SECTION 4D - TRANSFER CASE

Service Precaution

General Description

Transfer Rear Oil Seal

Transfer Rear Oil Seal and

Associated Parts

Removal

Installation

Transfer Case Assembly (A/T)

Transfer Case Assembly (A/T) and

Associated Parts

Removal

Installation

Transfer Rear Case Assembly (A/T)

Transfer Rear Case Assembly (A/T) and

Associated Parts

Removal

Installation

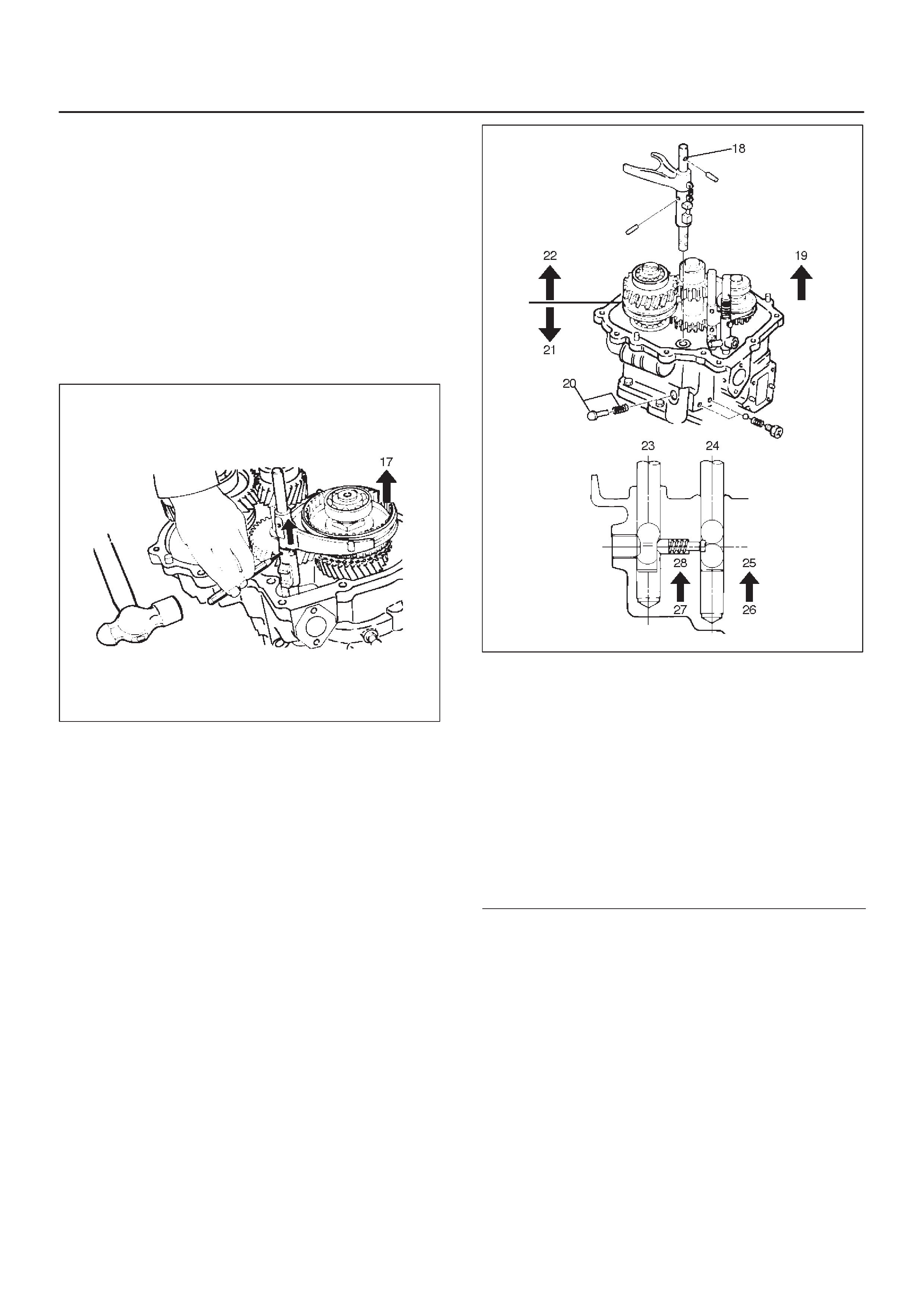

Transfer Rear Cover Assembly

Disassembly

Inspection and Repair

Reassembly

Detent, Shift Arm, and Interlock Pin

(Transfer Case Assembly)

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Transfer Case Assembly

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

Special Tools

Service Precaution

WARNING:THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION:Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener . When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

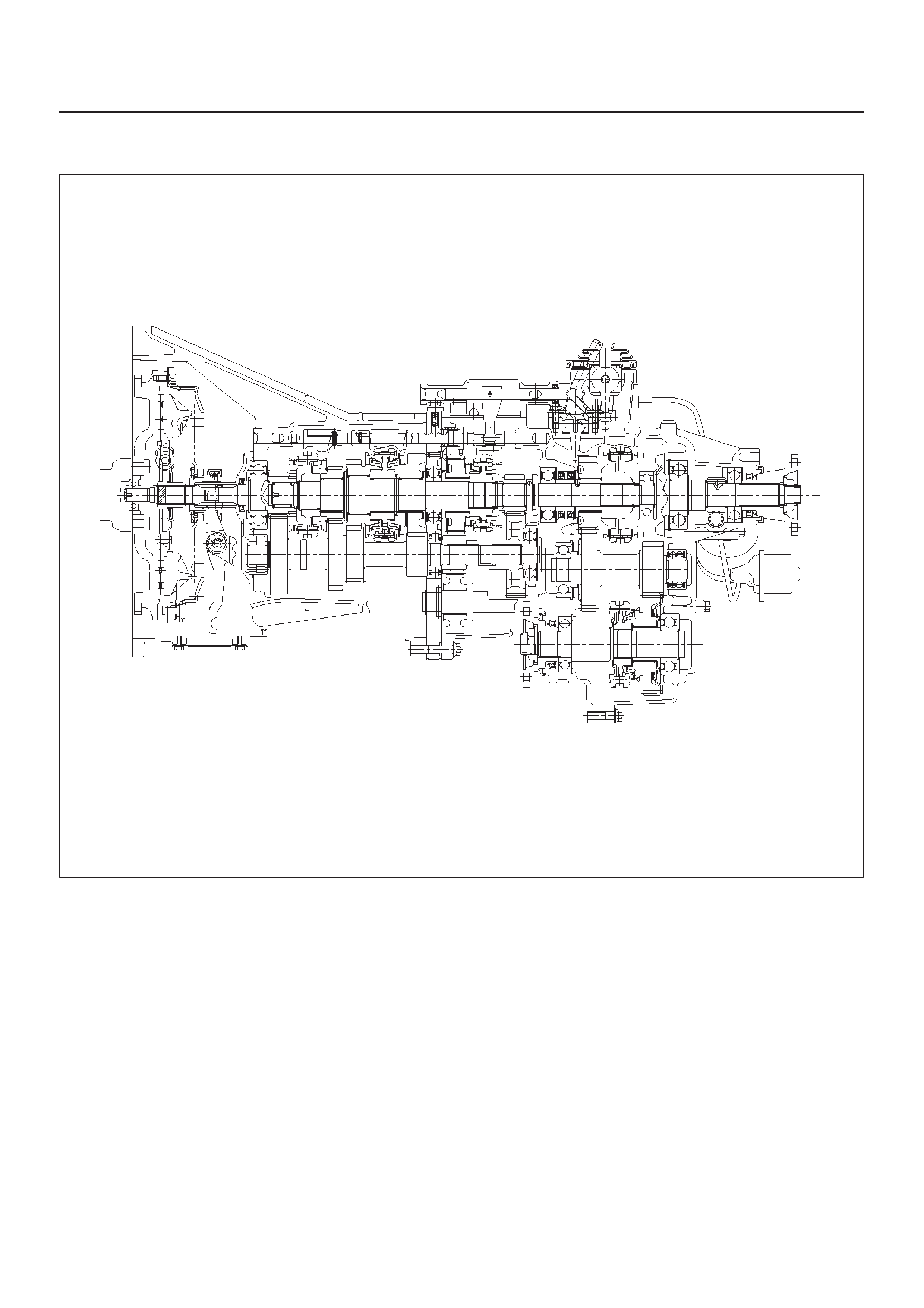

Transfer Case (for Manual Transmission)

A07RX005

Transfer Case (for Automatic Transmission)

A07RW001–1

The transfer case is used to provide a means of providing

power flow to the front axle. The transfer case also

provides a means of disconnecting the front axle,

providing better fuel economy and quieter operation when

the vehicle is driven on improved roads where four wheel

drive is not required. In addition, the transfer case

provides an additional gear reduction when placed in low

range, which is useful when difficult off–road conditions

are encountered.

A floor mounted shift lever is used to select the high–low

range. When four wheel drive switch has been turned on,

the four wheel drive indicator light is designed to come on

and the front axle has been engaged.

Transfer Rear Oil Seal

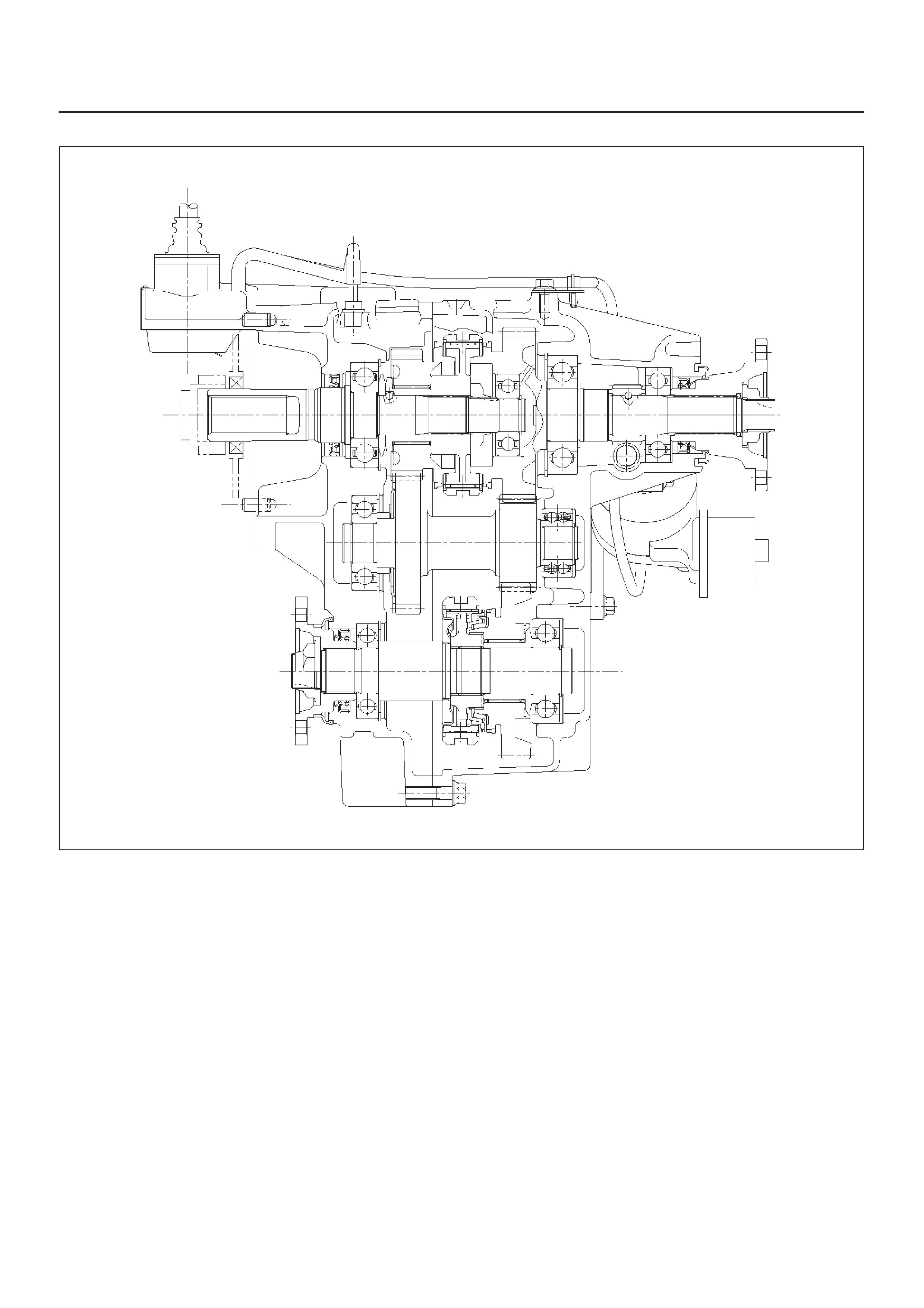

Transfer Rear Oil Seal and Associated Parts

220RS015

Legend

(1) Rear Propeller Shaft (2) End Nut and Rear Companion Flange

(3) Oil Seal

Removal

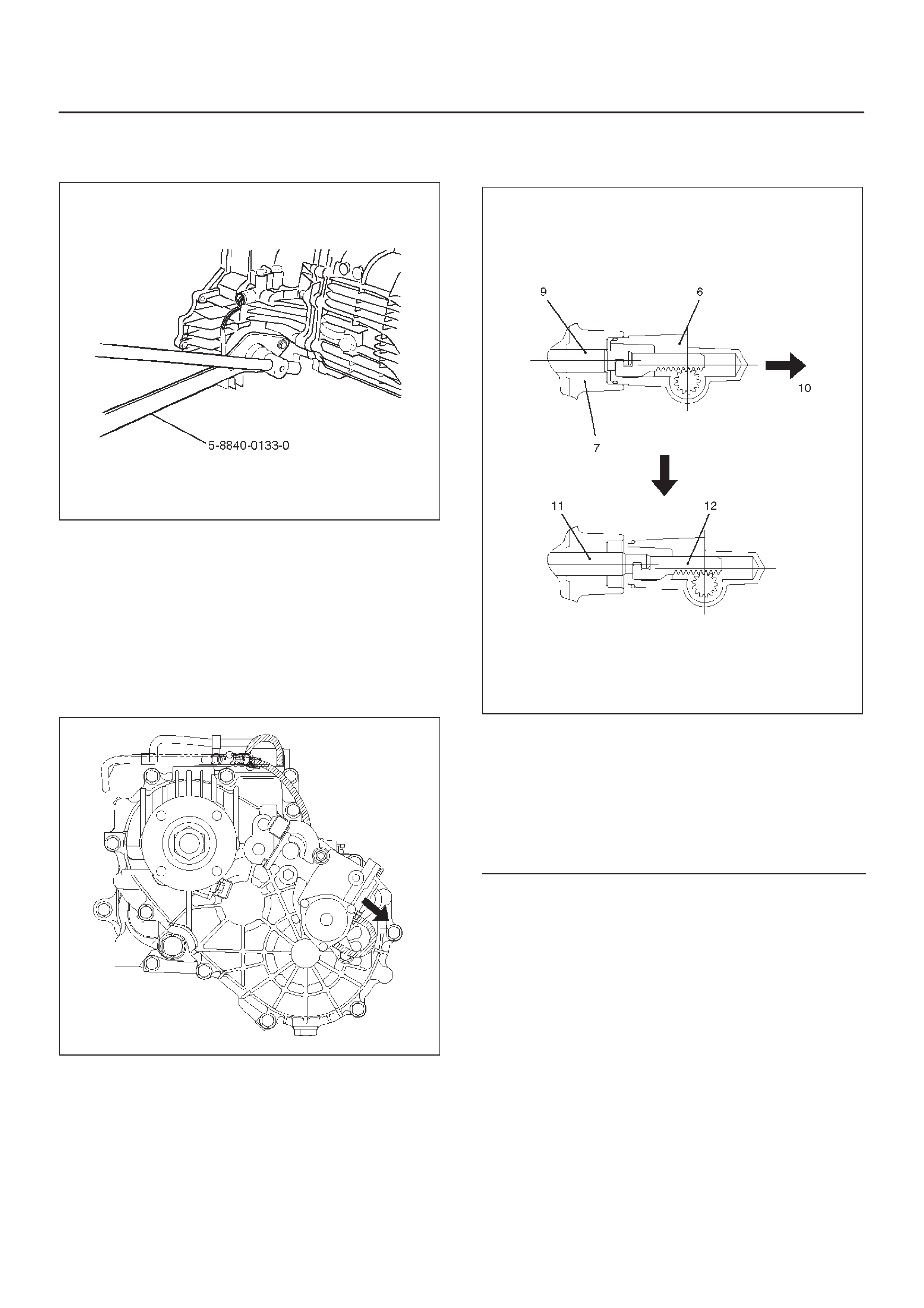

1.Disconnect the rear propeller shaft (1) from the

transfer case side.

2.Remove end nut and rear companion flange (2),

using the companion flange holder 5–8840–0133–0.

266RW026

3.Use the universal puller to remove the rear

companion flange and O–ring.

4.Remove the oil seal from the transfer case.

Installation

1.Install oil seal and apply engine oil to the oil seal outer

surfaces.

2.Apply the recommended grease (BESCO L2) or

equivalent to the oil seal lip.

3.Use the oil seal installer 5–8840–2292–0 to install the

rear seal (3) to the transfer rear case.

220RW105

4.Install the rear companion flange (2) and O–ring (2).

5.Use the companion flange holder 5–8840–0133–0 to

install a new end nut (2) and tighten to the specified

torque.

Torque: 167 N·m (17.0 kg·m/123 lb ft)

6.Use the punch 5–8840–2293–0 to stake the end nut

at two spots.

NOTE: Be sure to confirm that there is no crack at the

staked portion of the end nut (2) after staking.

266RW027

266RW002

7.Connect the rear propeller shaft to the transfer case

and tighten to the specified torque.

Torque: 63 N·m (6.4 kg·m/46 lb ft)

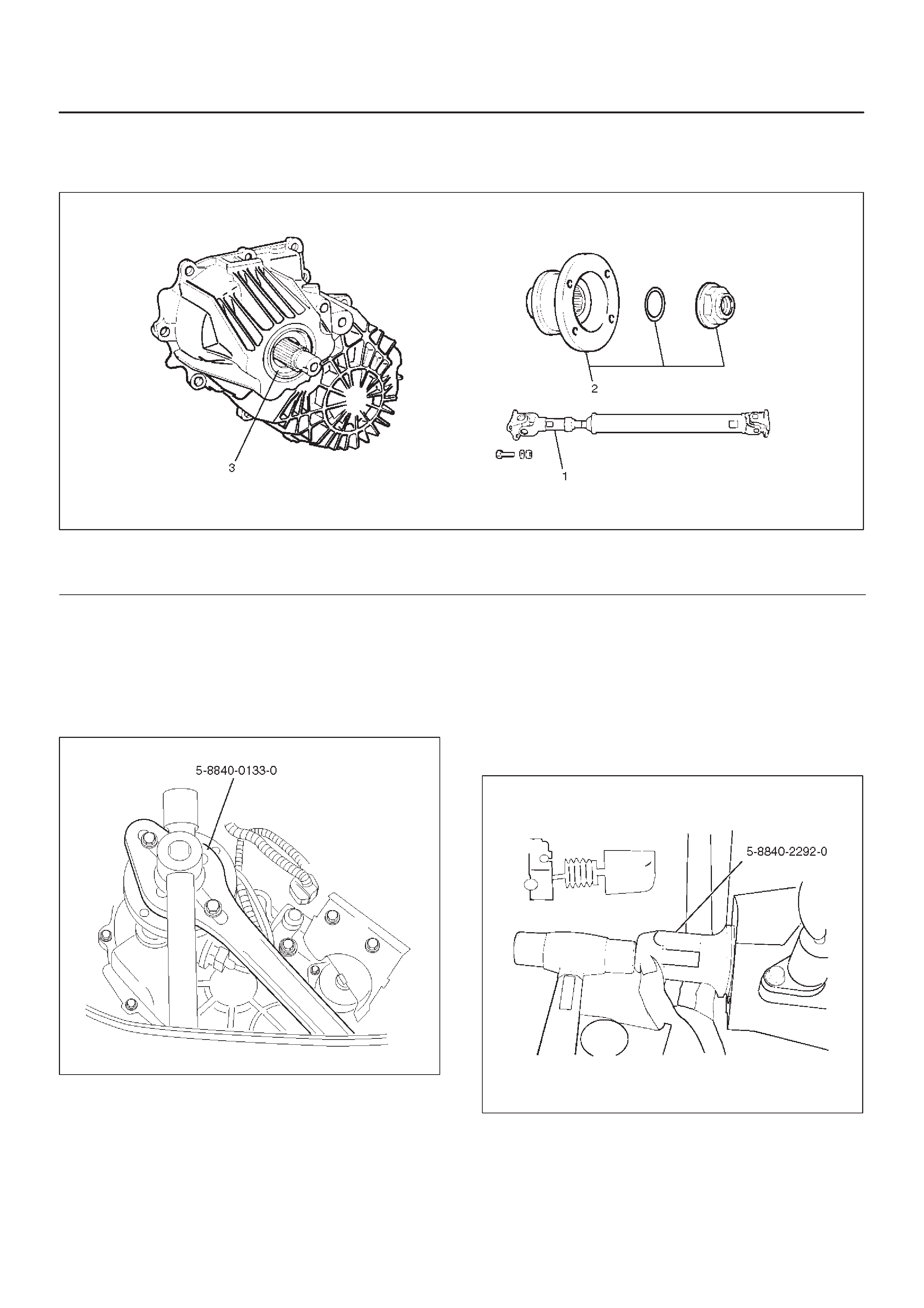

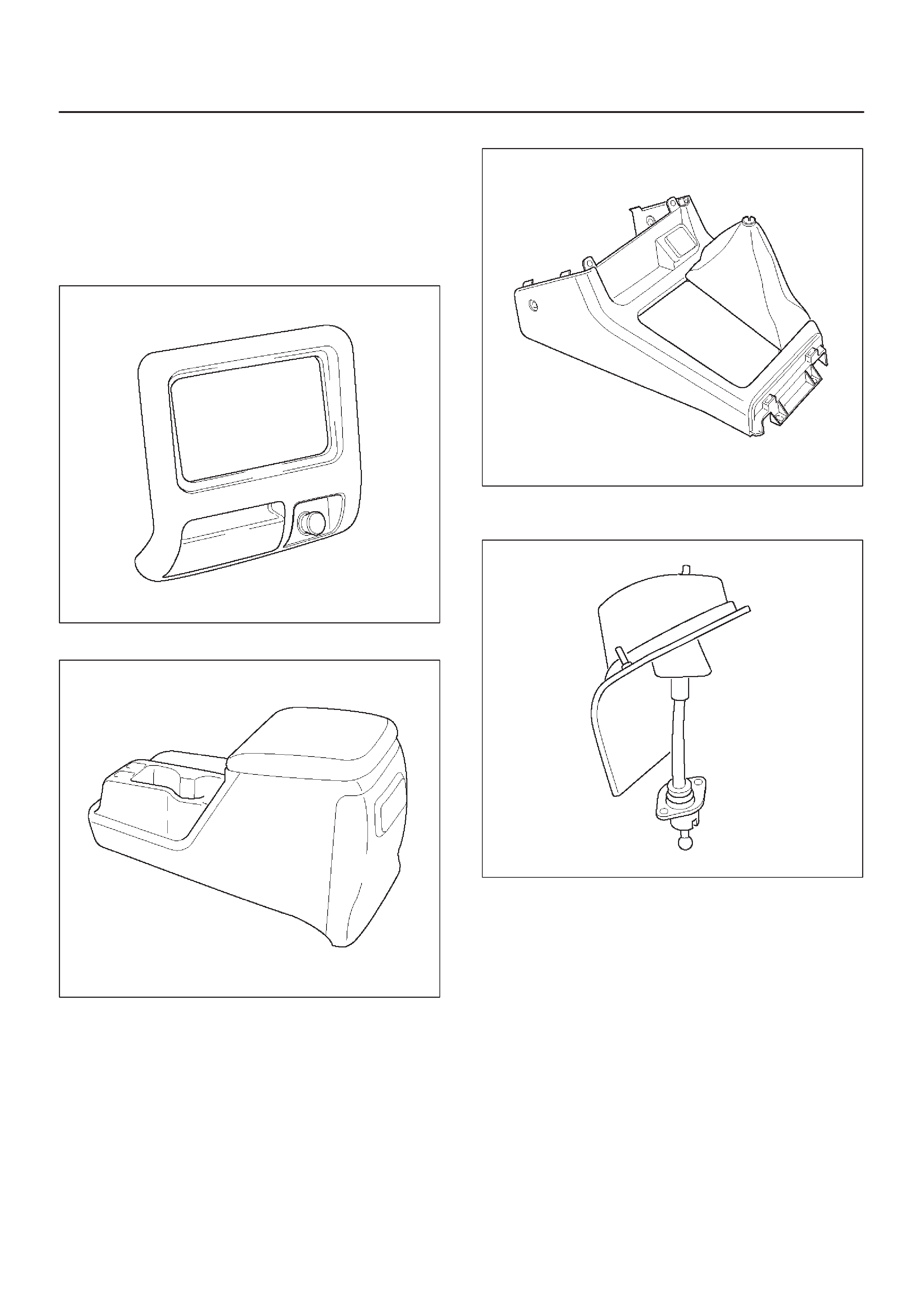

Transfer Case Assembly (A/T)

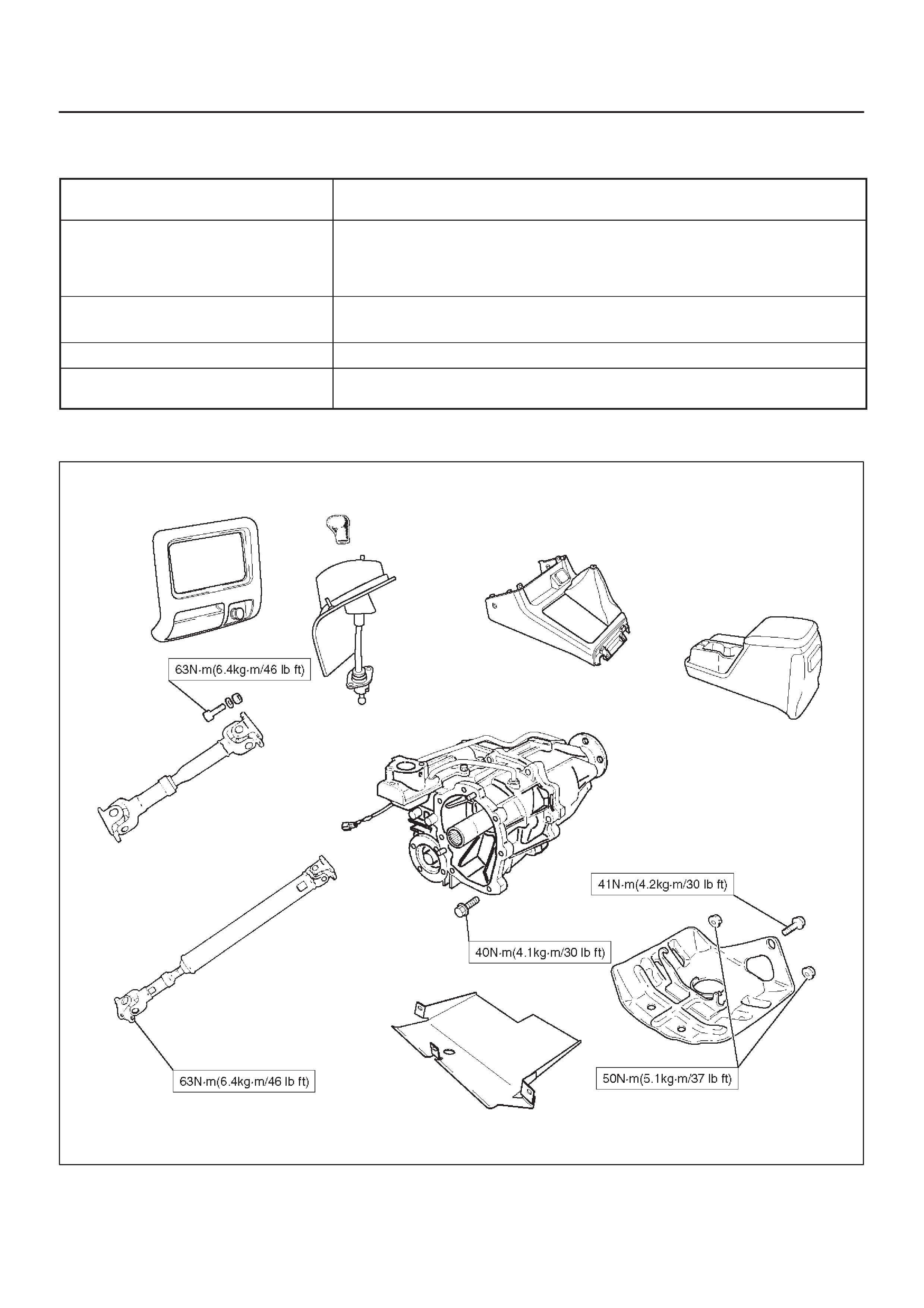

Transfer Case Assembly (A/T) and Associated Parts

260RX001

Legend

(1) Transfer Control Lever Knob

(2) Lower Cluster Assembly

(3) Rear Console

(4) Center Console

(5) Grommet Assembly and Transfer Control

Lever

(6) Transfer Protector

(7) Rear Propeller Shaft

(8) Front Propeller Shaft

(9) Transfer Case Assembly

Removal

NOTE: Before removing transmission and transfer

assembly from vehicle, change the transfer mode to 2WD

using the 4WD push button switch on dash panel.

1.Disconnect battery ground cable.

2.Remove transfer control lever knob (1).

3.Remove lower cluster assembly (2).

740RW021

4.Remove rear console (3).

256RW045

5.Remove center console (4).

256RW006

6.Remove grommet assembly and transfer control

lever (5).

256RW007

7.Raise and support vehicle with suitable stands. Drain

transfer case fluid.

8.Remove transfer protector (6).

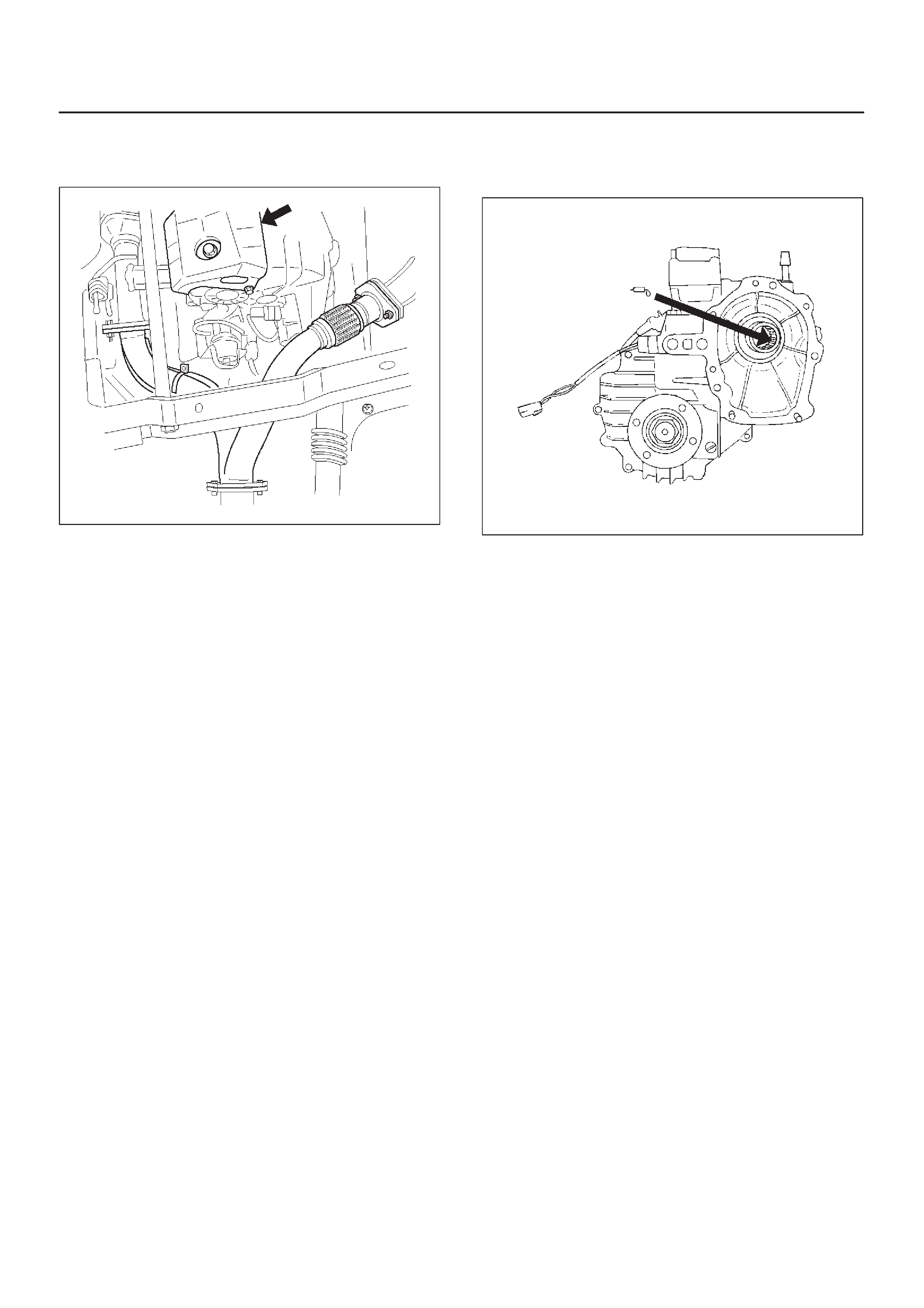

150RX010

9.Remove rear propeller shaft (7) and front propeller

shaft (8).

NOTE: Apply alignment marks on the flange at both front

and rear sides.

10.Disconnect harness connectors and clip.

Connector: transfer switch, 2WD–4WD actuator,

speed sensor.

11.Support transmission case with a transmission jack.

12. Remove the top position bolt from transfer control

lever hole and others under the floor.

Remove transfer case (9) from the vehicle.

Installation

1.Apply a thin coat of molybdenum disulfide grease to

the input shaft spline as shown in the figure.

260RW001

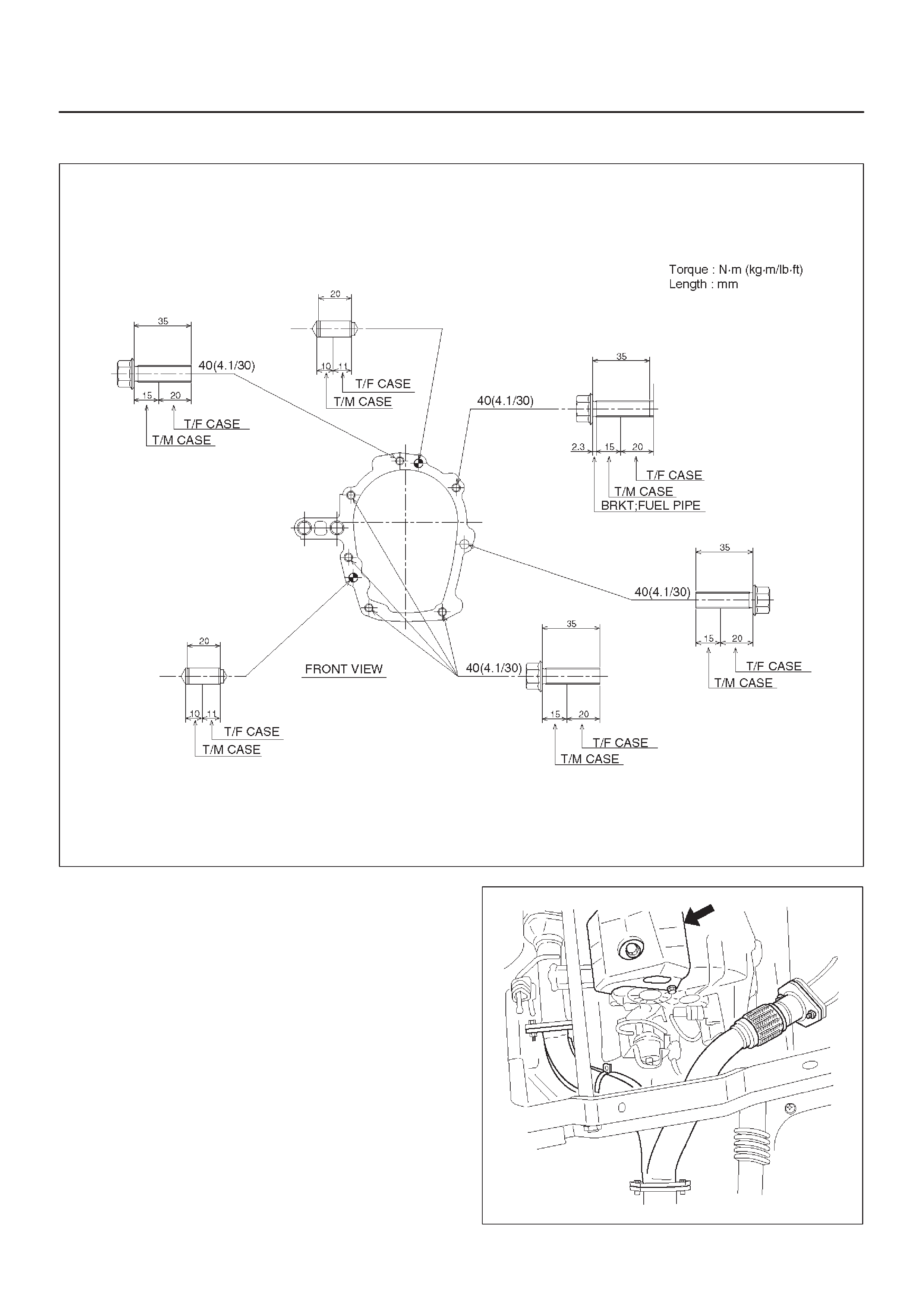

2.Install transfer case (9) to the transmission. Tighten

transfer bolts as shown in the figure.

261RX001

3.Remove the transmission jack from transmission

side.

4.Connect harness connectors and clip.

Connector: transfer switch, 2WD–4WD actuator,

speed sensor.

5.Install rear propeller shaft (7) and front propeller shaft

(8).

Torque: 63 N·m (6.4 kg·m/46 lb ft)

6.Install transfer protector (6).

150RX010

7.Fill transfer case fluid.

8.Lower the vehicle.

Install grommet assembly and transfer control lever

(5).

256RW007

9.Install center console (4), rear console (3) and lower

cluster assembly (2).

10.Install transfer control lever knob (1).

Transfer Rear Case Assembly (A/T)

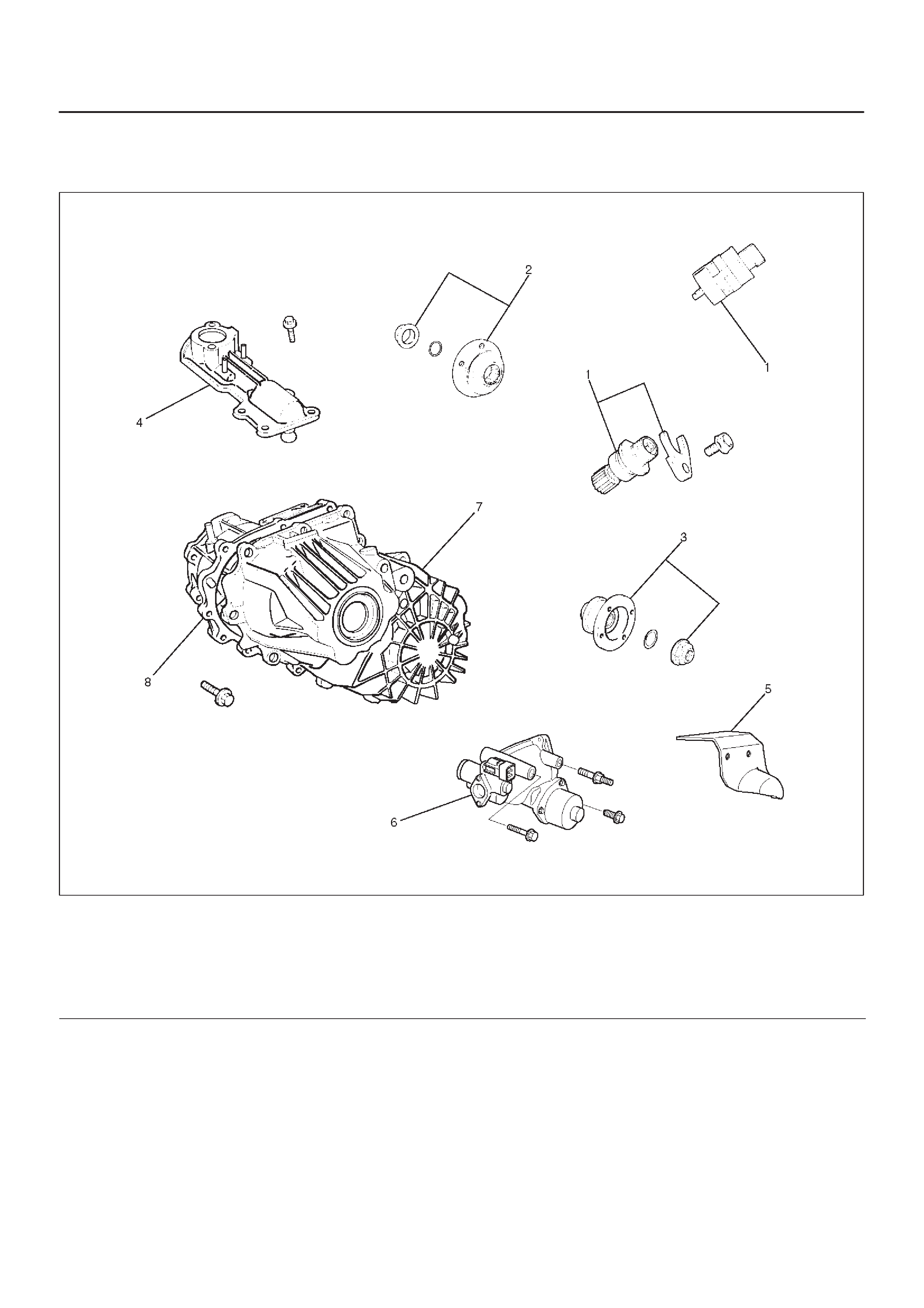

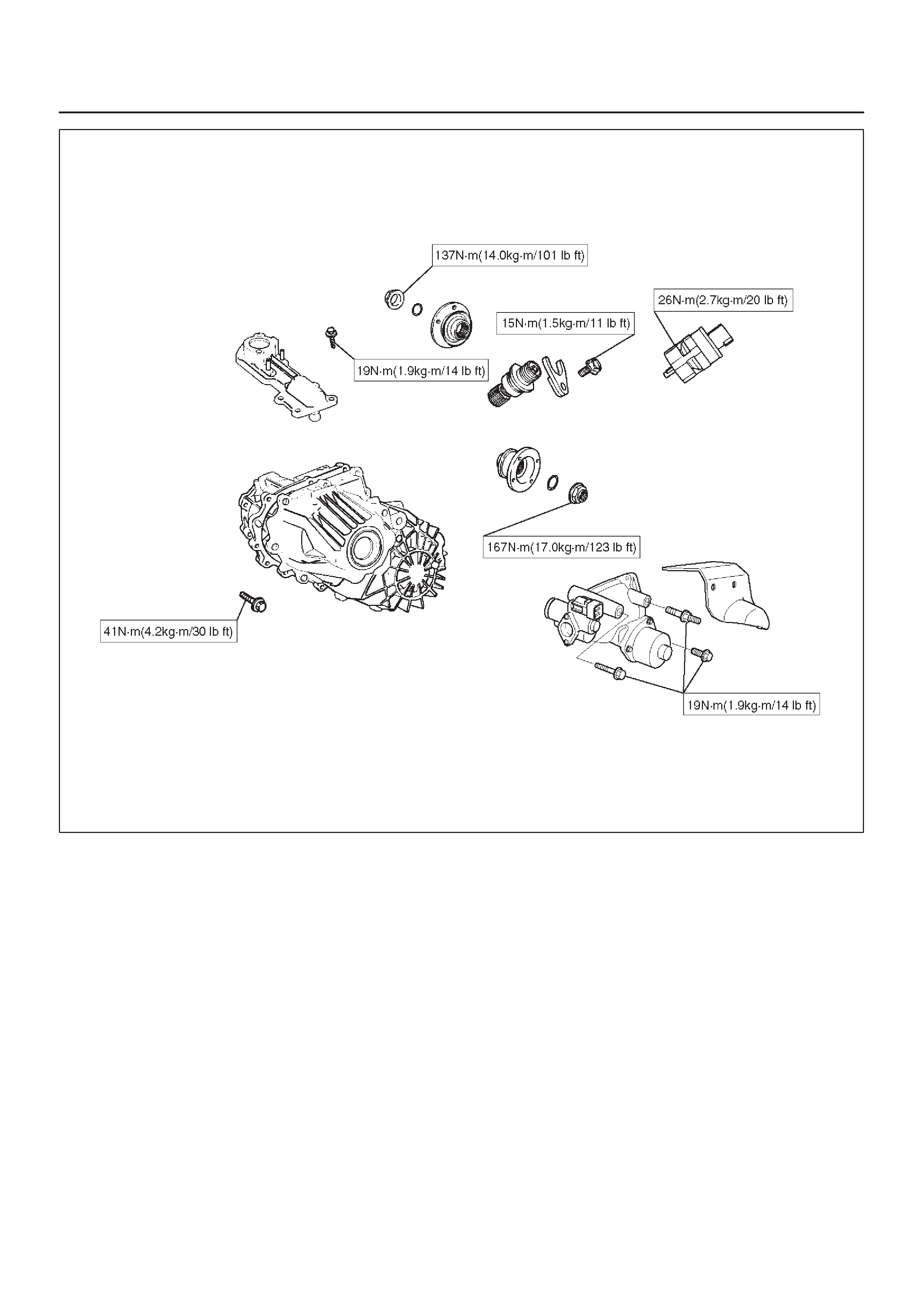

Transfer Rear Case Assembly (A/T) and Associated Parts

220RW133–1

Legend

(1) Speedometer Sensor, Speedometer Driven

Gear and Plate

(2) Front Companion Flange

(3) Rear Companion Flange

(4) Control Box Assembly

(5) 2WD–4WD Actuator Heat Protector

(6) 2WD–4WD Actuator Assembly

(7) Transfer Rear Cover Assembly

(8) Transfer Case Assembly

Removal

1.Remove the speedometer sensor (1).

2.Remove the plate (1).

3.Remove the speedometer driven gear bushing and

driven gear (1).

NOTE: Apply a reference mark to the driven gear bushing

before removal.

4.Remove front companion flange (2) and rear

companion flange (3), using the flange companion

holder 5–8840–0133–0 to remove the end nut.

262RW067

5.Remove the front and rear companion flange.

NOTE: Use the universal puller to remove the rear

companion flange.

6.Disconnect the actuator breather hose and transfer

breather hose from control box (4).

7.Remove control box assembly (4).

8.Disconnect the actuator breather hose and

2WD–4WD actuator heat protector (5) from the

2WD–4WD actuator assembly (6).

220RW085–1

9.Remove the 2WD–4WD actuator assembly bolts.

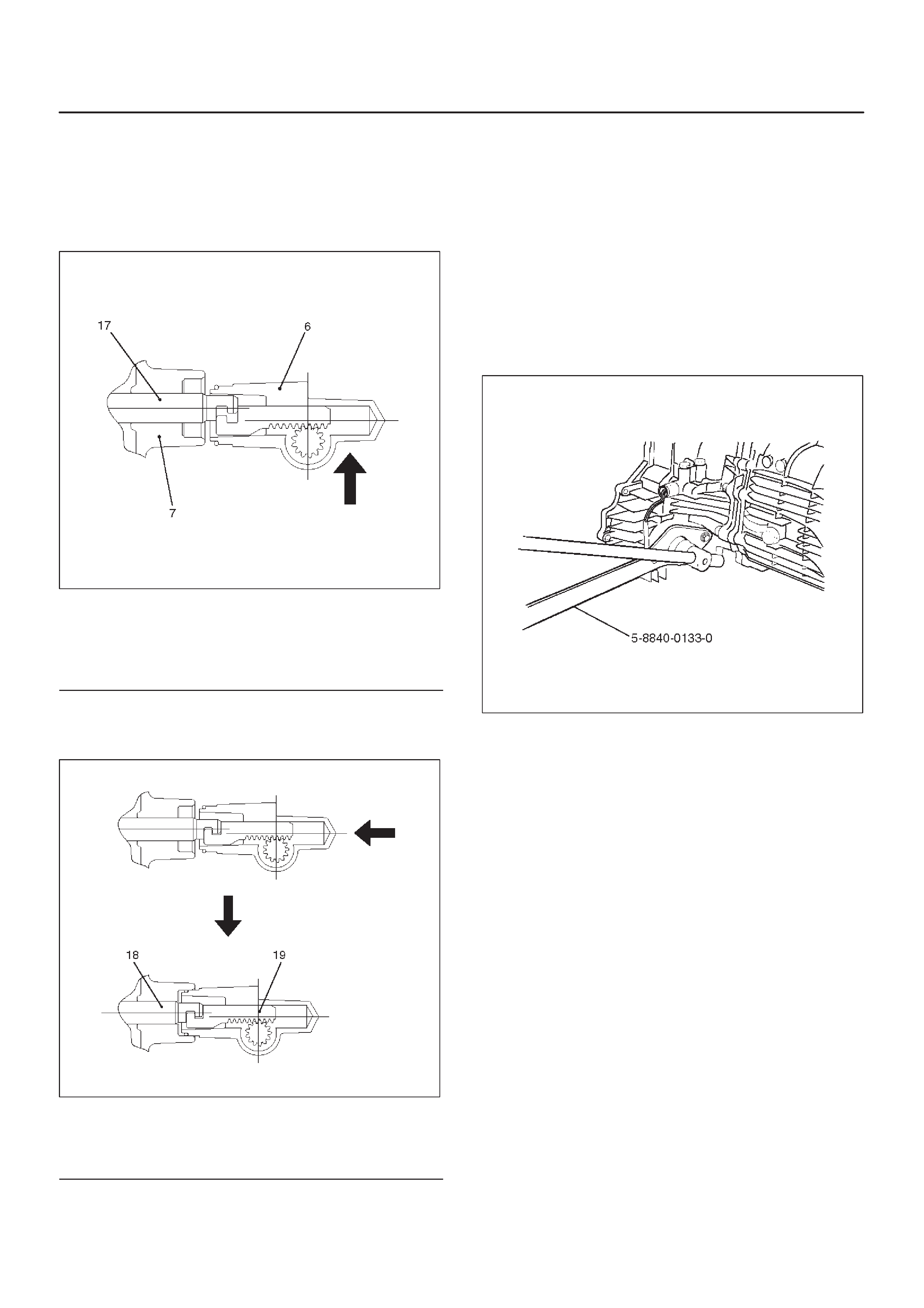

10.Pull the 2WD–4WD actuator assembly (6) with

2WD–4WD shift rod.

220RW065

Legend

(6) 2WD–4WD Actuator Assembly

(7) Rear Cover Assembly

(9) Shift Rod: 2WD–4WD (Position: 2WD)

(10) Pull

(11) Position: 4WD

(12) Mode: 2WD

11.Off set the actuator assembly.

220RW028

12.Remove the actuator assembly (6).

220RW066

Legend

(13) Position: 4WD

(14) Mode: 2WD

13.Remove transfer rear cover assembly (7) from

transfer case assembly.

Installation

1.Apply the recommended liquid gasket (LOCTITE

17430) or its equivalent to the transfer rear cover

fitting faces.

220RS017

2. Install transfer rear cover assembly (7) to transfer

case assembly (8).

3.Perform the following steps before fitting the transfer

rear case.

1. Shift the high–low shift rod to the 4H side.

2. The cut–away portion of the select rod head (15)

should align with that of the rear case hole’s

stopper (16).

230RW009

4.Tighten the transfer rear case bolts to the specified

torque.

Torque: 37 N·m (3.8 kg·m/27 lb ft)

5.Shift the 2WD–4WD shift rod (17) to the 4WD side.

6.Join the rod grooves of 2WD–4WD actuator

assembly (6) and shift rod (17).

220RW067

Legend

(6) 2WD–4WD Actuator Assembly (Mode: 2WD)

(7) Rear Cover Assembly

(17) Shift Rod: 2WD–4WD (Position: 4WD)

7.Push the 2WD–4WD actuator assembly (6) with

2WD–4WD shift rod (17) till the shift rod (17) reaches

the 2WD position.

220RW068

Legend

(18) Position: 2WD

(19) Mode: 2WD

8.Tighten the 2WD–4WD actuator bolts to the specified

torque.

Torque: 19 N·m (1.9 kg·m/14 lb ft)

9.Connect the actuator breather hose to actuator.

10.Install actuator heat protector (5).

11.Install control box assembly (4).

Torque: 19 N·m (1.9 kg·m/14 lb ft)

12.Connect breather hoses to control box (4).

13.Install rear companion flange (3) and front companion

flange (2), using the companion flange holder

5–8840–0133–0 to tighten the flange nuts to the

transfer case.

262RW067

14.Tighten the new transfer flange nuts to the specified

torque.

Torque

Rear companion flange: 167 N·m (17.0 kg·m/123

lb ft)

Front companion flange: 137 N·m (14.0 kg·m/101

lb ft)

15.Use the punch 5–8840–2293–0 to stake the rear

companion flange nut (3) at two spots.

266RW027

266RW002

16.Stake the front companion flange nut (2) at one spot.

NOTE: Be sure to confirm that there is no crack at the

staked portion of the flange nut after staking.

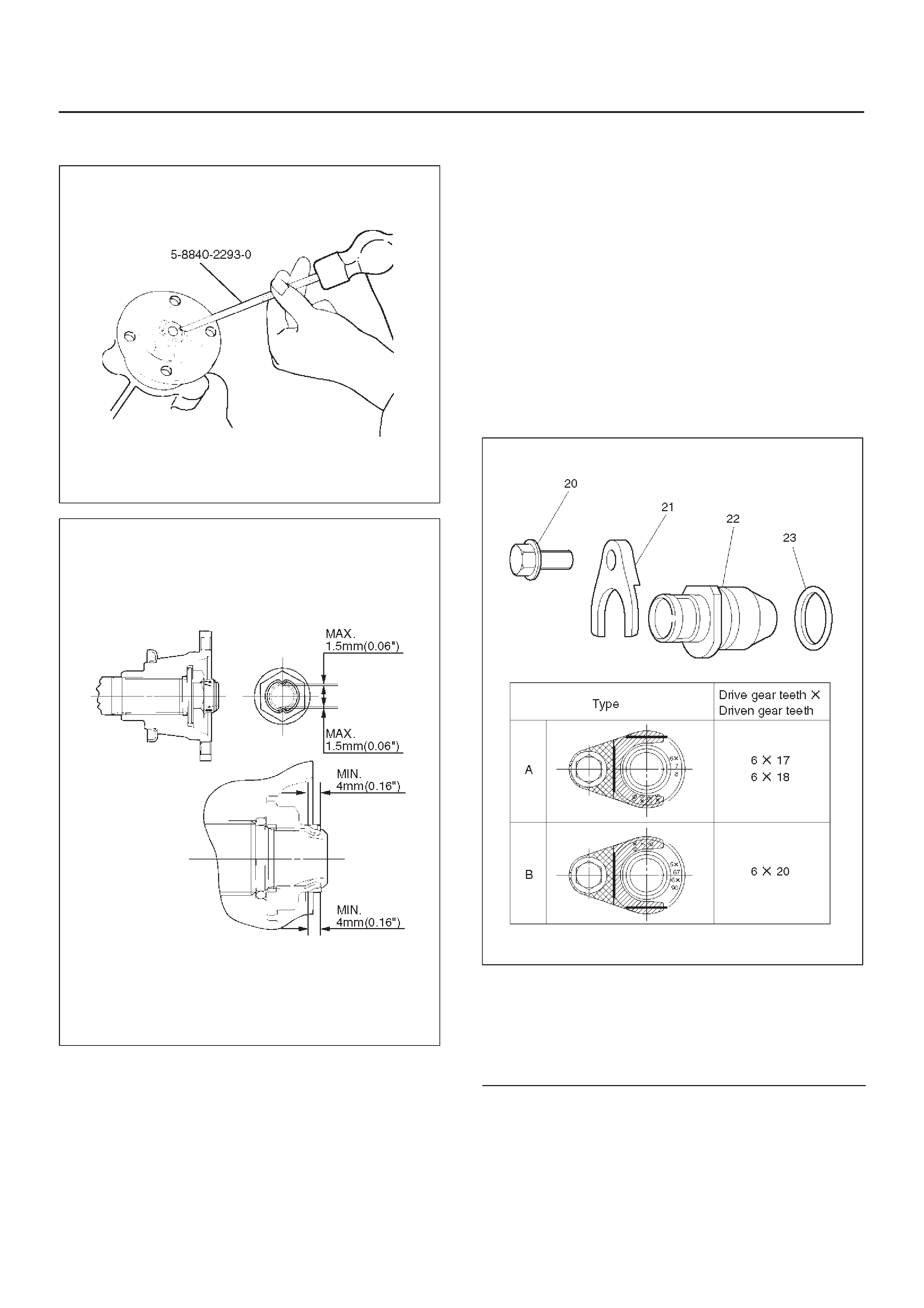

17.Install the O–ring (23) to the speedometer driven gear

bushing (22).

18.Install the driven gear to the speedometer driven gear

bushing (22).

19.Install the speedometer driven gear assembly to the

transfer rear cover.

20. Install the plate (21) to the transfer rear case and

tighten to the specified torque.

Torque: 15 N·m (1.5 kg·m/11 lb ft)

21.Install the speedometer sensor and tighten to the

specified torque.

Torque: 26 N·m (2.7 kg·m/20 lb ft)

225RW004

Legend

(20) Bolt

(21) Plate

(22) Bushing

(23) O–ring

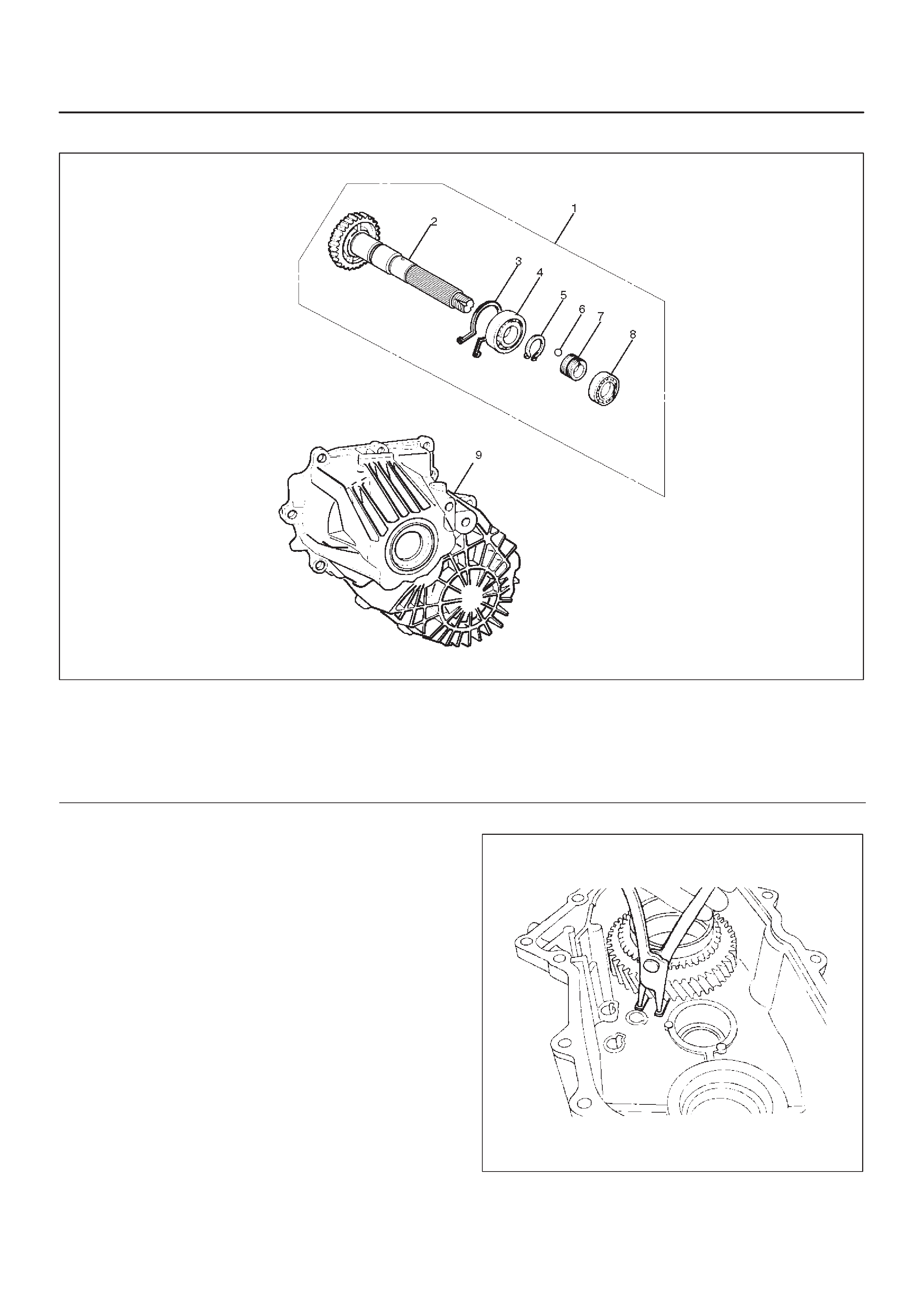

Transfer Rear Cover Assembly

226RW154

Legend

(1) Rear Output Shaft Assembly

(2) Rear Output Shaft

(3) Bearing Snap Ring

(4) Ball Bearing

(5) Bearing Snap Ring

(6) Ball

(7) Speedometer Drive Gear

(8) Ball Bearing

(9) Transfer Rear Cover (with oil seal)

Disassembly

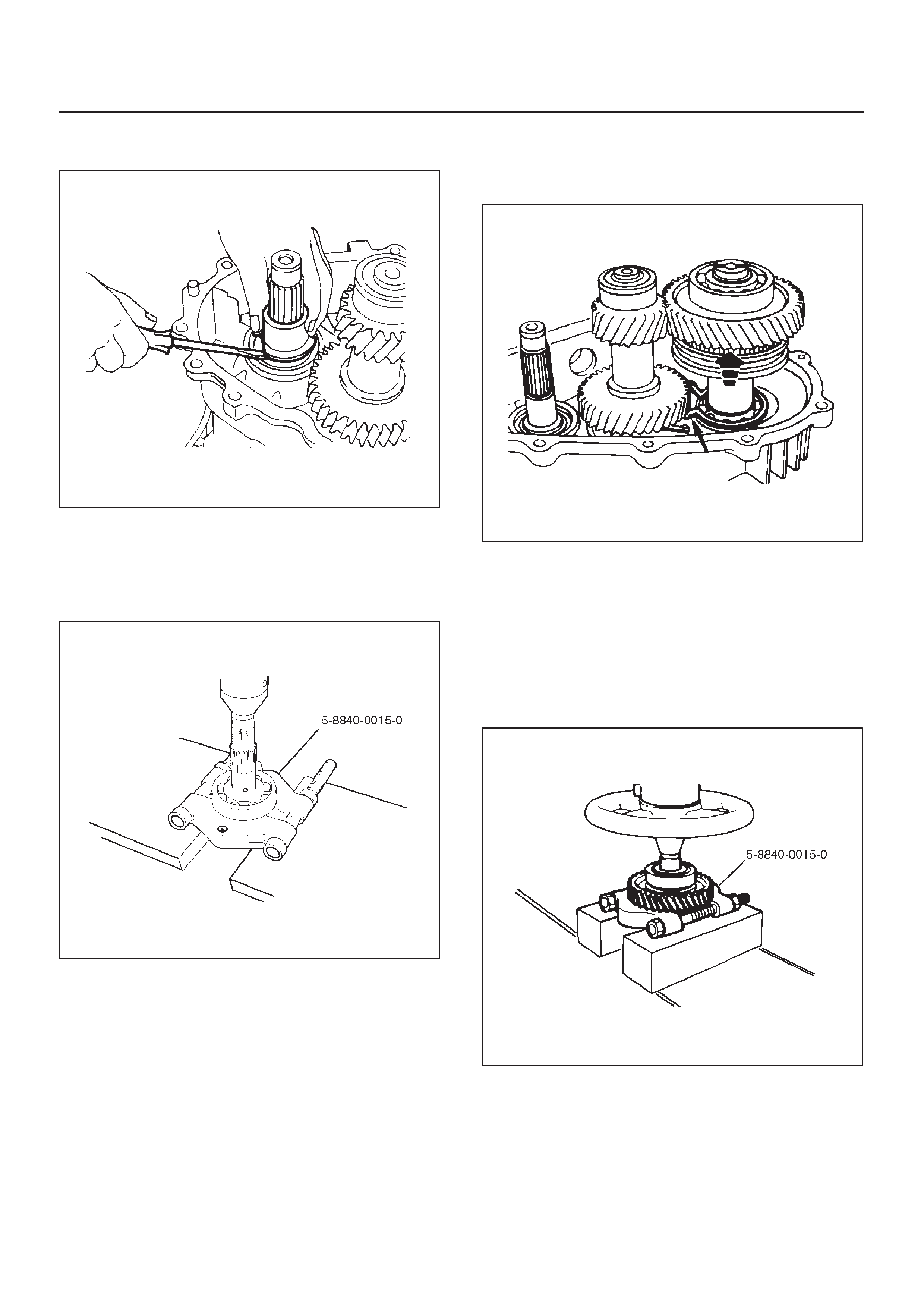

1.Remove bearing snap ring, use a pair of snap ring

pliers to remove the snap ring (3).

226RS060

2.Remove the rear output shaft assembly (1) from the

transfer rear cover (with oil seal) (9).

3.Remove ball bearing (8), using a bench press and the

bearing remover 5–8840–0015–0.

226RW186

4.Remove speedometer drive gear (7).

5.Remove ball (6).

6.Remove bearing snap ring (5), using a pair of snap

ring pliers.

7.Remove rear output shaft (2) from the ball bearing (4),

using a bench press and the bearing remover

5–8840–0015–0.

226RW187

Inspection and Repair

Refer to “TRANSFER CASE ASSEMBLY” in this section

for inspection and repair.

Reassembly

Transfer rear cover (with oil seal) (9). Oil seal

replacement.

DRemove the oil seal from the transfer rear cover.

DApply engine oil to the oil seal outer surfaces.

DFill in recommended grease (BESCO L2) or

equivalent in the oil seal lip.

DUse the oil seal installer 5–8840–2292–0 to install the

rear oil seal to the transfer rear cover.

220RW104

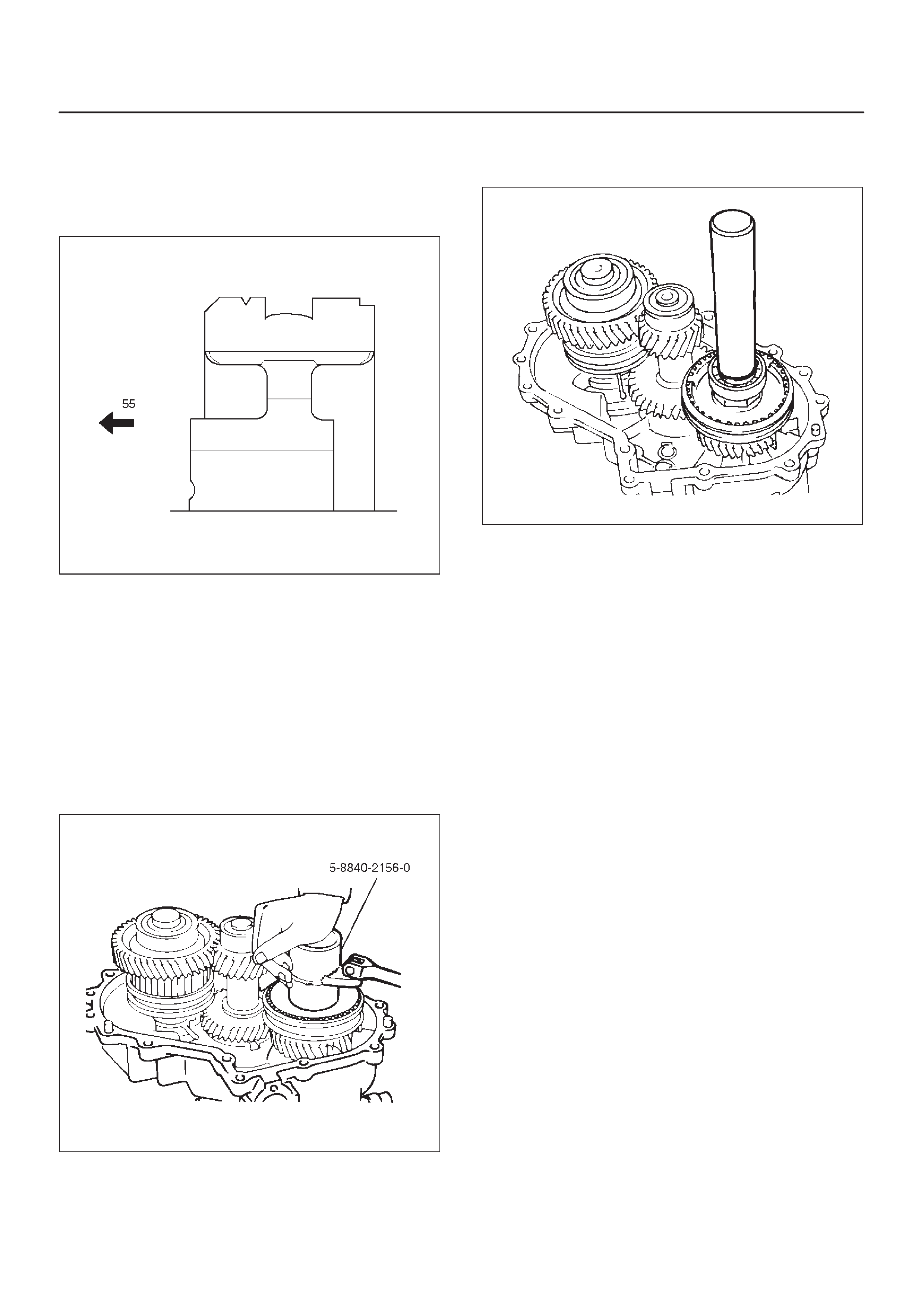

1. Install ball bearing (4) to the rear output shaft (2),

using the ball bearing installer 5–8840–2159–0 and

the adapter 5–8840–2192–1.

262RW068

2.Install bearing snap ring (5), using a pair of snap ring

pliers.

3.Install ball (6).

4.Install speedometer drive gear (7).

226RS064

5.Use the ball bearing installer 5–8840–2159–0 to

install the ball bearing (8).

226RW188

6.Install the rear output shaft assembly (1) to the

transfer rear cover (9).

7.Install bearing snap ring (3).

NOTE: The snap ring must be fully inserted into the

transfer rear cover snap ring groove.

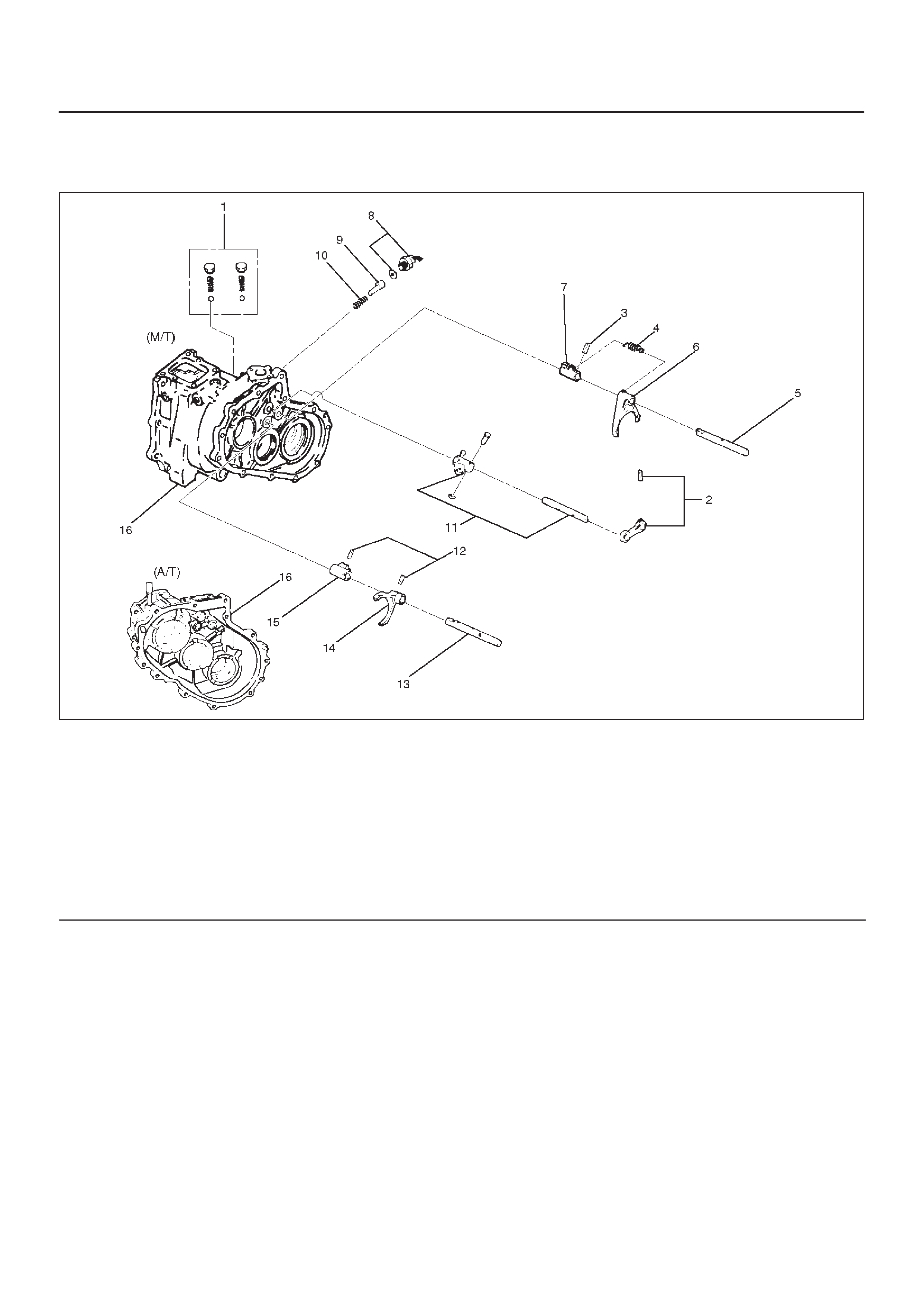

Detent, Shift Arm, and Interlock Pin (Transfer Case Assembly)

Disassembled View

262RW005

Legend

(1) Detent Ball, Spring and Plug

(2) Spring Pin and Bridge

(3) Spring Pin

(4) Spring

(5) 2WD–4WD Shift Rod

(6) Shift Arm

(7) Shift Block

(8) 4WD Indicator Switch

(9) Interlock Pin

(10) Spring

(11) Select Rod Assembly

(12) Spring Pin

(13) High–Low Shift Rod

(14) Shift Arm

(15) Shift Block

(16) Transfer Case

Disassembly

1.Remove detent ball, spring and plug (1).

2.Use a spring pin remover to remove the spring pin (2)

from the bridge (2).

262RW011

3.Remove spring (4).

4.Engage the 2WD–4WD sleeve with front output gear .

Remove the spring pin (3) from the block (7). Remove

the shift rod (5).

262RW022

5.Remove shift arm (6).

6.Remove shift block (7).

7.Remove 4WD indicator switch (8).

8.Use a magnetic tool to remove the interlock pin (9)

and spring (10) from the transfer case (16).

262RS005

9.Remove select rod assembly (11).

10. Use a spring pin remover to remove the shift arm

spring pin (12) from the shift arm (14) and shift block

(15). Remove the high–low shift rod (13) from transfer

case (16).

262RS006

11.Remove shift arm (14).

12.Remove shift block (15) from transfer case (16).

Inspection and Repair

Refer to “TRANSFER CASE ASSEMBLY” in this section

for inspection and repair.

Reassembly

1.Place shift block (15) in transfer case (16).

2.Set shift arm (14) on the High–Low sleeve.

3.Push High–Low shift rod (13) through shift arm (14)

and block (15).

4.Engage the High–Low sleeve with the 4H (1) side.

5.Install the spring pin (12) to the shift block (15) and

shift arm (14).

262RW034

6. Install select rod assembly (11), joining its lever to

shift block (15) groove.

7.Engage the High–Low sleeve with the 4H side and

install the interlock pin (9) and spring (10) in the

proper direction.

8.Place 2WD–4WD shift block (7) in the transfer case

(16).

9.Set 2WD–4WD shift arm (6) on the 2WD–4WD

sleeve.

10.Puh 2WD–4WD shift rod (5) through 2WD–4WD shift

arm (6) and 2WD–4WD shift block (7).

11.Install the 2WD–4WD shift rod (5) with interlock pin

pushed in.

262RW035

Legend

(18) 2WD–4WD

(19) 4H Side

(20) Interlock pin

(21) 2WD

(22) 4WD

(23) Rod: 2–4

(24) Rod: H–L

(25) 4H

(26) 4L

(27) 4×2

(28) 4×4

12.Install 4WD indicator switch and gasket (8).

Tighten to the specified torque.

Torque: 39 N·m (4.0 kg·m/29 lb ft)

13.Install spring (4).

14.Engage the 2WD–4WD sleeve with the 4WD side and

install the spring pin (3).

262RW022

15.Install spring pin (2) and bridge (2).

16.Install detent ball, spring and plug and tighten the plug

to the specified torque.

Torque: 25 N·m (2.5 kg·m/18 lb ft)

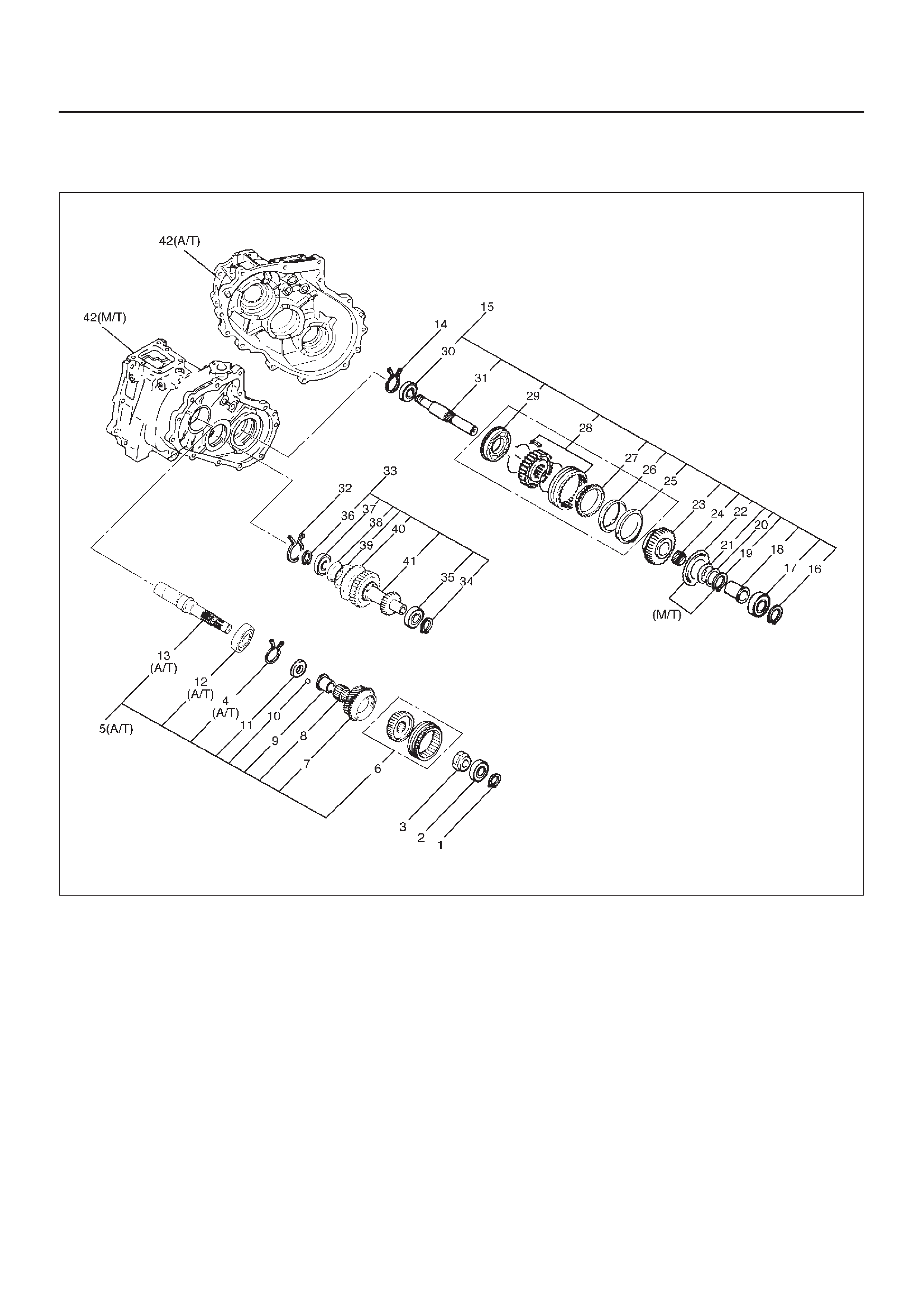

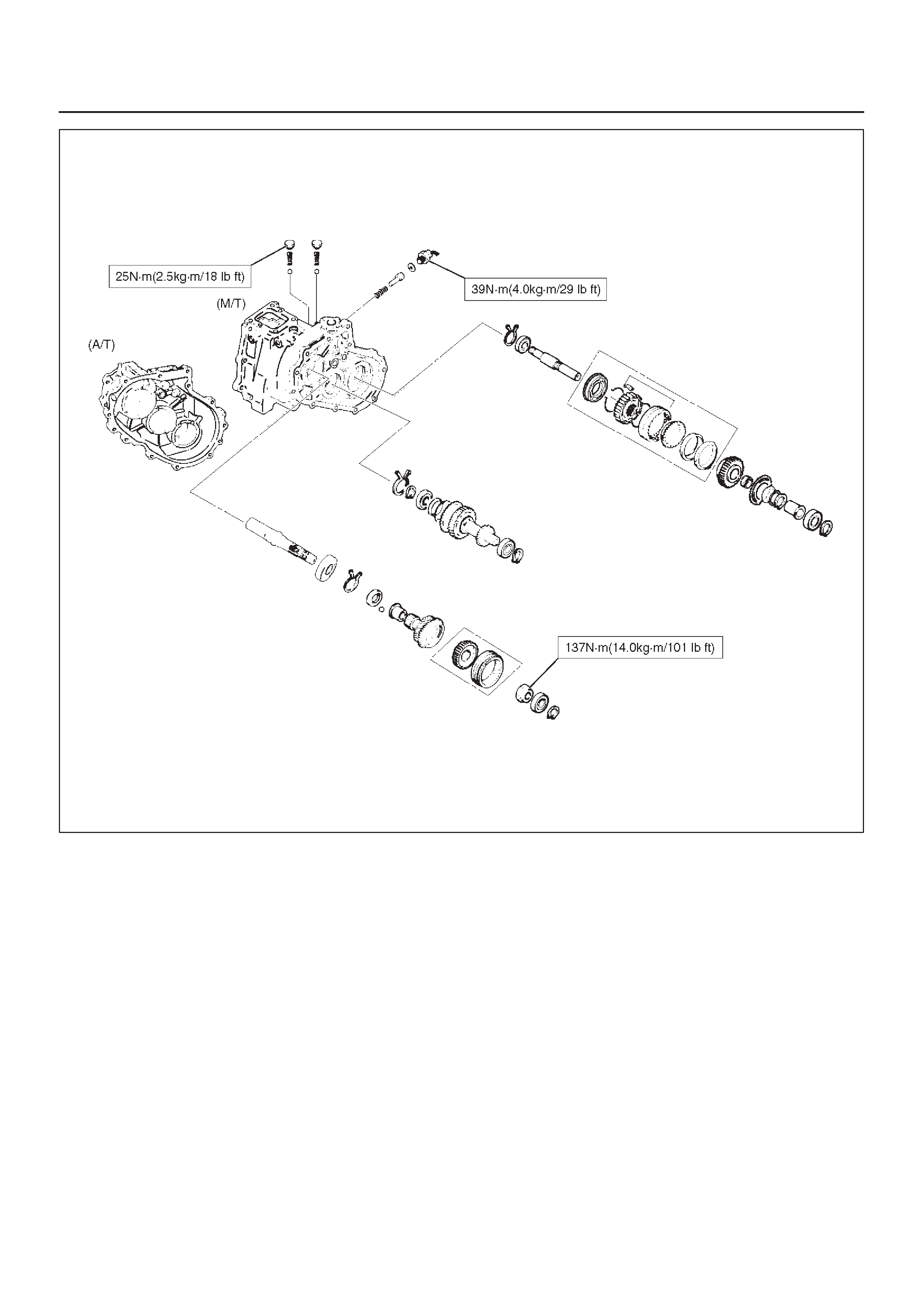

Transfer Case Assembly

Disassembled View

226RW209

Legend

(1) Bearing Snap Ring

(2) Ball Bearing

(3) Lock Nut

(4) Snap Ring (A/T)

(5) Input Shaft Assembly (A/T)

(6) High–Low Clutch Hub and Sleeve

(7) Transfer Input Gear

(8) Needle Bearing

(9) Bearing Collar

(10) Ball

(11) Plate

(12) Ball Bearing (A/T)

(13) Input Shaft (A/T)

(14) Bearing Snap Ring

(15) Front Output Gear Assembly

(16) Bearing Snap Ring

(17) Ball Bearing

(18) Bearing Collar

(19) Sub–Gear Snap Ring (M/T)

(20) Spacer (M/T)

(21) Belleville Spring (M/T)

(22) Sub–Gear (anti–lash plate) (M/T)

(23) Front Output Gear

(24) Needle Bearing

(25) Inside Ring

(26) Outside Ring

(27) Block Ring

(28) 2WD–4WD Clutch Hub and Sleeve Assembly

(29) Stopper Plate

(30) Ball Bearing

(31) Front Output Shaft

(32) Bearing Snap Ring

(33) Counter Gear Assembly

(34) Snap Ring

(35) Ball Bearing

(36) Snap Ring

(37) Ball Bearing

(38) Spacer

(39) Belleville Spring

(40) Sub–Gear (anti–lash plate)

(41) Counter Gear

(42) Transfer Case (with oil seal)

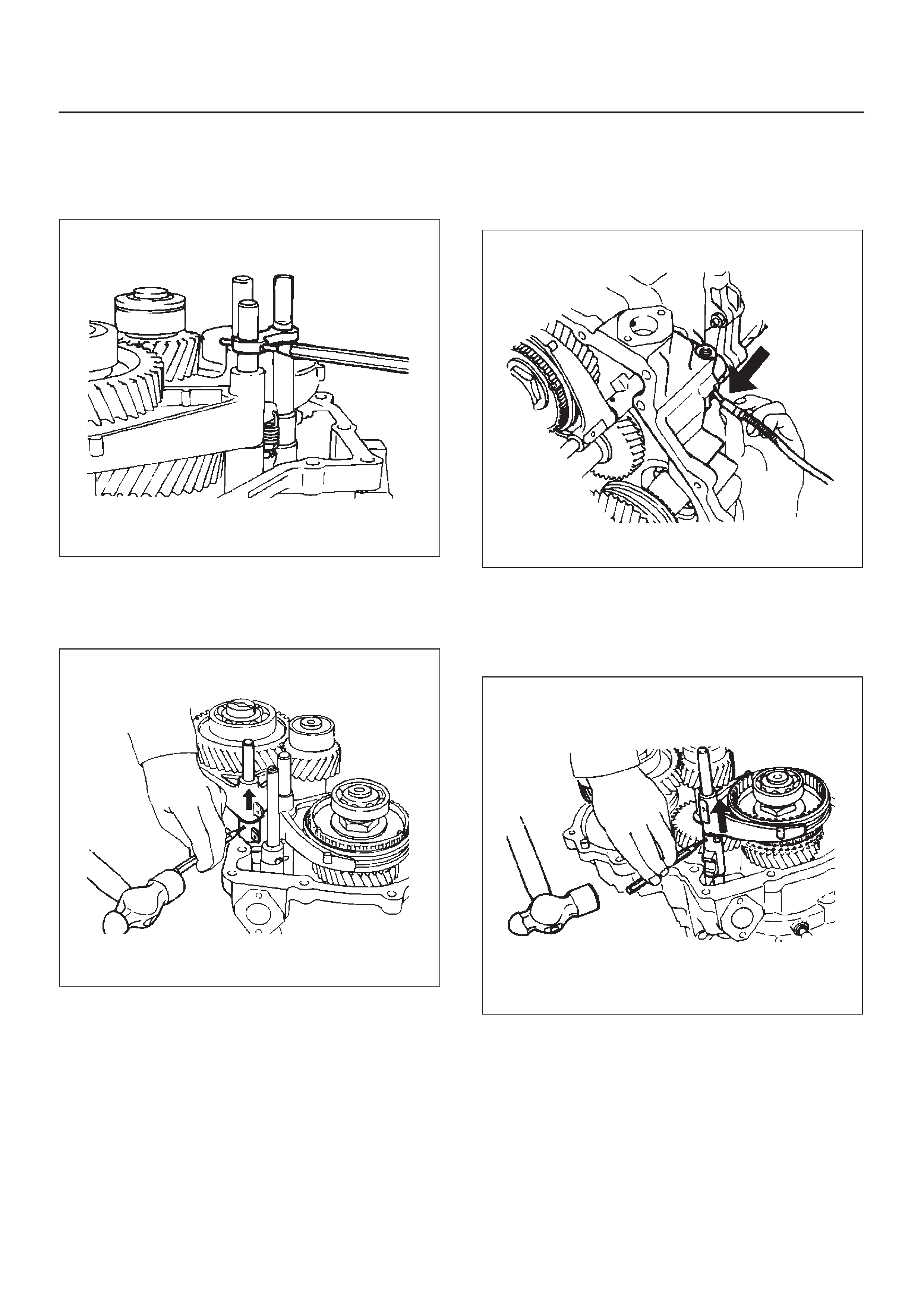

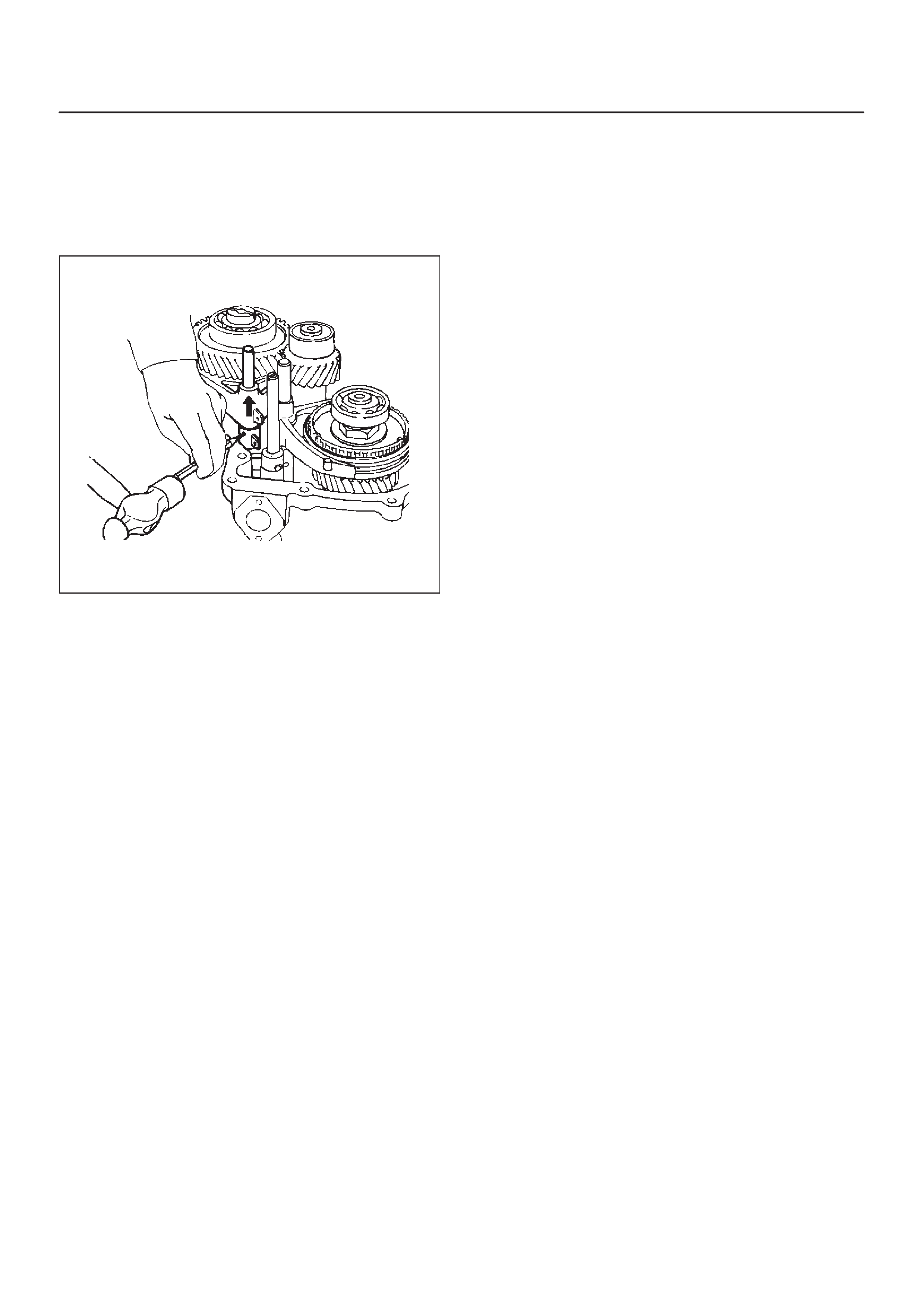

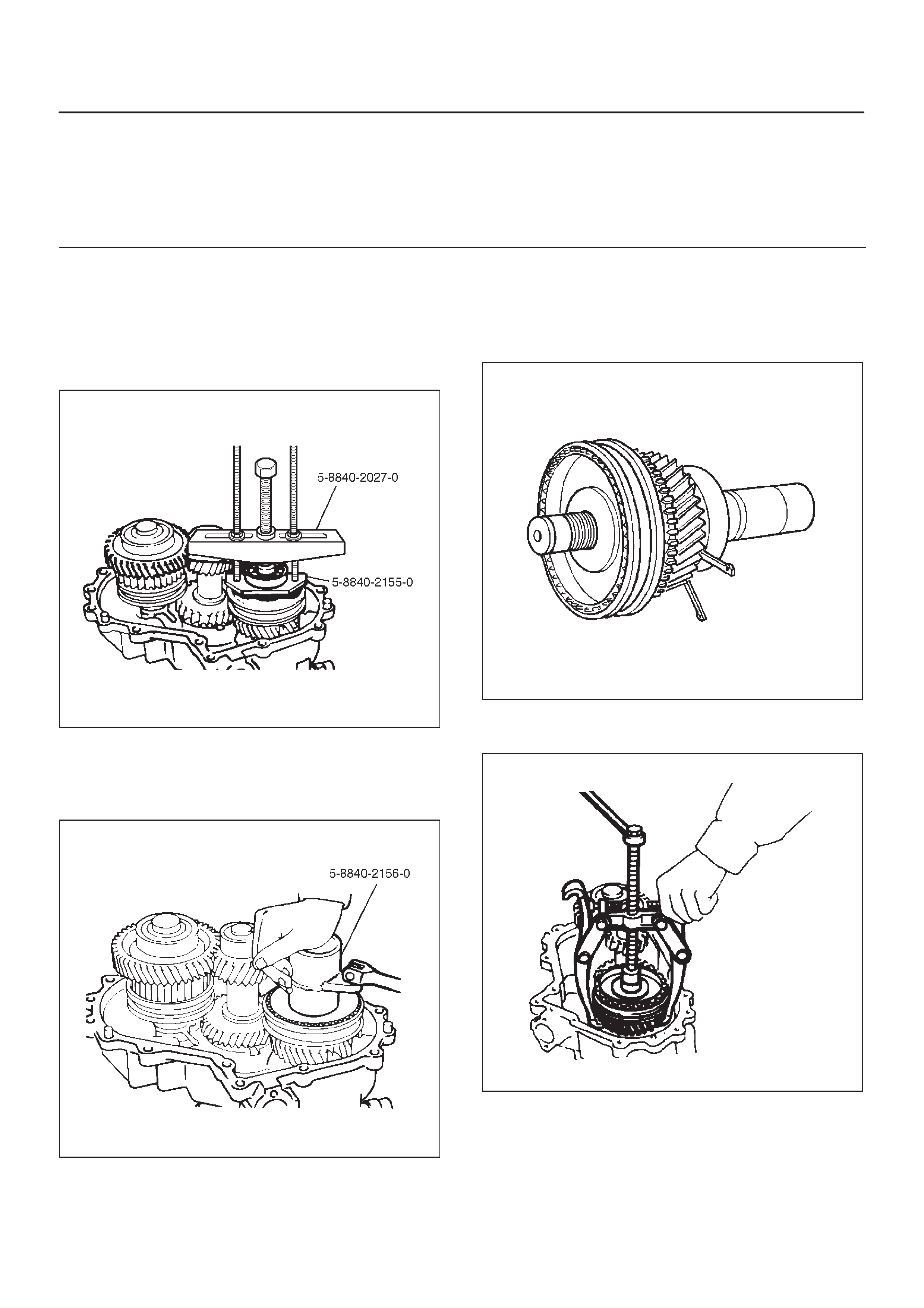

Disassembly

1.Use a pair of snap ring pliers to remove the snap ring

(1).

2.Use a bearing remover 5–8840–2155–0 and puller

5–8840–2027–0 to remove the ball bearing (2).

262RW069

3.Install the front companion flange temporarily.

4. Use the Companion flange holder 5–8840–0133–0

and lock nut wrench 5–8840–2156–0 to remove the

lock nut (3).

226RW190

5.Remove the front companion flange.

6.Remove snap ring (4). (A/T)

7.Remove the input shaft assembly (5) from the

transfer case (42). (A/T)

265RW001

8.Use the universal puller to remove the high–low

clutch hub and sleeve (6), and transfer input gear (7).

226RS070

9.Remove needle bearing (8).

10.Remove bearing collar (9).

226RS071

11.Remove ball (10).

12.Remove plate (11).

13.Use a bench press and the ball bearing remover

5–8840–0015–0 to remove the ball bearing (12) from

the input shaft (13). (A/T)

265RW013

14.Use a pair of snap ring pliers to remove the bearing

snap ring (14).

15. Use a plastic hammer to tap the front output gear

assembly (15) free.

262RS009

16.Remove bearing snap ring (16).

17.Use a bench press and the bearing remover

5–8840–0015–0 to remove the following parts.

18. Remove ball bearing (17), and bearing collar (18).

Remove sub–gear snap ring (19), spacer (20),

belleville spring (21), and sub–gear (anti–lash plate)

(22). (M/T)

Remove front output gear (23) and needle bearing

(24).

262RW070

19.Remove inside ring (25).

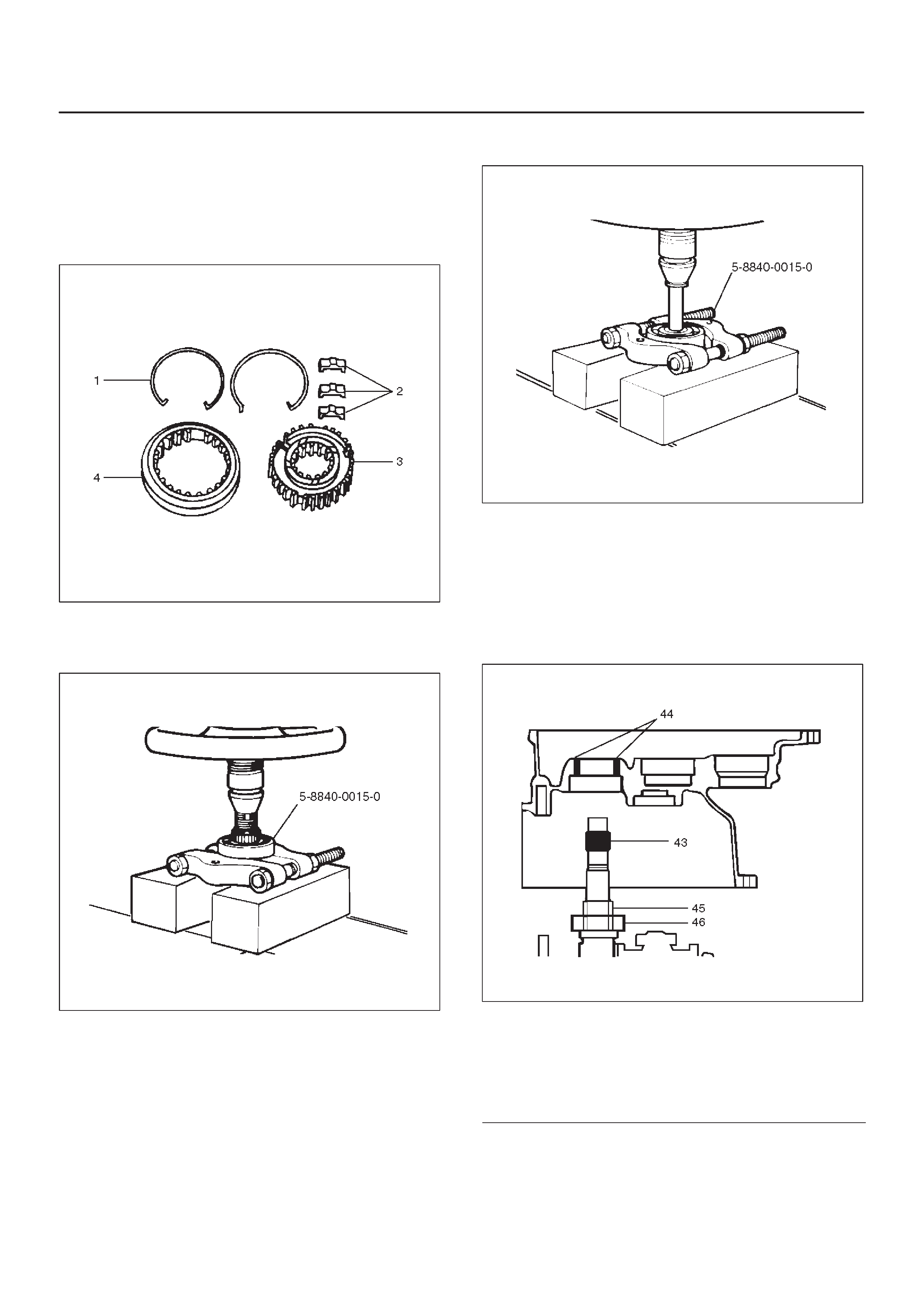

20.Remove outside ring (26).

21.Remove block ring (27).

22.Use a bench press and bearing remover

5–8840–0015–0 to remove 2WD–4WD clutch hub

and sleeve assembly (28) and stopper plate (29).

NOTE: Do not reuse the stopper plate.

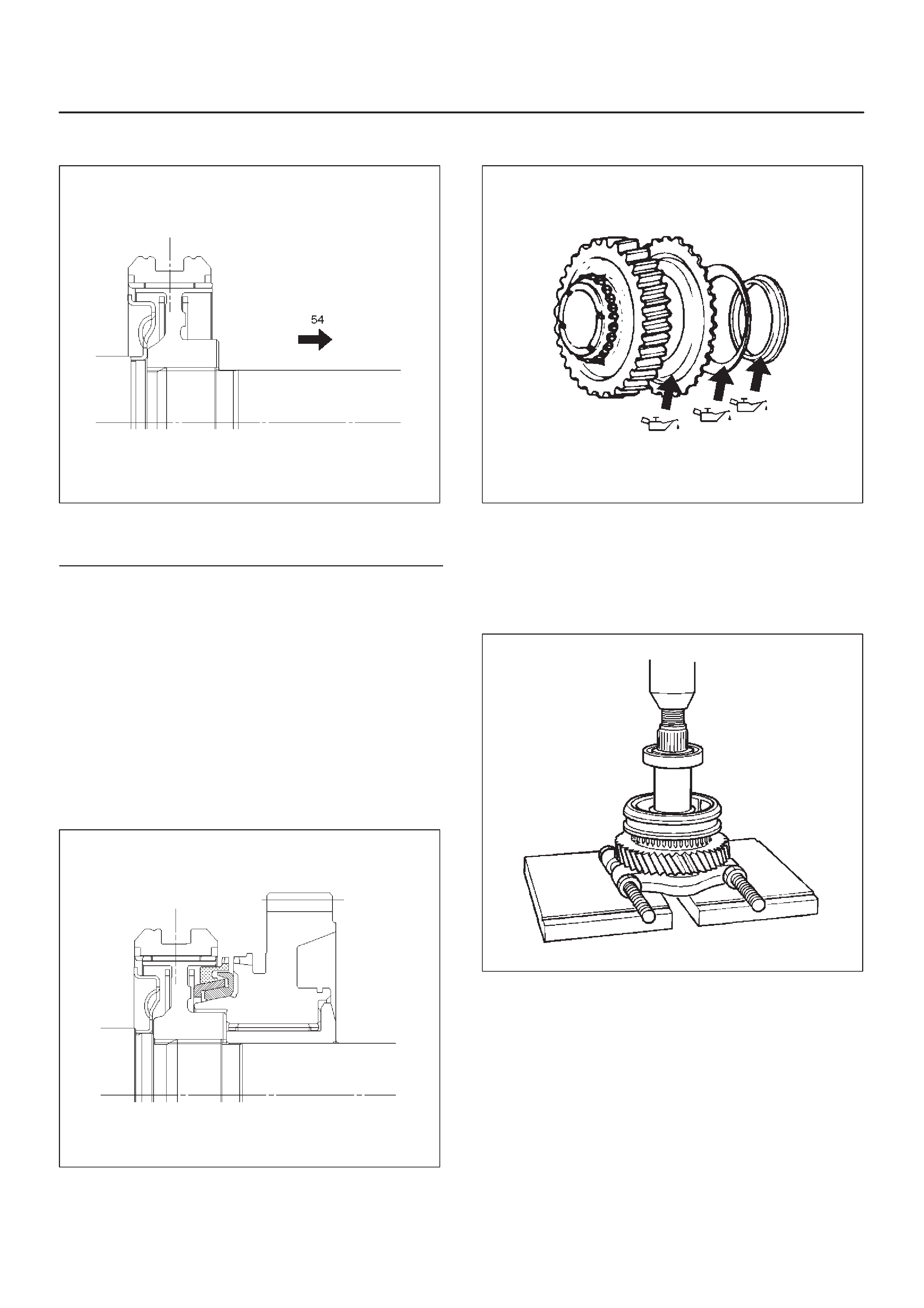

23.Disassemble the 2WD–4WD clutch hub and sleeve

assembly (28).

DSprings (1)

DInserts (2)

DClutch Hub (3)

DSleeve (4)

226RW133

24.Use a bench press and the ball bearing remover

5–8840–0015–0 to remove the ball bearing (30) from

front output shaft (31).

262RW071

25.Remove bearing snap ring (32).

26.Remove the counter gear assembly (33) from the

transfer case (42).

27.Use a pair of snap ring pliers to remove the snap ring

(34).

28.Use a bench press and the bearing remover

5–8840–0015–0 to remove the ball bearing (35).

29.Use a pair of snap ring pliers to remove the snap ring

(36).

30.Use a bench press and the bearing remover

5–8840–0015–0 to remove the ball bearing (37).

226RW208

31.Remove spacer (38).

32.Remove belleville spring (39).

33.Remove sub–gear (anti–lash plate) (40).

34.Remove counter gear (41).

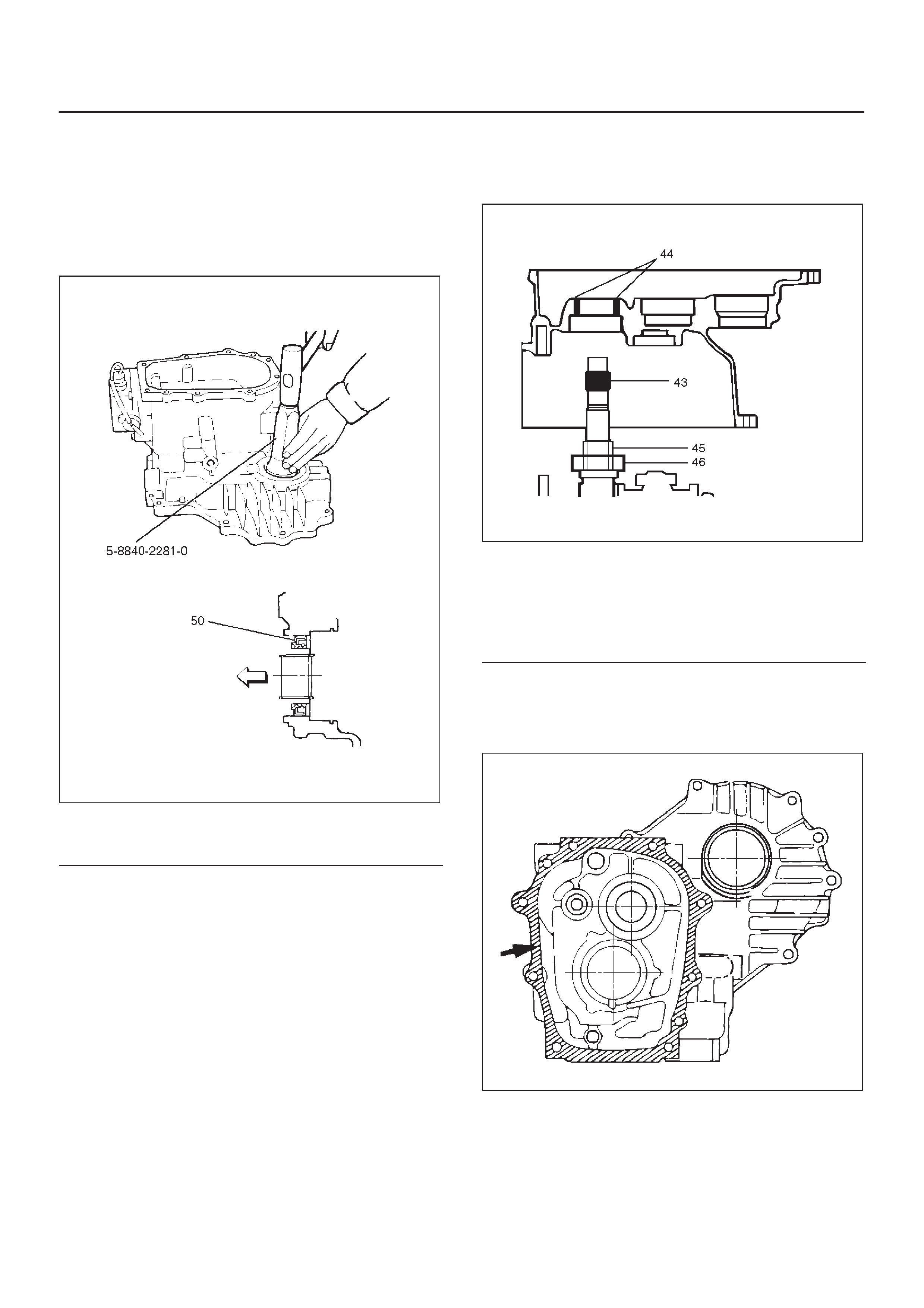

35.Remove transfer case (with oil seal) (42), performing

the following steps (M/T)

DCover the shaft splines with adhesive tape (43).

A07RW022

Legend

(43) Adhesive Tape

(44) Oil Seal Lip

(45) Oil Seal Collar

(46) Bearing

DRemove the transfer case together with

intermediate plate with gear assembly from the

transmission case (M/T).

DRemove the transfer case from the intermediate

plat with gear assembly (M/T).

Inspection and Repair

1. Make the necessary repair or parts replacement if

wear, damage or any other abnormal conditions are

found during inspection.

2.Wash all parts thoroughly in clean solvent. Be sure all

old lubricant, metallic particles, dirt, or foreign

material are removed from the surfaces of every part.

Apply compressed air to each oil feed port and

channel in each case half to remove any obstructions

or cleaning solvent residue.

Gears

1.Inspect all the gear teeth for signs of excessive wear

or damage and check all the gear splines for burrs,

nicks, wear or damage. Remove the minor nicks or

scratches on an oil stone. Replace any part exhibiting

excessive wear or damage.

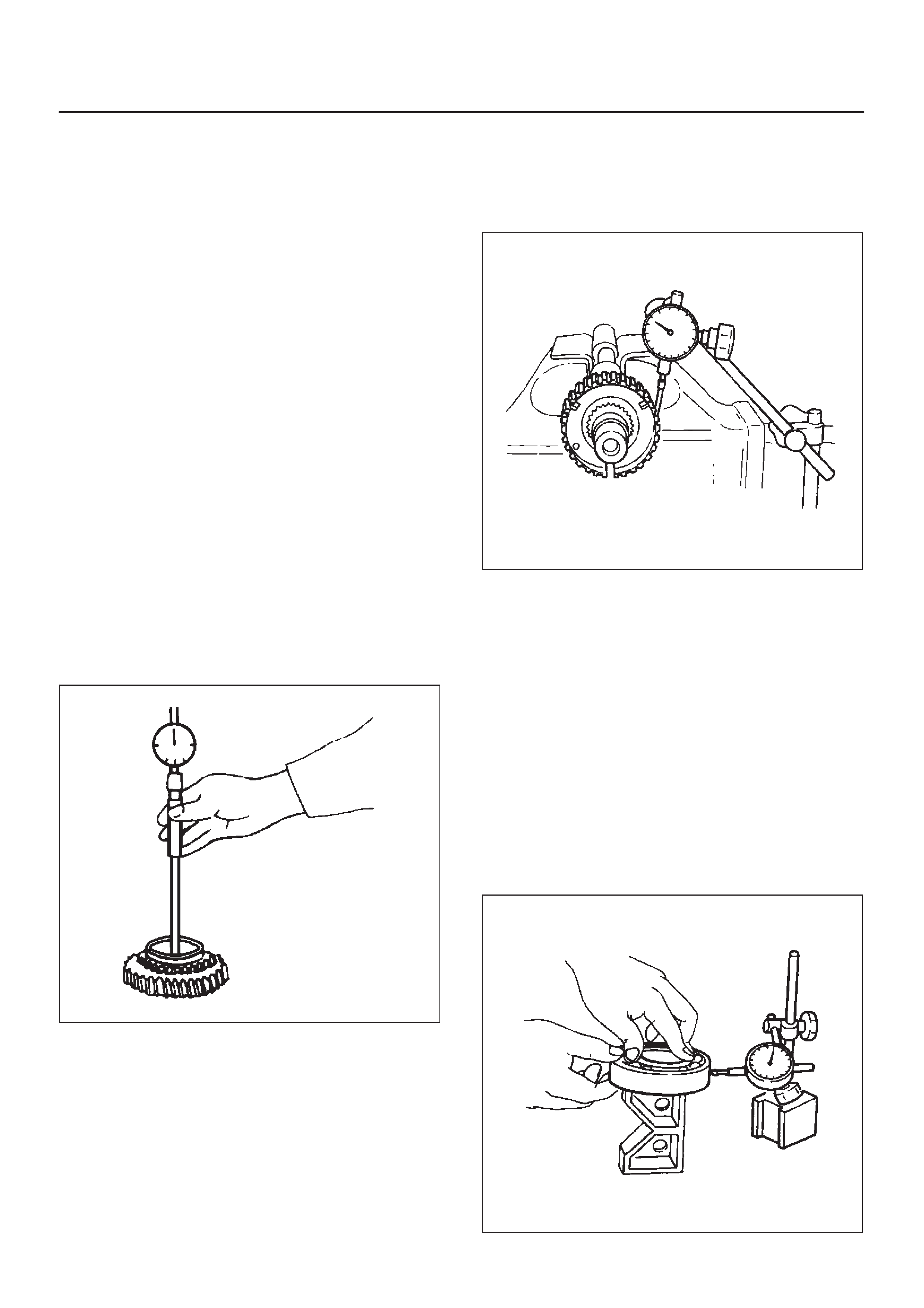

Front Output Gear Inside Diameter

1.Use an inside dial indicator to measure the gear inside

diameter.

2.If the measured value exceeds the specified limit, the

gear must be replaced.

Gear inside diameter

Standard : 48.000–48.013 mm (1.8898–1.8903 in)

Limit : 48.10 mm (1.894 in)

226RS040

Clutch Hub Spline Play

1.Set a dial indicator to the clutch hub to be measured.

2.Move the clutch hub as far as possible to both the right

and the left.

Note the dial indicator reading.

3.If the measured value exceeds the specified limit, the

clutch hub must be replaced.

Clutch hub spline play

Standard : 0–0.1 mm (0–0.004 in)

Limit : 0.2 mm (0.008 in)

226RS042

Bearings

1.Inspect the condition of all the needles and ball

bearings. Wash bearings thoroughly in a cleaning

solvent. Apply compressed air to the bearings.

NOTE: Do not allow the bearings to spin. Turn them

slowly by hand. Spinning bearings may damage the

rollers.

2.Lubricate the bearings with a light oil and check them

for roughness by slowly turning the race by hand.

Ball Bearing Play

1.Use a dial indicator to measure the ball bearing play.

2.If the measured value exceeds the specified limit, the

ball bearing must be replaced.

Limit : 0.2 mm (0.008 in)

226RS043

Synchronizers

The synchronizer hubs and sliding sleeves are a selected

assembly and should be kept together as originally

assembled.

Clean synchronizer components with clean solvent and

air dry.

Inspect the components for the following:

DTeeth for wear, scuffs, nicks, burrs or breaks.

DKeys and springs for wear, cracks or distortion,

replace if these conditions are present.

DIf scuffed, nicked or burred conditions cannot be

corrected with a soft stone or crocus cloth, replace the

component.

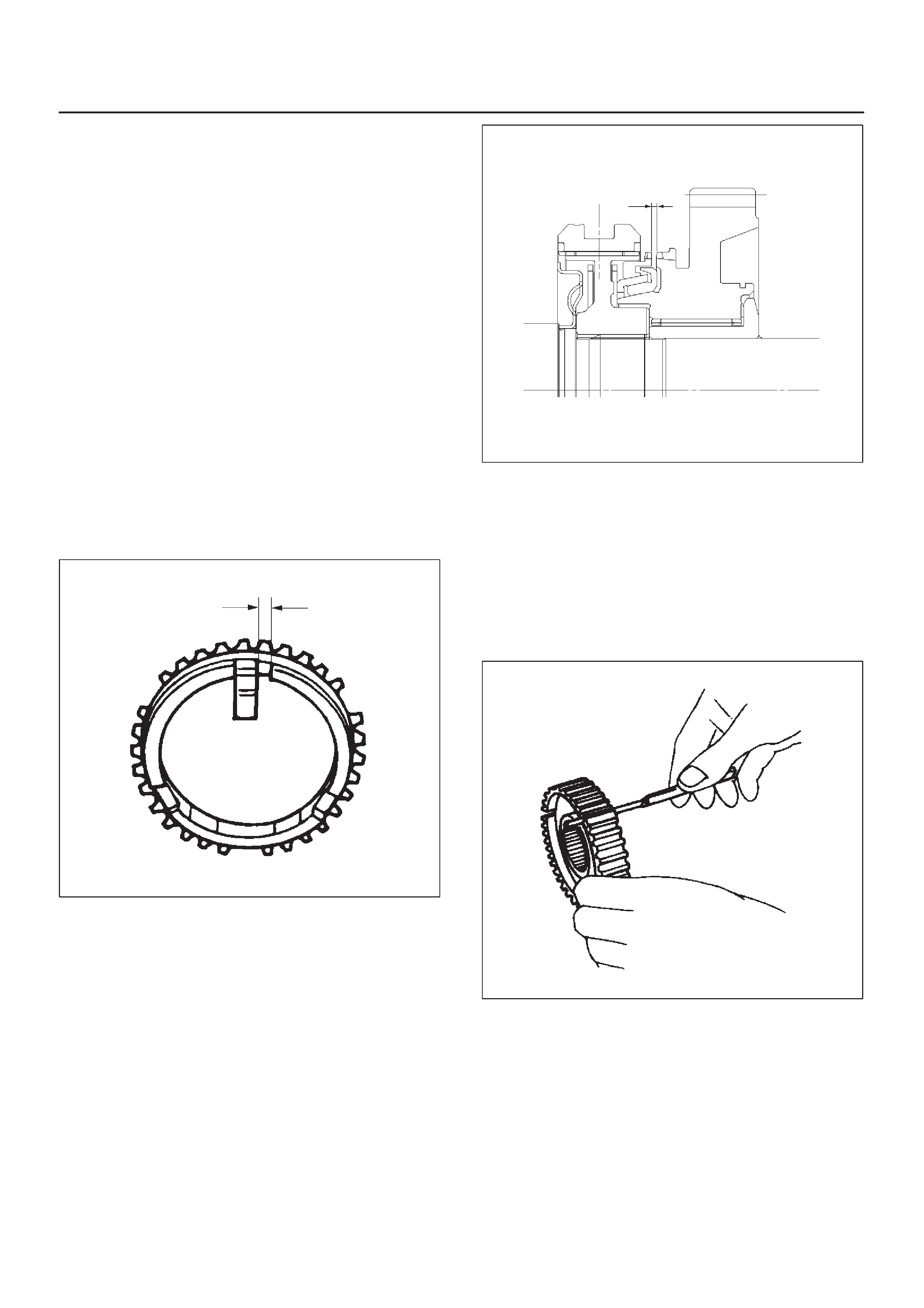

Block Ring and Insert Clearance

1.Use a vernier caliper to measure the clearance

between the block ring and the insert.

2.If the measured value exceeds the specified limit, the

block ring and the insert must be replaced.

Block ring and insert clearance

Standard : 2.46–2.74 mm (0.097–0.108 in)

Limit : 3.0 mm (0.118 in)

226RS037

2WD–4WD Synchronizer (3–Cone)

1.Use a thickness gauge to measure the clearance

between the block ring and the dog teeth.

2.If the measured value exceeds the specified limit, the

2WD–4WD synchronizer assembly must be

replaced.

Block ring and insert clearance

Standard : 1.5 mm (0.059 in)

Limit : 0.8 mm (0.031 in)

226RW142

Clutch Hub and Insert Clearance

1.Use a thickness gauge to measure the clearance

between the clutch hub and the insert.

2.If the measured value exceeds the specified limit, the

clutch hub and the insert must be replaced.

Clutch hub and insert clearance

Standard : 0.01–0.19 mm (0.0004–0.0075 in)

Limit : 0.3 mm (0.012 in)

226RS038

Detent Springs

1.Inspect the springs for distortion, cracks or wear.

Replace if these conditions are present.

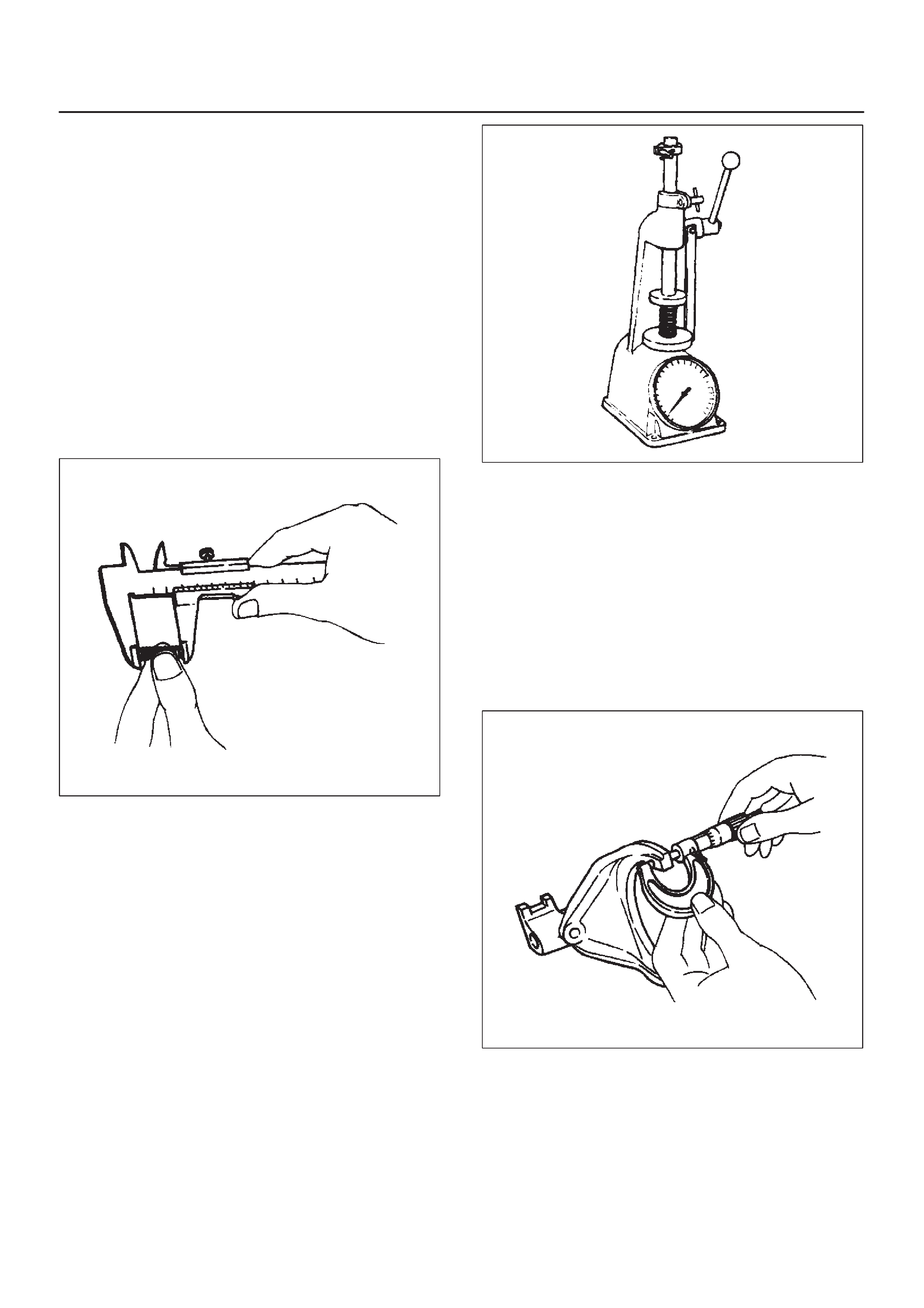

Detent Spring Free Length

1.Use a vernier caliper to measure the detent spring

free length.

2.If the measured value is less than the specified limit,

the detent spring must be replaced.

Detent spring free length

Detent ball

Standard : 23.4 mm (0.921 in)

Limit : 22.8 mm (0.898 in)

Interlock pin

Standard : 15.9 mm (0.626 in)

Limit : 15.3 mm (0.602 in)

220RW035

Detent Spring Tension

1.Use a spring tester to measure the detent spring

tension.

2.If the measured value is less than the specified limit,

the detent spring must be replaced.

Detent ball

Compressed height : 18.7 mm (0.736 in)

Standard : 68.6–88.2 N (7.0–9.0 kg /15.4–19.8 lb)

Interlock pin

Compressed height : 11.5 mm (0.453 in)

Standard : 9.8 N (1.0 kg/2.2 lb)

220RS013

Shift Arm

1.Inspect the shift arms for wear, distortion or scoring.

Replace if these conditions are present.

Shift Arm Thickness

1.Use a micrometer to measure the shift arm thickness.

2.If the measured value is less than the specified limit,

the shift arm must be replaced.

Shift arm thickness

Standard : 9.60–9.85 mm (0.378–0.388 in)

Limit : 9.0 mm (0.354 in)

230RS006

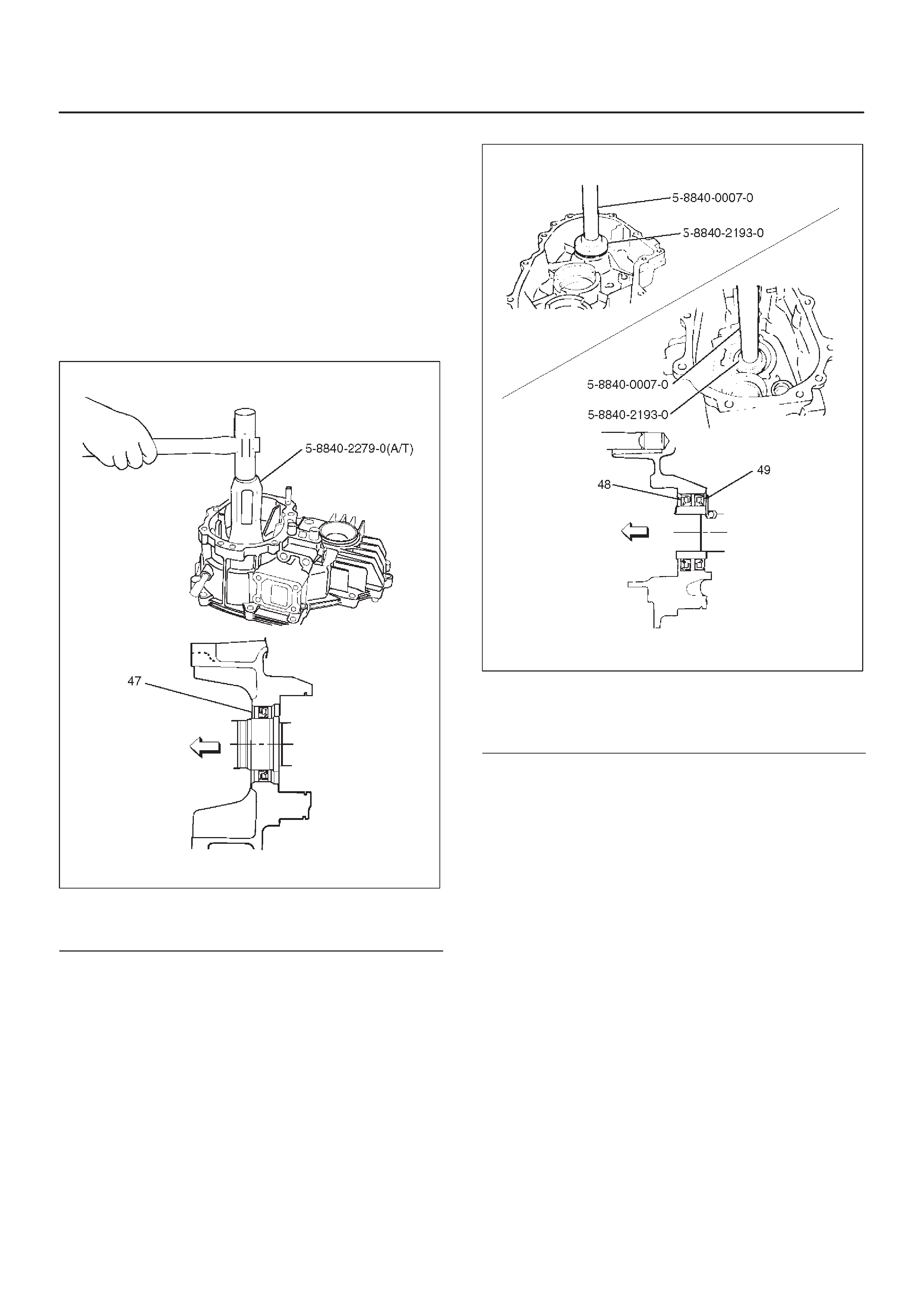

Reassembly

Input Shaft Oil Seal Replacement

1.Remove the oil seal from the transfer case.

2.Apply the engine oil to the oil seal outer surfaces.

3.Apply recommended grease (BESCO L2) or

equivalent to the oil seal lip.

4.Use the oil seal installer 5–8840–2279–0 (A/T)

5–8840–2193–0 (M/T) and driver handle

5–8840–0007–0 to install the oil seal to the transfer

case.

A/T

220RW130

Legend

(47) Oil Seal

M/T

220RW132

Legend

(48) Transmission Side Oil Seal

(49) Transfer Side Oil Seal

Front Output Shaft Oil Seal Replacement

1.Remove the oil seal from the transfer case.

2.Apply engine oil to the oil seal outer surfaces.

3.Apply recommended grease (BESCO L2) or

equivalent to the oil seal lip.

4.Use the oil seal installer 5–8840–2281–0 to install the

oil seal to the transfer case.

220RW131

Legend

(50) Front Output Shaft Oil Seal

1.Install the transfer case (with oil seal) (42), performing

the following steps. (M/T)

DCover the shaft splines with adhesive tape (43).

This will prevent damage to the oil seal lip (44).

A07RW022

Legend

(43) Adhesive Tape

(44) Oil Seal Lip

(45) Oil Seal Collar

(46) Bearing

DApply recommended liquid gasket (LOCTITE

17430) or its equivalent to the transmission,

intermediate plate and transfer case fitting surfaces

(M/T).

220RS026

Install the transfer case together with intermediate plate

with gear assembly to transmission case (M/T).

Tighten the transfer case bolts to the specified torque a

little at a time (M/T).

Torque : 37 N·m (3.8 kg·m/27 lb ft)

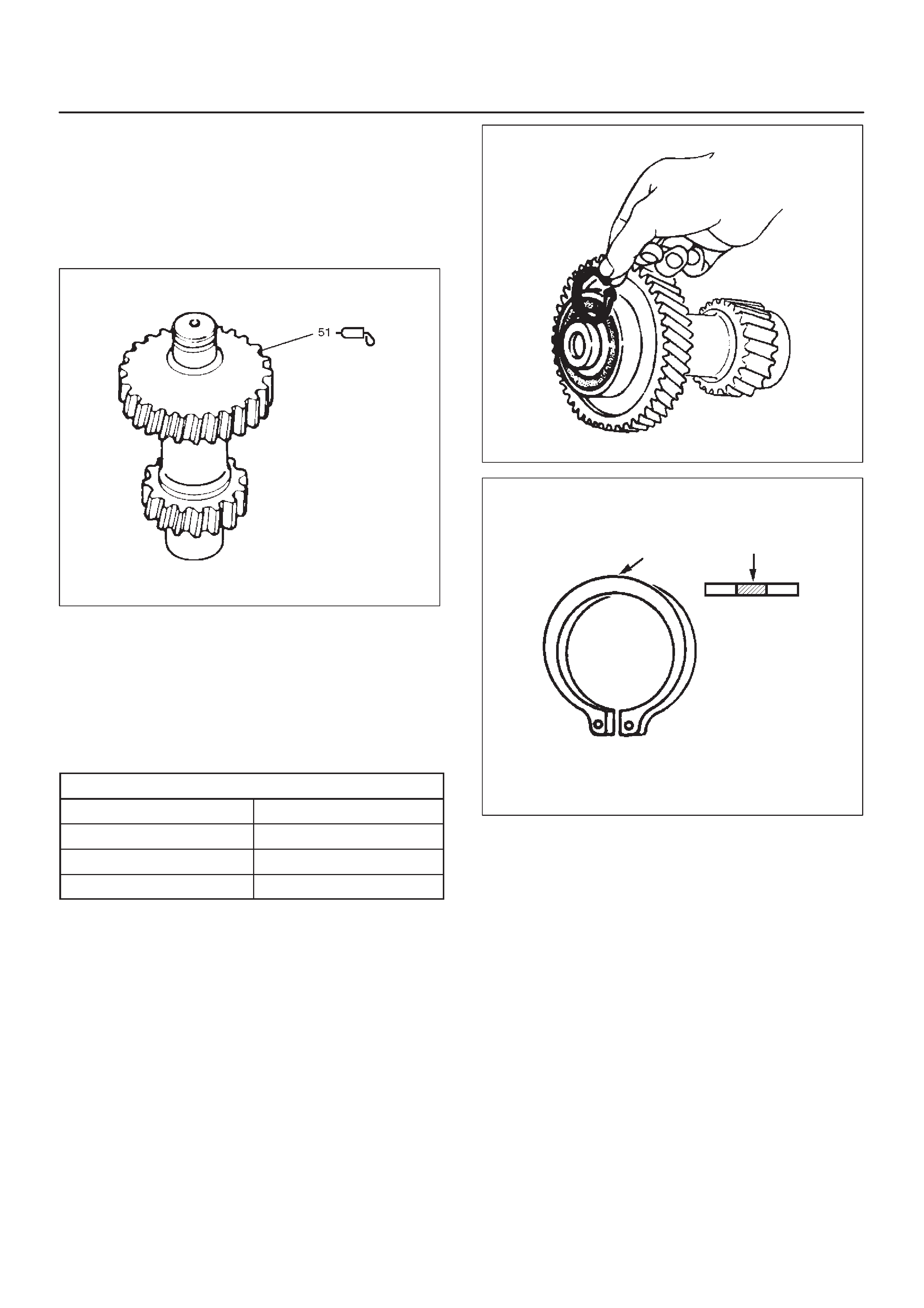

2.Apply chassis grease (51) to the sub–gear (40) and

the counter gear (41) thrust surfaces.

226RW155

3.Install sub–gear (40) to counter gear (41).

4.Install belleville spring (39).

5.Install spacer.

6.Install ball bearing, using a bench press.

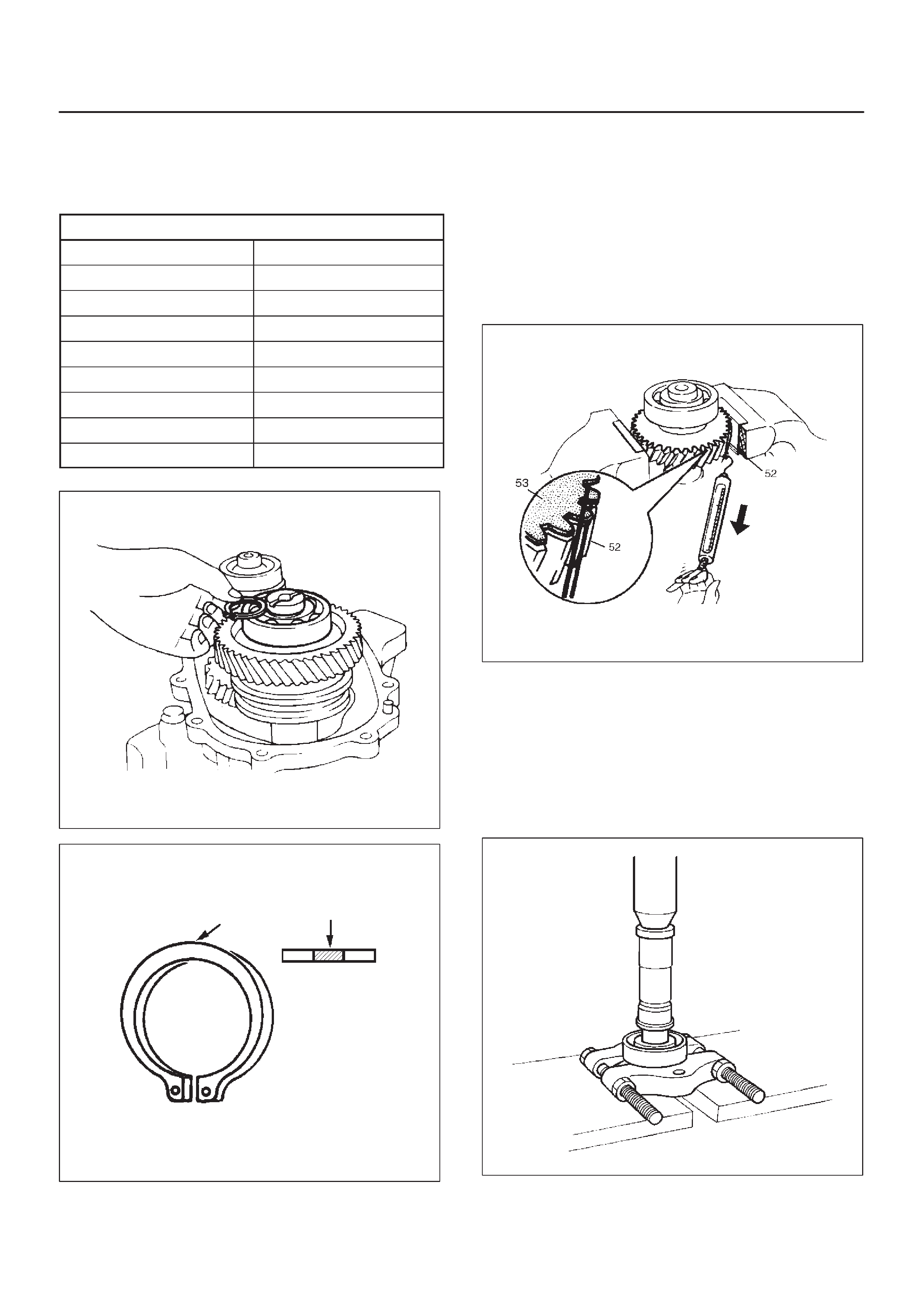

7.Select a snap ring that will allow the minimum axial

play.

Clearance : 0–0.1 mm (0–0.004 in)

Snap ring availability:

Thickness Color–coding

1.50 mm (0.059 in) White

1.55 mm (0.061 in) Yellow

1.60 mm (0.063 in) Blue

226RS170

226RS021

8.Use a pair of snap ring pliers to install the snap ring

(36) to the counter gear (41).

Sub–Gear (anti–lash plate) Preload

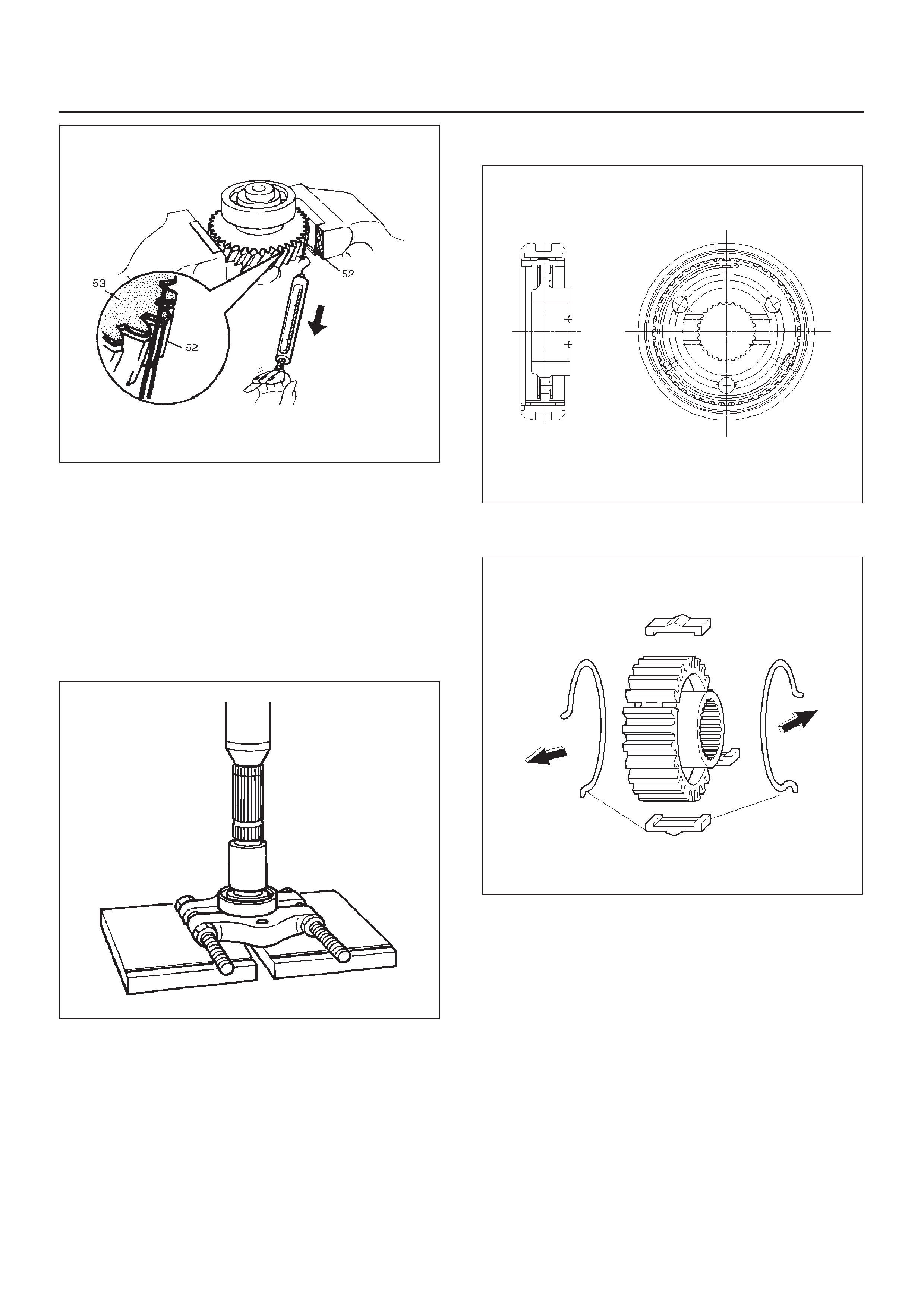

1. Hook a length of piano wire (52) over one of the

sub–gear (53) teeth.

2. Attach the other end of the piano wire (52) to a

spring balancer.

3. Measure the sub–gear preload.

Preload : 59–98 N (6.0–10 kg/13–22 lb)

226RW156

9.Install ball bearing (35), using a bench press.

10.Install snap ring (34).

11.Install the counter gear assembly (33) to the transfer

case (42).

12.Use a pair of snap ring pliers to install the snap ring

(32) to the transfer case (42).

NOTE: The snap ring must be fully inserted into the

transfer case snap ring groove.

13.Use a bench press to install the ball bearing (30) to the

front output shaft (31).

262RS012

14.Assemble the 2WD–4WD clutch hub and sleeve

assembly (28).

226RW140

15.Engage the springs in the same insert with the open

ends away from each other.

226RW141

16.Install a new stopper plate (29) and the clutch hub and

sleeve assembly (28) to the front output shaft (31).

226RW157

Legend

(54) Front Output Gear

17.The clutch hub face (with the heavy boss) must be

facing the front output gear side.

18.Use a bench press to slowly force the clutch hub and

sleeve assembly (28) together with the stopper plate

(29) into place.

19.Align the inserts with the block ring insert grooves.

Install the block ring (27) to the clutch sleeve and hub

assembly (28).

20.Install the outside ring (26), inside ring (25) and

needle bearing (24) to the front output gear (23) and

bearing collar (18).

NOTE: Coat all parts with transmission oil before

installing them.

226RW139

21.Apply engine oil to the thrust surfaces of the

sub–gear , the belleville spring, and the spacer (M/T).

262RW014

22.Install sub–gear (anti–lash plate) (22), belleville

spring (21) and spacer (20). (M/T)

23.Install sub–gear snap ring (19). (M/T)

24.Use a bench press to install the needle bearing collar

together with the front output gear assembly , aligning

inside ring claw with block ring groove.

262RS014

25.Install ball bearing (17), using a bench press.

26.Select a snap ring (16) that will allow the minimum

axial play.

Clearance : 0–0.1 mm (0–0.004 in)

Snap ring availability:

Snap ring thickness Color coding

1.55 mm (0.061 in) White

1.60 mm (0.063 in) Yellow

1.65 mm (0.065 in) Blue

1.70 mm (0.067 in) Pink

1.75 mm (0.069 in) Green

1.80 mm (0.071 in) Brown

1.85 mm (0.073 in) Red

1.90 mm (0.075 in) Orange

262RS015

226RS021

27.Use a pair of snap ring pliers to install the snap ring

(16) to the output shaft (31).

Sub-gear (anti-lash plate) preload (M/T)

1. Hook a length of piano wire (52) over one of the

sub–gear (53) teeth.

2. Attach the other end of the piano wire to (52) a

spring balancer.

3. Measure the sub–gear preload.

Preload: 59–98 N (6.0–10 kg/13–22 lb)

226RW156

28.Install front output gear assembly (15) to transfer

case (42).

29.Use a pair of snap ring pliers to install the snap ring

(14) to the transfer case (42).

NOTE: The snap ring must be fully inserted into the

transfer case snap ring groove.

30.Use a bench press to install the ball bearing (12) to the

input shaft (13). (A/T)

265RS003

31.Install plate (11), ball (10) and bearing collar (9).

NOTE: Put the snap ring (4) in the ball bearing side. (A/T)

32.Install needle bearing (8) and input gear (7).

33.The clutch hub face (with the heavy boss) must be

facing the transfer input gear side (55).

226RW158

34.Install high–low clutch hub and sleeve (6), using a

bench press.

35.Install input shaft assembly (5) to transfer case (42).

(A/T)

36.Install the snap ring (4) to the transfer case (42). (A/T)

NOTE: The snap ring must be fully inserted into the

transfer case snap ring groove.

37.Install the front companion flange temporarily and use

the flange holder 5–8840–0133–0 and lock nut

wrench 5–8840–2156–0 to install the lock nut (3).

Torque: 137 N·m (14.0 kg·m/101 lb ft)

226RW190

38.Use the punch to stake the lock nut (3) at one spot.

39. Use a suitable drift and hammer to install the ball

bearing (2).

226RS079

40.Install bearing snap ring (1).

Main Data and Specifications

General Specifications

Type Synchronized type gears shifting between the 2 and 4 wheel drive mode.

Constant mesh type gears shifting between “low” and “high”.

Control method Remote (A/T) and direct (M/T) control with the gear shift lever on the floor

for gears shifting between “low” and “high”.

Electric control with the button switch on the instrument panel for gears

shifting between the 2 and 4 wheel driver mode.

Gear ratio High; 1.000

Low; 2.050

Oil capacity 1.45 lit. (1.53 U.S. quart)

Type of lubricant Engine oil

Refer to chart in Section 0

Torque Specifications

E07RX012

E07RX021

E07RX011

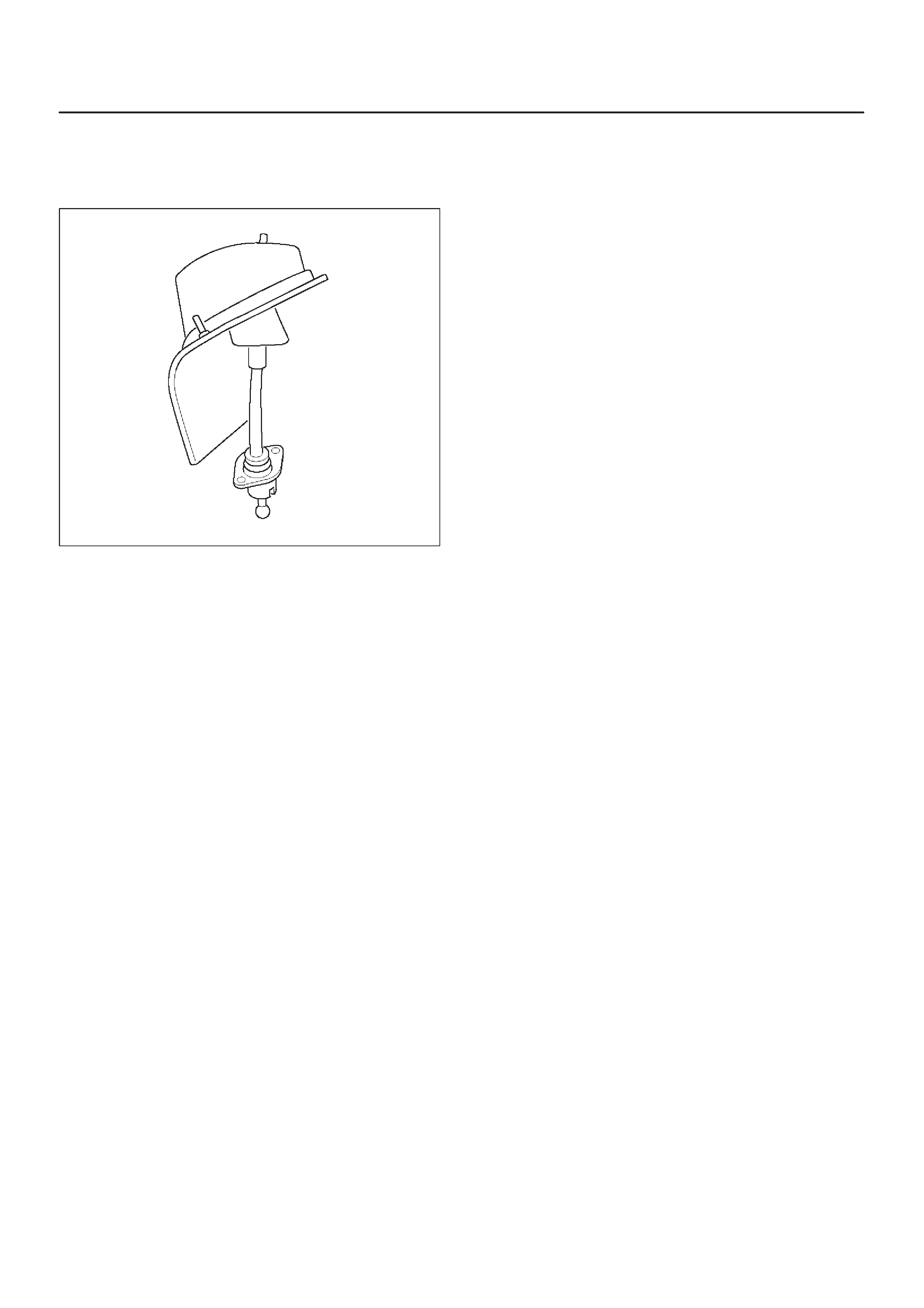

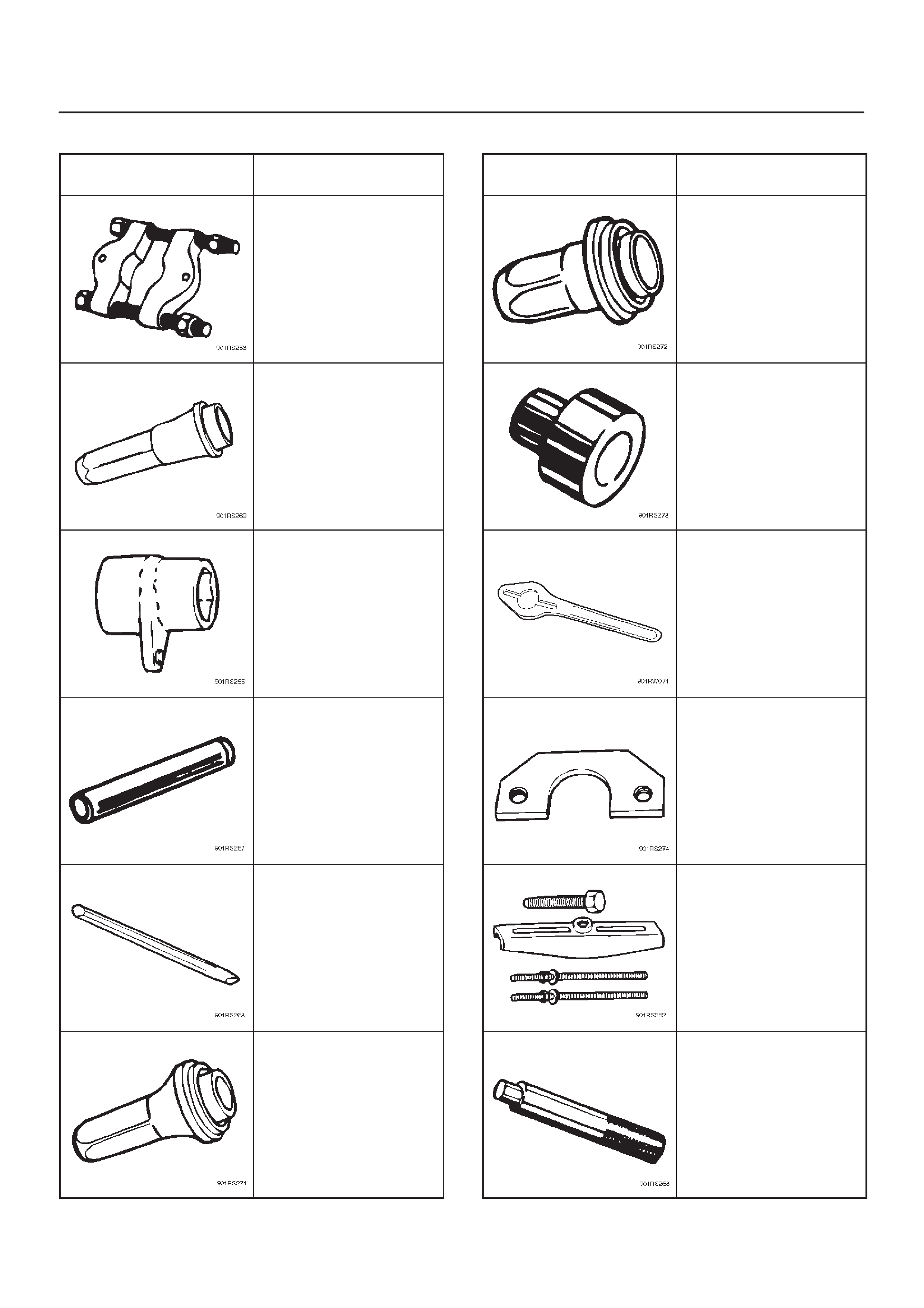

Special Tools

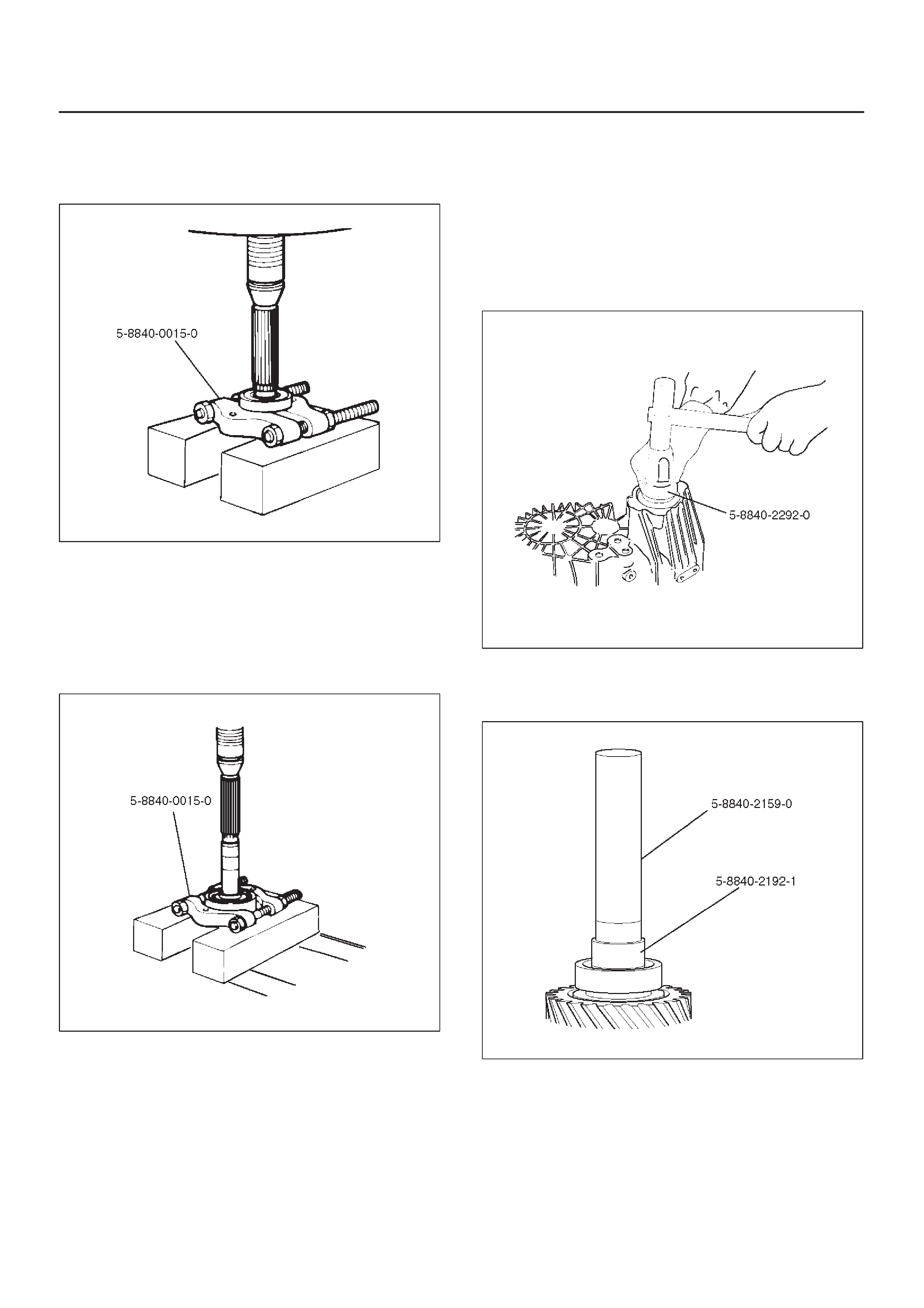

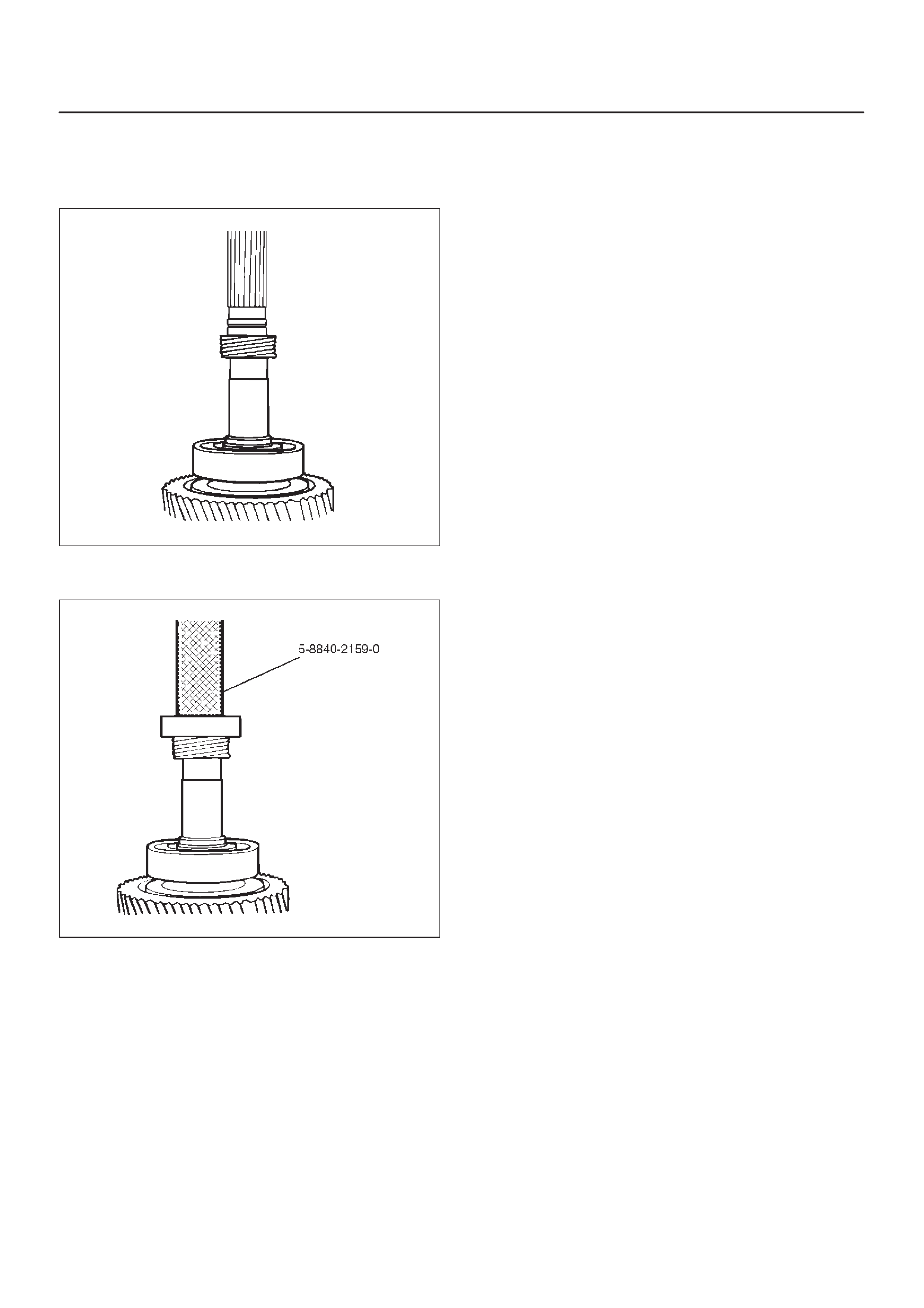

ILLUSTRATION PART NO.

PART NAME

5–8840–0015–0

Bearing

remover/installer

5–8840–2279–0

Transfer case oil seal

installer

5–8840–2156–0

Mainshaft nut wrench

5–8840–2159–0

Rear output shaft and

bearing installer

5–8840–2293–0

Punch; end nut

5–8840–2281–0

Front output shaft oil

seal installer

ILLUSTRATION PART NO.

PART NAME

5–8840–2292–0

Rear oil seal installer

5–8840–2192–1

Bearing installer adapter

5–8840–0133–0

Flange holder

5–8840–2155–0

Mainshaft end bearing

remover

5–8840–2027–0

Puller

5–8840–0007–0

Driver handle

ILLUSTRATION PART NO.

PART NAME

5–8840–2193–0

Transfer case oil seal

installer