SECTION 6C1 — 3.2L ENGINE DRIVEABILITY AND

EMISSIONS

Specifications

Torque Sp ecifications

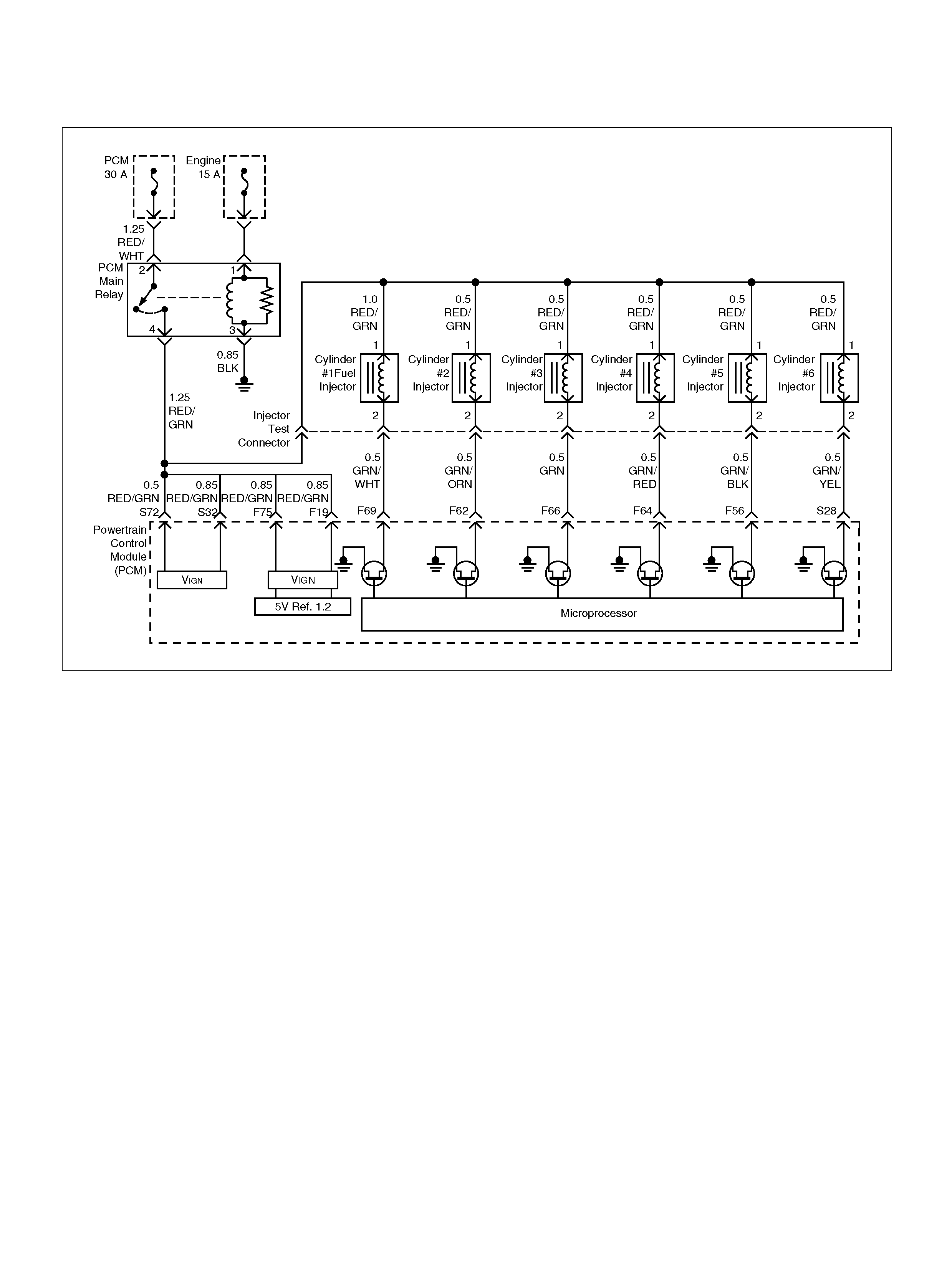

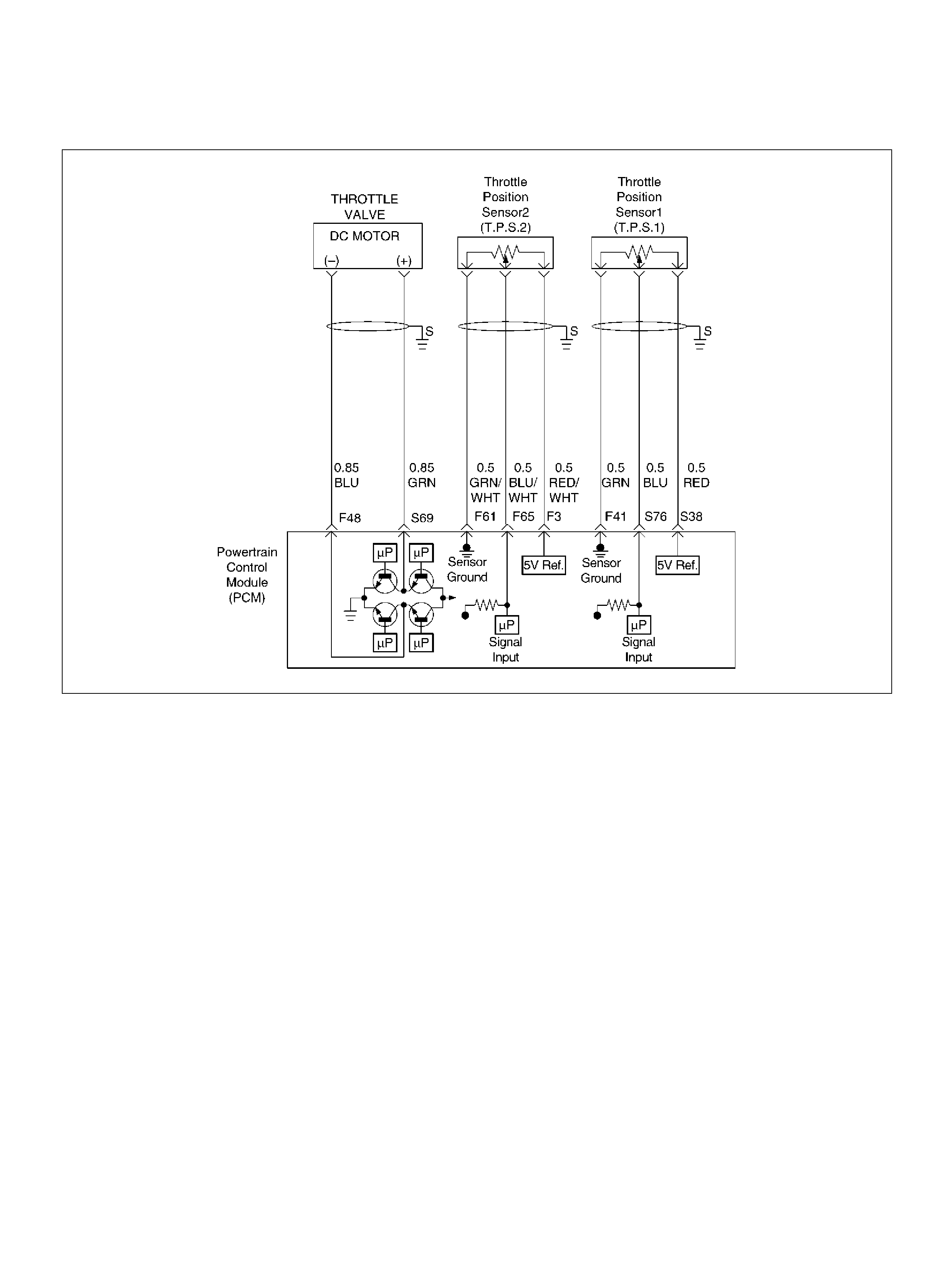

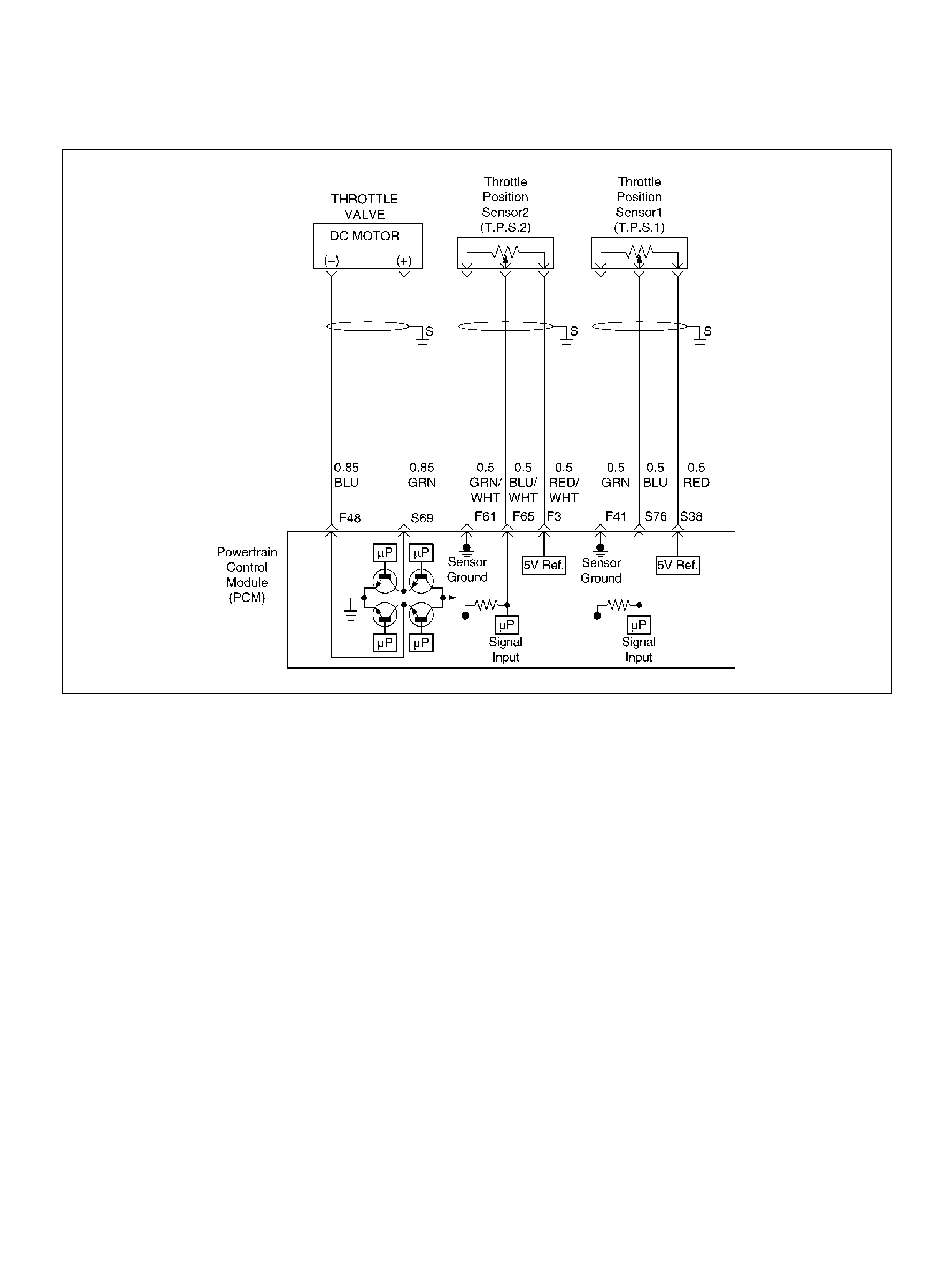

Diagram s and Schem atics

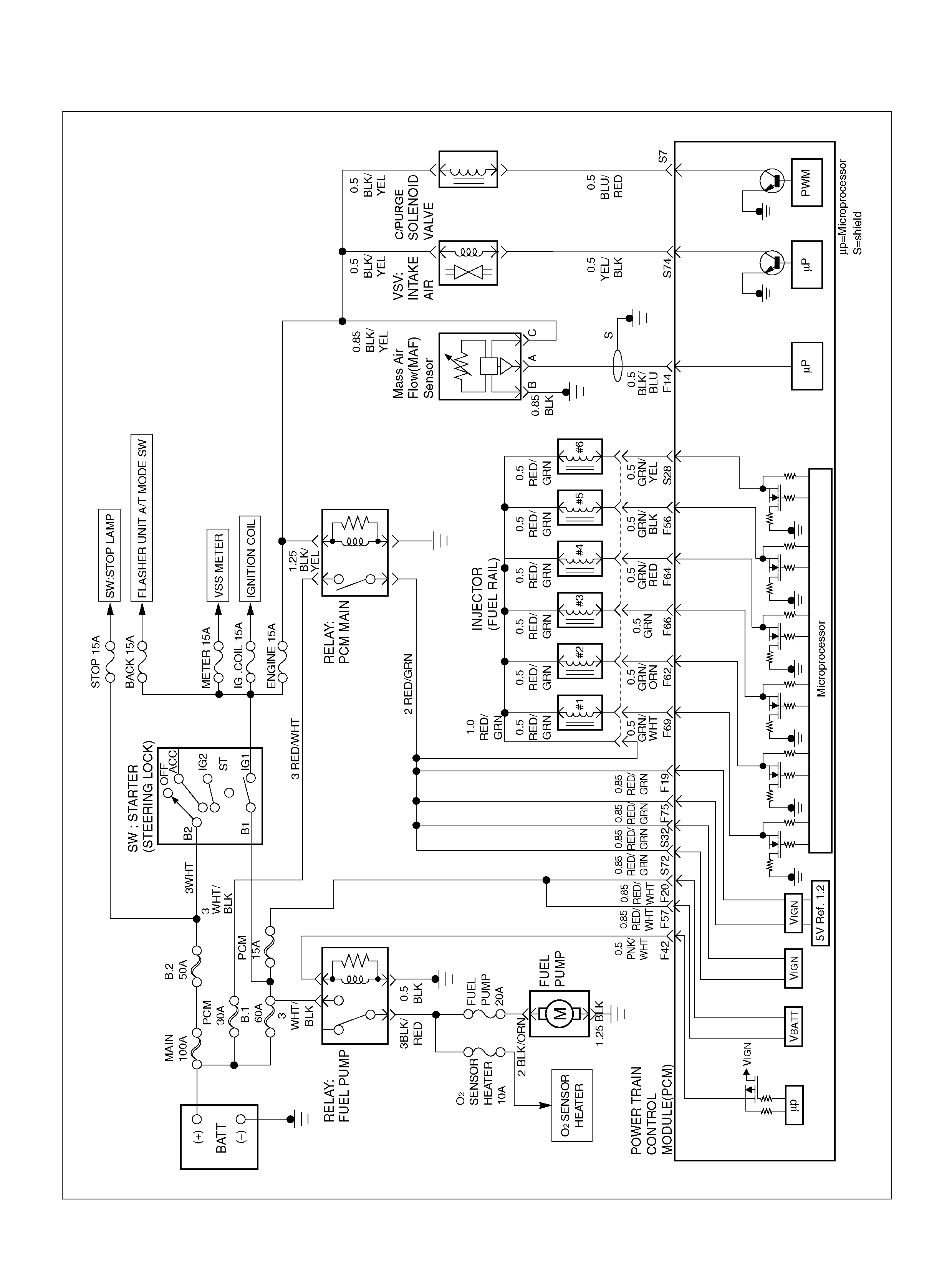

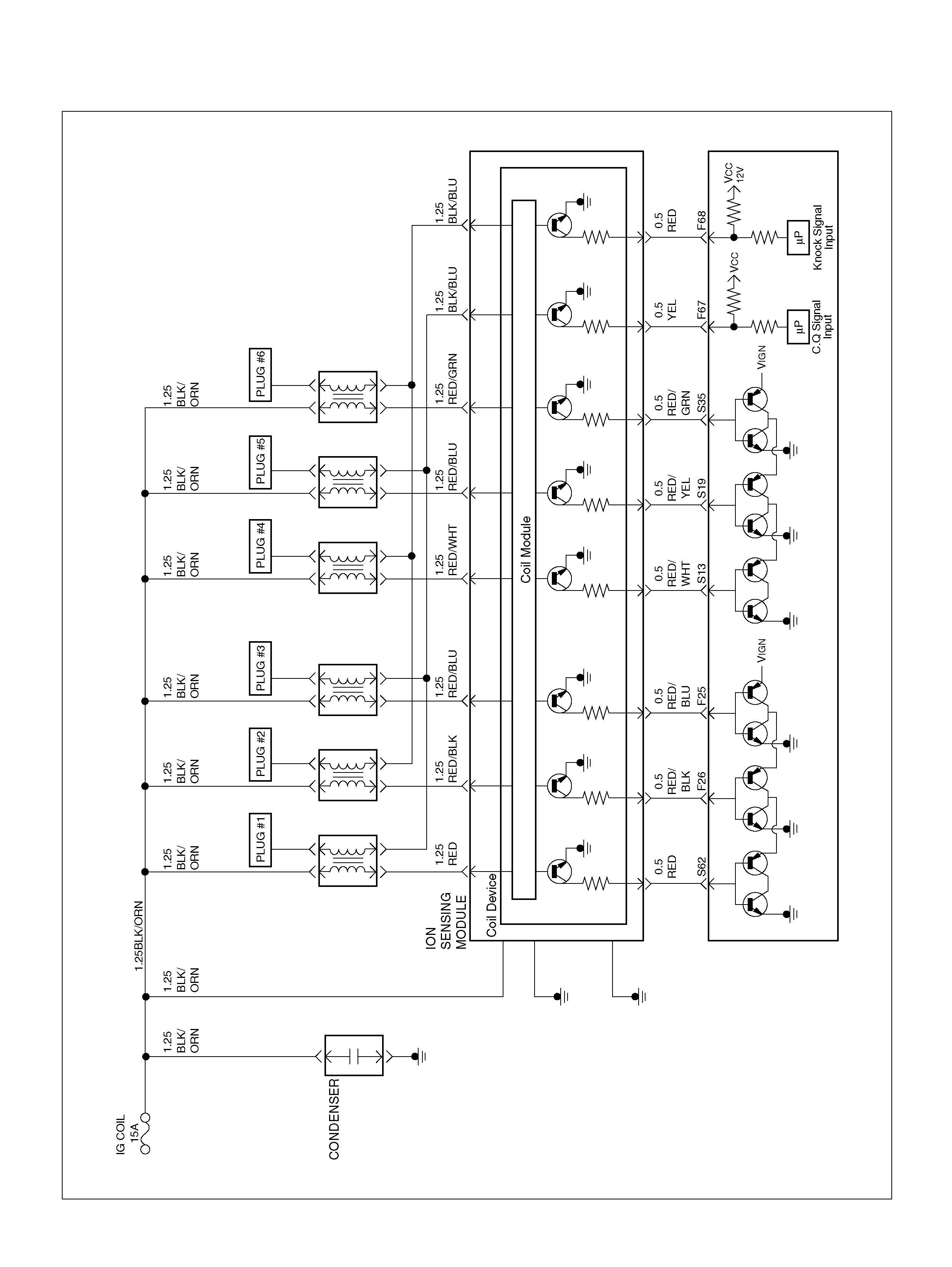

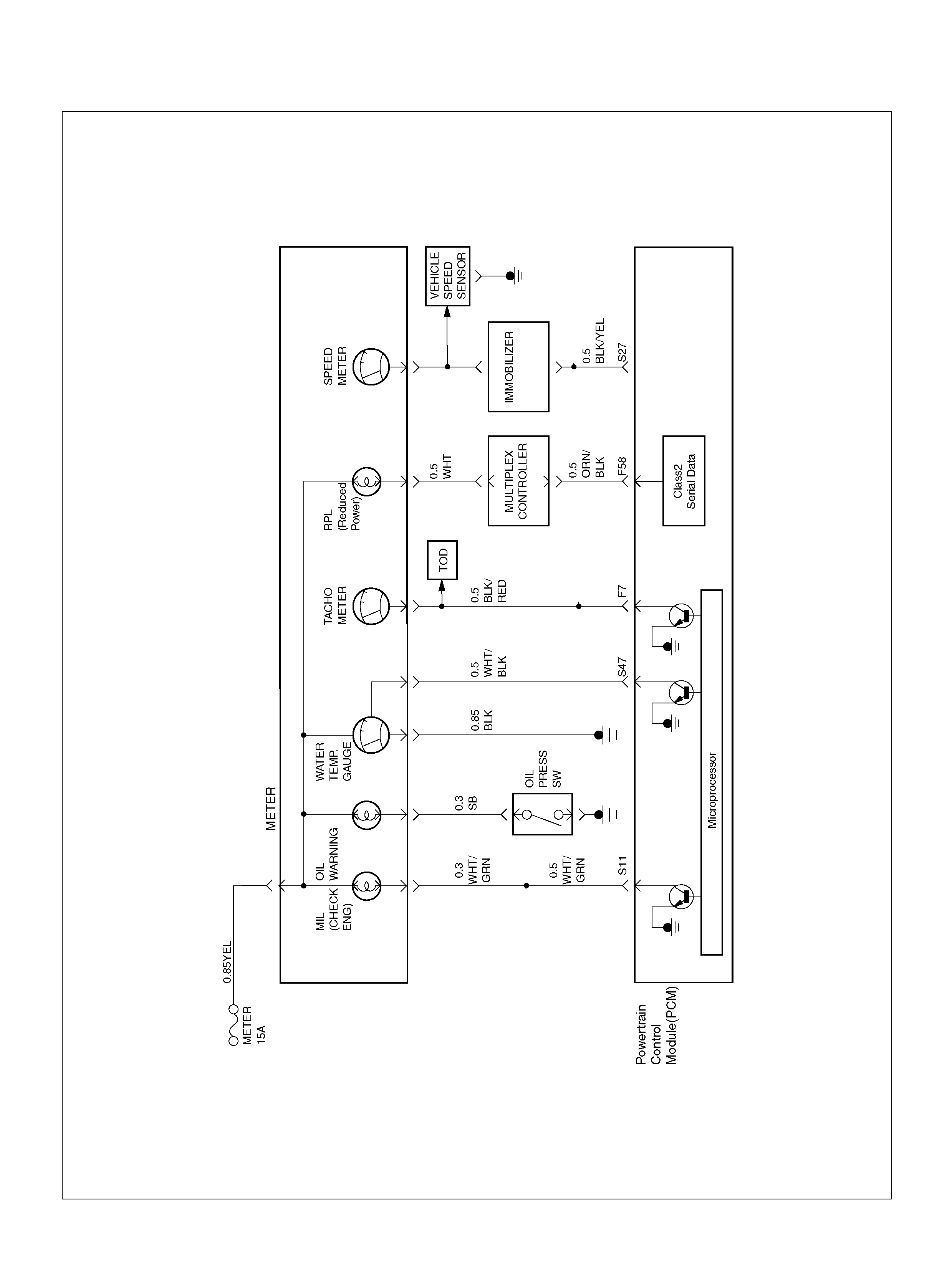

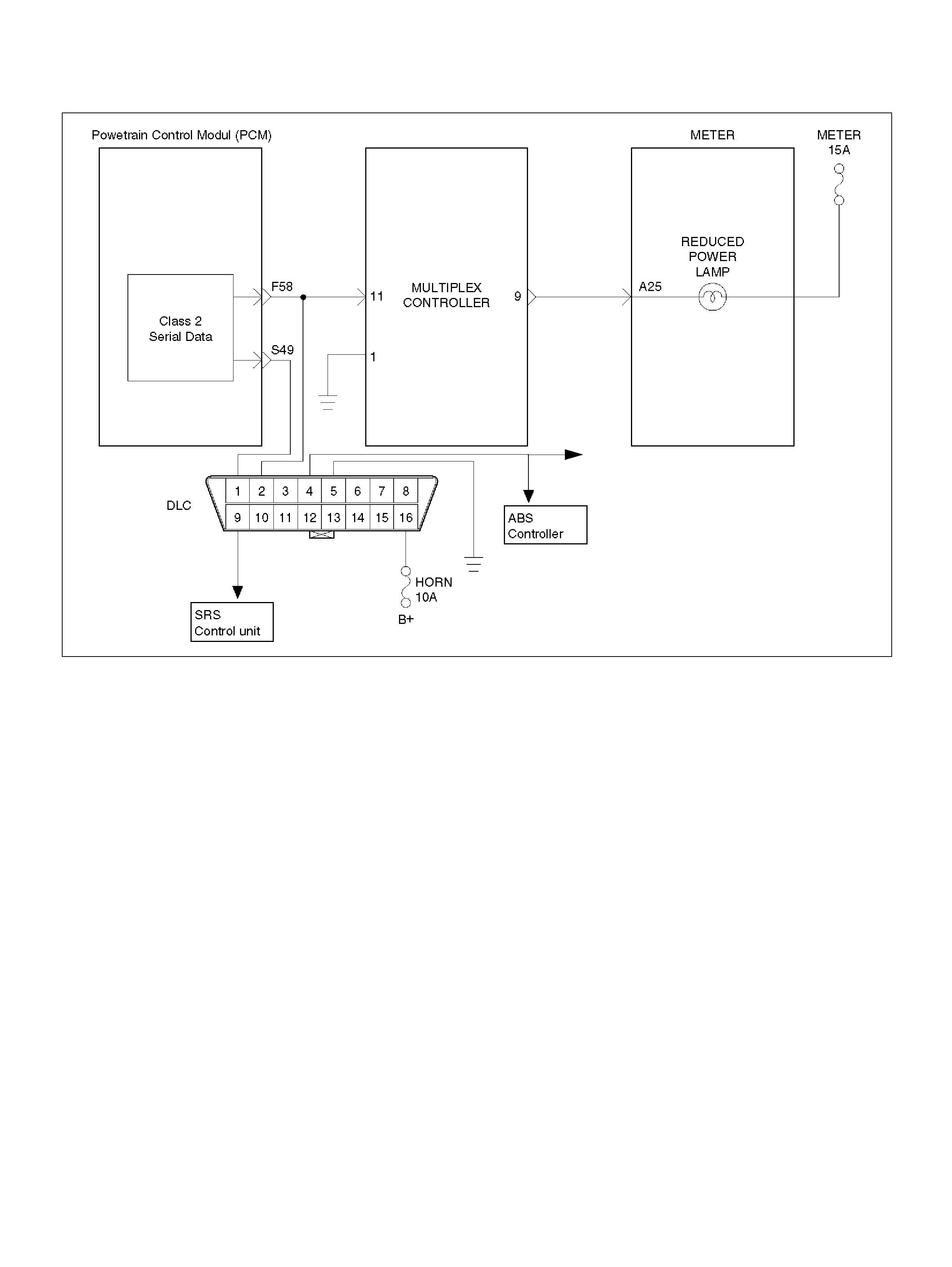

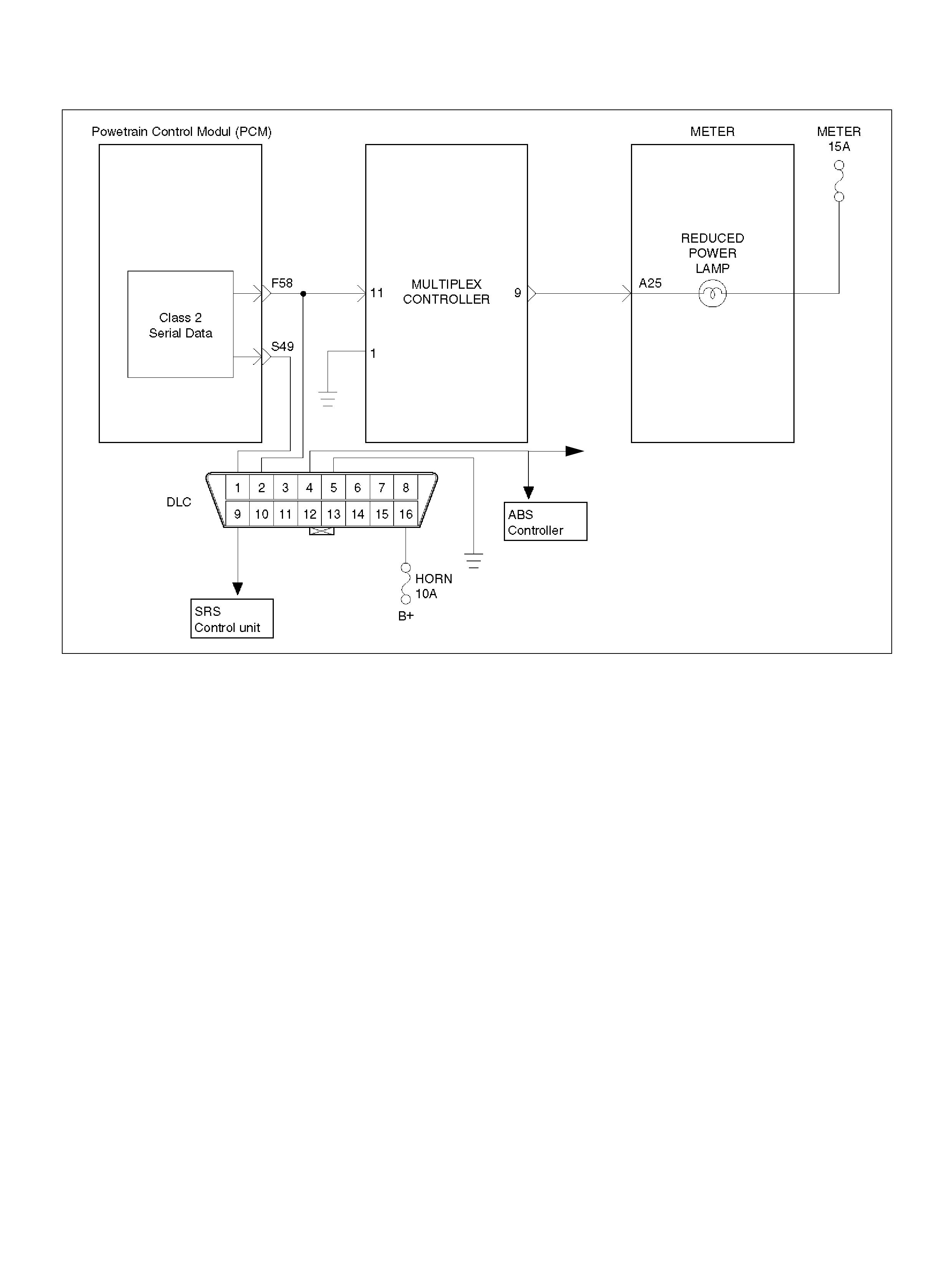

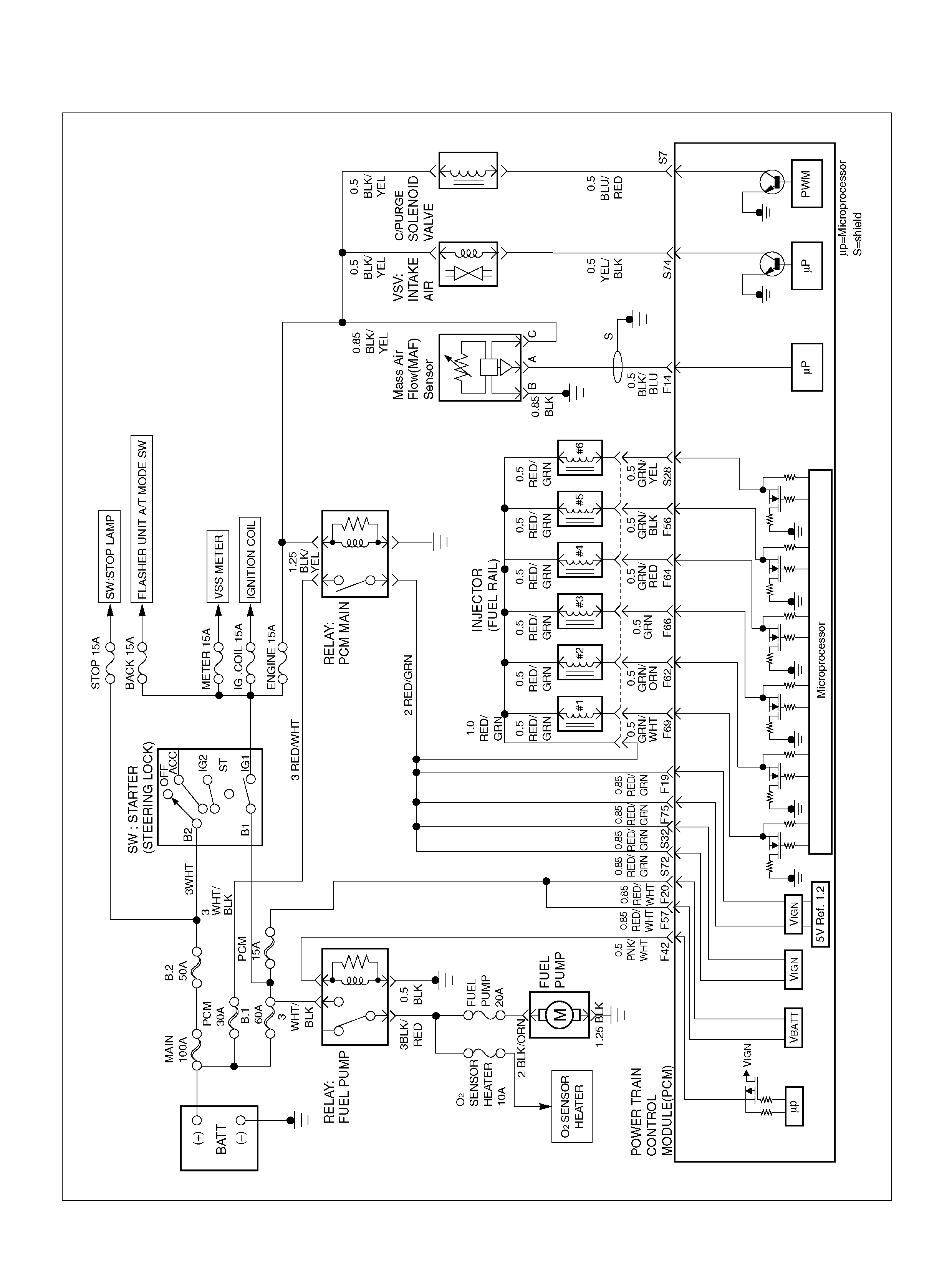

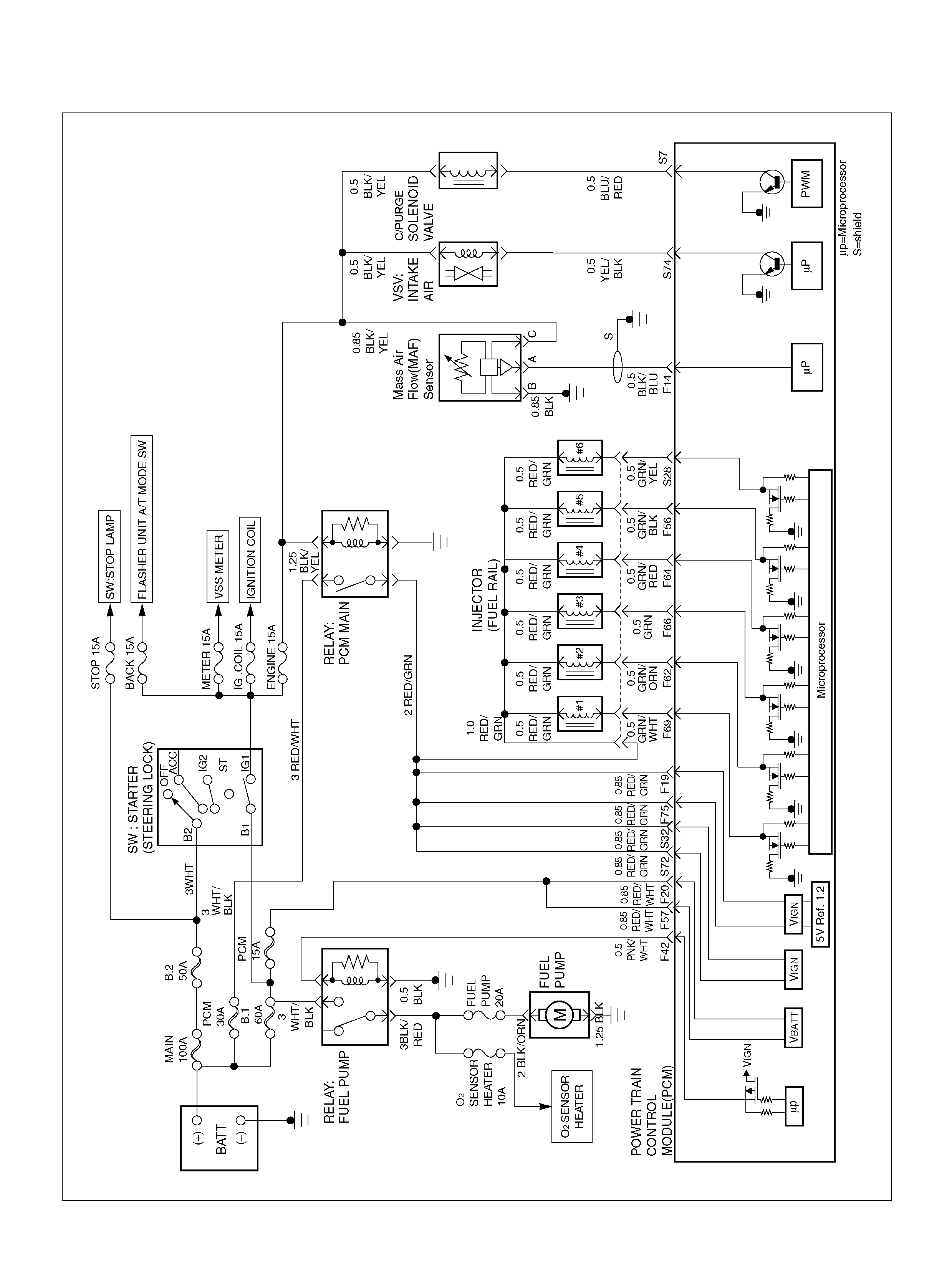

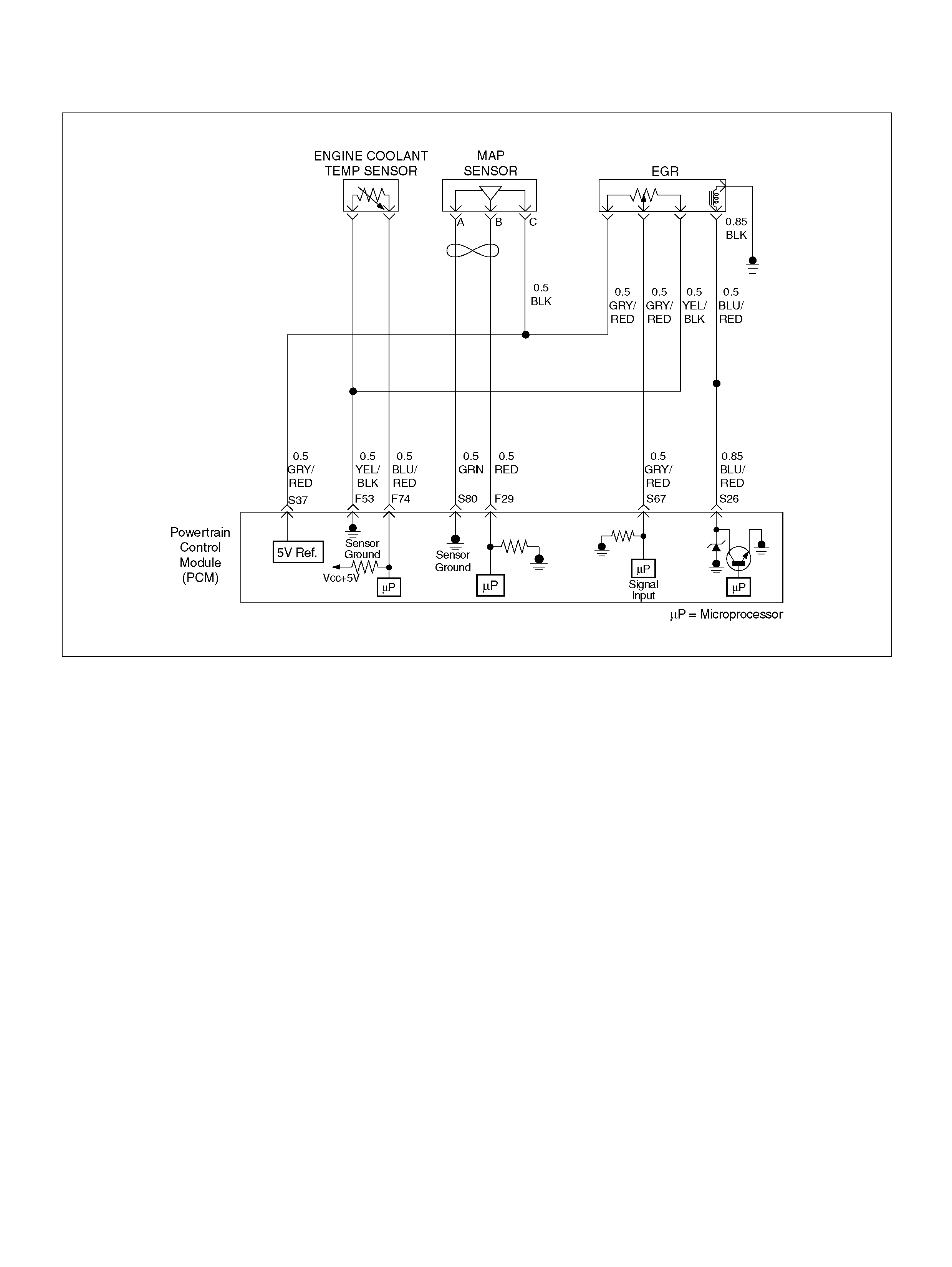

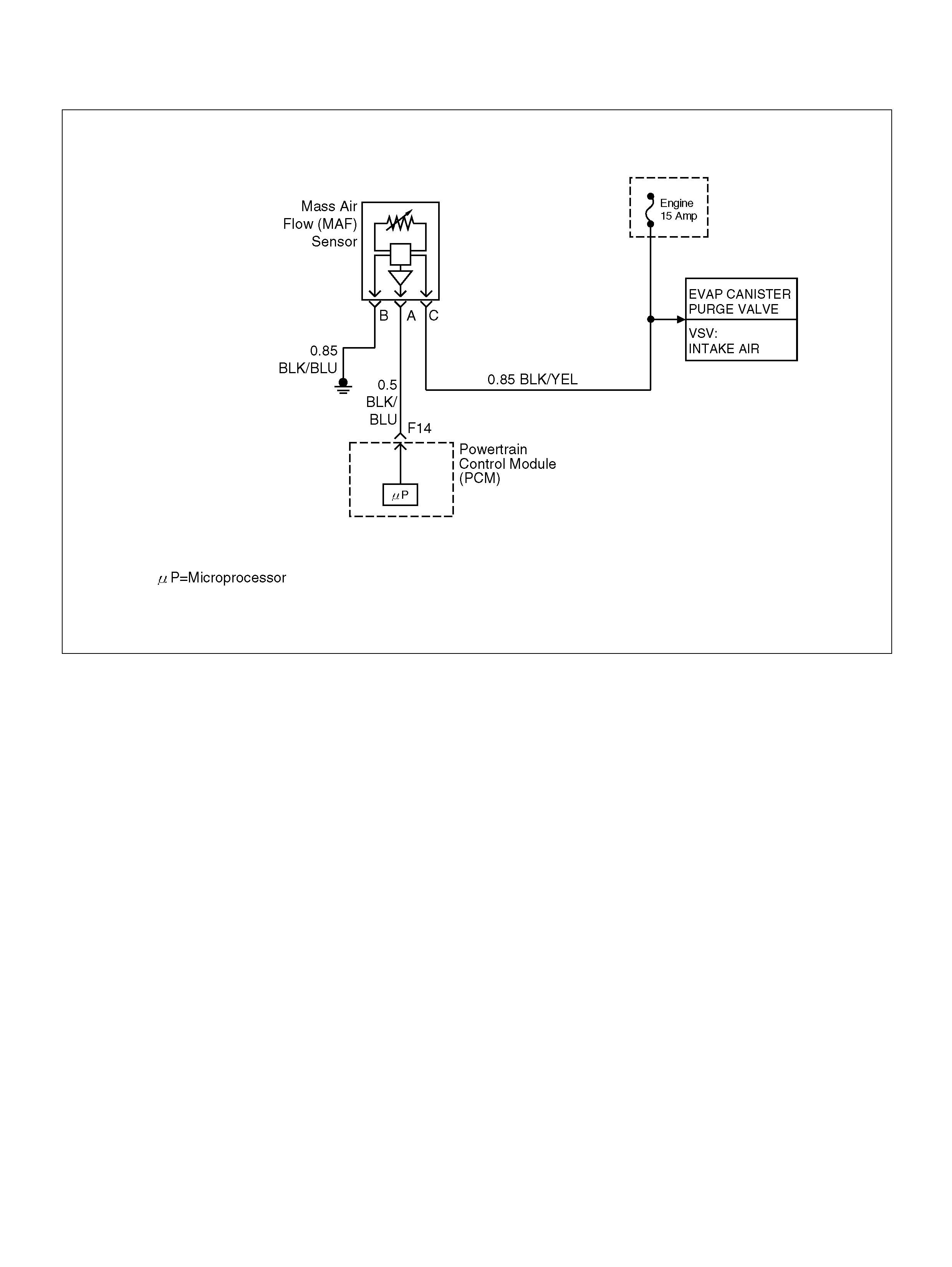

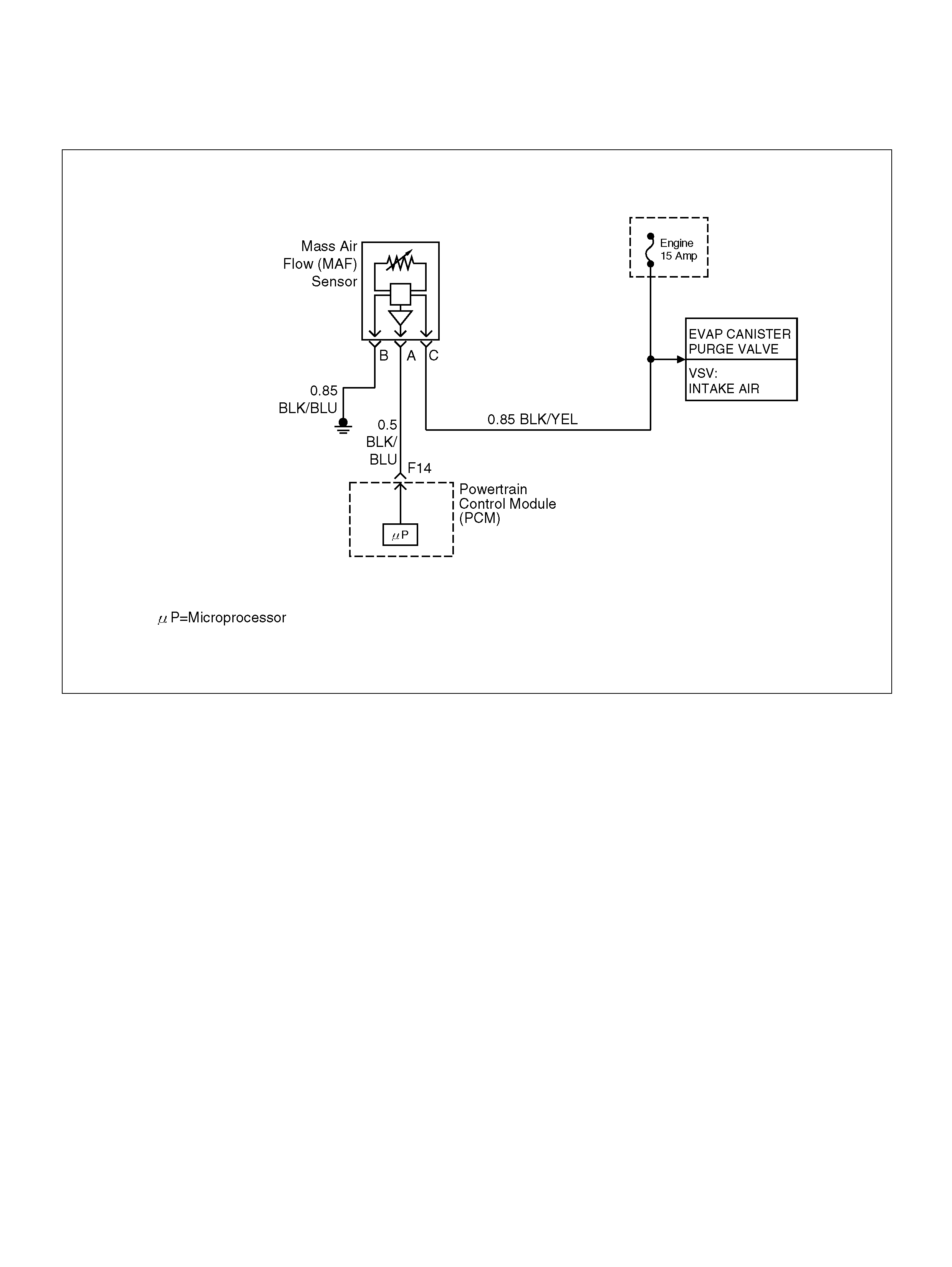

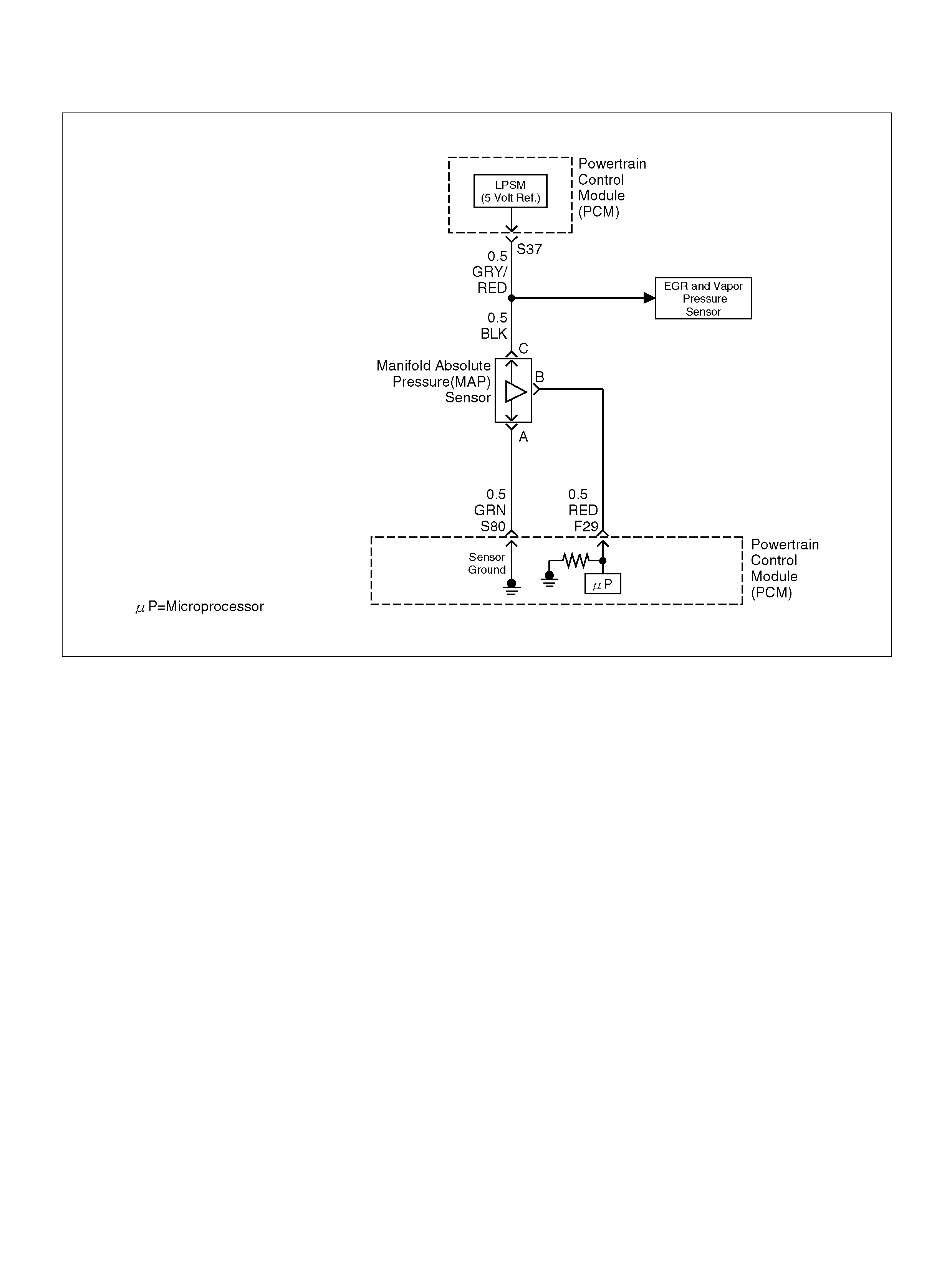

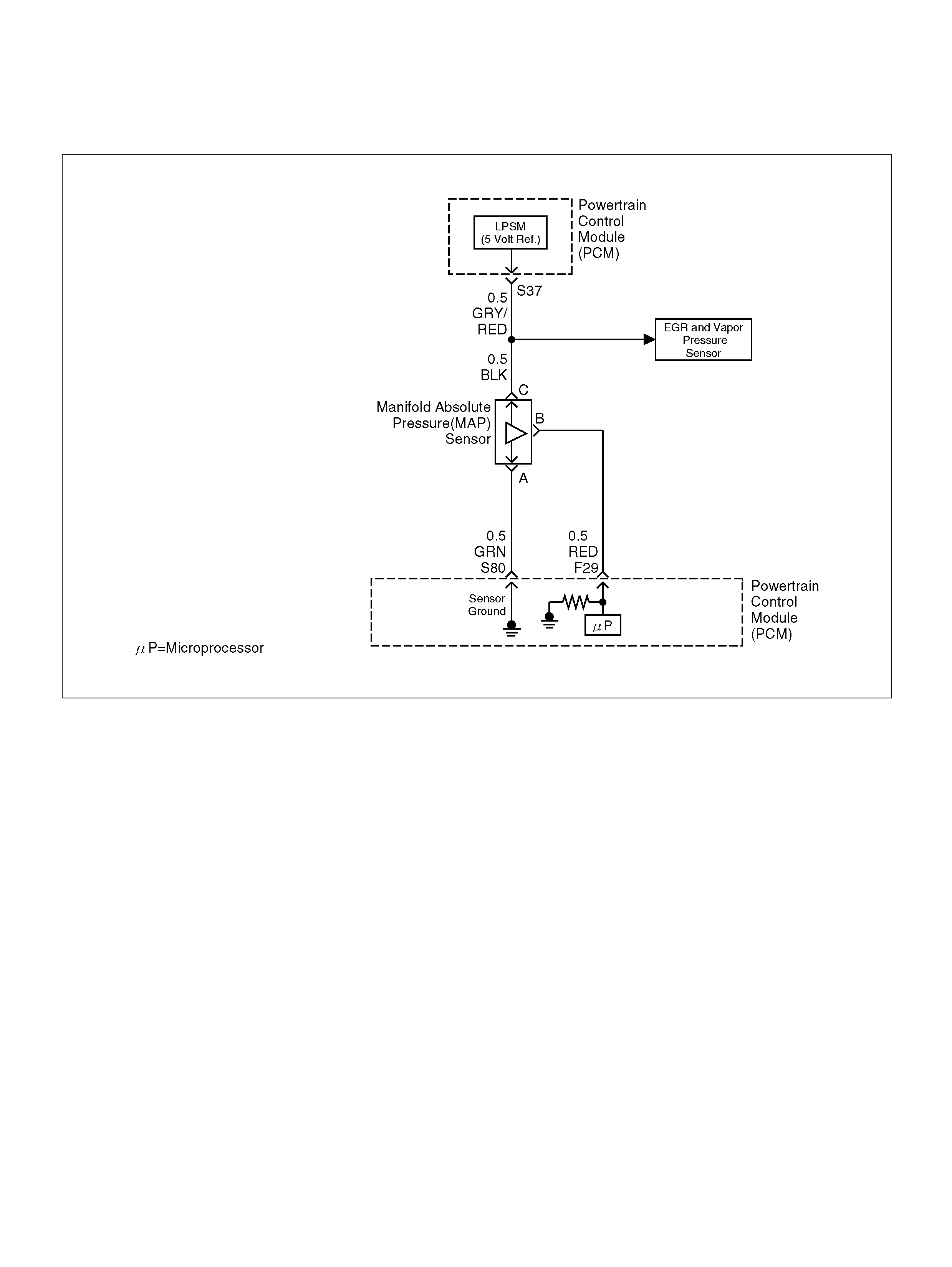

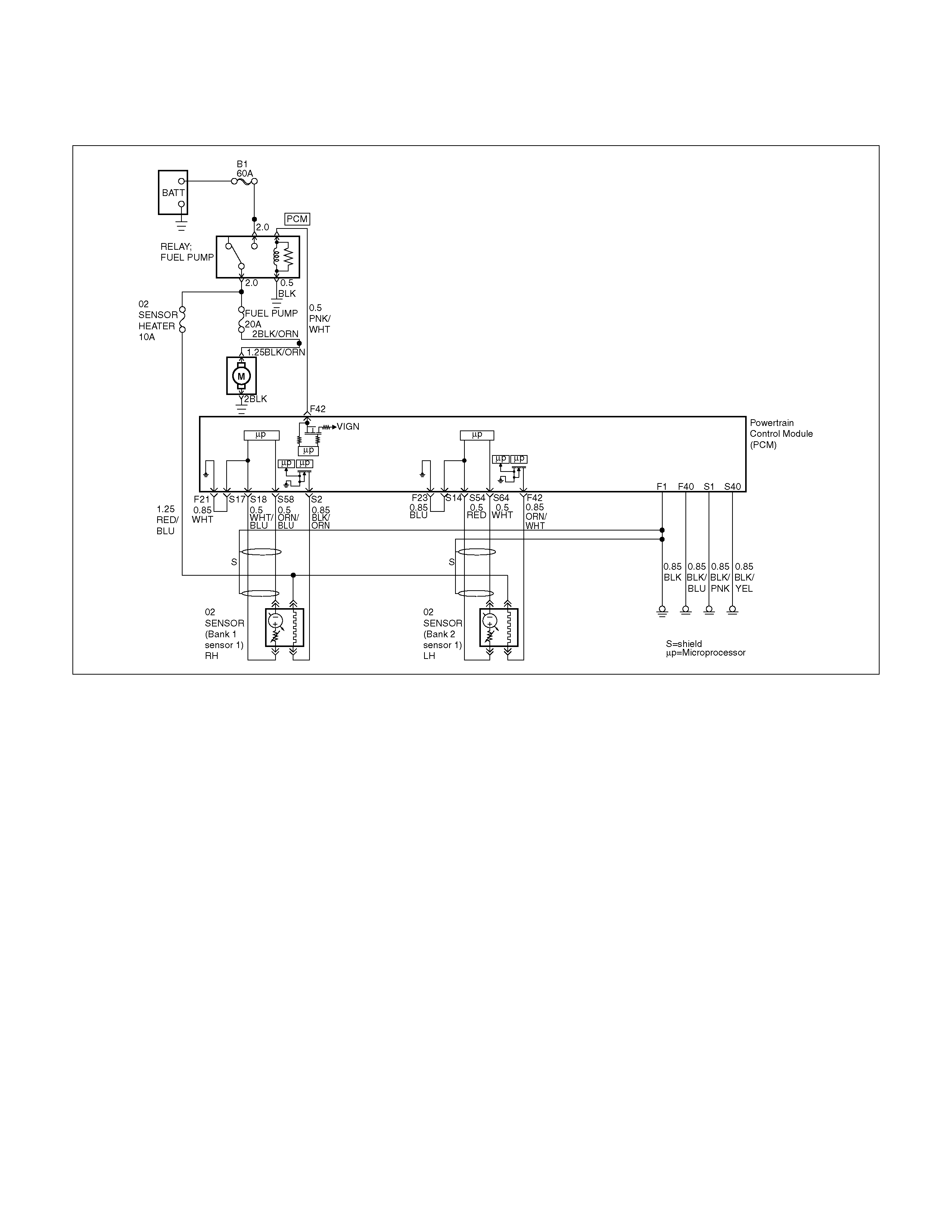

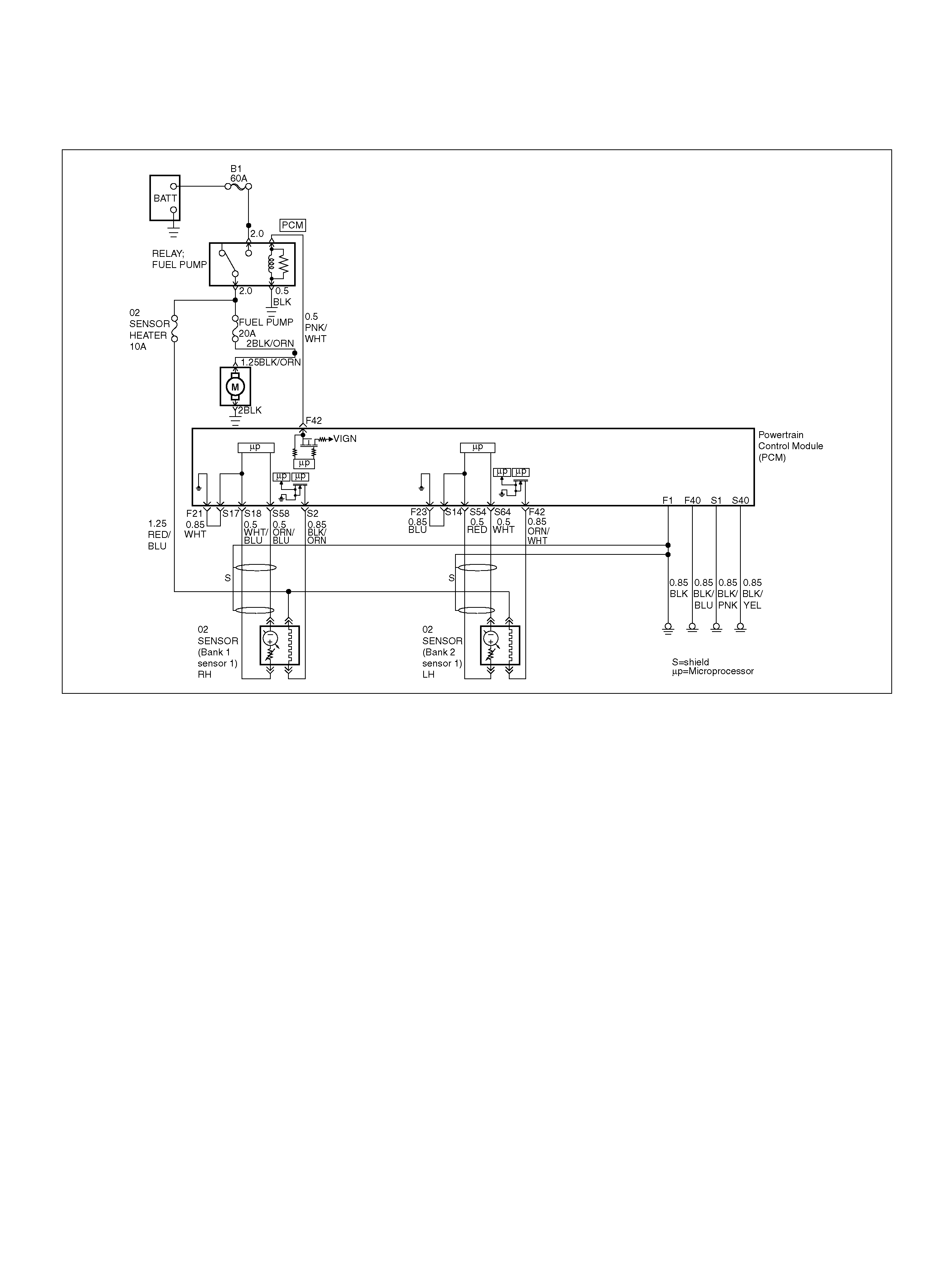

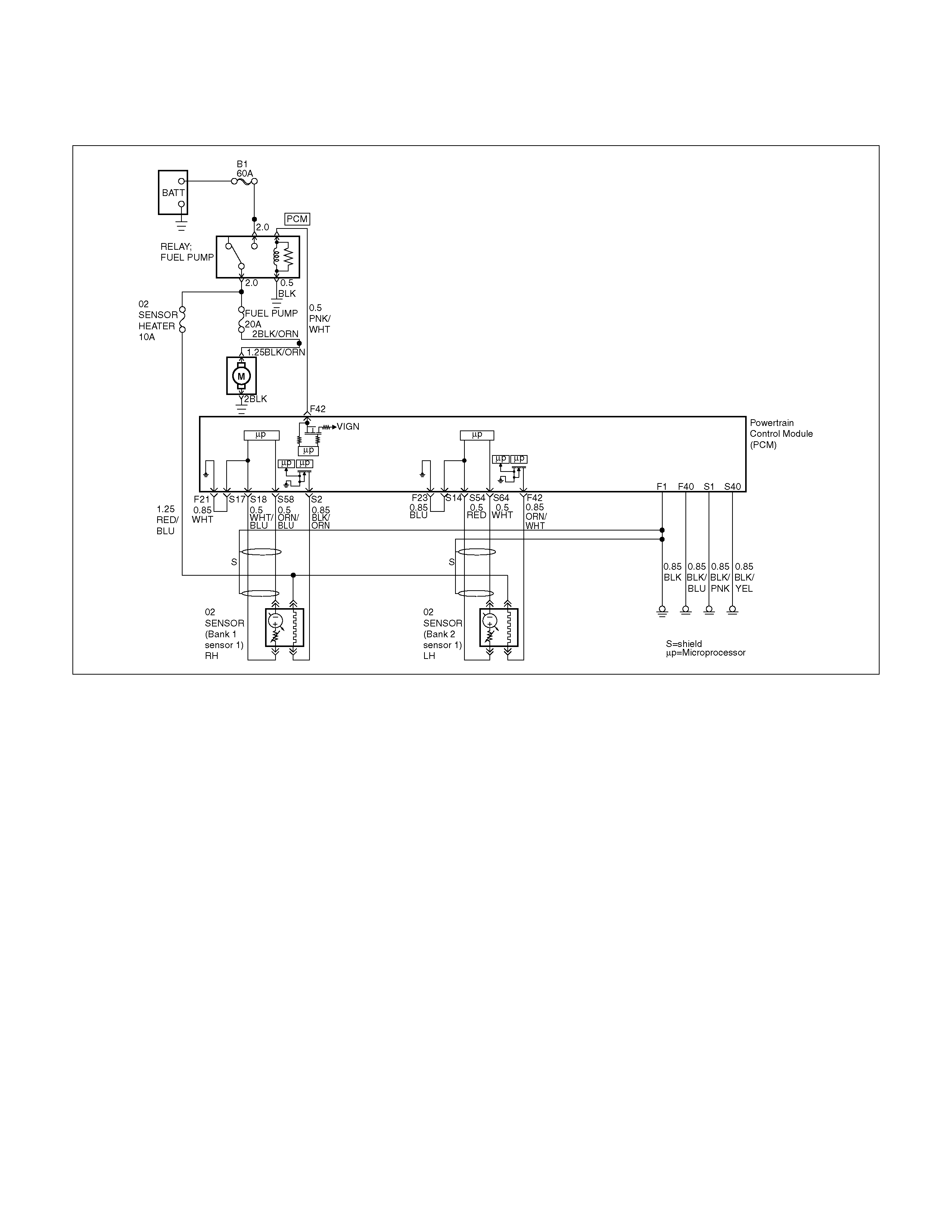

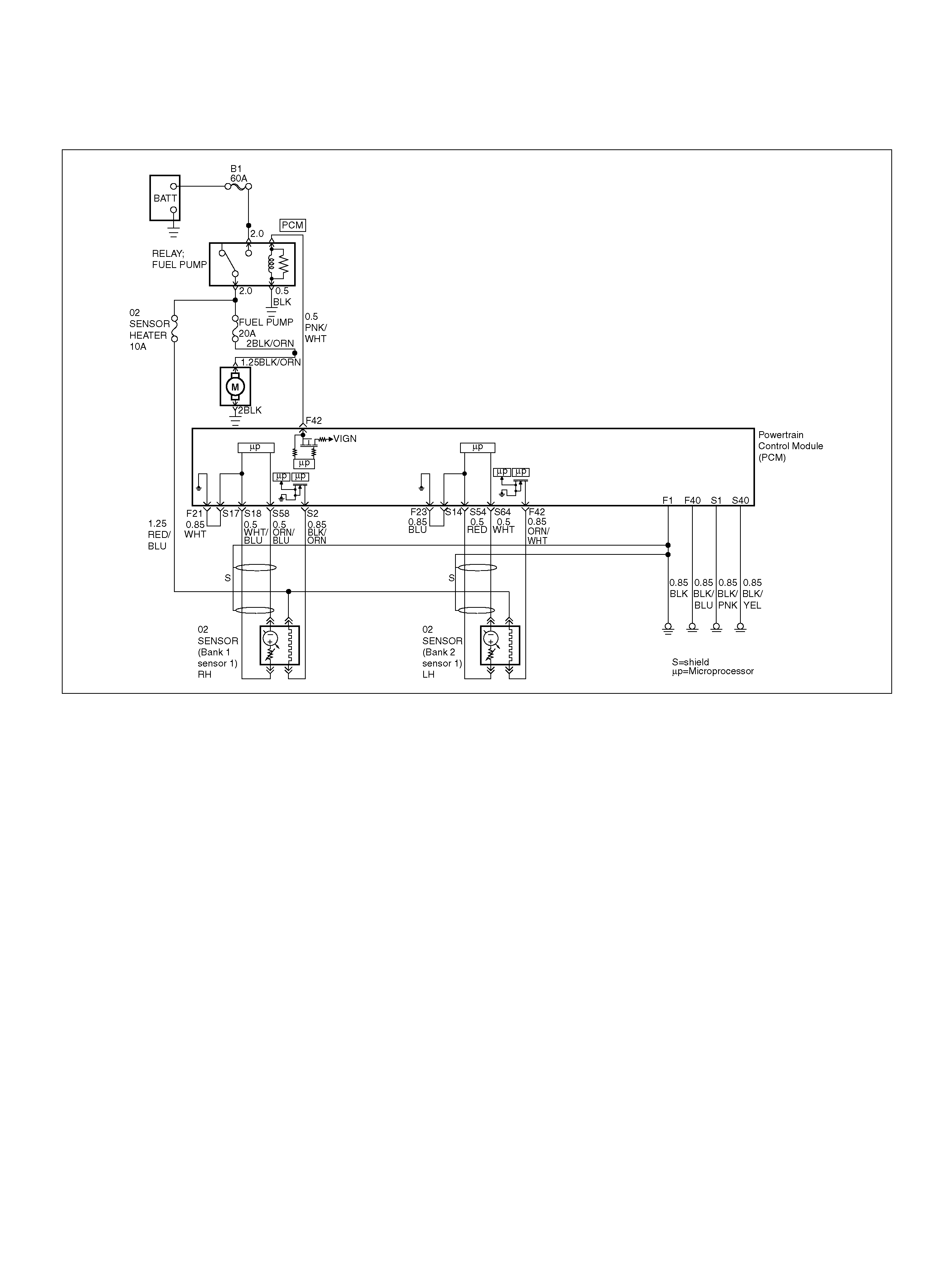

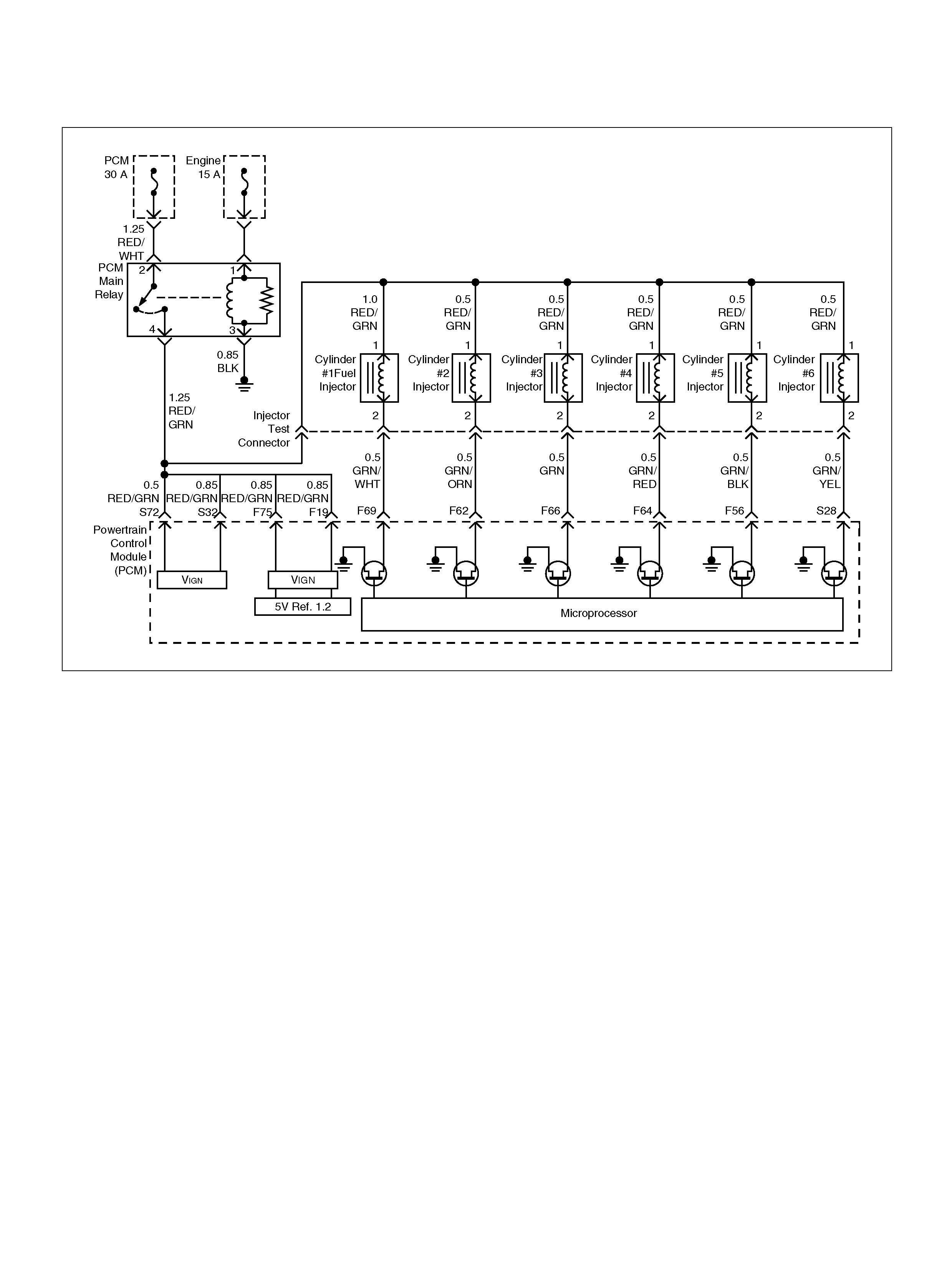

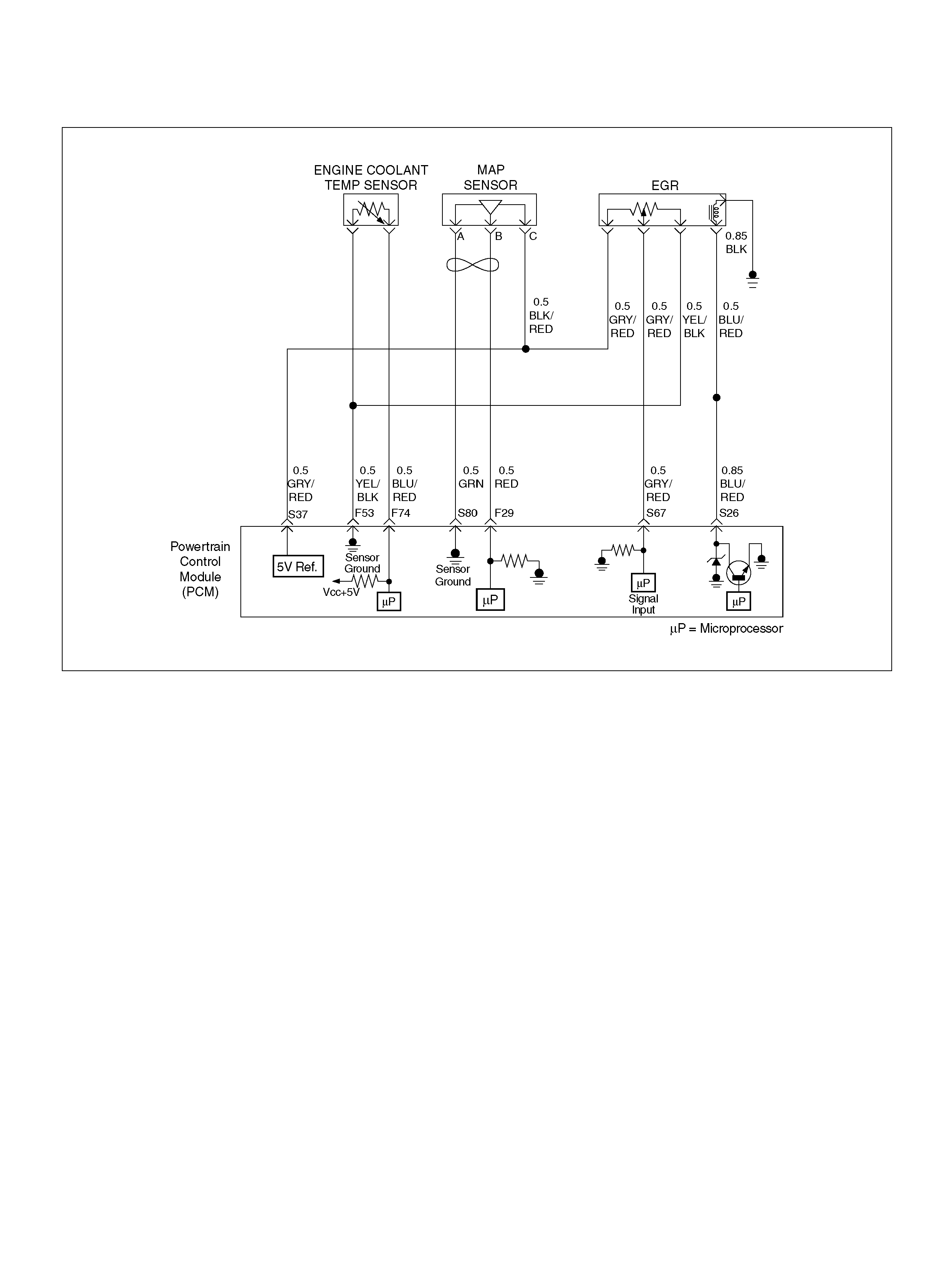

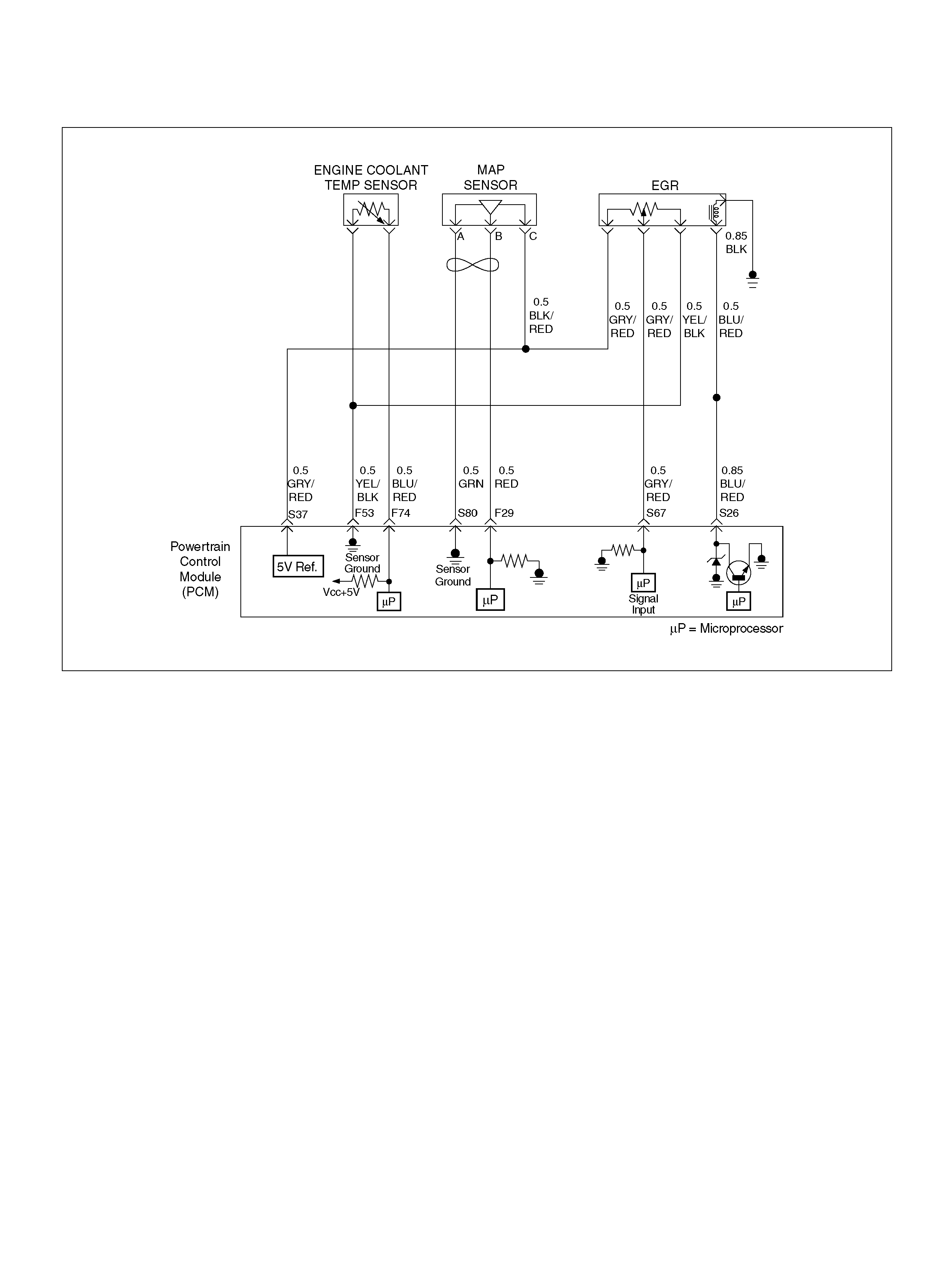

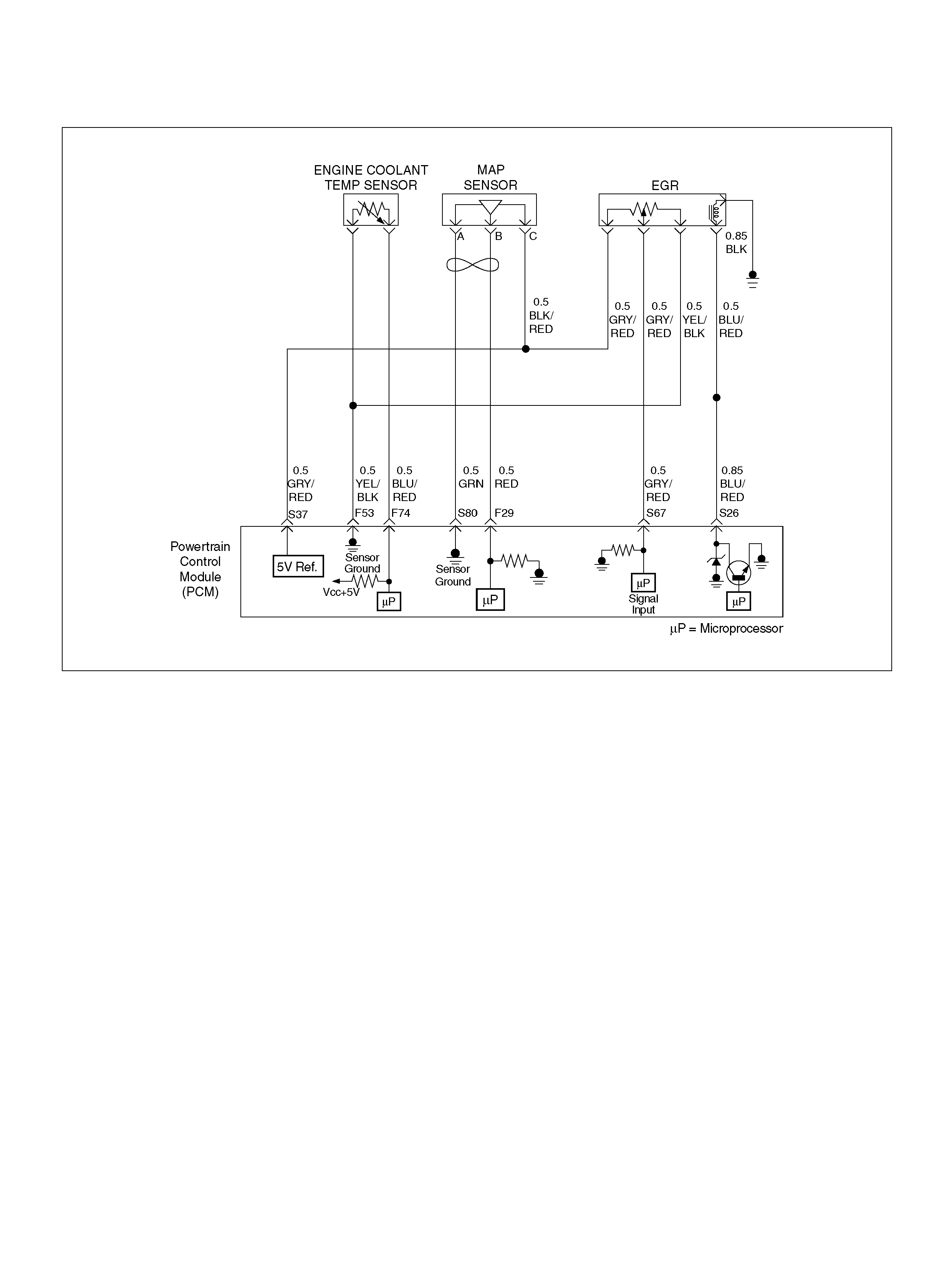

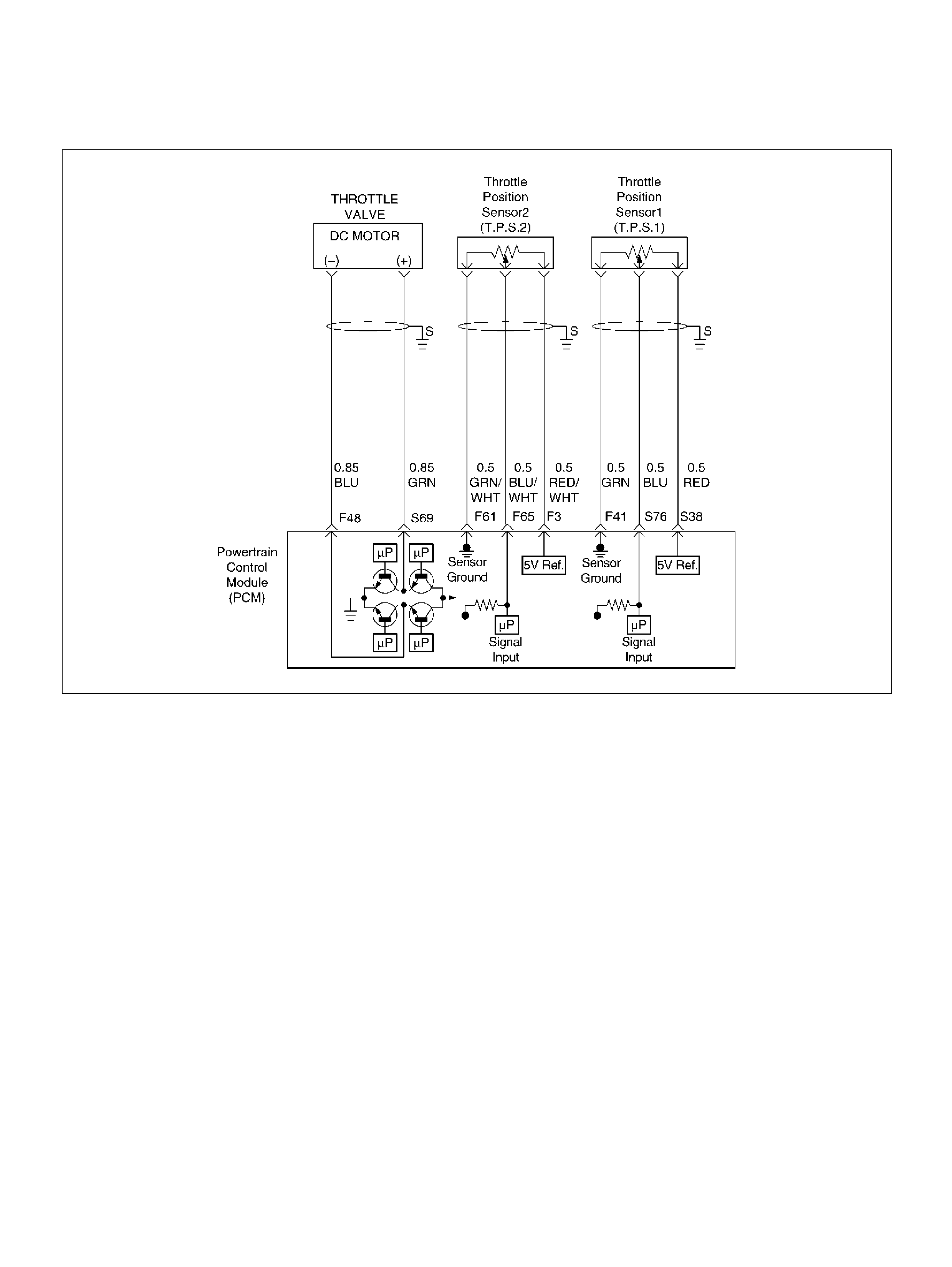

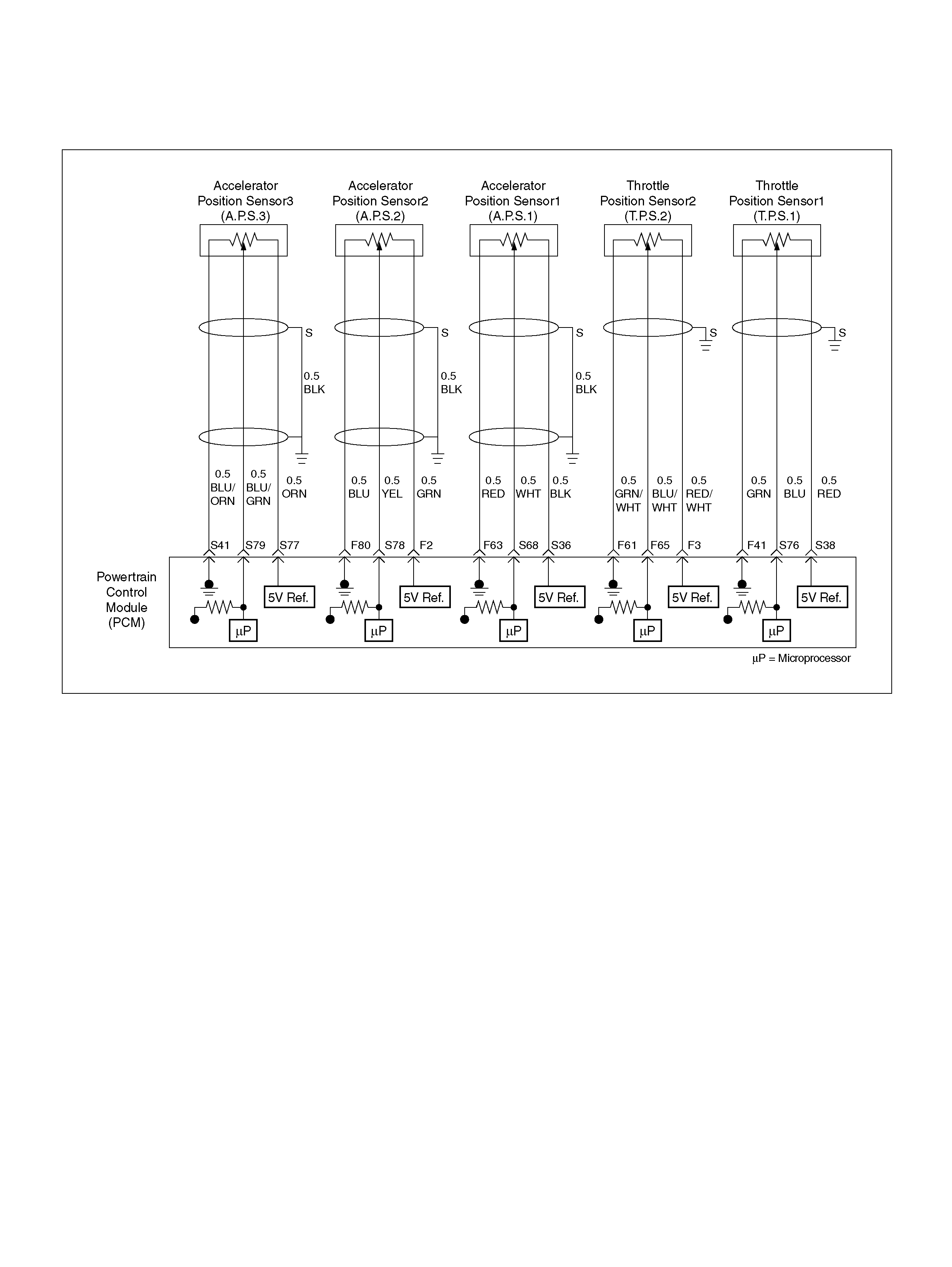

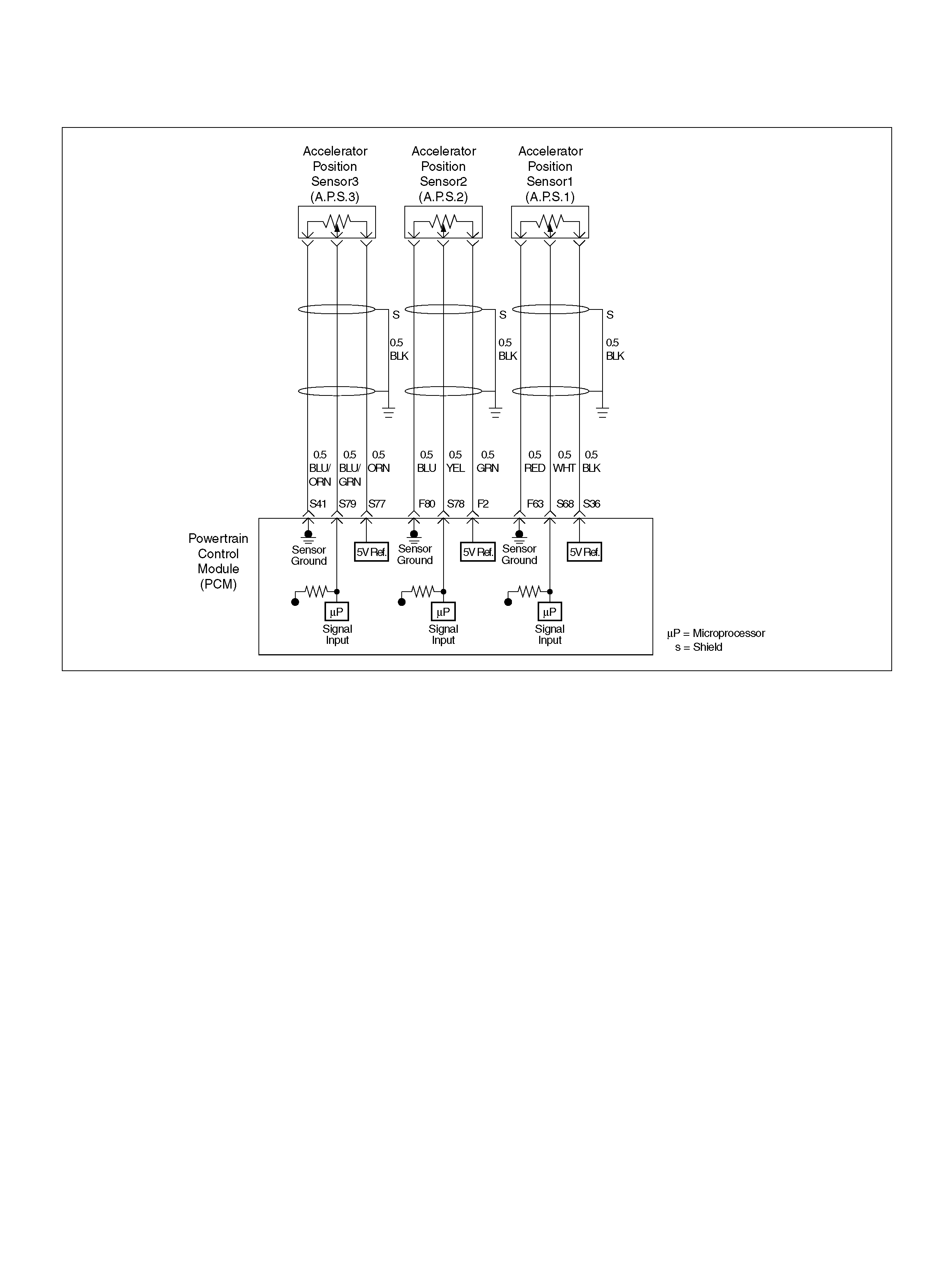

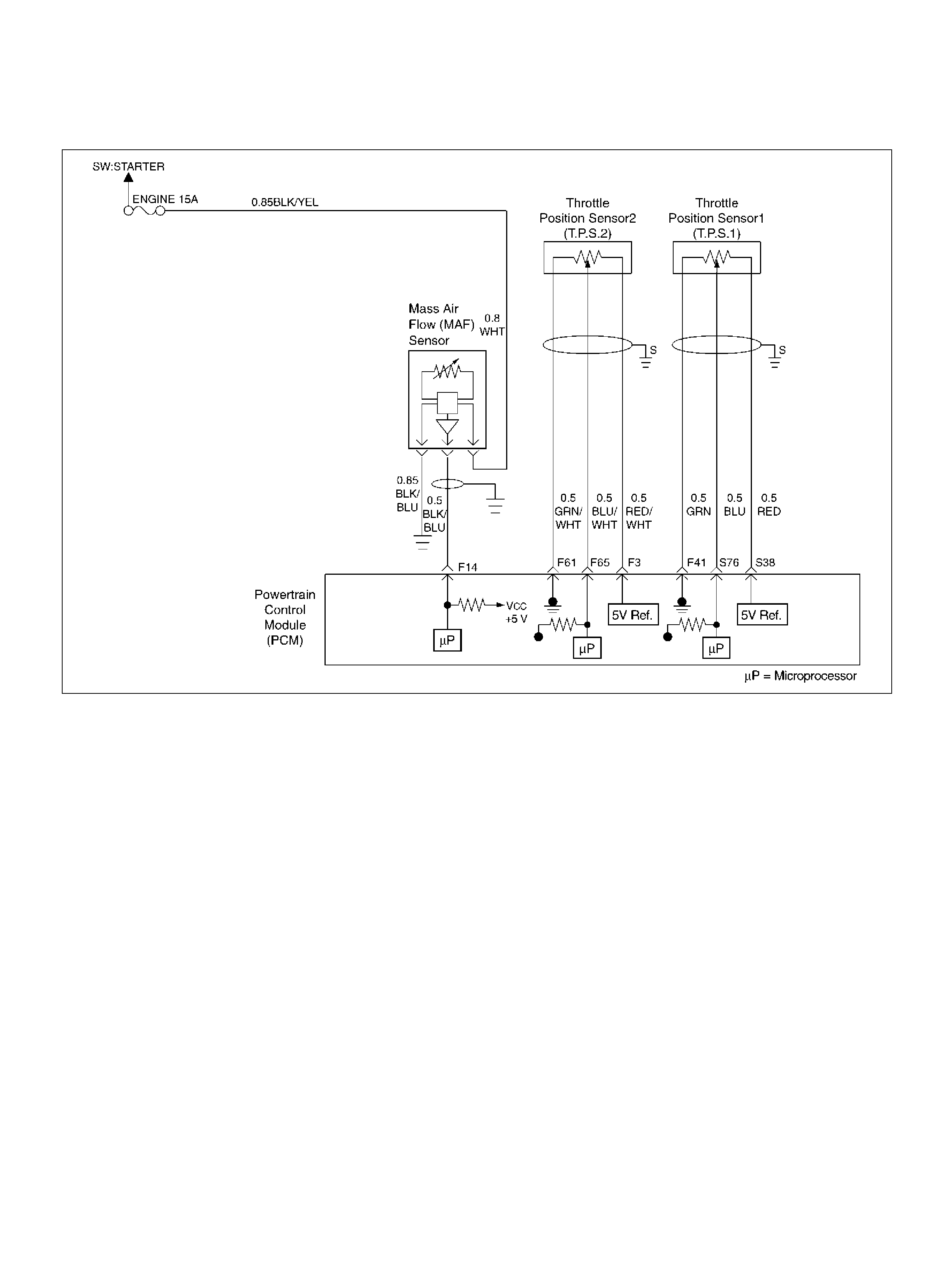

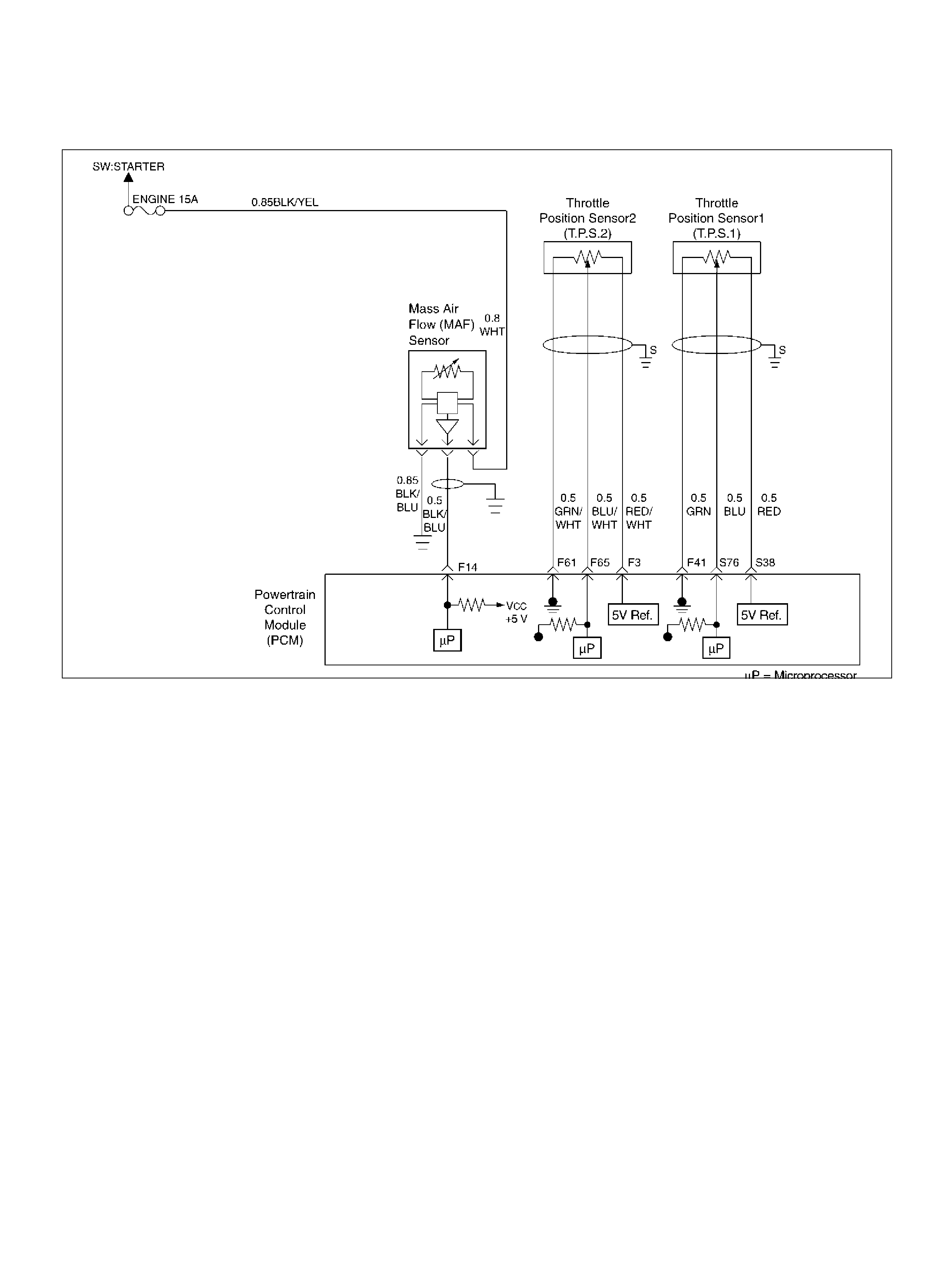

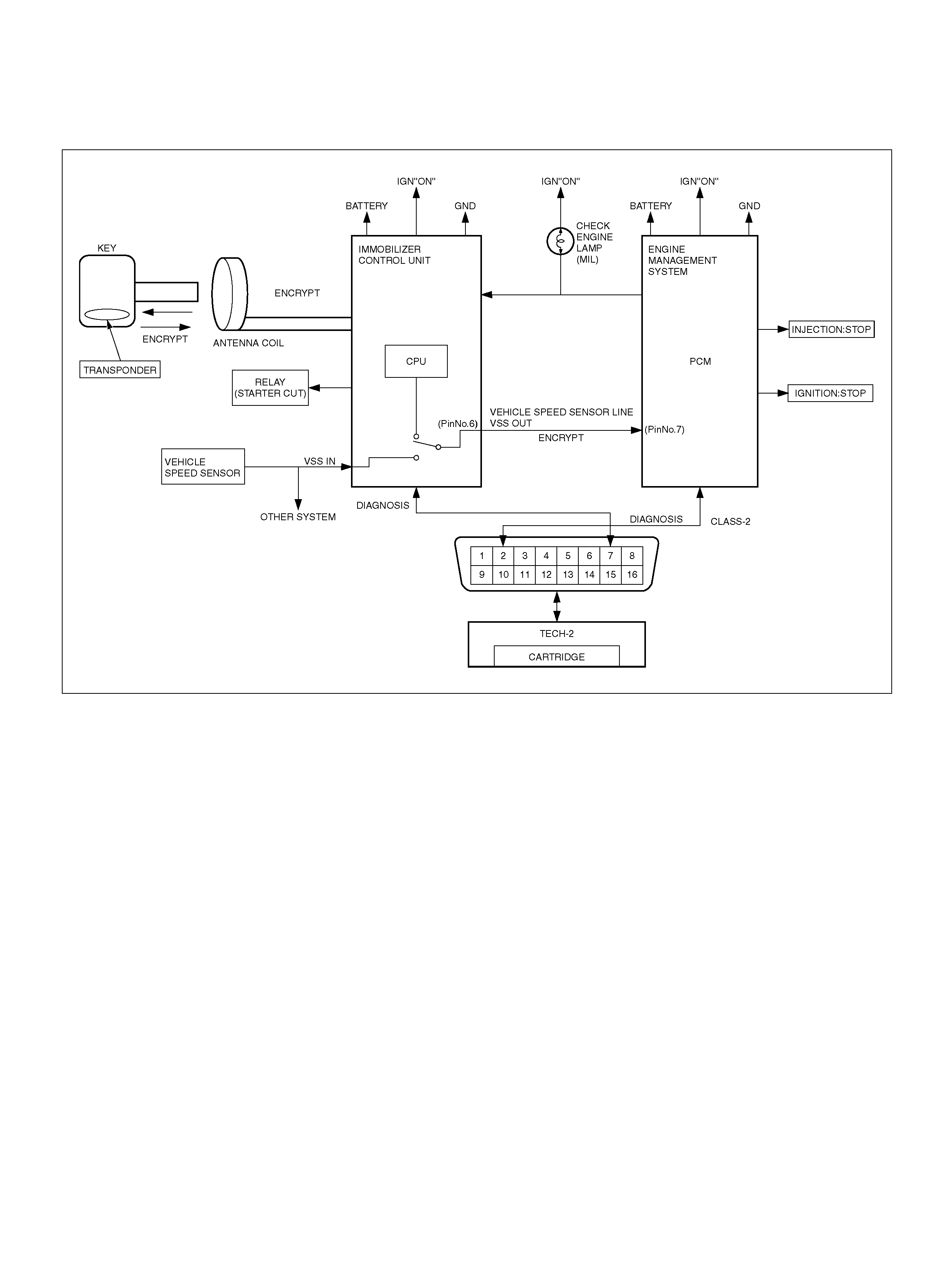

PCM Wiring Diagram (1 of 7)

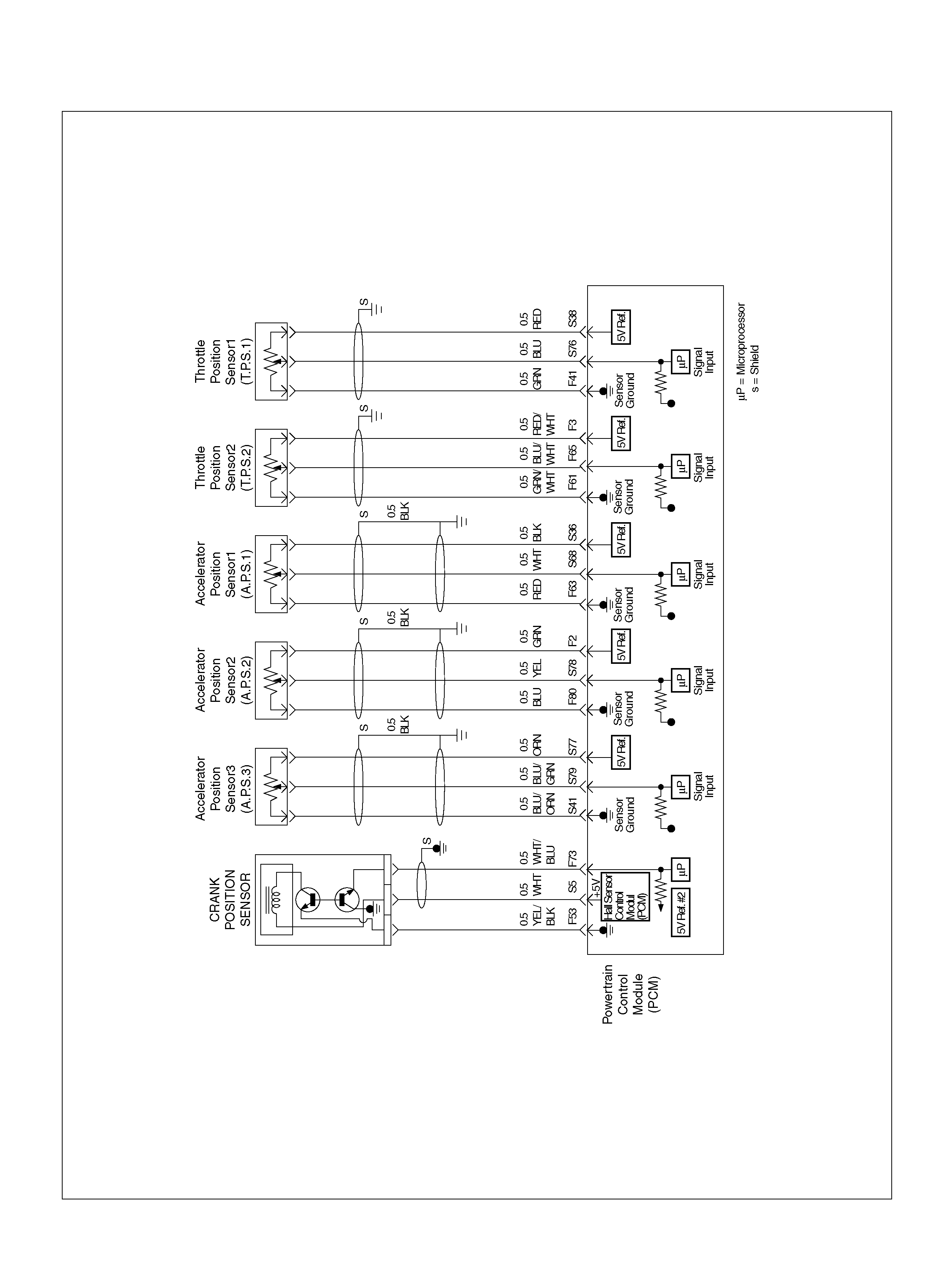

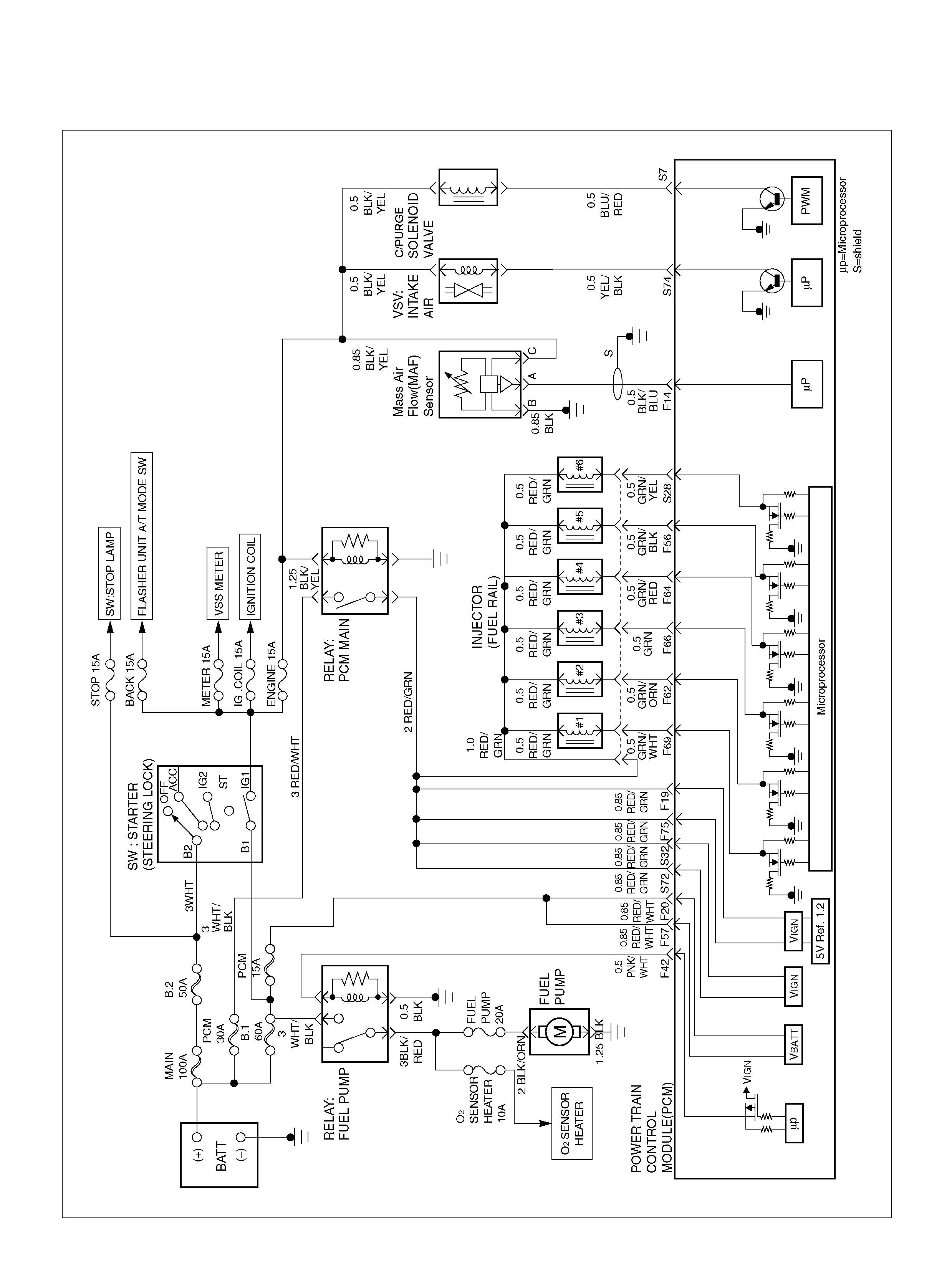

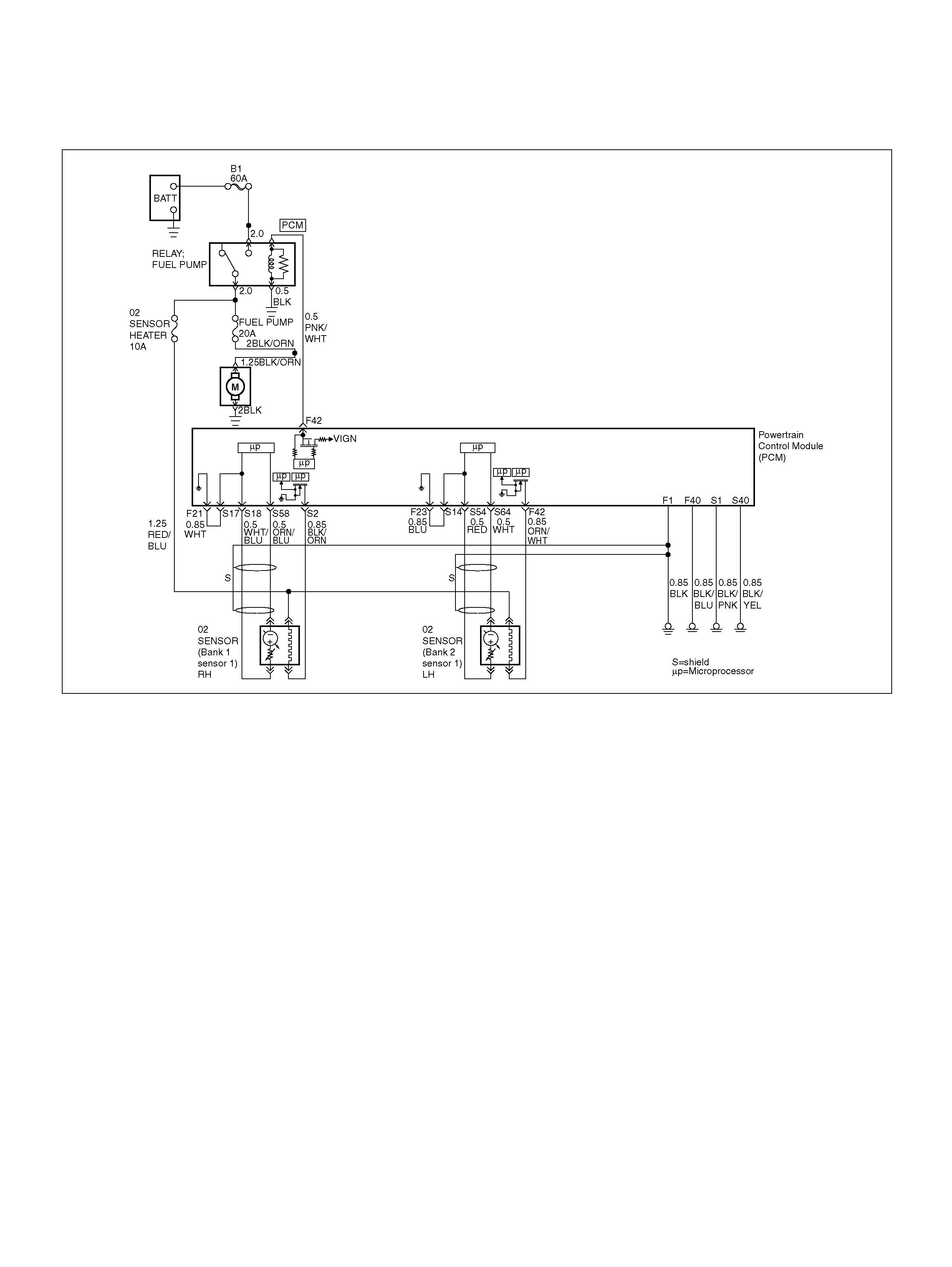

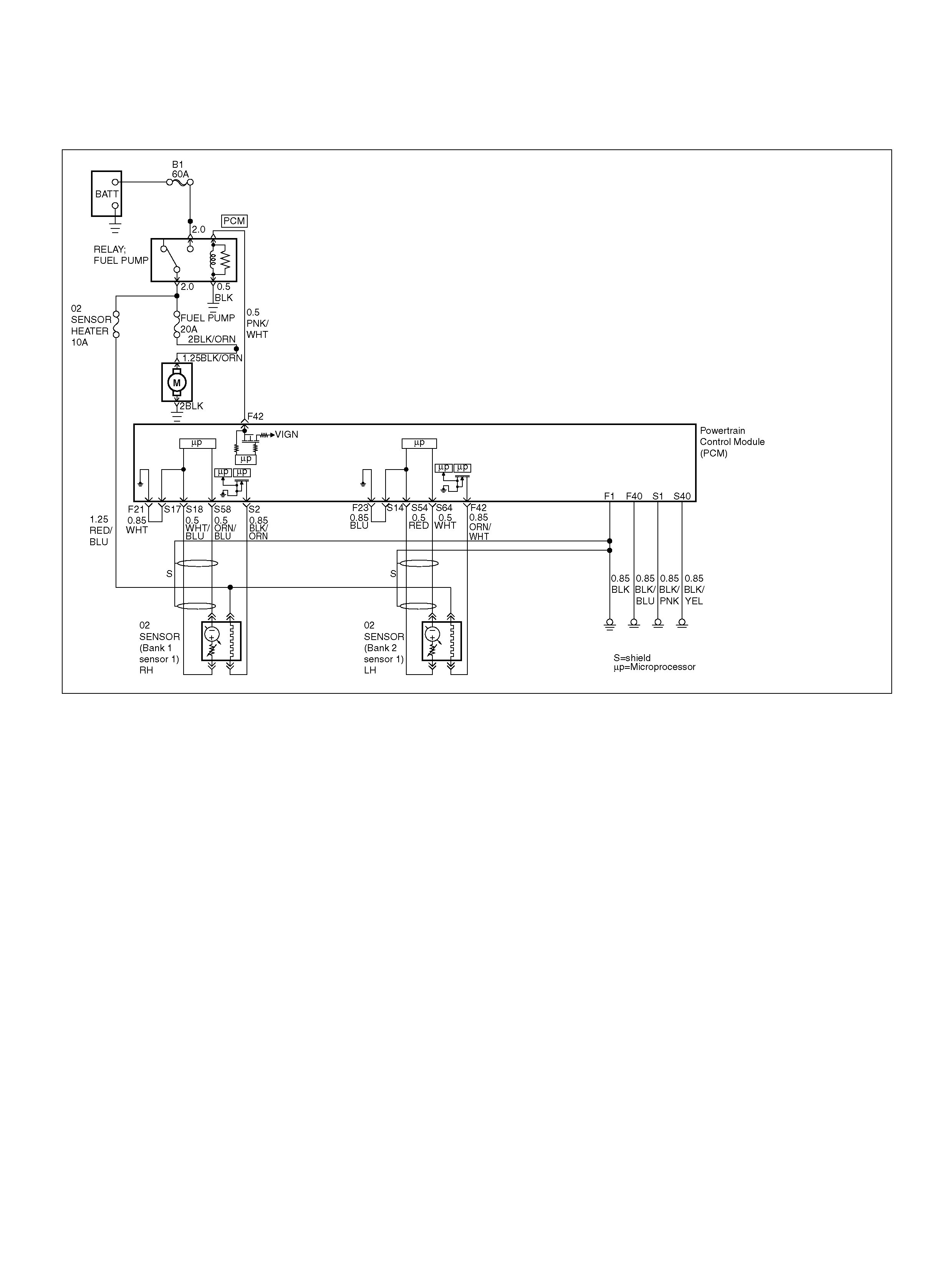

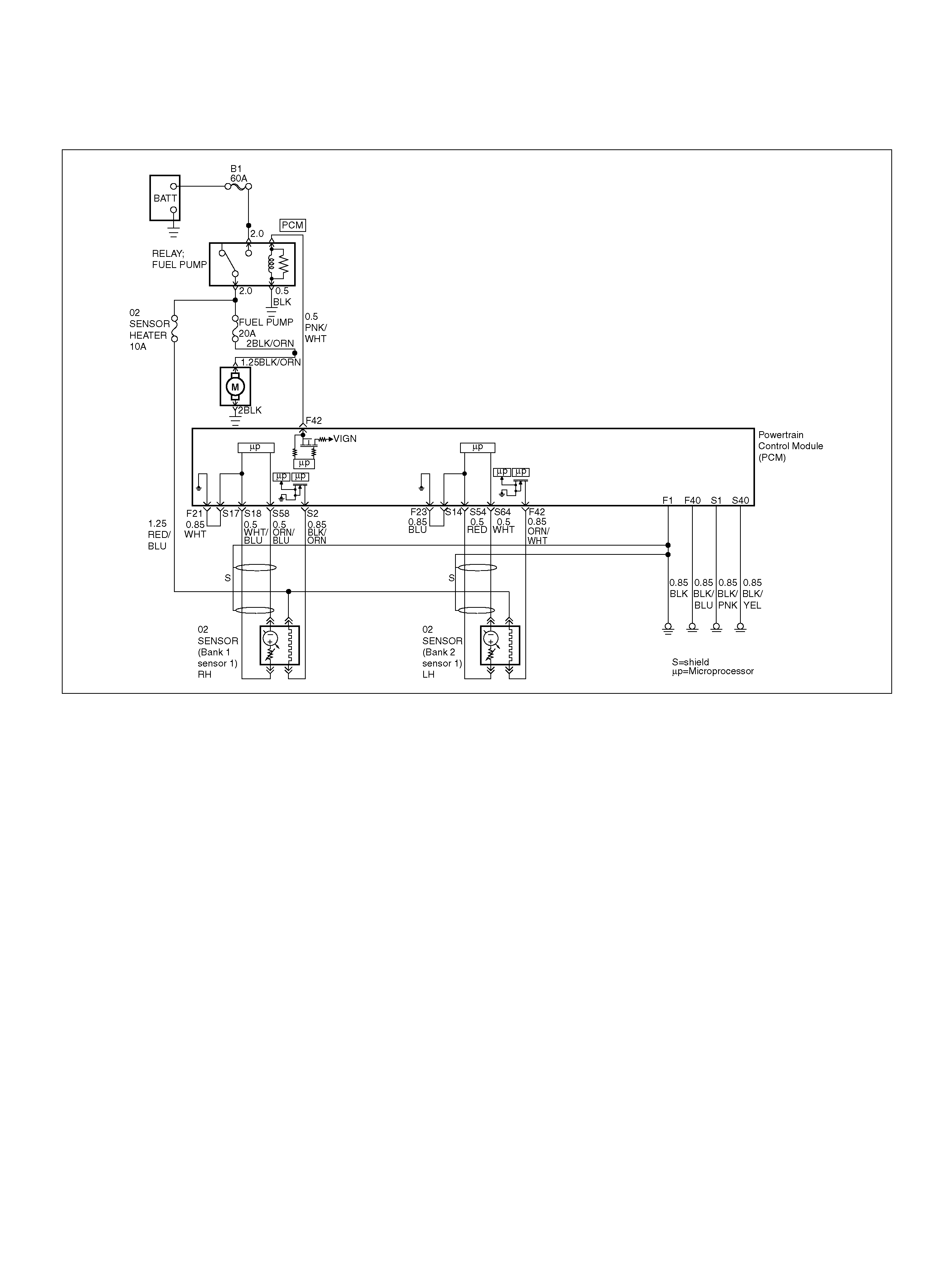

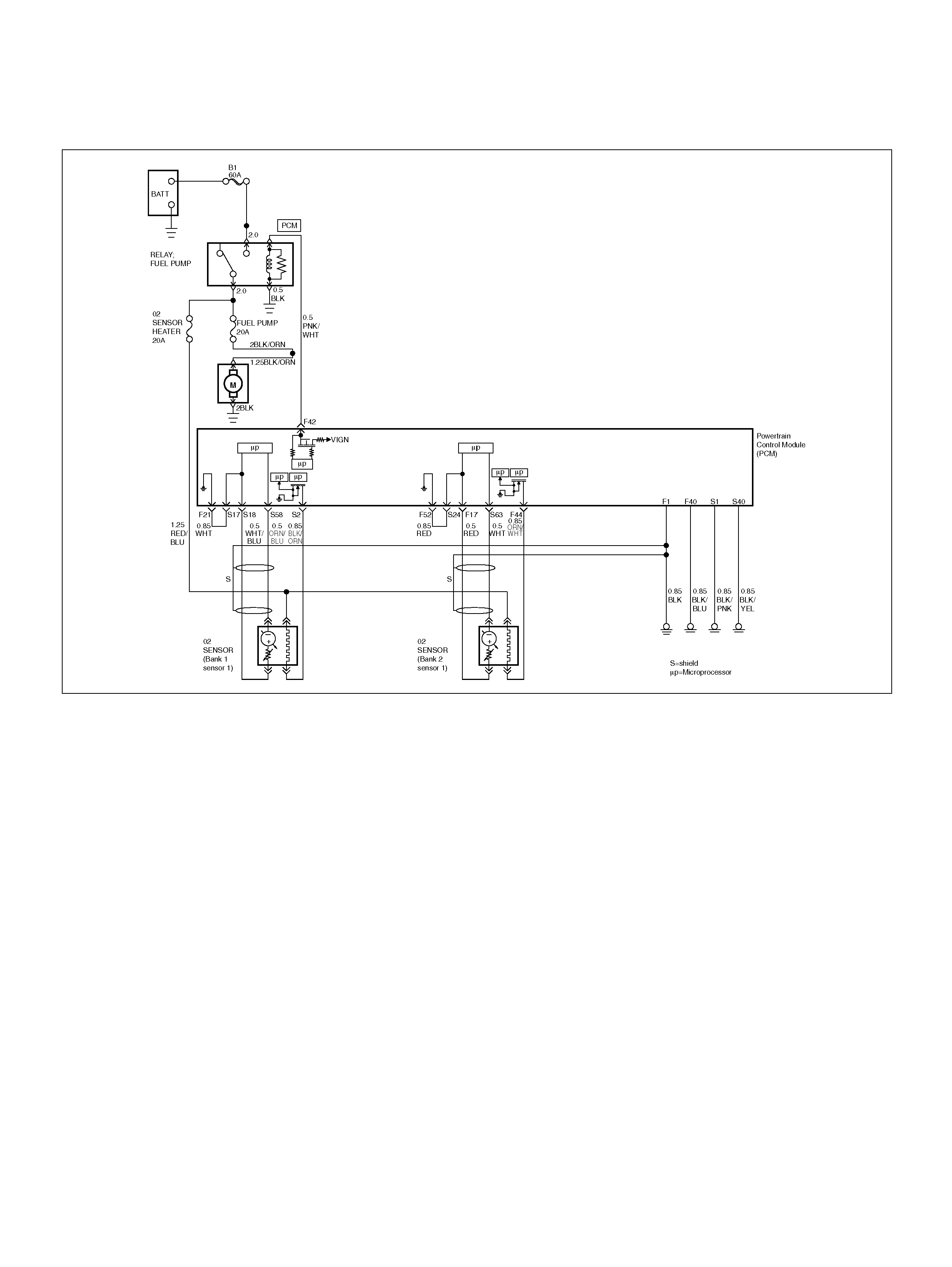

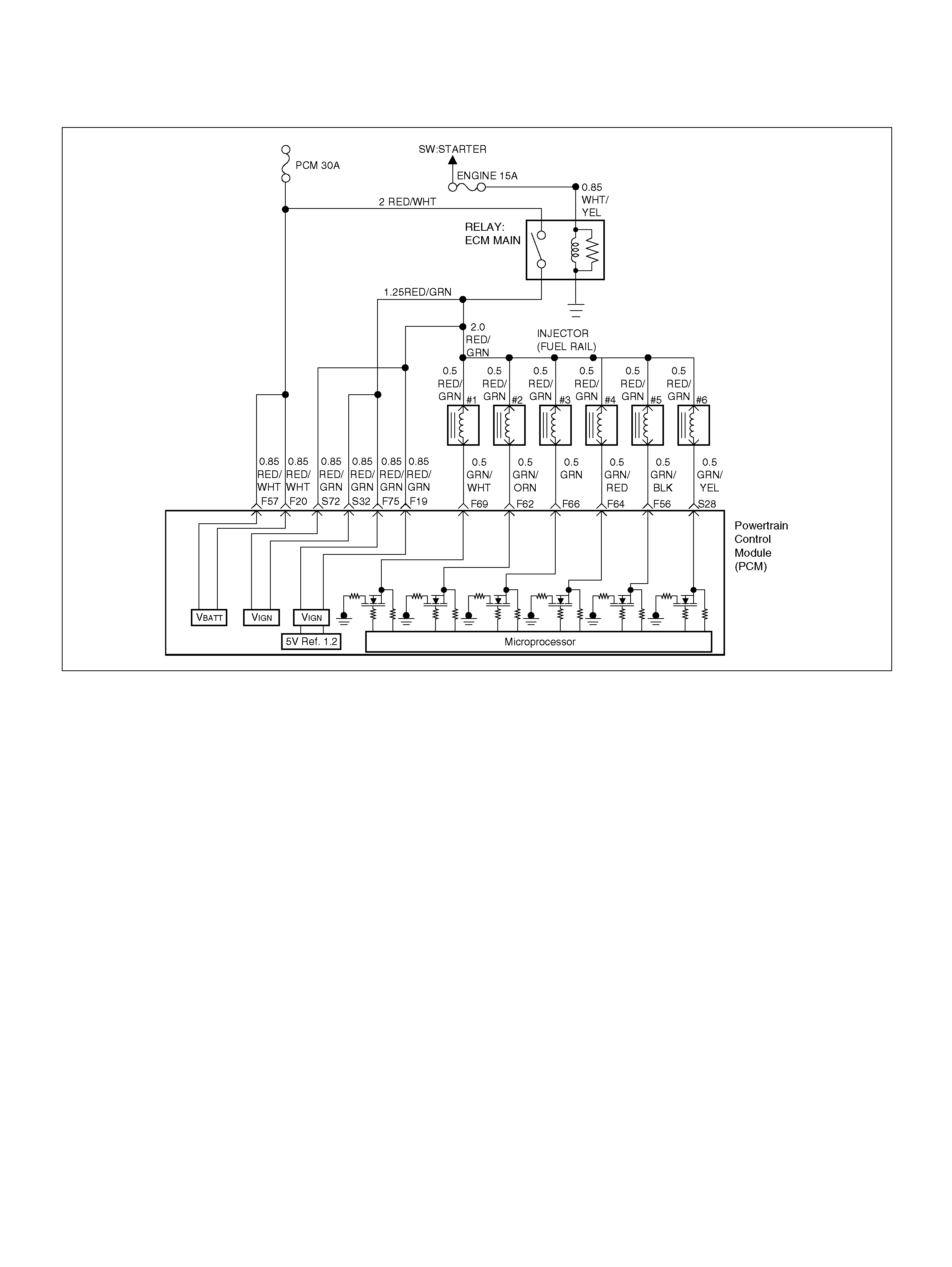

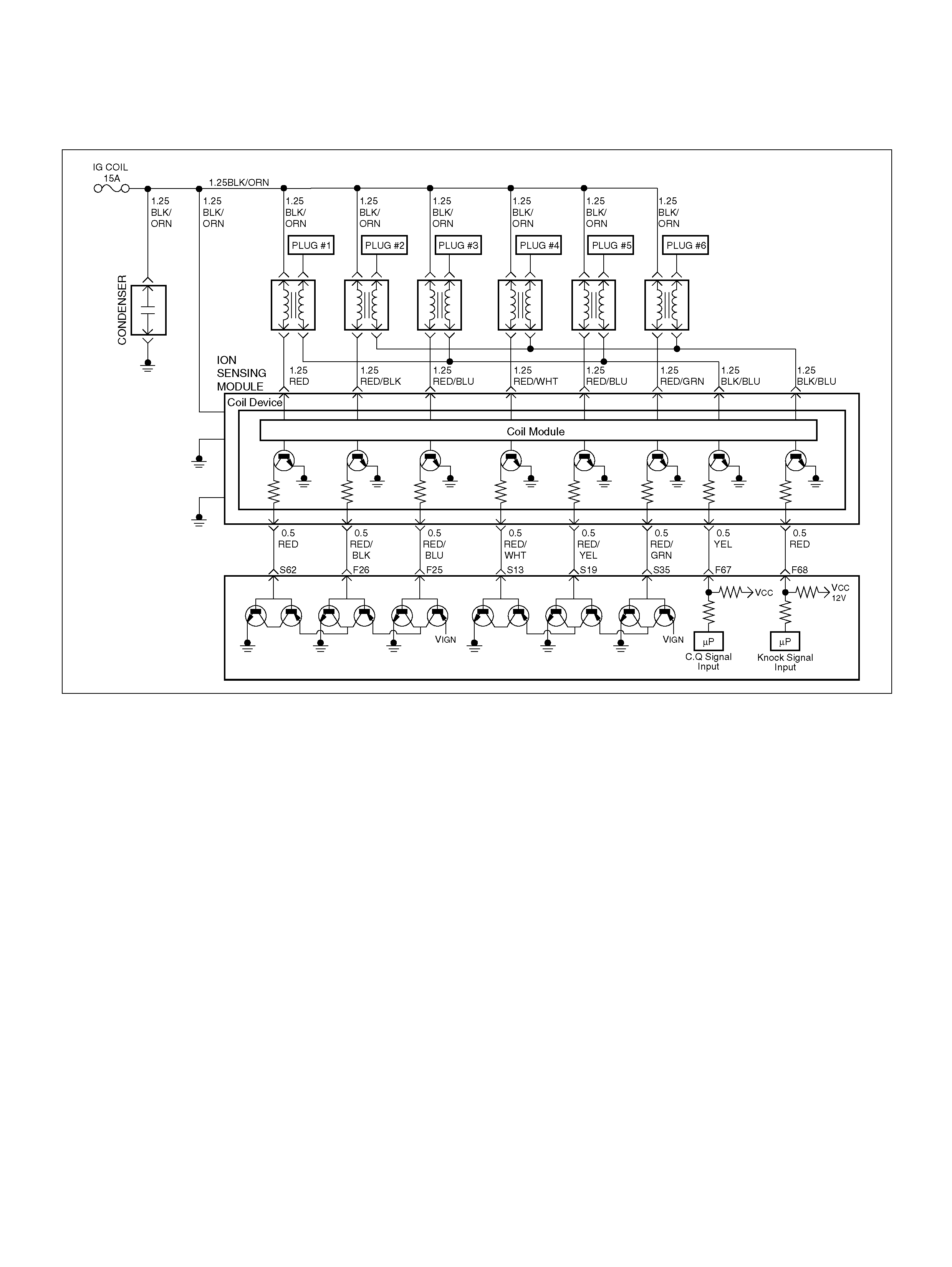

PCM Wiring Diagram (2 of 7)

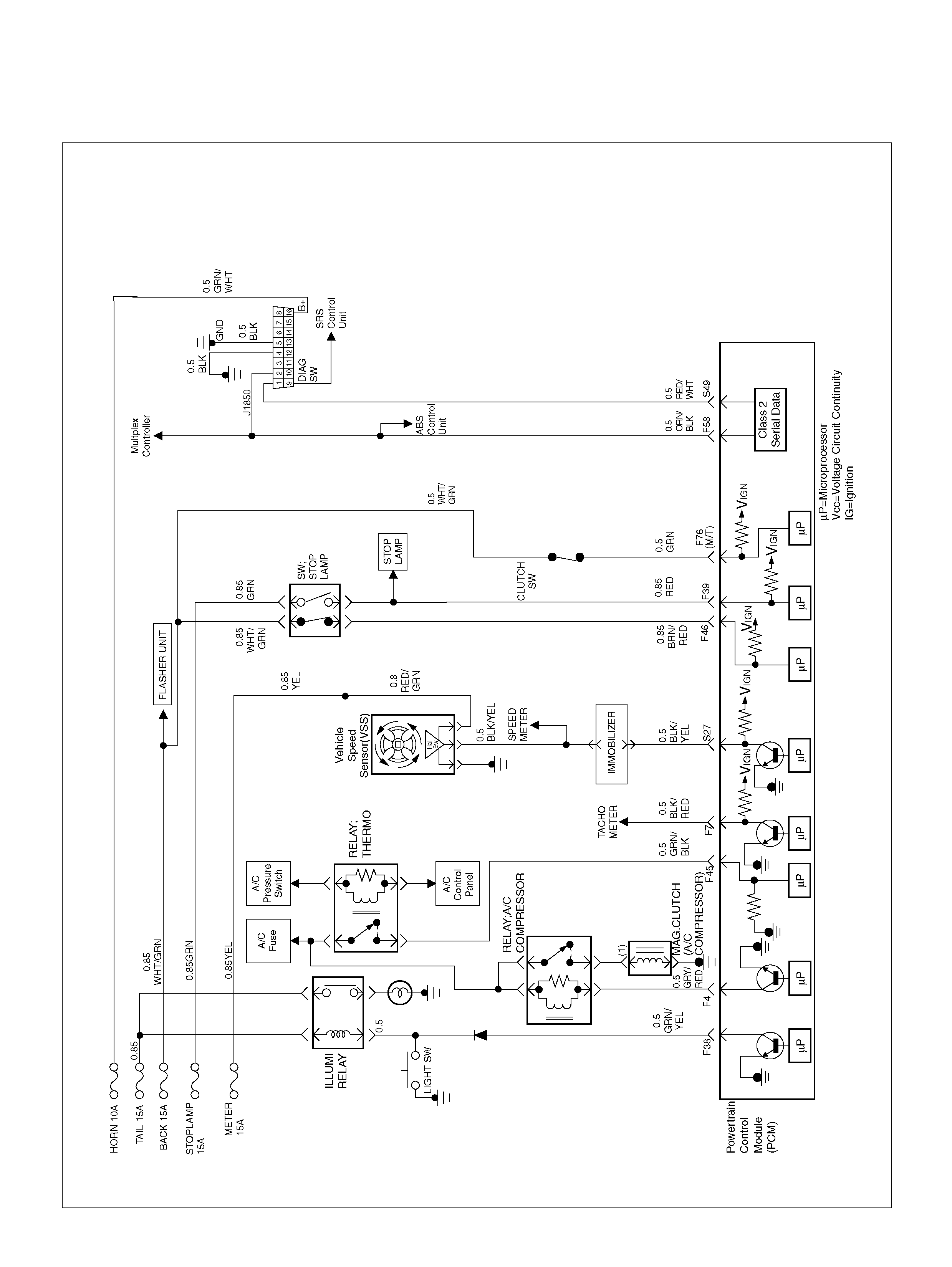

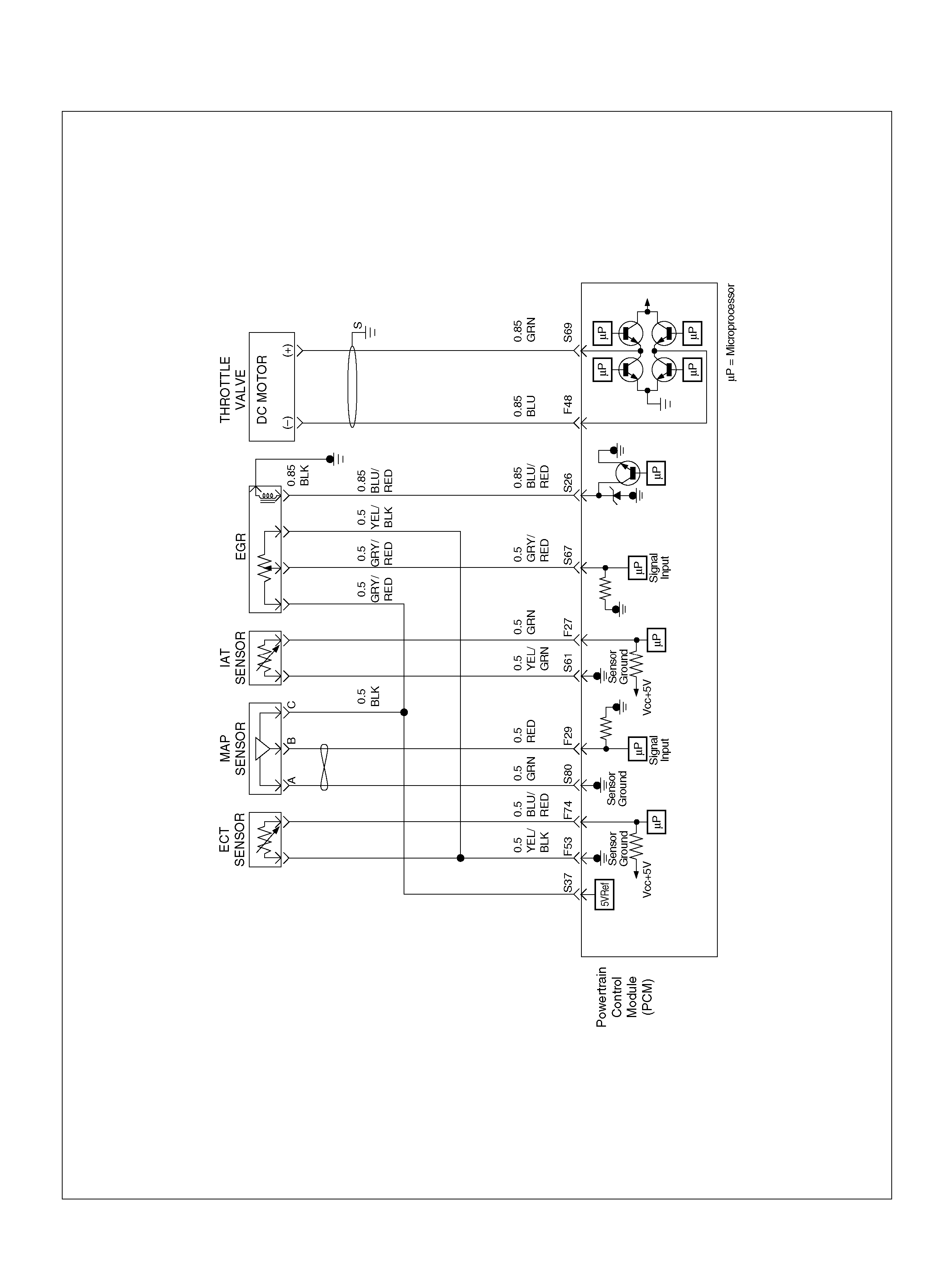

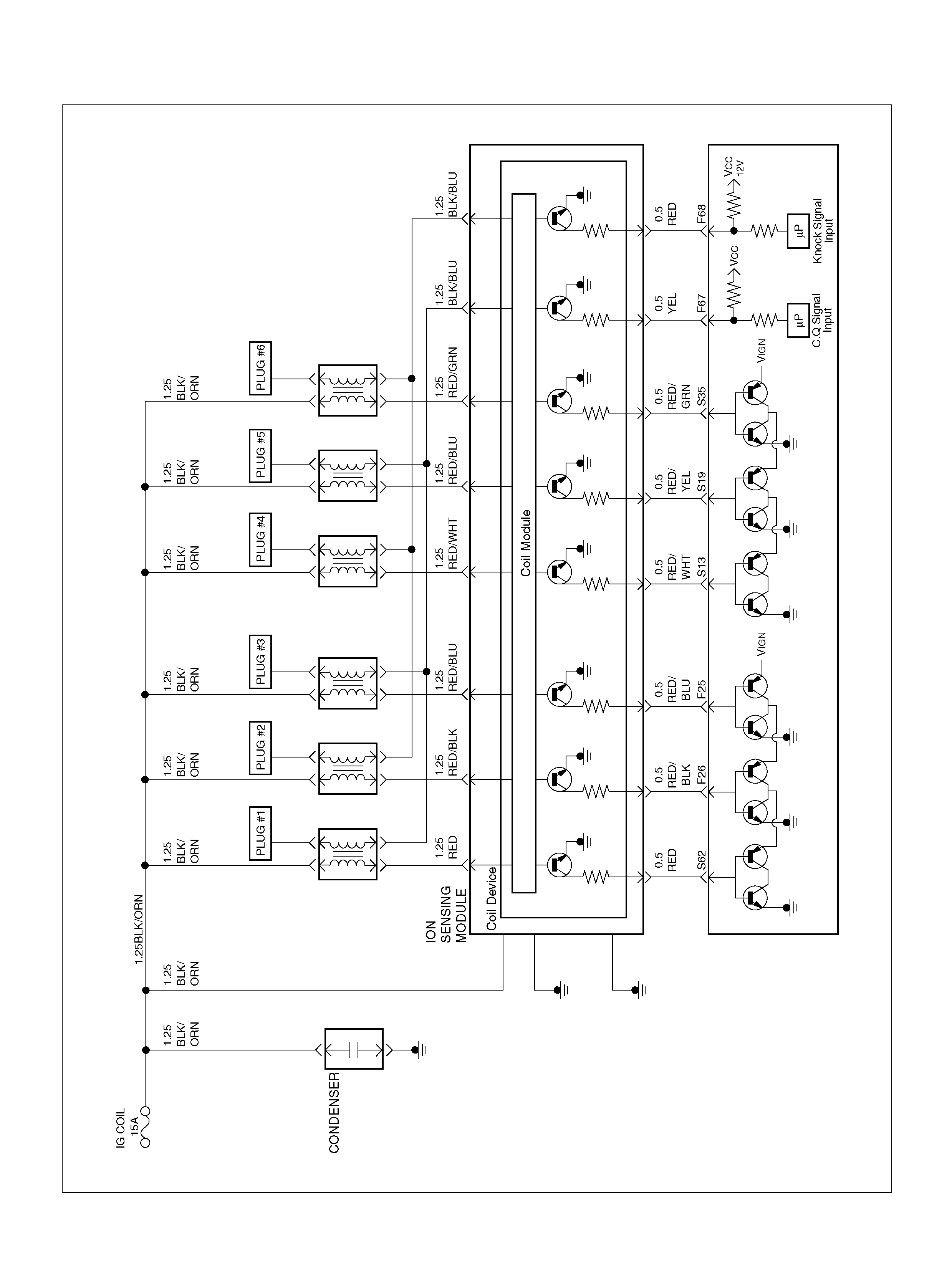

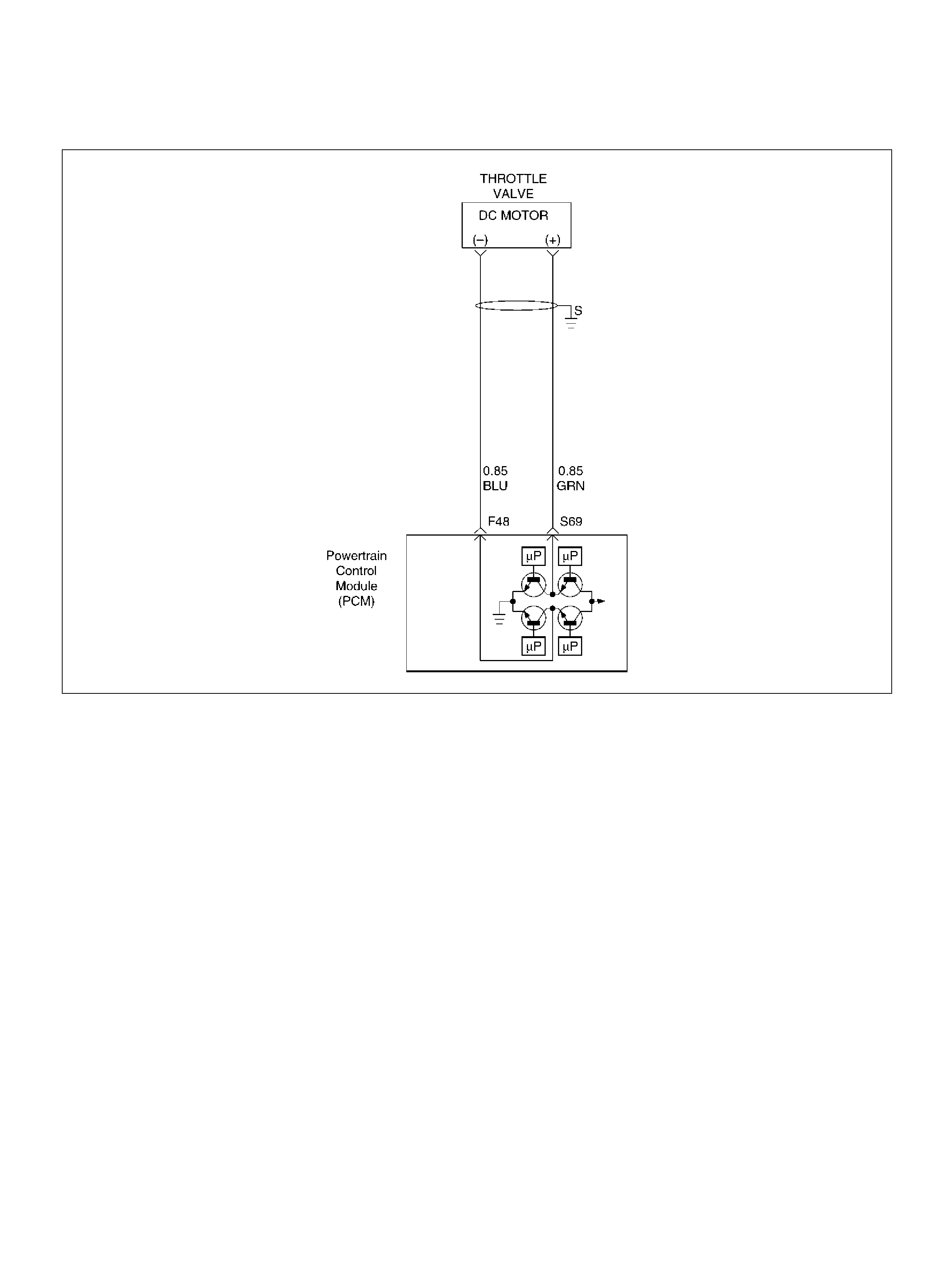

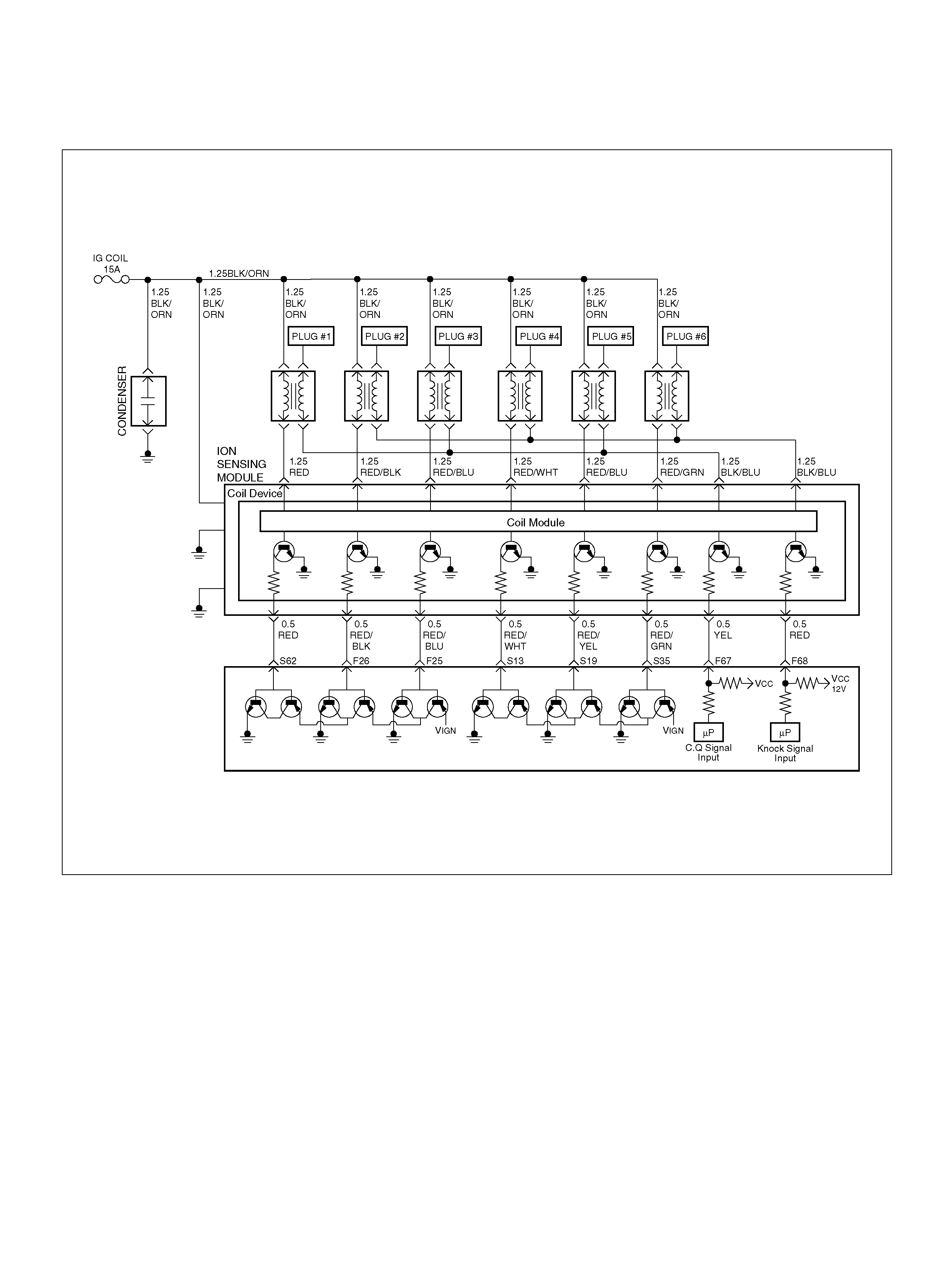

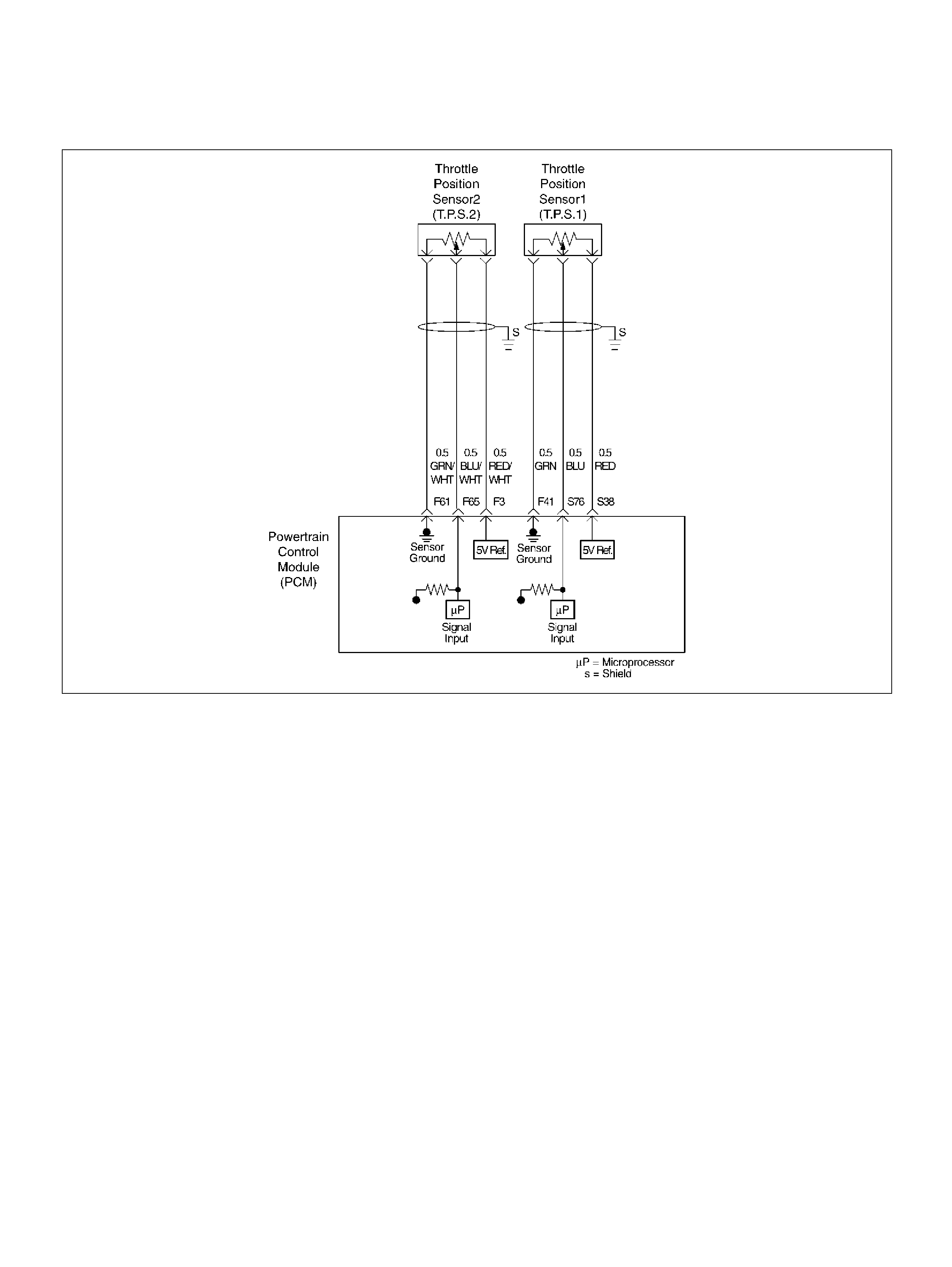

PCM Wiring Diagram (3 of 7)

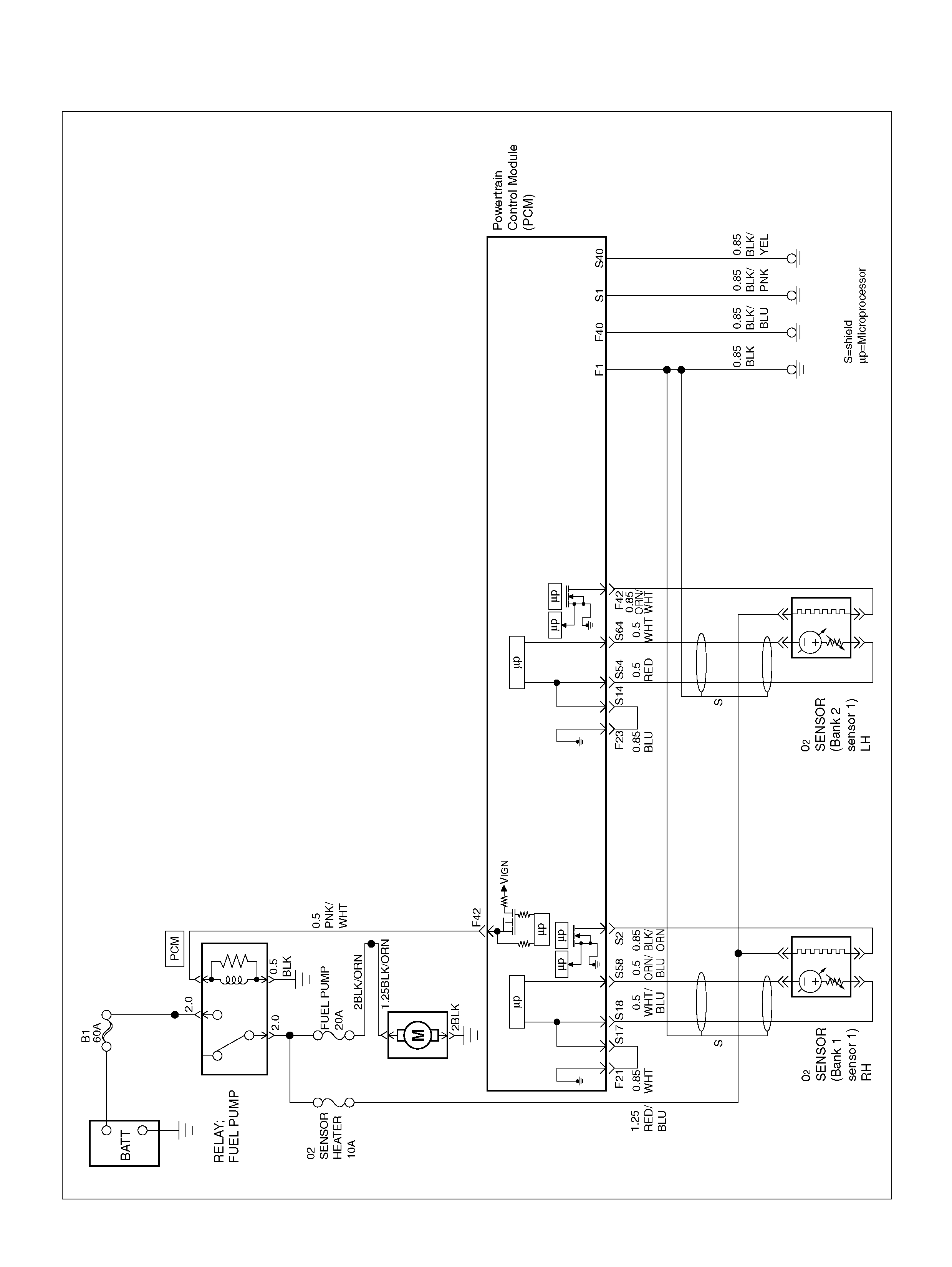

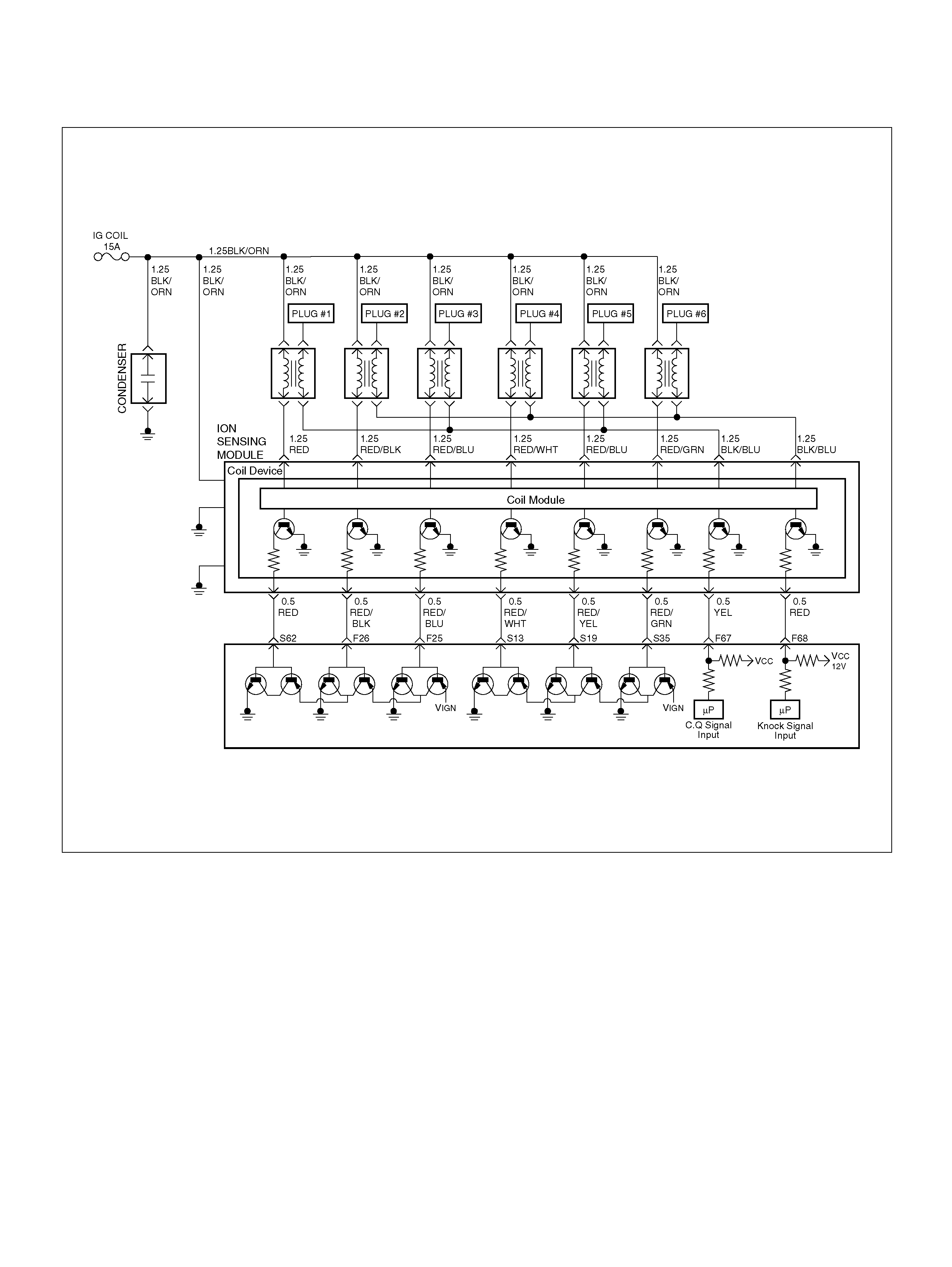

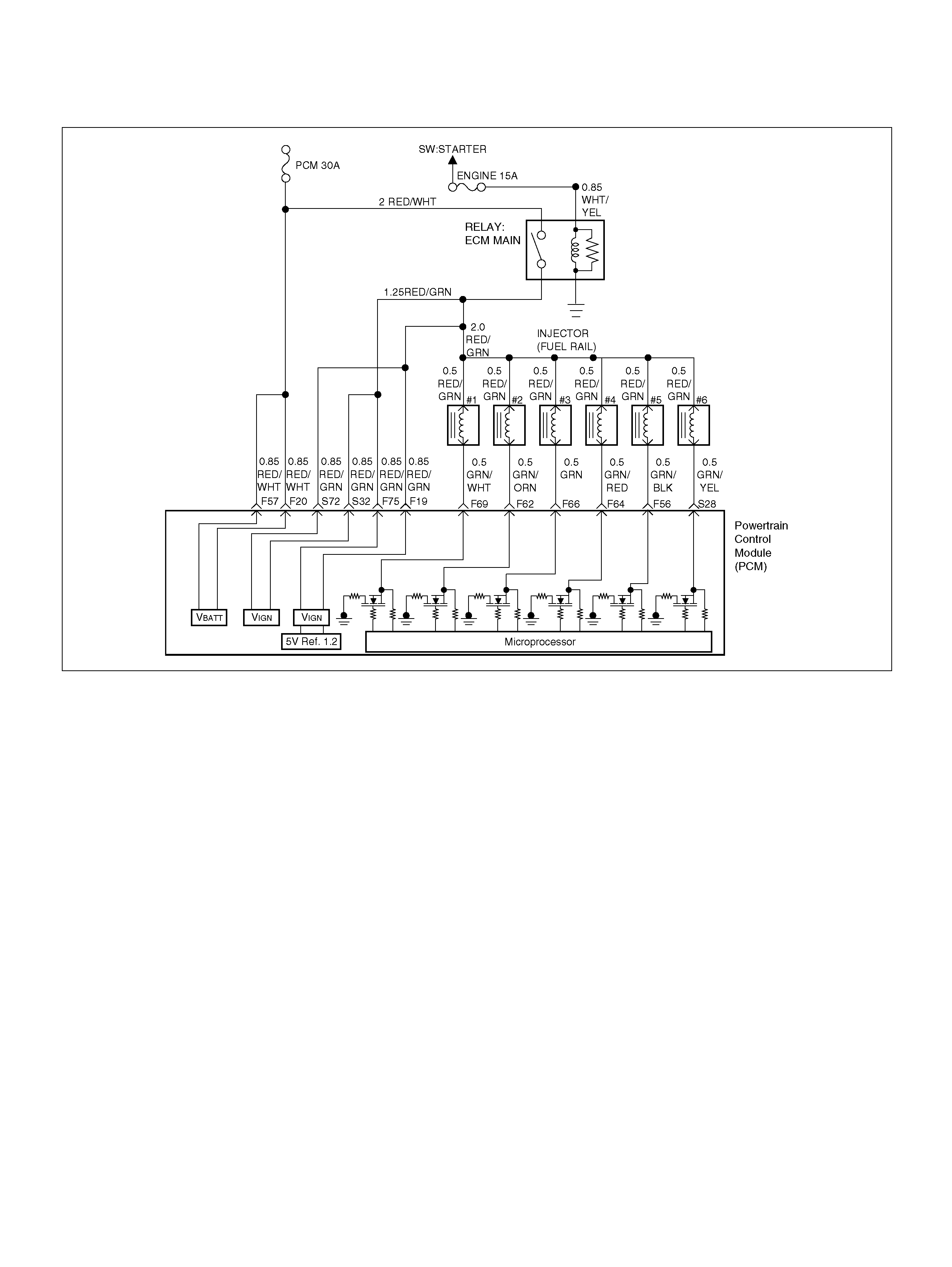

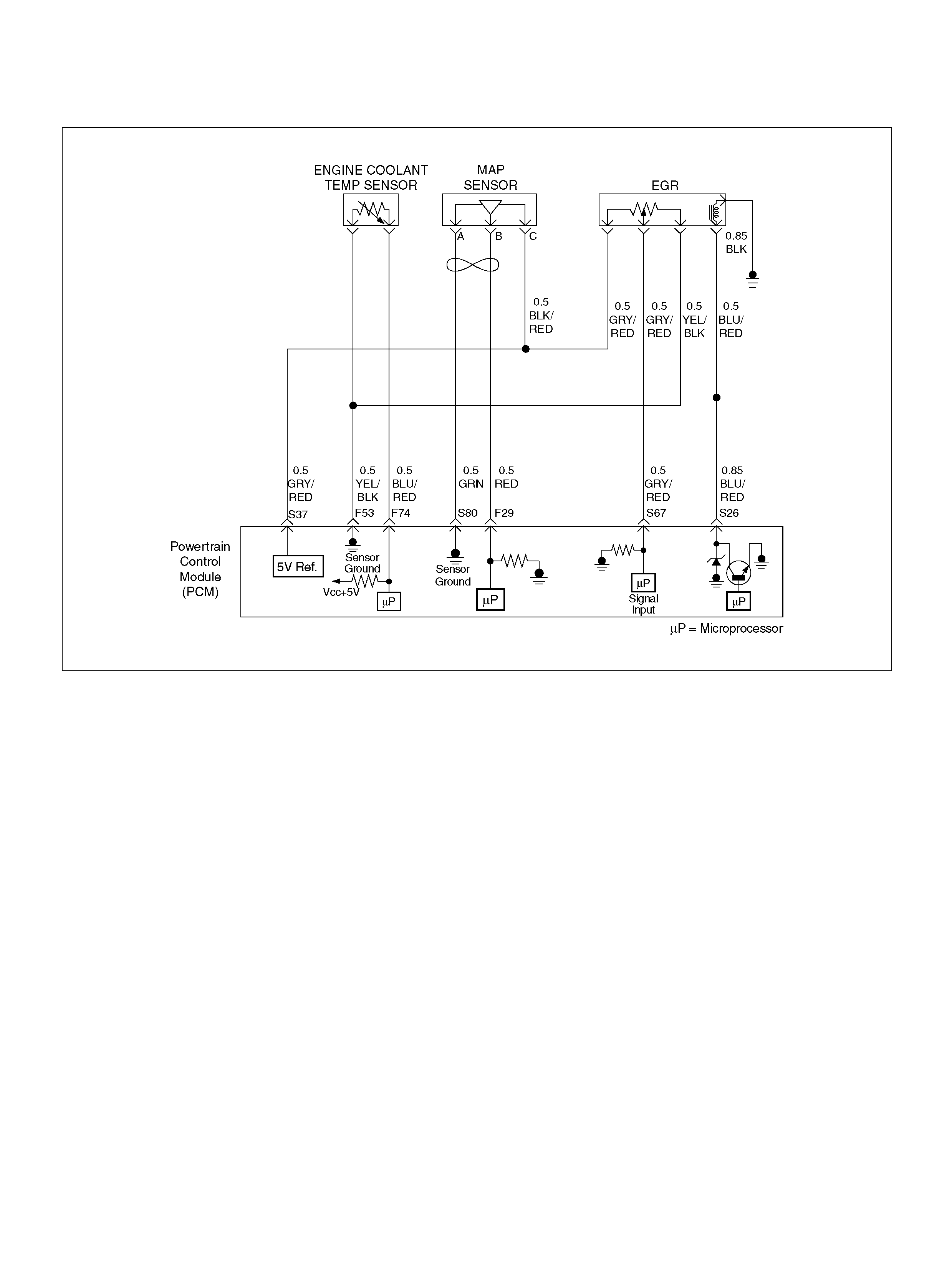

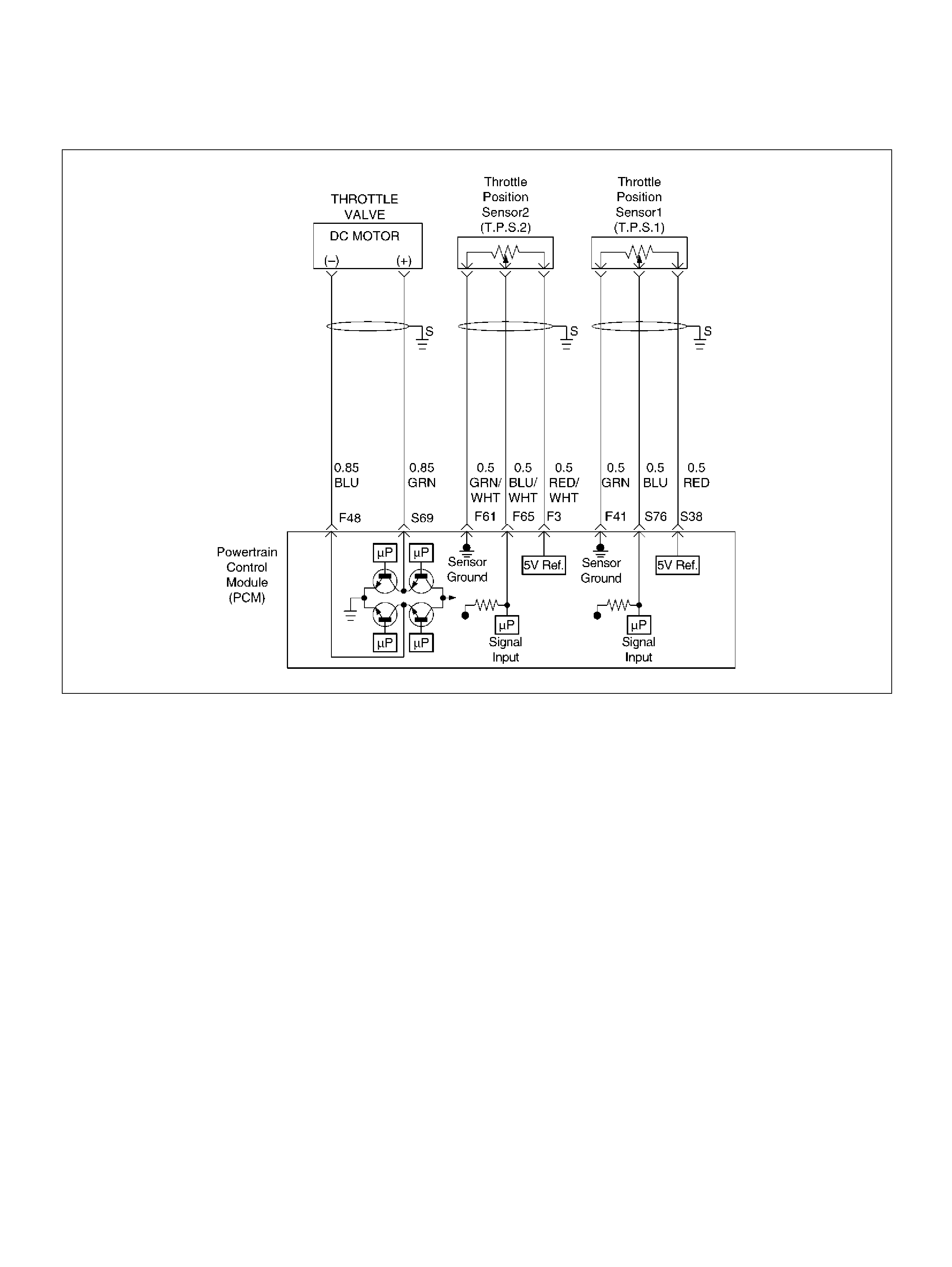

PCM Wiring Diagram (4 of 7)

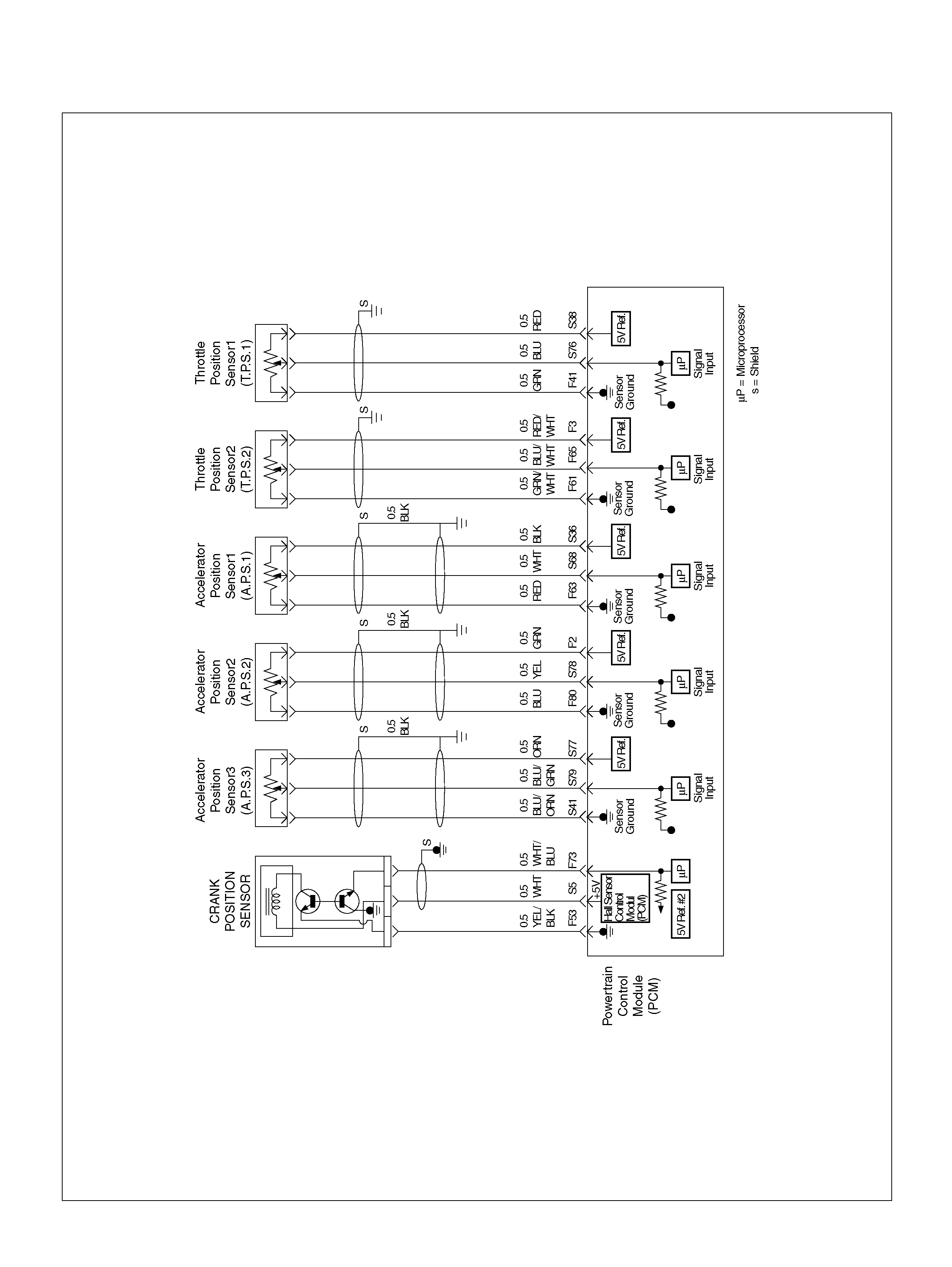

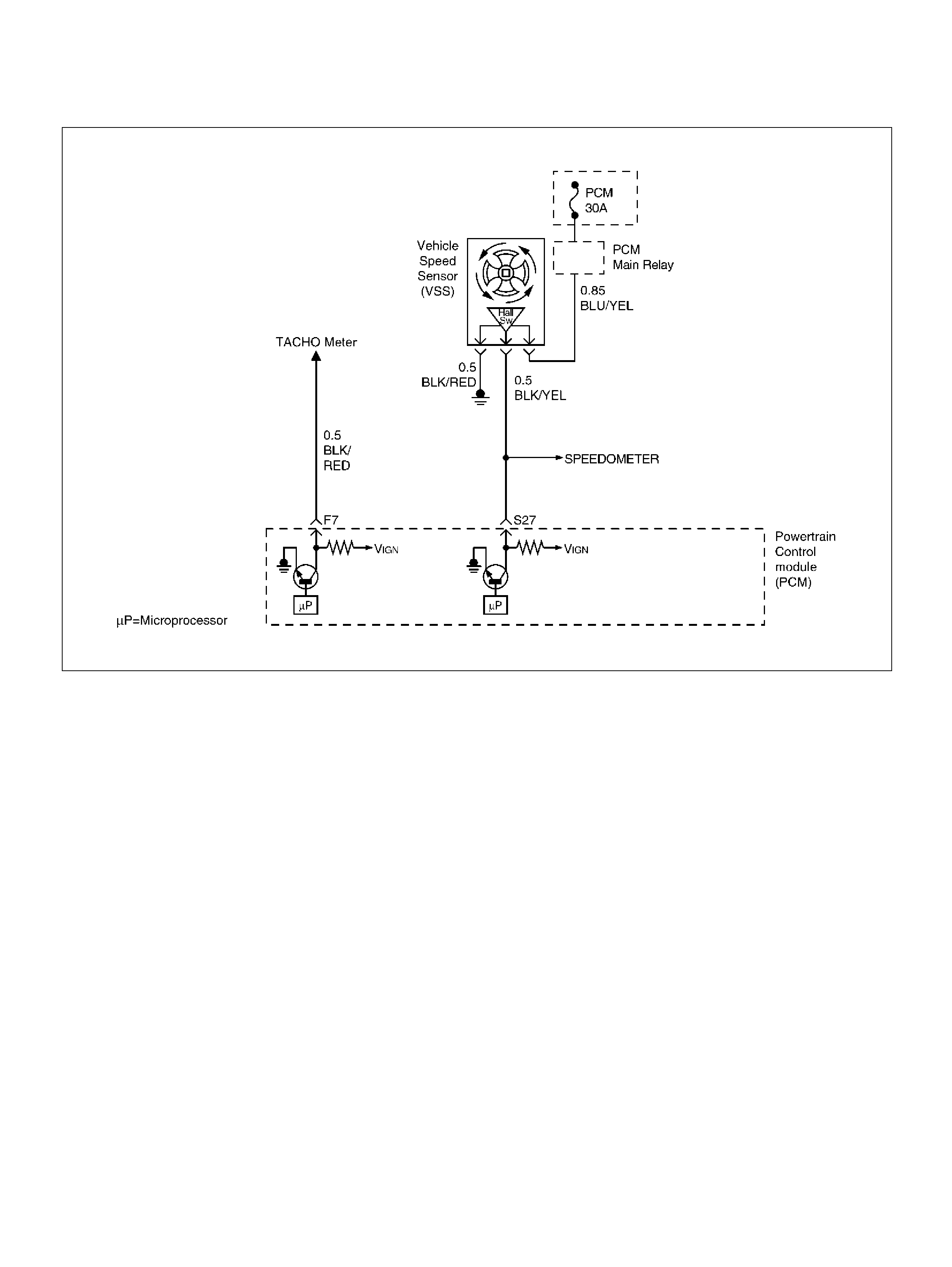

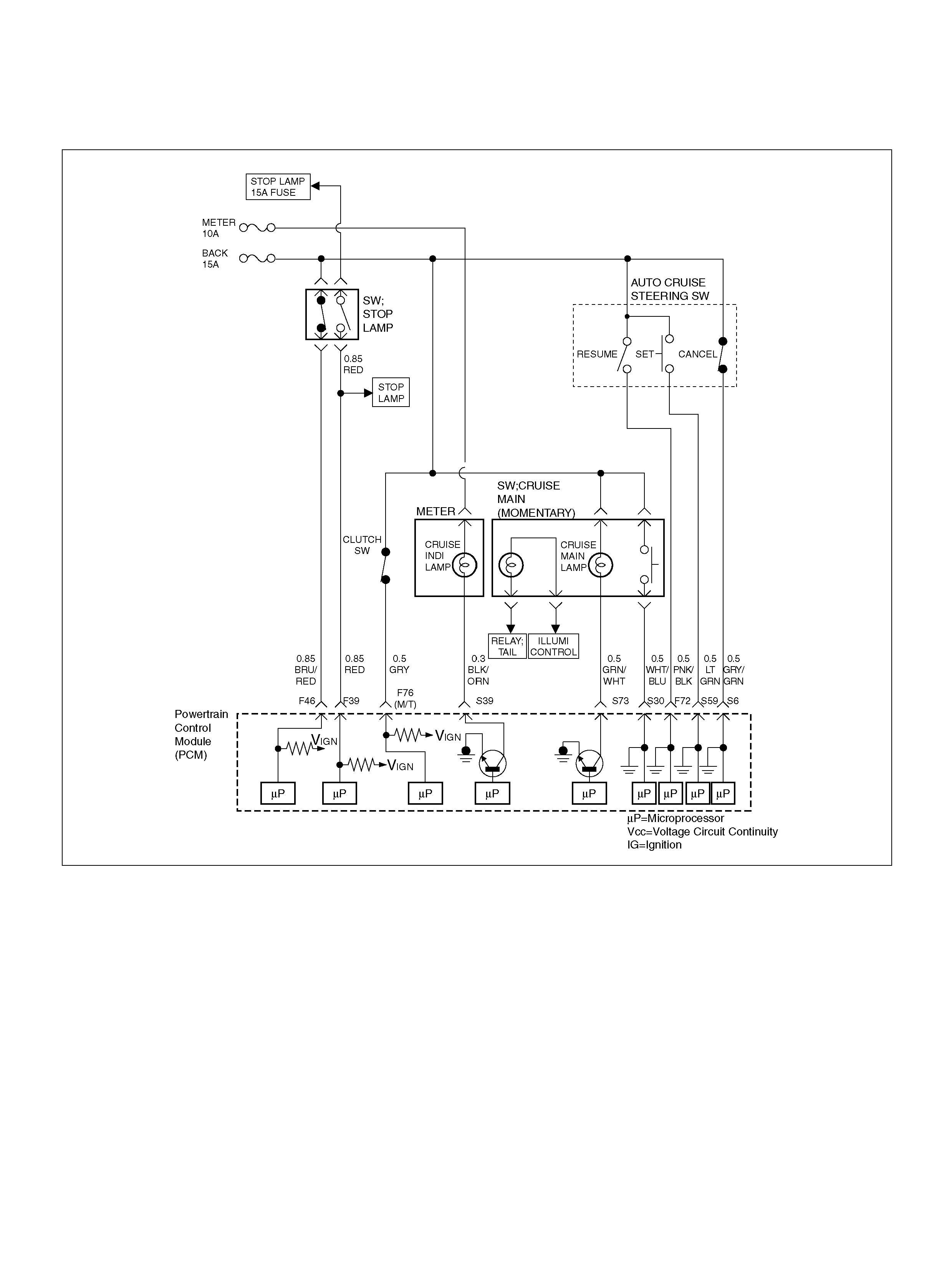

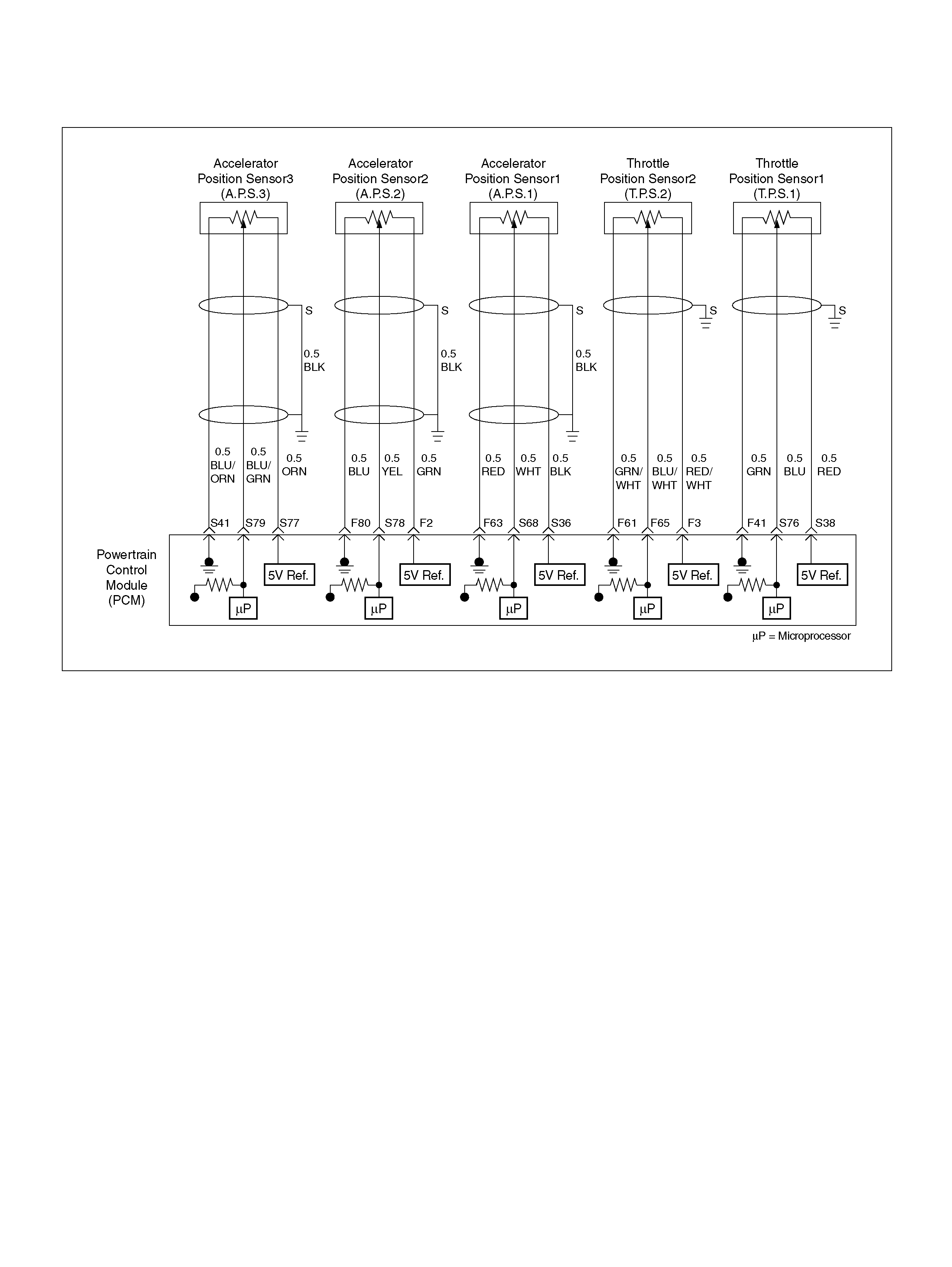

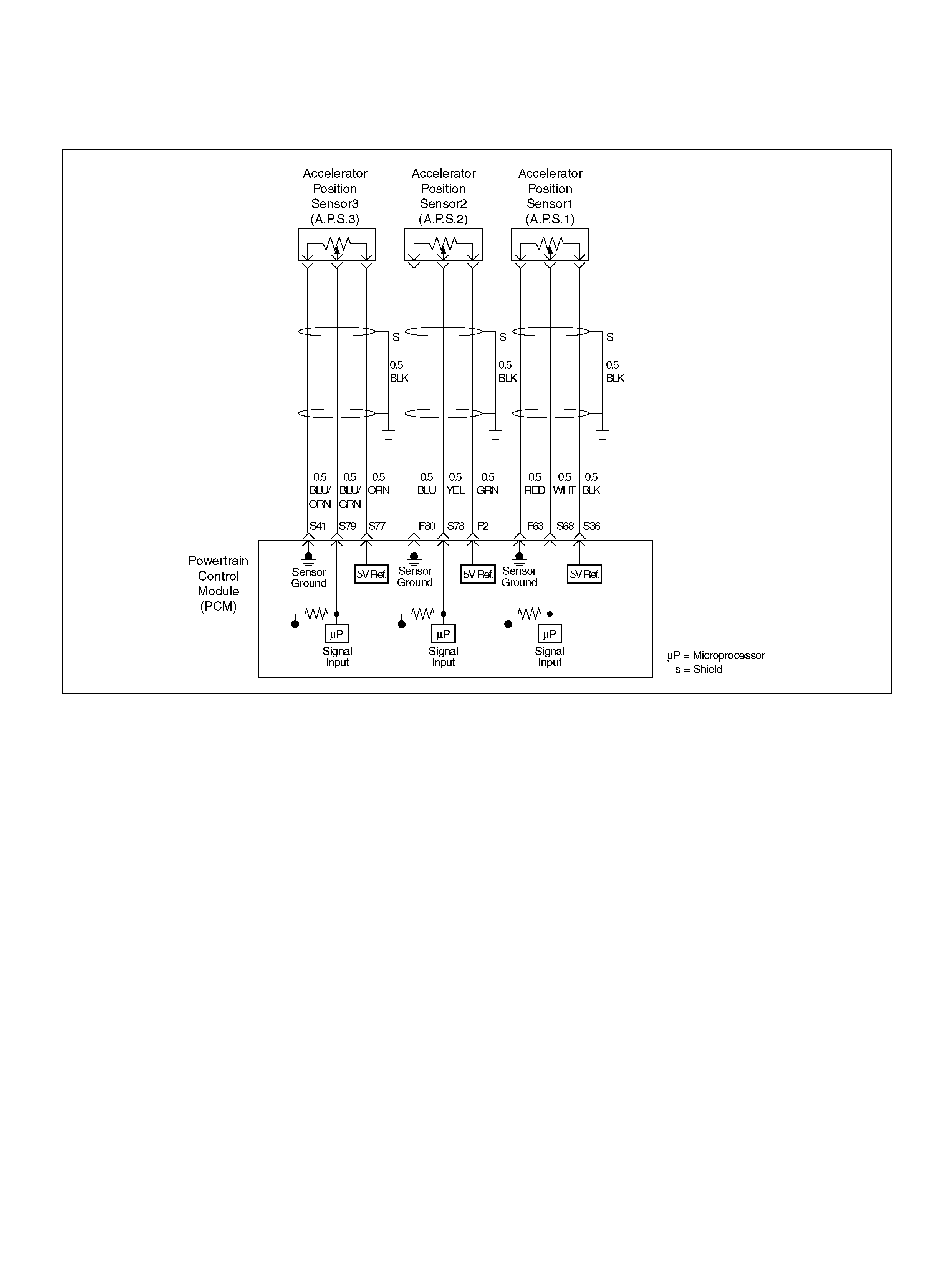

PCM Wiring Diagram (5 of 7)

PCM Wiring Diagram (6 of 7)

PCM Wiring Diagram (7 of 7)

PCM Pi n outs

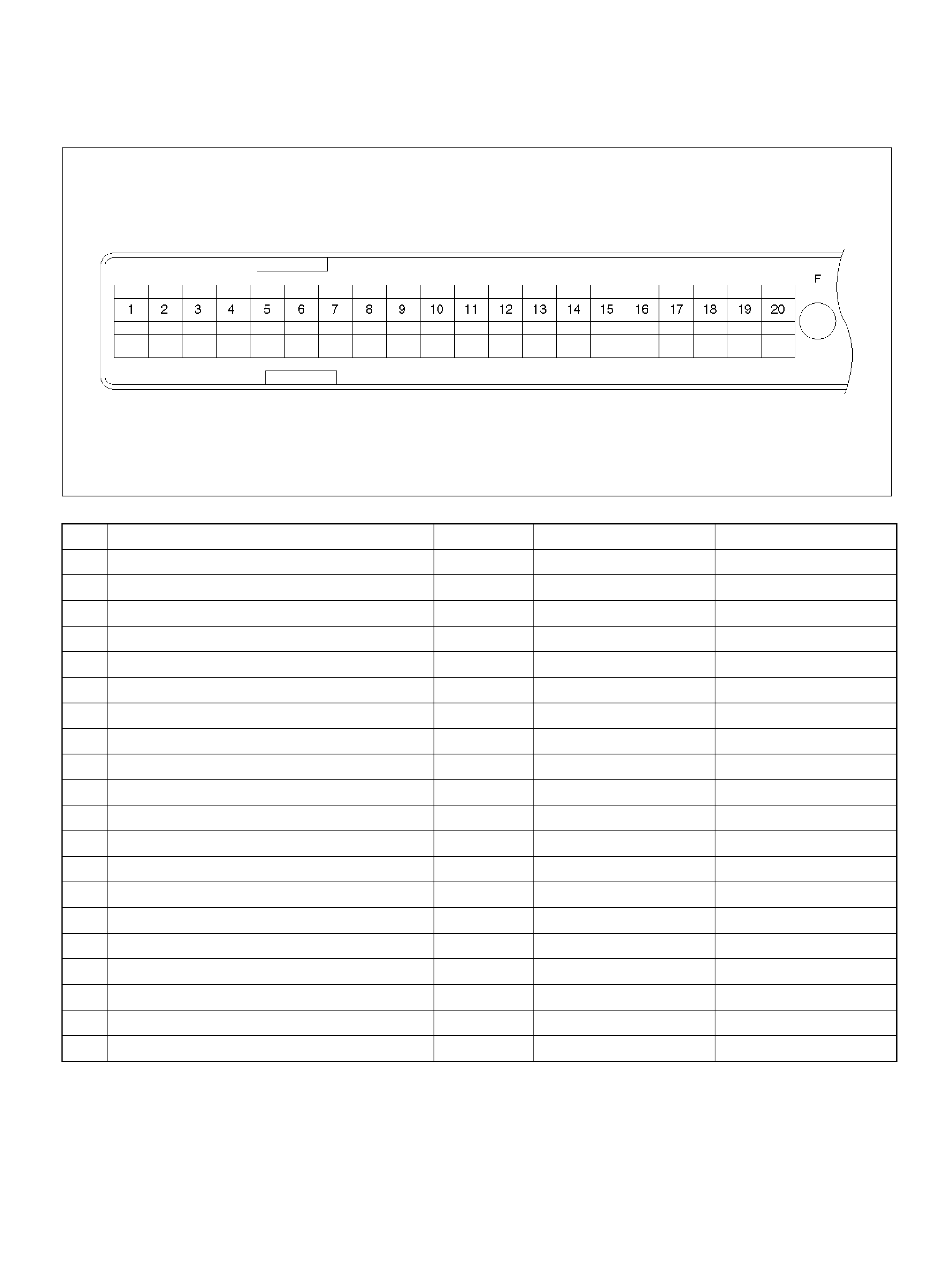

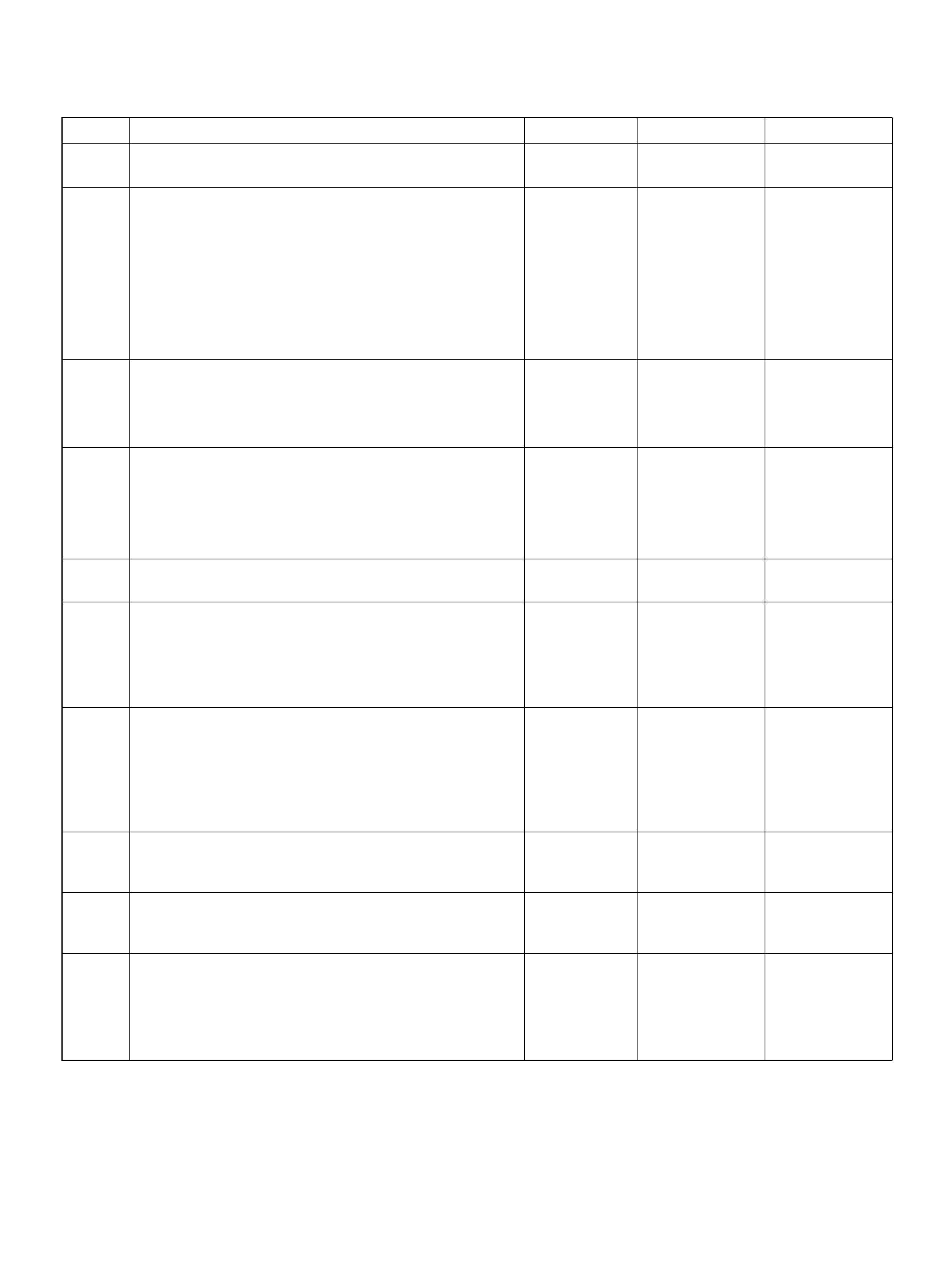

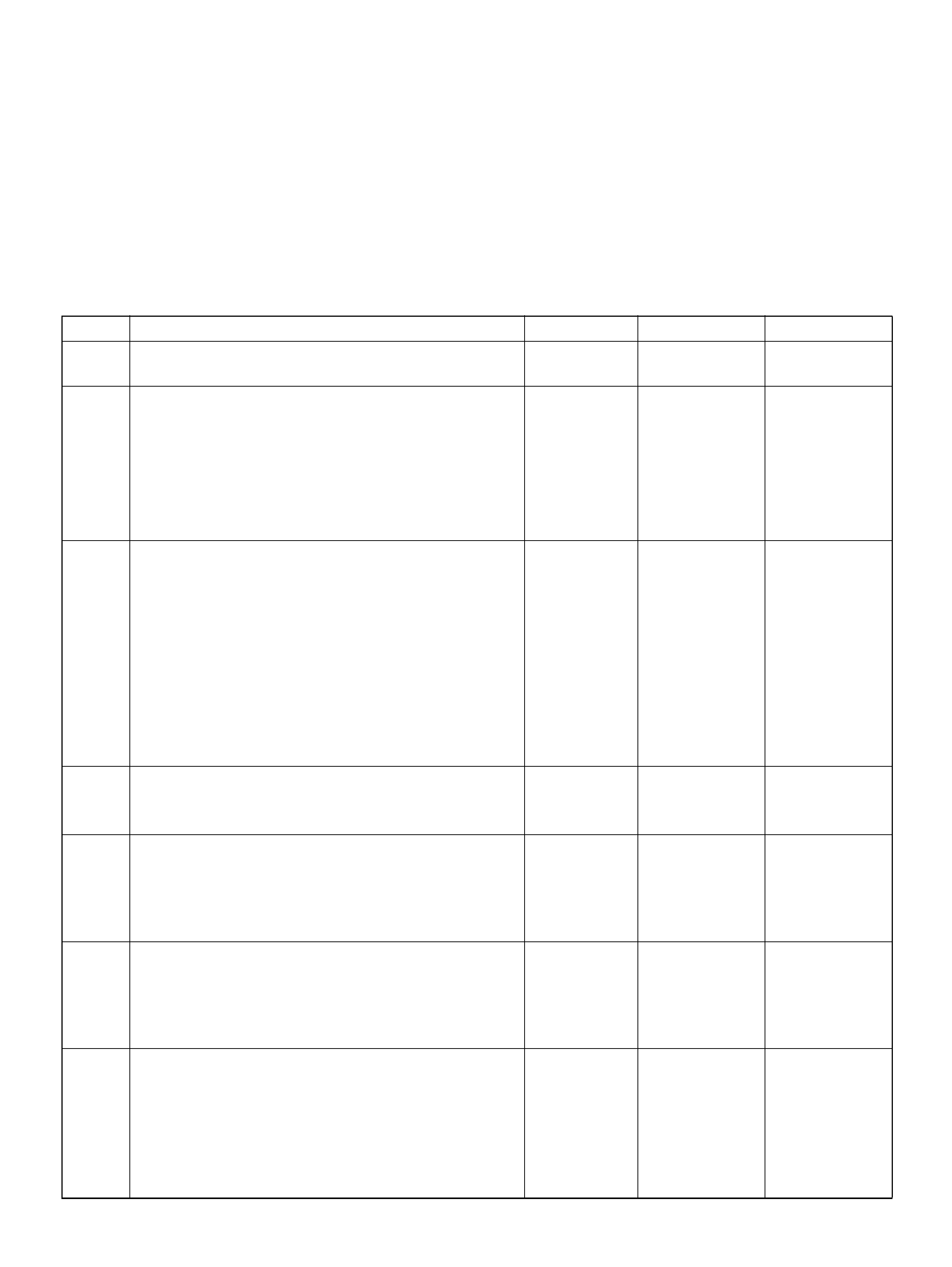

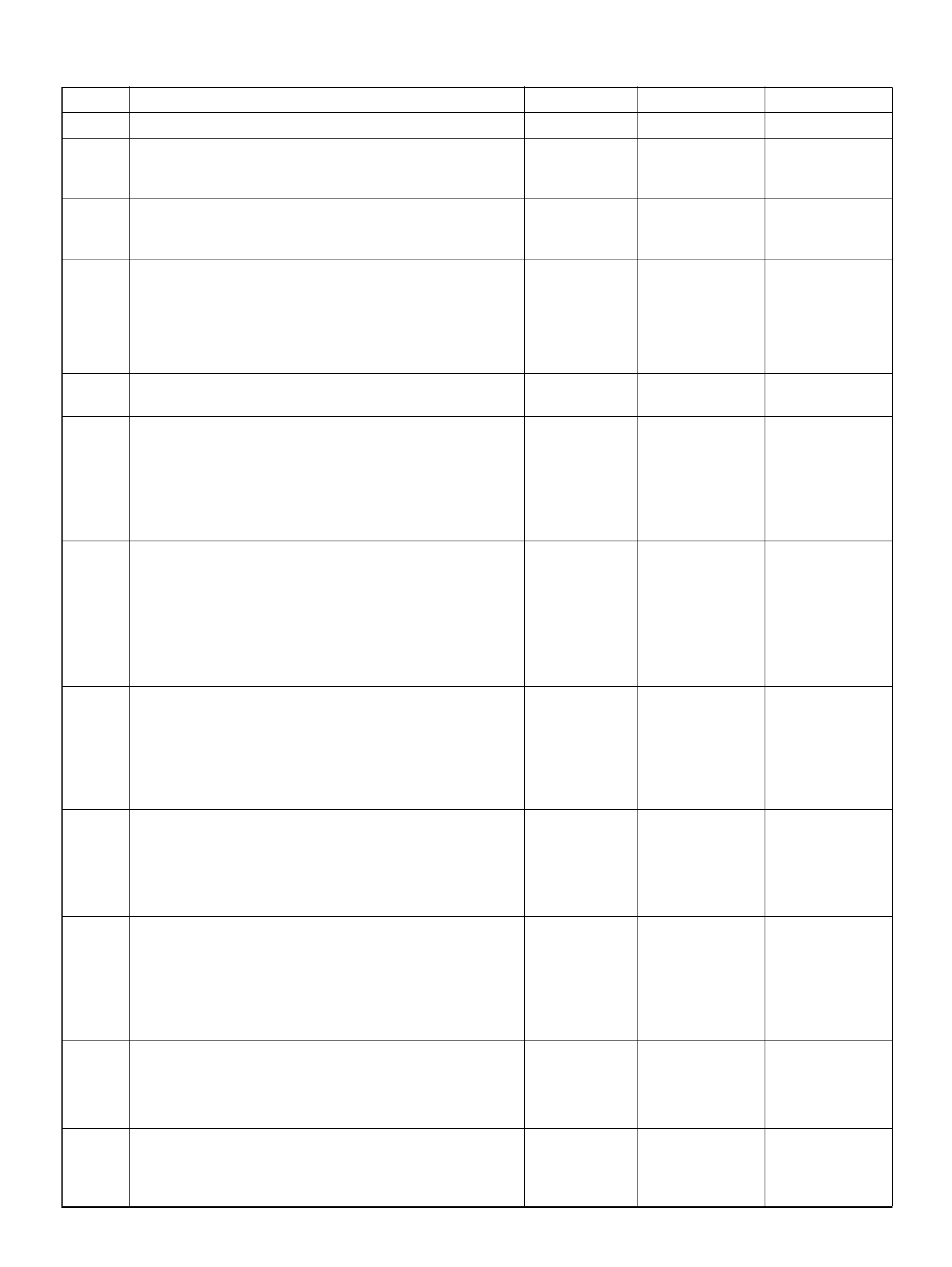

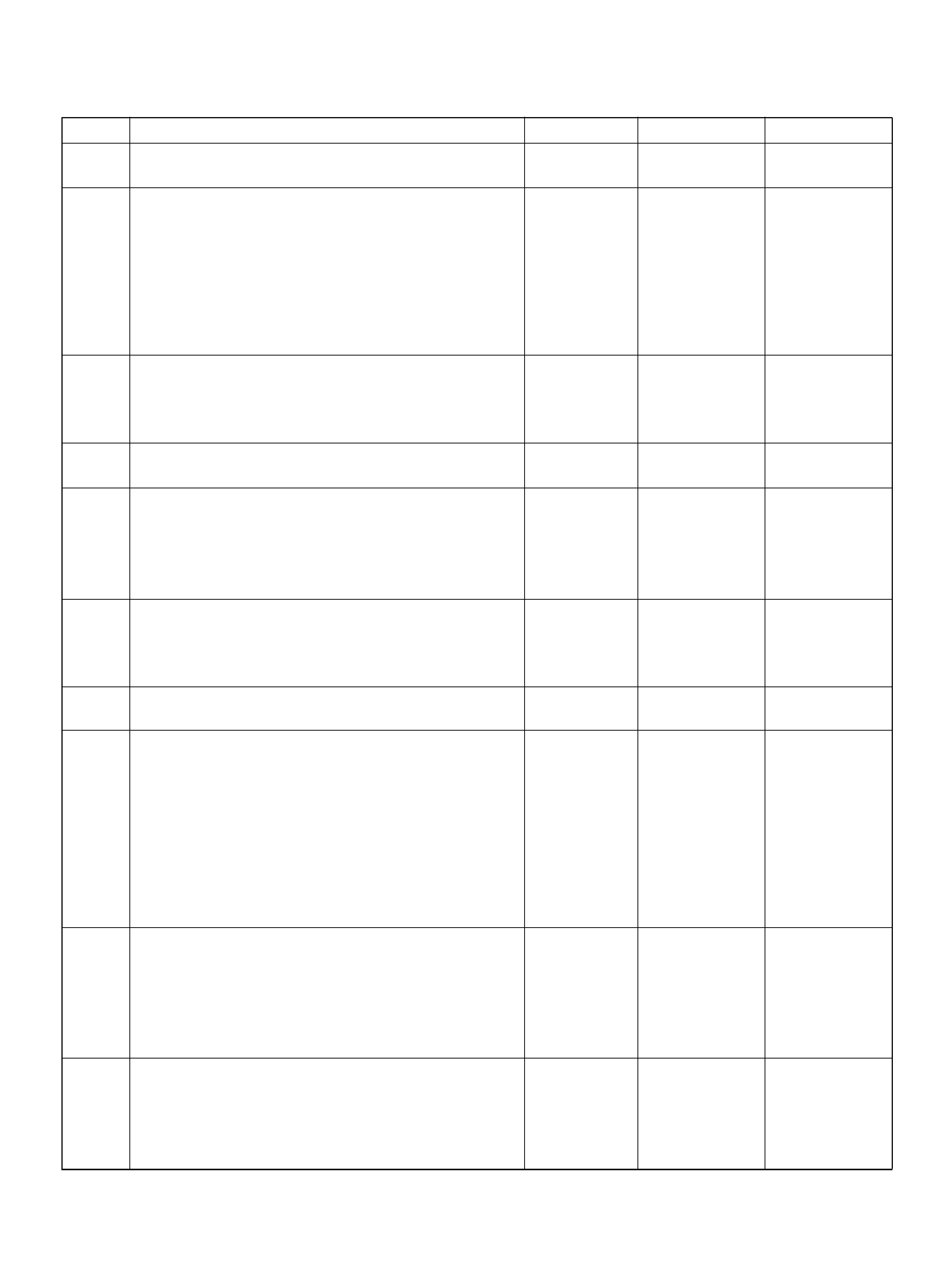

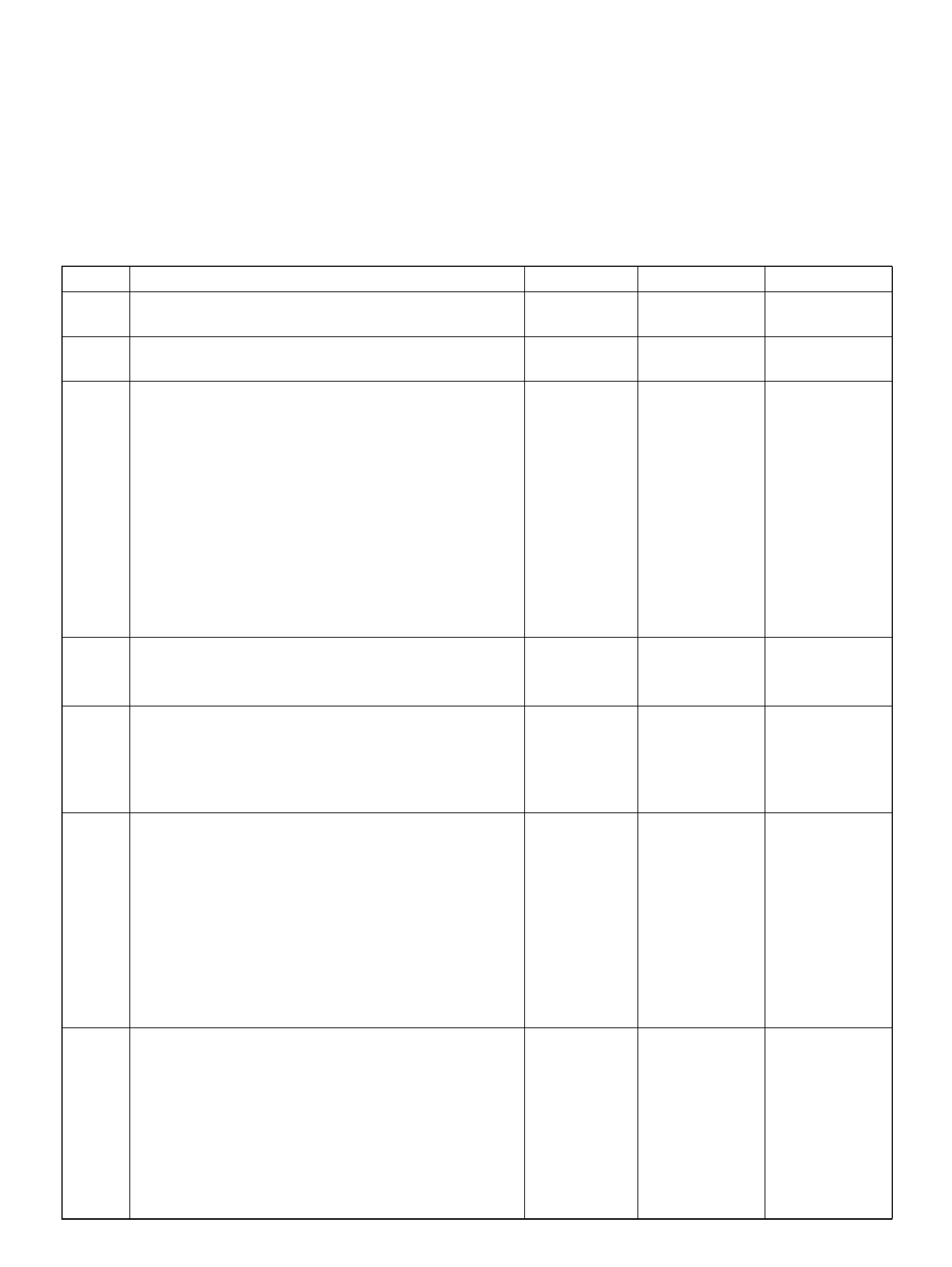

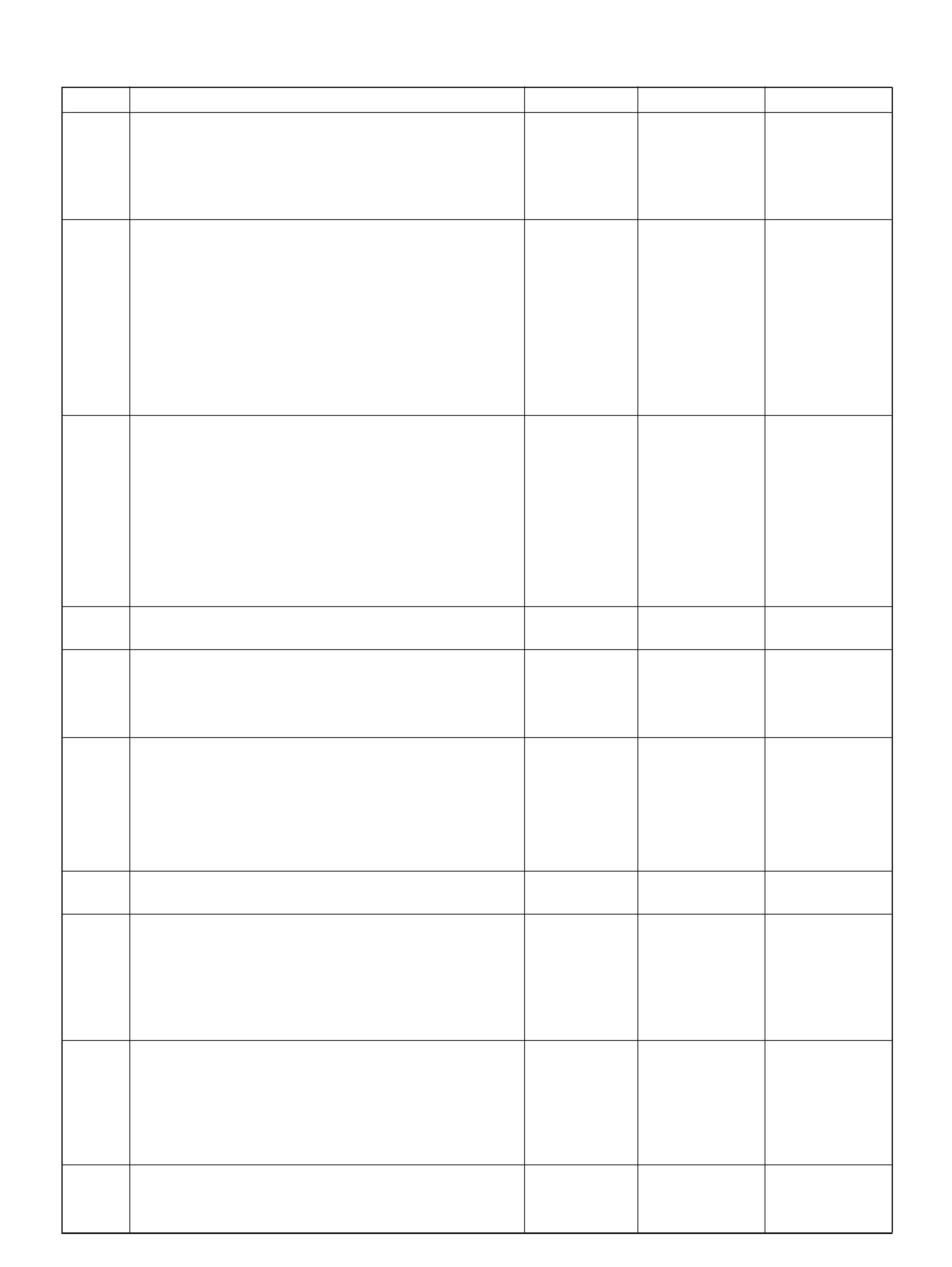

PCM Pinout Table, 80-Way Blue Connector

– Row “F1 ∼ 20"

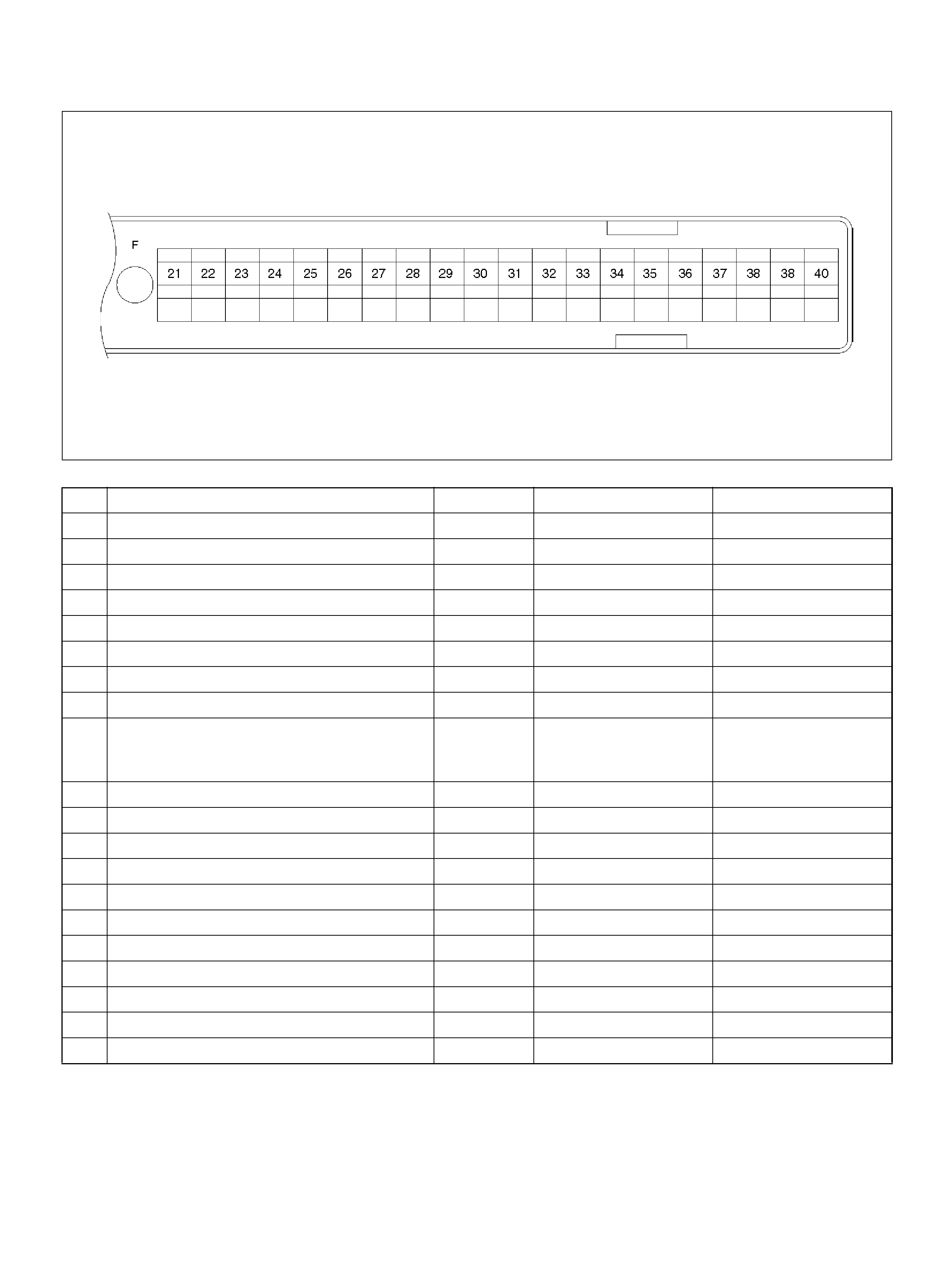

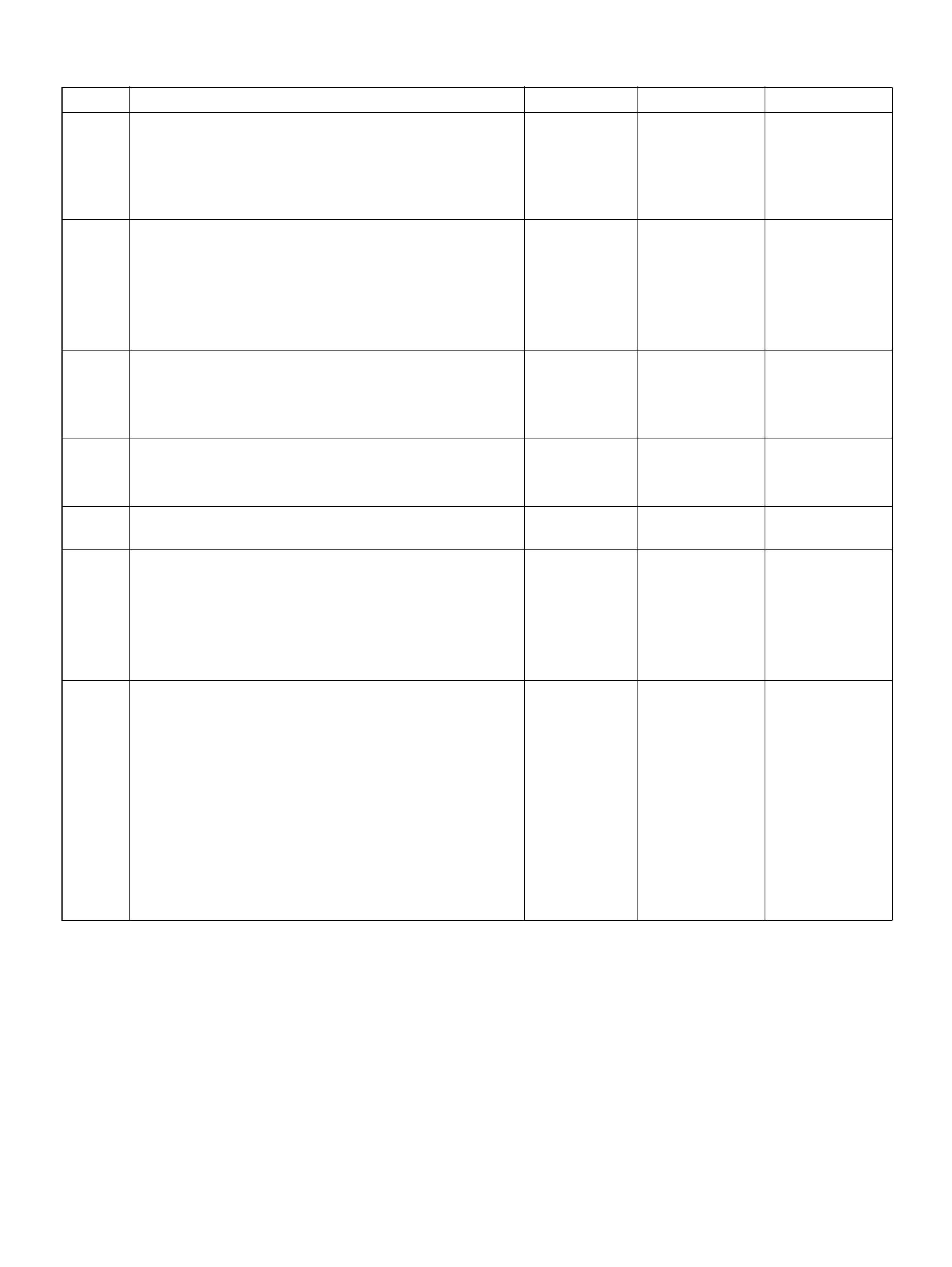

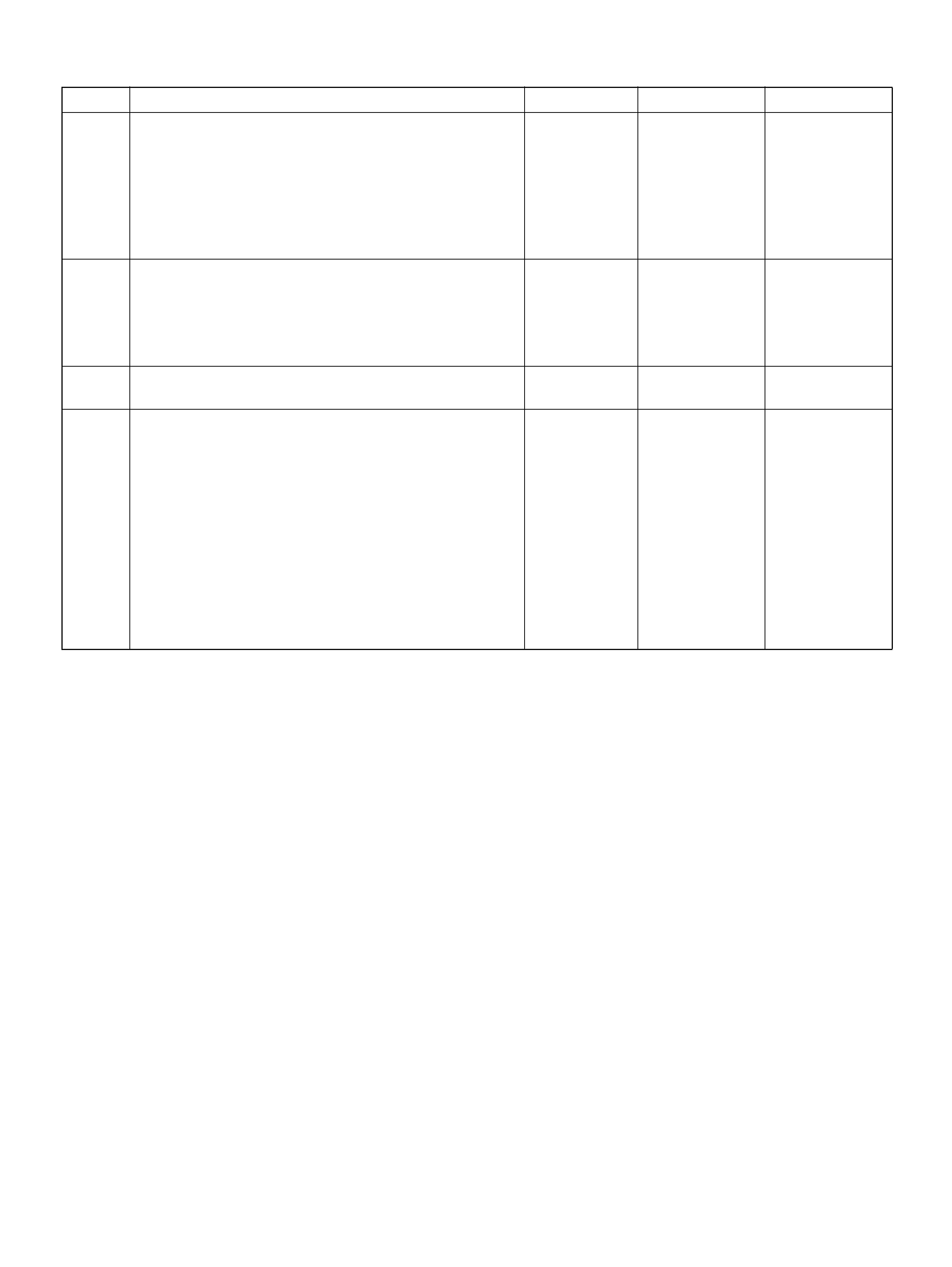

PCM Pinout Table, 80-Way Blue Connector

– Row “F20 ∼ 40"

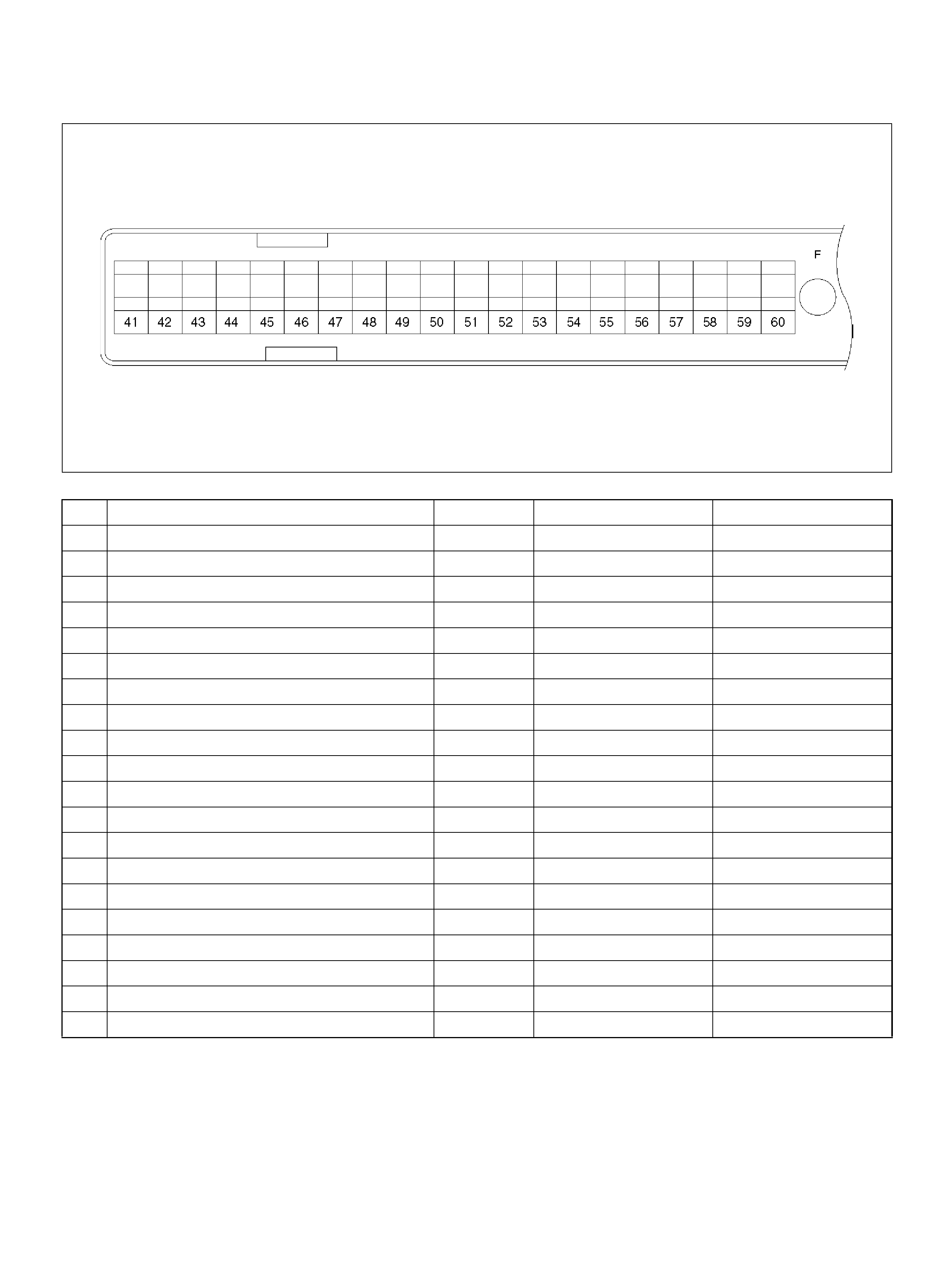

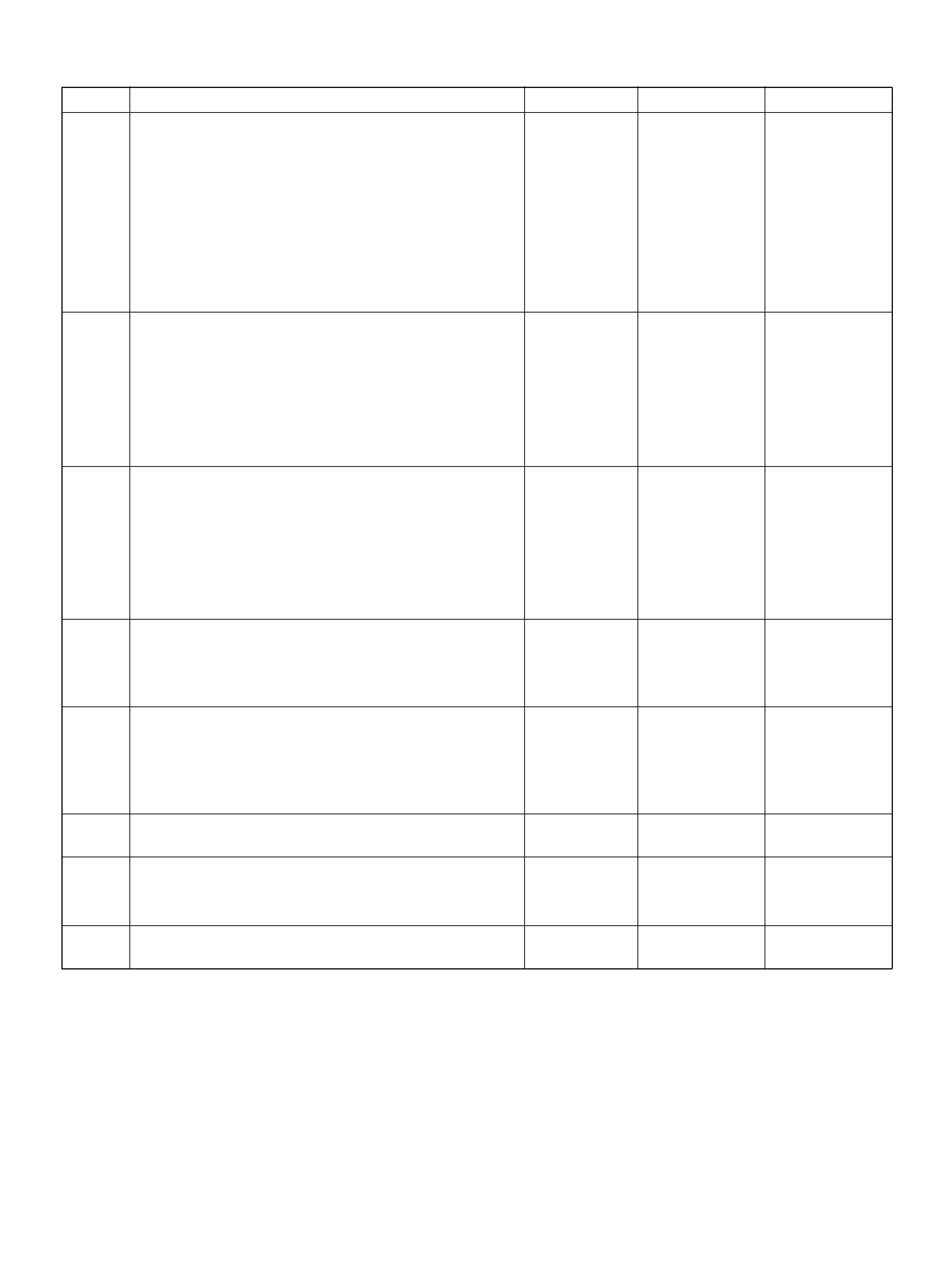

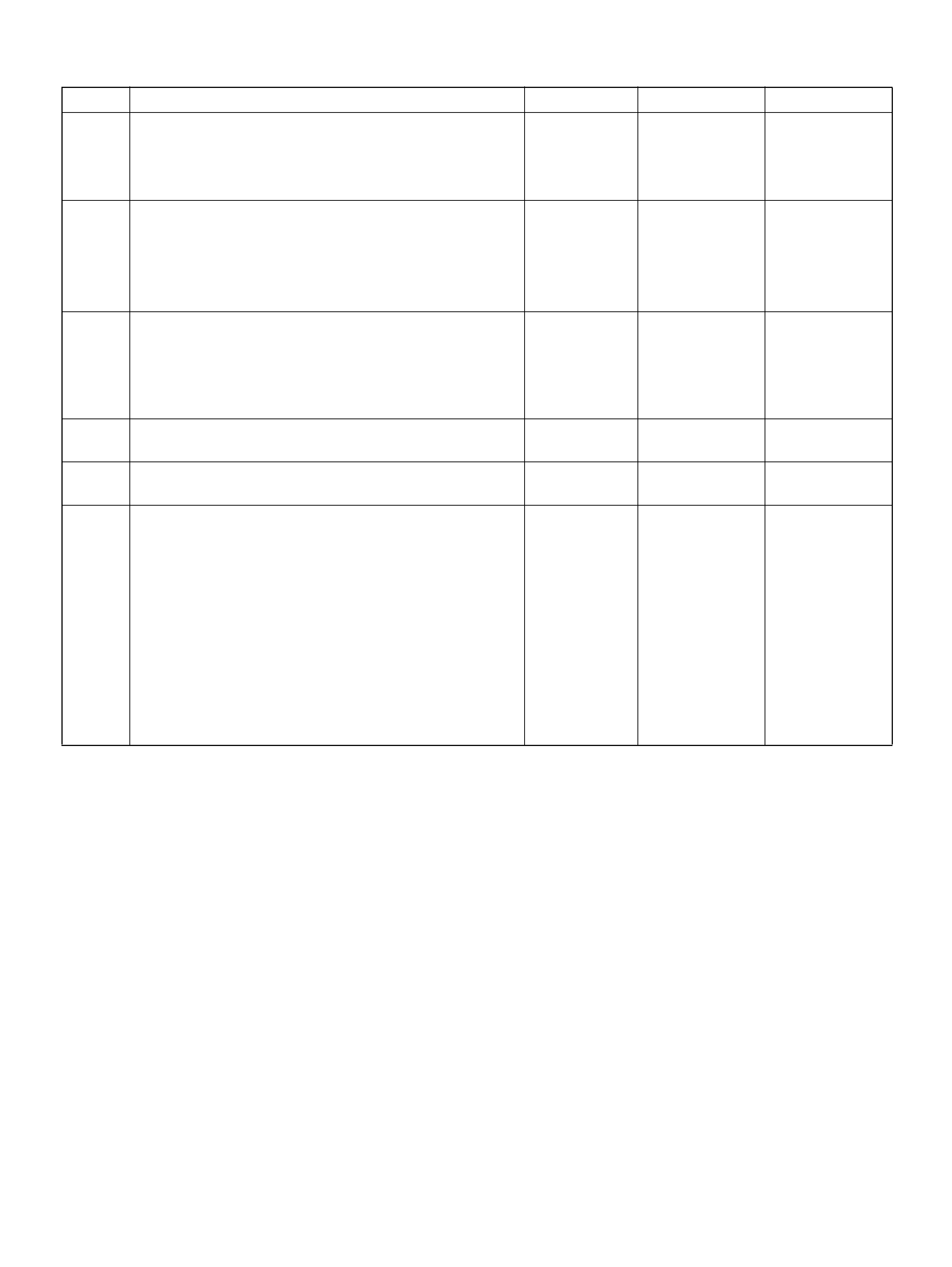

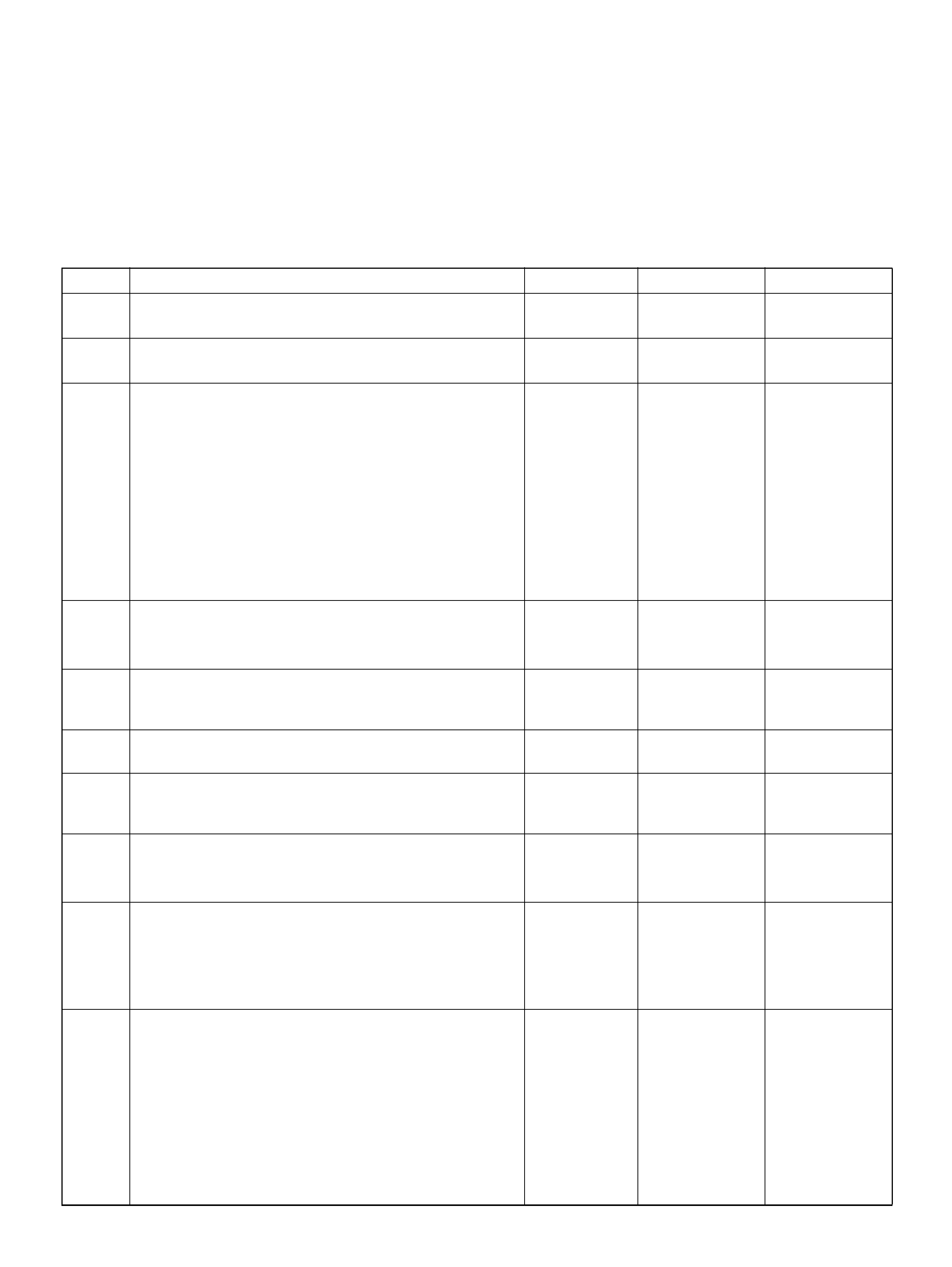

PCM Pinout Table, 80-Way Blue Connector

– Row “F41 ∼ 60"

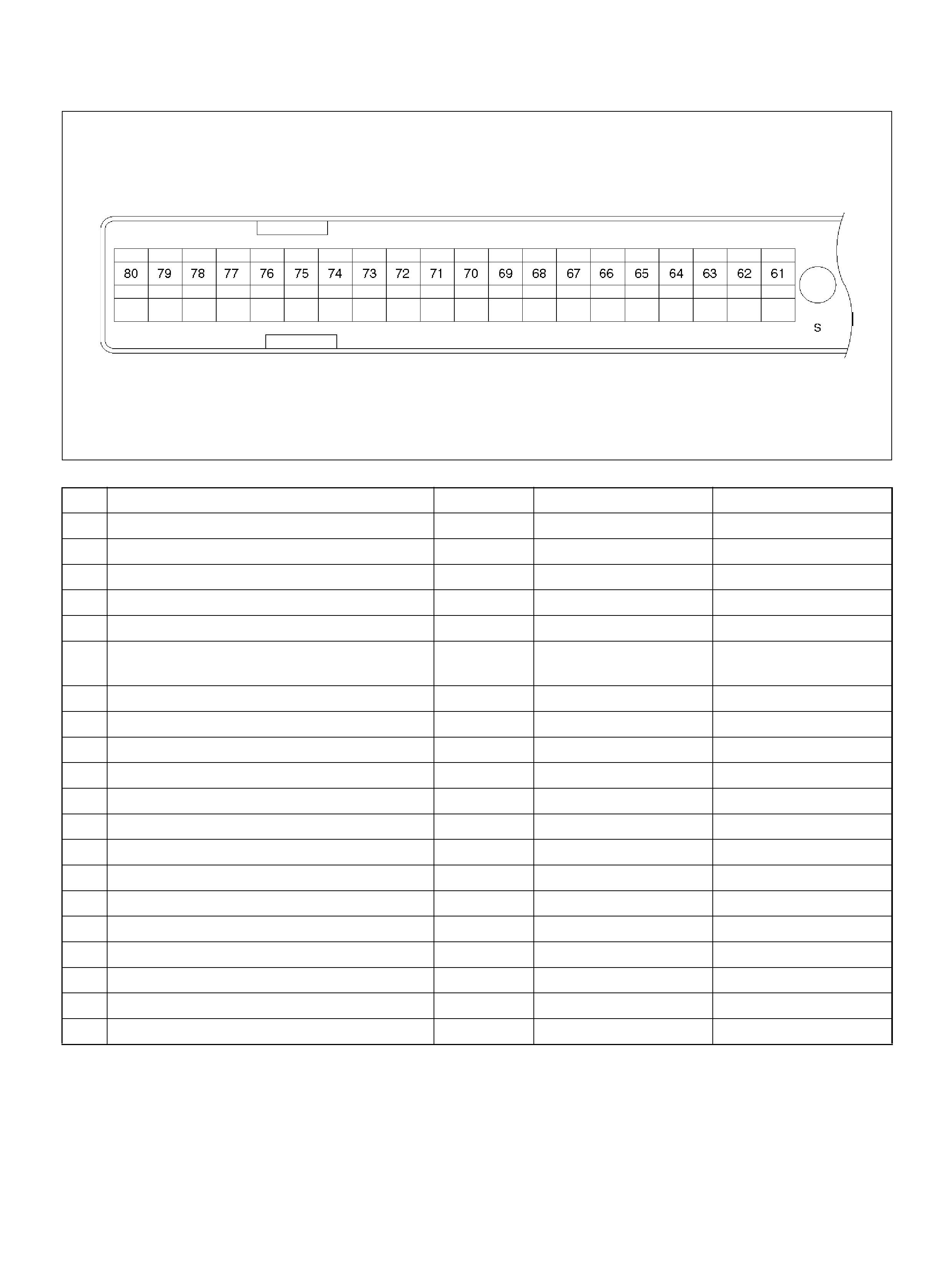

PCM Pinout Table, 80-Way Blue Connector

– Row “F61 ∼ 80"

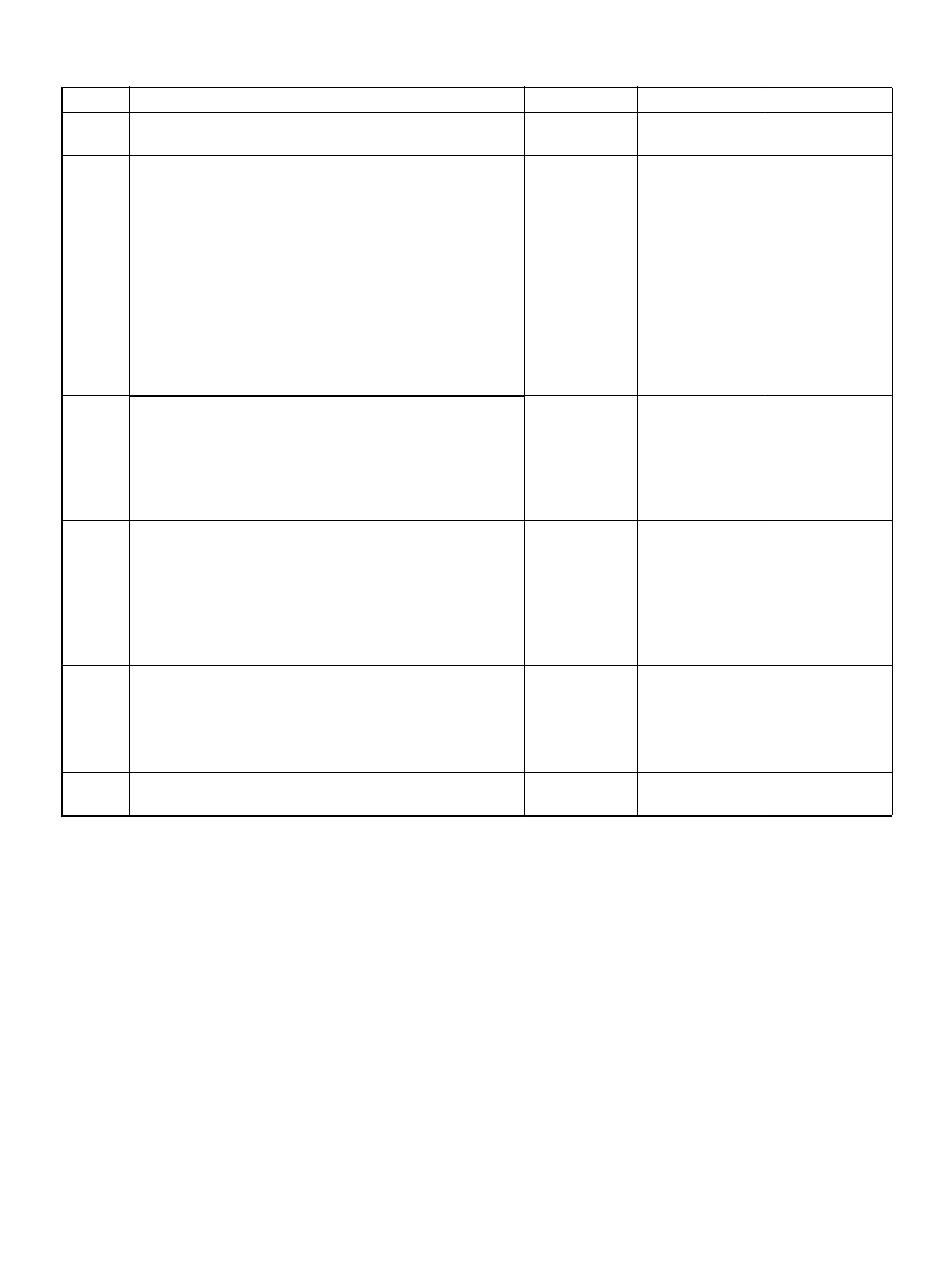

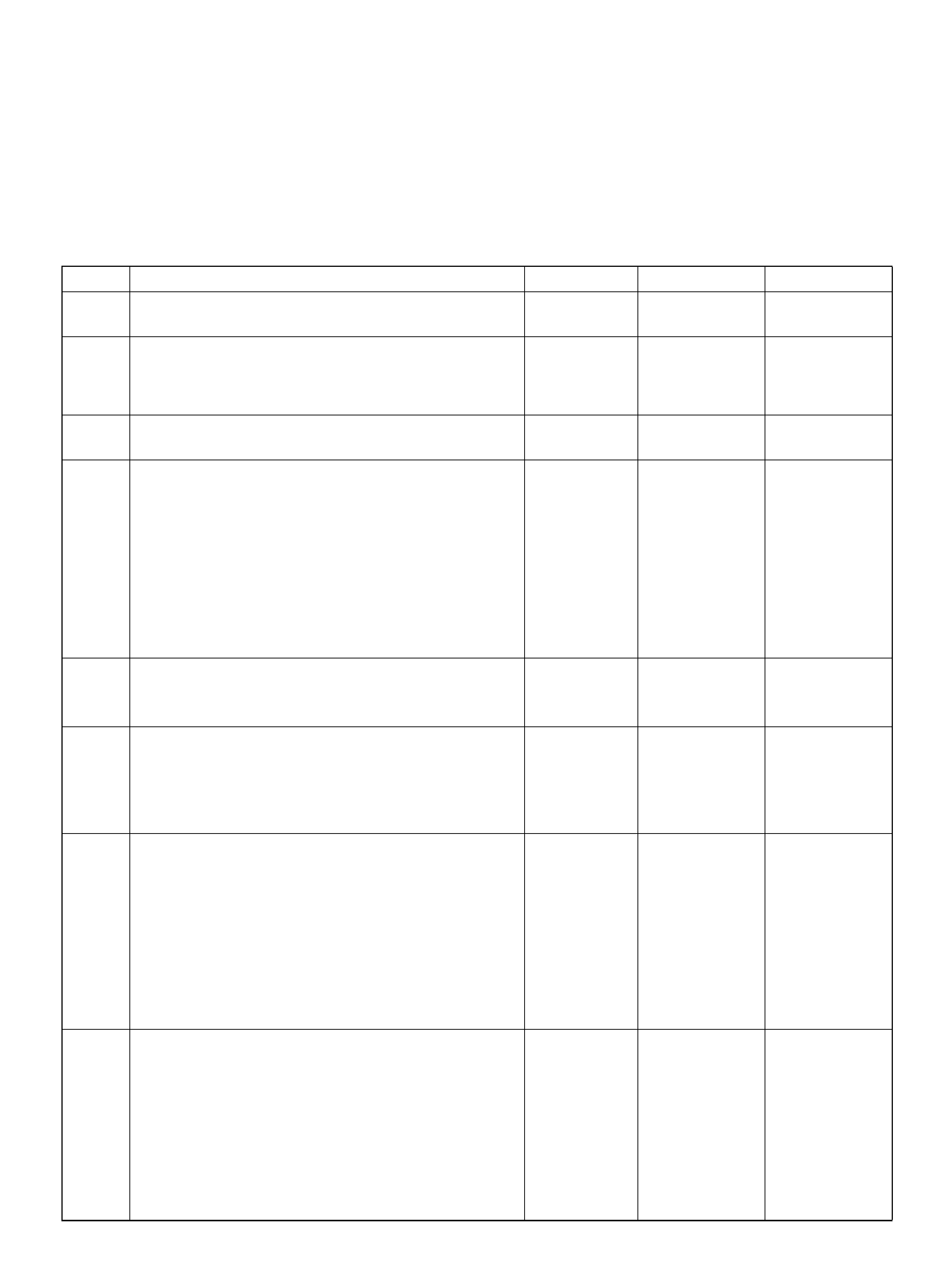

PCM Pinout Table, 80-Way Red Connector

– Row “S1 ∼ 20"

PCM Pinout Table, 80-Way Red Connector

– Row “S21 ∼ 40"

PCM Pinout Table, 80-Way Red Connector

– Row “S41 ∼ 60"

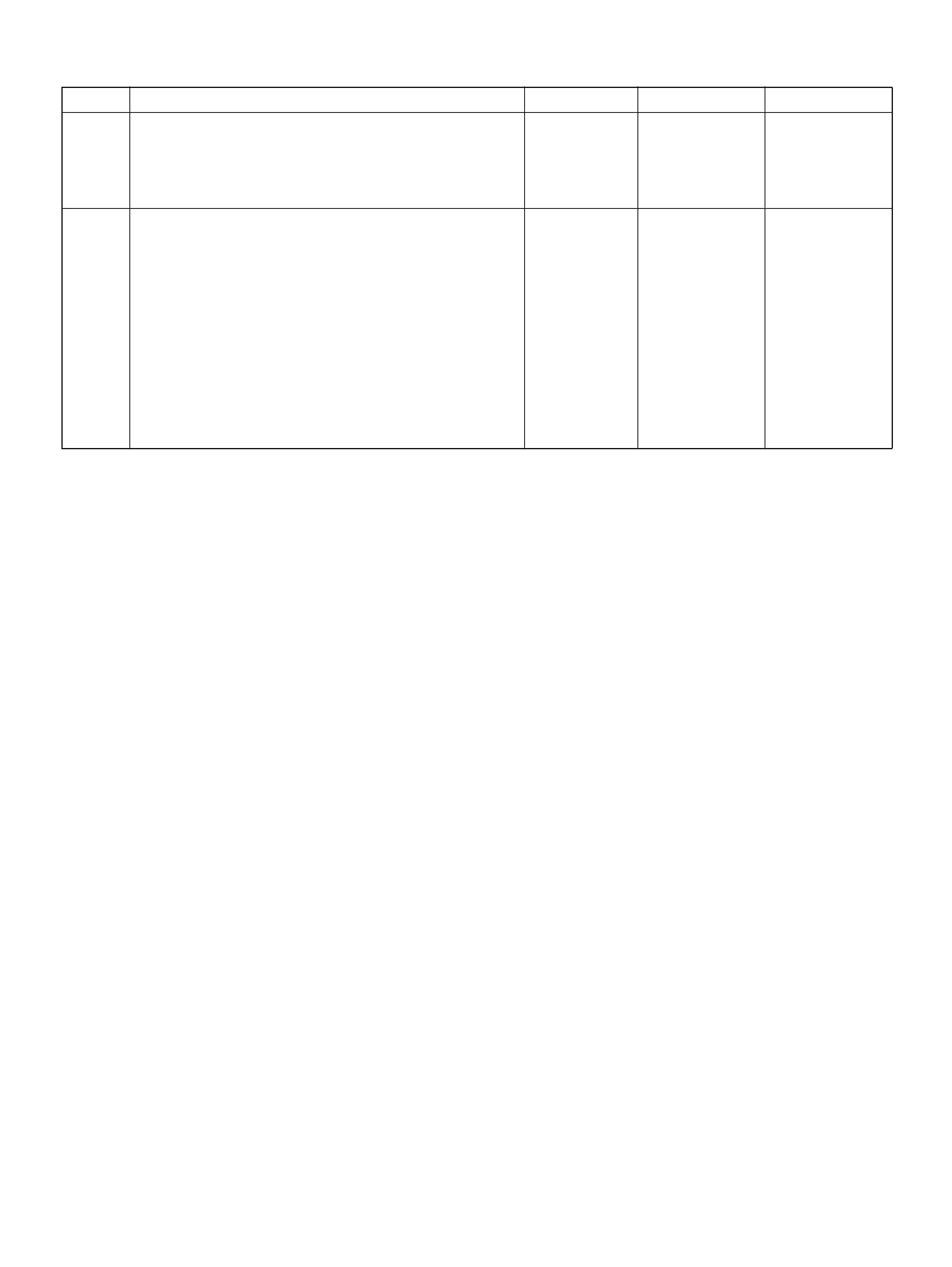

PCM Pinout Table, 80-Way Red Connector

– Row “S61 ∼ 80"

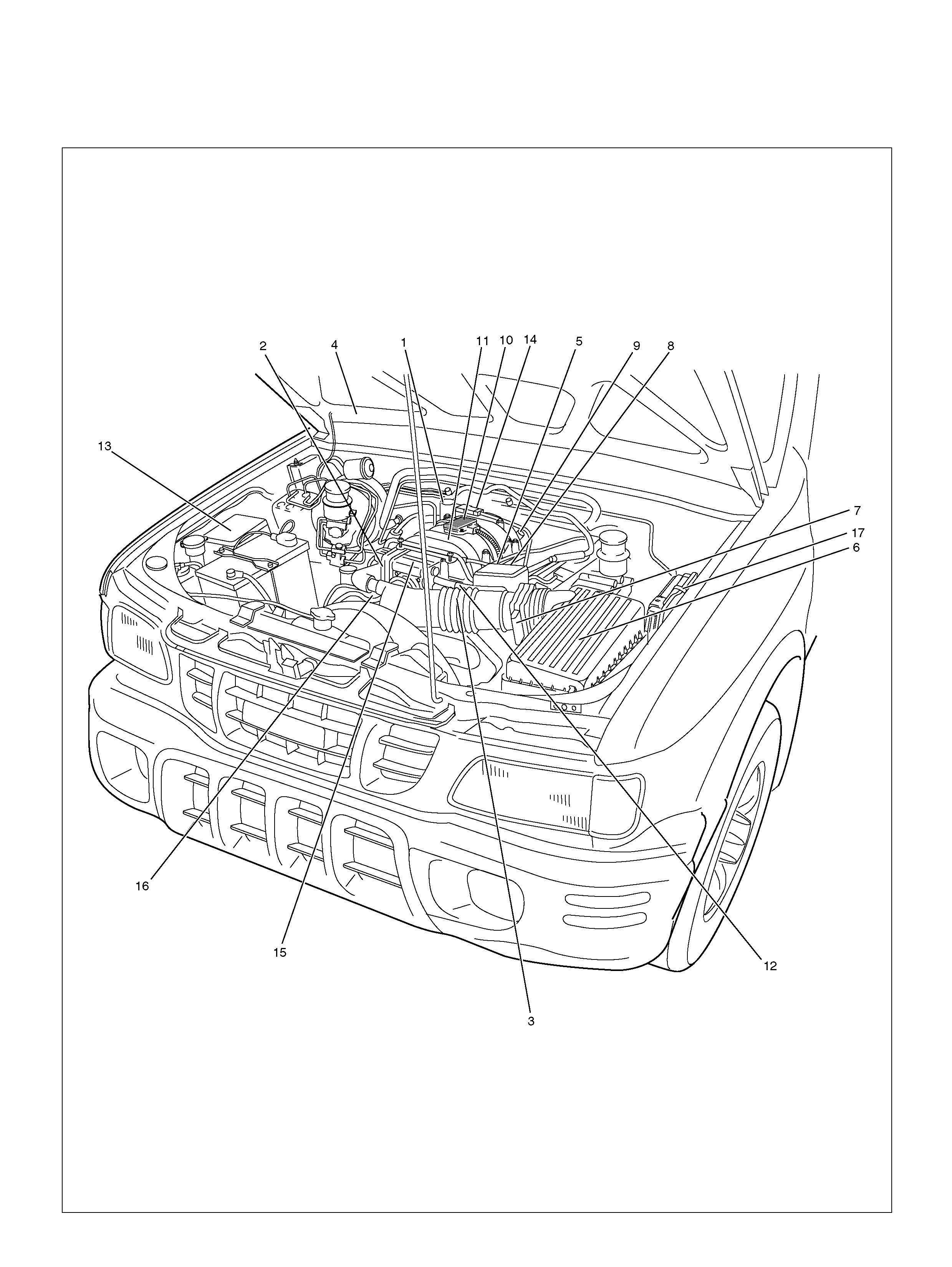

Compon ent Locat ors

Engine Component Locator

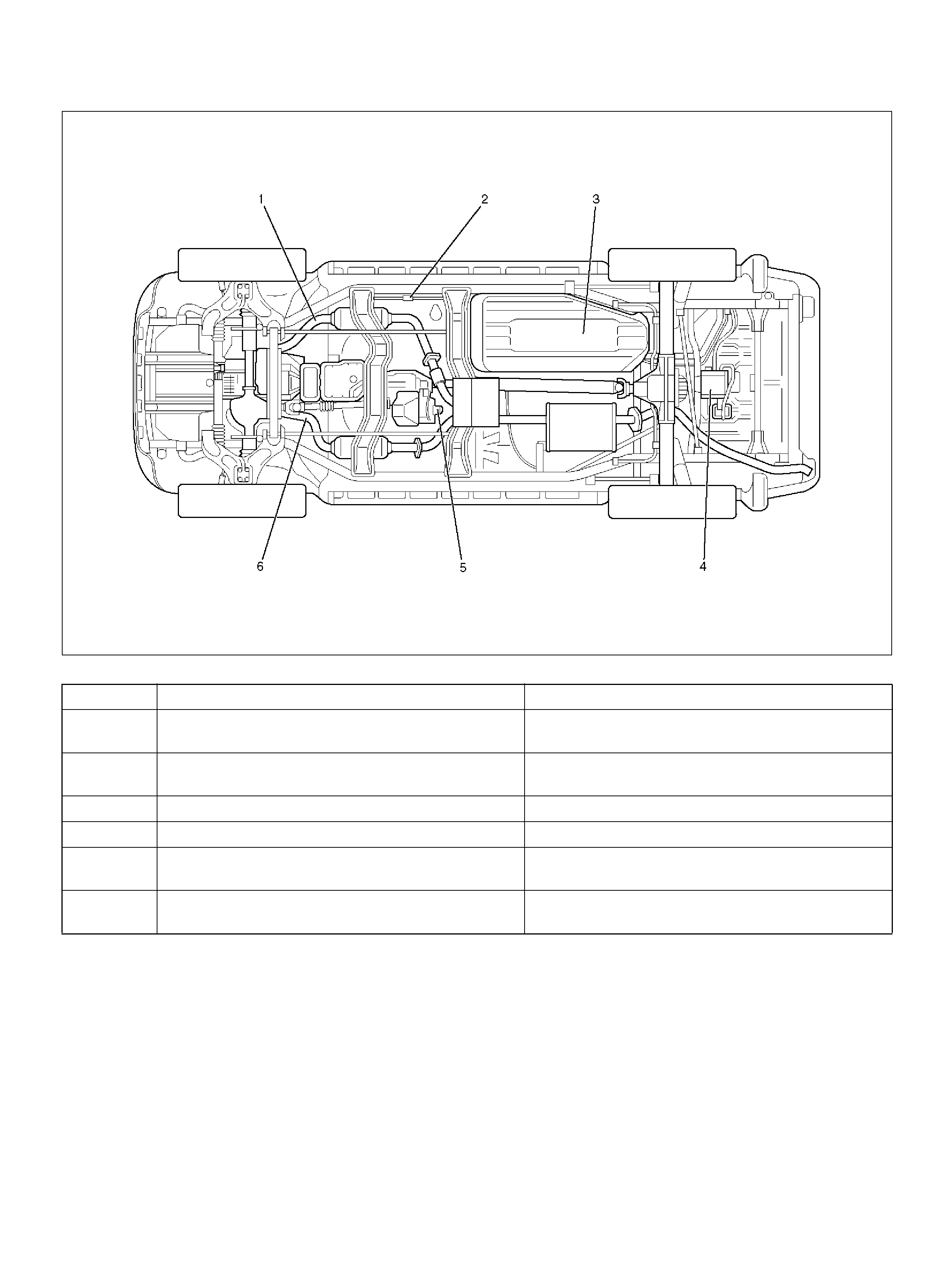

Undercarriage Component Locator

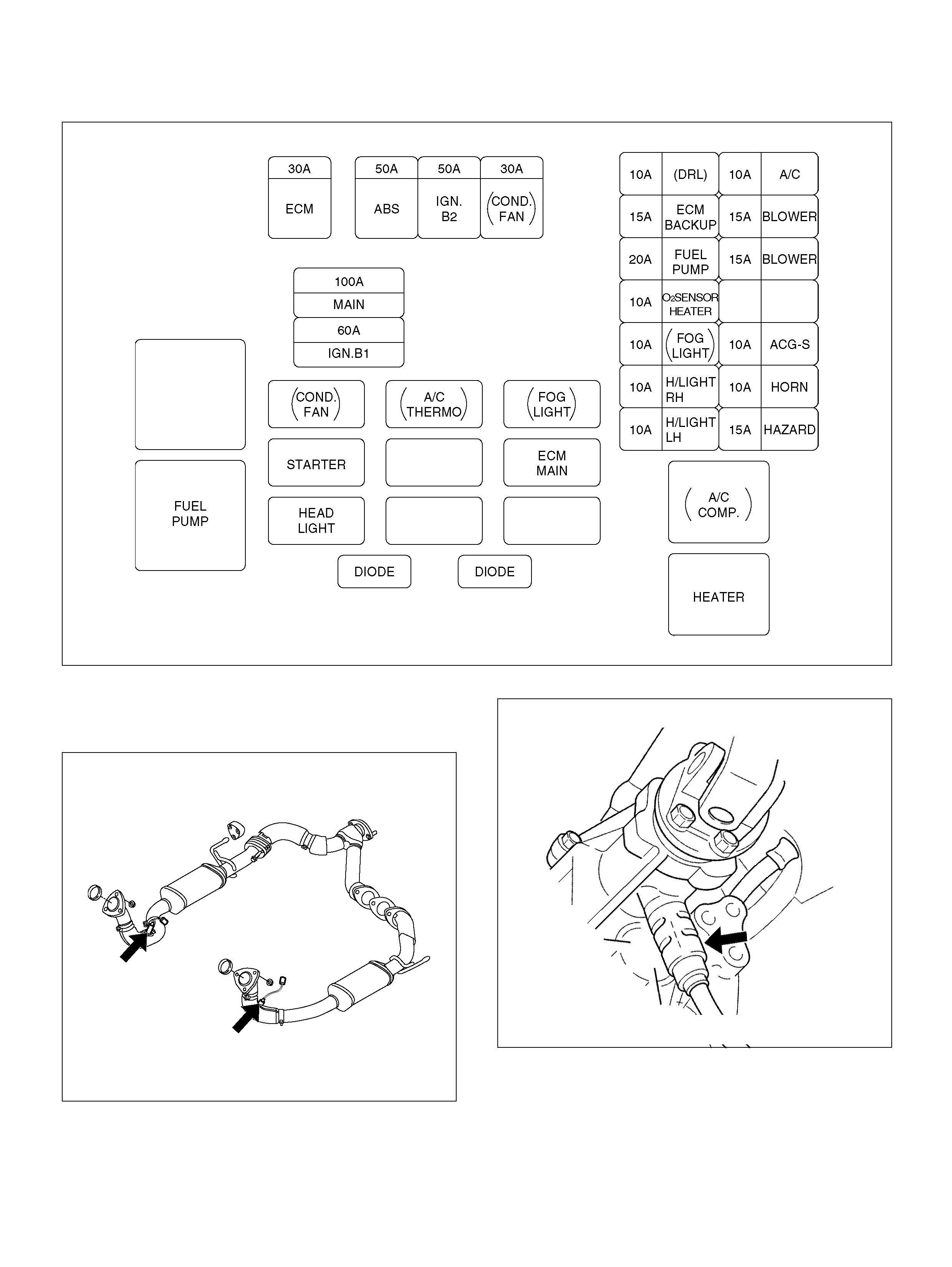

Fuse and Relay Panel (Underhood Electrical Center)

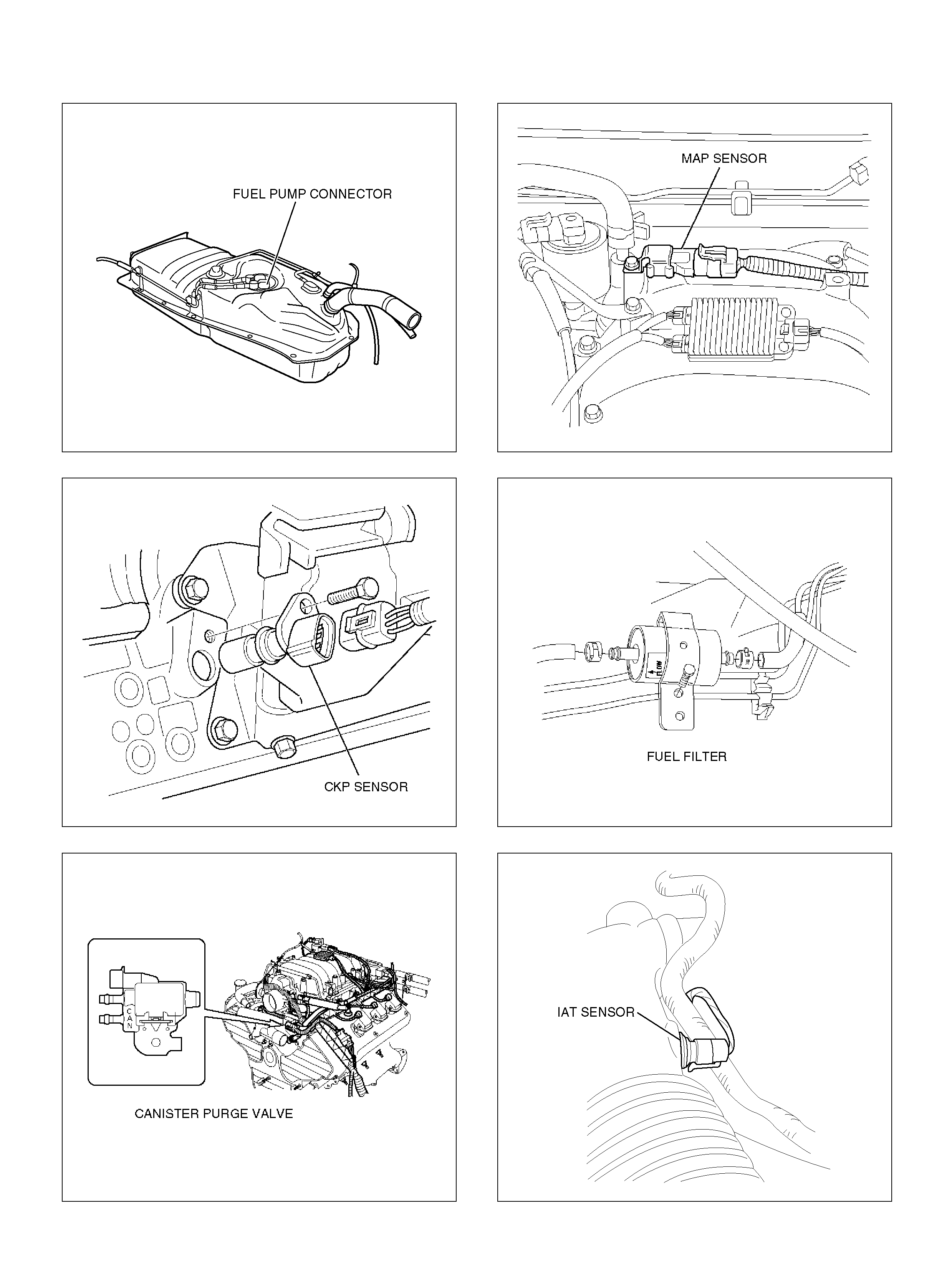

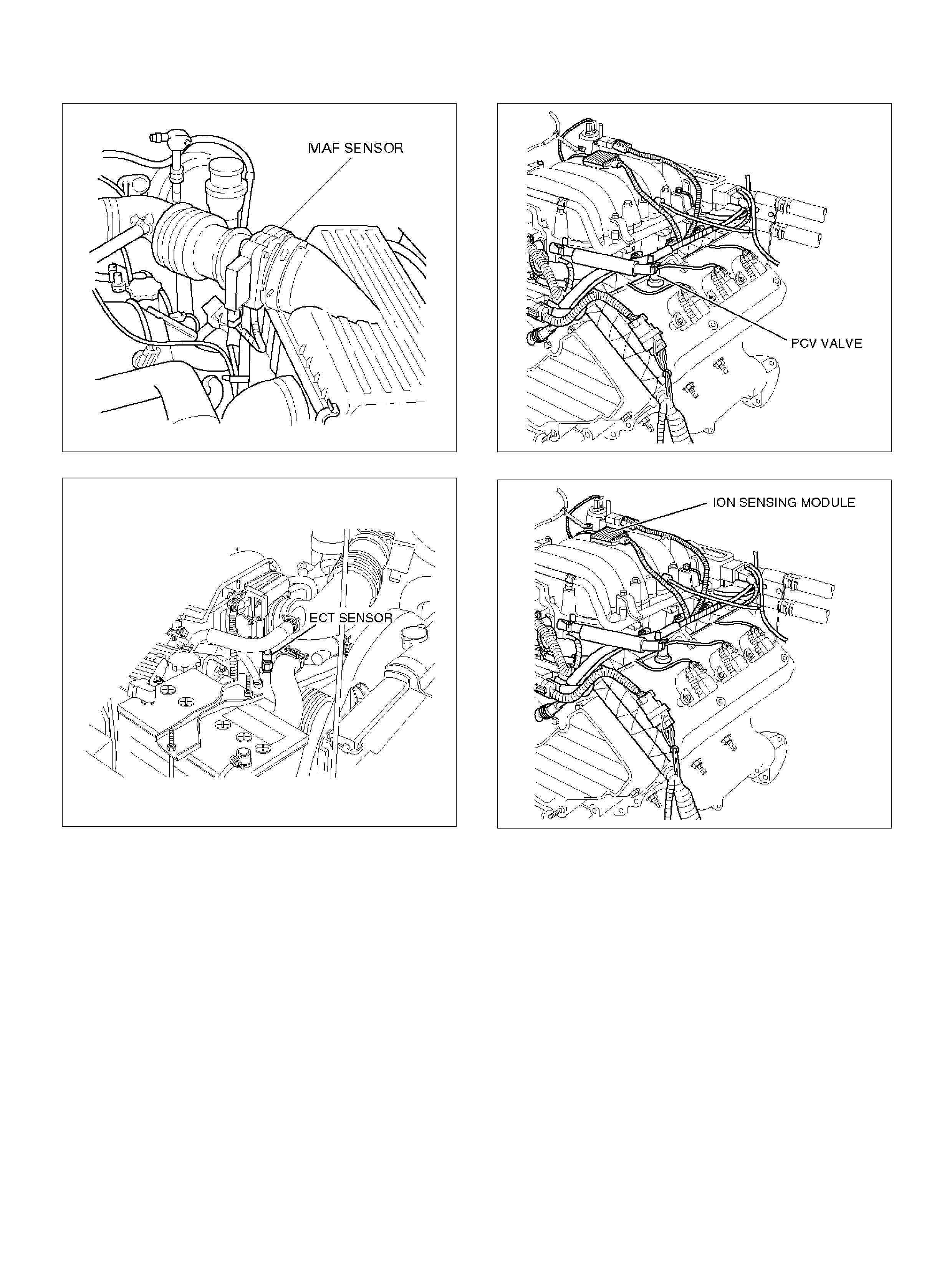

Sensors and Miscellaneous Component Locators

Diagnosis

Strategy-Bas ed Diagno stics

DTC Stored

No DTC

No Matching Sym ptom

Intermittents

No Trouble Foun d

Verifying Vehicle Repair

General Serv ice Information

OBD Serv iceability Issues

Visual / Physical Engine Compart me nt Inspection

Basic Knowledge of Tools Required

Serial Data Communications

Class 2 Serial Data Com m unicat ions

On-Board Diagnostic (OBD)

On-Board Diagnostic Tests

Comprehensive Component Monitor

Diagnostic Operation

The Diagnostic Executive

DTC Types

Decimal/Binary/ Hexadec imal Conversions

Verifying Vehicle Repair

Reading Diagno stic Trouble Codes Using

The Tech 2 Scan Tool

Tech 2

Tech 2 Features

Getting Started

Primary System-Based Diagnostic

Primary System-Ba sed Diagnostic

Fuel Control Heated Oxygen Sensor

HO2S Heater

On-Boar d Diagnostic (OBD) System Check

A/C Clutch Control Circuit Diagnos is

Electronic Ignition Syste m Diagnos is

Visual Check of The Evaporative E mission Canister

Fuel Metering System Check

Powertrain Control Module (PCM) Diagnosis

Multiple PCM Information Sensor DTCs Set

Exhaust Gas Recirculation (EGR) Diagnosis

Engin e Tech2 Data Definitions and Ranges

Typical Scan Data Va lues

No Malfunction Indica tor Lamp (MIL)

Malfunction Indicator Lamp (MIL) “ON" Steady

No Reduced Power Lamp (RPL)

Reduce d Power Lamp (RPL) “ON" Steady

Engine Cranks But Will Not Run

Fuel System Electrical Test

Electric T hrottle Control (ETC) Syste m Check

Fuel System Diagnosis

Exhaust Gas Recirculation (EGR) System Check

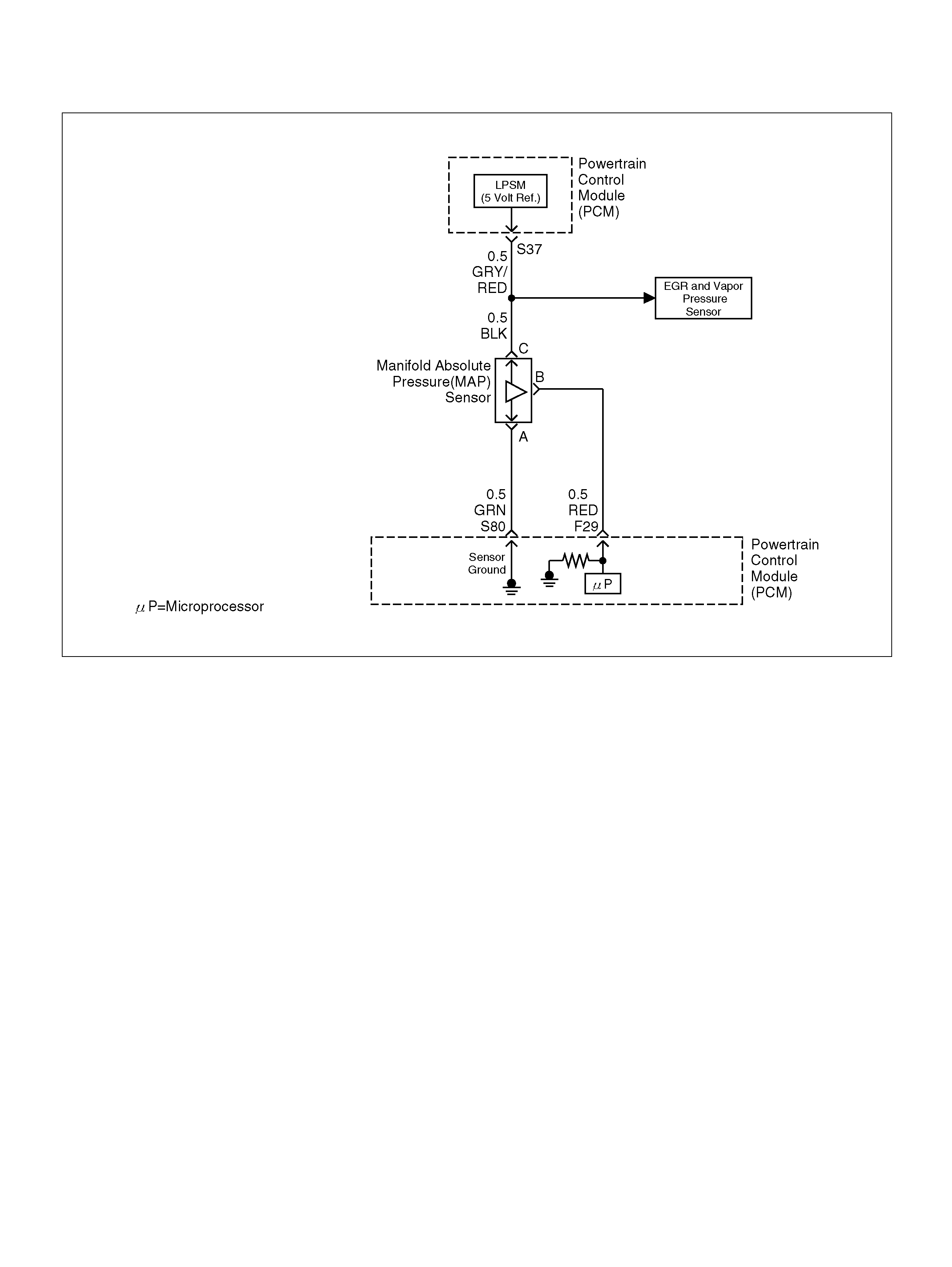

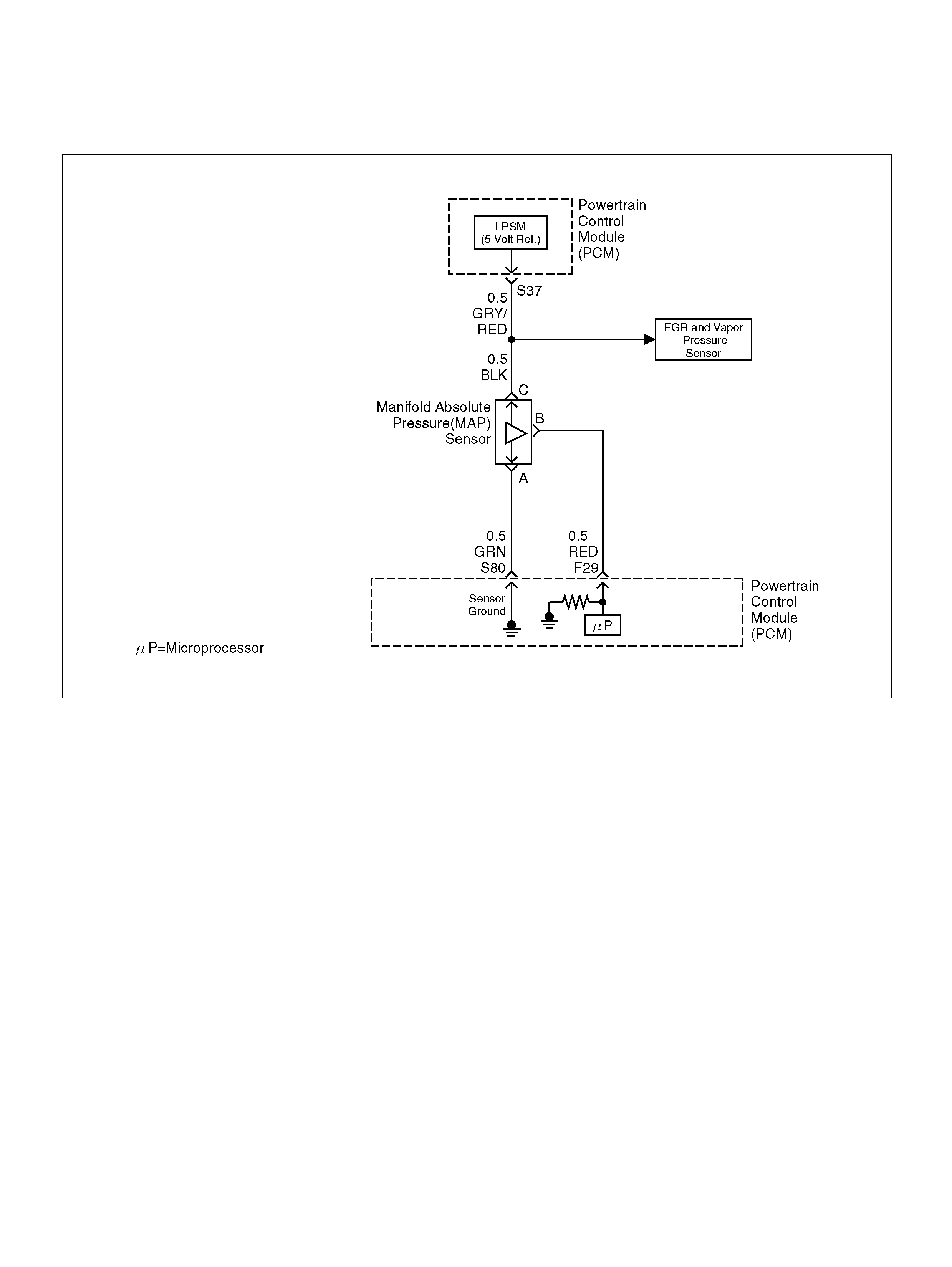

Manifold Absolute Pressure (MAP ) Output Check

Evaporat ive (EVAP) Emissions Ca nister Purge Valve

Check

PCM Diagnostic Trouble Codes

DTC P0101 MAF System Performance

DTC P0102 MAF Sensor Circuit Low Frequency

DTC P0103 MAF Sensor Circuit High Frequency

DTC P0106 MAP System Performance

DTC P0107 MAP Sensor Circuit Low Voltage

DTC P0108 MAP Sensor Circuit High Voltage

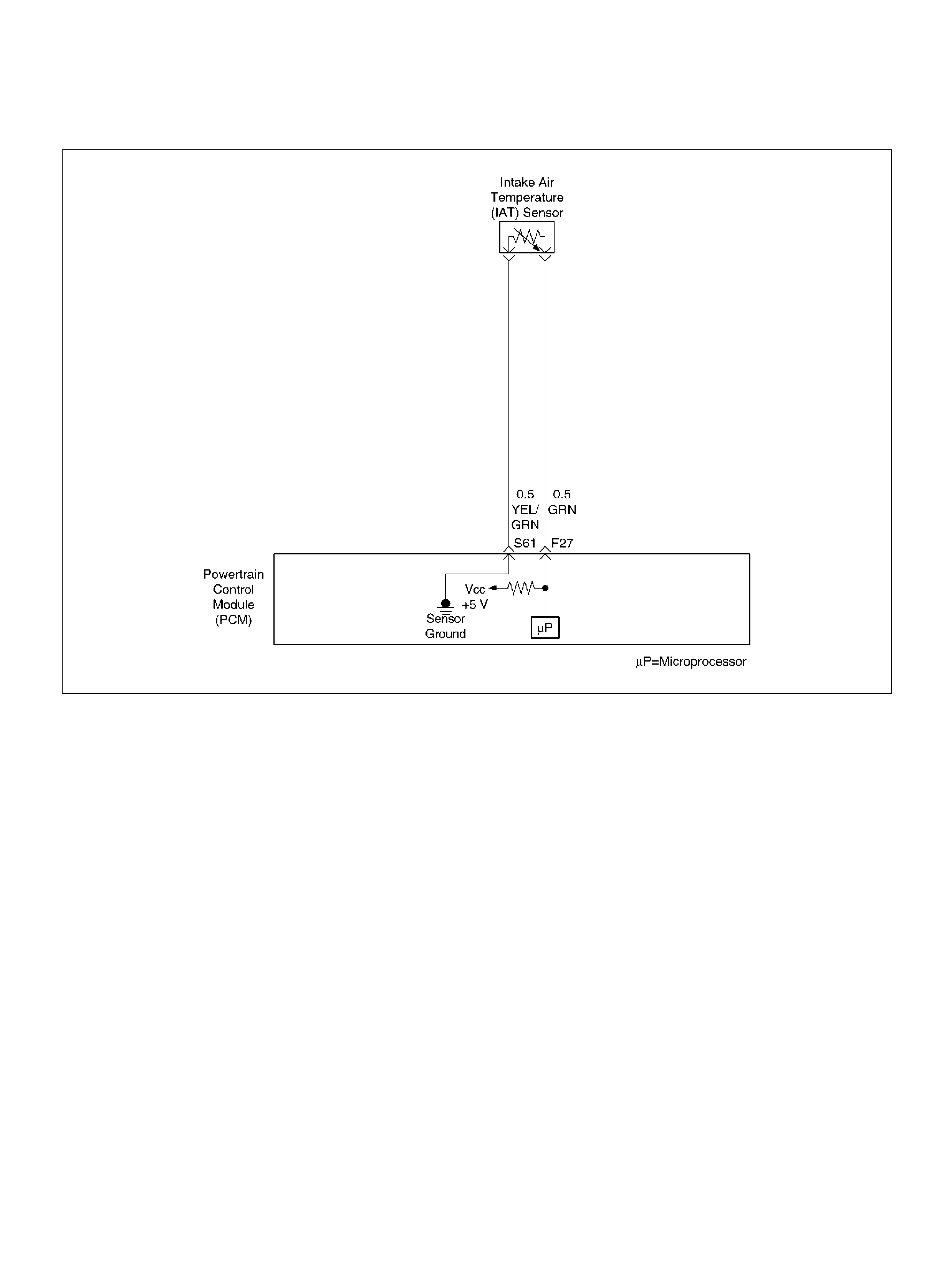

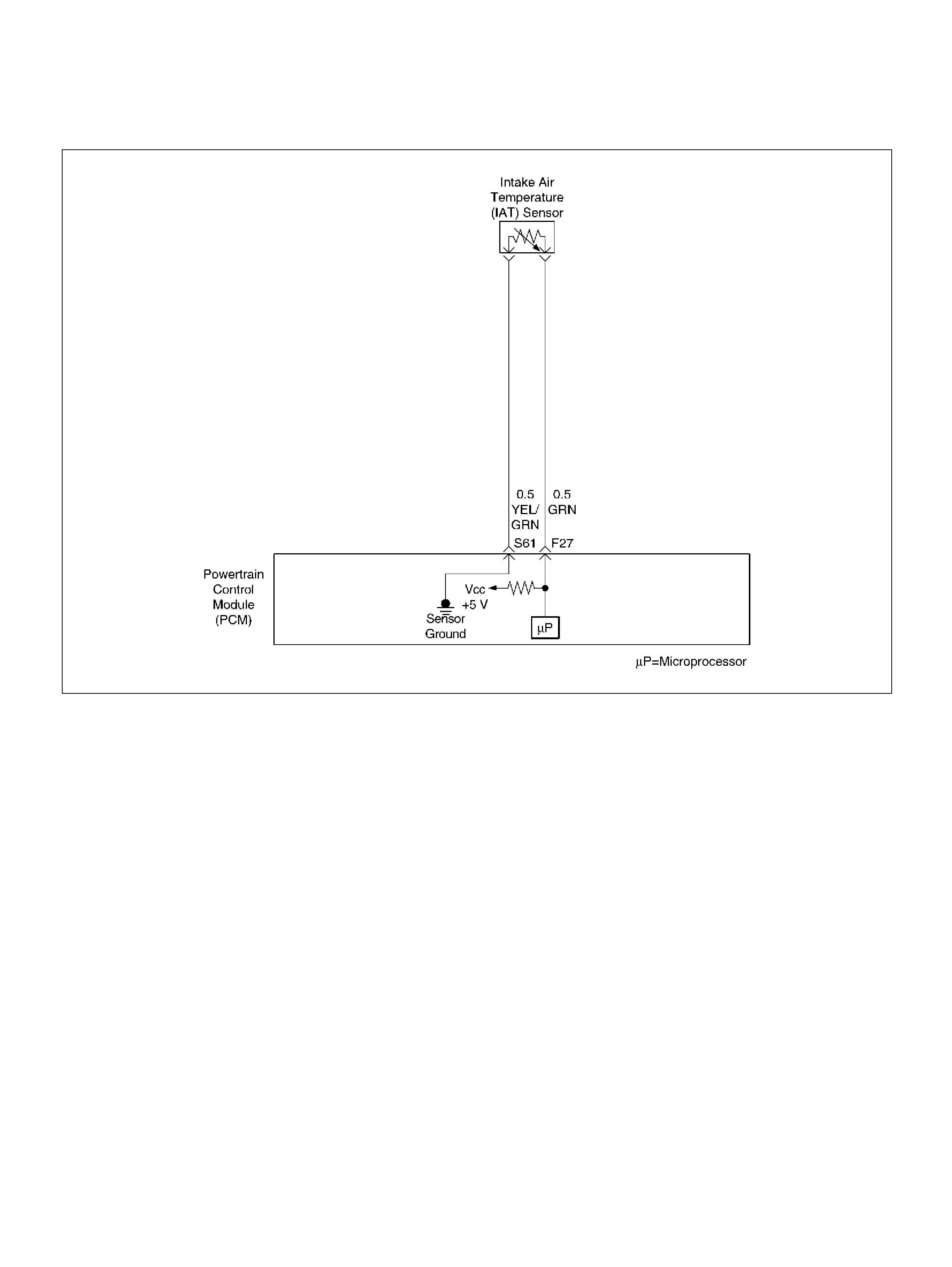

DTC P0112 IAT Sensor Circuit Low Voltage

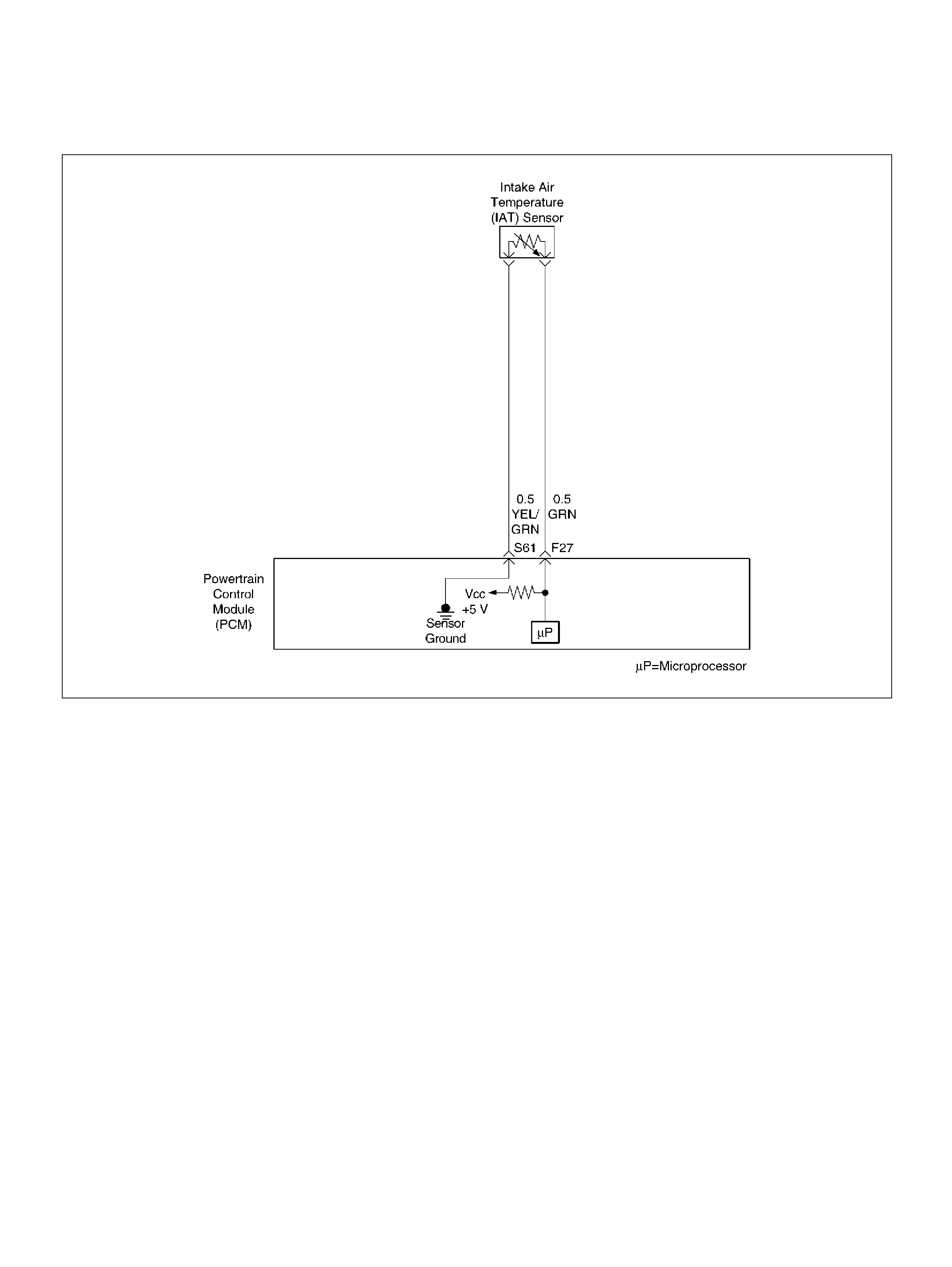

DTC P0113 IAT Sensor Circuit High Voltage

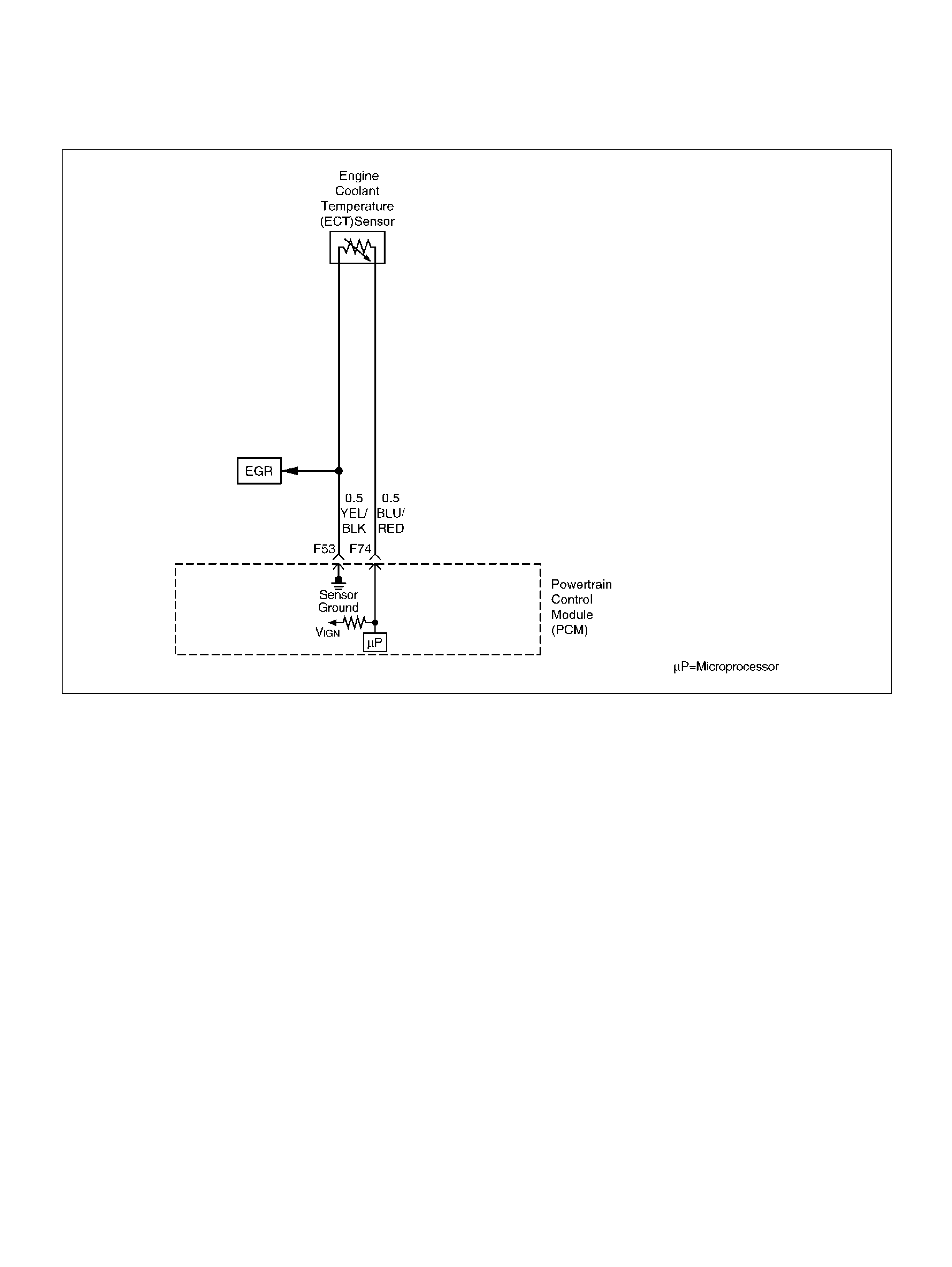

DTC P0117 ECT Sensor Circuit Low Voltage

DTC P0118 ECT Sensor Circ uit High Voltage

DTC P0131 HO2S Circuit Low Voltage

Bank 1 Se nsor 1

DTC P0132 HO2S Circuit High Voltage

Bank 1 Se nsor 1

Techline

Techline

Techline

DTC P0134 HO2S Circuit Insufficient

Activity Bank 1 Sensor 1

DTC P0135 HO2S Heater Circuit

Bank 1Sensor 1

DTC P0151 HO2S Circuit Low Volt age

Bank 2 Sensor 1

DTC P0152 HO2S Circuit High Voltage

Bank 2 Sensor 1

DTC P0154 HO2S Circuit Insufficient

Activity Bank 2 Sensor 1

DTC P0155 HO2S Heater Circuit Open

Bank 2 Sensor 1

DTC P0171 Fuel Trim System Lean Bank 1

DTC P0172 Fuel Trim System Rich Bank 1

DTC P0174 Fuel Trim System Lean Bank 2

DTC P0175 Fuel Trim System Rich Bank 2

DTC P0201 Injector 1 Control Circuit

DTC P0202 Injector 2 Control Circuit

DTC P0203 Injector 3 Control Circuit

DTC P0204 Injector 4 Control Circuit

DTC P0205 Injector 5 Control Circuit

DTC P0206 Injector 6 Control Circuit

DTC P0300 Engine Misfire Detected

DTC P0301 Cylinder Misfire Detected

DTC P0302 Cylinder Misfire Detected

DTC P0303 Cylinder Misfire Detected

DTC P0304 Cylinder Misfire Detected

DTC P0305 Cylinder Misfire Detected

DTC P0306 Cylinder Misfire Detected

DTC P0325 ION Sensing Module/ION

Sensing Knock Intensity Circuit Fault

DTC P0336 58X Reference Signal Circuit

DTC P0337 CKP Sensor Circuit

Low Frequency

DTC P0351 Ignition 1 Control Circuit

DTC P0352 Ignition 2 Control Circuit

DTC P0353 Ignition 3 Control Circuit

DTC P0354 Ignition 4 Control Circuit

DTC P0355 Ignition 5 Control Circuit

DTC P0356 Ignition 6 Control Circuit

DTC P0402 EGR Pintle Crank Error

DTC P0404 EGR Open Stuck

DTC P0405 EGR Low Voltage

DTC P0406 EGR High Voltage

DTC P0502 VSS Circuit Low Input

DTC P0506 Idle Air Control System

Low RPM

DTC P0507 Idle Air Control System

High RPM

DTC P0562 System Voltage Low

DTC P0563 System Voltage High

DTC P0565 Cruise Main Switch Circuit Error

DTC P0566 Cruise Cancel Switch Circuit Error

DTC P0567 Cruise Resume Switch Circuit Error

DTC P0571 No Brake Switch Signal

DTC P0601 PCM Memory

DTC P0602 PCM Programming Error

DTC P0604 PCM RAM Error

DTC P0606 PCM Internal Performance

DTC P1106 MAP Sensor Circuit Intermittent

High Voltage

DTC P1107 MAP Circuit Intermittent Low Voltage

DTC P1111 IAT Sensor Circuit Intermittent

High Voltage

DTC P1112 IAT Sensor Circuit Intermittent

Low Voltage

DTC P1114 ECT Sensor Circuit Intermittent

Low Voltage

DTC P1115 ECT Sensor Circuit Intermittent

High Voltage

DTC P1120-TPS 1 Throttle Position Sensor

(TP S1) Output Abnormal

DTC P1125 ETC (Electric Throttle Control)

Lim it Performance Mode

DTC P1167 Fuel System Rich During Decel

Fuel Cut Off (Bank 1)

DTC P1169 Fuel System Rich During Decel

Fuel Cut Off (Bank 2)

DTC P1171 Fuel System Lean During Accelerator

DTC P1220 Throttle Position Senser2

(TP S2) Circ ui t Fault

DTC P1221 TPS1 – TPS2 Cor relation

(Circuit Performance)

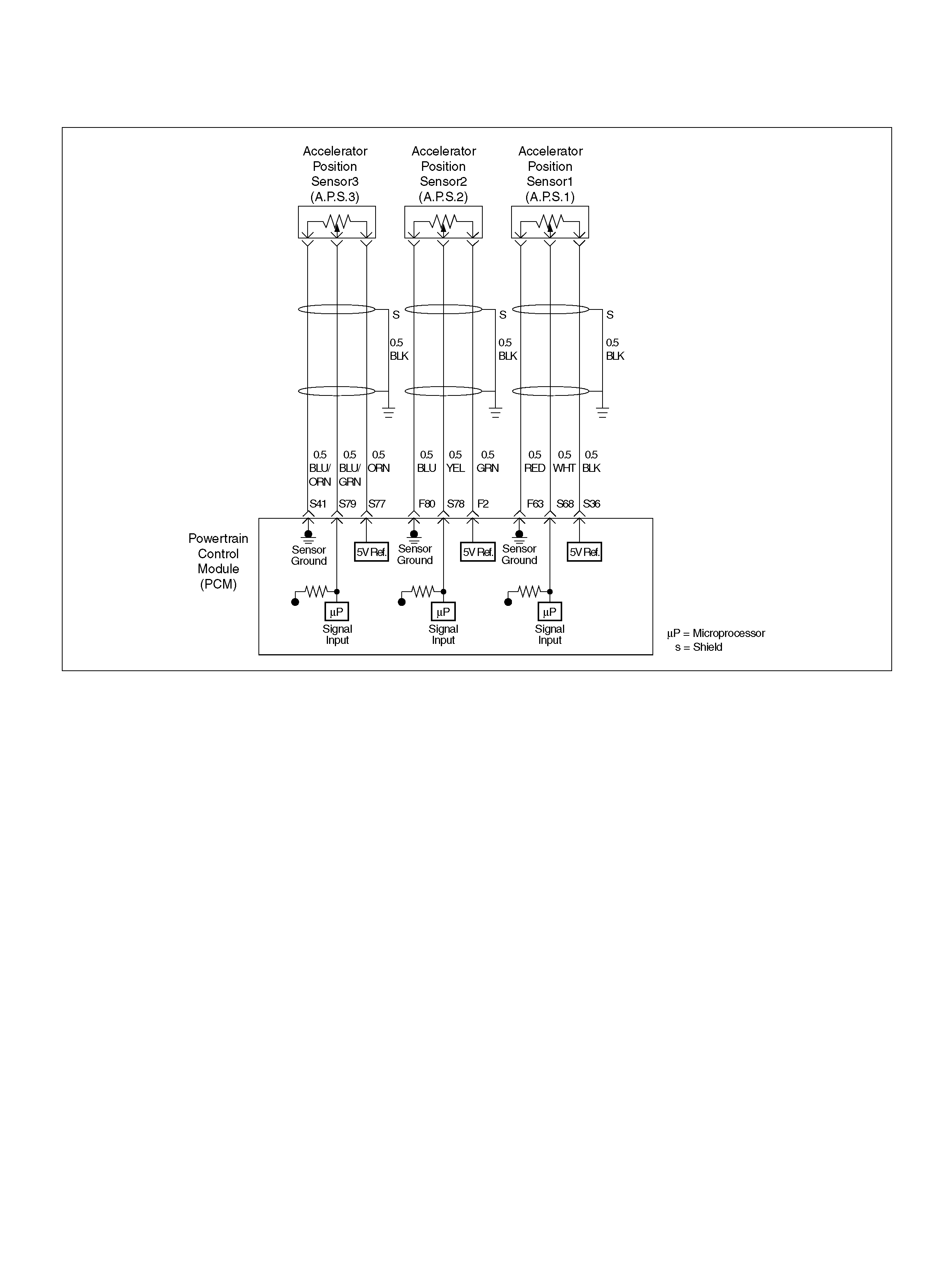

DTC P1271 APS 1- 2 Correlation Error

DTC P1272 APS 2 – 3 Correlation Error

DTC P1273 APS 1 – 3 Correlation Error

DTC P1275 APS 1 Output Fault

DTC P1280 APS 2 Output Fault

DTC P1285 APS 3 Output Fault

DTC P1290 ETC Forced Idle Mode

DTC P1295 ETC Power Management Mode

DTC P1299 ETC Forced Engine Shutdown Mode

DTC P1310 ION Sensing Module Diagnos is

DTC P1311 ION Sensing Module SEC

Line 1 Circuit Fault

DTC P1312 ION Sensing Module SEC

Line 2 Circuit Fault

DTC P1326 ION Sensing Module Com bust ion

Quali ty Input Circuit F ault

DTC P1340 ION Sensing Module Cylinder

ID Fault (Cylinder Synchronizat ion Fail)

DTC P1404 EGR Stuck Closed

DTC P1514 TPS - MAF Correlation Error

DTC P1515 Command - Actual TPS

Correlation Error

DTC P1516 Command - Actual TPS

Correlation Error

DTC P1523 Actuator Control Return Performance

DTC P1571 Brake Switch No Operation

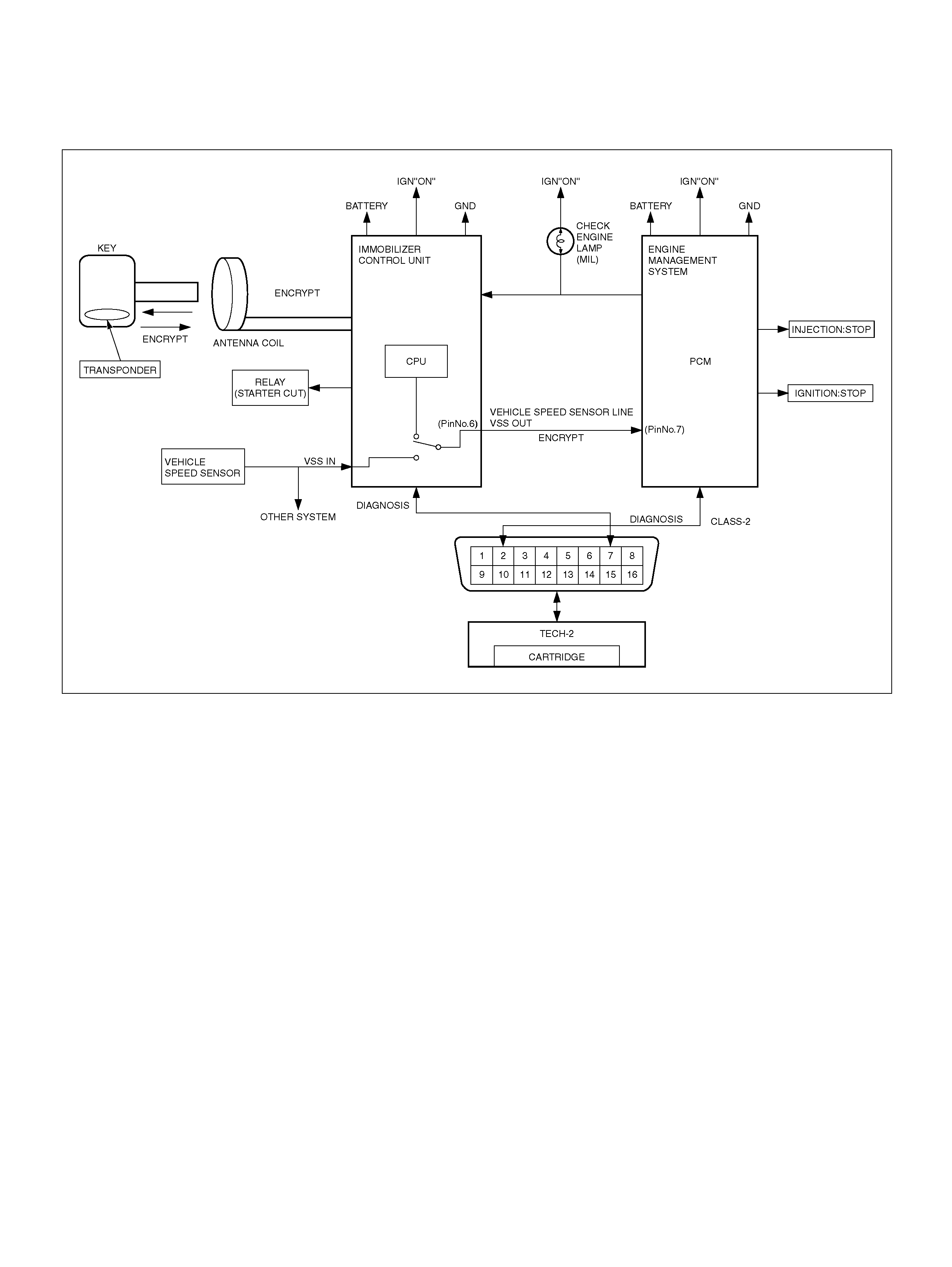

DTC P1626 No respons e from im mobiliz er

DTC P1631 Received response was not correct

DTC P1635 ence Voltage # 1 Circuit Fault

DTC P1639 Reference Voltage # 2 Circuit Fault

DTC P1640 Driver-1-Output Circuit Fault (ODM)

DTC P1648 Received incorrect security code

DTC P1649 Security code & security key

not programm ed

DTC P1650 Quad Driver Module “A" Fault

Symp tom Diagnosis

Defaul t Matrix Table

On Vehicle Service

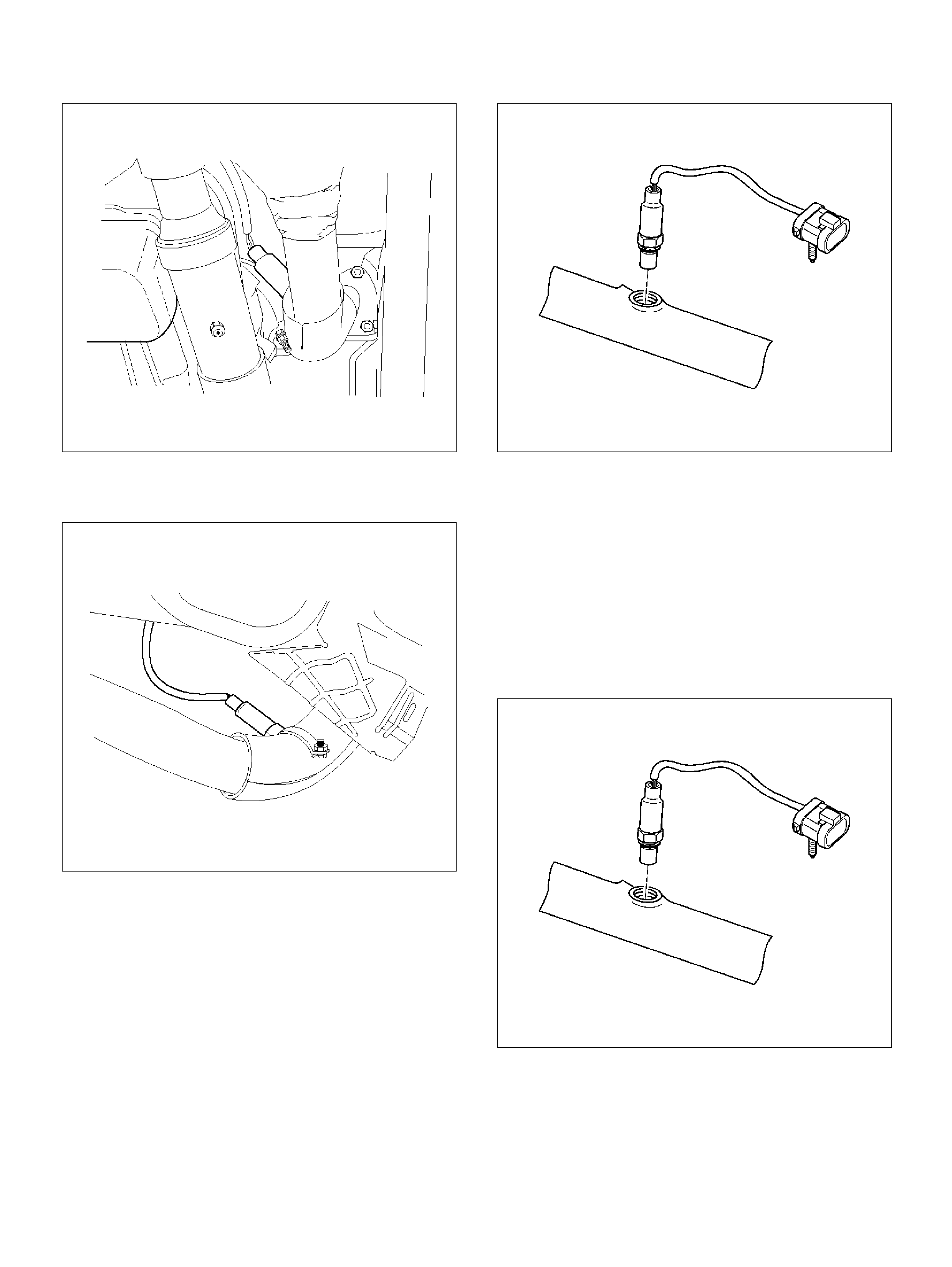

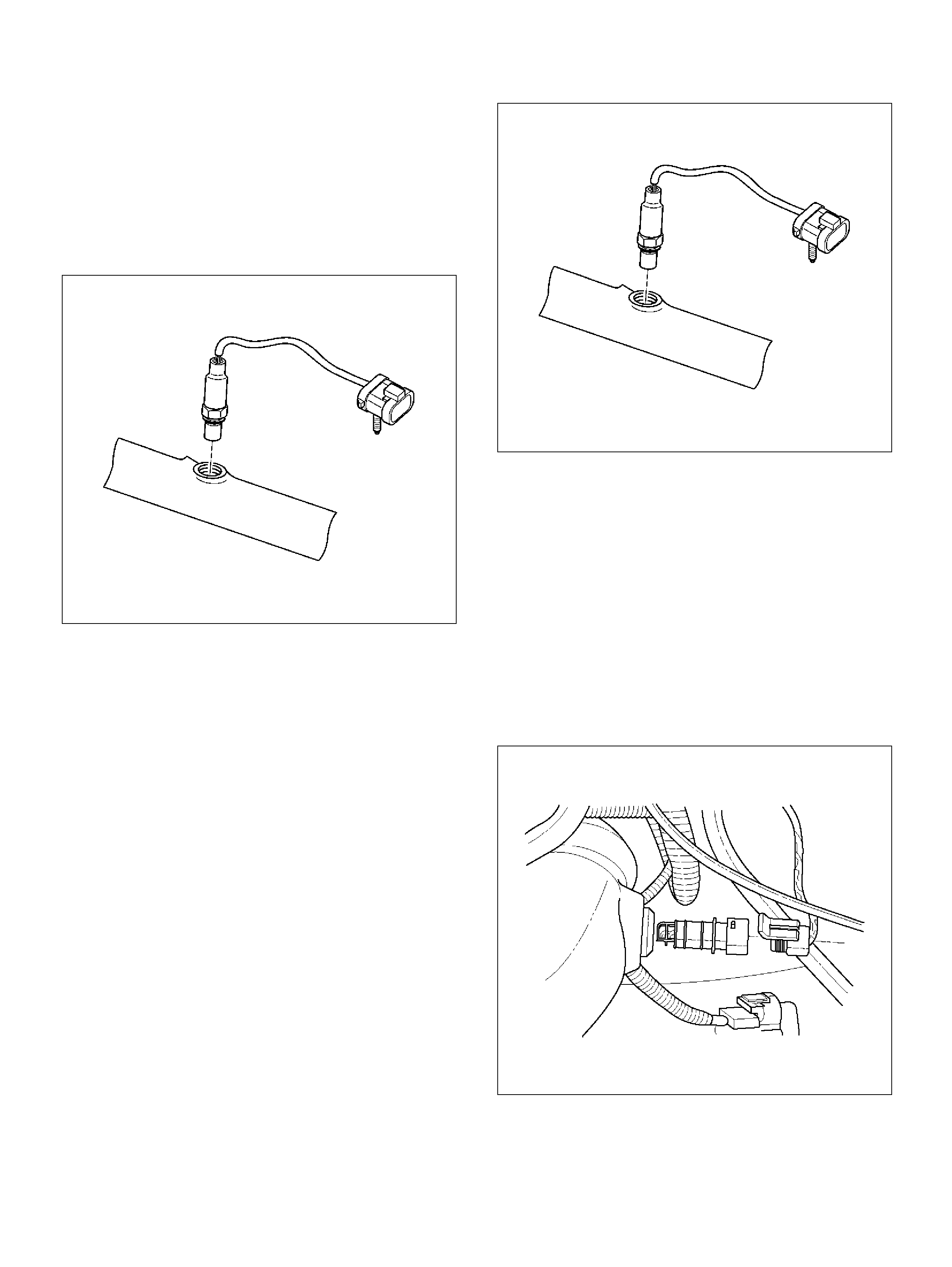

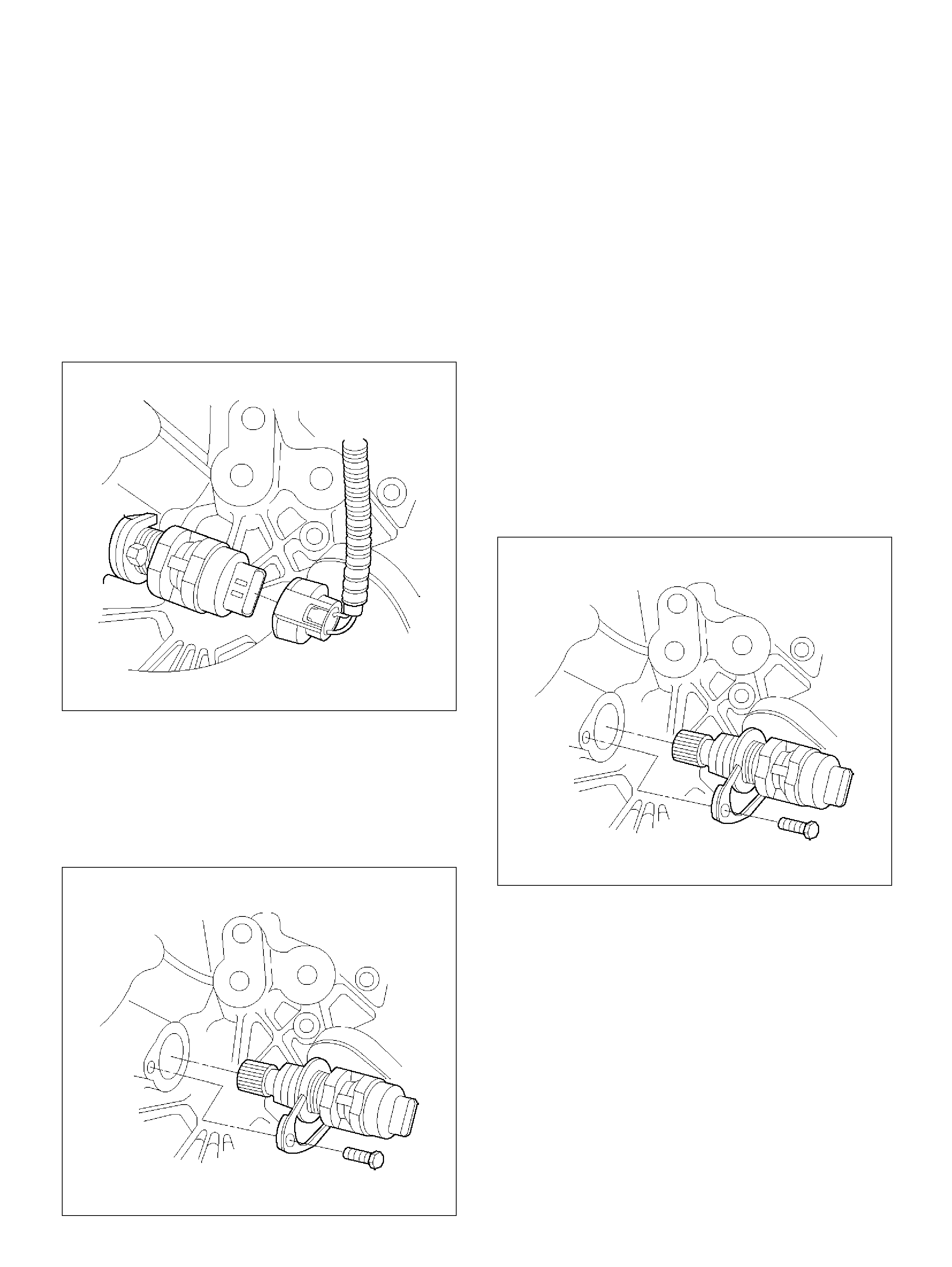

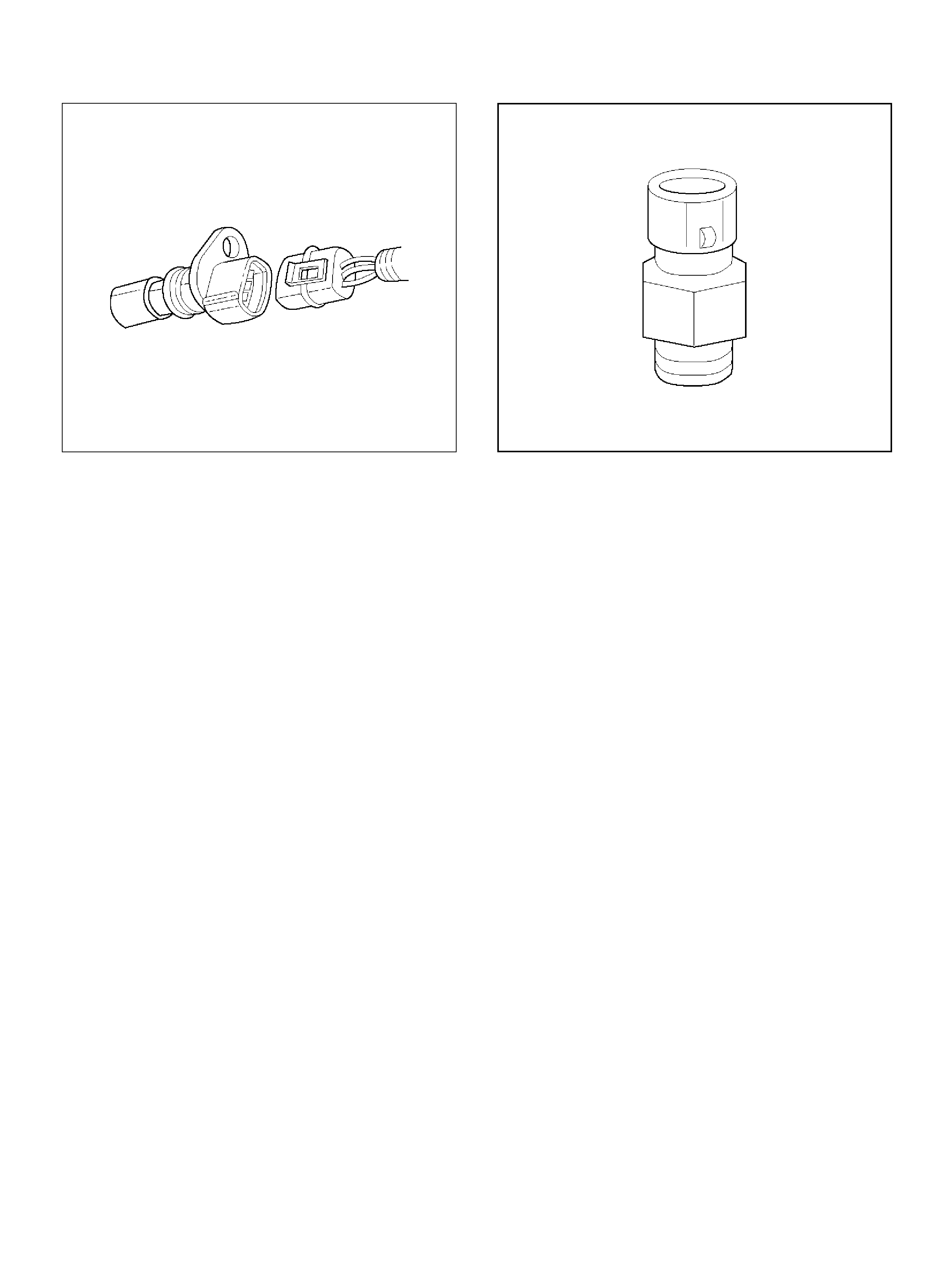

Crankshaft Position (CKP) Sensor

Removal Procedure

Inspection Procedure

Installation Procedure

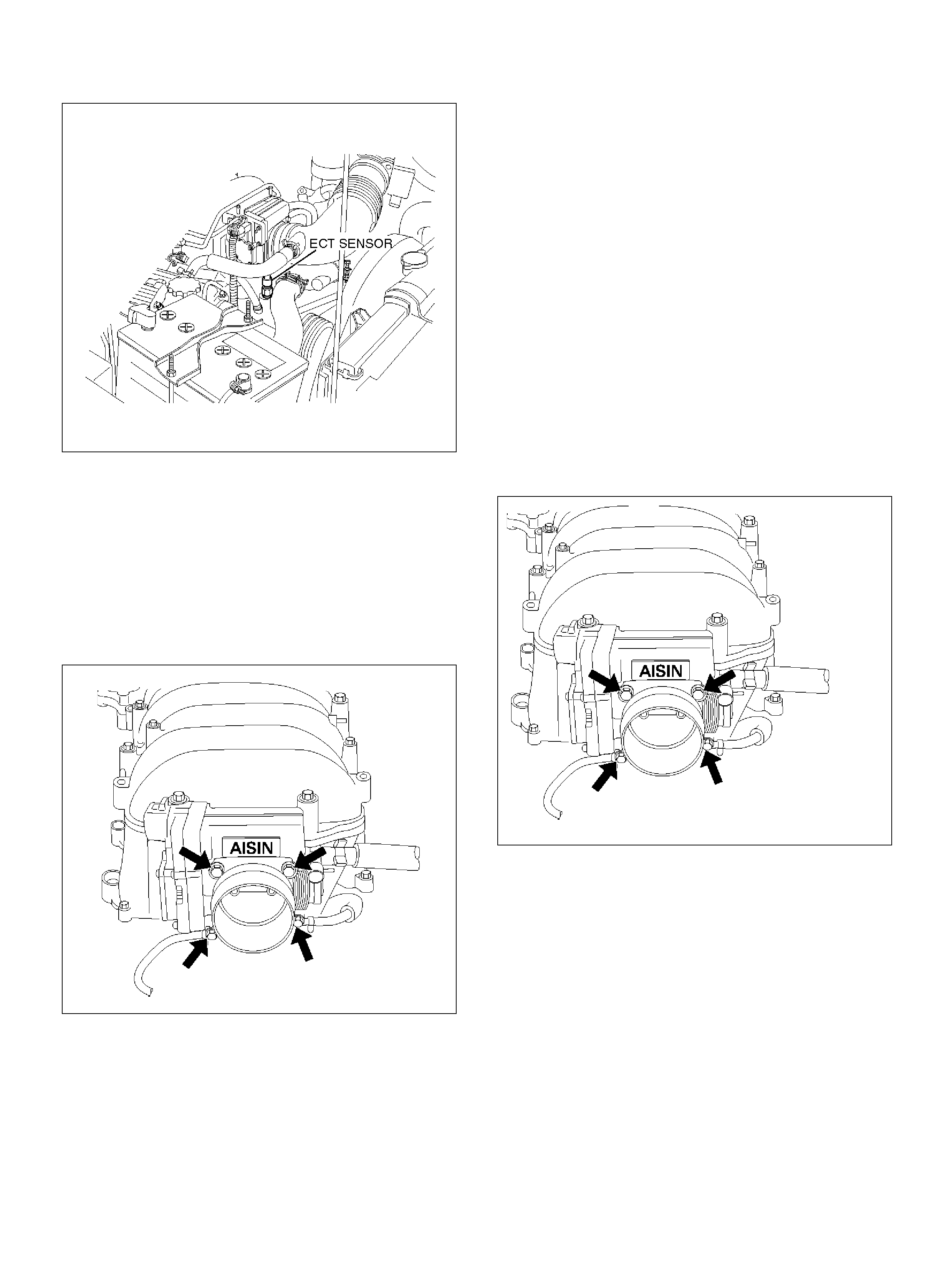

Engine Coolant Temperature (ECT) Sensor

Removal Procedure

Installation Procedure

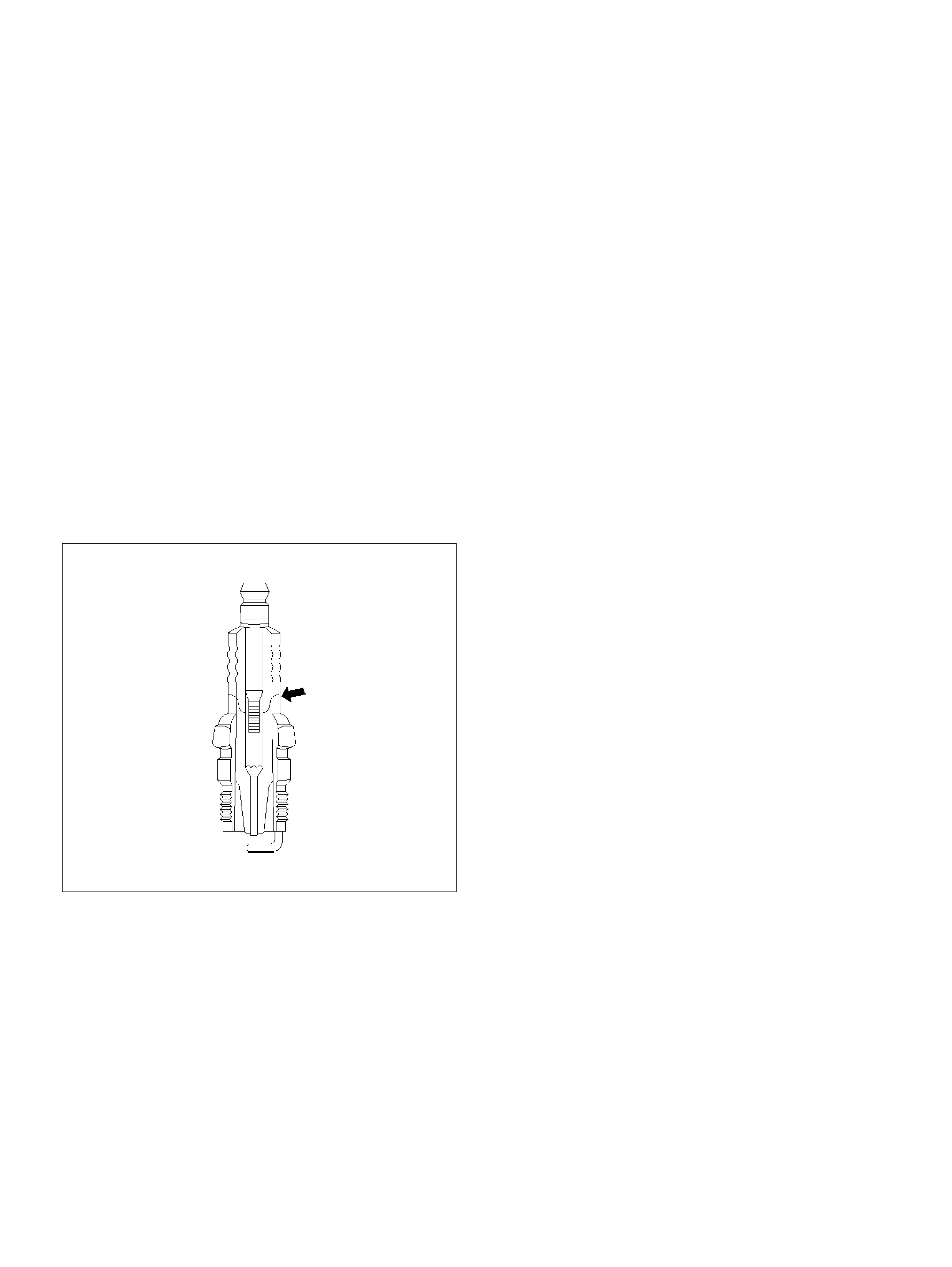

Heated Oxygen S ens or (HO2S )

Removal Procedure

Inspection Procedure

Installation Procedure

Intake Air Temperature (IAT) Sensor

Removal Procedure

Installation Procedure

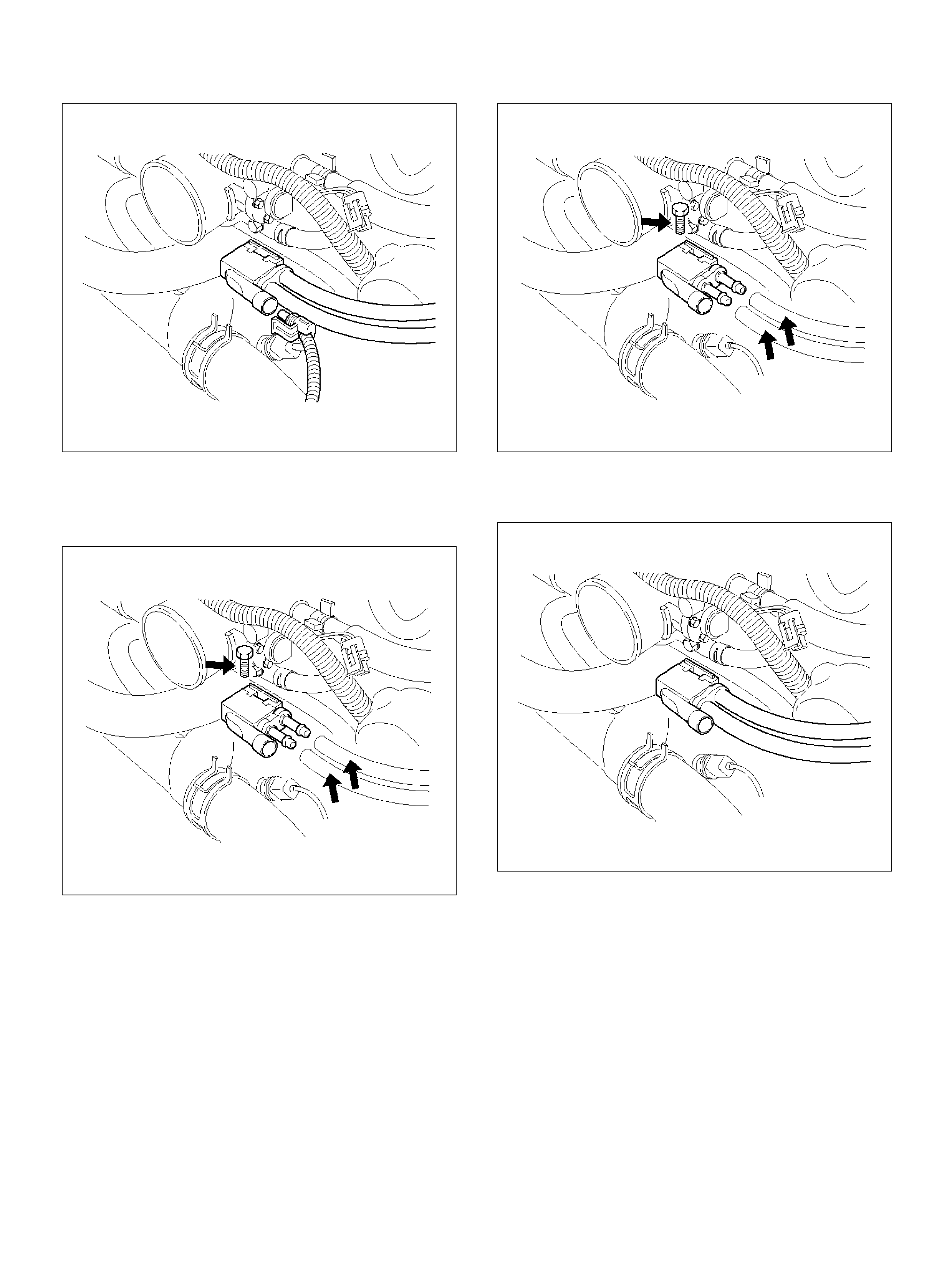

ION Sensing Mo dule

Removal Procedure

Installation Procedure

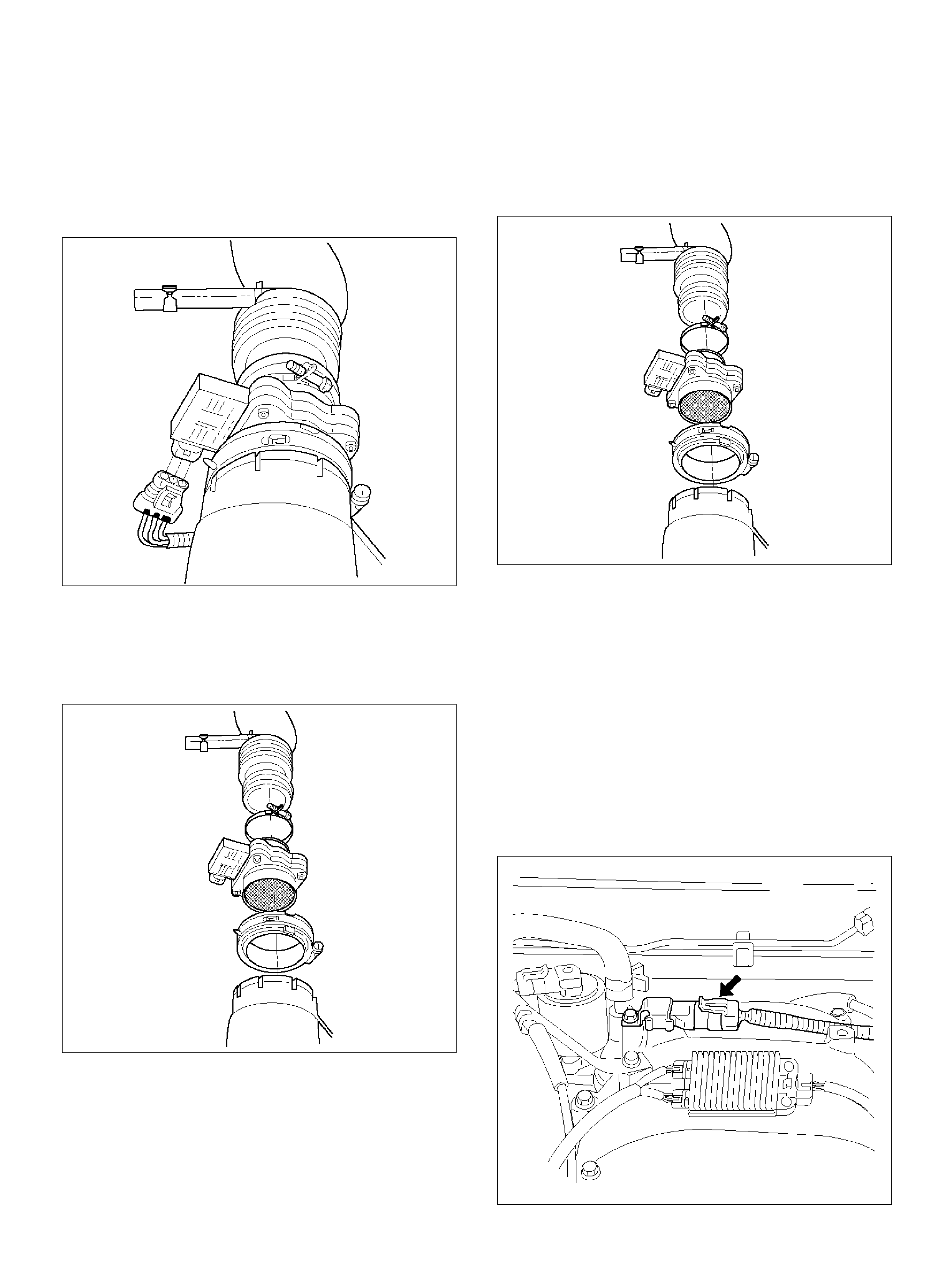

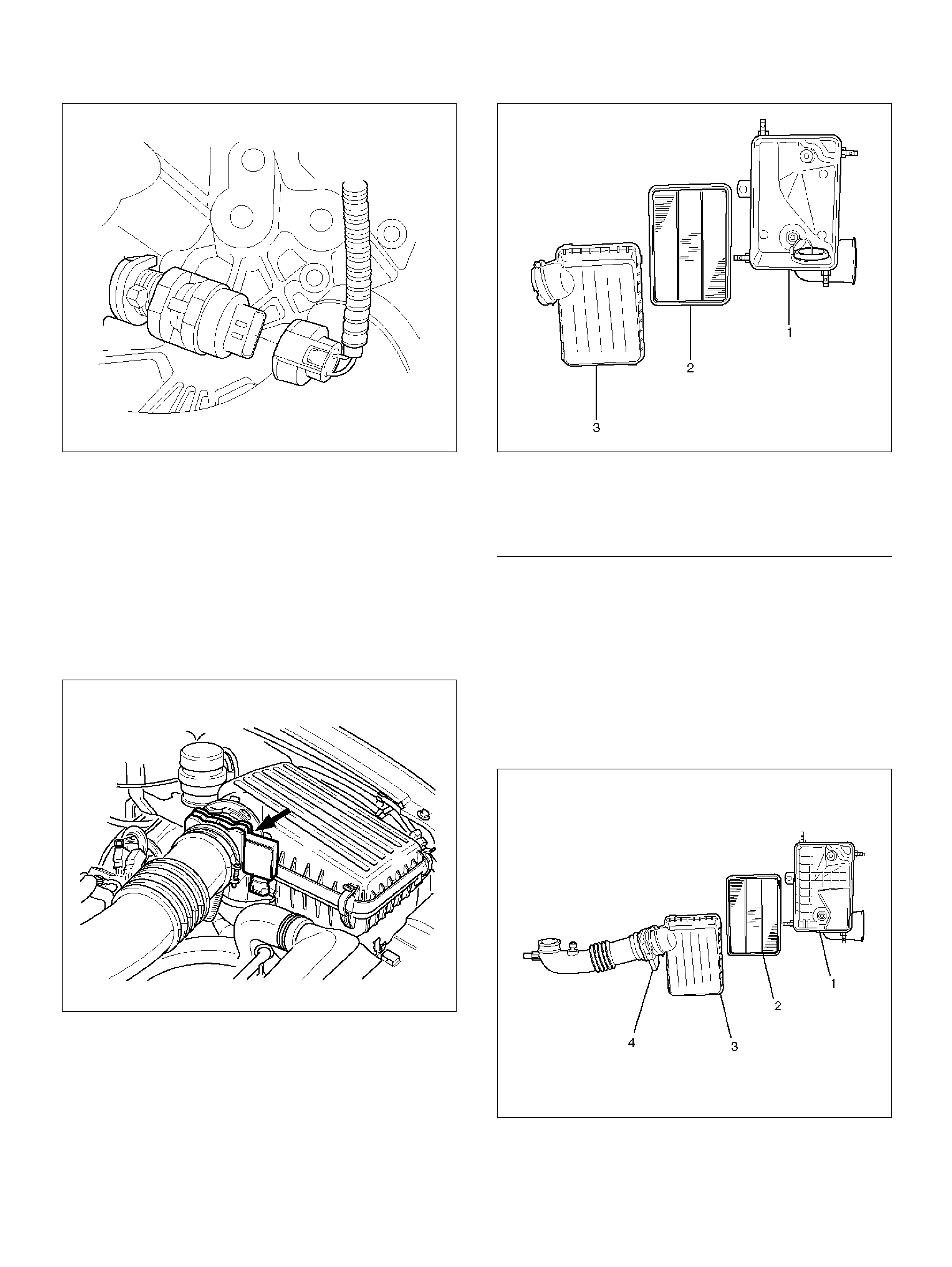

Mass Air Flow (MAF) Sensor

Removal Procedure

Installation Procedure

Manifold Absolute Pressure (MAP ) Sensor

Removal Procedure

Installation Procedure

Malfunction Indi cator Lamp (MIL)

Removal and Installation Procedure

Reduced Power Lamp

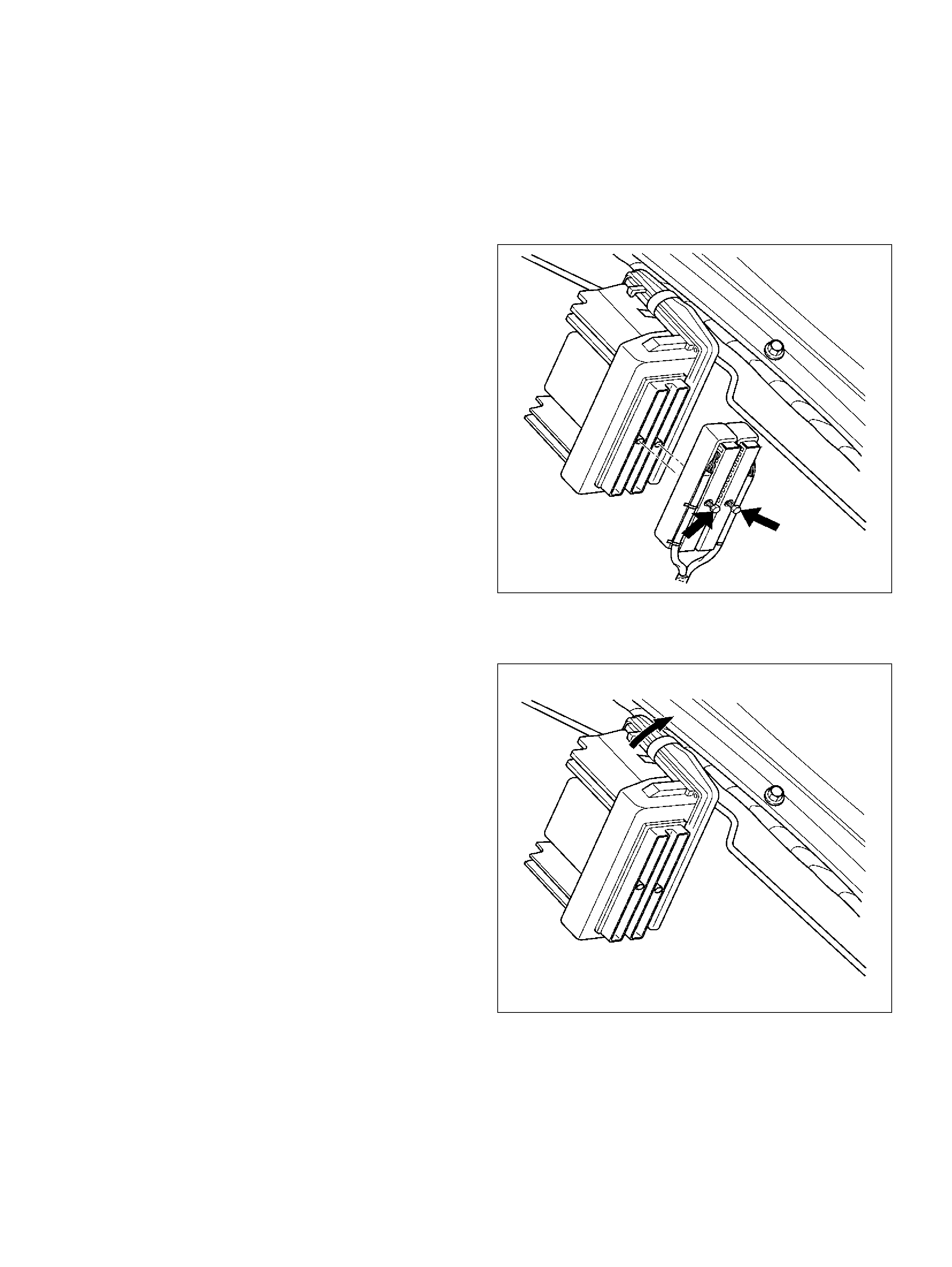

Powertrain Control Module (PCM)

Service Precaution

Electrostatic Discharge (ESD) Dama ge

Removal Proc edure

Installation Proced ure

Throttle Position (TP) Sensor

Removal Proc edure

Function Check

Installation Proced ure

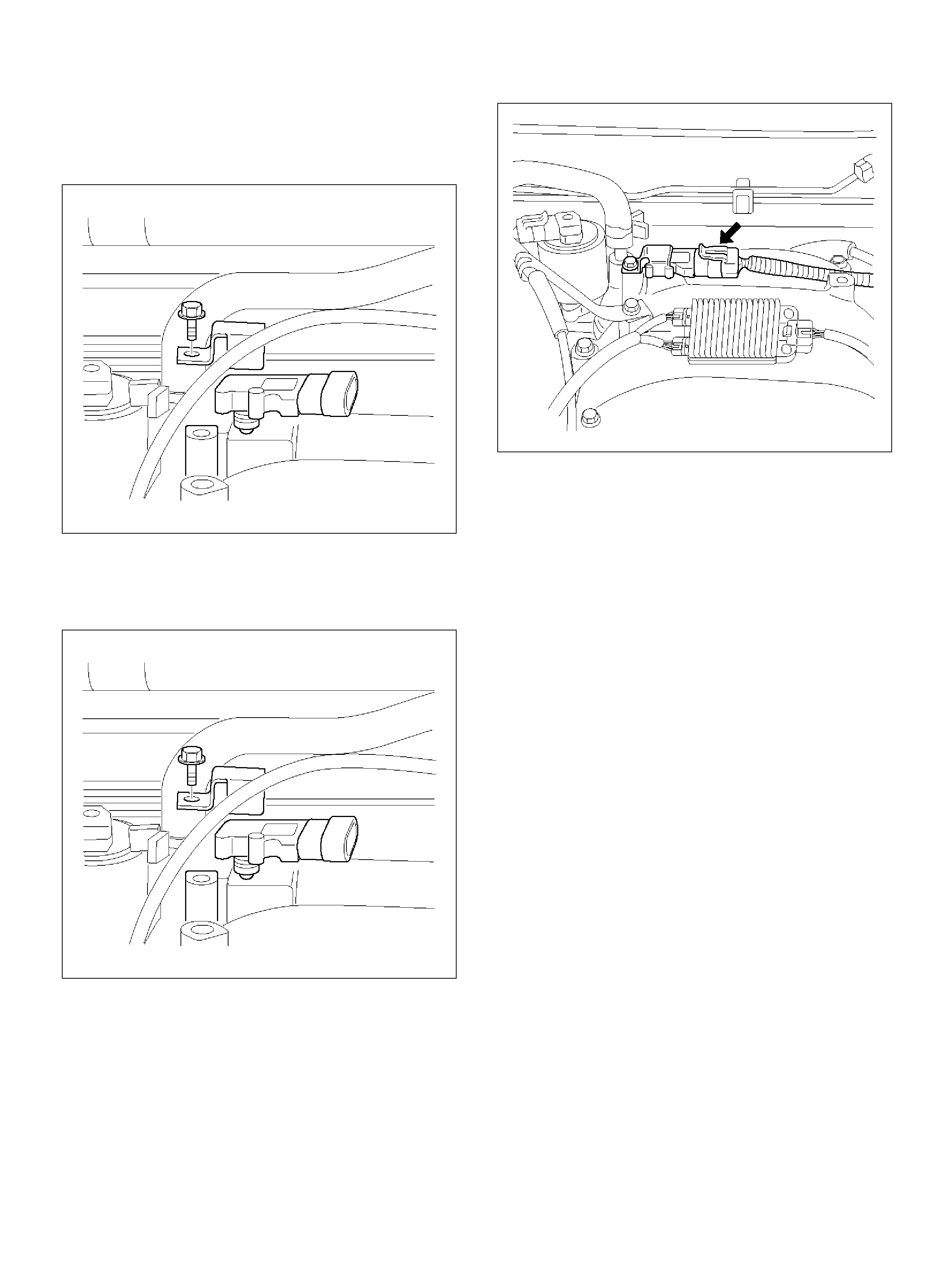

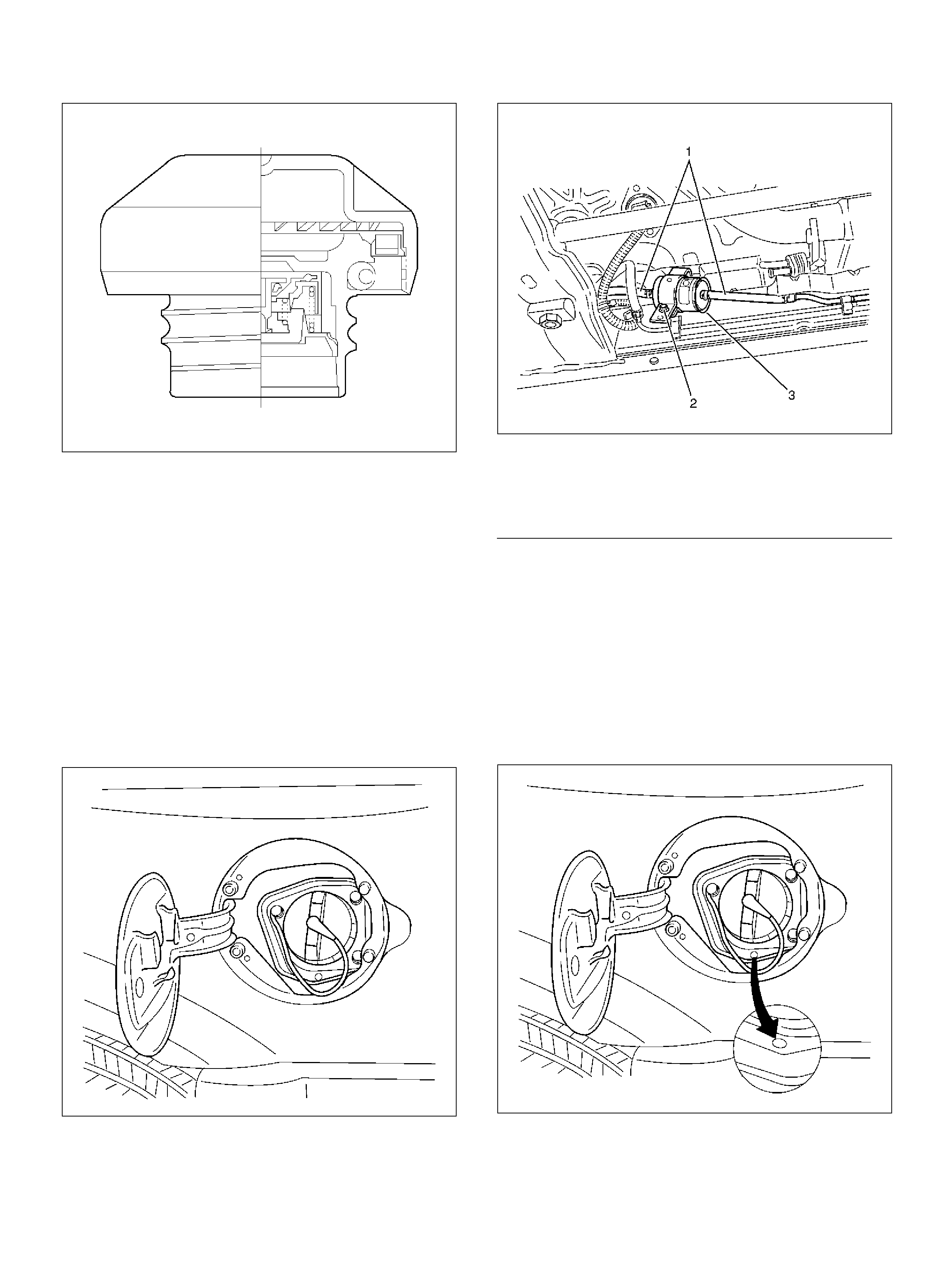

Vehicle Speed Sensor (VSS)

Removal Proc edure

Inspection Procedure

Installation Proced ure

Air Cleaner/Air Filt er

Removal Proc edure

Installation Proced ure

Comm on Cham ber

Removal and Ins tallation Proced ure

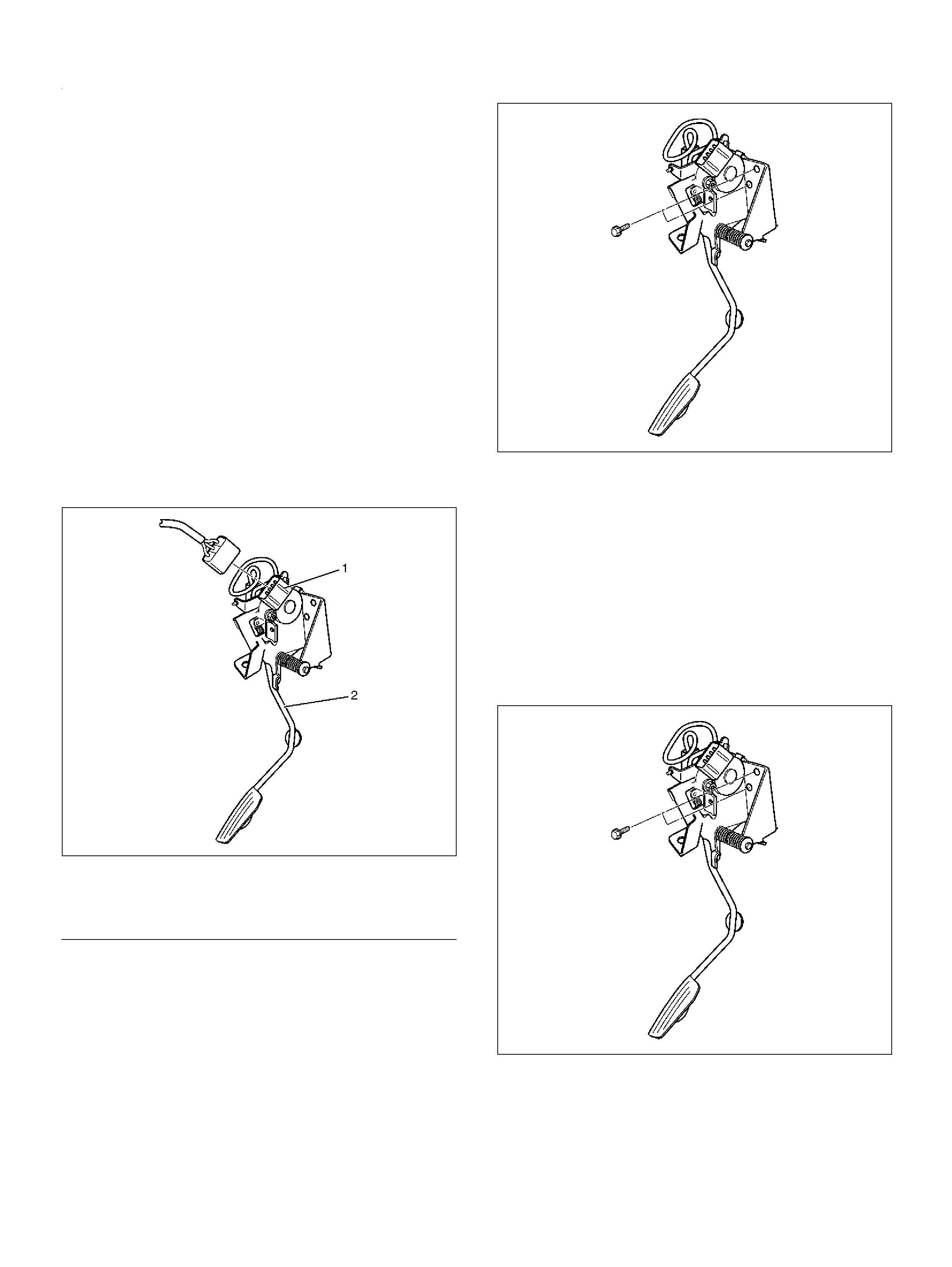

Accelerator Pedal Replacement

Removal Proc edure

Installation Proced ure

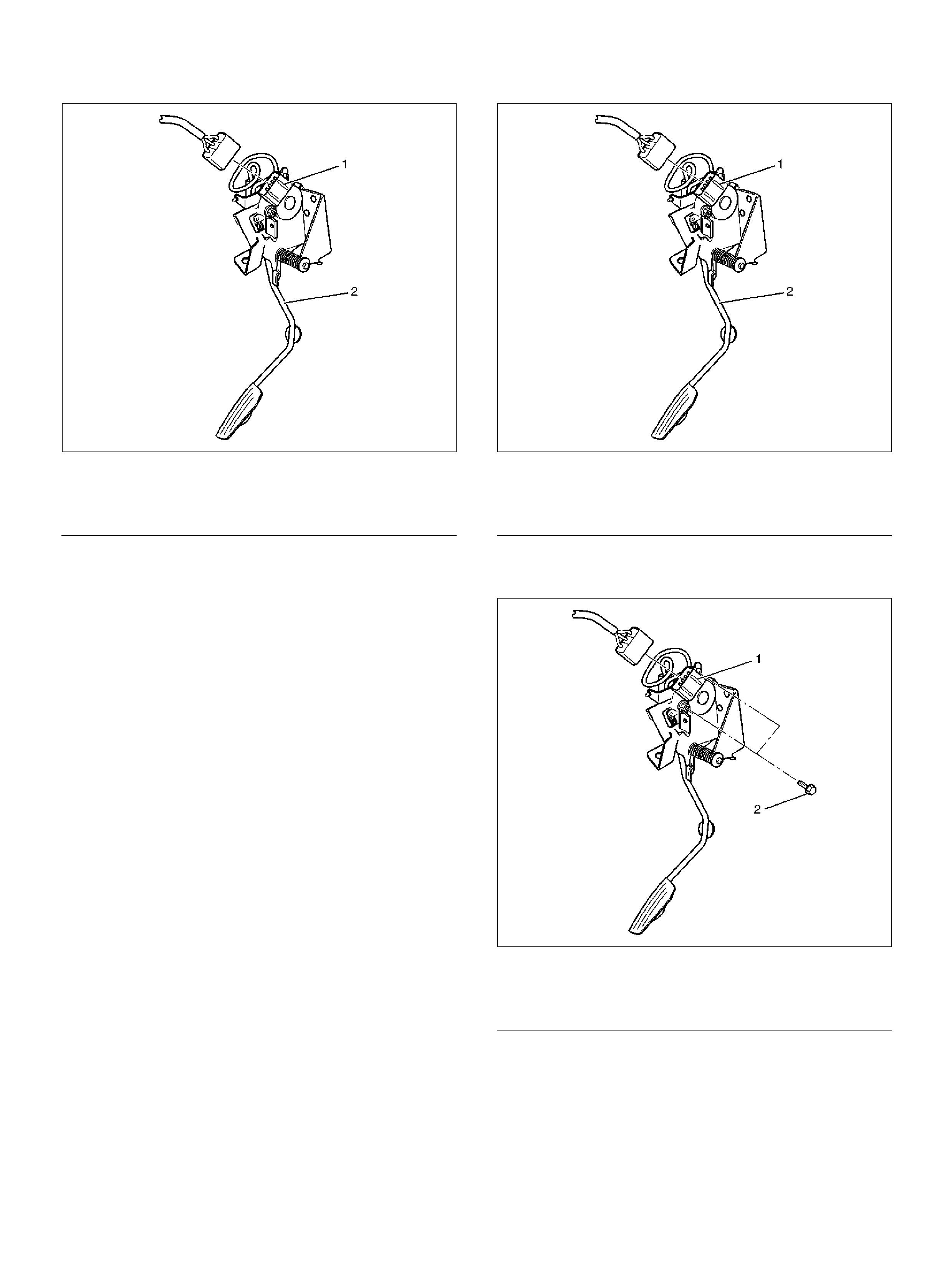

Accelerator Position Sensor Replacement

Removal Proc edure

Installation Proced ure

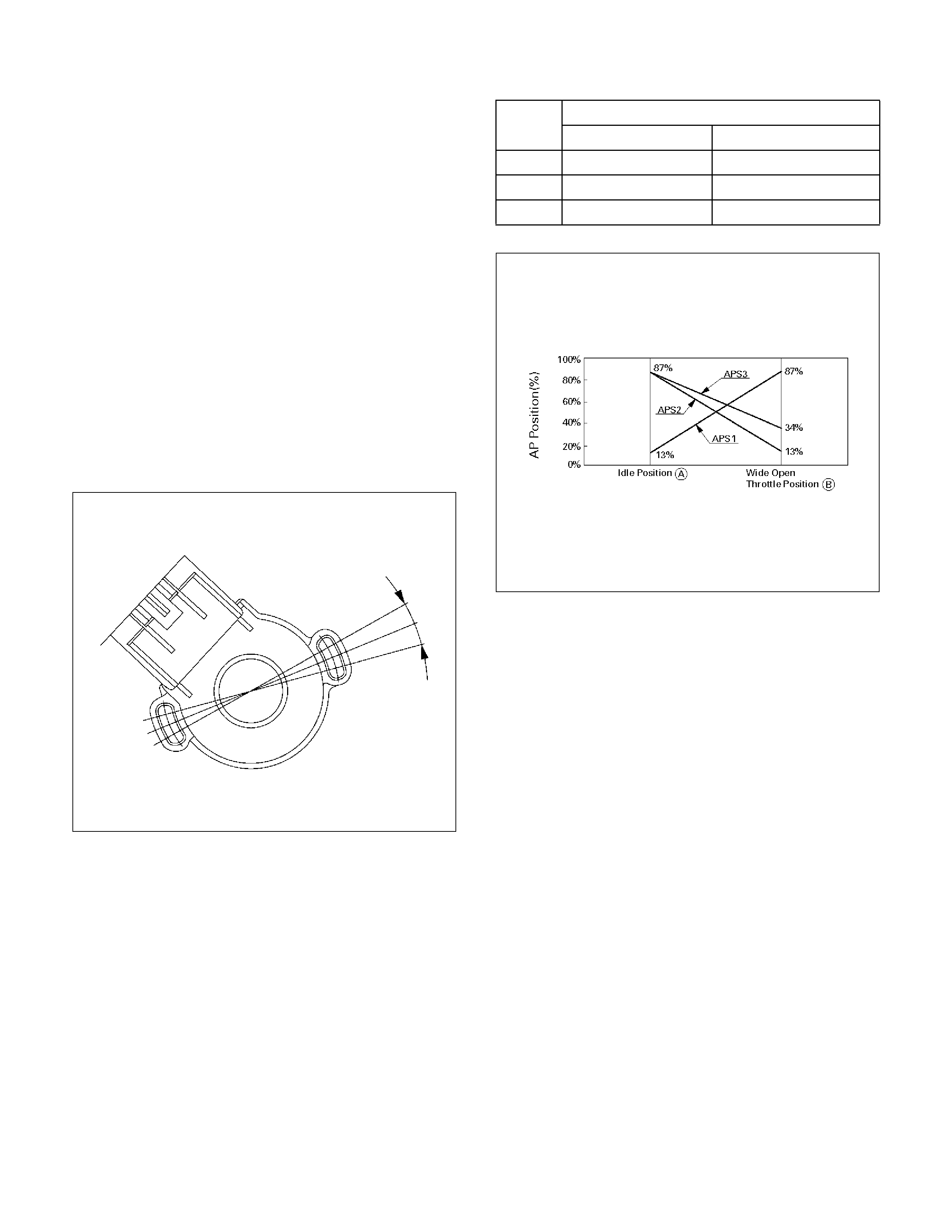

Accelerator Position Sensor Adjustment

Removal Proc edure

How To Adj u st For AP Senso r

Fuel Filler Cap

General Desc ription

Inspection Procedure

Fuel Filter

Removal Procedure

Inspection Procedure

Installation Proced ure

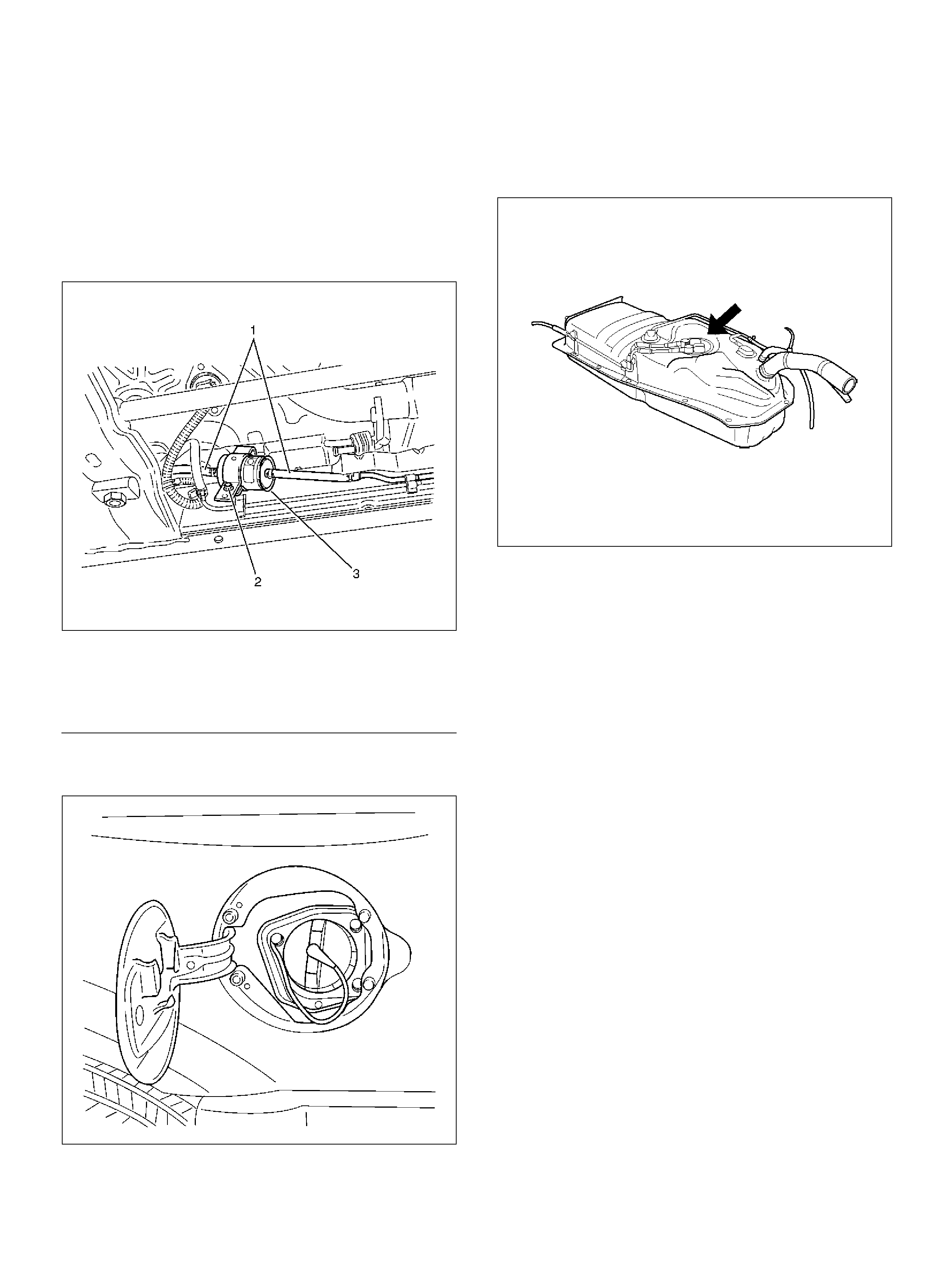

Fuel Gaug e Unit

Removal Procedure

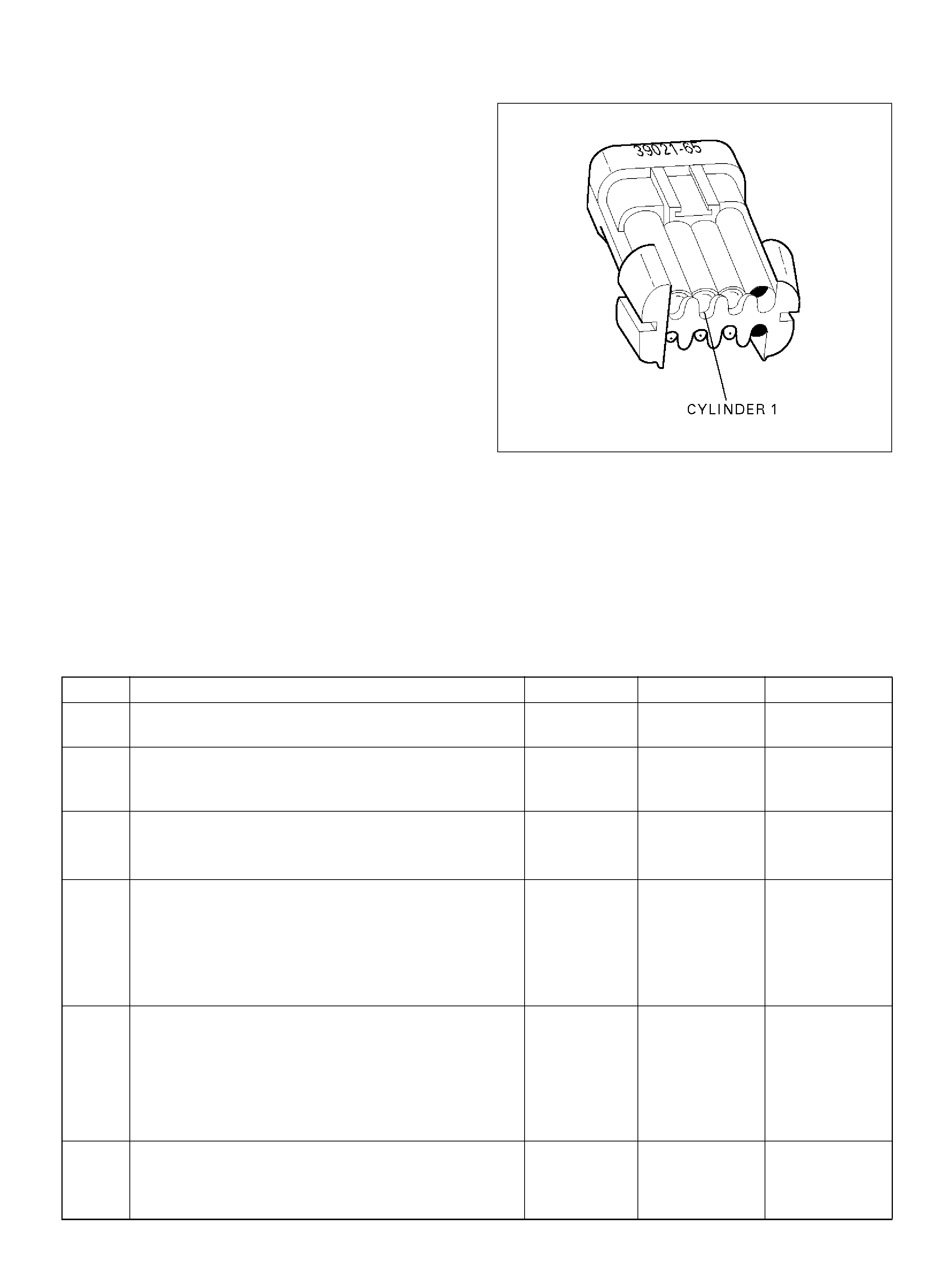

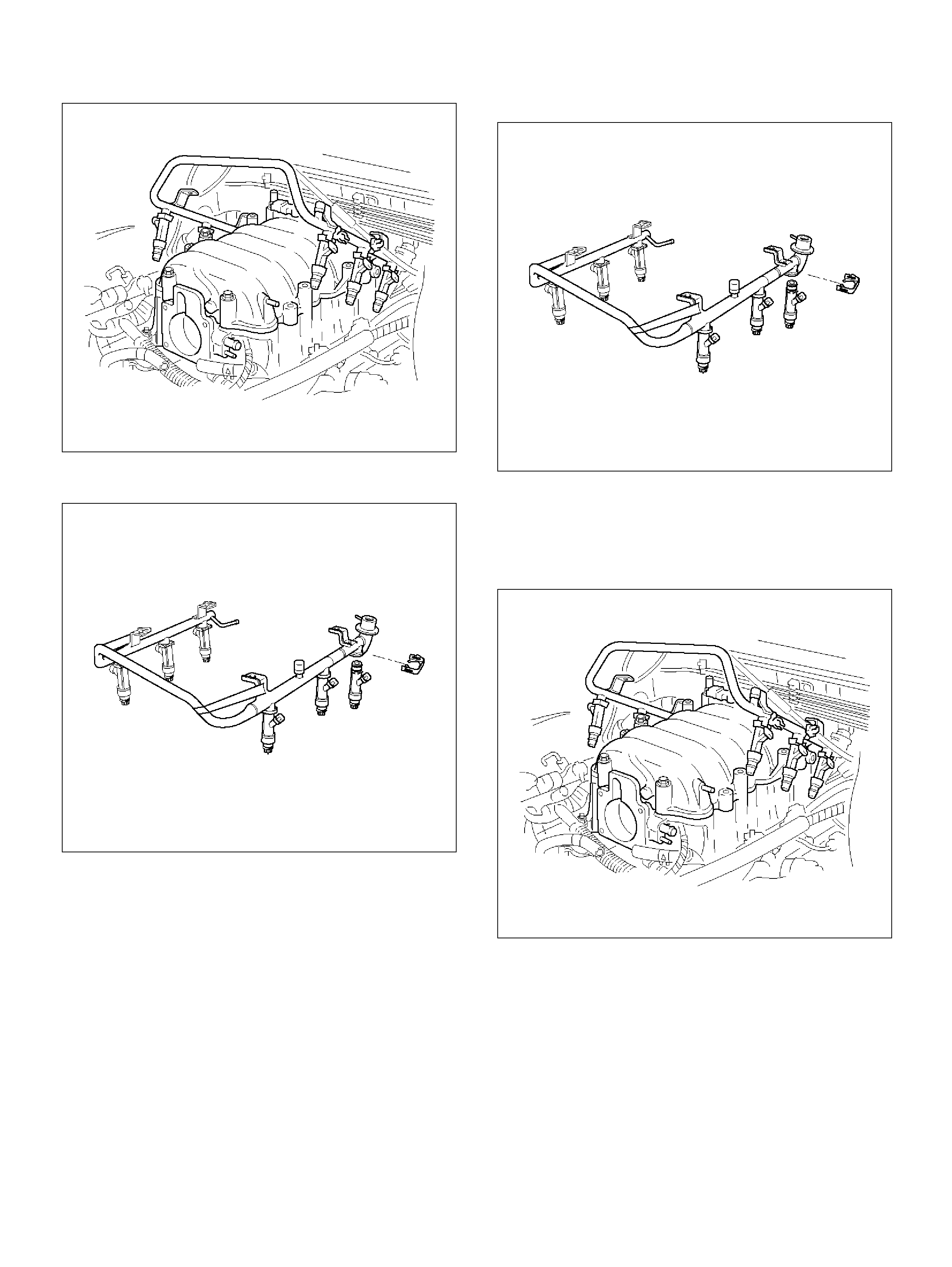

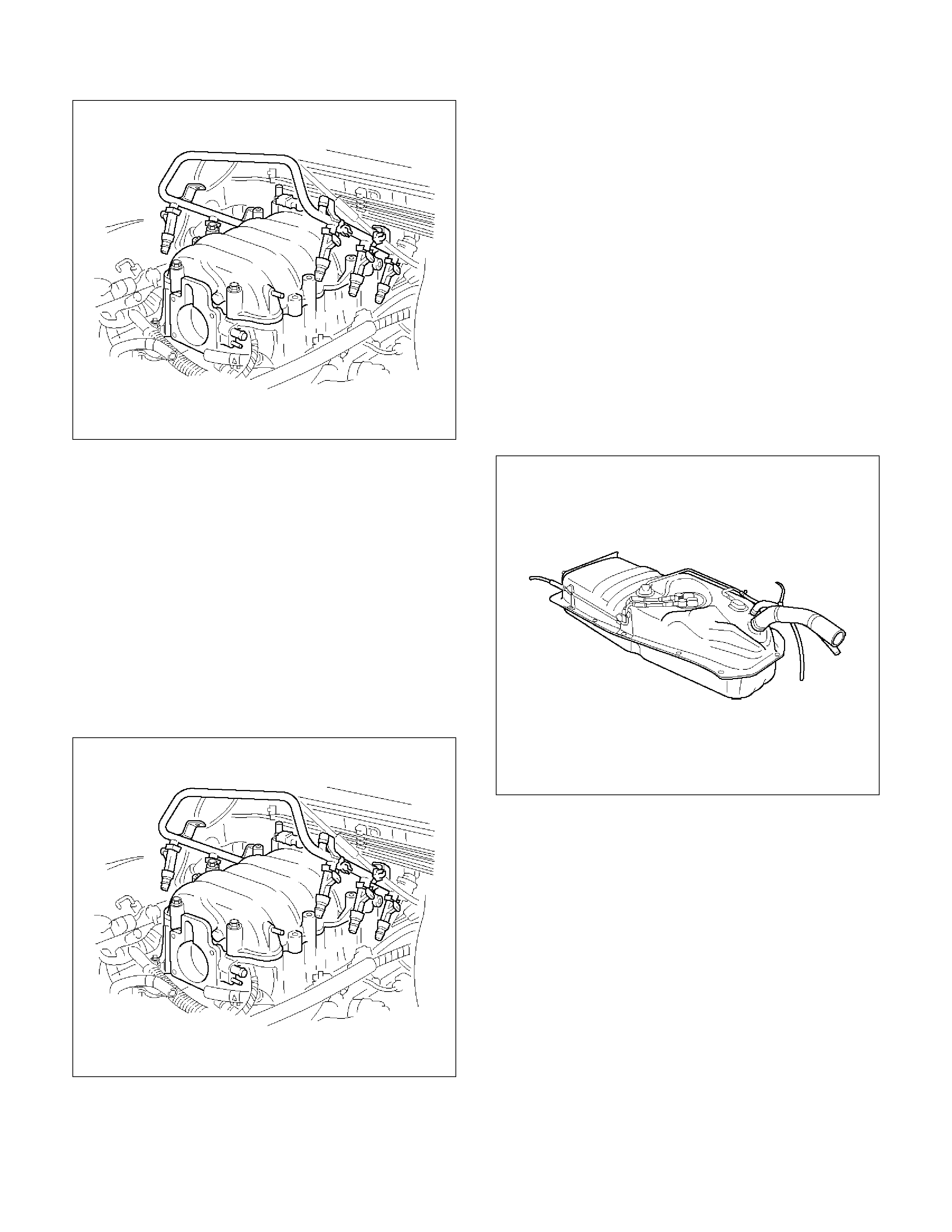

Fuel Injectors

Removal Procedure

Inspection Procedure

Installation Proced ure

Fuel Metering System

Fuel Pressure Relief Procedure

F ue l Pump As sembly

Removal Procedure

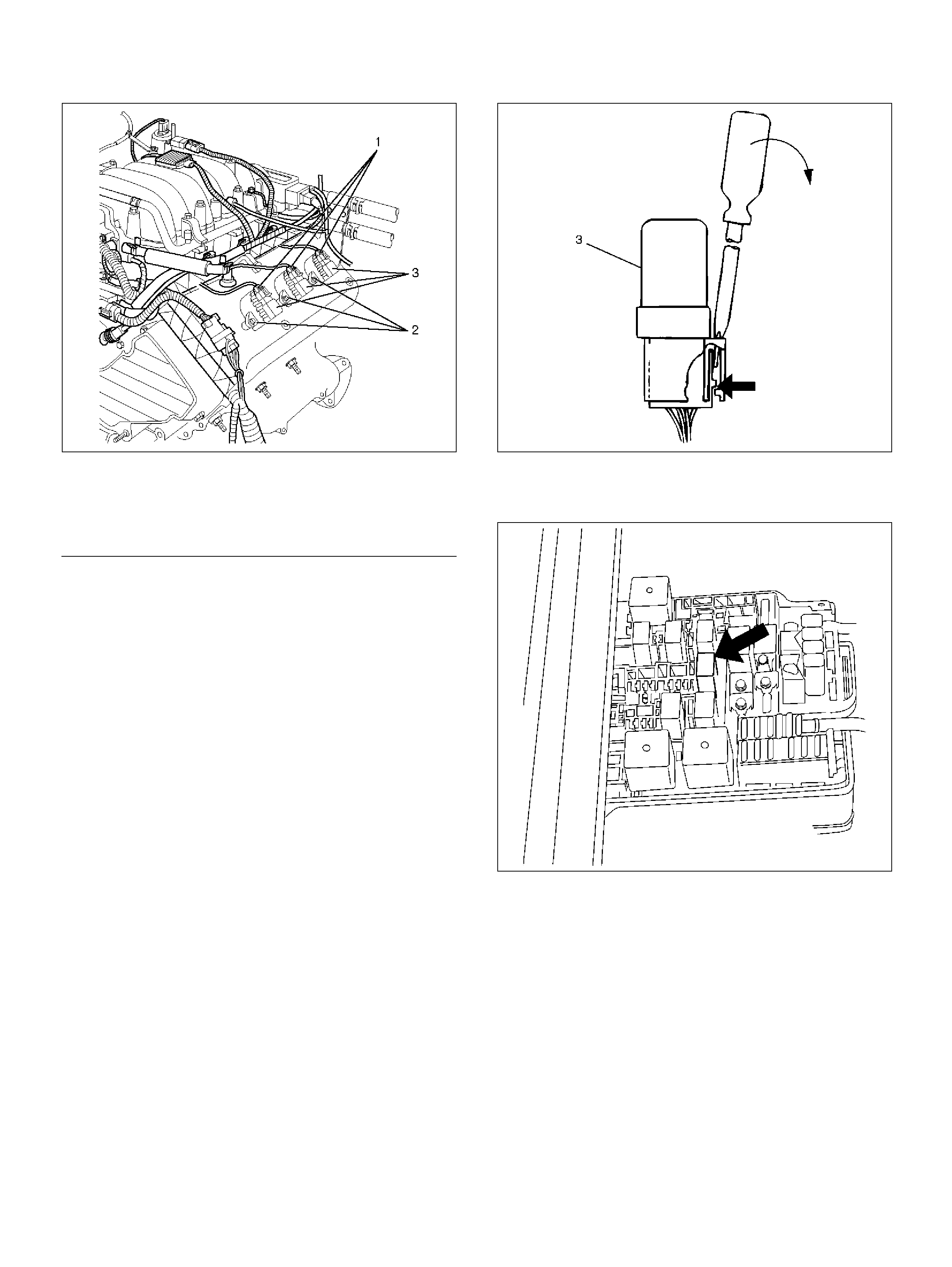

Fuel Pump Relay

Removal Procedure

Installation Proced ure

Fuel Rail Assembly

Removal Procedure

Installation Proced ure

Fuel Tank

Removal Procedure

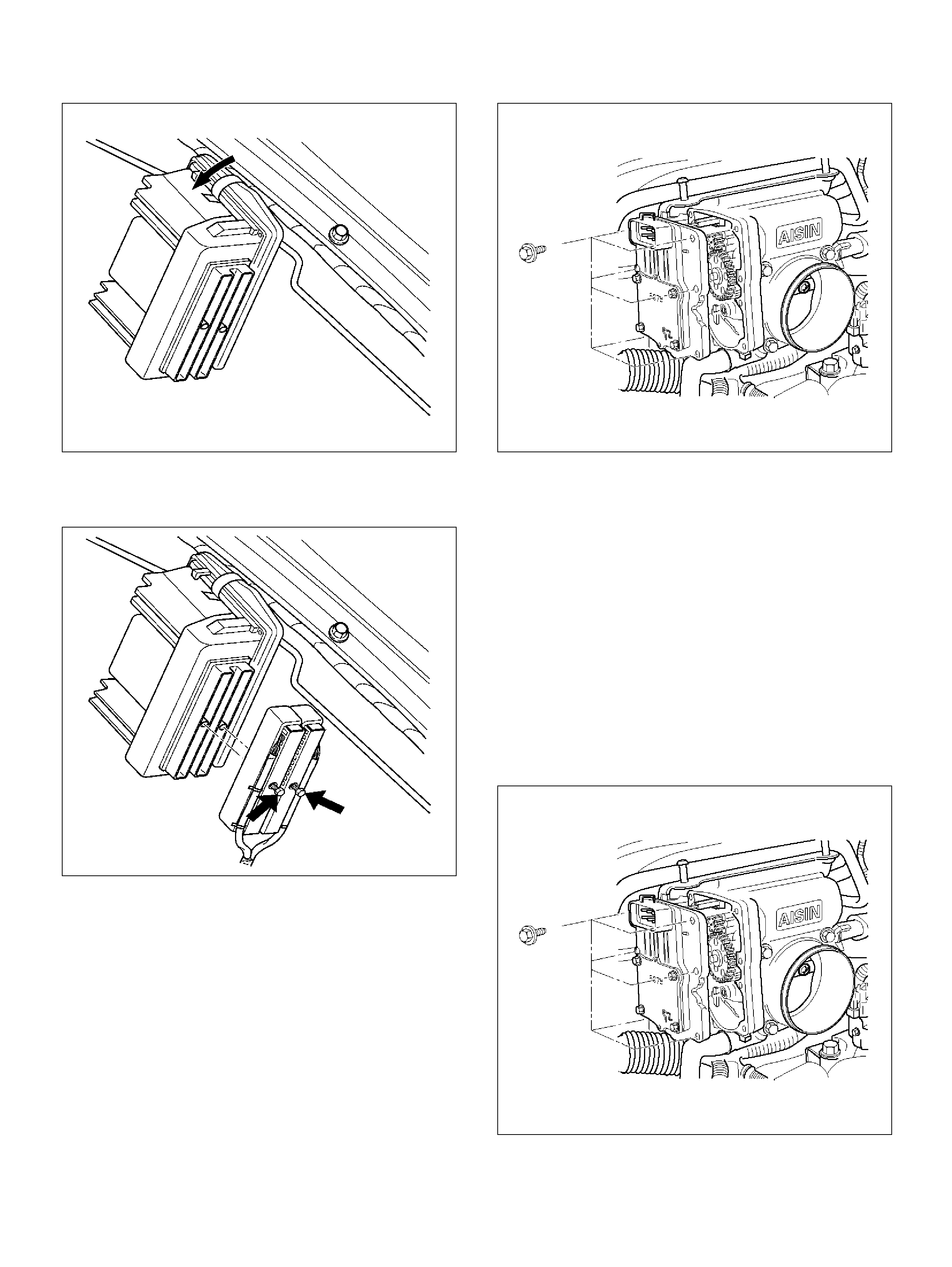

Throttle Body (TB)

Removal Procedure

Inspection Procedure

Installation Proced ure

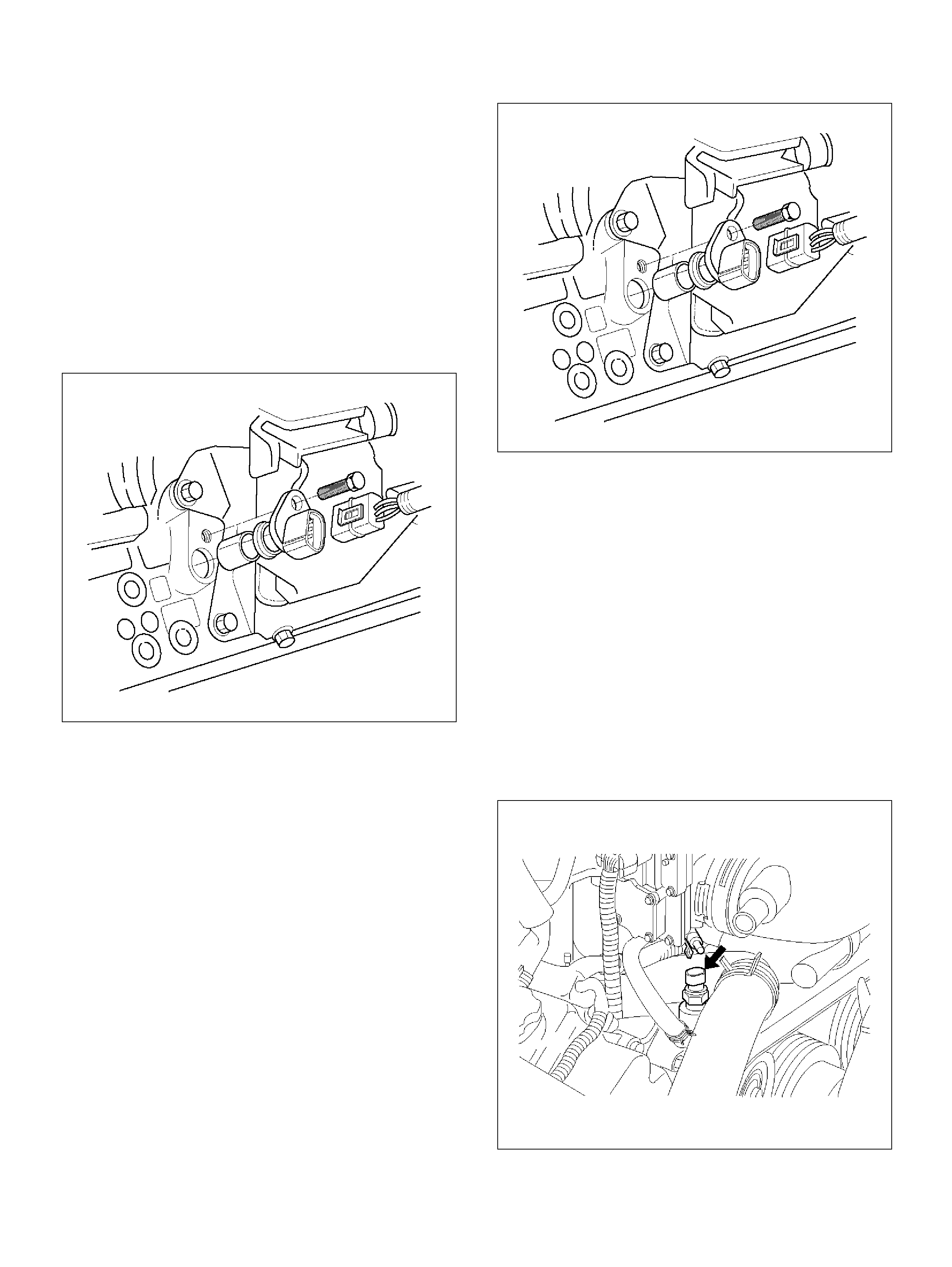

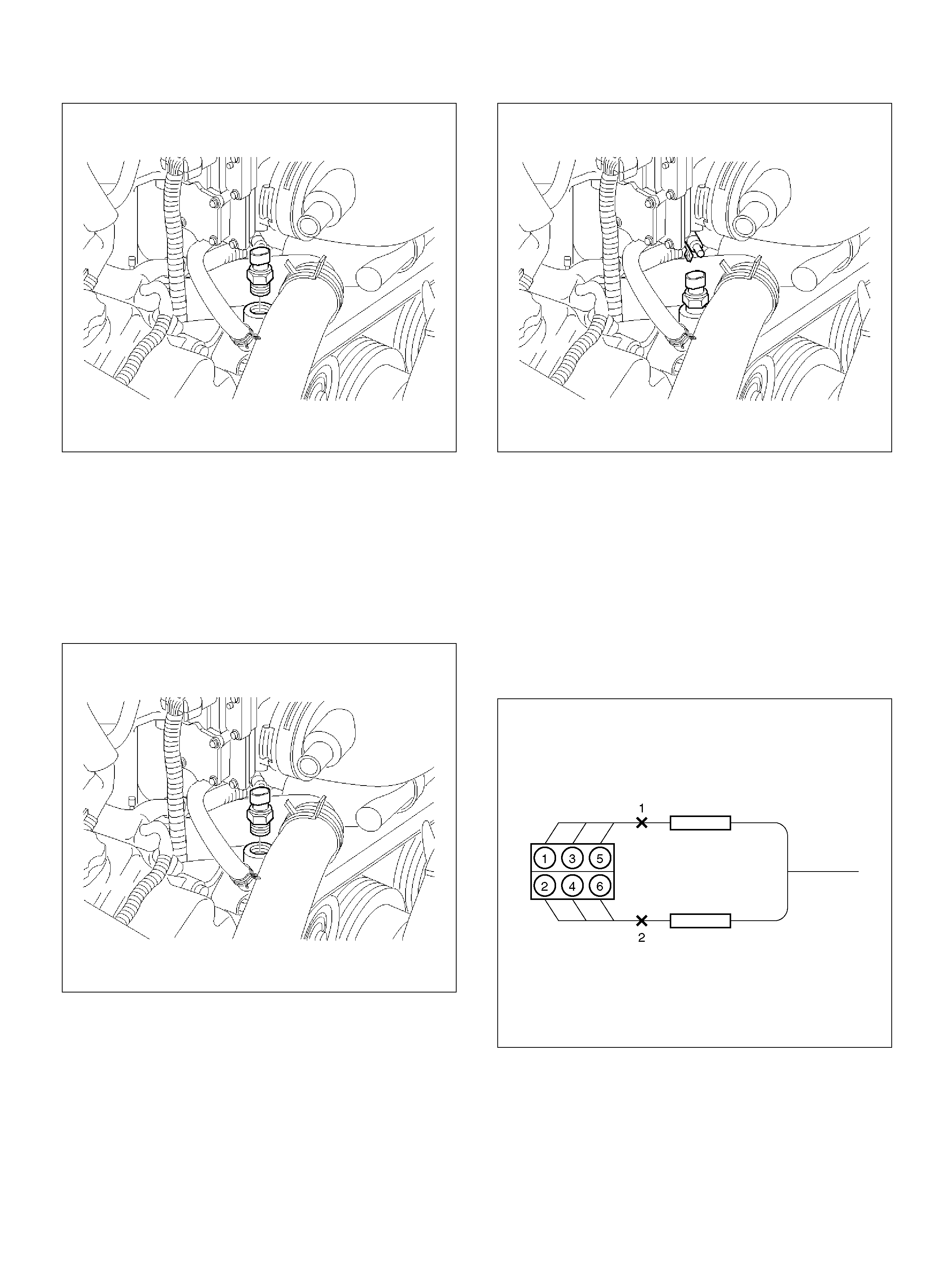

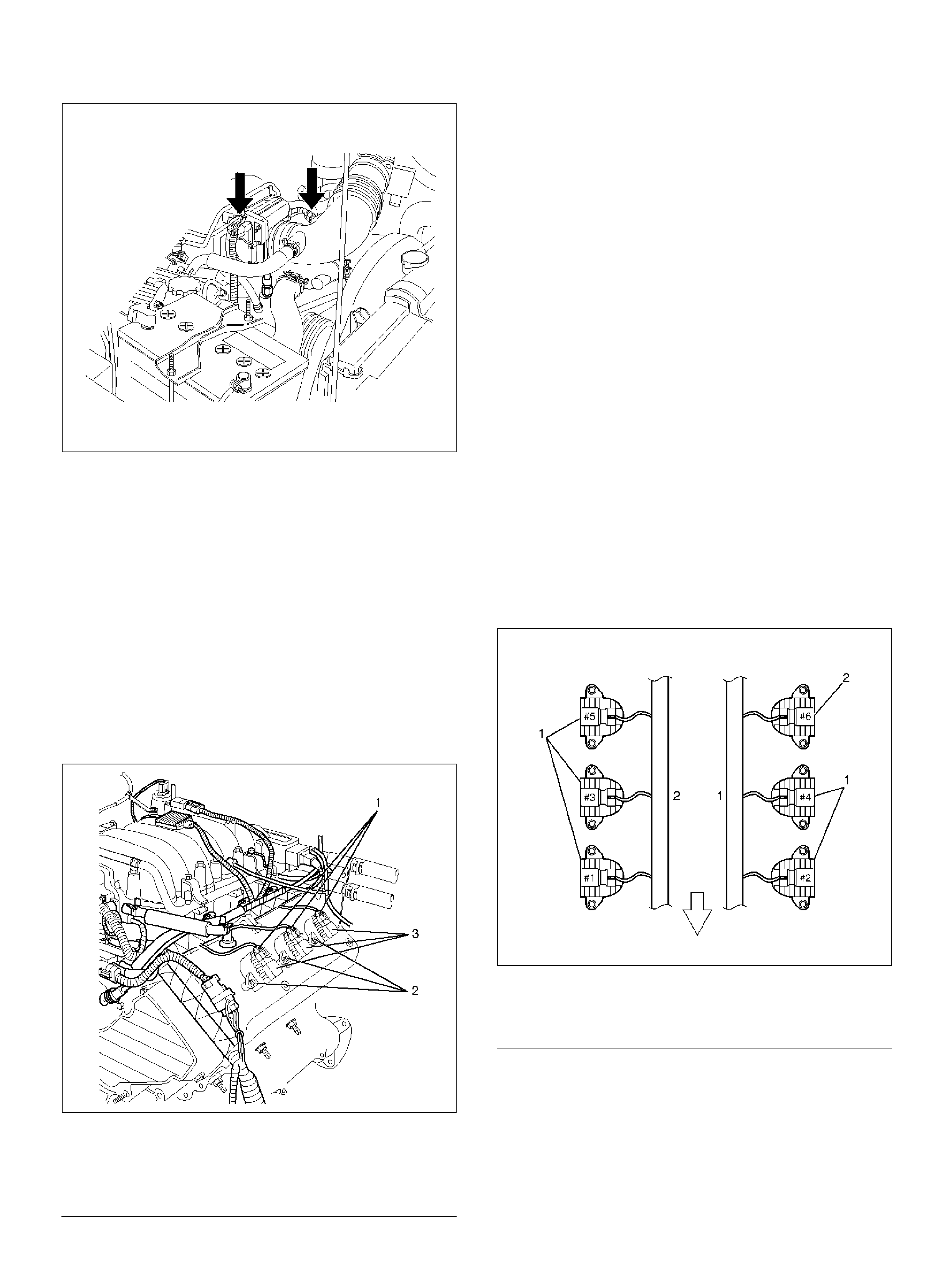

Electronic Igni tion Syste m

Removal Procedure

Installation Proced ure

Catalytic Converter

Removal and Installati on Procedu re

Air Conditioning Thermo Relay

Removal Procedure

Installation Proced ure

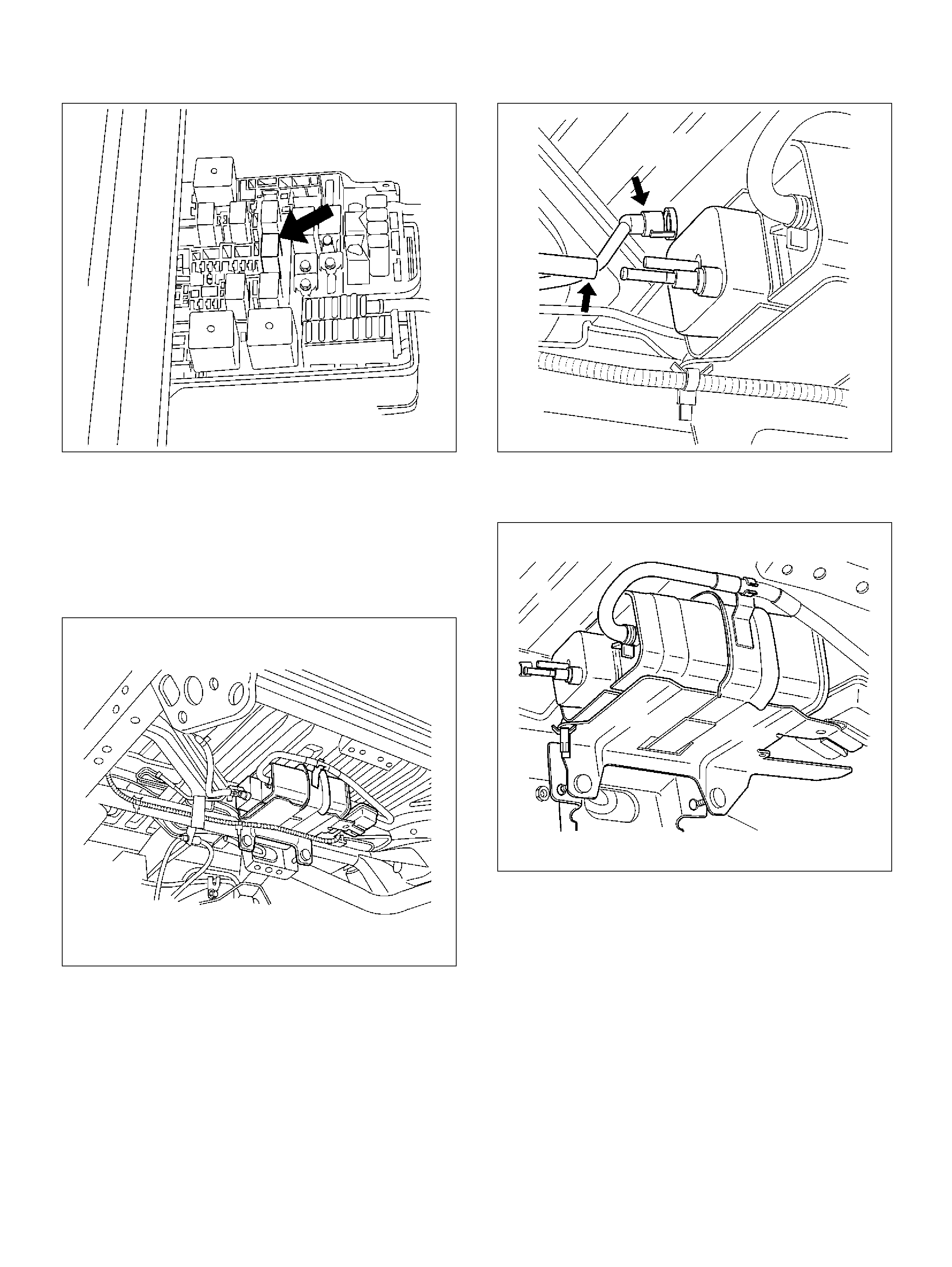

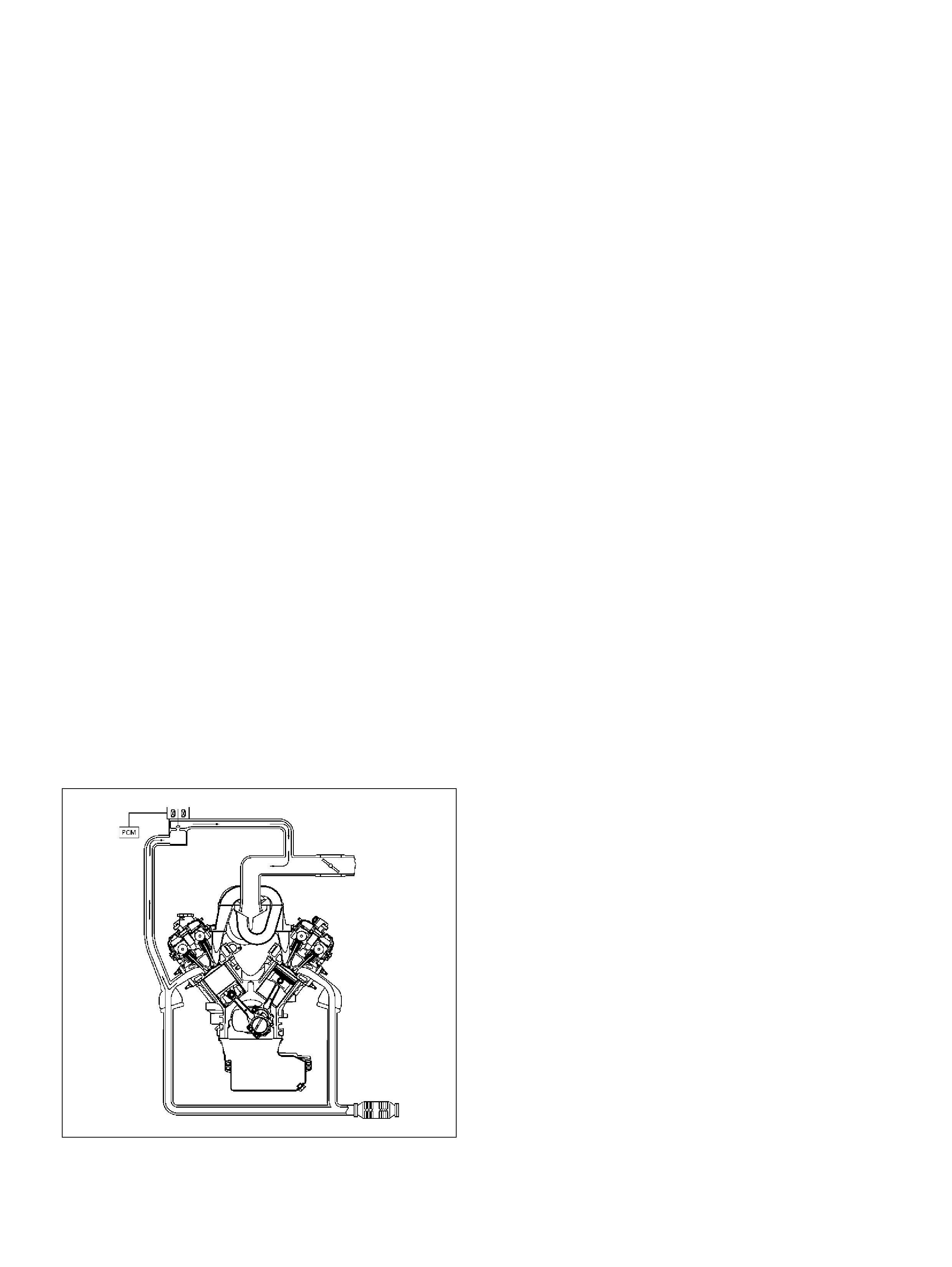

EVAP Canister

Removal Procedure

Inspection Procedure

Installation Proced ure

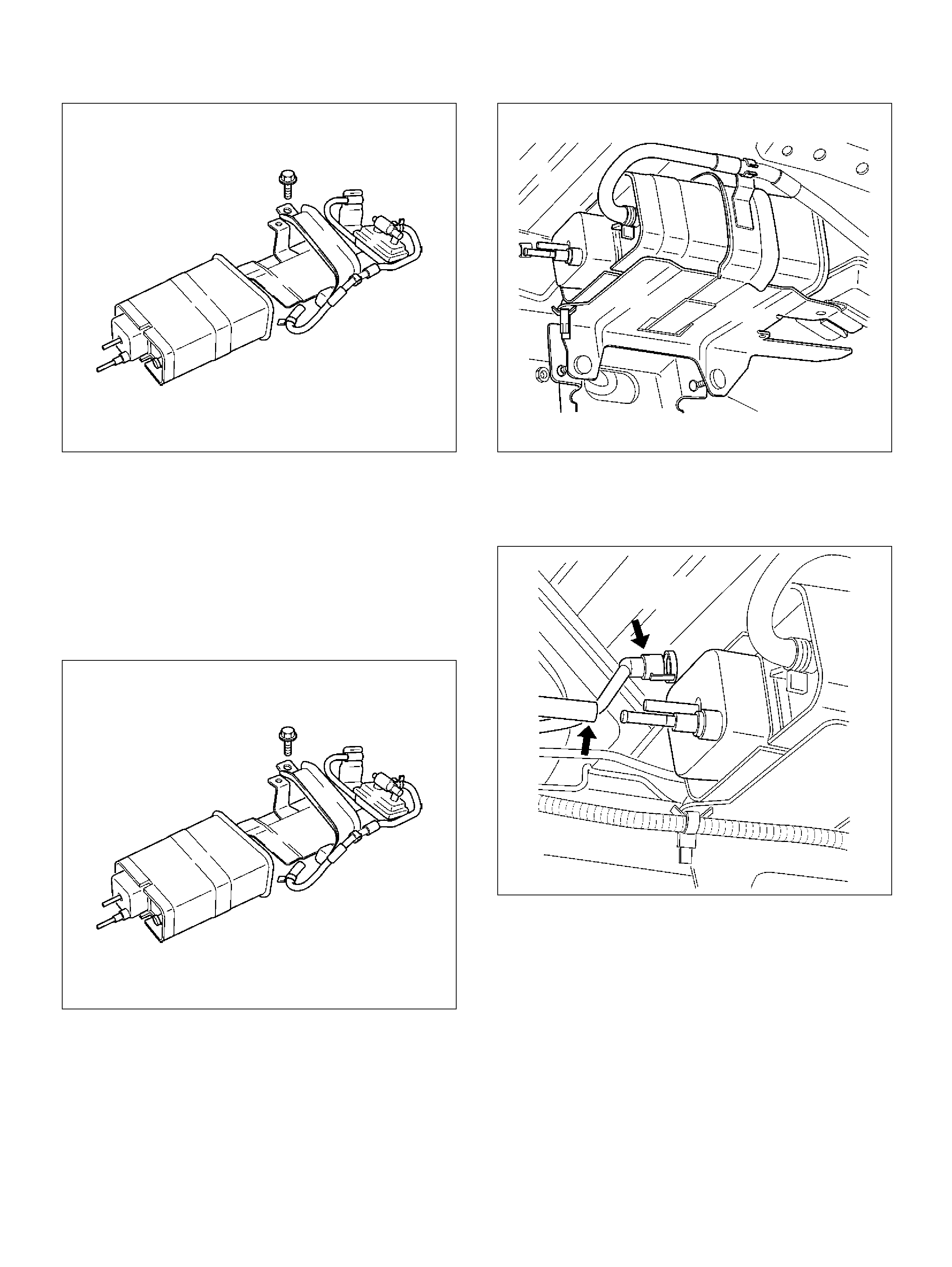

EVAP Can ister Purg e Solenoid

Removal Procedure

Installation Proced ure

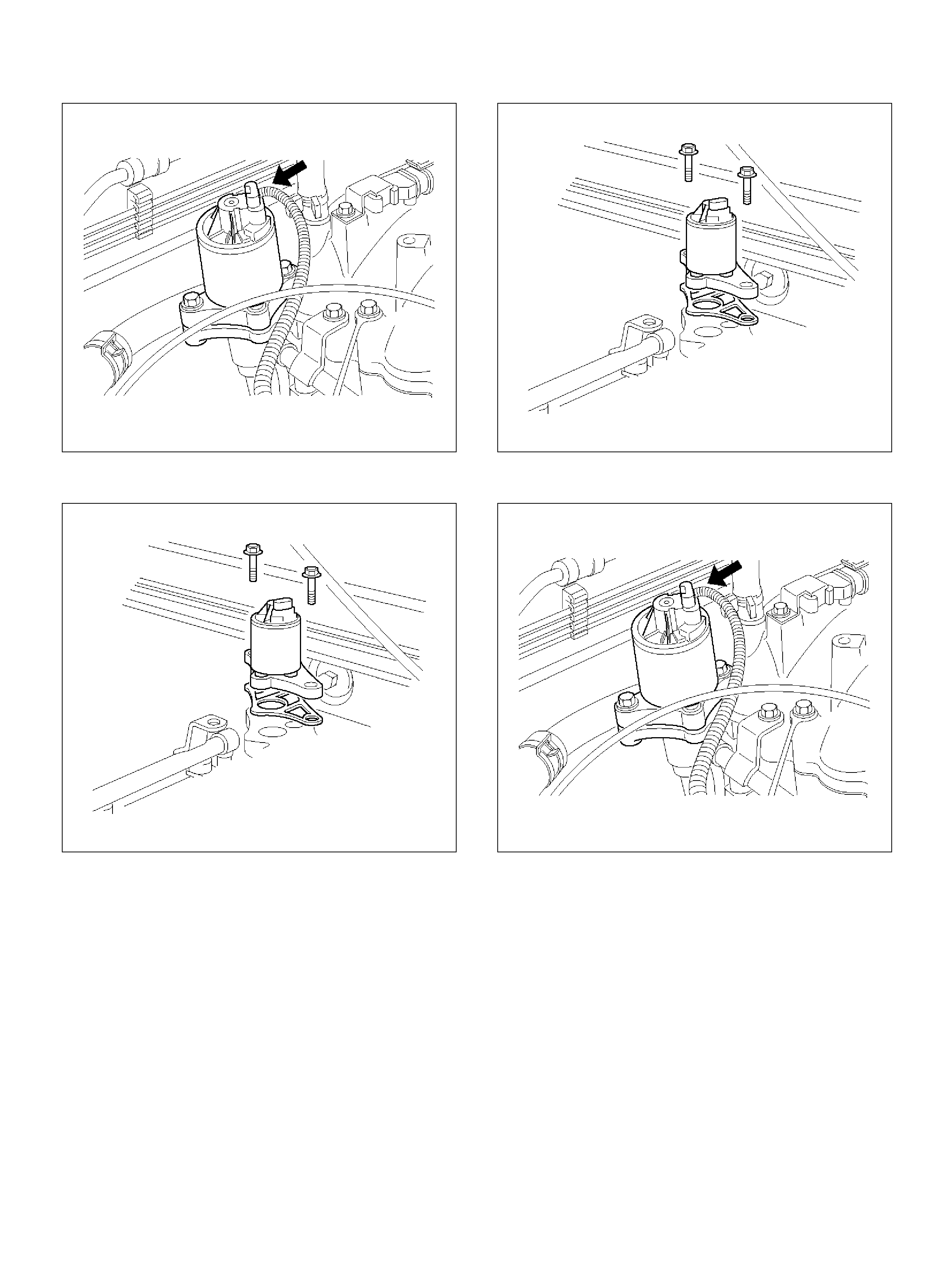

Linear Exhaust Gas Recirc. (EGR) Valve

Removal Procedure

Installation Proced ure

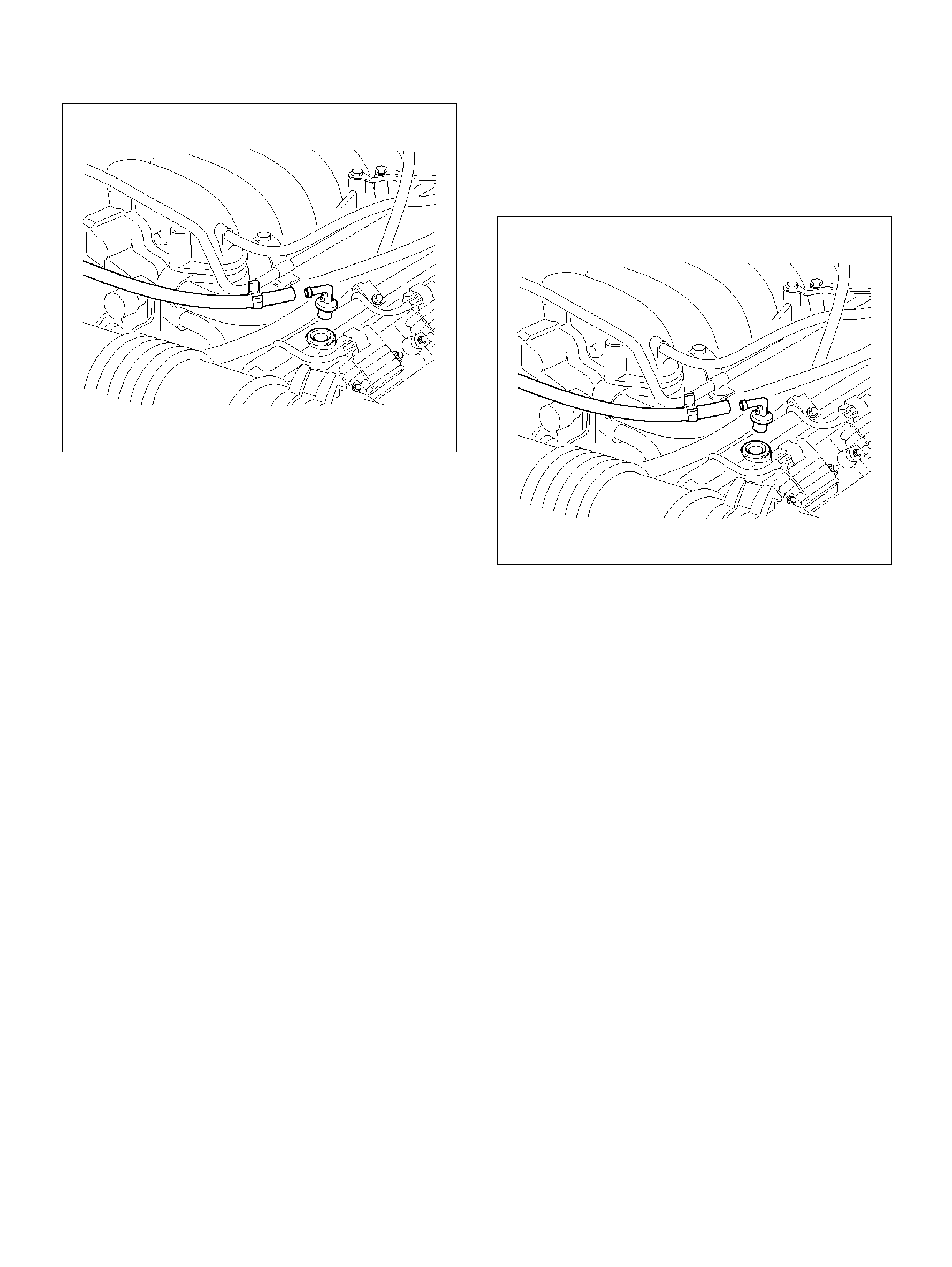

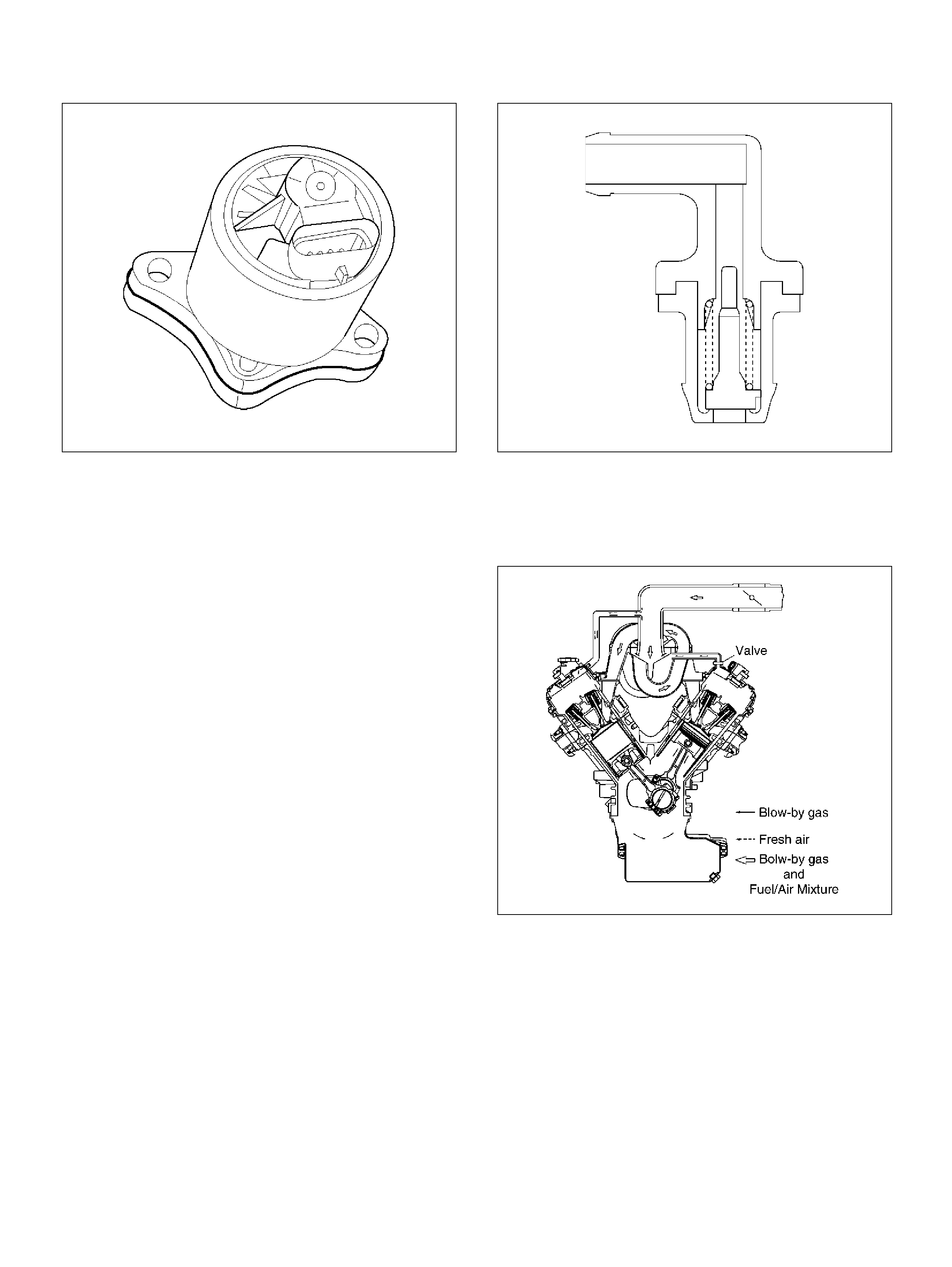

Posi ti ve Cr ankcase Ventilation (PCV) Valve

Removal Procedure

Inspection Procedure

PCV Valve

Installation Proced ure

Wiring and Connectors

Wiring Harness Service

Connectors and Terminals

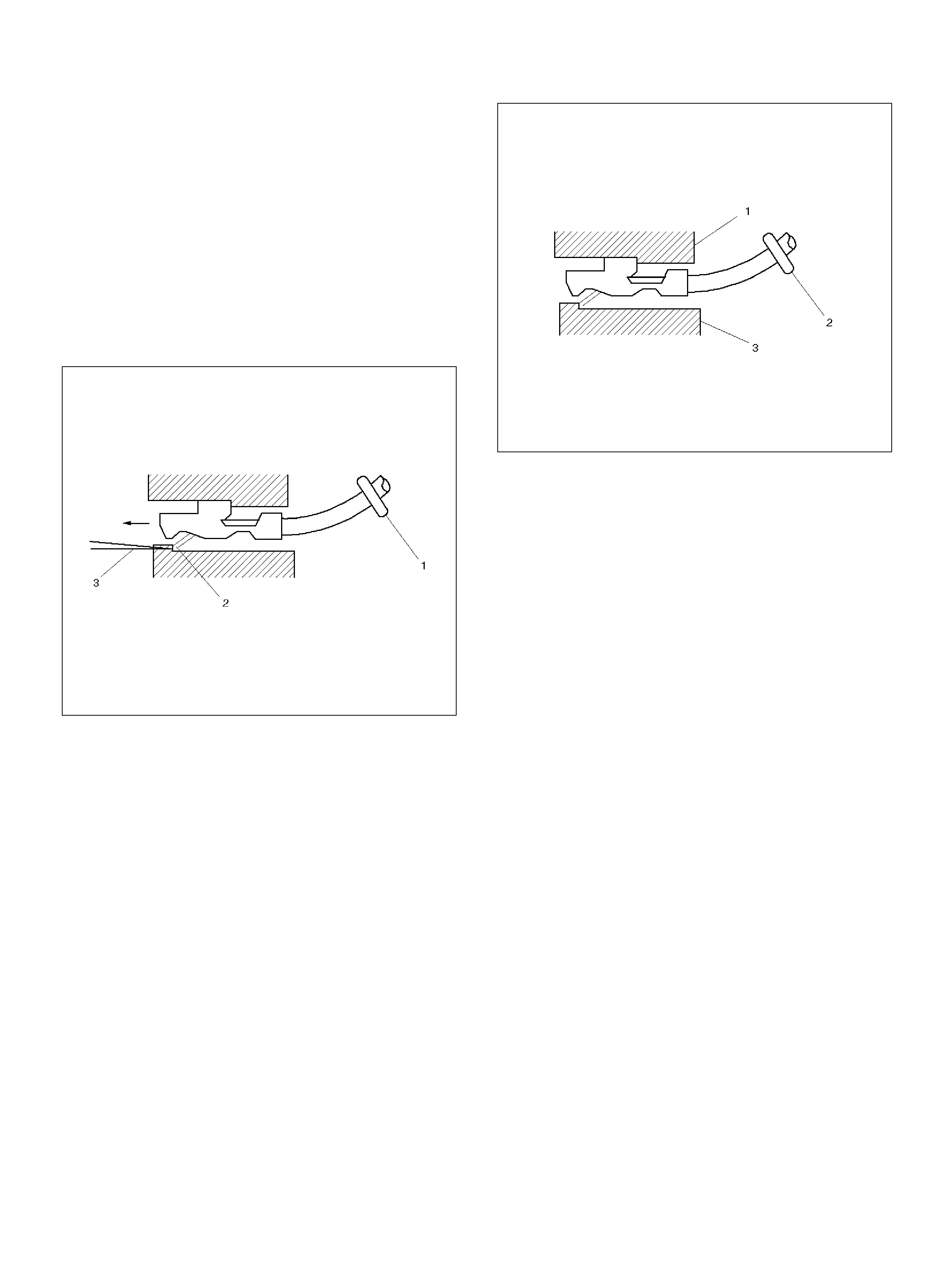

PCM Connectors and Terminals

Removal Procedure

Installation Proced ure

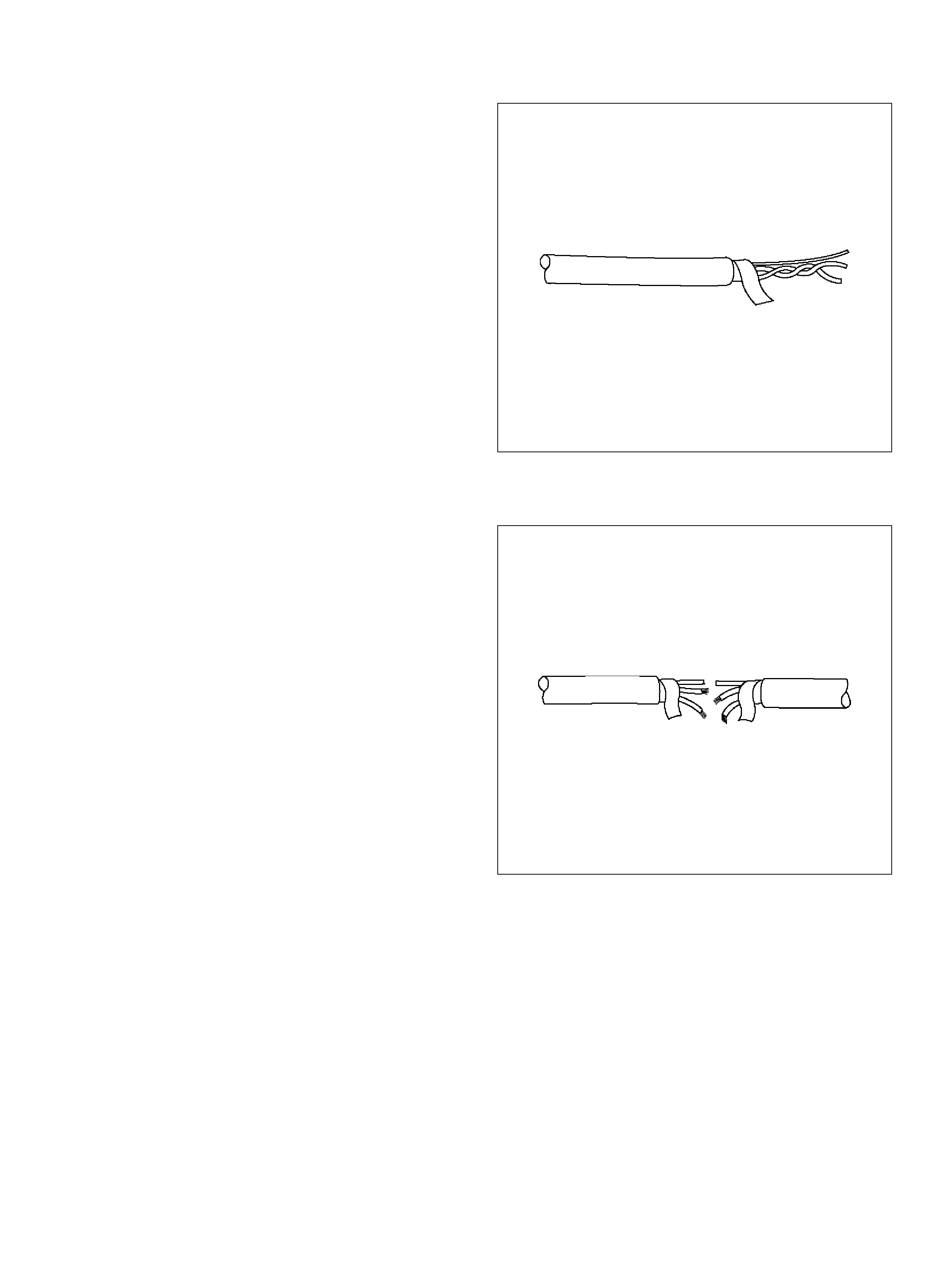

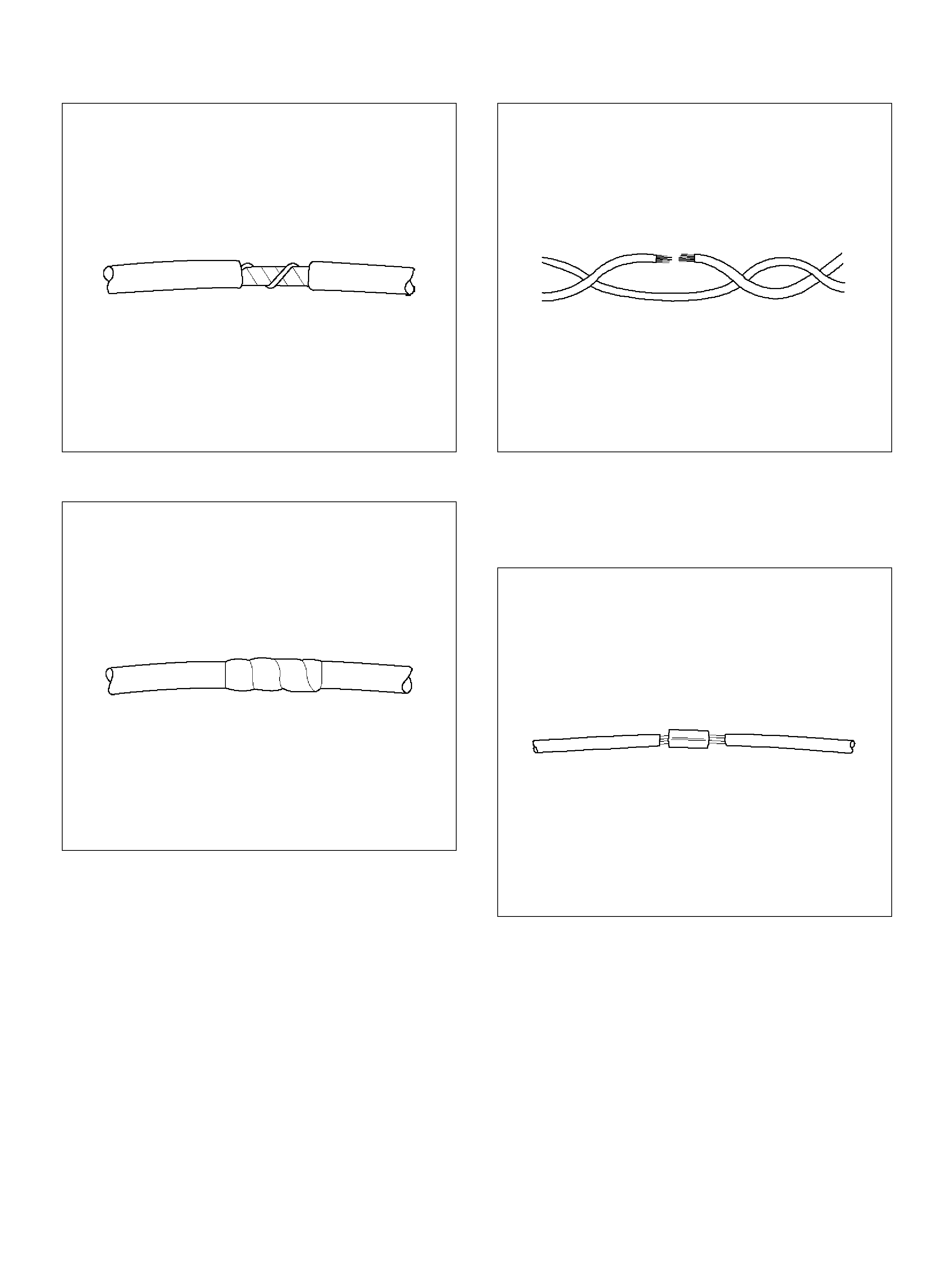

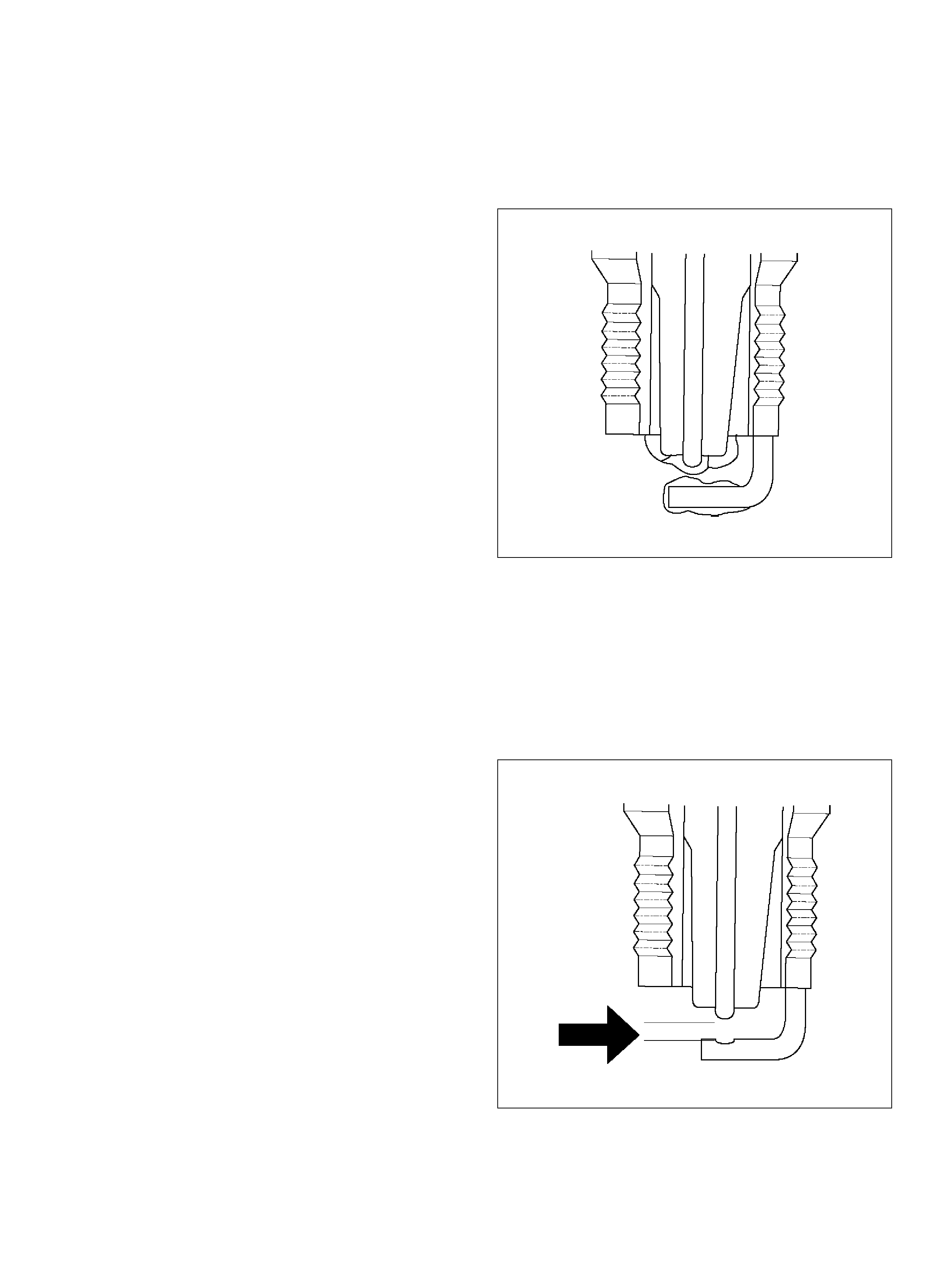

Wire Harness Repair: Shielded Cable

Removal Procedure

Installation Proced ure

Twisted Leads

Removal Procedure

Installation Procedure

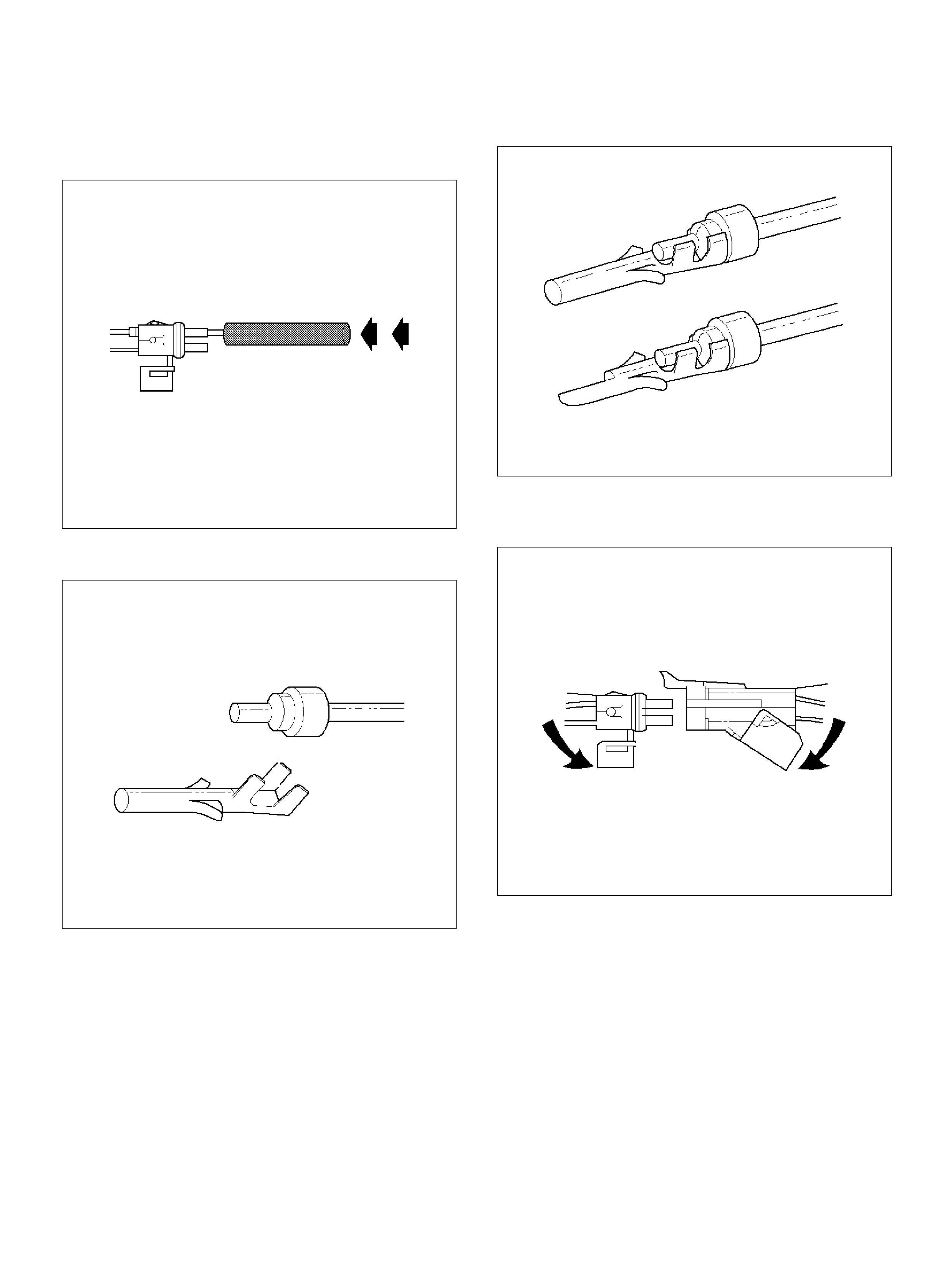

Weather-Pack Connector

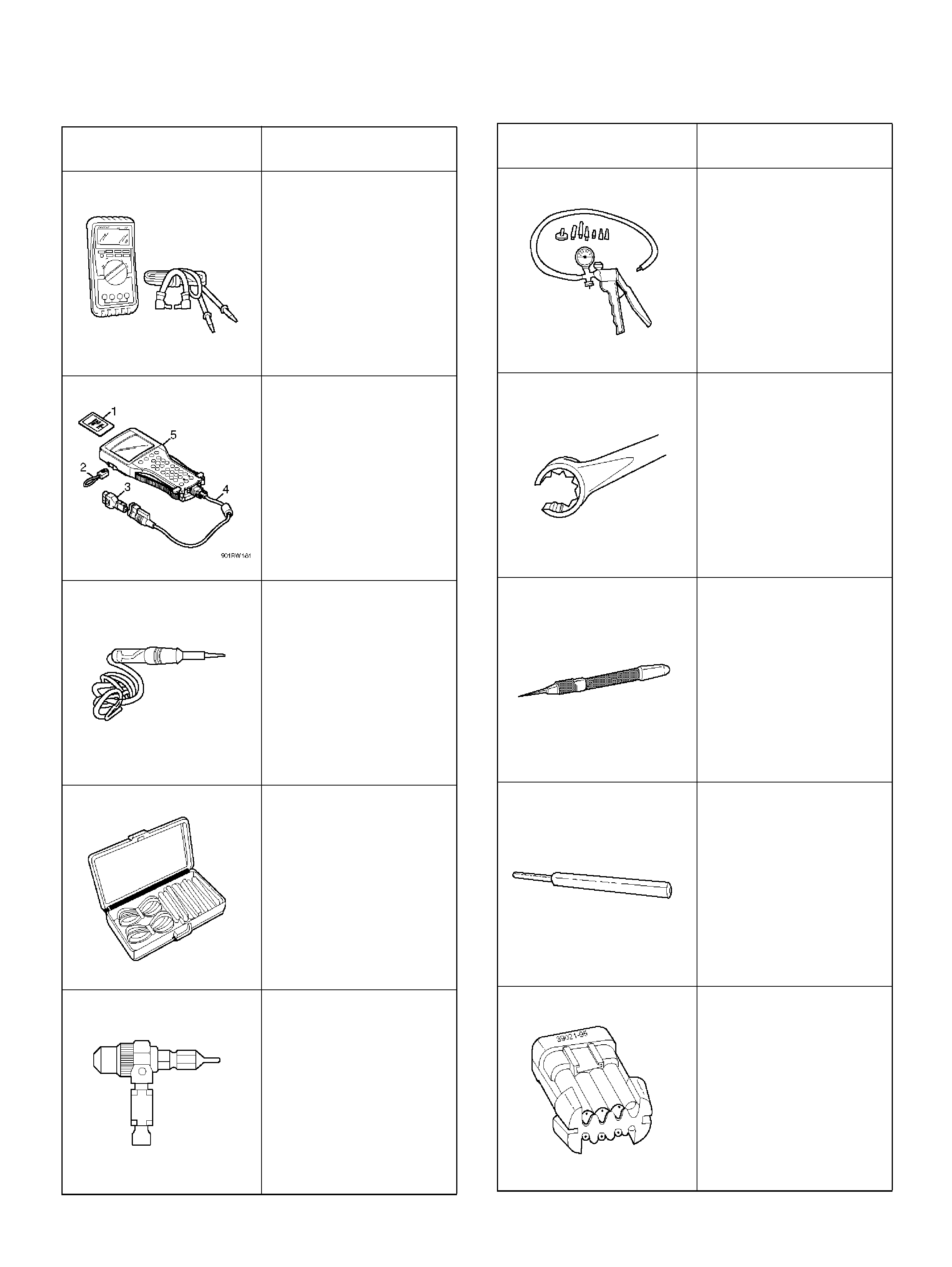

Tools Required

Removal Procedure

Installation Procedure

Com-Pack III

General Information

Metri-Pack

Tools Required

Removal Procedure

Installation Procedure

General Description (PCM and Sensors)

General Description (Air Induction)

General Description (Fuel Metering)

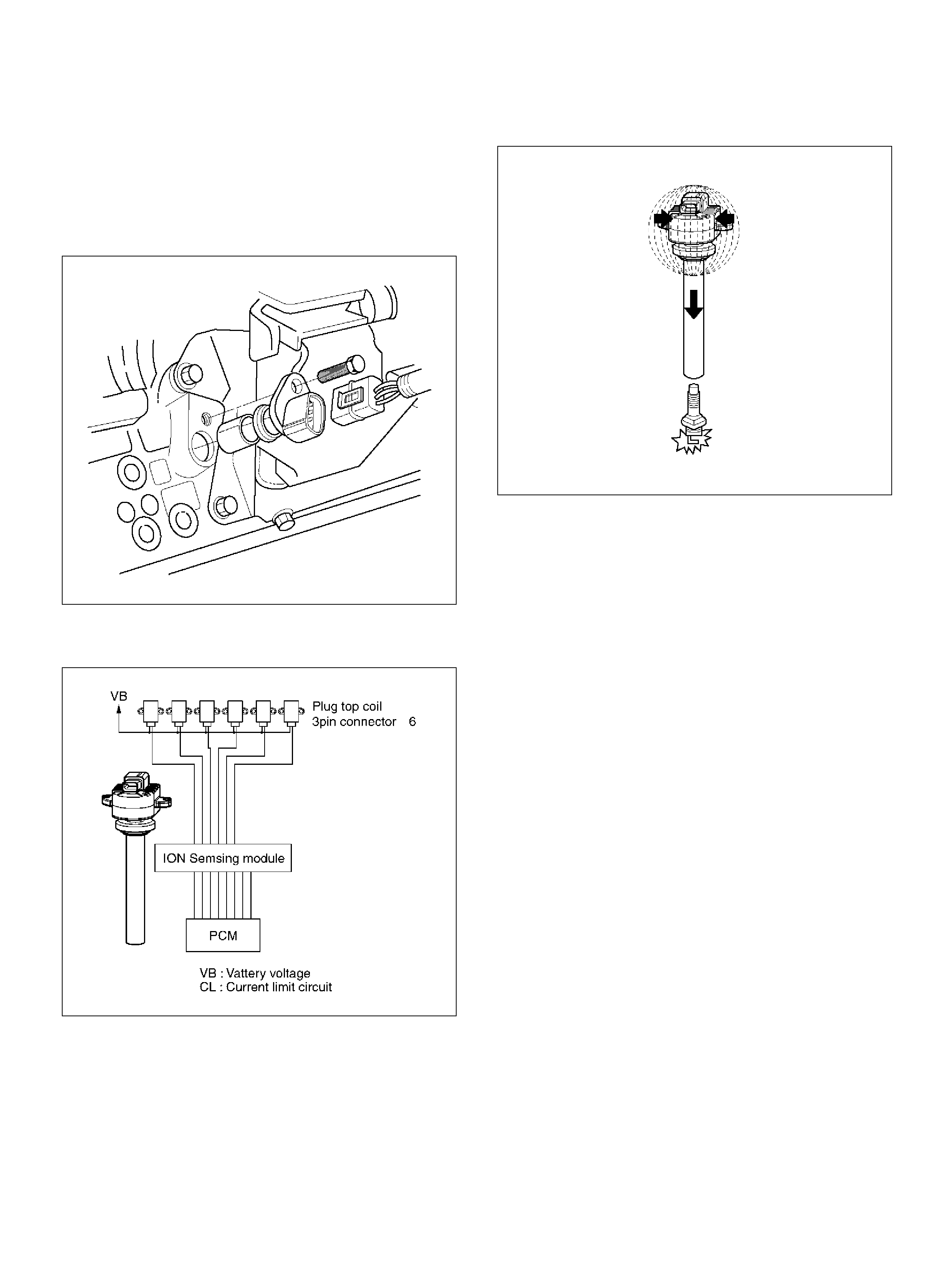

General Description (Electronic Ignition System)

A/C Clutch Di agnosis

General Description (Evaporative

(EVAP) Emission System)

General Description (Exhaust Gas

Recirculation (EGR) System)

General Description (Positive Crankcase

Ventilation (PCV) System)

Spe c ial To ols

SPECIFICATIONS

TORQUE SPECIFICATI ONS

Application N·m

EGR Bolt 25

Engine Coolant Temperature Sensor 30

Fuel Drain Plug 20

Fuel Pressure Regulator Attaching Screw 3

Fuel Rail Bolts 25

Fuel Tank Undercover Retaining Bolts 36

Heated Oxygen S ens or 55

Lower Intake Manifold to Engine Block Bolts 25

Lower Intake M ani fol d to Engine Block Nuts 25

Spark Plugs 18

Throttle Body Mounting B olts 10

Common C ham ber t o Lower Intake Mani fold Bo lts 25

VSS R etainin g Bolt 16

DIAGRAMS AND SCHEMATICS

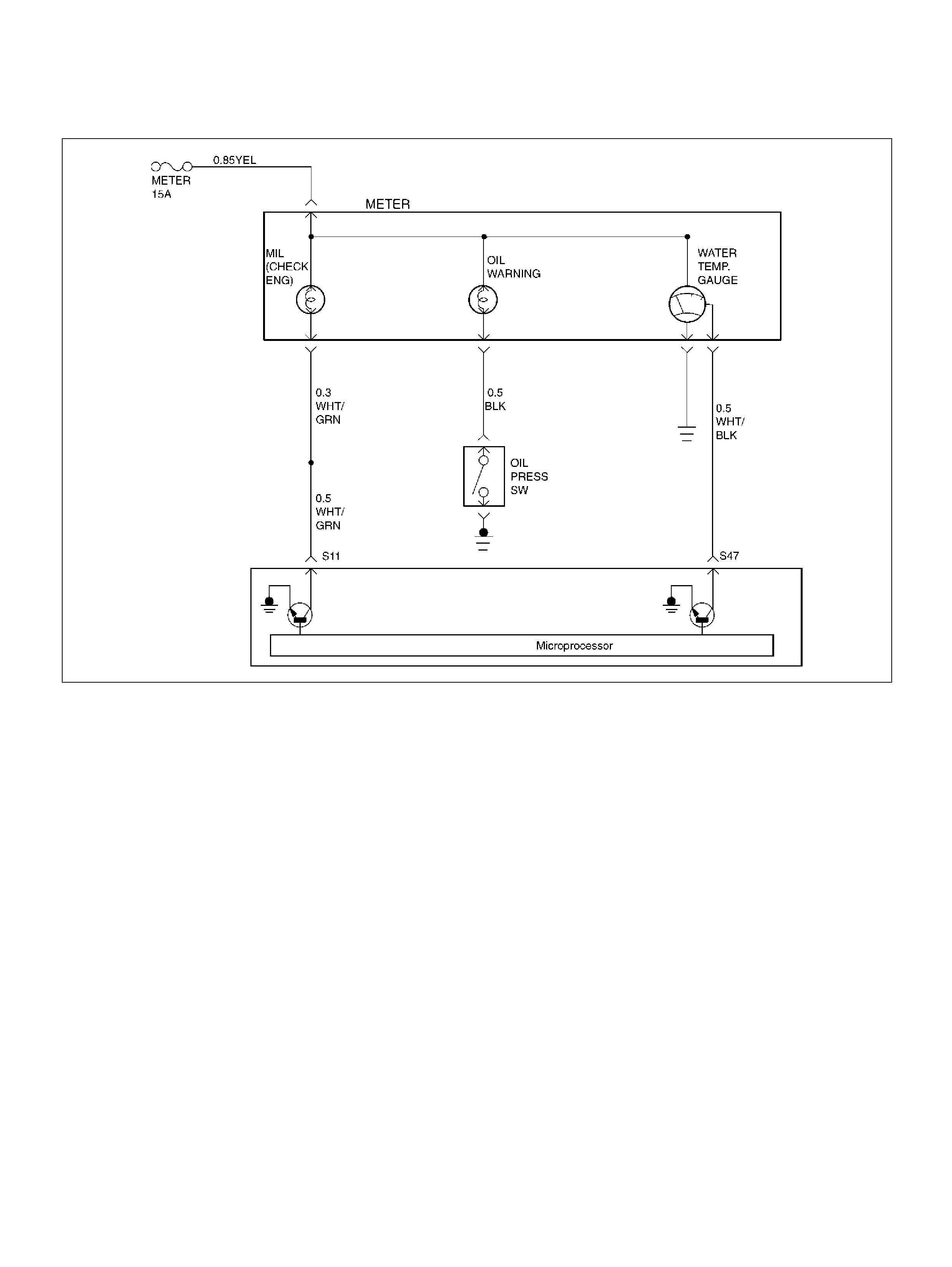

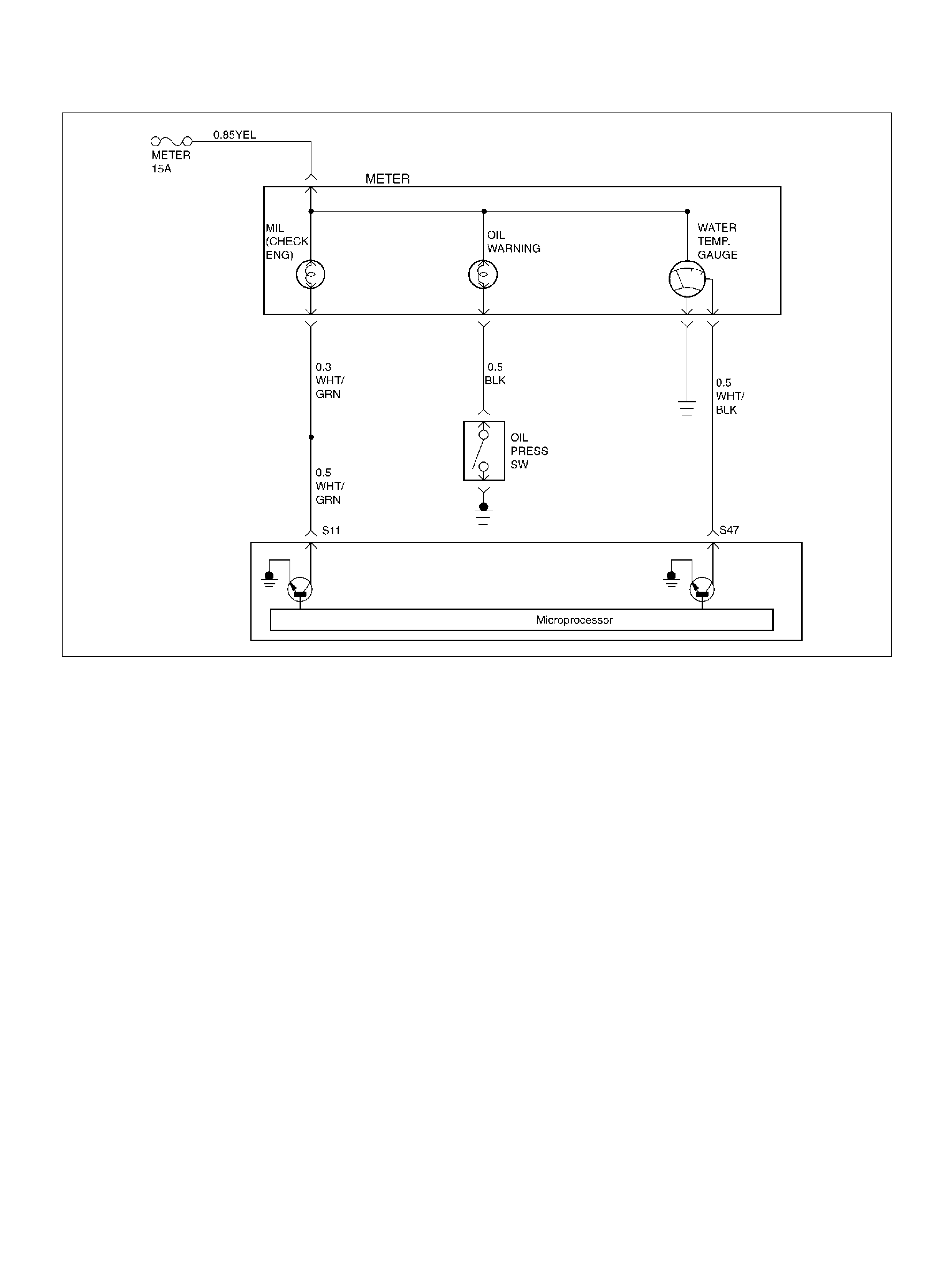

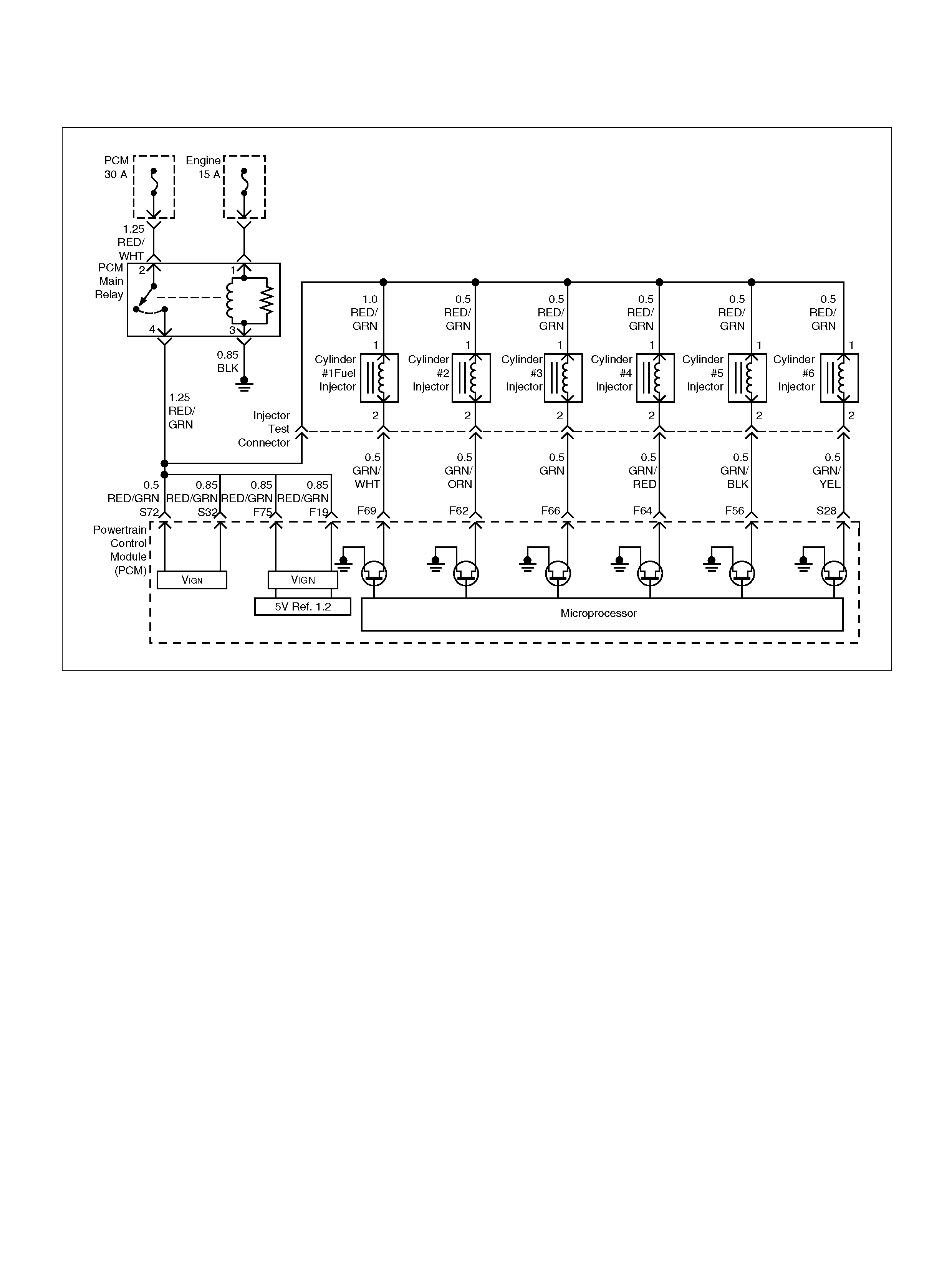

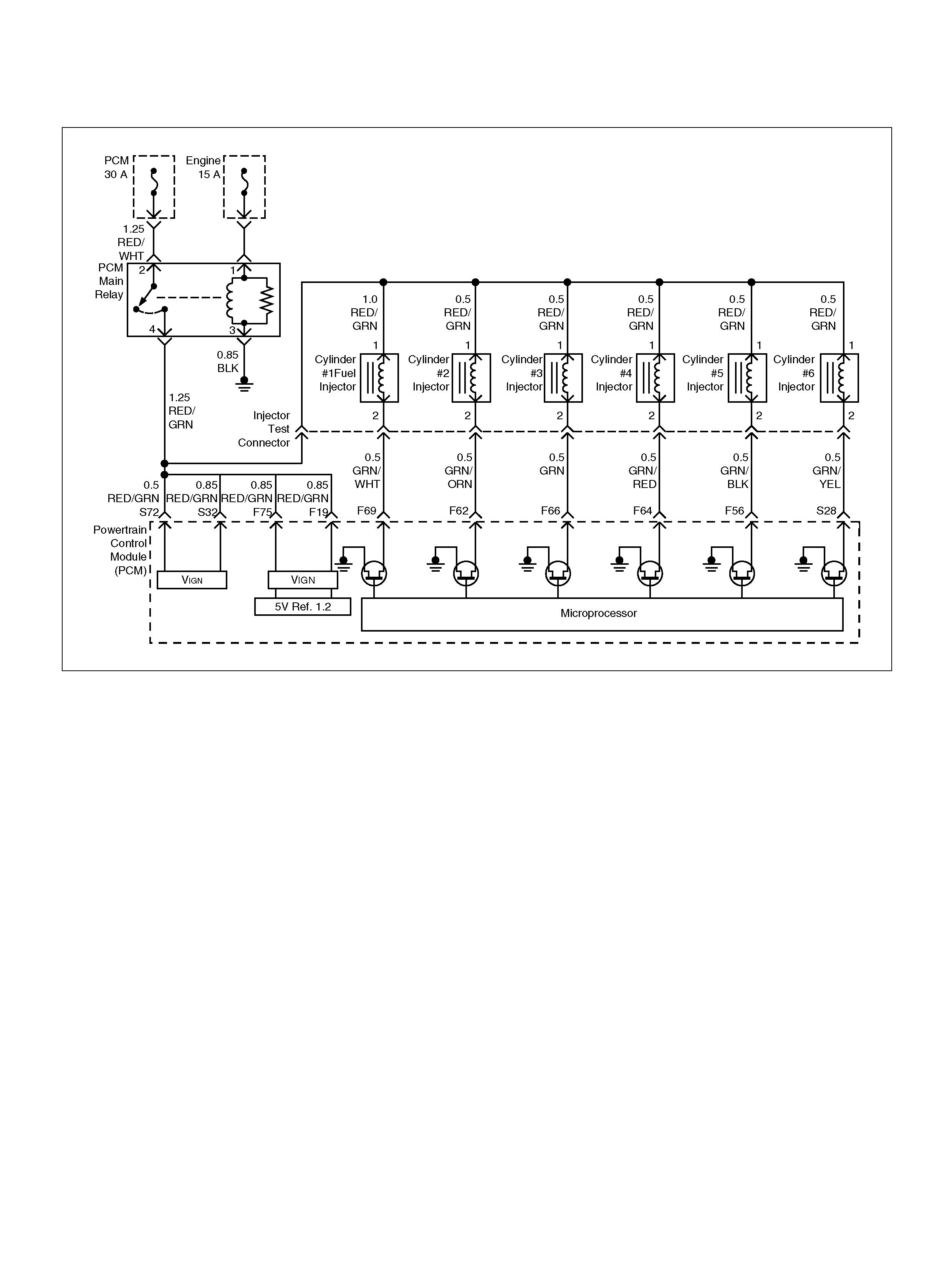

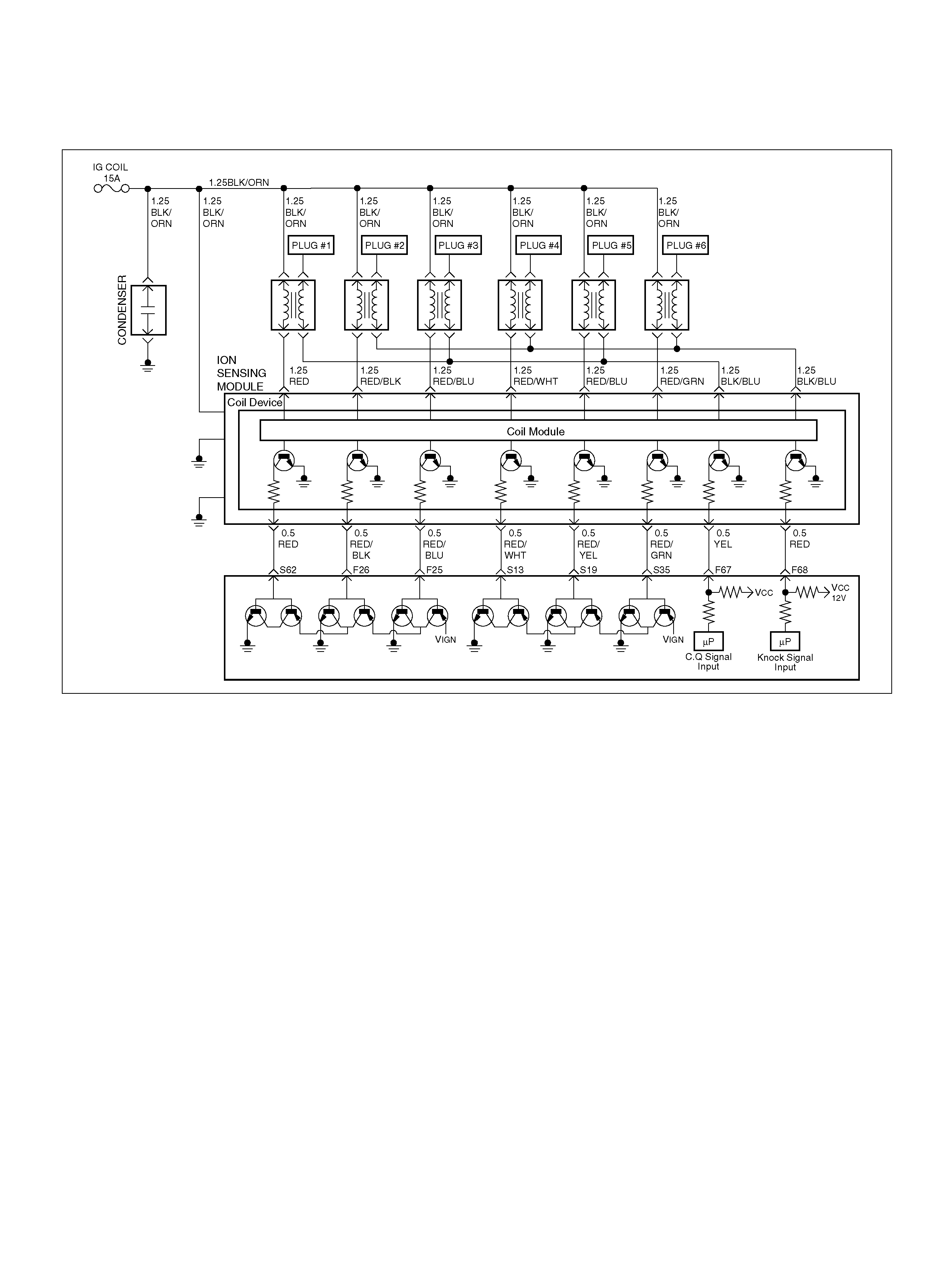

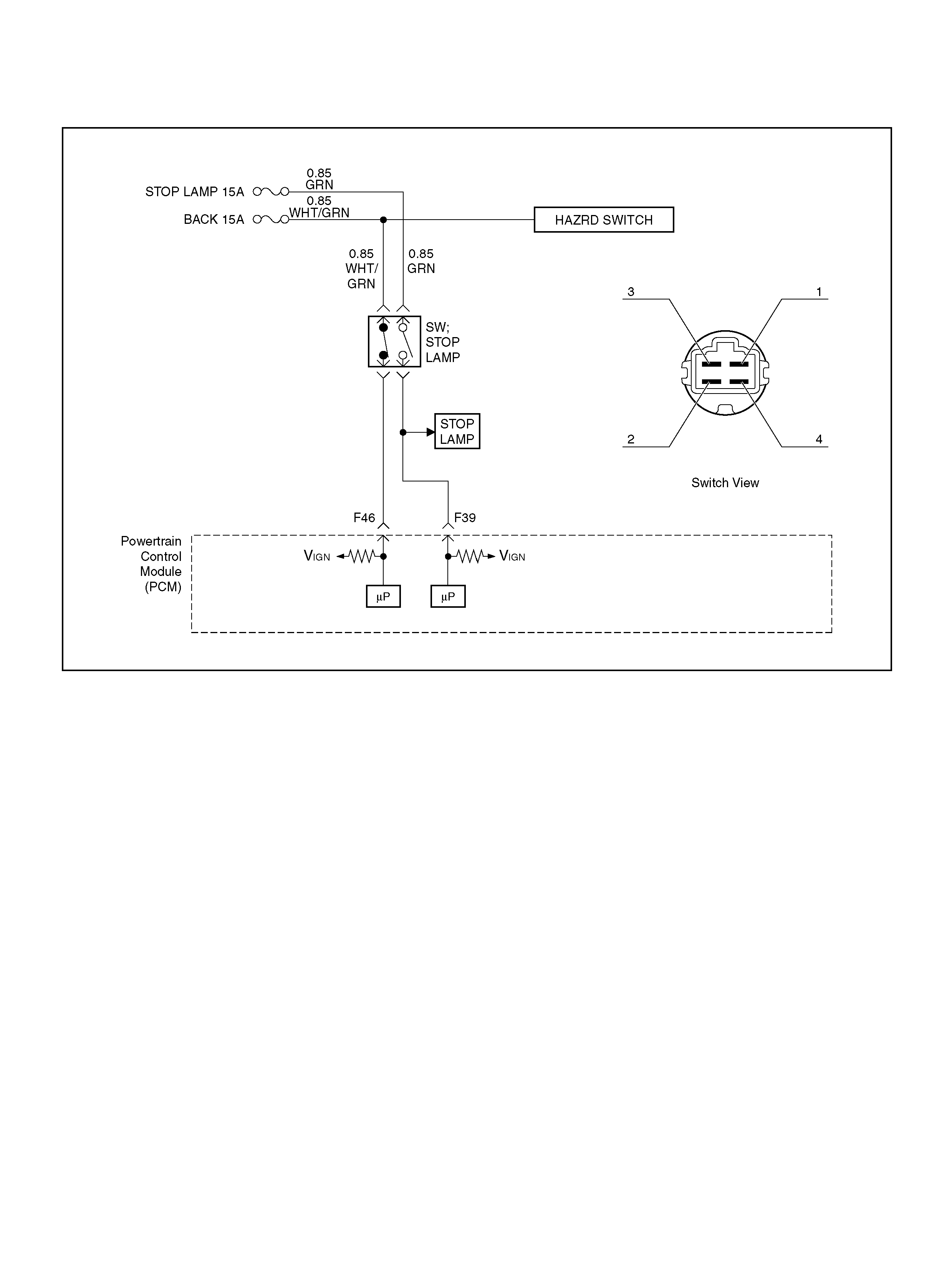

PCM WIRING DIAGRAM (1 OF 7)

060R100120

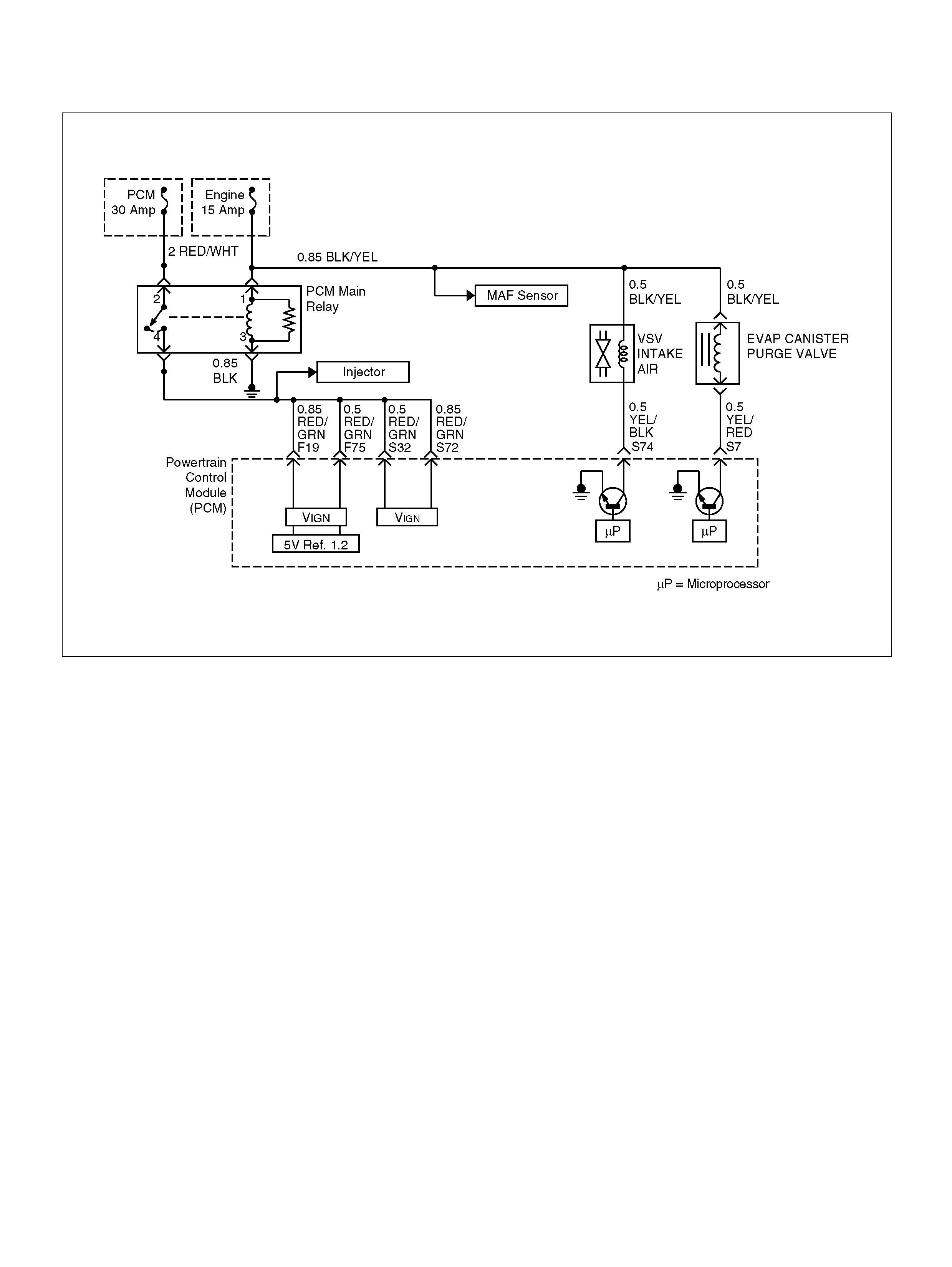

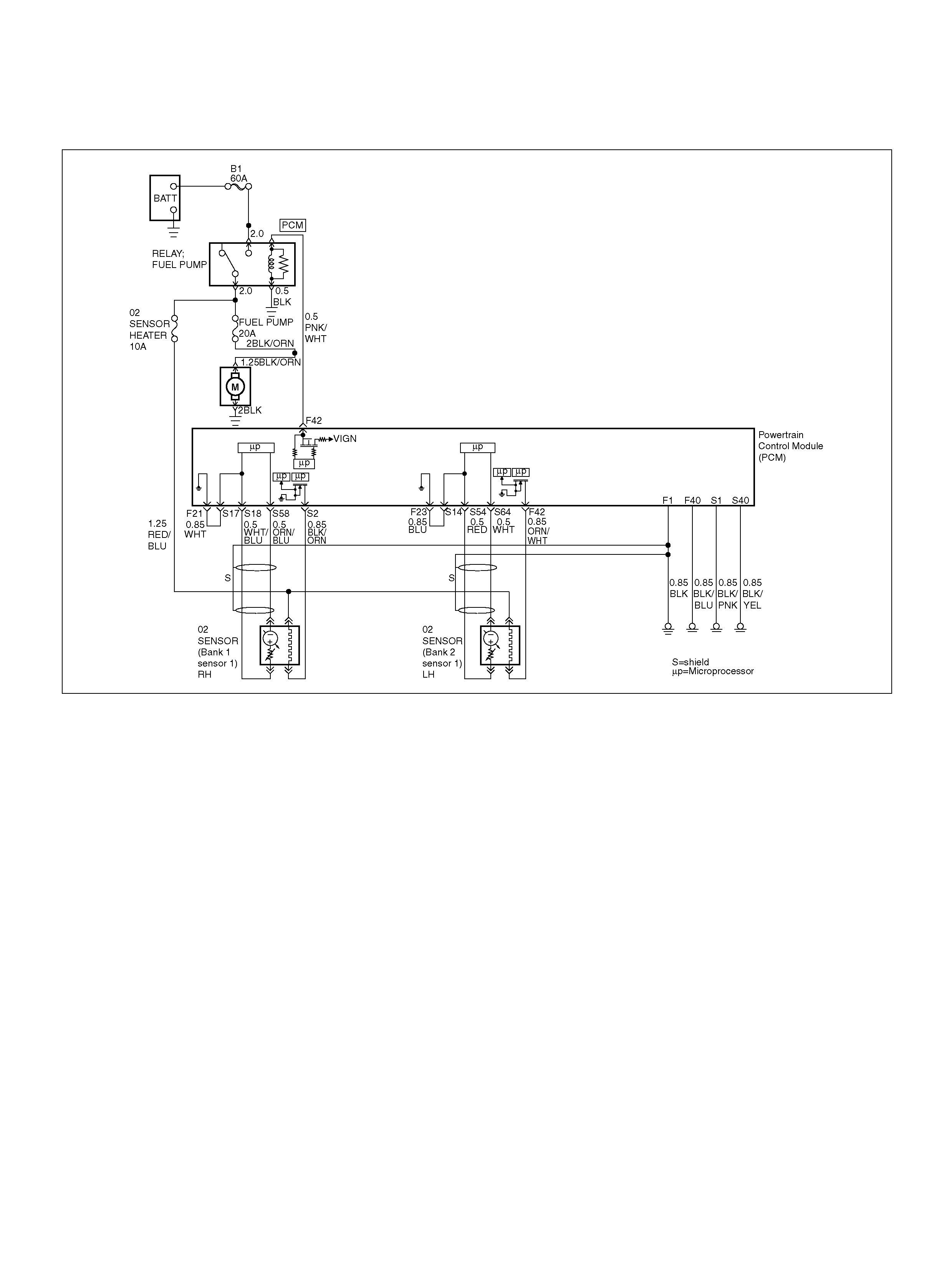

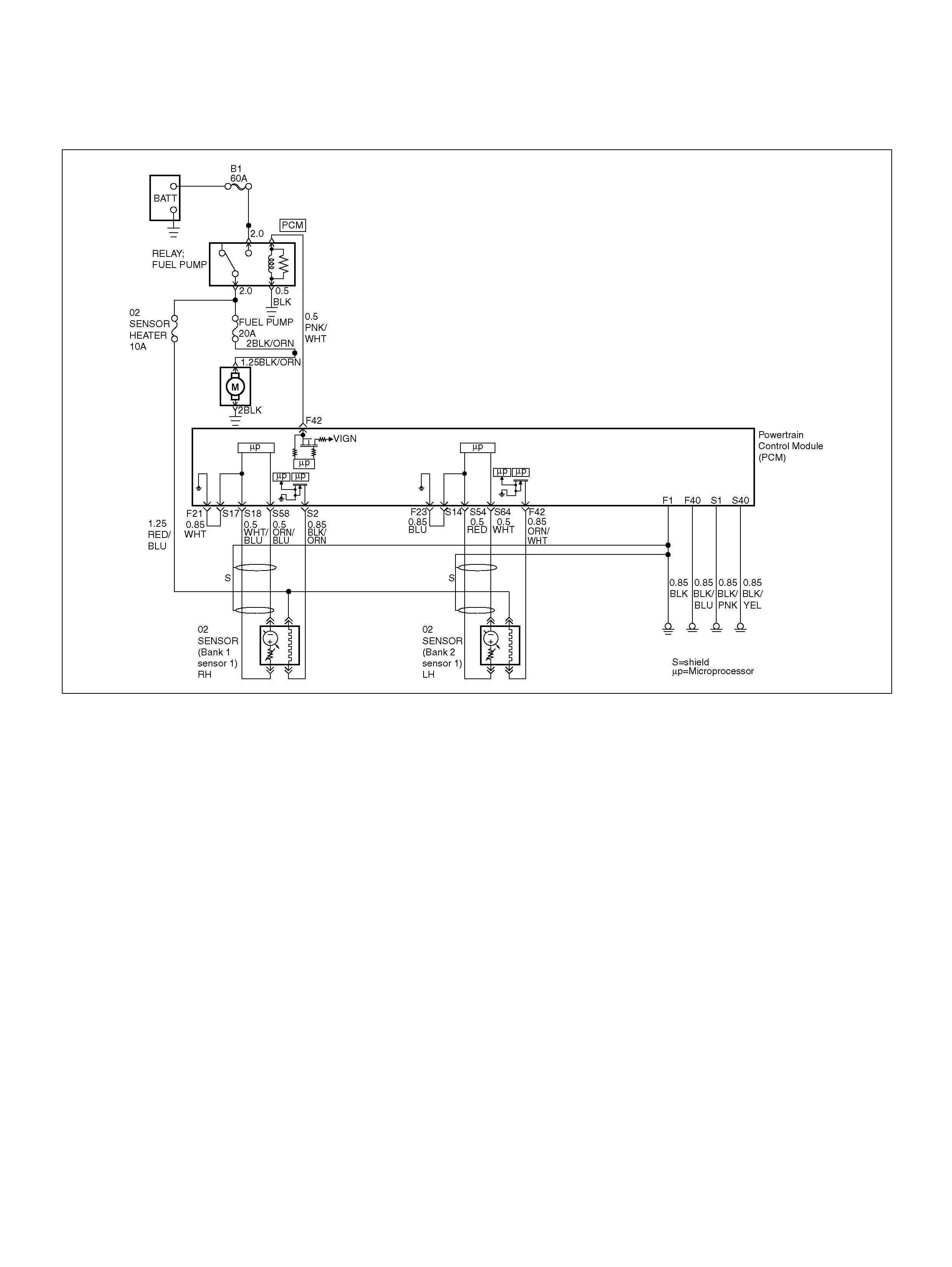

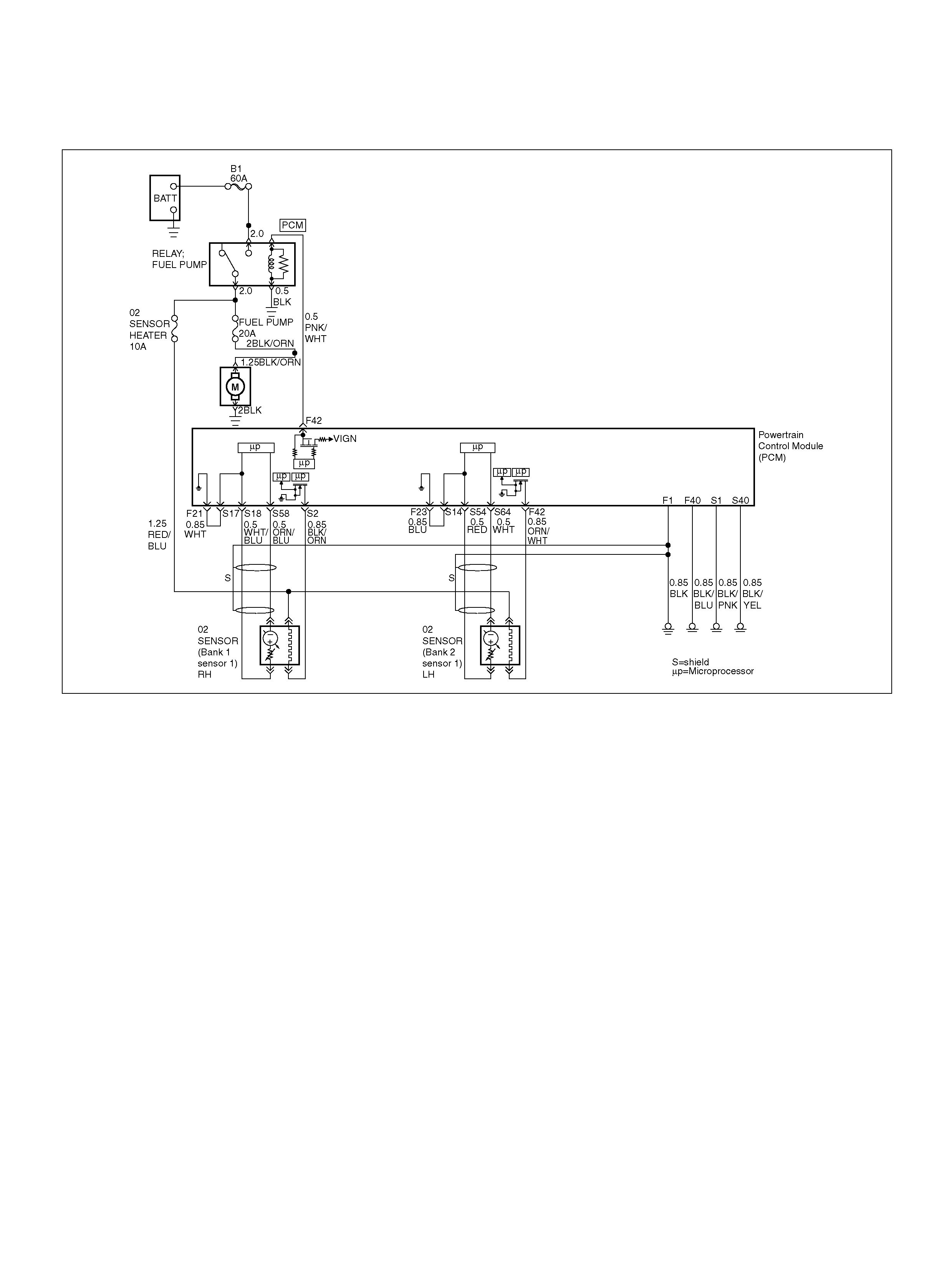

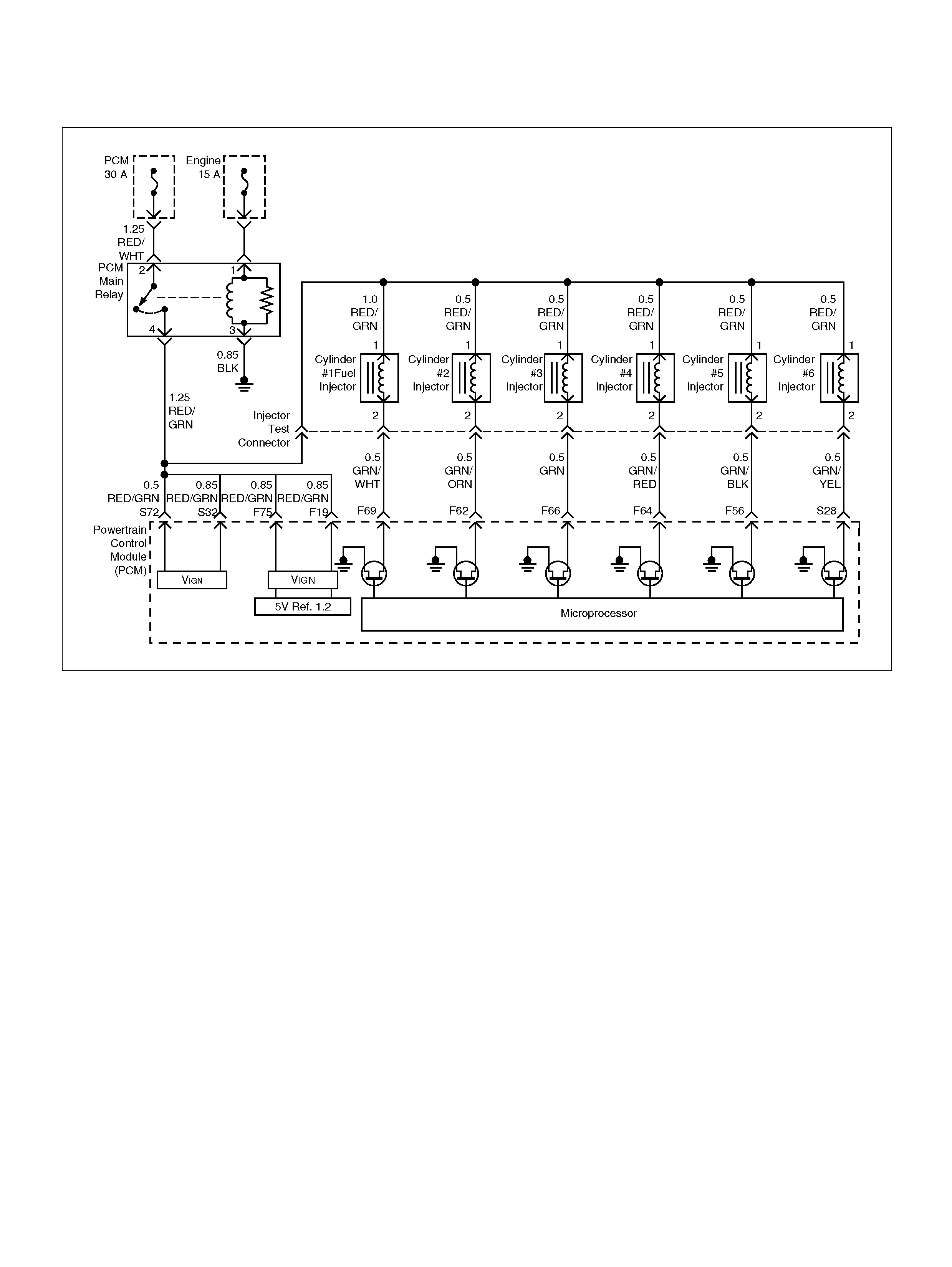

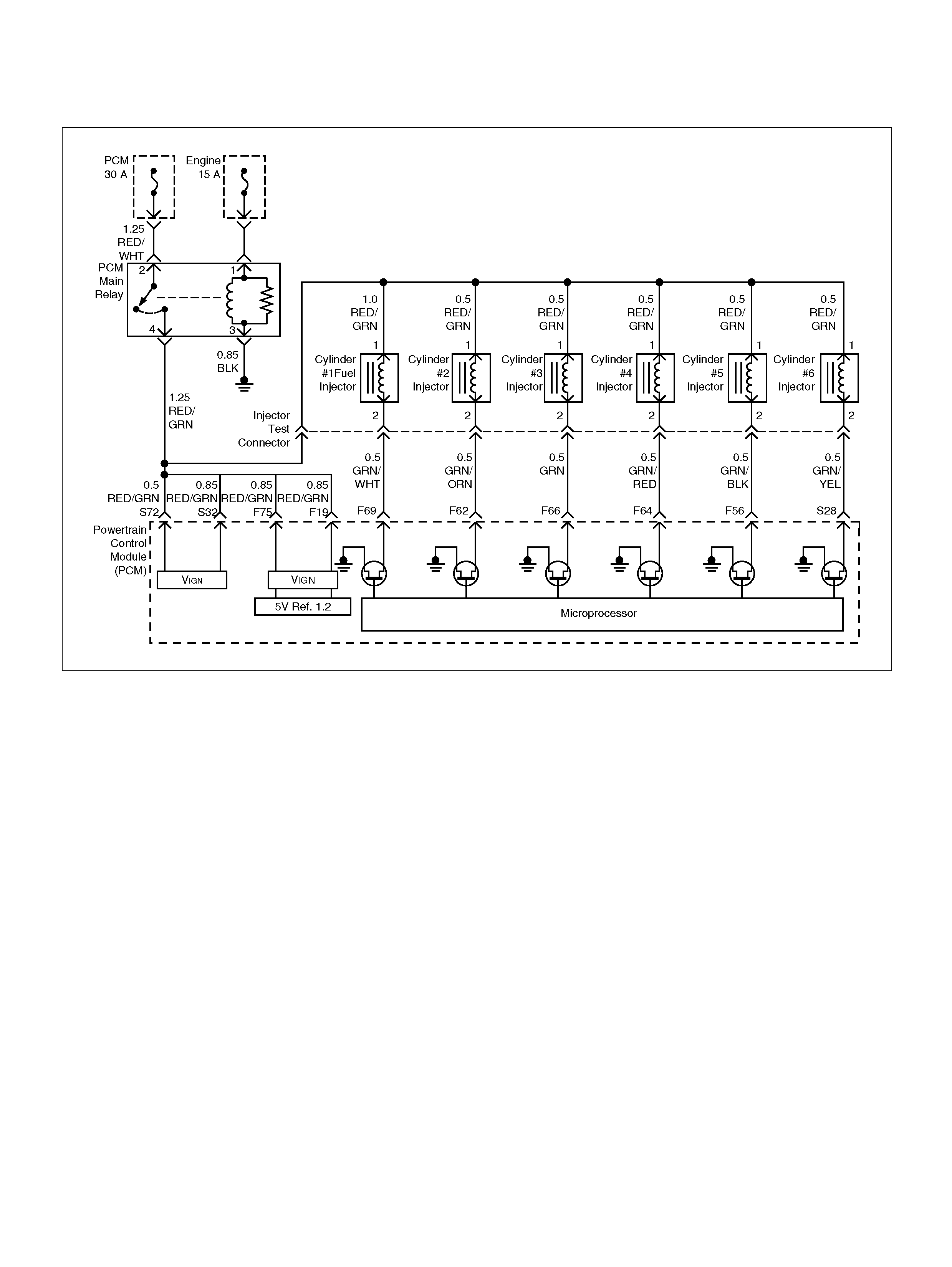

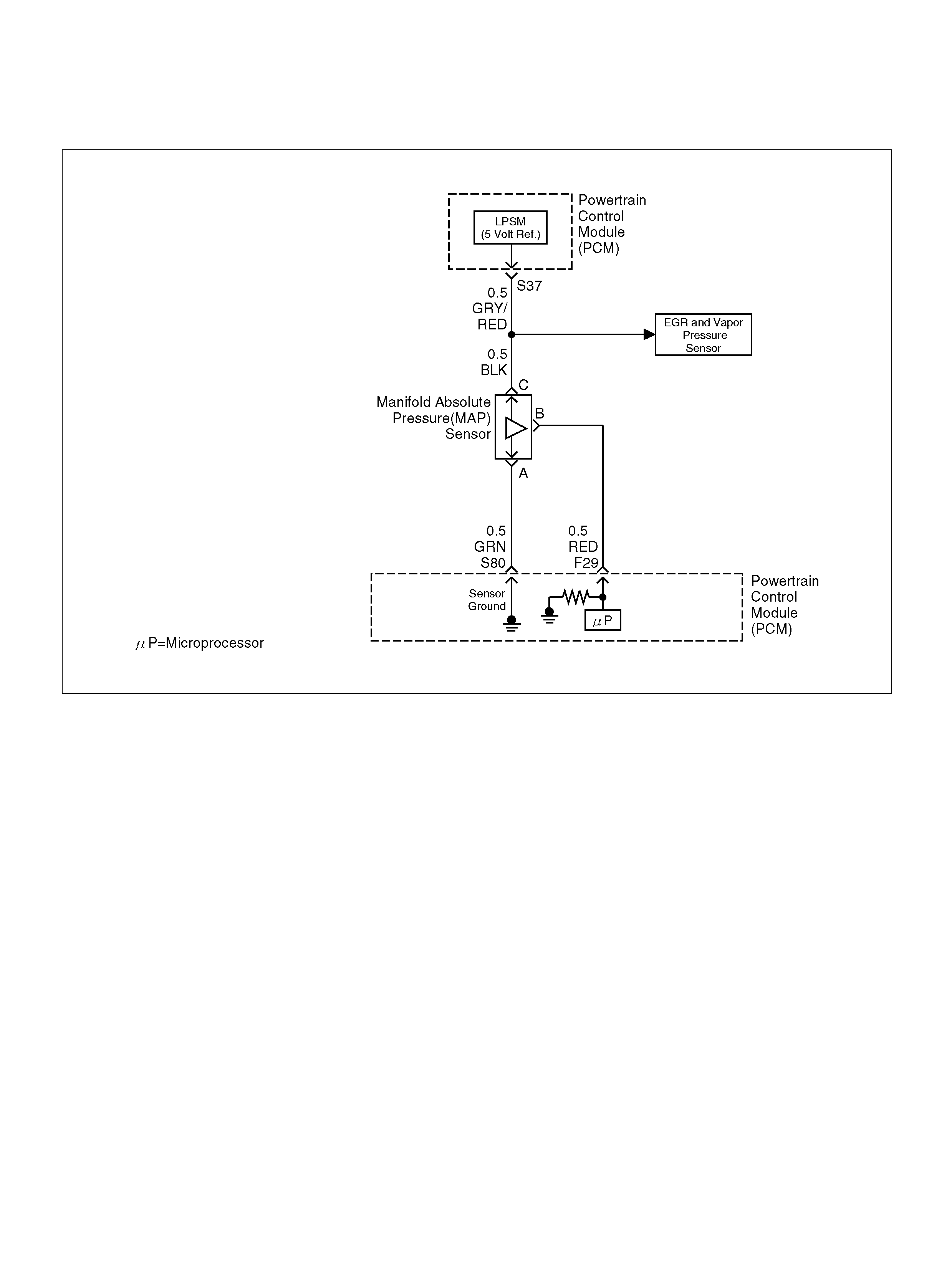

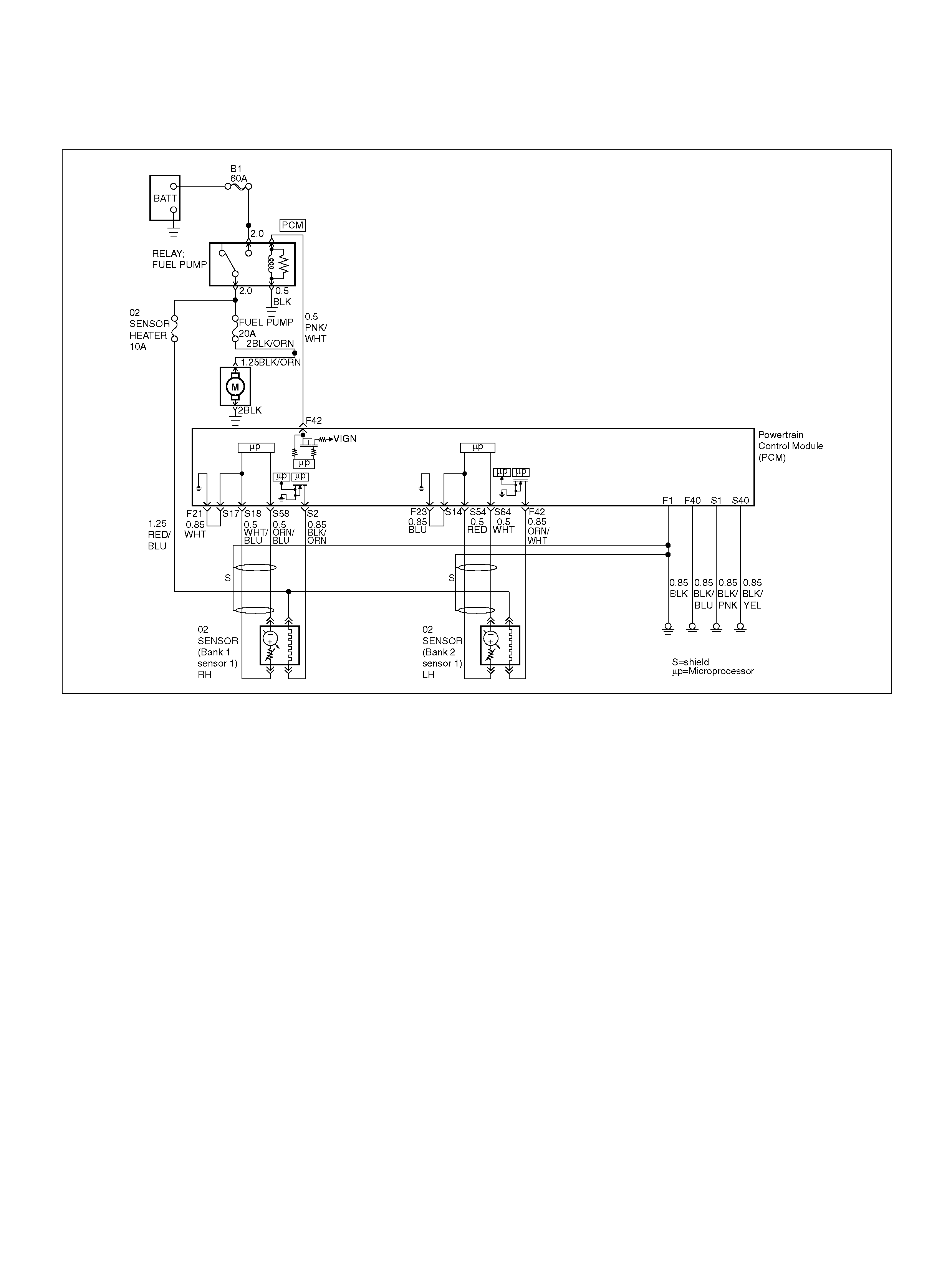

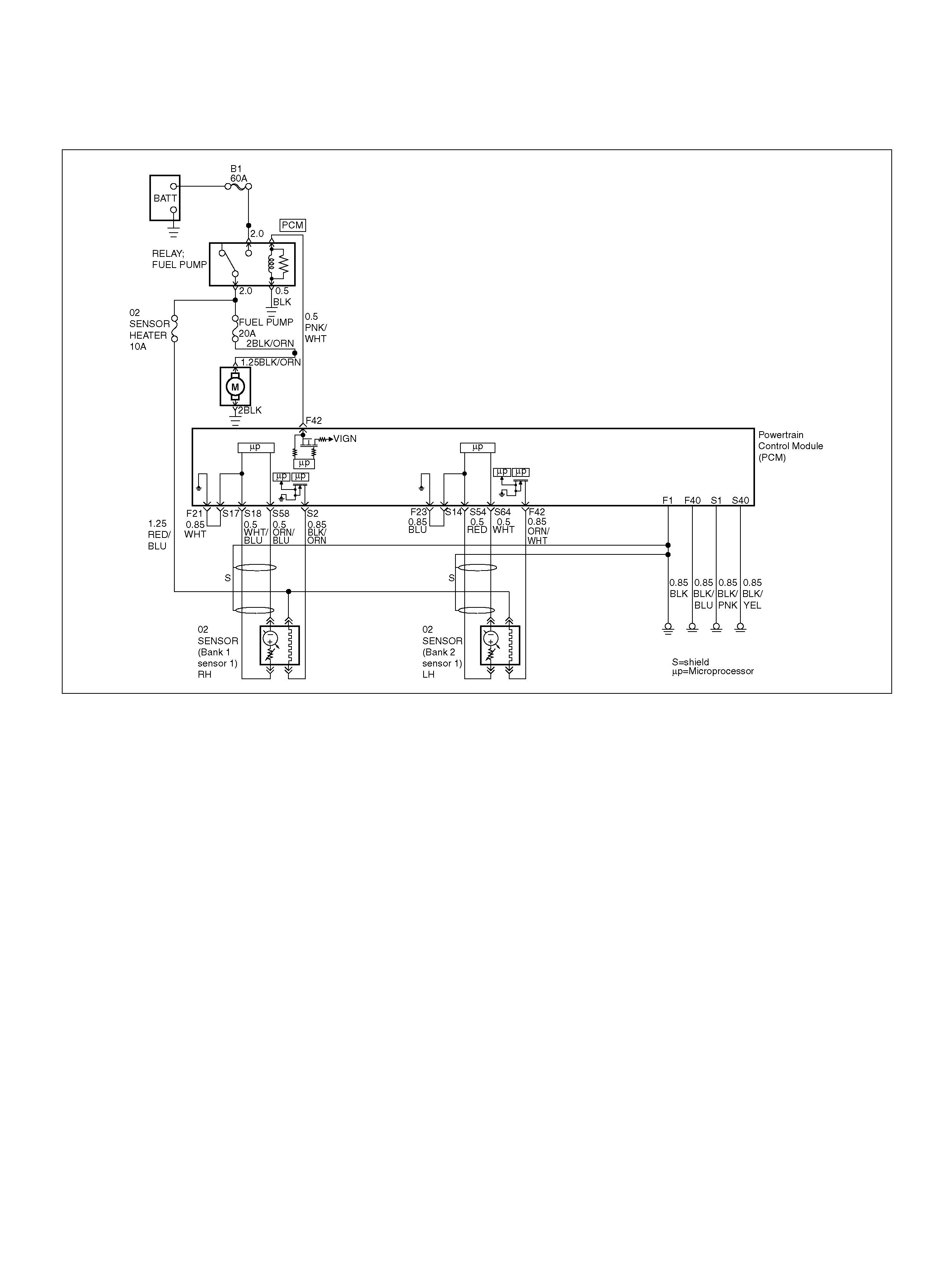

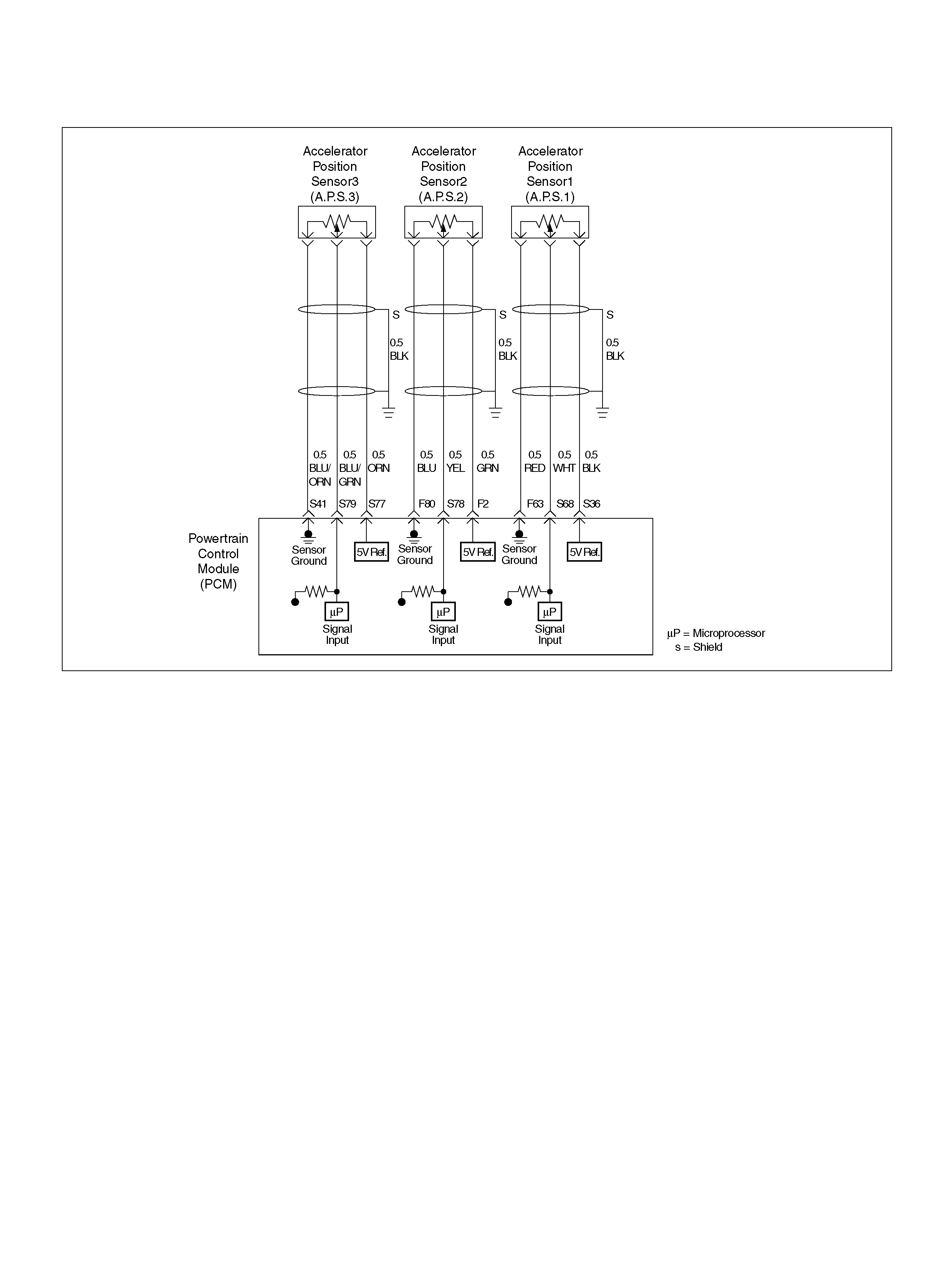

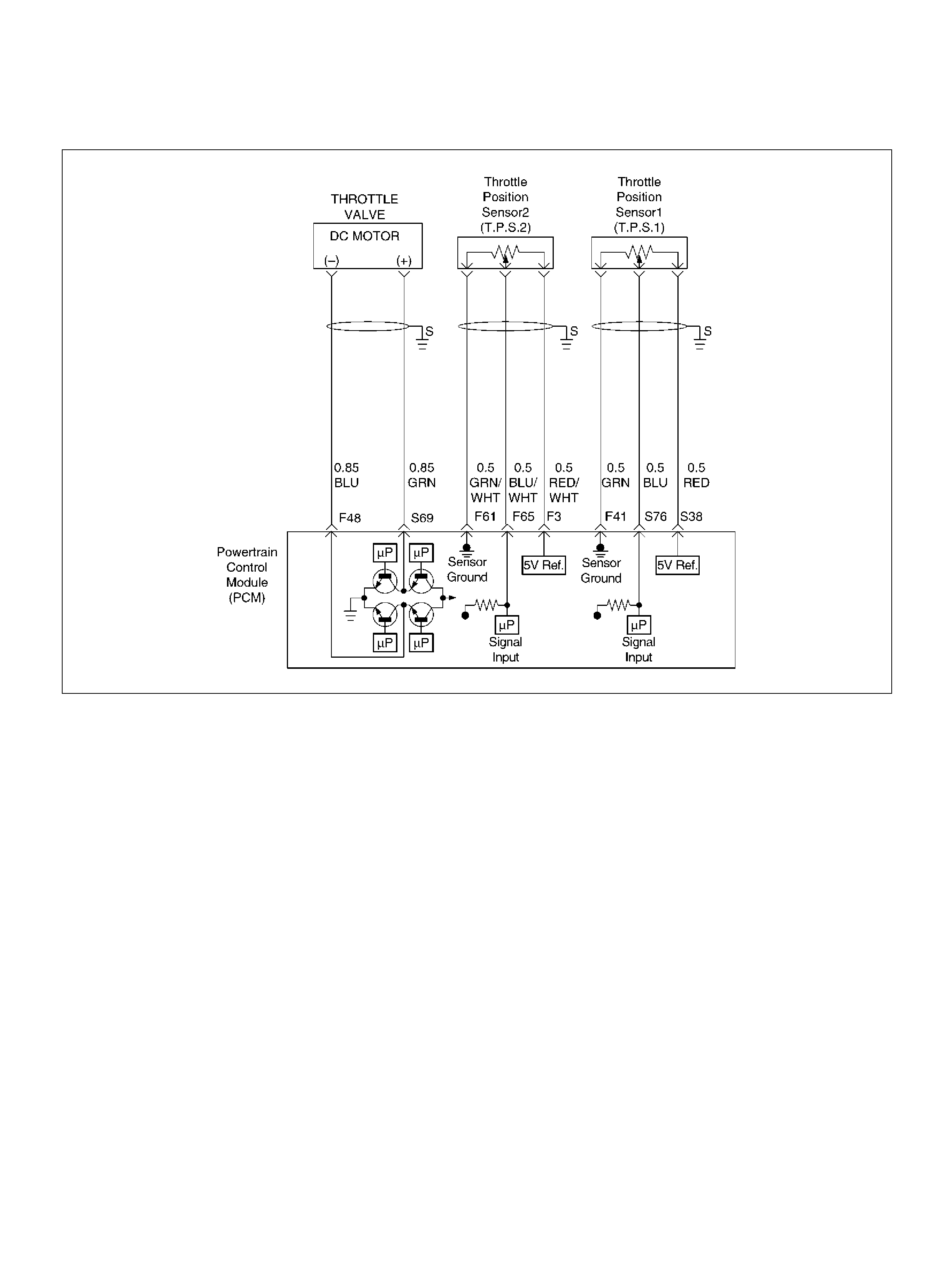

PCM WIRING DIAGRAM (2 OF 7)

060R100121

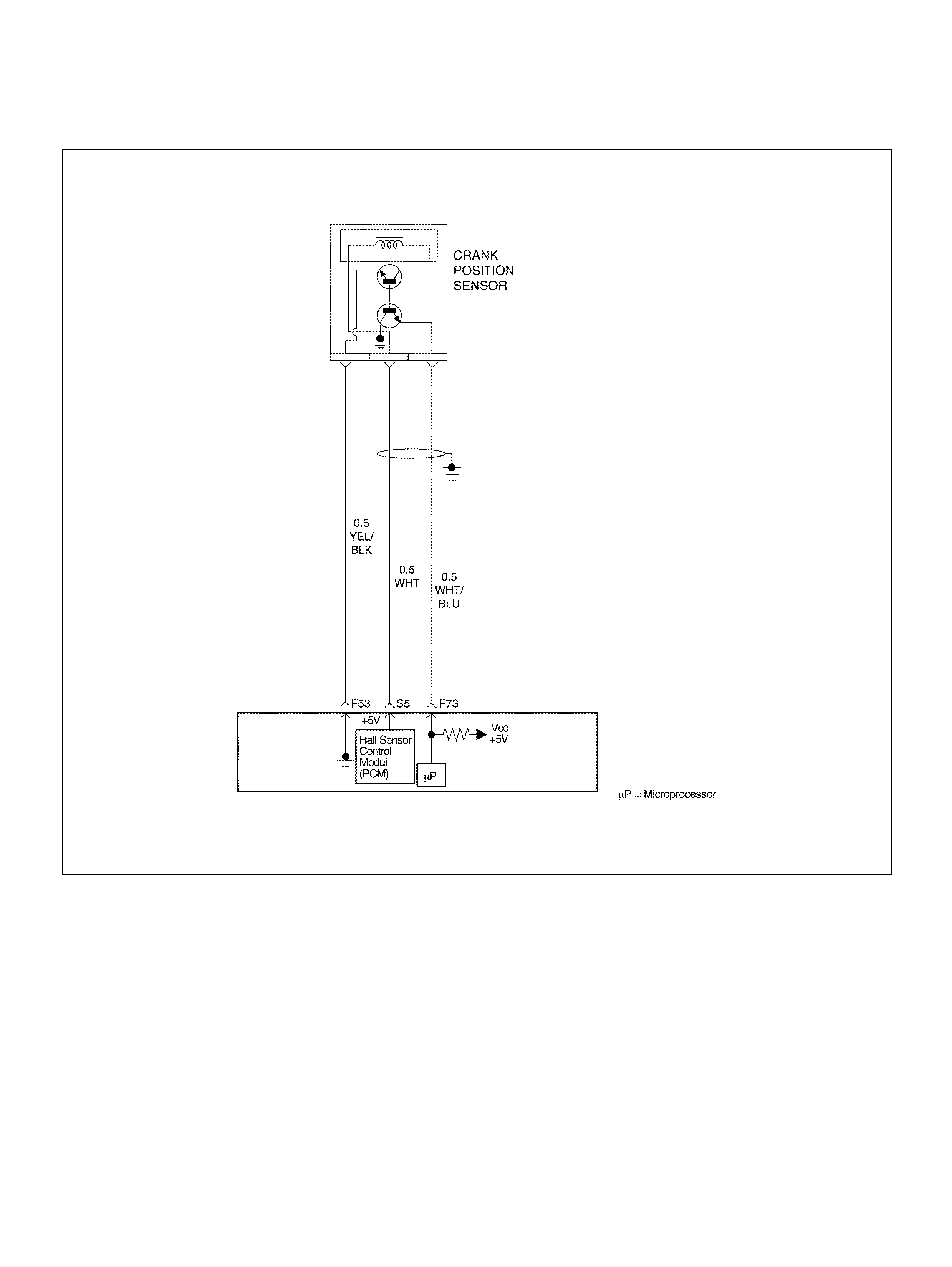

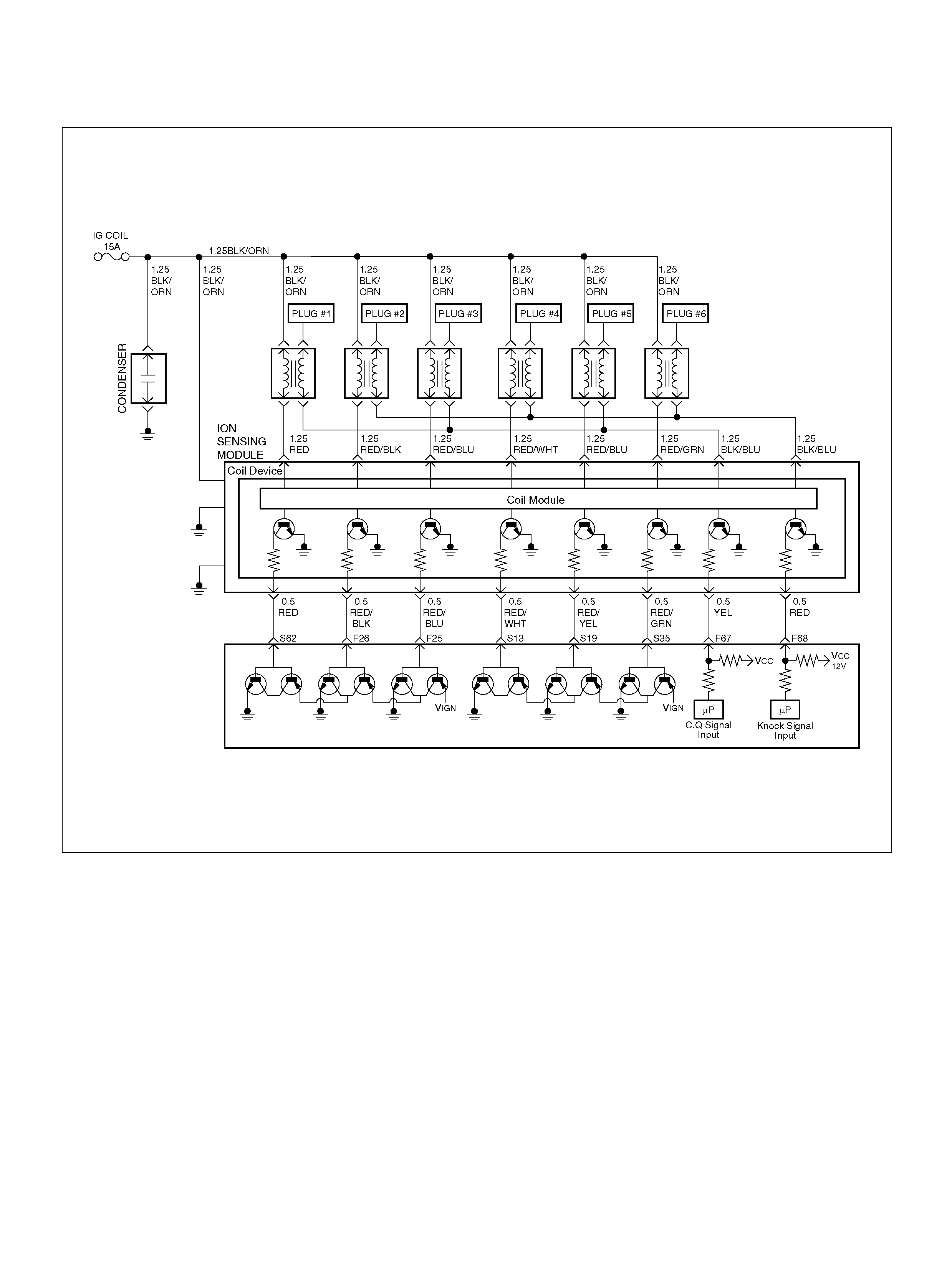

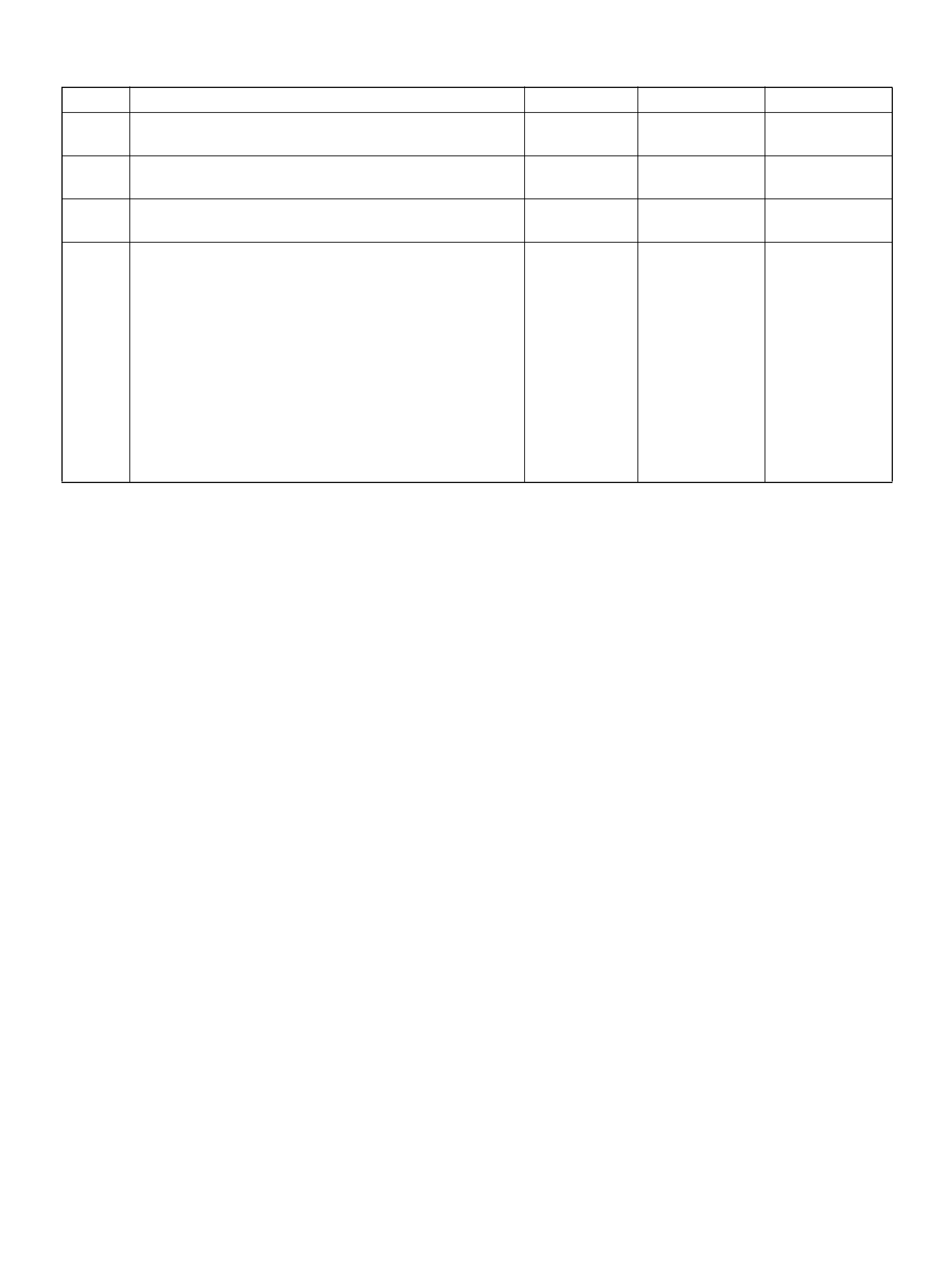

PCM WIRING DIAGRAM (3 OF 7)

060R100122

STATE

CAPACITOR

SOLID

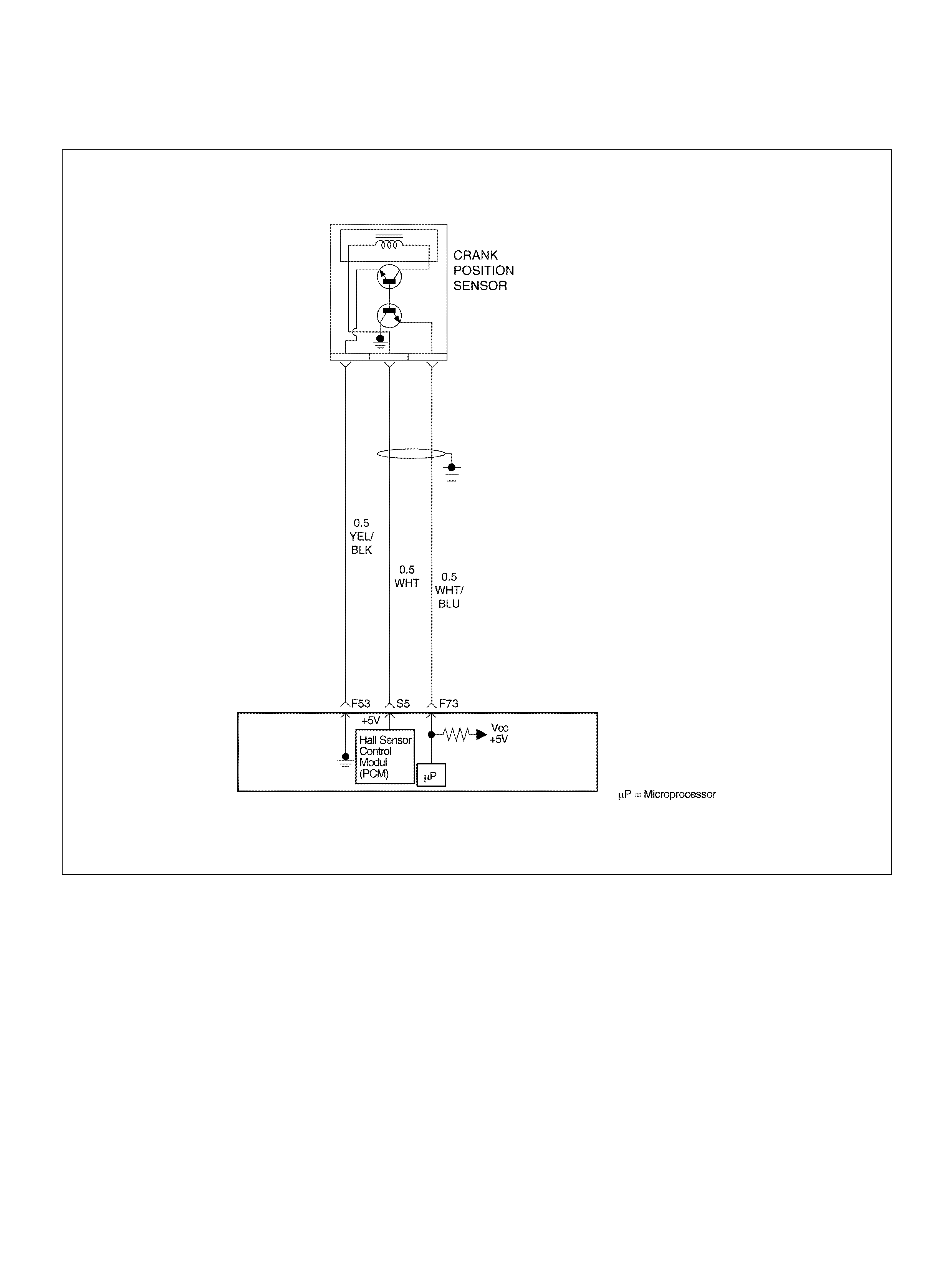

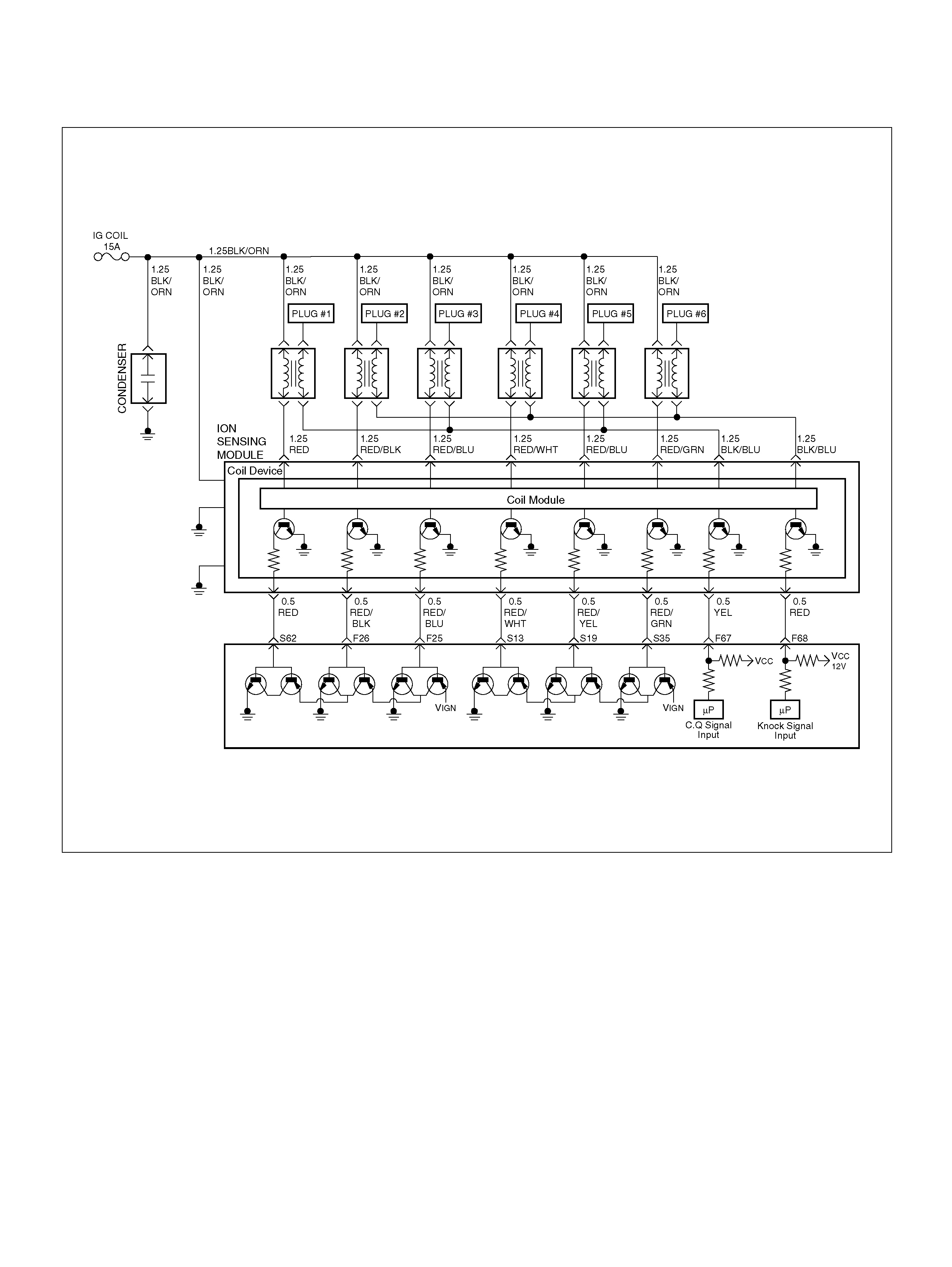

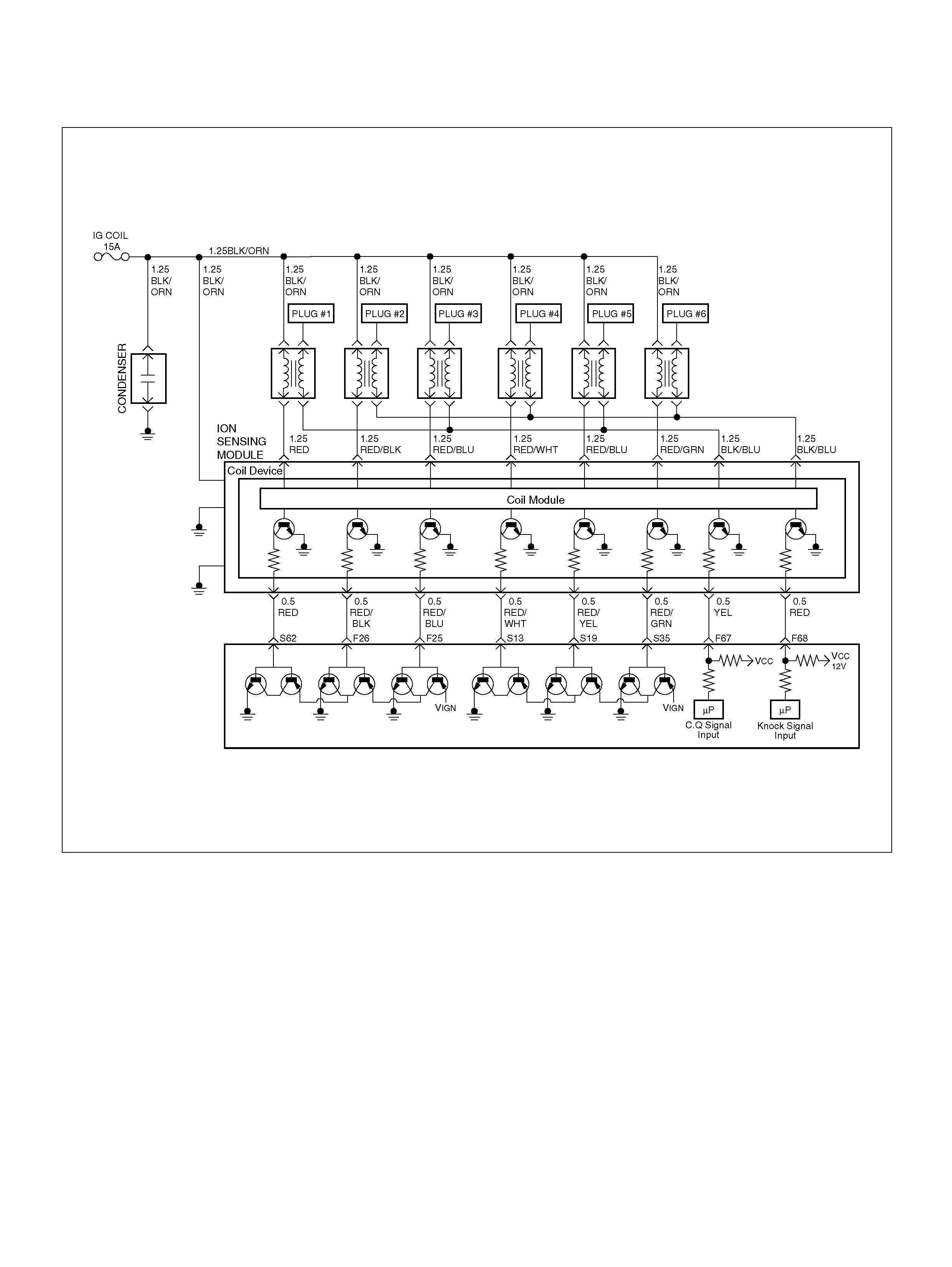

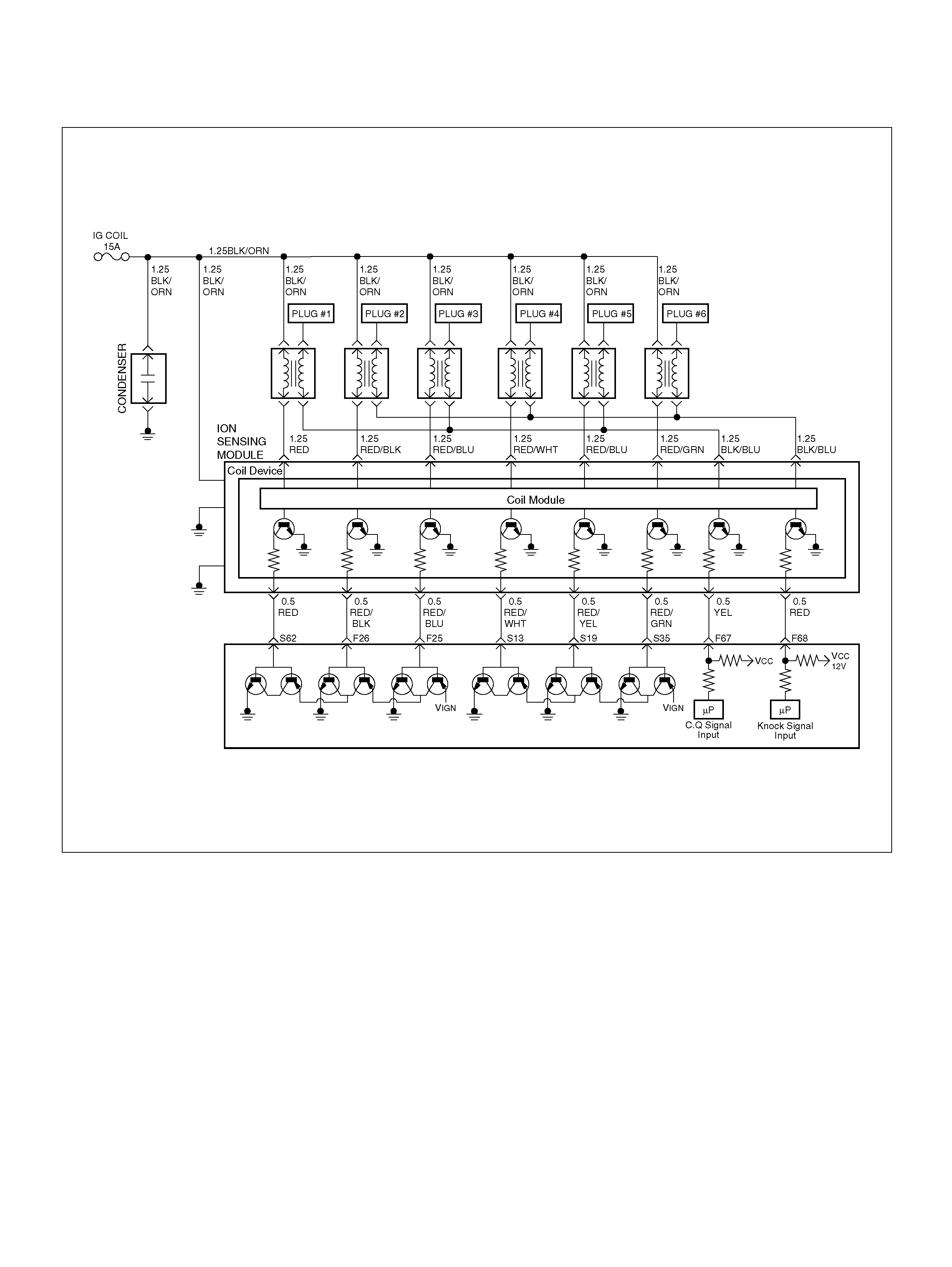

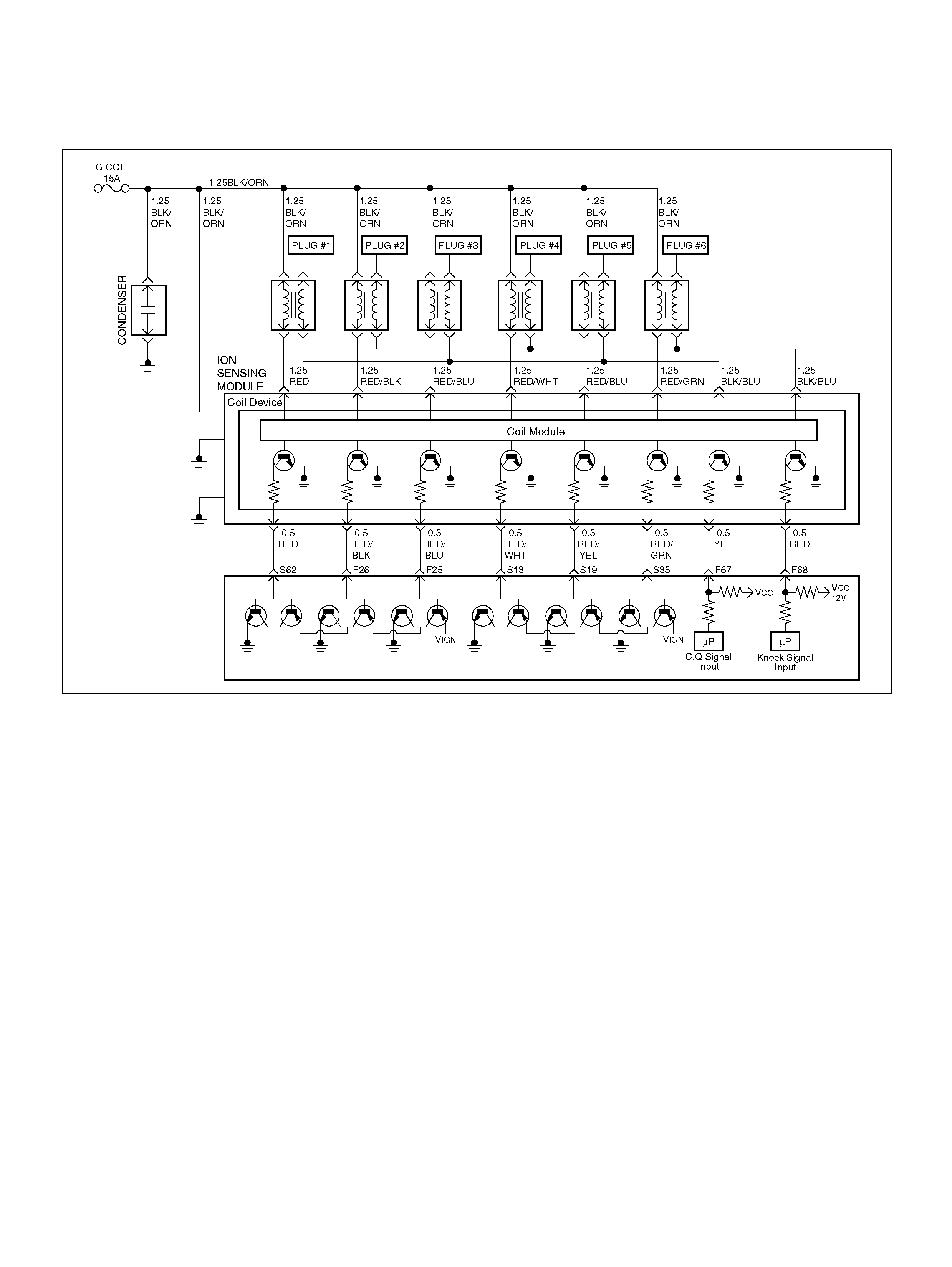

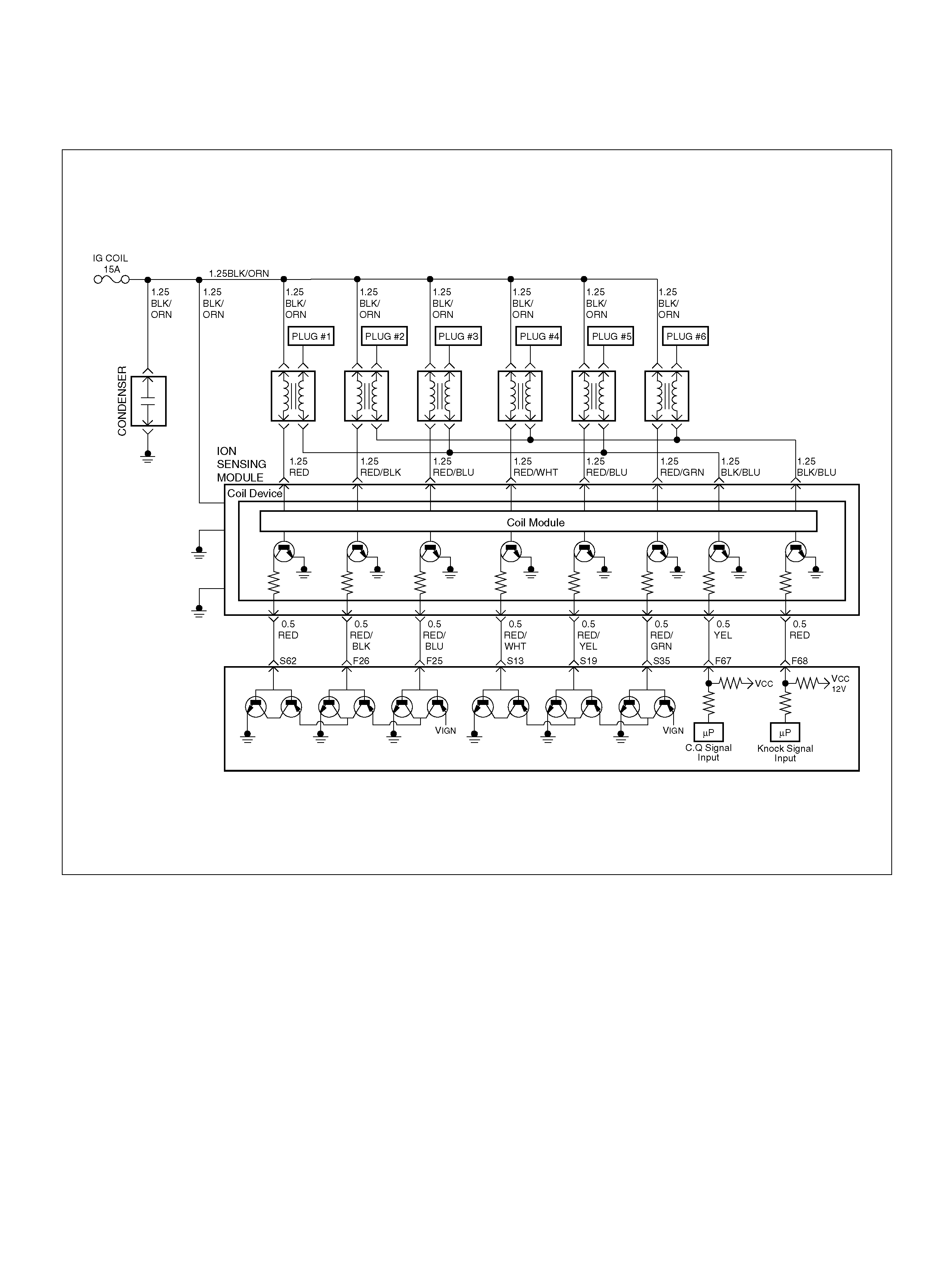

PCM WIRING DIAGRAM (4 OF 7)

060R100123

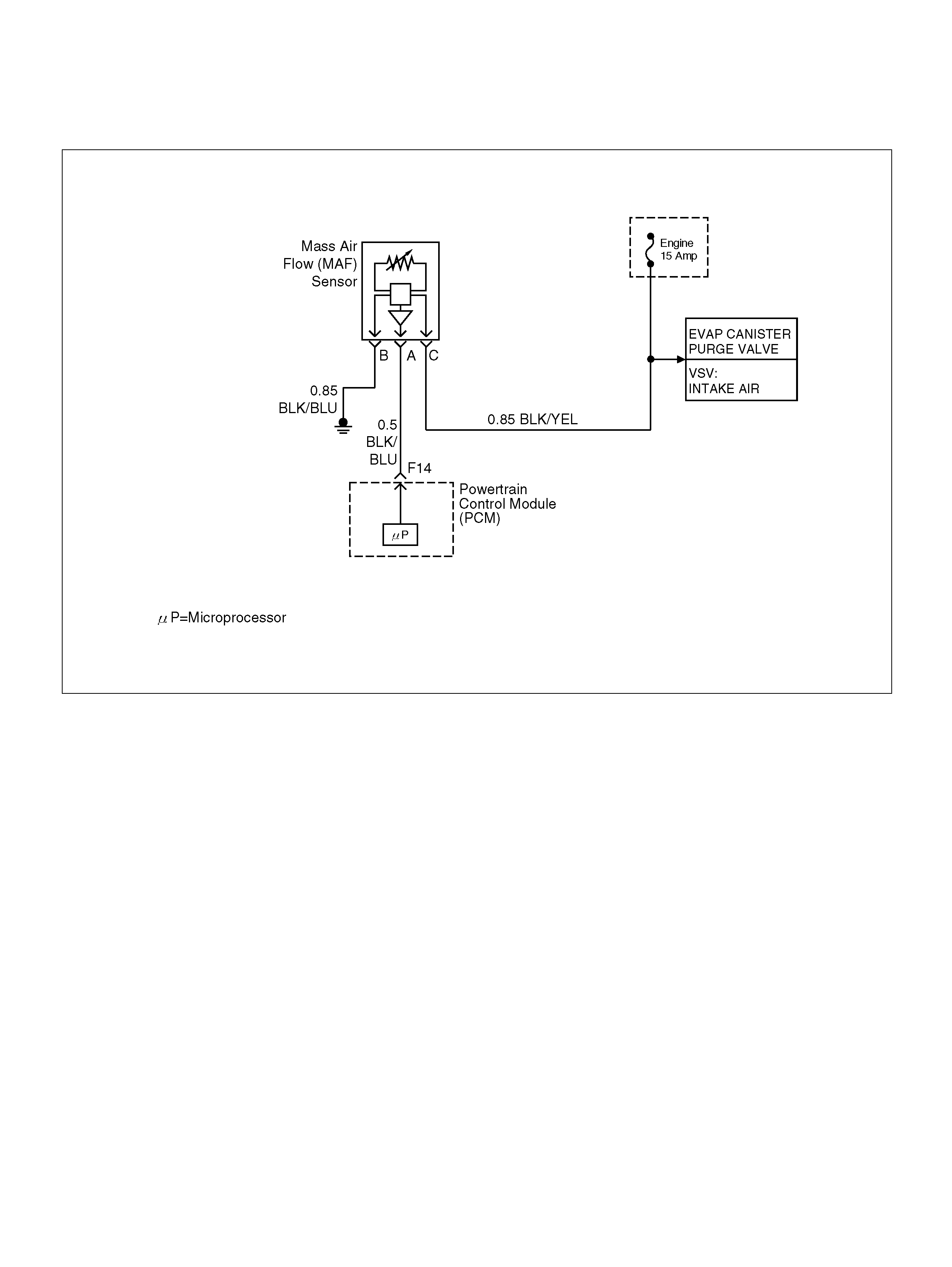

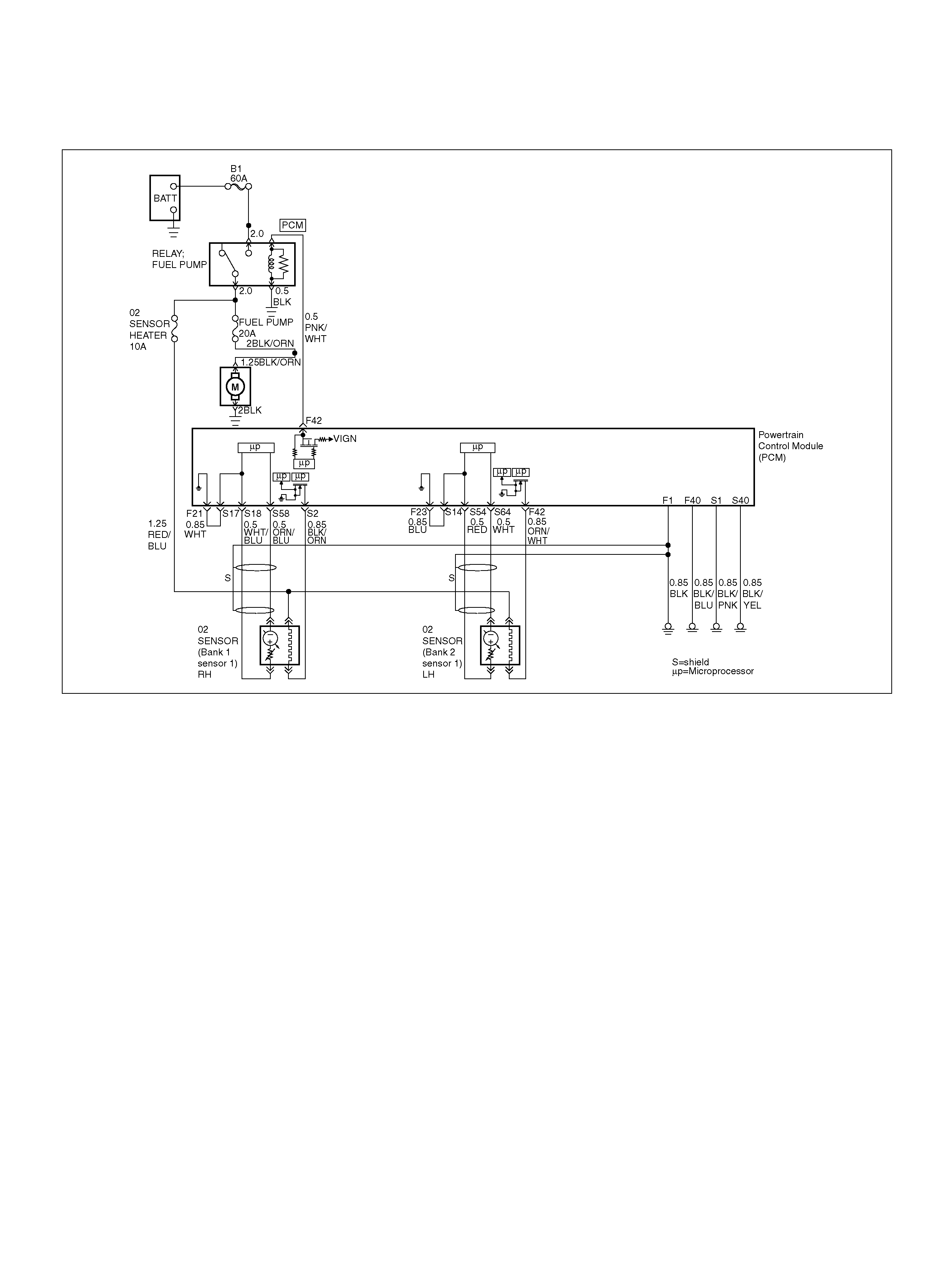

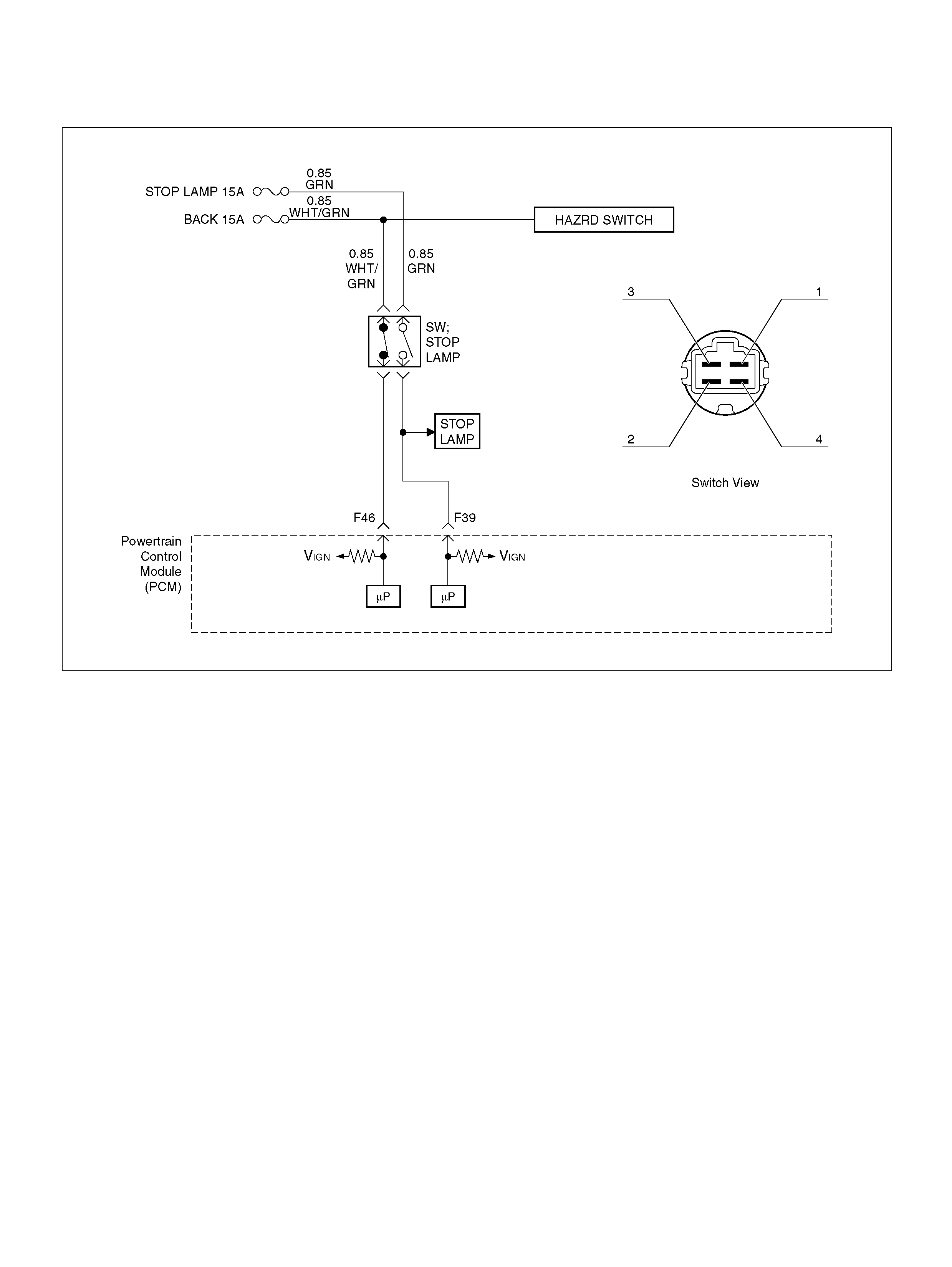

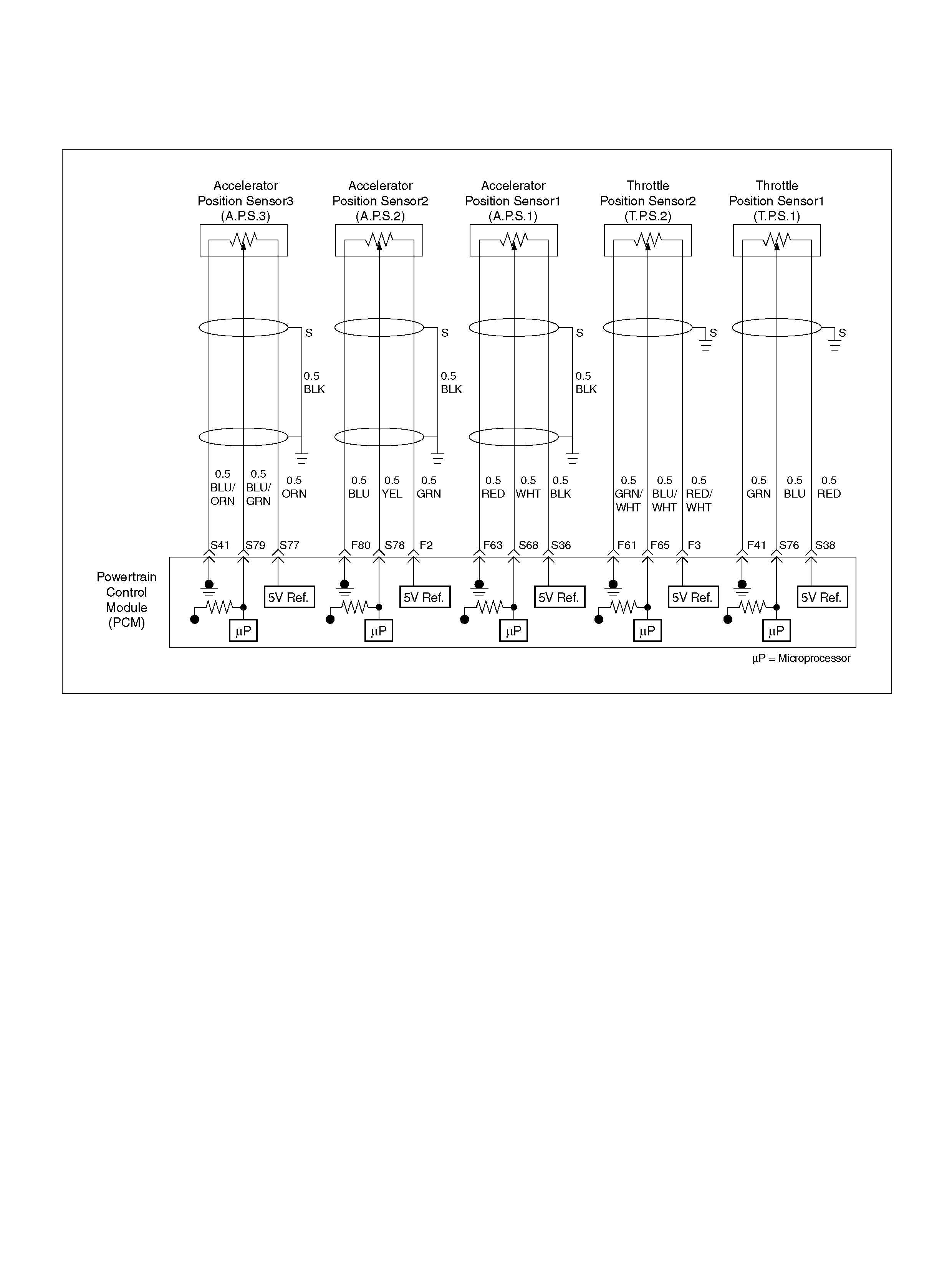

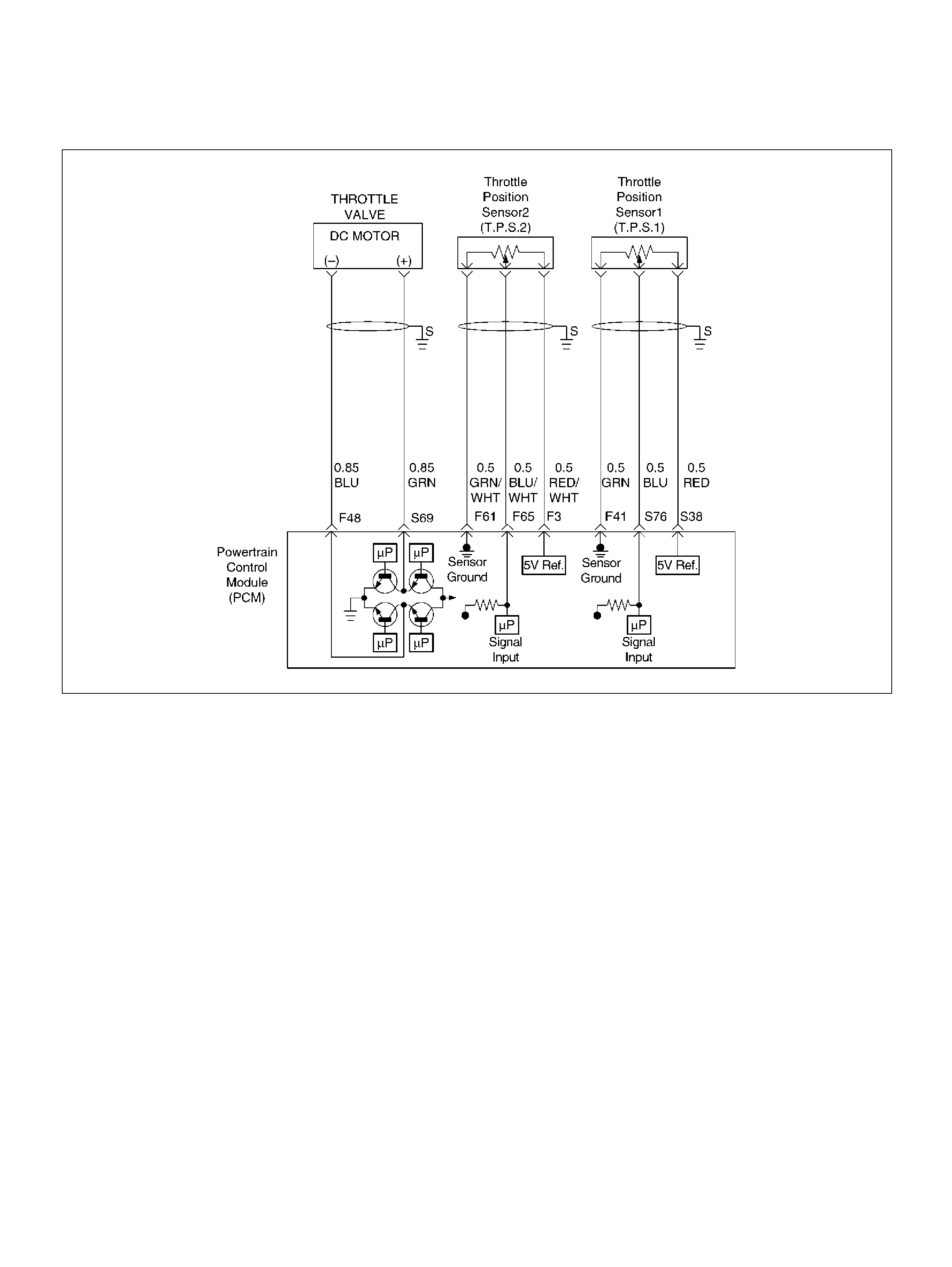

PCM WIRING DIAGRAM (5 OF 7) 060R100124

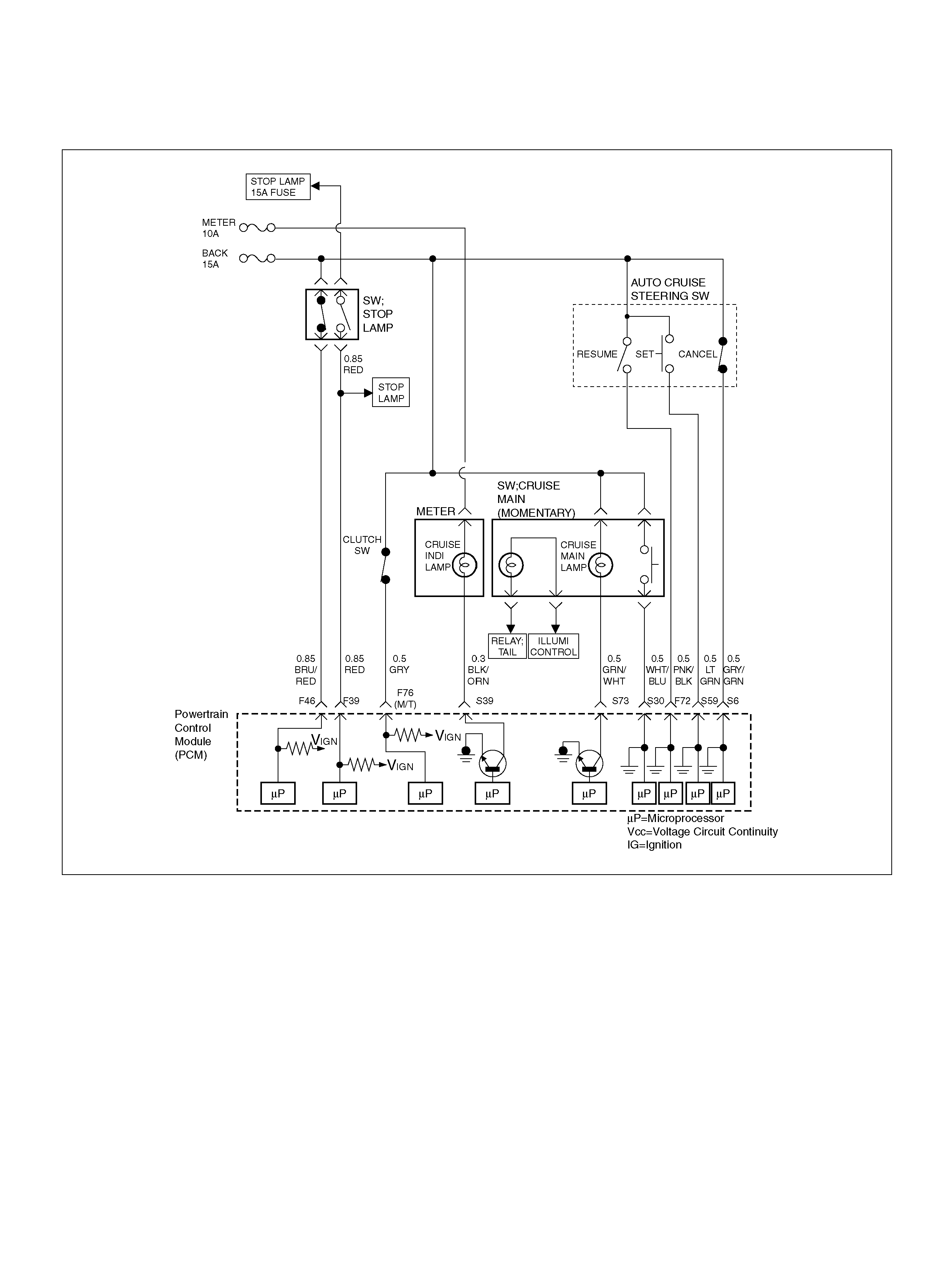

PCM WIRING DIAGRAM (6 OF 7)

060R100125

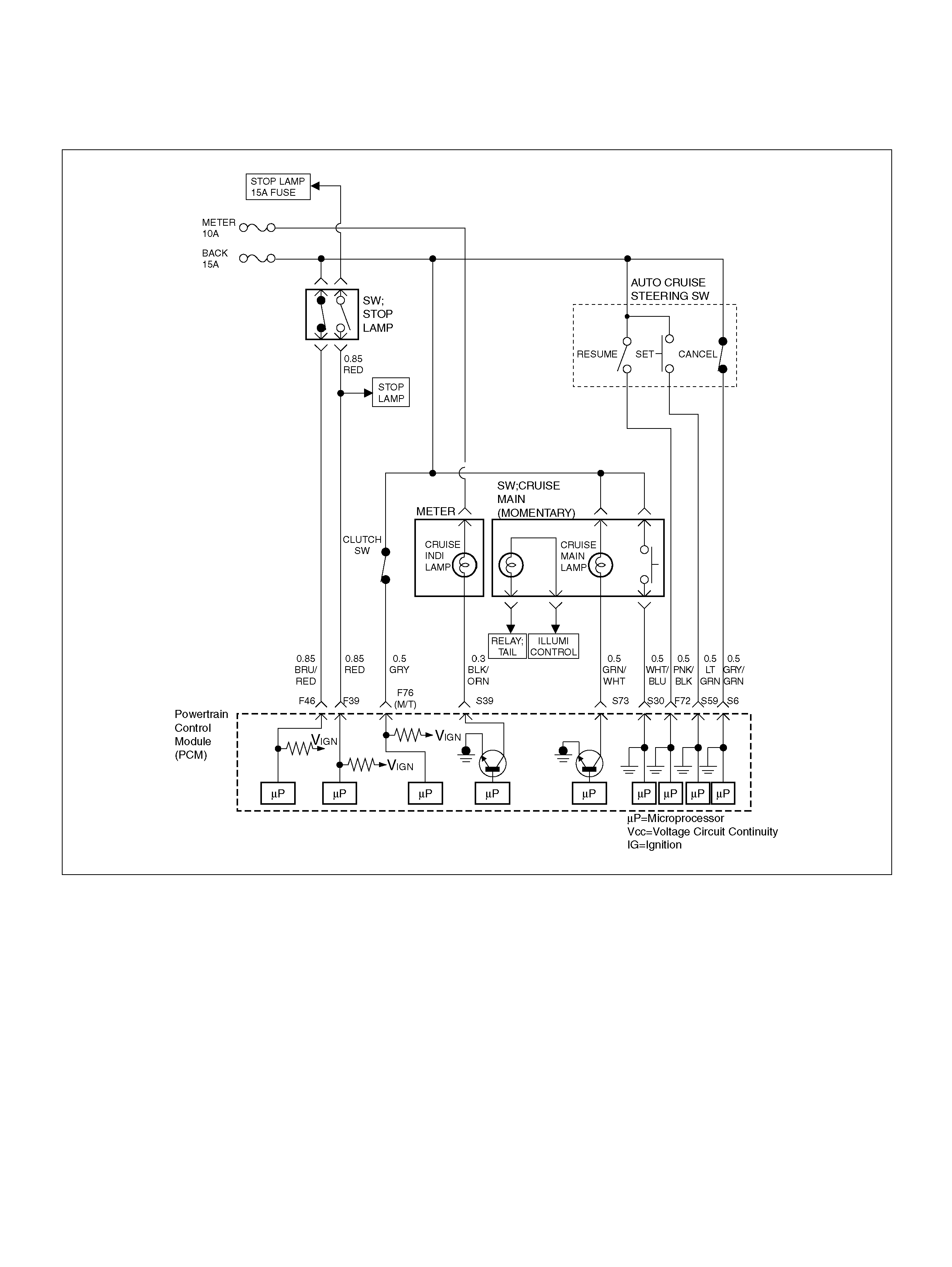

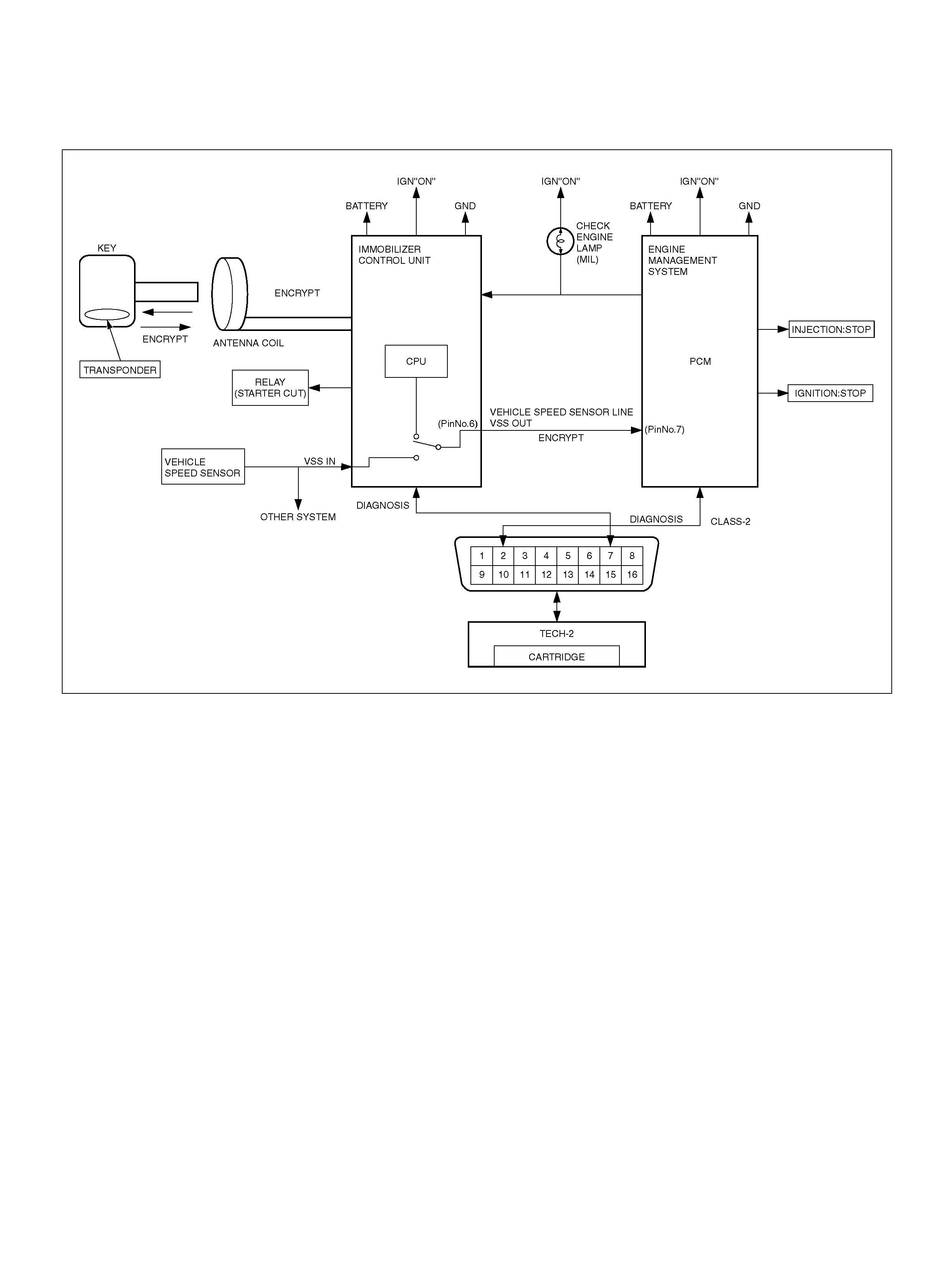

PCM WIRING DIAGRAM (7 OF 7)

060R100126

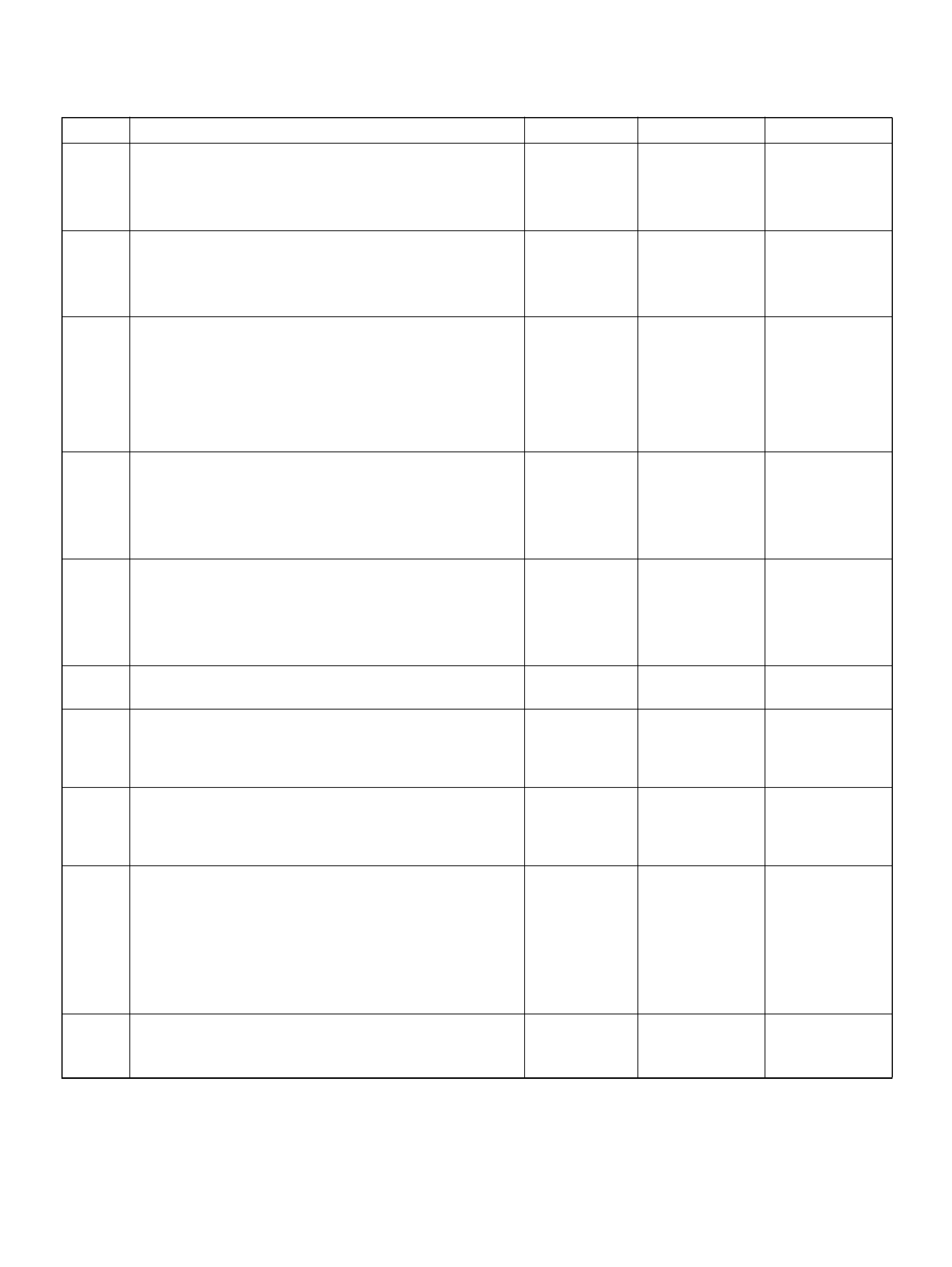

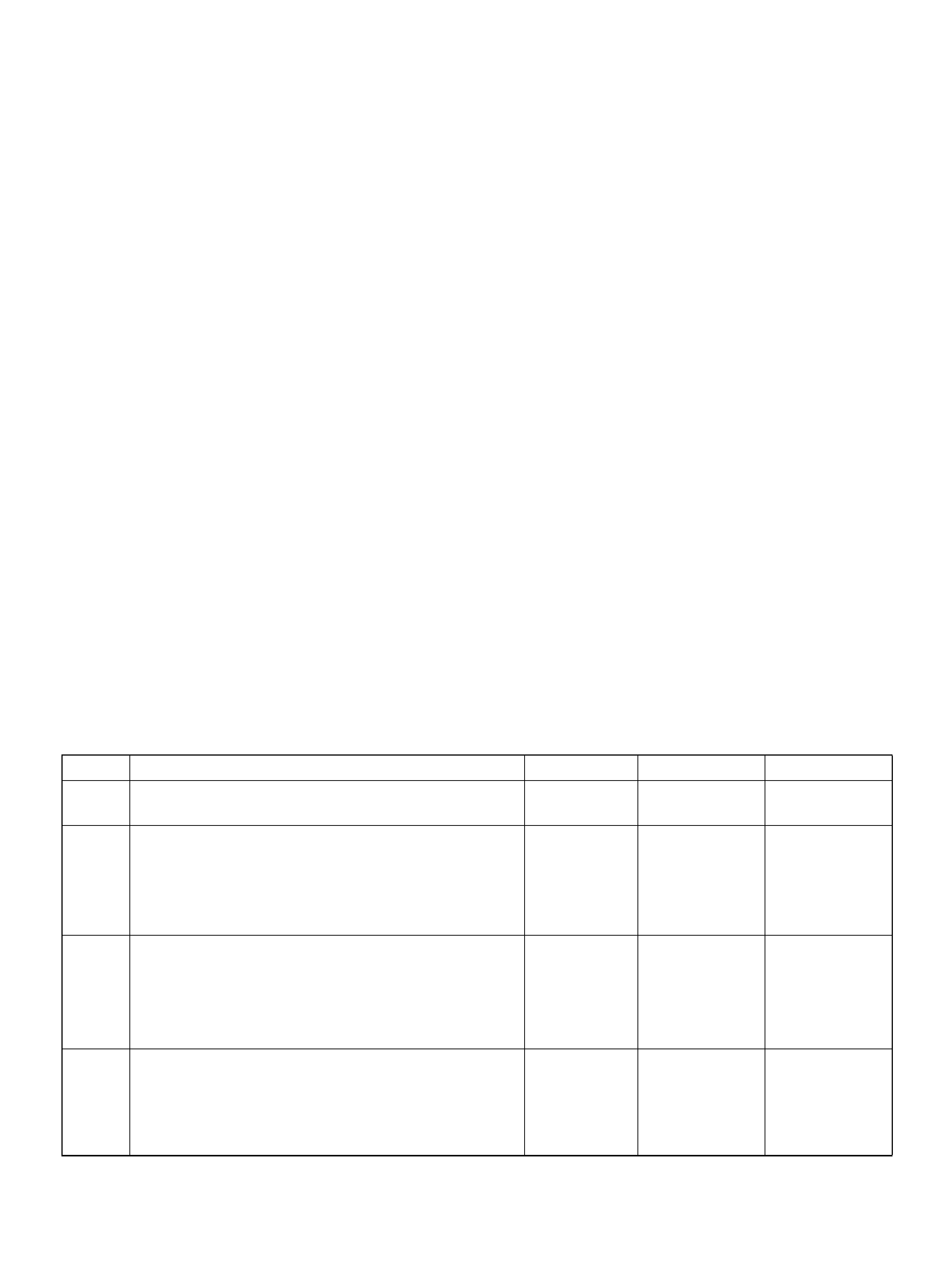

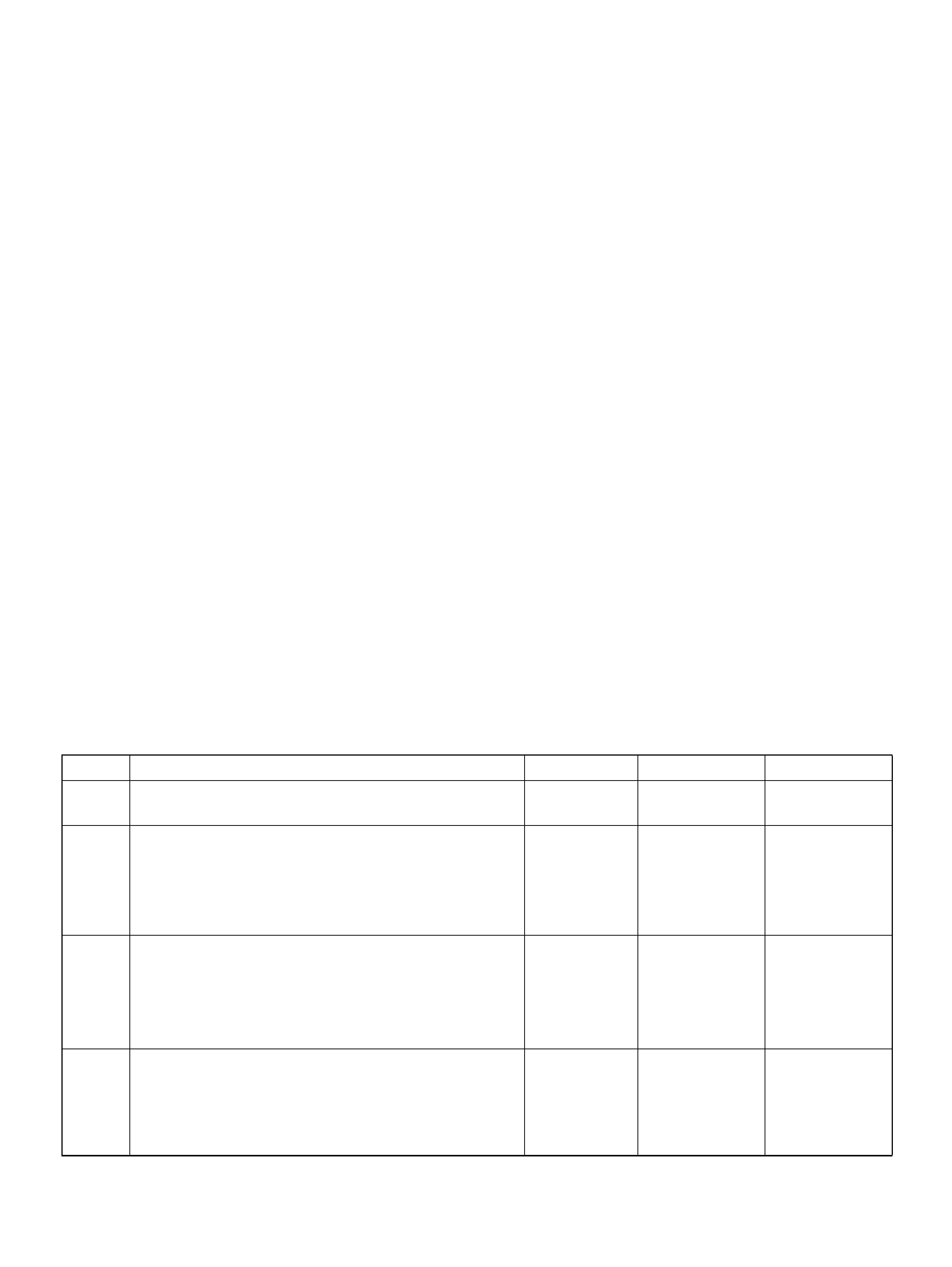

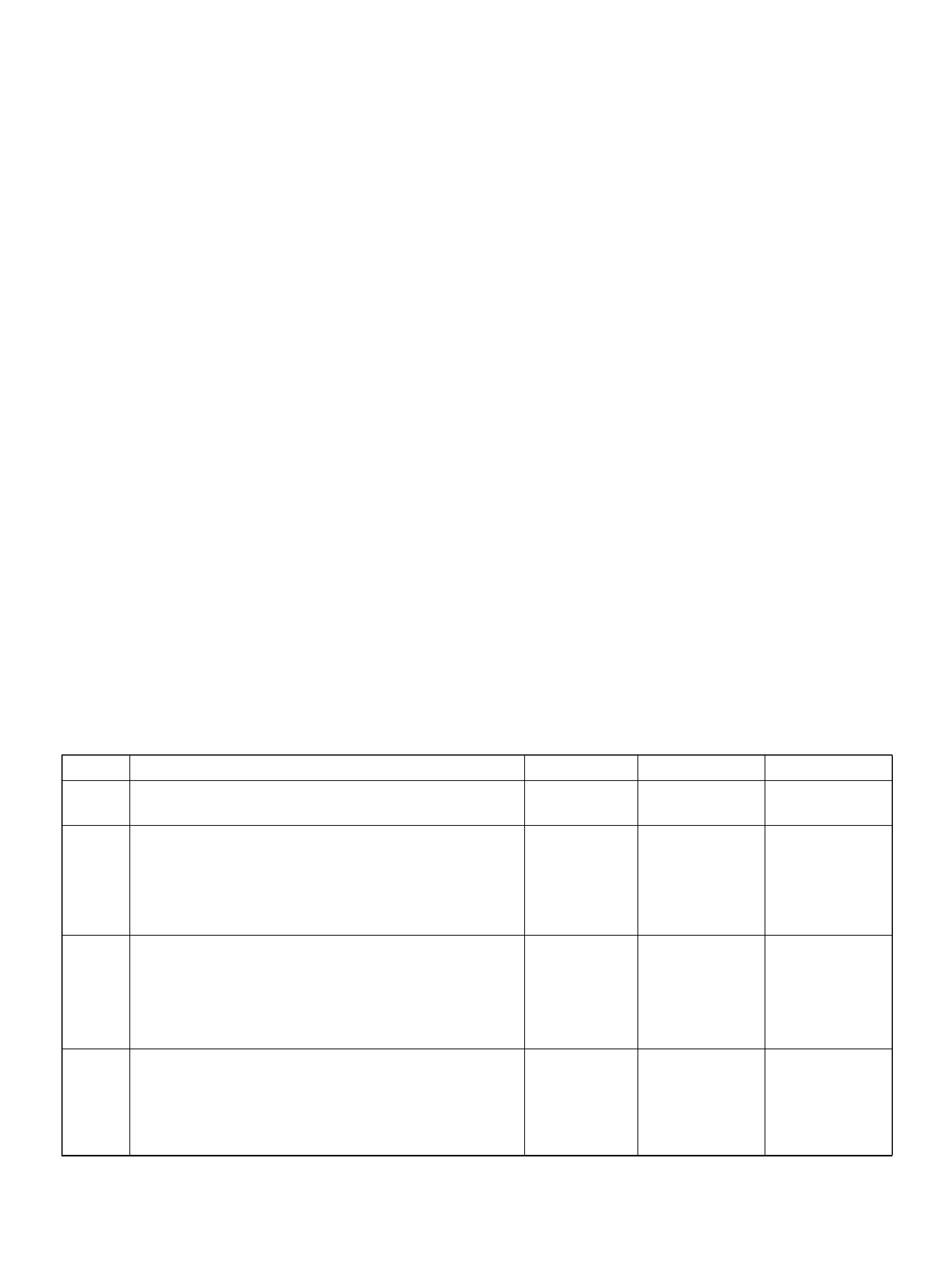

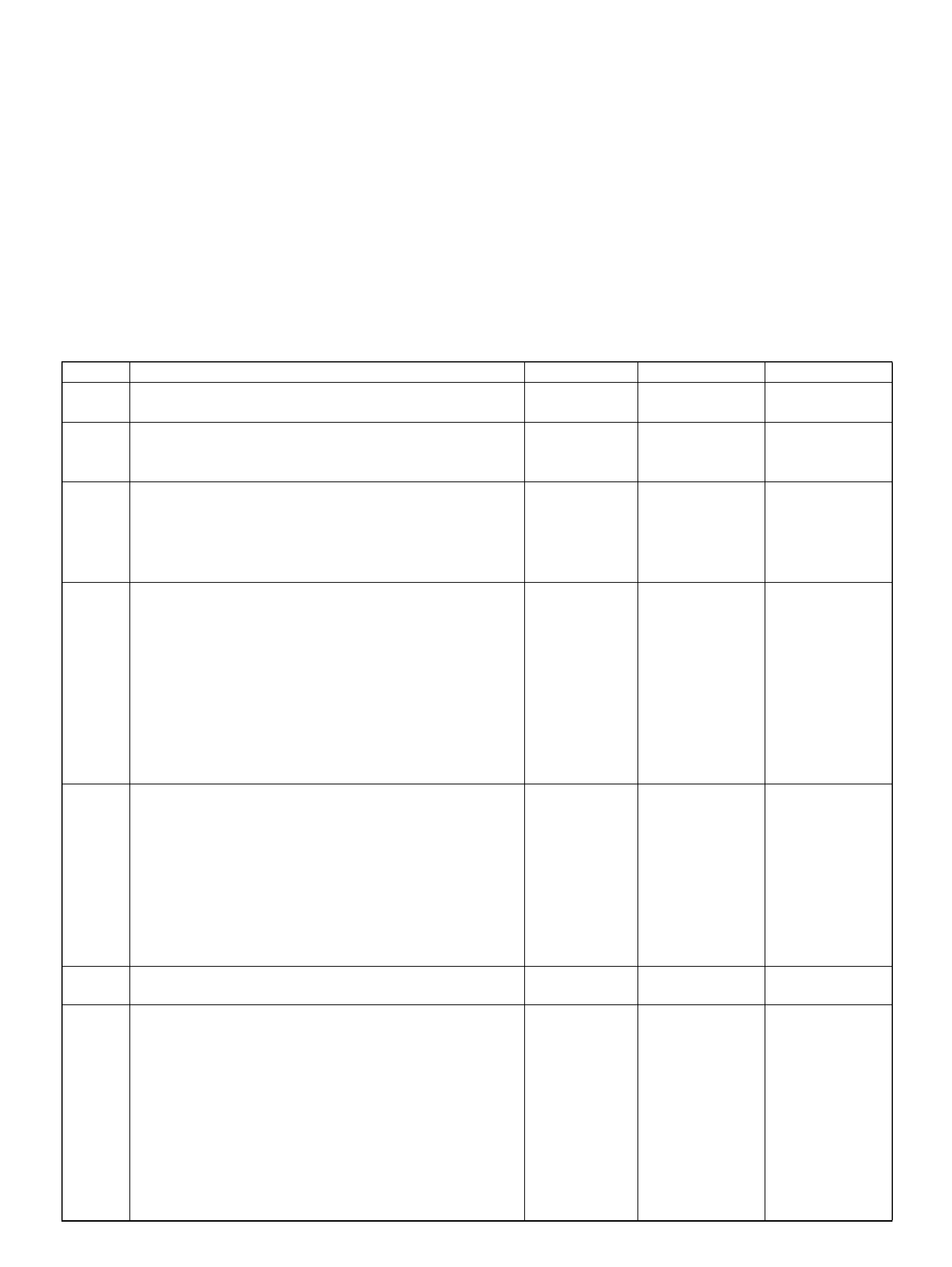

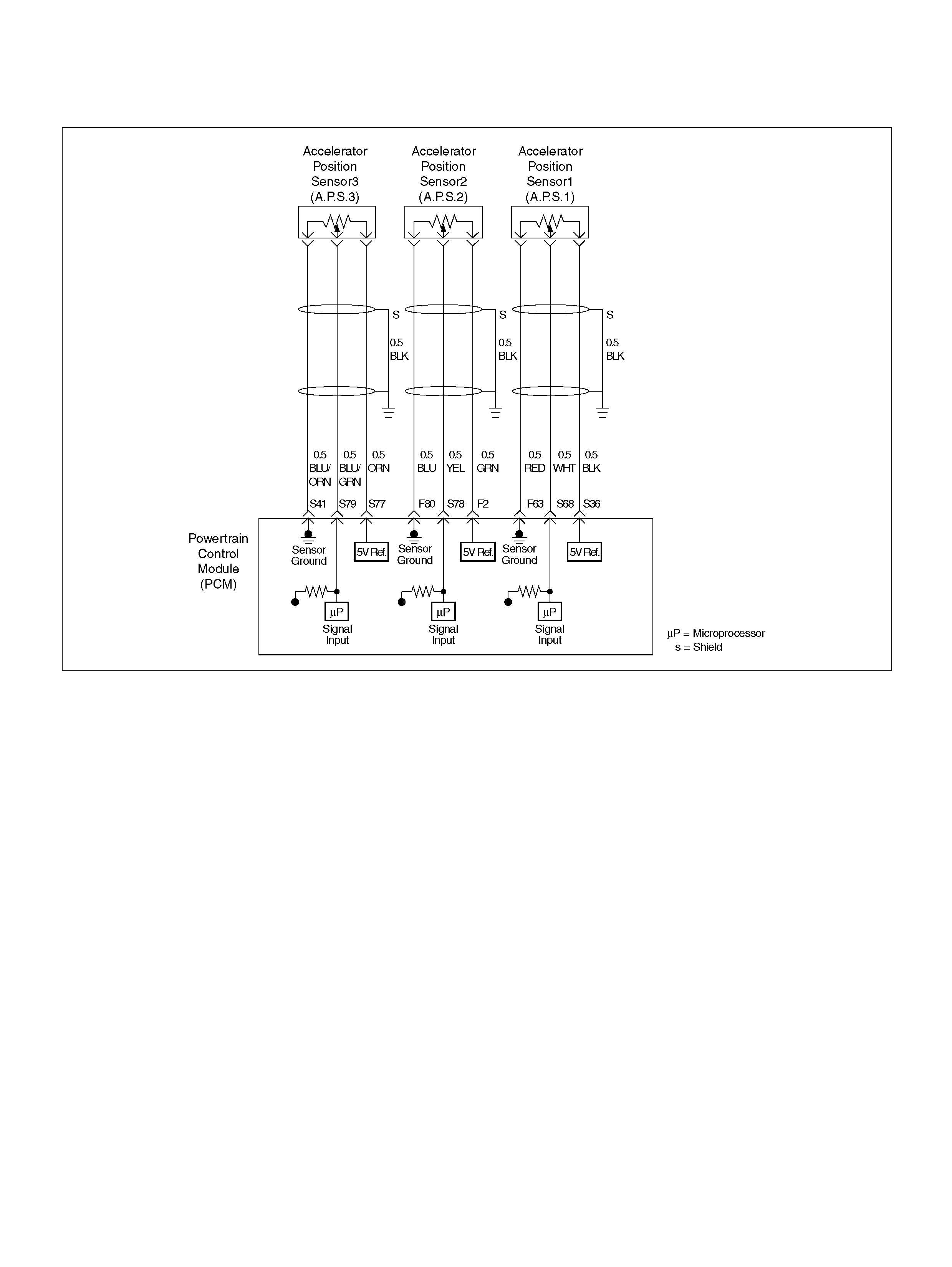

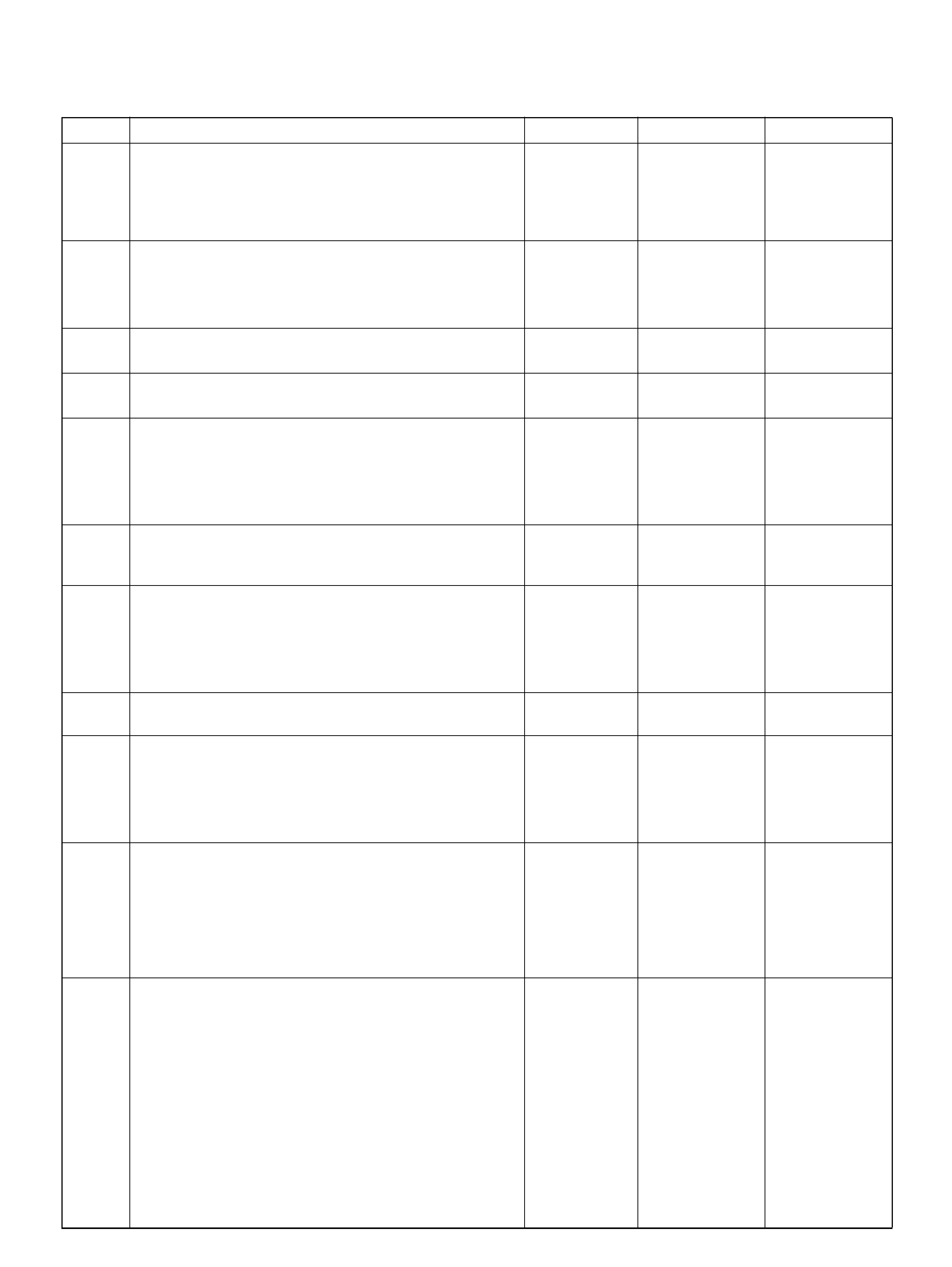

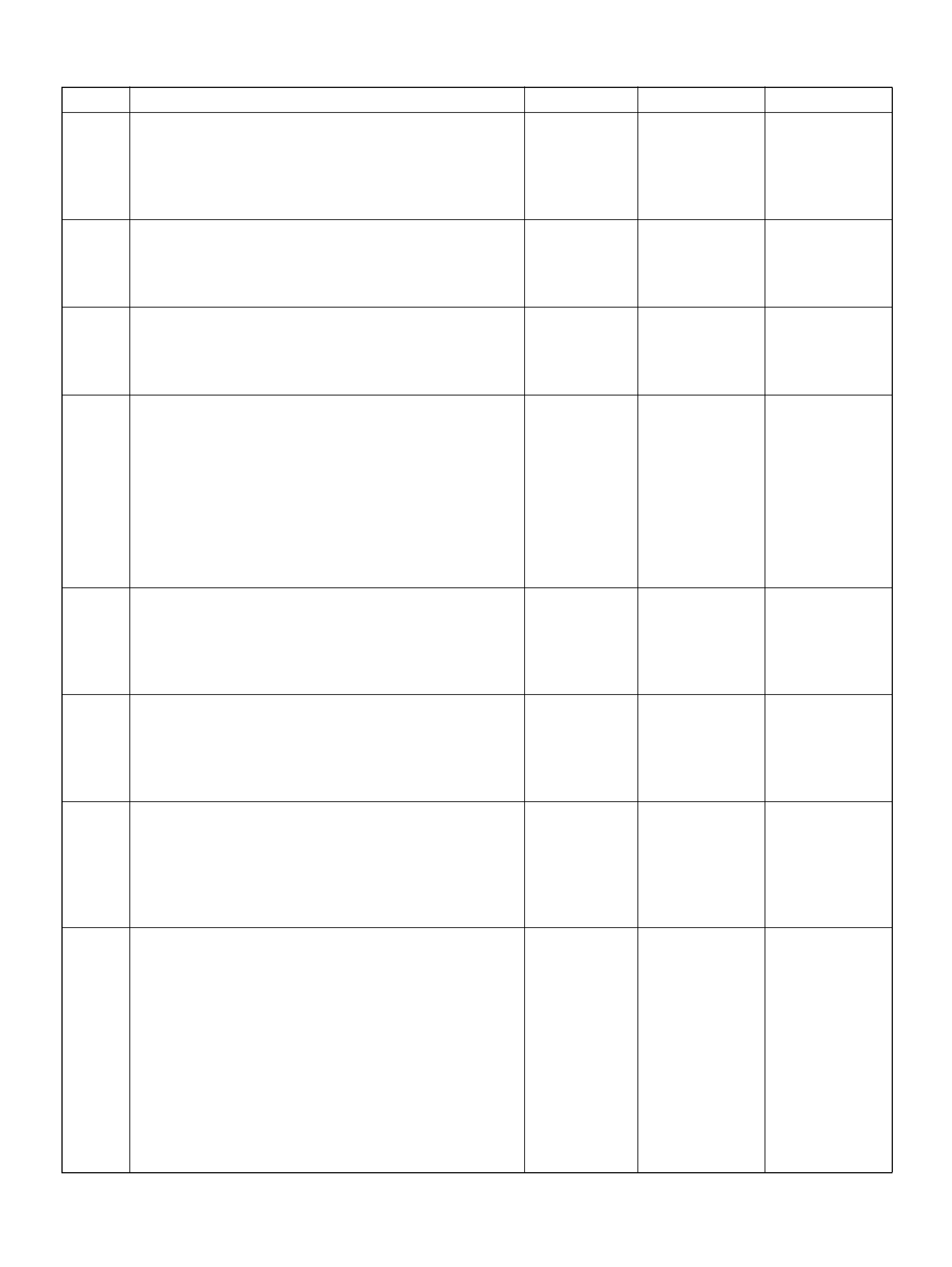

PCM PINOUTS

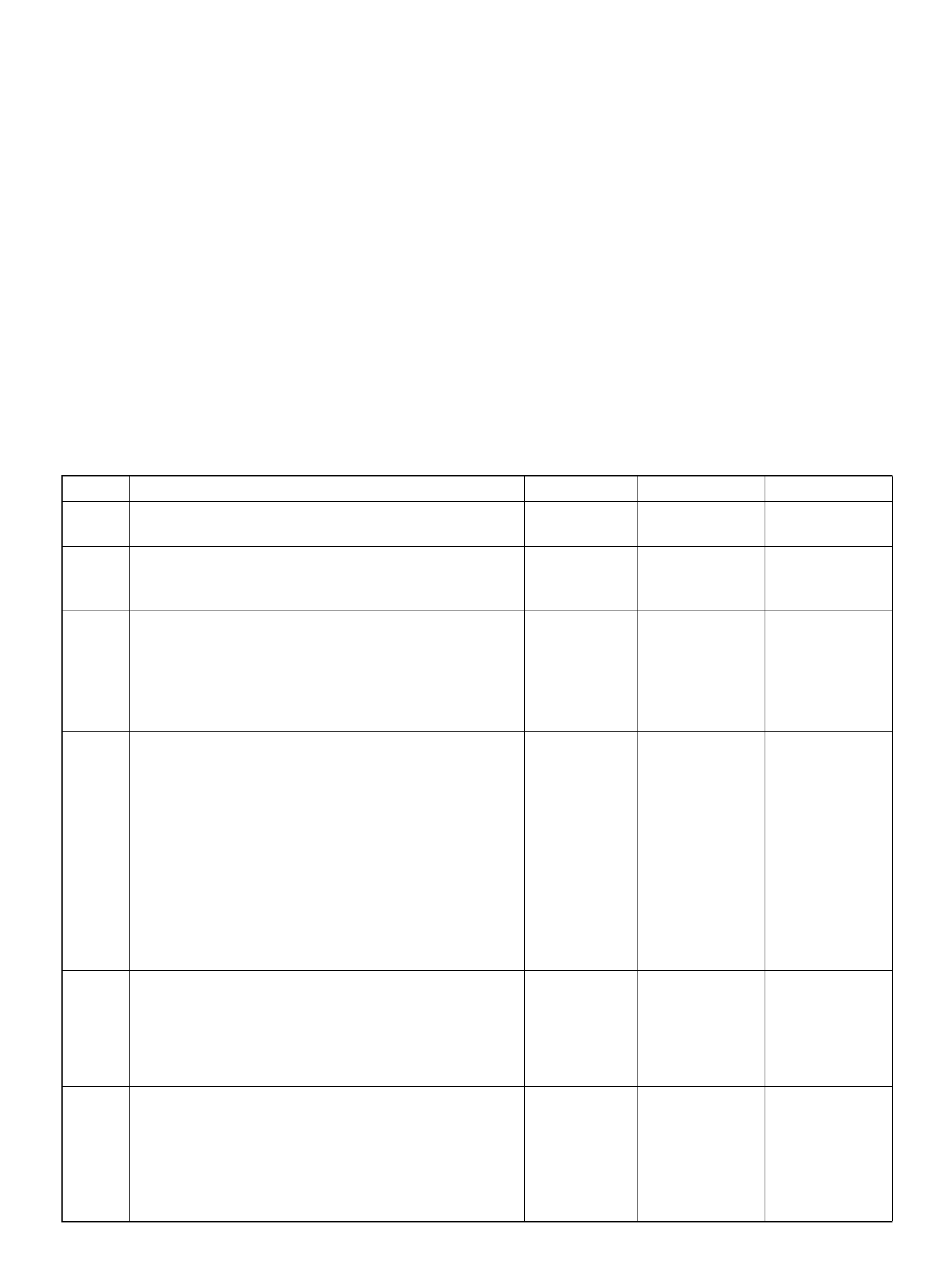

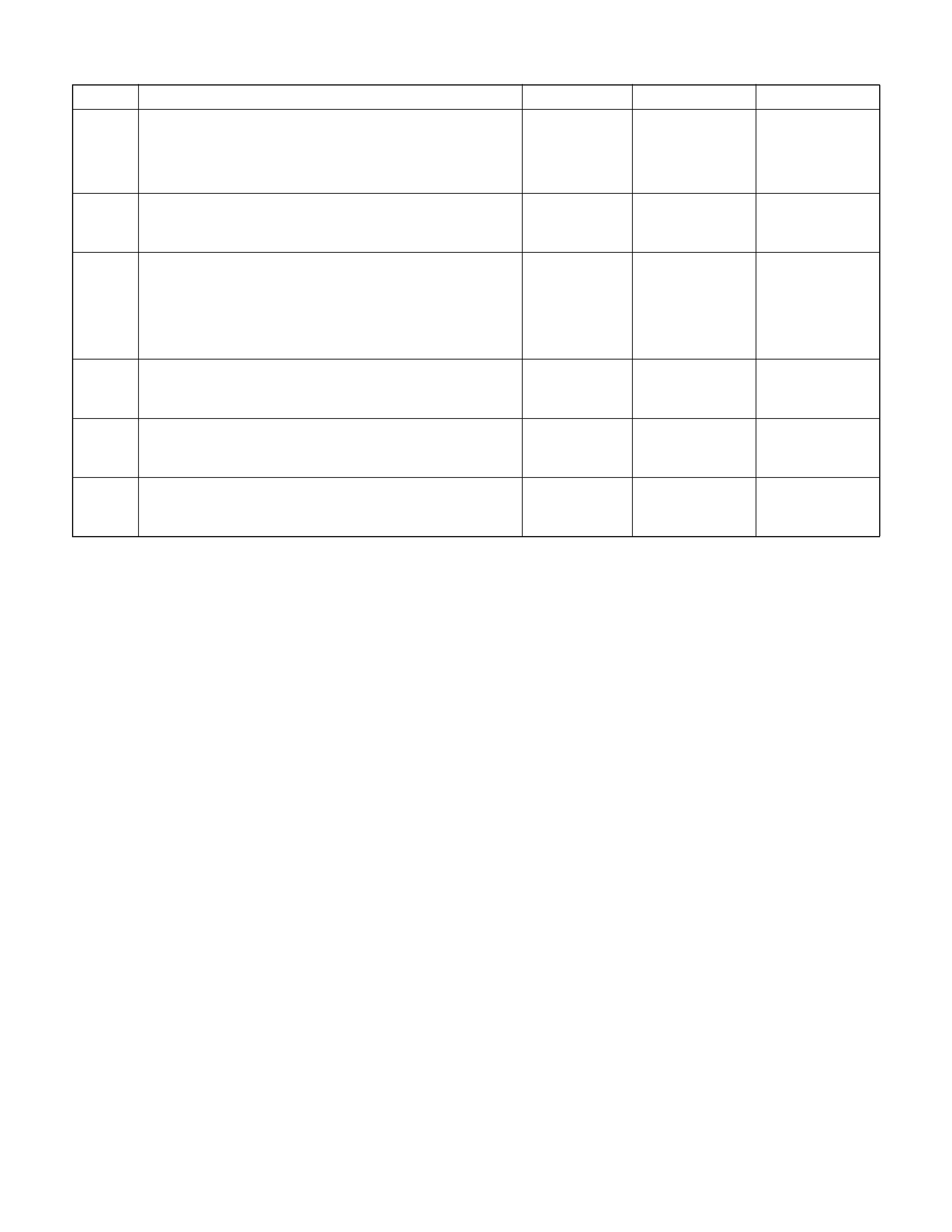

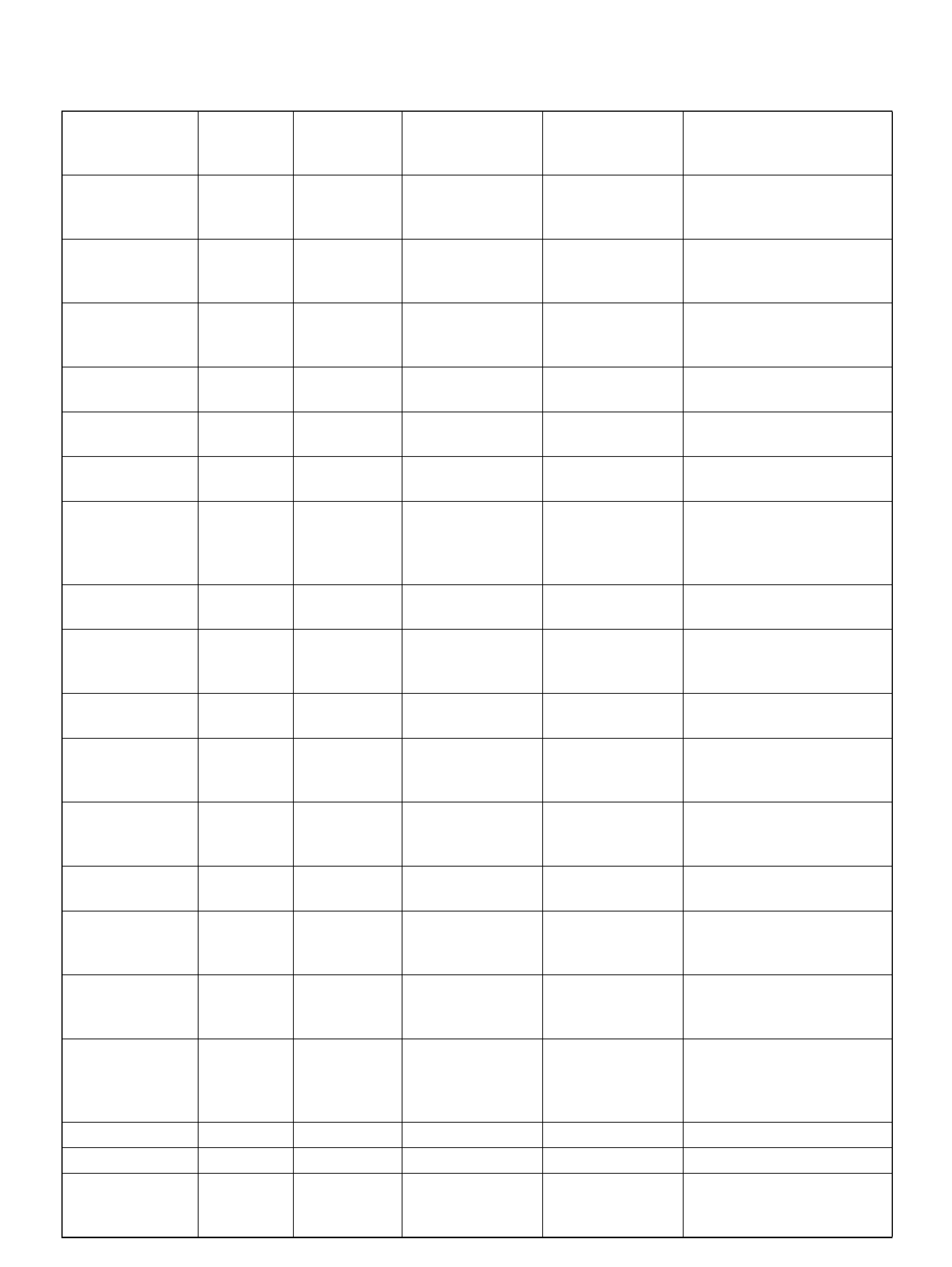

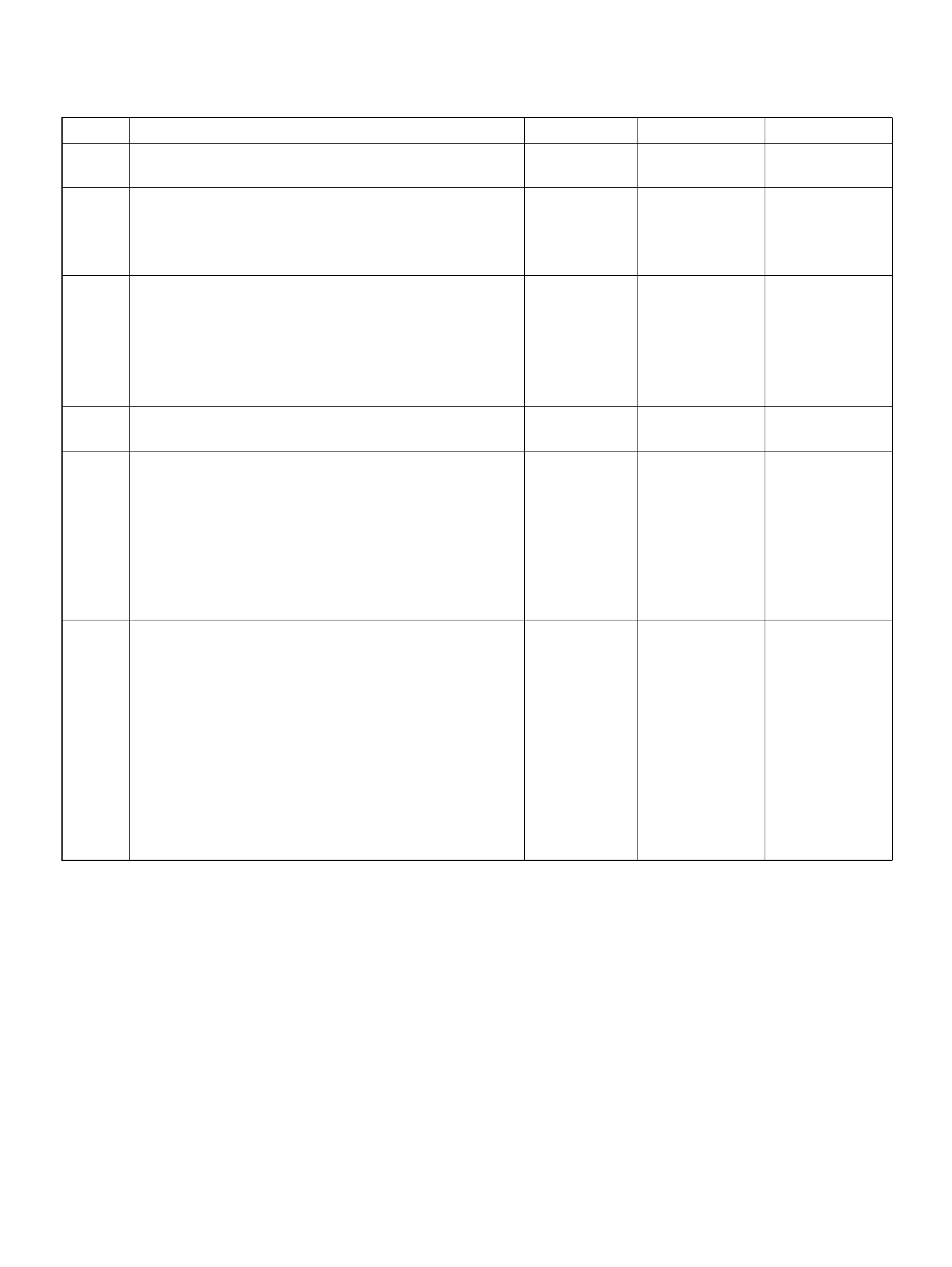

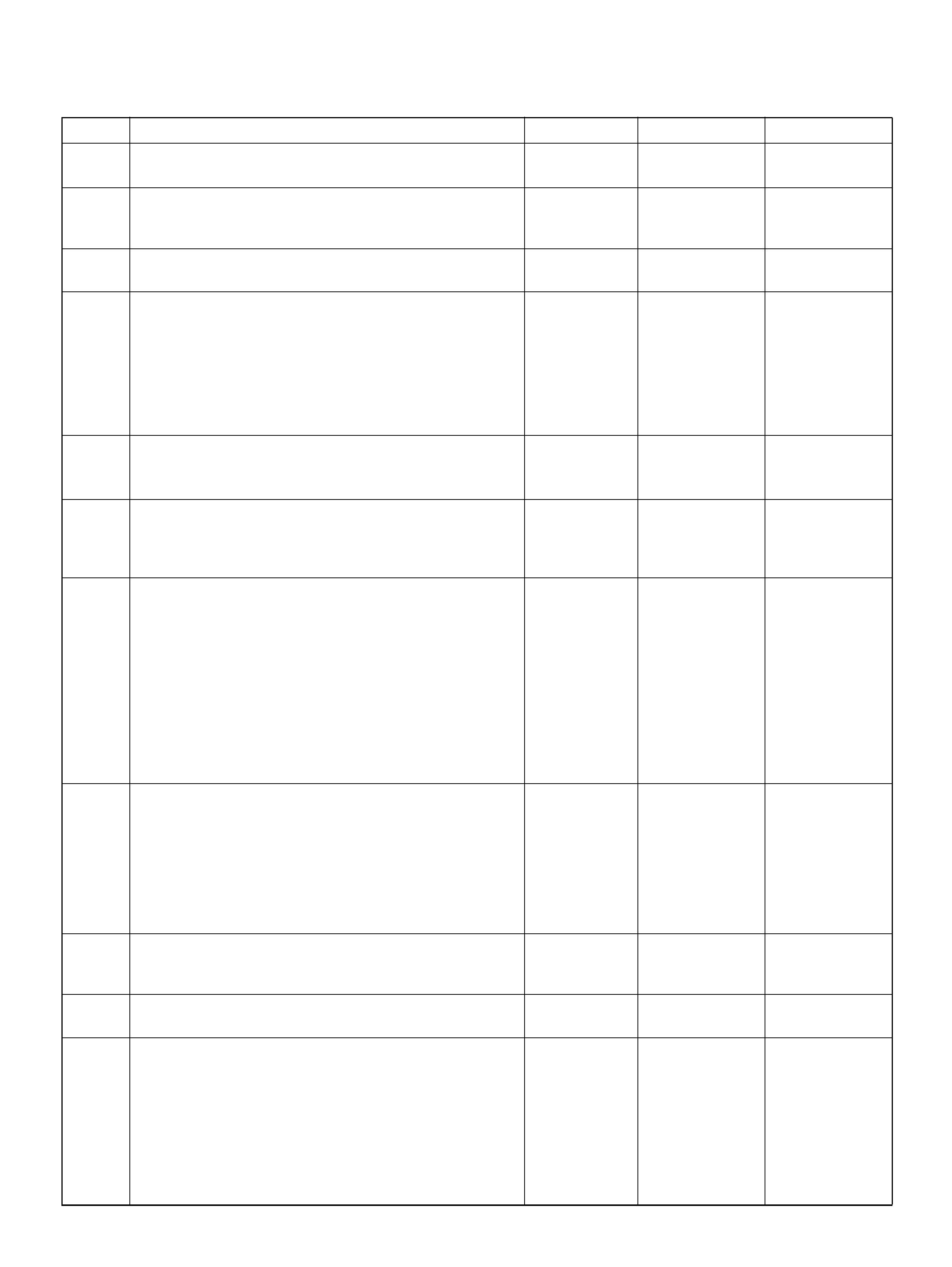

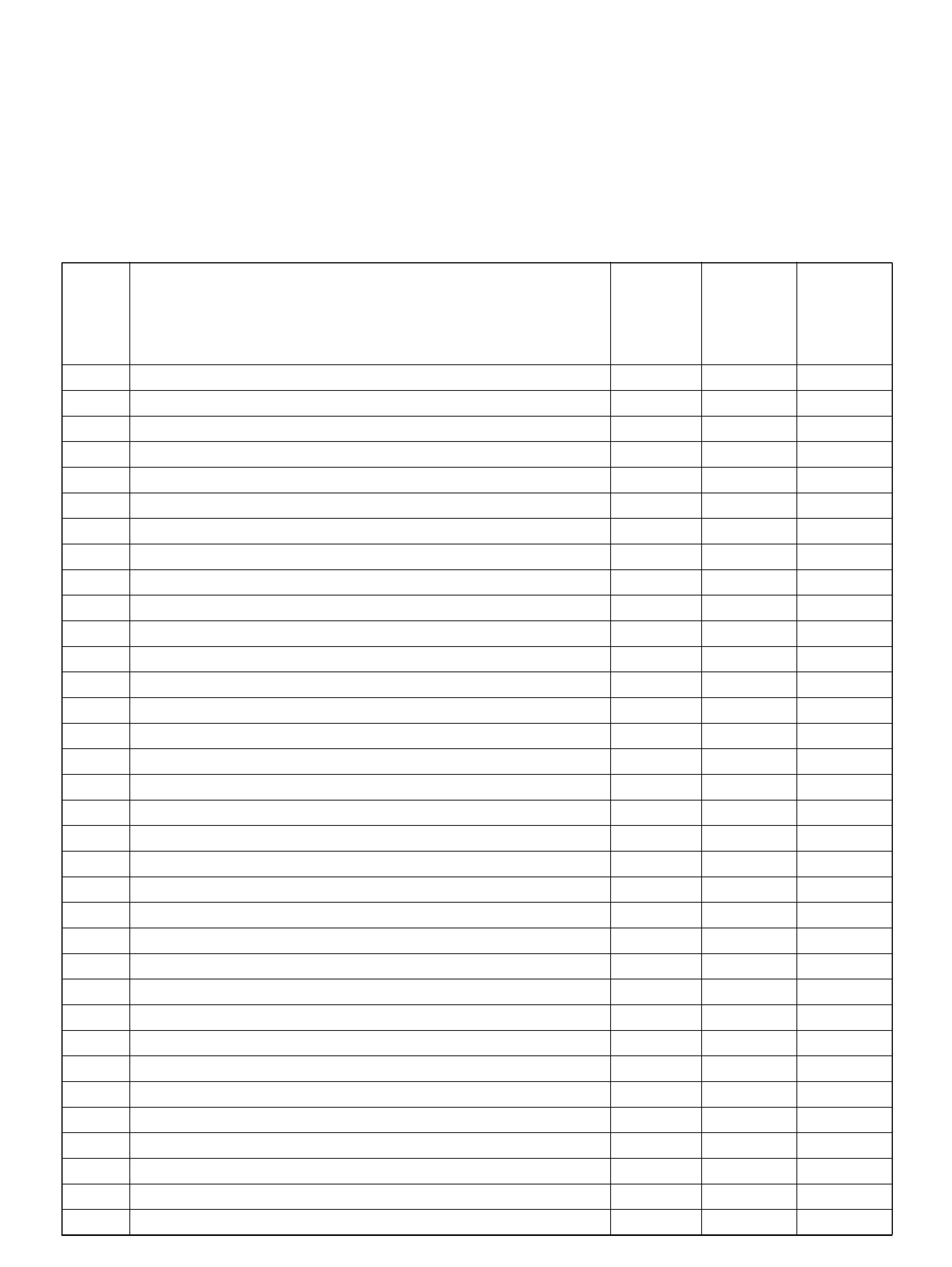

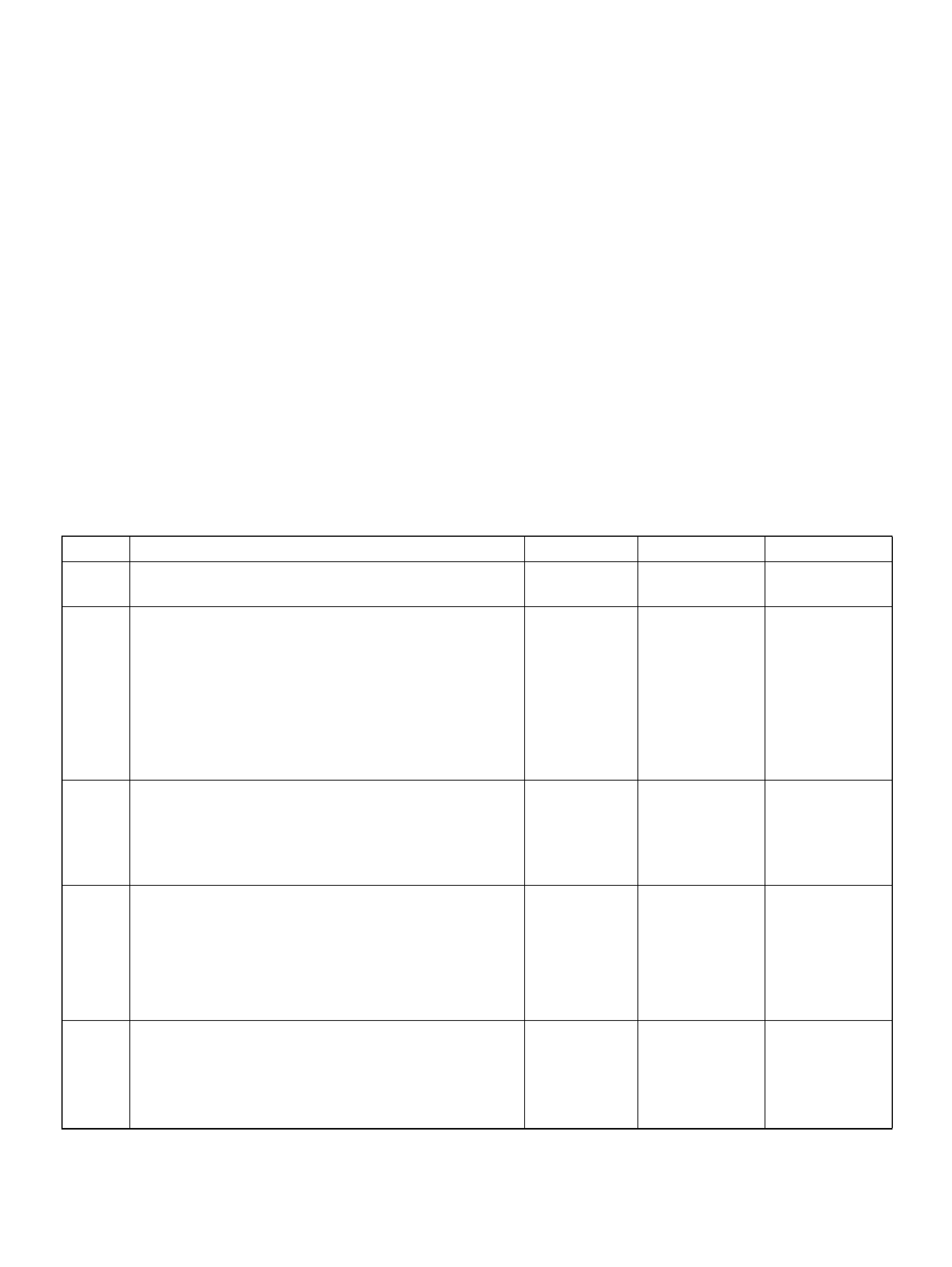

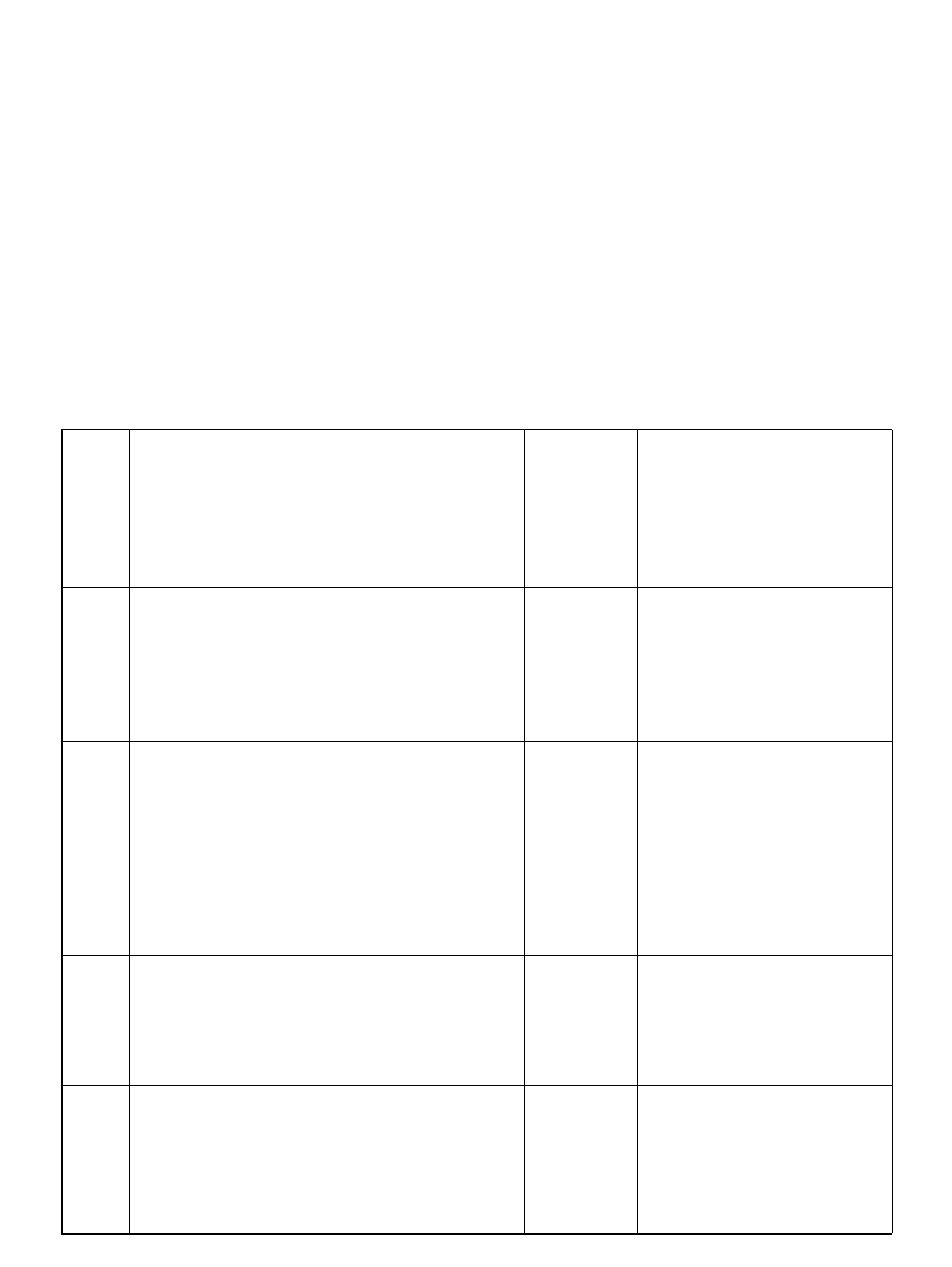

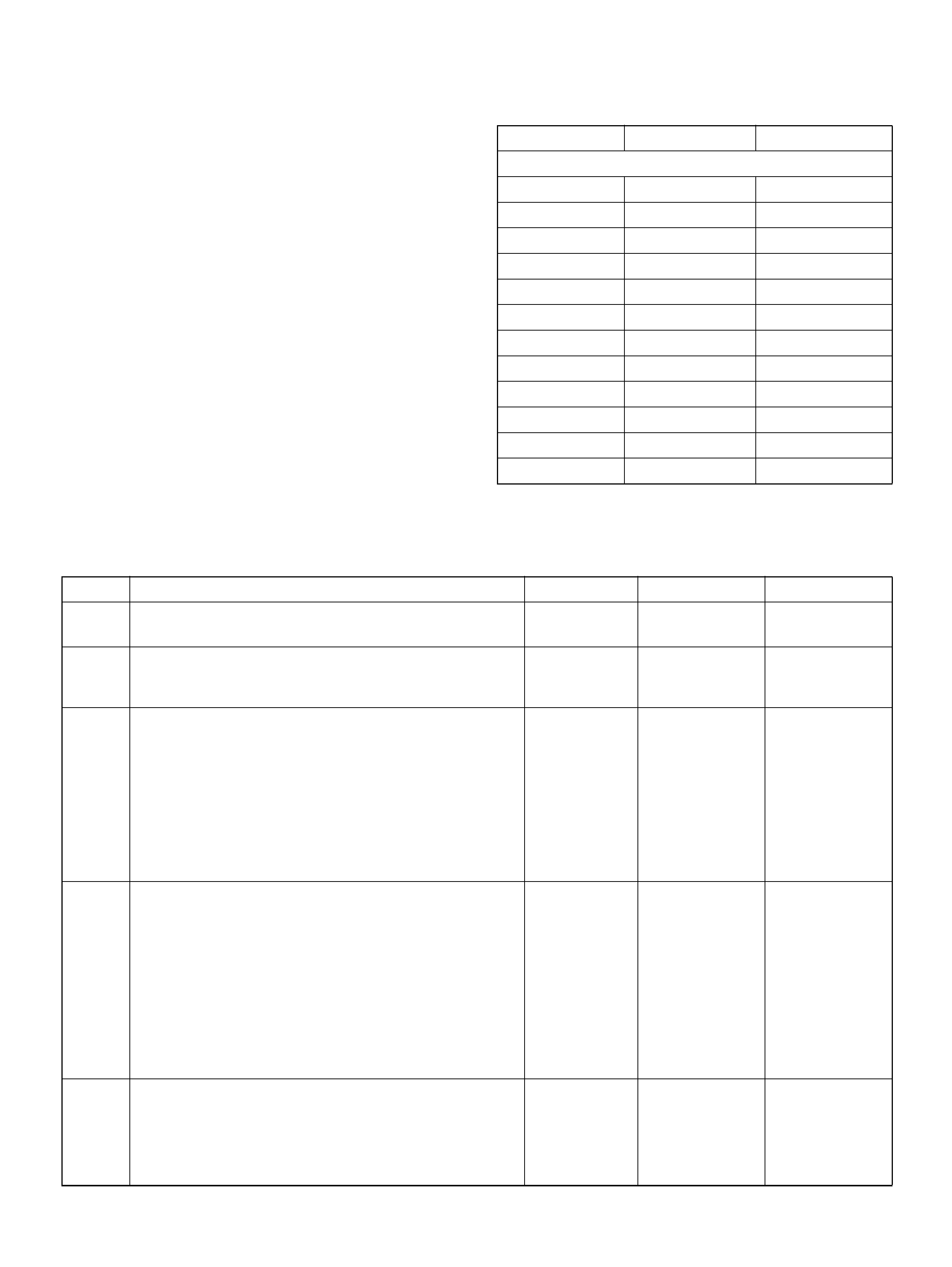

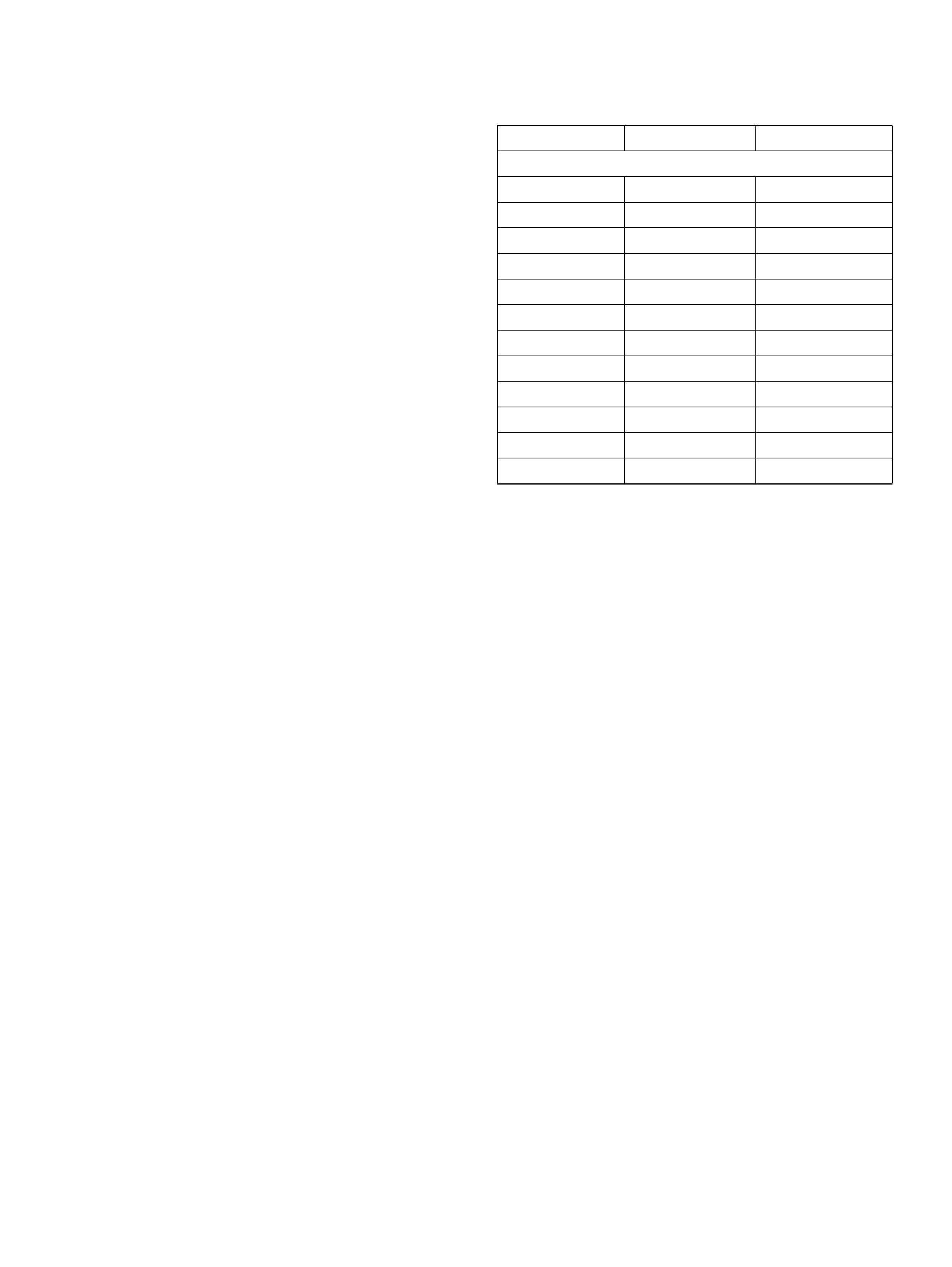

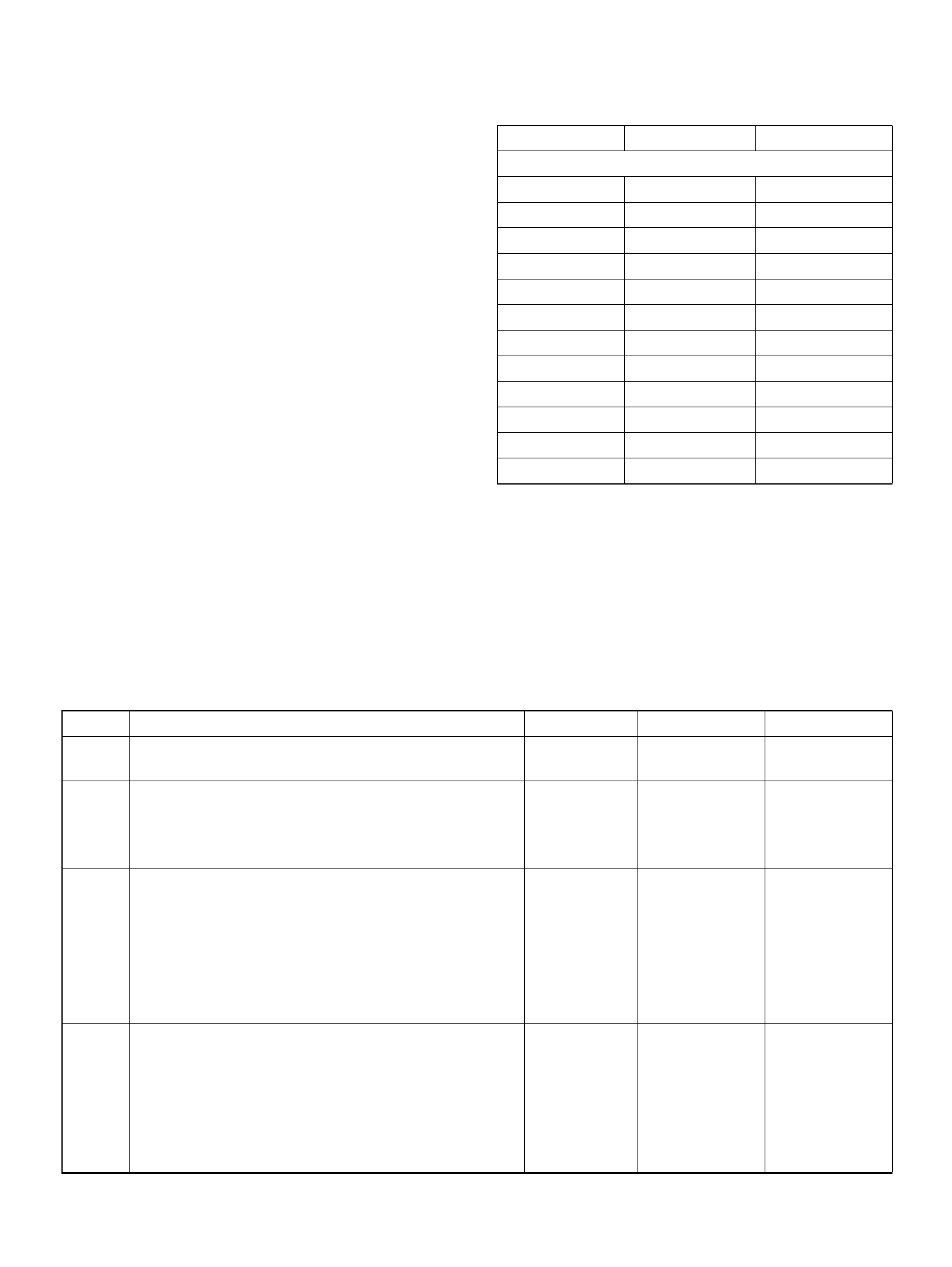

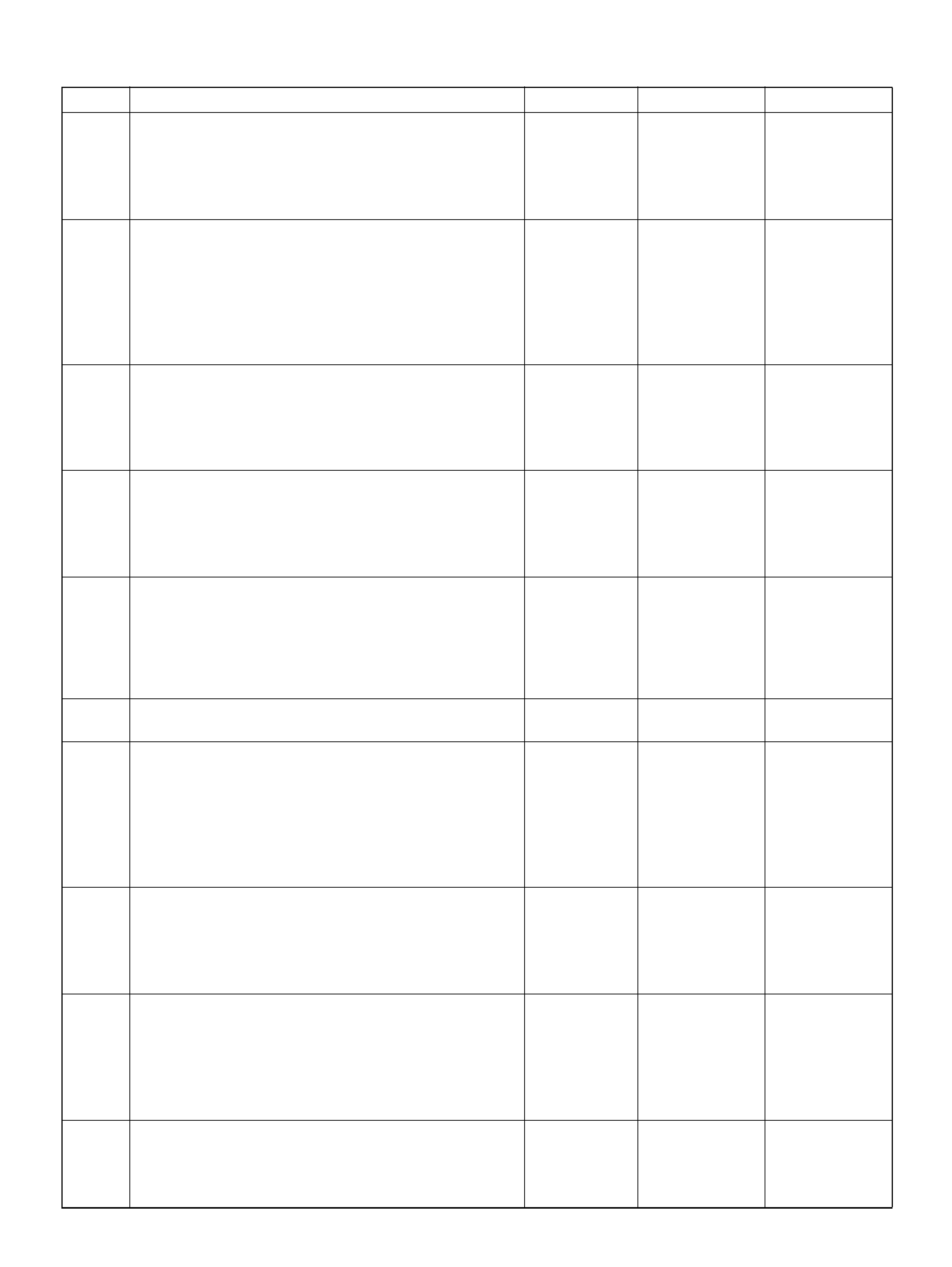

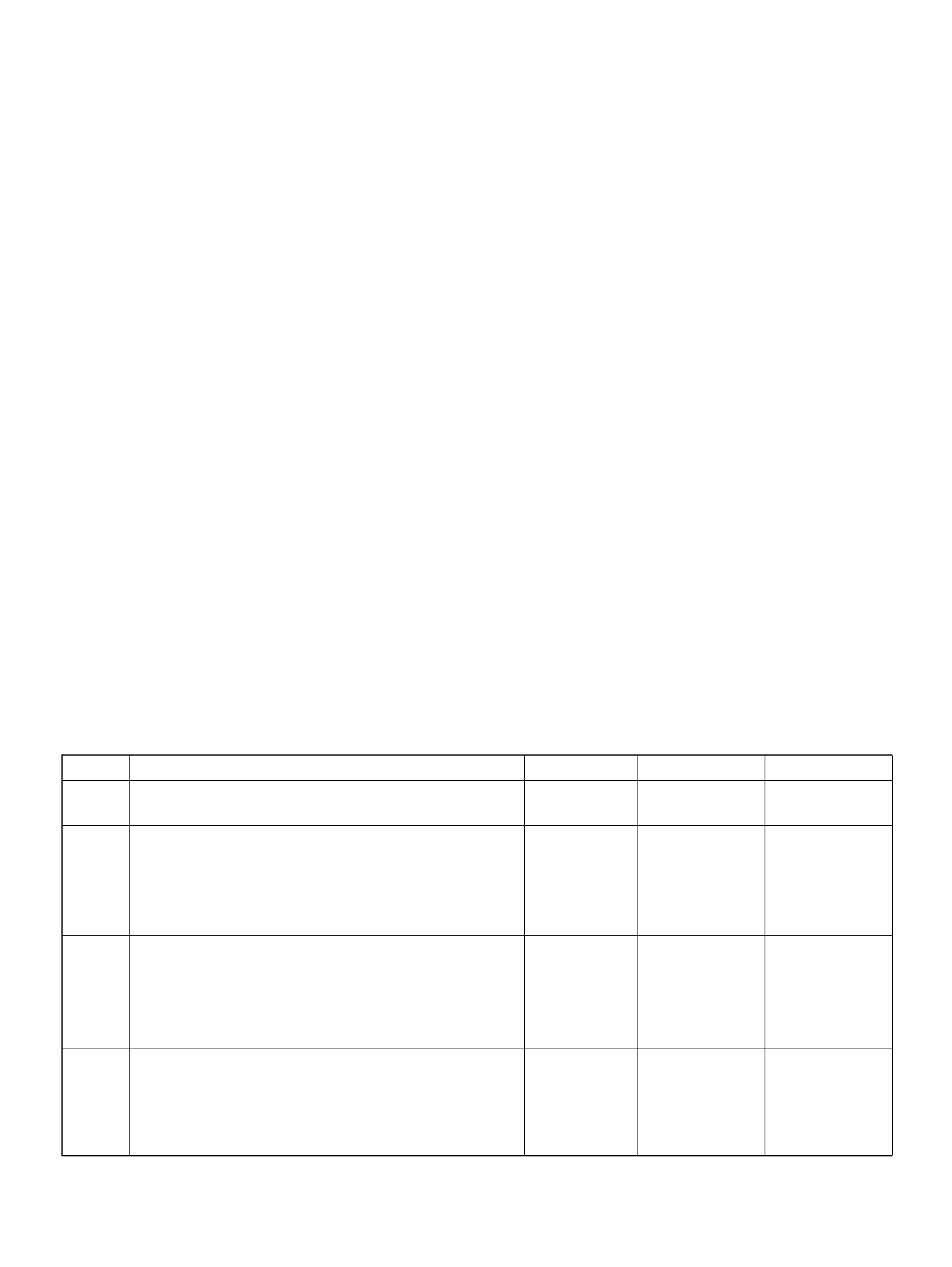

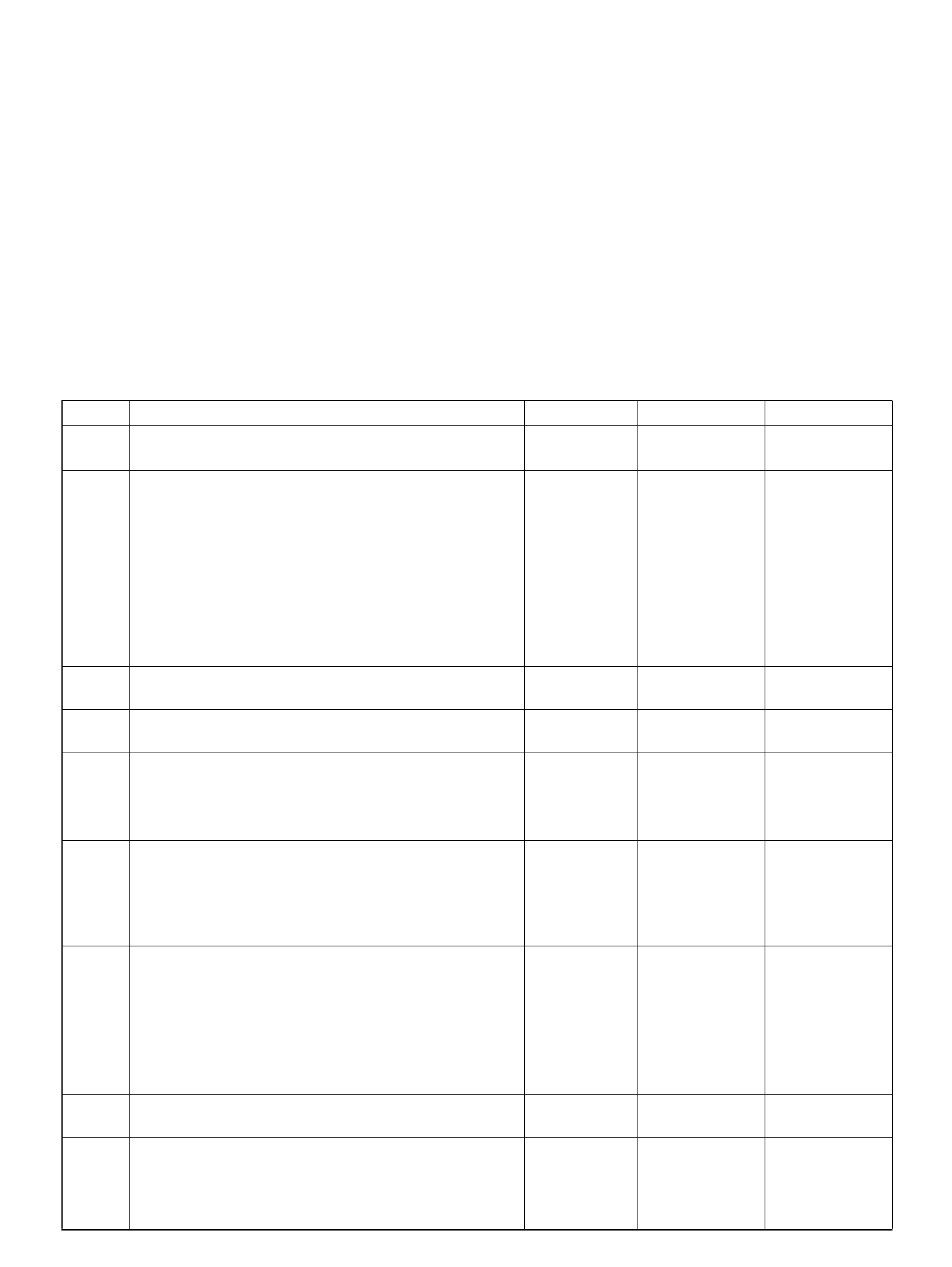

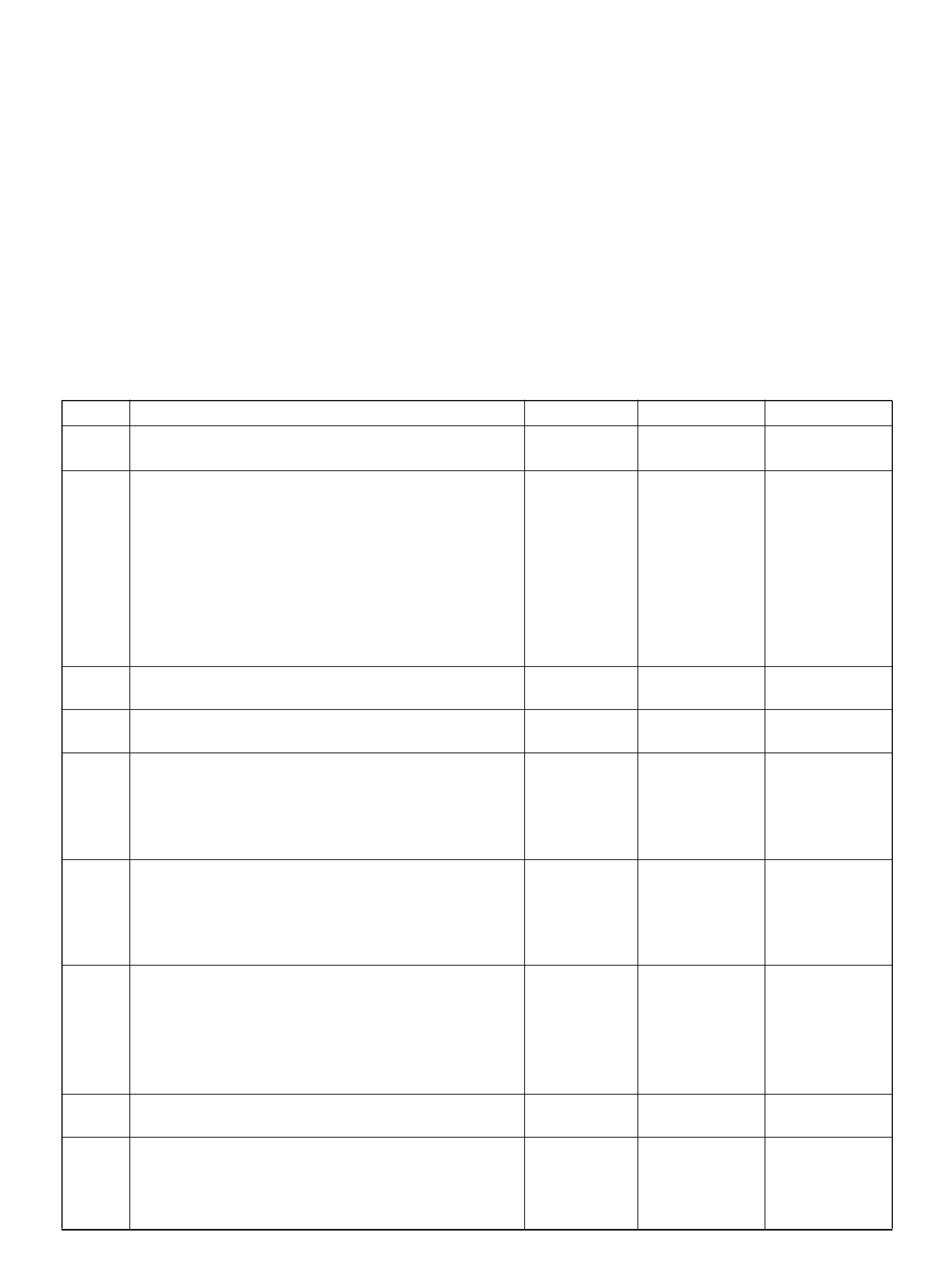

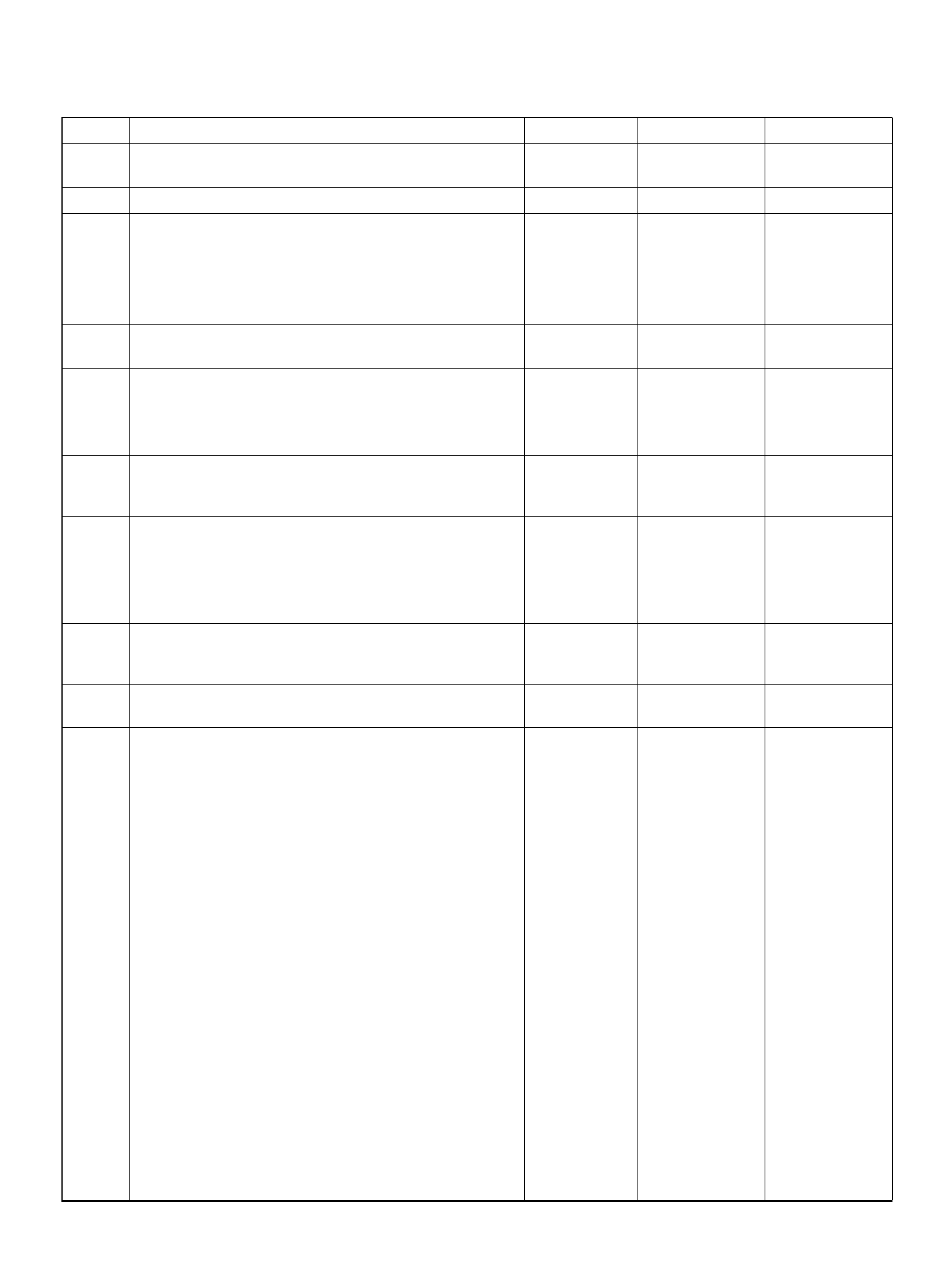

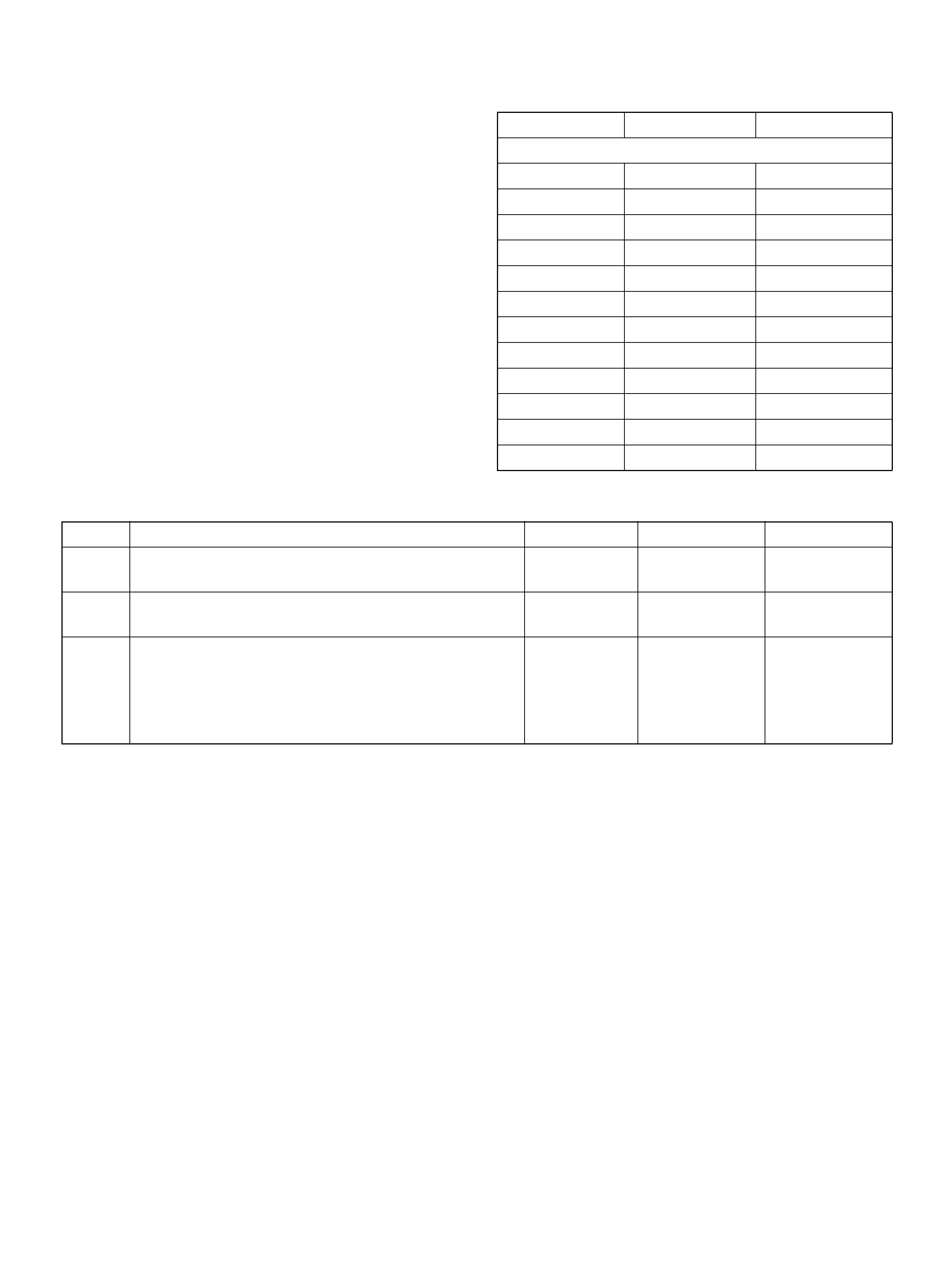

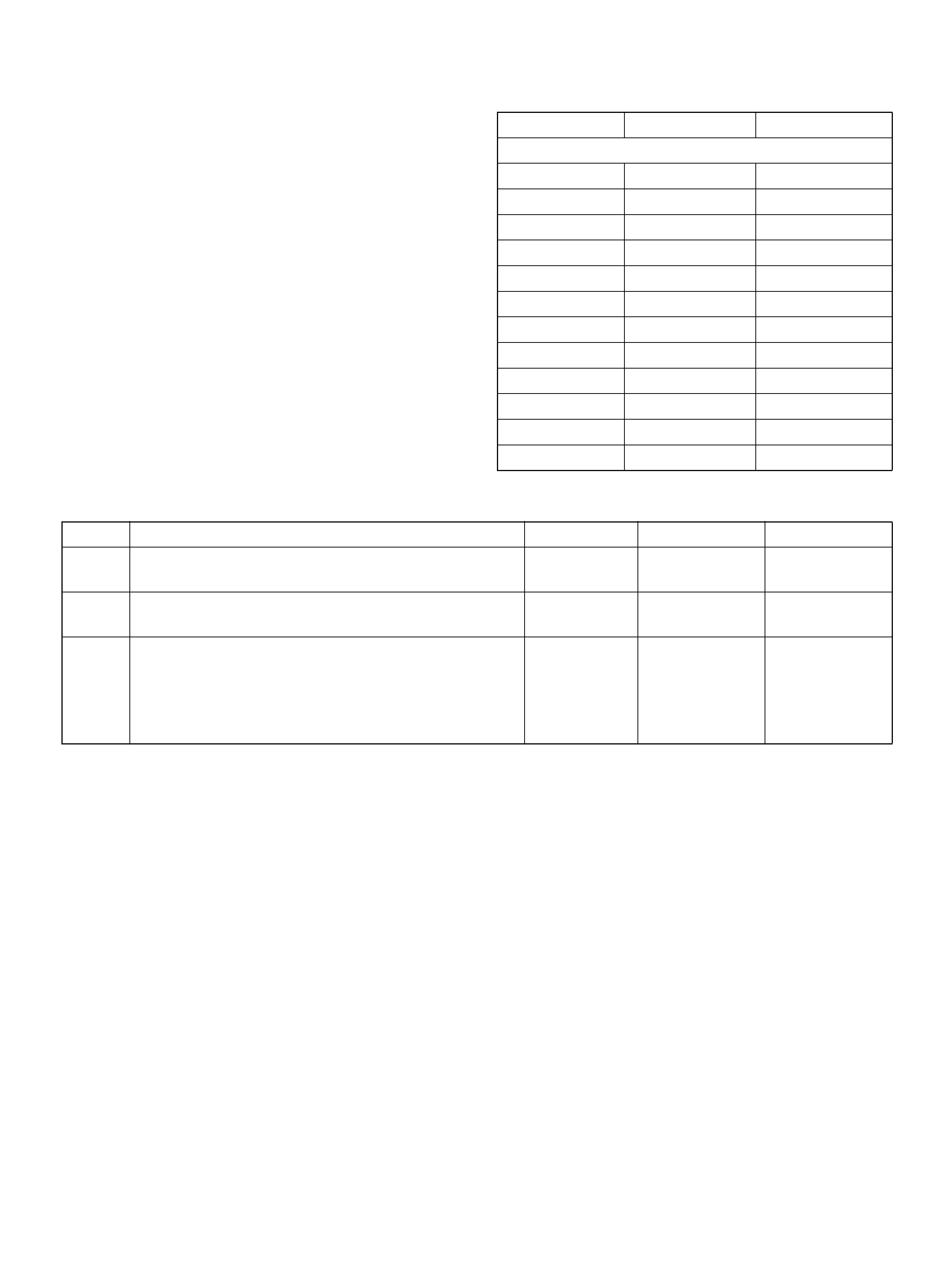

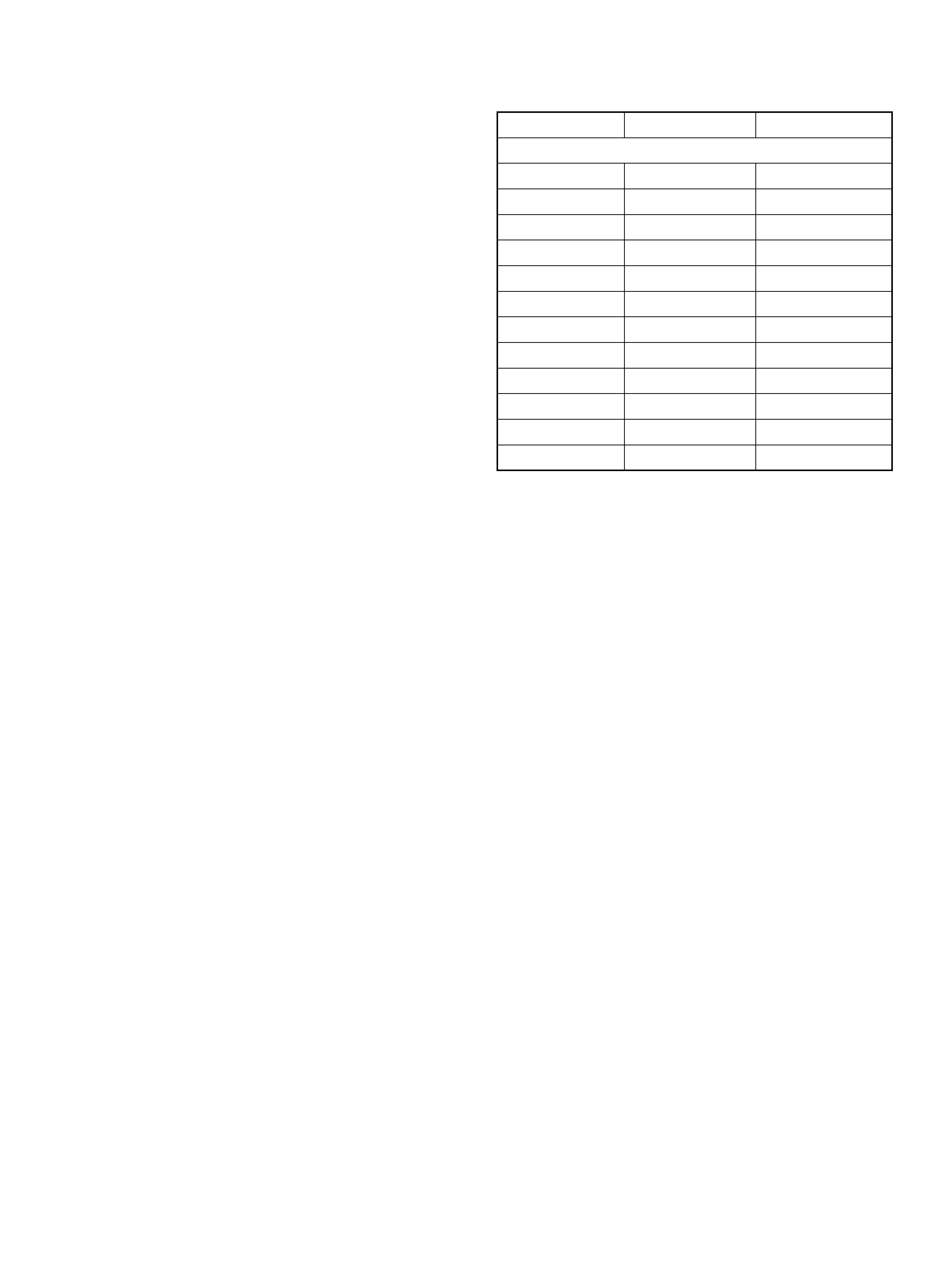

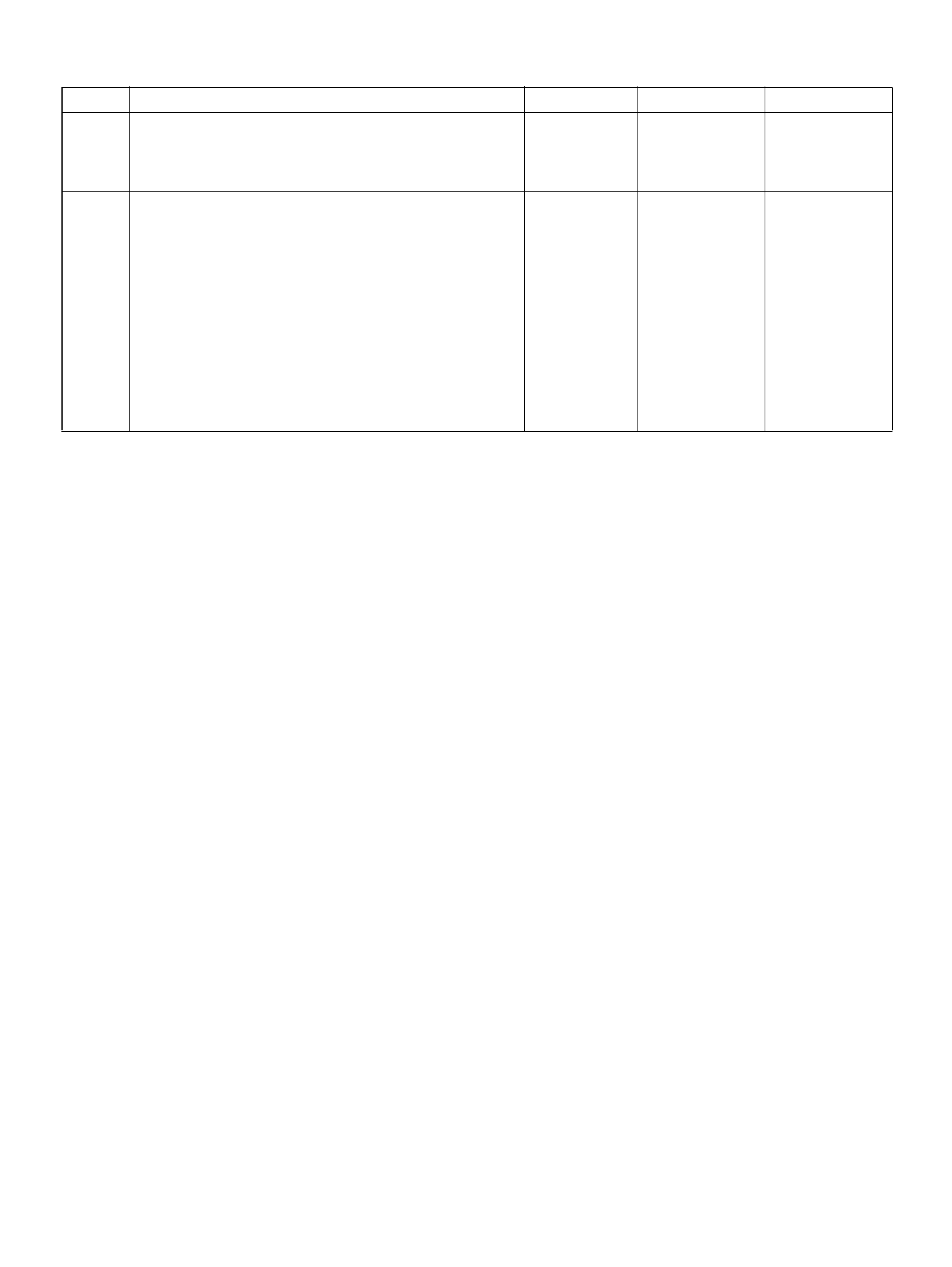

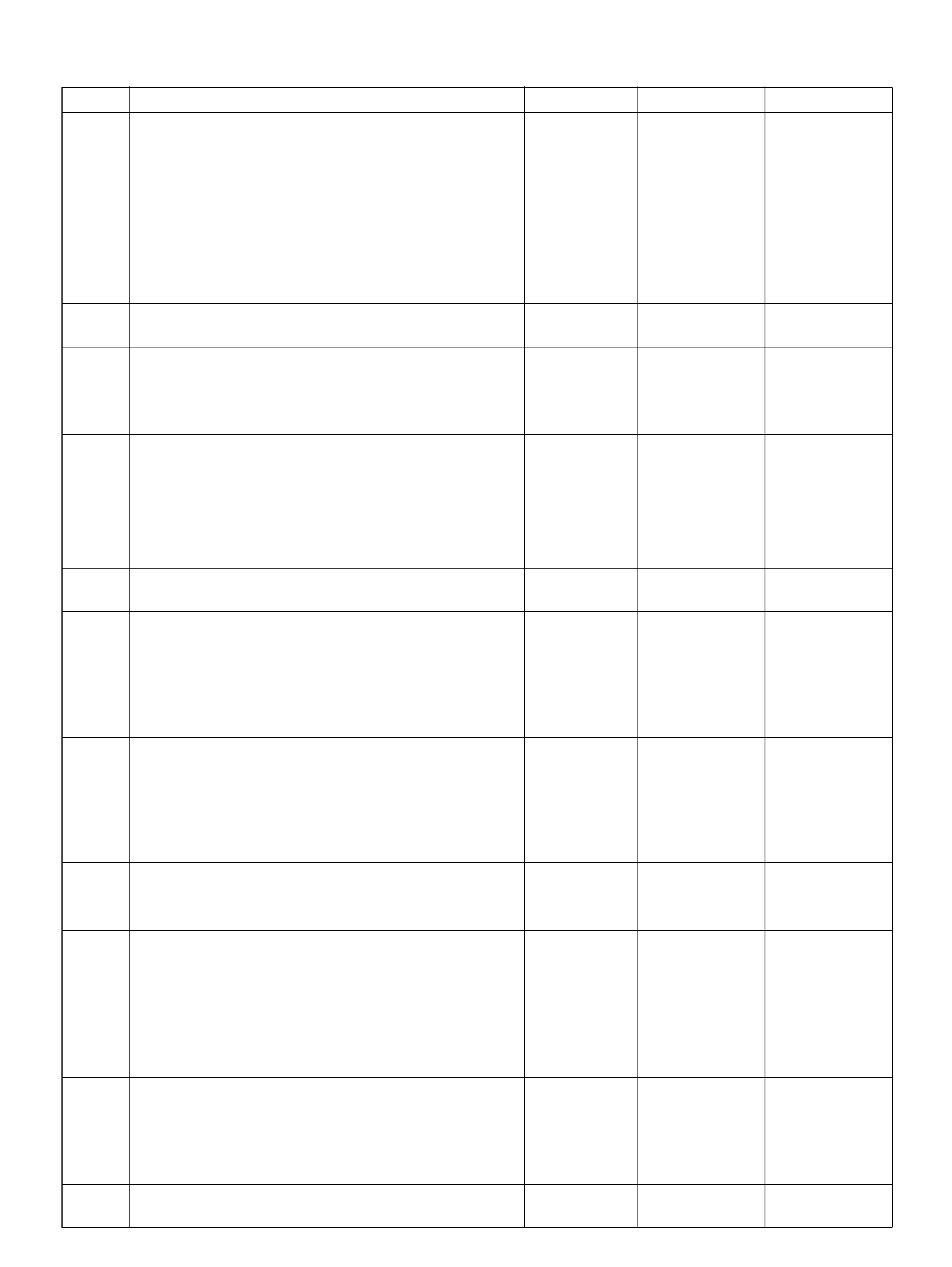

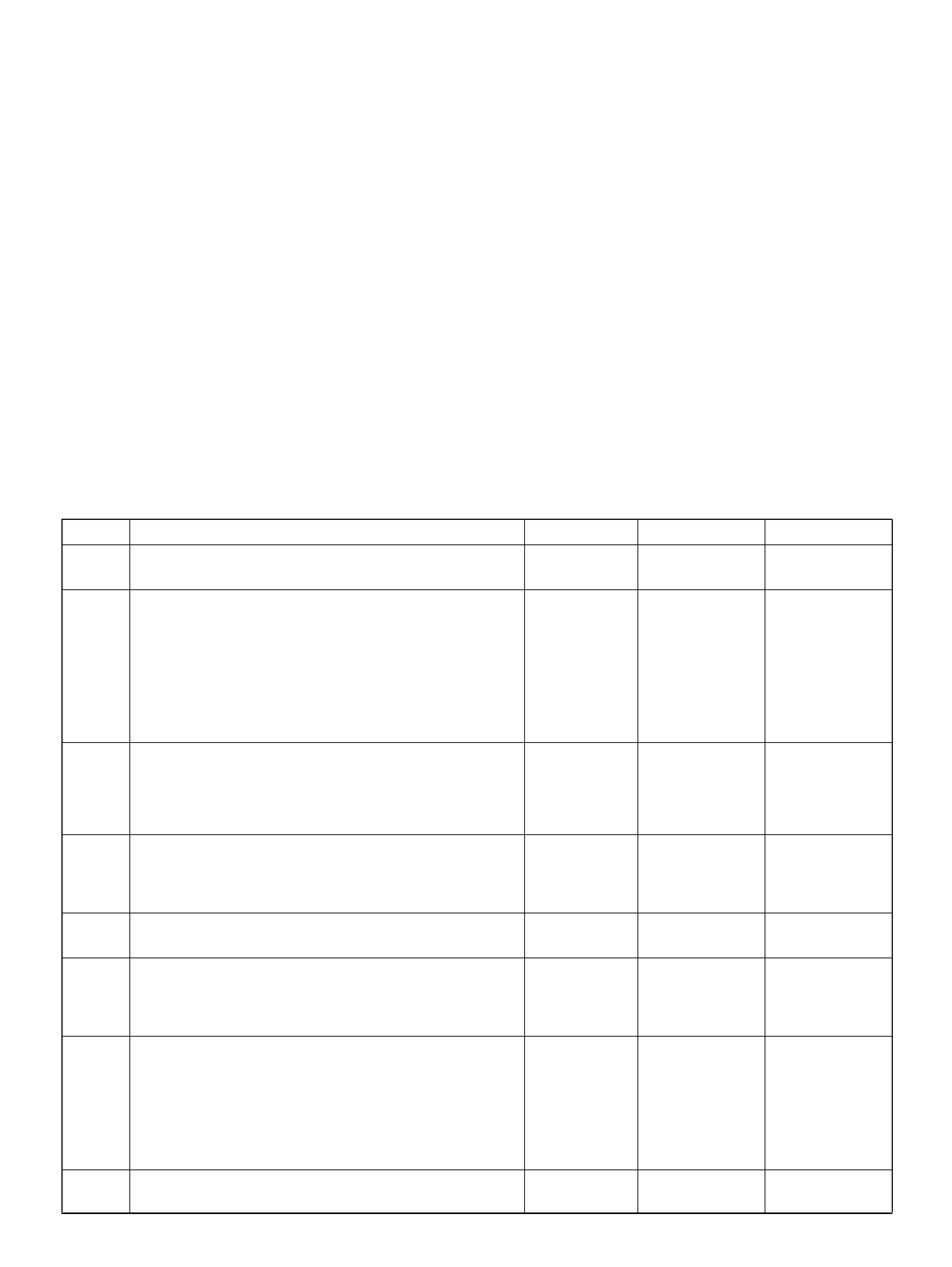

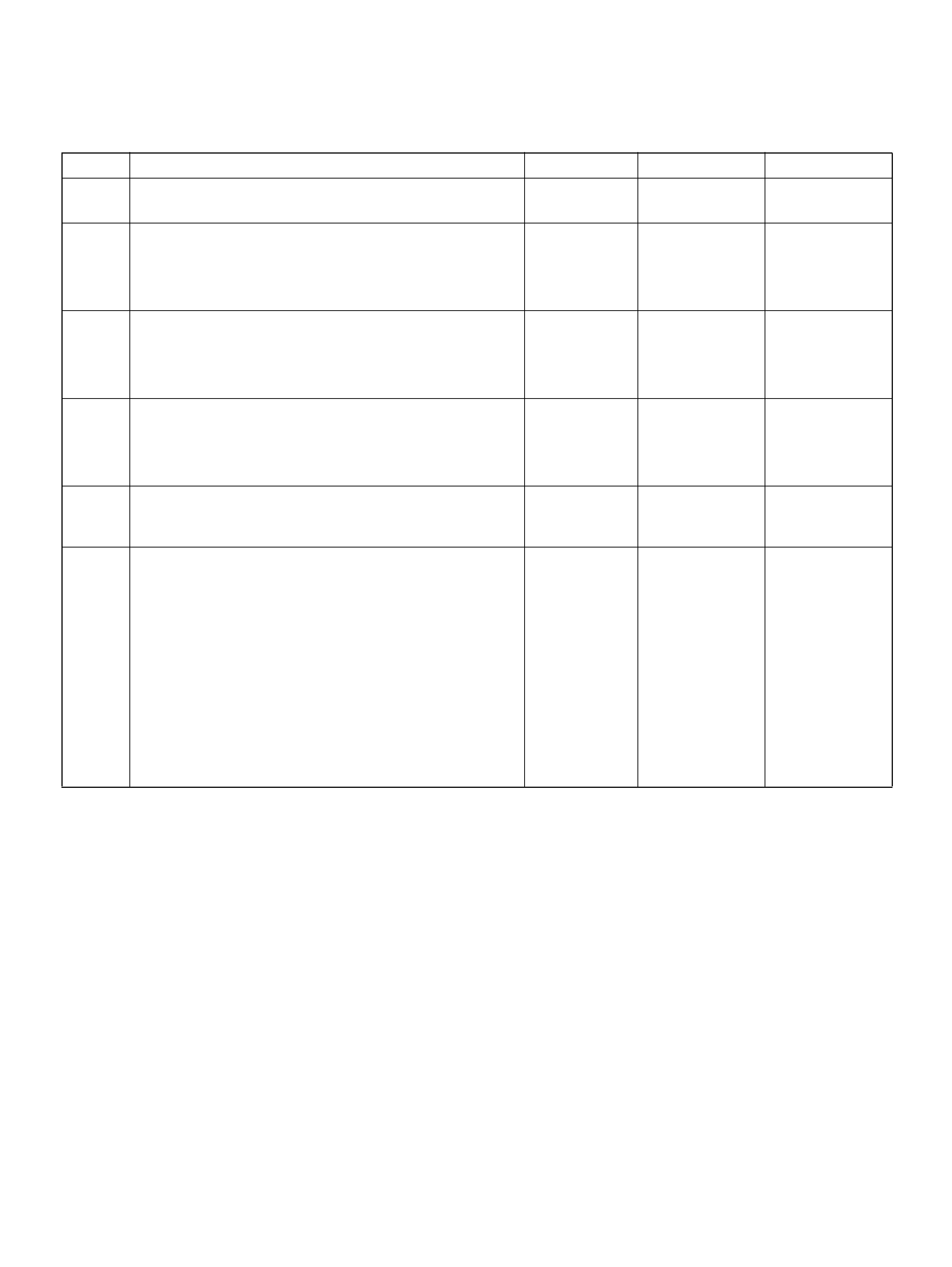

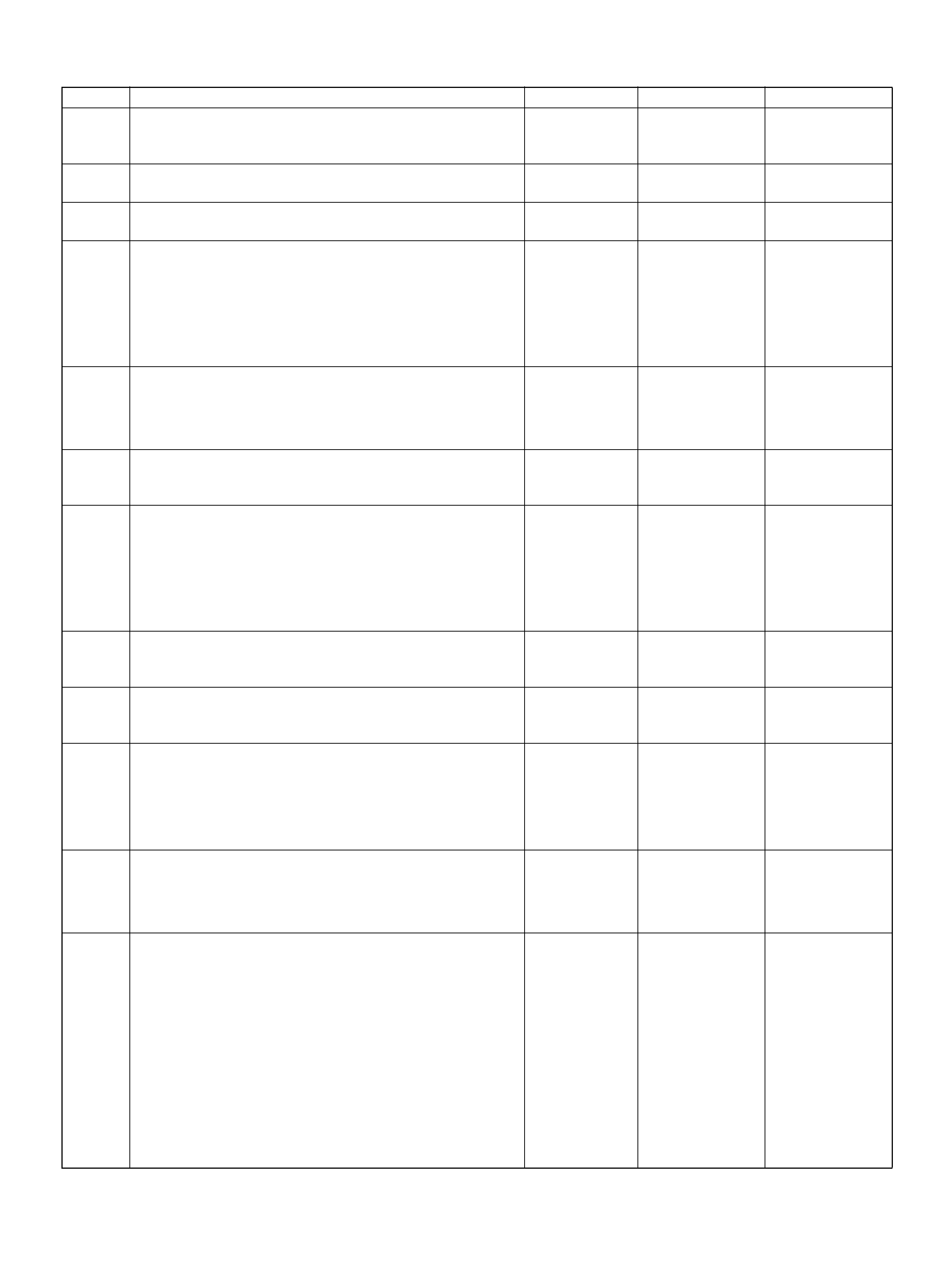

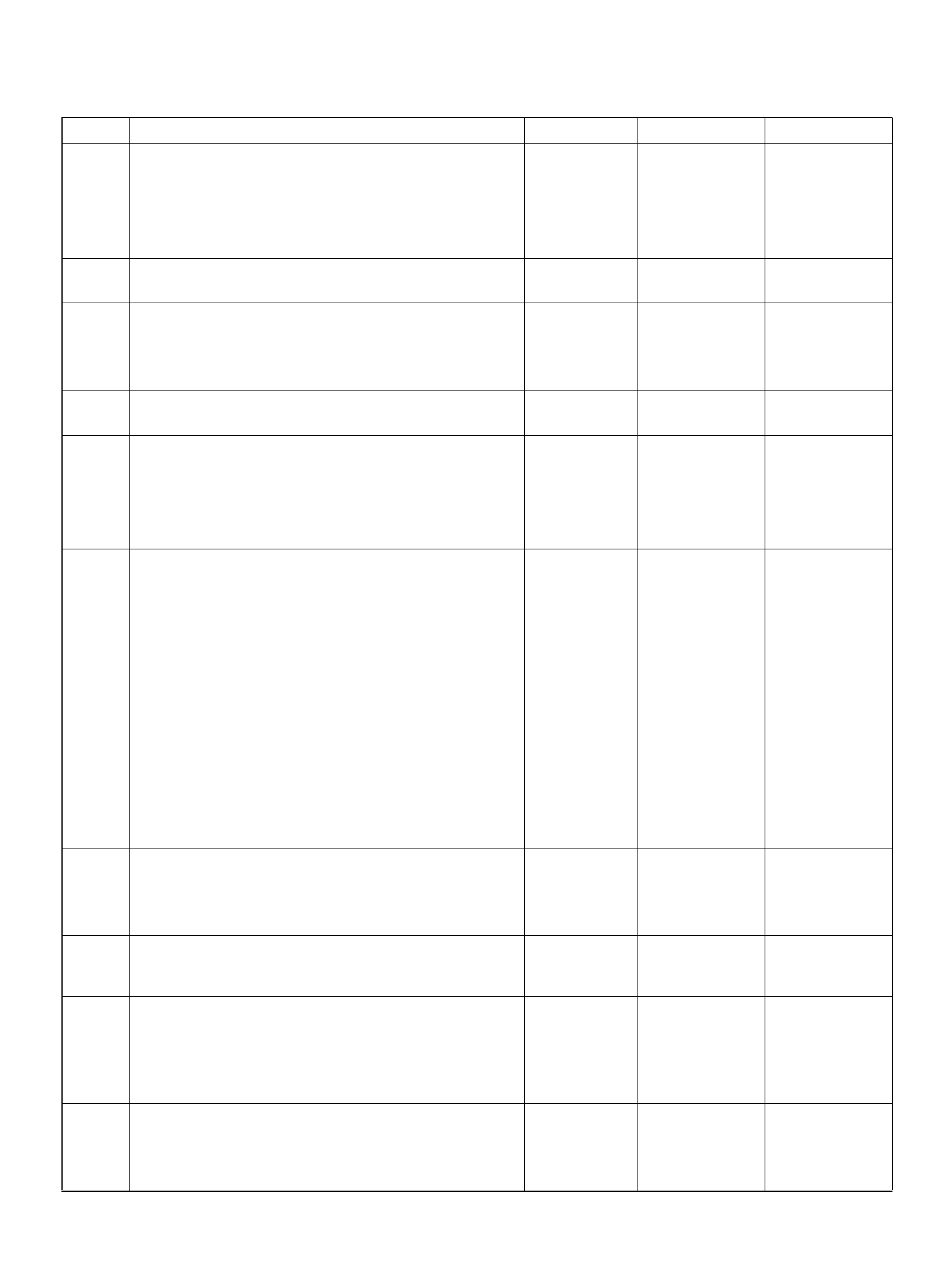

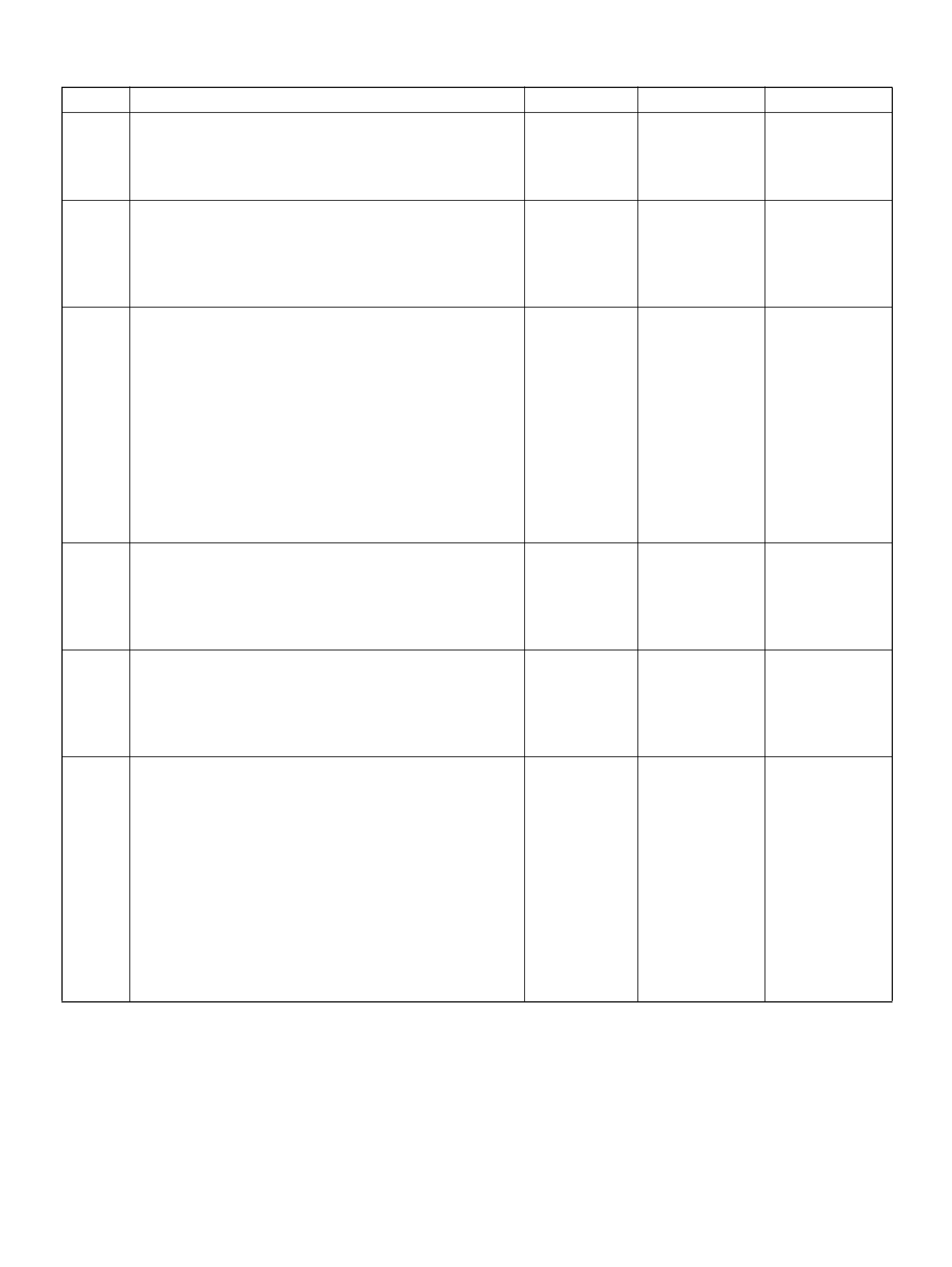

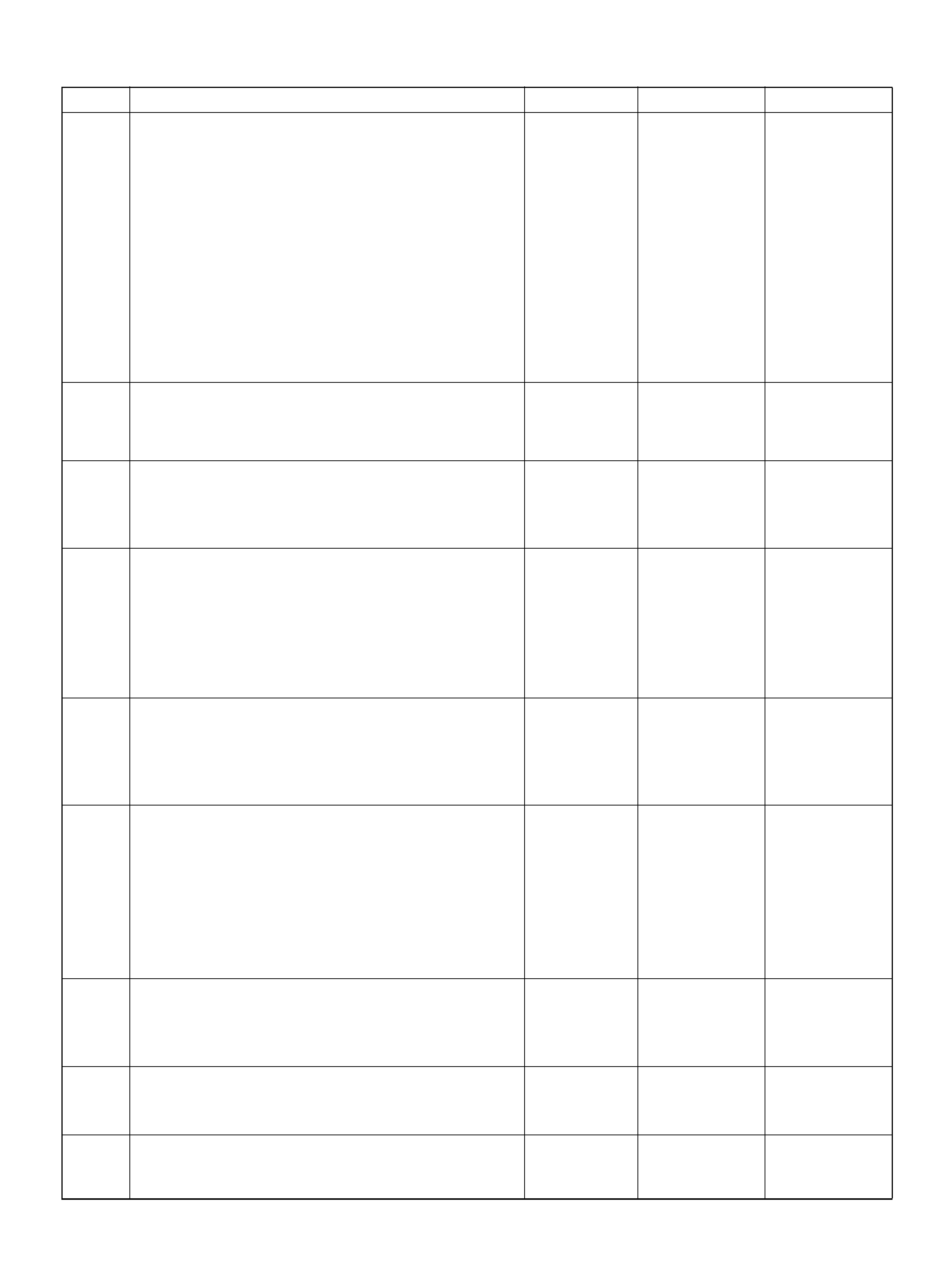

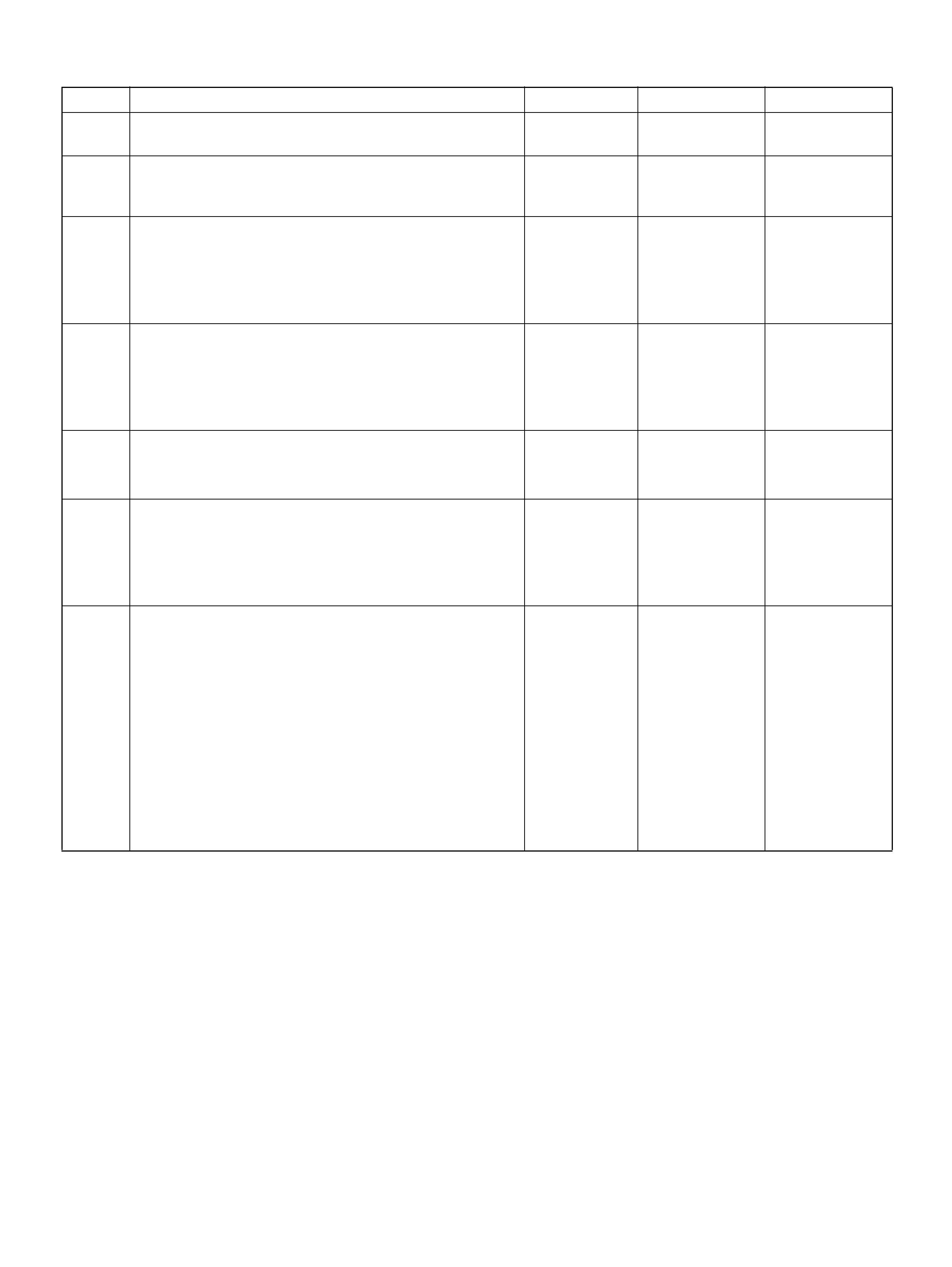

PCM PINOUT TABLE, 80-WAY BLUE CONNECTOR – ROW “F1 ∼ 20"

060RY00045

PIN PIN Function Wire Color IGN ON ENG RUN

F1 PCM Gr oun d BLK 0.0V 0.0 V

F2 5Volt Reference“2" (AP Sensor 2) GRN 5.0V 5.0V

F3 5Vol t Reference“2" (TP Sensor 2) RED/WHT 5.0V 5.0V

F4 A/C Clutch GRY/RED B+(A/C off) B+(A/C off )

F5 1-2/3-4 Shift Solenoid GRN/RED 0.0V 0.0V

F6 Not Used — — —

F7 Tachomet er BLK/RED 8.8V 10.0V (at idle)

F8 Not Used — — —

F9 Not Used — — —

F10 Not Used — — —

F11 TP Sensor (TOD) RED/WHT — —

F12 Not Used — — —

F13 Not Used — — —

F14 Mass Air Flow(MAF) BLK/BLU 4.9V 4 .2V

F15 Not Used — — —

F16 Not Used — — —

F17 Not Used — — —

F18 Not Used — — —

F19 Ignition Feed RED/GRN B+ B+

F20 Ignition Feed RED/WHT B+ B+

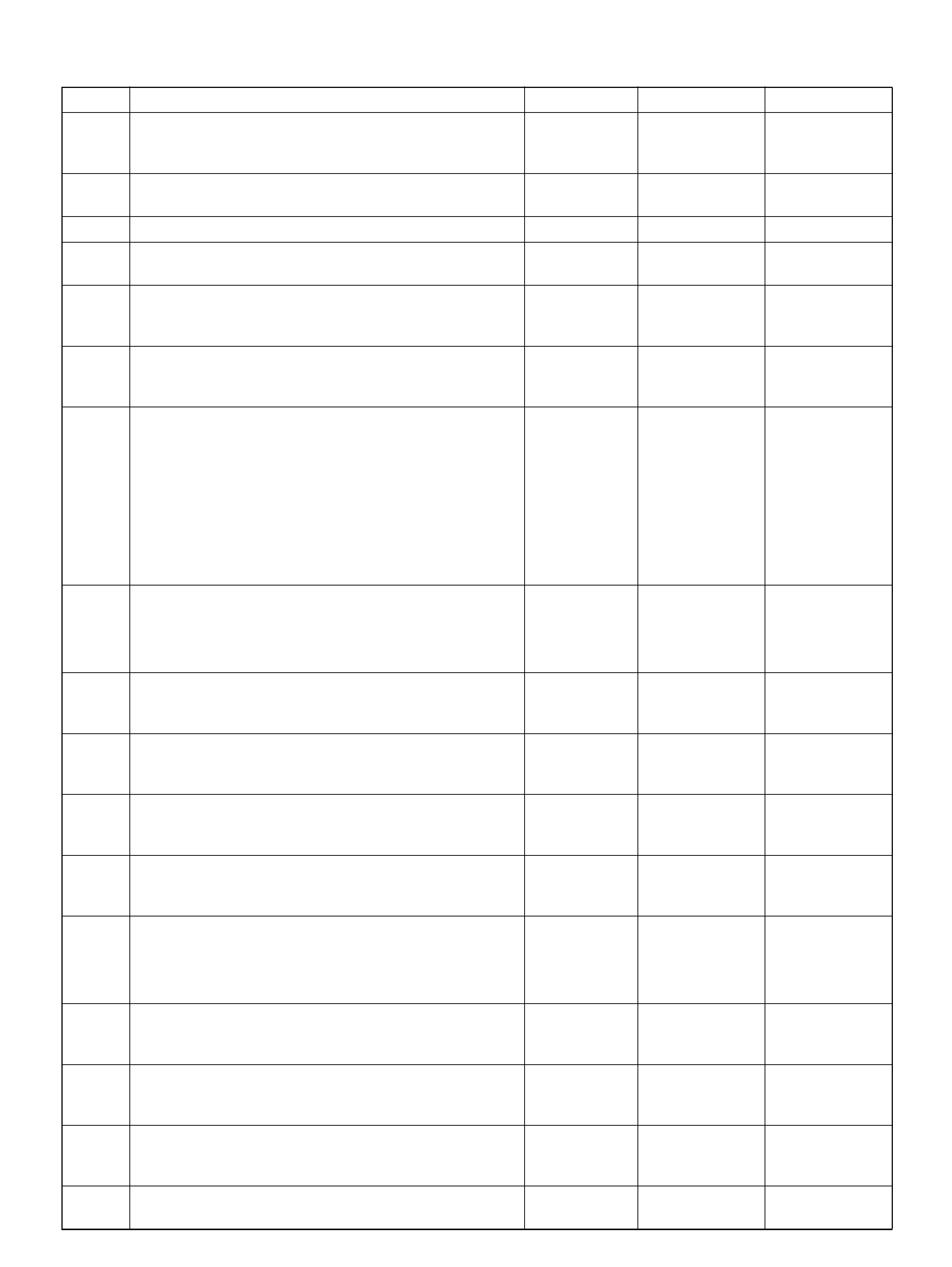

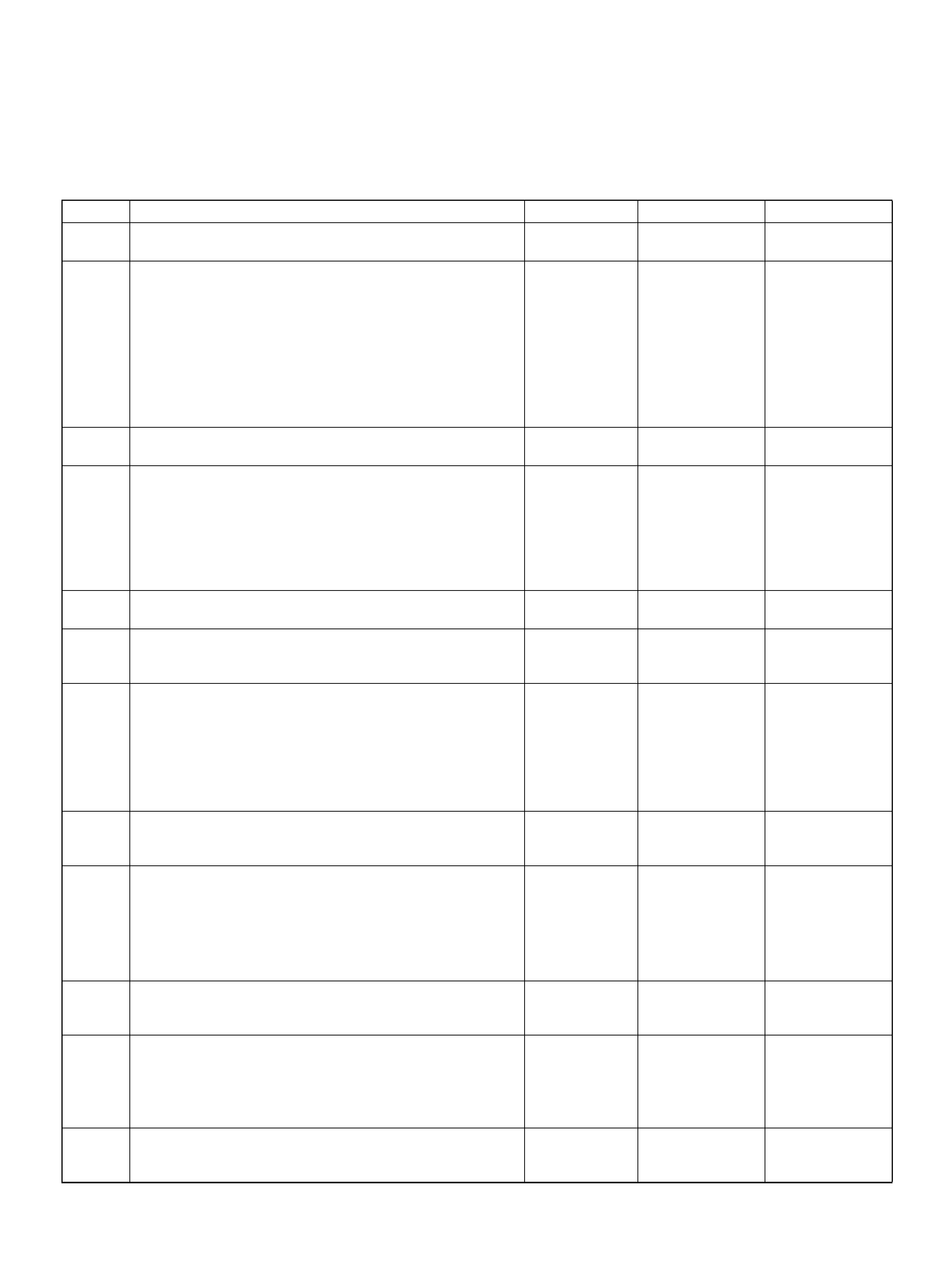

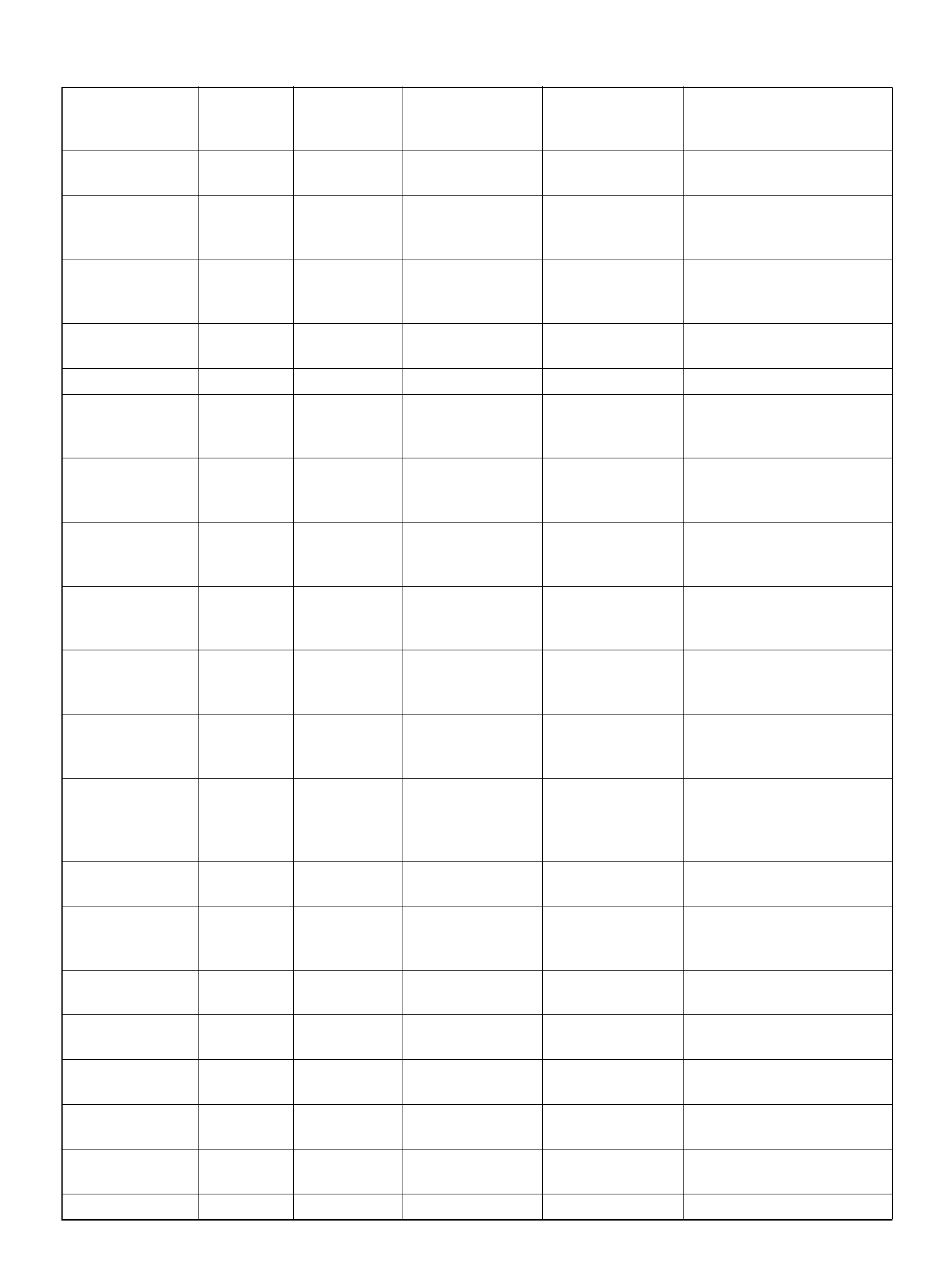

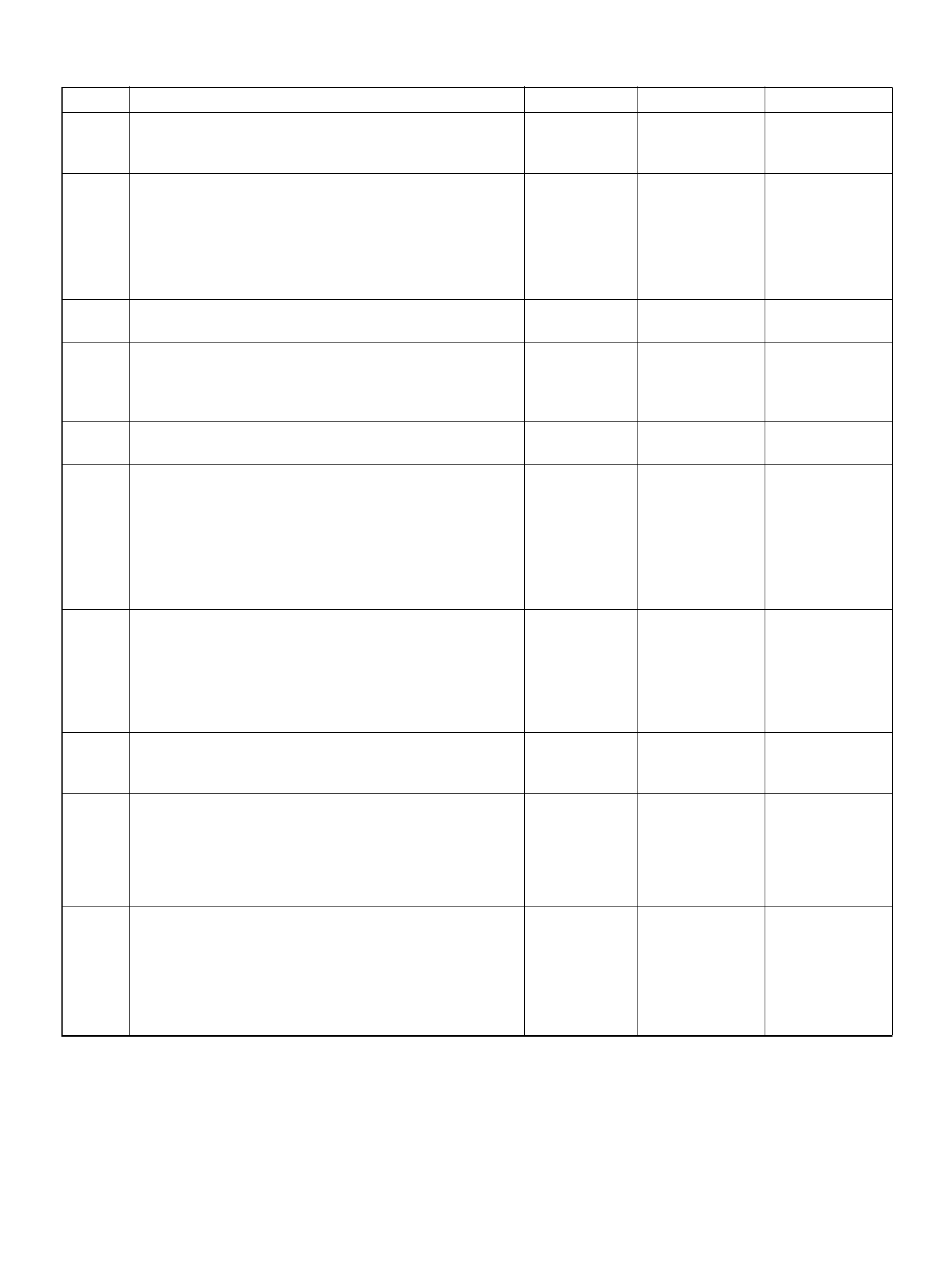

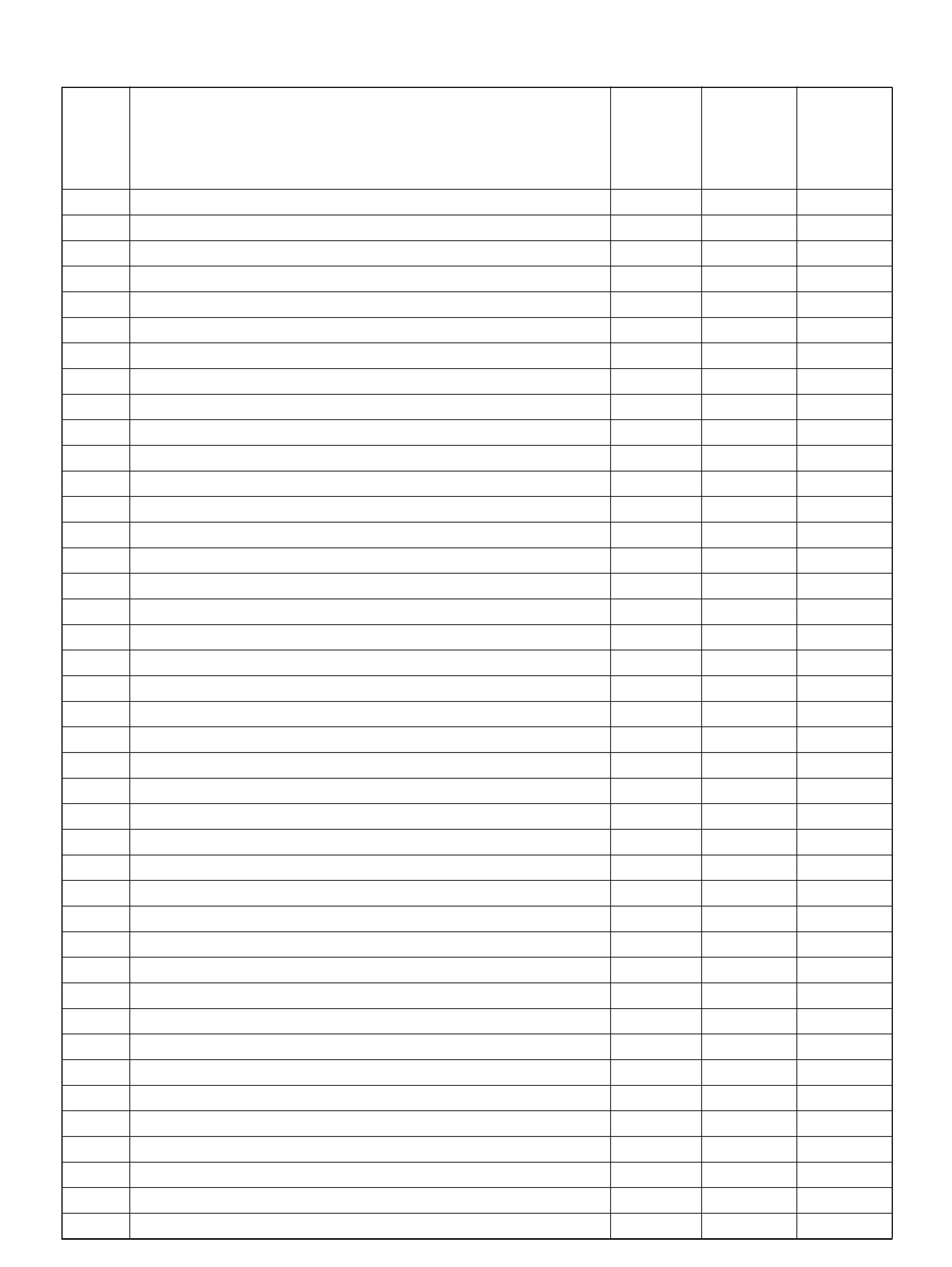

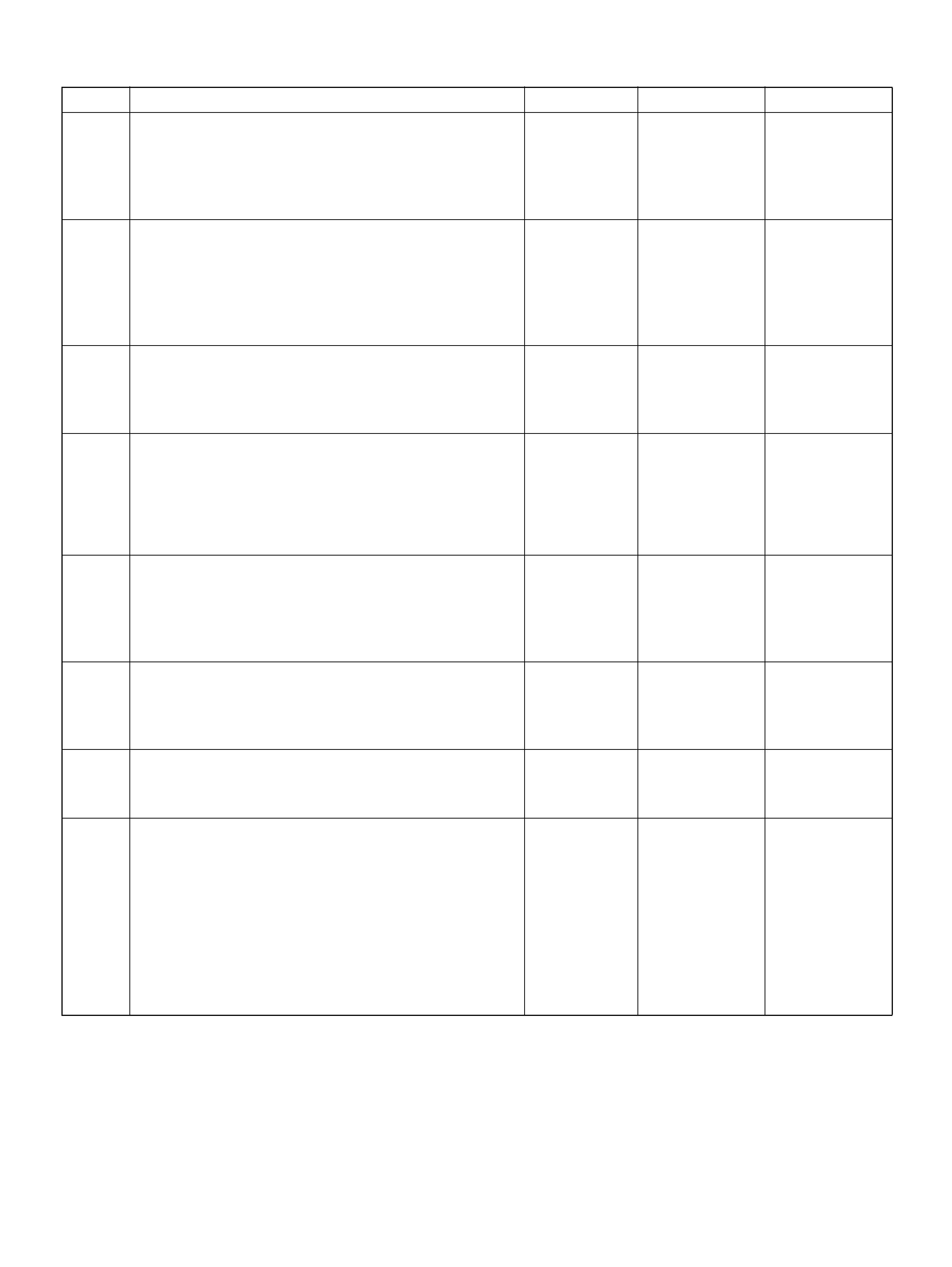

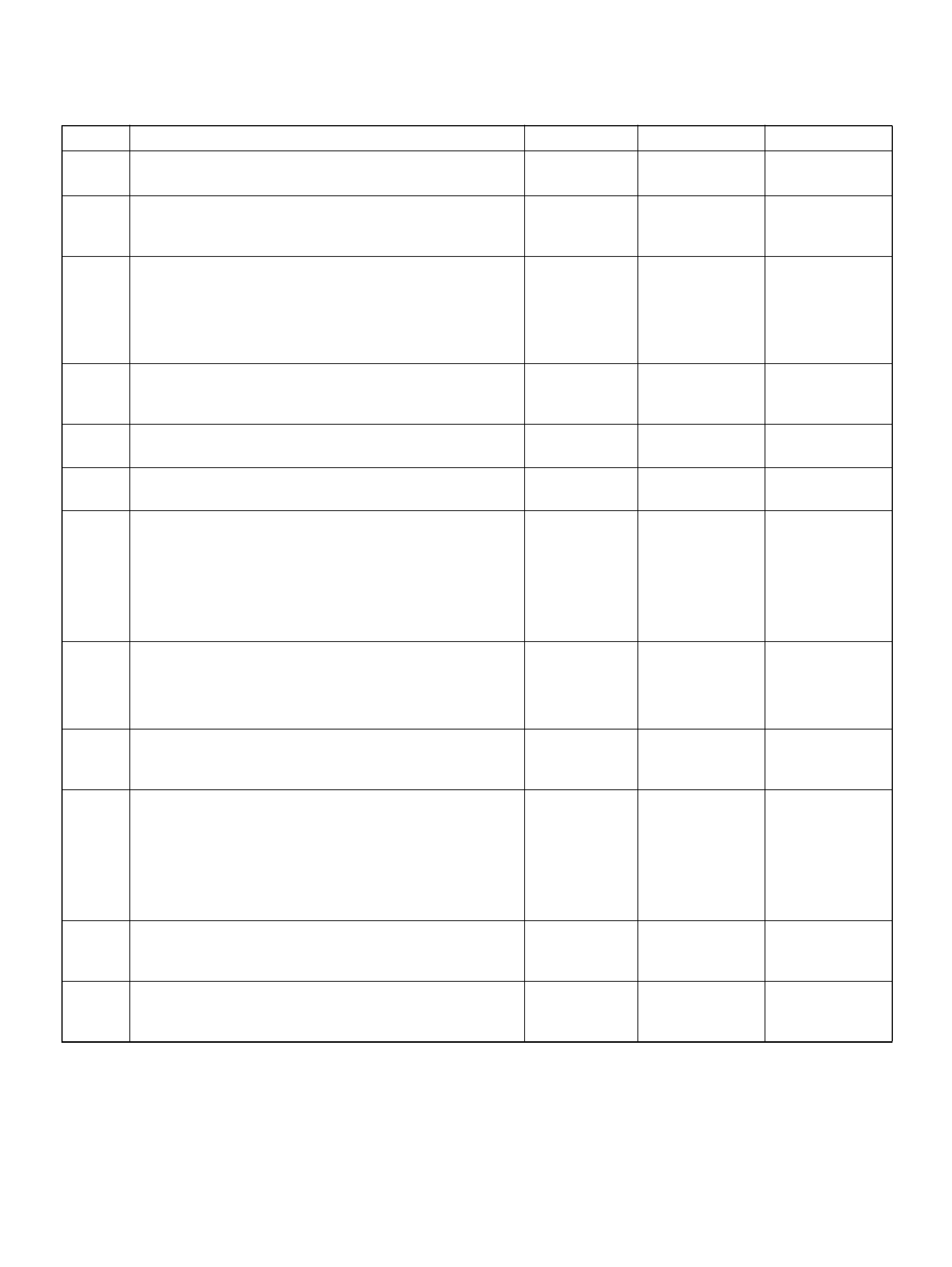

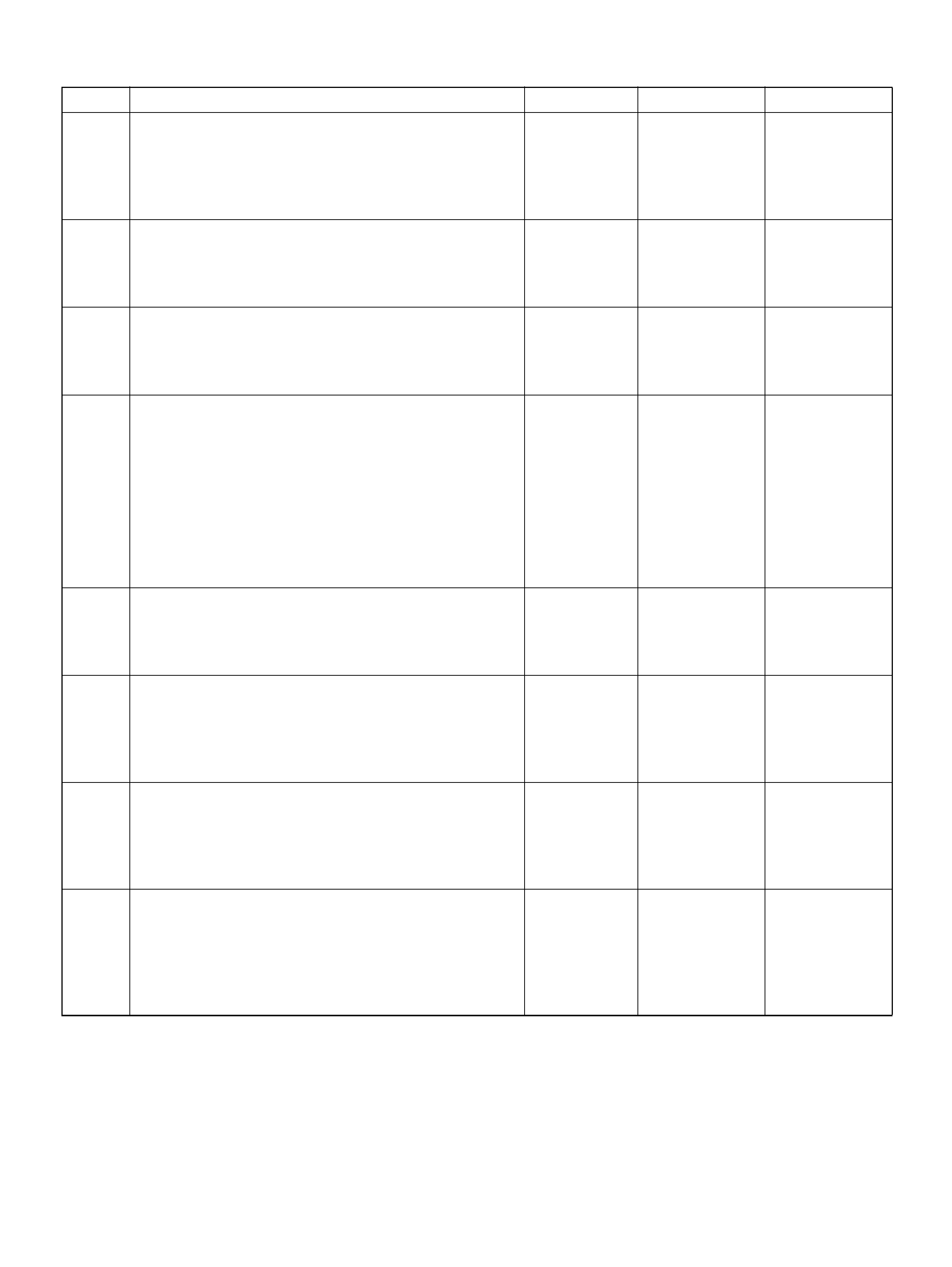

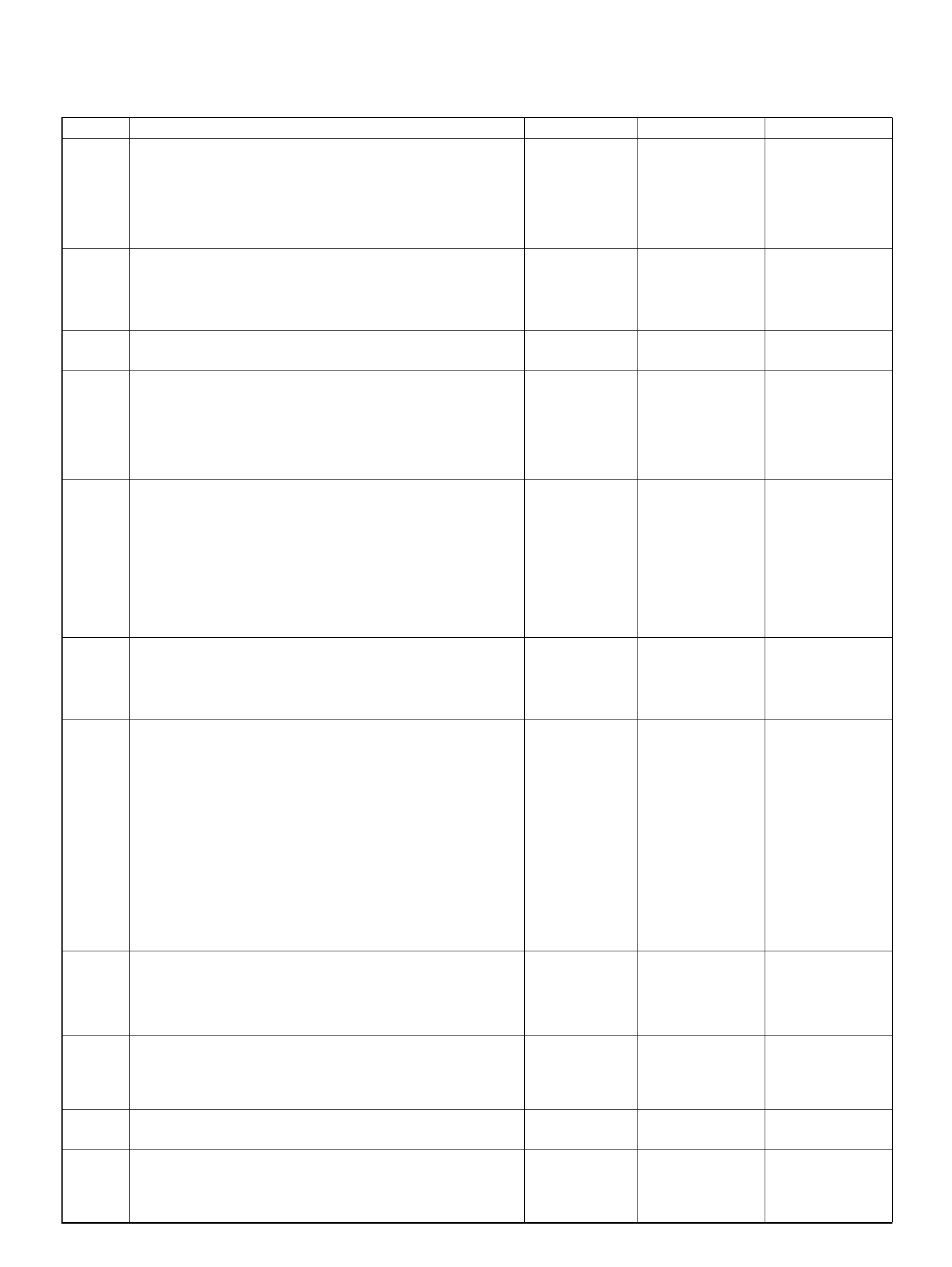

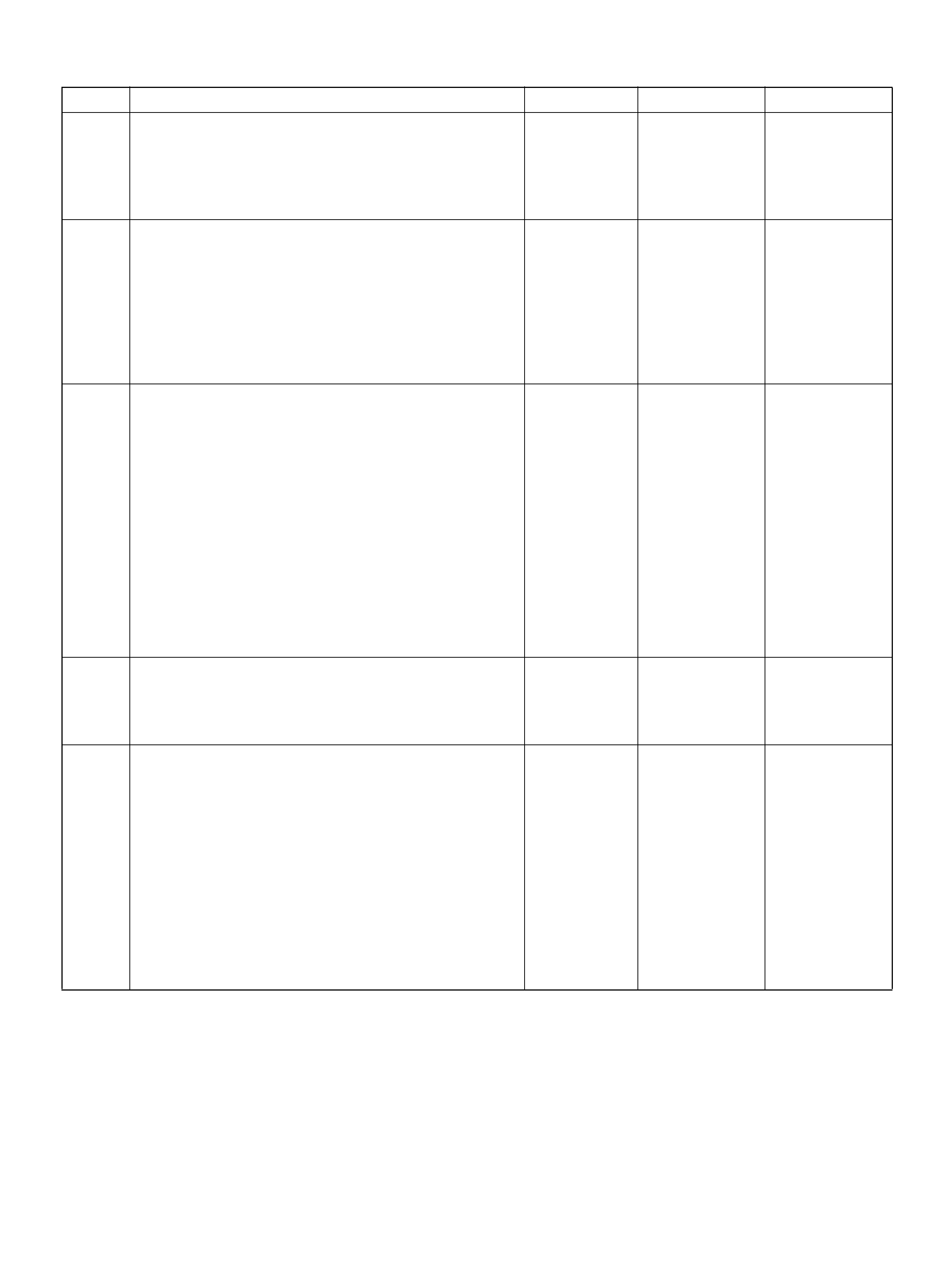

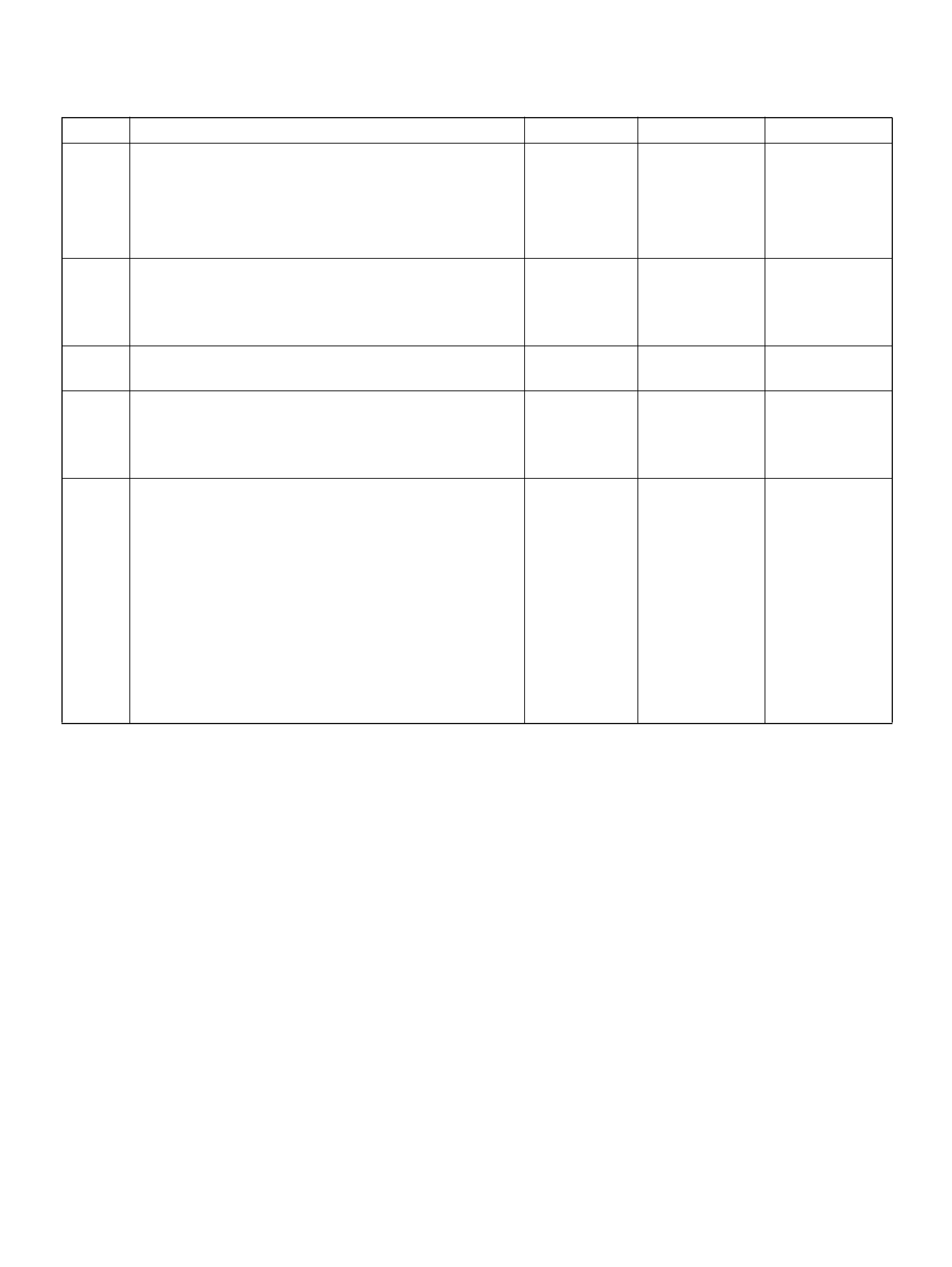

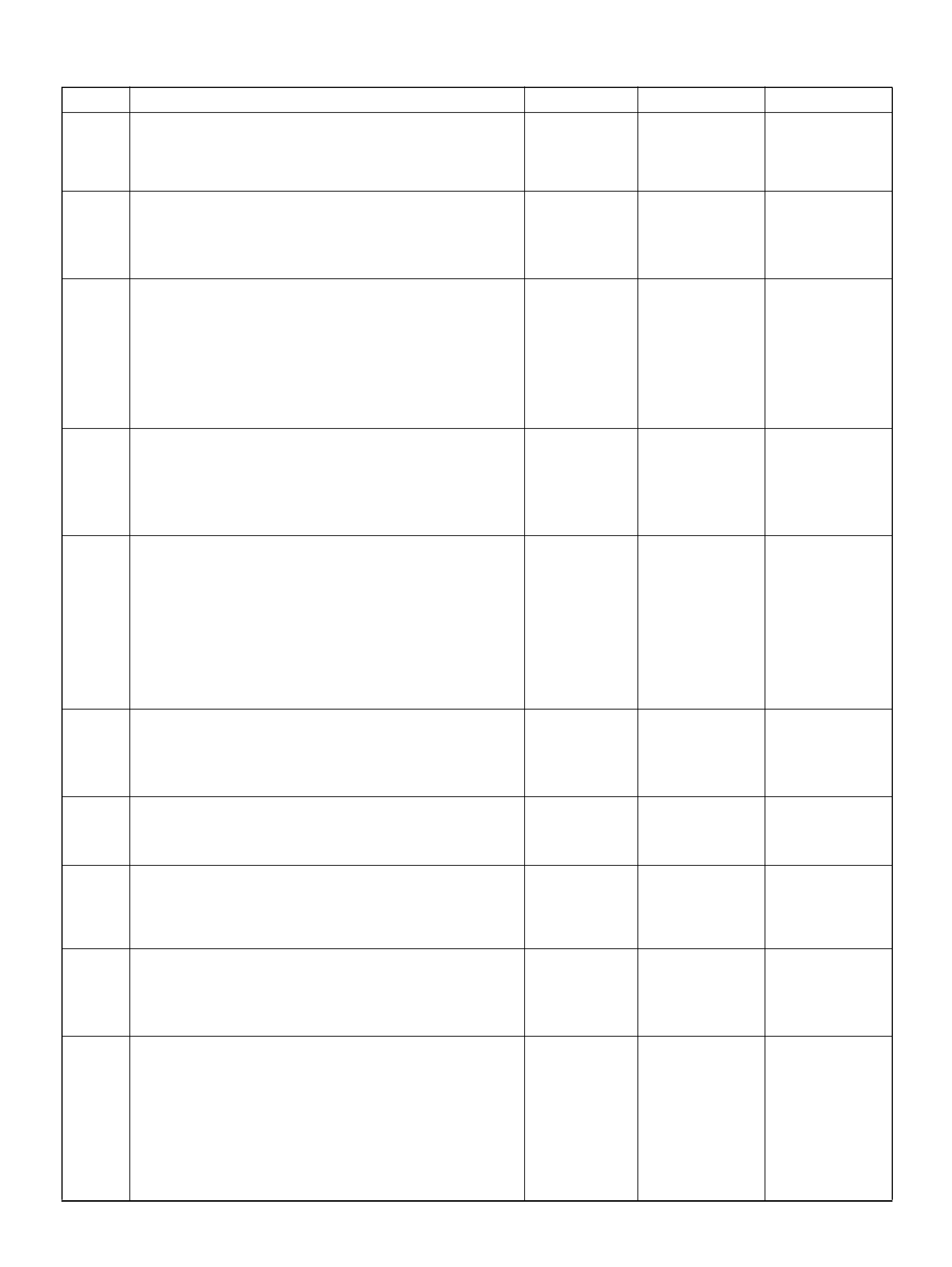

PCM PINOUT TABLE, 80-WAY BLUE CONNECTOR – ROW “F20 ∼ 40"

060RY00156

PIN PIN Function Wire Color IGN ON ENG RUN

F21 Bank 1 HO2S 1 Ground WHT 0.0V 0.0V

F22 Not Used — — —

F23 Bank 2 HO2S 1 Ground BLU 0.0V 0.0V

F24 Not Used — — —

F25 ION Sensing Mod ule RED/B LU 1.555V 1.555 V

F26 ION Sensing Mod ule RED/BLK 1. 555V 1 .555V

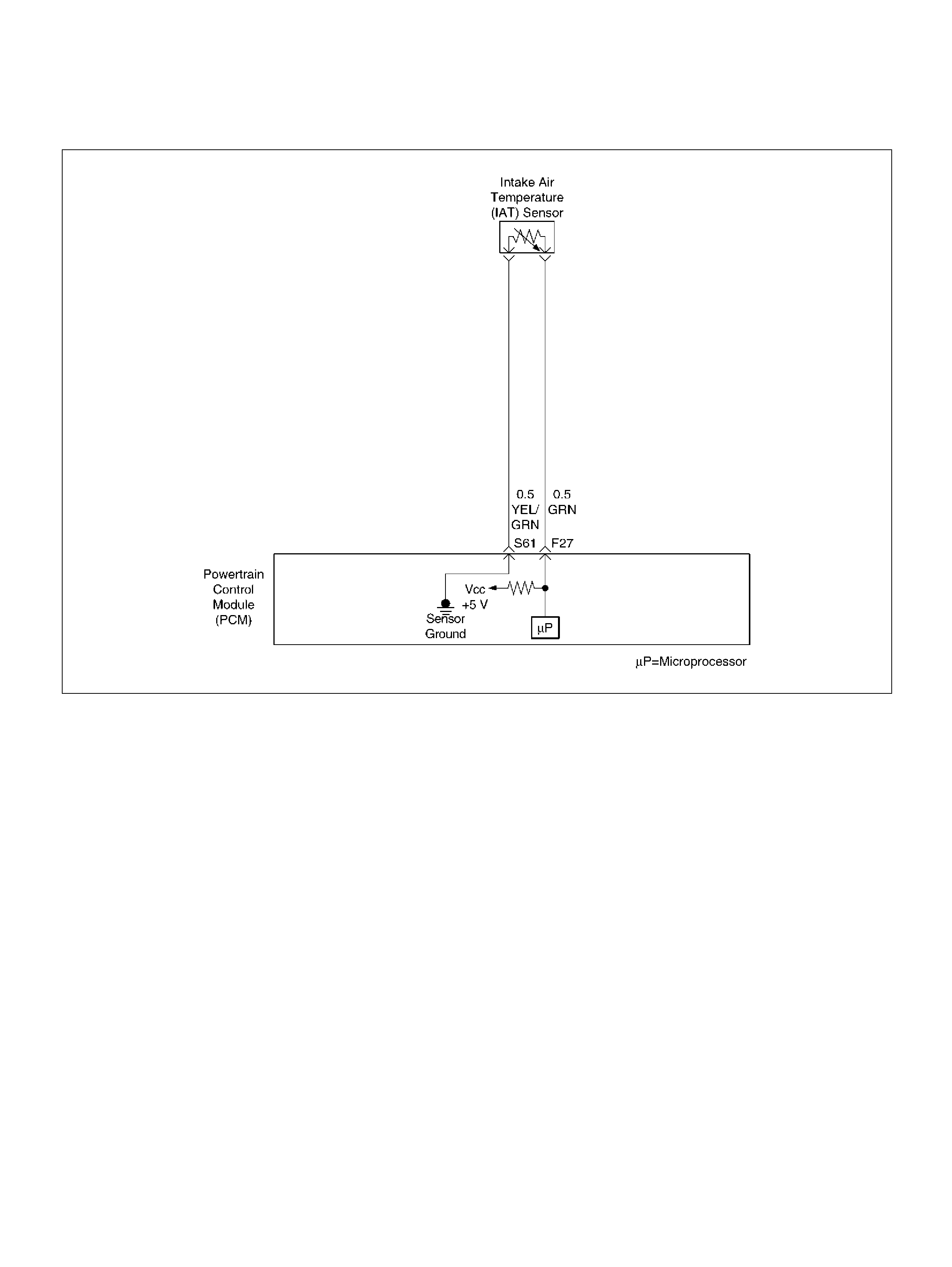

F27 Intake Air Temperature (IAT) Sensor GRN 0.5–4.9V 0.5–4.9V

F28 Not Used — — —

F29 Manifold Absolute Pressure (MAP ) RED 3.5V–4. 9V (depends

on altitude and

barometric pressure)

0.6-1.3V

F30 Not Used — — —

F31 Not Used — — —

F32 Not Used — — —

F33 Not Used — — —

F34 Not Used — — —

F35 Not Used — — —

F36 Not Used — — —

F37 Powe r Steering Pre ssu r e ( PSP) GRN/YEL B+ B+

F38 Illuminated Switch GRN/YEL B+ B+

F39 Brake Switch RED 0.0V 0. 0 V

F40 PCM Groun d BLK/BLU 0.0V 0.0V

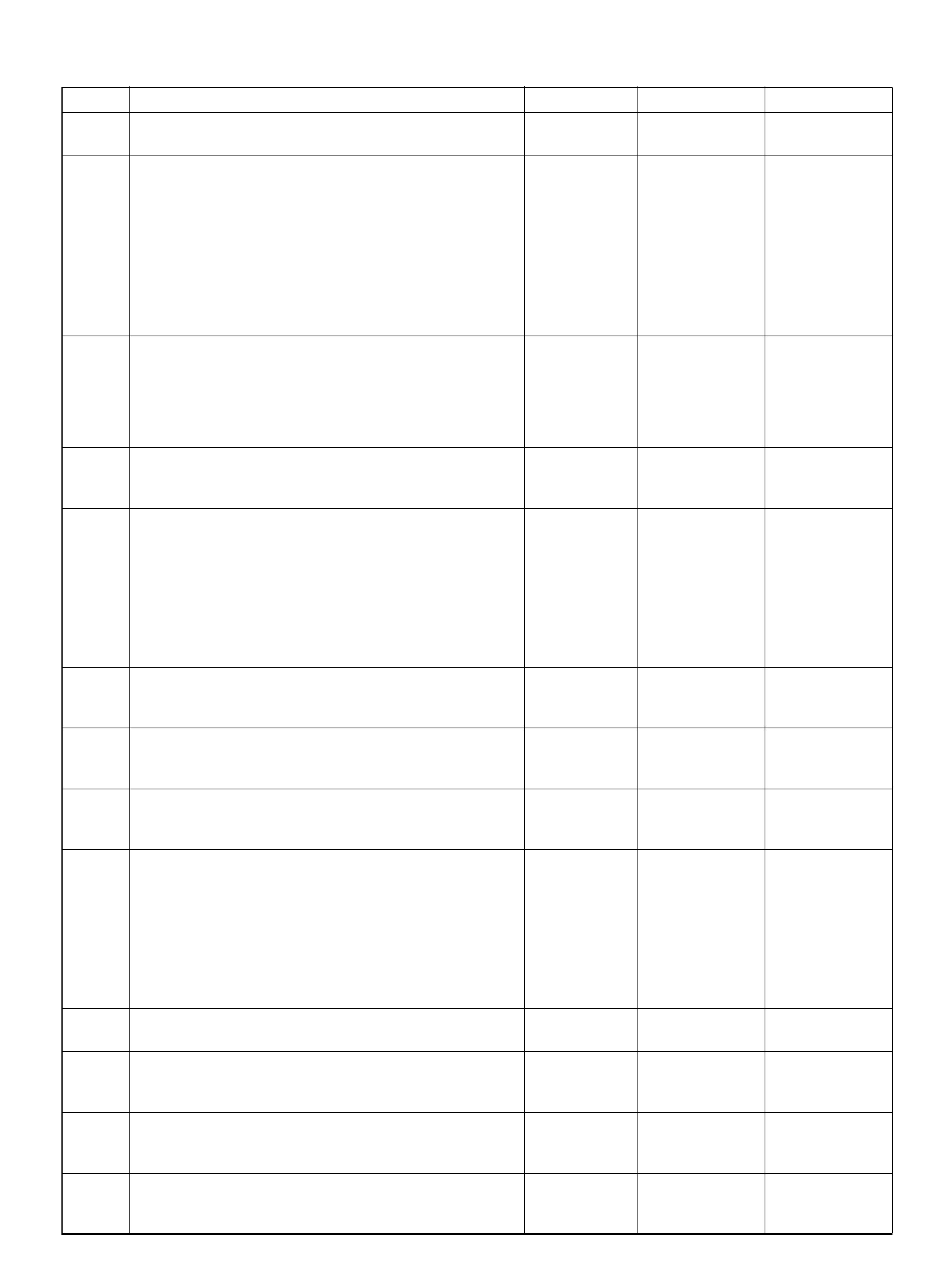

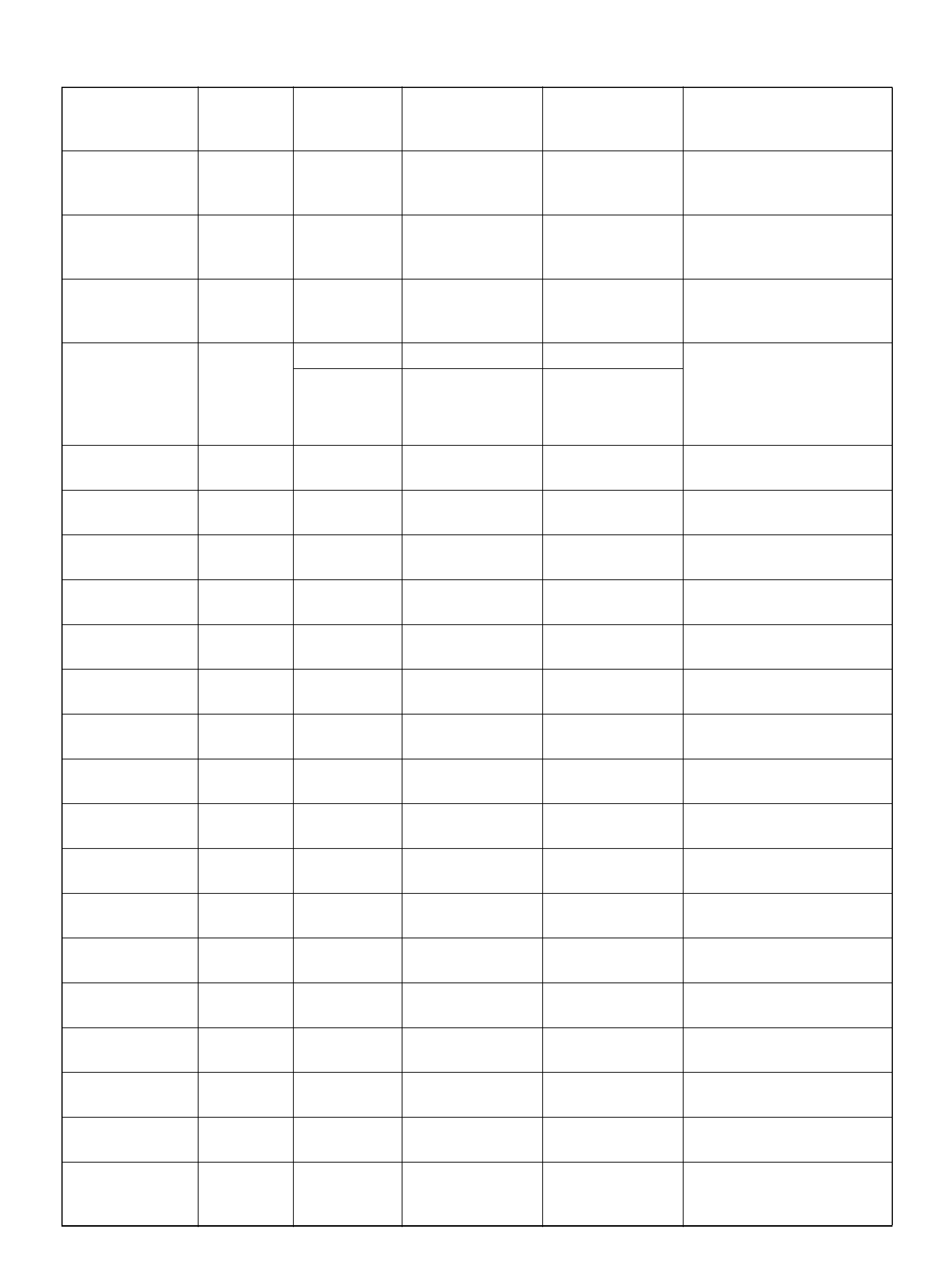

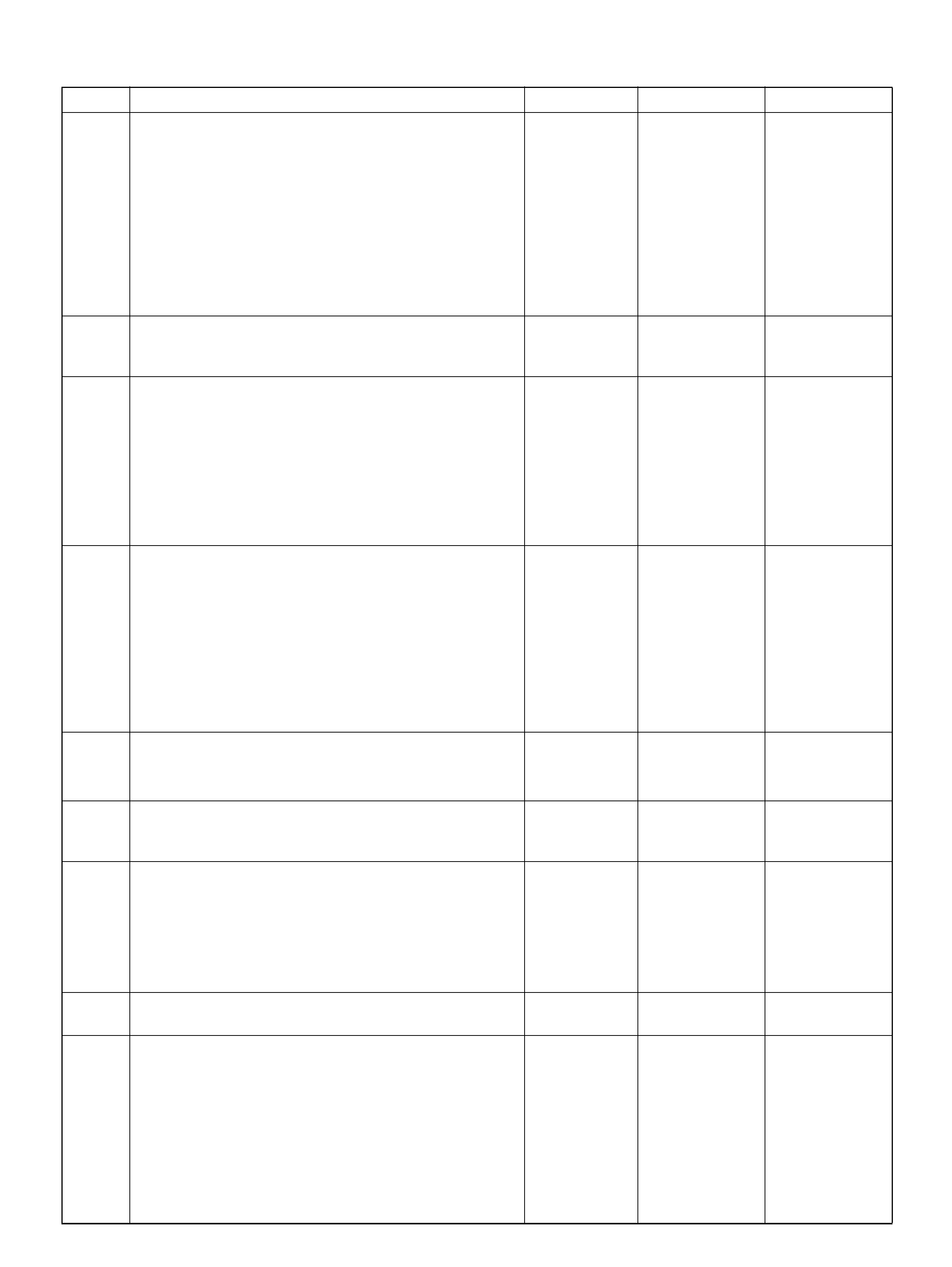

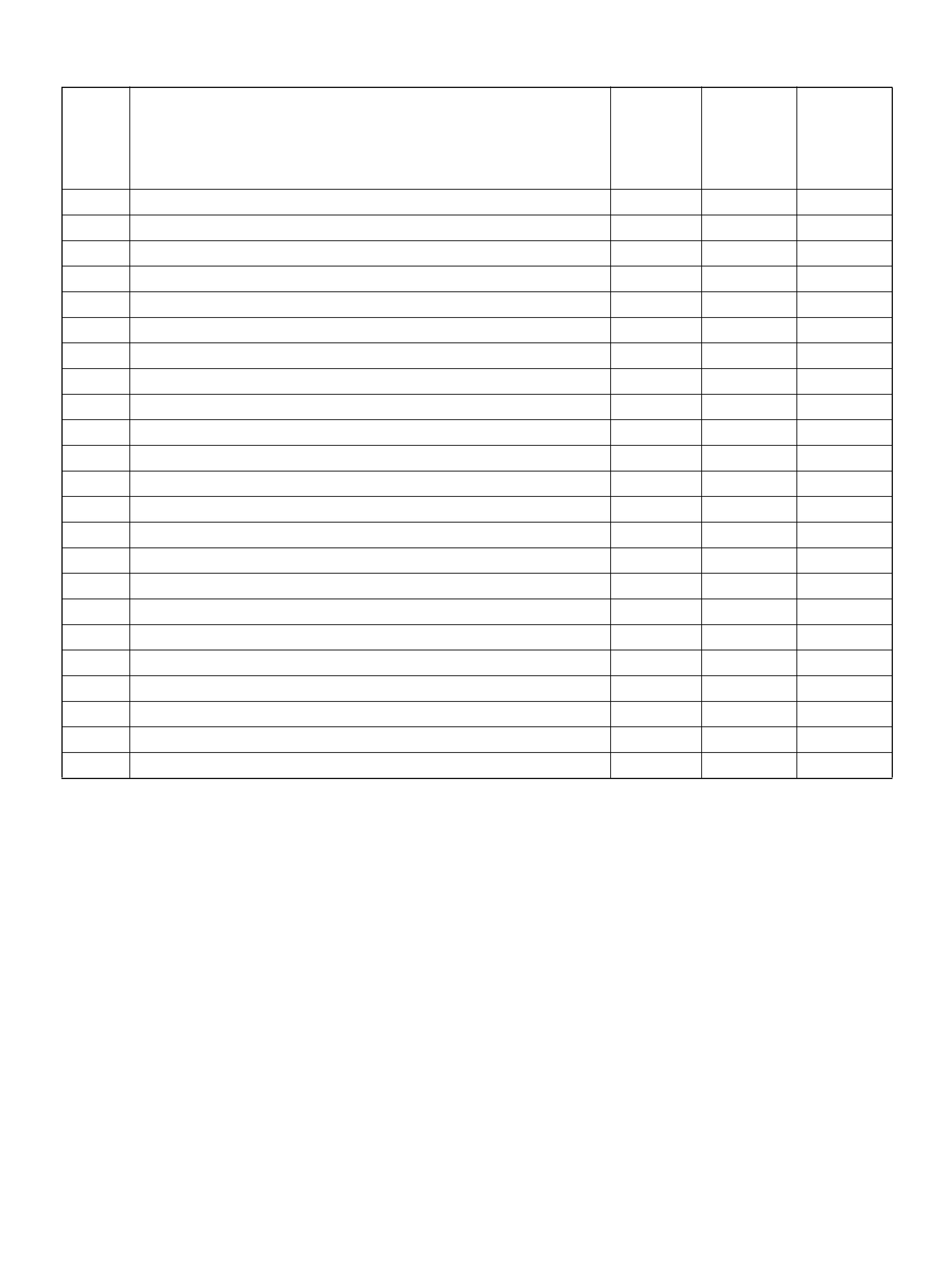

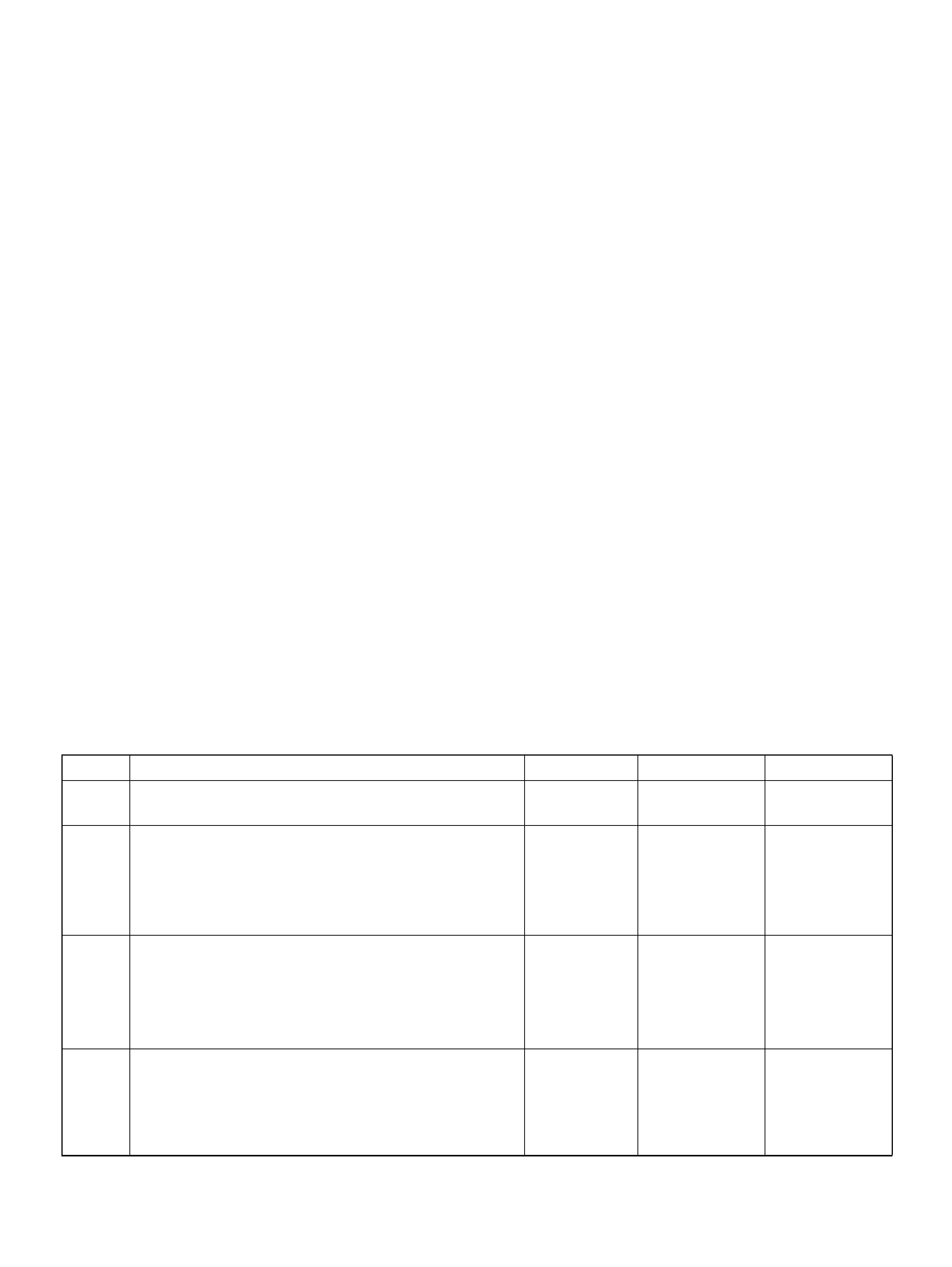

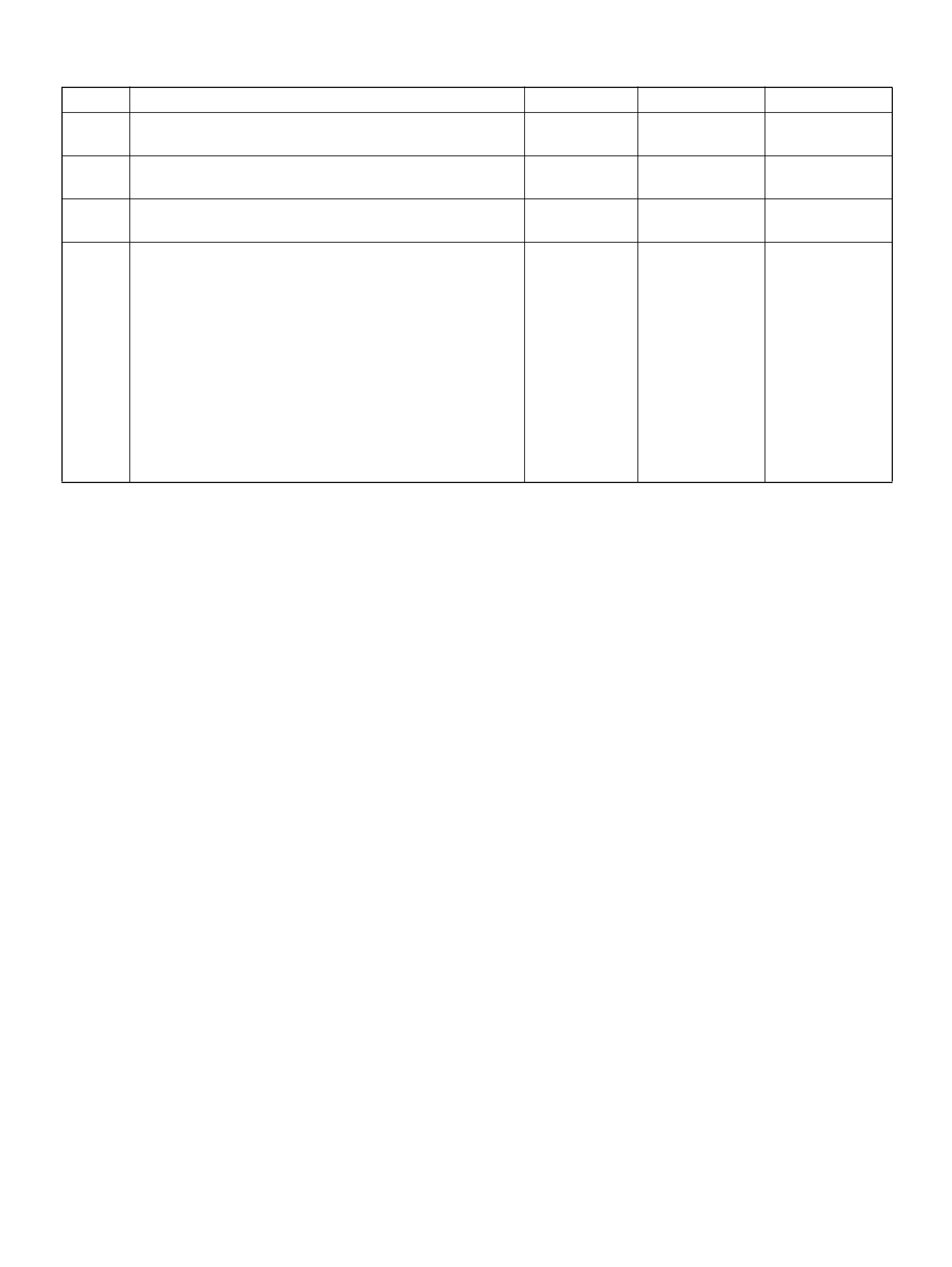

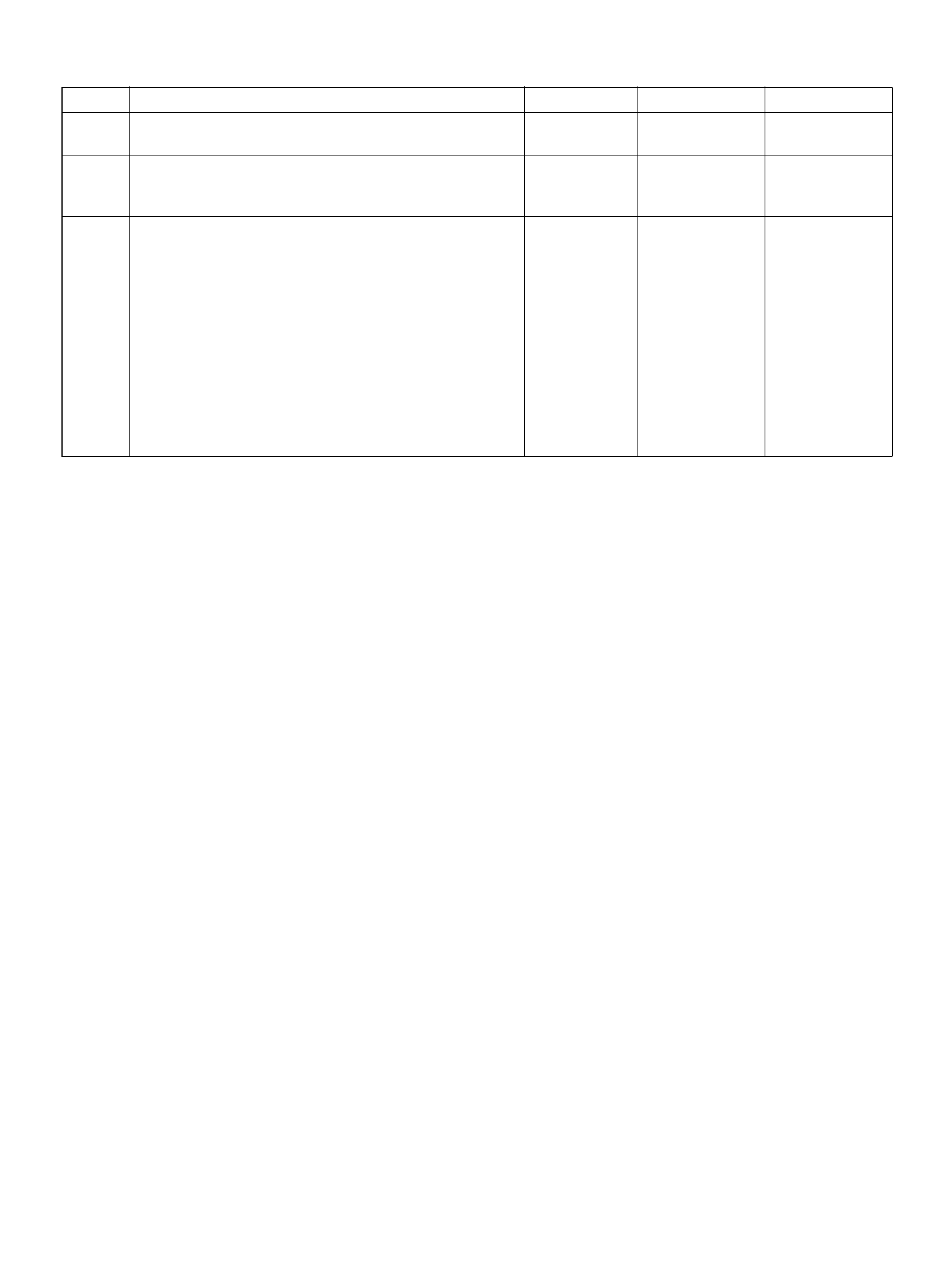

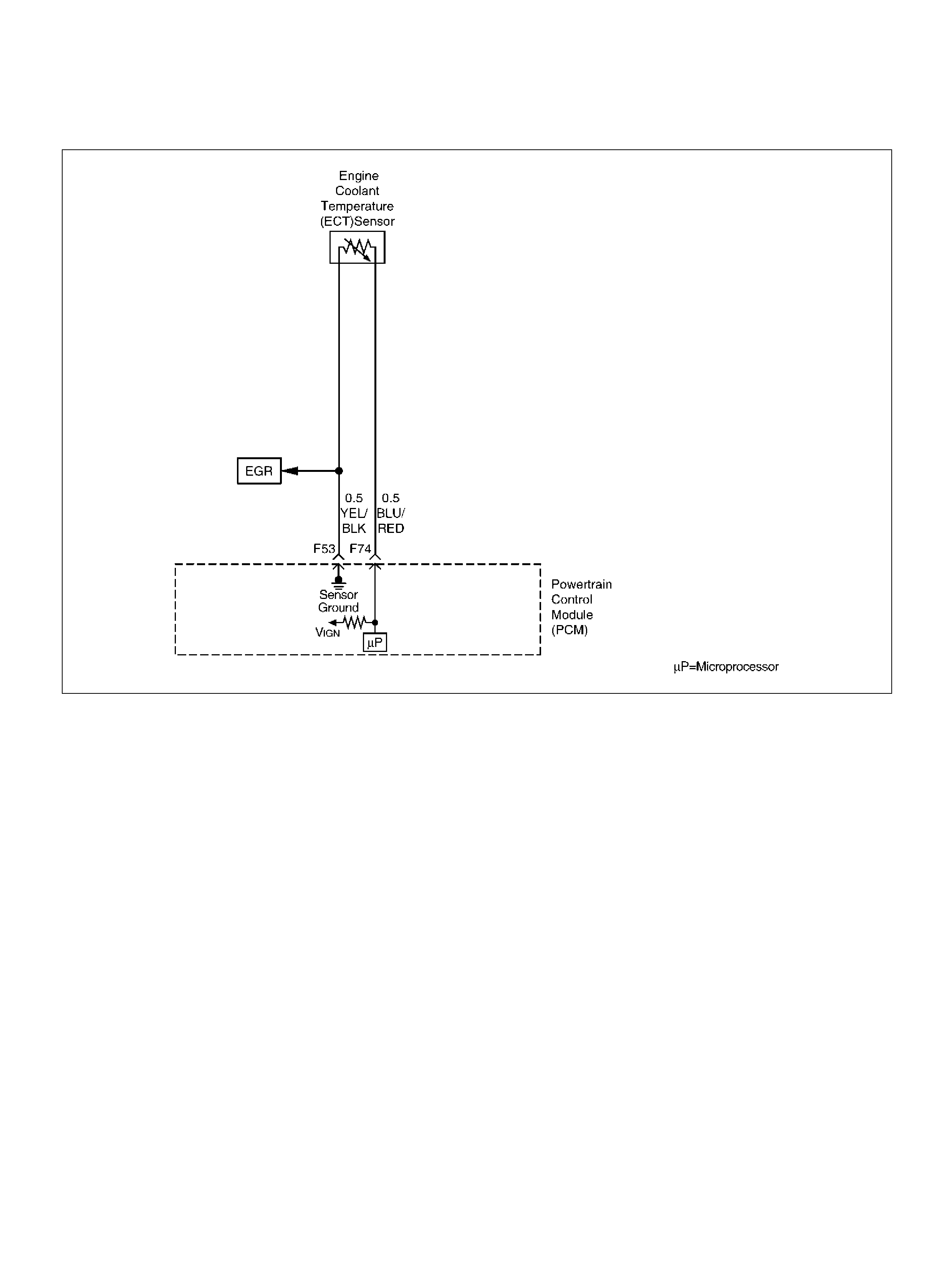

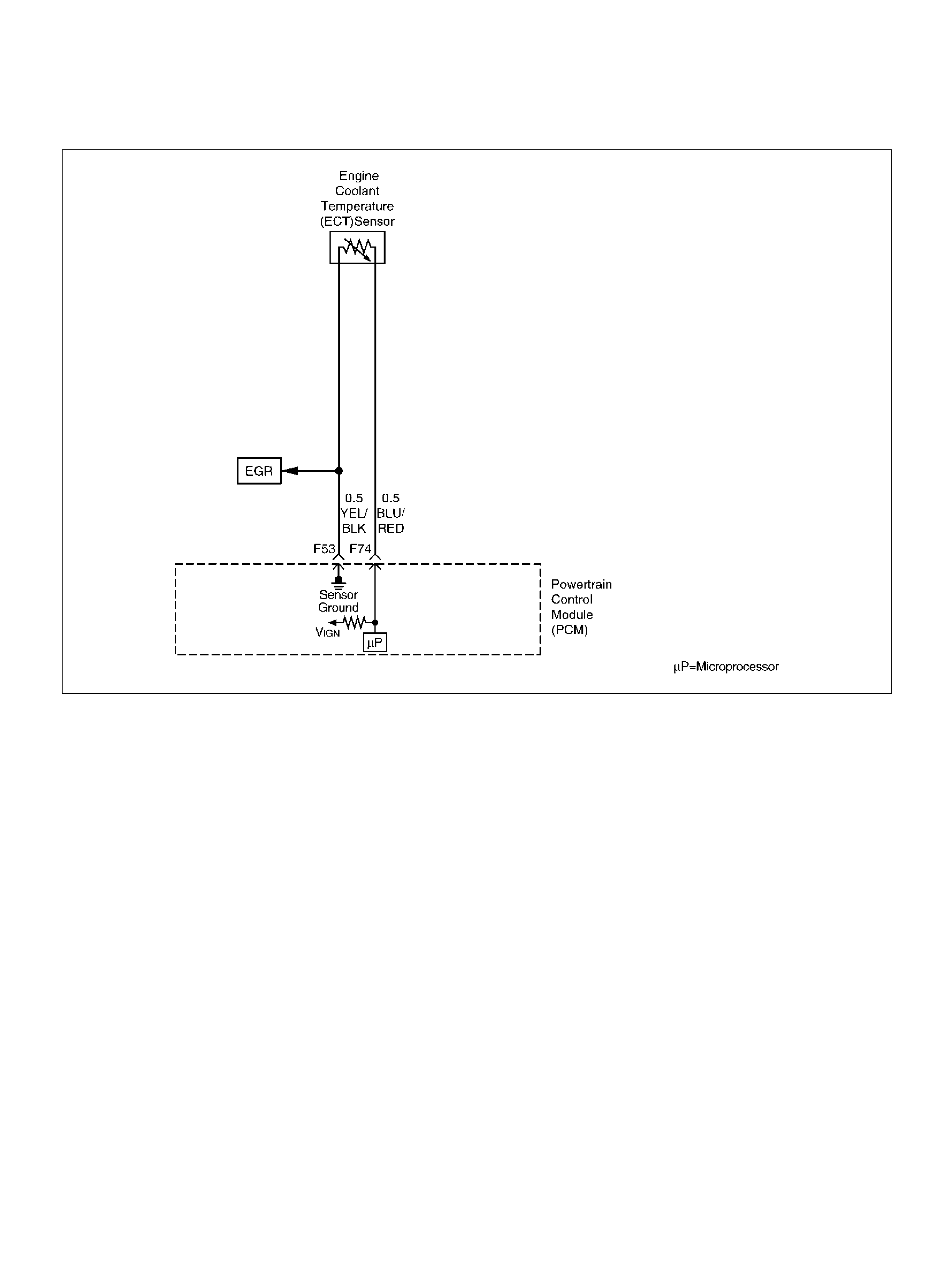

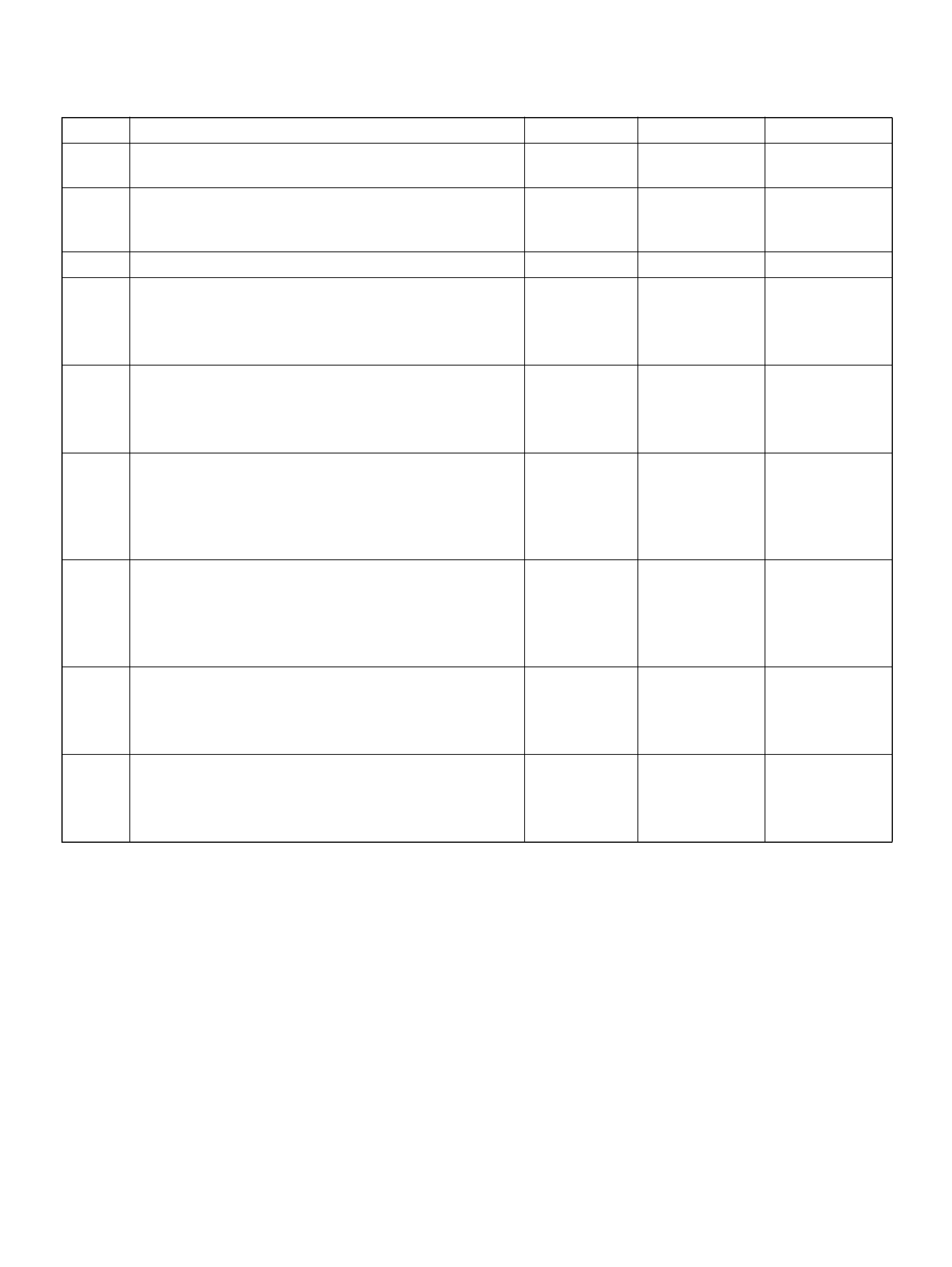

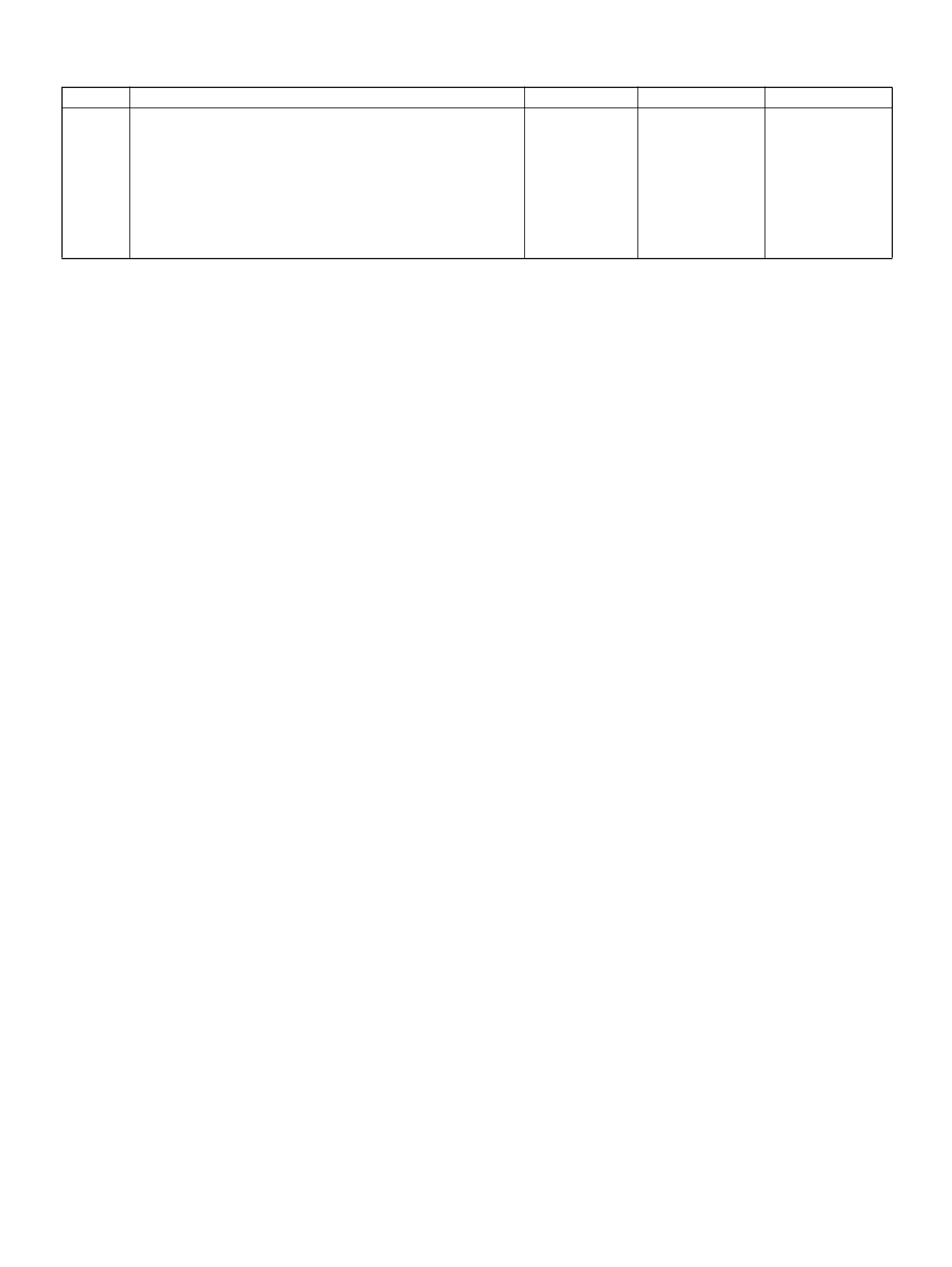

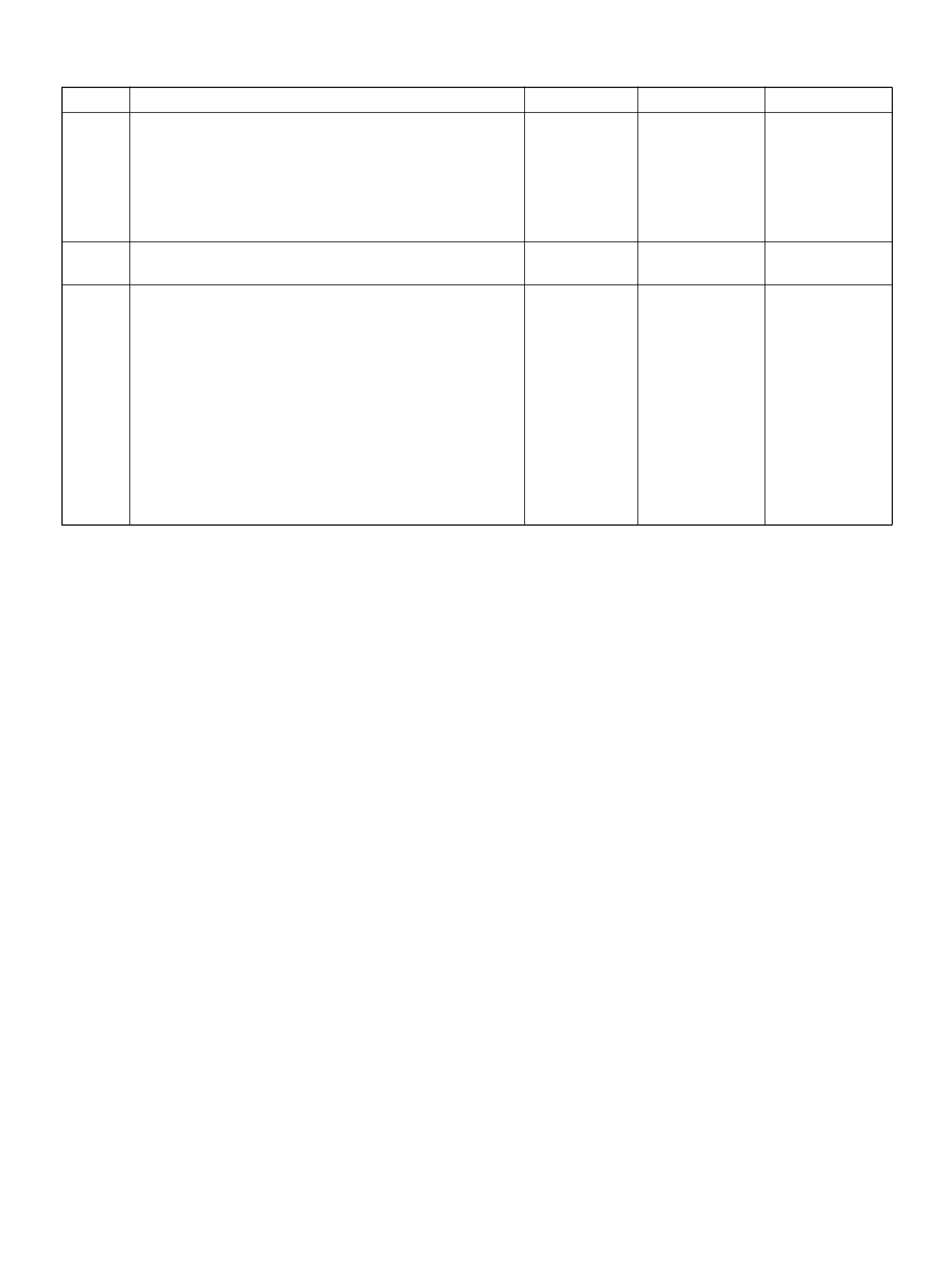

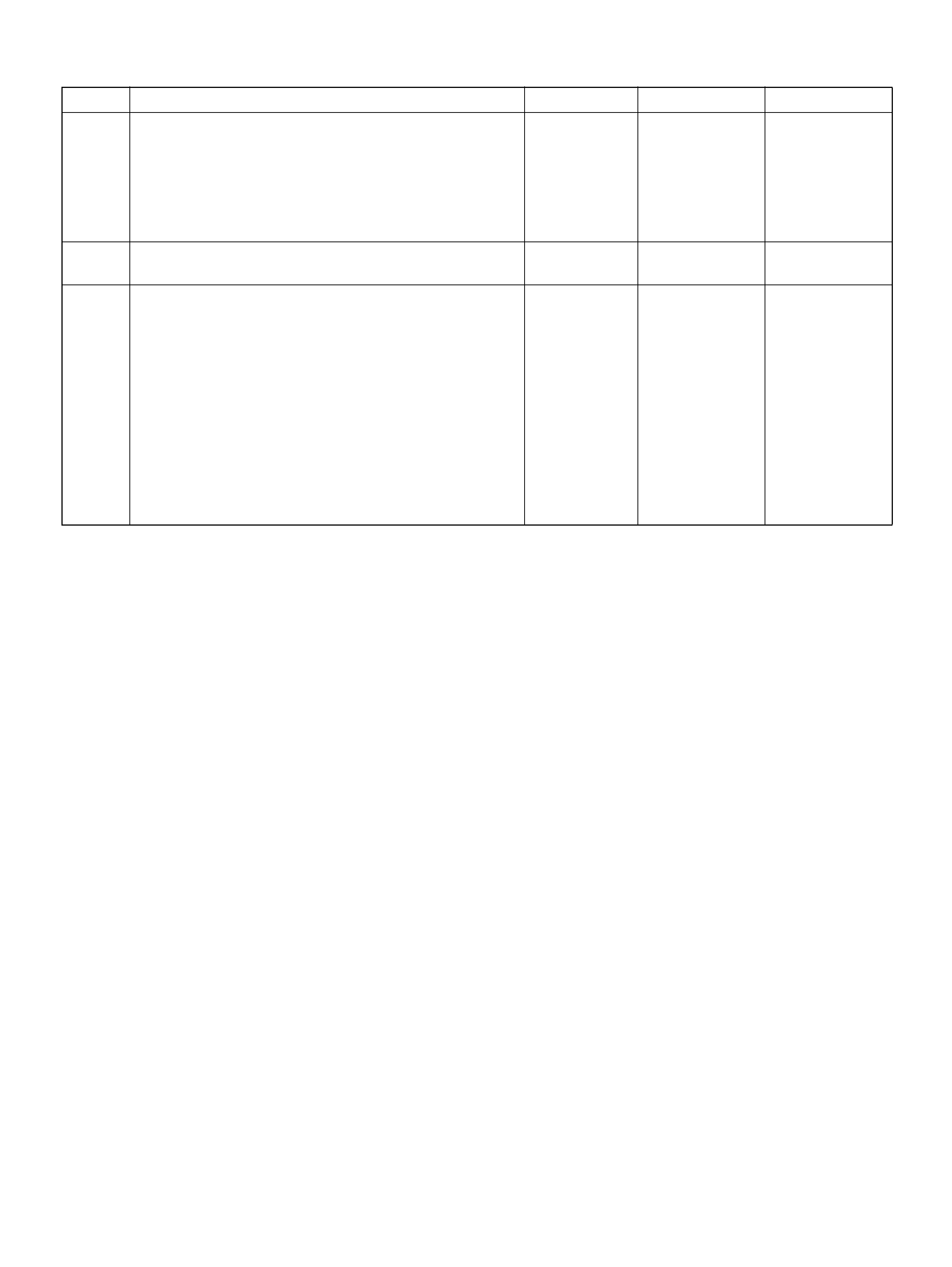

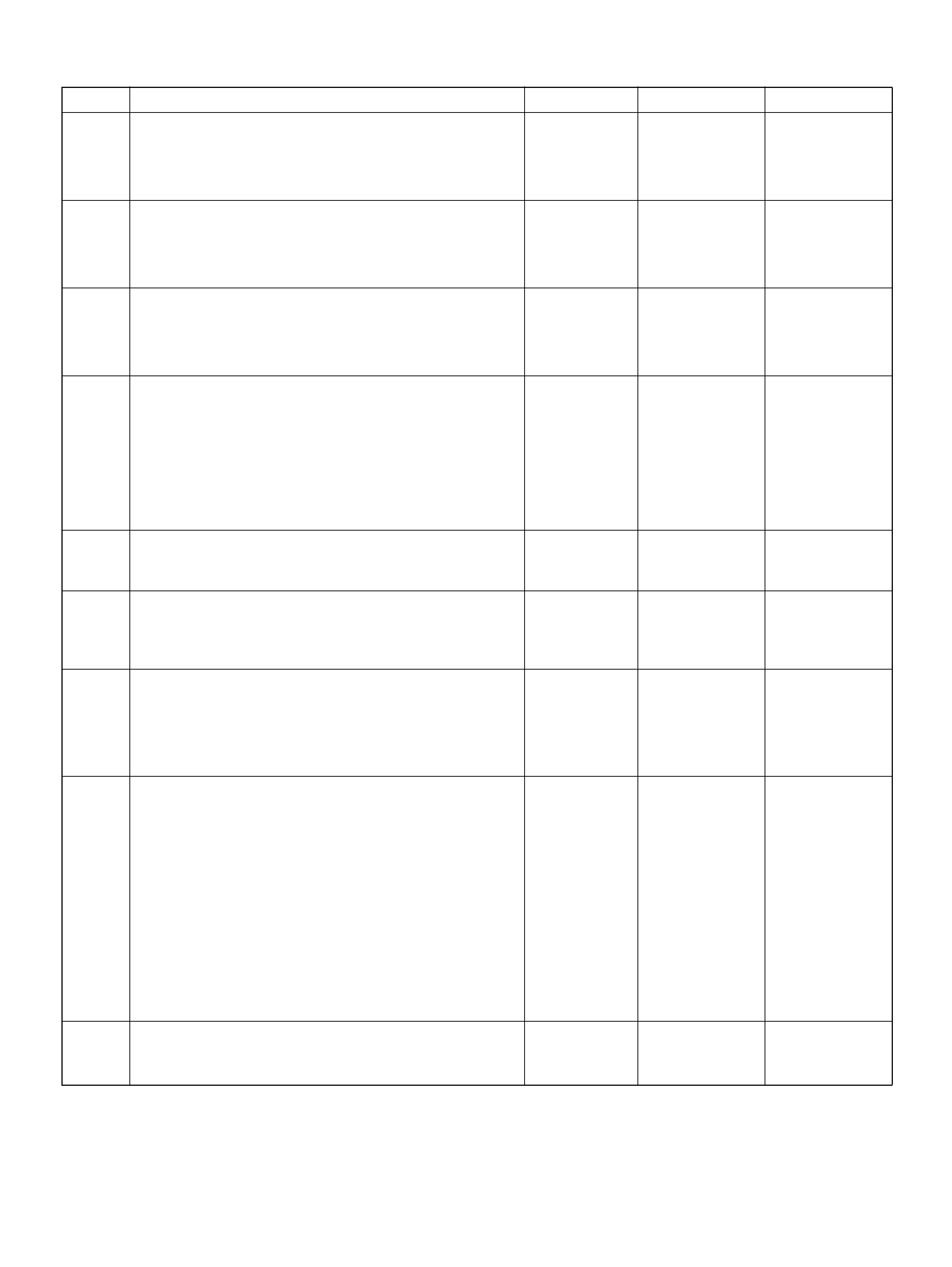

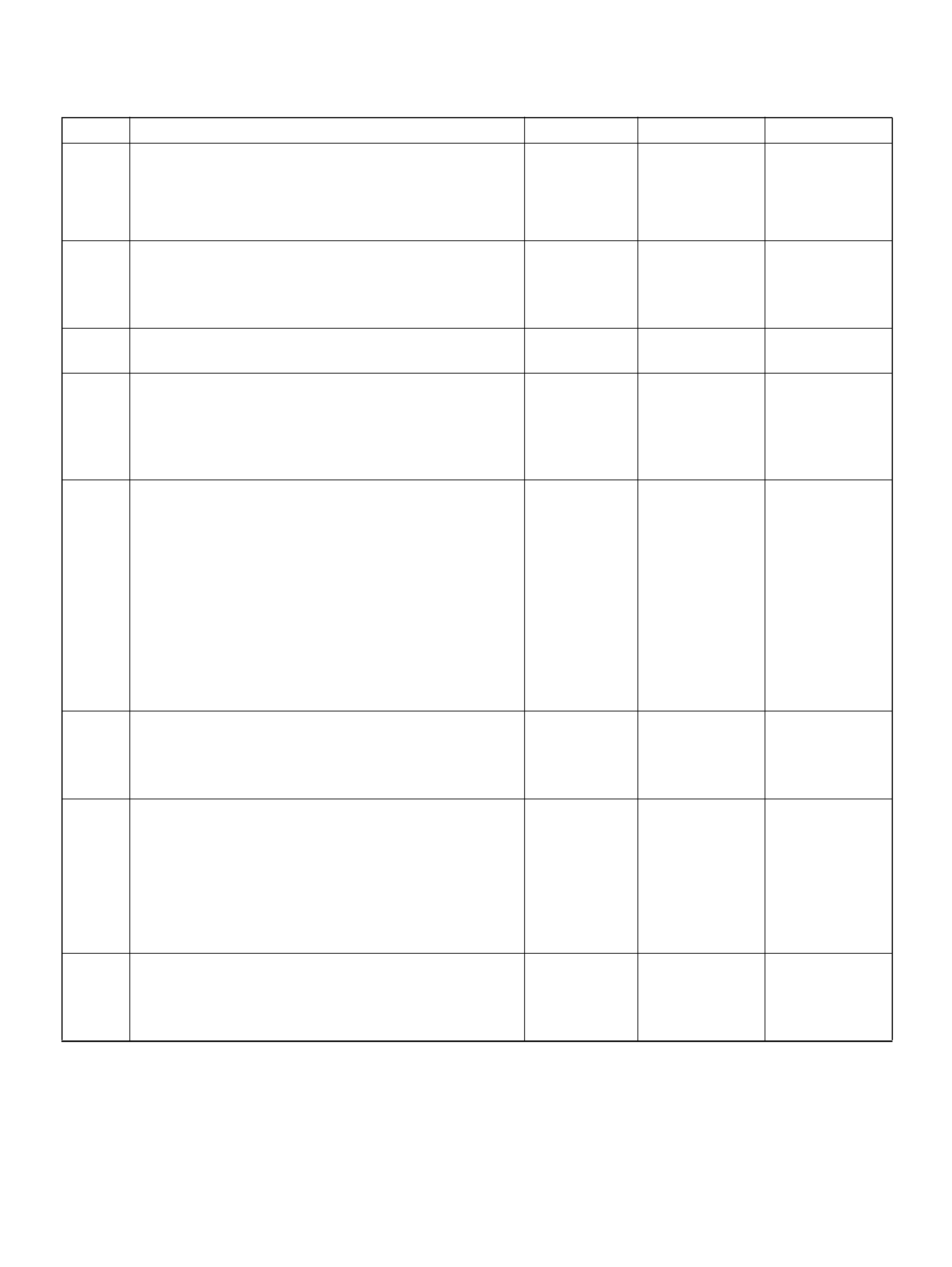

PCM PINOUT TABLE, 80-WAY BLUE CONNECTOR – ROW “F41 ∼ 60"

060RY00046

PIN PIN Function Wire Color IGN ON ENG RUN

F41 Throttle Position(TP) 1 Sensor Ground GRN 0.0V 0.0V

F 42 Fuel Pump R e lay PN K/ WH T 0.0V B+

F43 Adaptor Case VIO/RED 0.0V 0.0V

F44 Not Used — — —

F45 A /C Requ est GRN/BLK 0.0V 0.0V

F46 Stop Lamp Switch GRY/RED 0 .0 V 0.0V

F47 Adaptor Case VIO/WHT B+ B+

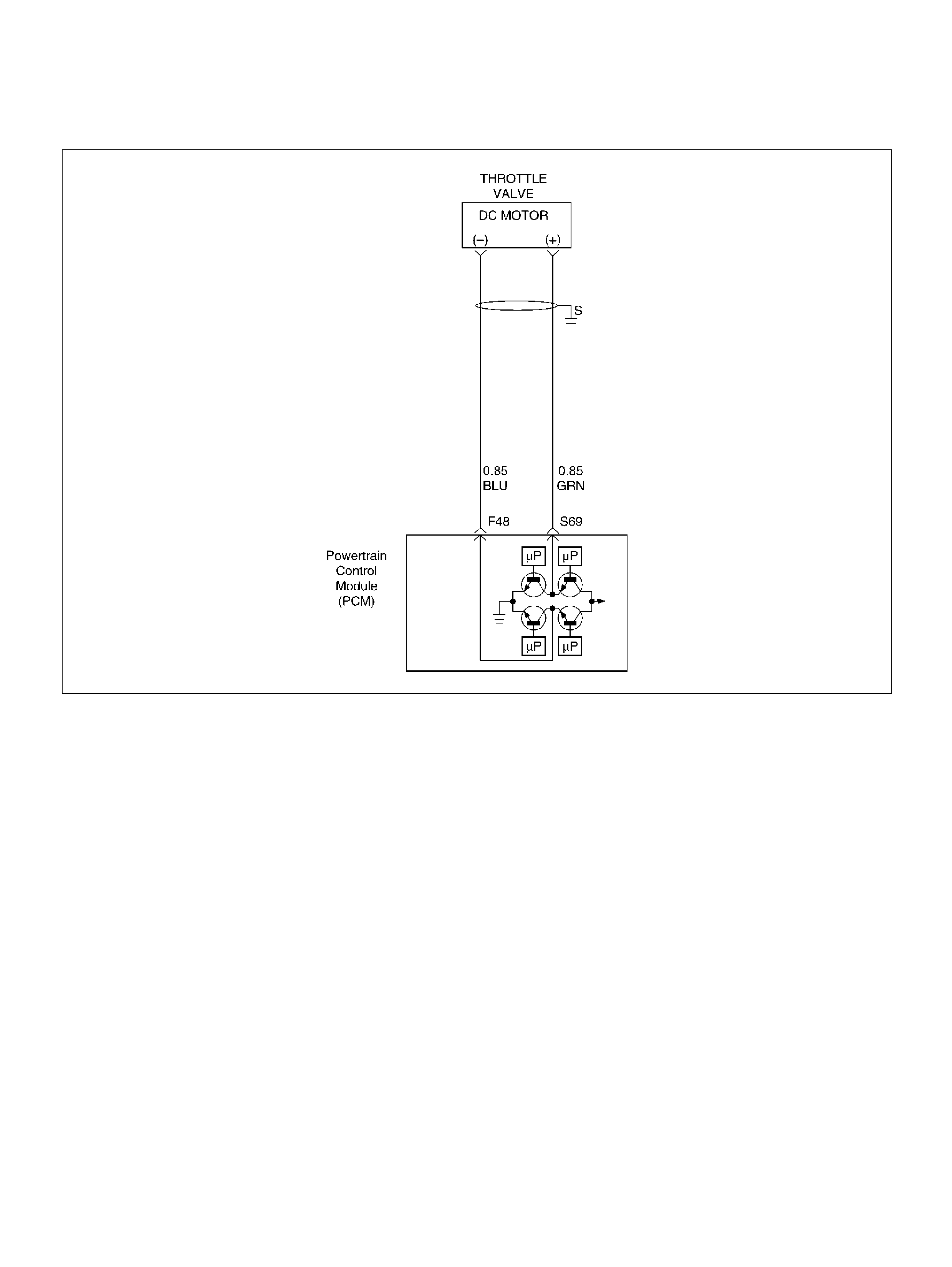

F48 Throttle Valve DC Motor(–) BLU Duty Cycle Duty Cycle

F49 Not Used — — —

F50 Not Used — — —

F51 Not Used — — —

F52 Not Used — — —

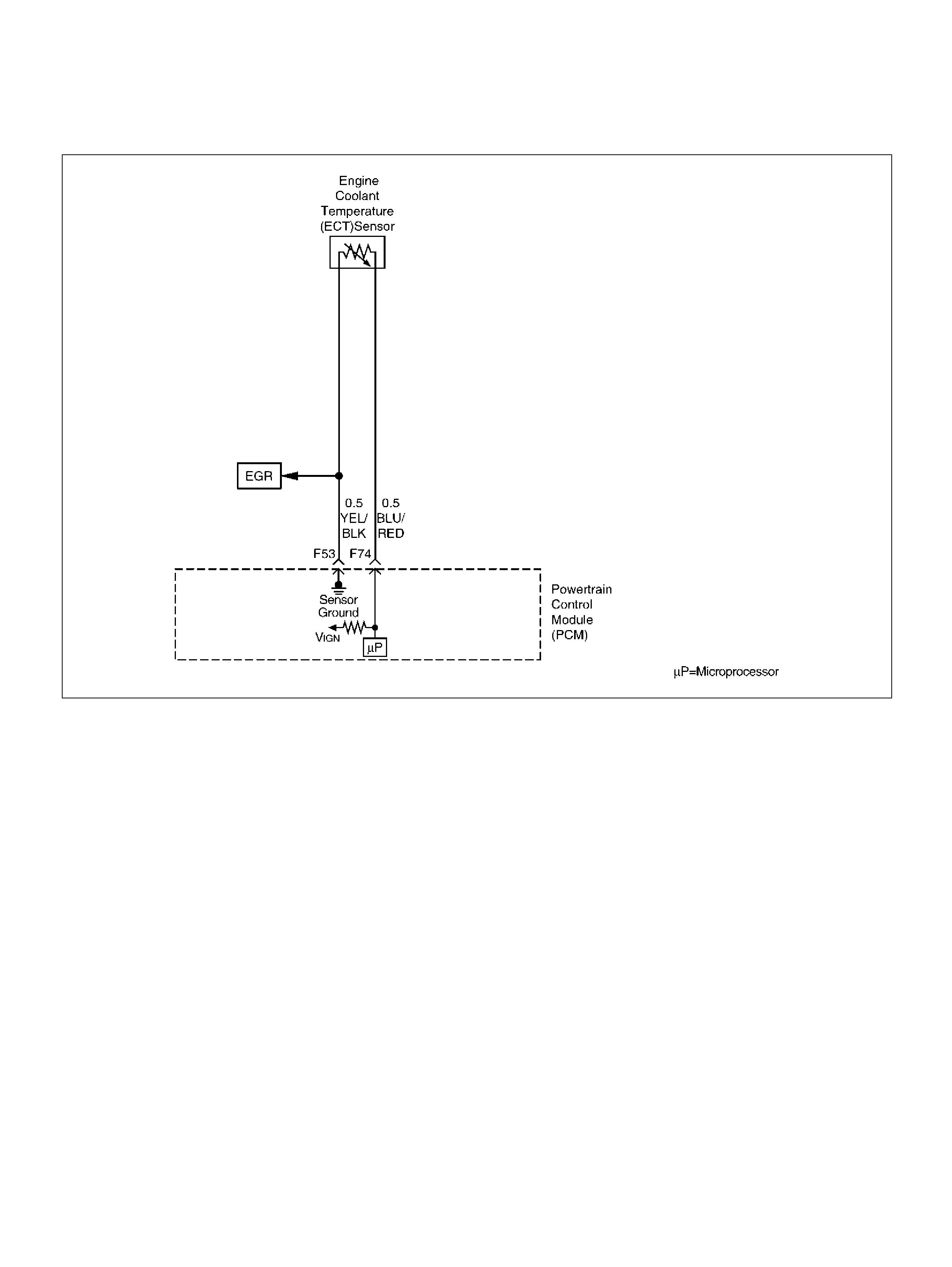

F53 ECT Groun d YEL/BLK 0.0V 0.0V

F54 Not Used — — —

F55 Not Used — — —

F56 Injector Cylinder #5 GRN/BLK B+ B+

F57 I gnition Feed RED/WHT B+ B +

F58 Class 2 Data ORN/BLK 0.0V 0.0V

F59 Not Used — — —

F60 Not Used — — —

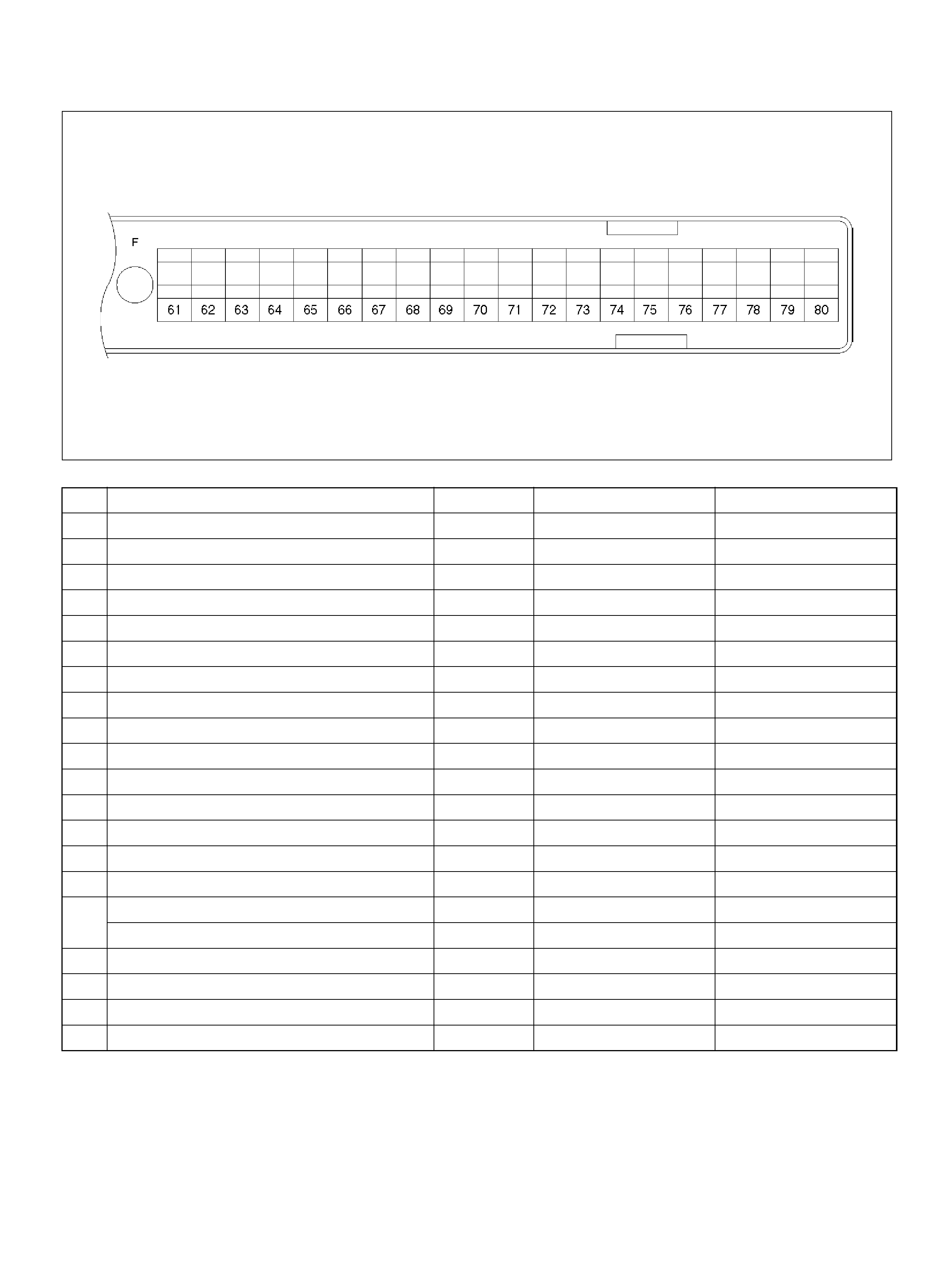

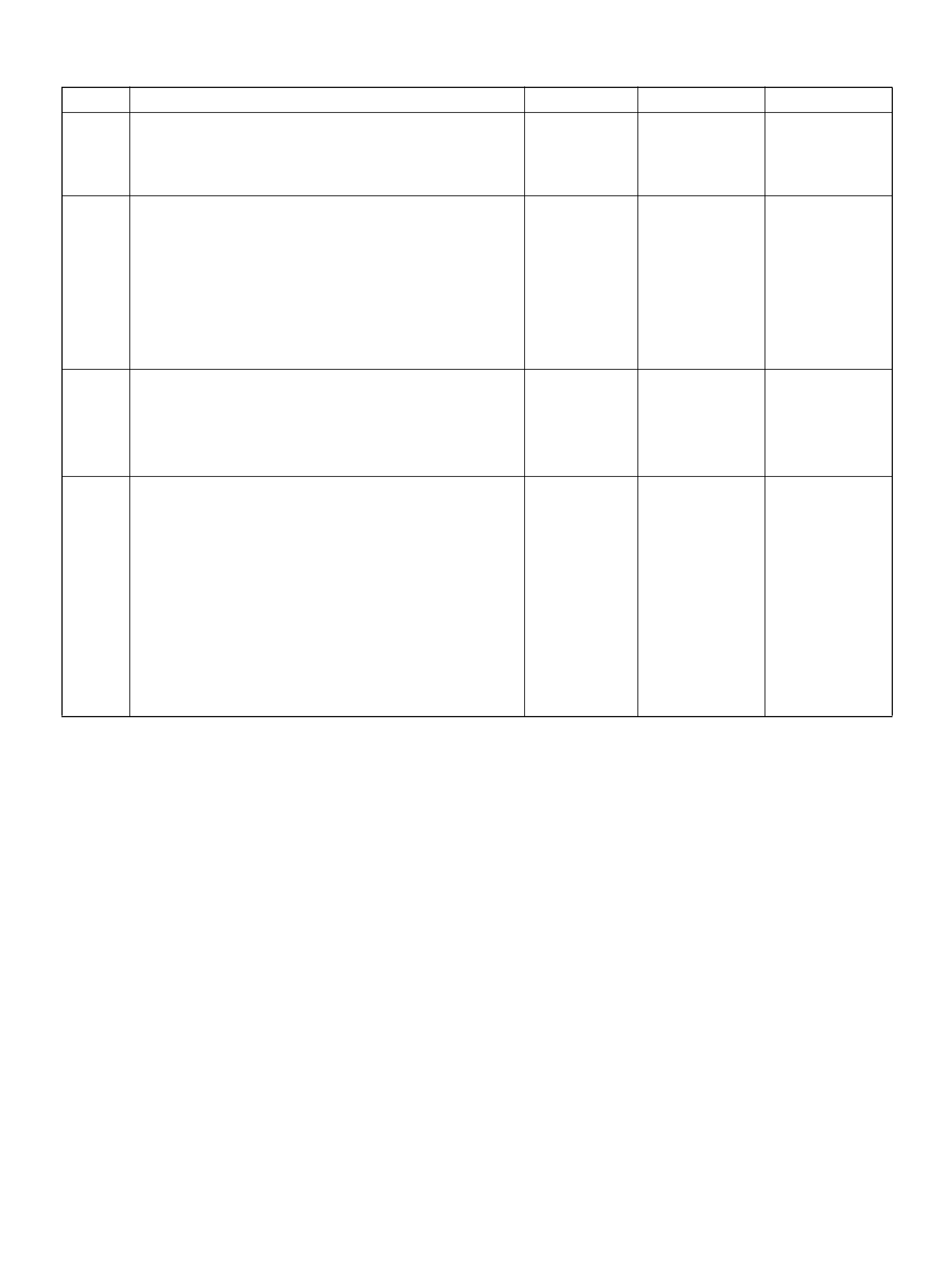

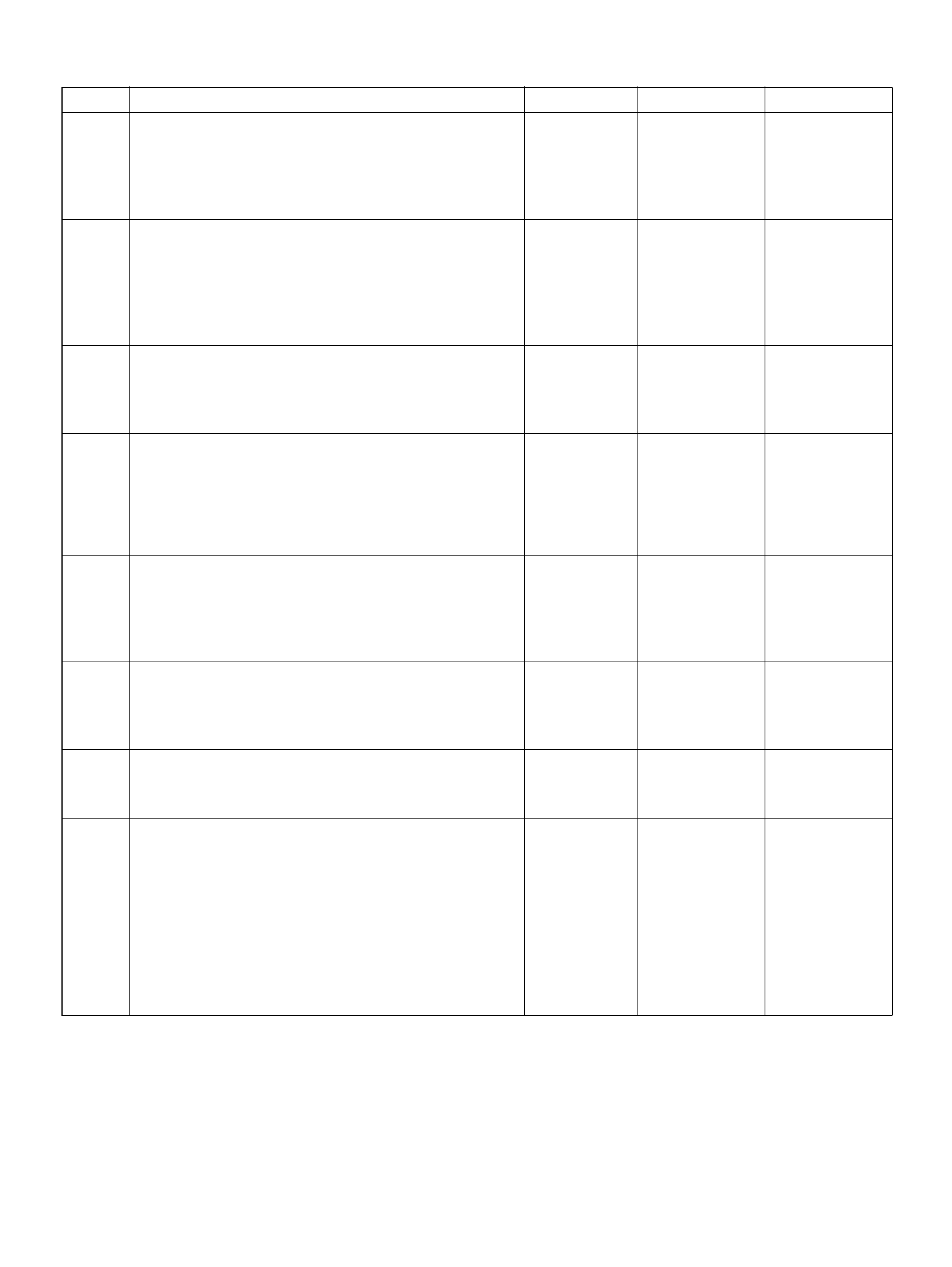

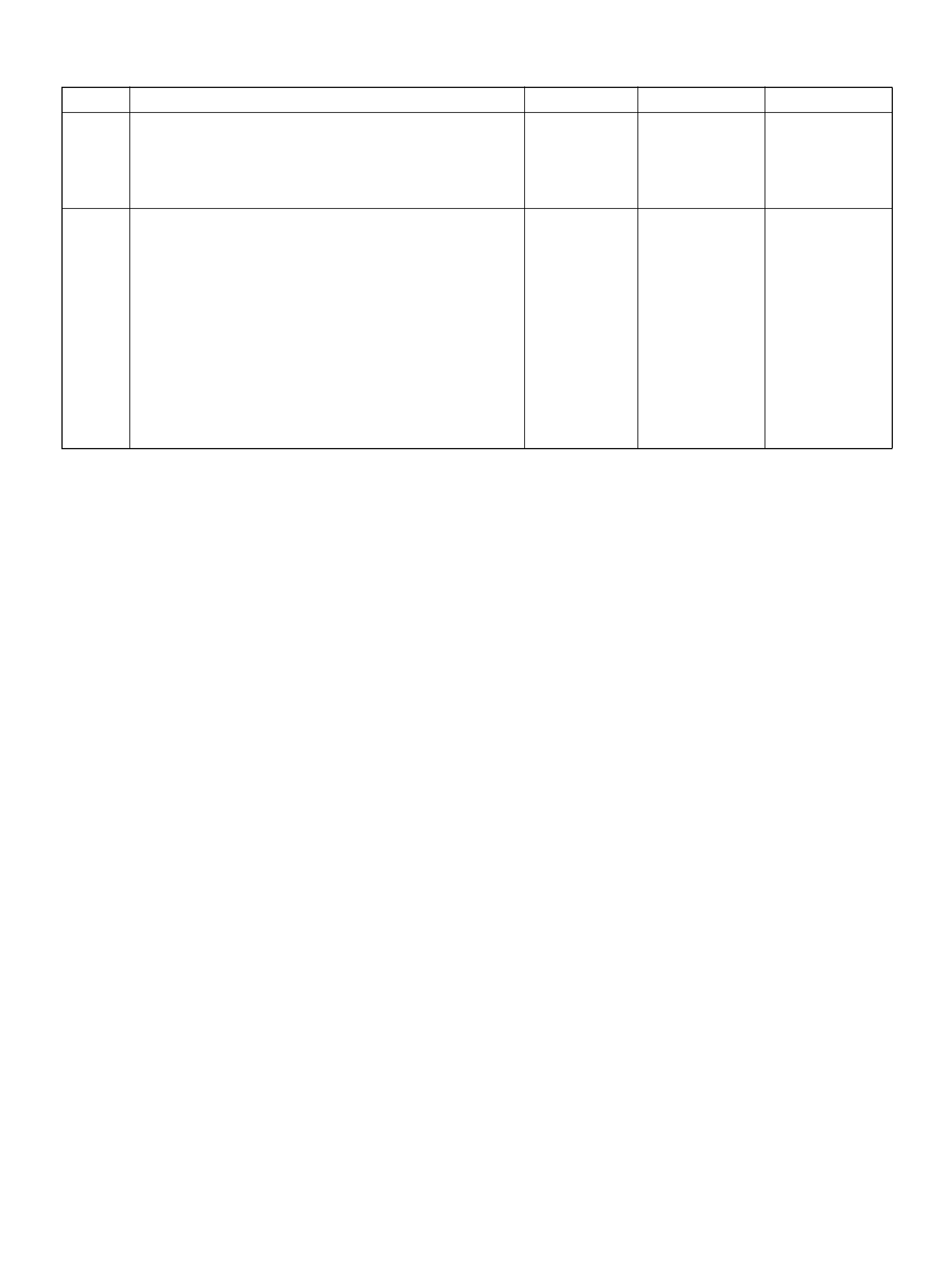

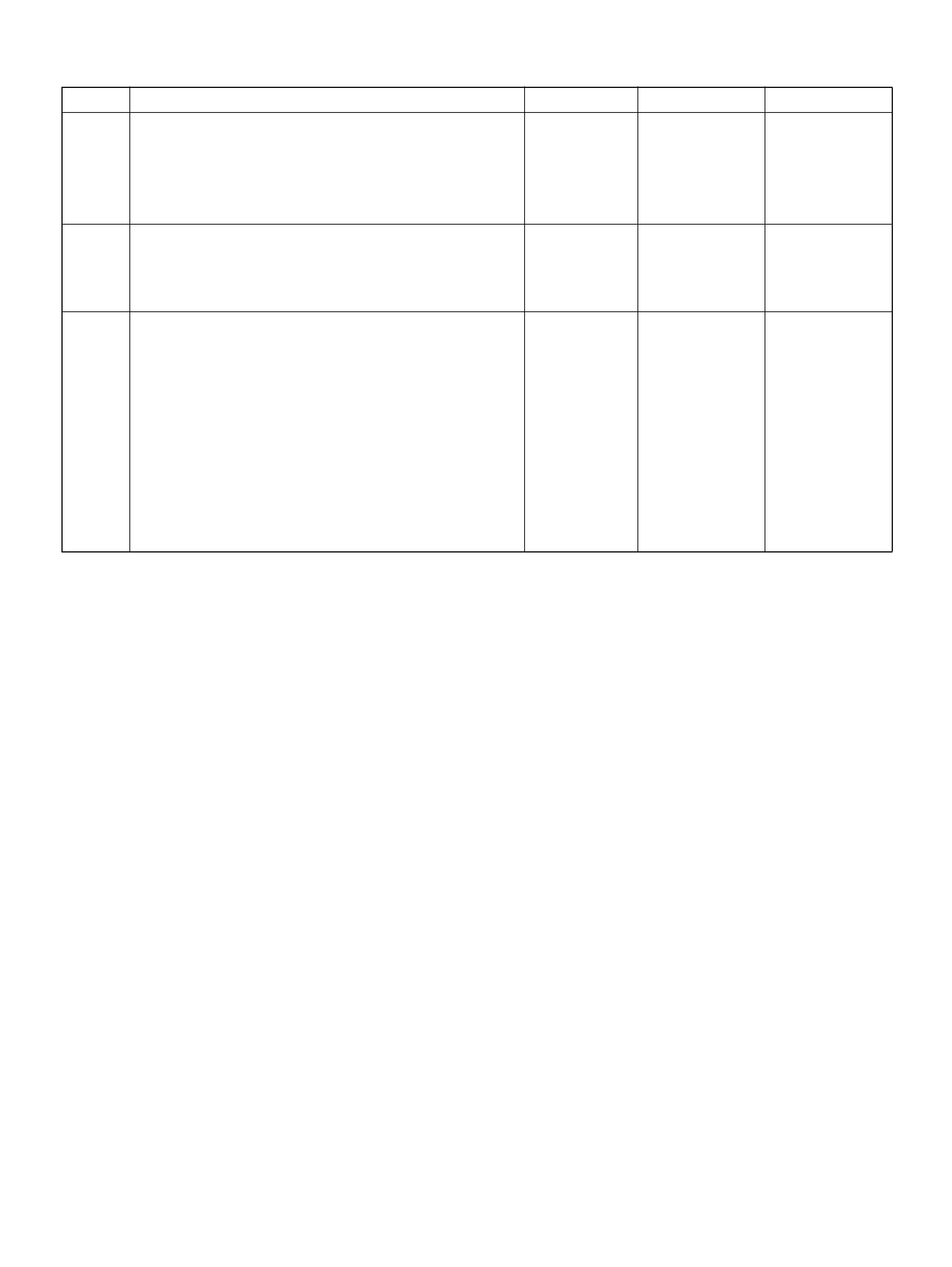

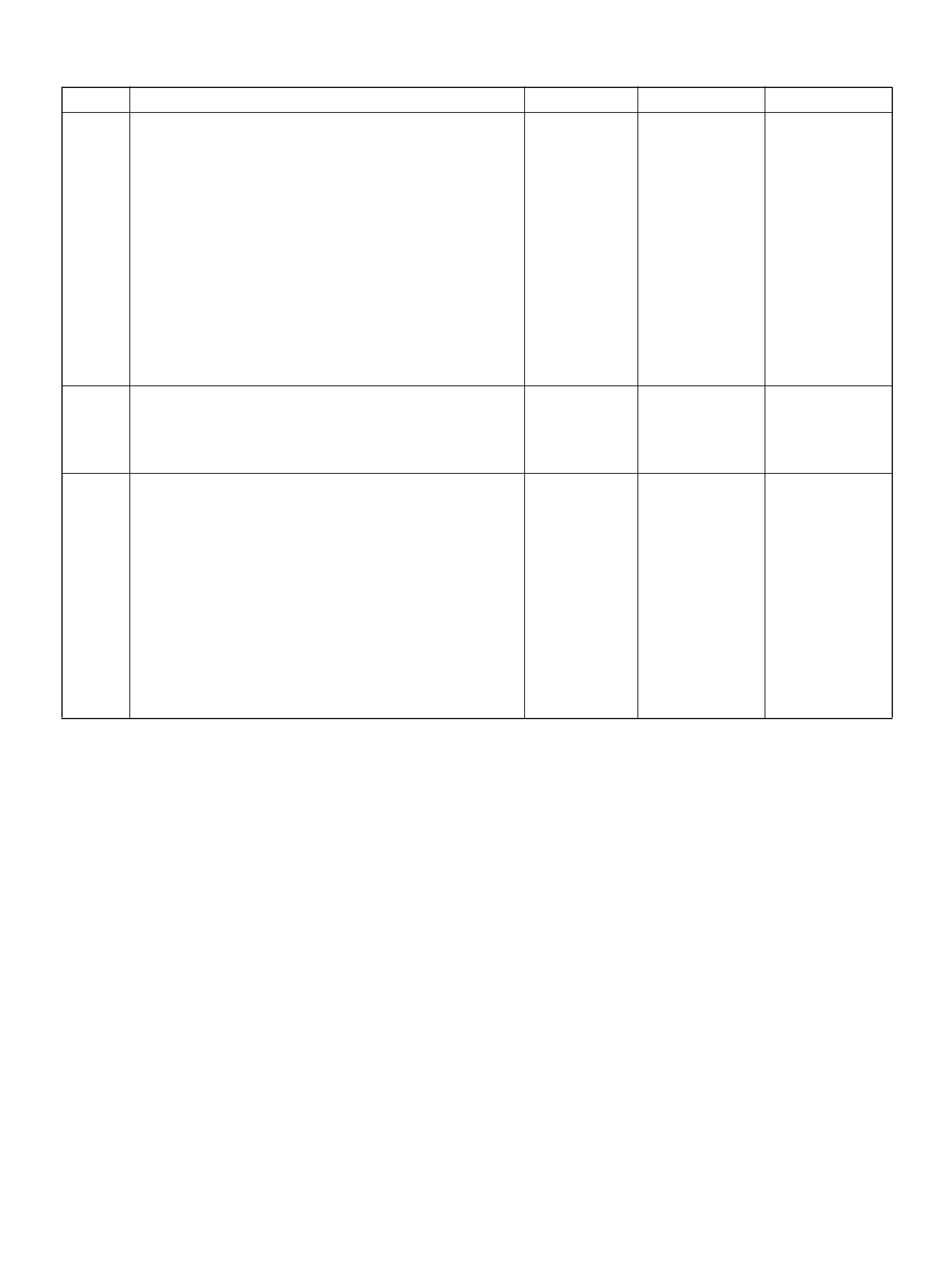

PCM PINOUT TABLE, 80-WAY BLUE CONNECTOR – ROW “F61 ∼ 80"

060RY00047

PIN PIN Function Wire Color IGN ON ENG RUN

F61 Throttle Position(TP) 2 Sensor Ground GRN/WHT 0.0V 0.0V

F62 Injector Cylinder #2 GRN/ORN B+ B+

F63 AP Sensor 1 Sensor Ground RED 0.0V 0.0V

F64 Injector Cylinder #4 GRN/RED B+ B+

F65 Throttle Position(TP) 2 Sensor Signal BLU/WHT 0.5– 0.8V 0.8–0.8V (at idle)

F66 Injector Cylinder #3 GRN B+ B+

F67 ION Sens ing Mod ule YEL 1.555V 1.555V

F68 ION Sens ing Module RE D 1.555V 1.555V

F69 Injector Cylinder #1 GRN/WHT B+ B+

F70 Not Used — — —

F71 Not Used — — —

F72 Auto Cruise Resume WHT/BLU 0.0V 0.0V

F73 Crankshaft Position Sensor WHT/BLU 0.3V 2.2V

F74 ECT Sensor BLU/RE D 0.5– 4.9V 0.5–4.9V

F75 Ignition Feed RED/GRN B+ B+

F76 Clutch Switch (M/T only) GRN B+ B+

Mode Sw itch (A/T only) PNK/BLK B + B+

F77 Mode Sw itch PNK/BLU B+ B+

F78 Mode Sw itch PN K/Y EL 0.0V 0.0V

F79 Mode Sw itch PNK 0.0V 0.0V

F80 AP Sensor 2 Ground BLU 0.0V 0.0V

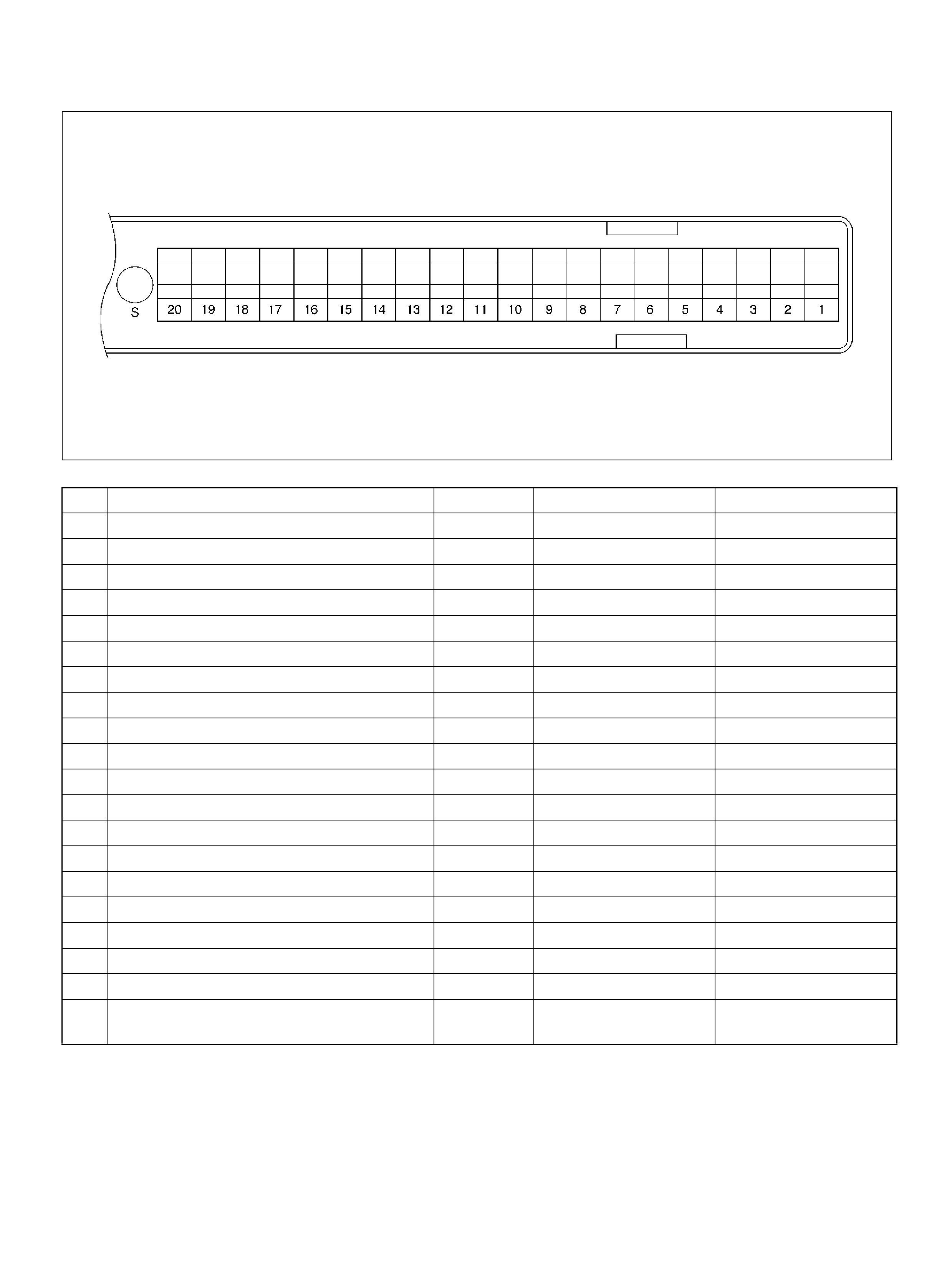

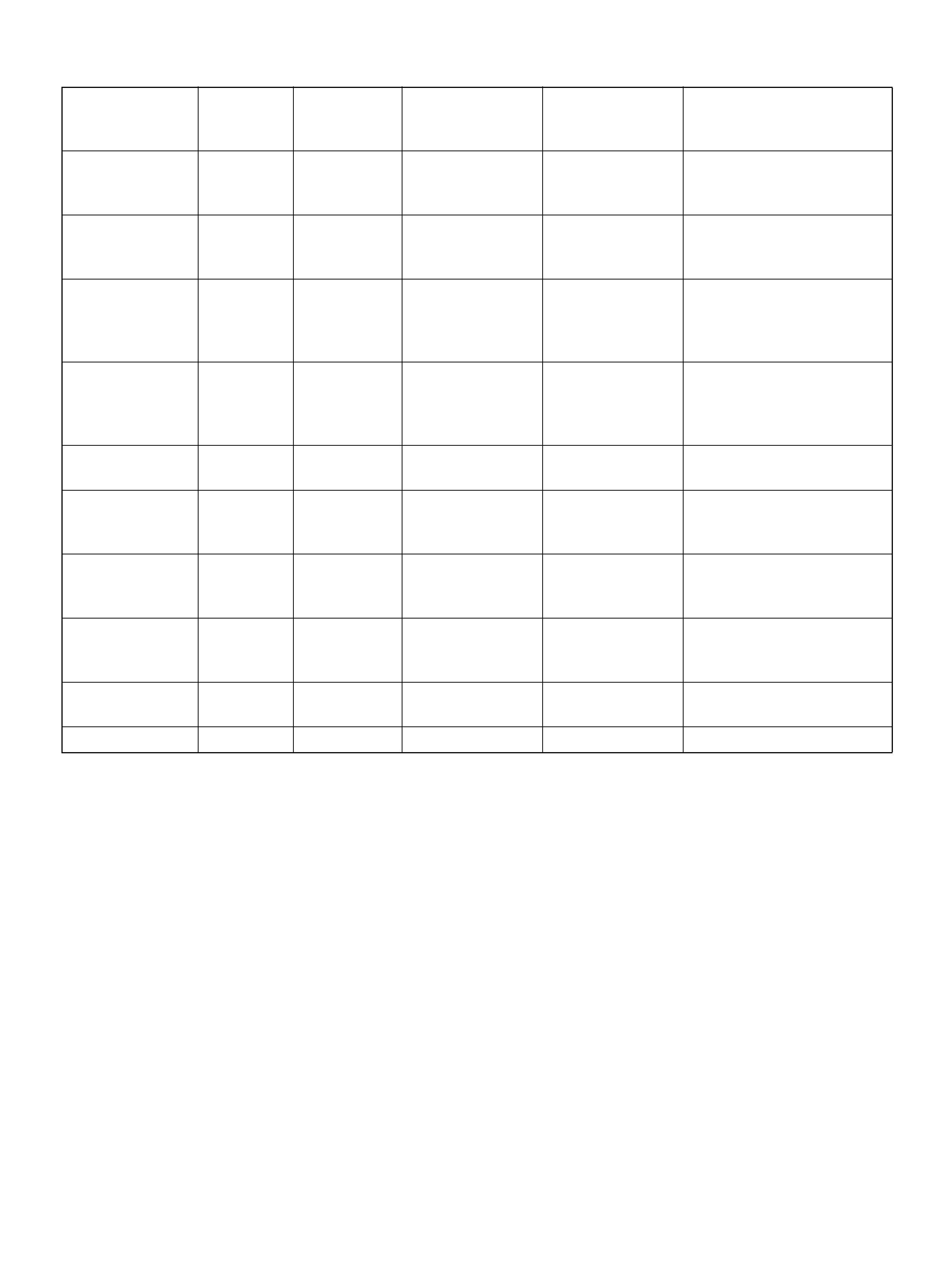

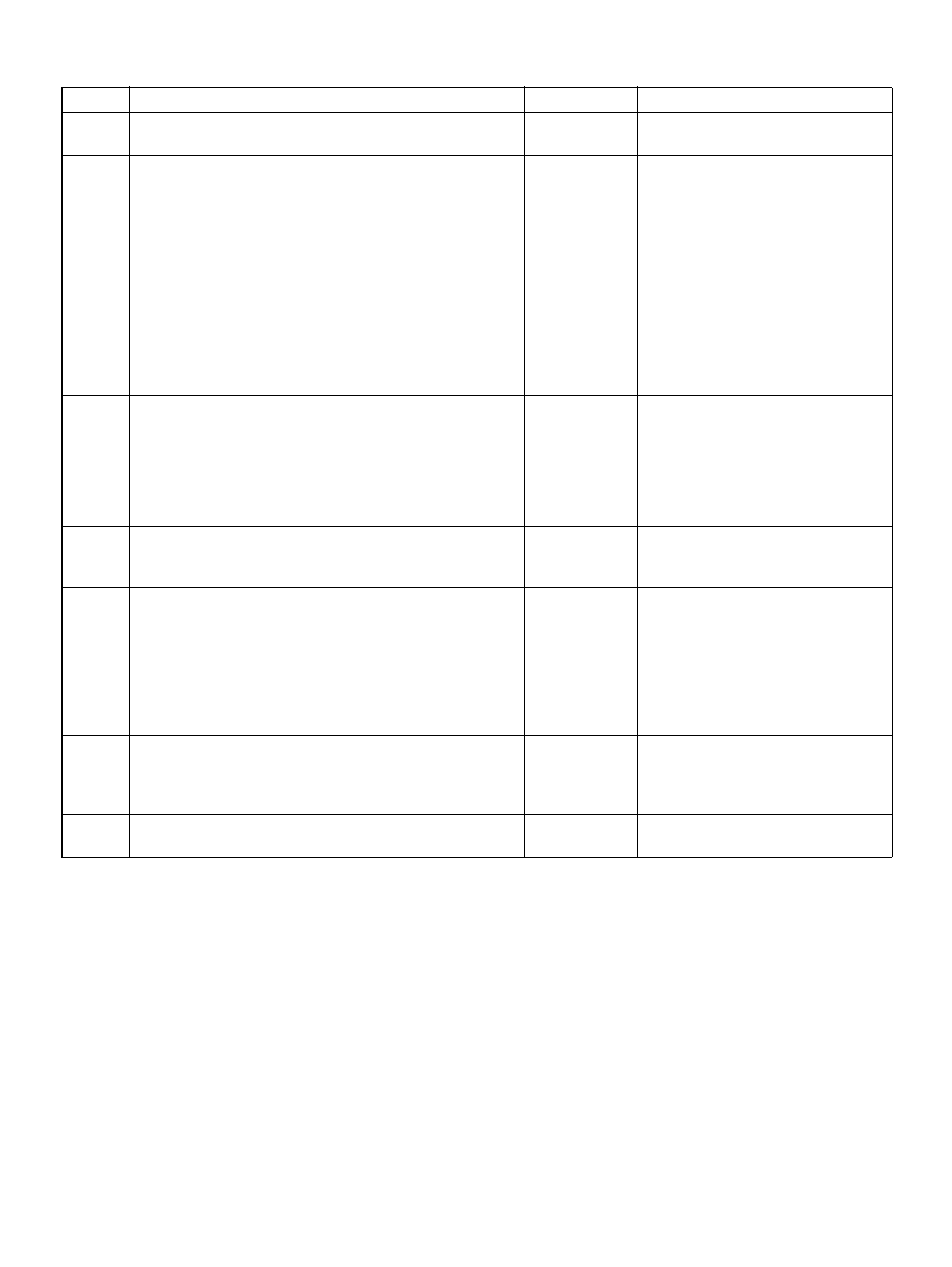

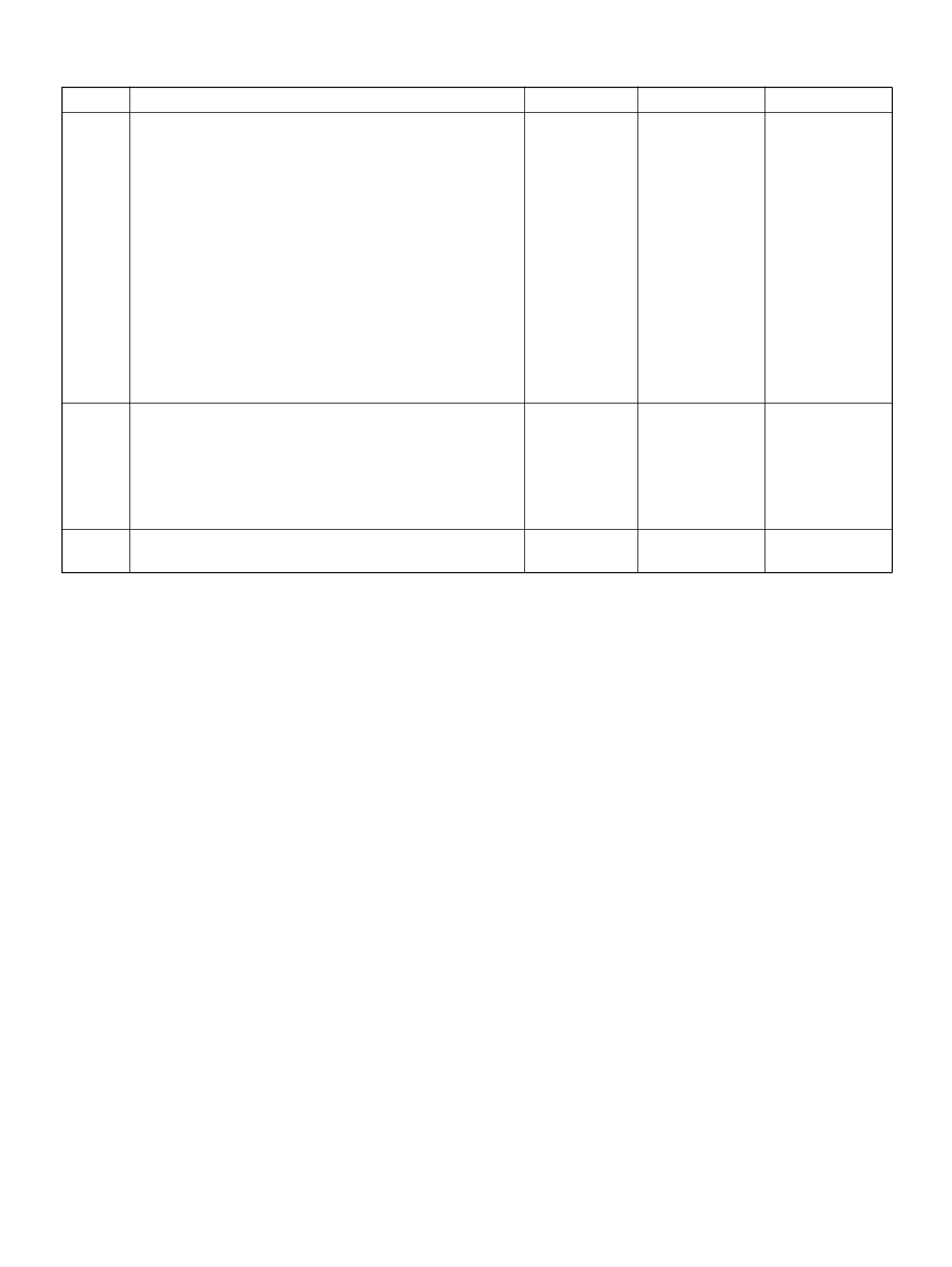

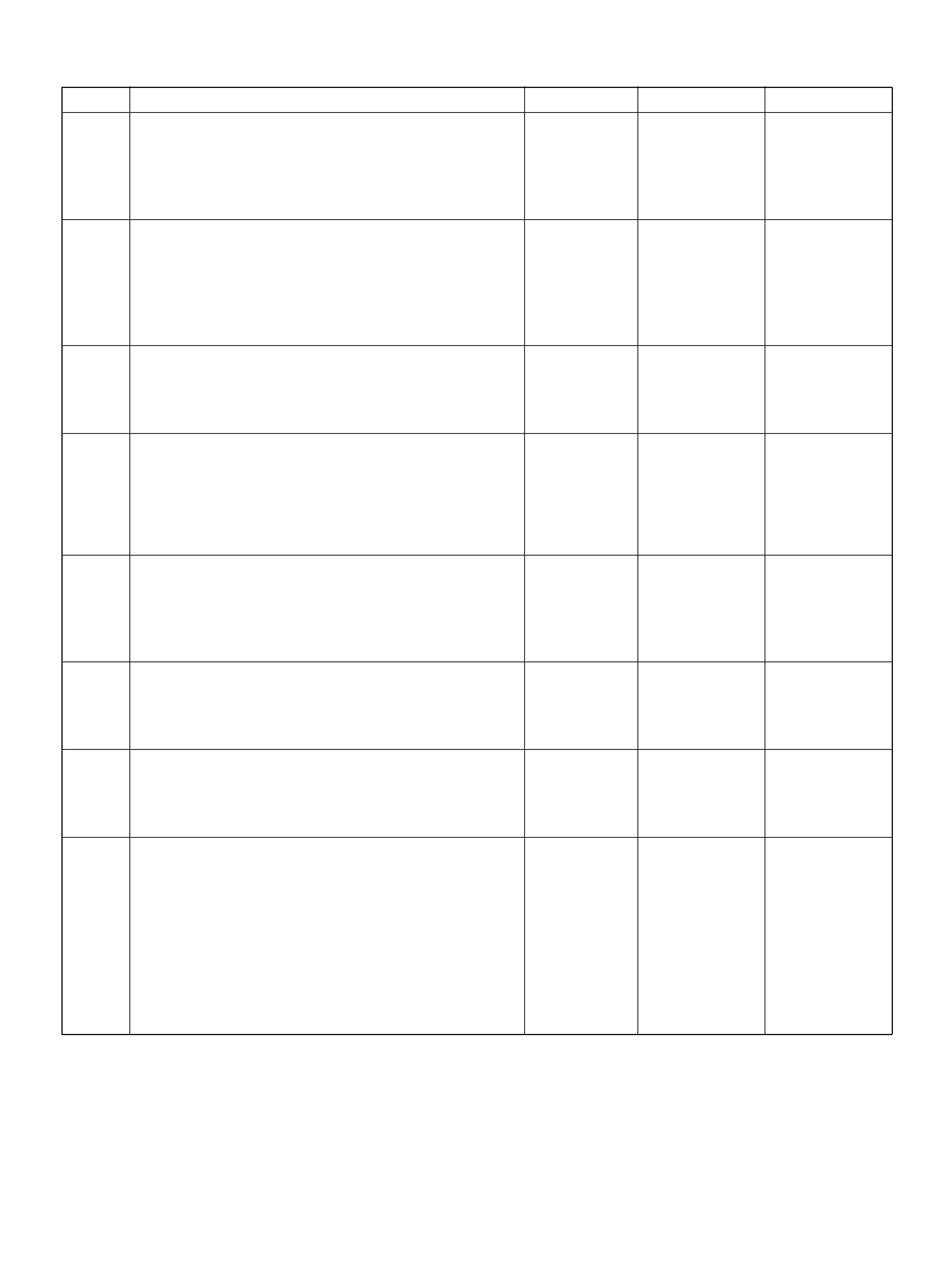

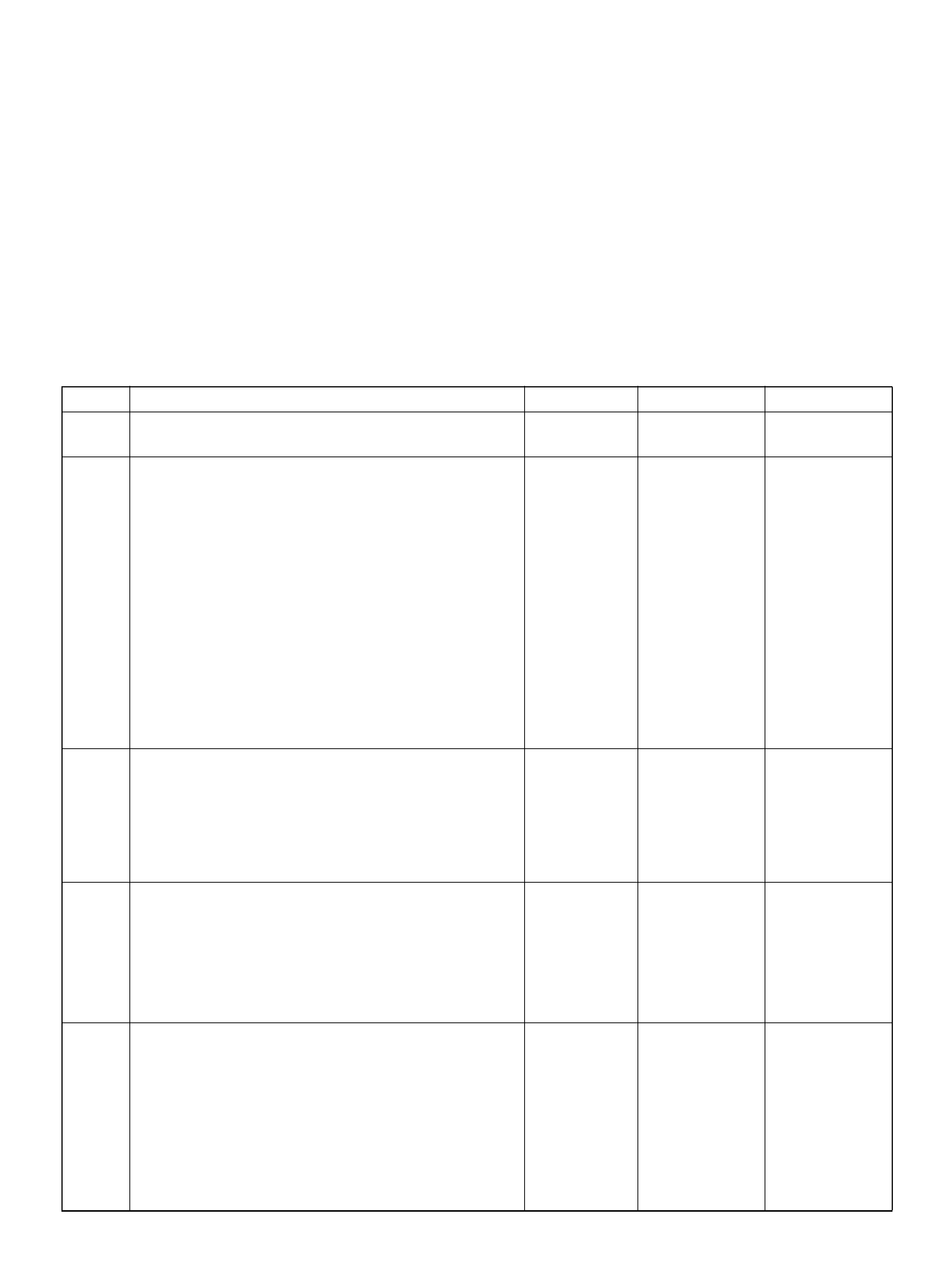

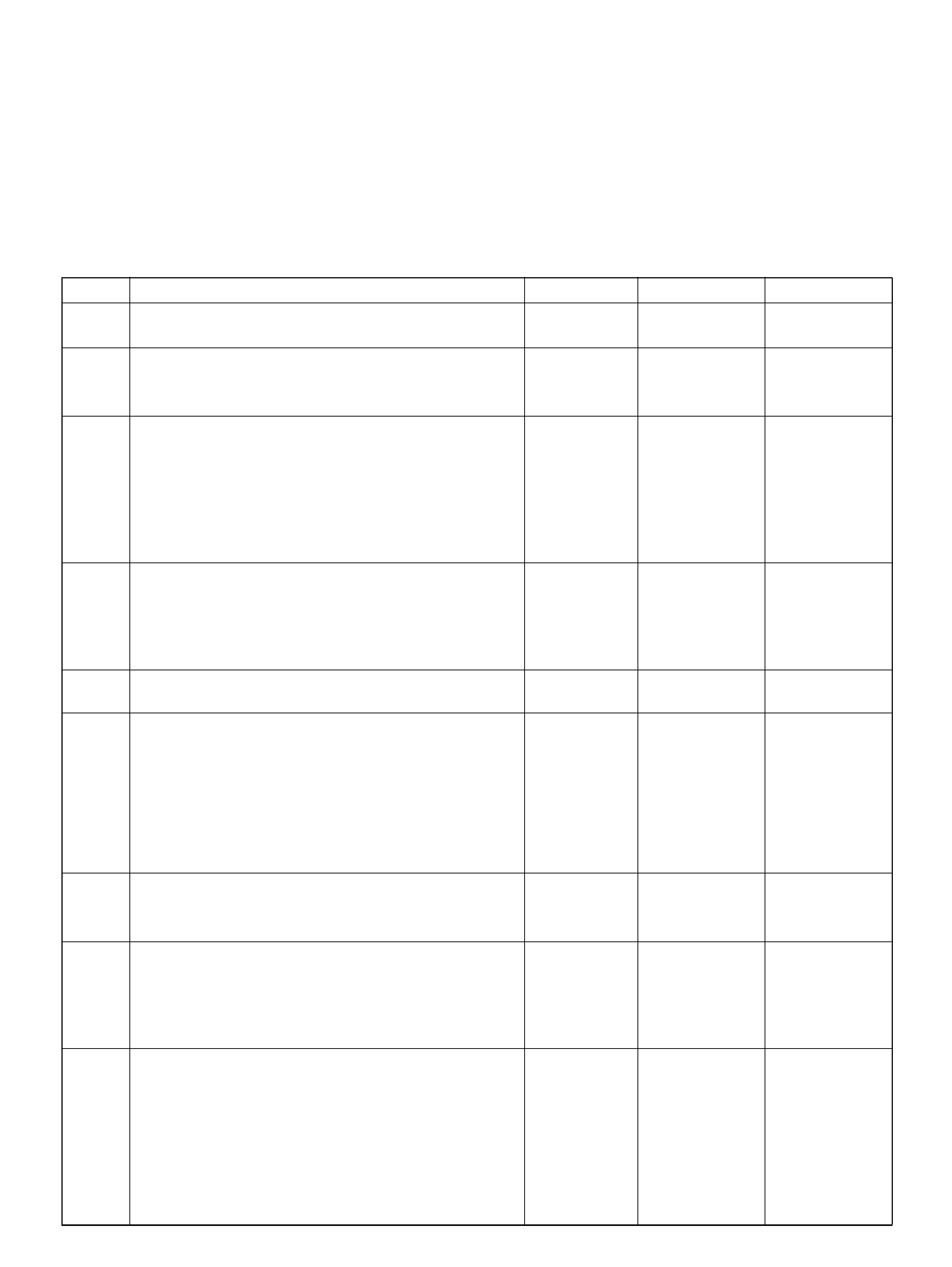

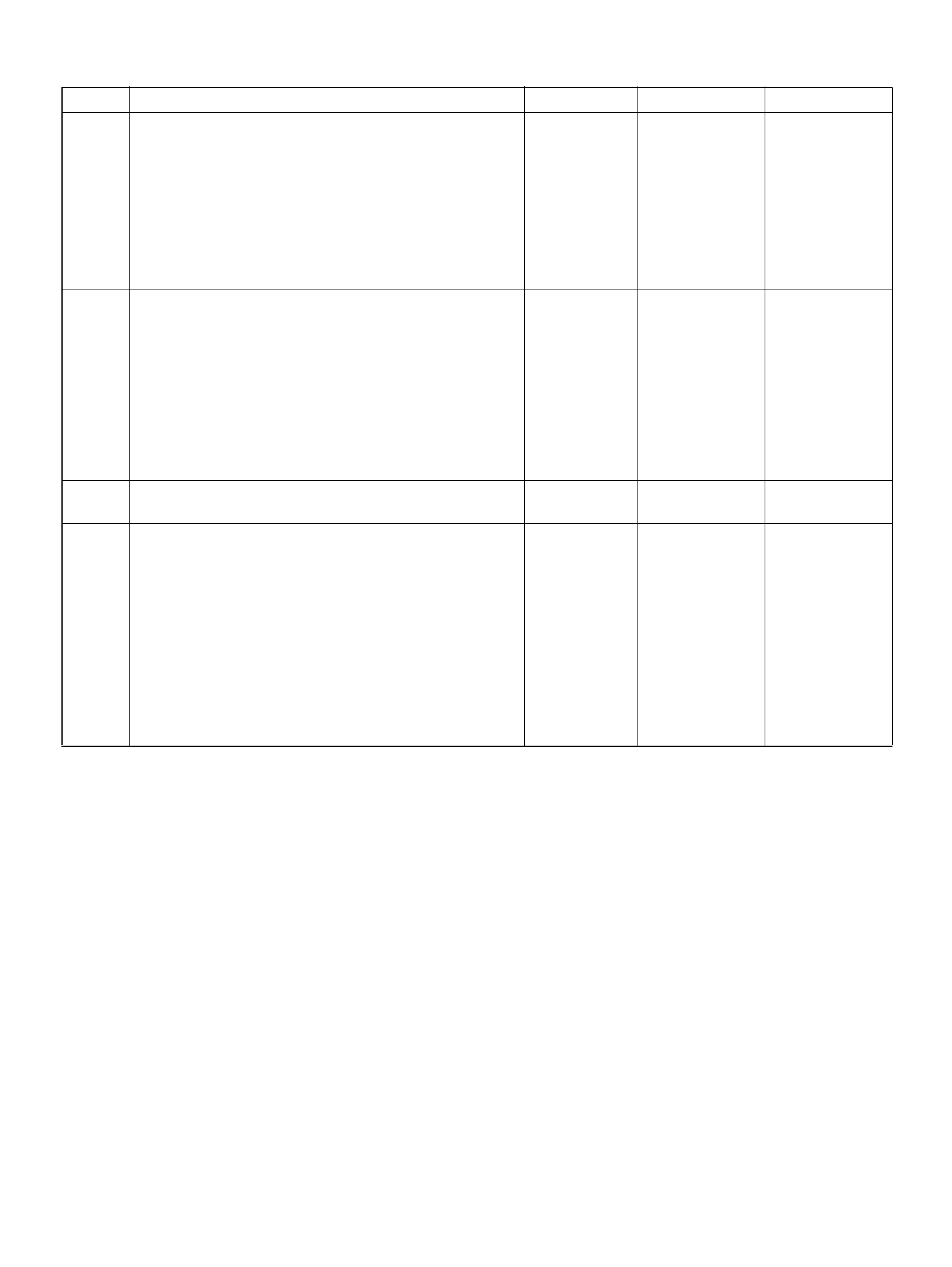

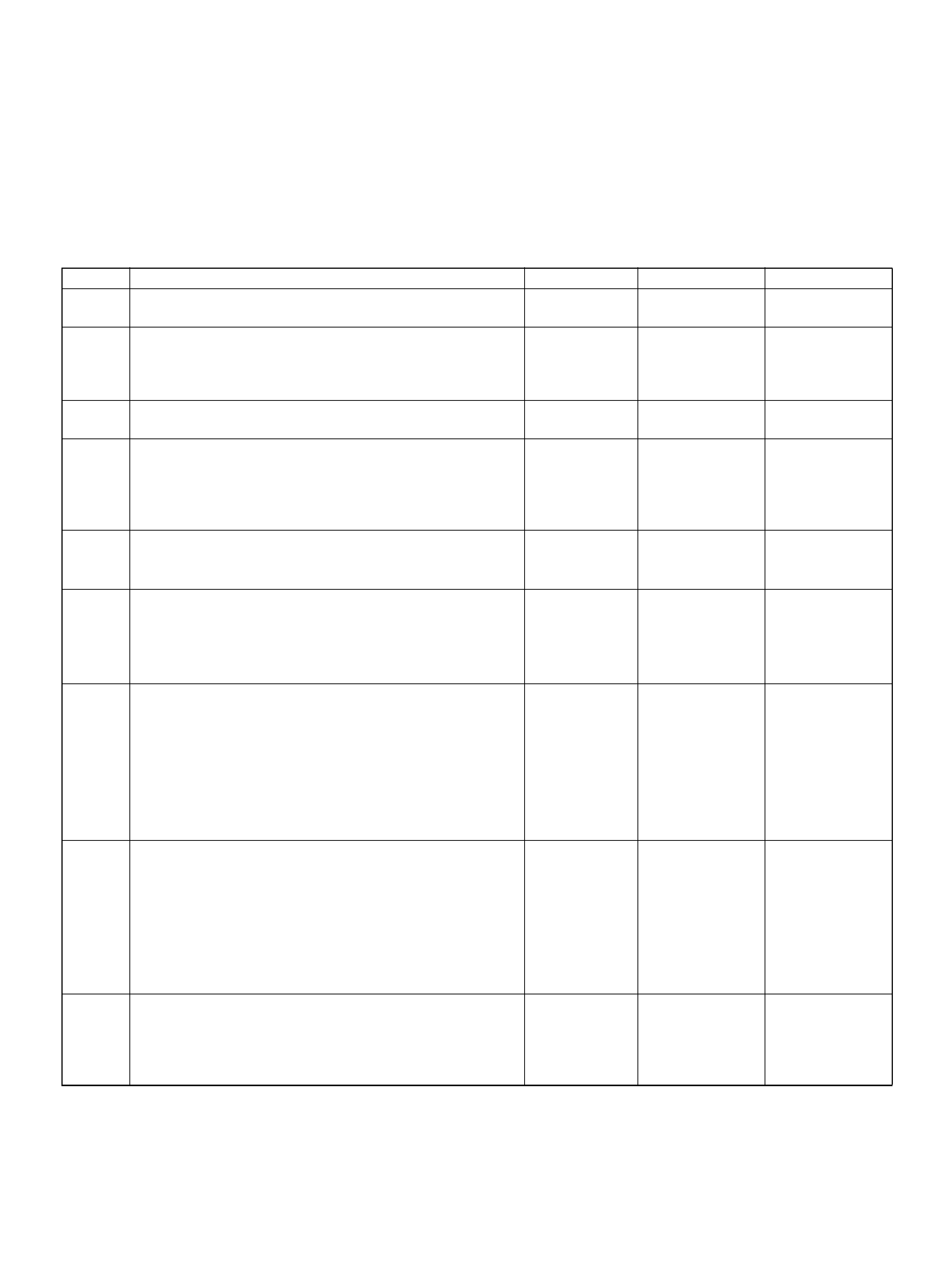

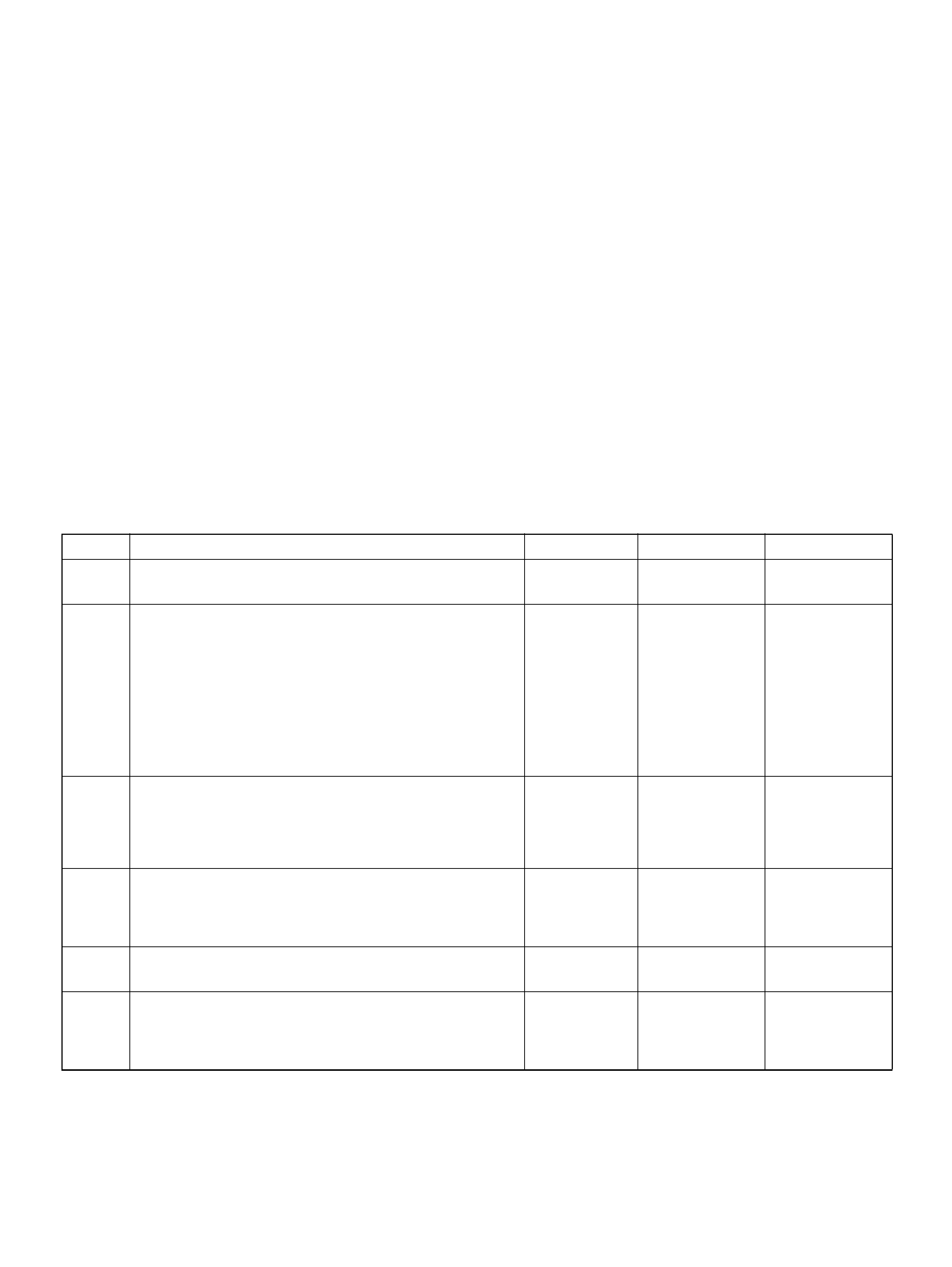

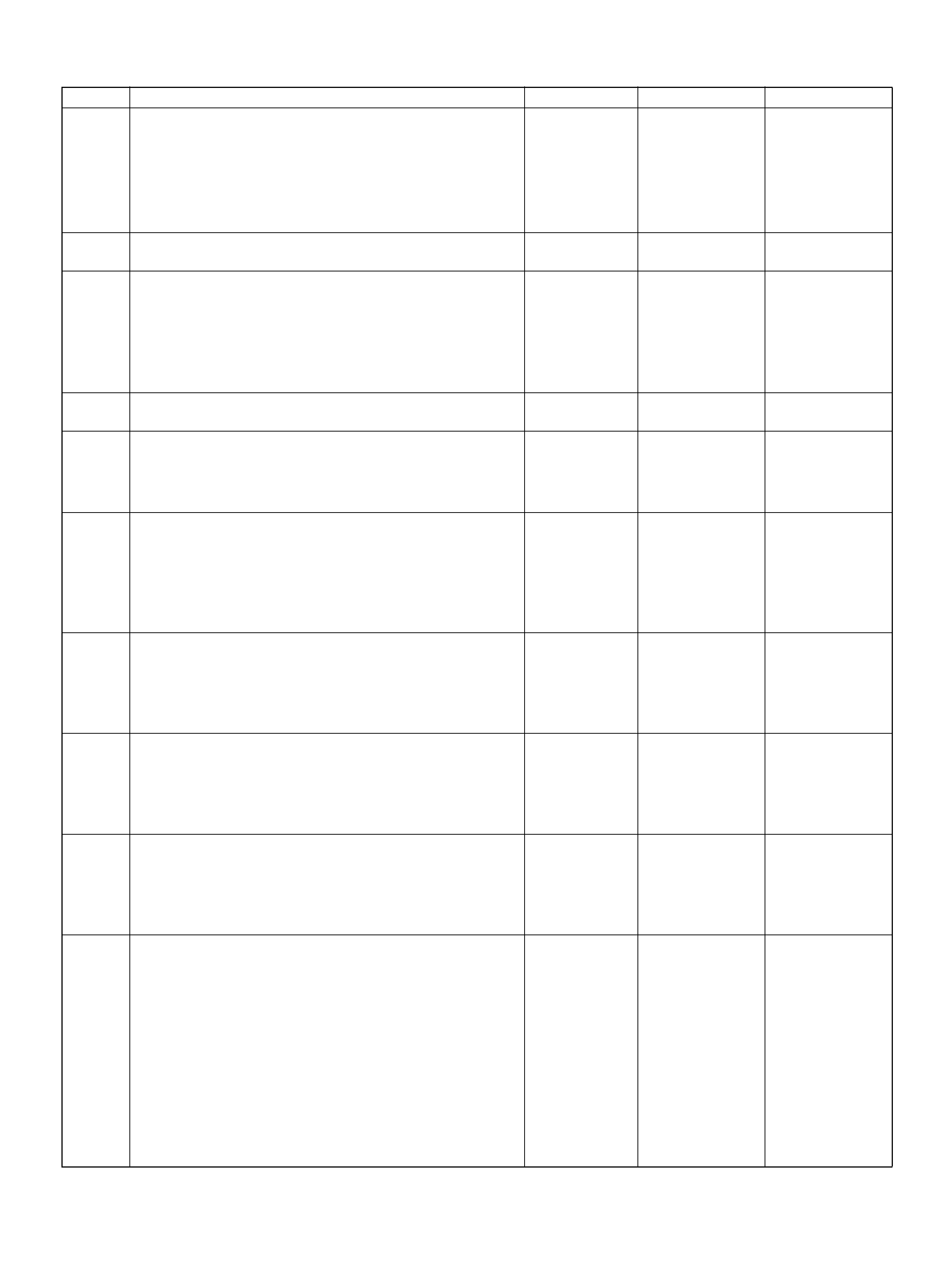

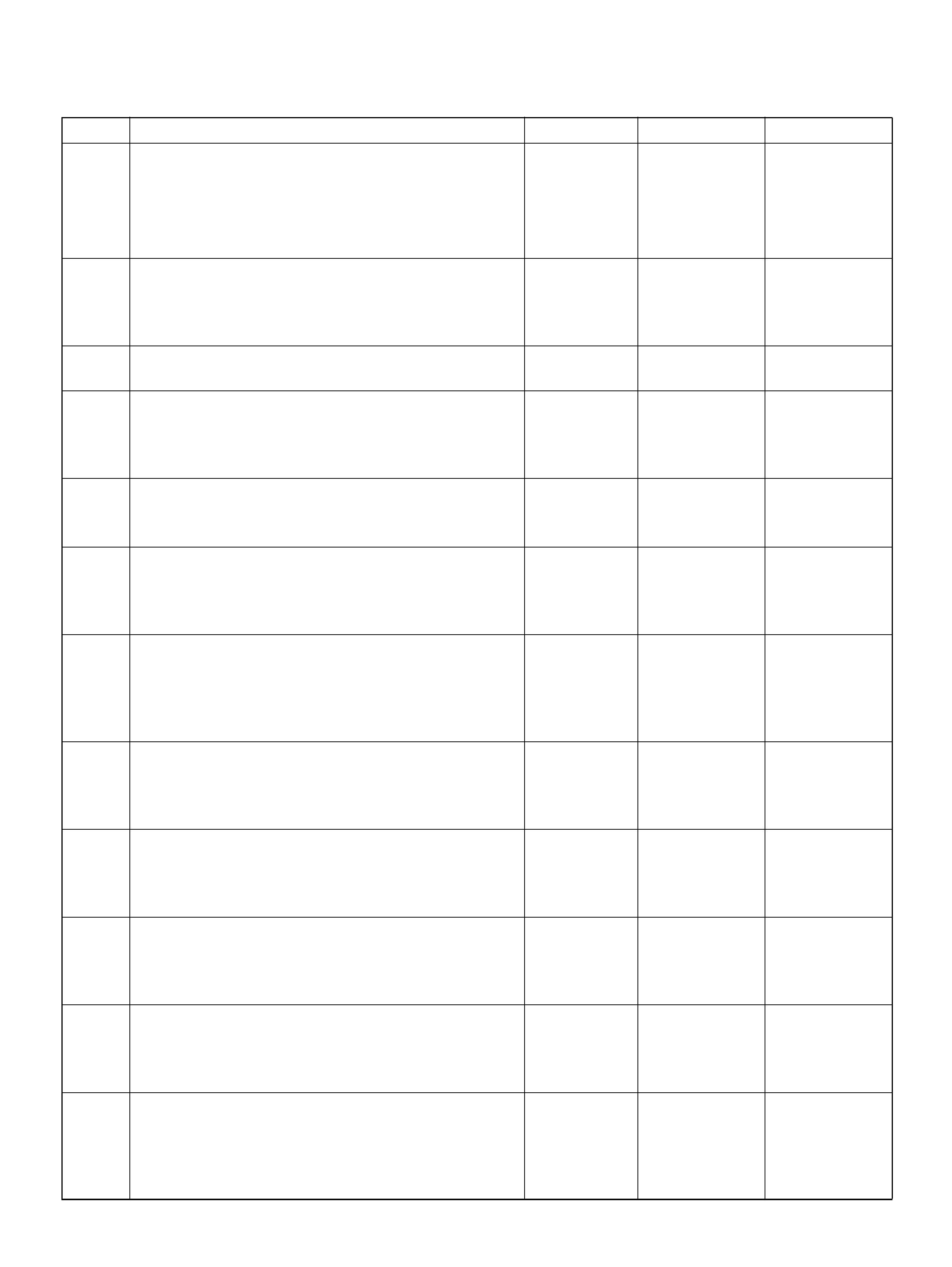

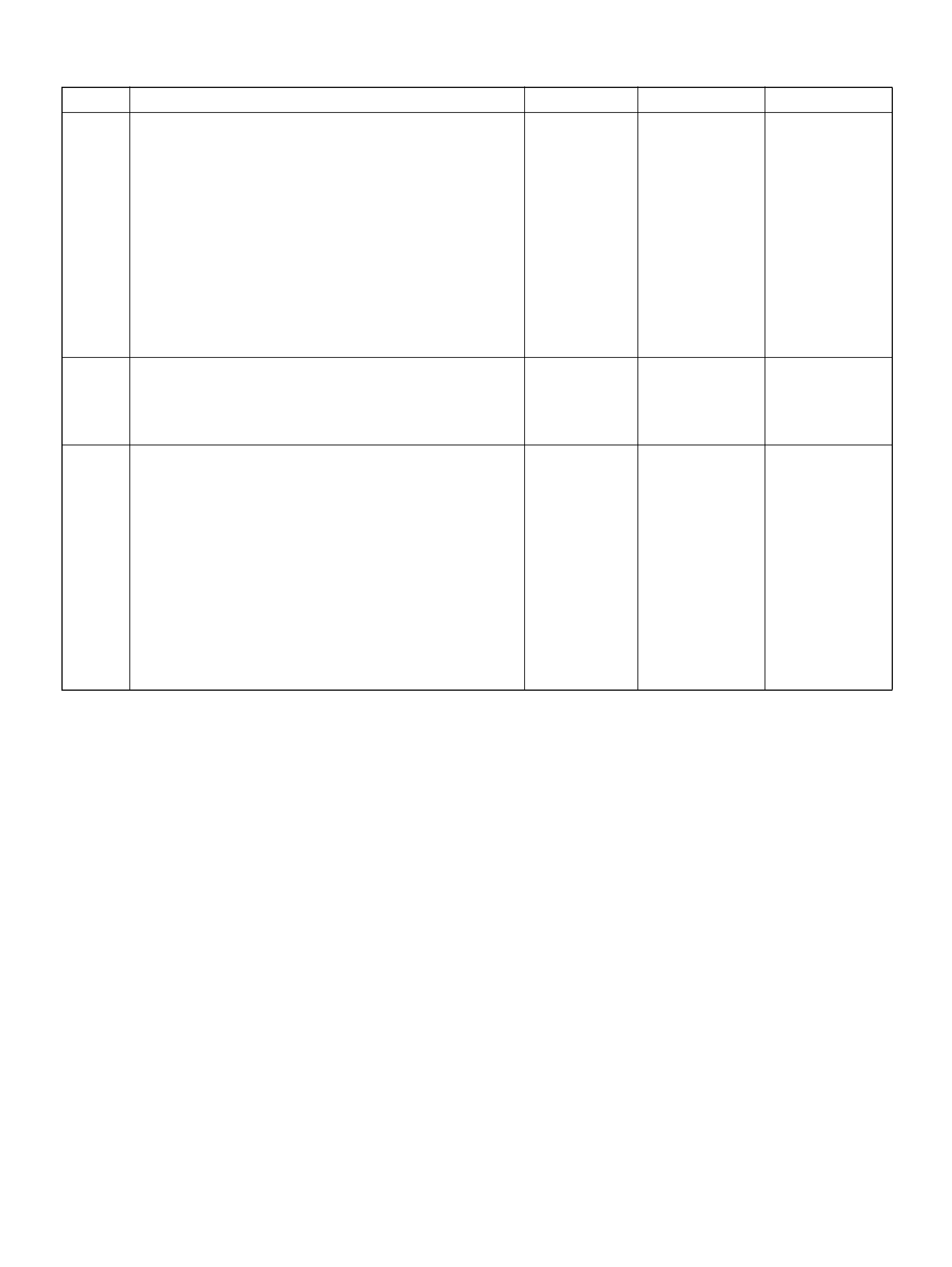

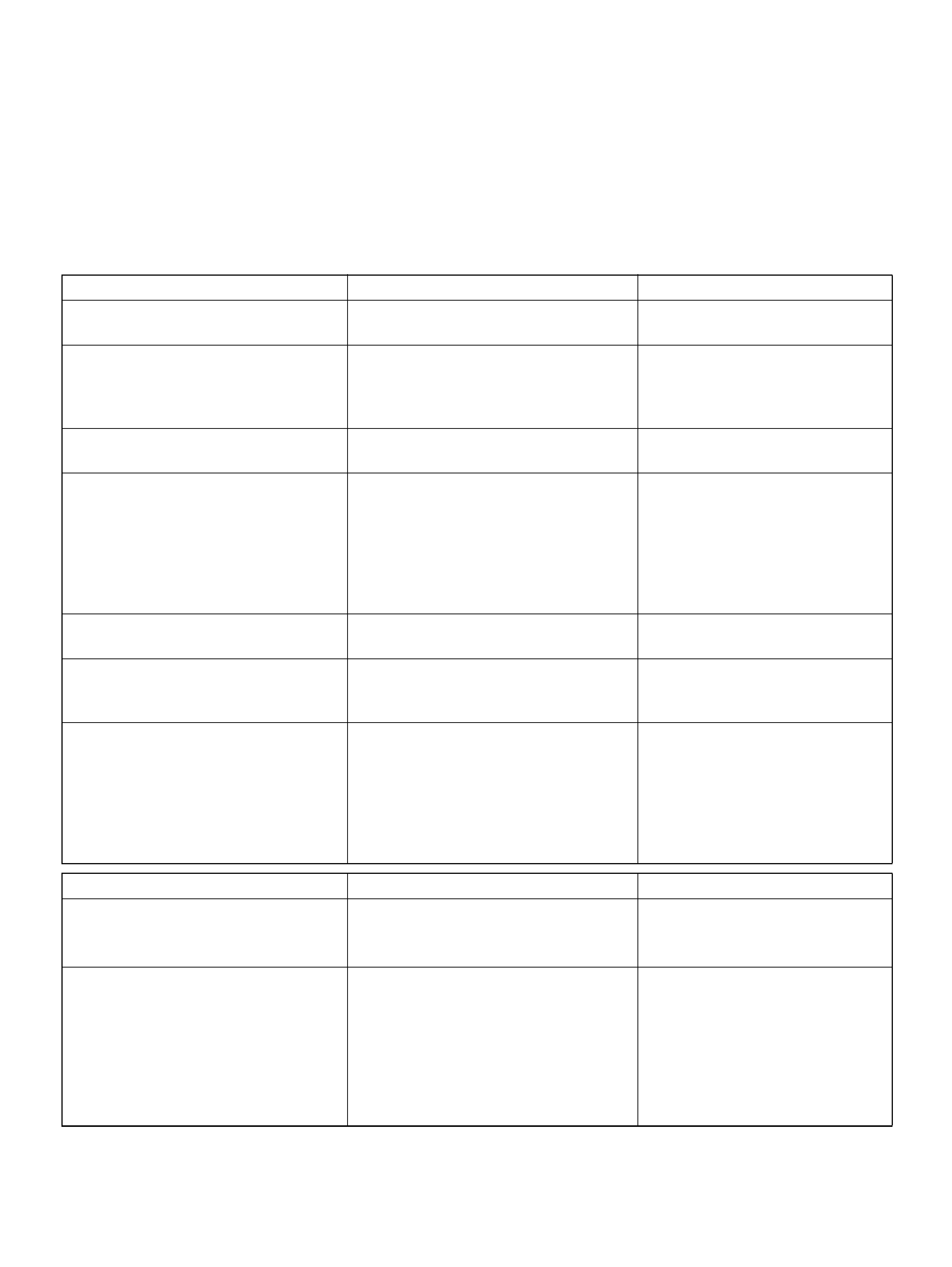

PCM PINOUT TABLE, 80-WAY RED CONNECTOR – ROW “S1 ∼ 20"

060RY00069

PIN PIN Function Wire Color IGN ON ENG RUN

S1 PCM Gr oun d BLK/PNK 0.0V 0.0V

S2 Bank 1 HO2S 1 Heater Ground BLK/ORN 0.0V 0.0V

S3 Not Used — — —

S4 Not Used — — —

S5 5Volt Reference“2" (CKP Sensor) WHT 5.0V 5 .0V

S6 Auto Cruise Control GRY/GRN 0.0V 0.0V

S7 C/P urge Solenoid Val v e YEL/RED B+ B+

S8 Not Used — — —

S9 Not Used — — —

S10 Shift High (Band Apply) BRN/YEL B+ B+

S11 Malfunction Indicator (Check Engine) Lamp WHT/GRN 0.0V B+

S12 Not Used — — —

S13 ION Sensing Module RED/ WHT 1.555V 1.555V

S14 Bank 2 HO2S 1 Ground BLU 0.0V 0.0V

S15 Not Used — — —

S16 Not Used — — —

S17 Bank 1 HO2S 1 Ground WHT 0.0V 0.0V

S18 Bank 1 HO2S 1 Low WHT/BLU 0.0V 0.1V

S19 ION Sensing Mod ule RED/YEL 1.555V 1.555V

S20 Transm ission Fluid Temperat ure Sens or

Ground RED/WHT 0.0V 0.0V

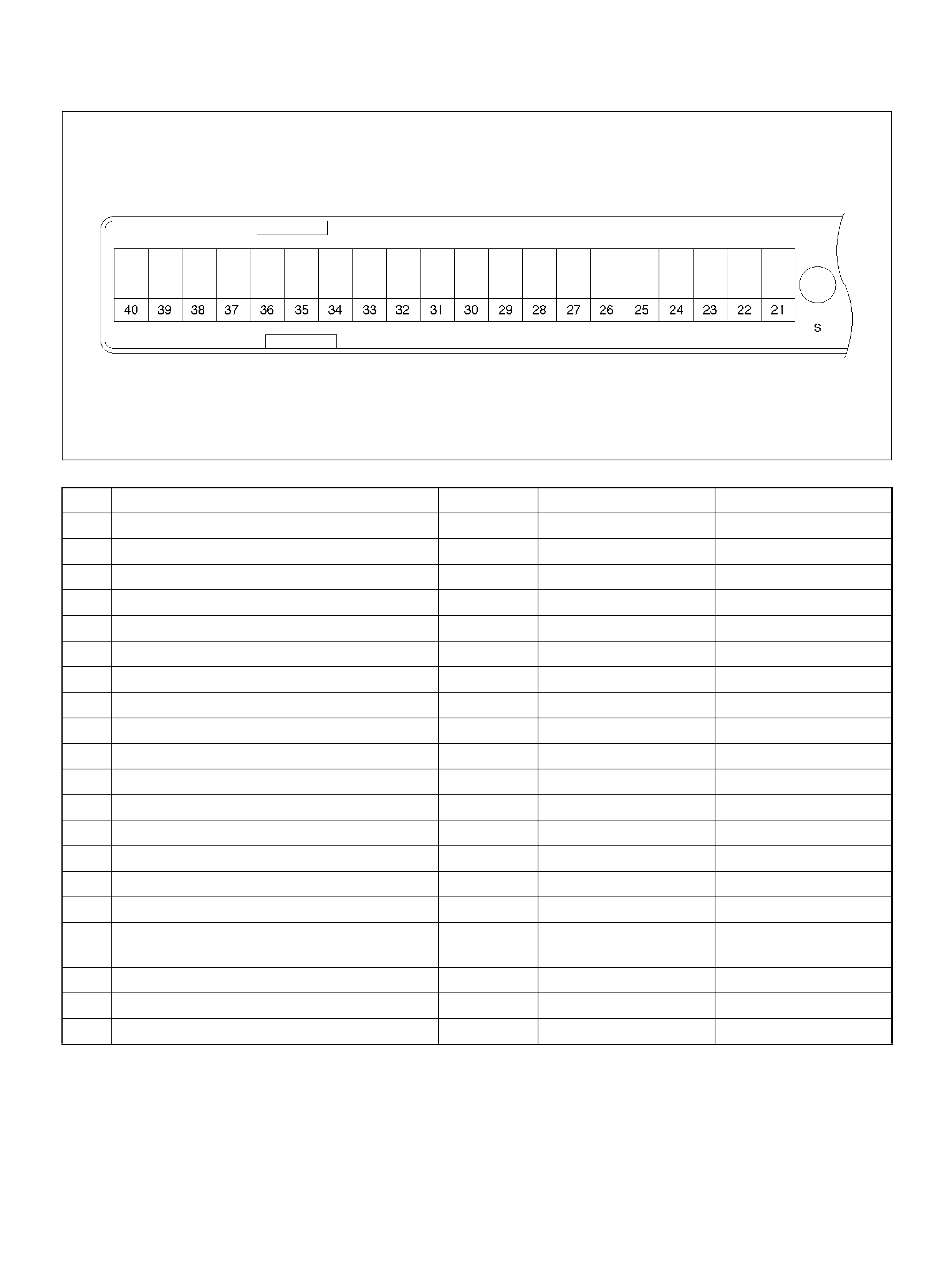

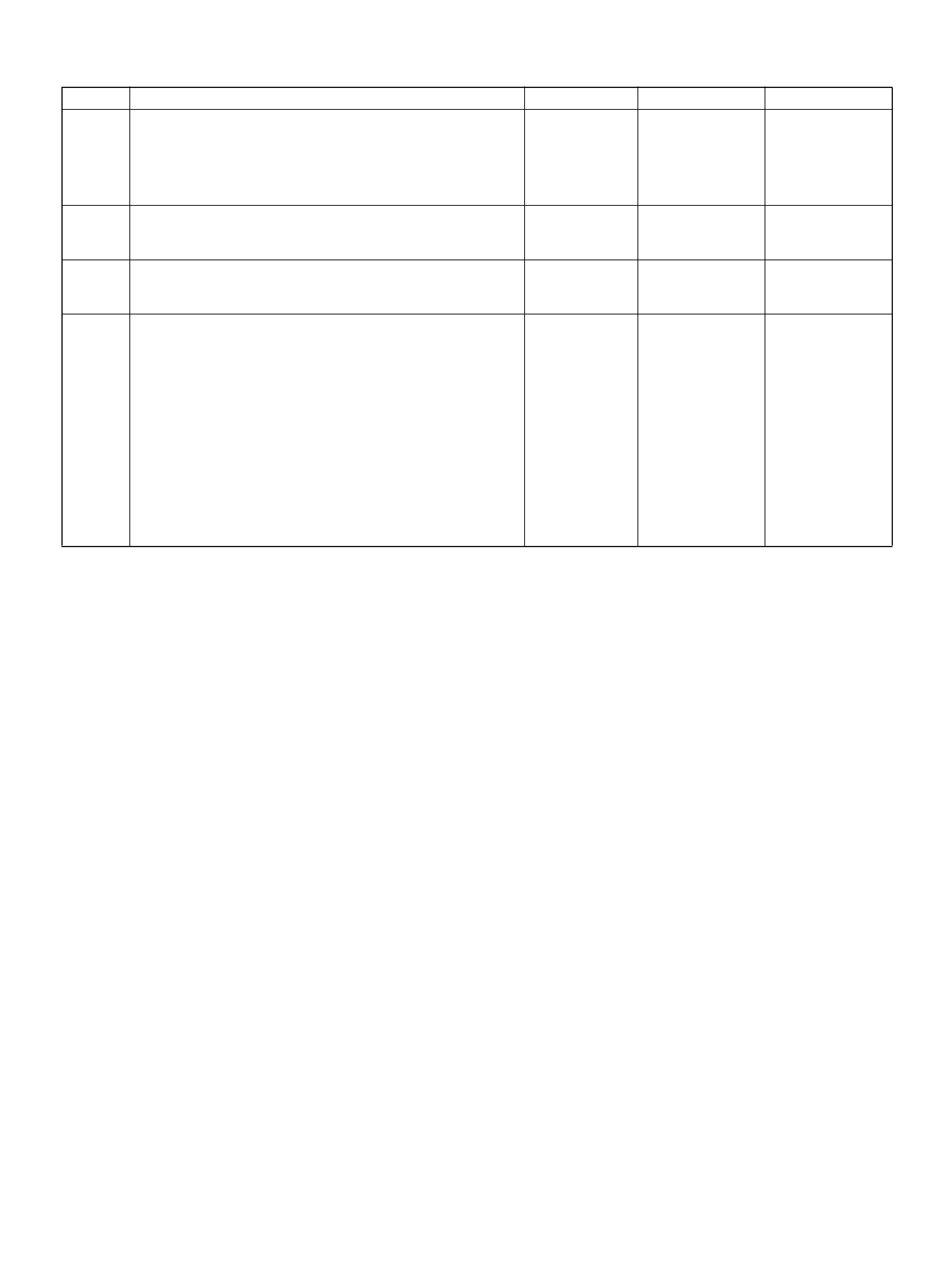

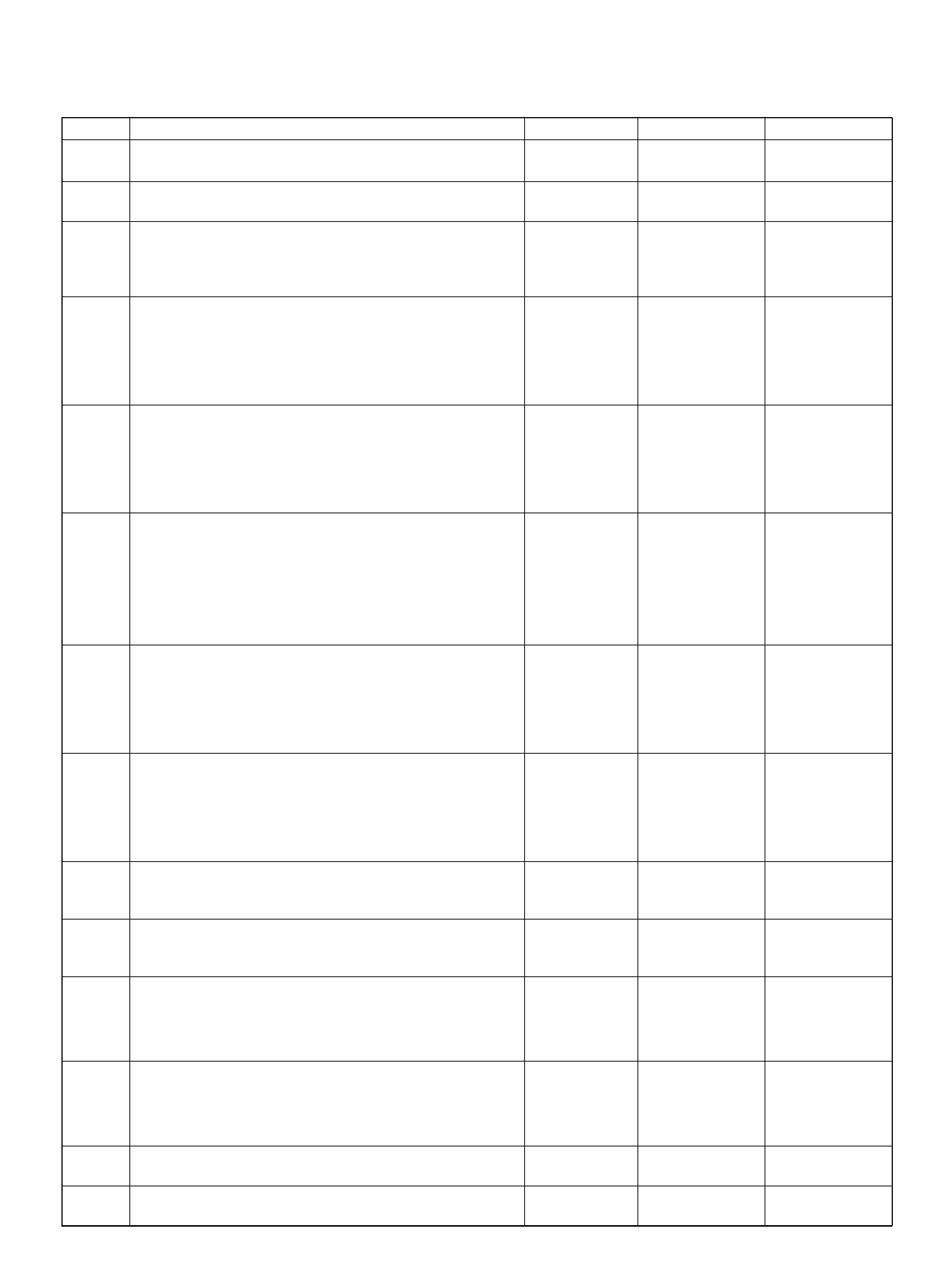

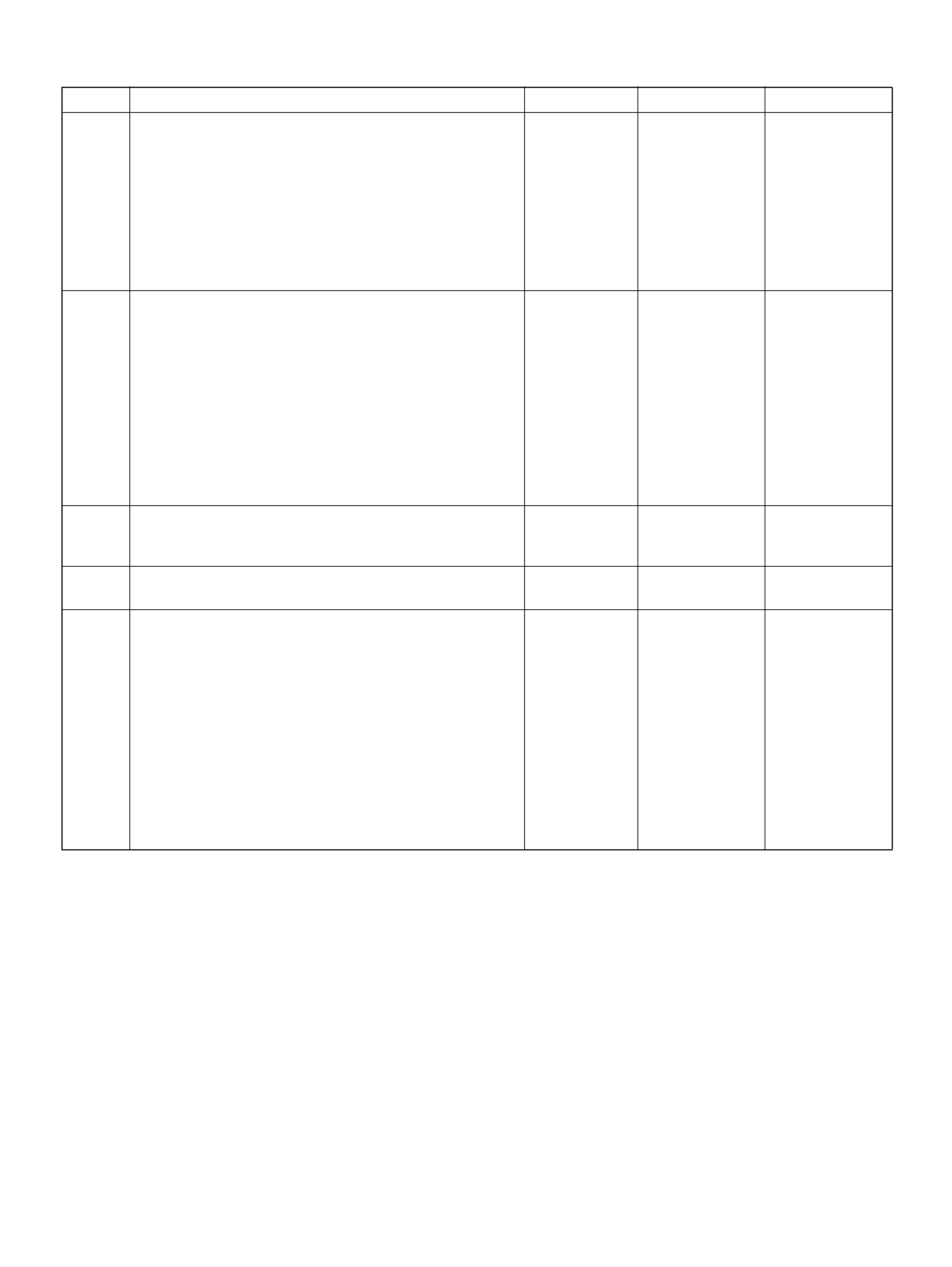

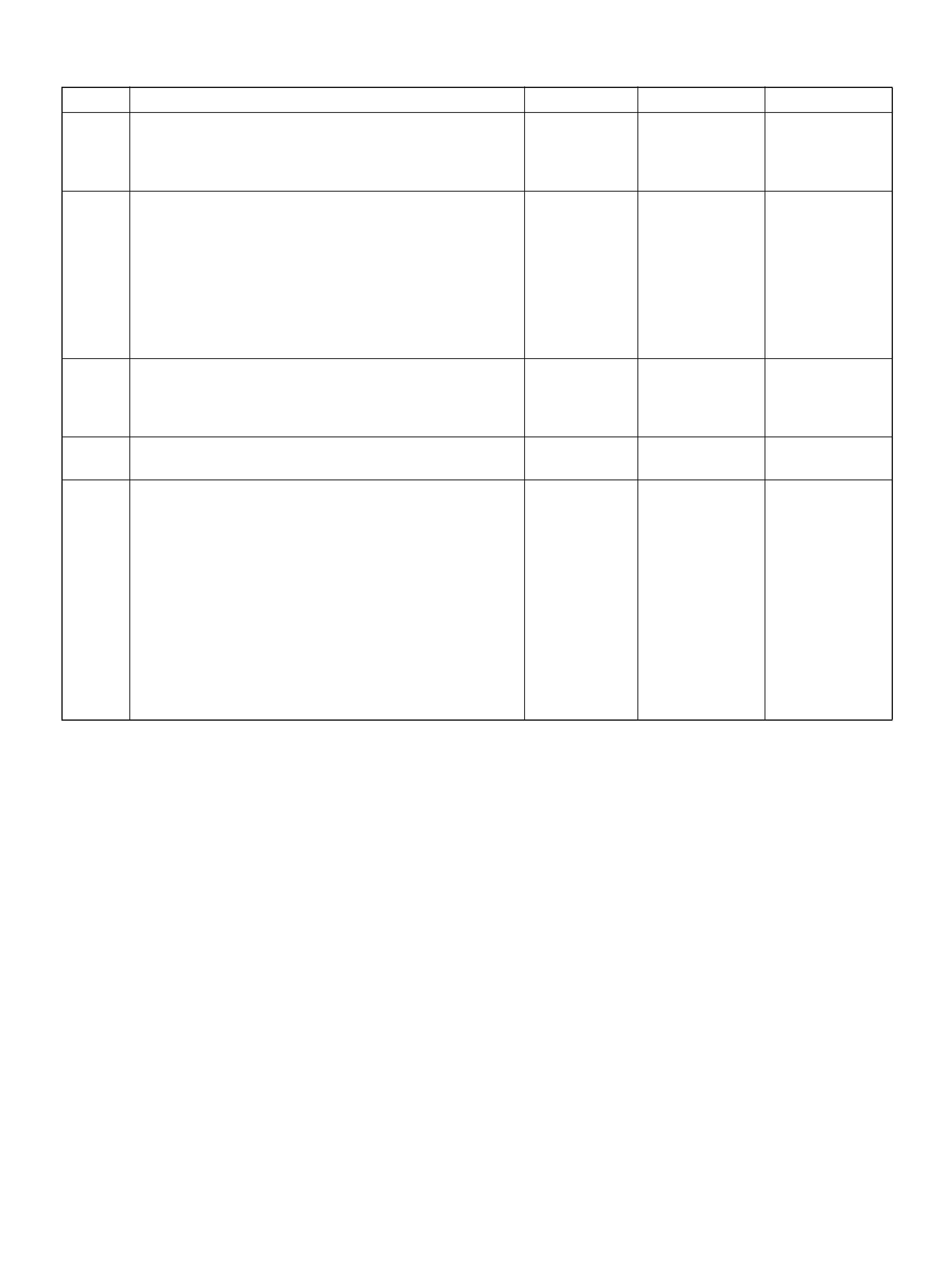

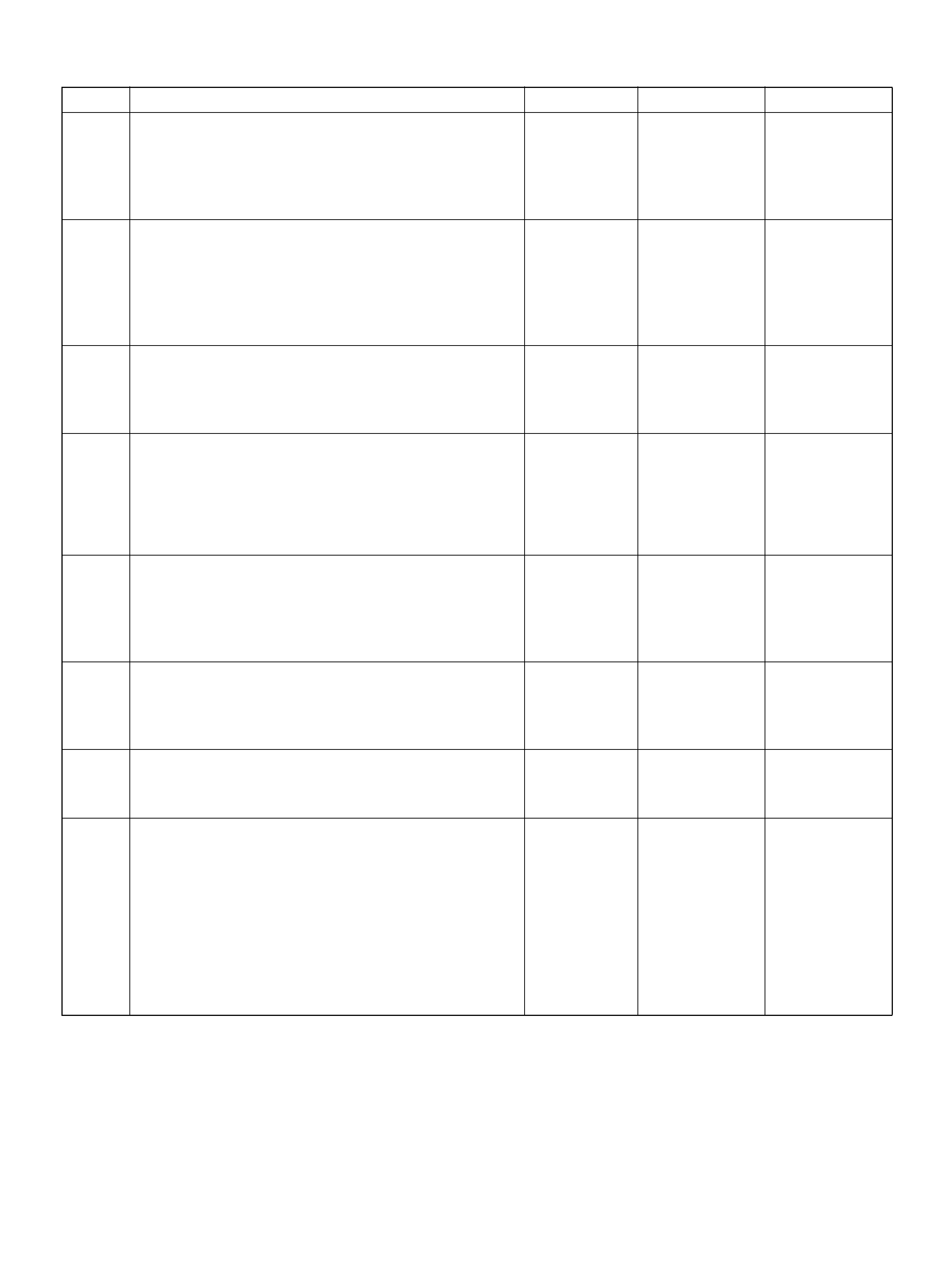

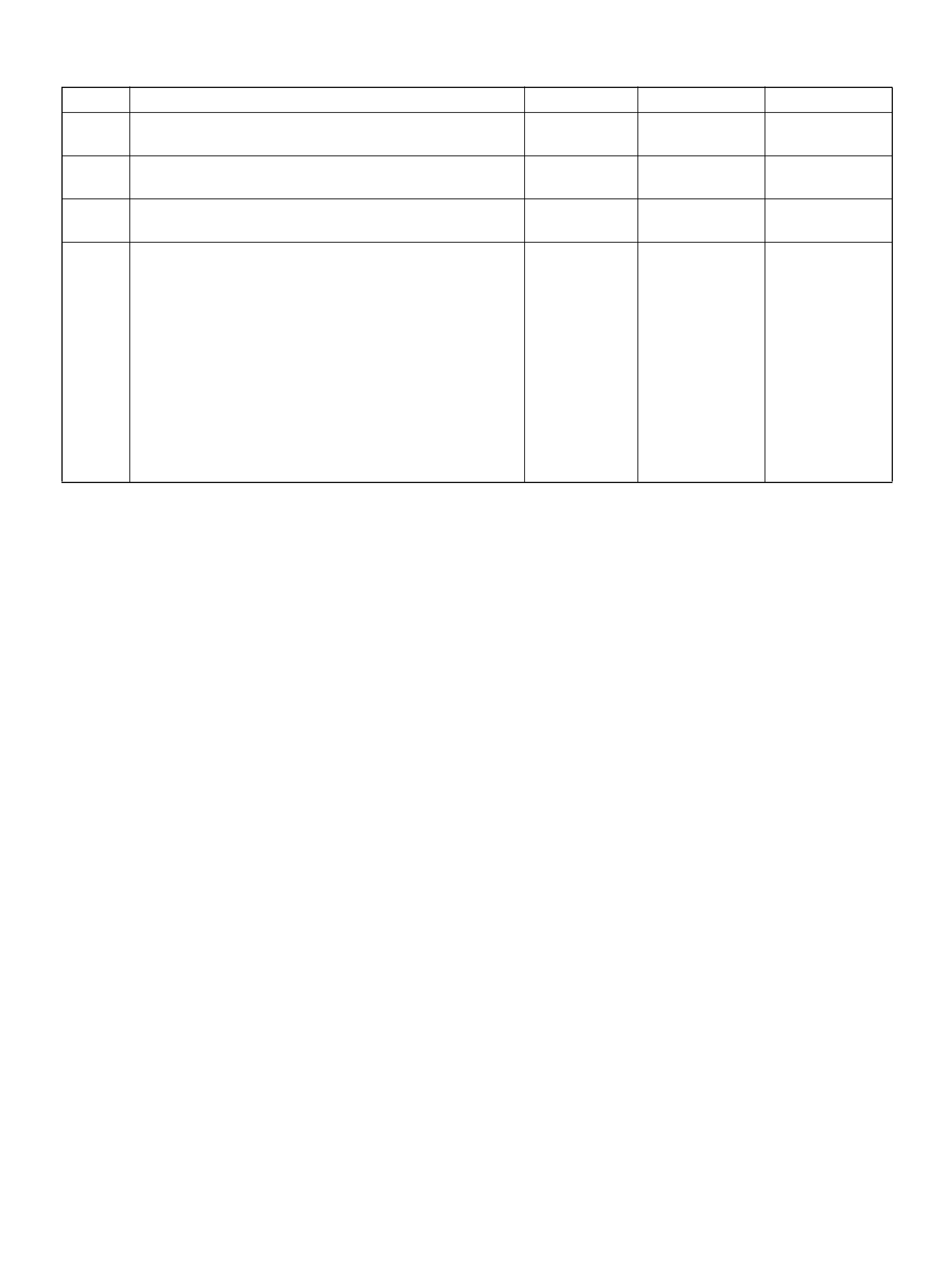

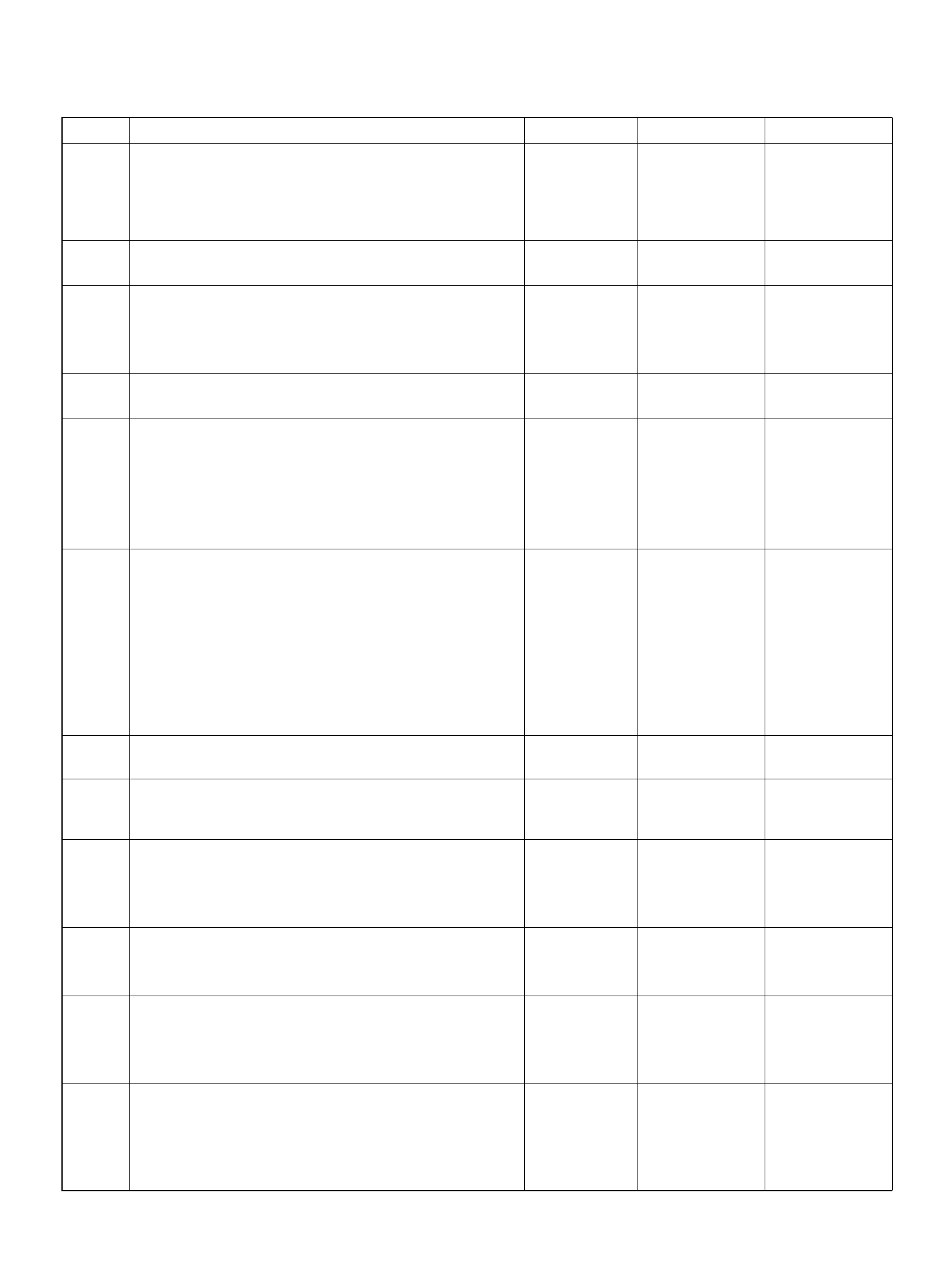

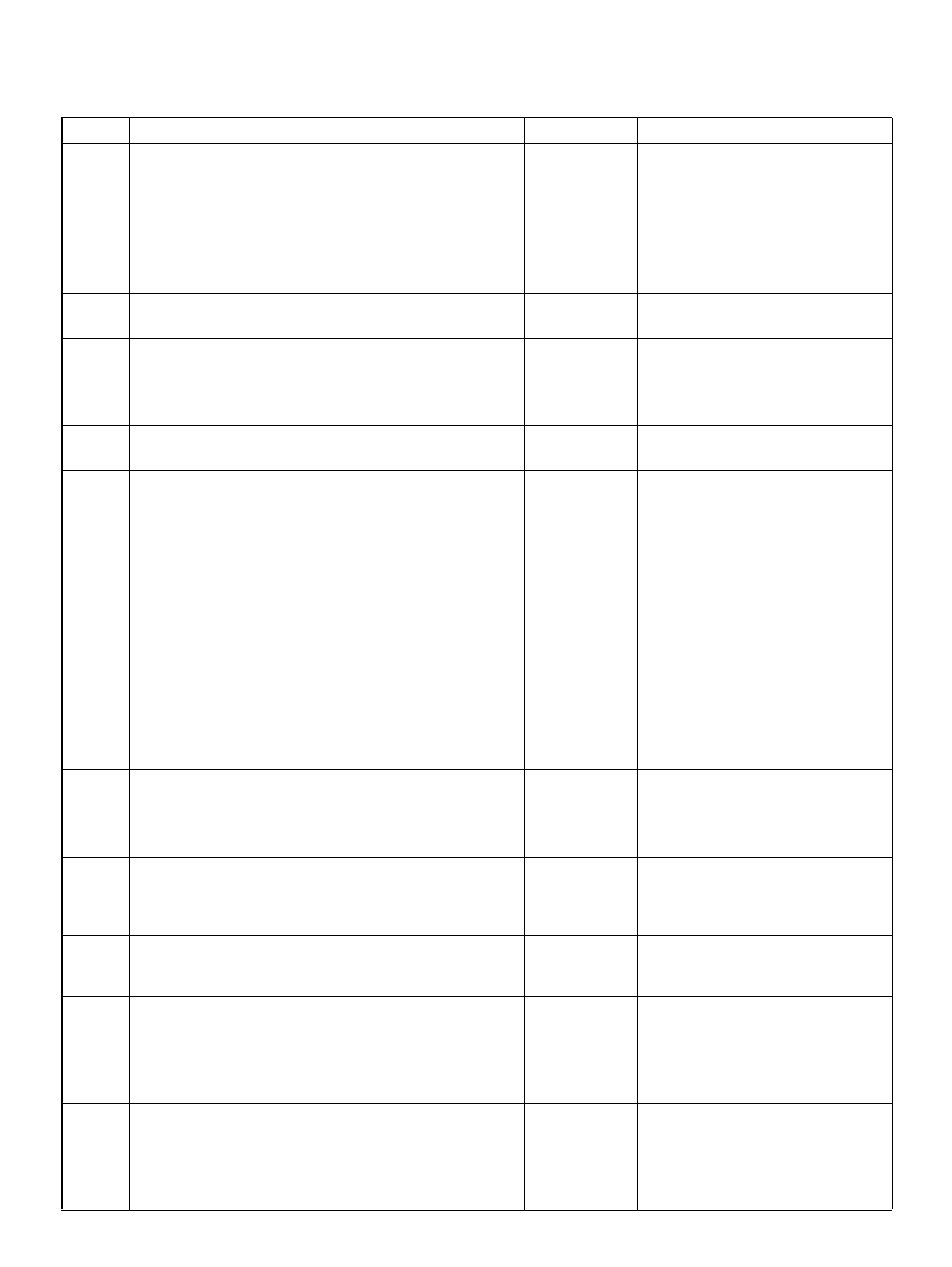

PCM PINOUT TABLE, 80 -WAY RED CONNECTOR – ROW “S21 ∼ 40"

060RY00049

PI N PIN Function Wire C ol or IGN ON EN G RUN

S21 Rr Window Demist Switch YEL/GRN — —

S22 Transmission Output Speed S ensor B LU/YEL 0.0V 0.0V

S23 PCM Groun d BLK 0. 0V 0.0V

S24 Not Used — — —

S25 Not Used — — —

S26 EGR Control High BLU/ RED B+ B+

S27 VSS Input BLK/YEL 0.0V 0.1V (at rest)

S28 Injector Cylinder #6 GR N/YEL B+ B+

S2 9 W inter Switc h VIO/ GR N B+ B +

S3 0 C r uis e Main Sw i tc h WHT/B LU 0.0V 0.0V

S31 Transm ission Range Signal“2–3'' GRN 0.0V 0.0V

S32 Ignition Feed R ED/GRN B+ B+

S33 TCC Soleno id BRN/WHT 0.0V 0.0V

S34 Not Used — — —

S35 ION Sensing Module RED/GRN 1.555V 1.555V

S36 5Volt Reference (AP Sensor 1) BLK 5.0V 5.0V

S37 5V olt Reference (MAP Sensor/EGR Position

Sensor) GRY/RED 5.0V 5.0V

S38 5Volt Reference (TP Sensor 1) RED 5. 0V 5.0V

S39 Auto Cruise Lamp WHT 0.0V 0.0V

S40 PCM Groun d BLK /YE L 0.0V 0.0V

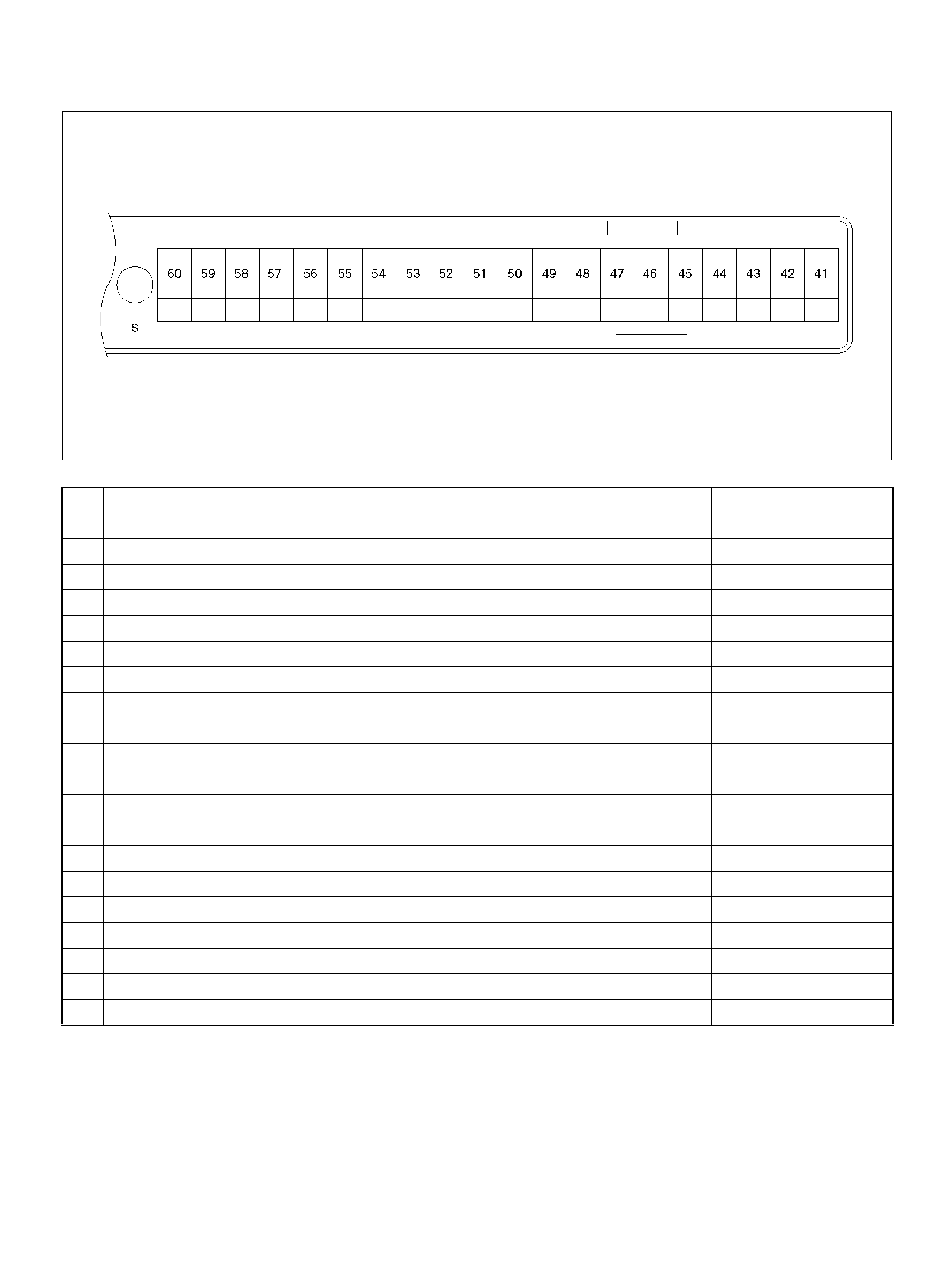

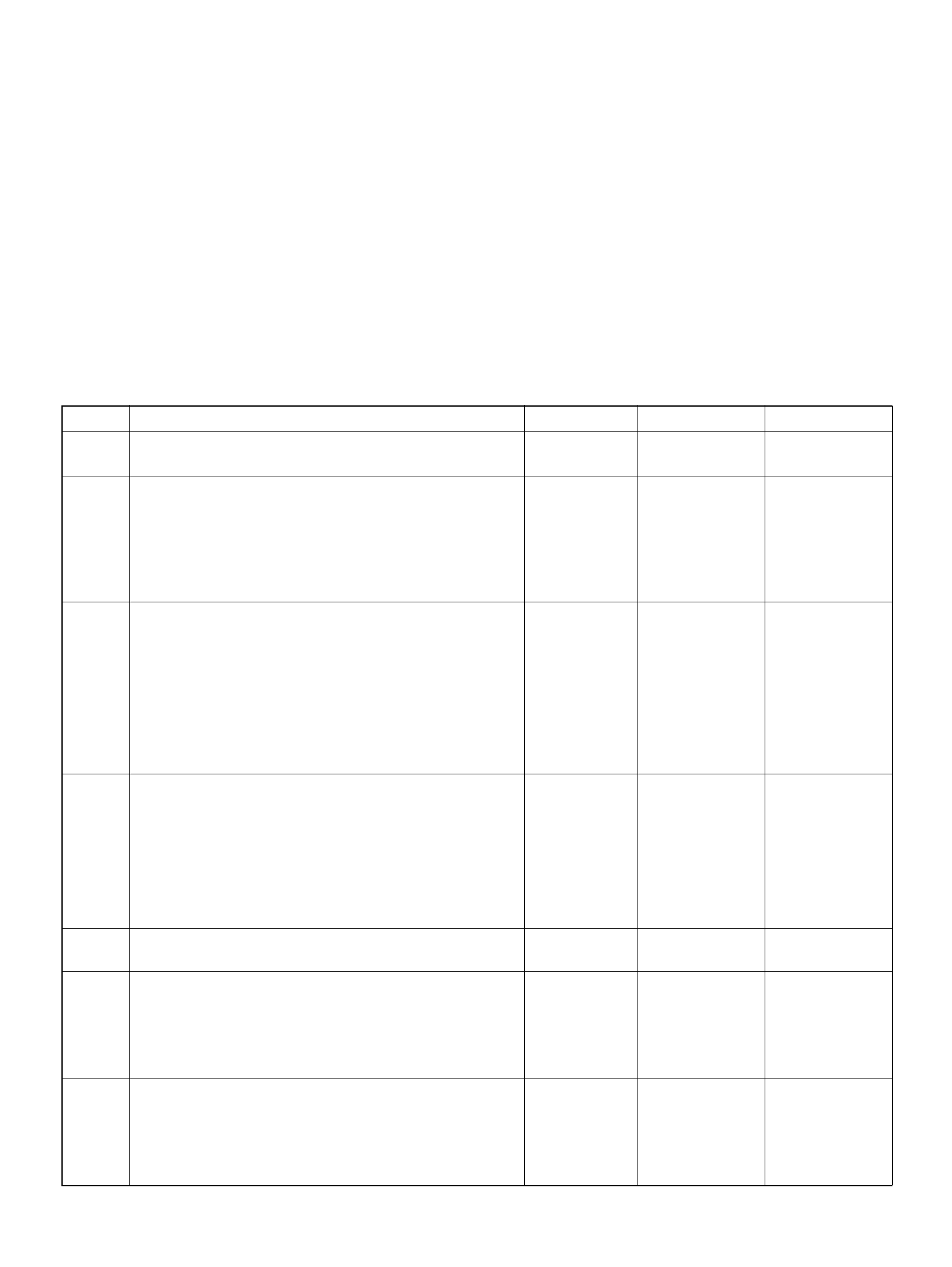

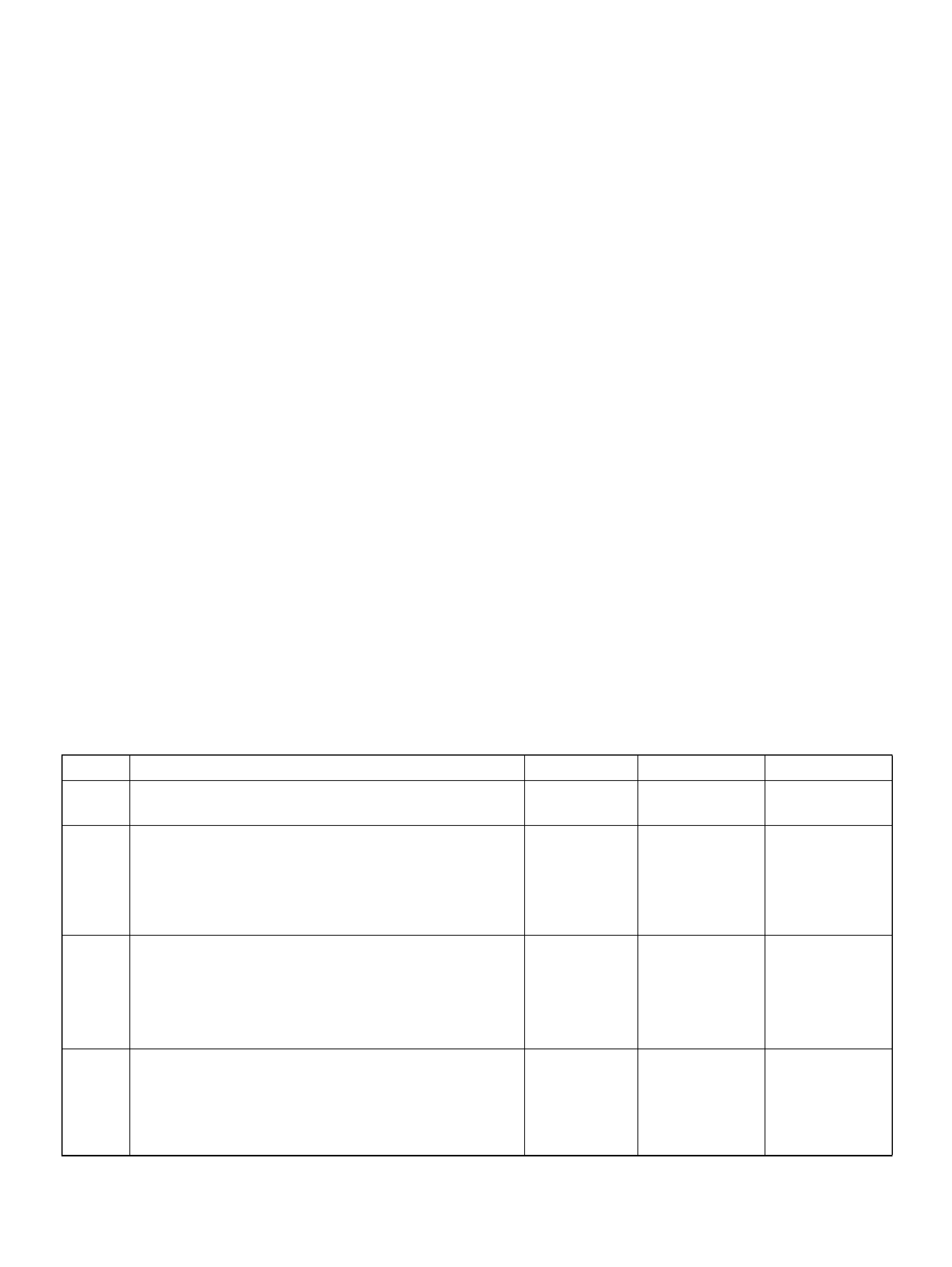

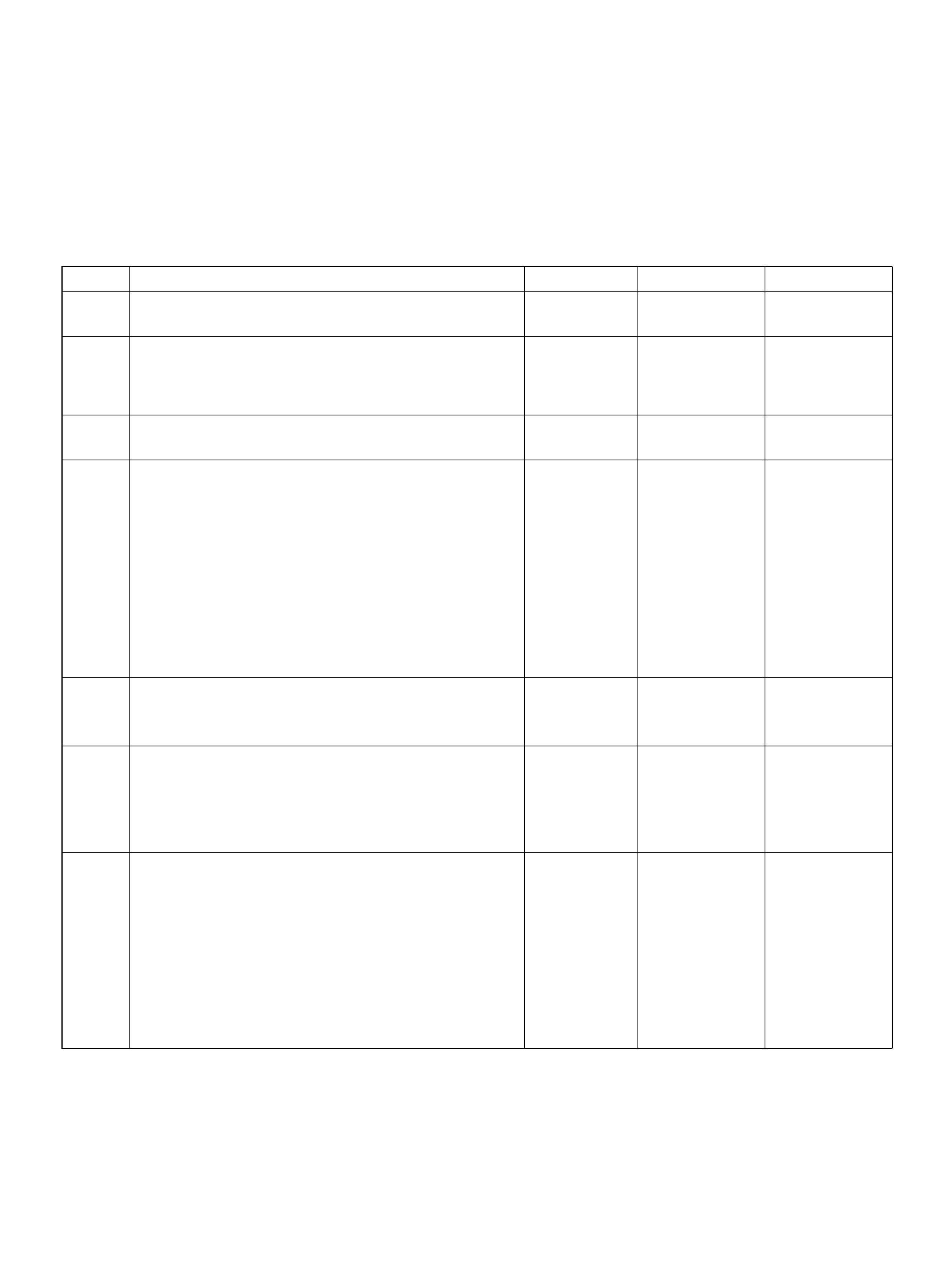

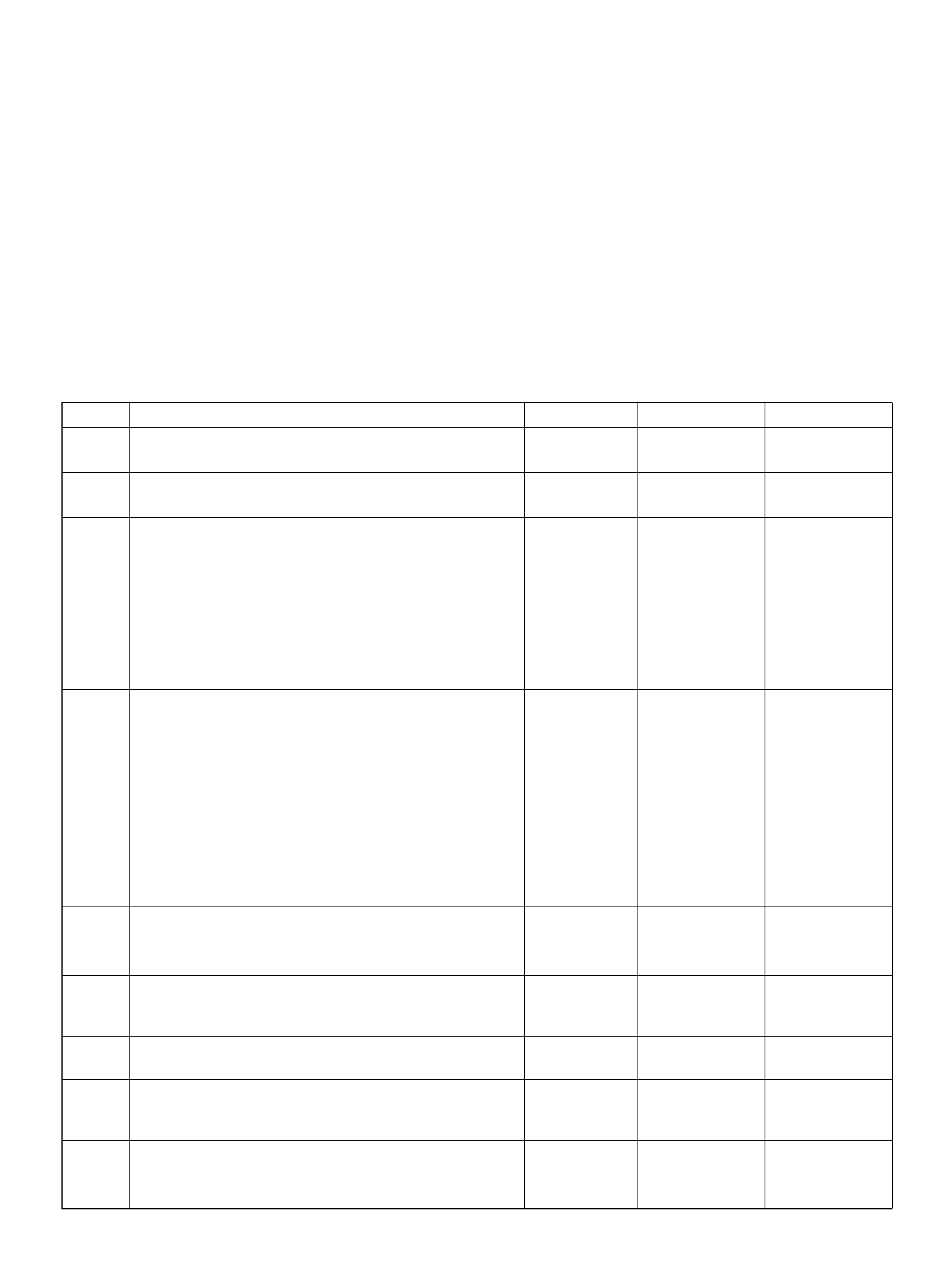

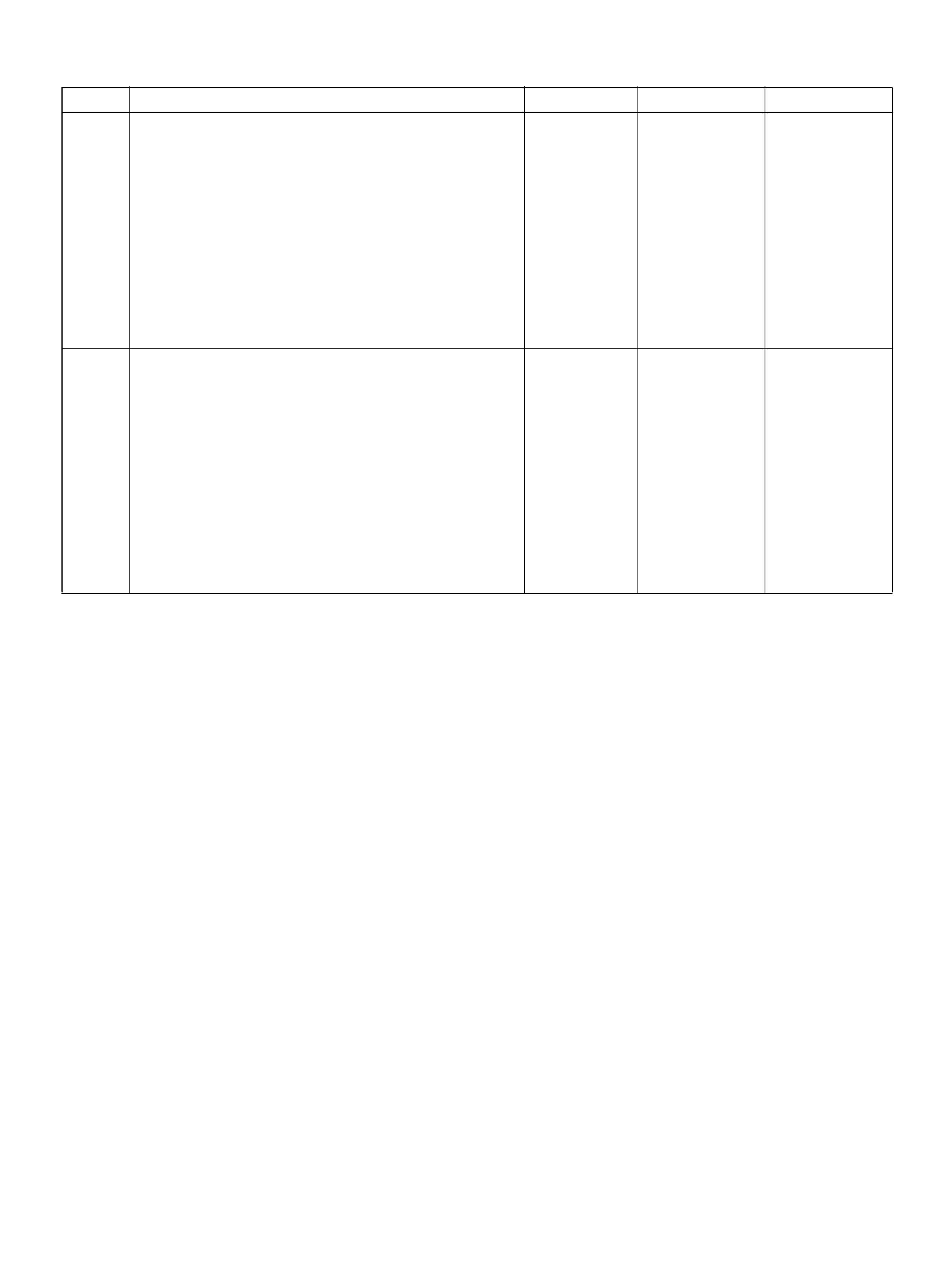

PCM PINOUT TABLE, 80 -WAY RED CONNECTOR – ROW “S41 ∼ 60"

060RY00050

P I N PIN Function Wire Color IGN ON ENG RU N

S41 AP Sensor 3 Senso r Ground ORN/ BLU 0. 0V 0.0V

S42 Bank 2 HO2S 1 Heater Ground WHT/RED 0.0V 0.0V

S43 Trans m ission Range Signal“1–2'' “3–4'' GRY/WHT B + B+

S44 Rr Def. Relay RED/WHT — —

S45 Not Used — — —

S46 Not Used — — —

S47 Water Temp. Gauge WHT/BLK B+ B+

S48 Not Used — — —

S49 DLC RED/WHT B+ B+

S50 Not Used — — —

S51 TCC Solenoid BRN/BLU 0.0V 0.0V

S52 Not Used — — —

S53 Power Switch VIO/RED B + B+

S54 Bank 2 HO2S 1 Low BLU 0.0V 0.1V

S55 T ransmission Output Sp eed Sensor BLU/GRN 0.0V 0.0V

S56 Not Used — — —

S57 Not Used — — —

S58 Bank 1 HO2S 1 High ORN/BLU 0.3V 0.1–0.9V

S59 Cruise Set GRN 0.0V 0.0V

S60 Not Used — — —

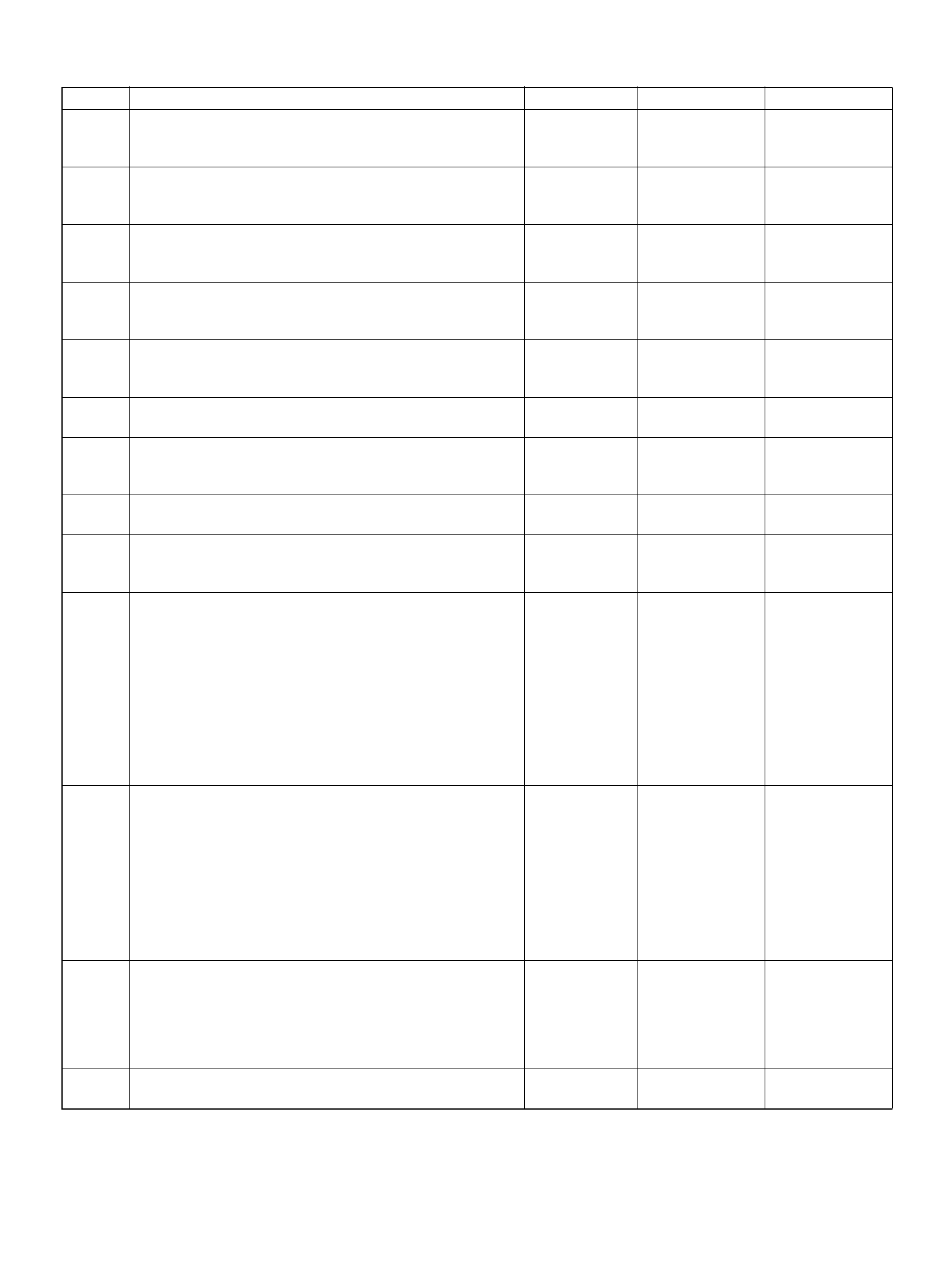

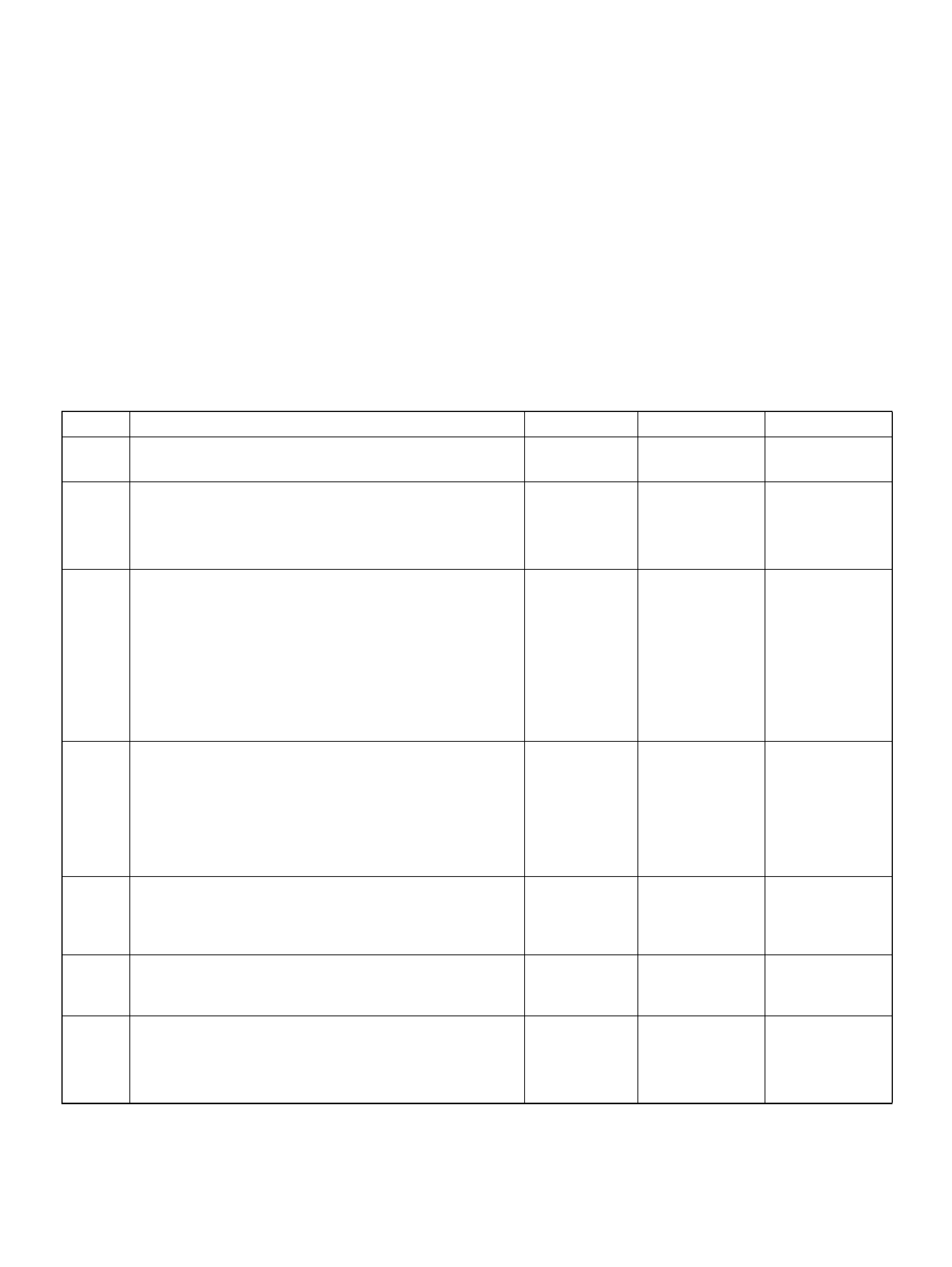

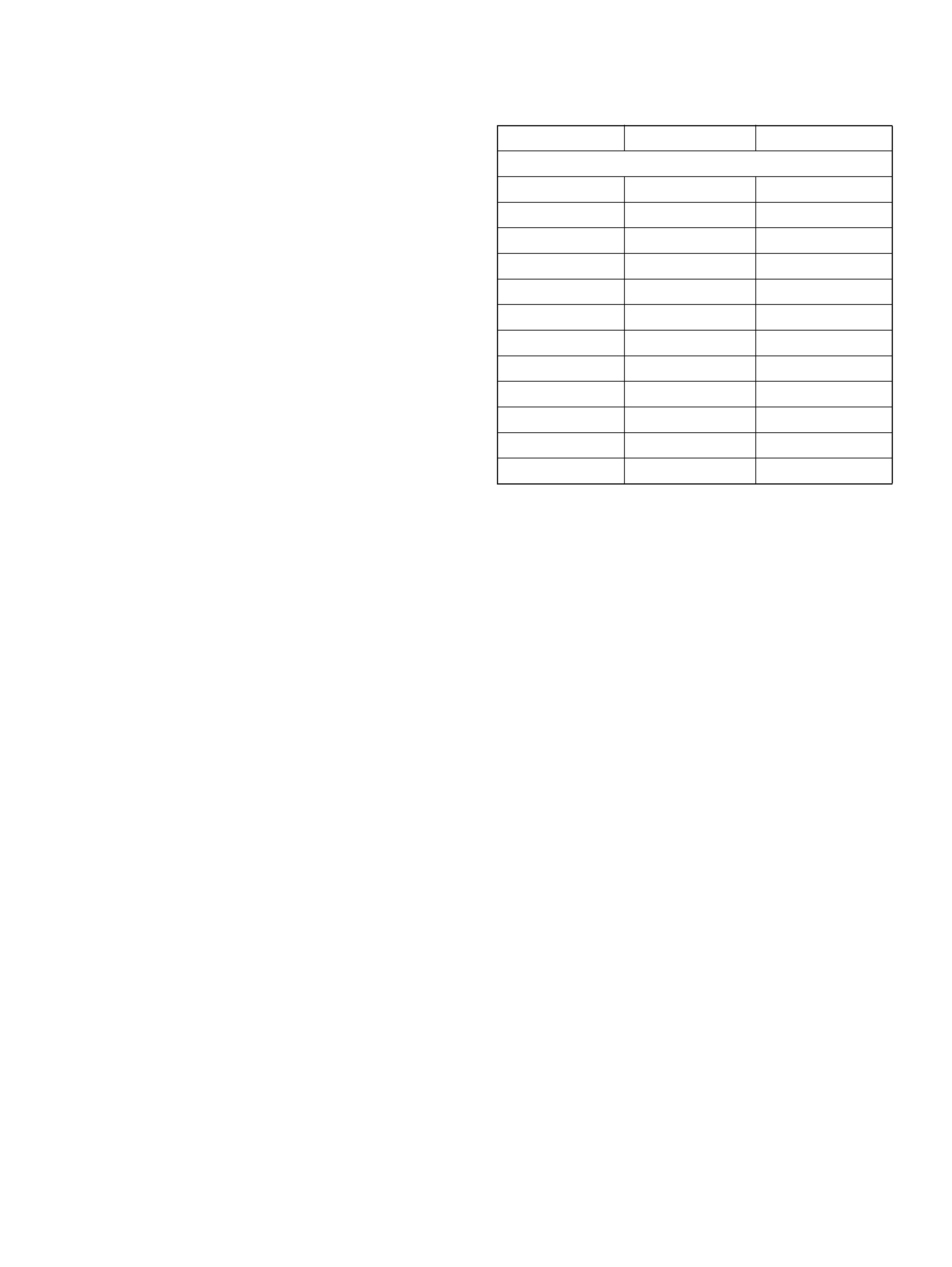

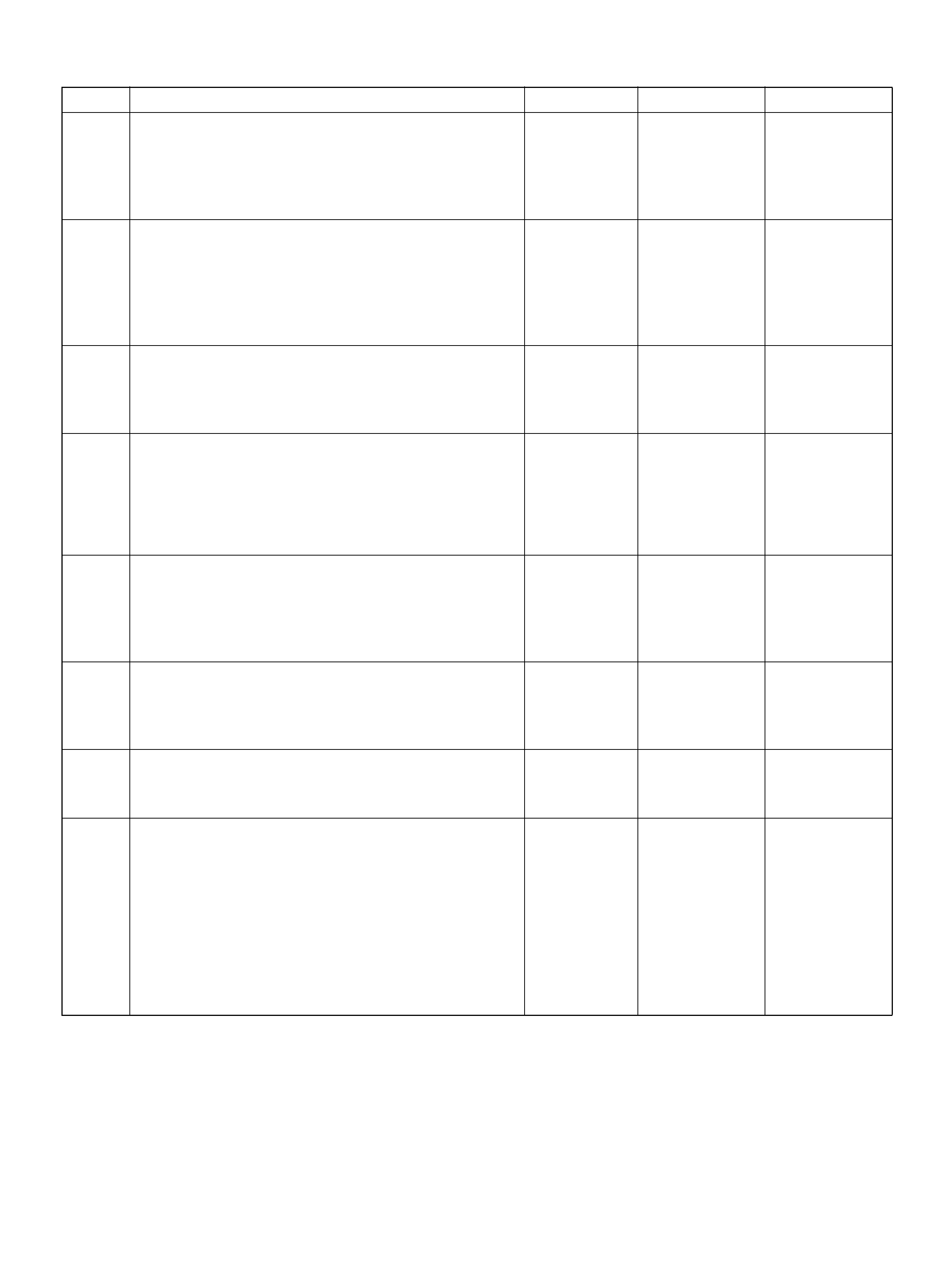

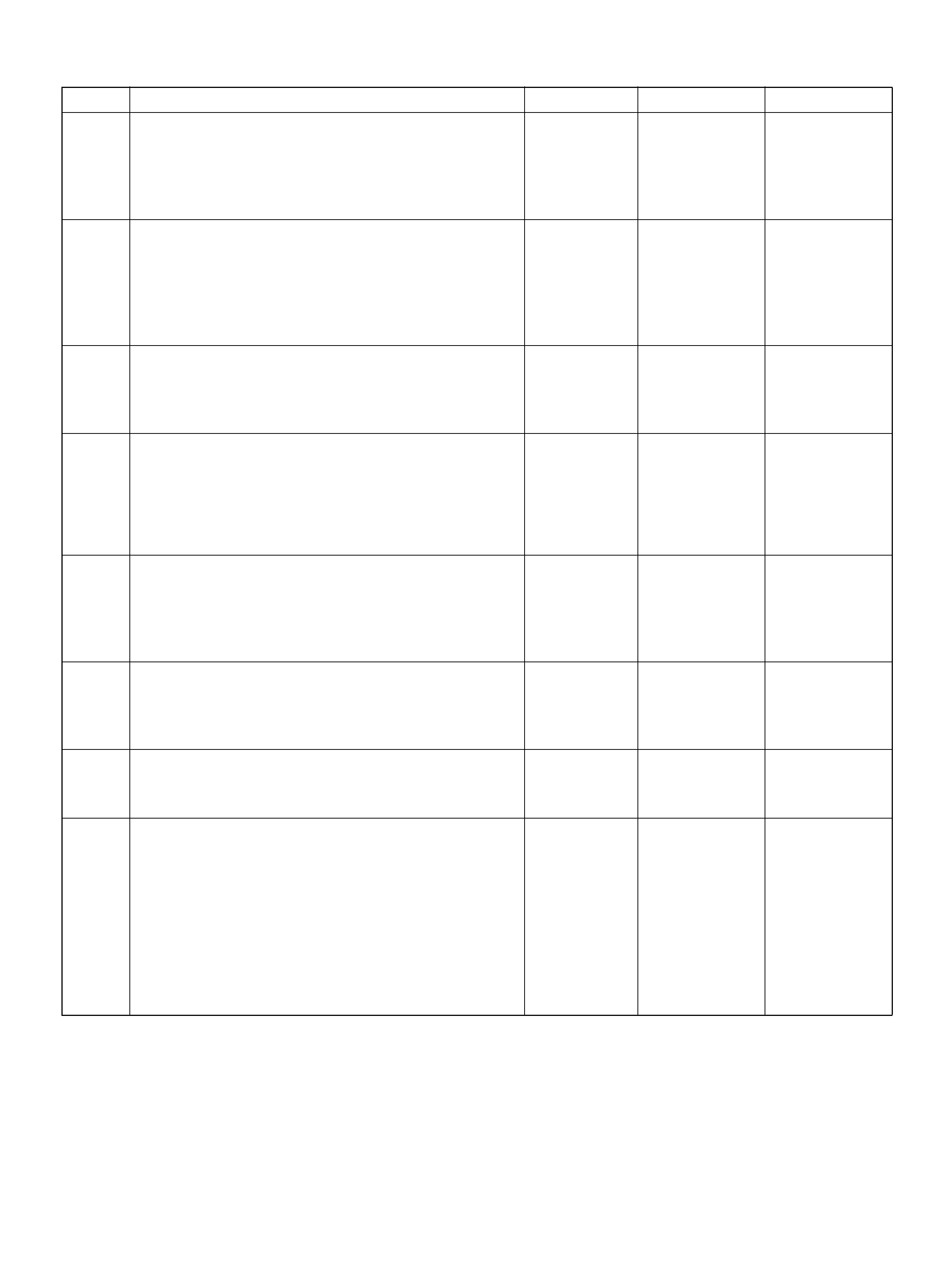

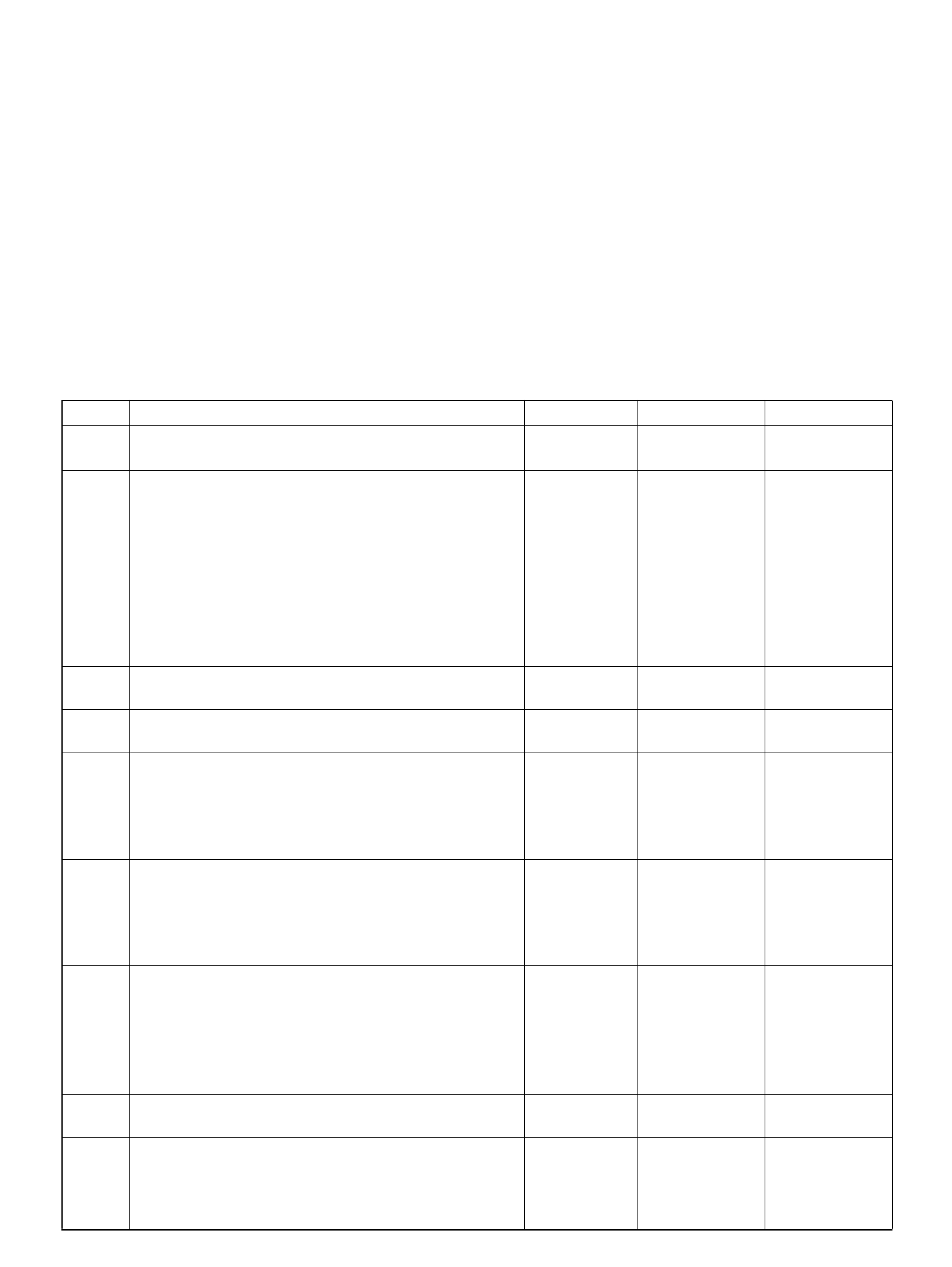

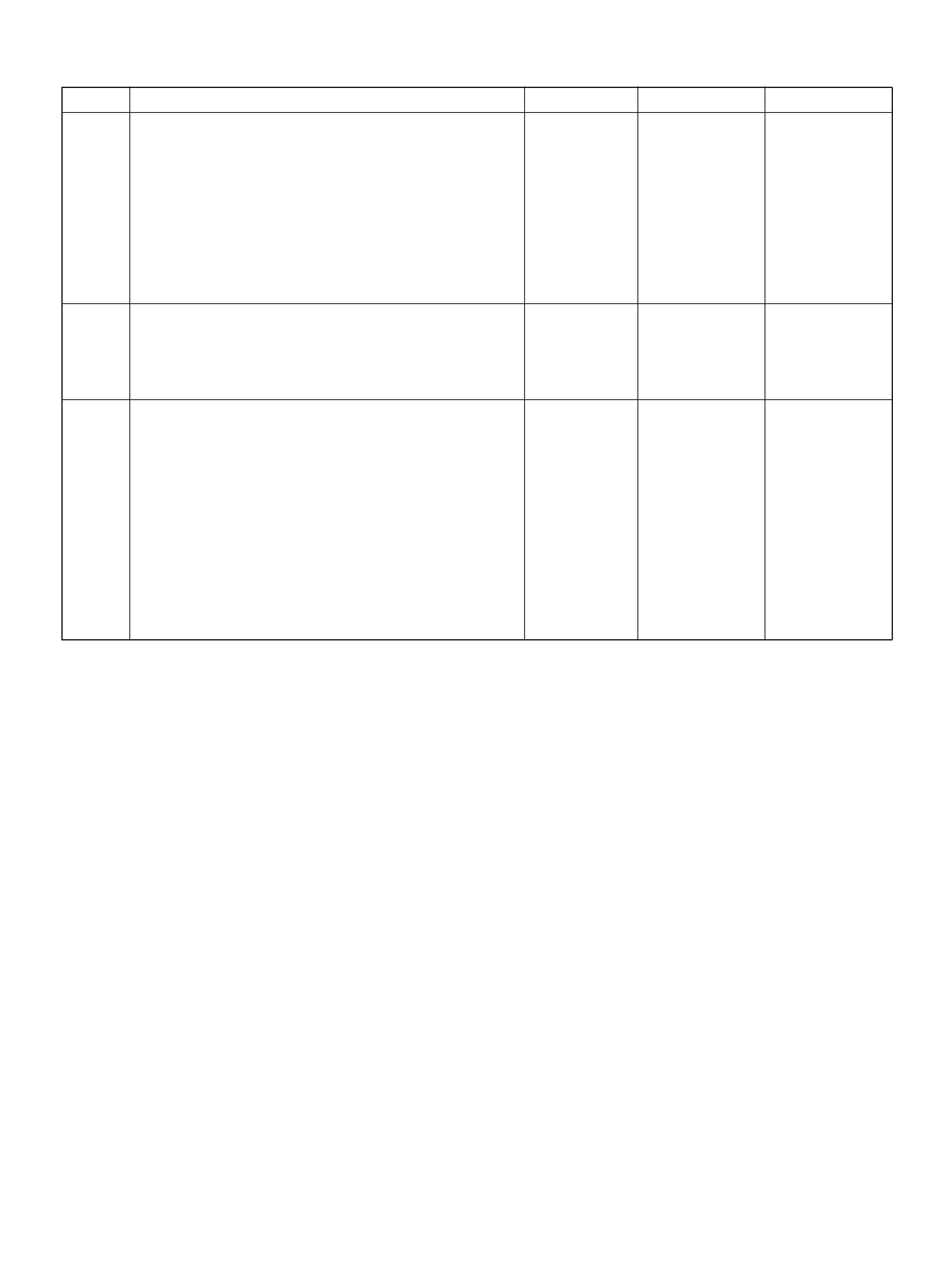

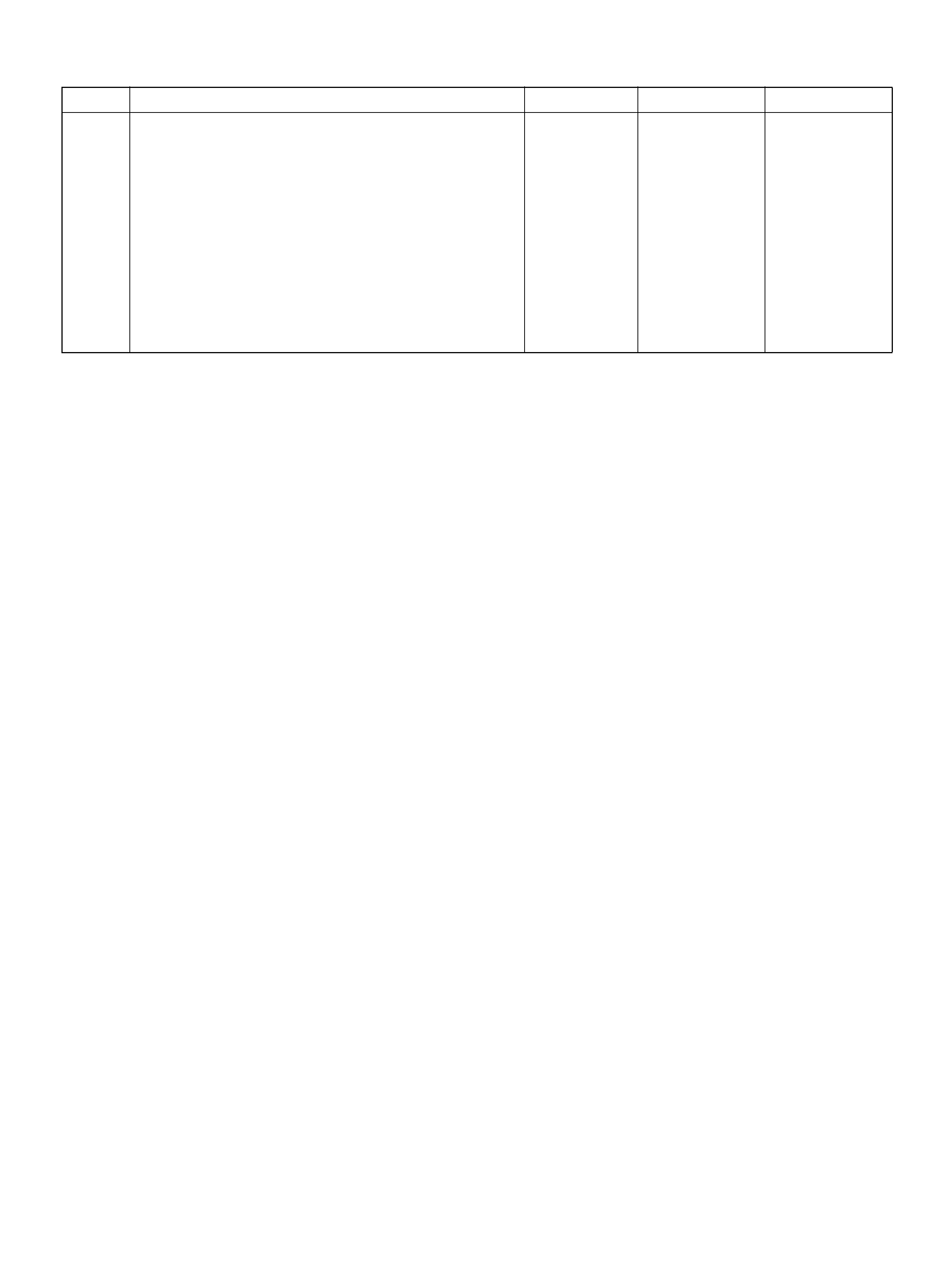

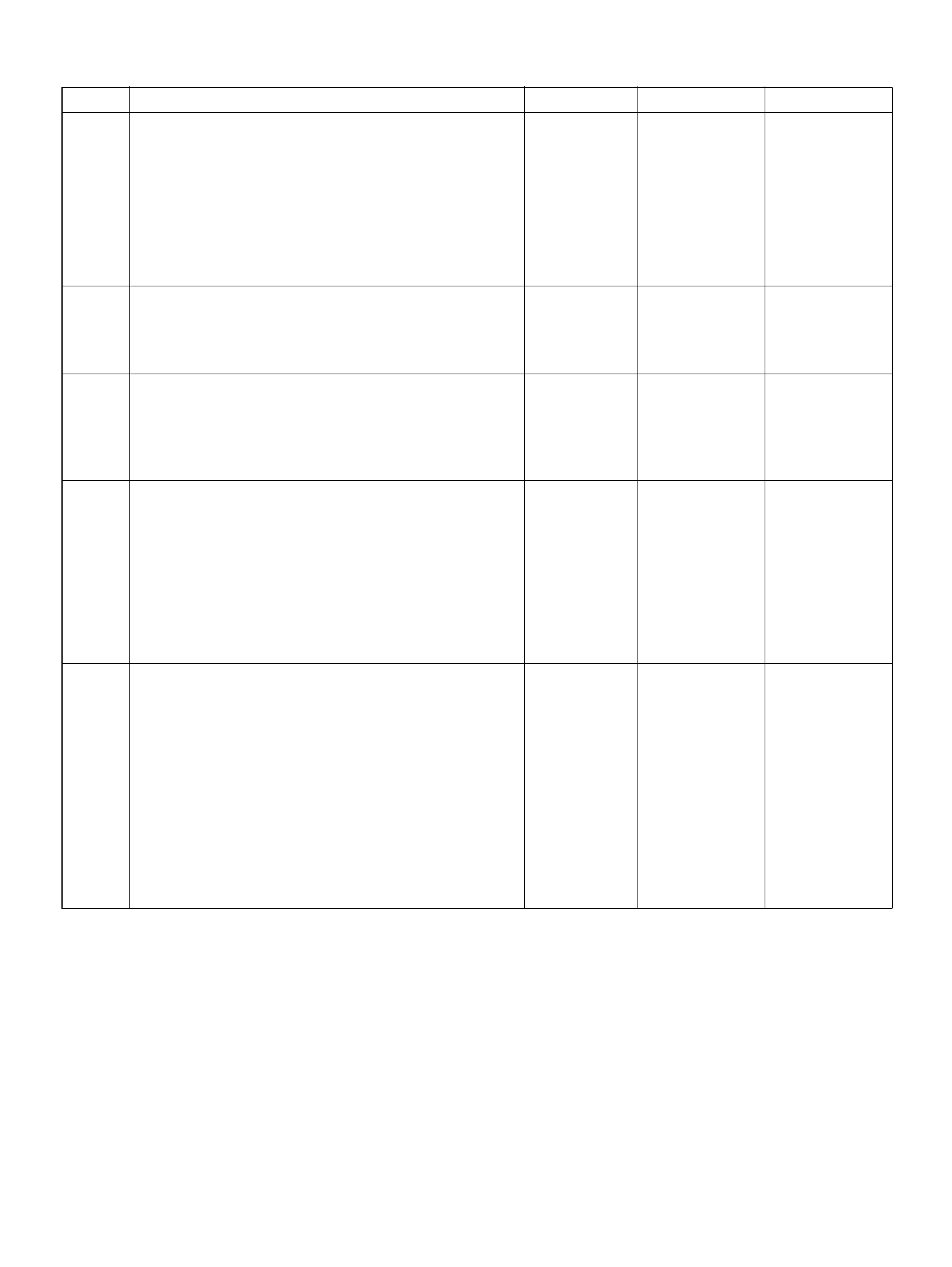

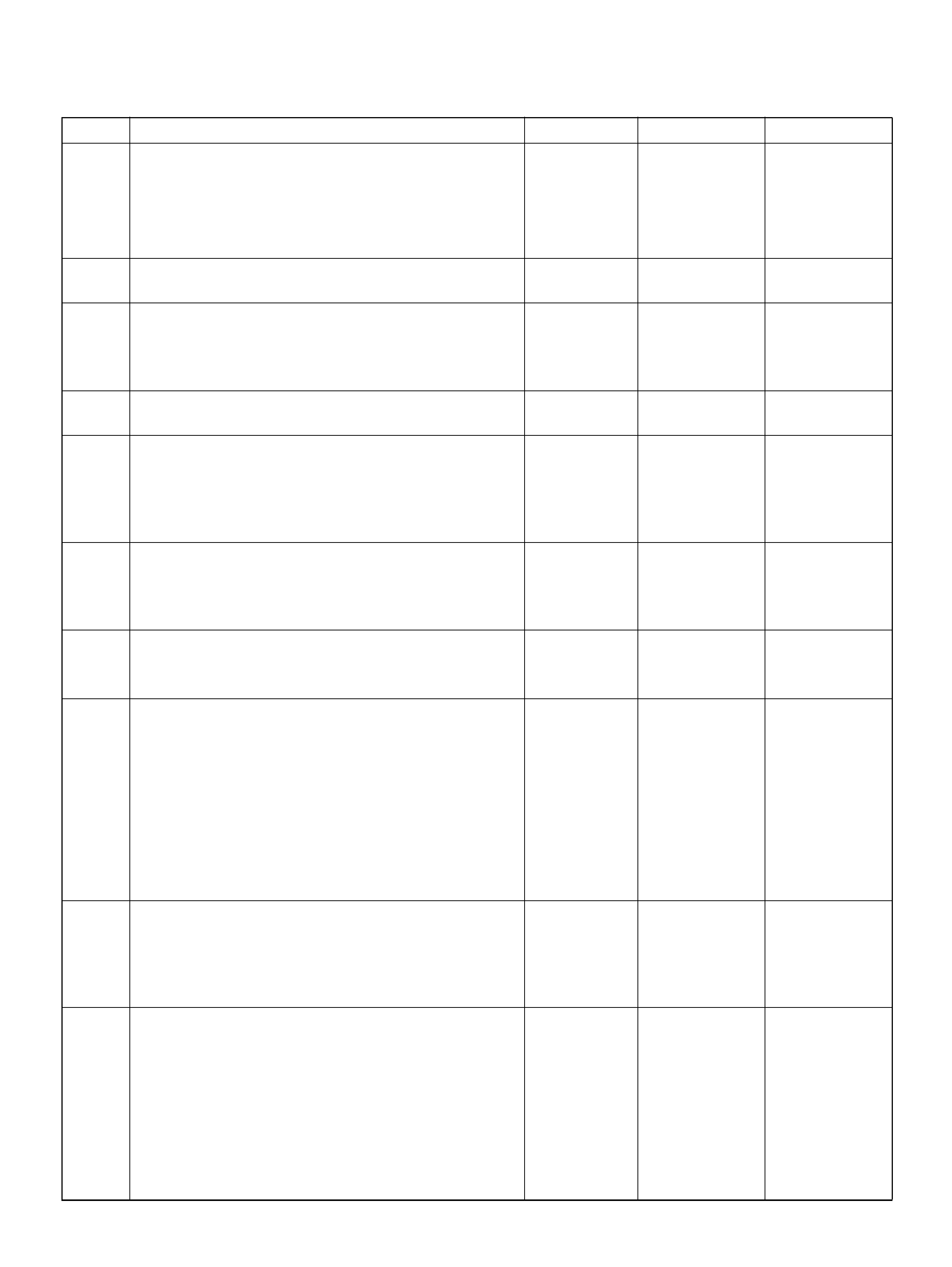

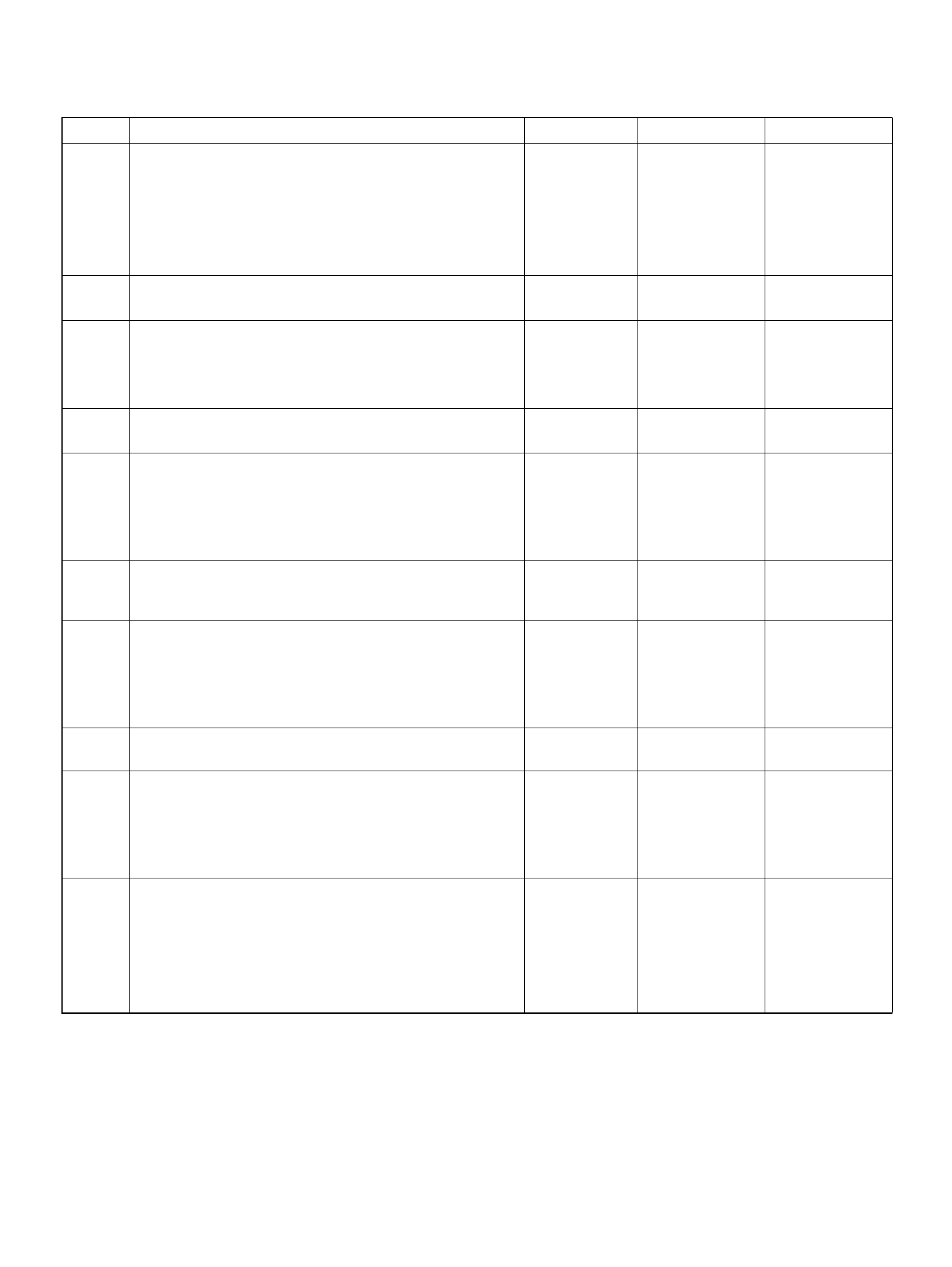

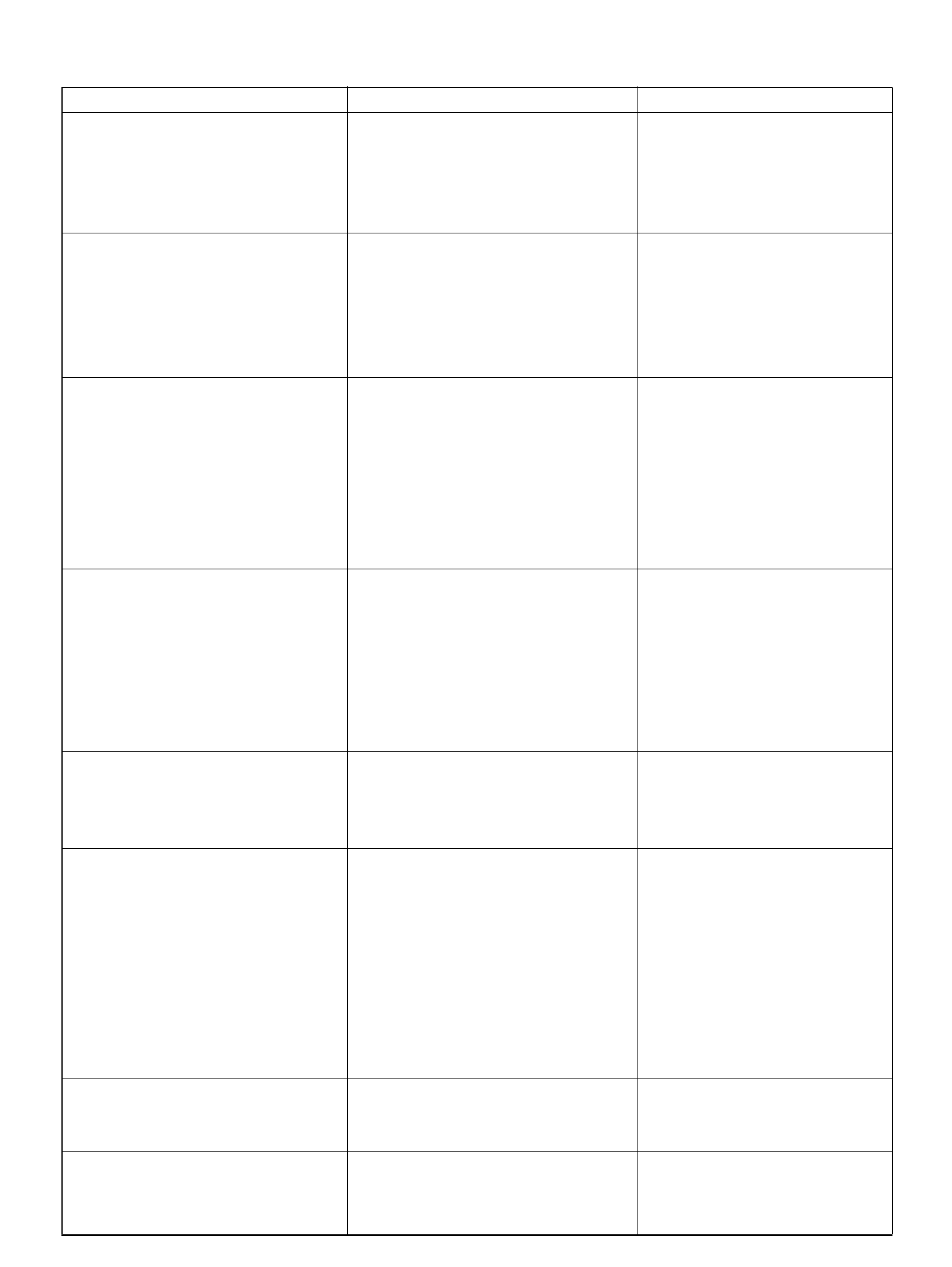

PCM PINOUT TABLE, 80 -WAY RED CONNECTOR – ROW “S61 ∼ 80"

060RY00051

PIN PIN Function Wire Color IGN ON ENG RUN

S61 Intake Air Temperature (IAT) Sensor Ground YEL/GRN 0.0V 0.0V

S62 ION Sensing Mod ule RED 1.555V 1.555 V

S63 Not Used — — —

S64 Bank 2 HO2S 1 High PNK 0.3V 0.1–0.9V

S65 Not Used — — —

S66 Transm ission Fluid Temperature S ensor RED/BLK 0.5–4.9V

( Vari e s with temp) 0.5–4.9V

(Va r i e s w i th te mp )

S67 Exhaust Ga s Recirculation (EGR) GRY/RED 0.6V 0.6V

S68 Accelerator Position (AP) Sensor 1 WHT 0.41–0.45V 0.41–0.45V

S69 Throttle Valve DC Motor(+) GRN Duty Cycle Duty Cycle

S70 Not Used — — —

S71 Not Used — — —

S72 Ignition Feed fo r ETC RED/GRN B+ B+

S73 Cruise Enable Lamp GRN/WHT 0.0V 0.0V

S74 Variable Intake Manifold YEL/BLK 0.0V B+ (>3600 rpm)

S75 Not Used — — —

S76 Throttle Position (TP) 1 Sensor Signal BLU 0.5–0.8V 0.5–0.8V (at idle)

S77 5Volt Reference (AP Sensor 3) ORN 5.0V 5.0V

S78 Accelerator Position (AP) Sensor 2 YEL 0.41–0.45V 0.41–0.45V

S79 Accelerator Position (AP) Sensor 3 BLU/GRN 4.55–4.99V 0.41–0.45V

S80 Manifold Absolute Pressure (MAP) GRN 0V 0V

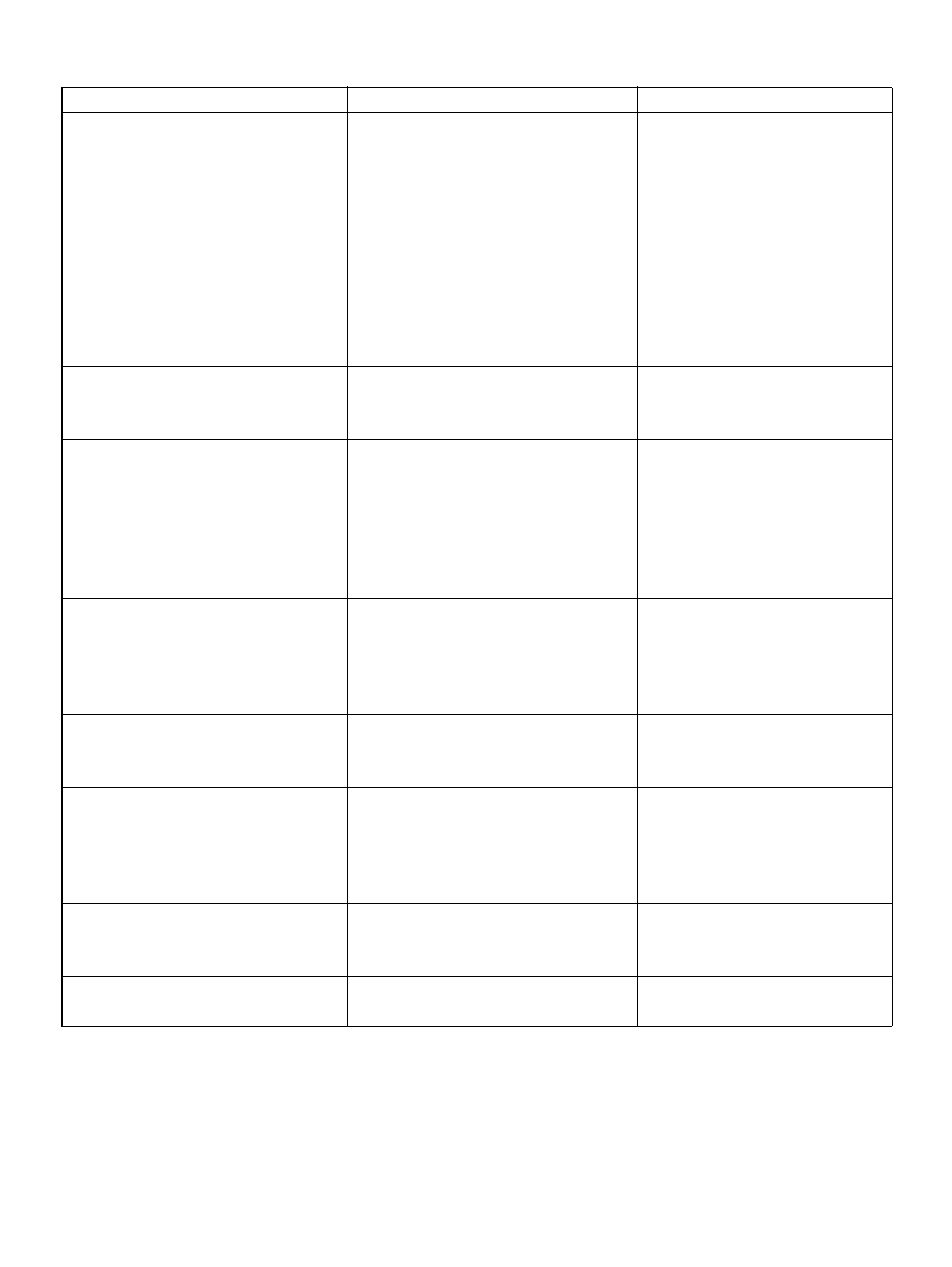

COMPONENT LOCATORS

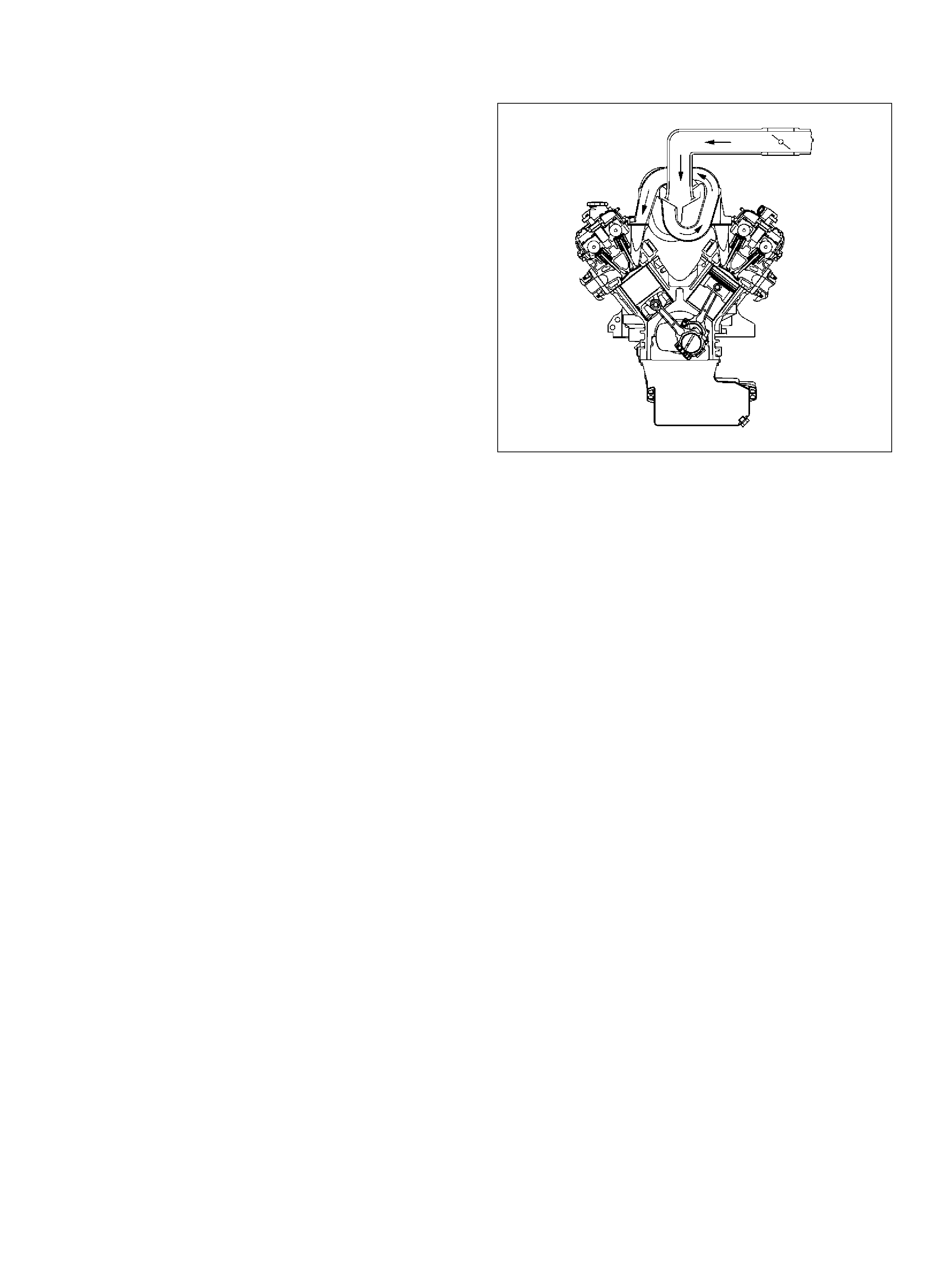

ENGINE COMPONENT LOCATOR

060R100144

Engine C omponent Loca tor Tab le

Number Name Location

1 Linear Exhaust Gas Recirculation (EGR) Valve Rear right side of the engine

2 Throttle Position (TP) Sensor On the throttle body

3 Intake Air Temperature (IAT) Sensor On the intake air duct near th e throttle body

4 Check Engine (MIL) Light On the instrument panel beneath the tachometer

5 Positive Crankcase Ventilation (PCV) Valve On the left of the cylinder head cover

6 Air Cleaner Left front of the engine bay

7 Mass Air Flow (MA F ) Sensor Attached to the air filter bo x

8 Fuel Rail On the Common Chamber

9 Fuel Pressure Regulator Left- Rear of the Common Cham ber

10 ION Sensing module Bolted to the top of the Common Chamber

11 Common Chamber Top of the engine

12 EVAP Duty Solenoid Valve Bolted to the front of the coolant pipe

13 Fuse/R ela y Box Along the inside of the right f ende r

14 Ma nifold Absolute Press ure (MAP ) Sensor Bolted to the top of the Common Chambe r

15 Throttle Body Between the intake air duct and the Common

Chamber

16 Engine Coolant Temperature Sensor On the coolant crossover pipe at the front of the

engine, near the throttle body

17 Power Train Control Module (PCM) Along the inside of the left fender

UNDERCARRIAGE COMPONENT LOCATOR

014RW188

Undercarriage Component Locator Table

Number Name Location

1 Heated Oxygen Sensor (Bank 2) Threaded into the exhaust pipe ahead the left-

hand catalytic converter

2 Fuel Filter Located along the inside of the right frame rail,

ahead of the propeller shaft

3 Fuel P um p and Gauge Unit Installed in the top of the f uel tank

4 Evaporative (EVAP) Canister Behind of the cross member

5 Vehicle Speed Sensor (VSS) Protrudes from the transmission housing, just

ahead of the fuel ta nk

6 Heated Oxygen Sensor (Bank 1) Threaded into the exhaust pipe ahead the right-

hand catalytic converter

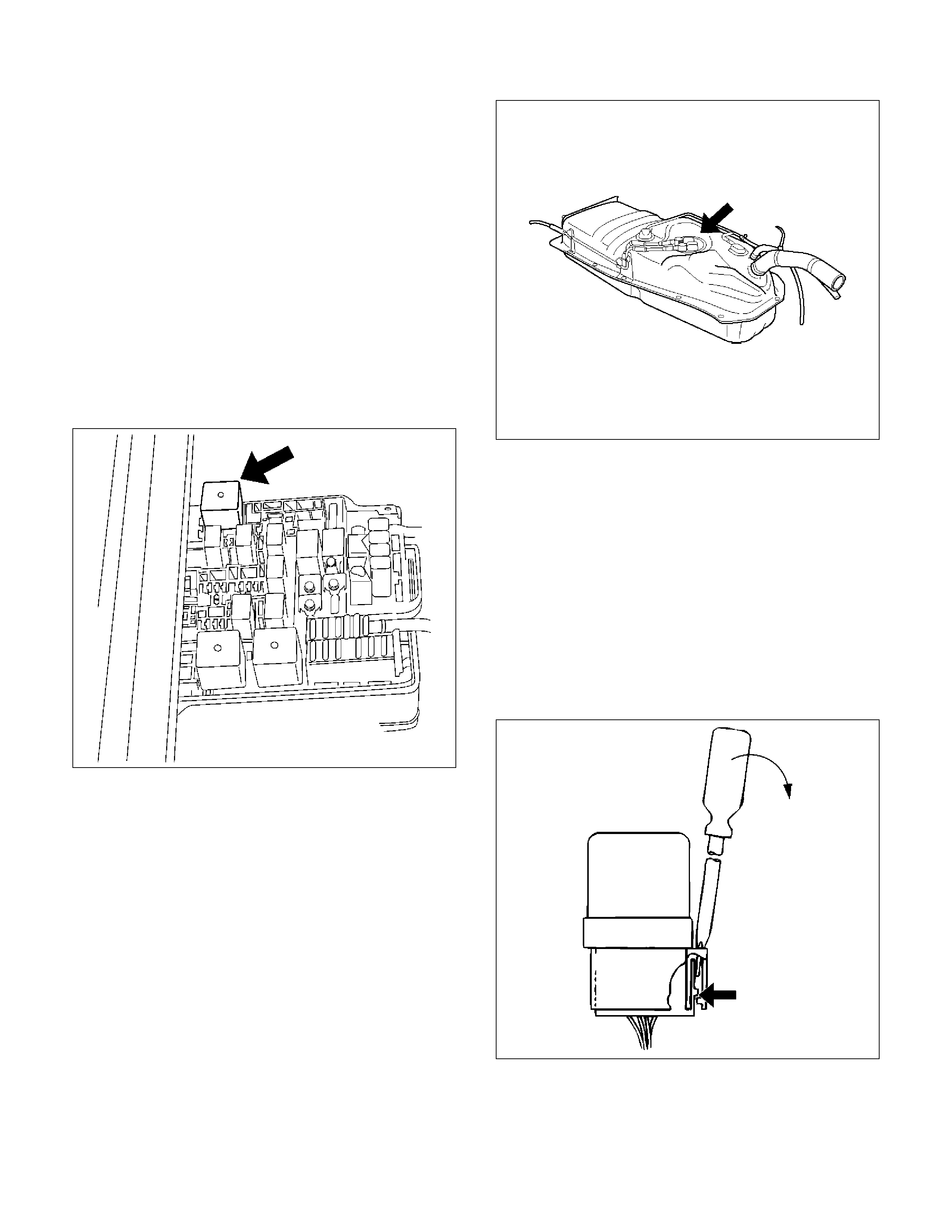

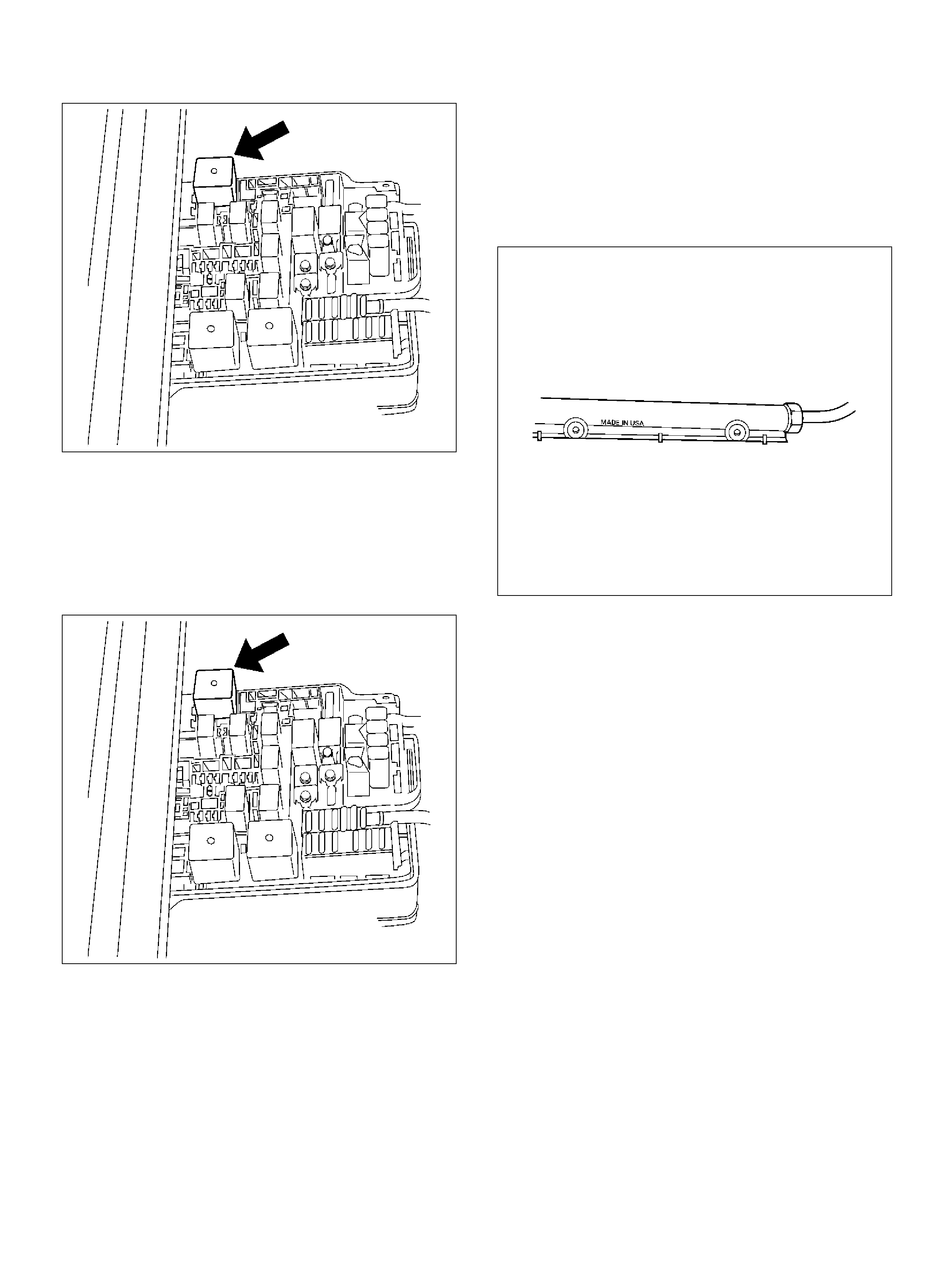

FUSE AND RELAY PANEL (UNDERHOOD ELECTRICAL CENTER)

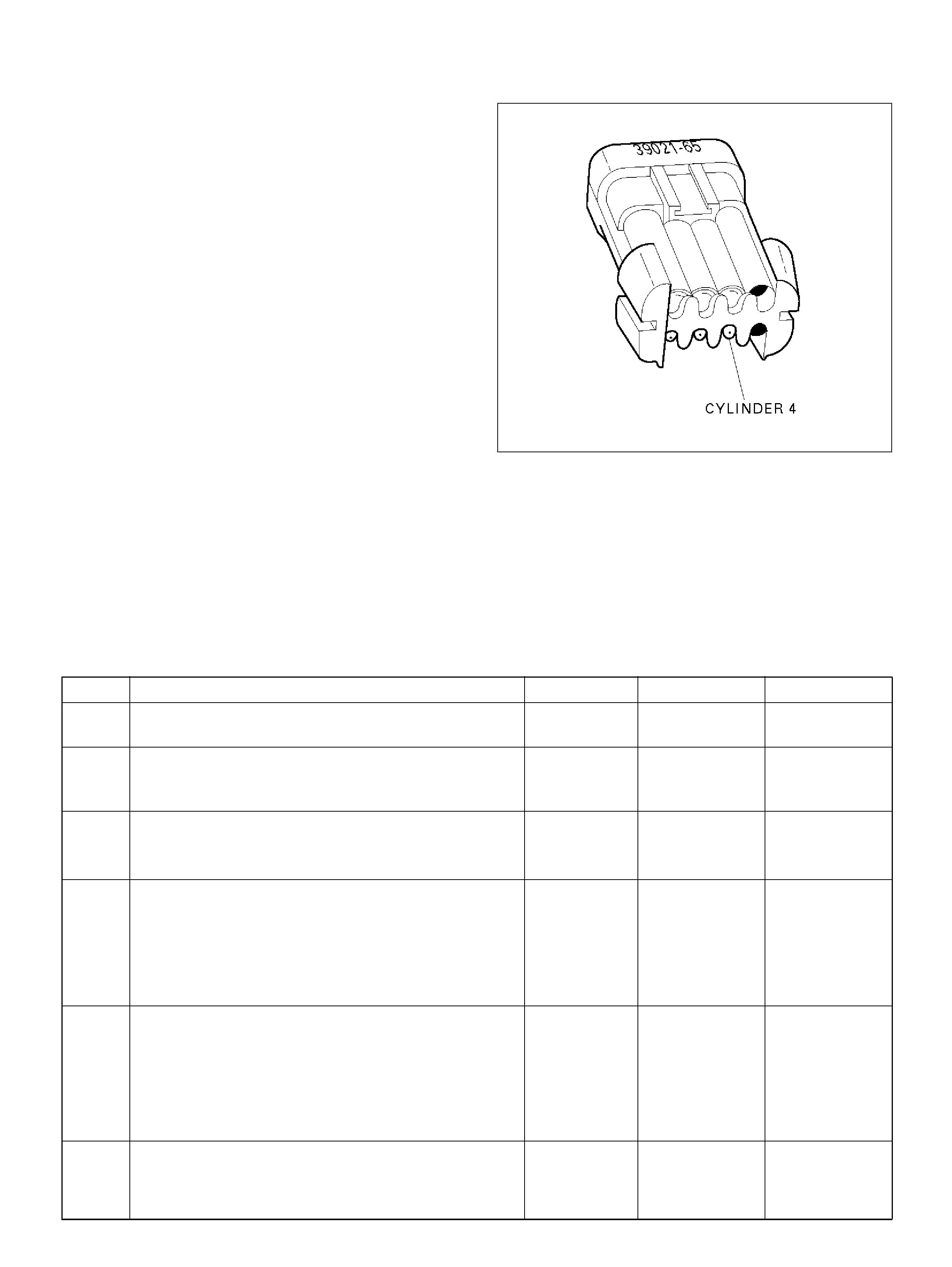

SENSORS AND MISCELLANEOUS

COMPONENT LO CATORS

HO2 Sensor

150RY00023

Vehicle Speed Sensor

035RW112

Fuel Tank

060R100129

CKP Sensor

060RW111

Canist er Purg e Valve

141R100005

Ma p S ensor

055RY00002

Fuel Fi l ter

041RW004

IAT Se nsor

060R100130

FUEL GAUGE AND

MA F S e nsor

T321078

EC T S ensor

060RY00014

PCV Valv e

060RY00016

ION Sensing Module

060RY00023

DIAGNOSIS

STRATEGY-BASED DIAGNOSTICS

Strategy-Based Diagnostics

The st ra tegy-based diagnostic is a uni form ap proach to

repair all Electrical/Electronic (E/E) systems. The

diagnostic flow can always be used to resolve an E/E

system problem and is a starting point when repairs are

necessary. The following steps will instruct the

technician how to proceed with a diagnosis:

1. Verify the customer complaint.

• To verify the customer complaint, the technician

shou ld know the normal operation of the system .

2. Perfo rm preliminary checks.

• Conduct a thorough vis ual inspection.

• Review the service history.

• Detect unusual sounds or odors.

• Gather diagnostic trouble code information to

achieve an effective repair.

3. Check bulletins and other service information.

• This includes videos, newsletters, etc.

4. Refer to service information check(s).

• “System checks" contain informa tion on a system

that m ay not be support ed by one or m ore DTCs.

System checks verify proper operation of the

system. This will lead the technician in an

organized approac h to diagnost ics .

5. Refer to service diagnostics.

DTC STORED

Follow the designated DTC chart exactly to make an

effective repair.

NO DTC

Select the symptom from the symptom tables. Follow

the diagnostic paths or suggestions to complete the

repair. You may refer to the applicable component/

system check in the system checks.

NO MATCHING SYMPTOM

1. A nalyze th e complaint.

2. Develop a plan for diagnostics.

3. Utilize the wiring diagrams and the theory of

operation.

Combine technician knowledge with efficient use of the

available service information.

INTERMITTENTS

Conditions that are not always present are called

intermittents. To resolve intermittents, perform the

following steps:

1. Observe history DTCs, DTC modes, and freeze

frame data.

2. Evaluate the symptoms and the conditions

described by the customer.

3. Use a check sheet or other method to identify the

circuit or elec t rical system component.

4. Follow the suggestions for intermittent diagnosis

found in the service documentation.

Most Scan Tools, such as the Tech 2, have

data-capturing capabilities that can assist in detecting

intermittents.

NO TROUBLE FOUND

This condition exists when the vehicle is found to

operate normally. The condition described by the

customer may be normal. Verify the customer complaint

against another vehicle that is operating normally. The

condition may be intermittent. Verify the complaint

under the conditions described by the customer before

releasing the vehicle.

1. Re-examine the compl aint.

When the complaint cannot be successfully found or

isolated, a re-evaluation is necessary. The

complaint should be re-verified and could be

intermittent as defined in Intermittents section, or

could be normal.

2. Repair and ve rify.

After isolating the cause, the repairs should be

made. Validate for proper operation and verify that

the symptom has been corrected. This may involve

road testing or other methods to verify that the

complaint has been resolved under the following

conditions:

• Conditions noted by the customer.

• If a DTC was diagnosed, verify a repair by

duplicating conditions present when the DTC was

set as noted in the Failure Records or Freeze

Frame data.

VERIFYING VEHICLE REPAIR

Verification of the vehicle repair will be more

comprehensive for vehicles with OBD system

diagnostics. Following a repair, the technician should

perform the following steps:

Important: Follow the steps below when you verify

repairs on OBD systems. Failure to follow these steps

could result in unnecessary repairs.

1. Review and record the Failure Records and the

Freeze Frame data for the DTC which has been

diagnosed (Freeze Frame data will only be stored

for an A or B type diagnostic and only if the

MIL("Check En gine" lamp) has been reques ted).

2. Clear the DTC(S).

3. Operate the vehicle within conditions noted in the

Failure Records and Freeze Frame data.

4. Monitor the DTC status information for the DTC

which has been diagnosed until the diagnostic test

associated with that DTC runs.

GENERAL SERVICE INFORMATION

OBD SERVICEABILITY ISSUES

With the introduction of OBD diagnostics across the

entire passenger car and light-duty truck market in

1996, illumination of the MIL (“Check Engine" lamp) due

to a non-vehicle fault could lead to misdiagnosis of the

vehicle, increased warranty expense and customer

dissatisfaction. The following list of non-vehicle faults

does not include every p ossible fault and may not apply

equally to all product lines.

Fuel Quality

Fuel quality is not a new issue for the automotive

industry, but its potent ial for t urning on the MIL (“Check

Engine" lamp) with OBD syste ms is new.

Fuel addi tives such as “dry gas" and “octane enhances"

may affect the performance of the fuel. If this results in

an incomplete combustion or a partial burn, it will show

up as a Misfire DTC P0300. The vapor pressure of the

fuel can also create problems in the fuel system,

especially during the spring and fall months when

severe ambient temperature swings occur . A high vapor

pressure could show up as a Fuel Trim DTC due to

excessive canister loa ding.

Using fuel with the wrong octane rating for the vehicle

may cause derivability problems. Many of the major fuel

companies advertise that using “premium" gasoline will

improve the performance of the vehicle. Most premium

fuels use alcohol to increase the octane rating of the

fuel. Although alcohol-enhanced fuels may raise the

octane rating, the fuel's ability to turn into vapor in cold

temperatures deteriorates. This may affect the starting

ability and cold derivability of the engine.

Low fuel levels can lead to fuel starvation, lean engine

operati on, and eventually engine misfire.

Non-OEM Parts

All of the OBD diagnostics have been calibrated to run

with OEM parts. Something as simple as a

high-performance exhaust system that affects exhaust

syste m back pressure co uld potenti a lly inte rfer e with t he

operation of the EGR v alve and thereby turn on the M IL

(“Check Engine" lamp). Small leaks in the exhaust

system near the post catalyst oxygen sensor can also

cause the MIL (“Check Engine" lamp) to turn on.

Aftermarket electronics, such as transceivers, stereos,

and anti-theft devices, may radiate EMI into the control

system if they are improperly installed. This may cause

a false sensor reading and turn on the MIL (“Check

Engine" lamp).

Environment

Temporary environmental conditions, such as localized

flooding, will have an effect on the vehicle ignition

system. If the ignition system is rain-soaked, it can

temporarily cause engine misfire and turn on the MIL

(“Check Engine" lamp).

Vehicle Marshaling

The transportation of new vehicles from the assembly

plant to the dealership can involve as many as 60 key

cycles within 2 to 3 miles of driving. This type of

operation contributes to the fuel fouling of the spark

plugs and will turn on the MIL (“Check Engine" lamp)

with a P0300 Misfire DTC.

Poor Vehicle Maintenance

The sensitivity of OBD diagnostics will cause the MIL

(“Check Engine" lamp) to turn on if the vehicle is not

maintained properly. Restricted air f i lters, fuel filt ers, and

crankcase deposits due to lack of oil changes or

improper oil viscosity can trigger actual vehicle faults

that were not previously monitored prior to OBD. Poor

vehicle maintenance can't be classified as a

“non-vehicle fault", but with the sensitivity of OBD

diagnostics, vehicle maintenance schedules must be

more closely followed.

Related System Faults

Many of the OBD system diagnostics will not run if the

PCM dete cts a fault on a related system or componen t.

One example would be that if the PCM detected a

Misfire fault, the diagnostics on the catalytic converter

would be suspended until Misfire fault was repaired. If

the Misfire fault was severe enough, the catalytic

converter could be damaged due to overheating and

would never set a Catalyst DTC until the Misfire fault

was repaired and the Catalyst diagnostic was allowed to

run to completion. If this happens, the customer may

have to make two trips to the dealership in order to

repair the vehic le .

VISUAL / PHYSICAL ENGINE

COMPARTMENT INSPECTION

Perform a careful visual and physical engine

compartment inspection when performing any

diagnostic procedure or diagnosing the cause of an

emission test failure. This can often lead to repairing a

problem without further steps. Use the following

guidelines when performing a visual/physical

inspection:

• Inspect all vacuum hoses for pinches, cuts,

disco nnections , and proper routing.

• Inspect hoses that are difficult to see behind other

components.

• Inspect all wires in the engine compartment for

pro per connections, burned or c hafed spo ts, pin ched

wires, contact with sharp edges or contact with hot

exh aust manif olds or pipes.

BASIC KNOWLEDGE OF TOOLS

REQUIRED

NOTE: Lack of basic knowledge of this powertrain

when performing diagnostic procedures could result in

an incorrect diagnosis or damage to powertrain

components. Do not attempt to diagnose a powertrain

problem without this basic knowledge.

A basic understanding of hand tools is necessary to

effectively use this section of the Serv ice M anual .

SERIAL DAT A COMMUNICATIONS

CLASS 2 SERIAL DATA

COMMUNICATIONS

Government regulations require that all vehicle

manufacturers establish a common communication

system. This vehicle utilizes the “Class 2"

communication system. Each bit of information can

have one of two lengths: long or short. This allows

vehicle wiring to be reduced by transmitting and

receiving multiple signals over a single wire. The

messages carried on Class 2 data streams are also

prioritized. If two messages attempt to establish

comm unications on the data line at the same time, only

the message with higher priority will continue. The

device with the lower priority message must wait. The

most significant result of this regulation is that it

provides Scan tool manufacturers with the capability to

access data from any make or model vehicle that is

sold.

The data displayed on other Scan tools will appear the

same, wi th some exceptions. Some Scan tools will only

be able to display certain vehicle parameters as values

that are a coded representation of the true or actual

value. On this vehicle the Scan tool displays the actual

values for vehicle parameters. It will not be necessary to

perform any conversions from coded values to actual

values.

ON-BOARD DIAGNOSTIC (OBD)

ON-BOARD DIAGNOSTIC TESTS

A di agnost ic test i s a series of steps, the resul t o f which

is a pass or fail reported to the diagnostic executive.

When a diagnostic test reports a pass result, the

diagnostic executive records the following data:

• The diagnostic test has been completed since the

last ignitio n cycle.

• The diagnostic test has passed during the current

ignition cy cle.

• The fault identified by the diagnostic test is not

currently active.

When a diagnostic test reports a fail result, the

diagnostic executive records the following data:

• The diagnostic test has been completed since the

last ignitio n cycle.

• The fault identified by the diagnostic test is currently

active.

• The fault has been acti ve during this ignition cycle.

• The operating condition s at the time of t he failure.

Remember, a fuel trim DTC may be triggered by a list of

vehicle faults. Make use of all information available

(other DTCs stored, rich or lean condition, etc.) when

diagnosing a fuel trim fault.

COMPREHENSIVE COMPONENT MONITOR

DIAGNOSTIC OPERATION

Comprehensive component monitoring diagnostics are

required to monitor emissions-related input and output

powertrain components. The OBD Comprehensive

Component Monitoring List Of Components Intended To

illuminate MIL is a list of components, features or

functions that could fall under this requirement.

In put Co m pone nts:

Input components are monitored for circuit continuity

and out-of-range values. This includes rationality

checking. Rationality checking refers to indicating a fault

when the signal from a sensor does not seem

reasonable, i.e. Throttle Position (TP) sensor that

indicates high throttle position at low engine loads or

MAP voltage. Input components may include, but are

not limited to the following sensors:

• Vehicle S peed Sensor (VSS)

• Crankshaft Position (CKP) sensor

• Throttle Position (TP) sensor

• Engine Coolant Tempe rature (ECT) sensor

• Manifold Absolute Pressure (MAP) sensor

• Mass Air Flow (MAF) sensor

In addition to the circuit continuity and rationality check,

the ECT sensor is monitored for its ability to achieve a

steady state temperature to enable closed loop fuel

control.

Ou t put C om ponents:

Output components are diagnosed for proper response

to control module commands. Components where

functional monitoring is not feasible will be monitored for

circuit continuity and out-of-range values if applicable.

Output components to be monitored include, but are not

limited to, the following circuits:

• Control module controlled EVAP Canister Purge

Valve

• Electronic Trans mission con trols

•A/C relays

• VSS outp ut

•MIL control

Refer to PCM and Se ns ors in General Descriptions.

Passive an d Active Diagnostic Tests

A passive test is a diagnostic test which simply monitors

a vehicle system or component. Conversely, an active

test, actually takes some sort of action when performing

diagnostic functions, often in response to a failed

passive test. For example, the EGR diagnostic active

test will force the E GR valve open du ring closed t hrottle

decel. Either action should result in a change in

manifold pressure.

Intrusive Diagnostic Tests

This is any on-board test run by the Diagnostic

Management System which may have an effect on

vehicle performance or emission levels.

Warm-Up Cycle

A warm-up cycle means that engine at temperature

must reach a minimum of 70°C (160°F) and rise at least

22°C (40°F) over the course of a trip.

Freeze Fra m e

Freeze Frame is an element of the Diagnostic

Management System which stores various vehicle

information at the moment an emissions-related fault is

stored in mem ory and when the MIL is com manded on.

These data can help to identify the cause of a fault.

Refer to Storing And Erasing Freeze Fram e D ata in this

section for more detailed information.

Failure Records

Failure Records data is an enhancement of the OBD II

Freeze Frame feature. Failure Records store the same

vehicle information as does Freeze Frame, but it will

store that information for any fault which is stored in

on-board memory, while Freeze Frame stores

information only for emission-related faults that

comm and the M IL on.

Enable Criteria

The term “enable criteria" is engineering language for

the conditions necessary for a given diagnostic test to

run. Each diagnostic has a specific list of conditions

which must be met before the diagnostic will run.

“Enable criteria" is another way of saying “conditions

required".

The enable criteria for each diagnostic is listed on the

first page of the DTC description in Section 6C1 under

the heading “Conditions for Setting the DTC". Enable

criteria varies with each diagnostic, and typically

includes, but is not limited to the following items:

• e ngine speed

• vehicle speed

•ECT

•MAF/MAP

• b arome tric pressure

•IAT

•TP

• h igh caniste r purge

• fuel tr im

• T CC enabled

•A/C on

Trip

Technically, a trip is a key on-run-key off cycle in which

all the enable criteria for a given diagnostic are met,

allowing the diagnostic to run. Unfortunately, this

concept is not quite that simple. A trip is official when all

the enable criteria for a given diagnostic are met. But

because the enable criteria vary fro m one diagnostic to

another, the definition of trip varies as well. Some

diagnostics are run when the vehicle is at operating

temperature, some when the vehicle first starts up;

some require that the vehicle be cruising at a steady

highway s peed, some run on ly when the veh icle is idle;

some diagnostics function with the TCC disabled. Some

run only immediately following a cold engine start-up.

A trip then, is defined as a key on-run-key off cycle in

which the vehicle was operated in such a way as to

satisfy the enabling criteria for a given diagnostic, and

this diagnostic will consider this cycle to be one trip.

However, another diagnostic with a different set of

enable criteria (which were not met) during this driving

event, would not consider it a trip. No trip will occur for

that particular diagnostic until the vehicle is driven in

such a way as to meet all t he enabl e criteria.

THE DIAGNOSTIC EXECUTIVE

The Diagnostic Executive is a unique segment of

software which is designed to coordinate and prioritize

the diag nostic procedu res as well as defi ne the protocol

for recording and displaying their results. The main

responsibilit ies of the Diagnost ic E x ecuti ve ar e l isted as

the following:

• Commanding the MIL (“Check Engine" lamp) on and

off

• DTC logging and clearing

• F reeze F ram e data f or the f irst em ission rel ated DTC

recorded

• Non-emission related Service Lamp

• Operating conditions Failure Records buffer, (the

number of records will vary)

• Current stat us information on each diagnostic

• Sy ste m Status (I/ M ready)

The Diagnostic Executive records DTCs and turns on

the MIL when e mission-related faults occur. It can also

turn off t he MIL if the conditions cease which caused the

DTC to set.

Diagnostic Inform ation

The diagnostic charts and functional checks are

designed t o lo cate a fau lty circuit or component throug h

a process of logical decisions. The charts are prepared

with the requirement that the vehicle functioned

correctly at the time of assembly and that there are no

multiple faults present.

There is a continuous self-diagnosis on certain control

functions. This diagnostic capability is complemented by

the diagnostic procedures contained in this manual. The

language of communicating the source of the

malfunction is a system of diagnostic trouble codes.

When a malfunction is detected by the control module, a

diagnostic trouble code is set and the Malfunction

Indicator Lamp (MIL) (“Check Engine" lamp) is

illuminated.

Malfunction Indicator Lamp (MIL)

The Malfunction Indicator Lamp (MIL) looks the same

as the MIL you ar e already familiar with (“Check Engine"

lamp). However, OBD require s t hat it illumi nate under a

strict set of guide lines.

Basically, the M IL is turned on when the PCM detects a

DTC that will imp act vehicle emissions.

The MIL is under the control of the Diagnostic

Executive. The MIL will be turned on if an

emissions-related diagnostic test indicates a

ma lf u nc t io n h as o c cu rre d. It w ill s tay on un ti l the s y ste m

or component passes the same test, for three

consecut ive trips, with no e mi ssions related faults.

Extinguishing the MIL

When the MIL is on, the Diagnostic Executive will turn

off the MIL after three(3) consecutive trips that a “test

passed" has been reported for the diagnostic test that

originally caused the MIL to illuminate.

Although the MIL has been turned off, the DTC will

remain in the PCM memory (both Freeze Frame and

Failure Records) until forty(40) warm-up cycles after no

faults have been comp leted.

If the MIL was set by eit her a fuel t rim or misfire -related

DTC, additional requirements must be met. In addition

to the requirements stated in the previous paragraph,

these requirements are as follows:

• The diagnostic tests that are passed must occur

within 375 RPM of the RPM data stored at the time

the last test failed.

• Plus or minus ten (10) percent of the engine load that

was stored at t he time t he l ast fail ed.

• Sim ilar engine temperat ure conditions (warm ed up or

w armin g up ) as those stored at the time the last test

failed.

Meeting these requirements ensures that the fault which

turned on the MIL has been corrected.

The MIL (“Check Engine" lamp) is on the instrument

panel and has the following function:

• It informs the driver that a fault affects vehicle

emission levels has occurred and that the vehicle

shou ld be taken for service as soon as possible.

• As a bul b and syste m check, the MIL will come “ON"

with the key “ON" and the engine no t running. When

the engi ne is starte d, the MIL will turn “OFF."

• When the MIL remains “ON" while the engine is

running, or when a m al function is s uspecte d due to a

derivability or emissions problem, a Powertrain

On-Board Diagnostic System Check must be

performed. The procedures for these checks are

given in On-Board Diagnostic (OBD) System Check.

These checks will expose faults which may not be

detected if other diagnostics are performed first.

DTC TYPES

Each DTC is directly related to a diagnostic test. The

Diagnostic Management System sets DTC based on

the failure of the tes ts during a trip or trips. Certain t ests

must fail two (2) consecutive trip s before the DTC is set.

The following are the four (4) types of DTCs and the

characteristics of those codes:

•Type A

• Emissions related

• Requests illumination of the MIL of the first trip with

a fail

• St ores a History DTC on t he first trip with a fail

• Stores a Freeze Frame (if empty)

• Stores a F ail Record

• Updates the Fail Record each time the diagnostic

test fails

•Type B

• Emissions related

• “Armed" aft er one (1) trip with a fail

• “Disarmed" after one (1) trip with a pass

• Requests illumination of the MIL on the second

consecutive trip with a fail

• Stores a History DTC on the second consecutive

trip with a fail (The DTC will be armed after the first

fail)

• Stores a Free ze Fram e on the se cond c onsec utive

tr ip wi th a fai l (i f em p ty)

• Stores a Fail Record when the first test fails (not

dependent on consecutive trip fails )

• Updates the Fail Record each time the diagnostic

test fails

(Some special conditions apply to misfire and fuel trim

DTCs)

• Typ e C (if t he vehicle is so equipped)

• Non-Emissions related

• Requests illumination of the Service Lamp

• St ores a History DTC on the fir st tr ip with a fai l

•Does not store a Freez e Fram e

• Stores Fail Record when test fails

• Updates the Fail Record each time the diagnostic

test fails

•Type D

• Non-Emissions related

• Not reque st illumin atio n of any lamp

• St ores a History DTC on the fir st tr ip with a fai l

•Does not store a Freez e Fram e

• Stores Fail Record when test fails

• Updates the Fail Record each time the diagnostic

test fails

Important: Only four Fa il Records can be stored. E ac h

Fail Record is for a different DTC. It is possible that

there will not be Fail Records for every DTC if multiple

DTCs are set.

Special Cases of Ty pe B Diagno stic Tests

Unique to the misfire diagnostic, the Diagnostic

Executive has the capability of alerting the vehicle

operator to potentially damaging levels of misfire. If a

misfire condition exists that could potentially damage

the catalytic converter as a result of hig h misfire levels,

the Diagnostic Executive will command the MIL to

“flash" at a rate of once per second during those the

time that the catalyst damaging misfire condition is

present.

Fuel trim and misfire are special cases of Type B

diagnost ics. Each time a fuel trim or misfire malfunction

is detected, engine load, engine speed, and engine

coolant temp erature are recorded.

When the ignition is turned off, the last reported set of

conditions remain stored. During subsequent ignition

cycles, the stored conditions are used as reference for

similar conditions. If a malfunction occurs during two

consecutive trips, the Diagnostic Executive treats the

failure as a normal Type B diagnostic, and does not use

the stored conditions. However, if a malfunction occurs

on two non-consecutive trips, the stored conditions are

compared with the current conditions. The M IL wil l the n

illuminate under the following conditions:

• When the engine load conditions are within 10% of

the previous te st that failed.

• Eng ine sp eed is within 37 5 rpm, of the previous test

that failed.

• Engine coolant temperature is in the same range as

the previous te st that failed.

Storing and Erasing Freeze Frame Data and Failure

Records

Government regulations require that engine operating

conditions be captu red whenev er the M IL is illuminat ed.

The data captured is called Freeze Frame data. The

Freeze Frame data is very similar to a single record of

operating conditions. Whenever the MIL is illuminated,

the corresponding record of operating conditions is

recorded to the Freeze Frame buffer.

Freeze Frame data can only be overwritten with data

associated with a misfire or fuel trim malfunction. Data

from these faults take preced ence over data asso ciated

with any other fault. The Freeze Frame data will not be

erased unles s the associated history DTC is cleared.

Each tim e a dia gnos tic t est rep orts a failure, the c urrent

engine op erating conditions are recorded in the Failure

Records buffer. A subsequent failure will update the

recorded operating conditions. The following operating

conditions for the diagnostic test which failed typically

include the following parameters:

• Air Fuel Ratio

•Air Flow Rate

• Fuel Trim

• Engine Speed

• Engine Load

• Engine Coolant Tem perature

• Vehicle Speed

• TP Angle

• MAP/BARO

• Injector Base Pulse Width

• Loop Status

Int erm i t te nt Malfunct i on I ndi c at o r La m p

In the case of an “intermittent" fault, the MIL (“Check

Engine" lamp) may illuminate and then (after three trips)

go “OFF". However, the corresponding diagnostic

trouble code will be stored in memory. When

unexpected diagnostic trouble codes appear, check for

an intermittent malfun ction.

A diagnostic trouble code may reset. Consult the

“Diagnostic Aid s" associated with the dia gnostic trouble

code. A physical inspection of the applicable

sub-system most often will resolv e the probl e m.

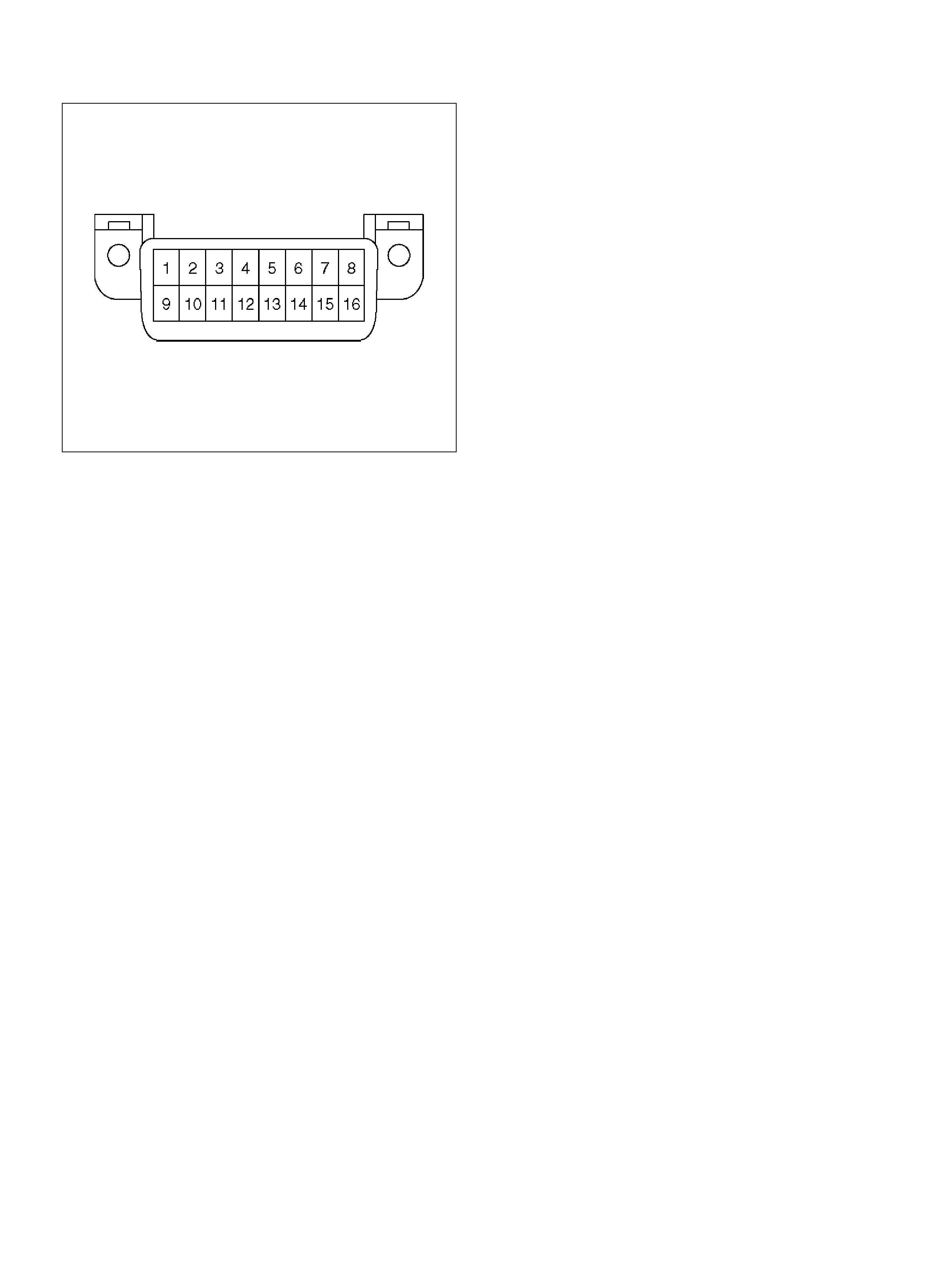

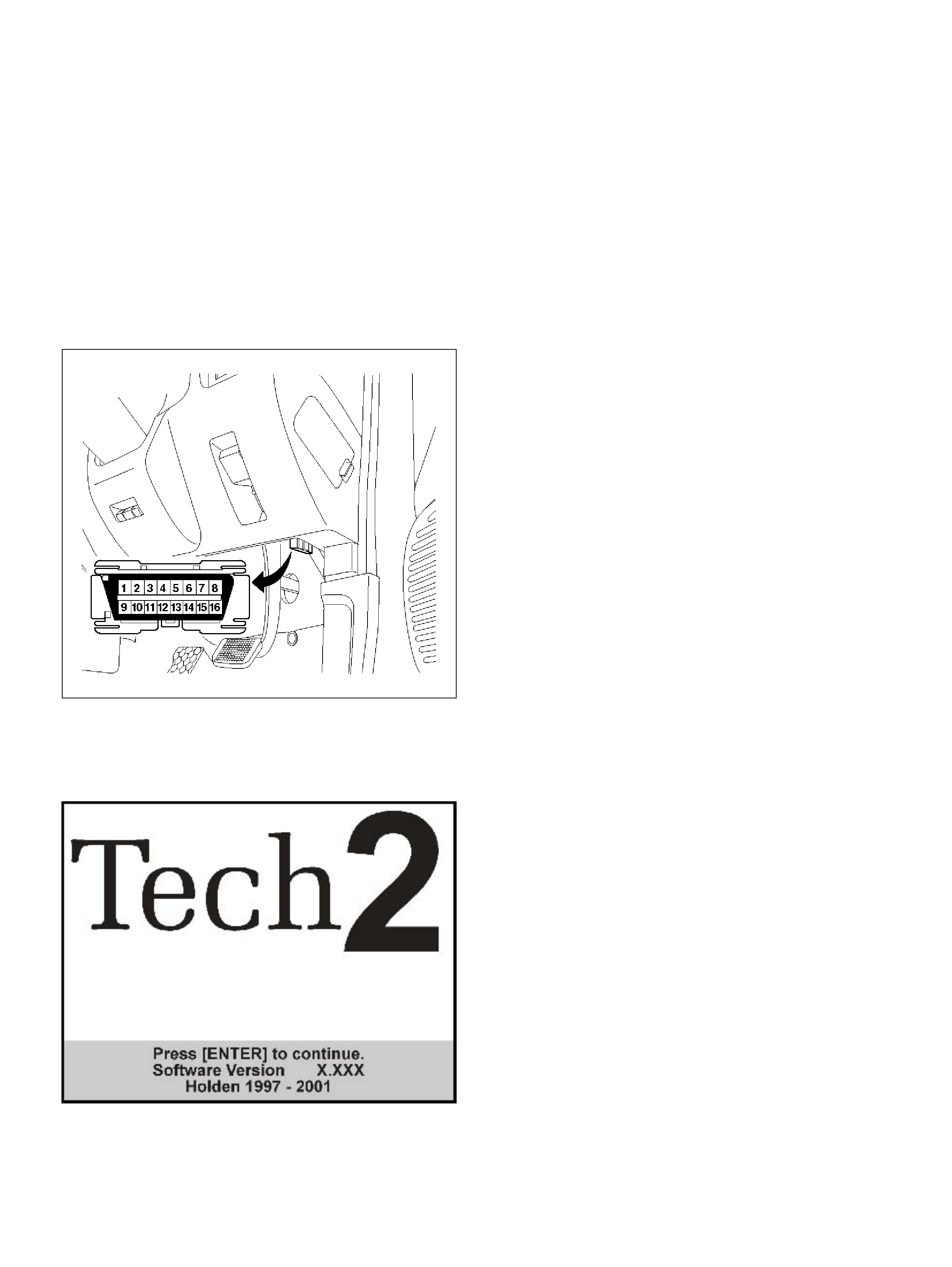

Data Link Connect or (D LC )

The provision for communication with the control

module is the Data Link Connector (DLC). It is located

at the lower left of the instrument panel behind a small

square cover. The DLC is use d to connect to the Tech 2

Scan Tool. Som e common us es of the Tech 2 are listed

below:

• Ident ifying stored Diagnosti c Troubl e Codes (DTCs).

• Cl earing DTCs.

• Perf orming outp ut control tests.

• Re ading serial data.

TS24064

DECIMAL/BINARY/HEXADECIMAL

CONVERSIONS

Beginning in 1996, Federal Regulations require that all

auto manufacturers selling vehicles in the United Stat es

provide Scan Tool manufacturers with software

information to display vehicle operating parameters. All

Scan Tool man ufacturers will display a va riety of vehicle

in formation wh ich will aid in repair ing th e vehic le. S ome

Scan Tools will display encoded messages which will

aid in determining the nature of the concern. The

met hod of enc odi ng invol ves the u se of a two additiona l

numbe ring systems: Binary and Hexade cimal.

The bina ry number system has a base of two numbers.

Each digit is either a 0 or a 1. A binary number is an

eight digit number and is read from right to left. Each

digit has a position number with the farthest right being

the 0 position and the farthest left being th e 7 position.

The 0 position, when displayed by a 1, indicates 1 in

decimal . Each position to the left is doubl e the previous

position and adde d t o any ot her po sition v alu es m arke d

as a 1.

A hexadecimal system is composed of 16 different

alpha numeric characters. The alpha numeric

characters used are numbers 0 through 9 and letters A

through F. The he xadecimal system is the most natural

and common approach for Scan Tool manufacturers to

display data represented by binary num bers and digital

code.

VERIFYING VEHICLE REPAIR

Verification of vehicle repair will be more

comprehensive for vehicles with OBD II system

diagnostic. Following a repair, the technician should

perform the following steps:

1. Review and record the Fail Records and/or Freeze

Frame d ata for the DTC which h as been diagno sed

(Freeze Frame data will only be stored for an A or B

type diagnostic and only if the MIL has been

requested).

2. Clear DT C(s).

3. Operate the vehicle within conditions noted in the

Fail Records and/or Freeze Frame data.

4. Monitor the DTC status information for the DTC

which has been diagnosed until the diagnostic test

associated with that DTC runs.

Following these steps are very important in verifying

repairs on OB D ll system s. Failure t o foll ow t hese steps

could result in unnecessary repairs.

READING DIAGNOSTIC TROUBLE CODES

USING THE TECH 2 SCAN TOOL

The procedure for reading diagnostic trouble code(s) is

to use a diagnostic Scan Tool. When reading DTC(s),

follow instructions supplied by tool manufacturer.

Clearing Diagnostic Trouble Codes

Important: Do not c lea r DTCs un less directed t o do so

by the service information provided for each diagnostic

procedure. When DTCs are cleared, the Freeze Frame

and Failure Record data which may help diagnose an

intermittent fault will also be erased from memory.

If the fault that caused the DTC to be stored into

memory has been corrected, the Diagnostic Executive

will begin to count the “warm-up" cycles with no further

faults detected, the DTC will automatically be cleared

from the PCM memory.

To clear Diagnostic Trouble Codes (DTCs), use the

diagnost ic Scan Tool “clear DTCs" or “clear inform ation"

function. When clearing DTCs follow instructions

supplied by the tool man ufacturer.

When a Scan Tool is not available, DTCs can also be

cleared by disconnecting one of the following sources

for at least thir ty (30) seconds.

NOTE: To prevent system damage, the ignition key

must be “OFF" when disconnecting or reconnecting

battery power.

• The power source to the control module. Examples:

fuse, pigtail at battery PCM connectors, etc.

•The negative battery cable. (Disconnecting the

negative battery cable will result in the loss of other

on-board mem ory data, such as preset radio tuning).

TECH 2

Holden dealer service departments are recommended

to use the TECH 2 Scan Tool. Refer to th e Secti on 0C

and Section 0C-1 for full instructions on the use of

TECH 2.

901RW180

EndOFCallout

TECH 2 FEATURES

1. Tec h 2 is a 12 volt system. Do not apply 24 volts.

2. After connecting and/or installing the Vehicle

Communications Interface (VCI) module, PCMCIA

card and DLC connector to the Tech 2, connect the

tool to the vehicle DLC.

3. Make sure the Tech 2 is OFF when removing or

installing the PCMCIA card.

4. The PCMCIA card has a capacity of 10 Megabytes

which is 10 times greater than the memory of the

Tech 1 Mass Storage Cartridge.

5. The Tech 2 has the capability of two snapshots.

6. The PCMCIA card is sensitive to magnetism and

static electricity, so care should be taken in the

handling of the card.

7. The Tech 2 can plot a graph when replaying a

snapshot.

8. Always return to the Main Menu by pressing the

EXIT key se vera l ti mes bef o re shutt ing down.

9. To clear Diagnostic Trouble Codes (DTCs), open

Application Menu and press “F1: Clear DTC Info".

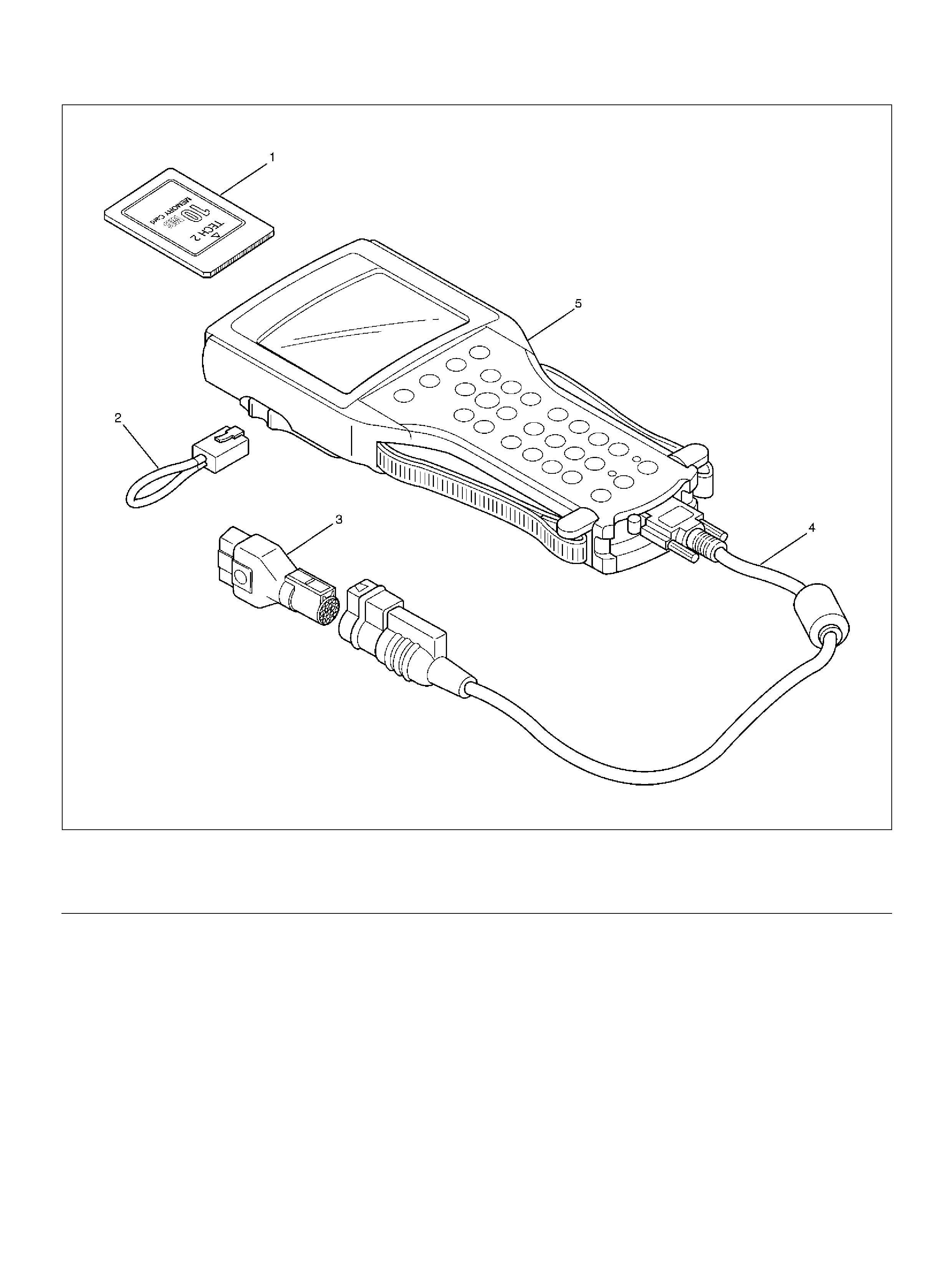

Legend

(1) P CM CIA Card

(2) RS 232 Loop Back Connector

(3) SAE 16/19 Ad apter

(4) DLC Cable

(5) Tech–2

GETTING STARTED

• Before operating the Holden PCMCIA card with the

Tech 2, the following steps must be performed:

1. Insert the Holden system PCMCIA card (1) into the

Tech 2 (5).

2. Connect the SAE 16/19 adapter (3) to the DLC

cable (4).

3. Connect the DLC cable to the Tech 2 (5)

4. M ake sure the vehicle ignition is off.

5. Connect the Tech 2 SAE 16/19 adapter to the

vehicle DLC.

810RW317

6. Turn on the vehicle ignition.

7. Power the Tech 2 ON and verify the Tech 2 power

up display.

Refer to Section 0C-1 TECH 2 Diagnosis - Engine

Application for further procedures.

NOTE: T he RS232 Loop ba ck connector is only to us e

for diagnosis of Tech 2. Refer to user guide of the

TECH 2.

PRIMARY SYSTEM-BASED

DIAGNOSTIC

PRIMARY SYSTEM-BASED DIAGNOSTIC

There are primary system-based diagnostics which

evaluate system operation and its effect on vehicle

emissions. The primary system-based diagnostics are

listed below with a brief description of the diagnostic

function:

Oxygen Sensor Diagnosis

The fuel control heated oxygen sensors are diagnosed

for the following conditions:

• Heater performance (time to activity on cold start)

• Slow response

• Response time (time to switch R/L or L/R)

• Inactive signal (output steady at bias voltage –

approx . 450 mV)

• Sig nal fixed high

• S ign al fix ed lo w

If the oxygen sensor pigtail wiring, connector or terminal

are damaged, the entire oxygen sensor assembly must

be replaced. DO NOT attempt to repair the wiring,

connector or terminals. In order for the sensor to

function properly, it must have clean reference air

provided to it. This clean air reference is obtained by

way of the oxygen sensor wire(s). Any attempt to repa ir

the wires, connector or terminals could result in the

obstruction of the reference air and degrade oxygen

sensor performance. Refer to On-Vehicle Service,

Heated Oxyg en Senso rs in this section.

FU E L CONTR O L HEATED OX YGEN

SENSOR

The main function of the fuel control heated oxygen

sensors is to provide the control module with exhaust

stream oxygen content information to allow proper

fueling and maintain emissions within mandated levels.

After it reaches operating temperature, the sensor will

generate a voltage, inversely proportional to the amount

of oxygen present in the exhaust gases. The control

module uses the signal voltage from the fuel control

heated oxygen sensors while in closed loop to adjust

fuel inject or pulse wi dt h. While in c losed lo op, the P CM

can adjust fuel delivery to maintain an air/fuel ratio

which allows the best combination of emission control

and deriva bility. The fuel control heated oxy gen sens ors

are also used to determine catalyst effi ciency.

HO2S HEATER

Heated oxygen sensors are used to minimize the

amount of time required for closed loop fuel control to

begin operation and to allow accurate catalyst

monitoring. The oxygen sensor heater greatly

decreases the amount of time required for fuel control

sensors (Bank 1 HO2S 1 and Bank2 HO2S 1) to

become ac tiv e.

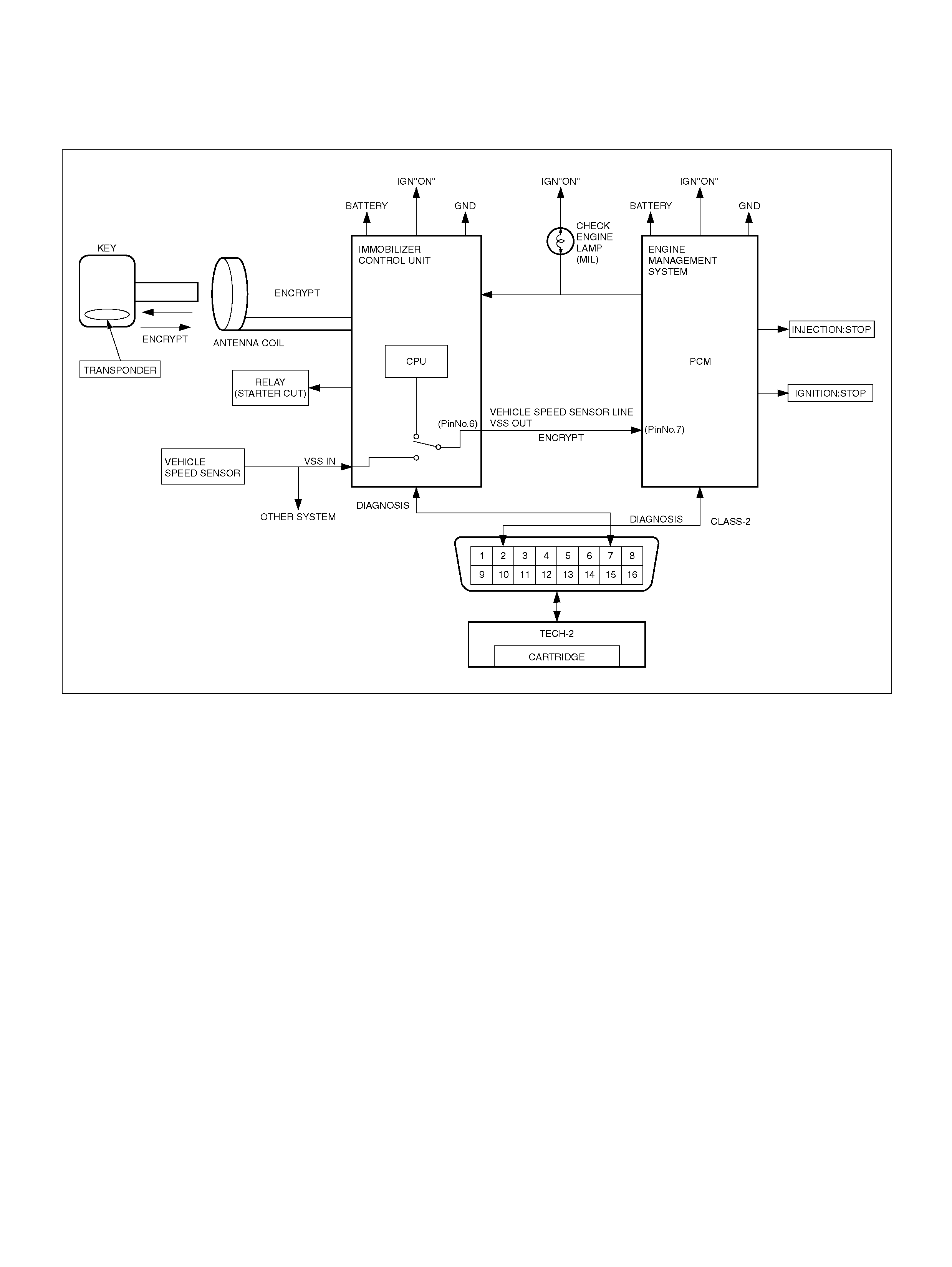

ON-BOARD DIAGNOSTIC (OBD) SYST EM CHECK 060R100062

Circuit Description

The on-board diagnostic system check is the starting

point for any derivability complaint diagnosis. Before

using this procedure, perform a careful visual/physical

check of the PCM and engine grounds for cleanliness

and tightness.

The on-board diagnostic system check is an organized

approach to identifying a problem created by an

electronic engine control system malfunction.

Diagn ostic Aids

An intermittent may be caused by a poor connection,

rubbed-through wire insulation or a wire broken inside

the insulation. Check for poor connections or a

damaged harness. Inspect the PCM harness and

connector for improper mating, broken locks, improperly

formed or damaged terminals, poor terminal-to-wire

conne ction , and damaged harness .

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

1.The MIL (“Check Engine lamp") should be “ON"

steady with the ignition “ON " and th e e ngine “OFF".

If not, the “No MIL" chart should be used to isolate

the ma lfunction.

3.Checks the Class 2 data circuit and ensures that the

PCM is able to transmit serial data.

4.This test ensures that the PCM is capable of

controlling the MIL (“Check Engine lamp") and the

MIL (“Check Engine lamp") driver circuit is not

shorted to ground.

5.This test ensures that the PCM is capable of

controlling the RPL (“Reduced Power lamp ") and the

RPL (“Reduced Power lamp") driver circuit is not

shorted to ground.

7.Check the DTCs (System ,Vol ts Supply circuit).

8.Check the DTCs (PCM{Software} detect Errors).

10.If the engine will not start, the Cranks But Will Not

Run chart should be used to diagnose the condition.

13.A Tech2 parameter which is not within the typical

range m ay help to isolate the area which is causing

the problem.

14.This vehicle is equipped with a PCM which utilizes

an electrically erasable programmable read only

memory (EEPROM). When the PCM is replaced, the

new PCM must be programmed. Refer to PCM

Replacement and Programming Procedures in

Powertrain Control Module (PCM) and Sensors of

t h is sect ion .

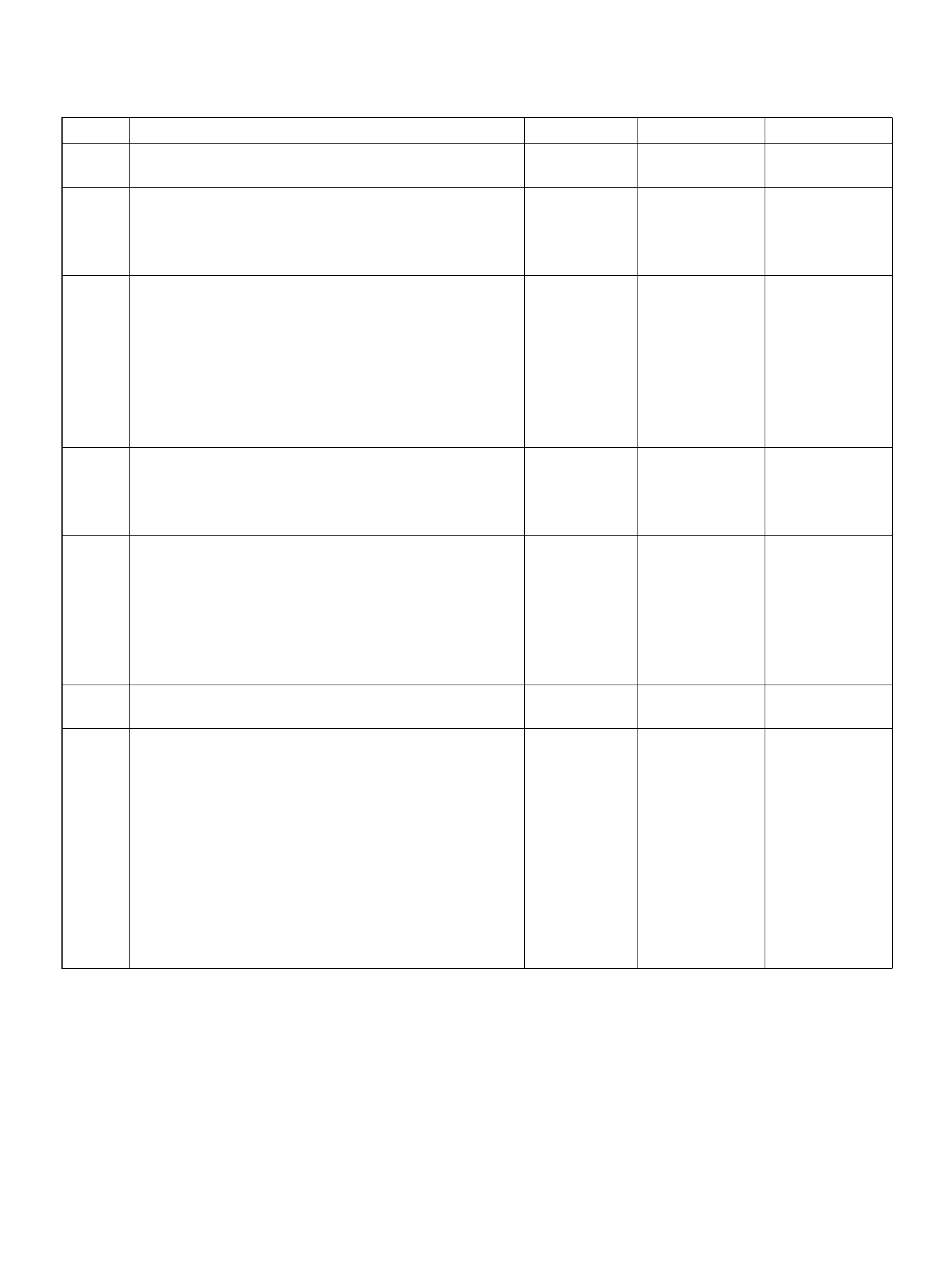

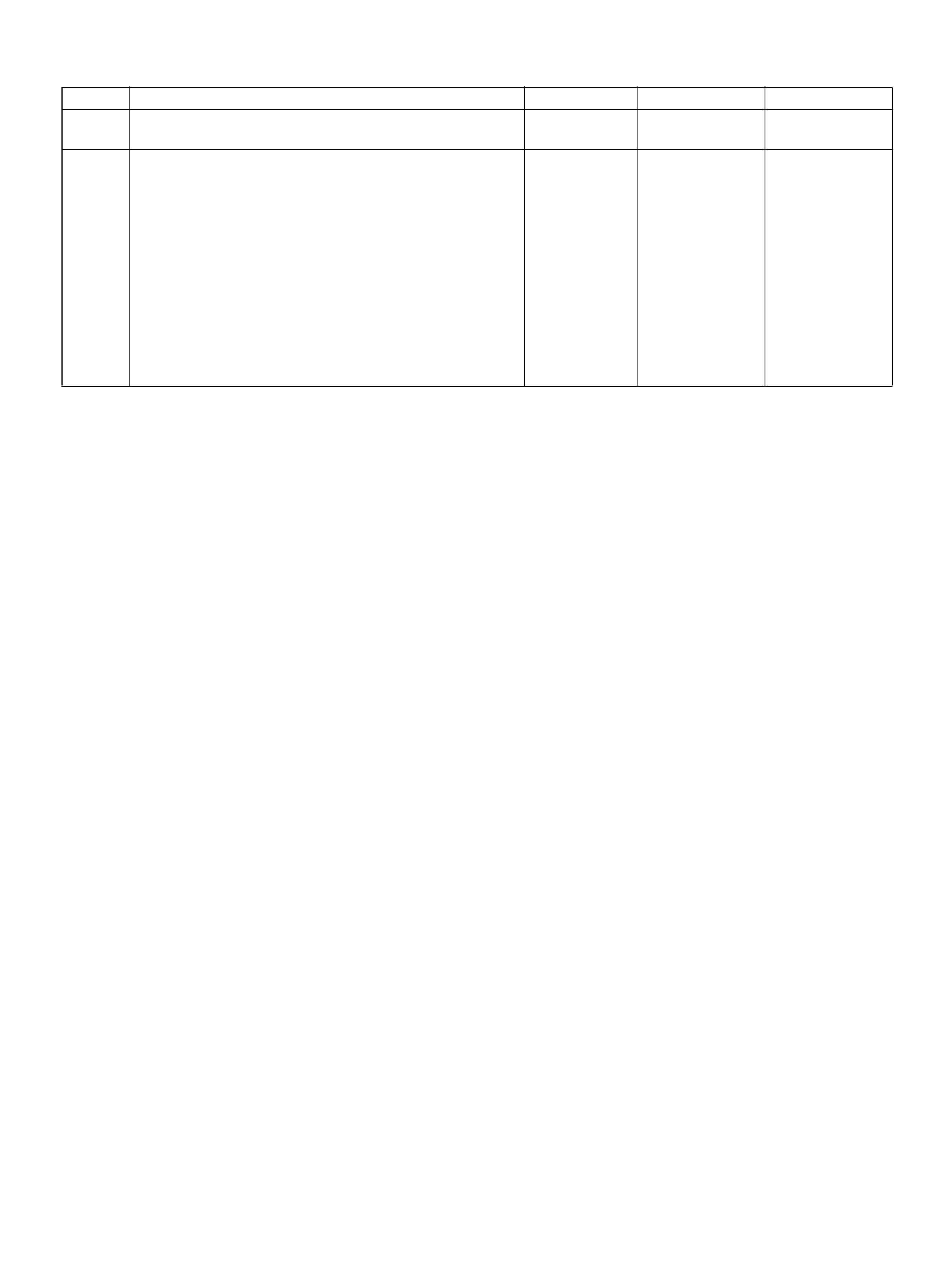

On-Board Diagnostic (OBD) System Check

Step Action Value(s) Yes No

1 1. Ignition “ON", engine “OFF".

2. Observe the malfunction indicator lamp (MIL or

“Check Engine lamp").

Is the MIL (“Check Engine lamp")“ON"? — Go to St ep 2

Go to No

MIL(“Check

Engi ne lamp" )

2 1. Ignition “ON", engine “OFF".

2. O bs erve the “Reduced Power lamp".

Is the RPL (“Reduced Power lamp") “ON" for 3

seconds? — G o to St ep 3

Go to No

RPL(“Reduced

Power lamp")

3 1 . Ig nit io n “ OFF" .

2 . Install Te ch2.

3. Ignition “ON".

4. Attempt to display PCM engine data with the

Tech2.

Does the Tech2 display PCM data? G o to St ep 4 Go to Step 12

4 1. Using th e Tech2 output tests funct ion, select MIL

(“Check Engine lamp") control and command the

MIL (“Check Engine lamp") “ON".

2. Observe the MIL (“Check Engine lamp").

Did the MIL (“Check Engine lamp") turn “ON"? — Go to Step 5

Go to

MIL(“Check

Engi ne lamp" )

On Steady

5 1. Using th e Tech2 output tests funct ion, select MIL

(“Check Engine lamp") control and command the

RPL (“Reduced Power lamp") “OFF".

2. Observe the RPL (“Reduced Power lamp").

Did the MIL (“Reduced Power lamp") turn “OFF"? — Go to Step 6

Go to

RPL(“Reduced

Power lamp")

On Steady

6 Select “Display DTCs" with the Tech2.

Are any DTCs stored? — Go to Step 7 Go to Step 11

7 Stored DTCs;

P0562, P 0563, P0601, P0602, P0604, P0 606, P1625,

P1635, P1 639, P1640, P1650

Are the any of the above DTCs stored? —

Go to

applicable DTC

table Go to Step 8

8 Stored DTCs;

P1514, P 1515, P15 16, P1523, P 1125, P 1290 , P1295,

P1299

Are the any of the above DTCs stored? —

Go to

applicable DTC

table Go to Step 9

9 Stored DTCs;

1. P0106, P0107, P1107, P0401, P1404, P0405,

P1120, P1221, P1515, P1516, P1275, P1635,

P1271, P12 73, P1285, P1 272

2. P0336, P0337, P1220, P1515, P1221, P1516,

P1280, P16 39, P1271, P1 272

Are the any of the above DTCs stored?

Go t o “Multiple

PCM

Information

sensor DTCs

Set" Go to Step 10

10 Attempt to start the engine.

Did the engine start and continue to run? —Go to Step 6

Go to Cranks

Bu t Will Not

Run

11 Compare P CM d ata values displayed on th e Tech2 to

the typical engine scan data values.

Are the displayed values normal or close to t he typical

values? —Go to Symptom

Refer to

indicated

Component

Syste m Checks

12 1. Ignition “OFF", disconnect the PCM.

2. Ignition “ON", engine “OFF".

3. Check the Class 2 data circuit for an open, short

to ground, or short t o vol t age. Also, check the DLC

ignition feed circu it for an op en or short to ground

and the DLC ground circuit for an open.

4. I f a problem is found, repair a s necess ary.

Was a problem found? — Go to St ep 2 Go to Step 13

13 1. Attempt to reprogram the PCM. Refer to

Powertrain Control Module (PCM) in On-Vehicle

Service.

2. Attempt to display PCM data with the Tech2.

Does the Tech2 display PCM engine data? — Go to Step 2 Go to Step 14

14 Replace the PCM.

Important: The replacement PCM must be

programmed. Refer to Section 0C-1 - Service

Program ming Syst em.

Important: Refer to Section 11 - Engin e Im mobiliser

System for the Immobiliser Programming procedure.

Important: Ensure the latest software program is

downloaded to the PCM.

Is the action complete ? —Go to St ep 2 —

Step Action Value(s) Yes No

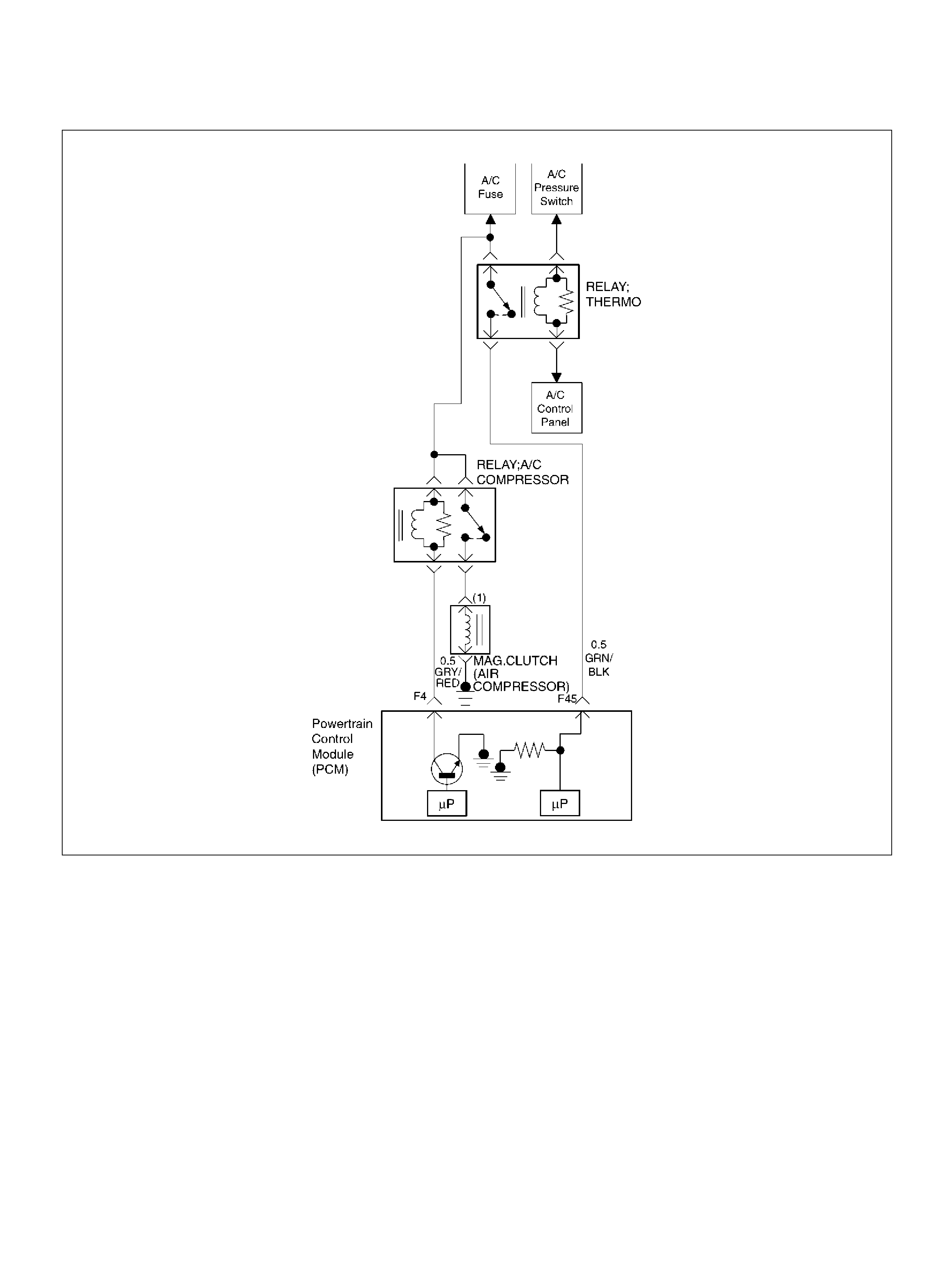

A/C CLUTCH CONTROL CIRCUIT DIAGNOSIS

060R100063

Circuit Description

W hen air conditioning and blo wer fan are selecte d, and

if the system has a sufficient refrigerant charge, a

12-vol t signal is supplied to the A/C request input of th e

powertrain control module (PCM). The A/C request

signal may be temporarily canceled during system

operati on b y the electro nic therm os tat in the evaporat or

case. When the A/C request signal is received by the

PCM, th e PCM supplies a ground from the compressor

clutch rela y if the e ngine operat ing con ditions are wi thin

acceptable ranges. With the A/C compressor relay

energized, voltage is supplied to the compressor clutch

coil.

The PCM will enable the compressor clutch to engage

whenever A/C has been selected with the engine

running, unless any of the following conditions are

present:

• T he ignition voltage is below 10.5 volts.

• The engine coolant temperature (ECT) is greater

than 119 °C (246 °F).

• The intake air temperature (IAT) is less than 5°C

(41°F).

• The power steering pressure switch signals a high

pressure condition during 3 seconds after ignition

“ON".

Diag nostic Ai ds

To diagnos e an the intermi ttent fault, check for following

conditions:

• Poor c onnection at the P CM–Inspe ct connections for

backed -out term inals, impr oper ma ting, broken locks,

improperly formed or damaged terminals, and poor

terminal-to-wire connection.

• Damaged harness–Inspect the wiring harness for

damage. If the harness appears to OK, observe the

A/C clutch while moving connectors and wiring

harnesses related to the A/C. A sudden clutch

malfunction will indicate the source of the intermittent

fault.

A/C Clutch Diagnosis

This chart should be used for diagnosing the electrical

portion of the A/C compressor clutch circuit. A Tech2

will be used in diagnosing the system. The Tech2 has

the ability to read the A/C request input to the PCM. The

Tech2 can display when the PCM has commanded the

A/C clutch “ON". The Tech2 should have the ability to

override the A/C request signal and energize the A/C

compressor relay.

Test Description

Important: Do not engage the A/C compressor clutch

with the engine running if an A/C mode is not selected

at the A/C control switch.

The numbers below refer to the step numbers on the

Diagnostic Chart:

3. This a test determine is the problem is with the

refrigerant system. If the switch is open, A/C

pressure gauges will be used to determine if the

pressure switch is faulty or if the system is partially

discharged or empty.

4. Although the normal complaint will be the A/C clutch

failing to engage, it is possible for a short circuit to

cause the clutch to run when A/C has not been

selected. This step is a test for that condition.

7. There is an extremely low probability that both relays

will fail at the same time, so the substitution process

is one way to check the A/C Thermostat relay. Use a

known good relay to do a substitution check.

A/C Clutch Control Circuit Diagnosis

Step Action Value(s) Yes No

1 Was the “On-Board Diagnostic (OBD) System Check"

performed? —Go to Step 2 Go to OBD

System Check

2 Are any other DTCs stored?

—

Go to the other

DTC chart(s)

firs t Go to Step 3

3 1. Disconnect the electrical connector at the

pressure switch located on the receiver/drier.

2. Use an ohmmeter to check continuity across the

pressure swit ch.

Is the pressure switch open? —

Go to Air

Conditioning to

diagnose t he

cause of the

open pressure

switch Go to Step 4

4Important: Before continuing with the diagnosis, the

following conditions mu st be met:

• The intake air temperature must be greater than

15°C. (60°F).

• The engine coolant temperature must be less than

119°C (246°F).

1. A/C “OFF".

2. Start th e engine and idle for 1 minute.

3. O bse rve the A/C compressor.

Is the A/C compressor clutch engaged even though A/

C has not been requested? — Go to Step 37 Go to S tep 5

5 1 . Idle the engine.

2. A/C “ON".

3. Blower “ON".

4. O bse rve the A/C compressor.

Is the A/C compressor magnetic clutch engaged? — Refer to

Diagnostic Aids Go to Step 6

6 1. Engine idling.

2. A/C “ON".

3. Blower “ON".

4. Observe the “A/C Request" display on the Tech2.

(Refer to the Miscellaneous test)

Does the tool “A/C Request" display indicate “Ye s"? — Go to Step 26 Go to Step 7

7 Temporarily substitute the A/C compressor relay in

place of the A/C thermostat relay, then repeat Step 5.

Did the “A/C Request " display indicate “Yes"? — Go to St ep 8 Go to Step 9

8 Replac e the original A/C thermostat rel ay.

Is the action complete ? — Verify r epair —

9 Does the blower operate? — Go to S tep 10 Go to Step 11

10 Repair the blower.

Is the action complete ? — Verify r epair —

11 Check for a faulty 10A A/C fuse in the underdash fuse

panel.

Was the 10A fuse OK ? — Go to S tep 13 Go to St ep 12

12 Check for short circuit and make repairs if necessary.

Replace the 10A A/C fuse.

Is the action complete ? — Verify r epair —

13 1. Remove the glove box to gain access to the A/C

thermostat.

2. Disconnect the thermostat connector.

3. Attach a fused jumper between ground and the

thermostat wire.

4. A/C “ON".

5. Blower “ON".

Dose A/C request indicate “YES" on the Tech2? — Go to Step 14 Go to St ep 17

14 1. Ignition “ON".

2. Use a DVM to check voltage at the electronic A/C

thermostat.

Was vol tage equal to the specified value? B+ Go to S t ep 17 Go to Step 15

15 Check for open wire between the thermostat and the

A/C switch.

Was the wire open? — Go to Step 16 Go to St ep 17

16 Repair the open wire between the therm ostat and the

A/C switch.

Is the action complete ? — Verify r epair —

17 Check for an open circuit between A/C thermostat

relay and PCM A/C request terminal (F45).

Was there an open c ircuit? — Go to Step 18 Go to St ep 19

18 Repair the open circuit between the PCM and A/C

thermostat relay.

Is the action complete ? — Verify r epair —

19 1. Ignition “ON".

2. Use a DVM to check voltage at the A/C pressure

switc h (BRN).

Was vol tage equal to the specified value? B+ Go to S t ep 21 Go to Step 20

20 Repair the open circuit between the 10A A/C fuse and

the pressure switch.

Is the action complete ? — Verify r epair —

21 Use an ohmmeter to check continuity between the

pressure switch and the A/C thermostat relay.

Was the circuit open? — Go to Step 22 Go to St ep 23

22 Repair the open circuit between the pressure switch

and the A/C thermostat relay.

Is the action complete ? — Verify r epair —

23 Check for damaged pin or terminal at F45 of the PCM.

Was a damaged pin or terminal found? — Go to St ep 24 Go to Step 25

Step Action Value(s) Yes No

24 Repair the damaged pin or terminal.

Is the action complete ? — Verify r epair —

25 Replace the PCM.

Important: The replacement PCM must be

programmed. Refer to On-Vehicle Service in

Powertrain Control Module Sensor s for procedures.

And also refer to latest Service Bulletin.

Check to se e if t he Latest software is released or not.

And then Down Load the LATEST PROGRAMMED

SOFTWARE to the replacement PCM.

Is the action complete ? — Verify r epair —

26 1. Remove the A/C compresso r rela y.

2. Ignition “ON".

3. Use a DVM to c heck volt age at bot h of the wires at

the A/C compresso r relay so cket.

Is the voltage equal to t he spec ified value? B+ Go to Step 28 Go to St ep 27

27 Repair the faulty wire between the A/C fuse and the A/

C compre ssor relay .

Is the action complete ? — Verify r epair —

28 1. A/C compresso r relay removed.

2. Engine idling.

3. A/C “ON".

4. Blower “ON".

5. Use a DVM to measure voltage between the wire

at the A/C compressor relay socket and battery±.

Did the DVM indicate the specified value? B+ Go to S tep 32 Go to St ep 29

29 Check for an open wire between PCM terminal F4 and

the A/C compressor re lay.

Was the wire open? — Go to Step 30 Go to St ep 31

30 Repair the open wire between the PCM and the A/C

compressor relay.

Is the action complete ? — Verify r epair —

31 Check for a damaged pin or terminal at F4 of the

PCM.

Was a damaged pin or a terminal found? — Go to Step 24 Go to St ep 25

32 1. A/C compresso r relay removed.

2. Connect a fused jumper at the A/C compressor

relay socket with eithe r wire.

3. Engine idling.

4. A/C “ON".

5. Blower “ON".

Did the compressor magnet ic clutch engage? — Go to Step 33 Go to St ep 34

33 Repair the A/C compressor relay.

Is the action complete ? — Verify r epair —

34 Check for an open circuit between the A/C

compressor relay and the A/C clutch.

Was an open circuit found? — Go to Step 35 Go to St ep 36

35 Repair the open circuit between the compressor

Clutch and the A/C compressor relay.

Is the action complete ? — Verify r epair —

36 Service the compressor clutch or replace the

compresso r due to a f aulty i nter nal overheat switch .

Is the action complete ? — Verify r epair —

Step Action Value(s) Yes No