SECTION 7B - TRANSMISSION & TRANSFER CASE - MUA 5C

Service Precaution

General Description

Diagnosis (MUA)

Transmission (MUA)

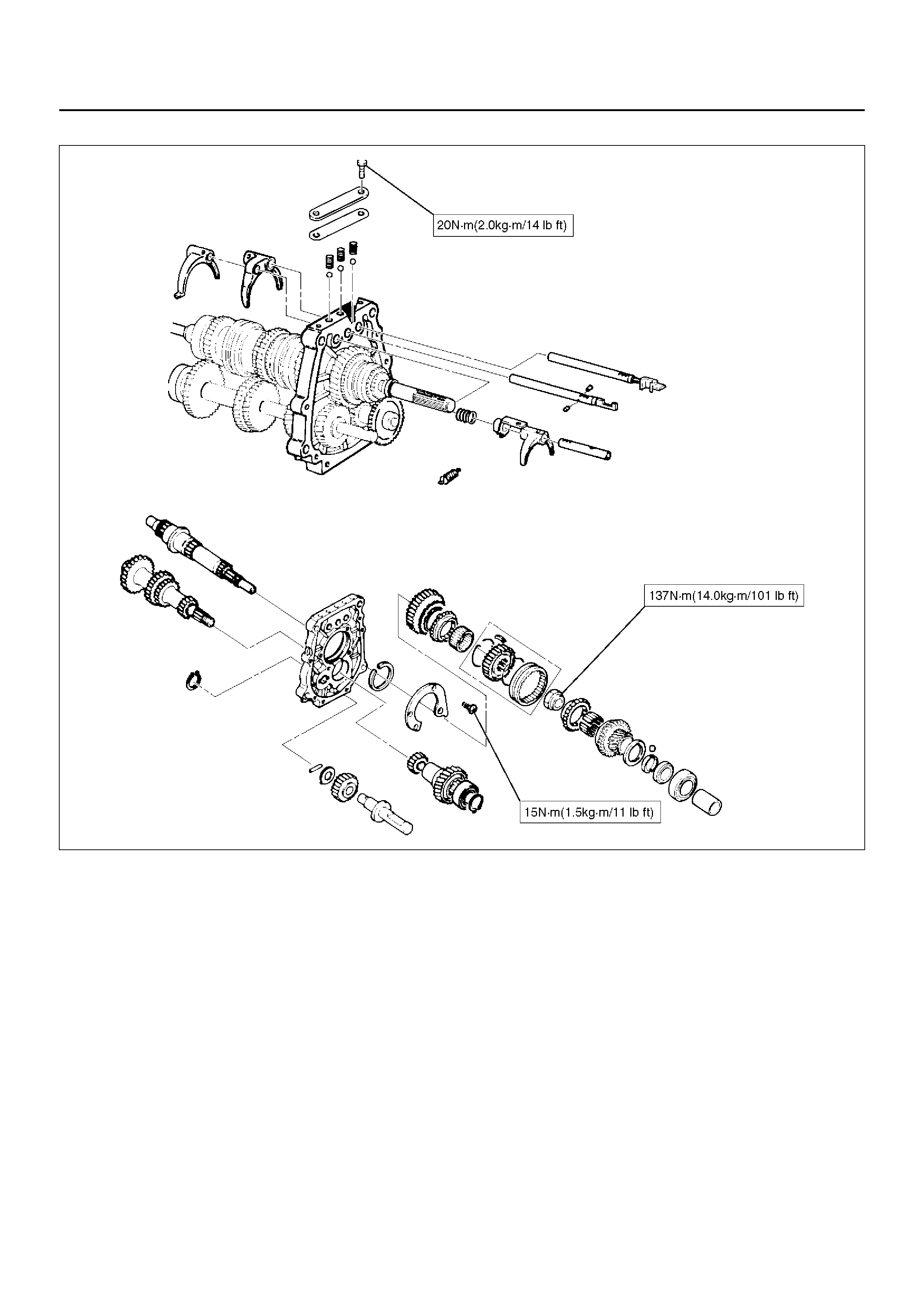

Disassembled View

Removal

Installation

Transmission Case and Transfer Case

Major Components (MUA)

Disassembly

Reassembly

Intermediate Plate with Gear Assembly,

Detent, Shift Arm, and Interlock Pin (MUA)

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Reverse Gear and 5th Gear (MUA)

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Top Gear Shaft, Main Gear Shaft, and

Counter Gear Shaft (MUA)

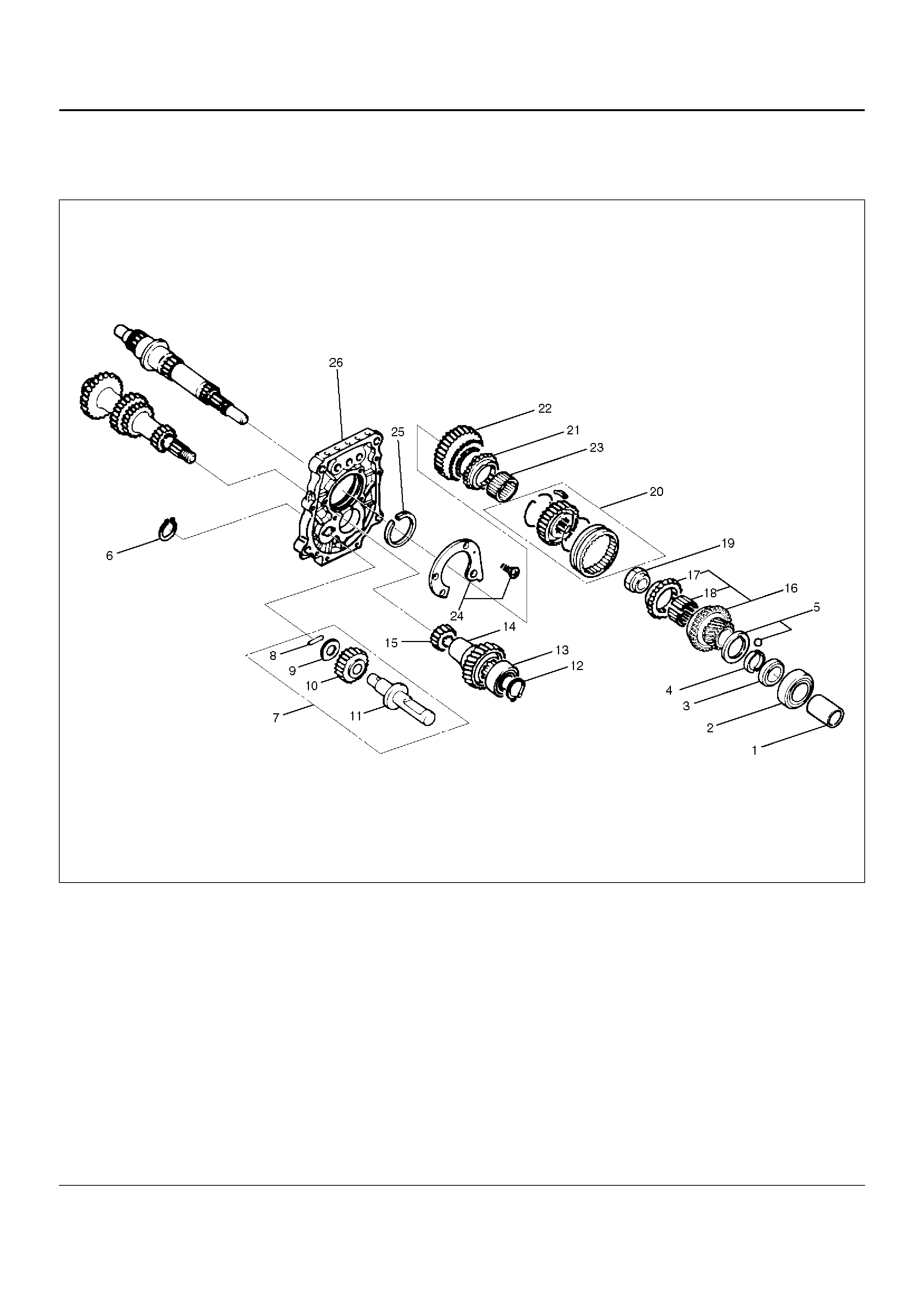

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

Special Tools (MUA)

SERVICE PRECAUTION

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the correct

tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

GENERAL DESCRIPTION

MUA5C Transmission

A07RX005

The MUA5C is a constant mesh transmission,

synchronized in all speeds. The transmission is

designed for reduced shift effort and quiet operation.

Principle parts of the transmission are the integral clutch

housing, intermediate plate, the transfer case, the rear

cover, and the gear set.

The transmission control housing and transfer control

housing are built into the transmission and transfer

case.

DIAGNOSIS (MUA)

Condition Possible cause Correcti on

Abnormal noise Flywheel pilot bearing worn Replace

Bearings worn or broken (Mainshaft,

counter shaft, and transfer shaft) Replace

Gear tooth contact surfaces worn or

scuffed (Mainsh aft, counte r shaft,

reverse idler gear and transfer

gears)

Replace

Splines worn (Mainsha ft,

sync hr onizer clutch hub) Replace

Gear or bearing thrust face seized Replace

Lack of backlash between meshing

gears Replace

Hard Shifting Improper clutch pedal free play Readjust

Change lever sliding portions worn Repair or replace Regrease

Shift block, shift rod and/or control

box sliding faces worn Replace

Shift arm and synchronizer sleeve

groove worn Replace worn parts

Thrust washer, collar, and/or gear

thrust faces worn (Mainshaft and

counter shaft thrust play)

Replace worn parts

Synchronizer parts worn Replace

Walking or Jumping out of gear Detent ball worn Replace

Detent spring weakened or broken Replace

Shift rod and/or control box sliding

faces wor n Replace

Shift arm and synchronizer sleeve

groove worn Replace worn parts

Thrust washer, collar, and/or gear

thrust faces worn (Mainshaft and

counter shaft thrust play)

Replace worn parts

Bearings worn or broken Replace

Splines worn (Mainsha ft,

sync hroni ze r hub ) Replace

Synchronizer spring weakened or

broken Replace

Oil leaks Loose drain plug(s) and/or filler

plug(s) Tighten Replenish oil

Defective or improperly installed

gasket(s) Replace

Oil seal worn or scratched Replace

TRANSMISSION (MUA)

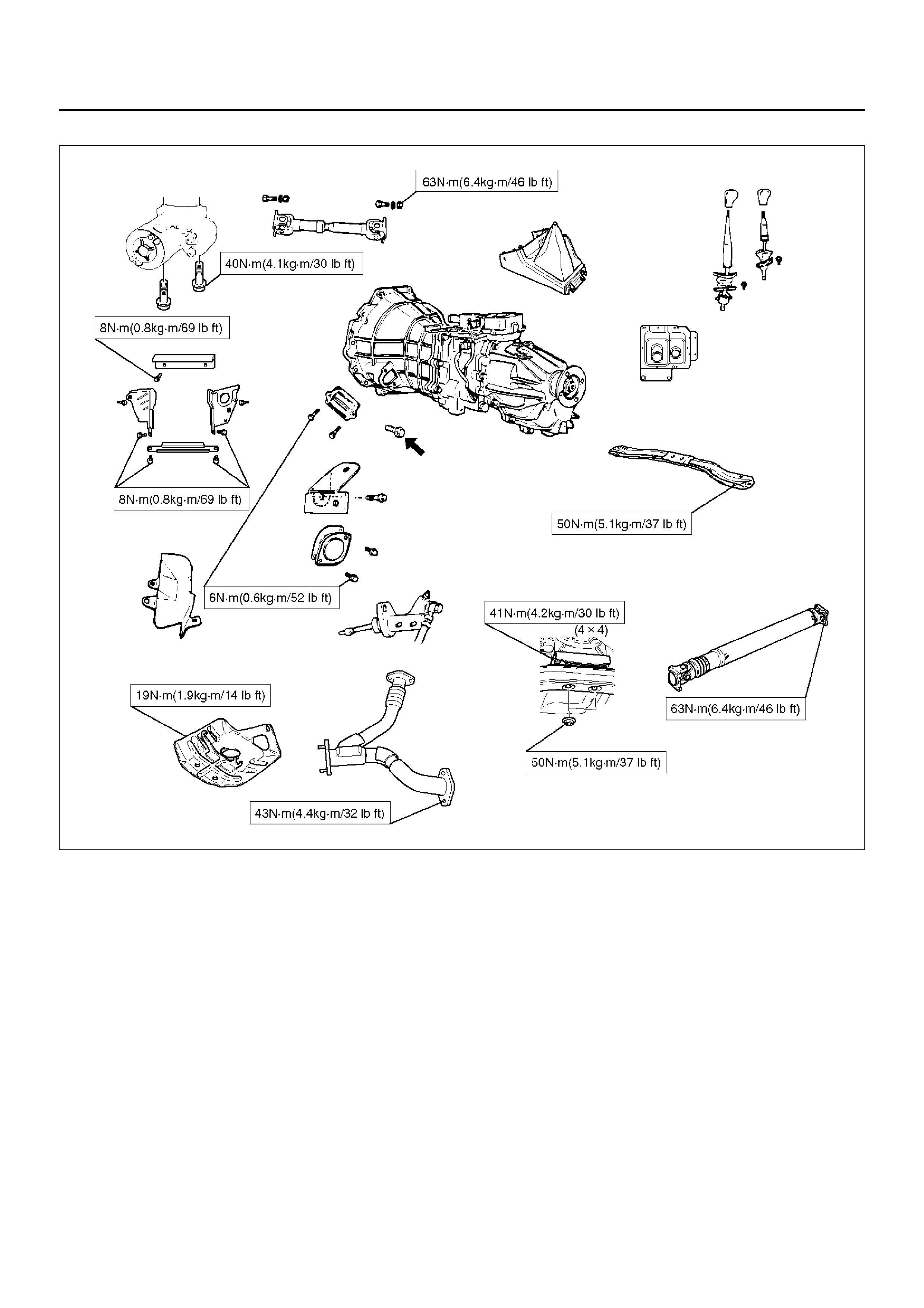

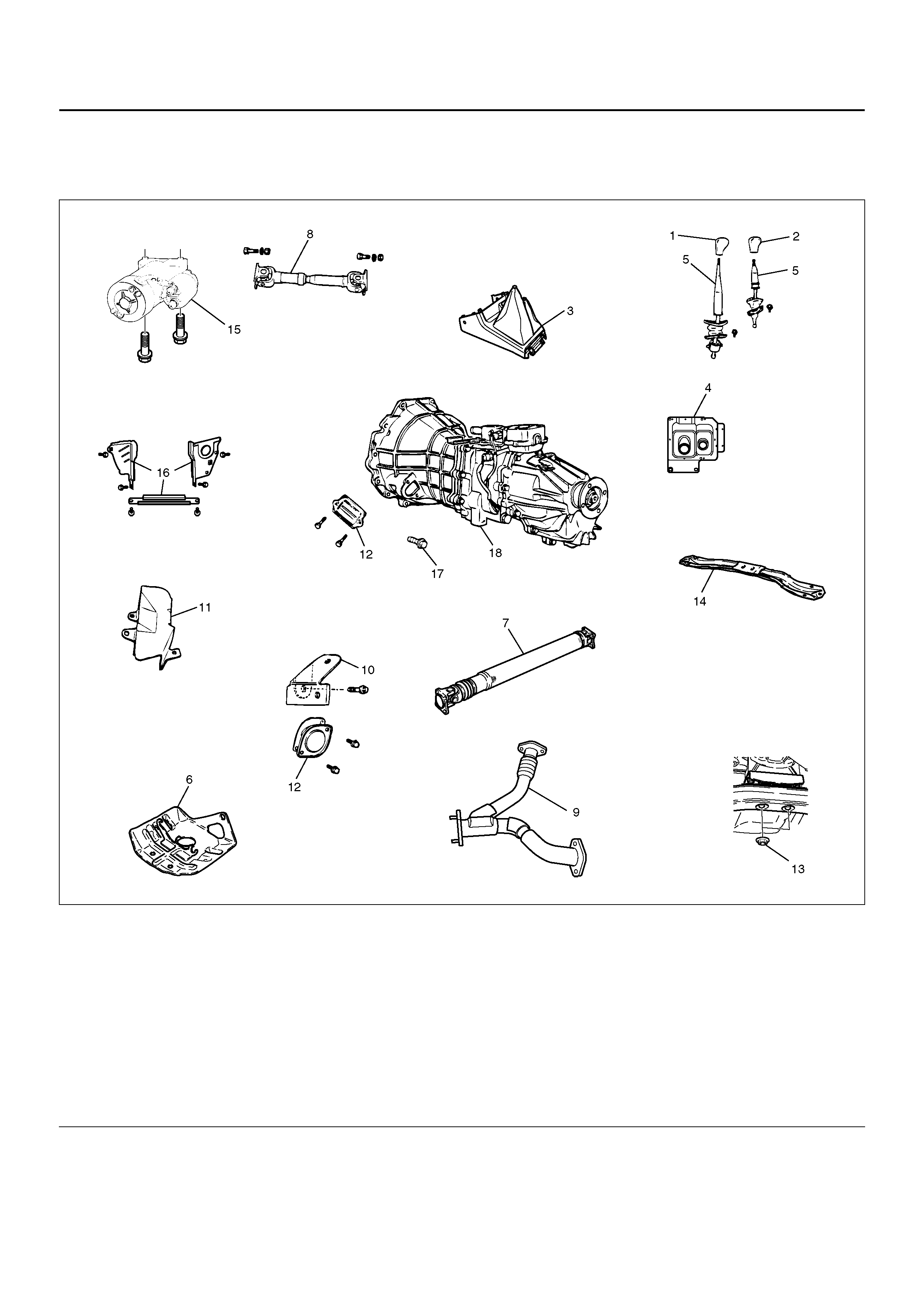

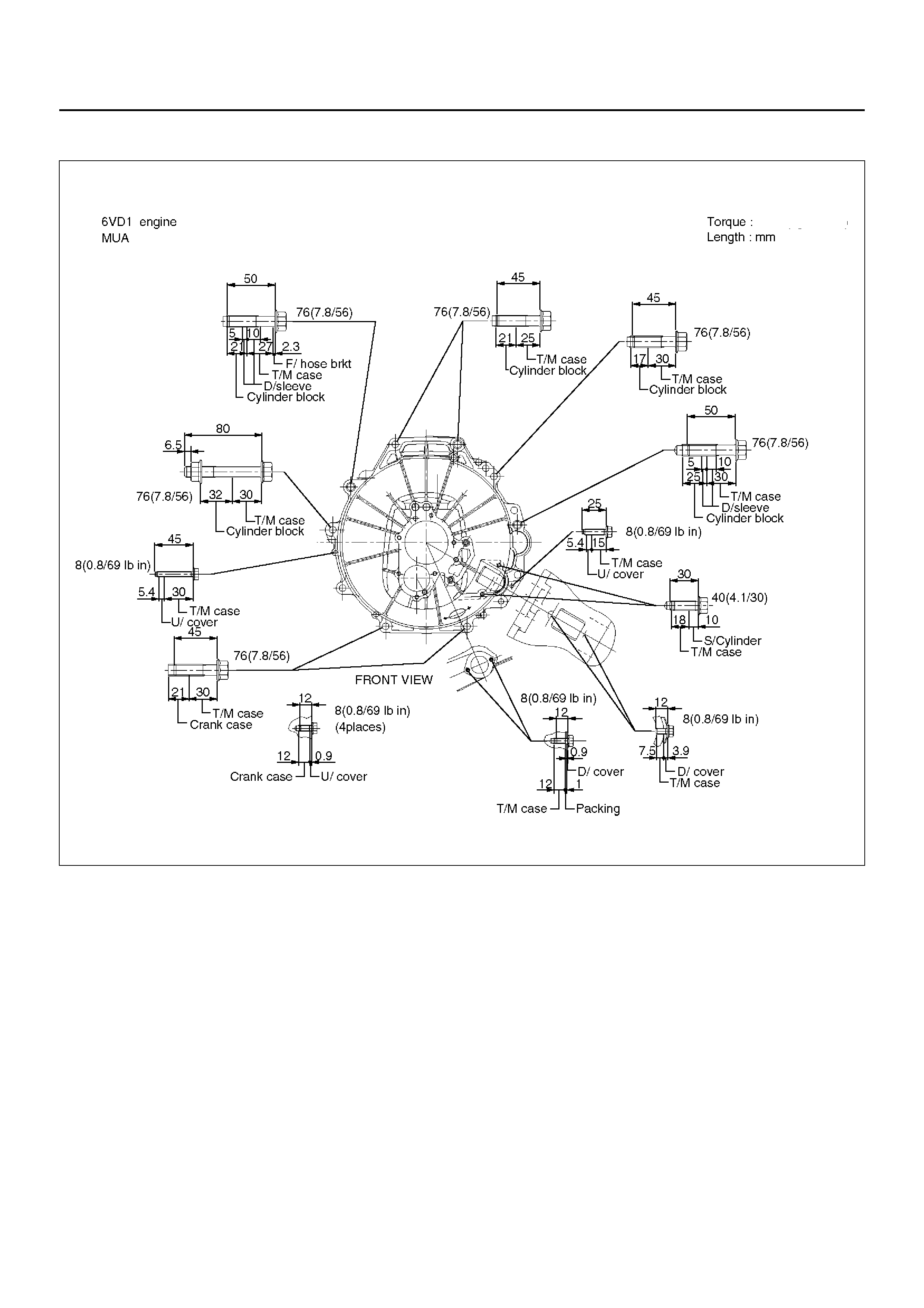

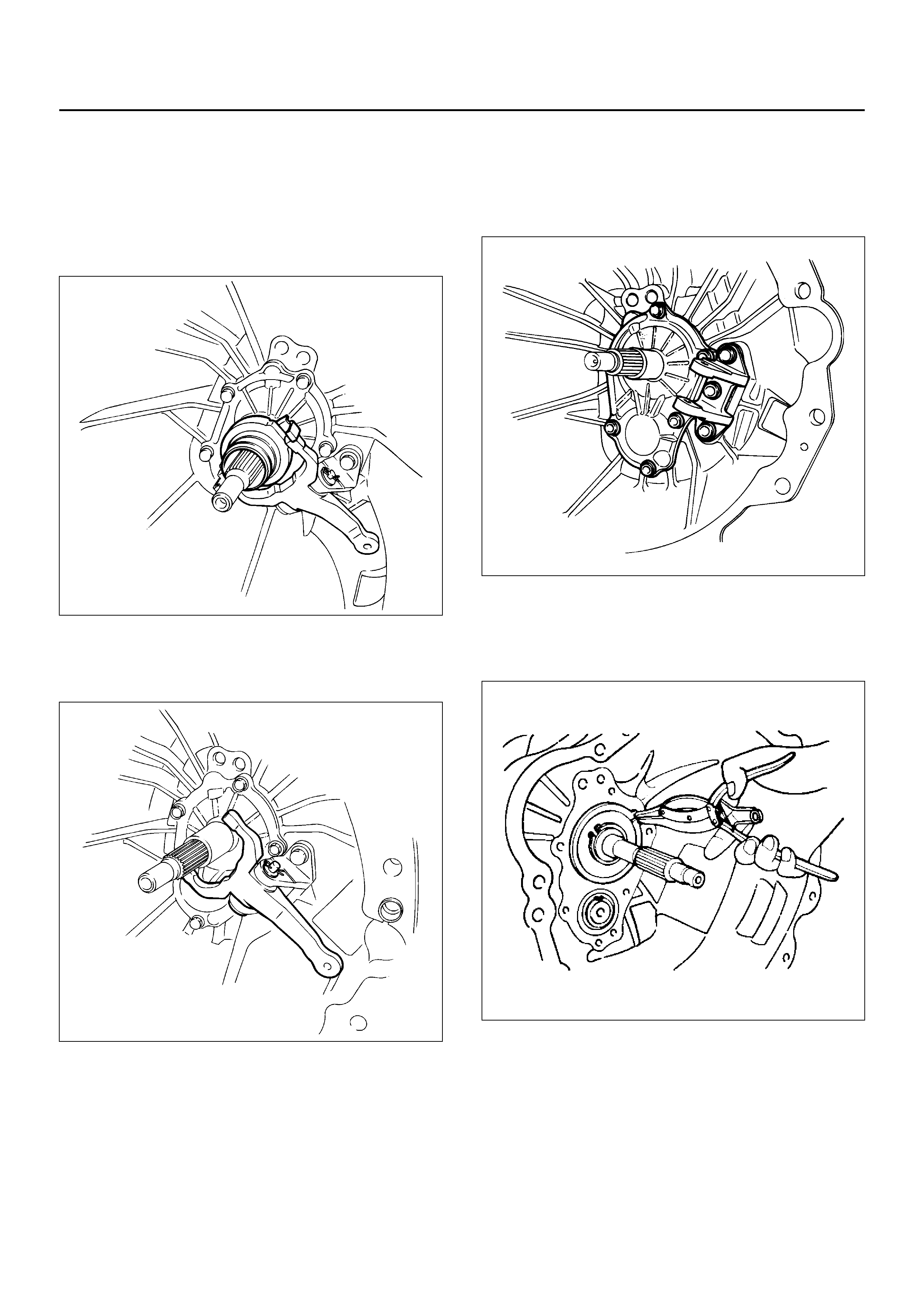

DISASSEMBLED VIEW

220R100002

EndOFCallout

REMOVAL

NOTE: Before removing transmission assembly from

vehicle, change the transfer mode to 2WD using the

4WD push button on dash panel.

1. Disconnect battery ground cable.

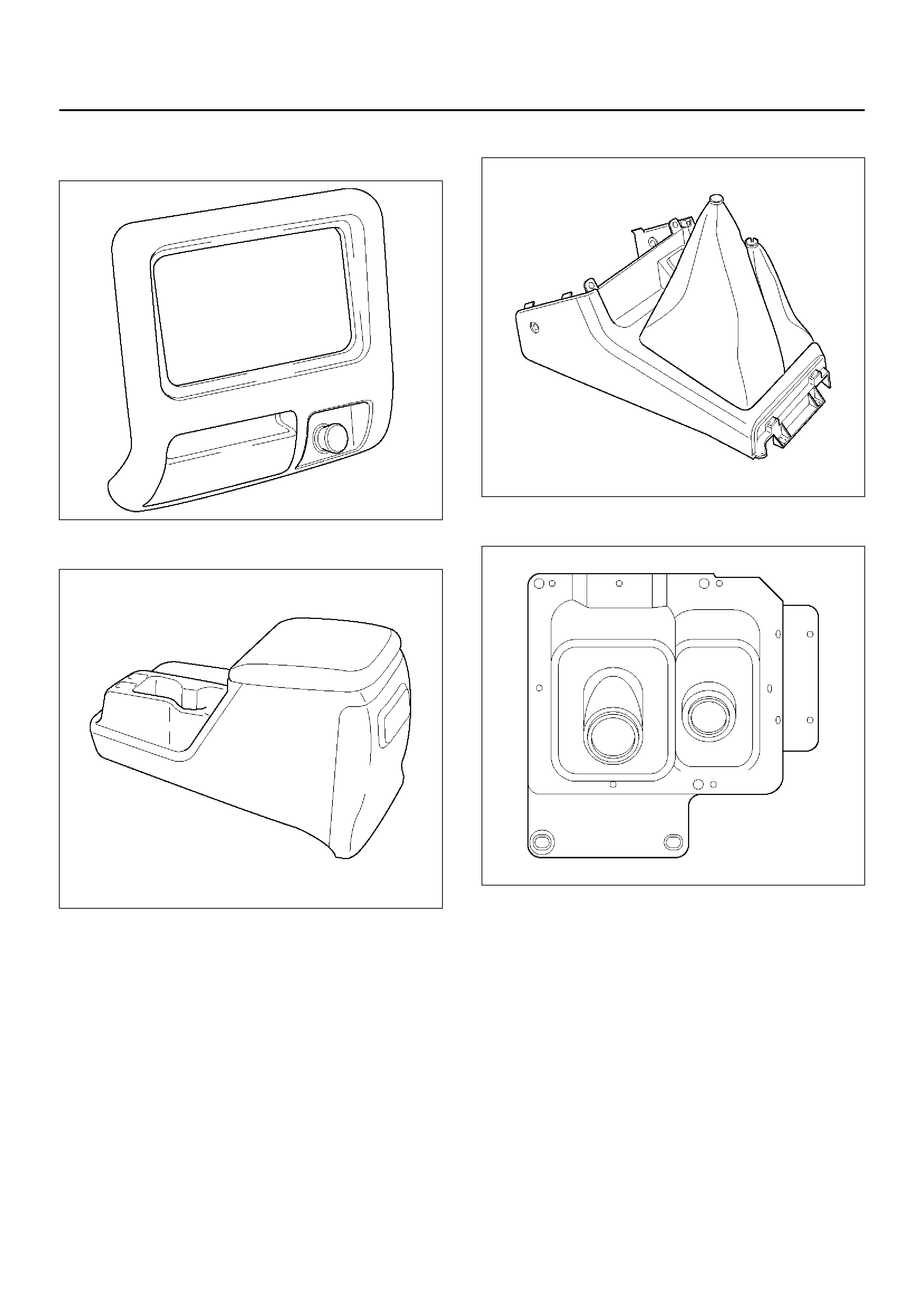

2. Remove gear control lever knob(1).

Legend

(1) Gear Control Leve r Kno b

(2) Transfer Control Lever Knob

(3) centre Co nsole

(4) Grommet Assembly

(5) Gear Control Lever and Transfer Control Lever

(6) Transfer Case Guard

(7) Rear Propeller Shaft

(8) Front Propeller Shaft

(9) centre Exhaust Pipe

(10) Harness Clamp

(11) Harness Heat Shield

(12) Dust Cover

(13) Rear Mount Nut

(14) Third Crossmember

(15) Starter

(16) Flywheel Undercover

(17) Transmission Retaining Nut and Bolt

(18) Transmission

3. Remove transfer control lever knob(2).

4. Remove lower cluster assembly.

740RW021

5. Remo ve rear consol e.

256RW045

6. Remove centre console(3).

F07RW018

7. Remove grommet assembly(4).

F07RW016

8. Remove gear control lever(5) and transfer control

lever(5).

9. Raise and support vehicle with suitable stands.

Remove transfer case guard(6).

150RX010

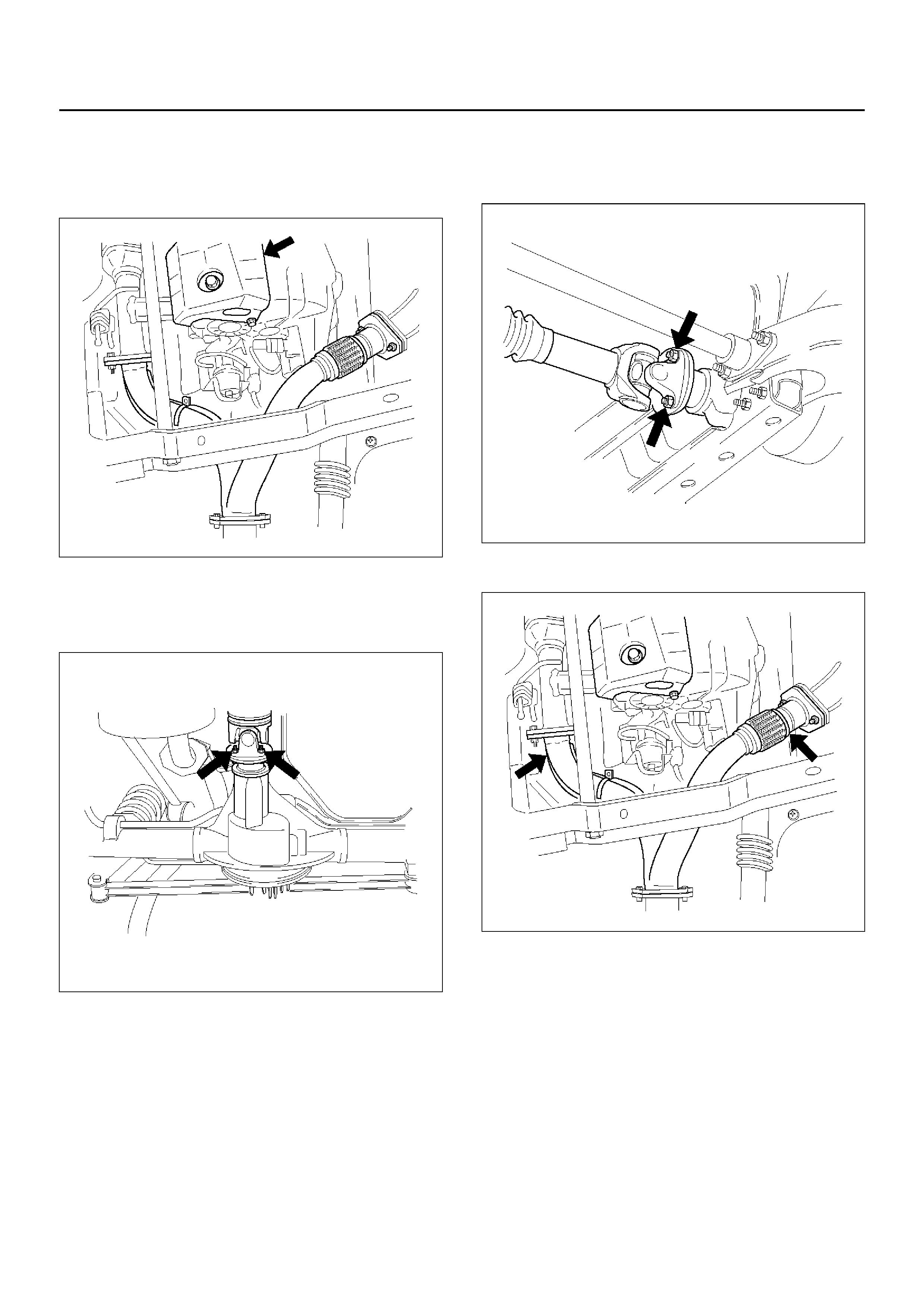

10. Remove rear propeller shaft(7).

NOTE: Apply alignment marks on the flange at both

front and rear sides.

401RW008

11. Remove front propeller shaft(8).

NOTE: Apply alignment marks on the flange at both

front and rear sides.

401RW007

12. Remove centre exhaust pipe(9).

150RX009

13. Disconnect transmission harness connectors and

clip.

Connectors: Transfer switch, 2–4 actuator, speed

sensor, back up switch.

14. Remo ve transmis sion harne ss clamps(10) from the

transmission case and bracket.

220RS028

15. Remove harness heat shield(11).

16. Remo ve dust cover s(1 2).

17. Support transmission with a transmission jack.

220RS001

18. Remove engine rear mount nuts(13) from third

crossmember.

F07RW008

19. Remove third crossmember(14) by removing six

fixing bolts.

20. Remove starter(15).

21. Remove flywheel under cover(16).

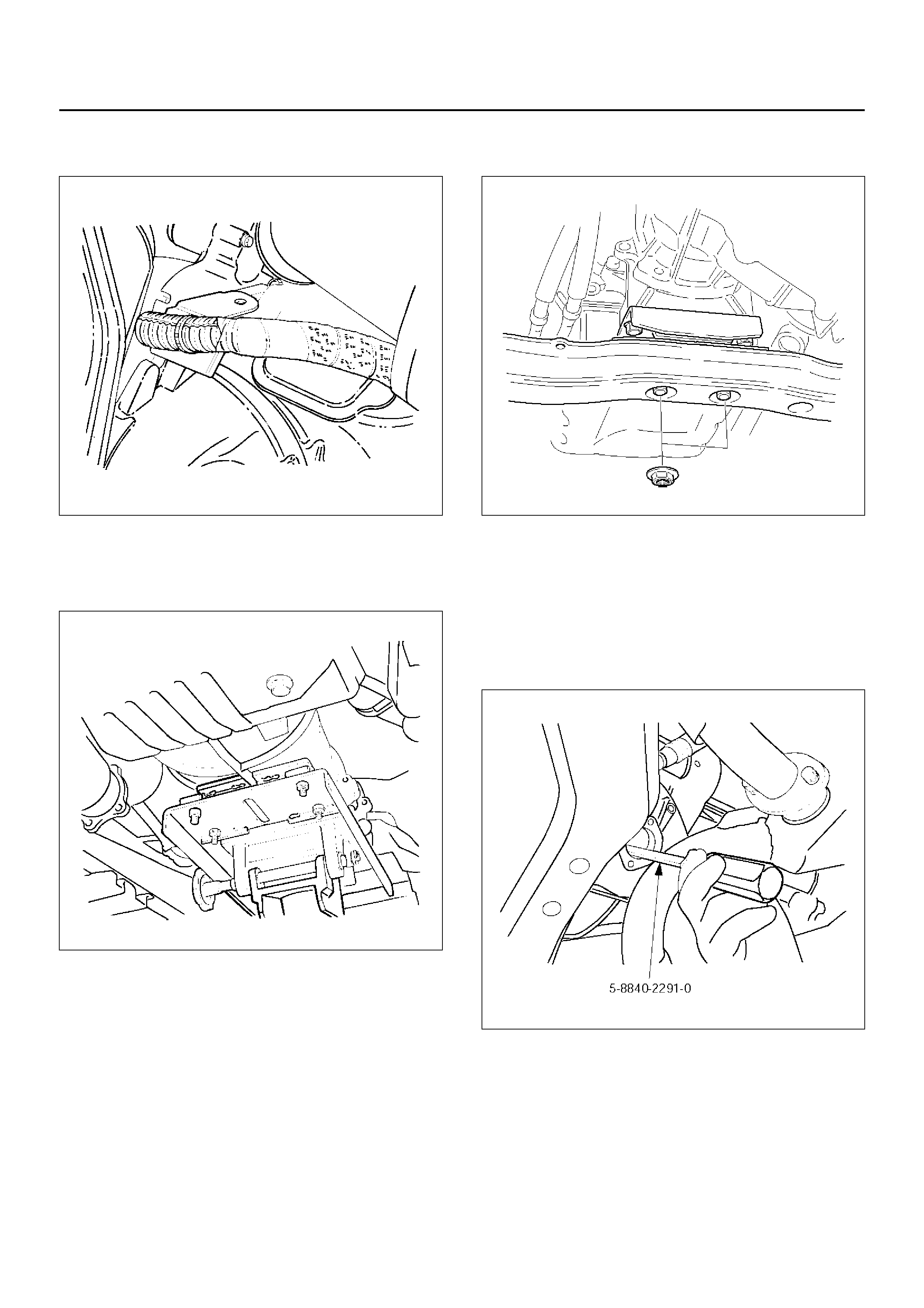

22. Use clutc h release beari ng remover 5– 8840–2291–

0 to disconnect the clutch release bearing from

the clutch pressure plate.

220RW109

23. Pull the shift fork toward the transmission to press

the clutch release bearing against the clutch

pressure plate.

24. Insert the clutch release bearing remover 5–8840–

2291–0 between the wedge collar and the release

bearing.

NOTE: Be sure not to insert the remover between the

wedge collar and the clutch.

220RS003

25. Turn the remover to separate the release bearing.

220RX007

26. Remove transmission retaining nut and bolts(17).

Remove transmission(18) from the vehicle.

INSTALLATION

1. Apply a thi n co at of mol ybdenum dis ulf ide gr ease to

the top gear shaft spline.

2. Slowly operate the transmission jack until the front

of transmission is aligned with the rear of the

engine.

The slope of the engine and the transmission must

be the same.

3. Align th e top gear s haft splin e with the clutch dr iven

plate spline.

220RS007

4. Install the transmission to the engine.

5. Tighten the transmission nut and bolts as shown in

the figure.

225RX004

Nm (kg/m,lb/ft)

6. Apply a force of 59–78N to the tip of the shift fork in

the direction of the transmission to engage the

clutch pressure plate and release bearing.

NOTE: A click sound is heard when the release bearing

and the tip of the diaphragm spring engage each other.

Check to see if they are securely engaged by pushing

the tip of the shift fork toward the engine side while

applying a force of about 25N If the shift fork will not

move, then they are securely engaged.

220RS006

7. Install flywheel under cover(16).

Torque: 8N·m

8. Install starter(15).

Torque: 40N·m

9. Install third crossmember(14).

Torque: 50N·m

10. Install engine rear mount nuts(13).

Torque: 40N·m

Remove the transmission jack from transmission

side.

11. Install clutch dust covers(12) to clutch housing.

Torque: 6N·m

12. Connect transmission harness connectors and clip.

Connector: transfer switch, 2–4 actuator, car speed

sensor.

13. Install bracket and transmission harness clamps(10)

to the transmission case.

14. Install harness heat shield(11).

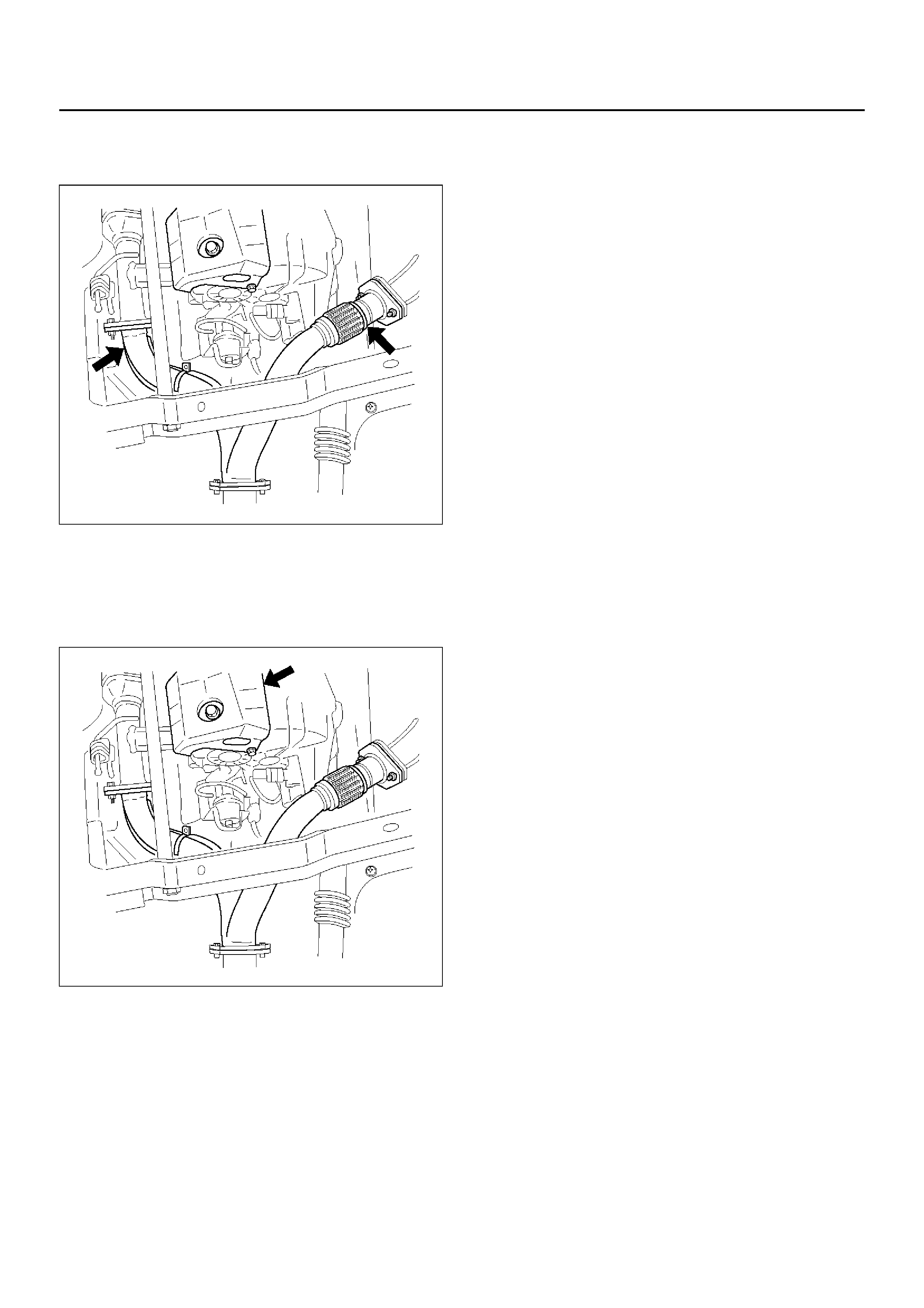

15. Connect fuel pipe to transmission side.

220RW046

220RW047

16. Install centre exhaust pipe(9).

Torque: 43N·m

150RX009

17. Install front(8) and rear propeller shaft(7).

Torque: 63N·m

18. Install transfer guard(6).

Lower the vehicle.

150RX010

19. Install gear control lever(5) and transfer control

lever(5).

20. Install grommet assembly(4).

21. Install centre console(3), rear console and lower

cluster assembly.

22. Install transfer control lever knob(2) and gear control

lever knob(1).

23. Connect battery ground cable.

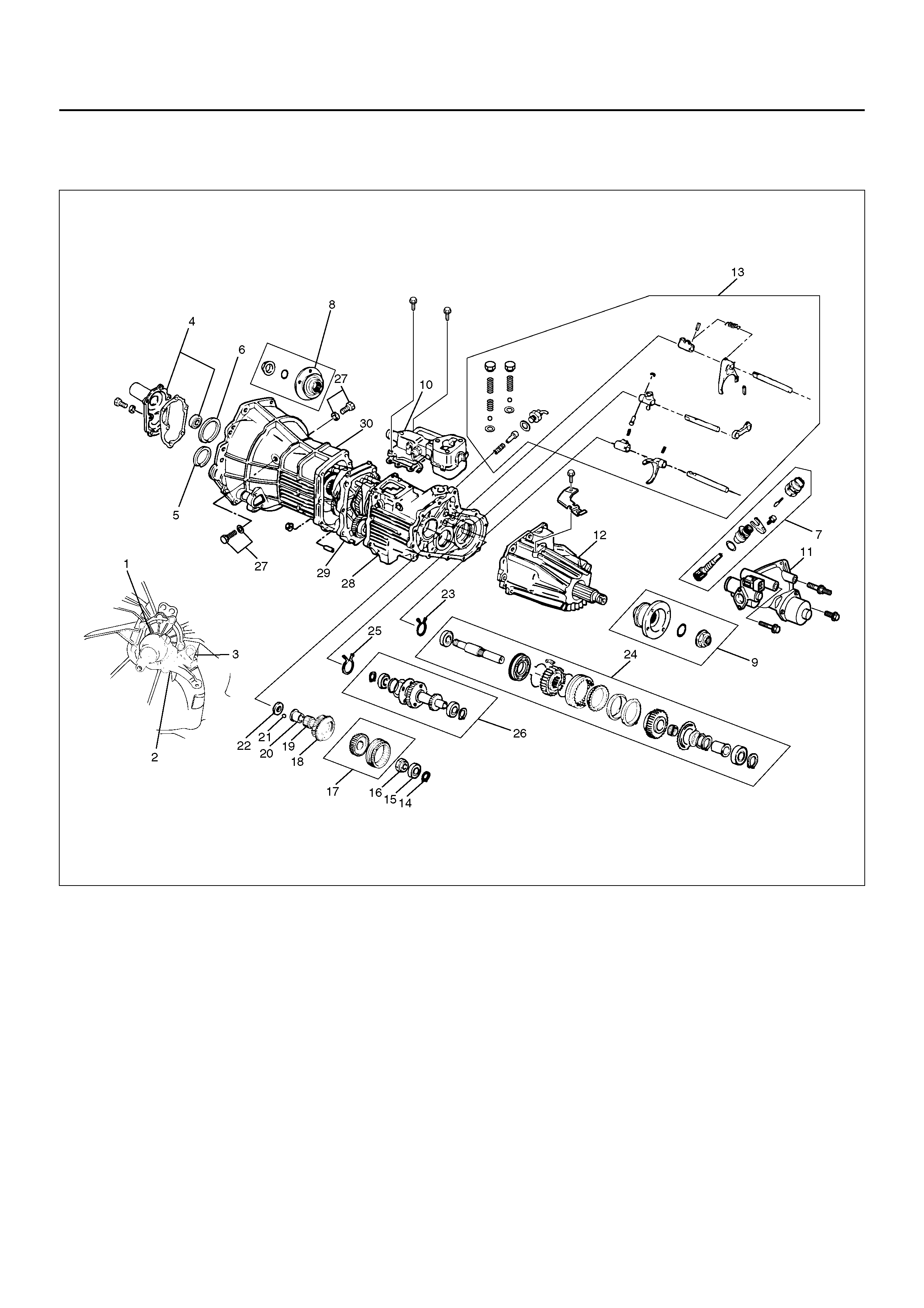

TRANSMISSION CASE AND TRANSFER CASE

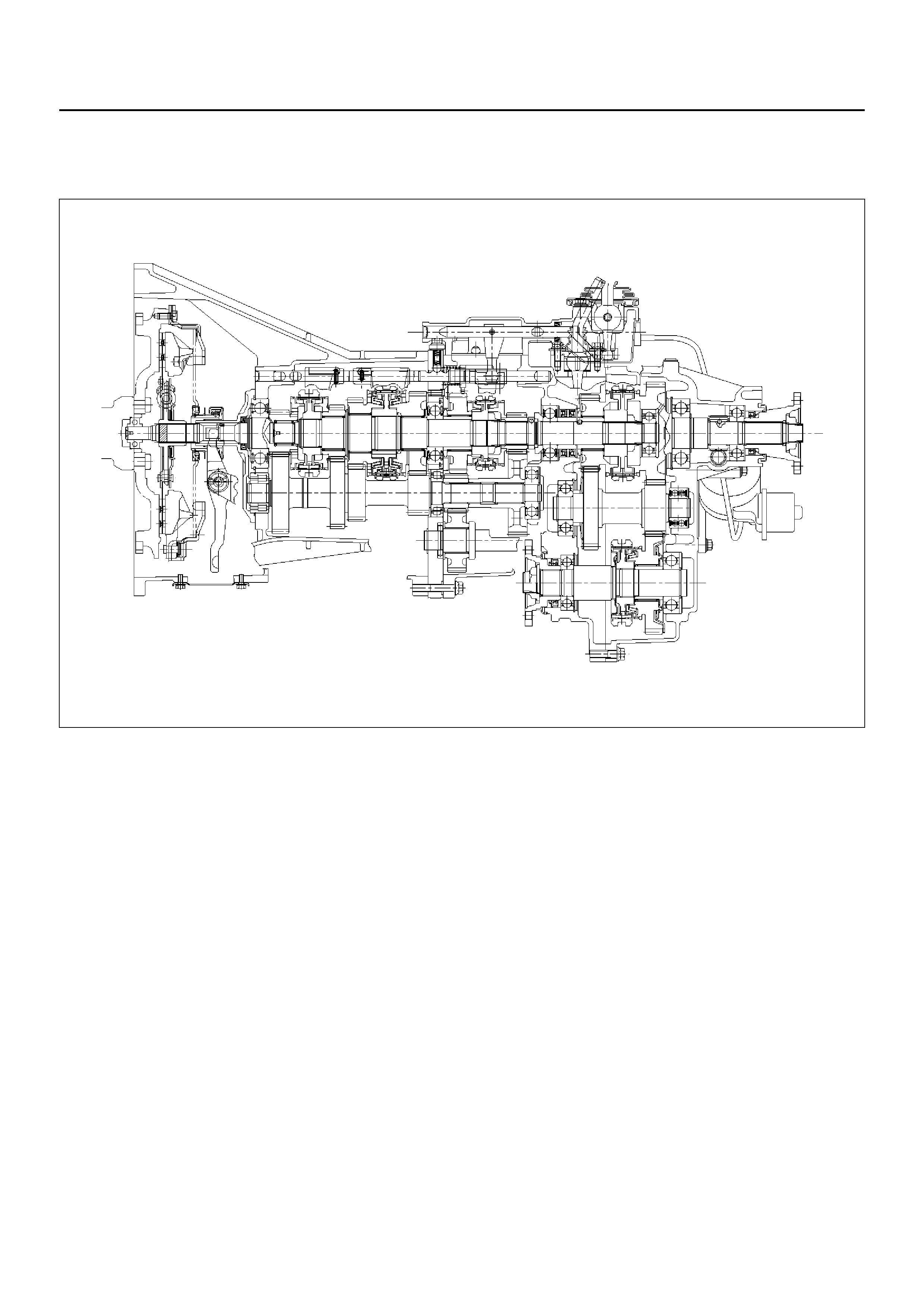

MAJOR COMPONENTS (MUA)

220R100003

Legend

(1) Clutch Release Bearing

(2) Shift Fork

(3) Fulcr um Bridge

(4) Front Cover (with Oil Seal)

(5) Counter Front Bearing Snap Ring

(6) Top Gear Bearing Snap Ring

(7) Speedometer Sensor and Speedometer Driven

Gear

(8) Front Companion Flange

(9) Rear Companion Flange

(10) Gear Control Box Assembly

(11) 2WD-4WD Actuator Assembly

(12) Transfer Rear Case Assembly

(13) Detent, Shift Arm, and Interlock Pin

(14) Bearing Snap Ring

(15) Ball Bearing

(16) Lock Nut

(17) High-Low Clutch Hub and Sleeve

(18) Transfer Input Gear

(19) Need le Bearing

(20) Bearing Collar

(21) Ball

(22) Plate

(23) Bearing Snap Ring

(24) Front Output Gear Assembly

(25) Bearing Snap Ring

(26) Counter Gear Assembly

(27) Plug and Gasket

(28) Transfer Case Assembly

(29) Intermediate Plate with Gear Assembly

(30) Transmission Case

DISASSEMBLY

1. Clean the exterior of the unit with solvent.

2. Remove the drain plug from the transmission case

and transfer case and drain the lubricant.

3. Remove the clutch release bearing(1) from the

transmission case.

201RS020

4. Remo ve the sn ap pin.

Remove the shift fork pin and shift fork(2) from the

fulcrum bridge(3).

201RS021

5. Remove the fulcrum bridge bolts.

• Remove the fulcrum bridge(3) from the

transmission case.

Remove the front cover(4) and gasket from the

transmission case.

201RS022

6. Remove counter front bearing snap ring(5) and top

gear bearing snap ring(6).

Use a pair of snap ring pliers to remove the snap

ring.

226RS001

7. Remove the speedometer sensor(7).

Remove the plate(7).

Remove the driven gear bushing and driven

gear(7).

NOTE: Apply a reference mark to the driven gear

bushing before removal.

8. Remove front companion flange(8) and rear

companion flange(9) using the flange holder

5–8840–0133–0 to remove the end nut.

266RW026

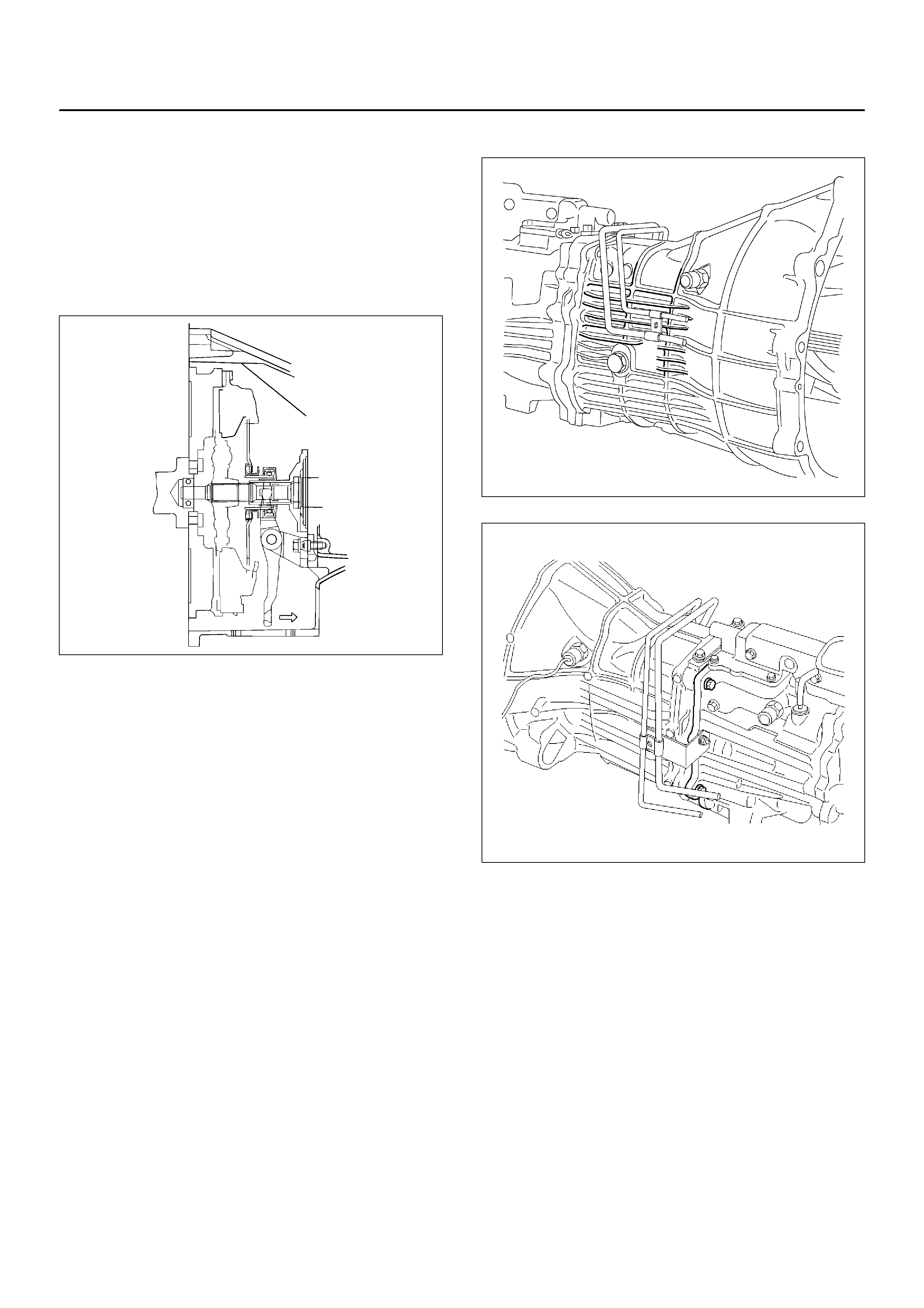

9. Disconnect breather hose from transmission and

remove gear control box assembly(10).

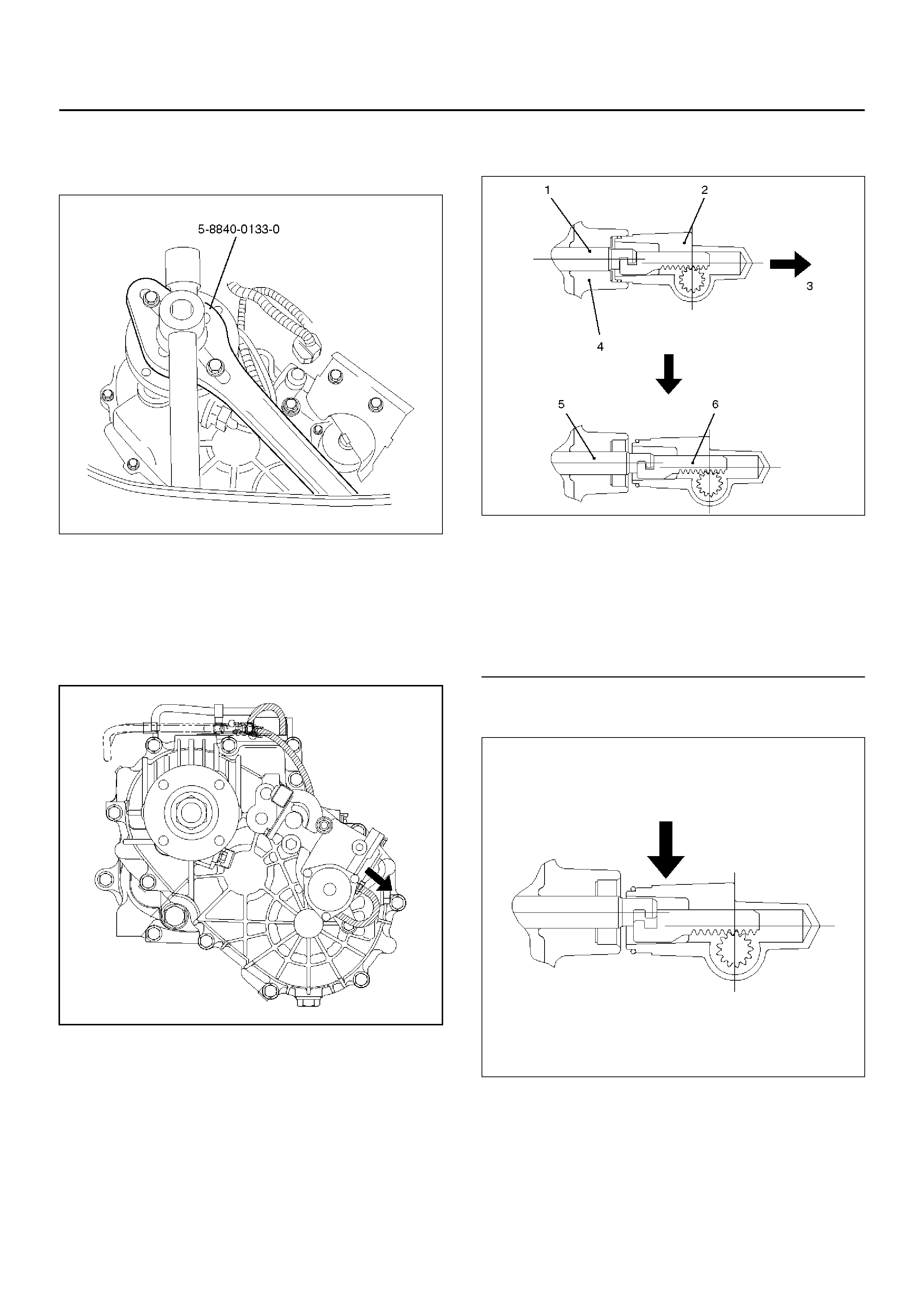

10. Remove 2WD–4WD actuator assembly(11) by

perfor ming the foll owi ng steps:

1. Disconnect the actuator breather hose from

2WD–4WD actuator assembly(11).

220RW085-1

2. Remove the 2WD–4WD actuator assembly

bolts.

3. Pull the 2WD–4WD actuator assembly with

2WD–4WD shift rod.

220RW027

EndOFCallout

4. Offset the actuator assembly.

220RW028

Legend

(1) Shift Rod: 2WD–4WD (Position: 2WD)

(2) 2WD –4 WD Ac tua tor Ass em bly

(3) Pull

(4) Rear Case Assembly

(5) Pos iti on: 4WD

(6) Pos iti on: 2WD

5. Remove the actuator assembly.

220RW029

EndOFCallout

NOTE: Before removing the transmission and transfer

assembly from vehicle, change the transfer mode to

2WD using the 4WD push button switch on dash panel.

11. Remove the transfer rear cover assembly(12) from

the transfer case(28).

12. Regarding detent, shift arm, and interlock pin(13)

disassembly, refer to Detent, Shift Arm, and

Interlock Pin in Drive Line/Axle section.

13. Use a pair o f snap ring pl iers to remo ve the bear ing

snap r ing(14).

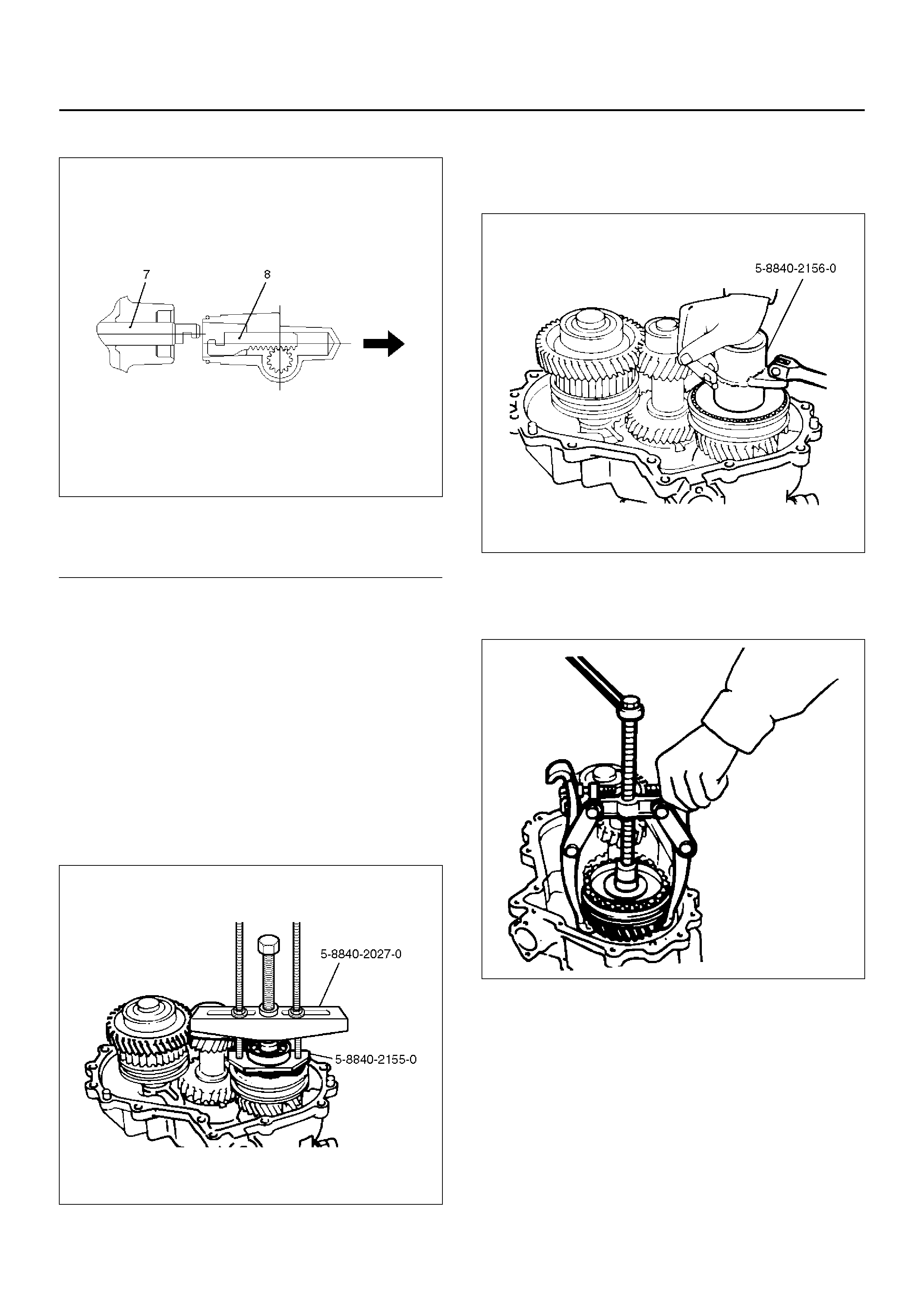

14. Use a bearing remover 5–8840–2155–0 and puller

5–8840–2027–0 to remove the ball bearing(15).

262RW069

15. Install the front companion flange temporarily.

Use the flan ge holder 5–8840–01 33–0 and lock nut

wrench 5–8840–2156–0 to remove the lock nut(16).

Remove the front companion flange.

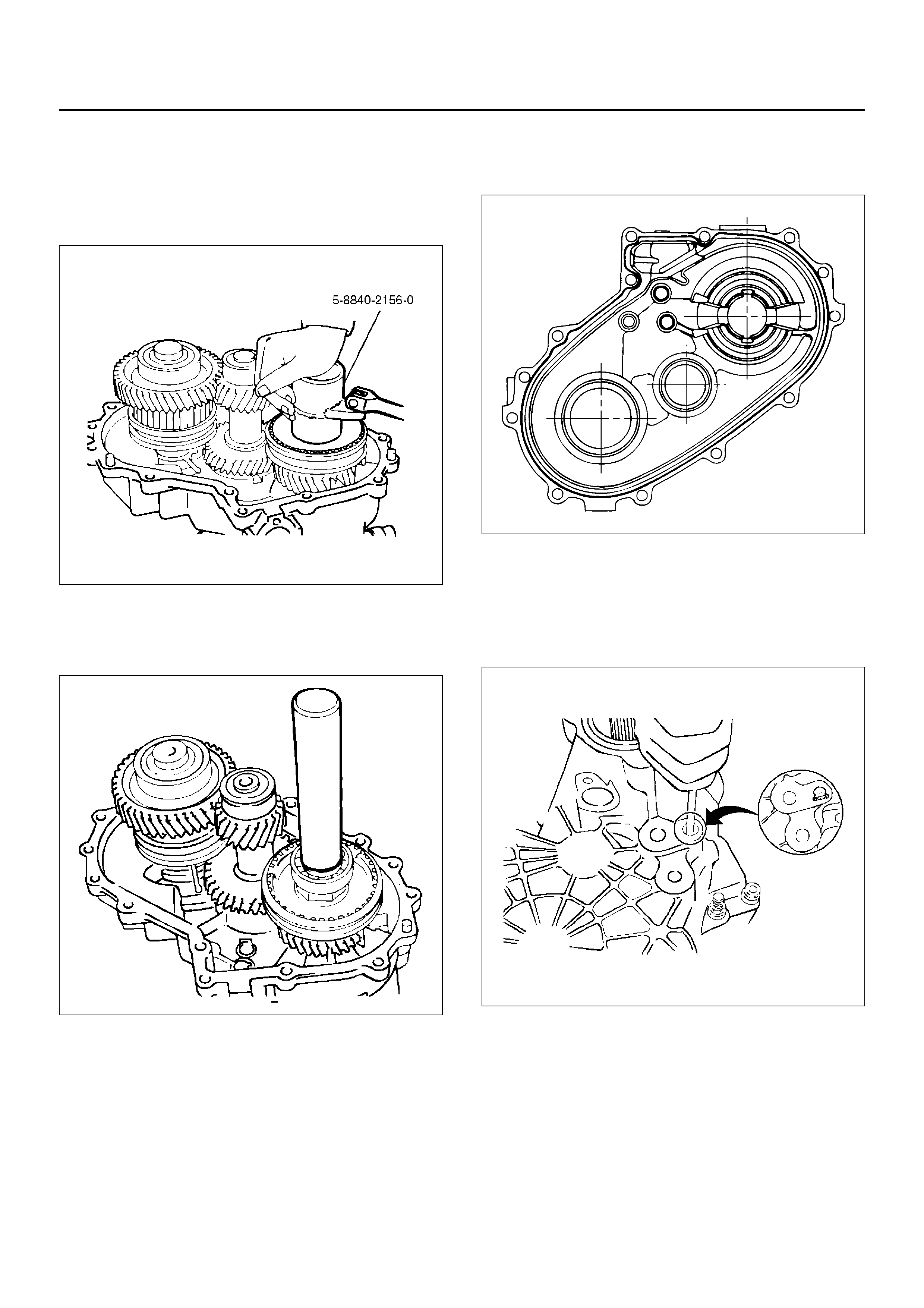

226RW190

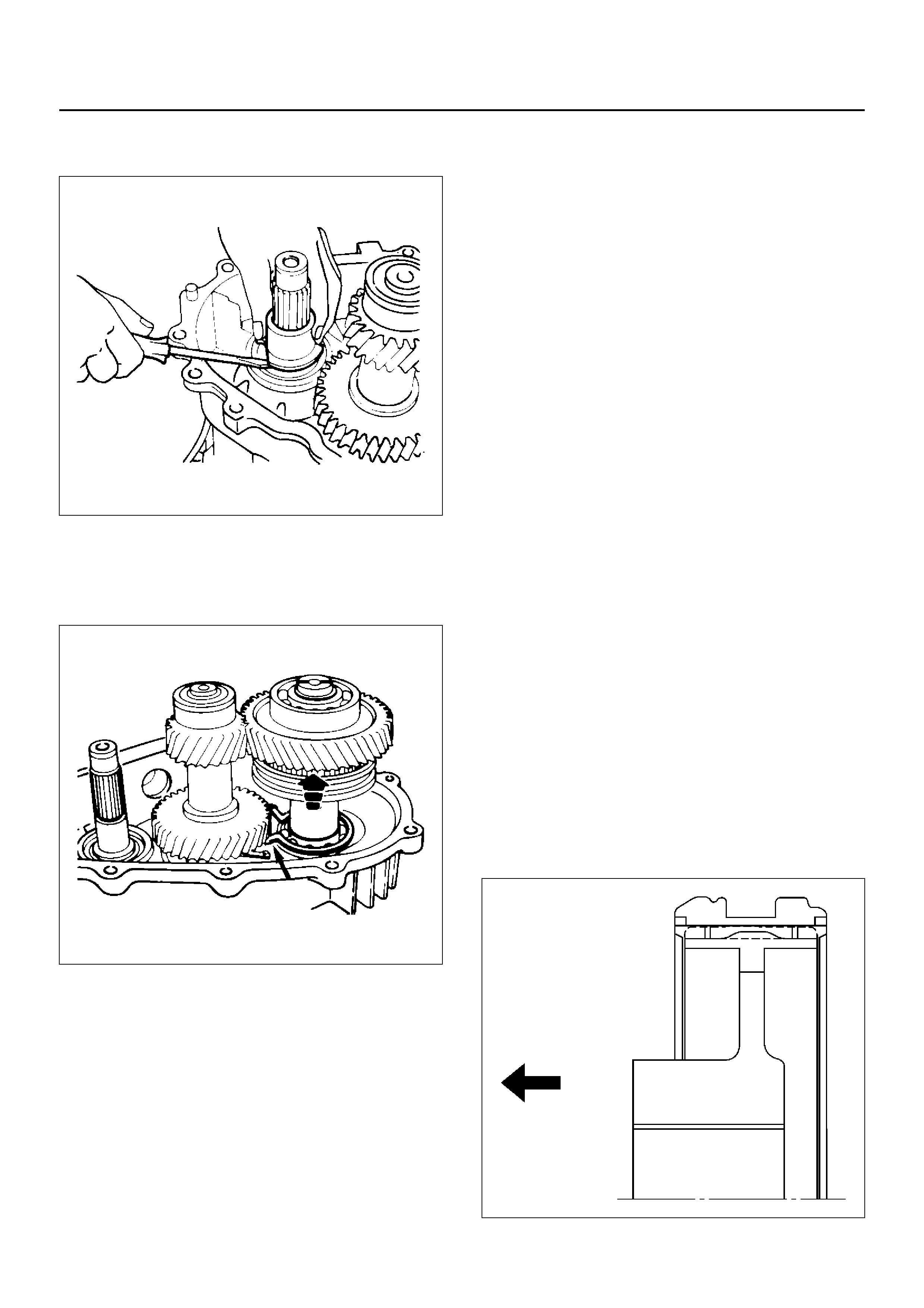

16. Remove high-low clutch sleeve(17).

Use the universal puller to remove the high-low

clutch hub(17) and transfer input gear(18).

226RS070

Legend

(7) Position: 4WD

(8) Mode: 2WD

17. Remove needle bearing(19), bearing collar(20),

ball(21), and plate(22).

226RS071

18. Use a pair of snap ring pliers to remove the bearing

snap ring(23).

19. Use a plastic hammer to tap the front output gear

assembly(24) free.

262RS009

20. Remove bearing snap ring(25) by using a pair of

snap ring pliers.

21. Remove the counter gear assembly(26) from the

transfer case(28).

22. Remove the transfer case assembly(28) from the

transmission case.

•Refer to Transfer Case Assembly in Drive Line/

Axle section for repair of transfer case assembly.

23. Pull out intermediate plate with gear assembly(29)

from transmission case.

REASSEMBLY

1. Apply recommended liquid gasket (LOCTITE

17430) or its equivalent to the transmission

case(30), intermediate plate(29) and transfer

case(28) fitting surfaces.

2. Install the intermediate plate with gear assembly(29)

to the transmission case(30).

Pull out the top gear shaft until the ball bearing snap

ring groove protrudes from the transmission case

front cover fitting face.

Avoid subjecting the mainshaft to sudden shock or

stress.

3. Install the transfer case assembly(28) to the

intermediate plate with gear assembly.

Tighten the eight transmission-transfer case bolts to

the specified torque.

Torque: 37N·m (3.8kg·m/27lbft)

Refer to Transfer Rear Case Assembly in Drive

Line/Axle section for oil seal rep lacement.

4. Install the co unter gea r assembly(26 ) to th e tr a nsf er

case(28).

5. Use a pair of snap ring pliers to install the snap

ring(25) to the transfer case(28).

NOTE: The snap ring must be fully inserted into the

transfer case snap ring groove.

6. Install front output gear assembly(24).

7. Use a pair of snap r ing p liers to i nstall the s nap r ing

(23) to the transfer case(28).

NOTE: The snap ring must be fully inserted into the

transfer case snap ring groove.

8. Install plate(22), ball(21), bearing collar(20), needle

bearing(19), and transfer input gear(18).

9. Install High-low clutch hub and sleeve(17).

The clutch hub face (with the heavy boss) must be

facing the tra ns fer input gear side.

226RW152

10. Install the front companion flange temporarily.

• Use the flange holder 5–8840–0133–0 and lock

nut wrench 5–8840–2156–0 to install the lock

nut(16).

Torque: 137N·m

226RW190

11. Use the punch to stake the lock nut at one spot.

12. Use a suitable drift and hammer to install the ball

bearing(15).

226RS079

13. Use a pair of snap ring pliers to install the bearing

snap ring(14).

14. Regarding detent, shift arm, and interlock pin(13)

assembly, refer to Detent, Shift Arm, and Interlock

Pin in Drive Line/Axle section.

15. Apply recommended liquid gasket (LOCTITE

17430) or its equivalent to the transfer rear case

fitting faces.

220RS017

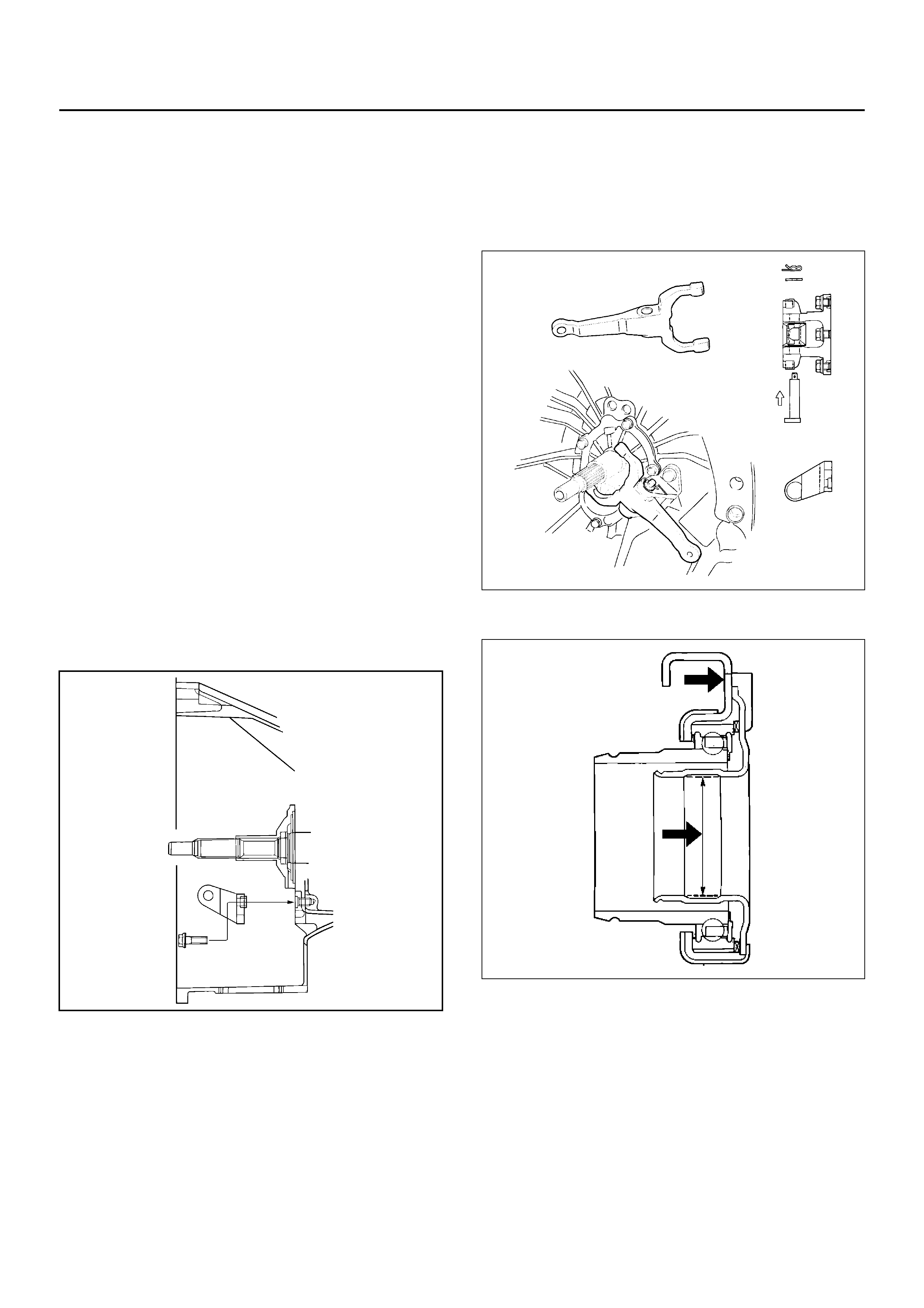

16. Perform the following steps before fitting the transfer

rear cove r(11):

1. Shift the High-Low shift rod to the 4H side.

2. The cut-away portion of select rod head should

align with the rear case hole's stopper.

230RS002

17. Tighten the eleven transfer rear case bolts to the

specified torque.

Torque: 37N·m

18. Install 2WD–4WD actuator assembly(11) by

perfor ming the foll owi ng steps.

1. Shift the 2WD–4WD shift rod to the 4WD side.

2. Join the rod grooves of 2WD–4WD actuator

assembly and shift rod.

220RW030

EndOFCallout

3. Push the 2WD–4WD actuator assembly with

2WD–4WD shift rod till the sh ift rod reaches th e

2WD position.

220RW031

EndOFCallout

4. Tighten the 2WD–4WD actuator bolts to the

specified torque.

Torque: 19N·m

5. Connect the actuator breather hose to actuator.

19. Install a new packing and gear control box

assembly(10).

Install the harness clips and brackets and then

tighten four new gear control box bolts to the

specified torque.

Torque: 20N·m (2.0kg·m/14lbft)

261RW043

Legend

(11) Shift Rod: 2WD–4WD (Position: 4WD)

(12) 2WD–4WD Actuator Assembly (Mode: 2WD)

(13) Rear Case Assembly

Legend

(14) Position: 2WD

(15) Mode: 2WD

20. Install the rear and front companion flange(9) (8).

Install the O-ring(9).

Use the flange holder J–8614–11 to tighten the

flange nuts(9) (8) to the transfer case.

Tighten new transfer flange nuts(9) (8) to the

specified torque.

Rear Companion Flange

Torque: 167N·m

Front Companion Flange

Torque: 137N·m

266RW026

21. Use the punch 5–8840–2293–0 to stake the rear

companion flange nut at two spots.

• Stake the front companion flange nut at one spot.

NOTE: Be sure to confirm that there is no crack at th e

staked portion of the flange nut after staking.

266RW027

266RS003

22. Install the O-ring (4) to the speedometer driven gear

bushing(3).

Install the driven gear to the speedometer driven

gear bushing(3).

Install the speedometer driven gear assembly(7) to

the transfer rear cover.

225RW008

23. Install the plate to the transfer rear cover.

Torque: 15N·m

24. Install the speedometer sensor.

Torque: 27N·m

25. Install top gear bearing snap ring(6) and counter

front bearing snap ring(5).

Use a pair of snap ring pliers to install the snap rings

to the mainshaft and countershaft.

The snap rings must be fully inserted into the

bearing snap ring groove.

26. Install a new packing and front cover (with oil seal)

(4) to the transmission case.

NOTE: Take care not to damage the oil seal.

Notes When Tightening the Bolt:

• After cleaning the bolt hole, dry it thoroughly with air .

• After cleaning the screw face of a removed bolt or

new one, dry it thoroughly. Apply recommended

liquid gasket (LOCTITE 242) or its equivalent before

tightening it.

Tighten six new front cover bolts to the specified

torque.

Torque: 25N·m

27. Install the fulcrum bridge(3) to the transmission

case.

Tighten three fulcrum bridge bolts to the specified

torque.

Torque: 38N·m

220RS009

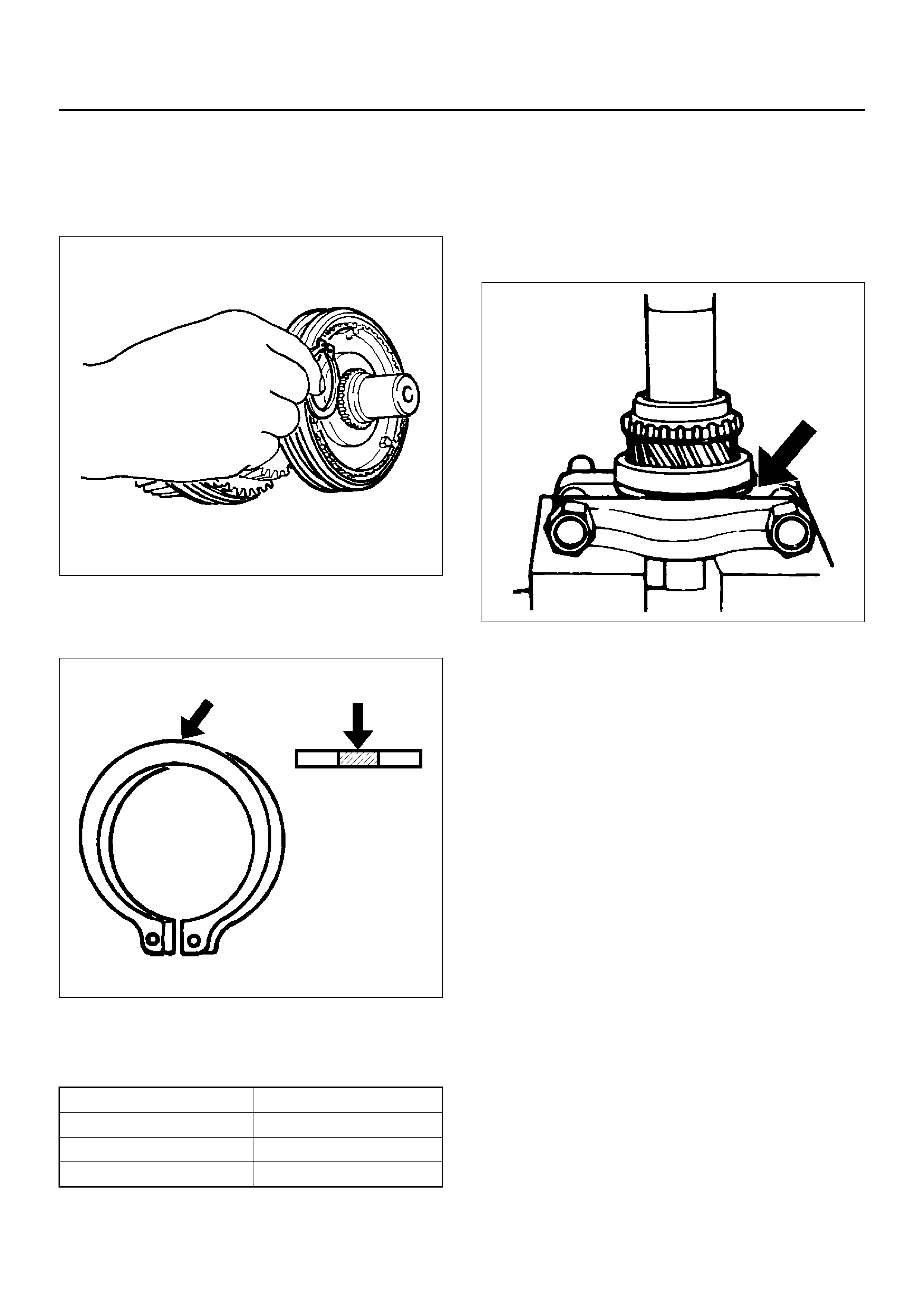

28. Apply grease to the pin hole inner circumferences

and thrust surfaces.

Attach the shift fork(2) to the fulcrum bridge(3) by

inserting the shift fork pin from the bottom side of

the fulcrum bridge.

Install the washer and snap pin.

201RS018

29. Apply grease to the areas shown in the figure.

201RW017

Install the release bearing(1) to the shift fork(2) in

the proper direction.

NOTE: Ensure release bearing is properly positioned

during installation, as shown in the figure.

201RS019

INTERMEDIATE PLATE WITH GEAR ASSEMBLY, DETENT, SHIFT

ARM, AND INTERLOCK PIN (MUA)

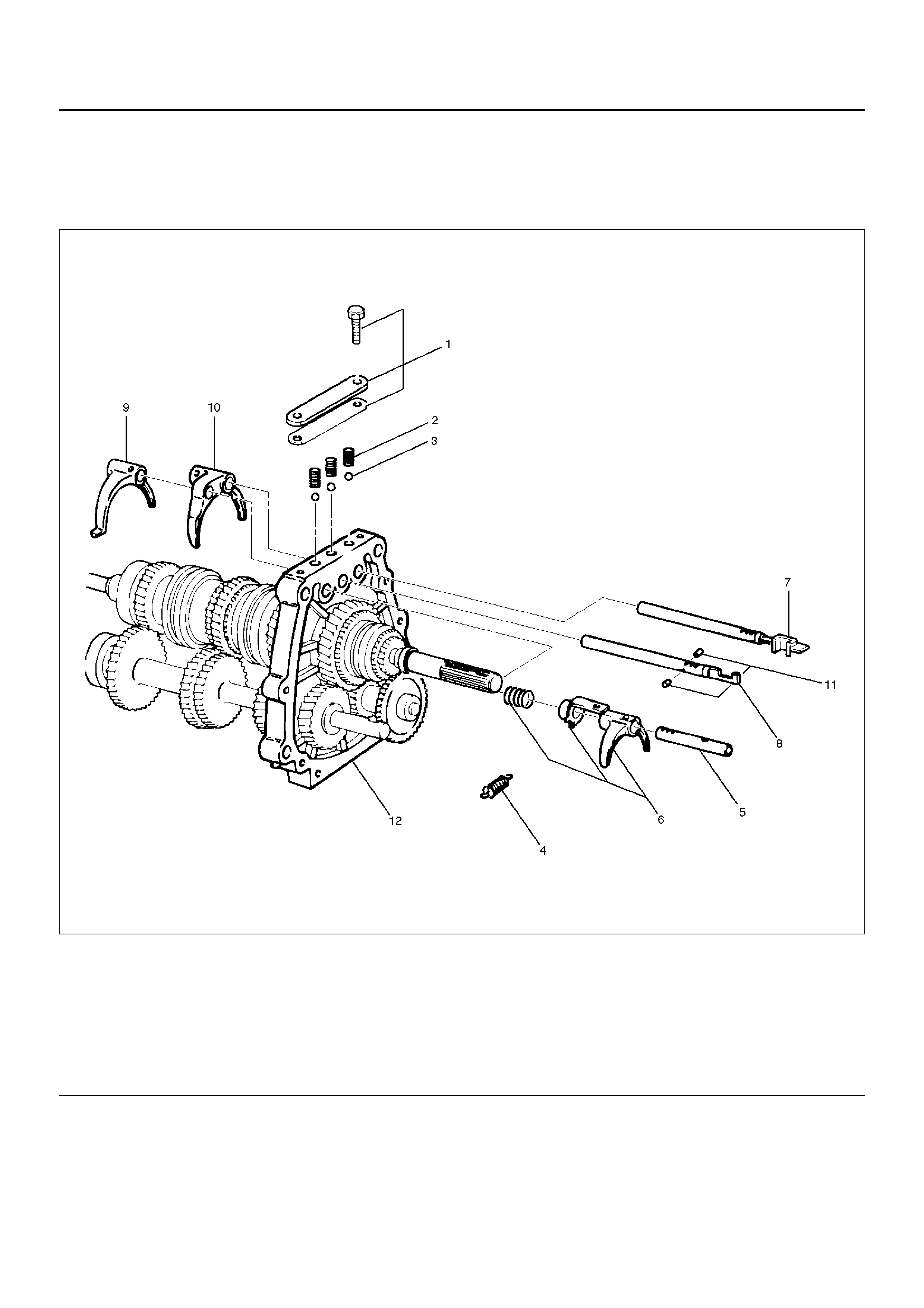

DISASSEMBLED VIEW

220RS010

EndOFCallout

Legend

(1) Detent Spri ng Pl ate and Gask et

(2) Detent Spring

(3) Detent Ball

(4) Spring

(5) Rev–5th Shift Rod

(6) Rev–5th Shift Arm and Reverse Inhibitor

(7) 1st–2 nd Shift Rod

(8) 3rd–4th Shift R od

(9) 3rd–4th Shift Ar m

(10) 1st–2 nd Shi ft Arm

(11) Interlock Pin

(12) Intermediate Plate and Gear Assembly

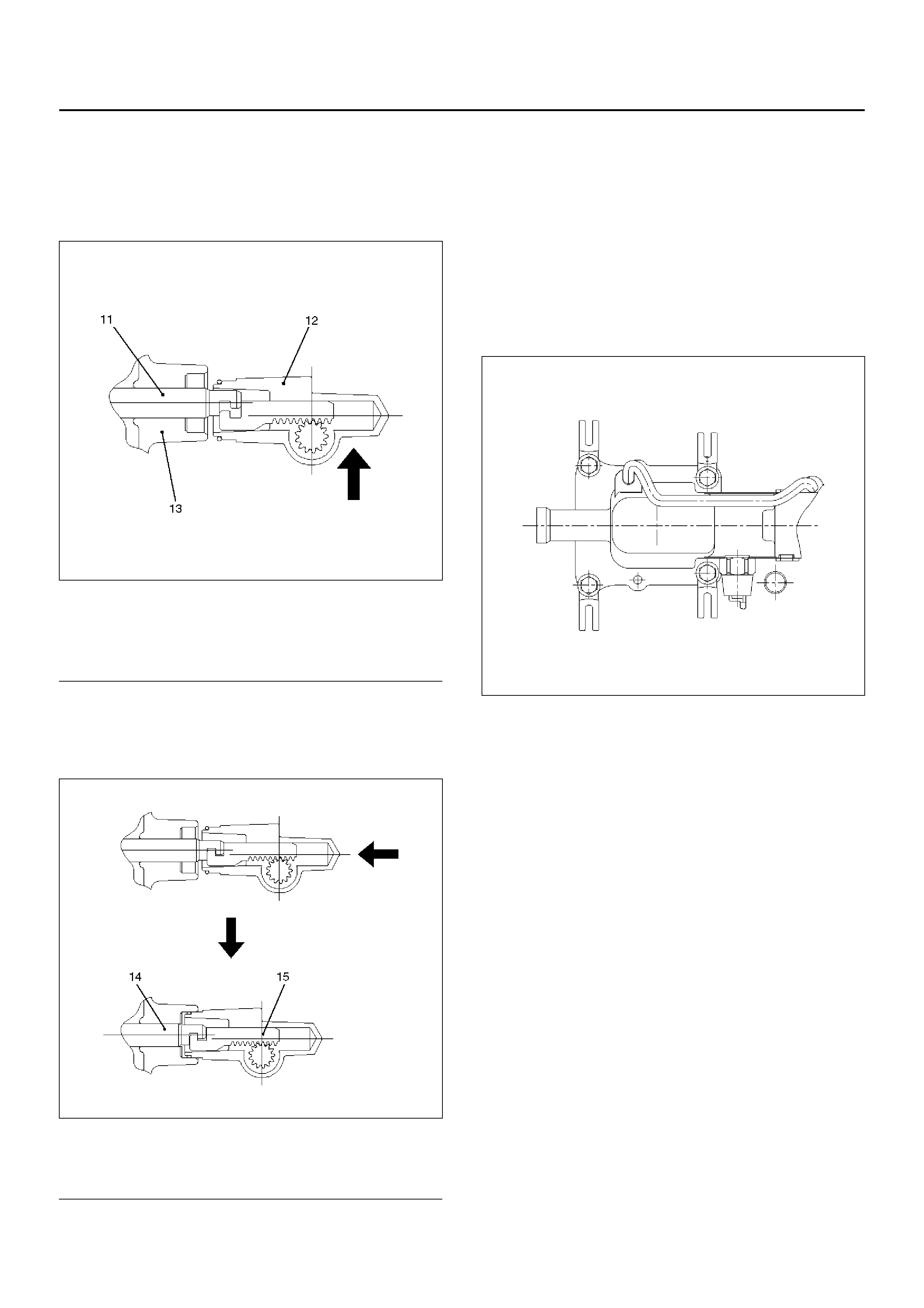

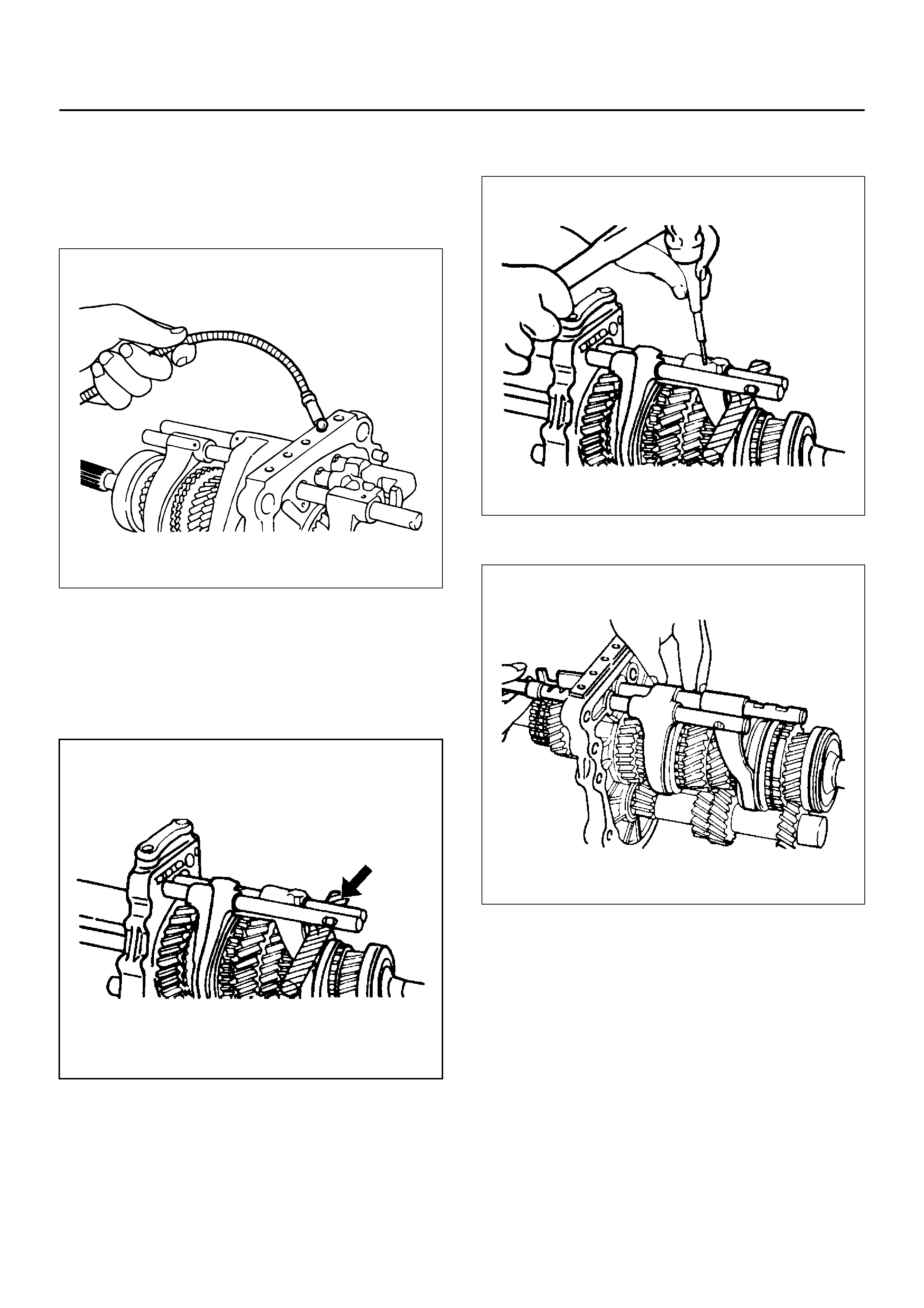

DISASSEMBLY

1. Remove detent spring plate and gasket(1), detent

spring(2) and detent ball(3).

Use a magnetic hand to remove the detent balls

from the intermediate plate.

220RS011

2. Remove spring(4).

3. Remove rev–5th shift rod(5), and rev-5th shift arm

and reverse inhibitor(6).

Remove 1st–2nd shift rod(7), 3rd–4th shift rod(8),

3rd–4th shift arm(9), and 1st–2nd shift arm (10).

• Hold a round bar against the shift rod end.

230RS003

• Use a spring pin remover to remove the shift arm

spring pins from the shift arms and the shift rods.

230RS004

• Move the 3rd–4th shift rod forward.

230RS005

• Remove the rev–5th, 1st–2nd and 3rd–4th shifter

rods carefully. Interlock pins are located

between the shifter rods in the intermediate plate.

4. Remove interlock pin(11) from intermediate plate

and gear assembly(12).

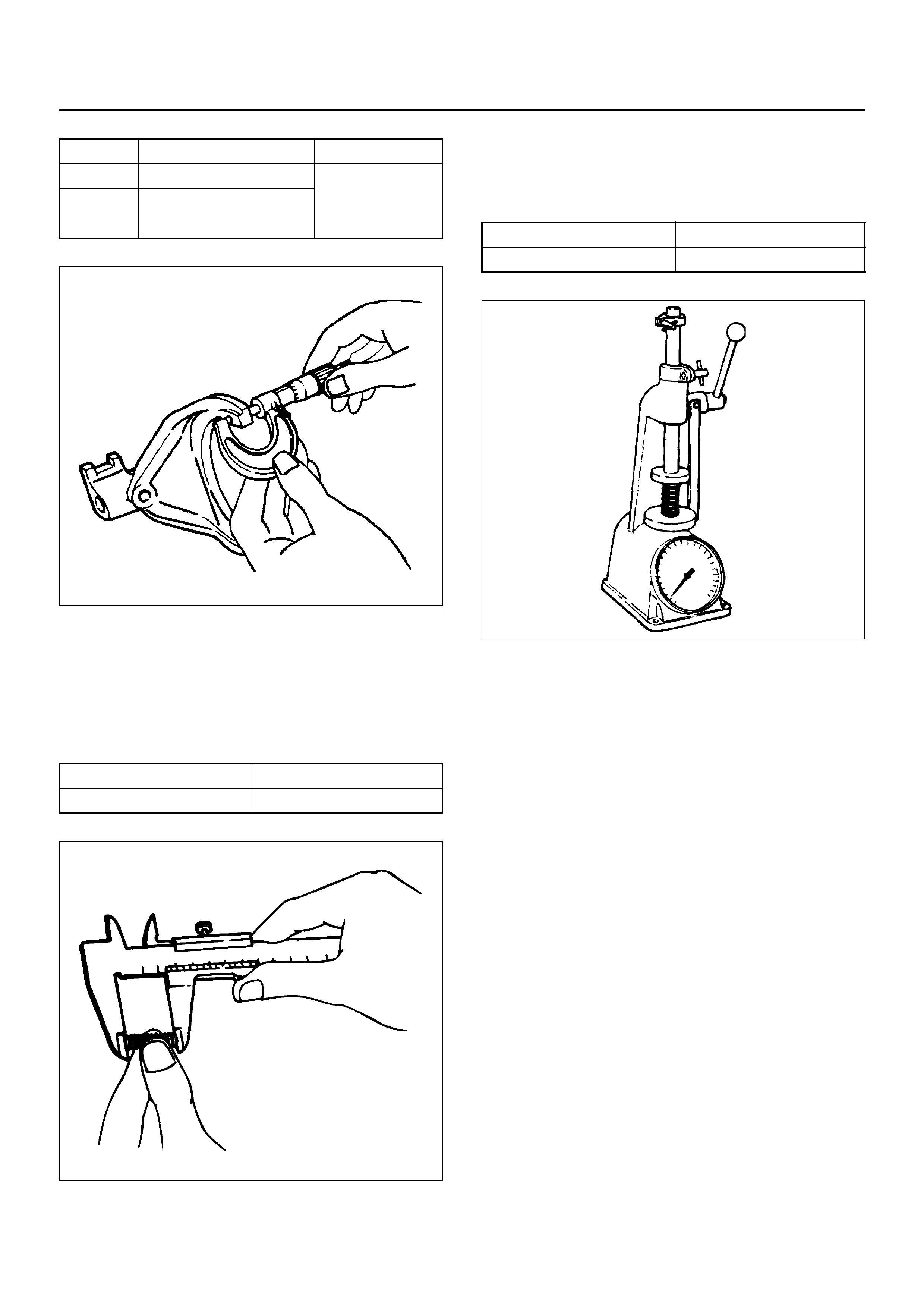

INSPECTION AND REPAIR

Make the necessary adjustments, and part

replacements if excessive wear or damage is

discovered during inspection.

Shift Arm Thickness

• Use a micrometer to measure the shift arm thickness.

If the m easured value is less than the specified limit,

the shift arm must be replaced.

Shift Arm Thickness

230RS006

Detent Spring Free Length

• Use a vernier caliper to measure the detent spring

free length.

If the measured value is less than the specified limit,

the detent spring must be replaced.

Detent Spring Free Length

220RS012

Detent Spring Tension

• Use a spring tester to measure the valve spring

tension.

If the measured value is less than the specified limit,

the detent spring must be replaced.

Detent Spring Tension

220RS013

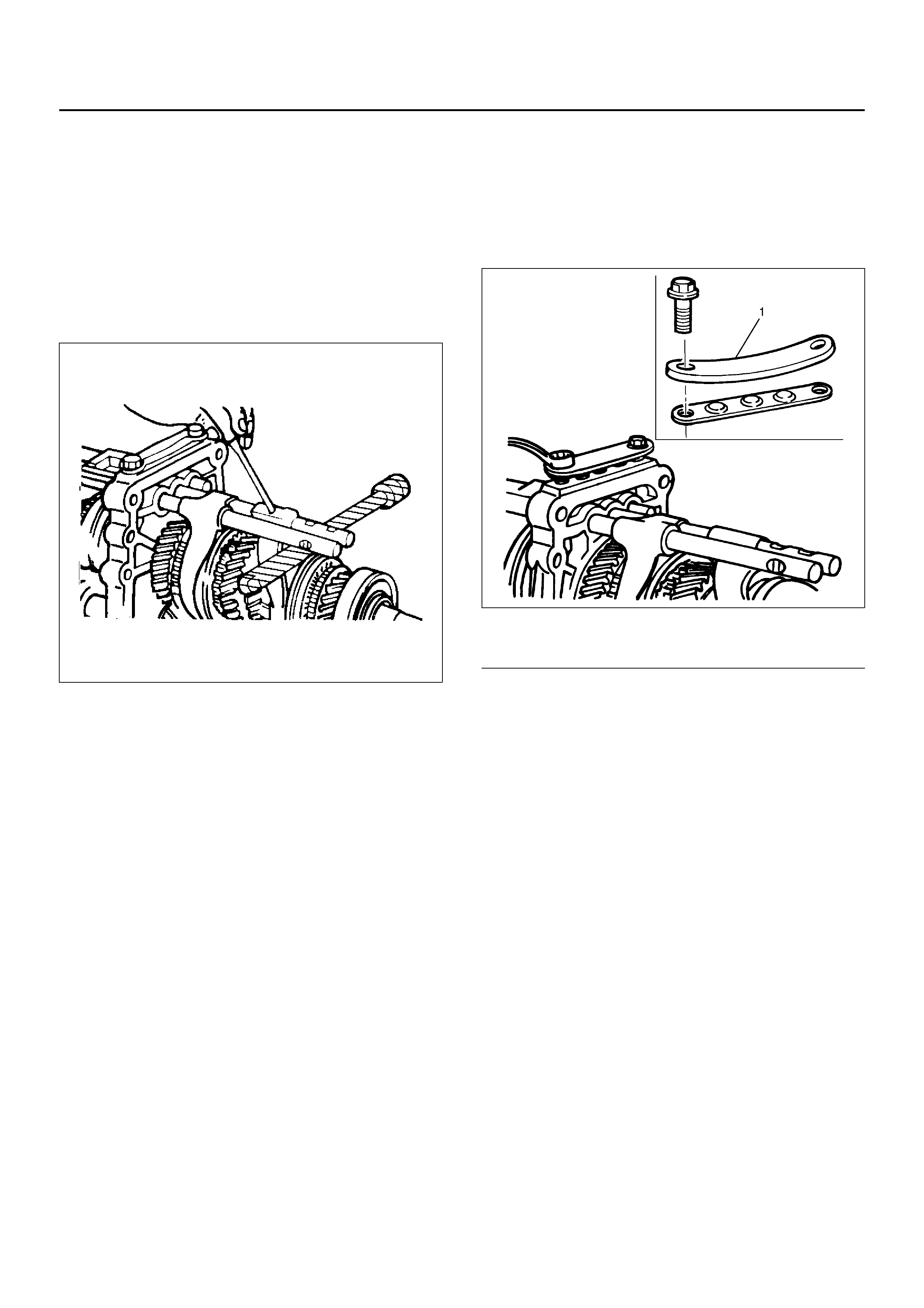

REASSEMBLY

1. Install 1st–2nd shift arm(10) and 3rd–4th shift

arm(9) to intermediate plate and gear assembly(12).

Standard Limit

1st–2nd 9.60–9.85mm 9.0mm 3rd–4th 9.60–9.80mm

Rev.5th

Standard Limit

26.8mm 26.2mm

Compressed height Standard

20mm 87.2–97.1N

2. Install 3rd–4th shift rod(8) and 1st–2nd shift rod(7).

• Install the interlock pin(11) to the shift rod.

• Install the shift rod together with the interlo ck pin

to the intermediate plate.

Do not allo w the interloc k pin to fall from the shift

rod.

• Hold a round bar against the shift rod end lower

face to protect it against damage.

• Install a new spring pin.

Never reinstall the used spring pin.

230RS007

3. Install rev– 5th shi ft arm and r everse inhib itor(6) an d

rev–5th shift rod(5).

• Apply oil to the reverse inhibitor inner surface.

• Install the interlock pin(11) to the shift rod.

• Install the shift rod together with the interlo ck pin

to the intermediate plate.

Do not allo w the interloc k pin to fall from the shift

rod.

• Hold a round bar against the shift rod end lower

face to protect it against damage.

• Install a new spring pin.

Never reinstall the used spring pin.

4. Install spring(4).

5. Put detent balls(3) in the intermediate plate holes.

• Apply oil to the detent balls.

6. Install de tent s prings (2) and deten t spr ing plate and

gasket(1).

• Install a new gasket and the detent spring plate.

• Tighten the detent spring plate bolts to the

specifi ed tor que .

Torque: 20N·m

220RS030

EndOFCallout

Legend

(1) Warped

REVERSE GEAR AND 5TH GEAR (MUA)

DISASSEMBLED VIEW

226RW213

EndOFCallout

Legend

(1) Oil Seal Collar

(2) Ball Bearing

(3) Retainer

(4) Thrust Plate

(5) Thrust Washer and Lock Ball

(6) Reverse Idler Gear Snap Ring

(7) Reverse Idler Gear Assembly

(8) Idle Shaft Pin

(9) Thrust Washer

(10) Reverse Idler Gear

(11) Reverse Idler Shaft

(12) Bearing Snap Ring

(13) Ball Bearing

(14) Counter 5th Gear

(15) Counter Reverse Gear

(16) 5th Gear

(17) 5th Block Ring

(18) Need le Bearing

(19) Mainshaf t Nut

(20) Rev–5th Synchronizer Assembly

(21) Reverse Block Ring

(22) Reverse Gear

(23) Needle Baring

(24) Bearing Plate and Screw

(25) Bearing Snap Ring

(26) Intermediate Plate

DISASSEMBLY

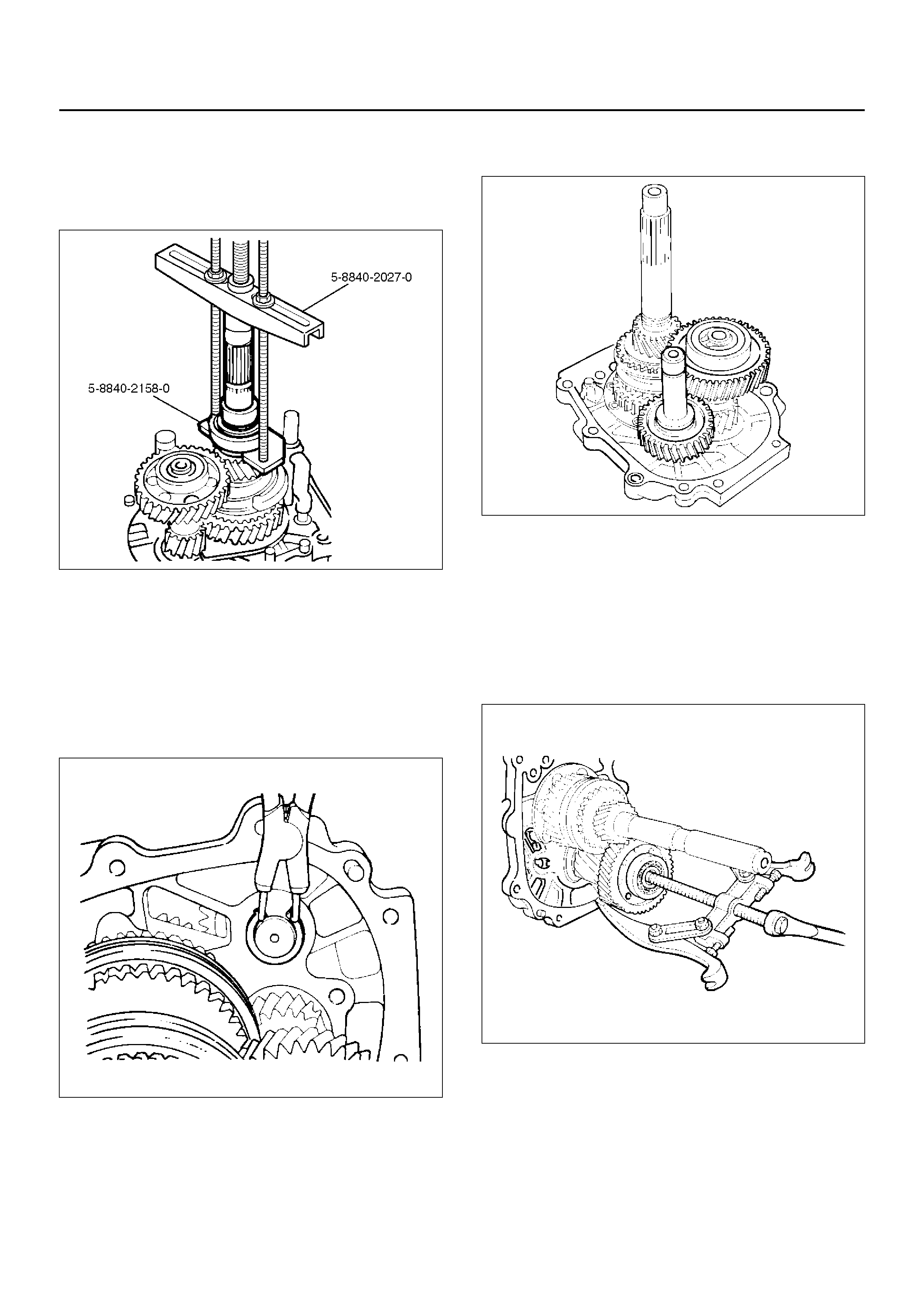

1. Set the retaining ring remover 5–8840–2158–0 and

puller 5–8840–2027–0 to the retainer(3) and the

mains haft end .

262RW079

2. Remo ve the retainer(3) together with the bearin g(2)

and the oil seal collar(1).

The universal puller may be used in place of the

retaining ring remover.

3. Remove thrust plate(4) and thrust washer and lock

ball(5).

4. Use a pair of snap ring pliers to remove reverse idler

gear snap ring(6).

226RS004

5. Remove the reverse idler gear assembly(7) from the

interm ediate plate(26 ).

226RS005

6. Remove idle shaft pin(8), thrust washer(9), reverse

idler gear(10), and reverse idler shaft(11).

7. Use a pair of snap ring pliers to remove the snap

ring(12).

8. Attach the bearing remover to the counter gear

shaft.

Use the bearing remover to remove the ball

bearing(13) and the counter 5th gear(14).

226RS006

9. Remove counter reverse gear(15).

10. Remove 5th gear(16), 5th block ring(17), and

needle bearing (2 piece type) (18).

226RS007

11. Attach the holding fix ture 5–8 840–216 0–0 and base

5–8840–0003–0 to the mainshaft and the counter

gear.

226RW212

12. Engage the 3rd–4th synchronizer with the 3rd gear.

Engage the 1st–2nd synchronizer with the 1st gear.

226RW210

Use the mainshaft nut wrench 5–8840–2156–0 to

remove the mainshaft nut(19).

226RW211

13. Use pry bars between the reverse gear(22) and

bearing plate(24) to remove the Rev–5th

synchronizer assembly(20) together with reverse

block ring(21) and reverse gear(22).

226RS010

14. Remove needle bearing(23).

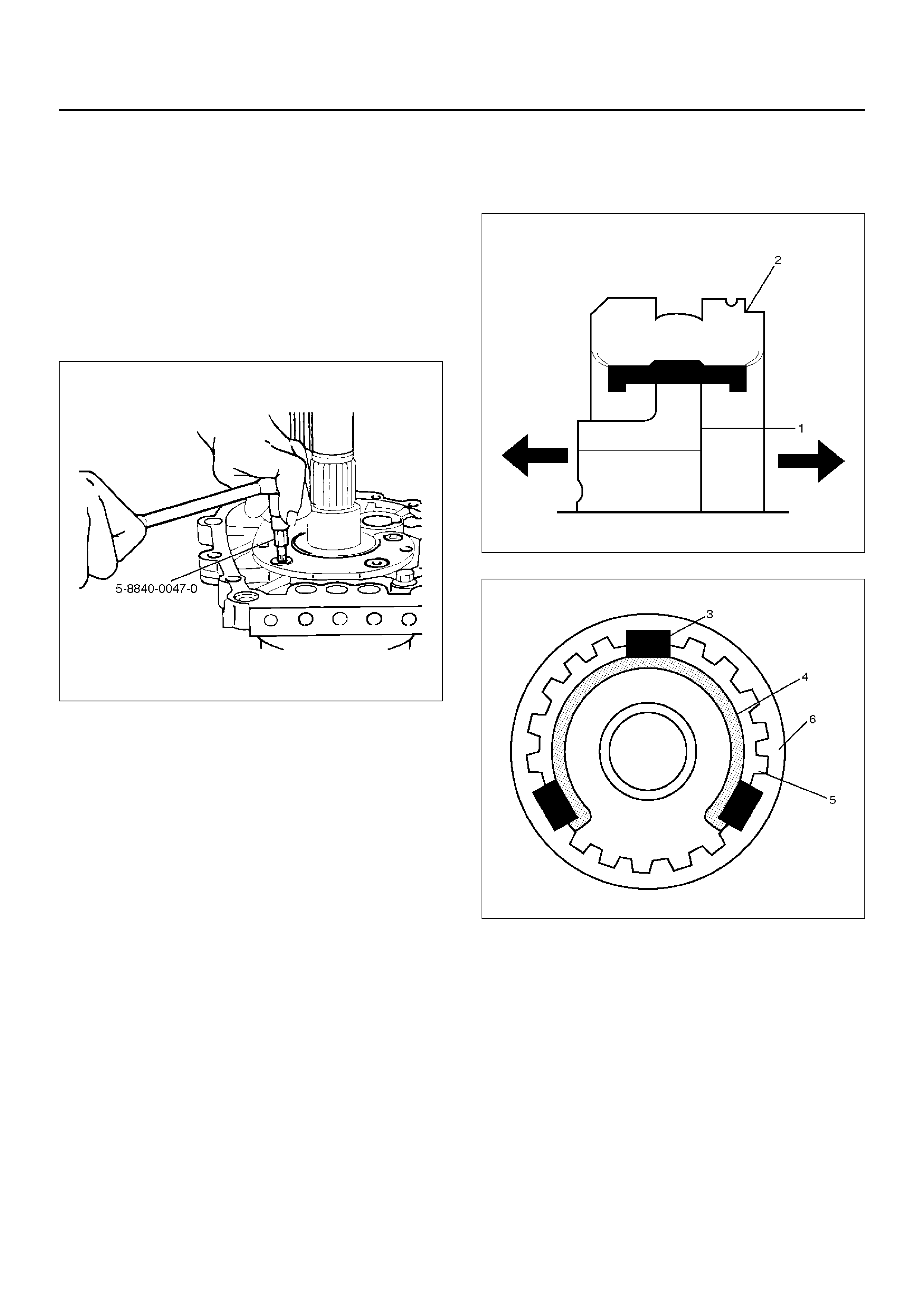

15. Use the torx bit wrench 5–8840–0047–0(T45) to

remove the bearing plate and screw(24) from the

intermediate plate.

220RW137

16. Use the snap ring pliers(1) to remove the mainshaft

bearing snap ring(29).

226RS011

17. Hold the snap ring open with the pliers.

Push the intermediate plate(26) toward the rear of

the transmission to remove it.

The bearing snap ring(25) will come free.

INSPECTION AND REPAIR

Refer to Top Gear Shaft, Main Gear Shaft, and Counter

Gear in this section for inspection and repair.

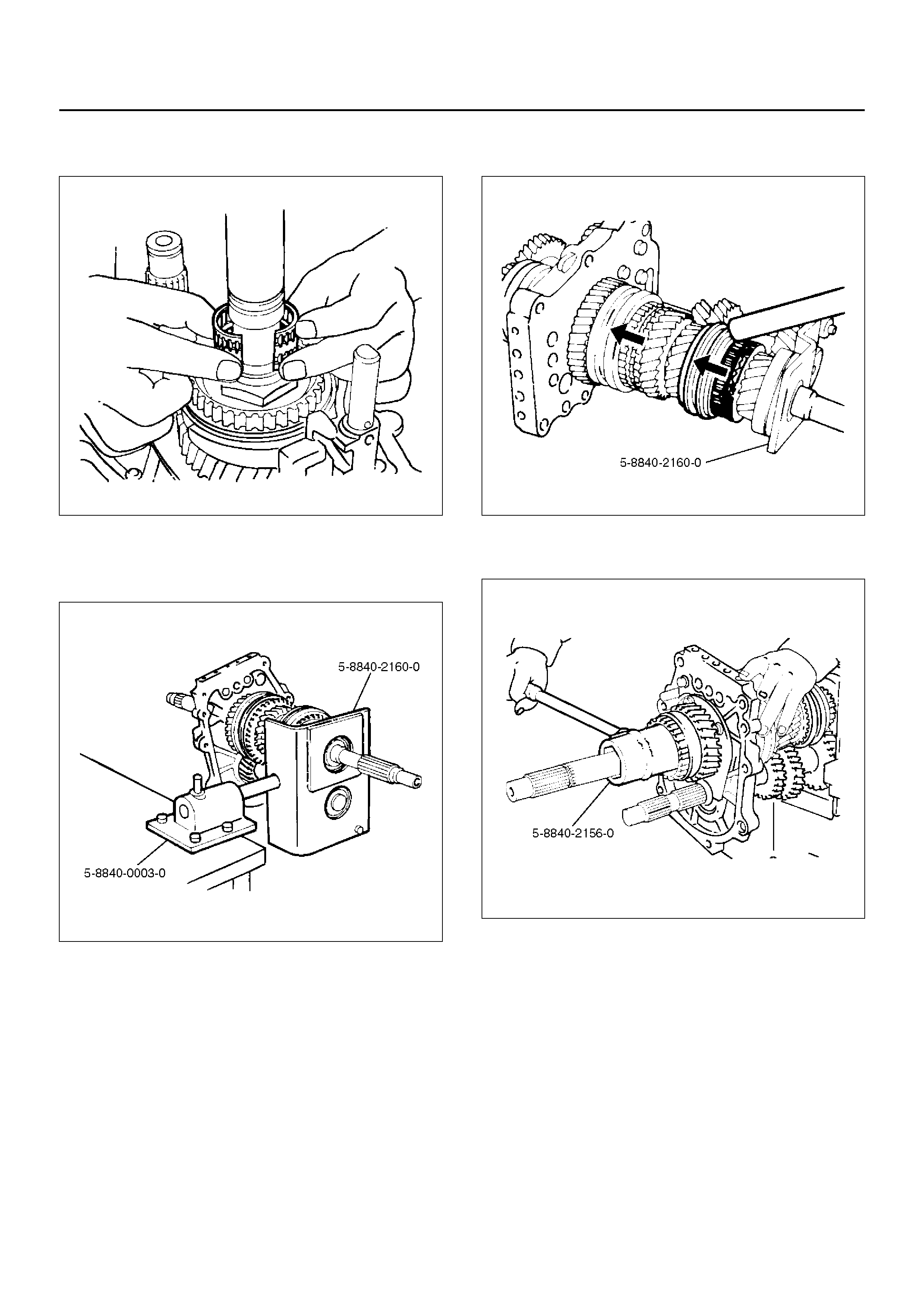

REASSEMBLY

1. Mesh the counter gear with the mainshaft assembly.

Install the holding fi xture 5–88 40–2160–0 and base

5–8840–0003–0 to the mainshaft and the counter

gear.

226RW212

2. Place the holding fixture (with the mainshaft and the

counter shaft) in a vise.

Install the i ntermediate plate(26).

3. Install bearing snap ring(25).

4. Apply recommended thread locking agents

(LOCTITE 242) or its equivalent to each of the

bearing plate screw threads.

Install bearing plate and screw(24).

Tighten the screws to the specified torq ue by using

torx bit wrench 5–8840–0047–0.

Torque: 15N·m

220RW137

5. Install needle bearing(23), reverse gear(22), and

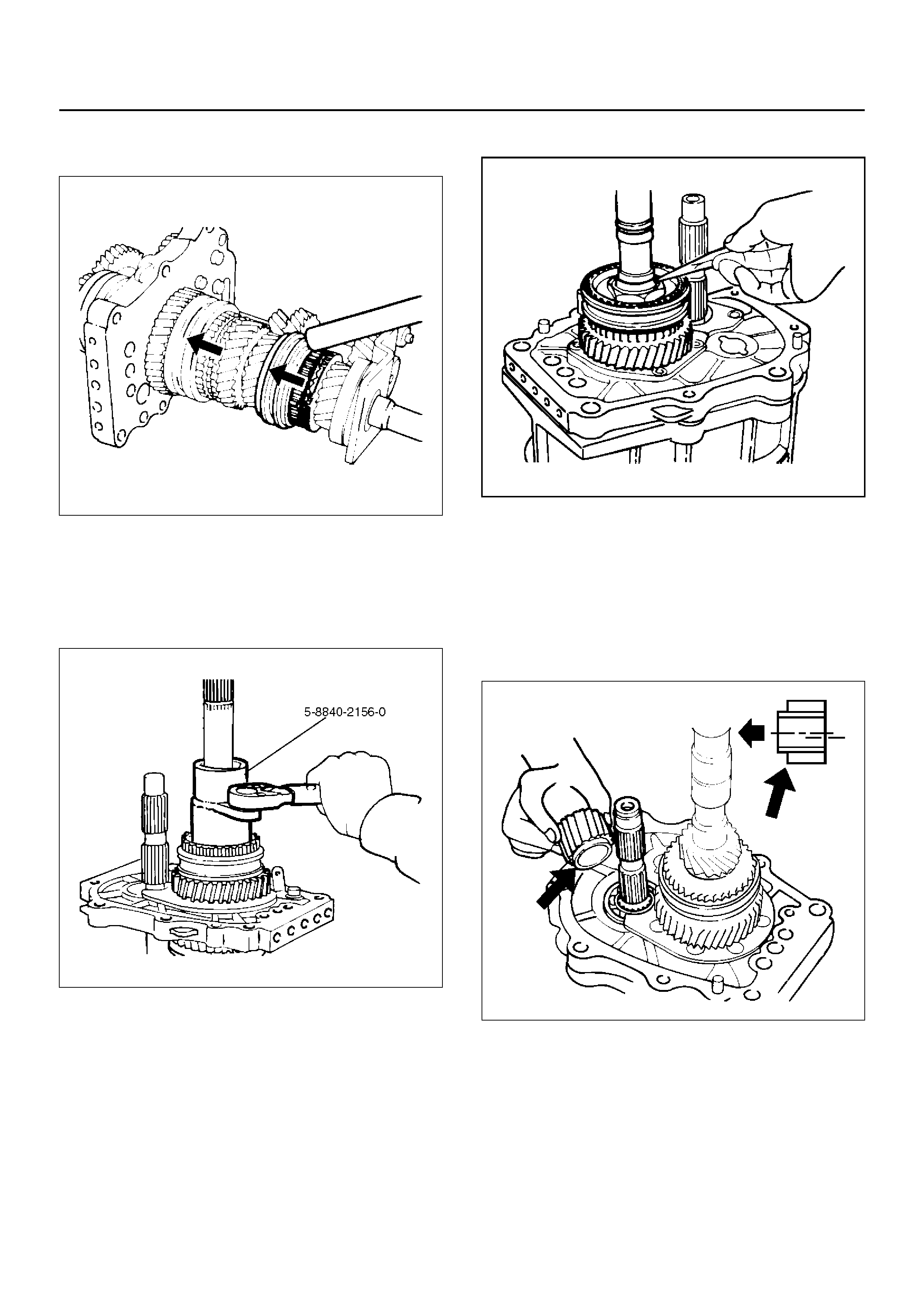

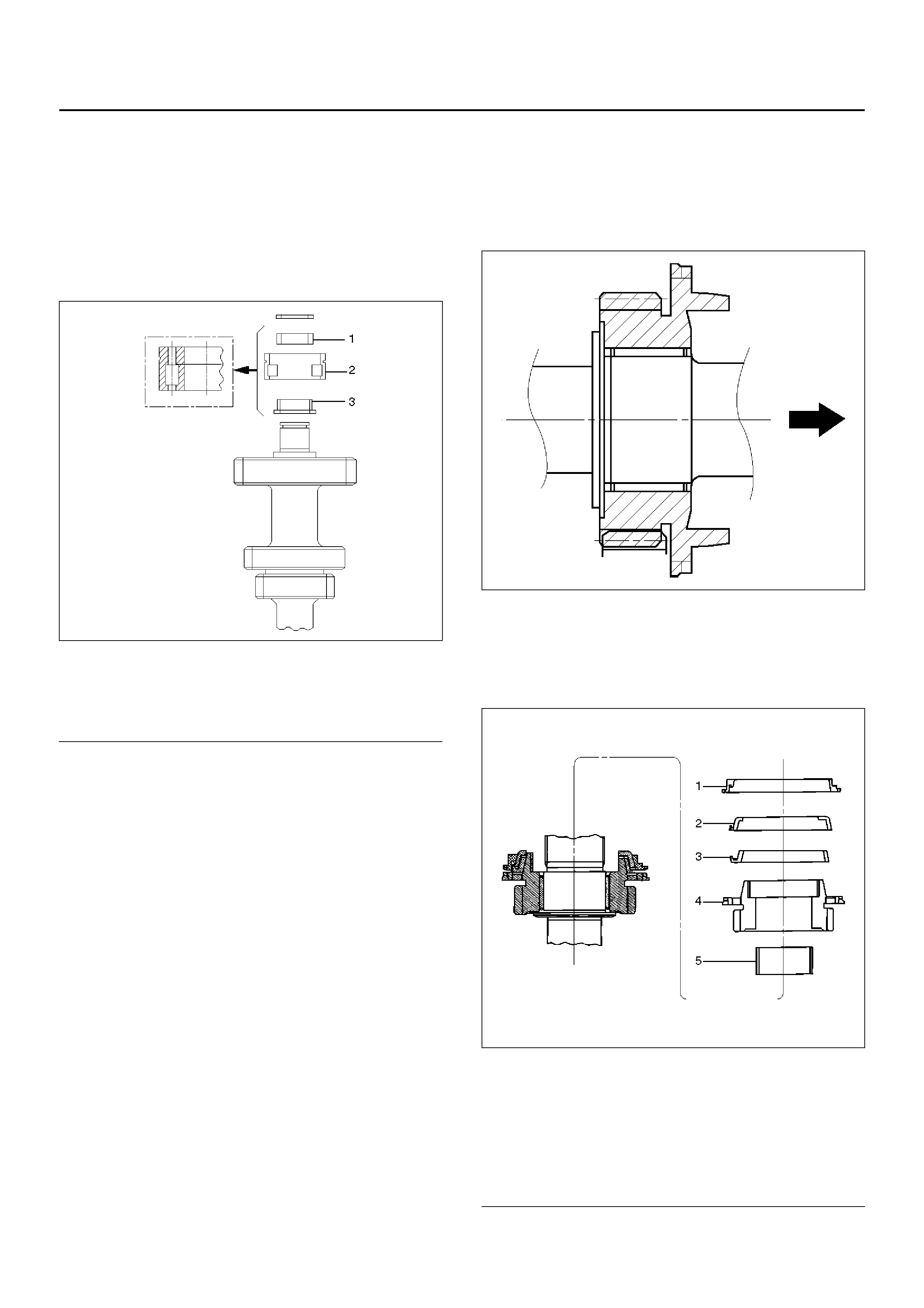

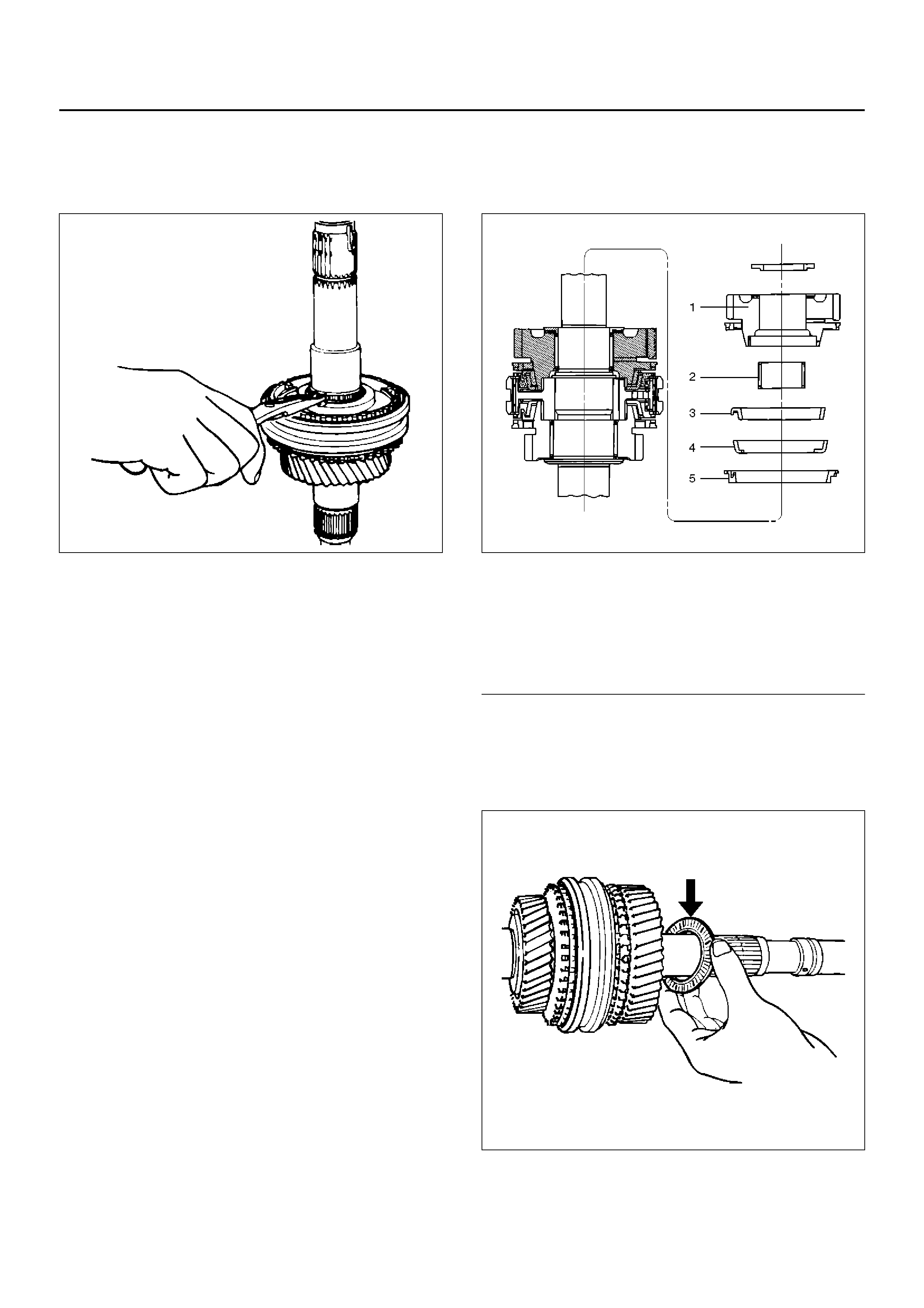

reverse block ring(21).

6. Assemble rev–5th synchronizer assembly(20) by

perfor ming the foll owi ng steps.

1. Turn the clutch hub face(1) toward the sleeve

groove(2) (rear side) on the outer

circumference.

2. Check that the inserts(3) fit snugly into the block

ring insert grooves.

3. Check that the inserts springs(4) are fitted to the

inserts as s hown in the illustration.

4. Check that the clutch hub(5) and the sleeve(6)

slide sm ooth ly.

5. Install the synchronizer assembly(20) to the

mainshaft.

The clutc h hub face (wi th the heavy b oss) must

be facing the reverse gear(22) side.

226RS013

226RS049

7. Mesh the 1st–2nd and 3rd–4th synchronizers with

both the 1st and 3rd gears (double engagement).

226RS015

This will prev ent the mains haft from tur nin g.

8. Install the new mainshaft hub nut(19).

Use the mainshaft nut wrench 5–8840–2156–0 to

tighten the mainshaft nut(19) to the specified torque.

Torque: 137N·m

226RW214

9. Use a punch to stake the mainshaft nut at one spot.

226RW153

10. Install needle bearing(18), 5th block ring(17), and

5th gear(16).

11. Apply engine oil to the counter reverse gear(15) and

the reverse gear(22).

Install the counter reverse gear(15) to the counter

shaft.

The reverse gear projection must be facing the

interm ediate plate.

226RW151

12. Install the counter 5th gear(14) to the transmission.

226RS019

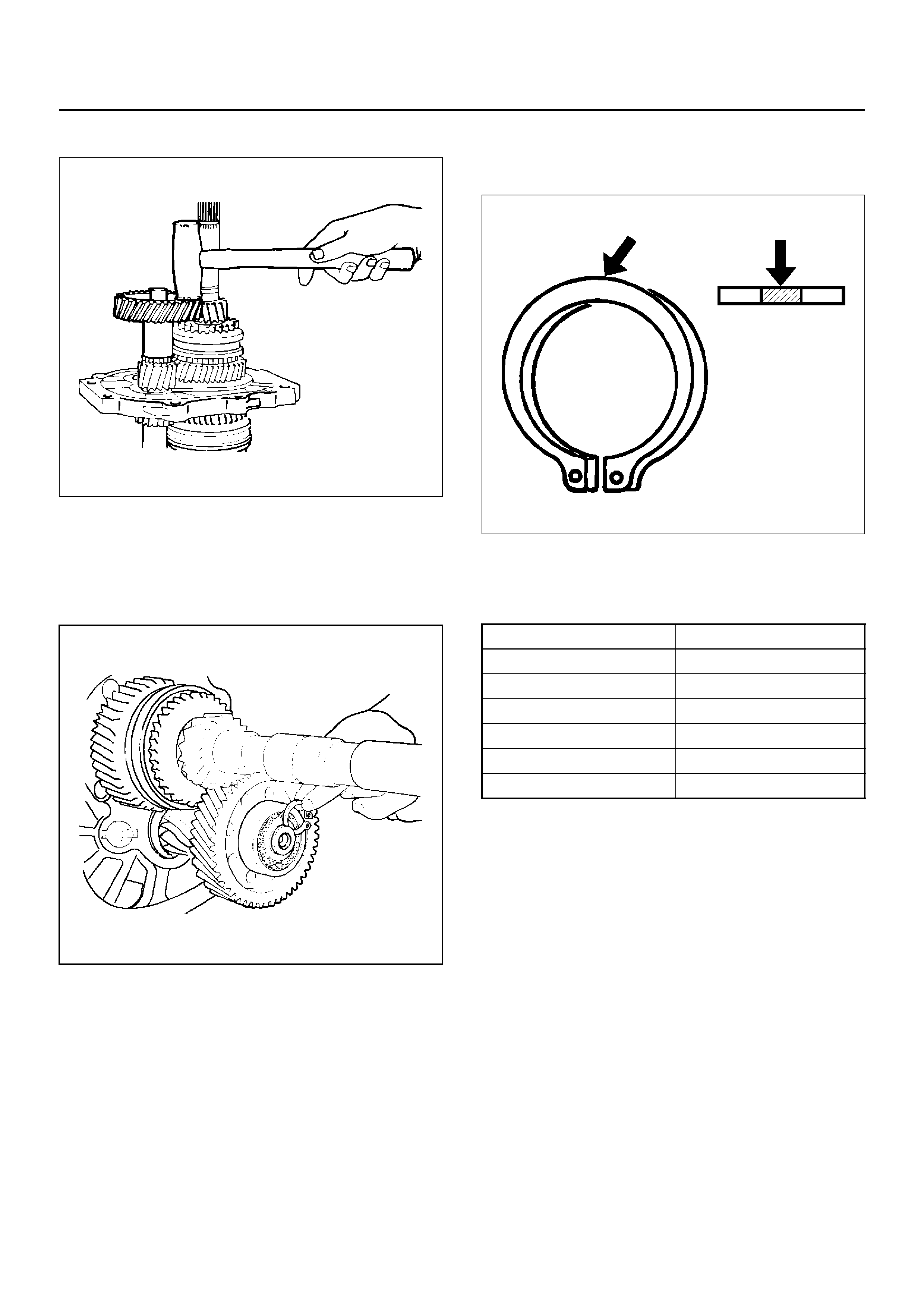

13. Install ball bearing(13) and bearing snap ring by

perfor ming the foll owi ng steps:

• Select the snap ring(12) which will provide the

minimum cl earance between the bal l b ear in g an d

the snap ring.

226RS020

• There are six snap ring sizes available.

The snap rings are color-coded to indicate their

thickness.

226RS021

Ball Bearing and Snap Ring Clearance

Standard: 0–0.15mm

Snap Ring A vailability

• Use a pair of snap ring pliers to install the snap

ring(12) to the counter gear shaft.

The snap ring must be fully inserted into the

counter gear shaft snap ring groove.

14. Assemble reverse idler shaft(11), reverse idler

gear(10), thrust washer(9), and idle shaft pin(8) into

reverse idler gear assembly(7).

Thickness Color Coding

1.1mm White

1.2mm Yellow

1.3mm Blue

1.4mm Pink

1.5mm Green

1.6mm Brown

15. Select reverse idler gear snap ring(6) which will

provide the minimum clearance between the

intermediate plate(26) and the snap ring(6).

226RS022

• There are three snap ring sizes available.

The snap rings are color-coded to indicate their

thickness.

Intermediate Plate and Snap Ring Clearance

Standard: 0–0.15mm

Snap Ring Availability

226RS021

• Use a pair of snap ring pliers to install the snap

ring to the reverse idler shaft.

The snap ring must be fully inserted into the

reverse idler shaft snap ring groove.

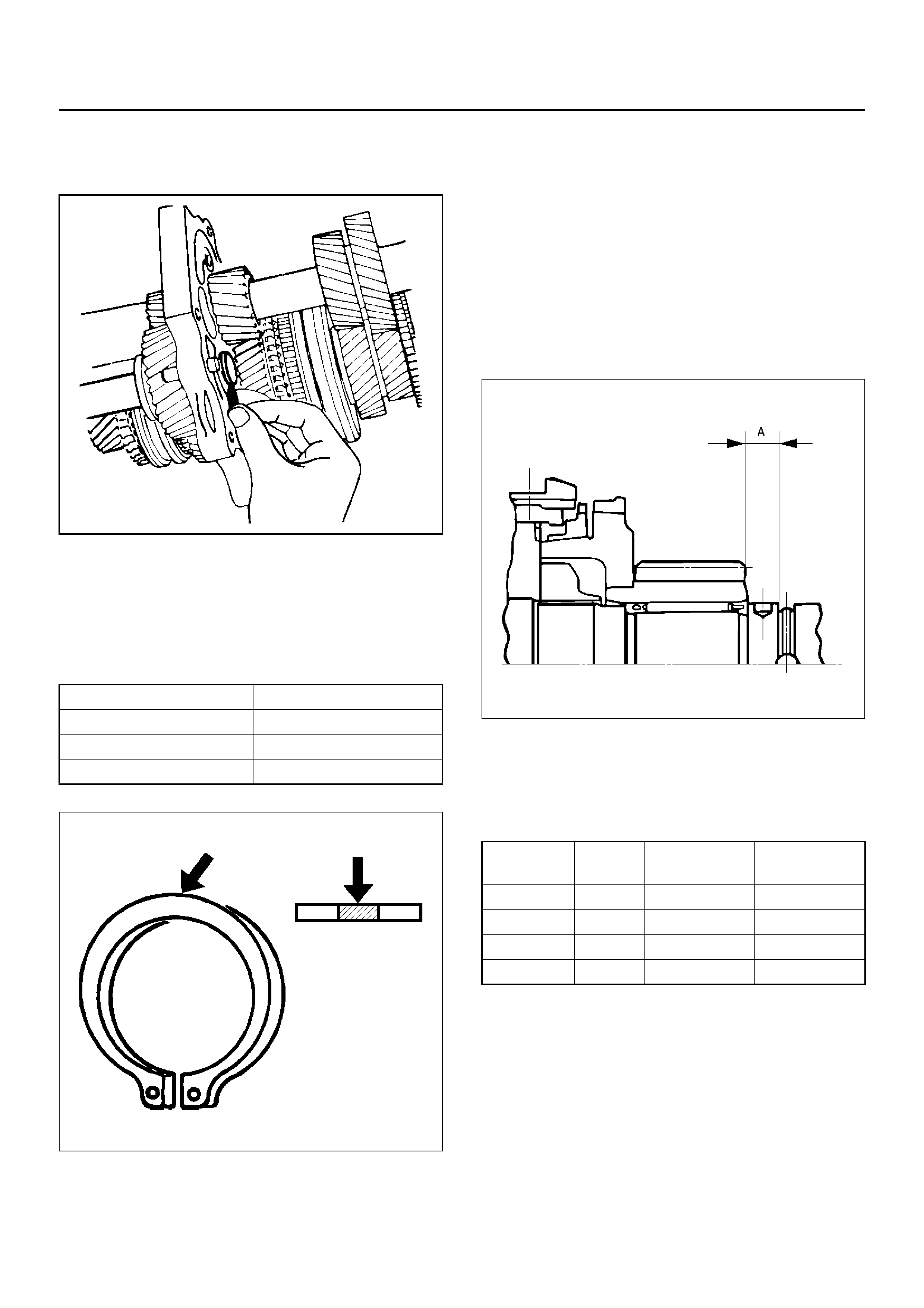

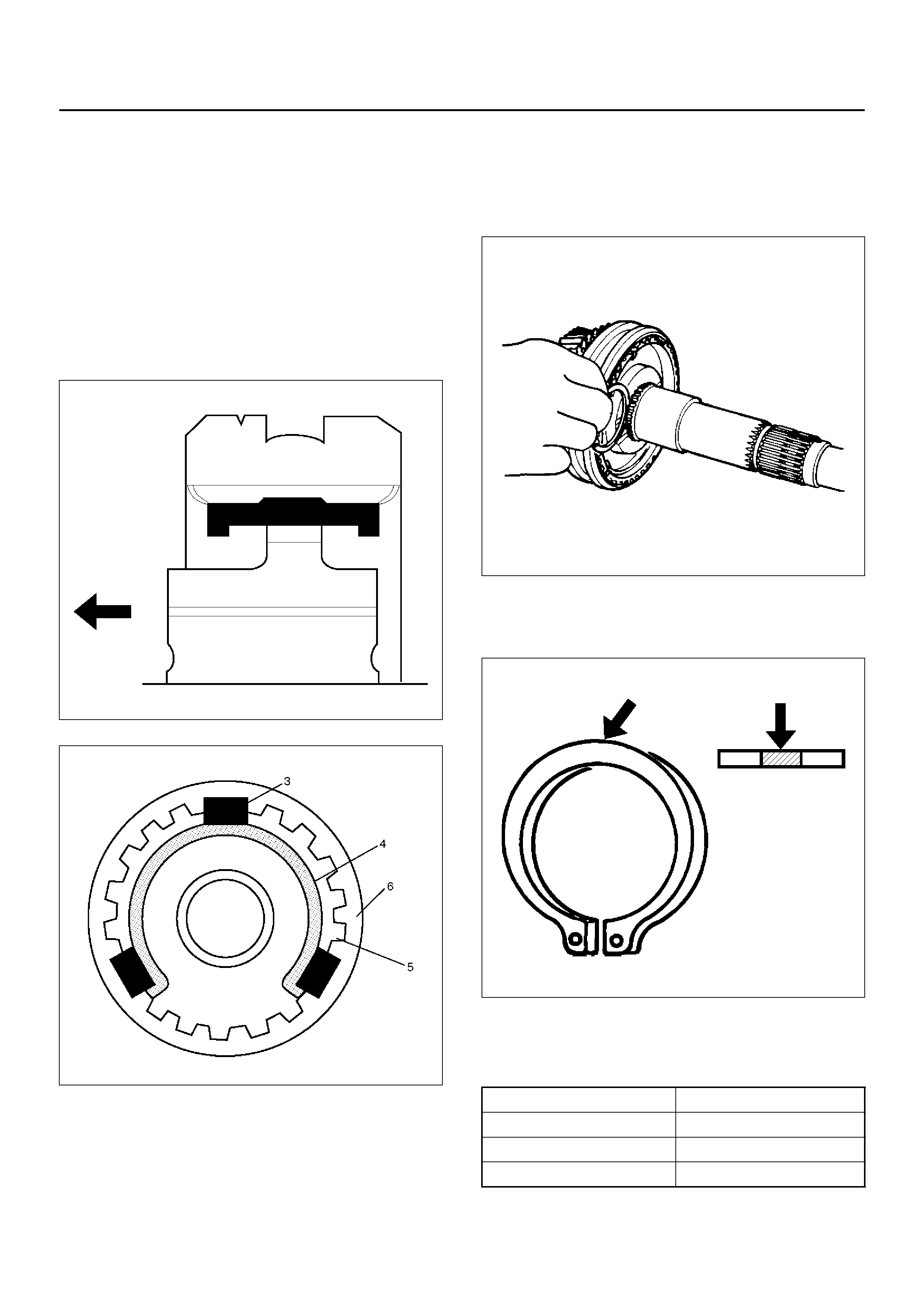

16. Install thrust washer and lock ball(5) by performing

the following steps:

• Use a thic kness g auge to measu re the clear ance

between the 5th gear and the thrust washer.

5th Gear and Thrust Washer Clearance

Standard: 0.10–0.25mm

• Measure clearance “A" as shown in the figure.

226RS023

• Select appropriate thrust washer from chart.

• There are four thrust washer sizes available.

• The thrust washers are color coded to indicate

their thickness.

Thrust Washer Availability

Thickness Color Coding

1.2mm White

1.3mm Yellow

1.4mm Blue

Thickness

mm Color

Coding A mm Clearance

mm

7.9 White 8.05–8.1 0.15–0.25

8.0 Yellow 8.1–8.2 0.1–0.25

8.1 Green 8.2–8.3 0.1–0.25

8.2 Bluen 8.3–8.36 0.1–0.21 )

226RS024

• Apply grease to the thrust washer and the lock

ball.

• Install the thrust washer and the lock ball.

17. Install thrust plate(4) and retainer(3).

18. Apply engine oil to the bearing inner and outer

circumference.

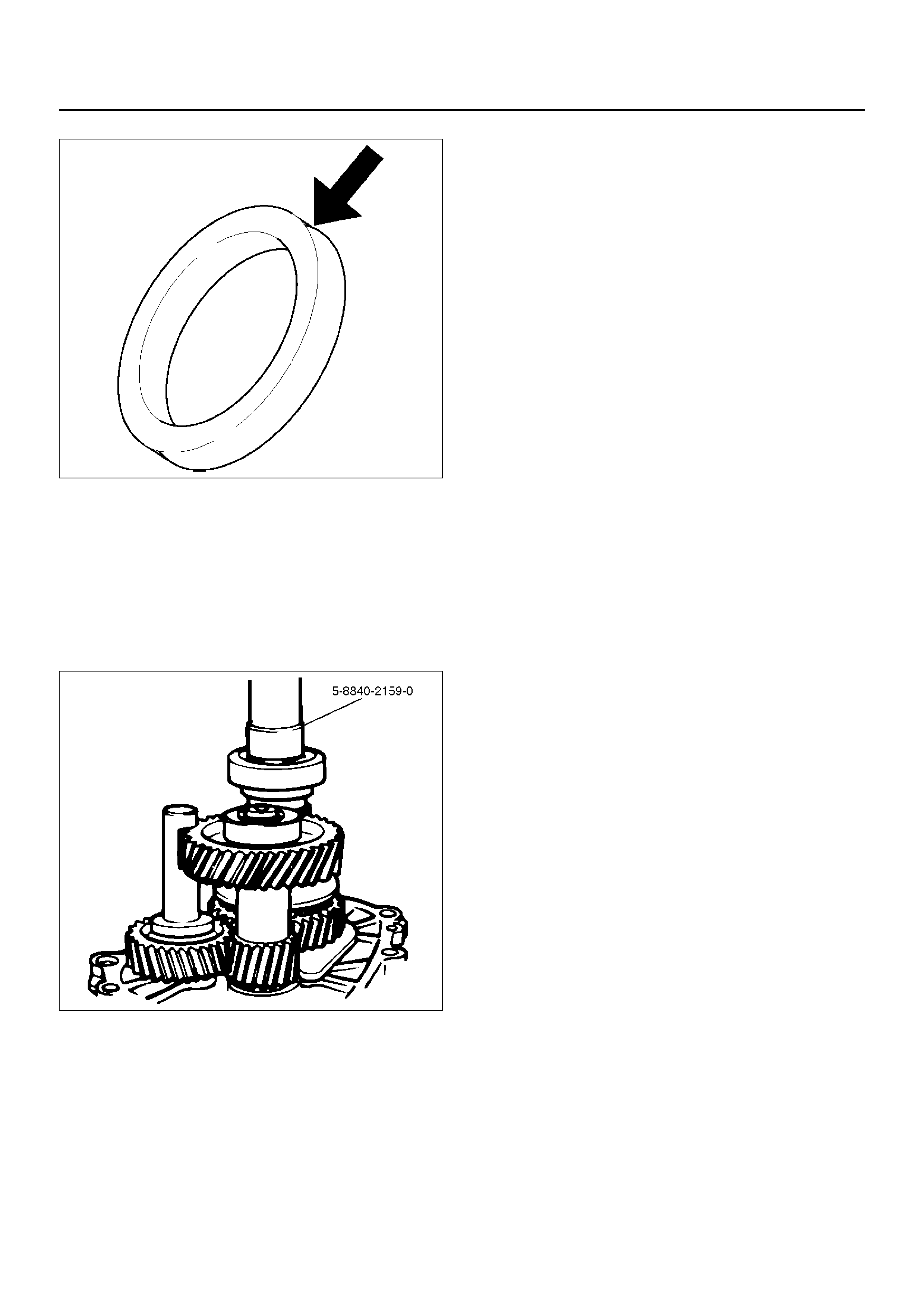

Use the installer 5–8840–2159–0 to install the ball

bearing(2) to the mainshaft in proper direction.

226RW215

19. Install oil seal collar(1).

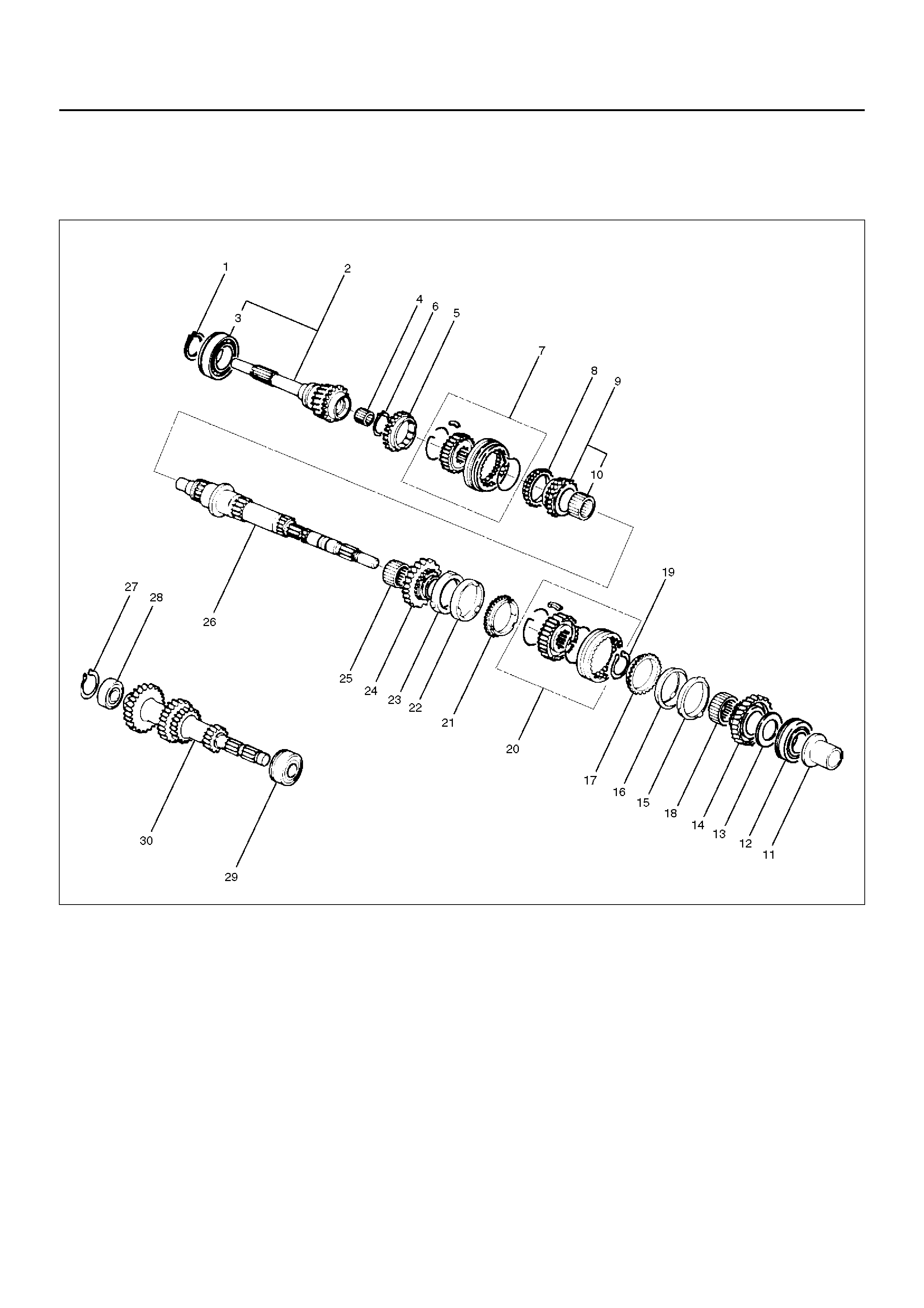

TOP GEAR SHAFT, MAIN GEAR SHAFT, AND COUNTER GEAR

SHAFT (MUA)

DISASSEMBLED VIEW

226RS026

Legend

(1) Top Gear Shaft Snap Ring

(2) Top Gear Shaft

(3) Ball Bearing

(4) Needle Bearing

(5) Top Block Ring

(6) Mainshaft Snap Ring

(7) 3rd–4th Synchronizer Assembly

(8) 3rd Block Ring

(9) 3rd Gear

(10) Needle Bearing

(11) Needle Bearing Collar

(12) Mainshaft Ball Bearing

(13) 1st Gear Thrust Bearing

(14) 1st Gear

(15) 1st Inside Ring

(16) 1st Outside Ring

(17) 1st Block Ring

(18) Need le Bearing

(19) Clutch Hub Snap Ring

(20) 1st–2 nd Sy nc hr onizer Assembly

(21) 2nd Block Ring

(22) 2nd Outside Ring

(23) 2nd Inside Ring

(24) 2nd Gear

(25) Need le Bearing

(26) Mainshaft

(27) Bearing Snap Ring

(28) Front Rol lar Beari ng

(29) centre Rol ler Beari ng

(30) Counter Gea r Shaft

DISASSEMBLY

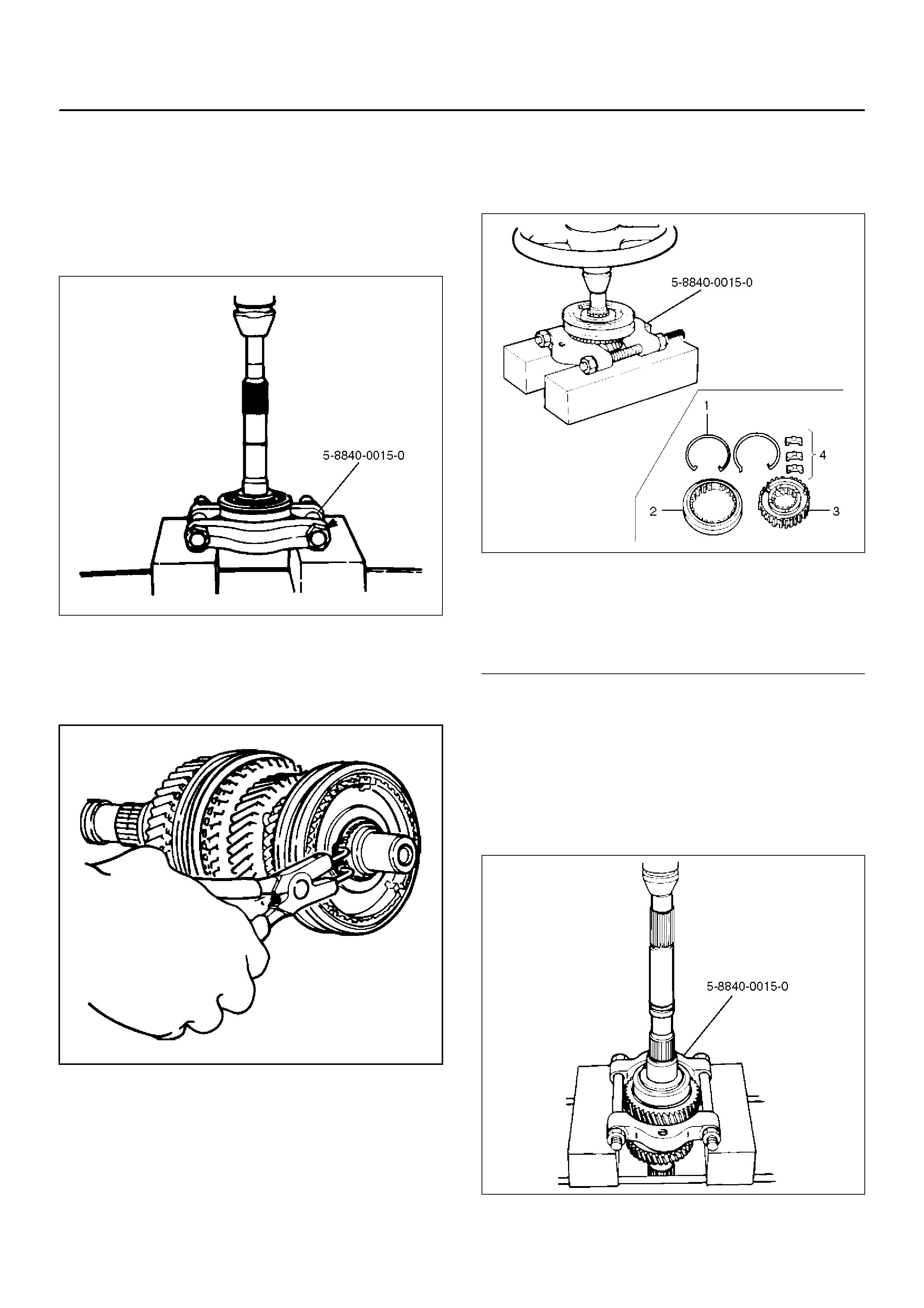

1. Use a pair of snap ring pliers to remove the top gear

shaft snap ring(1).

2. Remove top gear shaft(2) with ball bearing(3).

3. Use a bench press and the bearing remover

5–8840–0015–0 to remove the ball bearing(3).

226RW216

4. Remove needle bearing(4) and top block ring(5),

mains haft sn ap ring.

5. Use a pair of snap ring pliers to remove the

mains haft sn ap ring( 6).

226RS028

6. Use a bench press and the bearing remover 5–

8840–0015–0 to remove the 3rd–4th synchronizer

assembly (7) as a set.

Disassemble the synchronizer assembly.

226RW217

EndOFCallout

7. Remove 3rd block ring(8), 3rd gear(9), and needle

bearing(10).

8. Remove need le bea ri ng co ll ar(11 ).

9. Use a bench press and the bearing remover 5–

8840–0015–0 to remove the 1st gear(14) together

with the mainshaft ball bearing(12) and 1st gear

thrust bearing(13).

226RW218

Legend

(1) Springs

(2) Sleeve

(3) Clutch Hub

(4) Inserts

10. Disassemble 1st inside ring(15), 1st outside

ring(16), and 1st block ring(17).

11. Remove needle bearing(18).

12. Use a pair of snap ring pliers to remove the clutch

hub snap ring(19).

226RS031

13. Use a bench press and the bearing remover 5–

8840–0015–0 to remove the 2nd gear(24) together

with 1st–2nd synchronizer assembly(20), 2nd block

ring(21), 2nd outside ring(22), and 2nd inside

ring(23).

Disassemble the synchronizer assembly.

226RW220

EndOFCallout

14. Remove needle bearing(25) from mainshaft(26).

15. Remove bearing snap ring(27)

16. Use a bench press and the bearing remover 5–

8840–0015–0 to remove the front roller bearing(28).

226RW219

17. Remove centre roller bearing(29) from counter gear

shaft(30).

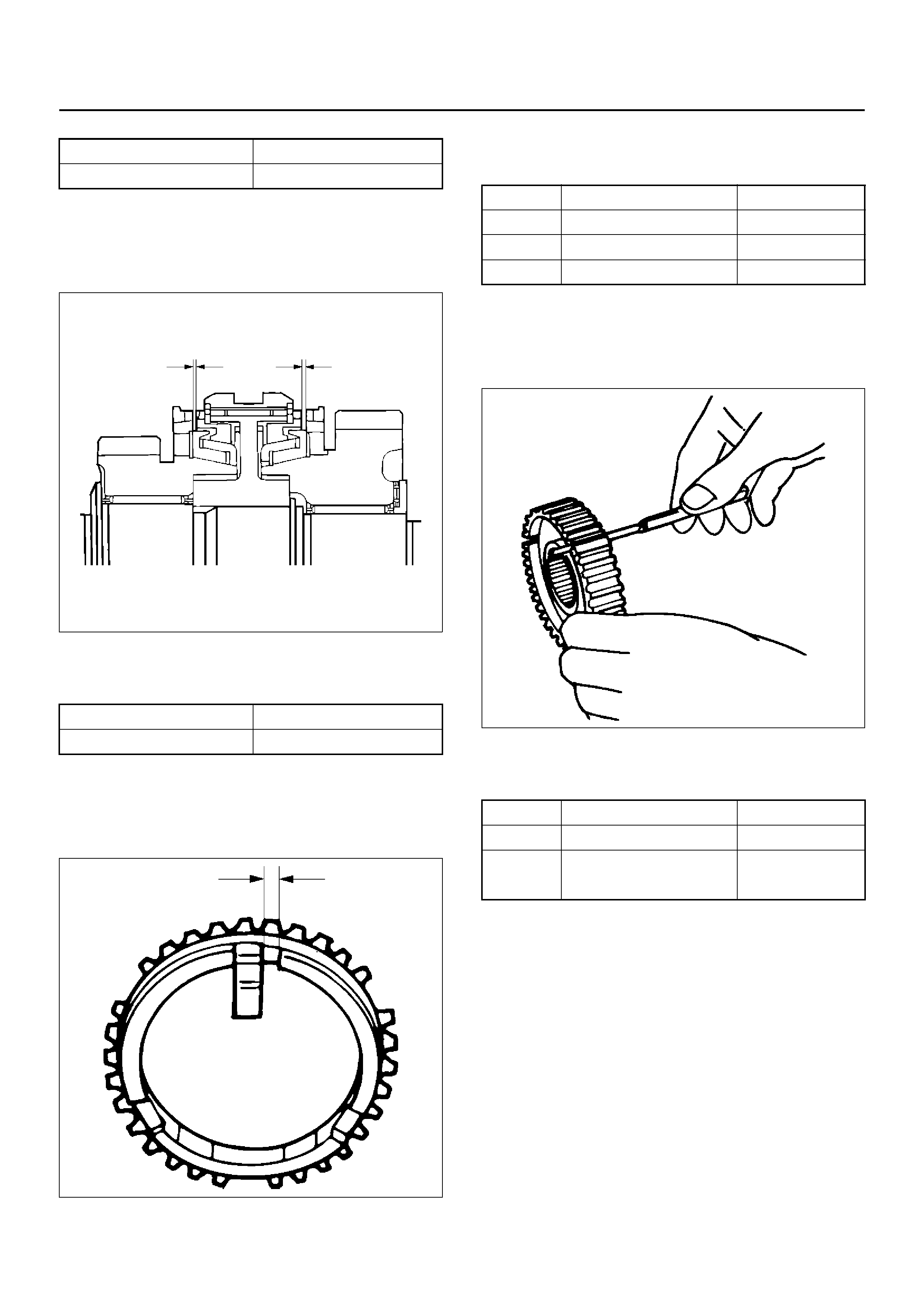

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is

discovered during inspection.

Block Ring and Dog Teeth Clearance

• Use a thickness gauge to measure the clearance

between the block ring and the dog teeth.

226RS035

If the measured value exceeds the specified limit, the

block ring mus t be replac ed.

Legend

(1) Springs

(2) Sleeve

(3) Clutch Hub

(4) Inserts

Block Ring and Dog Teeth Clearance

1st–2nd Synchronizer (3–CONE)

• Use a thickness gauge to measure the clearance

between the block ring and the dog teeth.

226RS036

If the meas ured value exceeds the specified li mit,the

1st–2nd synchronizer assembly must be replaced.

Block Ring and Dog Teeth Clearance

Block Ring and Insert Clearance

• Use a vernier caliper or thickness gau ge to measure

the clearance between the block ring and the insert.

226RS037

If the measured value exceeds the specified limit, the

block ring and the ins ert m ust be repl aced.

Block and Insert Clearance

Clutch Hub and Insert Clearance

• Use a thickness gauge to measure the clearance

between the clutch hub and the insert.

226RS038

If the measured value exceeds the specified limit, the

clutch hub and the insert must be replaced.

Clutch Hub and Insert Clearance

Standard Limit

1.5mm 0.8mm

Standard Limit

1.5mm 0.8mm

Standard Limit

3rd–4th 3.46–3.74mm 4.0mm

1st–2nd 4.34–4.66mm 4.9mm

Rev–5th 3.59–3.91mm 4.1mm

Standard Limit

3rd–4th 0.01–0.19mm 0.3mm

1st–2nd 0.09–0.31mm 0.4mm

Rev–5th

Mainsha ft Run-out

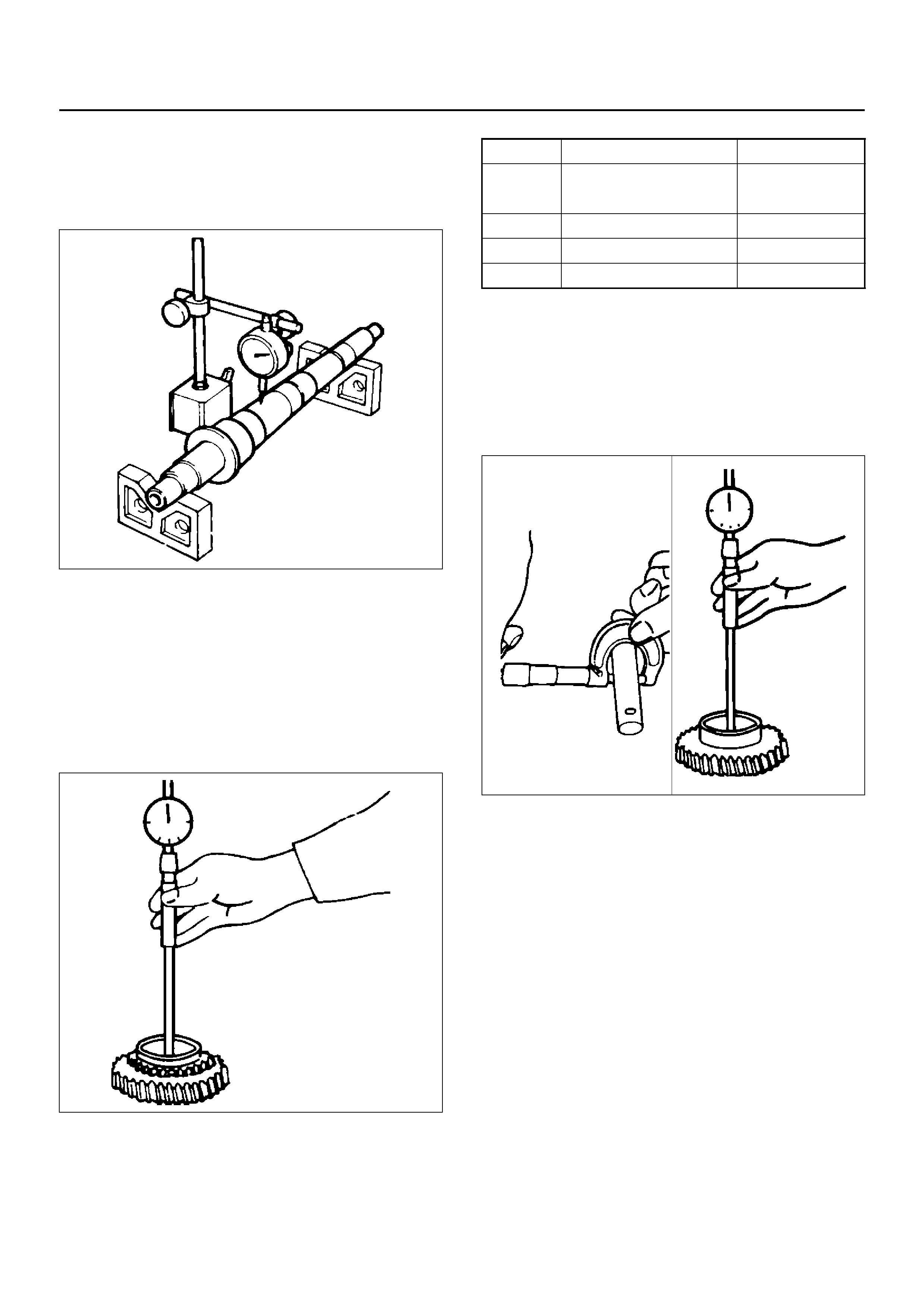

• Install the mainshaft to V-blocks.

• U se a di al in dicato r to meas ure the mains haft c entral

portion run-out.

226RS039

If the measured mainshaft run-out exceeds the

specified limit, the mainshaft must be replaced.

Mainshaft Run–out

Limit: 0.05mm

Gear Inside Diameter

• Use an inside dial indicator to measure the gear

inside diameter.

226RS040

If the m easured value is less th an the specif ied limit,

the gear must be replace.

Gear Inside Diameter

Reverse Idler Gear and Idler Gear Shaft

Clearance

• Use a micrometer to measure the idler gear shaft

diameter.

• Use an insi de dial in dicato r to me asure the idler gear

inside diameter.

226RS041

• Calculate the idler gear and idler gear shaft

clearance.

Idler g ear insi de diamet er-idler g ear shaft diameter =

idle gear and idler gear shaft clearance.

If the measured value exceeds the specified limit, the

idle gear and/or the idler gear shaft must be replaced.

Idler Gear and Idler Gear Shaft Clearance

Standard: 0.041–0.074mm

Limit: 0.150mm

Standard Limit

1st 45.000–45.013mm 45.100mm

3rd

2nd 52.000–52.013mm 52.100mm

Rev. 48.000–48.013mm 48.100mm

5th 32.000–32.013mm 32.100mm

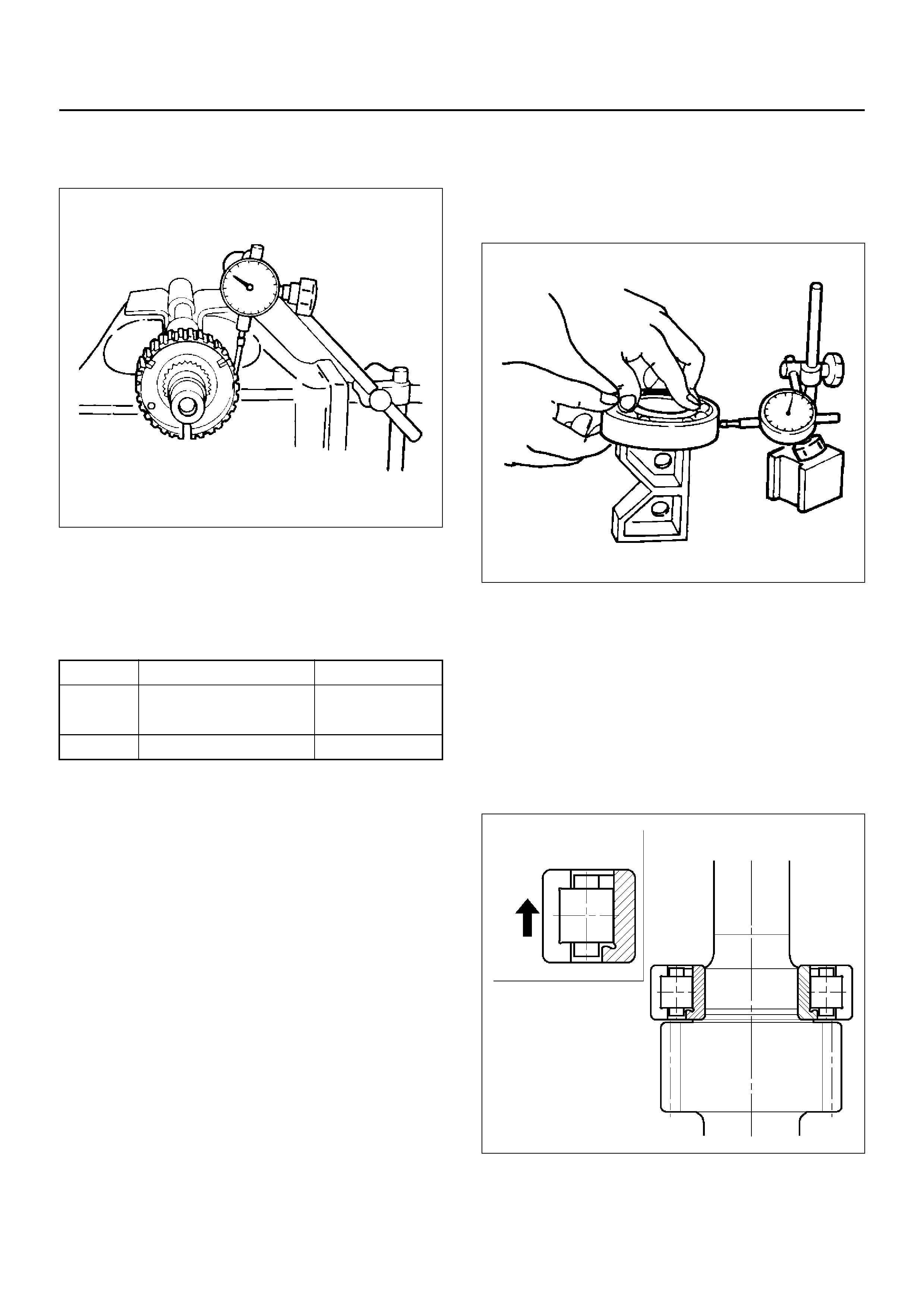

Clutch Hub Spline Play

• Set a dial indicator to the clutch hub to be measured.

226RS042

• Move the clutch hub as far as possible to both the

right and the left.

Note the dial indicator reading.

If the measured value exceeds the specified limit, the

clutch hub must be replaced.

Clutch Hub Spline Play

Ball Bearing Play

• Use a dial indicator to measure the ball bearing play.

Ball Bearing Play

Limit: 0.2mm

226RS043

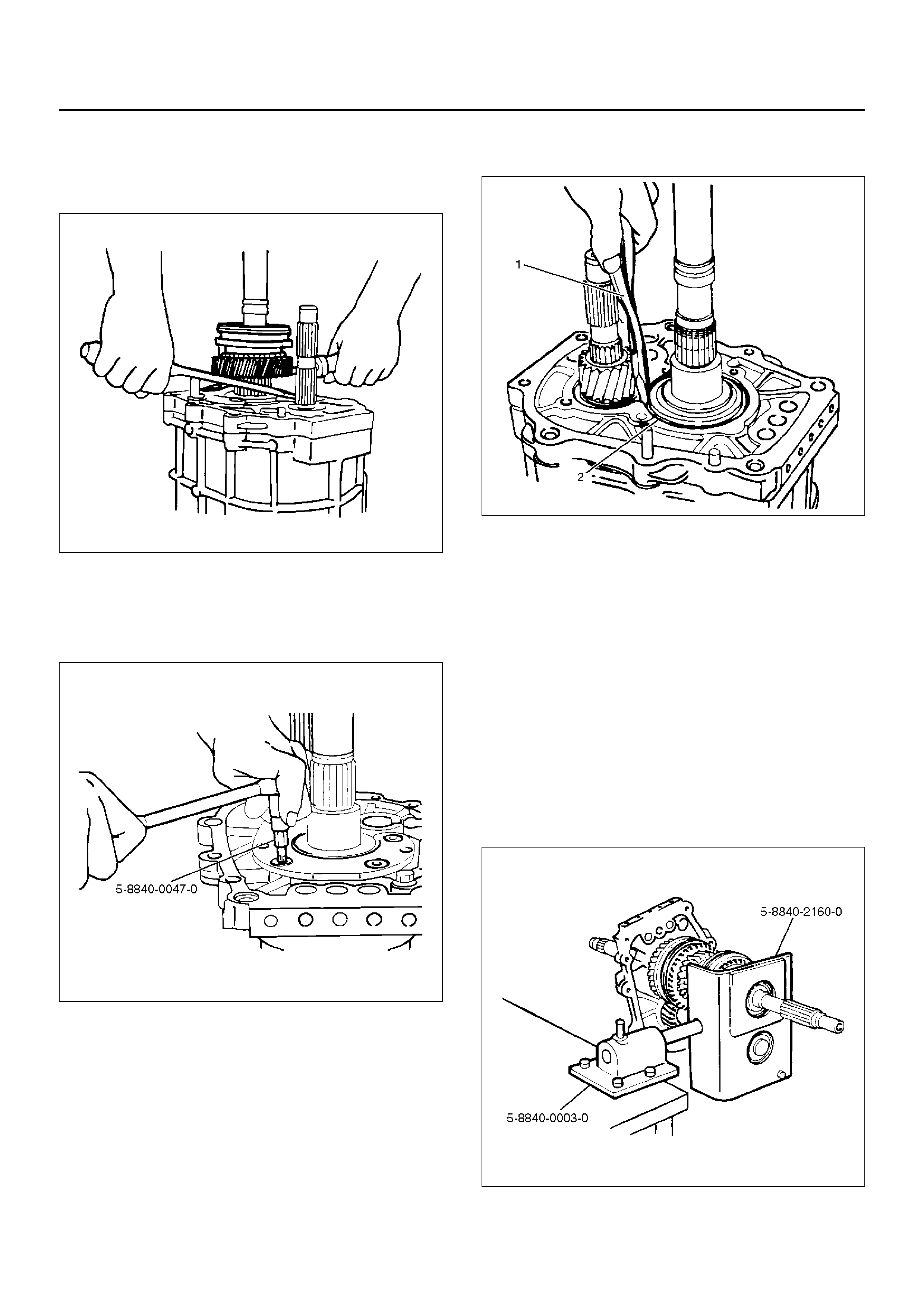

REASSEMBLY

1. Install centre roller bearing(29) to counter gear

shaft(30).

• Apply engine oil to the bearing inner and outer

circumferences.

• Install the roller bearing in the proper direction.

NOTE: Check that outer race moves only in the

direction of arrow.

226RS044

Standard Limit

1st–2nd 0–0.1mm 0.2mm

3rd–4th

Rev. 5th 0–0.2mm 0.3mm

2. Install front roller bearing(28) by performing the

foll owing steps.

• Use bearing installer to install the front roller

bearing inner race to the counter gear shaft.

• Install the outer race and roller assembly.

The snap ring groove must be facing the

transmission front side.

• Use bearing installer J–35283 to install the ring.

226RS045

EndOFCallout

3. Install bearing snap ring(27) to mainshaft(26).

4. Apply engine oil to the needle bearing(25) and the

2nd gear thrust surfaces.

Install the needle bearing(25) and the 2nd gear(24)

to the mainshaft.

The 2nd gear dog teeth must be facing the

transmission rear side.

226RS046

5. Assemble 2nd inside ring(23), 2nd outside ring(22),

and 2nd block ring(21).

• Apply engine oil to the synchronizer ring friction

surfaces.

226RS047

EndOFCallout

Legend

(1) Ring

(2) Outer Race and Roller Assembly

(3) Inner Race

Legend

(1) Block Ring

(2) Outside Ring

(3) Inside Ring

(4) 2nd Gear

(5) Needle Bearing

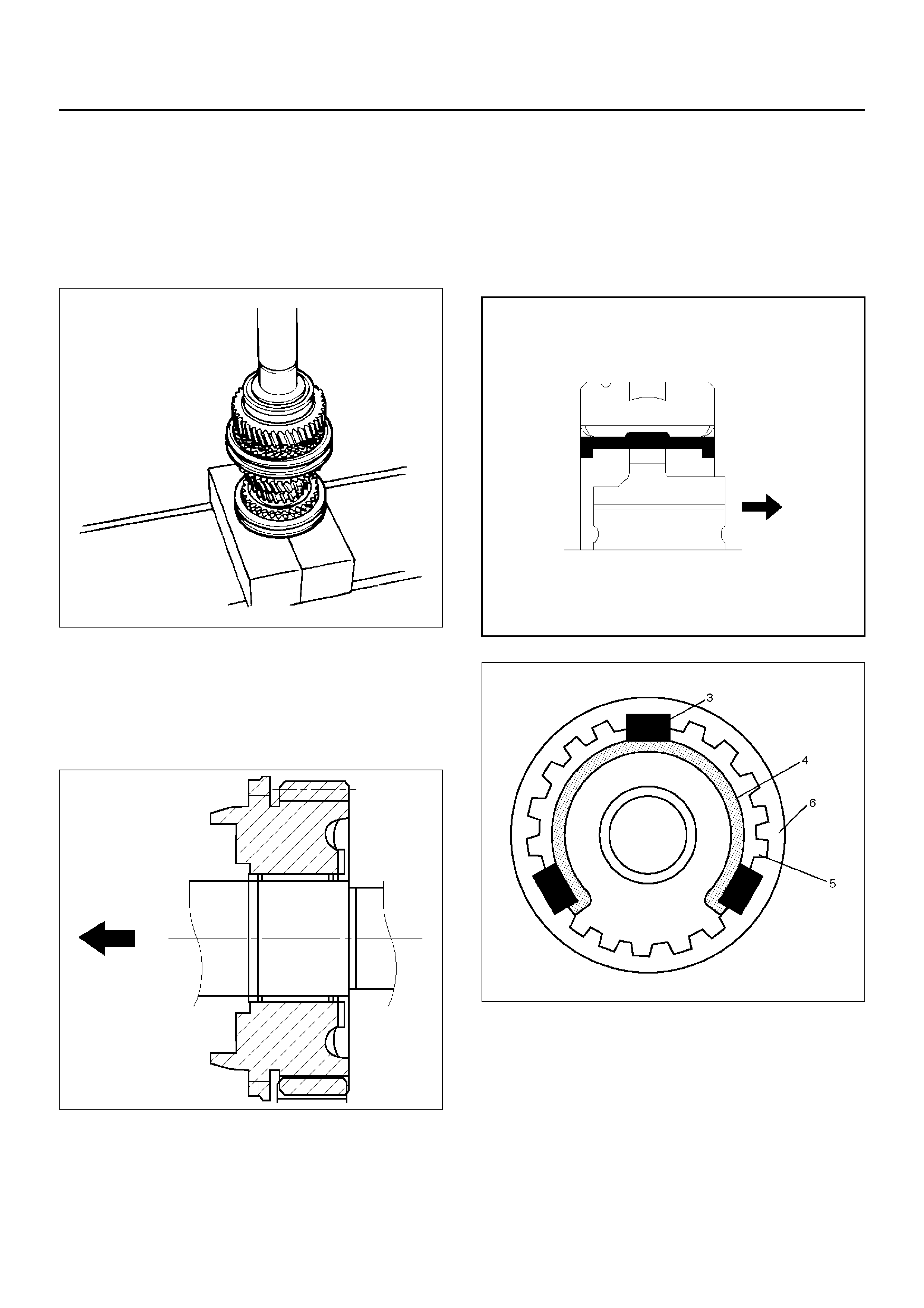

6. Assemble 1st–2nd synchronizer assembly by

perfor ming the foll owi ng steps:

1. Check that the inserts(3) fit snugly into the block

ring insert grooves.

2. Check that the inserts springs(4) are fitted to the

inserts as s hown in the illustration.

3. Check that the clutch hub(5) and the sleeve(6)

slide sm ooth ly.

4. Install the synchronizer assembly to the

mainshaft.

The cl utch hub face (with the heav y boss) must

be facing the 2nd gear side.

226RS048

226RS049

7. Install clutch hub snap ring(19) by performing the

following steps:

• Select the snap ring which will provide the

minimum clearance between the 1st–2nd clutch

hub and the snap ring.

226RS050

There are three snap ring sizes available.

The snap rings are color coded to indicate their

thickness.

226RS021

Clutch Hub and Snap Ring Clearance

Standard: 0–0.1mm

Snap Ring A vailability

Thickness Color Coding

1.80mm White

1.85mm Yellow

1.90mm Blue

• Use a pair of snap ring pliers to install the snap

ring to the mainshaft.

The snap ring must be fully inserted into the

mainshaft snap ring groove.

226RS031

8. Install needle bearing(18), 1st block ring(17), 1st

outside ring(16), 1st inside ring(15), and 1st

gear(14).

• Apply engine oil to the needle bearing, 1st gear

thrust surfaces and synchronizer ring friction

surfaces.

• I nstall the needle bear ing and the 1st gear to the

mainshaft.

The 1st gear dog teeth must be facing the

transmission front side.

226RS053

EndOFCallout

9. Install the 1st gear thrust bearing and the race(13)

to the main shaft.

The thrust bearing side must be facing the

transmission front side.

226RS054

Legend

(1) 1st Gear

(2) Needle Bearing

(3) Inside Ring

(4) Outside Ring

(5) Block Ring

10. Apply engine oil to the mainshaft ball bearing(12)

and the mainshaft(26).

Install the ball bearing(12) and needle bearing

collar(11) to the mainshaft(26).

The ball bearing snap ring groove must be facing

the transmission rear side.

Use a bench press and installer J–6133–01 to

slowly fo rce the col lar int o place.

226RS055

11. Apply engine oil to the needle bearing and the 3rd

gear thrust surfaces.

Install the nee dle bea ring (1 0) and the 3 r d ge ar (9) t o

the mainshaft.

The 3rd gear dog teeth must be facing the

transmission front side.

226RS056

12. Install 3rd block ring(8).

13. Chec k an d in stall 3rd –4th sy nc hroni z er ass em bly ( 7)

by the followi ng ste ps:

1. Check that the inserts(3) fit snugly into the block

ring insert grooves.

2. Check that the insert springs(4) are fitted to the

inserts as shown in the illustration.

3. Check that the clutch hub(5) and the sleeve(6)

slide smoothly.

4. Install the synchronizer assembly to the

mainshaft.

The clutc h hub face (wi th the heavy b oss) must

be facing the 3rd gear side.

226RW221-1

226RS049

14. Select and install mainshaft snap ring(6) in the

followi ng way :

• Select the snap ring which will provide the

minimum clearance between the 3rd–4th clutch

hub and the snap ring.

226RS058

There are three snap ring sizes available.

The snap rings are color coded to indicate their

thickness.

226RS021

Clutch Hub and Snap Ring Clearance

Standard: 0–0.1mm

Snap Ring Availability

• Use a pair of snap ring pliers to install the snap

ring to the mainshaft.

The snap ring must be fully inserted into the

mainshaf t snap ring groov e.

15. Install top bloc k ring(5).

16. Apply grease to the bearing inner and outer

circumferences and install needle bearing(4).

17. Use a bench press to install the top gear shaft ball

bearing(3) to the top gear shaft(2).

226RS059

The snap ring groove must be facing the

transmission front side.

18. Use a pair of snap ring pliers to install the top gear

shaft snap ring(1) to the bearing.

Thickness Color Coding

1.80mm White

1.85mm Yellow

1.90mm Blue

MAIN DATA AND SPECIFICATIONS

General Specifications

MUA 5C Manual Transmission 5 Speed

4X4

Transmission type Fully synchronized forward and reverse gears

T ransfer case Synchronized type gears shifting between the 2– and 4–wheel

drive mode.

Constant mesh type gears between “low" and “high"

Control method Remote control with the gear shift lever on the floor.

Gear ratio: Transmission 1st 3.767

2nd 2.248

3rd 1.404

4th 1.000

5th 0.809

Rev. 3.873

Gear ratio: Transfer High 1.000

Low 2.050

Transmission oil capacity 2.95lit.

Transfer oil capacity 1.45lit.

Type of lubricant Engine oil: Refer to the chart in “SECTION 0"

Torque Specifications (Cont'd)

220R100004

Torque Specifications (Cont'd)

E07RX013

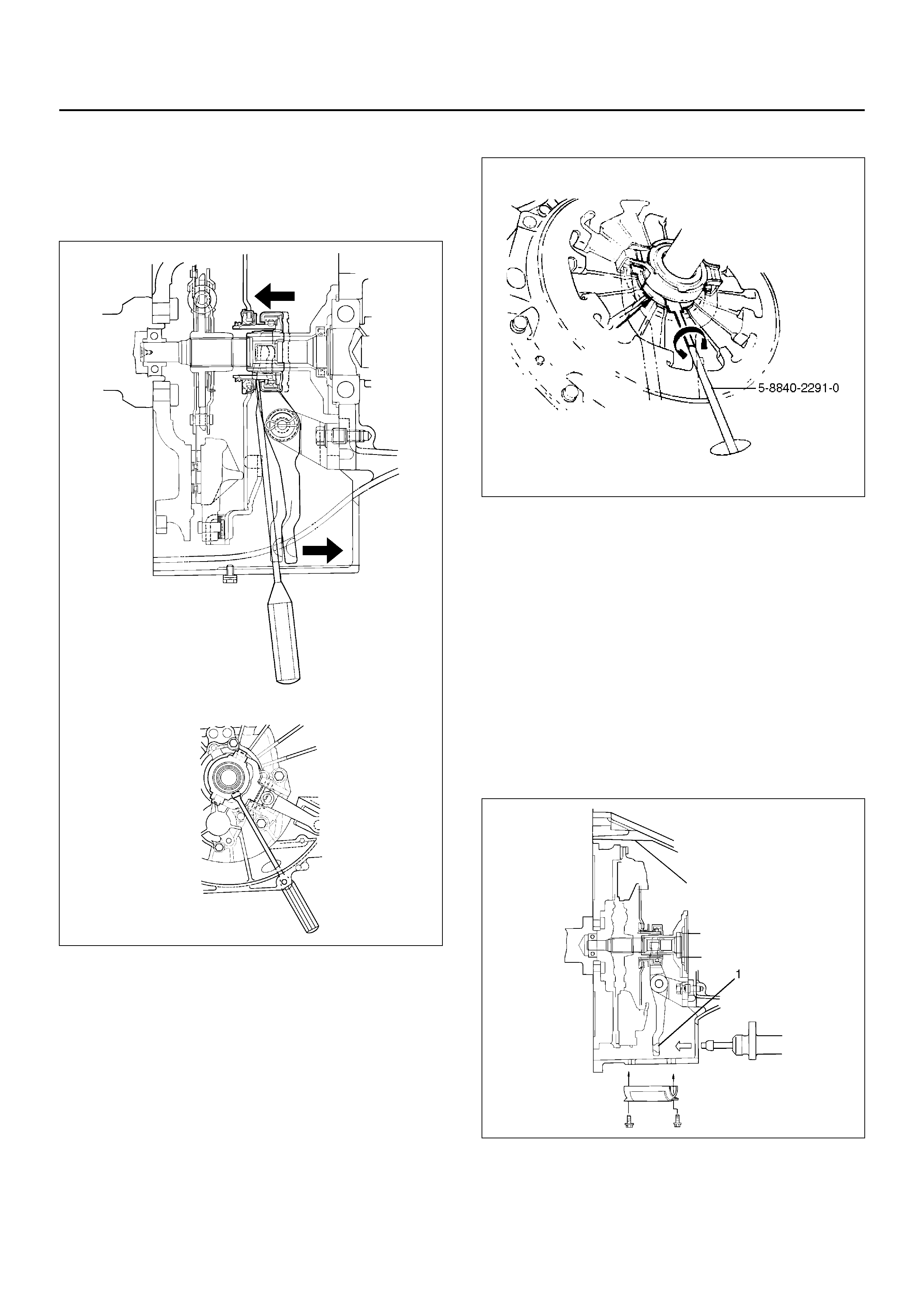

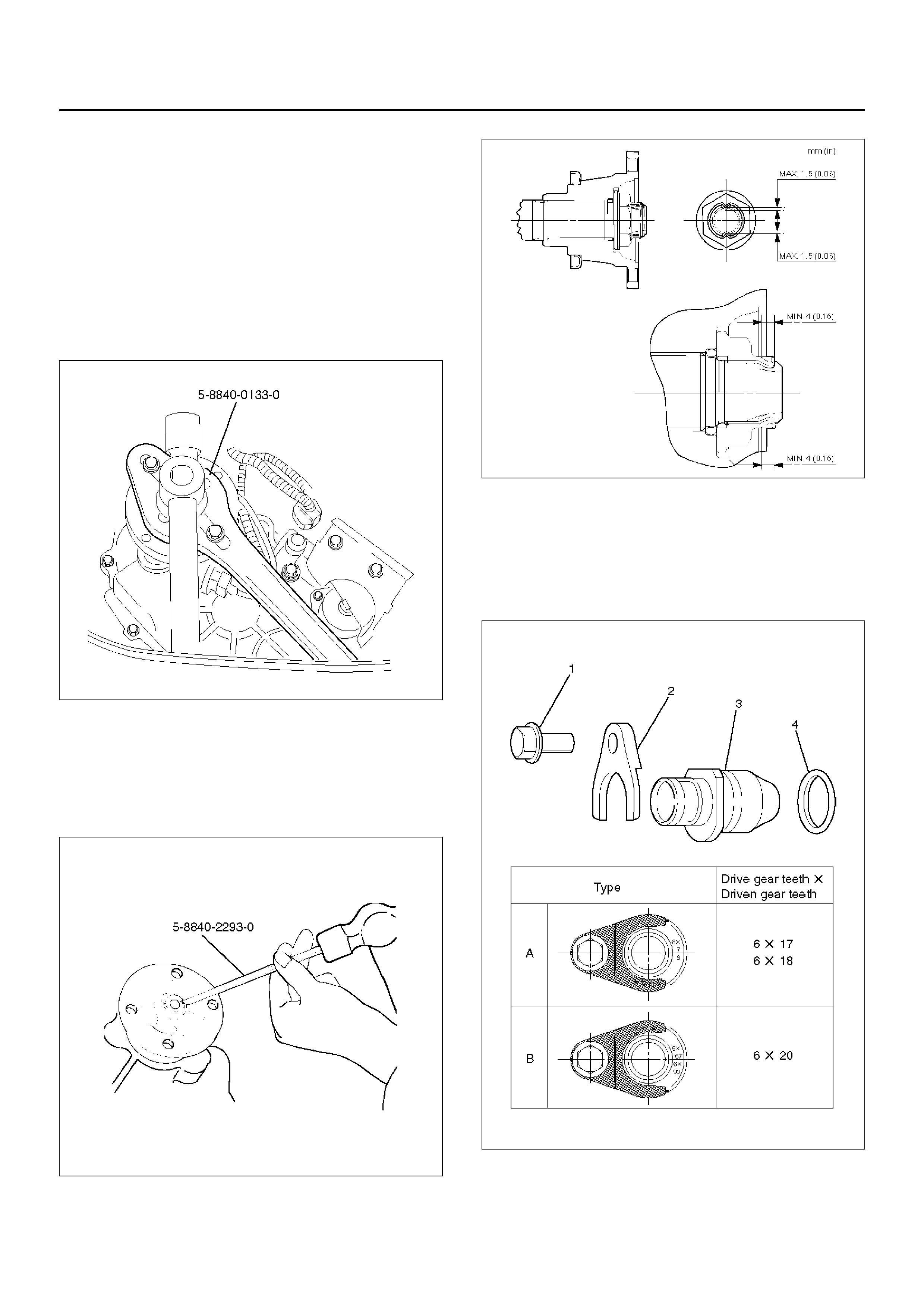

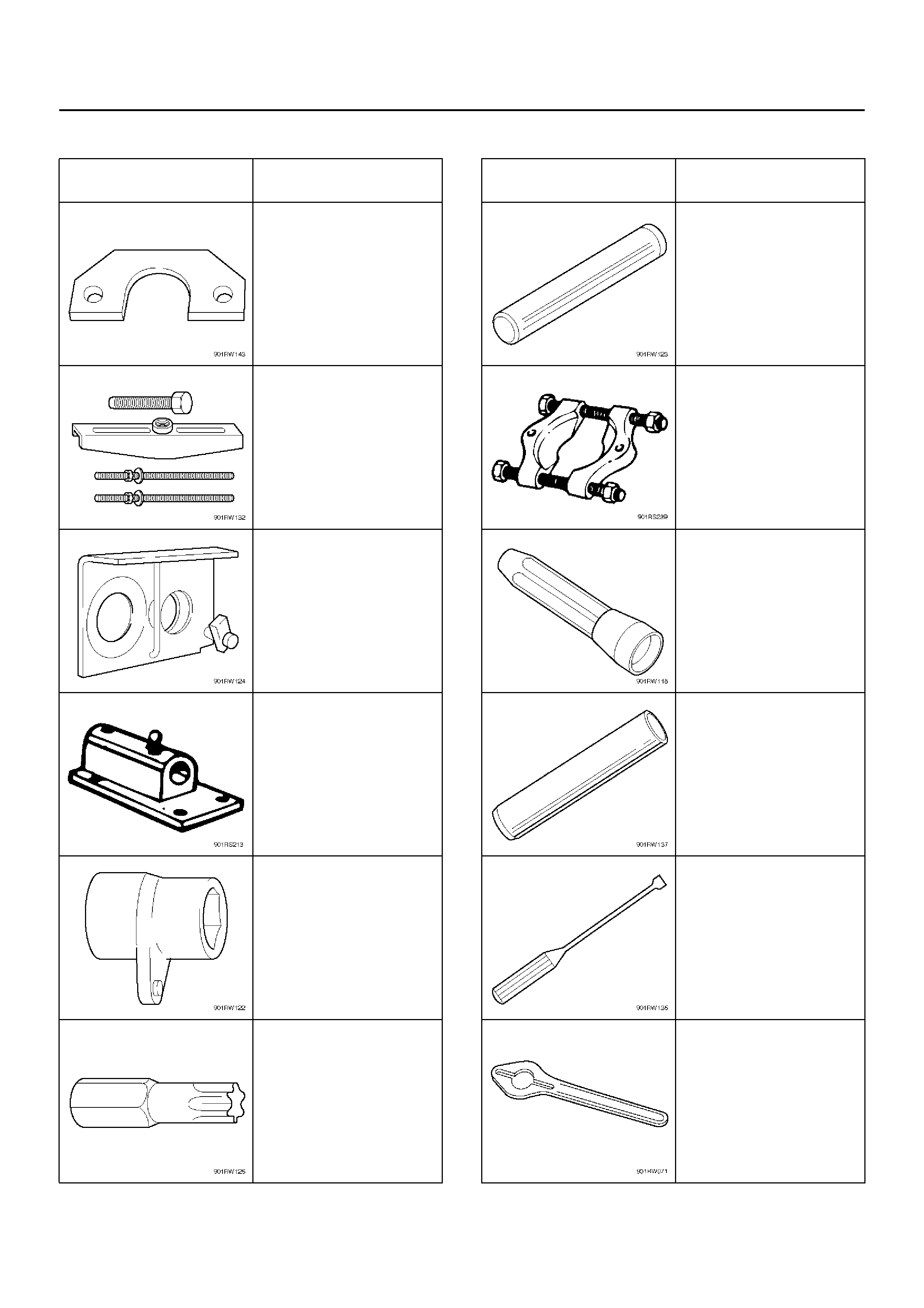

SPECIAL TOOLS (MUA)

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–2158–0

Mainshaft collar remover

5–8840–2027–0

Puller

5–8840–2160–0

Holding fixture

5–8840–0003–0

Holding fixture base

5–8840–2156–0

Wrench

5–8840–0047–0

Tork bit wrench

(T–45)

5–8840–2159–0

Mainshaft end bearing

installer

5–8840–0015–0

Bearing remover/installer

5–8840–0026–0

Front cover oil seal

installer

9–8522–1165–0

Mainshaft collar installer

5–8840–2291–0

Remover; Clutch release

bearing

5–8840–0133–0

Flange holder

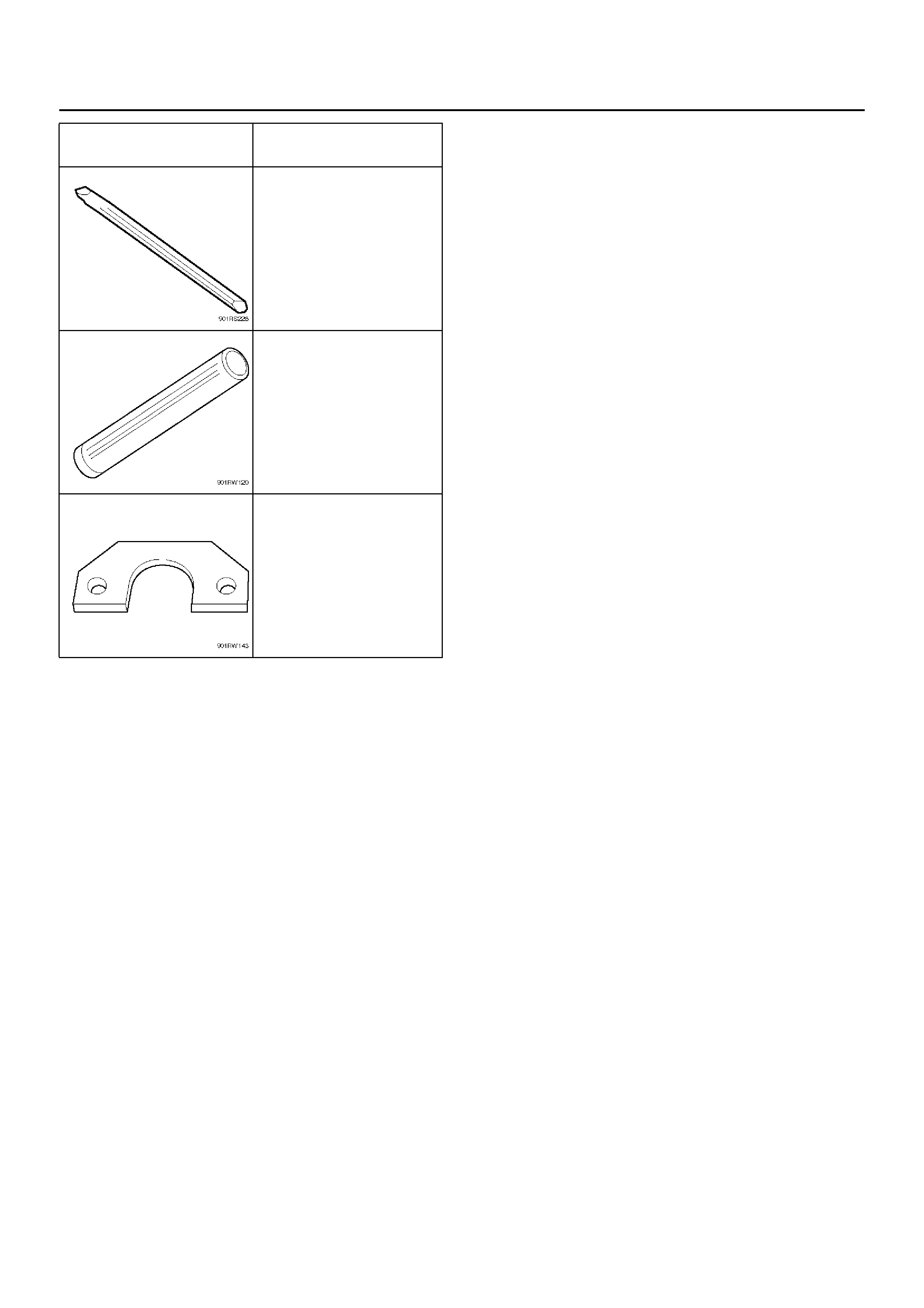

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–2293–0

Punch; end nut

5–8840–2194–0

Counter shaft bearing

installer

5–8840–2155–0

Bearing remover

ILLUSTRATION TOOL NO.

TOOL NAME