SECTION 9A - POWER-ASSISTED STEERING SYSTEM

Service Precaution

Diagnosis

General Description

Power Steering System Test

Maintenance

Fluid Level

Bleeding The Power Steering System

Bleeding Procedure

Flushing The Power Steering System

Steering Wheel Free Play Inspection

Front End Alignment Inspection

and Adjustment

Main Data and Specifications

Special Tools

Power Steering Unit

Power Steering Unit and Associated Parts

Removal

Installation

Power Steering Unit Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

Special Tools

Power Steering Pump

Power Steering Pump

and Associated Parts

Removal

Installation

Power Steering Pump Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

Transfer Gear Assembly

Transfer Gear Assembly

and Associated Parts

Removal

Inspection and Repair

Installation

Supplemental Restraint System

Steering Wheel & Column

Service Precaution

SRS Connectors

Inflator Module

Inflator Module and Associated Parts

Removal

Inspection and Repair

Installation

Steering Wheel

Steering Wheel and Associated Parts

Removal

Installation

Combination Switch

Combination Switch and Associated Parts

Removal

Installation

Lock Cylinder

Lock Cylinder and Associated Parts

Removal

Installation

System Inspection

Steering Column

Steering Column and Associated Parts

Removal

Insepction

Installation

System Inspection

Supplemental Restraint System Steering

Wheel & Column and Associated Parts

Main Data and Specifications

Special Tools

SERVICE PRECAUTION

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

DIAGNOSIS

Since the problems in steering, suspension, wheels and

tyres in volve several systems, they must all be

considered when diagnosing a complaint. To identify

the symptom, always road test the vehicle first.

Proceed with the following preliminary inspections and

correct any defects which are found.

1. Inspect tyres for proper pressure and uneven wear.

2. Raise vehicle on a hoist, then inspect front and rear

suspension and steering linkage for loose or

dama ged parts.

3. Spin the front wheels. Inspect for out-of-round

tyres, out-of-balance tyres, loose and/or rough

wheel bearings.

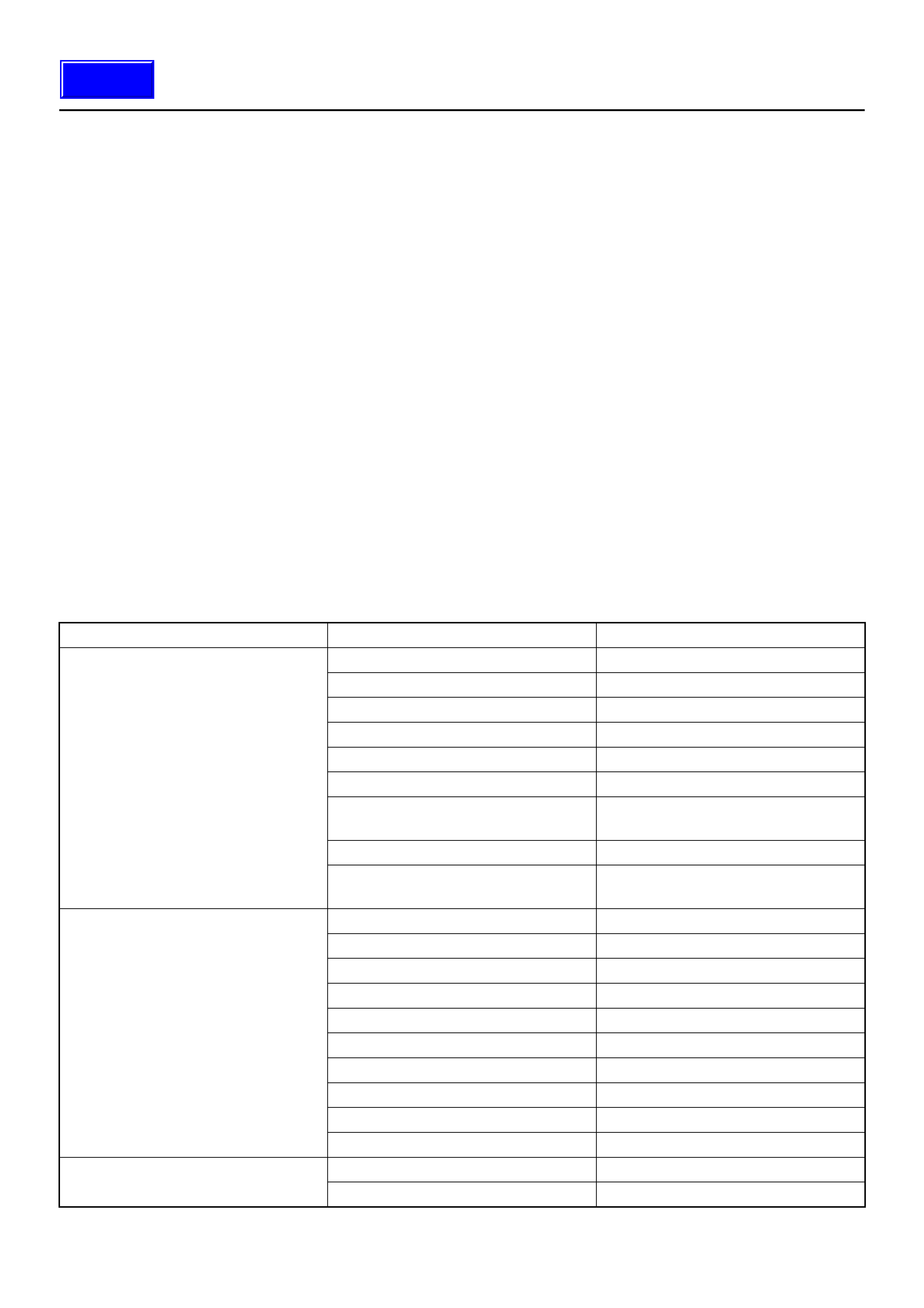

General Diagnosis

Condition Possible cause Correcti on

Vehicle Pulls Mismatched or uneven tyres. Replace tyre.

Tyres not adequately inflated. Adjust tyre pressure.

Broken or sagging springs. Replace spring.

Radial tyr e late ral for ce . Replac e tyre.

Improper wheel alignment. Adjust wheel alignment.

Brake dragging in one wheel. Repair brake.

Loose, bent or broken front or rear

suspension parts. Tighten or replace the appropriate

suspension part(s).

Faulty shock absorbers. Replace shock absorber.

Parts in power steering valve

defective. Replace power steering unit.

Abnormal or Excessive Tyre Wear Sagging or broken spring. Replace spring.

Tyre out of balance. Balance or replace t yre.

Improper wheel alignment. Check front end alignment.

Faulty shock absorber. Replace shock absorber.

Hard driving. Replace tyre.

Overloaded vehicle. Replace tyre and reduce load.

Tyres not rotated periodically. Replace or rotate tyre.

Worn or loose road wheel bearings. Replace wheel bearing.

Wobbly wheel or tyres. Replace wheel or tyre.

Tyres not adequately inflated. Adjust the pressure.

Wheel Hop Blister or bump on tyre. Replace tyre.

Improper shock absorber operation. Replace shock absorber.

Techline

Shimmy, Shake or Vibration Tyre or wheel out of balance. Balance wheels or replace tyre/or

wheel.

Loose wheel bearings. Replace wheel bearing.

Worn steering linkage ball joints. Replace ball joints.

Worn upper or lower end ball joints. Replace ball joints.

Excessive wheel run–out. Repair or replace wheel and/or tyre.

Blister or bump on tyre. Replace tyre.

Excessive loaded radial run–out of

tyre/wheel assembly. Replace tyre or wheel.

Improper wheel alignment. Check wheel alignment.

Loose or worn steering linkage. Tighten or replace steering linkage.

Loose steering unit. Tighten steering unit.

Tyres not adequately inflated. Adjust tyre pressure.

Loose, bent or broken front or rear

suspension parts. Tighten or replace the appropriate

suspension parts.

Faulty shock absorber. Replace shock absorber.

Hub bearing preload misadjustment. Adjust preload.

Parts in power steering valve

defective. Replace power steering unit.

Hard Steering Bind in steering linkage ball studs,

upper or lower end ball joint. Replace ball joint.

Improper wheel alignment. Check wheel alignment.

Tyre not adequately inflated. Inflate tyres to proper pressure.

Bind in steering column or shaft. Repair or replace.

Improper power steering system

operation. Repair or replace.

Refer to “Power steering system

diagnosis"

Too Much Play In Steering Wheel bearings worn. Replace wheel bearings.

Loose steering unit or linkage. Retighten or repair.

Worn or loose steering shaft

universal joint. Retighten or replace steering shaft.

Worn steering linkage ball joints. Replace ball joints.

Worn upper or lower end ball joints. Replace ball joints.

Poor Steering Wheel Returnability Bind in steering linkage ball joints. Replace ball joints.

Bind in upper or lower end ball

joints. Replace ball joints.

Bind in steering column and shaft. Repair or replace.

Bind in steeri ng gear. Check and repair ste ering gear.

Improper wheel alignment. Adjust wheel alignment.

Tyres not adequately inflated. Adjust tyre pressure.

Loose steering wheel nut. Retighten.

Worn wheel bearing. Replace.

Condition Possible cause Correcti on

Abnormal Noise Worn, sticky or loose upper or lower

ball joint, steering linkage ball joints

or drive axle joints.

Replace.

Faulty shock absorbers. Replace.

Worn upper or lower control arm

bushing. Replace.

Loose stabilizer bar. Retighten bolts or replace bushings.

Loose wheel nuts. Tighten nuts. Check for elongated

wheel nut holes.

Replace wheel if required.

Loose suspension bolts or nuts. Retighten suspension bolts or nuts.

Broken or otherwise damaged

wheel bearings. Replace wheel bearing.

Broken suspension springs. Replace spring.

Loose steering unit. Retighten mounting bolt.

Faulty steering unit. Replace steering unit.

Wandering or Poor Steering Stability Mismatched or unevenly worn tyres. Replace tyre or inflate tyres to

proper pressur e.

Loose steering linkage ball joints. Replace ball joints.

Faulty shock absorbers. Replace shock absorber.

Loose stabilizer bar. Tighten or replace stabilizer bar or

bushings.

Broken or sagging springs. Replace spring (pairs).

Improper wheel alignment. Adjust wheel alignment.

Erratic Steering When Braking Worn wheel bearings. Replace wheel bearings.

Broken or sagging springs. Replace spring (pairs).

Leaking caliper. Repair or replace caliper.

Warped discs. Replace brake disc.

Badly worn brake pads. Replace brake pads.

Tyres are inflated unequally. Inflate tyres to proper pressure.

Condition Possible cause Correcti on

Power Steering Sys tem

There is some noise in all power steering systems. One

of the most common is a hissing sound when the

steering wheel is fully turned and the car is not moving.

This noise will be most evident when the steering wheel

is operated while the brakes are applied. There is no

relationship between this noise and steering

performance. Do not replace the valve unless the

“hissing" noise is extremely objectionable. A

replacement valve will also have a slight noise, and is

not always a cure for the condition.

Condition Possible cause Correcti on

Rattle or Chucking Noise Pressure hose touching other parts

of vehicle. Adjust hose position. Do not bend

tubing by hand.

Tie rod ends loose. Tighten or replace tie rod end.

Loose steering unit mounting. Tighten steering unit mounting.

Poor Return of Steering Wheel to

Center Improper front wheel alignment. Adjust front wheel alignment.

Wheel bearing worn. Replace front wheel bearing.

Tie rod end binding. Replace tie rod end.

Ball joint binding. Replace ball joint.

Tight or frozen steering shaft

bearing. Replace steering assembly.

S ticky or plugged steering unit valve. Flush or replace steering unit.

Entry of air in the power steering

system. Bleed the system.

Momentary Increase In Effort When

Turning Wheel Fast To Right or Left High internal leakage. Repair steering gear.

Power steering fluid level low. Replenish fluid.

Steering Wheel Surges or Jerks

When Turning Especially During

Parking

Insu fficien t pump pr essure. Repair pump ass emb ly.

Sticky steering unit valve. Flush or replace steering unit.

Power steering fluid level low. Replenish fluid.

Excessive Wheel Kick Back or

Loose Steering Air in system. Bleed hydraulic system.

Tie rod end loose. Tighten tie rod end.

Wheel bearing worn. Replace wheel bearing.

Hard Steering or Lack or Power

Assist Sticky steering unit valve. Flush or replace steering unit.

Insu fficien t pump pr essure. Repair pump ass emb ly.

Excessive internal pump leakage. Repair pump assembly.

Excessive internal steering gear

leakage. Repair steering gear.

Power steering fluid level low. Replenish fluid.

Unstable Engine Idling or Stalling

When Turning Pressure switch of the power

steering pump or its harness is

faulty.

Repair or replace.

Power Steering Pump

Foaming milky power steering fluid, low fluid level, and

possible low pressure can be caused by air in the fluid,

or loss of fluid due to internal pump leakage. Check for

leak and correct. Bleed the system. Extremely cold

temperatures will cause air bubbles in the system if the

fluid level is low. If the fluid level is correct and the

pump still foams, remove the pump from the vehicle

and check housing for cracks. If the housing is cracked,

replace the pump housing.

Steering Column Lock System

Column

Condition Possible cause Correcti on

Low P re ssure Du e t o Steering P um p R el ief valv e sticki n g or inop er ati ve . Replace reli e f valve .

Side plate not flat against cam ring. Replace side plate.

Extreme wear of cam ring. Replace cam ring.

Scored side plate or rotor. Replace side plate or rotor.

Vanes sticking in rotor slots. Repair or replace vanes and rotor.

Cracked or broken side plate. Replace side plate.

High internal leakage. Repair internal leakage.

Low Pressure Due to Steering Gear Scored housing bore. Replace housing.

Growling Noise In Steering Pump Excessive back pressure in hoses or

steering unit caused by restriction. Repair steering unit or pump.

Scored side plate or rotor. Replace side plate or rotor.

Worn cam ring. Replace cam ring.

Groaning Noise In Steering Pump Air in the fluid. Bleed hydraulic system.

Low fluid level. Replenish fluid.

Pump mounting loose. Tighten mounting bolt.

Rattling Noise In Steering Pump Vanes sticking in rotor slots. Repair or replace vanes and rotor.

Vane improperly installed. Repair rotor and vane.

Swishing Noise In Steering Pump Damaged relief valve. Replace relief valve.

Whining Noise In Steering Pump Scored side plate and vanes. Replace side plate and vanes.

Condition Possible cause Correcti on

Will Not Unlock Damaged lock cylinder. Replace lock cylinder.

Damaged park lock cable. Replace park lock cable.

Will Not Lock Lock spring broken or worn. Replace lock cylinder.

Damaged lock cylinder. Replace lock cylinder.

Ignition switch stuck. Repair or replace ignition switch.

Park lock cable damaged. Replace park lock cable.

Key Cannot be Removed in

“OFF-LOCK" Ignition switch is not set correctly. Correct ignition switch.

Damaged lock cylinder. Replace lock cylinder.

Faulty shift lock mechanism. Repair or replace the shift lock

mechanism.

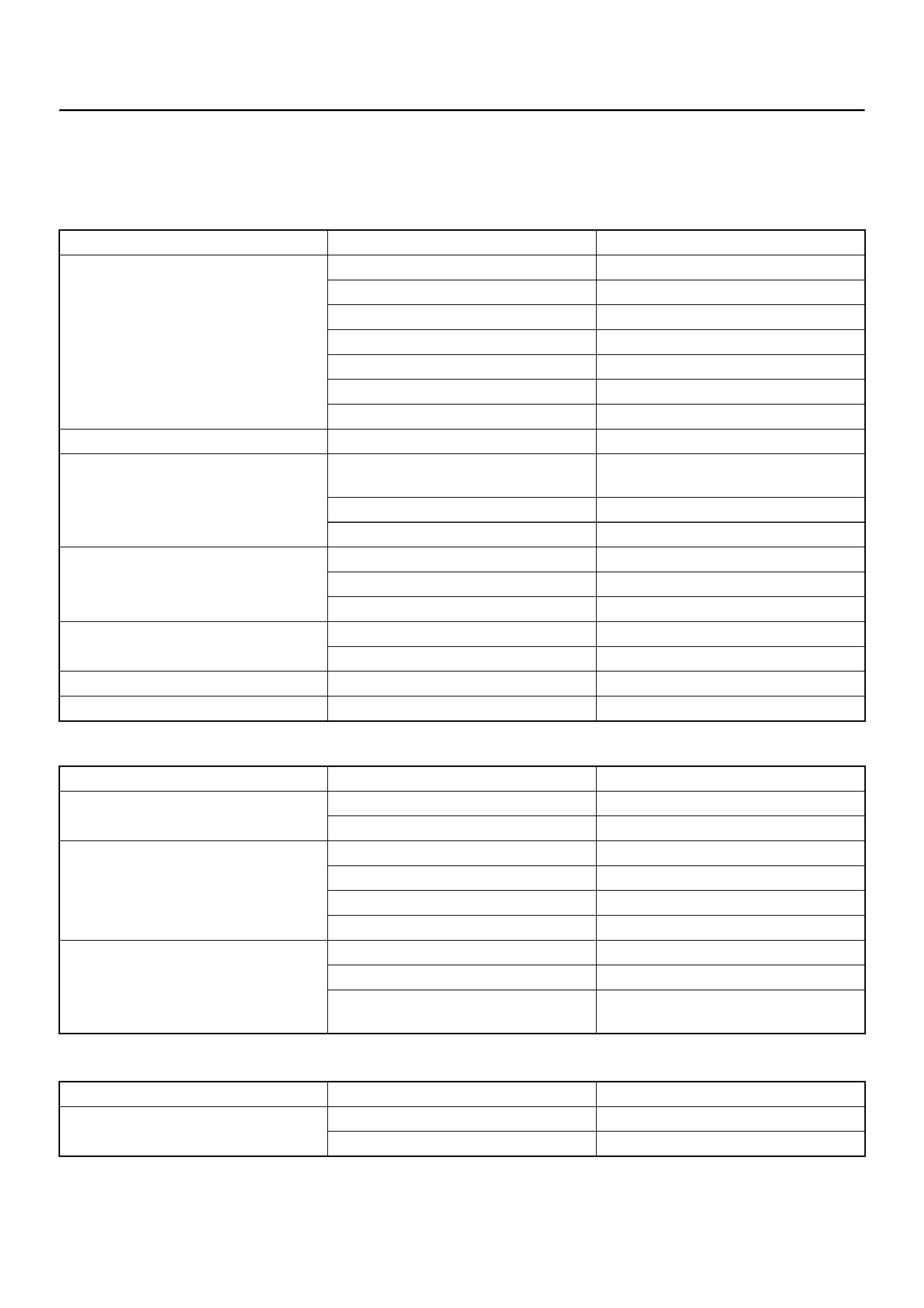

Condition Possible cause Correcti on

Noise in Column Universal joint loose. Tighten joint.

Shaft lock snap ring not seated. Place snap ring in proper position.

Turn Signal Switch

This diagnosis covers mechanical problems only. Refer

to Turn Signal Switch in Electrical section for electrical

diagnosis.

Condition Possible cause Correction

Turn Signal Will Not Stay In Turn

PositionForeign material or loose parts

preventing movement of yoke.Repair or replace signal switch.

Broken or missing detent or

canceling spring.Replace signal switch.

Turn Signal Will Not Cancel Loose switch mounting screws. Tighten mounting screws.

Switch or anchor bosses broken. Replace turn signal switch.

Broken, missing or out of position

detent, return or canceling spring. Replace turn signal switch.

Worn canceling cam. Replace turn signal switch.

Turn Signal Difficult To Operate Turn signal switch arm loose. Tighten arm screw.

Broken or distorted yoke. Replace turn signal switch.

Loose or misplaced springs. Replace turn signal switch.

Foreign parts and/or material. Repair turn signal switch.

Loose turn signal switch mounting

screws.Tighten mounting screws.

Turn Signal Will Not Indicate Lane

ChangeBroken lane change pressure pad or

spring hanger.Replace turn signal switch.

Broken, missing or misplaced lane

change spring. Replace turn signal switch.

Base of wire damaged. Replace turn signal switch.

Hazard Switch Cannot Be Turned

OffForeign material between hazard

switch to turn signal switch body.Repair or replace hazard switch.

No Turn Signal Lights Electrical failure in chassis harness. Refer to Electrical section.

Inoperative turn signal flasher unit. Replace flasher unit.

Loose chassis harness connector. Repair loose connector.

Front or Rear Turn Signal Lights Not

Flashing Burned-out or damaged turn signal

bulb. Replace bulb.

High resistance connection to

ground at bulb socket. Repair bulb socket.

Loose chassis harness connector. Repair loose connector.

GENERAL DESCRIPTION

The hydr aulic power steering system consi sts of a

pump, an oil reservoir, a steering unit, a pressure hose

and a return hose.

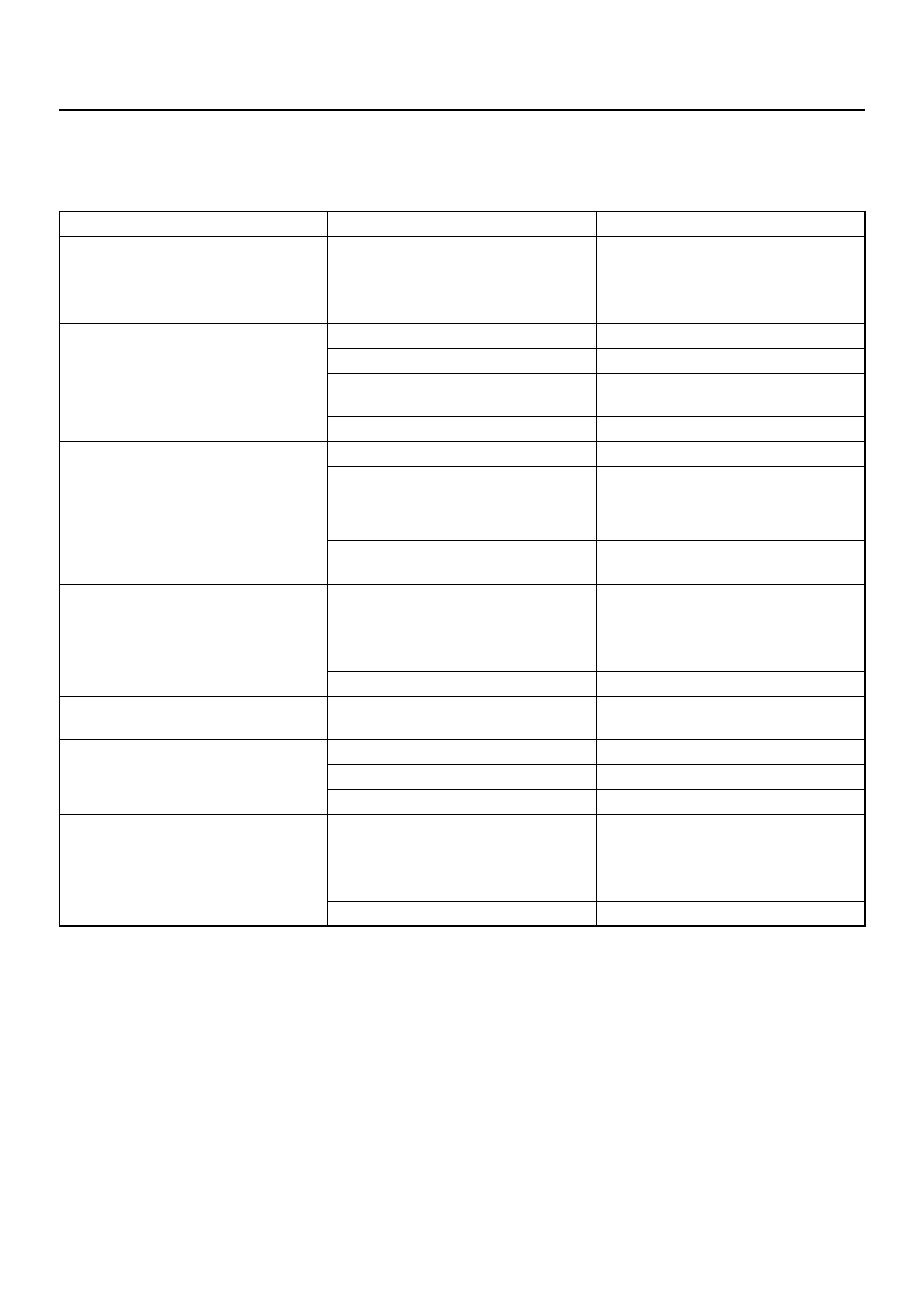

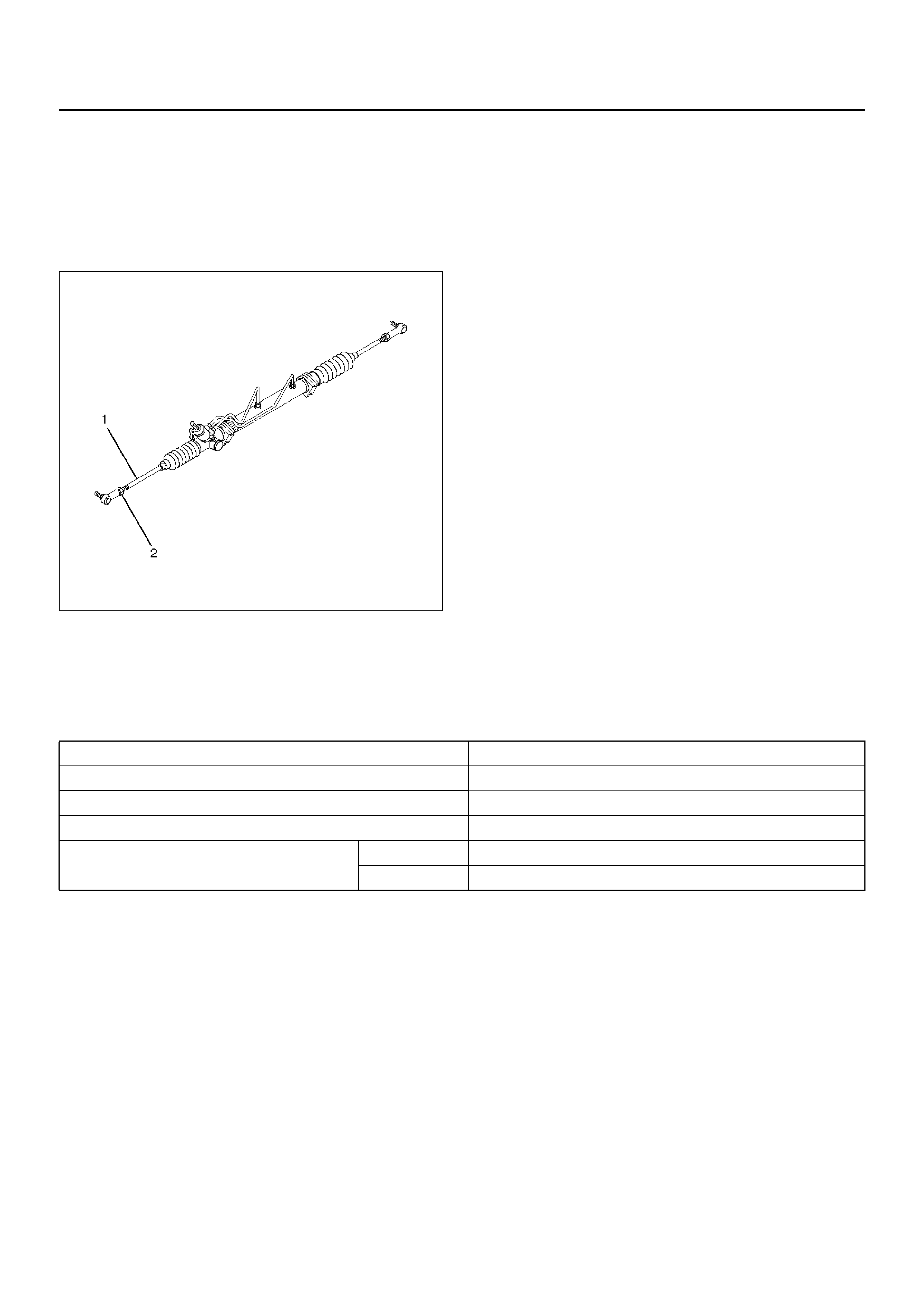

Power Steering Unit

A02RW007

The power steering unit is rack and pinion type.

The toe–in angle can be adjusted by turning the rod on

each side.

The steering housing cannot be disassembled.

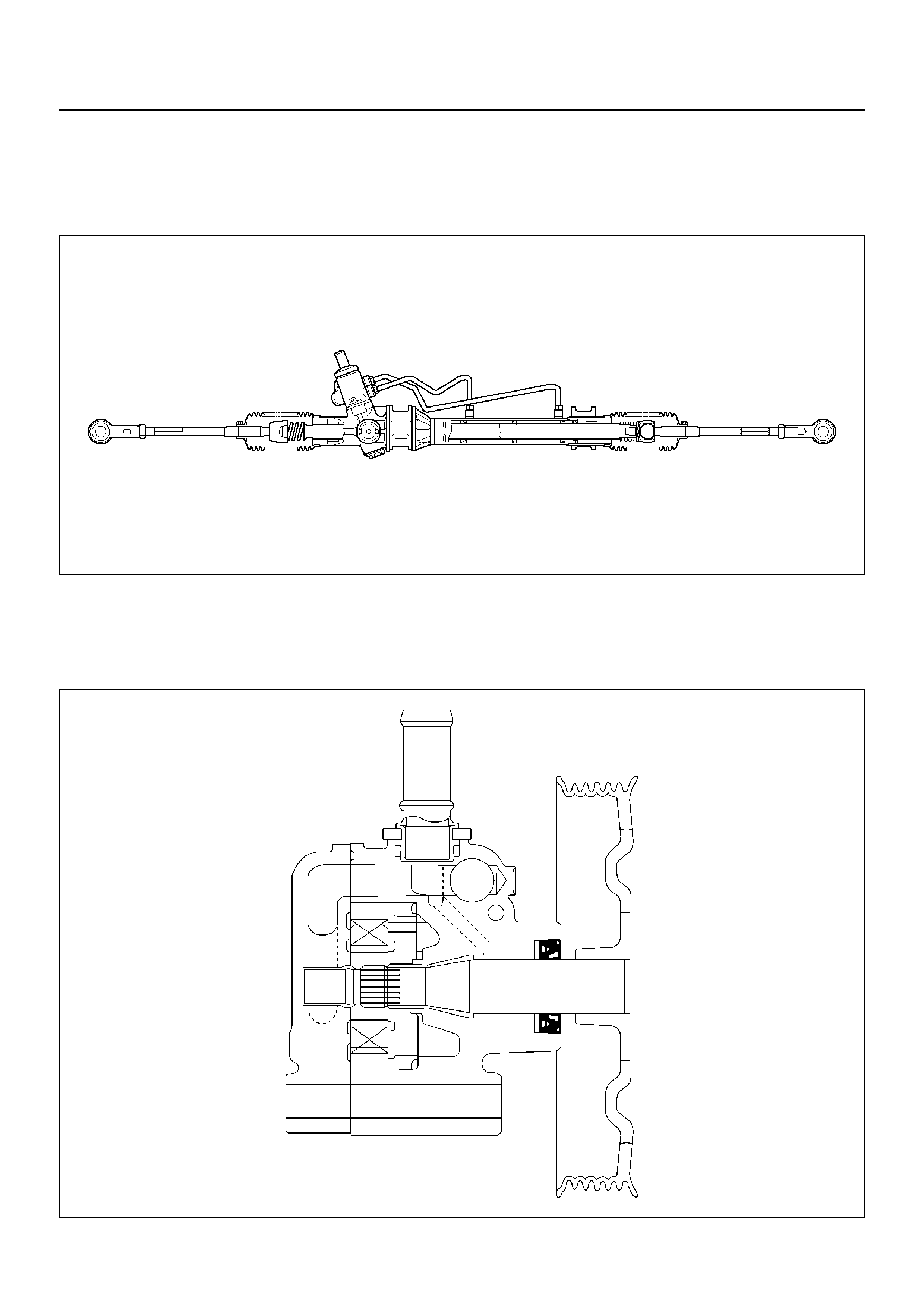

Hydraulic Pump

A02RX002

The hydraulic pump is vane-type design. The

submerged pump has housing and internal parts that

are inside the reservoir and operate submerged in oil.

There are two bore openings at the rear of the pump

housing. The larger opening contains the cam ring,

pressure plate, thrust plate, rotor and vane assembly,

and end plate. The smaller opening contains the

pressure line union, flow control valve and spring.

The flow control orifice is part of the pressure line union.

The pressure relief valve inside the flow control valve

limits the pump pressure.

Pressure Switch

When hydraulic pressure reaches 3430 kPa , the

pressure switch of the power steering pump closes

causing the Powertrain Control Module (PCM) to

actuate the throttle valve, which increases the engine

rpm to prevent the overload-induced engine speed slow

down. The switch opens when hydraulic pressure drops

to 2940 kPa.

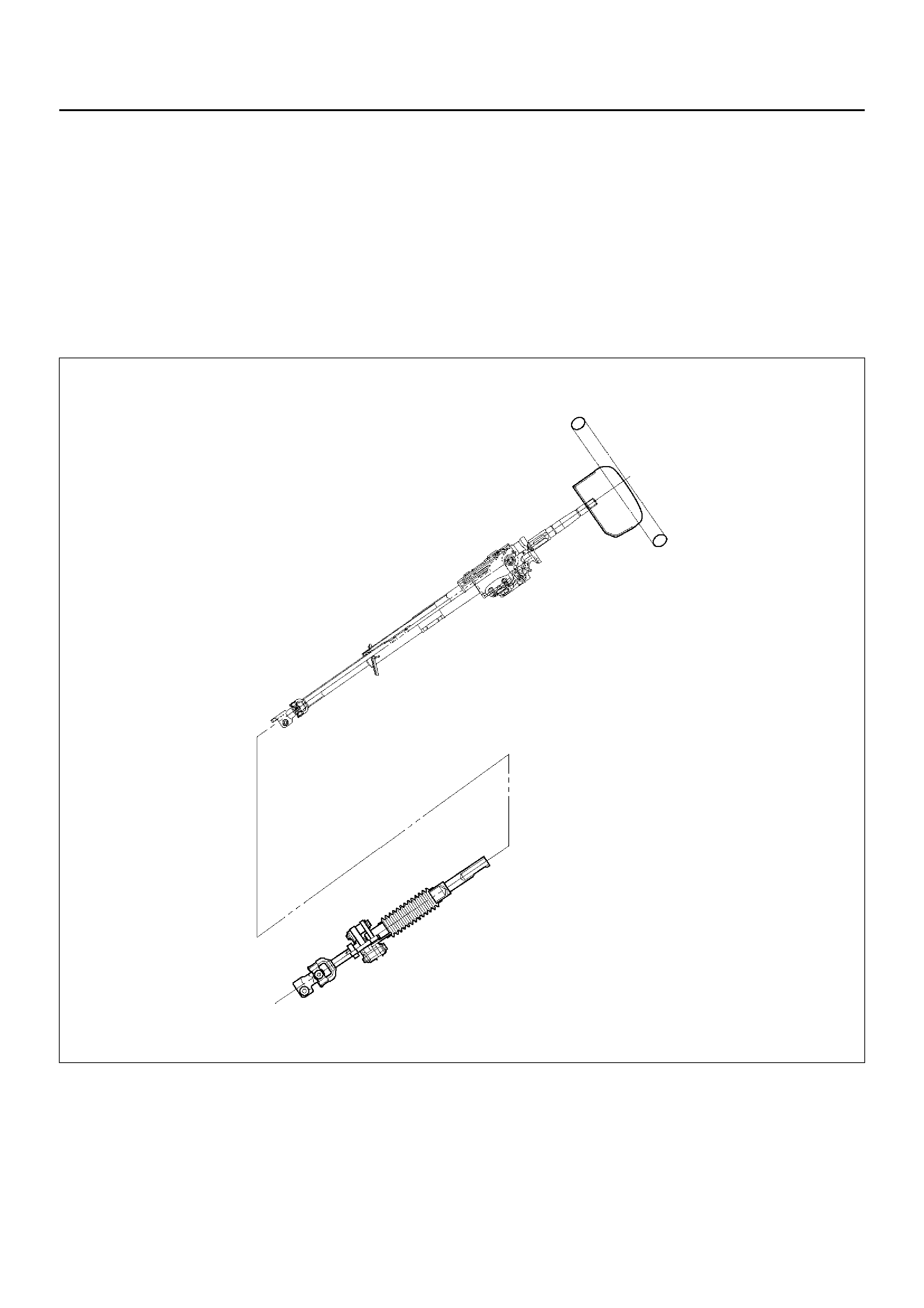

Steering Column

431RY00009

WARNING: TO AVOID DEPLOYMENT WHEN

TROUBLE-SHOOTING THE SRS SYSTEM, DO NOT

USE ELECTRICAL TEST EQUIPMENT SUCH AS

BATTERY-POWERED OR A/C-POWERED

VOLT-METER, OHMMETER, ETC., OR ANY TYPE

OF ELECTRICAL EQUIPMENT OTHER THAN

SPECIFIED IN THIS MANUAL. DO NOT USE A

NON-POWERED PROBE-TYPE TESTER.

INSTRUCTION IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PERSONAL

INJURY MAY RESULT.

When servicing a vehicle equipped with Supplemental

Restraint System, pay close attention to all

WARNINGS and CAUTION S.

For detailed explanation about SRS, refer to Restraints

section.

The steering column has three important features in

addition to the steering function:

1. The column is energy absorbing, designed to

compress in a front-end collision to minimize the

possibility of injury to the driver of the vehicle.

2. The ignition switch and lock are mounted

conveniently on the column.

3. With the column mounted lock, the ignition and

steering operation can be locked to prevent theft of

the vehicle.

The column can be disassembled and reassembled.

However, to insure the energy absorbing action, use

only the specified screws, bolts and nuts as designated,

and tighten them to the specified torque.

Handle the column with care when it is removed from

the vehicle. A sharp blow on the end of steering shaft or

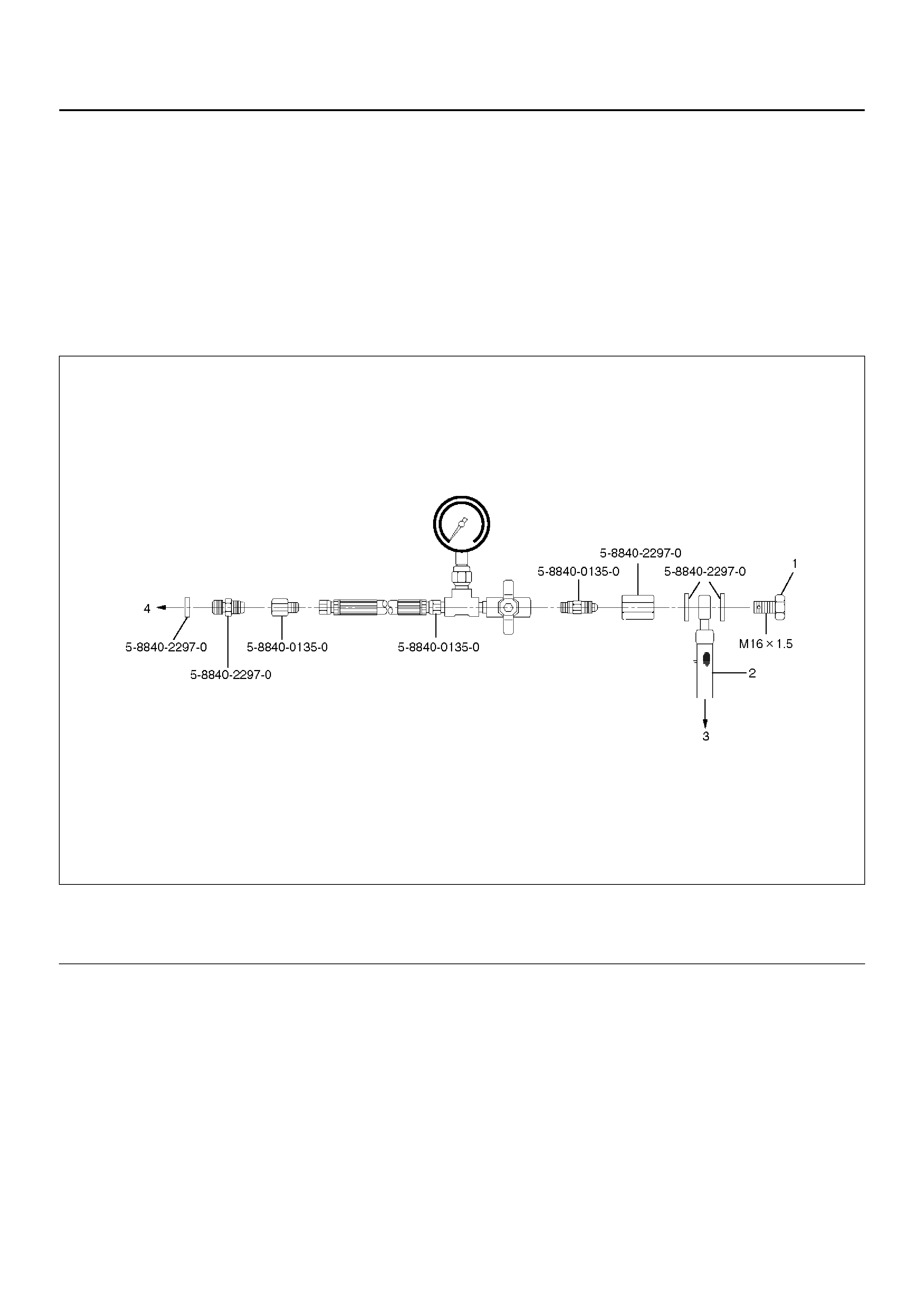

POWER STEERING SYSTEM TEST

Test Procedure

F02RX002

Legend

EndOFCallout

Test of fluid pressure in the power steering system is

performed to determine whether or not the oil pump and

power steering unit are functioning normally.

The power steering system test is used to identify and

isolate hydraulic circuit difficulties. Prior to performing

this test, the following inspections and corrections, if

necessary, must be made.

• Inspect pump reservoir for proper fluid level.

• Inspect pump belt for proper tension.

• Inspect pump driver pulley condition.

1. Place a container under the pump to catch the fluid

when disconnecting or connecting the hoses.

2. With the engine NOT running, disconnect the

pressure hose at the power steering pump and

install power steering tester 5–8840–0135–0 as

shown in the illustration. The gage must be

between the shutoff valve and pump. Open the

shutoff valve.

3. Check the fluid level. Fill the reservoir with power

steering fluid, to the “Full" mark. Start the engine,

then turn the steering wheel and momentarily hold it

against a stop (right or left). Turn the engine off and

check the connections at tester for leakage.

(1) Bolt

(2) Hose (3) Power Steering Unit

(4) Power Steering Pump

4. Bleed the system. Refer to Bleeding the Power

Steering System in this section.

5. Start the engine and check the fluid level. Add

power steering fluid if required. When the engine is

at normal operating temperature, increase engine

speed to 1500 rpm.

CAUTION: Do not leave shutoff valve fully closed

for more than 5 seconds, as the pump could

become damaged internally.

6. Fully close the shutoff valve. Record the highest

pressures.

• If the pressure recorded is within 9300–9800 kPa

(95–100 kg/cm2/1350–1420 psi), the pump is

functioning within its specifications.

• If the pressure recorded is higher than 9800 kPa

(100 kg/cm2/1420 psi), the valve in the pump is

defective.

• If the pressure recorded is lower than 9300 kPa

(95 kg/cm2/1350 psi), the valve or the rotating

group in the pump is defective.

7. If the pump pressures are within specifications,

leave the valve open and turn (or have someone

else turn) the steering wheel fully in both directions.

Record the highest pressures and compare with the

maximum pump pressure recorded in step 6. If this

pressure cannot be built in either side of the power

steering unit, the power steering unit is leaking

internally and must be replaced.

8. Shut the engine off, remove the testing gauge.

9. Reconnect the pressure hose, check the fluid level

and make the needed repairs.

10. If the problem still exists, the steering and front

suspension must be thoroughly examined.

MAINTENANCE

The hydraulic system should be kept clean and fluid

level in the reservoir should be checked at regular

intervals and fluid added when required. Refer to

Recommended Fluids and Lubricants in General

Information section for the type of fluid to be used and

the intervals for filling.

If the system contains some dirt, flush it as described in

this section. If it is exceptionally dirty, the pump must

be completely disassembled before further usage. (The

steering unit cannot be disassembled.)

All tubes, hoses, and fittings should be inspected for

leakage at regular intervals. Fittings must be tight.

Make sure the clips, clamps and supporting tubes and

hoses are in place and properly secured.

Power steering hoses and lines must not be twisted,

kinked or tightly bent. Air in the system will cause

spongy action and noisy operation. When a hose is

disconnected or when fluid is lost, for any reason, the

system must be bled after refilling. Refer to Bleeding

the Power Steering System in this section.

• Inspect belt for tightness.

• Inspect pulley for looseness or damage. The pulley

should not wobble with the engine running.

• Inspect hoses so they are not touching any other

parts of the vehicle.

• Inspect fluid level and fill to the proper level.

FLUID LEVEL

1. Run the engine until the power steering fluid

reaches normal operating temperature, about 55°C

(130°F), then shut the engine off.

2. Check the level of fluid in the reservoir.

3. If the fluid level is low, add power steering fluid as

specified in General Information to the proper level

and install the receiver cap.

4. When checking the fluid level after the steering

system has been serviced, air must be bled from the

system. Refer to Bleeding the Power Steering

System in this section.

BLEEDING THE POWER STEERING

SYSTEM

When a power steering pump or unit has been installed,

or an oil line has been disconnected, the air that has

entered the system must be bled out before the vehicle

is operated. If air is allowed to remain in the power

steering fluid system, noisy and unsatisfactory

operation of the system may result.

BLEEDING PROCEDURE

When bleeding the system, and any time fluid is added

to the power steering system, be sure to use only

power steering fluid as specified in General Information.

1. Fill the pump fluid reservoir to the proper level and

let the fluid settle for at least two minutes.

2. S t art the engine and let it run for a few seconds. Do

not turn the steering wheel. Then turn the engine

off.

3. Add fluid if necessary.

4. Repeat the above procedure until the fluid level

remains constant after running the engine.

5. Raise and support the front end of the vehicle so

that the wheels are off the ground.

6. Start the engine. Slowly turn the steering wheel

right and left, lightly contacting the wheel stops.

7. Add power steering fluid if necessary.

8. Lower the vehicle, set the steering wheel at the

straight forward position after turning it to its full

steer positions 2 or 3 times, and stop the engine.

9. Check the fluid level and refill as required.

10. If the fluid is extremely foamy, allow the vehicle to

set a few minutes, then repeat the above procedure.

FLUSHING THE POWER STEERING

SYSTEM

1. Raise and support the front end of the vehicle off the

ground until the wheels are free to turn.

2. Remove the fluid return line at the pump inlet

connector and plug the connector port on the pump.

Position the line toward a large container to catch

the draining fluid.

3. While running the engine at idle, fill the reservoir

with new power steering fluid. Turn the steering

wheel in both directions. Do not contact or hold the

steering wheel to the wheel stops. This will cause

the pump to go to pressure relief mode, which may

cause a sudden fluid overflow at the reservoir.

4. Install all the lines and hoses. Fill the system with

new power steering fluid and bleed the system as

described in Bleeding The Power Steering System.

Operate the engine for about 15 minutes.

Remove the pump return line at the pump inlet and

plug the connection on the pump. While refilling the

reservoir, check the draining fluid for contamination.

If foreign material is still evident, replace all lines,

disassemble and clean or replace the power

steering system components. Do not re-use any

drained power steering fluid.

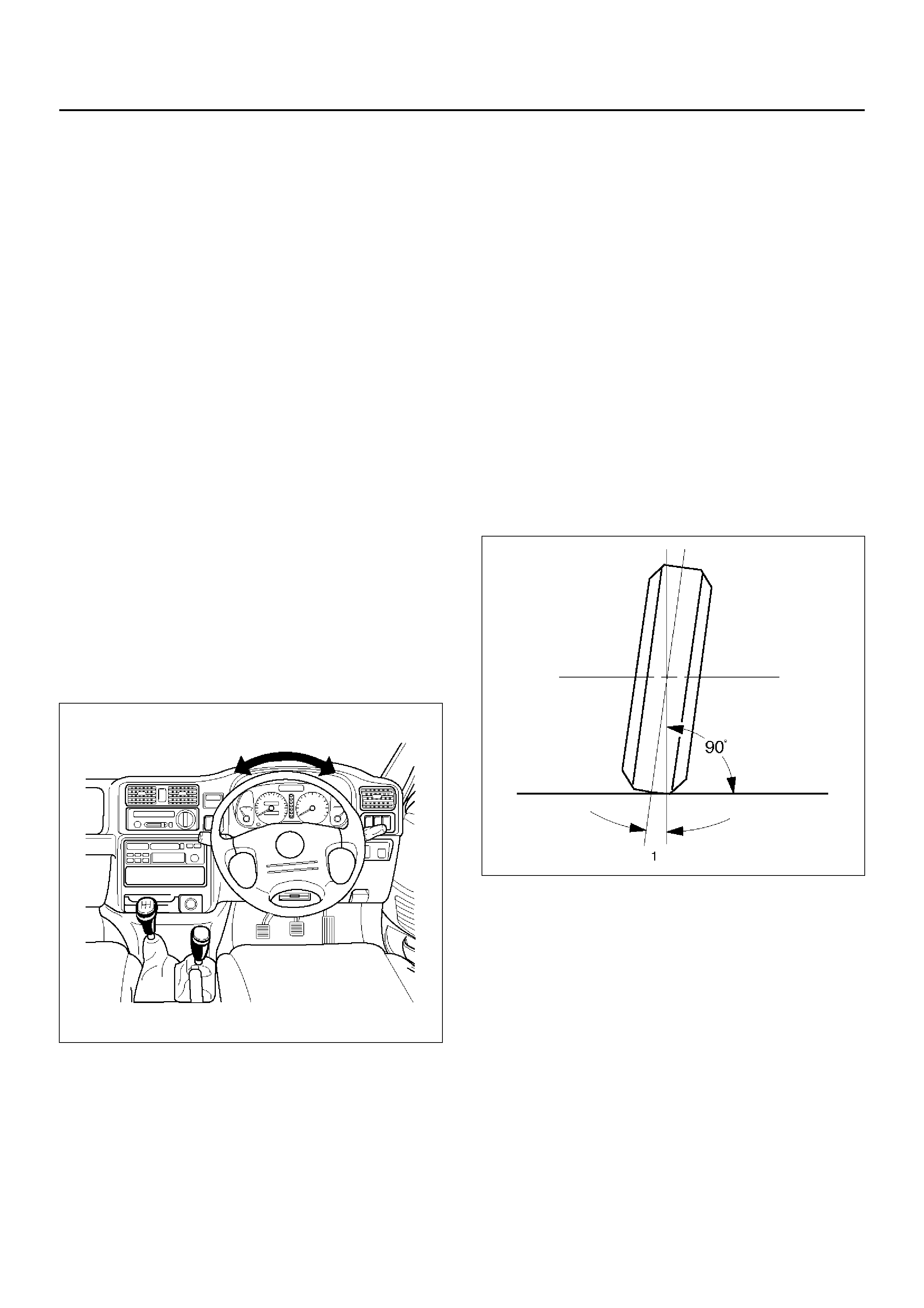

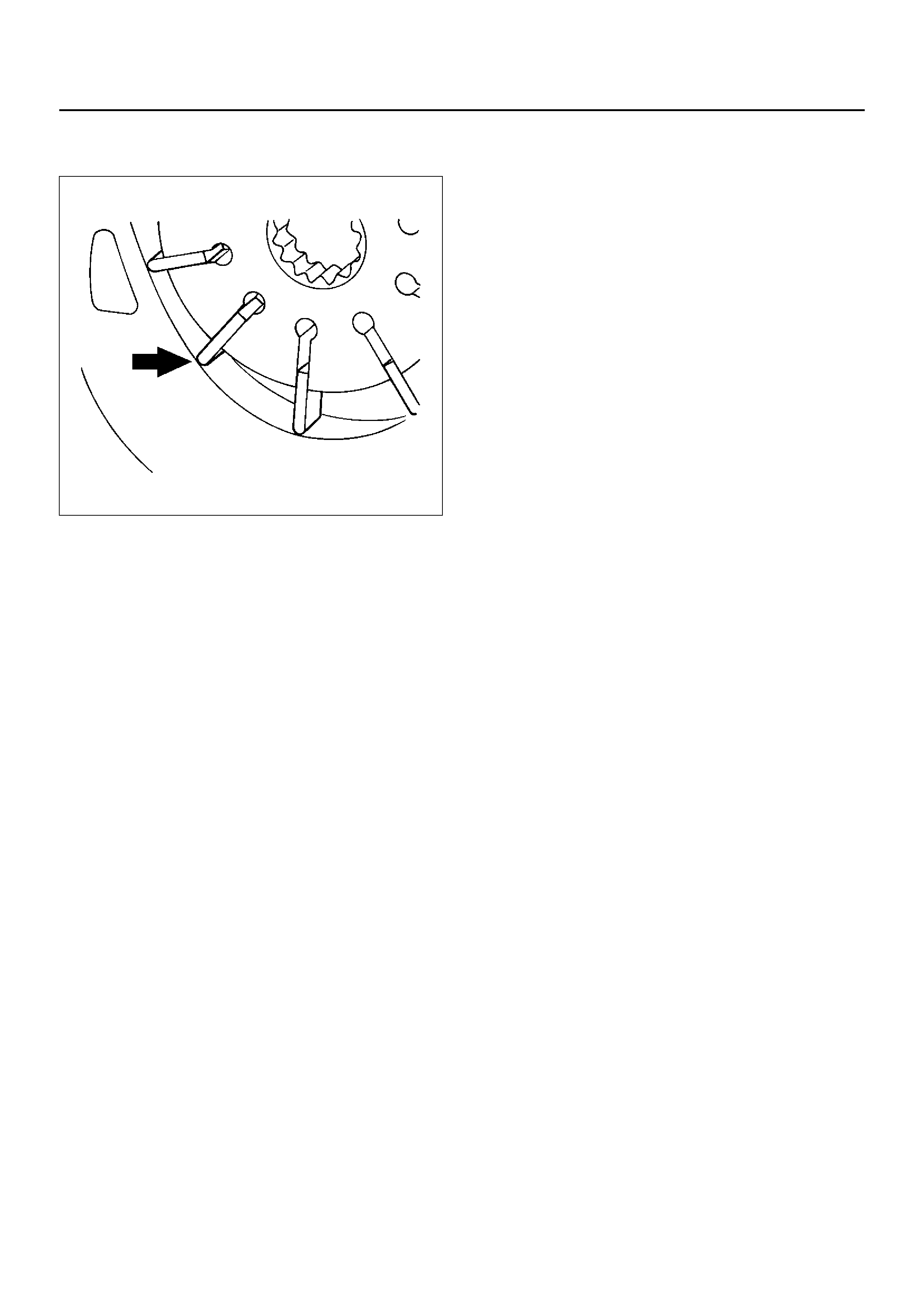

STEERING WHEEL FREE PLAY

INSPECTION

430RW020

1. With the tyres in the straight-ahead position, check

the amount of steering wheel play by turning the

wheel in both directions until the tyres begin to

move.

NOTE: The wheel free play should be checked with the

engine running.

Free play: 0 – 30mm (0 – 1.18in)

2. Also check the steering wheel for play and

looseness in the mount by moving it back and forth

and sideways. When test driving, check for hard

steering, steering shimmy and tendency to pull to

one side.

FRONT END ALIGNMENT

INSPECTION AND ADJUSTMENT

General Descript ion

“Front End Alignment" refers to the angular relationship

between the front wheels, the front suspension

attaching parts and the ground.

Proper front end alignment must be maintained in order

to insure efficient steering, good directional stability and

to prevent abnormal tyre wear.

The most important factors of front end alignment are

whee l toe-in, wheel camber and axle caste r.

Camber:

This illustration shows view from the front of the vehicle.

480RS004

Camber is the vertical tilting inward or outward of the

front wheels. When the wheels tilt outward at the top,

the camber is positive (+). When the wheels tilt inward

at the top, the camber is negative (-). The amount of tilt

measured in degrees from the vertical is called the

camber angle (1). If camber is extreme or unequal

between the wheels, improper steering and excessive

tyre wear will result. Negative camber causes wear on

the inside of the tyre, while positive camber causes

wear to the outside.

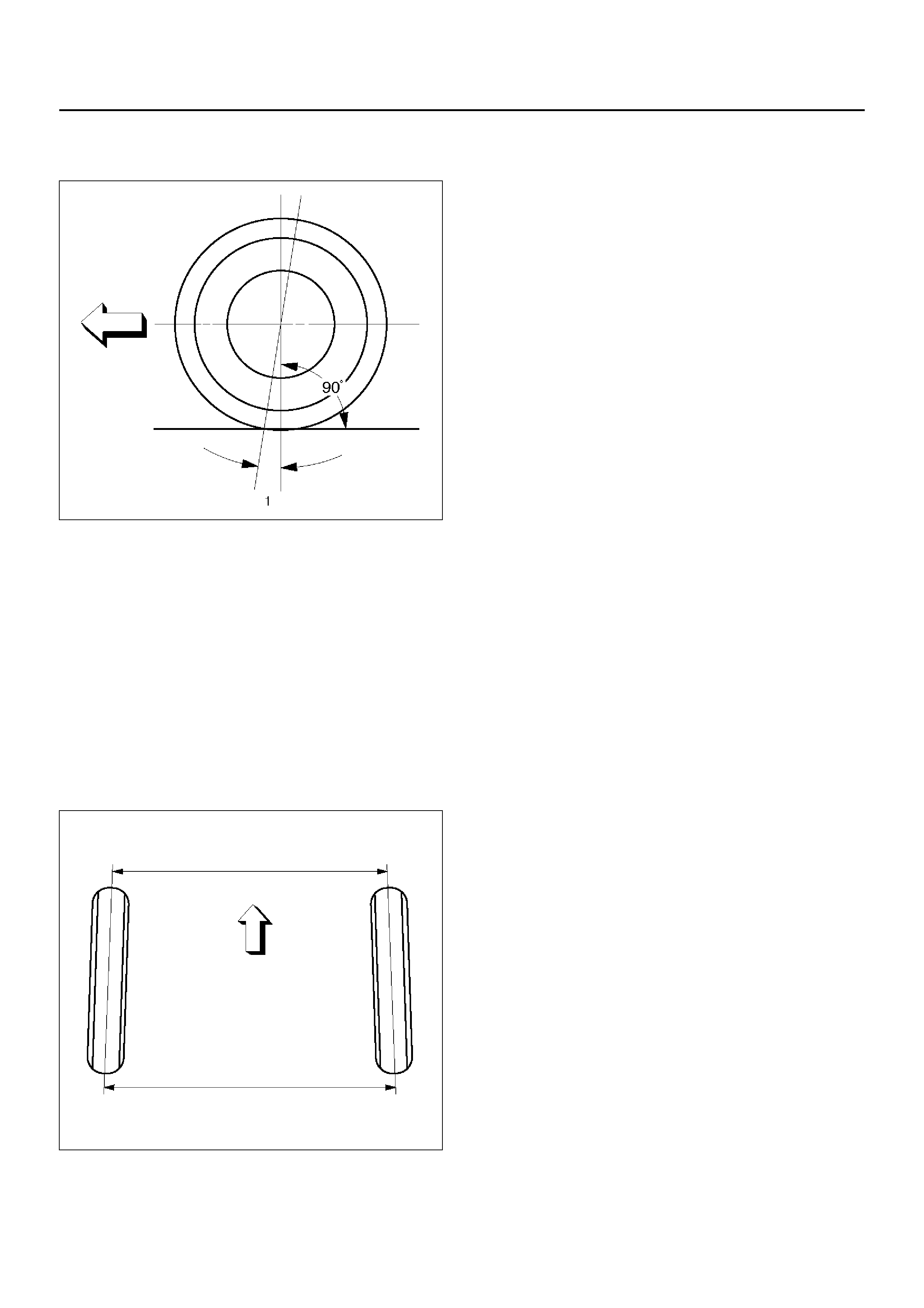

Caster:

This illustration shows view from the side of the vehicle.

480RS005

Caster (1) is the vertical tilting of the wheel axis either

forward or backward (when viewed from the side of the

vehicle). A backward tilt is positive (+) and a forward tilt

is negative (-). On the short and long arm type

suspension you cannot see a caster angle without a

special instrument, but if you look straight down from

the top of the upper control arm to the ground, the ball

joints do not line up (fore and aft) when a caster angle

other than 0 degree is present. With a positive angle,

the lower ball joint would be slightly ahead (toward the

front of the vehicle) of the upper ball joint center line.

Toe-in:

This illustration shows view from the top of the vehicle.

480RS003

Toe-in is the measured amount the front wheels are turn

in. The actual amount of toe-in is normally a fraction of

a meter. Toe-in is measured from the center of the tyre

treads or from the inside of the tyres. The purpose of

toe-in is to insure parallel rolling of the front wheels and

to offset any small deflections of the wheel support

system which occurs when the vehicle is rolling forward.

Incorrect toe-in results in excessive toe-in and unstable

steering. Toe-in is the last alignment to be set in the

front end alignment procedure.

Inspection

Before making any adjustments affecting caster,

camber or toe-in, the following front end inspection

should be made.

1. Inspect the tyres for proper inflation pressure. Refer

to Main Data and Specifications in Wheel and Tyre

System section 10.

2. Make sure that the vehicle is unladen condition

(With no passenger or loading).

3. Make sure that the spare tyre is installed at the

normal position.

4. Inspect the front wheel bearings for proper

adjustment. Refer to Front Hub and Disc in

Driveline section 4C.

5. Inspect the ball joints and tie rod ends. If excessive

looseness is noted, correct before adjusting. Refer

to Steering Linkage in this section.

6. Inspect the wheel and tyres for run-out. Refer to

Wheel Replacement in Wheel and Tyre System

section 10.

7. Inspect the trim height. If not within specifications,

the correction must be made before adjusting

caster.

8. Inspect the steering unit for looseness at the frame.

9. Inspect shock absorbers for leaks or any noticeable

noise. Refer to Shock Absorber in Suspension

section 3.

10. Inspect the control arms or stabilizer bar attachment

for looseness. Refer to Suspension section 3.

11. Inspect the front end alignment using alignment

equipment. Follow the manufacturer's instructions.

12. Park the veh icle must be on a level sur face.

Trim Height Adjustment

Adjust the trim height (1) by means of the adjusting bolt

on the height control arms.

CAUTION: When adjusting front end alignment, be

sure to begin with trim height first, as it may change

other adjusted alignments.

450RS003

410RS001

1. Check and adjust the tyre inflation pressures.

2. Park the vehicle on a level ground and move the

front of the vehicle up and down several times to

settle the suspension.

3. Make necessary adjustment with the adjusting bolt

on the height control arms.

Trim height: 119 ± 5mm

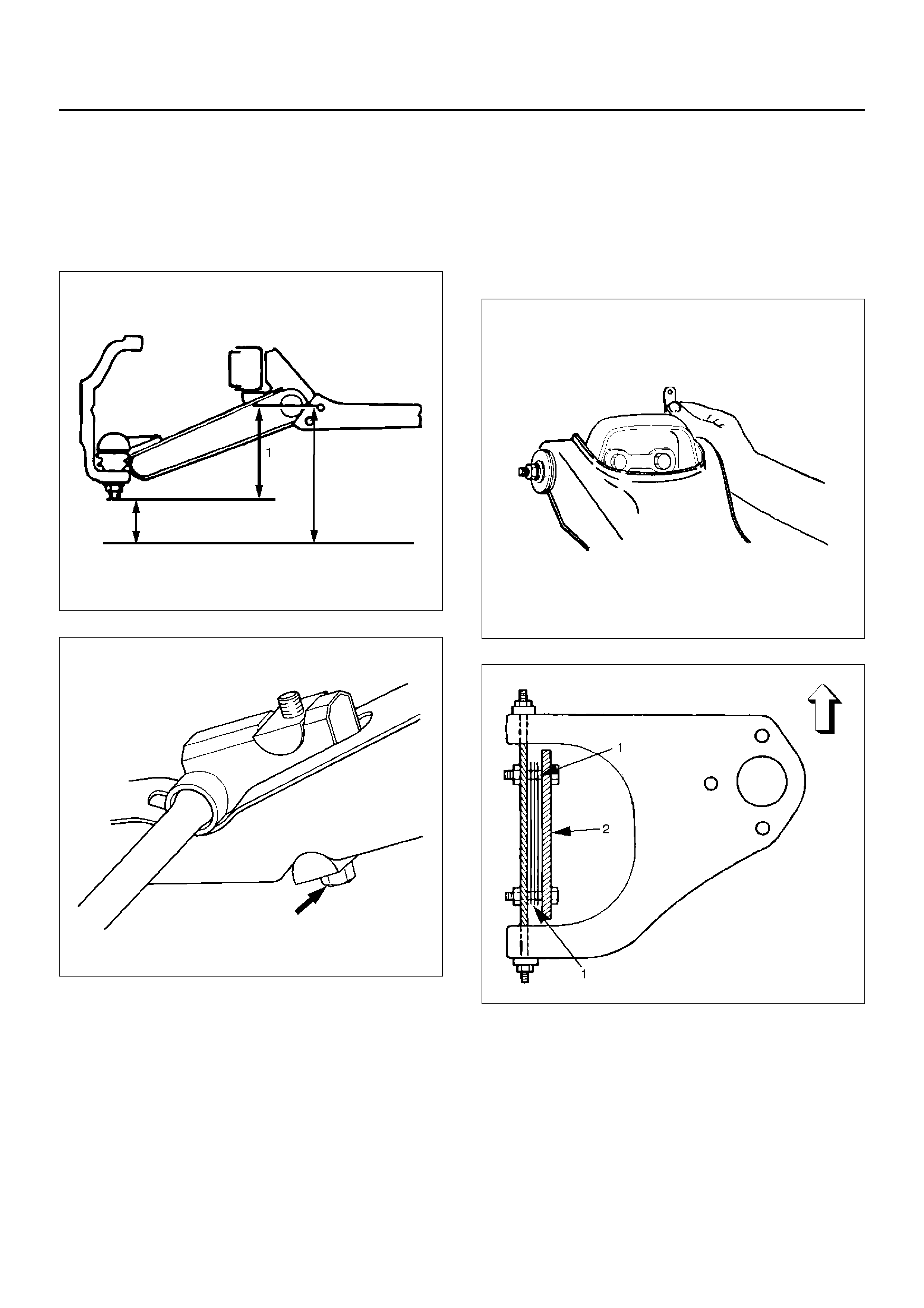

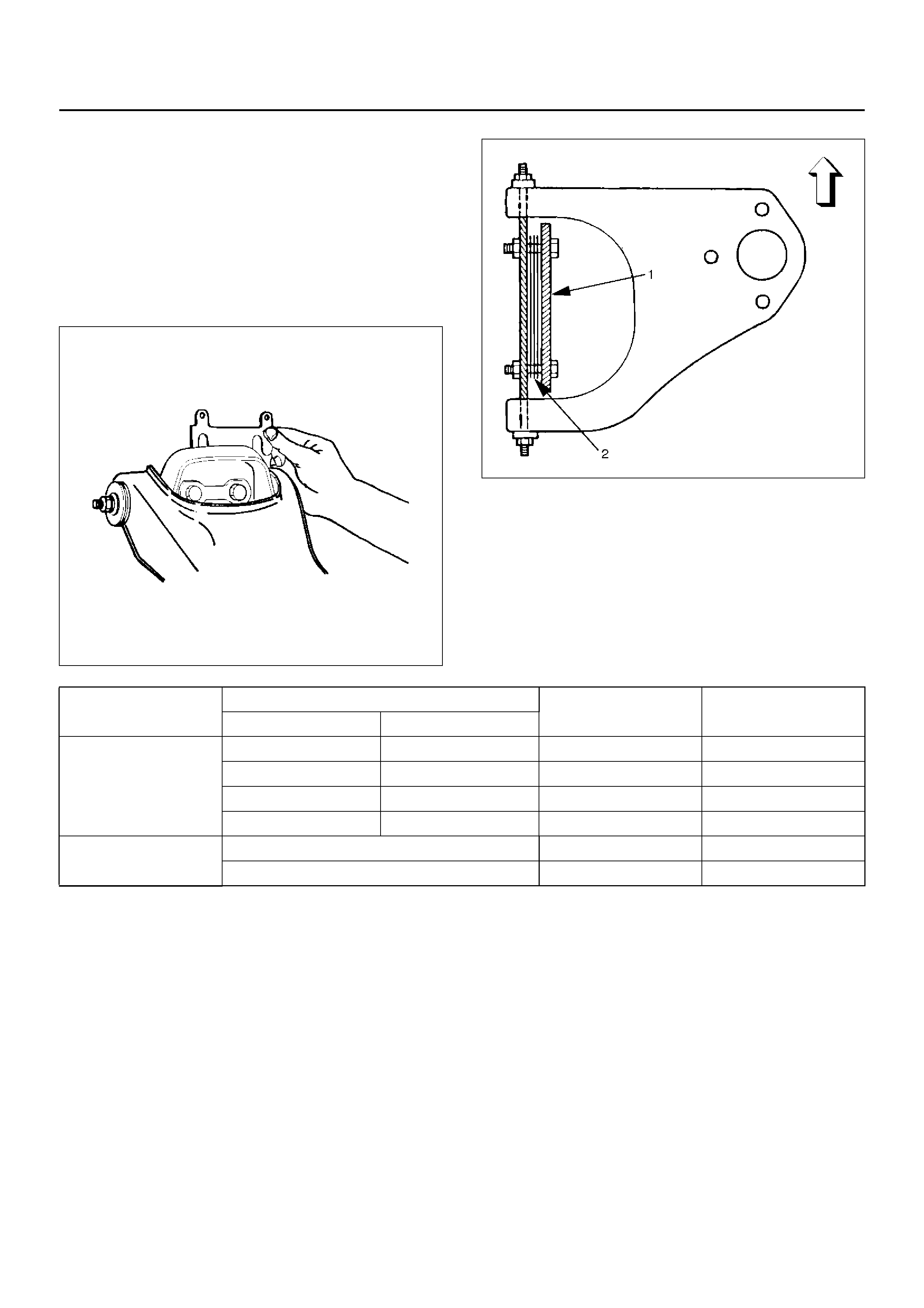

Caster Adjustment

The caster angle can be adjusted by means of the

caster shims (1) installed between the chassis frame

(2) and fulcrum pins.

Caster angle: 2°30' ± 1°

CAUTION: Left and right side must be equal within

30'.

450RW006

450RS002

NOTE: Difference of the caster shim front/rear

thickness should be 3.6mm (0.142in) or less. Overall

thickness of ca ster shim and camber shim should be

10.8mm (0.425in) or less.

Tighten the fulcrum pin bolt to the specified torque.

Torque: 152N·m

Camber Adjustment

The camber angle can be adjusted by means of the

camber shims (2) installed in position between the

chassis frame (1) and fulcrum pins.

Camber angle: 0° ± 30'

King pin inclination: 12°30' ± 30'

CAUTION: Left and right side must be equal within

30'.

450RW007

450RS005

NOTE: Overall thickness of caster shim and camber

shim should be 10.8mm (0.425in) or less.

Tighten the fulcrum pin bolt to the specified torque.

Torque: 152N·m

Position of shims Camber angle Caster angle

Front side Rear side

Caster shim

When added When removed Decreases Decreases

When removed When added Increases Increases

— When removed Unchanged Decreases

— When added Unchanged Increases

Camber shim When added Decreases Unchanged

When removed Increases Unchanged

Toe-in Adjustment

1. To adjust the toe-in angle, loosen the lock nuts (2)

on the tie rod (1) and turn the tie rod. Turn both rods

the same amount, to keep the steering wheel

centered .

Toe-in: 0 to +2mm

433RW006

2. Tighten the lock nut to the specified torque.

Torque: 98N·m

MAIN DATA AND SPECIFICATIONS

General Specification

Caster 2°30' ± 1°

Camber 0° ± 30'

Steering Axis inclination 12°30' ± 30'

Toe-in 0 to +2mm

Max. ste erin g angle i ns id e 32.6° (+0°30' to –2°30' )

outside 31.8°

Torque Specification

E02RX006

SPECIAL TOOLS

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–0135–0

(J–29877–A)

Tester;

Power steering

5–8840–2297–0

(J–39213)

Adapter;

Power steering tester

ILLUSTRATION TOOL NO.

TOOL NAME

POWER STEERING UNIT

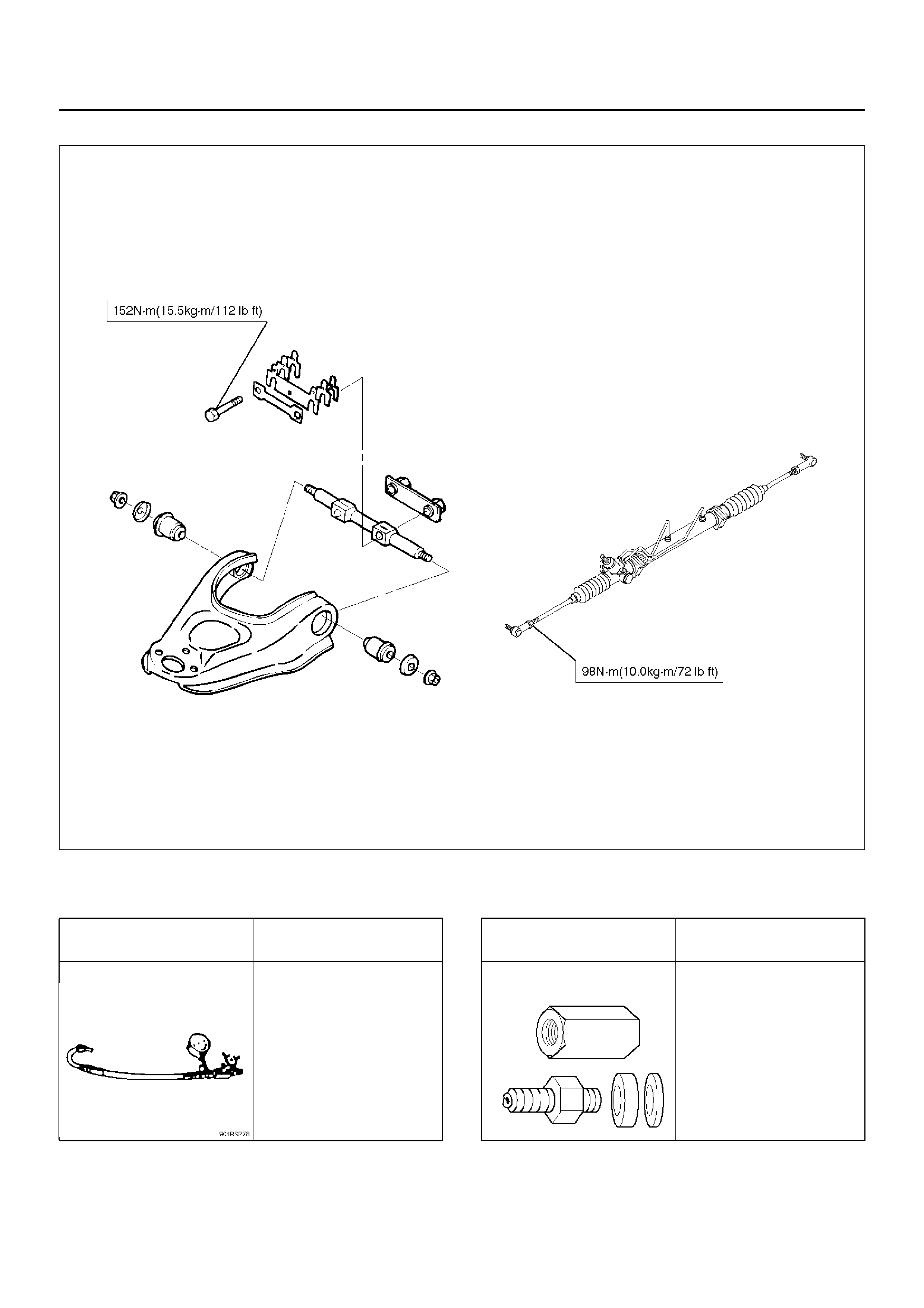

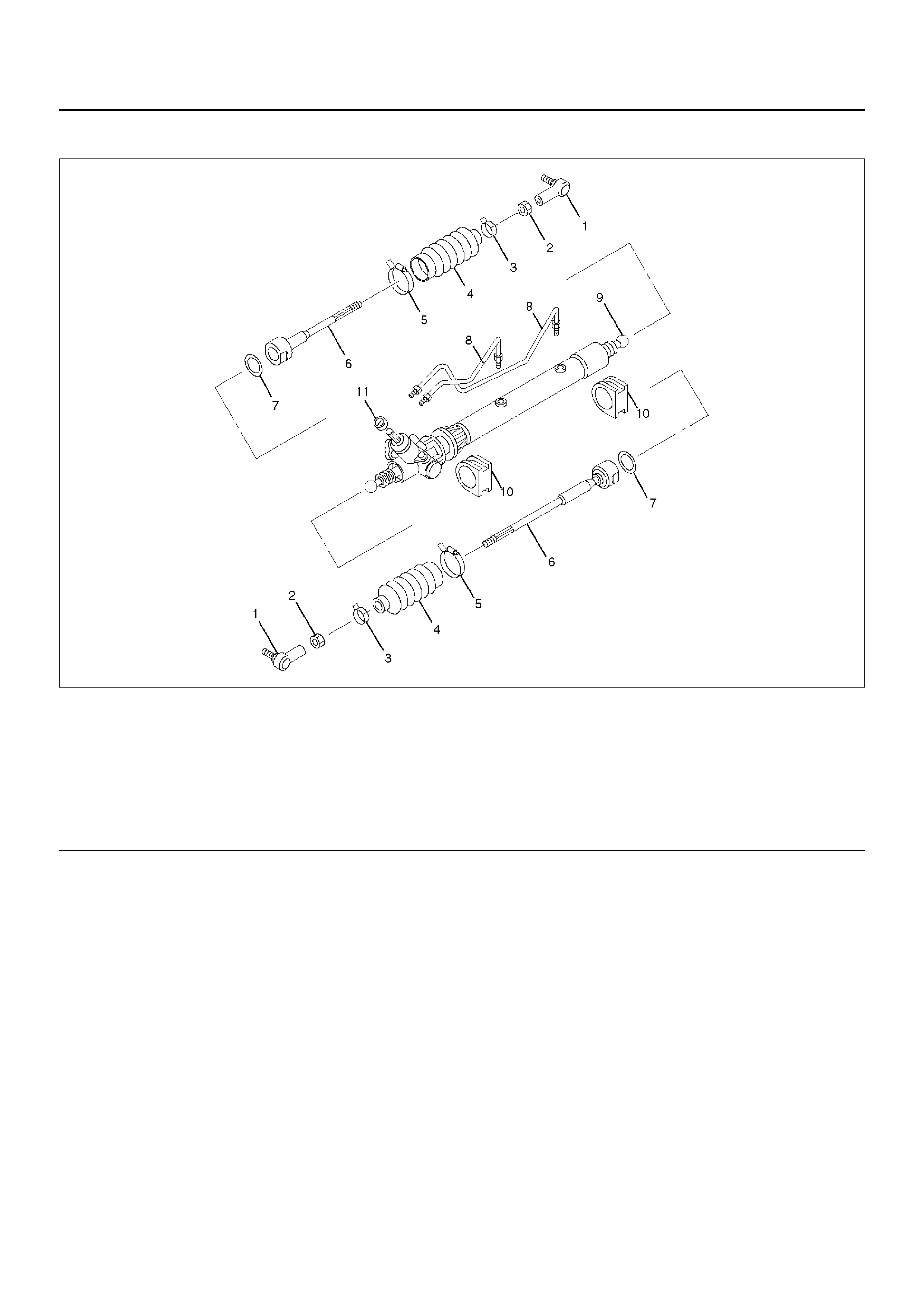

POWER STEERING UNIT AND ASSOCIATED PARTS

431R100006

Legend

EndOFCallout

REMOVAL

1. Remo ve the sto ne guard.

2. Remove the transfer gear assembly and universal

joint assembly.

Make a setting mark across the coupling flange and

steering unit to ensure reassembly of the parts in

the original position.

3. Drain power steering fluid.

4. Remove the tie rod end assembly from knuckle.

Use tie rod end remover 5–8840–2005–0.

901RW270

(1) Bracket

(2) Transfer Gear Assembly

(3) Joint Assembly

(4) Power Steering Unit Assembly

(5) Crossmember

5. Disconnect the feed line and return line from

steering unit.

Remove the clips on the crossmember and frame.

Wire the power steering line to frame.

NOTE: Take care to prevent foreign matter from entry

when disconnect the power steering line.

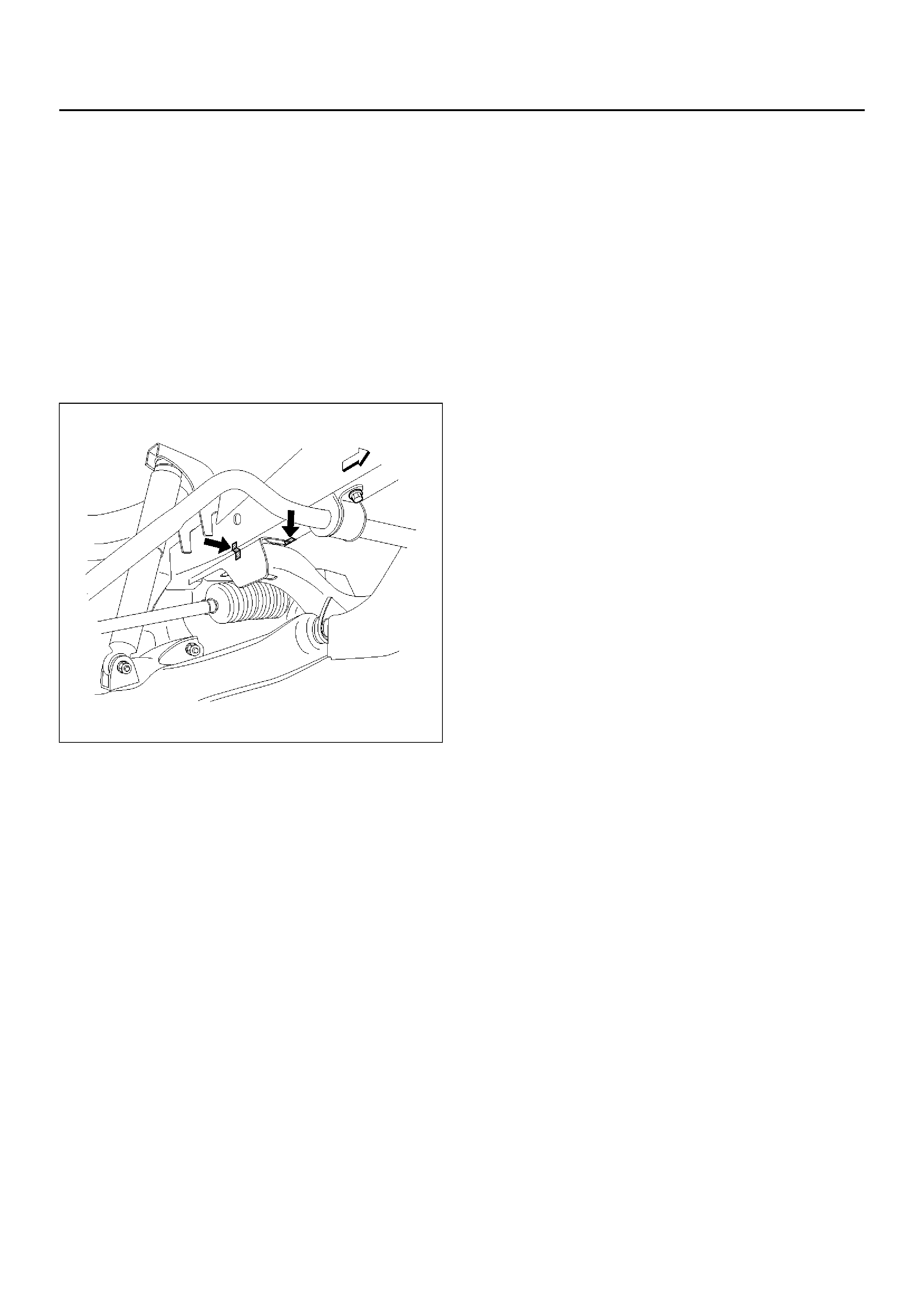

6. Remove the torsion bar. Refer to Front Suspension

in section 3.

7. Remove the lower control arm bolt (Frame side).

Refer to Front Suspension in Suspension section.

8. Apply a setting mark across the crossmember and

frame so parts can be reassembled in their original

position.

431RX013

9. Remove the crossmember fixing bolt.

10. Remove the power steering unit with the

crossmember.

11. Remove the power steering unit.

INSTALLATION

1. Install power steering unit to crossmember.

Tighten fixing bolt to specified torque.

Torque: 116N·m

2. Install power steering unit with crossmember to

frame by aligning the setting marks made when

removing.

Tighten crossmember mounting bolt to specified

torque.

Torque: 190N·m

3. Install lower control arm bolt.

Refer to Front Suspension in Suspension section.

4. Install torsion bar.

Refer to Front Suspension in Suspension section.

5. Connect the feed line and return line.

Torque: 25N·m

6. Install tie-rod end assembly to knuckle.

Torque: 118N·m

7. Align the setting marks on the universal joint

(applied at disassembly) with the setting marks on

the transfer gear assembly. Connect the universal

joint assembly to the transfer gear assembly.

Temporarily tighten the universal joint bolts on the

universal joint assembly side.

8. Temporarily tighten the universal joint bolts on the

steering shaft side.

9. Install the transfer gear assembly together with the

shims to the frame. Tighten the nuts and bolts to the

specified torque.

Torque: 54N·m

10. Tighten the universal joint bolts (bolts at either end

of the joint temporarily tightened in Step 1 and 2) to

the specified torque.

11. Install the stone guard.

12. Bleed the system.

Refer to Bleeding the Power Steering System in this

section.

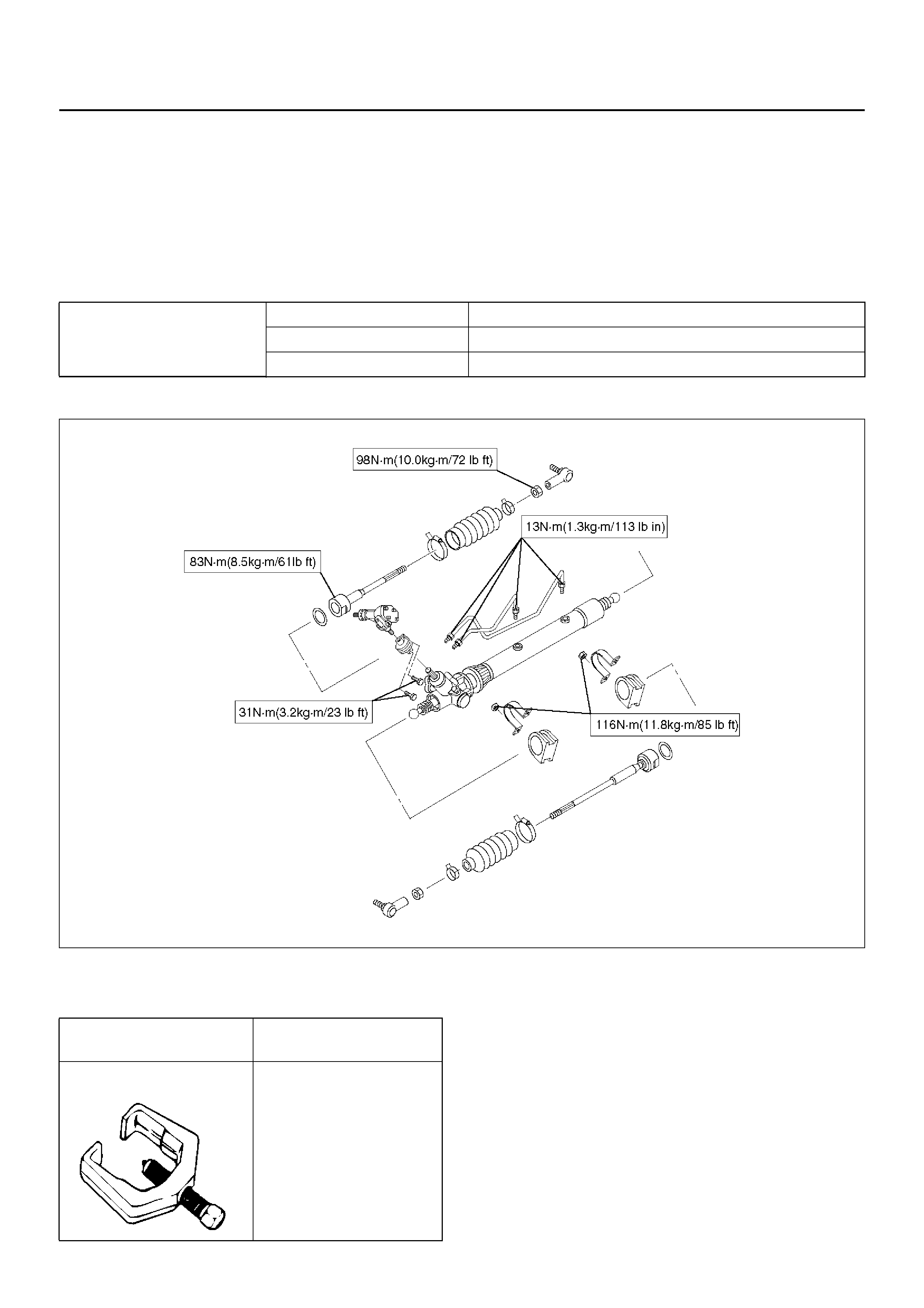

POWER STEERING UNIT DISASSEMBLED VIEW

440RW005

Legend

EndOFCallout

DISASSEMBLY

NOTE: The valve housing is made of aluminum and

care should be exercised when clamping in a vise, etc.

to prevent distortion or damage.

1. Loosen lock nut and remove tie–rod end.

2. Remove clip and band, then remove bellows.

3. Remove tie-rod assembly.

To remove, move the boot toward the tie-rod end,

then remove tab washer.

4. Remove oil line, mounting rubber and dust cover.

INSPECTION AND REPAIR

Inspect the following parts for wear, damage or any

abnormal conditions.

Tie-rod End

If looseness or play is found when checked by moving

the end of ball joint at tie-rod end, replace tie-rod end.

Tie-rod Assembly

If the resistance is insufficient or play is felt when

checked by moving the ball on the tie-rod, replace the

tie-rod assembly.

Rubber Parts

If wear or damage is found through inspection, replace

with new ones.

REASSEMBLY

1. Install mounting rubber and dust cover (If removed).

2. Install oil line.

Torque: 13N·m

3. Install tie-r od assembly with tab washer.

Apply grease to ball joint, install tie-rod and tab

washer, then tighten to specified torque.

Torque: 83N·m

After tightening, bend tab washer against width

across flat of inner ball joint.

(1) Tie-rod End

(2) Lock Nut

(3) Clip

(4) Bellows

(5) Band

(6) Tie-rod Assembly

(7) Tab Washer

(8) Oil Line

(9) Valve Housing Assembly

(10) Mounting Rubber

(11) Dust Cover

4. Apply a thin coat of grease to the shaft for smooth

installation. Then install bellows.

5. Install band and clip.

6. Install tie-rod end and tighten lock nut.

Torque: 98N·m

MAIN DATA AND SPECIFICATIONS

General Specifications

Torque Specifications

E02RX007

SPECIAL TOOLS

Power Steering unit Type Rack and pinion

Rack stroke 152mm

Lock to lock 3.64

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–2005–0

(J–29107)

Tie rod end remover

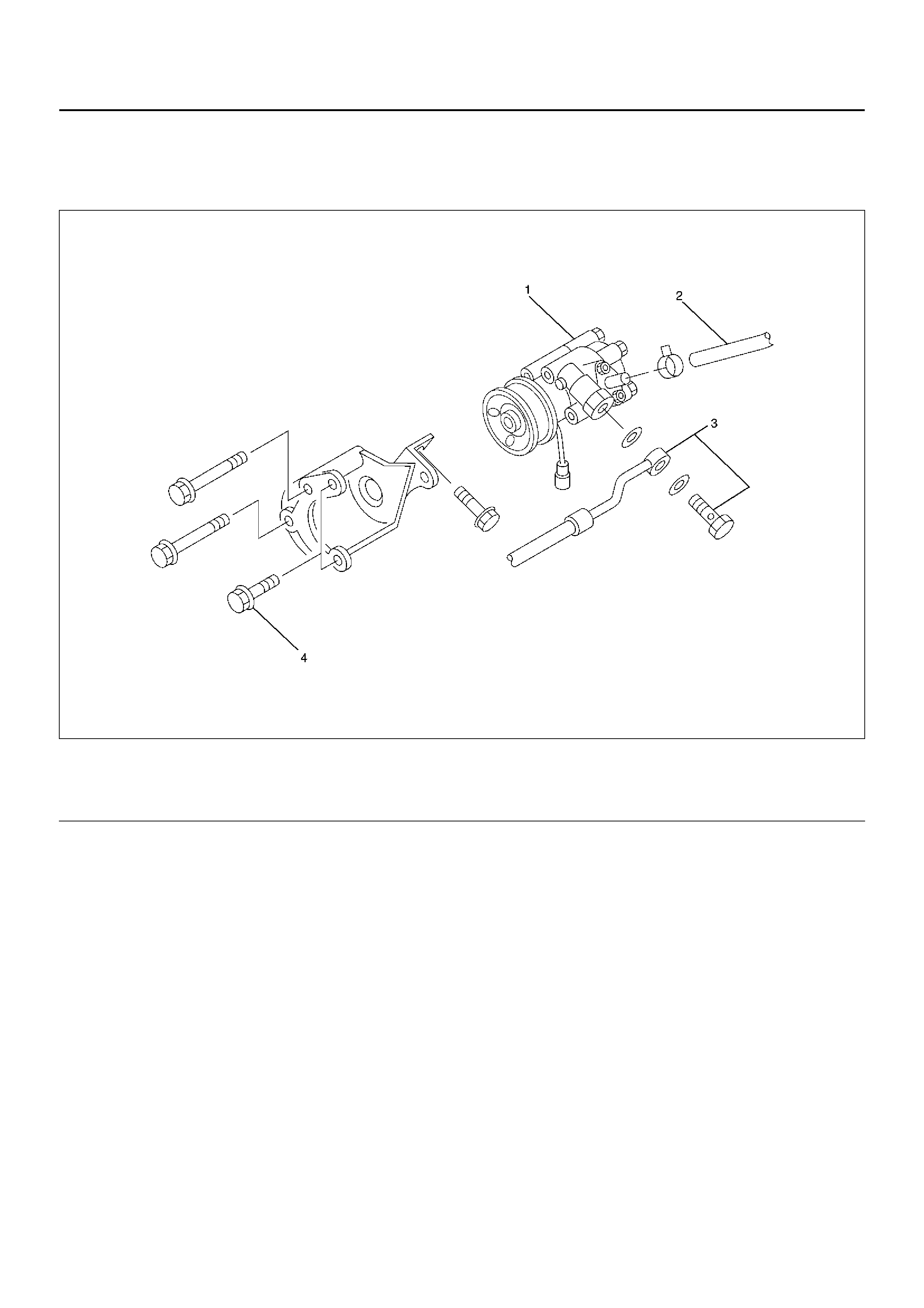

POWER STEERING PUMP

POWER STEERING PUMP AND ASSOCIATED PARTS

436RX001

Legend

EndOFCallout

REMOVAL

1. Remove the drive belt.

2. Place a drain pan below the pump.

3. Disconnect the suction hose.

4. Disconnect the flexible hose.

5. Remove the power steering fixing bolt and remove

the pump assembly.

INSTALLATION

1. Install the pump assembly to the pump braket,

tighten the fixing bolt to the specified torque.

Torque: 46N·m

2. Install the flexible hose.

Tighten the eye bolt to specified torque.

Torque: 54N·m

3. Install the drive belt.

4. Connect the suction hose, then fill and bleed

system.

Refer to Bleeding the Power Steering System in this

section.

(1) Pump Assembly

(2) Hos e, Suction (3) Hose, Flexible

(4) Bolt

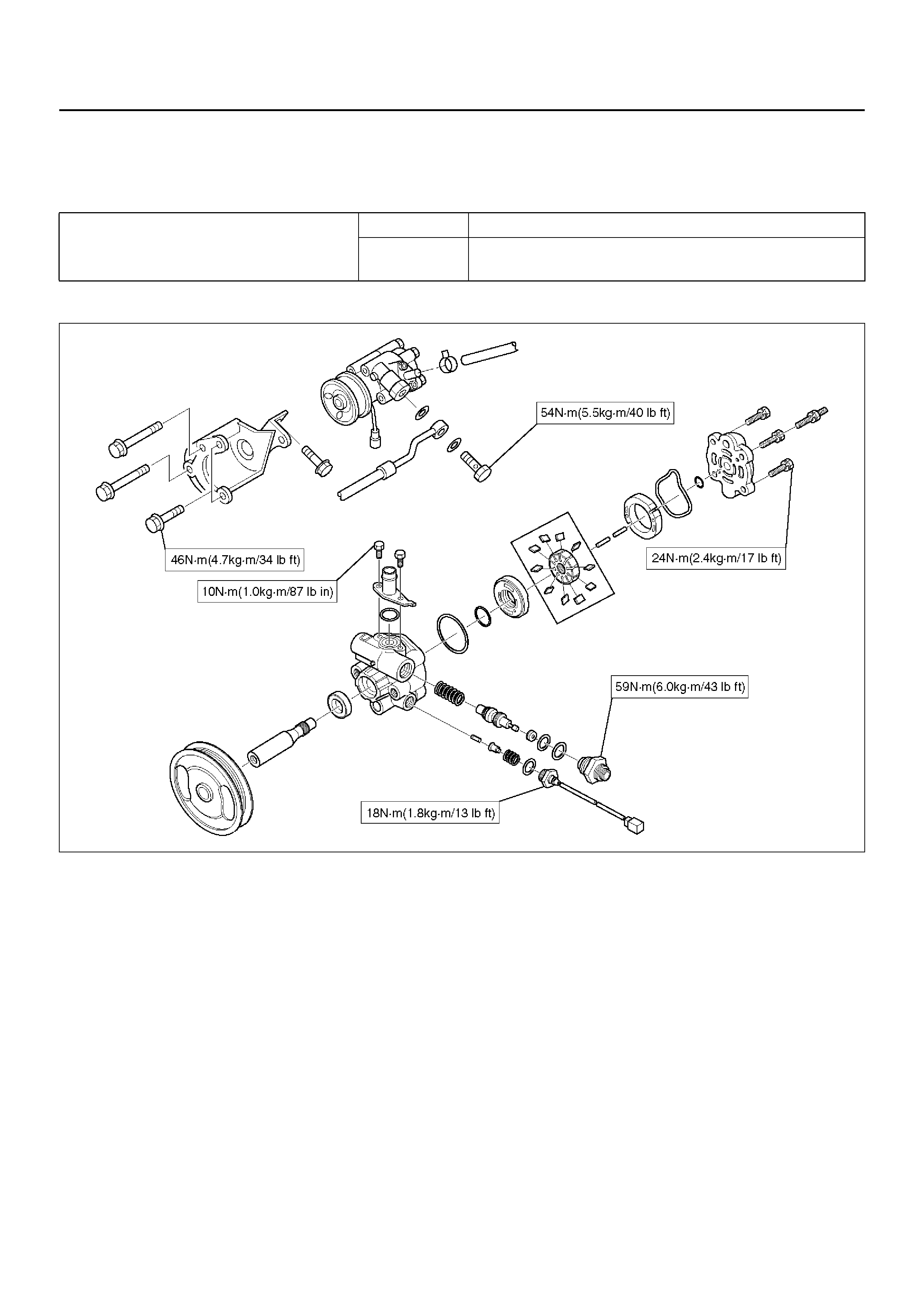

POWER STEERING PUMP DISASSEMBLED VIEW

442RX001

Legend

EndOFCallout

DISASSEMBLY

1. Clean the oil pump with solvent (plug the discharge

and suction ports to prevent the entry of solvent).

Be careful not to expose the oil seal of shaft

assembly to solvent.

2. Remove the bolt, suction pipe and O-ring.

3. Remove the connector, O-ring, relief valve and

spring.

4. Remove the pressure switch assembly.

5. Remove the bolt, rear housing and O-ring.

6. Remove the snap ring.

7. Remove the shaft assembly.

8. Remove the oil seal.

CAUTION: When removing the oil seal, be careful

not to damage the housing.

9. Remove the pump cartridge assembly from the front

housing.

10. Remove two O-rings.

(1) Bolt

(2) Suction Pipe

(3) O-ring

(4) Shaft Assembly

(5) Oil Seal

(6) Front Housing

(7) O-ring

(8) O-ring

(9) Side Plate

(10) Rotor and Vane

(11) Pin

(12) Cam

(13) Pump Cartridge Assembly

(14) O-ring

(15) Snap Ring

(16) Rear Housing

(17) Bolt

(18) Spring

(19) Relief Valve

(20) O-ring

(21) Connector

(22) Pressure Switch Assembly

INSPECTION AND REPAIR

Make all necessary adjustments, repairs, and part

replacements if wear, damage, or other problems are

discovered during inspection.

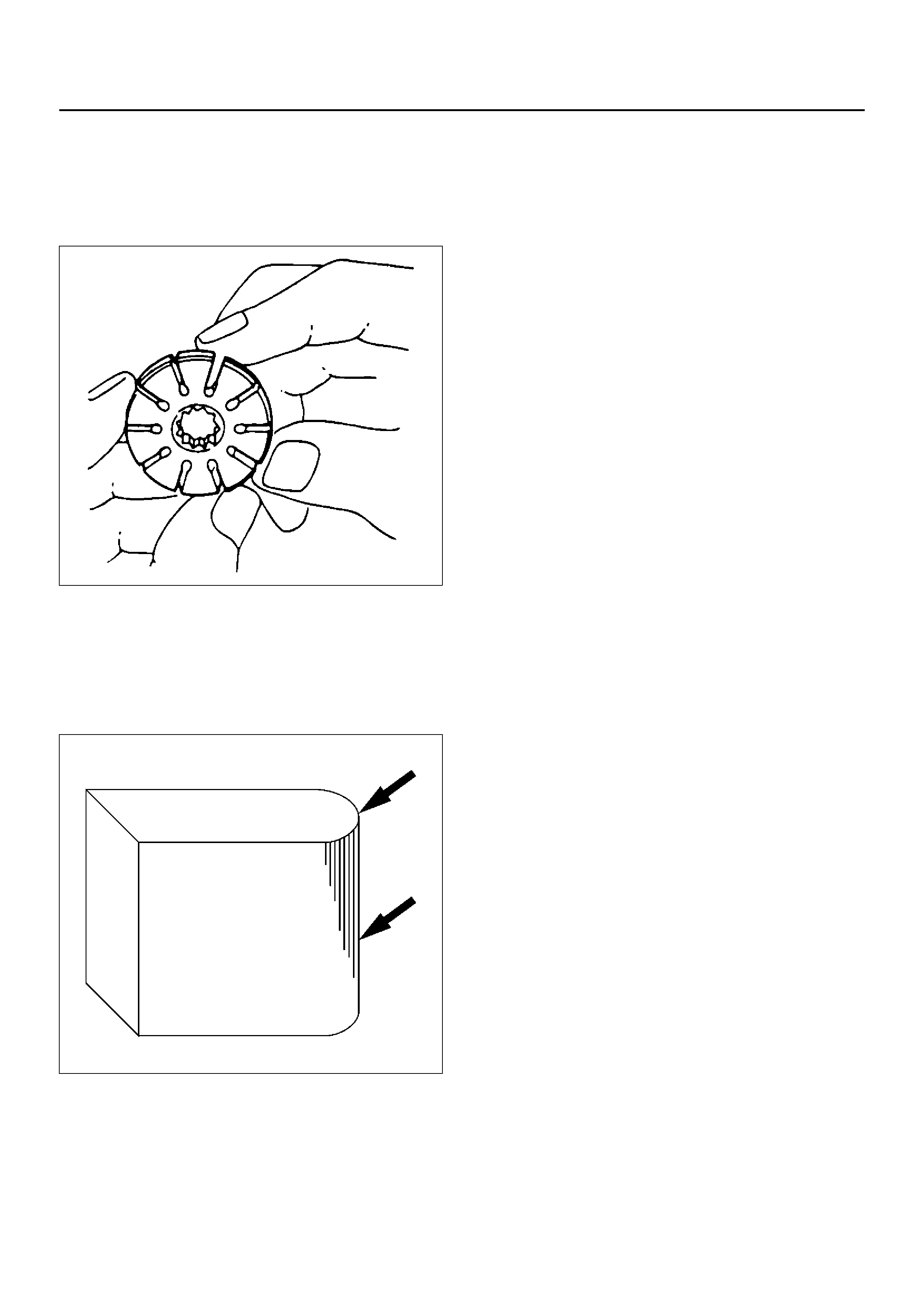

Rotor

442RS002

Check that the groove in the vane is free from excessive

wear and that the vane slides smoothly. When part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly.

Vane

442RS003

Sliding faces of the vane should be free from wear.

(Particularly the curved face at the tip that contact with

the cam should be free from wear and distortion). When

part replacement becomes necessary, the pump

cartridge should be replaced as a subassembly.

Cam

The inner face of the arm should have a uniform contact

pattern without a sign of step wear. When part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly.

Side Plate

The sliding faces of parts must be free from step wear

(more than 0.01 mm), which can be felt by the finger

nail.

The parts with minor scores may be reused after

lapping the face.

Relief Valve

The sliding face of the valve must be free from burrs

and damage. The parts with minor scores may be

reused after smoothing with emery cloth (#800 or finer).

Shaft

Oil seal sliding faces must be free from a step wear

which can be felt by the finger nail. Bushing fitting face

must be free from damage and wear.

O-ring, Oil Seal, Snap Ring

Be sure to discard used parts, and always use new

parts for installation. Prior to installation, lubricate all

seals and rings with power steering fluid.

Pressure Switch

Check the switch operation as follows:

With engine idling and A/C on, turn the steering wheel

fully to the left; compressor should interrupt and engine

idle speed will increase. Shut off A/C and again turn

steering fully to the left; engine idle will increase. If

system fails to function properly, disconnect connector

at the pressure switch and repeat system check while

testing continuity across disconnected SW connector.

REASSEMBLY

1. Install oil seal to front housing. Be sure to discard

used oil seal, and always use new parts for

installation.

CAUTION: When installing the oil seal, be careful

not to damage the oil seal contacting surface of the

housing.

2. Install shaft assembly.

3. Install the vanes to roter with curved face in contact

with the inner wall of cam.

442RS005

4. Install roter and vanes to cam.

5. Install pin to front housing.

6. Install two new O-rings to front housing. Be sure to

discard used O-ring.

7. Install side plate.

CAUTION: When installing side plate, be careful not

to damage its inner surface. Damaged side plate

may cause poor pump performance, pump seizure

or oil leakage.

8. Install pump cartridge assembly to front housing.

9. Install snap ring to shaft end.

10. Install rear housing with a new O-ring. Be sure to

discard used O-ring. Then install bolt and tighten it

to specified torque.

Torque: 24N·m

11. Install suction pipe with a new O-ring. Be sure to

discard used O-ring. Then install bolt and tighten it

to specified torque.

Torque: 10N·m

12. Install relief valve and spring.

13. Install connector with a new O-ring. Be sure to

discard used O-ring. Tighten the connector to

specified torque.

Torque: 59N·m

14. Install pres s ure switch asse mbly and tig hten it to

specified torque.

Torque: 18N·m

MAIN DATA AND SPECIFICATIONS

General Specifications

Torque Specifications

E02RX008

Oil pump Type Vane

Operating

fluid ATF DEXRON®–III

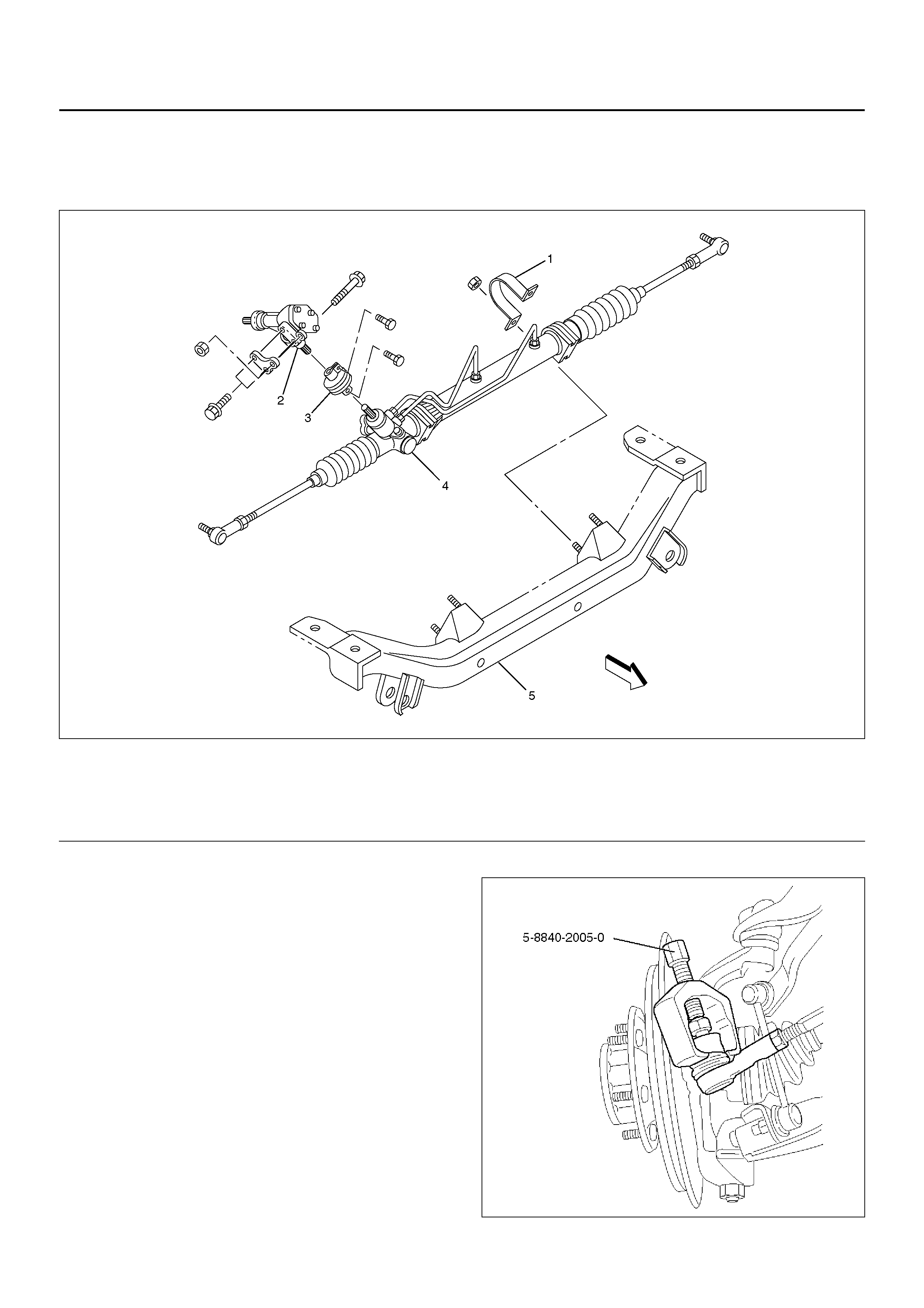

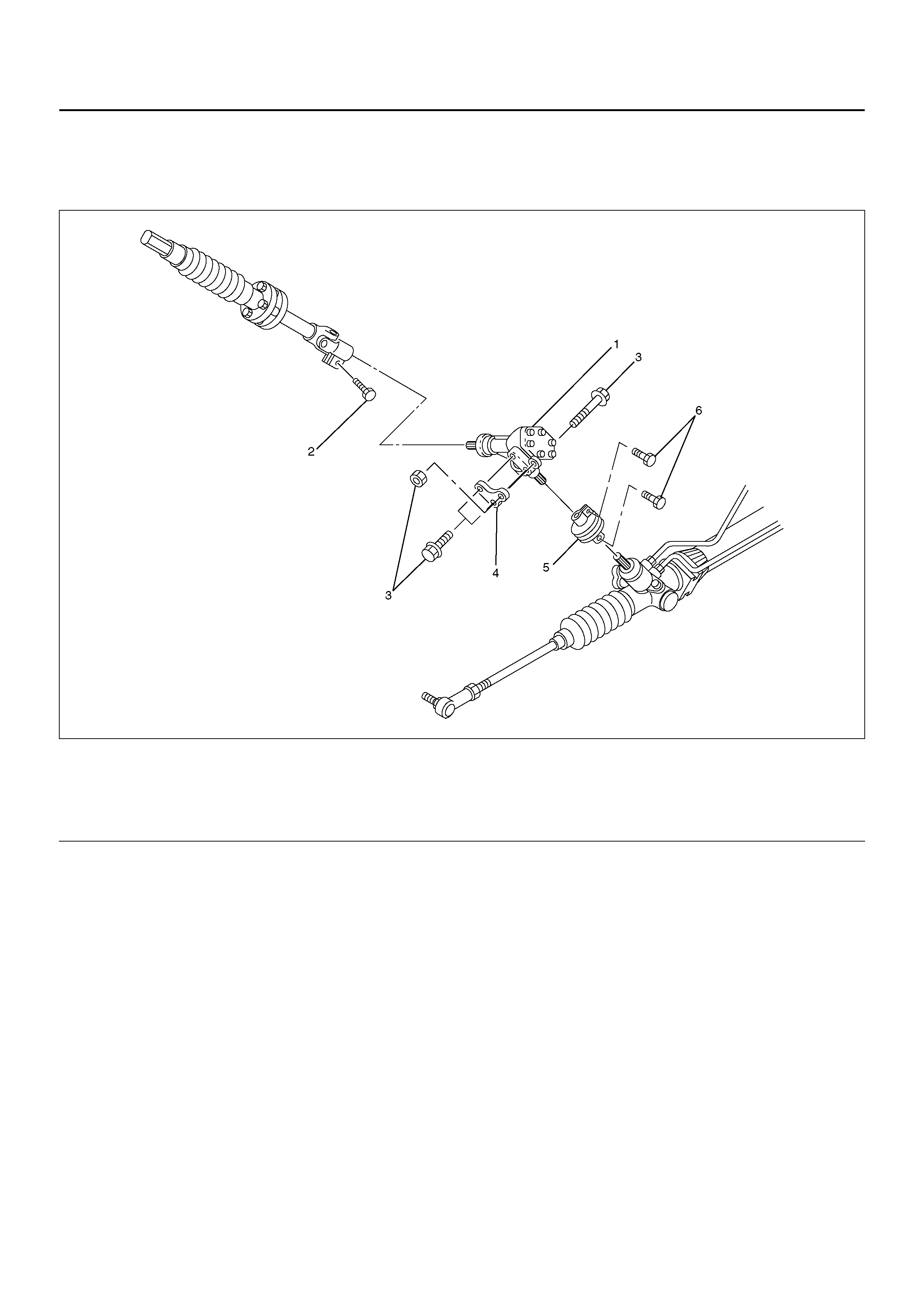

TRANSFER GEAR ASSEMBLY

TRANSFER GEAR ASSEMBLY AND ASSOCIATED PARTS

441R100001

Legend

EndOFCallout

REMOVAL

1. Apply a setting mark across the universal joint

(steering shaft side) and transfer gear assembly to

reassemble the parts in their original position.

2. Remove universal joint bolt (steering shaft side).

3. Apply a setting mark across the universal joint

assembly and the transfer gear assembly to

reassemble the parts in their original position.

4. Remove universal joint bolts (both of transfer gear

assembly side and power steering unit assembly

side).

5. Loosen fixing bolts and nut and remove transfer

gear assembly with shim.

INSPECTION AND REPAIR

The transfer gear assembly cannot be disassembled. If

damage or abnormal condition are found, replace to

new ones.

(1) Transfer Gear Assembly

(2) Bolt, Universal Joint (Steering Shaft Side)

(3) Fixing Bolt Nut

(4) Shim

(5) Universal Joint Assembly

(6) Bolt, Universal Joint (Universal Joint Side)

INSTALLATION

1. Install the transfer gear assembly to the universal

joint (steering shaft side) align the setting marks

made at removal.

Then tighten the universal joint bolt.

2. Install the universal joint assembly to the power

steering unit assembly align the setting marks made

at removal.

Then temporary tighten the universal joint bolt (both

of transfer gear assembly side and power steering

unit assembly side).

3. Install the transfer gear assembly with the shim to

frame.

Torque: 54N·m

4. Tighten the universal joint bolts to the specified

torque.

Torque: 31N·m

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL &

COLUMN

SERVICE PRECAUTION

This steering wheel and column repair section covers

the Supplemental Restraint System (SRS) steering

column. The following repair procedures are specific to

SRS components. When servicing a vehicle equipped

with Supplemental Restraint System, pay close

attention to all WARNINGS and CAUTIONS.

For detailed explanation about SRS, refer to Restraints

section.

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE

TO FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

SAFE HANDLING OF INFLATOR MODULES

REQUIRES FOLLOWING THE PROCEDURES

DESCRIBED BELOW FOR BOTH LIVE AND

DEPLOYED MODULES.

SAFETY PRECAUTIONS MUST BE FOLLOWED

WHEN HANDLING A DEPLOYED AIR BAG

ASSEMBLY (AIR BAG). AFTER DEPLOYMENT, THE

AIR BAG ASSEMBLY (AIR BAG) SURFACE MAY

CONTAIN A SMALL AMOUNT OF SODIUM

HYDROXIDE, A BY-PRODUCT OF THE

DEPLOYMENT REACTION, THAT IS IRRITATING TO

THE SKIN AND EYES. MOST OF THE POWDER ON

THE AIR BAG ASSEMBLY (AIR BAG) IS HARMLESS.

AS A PRECAUTION, WEAR GLOVES AND SAFETY

GLASSES WHEN HANDLING A DEPLOYED AIR

BAG ASSEMBLY, AND WASH YOUR HANDS WITH

MILD SOAP AND WATER AFTERWARDS.

WHEN CARRYING A LIVE AIR BAG ASSEMBLY,

MAKE SURE THE BAG AND TRIM COVER ARE

POINTED AWAY FROM YOU. NEVER CARRY AN

AIR BAG ASSEMBLY BY THE WIRES OR

CONNECTOR ON THE UNDERSIDE OF MODULE.

IN THE CASE OF AN ACCIDENTAL DEPLOYMENT,

THE BAG WILL THEN DEPLOY WITH MINIMAL

CHANCE OF INJURY. WHEN PLACING A LIVE AIR

BAG ASSEMBLY ON A BENCH OR OTHER

SURFACE, ALWAYS FACE THE BAG AND TRIM

COVER UP, AWAY FROM THE SURFACE.

NEVER REST A STEERING COLUMN ASSEMBLY

ON THE STEERING WHEEL WITH THE AIR BAG

ASSEMBLY FACE DOWN AND COLUMN VERTICAL.

THIS IS NECESSARY SO THAT A FREE SPACE IS

PROVIDED TO ALLOW THE AIR BAG ASSEMBLY

TO EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. OTHERWISE,

PERSONAL INJURY COULD RESULT.

TO AVOID DEPLOYMENT WHEN

TROUBLESHOOTING THE SRS SYSTEM, DO NOT

USE ELECTRICAL TEST EQUIPMENT, SUCH AS

BATTERY-POWERED OR A/C-POWERED

VOLT-METER, OHMMETER, ETC., OR ANY TYPE

OF ELECTRICAL EQUIPMENT OTHER THAN

SPECIFIED IN THIS MANUAL. DO NOT USE A

NON-POWERED PROBE-TYPE TESTER.

INSTRUCTIONS IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PERSONAL

INJURY MAY RESULT.

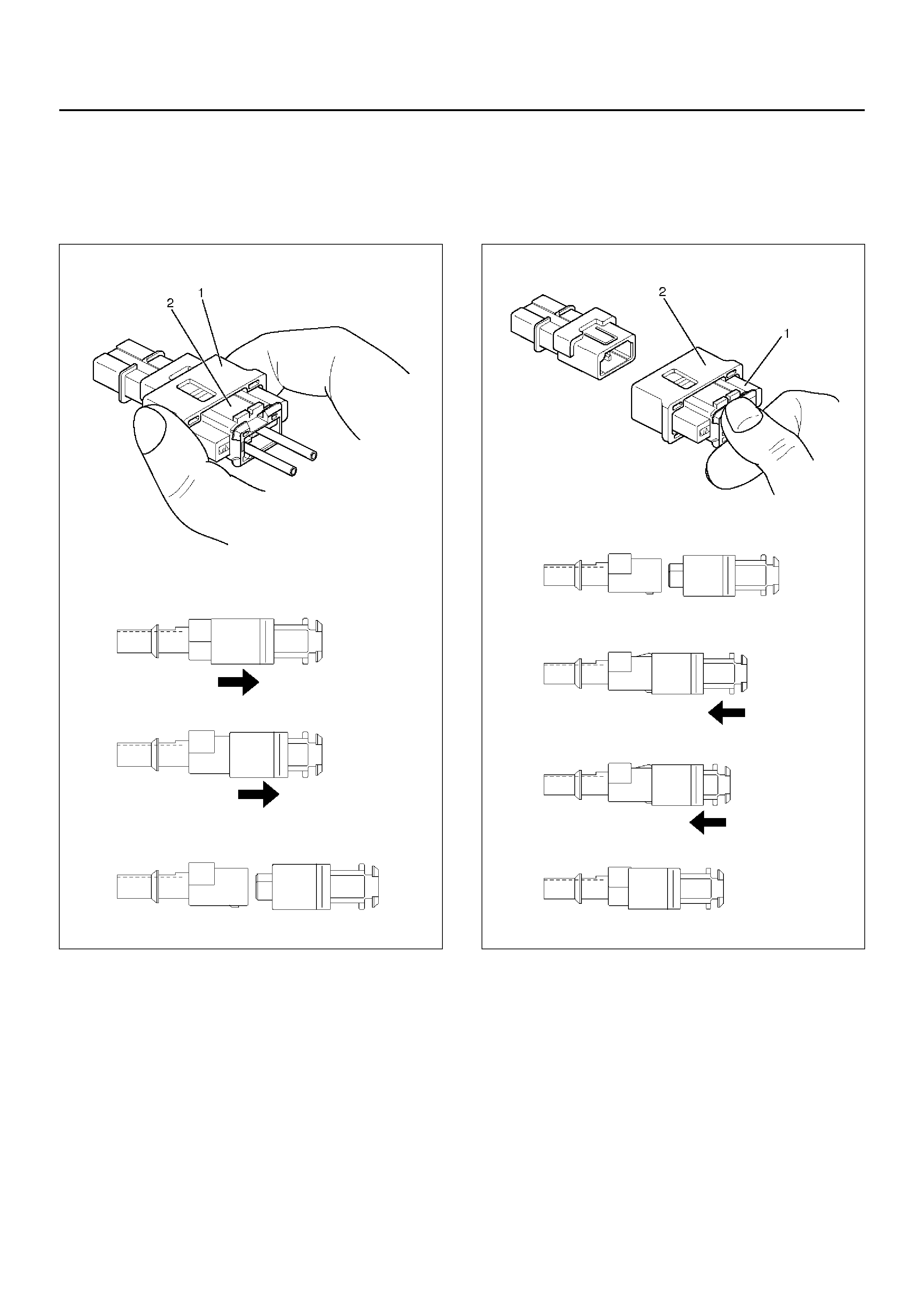

SRS CONNECTORS

CAUTION: The special yellow color connectors are

used for supplemental restraint system-air bag

circuit.

When removing the cable harness, do not pull the

cables. Otherwise, cable disconnection may occur.

When connect the SRS connector, insert the

connector completely. Imperfect locking may cause

malfunction of SRS circuit.

Removal

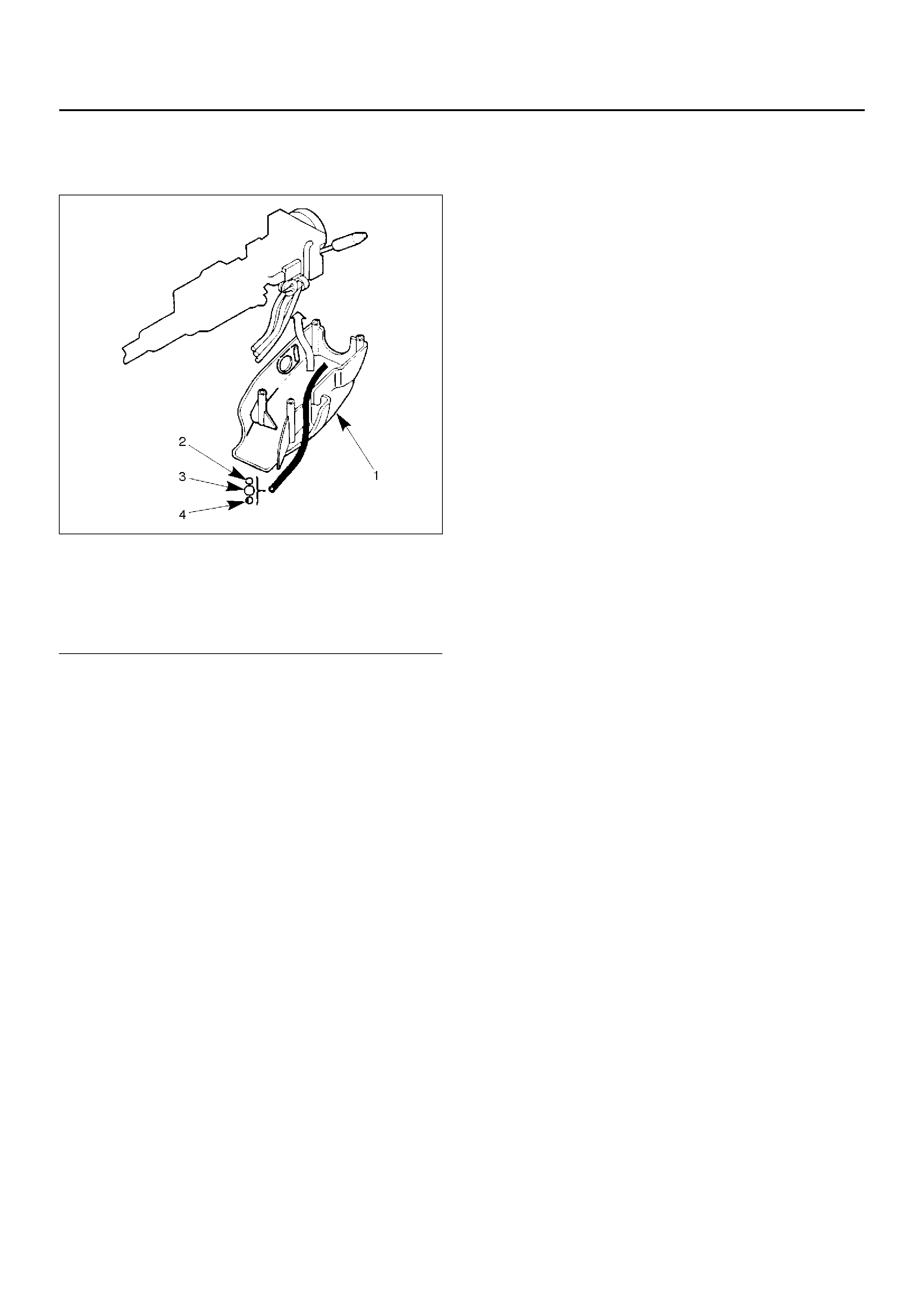

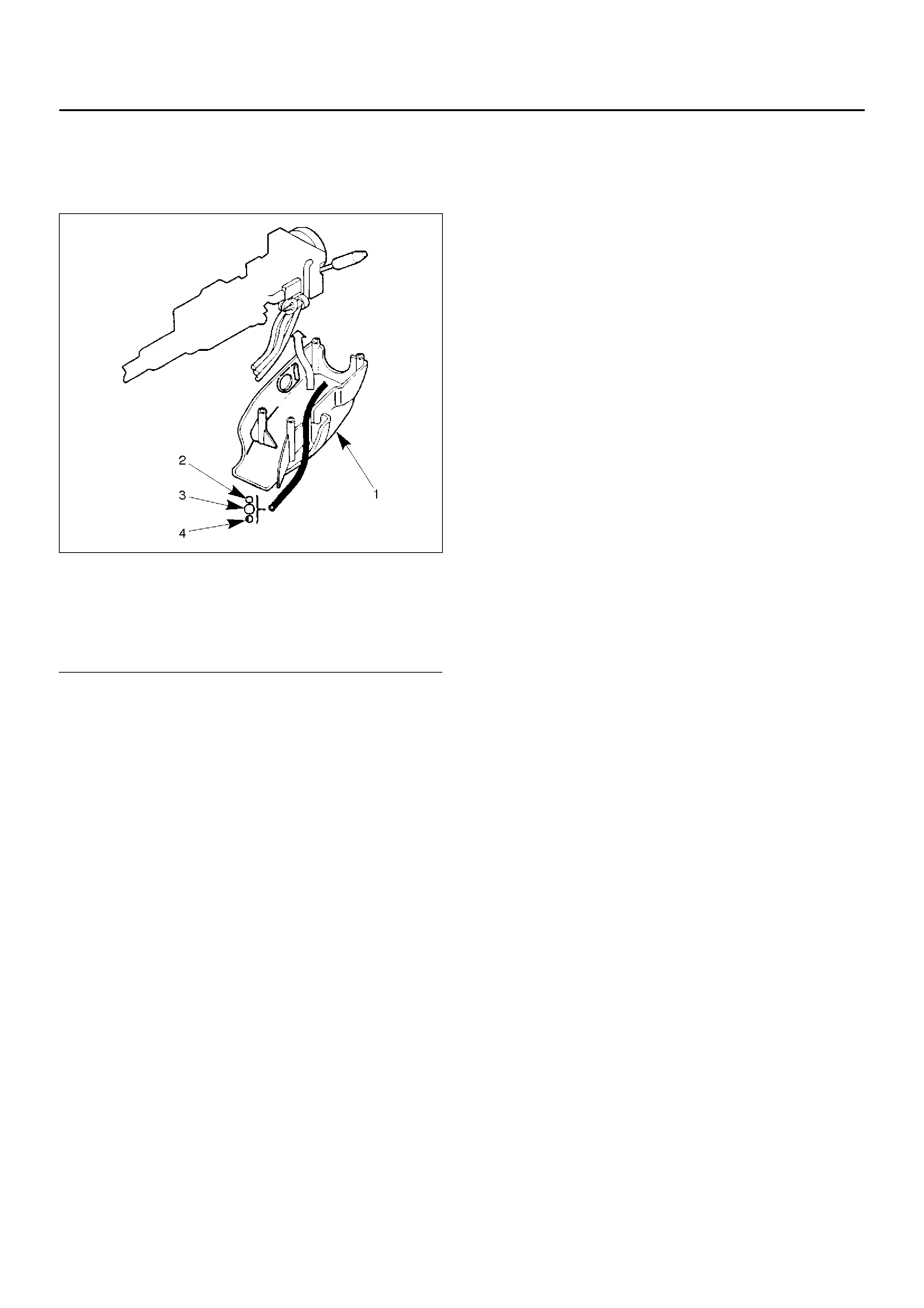

To remove the connec to r, hold the cover insul ator( 1)

and pull it. The cover insulator slides and lock will be

released.

Do not hold the socket insulator(2).

827RW028

Installation

To install the connector, hold the soket insulator(1) and

insert it. The cover insulator slides and connector will be

locked.

Do not hold the cover insulator(2).

827RW027

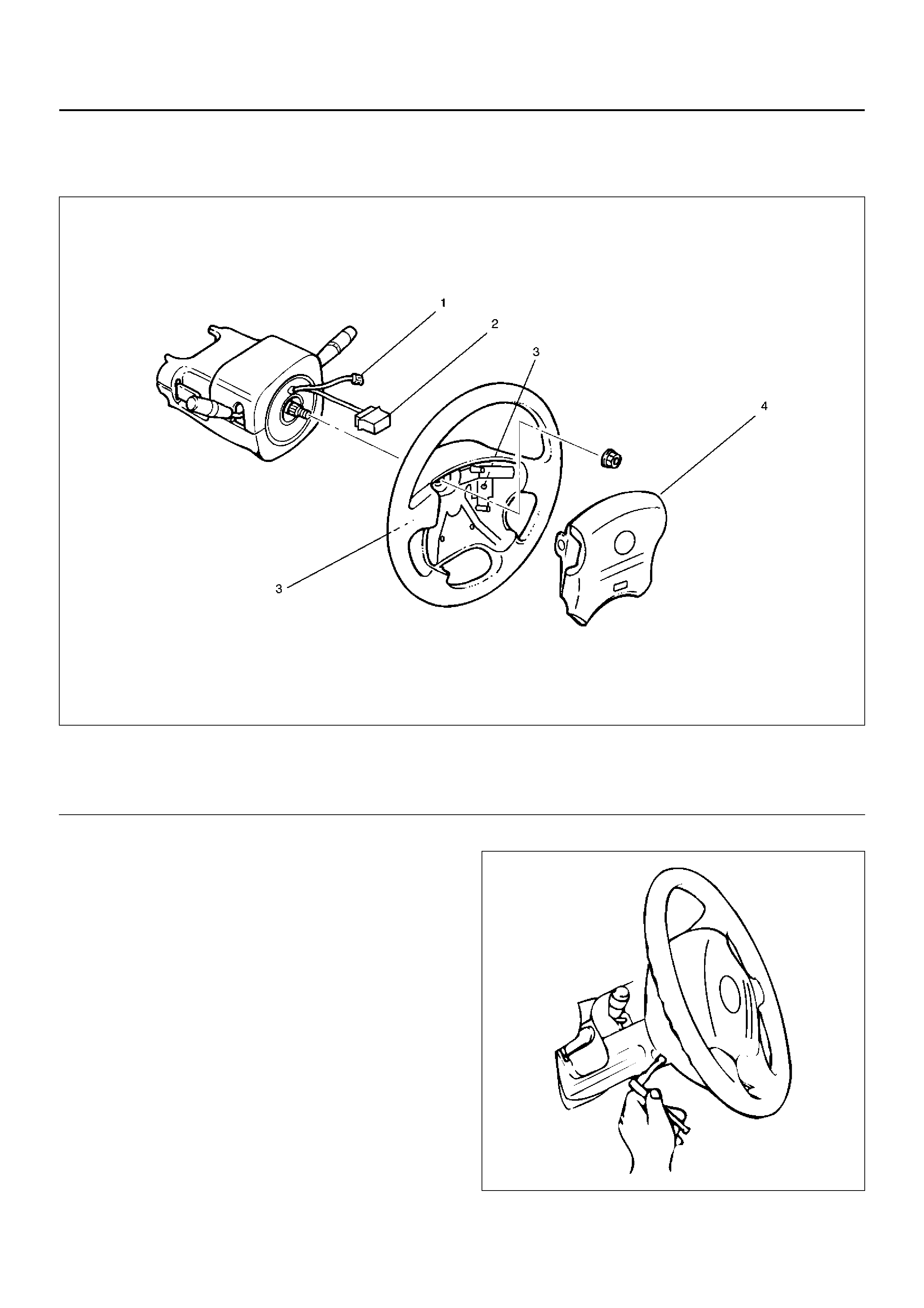

INFLATOR MODULE

INFLATOR MODULE AND ASSOCIATED PARTS

827RW071

Legend

EndOFCallout

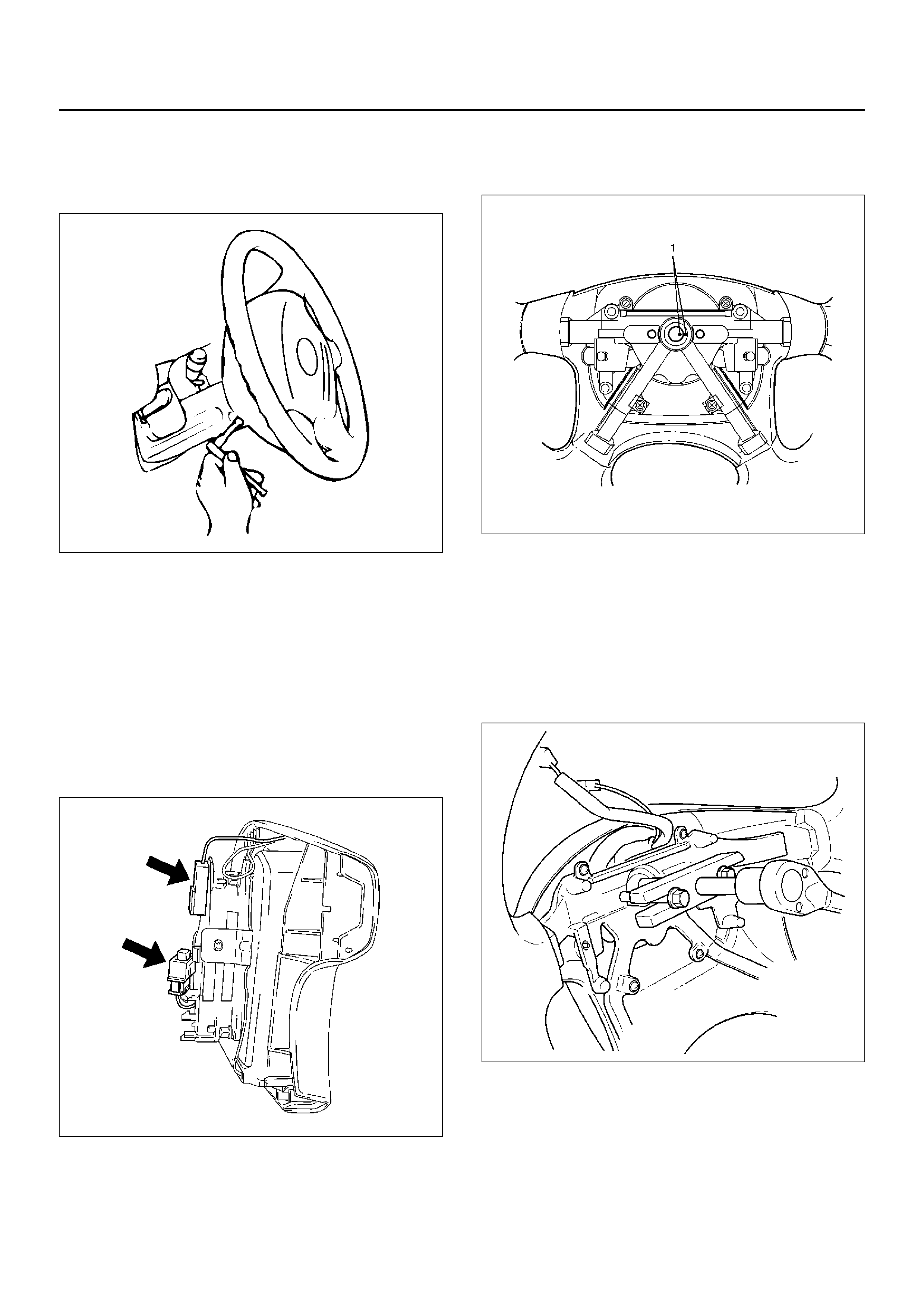

REMOVAL

1. T urn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2. Turn the ignition switch to “LOCK".

3. Disconnect the battery “–" terminal cable, and wait

at least 5 minutes.

4. Disconnect the yellow 2-way SRS connector located

under the steering column.

5. Loosen the inflator module fixing bolt from behind

the steering wheel assembly using a TORX® driver

or equivalent until the inflator module can be

released from steering assembly .

827RW070

(1) Horn Lead

(2) SRS Conn ec tor (3) Fixing Bolt

(4) Inflator Module

6. Disconnect the yellow 2-way SRS connector and

horn lead located behind the inflator module.

827RW073

7. Remove inflator module.

INSPECTION AND REPAIR

WARNING: THE INFLATOR MODULE SHOULD

ALWAYS BE CARRIED WITH THE URETHANE

COVER AWAY FROM YOUR BODY AND SHOULD

ALWAYS BE LAID ON A FLAT SURFACE WITH THE

URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW

THE AIR CUSHION TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY MAY RESULT .

827RW072

The inflator module consists of a cover, air bag, inflator,

and retainer. Inspect the inflator module mainly for the

following:

• Check for holes, cracks, severe blemishes and

deformation on the cover.

• Check that the retainer is not deformed.

• Check for defects such as damage and breakage in

the lead wire for the igniter.

If an abnormality is found as the result of the inspection,

replace the inflator module with a new one.

INSTALLATION

1. Install inflator module.

2. Support the module and carefully connect the

module connector and horn lead.

NOTE: Pass the lead wire through the tabs on the

plastic cover (wire protector) of inflator to prevent lead

wire from being pinched.

3. Tighten bolts to specified torque.

Torque: 9N·m

4. Connect the yellow 2-way SRS connector located

under the steering column.

5. Connect the battery “–" terminal cable.

6. Set ignition to “ON" while watching warning light.

Light should flash 7 times and then go off. If lamp

does not operate correctly, refer to Restraints

section.

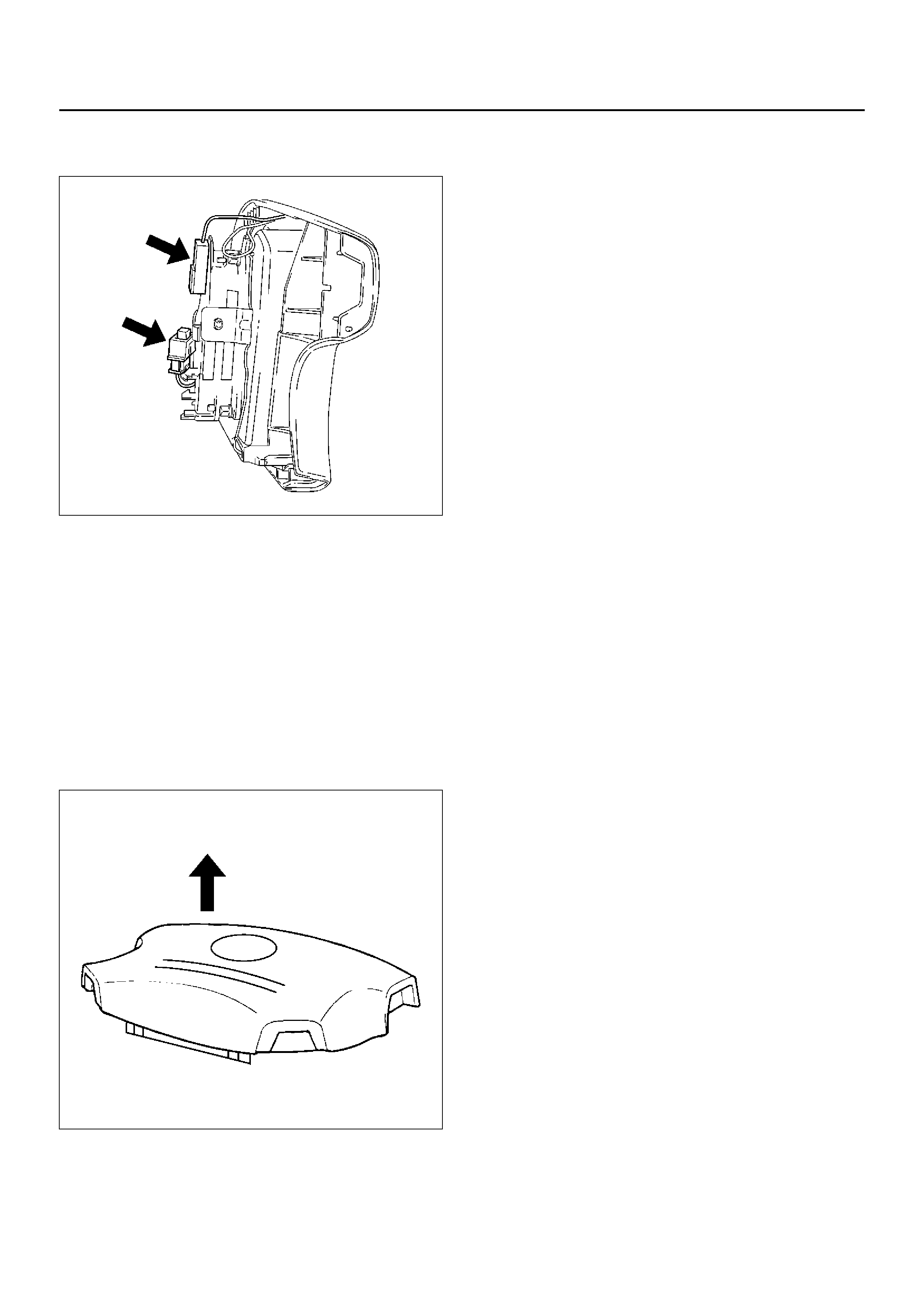

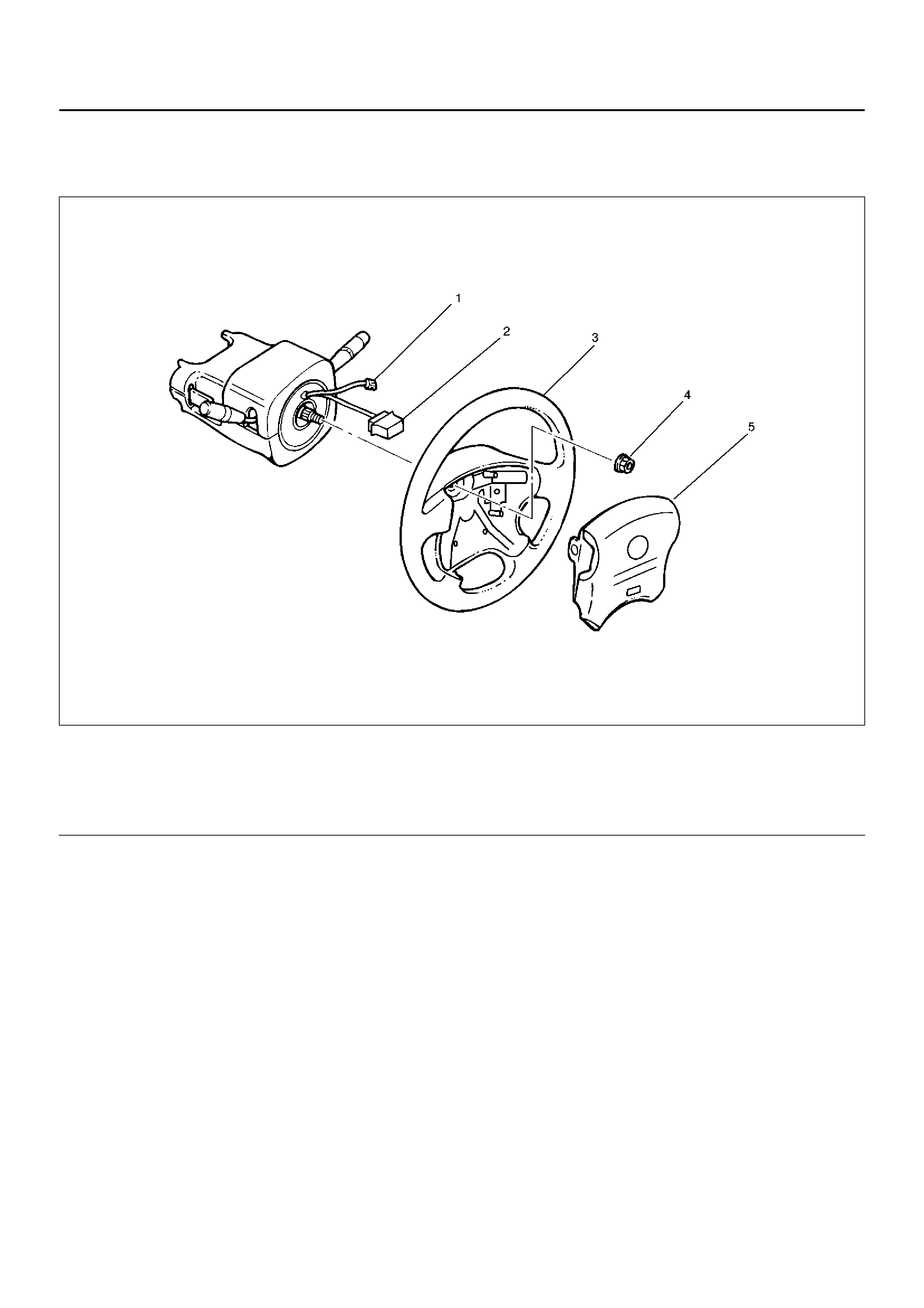

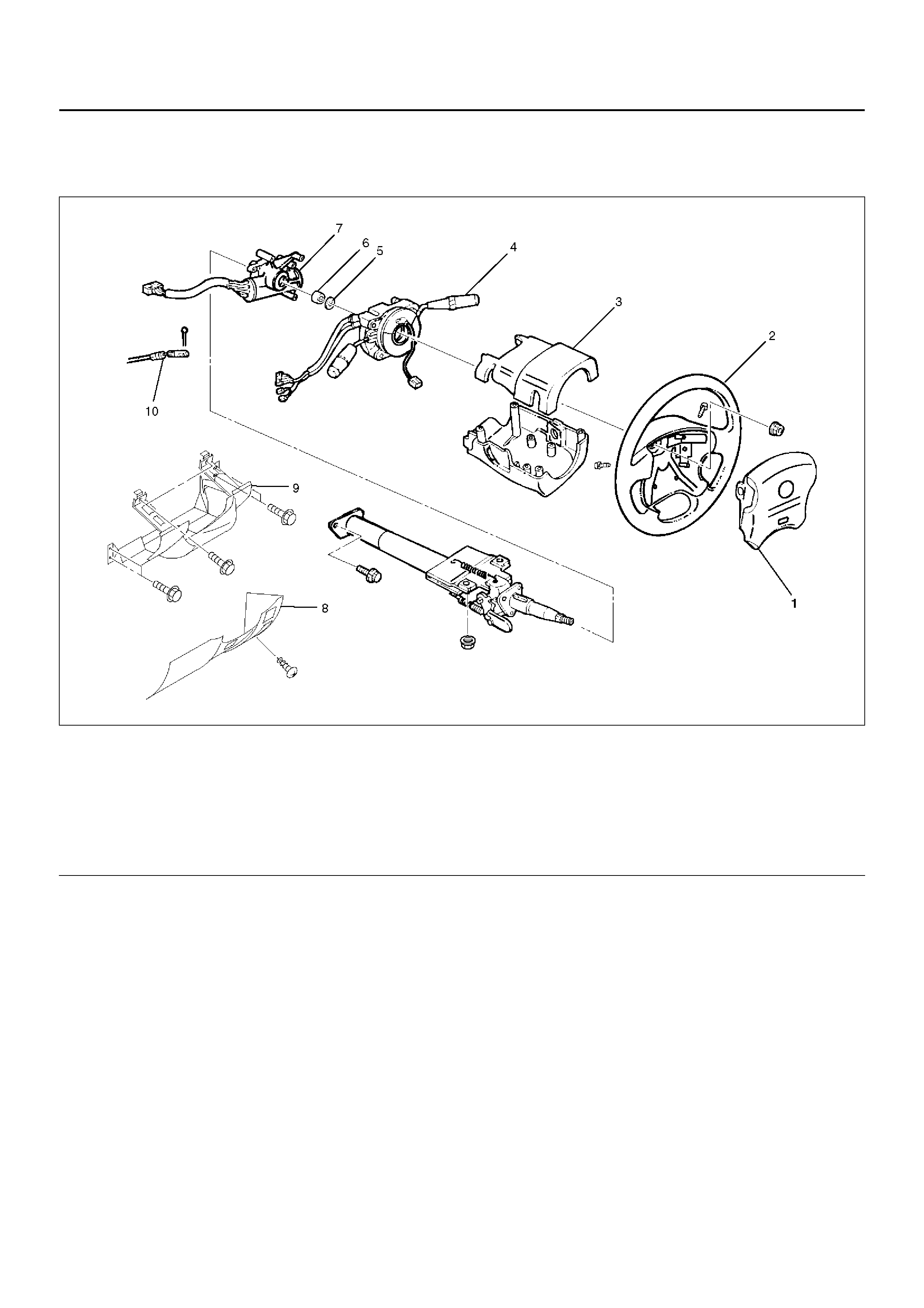

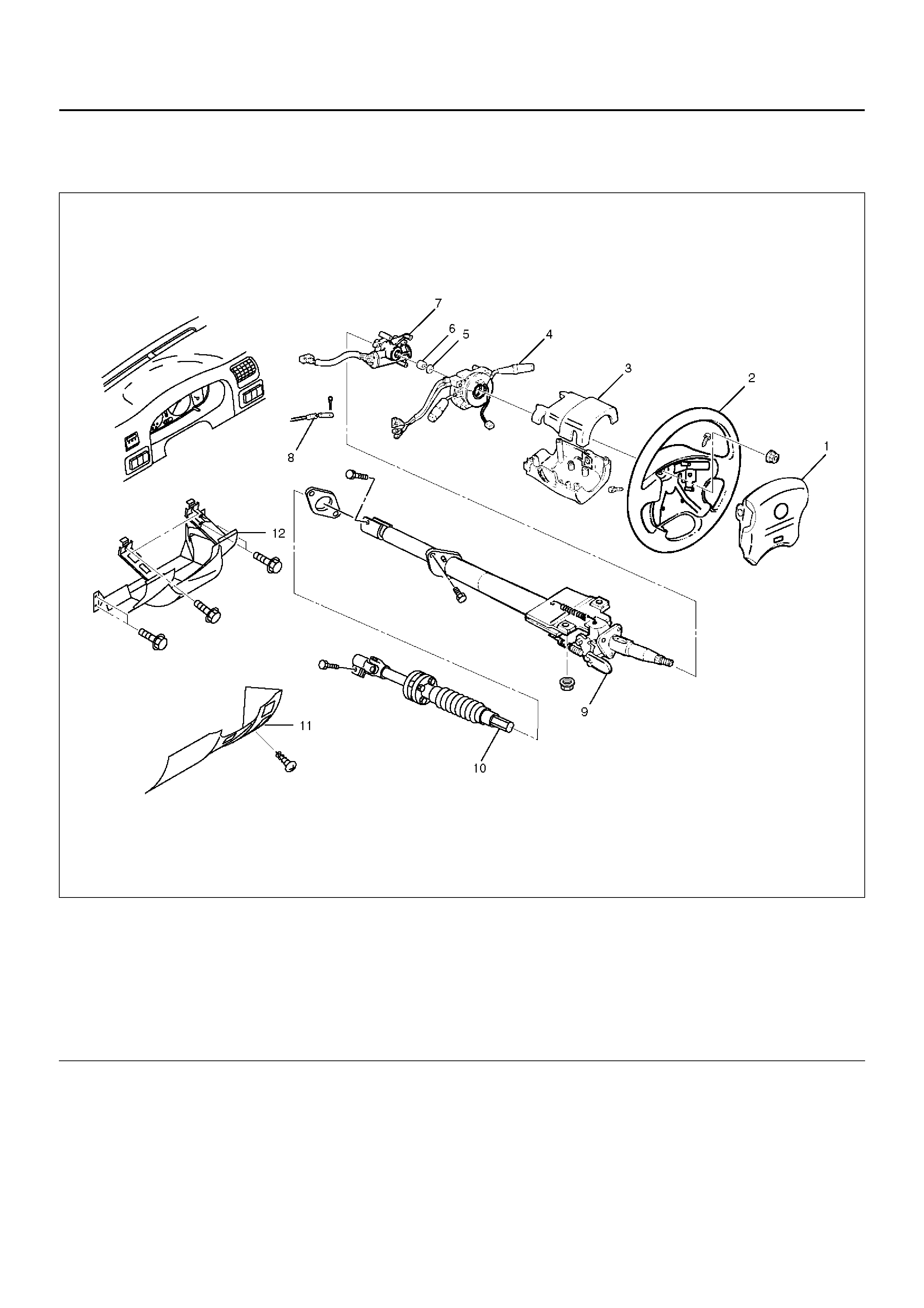

STEERING WHEEL

STEERING WHEEL AND ASSOCIATED PARTS

827RW069

Legend

EndOFCallout

CAUTION: Once the steering column is removed

from the vehicle, the column is extremely

susceptible to damage. Dropping the column

assembly on its end could collapse the steering

shaft or loosen the slide block which maintains

column rigidity. Leaning on the column assembly

could cause the jacket to bend or deform. Any of

the above damage could impair the column's

collapsible design. If it is necessary to remove the

steering wheel, use only the specified steering

wheel puller. Under no conditions should the end of

the shaft be hammered upon, as hammering could

loosen slide block which maintains column rigidity.

REMOVAL

1. T urn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2. Turn the ignition switch to “LOCK".

3. Disconnect the battery “–" terminal cable, and wait

at least 5 minutes.

4. Disconnect the yellow 2-way SRS connector located

under the steering column.

(1) Horn Lead

(2) SRS Conn ec tor

(3) Steering Wheel

(4) Steering Wheel Fixing Nut

(5) Inflator Module

5. Loosen the inflator module fixing bolt from behind

the steering wheel assembly using a TORX® driver

or equivalent until the inflator module can be

released from steering assembly.

827RW070

6. Disconnect the yellow 2-way SRS connector located

behind the inflator module.

WARNING: THE INFLATOR MODULE SHOULD

ALWAYS BE CARRIED WITH THE URETHANE

COVER AWAY FROM YOUR BODY AND SHOULD

ALWAYS BE LAID ON A FLAT SURFACE WITH THE

URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW

THE AIR CUSHION TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY MAY RESULT.

827RW073

7. Disconnect horn lead.

8. Remove steering wheel fixing nut.

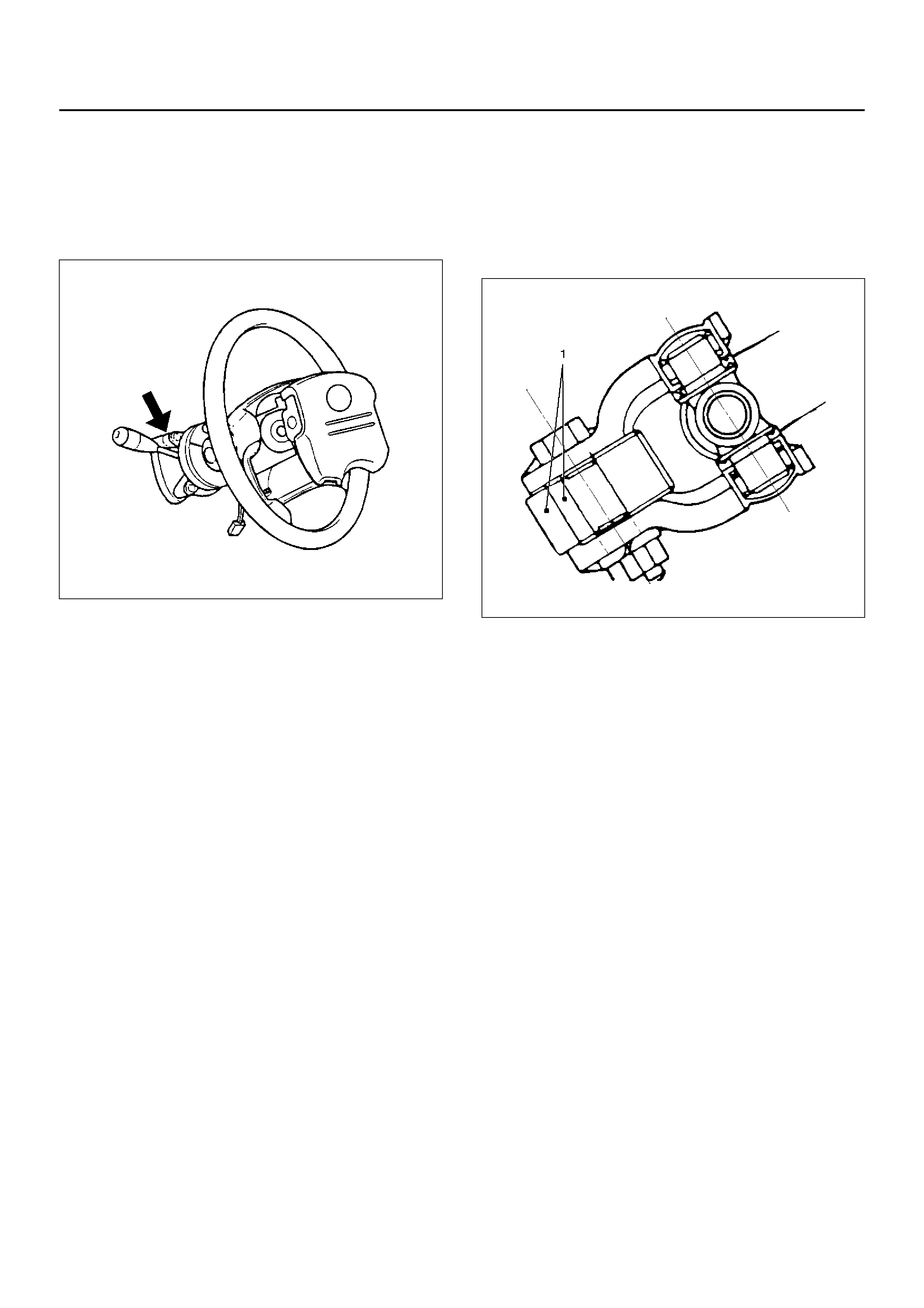

9. Apply a setting mark (1) across the steering wheel

and shaft so parts can be reassembled in their

original position, then remove steering wheel.

430RW021

10. Move the front wheels to the straight ahead position,

then use steering wheel remover 5–8521–0016–0 to

remove the steering wheel.

CAUTION: Never apply force to the steering wheel

in direction of the shaft by using a hammer or other

impact tools in an attempt to remove the steering

wheel. The steering shaft is designed as an energy

absorbing unit.

430RX005

INSTALLATION

1. Install steering wheel by aligning the setting marks

made when removing.

CAUTION: Never apply force to the steering wheel

in direction of the shaft by using a hammer or other

impact tools in an attempt to remove the steering

wheel. The steering shaft is designed as an energy

absorbing unit.

2. T ighten the steering wheel fixing nut to the specified

torque.

Torque: 34N·m

3. Connect horn lead.

4. Support the module and carefully connect the SRS

connector.

NOTE: Pass the lead wire through the tabs on the

plastic cover (wire protector) of inflator to prevent lead

wire from being pinches.

5. Tighten bolts to specified torque.

Torque: 9N·m

6. Connect the yellow 2-way SRS connector located

under the steering column.

7. Connect the battery “–" terminal cable.

8. Turn the ignition switch to “ON" while watching

warning light. Light should flash 7 times and then go

off. If lamp does not operate correctly, refer to

Occupant Restraint Section 12M.

COMBINATION SWITCH

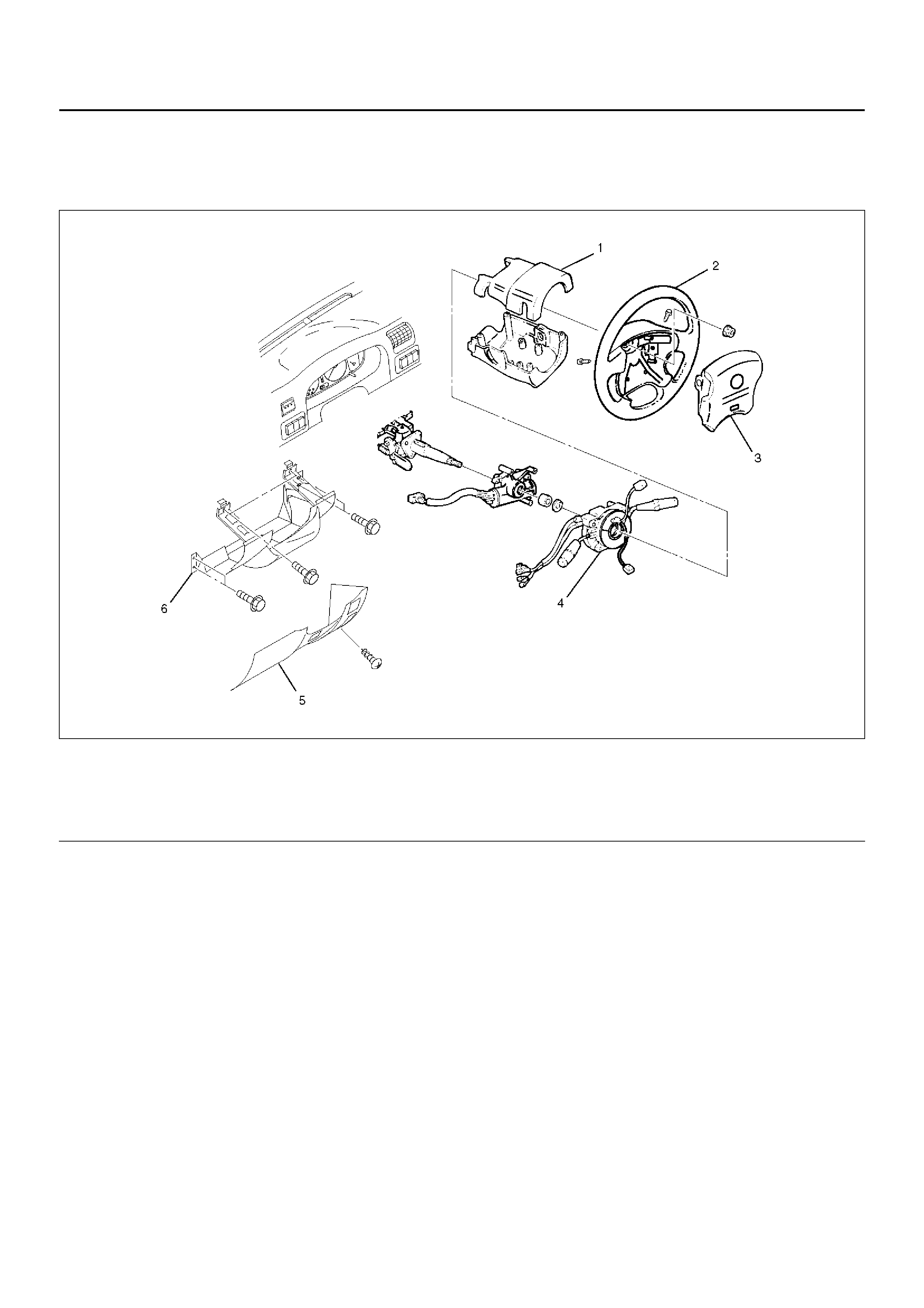

COMBINATION SWITCH AND ASSOCIATED PARTS

431RW028

Legend

EndOFCallout

REMOVAL

1. Turn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2. Turn the ignition switch to “LOCK".

3. Disconnect the battery “–" terminal cable, and wait

at least 5 minutes.

4. Disconnect the yellow 2-way SRS connector located

under the steering column.

CAUTION: The wheels of the vehicle must be

straight ahead and the steering column in the

“LOCK" position befor e disconnecting the steering

wheel. Failure to do so will cause the coil assembly

to become uncentered which will cause damage to

the coil assem bl y.

5. Remove the engine hood opening lever, then

remove instrument panel lower cover.

6. Remove the driver knee bolster (reinforcement).

(1) Steering Column Cover

(2) Steering Wheel

(3) Inflator Module

(4) Combination Switch and SRS Coil Assembly

(5) Instrument Panel Lower Cover

(6) Driver Knee Bolster (reinforcement)

7. Loosen the inflator module fixing bolt from behind

the steering wheel assembly using a TORX® driver

or equivalent until the inflator module can be

released from steering assembly. Disconnect the

yellow 2-way SRS connector and horn lead located

behind the inflator module, then remove inflator

module.

827RW070

827RW073

WARNING: THE INFLATOR MODULE SHOULD

ALWAYS BE CARRIED WITH THE URETHANE

COVER AWAY FROM YOUR BODY AND SHOULD

ALWAYS BE LAID ON A FLAT SURFACE WITH THE

URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SP ACE IS PROVIDED TO ALLOW

THE AIR CUSHION TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY MAY RESULT.

827RW072

8. Apply a setting mark (1) across the steering wheel

and shaft so parts can be reassembled in their

original position. Move the front wheels to the

straight ahead position, then use steering wheel

remover 5–8521–0016–0 to remove the steering

wheel.

430RW021

CAUTION: Never apply force to the steering wheel

in direction of the shaft by using a hammer or other

impact tools in an attempt to remove the steering

wheel. The steering shaft is designed as an energy

absorbing unit.

430RX005

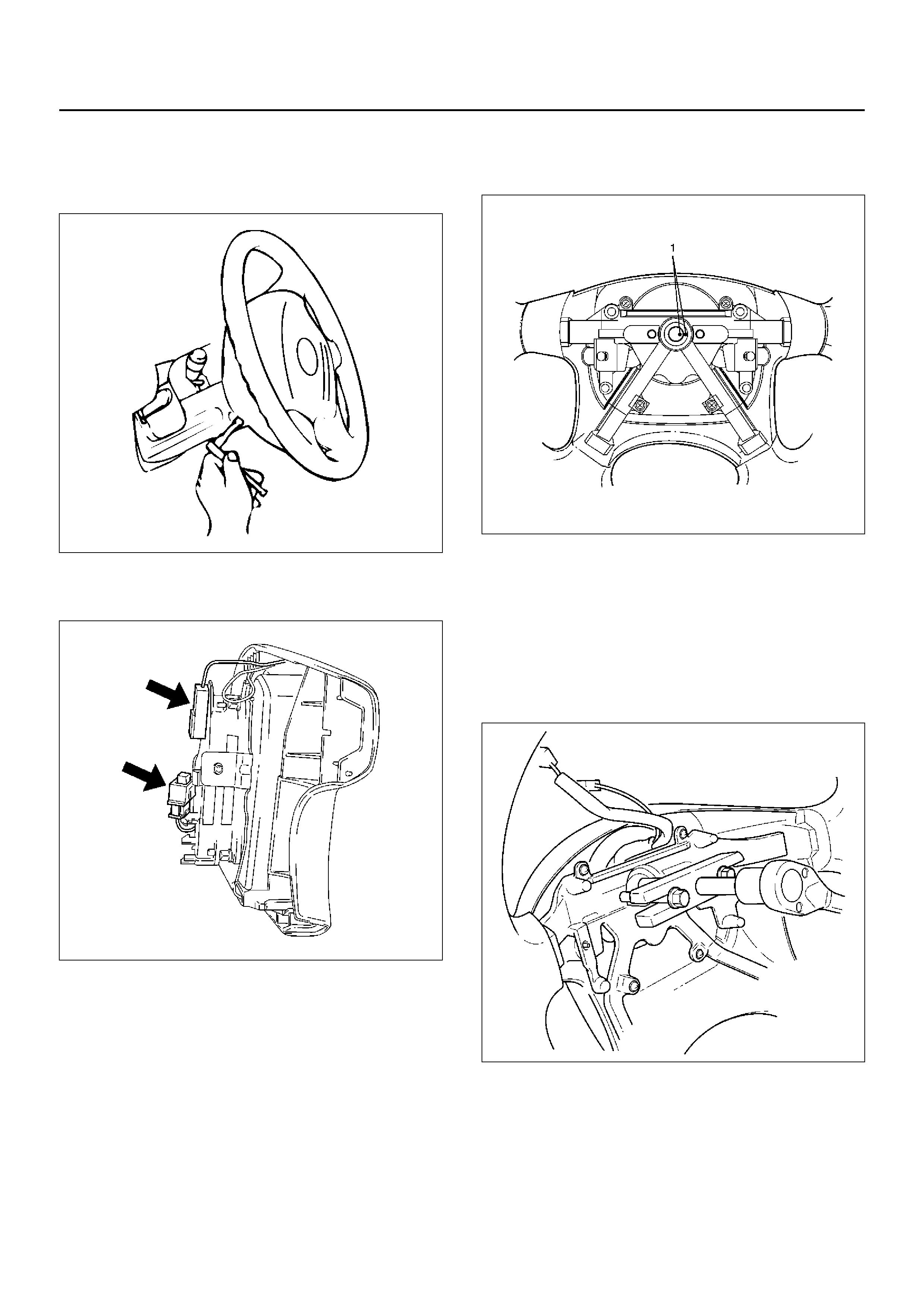

9. Remove steering column cover.

10. Disconnect the wiring harness connectors located

under the steering column then remove combination

switch and SRS coil assembly.

NOTE: The SRS coil is a part of the combination switch

assembly, which can not be replaced separately.

Therefore, be sure not to remove the SRS coil from the

combination switch assembly.

825RW288

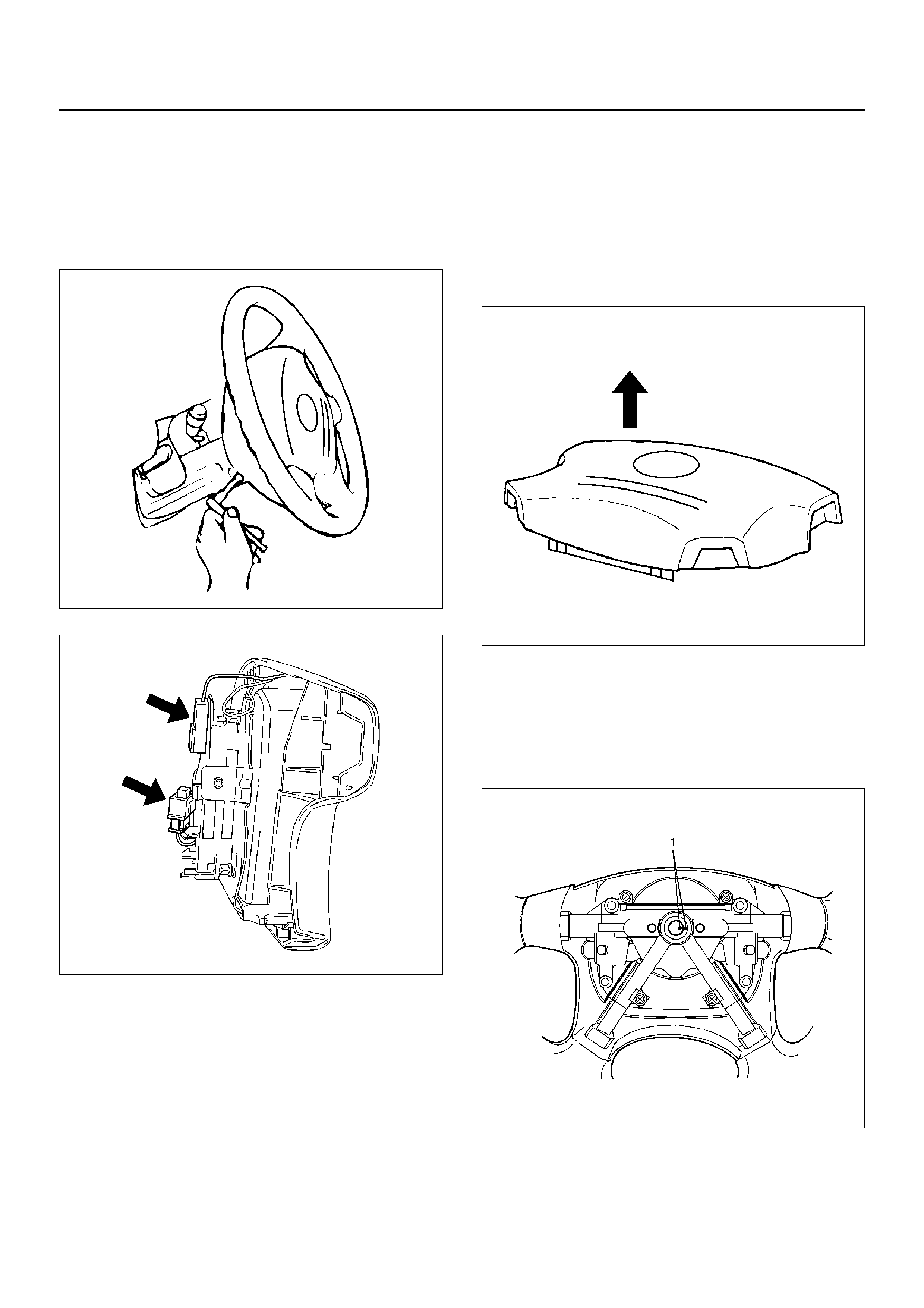

INSTALLATION

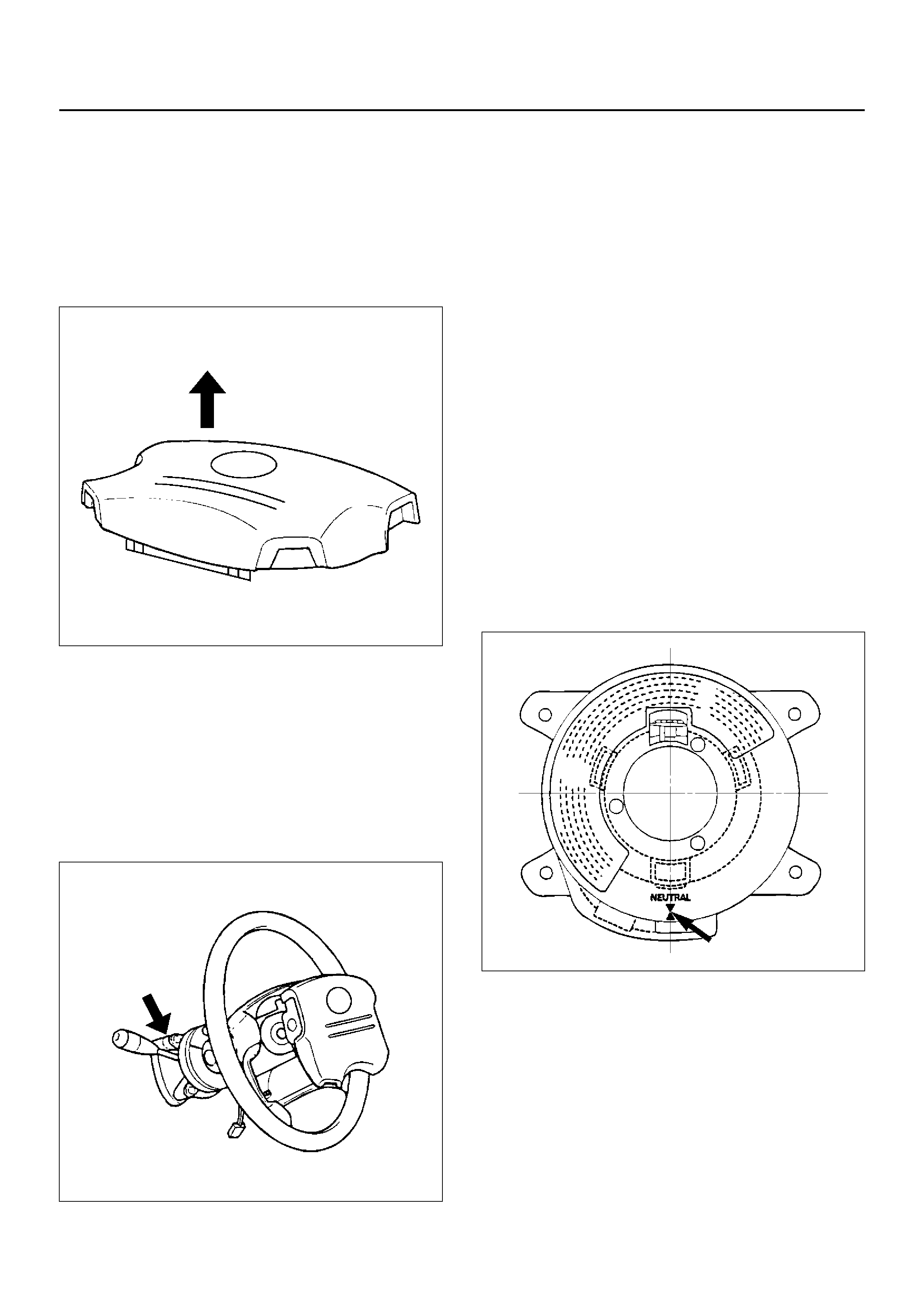

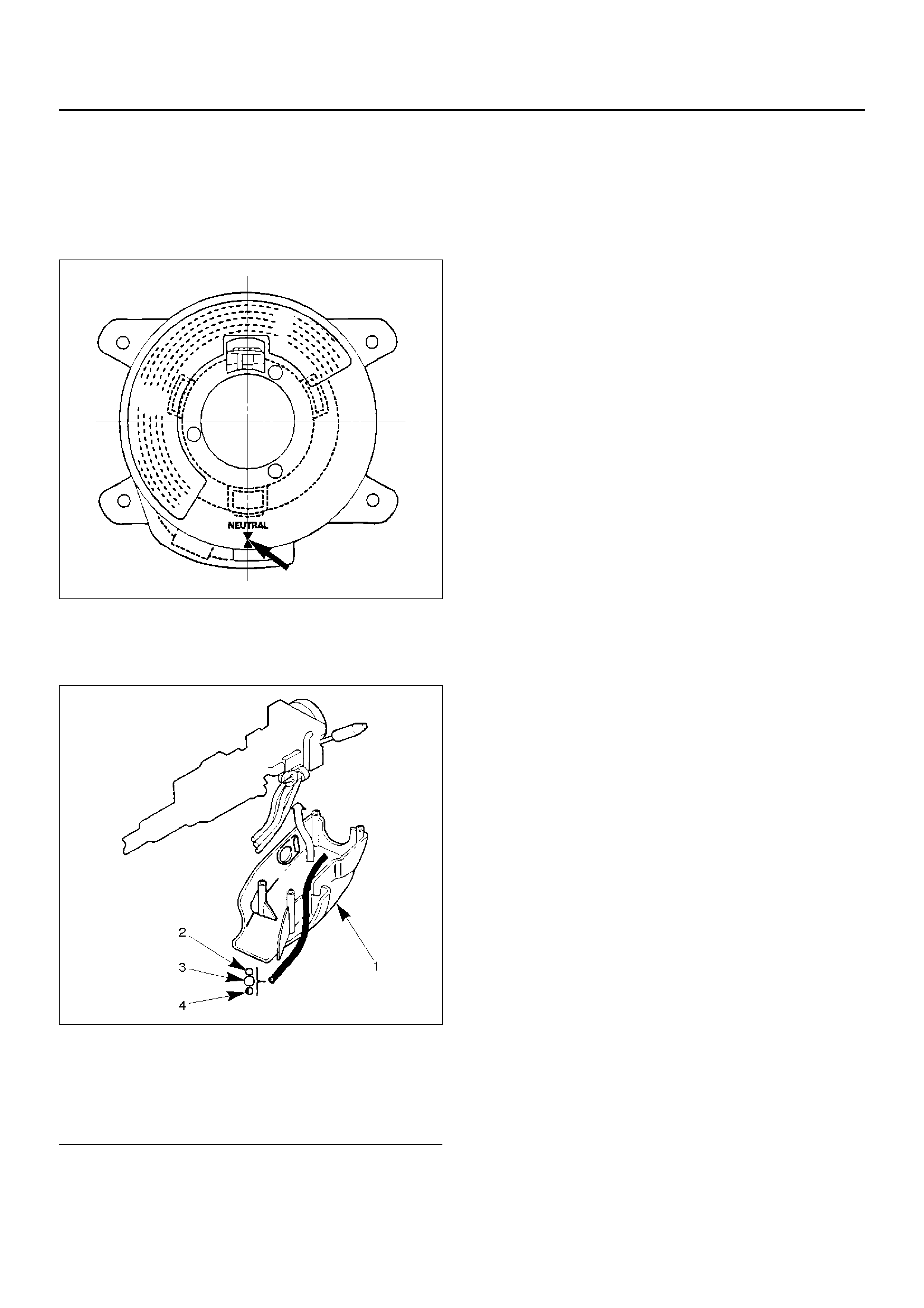

1. Install combination switch and SRS coil assembly.

After installation of combination switch assembly,

connect the combination switch wiring harness

connector and the SRS 2-way connector located

under the steering column. Then turn the SRS coil

counter clockwise to full, return about 3 turns and

align the neutral mark.

CAUTION: When turning the SRS coil counter

clockwise to full, stop turning if resistance is felt.

Forced further turning may damage to the cable in

the SRS coil.

825RW016

2. When installing the steering column cover, be sure

to route each wire harness as illustrated so that the

harnesses do not catch on any moving parts.

825RW017

Legend

EndOFCallout

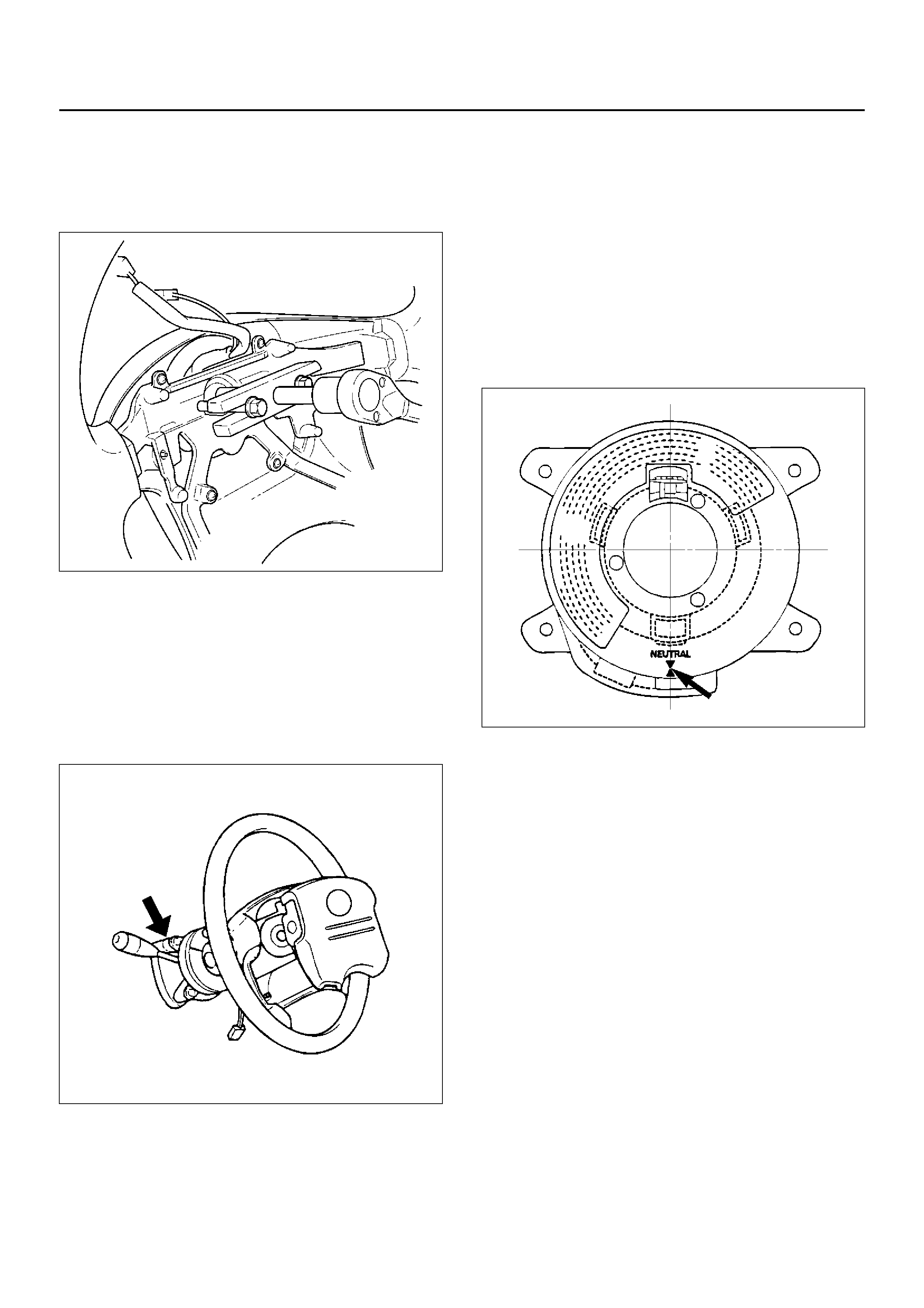

3. Align the setting marks made when removing then

install steering wheel.

CAUTION: Never apply force to the steering wheel

in direction of the shaft by using a hammer or other

impact tools in an attempt to remove the steering

wheel. The steering shaft is designed as an energy

absorbing unit.

4. Tighten the steering wheel fixing nut to the specified

torque.

Torque: 34N·m

5. Support the inflator module and carefully connect

the SRS connector and horn lead.

NOTE: Pass the lead wire through the tabs on the

plastic cover (wire protector) of inflator to prevent lead

wire from being pinched.

6. Tighten bolts to specified torque.

Torque: 9N·m

7. Install driver knee bolster (reinforcement).

8. Install instrument panel lower cover then Install the

engine hood opening lever.

9. Connect the SRS connector.

10. Connect the battery “-" terminal cable.

11. Turn the ignition switch to “ON" while watching

warning light and check the light should flash 7

times and then go off. If lamp does not operate

correctly, refer to Occupant Restraint Section 12M.

(1) Steering Column Cover

(2) Starter Switch Harne ss

(3) Combination Switch Harness

(4) Inflator Module Harness

LOCK CYLINDER

LOCK CYLINDER AND ASSOCIATED PARTS

431RW027

Legend

EndOFCallout

REMOVAL

1. Turn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2. Turn the ignition switch to “LOCK".

3. Disconnect the battery “–" terminal cable, and wait

at least 5 minutes.

4. Disconnect the yellow 2-way SRS connector located

under the steering column.

CAUTION: The wheels of the vehicle must be

straight ahead and the steering column in the

"LOCK" position before disconnecting the steering

wheel. Failure to do so will cause the coil assembly

to become uncentered which will cause damage to

the coil assem bl y.

5. Remove the engine hood opening lever and

stee ring lower cove r.

6. Remove driver knee bolster (reinforcement).

(1) Inflator Module

(2) Steering Wheel

(3) Steering Column Cover

(4) Combination Switch and SRS Coil Assembly

(5) Snap Ring

(6) Cushion Rubber

(7) Lock Cylinder Assembly

(8) Instrument Panel Lower Cover

(9) Driver Knee Bolster (reinforcement)

(10) Shift Lock Cable (for A/T)

7. Loosen the inflator module fixing bolt from behind

the steering wheel assembly using a TORX® driver

or equivalent until the inflator module can be

released from steering assembly.

827RW070

8. Disconnect the yellow 2-way SRS connector and

horn lead located behind the inflator module.

827RW073

9. Apply a setting mark (1) across the steering wheel

and shaft so parts can be reassembled in their

original position.

430RW021

10. Move the front wheels to the straight ahead position,

then use steering wheel remover 5–8521–0016–0

to remove the steering wheel.

CAUTION: Never apply force to the steering wheel

in direction of the shaft by using a hammer or other

impact tools in an attempt to remove the steering

wheel. The steering shaft is designed as an energy

absorbing unit.

430RX005

WARNING: THE INFLATOR MODULE SHOULD

ALWAYS BE CARRIED WITH THE URETHANE

COVER AWAY FROM YOUR BODY AND SHOULD

ALWAYS BE LAID ON A FLAT SURFACE WITH THE

URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW

THE AIR CUSHION TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY MAY RESULT.

827RW072

11. Remove steering column cover.

12. Disconnect the wiring harness connectors located

under the steering column.

13. Remove the combination switch assembly with SRS

coil.

NOTE: The SRS coil is a part of the combination switch

assembly, which can not be replaced separately.

Therefore, be sure not to remove the SRS coil from the

combination switch assembly.

825RW288

14. Remove snap ring.

15. Remove cushion rubber.

16. Remove shift lock cable (for A/T).

17. Disconnect the starter switch harness connector

located under the steering column then remove lock

cylinder assembly.

INSTALLATION

1. Install lock cylinder assembly.

2. Install shift lock cable (for A/T).

3. Install cushion rubber.

4. Install snap ring.

5. Install Combination switch and SRS coil assembly.

After installation of combination switch assembly,

connect the combination switch wiring harness

connector and the SRS 2-way connector located

under the steering column.

6. Turn the SRS coil counter clockwise to full, return

about 3 turns and align the neutral mark.

CAUTION: When turning the SRS coil counter

clockwise to full, stop turning if resistance is felt.

Forced further turning may damage the cable in the

SRS coil.

825RW016

7. When installing the steering column cover, be sure

to wire (through each harness) as illustrated so that

the harnesses starter switch, combination switch

and SRS coil may not catch wiring.

825RW017

Legend

EndOFCallout

8. Install steering wheel by aligning the setting marks

made during removal.

CAUTION: Never apply force to the steering wheel

in direction of the shaft by using a hammer or other

impact tools in an attempt to remove the steering

wheel. The steering shaft is designed as an energy

absorbing unit.

9. Tighten the steering wheel fixing nut to the specified

torque.

Torque: 34N·m

10. Support inflator module and carefully connect the

SRS connector and horn lead, then install inflator

module.

NOTE: Pass the lead wire through the tabs on the

plastic cover (wire protector) of inflator to prevent lead

wire from being pinched.

11. Tighten fixing bolts to specified torque.

Torque: 9N·m

12. Install driver knee bolster (reinforcement).

13. Install instrument panel lower cover, then install the

engine hood opening lever.

14. Connect the yellow 2-way SRS connector located

under the steering column.

15. Connect the battery “–" terminal cable.

SYSTEM INSPECTION

Turn the ignition switch to “ON" while watching warning

light.

The light should flash 7 times and then go off. If lamp

does not operate correctly, refer to Restraints section.

(1) Steering Column Cover

(2) Starter Switch Harne ss

(3) Combination Switch Harness

(4) Inflator Module Harness

STEERING COLUMN

STEERING COLUMN AND ASSOCIATED PARTS

431RW029

Legend

EndOFCallout

REMOVAL

1. Turn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2. Turn the ignition switch to “LOCK".

3. Disconnect the battery “–" terminal cable, and wait

at least 5 minutes.

4. Disconnect the yellow 2-way SRS connector located

under the steering column.

CAUTION: The wheel of the vehicle must be

straight ahead and the steering column in the

“LOCK" position before disconnecting the steering

column from the steering gear. Failure to do so will

cause the SRS coil assembly to become uncentered

which will cause damage to the SRS coil assembly.

(1) Inflator Module

(2) Steering Wheel

(3) Steering Column Cover

(4) Combination Switch and SRS Coil Assembly

(5) Snap Ring

(6) Cus hion Rubber

(7) Lock Cylinder Assembly

(8) Shift Lock Cable (For A/T)

(9) Steering Column Assembly

(10) S ec ond Steering Shaft

(11) Instrument Panel Lower Cover

(12) Driver Knee Bolster (reinforcement)

5. Remove the engine hood opening lever, then

remove instrument panel lower cover.

6. Remove driver knee bolster (reinforcement).

7. Loosen the inflator module fixing bolt from behind

the steering wheel assembly using a TORX® driver

or equivalent until the inflator module can be

released from steering assembly.

827RW070

8. Disconnect the yellow 2-way SRS connector and

horn lead located behind the inflator module.

9. Remove inflator module.

WARNING: THE INFLATOR MODULE SHOULD

ALWAYS BE CARRIED WITH THE URETHANE

COVER AWAY FROM YOUR BODY AND SHOULD

ALWAYS BE LAID ON A FLAT SURFACE WITH THE

URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW

THE AIR CUSHION TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYM ENT.

OTHERWISE, PERSONAL INJURY MAY RESULT.

827RW072

10. Apply a setting mark (1) across the steering wheel

and shaft so parts can be reassembled in their

original position. Move the front wheels to the

straight ahead position, then use steering wheel

remover 5–8521–0016–0 to remove the steering

wheel.

430RW021

430RX005

11. Remove steering column cover.

12. Disconnect the wiring harness connectors located

under the steering column.

13. Remove the combination switch assembly with SRS

coil.

NOTE: SRS coil is a part of combination switch

assembly, which can not be replaced singly. Therefore,

be sure not to remove the SRS coil from the

combination switch assembly.

825RW288

14. Remo ve sn ap ring.

15. Remo ve cu sh ion rubbe r.

16. Remove shift lock cable (For A/T).

17. Disconnect the starter switch harness connector

located under the steering column, then remove

lock cy li nd er assembl y.

18. Apply a setting mark (1) across the universal joint

and transfer gear to reassemble the parts in their

original position, then remove steering column

assembly and second shaft.

NOTE: A setting mark can be easily made if the shaft is

withdrawn a little by loosening the steering shaft

universal joint.

431RW009

INSPECTION

If the abnormal conditions are found through inspection,

replace the steering column assembly.

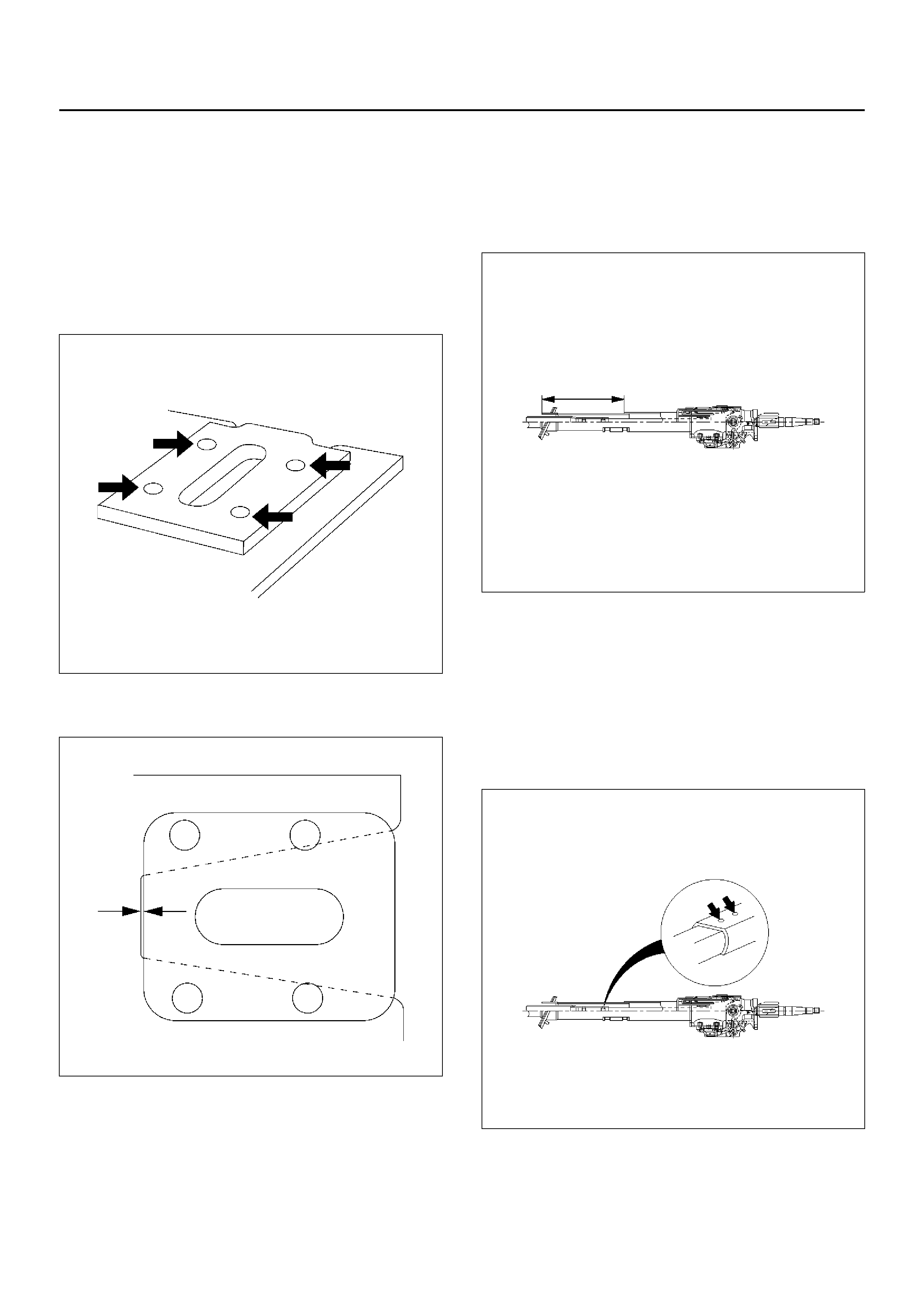

Column Capsule

Check capsules on steering column bracket assembly;

all must be securely seated in bracket slots and

checked for any loose conditions when pushed or pulled

by hand.

431RW030

Check clearance between capsule and bracket. If must

be within 1mm (0.039 in).

431RW031

Column Tube

Check for collapes by measuring the distance as shown

in the figure.

Standard distance: 162.2-165.8 mm (6.386-6.528

in)

431RY00010

Column Universal Joint for Tilt Mechanism

If the resistance is felt when checked by rotate the joint,

replace the steering column assembly.

Sheared Injected Plastic Pin

Check the sheared injected plastic pins for any loose

condi tion s or damage .

431RY00011

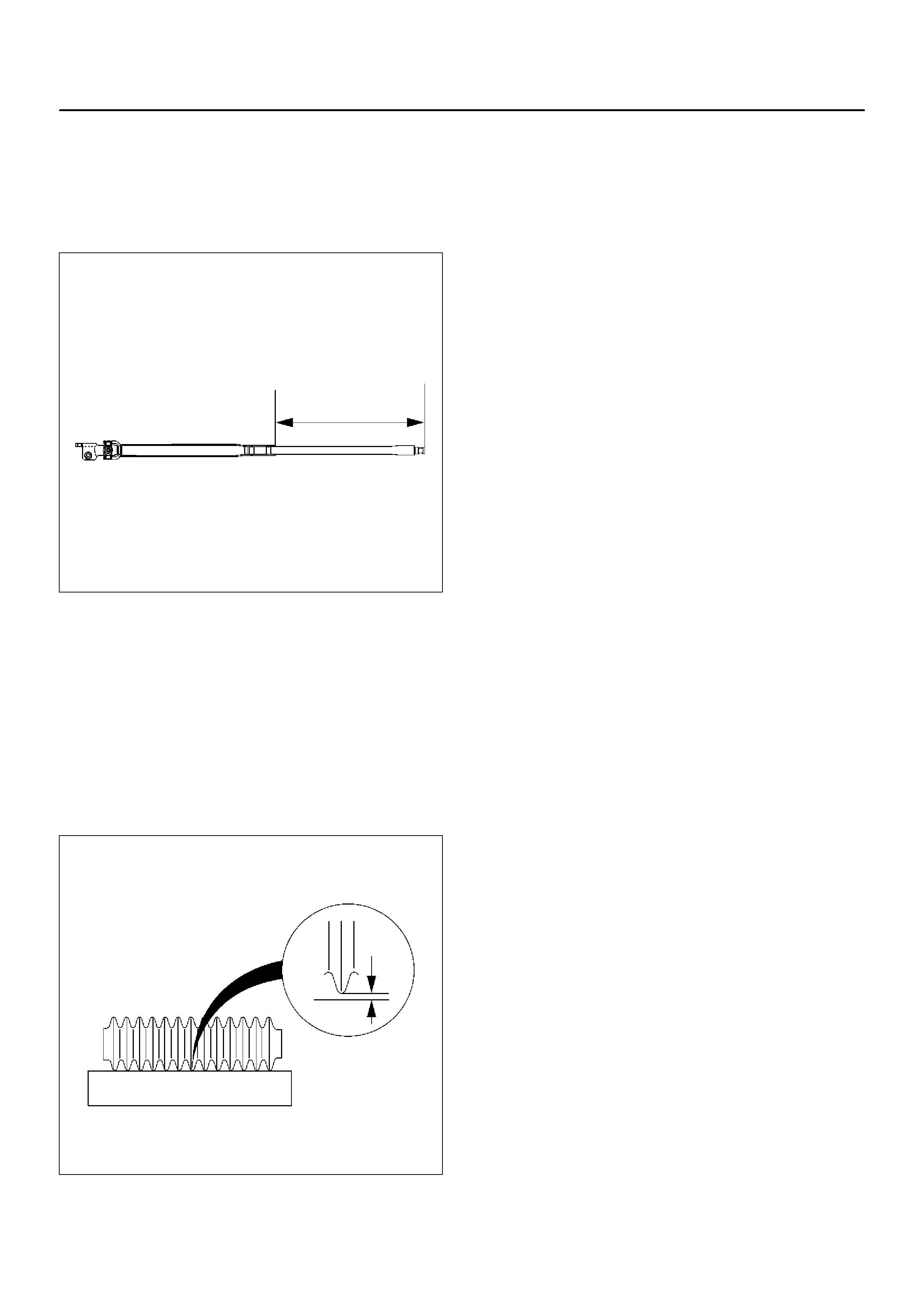

Shaft Length

Check the shaft length from the upper end of the slide

joint to the end of the shaft. If column length is not in

specifications, steering column should be replaced.

Standard length: 291.7-295.7 mm

431RW034

Shaft Universal Joint (Lower End)

If the resistance is felt when checked by rotate the joint,

replace the steering column assembly.

Shaft Bellows Pipe

Check the shaft bellows pipe for bend by using straight

edge. Measure the clearance between the bellows pipe

and the straight edge (at center of the bellows pipe).

Standard: Less than 1mm

431RW035

Tilt Mechanism

Tilt mechanism should moves smoothly.

While locked the tilt mechanism, be sure the steering

column latch securely by pushing the steering wheel

upward and downward.

INSTALLATION

1. Thread the steering column assembly through the

hole in the dashpanel. Temporarily tighten the

steering column fixing nuts (crossbeam side).

2. Tighten the steering column fixing bolt (dashpanel

side) to the specified torque.

Torque: 20N·m

3. Tighten the steering column fixing nuts (crossbeam

side) to the specified torque (this nut was

temporarily tightened in Step 1).

Torque: 17N·m

4. Align the setting marks on the universal joint and the

second steering shaft (applied at disassembly).

5. Connect the universal joint and the second steering

shaft. Tighten the universal joint bolts to the

specified torque.

Torque: 31N·m

6. Connect the steering column assembly to the

second steering shaft. Tighten the bolts to the

specified torque.

Torque: 31N·m

7. Install lock cylinder assembly.

8. Install shift lock cable (For A/T).

9. Install cushion rubber.

10. Install snap ring.

11. Install combination switch and SRS coil assembly.

After installation of combination switch assembly,

connect the combination switch wiring harness

connector and the SRS 2-way connector located

under the steering column.

12. Turn the SRS coil counter clockwise to full, return

about 3 turns and align the neutral mark.

CAUTION: When turning the SRS coil counter

clockwise to full, stop turning if resistance is felt.

Forced further turning may damage to the cable in

the SRS coil.

825RW016

13. When installing the steering column cover, be sure

to route each wire harness as illustrated so that the

harnesses do not catch any moving parts.

825RW017

Legend

EndOFCallout

14. Install steering wheel and align the setting marks

made when removing.

CAUTION: Never apply force to the steering wheel

in direction of the shaft by using a hammer or other

impact tools in an attempt to remove the steering

wheel. The steering shaft is designed as an energy

absorbing unit.

15. Tighten the steering wheel fixing nut to the specified

torque.

Torque: 34N·m

16. Support the module and carefully connect the

module connector and horn lead, then install inflator

module.

NOTE: Pass the lead wire through the tabs on the

plastic cover (wire protector) of inflator to prevent lead

wire from being pinched.

17. Tighten bolts to specified torque.

Torque: 9N·m

18. Install driver knee bolster (reinforcement).

19. Install instrument panel lower cover.

20. Install the engine hood opening lever.

21. Connect the yellow 2-way SRS connector and horn

lead located under the steering column.

22. Connect the battery “–" terminal cable.

SYSTEM INSPECTION

Turn the ignition switch to “ON" while watching warning

light.

The light should flash 7 times and then go off. If lamp

does not operate correctly, refer to Restraints section.

(1) Steering Column Cover

(2) Starter Switch Harne ss

(3) Combination Switch Harness

(4) Inflator Module Harness

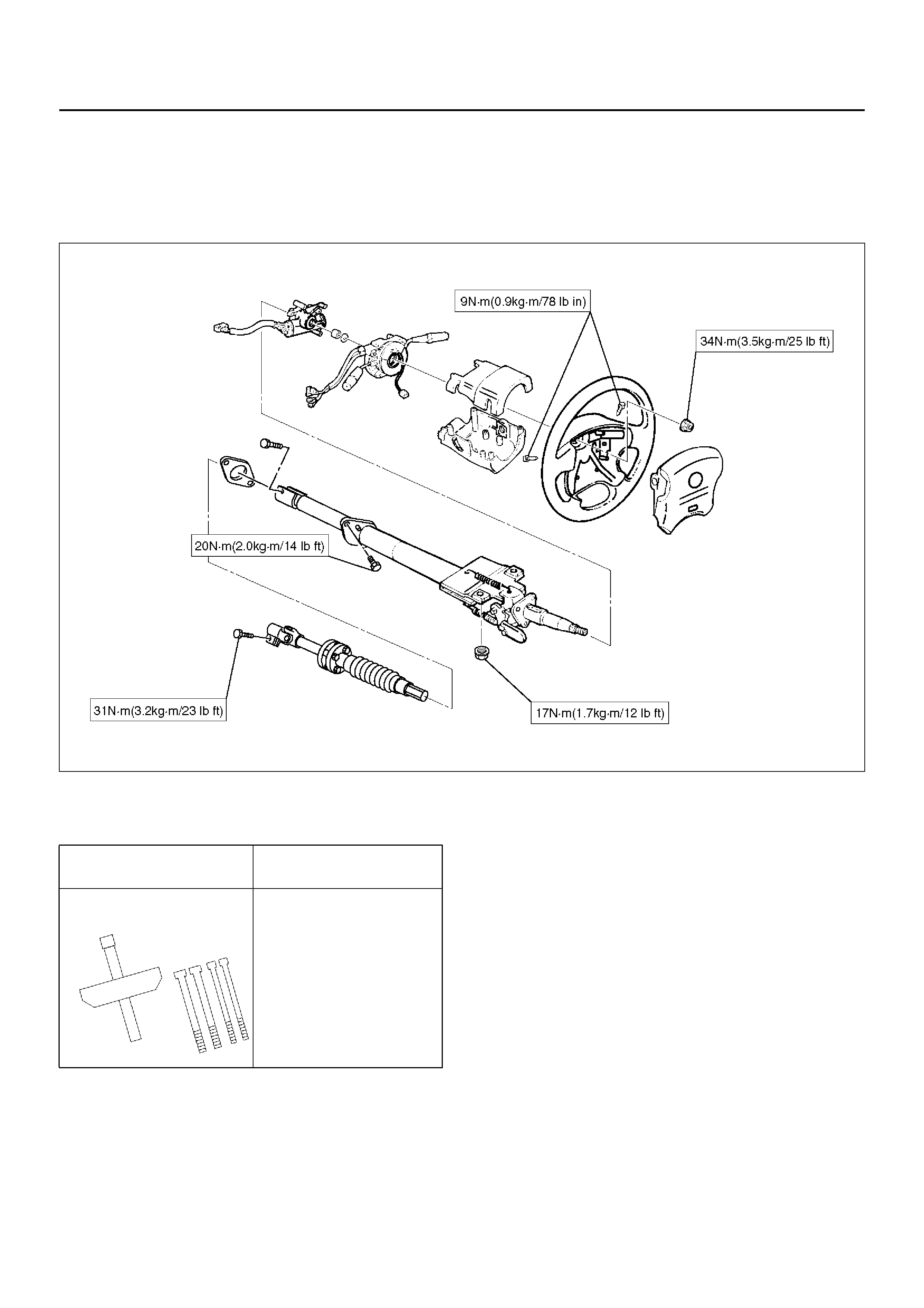

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL &

COLUMN AND ASSOCIATED PARTS

MAIN DATA AND SPECIFICATIONS

Torque Specifications

430RY00006

SPECIAL TOOLS

ILLUSTRATION TOOL NO.

TOOL NAME

5–8521–0016–0

(J–29752)

Steering wheel rem ov er