SECTION 6C - ENGINE FUEL

Service Precaution

General Description

Fuel Metering

Fuel Filter

Removal

Inspection

Installation

Inspection

In–Tank Fuel Filter

Fuel Pump Flow Test

Fuel Pump

Fuel Pump and Associated Parts

Removal

Installation

Fuel Tube / Quick – Connector Fittings

Precautions

Cautions During Work

Removal

Reuse of Quick–Connector

Assembling Advice

Fuel Pump Relay

General Description

Fuel Tank

Fuel Tank and Associated Parts

Removal

Installation

Fuel Gauge Unit

Removal and Installation

Fuel Filler Cap

General Description

Inspection

Main Data and Specifications

Service Precaution

WARNING:THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION:Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener . When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Techline

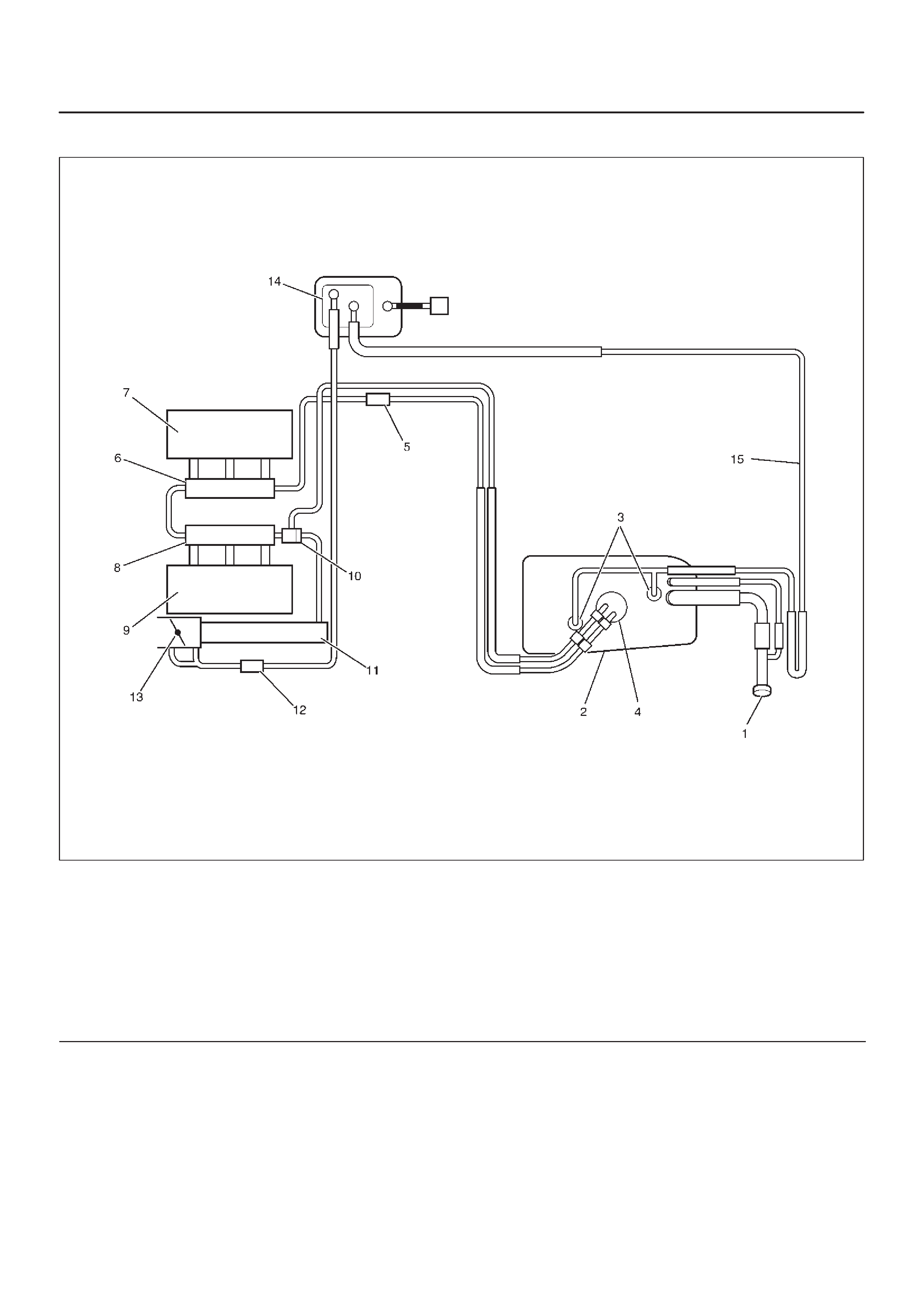

General Description

140RW066

Legend

(1) Fuel Filler Cap

(2) Fuel Tank

(3) Rollover Valve

(4) Fuel Pump and Sender Assembly

(5) Fuel Filter

(6) Fuel Rail Right

(7) Right Bank

(8) Fuel Rail Left

(9) Left Bank

(10) Fuel Pressure Control Valve

(11) Common Chamber

(12) Duty Solenoid Valve

(13) Throttle Valve

(14) Canister

(15) Evapo Pipe

When working on the fuel system, there are several

things to keep in mind:

DAny time the fuel system is being worked on,

disconnect the negative battery cable except for

those tests where battery voltage is required.

DAlways keep a dry chemical (Class B) fire

extinguisher near the work area.

DReplace all pipes with the same pipe and fittings that

were removed.

DClean and inspect “O” rings. Replace if required.

DAlways relieve the line pressure before servicing any

fuel system components.

DDo not attempt repairs on the fuel system until you

have read the instructions and checked the pictures

relating to that repair.

DAdhere to all Notices and Cautions.

All gasoline engines are designed to use only unleaded

gasoline. Unleaded gasoline must be used for proper

emission control system operation.

Its use will also minimize spark plug fouling and extend

engine oil life. Using leaded gasoline can damage the

emission control system and could result in loss of

emission warranty coverage.

All cars are equipped with an Evaporative Emission

Control System. The purpose of the system is to minimize

the escape of fuel vapors to the atmosphere.

Fuel Metering

The Powertrain Control Module (PCM) is in complete

control of this fuel delivery system during normal driving

conditions.

The intake manifold function, like that of a diesel, is used

only to let air into the engine. The fuel is injected by

separate injectors that are mounted over the intake

manifold.

The Manifold Absolute Pressure (MAP) sensor measures

the changes in the intake manifold pressure which result

from engine load and speed changes, which the MAP

sensor converts to a voltage output.

This sensor generates the voltage to change

corresponding to the flow of the air drawn into the engine.

The changing voltage is transformed into an electric

signal and provided to the PCM.

With receipt of the signals sent from the MAP sensor,

Intake Air Temperature sensor and others, the PCM

determines an appropriate fuel injection pulse width

feeding such information to the fuel injector valves to

effect an appropriate air/fuel ratio.

The Multiport Fuel Injection system utilizes an injection

system where the injectors turn on at every crankshaft

revolution. The PCM controls the injector on time so that

the correct amount of fuel is metered depending on

driving conditions.

Two interchangeable “O” rings are used on the injector

that must be replaced when the injectors are removed.

The fuel rail is attached to the top of the intake manifold

and supplies fuel to all the injectors.

Fuel is recirculated through the rail continually while the

engine is running. This removes air and vapors from the

fuel as well as keeping the fuel cool during hot weather

operation.

The fuel pressure control valve that is mounted on the fuel

rail maintains a pressure differential across the injectors

under all operating conditions. It is accomplished by

controlling the amount of fuel that is recirculated back to

the fuel tank based on engine demand.

See Section “Driveability and Emission” for more

information and diagnosis.

Fuel Filter

Removal

CAUTION:When repair to the fuel system has been

completed, start engine and check the fuel system

for loose connection or leakage. For the fuel system

diagnosis, see Section “Driveability and Emission”.

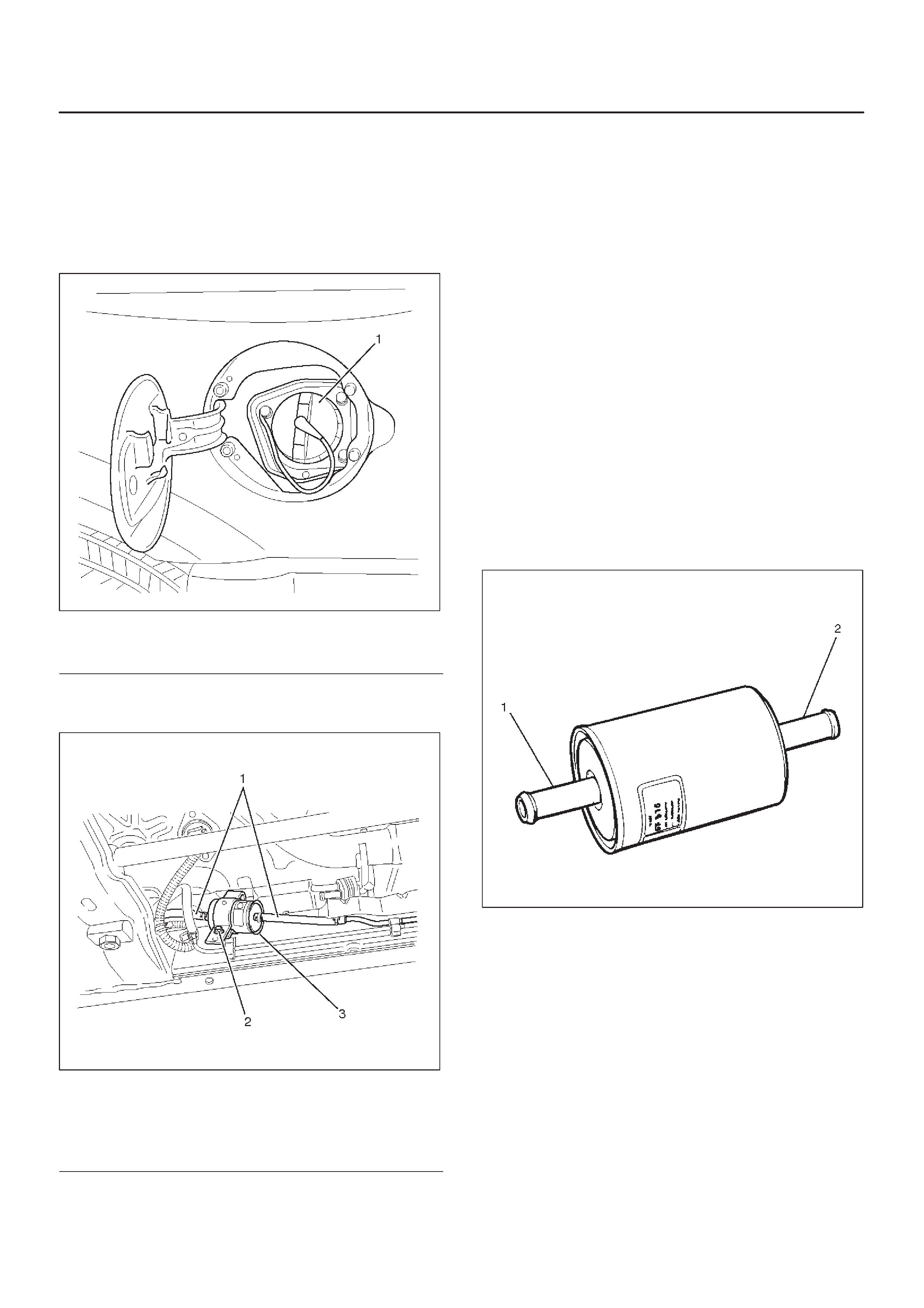

140RW010

Legend

(1) Fuel Filler Cap

1.Disconnect battery ground cable.

2.Remove Fuel filler cap(1).

041RW003

Legend

(1) Fuel Hose

(2) Fuel Filter Fixing Bolt

(3) Fuel Filter

3.Disconnect fuel hoses(1) from fuel filter on both

engine side and fuel tank side.

4.Fuel filter fixing bolt(2).

DRemove the fuel filter fixing bolt(2) on fuel filter

holder.

5.Remove fuel filter(3).

Inspection

1.Replace the fuel filter if the fuel leaks from fuel filter

body or if the fuel filter body itself is damaged.

2.Replace the filter if it is clogged with dirt or sediment.

3.Check the drain of receive rubber and if it is clogged

with dust, clean it up with air.

Installation

1.Install the fuel filter in the proper direction.

2.Install fuel filter holder fixing bolt.

3.Connect fuel hoses on engine side(1) and fuel tank

side(2).

041RW001

4.Install fuel filler cap

5.Connect the battery ground cable.

Inspection

After installation, start engine and check for fuel leakage.

In–Tank Fuel Filter

The filter is located on the lower end of fuel pickup tube in

the fuel tank. It prevents dirt from entering the fuel pipe

and also stops water unless the filter is completely

submerged in the water. It is a selfcleaning type, not

requiring scheduled maintenance. Excess water and

sediment in the tank restricts fuel supply to the engine,

resulting in engine stoppage. In such a case, the tank

must be cleaned thoroughly.

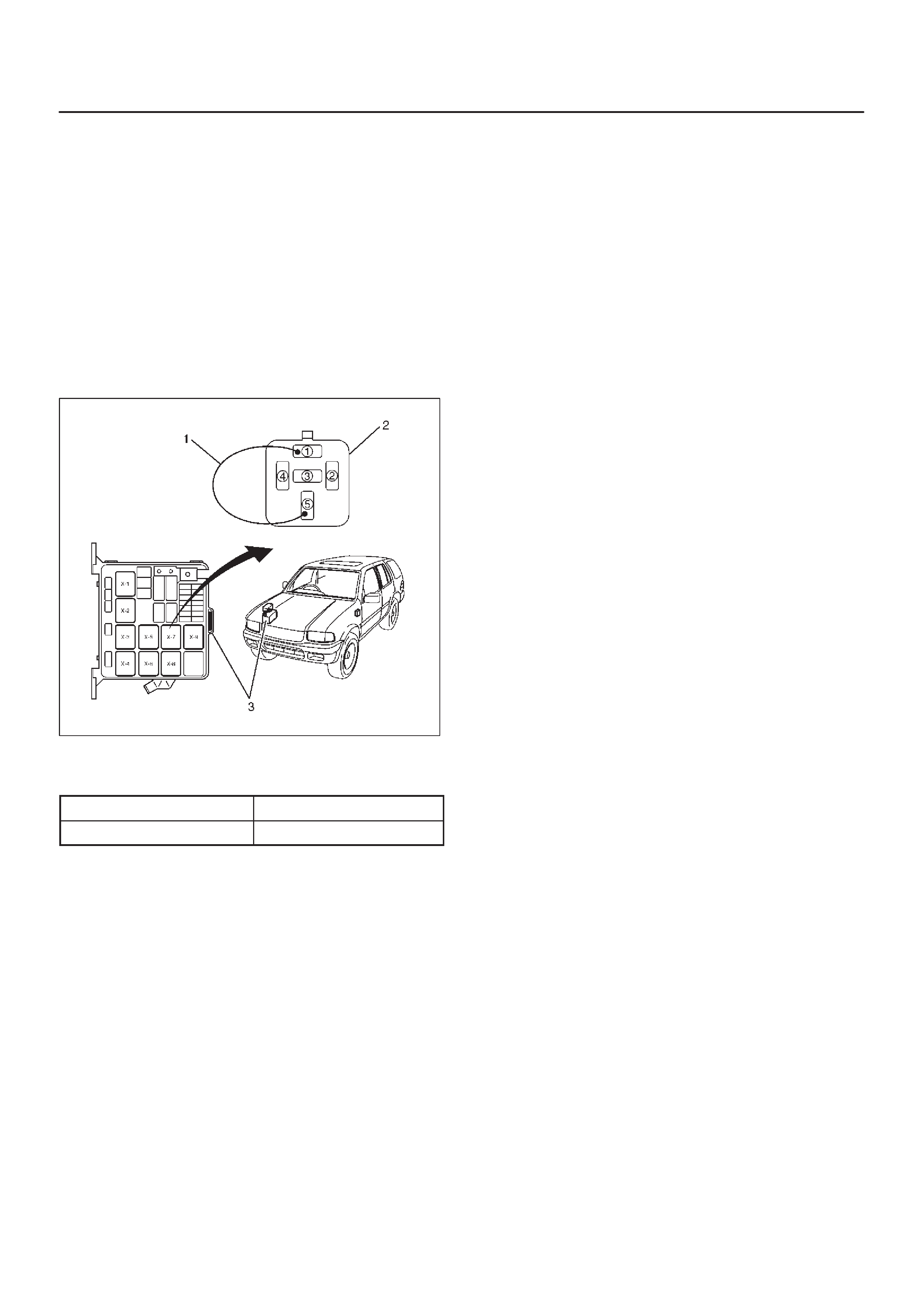

Fuel Pump Flow Test

If reduction of fuel supply is suspected, perform the

following checks.

1.Make sure that there is fuel in the tank.

2.With the engine running, check the fuel feed pipe and

hose from fuel tank to injector for evidence of

leakage. Retighten, if pipe or hose connection is

loose. Also, check pipes and hoses for squashing or

clogging.

3.Insert the hose from fuel feed pipe into a clean

container, and check for fuel pump flow rate.

4.Connect the pump relay terminals with a jumper

wire(1) as shown and start the fuel pump to measure

delivery.

140RX020

CAUTION:Never generate sparks when connecting

a jumper wire.

Delivery Delivery

15 seconds 0.38 liters minimum

If the measure value is out of standard, conduct the

pressure test.

Pressure test

For the pressure test to the fuel system, see Section 6E

“Fuel Control System”.

Fuel Pump

Fuel Pump and Associated Parts

140RX004

Legend

(1)Fuel Feed Port

(2)Fuel Tube/Quick Connector

(3)Fuel Return Port

(4)Fuel Pump and Sender Assembly

(5)Connector; Fuel Feed Pump

(6)Connector; Fuel Level Sensor

(7)Snap Ring

(8)Hose; Evaporative Fuel

(9)Hose; Air Breather

(10)Hose; Fuel Filler

(11)Fuel Tank Assembly

Removal

CAUTION:When repair to the fuel system has been

completed, start engine and check the fuel system

for loose connection or leakage. For the fuel system

diagnosis, see Section “Driveability and Emission”.

1.Disconnect battery ground cable.

2.Loosen fuel filler cap.

3.Support underneath of the fuel tank assembly (11)

with a lifter.

4.Remove fuel tank assembly(11). Refer to “Fuel Tank

Removal” in this section.

5.Remove Fuel Tube/Quick Connector (2).

NOTE:Handling of the fuel tube sure to refer “Fuel

Tube/Quick Connector Fittings” in this section.

6.Remove fuel pump and sender (FPAS) assembly (4)

fixing snap ring and remove the FPAS assembly.

NOTE: After removing pump assembly (4), cover fuel

tank to prevent any dust entering.

Installation

1.Install FPAS assembly(4).

2.Install Fuel Tube/Quick Connector (2).

NOTE:Handling of the fuel tube sure to refer “Fuel

Tube/Quick Connector Fittings” in this section.

3.Install fuel tank assembly(11). Refer to “Fuel Tank

Installation”.

4.Fill the tank with fuel and tighten fuel filler cap.

5.Connect battery ground cable.

Fuel Tube / Quick – Connector Fittings

Precautions

DLighting of Fires Prohibited.

DKeep flames away from your work area to prevent the

inflammable from catching fire.

DDisconnect the battery negative cable to prevent

shorting during work.

DWhen welding or conducting other heat-generating

work on other parts, be sure to provide pretreatment

to protect the piping system from thermal damage or

spattering.

Cautions During Work

Do not expose the assembly to battery electrolyte or do

not wipe the assembly with a cloth used to wipe off spilt

battery electorolyte.

The piping wet with battery electrolyte cannot be used.

Be careful not to give a bending or twisting force to the

piping during the work. If deformed, replace with a new

piping.

Removal

1.Open the fuel cap to relieve the fuel pressure in the

tank.

If the fuel quick-connect fittings are dusty, clean with

an air blower, etc. and then remove it.

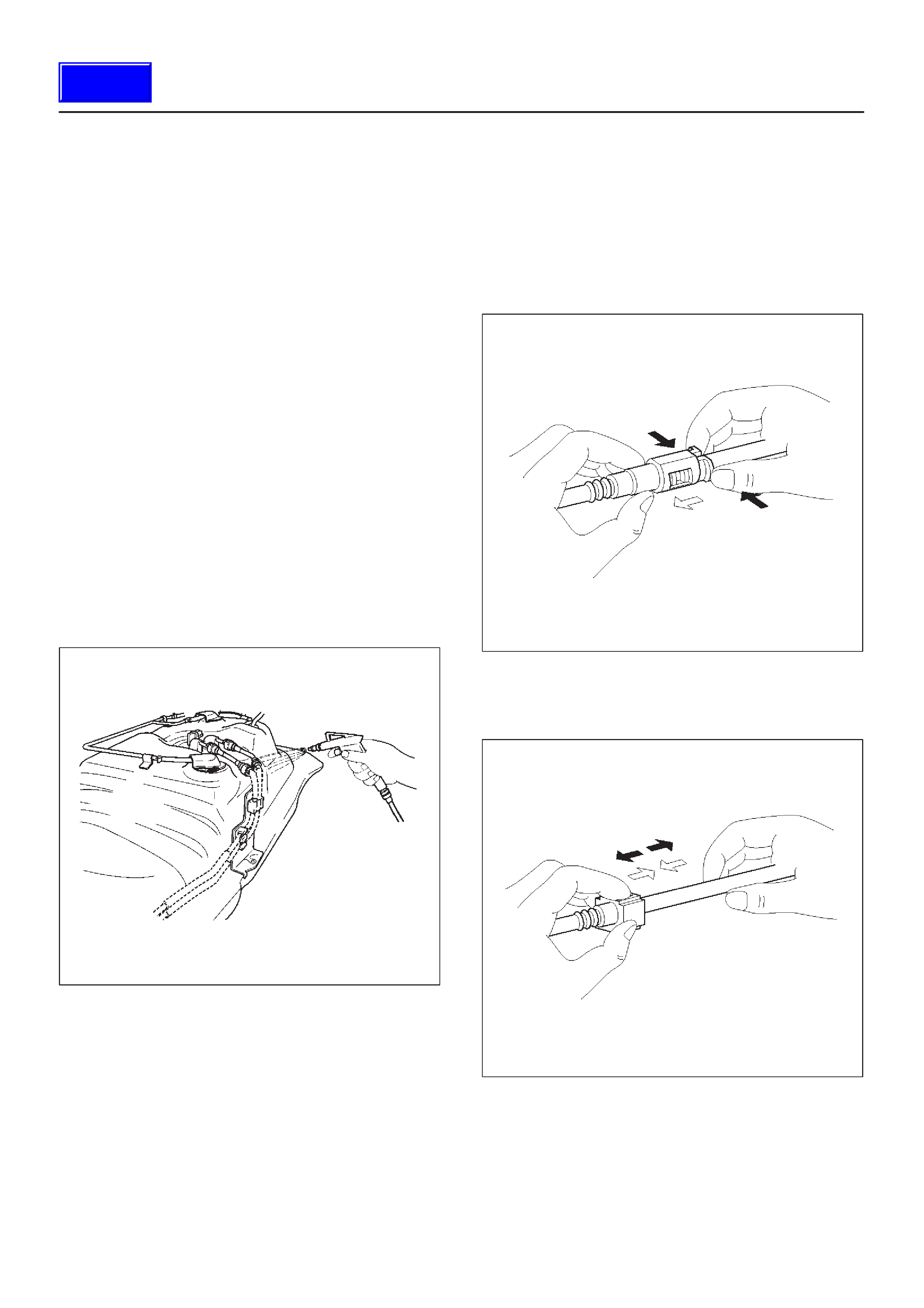

141RW036

As some pressure may remain in the piping, cover the

connector with a cloth, etc. to prevent the splashing

of fuel in the first disconnection of the piping.

2.For removal of the delivery pipe (feeding fuel to the

engine), hold the connector in one hand, and hold the

retainer tab with the other hand and pull out the

connector, as illustrated. The pipe can be removed

with the retainer attached.

141RW019

3. For removal of the return pipe (returnig fuel to the

tank), hold the pipe in one hand, and pull out the

connentor with the other hand while pressing the

square relieve button of the retainer, as illustrated.

141RW020

Techline

NOTE: This work should be done by hands. Do not use

any tools. Should the pipe can hardly be removed from

the connector, use a lubricant (light oil) and/or push and

pull the connector longitudinally until the pipe is removed.

141RW021

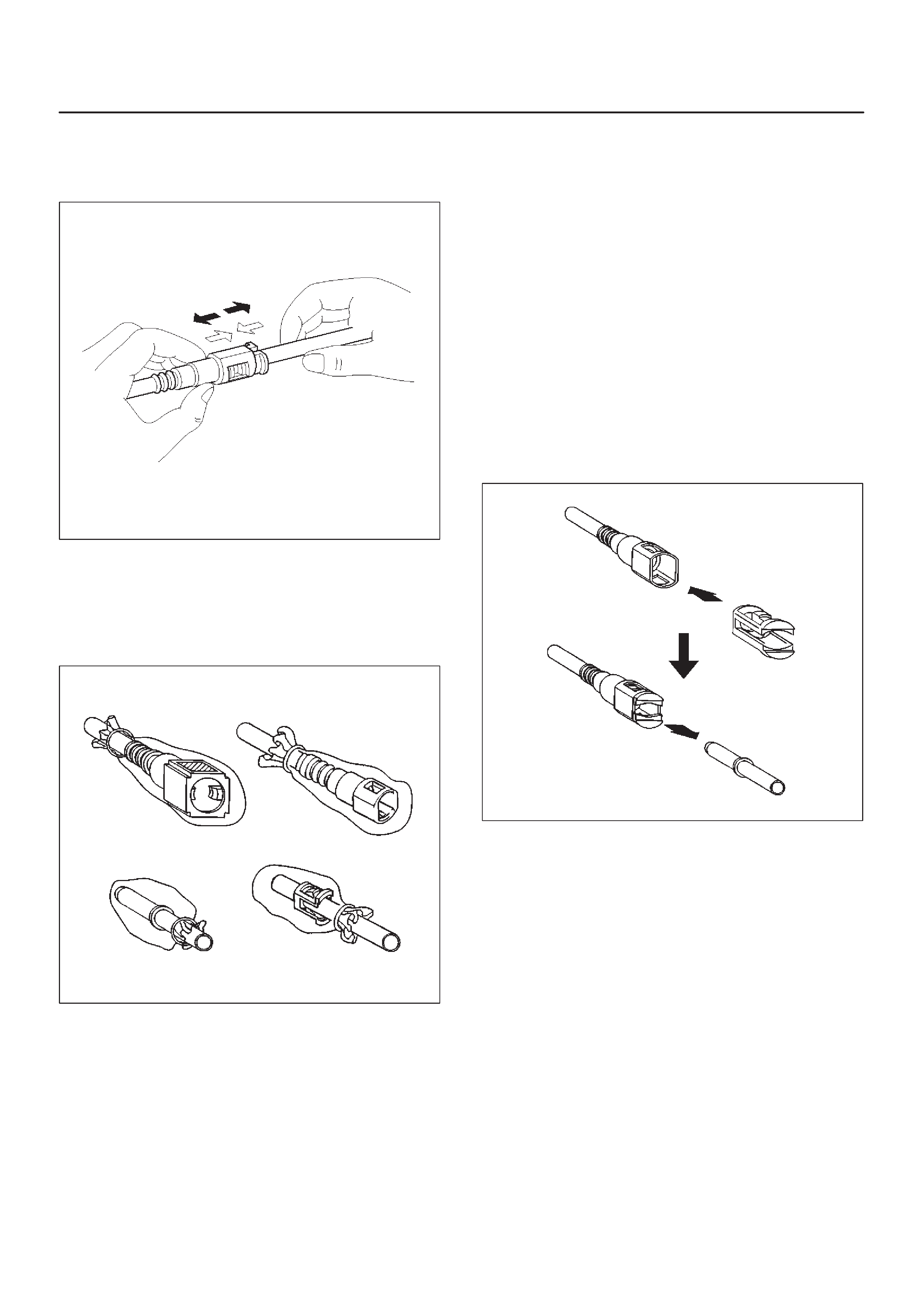

When reusing the delivery pipe retainer, reuse

without removing the retainer from the pipe. If the

retainer is damaged or deformed, however, replace

with a new retainer.

Cover the connectors removed with a plastic bag, etc.

to prevent the entry of dust or rain water.

141RW022

Reuse of Quick–Connector

(Delivery Pipe)

DReplace the pipe and connector if scratch, dent or

crack is found.

DRemove mud and dust from the pipe and make sure

that the end including spool is free of defects, such as

scratch, rust, and dent, which may cause poor

sealability. If defective, replace with a new pipe.

DIf the retainer removed according to the removal step

above is attached to the pipe, clean and insert it

straight into the quick-connector till it clicks. After it

clicks, try pulling it out to make sure that it is not drawn

and is securely locked.

NOTE: The retainer, once removed from the pipe, cannot

be reused. Just replace with a new retainer. Insert the

new retainer into the connector side until it clicks, and

connect the pipe as inserting it into the retainer until it

clicks.

141RW018

(Return Pipe)

DReplace the pipe and connector if scratch, dent or

crack is found.

DRemove mud or dust from the pipe and make sure

that the end including spool is free from defects, such

as scratch, rust, and dent, which may cause poor

sealability. If defective, replace with a new pipe.

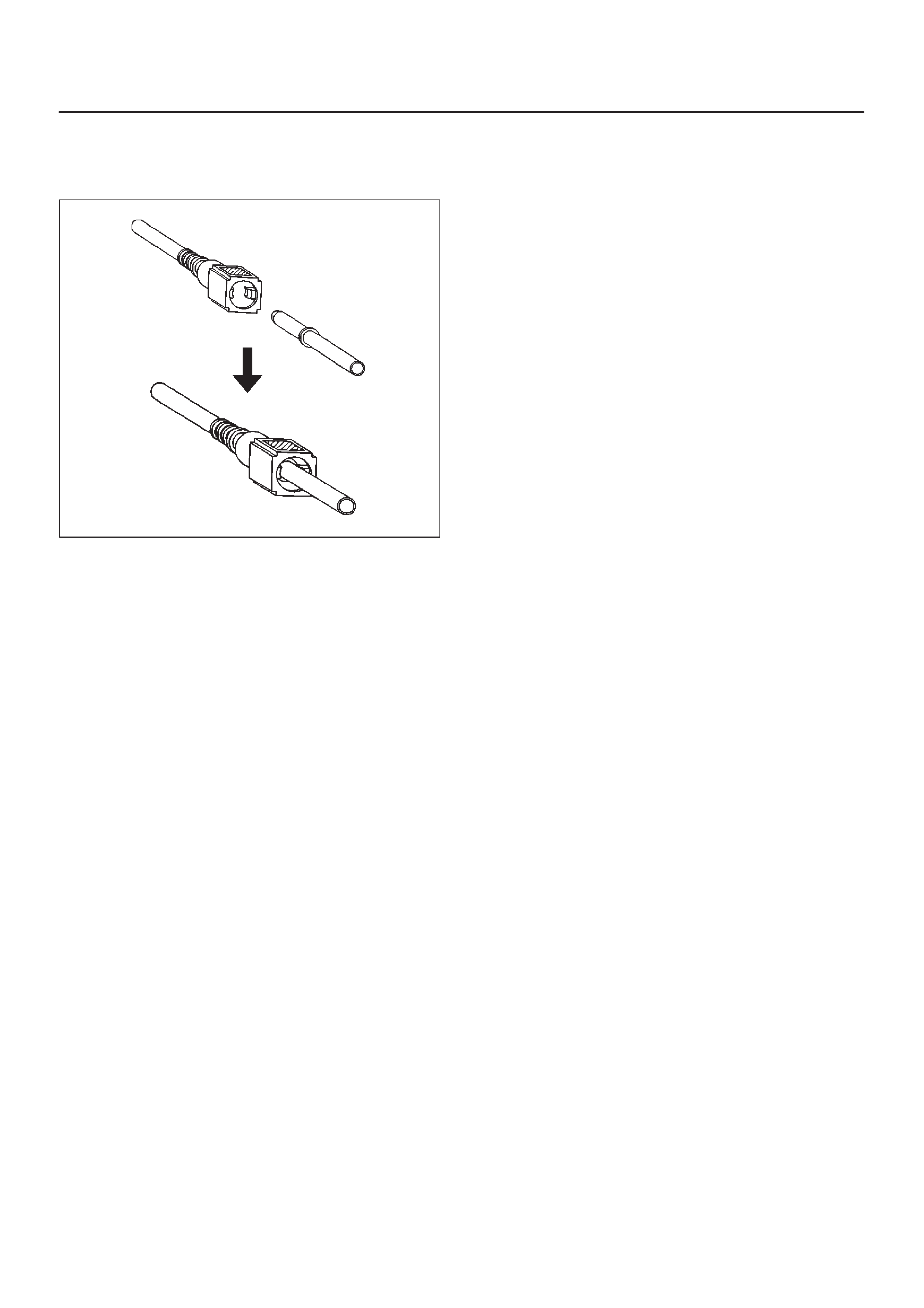

DAfter cleaning the pipe, insert it straight into the

connector until it clicks. After it clicks, try pulling it out

to make sure that it is not drawn and is securely

locked.

141RW017

Assembling Advice

Application of engine oil or light oil to the pipe facilitates

connecting work. The work should be started immediately

after lubrication, since dust may stick to the pipe surface

to cause poor sealability if a long time passes after

lubrication.

Test/Inspection After Assembling

1.Reconnect the battery negative cable.

2.Turn the ignition key to the “ON” position and check

pump startup sound. As the pump is actuated to raise

fuel pressure, check and see fuel leak from the piping

system.

3.Make sure of no fuel leakage by conducting the above

fuel leak check a few times.

4.Start the engine and make sure of stable idling speed

and normal vehicle run.The entry of dust during the

work may sometimes affect the fuel injection system.

Fuel Pump Relay

General Description

In order to control the FPAS operation, the FPAS relay is

provided. When the starter switch is turned to “ON”

position, the FPAS relay operates the FPAS for 2

seconds.

When it is turned to “ST ART” position, the Engine Control

Module receives the reference pulse from the Ignition

Control Module and it operates the relay, again causing

the FPAS to feed fuel.

Fuel Tank

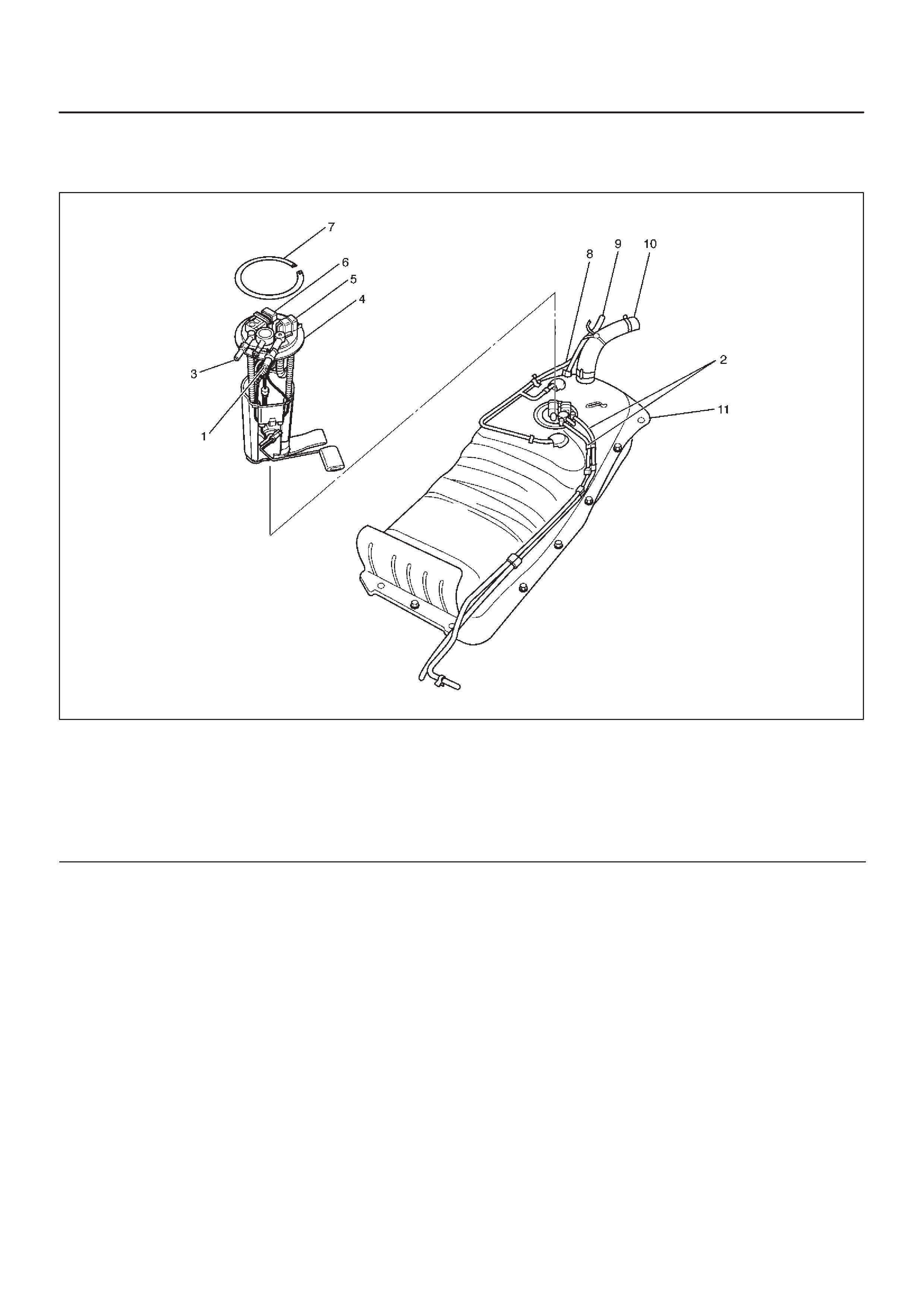

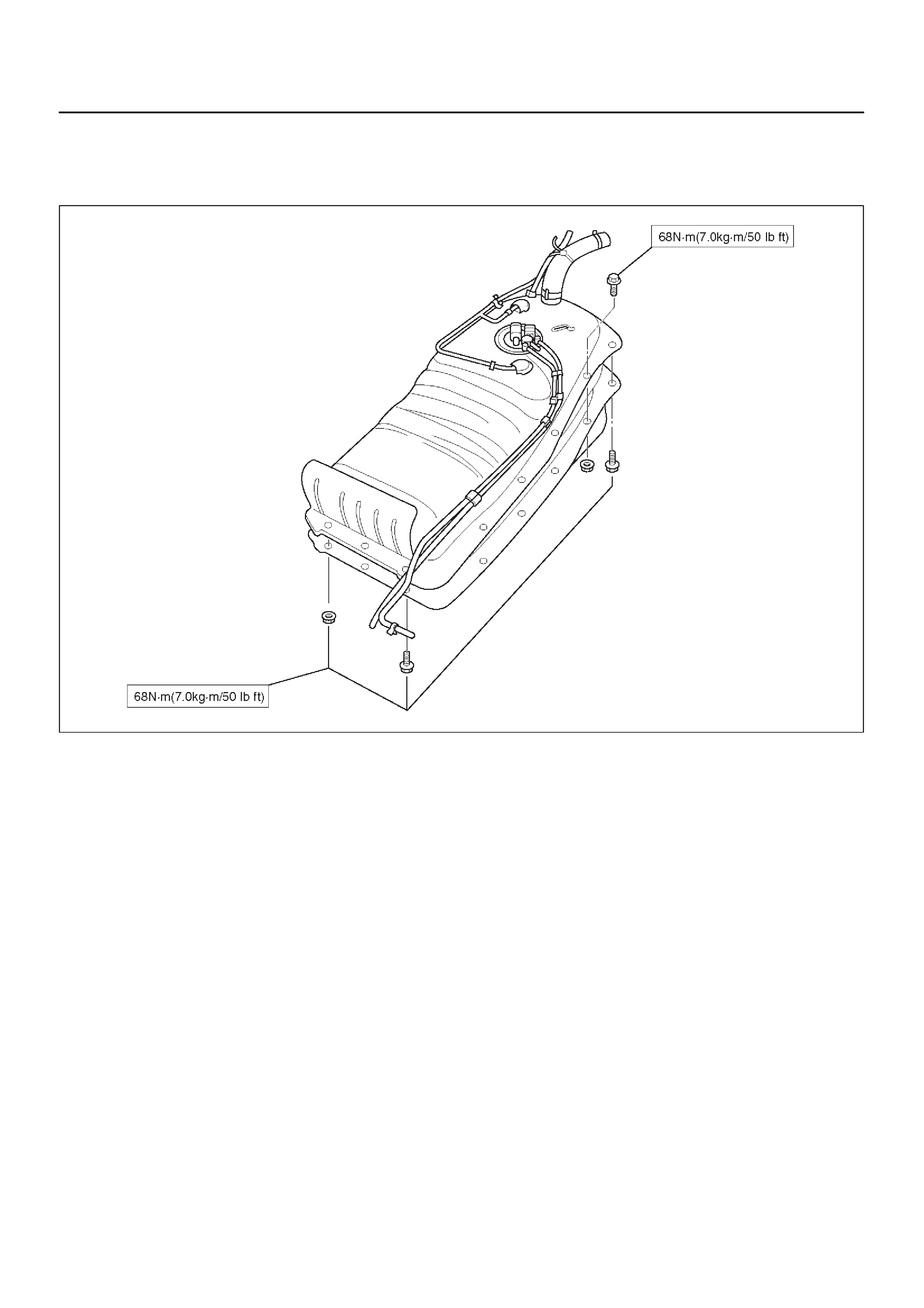

Fuel Tank and Associated Parts

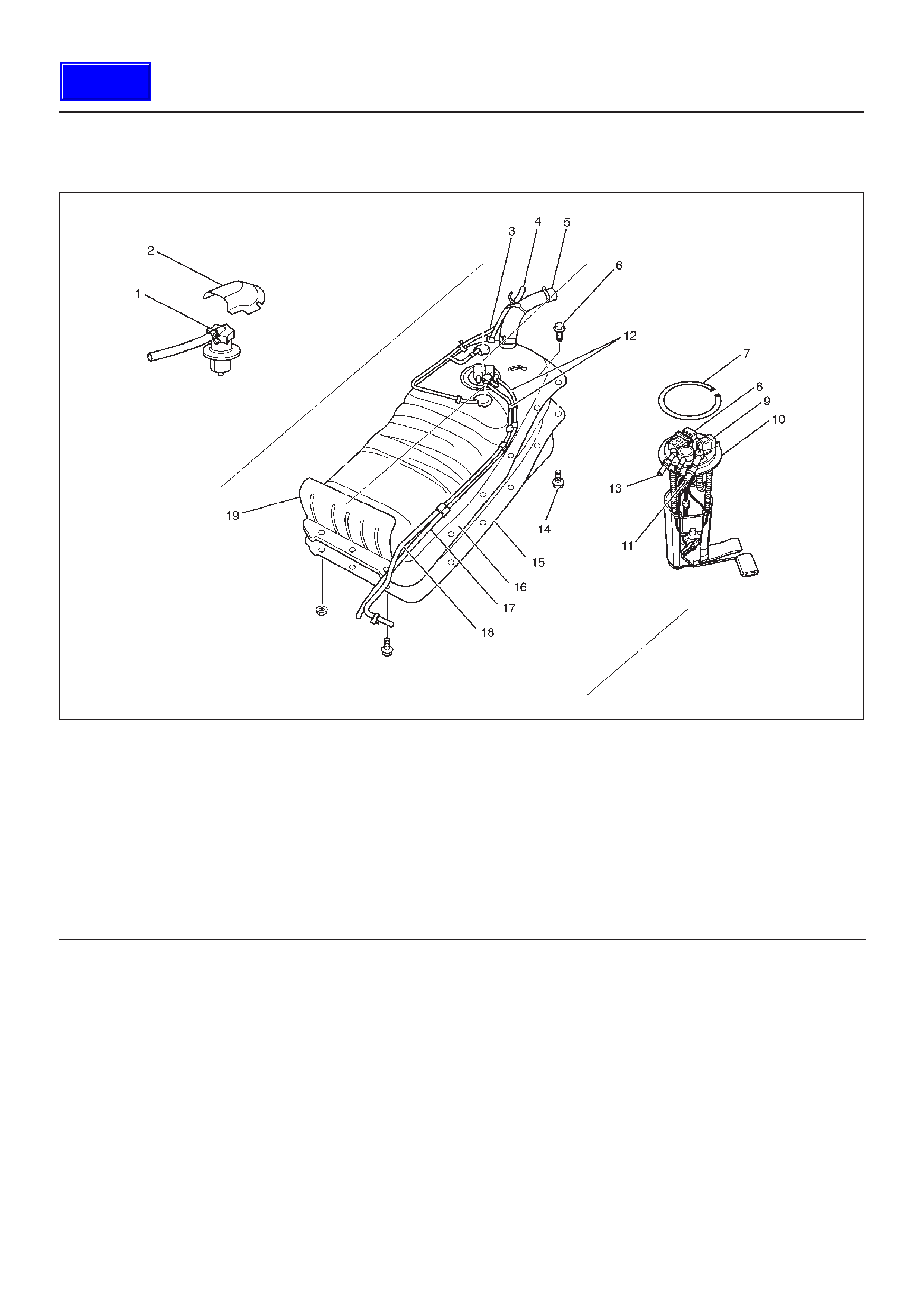

140RX005

Legend

(1)Roll Over&Float Valve

(2)Retaining Cover

(3)Hose; Evaporative Fuel

(4)Hose; Air Breather

(5)Hose; Fuel Filler

(6)Bolt; Fuel Tank Protector Fixing

(7)Snap Ring

(8)Connector; Fuel Level Sensor

(9)Connector; Fuel Feed Pump

(10)Fuel Pump and Sender Assembly

(11)Fuel Feed Port

(12)Fuel Tube/Quick Connector

(13)Fuel Return Port

(14)Bolt; Fuel Tank Asm. Fixing

(15)Protector; Fuel Tank

(16)Fuel Tank Assembly

(17)Hose; Fuel Feed

(18)Hose; Fuel Return

(19)Protector; Heat

Removal

CAUTION:When repair to the fuel system has been

completed, start engine and check the fuel system

for loose connection or leakage. For the fuel system

diagnosis, see Section “Driveability and Emission”.

1.Disconnect battery ground cable.

2.Loosen fuel filler cap.

3. Support underneath of the fuel tank protector (15)

with a lifter.

4.Disconnect evaporative fuel hose (3) at the canister.

5.Disconnect fuel feed hose (17) and fuel return hose

(18) near the fuel filter.

NOTE: Plug both ends of the fuel hoses to prevent fuel

leakage.

6.Disconnect air breather hose (4) and fuel filler hose

(5) at the fuel filler neck.

NOTE: Cover fuel hose to prevent any dust entering.

7.Remove the four fuel tank assembly fixing bolts (14)

at four corners of the tank.

8.Let down the tank and disconnect the wiring

connectors (8,9).

9.Remove fuel tank assembly along with protectors

(15,19) .

10.Remove retaining cover (2) and roll over & float valve

(1) along with the evaporative fuel hose and pipe (3).

Techline

11.Remove Fuel Tube/Quick Connector (12).

NOTE:Handling of the fuel tube sure to refer “Fuel

Tube/Quick Connector Fittings” in this section.

12.Remove fuel pump and sender assembly (10) by

removing the snap ring (7) along with the fuel hoses

(17,18).

13.Remove protectors (15,19) by removing the six fixing

bolts (6).

Installation

1.Install protectors (15,19) and tighten the six fixing

bolts to the specified torque.

Torque: 68 N·m (7.0 kg·m/50 lb ft)

2.Install fuel pump and sender assembly by fitting in of

the snap ring (7).

3.Install Fuel Tube/Quick connector (12).

NOTE:Handling of the fuel tube sure to refer “FuelTube/Quick Connector Fittings” in this section.4.Install roll over & float valve (1) by fitting in of the

retaining cover (2).

5.Lift up fuel tank assembly and connect the wiring

connectors (8,9).

6.Install fuel tank assembly along with protectors and

tighten the four fixing bolts to the specified torque.

Torque: 68 N·m (7.0 kg·m/50 lb ft)

7.Connect fuel filler hose (5) and air breather hose (4),

and clip them firmly.

8.Connect fuel feed hose (17) and fuel return hose (18),

and clip them firmly.

9.Connect evaporative fuel hose (3).

10.Tighten fuel filler cap.

11.Connect battery ground cable.

Fuel Gauge Unit

Removal and Installation

As for removal and installation of the Fuel Gauge Unit,

refer to “Fuel Tank” of this section 6C as the fuel gauge

unit is combined with the fuel pump and sender assembly.

Fuel Filler Cap

General Description

Fuel filler cap includes vacuum valve.

In case any high vacuum happen in tank, the valve works

to adjust the pressure to prevent the tank from being

damaged.

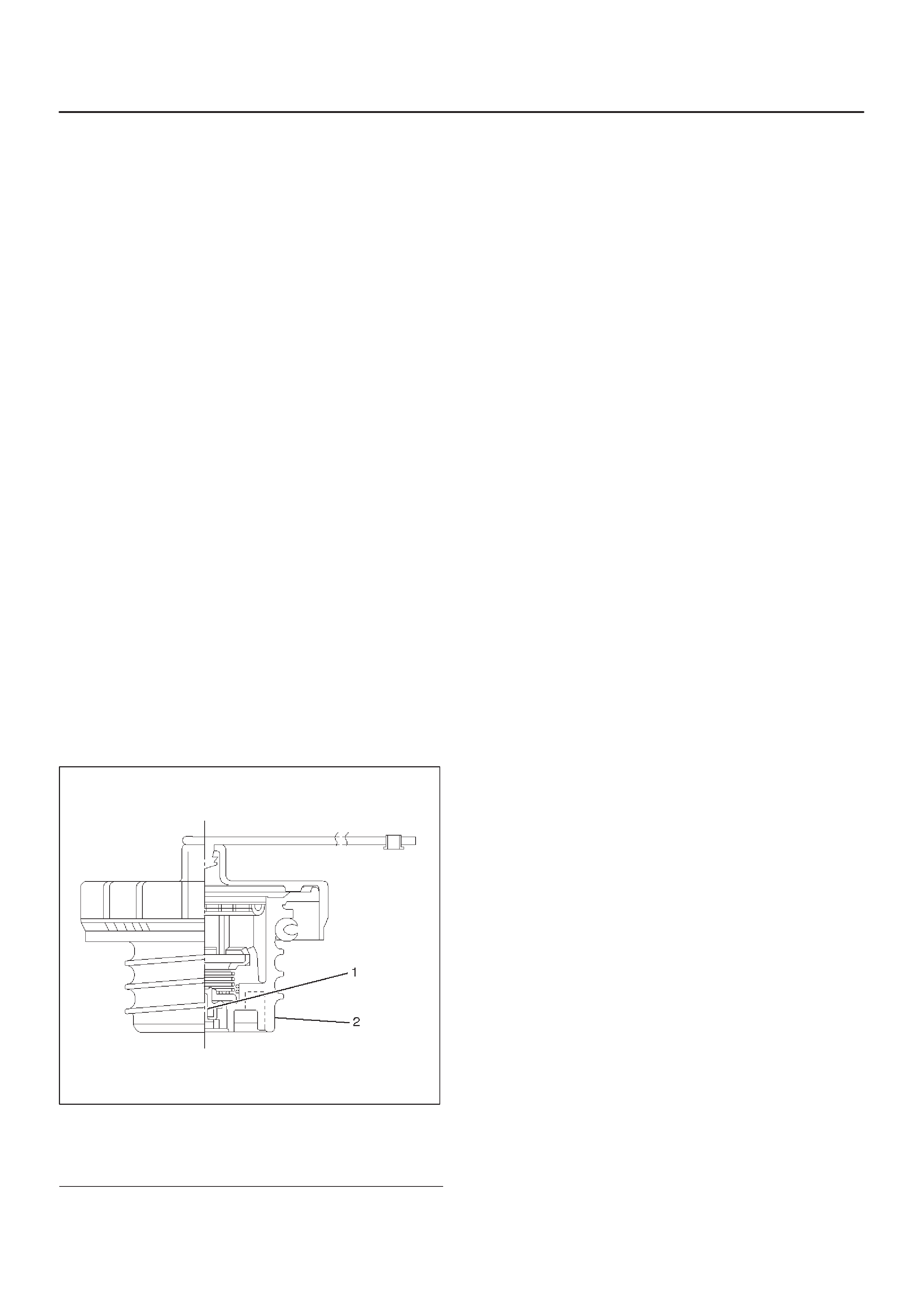

140RW014

Legend

(1)Vacuum Valve

(2)Fuel Filler Cap

Inspection

Check the seal ring in the filler cap for presence of any

abnormality and for seal condition.

Replace the filler cap, if abnormal.

CAUTION:

The fuel filler cap valve has characteristics.

A defective valve, no valve at all or a valve with the

wrong characteristics will do a lot of harm to engine

operating characteristics; be sure to use the same

fuel filler cap as installed in this vehicle.

Main Data and Specifications

Torque Specification

N·m (kg·m/lb ft)

140RX021