SECTION 0B - MAINTENANCE AND LUBRICATION

Maintenance Schedule List

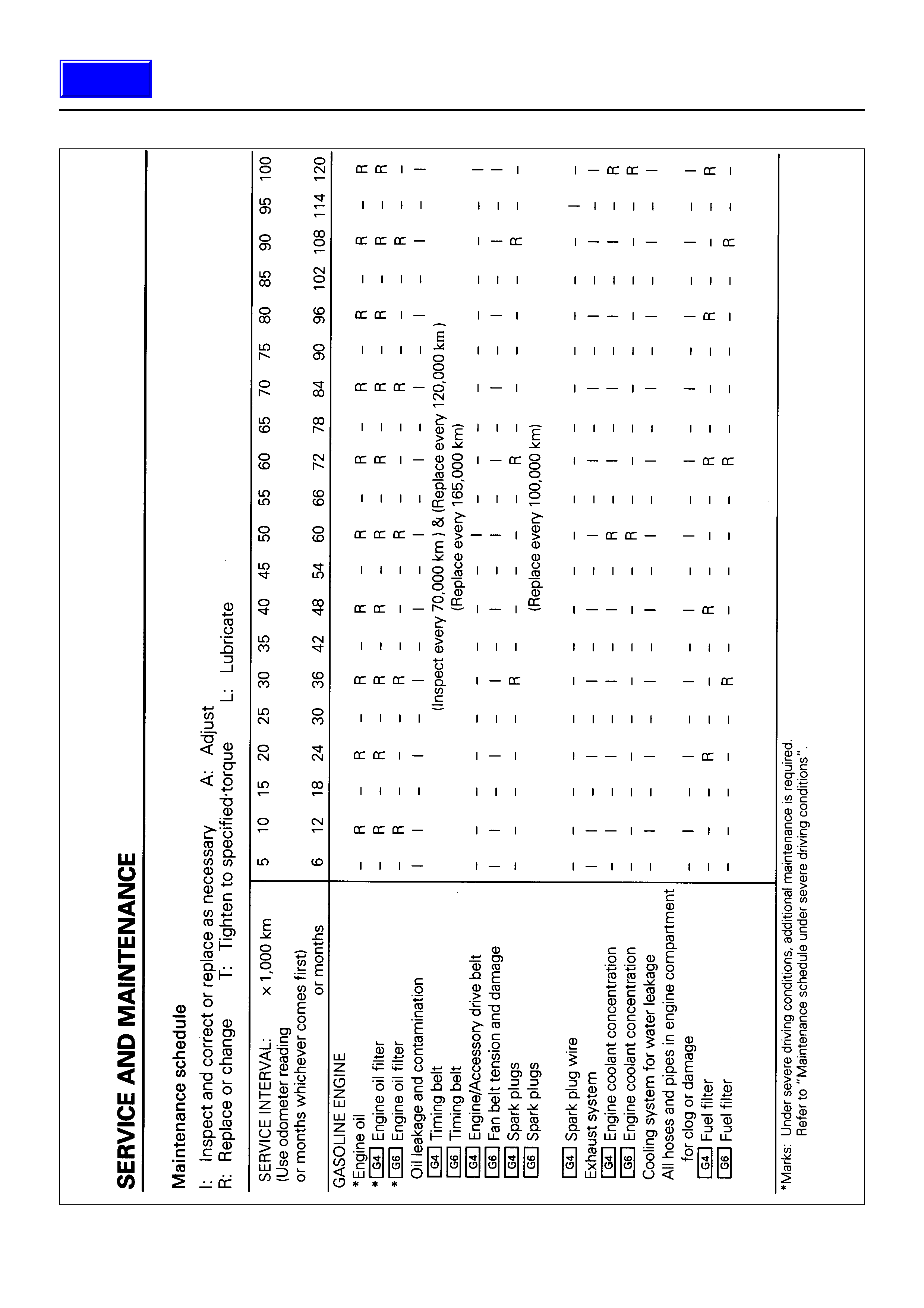

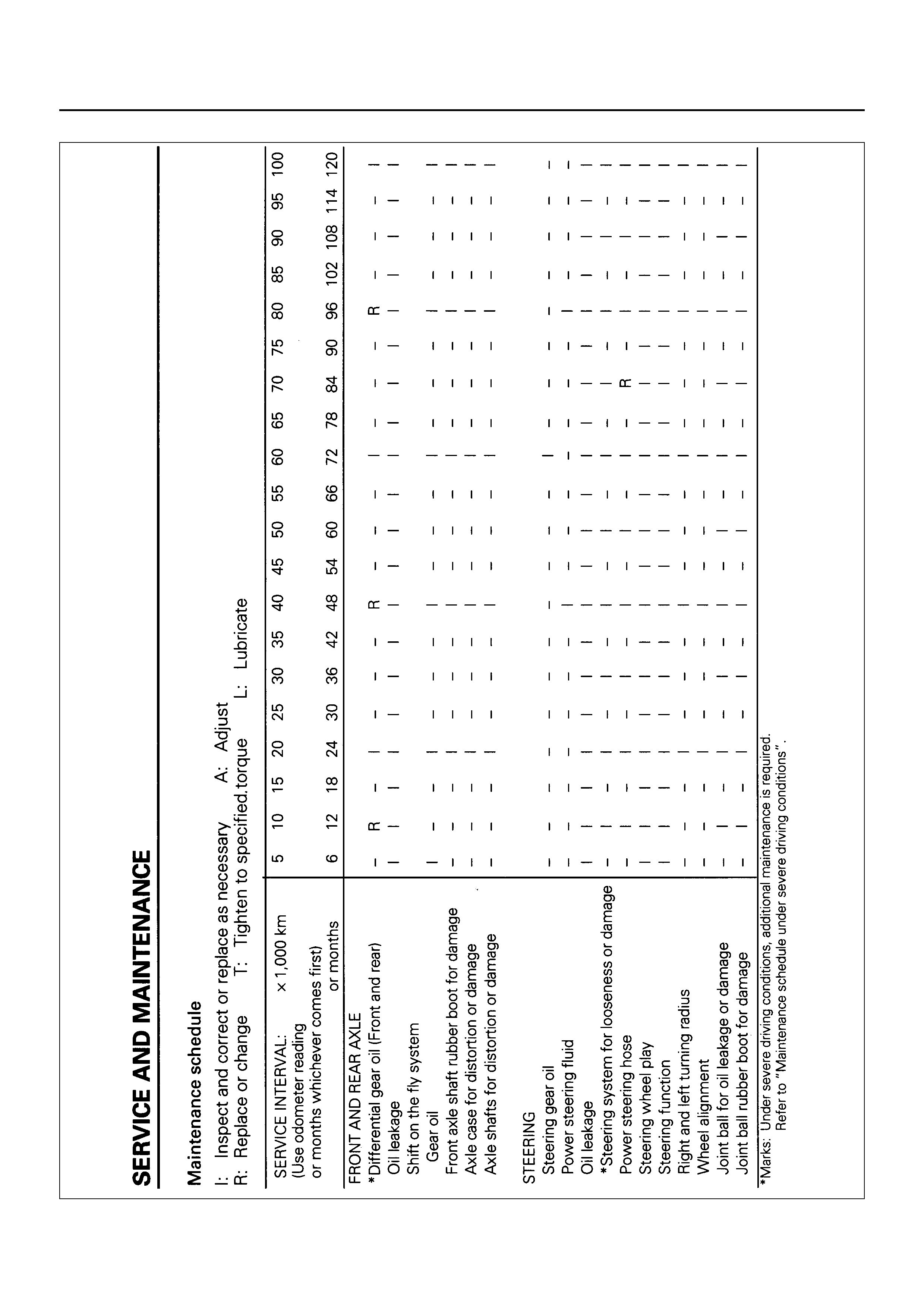

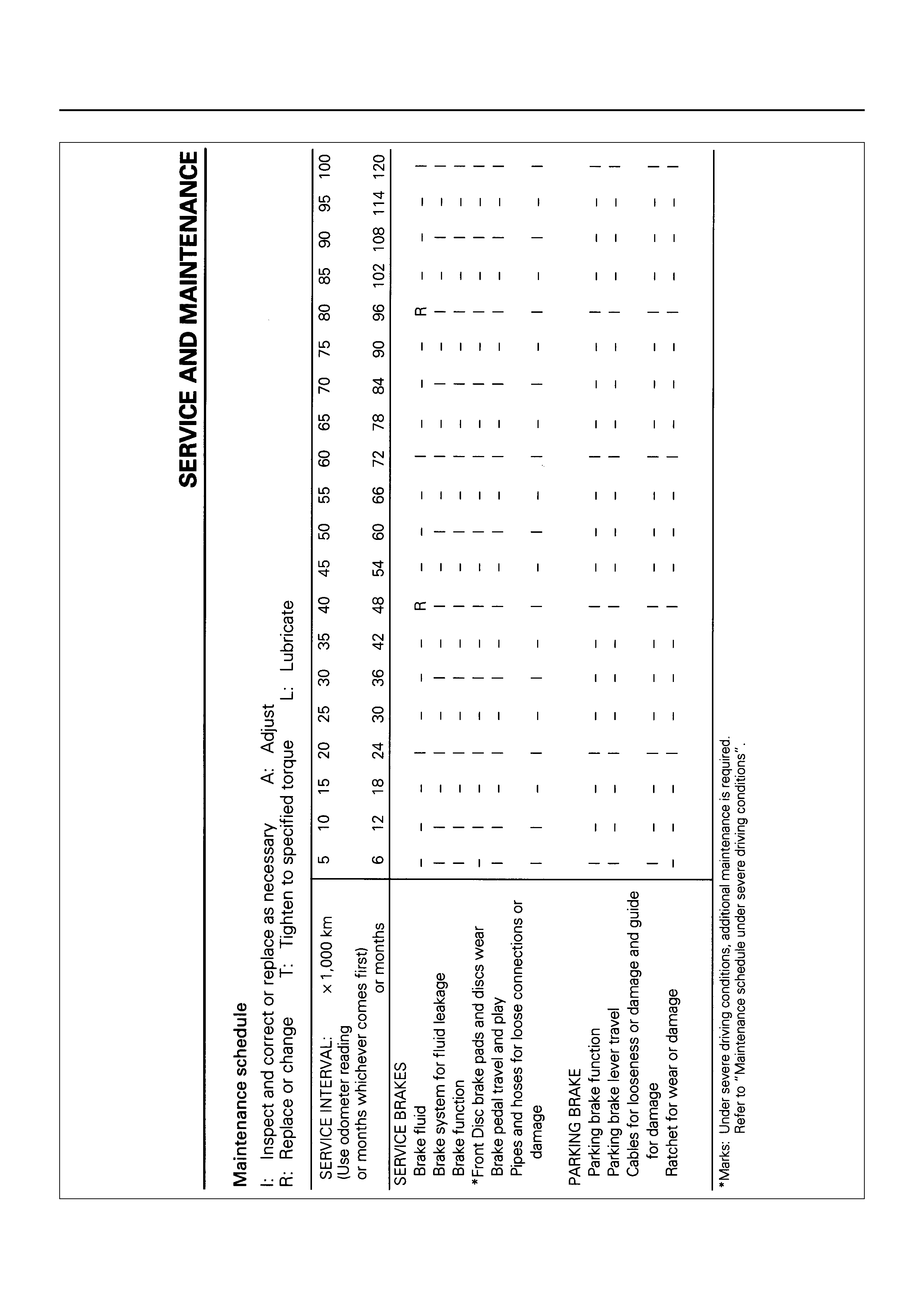

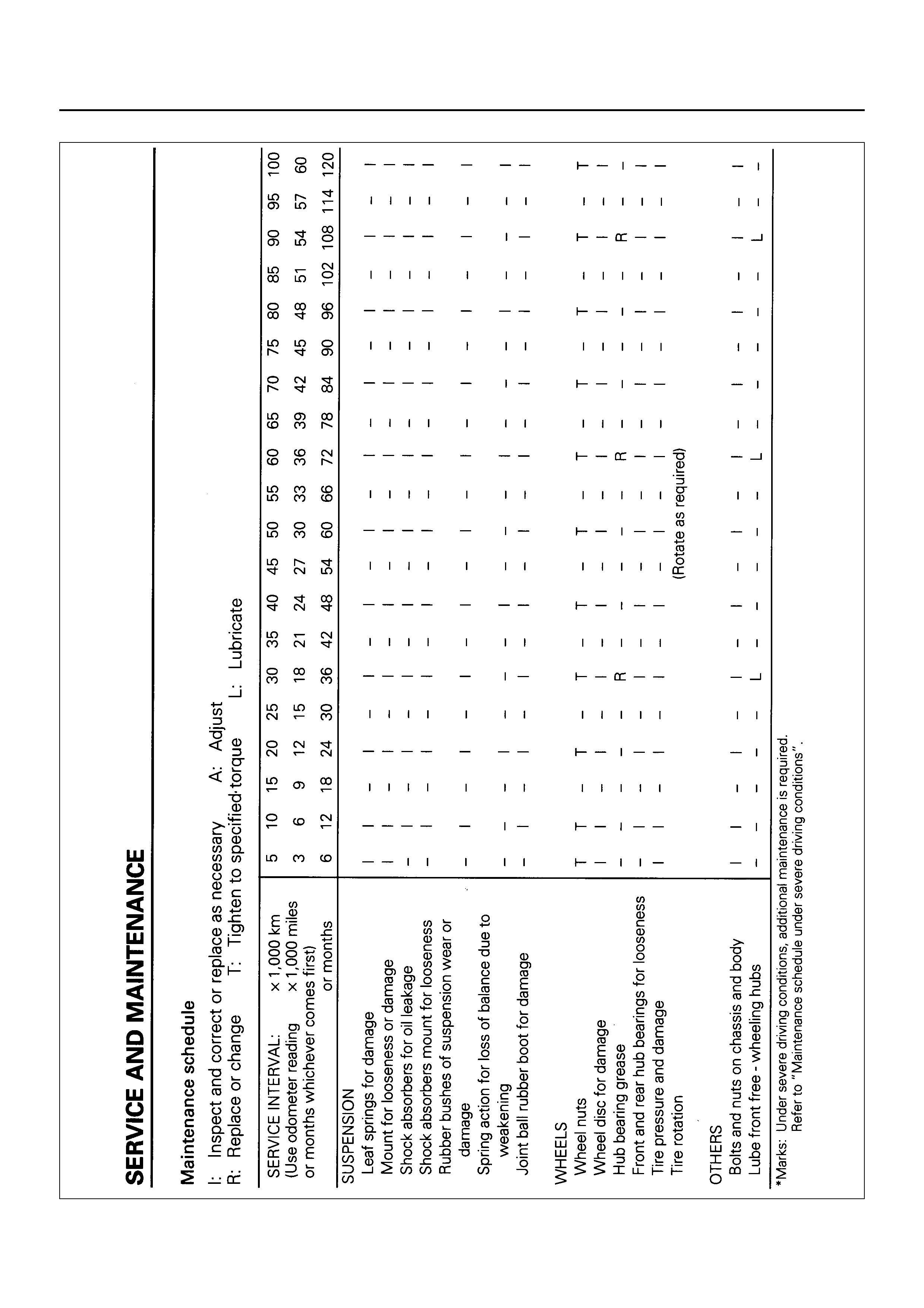

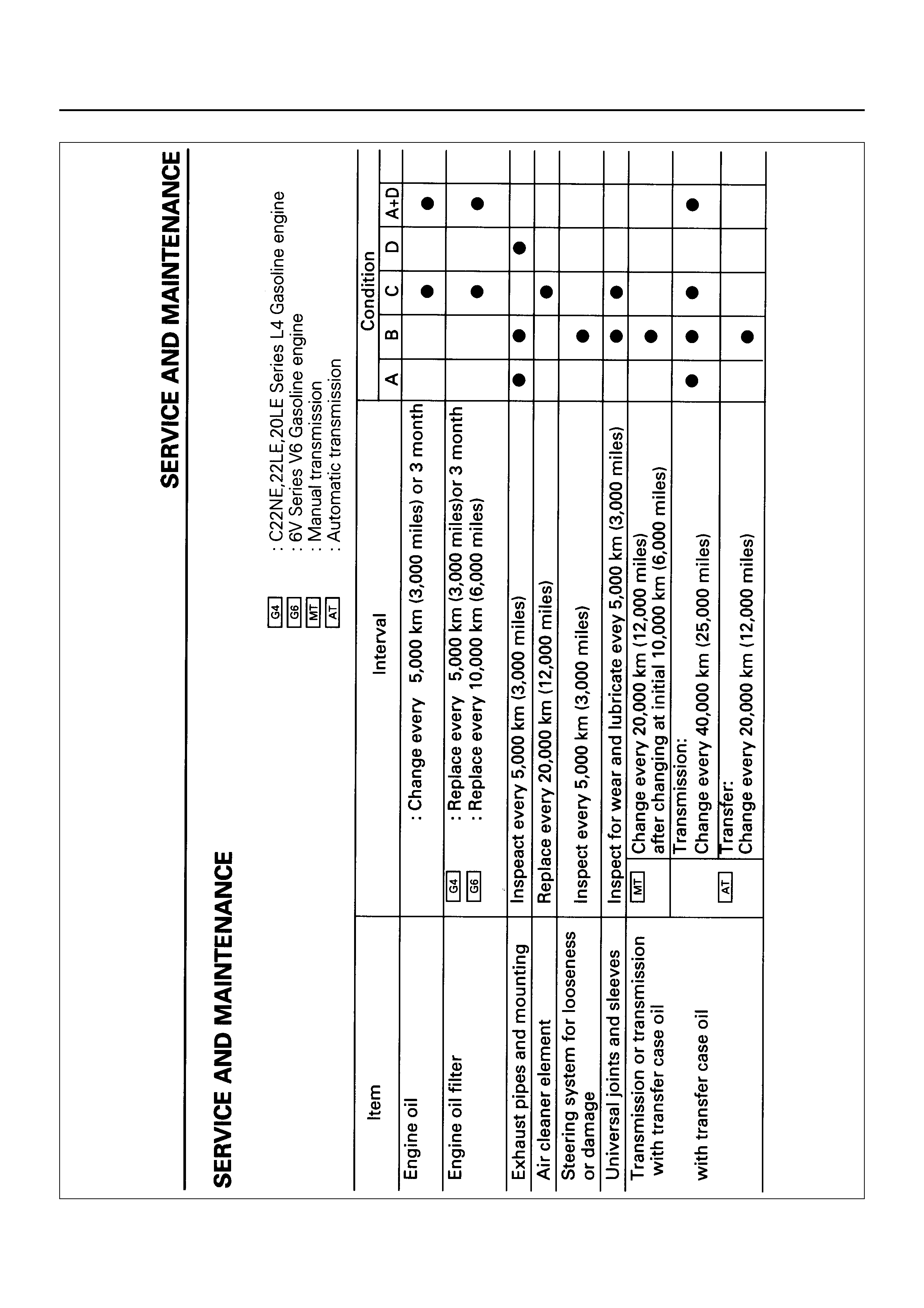

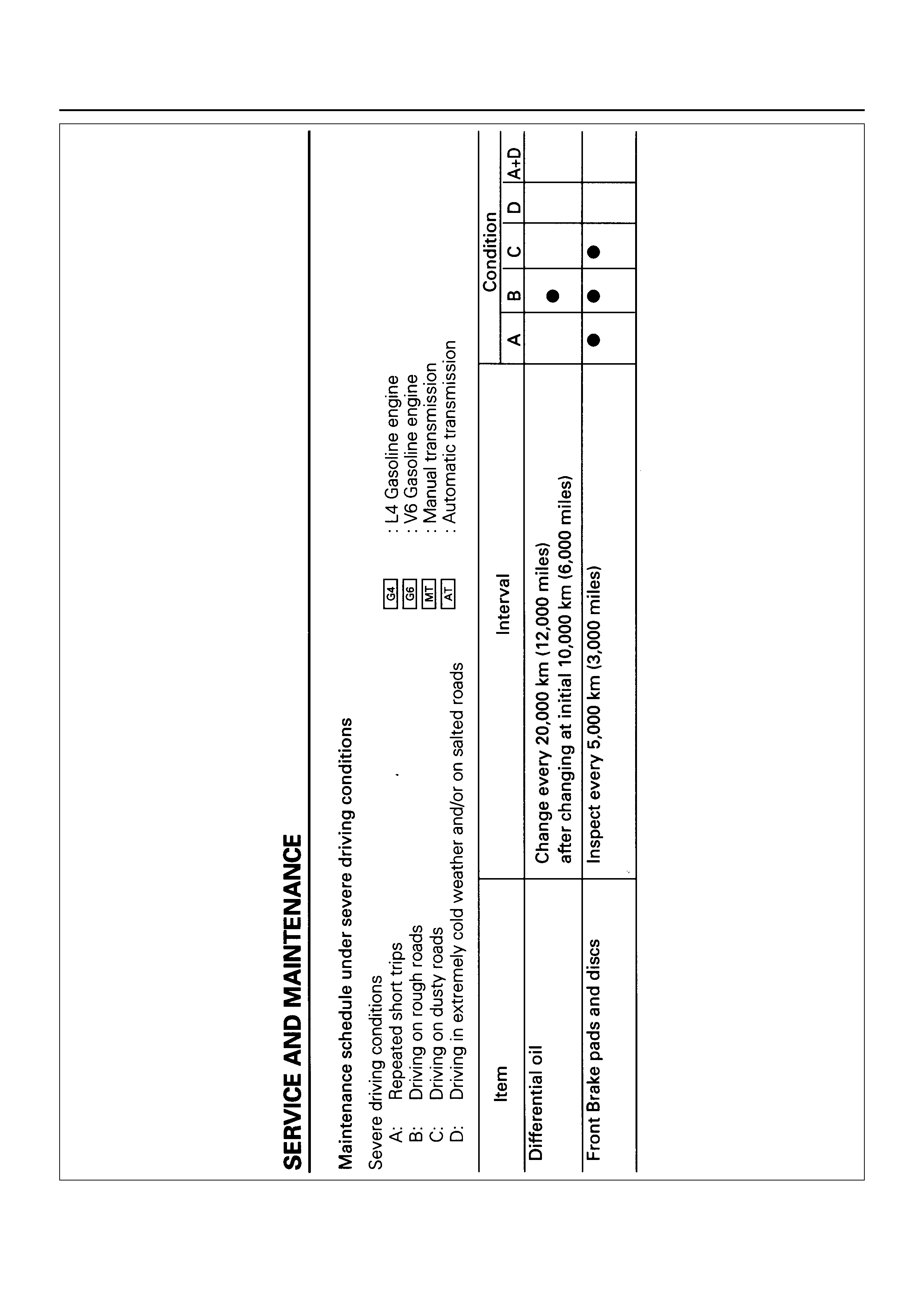

Service and Maintenance

Recommended Fluids and Lubricants

Lubricant Viscosity Chart

Recommended Liquid Gasket

Recommended Thread Locking Agents

Maintenance Service Data

Maintenance Schedule List

Normal Vehicle Use

The maintenance instructions in this Maintenance

Schedule are based on the assumption that the vehicle

will be used as designed:

• to carry passengers and cargo within the limitations

specified on the tire placard located on the inside of

the glove compartment door;

• to be driven on reasonable road surfaces within legal

operating li mit s;

• to be driven on a daily basis, as a general rule, for at

least several miles/kilometers;

• to be driven on unleaded fuel

Unusual or sev ere operating conditions will require more

frequent vehicle maintenance, as specified in the

following sections.

Techline

Recommended Fluids and Lubricants

USAGE FLUID/LUBRICANT

Engine API SE, SF, SG, SH or ILSAC GF-1 Engine oil (See oil

chart on the following page for proper viscosity)

Engine coolant Mixture of water and good quality ethylene glycol base

type antifreeze.

Brake system DOT-3 hydraulic brake fluid.

Power steering system DEXRON® -III Automatic transmission fluid.

A utomatic transmission DEXRON® -III Automatic transmission fluid.

MUA Type Manual transmission & Transfer case Engine oil

(See oil chart on following page for proper viscosity)

Rear axle and front axle GL-5 gear lub r ic ant (Sta ndard dif ferential)

GL-5 Limited slip differential gear lubricant together with

limited slip differential lubricant additive (Part No.

8-01052-358-0) or equivalent (If equipped with optional

limited slip differential) (See oil chart in this section for

proper visco sity)

Clutch system

a. Pivot points Chassi s grease

b. Clutch fork joint Chassis grease

c. Master cylinder DOT-3 hydraulic brake fluid

Hood latch assembly

a. Pivots and spring anchor Engine oil

b. Release pawl Chassis grease

Hood and door hinges Engine oil

Chassi s lubricati on Chas sis grease

Parkin g brake cables Chassi s grease

Front wheel bearings Multipurpose grease

Shift on the fly system GL-5 gear lubricant (SAE 75W-90)

Body door hinge pins and linkage, fuel door hinge, rear

compartment lid hinges Engine oil

Windshield washer solvent Washer fluid

Key lock cylinder Synthetic light weight engine oil (SAE 5W-30)

Accelerator linkage Chassis grease

Techline

Techline

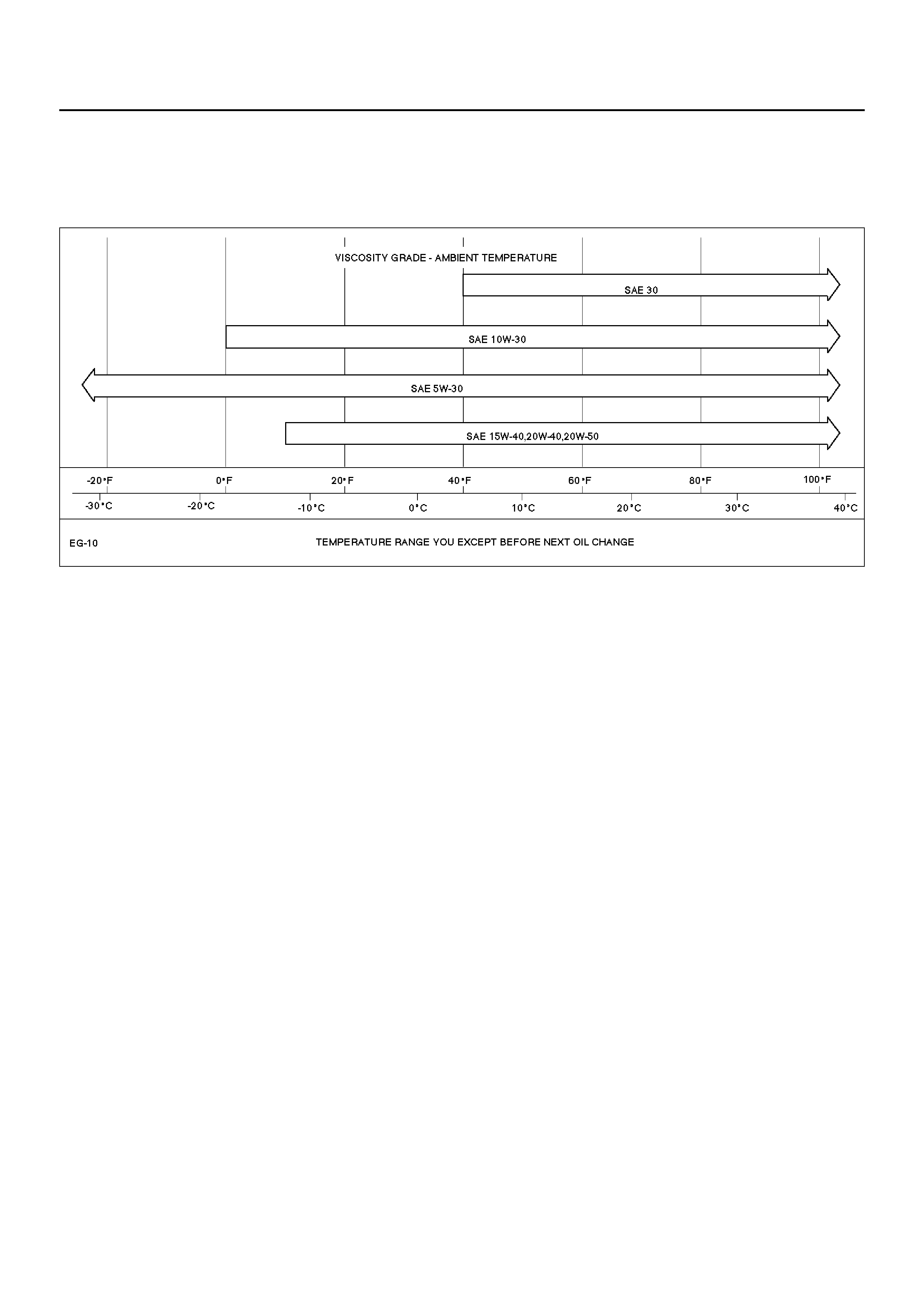

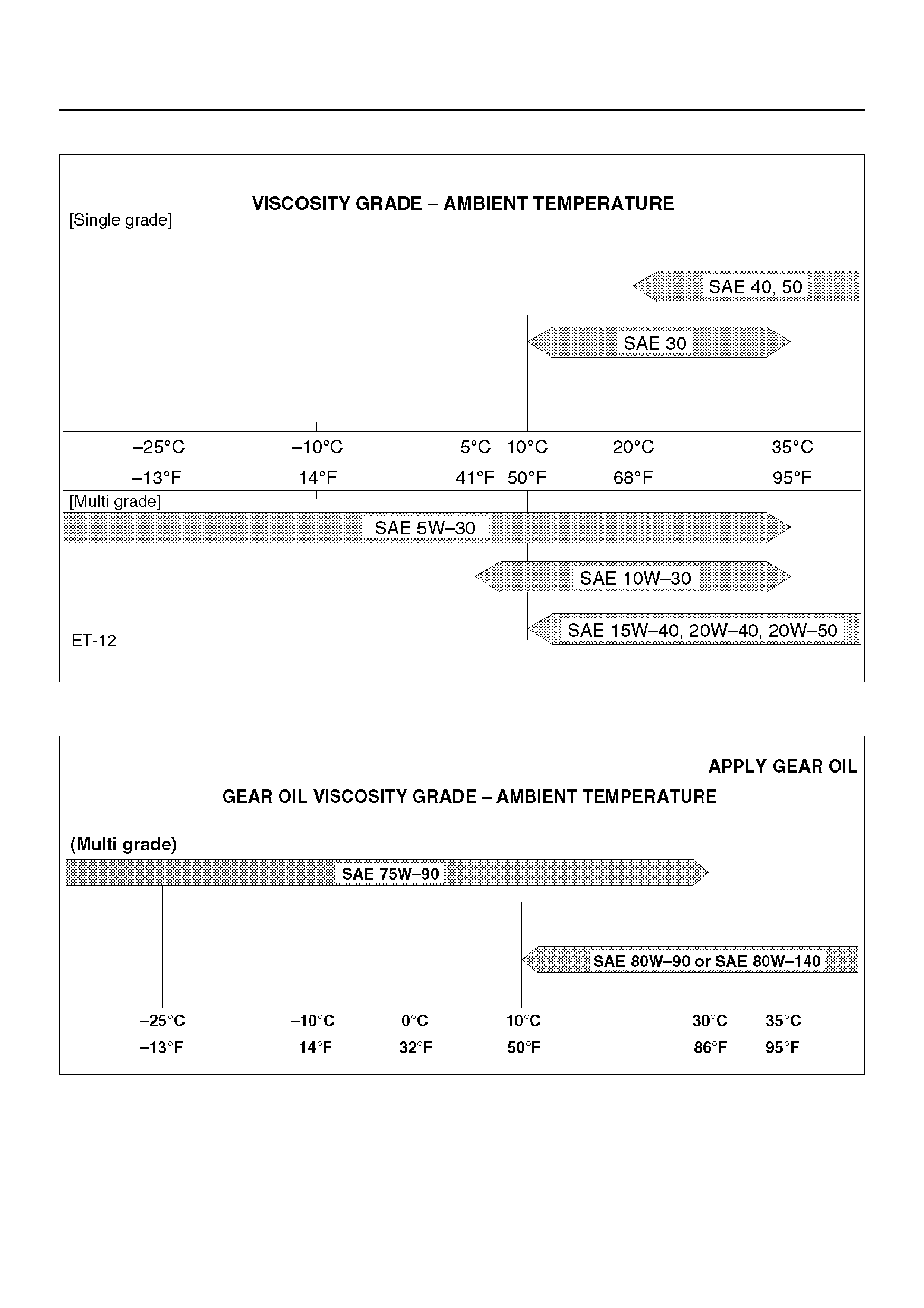

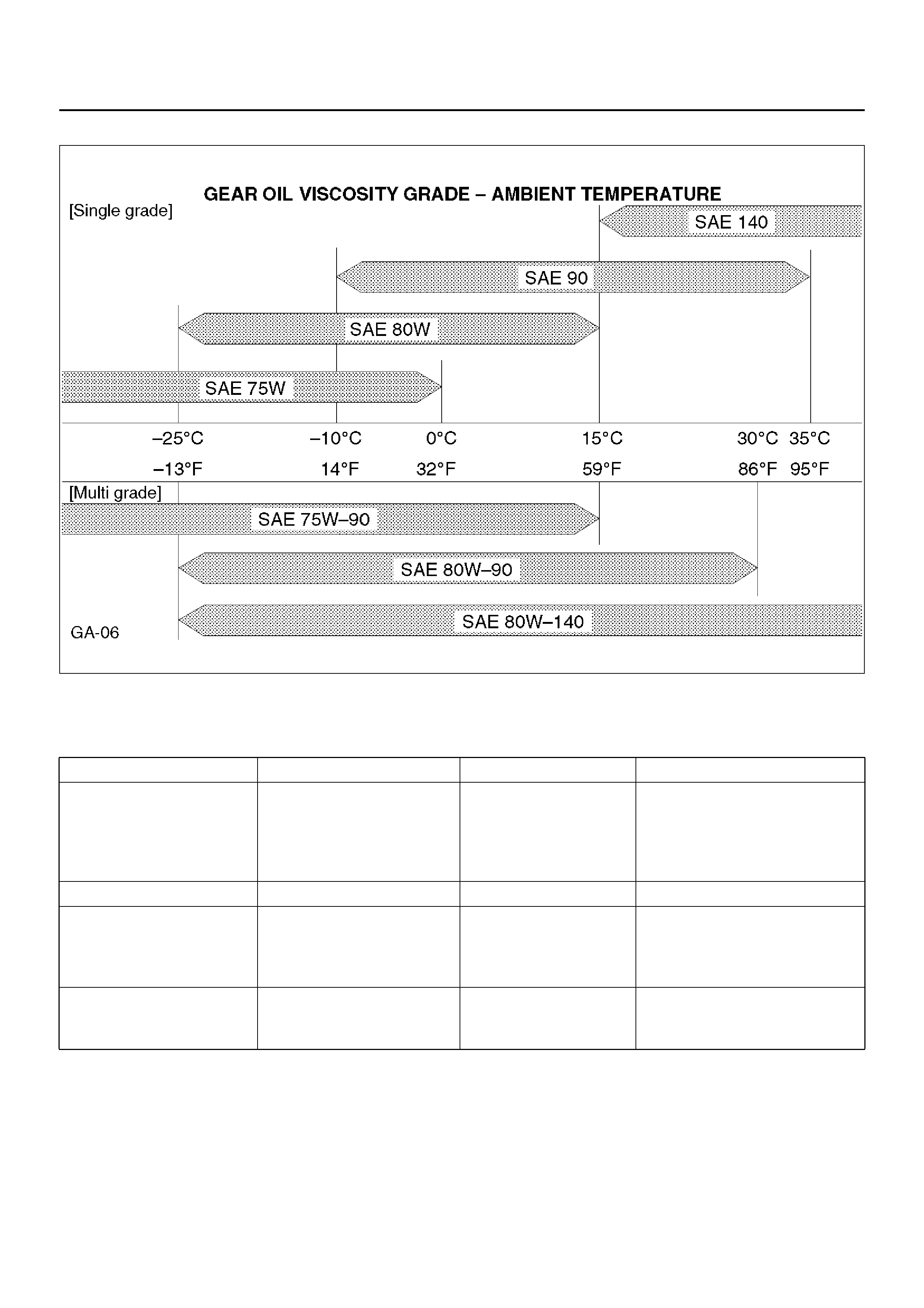

Lubricant Viscosity Chart

Lubricants should be carefully selected according to the

lubrication chart. It is also important to select viscosity

of lubricants according to the ambient temperature by

refe rring to the following table.

Oil Viscosity Chart for Gasoline Engine

905RT011

Oil Viscosity Chart for Manual Transmission and Transfer Case

B00RW002

Oil Viscosity Chart for Front Axle

B00RW003

Oil Viscosty Chart for Rear Axle

B00RW004

Recommended Liquid Gasket

* RTV: Room Temperature Vulcanizer

NOTE:

1. It is very important that the liquid gaskets listed

above or their exact equiv alent be used on the

vehicle.

2. Be careful to use the specified amount of liquid

gasket.

Follow the manufacturer's instructions at all times.

3. Be absolutely sure to remove all lubricants and

moisture from the connecting surf aces before

applying the liquid gasket.

The connecting surfaces must be perfectly dry.

4. Do not apply LOCTITE 17430, LOCTITE 515 and

LOCTITE 518 between two metal surfaces having a

clearance of greater than 0.25 mm (0.01 in). Poor

adhesion will result.

Type Brand Name Manufacturer Remarks

RTV*

Silicon Base

Three Bond 1207B

Three Bond 1207C

Three Bond 1215

Three Bond 1280

Three Bond 1281

Three Bond

Three Bond

Three Bond

Three Bond

Three Bond

For Engine Repairs

For Axle Case

Repairs T/M

Repairs T/M

Water Base Three Bond 1141E Three Bond For Engine Repairs

Solvent

Three Bond 1104

Belco Bond 4

Belco Bond 401

Belco Bond 402

Three Bond

Isuzu

Isuzu

Isuzu

For Engine Repairs

Anaerobic LOCTITE 515

LOCTITE 518

LOCTITE 17430

Loctite

Loctite

Loctite All

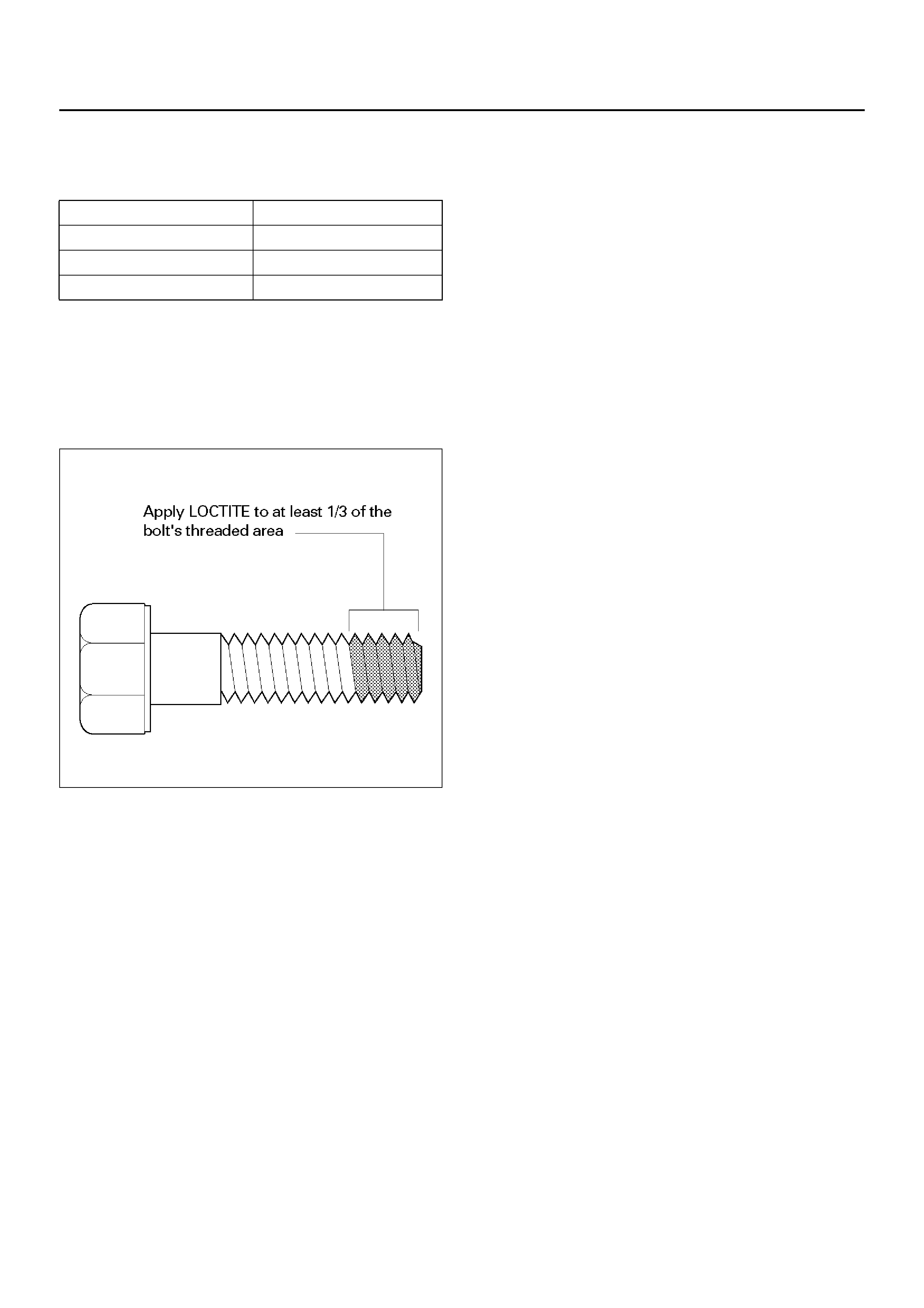

Recommended Thread Locking

Agents

Application Steps

1. Completely remove all lubricant and moisture from

the bolts and the f emale-threaded surfaces of the

parts to be joined.

The surfaces must be perfectly dry.

2. Apply LOCTITE to the bolts.

F00RW014

3. Tighten the bolts to the specified torque.

After tightening, be sure to keep the bolts free from

vibration and torque for at least an hour until

LOCTITE hardens.

NOTE: When the application procedures are specified

in this manual, f ollow them.

LOCTITE Type LOCTITE Color

LOCTIT E 242 Blue

LOCTITE 262 Red

LOCTITE 271 Red

Maintenance Service Data

Service Data and Specifications

* Unless otherwise specified on tire information label on the vehicle.

Approximate Capacities

*Crankcase capacities shown are approximate refill capacities. After refill, recheck oil level.

ENGINE Valve clearance (cold): only V6-3.2L ENG Intake 0.28±0.05 mm (0.011±0. 002 in)

Exhaust 0.3±0.05 mm (0.012±0.002 in)

Spark plug type K16PR-P11/PK16PR11/RC10PYP4

Spark plug gap 1.05 mm (0.04 in)

CLUTCH Clutch pedal free play 5-15 mm (0.20-0.59 in)

BRAKE Brake pedal free play 6-10 mm (0.24-0.39 in)

Parking brake travel 6-7 notches

WHEEL ALIGNMENT Toe-in (Front) 0±2 mm (0±0.08 in)

Toe-in (Rear) 0±5 mm (0±0.2 in)

Camber (Front) 0°±30'

Ca mb e r (R ear) 0°±1°

Caster (Front) 2° 30'±45'

Toe–Axis (Rear) ±1°

PROPELLER SHAFT Flange torque 63 N·m (46 lbft)

WHEEL AND TIRES Size 235/75R15

Wheel nut torque 118 N·m (87 lbft)

Tire inflation pressure (Front) 200 kpa (29 psi) 180 kpa

* Tire inflation pressure (Rear) 200 kpa (29 psi) 180 kpa

Items Metric Measure U.S. Measure

Fuel tank 80 L 21.1 Gal.

* Crankcase (V6–3.2L ENGINE) Oil Change with Filter 4.7 L 5.0 Qt

Oil Change without Filter 4.0 L 4.2 Qt

* Crankcase ( L4–2.2L ENGI NE) Oil Change wi th Filter 4.5 L 4.8 Qt

Oil Change without Filter 4.2 L 4.4 Qt

Coolant M/T (V6–3.2L ENG) 11.0 L 11.6 Qt

M/T (L4–2.2L ENG) 6.9 L 7.3 Qt

A/T 11.1 L 11.7 Qt

Transmission Manual (V6–3.2L ENG) 2.95 L 3.1 Qt

Manual (L4–2.2L ENG) 2.13 L 2.25 Qt

A utomatic 8.6 L 9.1 Qt

Transfer 1.45 L 1.5 Qt

Axle Rear 1.77 L 1.87 Qt

Front 1.25 L 1.33 Qt

Shift on the fly system 0.12 L 0.13 Qt

Power steering 1.0 L 1.1 Qt

Air conditioning (R-134a) 0.6 L 1.32 Qt