SECTION 6D2 - IGNITION SYSTEM (X22SE 2.2L)

Service Precaution

General Description

Diagnosis

Ignition Module

Removal

Installation

Spark Plug

Removal

Inspection and Repair

Installation

Crankshaft Angle Sensor

Removal

Installation

Main Data and Specifications

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or

other corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts

and systems.

General Description

Ignition is done by the Ignition Module that fires.

Since the cylinder on exhaust stroke requires less

energy to fire its spark plug, energy from the ignition

coils can be utilized to fire the mating cylinder on

compression stroke.

A notch in the timing disc on the crankshaft activates the

crank angle sensor which then sends information such

as firing order and starting timing of ignition coil to the

PCM.

By receiving signals such as crank position,engine

speed,water temperature and Manifold Absolute

Pressure (MAP),the PCM controls the ignition timing.

Diagnosis

Refer to Section Drivability and Emissions for the

diagnosis to electronic ignition system (El system).

Ignition Module

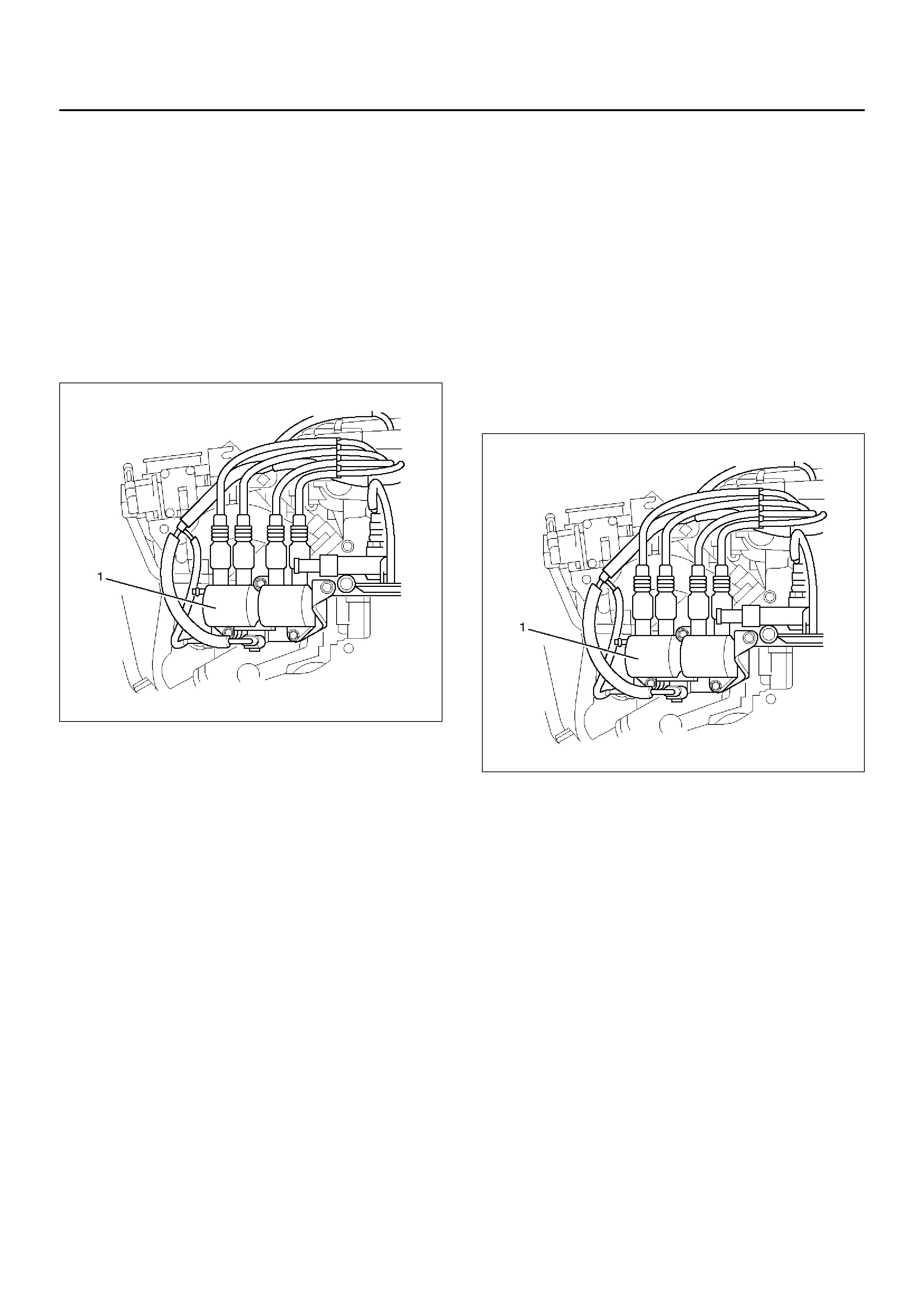

Removal

1. Disco nne ct batte ry ground ca ble.

2. Remove ABS hydraulic unit assembly.

3. Remove master Vac and brake booster assembly.

4. Remove heater hoses from water rail.

5. Disconnect ignition coil cabl e from ignition module.

6. Remove connector from ignition module.

7. Remove ignition module assembly with bracket (1).

080RW001

Installation

1. Install the ignition module assemb ly with brac k et (1).

2. Connect ignition module connector and ignition

coil,then tighten bolt to the specified torque.

Torque: 20 N·m (2.0 kg·m/15 lb ft)

3. Conne ct ign iti on co il ca ble.

4. Install heater hoses.

5. Insta ll master Va c and brake booster assembly.

6. Install ABS hydraulic unit assembly.

7. Bleed Air, brake system.

080RW001

8. Connect battery ground cable.

Spark Plug

Removal

1. Remove spark plugs.

Inspection and Repair

The spark plug affects entire engine performance and

therefore its inspection is very important.

• Check electrode and insulator for presence of

cracks,and replace if any.

• Check electrode for wear,and replace if necessary.

• Check gasket for damage,and replace if necessary.

• Measure insulation resistance with an ohmmeter,and

replace if faulty.

• Adjust spark plug gap to 0.7 mm (0.027 in) ∼ 0.8 µµ

(0.031 ιν).

• Check fuel and electrical systems if spark plug is

extremely dirty.

• Use spark plugs ha ving low heat value (hot type plug)

if fuel and electrical systems are normal.

• Use spark plugs having high heat value (cold type

plug) if insulator and electrode are ex tremely burned.

Sooty Spark Plugs

Much deposit of carbon or oil on the electrode and

insulator of spark plug reduces the engine performance.

Possible causes:

• Too rich mixture

• Presence of oil in combustion chamber

• Incorrectly adjusted spark plug gap

Burning Electrodes

This fault is characterized by scorched or heavily

oxidized electrode or blistered insulator nose.

Possible causes:

• Too lean mixture

• Improper heat value

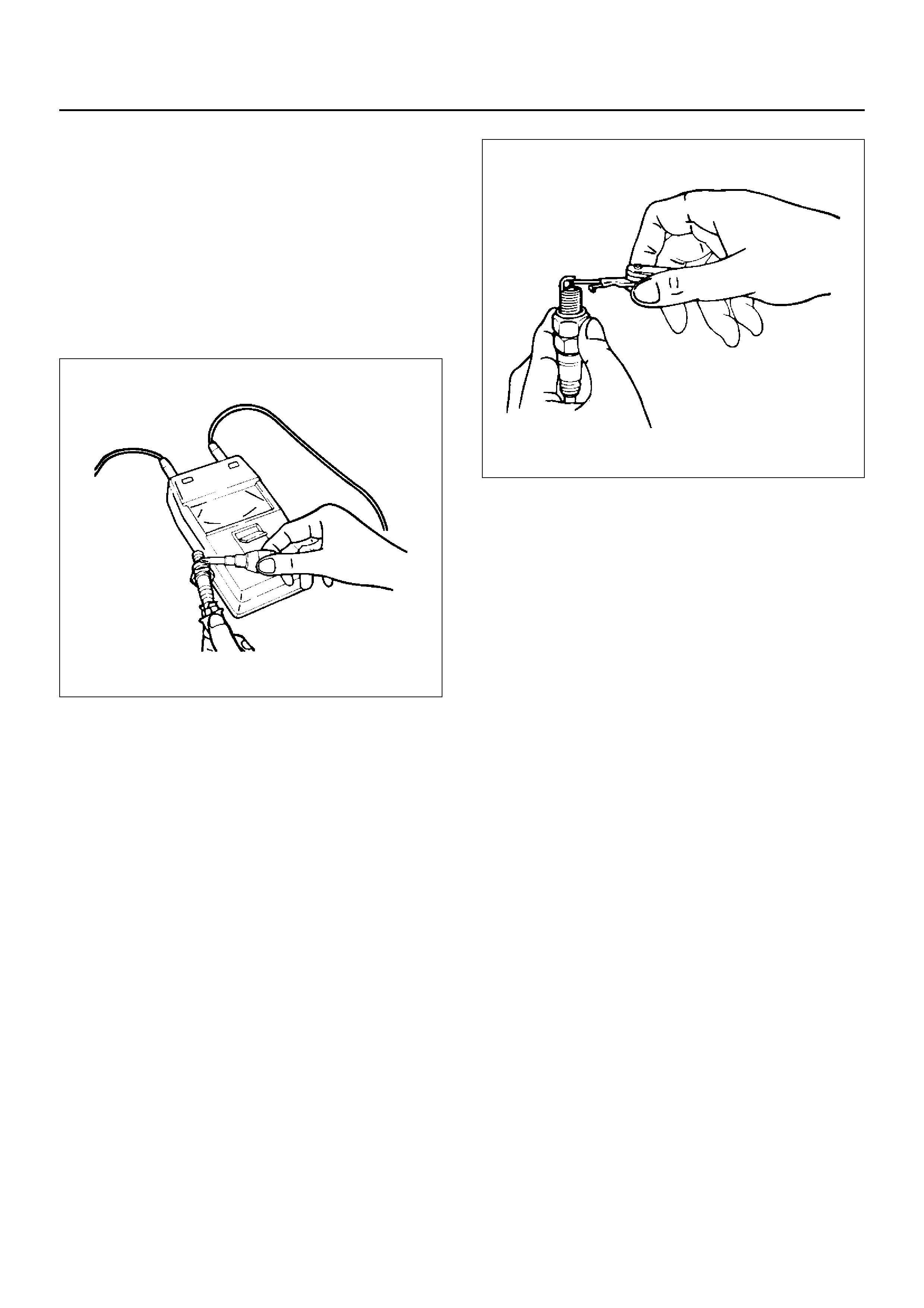

Measuring Insulation Resistance

• Measure insulation resistance using a 500 volt

megaohm mete r.

• Replace spark plugs if measured value is out of

standard.

Insulation resistance: 50 MΩ

ΩΩ

Ω or more

011RS010

Cleaning Spark Plugs

• Clean spark plugs with a spark plug cleaner.

• Raise the ground electrode to an angle of 45 to 60

degrees. if electrode is wet,dry it before cleaning.

• After spark plug is thoroughly cleaned,check insulator

for presence of cracks.

• Clean threads and metal body with a wire brush.

• File the electrode tip if electrode is e xtremely worn.

• Bend the ground electrode to adjust the spark plug

gap.

011RS011

Installation

1. Spark plugs

• Tighten spark plugs to the specified torque.

Torque: 25 N·m (2.5 kg·m/18 lb ft)

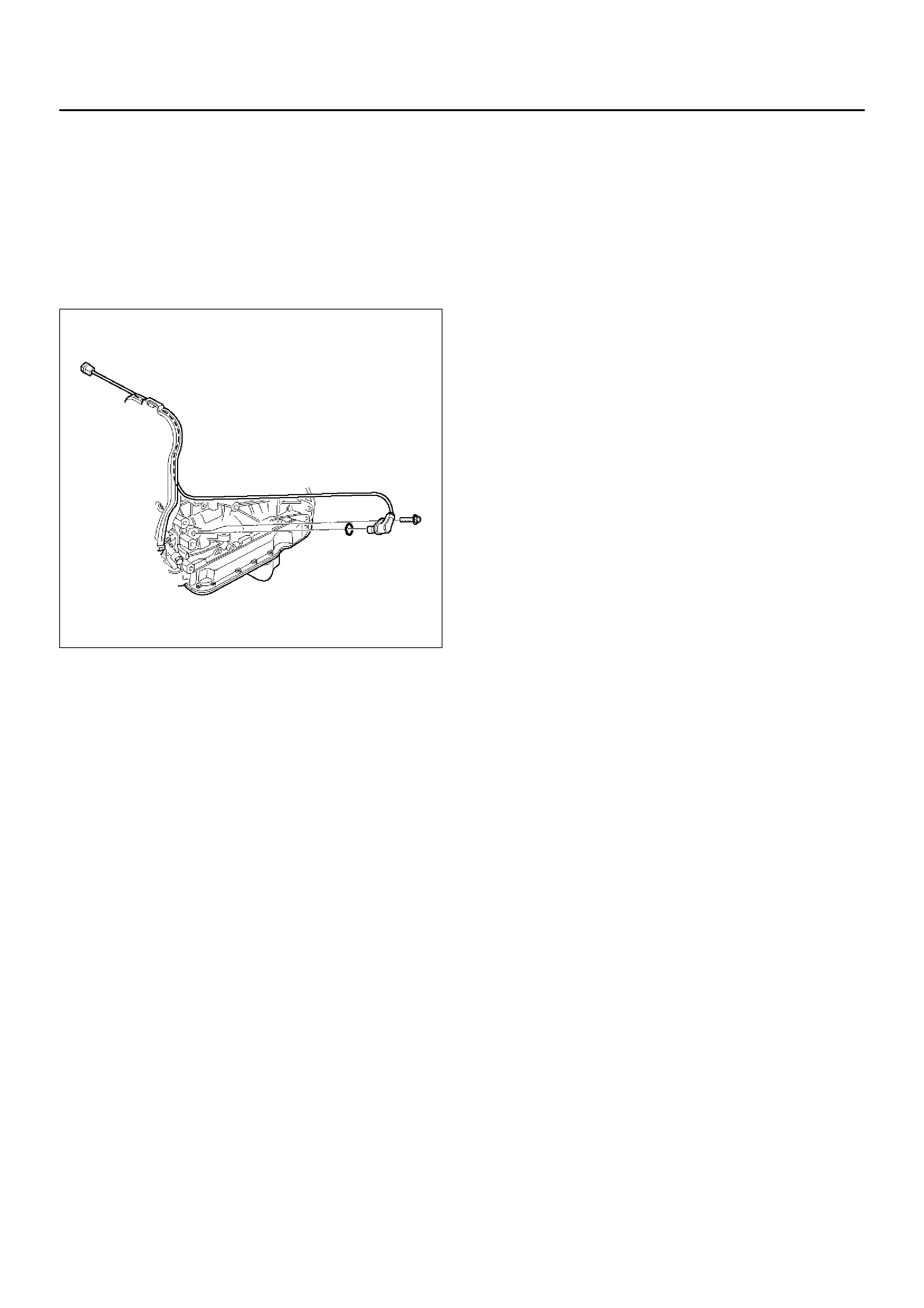

Crankshaft Angle Sensor

Removal

1.Disconnect battery ground cable

2. Wiring connector from crankshaft angle sensor.

3. Remove crankshaft angle sensor from cylinder

block.

015RW021

Installation

1. Install cr anksha ft angle sensor into the cylinder

block.

Before installation,apply small amount of engine oil

to the O–ring.

Torque: 6 N·m (0.6 kg·m/4 lb ft)

2. Reconnect wiring connector to crankshaft angle

sensor.

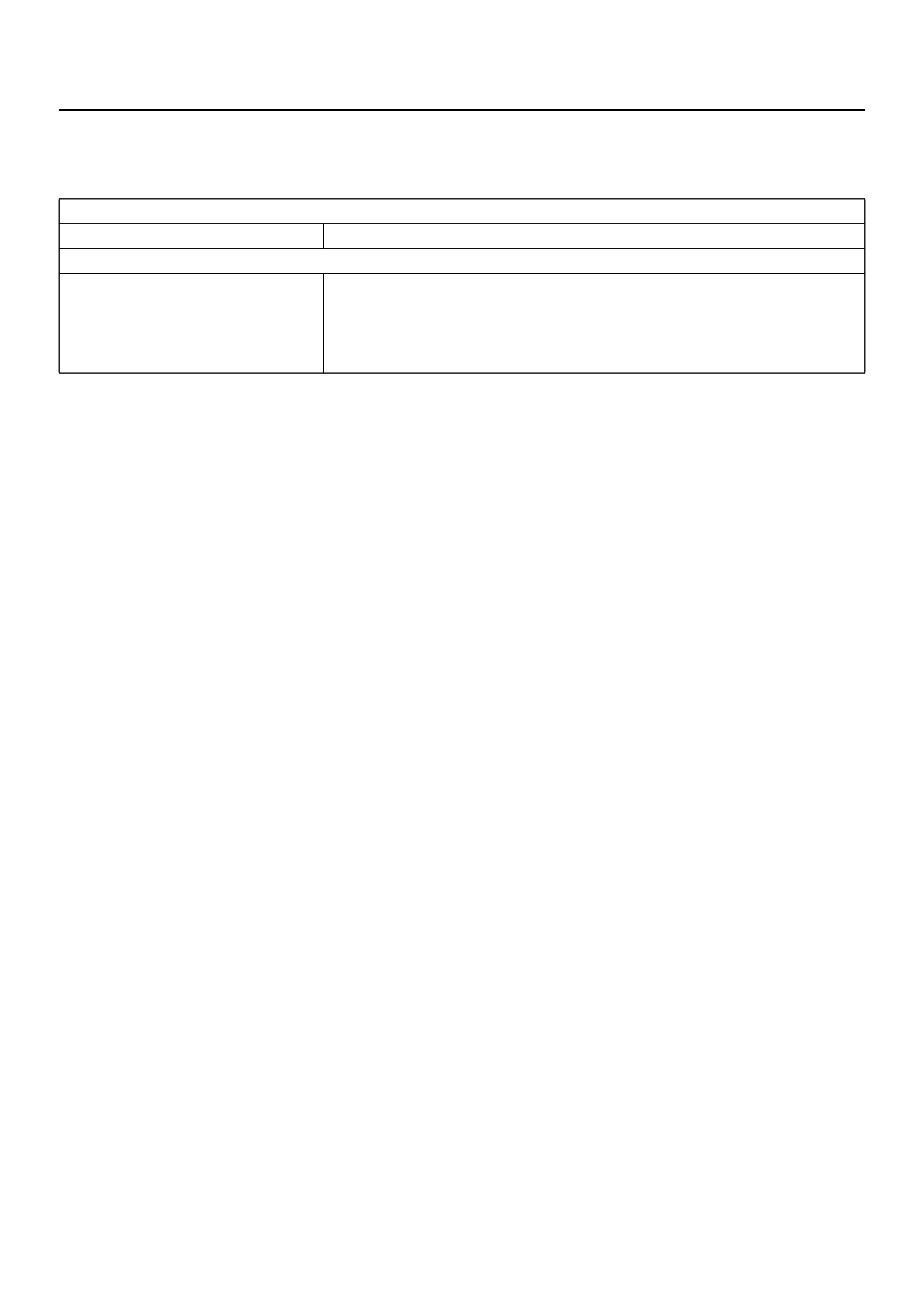

Main Data and Specifications

General Specifications

Ignition System

Ignition Form Electronic Ignition System (El system) with Crankshaft angle Sensor

Spark Plug Type Electronic Spark Control

No. of Coils and Type 2 Solid State

Coil Location Engine–mounted

Torque 20 N·m (2.0 kg·m/14 lb ft)