SECTION 7C1 - TRANSMISSION CONTROL SYSTEM (4L30-E)

Service Precaution

General Description

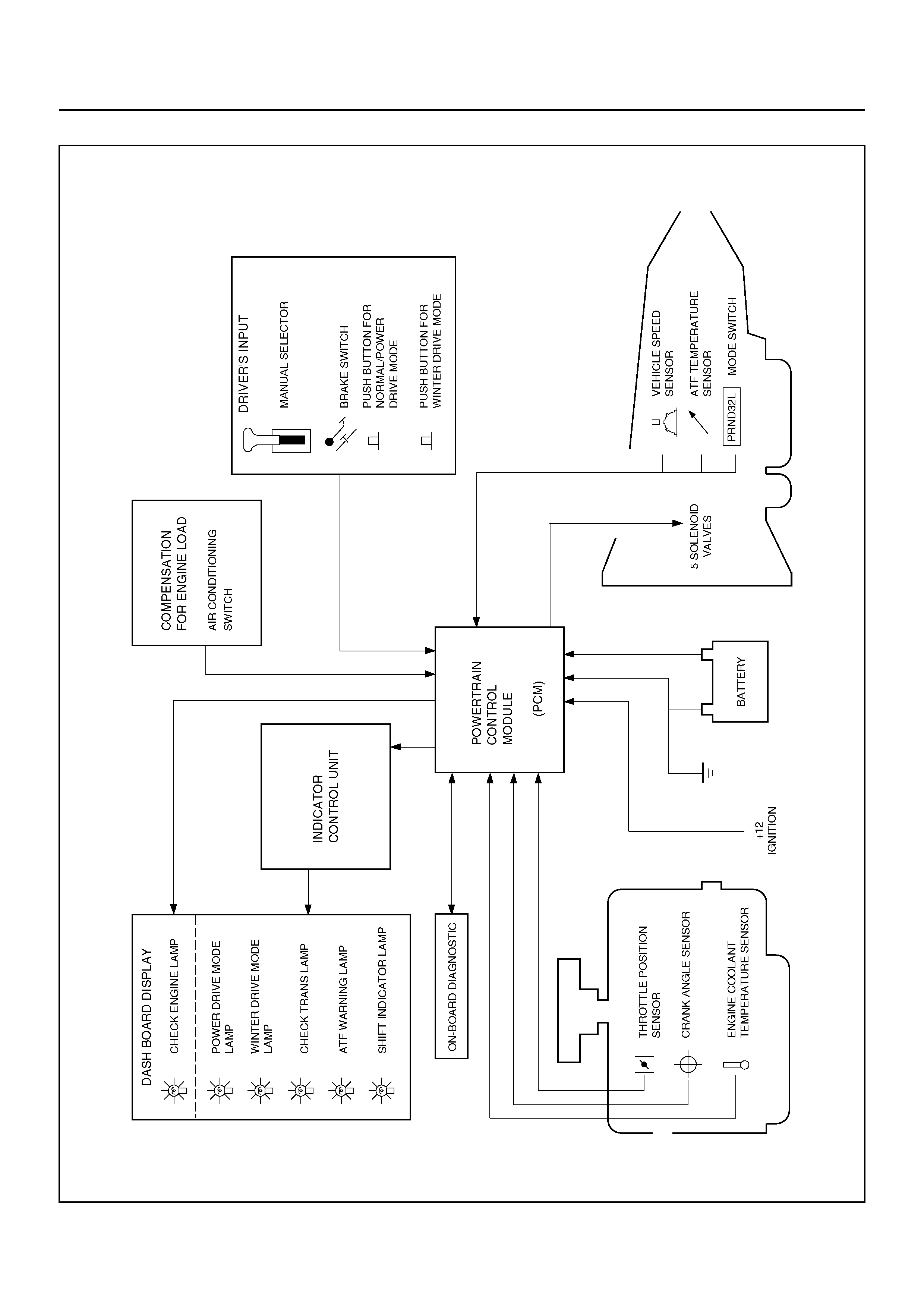

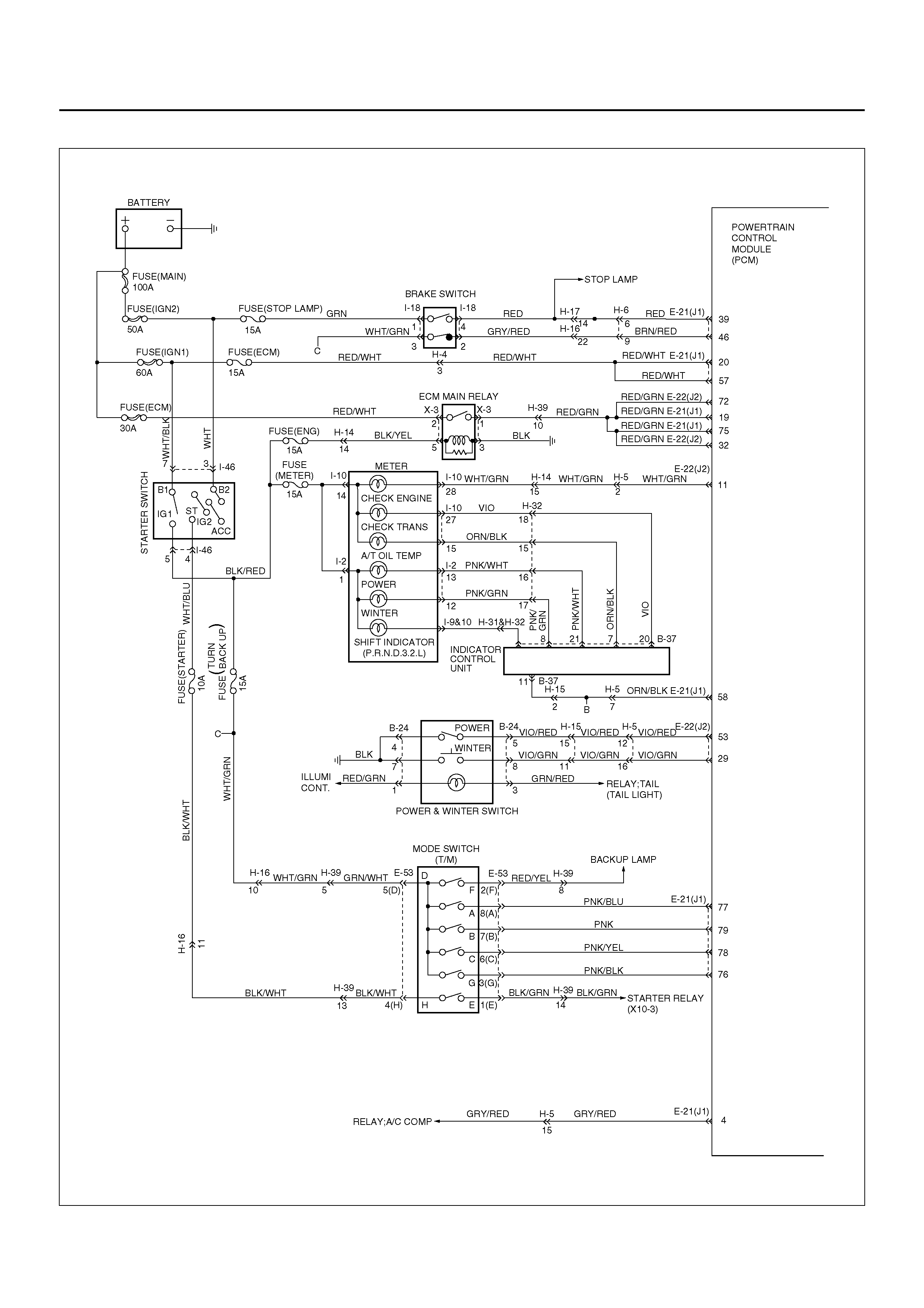

Electronic Control Diagram

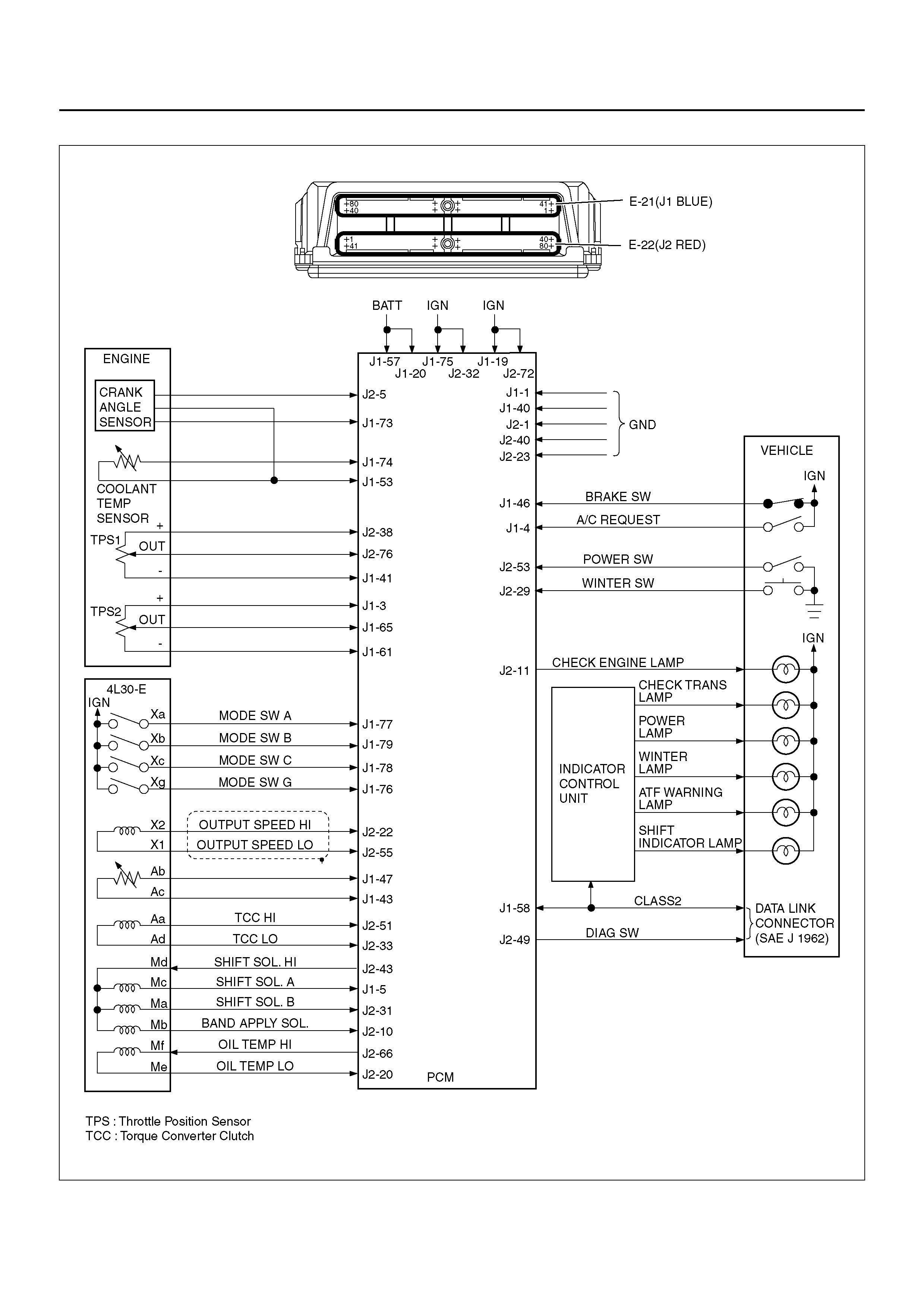

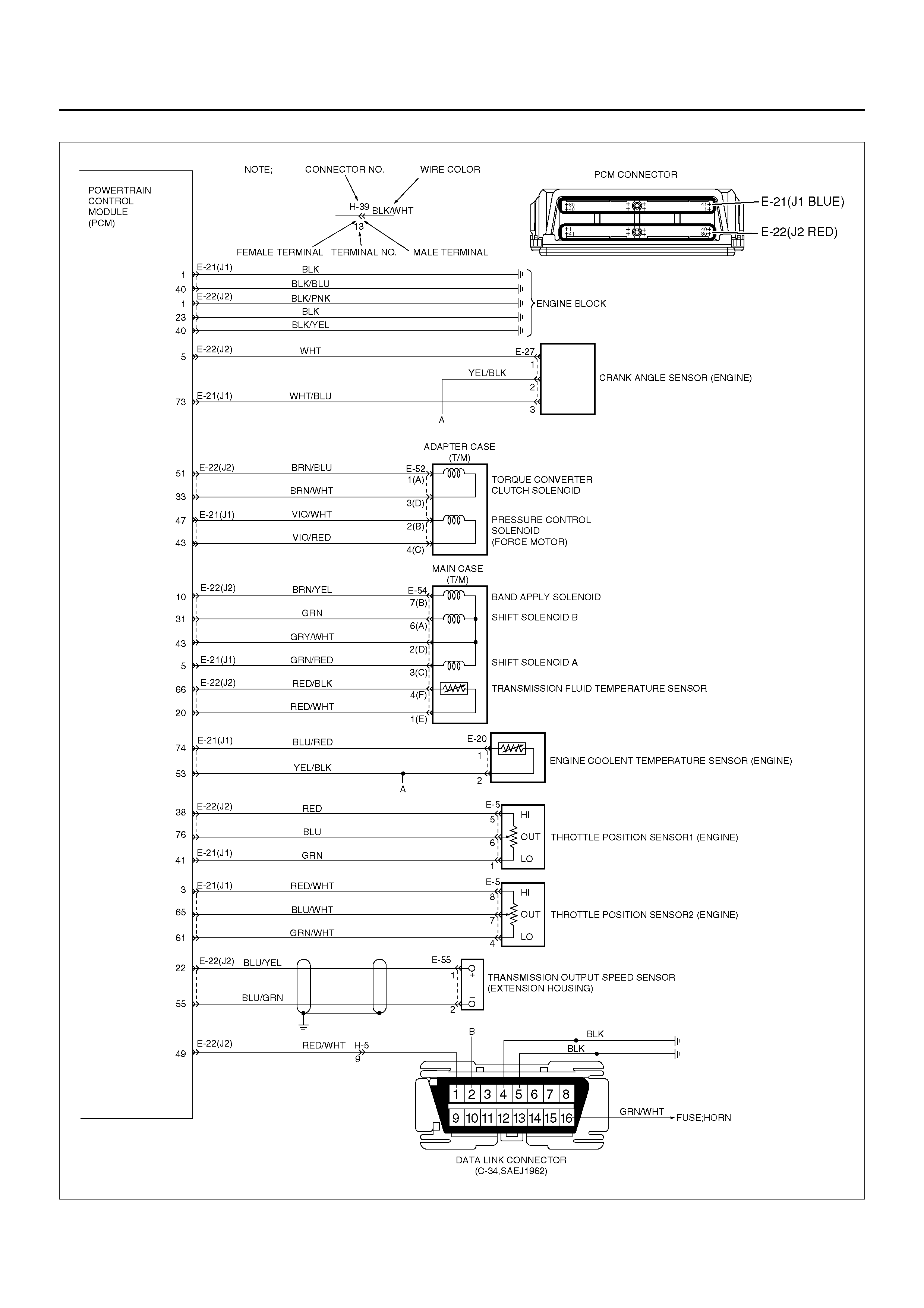

Powertrain Control Module (PCM)

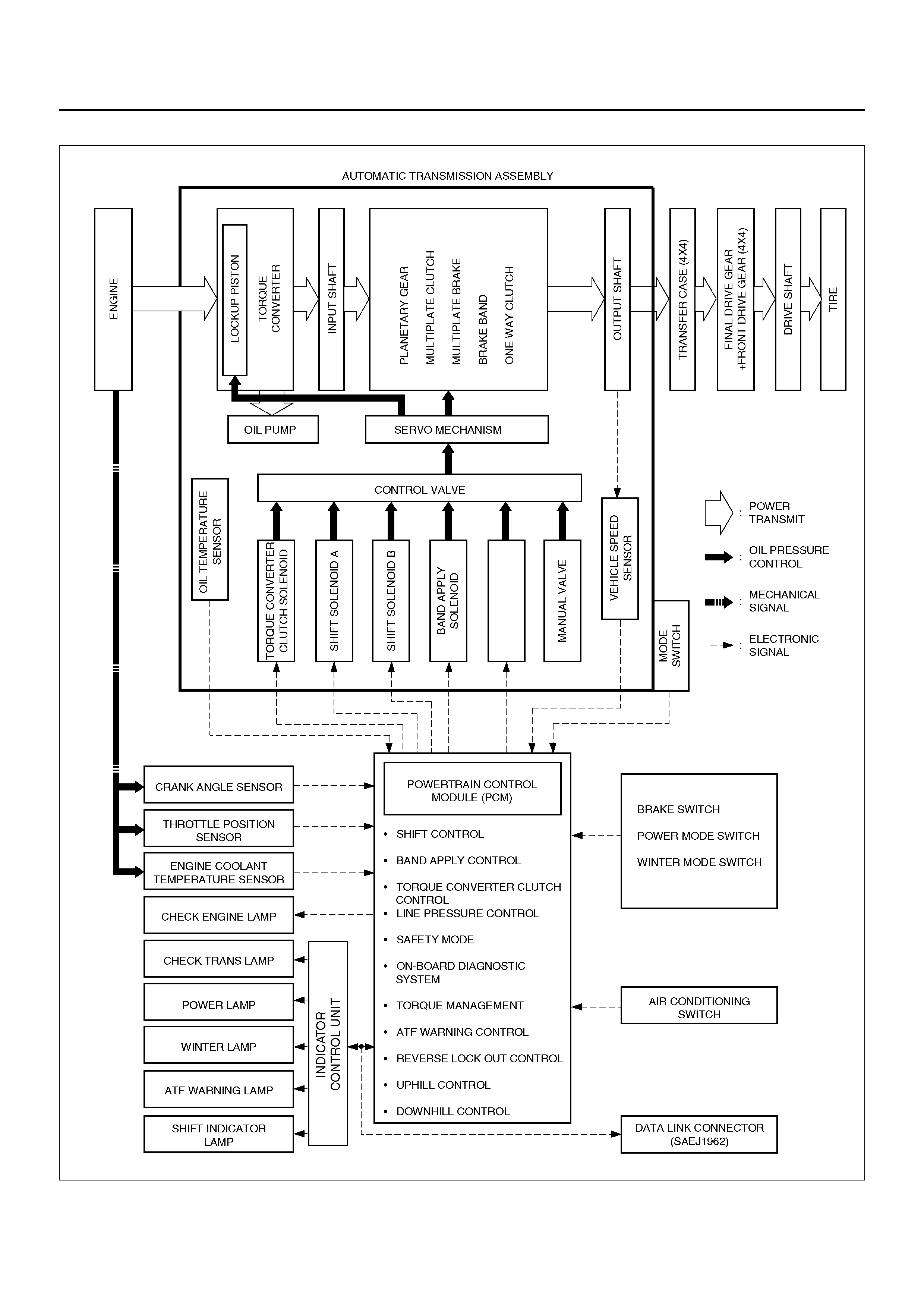

Control System Diagram

Shift Control

Band Apply Control

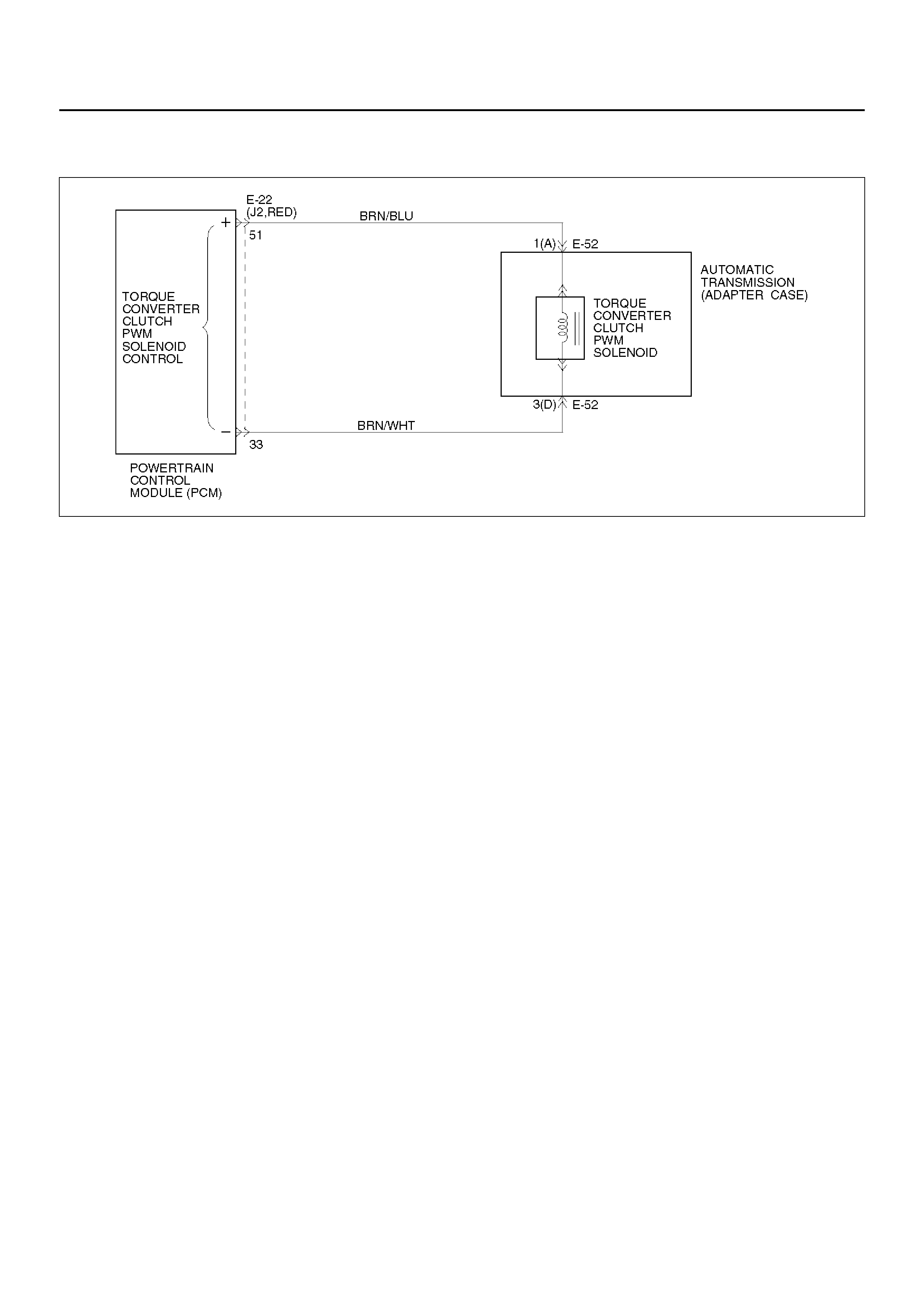

Torque Converter Clutch Control

Line Pressure Control

On–Board Diagnostic System

Fail Safe Mechanism

Torque Management Control

ATF Warning Control

Reverse Lock Out Control

Downhill Control

Uphill Control

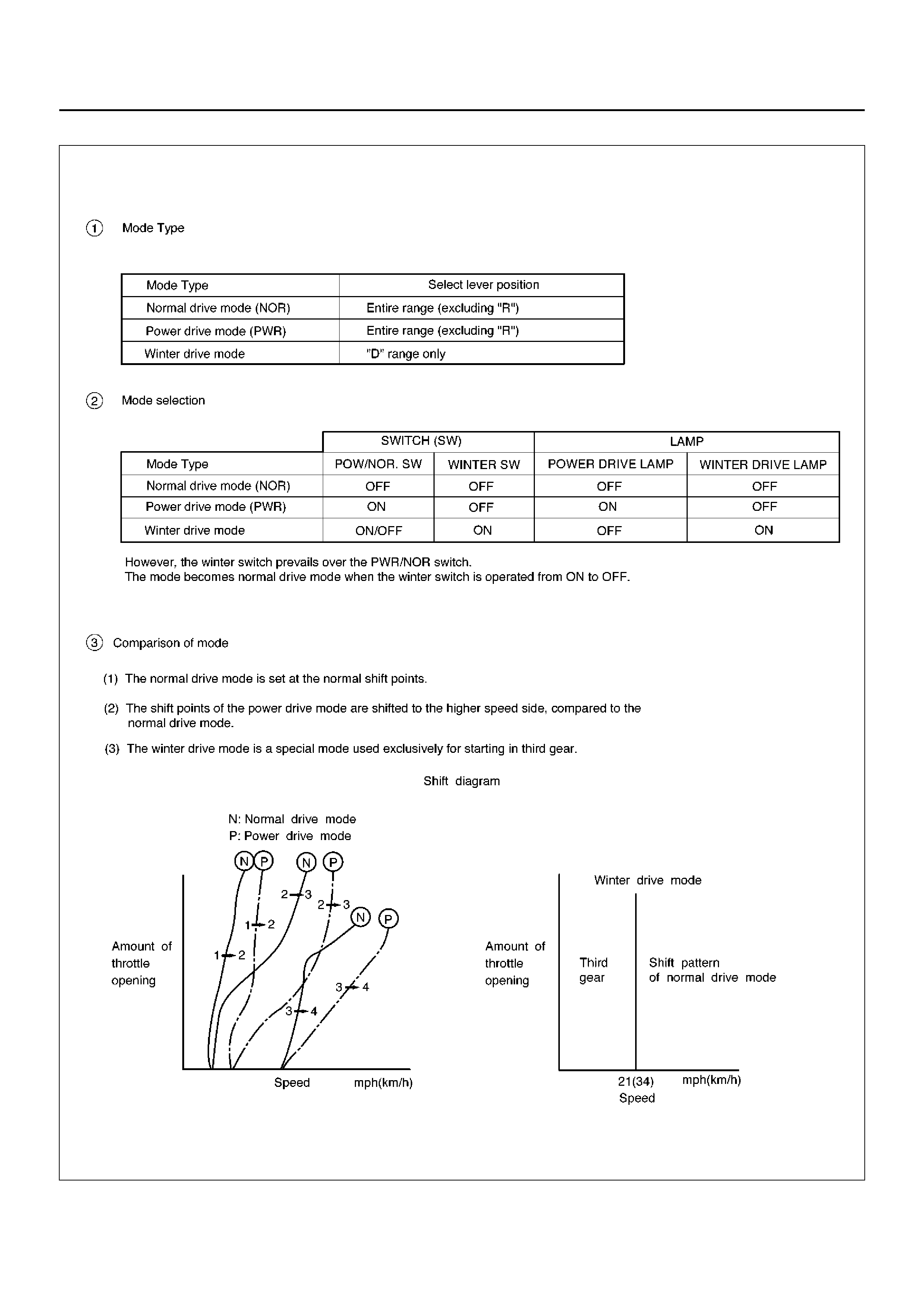

Shift Mode Control

Gear Shift Control

Winter Drive Mode

Backup Mode

Functions of Input / Output Components

Diagnosis

Electronic Diagnosis

Check Trans Indicator

Diagnostic Check

“Check Trans" Check

Tech 2 OBD II Connection

Transmission Data

Flashing Code

OBD II Diagnostic Management System

16 – Terminal Data Link Connector (DLC)

Malfunction Indicator Lamp (MIL)

DTC Types

Clear DTC

DTC Check

PCM Precaution

Information On PCM

Intermittent Conditions

Transmission and PCM Identification

Diagnostic Trouble Code (DTC)

Identification

DTC P0218/Flashing Code 71 Transmission

Fluid Over Temperature

DTC P0705/Flashing Code 73 Transmission

Range Switch (Mode Switch) Illegal Position

DTC P0706/Flashing Code 74 Transmission

Range Switch (Mode Switch) Performance

DTC P0712/Flashing Code 75 Transmission

Fluid Temperature (TFT) Sensor Circuit Low

Input

DTC P0713/Flashing Code 76 Transmission

Fluid Temperature (TFT) Sensor Circuit High

Input

DTC P0719/Flashing Code 77 TCC Brake

Switch Circuit High (Stuck On)

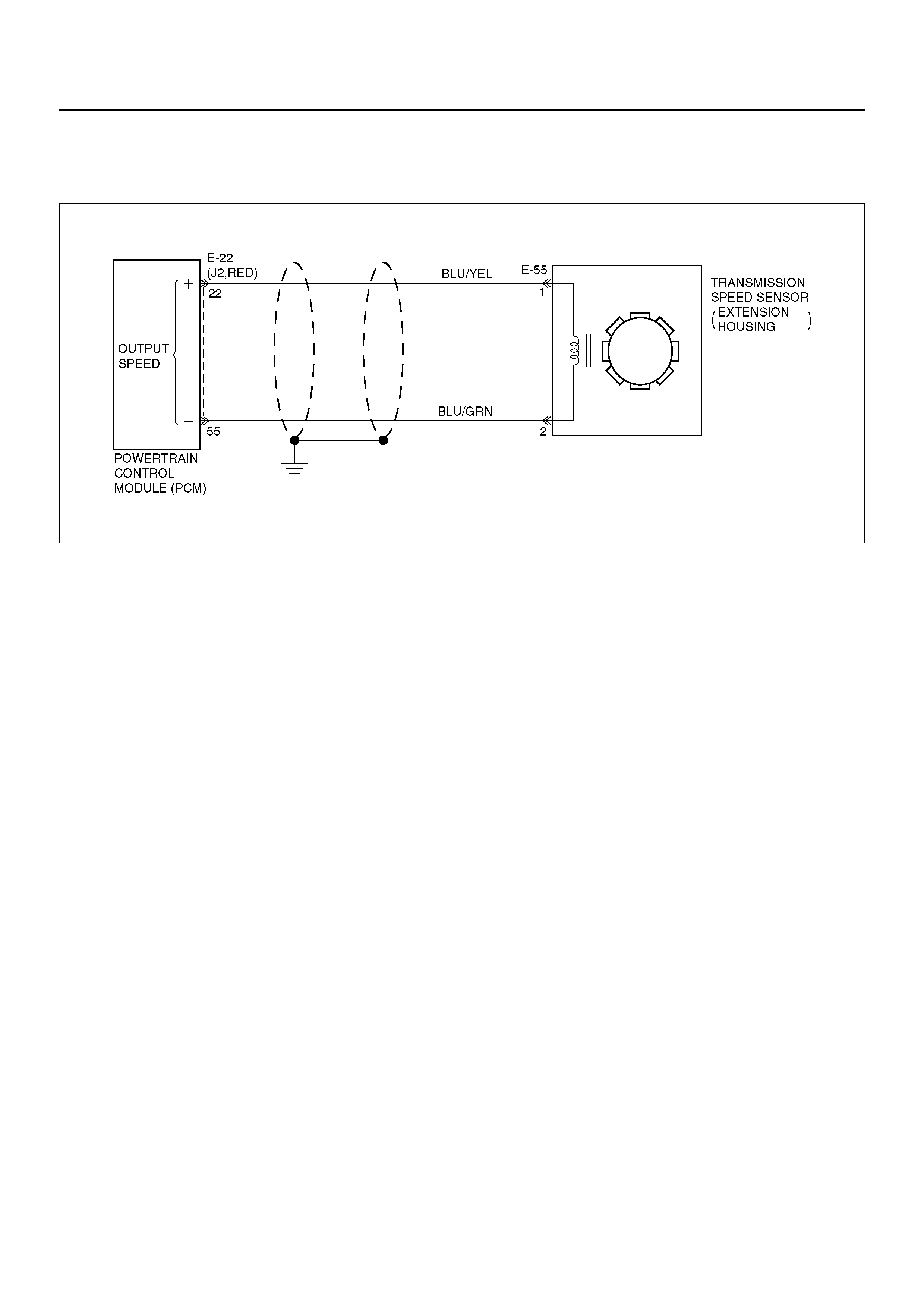

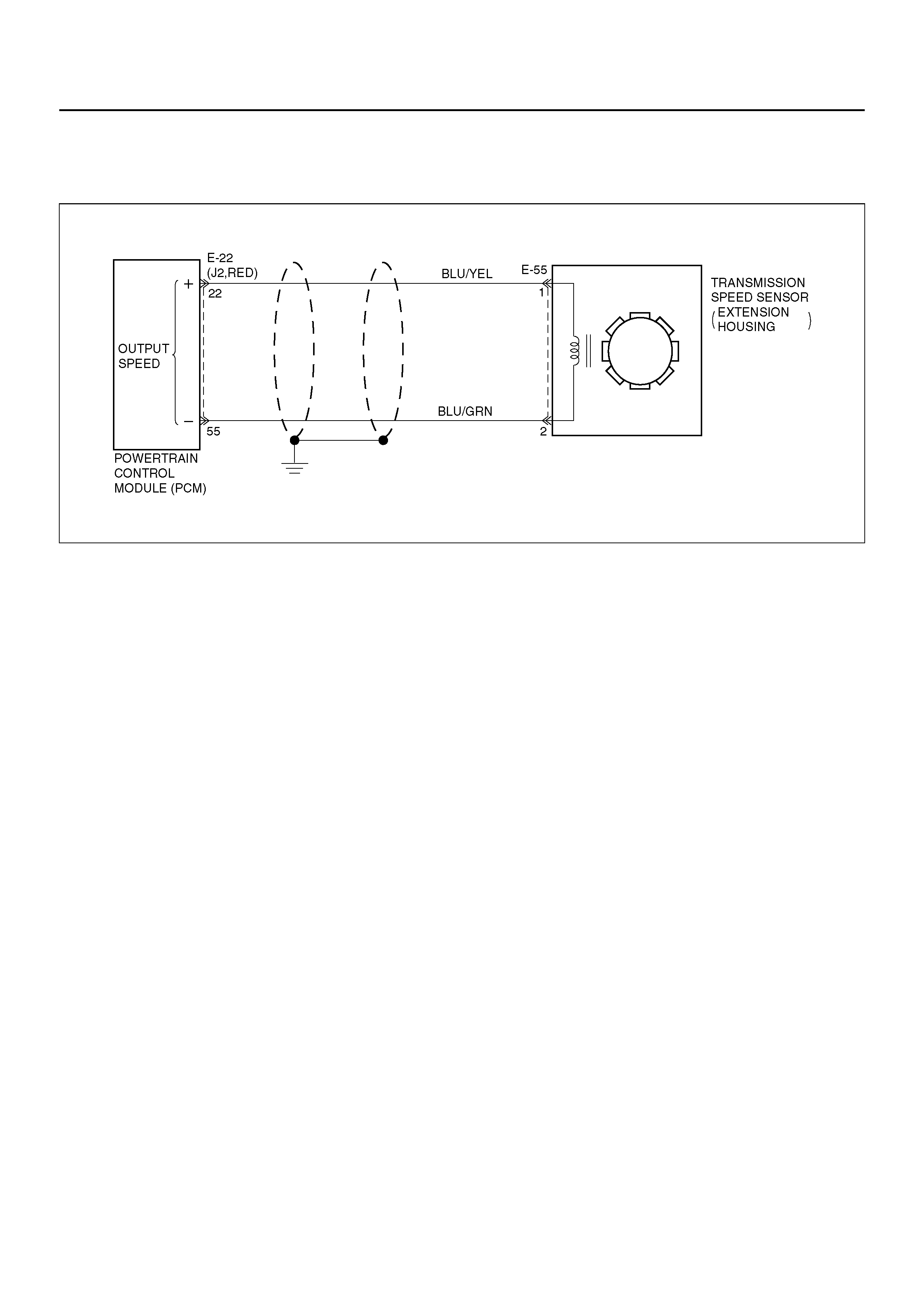

DTC P0722/Flashing Code 78 Transmission

Output Speed Sensor (OSS) Low Input

DTC P0723/Flashing Code 79 Transmission

Output Speed Sensor (OSS) Intermittent

DTC P0730/Flashing Code 81 Transmission

Incorrect Gear Ratio

DTC P0748/Flashing Code 82 Pressure

Control Solenoid (PCS) Circuit

Electrical

DTC P0753/Flashing Code 83 Shift Solenoid

A Electrical

DTC P0758/Flashing Code 84 Shift Solenoid

B Electrical

DTC P1850/Flashing Code 88 Brake Band

Apply Solenoid Malfunction

DTC P1860/Flashing Code 89 TCC Solenoid

Electrical

Circuit Diagram

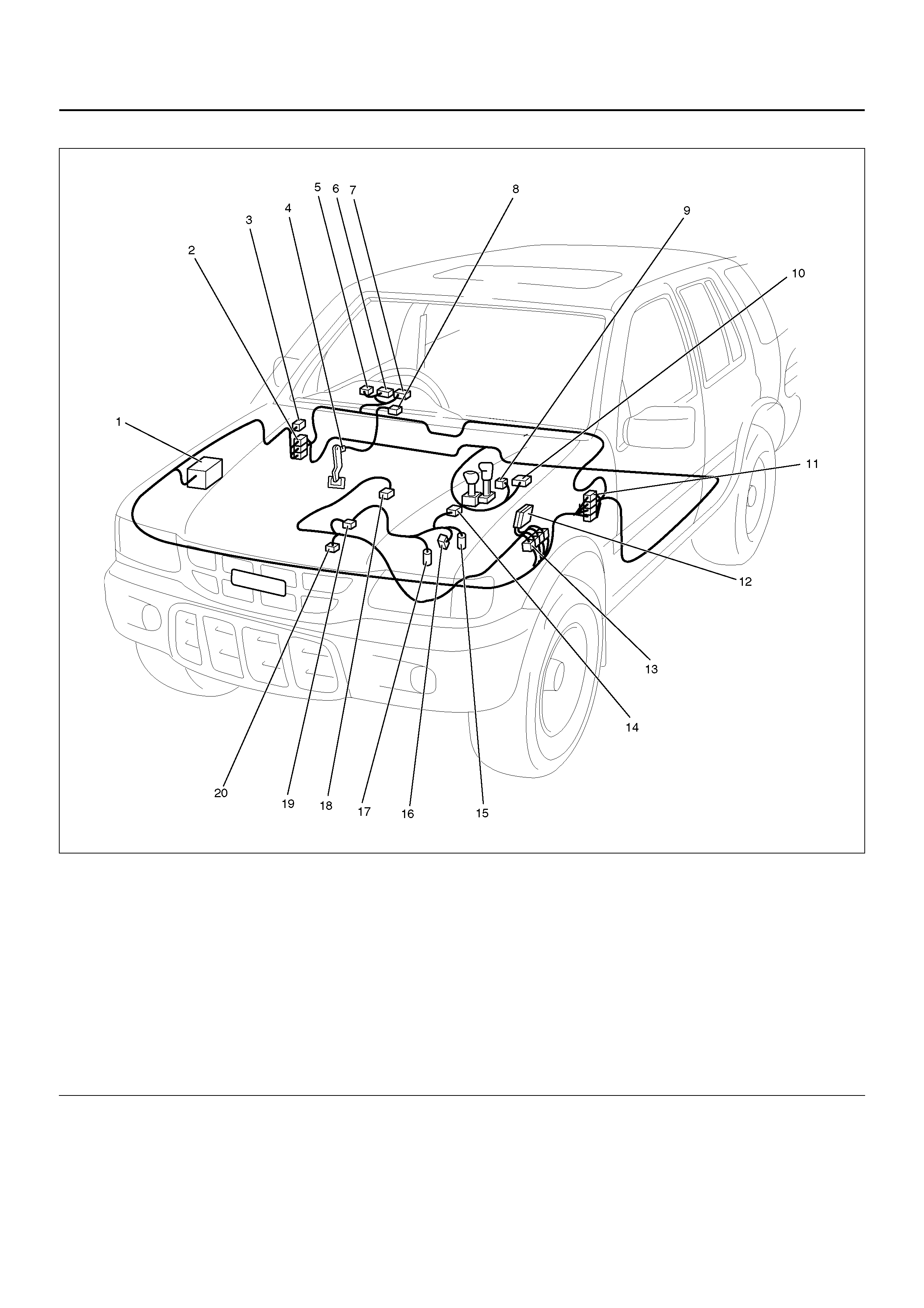

Parts Location

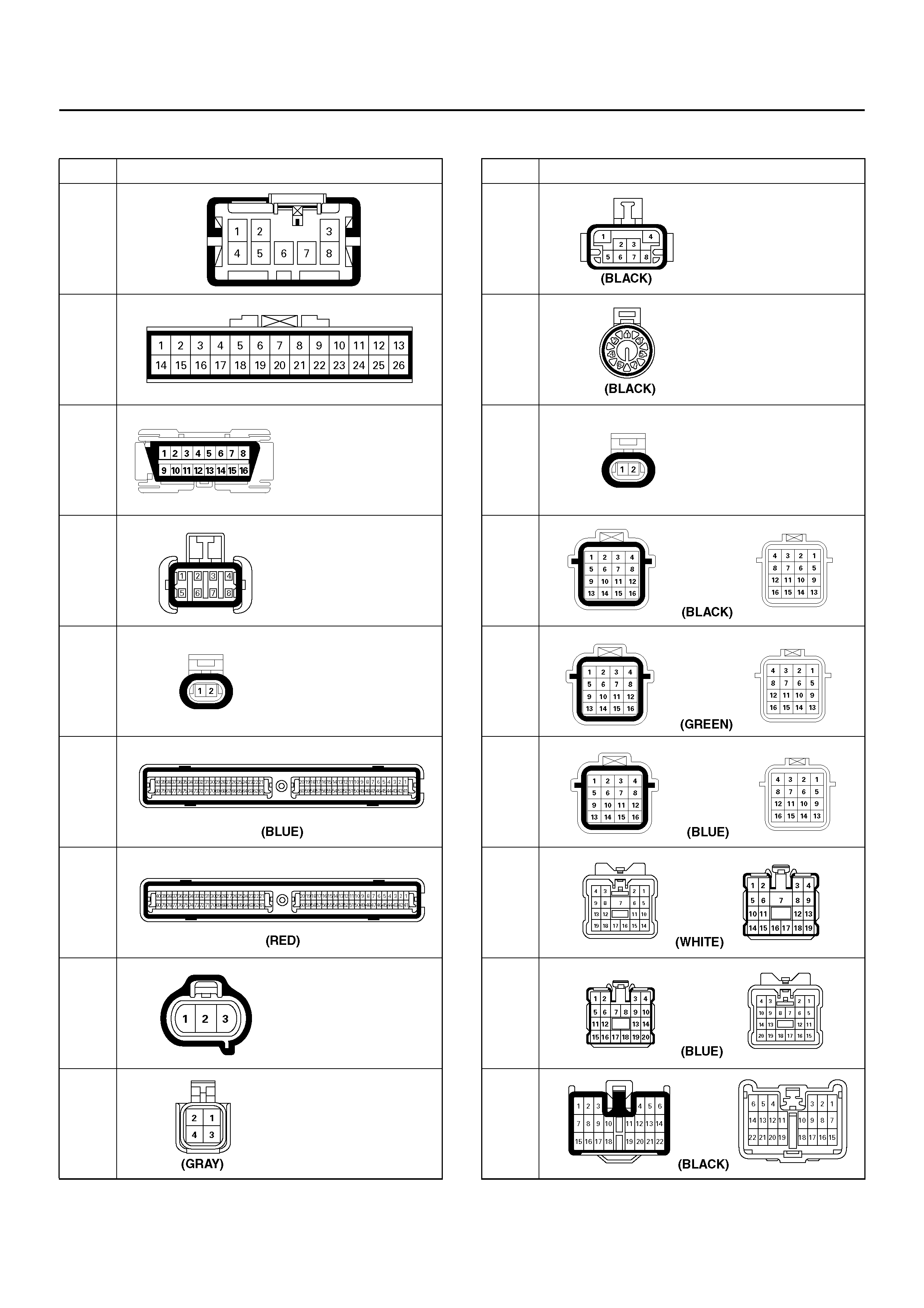

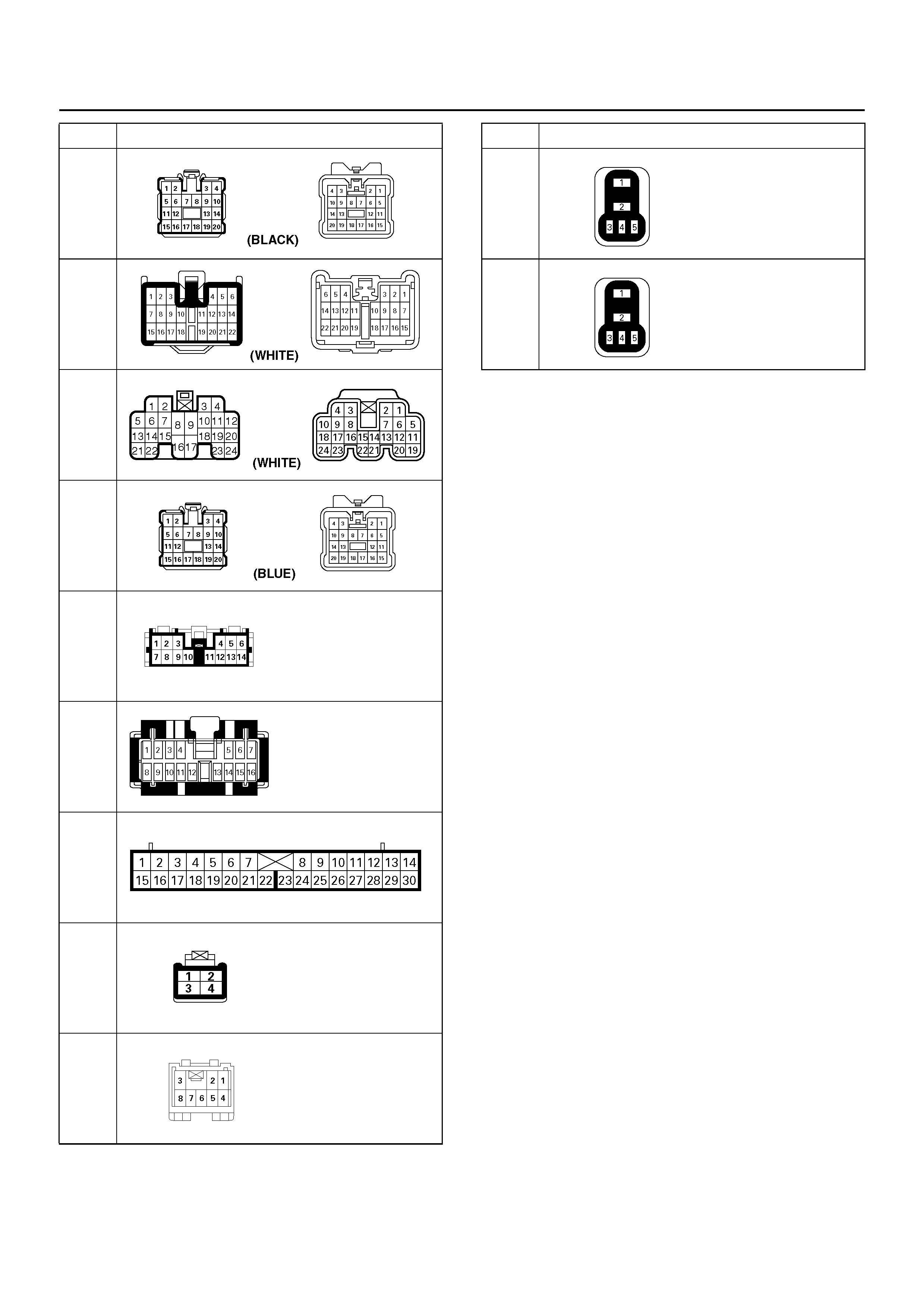

Harness Connector Faces

Transmission Fluid Temperature (TFT) Sensor

Specifications

SERVICE PRECAUTION

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS), REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

GENERAL DESCRIPTION

The 4L30–E is a 4–speed fully automatic transmission.

It uses a microcomputer as a control unit to judge

running conditions including throttle opening rate and

vehicle speed, then it sets the shifting point in the

optimum tim in g so that be st dr i ving pe rf or man ce can be

achieved.

In addition, the built–in shift mode select function can

select three shift modes according to the driver's

preference:

• Normal mode –Normal shift pattern.

• Winter mode –Starts in 3rd gear to reduce slippage

on ice or snow.

• Power mode has a delayed upshift for when more

powerful acceleration is required.

Also, the built–in fail safe function (“backup mode")

assure s driv ing pe rform ance even if the vehic le spee d

sensor, throttle signal or any solenoid fails.

Further, the self–di agnost ic fun ction co ndu cts diagnos is

in a short time when the control system fails, thus

improving serviceability.

The major features of 4L30–E are as follows:

• A compac t structure con sisting of 2 sets of planetary

gears and flat torque converter.

• Electronic control selects the optimum shift mode

according to the driving conditions.

• Electronic control maintains the optimum hydraulic

pressure for clutch, band brake as well as

transmission so that shift feeling is improved.

• Two sets of planetary gears reduce friction of power

train.

Also, a lockup mechanism in the torque converter

reduces fuel consumption.

• Wide gear ratio and high torque rate of torque

converter provide excellent starting performance.

ELECTRONIC CONTROL DIAGRAM

C07R200003

POWERTRAIN CONTROL MODULE (PCM)

C07R100004

Pressure Control Solenoid HI

Pressure Control Solenoid LO

CONTROL SYSTEM DIAGRAM

C07R100005

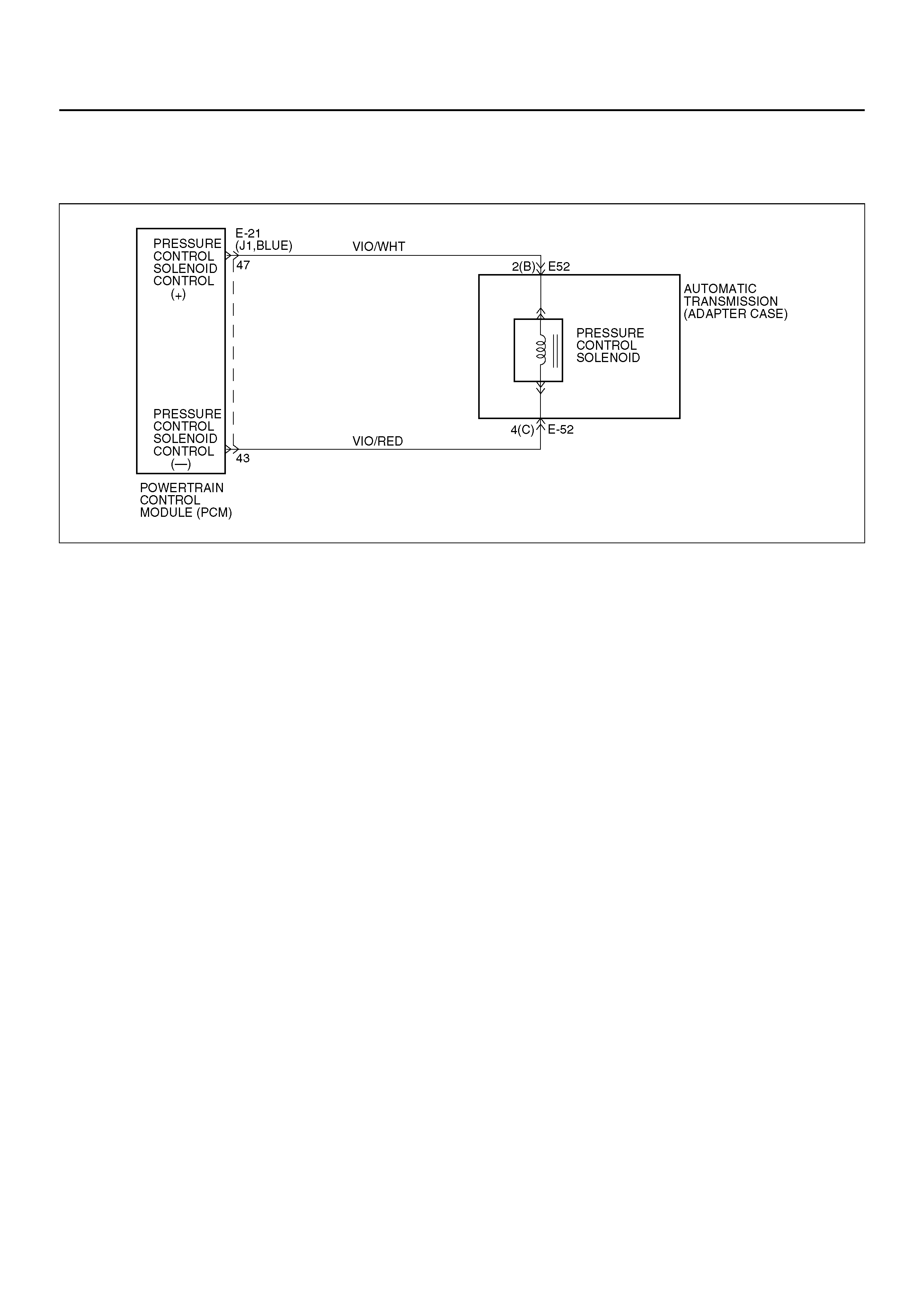

PRESSURE CONTROL

SOLENOID

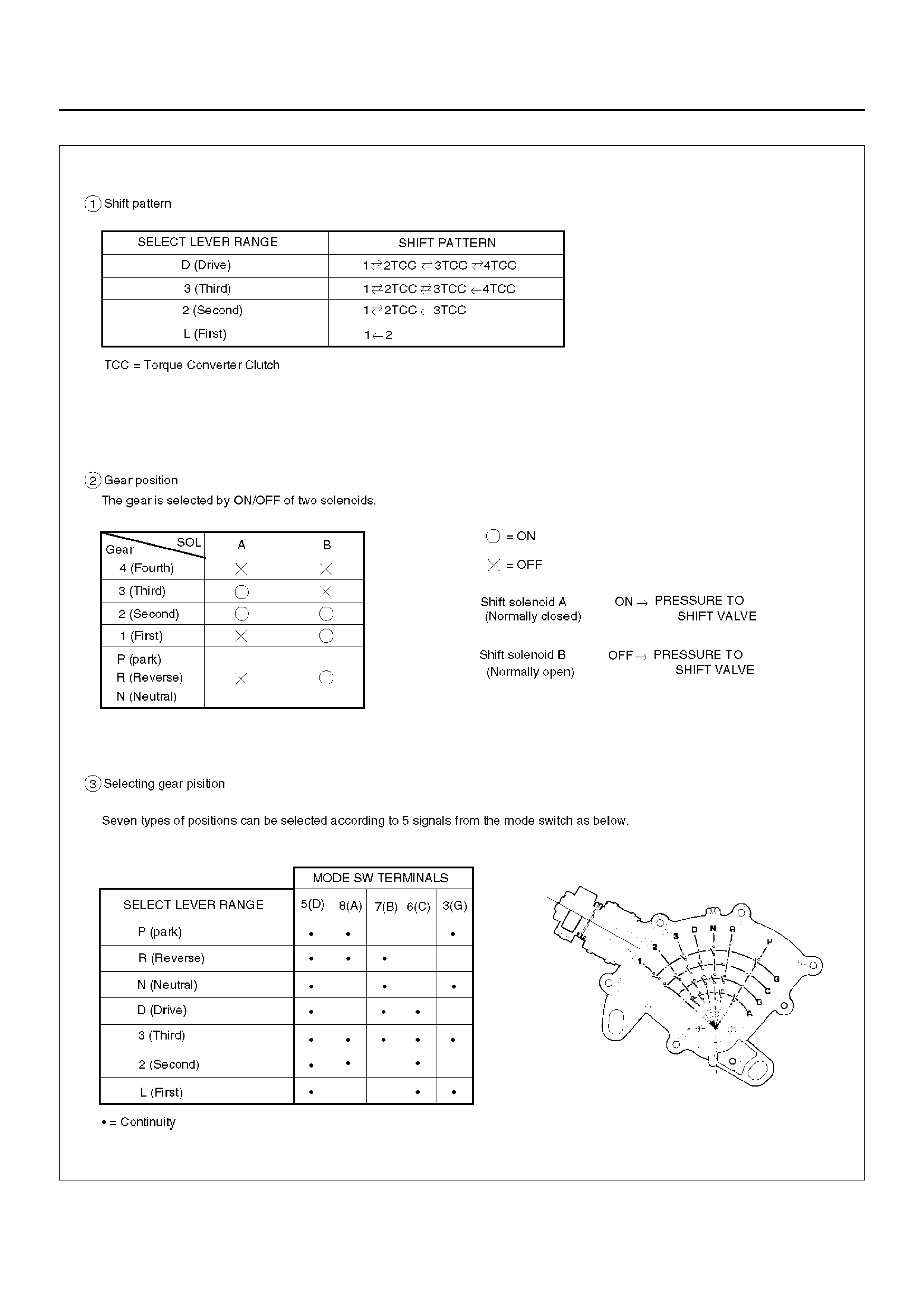

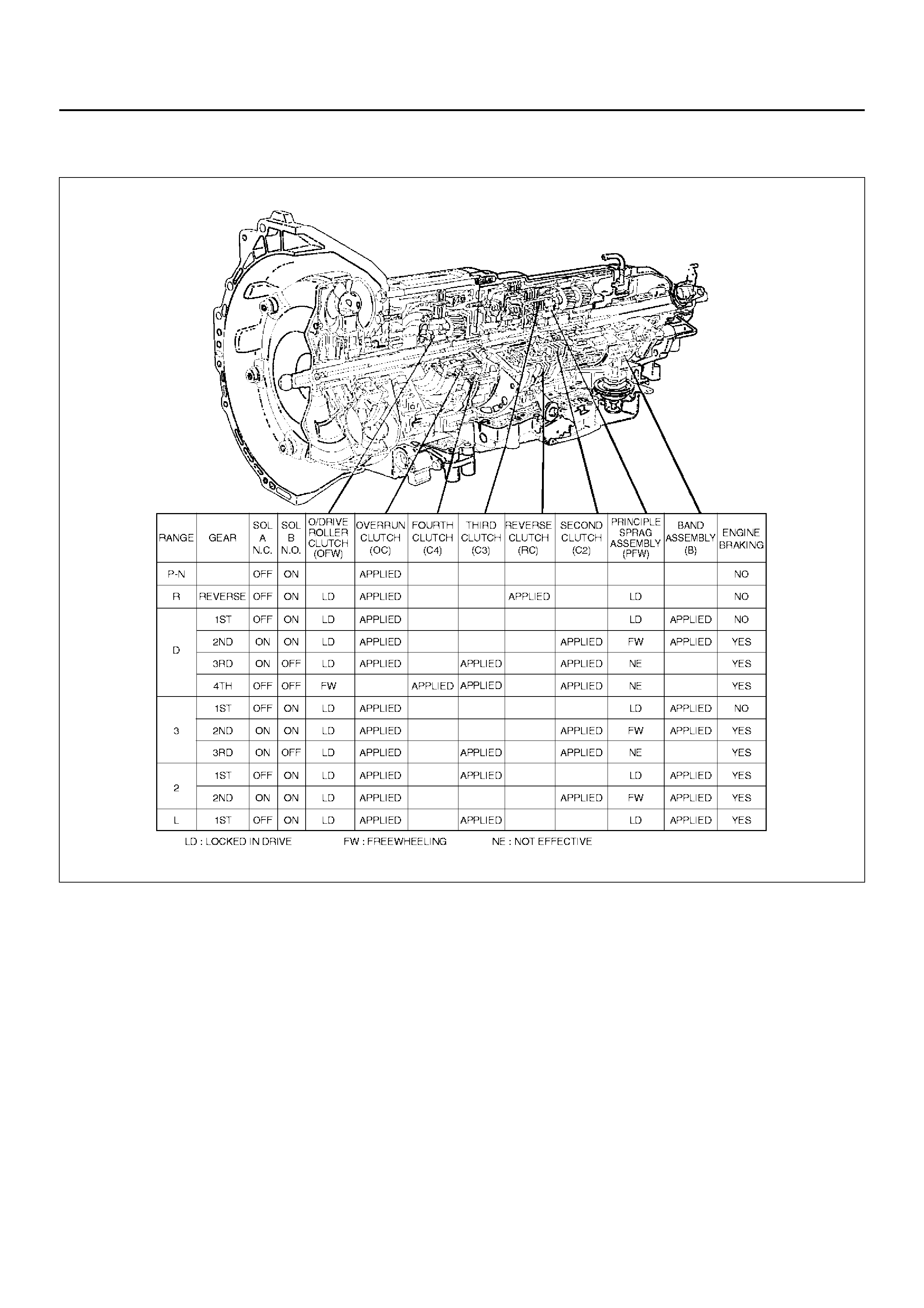

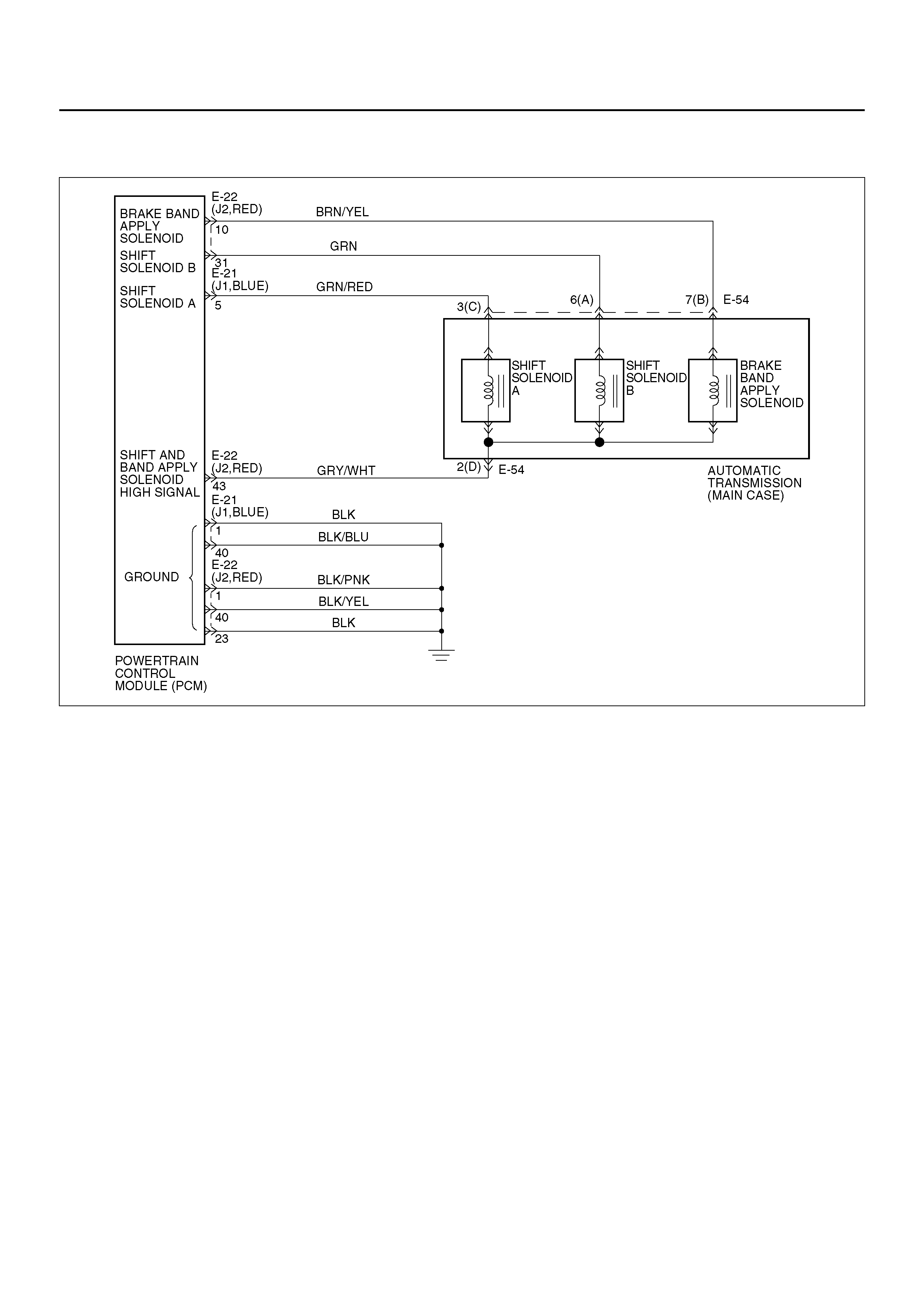

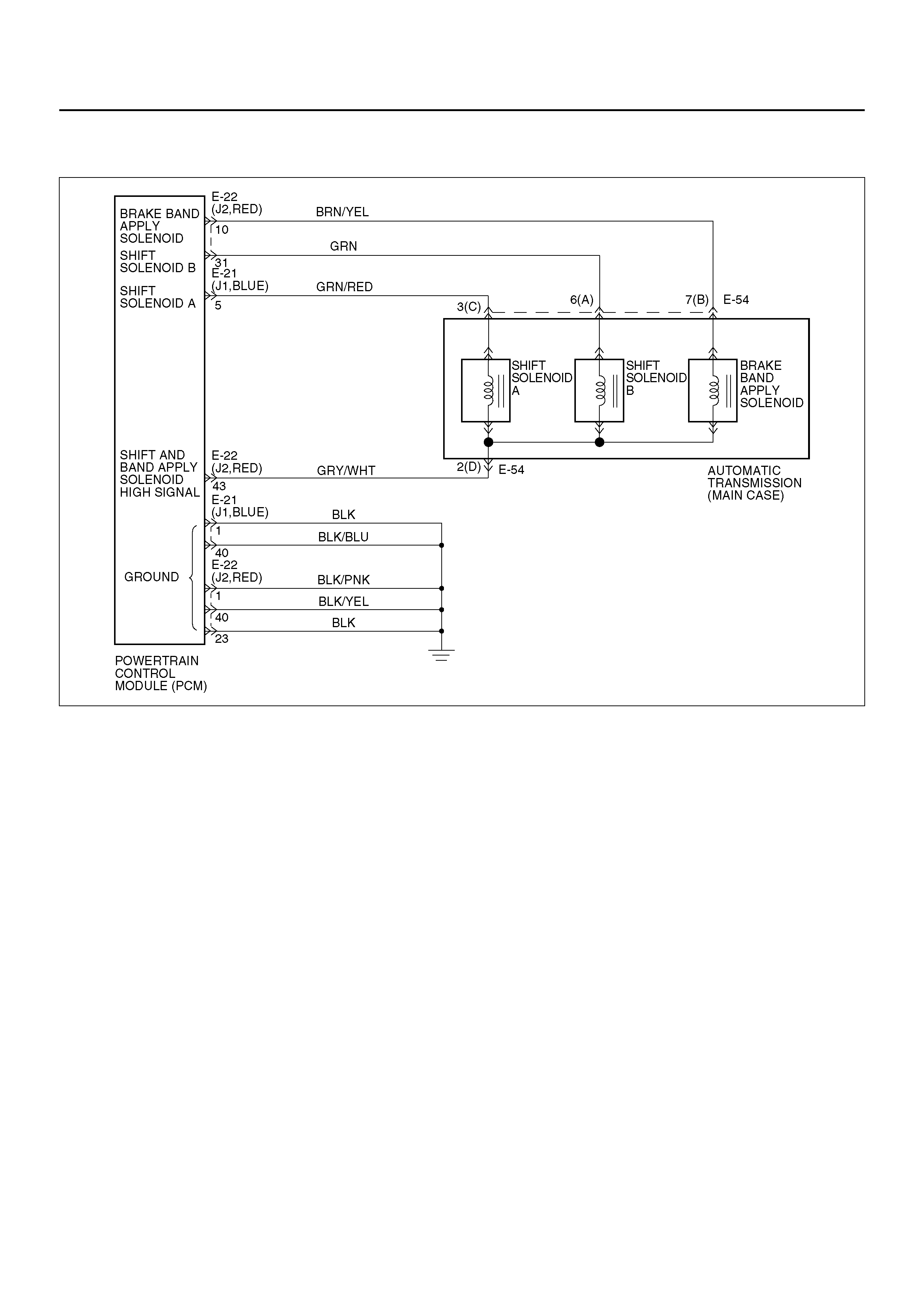

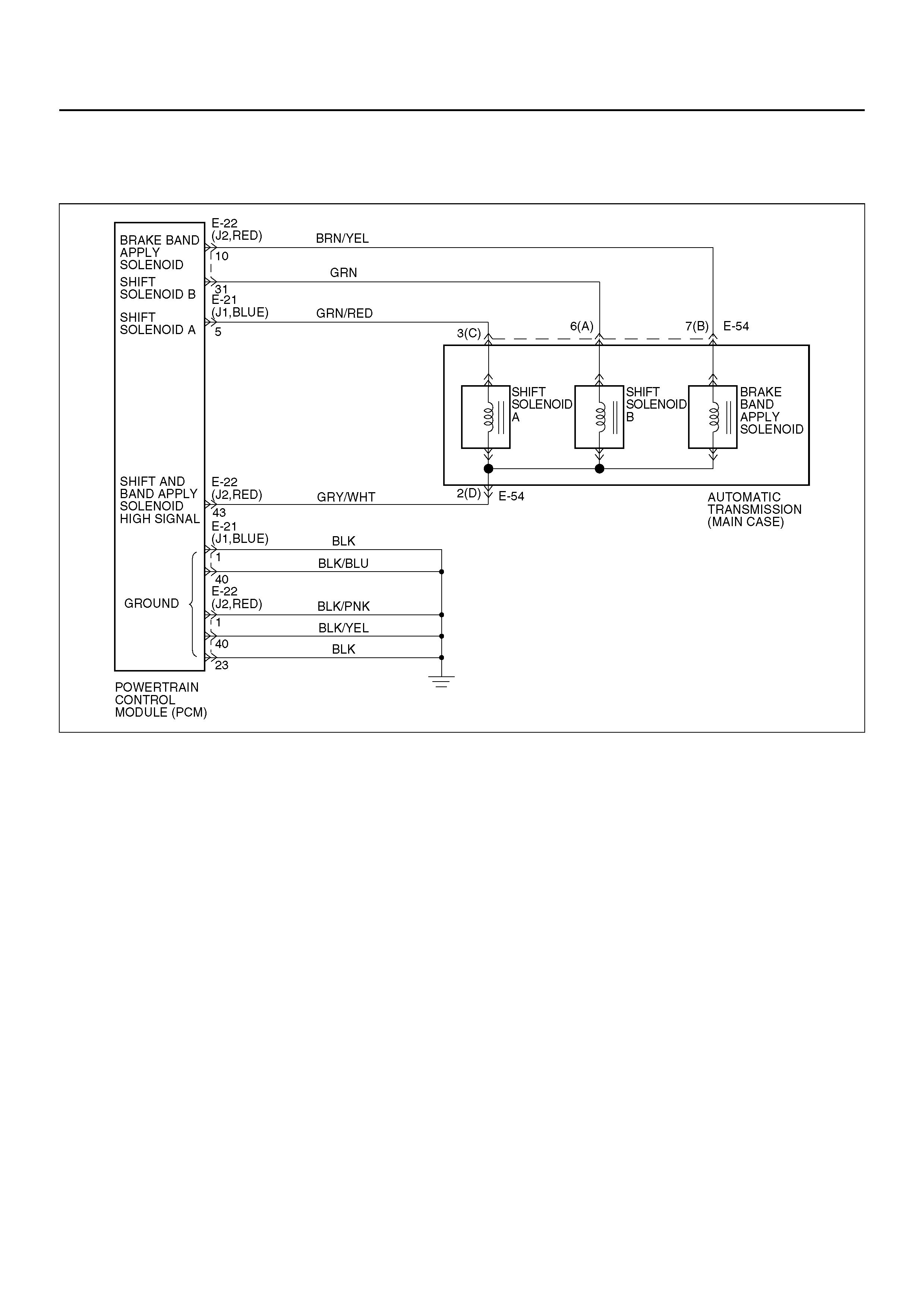

SHIFT CONTROL

The transmission gear is shifted according to the shift

pattern selected by the driver. In shifting gears, the

gear ratio is controlled by the ON/ OFF signal using the

shift solenoid A and the shift solenoid B.

BAND APPLY CONTROL

The band apply is controlled when in the 3–2 downshift

(engine overrun prevention) and the garage shift (shock

control).

The band apply solenoid is controlled by the signal from

the Pulse Width Modulation (PWM) to regulate the flow

of the oil.

TORQUE CONVERTER CLUTCH CONTROL

The clutch ON/OFF is controlled by moving the

converter clutch valve through shifting Torque Converter

Clutch (TCC) solenoid using the ON/OFF signal.

LINE PRESSURE CONTROL

The throttle signal allows the current signal to be sent to

the Pressure Control Solenoid. After receiving the

current signal, the Pressure Control Solenoid activates

the pressure regulator valve to regulate the line

pressure.

ON–BOARD DIAGNOSTIC SYSTEM

Several malfunction displays can be stored in the

Powertrain Control Module (PCM) memory, and read by

Tech 2..

The serial data lines, which are required for the testing

of the final assembly and the coupling to other

electronic modules, can be regulated by this function.

FAIL SAFE MECHANISM

If there is a problem in the transmission system, the

PCM will go into a “backup" mode.

The vehicle can still be driven, but the driver must use

the select lever to shift gears.

TORQUE MANAGEMENT CONTROL

The transmission control side sends the absolute spark

advance signal to the engine control side while the

transmission is being shifted. This controls the engine

spark timing according vehicle running condition,

improving shift quality.

ATF WARNING CONTROL

The oil temperature sensor detects the ATF oil

temperature to control the oil temperature warning, TCC

operation, and the winter mode.

REVERSE LOCK OUT CONTROL

With the selector lever in reverse position, the PCM will

not close the PWM solenoid until the vehicle is below 11

km/h, thus preventing reverse engagement above this

speed.

DOWNHILL CONTROL

This mode is automatically activated from NORMAL

mode only when downhill conditions are recognised.

The shift pattern is identical to NORMAL mode except

the 0% throttle 3-4 and 4-3 shift calibrations are

modified to provide engine braking over a greater speed

range.

UPHILL CONTROL

When uphill condition are recognized the 2-3 and 3-4

shift and TCC apply take place only when the engine

torque is sufficient to avoid shift hunting.

SHIFT MODE CONTROL

F07RX001

GEAR SHIFT CONTROL

F07RT034

WINTER DRIVE MODE

1. The winter switch will operate when switched on

after all of the following conditions are present:

a The gear select position is “D" range only.

b Vehicle speed is11km/h or less.

c Transmission oil temperature is 130°C or less.

d Accelerator opening is at 8% or less.

NOTE: Though the winter indicator lamp lights even on

P, R or N range except D range, the winter mode is not

activated until the winter mode activate conditions are

satisfied.

2. Cancel Release

1. Cancellation by driver

a Turning off the winter drive mode switch

b Shifting select position to “3", “2", or “L"

(Winter drive mode is not canceled by

selecting “N", “R", or “P" from “D")

c Ignition key is turned off.

2. Automatic cancellation

a When vehicle speed is greater than 34 km/h

for more for 1 second or more

b When transmission oil temperature reaches

130°C or above

NOTE: The mode returns to normal drive mode or

power drive mode after the winter drive mode is

canceled.

BACKUP MODE

If a major system failure occurs which could affect

safety or damage the transmission under normal vehicle

operation, the diagnostic system detects the fault and

overrides the Powertrain Control Module (PCM).

The “CHECK TRANS" light flashes to alert the driver,

and the transmission must be manually shifted as

follows:

Shifts are firmer to prevent clutch slip and consequent

wear. The fault should be corrected as soon as

possible.

Select lever position Gear Ratio Selected

D 4 (Fourth)

Manual 3 4 (Fourth)

Manual 2 3 (Third)

Manual L 1 (First)

RReverse

FUNCTIONS OF INPUT / OUTPUT COMPONENTS

Components Function

I

N

P

U

T

S

I

G

N

A

L

Speed sensor

(fixed to transmission (T/M)) Senses rotation of out put shaft and feeds the data to Powertrain Control Module

(PCM).

Throttle position sensor

(TPS)

(fixed to engi ne)

Senses the extent of throttle valve opening and the speed of the throttle valve

lever motion to open the valve. Feeds the data to PCM.

Brake Switch (SW)

(fixed to brake ped al) Senses whether the driver has pressed the brake pedal or not and feeds the

information to PCM.

Mode SW (fixed to T/M) Senses the select lever position, and feeds the information to PCM.

Power drive SW

(fixed to front console) Senses whether the driver has selected the power mode, and feeds the

information to PCM.

T/M oil temp. sensor Senses the T/M oil temperature and feeds the data to PCM

Engine co ol a nt tem p er at u re

sensor Senses the engine coolant temperature, and feeds the data to PCM.

Engine speed signal Feeds the signals monitoring engine speed to PCM from crank angle sensor.

Air conditioning information Senses whether the air conditioner has been switched on or not, and feeds the

information to PCM.

Winter switch (fixed to front

console) Senses whether the driver has selected the winter mode, and feeds the

information to PCM.

Cruise con tr oll er (Ove rd riv e

OFF signal) Downshift takes place when Overdrive OFF signal is received from auto cruise

control unit.

O

U

T

P

U

T

S

I

G

N

A

L

S

O

L

E

N

O

I

D

Shift soleno id A, B S elects sh ift point and gear po sitio n suite d to the vehi cle runn ing con dit ion on the

basis of PCM output.

Band apply solenoid Controls oil flow suited to the vehicle running condition on the basis of PCM

output.

Torque Converter Clutch

solenoid Controls clutch engagement/disengagement suited to the vehicle running

condition on the basis of PCM output.

Pressure Control

Solenoid

(Pressure regulator

valve)

Adjusts the oil pump delivery pressure to line pressure suited to the vehicle

running condition on the basis of PCM output.

Power drive mode lamp Informs the driver whether the vehicle is in power mode or not.

Winter drive mode lamp Informs the driver whether the vehicle is in winter mode or not.

“CHECK TRANS" lamp Informs the driver of failure in the system.

ATF warning lamp Lights when ATF oil temperature rises.

DIAGNOSIS

ELECTRONIC DIAGNOSIS

How To Diagnose The Problem

1. To avoid incorrect diagnostics, the information on

this CD needs to be followed accurately. Unless

stated, do not jump directly to a section that

could contain the solution. Some important

information may be missed.

2. The sections in CAPITALS and bold are the main

sections that can be found in the contents.

3. The GO TO “SECTION" means to continue to

check going to the “section".

4. The GO THROUGH “SECTION" means to go

through the “section" and then to go back to the

place the GO THROUGH was written.

5. BASIC ELECTRIC CIRCUITS:

You should understand the basic theory of

electricity. This includes the meaning of voltage,

amps, ohms, and what happens in a circuit with an

open or shorted wire. You should also be able to

read and understand wiring diagrams.

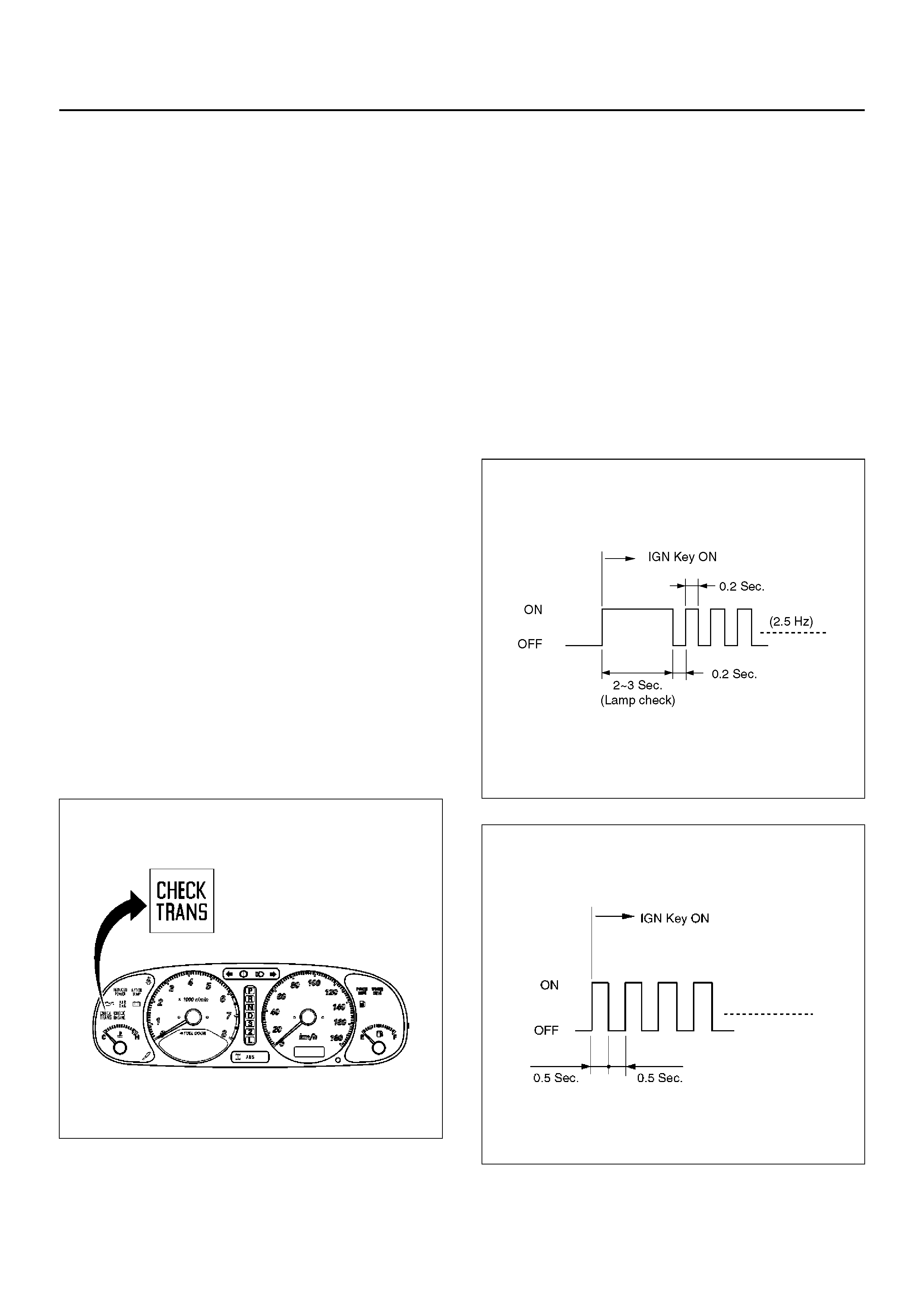

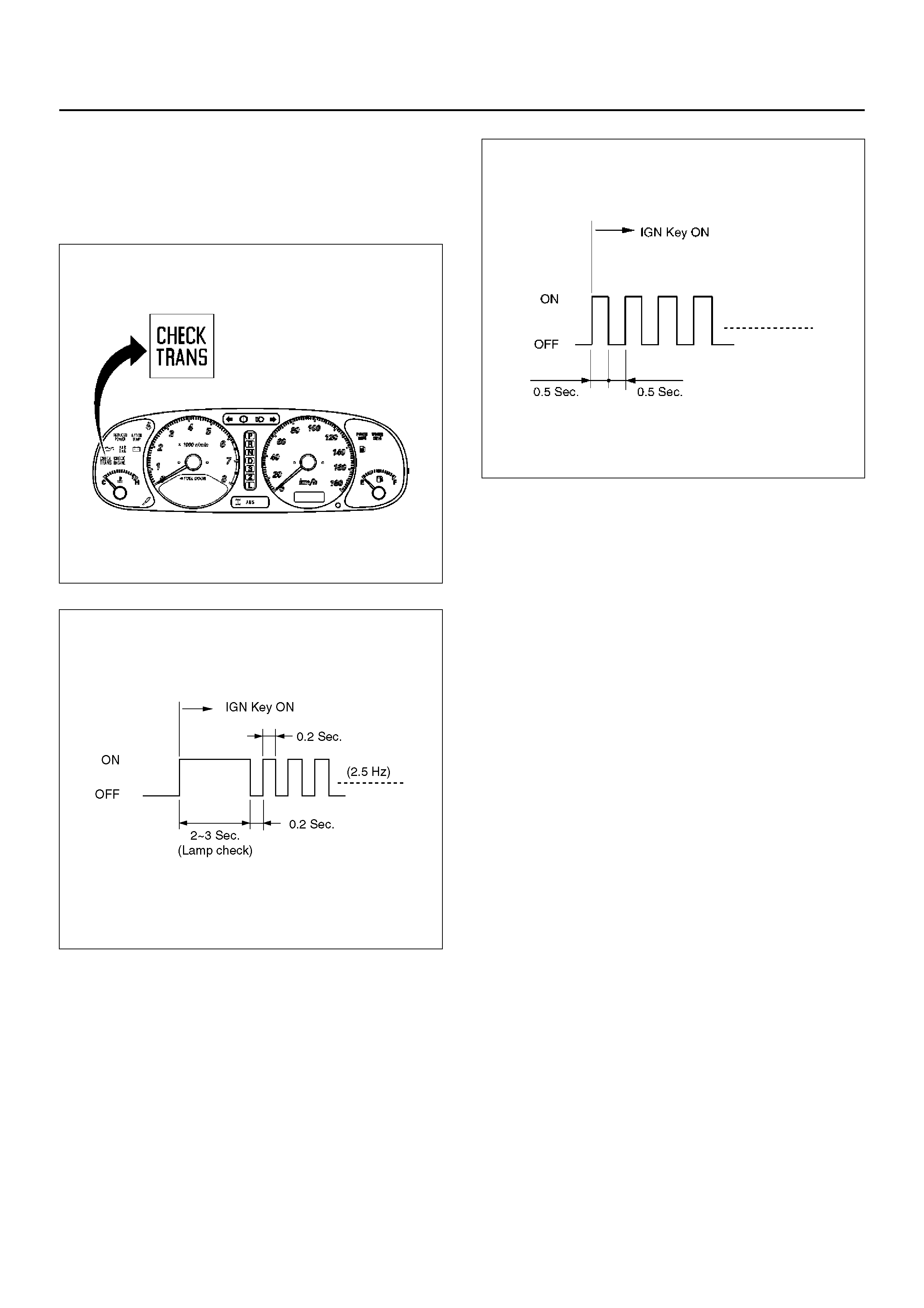

CHECK TRANS INDICATOR

Find CHECK TRANS indicator and verify if it is

A Flashing: GO TO DIAGNOSTIC CHECK.

B Staying on: GO THROUGH CHECK TRANS

CHECK.

C Is never ON when the ignition key is turned on: GO

THROUGH CHECK TRANS CHECK

D Is ON during 2 seconds at ignition but OFF after:

This is normal operation - No DTC or malfunction.

821RY00064

DIAGNOSTIC CHECK

This test determines if the transmission or its input, or

output, connections, or sensors are failing.

1. Connect t he Tech 2: G O THROU GH Tech 2 O BD II

CONNECTION.

2. Turn on the ignition but not the engine.

3. Push “F0" on Tech 2 to see the Diagnostic Trouble

Code (DTC):

4. Do you have a DTC?

YES: wr ite down all code numb ers and do the DTC

CHECK

NO: the DTC can not help you find the problem.

1. GO THROUGH “CHECK TRANS" CHECK

2. IF it is flas hing and the flash is 0.5 se conds ON

and 0.5 seconds OFF, this means that you

should have a DTC stored. Please recheck GO

TO DIAGNOSTIC CHECK and if you find the

same problem, replace the Powertrain Control

Module (PCM).

Normal

C07R200006

Abnormal

C07RY00058

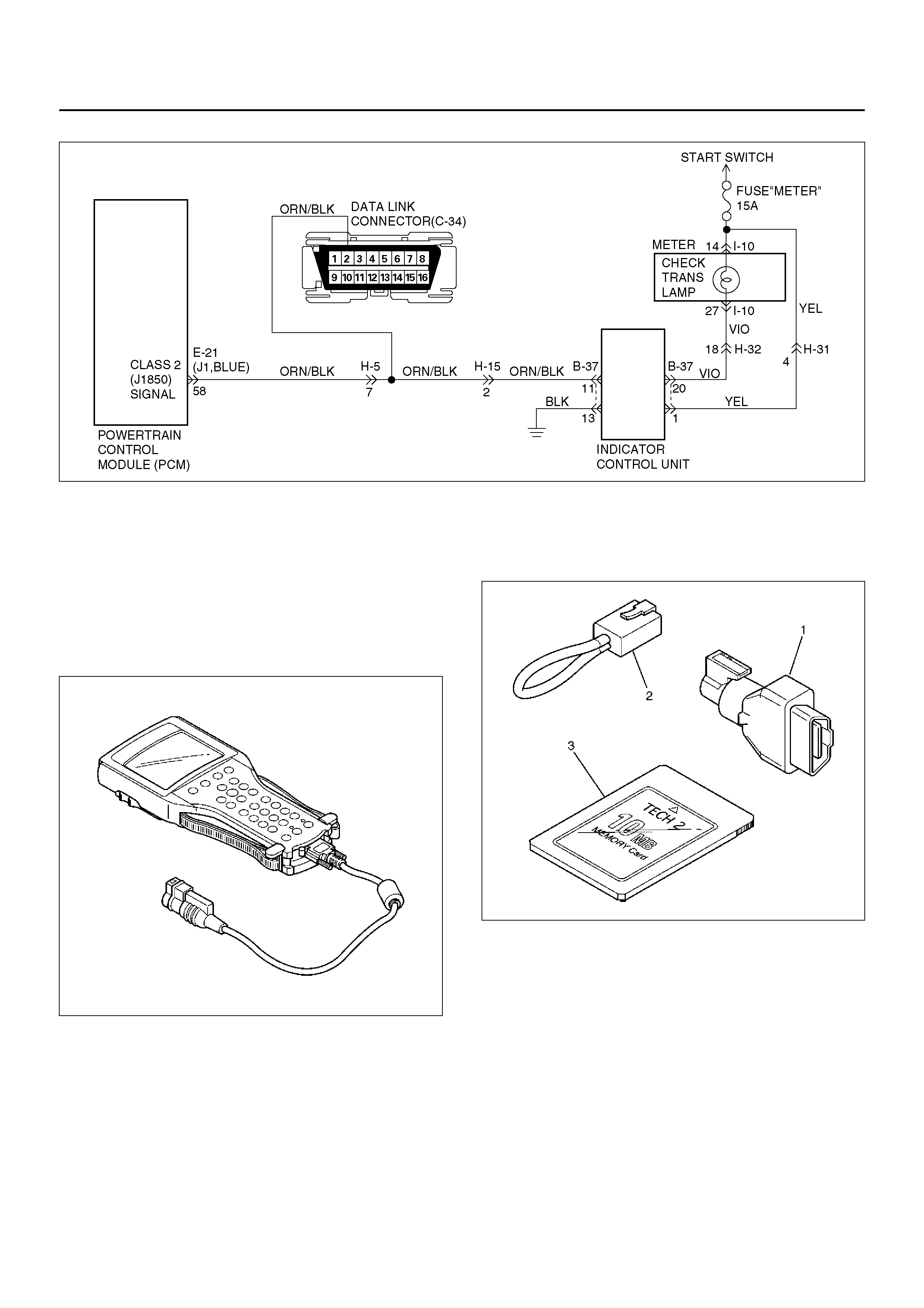

“CHECK TRANS" CHECK

1. Indicator is ON during 2 ∼ 3 seconds at ignition (or

when th e engin e is cran ked) but it is OFF afte r the

engine s tarts. The indicator is wor king normall y GO

TO DIAGNOSTIC CHECK.

821RY00064

Normal

C07R200006

2. Indicator is flashing and the flash is 0.5 seconds ON

and 0.5 seconds OFF always when ignition is on

(engine cranked or not). This means that there is a

malfunc ti on. GO TO DIAGNOSTIC CHECK.

Abnormal

C07RY00058

3. Indicator is staying ON always when Ignition is ON.

1. This means that connection between the lamp

and the PCM is shorted to ground.

2. Verify if instrument panel terminal 27 of

connector I–10 is shorted to ground.

3. Verify if th e in dica tor cont rol uni t co nnect or B– 37

terminal 20 is shorted to ground.

4. Verify that the instrument panel terminal 14 of

connector I–10 is connected to battery.

5. IF problem solved: GO TO CHECK TRANS

INDICATOR.

NO:Replace Powertrain Control Module (PCM).

4. Indicator is staying OFF with the ignition ON (engine

OFF).

1. This means that connection between the lamp

and the indicator control unit is shorted to

battery or opened.

2. Verify if instrument panel terminal 27 of

connector I–10 is shorted to battery or open.

3. Verify if th e in dica tor cont rol uni t co nnect or B– 37

terminal 20 is shorted to battery or open.

4. Verify that the instrument panel terminal 14 of

connector I–10 is connected to battery. If not,

check the fuses and t he connections (terminal

18 of connector H–32) voltage.

5. IF problem solved: GO TO CHECK TRANS

INDICATOR.

NO: Replace Powertrain Control Module (PCM).

D07R100031

TECH 2 OBD II CONNECTION

In order to access OBD II Powertrain Control Module

(PCM) data, use of the Tech 2 scan tool kit (7000086) is

required.

1. The electronic diagnosis equipment is composed of:

1. Tech 2 hand–held scan tool unit (700005 7) and

DLC cable (3000095).

901RW176

2. SAE 16/19 Pin Adapter (3000098)(1), RS232

Loop Back Connector (3000112)(2), and

PCMCIA Card (3000117)(3).

F07RW033

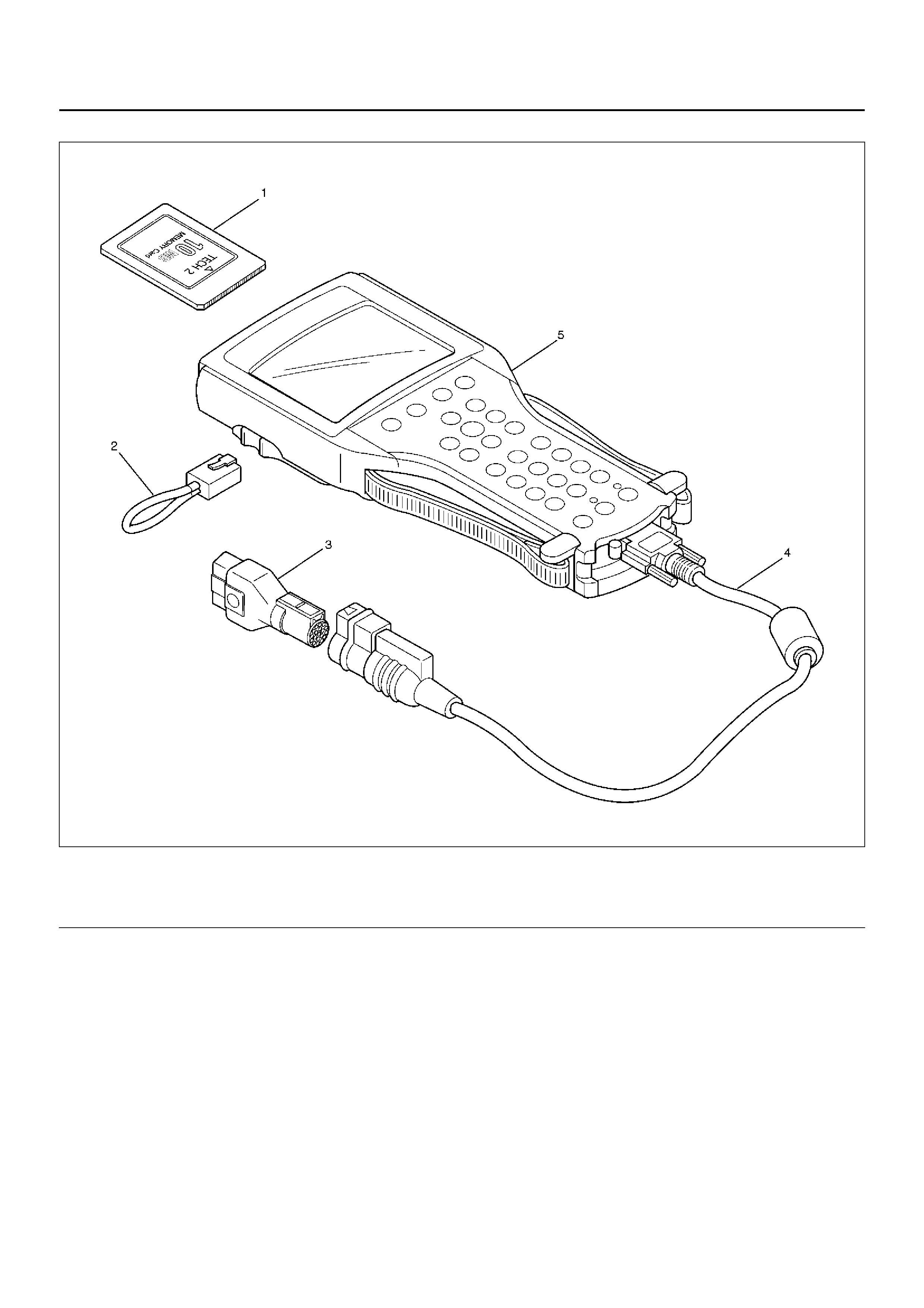

2. Connecting the Tech 2

901RW180

EndOFCallout

Legend

(1) PCMCIA Card

(2) RS 232 Loop Back Connector

(3) SAE 16/19 Adapter

(4) DLC Cable

(5) Tech 2

• Before operating the HOLDEN PCMCIA card with

the Tech 2, the following steps must be

performed:

1. The HOLDEN 2001 System PCMCIA card (1)

inserts into the Tech 2 (5).

2. Connect the SAE 16/19 adapter (3) to the DLC

cable (4).

3. Connect the DLC cable to the Tech 2 (5)

4. Mark sure the vehicle ignition is off.

5. Connect the Tech 2 SAE 16/19 adapter to the

vehicle DLC.

810RW317

6. The vehicle ignition turns on.

7. Veri fy the Tech 2 power up disp lay.

060RW009

NOTE: The RS232 Loop bac k connector is only to use

for diagnosis of Tech 2 and refer to user guide of the

Tech 2.

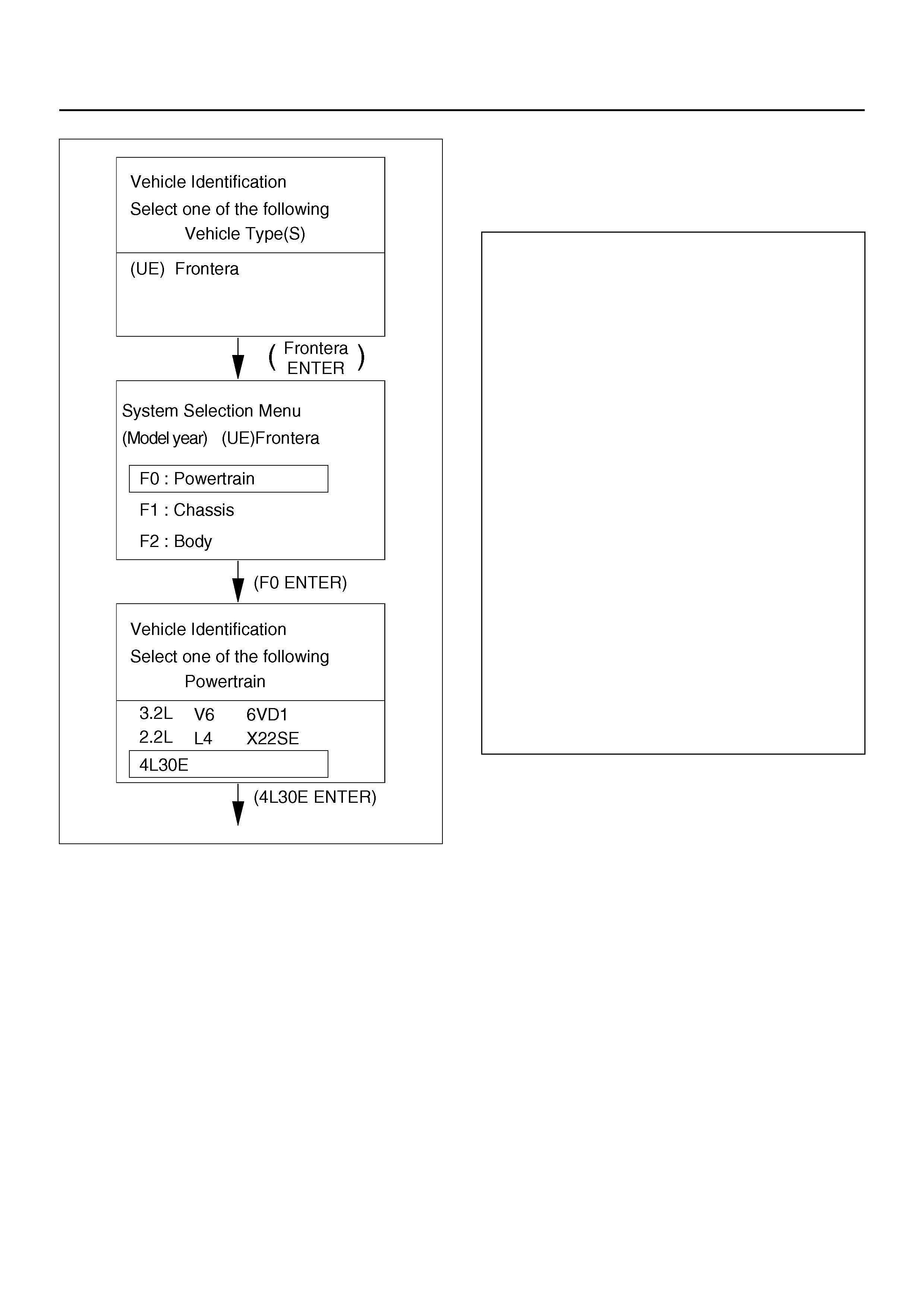

8. The power up screen is displayed when you

power up the tester with the HOLDEN systems

PCMCIA card. Follow the operating procedure

below.

060R100102

060R100104

Once the test vehicle has been identified an

“Application (Powertrain) Menu" screen appears.

Please select the appropriate application.

The following table show s, which f unctions are u sed f or

the available equipment versions.

F0: Diagnostic Trouble Codes

F0: Read DTC Info Ordered By Priority

F1: Clear DTC Information

F2: DTC Information

F1: Data Display

F0: Transmission Data

F2: Snap Shot

F3: Actuator Tests

F0: Lamps

F0: Check Light

F1: Winter Drive Lamp

F2: Power Drive Lamp

F3: AT Oil Temperature Lamp

F1: Solenoids

F0: Solenoid 1-2/3-4 Test

F1: Solenoid 2-3 Test

F2: TCC Sole noi d

F3: Band Appl y So len o id

F4: Pressure Contr ol Sol en oid (PCS)

F4: Function Tests

F0: Reset Oil Life Monitor

Diagnostic Trouble Codes

The purpose of the “Diagnostic Trouble Codes" mode is

to display stored PCM trouble codes.

When “Diagnostic Trouble Codes" is selected an

“Application Menu" screen appears.

Clear DTC Information

The purpose of the “Clear DTC Information" mode is to

command the clearing of stored PCM trouble codes.

When “Clear DTC Information" is selected, a “Clear

DTC Information", warning screen appears. This screen

informs you that by cleaning DTC's, “all stored DTC

information in controller will be erased".

Do you want to clear DTC's (Yes/No).

Press either the Yes or No key when answering.

After clearing codes, confirm system operation by test

driving the vehicle.

Allow the vehicle to shift through all four forward gears

in a manner which attempts to repeat the failure

condition.

NOTE: When the trouble has not been repaired and the

trouble code cannot be erased, check the vehicle again.

DTC Information

When “DTC Information" is selected, an “Application

Menu" appears with a list of DTC information function

keys addressing DTC specifics and their origins.

Function key selections may vary for particular vehicle

and/or system.

Data Display

The purpose of the “Data Display" mode is to

continuously monitor data parameters.

The current actual values of all important sensors and

signals in the system are display through F1 mode.

When “Data Display" is selected an “Application Menu"

appears. Please select either “Engine" or “Transmission

Data Display".

See “Transmission Data" on next page.

Snapshot

When “Snapshot" is selected an “Application Menu"

appears.

When “Transmission Snapshot" application is selected

from the “Application Menu", a “Snapshot Menu"

appears, displaying several options. “Snapshot" options

may vary from one system to another.

“Snapshot" allows a recording of all vehicle parameters.

There parameters may then be replayed at a future

point in time.

This action allows you to focus on making the condition

occur, rather than trying to view all of the data in

anticipation of the fault. The snapshot will collect

parameter information around a trigger point that you

select.

When a snapshot is taken. It is recorded onto the

PCMCIA memory card. When the Tech2 is powered

down. Snapshots are not lost.

Actuator Tests

The purpose of “Actuator Tests" mode is to check for

correct operation of electronic system actuators.

Lamps

You can operate the lamps by pressing the “ON" and

“OFF" buttons.

Preconditions: none

Solenoid

Solenoid 1-2/3-4, Solenoid 2-3, TCC Solenoid

You can operate the solenoids by pressing the “ON" and

“OFF" buttons.

Preconditions: P–N position, no vehicle speed, no

engine speed

Band Apply Solenoid

You can operate the solenoid by pressing the “ON" and

“OFF" buttons.

Preconditions: P-N position, idle engine speed, no

vehicle speed.

Pressure Control Solenoid (PCS)

You can set desired PCS Current using the “Increment"

(+20) and “Decrement" (-20) button. The PC Solenoid

Data informs about PCS Current, Pressure and Duty

Cycle.

Preconditions: P–N position, no engine speed, no

vehicle speed

Reset Oil Life Monitor

Displays parameter “Oil Life Monitor" and resets to

100% if Yes-button is pressed on Reset-question. “No"

leaves test.

NOTE:

Freeze Frame (Powertrain DTC A/B Type)

Freeze Frame is an element of the Diagnostic

Management System which stores various vehicle

information at the moment an emission-related fault

is stored in memory and when the MIL is

commanded on. These data can help to identity the

cause of a fault. Refer to Section 0C for more detailed

information.

Failure Records (Powertrain DTC C/D Ty pe)

Failure Records data is an enhancement of the OBD II

Freeze Frame feature. Failure Records store the

same vehicle information as does Freeze Frame, but

it will store that information for any fault which is

stored in on- board memory, while Freeze Frame

sotres information only for emission-related faults

that commands the MIL on.

TRANSMISSION DATAItem Unit Engine running at idle

Ignition Voltage V 12.8 ∼ 14.1 V

Engine Speed RPM 750 ∼ 900 RPM

Vehicle Speed km/h, MPH 0 MPH

AT Output Speed (Automatic Transmission) RPM 0 RPM

AT Input Speed Ratio (Automatic Transmission) 0

Throttle Posi tion % 0 %

AT Oil Temperature (Automatic Transmission) °C, °F70 ∼ 80°C (158 ∼ 176°F)

Transmission Temperature °C, °F75 ∼ 110°C (167 ∼ 230°F)

AT Oil Temperature Lamp (Automatic Transmission) On/Off Off

AT Oil Life Monitor (Automatic Transmission) % 100 %

AT Oil Life Lamp (Automatic Transmission) On/Off Not used

Commanded Gear 1

Current Gear 1

Mode Switch A Inactive/Active Active

Mode Switch B Inactive/Active Inactive

Mode Switch C Inactive/Active Inactive

Mode Switch G Inactive/Active Active

Selector Position Park

1–2 Shift Solenoid A On/Off Off

2–3 Shift Solenoid B On/Off On

Solenoid Brake Band On/Off Off

TCC Slip Speed RPM 750 ∼ 900 RPM

TCC Solenoid On/Off Off

TCC Duty Cycle % 0 %

PCS Current (Pressure Control Solenoid) A approx. 1.0 A

PCS Duty Cycle (Pressure Control Solenoid) % approx. 45 ∼ 60 %

Desired PCS Pressure (Pressure Control Solenoid) kPa 43 ∼ 52 kPa

Shift Pressure kPa 43 ∼ 52 kPa

Brake Swit ch On/Off On

Winter Switch On/Off Off

Winter Drive Lamp On/Off Off

Power Switch Normal Normal

Power Drive Lamp On/Off Off

Emergency Mode Inactive, Active Inactive

ABS Status On/Off (Not used)

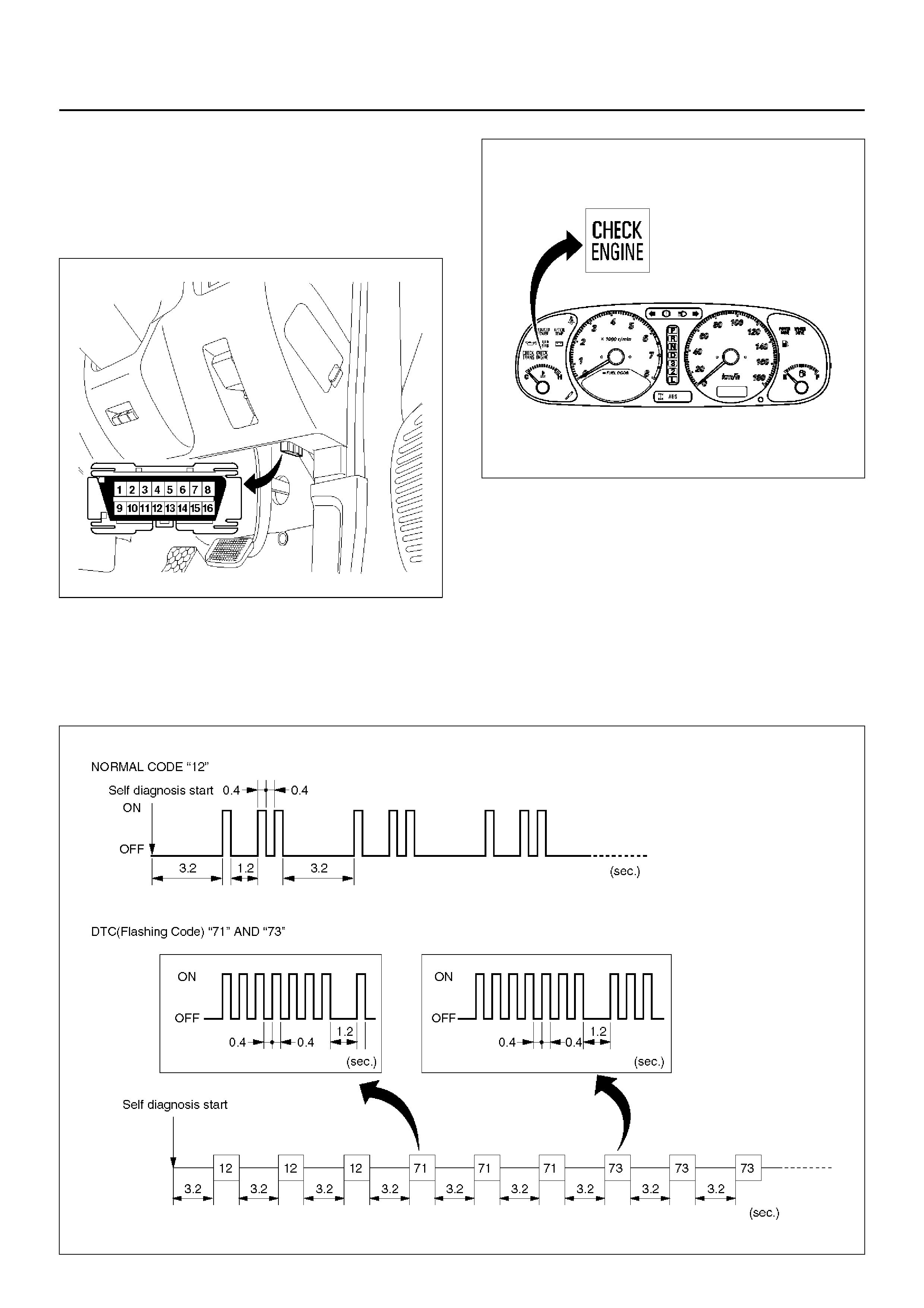

FLASHING CODE

1. A DTC (Flashing Code) can be displayed by the

Powertrain Control Module (PCM) by shorting

together terminals 6 and 4 or 5 (GND) of the Data

Link Connector (DLC) located right side of the

drivers side instrument panel.

810RW317

821RY00065

2. 1. In case there is no DTC stored in memory. The

CHECK ENGINE indicator flashes Normal Code

“12" repeatedly.

2. In case there is DTC stored in memory. First,

Normal Code “12" is displayed three times and

then any other DTC`s are displayed three times.

When all DTC`s have been displayed they are

displayed again beginning from the first one.

3. Write down all co des num bers and GO TO DTC

CHECK.

C07RX006

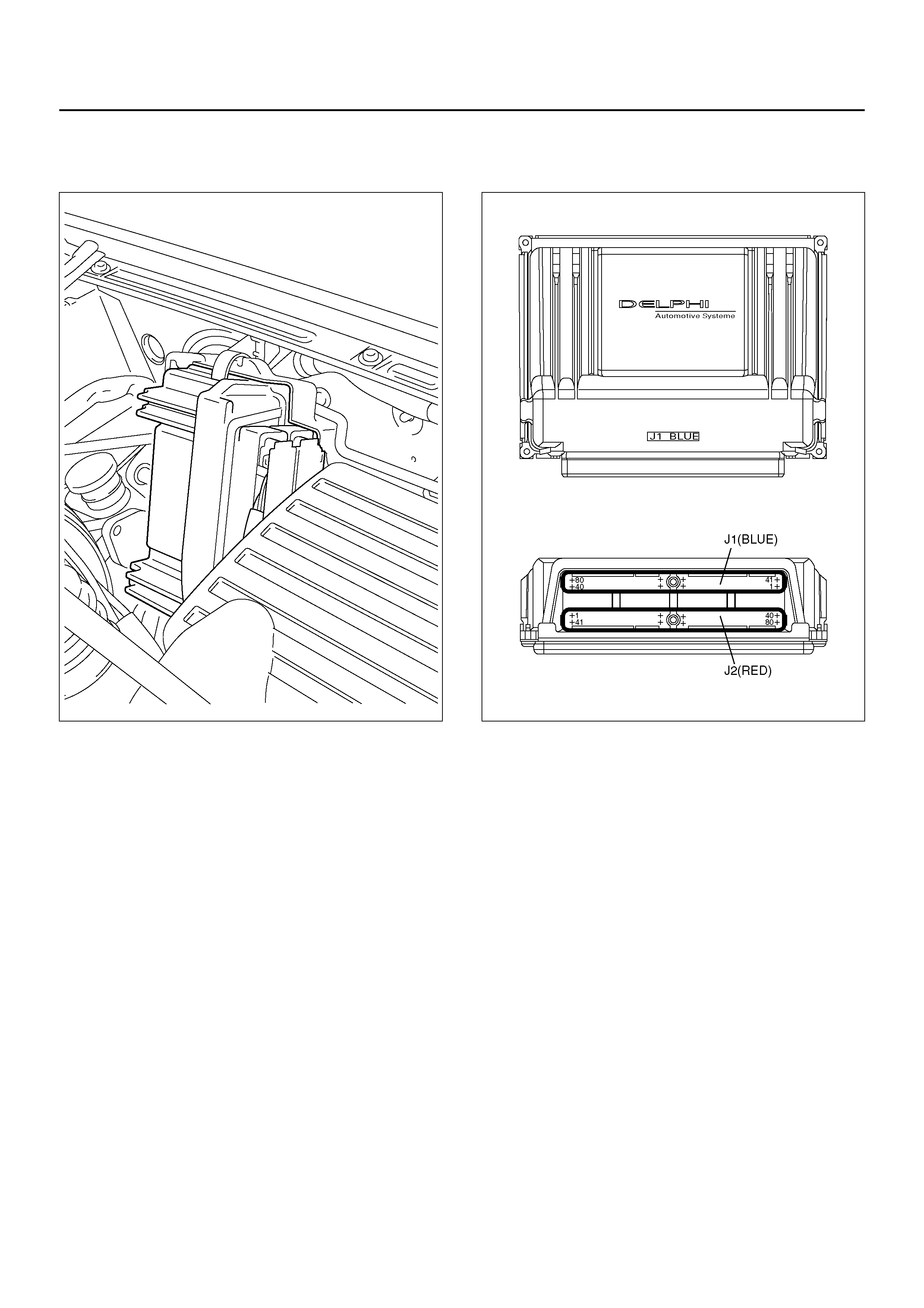

OBD II DIAGNOSTIC MANAGEMENT SYSTEM

Powertrain Control Module (PCM) Location

825R100018 826RY002

Class 2 Serial Data Bus

OBD II technology requires a much more sophisticated

PCM than does OBD I technology. The OBD II PCM

diagnostic management system not only monitors

systems and components that can impact emissions,

but they also run active tests on these systems and

components. The decision making functions of OBD II

PCM have also greatly increased. To accommodate

this expansion in diagnostic complexity, HOLDEN

engineers have designed the Class 2 serial data bus,

which meets SAE J1850 recommended practice for

serial data.

“Serial Data" refers to information which is transferred in

a linear fashion – over a single line, one bit at a time. A

“Data Bus" is an electronic pathway through which serial

data travels.

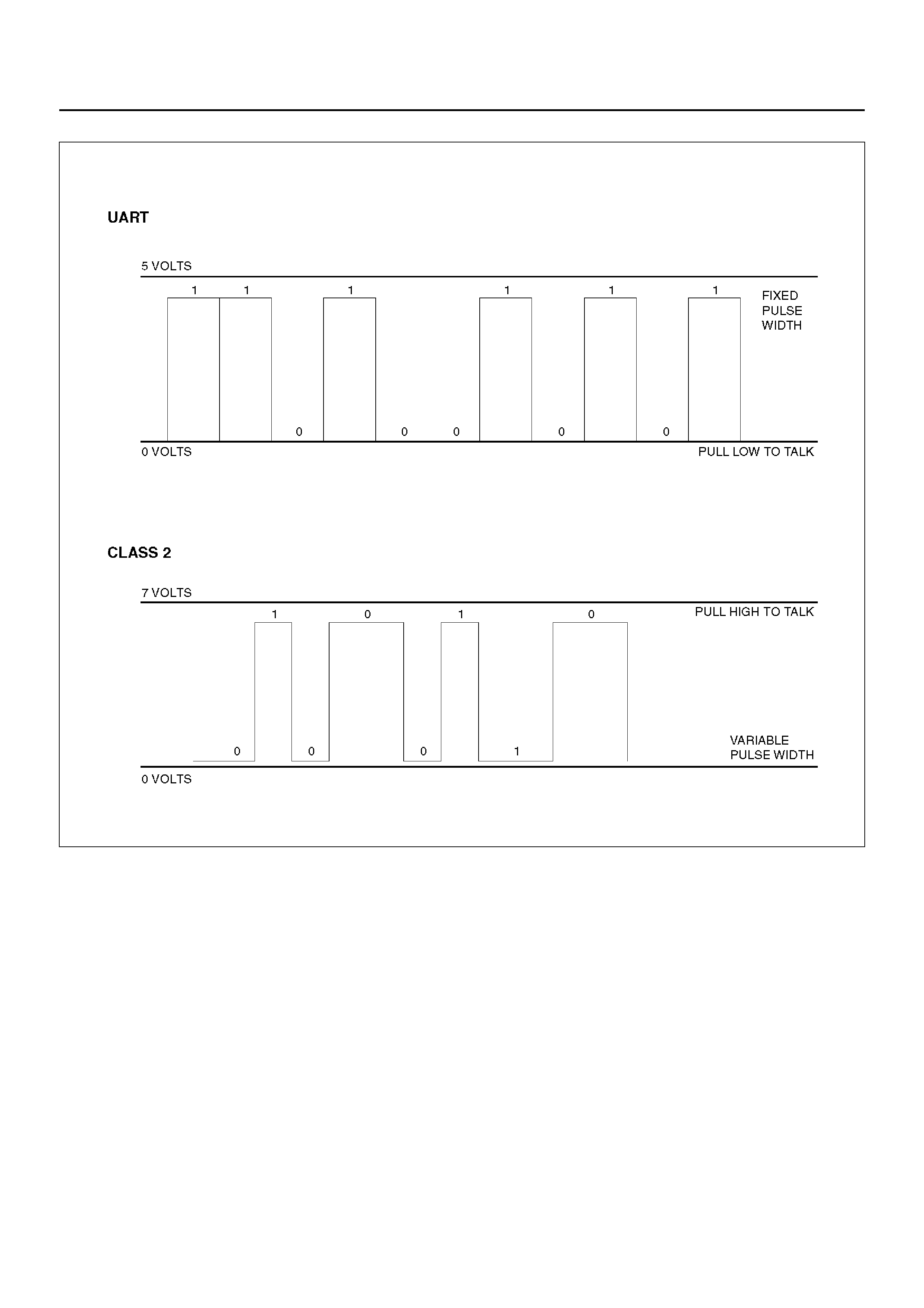

FRONTERA previously used a 5 volt data bus called

UART, which is an acronym for “Universal

Asynchronous Receive and Transmit". When neither the

vehicle's control module nor the diagnostic tool, such as

a Tech 2, are “talking," the voltage level of the bus at

rest is 5 volts. The two computers talk to each other at a

rate of 8,192 bits per se cond, by toggl ing or swit ching

the voltage on the data bus from 5 volts to ground.

Class 2 data, wh ich is used on OBD II veh icles, is quite

different. Data is transferred at a rate of 10.4 kilobits

per second, and the voltage is toggled between zero

and 7 volts.

C07RT006

Class 2 data is also pulse width modulated. Each bit of

information can have one of two lengths: long or short.

On the other hand, UART data bits come in only one

length (short). The pulse width modulation of Class 2

data allows better utilization of the data line.

The message carried on Class 2 data streams are also

prioritized. This means that if two devices try to

communication on the data line at the same time, only

the higher priority message will continue. The device

with the lower priority message must wait.

NOTE: The Class 2 data wire is always terminal 2 of

the new 16–terminal Data Link Connector (DLC).

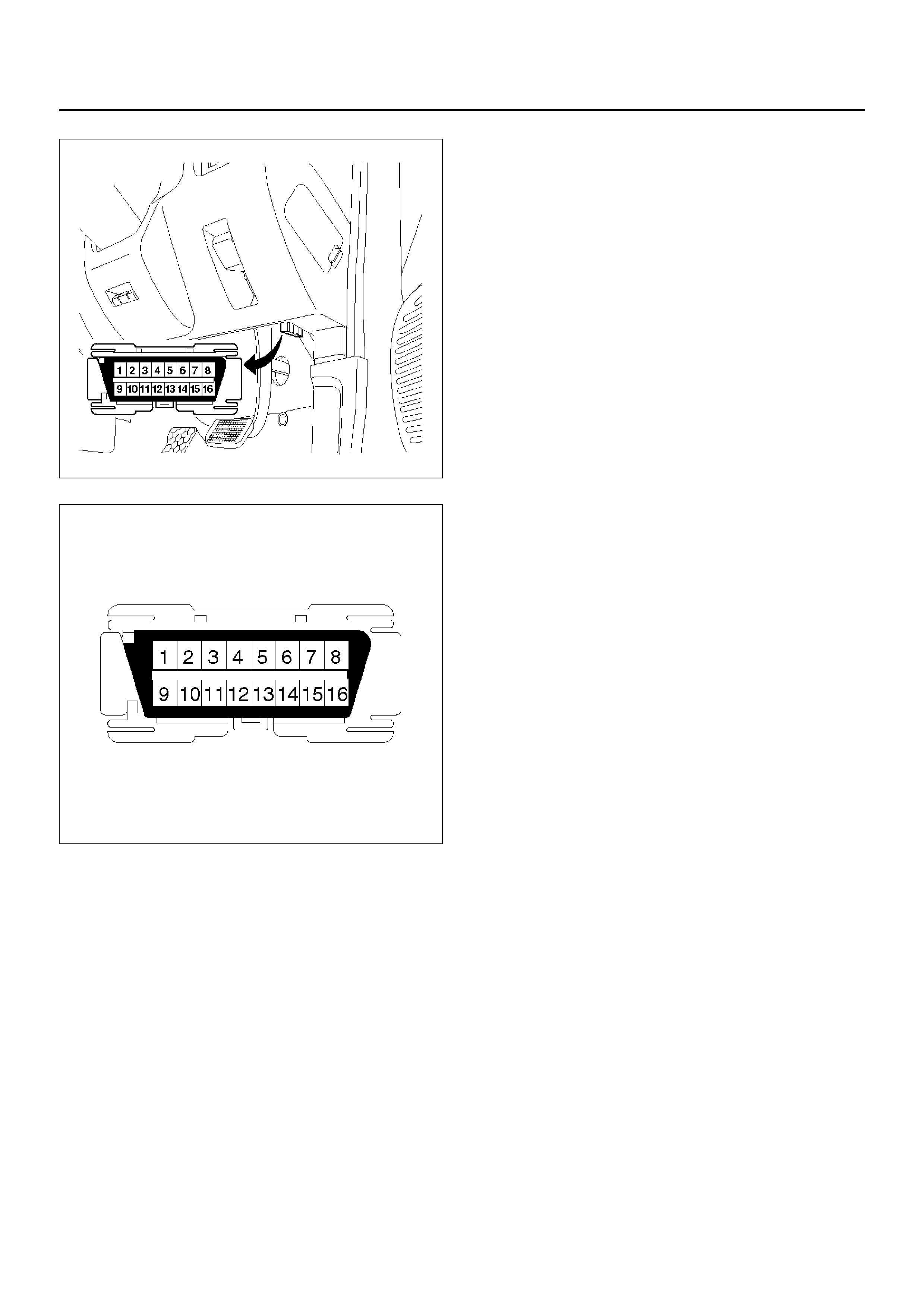

16 – TERMINAL DATA LINK CONNECTOR

(DLC)

OBD II standardizes Data Link Connector (DLC)

configurations. The DLC, formerly referred to as the

ALDL, will be a 16–terminal connector found on the

lower right side of the driver's side instrument panel. All

manufacturers must conform to this 16–terminal

standard.

810RW317

810RT022

MALFUNCTION INDICATOR LAMP (MIL)

The Malfunction Indicator Lamp (MIL) looks the same

as the MIL you are already familiar with (“CHECK

ENGINE" lamp). However, OBD II requires that it

illuminate under a strict set of guidelines. Basically, the

MIL is turned on when the PCM detects a DTC that will

impact the vehicle's emissions.

The MIL is under the control of the Diagnostic

Executive. The MIL will be turned on if a component or

system which has an impact on vehicle emissions

indicates a malfunction or fails to pass an emissions–

related diagnostic test. It will stay on until the system or

component passes the same test, for three consecutive

trips, with no emissions–related faults.

DTC TYPES

Each DTC is directly related to a diagnostic test. The

Diagnostic Management System sets DTC based on

the failure of the tests during a trip or trips. Certain

tests m ust fail two (2) co nsecutive t rips before the DTC

is set. T he fol lowing are the four (4) t yp es of DTCs and

the characteristics of those codes:

•Type A

– Emissions related

– Requests illumination of the MIL of the first trip with

a fail

– Stores a History DTC on the first trip with a fail

– Stores a Freeze Frame (if empty) (DTC

Information for 6VD1 engine)

– Stores a Fail Record

– Updates the Fail Record each time the diagnostic

test fails

•Type B

– Emissions related

– “Armed" after one (1) trip with a fail

– “Disarmed" after one (1) trip with a pass

– Requests illumination of the MIL on the second

consecutive trip with a fail

– Stores a History DTC on the second consecutive

trip with a fail (The DTC will be armed after the first

fail)

– Stores a Fr eeze F r ame on the se con d c ons ecuti ve

trip with a fail (if empty) (DTC Information for 6VD1

engine)

– Stores a Fail Record when the first test fails (not

dependent on consecutive trip fails)

– Updates the Fail Record each time the diagnostic

test fails

(Some special conditions apply to misfire and fuel trim

DTCs)

• Type C (if the vehicle is so equipped)

– Non- Em is s ion s related

– Requests illumination of the Service Lamp or the

service message on the Drive Information Center

(DIC) on the first trip with a fail

PIN 1 – (Not used)

PIN 2 – J1850 Bus + L line on 2–wire systems, or

single wire (Class 2)

PIN 3 – (Not used)

PIN 4 – Chassis ground pin

PIN 5 – Signal ground pin

PIN 6 – PCM diagnostic enable

PIN 7 – (Not used)

PIN 8 – (Not used)

PIN 9 – Primary UART

PIN 10 – (Not used)

PIN 11 – (Not used)

PIN 12 – ABS diagnostic or CCM diagnostic enable

PIN 13 – SIR diagnosti c enable

PIN 14 – (Not used)

PIN 15 – (Not used)

PIN 16 – Battery power from vehicle unswitched (4

AMP MAX.)

– Stores a History DTC on the first trip with a fail

– Does not store a Freeze Frame

– Stores Fail Record when test fails

– Updates the Fail Record each time the diagnostic

test fails

•Type D

– Non-Emissions related

– Not request illumination of any lamp

– Stores a History DTC on the first trip with a fail

– Does not store a Freeze Frame

– Stores Fail Record when test fails

– Updates the Fail Record each time the diagnostic

test fails

Important: Only four Fail Records can be stored. Each

Fail Record is for a different DTC. It is possible that

there will not be Fail Records for every DTC if multiple

DTCs are set.

CLEAR DTC

NOTE: If you clear the DTC (Diagnostic Trouble

Codes) you will not be able to read any codes recorded

during the last occurrence.

NOTE: To use the DTC again to identify a problem, you

will need to reproduce the fault or the problem. This

may require a new test drive or just turning the ignition

on (this depends on the nature of the fault).

1. IF you have a Tech 2:

1. Connect the Tech 2 if it is still not connected go

through Tech 2 OBD II CONNECTION.

2. Push “F1: Clear DTC Information" in the

Application Menu and answer “Yes" to the

question “Do you want to clear DTC's?"

a When a malfunction still exists and the Tech

2 displays “4L30E CODES NOT

CLEARED". This means that the problem

is still there or that the recovery was not

done. Please go to DTC CHECK.

b When a malfunction has been repaired and

the recovery is done the Tech 2 displays

“4L30E CODES CLEARED".

2. IF you have no Tech2, disconnect the PCM battery

feed as necessary.

DTC CHECK

1. Diagnostic Trouble Codes (DTC) have been

identified by Tech 2.

2. You have written the list of the DTCs. The order of

the malfunctions has no meanings for this PCM.

Usually only one or two malfunctions should be set

for a given problem.

3. Check directly the DTCs you identified. The DTCs

are sorted by number. Refer to Diagnostic Trouble

Code (DTC) Identification in this section.

PCM PRECAUTION

The PCM can be damaged by:

1. The electrostatic discharge

2. The short circuit of some terminals to voltage or to

ground.

Electrostatic Discharge Damage Description:

1. Electronic components used to control systems are

often designed to carry very low voltage, and are

very susceptible to damage caused by electrostatic

discharge. It is possible for less than 100 volts of

static electricity to cause damage to some electronic

components. By comparison, it takes as much as

4,000 volts for a person to even feel the zap of a

static discharge.

2. There are several ways for a person to become

statically charged. The most common methods of

charging are by friction and induction. An example

of charging by friction is a person sliding across a

car seat, in which a charge of as much as 25,000

volts can build up. Charging by induction occurs

when a person with well insulated shoes stands

near a highly charged object and momentarily

touches ground. Charges for the same polarity are

drained off, leaving the person highly charged with

the opposite polarity. Static charges of either type

can cause damage, therefore, it is important to use

care when handling and testing electronic

components.

To prevent possible electrostatic discharge damage:

1. Do not touch the PCM connector pins or soldered

components on the PCM circuit board.

2. Be sure to follow the guidelines listed below if

servicing any of these electronic components:

3. Do not open the replacement part package until it is

time to install the part.

4. Avoid touching electrical terminals of the part.

5. Before removing the part from its package, ground

the package to a known good ground on the vehicle.

6. Always touch a known good ground before handling

the part. This step should be repeated before

installing the part if the part has been handled

while sliding across the seat, while sitting down from

a standing position or while walking some distance.

INFORMATION ON PCM

1. The Powertrain Control Module (PCM) is located in

the cente r console and is the co ntrol center o f the

electronic transmission control system.

2. The PCM must be maintained at a temperature

below 85°C (185°F) at all times. This is most

essent ial if the vehicle is put throug h a paint bak ing

process. The PCM will become inoperative if its

temperature exceeds 85°C (185°F). Therefore, it is

recommended that the PCM be removed or that

temporary insulation be placed around the PCM

during the time the vehicle is in a paint oven or other

high temperature process.

3. The P CM is des igned to p rocess the various in puts

and then respond by sending the appropriate

electrical signals to control transmission upshift,

downshift, shift feel and torque converter clutch

engagement.

4. The PCM constantly interprets information from the

various sensors, and controls the systems that

affect transmission and vehicle performance. By

analyzing operational problems, the PCM is able to

perform a diagnostic function by displaying DTC(s)

and aid the technician in making repairs.

INTERMITTENT CONDITIONS

If the Tech 2 displays a diagnostic trouble code as

intermittent, or if after a test drive a DTC does not

reappear though the detection conditions for this DTC

are present, the problem is most likely a faulty

electrical connection or loose wiring. Terminals and

grounds should always be the prime suspect.

Intermitt ents rarel y occur insid e soph istic ated e lectron ic

components such as the PCM.

Use the DTC information to understand which wires and

sensors are involved.

When an intermittent problem is encountered, check

suspect circuits for:

1. Poor terminal to wire connection.

2. Terminals not fully seated in the connector body

(backed out).

3. Improperly formed or damaged terminals.

4. Loose, dirty, or corroded ground connections:

HINT: Any time you have an intermittent in more

than one circuit, check whether the circuits share a

common ground connection.

5. Pinched or damaged wires.

6. Electromagnetic Interference (EMI):

HINT: Check tha t all wi res ar e proper ly rou ted away

from spark plug wires, distributor wires, coil, and

generator. Also check for improperly installed

electrical options, such as lights, 2–way radios, etc.

Use the F2: SNAPSHOT mode of the Tech 2 to help

isolate the cau se of a n i nterm ittent faul t. Th e s napshot

mode will record information before and after the

problem occurs. Set the snapshot to “trigger" on the

suspect DTC or, if you notice the reported symptom

during the test driv e, tri gge r the snapshot man ual ly.

After the snapshot has been triggered, command the

Tech 2 to play back the flow of data recorded from

each of the various sensors. Sign of an intermittent fault

in a sensor circuit is a sudden unexplainable jump in

data values out of the normal range.

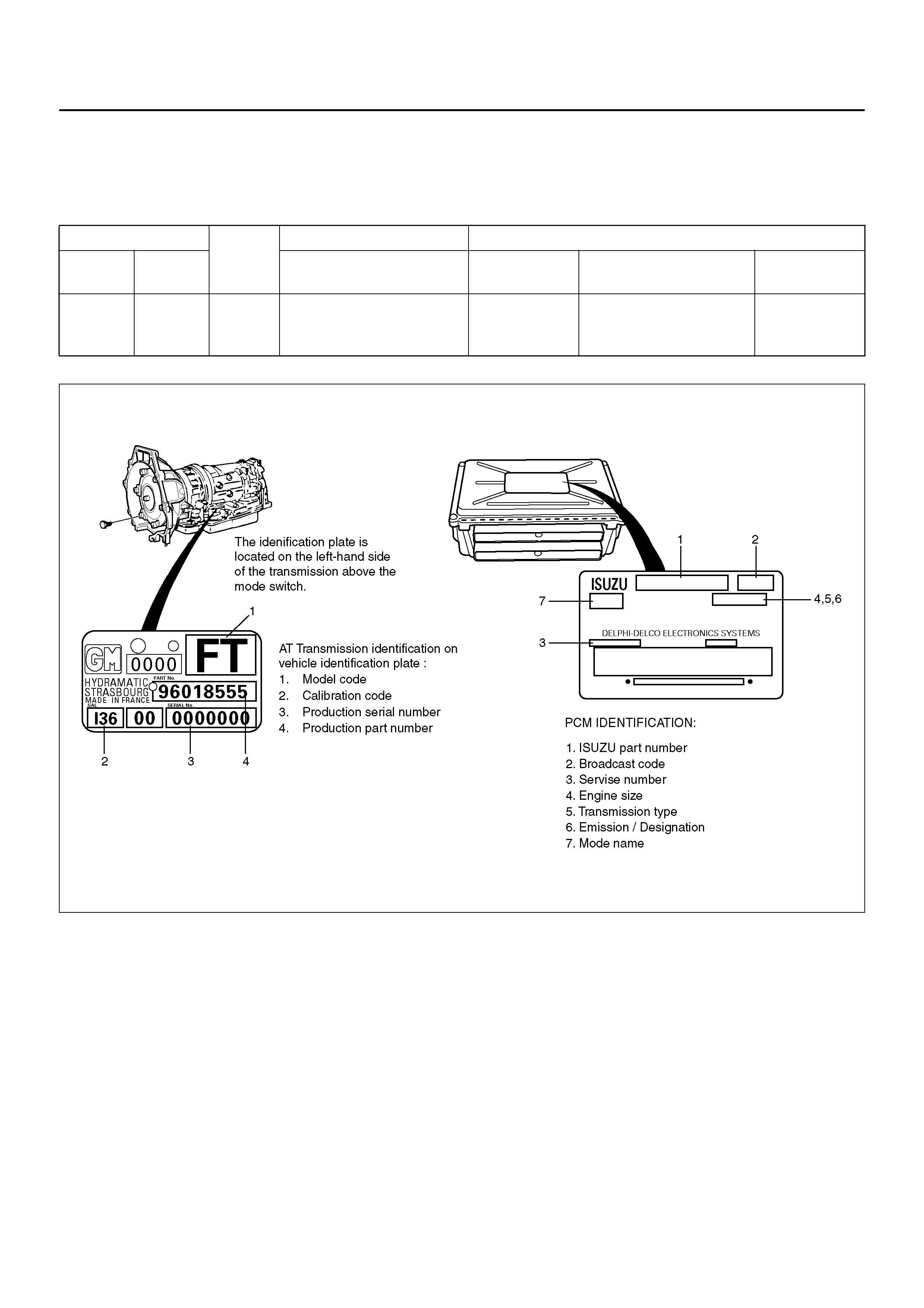

TRANSMISSION AND PCM IDENTIFICATION

The chart below contains a list of all important

information concerning rear axle ratio, Powertrain

Control Module (PCM), and transmission identification.

240R100011

VEHICLE Rr axle

Ratio PCM TRANSMISSION

Type Engine HOLDEN Parts No. Calibration

Code HOLDEN Part No. Model Code

HOLDE

N/

Frontera 3.2L V6 4.100 8–12207–159–0 I36 8–96018–555–0 FT (4×4)

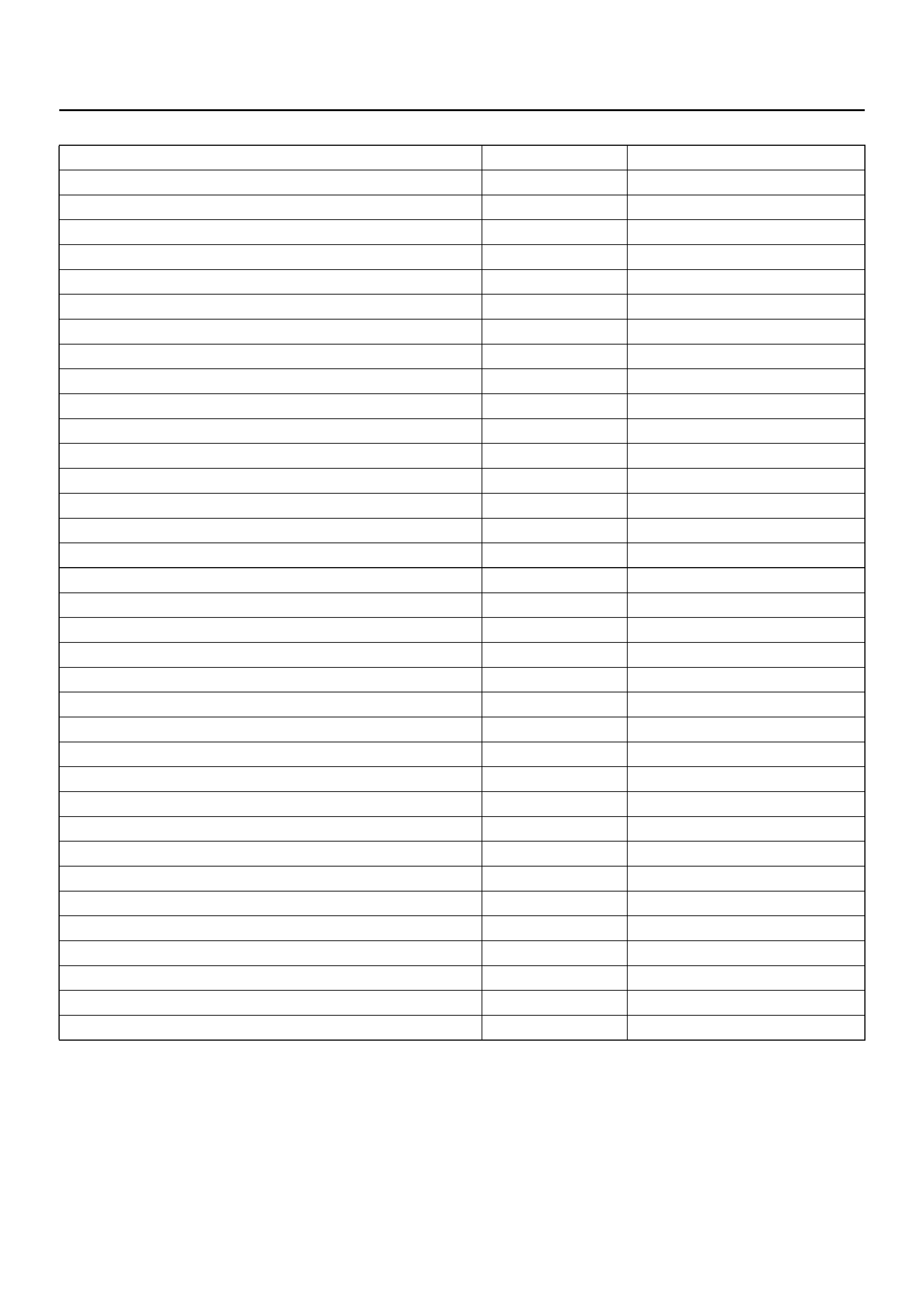

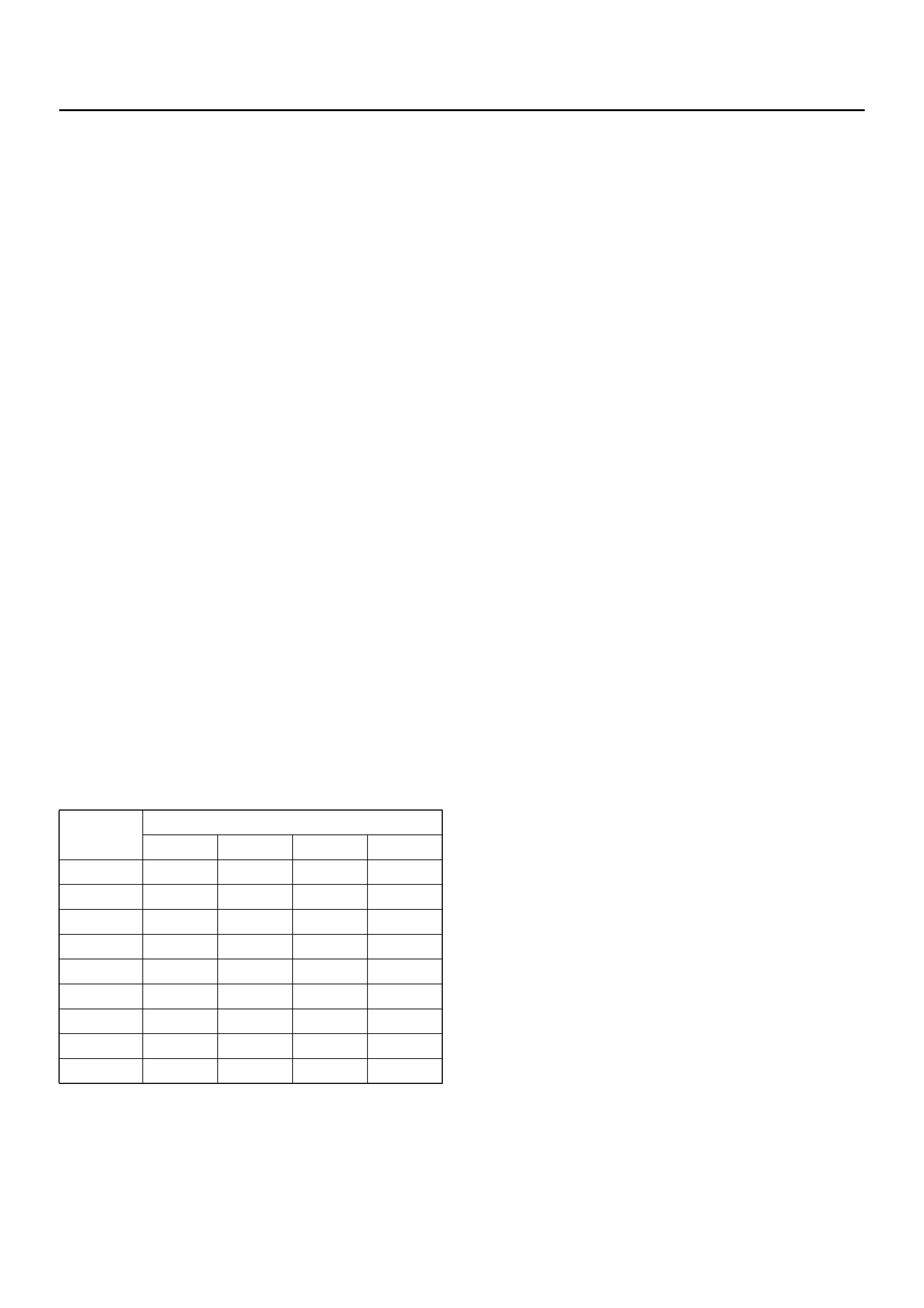

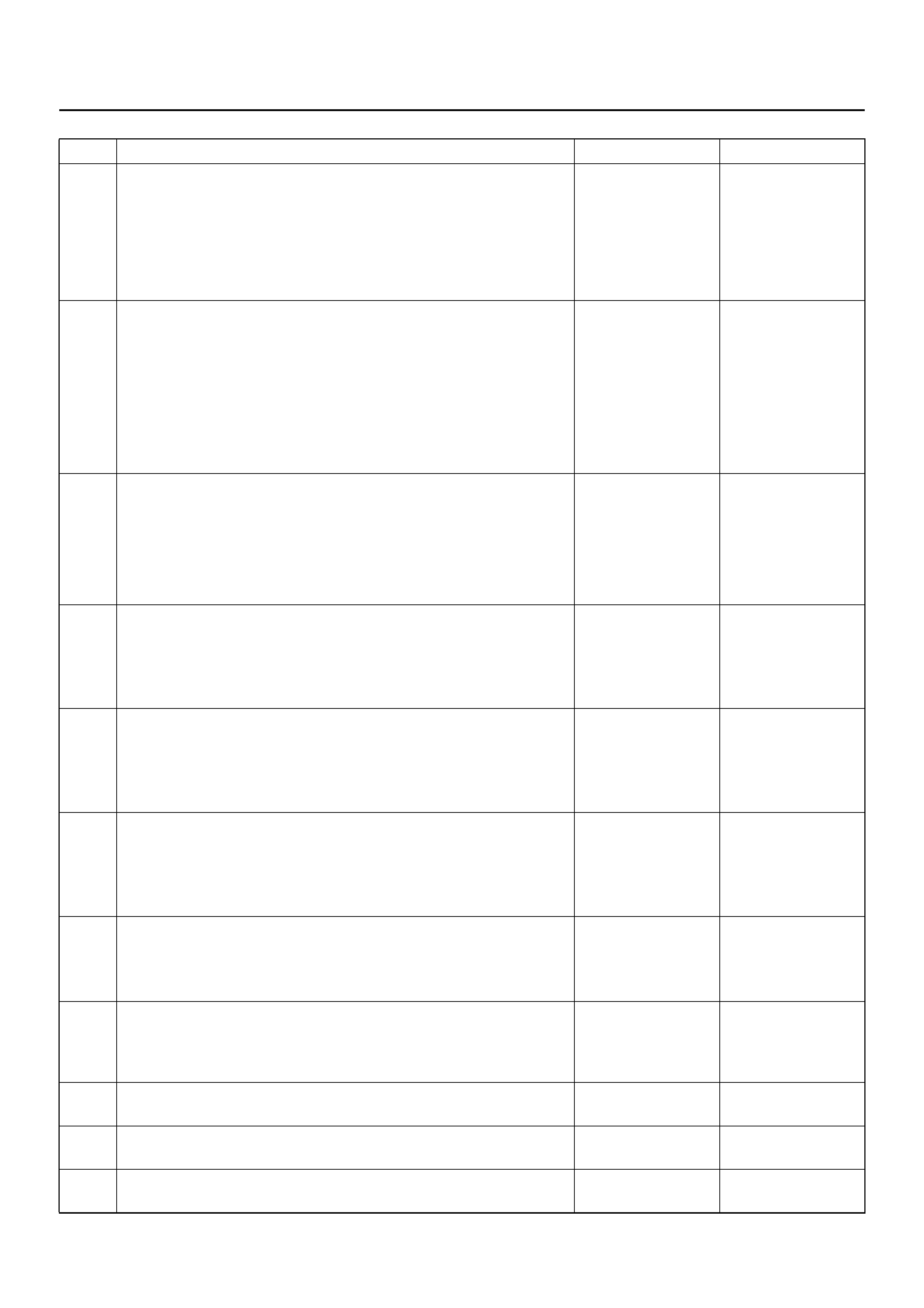

DIAGNOSTIC TROUBLE CODE (DTC) IDENTIFICATION

DTC

NUMBER FLASHING

CODE DTC NAME DTC TYPE “CHECK

TRANS"

P0218 71 Transmission Fluid Over Temperature D

P0705 73 Transmission Range Switch (Mode Switch) Illegal

Position D

P0706 74 Transmission Range Switch (Mode Switch)

Performance D

P0712 75 Transmission Fluid Temperature (TFT) Sensor Circuit

Low Input D

P0713 76 Transmission Fluid Temperature (TFT) Sensor Circuit

High Input D

P0719 77 TCC Brake Switch Circuit High (Stuck ON) D

P0722 78 Transmission Output Speed Sensor (OSS) Low Input C Flash

P0723 79 Transmission Output Speed Sensor (OSS) Intermittent C Flash

P0730 81 Transmission Incorrect Gear Ratio C Flash

P0748 82 Pressure Control Solenoid (PCS) Circuit Electrical C Flash

P0753 83 Shift Solenoid A Electrical C Flash

P0758 84 Shift Solenoid B Electrical C Flash

P1850 88 Brake Band Apply Solenoid Malfunction D

P1860 89 TCC Solen oid Elec tric al C Flash

DTC TYPE DEFINITION

C Flashing Check Trans on 1st failure

DNo lamps

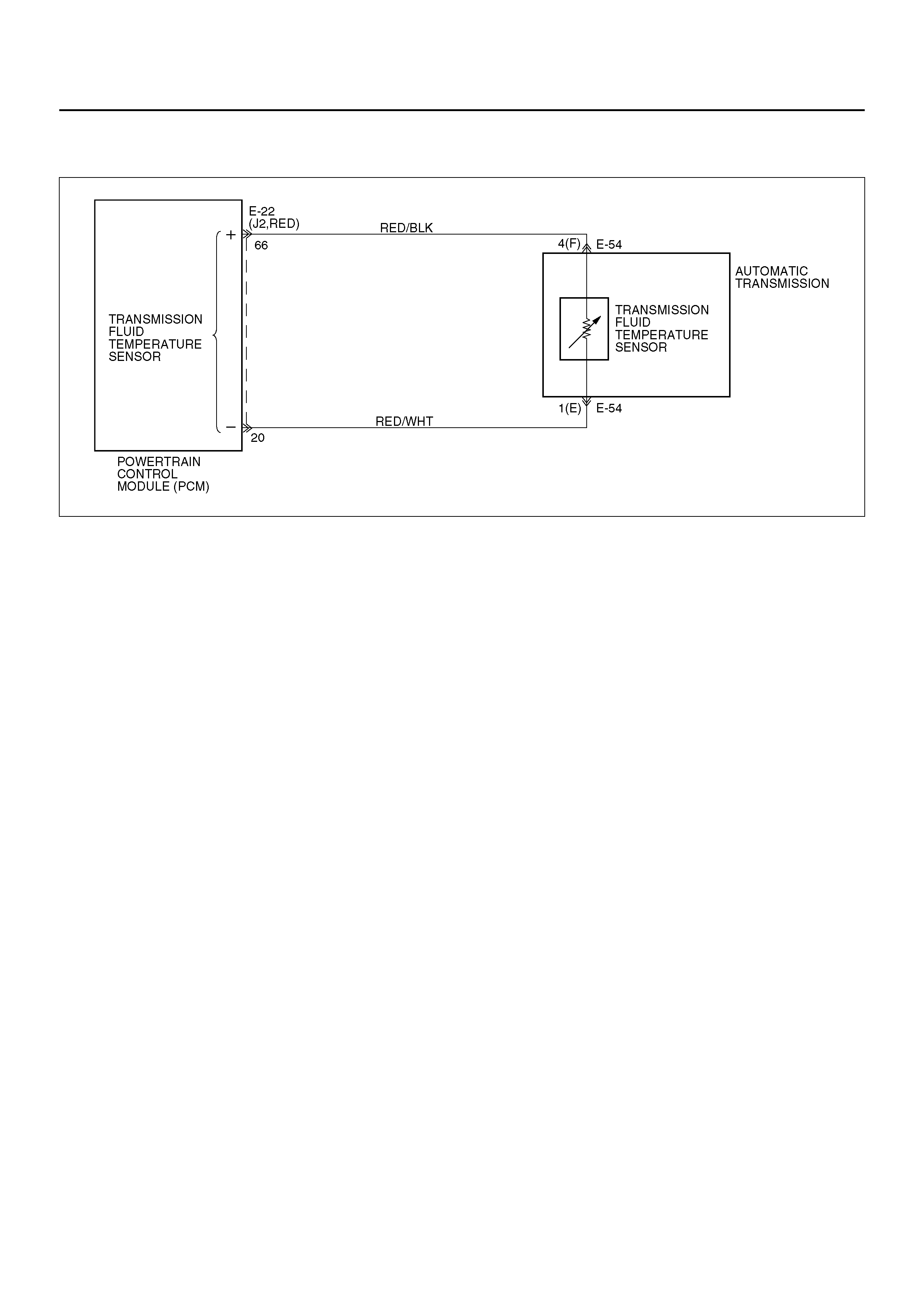

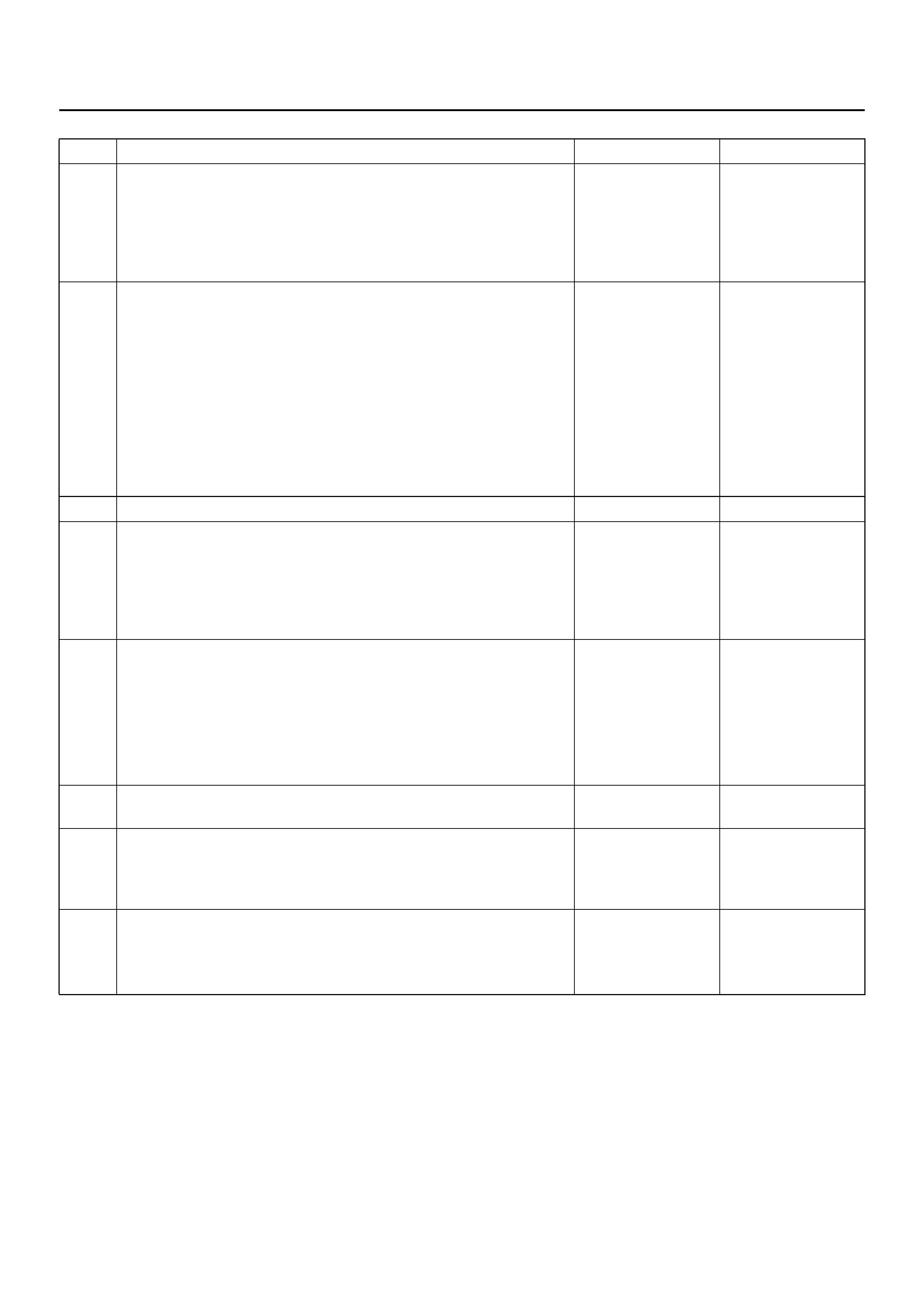

DTC P0218/FLASHING CODE 71 TRANSMISSION FLUID OVER TEMPERATURE

D07R100026

Circuit Description

The Transmission Fluid Temperature (TFT) sensor is a

thermister that controls the signal voltage to the PCM.

The PCM supplies a 5–volt reference to the sensor on

circuit RED/ BLK . When th e t ra nsmis s ion flui d i s c old ,

the sensor resistance is high and the PCM will sense

high signal voltage. As the fluid temperature warms to a

normal transmission operating temperature of 100°C

(212°F), the sensor resistance becomes less and the

voltage decreases to 1.5 to 2.0 volts.

This DTC detects a high trans missio n temper ature for a

long period of time. This is a type “D" DTC.

Conditions For Setting The DTC

• No TFT DTCs P0712 (Flashing Code 75) or P0713

(Flashing Code 76).

• TFT is greater than 135°C (275°F).

• All conditions met for 21 seconds.

Action Taken When T h e DTC Sets

• Hot mode TCC Shift Pattern.

• The PCM will not illuminate the CHECK TRANS

Lamp.

• ATF Lamp ON. (greater than 145°C (293°F))

• Disable E–side TCC OFF request.

Conditions For Clearing The DTC

• The DTC can be cleared from the PCM history by

using a scan tool.

• The DTC will be cleared from history when the

vehicle has achieved 40 warm–up cycles without a

failure reported.

• The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled

“off" long enough to power down the PCM.

Diagnostic Aids

• Inspect the wiring for poor electrical connections at

the PCM and at the transmission 7–way connector.

Look for possible bent, backed out, deformed or

damaged terminals. Check for weak terminal

tension as well.

Also check for a chafed wire that could short to bare

met a l o r o t he r w ir i ng . In s pe c t f o r a broken w i re in si d e

the insulation.

• When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

• Check harnes s ro uting f or a p otentia l sho rt to g round

in circuit RED/BLK.

• Scan tool TFT sensor temperature should rise

steadily to about 100°C (212°F), then stabilize.

• Check for a “skewed" (mis–scaled) sensor by

comparing the TFT sensor temperature to the

ambient temperature after a vehicle cold soak. A

“skewed" sensor can cause delayed garage shifts or

TCC complaints.

• Check for a possible torque converter stator problem.

• Verify customer driving habits, trailer towing, etc.

TEST DESCRIPTION

The numbers below refer to the step numbers on the

diagnostic chart.

2. This test checks for a “skewed" sensor or shorted

circuit.

3. This test simulates a TFT DTC P0713.

DTC P0218/Flashing Code 71 Transmission Fluid Over Temperature

Step Action Yes No

1 Perform the following checks:

• Check for possible engine system problems.

• Transmission fluid checking procedure. Refer to Checking

Transmission Fluid Level and Condition in Automatic

Transmission (4L30–E) Section.

Were the checks performed? Go to Step 2 Refer to “Engine

Manual"

2 1. Install the scan tool.

2. With the engine “of f", turn the ignition switch “on".

NOTE: Before clearing DTC(s), use the scan tool to record

“Failure Records" for reference, as data will be lost when “Clear

Info" function is used.

3. Record the DTC “Failure Records".

Is the TFT sensor signal voltage less than 1.54 volts? Go to Step 3 Go to Diagnostic

Aids

3 1. Turn the ignition “off".

2. Disconnect the transmission 7–way connector E–54

(additional DTCs may set).

3. With the engine “of f", turn the ignition switch “on".

Is the TFT sensor signal voltage greater than 4.92 volts?

Go to Internal

Wiring Harness

Check Go to S tep 4

4 Inspect/repair circuit RED/BLK for a short to ground.

Was a problem found? Go to Step 6 Go to S tep 5

5 1. Inspect the PCM for poor connections.

2. Replace the PCM if no poor connections were found.

Is the replacement complete? Go to Step 6 —

6 1. After the repair is complete, use the scan tool to select

“DTC", then “Clear Info" function and ensure the following

conditions are met:

TFT is less than 125°C (257°F) for at least 10 seconds.

2. Review the scan tool “DTC Info".

Has the last test failed or is the current DTC displayed?

Begin diagnosis

again

Go to Step 1 Repair verified

Exit DTC table

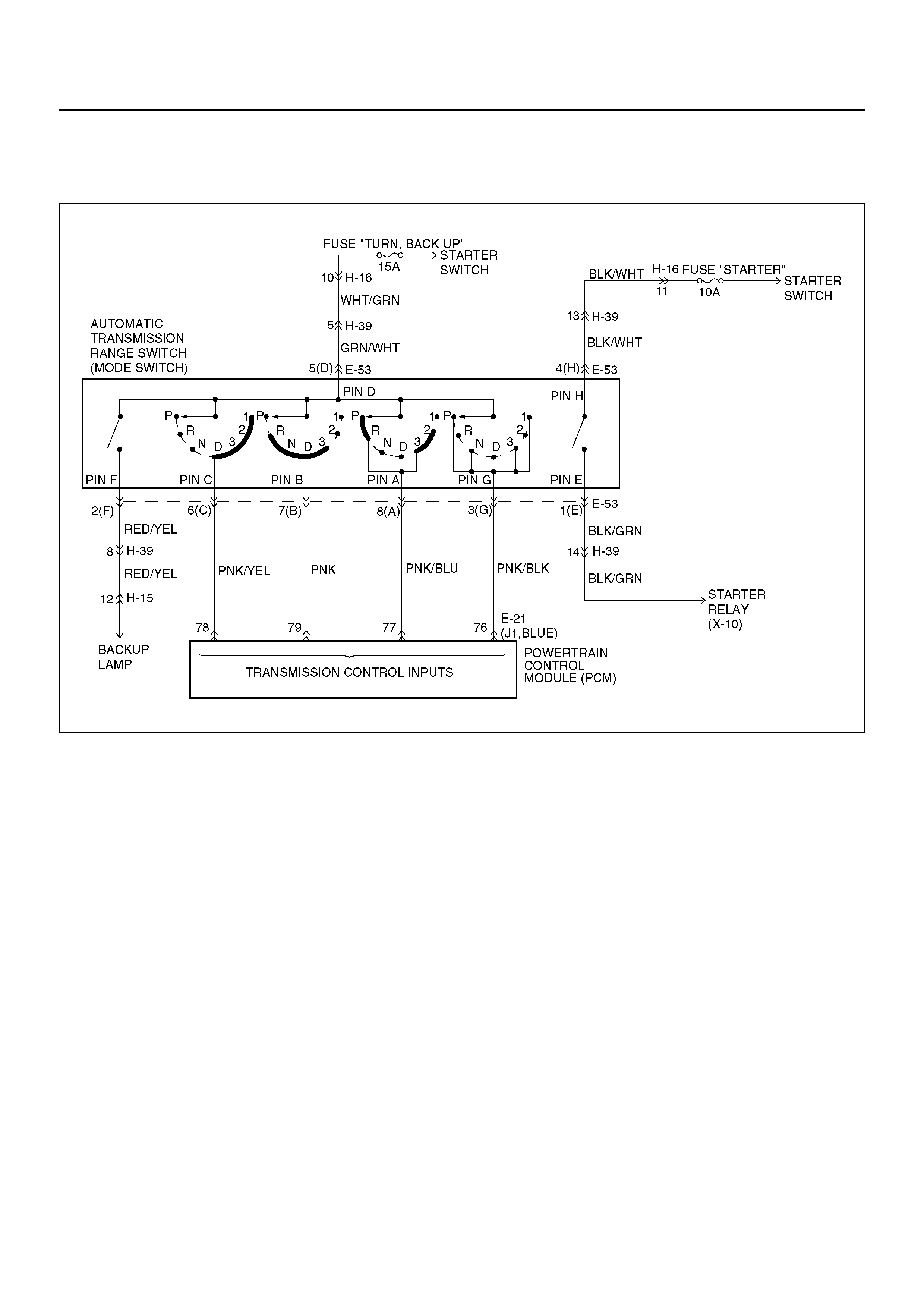

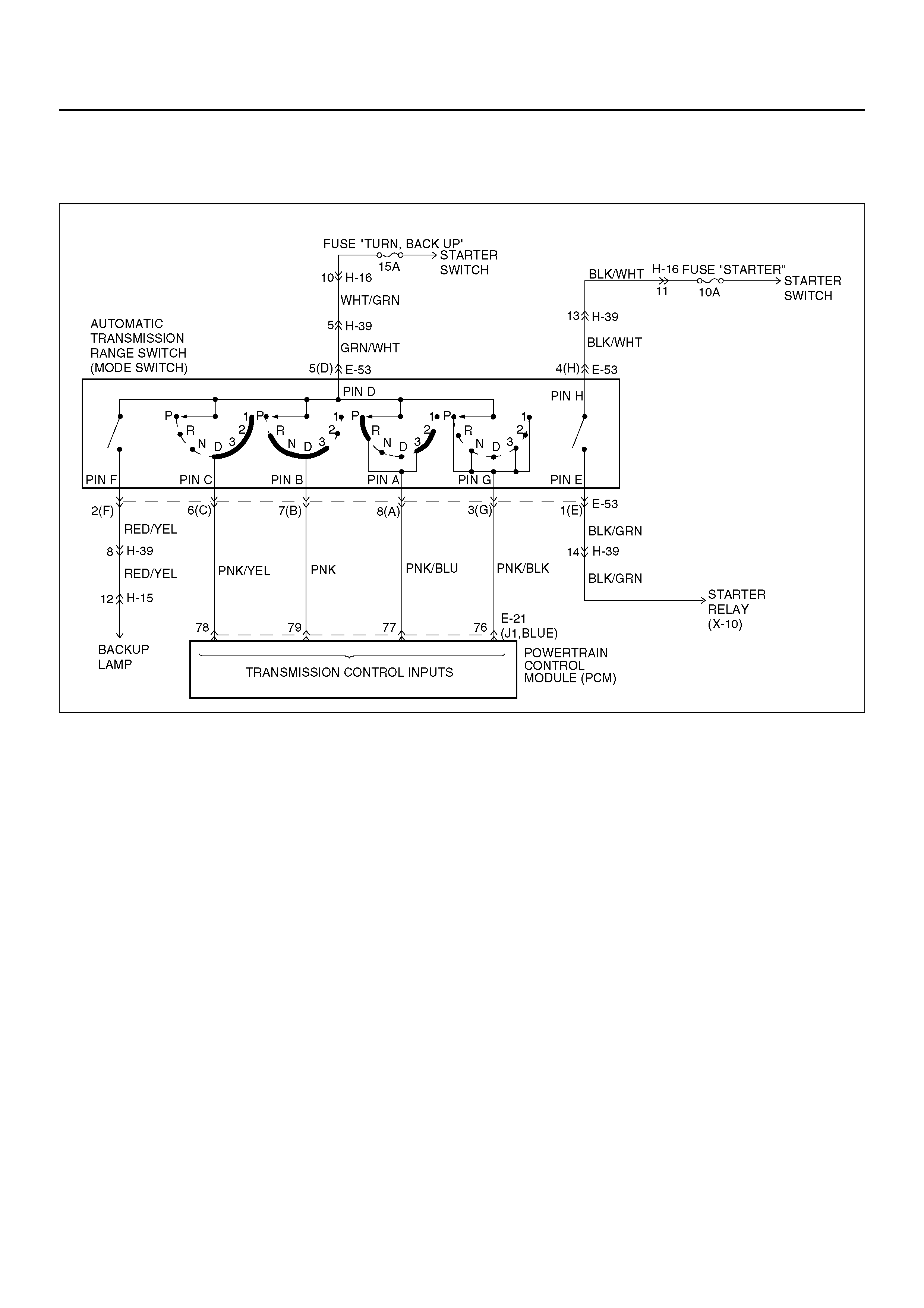

DTC P0705/FLASHING CODE 73 TRANSMISSION RANGE SWITCH (MODE

SWITCH) ILLEGAL POSITION

D07R100027

Circuit Description

• The range switch supplies the Powertrain Control

Module (PCM) with information regarding the selector

lever position: P, R, N, D 3, 2 or L. The selector lever

position is indicated by the state of four ON/OFF

contracts. The range switch is located on one side of

the transmission. It is on the transmission manual

shaft and is fixed to the main case.

• The range switch is also used to provide the

inform ation P or N to the en gine crank wir ing. The

engine can be cranked only if connector E–53

terminal 4(H) is connected to terminal 1(E) which is

connected to ground.

• The range switch is also used to provide the backup

lamp power in reverse. This is the reason why the

range switch is supplied through a 15A fuse (TURN,

BACK UP). T his fuse can burn due to a sho rt circui t

in the back up lamp.

This DTC detects when a fuse is open or the range

switch circuit does not work. This is a type “D" DTC.

Conditions For Setting The DTC

• Range switch illegal positions met for 5 seconds.

Action Taken When The DTC Sets

• Default to D position.

• Inhibit torque management.

• Turn Pressure Control Solenoid off.

• Maximum line pressure.

• The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

• The DTC can be cleared from the PCM history by

using a scan tool.

• The DTC will be cleared from history when the

vehicle has achieved 40 warmup cycles without a

failure reported.

• The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled

“off" long enough to power down the PCM.

Diagnostic Aids

• Refer to accompanying chart for the normal range

signals and the illegal combinations.

• Inspect the wiring for poor electrical connections at

the PCM and at the transmission 8–way connector.

Look for possible bent, backed out, deformed or

damaged terminals. Check for weak terminal tension

as well. Also check for a chafed wire that could short

to bare metal or other wiring. Inspect for a broken

wire inside the insulation.

• When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

• Refer to the “Range Switch Logic Table" for further

information.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

2. This test checks the indicated range signal to the

manual valve actually selected.

5. This test checks for continuity between each selected

range switch connector terminals.

Range Switch Logic Table

Range

Position Range Switch Pin

A B C P(G)

Park ON OFF OFF ON

Reverse ON ON OFF OFF

Neutral OFF ON OFF ON

D4 OFF ON ON OFF

D3 ON ON ON ON

2 ON OFF ON OFF

L OFF OFF ON ON

Illegal OFF OFF OFF OFF

Illegal OFF OFF OFF ON

DTC P0705/Flashing Code 73 Transmission Range Switch (Mode Switch) Illegal Position

Step Action Yes No

1 Perform the following checks:

• The transmission linkage from the select lever to the manual

valve is adjusted properly.

• Diagnostic circuit check.

Were the checks performed? Go to Step 2

Refer to Select

Lever, and Mode

Switch in

Automatic

Transmission

(4L30–E) section

2 1. Install the scan tool.

2. With the engine “of f", turn the ignition switch “on".

NOTE: Before clearing DTC(s), use the scan tool to record

“Failure Records" for reference, as data will be lost when the

“Clear Info" function is used.

3. Record the DTC “Failure Records".

4. Select each transmission range: DL, D2, D3, D4, N, R, and

P.

Does each selected transmission range match the scan tool

“Range Switch" display? Go to Diagnostic

Aids Go to Step 3

3 Are all range switch pin displays incorrect? Go to Step 4 Go to S tep 5

4 Check fuse and wiring to the 8–way connector terminal 5(D) for

opens.

Refer to ode Switc h i n Aut o mat ic Transmi ssi on (4 L3 0–E ) se ct i on.

If no problem was found, replace the range switch.

Is the replacement complete? Go to Step 8 —

5 1. Disconnect the 8–way range switch connector.

2. Using ohmmeter, check continuity between terminal 5(D) and

respectiv el y termi nal s 3 (G) , 6 (C), 7 (B ) and 8( A) of the 8–way

range switch connector.

3. Move shift selector lever through all positions and compare

results with “Range Switch Logic Table".

Is one range switch pin display incorrect? Go to Step 6 Go to Step 7

6 Check the affected wiring and connector, and repair.

Is the repair complete? Go to Step 8 —

7 Check the Powertrain Control Module (PCM) connectors for poor

connection.

If no problem was found, replace the PCM.

Is the replacement complete? Go to Step 8 —

8 1. After the repair is complete, use the scan tool to select

“DTC", then “Clear Info" function and road test the vehicle.

2. Review the scan tool “DTC Info".

Has the last test failed or is the current DTC displayed?

Begin diagnosis

again

Go to Step 1 Repair verified

Exit DTC table

DTC P0706/FLASHING CODE 74 TRANSMISSION RANGE SWITCH (MODE

SWITCH) PERFORMANCE

D07R100027

Circuit Description

• The range switch supplies the Powertrain Control

Module (PCM) with information regarding the selector

lever position: P, R, N, D, 3, 2 or L. The selector lever

position is indicated by the state of four ON/OFF

contracts. The range switch is located on one side of

the transmission. It is on the transmission manual

shaft and is fixed to the main case.

• The range switch is also used to provide the

information P or N to the engine crank wiring. The

engine can be cranked only if connector E–53

terminal 4(H) is connected to terminal 1(E) which is

connected to ground.

• The r ange s witch is al so used to pr ovide the ba ck u p

lamp power in reverse. This is the reason why the

mode switch is supplied through a 15A fuse (TURN,

BACK UP). T his fuse can burn due to a sho rt circui t

in the back up lamp.

• This DTC detec ts an inv alid s tate of the ran ge swi tch

or the range switch circuit by deciphering the range

switch inputs. This is a type “D" DTC.

Conditions For Setting The DTC

This DTC will set if any of the following conditions

occurs:

Condition 1 (“R" bad position):

• Engine is running.

• No output speed DTC P0722 (Flashing Code 78),

P0723 (Flashing Code 79).

• Output speed greater than 3,200 RPM.

• Range switch indicates “R".

• All conditions met for 4 seconds.

Condition 2 (“P" or “N" bad position):

• Engine is running.

• No TPS codes.

• Engine speed is less than 3,000 RPM.

• TP angle is greater than 20%.

• Range switch indicates “P" or “N".

• All conditions met for 4 seconds.

Action Taken When The DTC Sets

• Default to “D" position.

• The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

• The DTC can be cleared from the PCM history by

using a scan tool.

• The DTC will be cleared from history when the

vehicle has achieved 40 warmup cycles without a

failure reported.

• The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled

“off" long enough to power down the PCM.

Diagnostic Aids

• Refer to the accompanying chart for the normal range

signal s and the il leg al co mbi nati on s.

• Inspect the wiring for poor electrical connections at

the PCM and at the transmission 8–way connector.

Look for possible bent, backed out, deformed or

damaged terminals. Check for weak terminal

tension as well. Also check for a chafed wire that

could shor t to bare metal or other wir ing. Inspect for

a broken wire inside the insulation.

• When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

• Refer to the “Range Switch Logic Table" for further

information.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

2. This test checks the indicated range signal to the

manual valve actually selected.

5. This test checks for continuity between each selected

range switch connector terminals.

Range Switch Logic Table

Range

Position Range Switch Pin

A B C P(G)

Park ON OFF OFF ON

Reverse ON ON OFF OFF

Neutral OFF ON OFF ON

D4 OFF ON ON OFF

D3 ON ON ON ON

2 ON OFF ON OFF

L OFF OFF ON ON

Illegal OFF OFF OFF OFF

Illegal OFF OFF OFF ON

DTC P0706/Flashing Code 74 Transmission Range Switch (Mode Switch) Performance

Step Action Yes No

1 Perform the following checks:

• The transmission linkage from the select lever to the manual

valve is adjusted properly.

• Diagnostic circuit check.

Were the checks performed? Go to Step 2

Refer to Select

Lever, and Mode

Switch in

Automatic

Transmission

(4L30–E) section

2 1. Install the scan tool.

2. With the engine “of f", turn the ignition switch “on".

NOTE: Before clearing DTC(s), use the scan tool to record

“Failure Records" for reference, as data will be lost when the

“Clear Info" function is used.

3. Record the DTC “Failure Records".

4. Select each transmission range: DL, D2, D3, D4, N, R, and

P.

Does each selected transmission range match the scan tool

“Range Switch" display? Go to Diagnostic

Aids Go to Step 3

3 Are all range switch pin displays incorrect? Go to Step 4 Go to S tep 5

4 Check fuse and wiring to the 8–way connector terminal 5(D) for

opens.

Refer to Mode Switch in Automatic Transmission (4L30–E)

section.

If no problem was found, replace the range switch.

Is the replacement complete? Go to Step 8 —

5 1. Disconnect the 8–way range switch connector.

2. Using ohmmeter, check continuity between terminal 5(D) and

respectiv el y termi nal s 3 (G) , 6 (C), 7 (B ) and 8( A) of the 8–way

range switch connector.

3. Move shift selector lever through all positions and compare

results with “Range Switch Logic Table".

Is one range switch pin display incorrect? Go to Step 6 Go to Step 7

6 Check the affected wiring and connector, and repair.

Is the repair complete? Go to Step 8 —

7 Check the Powertrain Control Module (PCM) connectors for poor

connection.

If no problem was found, replace the PCM.

Is the replacement complete? Go to Step 8 —

8 1. After the repair is complete, use the scan tool to select

“DTC", then “Clear Info" function and road test the vehicle.

2. Review the scan tool “DTC Info".

Has the last test failed or is the current DTC displayed?

Begin diagnosis

again

Go to Step 1 Repair verified

Exit DTC table

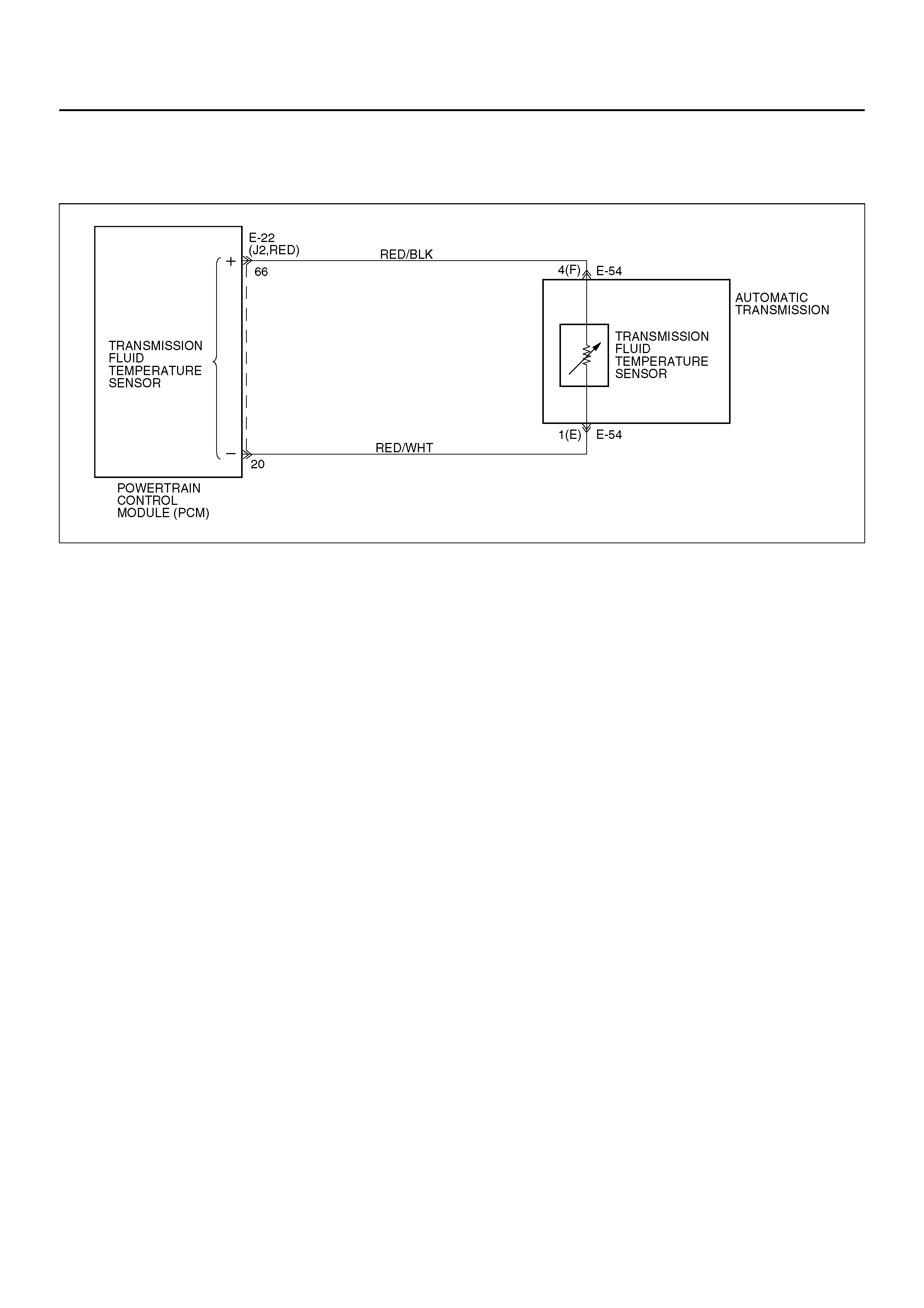

DTC P0712/FLASHING CODE 75 TRANSMISSION FLUID TEMPERATURE (TFT)

SENSOR CIRCUIT LOW INPUT

D07R100026

Circuit Description

The TFT sensor is a thermister that controls the signal

voltage to the PCM. The PCM supplies a 5–volt

reference signal to the sensor on circuit RED/BLK.

When the transmission fluid is cold, the sensor

resistance is high. The PCM detects high signal

voltage. As the transmission fluid temperature

increases to the normal operating temperature of 100°C

(212°F), the sensor resistance becomes less and the

voltage decreases to 1.5 to 2 volts. With transmission

fluid over temperature and DTC P0218 (Flashing Code

71) also set, check the transmission cooling system.

This DTC detects a continuous short to ground in the

TFT sign al circuit or the TFT se nsor. This is a type “D"

DTC.

Conditions For Setting The DTC

• Battery voltage is between 10 and 16 volts.

• Ignition is “on".

• TFT sensor indicating a voltage less than 0.4 volts.

• All conditions met for 20 seconds.

Action Taken When T h e DTC Sets

• Transmission default temperature will be:

80°C (176°F) if engine temperature code is set.

100°C (212°F) if engine temperature is warm.

80°C (176°F) if engine run time is greater than 5

minutes.

21°C (69.8°F) if engine run time is less than 5

minutes.

• The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

• The DTC can be cleared from the PCM history by

using a scan tool.

• The DTC will be cleared from history when the

vehicle has achieved 40 warmup cycles without a

failure reported.

• The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled

“off" long enough to power down the PCM.

Diagnostic Aids

• Check harnes s ro uting f or a p otentia l sho rt to g round

in circuit RED/BLK. Scan tool TFT display should rise

steadily to about 100°C (212°F), then stabilize.

• Inspect the wiring for poor electrical connection at the

PCM and at the transmission 7–way connector.

Look for possible bent, backed out, deformed or

damaged terminals. Check for weak terminal tension

as well. Also check for a chafed wire that could short

to bare metal or other wiring. Inspect for a broken

wire inside the insulation.

• When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

• The temperature to resistance value scale may be

used to test the TFT sensor at the various

temperature levels to evaluate the possibility of a

“skewed" (mis–scaled) sensor.

A “skewed" sensor could result in delayed garage

shifts or TCC com plaints.

• Verify customer driving habits, trailer towing, etc.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

2. This test checks for a short to ground or a “skewed"

sensor.

3. This test checks for an internal fault within the

transmission by creating an open.

DTC P0712/Flashing Code 75 Transmission Fluid Temperature (TFT) Sensor Circuit Low Input

Step Action Yes No

1 Perform the transmission fluid checking procedure. Refer to

Checking Transmission Fluid Level and Condition in Automatic

Transmission (4L30–E) section.

W as the fluid checking procedure performed?

Go to Step 2

Refer to Checking

T ransmission Fluid

Level and

Condition in

Automatic

Transmission

(4L30–E) section

2 1. Install the scan tool.

2. With the engine “of f", turn the ignition switch “on".

NOTE: Before clearing DTC(s), use the scan tool to record

“Failure Records" for reference, as data will be lost when the

“Clear Info" function is used.

3. Record the DTC “Failure Records".

Does the scan too l dis play a TFT sen sor si gnal vol tage less th an

0.4 volts? Go to Step 3 Go to Diagnostic

Aids

3 1. Turn the ignition “off".

2. Disconnect the transmission 7–way connector E–54.

3. Turn the ignition “on".

Does the TFT signal voltage change to match the voltage 4.92

volt s? Go to Step 4 Go to S tep 9

4 Using the J39200 DVOM, measure the resistance between

terminals 3(C) and 5 (D).

Is the resistance within specifications? (See Transmission Fluid

Temperature (TFT) Sensor Specifications.) Go to Diagnostic

Aids Go to Step 5

5 1. Disconnect the transmission 7–way connector E–54.

2. Using the J39200 DVOM, measure the resistance between

terminals E54–4(F) and E54–1(E).

Is the resistance within specifications? (See Transmission Fluid

Temperature (TFT) Sensor Specifications.) Go to Diagnostic

Aids Go to Step 6

6 1. Remove t he transmissio n oil pan. Refer to Transmission Oil

Temperature Sensor (Adapter Case) in Automatic

Transmission (4L30–E) section.

2. Check the internal wiring harness for a short to ground.

Was a problem found? Go to Step 8 Go to S tep 7

7 1. Disconnect the internal wiring harness at the TFT sensor.

2. Measure the resistance of the TFT sensor.

Is the resistance within specifications? (See Transmission Fluid

Temperature (TFT) Sensor Specifications.) Go to Diagnostic

Aids Go to Step 8

8 Replace the TFT Sensor.

Is the replacement complete? Go to Step 12 —

9 Check circuit RED/BLK for a short to ground.

Was a problem found? Go to Step 12 Go to Step 10

10 Check the PCM for faulty connections.

Was a problem found? Go to Step 12 Go to Step 1 1

11 Replace the PCM. Refer to Powe rtrain Control Module (PCM) in

Automatic Transmission (4L30–E) section.

Is the replacement complete? Go to Step 12 —

12 1. After the repair is complete, use the scan tool to select

“DTC", then “Clear Info" function and ensure the following

conditions are met:

TFT sensor indicates a voltage greater than 0.33 volts for 2

seconds.

2. Review the scan tool “DTC info".

Has the last test failed or is the current DTC displayed?

Begin diagnosis

again

Go to Step 1 Repair verified

Exit DTC table

Step Action Yes No

DTC P0713/FLASHING CODE 76 TRANSMISSION FLUID TEMPERATURE (TFT)

SENSOR CIRCUIT HIGH INPUT

D07R100026

Circuit Description

The TFT sensor is a thermistor that controls the signal

voltage to the PCM. The PCM supplies a 5–volt

reference signal to the sensor on circuit RED/BLK.

When the transmission fluid is cold, the sensor

resistance is high and the PCM will sense high signal

voltage. As the transmission fluid temperature warms to

the normal operating temperature of 100°C (212°F), the

sensor resistance becomes less and the voltage

decreases to about 1.5 to 2 volts.

This DTC detects a continuous open or short to power

in the TFT signal circuit or the TFT sensor. This is a

type “D" DTC.

Conditions For Setting The DTC

• Battery voltage is between 10 and 16 volts.

• Ignition is “on".

• TFT sensor indicating a voltage greater than 4.86

volts.

• All conditions met for 20 seconds.

Action Taken When T h e DTC Sets

• Transmission default temperature will be:

80°C (176°F) if engine temperature code is set.

100°C (212°F) if engine temperature is warm.

80°C (176°F) if engine run time is greater than 5

minutes.

21°C (69.8°F) if engine run time is less than 5

minutes.

• The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

• The DTC can be cleared from the PCM history by

using a scan tool.

• The DTC will be cleared from history when the

vehicle has achieved 40 warmup cycles without a

failure reported.

• The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled

“off" long enough to power down the PCM.

Diagnostic Aids

• Inspect the wiring for poor electrical connection at the

PCM and at the transmission 7–way connector . Look

for possible bent, backed out, deformed or damaged

terminals. Check for weak terminal tension as well.

Also check for a chafed wire that could short to bare

met a l o r o t he r w ir i ng . In s pe c t f o r a broken w i re in si d e

the insulation.

• When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

• Scan tool displays transmission fluid temperature in

degrees. After transmission is operating, the

temperature should rise steadily to about 100°C

(212°F), then stabilize.

• The temperature to resistance value scale may be

used to check the TFT sensor at the various

temperature levels to evaluate the possibility of a

“skewed" (mis–scaled) sensor.

A “skewed " sensor could r esult in hard s hifts or TC C

complaints.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

2. This c heck verifies problem in the TFT sensor circ uit.

3. This test simulates a TFT sensor DTC P0712. If the

PCM recognizes the low signal voltage (high

temperature), and the scan tool displays 146°C

(295°F) or greater, the PCM and wiring are OK.

4. This test checks the TFT sensor and internal wiring

harness.

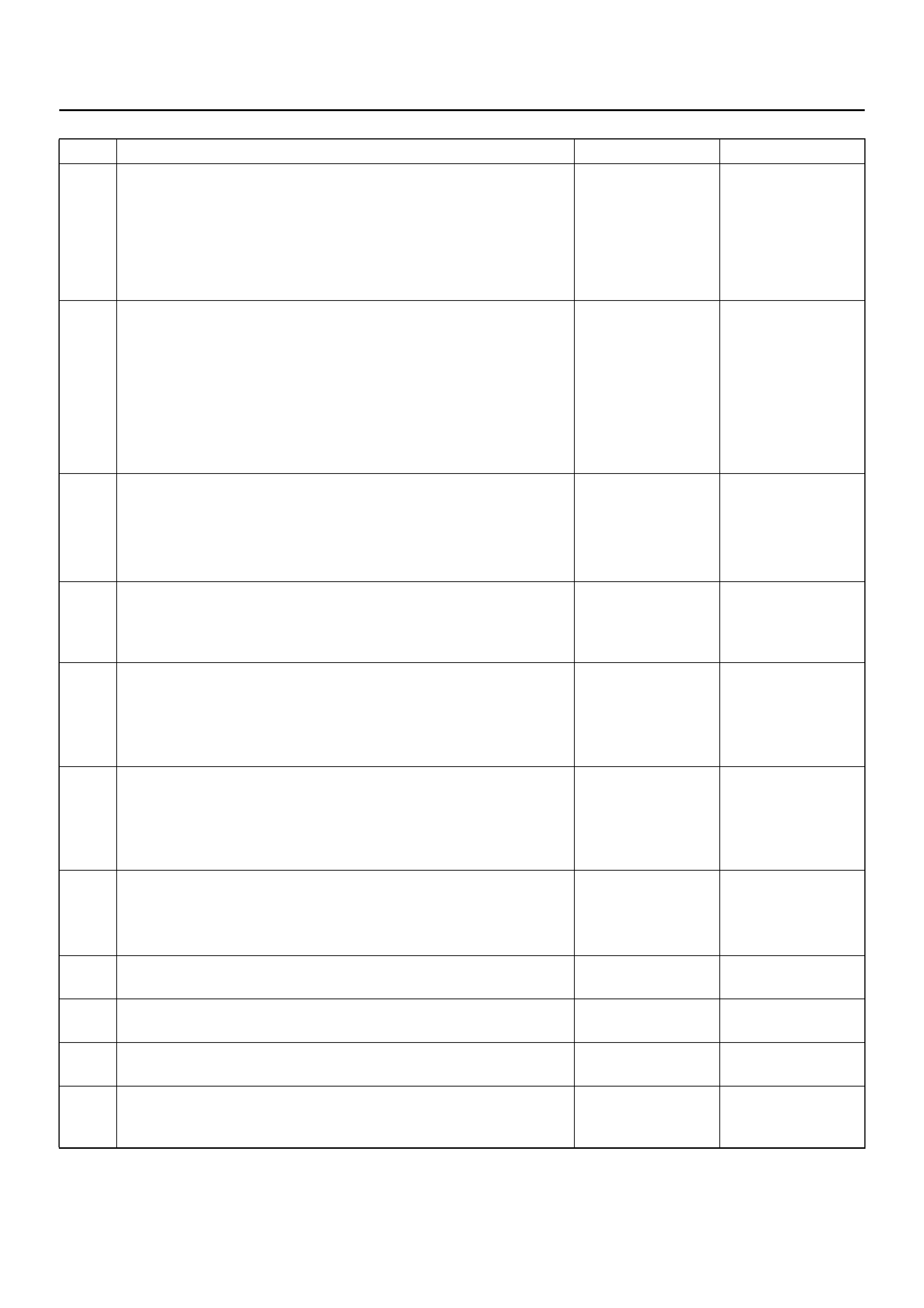

DTC P0713/Flashing Code 76 Transmission Fluid Temperature (TFT) Sensor Circuit High Input

Step Action Yes No

1 Perform the transmission fluid checking procedure.

Refer to Checking Transmission Fluid Level and Condition in

Automatic Transmission (4L30–E) section.

W as the fluid checking procedure performed?

Go to Step 2

Refer to Checking

T ransmission Fluid

Level and

Condition in

Automatic

Transmission

(4L30–E) section

2 1. Install the scan tool.

2. With the engine “of f", turn the ignition switch “on".

NOTE: Before clearing DTC(s), use the scan tool to record

“Failure Records" for reference, as data will be lost when the

“Clear Info" function is used.

3. Record the DTC “Failure Records".

Does the scan tool display a TFT sensor signal voltage greater

than 4.86 volts? Go to Step 3 Go to Diagnostic

Aids

3 1. Turn the ignition “off".

2. Disconnect the transmission 7–way connector E–54.

3. Install a fused jumper wire from terminal E54–4(F) to E54–

1(E) on the engine harness.

4. Turn the ignition “on".

Does the TFT signal voltage drop to less than 0.4 volts? Go to Step 4 Go to S tep 9

4 1. Turn the ignition “off".

2. Using the J39200 DVOM, measure the resistance between

terminals E54–4(F) and E54–1(E).

Is the resistance within specifications? (See Transmission Fluid

Temperature (TFT) Sensor Specifications.) Go to Diagnostic

Aids Go to Step 5

5 1. Disconnect the transmission 7–way connector E–54.

2. Using the J39200 DVOM, measure the resistance between

terminals E54–4(F) and E54–1(E).

Is the resistance within specifications? (See Transmission Fluid

Temperature (TFT) Sensor Specifications.) Go to Diagnostic

Aids Go to Step 6

6 1. Remove the transmission oil pan.

2. Check the internal wiring harness for an open. Refer to

Transmission Oil Temperature Sensor (Adapter Case) in

Automatic Transmission (4L30–E) section.

W as a problem found and corrected? Go to Step 13 Go to Step 7

7 1. Disconnect the internal wiring harness at the TFT sensor.

2. Measure the resistance of the TFT sensor.

Is the resistance within specifications? (See Transmission Fluid

Temperature (TFT) Sensor Specifications.) Go to Diagnostic

Aids Go to Step 8

8 Replace TFT sensor. Refer to Transmission Oil Temperature

Sensor (Adapter Case) in Automatic Transmission (4L30–E)

section.

Is the replacement complete? Go to Step 13 —

9 Check circuit RED/BLK for an open or short to B+.

Was a problem found? Go to Step 13 Go to Step 10

10 Check circuit RED/WHT for an open.

Was a problem found? Go to Step 13 Go to Step 1 1

11 Check the PCM for faulty or intermittent connections.

Was a problem found? Go to Step 13 Go to Step 12

12 Replace the PCM. Refer to Powertrain Contr ol Module (PCM) i n

Automatic Transmission (4L30–E) section.

Is the replacement complete? Go to Step 13 —

13 1. After the repair is complete, use the scan tool to select

“DTC", then “C lear Info " functio n and ensur e the foll owing

conditions are met:

TFT sensor indicates a voltage less than 4.92 volts for 2

seconds.

2. Review the scan tool “DTC Info".

Has the last test failed or is the current DTC displayed?

Begin diagnosis

again

Go to Step 1 Repair verified

Exit DTC table

Step Action Yes No

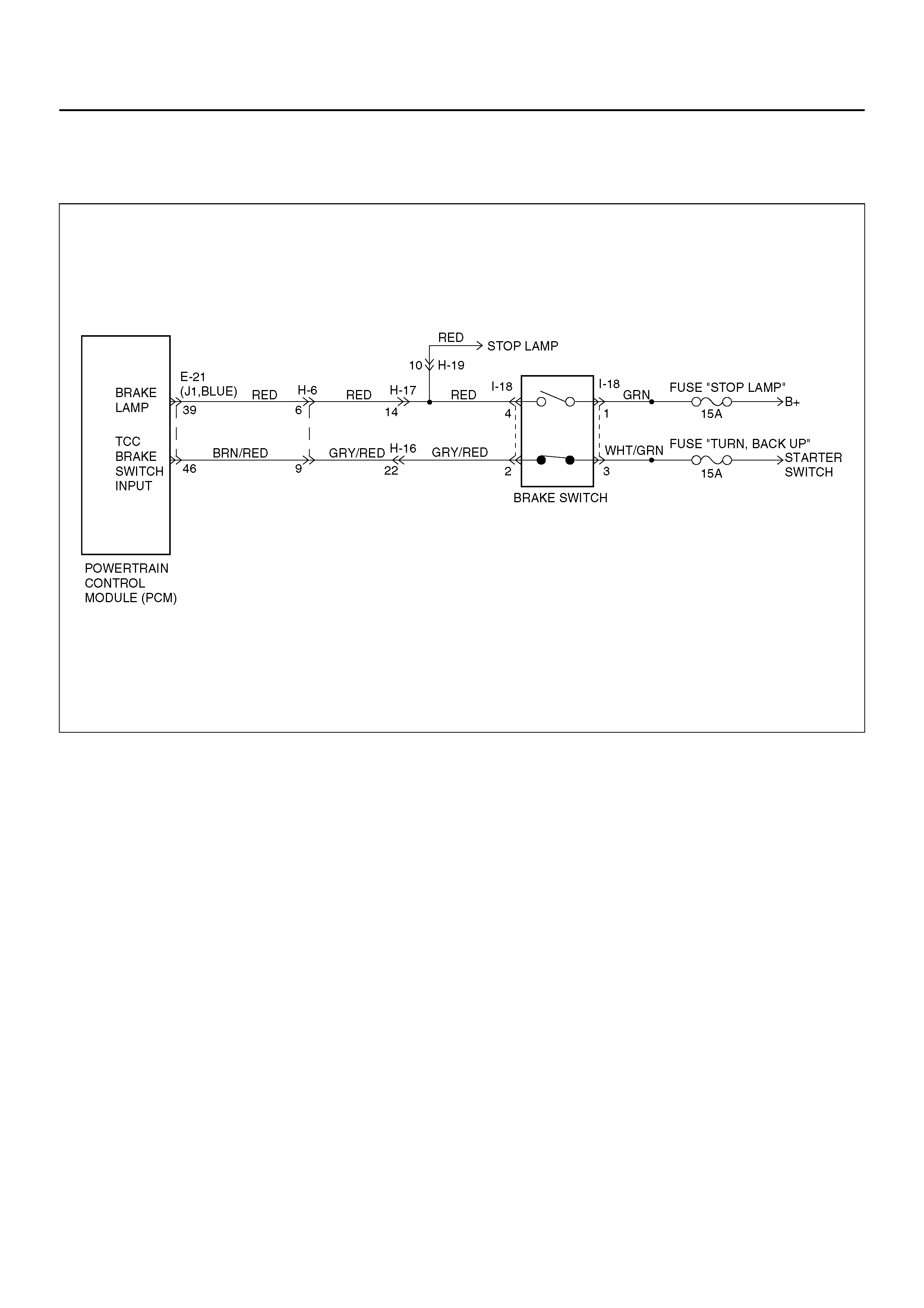

DTC P0719/FLASHING CODE 77 TCC BRAKE SWITCH CIRCUIT HIGH

(STUCK ON)

D07R100028

Circuit Description:

The brake switch indicates brake pedal status to the

Powertrain Control Module (PCM). The brake switch is

a normally–closed switch that supplies battery voltage

on circuit GRY/RED–BRN/RED to the PCM. Applying

the brake pedal opens the switch, interrupting voltage to

the PCM. When the brake pedal is released, the PCM

receiv es a constant v oltage signal . If the PCM receives

a zero voltage signal a t the brake switch input, and th e

Torque Converter Clutch (TCC) is engaged, the PCM

de–energizes the Torque Converter Clutch Solenoid

Val ve (TCC Sol. Valve). Th e PCM disregar ds the brake

switch input for TCC scheduling if there is a brake

switch circuit fault (Refer to Diagnos ti c Ai ds ).

When the PCM detects an open brake switch circuit (0

volts, low input) during accelerations, then DTC P0719

sets. DTC P0719 is a type D DTC.

Conditions For Setting The DTC

• No OSS Assy. DTCs P0722 (Flashing Code 78) or

P0723 (Flashing Code 79).

• The PCM detects an open brake switch or circuit (0

volts) fo r 15 mi nutes without chan ging fo r 2 sec onds ,

and the following events occur seven consecutive

times.

– The vehicle speed is less than 8 km/h (5 mph).

– then the vehicle speed is 8–32 km/h (5–20 mph)

for 4 seconds.

– then the vehi cle speed is gre ater than 32 k m/h (20

mph) for 4 seconds.

Action Taken When The DTC Sets

• The PCM does not illuminate the Malfunction

Indicator Lam p (MIL).

• DTC P0719 stores in PCM history.

Conditions For Clearing The DTC

• A scan tool can clear the DTC from the PCM history.

• The PCM clear s the DT C from the PCM h istory if the

vehicle completes 40 warm–up cycles without a

failure reported.

• The PCM cancels the DTC default actions when the

fault no longer exists and the ignition is OFF long

enough in order to power down the PCM.

Diagnostic Aids

• Inspect the wiring for poor electrical connections at

the PCM and brake switch. Look for possible bent,

backed out, deformed or damaged terminals. Check

for weak terminal tension as well. Also check for a

chafed wire that could short to bare metal or other

wiring. Inspect for a broken wire inside the insulation.

• When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

• Chec k cus tome r d rivi ng habi ts and/o r unus ual driv in g

conditions (i.e. stop and go, highway).

• Check brake switch for proper mounting and

adjustment.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart.

2. This step isolates the brake switch as a source for

setting the DTC.

DTC P0719/Flashing Code 77 TCC Brake Switch Circuit High (Stuck On)

Step Action Yes No

1 1. Install the scan tool.

2. With the engine “off," turn the ignition switch to the “on"

position.

NOTE: Before clearing the DTC(s), use the scan tool in order to

record the “Failure Records" for reference. Using the “Clear Info"

function will erase the stored “Failure Records" from the PCM.

3. Record the “Failure Records", then clear the DTC(s).

4. Select “Brake Switch" on the scan tool.

5. Disconnect the brake switch connector from the brake switch.

6. Connect a test lamp from cavity I18–3 of the brake switch

connector to a known good ground.

Is the test lamp ON? Go to Step 2 Go to Step 3

2 Install a J36169–A Fused Jumper Wire from terminal I18–2 to

terminal I18–3 of the brake switch connector.

Did the TCC Brake Switch status change from Open to Closed? Go to Step 6 Go to Step 8

3 1. Remove the fuse “TURN, BACK UP" (15A).

2. Inspect the fuse for an open.

Is the fuse open? Go to Step 4 Go to Step 7

4 Inspect circuit WHT /GRN for a s hort to gro und condition. Repair

the circuit if necessary.

Did you find a short to ground condition? Go to Step 10 Go to Step 5

5 Inspect circuit GRY/RED–BRN/RED for a short to ground

condition. Repair the circuit if necessary.

Did you find a short to ground condition? Go to Step 10 Go to Step 9

6 Replace the brake switch.

Is the replacement complete? Go to Step 10 —

7 Inspect circuit WHT/GRN for an open condition. Repair the circuit

if necessary.

Did you find and correct an open condition? Go to Step 10 —

8 Inspect circuit GRY/RED–BRN/RED for an open.

Did you find an open condition? Go to Step 10 Go to Step 9

9 Replace the PCM.

Is the replacement complete? Go to Step 10 —

10 In order to verify your repair, perform the following procedure:

1. Select DTC.

2. Select Clear Info.

3. With the engine “off," turn the ignition switch to the “on"

position.

4. Do not depress the brake pedal.

5. Verify that the TCC Brake Switch status indicates “Closed"

(12 volts) for 2 seconds.

6. Select Specific DTC. Enter DTC P0719.

Has the test run and passed? System OK

Begin the

diagnosis

again.

Go to Step 1

DTC P0722/FLASHING CODE 78 TRANSMISSION OUTPUT SPEED SENSOR

(OSS) LOW INPUT

D07RY00032

Circuit Description

Output speed information is provided to the PCM by the

OSS, which is a permanent magnet (PM) generator.

The PM generator pr oduces a puls ing A C voltage. T he

AC voltage level and number of pulses increases as the

speed of the vehicle increases. The PCM then converts

the pulsing voltage to output speed, which is used for

calculations. The vehicle speed can be displayed with a

scan tool.

This DTC detects a low output speed when there is a

high engi ne s peed i n a d rive g ear ran ge. T his is a t ype

“C" DTC.

Conditions For Setting The DTC

• No MAP DTCs P0107 or P0108, P0106, P1106,

P1107.

• No TPS DTCs P0122 or P0123.

• Not in Park or Neutral.

• TPS angle is greater than 10%.

• Engine va cu um is betw een 0 and 70kP a.

• Engine speed is between 3000 and 7000 rpm.

• Transmission output speed is less than 0 rpm.

• All conditions met for 5 seconds.

Action Taken When T h e DTC Sets

• Fixed to 4th gear.

• Maximum line pressure.

• Inhibit TCC engagement.

• The PCM will illuminate the CHECK TRANS Lamp.

Conditions For Clearing The DTC/CHECK

TRANS Lamp

• The PCM wil l tur n o ff the CH ECK T RA NS Lam p after

three consecutive ignition cycles without a failure

reported.

• The DTC can be cleared from the PCM history by

using a scan tool. The DTC will be cleared from

history when the vehicle has achieved 40 warmup

cycles without a failure reported.

• The PCM will cancel the DTC default actions when