SECTION 0A - GENERAL INFORMATION

General Repair Instruction

Illustration Arrows

Identification

Lifting Instructions

Standard Bolts Torque Specifications

Abbreviations Charts

Service Parts Identification Plate

General Repair Instruction

1. If a floor jack is used, the following precautions are

recommended.

Park vehicle on level ground, “block" front or rear

wheels, set jack against the recommended lifting

points (see “Lifting Instructions" in this section),

raise vehicle and support with chassis stands and

then perform the service operations.

2. Before performing service operations, disconnect

ground cab le from the battery to reduce the chance

of cable damage and burning due to short circuiting.

3. Use a cov er on body, seats and floor to protect them

against damage and contamination.

4. Brake fluid and anti–freeze solution must be

handled with reasonable care, as they can cause

paint damage.

5. The use of proper tools and recommended essential

and av ailable tools, where specified, is important for

efficient and reliable performance of service repairs.

6. Use genuine Isuzu parts.

7. Used cotter pins, plastic clips, gaskets, O–rings, oil

seals, lock washers and self–locking nuts should be

discarded and new ones should be installed, as

normal function of the parts cannot be maintained if

these parts are reused.

8. To facilitate proper and smooth reassembly

operation, keep disassembled parts neatly in

groups. Keeping fixing bolts and nuts separate is

very important, as they v ary in hardness and design

depending on position of installation.

9. Clean the parts before inspection or reassembly.

Also clean oil ports, etc. using compressed air, and

make certain they are free from restrictions.

10. Lubricate rotating and sliding f aces of the parts with

oil or grease before installation.

11. When necessary, use a sealer on gaskets to pre vent

leakage.

12. Carefully observe all specifications for bolt and nut

torques.

13. When removing or replacing parts that require

refrigerant to be discharged from the air

conditioning system, be sure to use the Vehicle

Refrigerant Recovery and Recycling Equipment

(VRRRE) to recover and recycle Refrigerant–134a.

14. When a service operation is completed, make a final

check to be sure the service has been done

properly and the problem has been corrected.

15. SUPPLEMENTAL RESTRAINT SYSTEM

The vehicle is equipped with a Supplemental

Restraint System (SRS) – Air Bags. This system is

not to be serviced without consulting the

appropriate service inf ormation. Consult Section 9J

“SRS System" if work is to be done on the front of

the vehicle such as bumper, sheet metal, seats,

wiring, steering wheel or column. Also revie w SRS

system information if any arc welding is to be done

on the vehicle. The SRS system equipped vehicle

can be identified by:

1. “AIR BAG" warning light on the instrument

cluster.

2. A Code “J" for fifth digit of Vehicle Identification

Number.

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

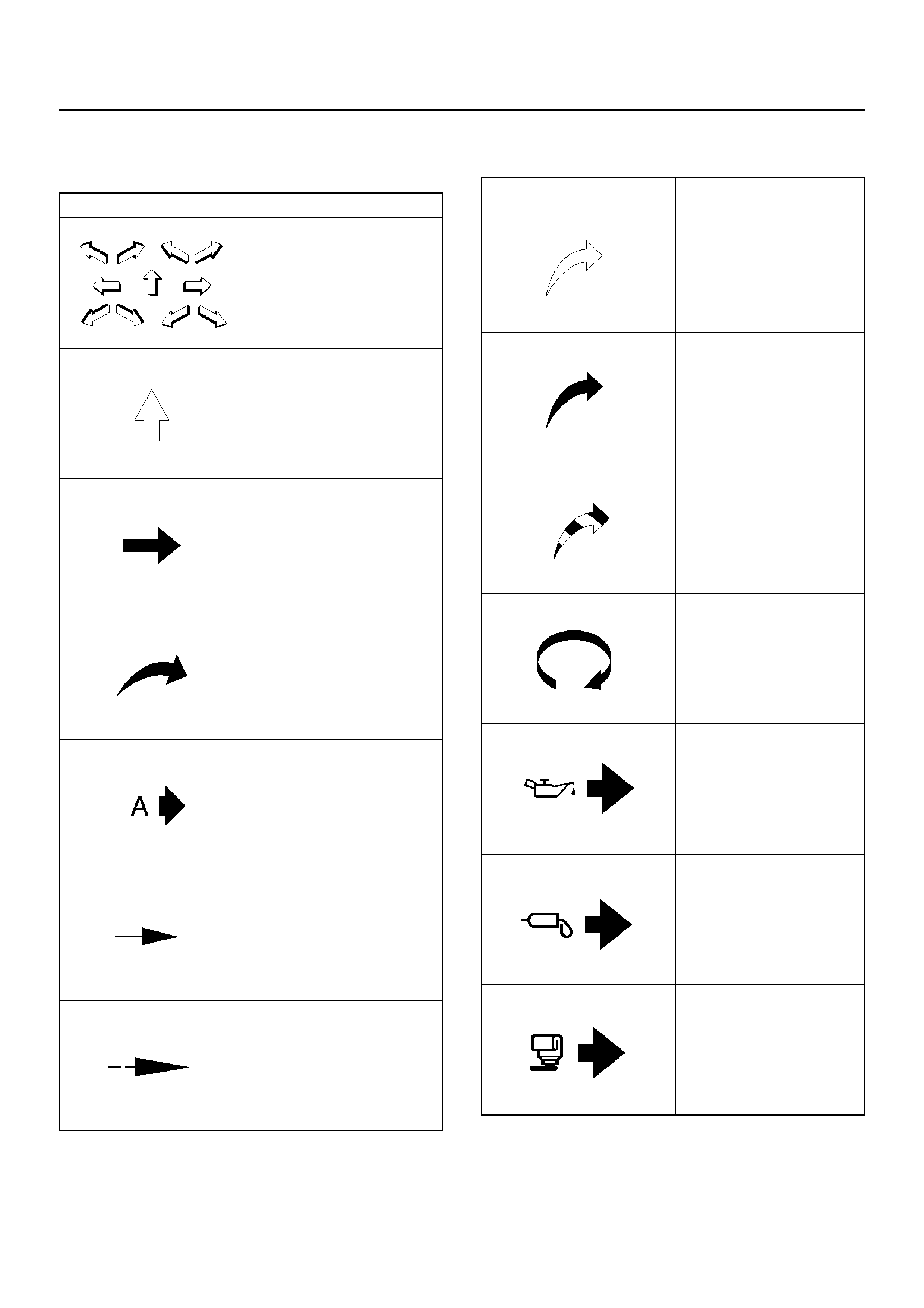

Illustration Arrows

Arrows are designed for specific purposes to aid your understanding of technical illustrations.

Arrow Type Application

Front of vehicle

Up Side

Task Related

View Detail

View Angle

Dimension (1:2)

Sectioning (1:3)

• Ambient/Clean air flow

• Cool air flow

• Gas other than

ambient air

• Hot air flow

• A mbient a ir mixed with

another gas

• Can indicate

temperature change

Motion or direction

Lubrication point oil or

fluid

Lubrication point grease

Lubrication point jelly

Arrow Type Application

Engine Serial Number

• 6VD1 Engine

The gasoline engine serial number is stamped on the

left rear lower area of the cylinder block above the

starter.

F06RW001

• X22SE Eng in e

The gasoline engine serial number is stamped on the

rear end raised area of the cylinder bl ock left side.

035RW022

Transmission Serial Number

Manual : Stamped on the left side of the transmission

intermediate plate.

220RS025

A utomatic : Stamped on the identification plate, located

on the left side of the transmission above the mode

switch.

240RW019

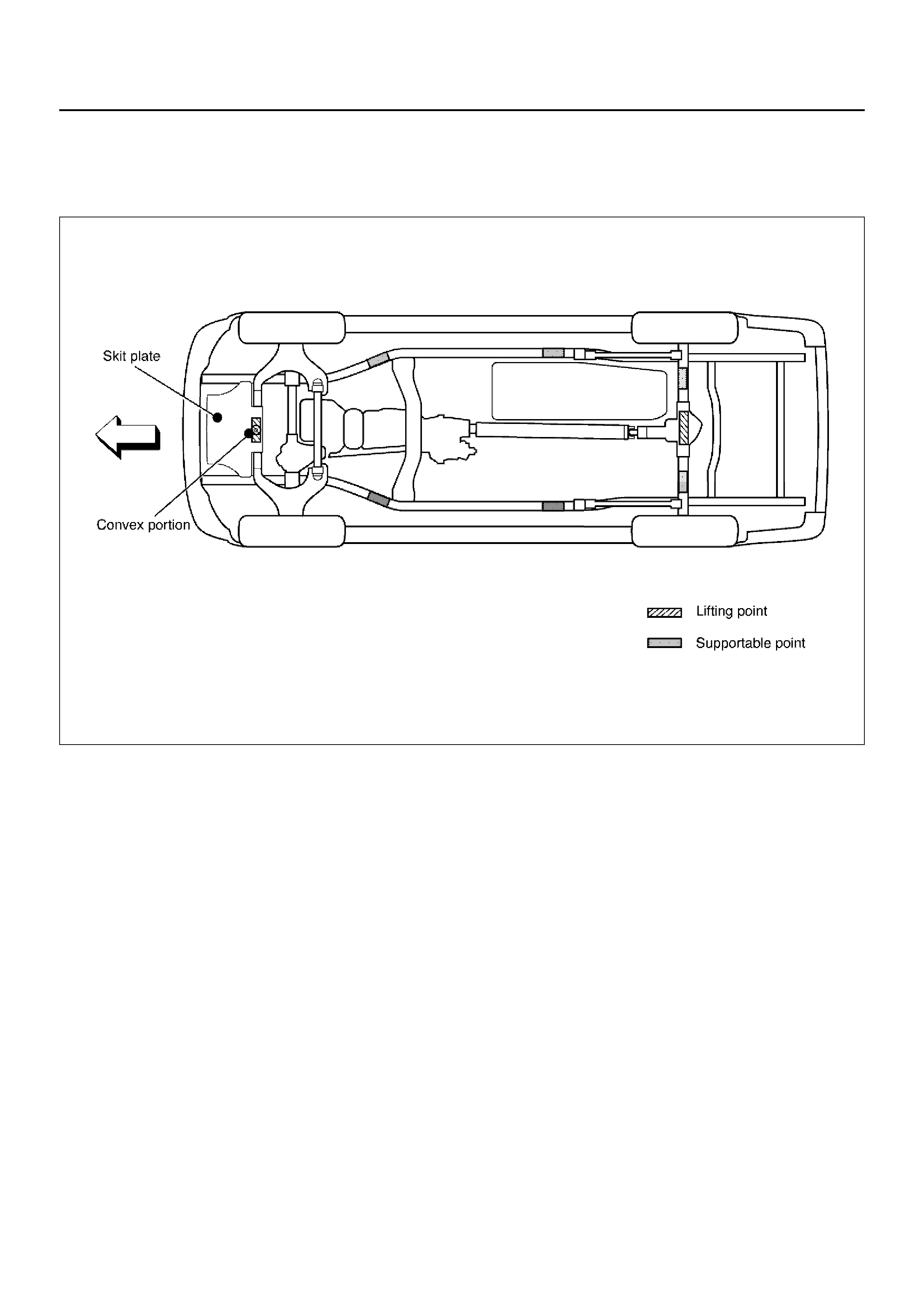

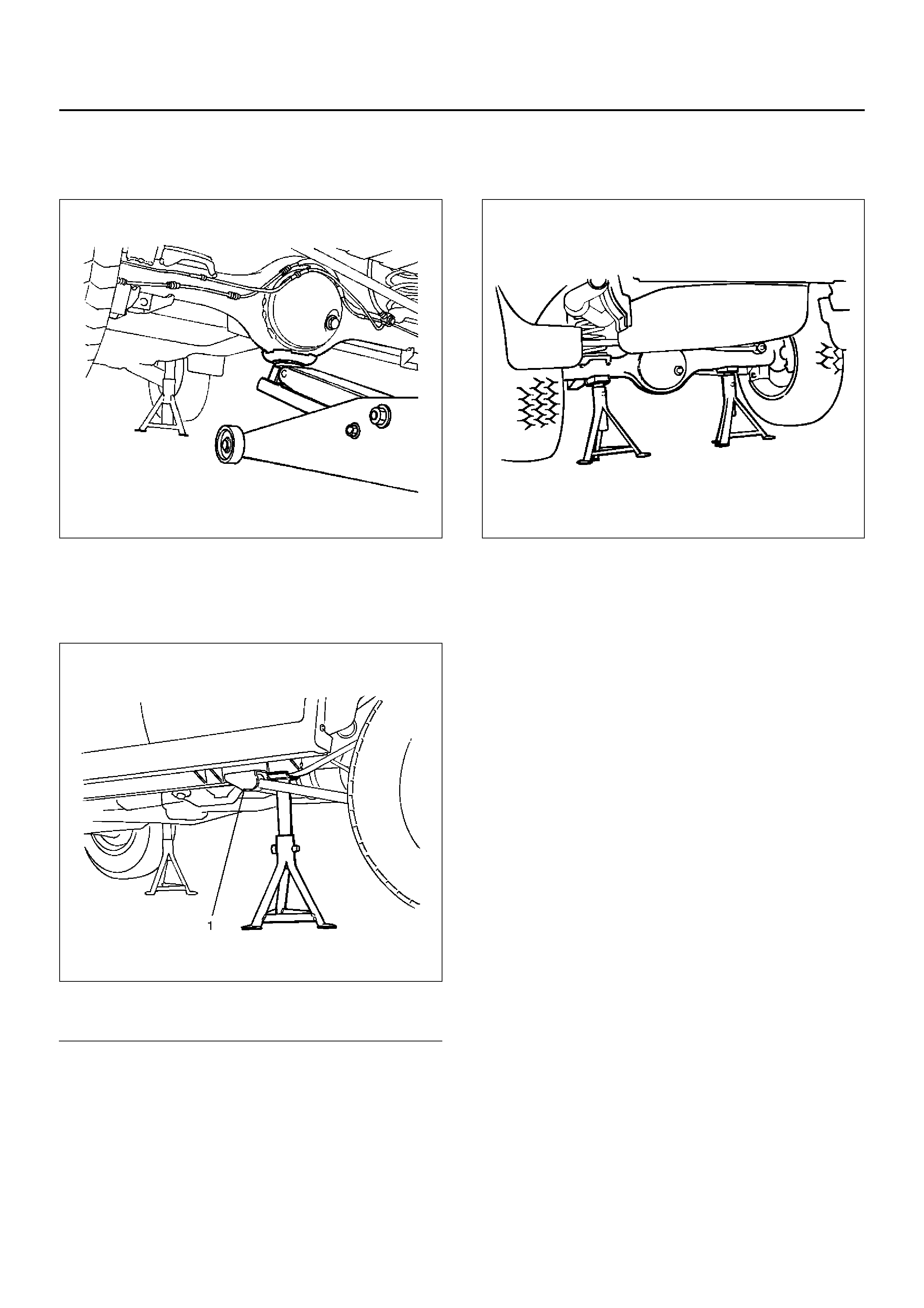

Lifting Instructions

Lifting Points and Supportable Point Locations

4 Door Model

C00RX002

2 Door Model

C00RX001

Lifting Point: Front

• When using a floor jack, lift on the Convex portion of

the skid plate.

545RS001

Supportable Point: Front

• P osition the chassis stands at the bottom of the frame

sidemember, behind the front wheel.

501RS003

Lifting Point: Rear

• Position the floor jack at the center of the rear axle

case when lifting the vehicle.

420RS002

Supportable Point: Rear

• P osition the chassis stands at the bottom of the frame

sidemember, just behind the trailing link bracket.

501RW002

Legend

EndOFCallout

Supportable Point: Rear

• Position the chassis stands at the bottom of the rear

axle case.

420RS001

(1) Trailing Link Bracket

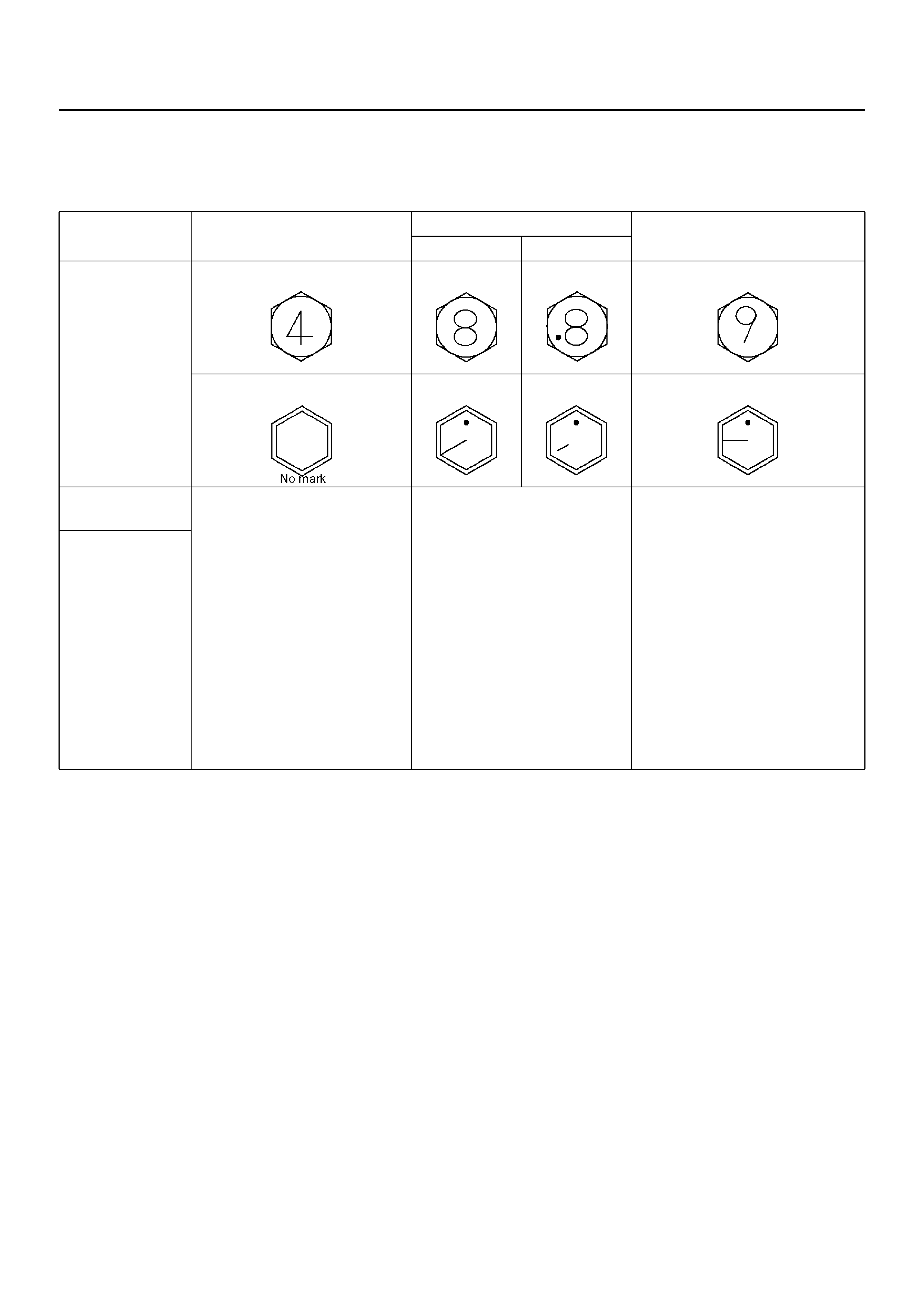

Standard Bolts Torque Specifications

The torque values given in the following table should be

applied where a particular torque is not specified.

The asterisk * indicates that the bolts are used for

female–threaded parts that are made of soft materials

such as casting, etc.

Strength Class 4.8 8.8 9.8

Refined Non-Refined

Bolt

Identification

Bolt Diameter ×

××

×

Pitch (mm)

M 6X1.0

M 8X1.25

M 10X1.25

* M10X1.5

M12X1.25

* M12X1.75

M14X1.5

* M14X2.0

M16X1.5

* M16X2.0

M18X1.5

M20X1.5

M22X1.5

M24X2.0

4 – 8 N·m (3 – 6 lb ft)

8 – 18 N·m (6 – 13 lb ft)

21 – 34 N·m (15 – 25 lb ft)

20 – 33 N·m (14 – 25 lb ft)

49 – 74 N·m (36 – 54 lb ft)

45 – 69 N·m (33 – 51 lb ft)

77 – 115 N·m (56 – 85 lb ft)

72 – 107 N·m (53 – 79 lb ft)

104 – 157 N·m (77 – 116 lb ft)

100 – 149 N·m (74 – 110 lb ft)

151 – 226 N·m (111 – 166 lb ft)

206 – 310 N·m (152 – 229 lb ft)

251 – 414 N·m (185 – 305 lb ft)

359 – 539 N·m (265 – 398 lb ft)

5 – 10 N·m (4 – 7 lb ft)

12 – 23 N·m (9 – 17 lb ft)

28 – 46 N·m (20 – 34 lb ft)

28 – 45 N·m (20 – 33 lb ft)

61 – 91 N·m (45 – 67 lb ft)

57 – 84 N·m (42 – 62 lb ft)

93 – 139 N·m (69 – 103 lb ft)

88 – 131 N·m (65 – 97 lb ft)

135 – 204 N·m (100 – 150 lb ft)

130 – 194 N·m (95 – 143 lb ft)

195 – 293 N·m (144 – 216 lb ft)

270 – 405 N·m (199 – 299 lb ft)

363 – 544 N·m (268 – 401 lb ft)

431 – 711 N·m (318 – 524 lb ft)

–

17 – 30 N·m (12 – 22 lb ft)

37 – 63 N·m (27 – 46 lb ft)

36 – 60 N·m (27 – 44 lb ft)

76 – 114 N·m (56 – 84 lb ft)

72 – 107 N·m (53 – 79 lb ft)

114 – 171 N·m (84 – 126 lb ft)

107 – 160 N·m (79 – 118 lb ft)

160 – 240 N·m (118 – 177 lb ft)

153 – 230 N·m (113 – 169 lb ft)

230 – 345 N·m (169 – 255 lb ft)

317 – 476 N·m (234 – 351 lb ft)

425 – 637 N·m (313 – 469 lb ft)

554 – 831 N·m (409 – 613 lb ft)

Abbreviations Charts

List of automotive abbreviations which ma y be used

in this manual

A — Ampere(s)

ABS — Antilock Brake System

AC — Alternating Current

A/C — Air Conditioning

ACCEL — Accelerator

ACC — Accessory

ACL — Air Cleaner

Adj — Adjust

A/F — Air Fuel Ratio

AIR — Secondary Air Injection System

Alt — Altitude

AMP — Ampere(s)

ANT — Antenna

ASM — Assembly

A/T — Automatic Transmissi on/Transaxle

ATDC — After Top Dead Center

ATF — A utomatic Transmission Fluid

Auth — Authority

Auto — Automatic

BARO — Barometric Pressure

Bat — Battery

B+ — Battery Positive Voltage

Bbl — Barrel

BHP — Brake Horsepower

BPT — Backpressure Transducer

BTDC — Before Top Dead Center

° C — Degrees Celsius

CAC — Charge Air Cooler

Calif — California

cc — Cubic Centimeter

CID — Cubic Inch Displacement

CKP — Crankshaft Position

CL — Closed Loop

CLCC — Closed Loop Carburetor Control

CMP — Camshaft Position

CO — Carbon Monoxide

Coax — Coaxial

Conn — Connector

Conv — Converter

Crank — Crankshaft

Cu. In. — Cubic Inch

CV — Constant Velocity

Cyl — Cylinder(s)

DI — Distributor Ignition

Diff — Differential

Dist — Distributor

DLC — Data Link Connector

DOHC — Double Overhead Camshaft

DTC — Diagnostic Trouble Code

DTM — Diagnostic Test Mode

DTT — Diagnostic Test Terminal

DVM — Digital Voltmeter (10 meg.)

DVOM — Digital Volt Ohmmeter

EBCM — Electronic Brake Control Module

ECM — Engine Contr ol Module

ECT — Engine Coolant Temperature

EEPROM — Electronically Erasable Programmable

Read Only Memory

EGR — Exhau st Ga s Rec irc ula tion

EI — Electronic Ignition

ETR — Electronically Tuned Receiver

EVAP — Evaporation Emission

Exh — Exhaust

° F — Degrees Fahrenheit

Fed — Federal (All States Except Calif.)

FF — Front Drive Front Engine

FL — Fusible Link

FLW — Fusible Link Wire

FP — Fuel Pump

FRT — Front

ft — Foot

FWD — Front Wheel Drive

4WD — Four Wheel Drive

4 x 4 — Four Wheel Drive

4 A/T — Four Speed Automatic Transmission/Transaxle

Gal — Gallon

GEN — Generator

GND — Ground

Gov — Governor

g — Gram

Harn — Har nes s

HC — Hydrocarbons

HD — Heavy Duty

Hg — Hydrargyrum (Mercury)

HiAlt — High Altitude

HO2S — Heated Oxygen Sensor

HVAC — Heater–Vent–Air–Conditioning

IAC — Idle Air Control

IAT — Intake Air Temperature

IC — Integrated Circuit / Ignition Control

ID — Identification / Inside Diameter

IGN — Ignition

INJ — Injection

IP — Instrument Panel

IPC — Instrument Panel Cluster

Int — Intake

ISC — Idle Speed Control

J/B — Junction Block

kg — Kilograms

km — Kilometers

km/h — Kilometer per Hour

kpa — Kilopascals

kV — Kilovolts (thousands of volts)

kW — Kilowatts

KS — Knock Sensor

L — Liter

lb ft — Foot Pounds

lb in — Inch Pounds

LF — Left Front

LH — Left Hand

LR — Left Rear

LS — Left Side

LWB — Long Wheel Base

L–4 — In–Line Four Cylinder Engine

MAF — Mass Air Flow

MAN — Manual

MAP — Manifold Absolute Pressure

Max — Maximum

MC — Mixture Control

MFI — Multiport Fuel Injection

MIL — Malfunction Indicator Lamp

Min — Minim um

mm — Millimete r

MPG — Miles Per Gallon

MPH — Miles Per Hour

M/T — Manual Transmission/Transaxle

MV — Millivolt

N — Newtons

NA — Natural Aspirated

NC — Norm ally Closed

N·M — Newton Meters

NO — Normally Open

NOX — Nitrogen, Oxides of

OBD — On-Board Diagnostic

OD — Outside Diameter

O/D — Over Drive

OHC — Overhe ad Camshaft

OL — Open Loo p

O2 — Oxygen

O2S — Oxygen Sensor

PAIR — Pulsed Secondary Air Injection System

P/B — Power Brakes

PCM — Powertrain Control Module

PCV — Positive Crankcase Ventilation

PRESS — Pressure

PROM — Programmable Read Only Memory

PNP — Park/Neutral Position

P/S — Power Steering

PSI — Pounds per Square Inch

PSP — Power Steering Pressure

Pt. — Pint

Pri — Primary

PWM — Pulse Width Modulate

Qt. — Quart

REF — Reference

RF — Right Front

RFI — Radio Frequency Interference

RH — Right Hand

RPM — Revolutions Per Minute

RPM Sensor — Engine Speed Sensor

RPO — Regular Production Option

RR — Right Rear

RS — Right Side

RTV — Room Temperature Vulcanizing

RWAL — Rear Wheel Antilock Brake

RWD — Rear Wheel Drive

SAE — Society of Automotive Engineers

Sec — Secondary

SFI — Sequential Multiport Fuel Injection

SI — System International

SIR — Supplemental Inflatable Restraint System

SOHC — Single Overhead Camshaft

Sol — Solenoid

SPEC — Specif ic ati on

Speedo — Speedometer

SRS — Supplemental Restraint System

ST — Start / Scan Tool

Sw — Sw itch

SWB — Short Wheel Base

SYN — Synchronize

Tach — Tachometer

TB — Throttle Body

TBI — Throttle Body Fuel Injection

TCC — Torque Converter Clutch

TCM — Transmission Control Module

TDC — Top Dead Center

Term — Terminal

TEMP — Temperature

TOD— Torque On Demand

TP — Throttle Position

TRANS — Transmission/ Transaxle

TURBO — Turbocharger

TVRS — Television & Radio Suppression

TVV — Thermal Vacuum Valve

TWC — Three Way Catalytic Converter

3 A/T — Three Speed Automati c Transmission/

Transaxle

2WD — Two Wheel Drive

4 x 2 — Two Wheel Drive

U–joint — Universal Joint

V — Volt(s)

VA C — Vacuum

VIN — Vehicle Identification Number

VRRRE — Vehicle Refrigerant Recov ery and Recycling

Equipment

V–ref — ECM Refe rence Voltage

VSS — Vehicle Speed Sensor

VSV — Vacuum Switch Valve

V–6 — Six Cylinder “V" Engine

V–8 — Eight Cylinder "V" Engine

W — W att(s)

w/ — With

w/b — Wheel Base

w/o — Wit hout

WOT — Wide Open Throttle

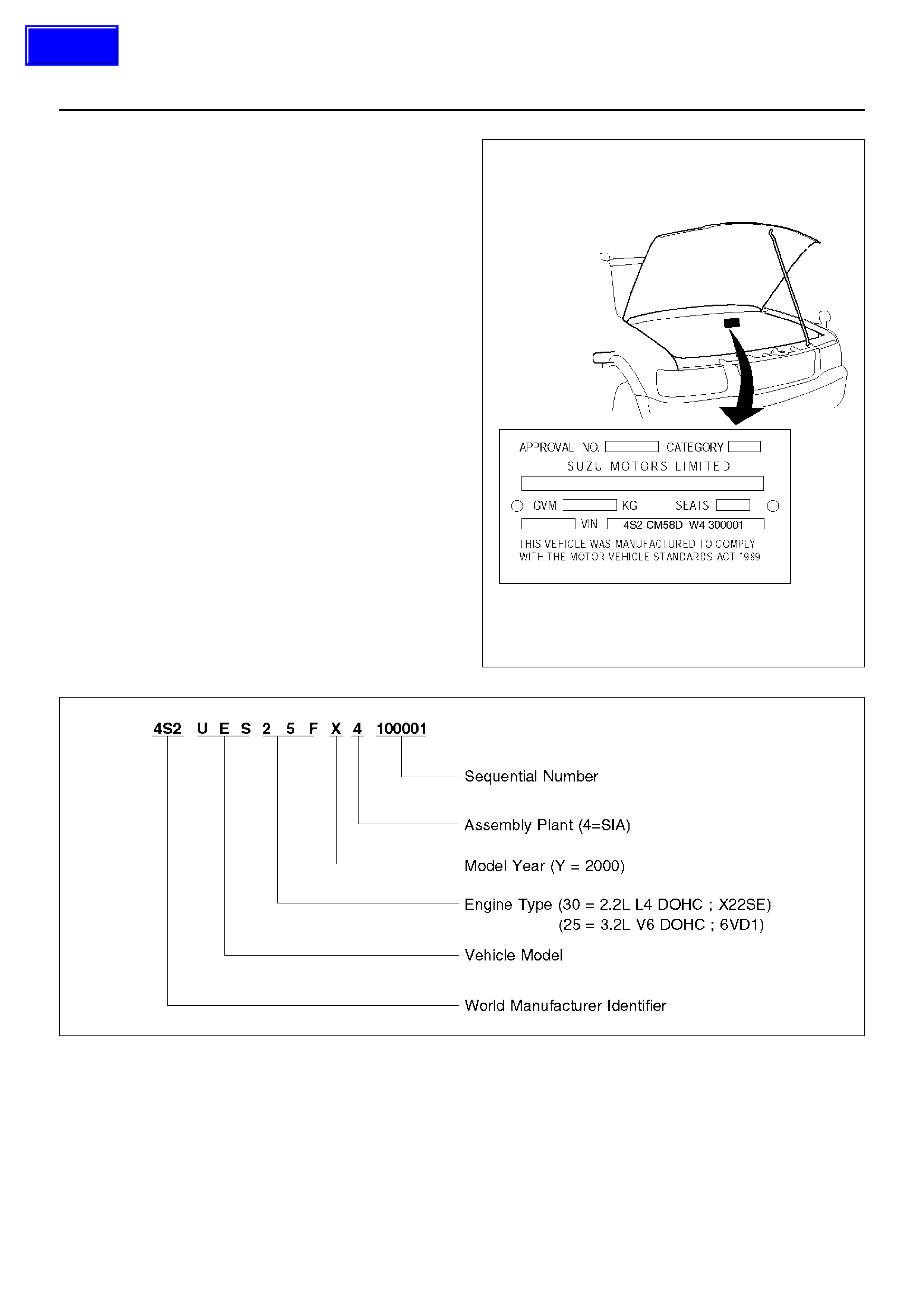

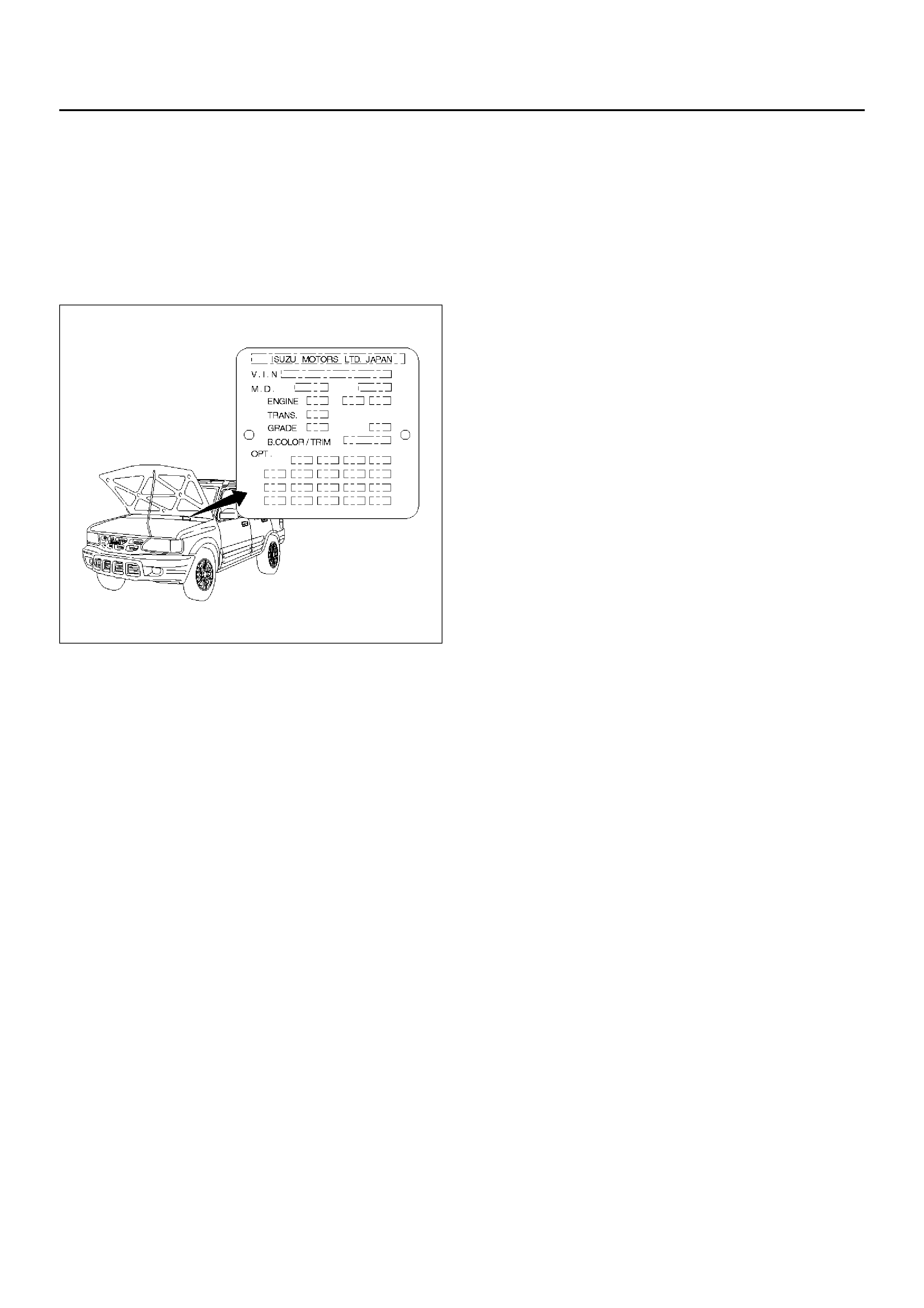

Service Parts Identification Plate

The Vehicle Information Plate (Service Parts ID plate) is

provided on all vehicle models.

It is located on the center dash wall inside the engine

compartment. The plate lists the VIN (Vehicle

Identification Number), paint information and all

production options and special equipment on the

vehicle when it was shipped from the factory.

905RY00010