SECTION 6D - CHARGING SYSTEM

Service Precaution

Charging System

General Description

General On–Vehicle Inspection

Generator

Removal

Inspection

Installation

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Bench Test

Main Data and Specifications

SERVICE PRECAUTION

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS), REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDE N will call out those f asten ers th at requir e a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints , greases,

or other corrosion inhibitors ) on threaded fast eners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

CHARGING SYSTEM

GENERAL DESCRIPTION

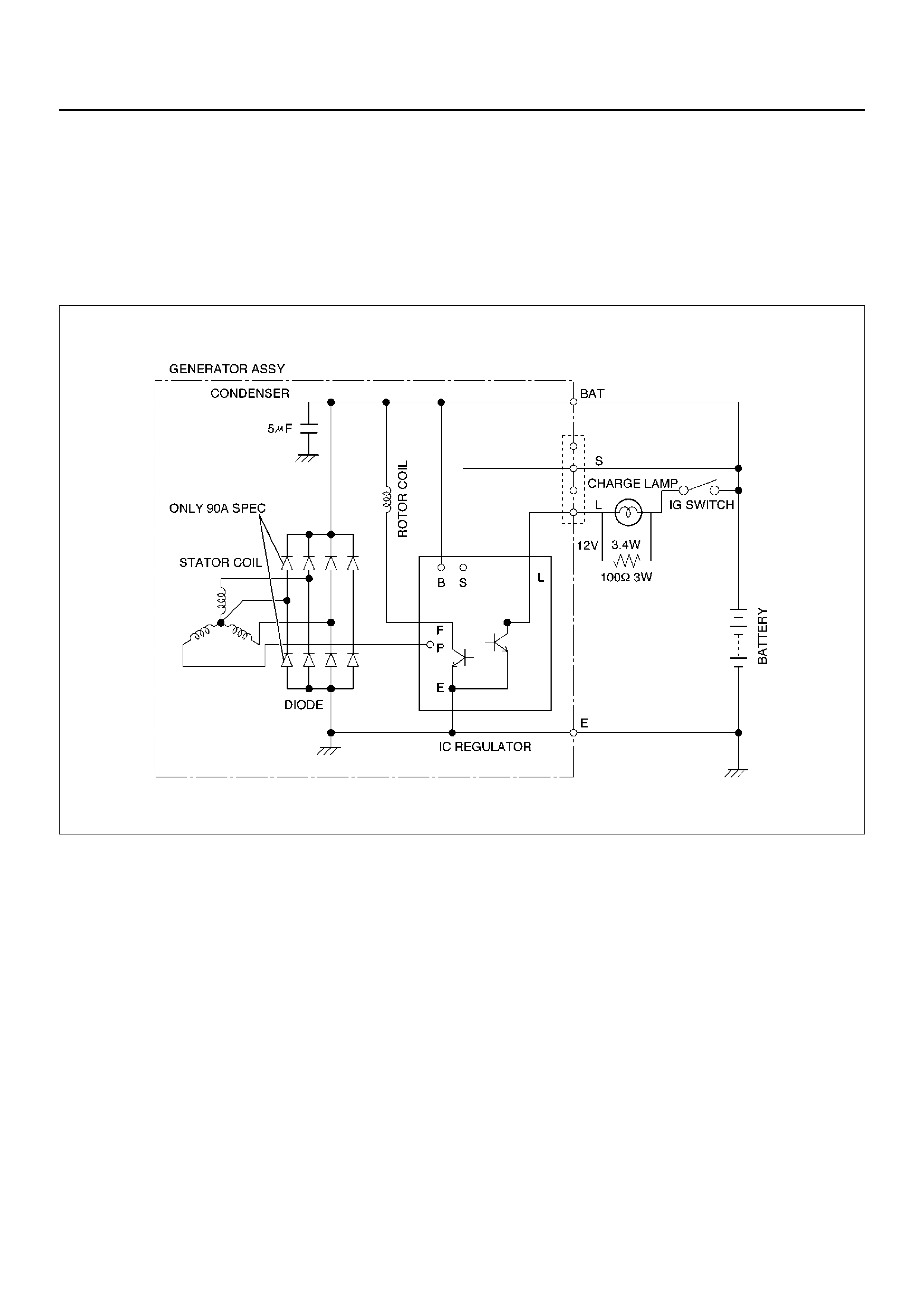

The IC integral regulator charging system and its main

components are connected as shown in illustration.

The regulator is a solid state type and it is mounted

along with the brush holder assembly inside the

generator installed on the rear end cover.

The generator does not require particular maintenance

such as vo ltag e adju stm ent.

The rectifier connected to the stator coil has diodes to

transform AC voltage into DC voltage.

This DC voltage is connected to the output terminal of

generator.

F06RX002

GENERAL ON–VEHICLE INSPECTION

A basic wiring diagram is shown in the illustration. When

operating normally, the indicator bulb will come on when

the switch is turned on, and will then go out when the

engine starts. If the indicator operates abnormally, or if

an undercharged or overcharged battery condition

occurs, the following procedure may be used to

diagnose the charging system. Remember that an

undercharged battery is often caused by accessories

being left on overnight, or by a defective switch which

allows a bu lb, such as a trunk or glo ve box light, to s tay

on.

OBSERVE THE FOLLOWING PRO C EDURE:

1. Visually check drive belt and wiring.

2. Go to step 5. for vehicles without charge indicator

light.

3. Ignition on, engine stationary, light should be on. If

not, detach harness at generator, ground “L"

terminal lead.

a Lamp lights, replace or repair generator.

b Lamp dose not light, locate open circuit between

groundi ng lead and ig nition switch. Bu lb may be

open.

4. Switch on, eng ine runni ng at moder ate sp eed. Ligh t

should be off. If not, detach wiring harness at

generator.

a If light goes off, replace or repair generator.

b If light stays on, ch eck for gr ounded “L" termi nal

wire in harness.

5. Battery undercharged or overcharged.

a Detach wiring harness connector from

generator.

b With switch on, engine not running connect

voltmeter from ground to “L" terminal in wiring

harness, and to “IG" terminal. If used. Wiring

harness may connect to either “L" or “IG" or

both.

c Zero reading indicates open circuit between

terminal and battery. Connect as required.

d Re-con nec t harne ss c onne ct or to gen er ator, run

engine at moderate speed, with electrical

accessories turned off.

e Measur e voltage acros s battery. If abo ve 16.0V,

replace or repair generator.

f Connect ammeter at generator output terminal.

Turn on accessories, load battery with carbon

pile to obtain maximum amperes output.

Maintain voltage at 13.0V or above.

1 If within 15 amperes of rated output,

generato r is OK.

2 If not within 15 amperes of rated output,

replace or repair generator.

GENERATOR

REMOVAL

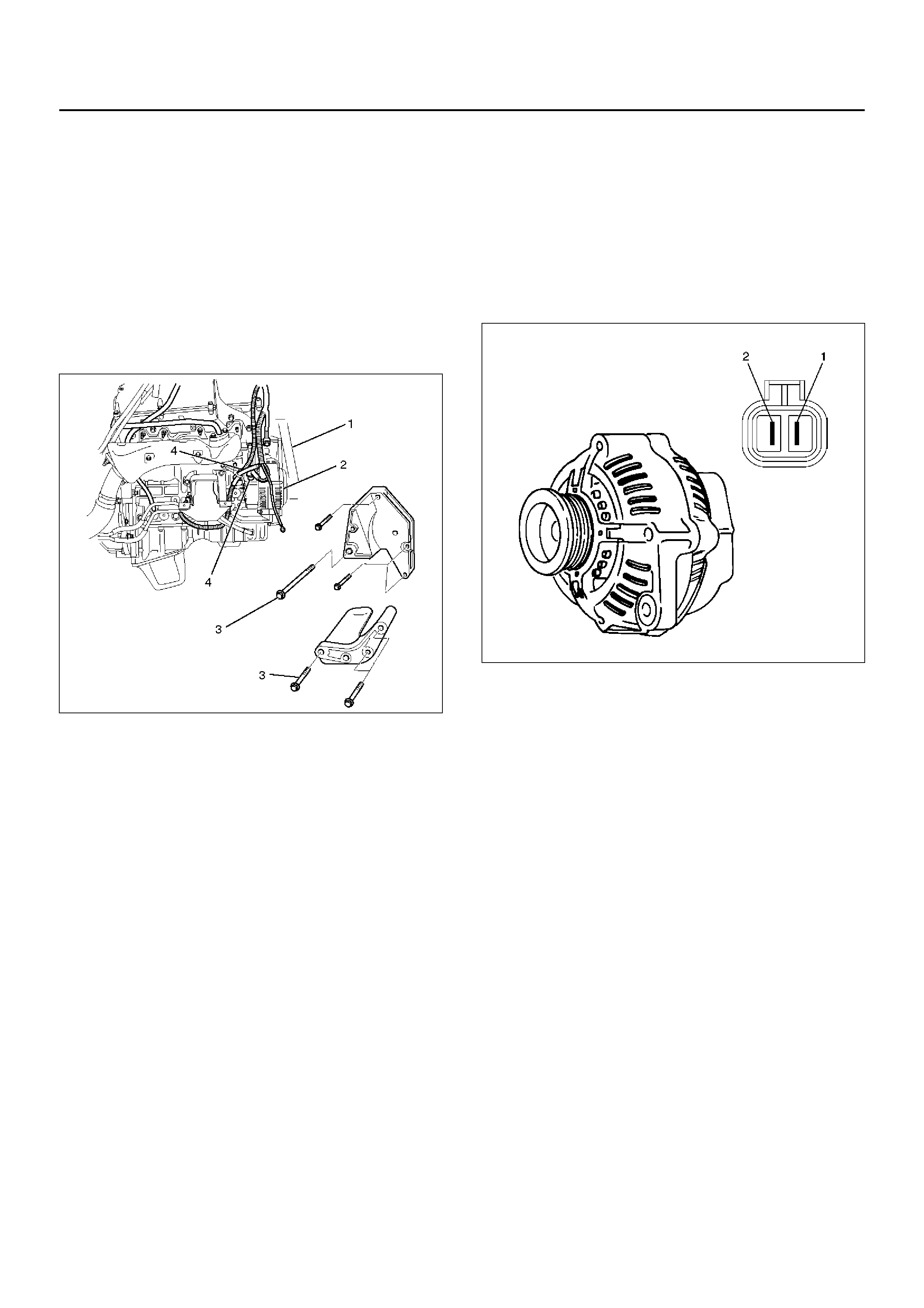

1. Disconnect battery ground cable.

2. Move drive belt tensioner to loose side using

wrench then remove drive belt (1).

3. Disconnect the wire from terminal “B" and

disconnect the connector (4).

4. Remove generator fixing bolt (3).

5. Remove generator assembly (2).

060RW002

INSPECTION

1. Disconnect the wiring connector from generator.

2. With the engine stopped, turn starter switch to “on"

and connect a voltmeter between connector

terminal L (1) and ground or between terminal IG (2)

and ground.

066RX002

If voltage is not present, the line between battery

and connector is disconnected and so requires

repair.

3. Reconnect the wiring connector to the generator,

run the engine at middle speed, and turn off all

electrical devices other than engine.

4. Measure battery voltage. If it exceeds 16V, repair or

replace the generator.

5. Connect an ammeter to output terminal of

generator, and measure output current under load

by turning on the other electrical devices (eg.,

headlights). At this time the amperes must not be

less than 15A and the voltage must not be less than

13V.

INSTALLATION

1. Install generator assembly to the position.

2. Install generator assembly and tighten the fixing

bolts to the specified torque.

Torque:

M10 bolt: 41N·m, M8 bolt: 21N·m

3. Connect wiring harness connector and direct

termina l “B ".

4. Move drive belt tensioner to loose side using

wrench, then install drive belt to normal position.

5. Reconnect battery ground cable.

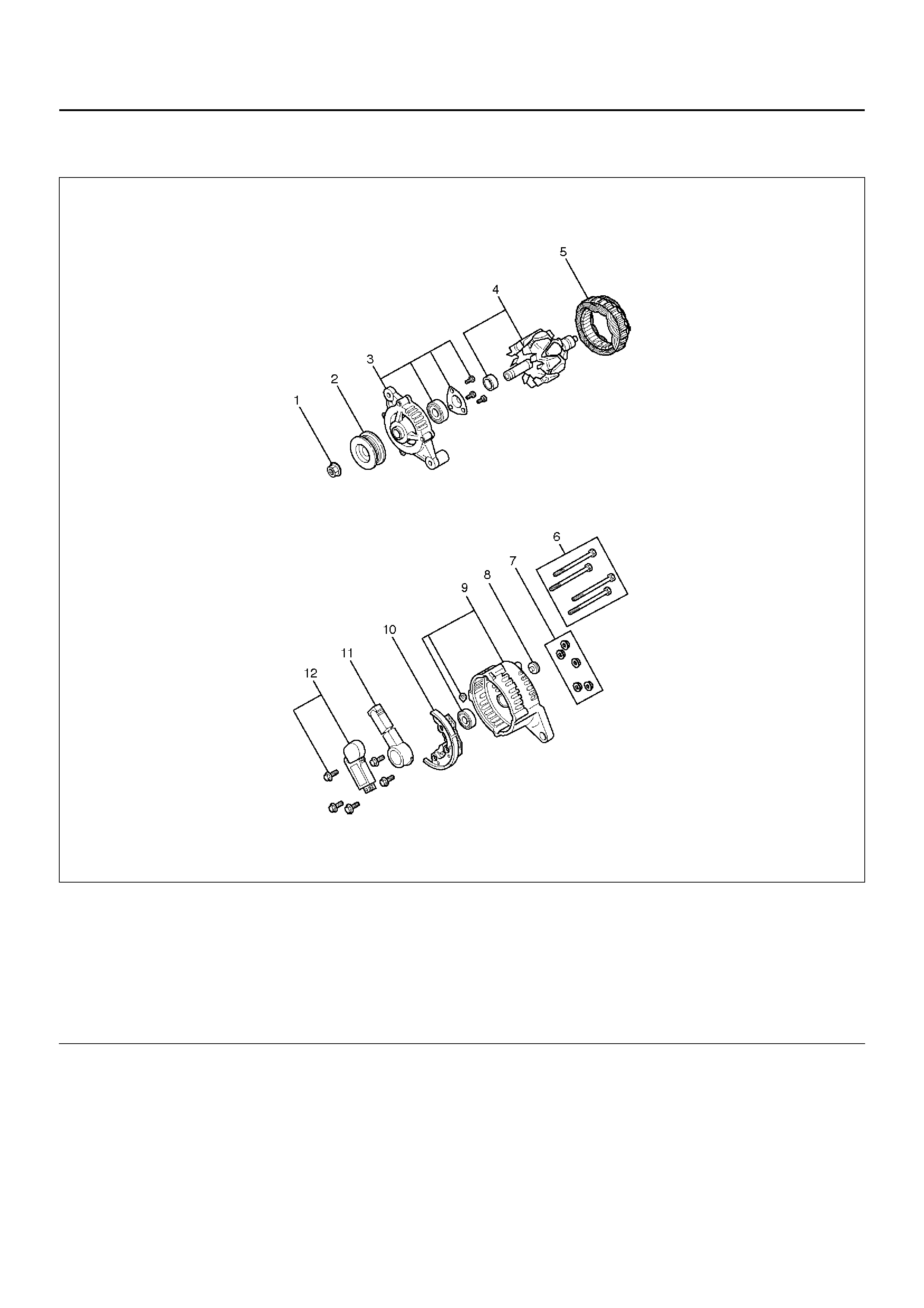

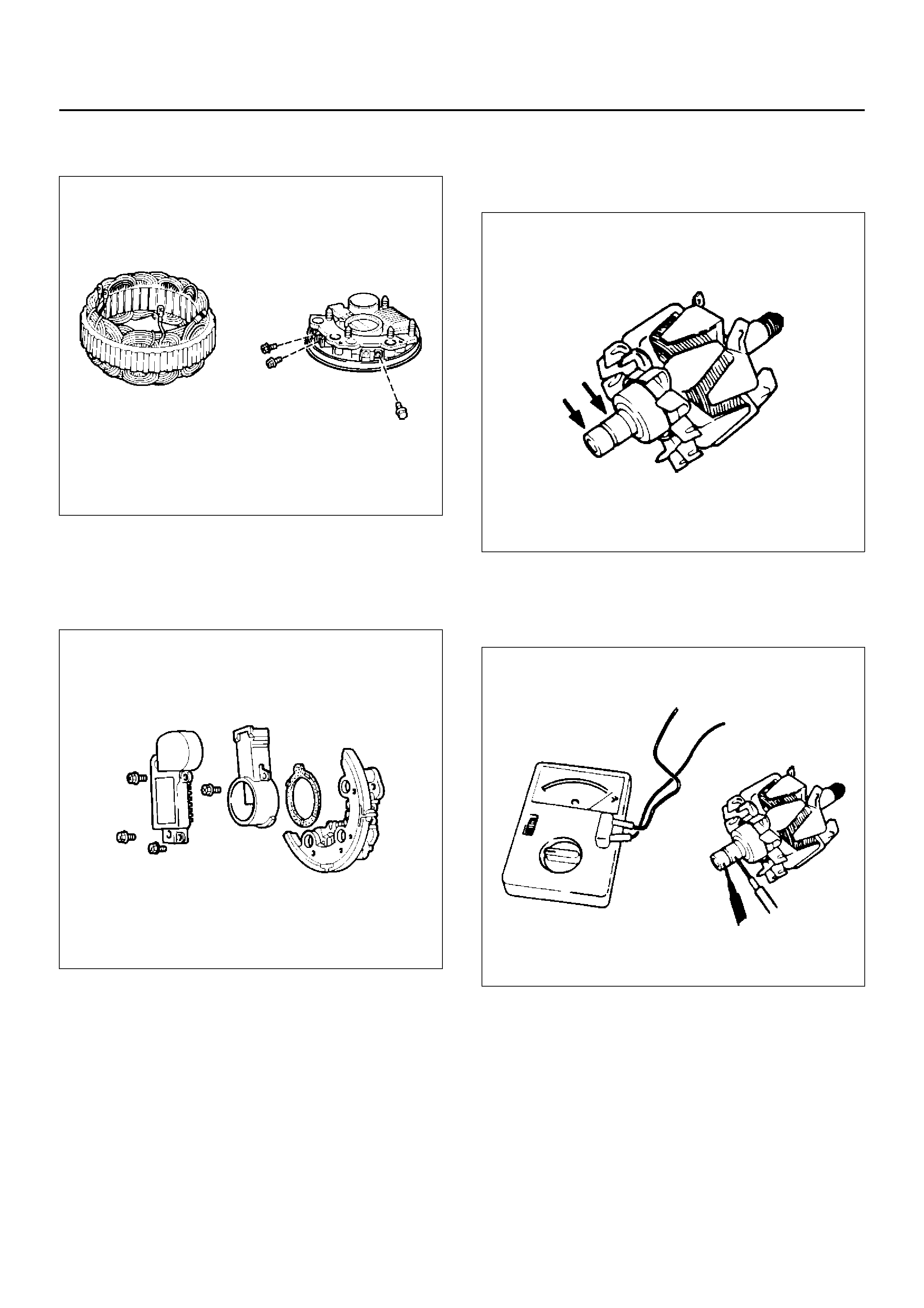

DISASSEMBLED VIEW

066RW022

EndOFCallout

Legend

(1) Pulley Nut

(2) Pulley

(3) Front Cover Assembly

(4) Rotor Assembly

(5) Stator Assembly

(6) Thr ou gh Bol t

(7) Nut

(8) Terminal Insulator

(9) Rear Cover Assembly

(10) Rectifier

(11) Brush Holder Assembly

(12) Regulator Assembly

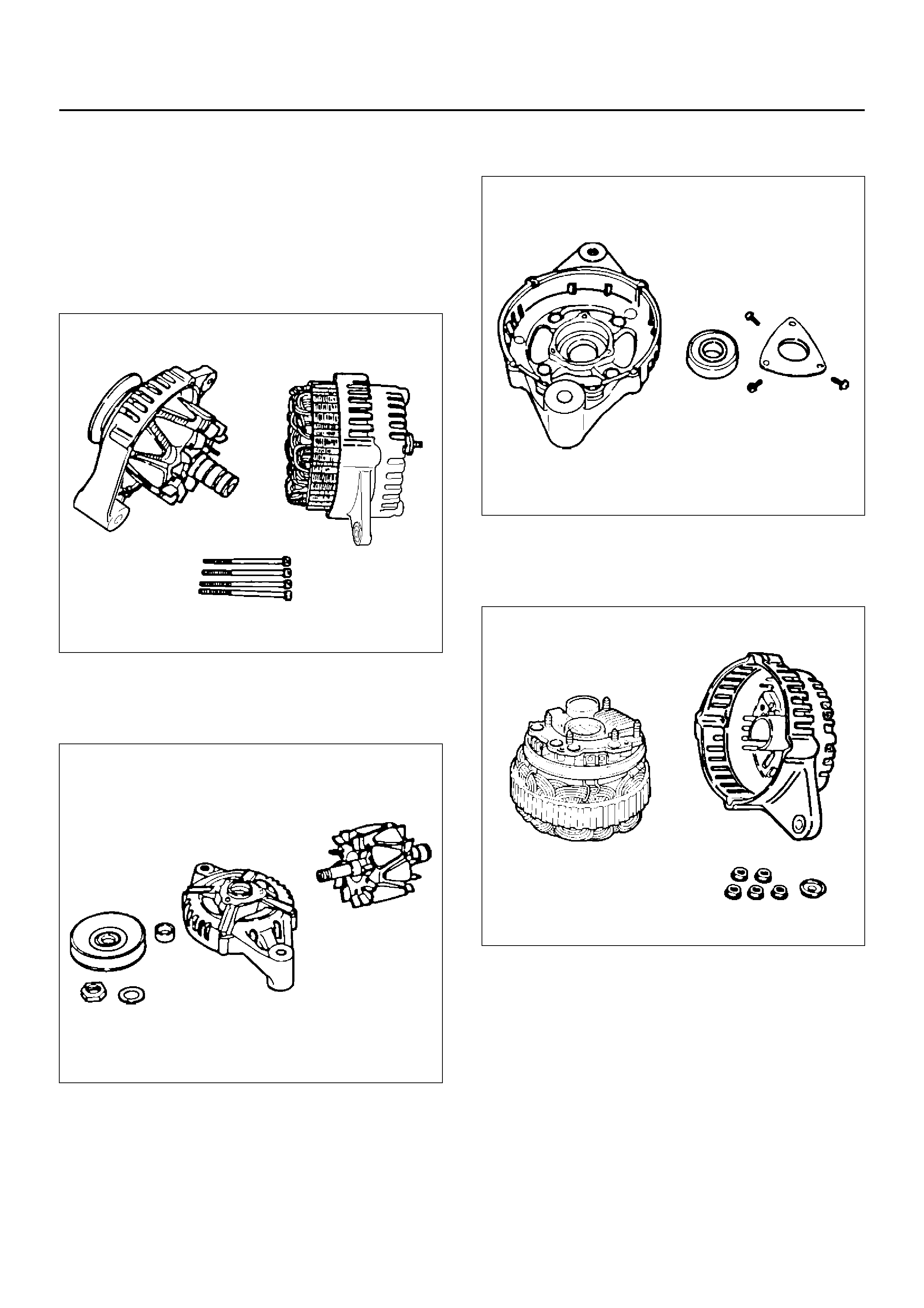

DISASSEMBLY

1. Remo ve the throug h bolt.

Inser t the tip of a pry bar into the g aps between the

front cover and the stator core.

Pry apart and separate the front cover, rotor, the

rear co ver and stator.

NOTE: Take care not to scratch or otherwise damage

the stator coil with pry bar.

F06RT021

2. Clamp the rotor in a vise and then remove the nut

and pulley.

3. Remove the rotor assemb ly from front cover.

F06RT022

4. Remove screws with bearing retainer from front

cover and remove bearing.

F06RT023

5. Remove the m ounting n uts h old in g t he “ B" te rmin al ,

the diode, and the brush holder.

6. Separate the rear cover from the stator.

F06RT024

7. Remove bolts which secure stator terminal to

rectifier terminal, and remove stator.

066RS030

8. Remove Bolts which secure regulator, rectifier and

brush-holder, and separate these parts.

NOTE: Do not apply a shock or load to regulator,

rectifier and brush holder.

066RW025

INSPECTION AND REPAIR

Repair or replace necessary parts if extreme wear or

damage is found during inspection.

Rotor Assembly

1. Check the face of the slip rings for contamination

and roughness. If found to be scored, dress with a

fine sandpaper (#500 –600). If found to be

contaminated, clean with a cloth saturated with

alcohol.

2. Measure the outside diameter of the slip rings.

Standard: 27mm (1.06in)

Limit: 26mm (1.02in)

066RS032

3. Check resistance between slip rings, and replace if

there is no continuity.

Standard: 3.75Ω or less

066RS033

4. Check for continuity between slip ring and rotor

core.

In case of continuity, replace the rotor assembly.

066RS017

Stator Coil

1. Check for continuity across the stator coils. If no

continuity exist s, replace the coils.

Resistance value at 20°C.

Standard: Approx. 0.07Ω

066RS034

2. Check for continuity across one of the stator coils

and stator core. If a continuity exists, replace the

coil.

Standard: More than 1MΩ

066RS035

Brush

Measur e the brus h lengt h.

If more than limit, replace the brush.

Standard: 18.0mm (0.709in)

Limit: 5.5mm (0.217in)

066RW024

Rectifier Assembly

1. Measure the resistance between each diode

terminal and aluminum diode fin in forward and

reverse directions with the connection of the tester

leads switched. The diodes are normal if resistance

is near ly zero ohms in one directio n and is infin itely

high in the other direction.

2. If a diode has no resistance or equal resistance in

both directions, it is defective and should be

replaced together with the holder.

066RS036

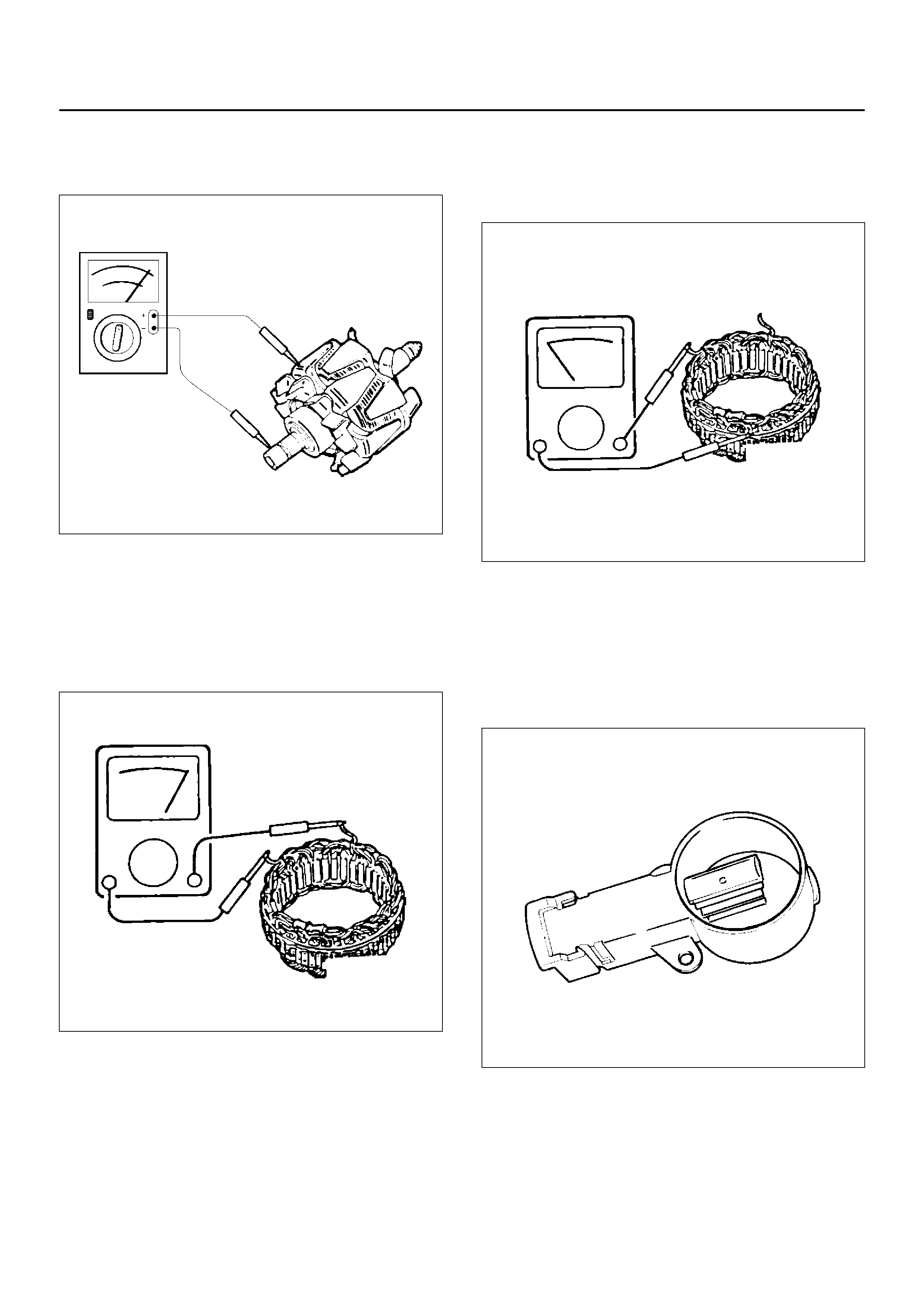

IC Regulator Assembly

Connect a variable resistor, two 12V batteries, a fixed

resistor, and a voltmeter to the IC regulator as shown in

illustration.

a Measuring equipment specifications

1 Fixed resistor (R1) : 10 Ohms /3W

2 Variable resistor (Rv) : 0-300 Ohms/12W

3 Batteries (BAT1, BAT2) : 12V (2 Batteries)

4 DC voltmeter : 0-50V/0.5 steps (4 Check points)

b Measuring procedure

1 Measure the voltage “V1" across the first battery

(BAT1). If the reading is between 10 and 13

volts, the battery is normal.

2 Measure the voltage “V3" across both the

batteries (BAT1, BAT2). If the reading is

between 20 and 26 bolts, the batteries are

normal.

3 Gradually increase the resistance of the variable

resistor from zero. Measure the voltage “V2"

(the voltage across the F and E terminals).

Check to see that the voltage across “V1"

changes at this time. If there is no change, the

voltage regulator is faulty and must be replaced.

4 Measure the voltage at “V4" (the voltage across

the variable resistor center tap and terminal E

with the variable resistor resistance held

constant). The measure voltage should be

within the specified (14.4±0.3 volts) limits. If it is

not, the regulator must be replaced.

066RX003

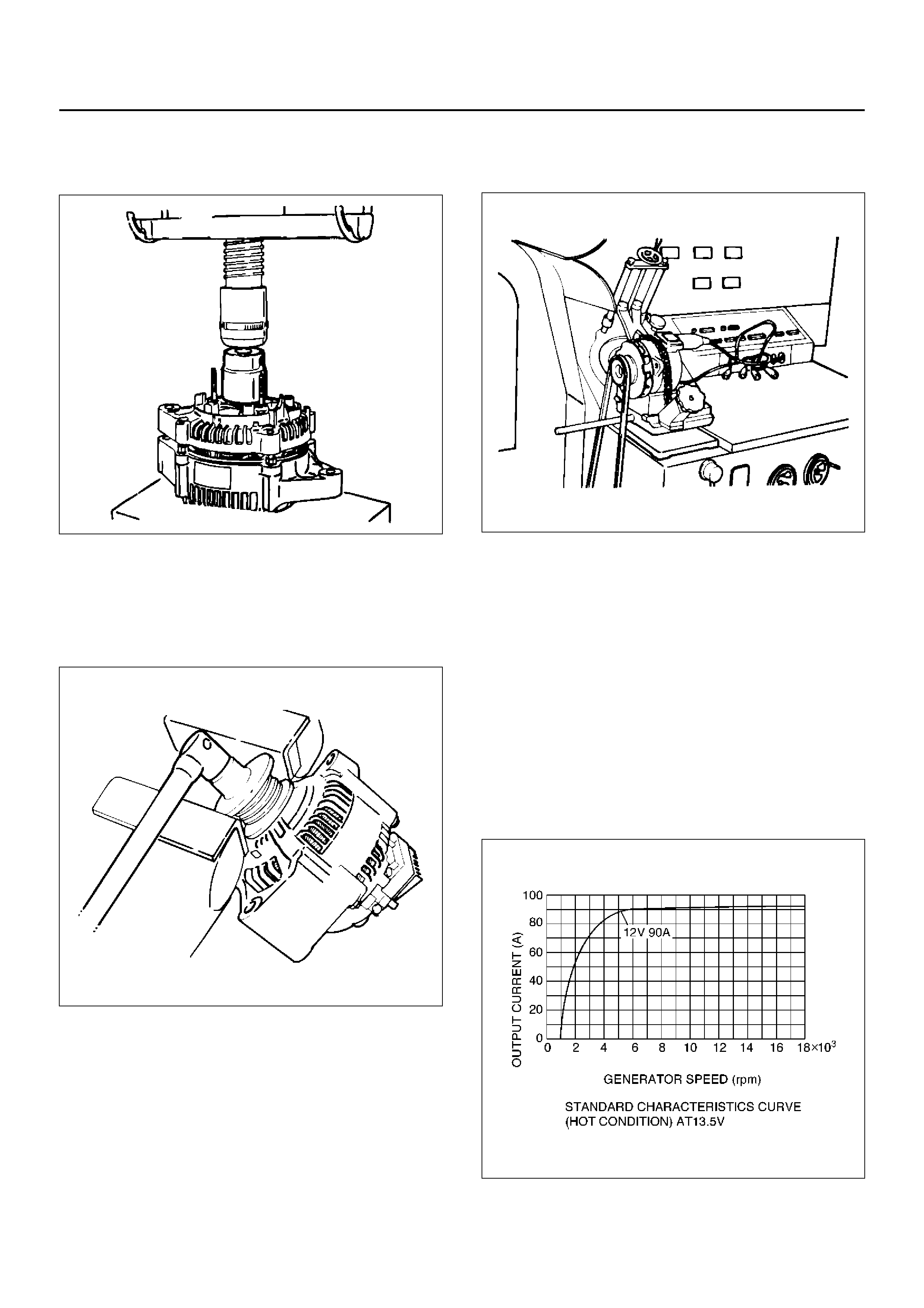

REASSEMBLY

To reassemble, follow the disassembly steps in the

reverse order, noting the following points:

NOTE:

• Never make battery connections with polarities

reversed, or battery will be shorted via the diodes.

This will cause damage to the diodes.

• Do not connect generator B terminal to ground; it is

connected directly to the battery.

This cable will burn if it is connected to ground.

• Make sure to disconnect the positive (+) terminal of

the battery when quick-charging battery .

Diodes may be damaged due to abnormal pulse

voltage generated bye the quick charger.

• When reassembling the front section to rear section,

inse rt a stiff wire into hol e in the rear face of the rear

cover from the outboard side to support the brush in

raised position, then insert the front section to which

rotor is assembled.

• Reassemble parts carefully to be sure they fit into

their original position, paying attention to the

insulated portions.

• Wipe insulat ing tubes , washers an d plates clean and

install the m in posi tion ca refull y to av oid ge tting o il or

grease on them.

1. Using a press with a socket wrench attached,

reassemble rotor and rear end cover assembly in

the front cover.

066RS022

2. Install pulley on the rotor.

Secure the pulley directly in the vise between two

copper plates, and tighten nut to the specified

torque.

Torque: 111N·m (11.3kg·m/82lbft)

066RS010

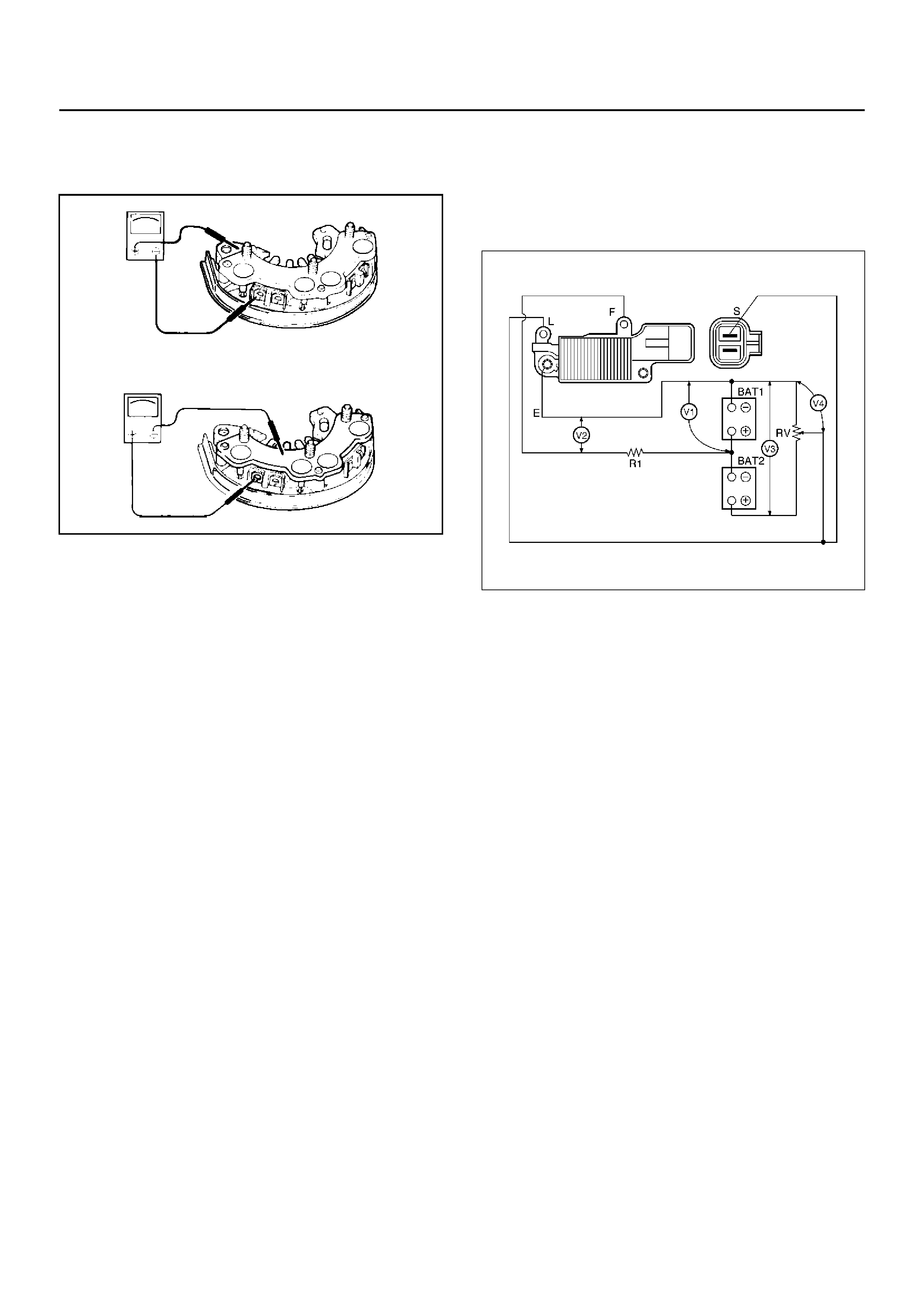

BENCH TEST

Conduct a bench test of the generator.

066RS023

Preparation

Remove generator from the vehicle (see “Generator

removal").

1. Secure generator to the bench test equipment and

connect wires.

Terminal “IG" for energization

Terminal “L" for neutral (warning lamp)

Terminal “B" for output

2. Conduct the generator characteristic test.

Characteristics of generator are shown in

illustration.

Repair or replace the generator if its outputs are

abnormal.

066RX001

MAIN DATA AND SPECIFICATIONS

General Specifications

Battery voltage V 12

Rated output A 90

Direction of rotation

(as viewed from pulley side) Clockwise

Rated rotation speed rpm 5000

Maximum speed rpm 18000