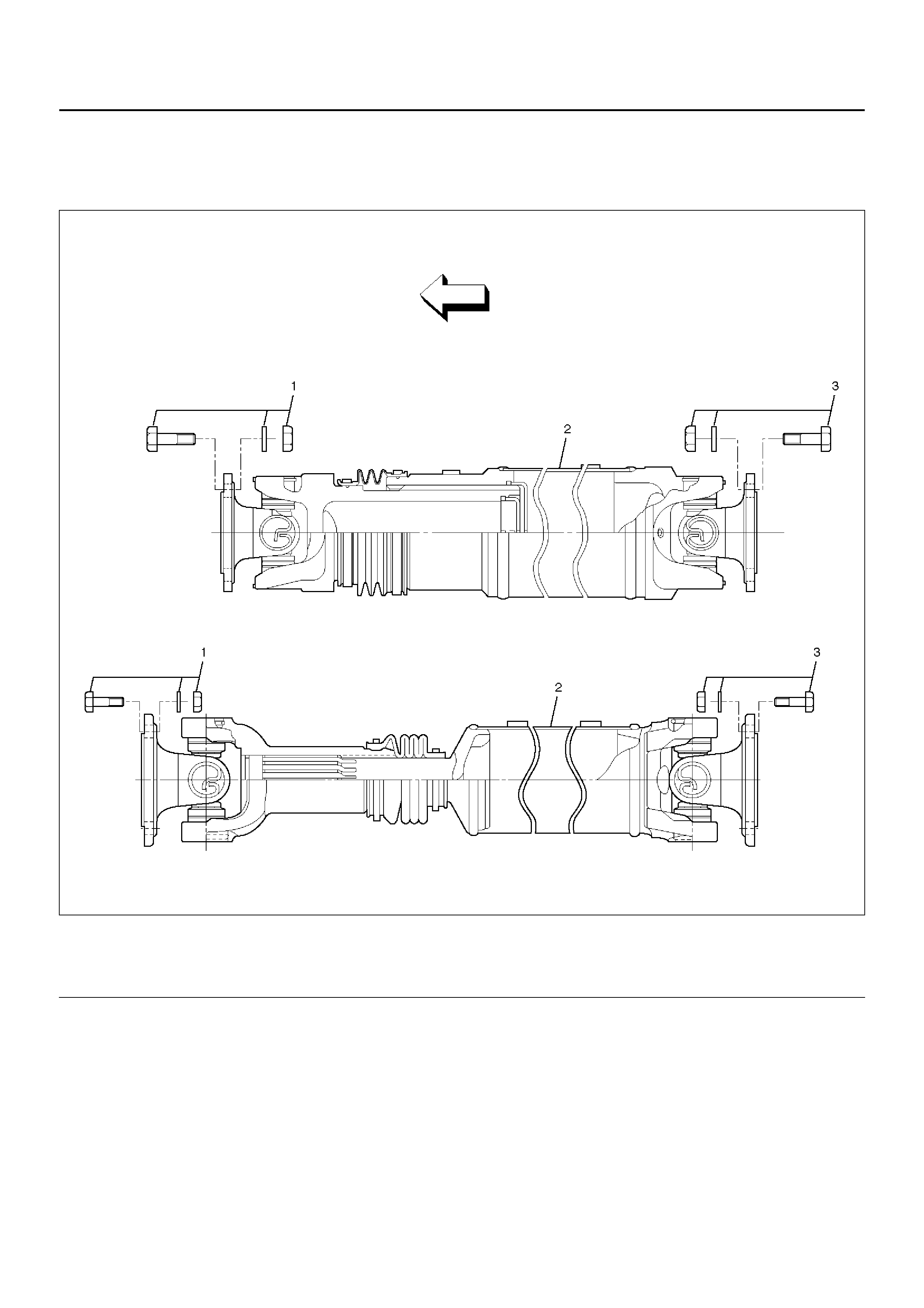

FRONT PROPELLER SHAFT AND ASSOCIATED PARTS

401R100004

Legend

EndOFCallout

REMOVAL

1. Raise the vehicle on a hoist.

NOTE: Apply alignment marks to all flanges as

shown .

401RS020

(1) Bolt, Nut and Washer (Front Axle Side)

(2) Front Propeller Shaft

(3) Bolt, Nut and Washer (Transfer Case Side)

(4) Bolt and Washer (Front Axle Side)

(5) Fr ont Prope ll er Shaft (Wit h TOD)

(6) Bolt and Washer (Transfer Case Side)

401RW053

401RW052

2. Remove bolt, nut and washer (Front axle side).

3. Remove bolt, nut and washer (Transfer side).

4. Remove front propeller shaft.

NOTE: If equipped with torque on demand (TOD),

when removing, installing or carring for front propeller

shaft, the boot may be damaged if bending force is

applied to the constant velocity joint of the shaft.

401RW051

INSTALLATION

NOTE: Never insta ll the sh aft assembly backwards.

Completely remove the black paint from the connecting

surface of flange coupling on each end of propeller

shaft. Clean so that no foreign matter will be caught in

between.

1. Align the mark which was applied at removal. Install

front propeller shaft and tighten the bolts to the

specified torque.

Torque:63N·m

2. After installing the propeller shaft, be sure to apply

black paint (1) to exposed area (other than

connecting surface) of the entire surface of flange

coupli ng .

401RS019

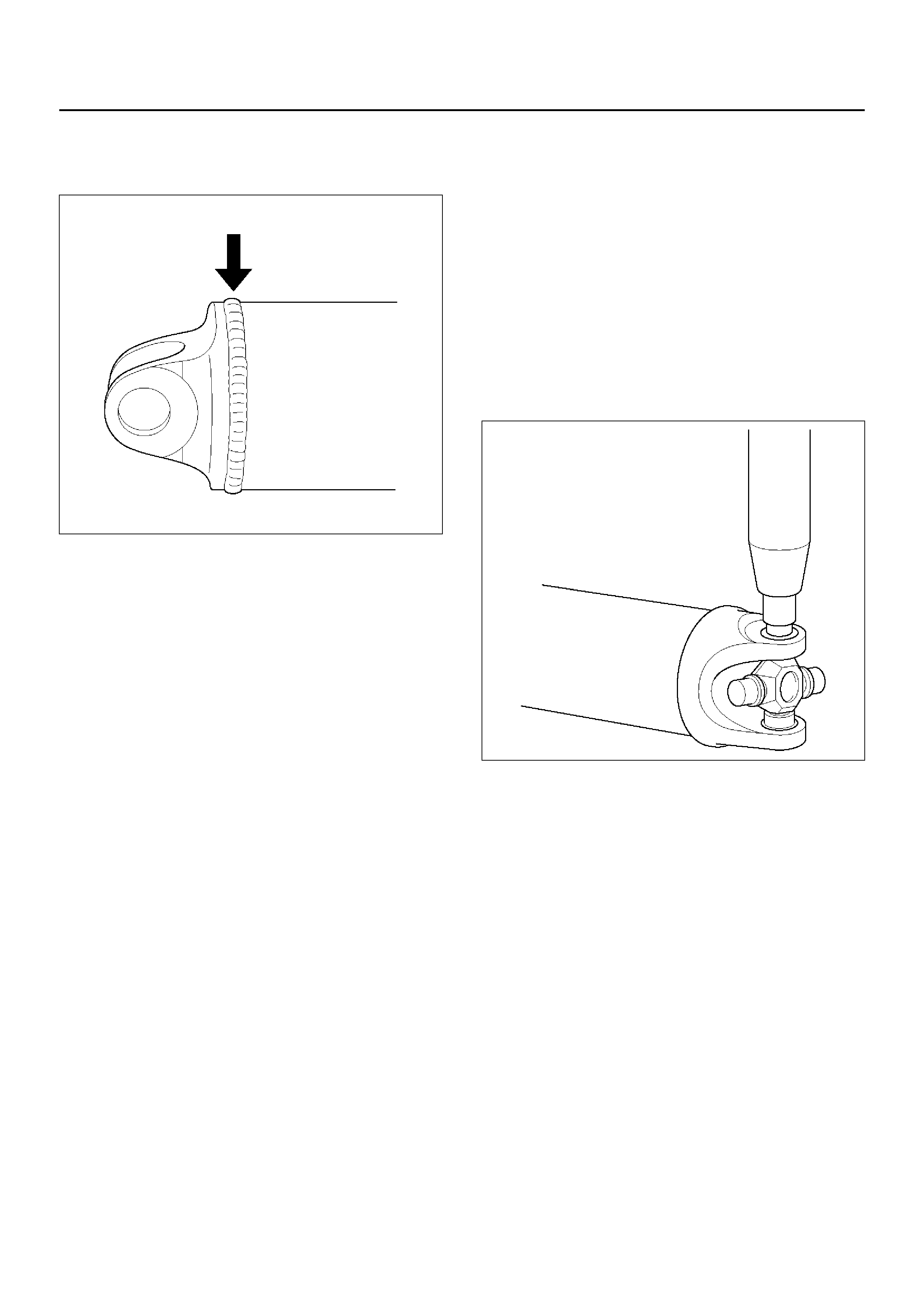

SLIP JOINT DISASSEMBLY

401RW032

Legend

EndOFCallout

1. Lay the shaft horizontally on a bench and secure. 2. Indicate the original assembled position (1) by

marking the phasing of the shaft prior to

disassembly.

(1) Spline Yoke Assembly

(2) Clamp

(3) Boot

(4) Clamp

(5) Tube Assembly

401RW037

3. Using the flat blade of a screwdriver, pry the loose

end of the boot clamp upwards and away from the

propeller shaft boot. Be careful not to damage the

boot.

4. When boot clamps becomes loose, remove by

hand.

5. Repeat for the other boot clamp.

6. Remove the spline yoke assembly from the tube

assembly, by securing the boot with one hand and

pulling on the spline yoke.

7. Remove the boot from the tube assembly.

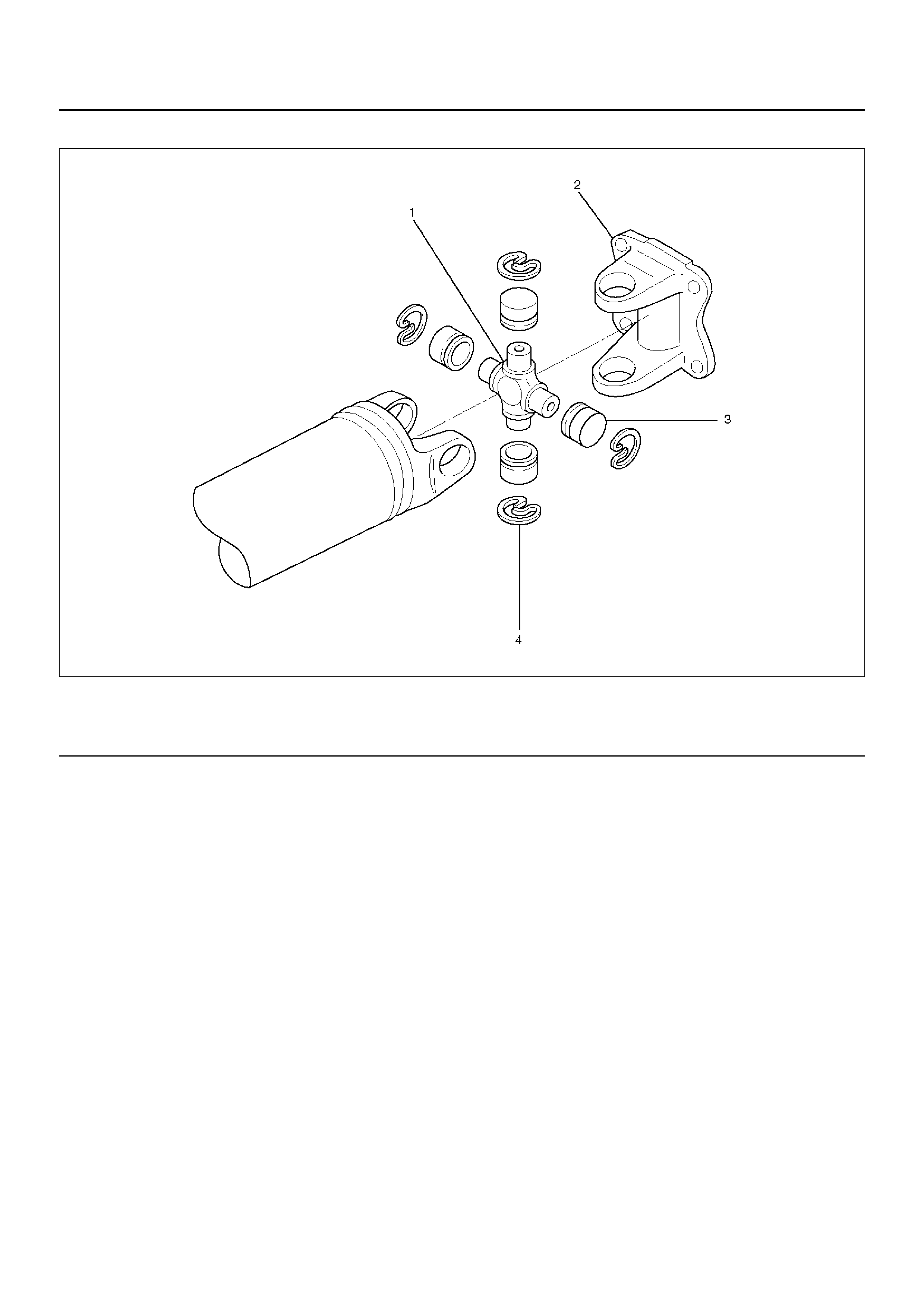

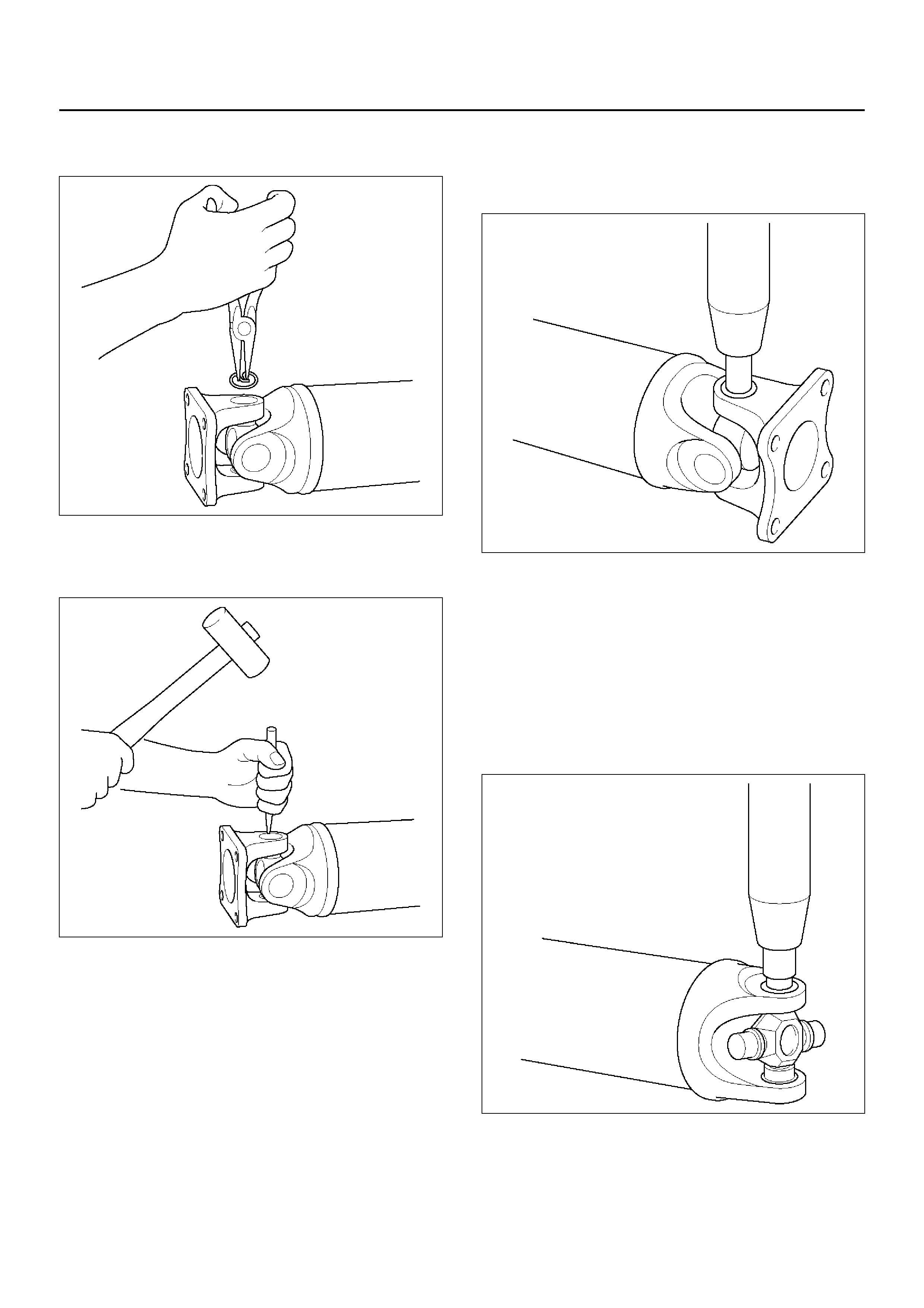

UNIVERSAL JOINT DISASSEMBLY

401RW031

Legend

EndOFCallout

(1) Flange Yoke

(2) Snap Ring (3) Spider

(4) Needle Roller Bearing

1. Using a soft drift, tap the outside of the bearing cup

assembly to loosen snap ring. Tap bearing only

hard enough to break assembly away from snap

ring.

Remove snap ring from yoke. Turn joint over, tap

bearing away from snap ring, then remove opposite

snap ring.

Apply alignment marks (1) on the yokes of the

universal joint, then remove snap ring.

401RW018

2. Set the yoke in the arbor press with a piece of tube

stock beneath it.

Place a solid plug on the upper bearing assembly

and press it through to release the lower bearing

assembly.

401RW020

3. If the bearing assembly will not pull out by hand

after pressing, tap the base of the lug near the

bearing assembly to dislodge it.

4. To remove the opposite bearing, turn the yoke over

and straighten the spider in the open hole. Then

carefully press on the end of the spider so the

remaining bearing moves straight out of the bearing

spider hole. If the spider or bearing are cocked, the

bearing will score the walls of the spider hole and

ruin the yoke.

5. Repeat this procedure on the remaining bearing to

remove the spider from the yoke.

6. Make sure of proper position for reinstallation by

applying setting marks, then remove spider .

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear ,

damage, corrosion or any other abnormal condition is

found through inspection.

NOTE: When any part of the journal assembly (spider,

needle roller bearing) requires replacement, be sure to

replace the entire assembly.

Check the following parts for wear, damage, noise or

any other abnormal conditions.

1. Spider

2. Needle roller bearing

3. Yoke

4. Flange

5. Boot

Spider pin for wear

Spider pin should be smooth and free from fretting or

galling. Needle marking is normal, but wear should not

be felt.

401RW038

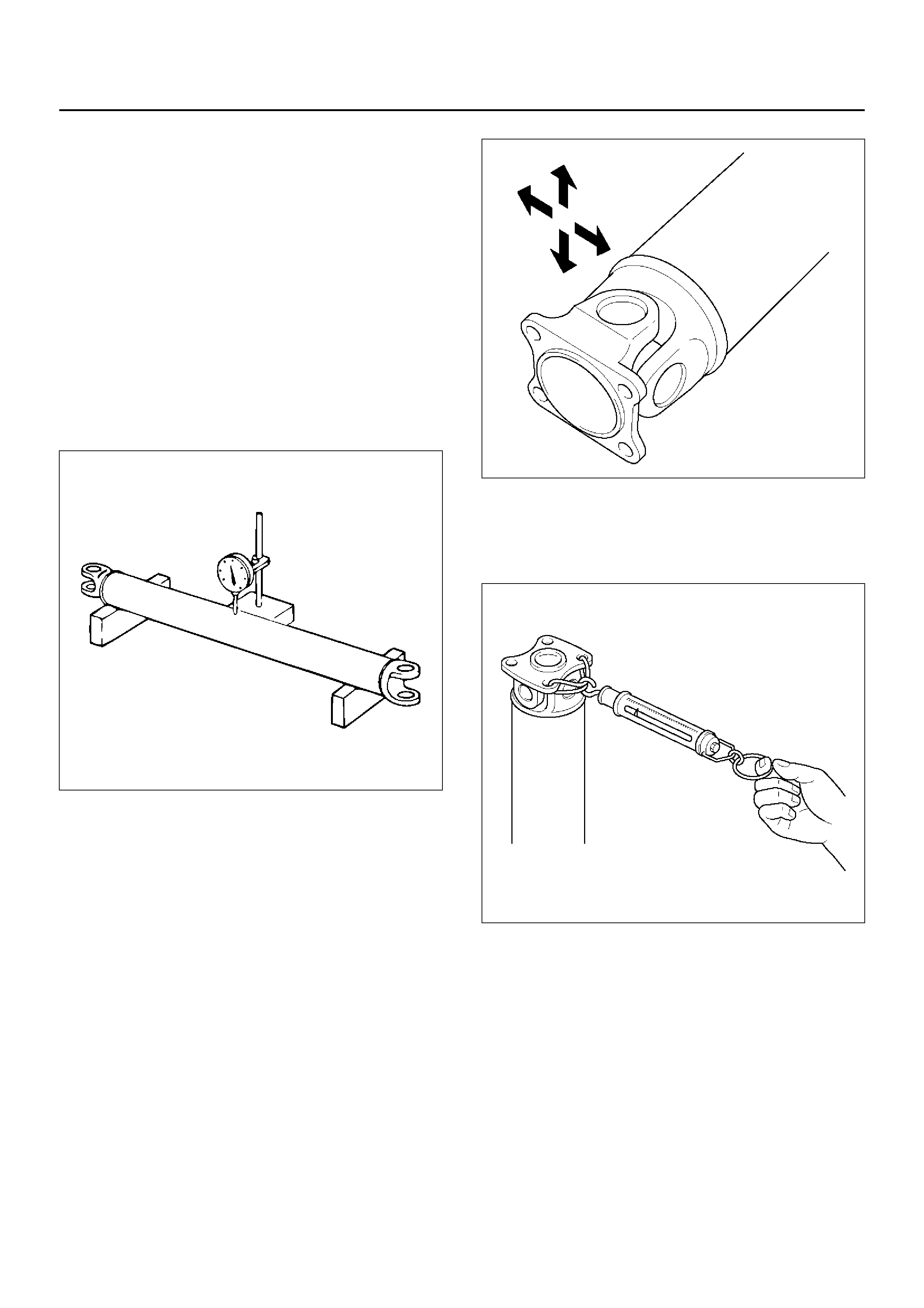

Propeller shaft runout

Support the propeller shaft on V-blocks (2) and check

for runout by holding the probe of a dial indicator (1) in

contact with the shaft.

Static runout limit:

0.13mm - Total Indicator Reading on the neck of

the slip tube shaft (with a boot ).

0.25mm - Total Indicator Reading on the ends of

the tubing 3 inch from the welds.

0.38mm - Total Indicator Reading at the linear

center of the tube.

0.38mm - Total Indicator Reading for the full

length of tube with 30" or less of tubing.

401RS027

Spline

The nylon-coated spline should be free from nicks and

dings and the underlying steel spline should not be

visible.

After cleaning the nylon coating spline, the coating

should exhibit only a slight indication of wear.

Grease volume is approximately 10 grams of grease in

total. Grease should be evenly applied to both the

female and the male slip splines using a small brush.

After assembly of the slip joint, the sliding joint should

be fully worked from the full collapsed to the full

extended position.

Play in the universal joint

Limit:Less than0.15mm

401RW023

Preload of the universal joint

Preload should be 0 to 24.9 kg. Joints should rotate

smoothly and freely and should exhibit no rough or

ratchety movement.

401RW085

Boot

Check the boot for crack or damage. If necessary,

replace the boot.

If abnormal condition are found on the boot, inspect the

grease for mixing of foreign material.

If the grease is good condition, and slip joint works well,

replace the boot, replenish grease, and reassemble the

slip joint.

If the foreign material is found in the grease, check the

spline for wear and damage.

UNIVERSAL JOINT REASSEMBLY

1. Install spider to flange yoke. Be sure to install the

spider by aligning the setting marks made during

disassembly.

2. Pack the four grease cavities of the spider with a

high quality, extreme pressure N.L.G.I. Grade 2

grease. Do not add additional grease to the bearing

cup assembly.

3. Move one end of the spider to cause a trunnion to

project through the spider hole beyond the outer

machined face of the yoke lug. Place a bearing

over the trunnion diameter and align it to the spider

hole. Using an arbor press, hold the trunnion in

alignment with the spider hole and place a solid plug

on the upper bearing. Press the bearing into the

spider hole enough to install a snap ring.

401RW020

4. Install a snap ring.

Be sure the snap rings are properly seated in the

grooves.

5. Repeat steps 3 and 4 to install the opposite bearing.

If the joint is stiff, strike the yoke ears with a soft

hammer to seat needle bearings.

6. Align setting marks (1) and join the yokes.

401RW018

7. Install snap ring.

SLIP JOINT REASSEMBLY

401RW032

Legend

EndOFCallout

1. Apply grease evenly to both the female and male

splines.

2. Apply a small amount of grease by finger to the

outer lips of the boot.

3. Slide the boot (smaller diameter side) onto the

spline yoke shaft being careful not to damage the

spline coating or boot.

4. Insert the spline yoke shaft into the tube assembly

being careful to maintain proper phasing. The

spider holes should be in line and as per originally

marked prior to disassembly.

5. Position boot onto tube and yoke shaft in final

position over boot grooves.

6. Attach boot clamps and secure using pliers.

7. Be sure clamp is properly seated and secure.

CAUTION: Use a new clamp which is of the same

part number as the original. The use any other

clamp may result in an unbalanced shaft and boot

damage.

(1) Spline Yoke shaft

(2) Clamp

(3) Boot

(4) Clamp

(5) Tube Assembly

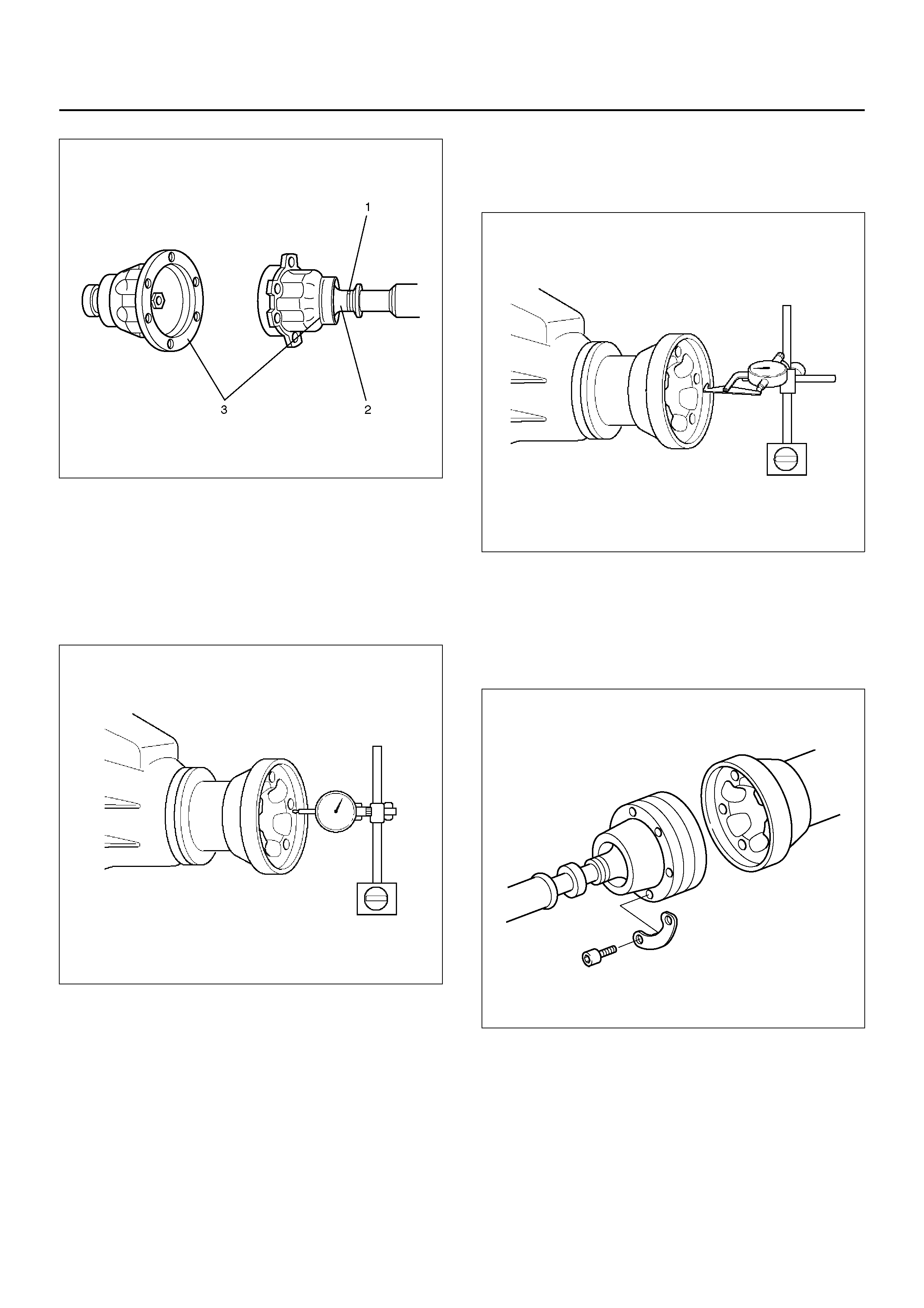

With TO D (Torque On Demand 4×4)

401R100006

Legend

EndOFCallout

Constant Velocity Joint

LJ and BJ constant velocity joints are unremovable

types. Check the joint for play and the boot for damage,

wear, and leak of grease. If abnormality is found,

replace propeller shaft as an assembly.

Play in Constant Velocity Joint

Hold the shaft in a vice between two pieces of wood,

and try to move the joint vertically, right and left, and

back and forth to make sure of smooth motions and no

remarkable play.

401RW050

401R100007

Boot of Constant Velocity Joint

Check the boot (2) for crack, damage and grease leak,

and the boot band (1) for loosening and damage. Check

the both sides of the joint and make sure that there is no

leak of grease from the cover press-in parts(3).

401RW048

(1) LJ Constant Velocity Joint

(2) BJ Constant Velocity Joint

401R100008

Front Axle Flange Run-out

1. Set a dial gage at right angle near the outer

circumference of the flange face and check the

run-out of the flange face.

Limit:0.15mm

401RW046

2. Set a dial gage at right angle near the inner

circumference and check the run-out of the flange.

Limit:0.15mm

401RW045

3. If vibration is felt during the 4H AUTO drive,

disconnct the propeller shaft at the front axle.

Reinstall the propeller shaft at 60°, 120°, 180°, 240°,

and 300° and conduct test drive in each position

and check if there is vibration.

401R100009

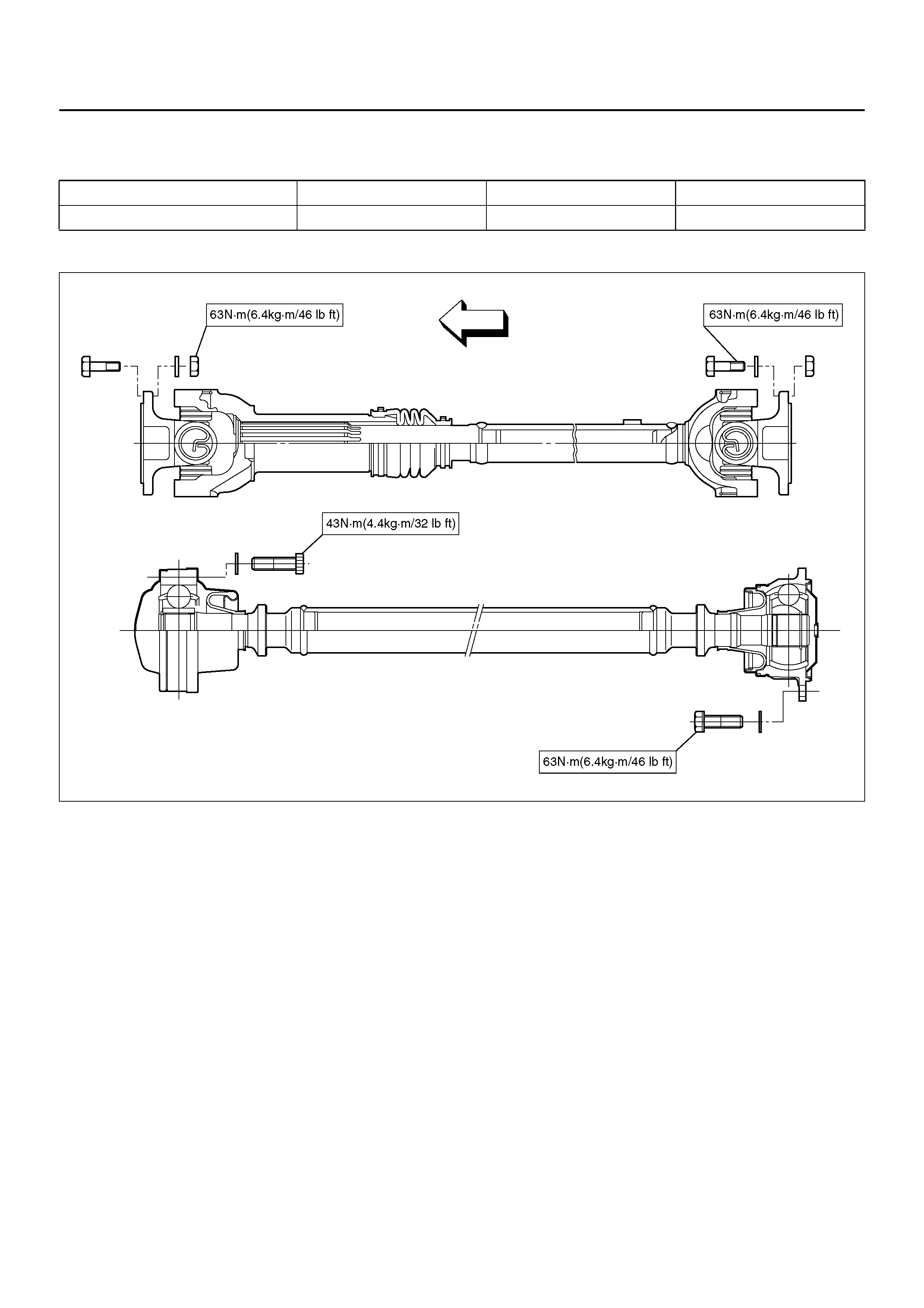

MAIN DATA AND SPECIFICATIONS

General Specifications

Torque Specifications

401R100005

Transmission M/T A/T (Normal Tr ansfer) A/T (With TOD)

Length (between two frange) 467 mm 632 mm 626 mm

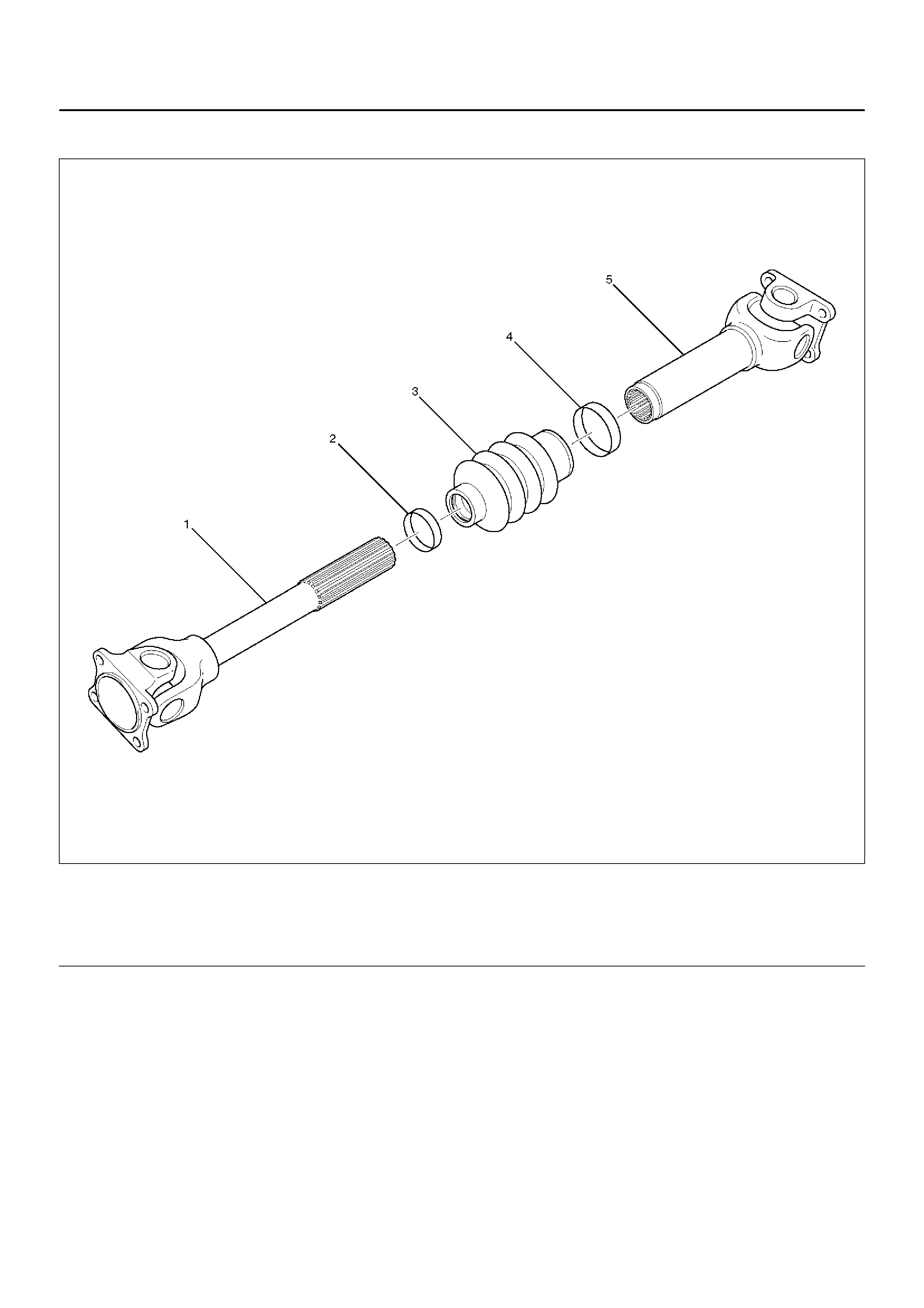

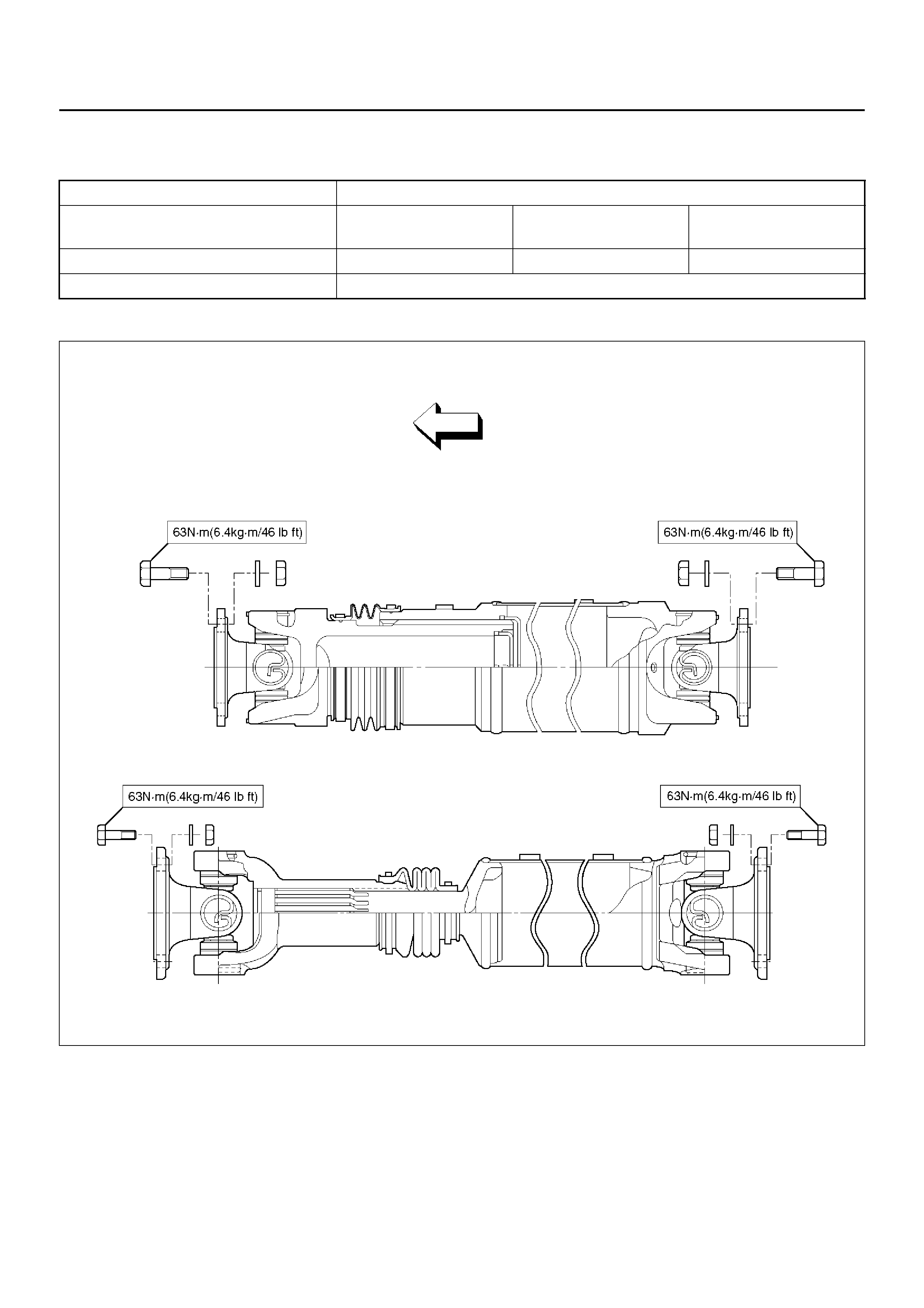

REAR PROPELLER SHAFT

REAR PROPELLER SHAFT AND ASSOCIATED PARTS

401RX028

Legend

EndOFCallout

REMOVAL

1. Raise the vehicle on a hoist.

NOTE: Apply alignment marks on the flange at the rear

propeller shaft both front and rear side.

2. Remove transfer side bolt, nut and washer.

3. Remove rear axle side bolt, nut and washer.

4. Remove rear propeller shaft.

INSTALLATION

NOTE: Never insta ll the sh aft assembly backwards.

Never insert bar between yoke lugs when tightening or

removing bolts.

Completely remove the dust or foreign matter from the

connecting surface of flange coupling on each end of

the propeller shaft.

1. Align the mark which is applied at removal.

2. Install rear propeller shaft and tighten the bolts to

the specified torque.

Torque:63N·m

(1) Bolt, Nut and Washer (Transfer Case Side)

(2) Rear Propeller Shaft (3) Bolt, Nut and Washer (Rear Axle Side)

SLIP JOINT DISASSEMBLY

401RX004

Legend

EndOFCallout

1. Lay the shaft horizontally on a bench and secure.

2. Indicate the original assembled position by marking

the phasing of the shaft prior to disassembly.

3. Using the flat blade of a screwdriver, pry the loose

end of the boot clamp upwards and away from the

propeller shaft boot. Be careful not to damage the

boot.

4. When boot clamps becomes loose, remove by

hand.

5. Repeat for the other boot clamp.

6. Remove the slip yoke assembly from the driveshaft,

by securing the boot with one hand and pulling on

the slip yoke.

7. Remove the boot from the shaft assembly.

(1) Spline Yoke and Universal Joint Assembly

(2) Clamp

(3) Boot

(4) Clamp

(5) Tube and Universal Joint Assembly

UNIVERSAL JOINT DISASSEMBLY

401RX022

Legend

EndOFCallout

NOTE: Aluminum is softer than steel. Care must be

taken not to remove excessive material or damage

bearing holes .

If the vehicle has aluminum tube type propeller shaft,

flange yoke, boot kit, journal kit can be replaced. If other

parts are damaged, replace propeller shaft as assembly .

(1) Spider

(2) Flange Yoke (3) Bearing

(4) Snap Ring

1. Apply alignment marks on the yokes of the universal

joint, then remove the snap ring.

401RW024

If the snap ring is stuck in position, remove paint

from the hole in the yoke or tap around the edge of

the bearing lightly with a soft drift.

401RW025

2. Set the yoke in the arbor press with a piece of tube

stock beneath it.

Place a solid plug on the upper bearing and press it

through to release the lower bearing.

401RW027

3. If the bearing will not pull out by hand after pressing,

tap the base of the lug near the bearing to dislodge

it.

4. To remove the opposite bearing, turn the yoke over

and straighten the spider in the open spider hole.

Then carefully press on the end of the spider so the

remaining bearing moves straight out of the bearing

spider hole. If the spider or bearing are cocked, the

bearing will score the walls of the spider hole and

ruin it.

401RW026

5. Repeat this procedure on the remaining bearing to

remove the spider from the yoke.

INSPECTION

• Propeller shaft for run-out Aluminum tube type.

Static run-out limit :

1.0mm - Total Indicator Reading full length of tubing.

• Propeller shaft for runout (Steel tube type).

Static runout limit :

0.13mm - Total Indicator Reading on the neck of the

slip tube shaft (with a boot).

0.25mm - Total Indicator Reading on the ends of the

tubing 3 inch from the welds.

0.38mm - Total Indicator Reading at the linear center

of the tube.

0.38mm - Total Indicator Reading for the full length of

tube with 750mm or less of tubing.

401RW017

• Play in universal joint.

Limit: Less than0.15mm

• Spider pin should be smooth and free from fretting or

galling.

Visib le signs of needle presence is normal, but wear

should not be felt.

401RW028

• Preload of the universal joint.

Preload should be 0 to 49 N .

Joints should rotate smoothly and freely and should

exhibit no rough or ratchety movement.

401RW019

• I nspect spli nes of slip joint for wear.

The nylon-coated spline should be free from nicks

and dings and the underlying steel spline should not

be visible.

After cleaning the nylon coating spline, the coating

should exhibit only slight indicator of wear.

Grease volume is approximately 10 grams of grease

in total. Grease should be evenly applied to both the

female and the male slip splines using a small brush.

After assembly of the slip joint, the sliding joint should

be fully worked from the full collapsed to the full

extended position.

• Aluminum tube type only: Inspect the aluminum

tubing for surface scratches and dents. These

scratches may not exceed 0.2 mm in depth.

401RW022

• Aluminum tube type only: Visually inspect the circle

welds and fittings for any signs of cracks or signs of

deterioration. If there are any cracks that exceed 0.2

mm in depth, the assembly must be replaced.

• Aluminum tube type only: Check to be sure there

are no missing balance weights. If balance weights

are missing and void has occurred in the aluminum

tubing greater than 0.2 mm, the assembly must be

replaced.

UNIVERSAL JOINT REASSEMBLY

1. Pack the four grease cavities of the spider with a

high quality, extreme pressure N.L.G.I. Grade 2

grease. Do not add additional grease to bearing

cup asse mbl y.

2. Move one end of the spider to cause a trunnion to

project through the spider hole beyond the outer

machined face of the yoke lug. Place a bearing

over the trunnion diameter and align it to the spider

hole.

Using an arbor press, hold the trunnion in alignment

with the spider hole and place a solid plug on the

upper bearing. Press the bearing into the spider

hole enough to install snap ring.

401RW026

3. Install a snap ring.

NOTE: Be sure the snap rings are properly seated in

the grooves.

4. Repeat steps 2 and 3 to install the opposite bearing.

If the joint is stiff, strike the yoke ears with a soft

hammer to seat the bearing.

5. Align the setting marks and join the yokes.

SLIP JOINT REASSEMBLY

401RX004

Legend

EndOFCallout

1. Apply grease evenly to both the female and male

splines.

2. Apply a small amount of grease by finger to the

outer lips of the boot.

3. Slide the boot (smaller diameter side) onto the

spline yoke shaft being careful not to damage the

spline coating or boot.

4. Insert the spline yoke shaft spline into the tube

assembly being careful to maintain proper phasing.

The spider holes should be in line and as per

originally marked prior to disassembly.

5. Position boot onto tube and yoke shaft in final

position.

6. Attach boot clamps and secure using pliers.

7. Be sure clamp is properly seated and secure.

CAUTION: Use a new clamp which is of the same

part number as the original. The use any other

clamp may result in an unbalanced shaft and boot

damage.

(1) Spline Yoke and Universal Joint Assembly

(2) Clamp

(3) Boot

(4) Clamp

(5) Tube and Universal Joint Assembly

MAIN DATA AND SPECIFICATIONS

General Specifications

Torque Specifications

E04RX013

4WD Model

Engine (Transmission) 6VD1 (M/T) 6VD1 (A/T·No rm al

transfer) 6VD1 (A/T·TOD)

Length (between two frange) 1302.2mm 1133.1mm 1121.9mm

Universal joint type Cardan type