SECTION 6D3 - STARTING AND CHARGING SYSTEM

Service Precaution

Starting System

General Description

Diagnosis

Starter

Removal

Installation

Disassembled View

Disassembly

Inspection and Repair

Reassemble

Main Data and Specification

Charging System

General Description

General On–Vehicle Inspection

Generator

Removal

Inspection

Installation

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Bench Test

Main Data and Specification

Service Precaution

WARNING:THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS), REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION:Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener . When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Starting System

General Description

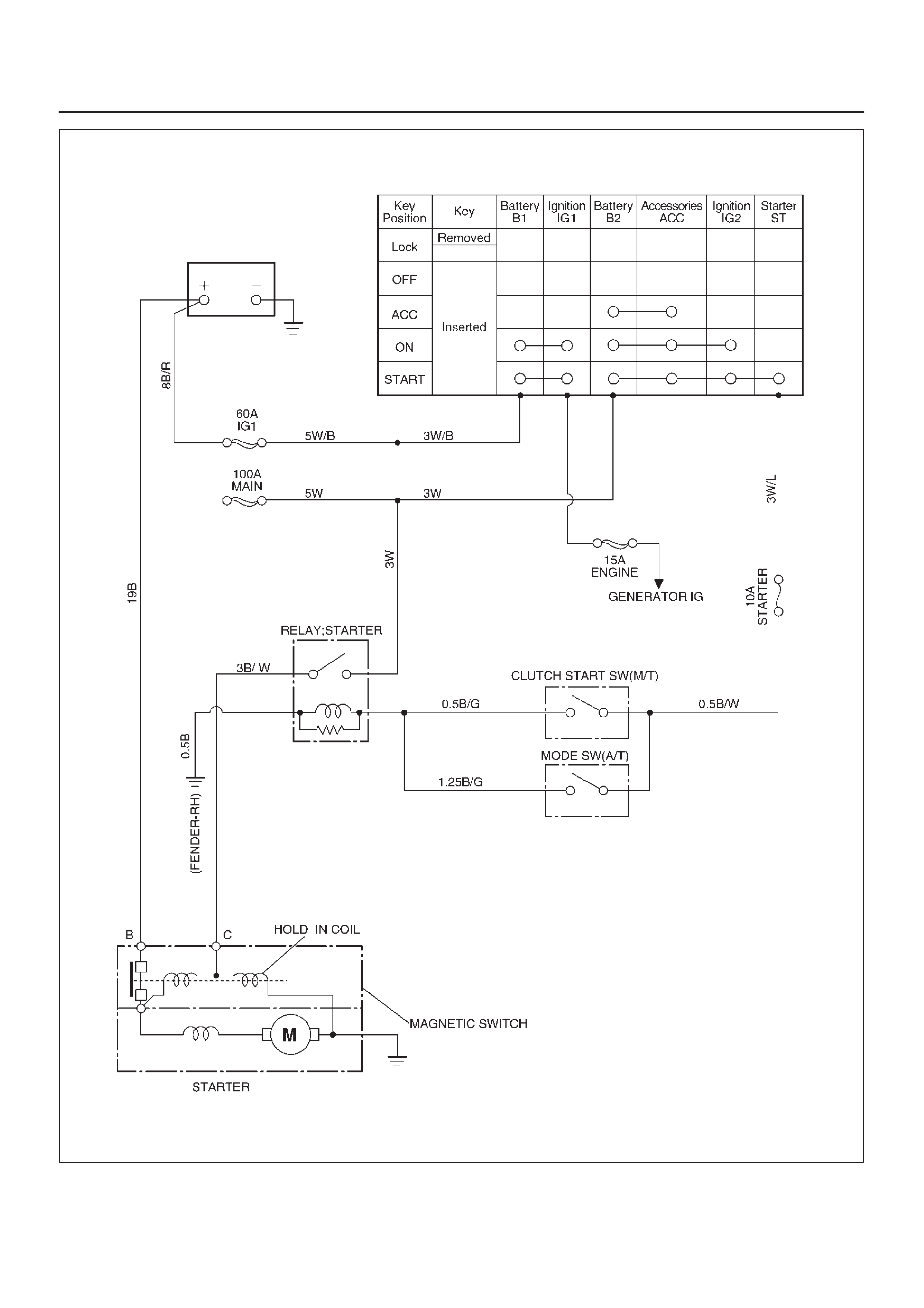

Cranking Circuit

The cranking system consists of a battery, starter , starter

switch, starter relay, etc. These main components are

connected.

Starter

The cranking system employs a magnetic type reduction

starter in which the motor shaft is also used as a pinion

shaft. When the starter switch is turned on, the contacts of

magnetic switch are closed, and the armature rotates. At

the same time, the plunger is attracted, and the pinion is

pushed forward by the shift lever to mesh with the ring

gear.

Then, the ring gear runs to start the engine. When the

engine starts and the starter switch is turned off, the

plunger returns, the pinion is disengaged from the ring

gear, and the armature stops rotation. When the engine

speed is higher than the pinion, the pinion idles, so that

the armature is not driven.

C06RX004

Diagnosis

Starter does not run Charging failure Repair charging system

Battery Failure Replace Battery

Terminal connection failure Repair or replace terminal connector

and/or wiring harness

Starter switch failure Repair or replace starter switch

Starter failure Repair or replace starter

Starter

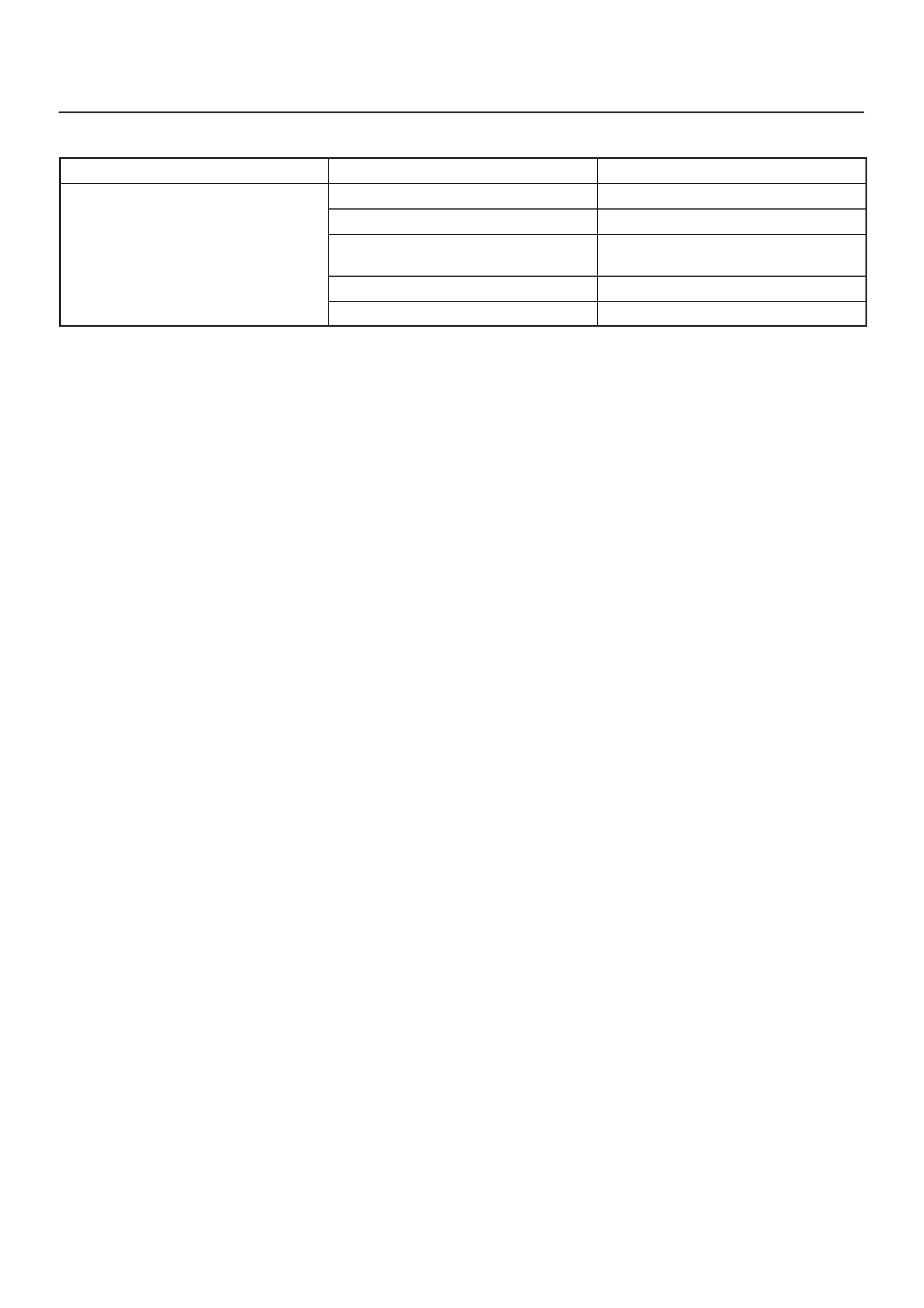

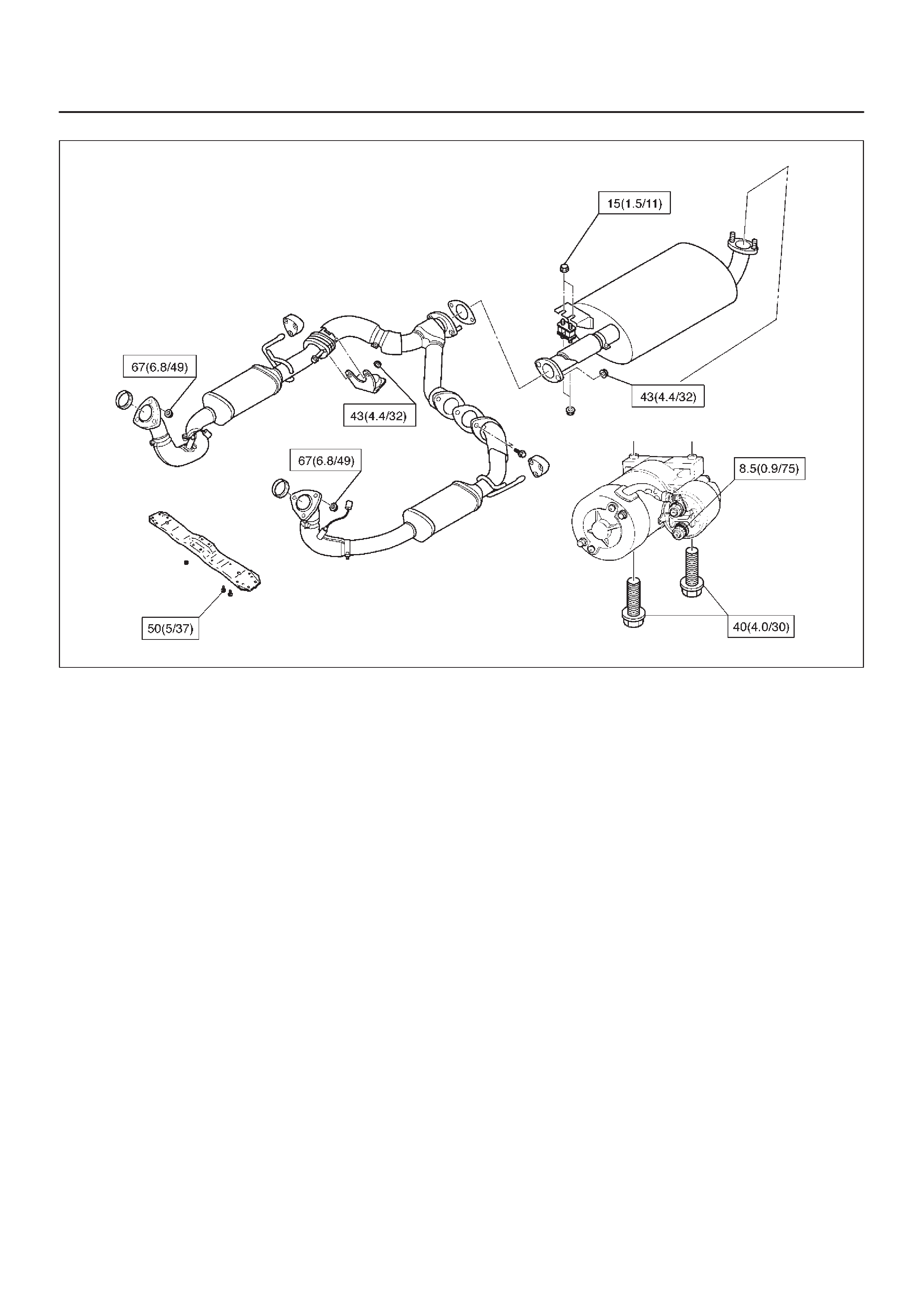

Removal

1.Battery ground cable.

2.Disconnect heated oxygen (O2) sensor connector

(1).

3.Remove exhaust front left pipe(2).

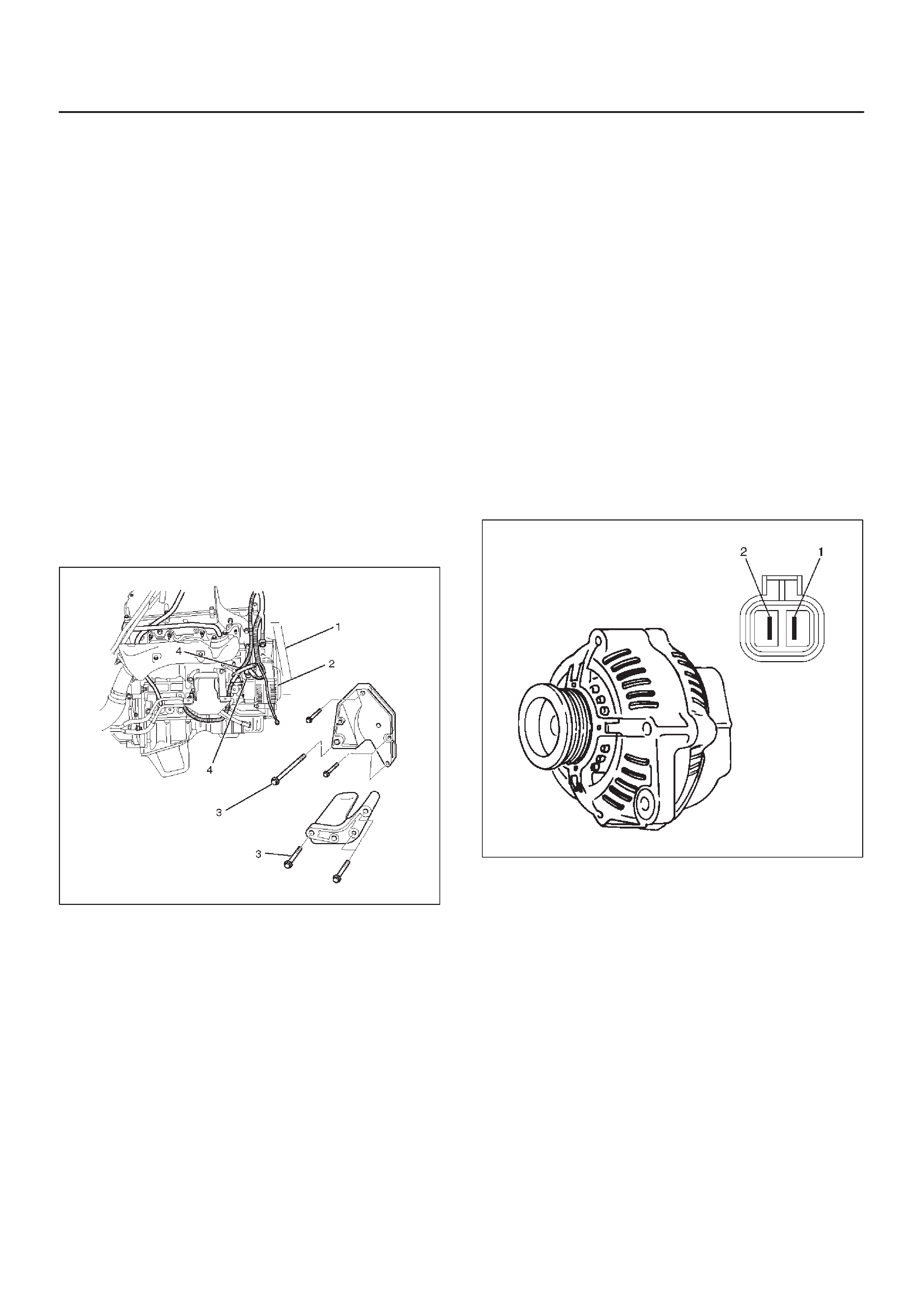

150RX015

4.Remove heat protector(3).

5. Disconnect starter wiring connector from terminals

“B” and “S”(4).

6.Remove starter assembly mounting bolts on inside

and outside(5).

7.Remove starter assembly toward the bottom of

engine(6).

065RW027

Installation

1.Install starter assembly(6).

2.Install mounting bolts and tighten bolts to specified

torque(5).

Torque: 40 N·m (4.1 Kg·m/30 lb ft)

3.Reconnect the connectors to terminals “B” and “S”

and tighten Terminals “B” to specified torque.

Torque: 9 N·m (0.9 Kg·m/80 lb in)

4.Install heat protector(3).

065RW027

5. Install exhaust front left pipe and tighten bolts and

nuts to specified torque(2).

Stud Nuts

Torque: 67 N·m (6.8 Kg·m/49 lb ft)

Nuts

Torque: 43 N·m (4.4 Kg·m/32 lb ft)

6.Connect O2 sensor connector (2).

150RX015

7.Reconnect the battery ground cable.

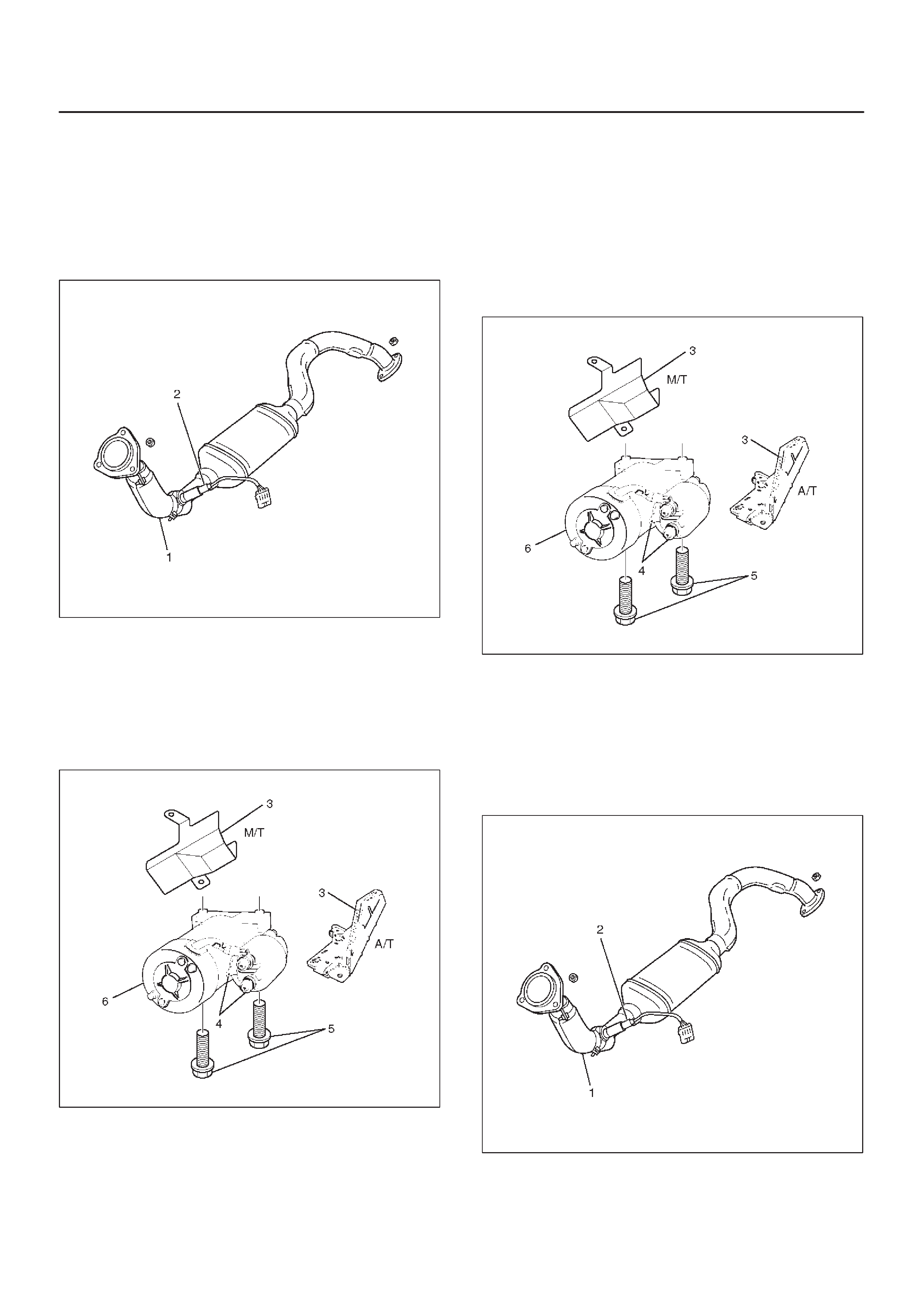

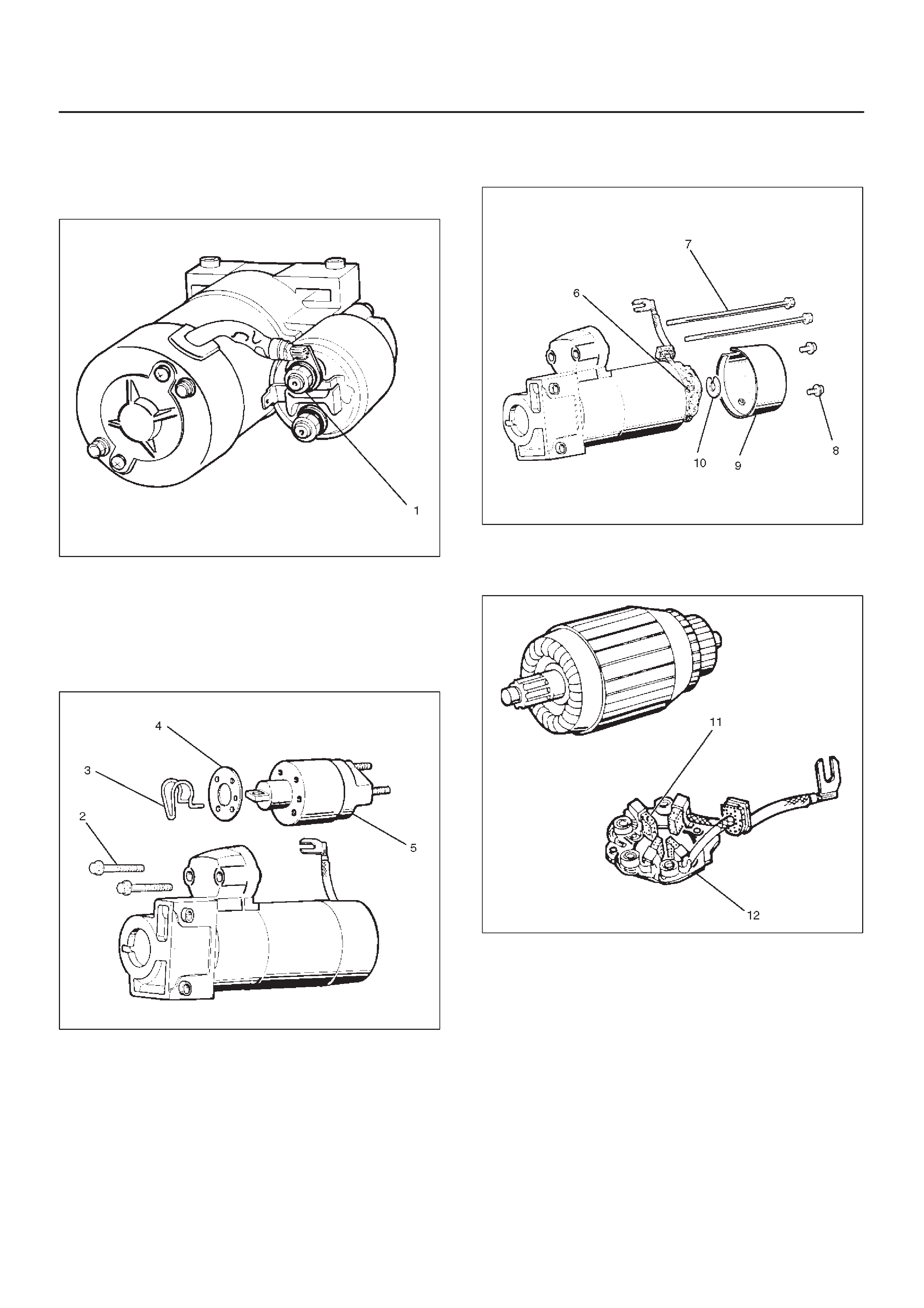

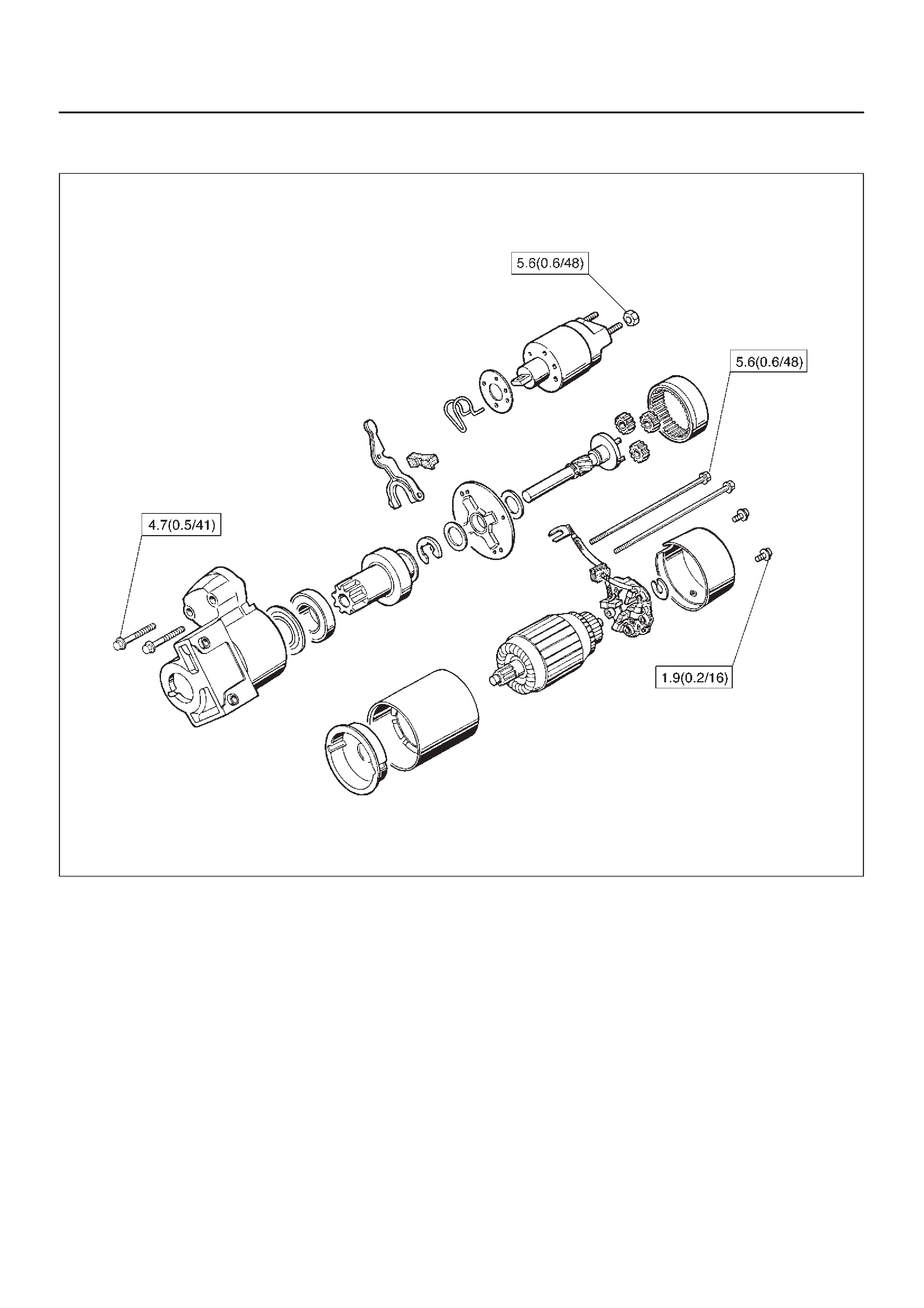

Disassembled View

065RW002

Legend

(1) Bolt (2 pcs)

(2) Ball Bearing

(3) Pinion

(4) Shift Lever

(5) Dust Cover

(6) Torsion Spring

(7) Dust Cover

(8) Magnetic Switch

(9) Nut

(10) Gear Case

(11) Bearing Cover

(12) E–Ring

(13) Thrust Washer (2)

(14) Center Bracket

(15) Pinion Shaft

(16) Planet Gear (3)

(17) Internal Gear

(18) Center Bracket (A)

(19) Yoke Assembly

(20) Armature

(21) Brush

(22) Brush Holder

(23) Thrust Washer

(24) Rear Cover

(25) Screw (2 pcs)

(26) Through Bolt (2 pcs)

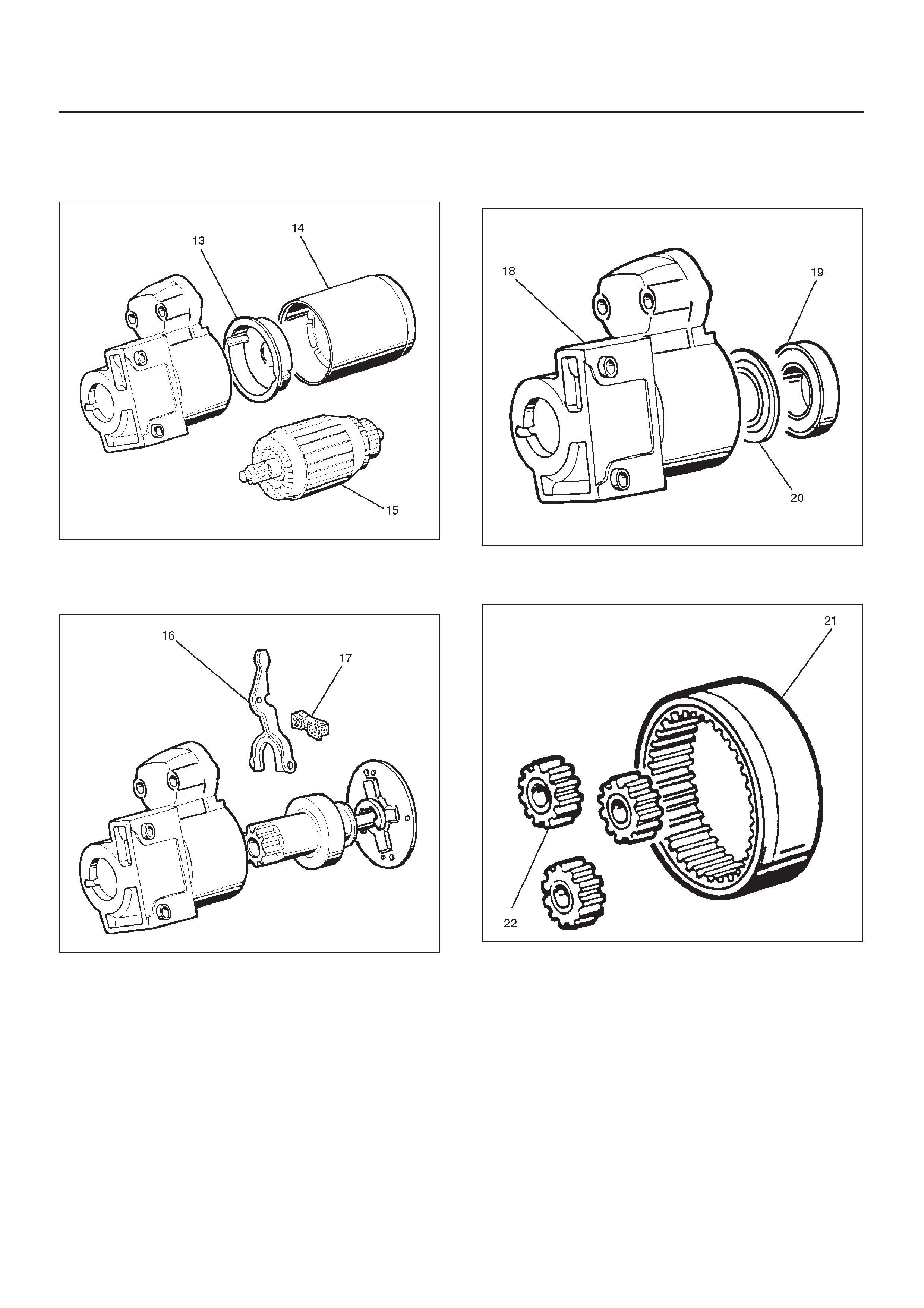

Disassembly

1.Loosen the nut(1) on terminal “M” of magnetic switch

and disconnect the connector cable.

2.Remove bolt (2 pcs) (2).

065RW003

3.Remove magnetic switch(5).

4.Remove dust cover(4).

5.Remove torsion spring bolts, then the magnetic

switch assembly.

6.Remove torsion spring(3) from magnetic switch

assembly(5).

065RW004

7.Remove screw (2 pcs) (8).

8.Remove through bolt (2 pcs) (7).

9.Remove screws and through bolts, then the rear

cover(9) then remove thrust washer(10).

10.Remove brush holder(6).

065RW005

11.Raise a brush spring to detach brushes (4 pcs) from

the commutator face and pull off the brush holder(12)

and brush(11).

065RW006

12.Remove yoke assembly(14).

13.Remove armature(15).

14.Pull off the yoke assembly, then remove armature,

washer and center bracket.(A) (13).

NOTE: In disassembling the yoke assembly, hold the

armature and pull off slowly the yoke assembly. Because

of strong magnetic force, avoid placing a metallic part

near armature.

065RW007

15.Remove dust cover(17).

16.Remove a dust cover and shift lever(16) from the gear

case.

065RW008

17.Remove ball bearing(19).

18.Remove bearing cover(20).

19.Remove a ball bearing and bearing cover from the

gear case(18).

065RW021

20.Internal gear(21).

21.Remove internal gear and planet gear(3) (22).

065RW009

22.Remove an E–ring(23) from the pinion shaft using a

flat blade screwdriver.

065RW010

23.Holding the pinion shaft, push pinion toward the

center bracket. and turn the pinion clockwise or

counterclockwise by one tooth of spline, then pull of f

the pinion.

24.Remove thrust washer(24).

25.Remove center bracket

26.Remove pinion shaft.

065RW011

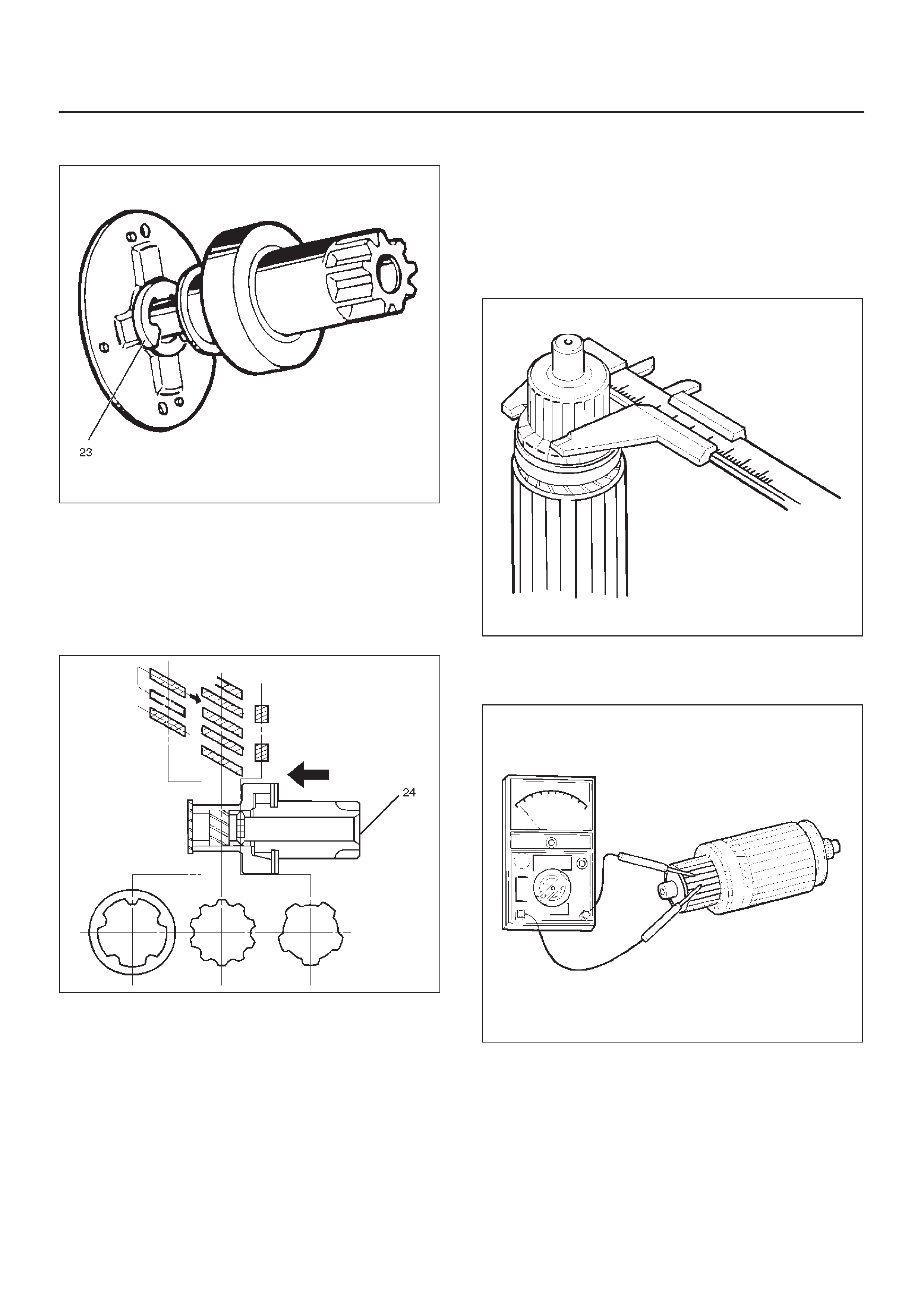

Inspection and Repair

Repair or replace necessary parts if extreme wear or

damage is found during inspection.

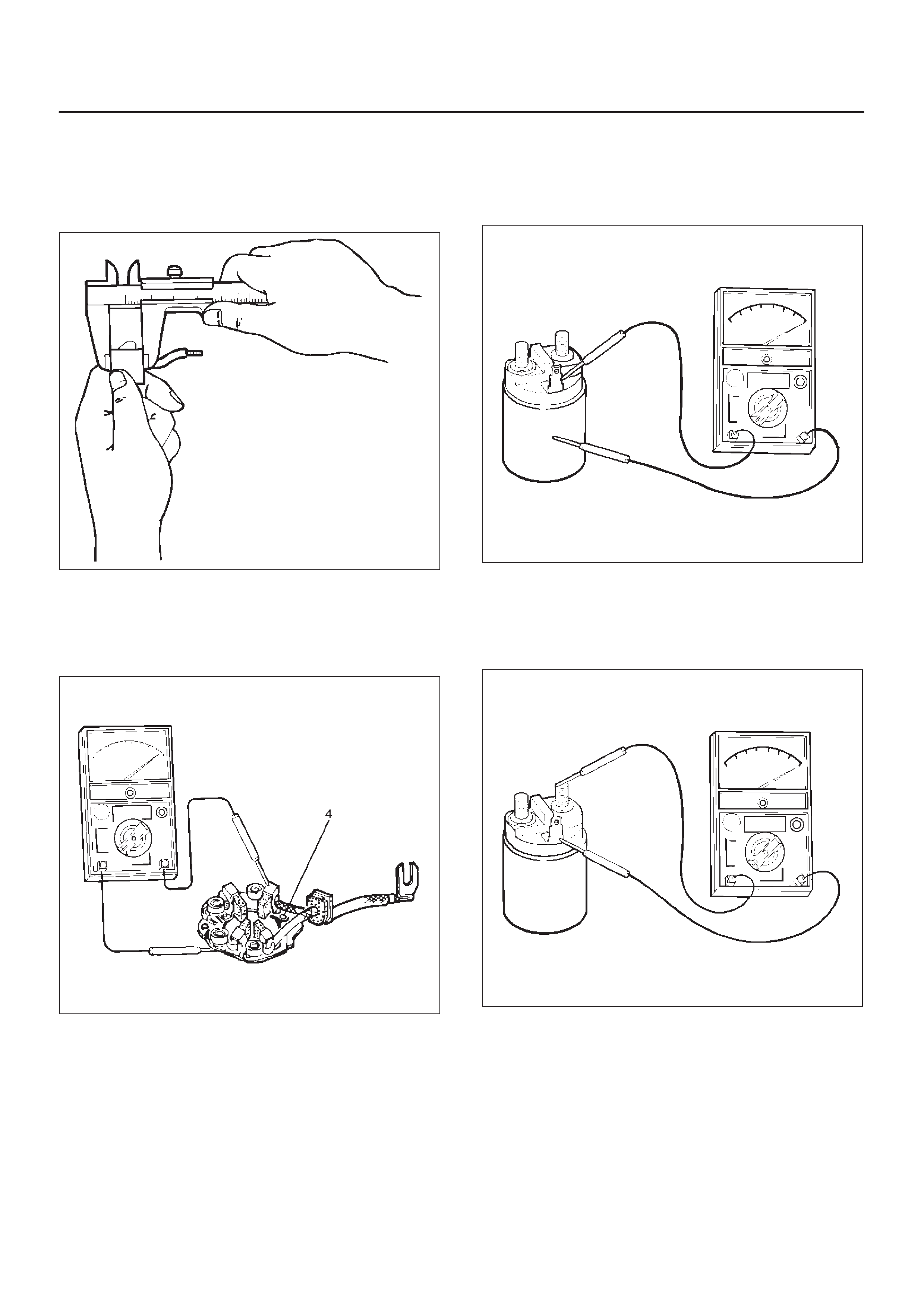

Armature

Measure the outer diameter of commutator, and replace

with a new one if it is out of the limit.

Standard: 33.0 mm (1.30 in)

Limit: 32.0 mm (1.26 in)

065RS014

Check for continuity between commutator and segment.

Replace commutator if there is no continuity (i.e.,

disconnected).

065RS015

Check for continuity between commutator and shaft.

Also, check for continuity between commutator and

armature core,armature core and shaft. Replace

commutator if there is continuity (i.e., internally

grounded).

065RS016

Measure runout of armature core and commutator with a

dial gauge. Repair or replace, if it exceeds the limit.

Armature

Standard: 0.05 mm (0.002 in) Max.

Limit: 0.10 mm (0.004 in)

Commutator

Standard: 0.05 mm (0.002 in) Max.

Limit: 0.10 mm (0.004 in)

065RS017

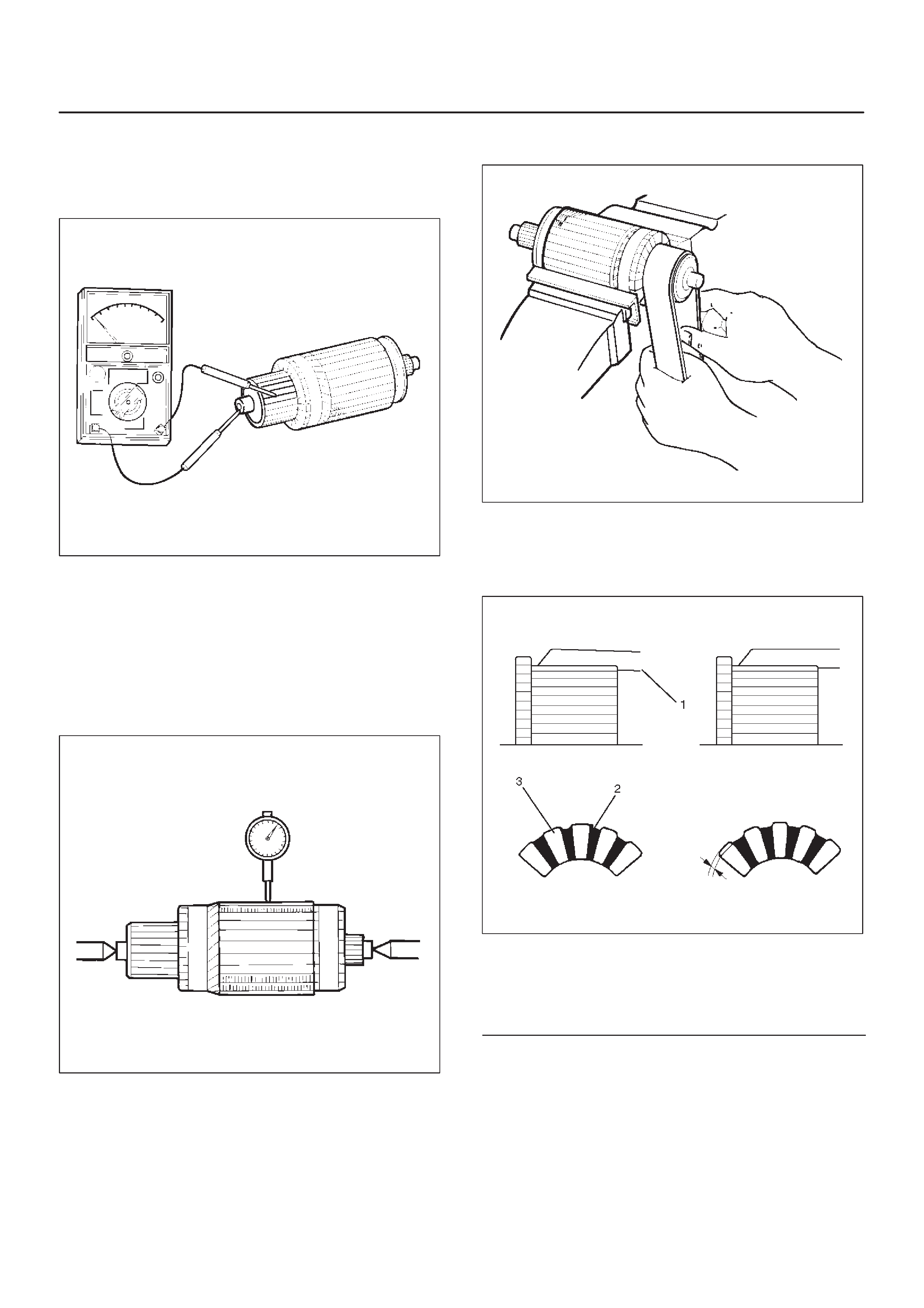

Polish the commutator surface with sandpaper #500 to

#600 if it is rough.

065RW012

Measure the depth of insulator in commutator. Repair, if it

is below the limit.

Standard: 0.05 mm to 0.8 mm (0.02 in to 0.03 in)

Limit: 0.2 mm (0.008 in)

065RW013

Legend

(1) Steel Saw

(2) Insulator

(3) Commutator Segments

Brush

Measure the length of brush.

Replace with a new one, if it is below the limit.

Standard: 16 mm (0.63 in)

Limit: 11 mm (0.43 in)

065RW014

Brush Holder

Check for continuity between brush holder (+) (4) and

base (–). Replace, if there is continuity (i.e., insulation is

broken).

065RW015

Magnetic Switch

Check for continuity of shunt coil between terminals S and

M.

Replace, if there is no continuity (i.e., coil is

disconnected).

065RW016

Continuity of Series Coil

Check for continuity between terminals S and M.

Replace, if there is no continuity (i.e., coil is

disconnected).

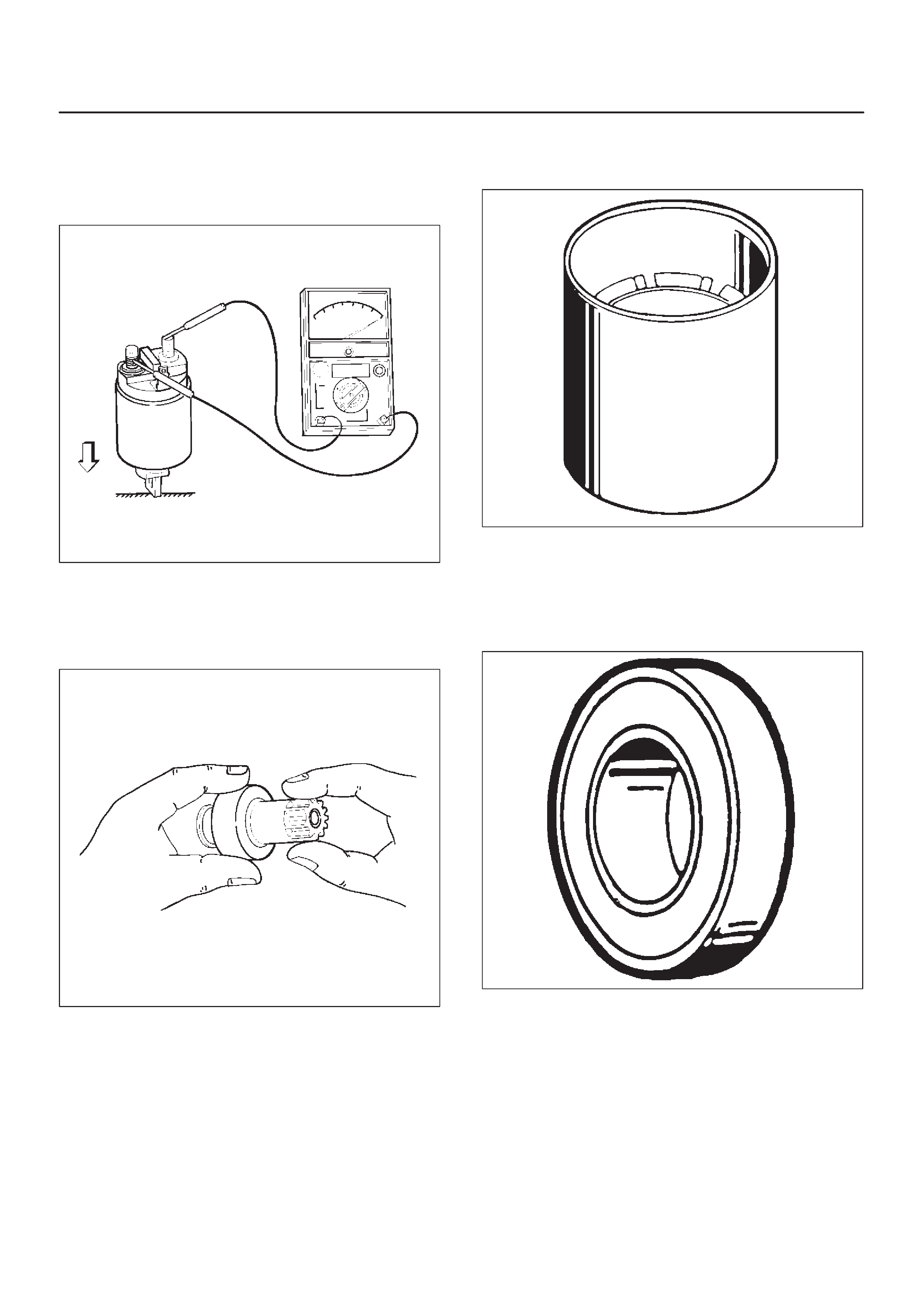

065RW017

Continuity of Contacts

With the plunger faced downward, push down the

magnetic switch. In this state, check for continuity

between terminals B and M. Replace, if there is no

continuity (i.e., contacts are faulty).

065RW018

Pinion

Check if the pinion rotates smoothly in drive direction by

hand, or if it is locked when it is rotated in reverse. If not,

replace the pinion.

065RS025

Yoke Assembly

Check a magnet inside the yoke.

Replace the yoke assembly if it is broken.

065RS026

Ball Bearing

Clamp the inner race of the ball bearing with your finger,

and check for sticking or play when rotating the outer

race.

Replace, if abnormality is found.

065RS027

Measure inner diameter of bushing in the rear cover , and

replace if it exceeds the limit.

Standard: 12.50 mm to 12.527 mm (0.492 in to

0.4932 in)

Limit: 12.60 mm (0.4961 in)

065RS028

Measure inner diameter of bushing in the center bracket

(P), and replace if it exceeds the limit.

Standard: 18.01 mm to 18.127 mm (0.7091 in to

0.7137 in)

Limit: 18.15 mm (0.7146 in)

065RS029

Reassembly

To install, follow the removal steps in the reverse order,

noting the following points:

Grease application places

DBushing in rear cover and center bracket

DGears in reduction gear

DShift lever operating portion

DSliding portion of pinion

DPlunger sliding portion of magnetic switch

Reassembling Yoke Assembly

Before reassembly, make sure that no metallic parts

attach to the yoke assembly . Because of strong magnetic

force, hold the yoke assembly and insert it slowly into the

armature.

Torque

Torque for each part (See Torque Specifications in

this section)

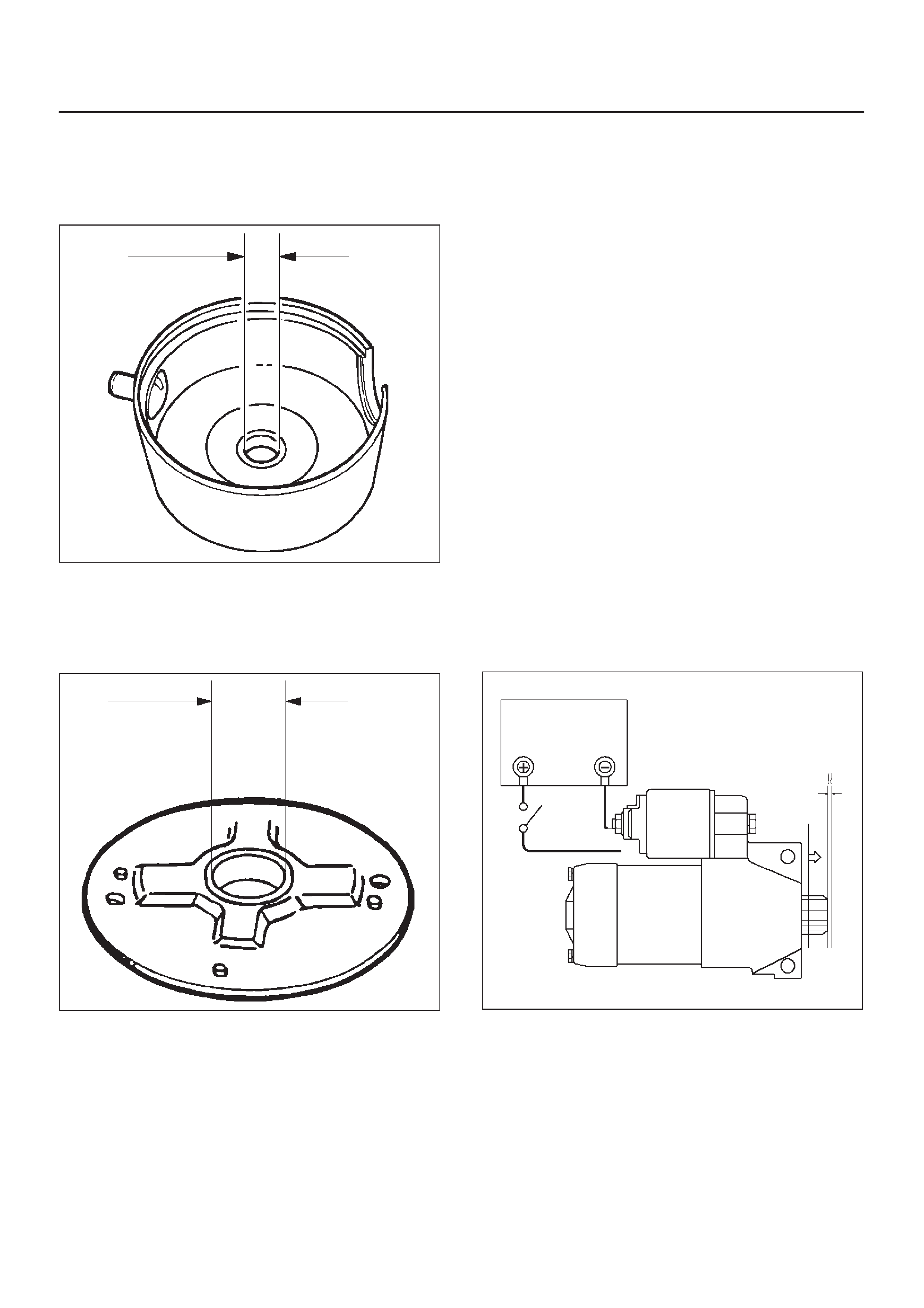

Pinion Jump–out Dimension

Connect the “+” cable of battery to terminal S and the “–”

cable to terminal M. Turn the switch on, and measure

pinion travel dimension in thrust direction from the

jump–out position.

In measuring the dimension, pull the pinion out a little in

the arrow direction.

Dimension(L): 0.05 mm to 1.5 mm (0.002 in to

0.06 in)

065RS030

If the measured value is out of standard, insert dust cover,

or disassemble and adjust.

065RW019

Characteristic Test

For easily confirming the characteristics, conduct the no

load test as follows:

Rating as short as 30 seconds requires rapid testing.

Fix the starter on the test bench, and wire as shown in

illustration. When the switch is closed, the current flows

and the starter runs under no load. At this time, measure

current, voltage and speed to check if they satisfy the

standard.

065RW020

Legend

(1) Volt Meter

(2) Tachometer

(3) Battery

(4) Ammeter

(5) Switch

Main Data and Specifications

General Specifications

Model Specification

Rating

Voltage 12 V

Output 1.4 Kw

Time 30 sec

Number of teeth of pinion 9

Rotating direction(as viewed from pinion) Clockwise

Weight(approx.) 37 N

No load characteristics

Voltage /Current 11.5V/90A or less

Speed 3000rpm or more

Load characteristics

Voltage/current 8.5V/350A or more

Torque 13.2N·m(117lb·in.) or more

Speed 1000rpm or more

Locking characteristics

Voltage/current 2.4V/500A or less

Torque 11.8N·m(104lb·in) or more

Torque Specifications

N·m (Kg·m/lb ft)

E06RW044

N·m (Kg·m/lb ft)

150RX016

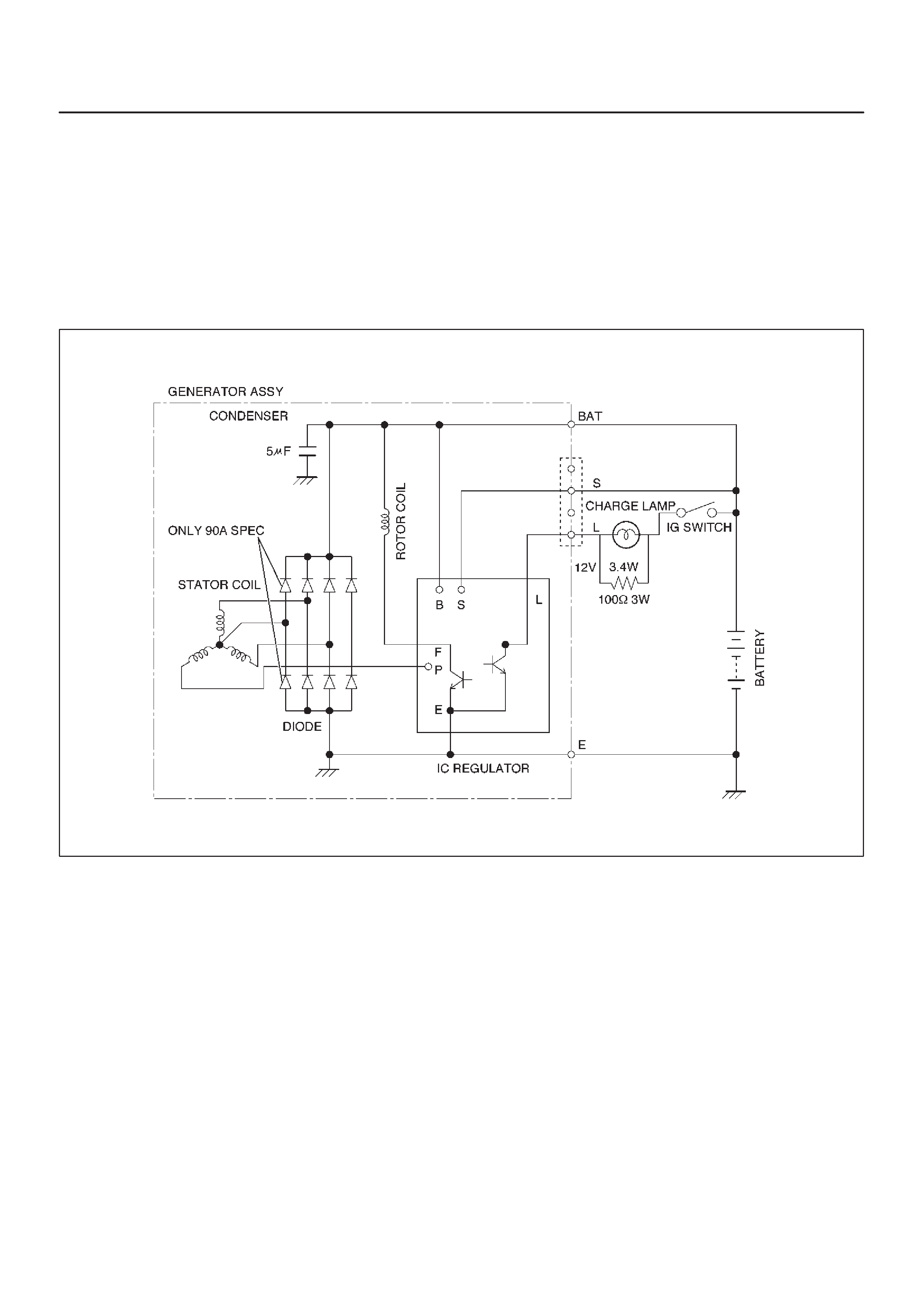

Charging System

General Description

The IC integral regulator charging system and its main

components are connected as shown in illustration.

The regulator is a solid state type and it is mounted along

with the brush holder assembly inside the generator

installed on the rear end cover.

The generator does not require particular maintenance

such as voltage adjustment.

The rectifier connected to the stator coil has diodes to

transform AC voltage into DC voltage.

This DC voltage is connected to the output terminal of

generator.

F06RX002

General On–Vehicle Inspection

A basic wiring diagram is shown in the illustration. When

operating normally, the indicator bulb will come on when

the switch is turned on, and will then go out when the

engine starts. If the indicator operates abnormally , or if an

undercharged or overcharged battery condition occurs,

the following procedure may be used to diagnose the

charging system. Remember that an undercharged

battery is often caused by accessories being left on

overnight, or by a defective switch which allows a bulb,

such as a trunk or glove box light, to stay on.

OBSERVE THE FOLLOWING PROCEDURE:

1.Visually check belt and wiring.

2. Go to step 5. for vehicles without charge indicator

light.

3.Switch on, engine stopped, light should be on. If not,

detach harness at generator, ground “L” terminal

lead.

a. Lamp lights, replace or repair generator.

b. Lamp dose not light, locate open circuit between

grounding lead and ignition switch. Bulb may be

open.

4.Switch on, engine running at moderate speed. Light

should be off. If not, detach wiring harness at

generator.

a. If light goes off, replace or repair generator.

b. If light stays on, check for grounded “L” terminal

wire in harness.

5.Battery undercharged or overcharged.

a. Detach wiring harness connector from generator.

b. With switch on, engine not running connect

voltmeter from ground to “L” terminal in wiring

harness, and to “IG” terminal. If used. Wiring

harness may connect to either “L” or “IG” or both.

c. Zero reading indicates open circuit between

terminal and battery. Connect as required.

d. Re-connect harness connector to generator, run

engine at moderate speed, with electrical

accessories turned off.

e. Measure voltage across battery. If above 16.0V,

replace or repair generator.

f. Connect ammeter at generator output terminal.

T urn on accessories, load battery with carbon pile

to obtain maximum amperes output.

Maintain voltage at 13.0V or above.

1. If within 15 amperes of rated output, generator is

OK.

2. If not within 15 amperes of rated output, replace or

repair generator.

Generator

Removal

1.Disconnect battery ground cable.

2.Move drive belt tensioner to loose side using wrench

then remove drive belt (1).

3.Disconnect the wire from terminal “B” and disconnect

the connector (4).

4.Remove generator fixing bolt (3).

5.Remove generator assembly (2).

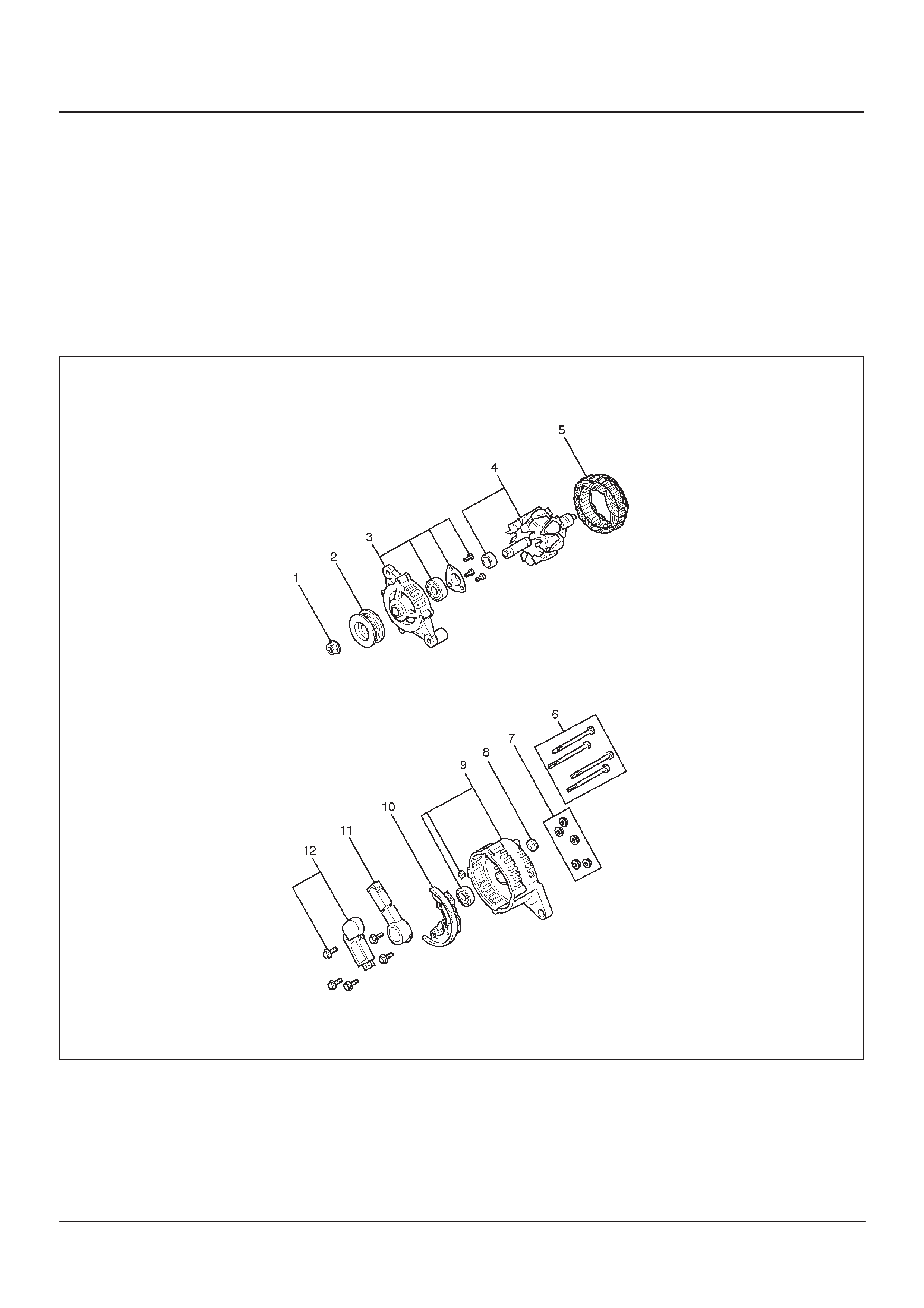

060RW002

Inspection

1.Disconnect the wiring connector from generator.

2.With the engine stopped, turn starter switch to “on”

and connect a voltmeter between connector terminal

L (1) and ground or between terminal IG (2) and

ground.

066RX002

If voltage is not present, the line between battery and

connector is disconnected and so requires repair.

3.Reconnect the wiring connector to the generator , run

the engine at middle speed, and turn off all electrical

devices other than engine.

4.Measure battery voltage. If it exceeds 16V, repair or

replace the generator.

5.Connect an ammeter to output terminal of generator ,

and measure output current under load by turning on

the other electrical devices (eg., headlights). At this

time the amperes must not be less than 15A and the

voltage must not be less than 13V.

Installation

1.Install generator assembly to the position.

2.Install generator assembly and tighten the fixing bolts

to the specified torque.

Torque:

M10 bolt: 41 N·m (30 Ib ft)

M8 bolt: 21 N·m (15 Ib ft)

3.Connect wiring harness connector and direct terminal

“B”.

4.Move drive belt tensioner to loose side using wrench,

then install drive belt to normal position.

5.Reconnect battery ground cable.

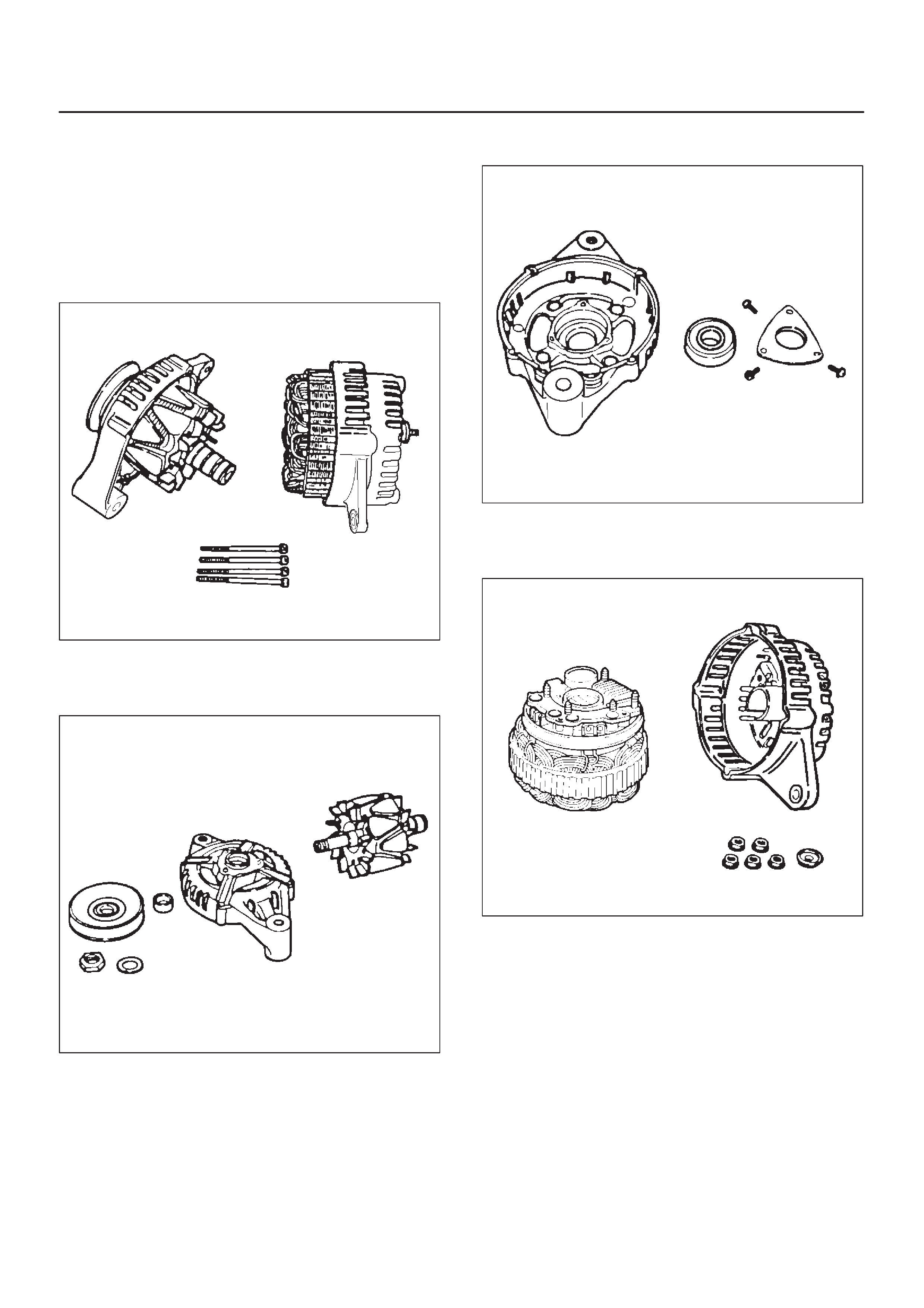

Disassembled View

066RW022

Legend

(1) Pulley Nut

(2) Pulley

(3) Front Cover Assembly

(4) Rotor Assembly

(5) Stator Assembly

(6) Through Bolt

(7) Nut

(8) Terminal Insulator

(9) Rear Cover Assembly

(10) Rectifier

(11) Brush Holder Assembly

(12) Regulator Assembly

Disassembly

1.Remove the through bolt.

Insert the tip of a pry bar into the gaps between the

front cover and the stator core.

Pry apart and separate the front cover , rotor, the rear

cover and stator.

NOTE: Take care not to scratch or otherwise damage the

stator coil with pry bar.

F06RT021

2.Clamp the rotor in a vise and then remove the nut and

pulley.

3.Remove the rotor assembly from front cover.

F06RT022

4.Remove screws with bearing retainer from front cover

and remove bearing.

F06RT023

5.Remove the mounting nuts holding the “B” terminal,

the diode, and the brush holder.

6.Separate the rear cover from the stator.

F06RT024

7.Remove bolts which secure stator terminal to rectifier

terminal, and remove stator.

066RS030

8. Remove Bolts which secure regulator, rectifier and

brush-holder, and separate these parts.

NOTE: Do not apply a shock or load to regulator , rectifier

and brush holder.

066RW025

Inspection and Repair

Repair or replace necessary parts if extreme wear or

damage is found during inspection.

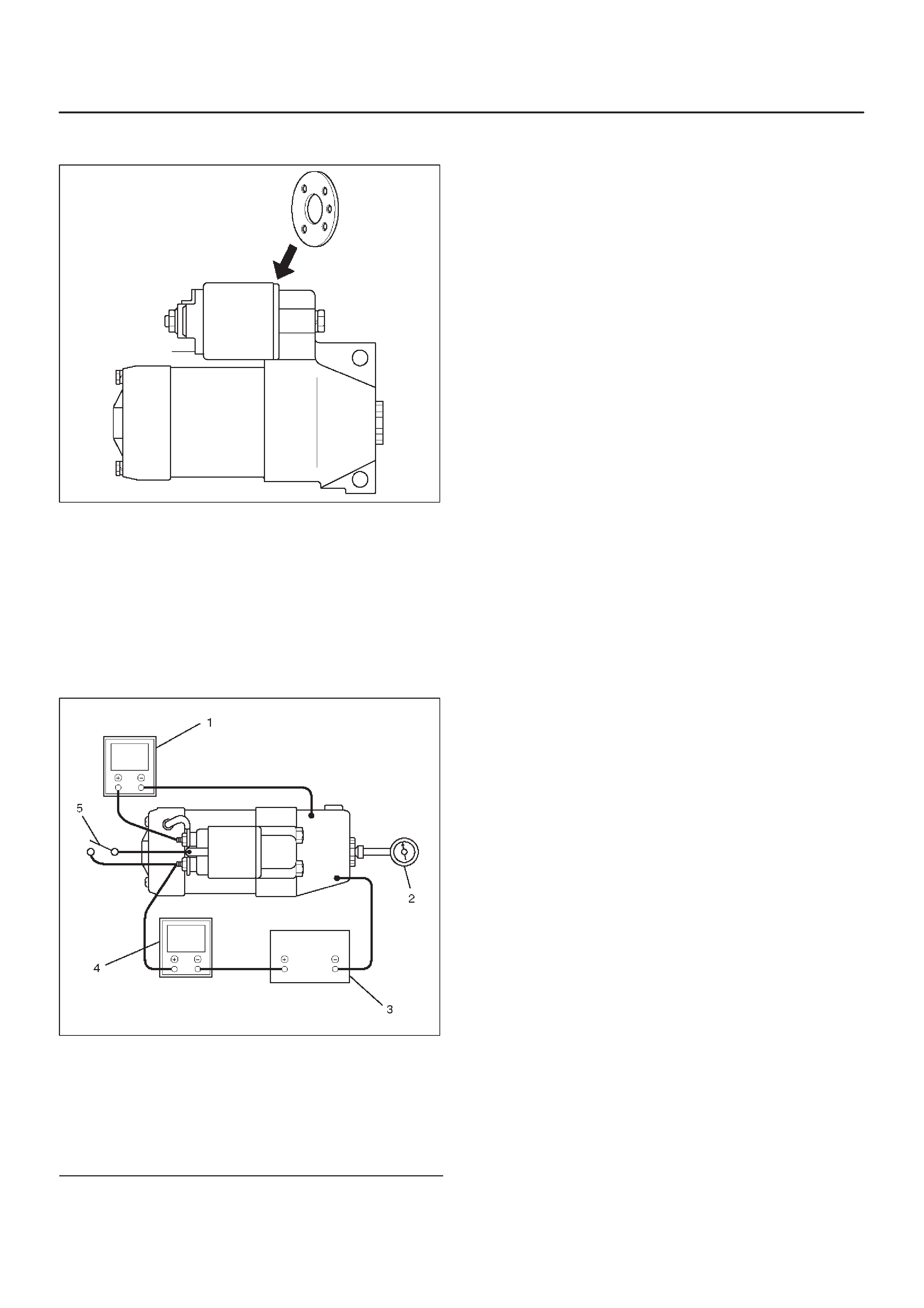

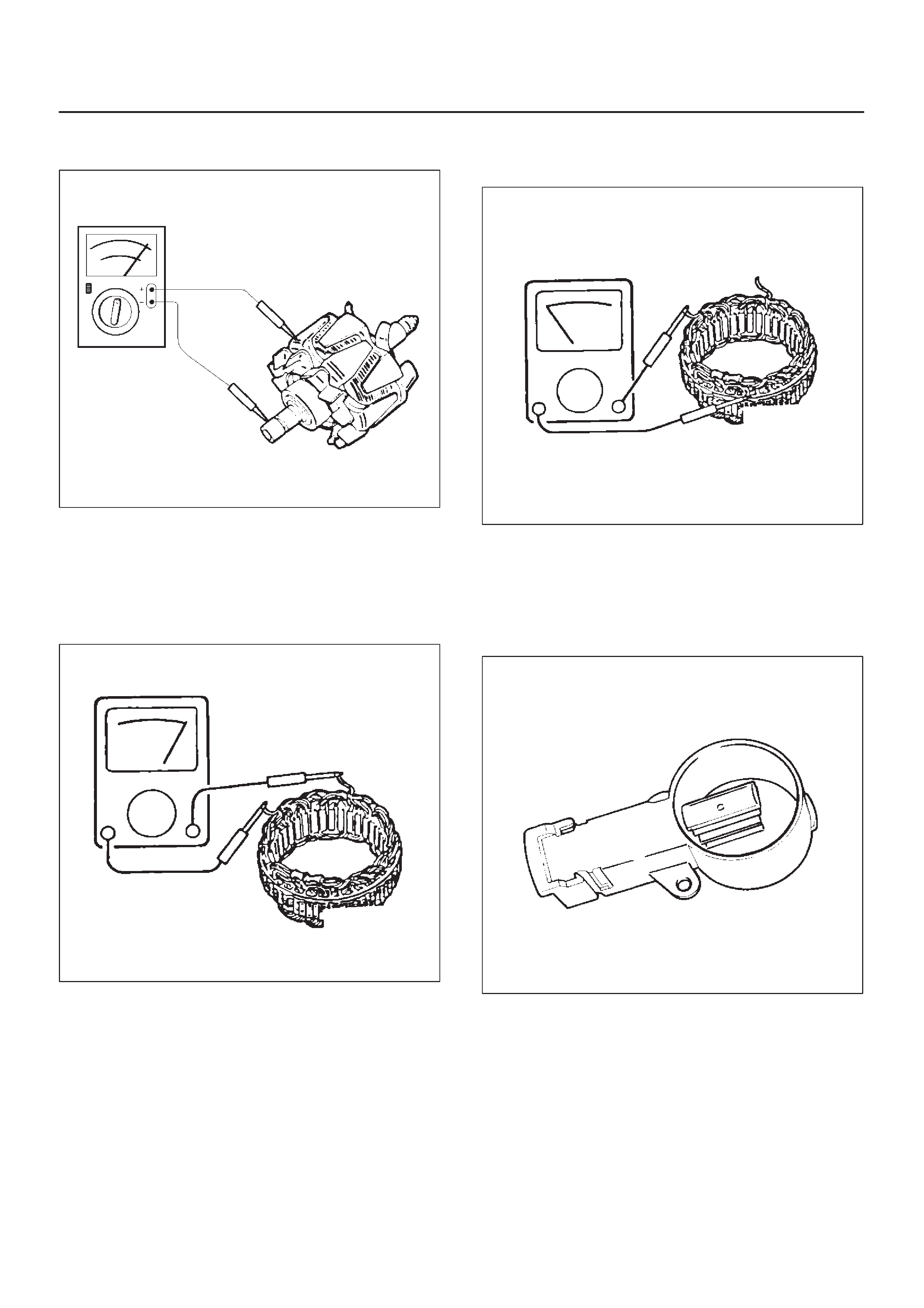

Rotor Assembly

1.Check the face of the slip rings for contamination and

roughness. If found to be scored, dress with a fine

sandpaper (#500 –600). If found to be contaminated,

clean with a cloth saturated with alcohol.

2.Measure the outside diameter of the slip rings.

Standard: 27mm (1.06in)

Limit: 26mm (1.02in)

066RS032

3.Check resistance between slip rings, and replace if

there is no continuity.

Standard: 3.75W or less

066RS033

4.Check for continuity between slip ring and rotor core.

In case of continuity, replace the rotor assembly.

066RS017

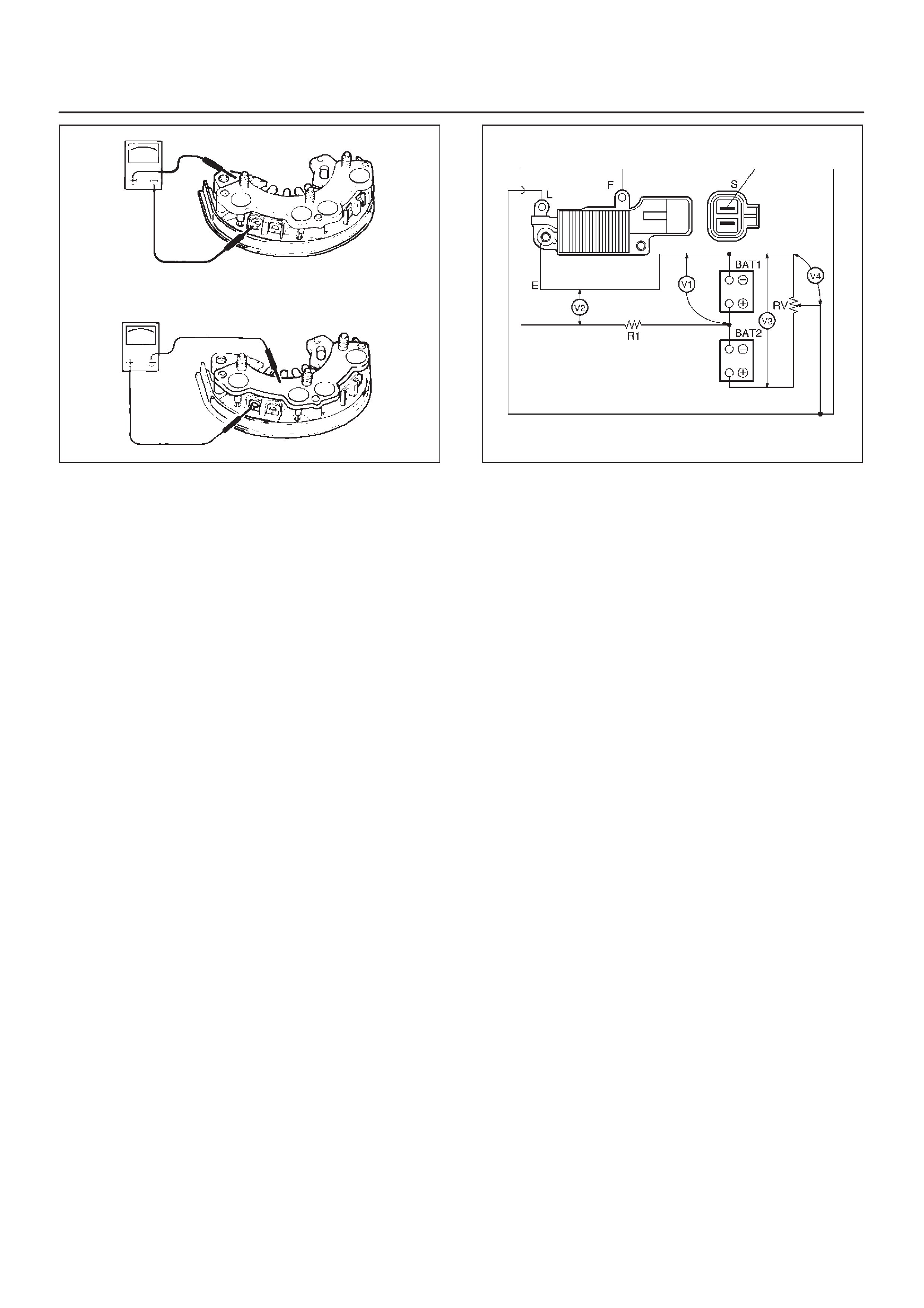

Stator Coil

1. Check for continuity across the stator coils. If no

continuity exists, replace the coils.

Resistance value at 20°C.

Standard: Approx. 0.07W

066RS034

2.Check for continuity across one of the stator coils and

stator core. If a continuity exists, replace the coil.

Standard: More than 1MW

066RS035

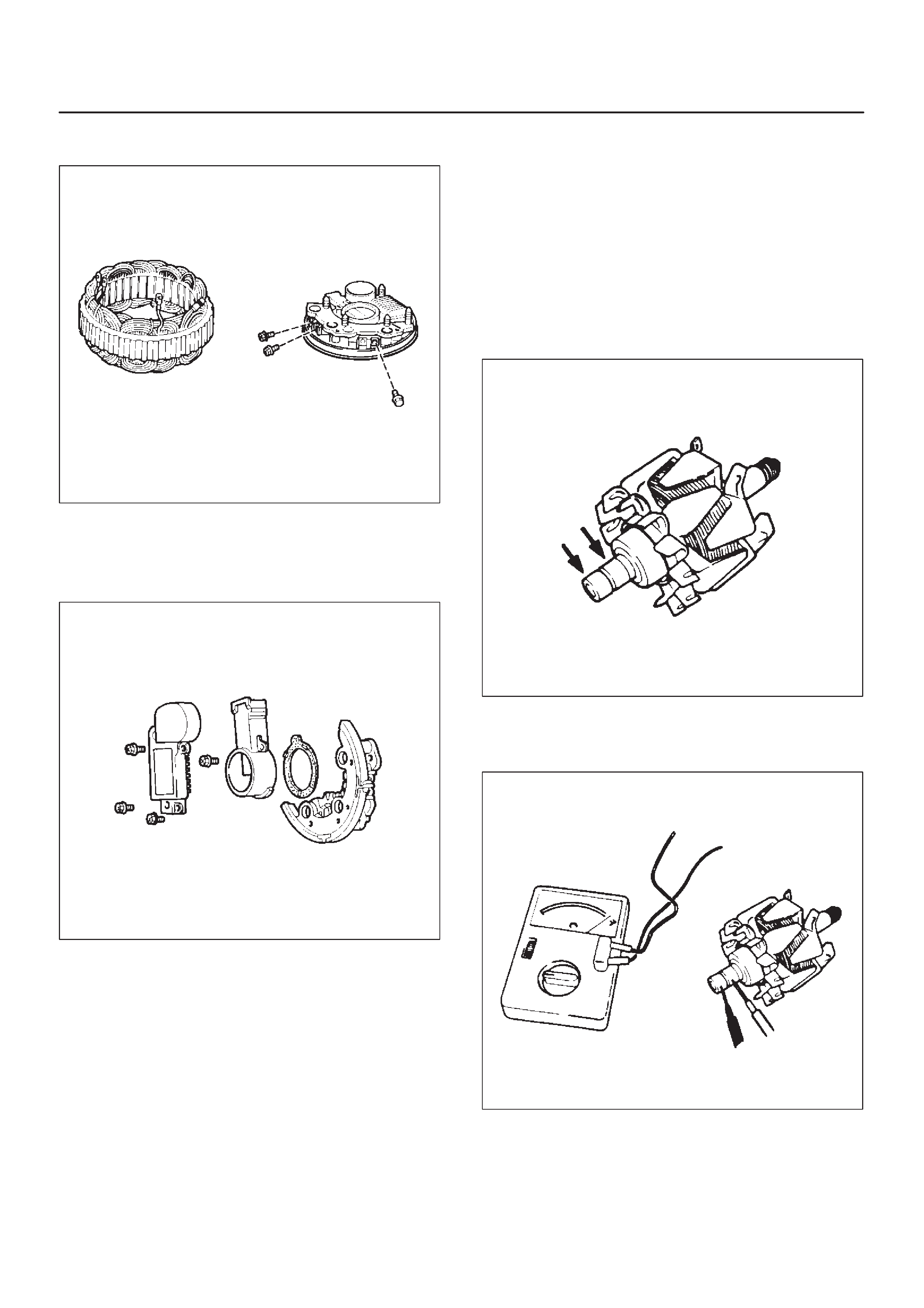

Brush

Measure the brush length.

If more than limit, replace the brush.

Standard: 18.0mm (0.709in)

Limit: 5.5mm (0.217in)

066RW024

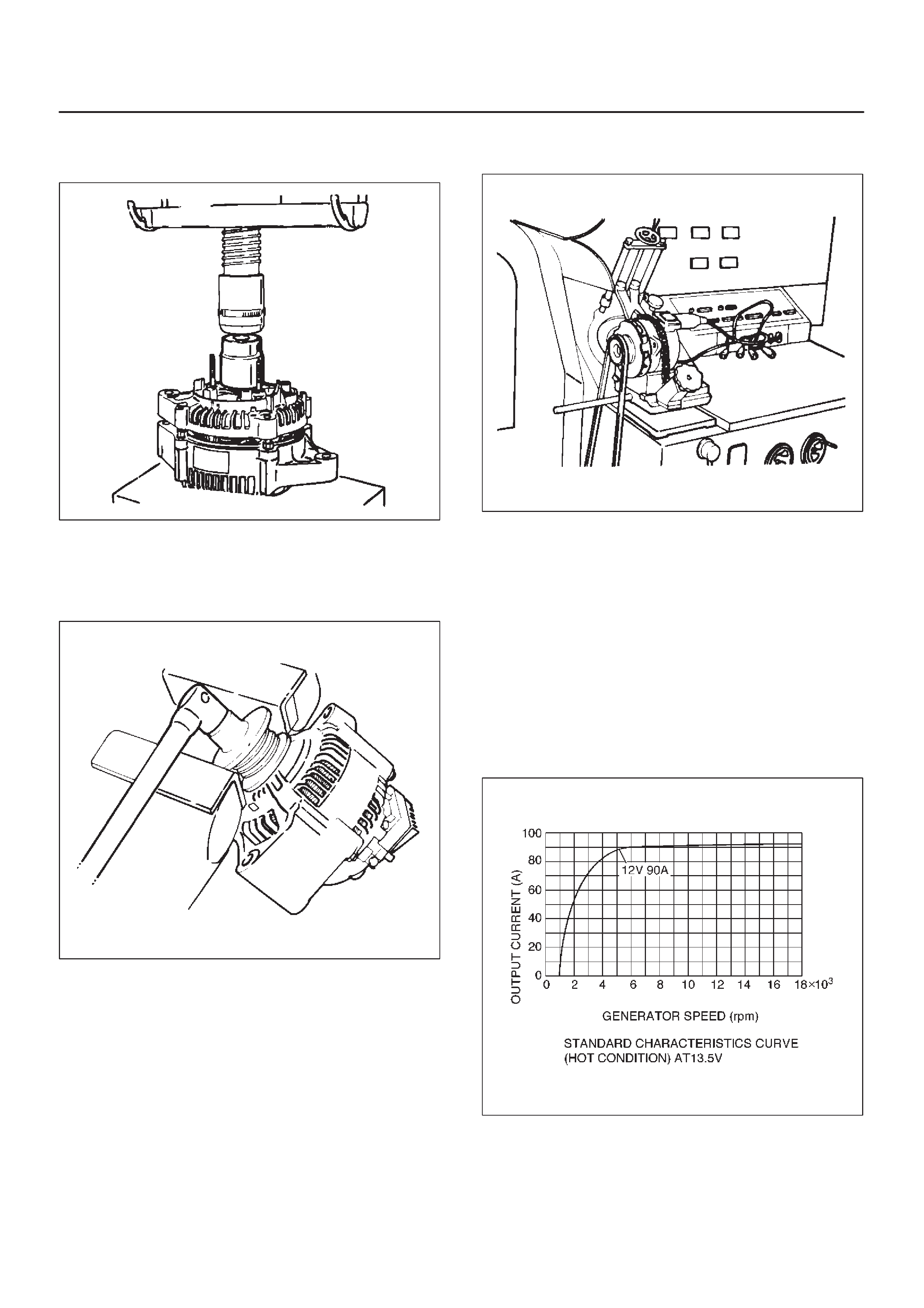

Rectifier Assembly

1.Measure the resistance between each diode terminal

and aluminum diode fin in forward and reverse

directions with the connection of the tester leads

switched. The diodes are normal if resistance is

nearly zero ohms in one direction and is infinitely high

in the other direction.

2.If a diode has no resistance or equal resistance in

both directions, it is defective and should be replaced

together with the holder.

066RS036

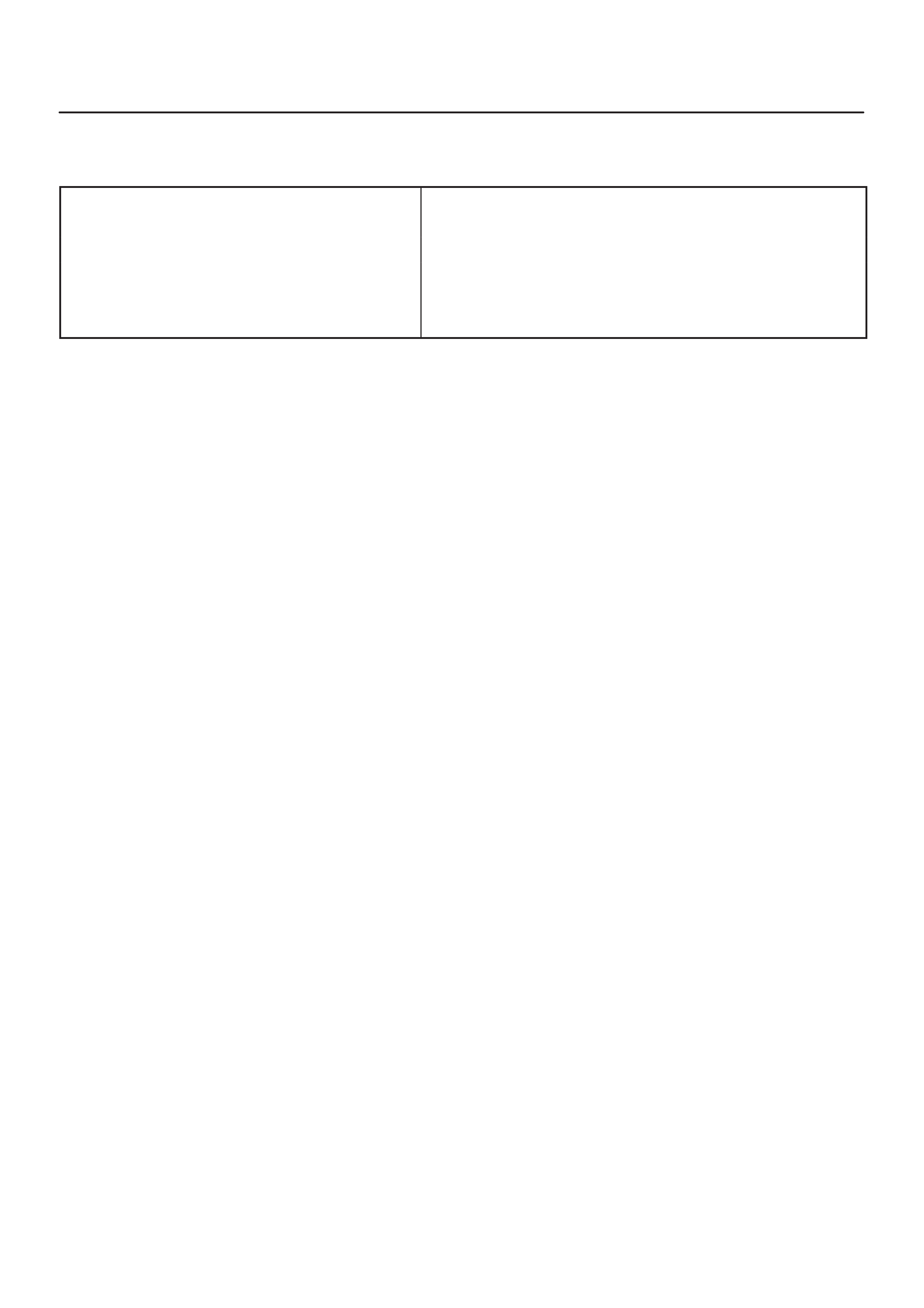

IC Regulator Assembly

Connect a variable resistor, two 12V batteries, a fixed

resistor, and a voltmeter to the IC regulator as shown in

illustration.

a. Measuring equipment specifications

1. Fixed resistor (R1) : 10 Ohms /3W

2. Variable resistor (Rv) : 0-300 Ohms/12W

3. Batteries (BAT1, BAT2) : 12V (2 Batteries)

4. DC voltmeter : 0-50V/0.5 steps (4 Check points)

b. Measuring procedure

1. Measure the voltage “V1” across the first battery

(BAT1). If the reading is between 10 and 13 volts,

the battery is normal.

2. Measure the voltage “V3” across both the batteries

(BAT1, BAT2). If the reading is between 20 and 26

bolts, the batteries are normal.

3. Gradually increase the resistance of the variable

resistor from zero. Measure the voltage “V2” (the

voltage across the F and E terminals).

Check to see that the voltage across “V1” changes at

this time. If there is no change, the voltage regulator

is faulty and must be replaced.

4. Measure the voltage at “V4” (the voltage across the

variable resistor center tap and terminal E with the

variable resistor resistance held constant). The

measure voltage should be within the specified

(14.4±0.3 volts) limits. If it is not, the regulator must

be replaced.

066RX003

Reassembly

To reassemble, follow the disassembly steps in the

reverse order, noting the following points:

NOTE:

DNever make battery connections with polarities

reversed, or battery will be shorted via the diodes.

This will cause damage to the diodes.

DDo not connect generator B terminal to ground; it is

connected directly to the battery.

This cable will burn if it is connected to ground.

DMake sure to disconnect the positive (+) terminal of

the battery when quick-charging battery .

Diodes may be damaged due to abnormal pulse

voltage generated bye the quick charger.

DWhen reassembling the front section to rear section,

insert a stiff wire into hole in the rear face of the rear

cover from the outboard side to support the brush in

raised position, then insert the front section to which

rotor is assembled.

DReassemble parts carefully to be sure they fit into

their original position, paying attention to the

insulated portions.

DWipe insulating tubes, washers and plates clean and

install them in position carefully to avoid getting oil or

grease on them.

1.Using a press with a socket wrench attached,

reassemble rotor and rear end cover assembly in the

front cover.

066RS022

2.Install pulley on the rotor.

Secure the pulley directly in the vise between two

copper plates, and tighten nut to the specified torque.

Torque: 111 N·m (82 lb ft)

066RS010

Bench Test

Conduct a bench test of the generator.

066RS023

Preparation

Remove generator from the vehicle (see “Generator

removal”).

1.Secure generator to the bench test equipment and

connect wires.

Terminal “IG” for energization

Terminal “L” for neutral (warning lamp)

Terminal “B” for output

2.Conduct the generator characteristic test.

Characteristics of generator are shown in illustration.

Repair or replace the generator if its outputs are

abnormal.

066RX001

Main Data and Specifications

General Specifications

Battery voltage V 12

Rated output A90

Direction of rotation

(as viewed from pulley side) Clockwise

Rated rotation speed rpm 5000

Maximum speed rpm 18000