SECTION 4B - DRIVELINE CONTROL SYSTEM

Service Precaution

Shift On The Fly System

Outline of Shift on The Fly System

Functions of Indicator Lamp

Diagnosis

Shift On The Fly Vacuum Piping and

Electrical Equipment

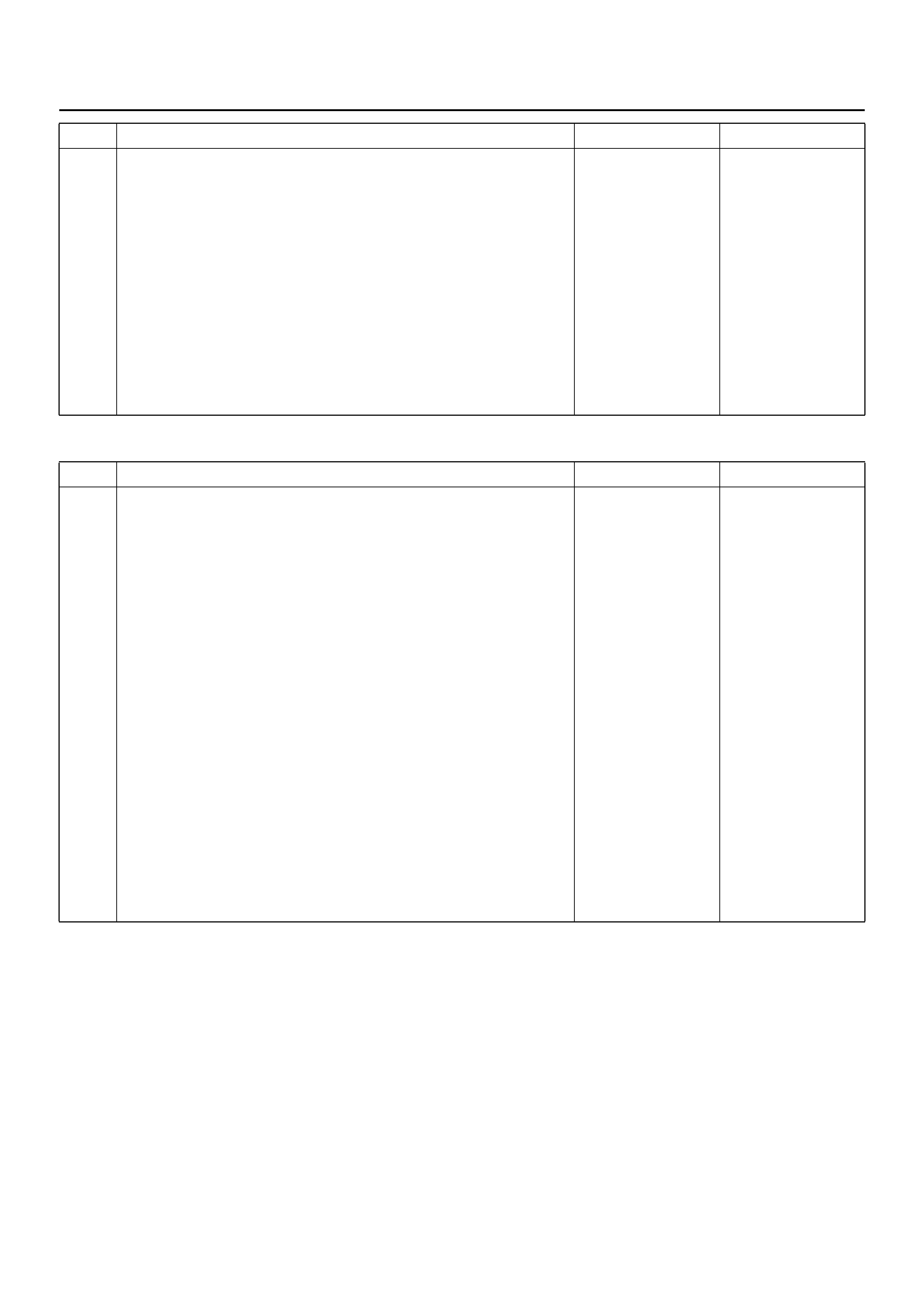

Vacuum Piping Diagram

Actuator Assembly

Vacuum Tank

Inspection and Repair

4WD Control Unit

4WD Control Unit Associated Parts

Removal

Installation

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or

other corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping f or ce, and may dama ge the fastener . Wh en

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts

and systems.

Shift On The Fly System

Outline of Shift on The Fly System

The shift on the fly system switches between 2 wheel

drive (2WD) and 4 wheel drive (4WD) electrically by

driver's pressing the 4WD switch (push button type) on

instrument panel.

This system controls below operations. (Shifting

between “4H" and “4L" must be performed by transfer

control lever on the floor.)

1. Shifting the transfer front output gear (Connecting

to, and disconnecting from, front propeller shaft by

motor actuator).

2. Retrial of shifting the transfer front output gear.

3. Connecting front wheels to , and disconnecting them

from, the front axles by vacuum actuator.

4. Indicator on instrument panel.

5. 4WD out signal to other Electronic Hydraulic Control

Unit.

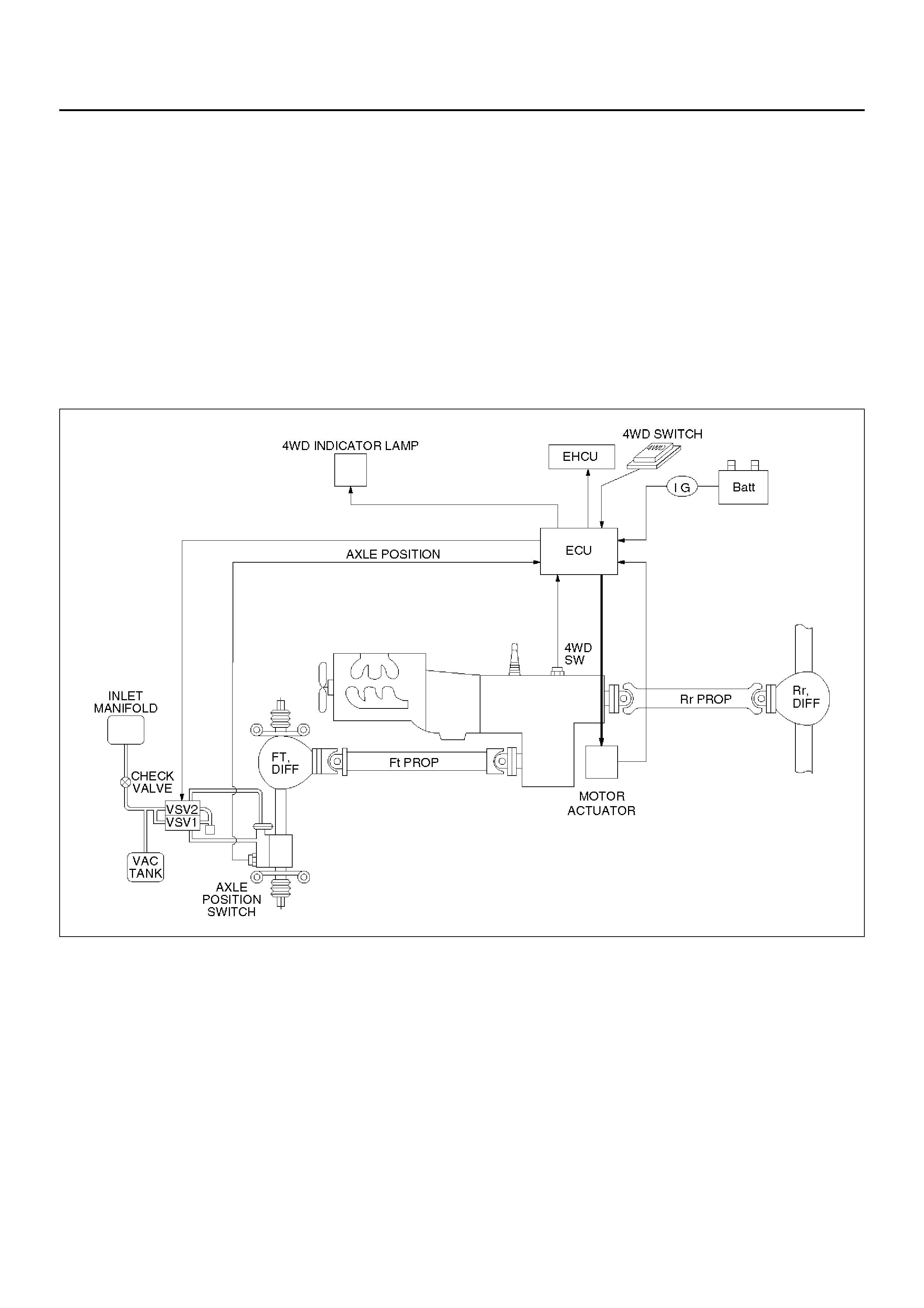

Syst em Diagram s

412RX009

Normal Operation

The motor actuator mounted on transfer rear case is

driven by signal from 4WD switch on instrument panel.

After complete the connecting transfer front output gear

to, or disconnecting it from, front propeller shaft,

condition of the transfer position switch changes. The

vacuum solenoid valve (VSV) is driven by the signal

from transfer position switch and the vacuum actuator

connects front wheels to, or disconnect them from, front

axles.

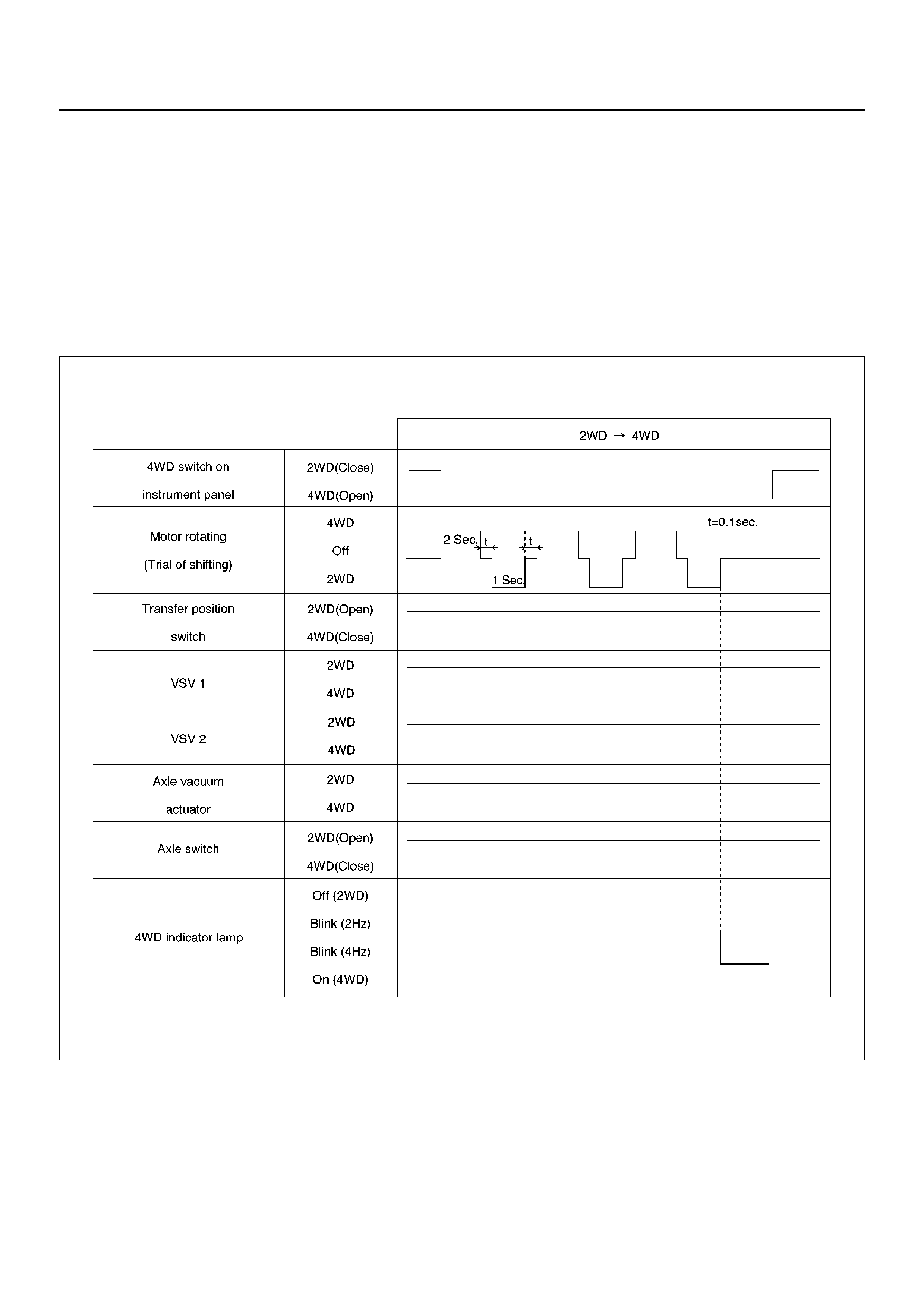

Time Chart of Shifting Under Normal Condition

F04RW002

Retrial

The motor actuator starts transfer gear shifting after

signal from 4WD switch on instrument panel has been

received. But the shifting may be impossible in cold

weather or under high speed condition. When 2

seconds have passed since transfer gear shifting

started and the transf er position switch dose not turn on

(the gear engagement is not completed), the motor

reverses its rotation for 1.2 seconds and tries again to

shift transfer gear. This procedure is repeated 3 times

in maximum. While this procedure, 4WD indicator lamp

blinks by 2 Hz.

If the transfer position switch does not turn on after

aforementioned procedure has been repeated 3 times,

the gear shifting is stopped and 4WD indicator lamp's

blinking changes from 2Hz to 4Hz to notify driver that

the gear shifting is stopped. This blinking of indicator

lamp continues until 4WD switch is returned from 4WD

to 2 WD.

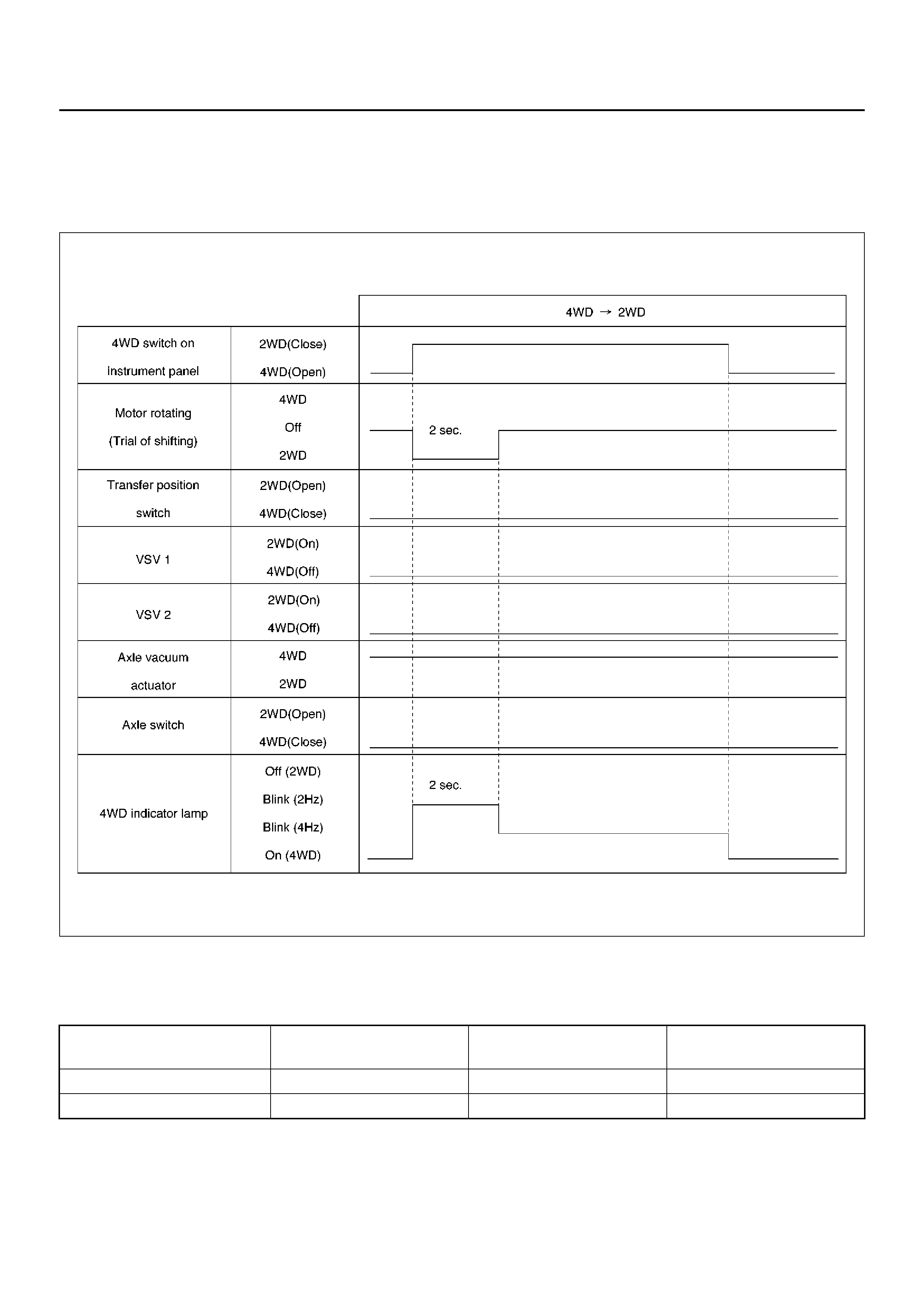

Time Chart of Shifting Under Severe Condition (retrial)

F04RX004

Warning at “4L" position :In view of the shifting

mechanism of transfer, the gear shifting from 4WD to

2WD at “4L" condition is impossible. Therefore, the

transfer position switch can not be turned off by 4WD

s witch when vehicle is in “4L" condition. In the case this

condition continues for 2 seconds, the shifting to 2WD is

stopped and the indicator lamp's blinking changes from

2Hz to 4Hz to notify driver of wrong operation.

Time Chart of Shifting from 4WD to 2WD at “4L" Condition

F04RX005

4WD out signal to other Electronic Hydraulic

Control Unit : ECU of shift on the fly sends 4WD out

signal to other Electronic Hydraulic Control Unit as

below. 4WD out signal

(Period) Vehicle Condition Transfer position switch Front axle switch

120 ms 2WD 2WD (Open) 2WD (Op en)

240 ms 4WD 4WD (Close) 4WD (Close)

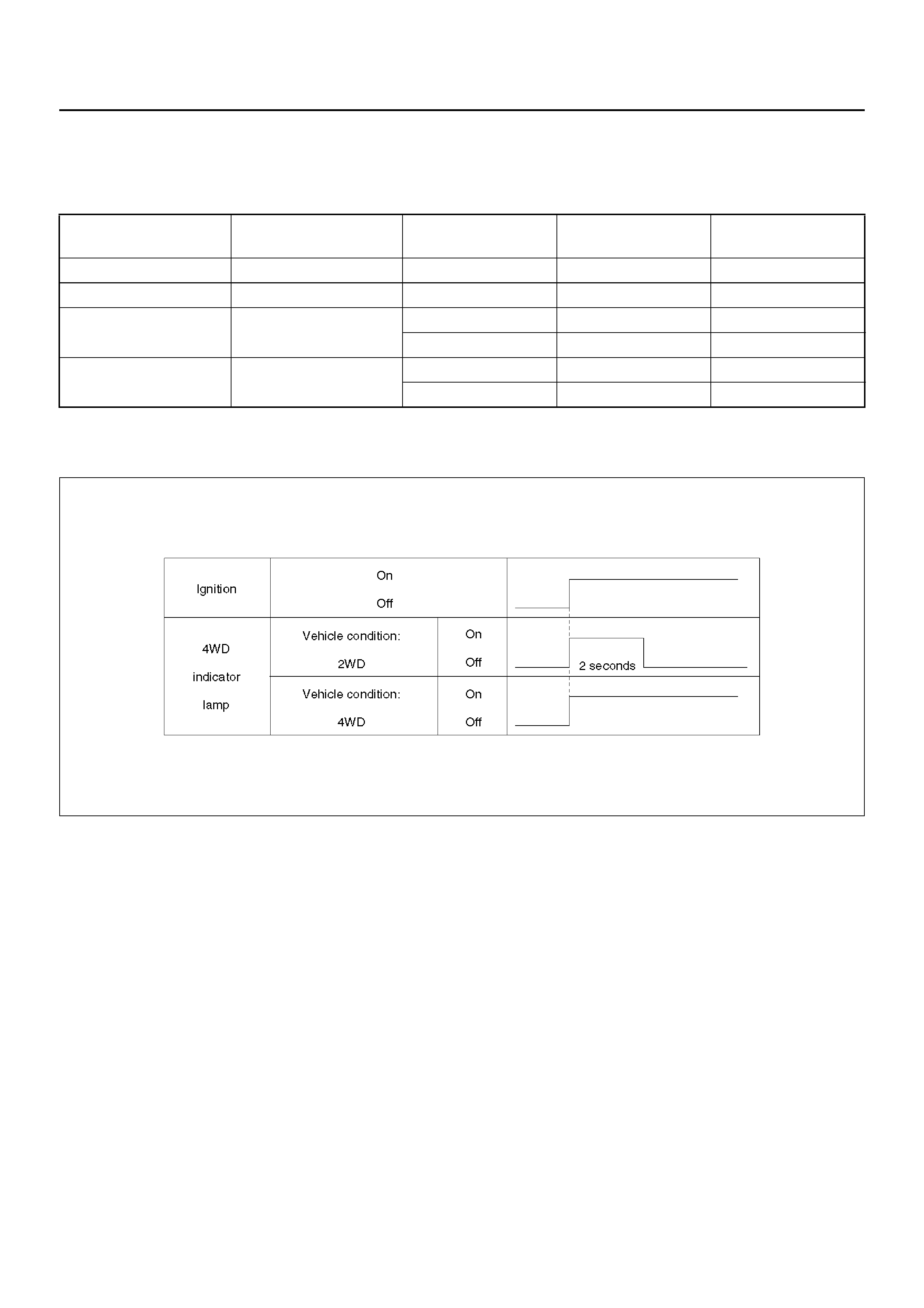

Functions of Indicator Lamp

Indication of vehicle condition : Indicator lamp is

controlled by ECU of shift on the fly and shows vehicle

conditions as below.

Bulb chec k :The bulb of indicator lamp is checked for 2

seconds when ignition ke y is turned on.

Time Chart of Bulb Checking

F04RW004

Retrials from 2WD to 4WD :In cold weather or under

high speed condition, the gear shifting (engagement)

some t imes dose no t comp l et e by 3 trials . I n su ch ca se,

the indicator lamp inform driver of this incident as

aforementioned chart (shown at Retrial in Outline of

shift on the fly system.)

Indicator Vehicle condition 4WD switc h Transfer position

switch Front axle switch

Off 2WD Off (Close) 2WD (Open) 2WD (Open)

On 4WD On (Open) 4WD (Close) 4WD (Close)

Blink (2Hz) Operating On (Open) 4WD (Close) 2WD (Open)

Off (Close) 2WD (Open) 4WD (Close)

Blink (4Hz) Stop operating On (Open) 2WD (Open) 2WD (Open)

Off (Close) 4WD (Clo se) 4WD (Clo se)

Diagnosis

Before Judging That Troubles Occur

(Unfaulty mode)

When Switching from 2WD to 4WD

1. In case that blinking frequency of the 4WD

indicator changes from 2Hz to 4Hz.

When heavy synchronization load is needed, the

motor actuator tries the shifting transfer gear three

times including the activation shifting. While the

motor actuator tries shifting, the indicator blinks by

2Hz. If the third shifting f ails, the indicator's blinking

changes from 2Hz to 4Hz at the same time that the

motor actuator shifted back to 2WD.

Heavy synchronization load occurs by

• extremely lower temperature.

• higher speed.rotation difference of wheels during

cornering.

Solution 1: Operate again after stop the vehicle

or slow down.

2. In case that the 4WD indicator continues

blinking by 2Hz for more than 11.5 seconds.

When there is rotation difference of wheels or there

is phase difference between front wheels and axles,

it is difficult to connect front wheels to front axles.

The blinking by 2Hz shows that shifting the transfer

gear or connecting the front wheels is in the middle

of operating. In above case, the indicator's blinking

by 2Hz shows that connecting the front wheels is

not completed (because the indicator's blinking

changes to 4Hz when the shifting transfer gear is

impossible.). And removal of rotation or phase

difference make connecting the front wheels

possible.

Solution 2: When vehicle is running, drive

straight ahead while accelerating and

decelerating. When vehicle is at a stop, move

the vehicle forward and backward from 2 to 3

meters.

When Switching from 4WD to 2WD

1. In case that the 4WD indicator continues

blinking by 2Hz .

The 4WD indicator continues blinking by 2Hz until

both shifting the transf er gear and disconnecting the

front wheels are completed when switching 4WD to

2WD. When driv e line is loaded with torsional

torque, the shifting transfer gear and disconnecting

front wheels are impossible. In this case, removal of

torsional torque on drive line make the shifting

transfer gear and disconnecting front wheels

possible.

Solution 3: When vehicle is running, drive

straight ahead while accelerating and

decelerating. When vehicle is at a stop, move

the vehicle forward and backward from 2 to 3

meters.

2. In case that the 4WD indicator's blinking changes

from 2Hz to 4Hz.

Check the position of transfer lever. Is it at “4L"

position? In view of the shifting mechanism of

transfer, the gear shifting from 4WD to 2WD at “4L"

condition is impossible.

Solution 4: Push the 4WD switch to 4WD, shift

the transfer lever to “High" position and re-

operate the 4WD switc h to 2WD.

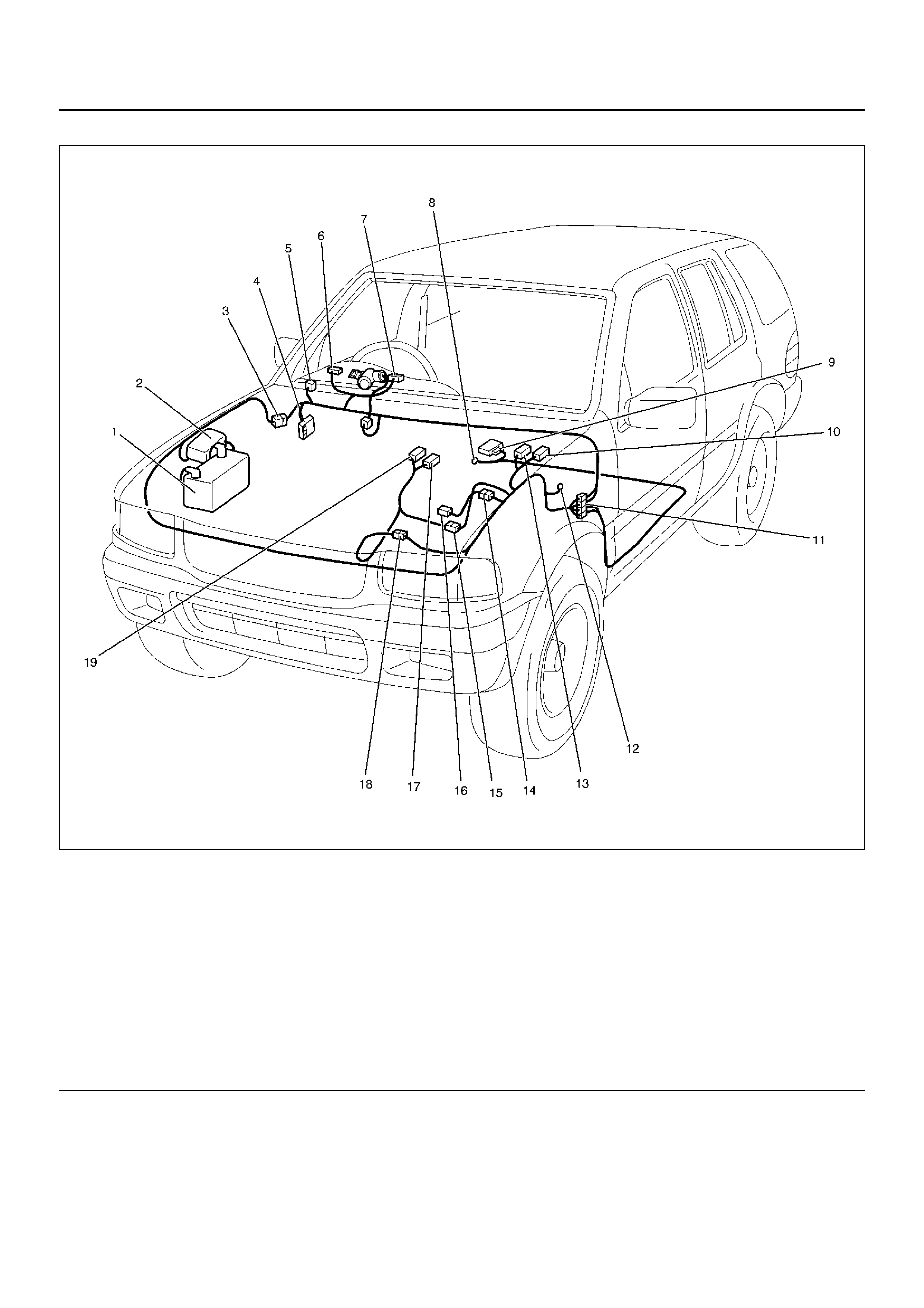

Parts Location

D08RX290

Legend

EndOFCallout

(1) Battery

(2) Relay & Fuse Bo x (Engine Room)

(3) H–32

(4) Relay & Fuse Box (Instrument Panel)

(5) I–19

(6) I–1

(7) I–2

(8) B–8

(9) B–19

(10) C–32

(11) H–15

(12) C–16

(13) C–31

(14) H–18

(15) H–9 ( X22SE)

(16) C–15

(17) M–21

(18) H–9 ( 6VD1), H–10

(19) M– 11, M–1 2

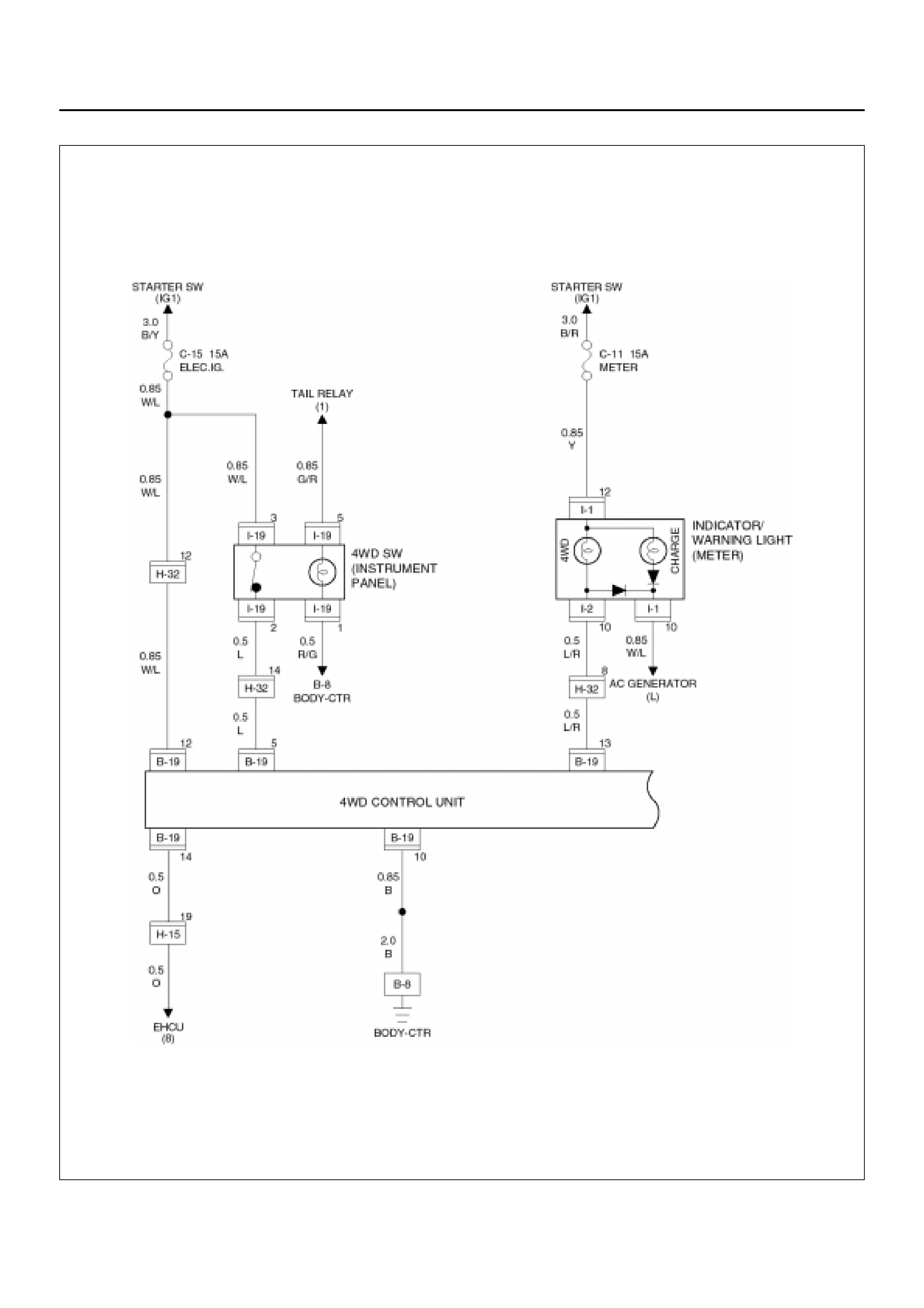

Wiring Diagra m – 1

D08RX272

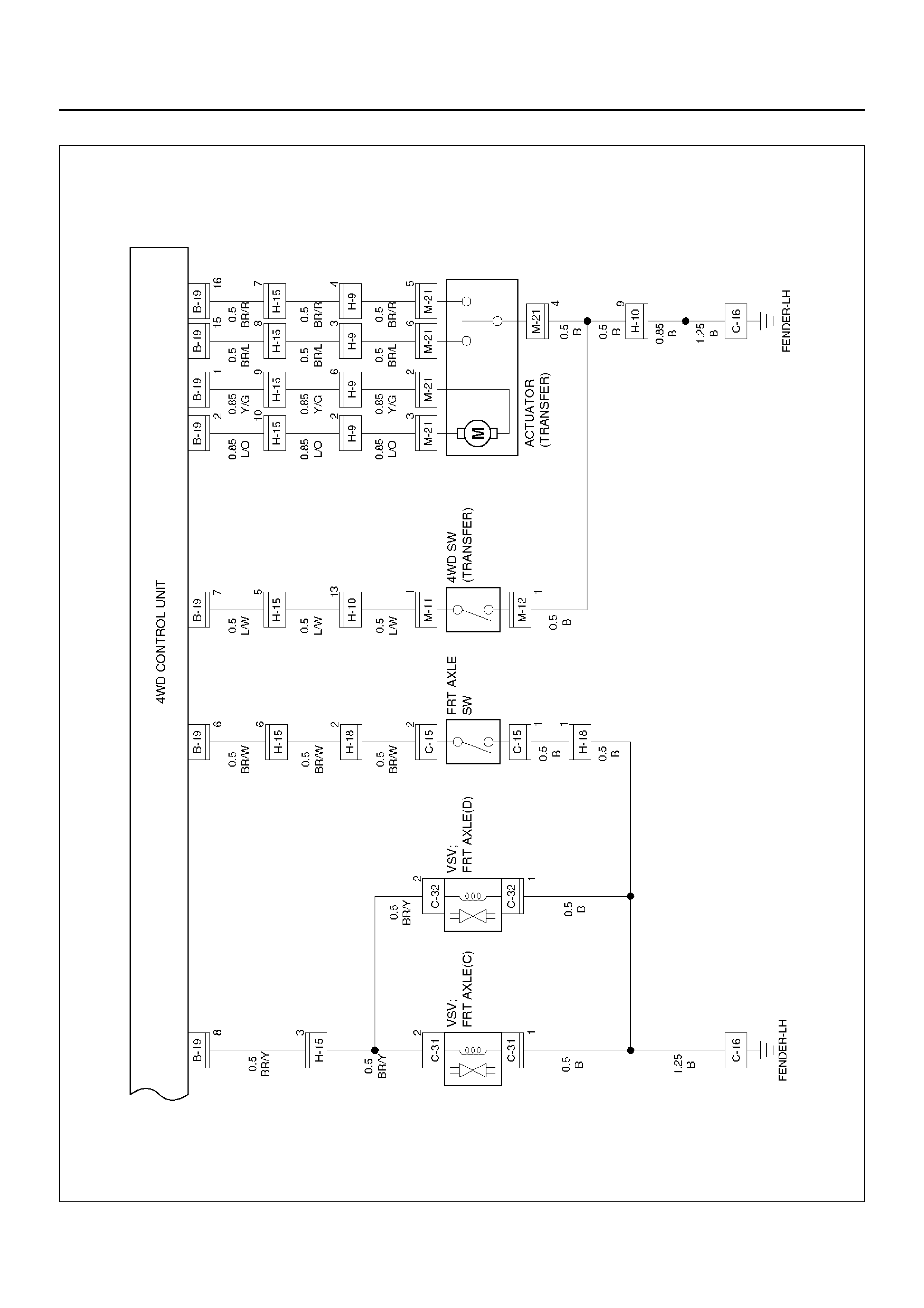

Wiring Diagram – 2 (6VD1)

D08RX274

Wiring Diagram – 2 (X22SE)

D08RX273

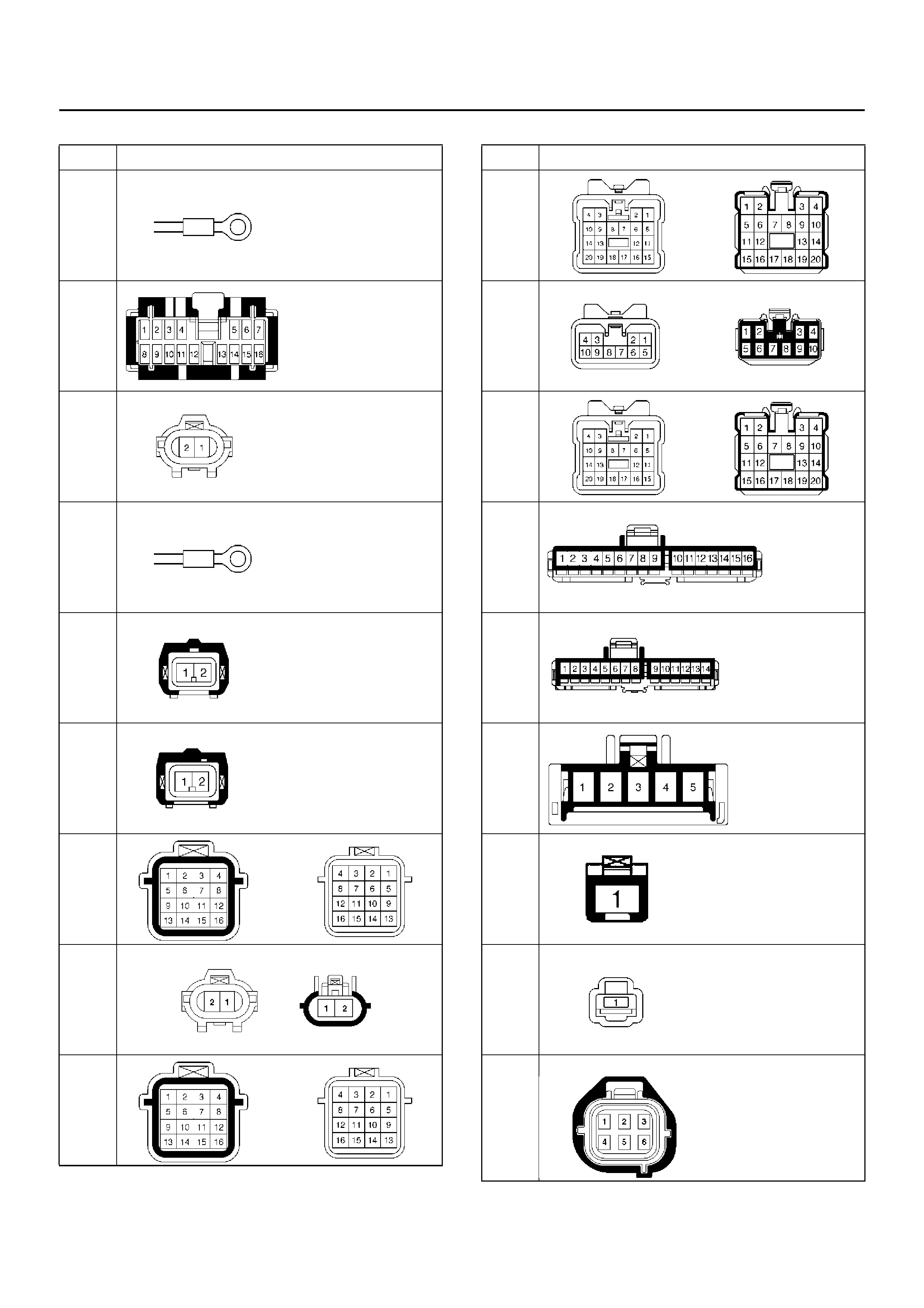

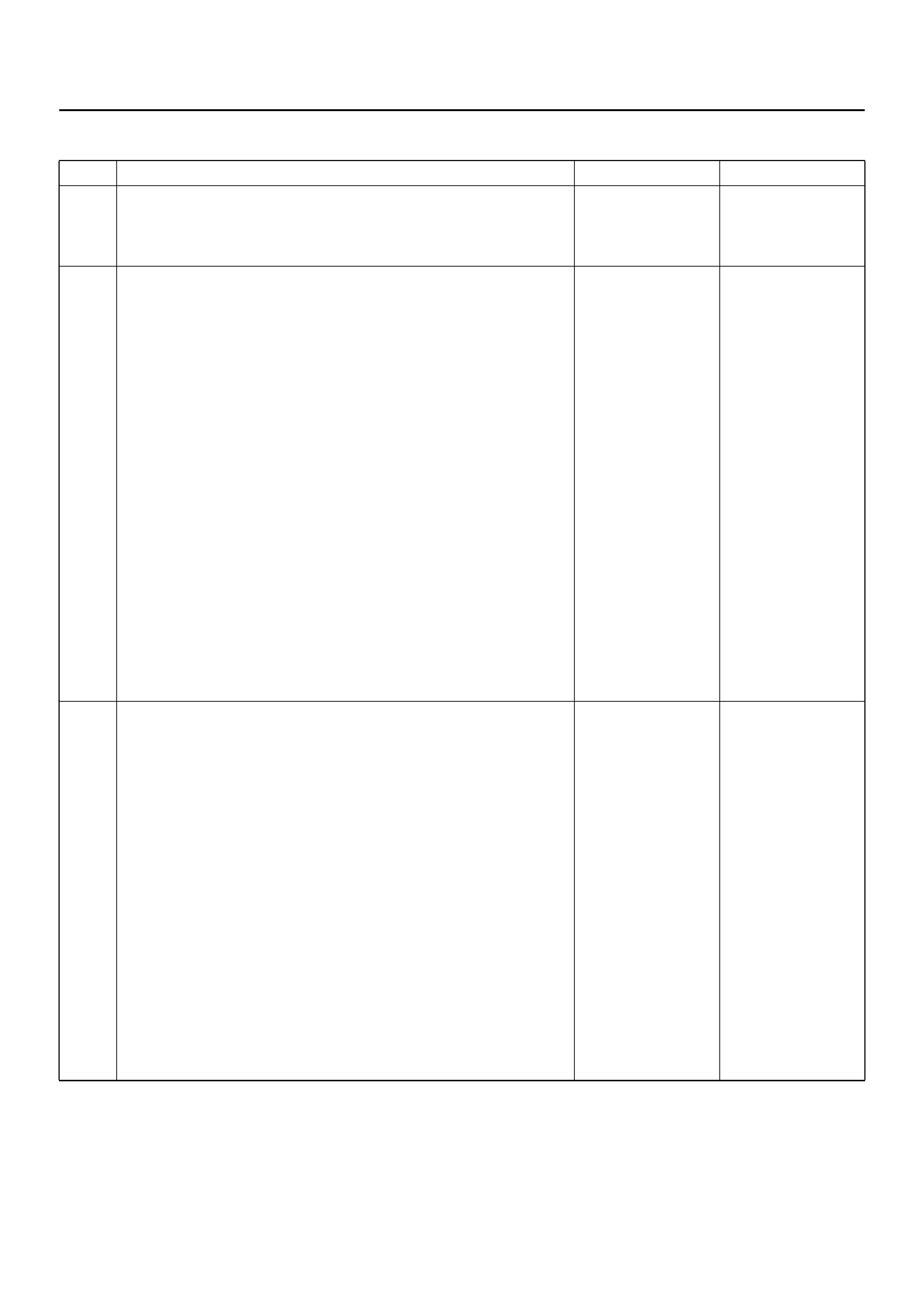

Connector List

No. Connector face

B-8

B-19

C-15

C-16

C-31

C-32

H-9

H-10

(6VD1

)

H-10

(X22S

E)

H-15

H-18

H-32

I-1

I-2

I-19

M-11

M-12

M-21

No. Connector face

Diagnosis of The Faults Based on the

Status of 4WD Indicator Lamp, 4WD Switch

and T/F Change Lever

Diagnosis charts are shown on below. If troubles can

not be solved after e v ery chart was traced, troubles may

occur in the ECU . In this case, replace the ECU and

trace every chart again.

Fault on Switching from 2WD to 4WD

1. In case that 4WD indicator's blinking changes

from 2Hz to 4Hz after Solution 1 is carried out.

Faults occur in the motor actuator or the transfer

case assembly. Remove the motor actuator and

check function. If problem was found and it was

repaired, try Solution 1 again. After that,

disassemble the transfer case assembly for check

and repair or replace. If incident is not improved

after above mentioned actions were taken, replace

the ECU.

2. In case that 4WD indicator does not blink nor

light, when switching from 2WD to 4WD.

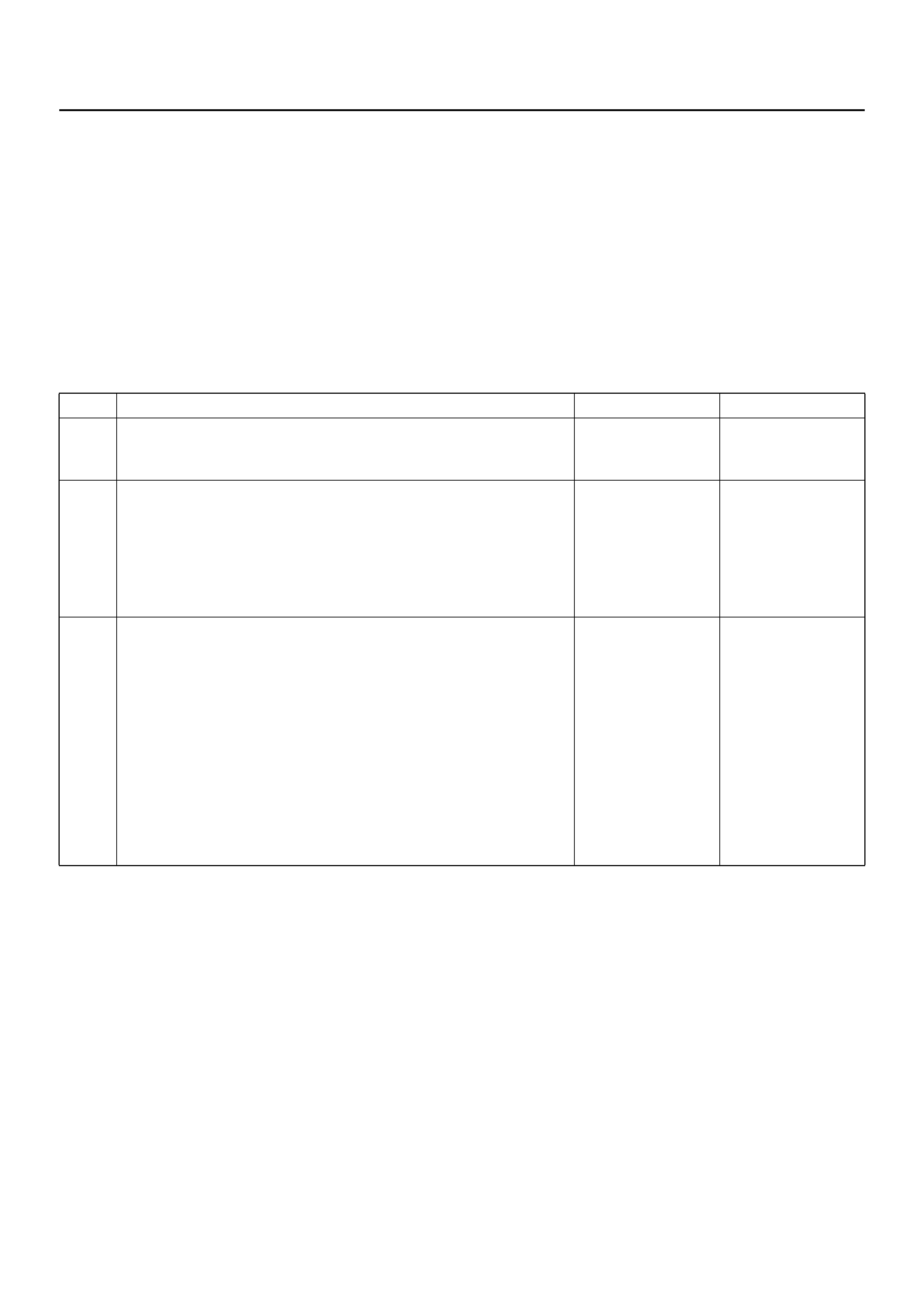

Step Action Yes No

1 Is ignition turned on? Go to Step 2

Turn on the ignition

and trace this chart

from start.

2 Does the indicator light during two seconds initialization after

ignition is turned on?

Go to Step 3

Burning out of

indicator lamp or

disconnection of

harness wire.

Trace this chart

from the start after

repair or replace.

3 Is the 4WD switch turned from 2WD to 4WD? Short-circuit

(body short) on

harness of the

4WD switch.

Fault of the

4WD switch

(holding the

closed

condition).

Trace this chart

from the start

after repair or

replace. Push the 4WD

switch to 4WD.

3. Case that the indicator keeps blinking by 2Hz

after aforementioned Solu tion 2 is carried out.

Step Action Yes No

1 Check the air pressure and wear of all tires.

W ere problems found? Try Solution 2

after adjust the air

pressure and

replace worn tires. Go to Step 2

2 Can the transfer lever be operated from High to 4L or vice versa?

Go to Step 3

Disconnection

of the motor

actuator

harness wiring.

Trac e this ch art

from the start

after repair or

replace.

Faults on the

motor actuator.

Trac e this ch art

from the start

after replace.

Internal faults of

transfer case.

Disassemble

the transfer

case f or check.

Trac e this ch art

from the start

after repair or

replace.

3 Pull out the hoses from vacuum actuator and operate 4WD

switch.

Is there negative pressure on either of hoses?

Go to Step 4

Faults on the

transfer position

switch or its

harness. Trace

this chart from

the start after

repair or

replace.

Faults on the

VSV main body,

its harness or

vacuuming

system. Trace

the diagnosis

chart in Front

Axle ASM

section. After

that, trace this

chart from the

start.

Fault on Switching from 4WD to 2WD

1. Case that indicator dose not blink nor turn out.

4 Check the axle switch.

W ere problems found?

Internal faults on

axle switch. Trace

this chart from the

start after replace.

Disconnection

on the axle

harness. Trace

this chart from

the start after

repair or

replace.

Faults on Front

Axle ASM.

Trace the

diagnosis chart

in Front Axle

ASM section.

Af ter that , trac e

this chart from

the start.

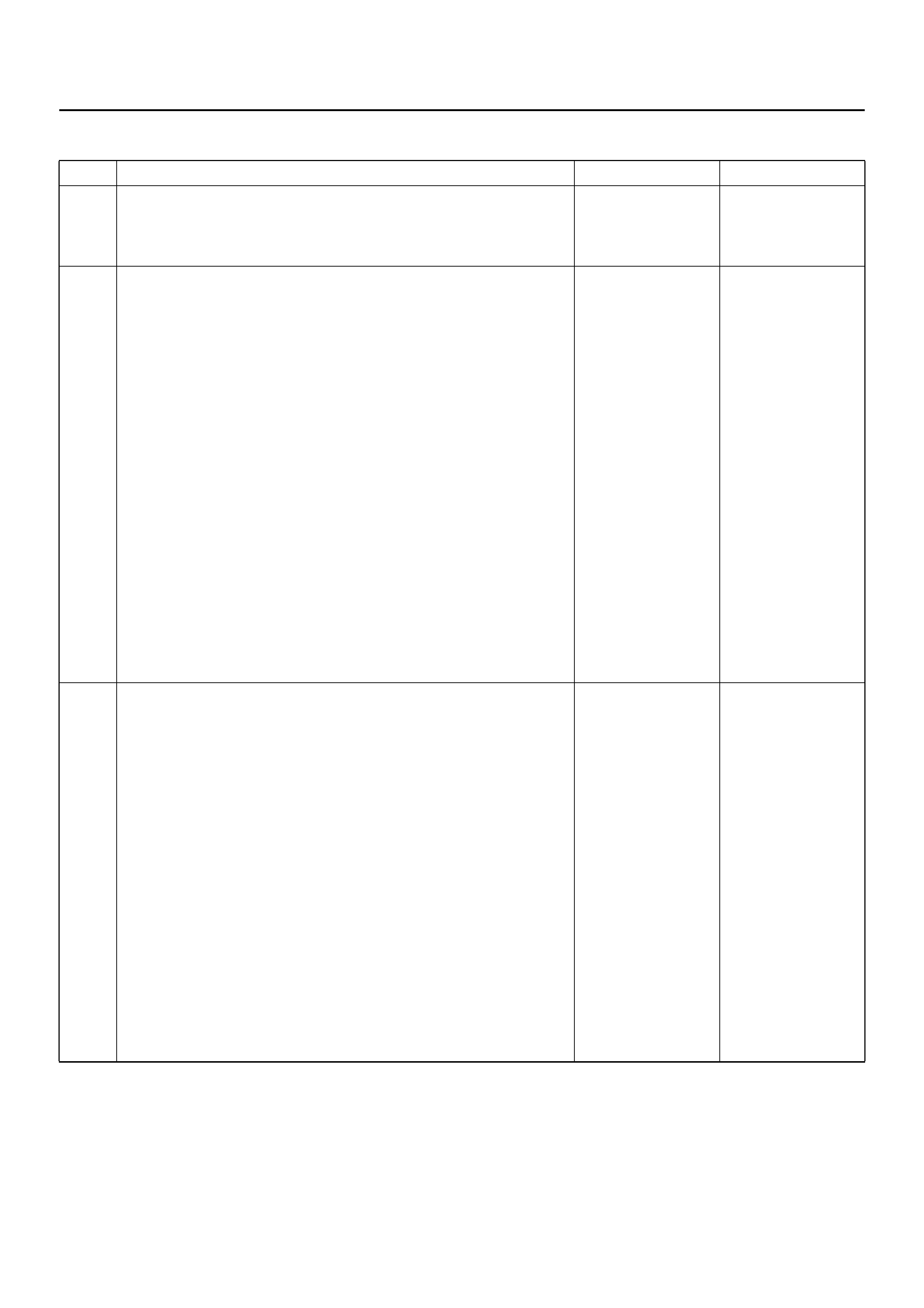

Step Action Yes No

Step Action Yes No

1 Does the indicator turn out by ignition off? Go to Step 2 Short circuit of the

indicato r harn es s.

2 Is the 4WD switch on 2WD position? Disconnection on

the 4WD switch

harness or

breakdown of the

4WD switch in

open state. Trace

this chart from the

start after repair or

replace.

Turn the 4WD

switch to 2WD

position. Trace this

chart from the

start.

2. Case that indicator keeps 2Hz blinking after aforementioned Solution 3 is carried out.

Step Action Yes No

1 Check the air pressure and wear of all tires.

W ere problems found? Try Solution 3

after adjust the air

pressure and

replace worn tires. Go to Step 2

2 Can the transfer lever be operated from High to 4L or vice versa? Faults on the

harness wiring

of motor

actu ator. Tr ac e

this chart from

the start after

repair or

replace.

Internal faults

on transfer

case.

Disassemble

the transfer

case for check.

Trace this chart

from the start

after repair or

replace.

Faults on the

motor actuator.

Trace this chart

from the start

after or replace. Go to Step 3

3 Pull out the hoses from vacuum actuator and operate 4WD

switch.

Is there negative pressure on either of hoses?

Go to Step 4

Faults on the

transfer position

switch or its

harness. Trace

this chart from

the start after

repair or

replace.

Faults on the

VSV main body,

its harness or

vacuuming

system. Trace

the diagnosis

chart in Front

Axle ASM

section. After

that, trace this

chart from the

start.

3. Case that indicator's blinking changes to 4Hz

after aforementioned Solu tion 4 is carried out.

4 Check the axle switch.

W ere problems found? Internal faults

on axle switch.

Trace this chart

from the start

after replace.

Faults on Front

Axle ASM.

Trace the

diagnosis chart

in Front Axle

ASM section.

After that, trace

this chart from

the start.

Short circuit (bod y

short) or

disconnection of

the ax le ha rness .

Trace this chart

from the start after

repair or replace.

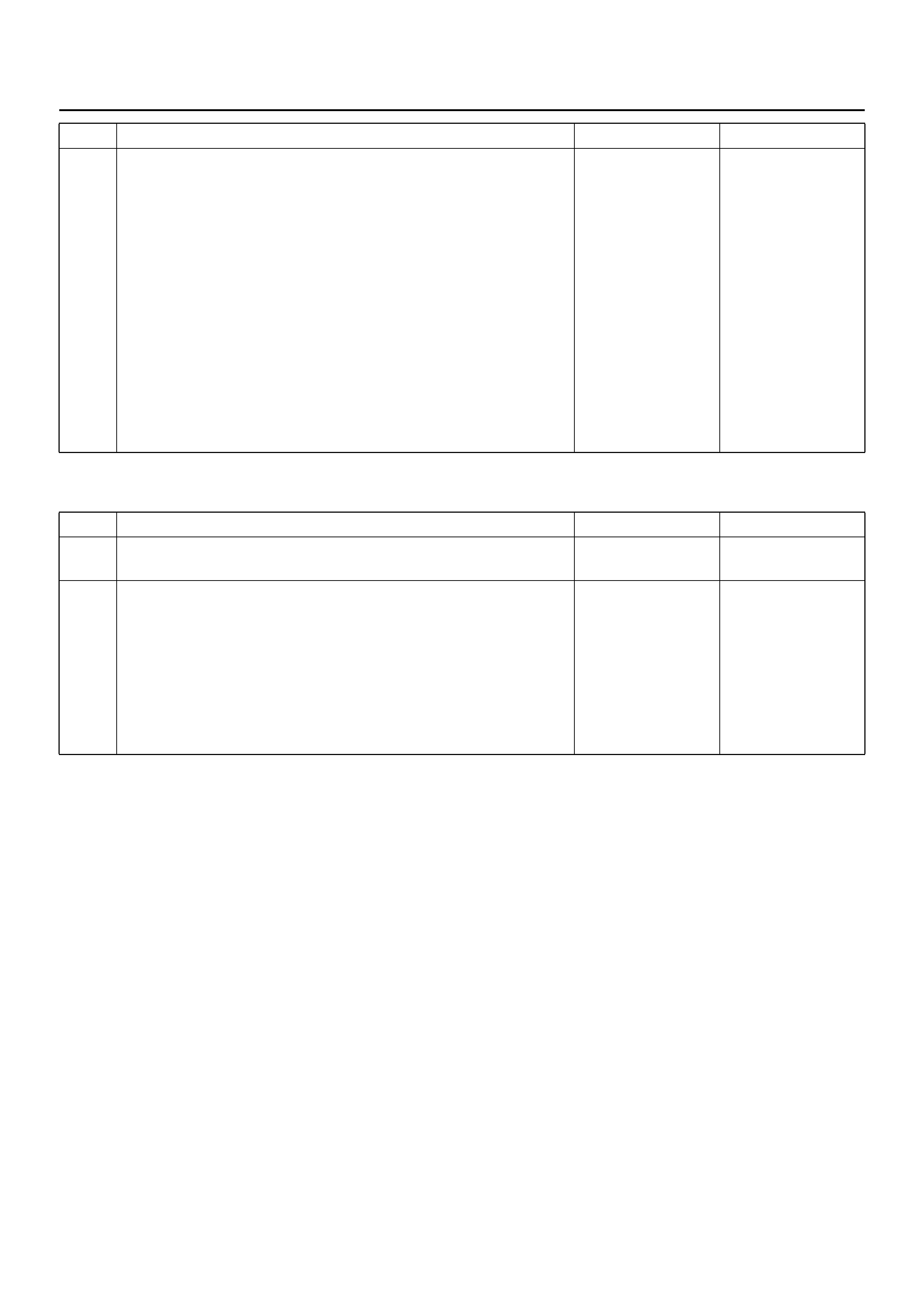

Step Action Yes No

Step Action Yes No

1 Can the transfer lever be operated from High to 4L or vice versa? Faults on the

harness wiring

of motor

actu ator. Tr ac e

this chart from

the start after

repair or

replace.

Faults on the

motor actuator.

Trace this chart

from the start

after replace.

Internal faults

on transfer

case.

Disassemble

the transfer

case for check.

Trace this chart

from the start

after repair or

replace.

Faults on the ECU.

Trace this chart

from the start after

replace.

Shift On The Fly Vacuum Piping and Electrical Equipment

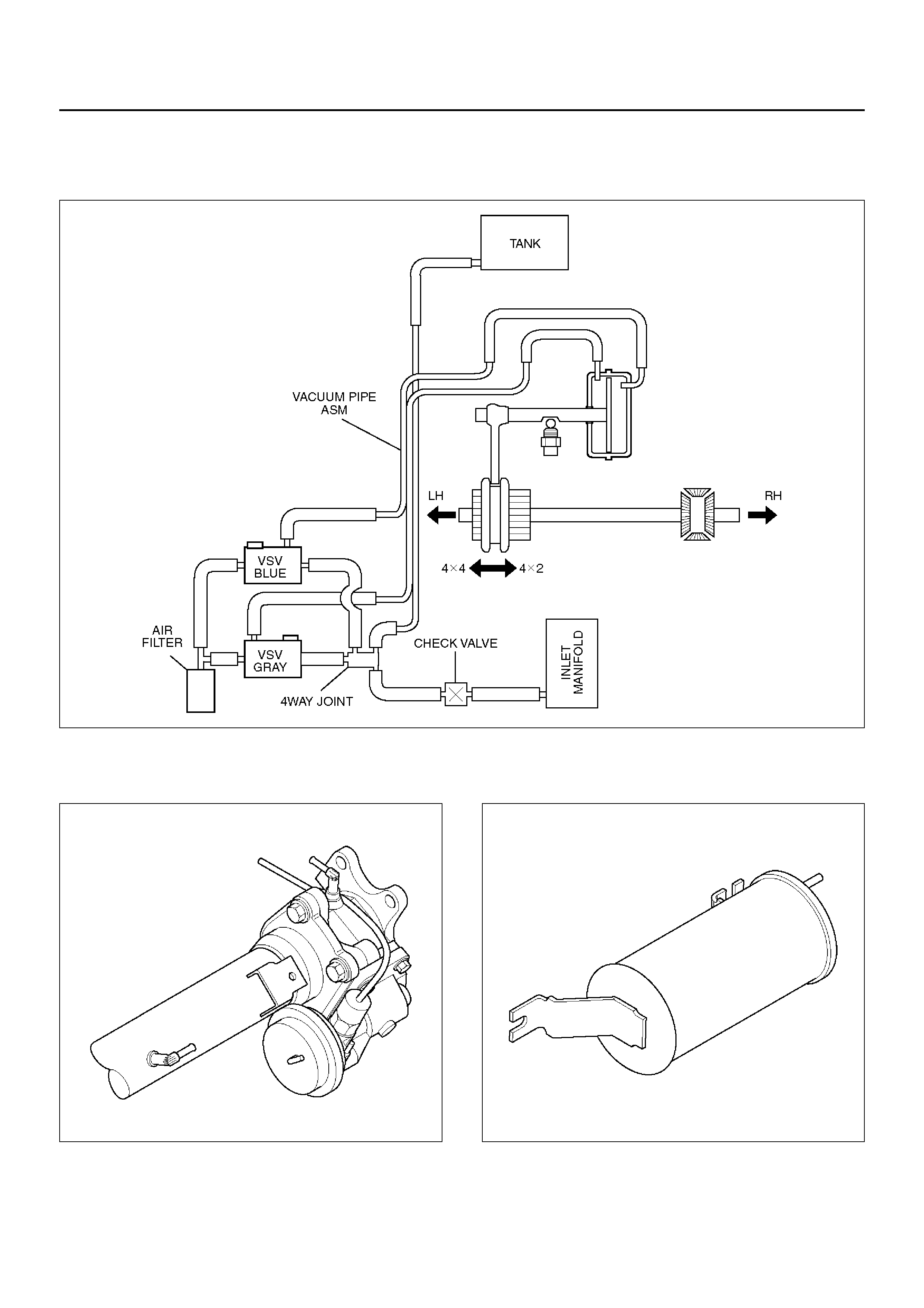

Vacuum Piping Diagram

C04RX001

Actuator Assembly

412RW024

Vacuum Tank

412RW025

Inspection and Repair

Vacuum Piping

C04RW004

1. Pull out the Hose A in figure and install a vacuum

gauge.

2. Plug up Hose B in figure to prevent the leak of

vacuum.

3. Start the engine and measure vacuum 2 or 3

minutes afterward.

4. Repeat 1) and 2) but with Hose A plugged and Hose

B pulled out.

5. If vacuum measures –400mmHg, or if it shows a

sudden drop immediately after engine stop, inspect

the hose, tank, and pipe for damage.

NOTE: Be careful not to permit the entry of dust and

water during inspection.

6. Pull out Hose D in above illustration.

7. Plug Hose E in ab ove illustrat ion.

8. Make sure that Hose D in above illustration is under

atmo sp heric pres su re.

9. Pull out Hose E and plug Hose D, and make sure

that Hose E is under atmospheric pressure.

10. If Check 8) or 9) has revealed stoppage, check and

see that there is no bend, foreign matter in the hose

or in the filter. If there is trouble, repair or replace.

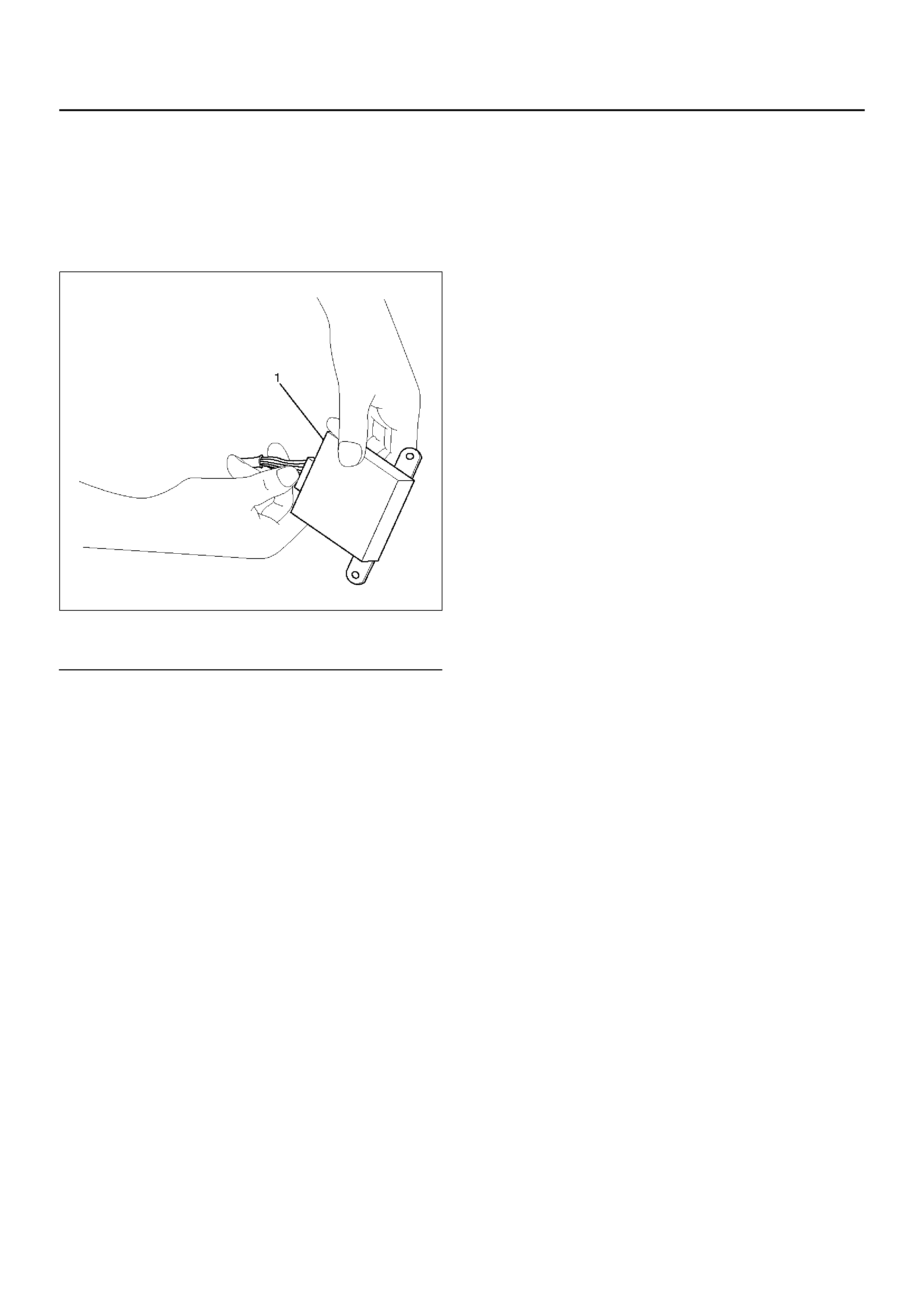

Check Valve

C04RS004

1. Apply vacuum from the orange colored side(1).

Vacuum:–400mmHg

2. Check leakage of vacuum.

3. Make sure that vacuum cannot be applied from the

black colored side(2).

4. If vacuum is not applicable as much as –400mmHg,

and if there is resistance on the intake side, replace

with a new check v a lve.

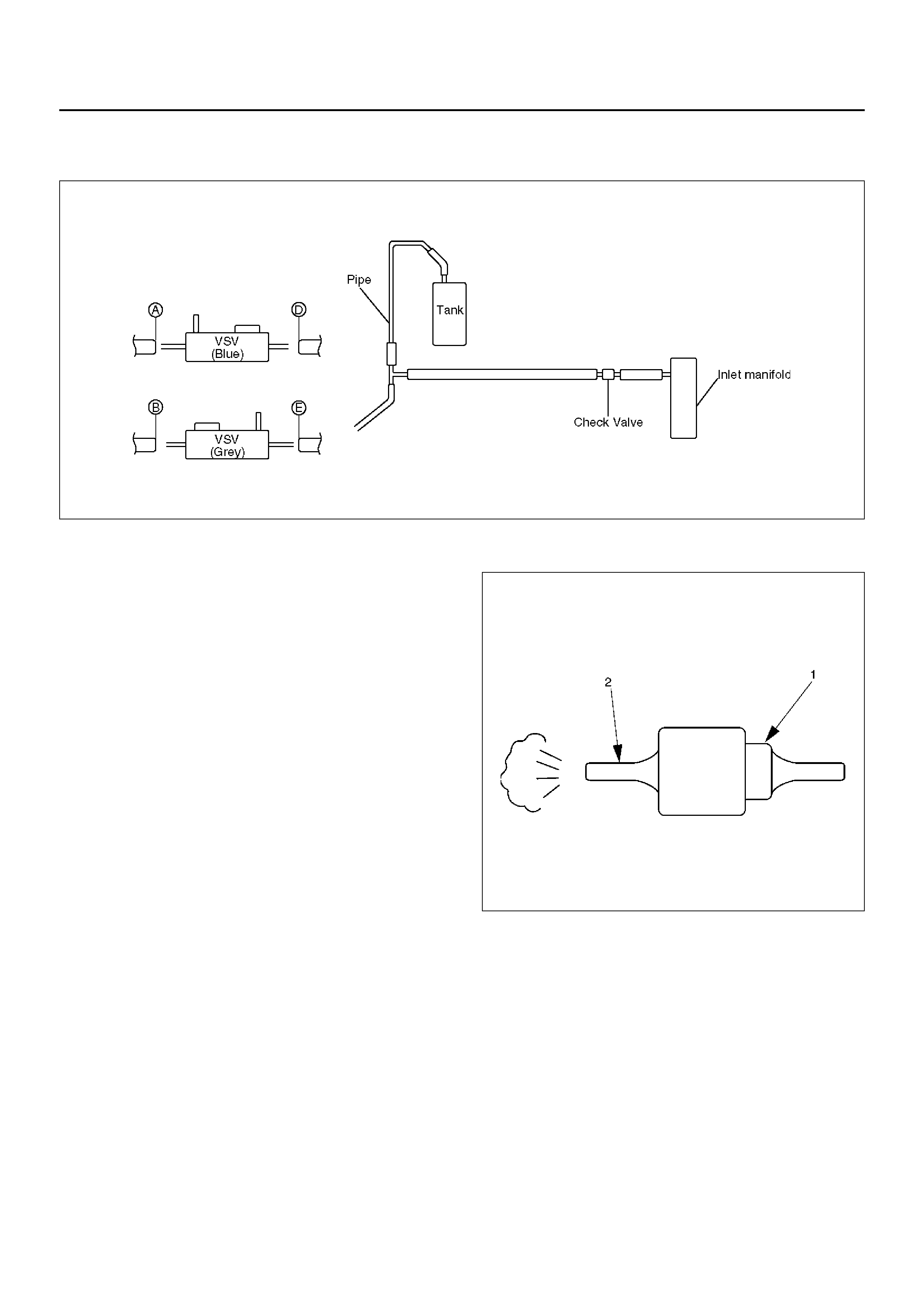

VSV As se mbly

Inspect the vehicle side harness as follows:

412RX008

Legend

EndOFCallout

1. Remove connector.

2. Shift transfer lever to 2H and start the engine.

NOTE: The vehicle should not be started, with the

engine idling.

3. Make sure that there is continuity in the vehicle side

of harness. If there is no continuity, check transfer

shift switch and wiring.

Inspect the both VSVs as follows

F04RS004

1. With battery not connecte d (Usual ).

A–C:There is continuity

B:Closed

2. With battery connected

A – B:There is continuity

C:Closed

3. If 1) and 2) fail, replace with a new VSV.

Functional Detective Switch

412RW067

1. With ball (1) being free

A–B:There is continuity

2. With ball forced into the switch

A–B:No continuity

3. If 1) and 2) fail, replace with a new switch.

Motor Actuator Assembly

Inspect the function of the motor actuator assembly as

follows:

1. Disassemble the motor actuator from transfer rear

case.

(1) Grey

(2) Blue

412RW037

Legend

EndOFCallout

2. Connect the terminals as shown in figure.

Shift rod of the motor actuator moves and stops

at 4WD position.

412RX001

Legend

EndOFCallout

3. Connect the terminals as shown in figure.

Shift rod of the motor actuator moves and stops

at 2WD position.

412RX002

Legend

EndOFCallout

4. If 2) and 3) fail, replace with a new motor actuator.

Transfer Positi on Switch

412RW040

Legend

EndOFCallout

1. With ball being free.

A–B : There is continuity.

2. With ball forced into the switch.

A–B : No continuity.

3. If 1) and 2) fail, replace with a new switch.

(3) Shift Rod

(4) Connector

(1) 2WD

(2) 4WD

(3) Shift Rod

(4) Connector

(1) 2WD

(2) 4WD

(3) Shift Rod

(4) Connector

(1) Ball

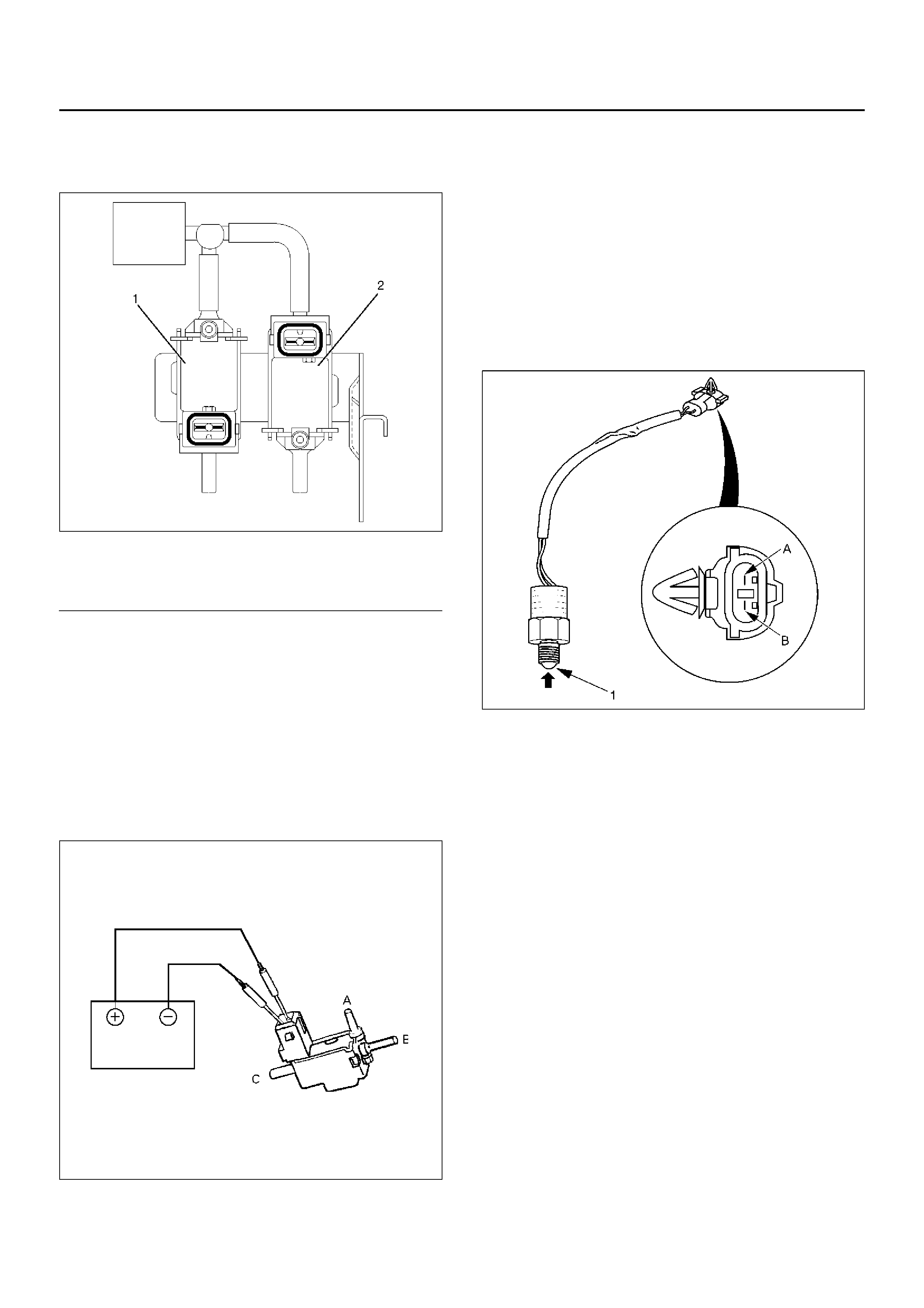

4WD Control Unit

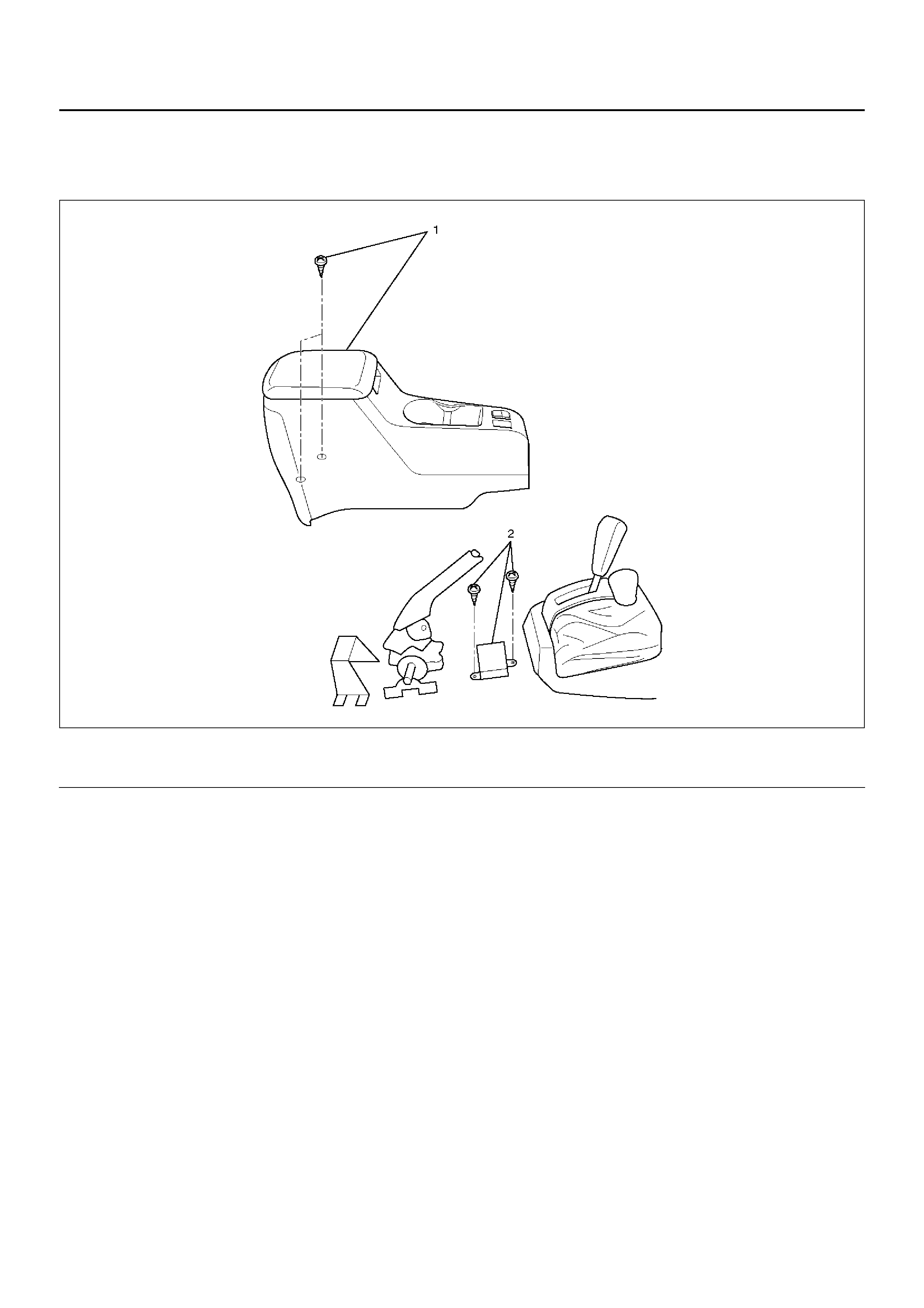

4WD Control Unit Associated Parts

412RW042

Legend

EndOFCallout

(1) Center Console Assembly (2) 4WD Control Unit

Removal

1.Remove center console assembly.

Refer to Interior Trim in Body and Accessories

section.

2. Remove two screws and harness connector (1) from

4WD control unit.

412RW041

Legend

EndOFCallout

Installation

1. Connect harness connector, then install 4WD

contr ol uni t.

2. Install center console assembly.

(1) Harness Connector