SECTION 4A2 - DIFFERENTIAL (REAR)

Service Precaution

General Description

Diagnosis

Axle Housing

Axle Housing and Associated Parts

Removal

Installation

Axle Shaft, Oil Seal and Bearing

Axle Shaft and Associated Parts

Removal

Inspection

Installation

Pinion Oil Seal

Pinion Oil Seal and Associated Parts

Removal

Inspection and Repair

Installation

Differential Assembly

Disassembled View

Inspecting the Axle Before Disassembly

Disassembly

Inspection and Repair

Reassembly

Side Bearing Preload Adjustment

Pinion Installation

Determination of Backlash

& Preload Shims

Backlash Adjustment

Gear Tooth Pattern Check

Adjustments Affecting Tooth Contact

Differential Case Assembly

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Limited Slip Differential Assembly

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data And Specifications

Special Tools

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM(SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE REFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFOMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or

other corrosion inhibitors) on threade d fasteners or

fastener joint interfaces. Generally,such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener.

When you install fasteners, use the correct

tightening sequence and specification. Following

these instructions can help you avoid damage to

parts and systems.

Techline

Techline

General Description

The rear axle assembly is of the semi–floating type in

which the v ehicle weight is carried on the axle housing .

The center line of the pinion gear is below the center

line of the ring gear (hypoid drive).

All parts necessary to transmit power from the propeller

shaft to the rear wheels are enclosed in a salisbury type

axle housing (a carrier casting with tubes pressed and

welded into the carrier). A removable aluminum cover

at the rear of the axle housing permits rear axle service

without removal of the entire assembly from the vehicle.

The 8.9 inch ring gear rear axle uses a conventional ring

and pinion gear set to transmit the driving f orce of the

engine to the rear wheels. This gear set transfers this

driving force at a 90 degree angle from the propeller

shaft to the drive shafts.

The axle shafts are supported at the wheel end of the

shaft by a roller bearing.

The pinion gear is supported by two tapered roller

bearings. The pinion depth is set by a shim pack located

between the gear end of the pinion and the roller

bearing that is pressed onto the pinion. The pinion

bearing preload is set by crushing a collapsible spacer

between the bearings in the axle housing.

The ring gear is bolted onto the diff erential case with 10

bolts.

The diff erential case is supported in the axle housing by

two tapered roller bearings. The differential and ring

gear are located in relationship to the pinion by using

selective shims and spacers between the bearing and

the differential case. To move the ring gear, shims are

deleted from one side and an equal amount are added

to the other side. These shims are also used to preload

the bearings which are pressed onto the differential

case. Two bearing caps are used to hold the differential

into the rear axle housing.

The differential is used to allow the wheels to turn at

different rates of speed while the rear axle continues to

transmit the driving force. This prevents tire scuffing

when going around corners and prevents premature

wear on internal axle parts.

The rear axle is sealed with a pinion seal, a seal at each

axle shaft end, and by a liquid gasket between the rear

cover and the axle hous i ng.

Limited Slip Differential (LSD)

The axle assembly ma y be equipped with an limited slip

differential (LSD). It is similar to the standard differential

except that part of the torque from the ring gear is

transmitted through clutch packs between the side

gears and differential case.

The LSD construction permits differential action when

required for turning corners and transmits equal torque

to both wheels when driving straight ahead. However,

when one wheel tries to spin due to a patch of ice, etc.,

the clutch packs automatically provide more torque to

the wheel which is not trying to spin.

In diagnosing customer complaints, it is important to

recognize two things:

1. If, both wheels slip, with unequal traction, the LSD

has done all it can possibly do.

2. In extreame cases of differences in traction, the

wheel with the least traction may spin after the LSD

has transferred as much torque as possible to the

non-slipping wheel.

Limited Slip Differntials impose additional requirements

on lubricants, and require a special lubricant or lubricant

additive. Use 80W90 GL–5 LSD lubricant.

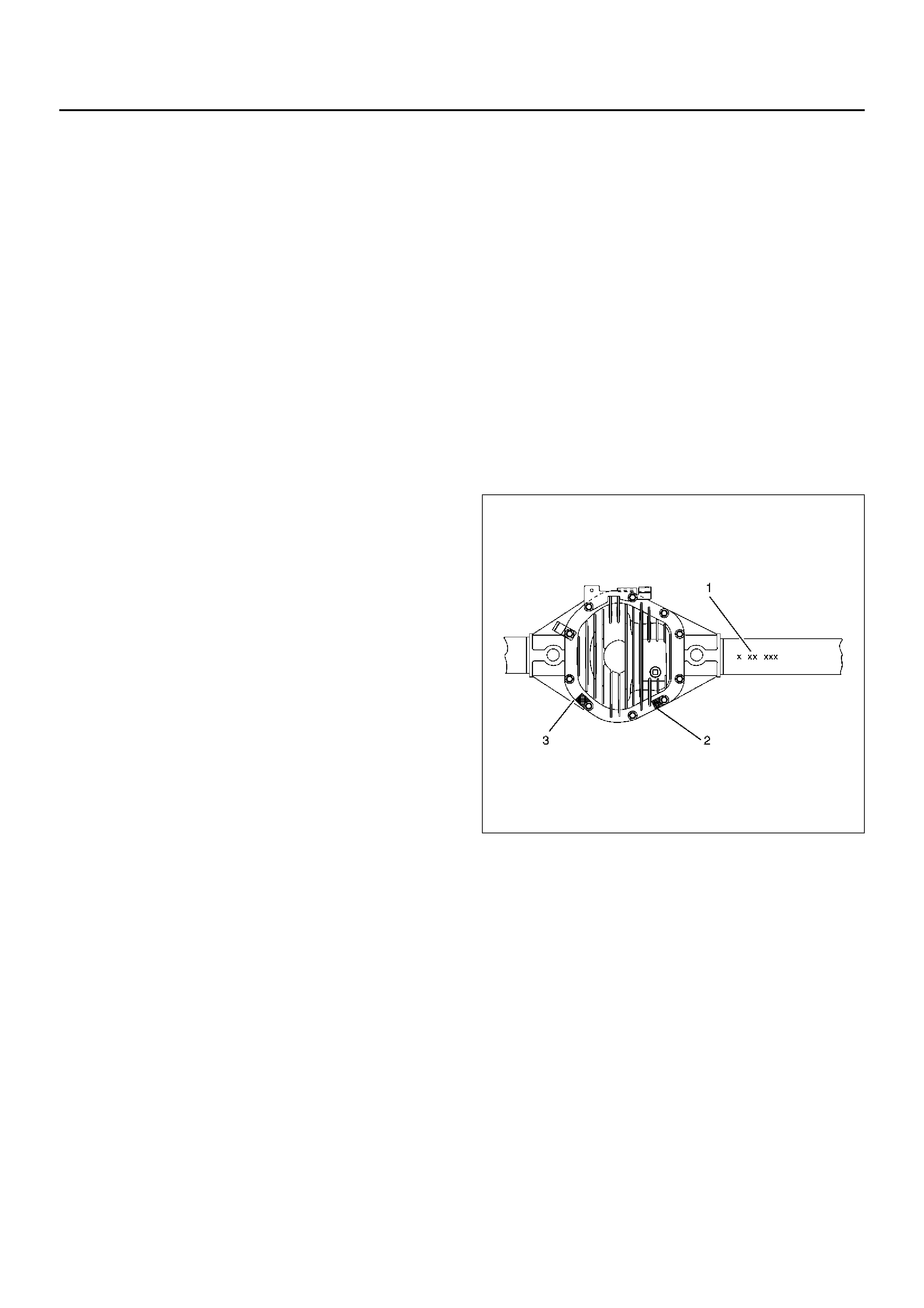

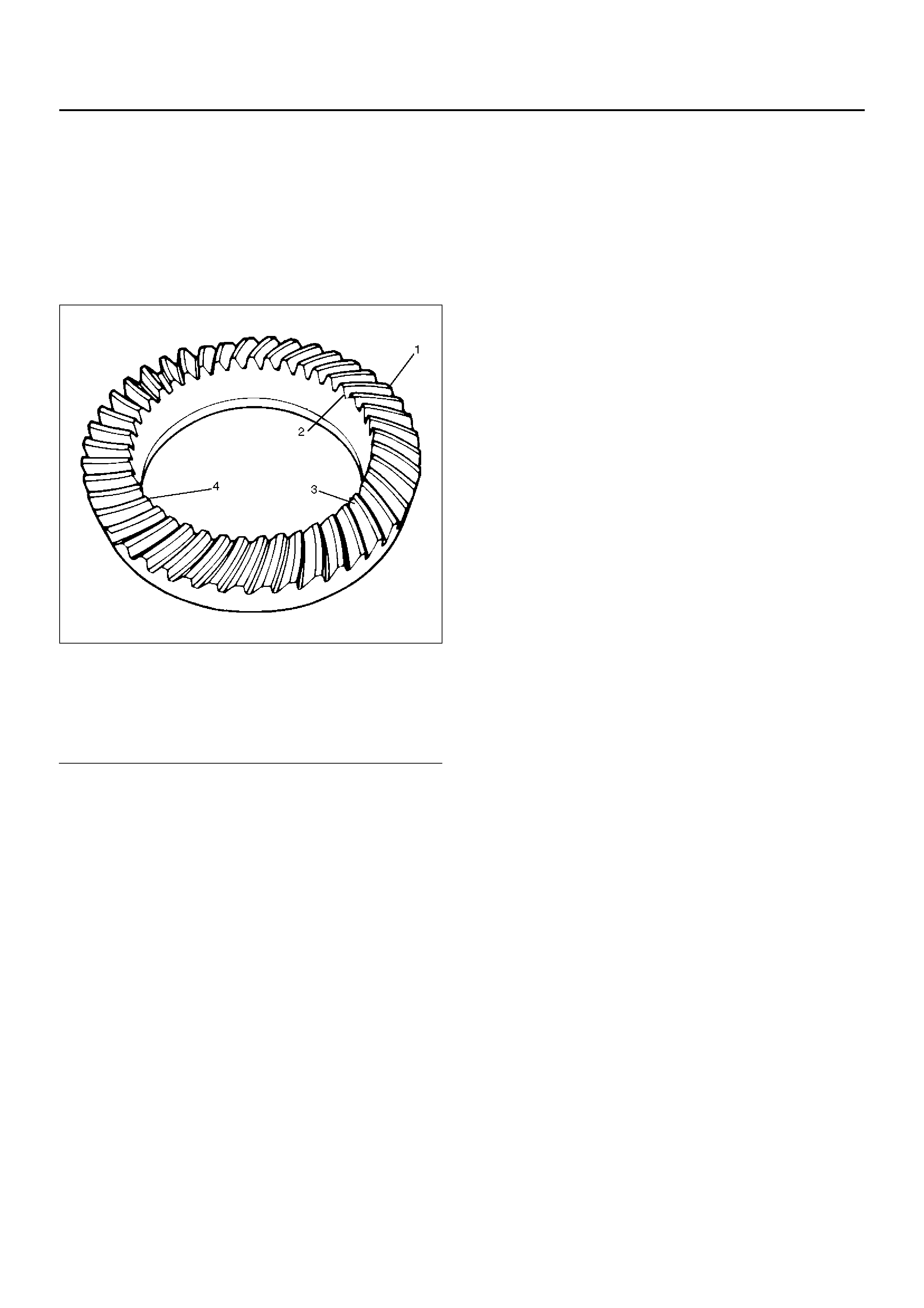

Rear Axle Ident if ica t ion

The Bill of Material and build date information(1) is

stamped on the right axle tube on the rearward side.

The axle ratio is identified by a tag(3) which is secured

by a cover bolt. If the axle has limited-slip differntial, it

also will be identified with a tag(2) secured by a cover

bolt.

425RX001

Diagnosis

Many noises that seem to come from the rear axle

actually originate from other sources such as tires, road

surface, wheel bearings, engine, transmission, muffler,

or body drumming. Investigate to find the source of the

noise before disassembling the rear axle. Rear axles,

like any other mechanical device, are not absolutely

quiet but should be considered quiet unless some

abnormal noise is present.

To make a systematic check for axle noise, observe the

following:

1. Select a le vel asphalt road to reduce tire noise and

body drumming.

2. Check rear axle lubricant level to assure correct

level, and then drive the vehicle far enough to

thoroughly warm up the rear axle lubricant.

3. Note the speed at which noise occurs. Stop the

vehicle and put the transmission in neutral. Run the

engine speed slowly up and down to determine if

the noise is caused by exhaust, muffler noise, or

other engine conditions.

4. Tire noise changes with diff erent road surfaces; axle

noises do not. Temporarily inflate all tires to 344 kP a

(50 psi) (for test purposes only). This will change

noise caused b y ti res b ut will n ot aff ect no ise caus ed

by the rear axle.

Rear axle nose usually stops when coasting at

speeds under 48 km/h (30 mph); howe v er , tire noise

continues with a lower tone. Rear axle noise usually

changes when comparing pull and coast, but tire

noise stays about the same.

Distinguish between tire noise and rear axle noise

by noting if the noise change s with variou s spe eds

or sudden acceleration and deceleration. Exhaust

and axle noise vary under these conditions, while

tire noise remains constant and is more pronounced

at speeds of 32 to 48 km/h (20 to 30 mph). Further

check for tire noise by driving the vehicle over

smooth pav ements or dirt roads (not gra vel) with the

tires at normal pressure. If the noise is caused by

tires, it will change noticeably with changes in road

surface.

5. Loose or rough front wheel bearings will cause

nois e which may be confused with rear axle noise;

howe ver , front wheel bearing noise does not change

when comparing drive and coast. Light application

of the brake while holding vehicle speed steady will

often cause wheel bearing noise to diminish. Front

wheel bearings may be chec ked for noise by jack ing

up the wheels and spinning them or by shaking the

wheels to determine if bearings are loose.

6. Rear suspension rubber bushings and spring

insulators dampen out rear axle noise when

correctly installed. Check to see that there is no link

or rod loosened or metal–to–metal contact.

7. Make sure that there is no metal–to–metal contact

between the floor and the frame.

After the noise has been determined to be in the axle,

the type of axle noise should be determined, in order to

make any necessary repairs.

Gear Noise

Gear noise (whine) is audible from 32 to 89 km/h (20 to

55 mph) under four driving conditions.

1. In drive under acceleration or heavy pull.

2. Driving under load or under constant speed.

3. When using enough throttle to keep the vehicle from

driving the engine while the vehicle slows down

gradually (engine still pulls slightly).

4. When coasting with the vehicle in gear and the

throttle closed. The gear noise is usually more

noticeable between 48 and 64 km/h (30 and 40

mph) and 80 and 89 km/h (50 and 55 mph).

Bearing Noi se

Bad bearings generally produce a rough growl or

grating sound, rather than the whine typical of gear

noise. Bearing noise frequently “wow–w ows" at bearing

rpm, indicating a bad pinion or rear axle side bearing.

This noise can be confused with rear wheel bearing

noise.

Rear Wheel Be aring Noi se

Rear wheel bearing noise continues to be heard while

coasting at low speed with transmission in the neutral.

Noise may diminish by gentle braking. Jac k up the rear

wheels, spin them by hand and listen for noise at the

hubs. Replace any faulty wheel bearings.

Knock At Low Speeds

Low speed knock can be caused by worn universal

joints or a side gear hub counter bore in the cage that is

worn oversiz e. Inspect and replace universal joints or

cage and side gears as required.

Backlash Clunk

Excessive clunk on acceleration and deceleration can

be caused by a worn rear axle pinion shaft, a worn

cage, exces sive clearance between the axle and the

side gear splines, excessive clearance between the side

gear hub and the counterbore in the cage, worn pinion

and side gear teeth, worn thrust washers, or excessive

drive pinion and ring gear backlash. Remov e worn parts

and replace as required. Select close–fitting parts when

possible. Adjust pinion and ring gear backlash.

Rear Axle Noise

Limited Slip Differential

Condition Possible cause Correction

Noise in Drive Excessive pinion to ring gear

backlash. Adjust.

W orn pinion and ring gear. Replace

W orn pinion .bearings. Replace.

Loose pinion bearings. Adjust.

Excessive pinion end play. Adjust.

W orn side bearings. Replace.

Loose side bearings. Adjust.

Excessive ring gear run-out. Replace.

Low oil level. Replenish.

Wrong or poor grade oil. Replace.

Bent axle housing. Replace.

Noisy when coasting Axle noise heard when driving will

usually be heard also on coasting,

although not as loud.

Adjust or replace.

Pinion and ring gear too tight

(audible when slowing down and

disappears when driving).

Adjust.

Intermittent noise Warped bevel ring. Replace.

Loose differential case bolts. Tighten.

Constant noise Flat spot on pinion or ring gear

teeth. Replace.

Flat spot on bearing. Replace .

W orn pinion splines. Replace.

W orn axle shaft dowel holes. Replace.

W orn hub studs. Replace.

Bent axle shaft. Replace.

Noisy on turns W orn differential side gears and

pinions. Replace.

Worn differential shaft. Replace .

Worn axle shaft splines. Replace.

Condition Possible cause Correction

Does not lock Broken clutch plates. Replace the clutch plates.

Chatters in turns Lubricant contaminated. Drain lube when hot. Wipe carrier

clean. Refill with lube specified in

Main Data and Specifications at the

end of this section.

Clutch plates dateriorated. Replace clutch plates.

Noise (in addition to normal clutch

engagement) Broken clutch plates. Replace clutch plates.

Damaged case. Replace unit.

Broken differential gears. Replace gears.

Axle Housing

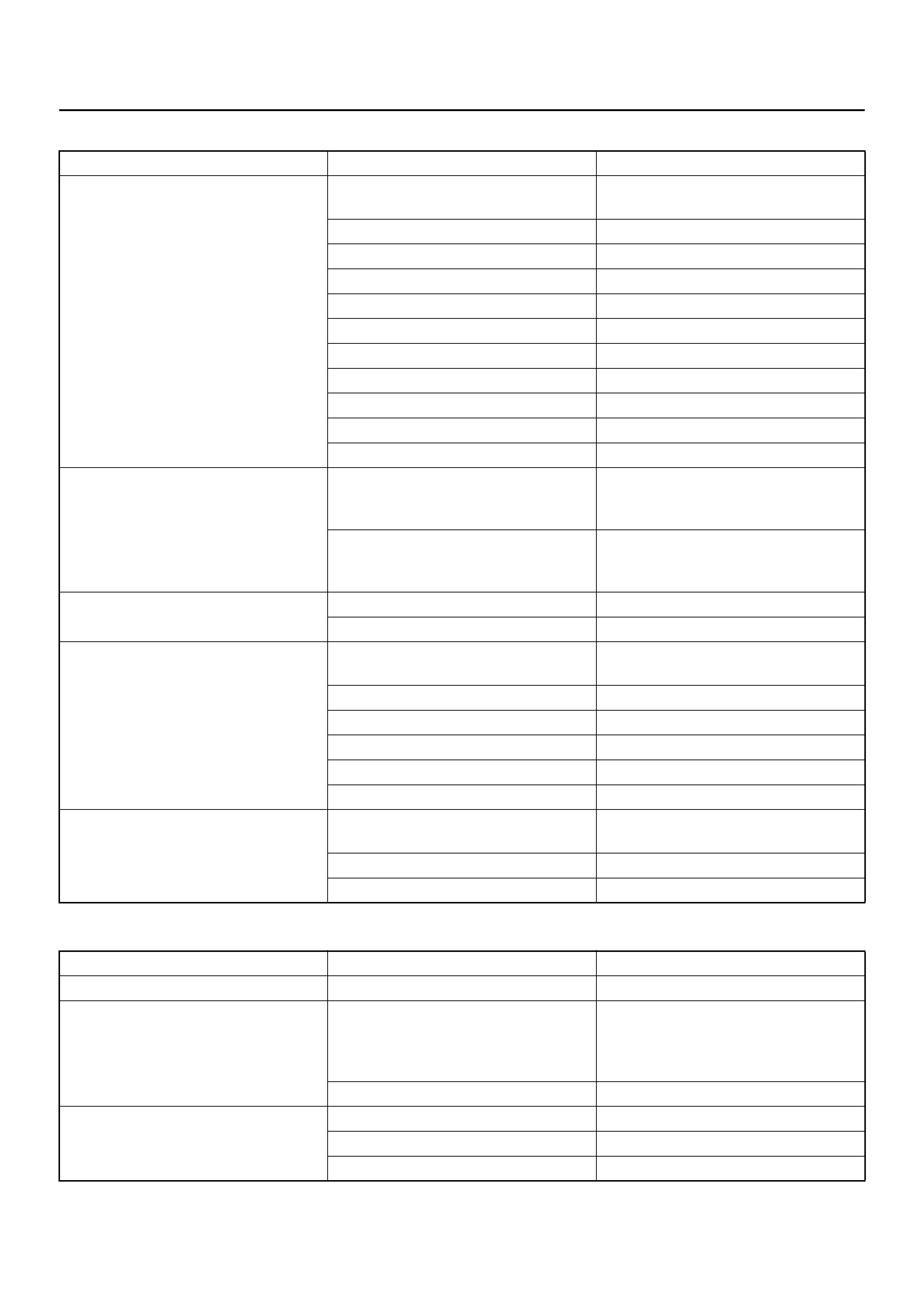

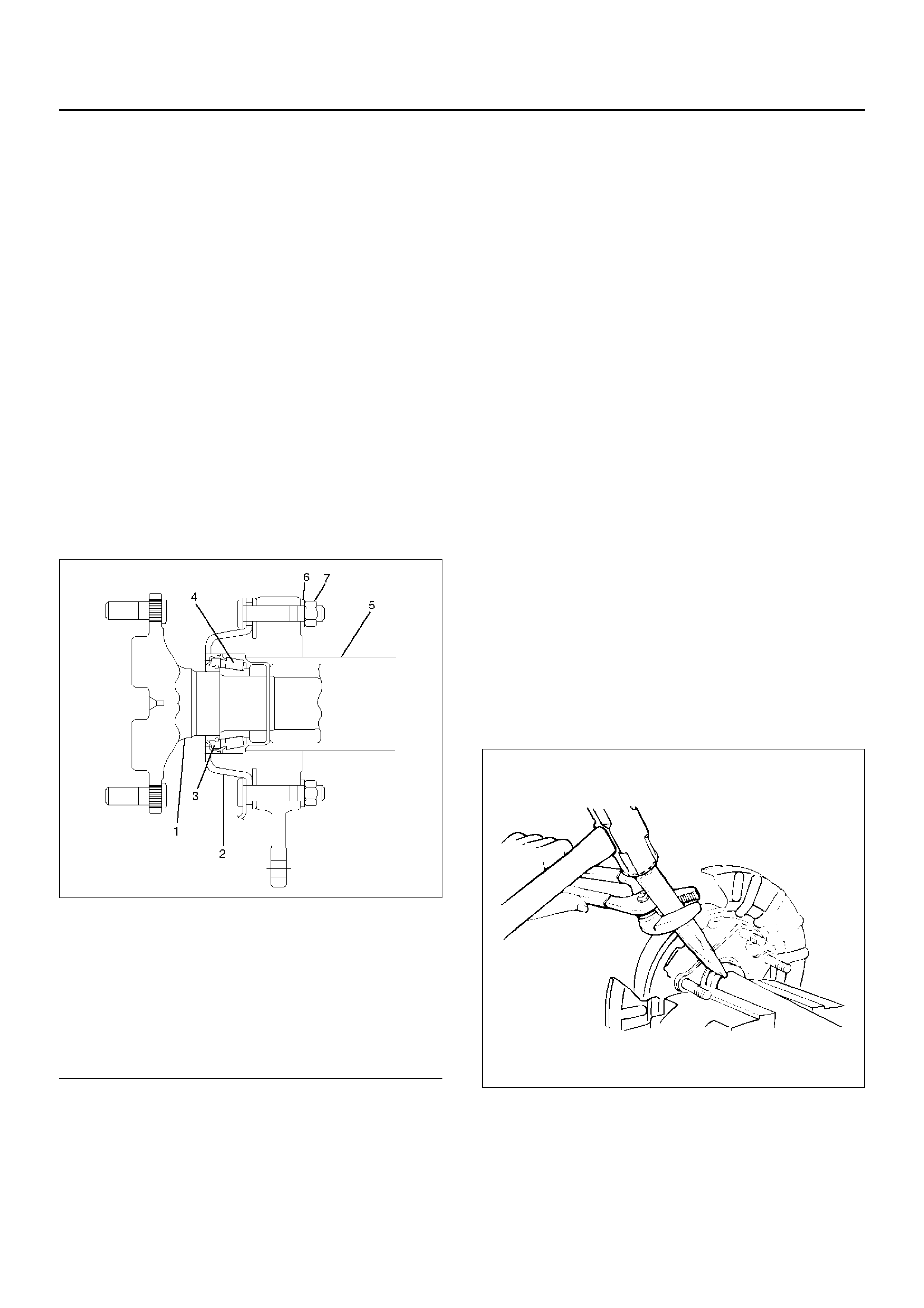

Axle Housing and Associated Parts

420RW030

Legend

EndOFCallout

Removal

1.Raise the vehicle and support it with suitable safety

stands.

The hoist must remain under the rear axle housing.

2.Take out brake fluid. Refer to Hydraulic Brakes in

Brake section.

3.Remove rear wheels and tires. Refer to Wheel

Replacement in Suspension section.

4.Remove propeller shaft. Refer to Rear Propeller

Shaft in this section.

5. Drain the rear axle oil into a proper container.

6. Remove parking brake cab le, release the

connection between the cable fixing clip equalizer.

Refer to Parking Brakes in Brake section.

7. Move the clip aside and pull out the breather hose.

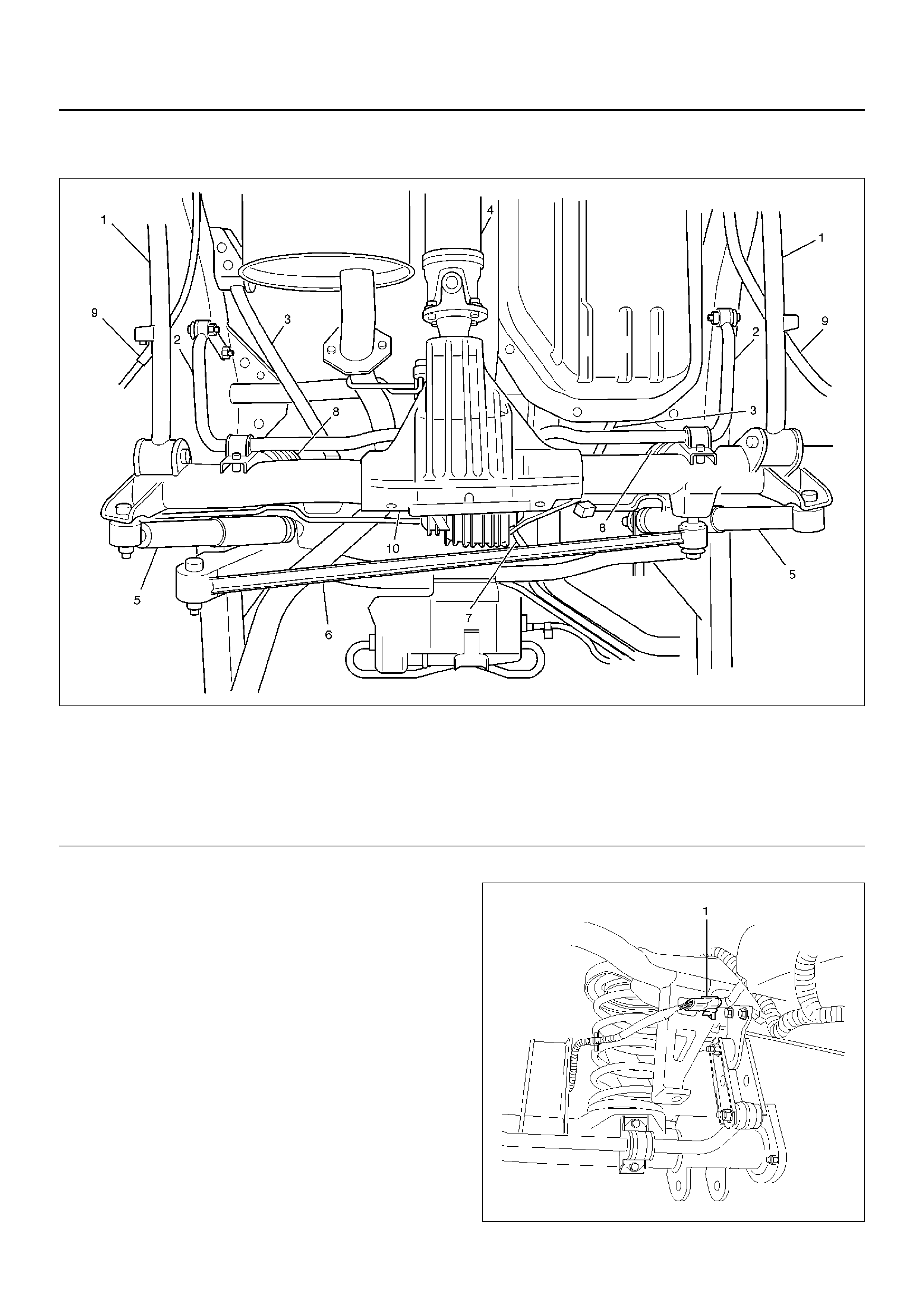

8. Disconnect the ABS connectors (1) and remove the

brackets attached to the frame and center link. 350RW023

(1) Lower Link

(2) Stabilizer

(3) Upper Link

(4) Rea r Propeller shaft

(5) Shock Absorber

(6) Lateral Rod

(7) Brake Hose

(8) Coi l Spring

(9) Parking Cable

(10) Axle Assembly

9. Loosen the brake tube flare nut, remov e the clip and

take out the brake tube.

350RW020

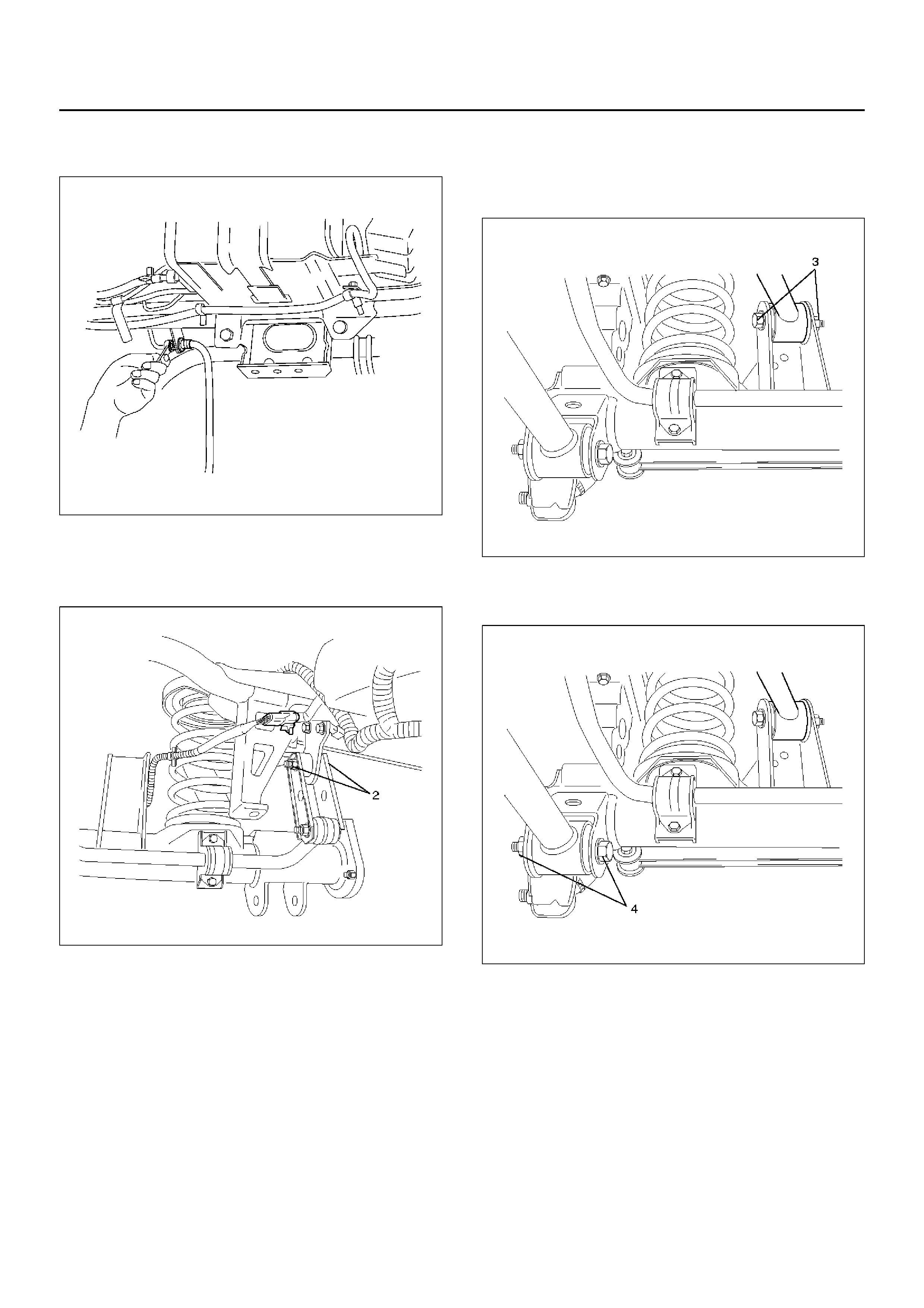

10. Remove the shock absorber.

11. Remove the stabilizer linkage mounting bolts and

nuts (2) from the frame side.

350RW024

12. Remove the lateral rod fixing bolt and nut from the

frame.

13. Remove the upper link mounting bolt and nut (3)

from the axle housing.

460RW015

14. Remove the lower link fixing bolt and nut (4) from

the axle housing.

460RW016

15. Jack down and remove the coil spring and insulator.

16. Axle housing assembly can be separated from the

vehicle on completion of steps 1 – 15.

17. Remove the brake caliper fixing bolt, loosen the

flare nut, release the clip and take out the brak e

caliper together with the flexible hose.

18. Remove brake disc.

19. Remove antilock brake system speed sensor fixing

bolt and the clip and bracket on the axle housing.

20. Remove the brake pipe clip and fixing bolt on the

axle housing and take out the brake pipe.

Installation

1.Install brake pipe.

2.Connect Antilock brake system (ABS) speed sensor

and harness, refer to Anti–Lock Brake System in

Brake section.

3.Install brake disc.

4.Install brake caliper. Refer to Disk Brakes in Brake

section.

5.Install axle housing assembly.

6.Install coil spring and insulator.

7.Install the lower link fixing bolt and nut to the axle

housing. For the procedures in items 7–11, refer to

Suspension section.

8.Install the upper link bolt and nut to the axle

housing.

9.Install the lateral rod fixing nut and bolt to the frame

side.

10.Install the stabilizer linkage mounting nut and bolt to

the frame side.

11.Install the shock absorber.

12.Install brake tube flare nut, Refer to Disk Brakes in

Brake section.

13.Install ABS connector and bracket.

14.Connect breather hose.

15.Install parking brake cable, Refer to Parking Brakes

in Brake section.

16.Bleed brakes. Refer to Hydraulic Brakes in Brake

section.

Axle Shaft, Oil Seal and Bearing

Axle Shaft and Associated Parts

420RW008

Legend

EndOFCallout

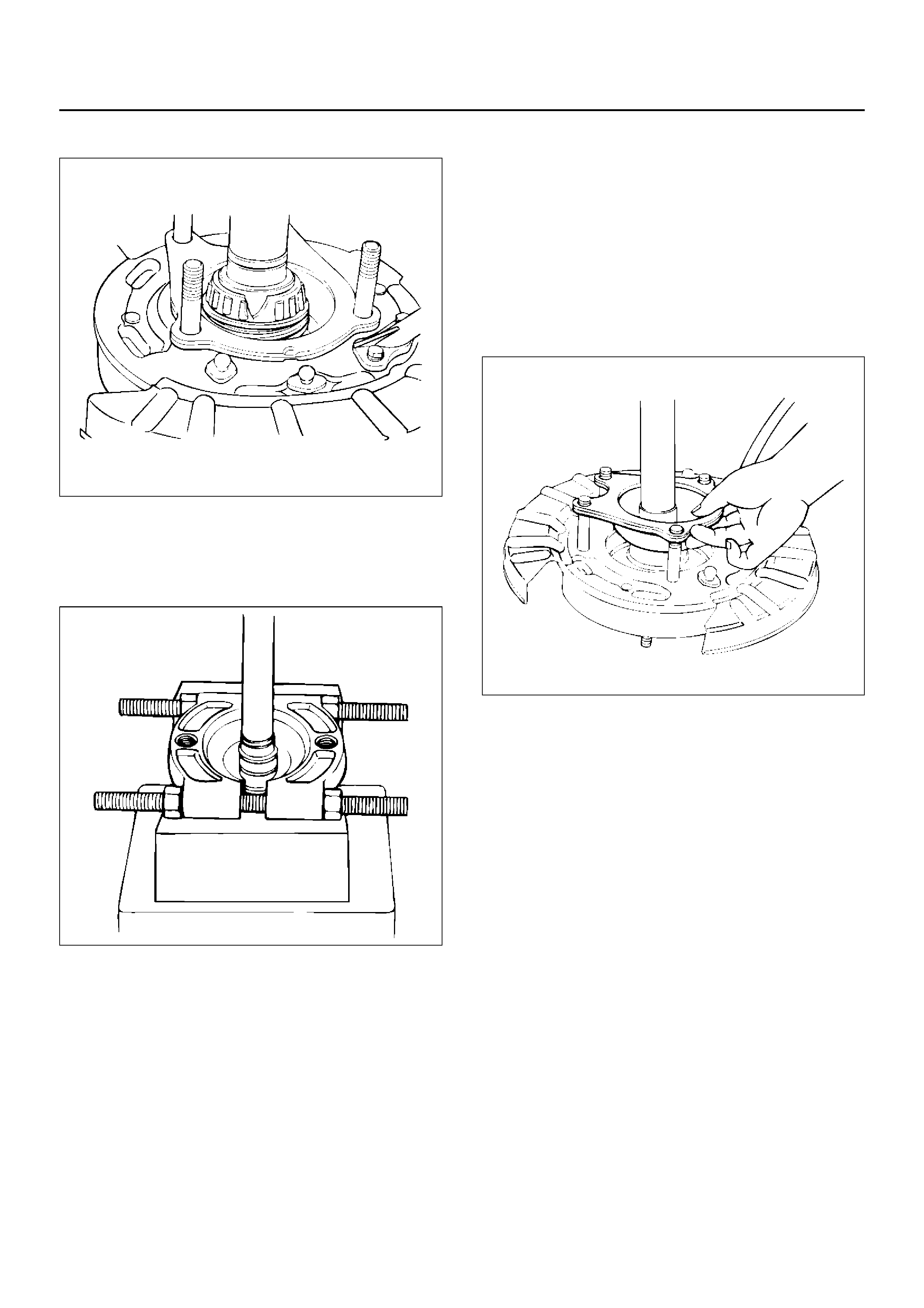

Removal

1. Raise the vehicle.

2. Remove rear wheels and brake calipers or drums.

Do not let calipers hang from the vehicle by the

brake line or hose. Wire them to frame of vehicle to

prevent damage.

3. Remove four nuts and lockwashers.

4. Remove shaft assembly from the axle housing.

5. Remove snap ring and bearing cup.

6. Break retainer ring with hammer and chisel.

420RS026

(1) Axle Shaft

(2) Backing Plate

(3) Oil Seal

(4) Bearing

(5) Axle Housing

(6) Lock Washer

(7) Nut

7. Break bearing cage with hammer and chisel.

420RS027

8. Remove oil seal, retainer, and emergency brake

assembly.

9. Remove inner race from shaft with OTC–1126

bearin g splitter and press.

420RS028

Inspection

• Shaft for spalling or grooves from seal wear.

• Retainer – bent or damaged.

• Rep la ce ite ms if requi red.

Installation

1. Emerge nc y brake assembly.

2. Install retainer.

Note direction – do not install backw ards.

420RS029

3. Install oil seal. Note direction.

4. Install bearing assembly, using installer and press.

420RS030

NOTE: Install bearing with cup towards inboard side.

420RS031

5. Install retainer ring, using installer and press.

420RS033

6. Install snap ring.

7. Install axle shaft assembly into housing.

8. Install bolts, lockwashers, and nuts.

Tighten the retainer nuts to the specified torque.

Torque : 75N·m (7.6kg·m/55lbft)

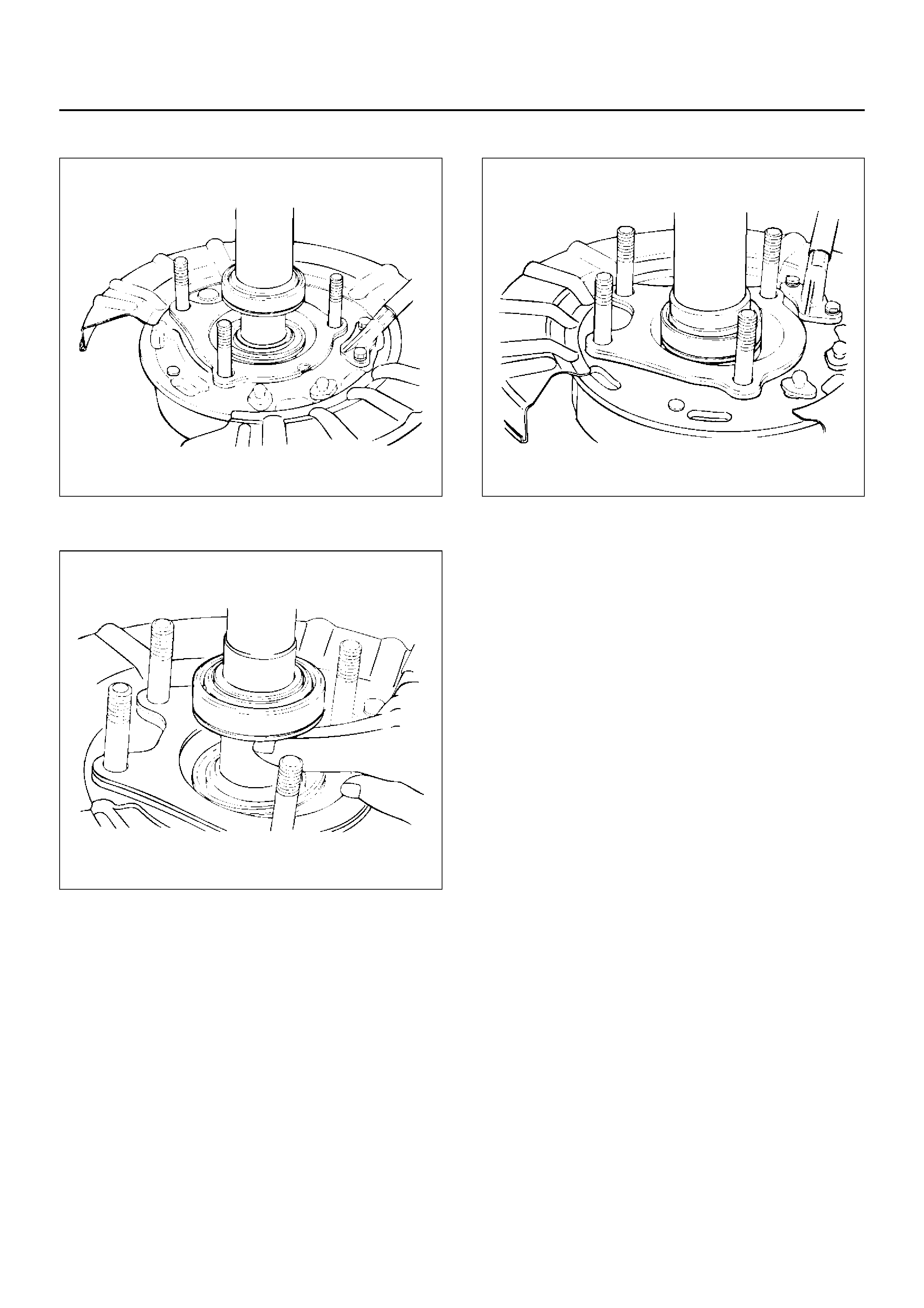

Pinion Oil Seal

Pinion Oil Seal and Associated Parts

420RW013

Legend

EndOFCallout

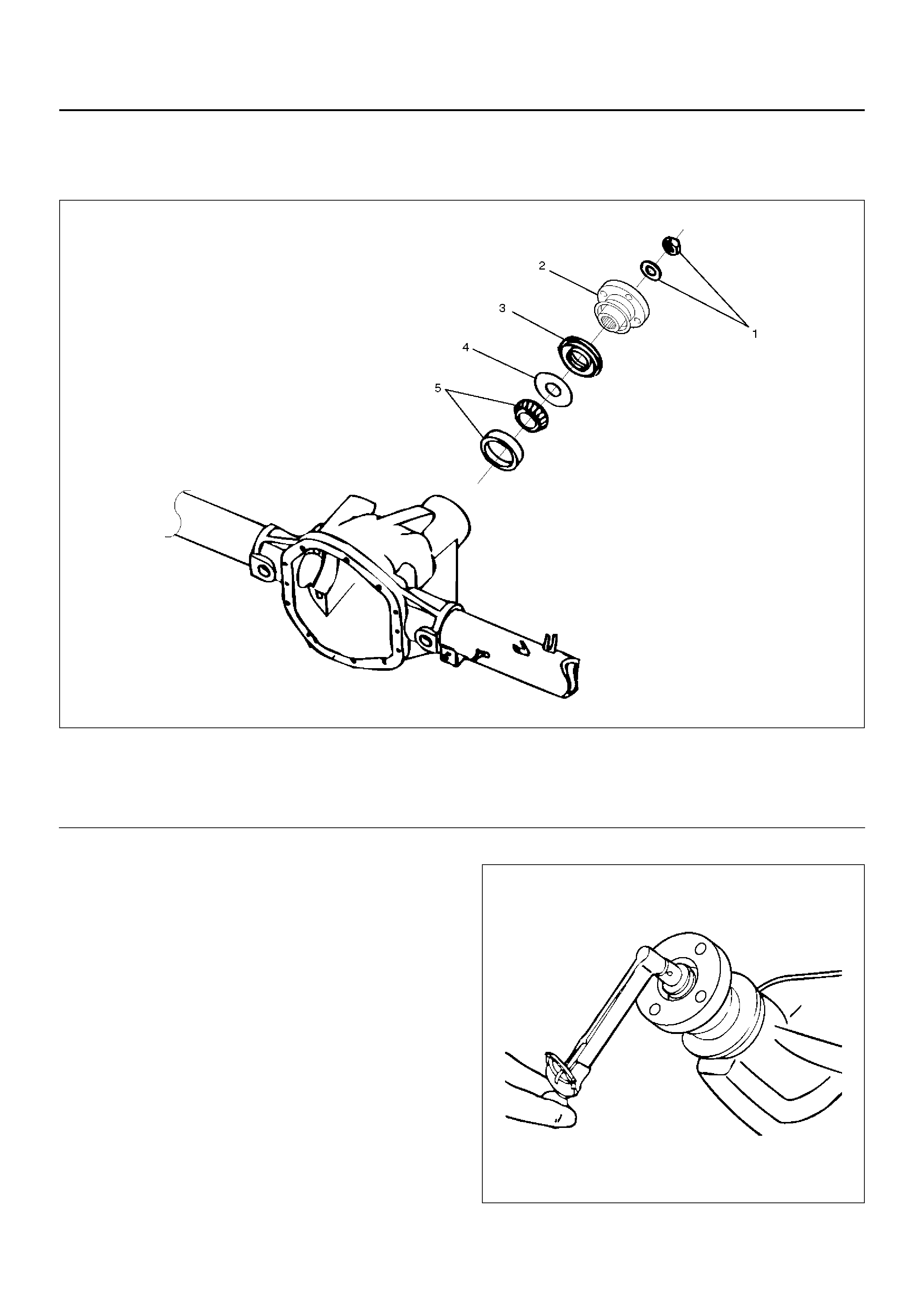

Removal

1.Remove the rear propeller shaft. Refer to Rear

Propeller Shaft in this section.

2. Drain the rear axle oil.

3. Check and record preload with an inch pound

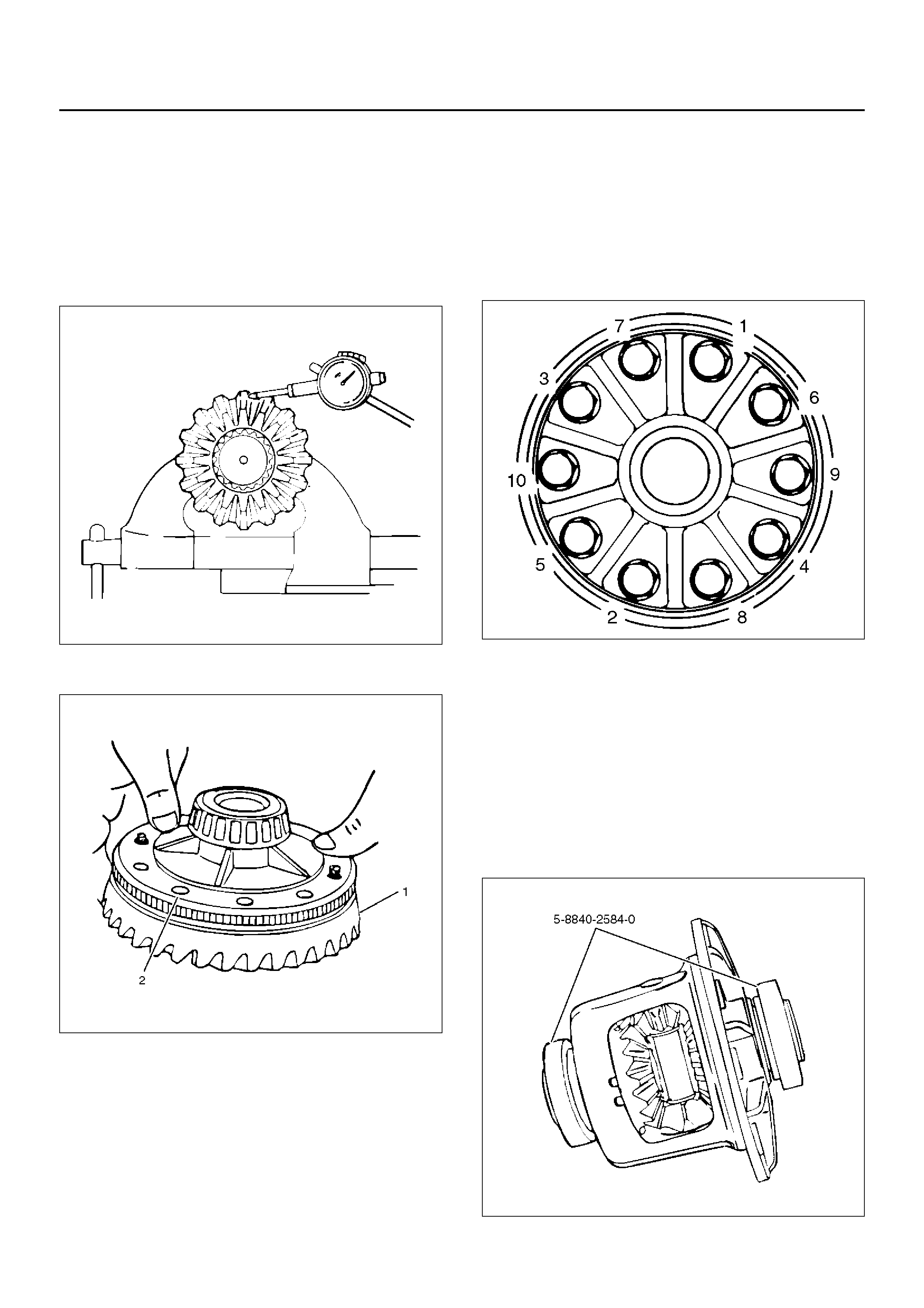

torque wrench. This will give combined pinion

bearing, seal, carrier bearing, axle bearing and seal

preload.

425RW018

(1) Flange Nut and Washer

(2) Flange

(3) Oil Seal

(4) Outer Oil Seal Slinger

(5) Outer Pinion Bearing (Cup and Cone)

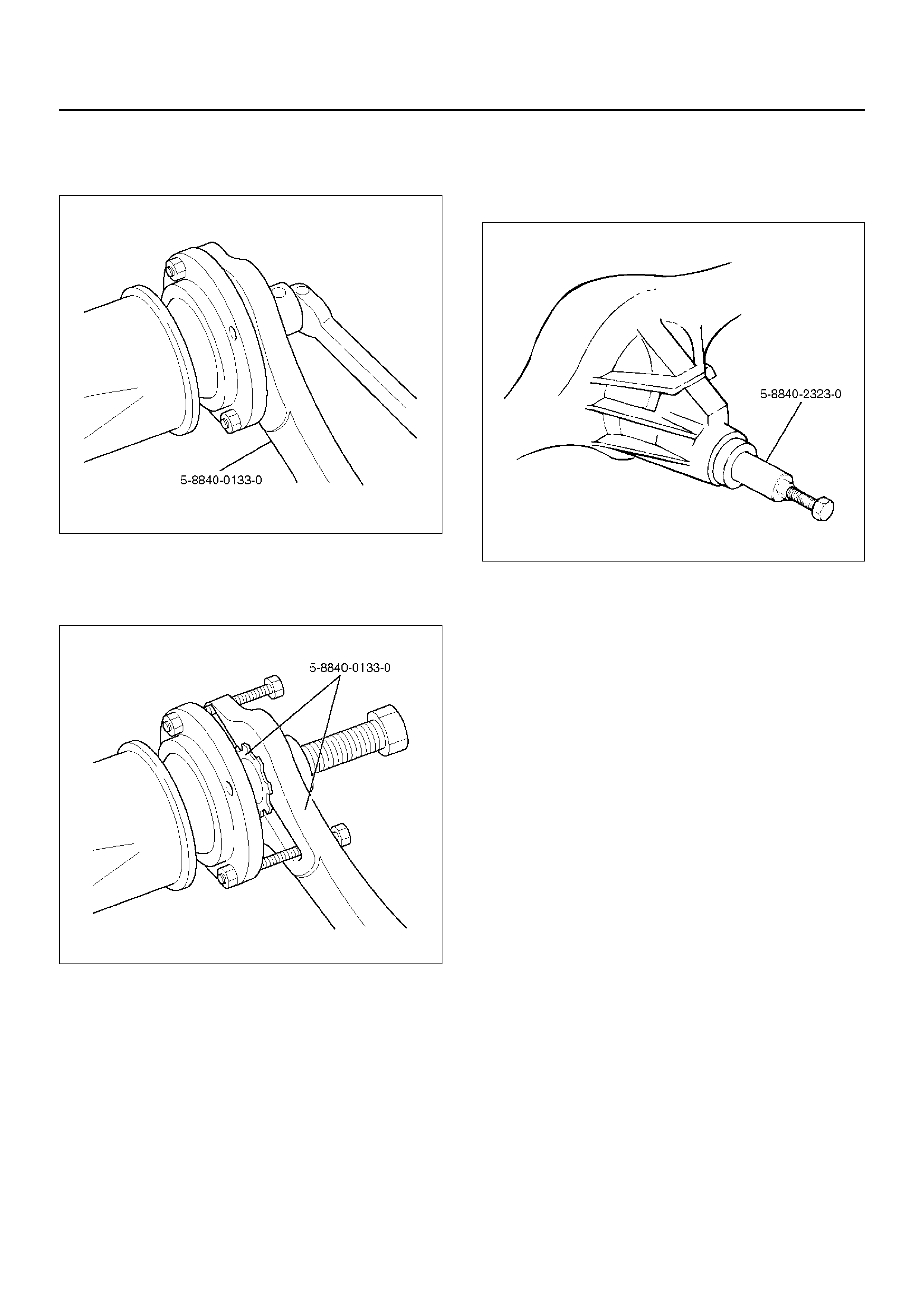

4. Remove flange nut and washer by using pinion

flange holder 5–8840–0133–0 after raising up its

staked parts completely.

425RW070

5. Remove flange by using 5–8840–0133–0.

• Have a suitable container in place to catch

lubricant.

425RW071

6. Remove oil seal.

7. Remove pinion oil seal slinger.

8. Remove outer bearing by using remover 5–8840–

2323–0.

425RW072

9. Remove collapsible spacer.

Inspection and Repair

Make necessary correction or parts replacement if

wear, damage, corrosion or any other abnormal

condition are found through inspection.

Check the following parts.

1. Seal surface of the flange.

2. Cage bore for burns.

Installation

1. Install collapsible spacer, discard the used

collapsible spacer and install a new one.

2. Install outer bearing.

NOTE: Do not drive in, but just temporarily set in the

outer bearing by hand, which should be indirectly

pressed in finally by tightening the flange nut.

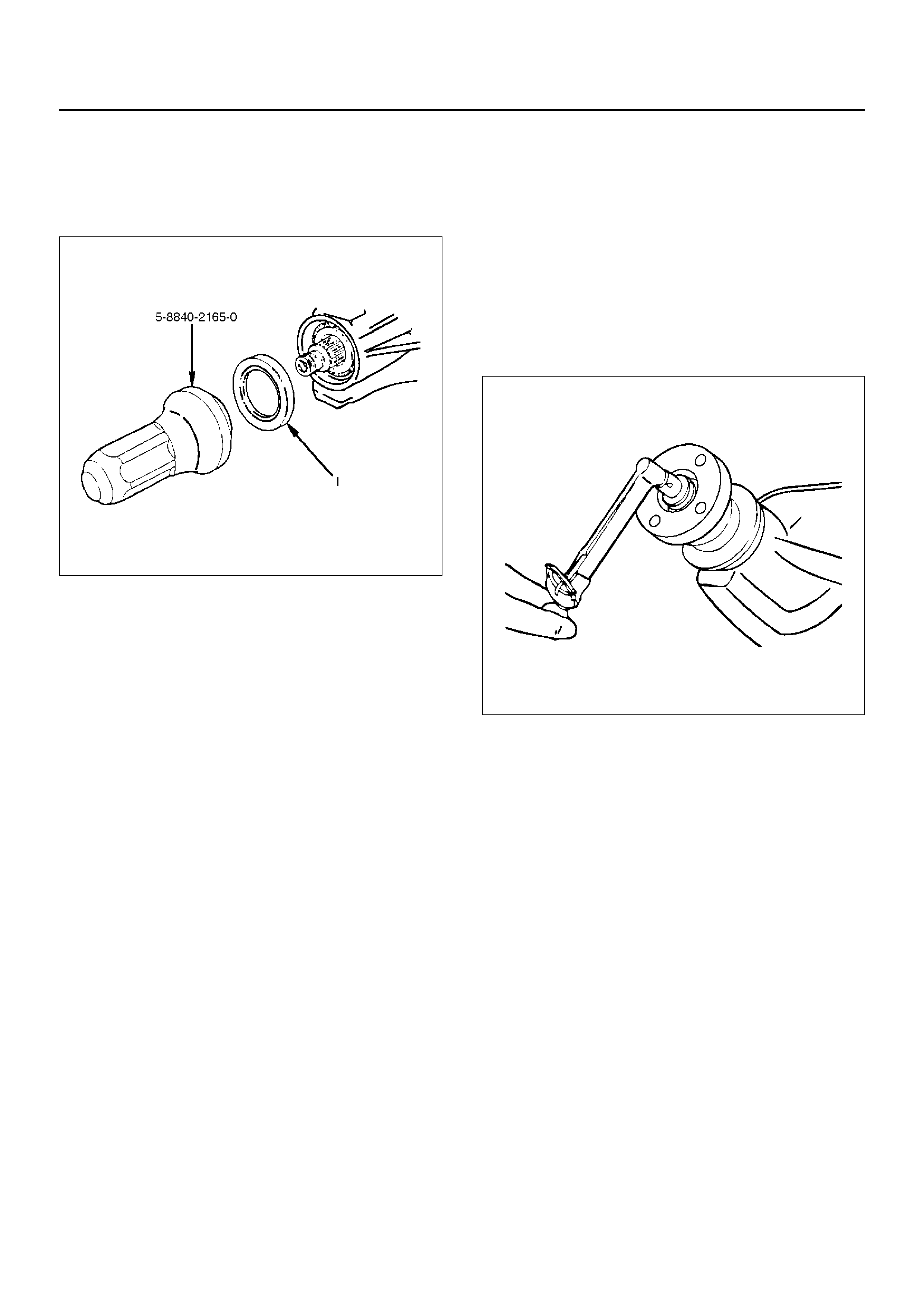

3. By using the seal installer 5–8840–2165–0, install a

new oil seal (1) that has grease on seal lip.

425RW050

4. Install flange.

5. The pinion washer and a new nut while holding the

pinion fla nge with 5–8840 –01 33– 0.

• Tighten the nut until the pinion end play is just

taken up. Rotate the pinion while tightening the

nut to seat the bearings. Once there is not end

play in the pinion, the preload torque should be

checked.

• Remove 5–8840–0133–0. Using an inch-pound

torque wrench, check to make sure the pinion

preload is equal to or slightly over the reading

record ed dur i ng re moval.

425RW018

6. Install propeller shaft to the frange.

7. Install bolt and nut. Tighten the bolt and nut to the

specified torque.

Torque: 63N·m (6.4kg·m/46lbft)

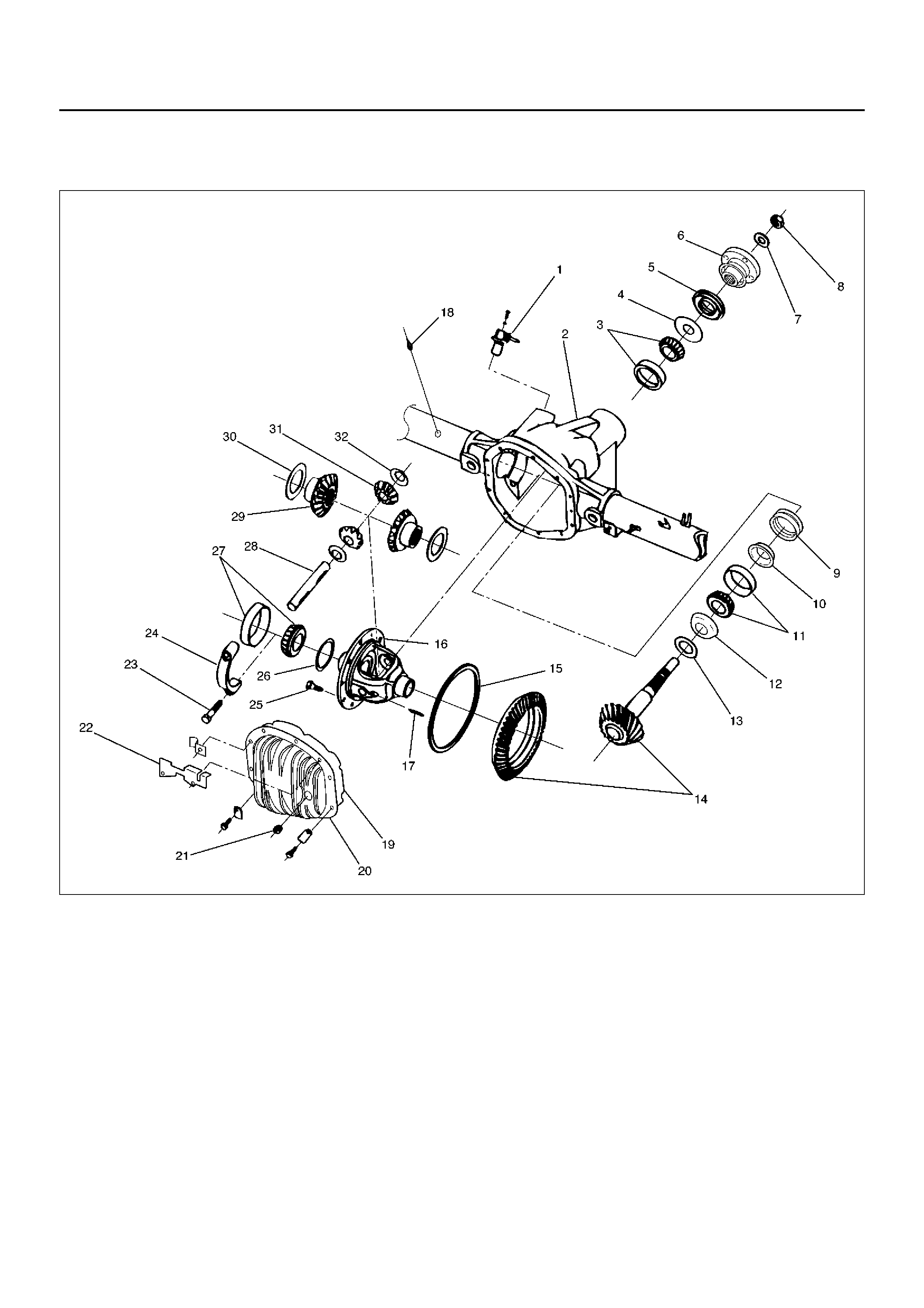

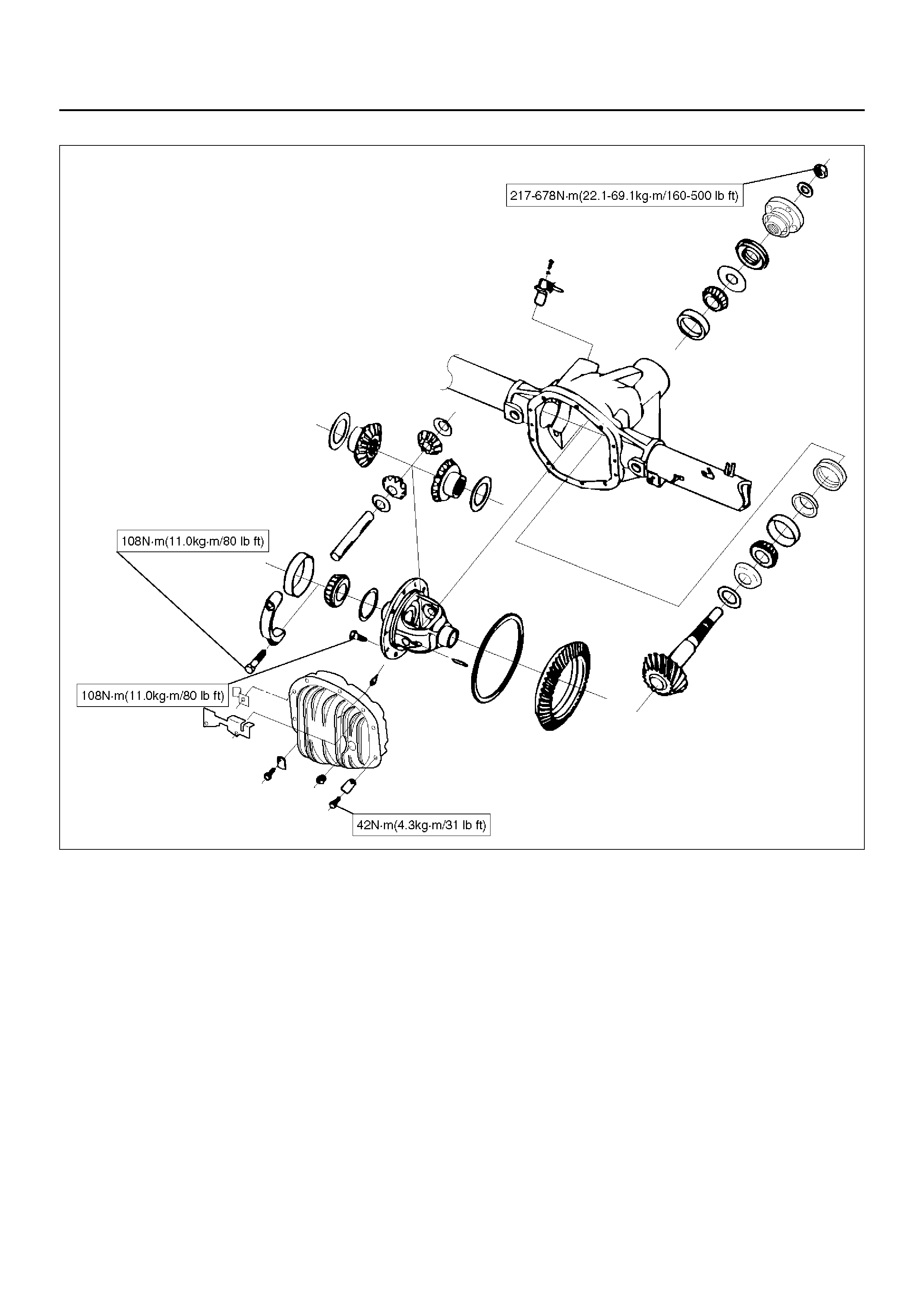

Differential Assembly

Disassembled View

420RW018

Legend

(1) ABS Speed Sensor

(2) Housing

(3) Outer Pinion Bearing (Cup and Cone)

(4) Outer Oil Slinger

(5) Oil Seal

(6) Companion Flange Assembly

(7) Pinion Nut Washer

(8) Pinion Nut

(9) Collapsible Spacer

(10) Baffle Plate

(11) Inner Pinion Bearing (Cup and Cone)

(12) Inner Oil Slinger

(13) Pinion gear adj. Shim-Selective (Position)

(14) Ring gear and Pinion Gear Assembly

(15) Exciter Ring

(16) Differential Case

(17) Loc k Pin

(18) Axle Vent

(19) Gasket

(20) Cover and Clip Assembly

(21) Fill Pl ug (with Magn et)

(22) Mounting Bracket

(23) Side Bearing Cap Bolt

(24) Side Bearing Cap

(25) Drive Gear Bolts

(26) Differential Adjustment Shims (Side Bearing

Preload and Ring Gear/Pinion Backlash)

(27) Side Bearing (Cup and Cone)

(28) Differential Shaft

(29) Differential Side Gears

EndOFCallout

Inspecting the Axle Before

Disassembly

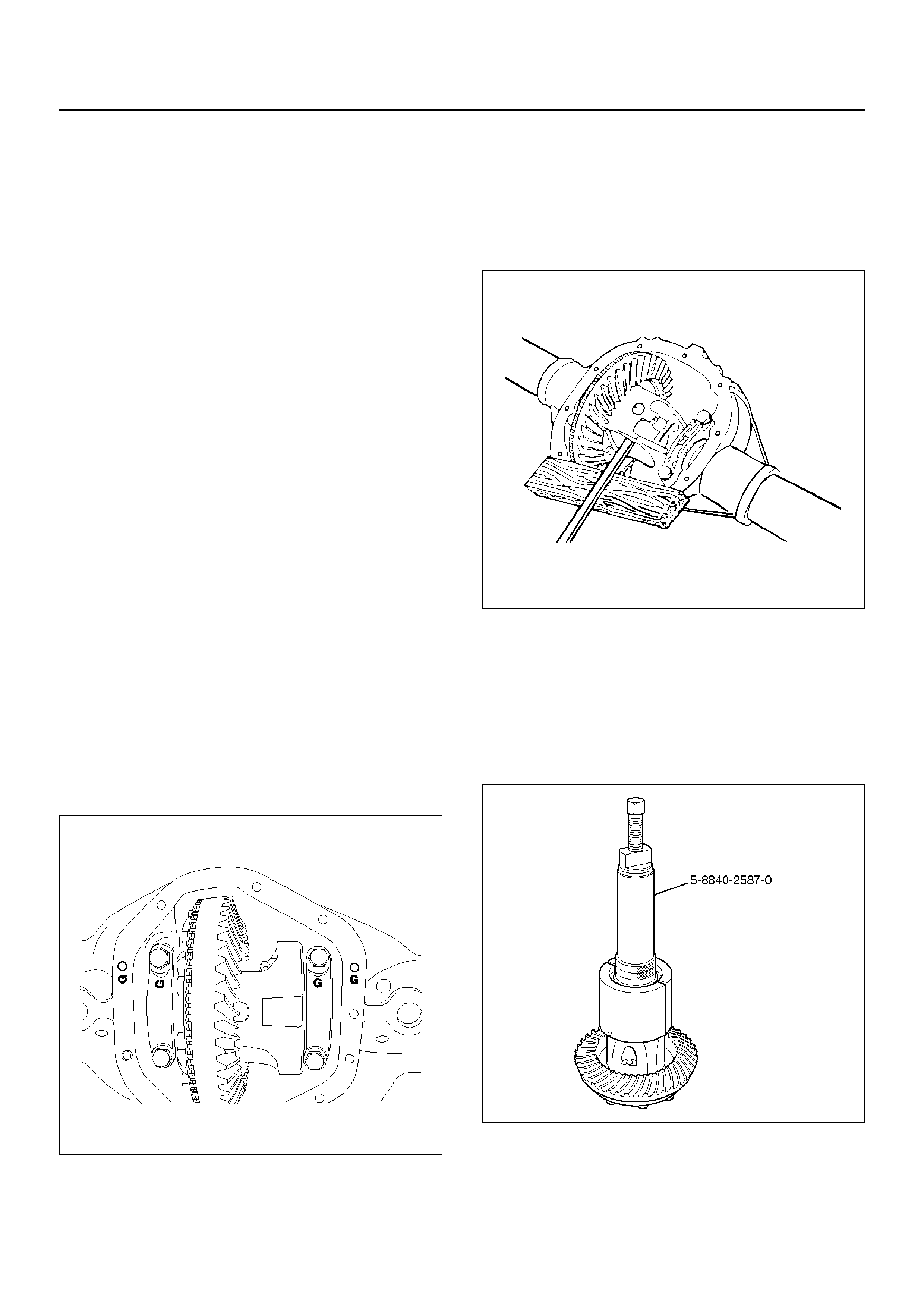

1.Remove the axle cover from the rear axle and drain

the axle lubricant into a suitable container.

2.Check ring gear backlash. Refer to “BACKLASH

ADJUSTMENT" in this section. This information can

be used to determine the cause of the axle problem.

It will also help when setting up the shim packs for

locating and preloading the differential cage.

3.Check case for metal chips and shavings.

Determine where these ships and shavings come

from, such as a broken gear or bearing cage.

•If possible, determine the cause of the axle

problem before disassembly.

Disassembly

1.Remove axle shafts.

•Refer to axle shaft replacement in this section.

2.Remove ABS sensor.

3.Remove bearing caps and bolts.

•Mark the caps and the housing as left and right.

CAUTION: Bearing caps are machined with the

housing and must be assembled in the same

position as removed. Note the matched letter

stamped on the caps and carrier. When assembled,

the letters on the caps must agree in both the

hosizontal and vertical position with the letters on

the carrier.

420RW003

4.Remove Differential case.

•Pry the case from the axle housing at the

differential “window".

420RW010

5.Remove side bearing outer races and shims.

•Mark the races and shims as left and right, and

place them with the bearing cups.

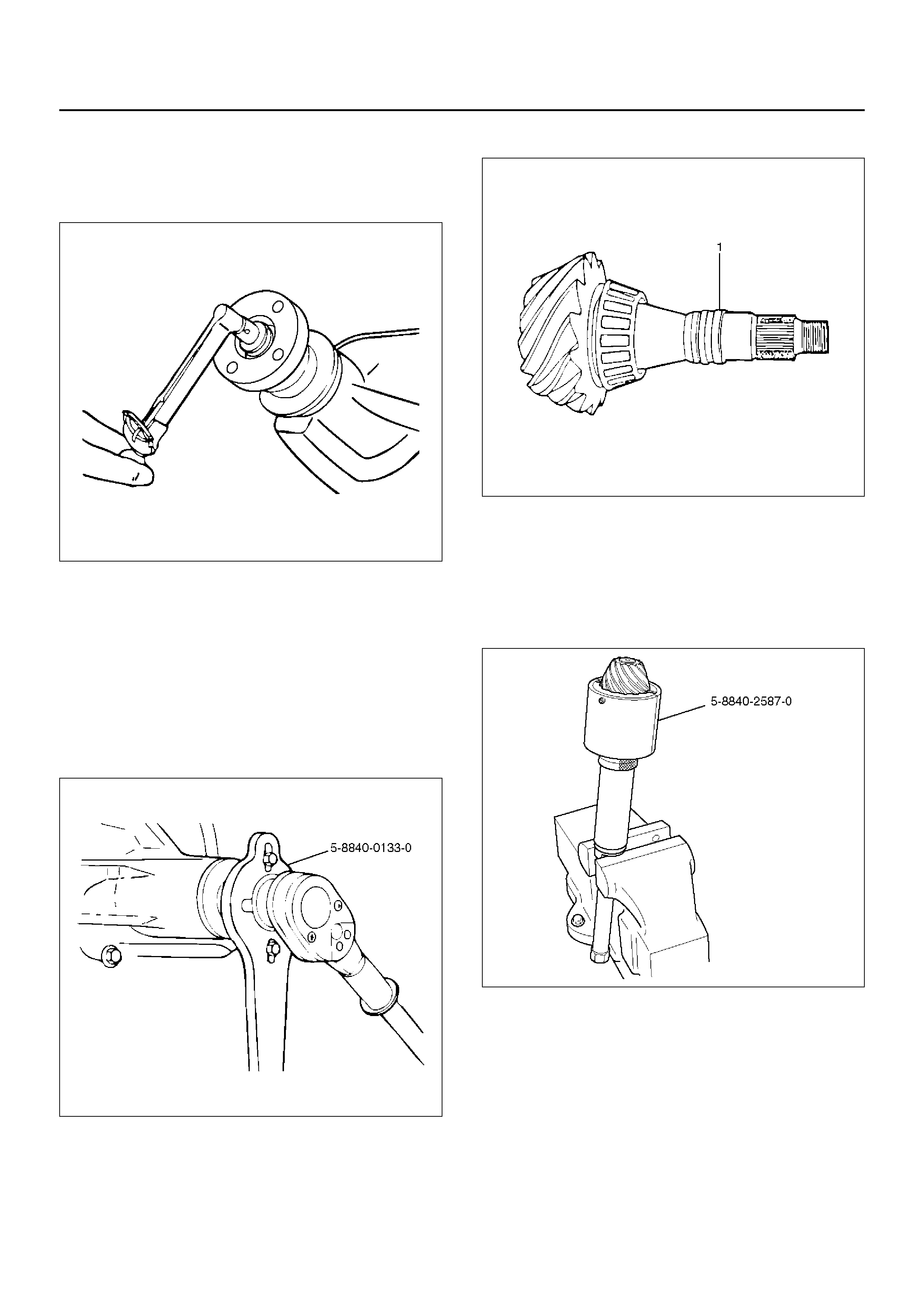

6.Remove differential side bearings using remover 5–

8840–2587–0 and plug 5–8840–2585–0.

•Select insert ; 303174 and collet halves ; 44801 in

remover kit 5–8840–2587–0.

415RW041

7.Remove ring gear bolts.

•Ring gear bolts use right handed threads.

CAUTION: Do not pry the ring gear from the case.

This will damage the ring and the differential case.

(30) Side Gear Thrust Washer

(31) Pinion Mate Gears (32) Thrustwasher-Differential Pinion Mate Gear

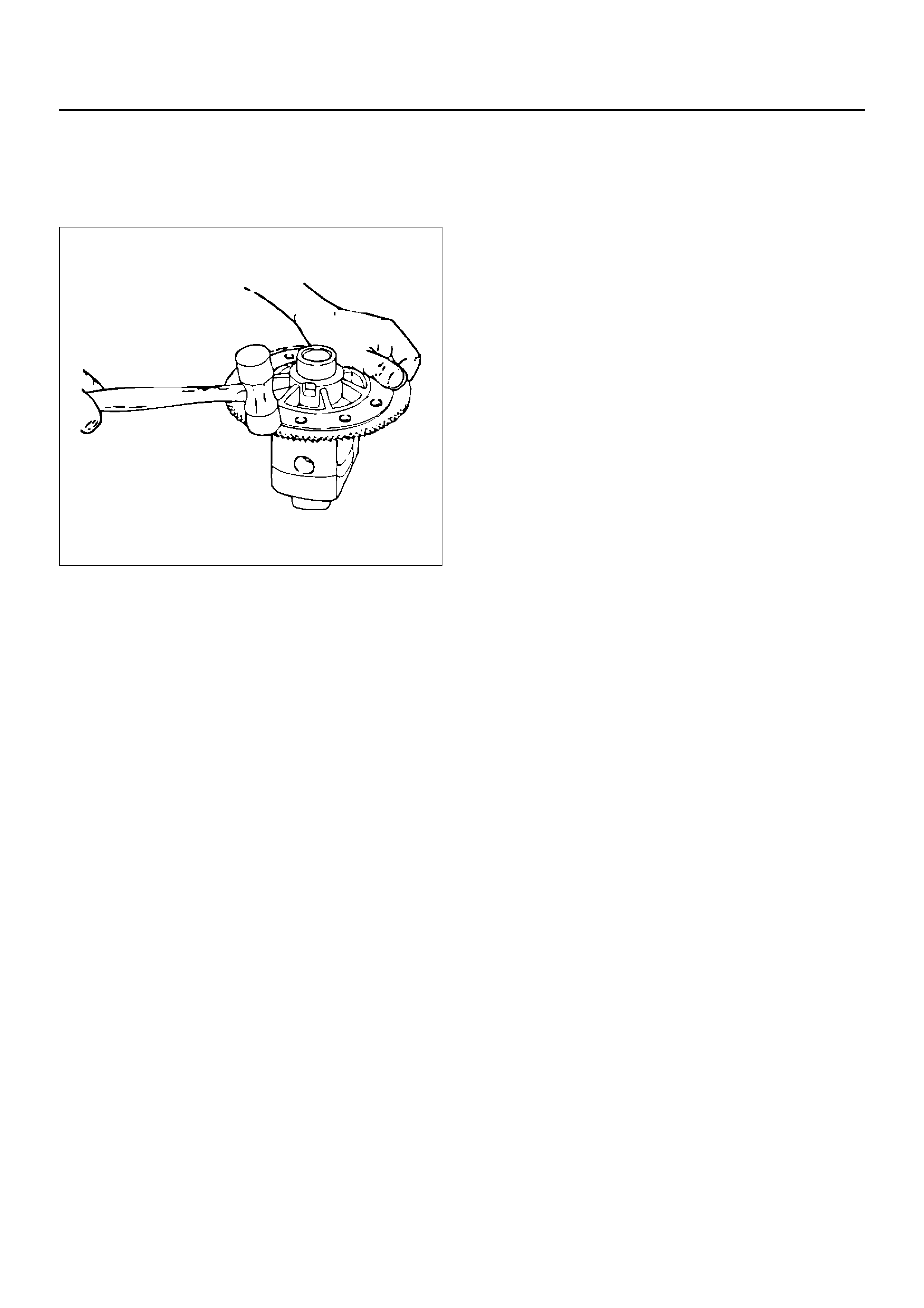

8. Remove ring gear from the differential.

• Drive the ring gear off with a brass drift if

necessary.

• Check drive pinion bearing preload.

425RW018

• Check the pinion assembly for looseness by

moving it back and forth. (Looseness indicates

excessive bearing wear.)

9. Remove pinion flange nut and washer.

• Use flange holder 5–8840–0133–0 to hold the

pinion flange.

10. Remove pinion flange.

• Use flange holder 5–8840–0133–0 to remov e the

pinion flange.

415RW040

11. Remove pinion from the axle housing.

• Thread the pinion nut halfway onto the pinion.

• Drive the pinion out of the housing with a hammer

and a soft drift.

• Remove the nut and then remove the pinion.

12. Remove collapsible spacer (1).

415RW011

13. Remov e outer seal, outer oil slinger and outer pinion

bearing.

14. Remove inner bearing, inner oil slinger and shim

from the pinion.

• Press the bearing off the pinion using remover 5–

8840–2587–0.

415RW042

• Select insert ; 303174 and collet halv es ; 44801 in

remover kit 5–8840–2587–0.

• Remove the shim.

15. Remov e bearing cups and baffle plate from the axle

housing using a hammer and a punch.

• Work the cups out of the housing evenly, moving

the punch back and forth between one side of the

cup and the other.

• The baffle plate will be destroyed and should be

replaced with a new one.

16. Remove exciter ring.

• Remov e the exciter ring from the differential using

a mallet or a brass hammer if it is required.

NOTE: Discard the exciter ring after removal.

425RS097

Cleaning

Do not steam clean drive parts which have ground and

polished surfaces such as gears, bearings, and shafts.

These parts should be cleaned in a suitable solvent. All

parts should be disassembled bef ore cleaning.

Parts should be thoroughly dried immediately after

cleaning. Use soft, clean, lintless rags. Parts may be

dri ed with cimpr e ssed air. Do not allow the bear ing s to

spin while drying them with compressed air.

Inspection and Repair

It is very important to carefully and thoroughly inspect

all drive unit parts before reassembly.

Thorough inspection of the drive parts f or wear or stress

and subsequent replacement of worn parts will

eliminate costly drive component repair after

reassembly.

Axle Housing

• The carrier bore for nicks or burrs that would prevent

the outer diameter of the pinion seal from sealing,

Remove any burrs that are found.

• The bearing cap bores for nicks or burrs.

Remove any burrs that are found.

• The housing for cracks. Replace the housing if any

crac ks are f ound.

• The housing for f oreign material such as metal chips,

dirt, or rust.

Pinion and Ring Gear

• Pinion and ring gear teeth for cracking, chipping,

scoring, or excessive wear.

• Pinion splines for wear.

• P ini on fla nge sp li nes fo r wear.

• The se ali ng su rface of the pinion flange fo r nicks,

burrs, or rough tool marks which would cause

damage to the seal's inside diameter and result in an

oil leak.

• Replace all worn or broken parts.

• Ring and pinion gears are matched sets and are both

replaced anytime a replacement of either is

necessary.

Bearings

• Bearings visually and by feel.

• The bearings should feel smooth when oiled and

rotated while applying as much hand pressure as

possible.

The large end of the bearing rollers for wear.

This is where tapered roller bearing wear is most

evident.

• Bearing cups for wear, cracks, brinelling and scoring.

• Bearing and cups are only replaced as sets.

• If the rear axle was operated for an extended period

of time with very loose bearings, the ring gear and

drive pinion will also require replacement.

• Low mileage bearings may have minute scratches

and pits on the rollers and the bearing cups from the

initial pre-load. Do not replace a bearing for this

reason.

• Bearing cups for cracks or chips.

Shims

• Shims for cracks and chips. Damaged shims should

be replaced with an equally sized service shim.

Reassembly

1. Install pini on bearing races and baffle pla te usi ng

outer bearing race installer 5–8840–0008–0 / inner

bearing race installer 5–8840–2569–0 and drive

handle 5–8 840–0007–0 .

NOTE: Baffle plate must be installed, when install the

inner pinion bearing race.

425RW073

425RW074

2. Clean all the gauge parts.

3. Lubricate the outer and inner bearings with axle

lubricant.

4. Place the bearings into the pinion bearing races.

5. Place the inner oil slinger onto the inner pinion

bearing.

NO TE: The inner oil slinger must be placed between

gauge plate and inner pinion bearing when measuring

the pinion depth.

6. Install gauge plate 5–8840–2578–0, inner pilot 5–

8840–2573–0 stud and nut 5–8840–0127–0 and

outer pilot 5–8840–2575–0 to the pinion bore.

420RW075

7. Hold the stud stationary at the flats of the stud

(and).

Tighten the stud nut

Torque: 2.2N·m (0.2kg·m/1.6lbft)

8. Rotate the gauge plate and bearings several

complete revolutions to seat the bearings.

9. Tighten the stud nut until a torque of 1.6 to 2.2 N·m

(0.16 – 0.22kg·m/1.2 to 1.6lbft.) is required to keep

the gauge plate in rotation.

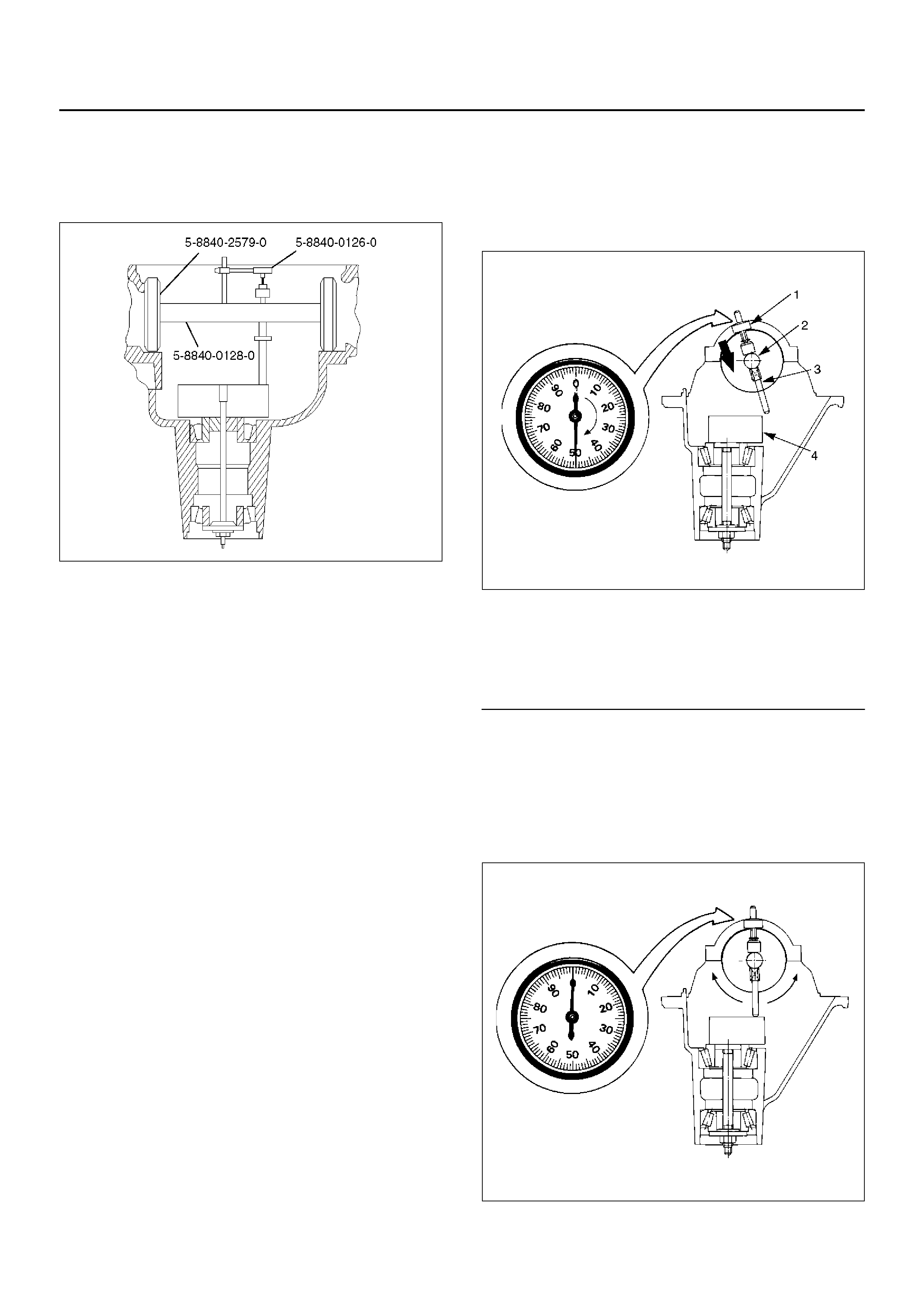

10. Assemble discs 5–8840–2579–0, arbor 5–8840–

0128–0 and dial indicator 5–8840–0126–0 to the

side bearing bores.

NOTE: The bearing bores must be clean and burr-free.

420RW076

11. Install the side bearing caps and tighten the bolts to

the specified torque.

Torque: 108N·m (11.0kg·m/80lbft)

12. Rotate the gauge plate until the gauging area is

parallel with the discs.

13. P osition the arbor assembly in the carrier so that the

plunger is centered on the gauge area of the gauge

plate.

14. Set the dial indicator to “0". Place it on the mounting

post of the gauging arbor with the contact button

touching the indicator pad.

Force the dial indicator downward until the needle

has made a half turn clockwise. Tighten down the

dial indicator in this position.

425RS020

Legend

EndOFCallout

15. Position the plunger on the gauge plate. Move the

gauging arbor slowly back and forth and locate the

position at which the dial indicator shows the

greatest defection. At this point, once again set the

dial indicator to “0".

Repeat the procedure to verify the “0" setting.

425RS021

(1) Di al Indi c ator

(2) Ganging Arbor

(3) Plunger

(4) Gaug Plate

16. After the ZERO setting is obtained, rotate the

gauging arbor until the dial indicator rod does not

touch the gauging plate.

Record the number the dial indicator needle points

to.

425RS022

Legend

EndOFCallout

17. Record the pinion depth code on the head of the

drive pinion.

The number indicates a necessary change in the

pinion mounting distance. A plus number indicates

the need f or a greater mounting distance (which can

be achieved by decreasing the shim thickness). A

minus number indicates the need for a smaller

mounting distance (which can be achieved by

increasing the shim thickness). If examination

reveals pinion depth code “0", the pinion is

“nominal".

425RS023

(1) Example=Dial indicator reading of 0.085

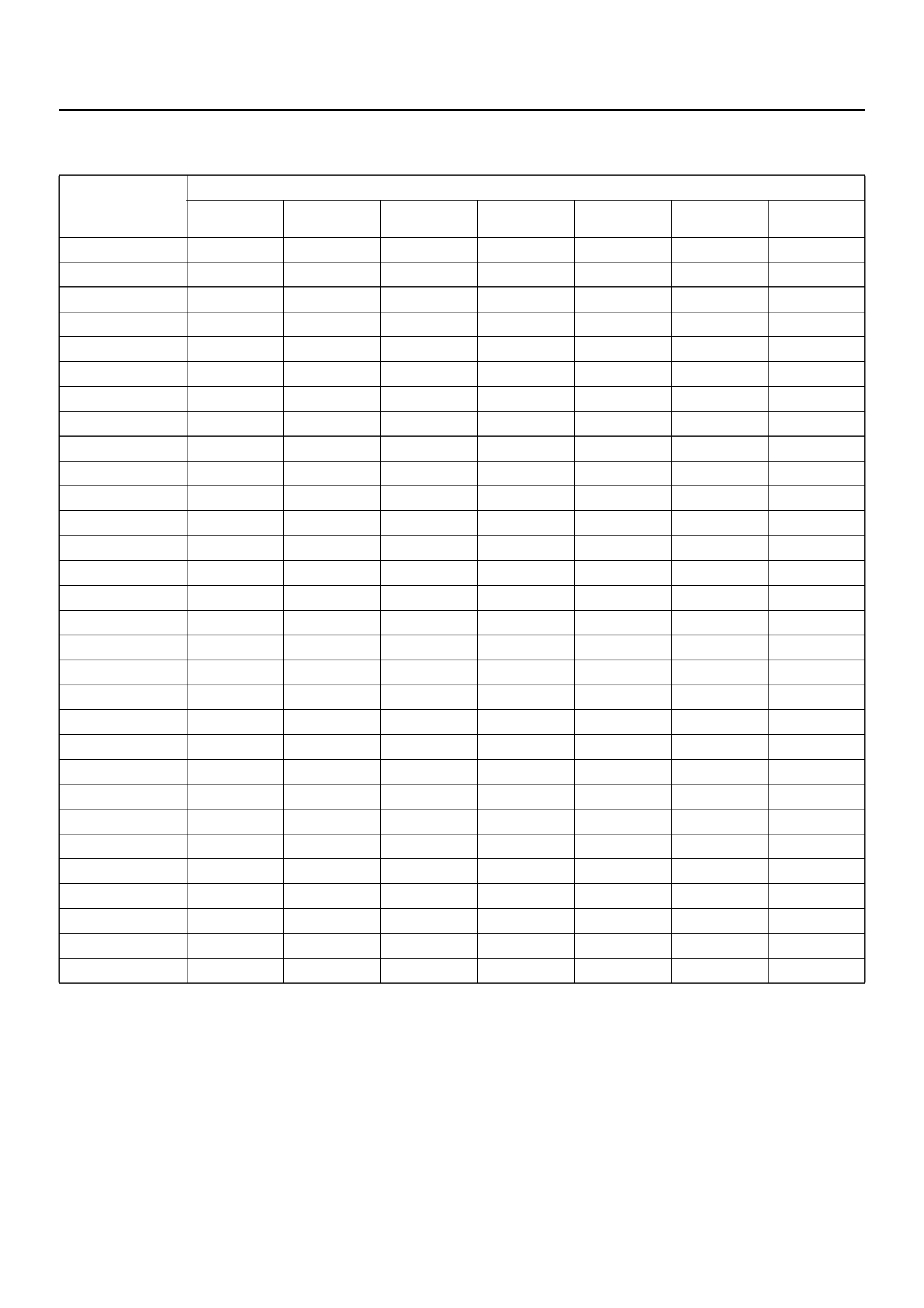

18. Select the shim using the chart;

Dial Indicator

Reading

(inches)

Marking (inches)

+3 +2 +1 0 -1 -2 -3

0.027 0.030

0.028 0.030 0.031

0.029 0.030 0.031 0.032

0.030 0.030 0.031 0.032 0.033

0.031 0.030 0.031 0.032 0.033 0.034

0.032 0.030 0.031 0.032 0.033 0.034 0.035

0.033 0.030 0.031 0.032 0.033 0.034 0.035 0.036

0.034 0.031 0.032 0.033 0.034 0.035 0.036 0.037

0.035 0.032 0.033 0.034 0.035 0.036 0.037 0.038

0.036 0.033 0.034 0.035 0.036 0.037 0.038 0.039

0.037 0.034 0.035 0.036 0.037 0.038 0.039 0.040

0.038 0.035 0.036 0.037 0.038 0.039 0.040 0.041

0.039 0.036 0.037 0.038 0.039 0.040 0.041 0.042

0.040 0.037 0.038 0.039 0.040 0.041 0.042 0.043

0.041 0.038 0.039 0.040 0.041 0.042 0.043 0.044

0.042 0.039 0.040 0.041 0.042 0.043 0.044 0.045

0.043 0.040 0.041 0.042 0.043 0.044 0.045 0.046

0.044 0.041 0.042 0.043 0.044 0.045 0.046 0.047

0.045 0.042 0.043 0.044 0.045 0.046 0.047 0.048

0.046 0.043 0.044 0.045 0.046 0.047 0.048 0.049

0.047 0.044 0.045 0.046 0.047 0.048 0.049 0.050

0.048 0.045 0.046 0.047 0.048 0.049 0.050 0.051

0.049 0.046 0.047 0.048 0.049 0.050 0.051 0.052

0.050 0.047 0.048 0.049 0.050 0.051 0.052 0.053

0.051 0.048 0.049 0.050 0.051 0.052 0.053

0.052 0.049 0.050 0.051 0.052 0.053

0.053 0.050 0.051 0.052 0.053

0.054 0.051 0.052 0.053

0.055 0.052 0.053

0.056 0.053

19. Remove bearing caps and depth gauging tools.

20. Install the correct pinion shim and inner oil slinger

onto pinion.

NOTE: Do not install pinion gear into housing at this

time.

21. If the exciter ring was removed, install the new

exciter ring onto the differential case by pressing

using the ring gear as a pilot.

425RS047

22. Install ring gear(1) to the differential case(2)

425RW021

23. Install new ring gear bolts.

• Tighten the ring gear bolts alternately in stages,

gradually pulling the ring gear onto the differential

case.

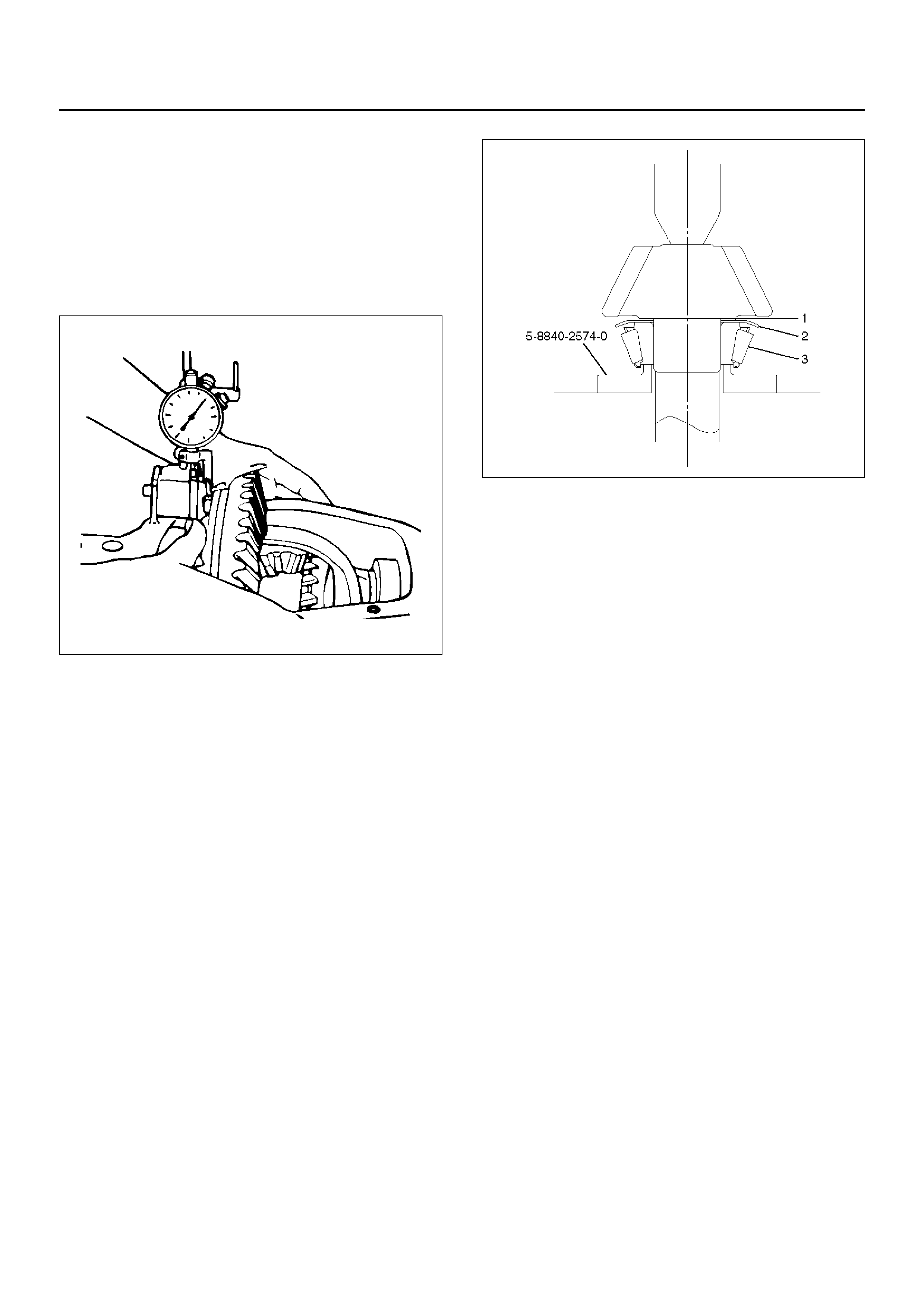

Tighten the ring gear bolts in sequence

Torque: 108N·m (11.0kg·m/80lbft)

NO TE: Discard used bolts and install new ones.

415RS016

Side Bearing Preload Adjustment

1. The side bearing preload adjustment must be made

before insta lling the pinion.

2. The side bearing preload is adjusted by changing

the thickness of both hte left and right shims equally .

This mainta in the or ig in al backlash.

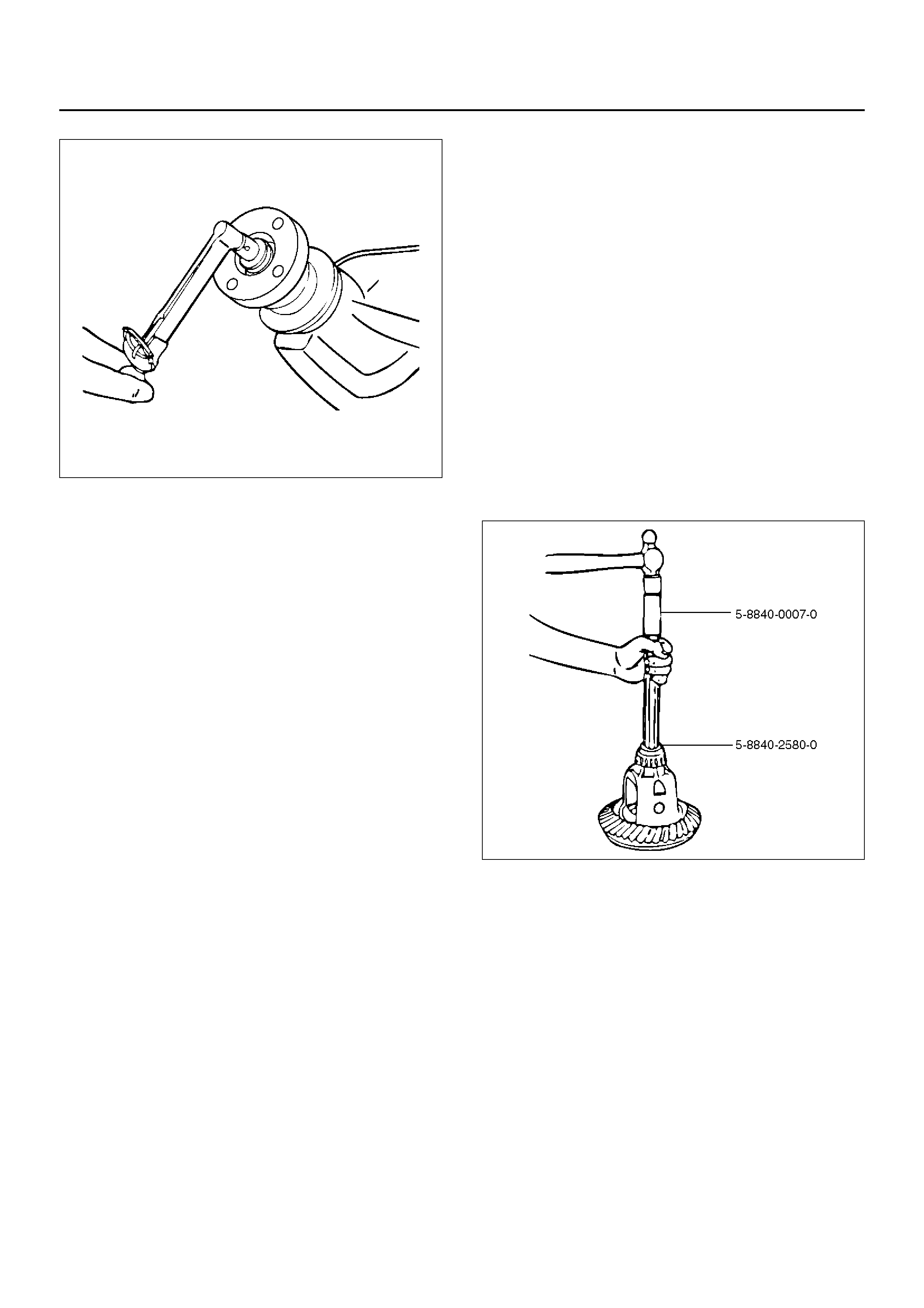

3. Install maste r side bearings 5–8840–258 4–0 onto

the case.

Remove all nicks, b urrs, dirt etc., from the hubs to

allow the master bearings to rotate freely.

425RW077

4. Assemble the diff erential case into the housing (less

pinion). Install bearing caps and finger tight bolts.

Mount a dial indicator with a magnetic base to the

housing and indicate on the flange or head of screw.

Force the differential assembly as f ar as possible in

the dirction towards the indicator.

With force still applied, set indicator at zero(0).

NOTE: Dial indicator set should be capable of a

minimum travel of 5.08mm (0.2in) .

425RS107

5. Force the differetial assembly as far as it will go in

the opposite direction. Repeat these steps until the

same reading is obtained.

6. RECORD THE READING OF THE INDICATOR.

This amount, in shims, will be included in the final

assembly shim stack to establish side bearing

preload and ring gear and pinion backlash.

7. After marking sure the readings are correct, remov e

the indicator and differetial assembly from the

housing.

Pinion Installation

• The bearing cups should have been installed in

Pinion Depth Adjustment in this section.

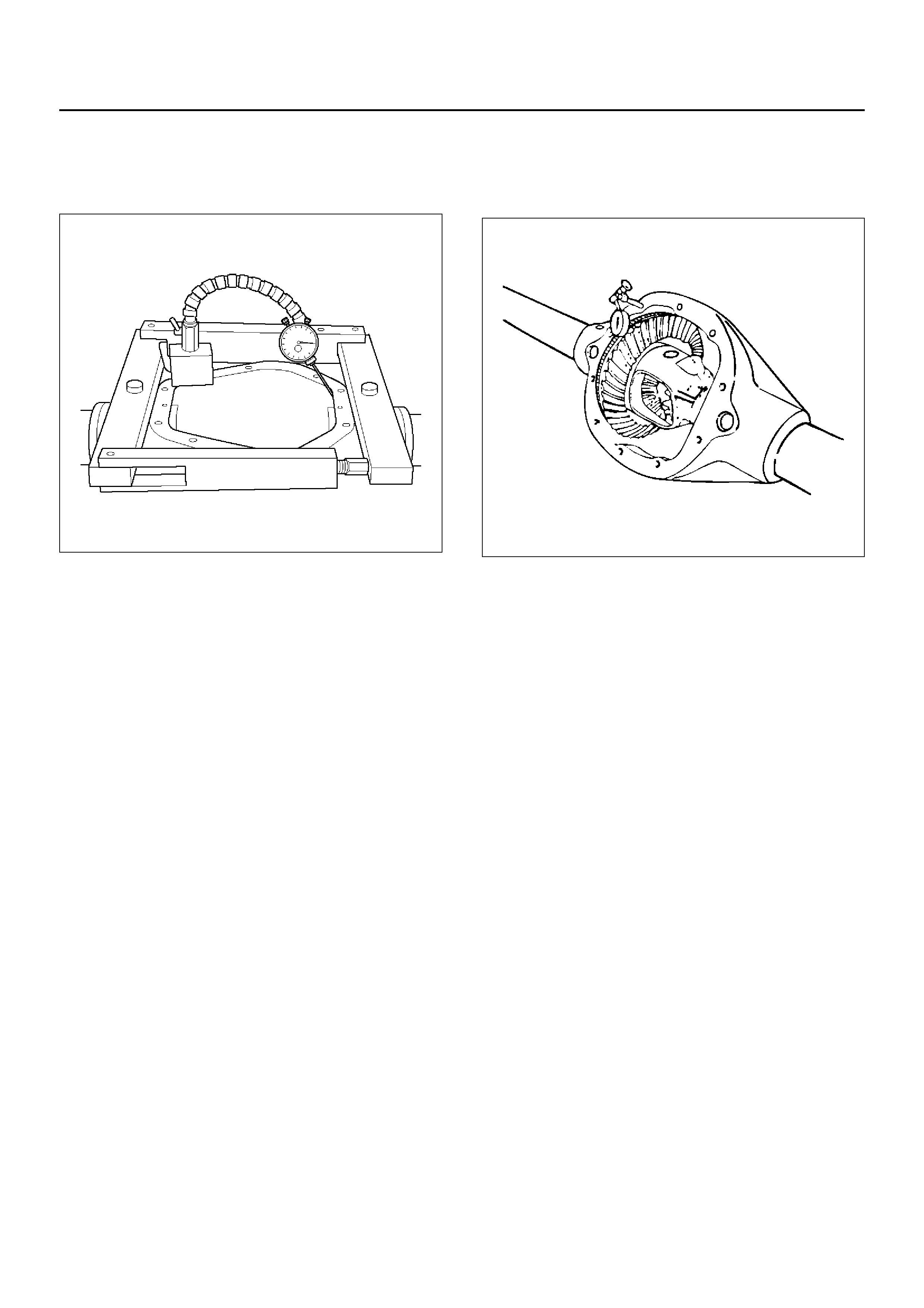

1. Place the shim(1) and inner oil slinger(2) on the

pinion gear, then install the pinion inner bearing(3)

using inst a ller 5–8840 –257 4–0 .

425RW078

• Drive the bearing until the bearing cone seats on

the pinion shims.

2. Install a new collpsible spacer.

• Lubracate the pinion bearings with axle lublicant.

3. Install pinion to the axle housing.

4. Install outer pinion bearing onto the pinion.

• Hold the pinion f orward from inside the case while

driving the bearing onto the pinion.

5. Install oil seal slinger.

6. Install pinion oil seal using installer 5–8840–2165–0.

7. Install the pinion flange to the pinion by tapping it

with a rawhide hammer until a f ew threads show

through the pinion flange.

8. Install pinion washer and a new nut while holding

the pinion flange with flange holder 5–8840–0133–

0.

• Tighten the nut until the pinion end play is just

taken up. Rotate the pinion while tightening the

nut to seat the bearings.

Torque:217-678N·m (22.1-69.1kg·m/160-500lbft)

Once there is no end play in the pinion, the

preload torque should be checked.

• Remove flange holder 5–8840–0133–0. Using a

torque wrench, check the pinion preload by

rotating the pinion with the wrench.

425RW018

Preload should be at 1.0 to 1.6N·m

(10.2-16.3kg·cm/8 to 14inlbs.) on new bearings,

or 0.46 to 0.69N·m (4.7-7.0kg·cm/4 to 6inlbs.) for

used bearings.

• If the preload torque is below the preloads given

above, continue torquing the nut in small

increments. Check the preload after each

tightening. Each tightening increases the bearing

preload by sev eral pounds. If the bearing preload

is exceeded, the pinion will have to be removed,

and a new collapsible spacer installed.

• Once a preload of 1.0 to 1.4N·m

(10.2-14.3kg·cm/8 to 12inlbs.) has been

obtained, rotate the pinion several times to

assure that the bearings have seated. Recheck

the preload, and adjust if necessary.

Determination of Backlash & Preload

Shims

1. Install master side bearings onto the case.

2. Install differential assembly into the carrier.

3. Install the bearing cap and finger tight bolts.

4. Set up the dial indicator.

5. F orce the differential assembly awa y from the pinion

gear until it is completely seated against the cross

bore face of the carrier.

6. With force still applied to the differential case, place

the tip of dial indicator on a machined surface of the

differential case, if av ailable, or on the head of a ring

gear screw, and set the indicator at zero(0).

7. Force the ring gear to mesh with the pinion gear.

Rock the ring gear slightly to make sure the gear

teeth are meshed. Repeat this procedure several

times until the same reading is obtained each time.

Be sure the indicator reads z ero(0) each time the

ring gear is forced back into contact with the cross

bore face. This reading will be the necessary

amount of thims to be placed between the

diff erential case and side bearing cone on the ring

gear side.

8. The remaining amount of shims, which is the

diff erence between the overall found in step 6 of

Side Bearing Pre-load Adjustment and step(7)

above, should be placed on the other side of the

diff erential case, plus additional 0.38mm (0.015in)

for obtaining preload and backlash.

9. Place the required amount of shims on each hub as

determined in the previous steps and assemble side

bearing cone by using installer 5–8840–2580–0 and

handle 5–8840–0007–0.

425RW079

10. Total torque to rotate — Increase of pinion torque to

rotate due to differential case assembly shall not

exceed 3.4N·m (34.7kg·cm/30inlbs.) divided by the

gear ratio.

11.Assembly the spreader 5–8840–2581–0 and

indicator to the carrier as shown in figure. Spread

the carrier 0.5mm (0.02in) for differential

installation.

420RW004

CAUTION: Do not spread the carrier over 0.5mm

(0.02in).

12. Remove the indicator.

Backlash Adjustment

1. Install the differential case assembly and bearing

caps.

2. Rotate the case several times to seat the bearings.

3. Remove the spreader.

4. Install the side bearing cap bolts.

Tighten side bearing cap bolts

Torque: 108N·m (11.0kg·m/80lbft)

5. Install a dial indicator to the case using a magnetic

base.

6. Place the indicator stem at the heel end of a tooth.

• Set the dial indicator so that the stem is in line

with the gear rotation and perpendicular to the

tooth angle.

425RS087

7. Check and record the backlash at three points

around the r in g gear.

• The pinion must be held stationary when

checking backlash.

• The backlash should be the same at each point

within 0.07mm (0.003in). If the backlash varies

more than 0.07mm (0.003in), check for burrs, a

distorted case flange, or uneven bolting

conditions.

8. Backlash at the minimum lash point measured

should be between 0.13 and 0.20mm (0.005 and

0.008in) for all new gear sets.

9. If the backlash is not within specifications, move the

ring gear in or out from the pinion by increasing the

thickness of one shims, and decreasing the

thickness of the other shim by the same amount.

This will maintain the correct rear axls side bearing

preload.

• Moving 0.05mm (0.002in) worth of shim from one

side of the differential to the other will change the

backlash adjustment by 0.03mm (0.001in).

10. After obtaining correct tooth contact described in

later, install ABS speed sensor.

11. Install the cover with sealant.

Torque: 42N·m (4.3kg·m/31lbft)

12. Fill the axle lubricant.

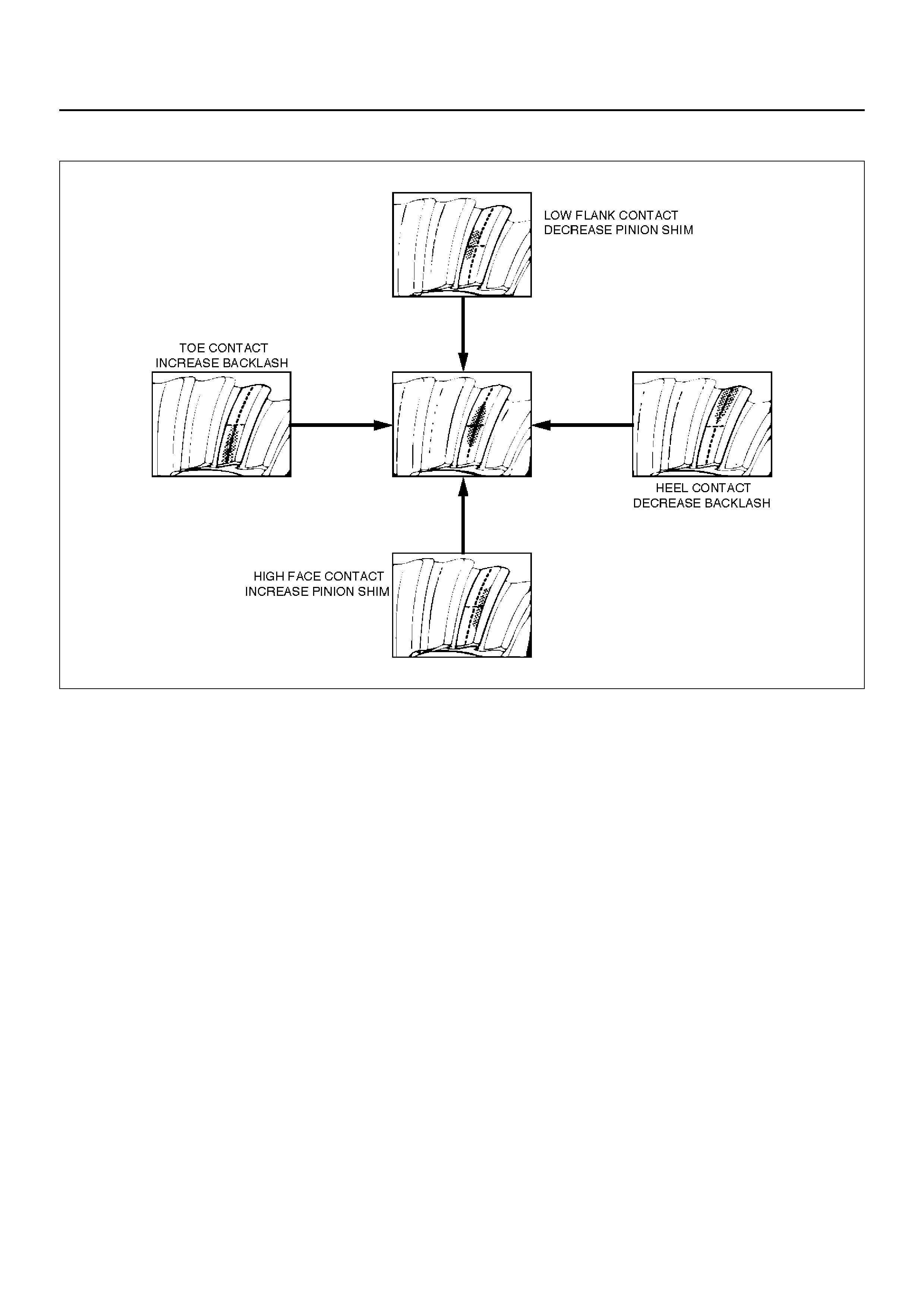

Gear Tooth Pattern Check

Checking the ring gear to pinion tooth pattern is to be

done only after setting up the axle according to the

methods in this section. The pattern check is NEVER to

be used as an initial chec k, or instead of checking pinion

depth and backlash adjustments.

This check is only to be verify the correct adjustment of

the gear set after set up.

425RS038

Legend

EndOFCallout

1. Wipe all oil out of the carrier, and carefully clean

each tooth of the ring gear.

2. Use gear marking compound 1052351 or equivalent

and apply this mixture sparingly to all ring gear

teeth, using a medium-stiff brush. When properly

used, the area of pinion tooth contact will be visible

when hand load is applied.

3. Tighten the bearing cap bolts to the specified

torque.

4. Expand the brake shoes until a torque of 54 to

68N·m (5.5 to 6.9kg·m/40 to 50 lbft.) is required to

turn the pinion. A test made without loading the

gears will not give a satisfactory pattern. Turn the

pinion flange with a wrench so that the ring gear

rotates one full revolution, then reverse the rotation

so that the ring gear rotates one revolution in the

opposite direction.

(1) Heel

(2) Toe

(3) Concave Side (Coast)

(4) Convex Side (Drive)

5. Observe the pattern on the ring gear teeth and

compare this with figure .

425RS039

Adjustments Affecting Tooth Contact

Two adjustments can be made which will affect tooth

contact pattern: backlash, and the position of the drive

pinion in the case. The effects of bearing preloads are

not readily apparent on head loaded tooth contact

pattern tests; however, these adjustments shuld be

within specifications before proceeding with backlash

and drive pinion adjustments.

The position of the drive pinion is adjusted by increasing

or decreasing the distance between the pinion head and

the centerline of the ring gear.

Decreasing the distance will move the pinion closer to

the centerline of the ring gear. Increasing the distance

will move the pinion farther away from the centerline of

the ring gear.

Backlash is adjusted by means of the side bearing

adjusting shims which move the entire case and ring

gear assembly closer to, or f arther from, the drive

pinion. (The adjusting shims are also used to set side

bearing preload.)

If the thickness of the right shim is increased (along with

decreasing the left shim thickness), backlash will

increase.

The backlash will decrease if the left shim thickness is

increased (along with a decrease in right shim

thickness).

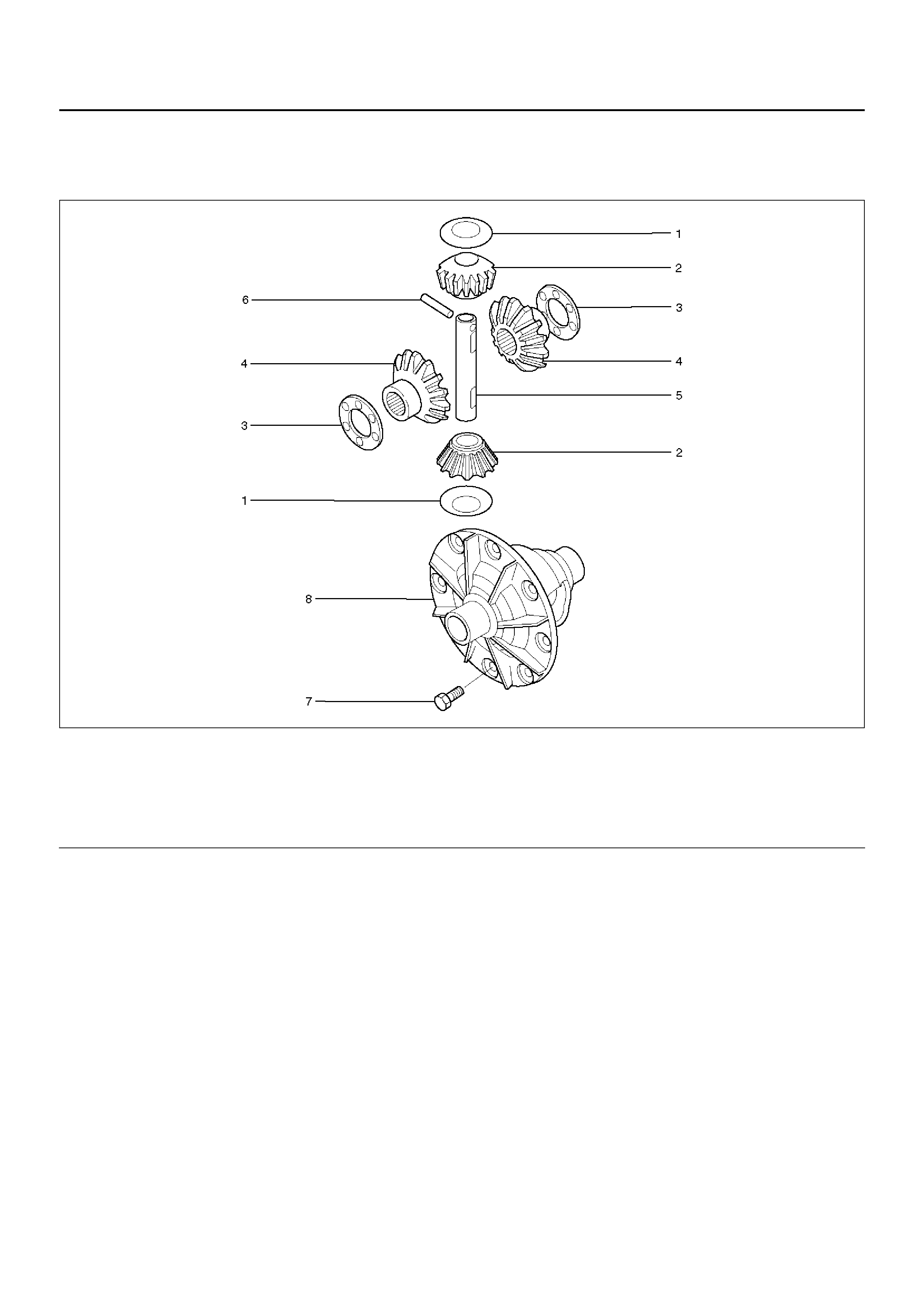

Differential Case Assembly

Disassembled View

425RW014

Legend

EndOFCallout

(1) Thrust Washer (for Pinion Gear)

(2) Pinion Mate Gear

(3) Thrust Washer(for Side Gear)

(4) Side Gear

(5) Differential Shaft

(6) Lock Pin

(7) Bolt

(8) Differential Case

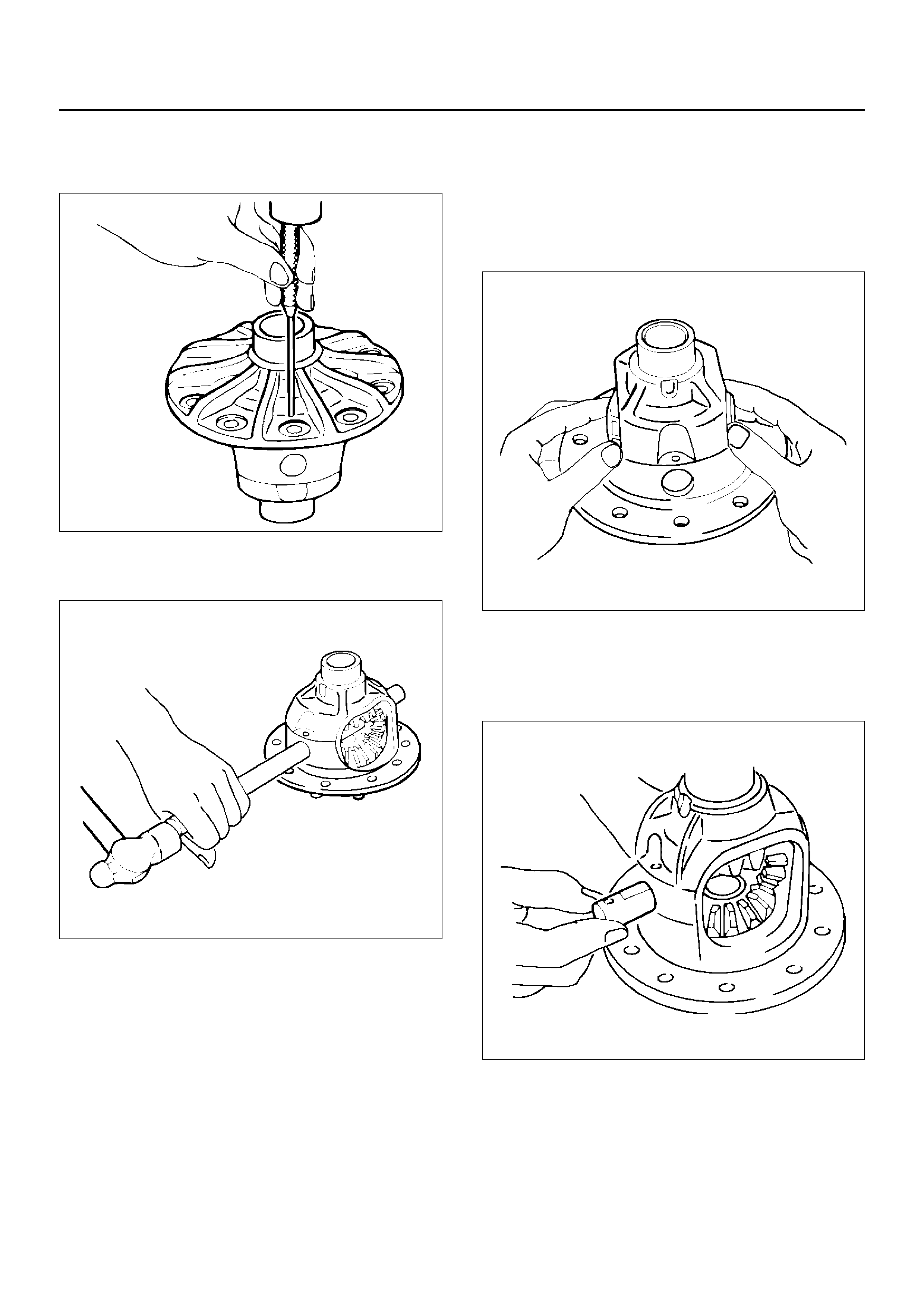

Disassembly

1. Remove lock pin using a small drift.

425RS098

2. Remove the differential shaft by using a soft metal

rod and a hammer.

425RS043

3. Remove pinion mate gear and thrust washer.

4. Remove side gear and thru st washe r.

Inspection and Repair

Make necessary correction or parts replacement if

wear, damage, corrosion or any other abnormal

condition are found through inspection.

Check the following parts.

• Ring gear, pinion gear

• Bearing

• Side gear, pinion mate gear, differential shaft

• Differential case, carrier

• Thrust washer

• Oil seal

Reassembly

1.Install side gear with thrust washer.

2. Install the pinion mate gear with thrust washer by

engaging it with the side gears while turning both

pinion mate gears simultaneously in the same

direction.

425RS048

3. Install differential shaft.

1. Be sure to install the differential shaft so that it is

in alignment with the lock pin hole in the

diff erential case.

425RS049

4. Install lock pin.

After lock pin installation, stake the case to secure

the lock pin.

Limited Slip Differential Assembly

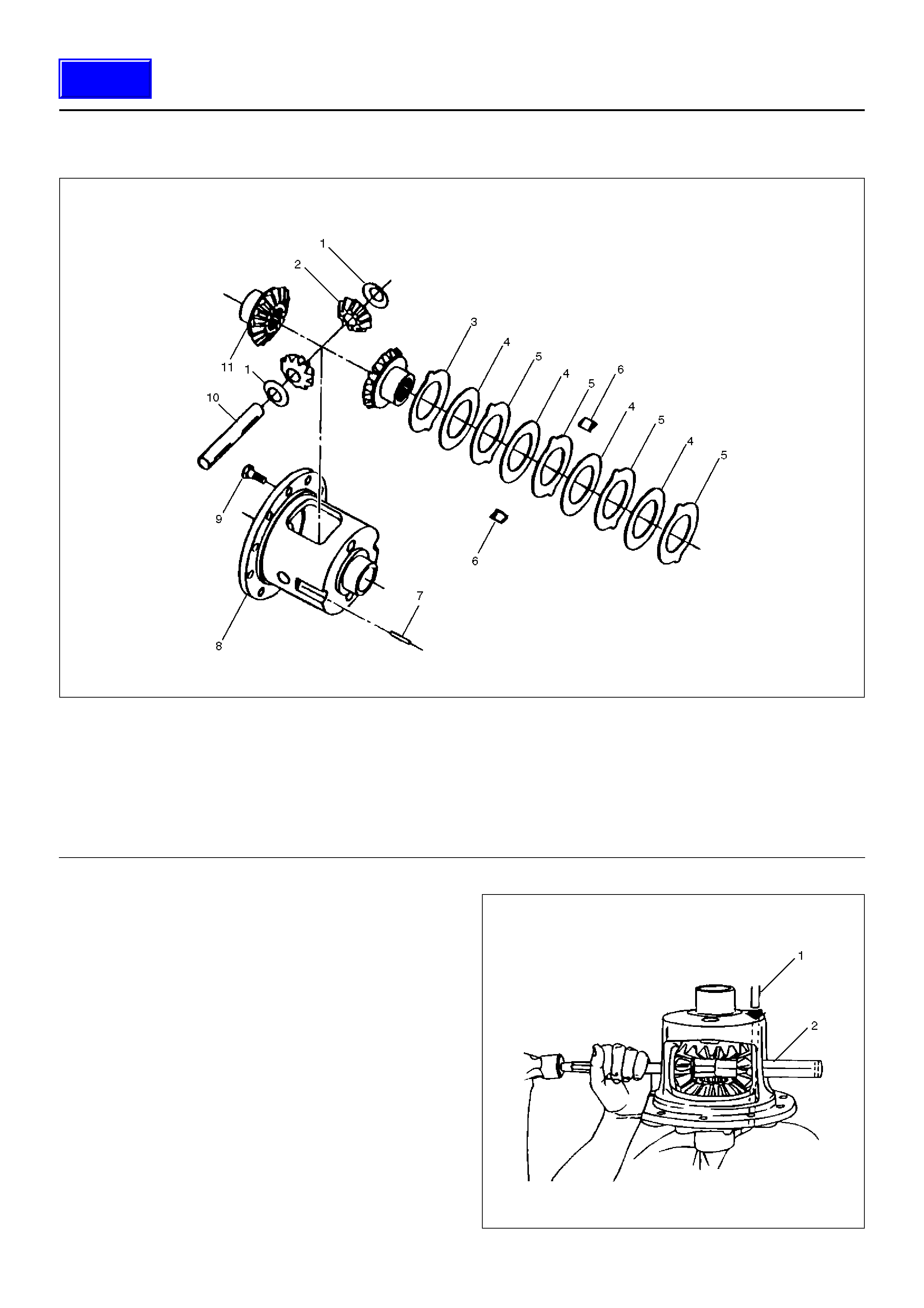

Disassembled View

425RW004

Legend

EndOFCallout

Disassembly

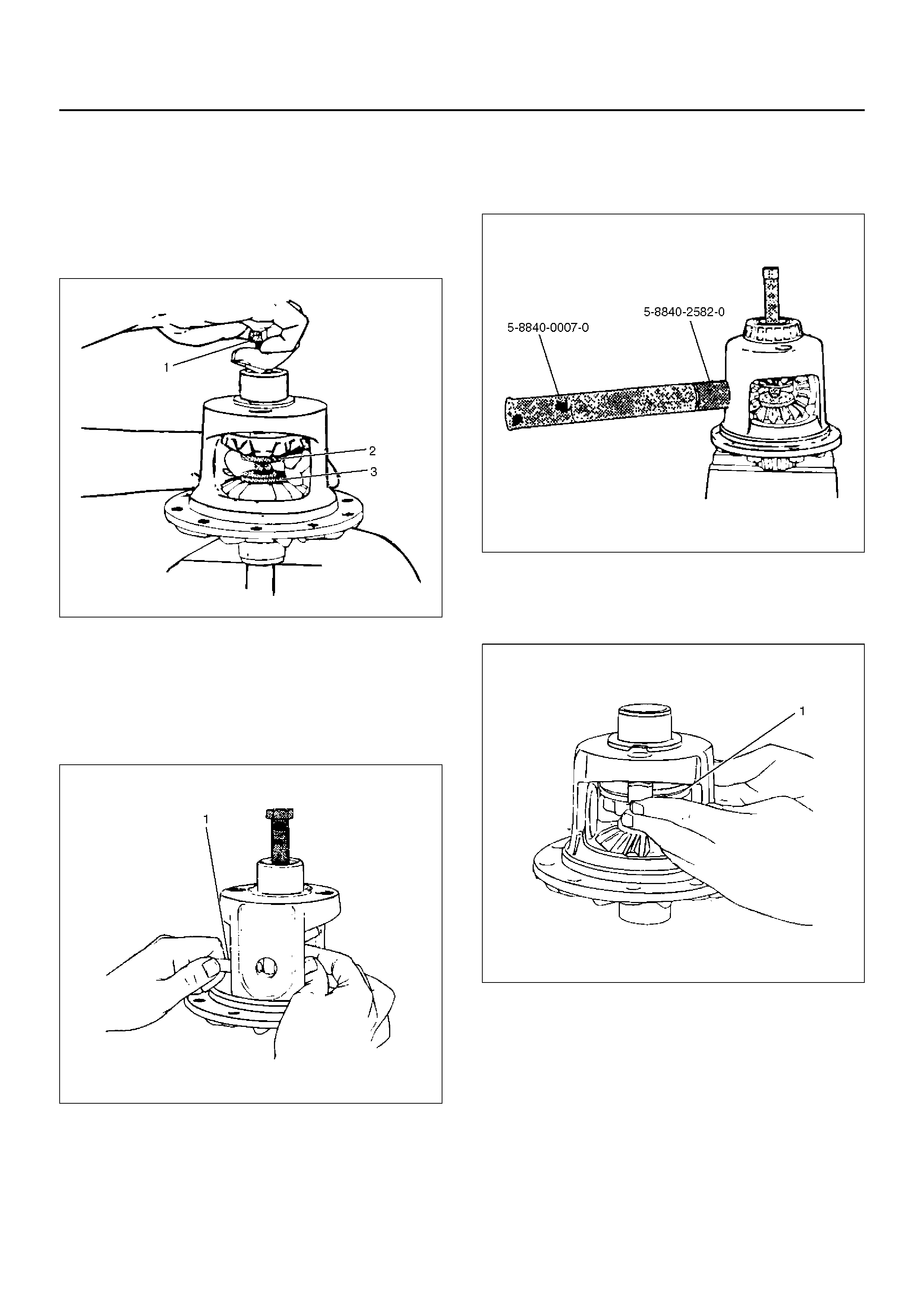

1.Place the holder 5–8840–2583–0 into a vise.

Position the differential on the holder with the ring

gear side down.

2. Remove Lock pin (1) from differential shaft using a

punch.

3. Remove Differential shaft (2) using hammer and

punch.

Place shop towel behind case to prevent differential

shaft from dropping out of case.

425RW005

(1) Thrust Washer–Differential Pinion Mate Gear

(2) Pinion Mate Gear

(3) Dished Spacer

(4) Disc

(5) Plate

(6) Differential Plate Retainer

(7) Lock Pin

(8) Differential Case

(9) Ring Gear Bolts

(10) Differential Shaft

(11) Differential Side Gear

Techline

4. Assemble clutch pack unloading tool 5–8840–2586–

0.

a Install cap(3) to the bottom differential side gear.

b Install threaded scre w cap(2) to top differential

side gear. Thread forcing screws(1) into

threaded screw cap until it becomes centered

into the bottom cap.

901RW288

c Tighten forcing screw until tight enough to

collapse dished spacers and and allow

looseness between side and pinion mate gears.

5. Both pinion mate gear thrust washers using a shim

stock (1) of 0.51 mm (0.020 in.) or equivalent tool to

push out washers.

425RW007

6. Relieve tension of dished spacers by loosening

forcing screw.

NOTE:

• You may ha ve to adjust the forcing screw slightly to

allow the case to rotate.

7. Assemble LSD service adapter 5–8840–2582–0

onto long drive handle 5–8840–0007–0. Insert it into

diff erential shaft hole of case. Pull on handle and

rotate case until pinion mate gears can be removed.

901RW289

8. Remove pinion mate gears.

9. Hold side gear top clutch pack (1) with one hand

and remove positraction unloading tools.

425RW008

10. Remove top side gear and clutch pack.

NOTE:

• Keep the stack of plates and discs intact and in

exactly the same position while they are being

removed.

11. Remove case from holder. Turn case with flange or

ring gear side up to allow side gear and clutch pack

to be removed from case.

12. Remove differential plate retainer from both clutch

packs to allow separation of the plates and discs.

NOTE:

• Keep the discs and plates in the same order as they

were removed.

425RW009

Legend

EndOFCallout

Inspection and Repair

Cleaning

• All parts with solvent.

Visual Inspection

• Clean all parts with solvent.

• Plates and Discs. If any one disc or plate in either

stack shows evidence of excessive wear or scoring,

the complete stack is to be replaced on both sides.

• Side Gears and Pinion Mate Gears. The gear teeth of

these parts should be checked for extreme wear and

possible cracks. The external teeth of the side gear,

which retain the concentric groove discs, should also

be checked for wear or cracks.

• If replacement of one gear is required due to wear,

etc., then both side gears, pinion mate gears, and

thrust washers are to be replaced.

• Differential Shaft. If excessive wear is evident, the

differential shaft should be replaced.

• Differential Plate Retainers. If wear is evident on any

one of the differential plate retainers, all four

retainers must be replaced.

• Differential Case. If scoring, wear or metal pickup is

ev ident on the machined surf aces, replacement of the

case is necessary.

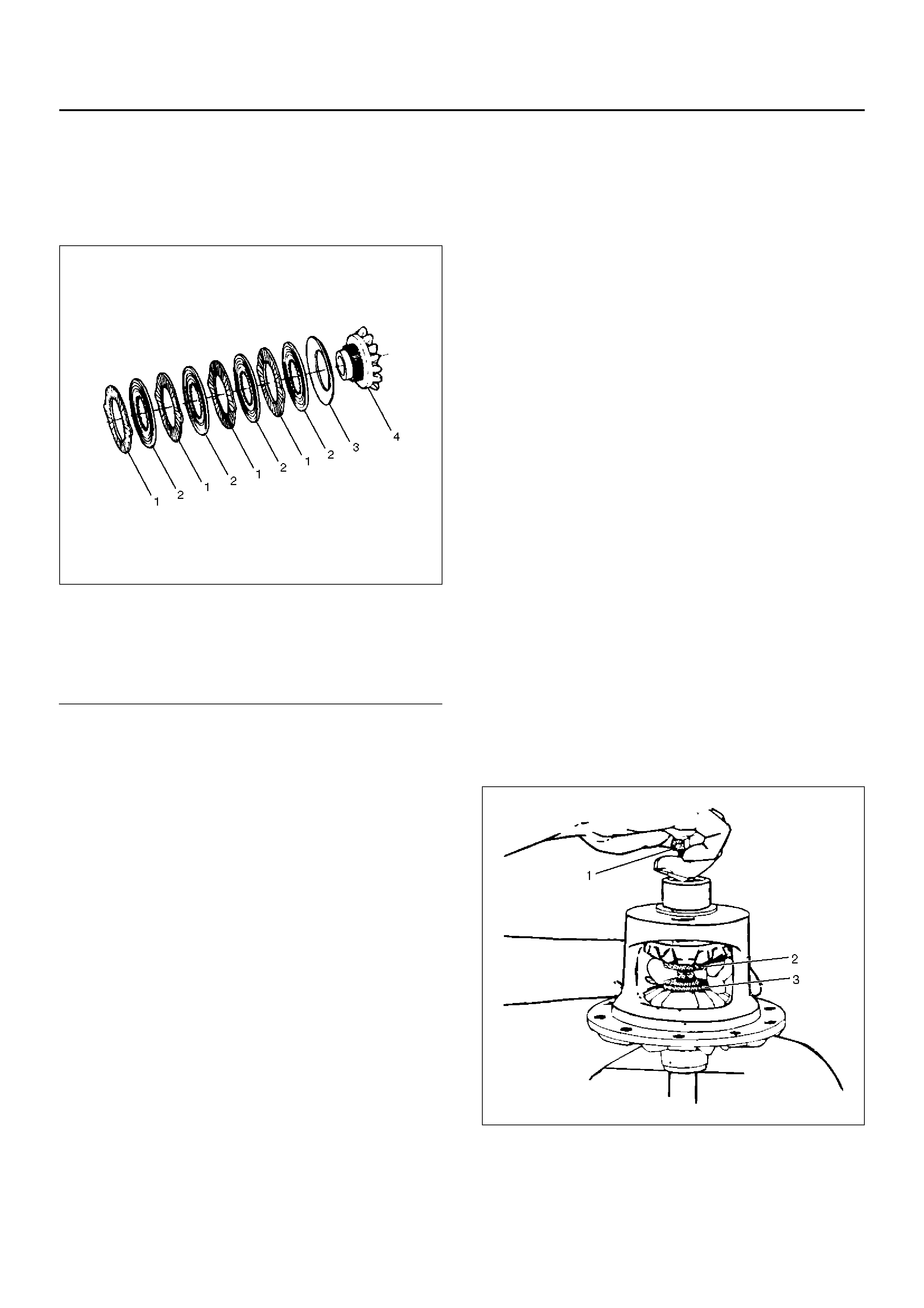

Reassembly

1. Lubricate thrust face of side gears, plates and discs

with the proper limited slip rear axle lubricant.

2. Assemble plates and discs in exactly in the same

position as they were removed, regardless of

whether they are new or original.

3. Install differential plate retainer to ears of plates.

NOTE:

• Make sure both retainers are completely seated on

ears of plates.

4. Install clutch pack and side gear into bottom side

gear bore. Make sure clutch pack stay s assembled

to side gear splines, and that retainers are

completely seated into pockets of case.

NOTE:

• To prevent clutch pack from falling out of case, hold

clutch pack in place by hand while repositioning case

on bench.

5. Install other side gear and clutch pack. Make sure

clutch pack stays assembled to side gear splines,

and retainers are completely seated into pockets of

case.

6. Hold clutch pack in position and assemble screw

cap(2), cap(3) and forcing screw(1). Tighten f orcing

screw into bottom cap to hold both clutch packs in

position.

7. With tools assembled to case, position case on

holder 5–8840–2583–0 by aligning splines of side

gear with those of shaft. Tighten forcing screw to

compress clutch packs in order to provide

clearance for pinion mate gears.

901RW288

8. Install pinion mate gears.

• Place the pinion mate gears into the diff erential

180 degrees apart.

(1) Differential Plate

(2) Differential Disc

(3) Dished Spacer

(4) Side Gear

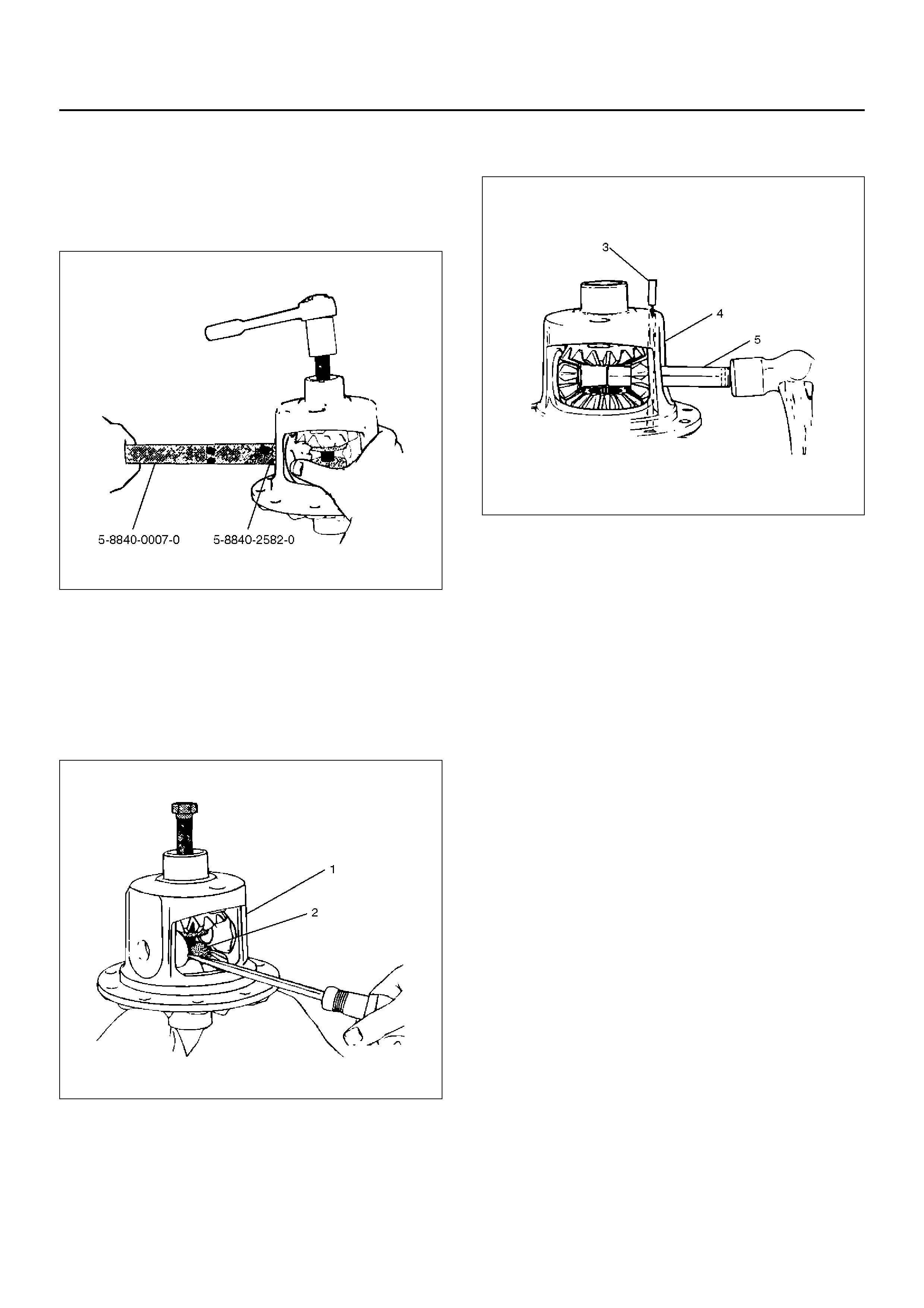

9. While holding gears in place, insert LSD service

adapter 5–8840–2582–0 with long drive handle 5–

8840–0007–0 in differential shaft hole of case. Pull

on long drive handle and rotate case, allowing

gears to turn. Make sure that holes in pinion mate

gears align with holes in case.

901RW290

• It may be necessary to adjust tension on forcing

scre w to rotate case.

10. Tighten f orcing screw to compress the clutch packs,

to allow installation of spherical thrust washers.

11. Lubricate spherical thrust washers (2), and

assemble into ca se (1 ). Use a sm a ll scr e w d river to

push washers into place. Remove tools.

425RW012

12. Position differential shaft in case and drive in with

hammer. Be sure lock pin hole of differential shaft

(5) is properly aligned to allow installation of lock

pin (3). Be sure that thrust washers and differential

pinion mate gears are aligned with the differential

case (4). Install new lock pin to proper depth using a

punch.

Stake metal of case over pin in two places, 180

degrees apart.

425RW013

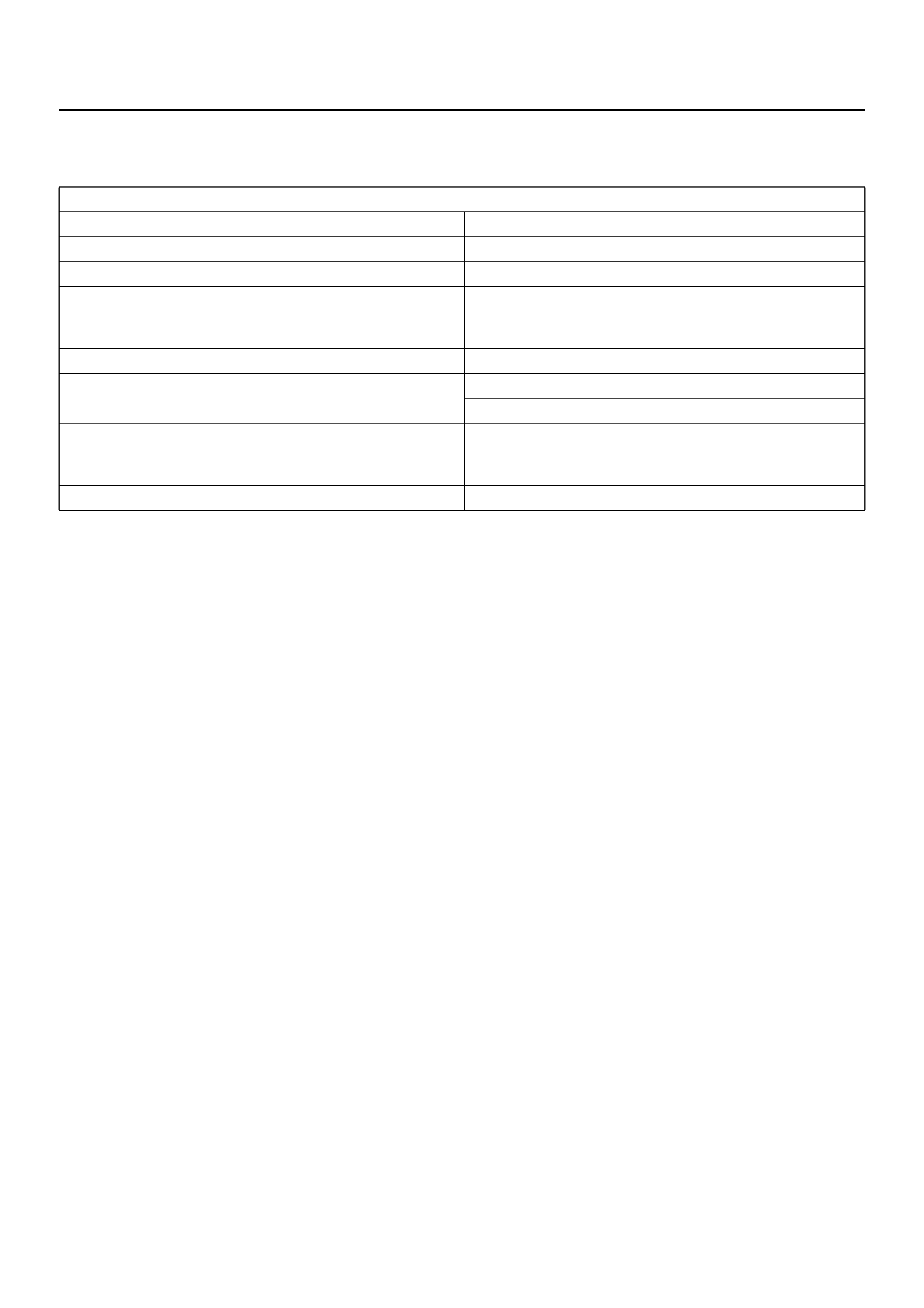

Main Data And Specifications

General Specifications

Rear axle

Type Salisbur y, Semi–floating

Rear axle Size 226mm (8.9in)

Gear type Hypoid

Gear ratio (to 1) 4.100 (6VD1 with A/T)

4.300 (6VD1 with M/T)

4.777 (X22SE with M/T)

Diff erential type Two pinion

Lubricant Grade GL–5: (Standard differential)

GL–5, LSD: (Limited slip differential)

Locking Differential Lubricant 80W90 GL–5

(USE Limited Slip Differential Gear Lubricant or Friction

Modifier Organic Additive)

Capacity 1.77 liter (1.87 US qt)

Torque Specifications

E04RX010

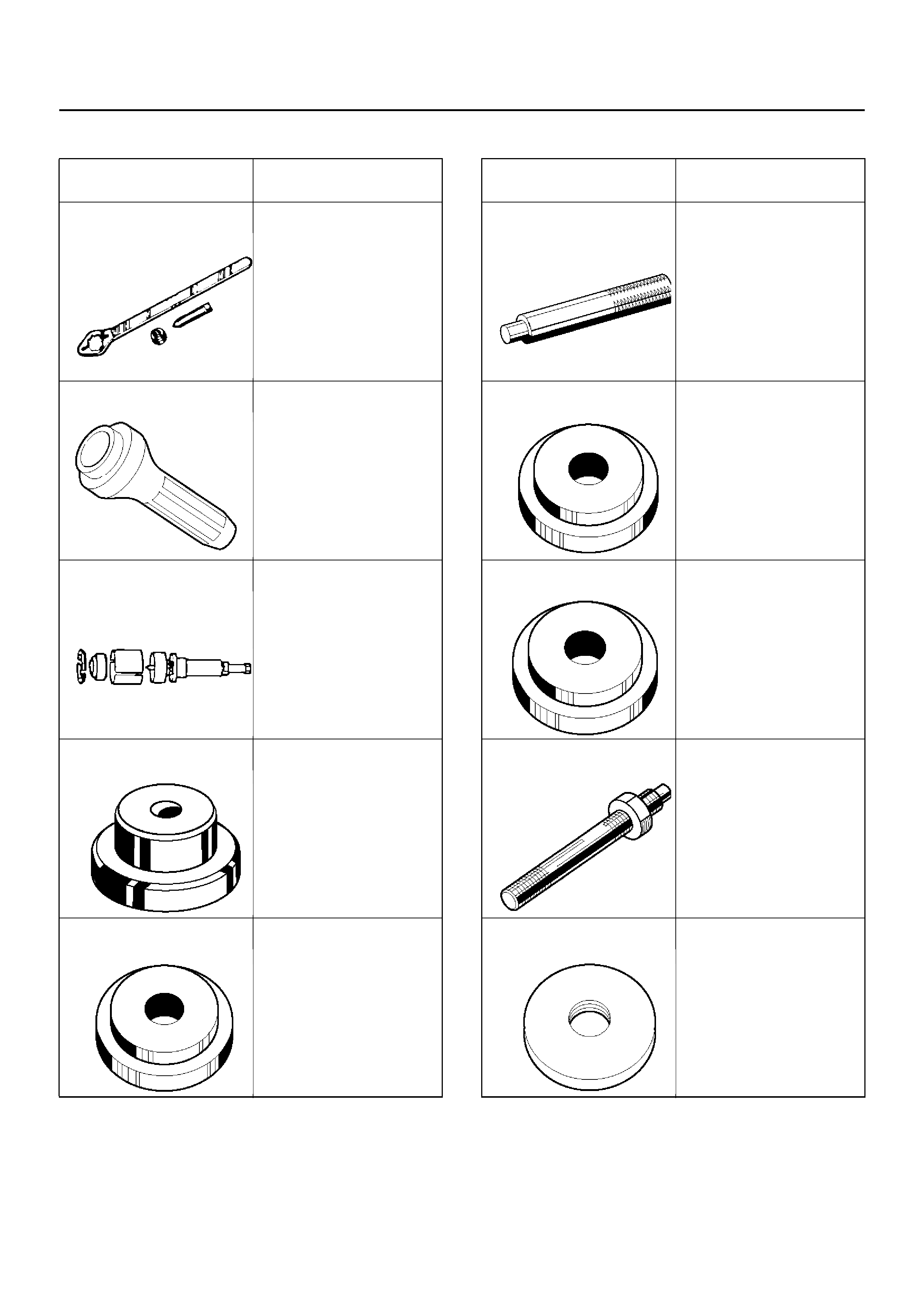

Special Tools

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–0133–0

(J–8614–01)

Pinion flan ge hol der

5–8840–2165–0

(J–37263)

Installer; Pinion oil seal

5–8840–2587–0

(J–42379)

Remover; Bearing

5–8840–2585–0

(J–39830)

Adapter; Side bearing

plug

5–8840–0008–0

(J–8611–01)

Installer; Outer bearing

outer race

5–8840–0007–0

(J–8592)

Grip

5–8840–2569–0

(J–42836)

Installer; Inner bearing

outer race

5–8840–2575–0

(J–42824)

Pilot;Outer

5–8840–0127–0

(J–21777–43)

Nut & Stud

5–8840–2573–0

(J–42827)

Pilot;Inner

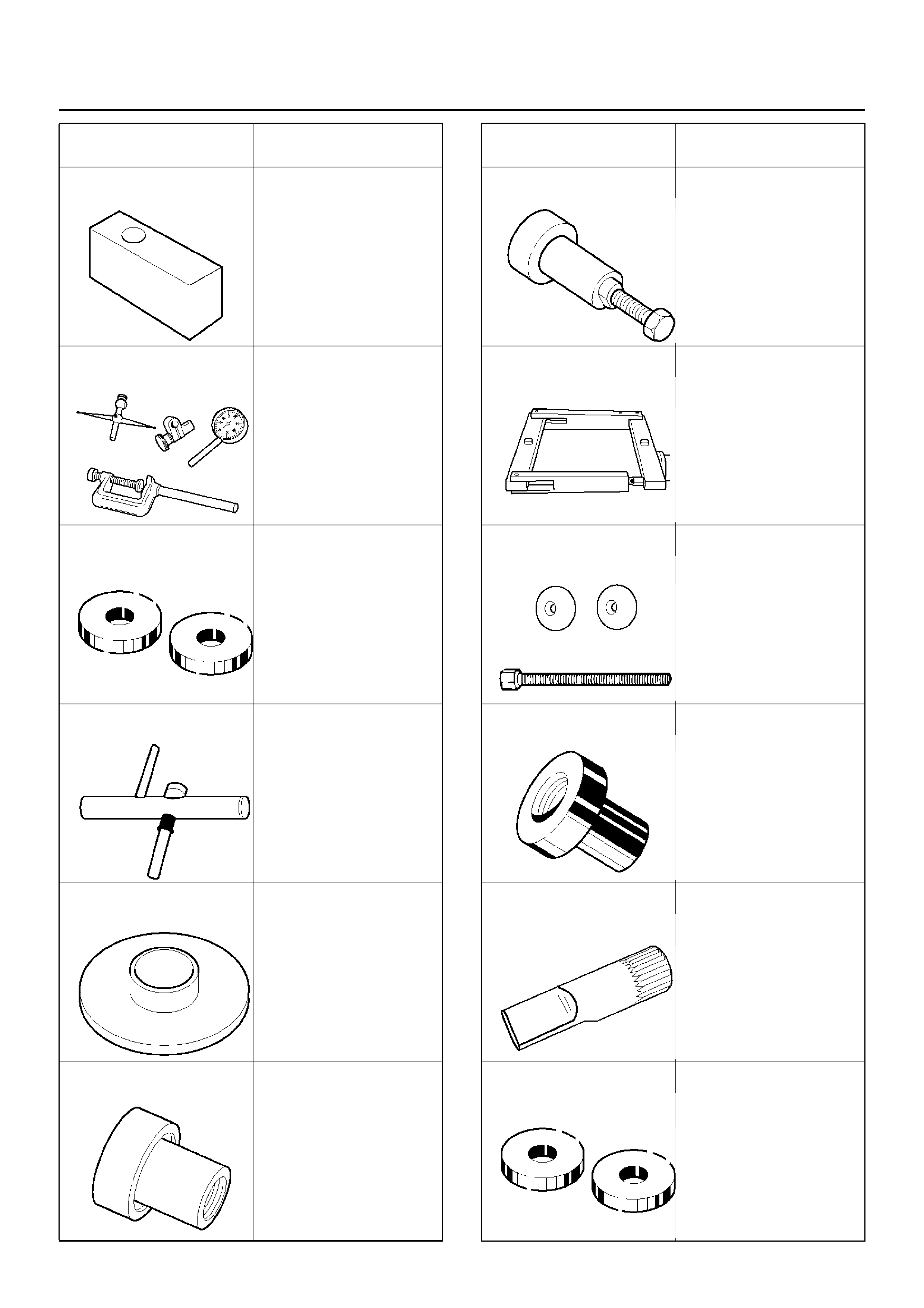

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–2578–0

(J–39837–2)

Gauge plate

5–8840–0126–0

(J–8001)

Dial indicator

5–8840–2579–0

(J–39837–1)

Disc (2 required)

5–8840–0128–0

(J–23597–1)

Arbor

5–8840–2574–0

(J–42828)

Installer; Pinion bearing

5–8840–2580–0

(J–21784)

Installer; Side bearing

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–2323–0

(J–39602)

Remover; Outer bearing

5–8840–2581–0

(J–24385–B)

Spreader

5–8840–2586–0

(J–39858)

Clutch pack unloading

tool kit

5–8840–2582–0

(J–39834)

Limited–s l ip differential

(LSD) service adapter

5–8840–2583–0

(J–39824)

Holder

5–8840–2584–0

(J–39836)

Side bearing preload

master bearings

ILLUSTRATION TOOL NO.

TOOL NAME