SECTION 8D - WIRING SYSTEM

Service Precaution

General Description

Main Data and Specifications

Fuse, Fusible Link and Circuit Breaker

Location

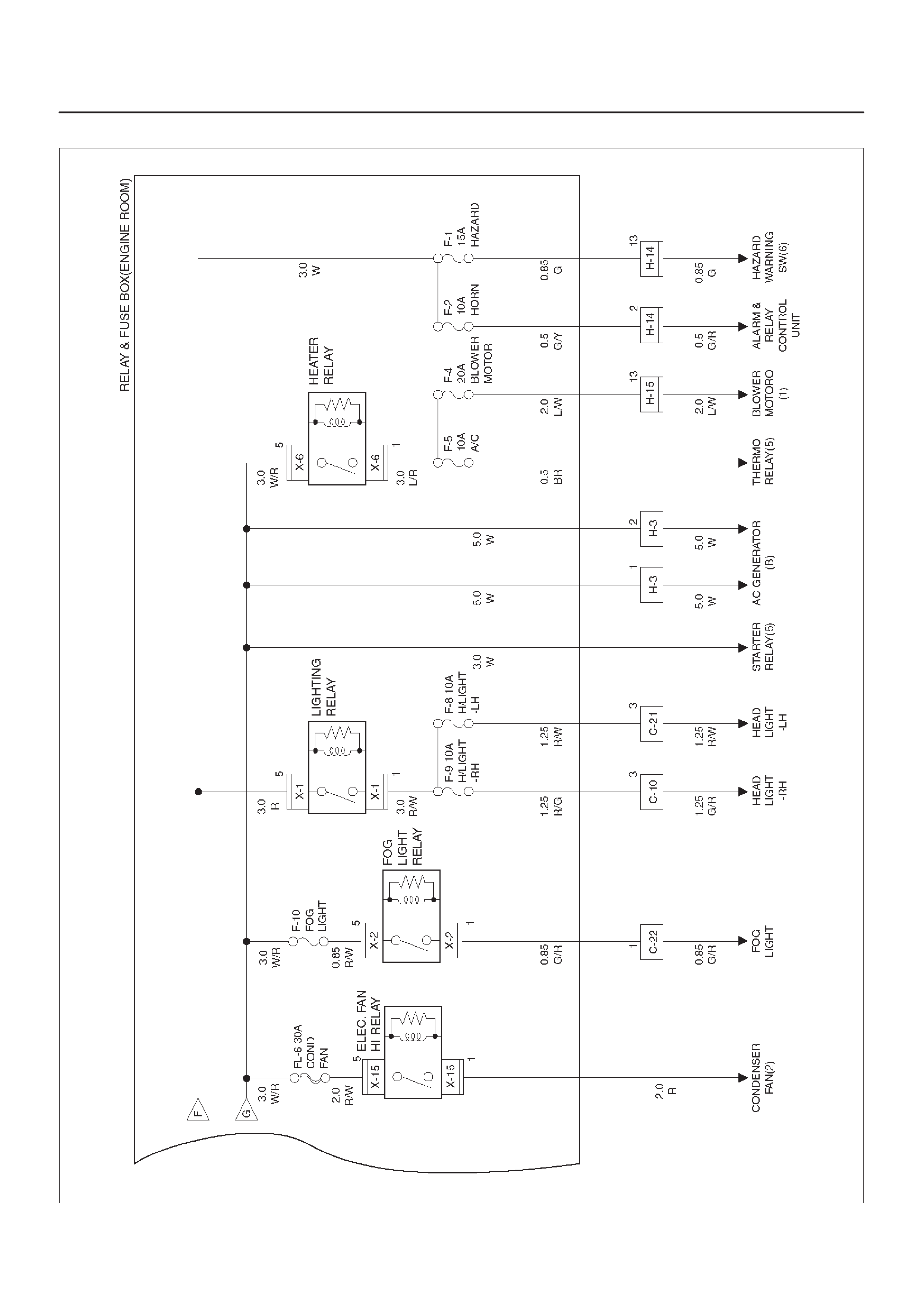

Relay & Fuse Box (Engine Room)

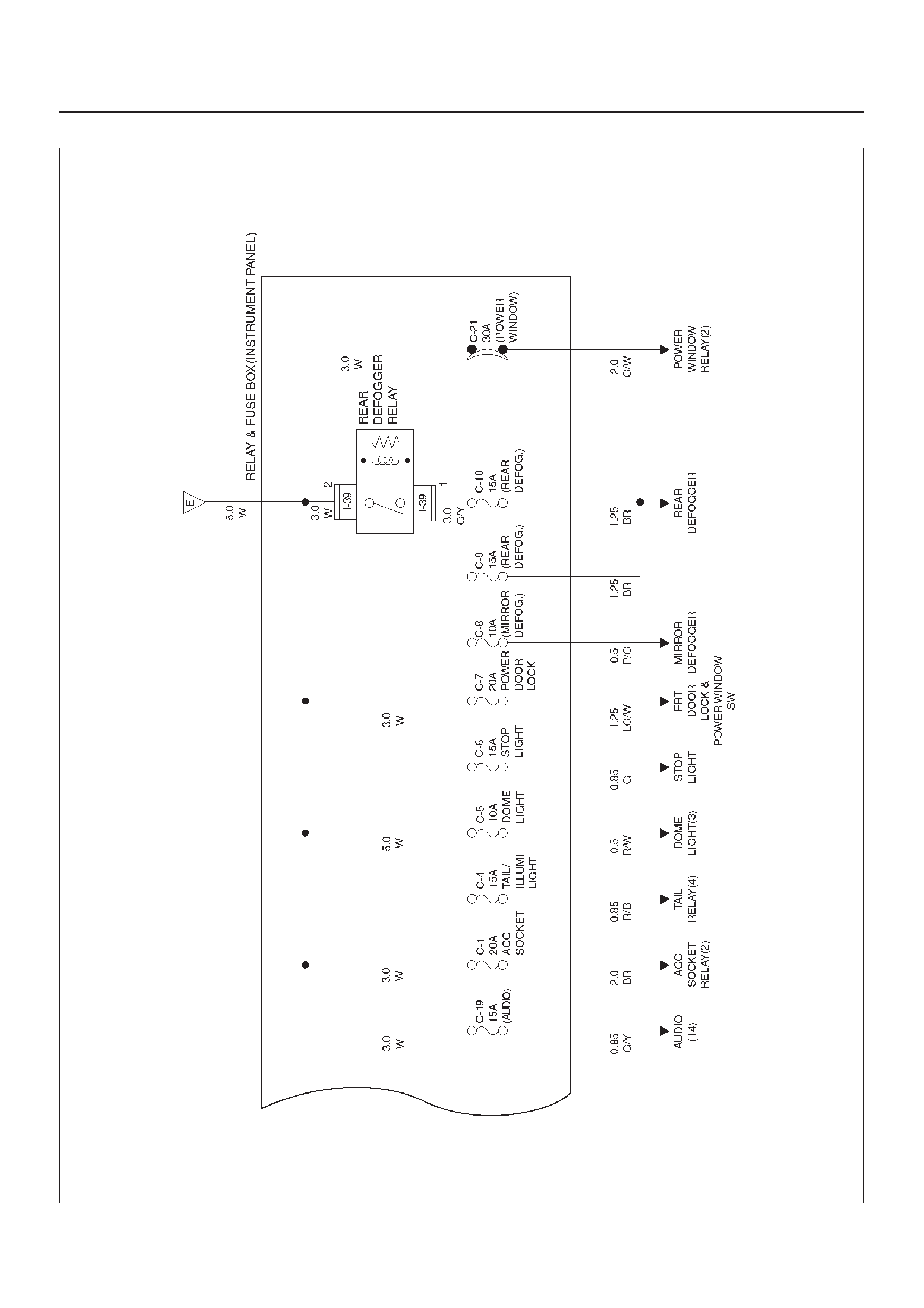

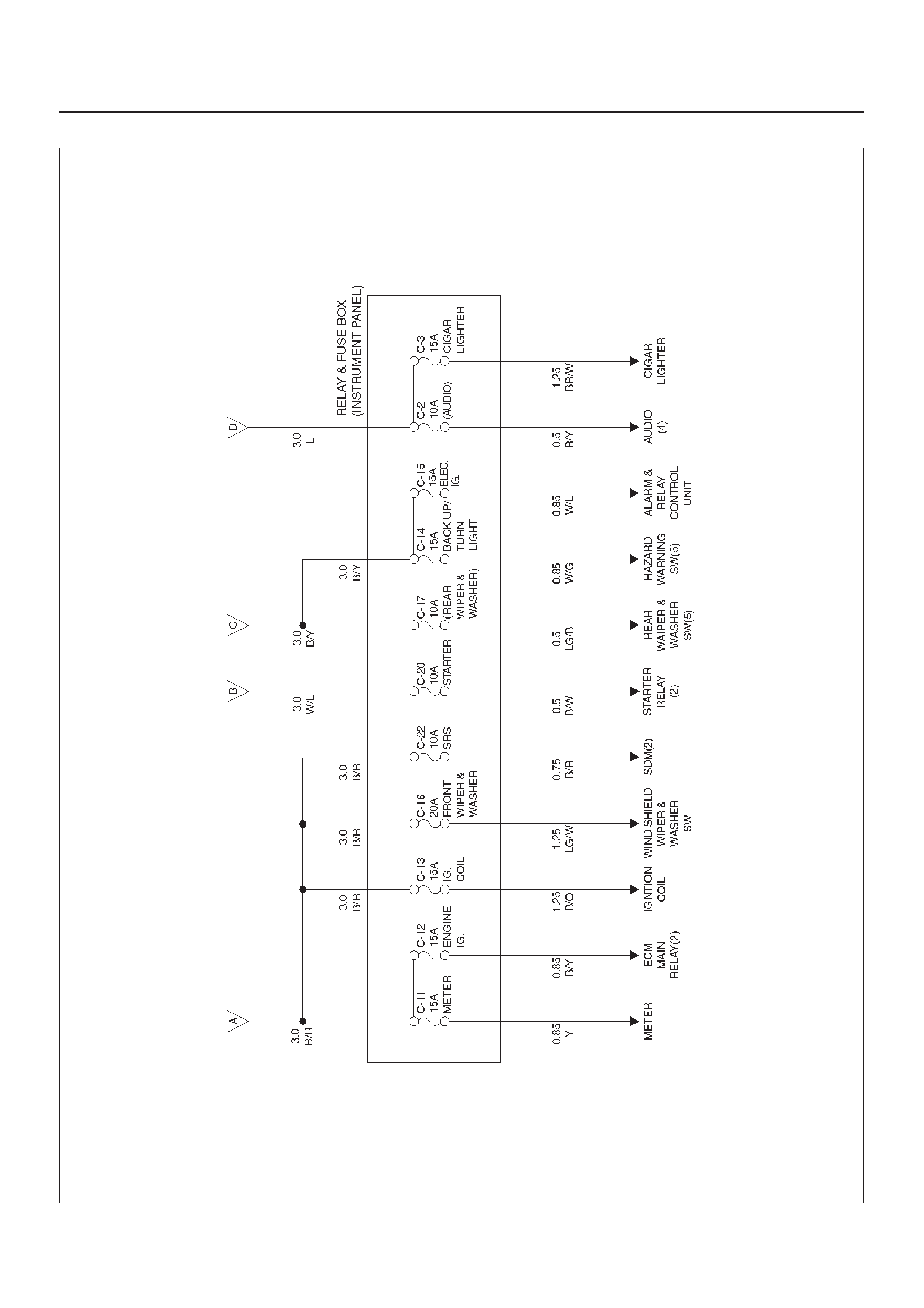

Relay & Fuse Box (Instrument panel)

Fuse Block Circuit

Reference Table of Fuse, Fusible Link and

Circuit Breaker

Relay Location

Diode Location

Grounding Point

Cable Harness Routing

Start and Charging

General Description

Circuit Diagram

Parts Location

Powertrain Control Module (PCM)

General Description

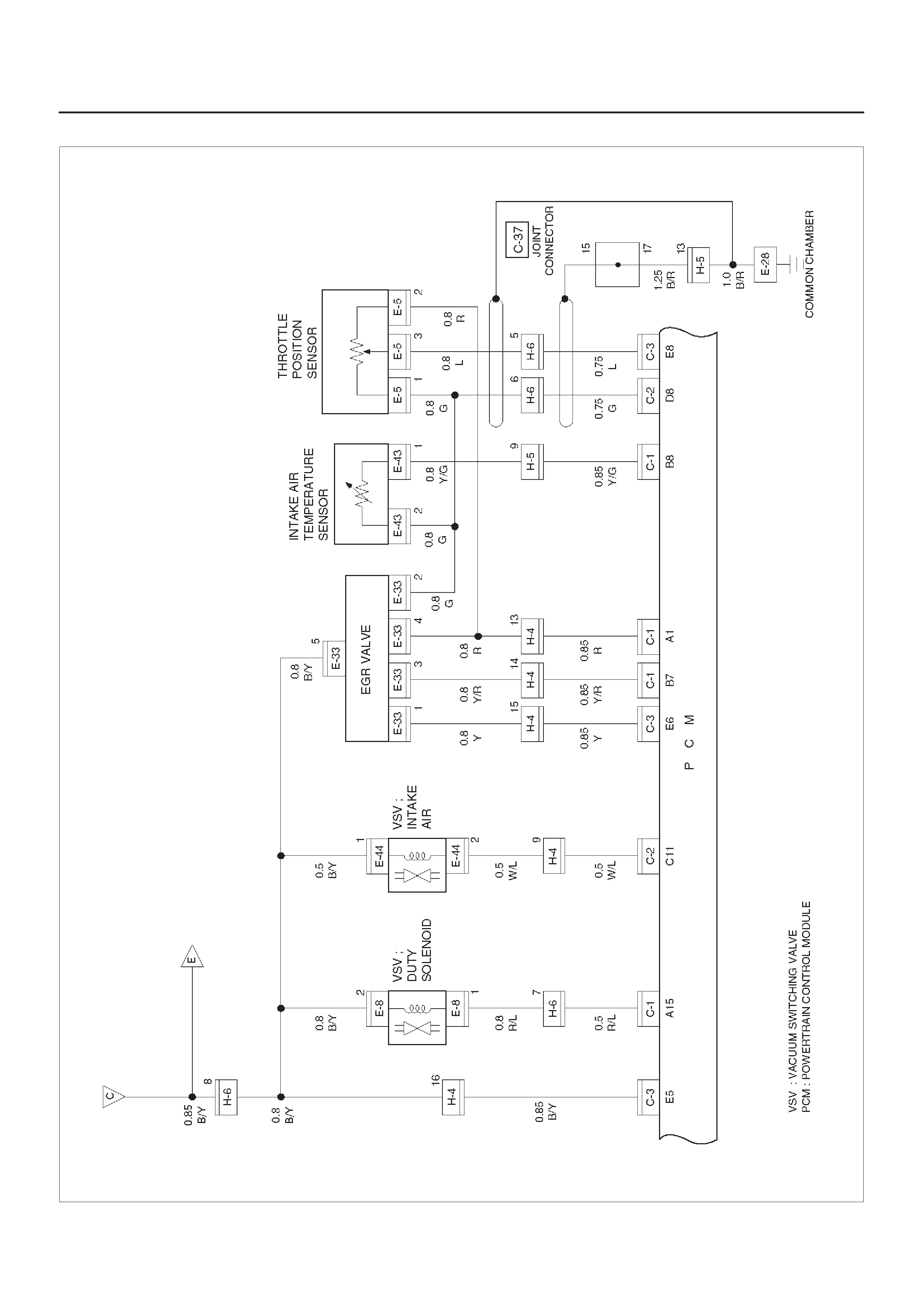

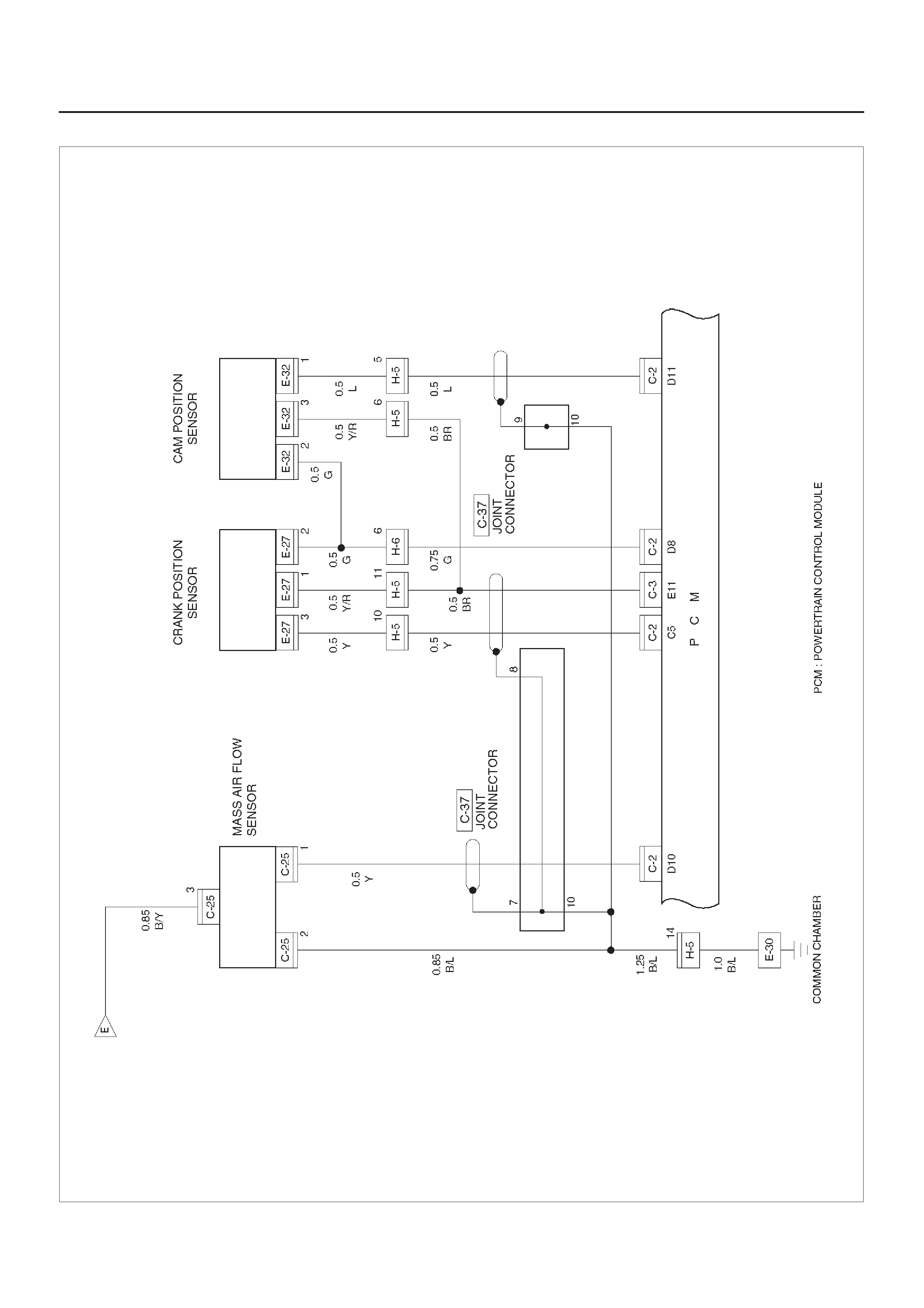

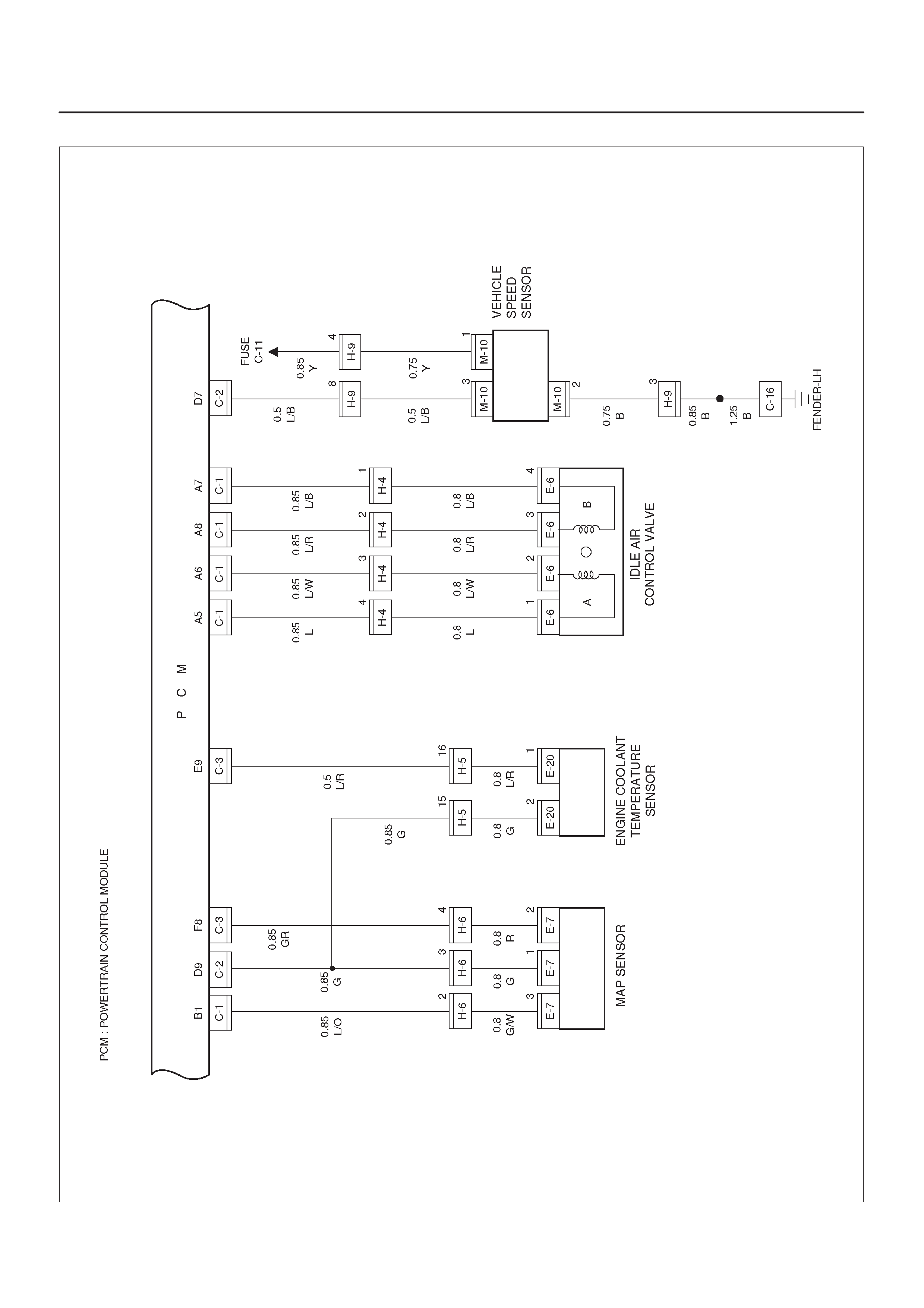

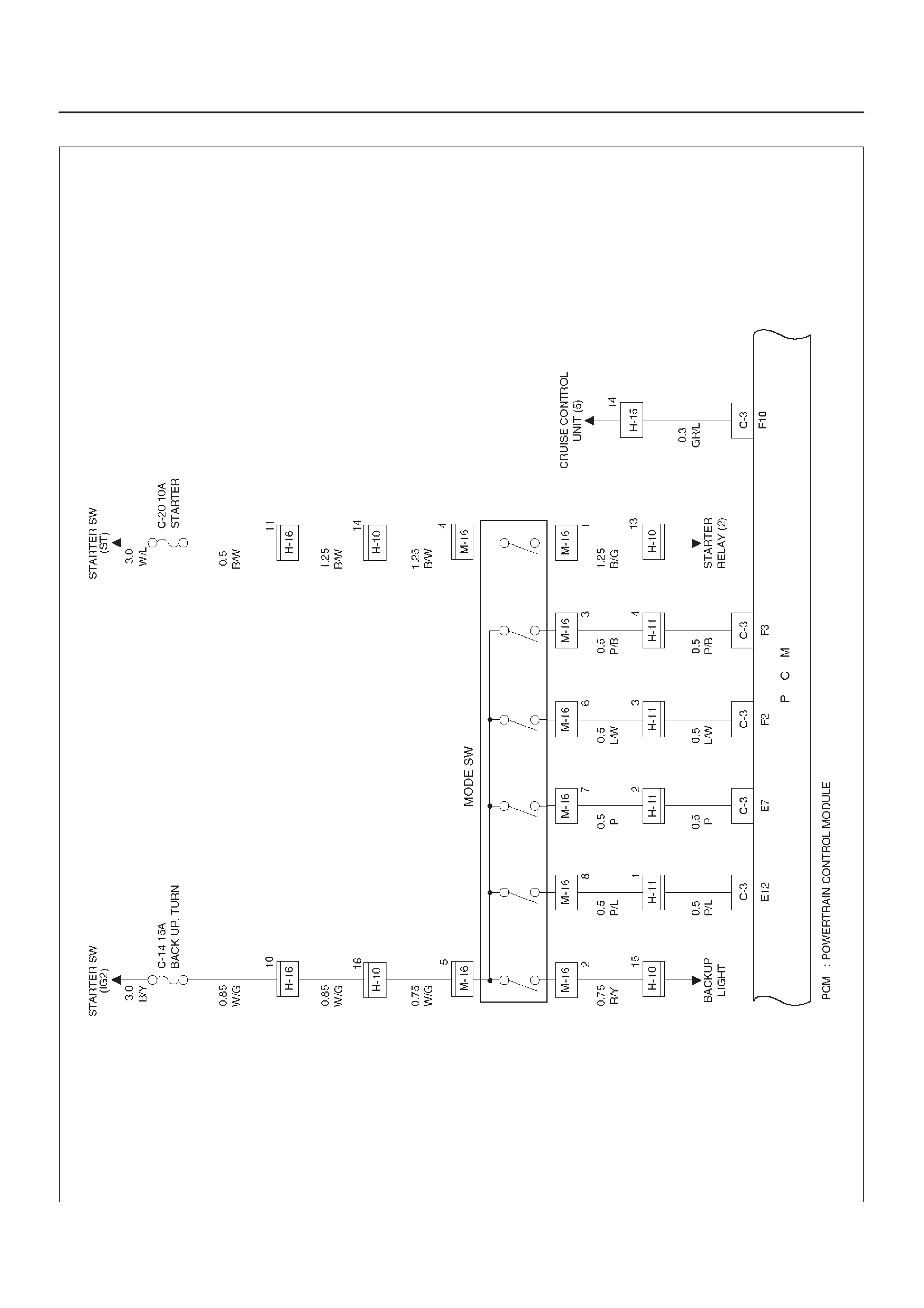

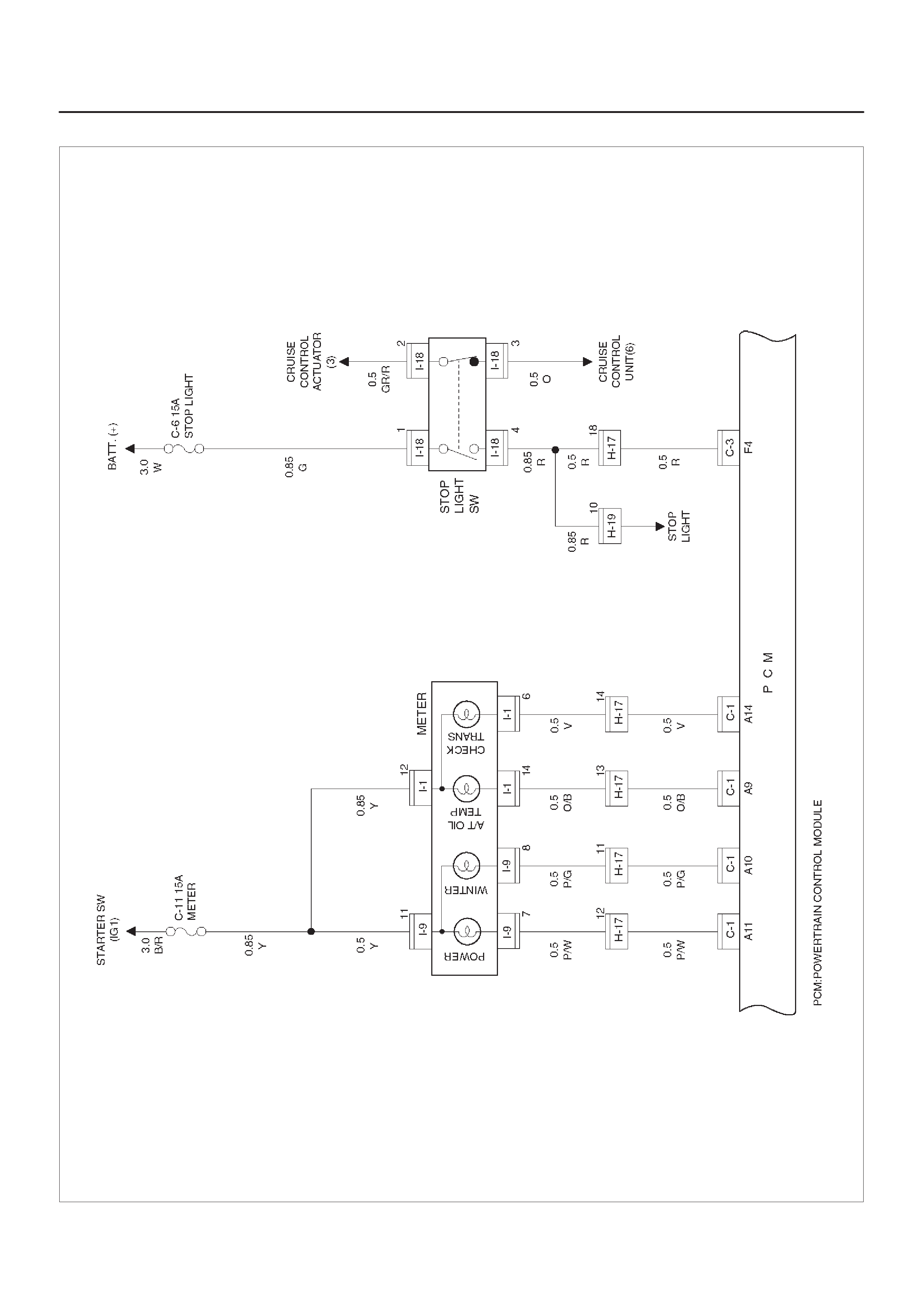

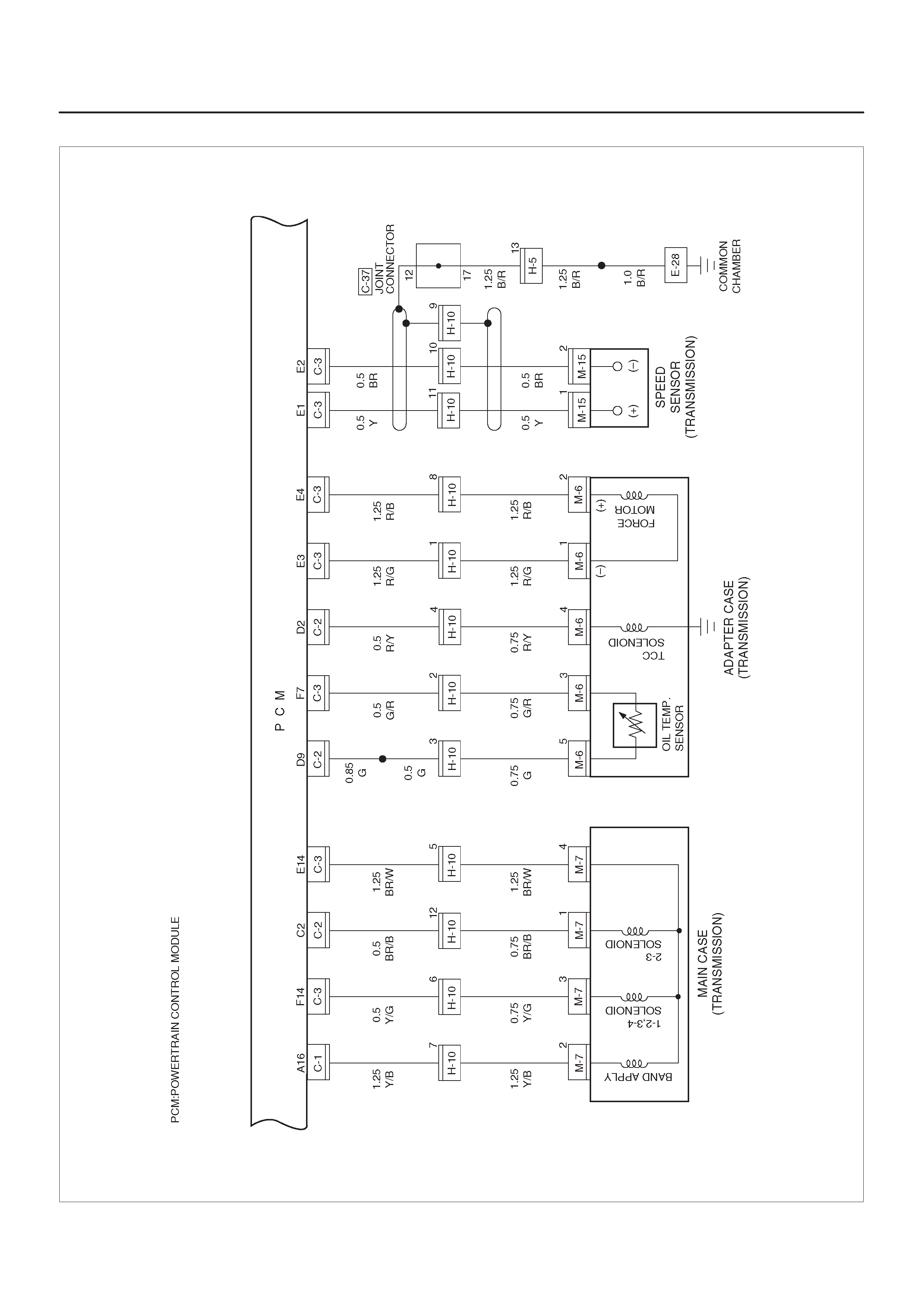

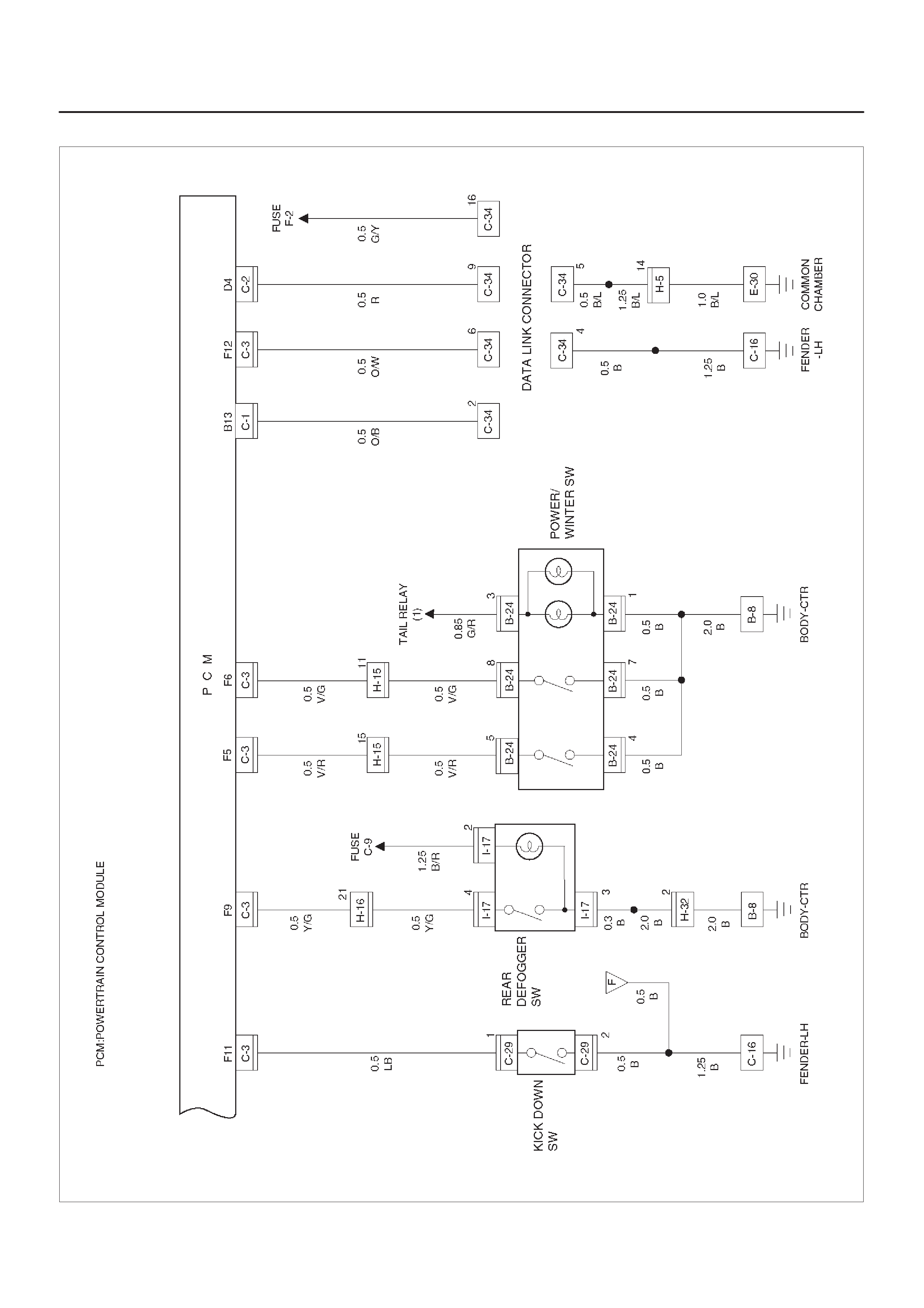

Circuit Diagram

Parts Location

Circuit Diagram

Parts Location

Headlight and Fog Light

General Description

Circuit Diagram

Parts Location

Diagnosis

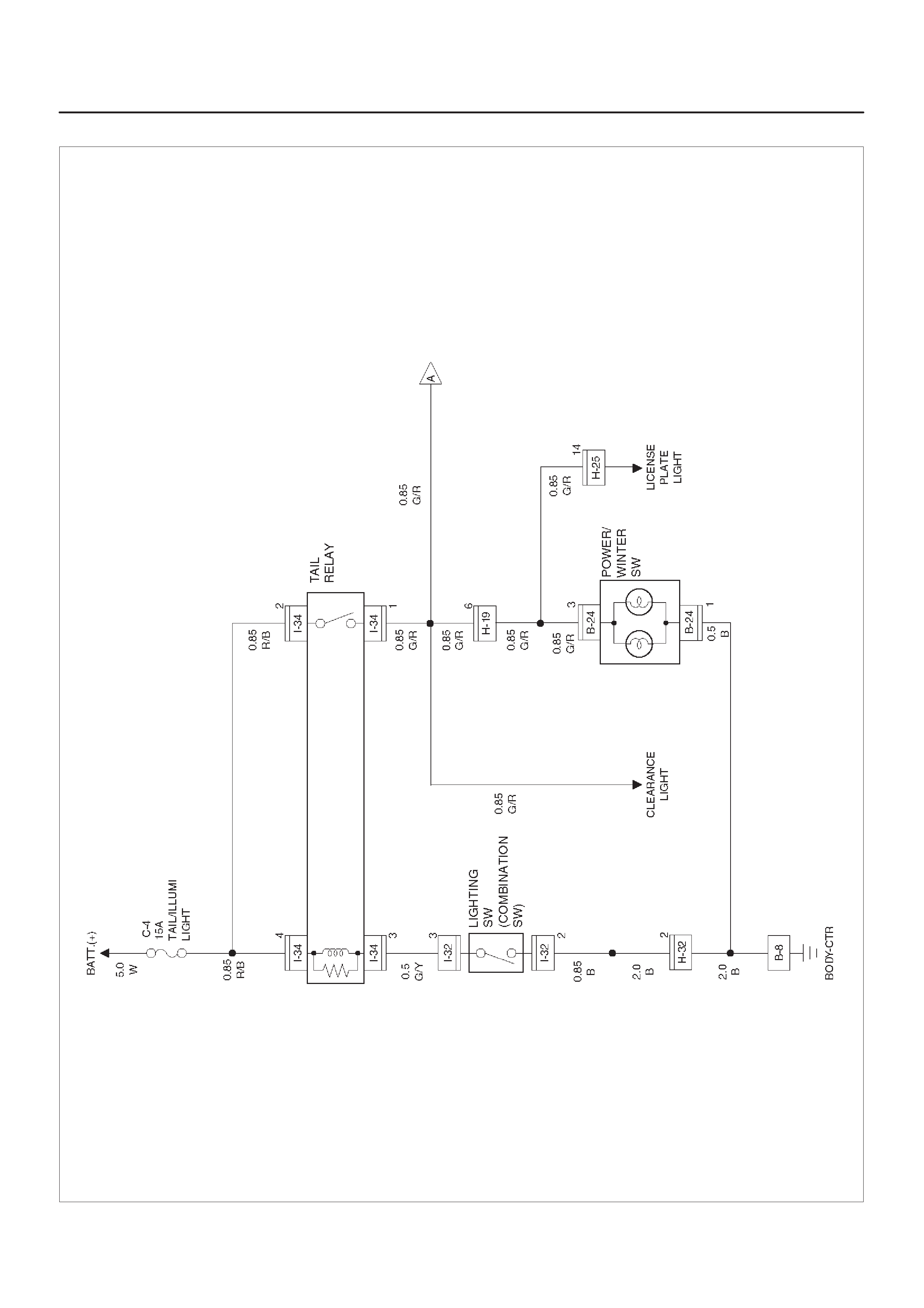

Clearance Light, Tail Light and License

Plate Light

General Description

Circuit Diagram

Parts Location

Diagnosis

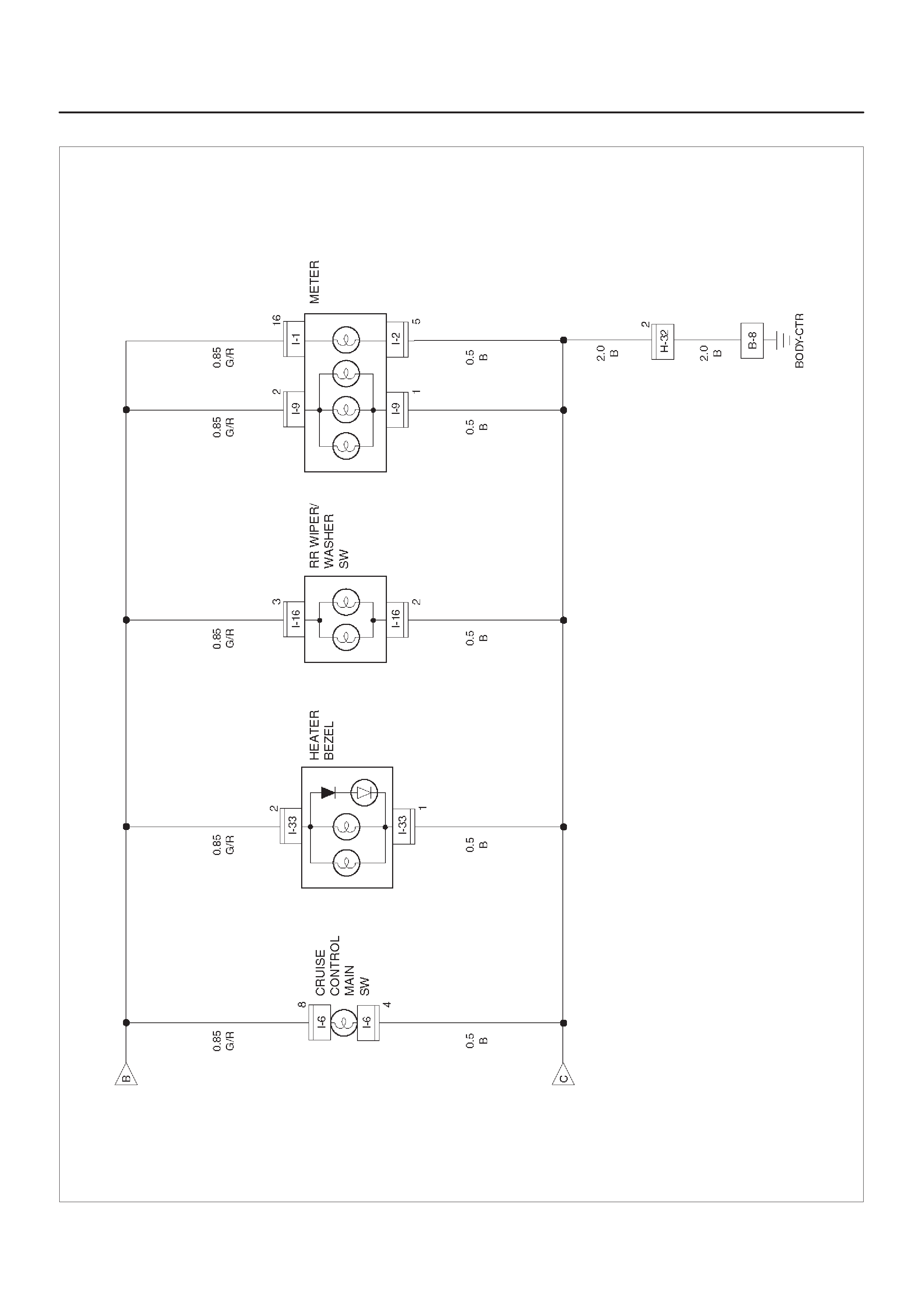

Interior Illumination Light

General Description

Circuit Diagram

Parts Location

Diagnosis

Turn Signal Light, Hazard Warning Light

General Description

Circuit Diagram

Parts Location

Diagnosis

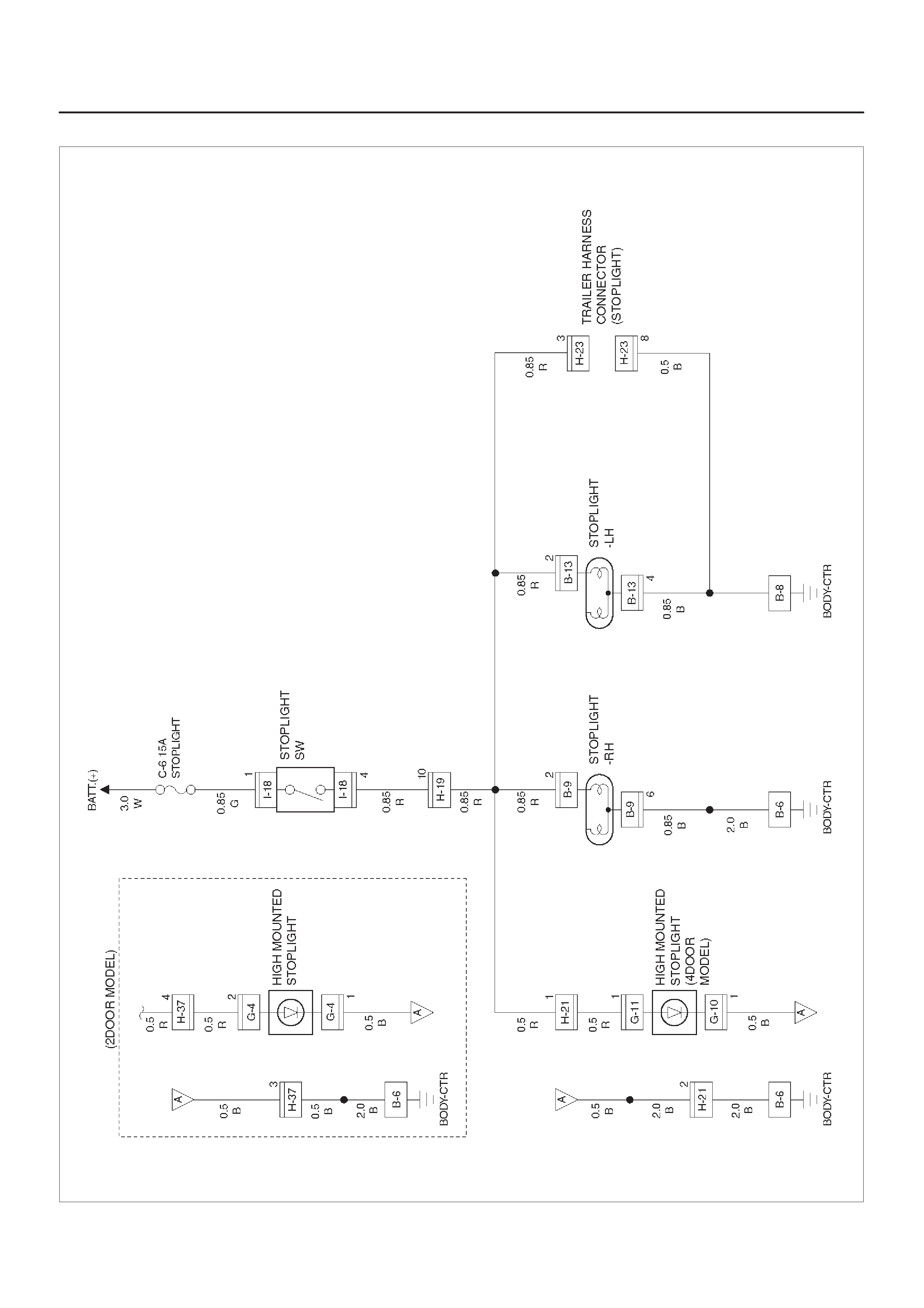

Stoplight

General Description

Circuit Diagram

Parts Location

Diagnosis

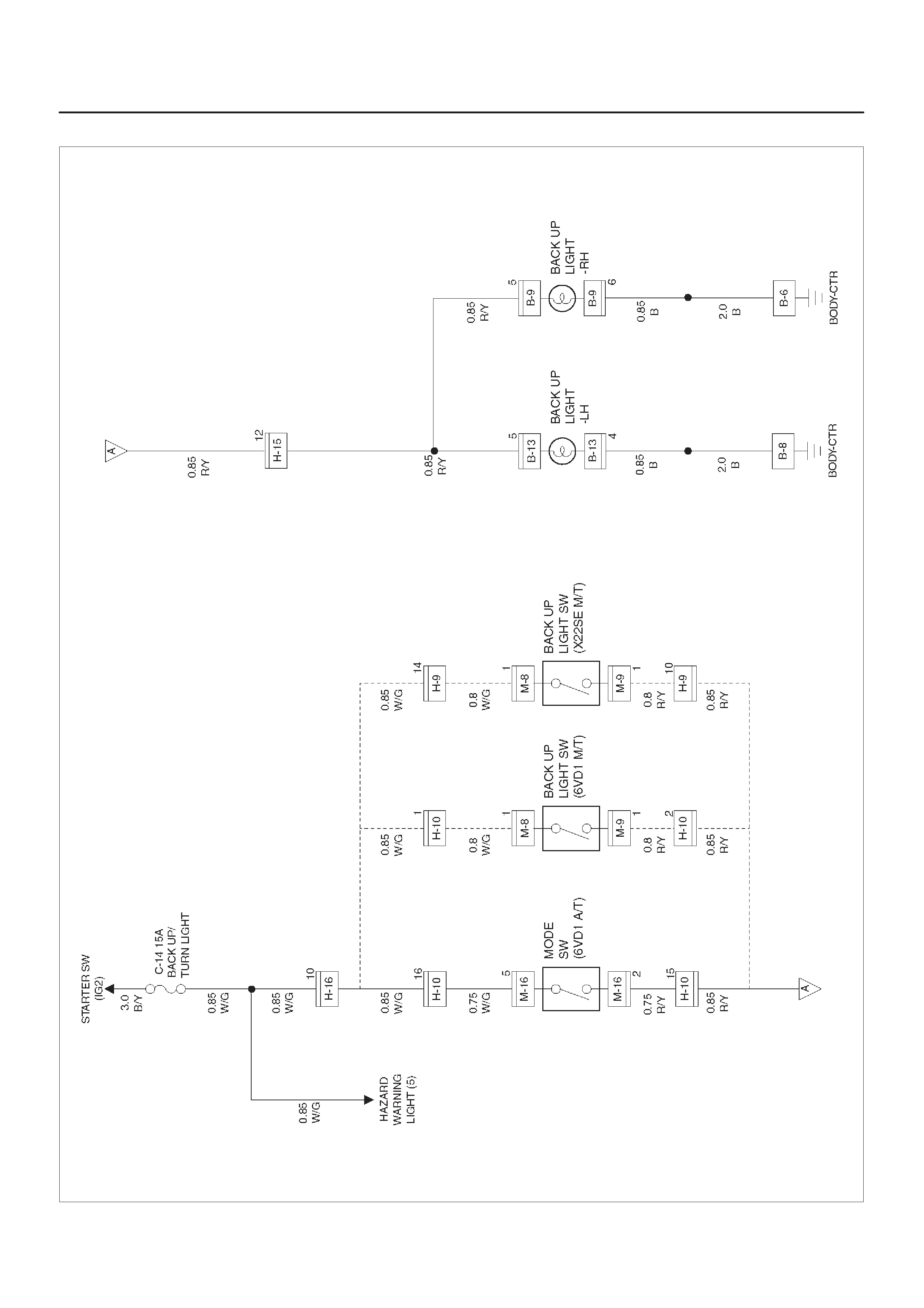

Backup Light

General Description

Circuit Diagram

Parts Location

Diagnosis

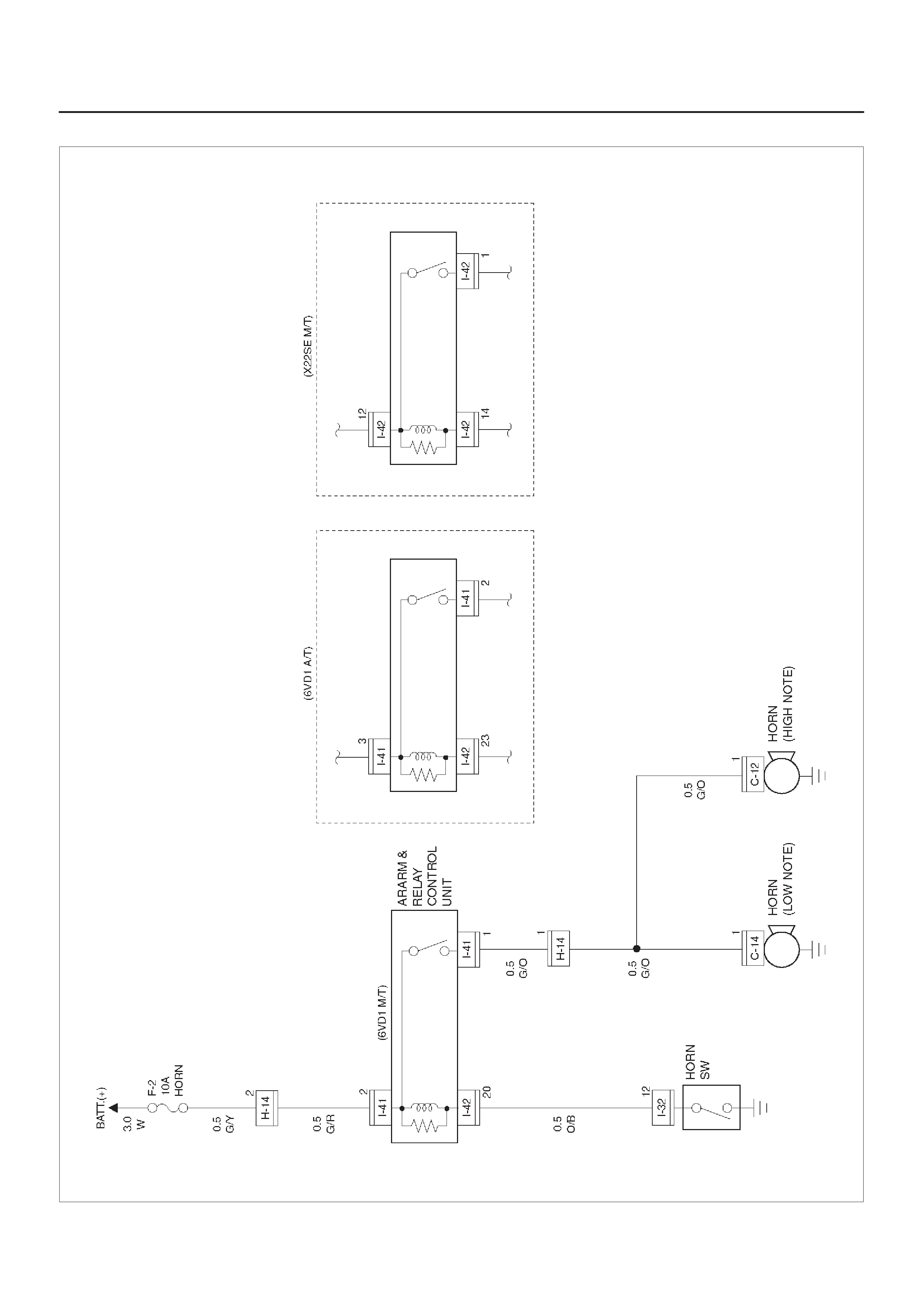

Horn

General Description

Circuit Diagram

Parts Location

Diagnosis

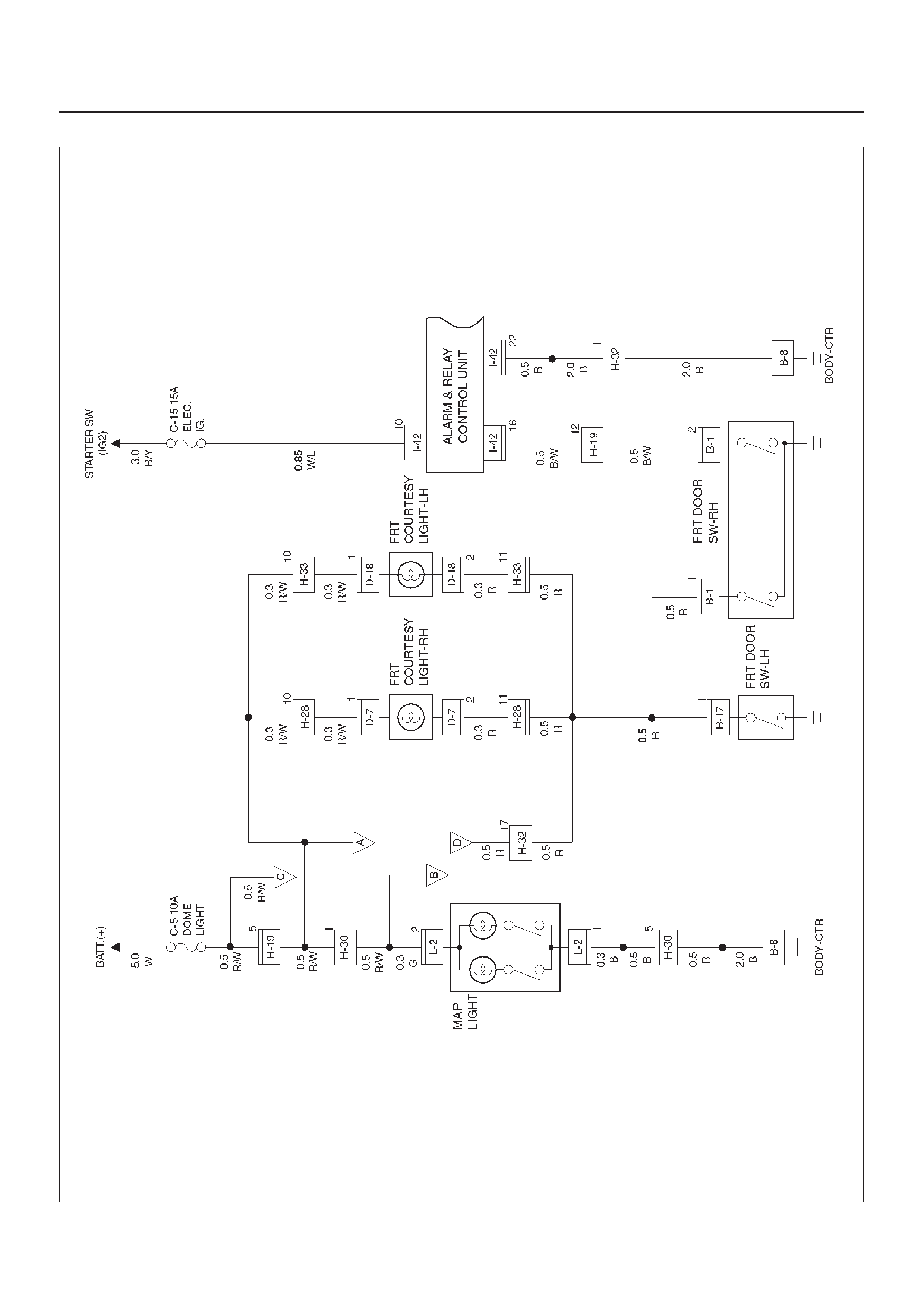

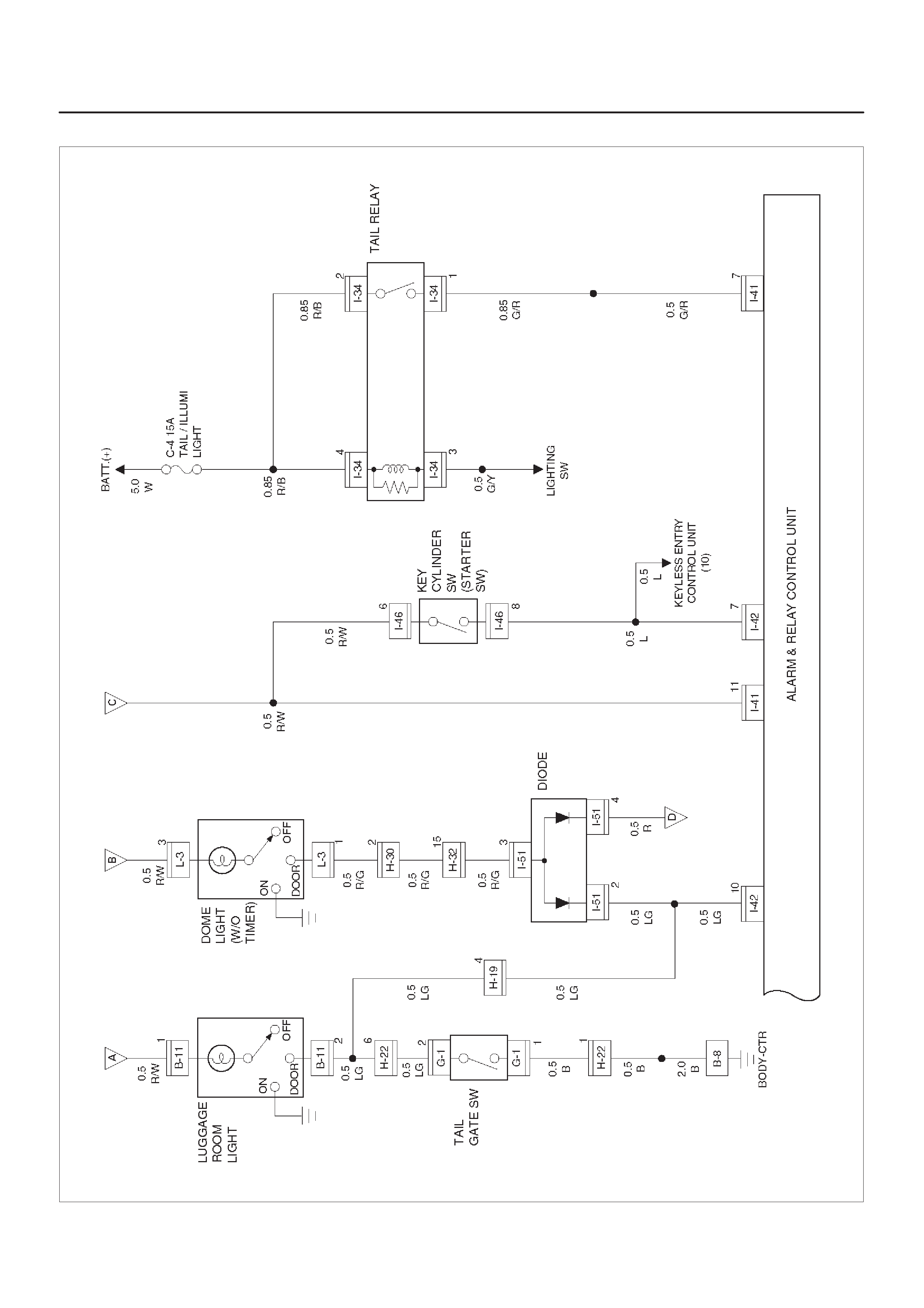

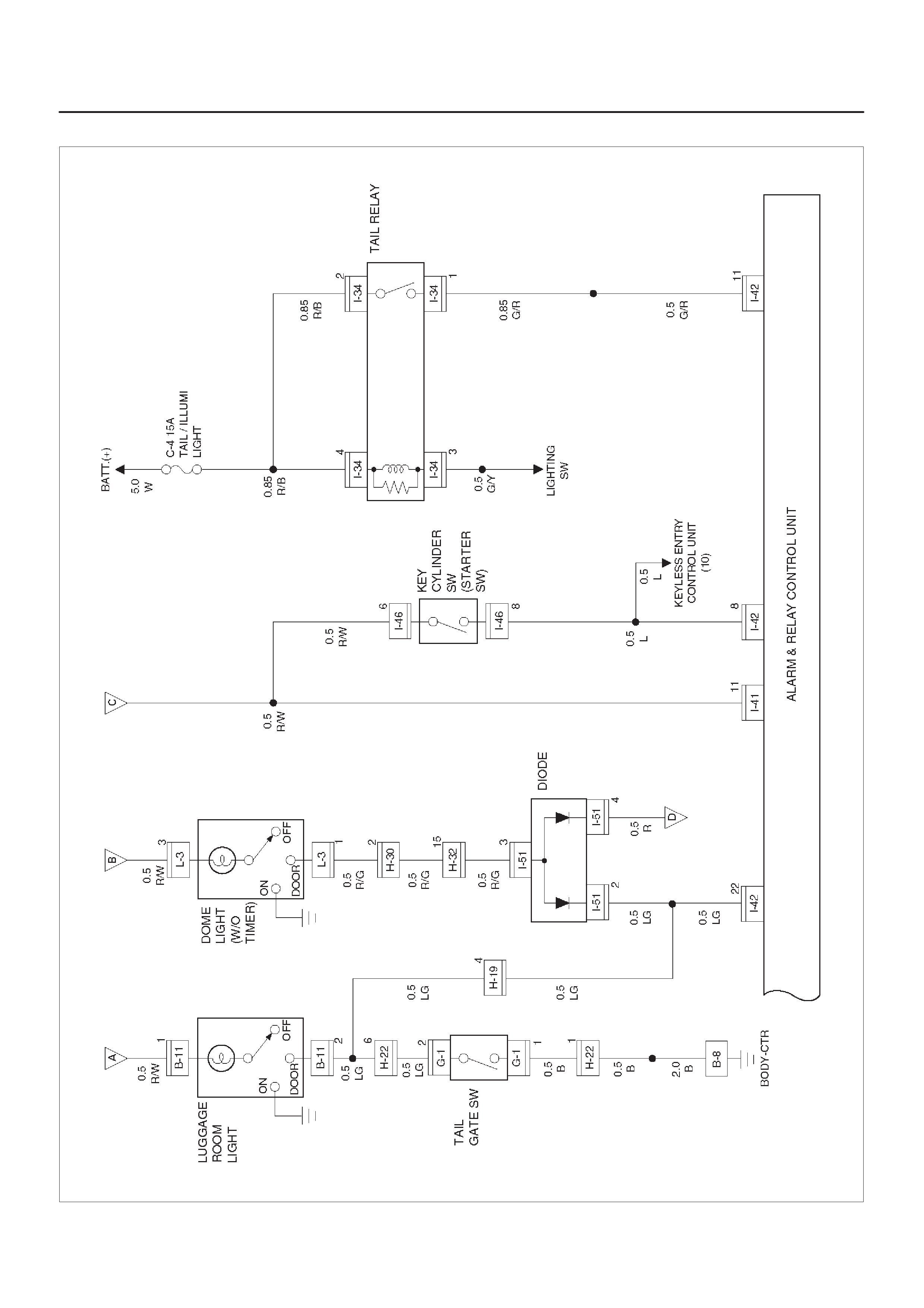

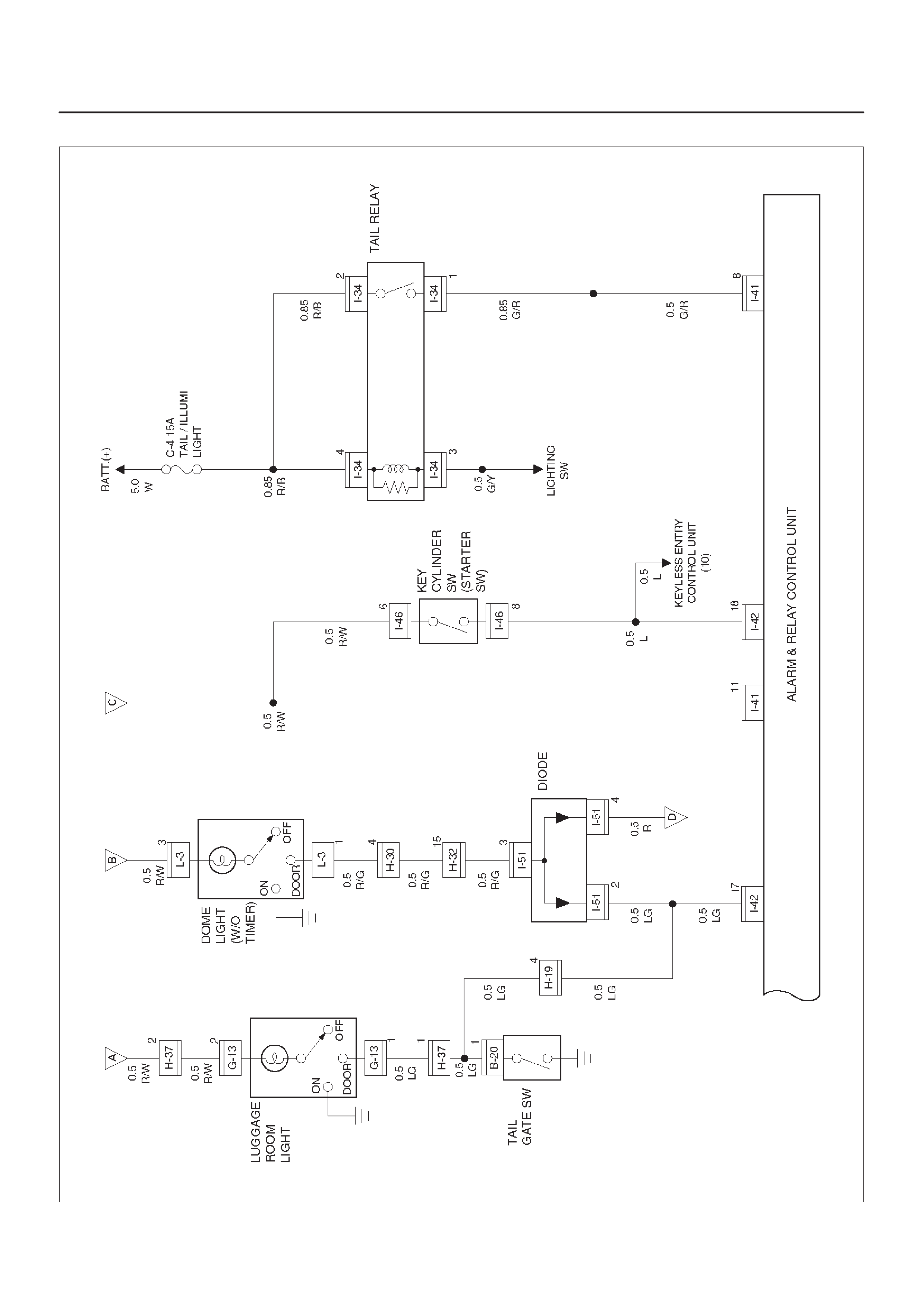

Dome Light, Luggage Room Light, Courtesy

Light, Map Light, Seat Belt Switch and

Warning Buzzer

General Description

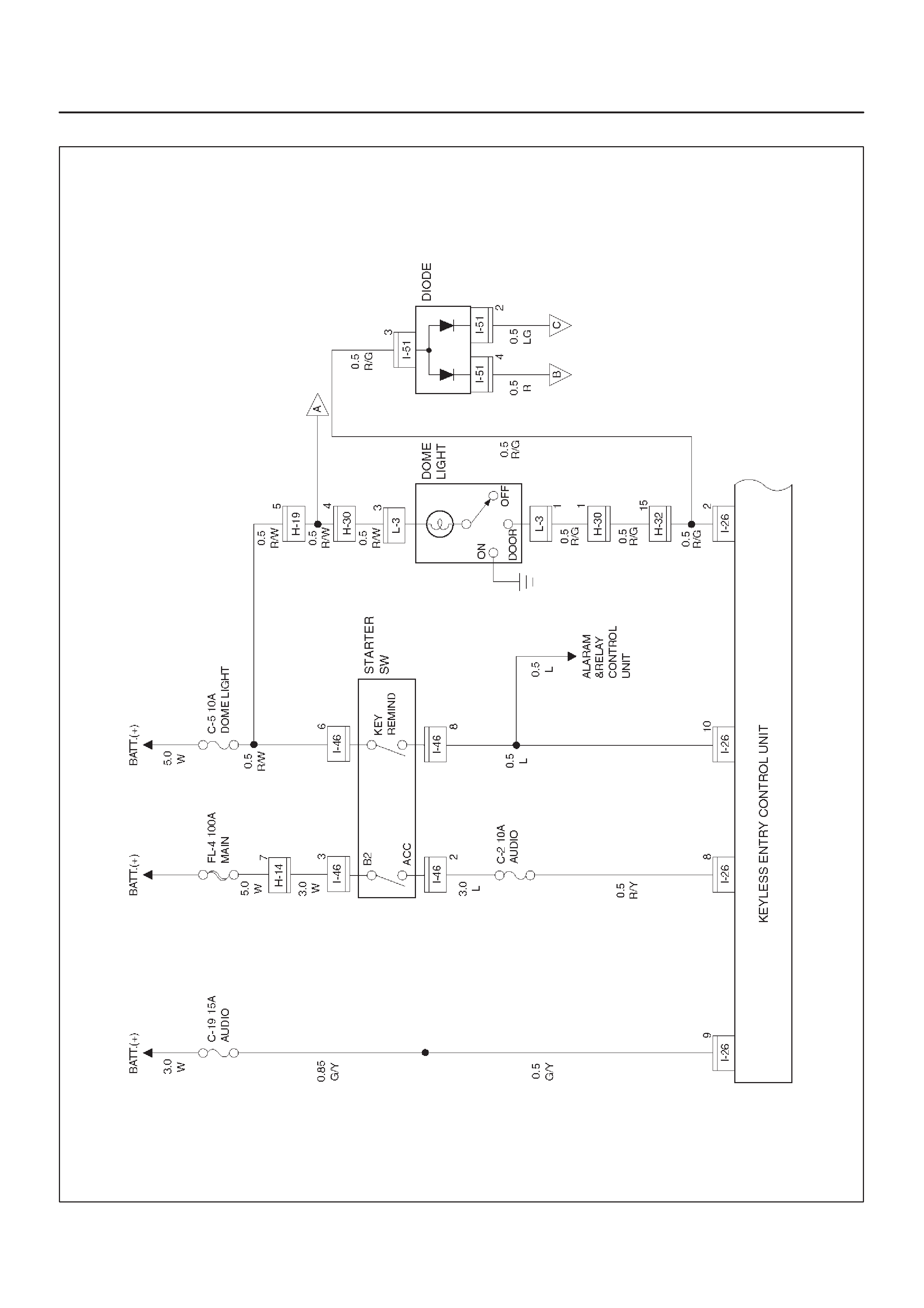

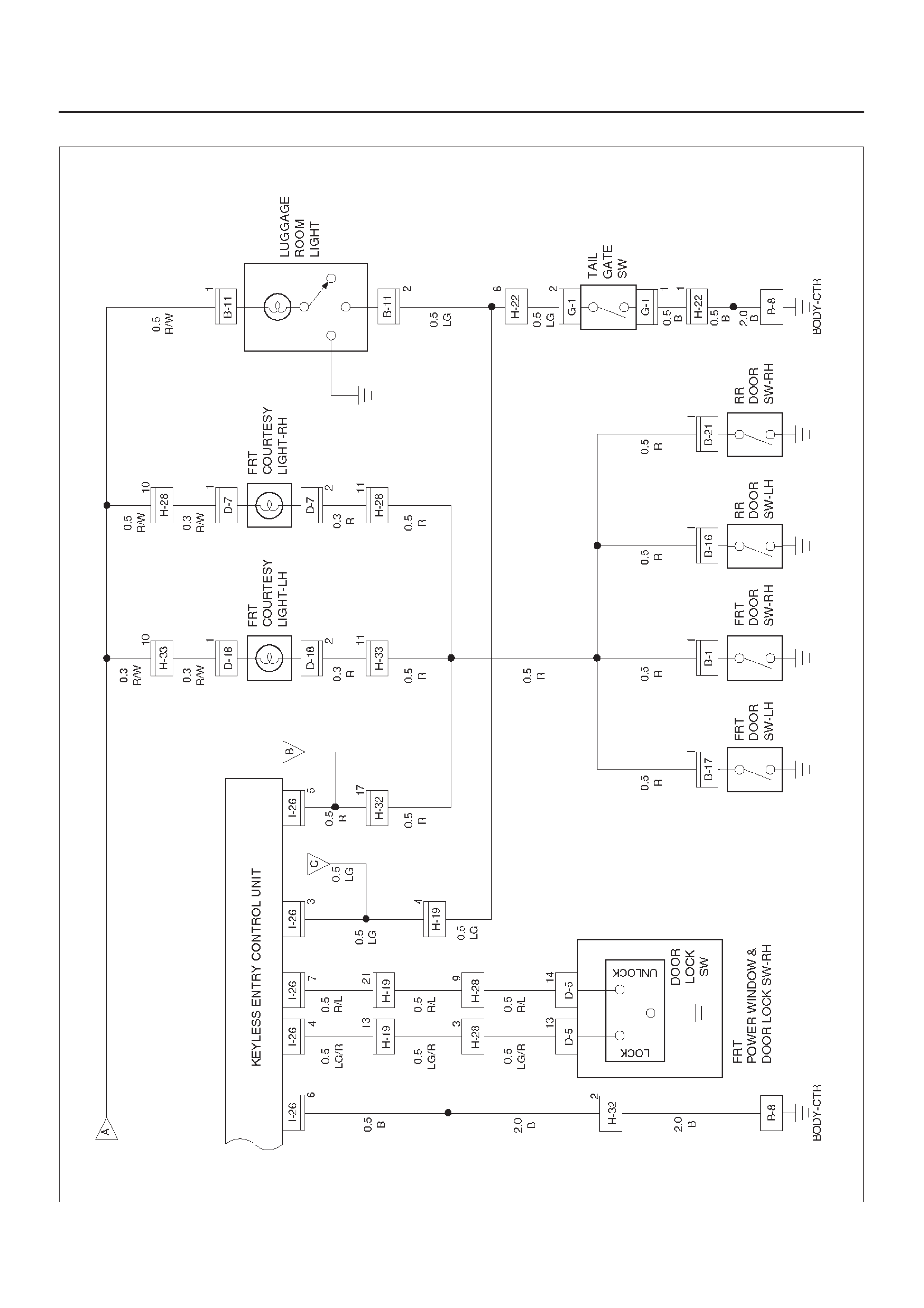

Circuit Diagram

Parts Location

Diagnosis

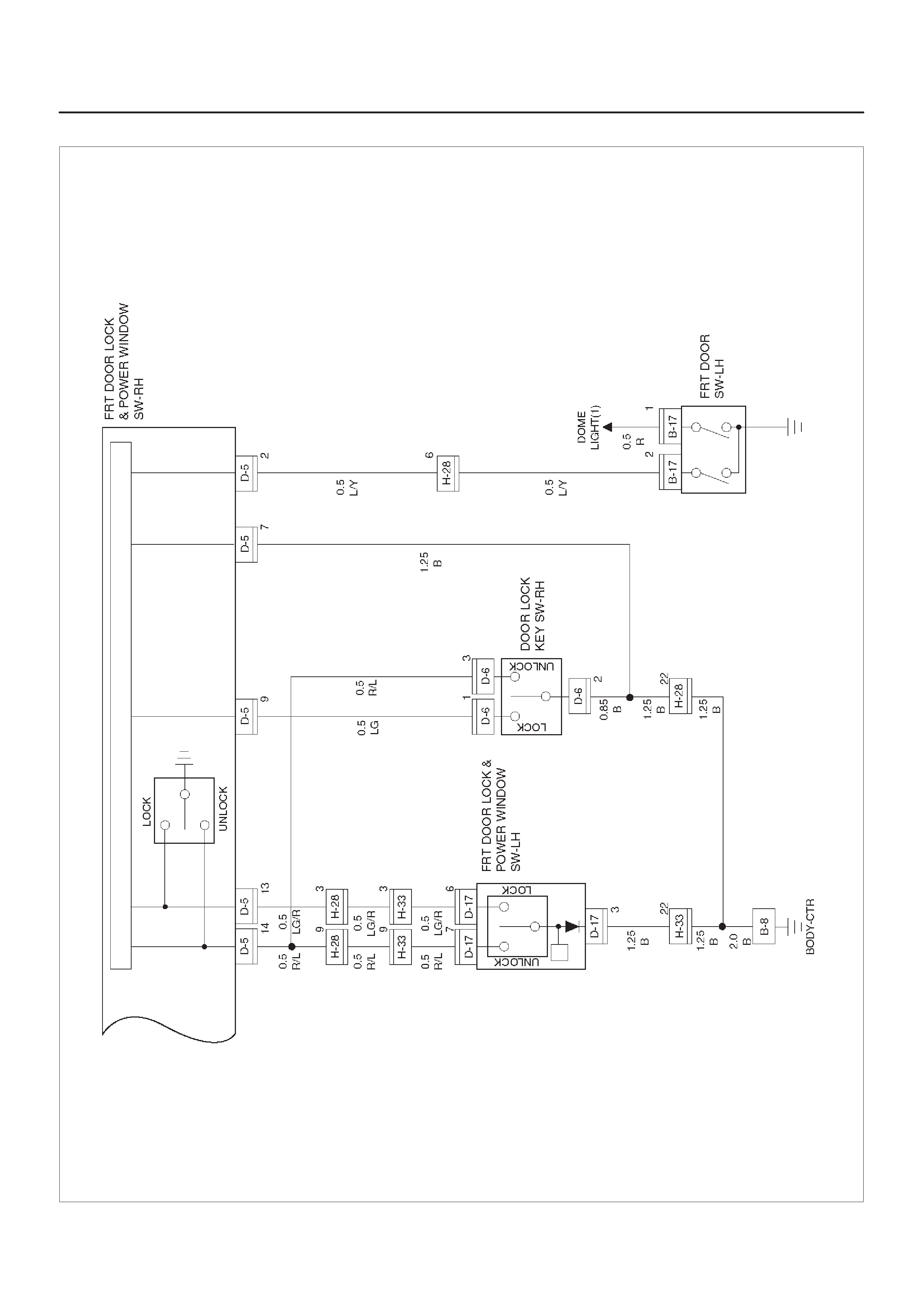

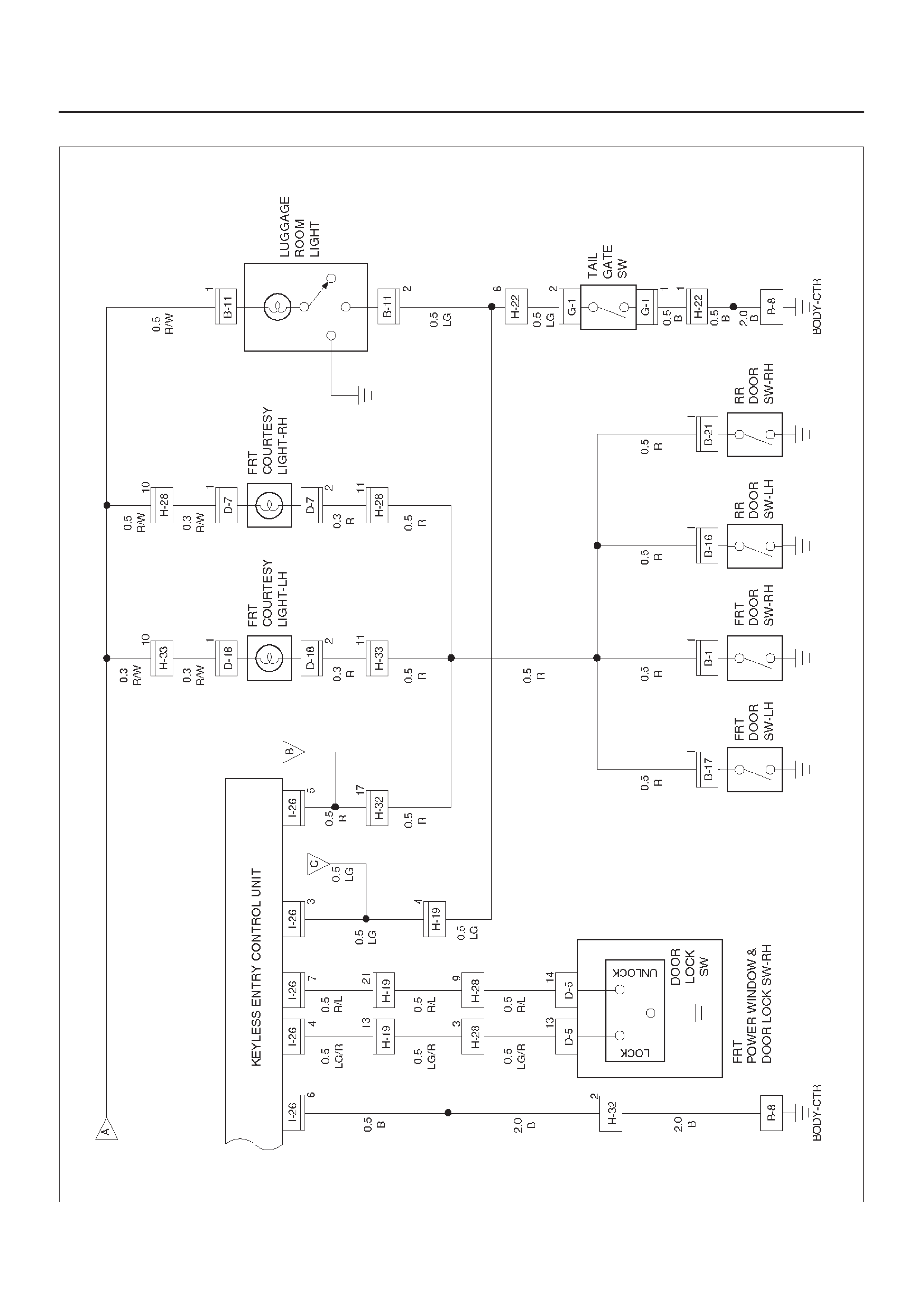

Power Door Lock

General Description

Circuit Diagram

Parts Location

Diagnosis

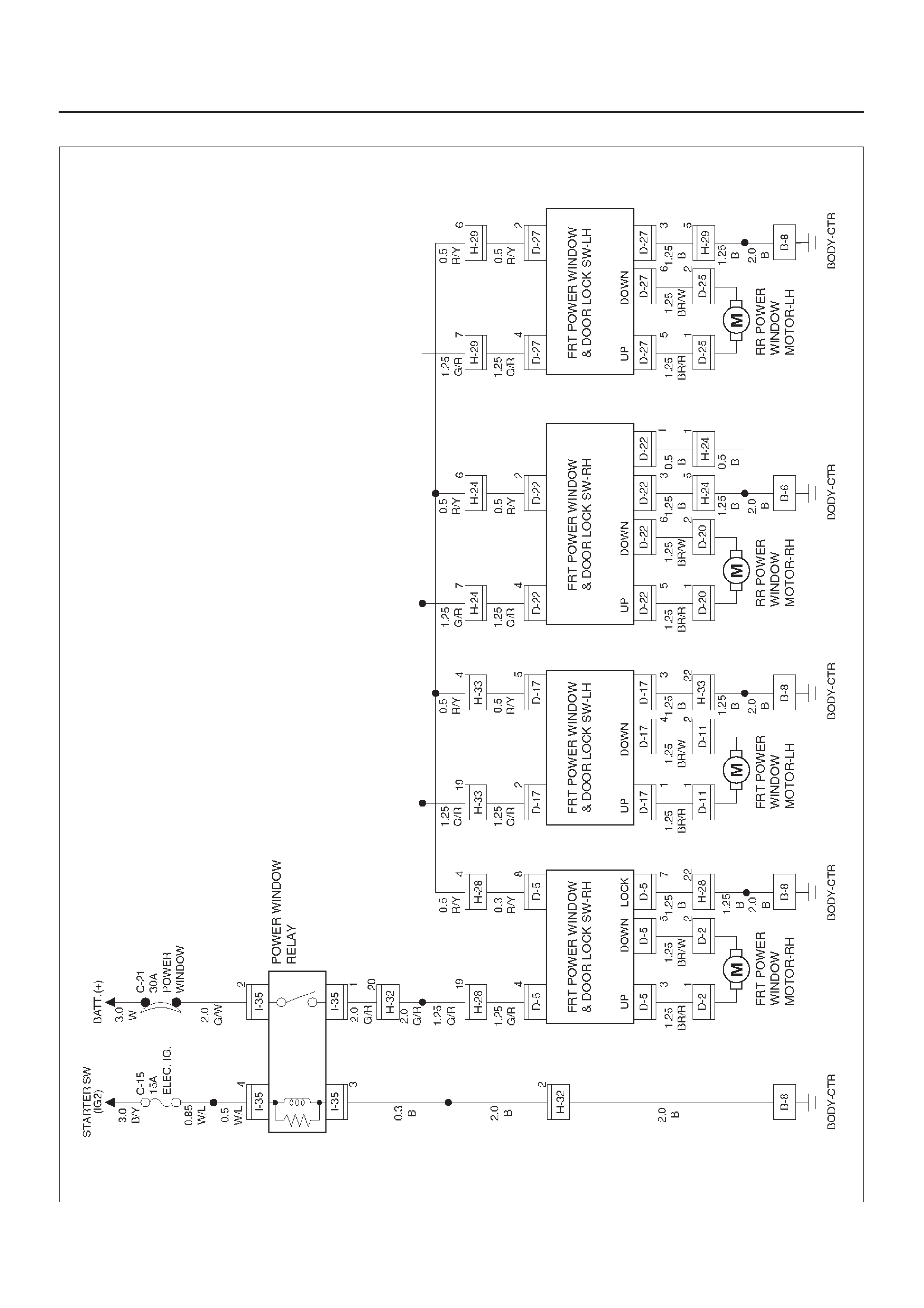

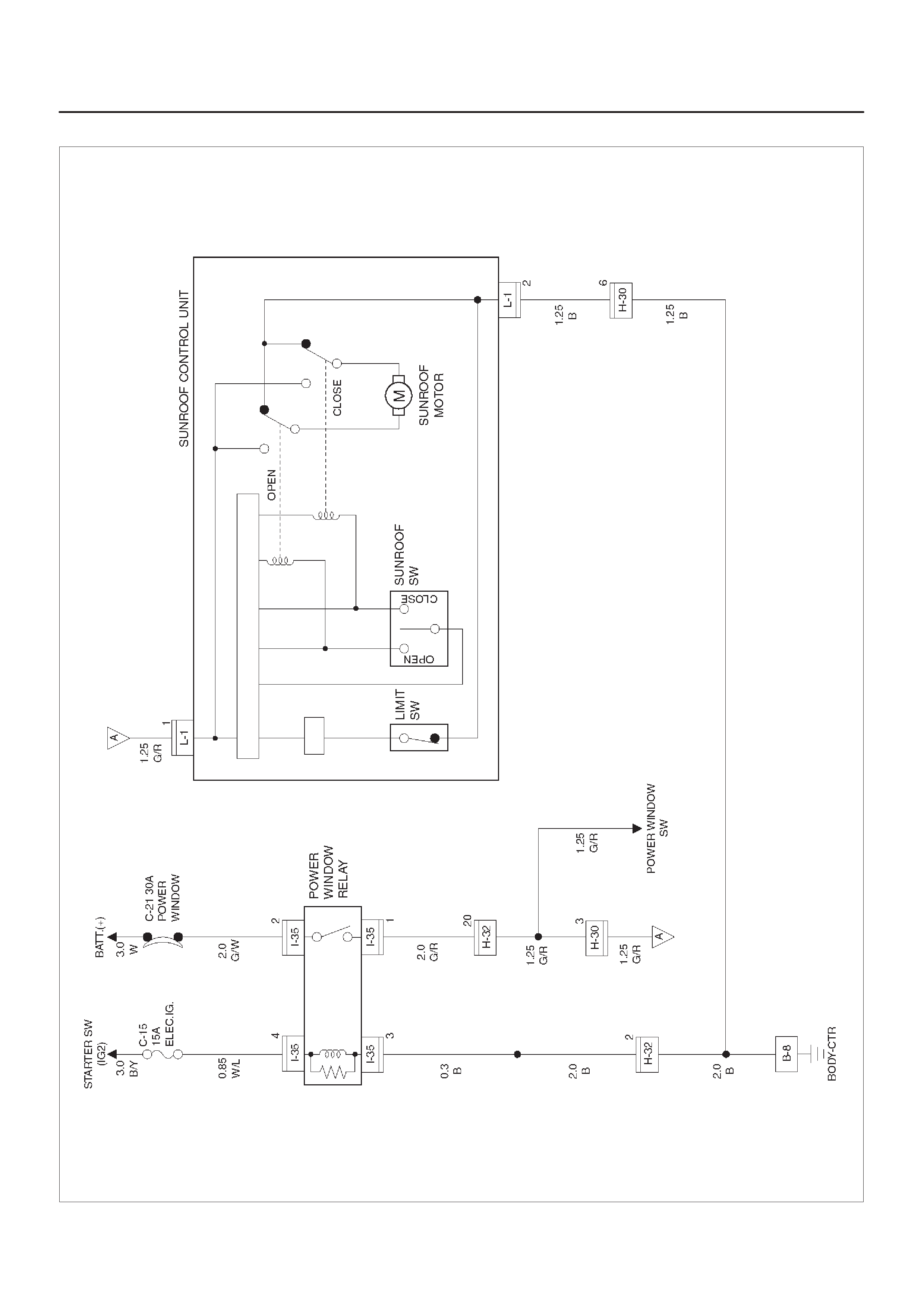

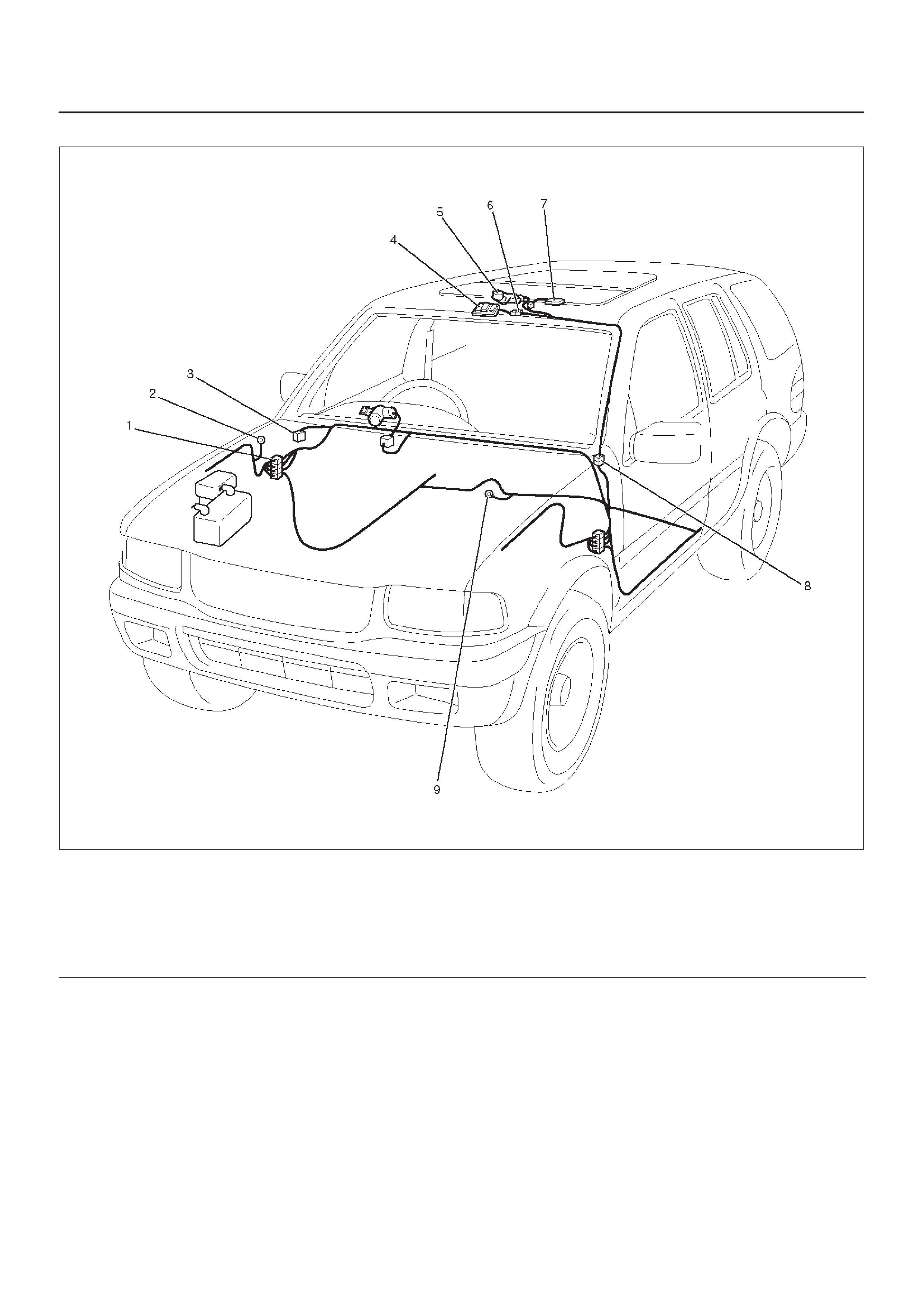

Power Window

General Description

Circuit Diagram

Parts Location

Diagnosis

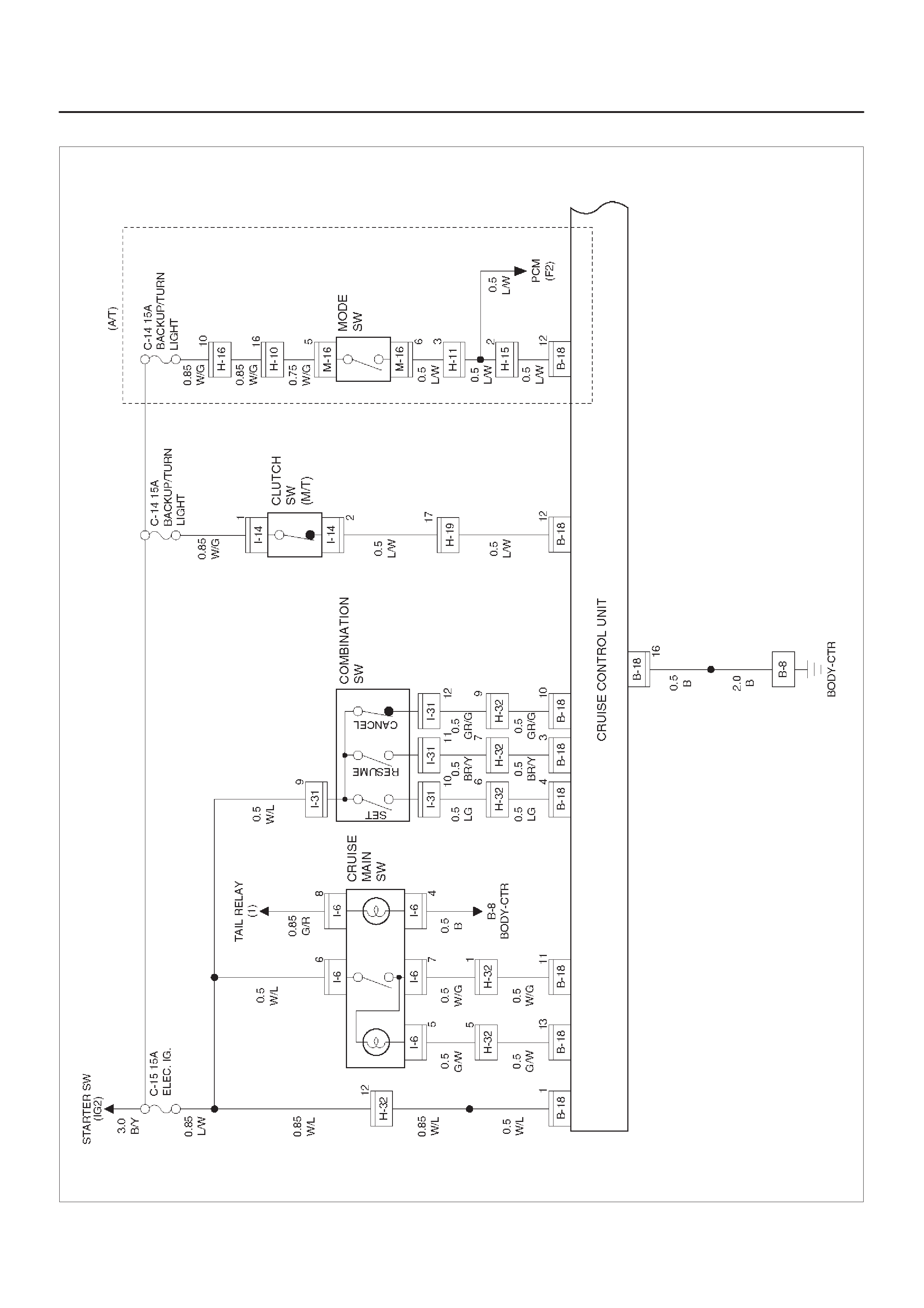

Cruise Control

General Description

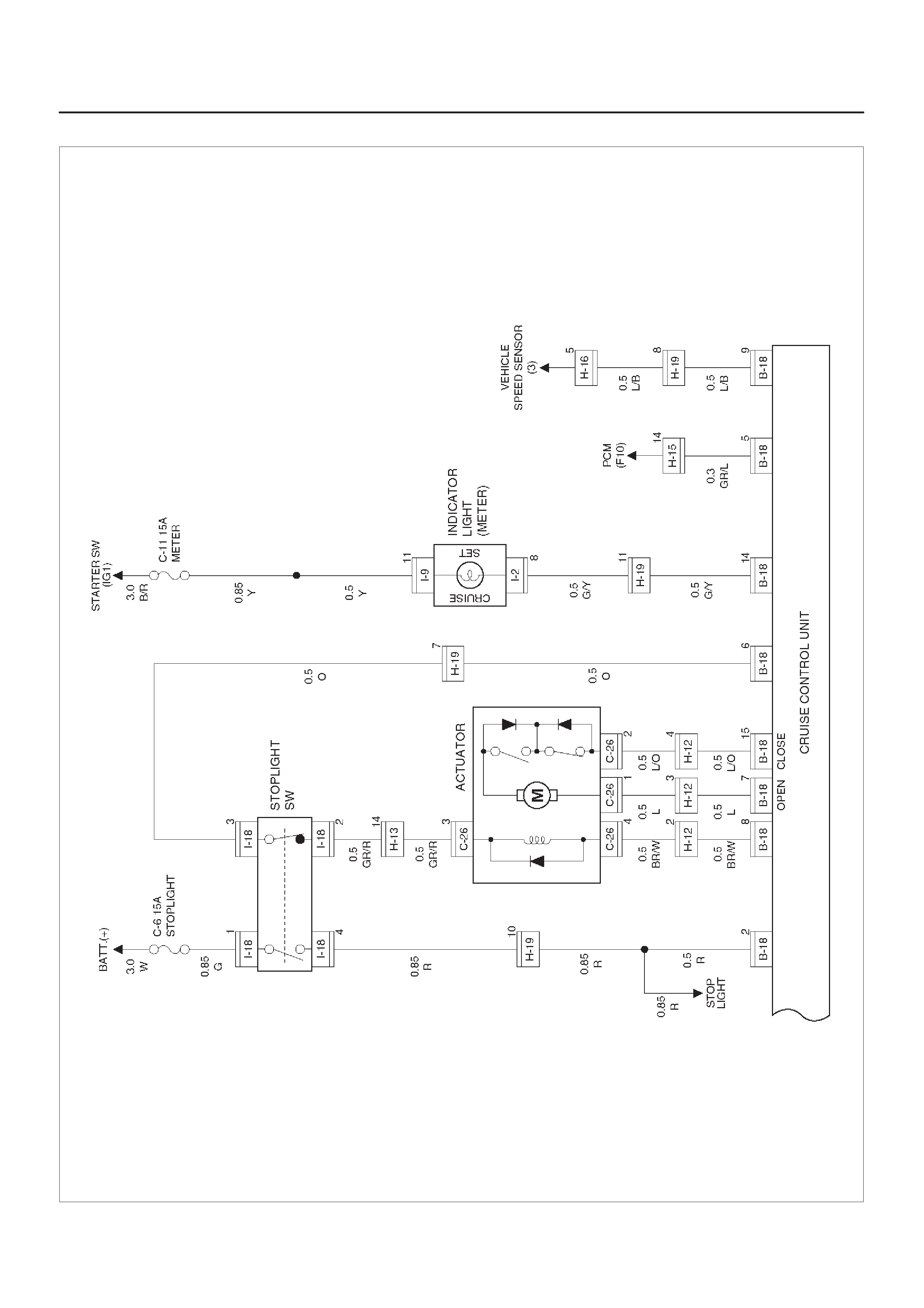

Circuit Diagram

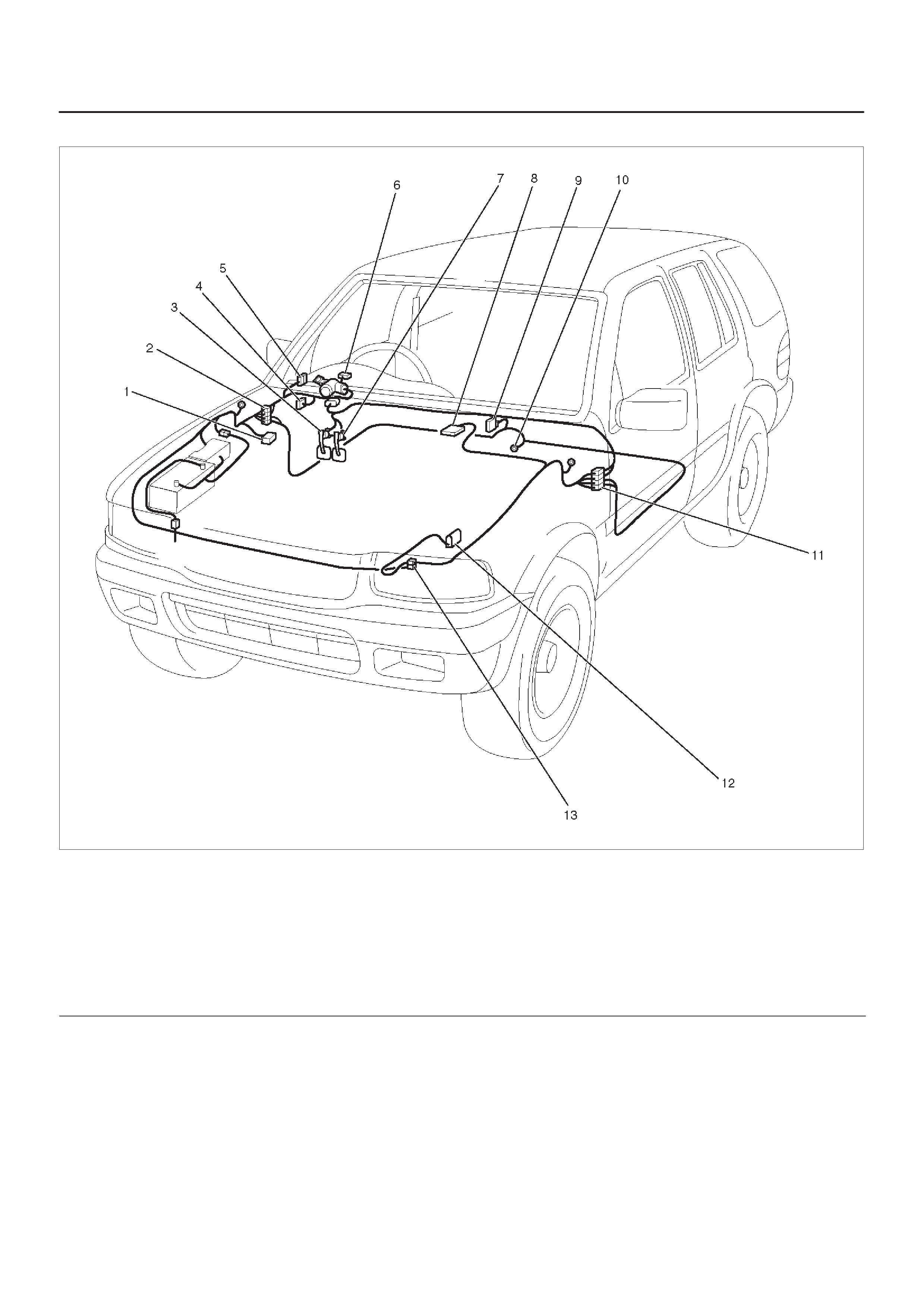

Parts Location

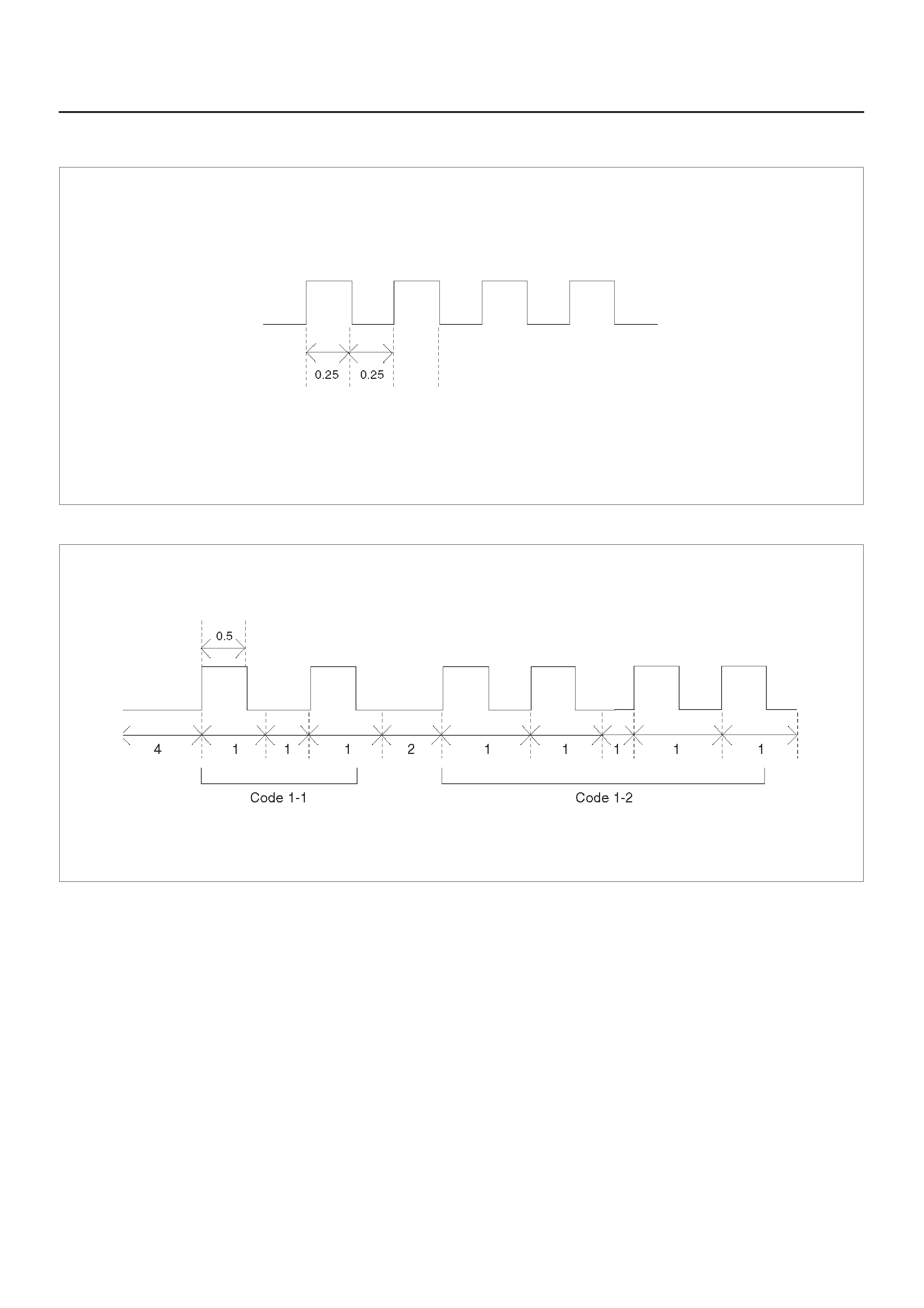

Diagnosis

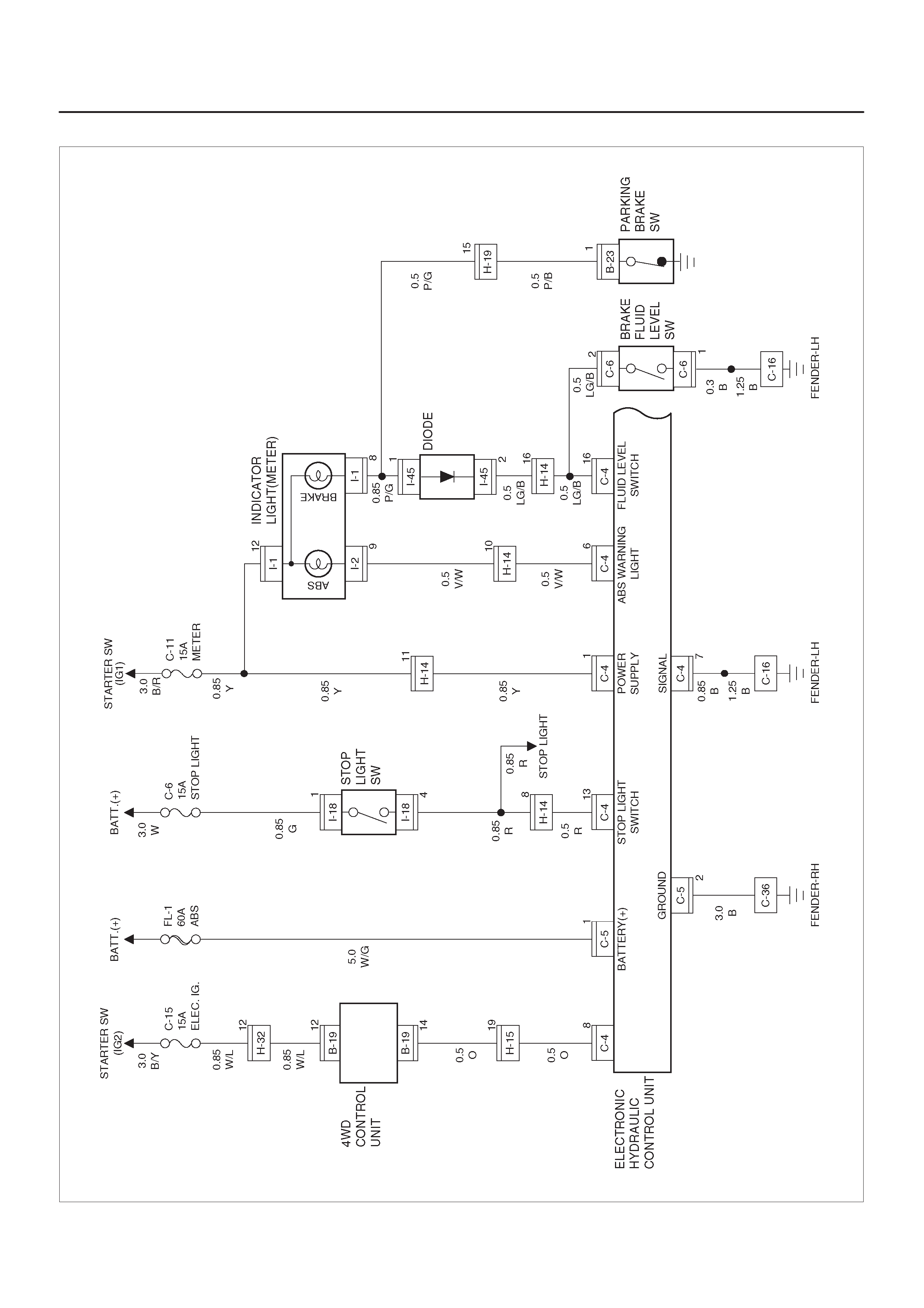

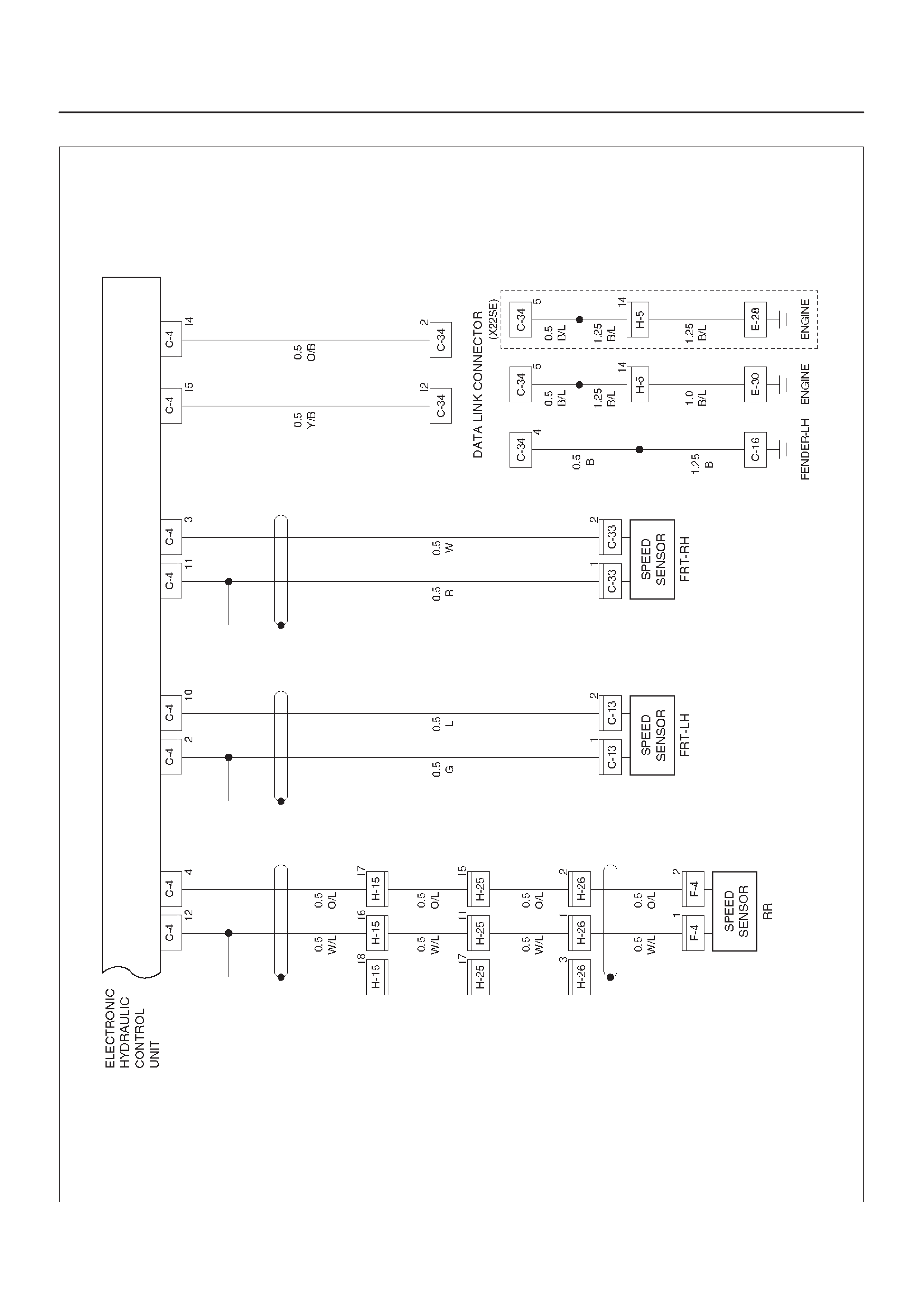

Anti–Lock Brake System (ABS)

General Description

Circuit Diagram

Parts Location

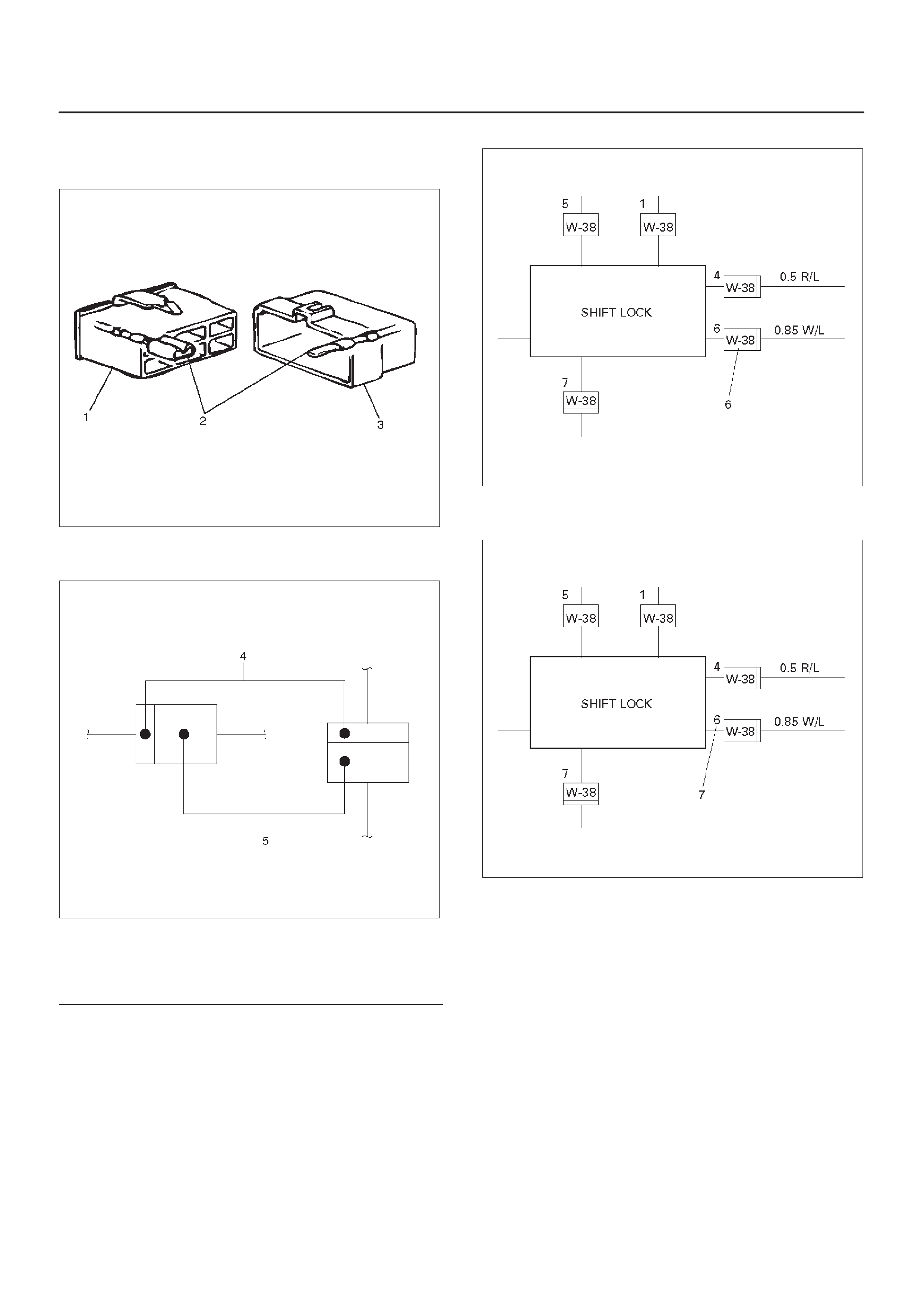

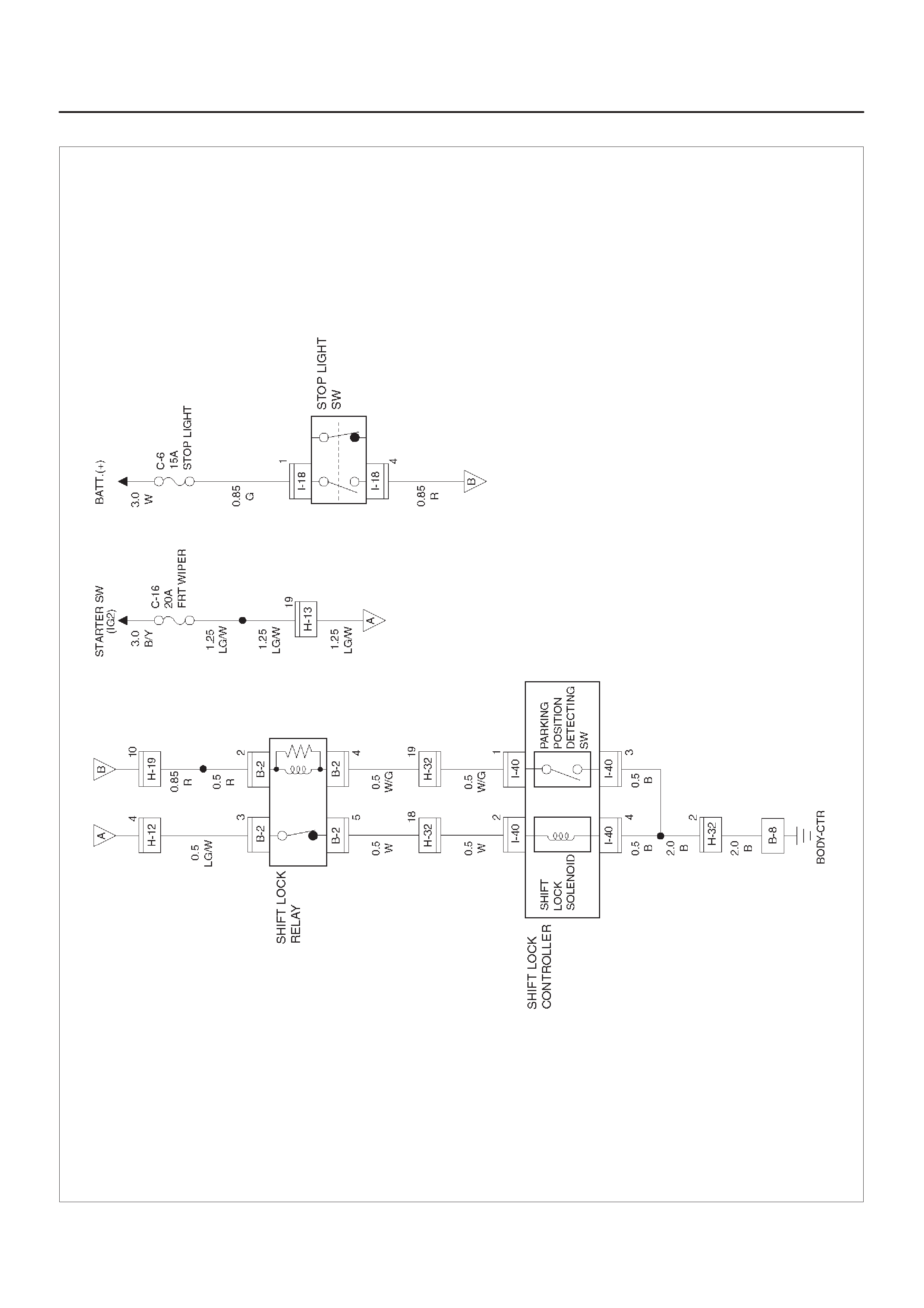

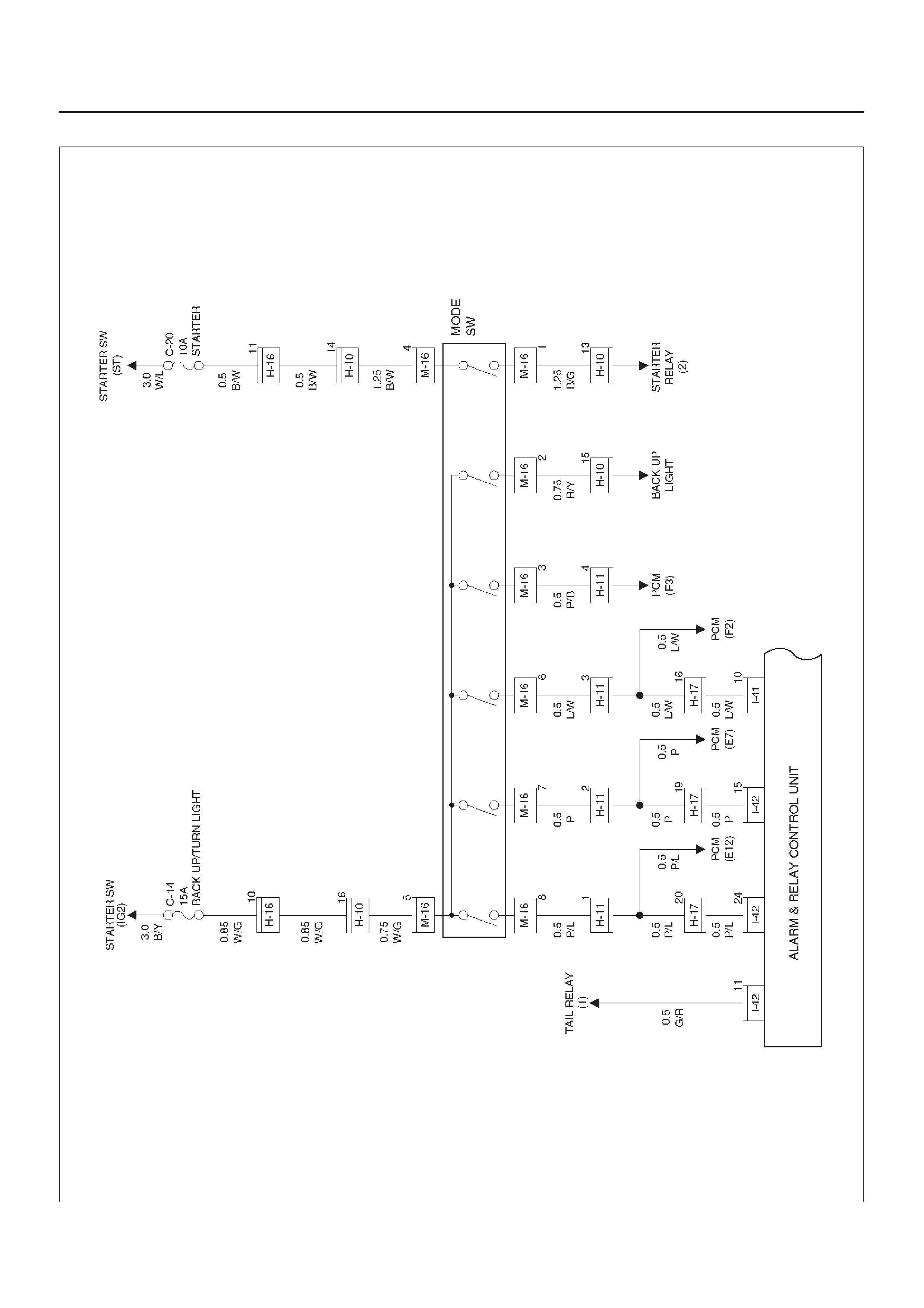

A/T Shift Lock

General Description

Circuit Diagram

Parts Location

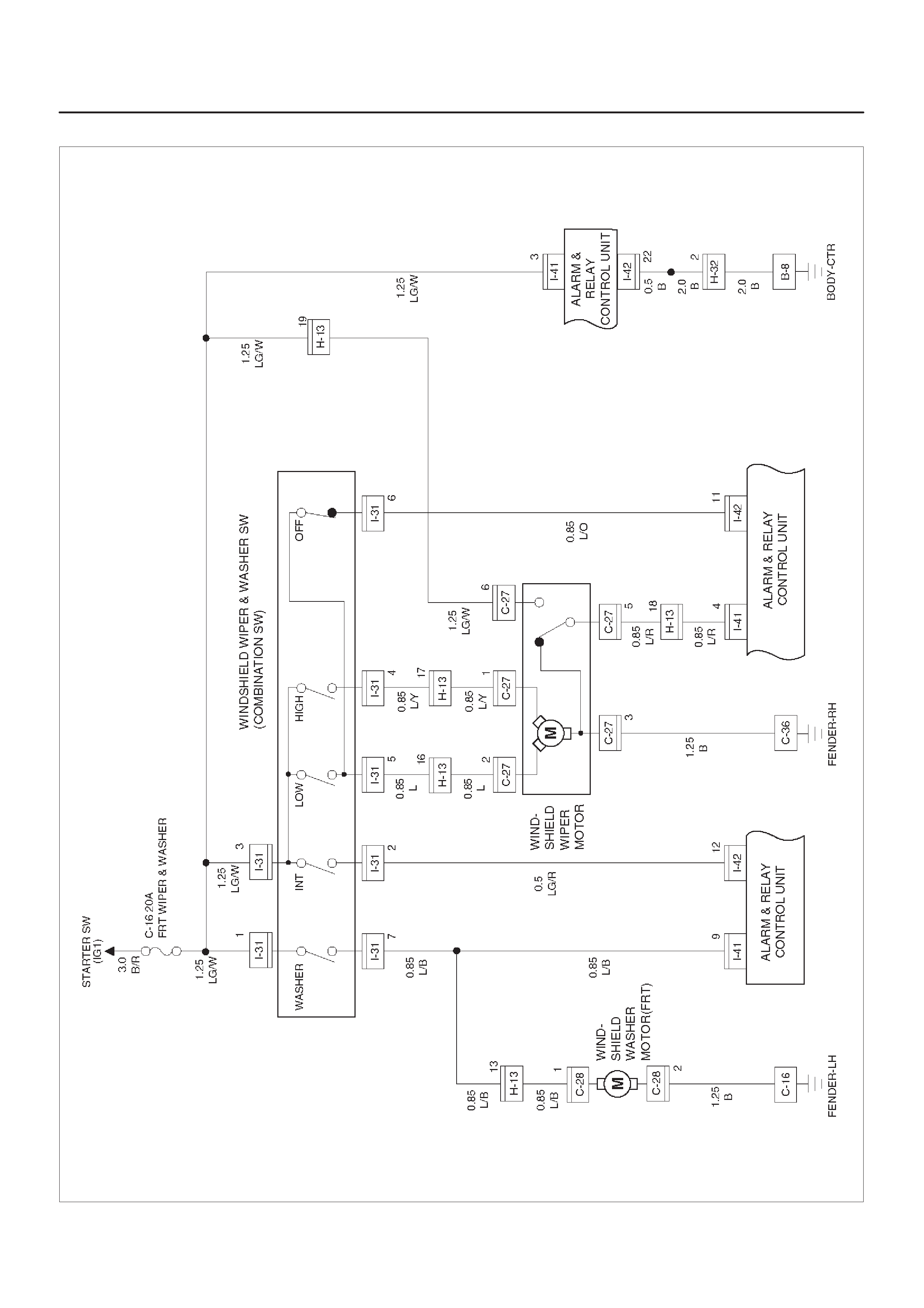

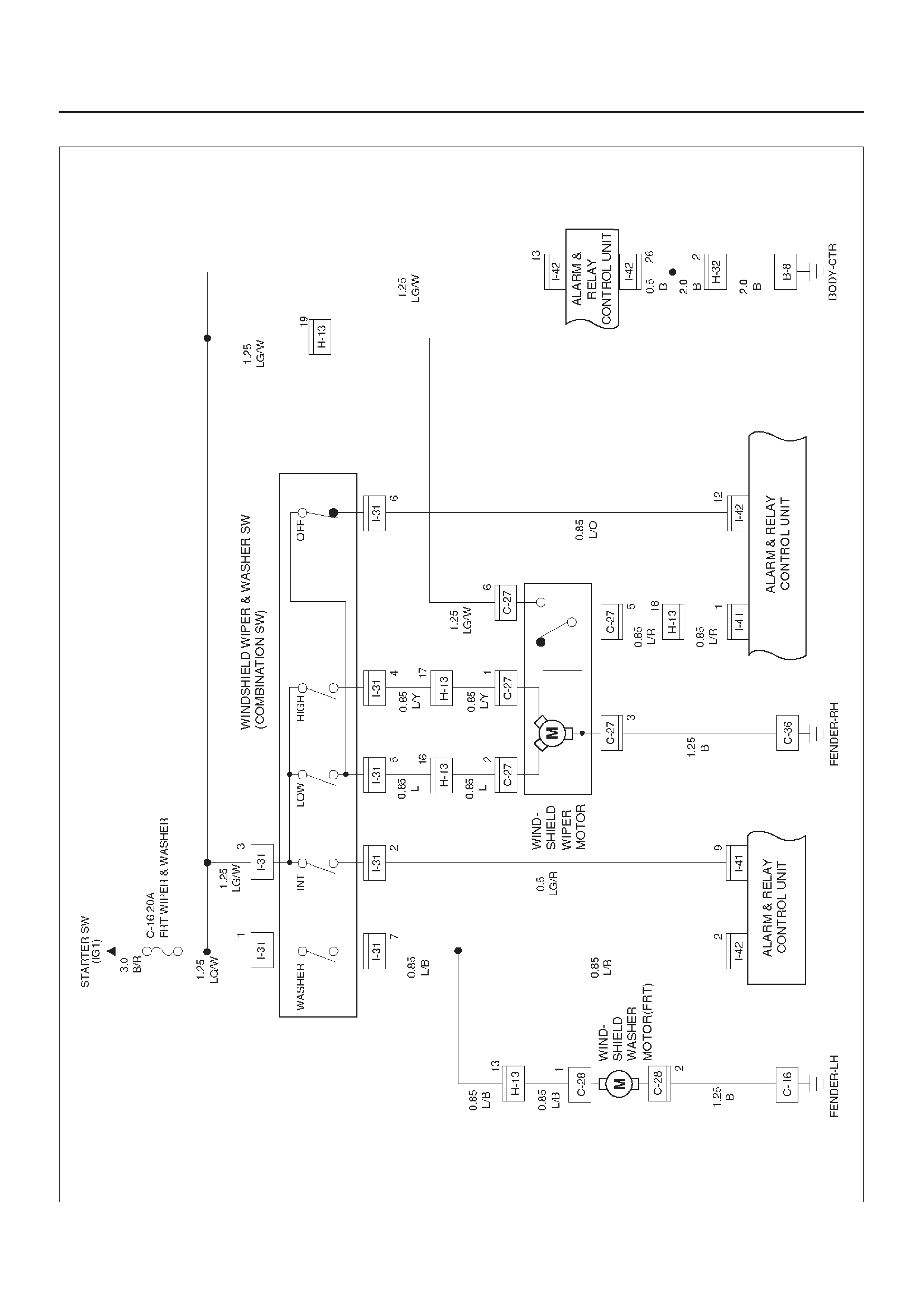

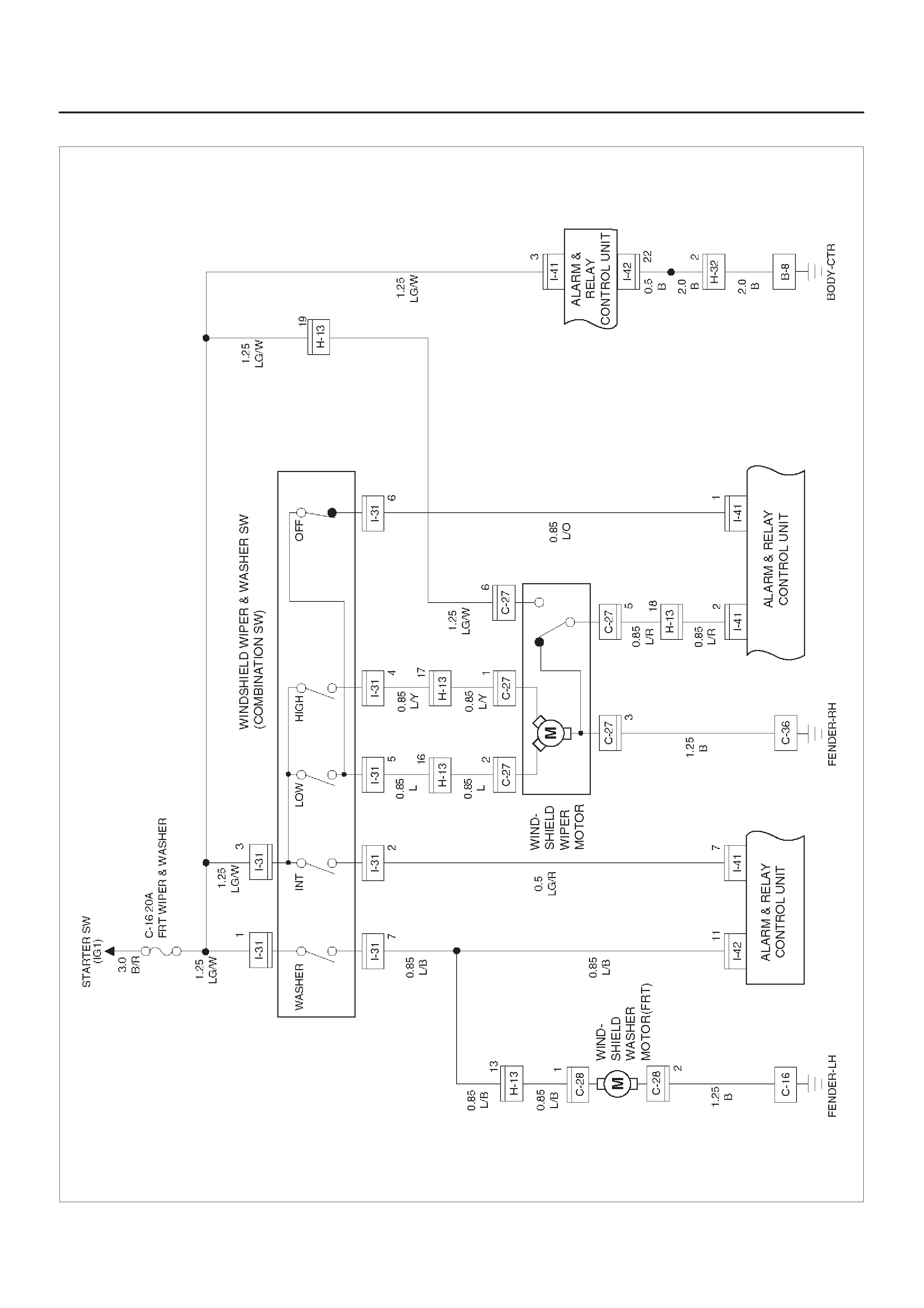

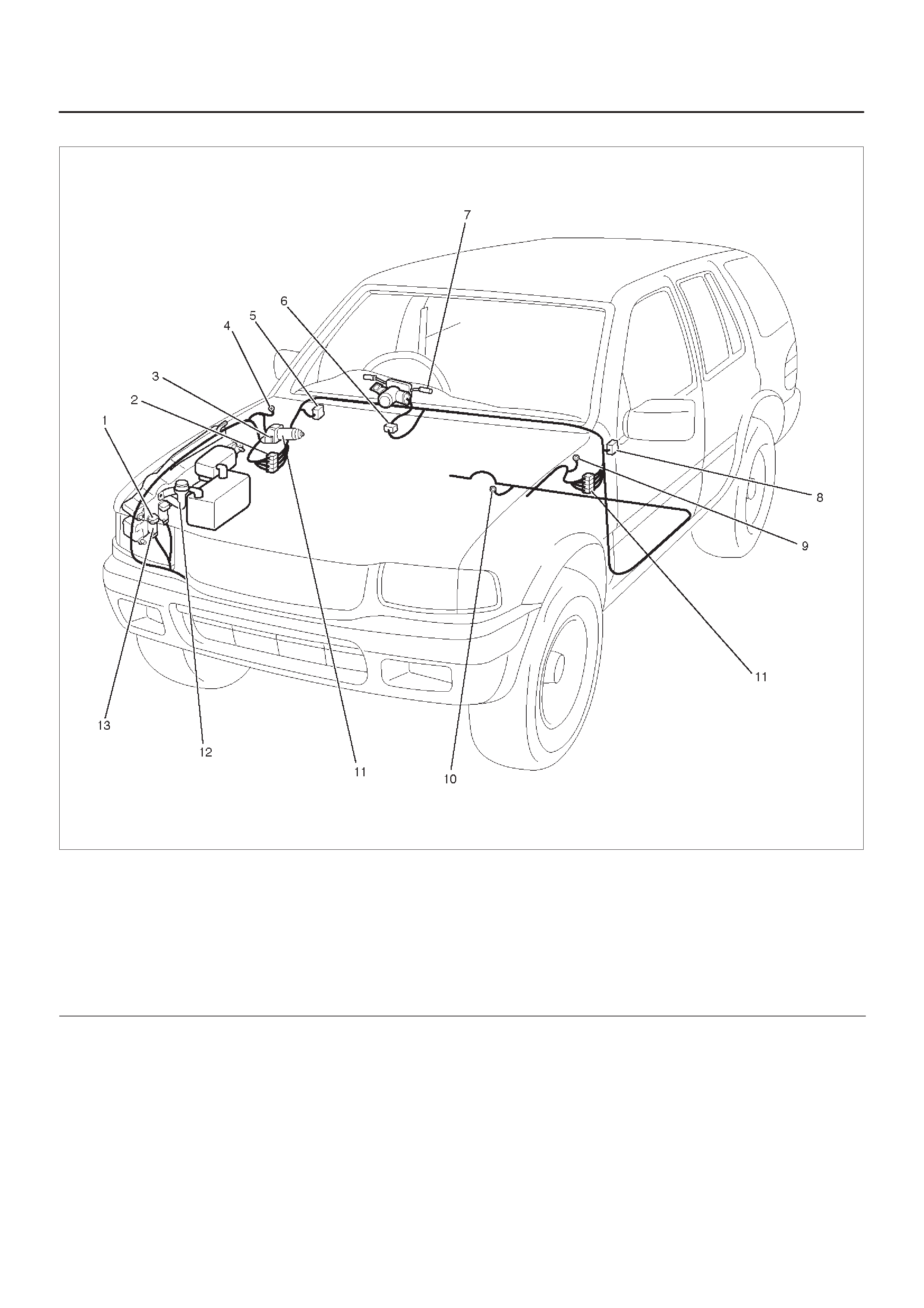

Windshield Wiper and Washer

General Description

Circuit Diagram

Parts Location

Diagnosis

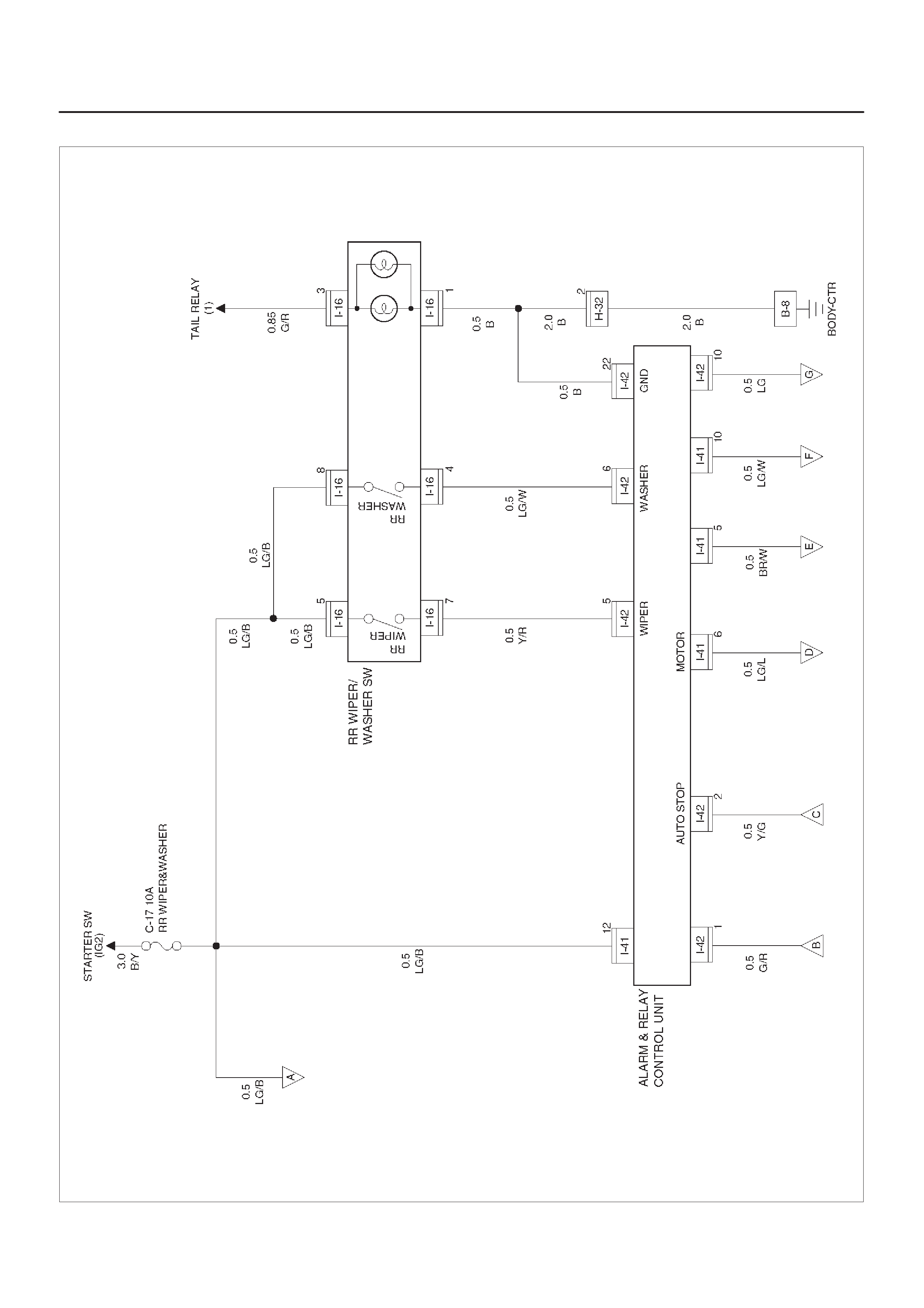

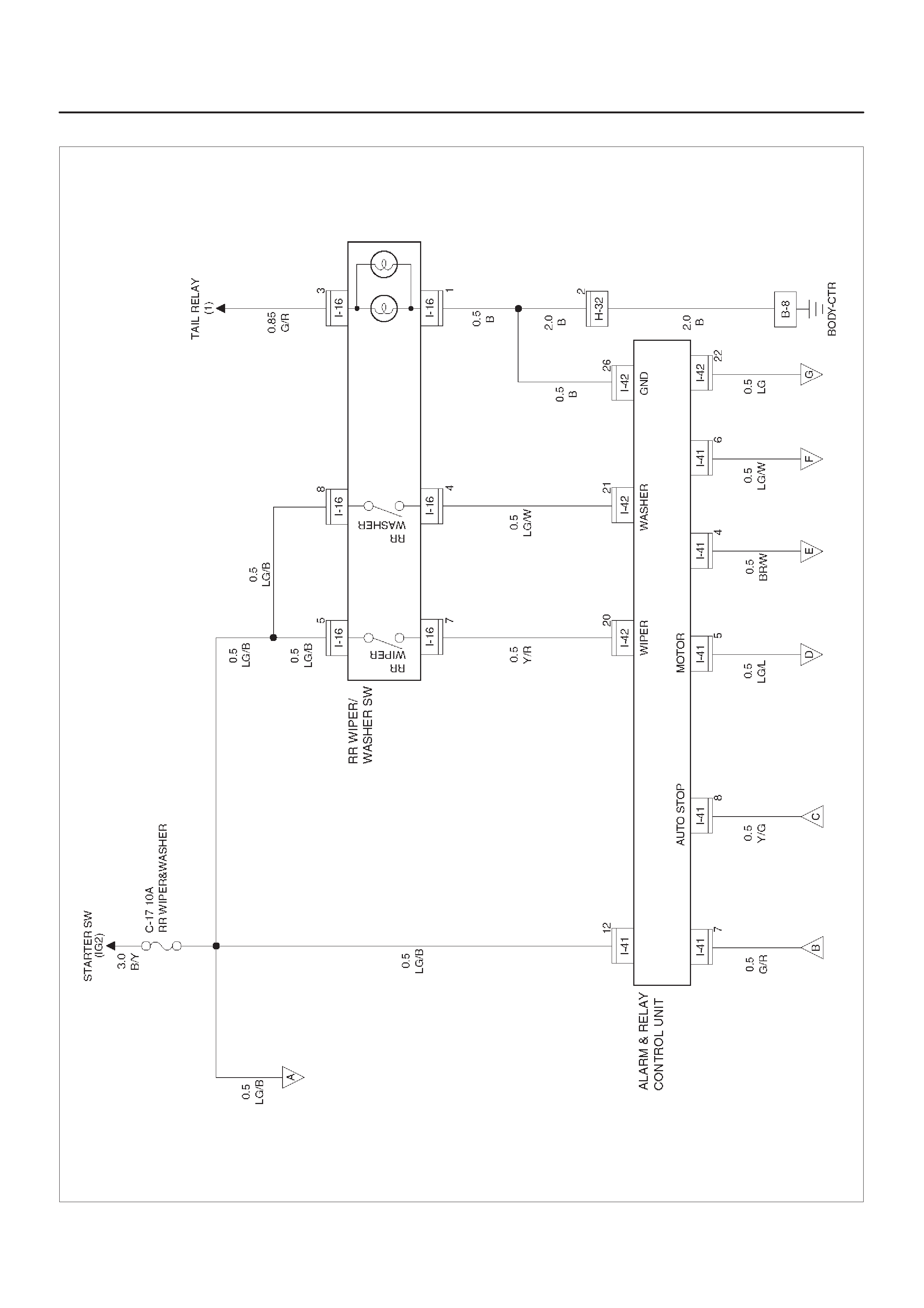

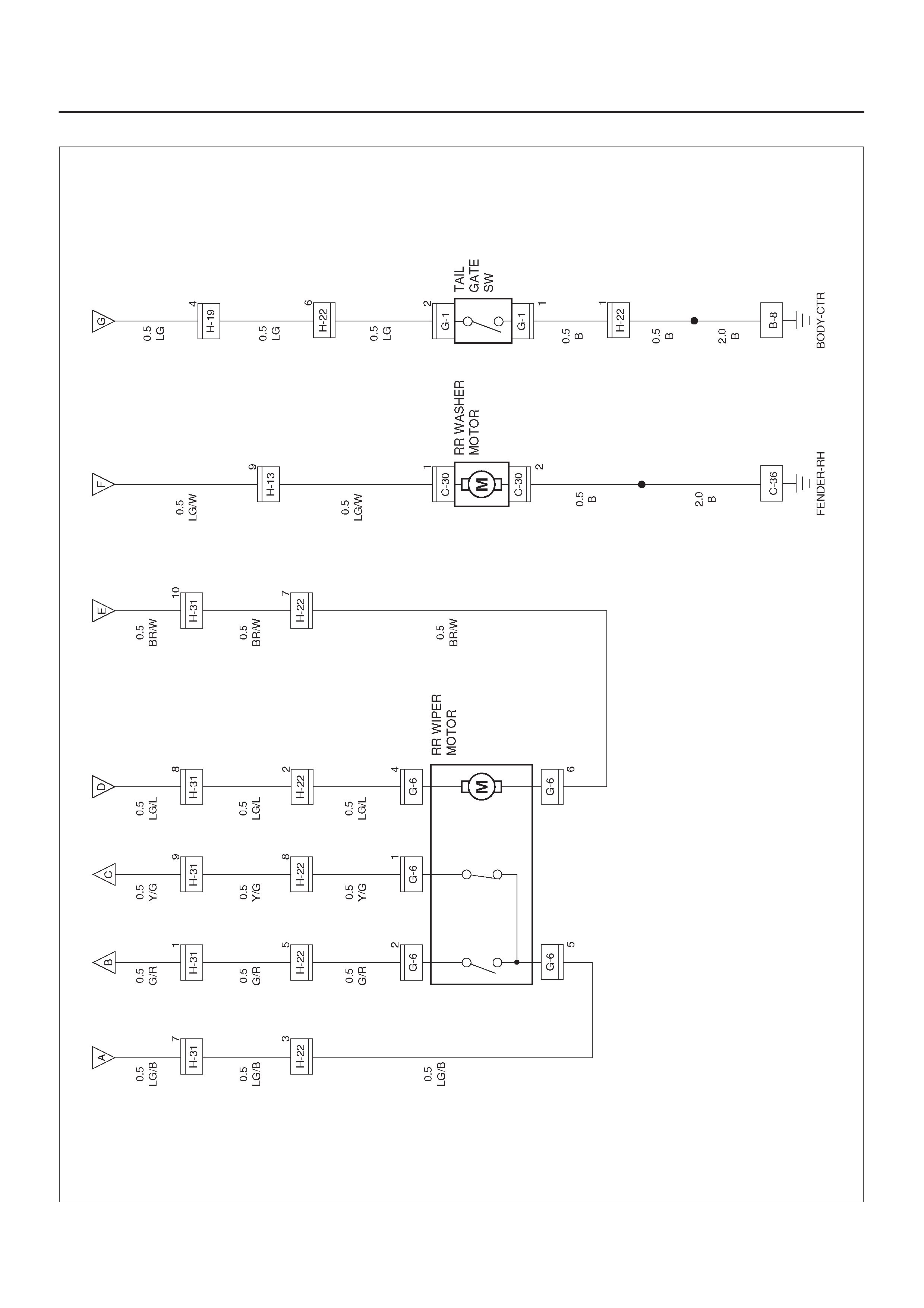

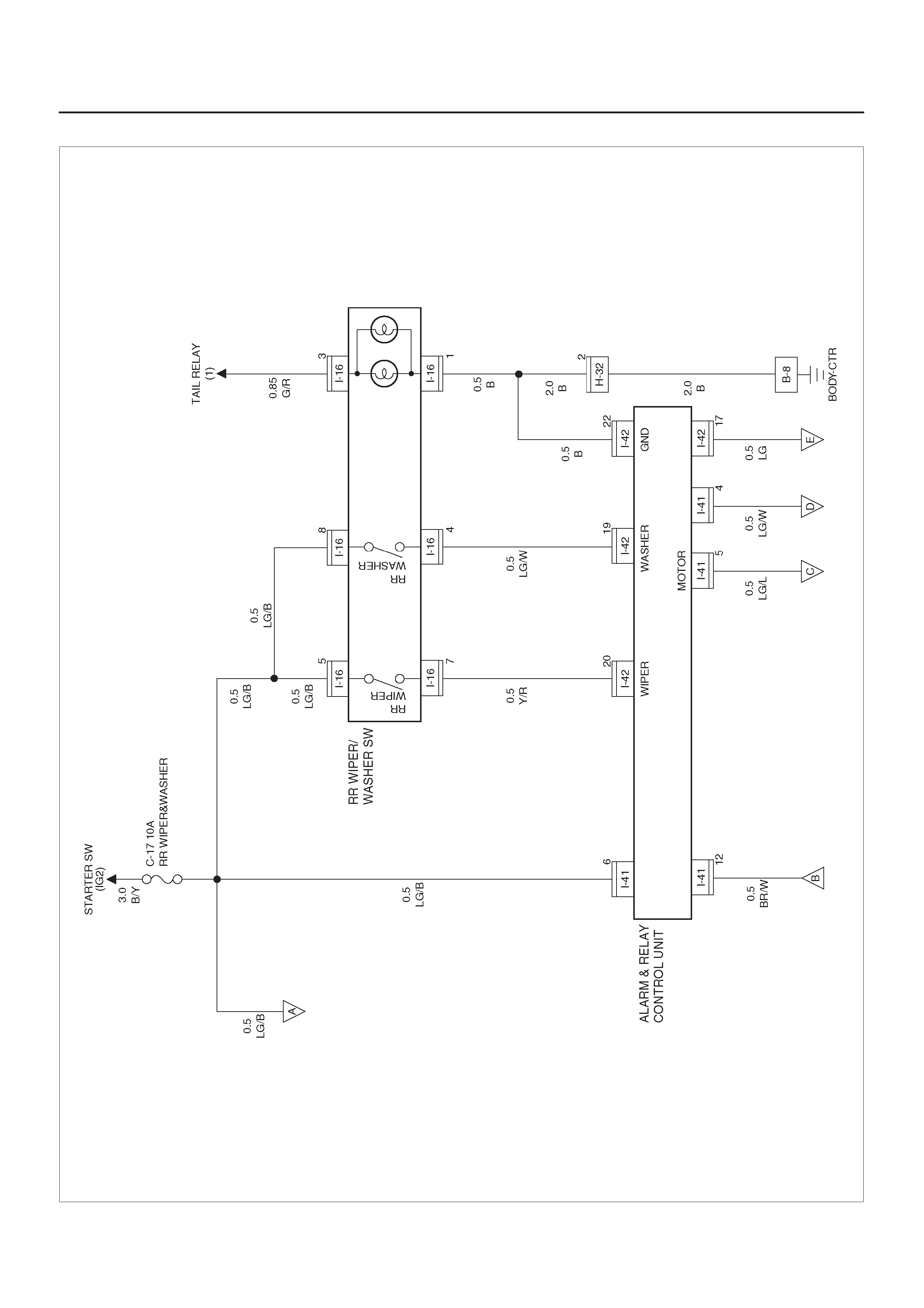

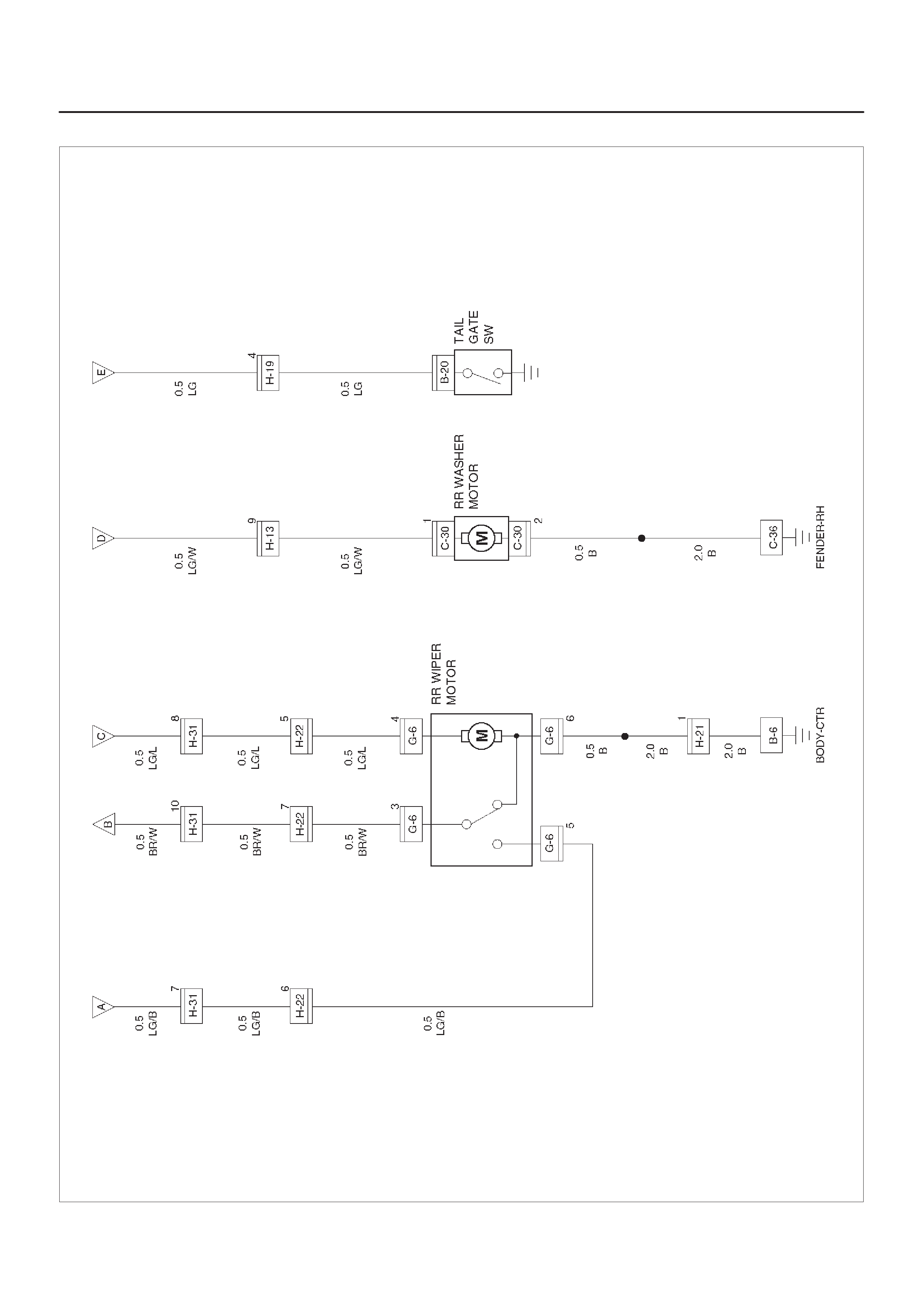

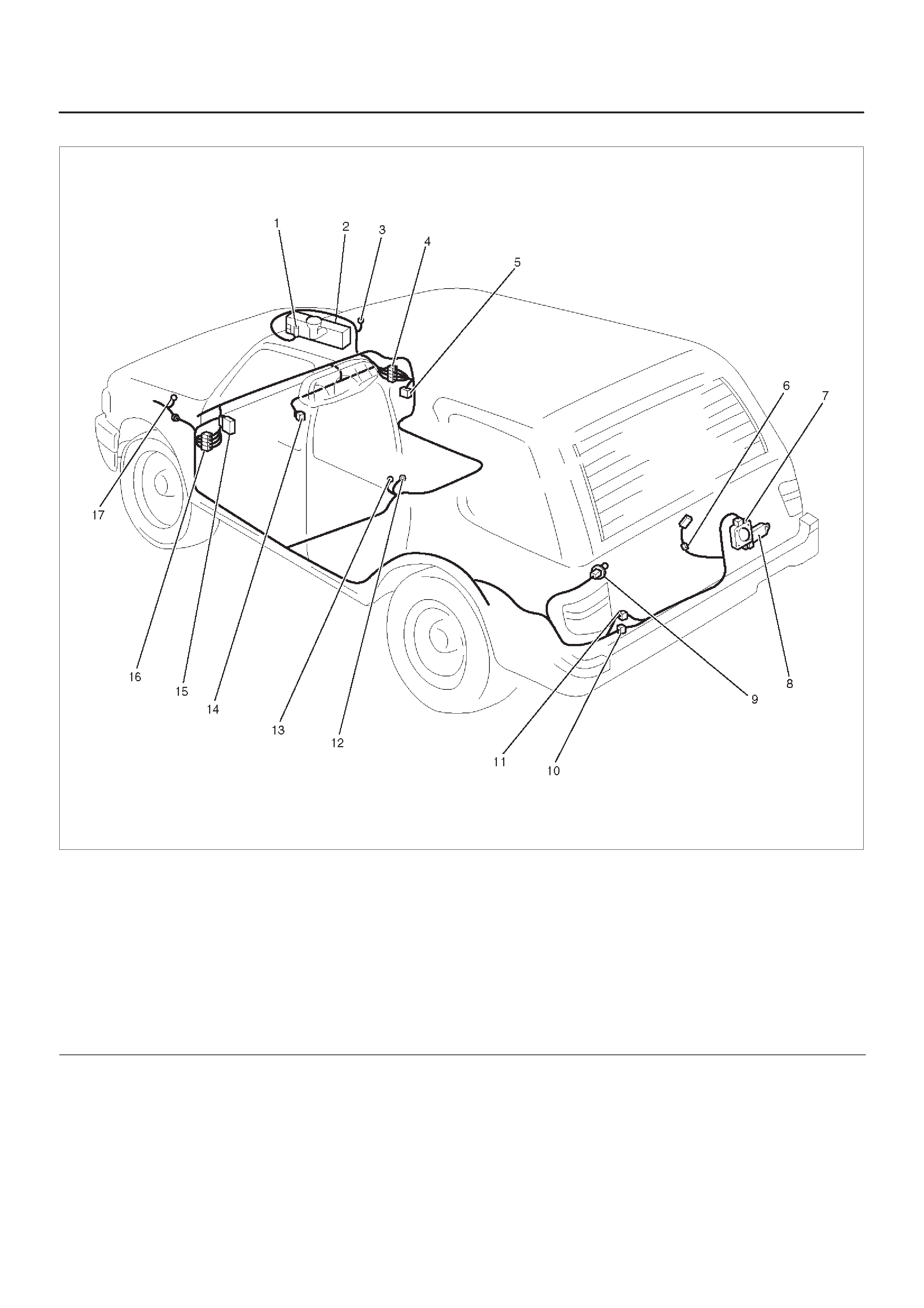

Rear Wiper/Washer

General Description

Circuit Diagram

Parts Location

Diagnosis

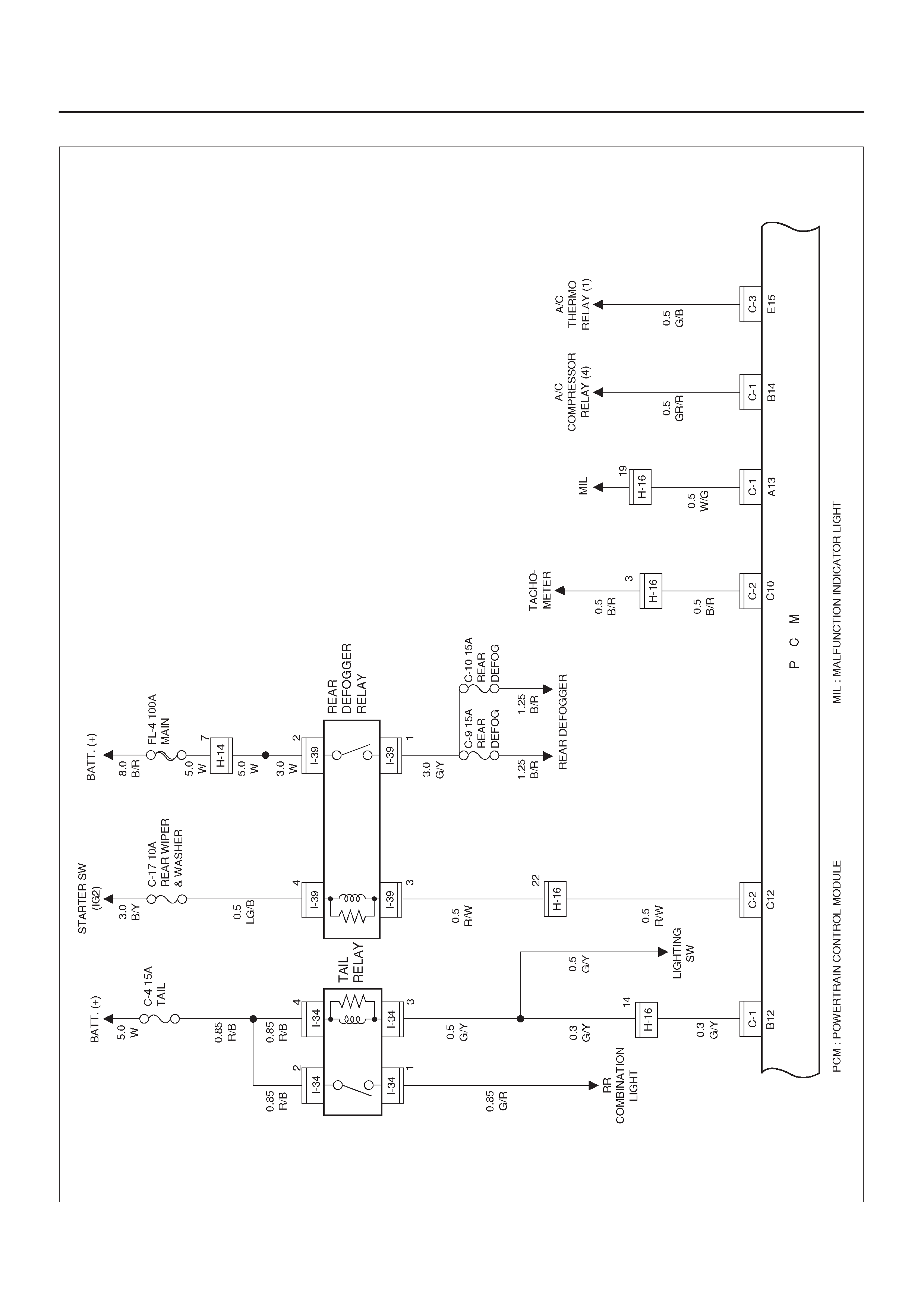

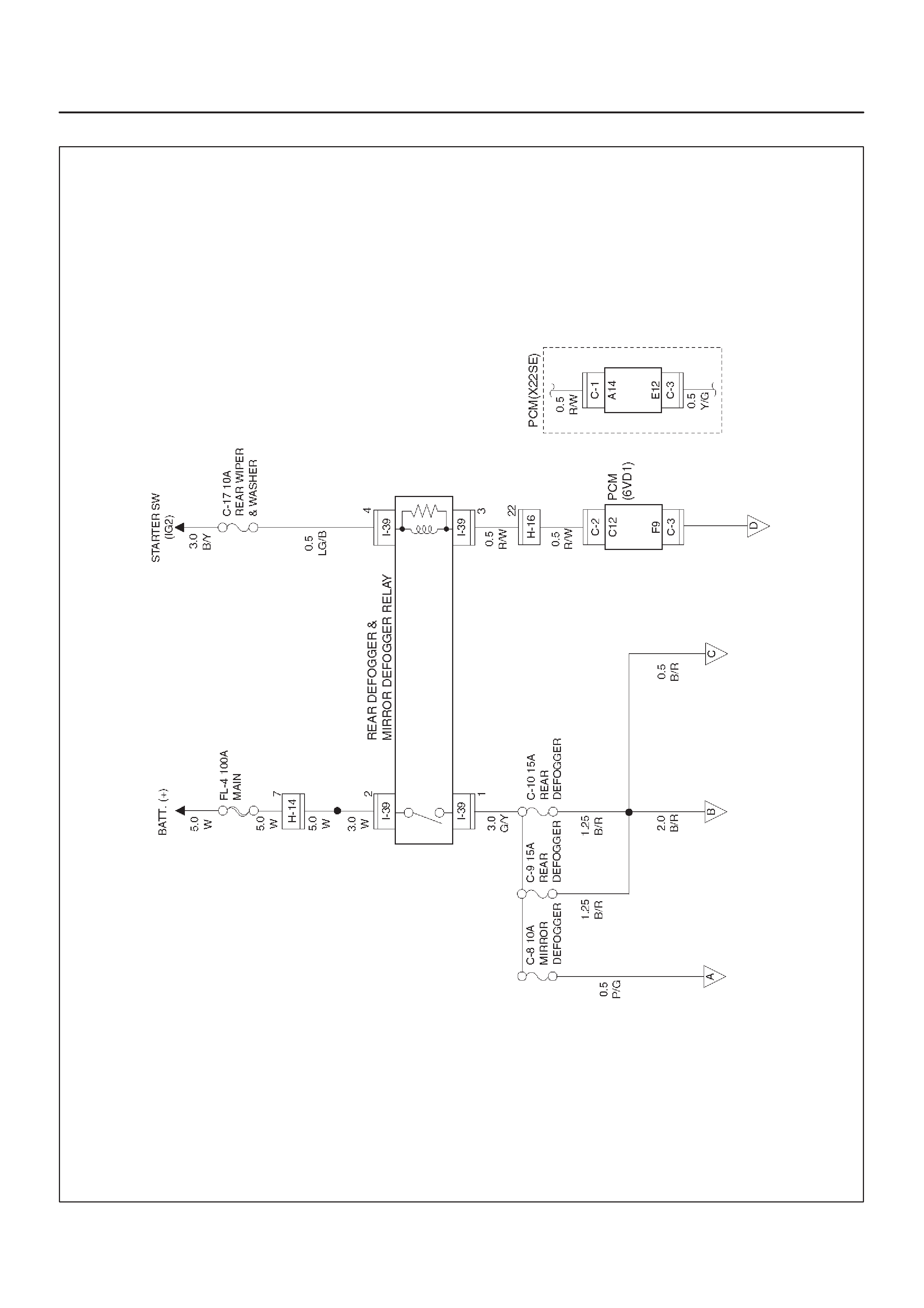

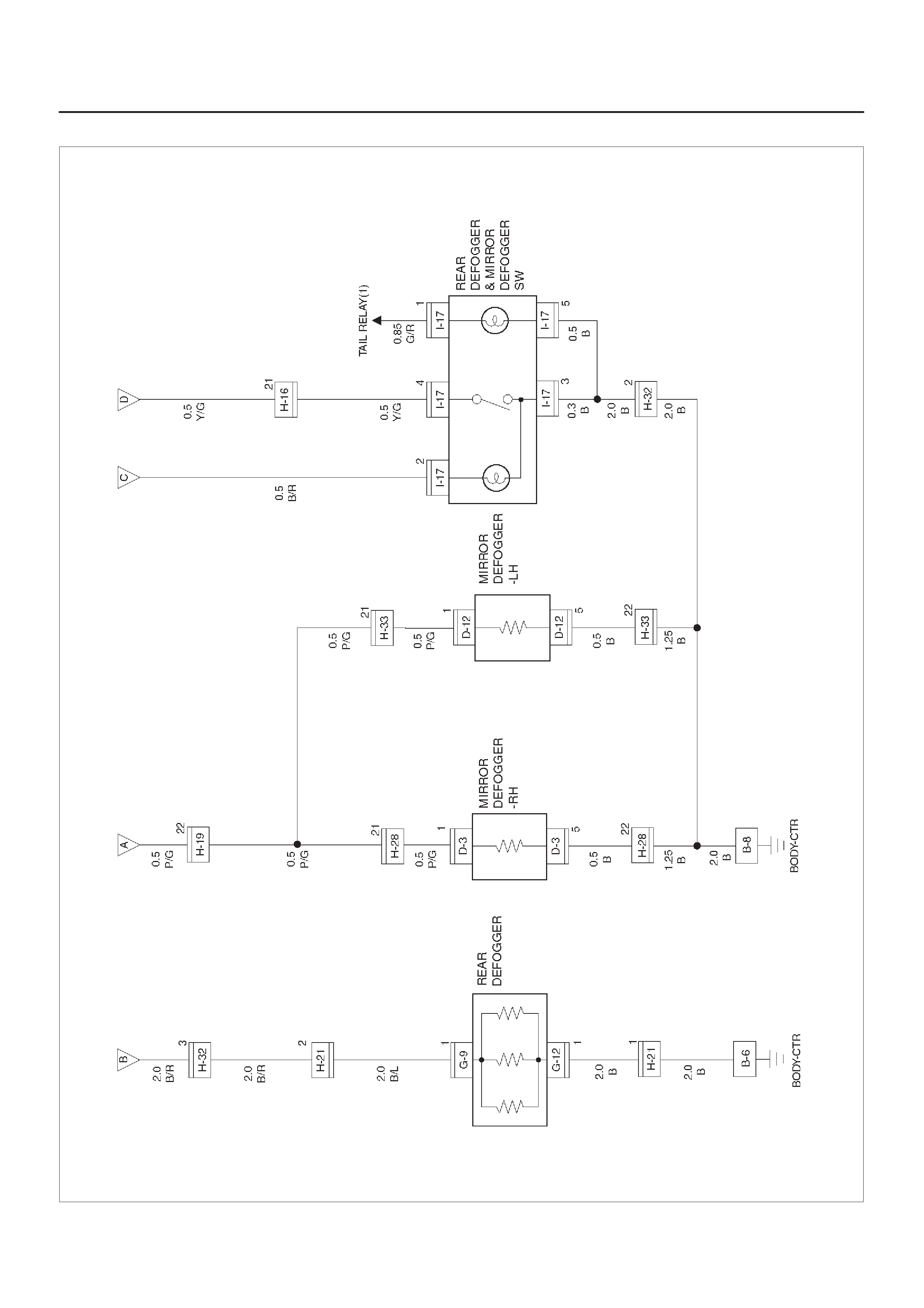

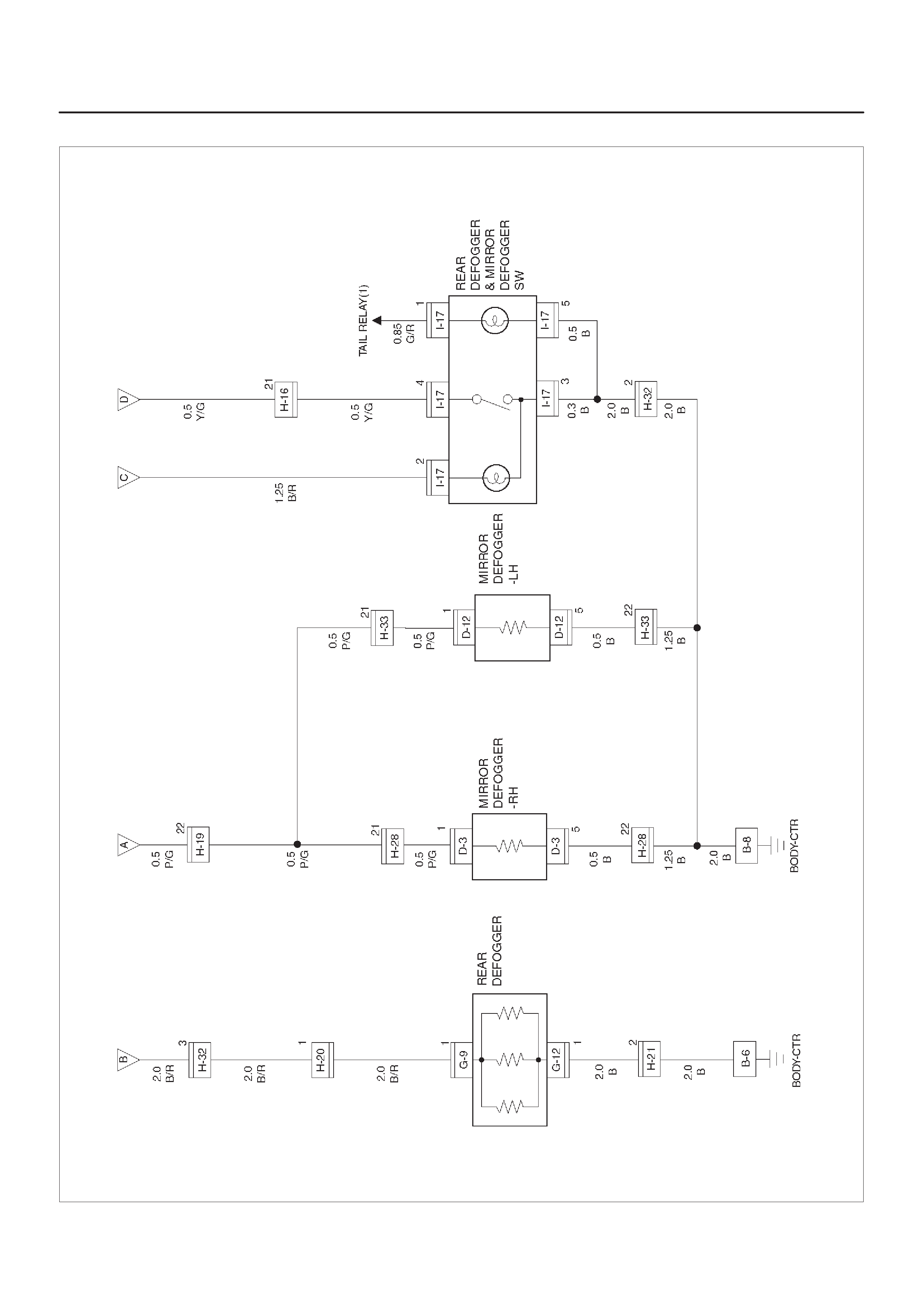

Rear Defogger/Mirror Defogger

General Description

Circuit Diagram

Diagnosis

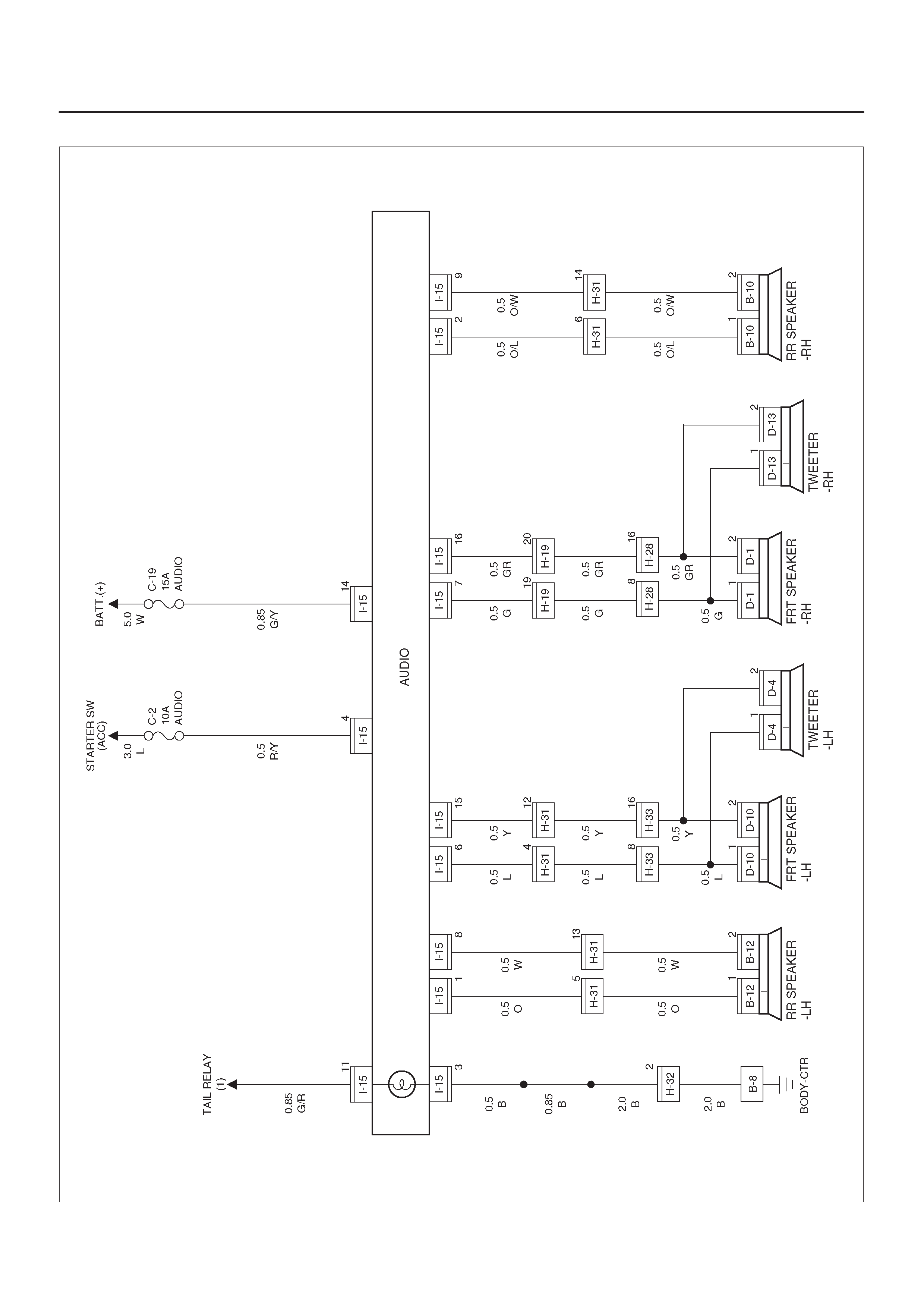

Audio

General Description

Circuit Diagram

Parts Location

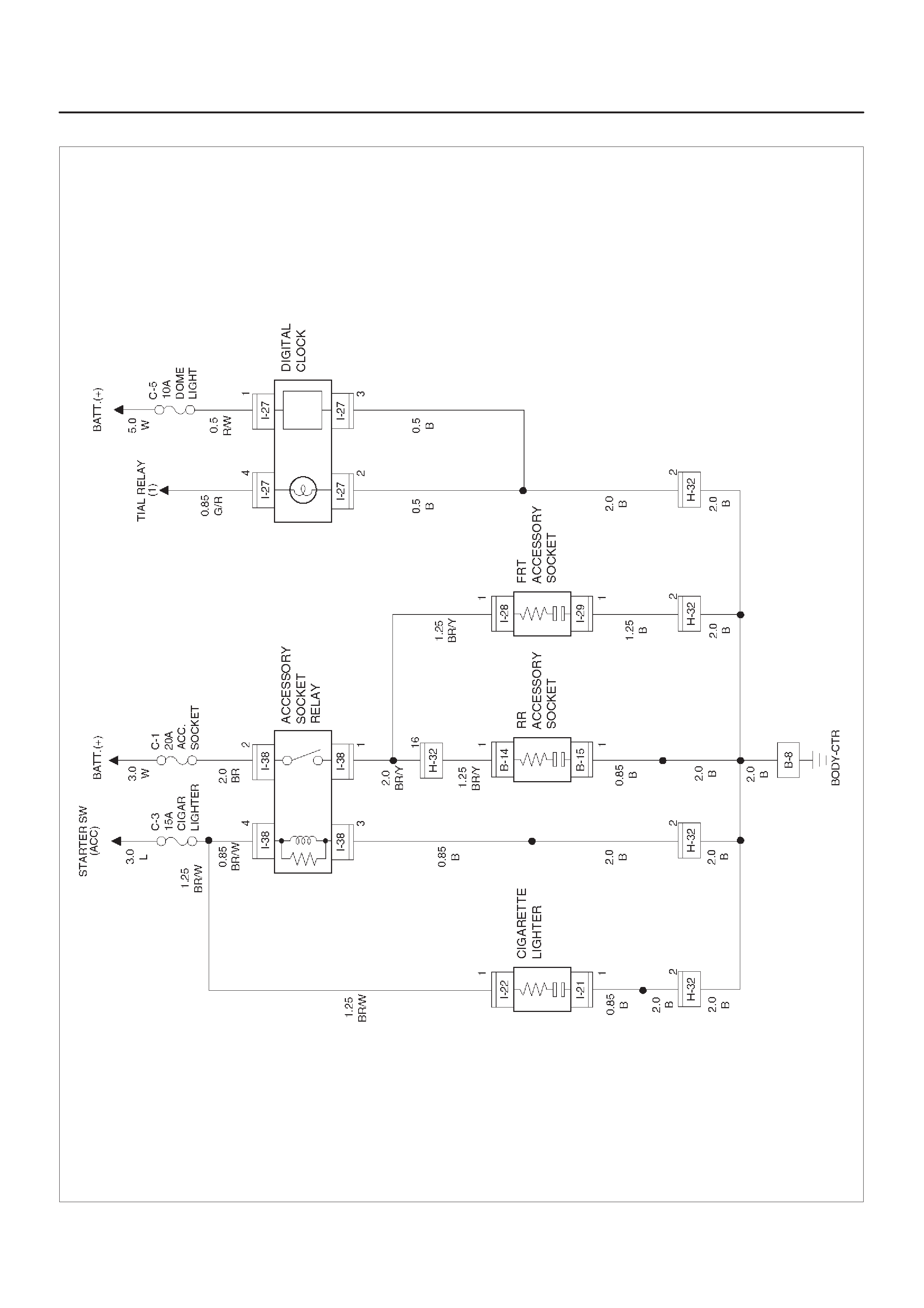

Cigarette Lighter, Digital Clock and

Accessory Socket

General Description

Circuit Diagram

Parts Location

Diagnosis

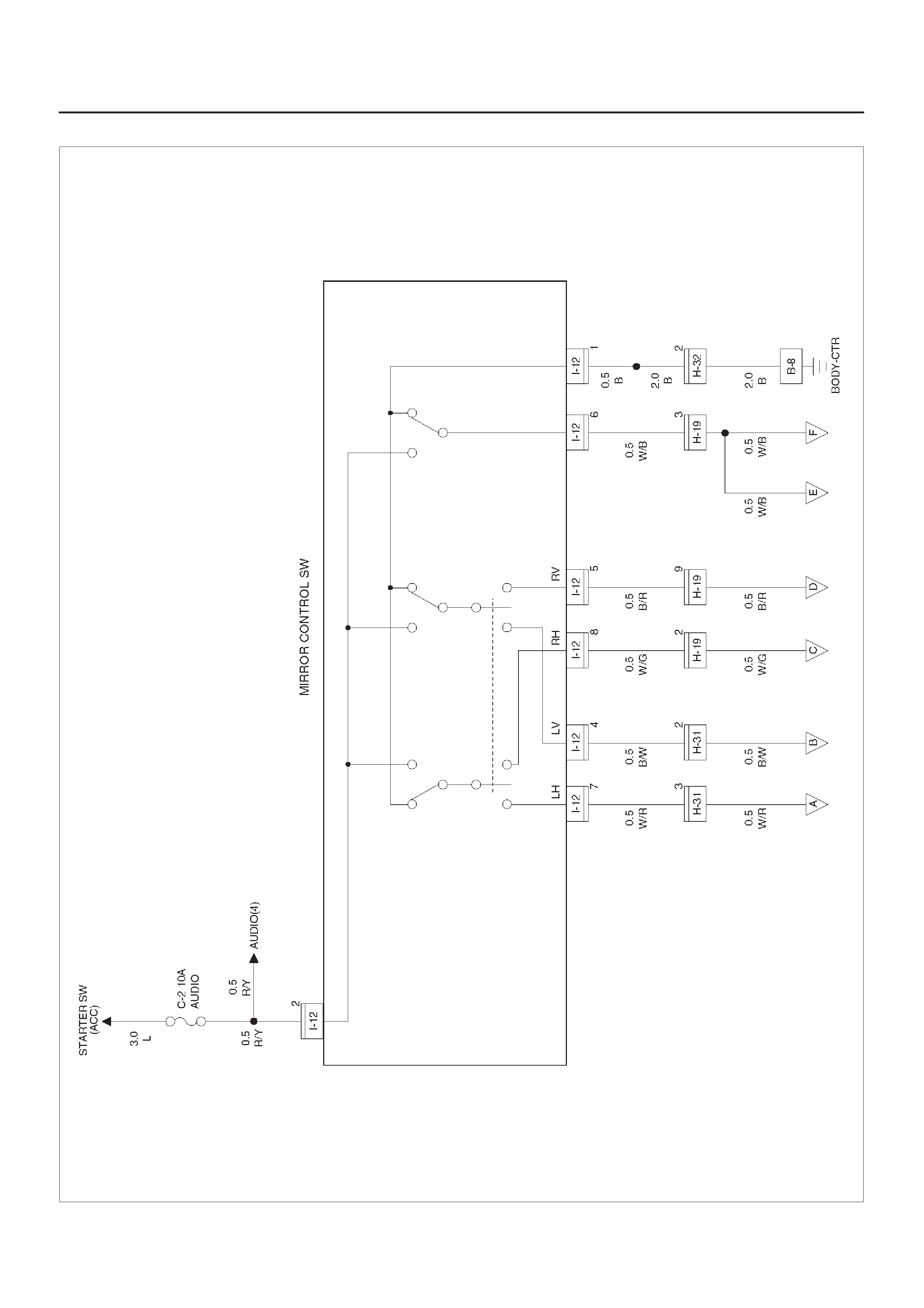

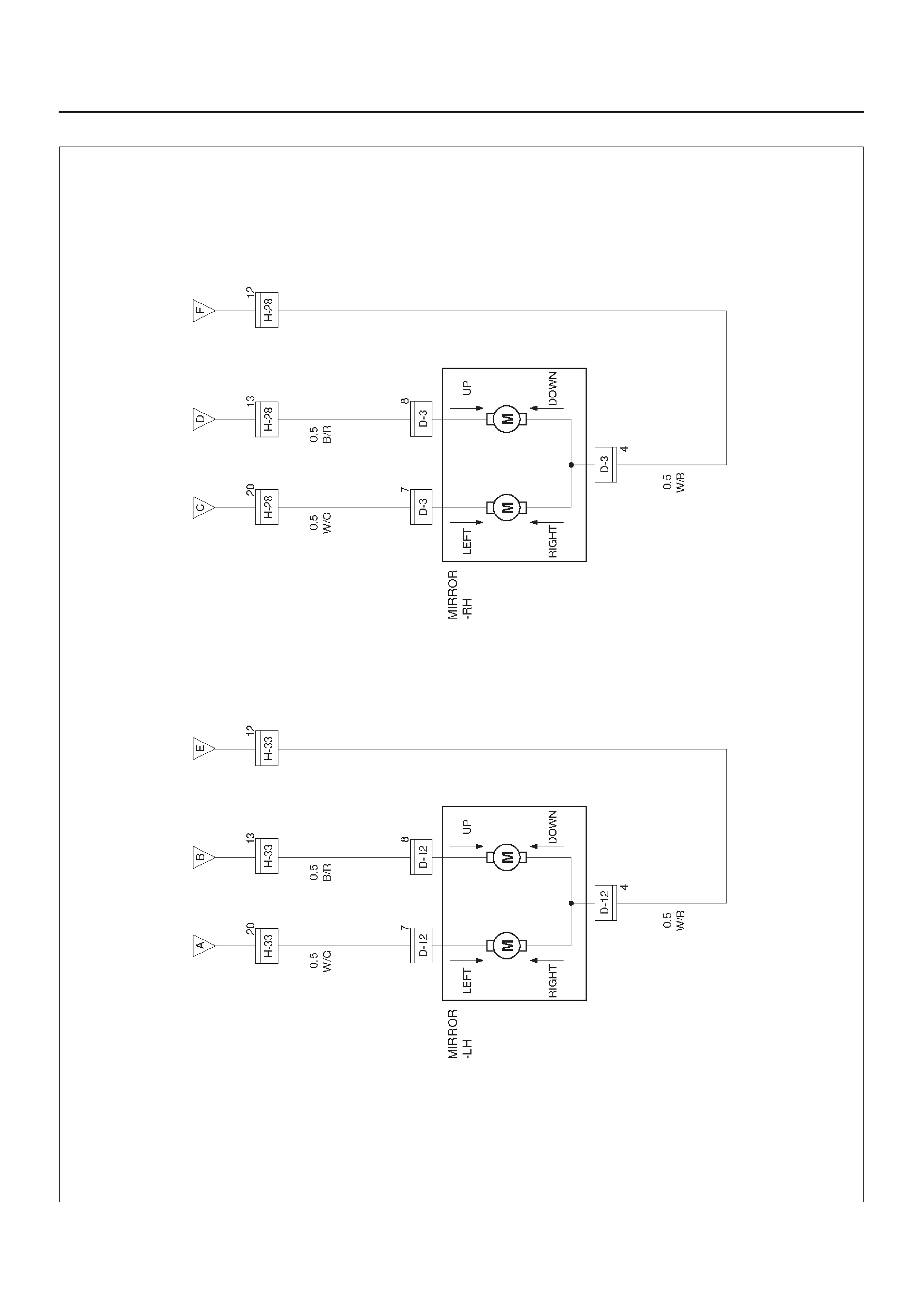

Power Door Mirror

General Description

Circuit Diagram

Parts Location

Diagnosis

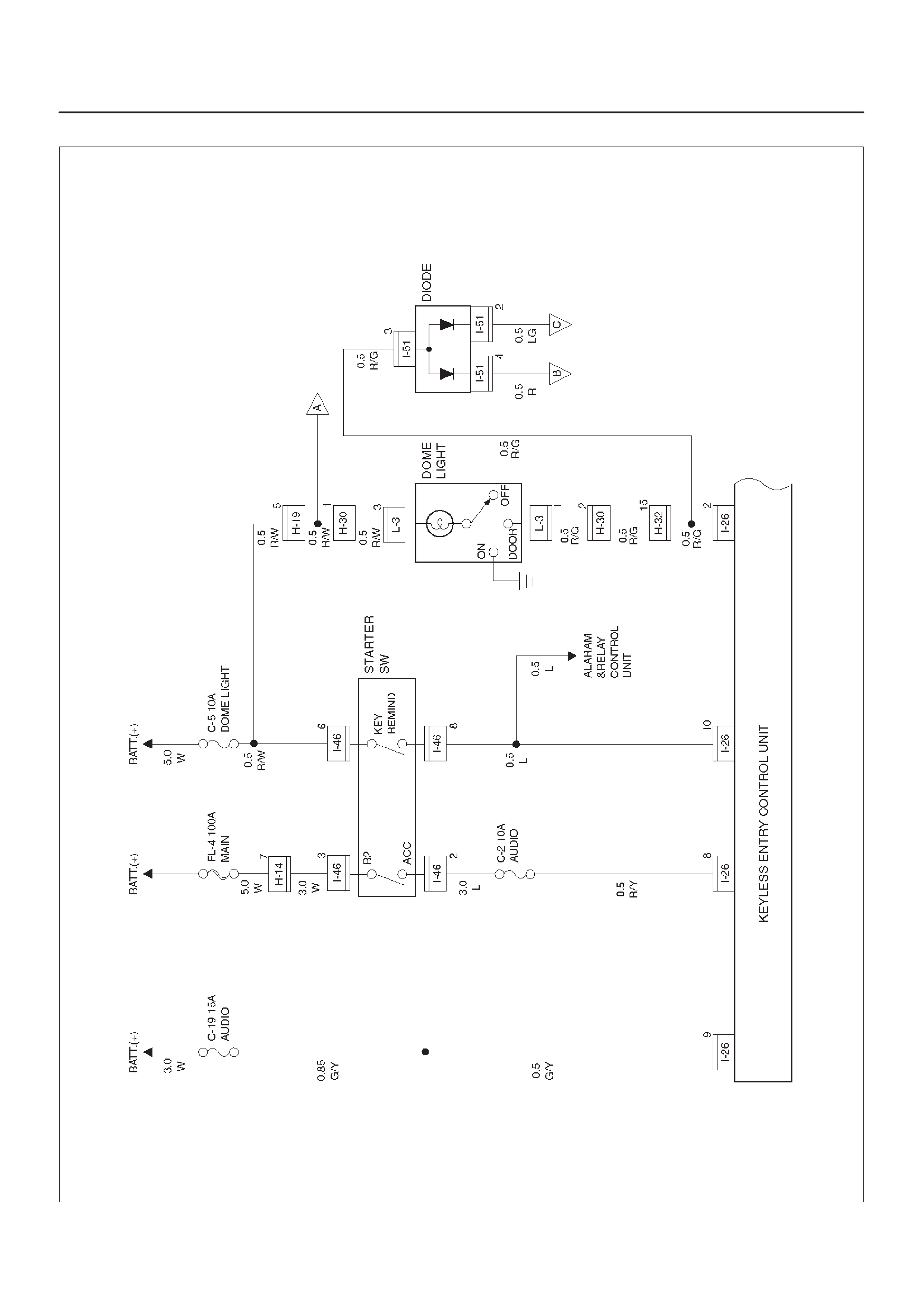

Keyless Entry

General Description

Circuit Diagram

Parts Location

Keyless Entry System

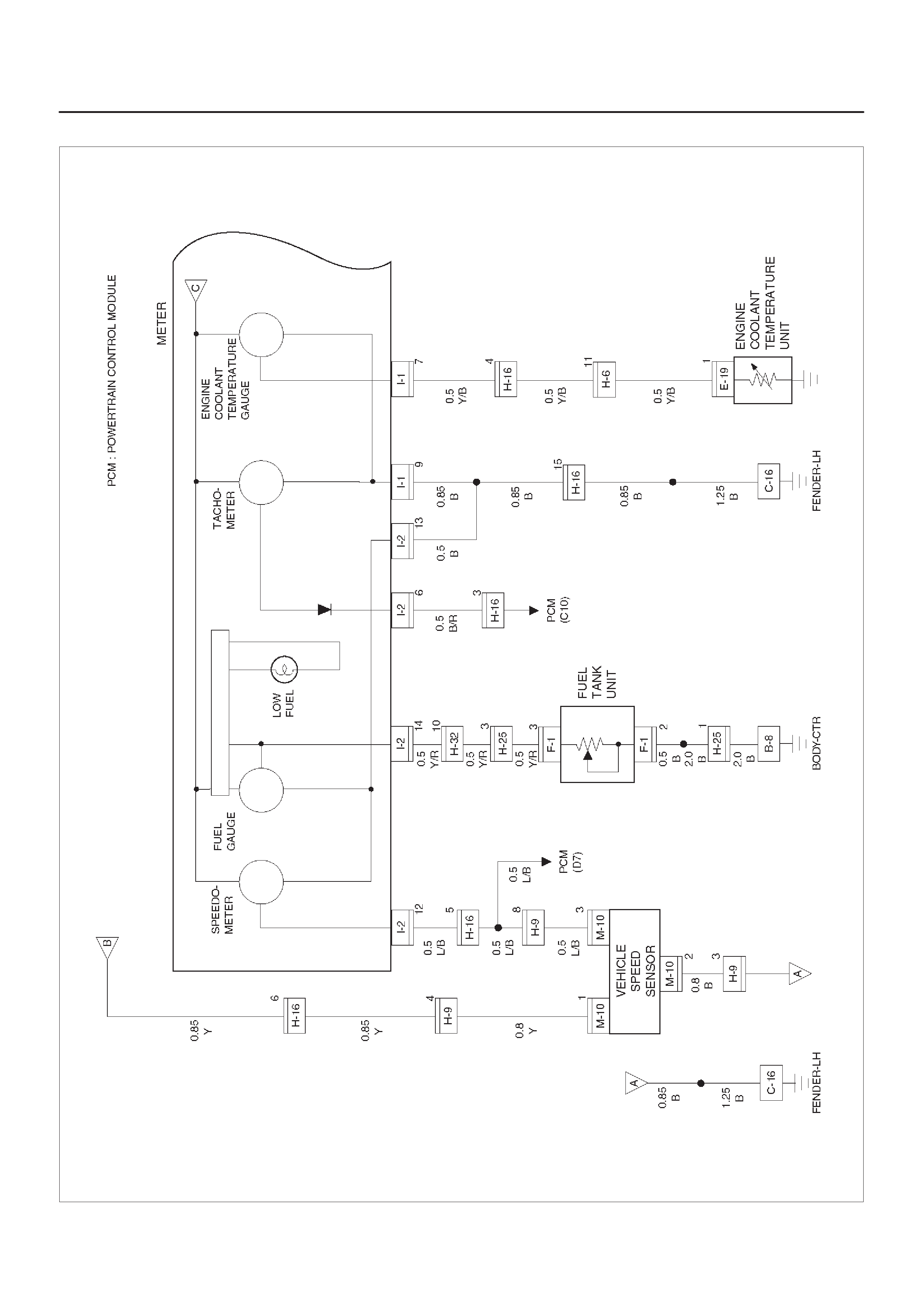

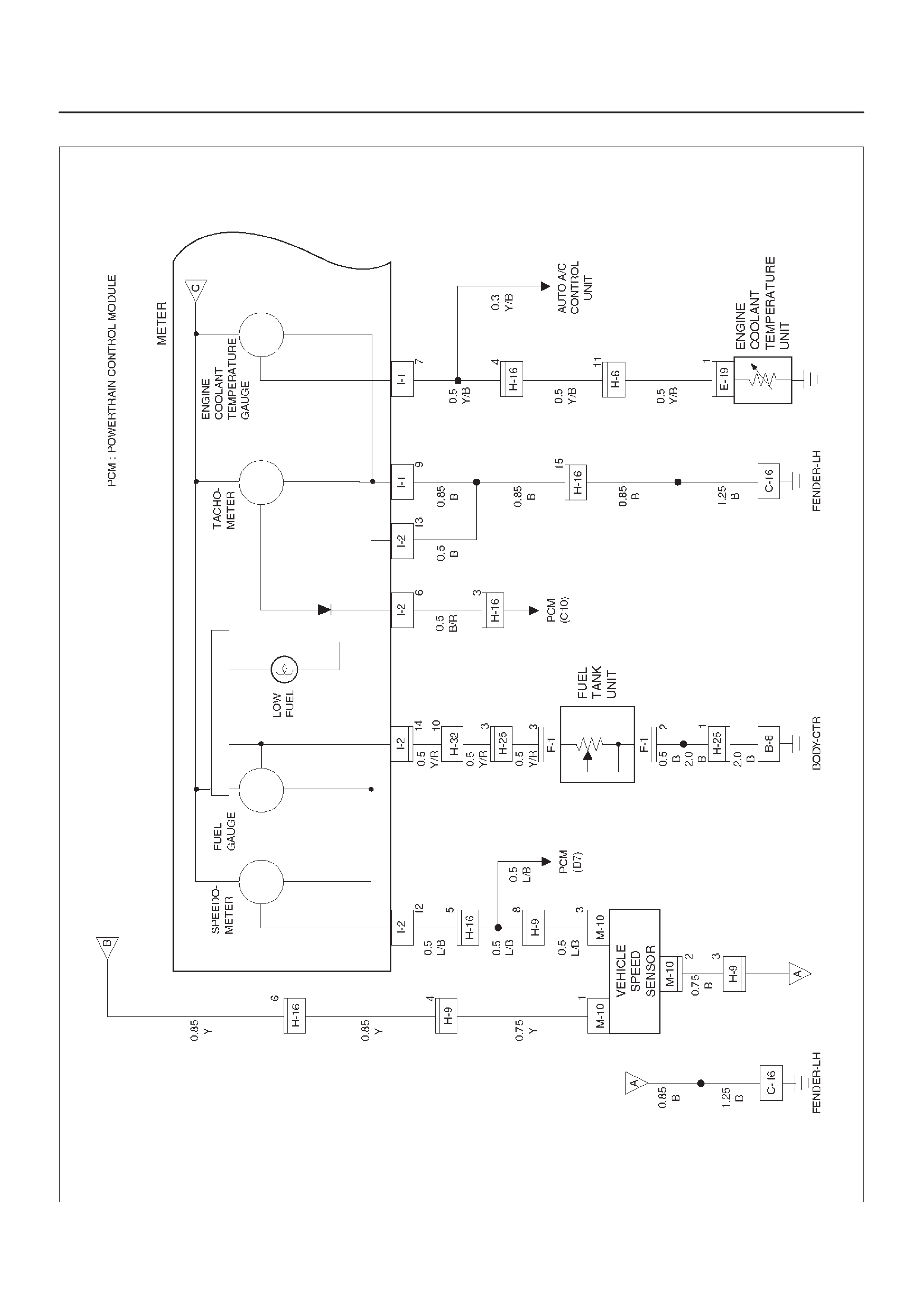

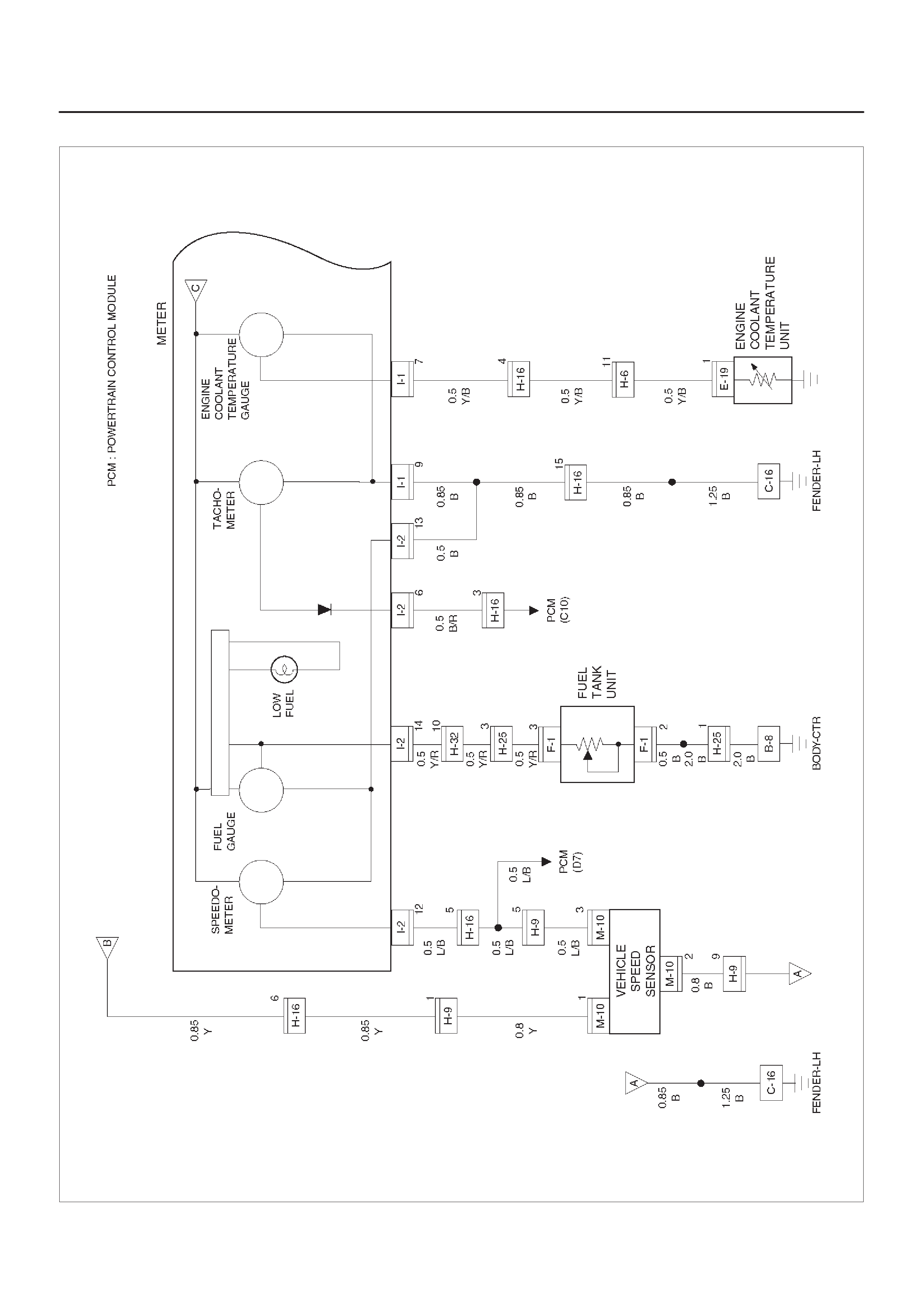

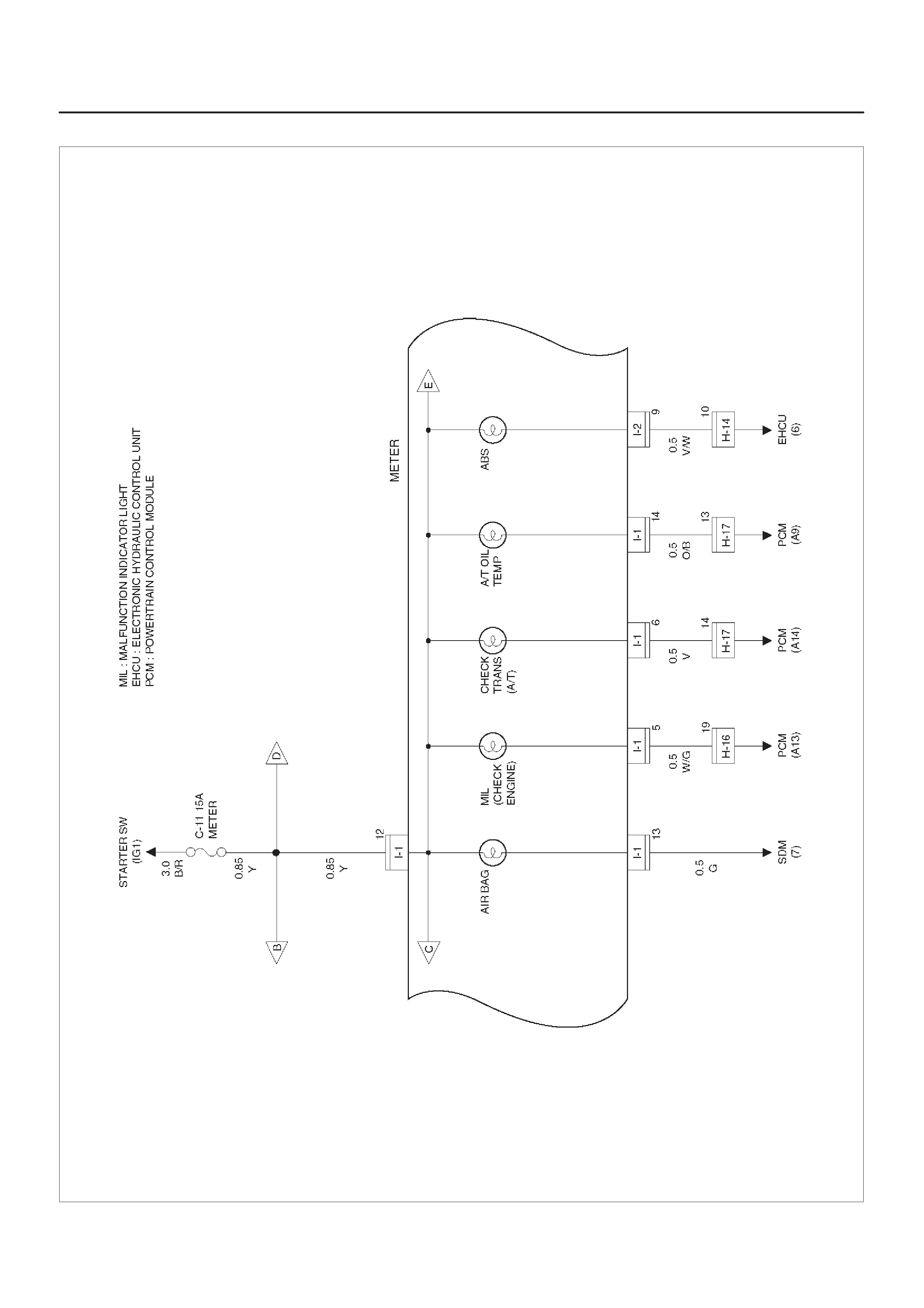

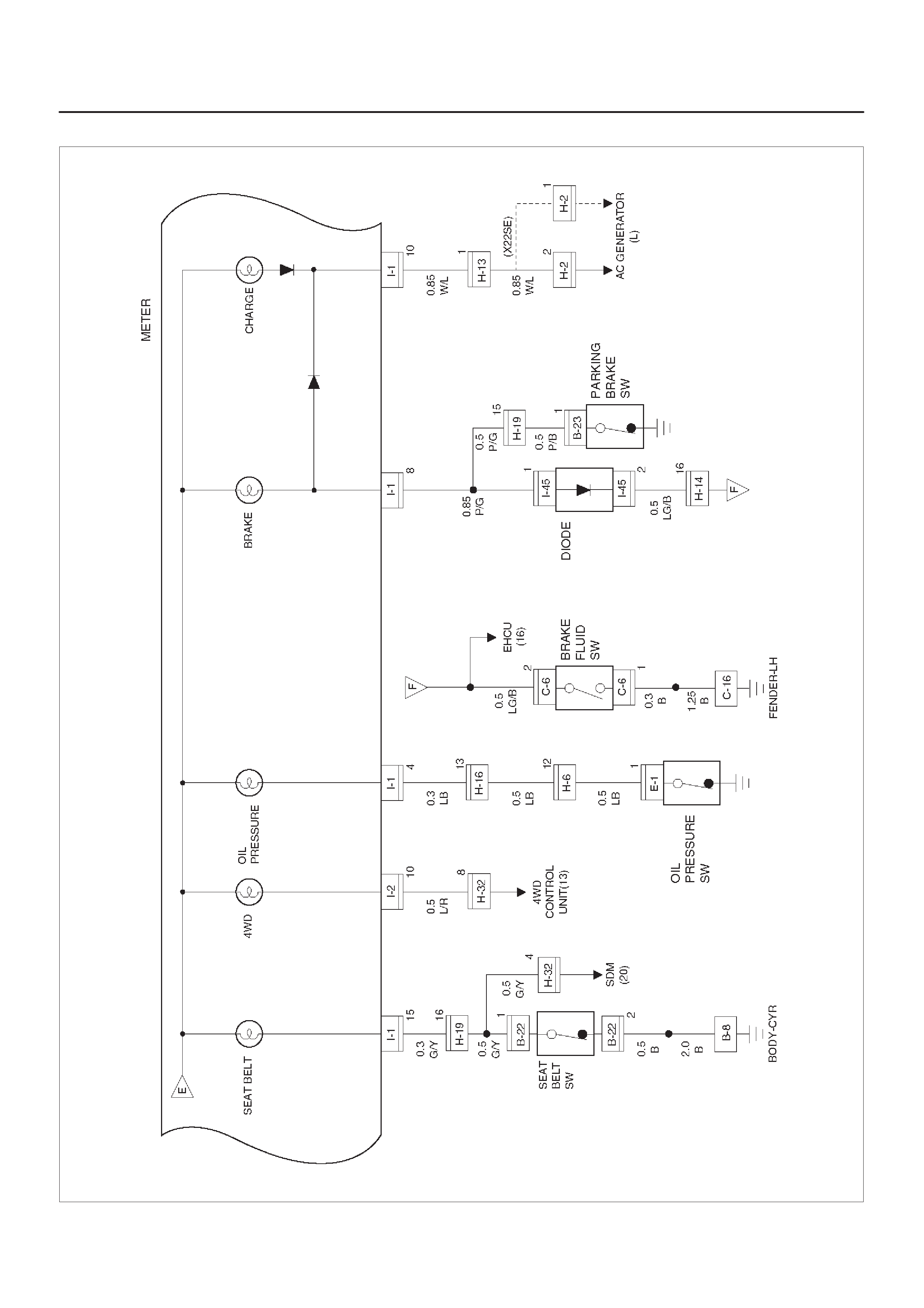

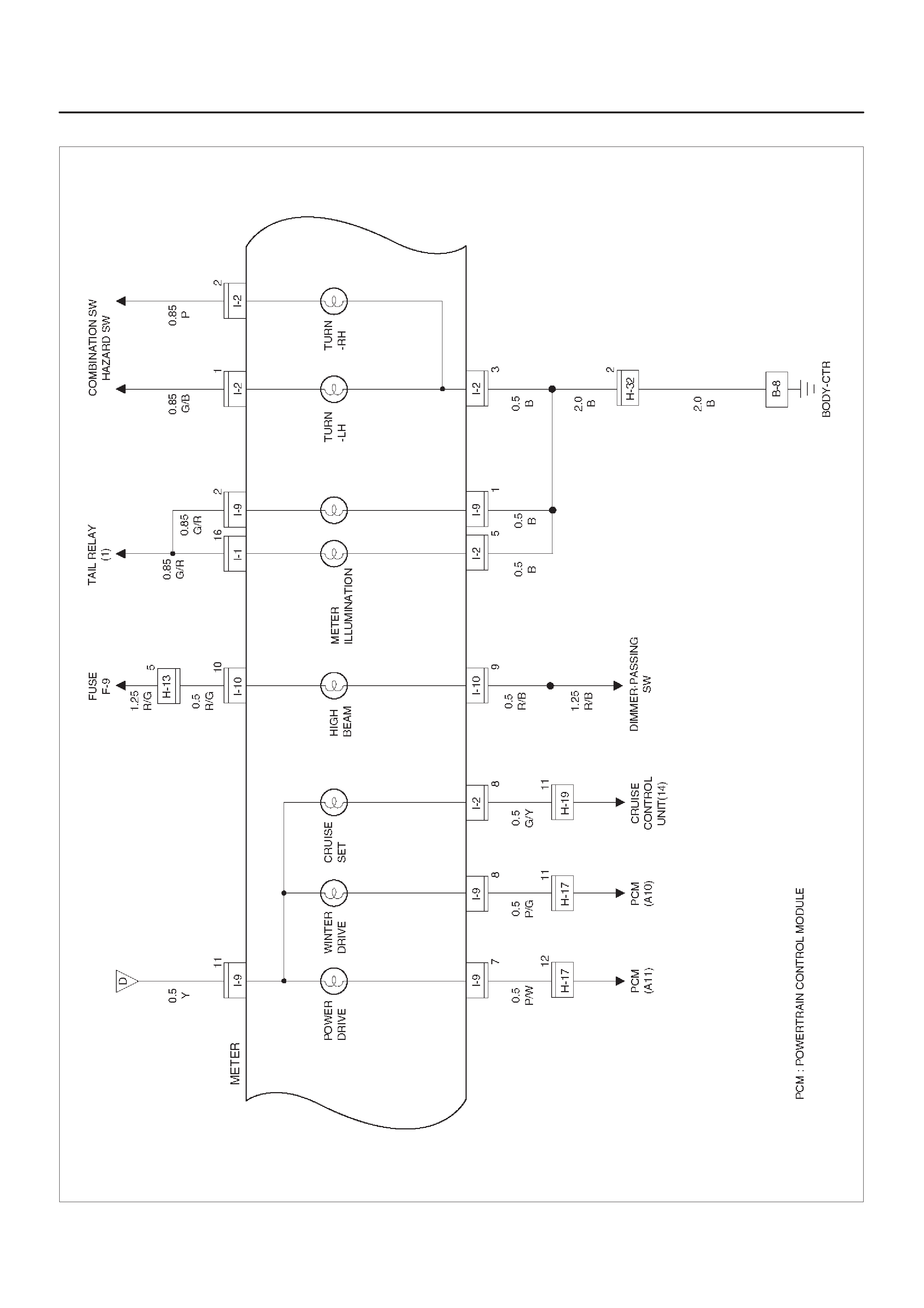

Meter and Warning/Indicator Light

General Description

Circuit Diagram

Parts Location

Diagnosis

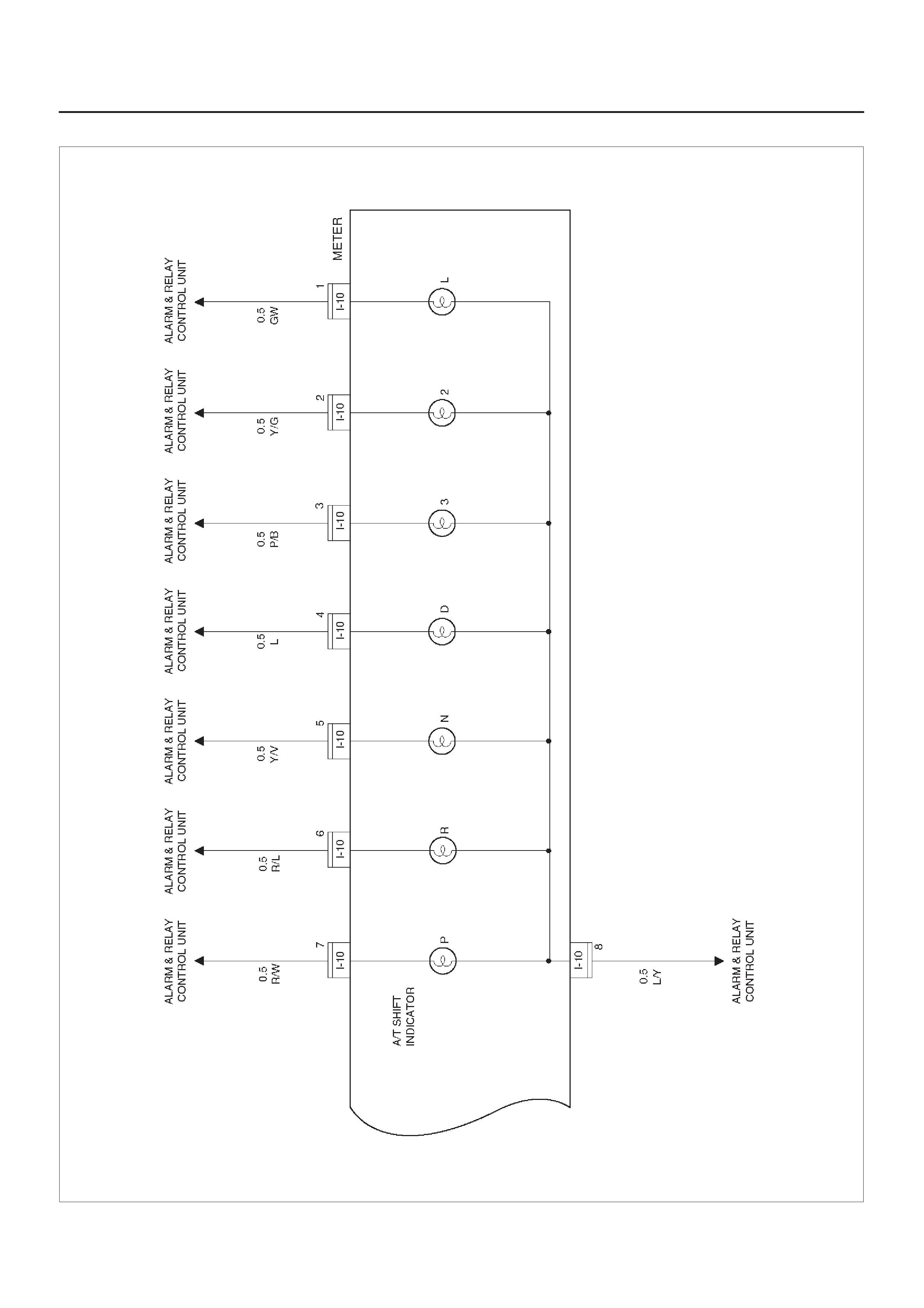

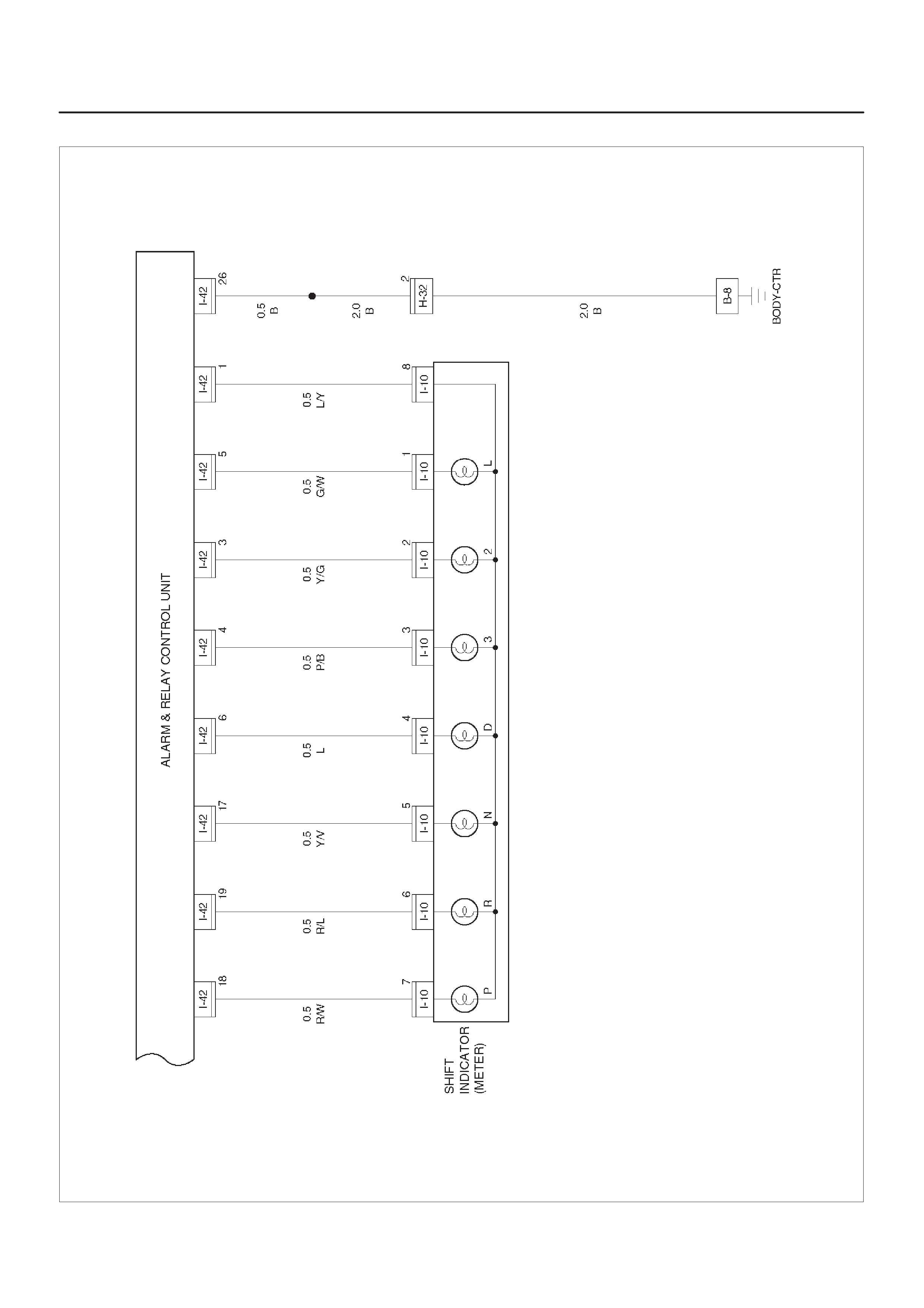

A/T Shift Indicator

General Description

Circuit Diagram

Parts Location

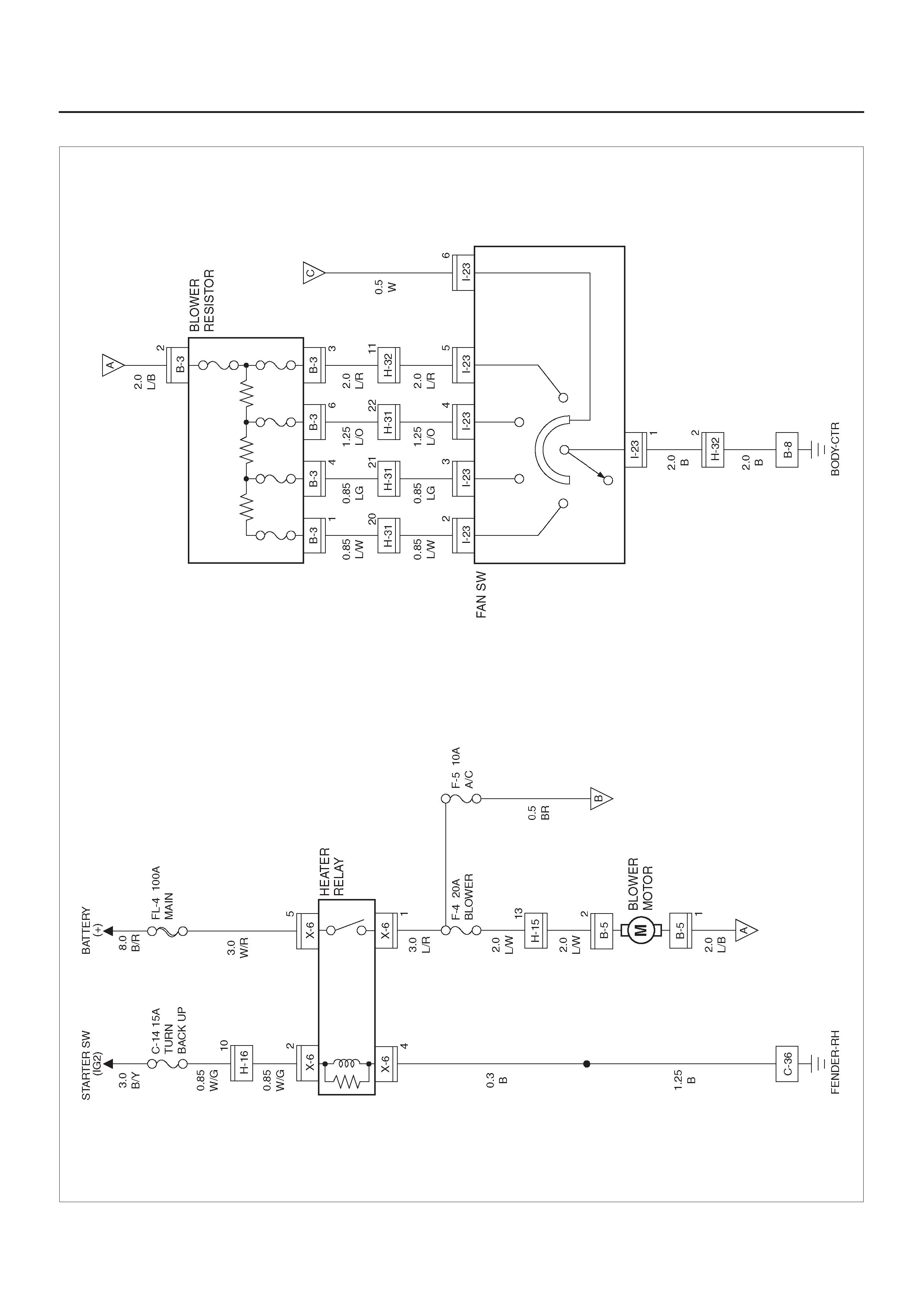

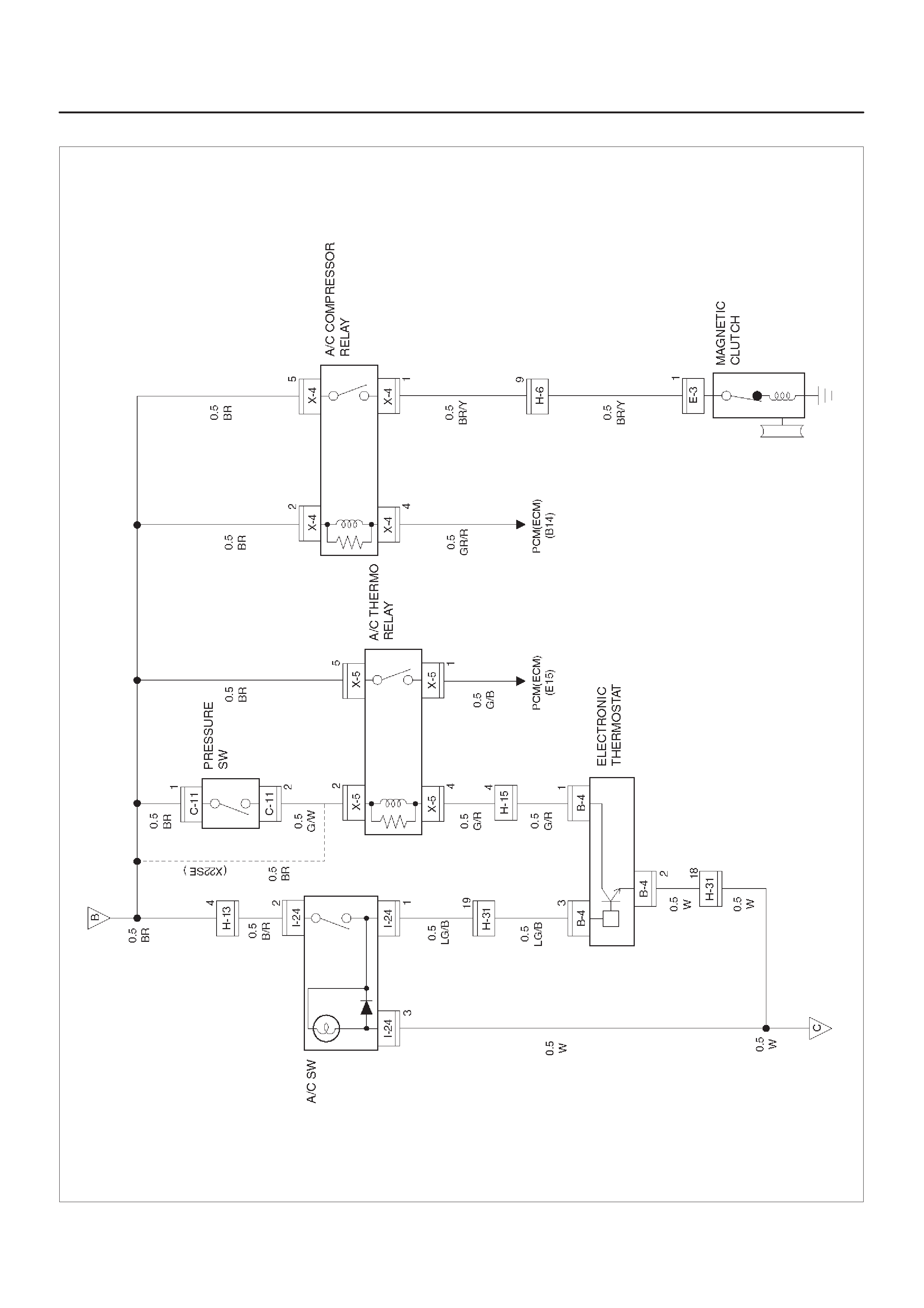

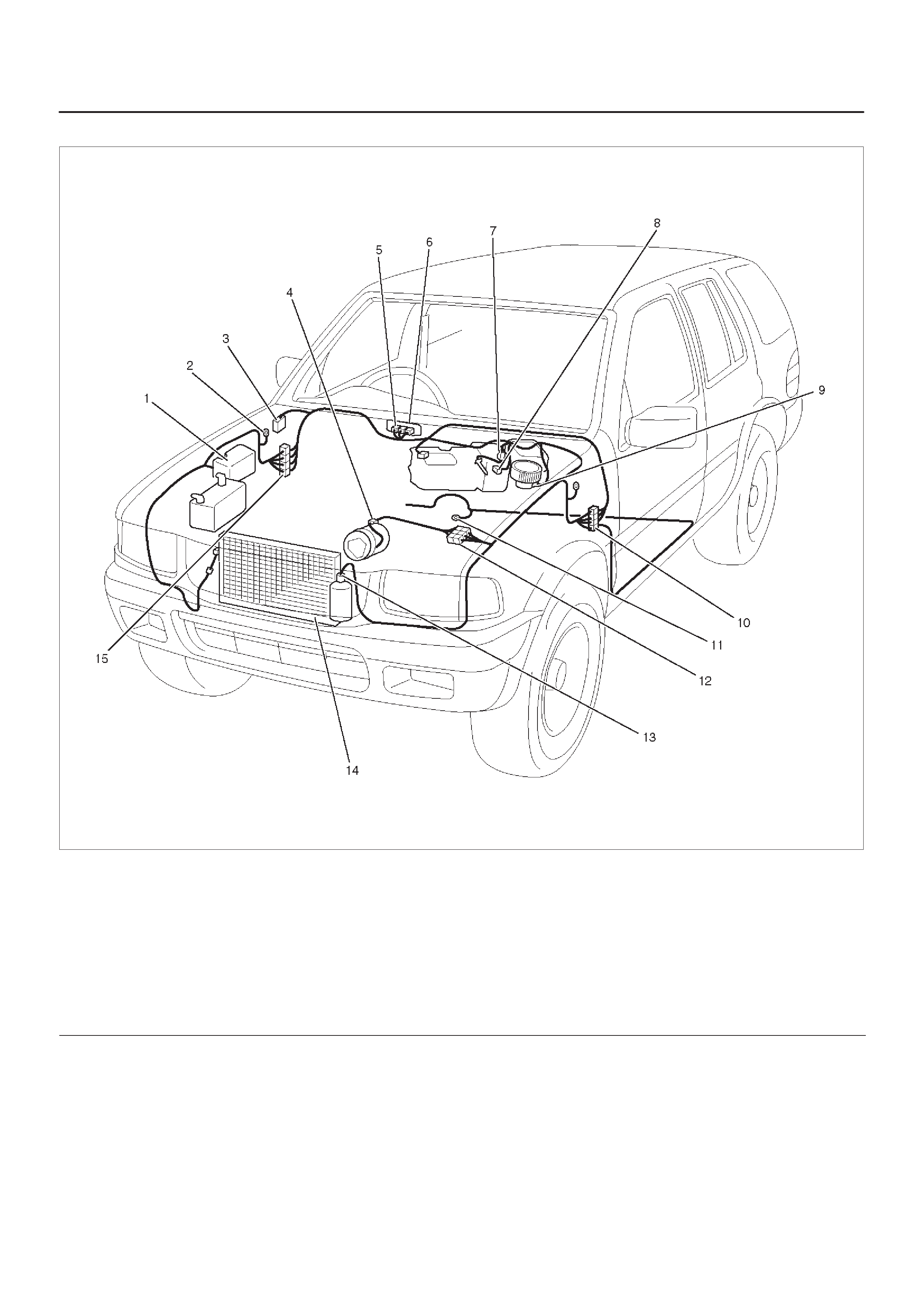

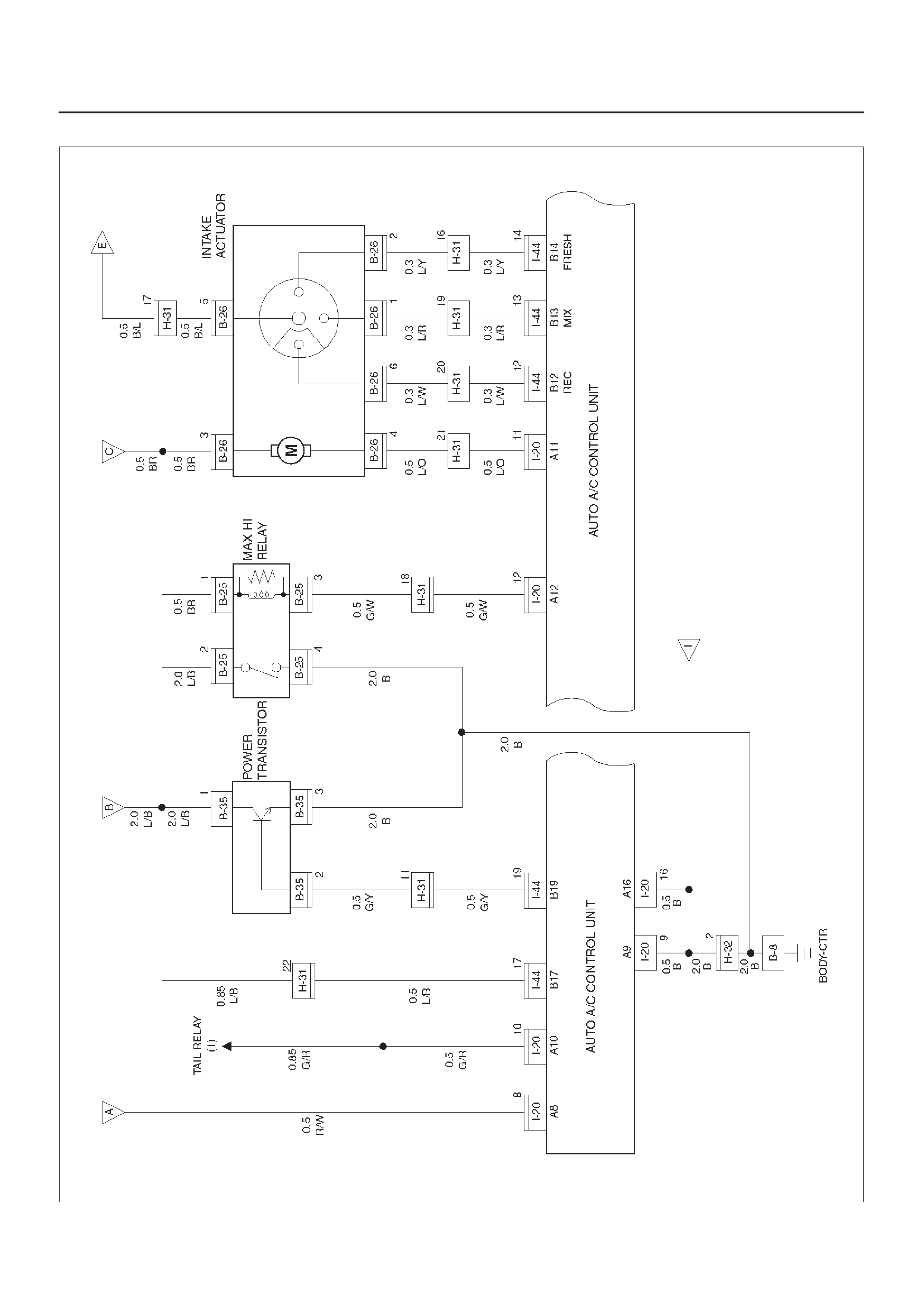

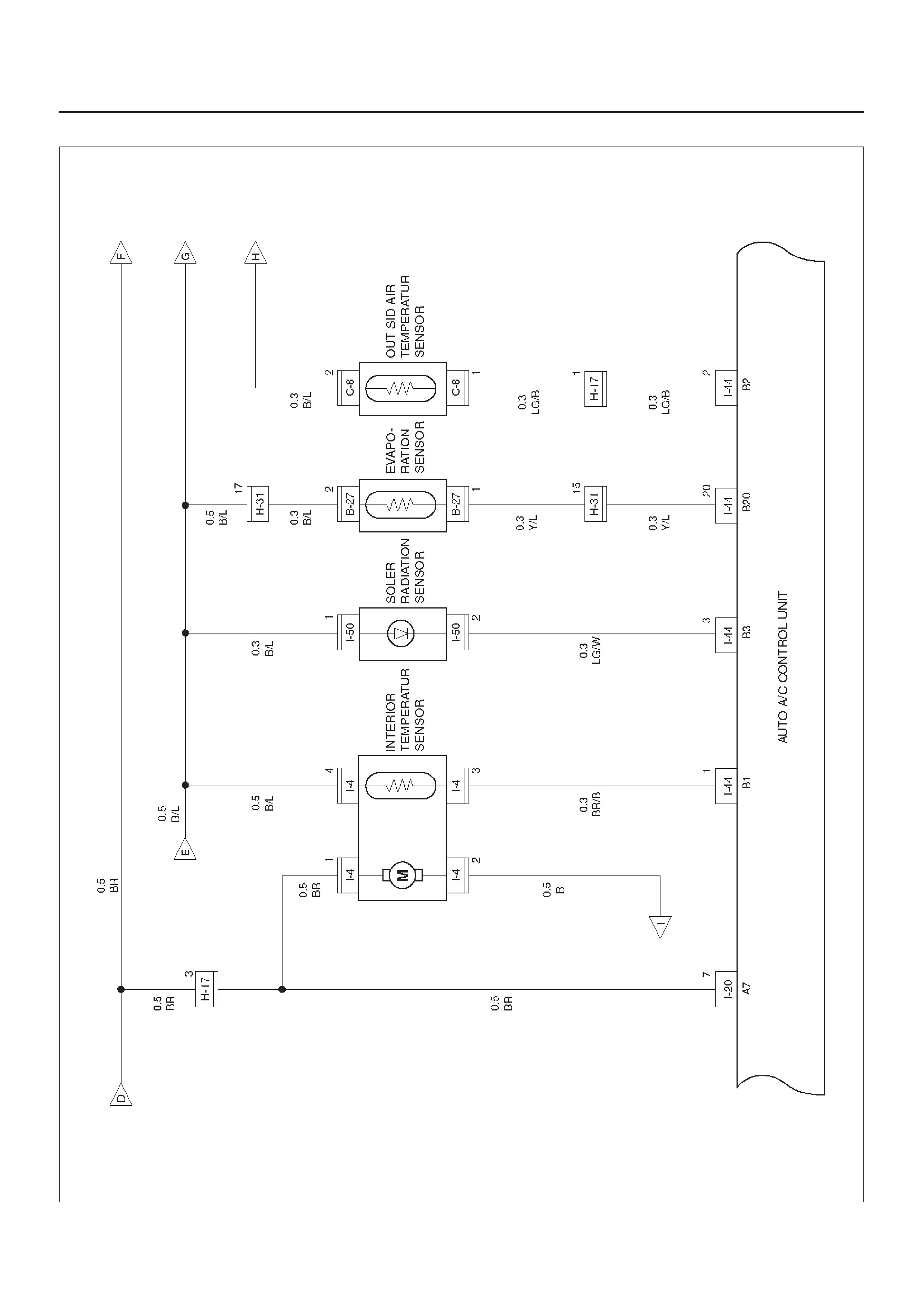

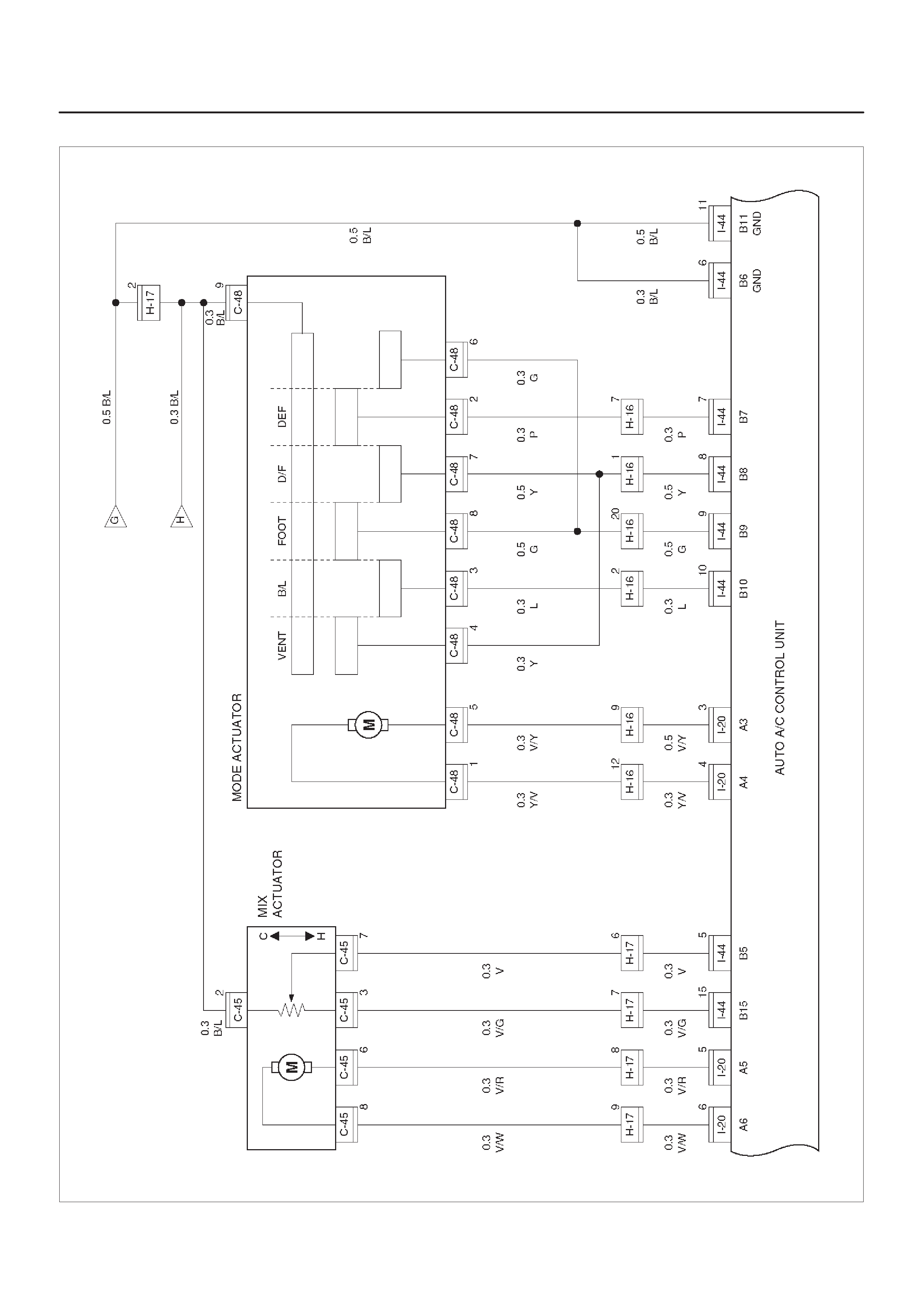

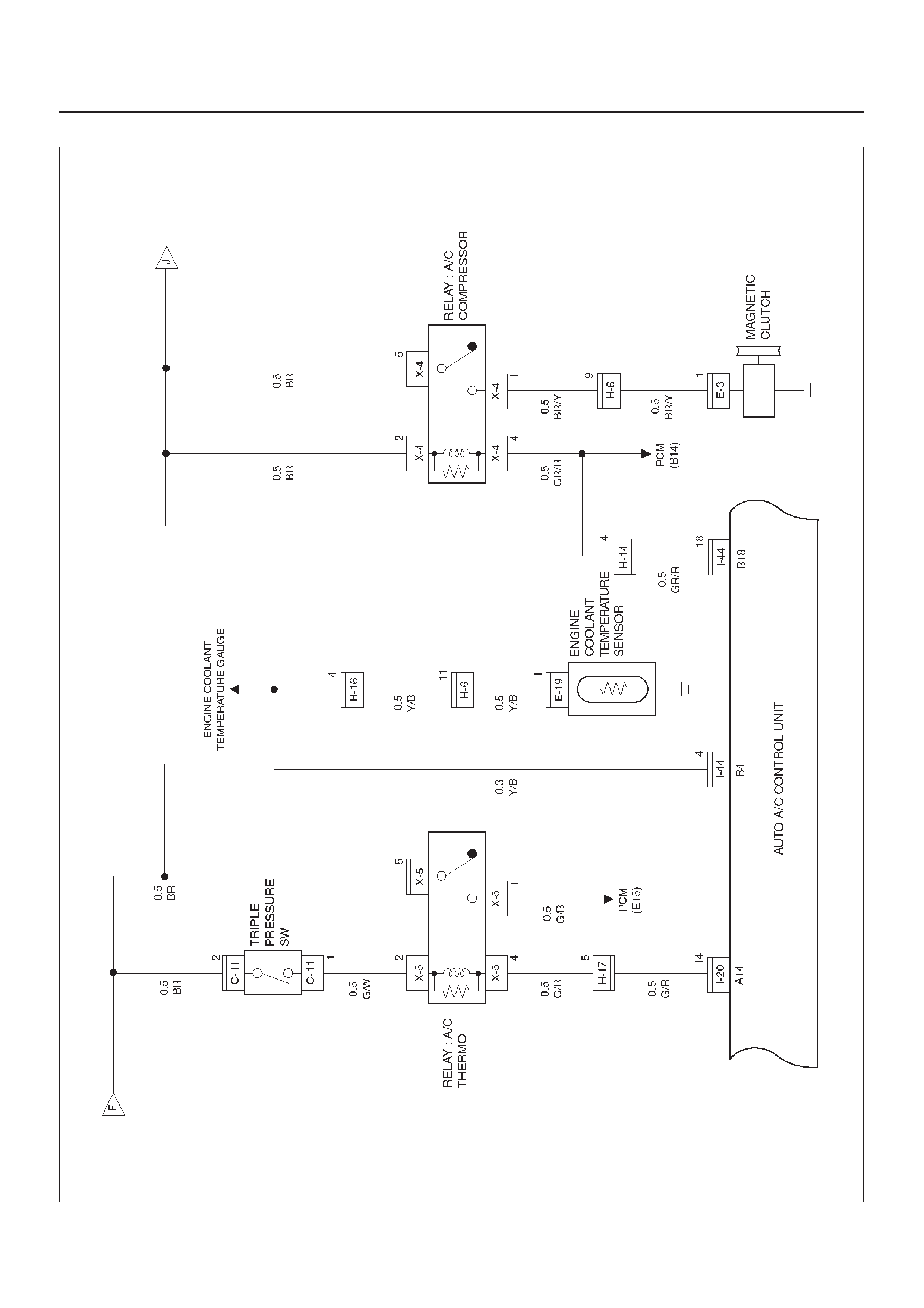

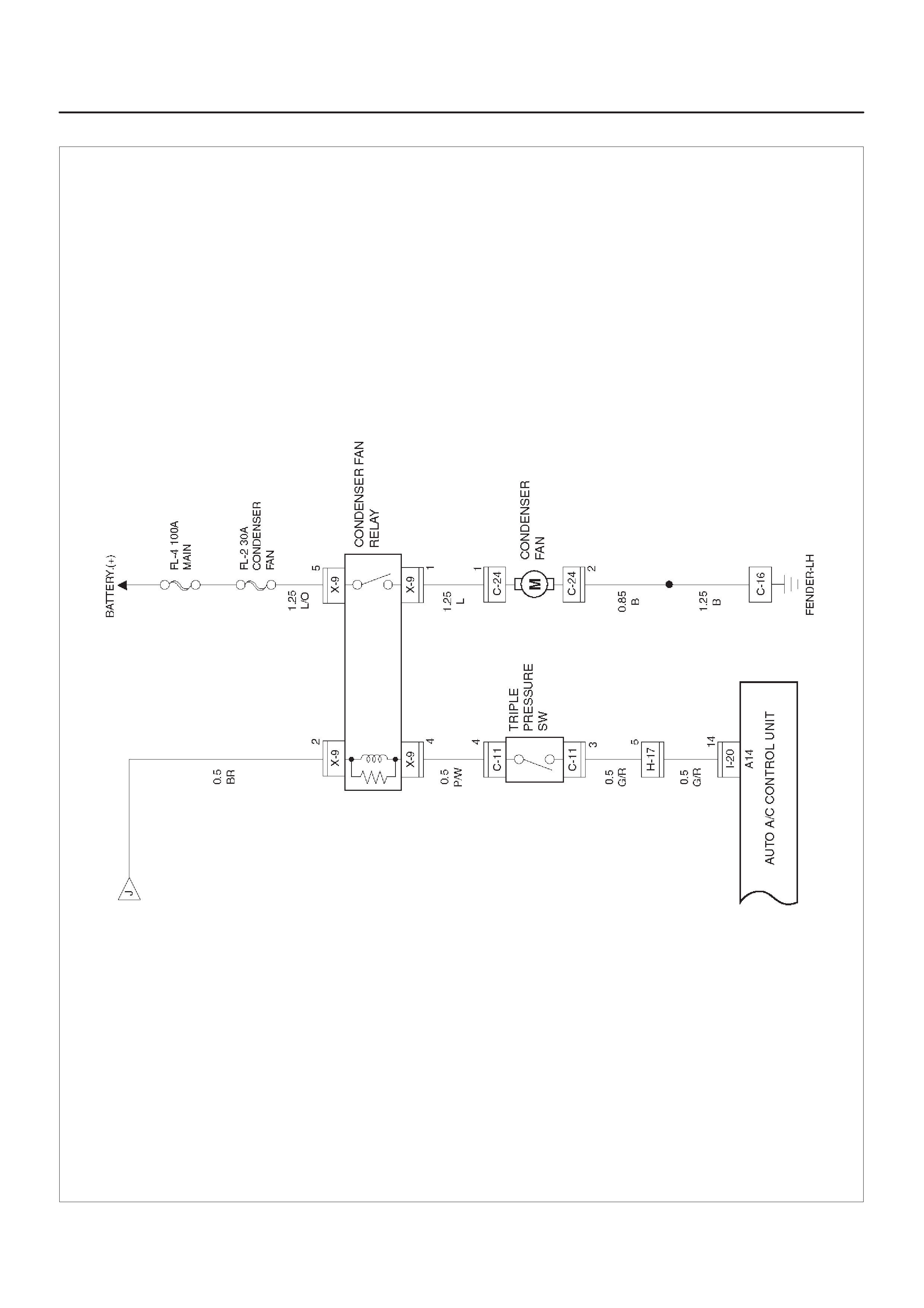

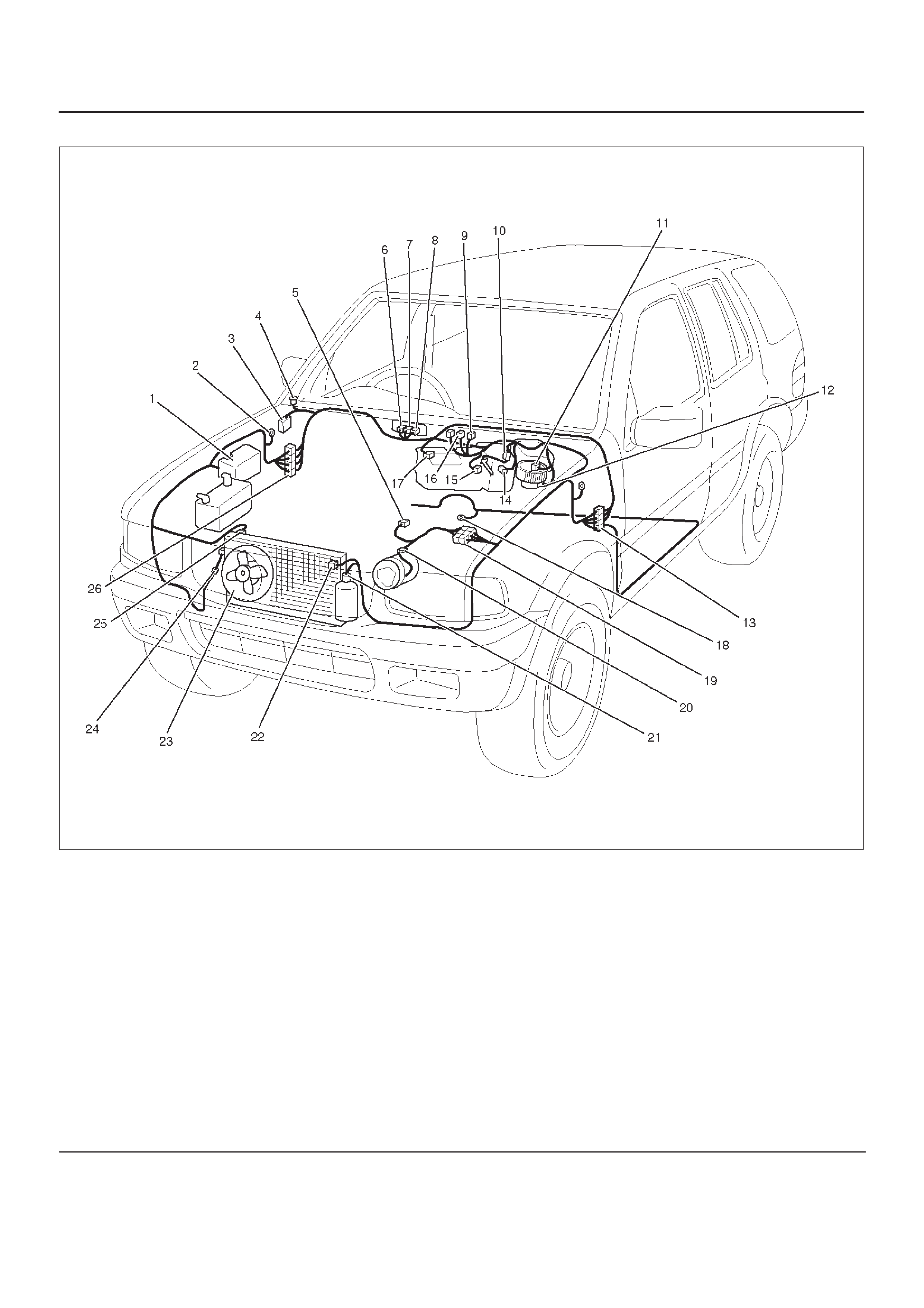

Heater and Air Conditioning

General Description

Circuit Diagram

Parts Location

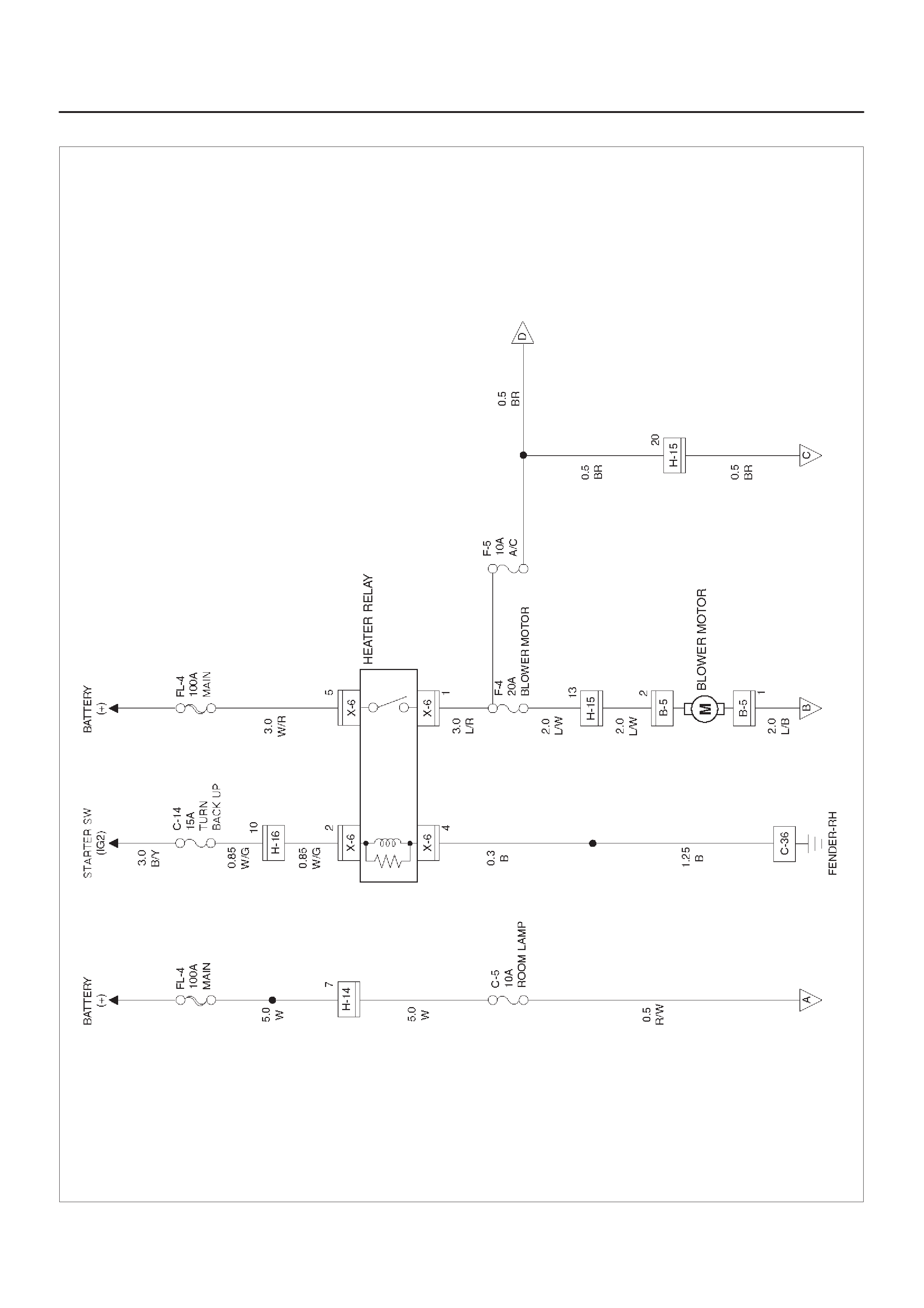

Heater and Air Conditioning

General Description

Circuit Diagram

Parts Location

Sunroof

General Description

Circuit Diagram

Parts Location

Diagnosis

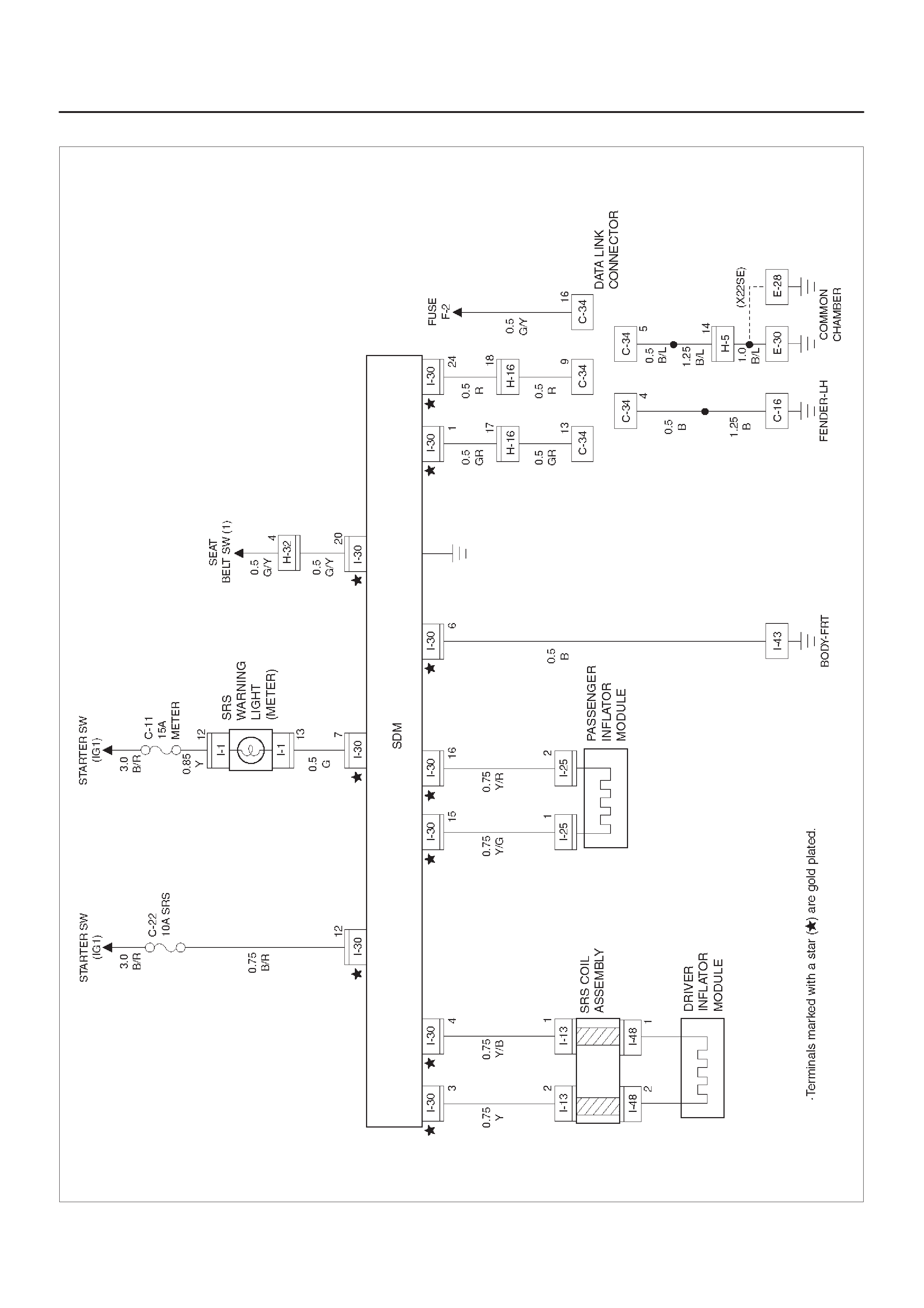

Supplemental Restraint System (SRS)

– Air Bag

General Description

Circuit Diagram

Parts Location

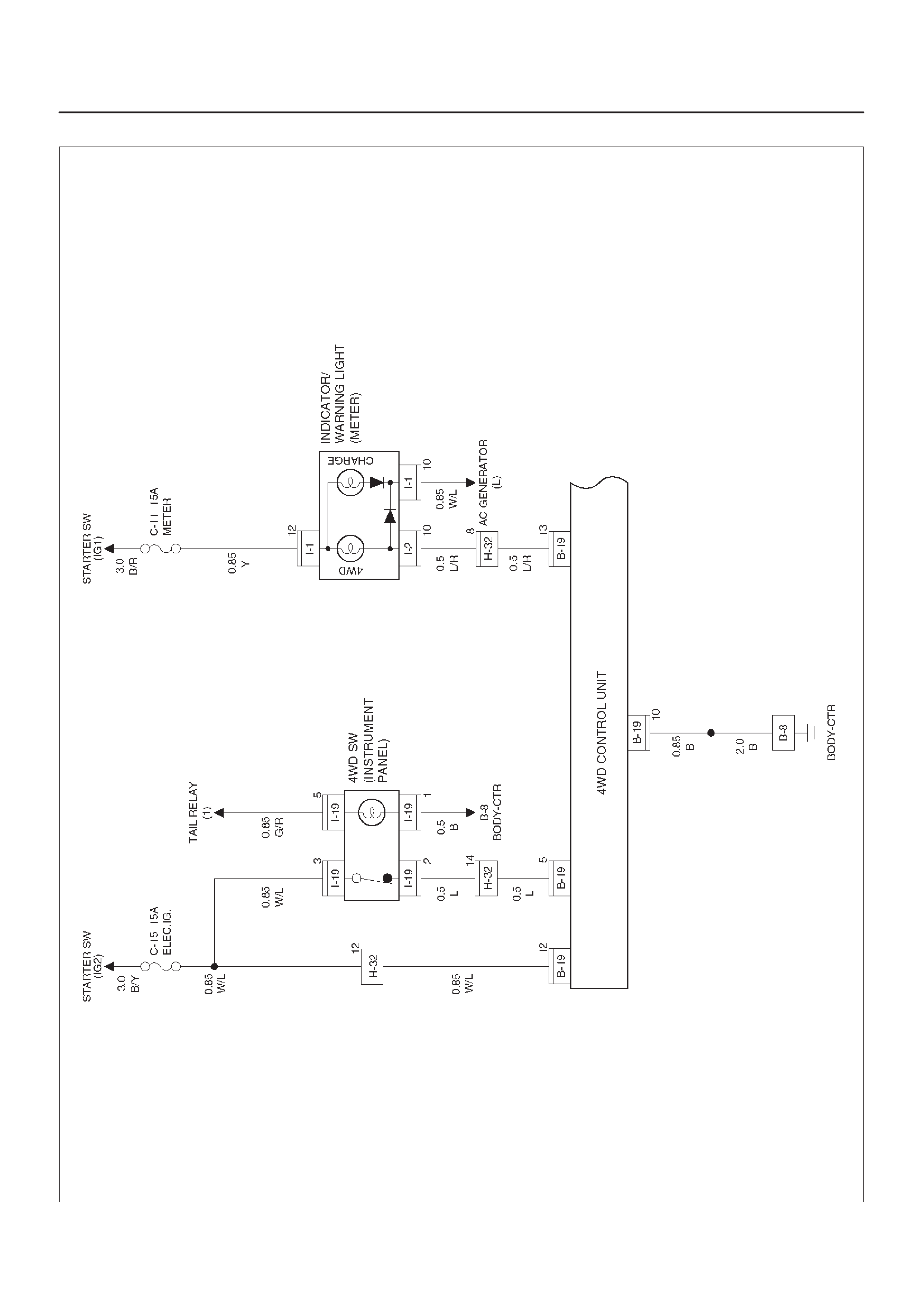

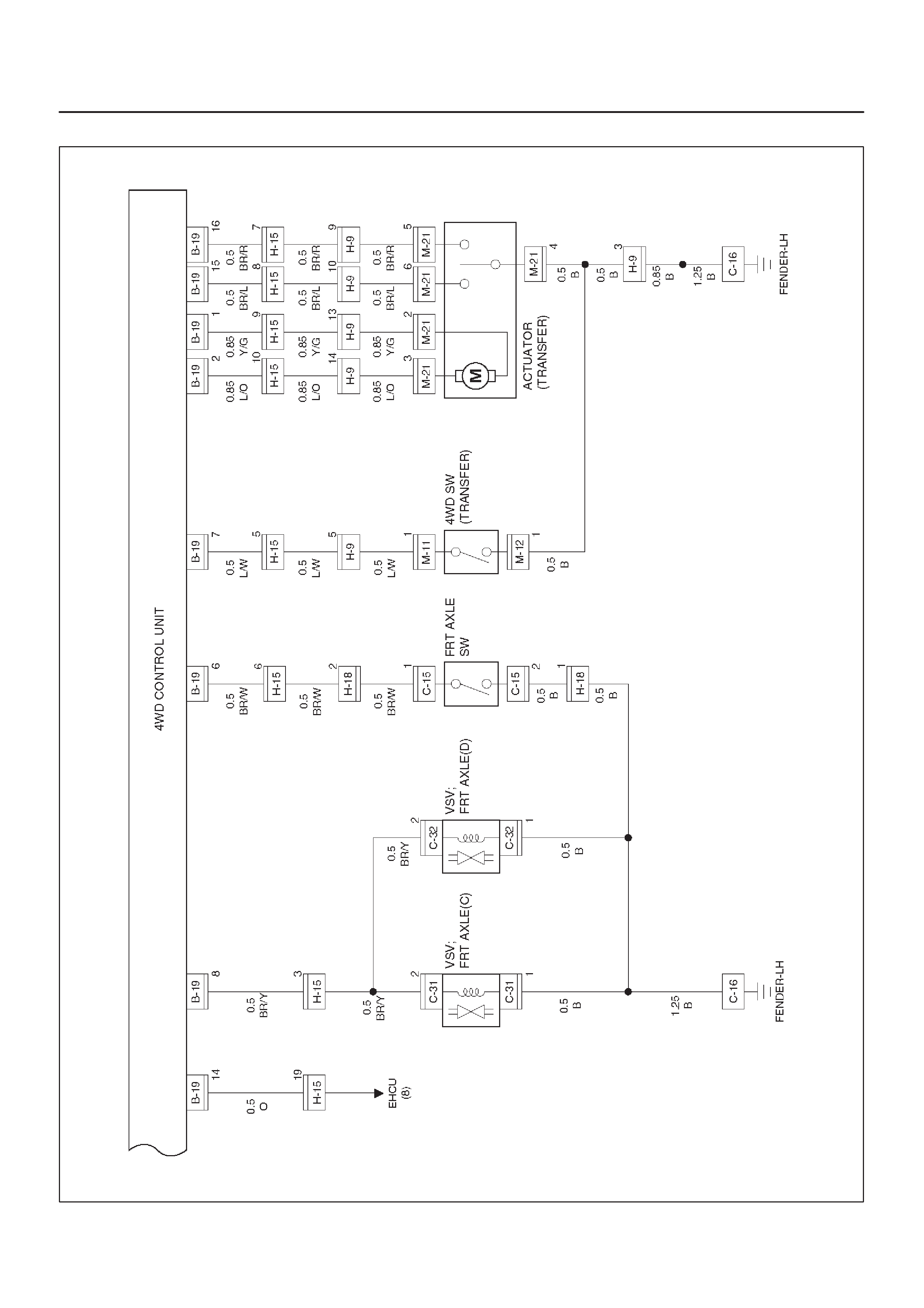

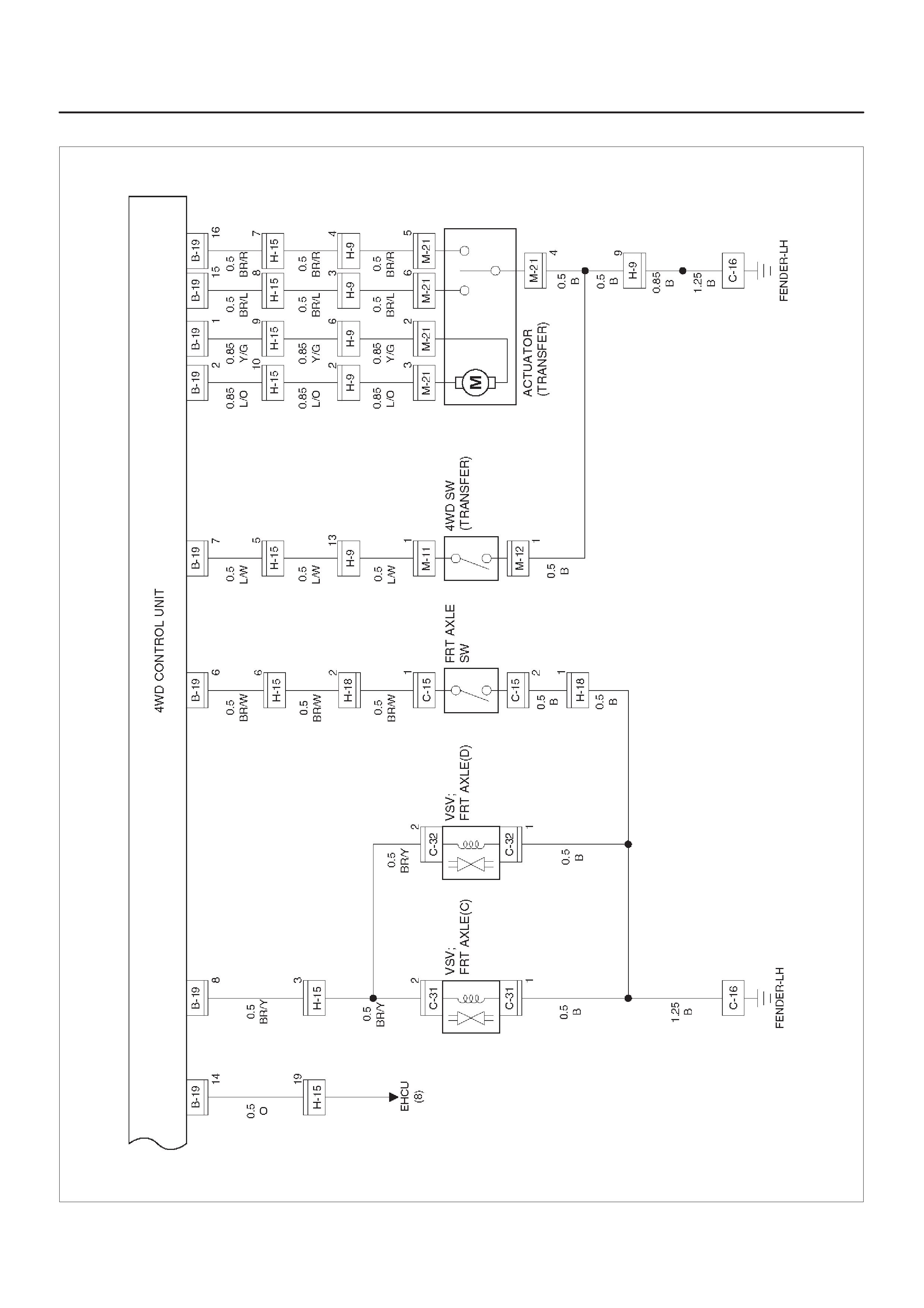

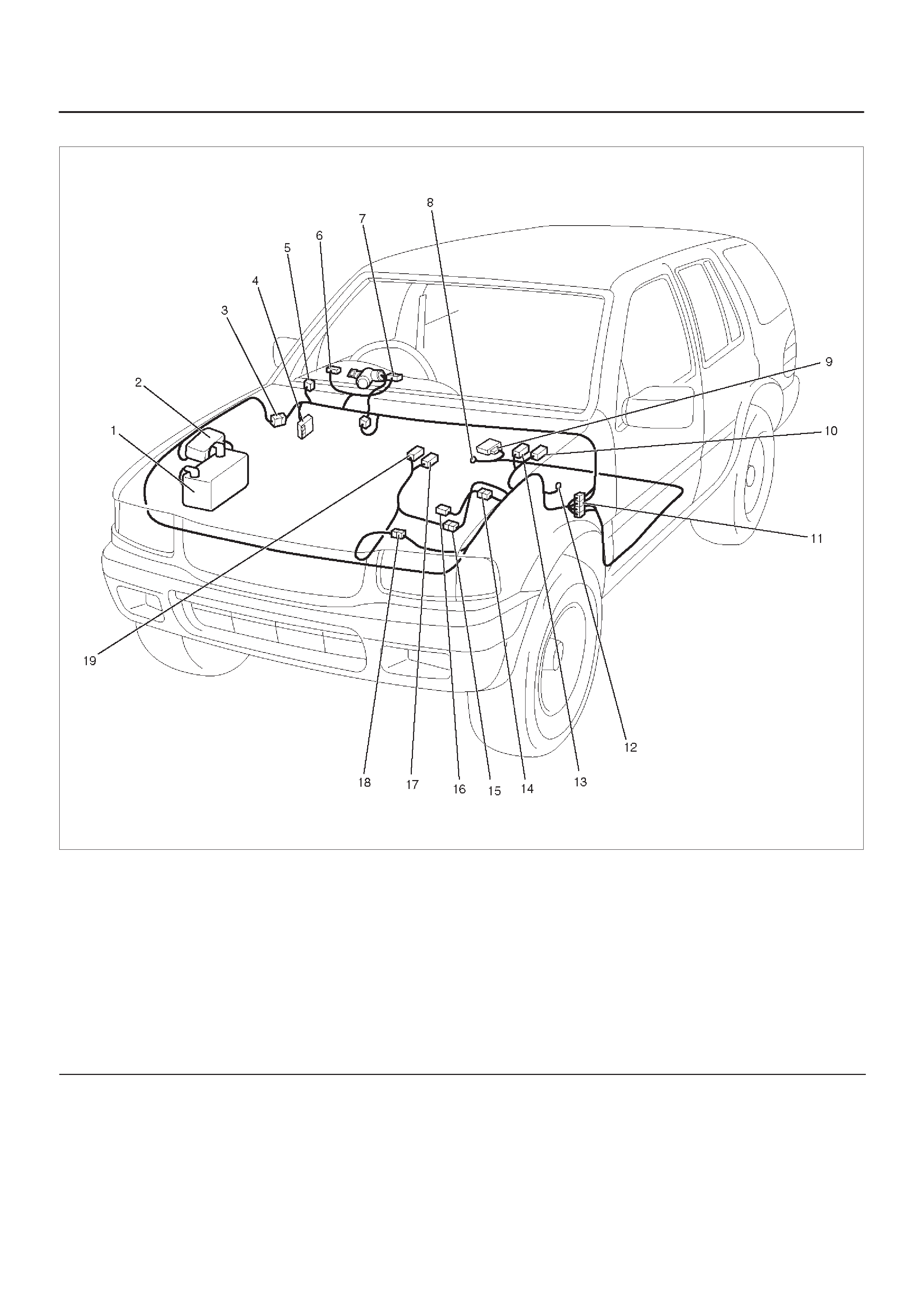

Shift on the Fly System

General Description

Circuit Diagram

Parts Location

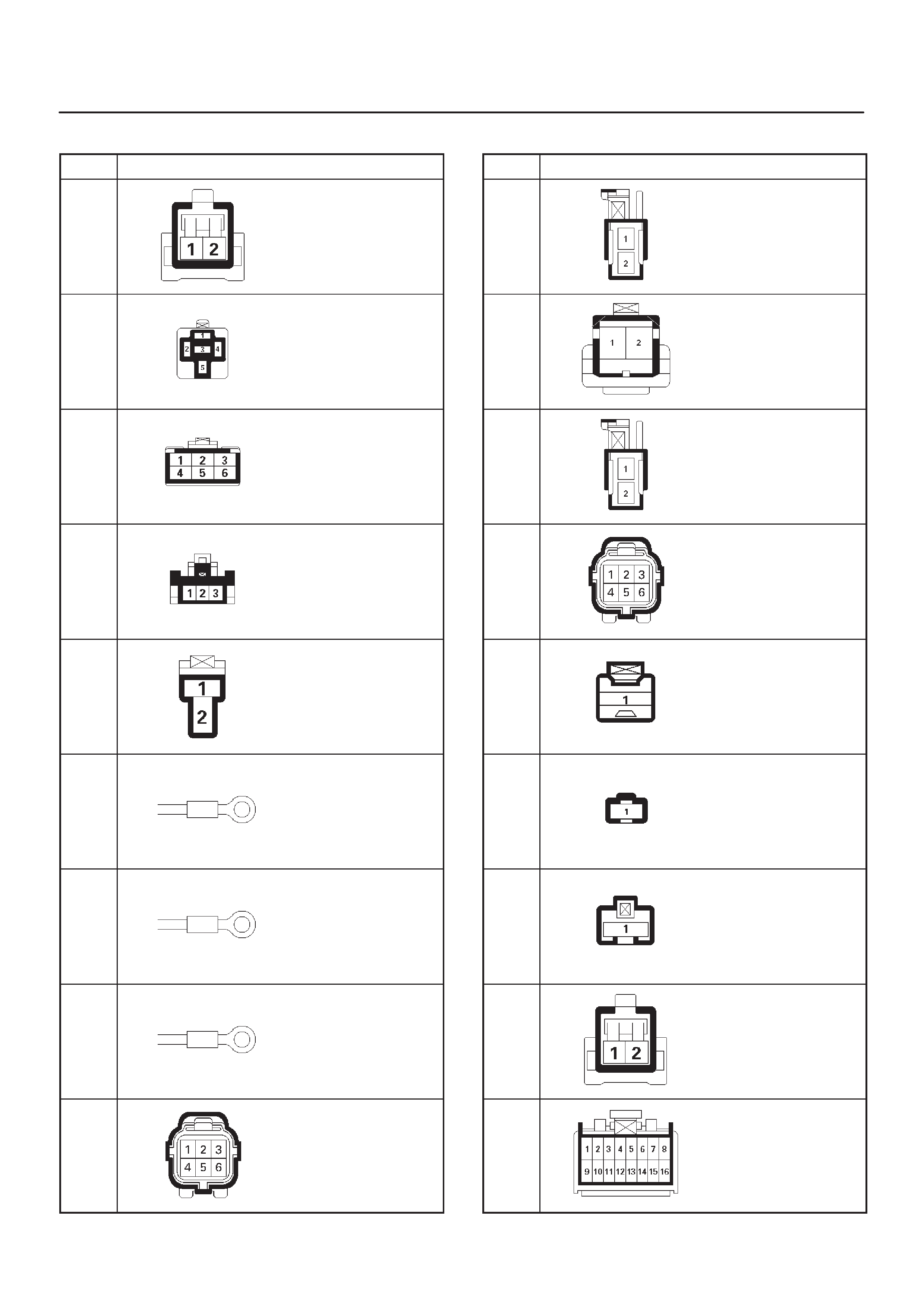

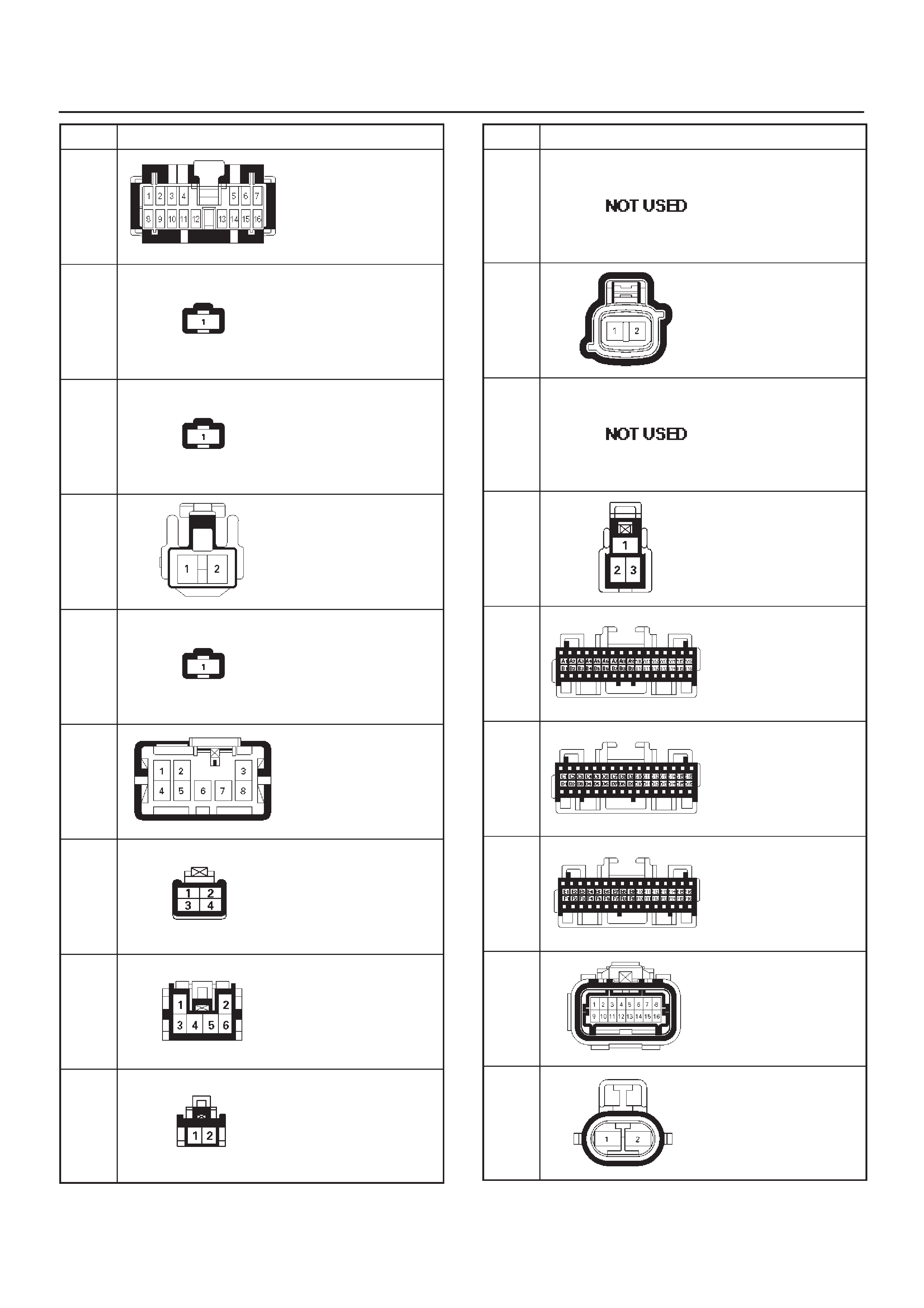

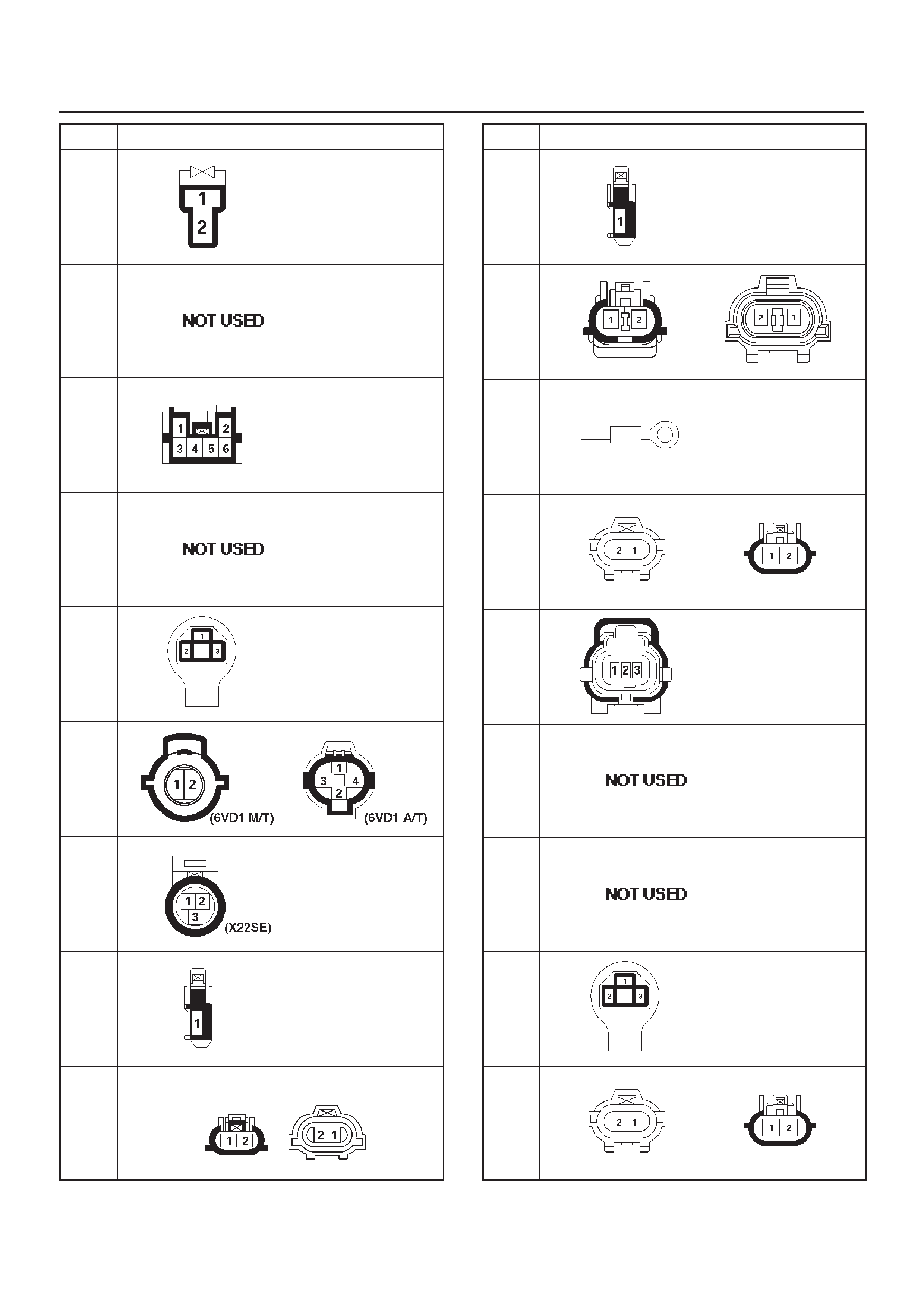

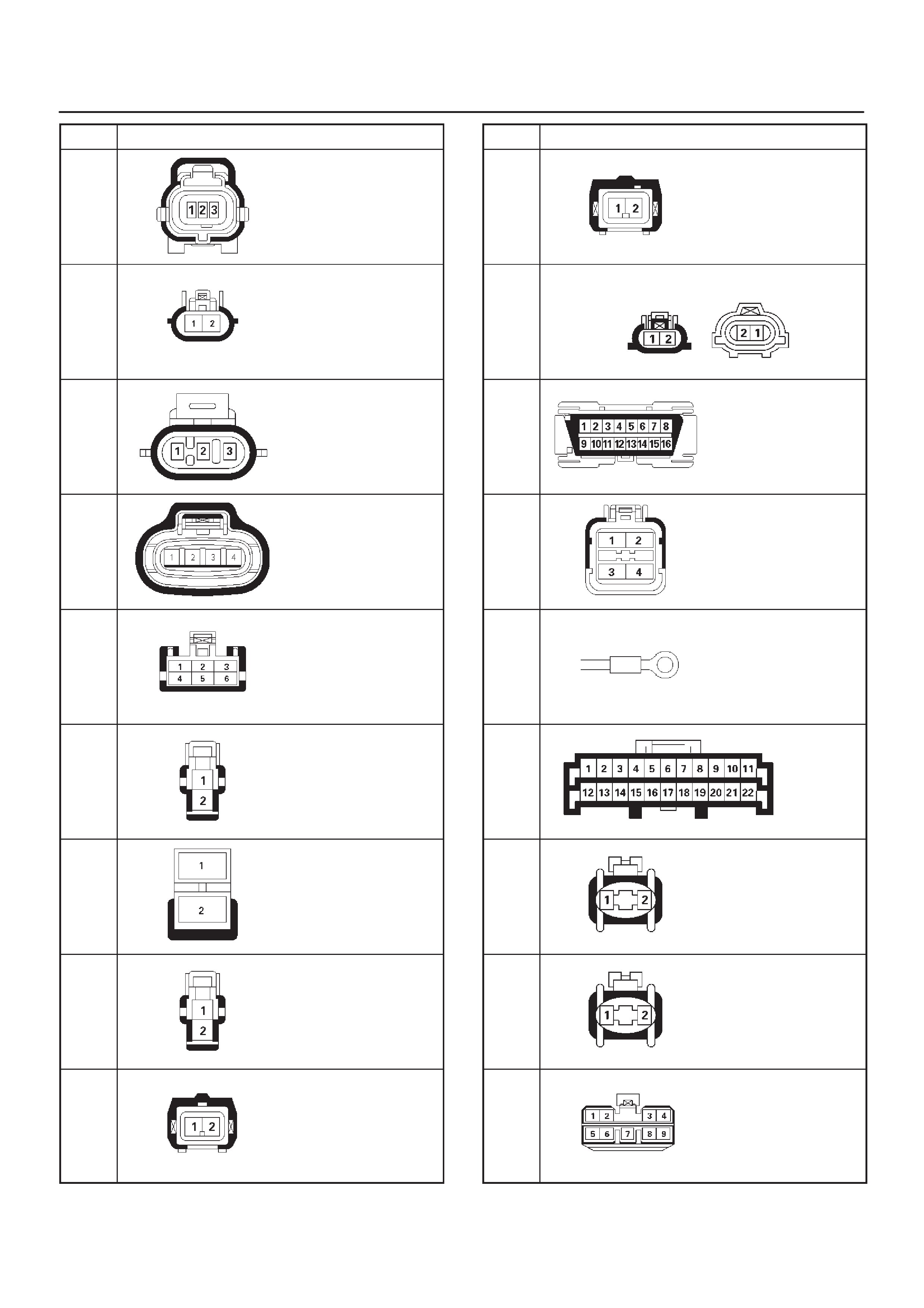

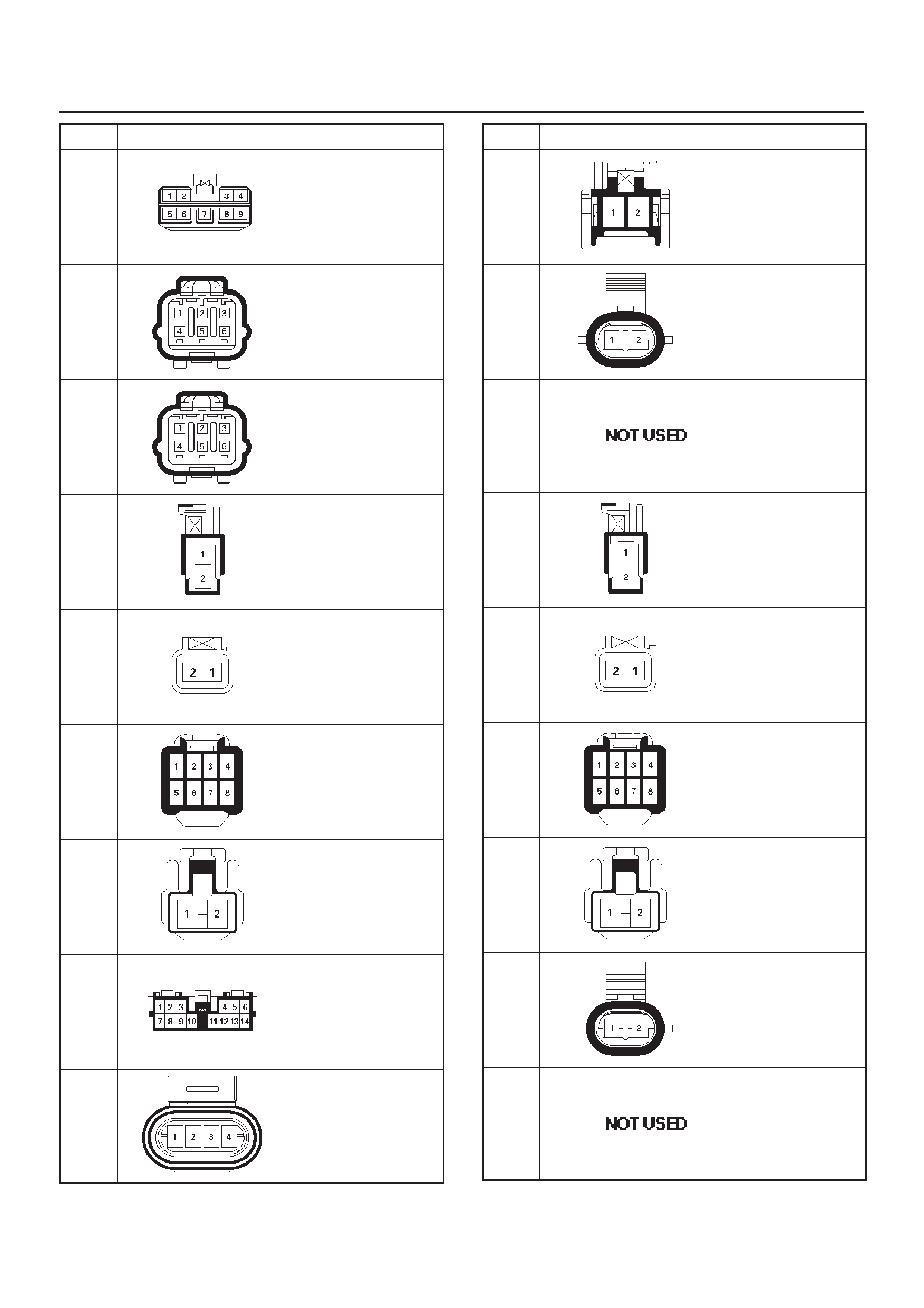

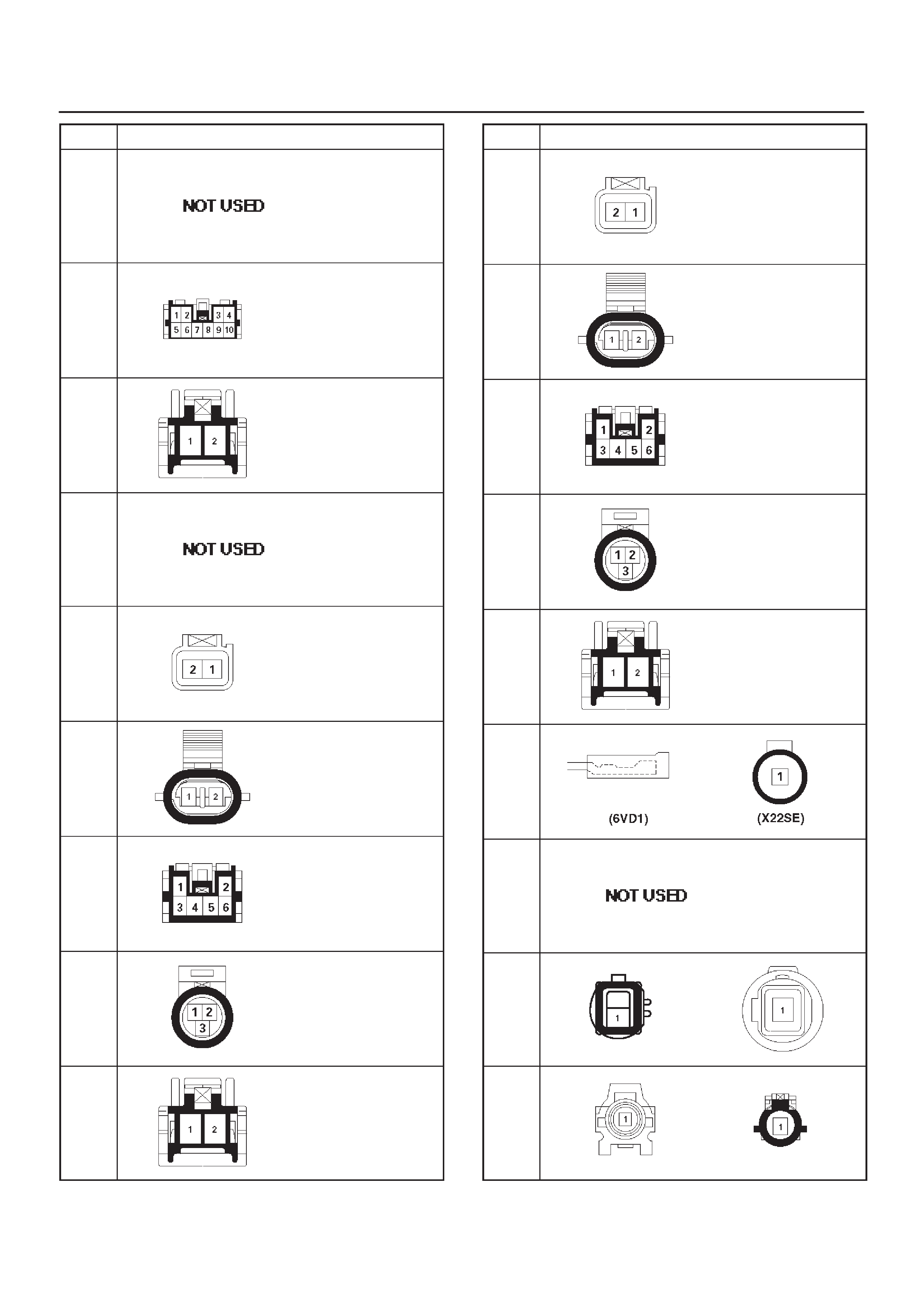

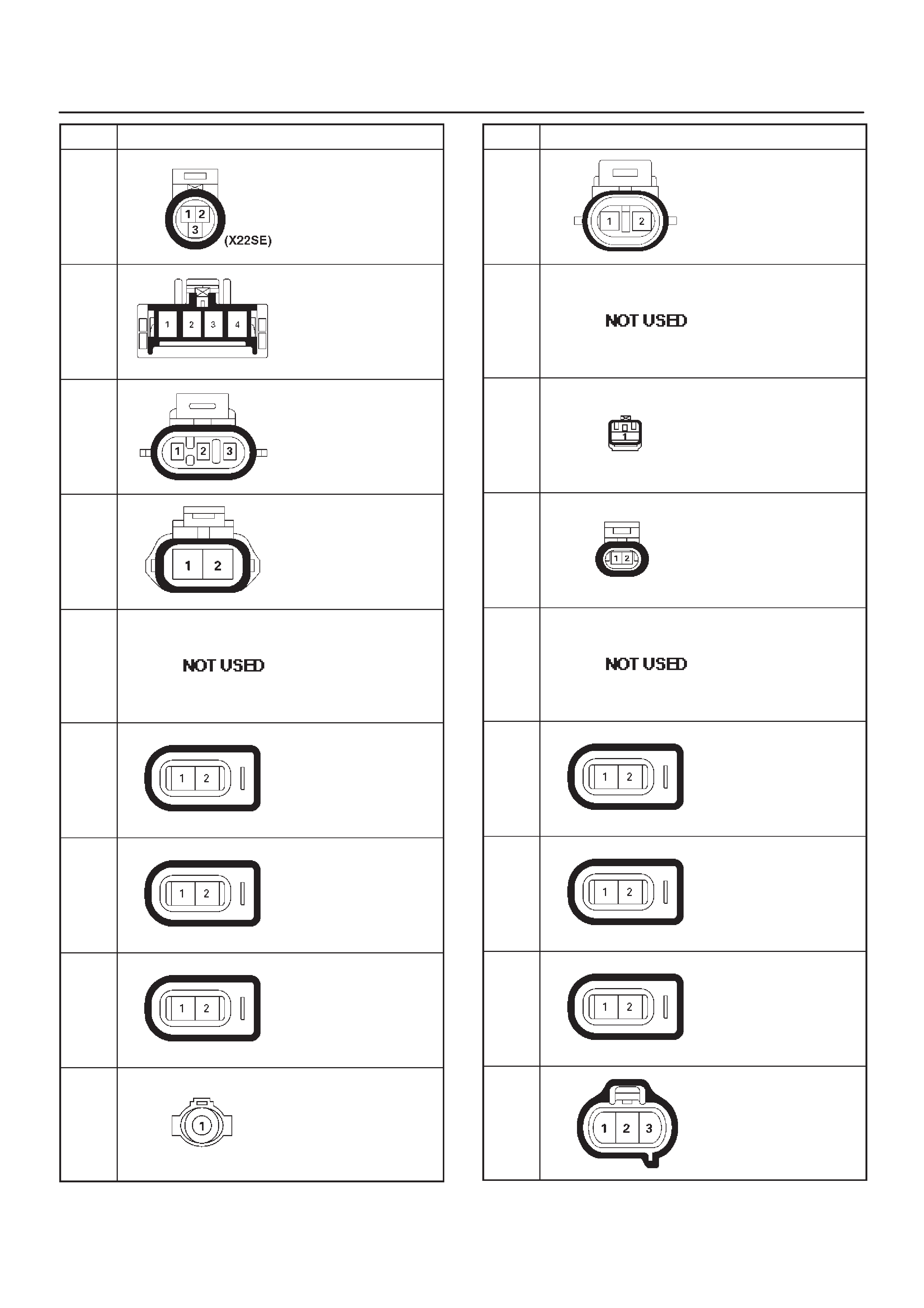

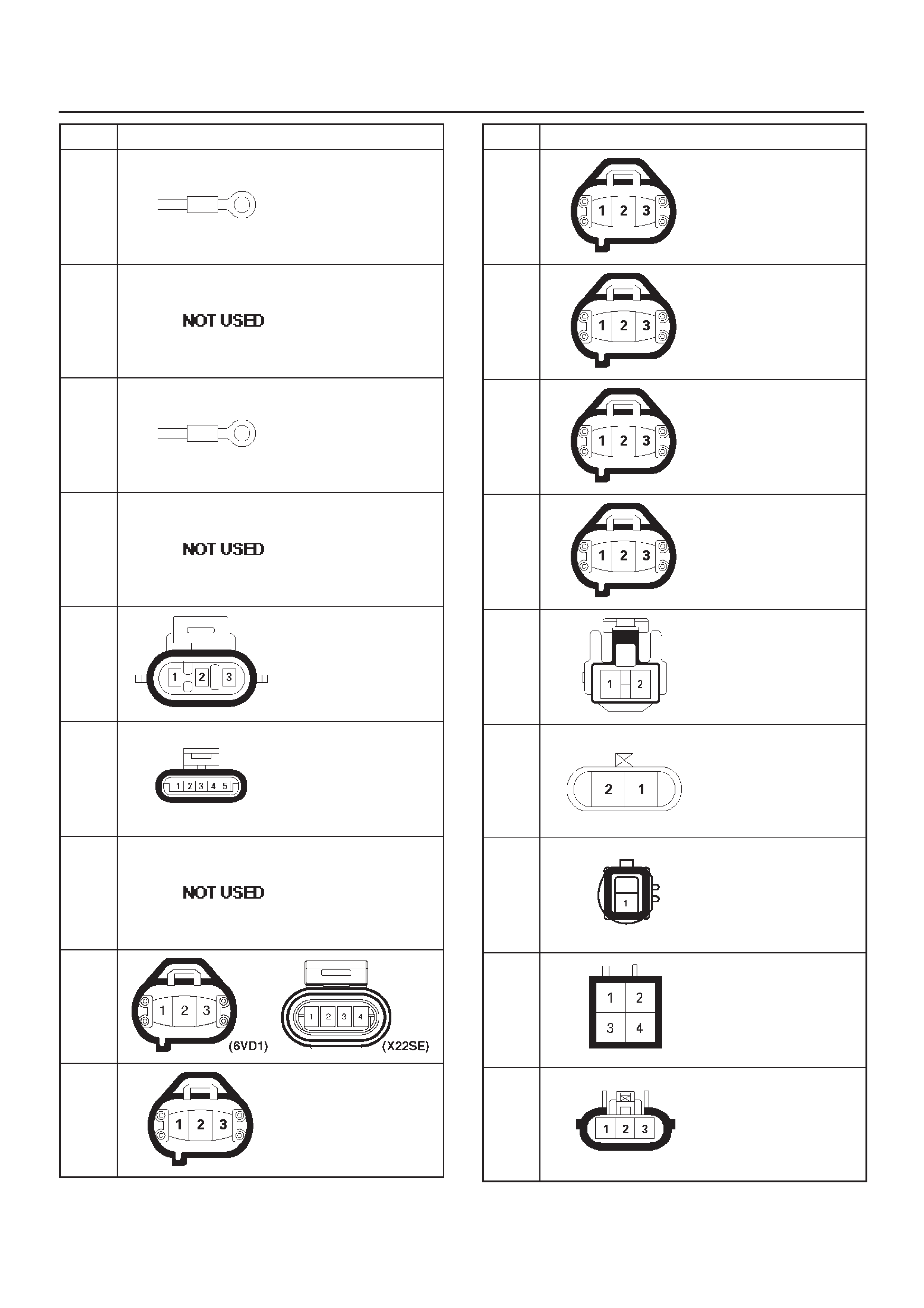

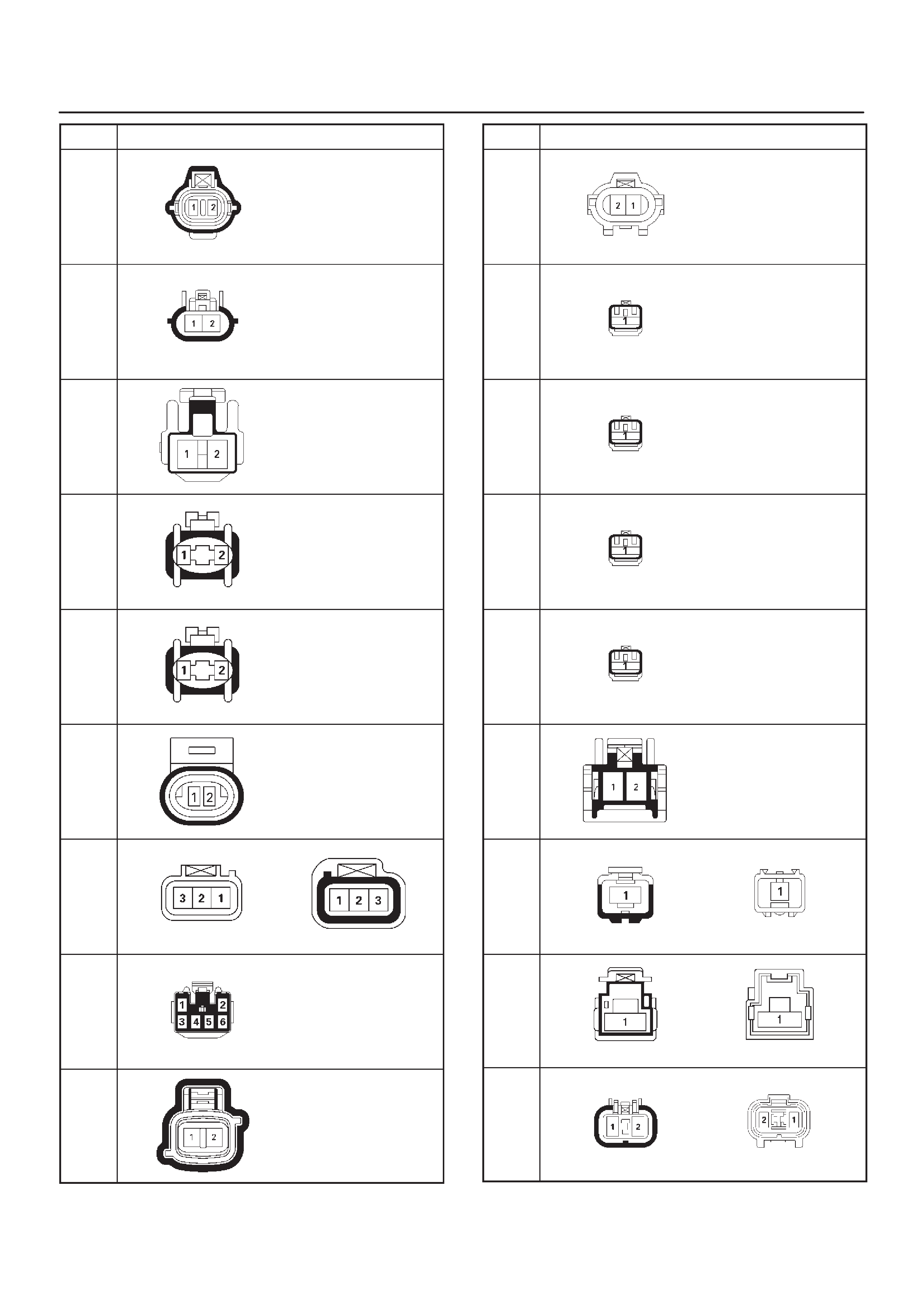

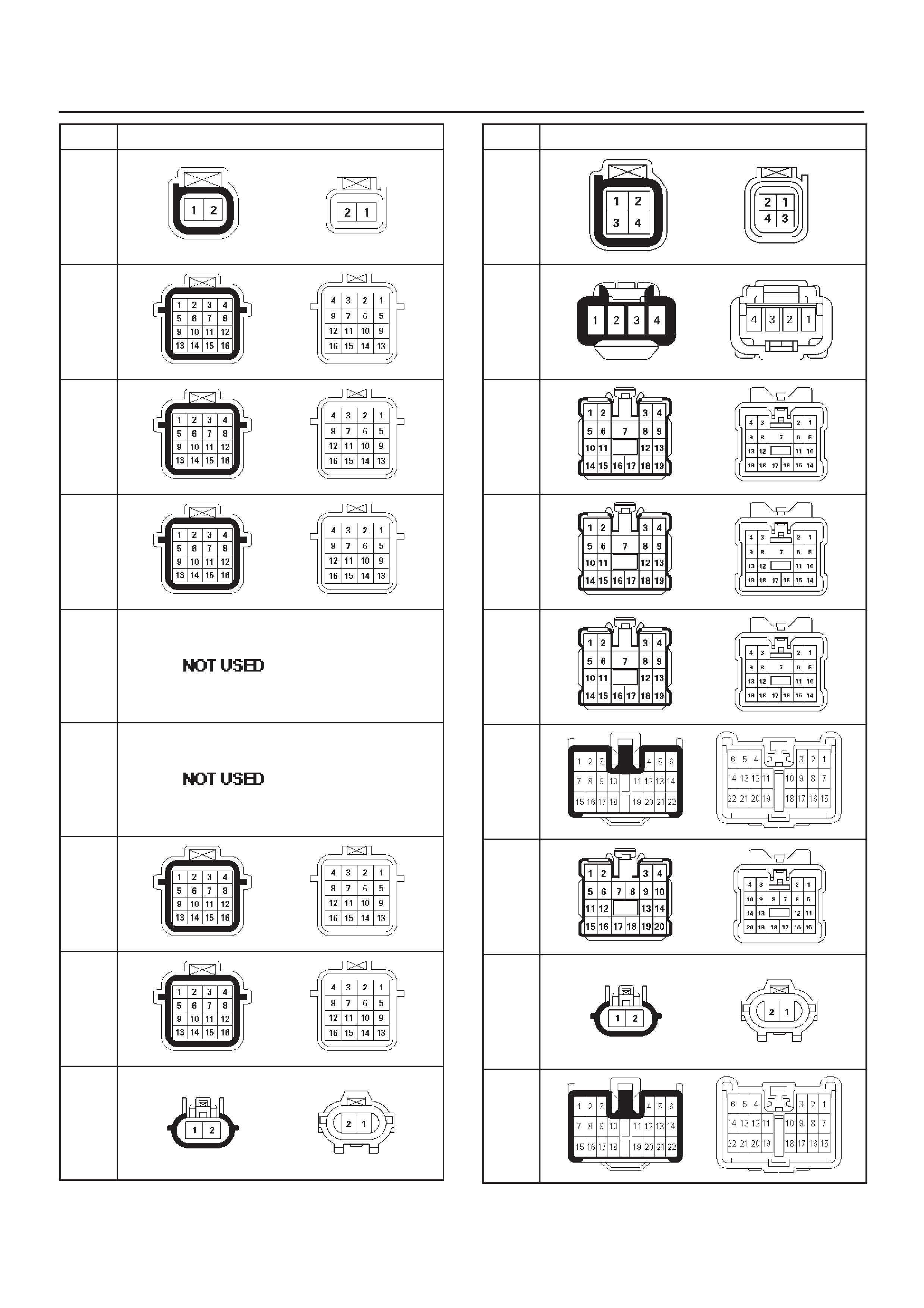

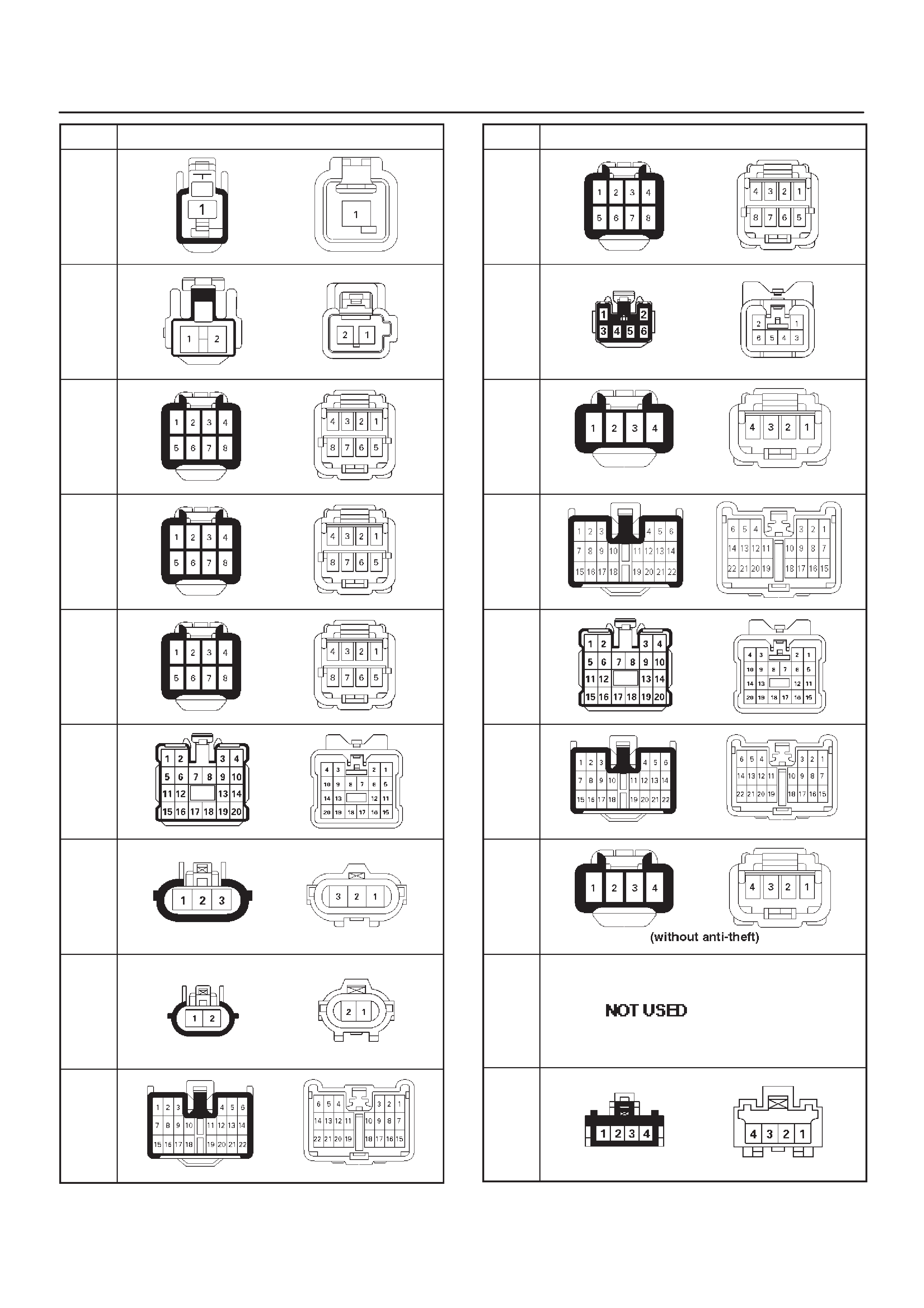

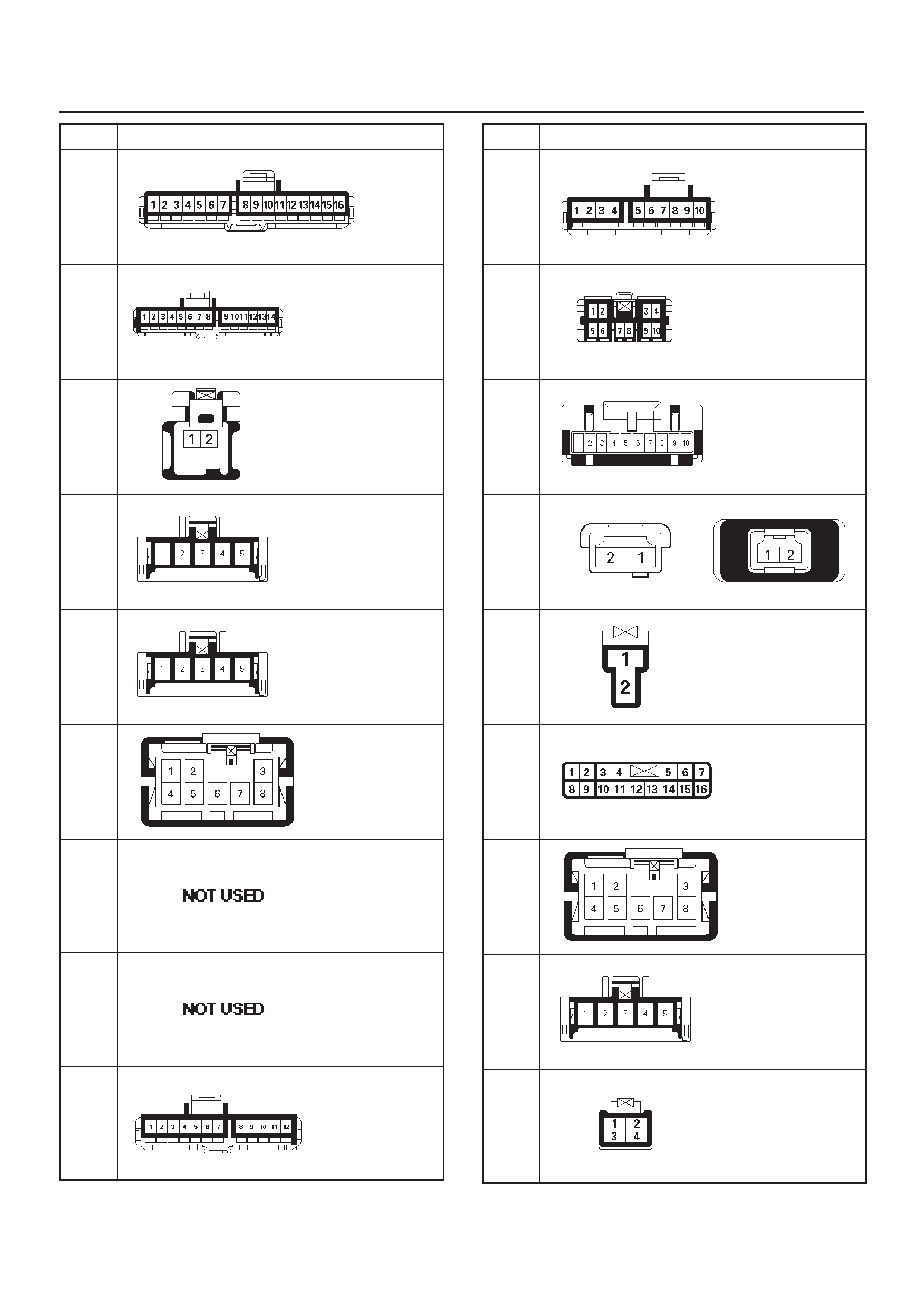

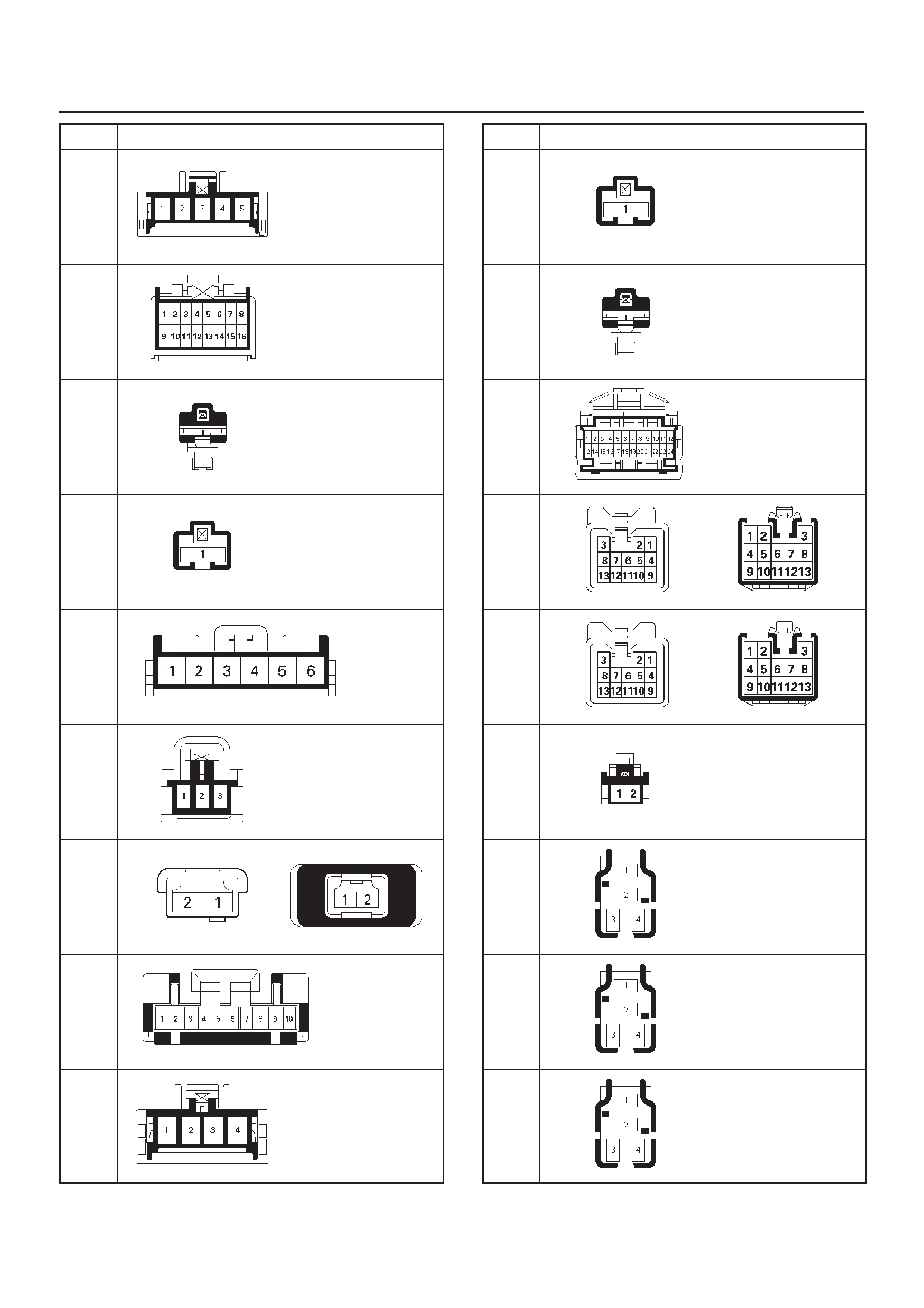

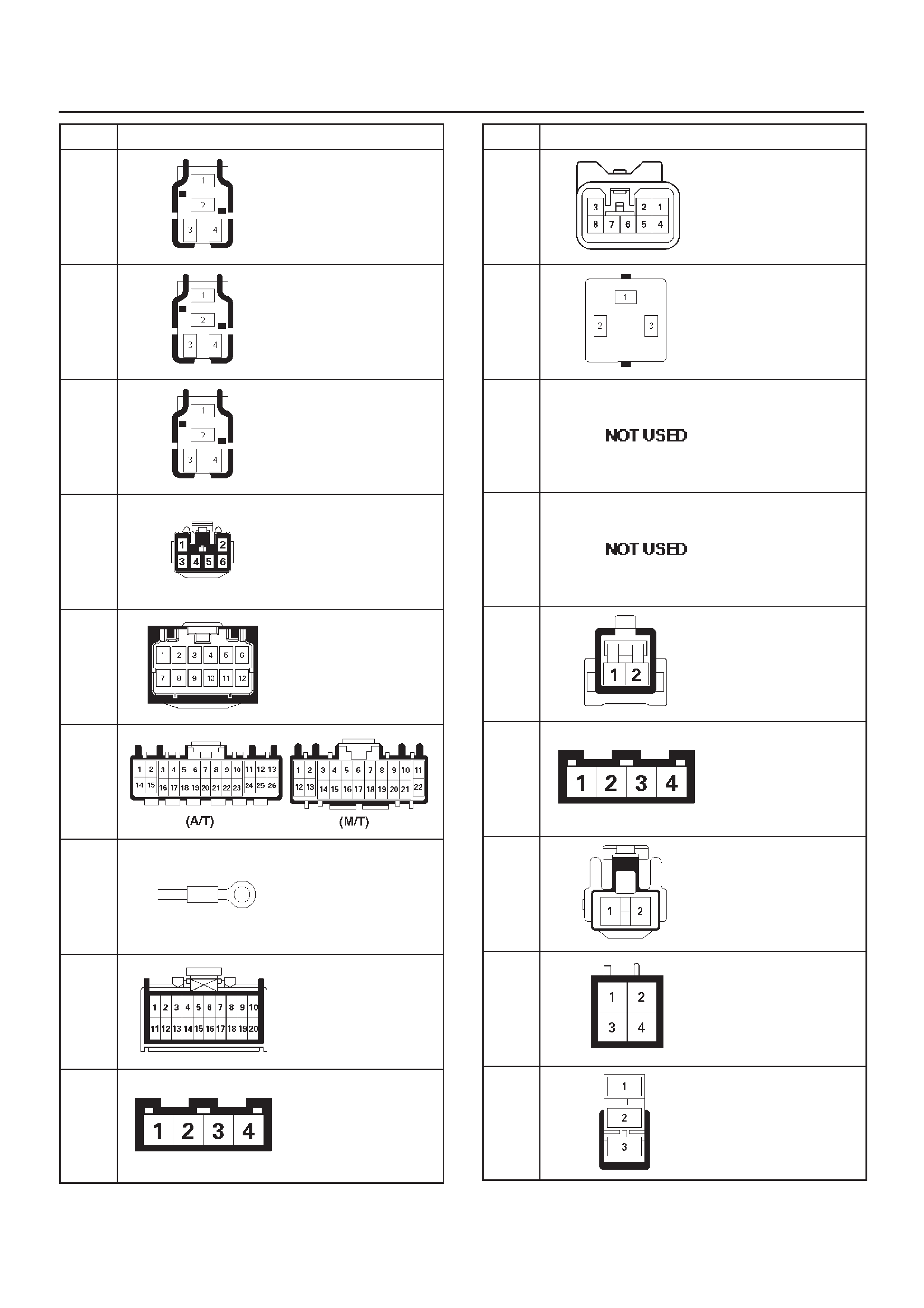

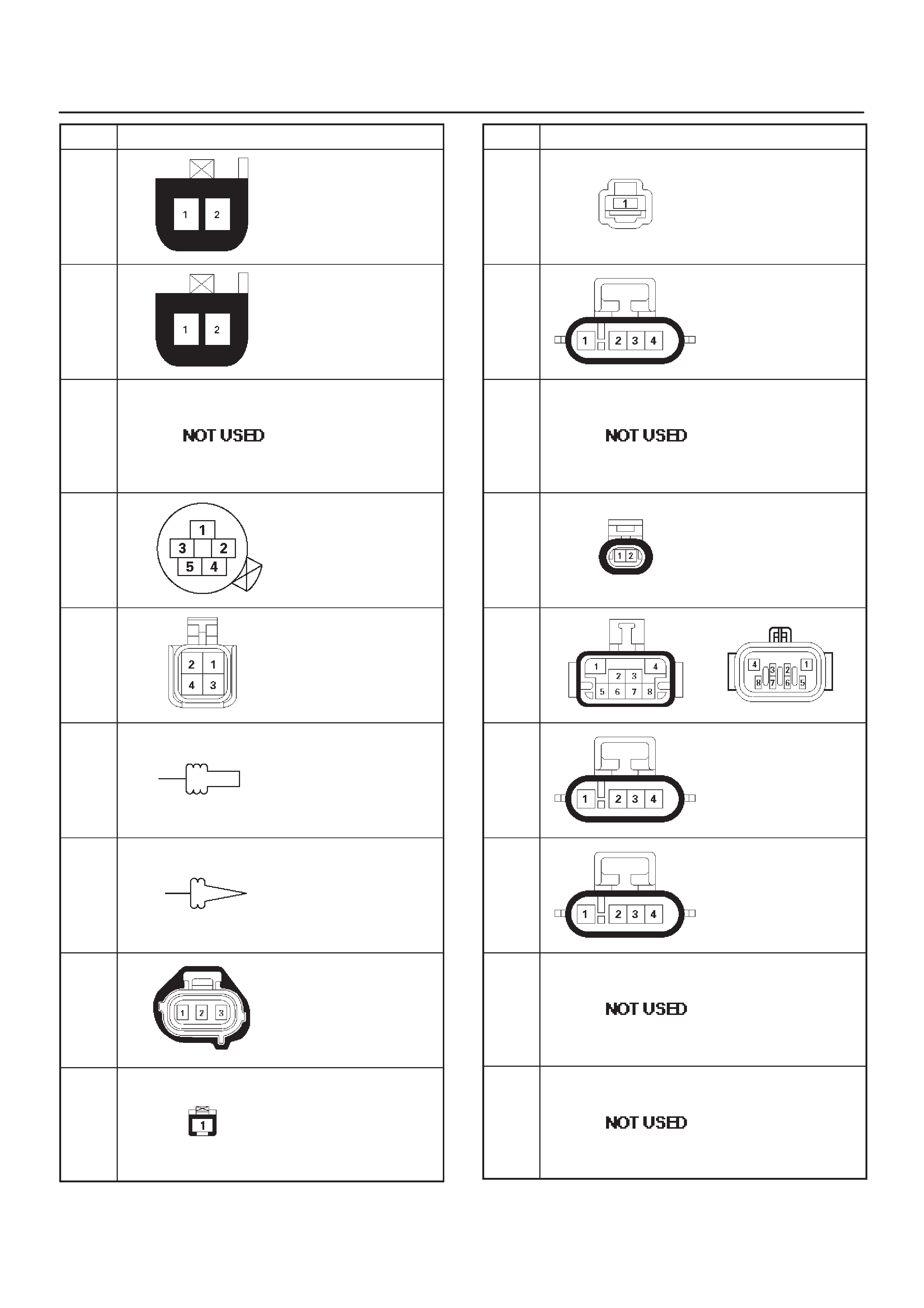

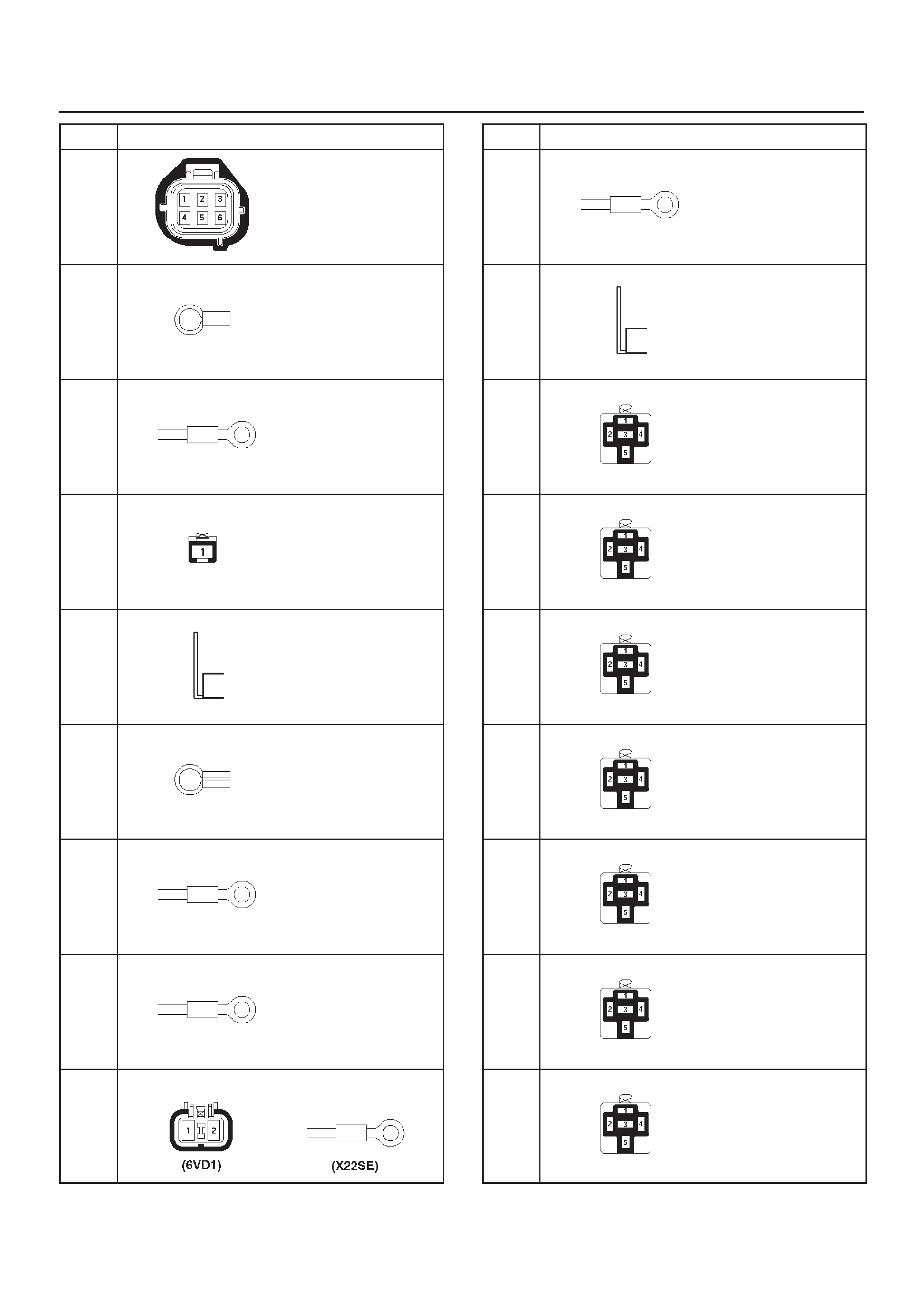

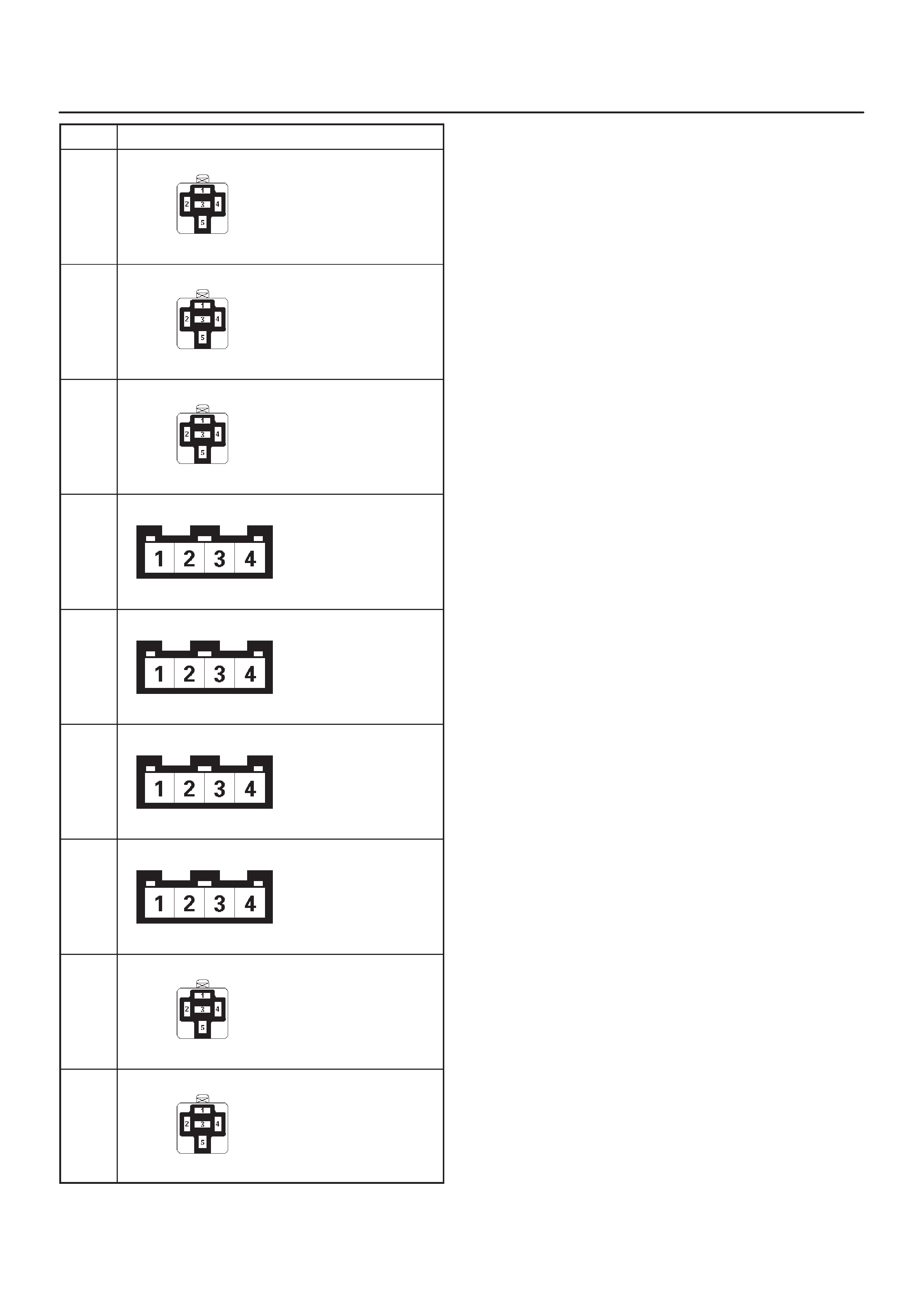

Harness Connector Faces

Service Precaution

WARNING:THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SER VICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHER WISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION:Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fasteners joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fasteners.

When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

General Description

The chassis electrical system is a 12–volt system with a

negative ground polarity.

Wire size are appropriate to respective circuits, and

classified by color. (The classification of harnesses by

color is shown on the circuit diagram for ease of harness

identification.)

The wire size is determined by load capacity and the

length of wire required.

The vehicle harness are: body harness, chassis harness,

engine room harness, instrument harness, transmission

harness, engine ECGI harness, dome light harness, door

harness, rear body harness, tailgate harness, SRS

harness and battery cables.

The harnesses are protected either by tape or corrugated

tube, depending on harness location.

The circuit for each system consists of the power source,

wire, fuse, relay, switch, load parts and ground, all of

which are shown on the circuit diagram.

In this section, each electrical device is classified by

system.

For major parts shown on the circuit based on the circuit

diagram for each system, a summary, diagnosis of

troubles and inspection procedures are detailed.

Notes for Working on Electrical Items

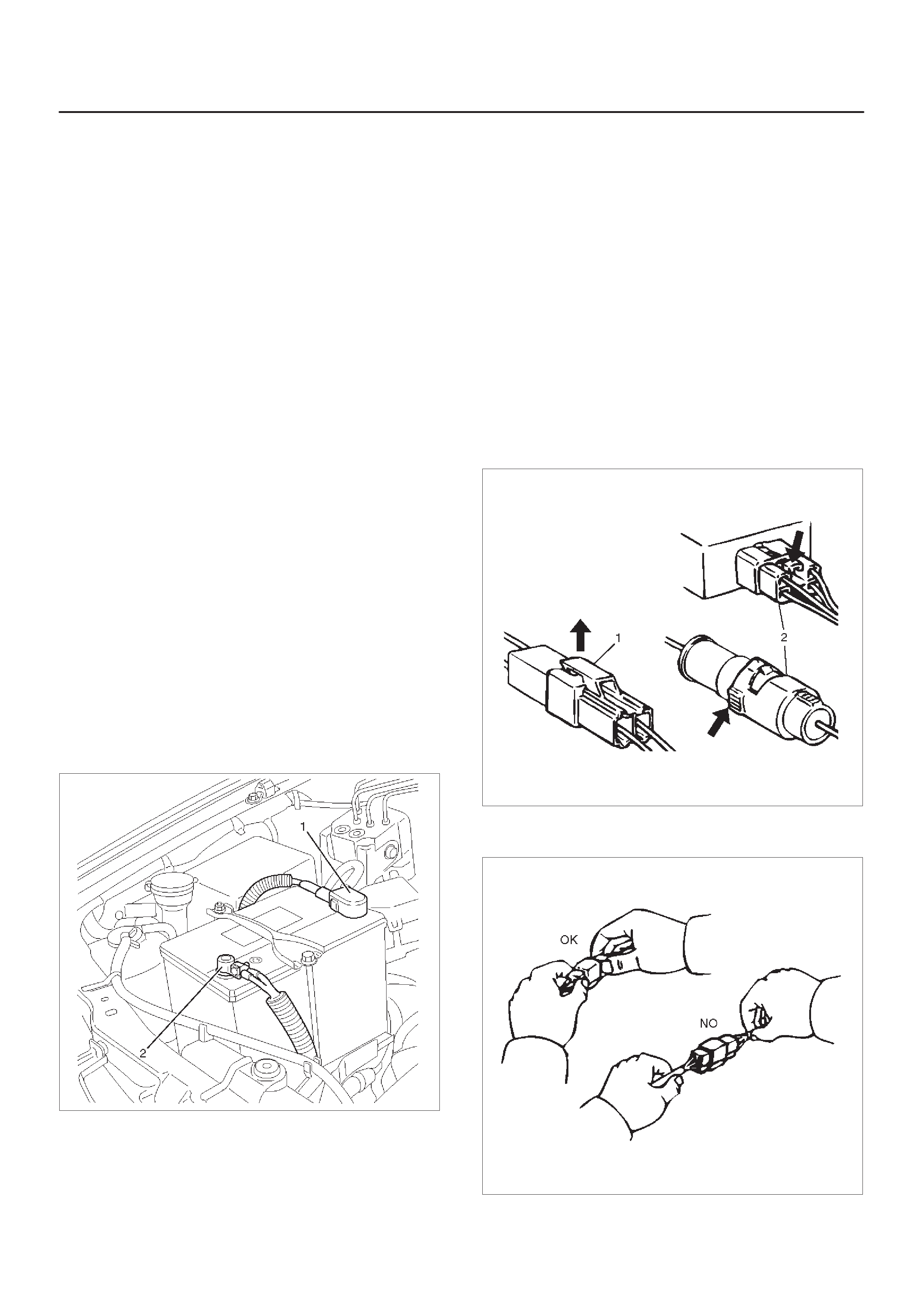

Disconnecting the Battery Cable

1.All switches should be in the “OFF” position.

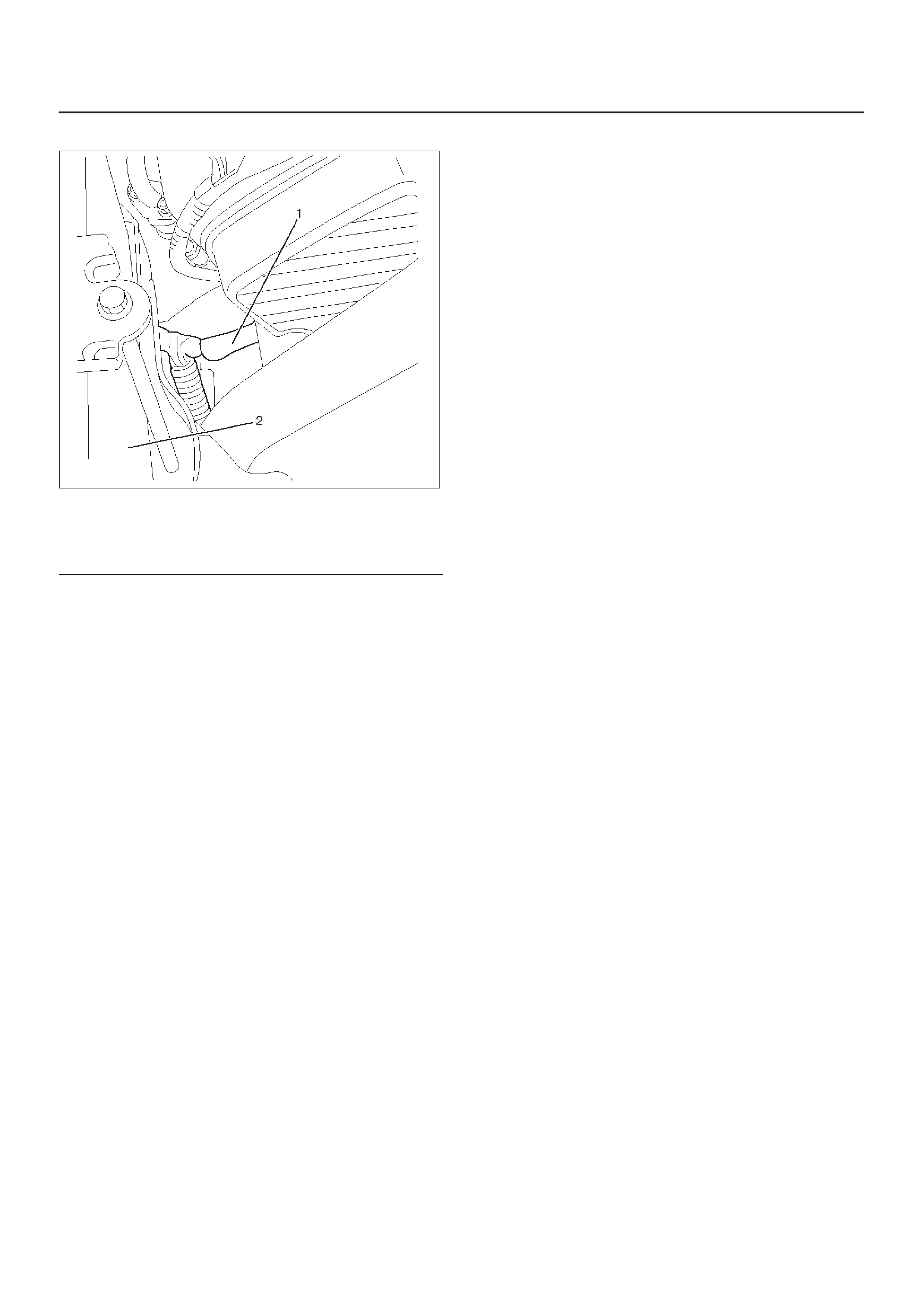

2.Disconnect the battery ground cable (2).

3.Disconnect the battery positive cable (1).

CAUTION:It is important that the battery ground

cable be disconnected first. Disconnecting the

battery positive cable first can result in a short

circuit.

061RW002

Connecting the Battery Cable

Follow the disconnecting procedure in the reverse order.

CAUTION:Clean the battery terminal and apply a

light coat of grease to prevent terminal corrosion.

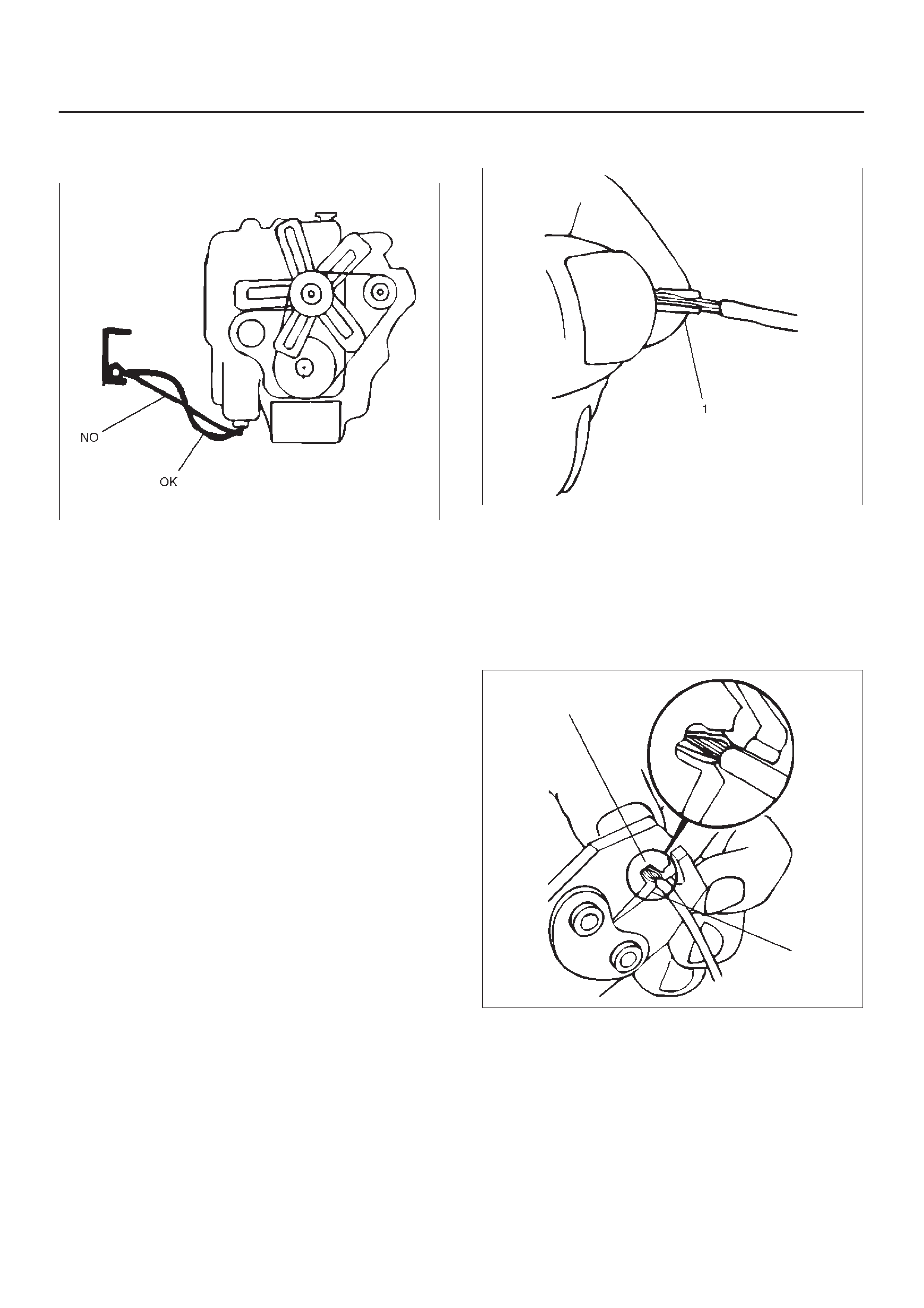

Disconnecting the Connector

Some connectors have a tang lock to hold the connectors

together during vehicle operation.

Some tang locks are released by pulling them towards

you (1).

Other tang locks are released by pressing them forward

(2).

Determine which type of tang lock is on the connector

being handled.

Firmly grasp both sides (male and female) of the

connector.

Release the tang lock and carefully pull the two halves of

the connector apart.

D08RW128

Never pull on the wires to separate the connectors. This

will result in wire breakage as shown in the figure.

D08RW129

When removing the connector for relay (MR5B type) (3),

unfasten the tang lock of the connector by using a

screwdriver , then pull the relay out as shown in the figure.

D08RW131

Connecting the Connector

Firmly grasp both sides (male and female) of the

connector. Be sure that the connector pins and pin holes

match, Be sure that both sides of the connector are

aligned with each other.

Firmly but carefully push the two sides of the connector

together until a distinct click is heard.

D08RW130

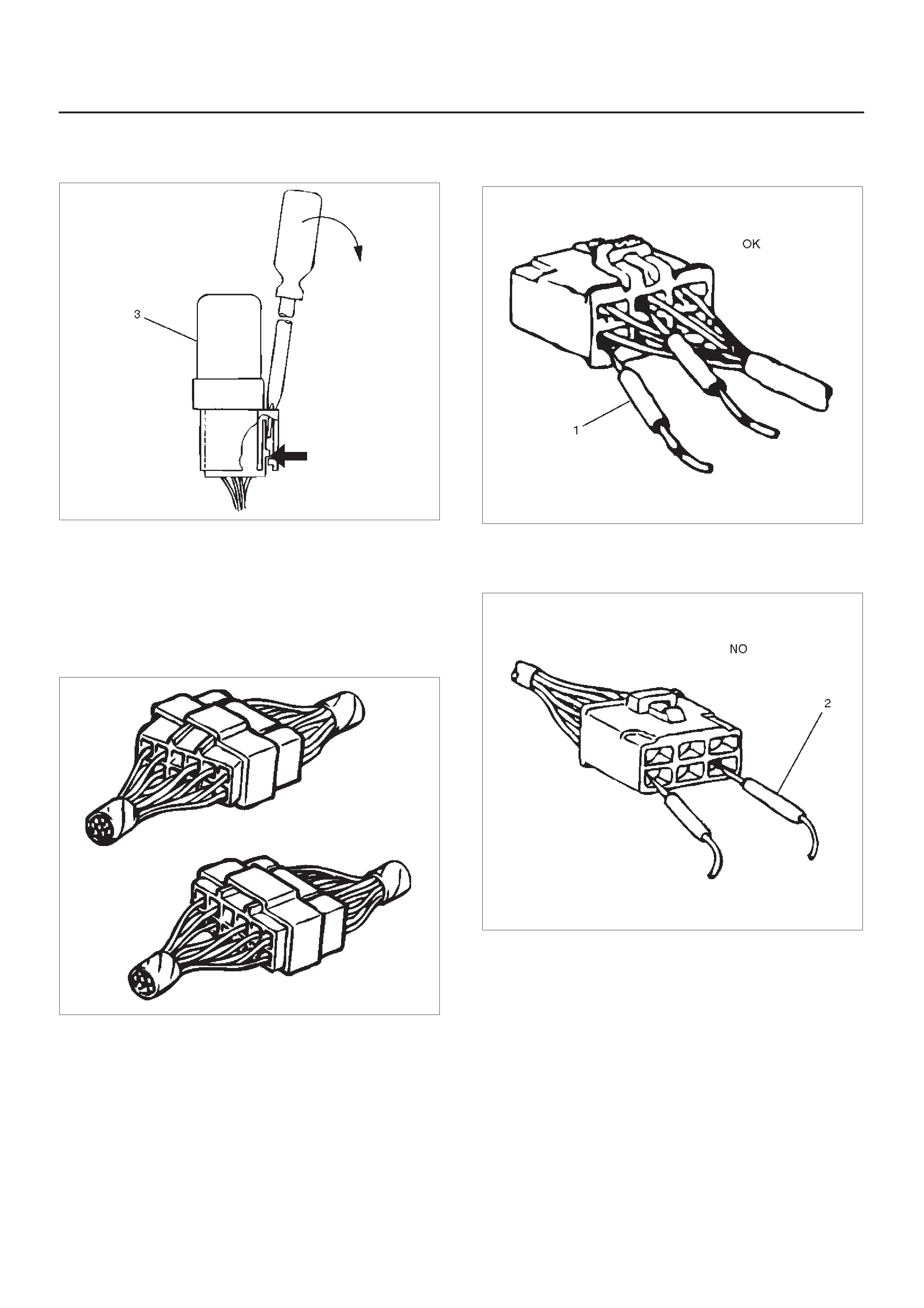

Connector Inspection

Use a circuit tester to check the connector for continuity.

Insert the test probes (1) from the connector wire side.

D08RW132

Never insert the circuit tester test probes (2) into the

connector open end to test the continuity.

Broken or open connector terminals will result.

D08RW133

Waterproof Connector Inspection

It is not possible to insert the test probes (2) into the

connector wire side of a waterproof connector.

Use one side of a connector (1) with its wires cut to make

the test. Connect the test connector (3) to the connector

to be tested. Connect the test probes to the cut wires to

check the connector continuity.

D08RW134

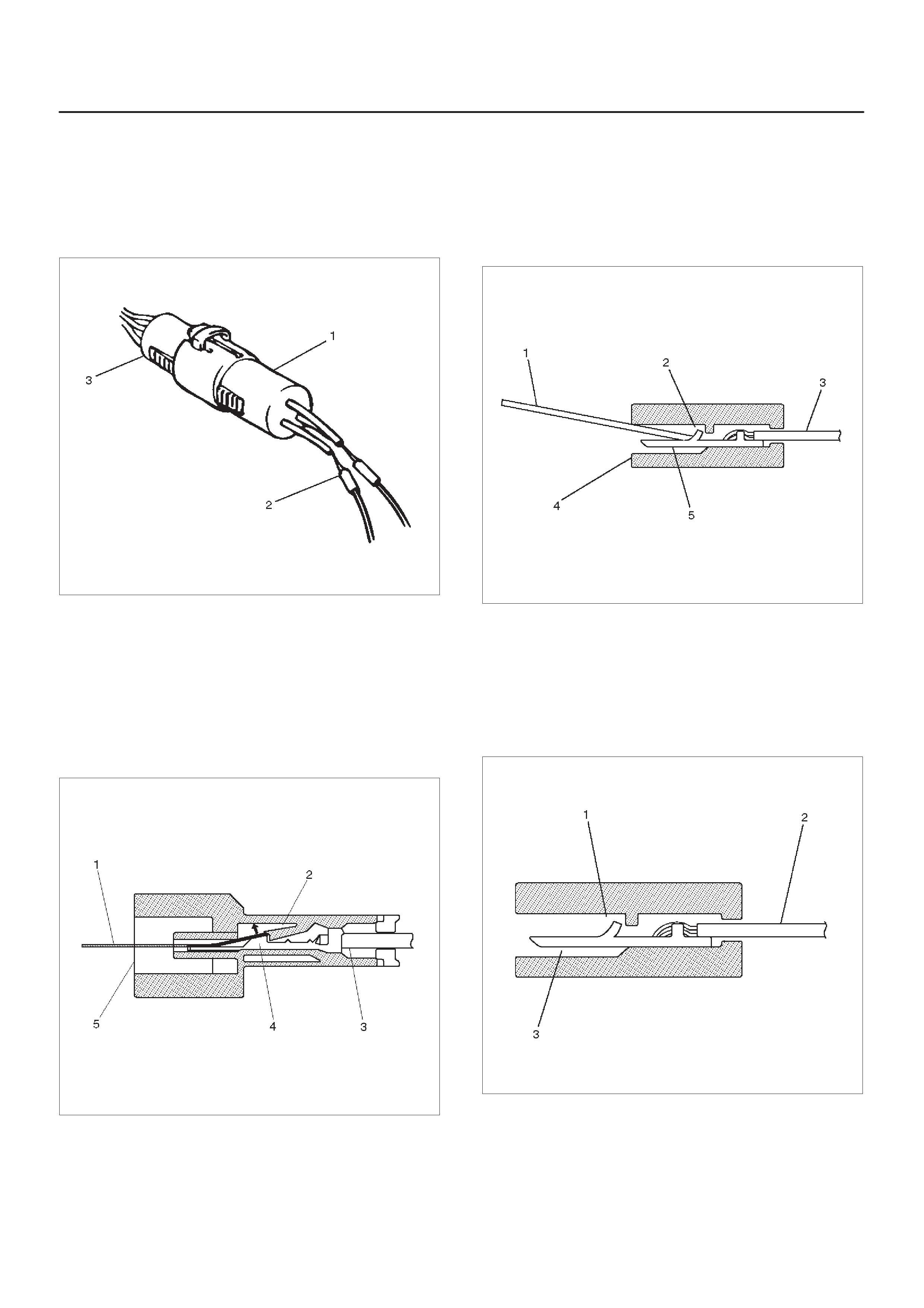

Connector Pin Removal – Connector Housing Tang

Lock Type

1.Insert a slender shaft (1) into the connector housing

open end (5).

2.Push the tang lock (2) up (in the direction of the arrow

in the illustration).

Pull the wire (3) with pin (4) free from the wire side of

the connector.

D08RW135

Connector Pin Removal – Pin Tang Lock Type

1.Insert a slender shaft (1) into the connector housing

open end (5).

2.Push the tang lock (2) flat (toward the wire (3) side of

the connector.

Pull the wire with pin (4) free from the wire side of the

connector.

D08RW136

Connector Pin Insertion

1.Check that the tang lock (1) is fully up.

2.Insert the pin (3) from the connector wire (2) side.

Push the pin in until the tang lock closes firmly.

3.Gently pull on the wires to make sure that the

connector pin is firmly set in place.

D08RW137

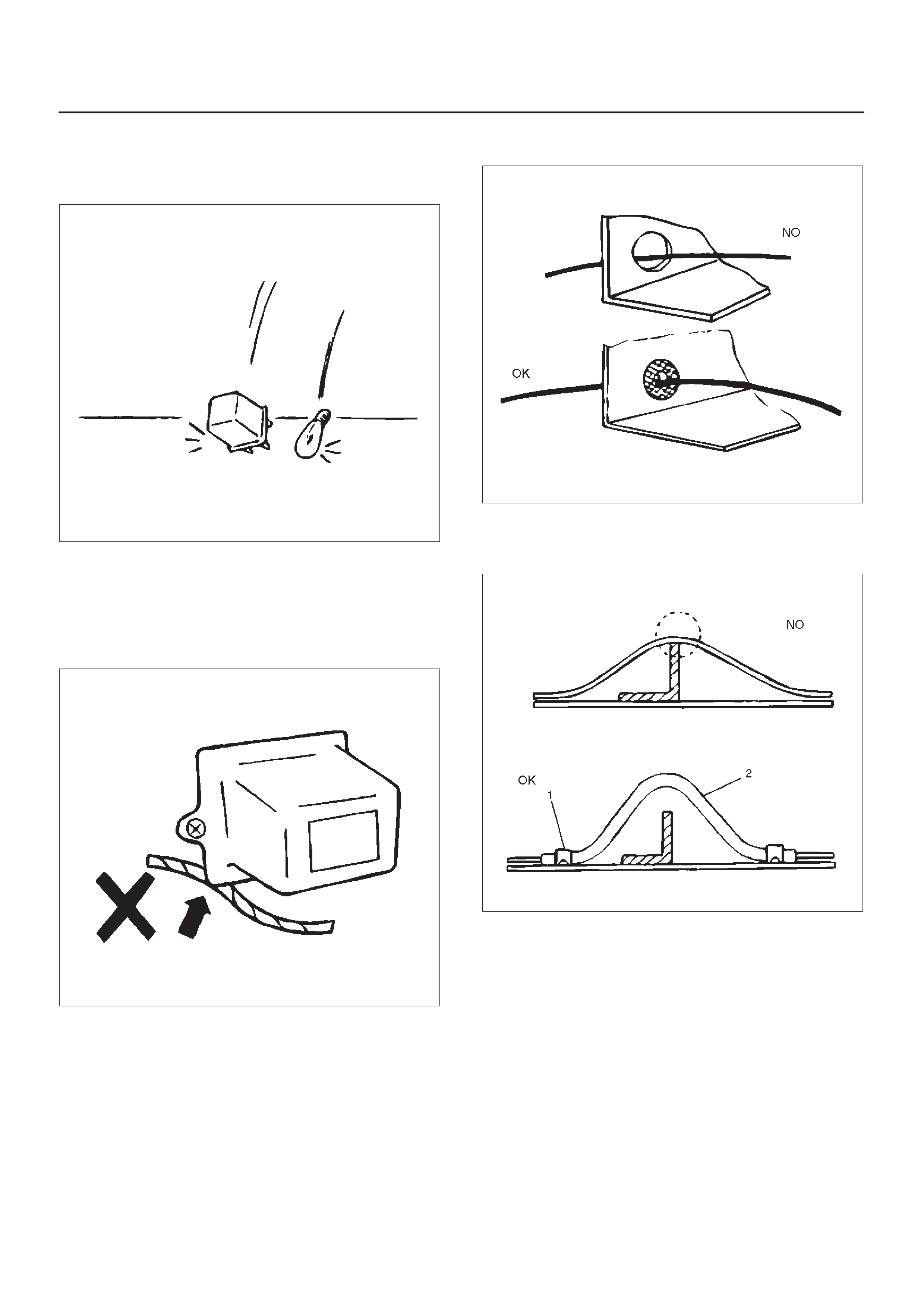

Parts Handling

Be careful when handling electrical parts. They should not

be dropped or thrown, because short circuiting or other

damage may result.

D08RW138

Cable Harness

1.When installing the parts, be careful not to pinch or

wedge the wiring harness.

2.All electrical connections must be kept clean and

tight.

D08RW139

3.Use a grommet or guard tube to protect the wiring

harness from contacting a sharp edge or surface.

D08RW139

4. Position the wiring harness with enough clearance

from the other parts and guard the wiring harness with

a vinyl tube (2) and clips (1) to avoid direct contact.

D08RW141

5.The wiring harness between engine and chassis

should be long enough to prevent chafing or damage

due to various vibrations.

D08RW142

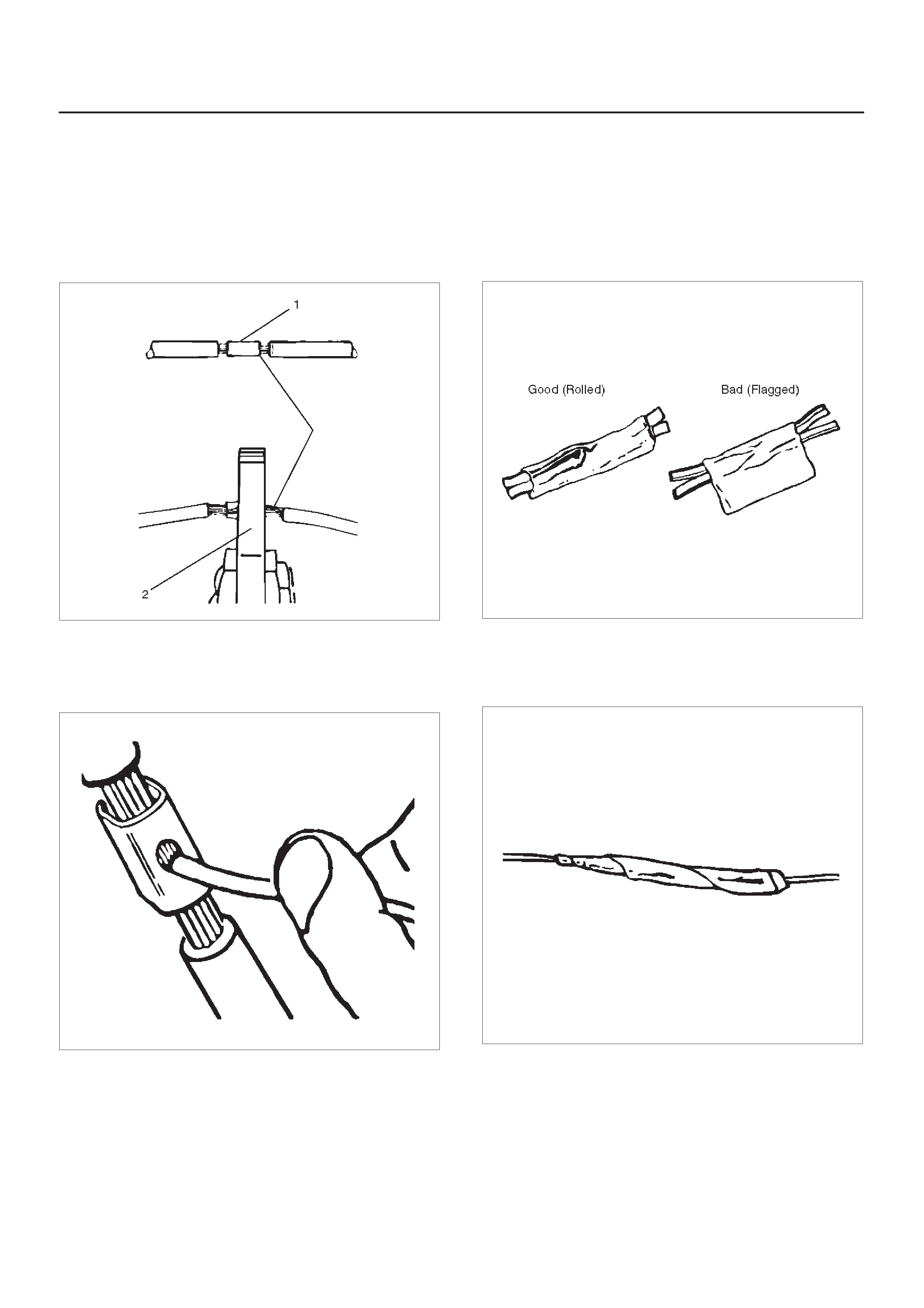

Splicing Wire

1.If the harness is taped, remove the tape. T o avoid wire

insulation damage, use a sewing “seam ripper”

(available from sewing supply stores) to cut open the

harness.

If the harness has a black plastic conduit, simply pull

out the desired wire.

2.Begin by cutting as little wire off the harness as

possible. Y ou may need the extra length of wire later if

you decide to cut more wire off to change the location

of a splice. You may have to adjust splice locations to

make certain that each splice is at least 1–1/2” (40

mm) away from other splices, harness branches, or

connectors.

3.When replacing a wire, use a wire of the same size as

the original wire.

Check the stripped wire for nicks or cut stands. If the

wire is damaged, repeat the procedure on a new

section of wire. The two stripped wire ends should be

equal in length.

4.Select the proper clip to secure the splice.

To determine the proper clip size for the wire being

spliced, follow the directions included with your clips.

Select the correct anvil on the crimper. (On most

crimpers your choice is limited to either a small or

large anvil.)

Overlap the two stripped wire ends and hold them

between your thumb and forefinger as shown in the

figure.

The center the spline clip (1) under the stripped wires

and hold it in place.

D08RW143

fOpen the crimping tool to its full width and rest one

handle on a firm flat surface.

fCenter the back of the splice clip on the proper anvil

and close the crimping tool to the point where the

back of the splice clip touches the wings of the clip.

fMake sure that the clip and wires are still in the correct

position. Then, apply steady pressure until the

crimping tool closes as shown in the figure.

D08RW144

Before crimping the ends of the clip (1), be sure that:

fThe wires extend beyond the clip in each direction.

fNo strands of wire are cut loose, and

fNo insulation is caught under the clip.

Crimp the splice again, once on each end.

Does not let the crimping tool (2) extend beyond the edge

of the clip or you may damage or nick the wires as shown

in the figure.

D08RW145

5.Apply 60/40 resin core solder to the opening in the

back of the clip as shown in the figure.

Follow the manufacturer’s instructions for the solder

equipment you are using.

D08RW146

6.Center and roll the splicing tape.

The tape should cover the entire splice.

Roll on enough tape to duplicate the thickness of the

insulation on the existing wires.

Does not flag the tape. Flagged tape may not provide

enough insulation, and the flagged ends will tangle

with the other wires in the harness as shown in the

figure.

D08RW147

If the wire does not belong in a conduit or other

harness covering, tape the wire again. use a winding

motion to cover the first piece of tape as shown in the

figure.

D08RW148

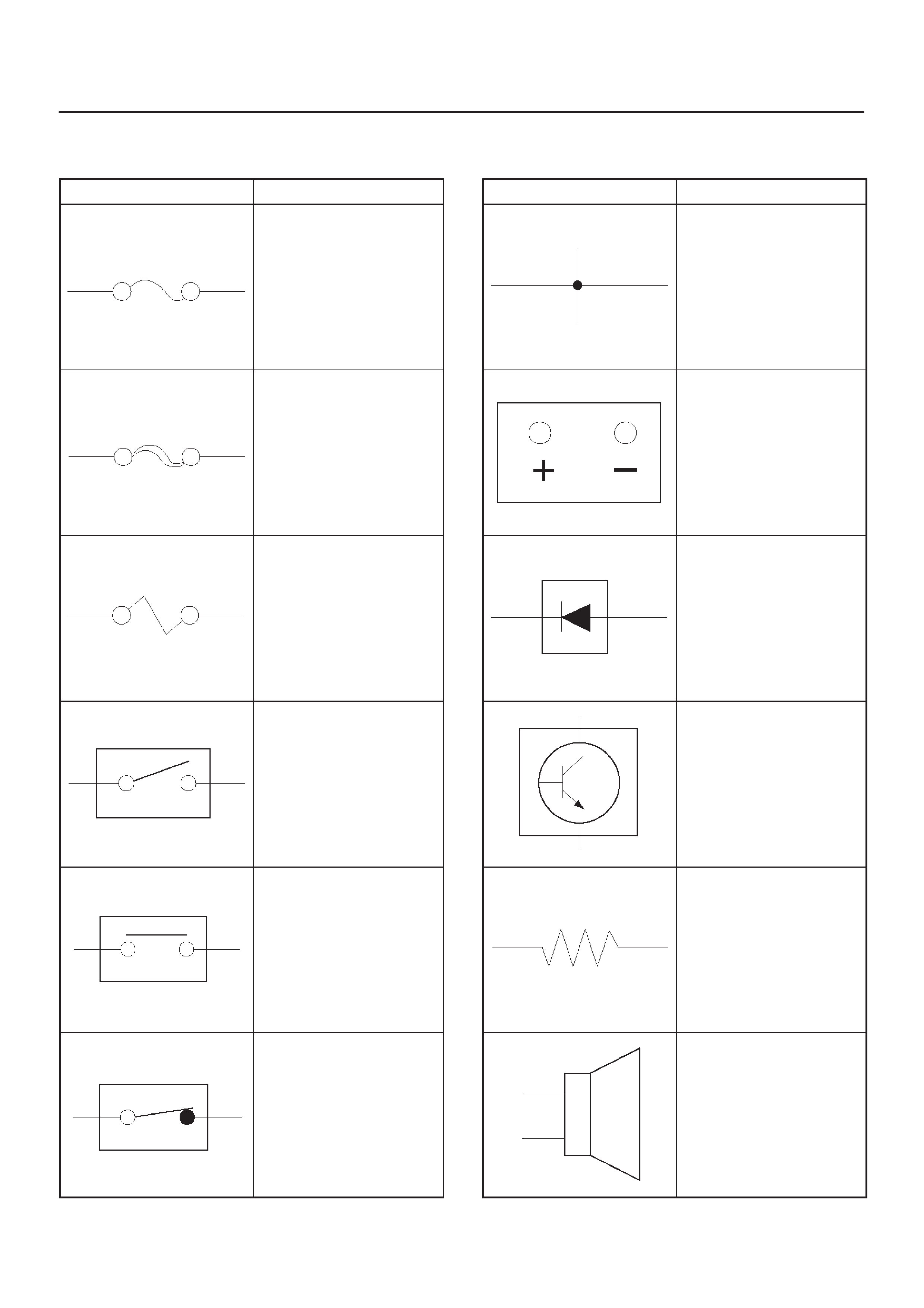

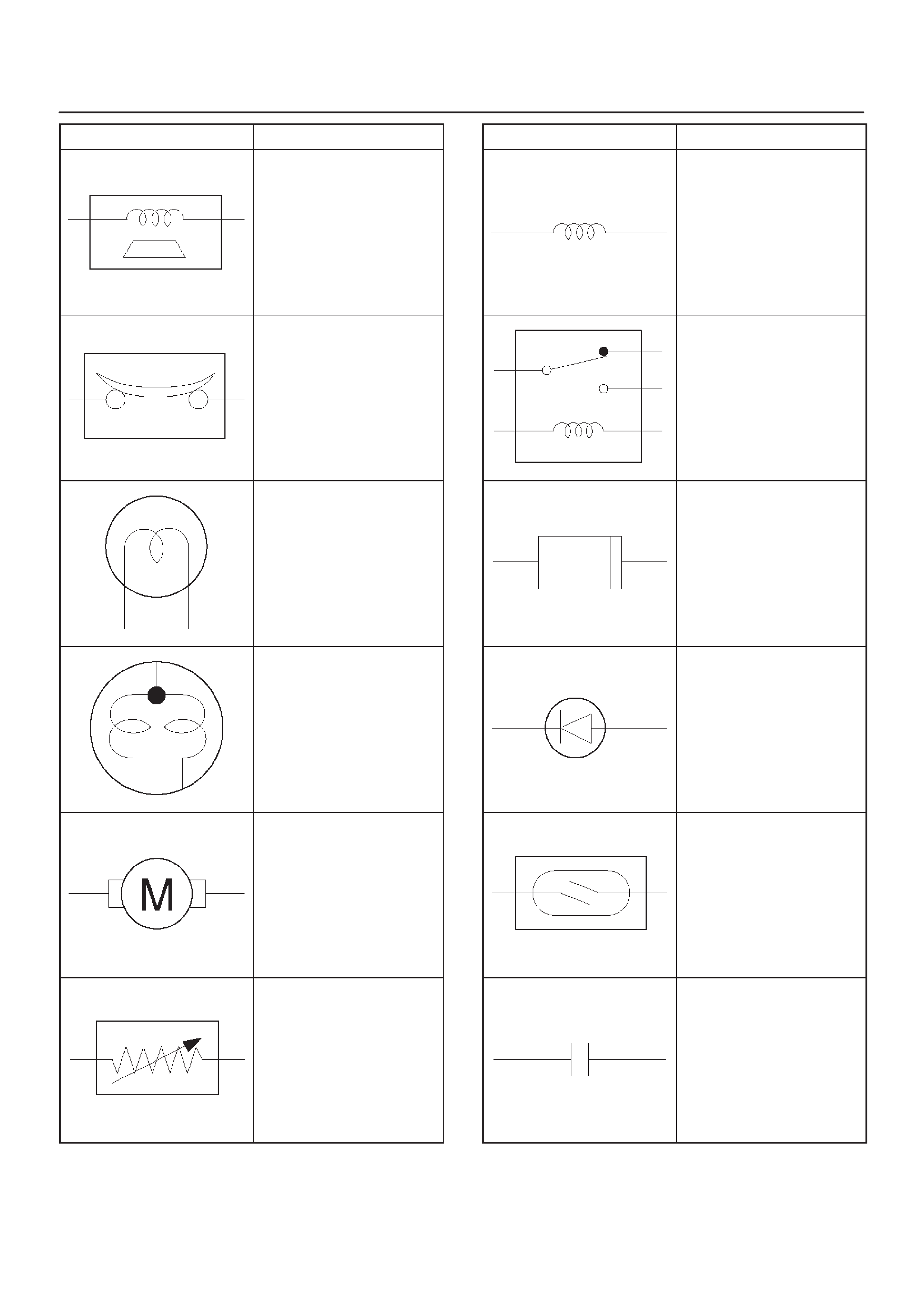

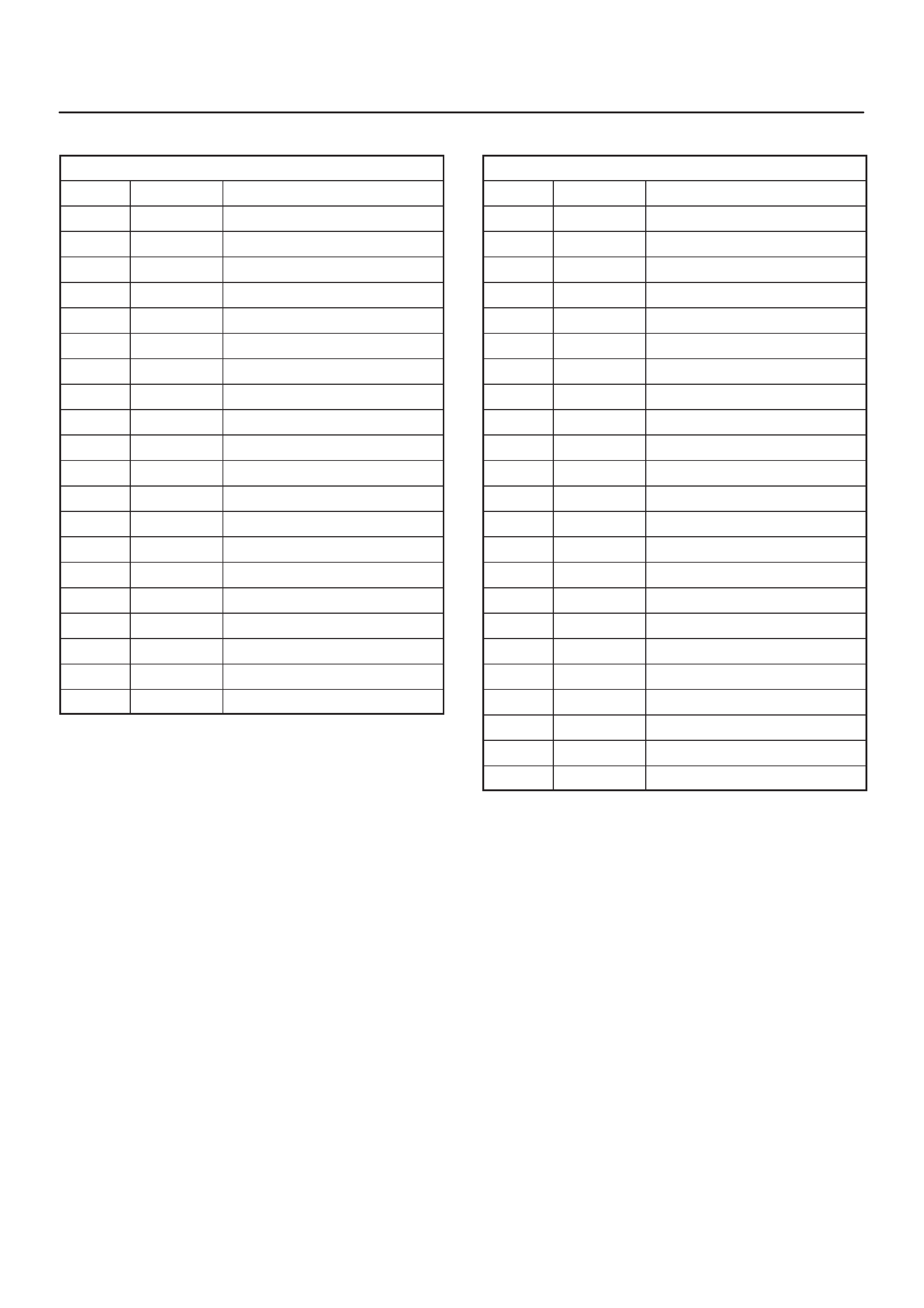

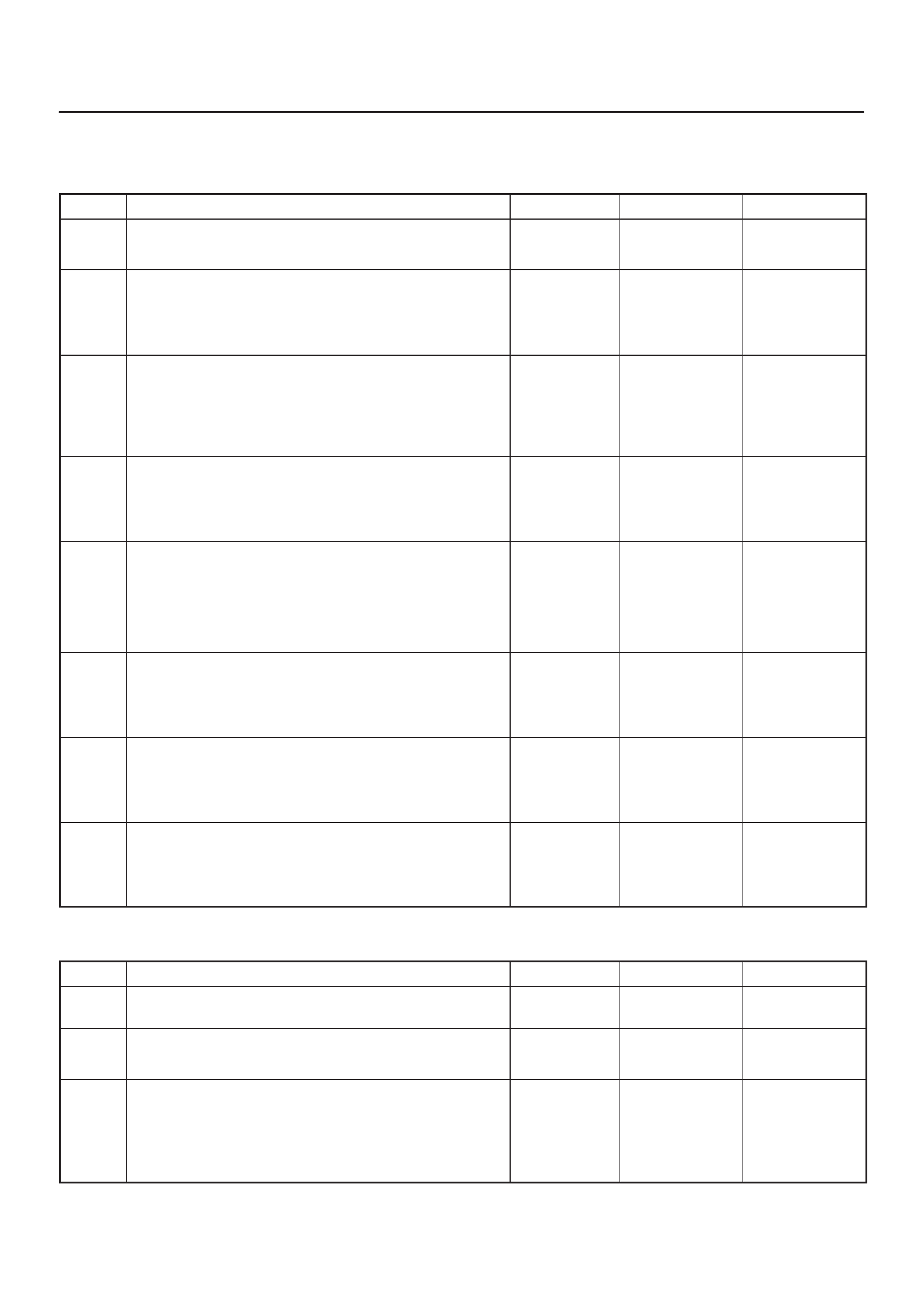

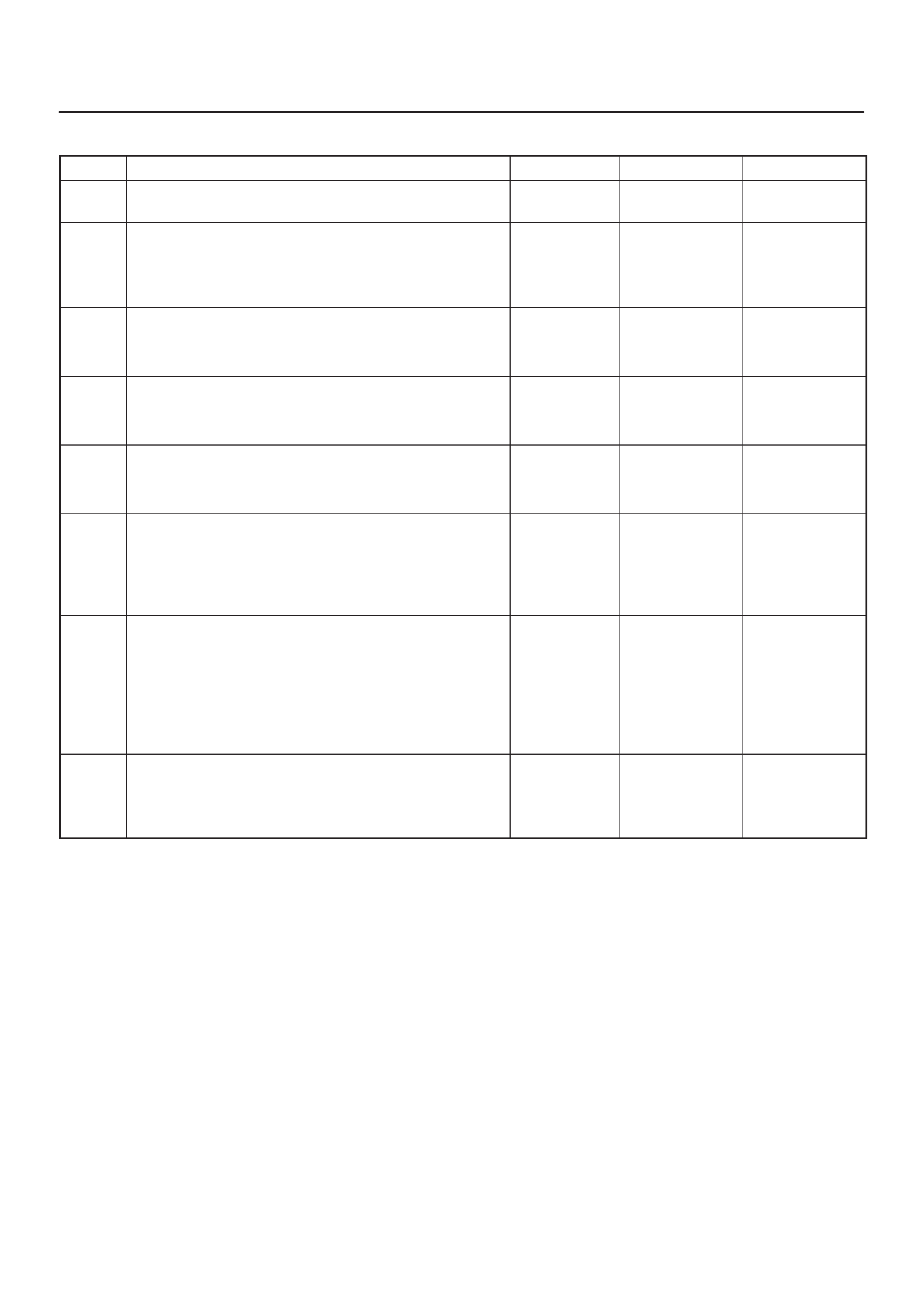

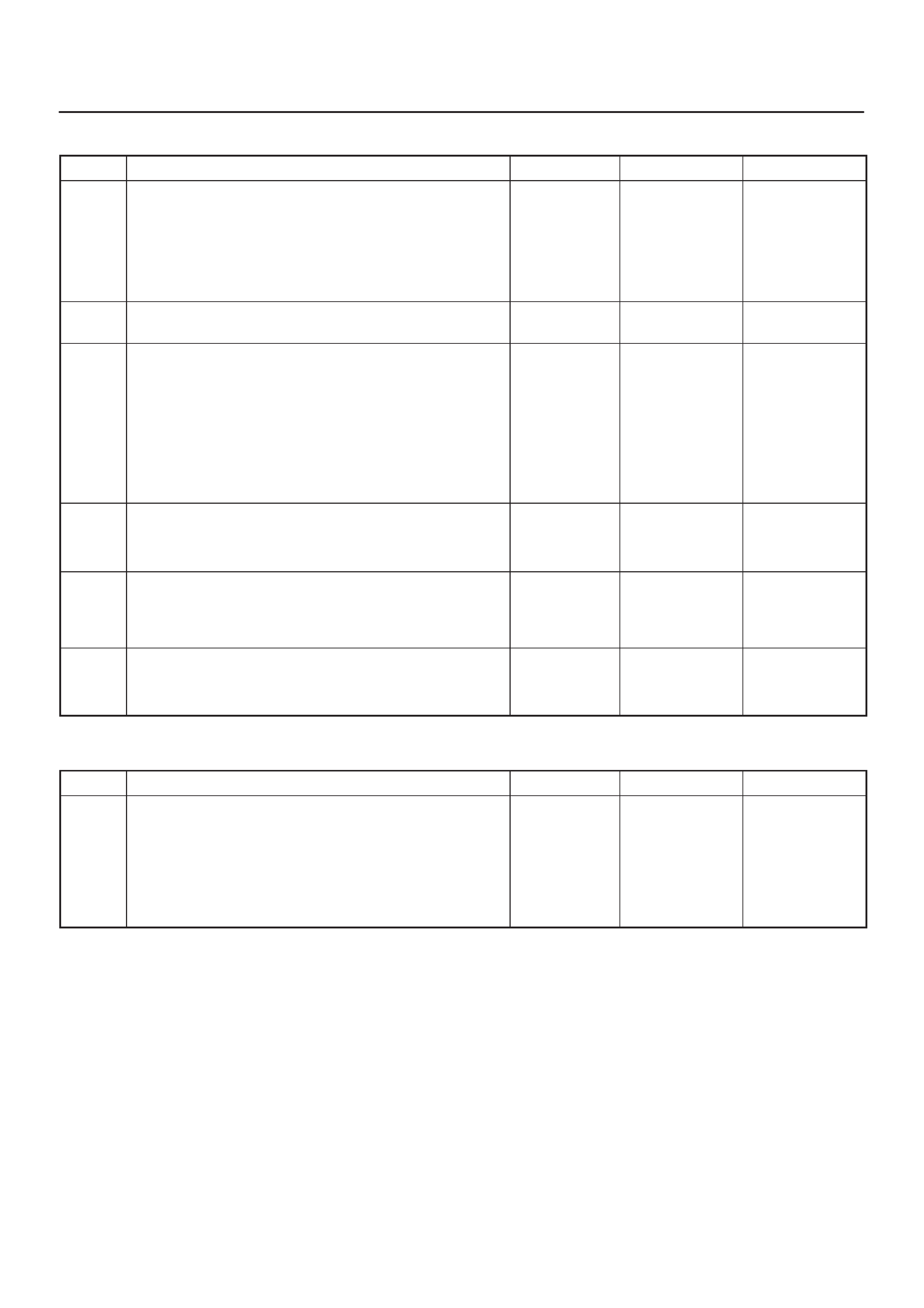

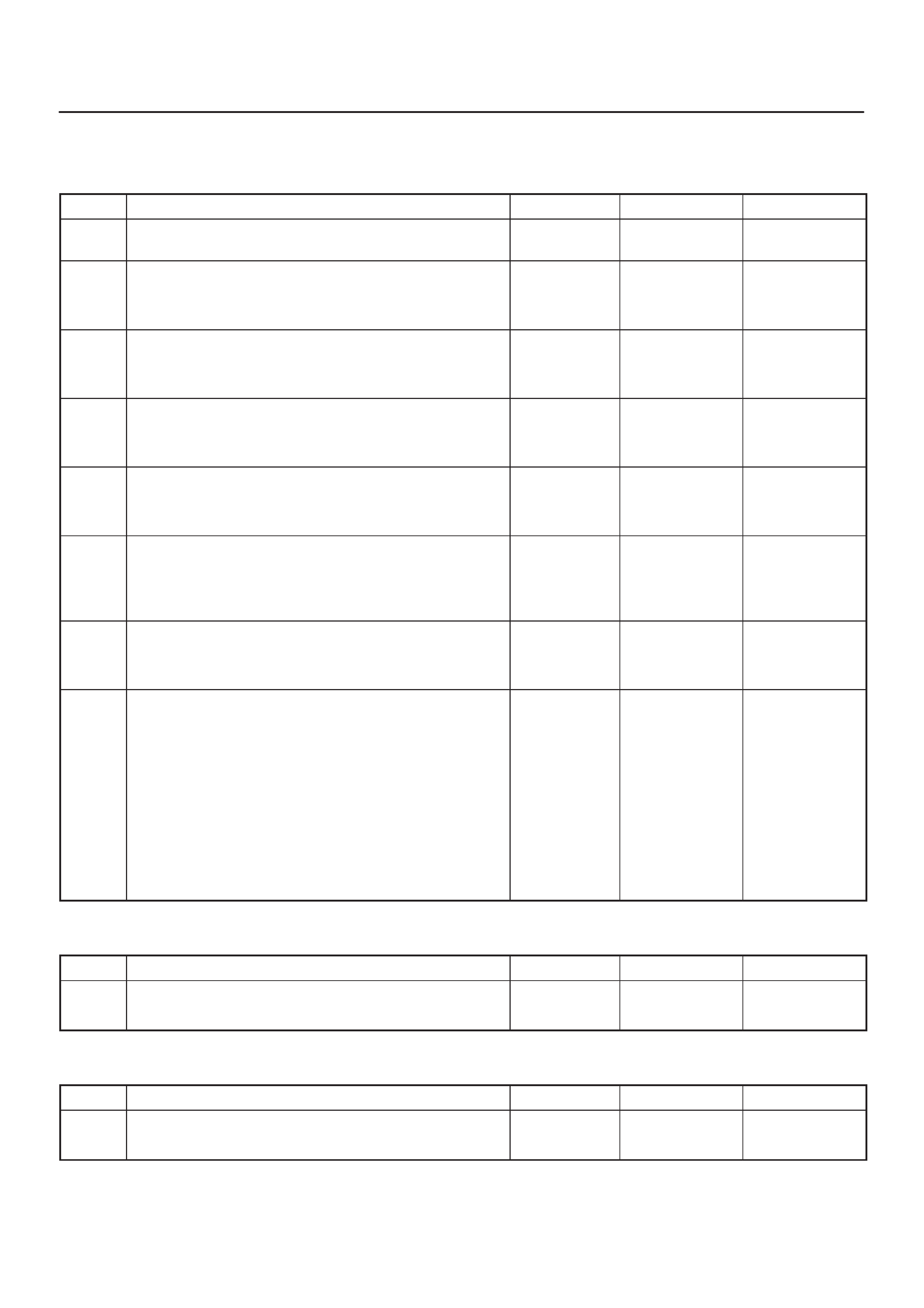

Symbols and Abbreviations

Symbols

Symbol Meaning of Symbol

Fuse

Fusible link

Fusible link wire

Switch

Switch

Switch

(Normal close type)

Symbol Meaning of Symbol

Contact wiring

Battery

Diode

Electronic parts

Resistor

Speaker

Symbol Meaning of Symbol

Buzzer

Circuit breaker

Bulb

Double filament bulb

Motor

Variable register Rheo-

stat

Symbol Meaning of Symbol

Coil (inductor), solenoid,

magnetic valve

Relay

Connector

Light emitting diode

Reed switch

Condenser

Symbol Meaning of Symbol

Horn

Vacuum switching valve

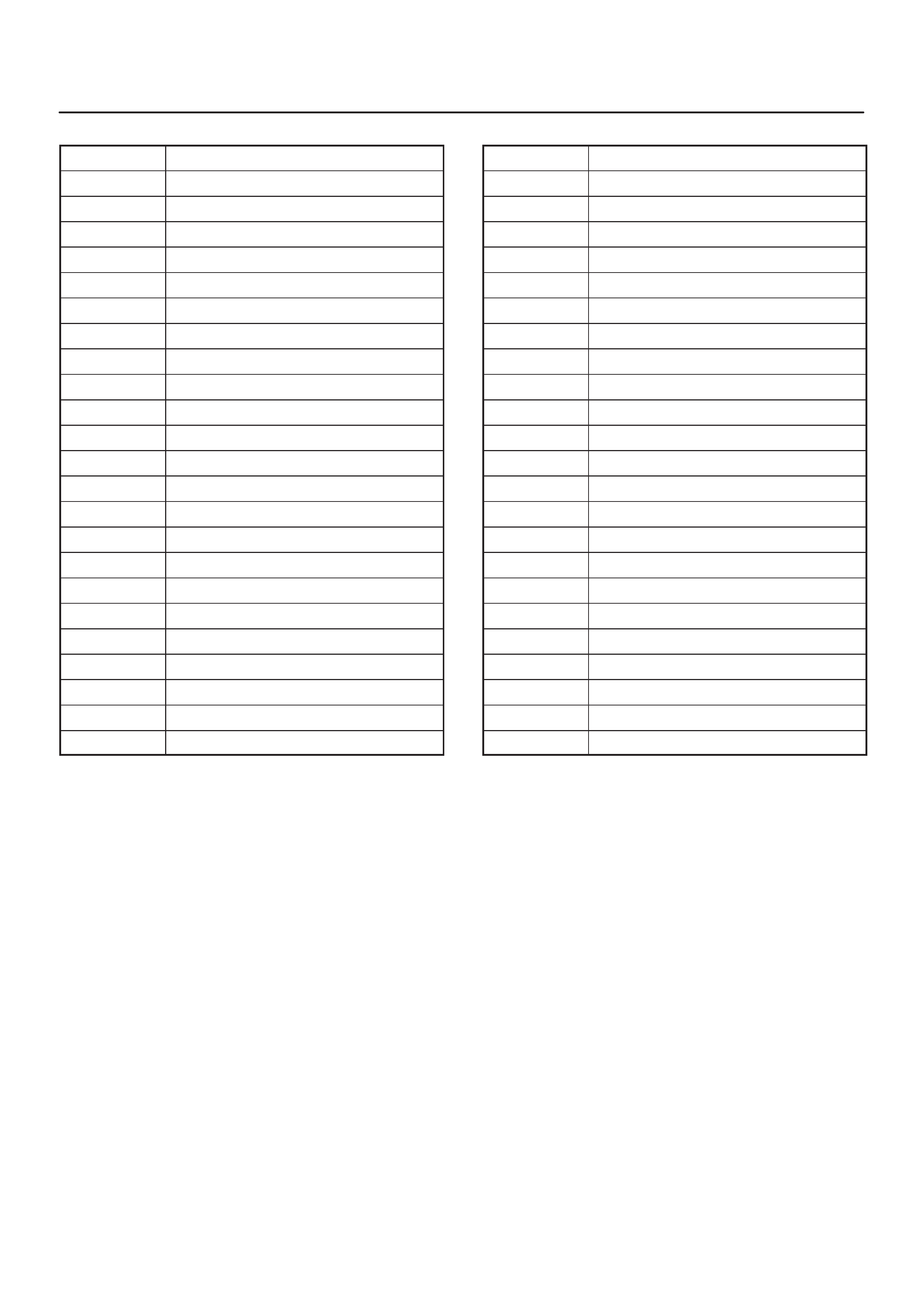

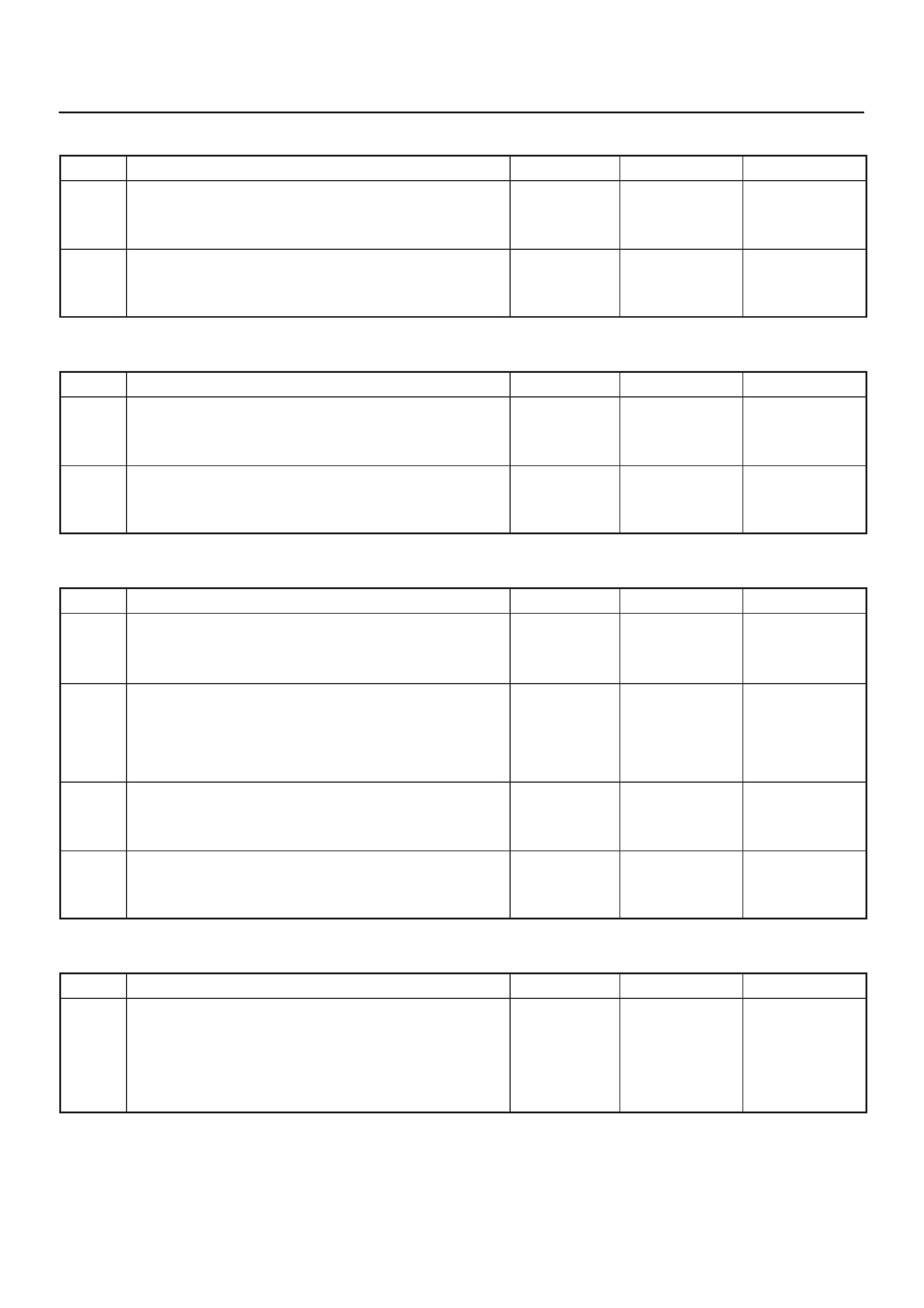

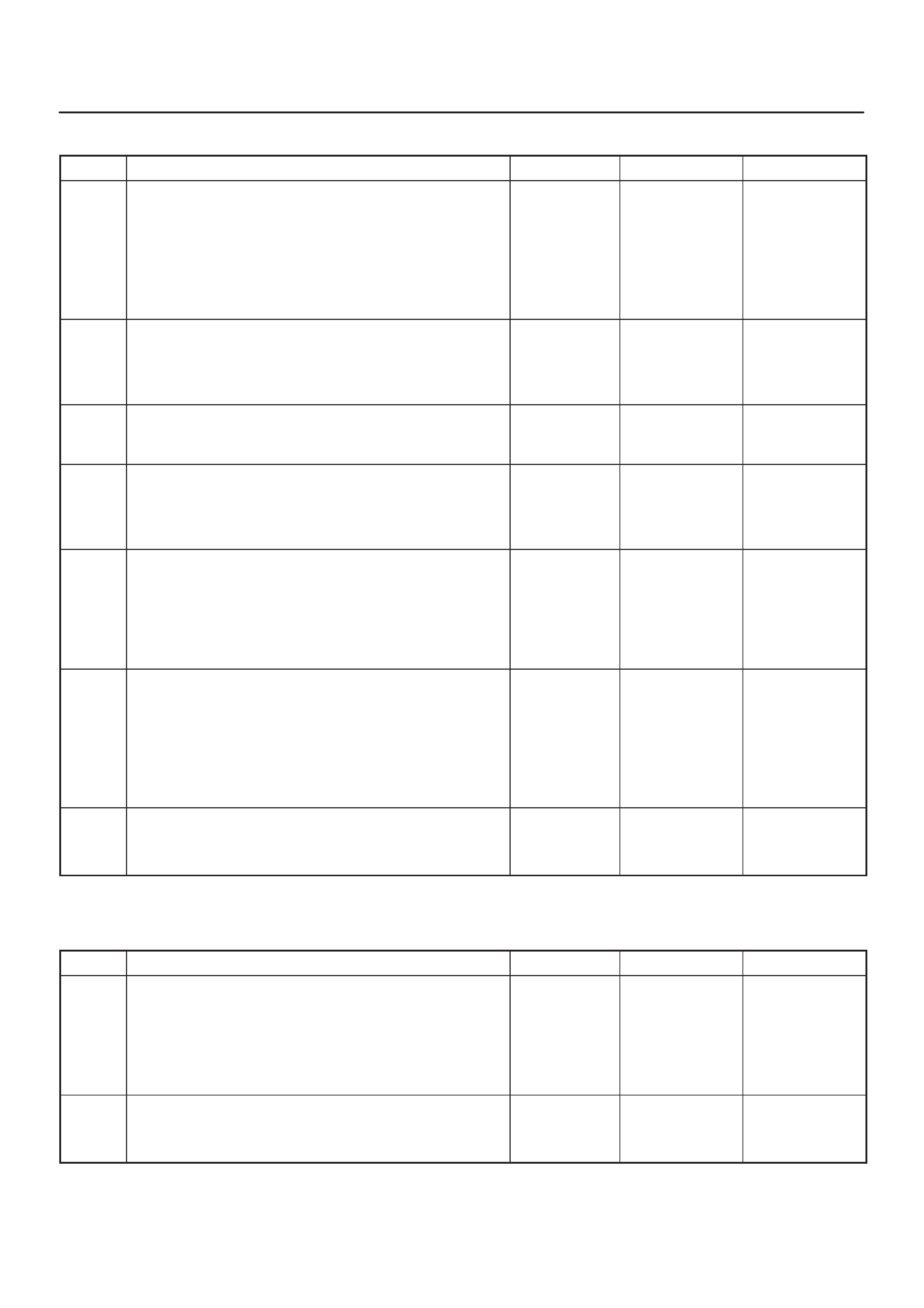

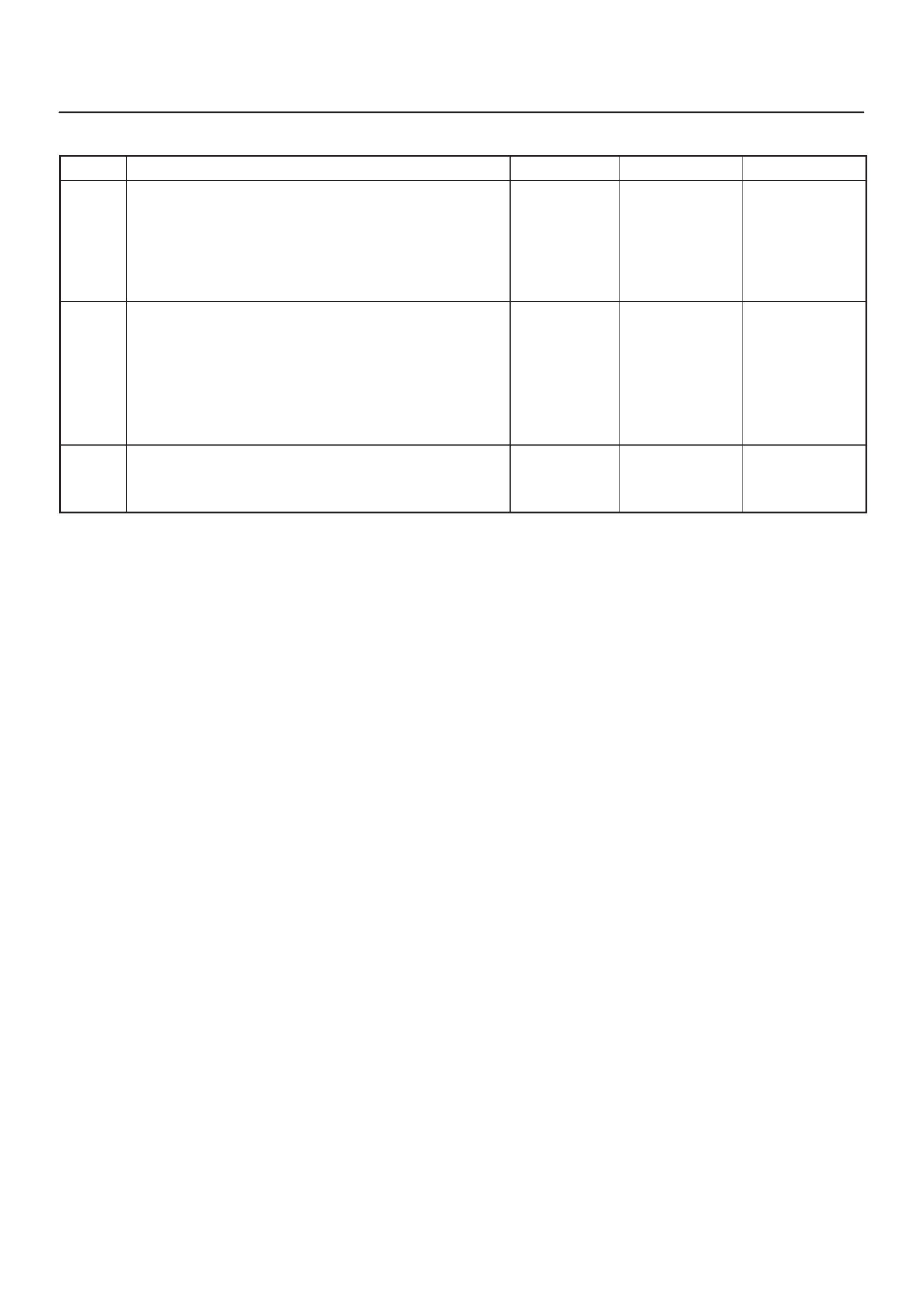

Abbreviations

Abbreviation Meaning of Abbreviation

AAmpere (S)

ABS Anti-lock brake system

ASM Assembly

AC Alternating current

A/C Air conditioner

ACC Accessories

A/T Automatic transmission

C/B Circuit breaker

CSD Cold start device

DIS Direct ignition system

EBCM Electronic brake control module

ECGI Electronic control gasoline injection

ECM Engine control module

ECU Electronic control unit

EFE Early fuel evaporation

EGR Exhaust gas recirculation

4A/T 4-speed automatic transmission

4WD Four-wheel drive

FL Fusible link

FRT Front

H/L Headlight

IC Integrated circuit

IG Ignition

Abbreviation Meaning of Abbreviation

kW Kilowatt

LH Left hand

LWB Long wheel base

M/T Manual transmission

OD Over drive

OPT Option

PCM Powertrain control module

QOS Quick on start

RH Right hand

RR Rear

SDM Sensing and diagnostic module

SRS Supplemental restraint system

ST Start

STD Standard

SW Switch

SWB Short wheel base

3A/T 3-speed automatic transmission

V Volt

VSV Vacuum switching valve

WWatt (S)

WOT Wide open throttle

W/ With

W/O Without

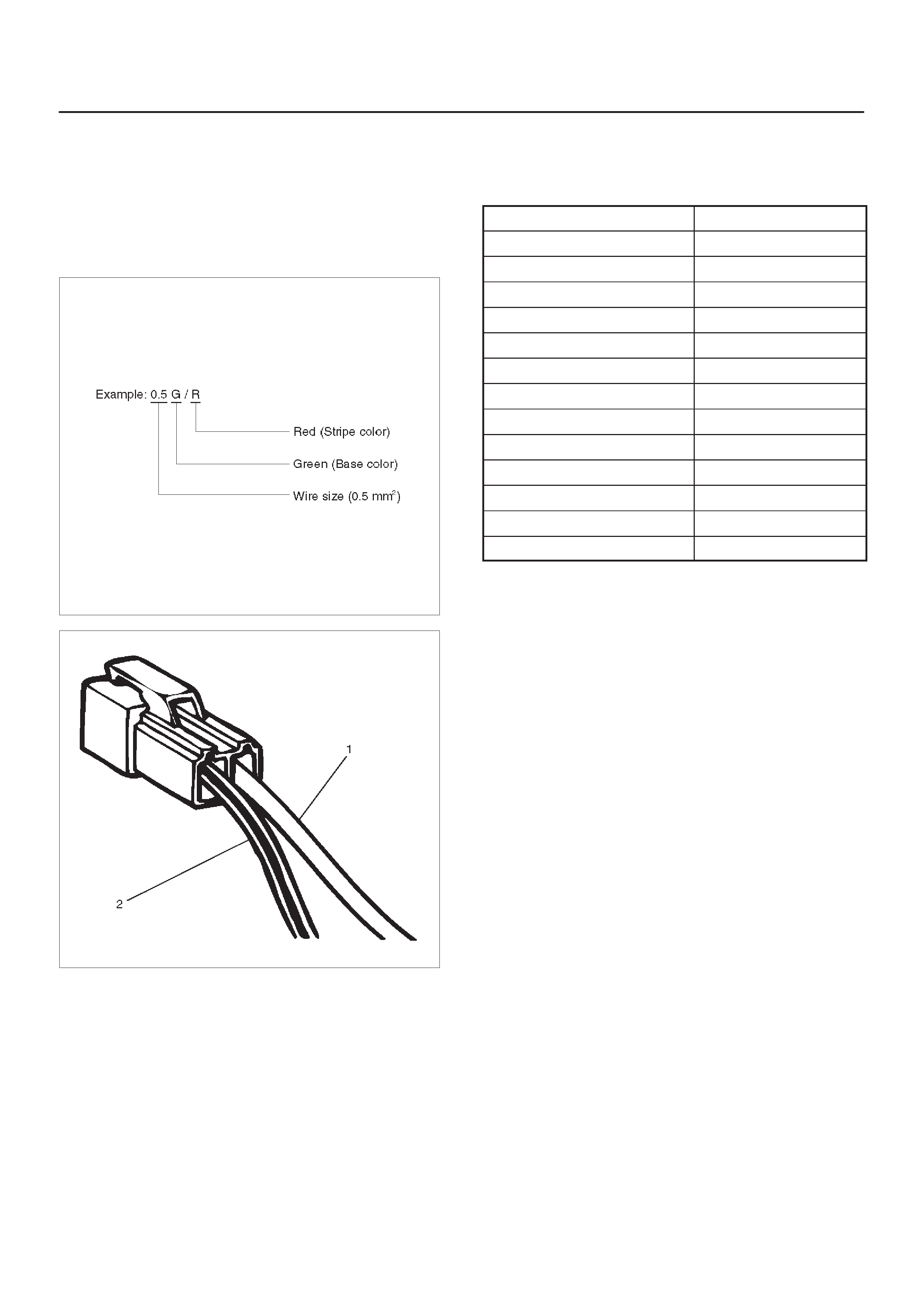

Parts for Electrical Circuit

Wiring – Wire color

All wires have color–coded insulation.

Wires belonging to a system’s main harness will have a

single color (1). Wires belonging to a system’s subcircuits

will have a colored stripe (2). Striped wires use the

following code to show wire size and colors.

F08RW001

D08RW150

Wiring – Wire Color Coding

Abbreviations are used to indicate wire color within a

circuit diagram.

Refer to the following table.

Color–coding Meaning

B Black

W White

R Red

G Green

Y Yellow

L Blue

O Orange

BR Brown

LG Light green

GR Grey

P Pink

LB Light blue

V Violet

Wiring – Wire Size

The size of wire used in a circuit is determined by the

amount of current (amperage), the length of the circuit,

and the voltage drop allowed. The following wire size and

load capacity, shown below, are specified by AWG

(American Wire Gauge) (Nominal size means

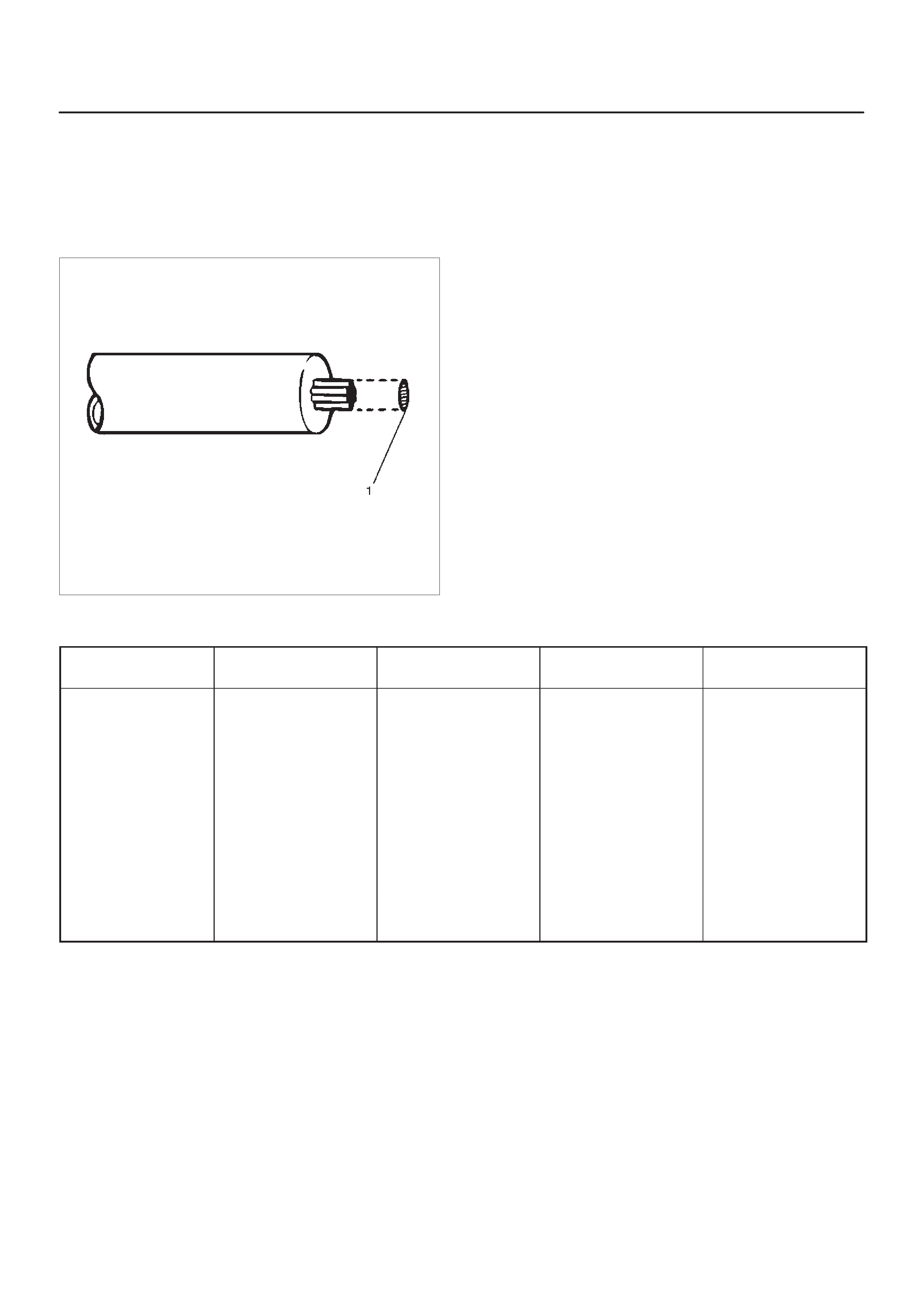

approximate cross sectional area (1).)

D08RW151

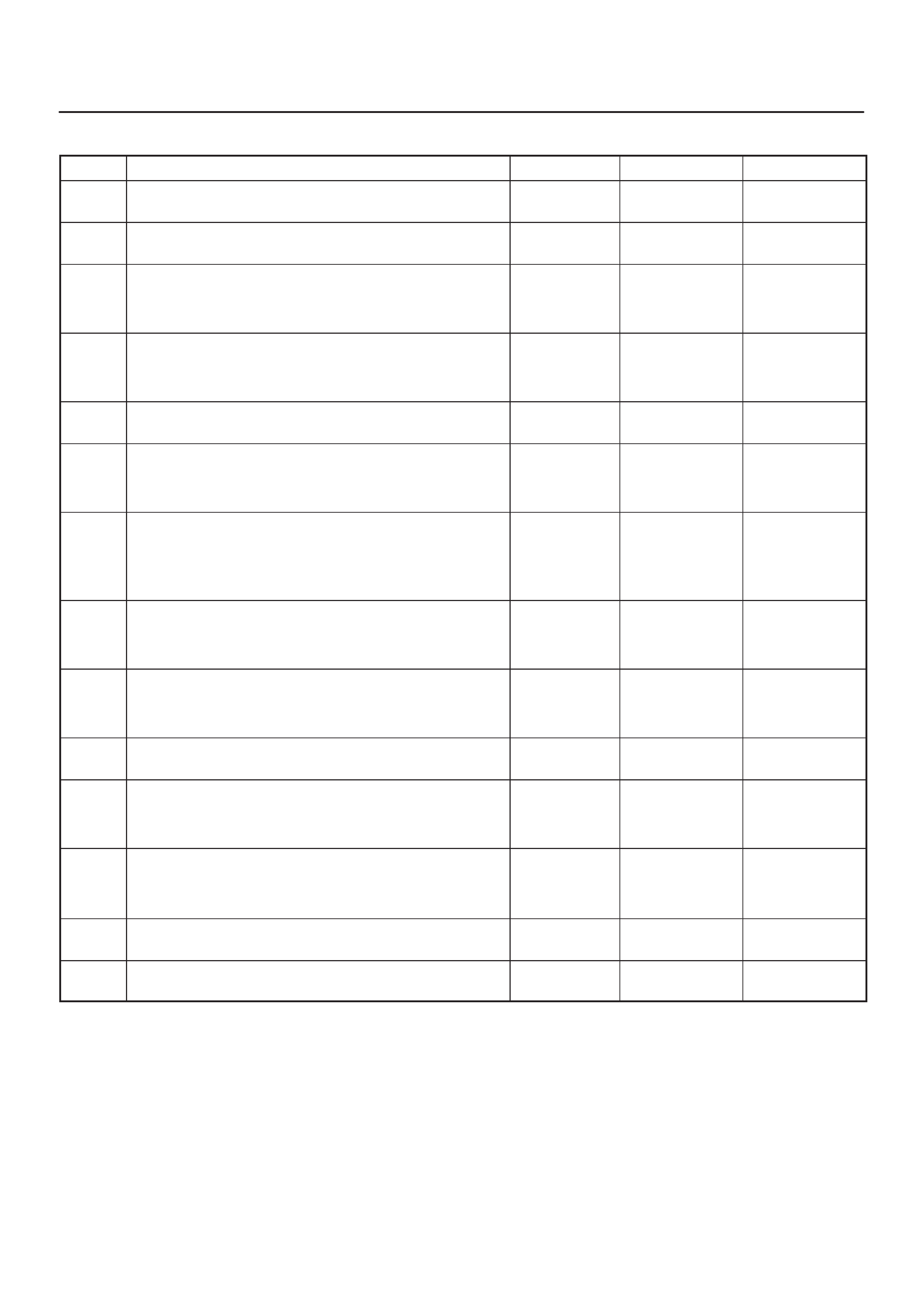

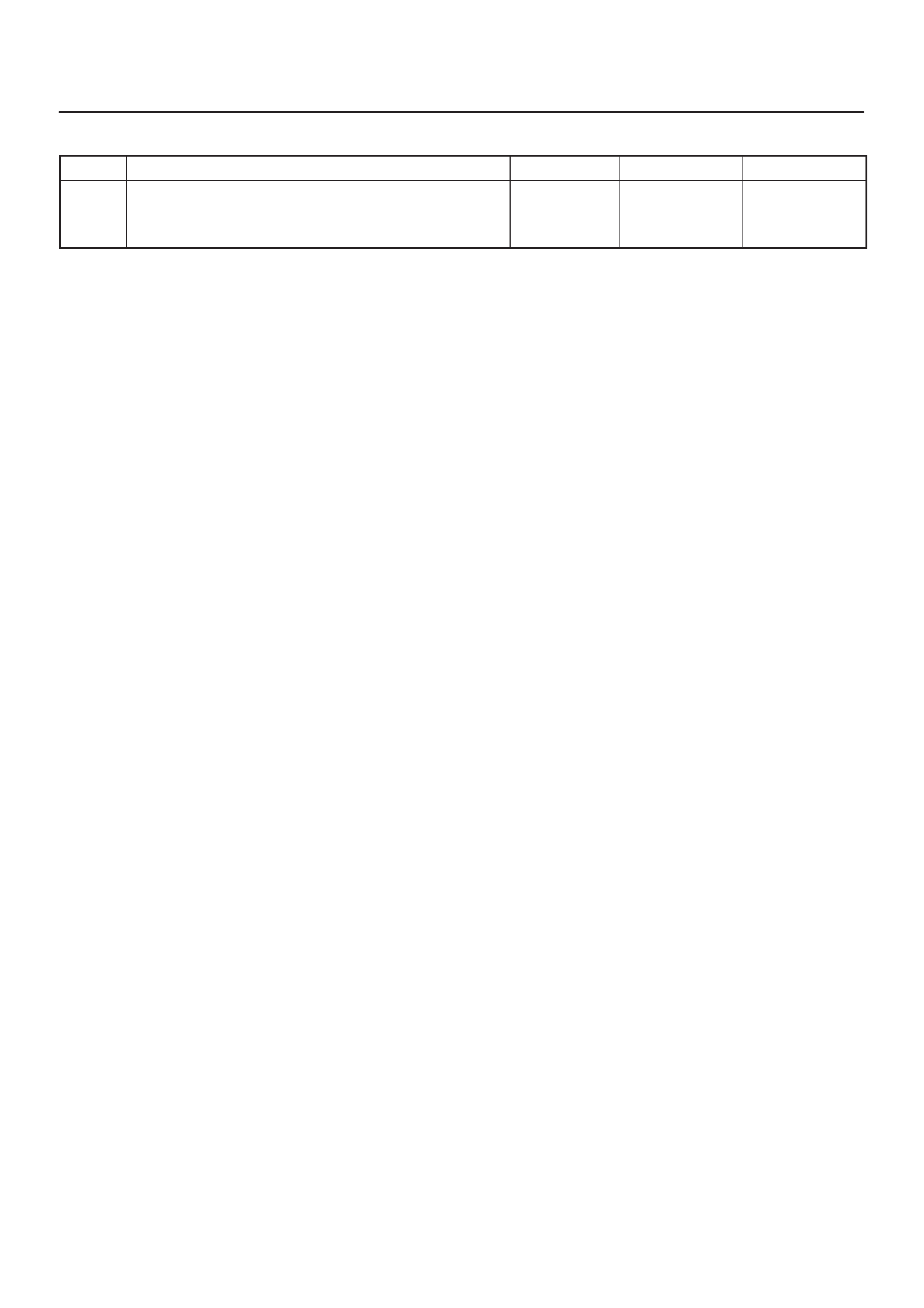

Wiring – Wire Size Table

Nominal size Cross sectional area

(mm@)Outside diameter

(mm) Allowable current (A) AWG size

(cross reference)

0.3 0.372 1.5 9 22

0.5 0.563 1.7 12 20

0.85 0.885 1.9 16 18

1.25 1.287 2.2 21 16

2 2.091 2.7 28 14

3 3.296 3.6 37.5 12

5 5.227 4.4 53 10

8 7.952 5.5 67 8

15 13.36 7.0 75 6

20 20.61 8.2 97 4

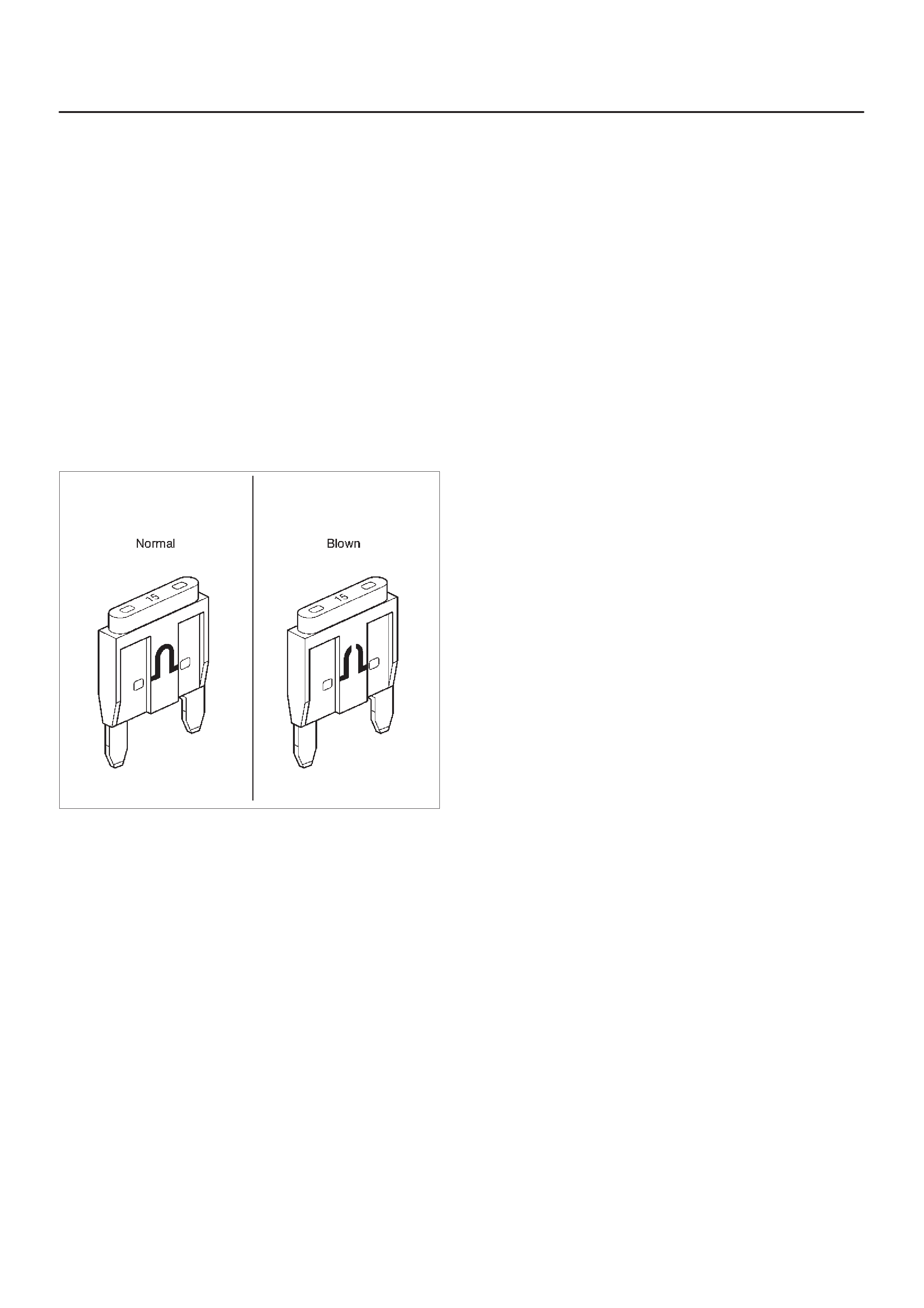

Fuse

Fuses are the most common form of circuit protection

used in vehicle wiring. A fuse is a thin piece of wire or strip

of metal encased in a glass it or plastic housing. It is wired

in series with the circuit in protects. When there is an

overload of current in a circuit, such as a short of a

ground, the metal strip is designed to burn out and

interrupt the flow of current. This prevents a surge of high

current from reaching and damaging other components in

the circuit.

Determine the cause of the overloaded before replacing

the fuse.

The replacement fuse must have the same amperage

specification as the original fuse.

Never replace a blown fuse with a fuse of a different

amperage specification.

Doing so can result in an electrical fire or other serious

circuit damage. A blown fuse is easily identified as shown

in the figure.

810RX001

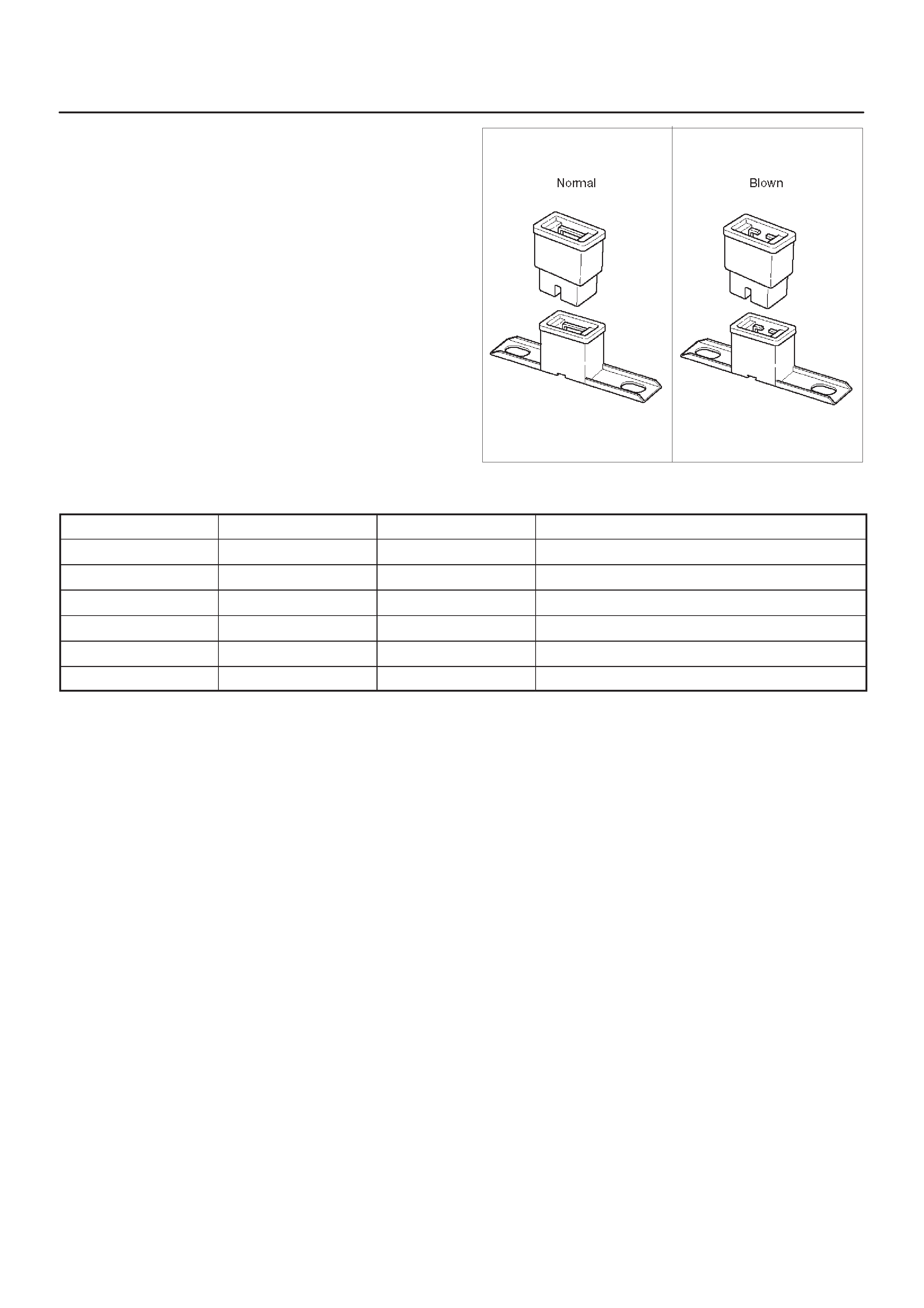

Fusible Link

The fusible link is primarily used to protect circuits where

high amounts of current flow and where it would not be

practical to use a fuse. For example, the starter circuit.

When a current overload occurs, the fusible link melts

open and interrupts the flow of current so as to prevent the

rest of the wiring harness from burning.

Determine the cause of the overload before replacing the

fusible link. the replacement fusible link must have the

same amperage specification as the original fusible link.

Never replace a blown fusible link with fusible link of a

different amperage specification. Doing so can result in

an electrical fire or other serious circuit damage.

A blown fusible link is easily identified as shown in the

figure.

D08RW154

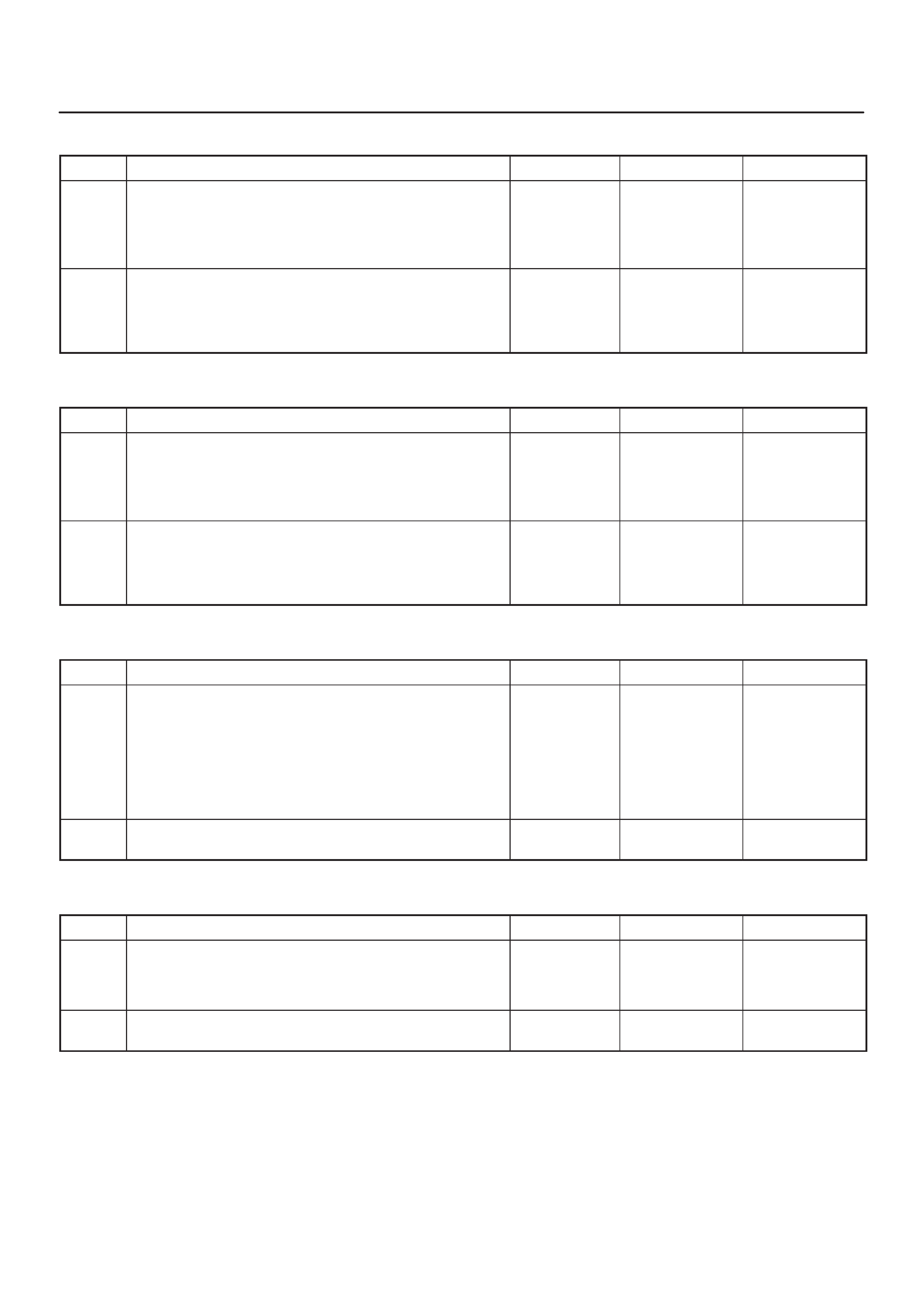

Fusible Link Specifications

Type Rating Case Color Maximum Circuit Current (A)

Connector 30A Pink 15

Connector 40A Green 20

Bolted 50A Red 25

Bolted/Connector 60A Yellow 30

Bolted 80A Black 40

Bolted 100A Blue 50

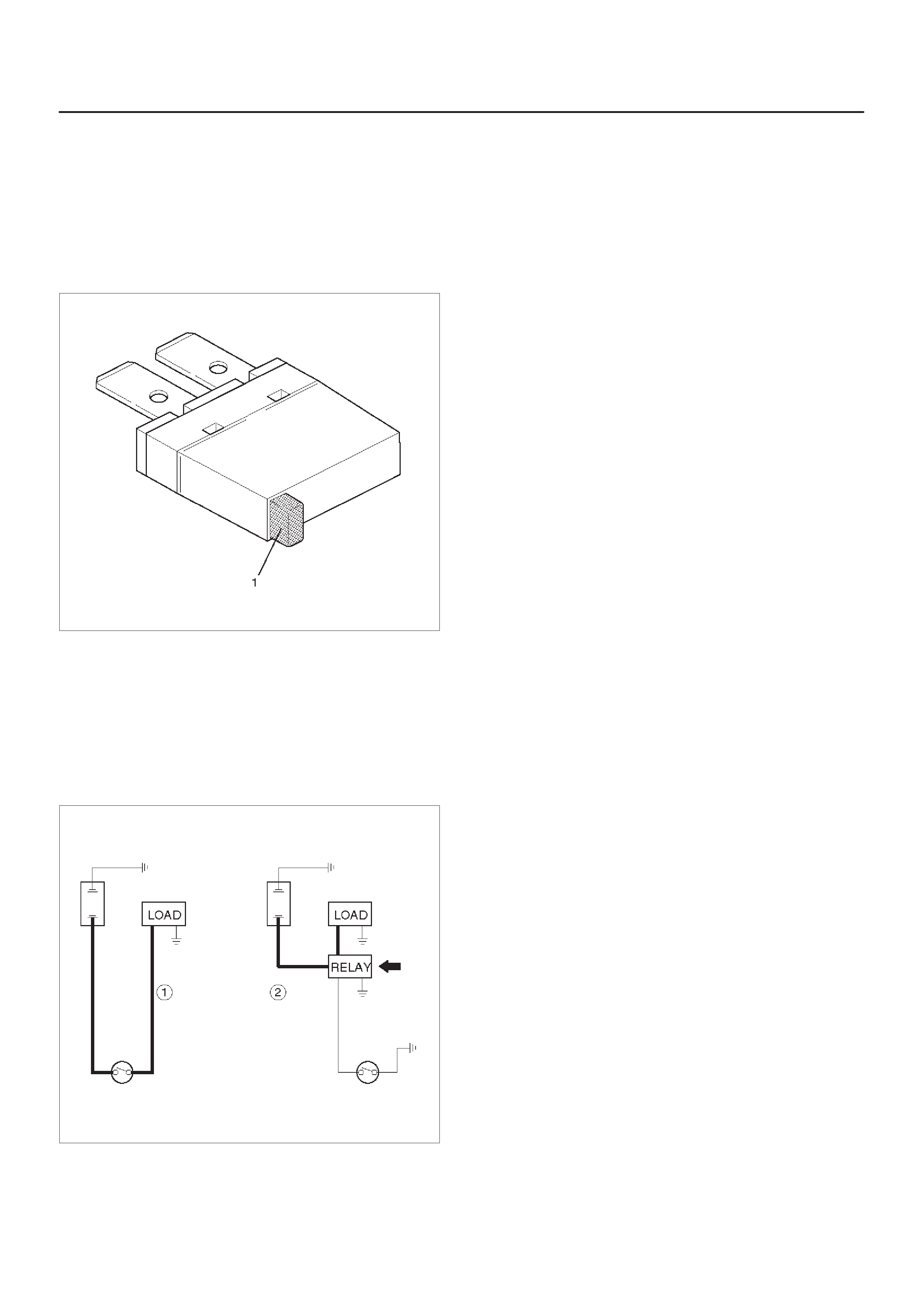

Circuit Breaker

The circuit breaker is a protective device designed to

open the circuit when a current load is in excess of rated

breaker capacity. If there is a short or other type of

overload condition in the circuit, the excessive current will

open the circuit between the circuit breaker terminals.

The reset knob (1) pops out when the circuit is open. Push

the reset knob in place to restore the circuit after repairing

it.

D08RW155

Relay

Battery and load location may require that a switch be

placed some distance from either component. This

means a longer wire and a higher voltage drop (1).

The installation of a relay between the battery and the

load reduces the voltage drop (2).

Because the switch controls the relay , amperage through

the switch can be reduced.

D08RW156

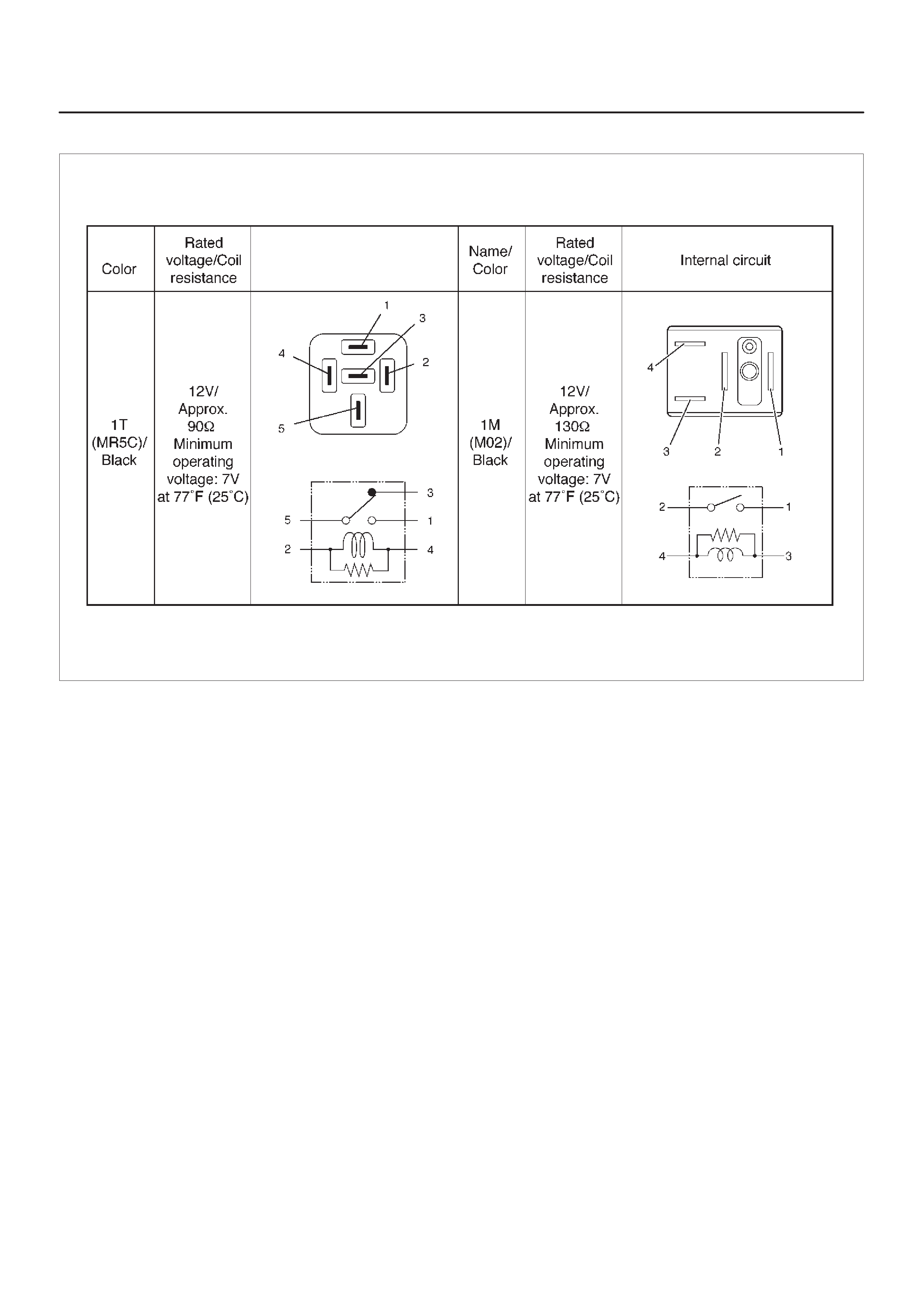

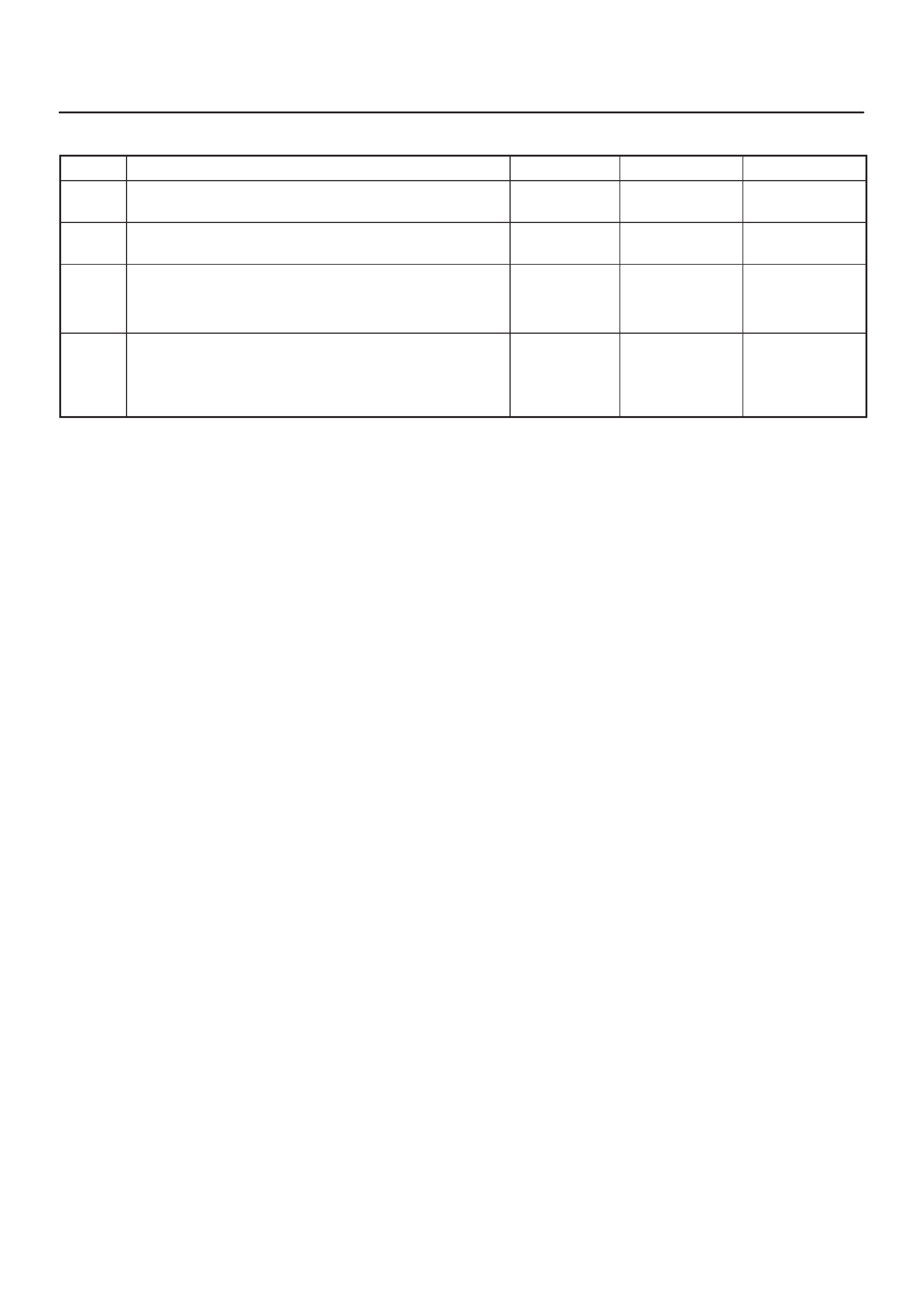

Relay Specifications and Configurations

F00RX012

*Relay contact shown in the wiring diagram indicates

condition before actuation.

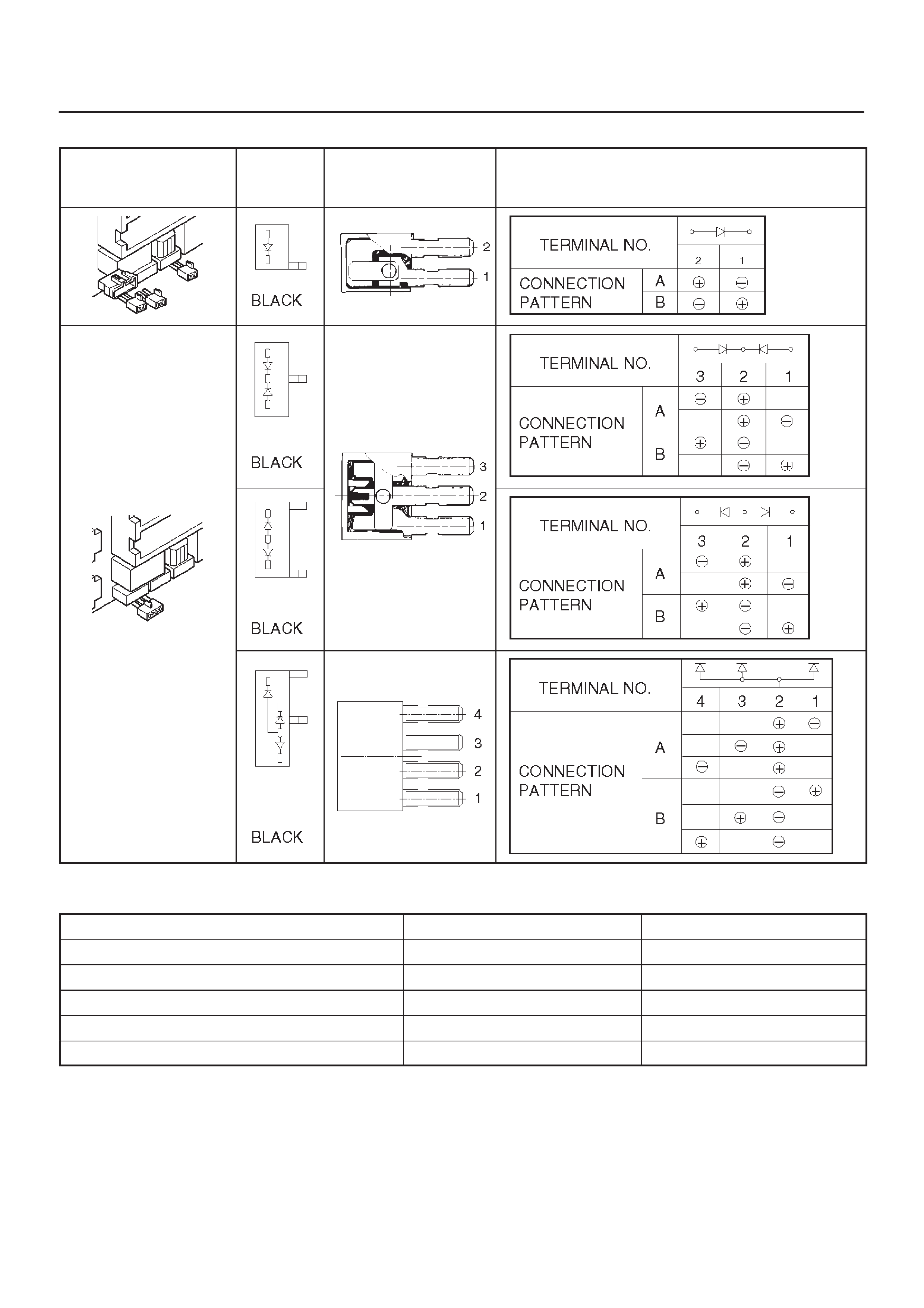

Diode – Diode Specifications and Configurations

SHAPE MARK /

COLOR CONSTRUCTION CHECKING: THERE SHOULD BE CONTINUITY

IN EITHER A OR B WHEN A CIRCUIT TESTER

IS CONNECTED WITH DIODE TERMINAL

Diode – Maximum Rating (Temp. = 77°F (25°C)

Items Rating Remarks

Peak reverse voltage 400V

Transient peak reverse voltage 500V

Average output current 1.5A Temp. = 104°F (40°C)

Working ambient temperature –22°F∼176°F (–30°C∼80°C)

Storage temperature –40°F∼212°F (–40°C∼100°C)

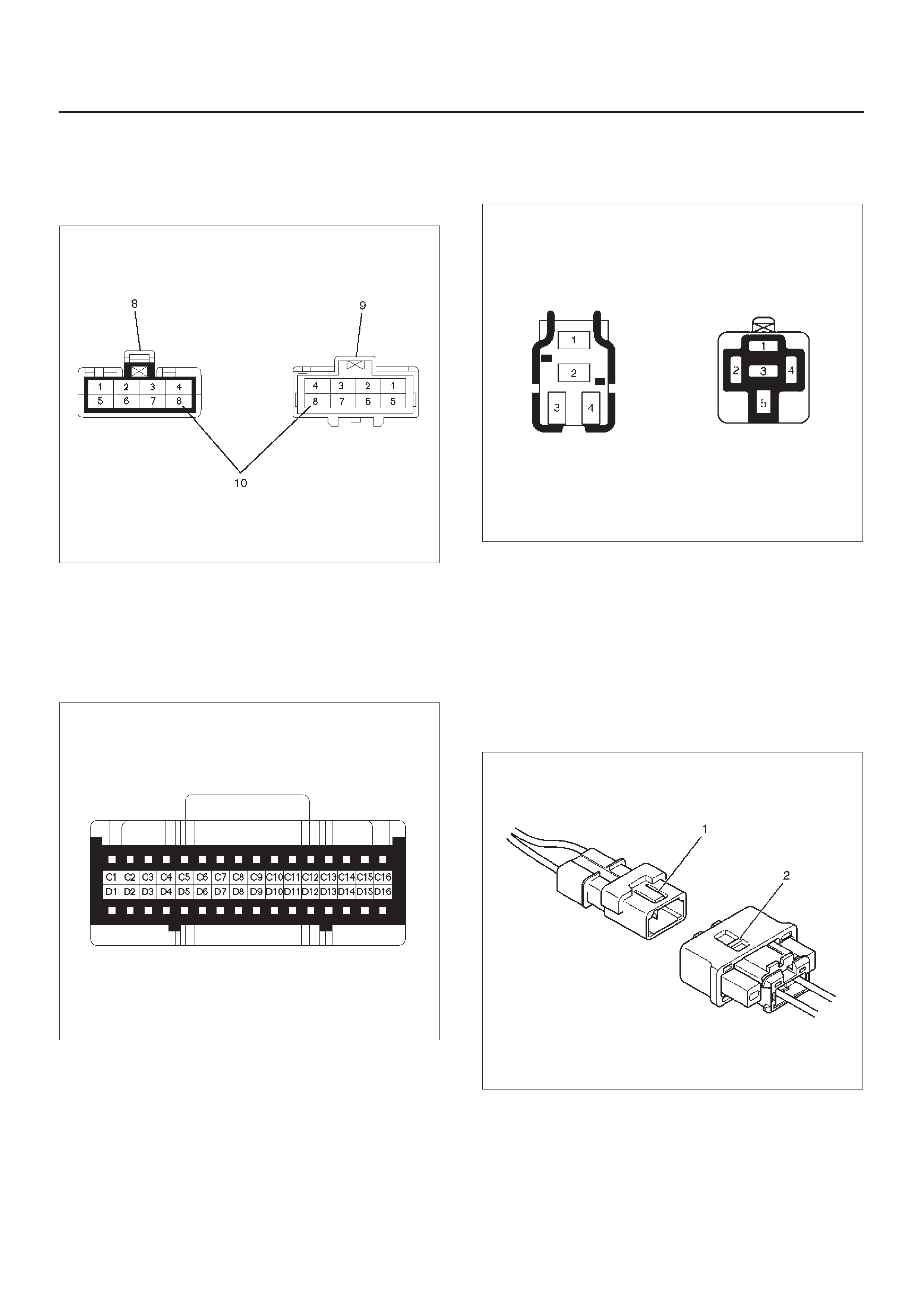

Connector

fThe connector pin shape (2) determines whether the

connector is male (3) or female (1).

D08RW159

fThe symbol illustrated in the figure is used as

connector, in the circuit of this section.

D08RW160

Legend

(4) Female Side Connector

(5) Male Side Connector

fConnector is identified with a connector number (6)

D08RW161

fThe applicable terminal number (7) is shown for each

connector.

D08RW162

fConnector terminal numbers (10) are clearly shown.

Make side connector (9) terminal numbers are in

sequence from upper right to lower left.

Female side connector (8) terminal numbers are in

sequence from upper left to lower right.

D08RW163

NOTE:

1. For those connectors on which specific terminal

numbers or symbols are shown (such as PCM), the

terminal numbers or symbols are used in the circuit

diagram, irrespective of the above rule.

Refer to the following figure.

D08RW164

2. The connectors used for relays have their own

terminal number assignment, irrespective of the

above rule.

Refer to the following figure.

Double Lock Type Connector

Doublelock type yellow color connectors are used for

supplemental restraint system–air bag circuit. When

removing the cable harness, disconnect the connector by

unlocking at two places, outside (1) and inside (2). In such

a case, do not pull the cables. Otherwise, cable

disconnection may occur.

When connecting the connector, insert the connector

completely and lock at outside. Imperfect locking may

cause malfunction of SRS system circuit.

F00RX010

Reading the Circuit Diagram

In this section, each system has its own parts location

illustration and circuit diagram. And harness connector

faces used in the circuit diagram are shown at the end of

this section.

Parts Location

The parts location shows the location of the connectors

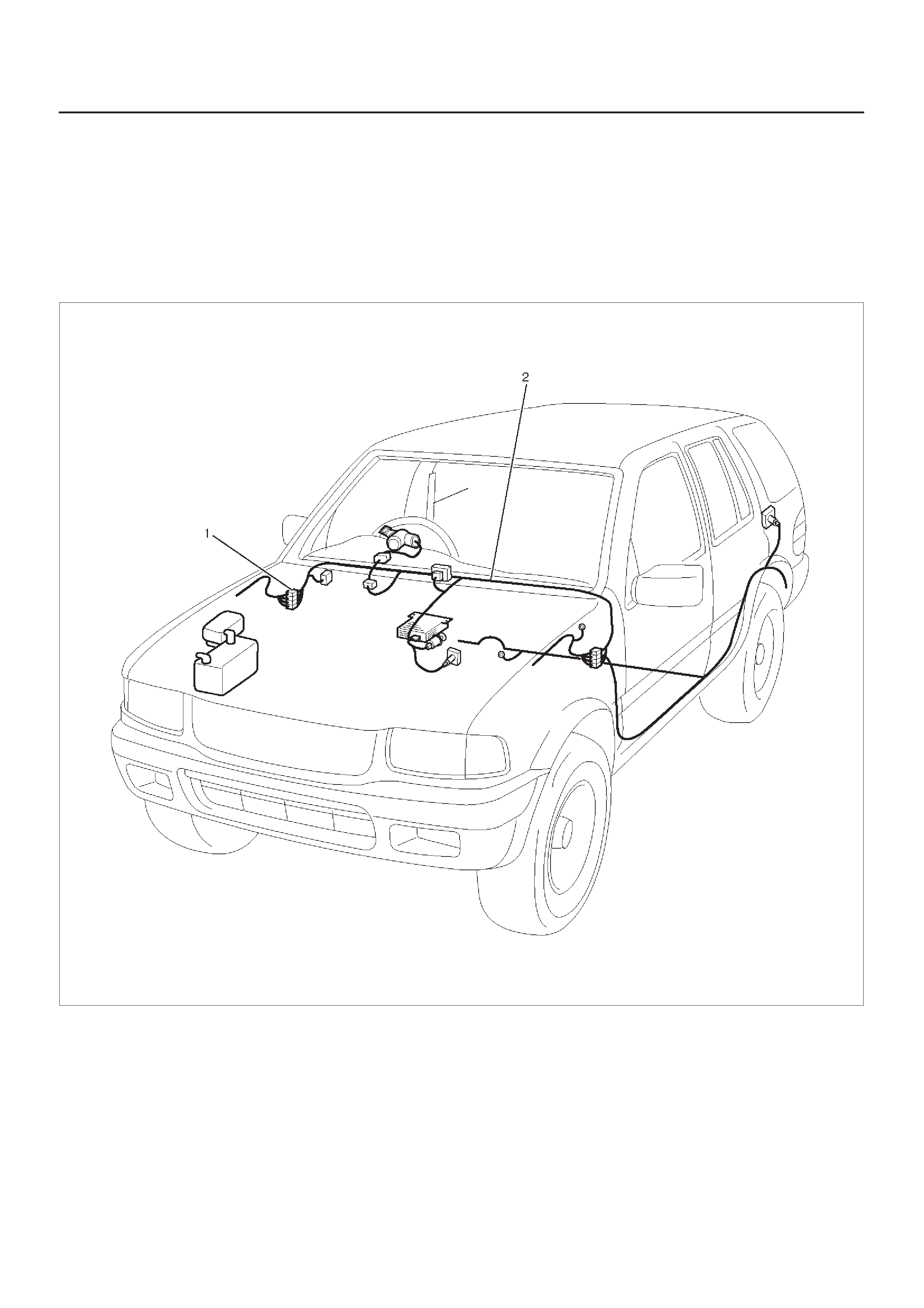

(1) and the harness (2) used in each harness routing.

D08RWD38

Circuit Diagram

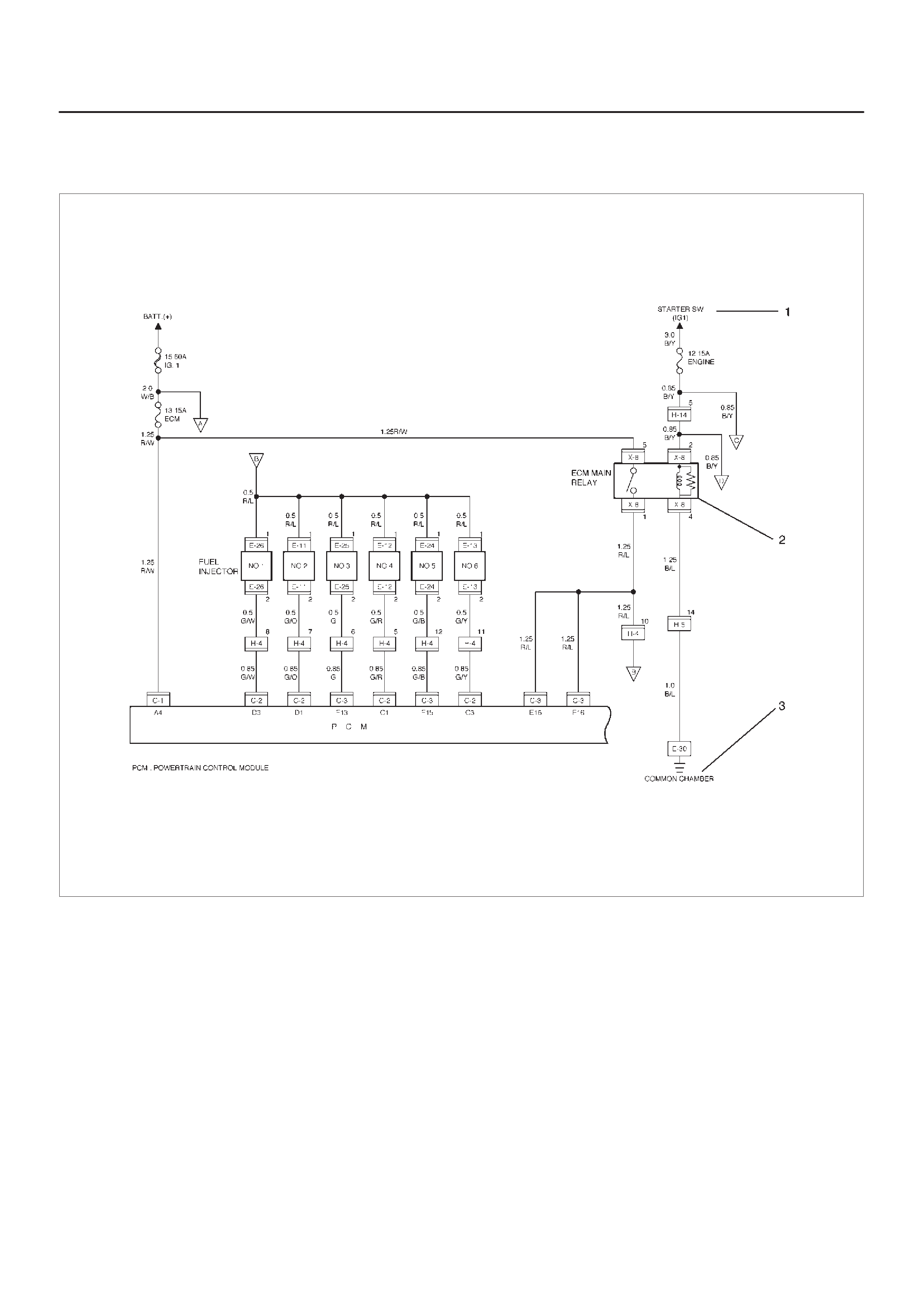

The circuit diagram shows the power supply (1) the load

or loads (2) and the grounding point(s) (3).

D08RX124

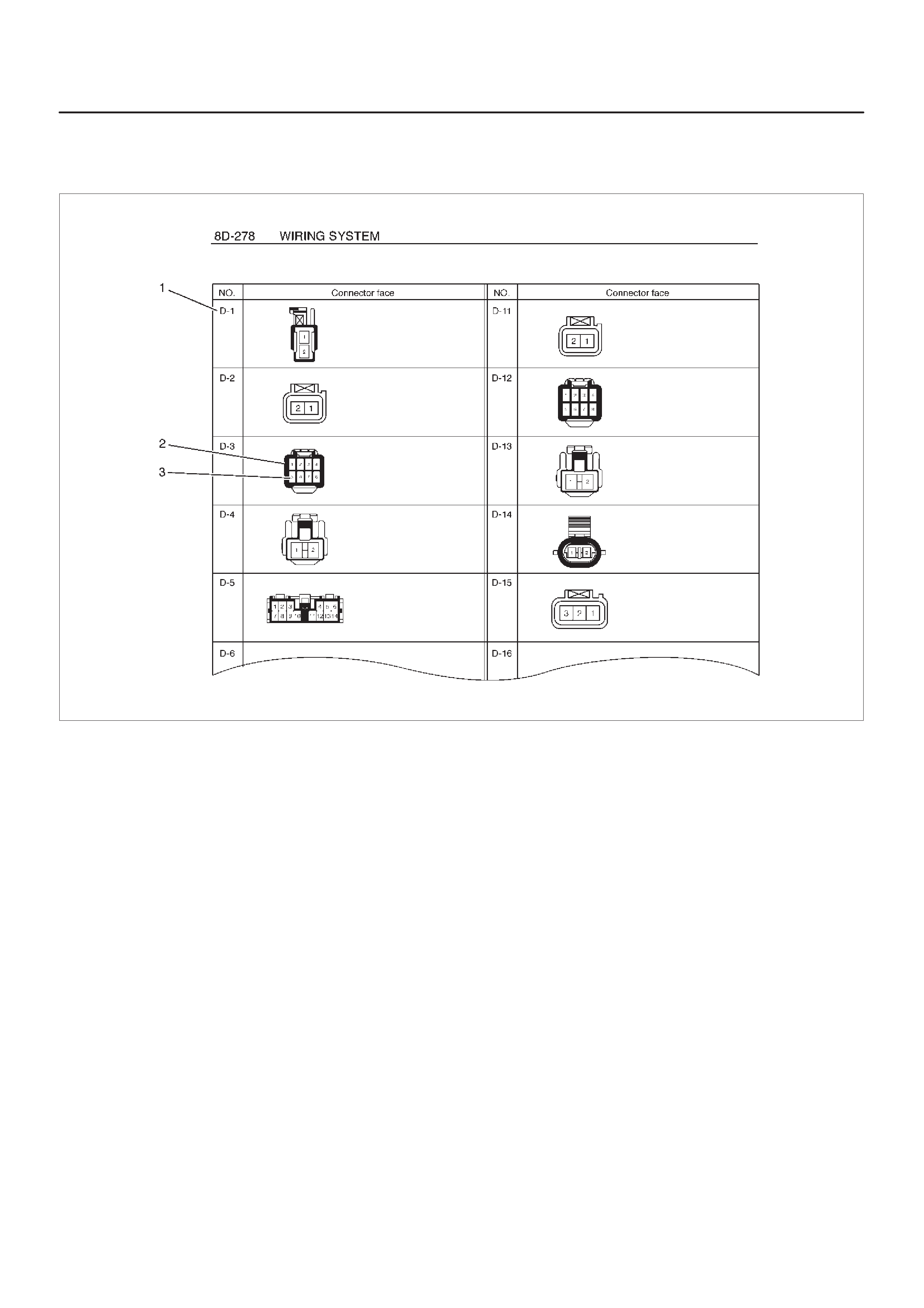

Harness Connector Faces

The harness connector faces show each connector’s

number (1), configuration (2) and the pin number (3).

F00RX011

Main Data and Specifications

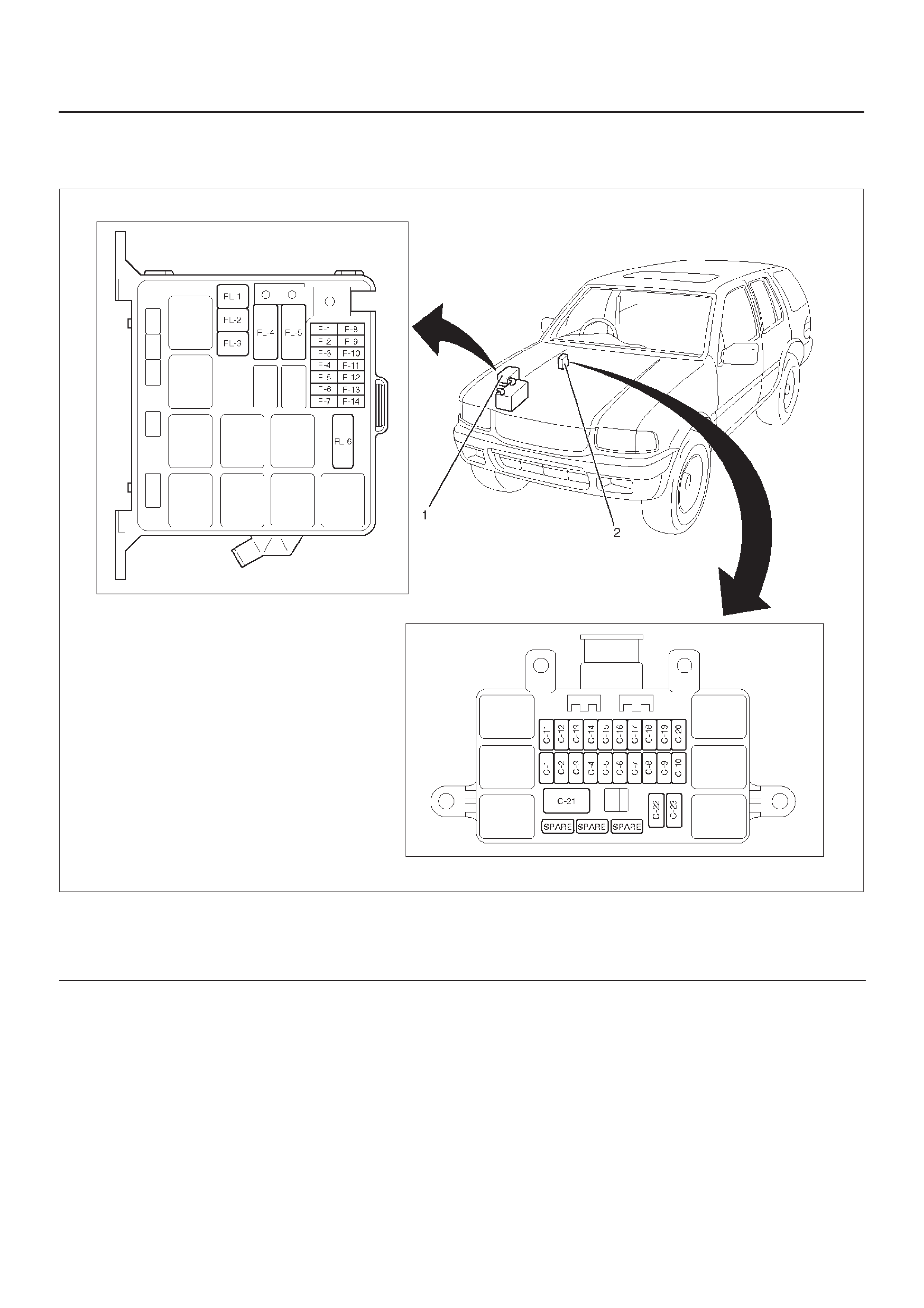

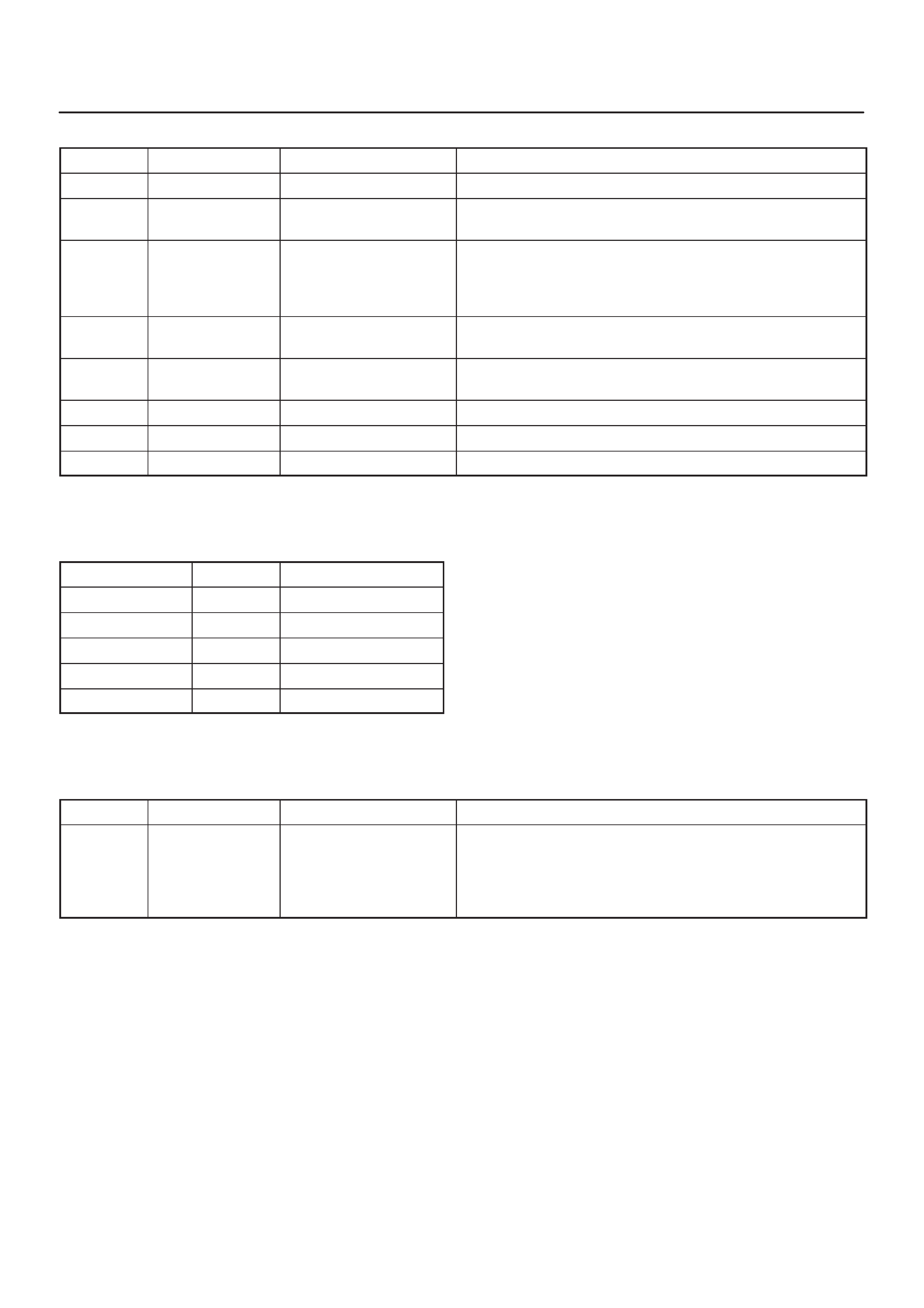

Fuse, Fusible Link and Circuit Breaker Location

810RX013

Legend

(1) Relay & Fuse Box (Engine Room)

(2) Relay & Fuse Box (Instrument panel)

Relay & Fuse Box (Engine Room)

Fuse

No. Capacity Indication on label

F-1 15A HAZARD

F-2 10A HORN

F-3 – –

F-4 20A BLOWER

F-5 10A A/C

F-6 – –

F-7 – –

F-8 10A H/L LIGHT-LH

F-9 10A H/L LIGHT-RH

F-10 15A FOG LIGHT

F-11 20A O2 SENSOR

F-12 20A FUEL PUMP

F-13 15A ECM

F-14 – –

FL-1 60A ABS

FL-2 30A (COND.FAN)

FL-3 – –

FL-4 100A MAIN

FL-5 60A IGN.

FL-6 30A ELEC. FAN

Relay & Fuse Box (Instrument panel)

Fuse

No. Capacity Indication on label

C-1 20A ACC. SOCKET

C-2 10A (AUDIO)

C-3 15A CIGAR LIGHTER

C-4 15A TAIL/ILLUMI. LIGHT

C-5 10A DOME LIGHT

C-6 15A STOP LIGHT

C-7 20A (POWER DOOR LOCK)

C-8 10A (MIRROR DEFOG)

C-9 15A (REAR DEFOG)

C-10 15A (REAR DEFOG)

C-11 15A METER

C-12 15A ENGINE IG.

C-13 15A IG. COIL

C-14 15A BACK UP/TURN LIGHT

C-15 15A ELEC. IG.

C-16 20A FRONT WIPER & W ASHER

C-17 10A (REAR WIPER & W ASHER)

C-18 – –

C-19 15A (AUDIO)

C-20 10A STARTER

C-21 30A (POWER WINDOW)

C-22 10A SRS

C-23 – –

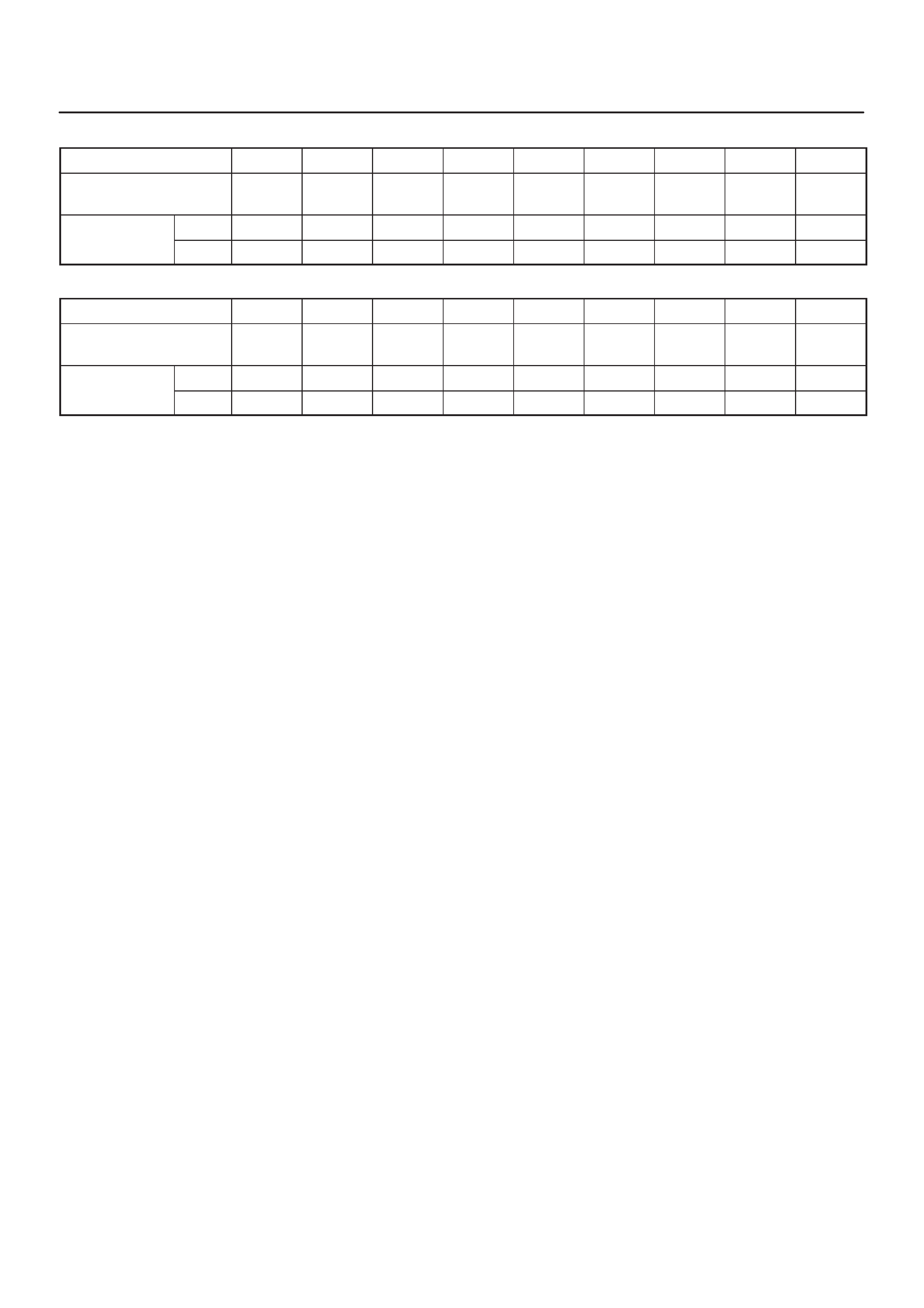

Fuse Block Circuit–1 (6VD1)

D08RX278

Fuse Block Circuit–1 (X22SE)

D08RX279

Fuse Block Circuit–2 (6VD1)

D08RX280

Fuse Block Circuit–2 (X22SE)

D08RX281

Fuse Block Circuit–3

D08RX282

Fuse Block Circuit–4

D08RX283

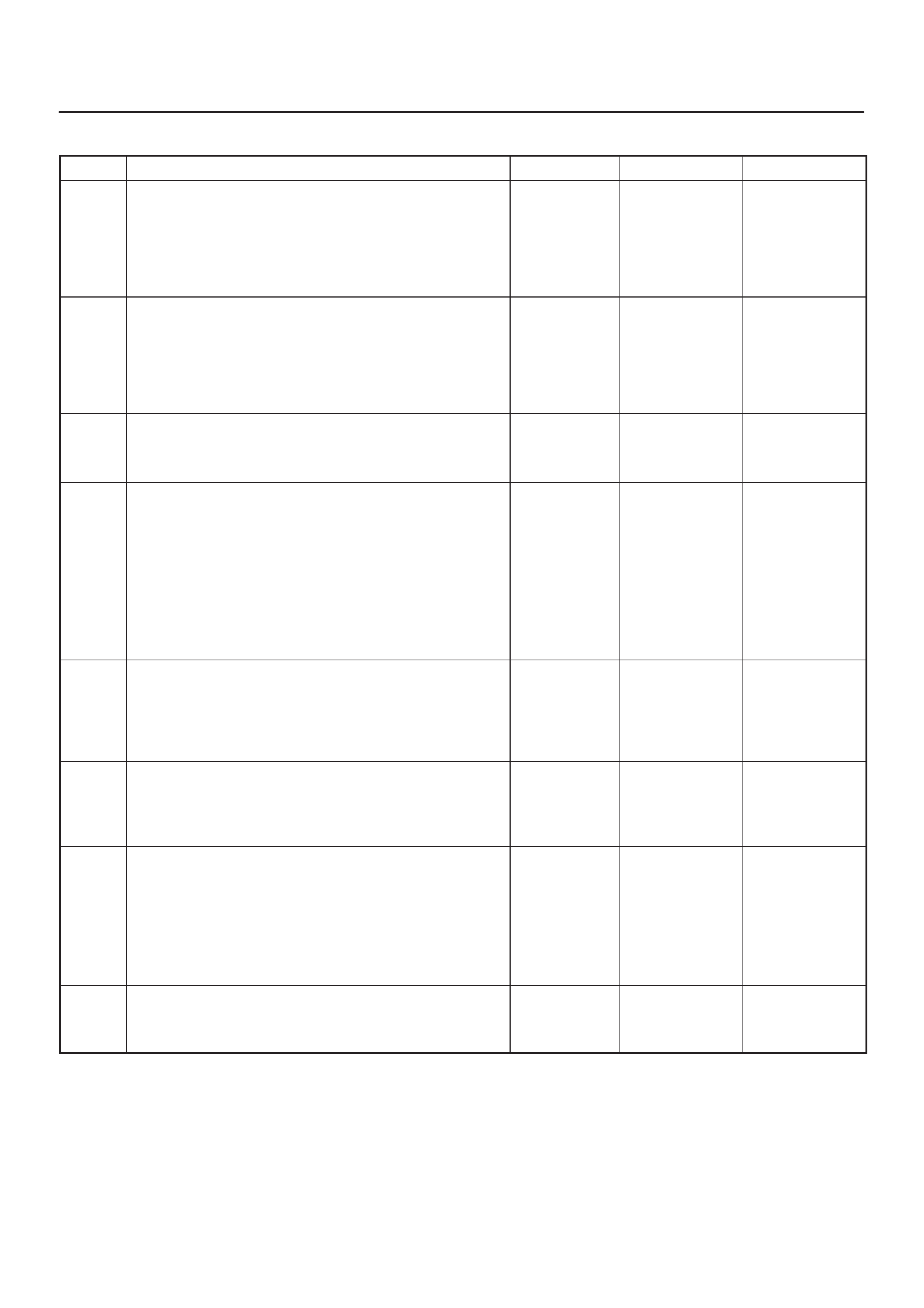

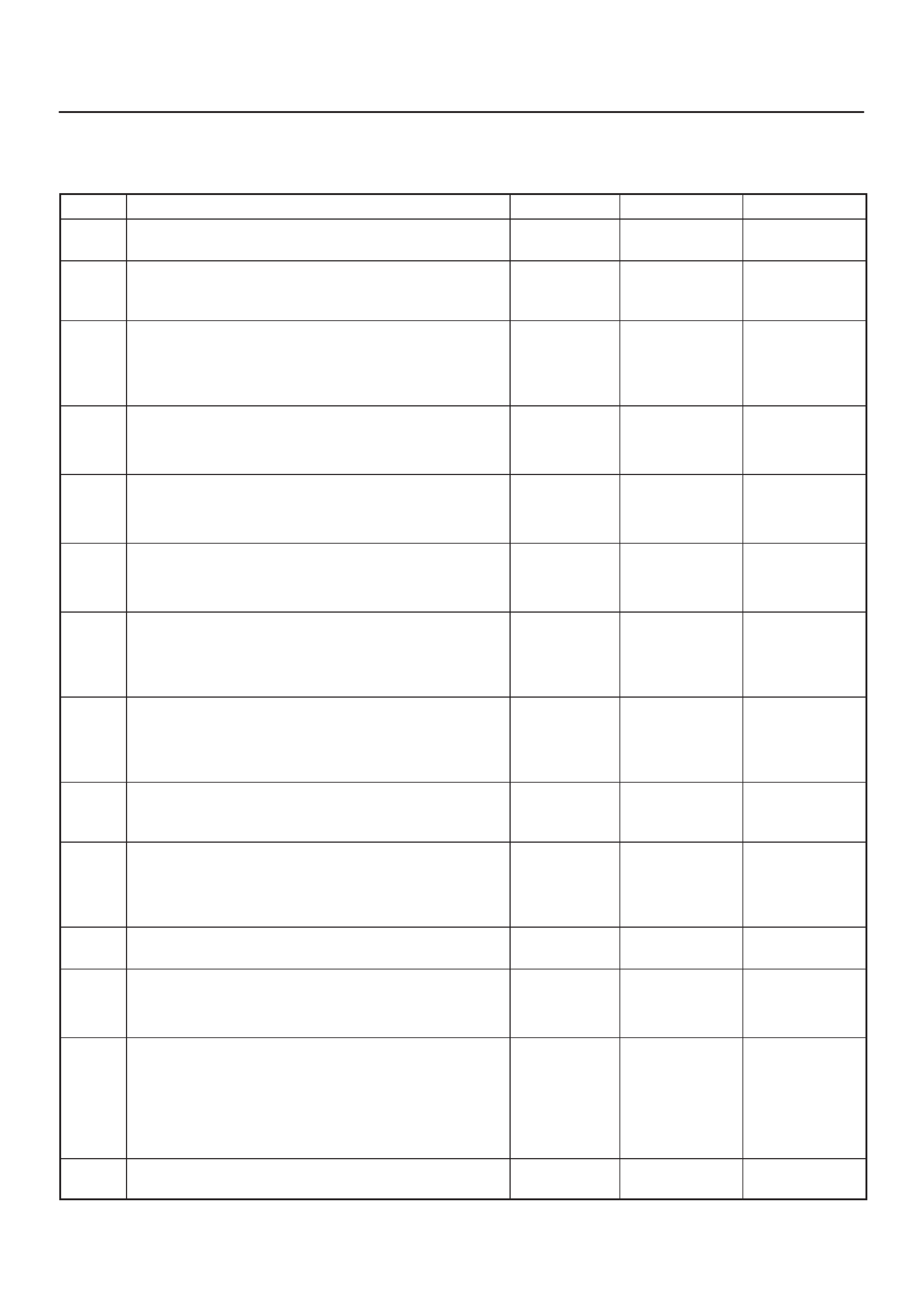

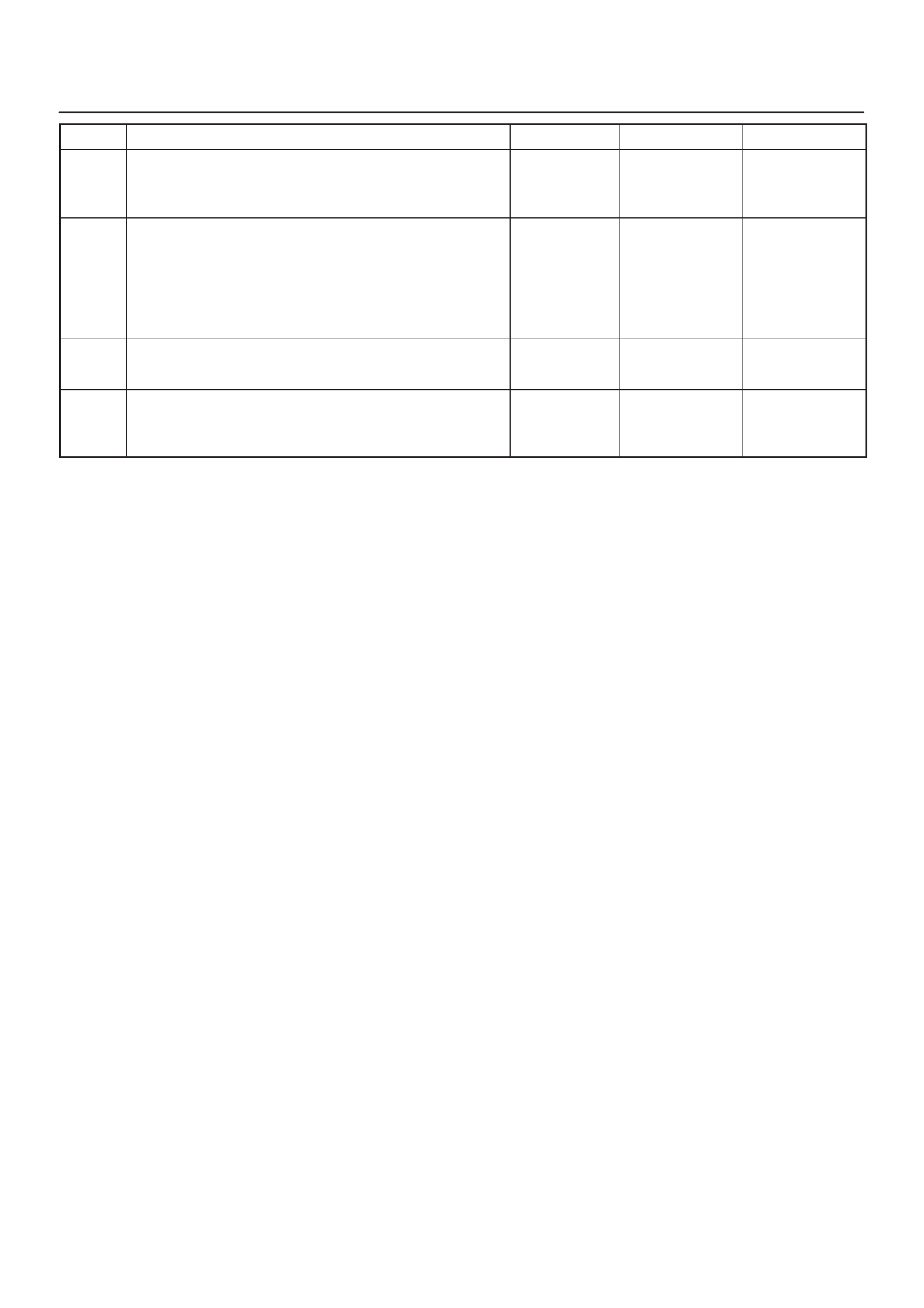

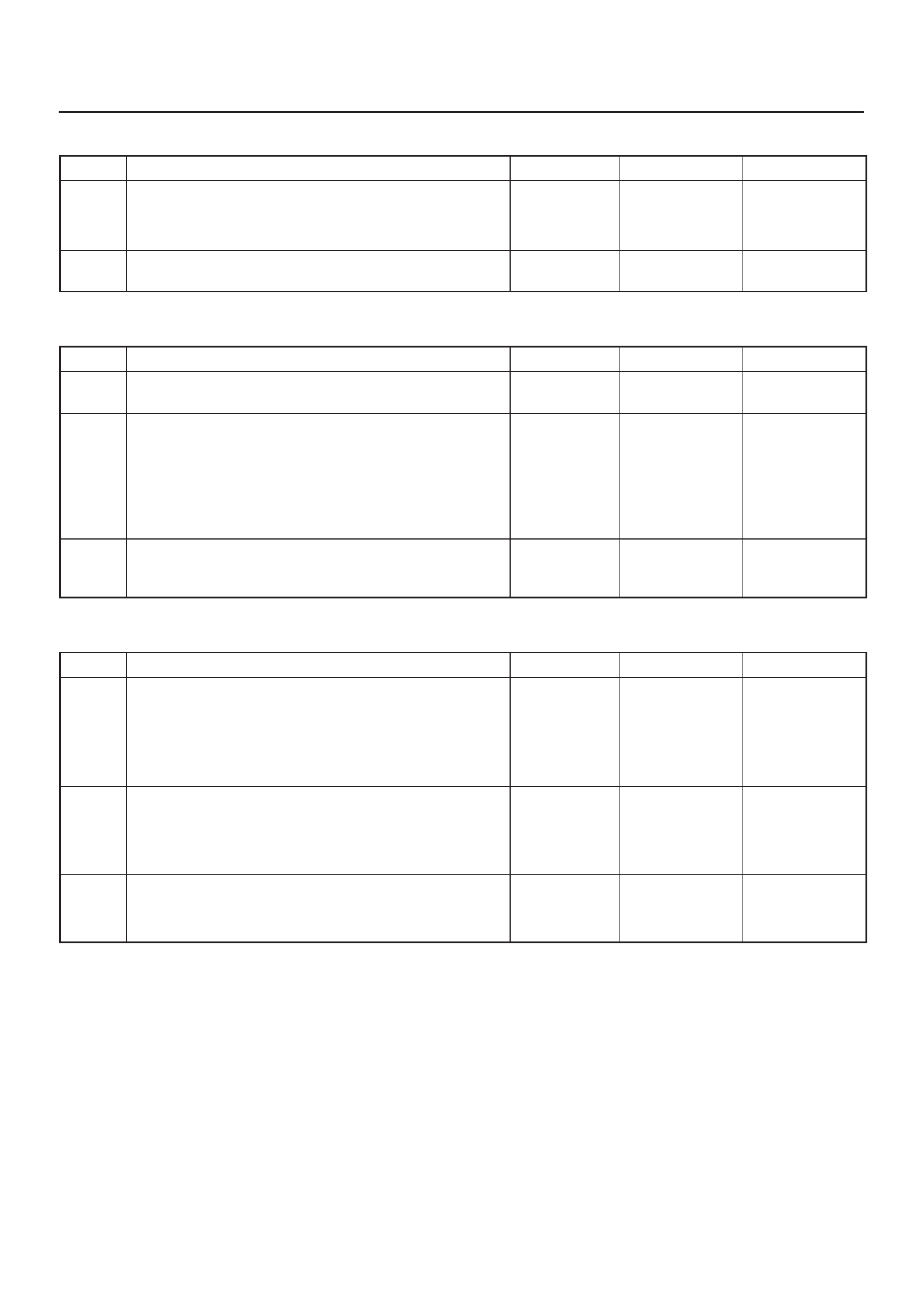

Reference Table of Fuse, Fusible Link and Circuit Breaker

Fuse (Relay and Fuse Box · Engine Room)

Fuse No. Capacity Indication on label Parts (Load)

F-1 15A HAZARD Hazard warning light

F-2 10A HORN Alarm & relay control unit, Horn, Anti - theft horn

F-4 20A BLOWER Blower motor, Blower resistor

F-5 10A A/C A/C thermostat relay, Electronic thermostat,

A/C compressor relay, Magnetic clutch

F-8 10A H/L LIGHT - LH Headlight - LH, High beam indicator light, Fog light relay

F-9 10A H/L LIGHT - RH Headlight - RH

F-10 15A FOG LIGHT Fog light

F-11 20A O2SENSOR Oxygen sensor

F-12 20A FUEL PUMP Fuel pump

F-13 15A ECM Engine control module

F-14 – – –

FL-1 60A ABS EHCU

FL-2 30A COND.FAN (6VD1) Condenser fan unit

FL-4 100A MAIN

FL-5 60A IGN.

FL-6 30A ELEC. FAN (X22SE) Electric fan relay, Electric fan

Fuse (Relay & Fuse Box · Instrument Panel)

Fuse No. Capacity Indication on label Parts (Load)

C-1 20A ACC. SOCKET Acc socket relay, Acc socket

C-2 10A (AUDIO) Audio

C-3 15A CIGAR LIGHTER Cigarette Lighter

C-4 15A TAIL/ILLUMI. LIGHT Tail relay, Parking light & Side marker light, Tail light

License plate light, Illumination controller, Illumination

light, A/T shift indicator control unit

C-5 10A DOME LIGHT Stop light, Dome light, Courtesy light - LH, Courtesy light

- RH, Courtesy light RR - LH, Courtesy light RR - RH,

Luggage room light, Alarm & relay control unit, Digital

clock, Audio

C-6 15A STOP LIGHT Stop light switch, Rear combination light - LH, Rear

combination light - RH, High mounted stop light

C-7 20A (POWER DOOR

LOCK) FRT door lock & Power window SW, Door lock actuator,

Anti- theft indicator light

C-8 10A (MIRROR DEFOG) Mirror defogger

C-9 15A (REAR DEFOG) Rear defogger

C-10 15A (REAR DEFOG) Rear defogger

C-11 15A METER Indicator and warning lights (meter), Meter gauge,

Vehicle speed sensor

C-12 15A ENGINE IG. Generator, ECM main relay, VSV; purge solenoid, Coil

drive, PCM, EGR valve

Fuse (Relay & Fuse Box · Instrument Panel)

Fuse No. Capacity Indication on label Parts (Load)

C-13 15A IG. COIL Ignition coil

C-14 15A BACKUP/TURN

LIGHT Mode SW, PCM, Turn signal light, Backup light, Cruise

control unit, A/T shift indicator control unit

C-15 15A ELEC. IG. Alarm & relay control unit, Rear defogger relay, Mirror

defogger - LH, Mirror defogger - RH, Rear defogger SW,

Power window relay, Cruise control unit, Shift lock relay,

4WD control unit, VSV; FRT axle (c), VSV; FRT axle (d)

C-16 20A FRONT WIPER &

WASHER Windshield wiper motor, Windshield washer motor,

Alarm & relay control unit

C-17 10A (REAR WIPER &

WASHER Rear wiper motor, Rear washer motor, Alarm & relay &

control unit

C-19 15A (AUDIO) Audio

C-20 10A STARTER Starter, Starter relay, Anti - theft cotroller

C-22 10A SRS SRS warning light, SDM

PCM: Power train module, VSV : V acuum switching valve

Fusible Link (Relay and Fuse Box · Engine Room)

Fuse Link No. Capacity Indication on label

FL-1 60A ABS

FL-2 30A COND. FAN

FL-4 100A MAIN

FL-5 60A IGN.

FL-6 30A ELEC. FAN

ABS: Anti - lock Brake System

Circuit Breaker (Relay & Fuse Box · Instrument Panel)

Fuse No. Capacity Indication on label Parts (Load)

C-21 30A (POWER WINDOW) Power window relay, Power window SW, Power window

motor, Sun roof motor, Sun roof control unit, Sun roof

SW, Safety stop SW, Limit SW, Power seat switch, Front

tilt motor & SW, Rear tilt motor & SW, Slide motor, Re-

cliner moror & SW

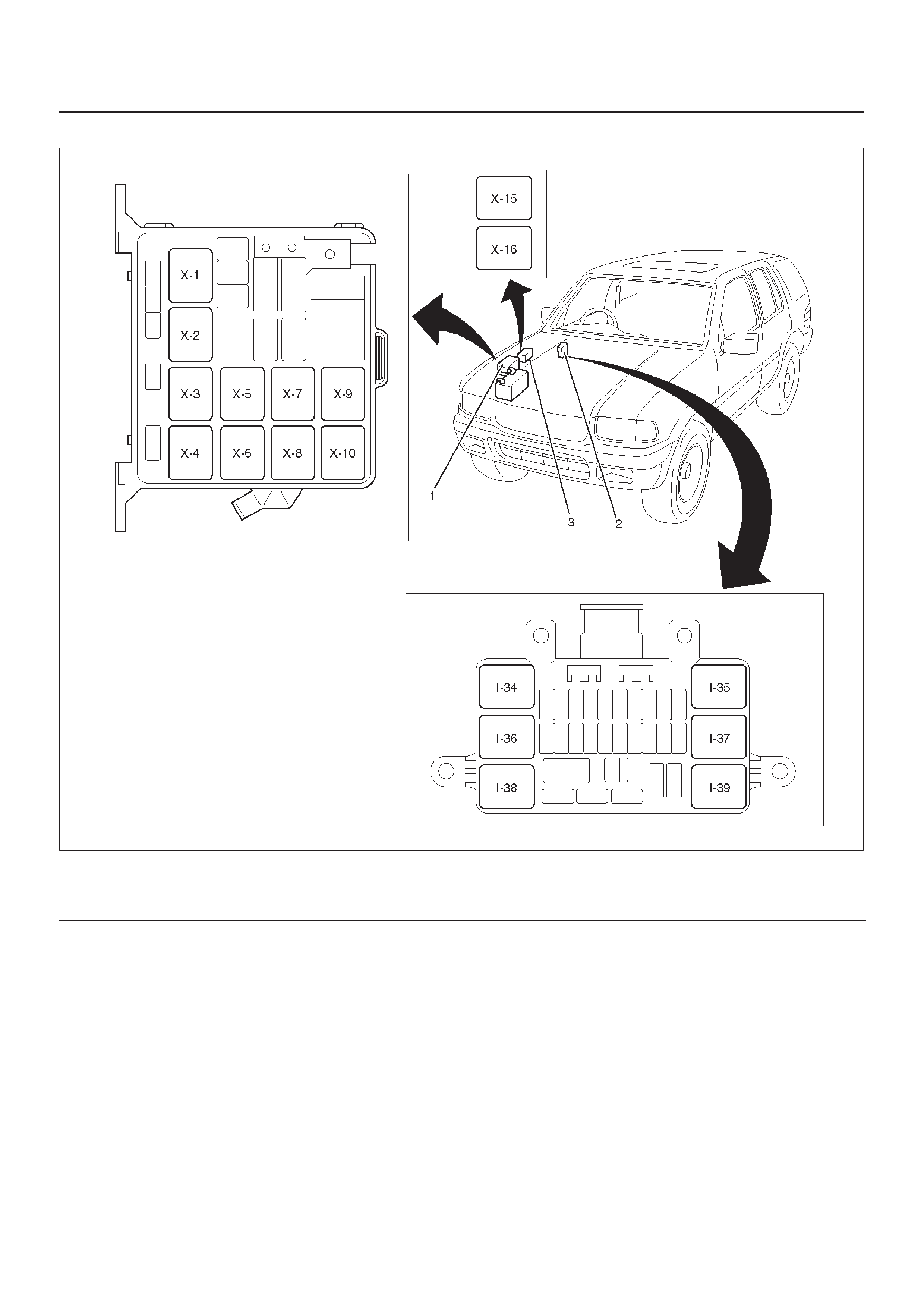

Relay Location

810RX014

Legend

(1) Relay & Fuse Box (Engine Room) (2) Relay & Fuse Box (Instrument panel)

(3) Relay Box (Engine Room)

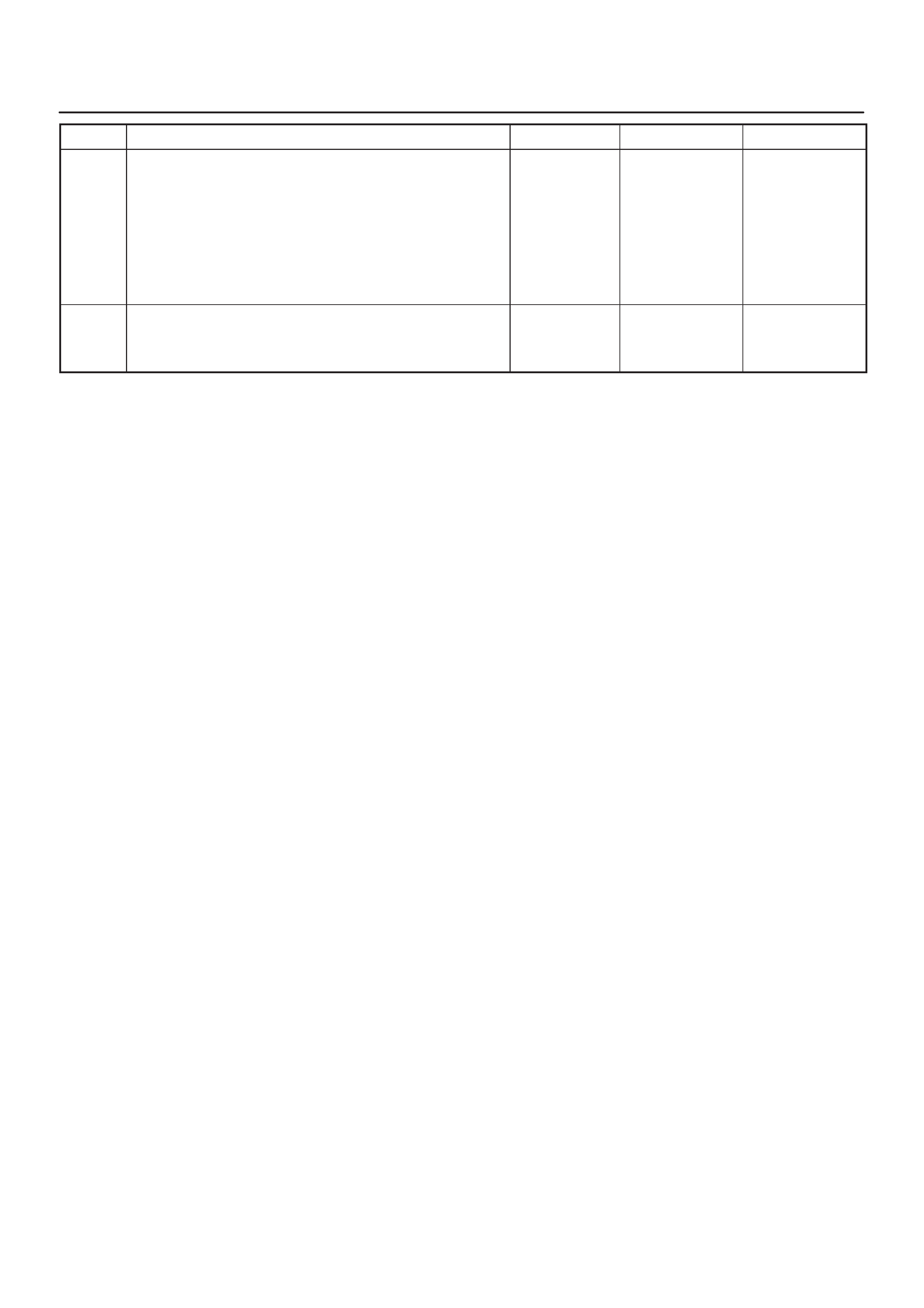

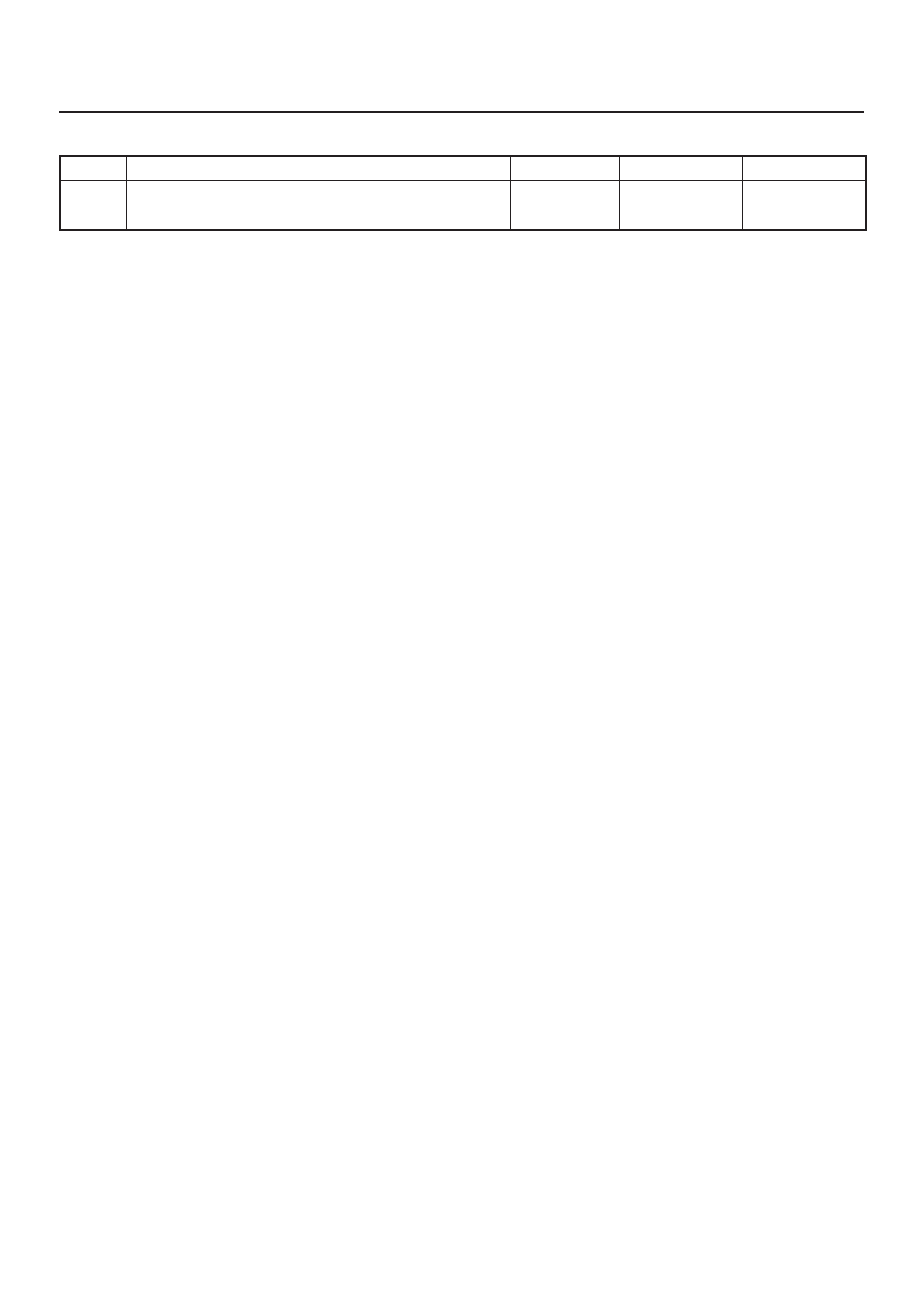

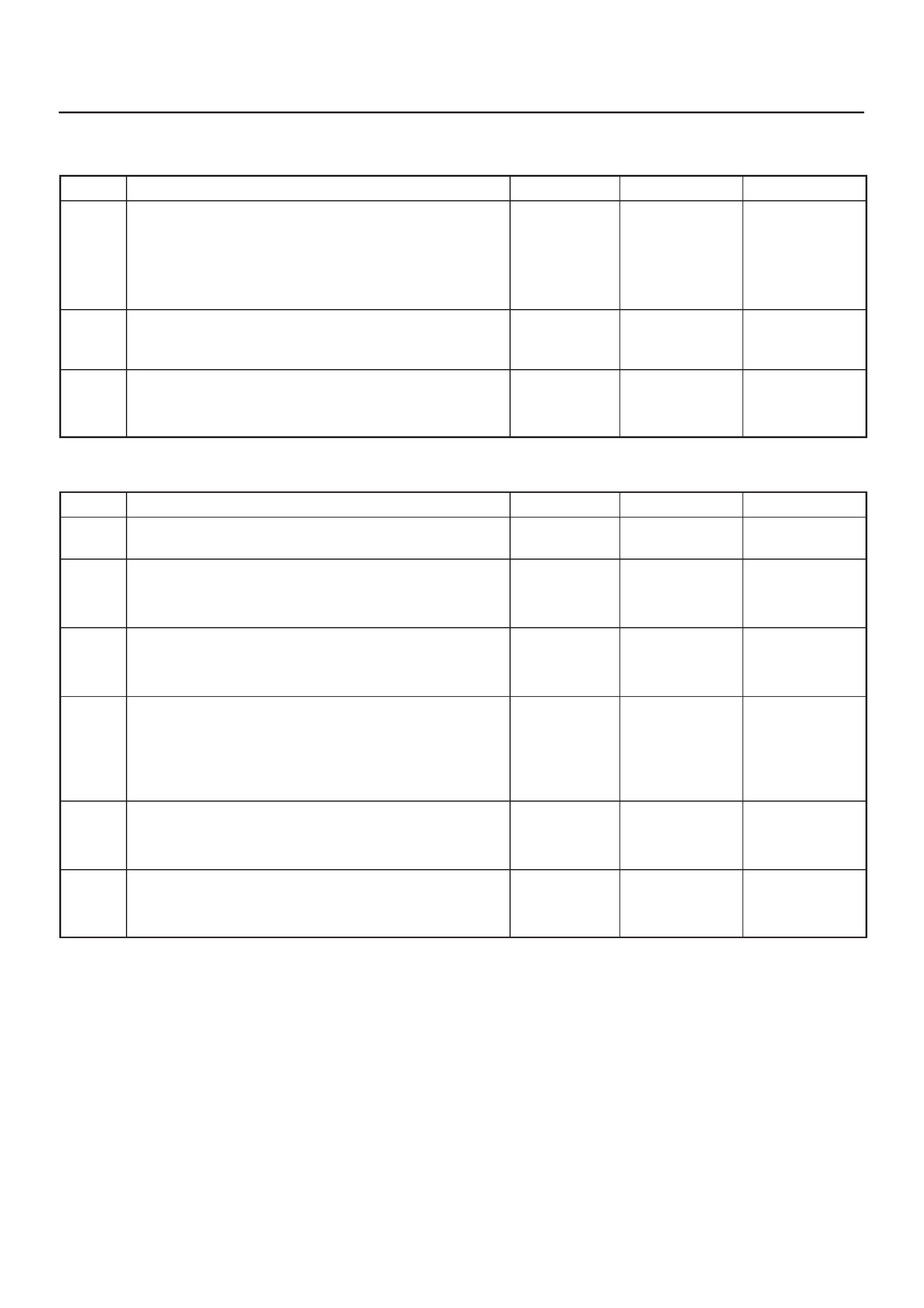

Relay List

Connector No. X–1 X–2 X–3 X–4 X–5 X–6 X–7 X–8 X–9

Usage Head

light Fog

light Starter A/C

comp. Thermo Heater Fuel

pump ECM COND

FAN

Engine 6VD1 f f f f f f f f f

X22SE f f f f f f f f –

Connector No. X–10 X–15 X–16 I–34 I–35 I–36 I–37 I–38 I–39

Usage – Elec-

fan-hi Elecfan-

lo Taillight Power

window – – ACC

socket Rear de-

fogger

Engine 6VD1 – – – f f – – f f

X22SE – f f f f – – f f

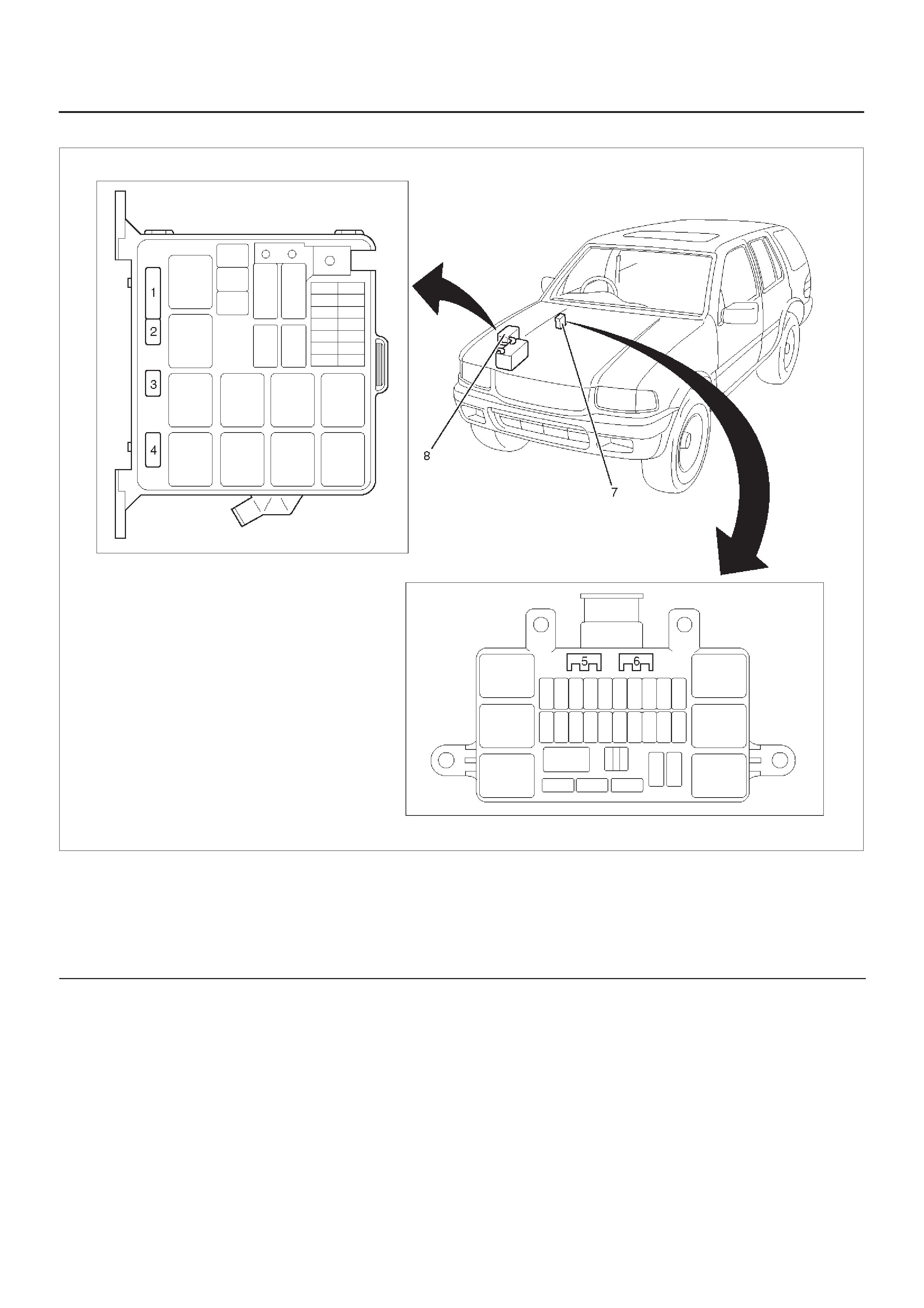

Diode Location

810RW320–1

Legend

(1) X–11

(2) X–12

(3) X–13

(4) X–14

(5) I–51

(6) I–45

(7) Relay & Fuse Box (Instrument panel)

(8) Relay & Fuse Box (Engine Room)

Diode List

Connector No. X–11 X–12 X–13 X–14 I–51 I–45

Usage Brake – – – Tailgate SW,

Door SW.

Doom light

Alarm &

relay control

unit

Engine 6VD1 f– – – f f

X22SE f– – – f f

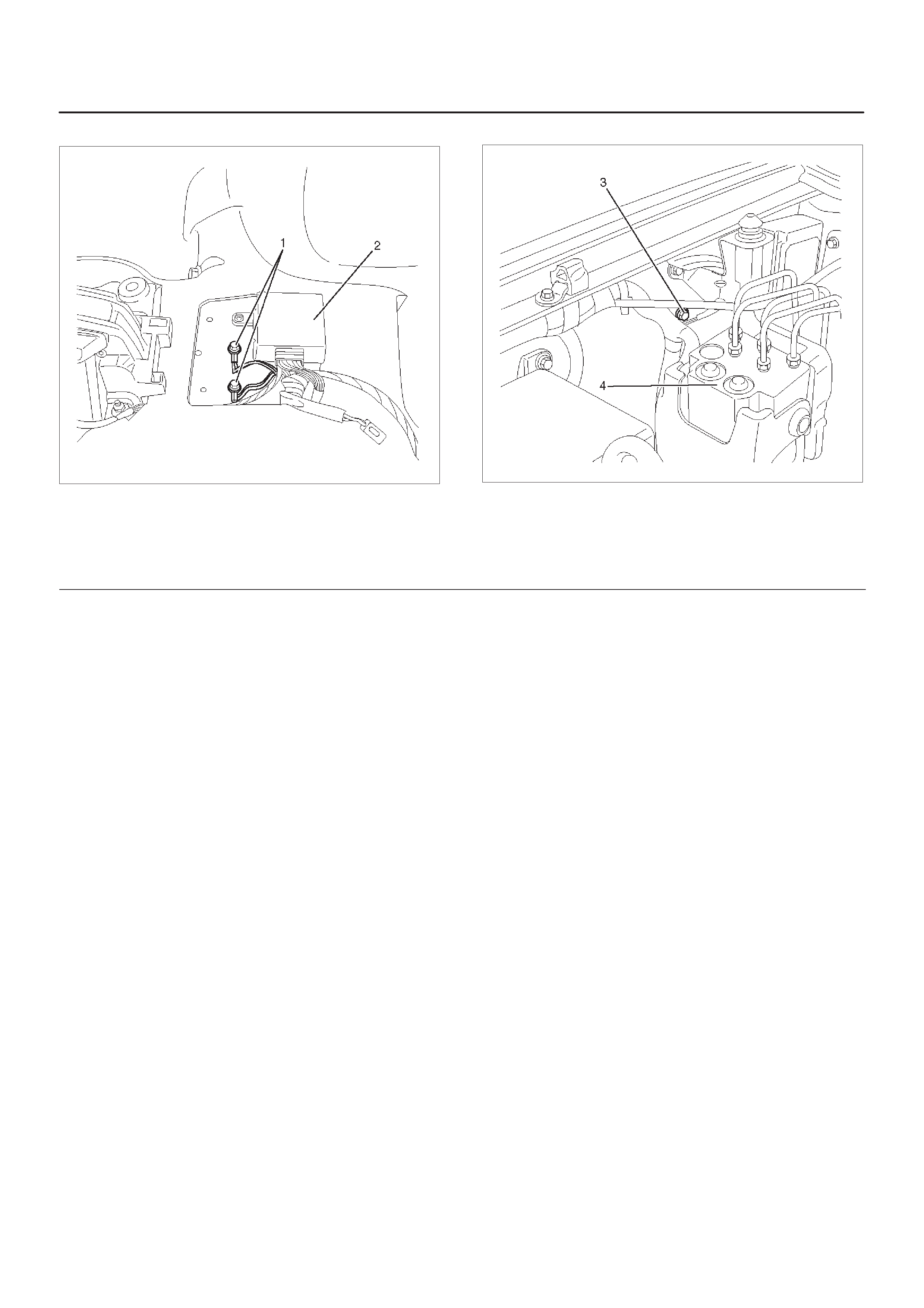

Grounding Point

Reference Table

Connector No. Cable harness Location Parts (Load)

B–6 Vanity mirror illumination, RR turn signal light - RH, Sun

roof control unit, Sun roof motor, Spot light, Taillight - RH,

Stoplight - RH

B–8

Body harness Body–Center

Vanity mirror illumination, Rear defogger relay, Rear

defogger SW, FRT door lock & power window SW – RH,

Cruise control unit, Digital clock, Cigarette lighter, Mirror

defogger – RH, Blower motor, Blower resistor, Electronic

thermostat, A/T shift lock, Flasher unit, Audio

Door lock actuator, FRT power window & door lock SW –

LH, RR wiper intermittent relay, Mirror defogger – LH,

Seat belt SW, Stoplight – LH

Anti – theft controller, Heater & A/C relay, Tail relay,

PCM, Headlight, High beam indicator light, Lighting relay,

Fog light relay, Illumination controller, Flasher unit,

Cornering relay, Power window relay, Headlight wiper

motor, Turn signal indicator light, Luggage room light,

Map light, Alarm & relay control unit

Fuel pump, RR door lock & power window SW, Shift lock

controller, Power door mirror motor, Mirror defogger SW,

Seat belt warning light

Fuel tank unit, Fuel warning light.

C–16 Engine room

harness Fender–LH

FRT combination light – LH, FRT turn signal light – LH,

Cornering light – LH, Vehicle speed snsor

Windshield washer motor (FRT)

Brake warning light, PCM

Data link connector

FRT combination light – RH, Cornering light – RH, FRT

turn signal light – RH

Fog light, EHCU

Kick down SW

Oxygen sensor, FRT-LH, FRT-RH, RR-LH, RR-RH, 4WD

indicator light, VSV; FRT axle

C–36 Engine room

harness Fender–RH Windshield wiper motor

Engine hood SW

Windshield washer motor, Windshield washer motor

E–28 Engine ECGI

harness

Common

chamber

Ignition coil, Coil driver, EGR valve, I.A.T.S., T.P.S.

PCM, ECM main relay, Fuel pump relay, Cam position

sensor

E–30

harness

chamber

Crank position sensor, Knock sensor, PCM, Mass air flow

sensor, Data link connector

I–43 Instrument

harness Body-FRT SDM

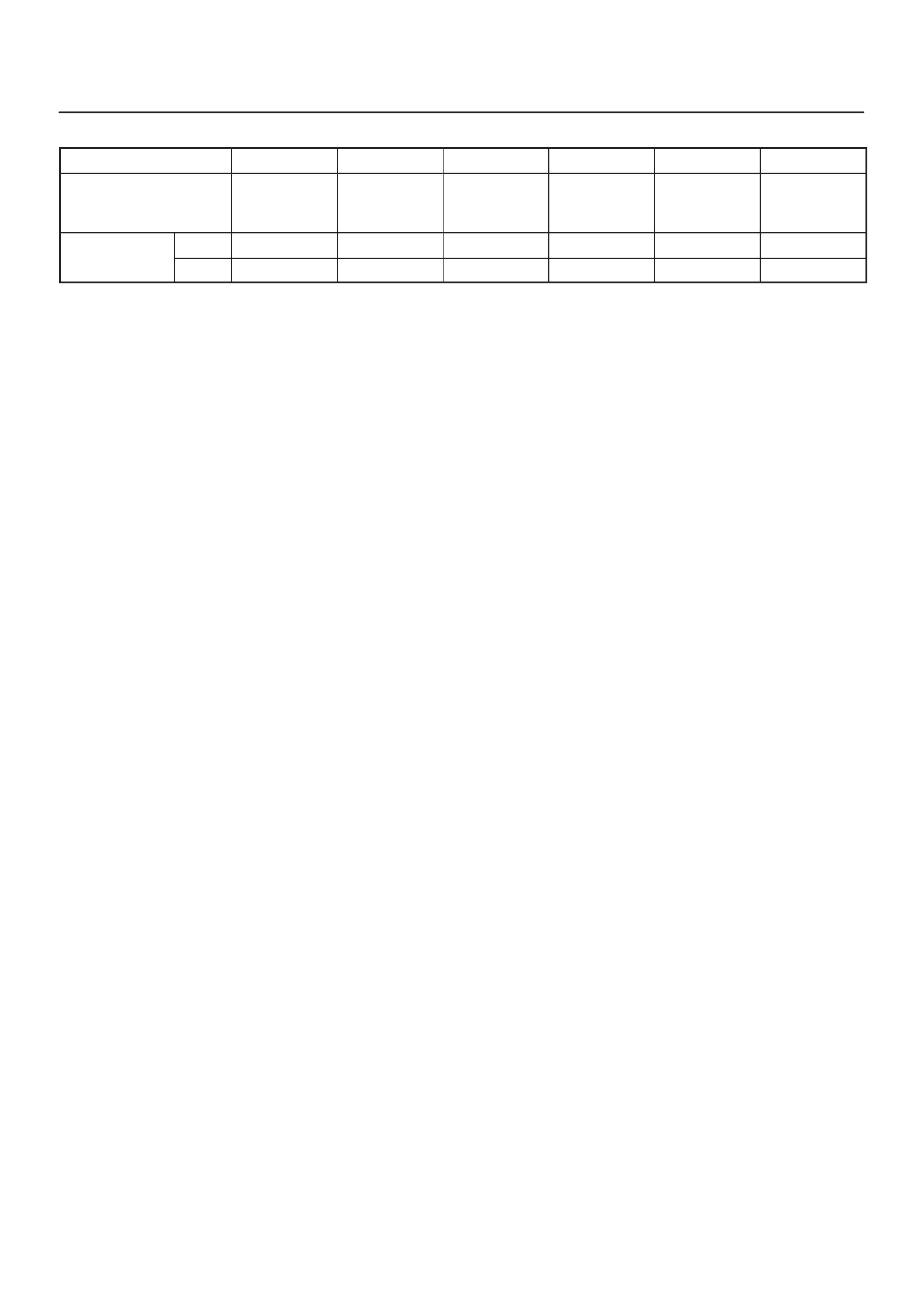

Location – 1

D08RW050 D08RW054

Legend

(1) B–6, B–7, B–8

(2) 2–4WD Control Unit

(3) C–36

(4) EHCU

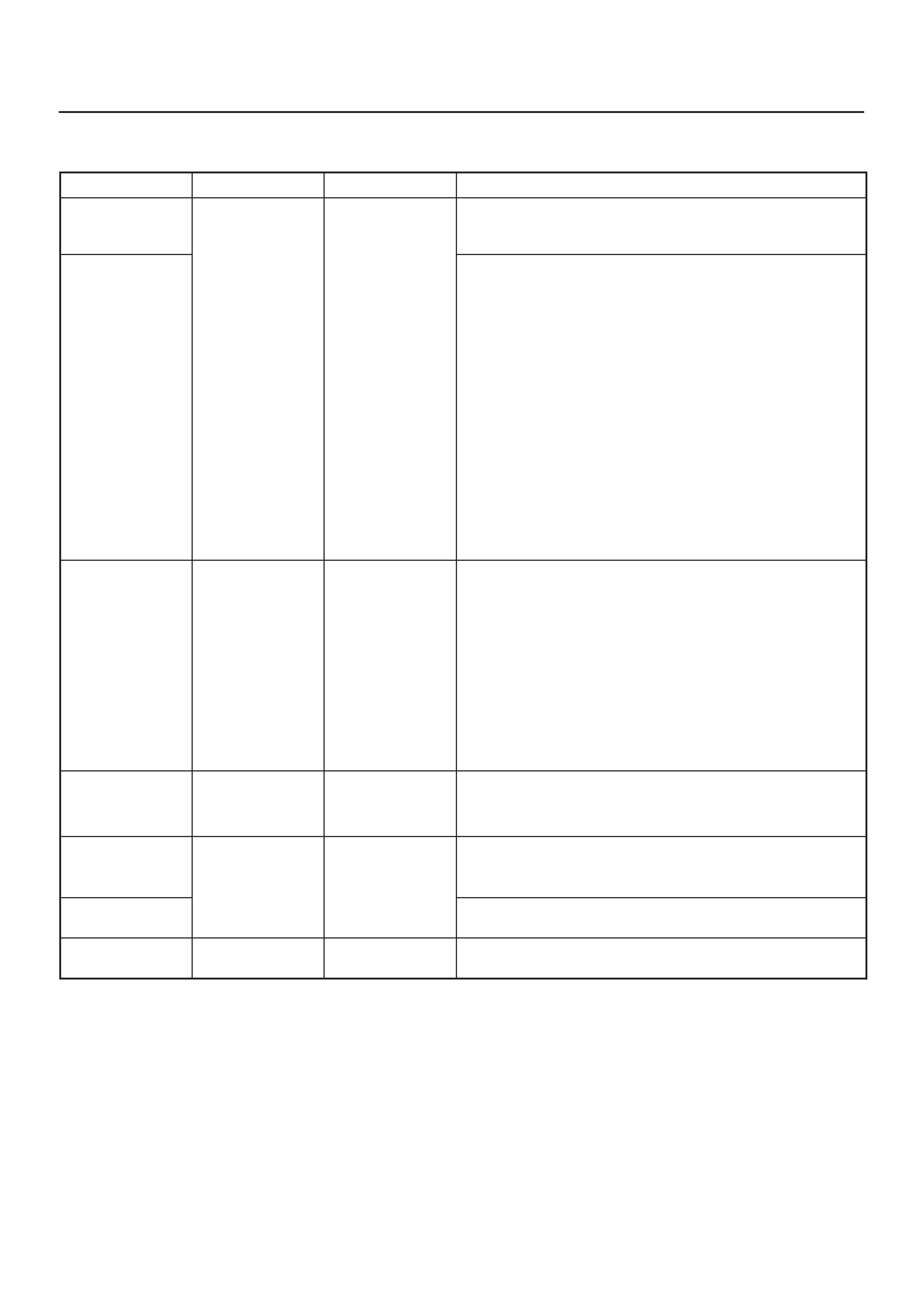

Location – 2

D08RW048

D08RW052

D08RWD07

D08RW053

Legend

(1) E–28

(2) I–43

(3) H–15

(4) P–6

(5) Cruise Control Actuator

(6) P–7

(7) Frame

Location – 3

D08RW051

Legend

(1) P–10

(2) Battery

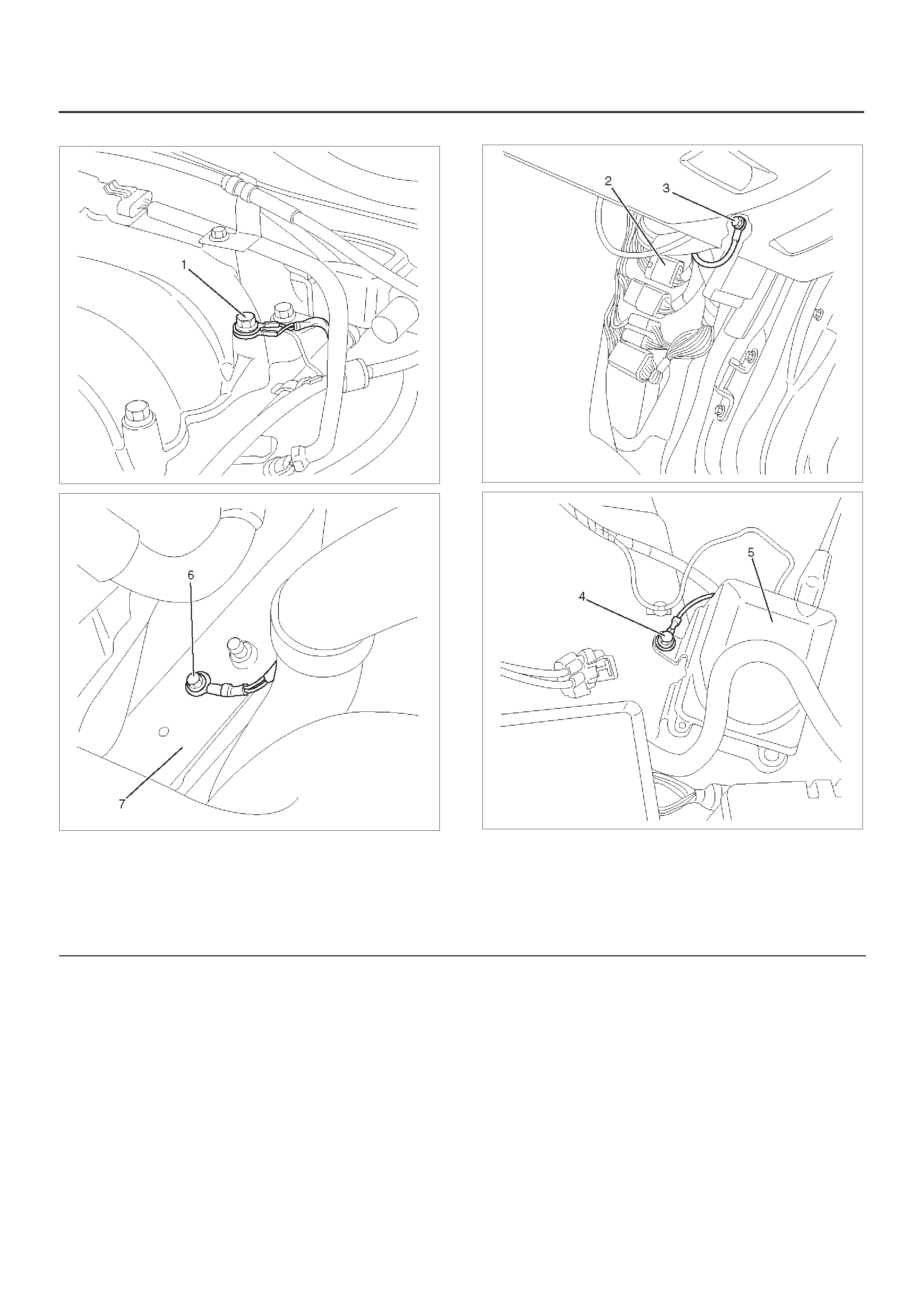

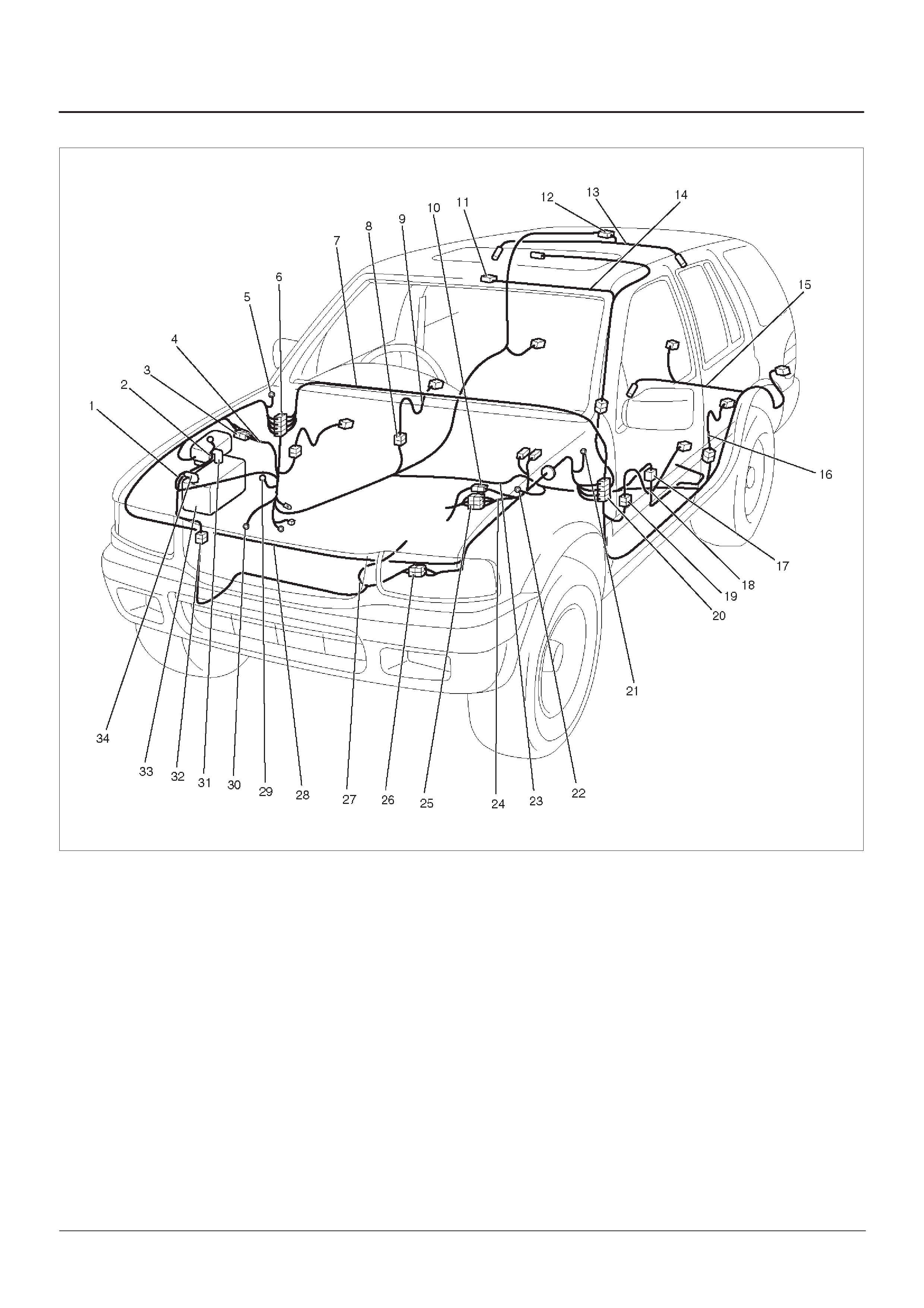

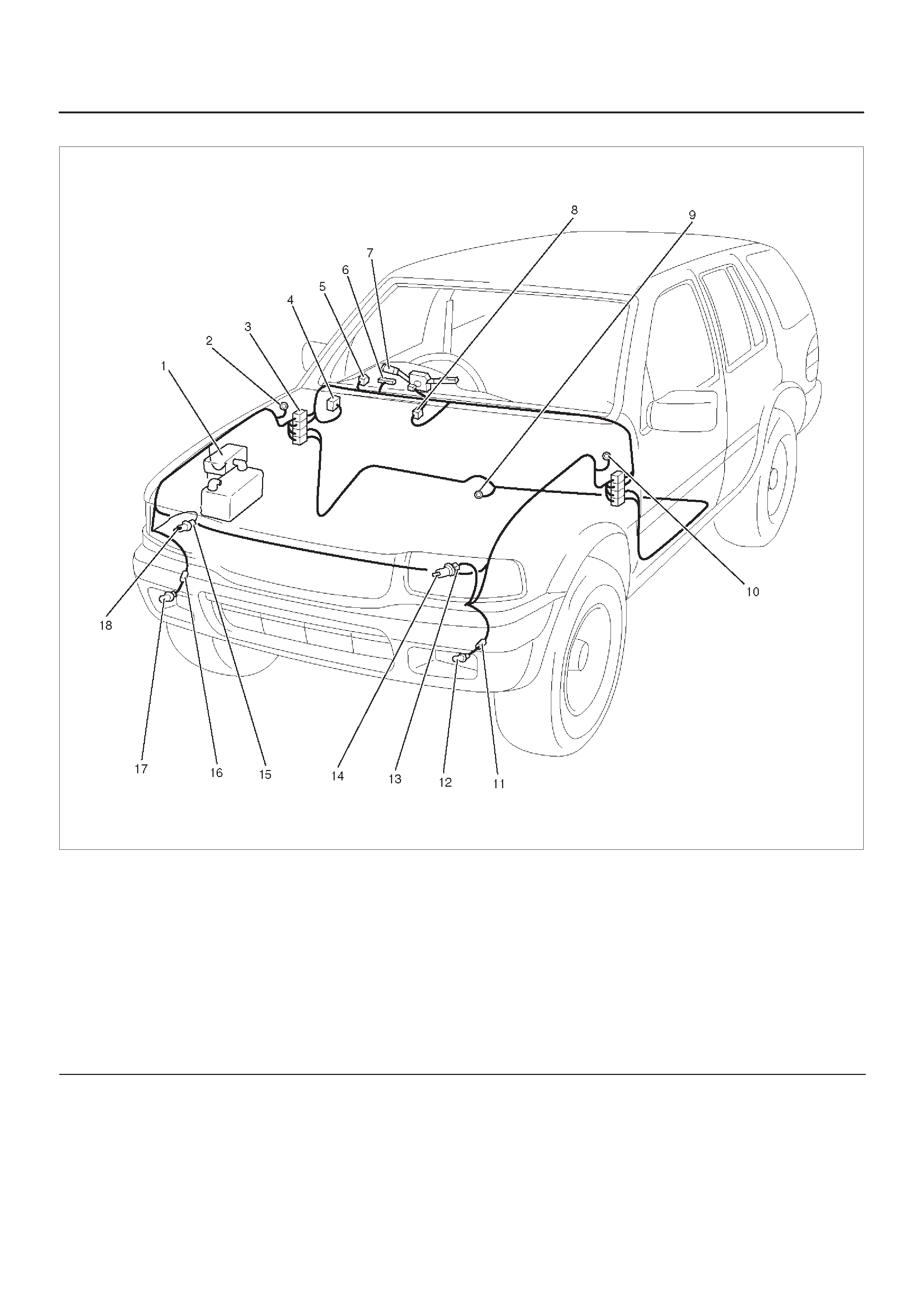

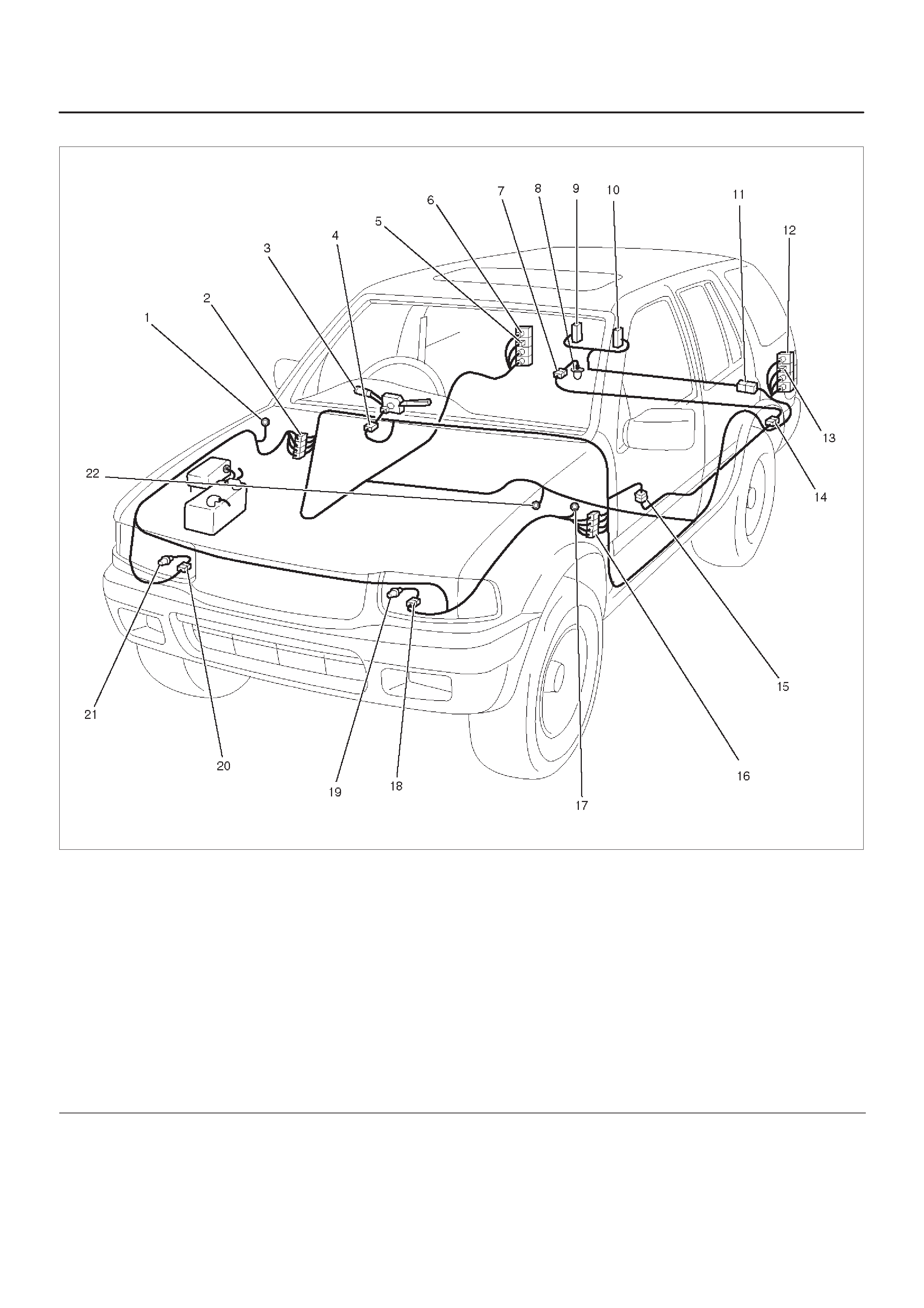

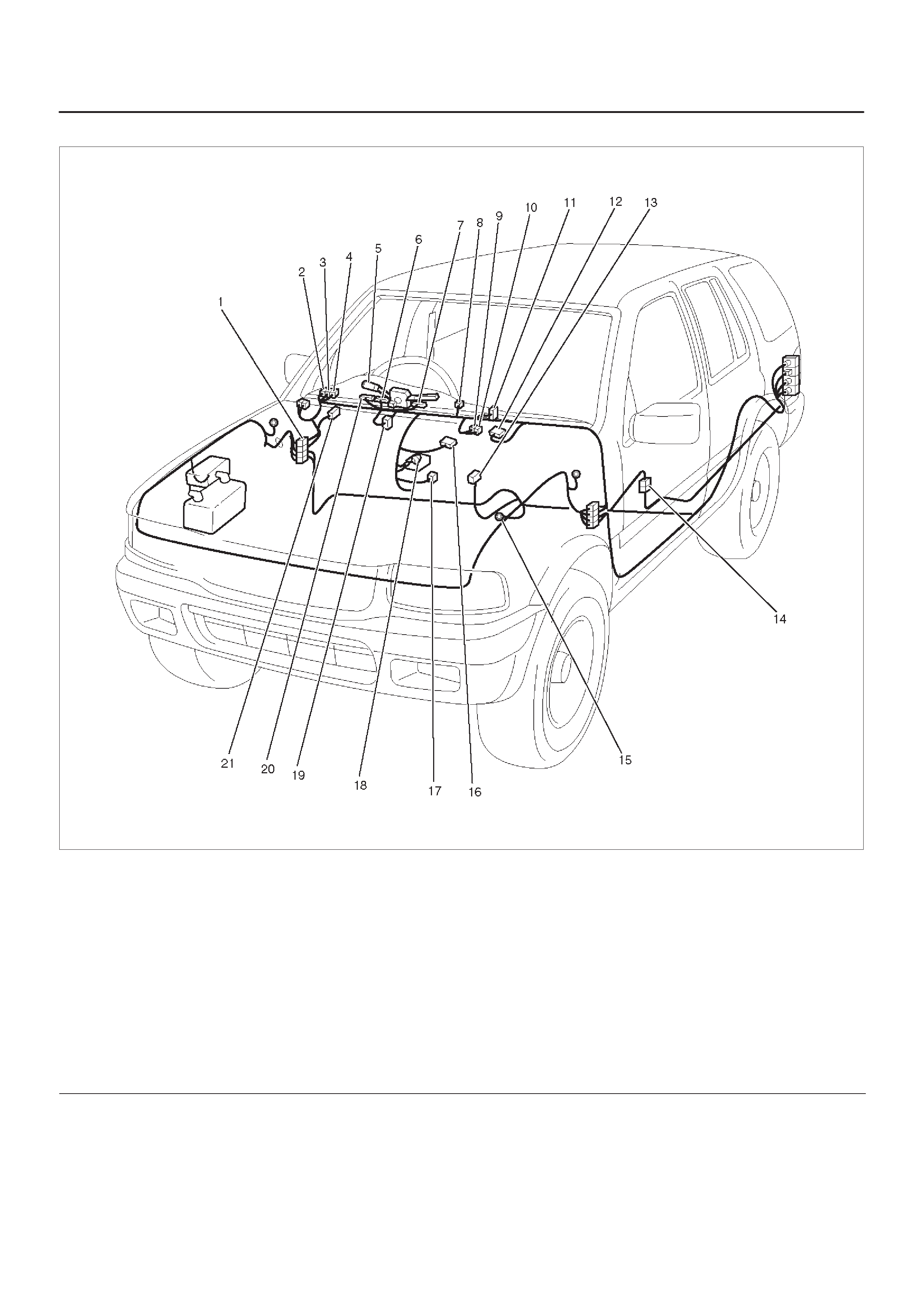

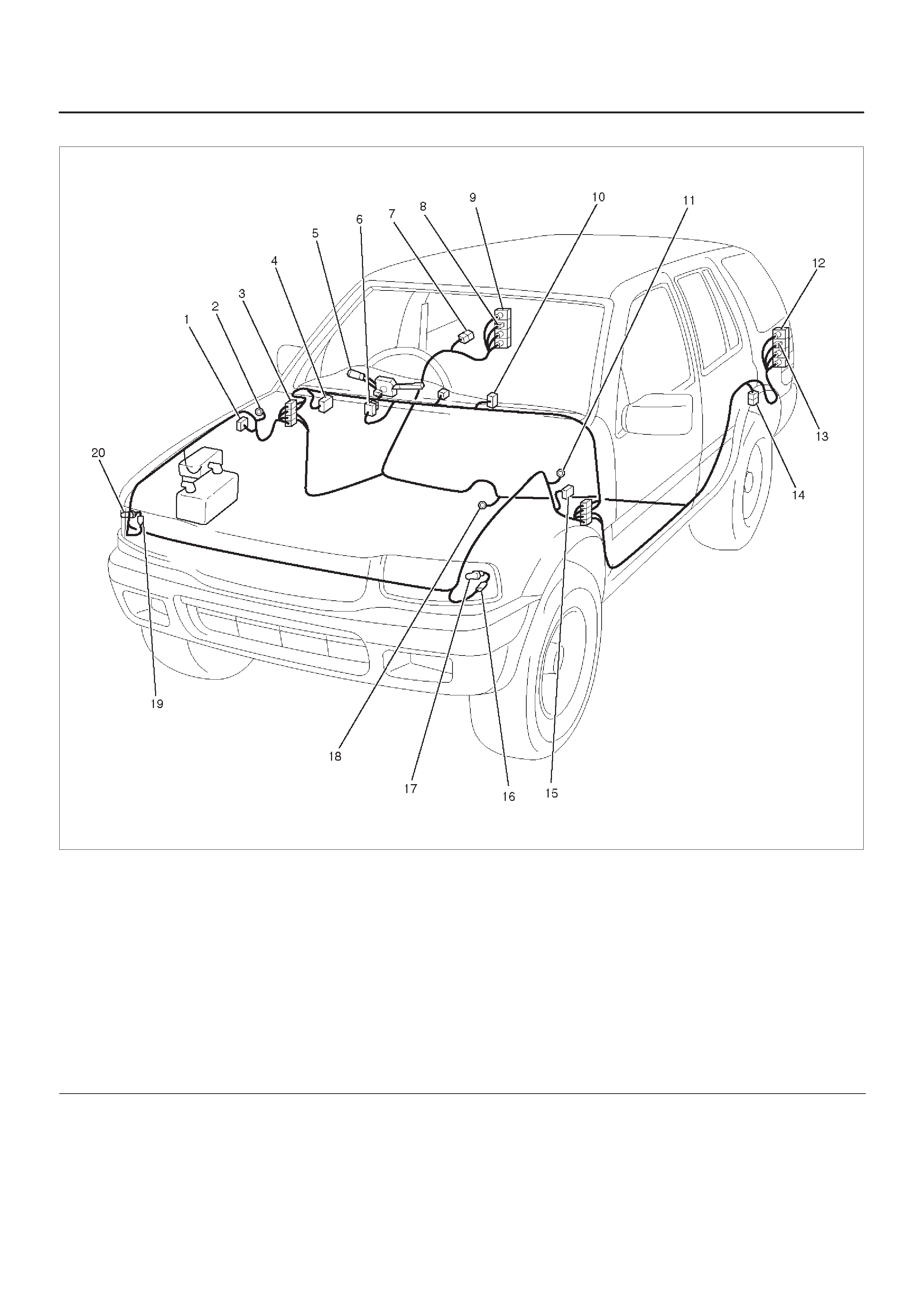

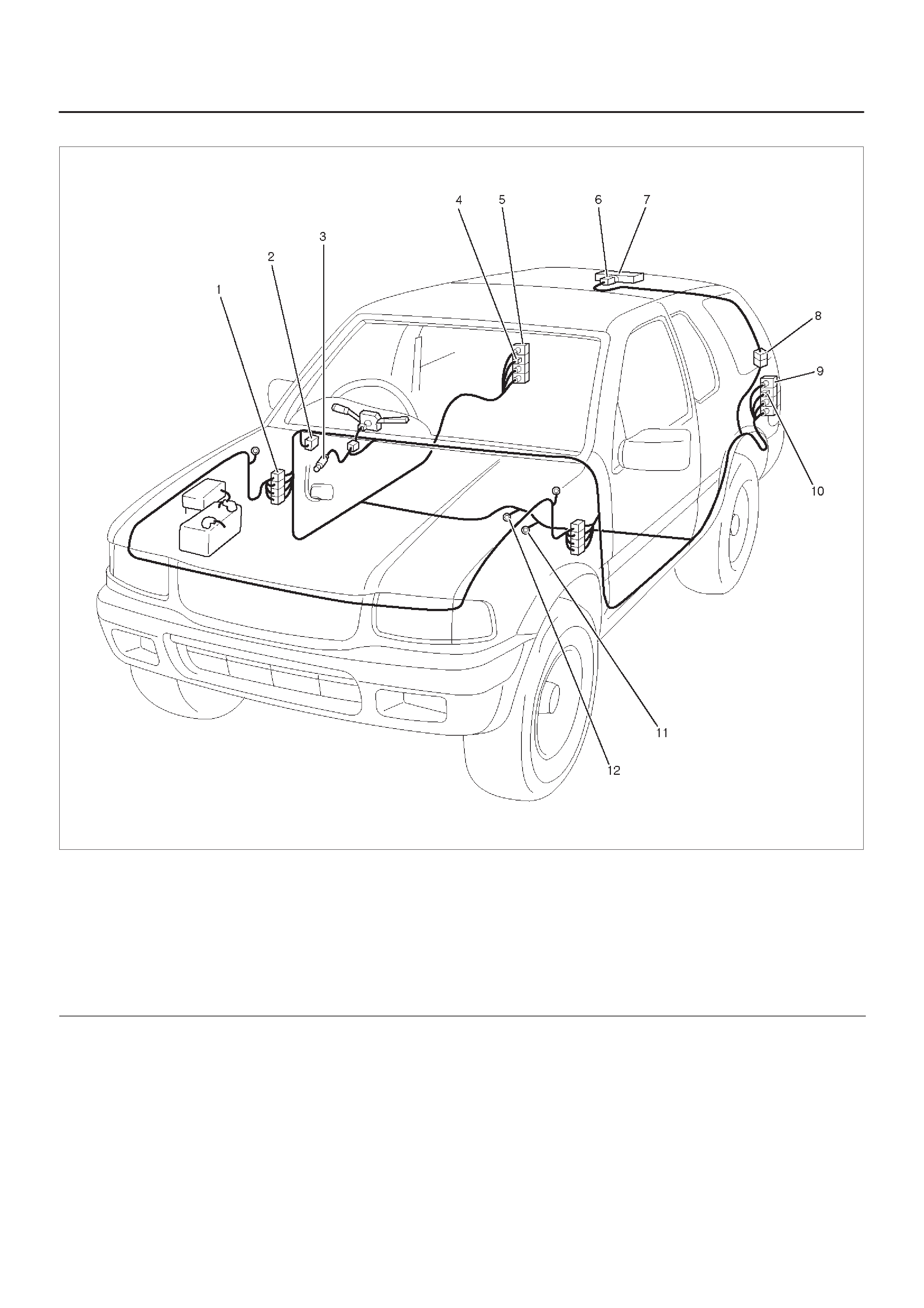

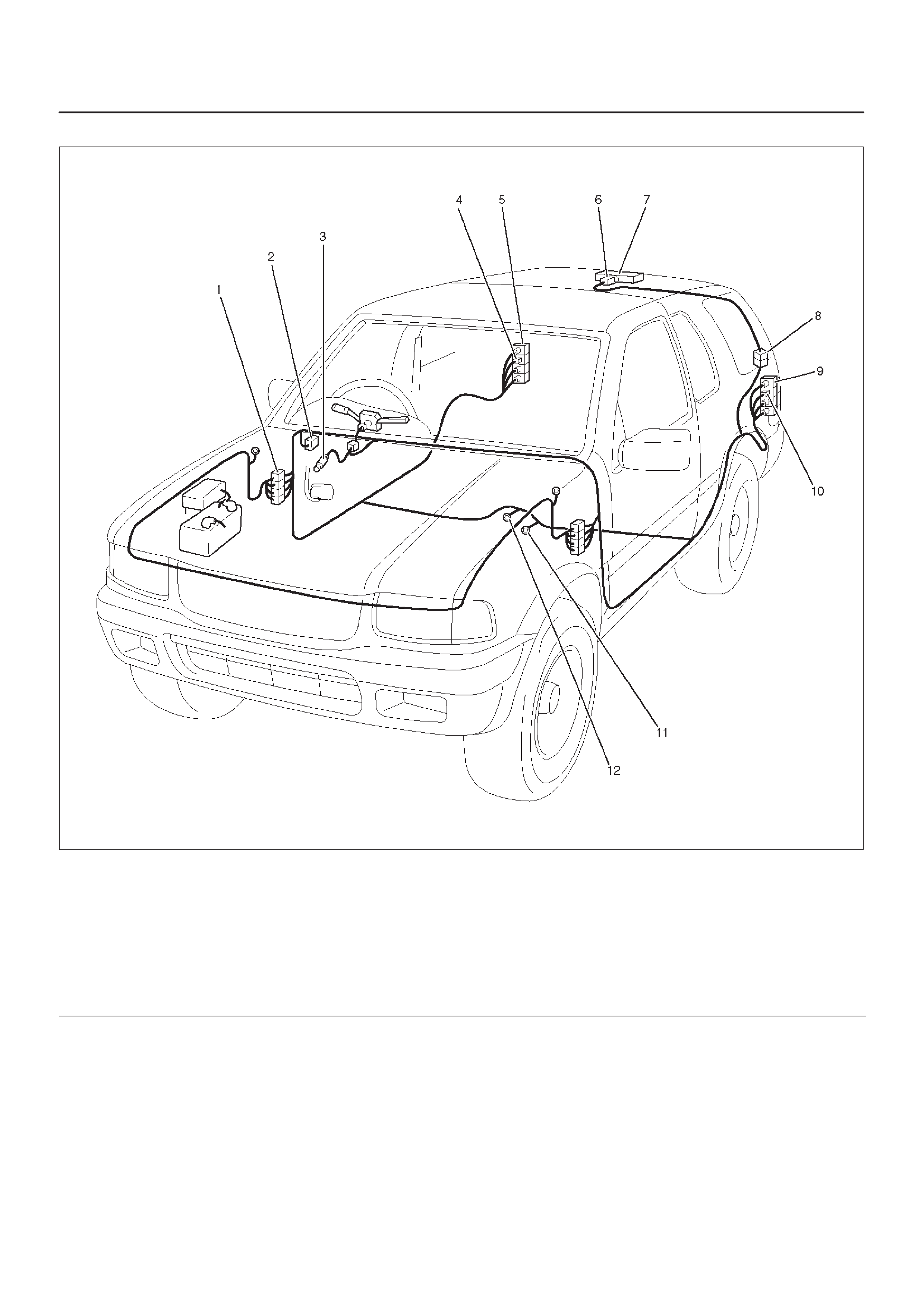

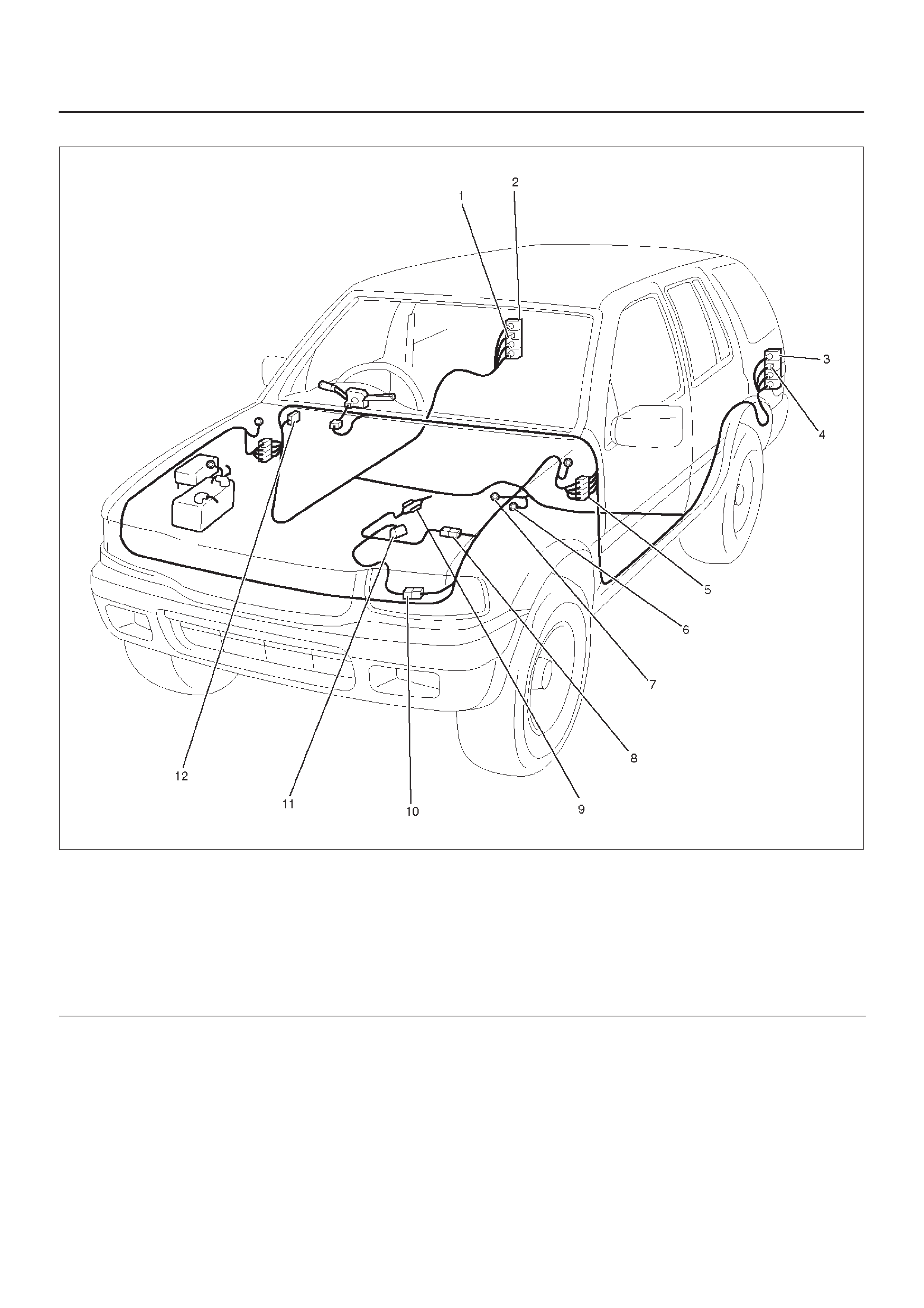

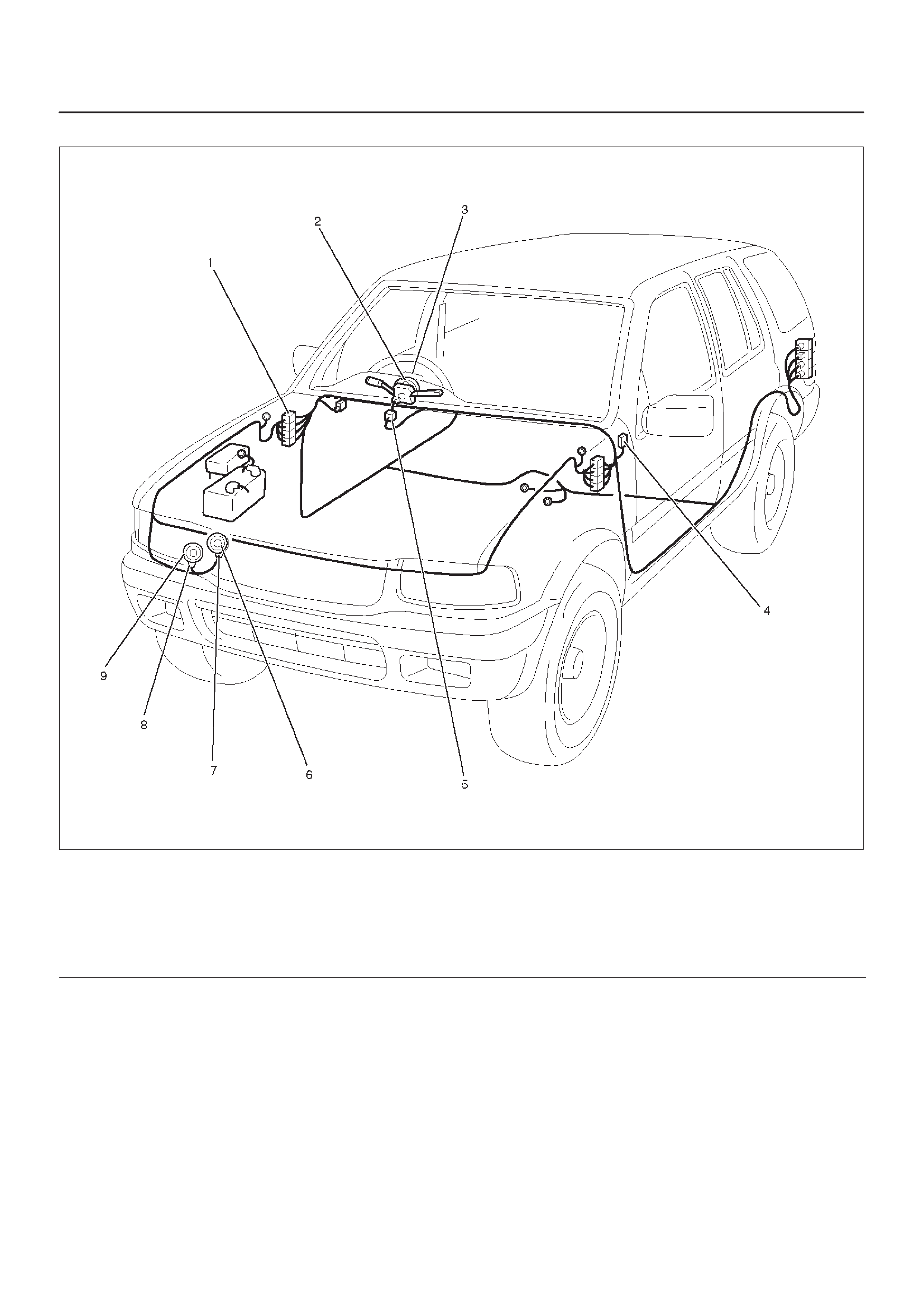

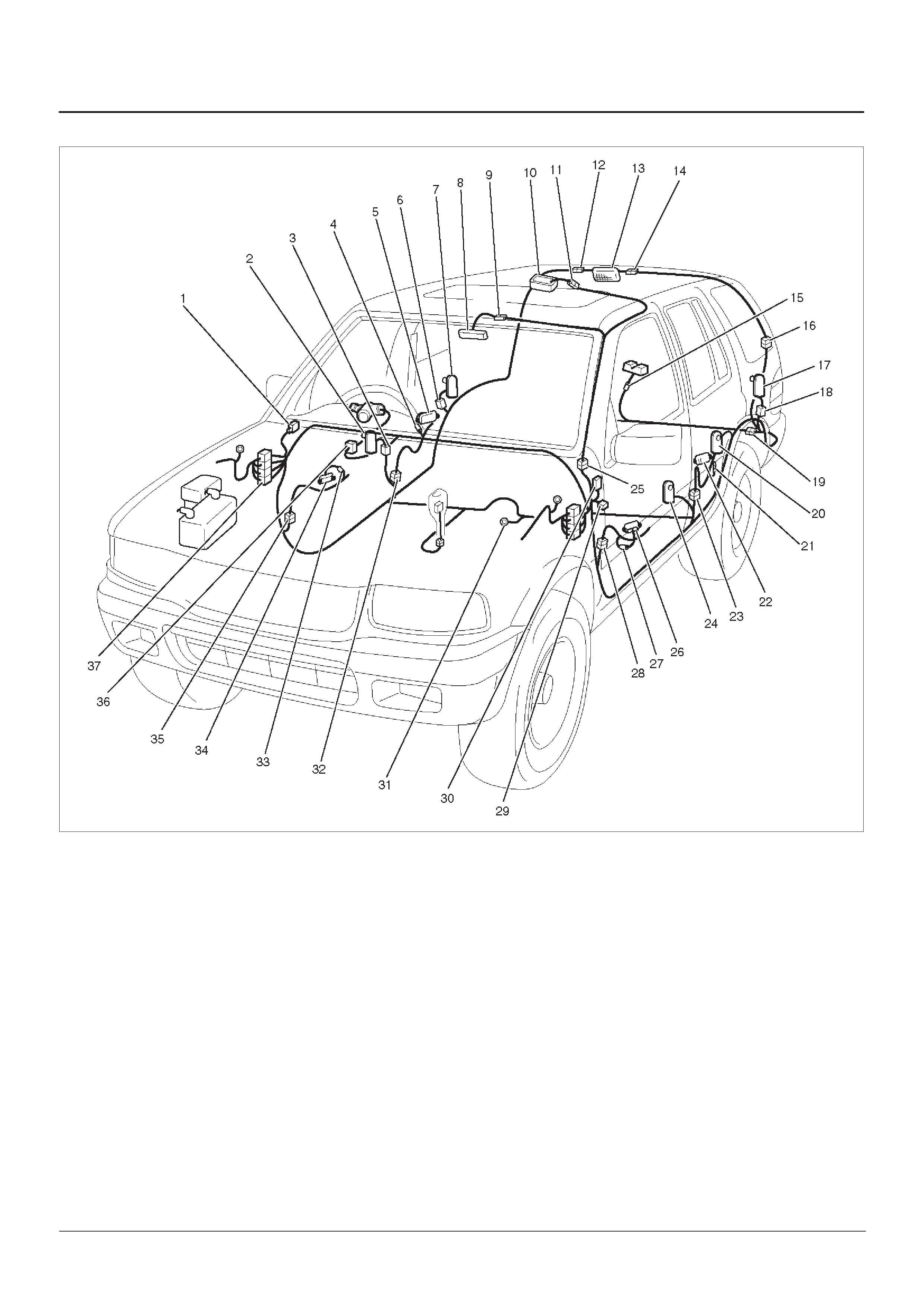

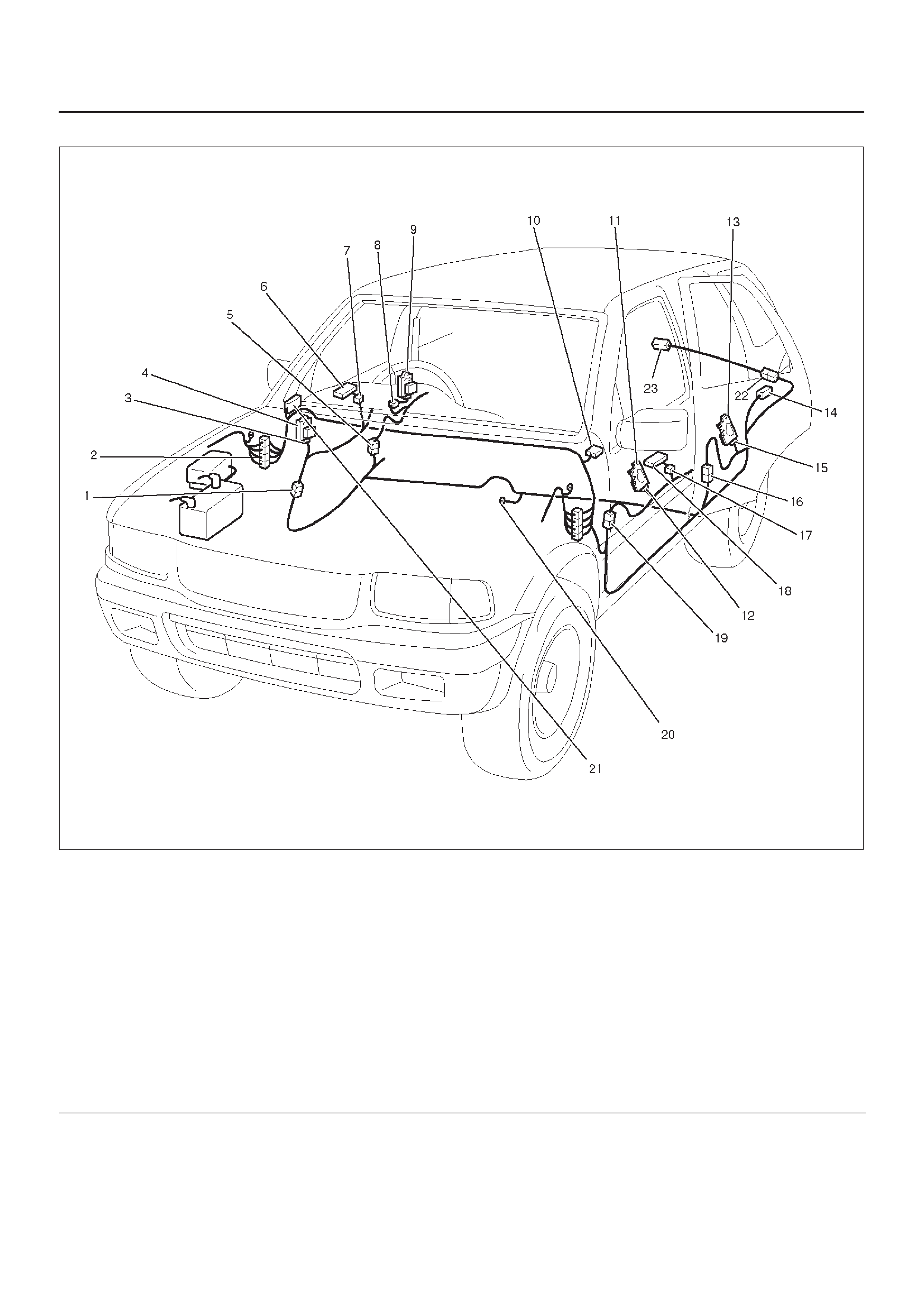

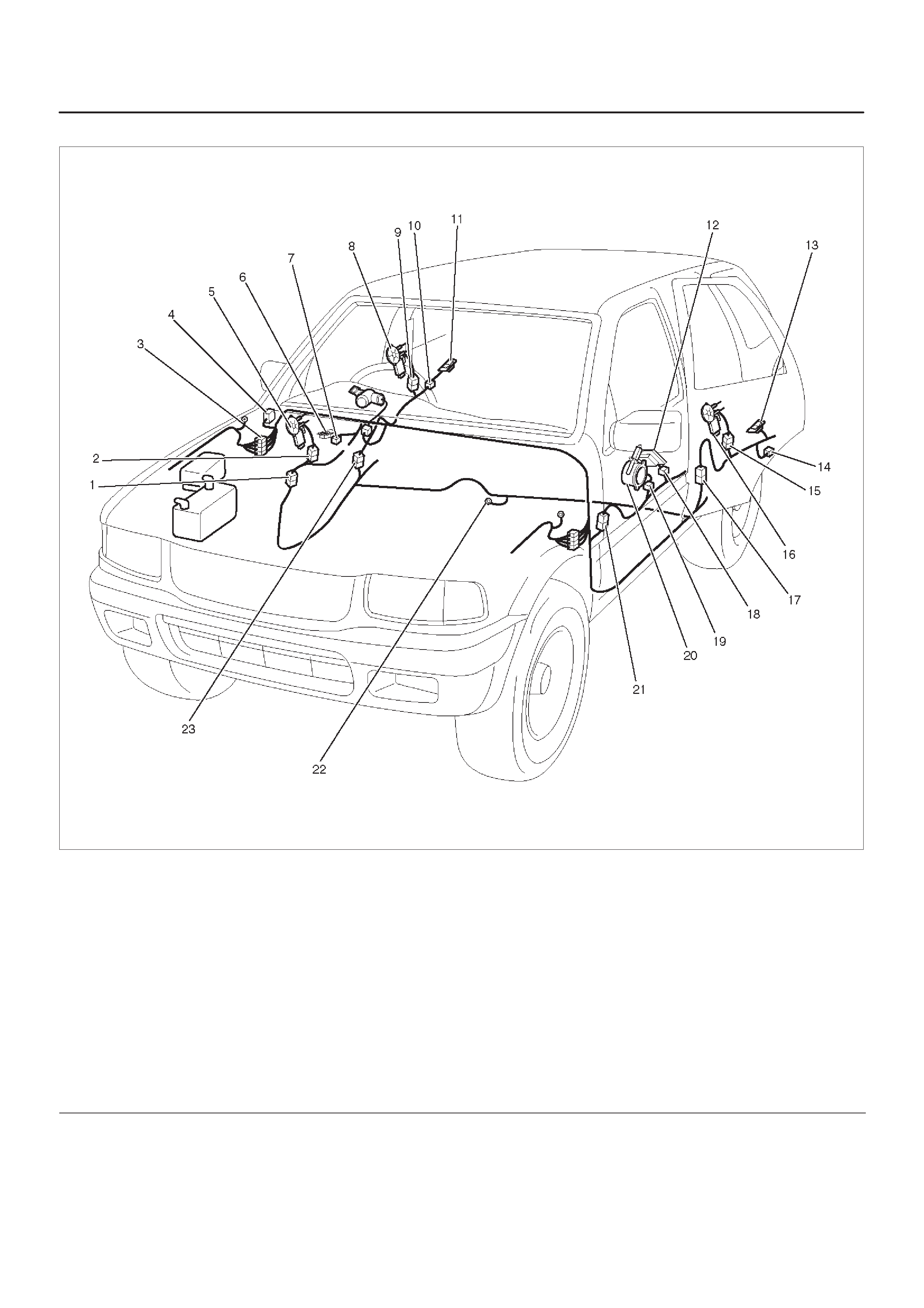

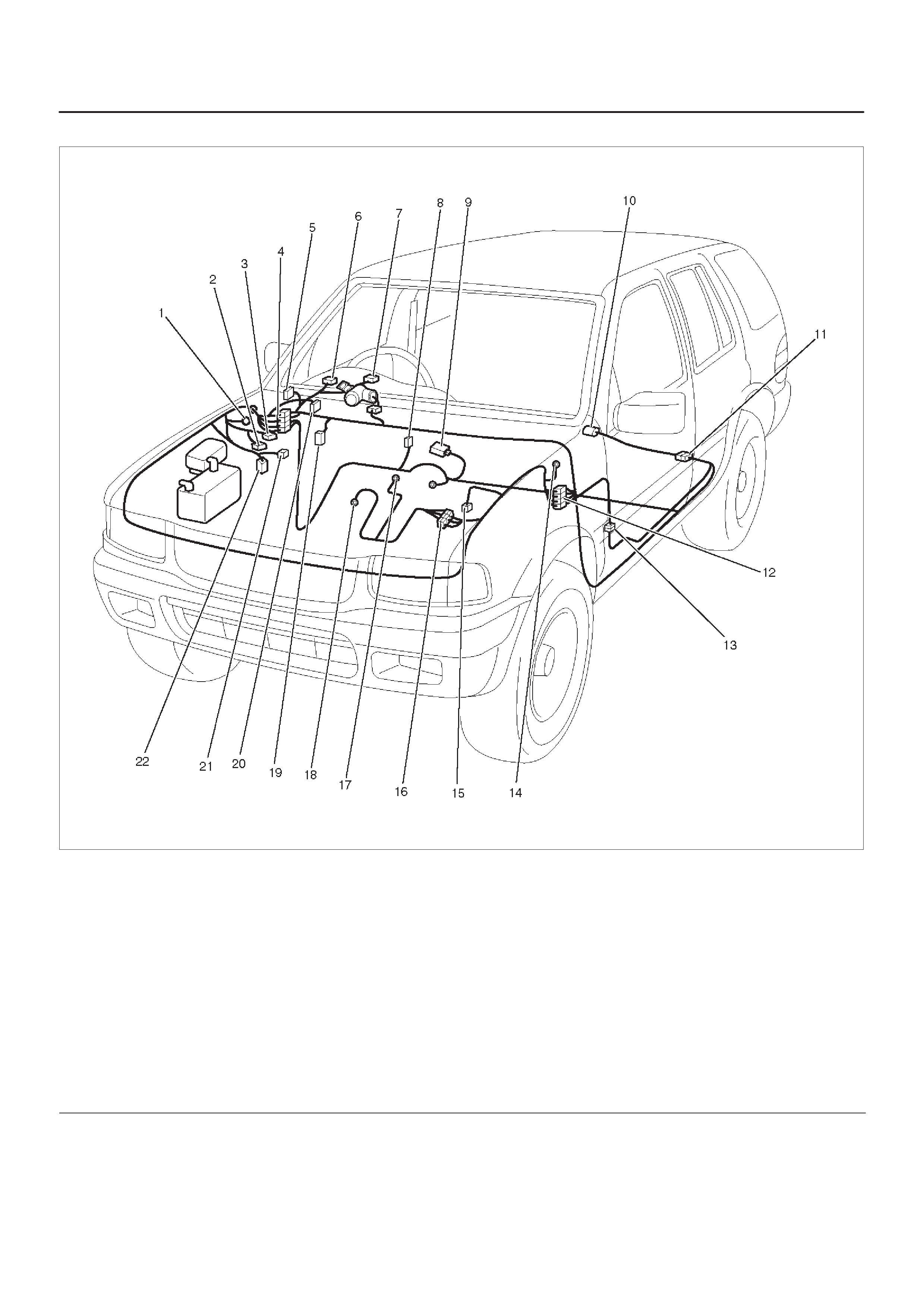

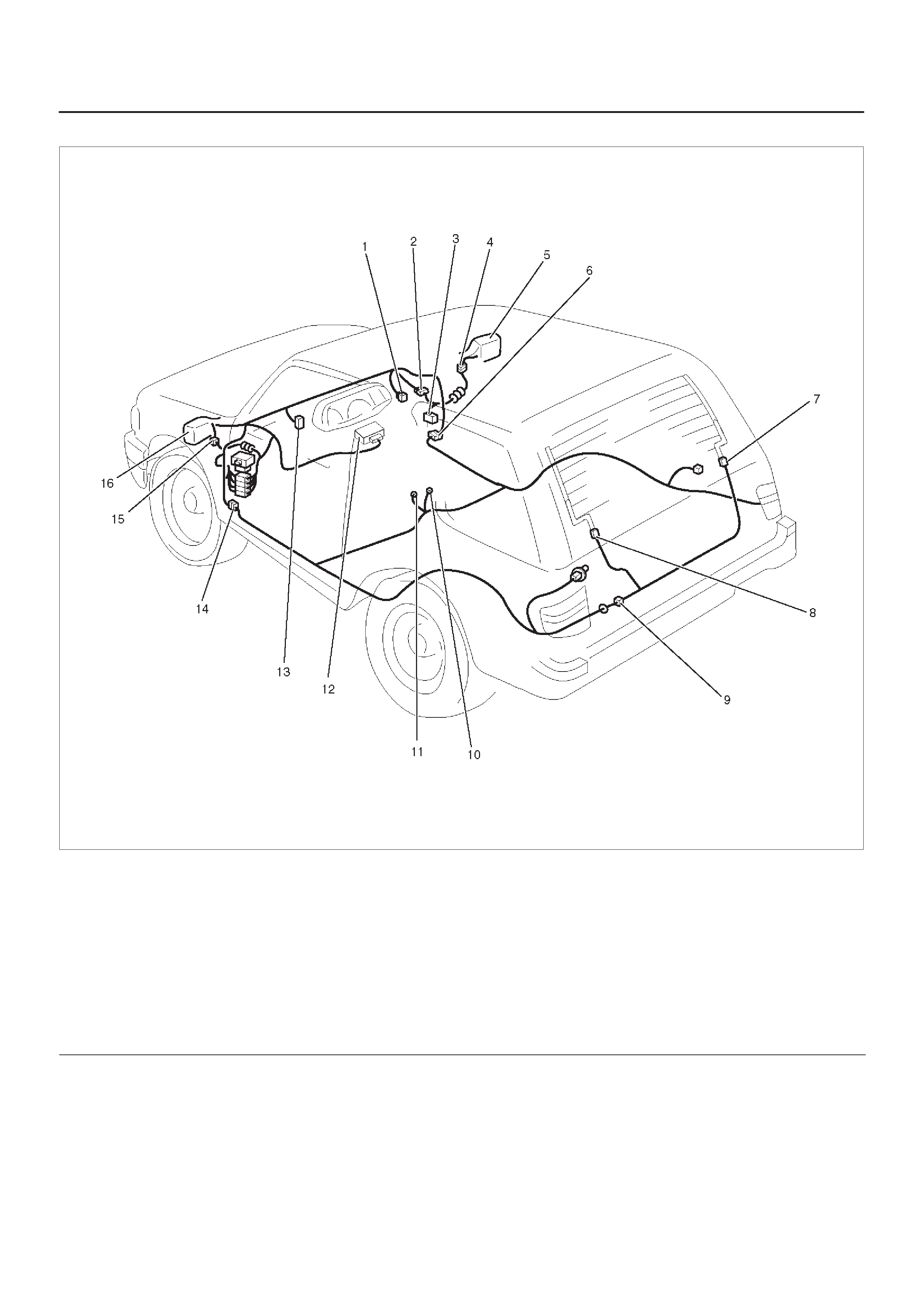

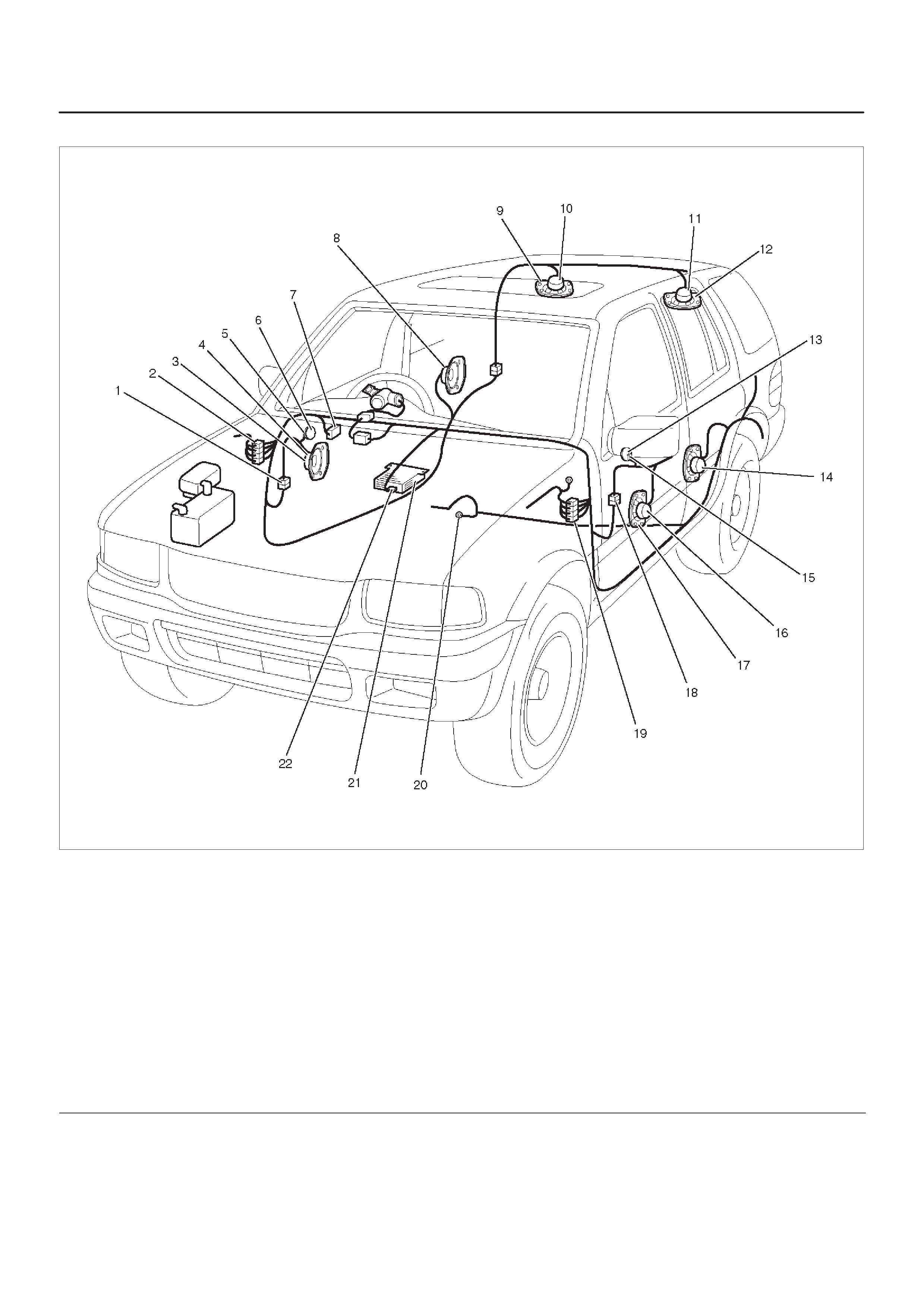

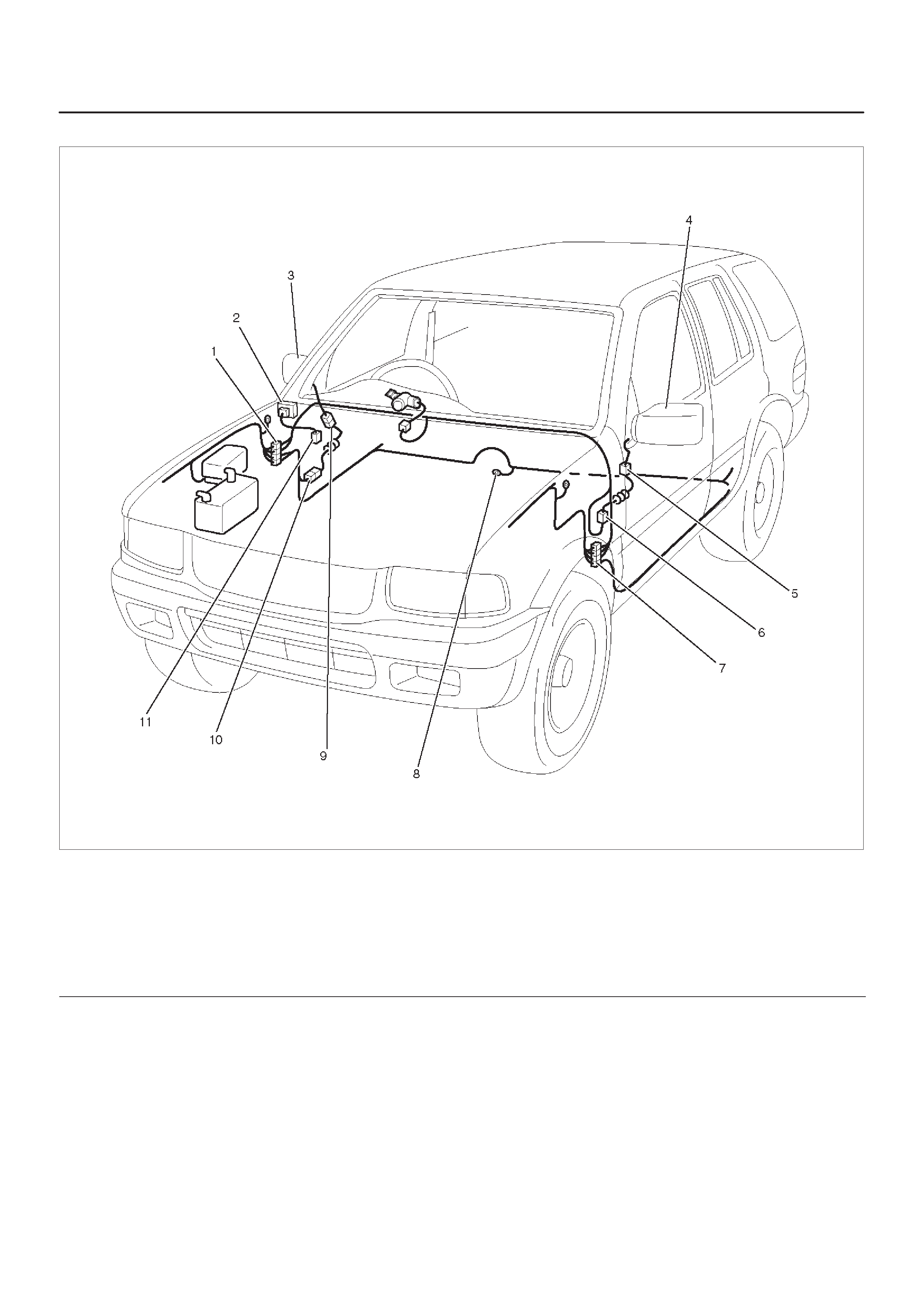

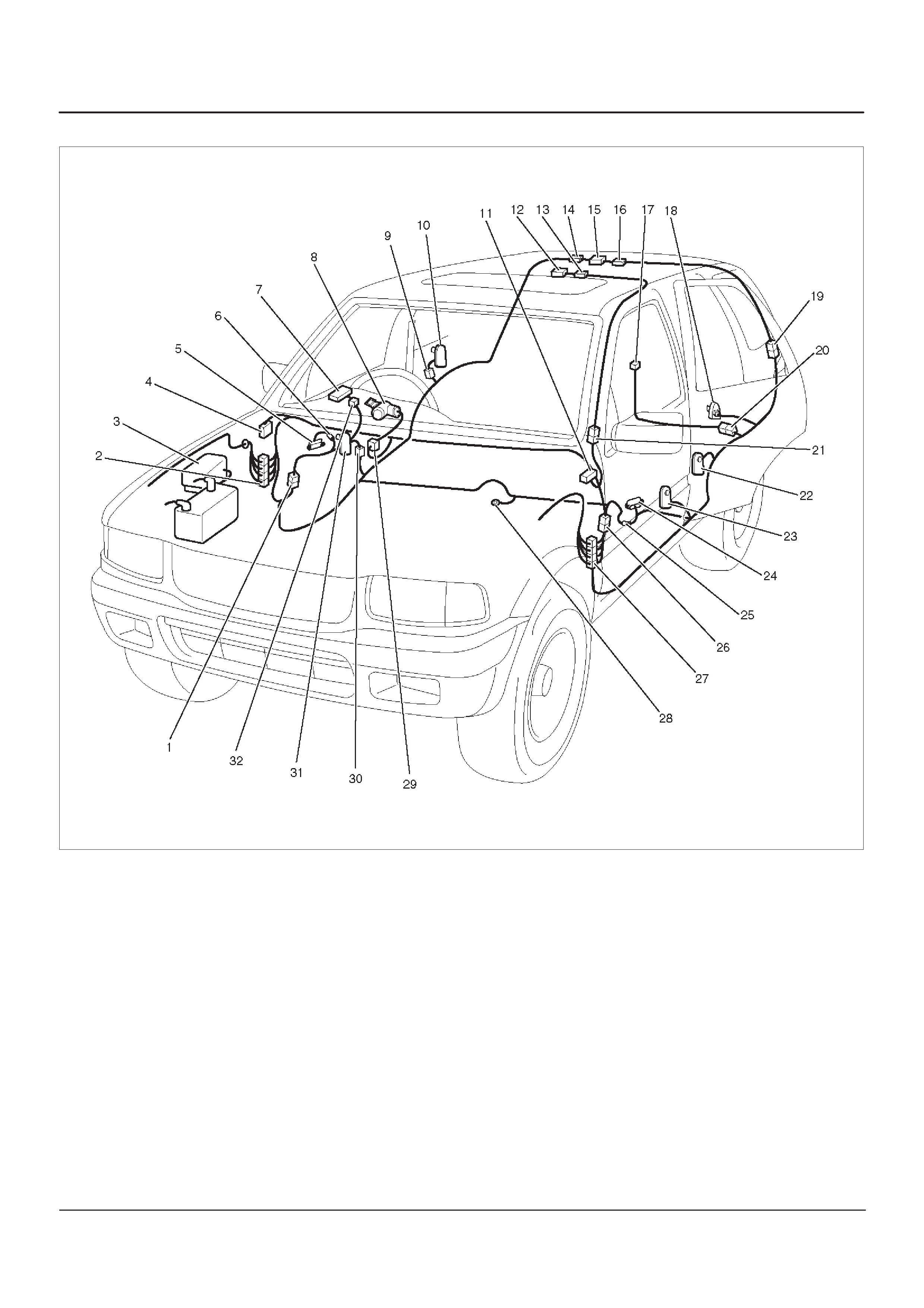

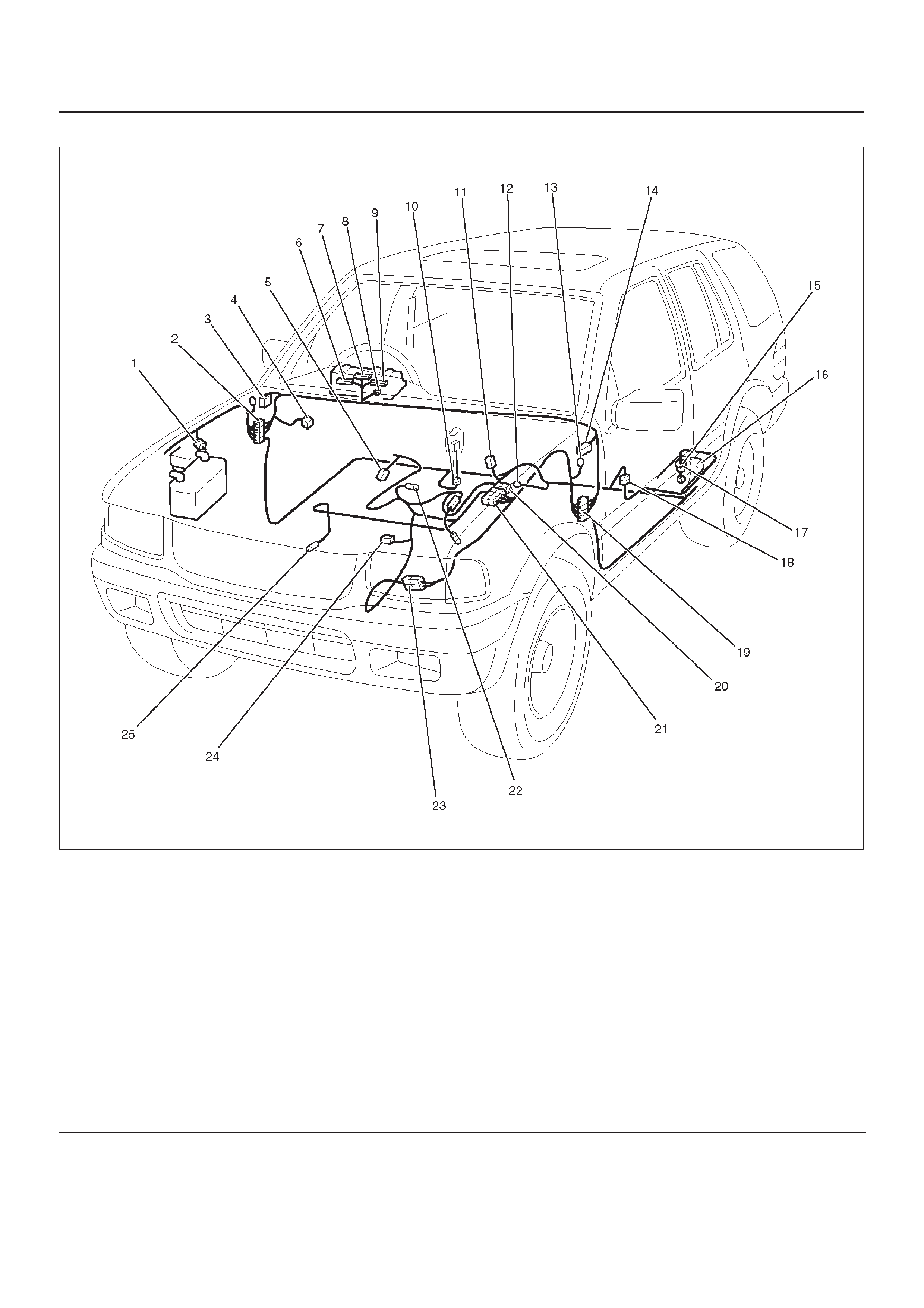

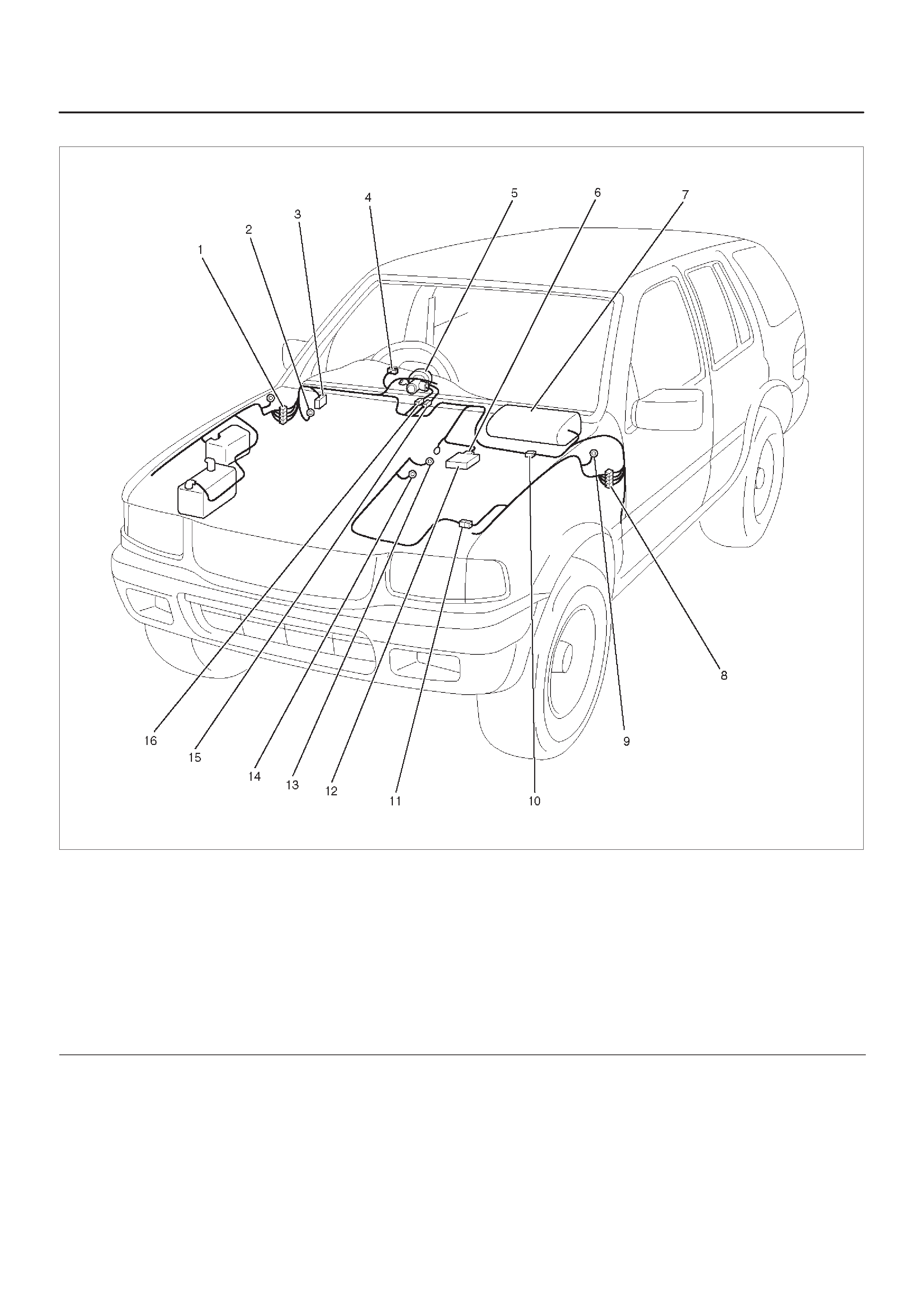

Cable Harness Routing

D08RX275

Legend

(1) Battery (–) Cable

(2) Battery (+) Cable

(3) H–2, H–3

(4) Battery Cable Harness

(5) C–36

(6) H–13, H–14, H–19, H–32

(7) Instrument Harness

(8) H–24

(9) RR Door Harness – RH

(10) Transmission Harness (X22SE)

(11) L–2 (Map Light)

(12) H–21

(13) Hatch Galss Harness

(14) Roof Harness

(15) Tair Gate Harness

(16) RR Door Harness – LH

(17) Chassis Harness

(18) FRT Door Harness – LH

(19) H–33

(20) H–15, H–16, H–17, H–31

(21) C–16

(22) B–8

(23) Body Harness

(24) Engine Harness

(25) H–4, H–5, H–6

(26) H–9, H–10, H–11 (6VD1)

(27) Transmission Harness (6VD1)

(28) Engine Room Harness

(29) P–7

(30) P–9

(31) P–1

(32) H–1

(33) Battery

(34) P–5

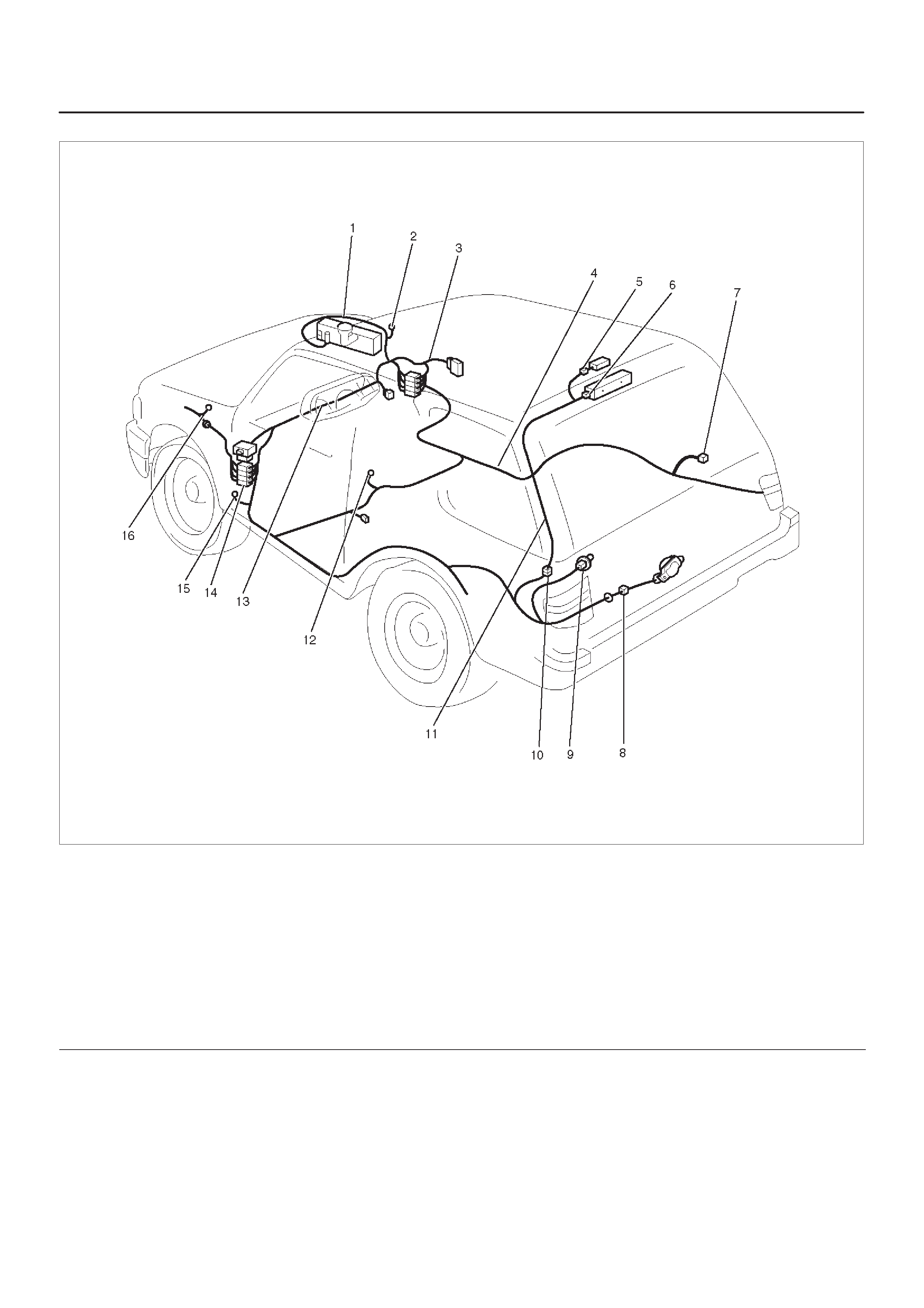

(2Door Model)

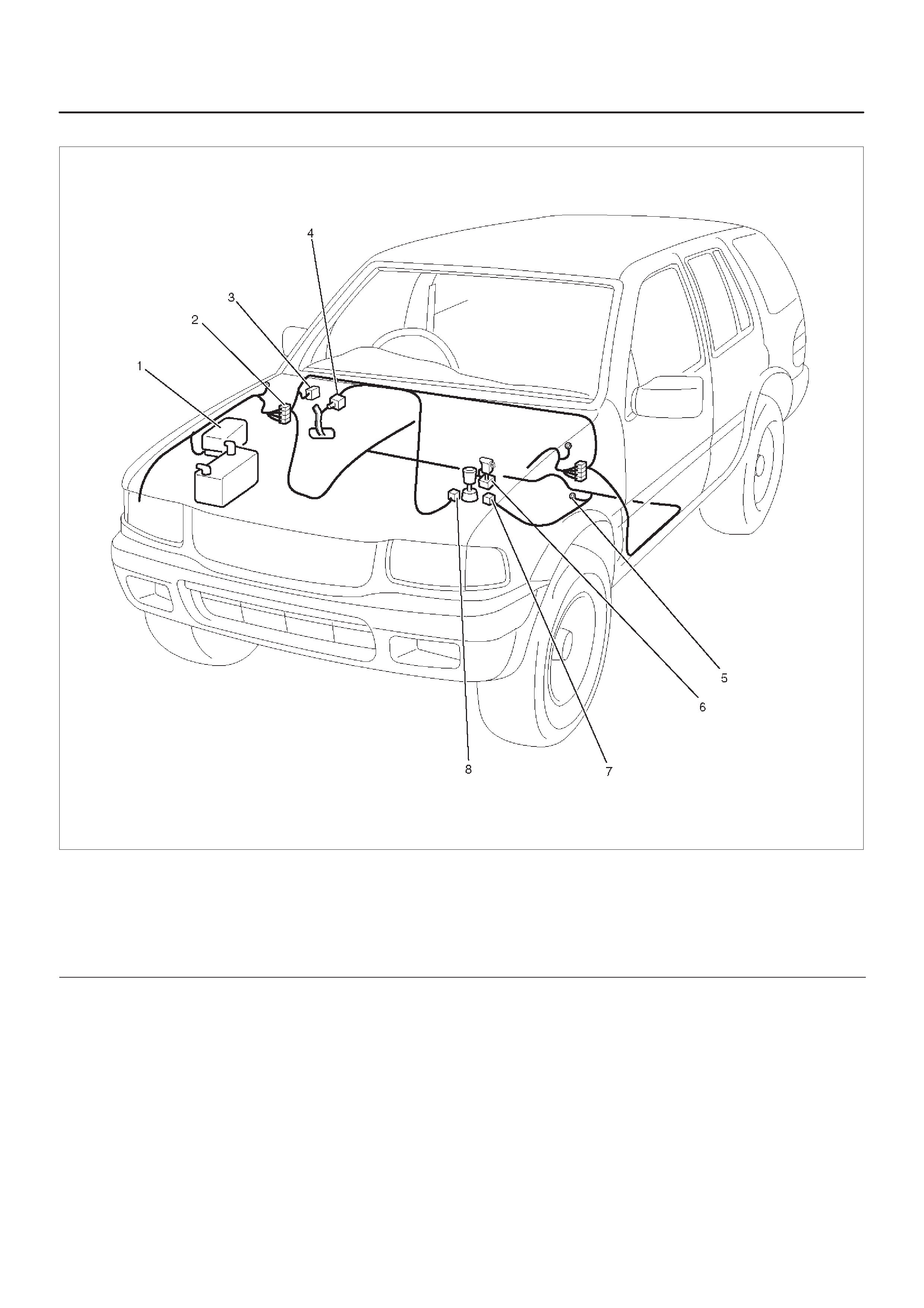

D08RX277

Legend

(1) Engine Room Harness

(2) C–36

(3) Instrument Harness

(4) Body Harness

(5) B–11

(6) Hight Mounted Stoplight (G–4)

(7) Tailer Connector

(8) H–34 (Tail Gate Harness Connector)

(9) B–20

(10) H–37

(11) Resin Harness

(12) B–8

(13) Instrument Harness

(14) Body Harness & Engine Room Harness

Connector

(15) I–43

(16) C–16

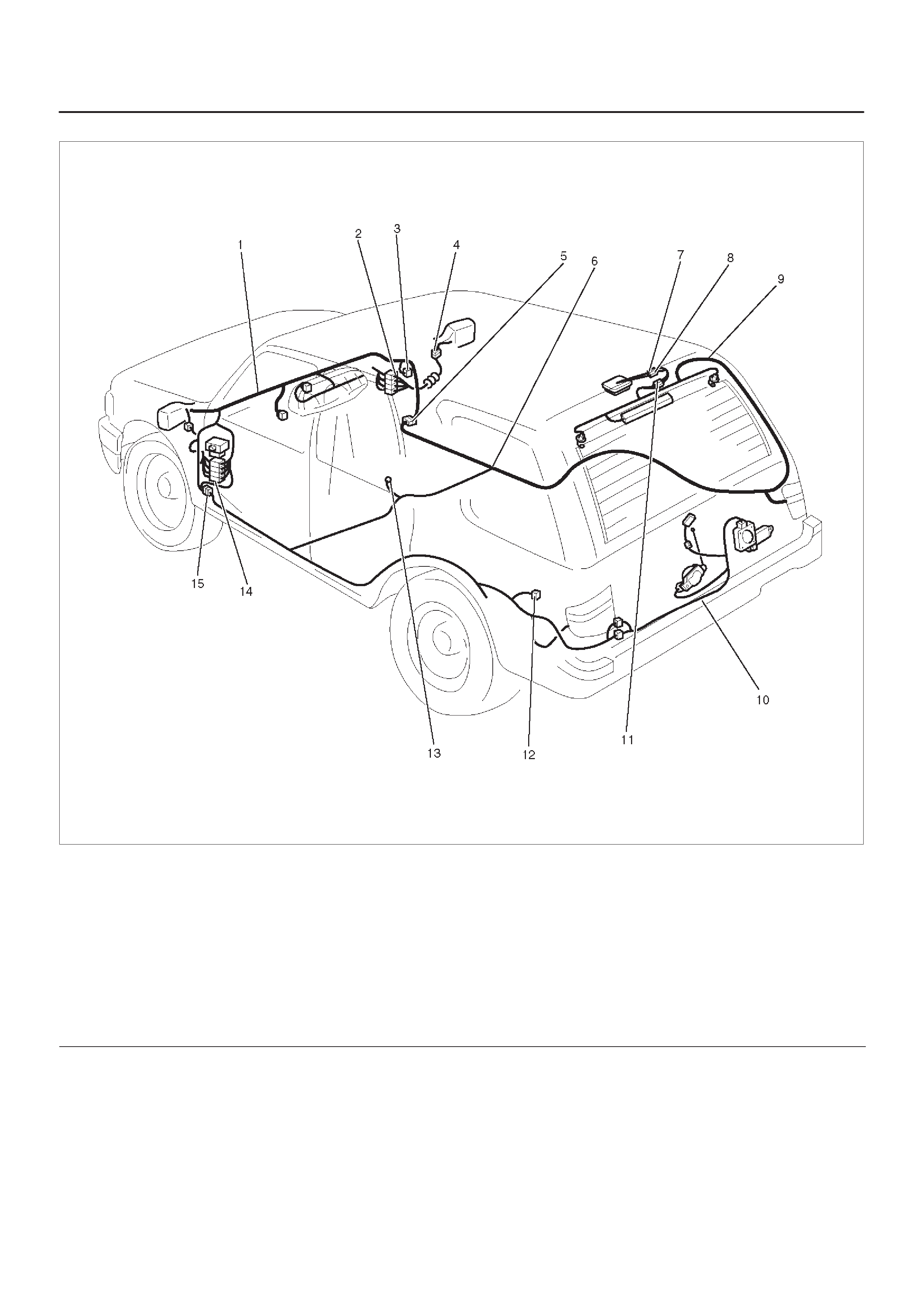

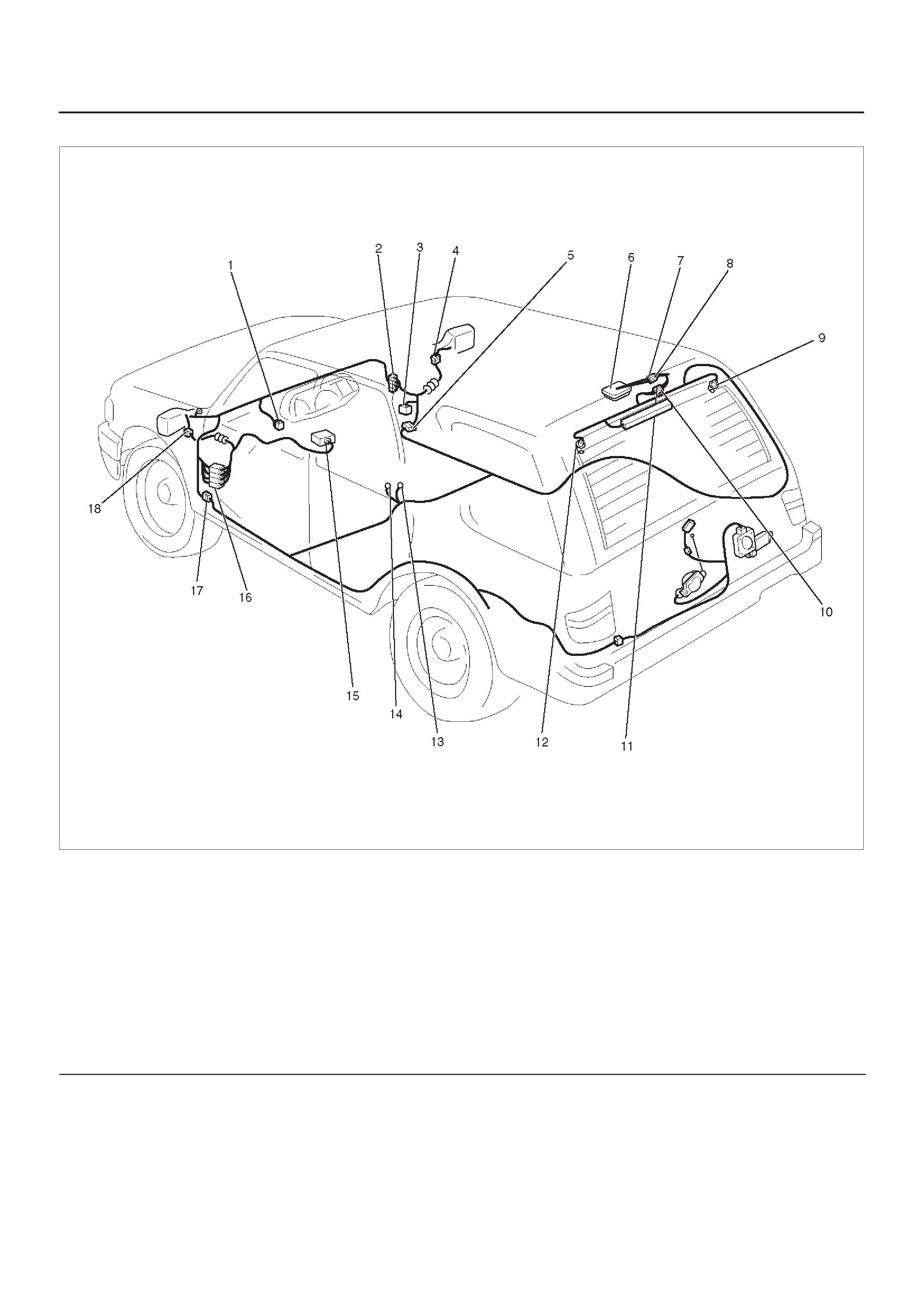

(4Door Model)

D08RX276

Legend

(1) Instrument Harness

(2) Engine Room Harness & Body Harness

Connector

(3) Relay & Fuse Box (Instrument Panel)

(4) FRT Door Harness – RH

(5) H–28

(6) Body Harness

(7) H–20

(8) H–21

(9) Hatch Glass Harness

(10) Tail Gate Harness

(11) G–11

(12) TRAILER Connector

(13) B–8

(14) Body Harness & Engine Room Harness

Connector

(15) H–33

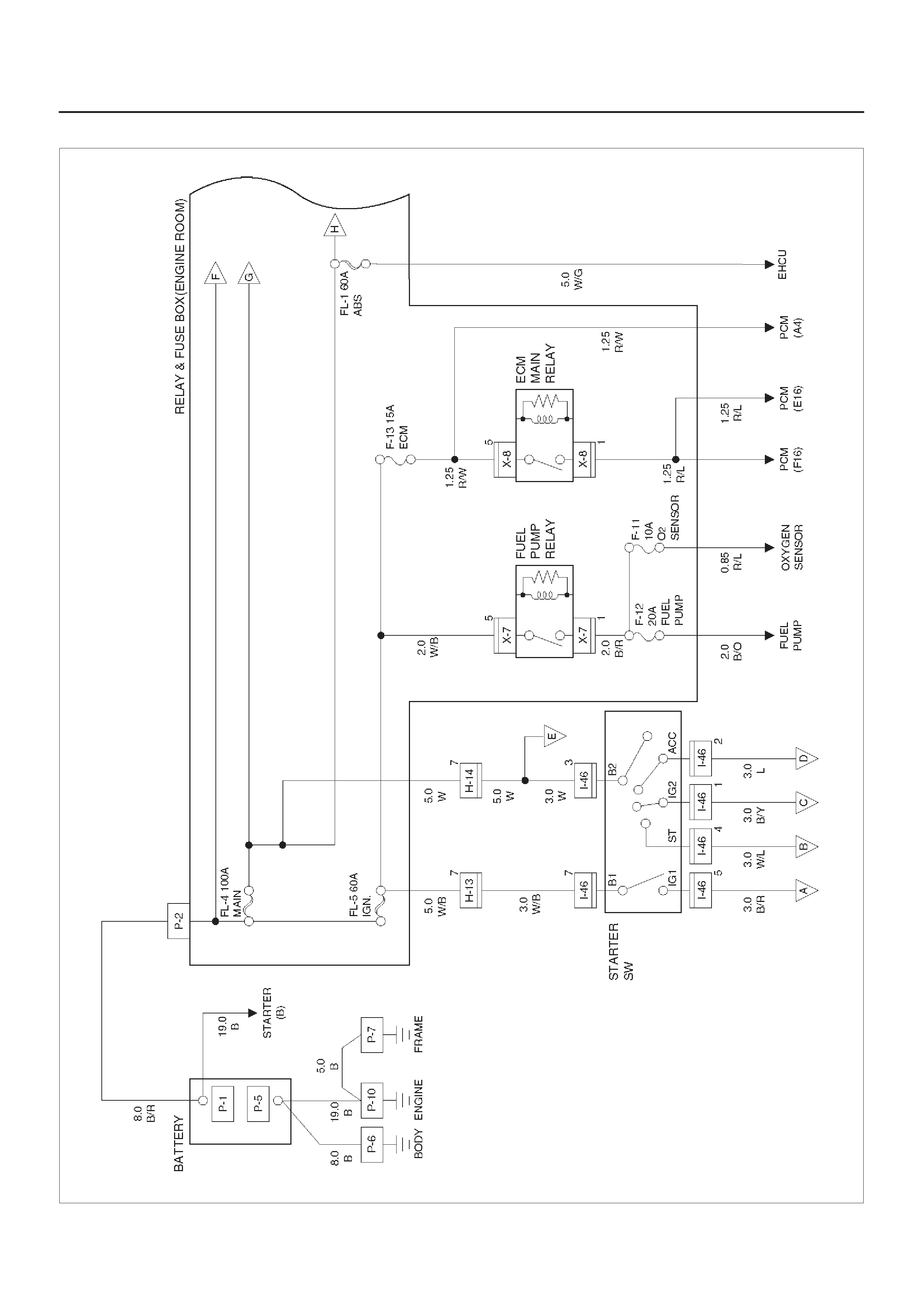

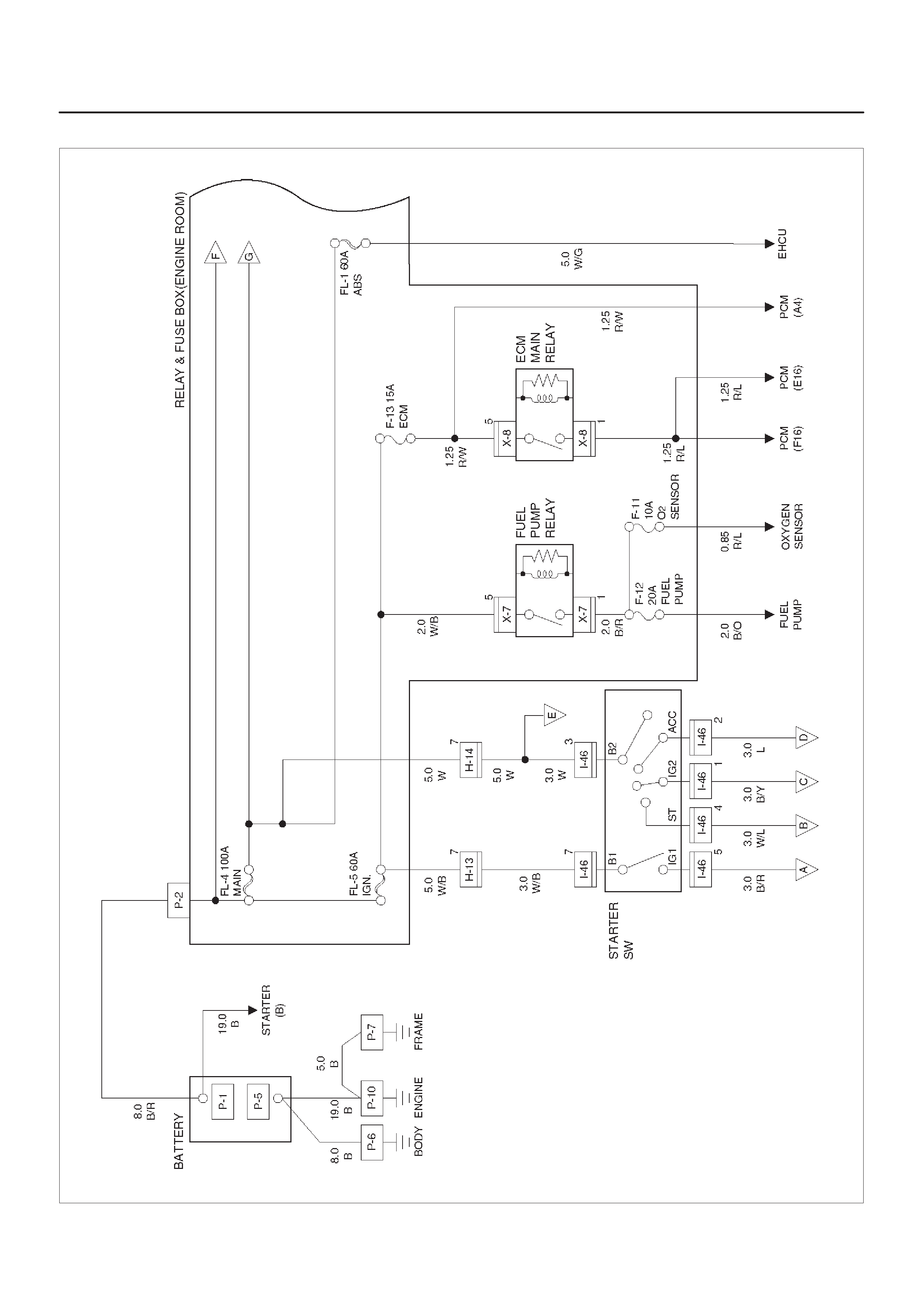

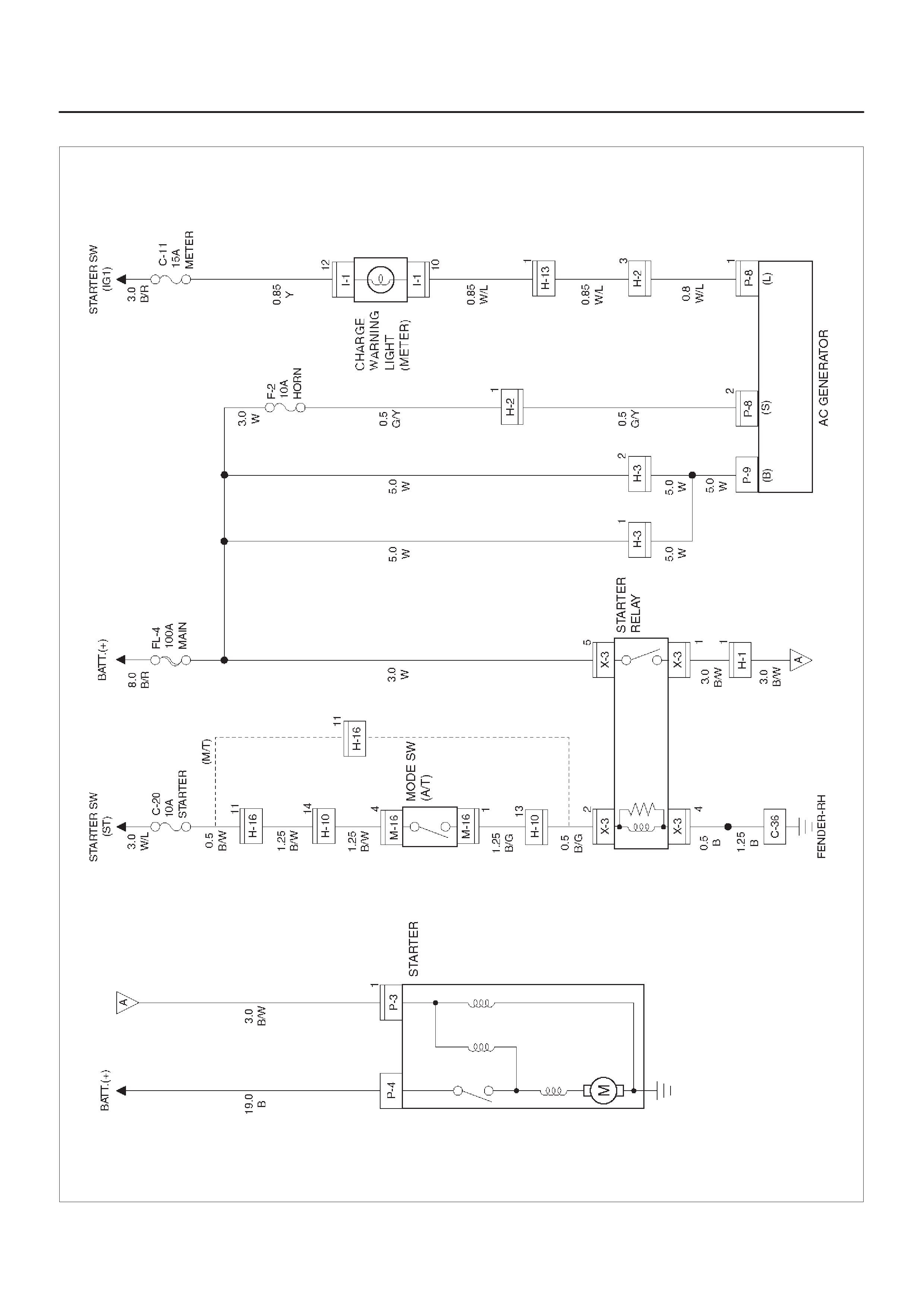

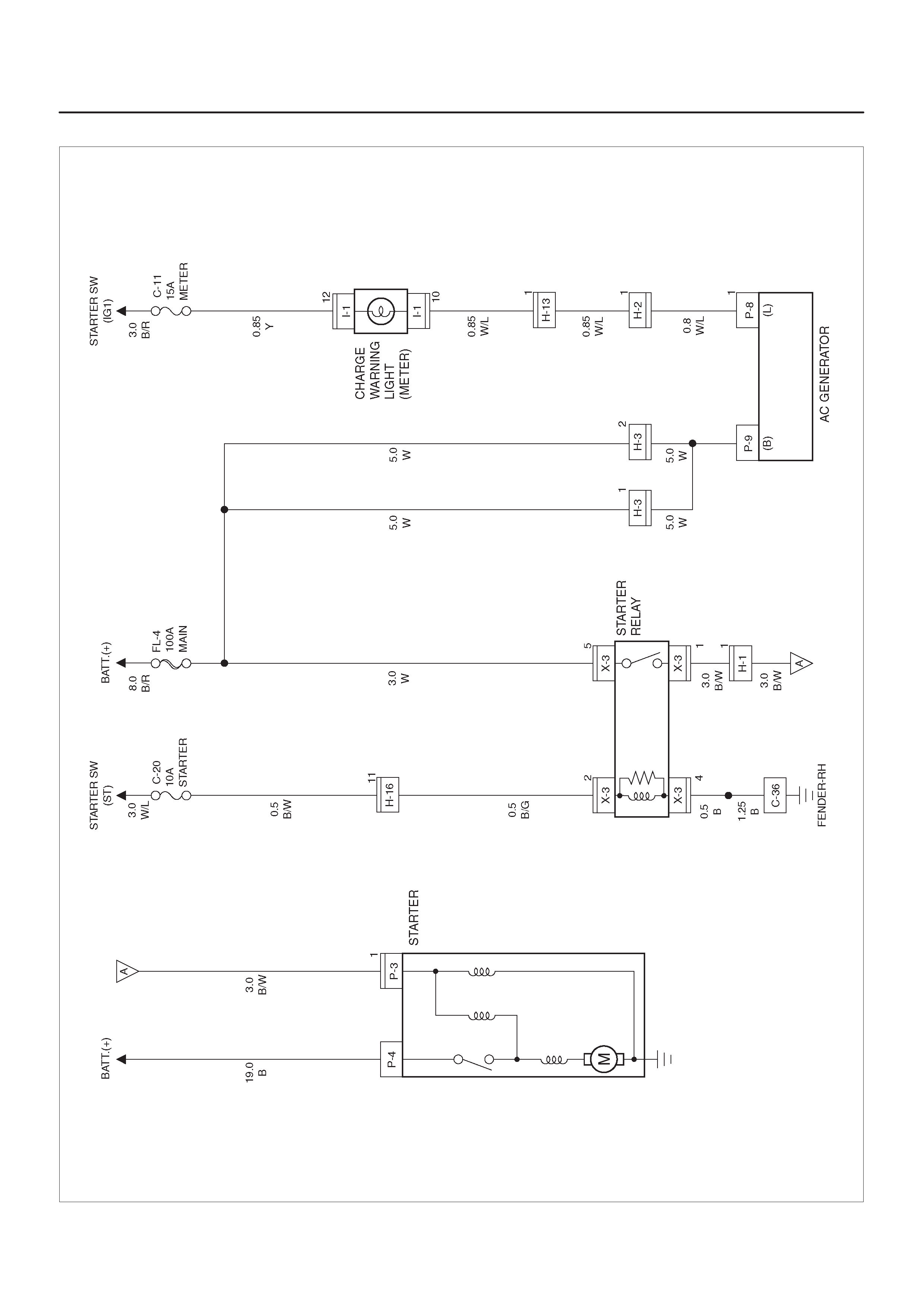

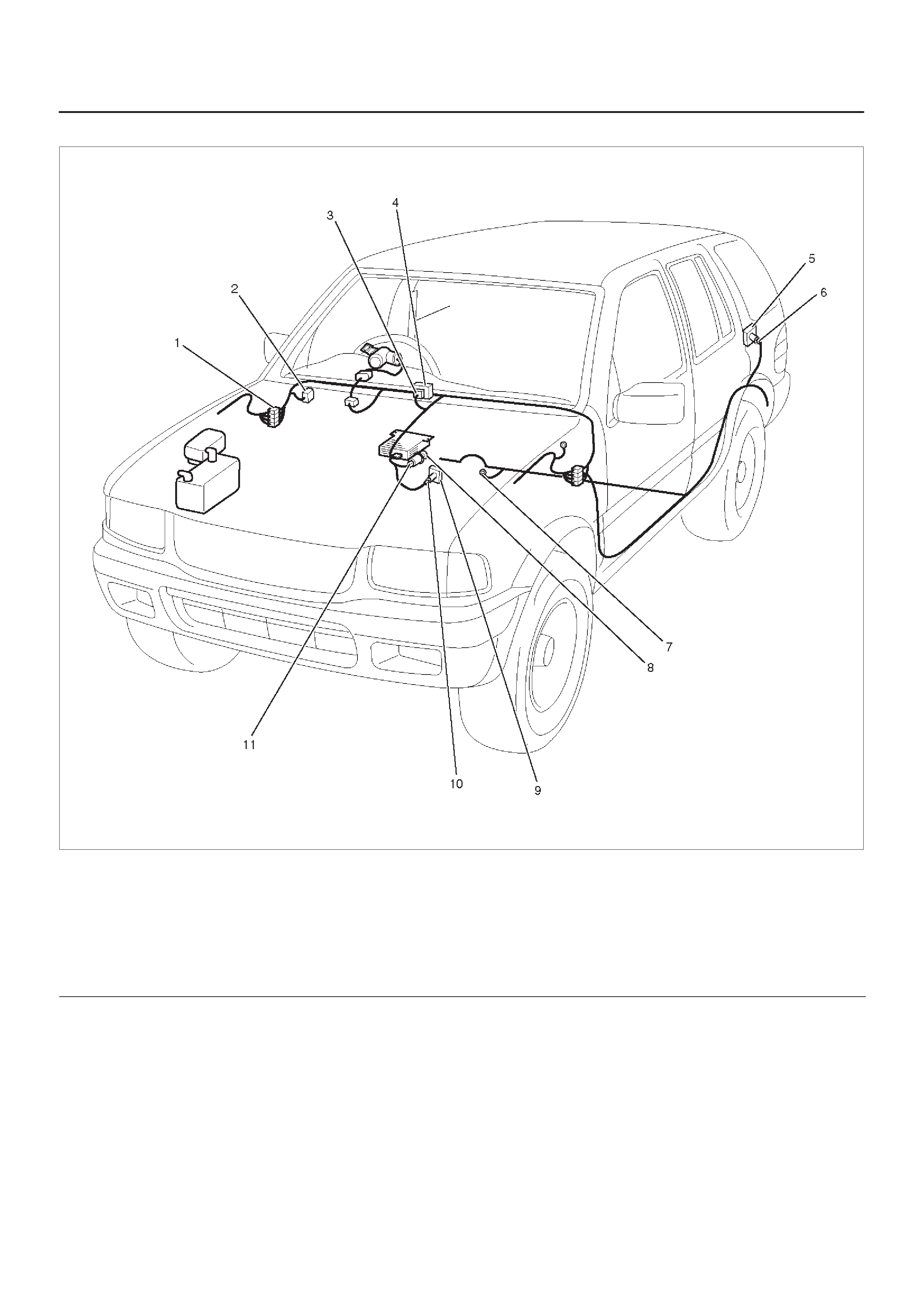

Start and Charging

General Description

This system consists of starter, AC generator, starter

relay , clutch start SW (M/T), mode SW (A/T) and heater &

A/C relay.

When starter SW is set to “ST” position with A/T select

lever at “P” (Parking) or “N” (Neutral) position (Mode SW

“ON”), or clutch pedal depressed (Clutch start SW “ON”),

battery positive voltage is applied to starter solenoid coil

through starter relay to start starter. At the some time,

starter relay cuts off blower motor and A/C circuit.

Circuit Diagram–1 (6VD1)

D08RX189

Circuit Diagram–1 (X22SE)

D08RY00936

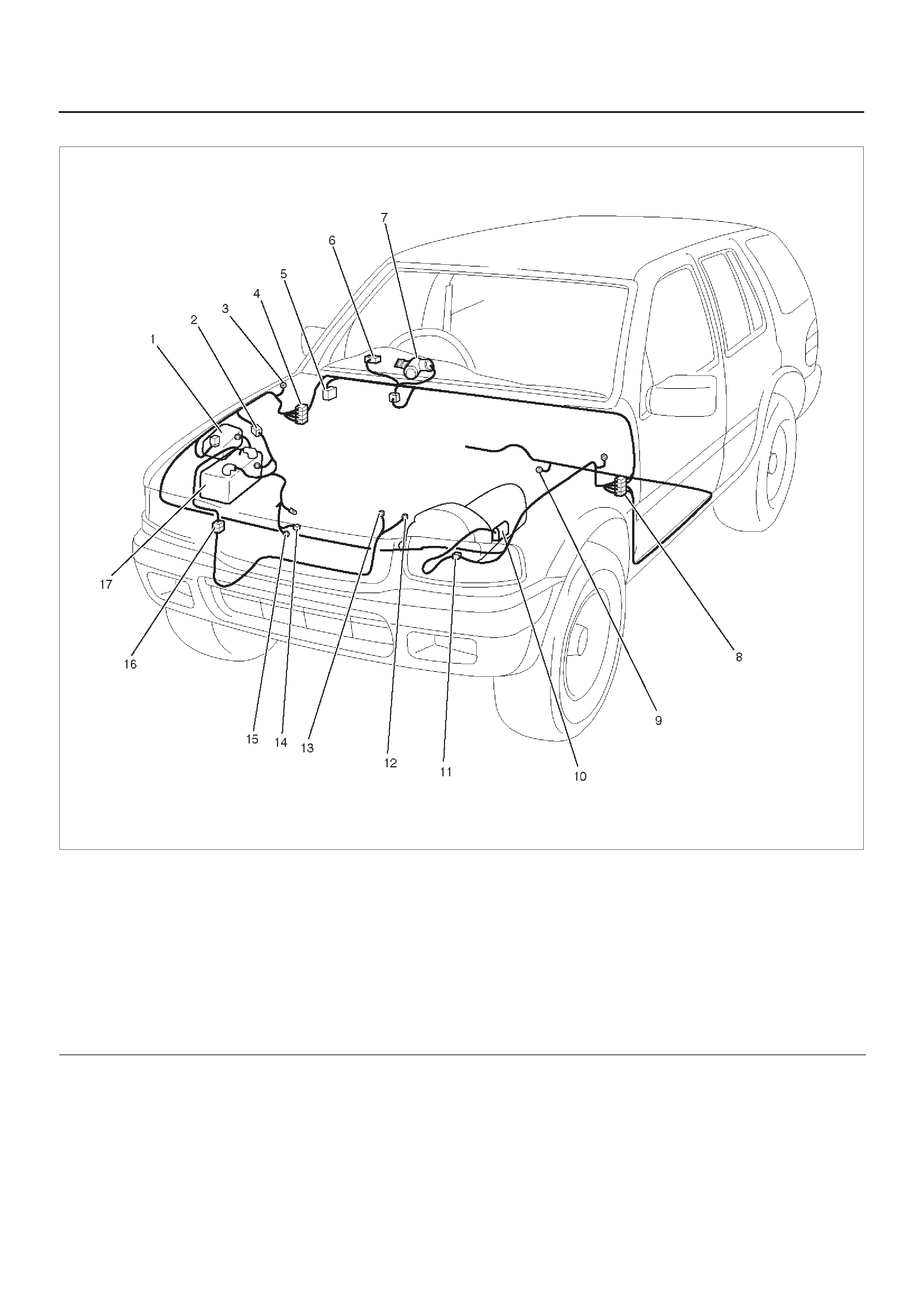

Parts Location

D08RX190

Legend

(1) X–3

(2) H–2, H–3

(3) C–36

(4) H–13

(5) Relay & Fuse Box (C–11, C–20)

(6) I–1

(7) Starter Switch

(8) H–16

(9) B–8

(10) Mode Switch (M–16)

(11) H–10

(12) P–4

(13) P–3

(14) P–8

(15) P–9

(16) H–1

(17) Battery

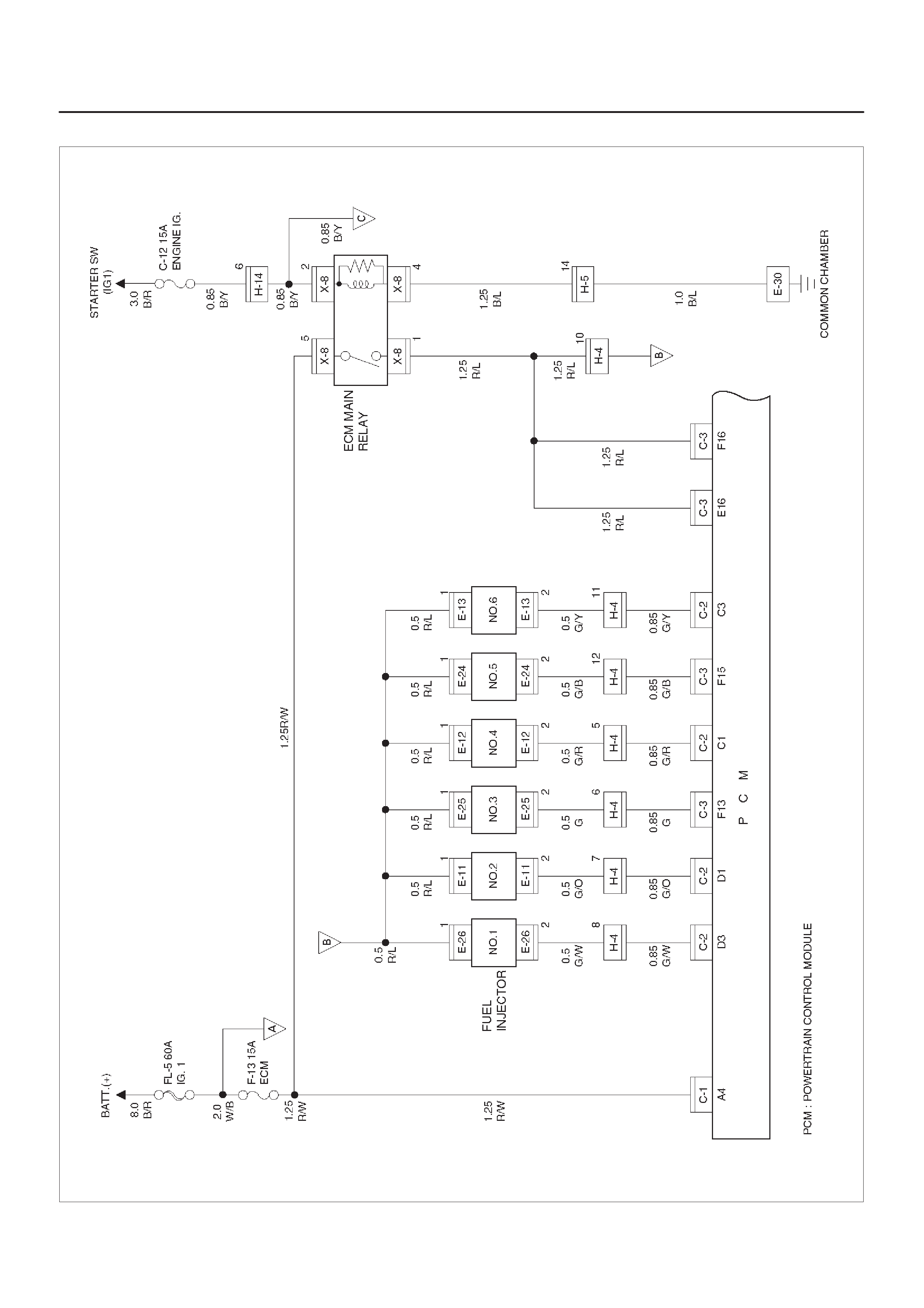

Powertrain Control Module (PCM)

General Description

The Powertrain Control Module (PCM) is located in the

passenger compartment.

The PCM constantly monitors the information from

various sensors, and controls the systems that affect

vehicle performance.

The PCM performs the diagnostic function of the system.

It can recognize operational problems, alert the driver

through the Malfunction Indicator Light (MIL) and store a

Diagnostic Trouble Code (DTC) or DTC(s) which identify

the problem areas to aid the technician in making repairs.

The PCM is designed to process the various input

informations and then send the necessary electrical

responses to control fuel delivery, spark timing and other

emission control systems. The input information has an

interrelation to more than one output therefore, if the one

input failed, it could affect more than one system

operation.

Refer to Driveability and Emission in Engine Section and

Automatic Transmission in Transmission section.

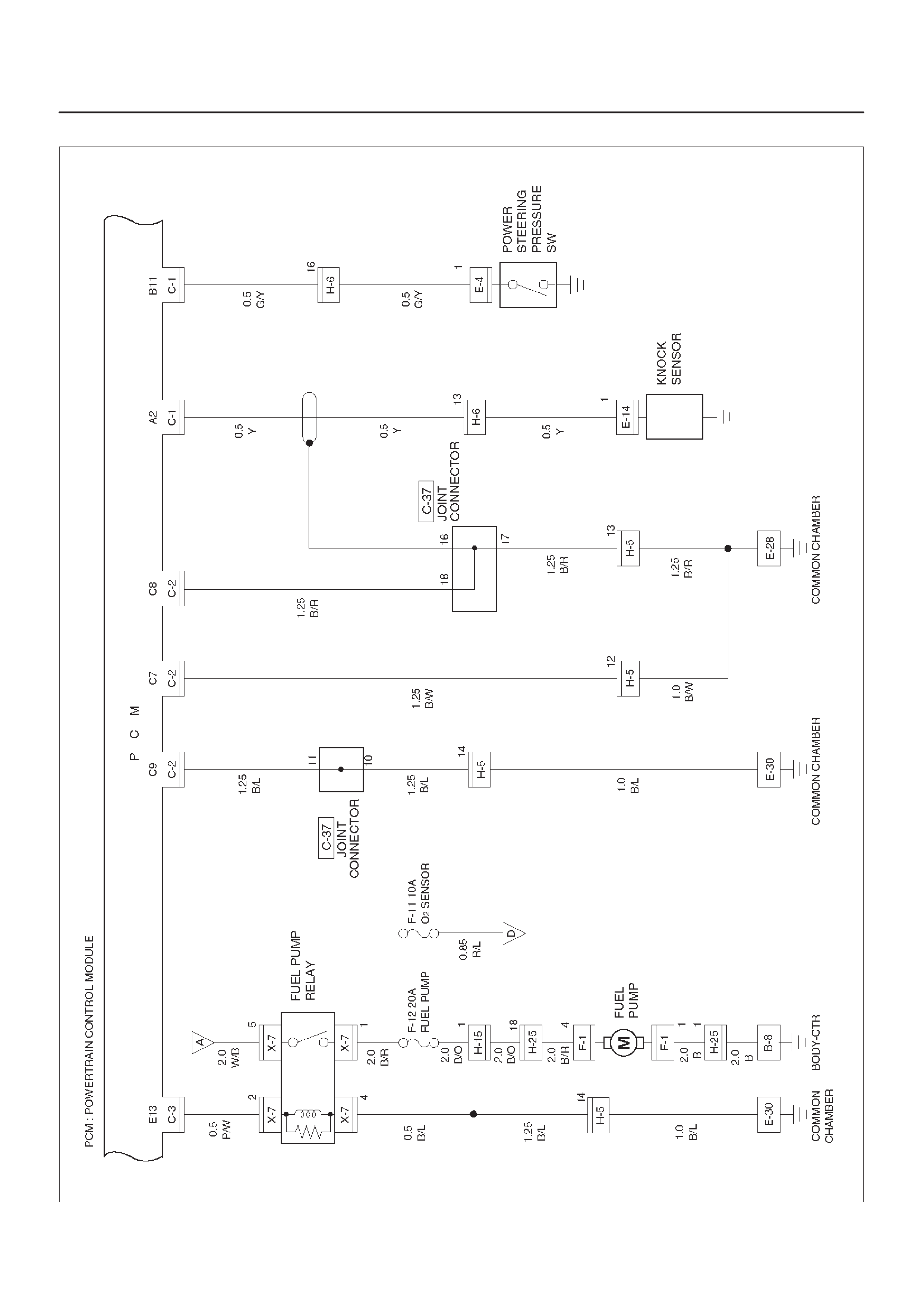

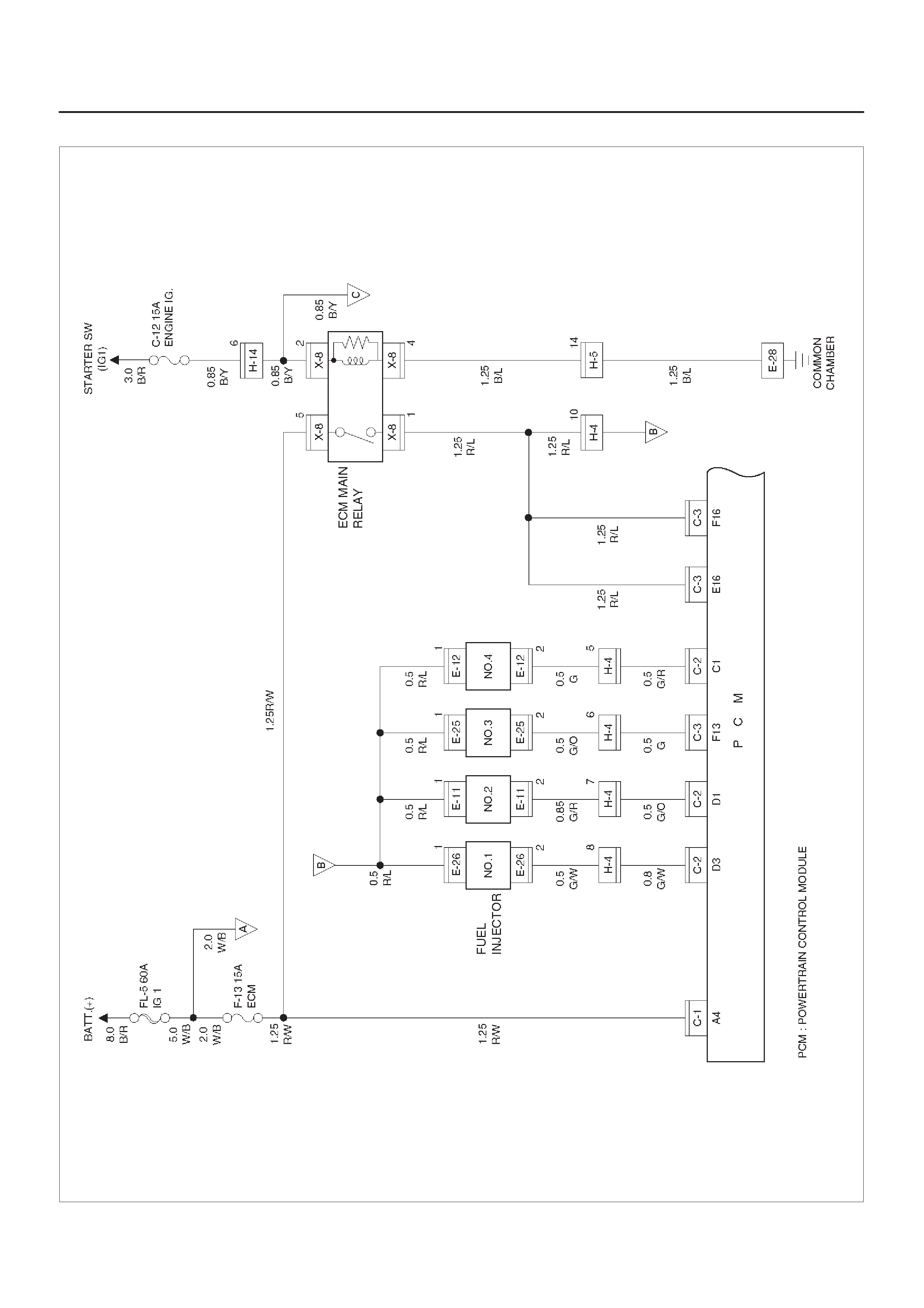

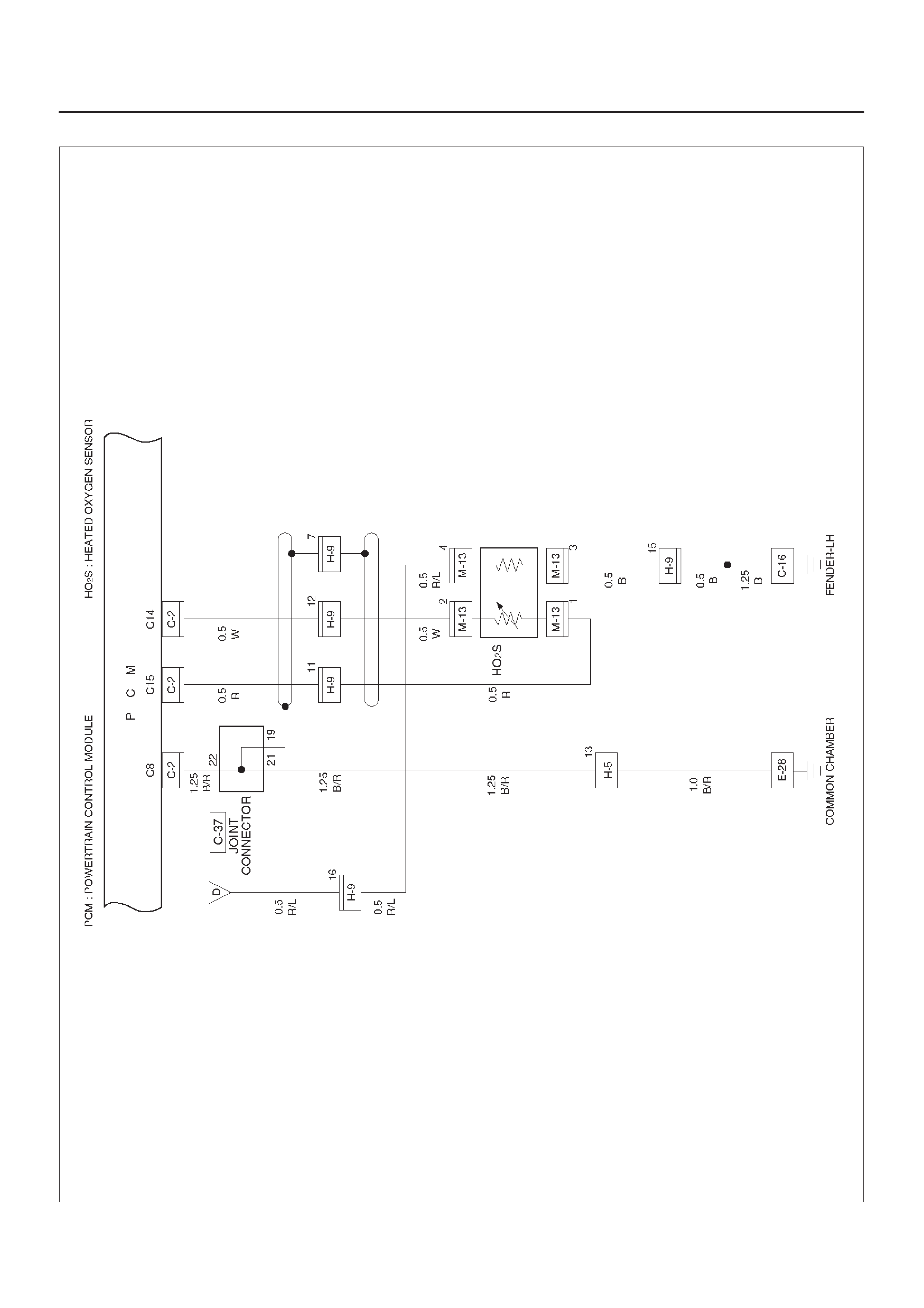

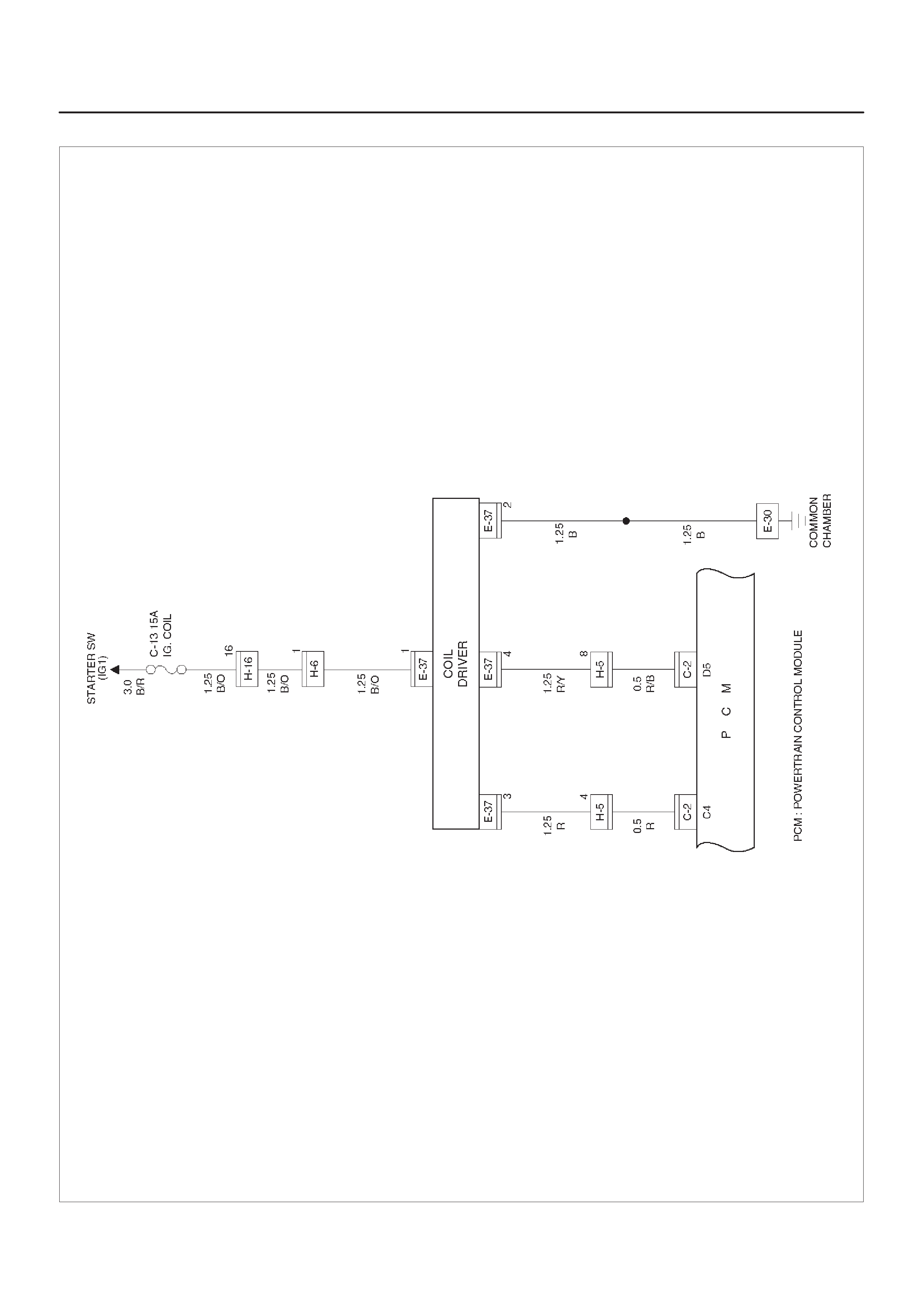

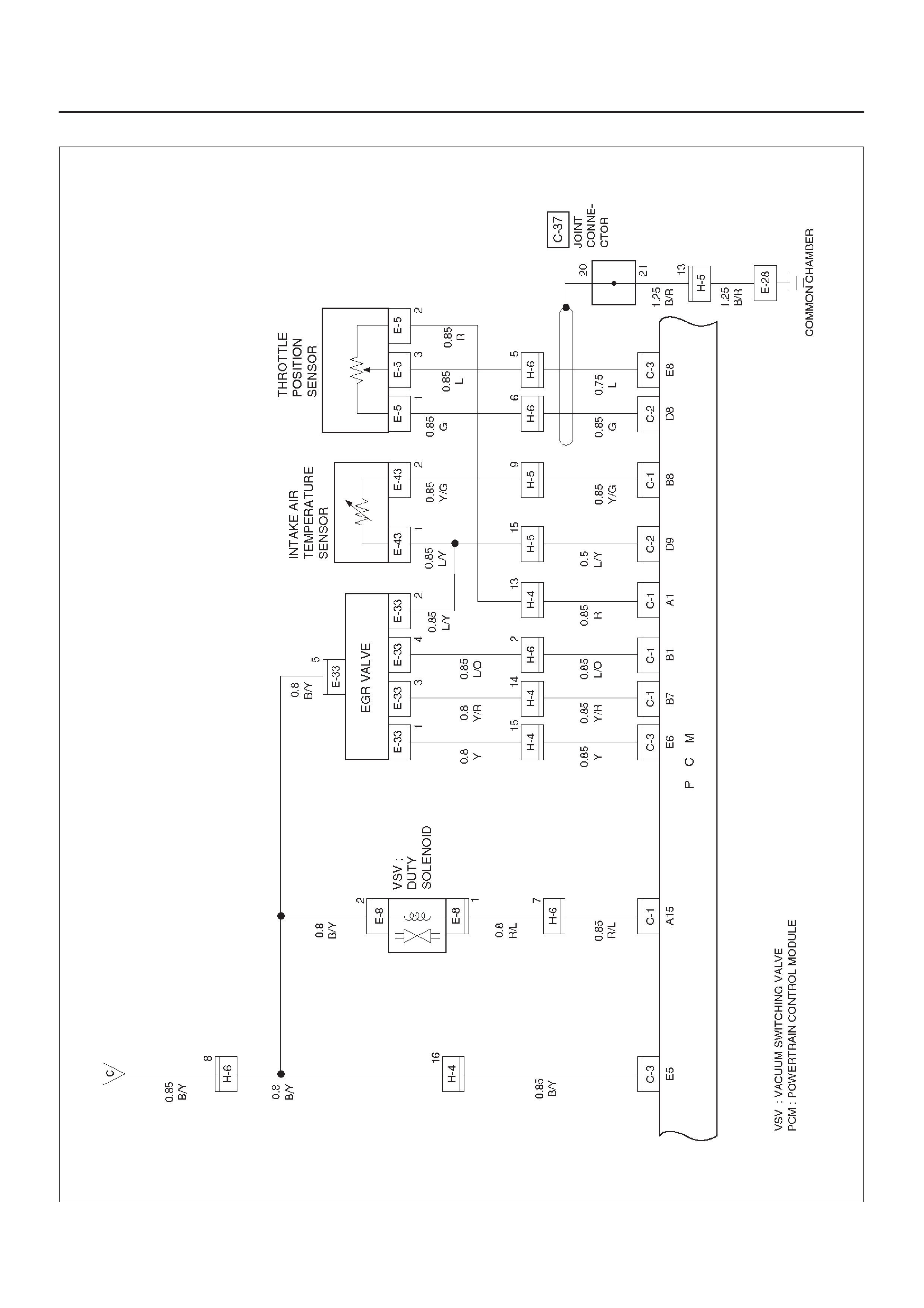

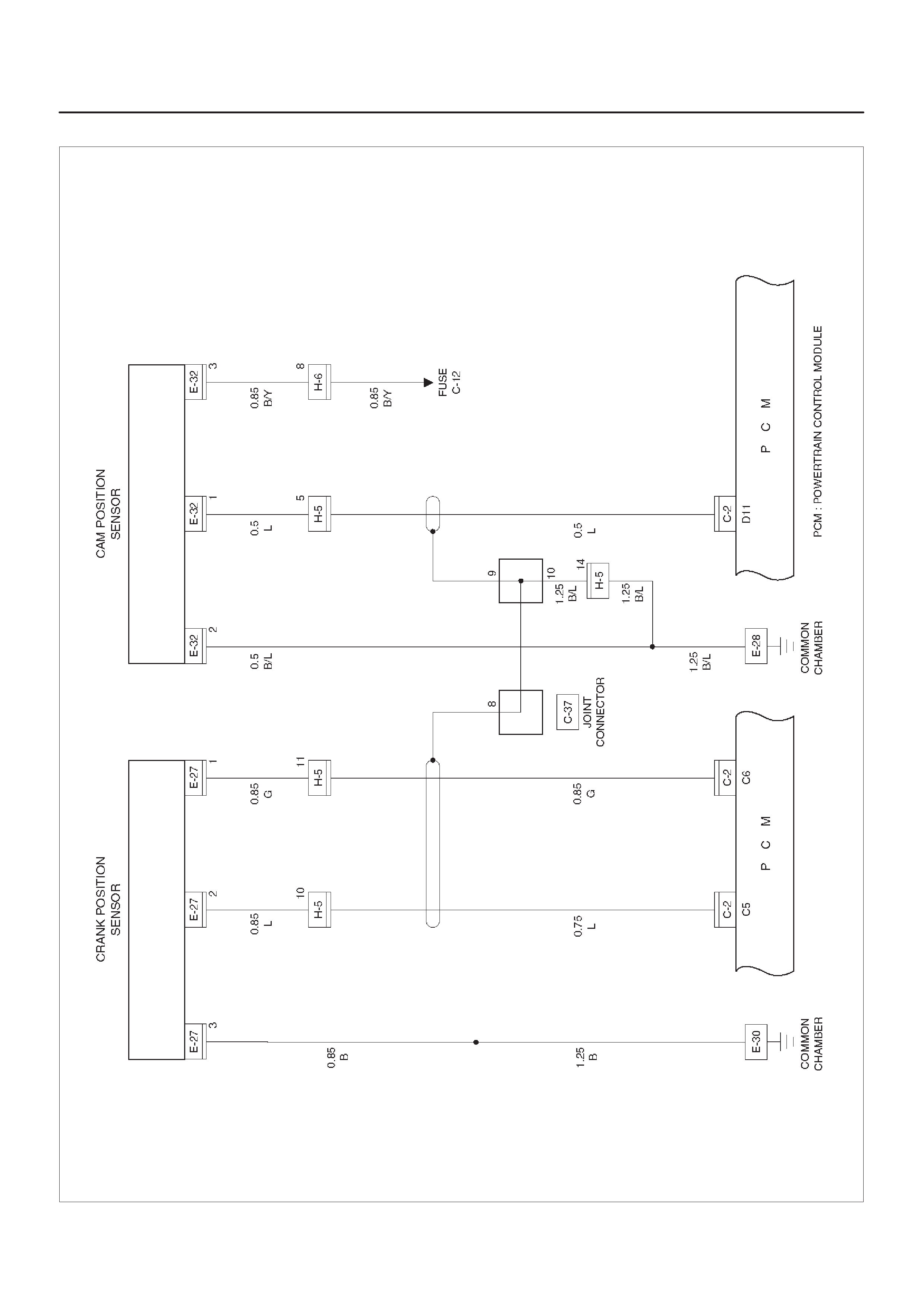

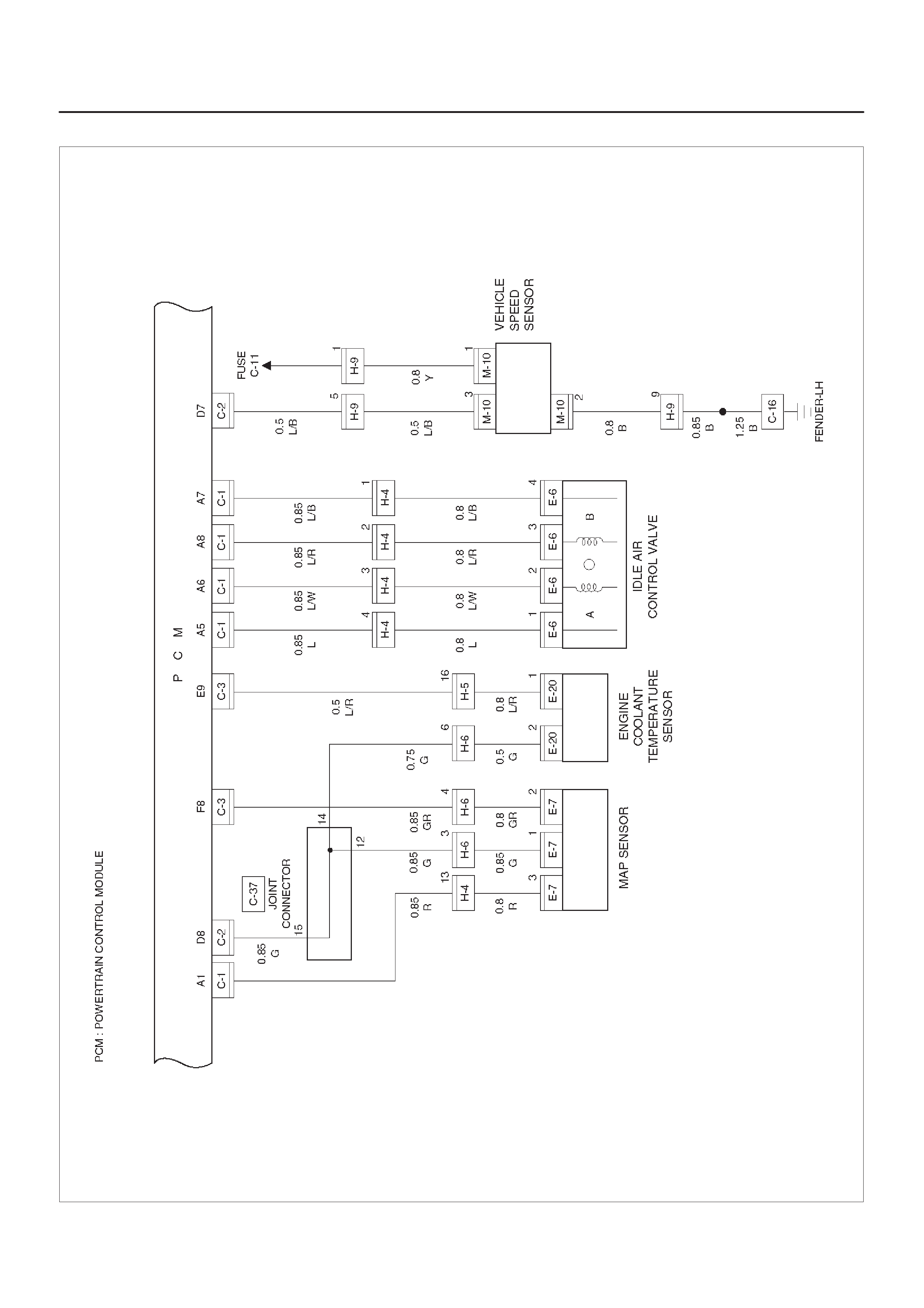

Circuit Diagram–1 (6VD1)

D08RX158

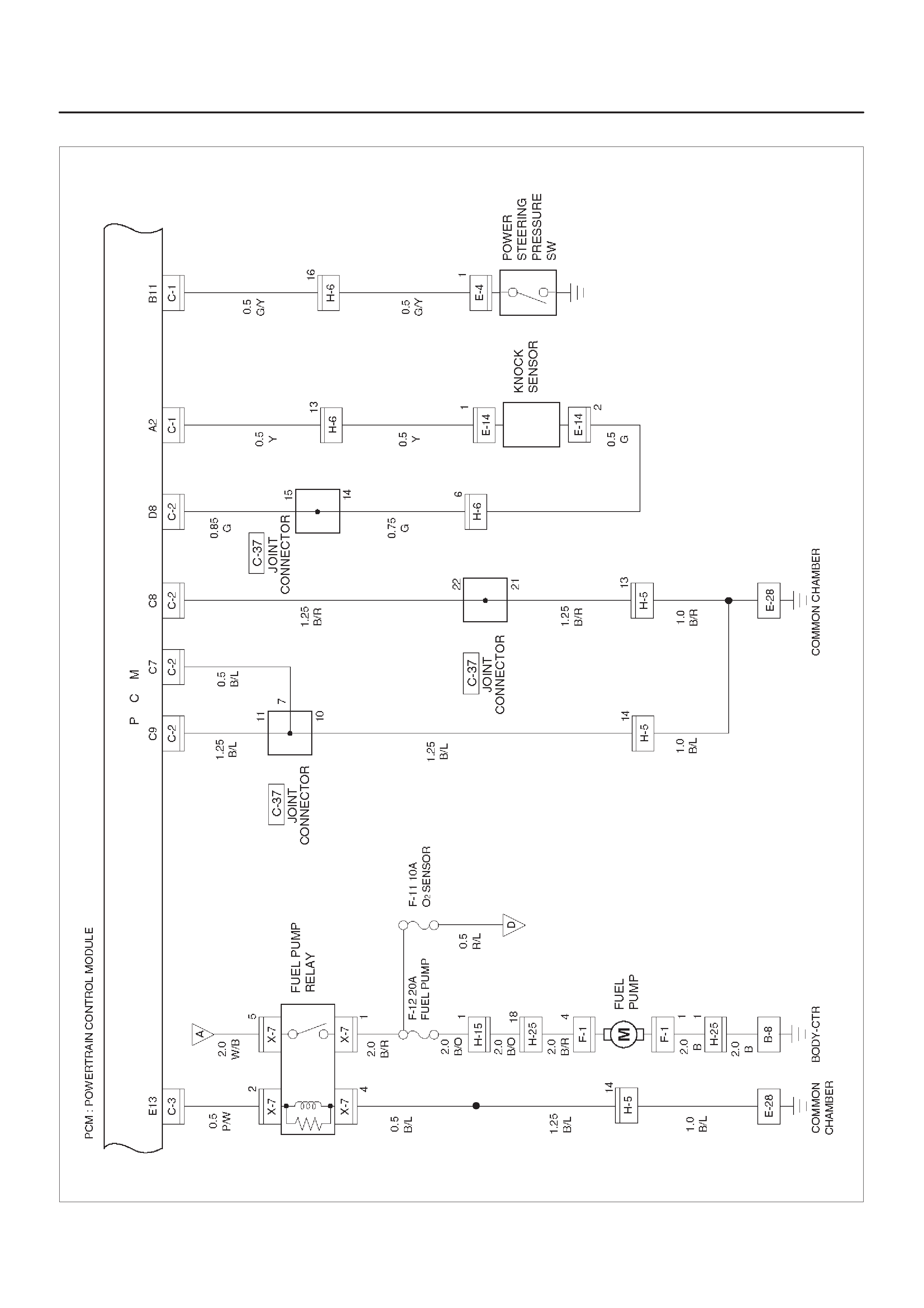

Circuit Diagram–2 (6VD1)

D08RX159

Circuit Diagram–3 (6VD1 M/T)

D08RX176

Circuit Diagram–3 (6VD1 A/T)

D08RX160

Circuit Diagram–4 (6VD1)

D08RX161

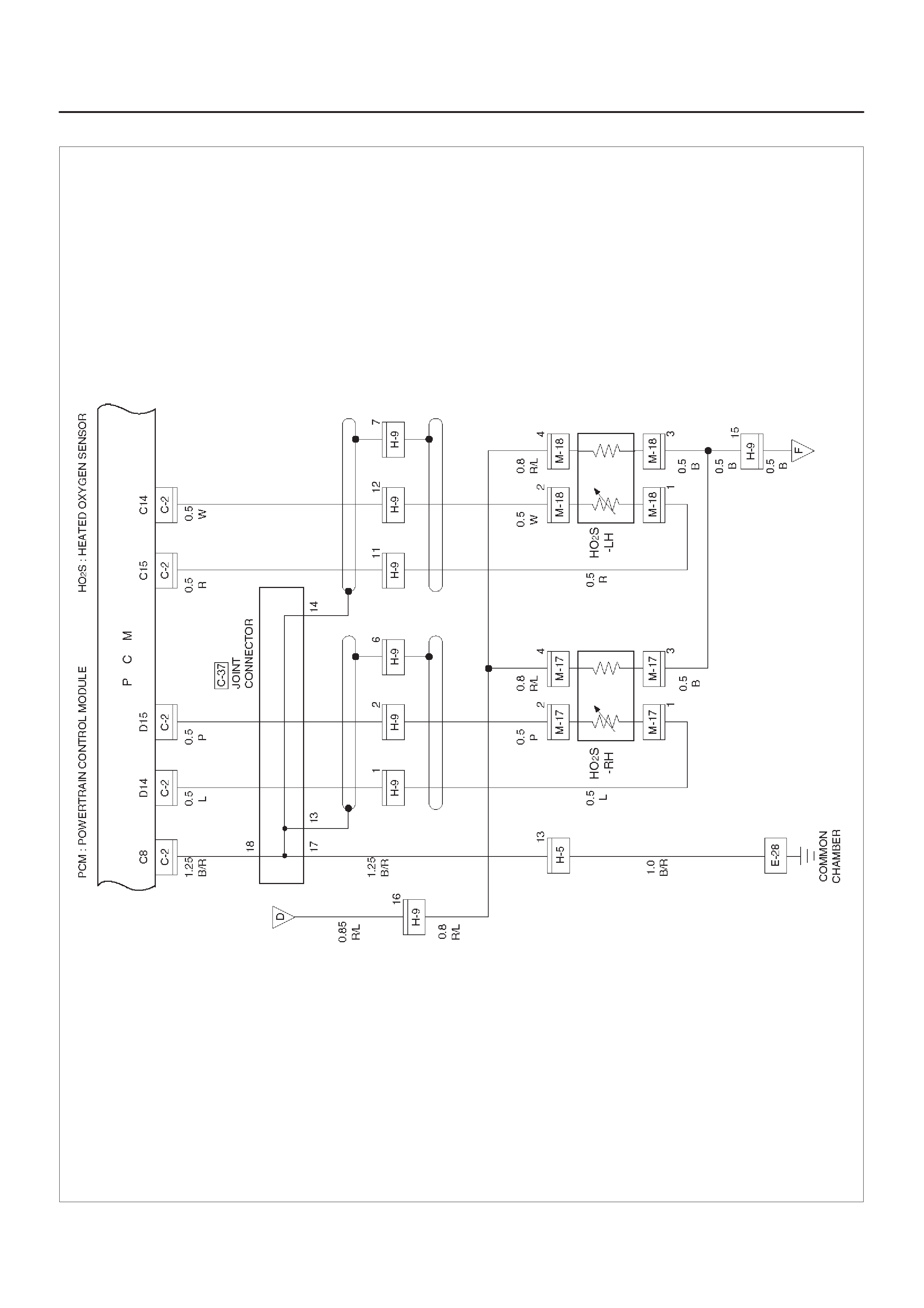

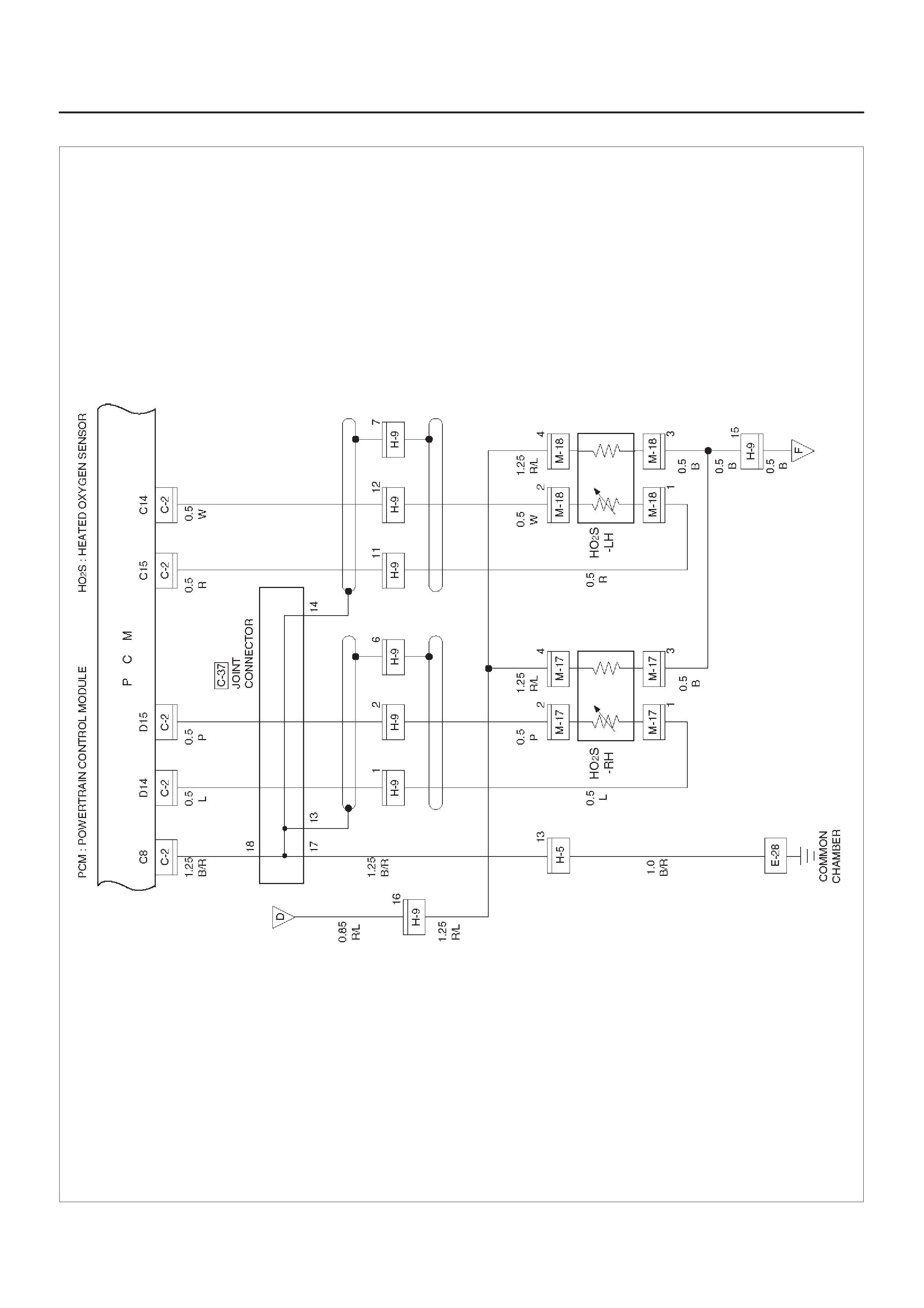

Circuit Diagram–5 (6VD1)

D08RX162

Circuit Diagram–6 (6VD1)

D08RX163

Circuit Diagram–7 (6VD1)

D08RY00926

Circuit Diagram–8 (6VD1)

D08RY00927

Circuit Diagram–9 (6VD1)

D08RX166

Circuit Diagram–10 (6VD1)

D08RX167

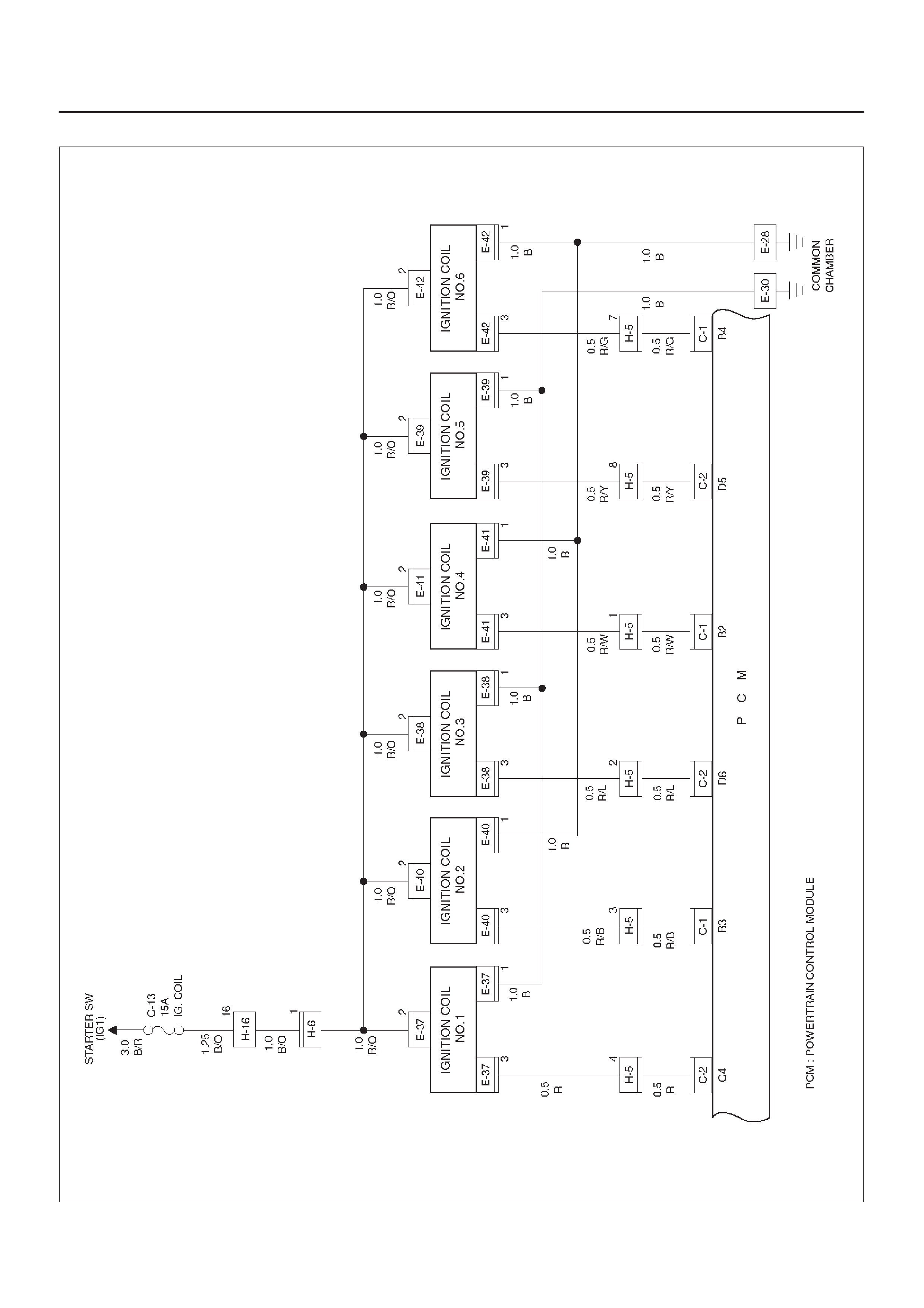

Circuit Diagram–11 (6VD1)

D08RY00928

Circuit Diagram–12 (6VD1)

D08RX169

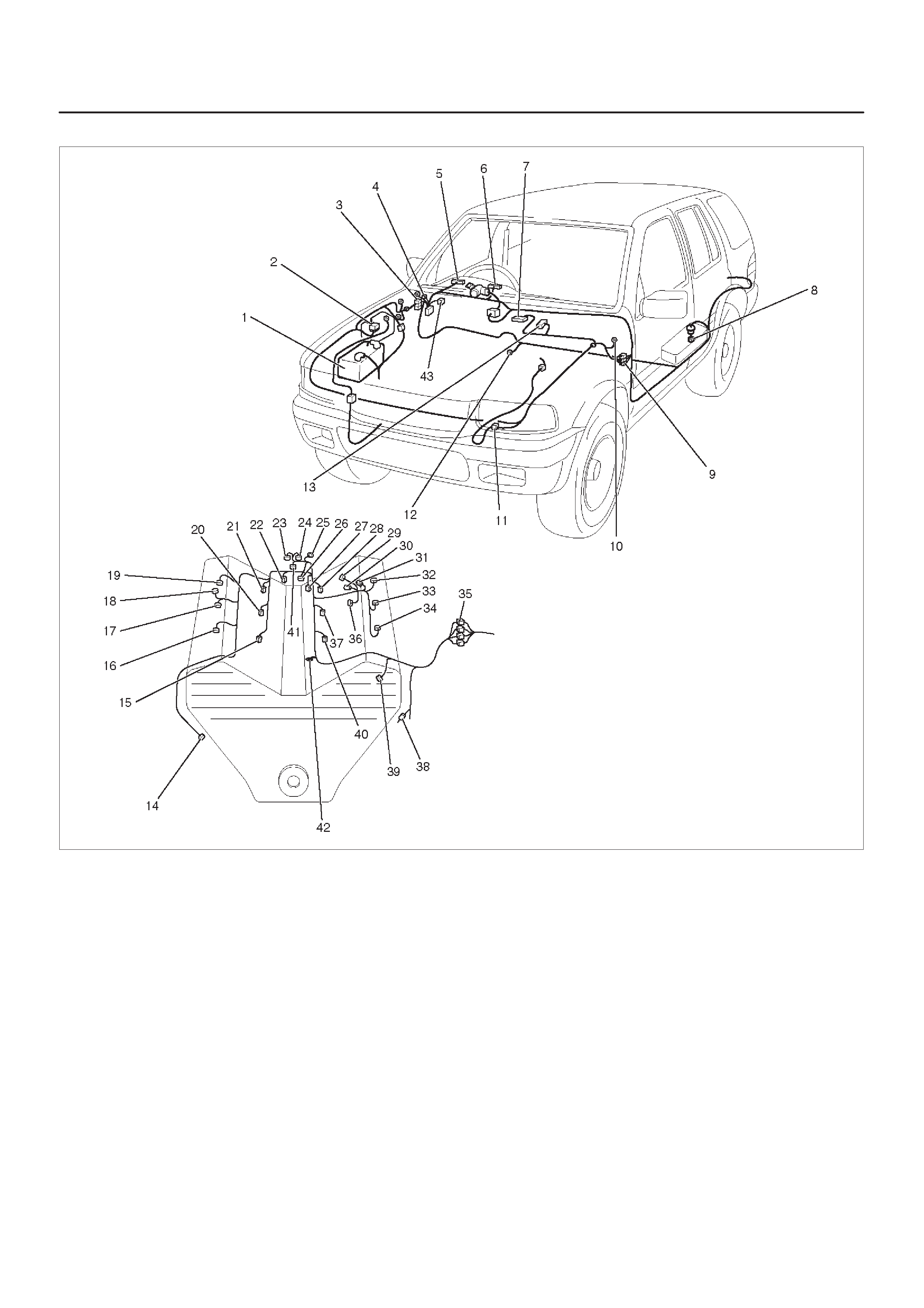

Parts Location – 1 (6VD1)

D08RX170

Legend

(1) Battery

(2) X–7, X–8

(3) H–12, H–13, H–14, H–19, H–32

(4) Relay & Fuse Box (I–34, I–39)

(5) I–1

(6) I–9

(7) PCM (C–1, C–2, C–3)

(8) F–1

(9) H–15, H–16, H–17

(10) C–16

(11) H–9, H–10, H–11

(12) B–8

(13) C–37

(14) E–27

(15) E–26

(16) E–37

(17) E–38

(18) E–7

(19) E–39

(20) E–25

(21) E–24

(22) E–20

(23) E–34

(24) E–35

(25) E–30

(26) E–8

(27) E–14

(28) E–13

(29) E–33

(30) E–5

(31) E–43

(32) E–42

(33) E–41

(34) E–40

(35) H–4, H–5, H–6

(36) E–6

(37) E–12

(38) E–4

(39) E–32

(40) E–11

(41) E–36

(42) E–28

(43) C–34

Parts Location – 2 (Transmission control)

D08RX171

Legend

(1) M–10

(2) H–12, H–13, H–14, H–19, H–32

(3) C–34

(4) I–17

(5) I–1

(6) I–9

(7) I–18

(8) B–19

(9) B–8

(10) H–15, H–16, H–17

(11) M–10

(12) M–15

(13) M–7

(14) M–16

(15) M–6

(16) M–17

(17) M–18

(18) H–9, H–10, H–11

(19) E–5

(20) C–29

(21) B–24

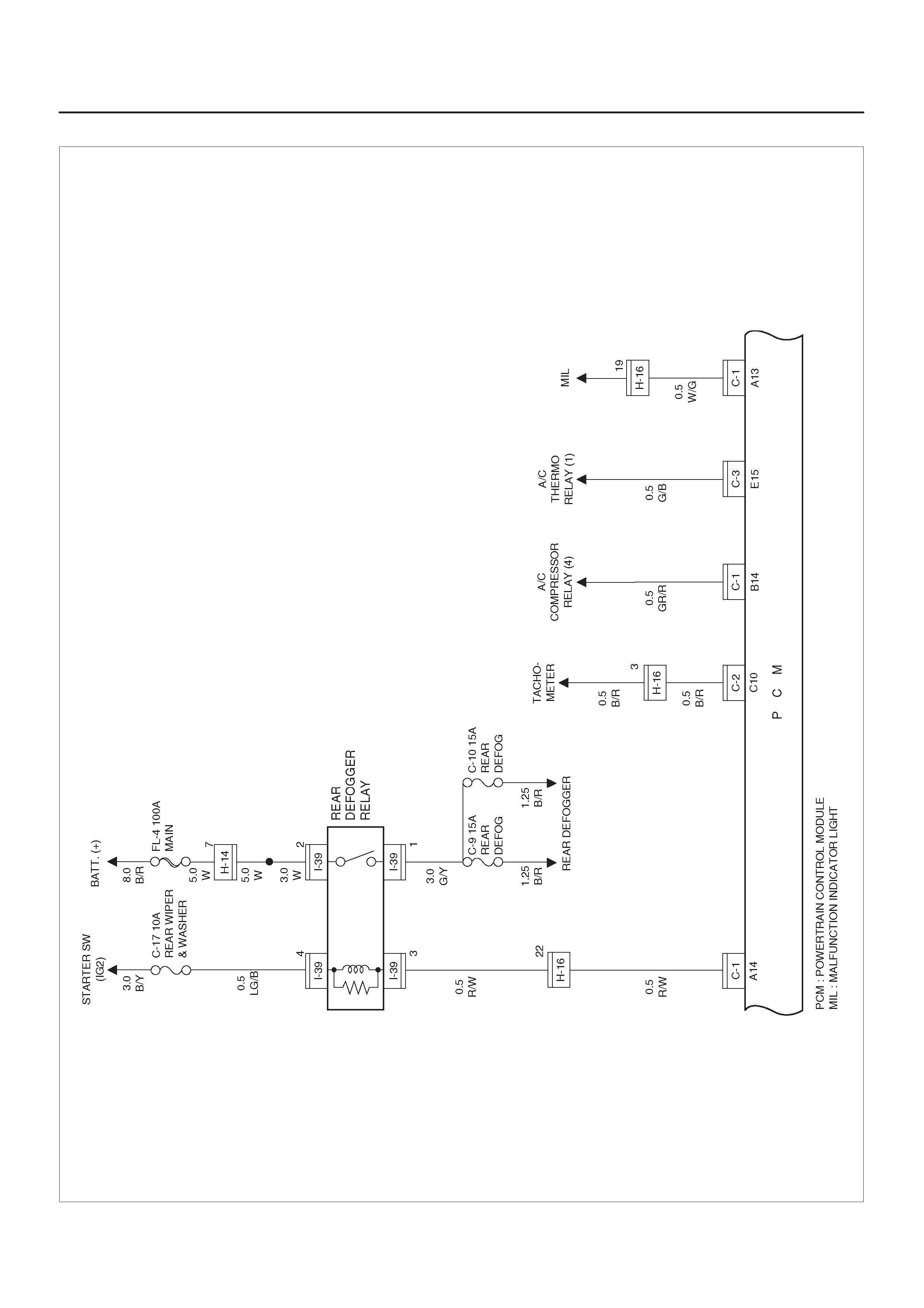

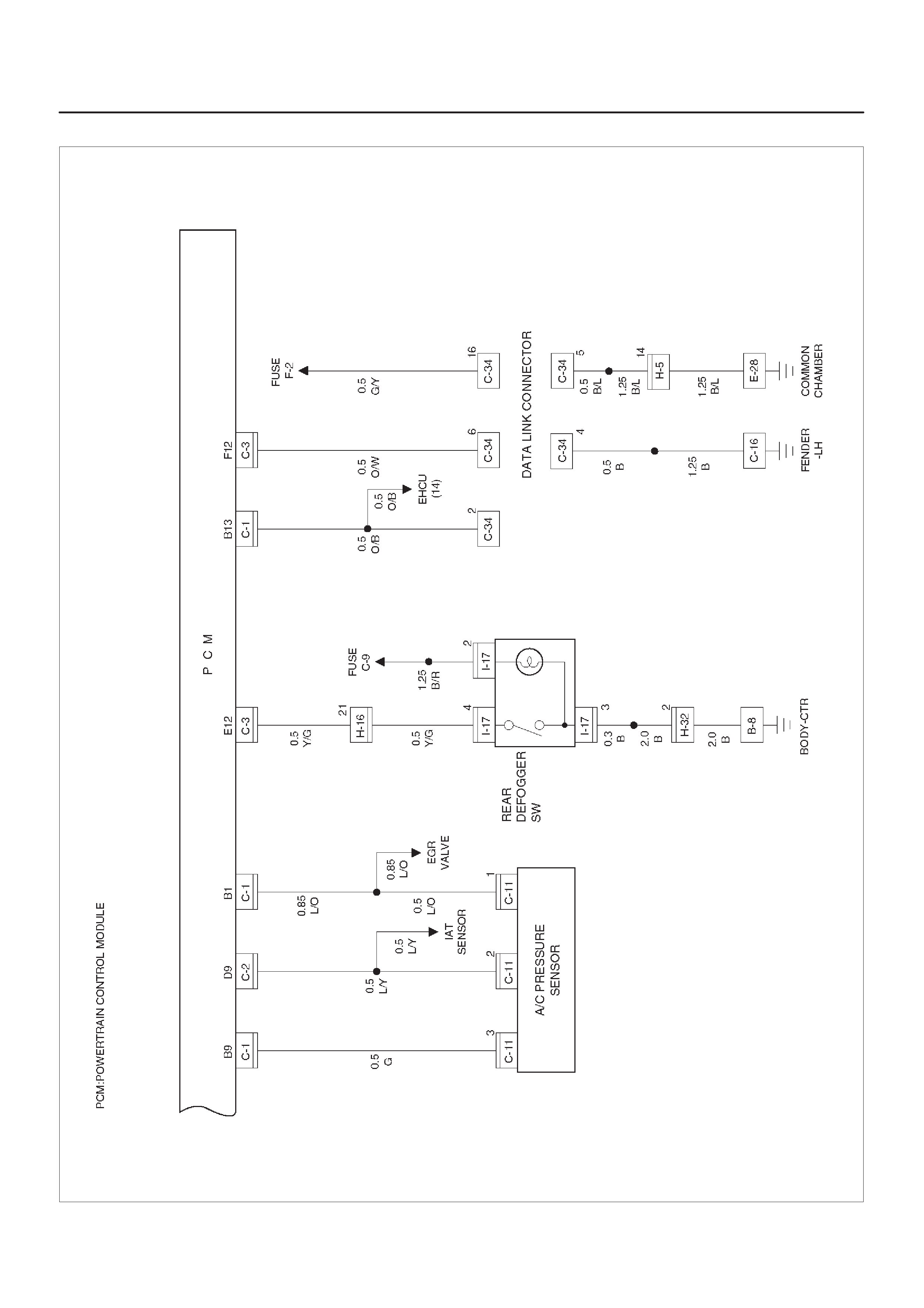

Circuit Diagram–1 (X22SE)

D08RX177

Circuit Diagram–2 (X22SE)

D08RX178

Circuit Diagram–3 (X22SE)

D08RX179

Circuit Diagram–4 (X22SE)

D08RX180

Circuit Diagram–5 (X22SE)

D08RX181

Circuit Diagram–6 (X22SE)

D08RX182

Circuit Diagram–7 (X22SE)

D08RX183

Circuit Diagram–8 (X22SE)

D08RY00929

Circuit Diagram–9 (X22SE)

D08RX185

Circuit Diagram–10 (X22SE)

D08RX186

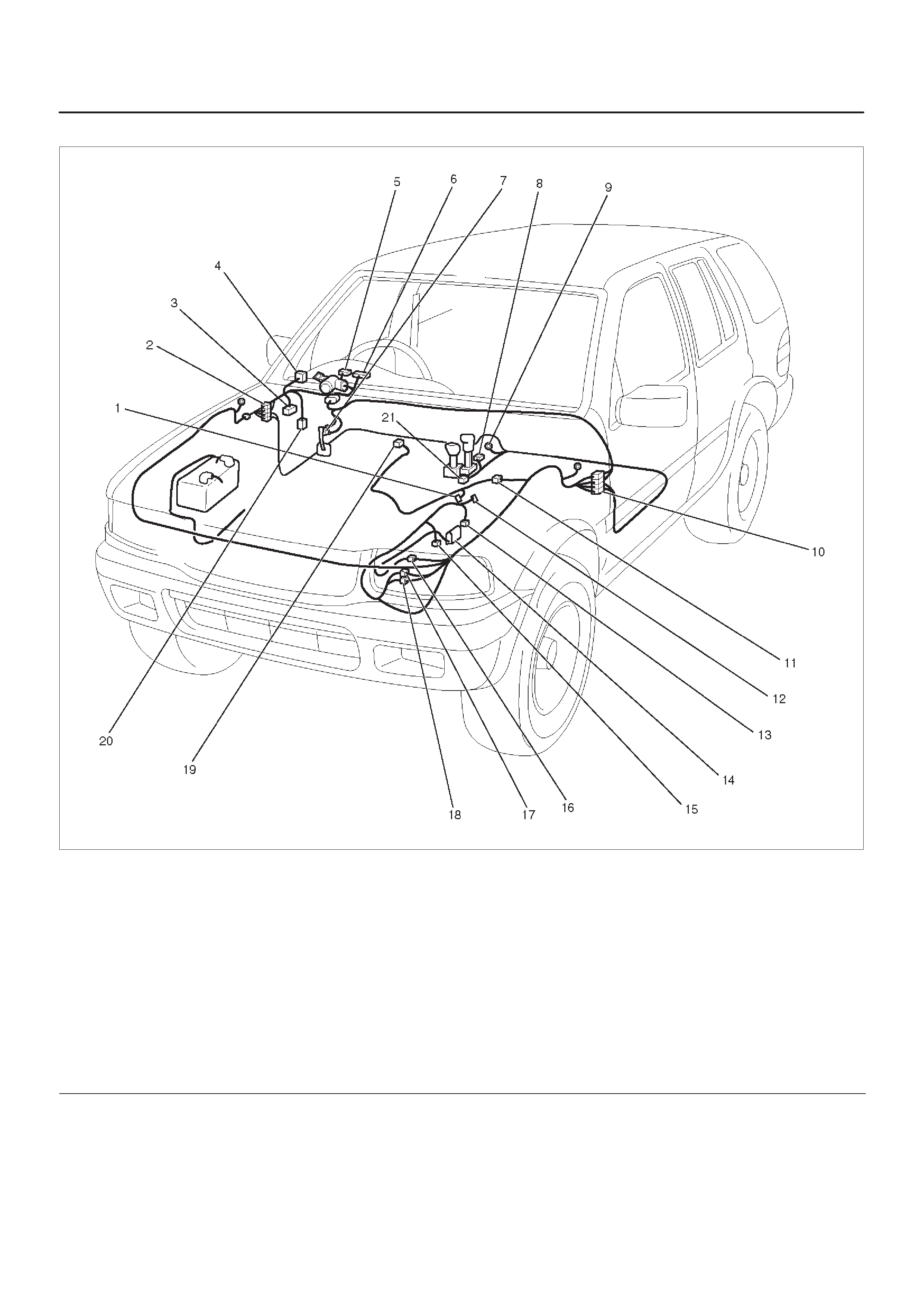

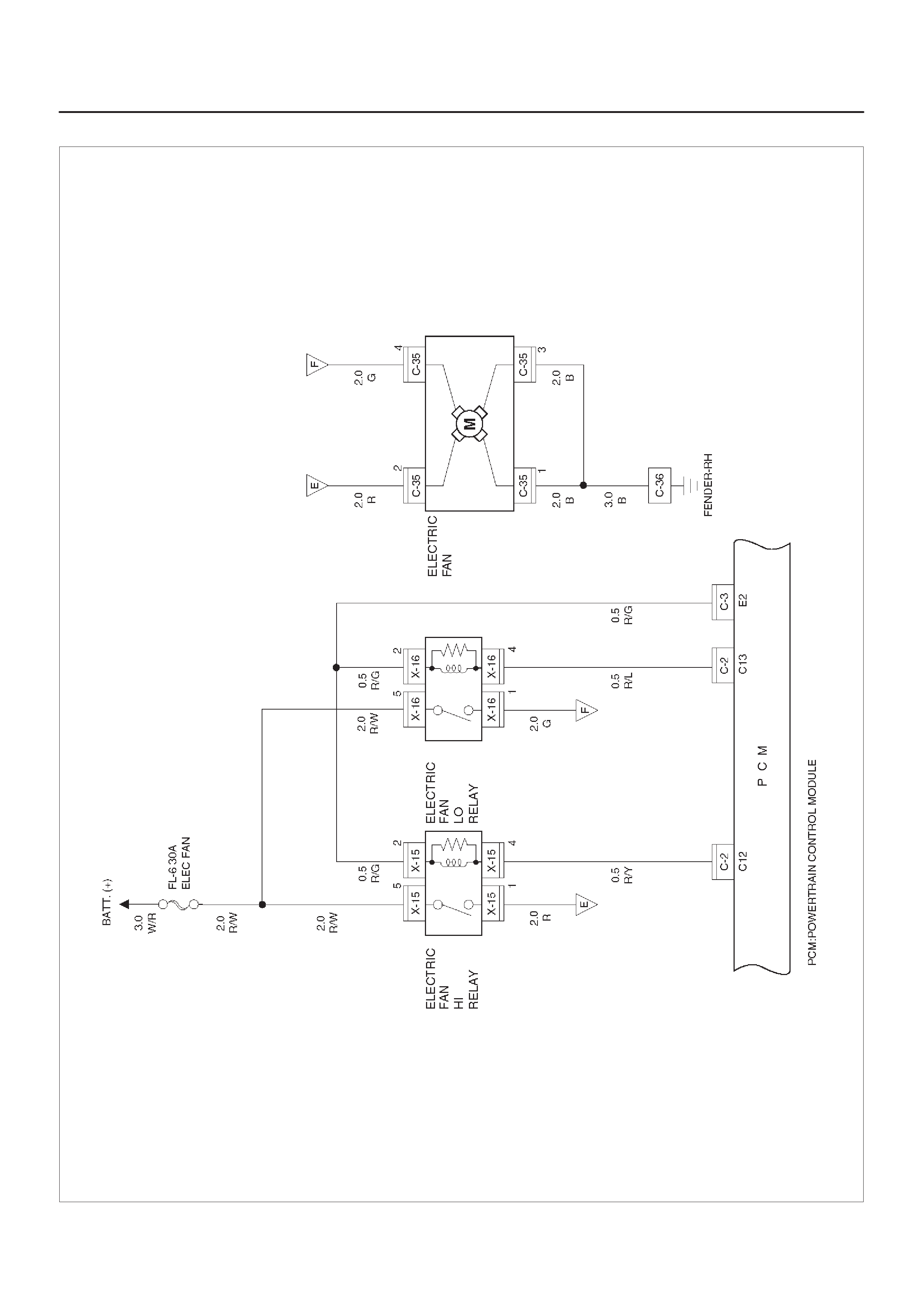

Parts Location

D08RX187

Legend

(1) X–7, X–8

(2) X–15, X–16

(3) C–36

(4) H–32

(5) I–41, I–42

(6) Relay & Fuse Box

(7) C–1, C–2, C–3 (PCM)

(8) C–37

(9) H–16

(10) F–3

(11) F–1

(12) E–1

(13) E–14

(14) E–27

(15) E–7

(16) E–28, E–30

(17) E–37

(18) E–8

(19) E–5

(20) E–6

(21) E–12

(22) E–33

(23) E–25

(24) E–11

(25) E–26

(26) E–32

(27) E–43

(28) E–9

(29) E–4

(30) E–3

(31) H–6

(32) H–5

(33) H–4

(34) H–25

(35) C–16

(36) B–8

(37) H–9

(38) M–13

(39) C–11 (40) M–10

(41) C–35

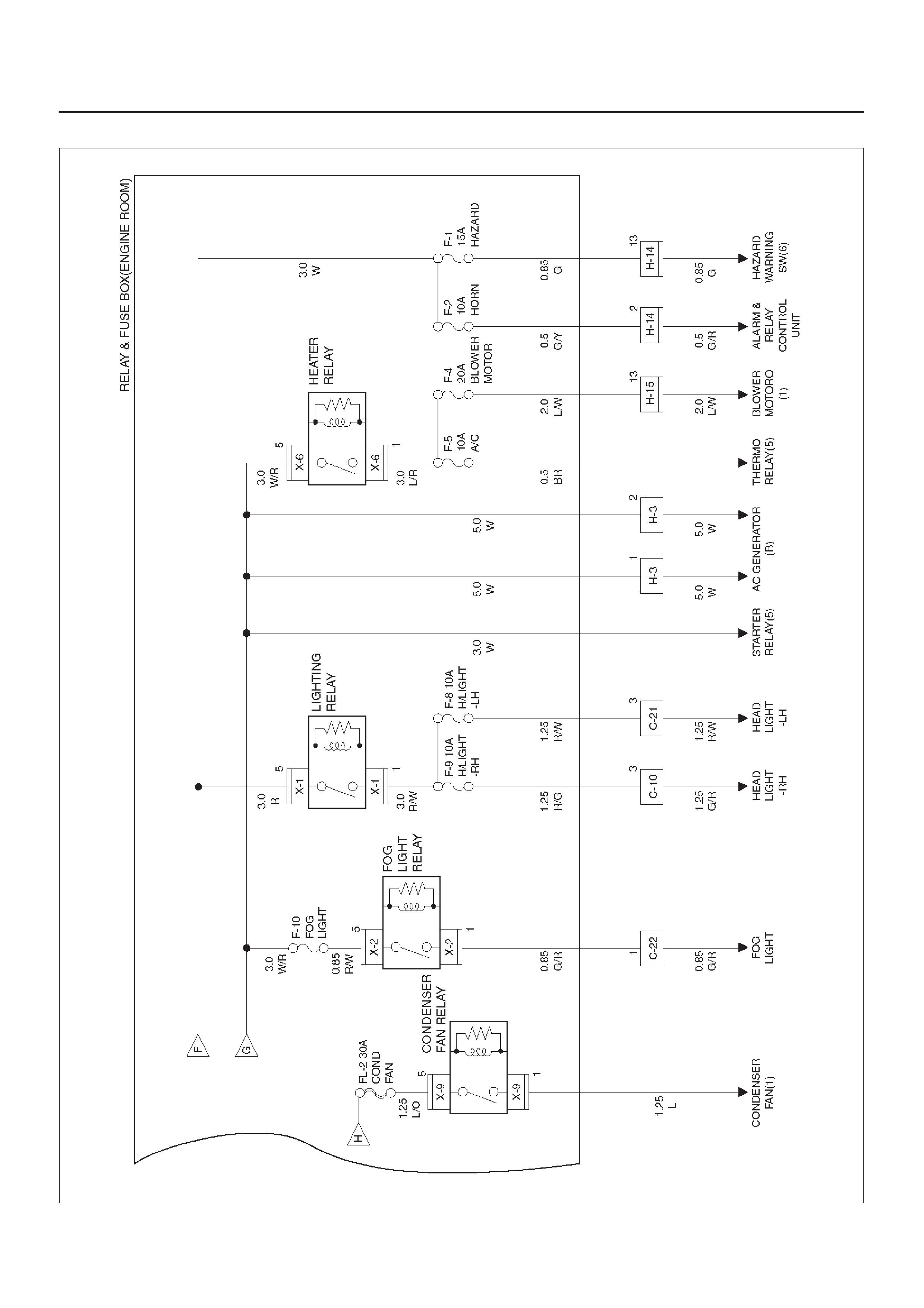

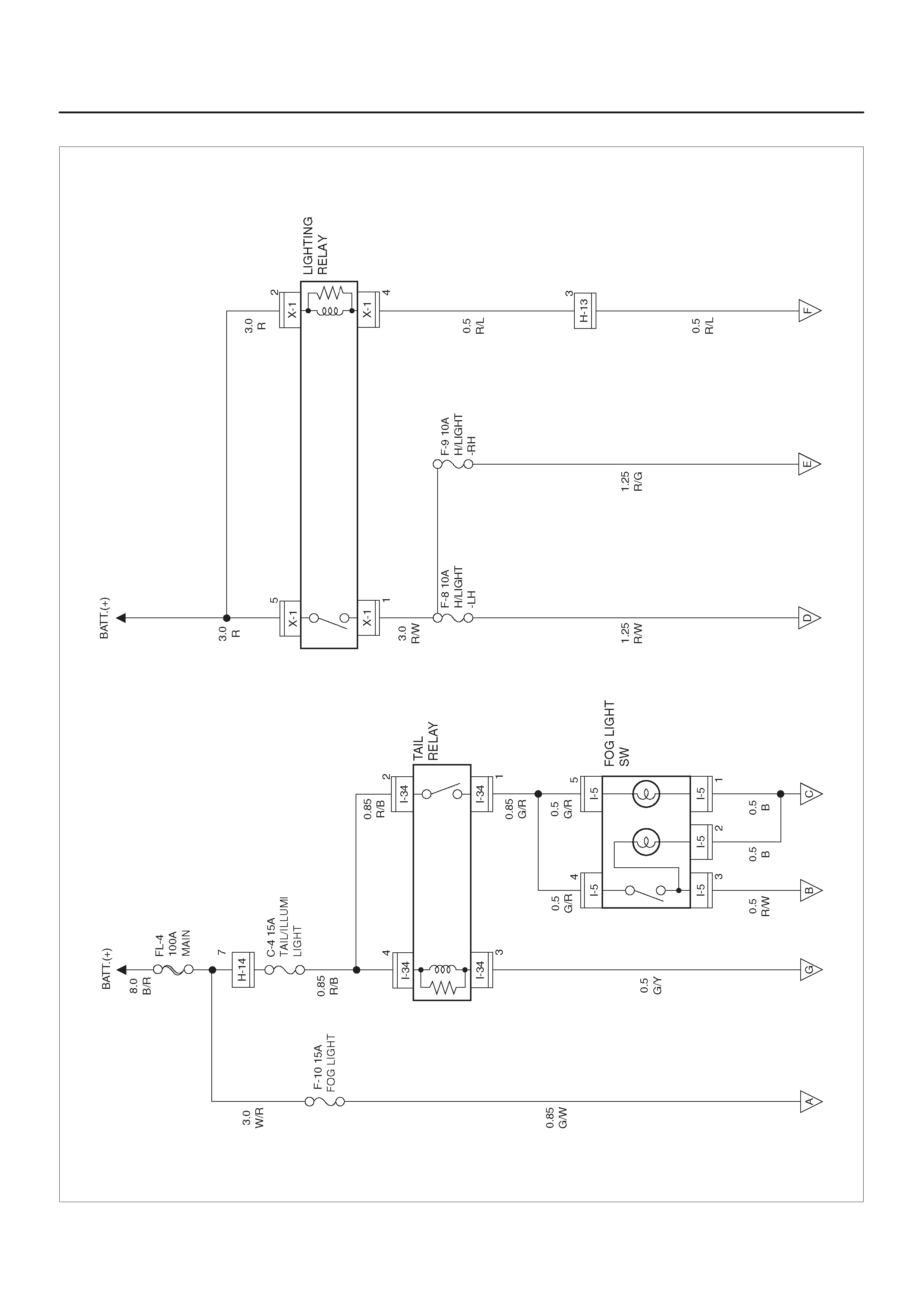

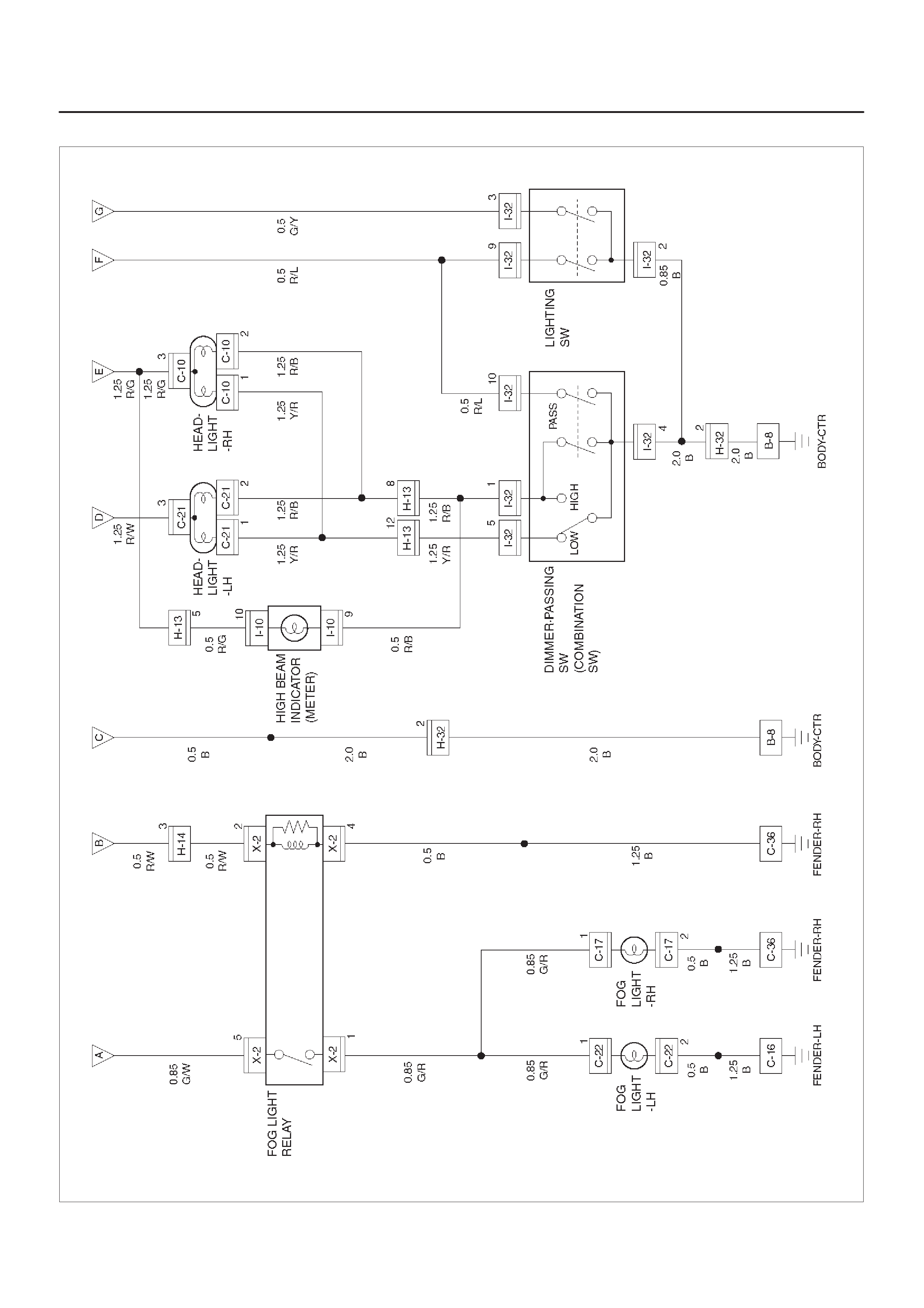

Headlight and Fog Light

General Description

The circuit consists of headlight, fog light, lighting switch,

dimmer·passing switch, fog light switch, high beam

indicator, lighting relay and fog light relay. When starter

switch is turned on by setting it at headlight position,

lighting relay is activated to turn on headlight. Optical axis

of headlight can be turned up or down by operating

dimmer switch while headlight is on. Passing switch is

independent of lighting switch, and optical axis of passing

light can be turned up only while switch lever is pulled up

and held in this state.

When fog light switch is turned on while headlight on at

low–beam, fog light relay is activated to turn on fog light.

Circuit Diagram–1

D08RY00930

Circuit Diagram–2

D08RX191

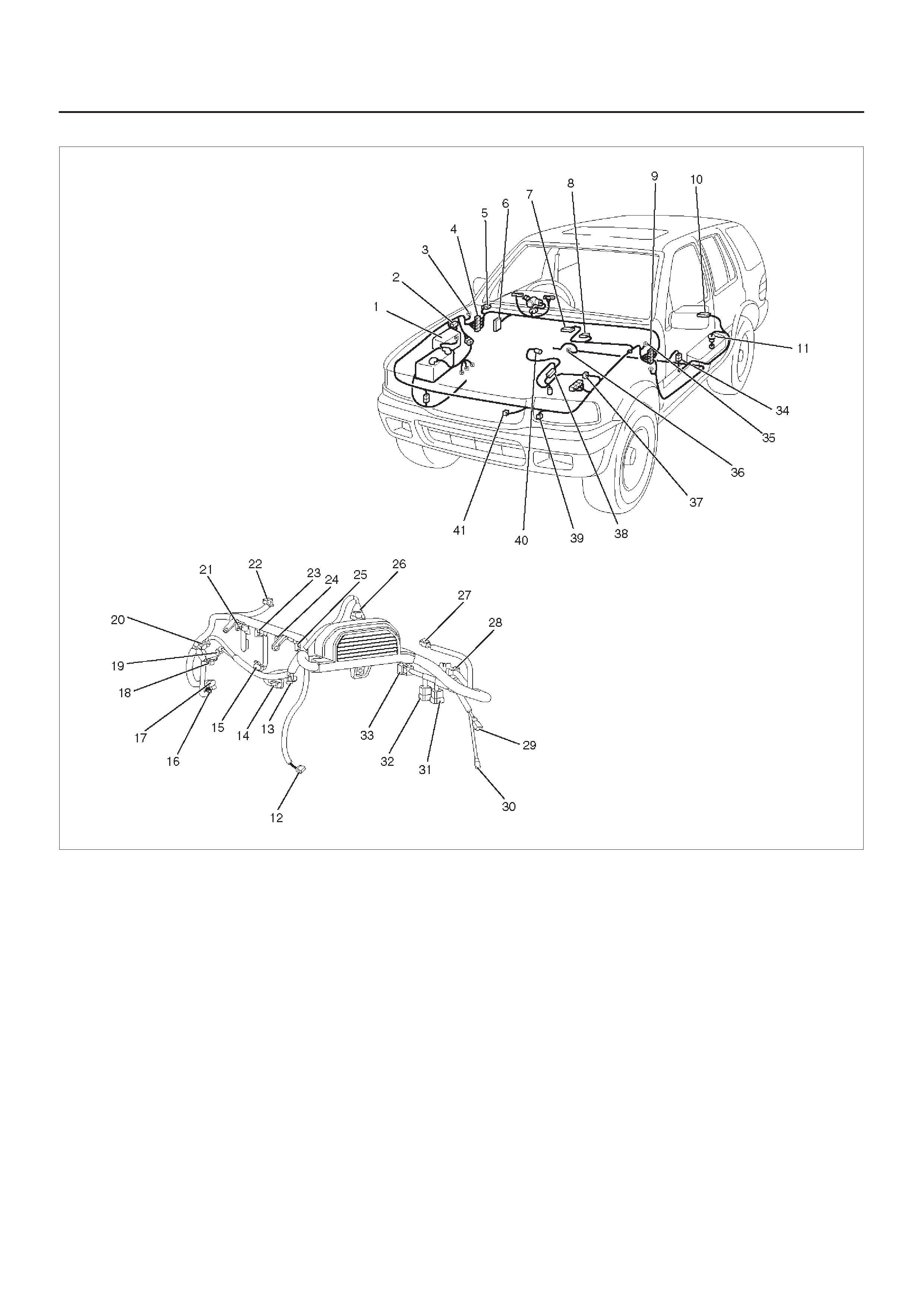

Parts Location

D08RWD00–1

Legend

(1) X–1, X–2

(2) C–36

(3) H–13, H–14, H–32

(4) Relay & Fuse Box

(5) I–5

(6) I–10

(7) Lighting Switch

(8) I–32 (Combination Switch)

(9) B–8

(10) C–16

(11) C–22

(12) Fog Light – LH

(13) C–21

(14) Head Light – LH

(15) C–10

(16) C–17

(17) Fog Light – RH

(18) Head Light – RH

Diagnosis

Both Headlights Inoperative

Step Action Value(s) Yes No

1Check the ground terminal B–8.

Is B–8 grounded securely? —Go to Step 2 Ground it

securely

2Disconnect the combination switch connector I–32.

Is there continuity between switch side connector I–32

terminals 9 and 2 with the switch turned to headlight

position? —Go to Step 2 Replace the

switch

3Check continuity of dimmer-passing switch.

Is there continuity between switch side connector I–32

terminal 5 and 4 with the switch turned to low position,

and terminal 1 and 4 with the switch turned to high

position? —Go to Step 3 Replace the

switch

4Check continuity between the lighting switch and the

ground B–8.

Is there continuity between harness side connector

I–32 terminal 2 and the ground? —Go to Step 5 Repair an

open circuit

5Remove the lighting relay from the relay and fuse box.

Is the battery voltage applied between harness side

connector X–1 terminal 5 and the ground, X–1 terminal

2 and the ground? Approx. 12V Go to Step 6

Repair an

open circuit

between

battery and

the lighting

relay

6Check continuity between the lighting relay and the

lighting switch.

Is there continuity between harness side connector

X–1 terminal 4 and I–32 terminal 9? —Go to Step 7 Go to Step 6

7Check continuity between the lighting relay and fuse

F–8 or F–9.

Is there continuity between harness side connector

X–1 terminal 3 and fuse F–8 or F–9? —Go to Step 8 Repair an

open circuit

8Check continuity between the dimmer-passing switch

and the ground.

Is there continuity between switch side connector I–32

terminal 4 and the ground B–8? —Repair an

open circuit —

Headlight On The Left (or Right) Side Inoperative

Step Action Value(s) Yes No

1 Is the fuse F–8 or F–9 normal? —Go to Step 2 Replace the

fuse

2Remove the headlight bulb on the left or right side.

Is the bulb normal? —Go to Step 3 Replace the

bulb

31. Reinstall the bulb.

2. Turn the lighting switch to headlight position.

Is the battery voltage applied between harness side

connector C–21 terminal 3 and the ground or C–10

terminal 3 and the ground? Approx. 12V

Reconnect

the headlight

connector

securely

Repair an

open circuit

between the

fuse and

headlight

Headlights In Low–Beam Inoperative

Step Action Value(s) Yes No

1Disconnect the combination switch connector I–32.

Is there continuity between switch side connector I–32

terminal 5 and 4 with the switch at low-beam position? —Go to Step 2

Repair or

replace the

switch

2Repair an open circuit between connector H-13

terminal 15 and connector I-32 terminal 5.

Is the action complete? — Verify repair —

Headlight In High–Beam Inoperative

Step Action Value(s) Yes No

1Disconnect the combination switch connector I–32.

Is there continuity between switch side connector I–32

terminal 1 and 4 with the switch at high-beam position? —Go to Step 2

Repair or

replace the

switch

2Repair an open circuit between connector H–13

terminal 14 and connector I–32 terminal 1.

Is the action complete? — Verify repair —

Headlights Remain On When Lighting Switch Turned Off

Step Action Value(s) Yes No

11. Turn the lighting switch to off position.

2. Disconnect the combination switch connector I–32.

Do the headlights still remain on? —Go to Step 3 Go to Step 2

2Repair or replace the lighting switch.

NOTE: There should be no continuity between switch

side connector I–32 terminal 9 and 2.

Is the action complete? —Go to Step 1 —

3Remove the lighting relay.

Is there continuity between the relay side connector

X–1 terminal 1 and 5? —Replace the

relay Go to Step 4

4Repair short circuit between the lighting relay and the

lighting switch.

Is the action complete? — Verity repair —

Headlight Comes On With Lighting Switch At Parking Light Position

Step Action Value(s) Yes No

1Repair or replace the lighting switch.

NOTE: There should be no continuity between switch

side connector I–32 terminal 9 and 2 when the switch is

turned to parking light position.

Is the action complete? — Verify repair —

(While Headlight Is On In Low–Beam) Both Fog Lights Inoperative

Step Action Value(s) Yes No

1Are the fuse F–10 and C–4 normal? —Go to Step 2 Replace the

fuse(s)

2Is C–36 grounded securely? —Go to Step 3 Ground it

securely

3Remove the foglight relay.

Is the battery voltage applied between harness side

connector X–2 terminal 5 and the ground? Approx. 12V Go to Step 5 Go to Step 4

4Repair an open circuit between Fuse F–10 connector

X–2 terminal 5.

Is there action complete? —Go to Step 3 —

5Is there continuity between harness side connector

X–2 terminal 4 and the ground? —Go to Step 7 Go to Step 6

6Repair an open circuit between connector X–2 terminal

4 and the ground C–36.

Is the action complete? —Go to Step 5 —

71. Turn the lighting switch to clearance light position.

2. Turn the fog light switch on.

Is the battery voltage applied between harness side

connector X–2 terminal 2 and the ground? Approx. 12V Replace the

fog light relay Go to Step 8

8Disconnect the lighting switch connector I–32.

Is there continuity between the switch side connector

terminal 2 and 3? —Go to Step 9

Repair or

replace the

switch.

9Disconnect the tail relay.

Is there continuity between harness side connector

I–32 terminal 3 and I–32 terminal 3? —Go to Step 10 Repair an

open circuit

10 Is the battery voltage applied between harness side

connector I–34 terminal 2, 4 and the ground? Approx. 12V Go to Step 12 Go to Step 11

11 Repair an open circuit between the fuse C–4 and

connector I–34 terminal 2 or 4.

Is the action complete? —Go to Step 10 —

12 1. Disconnect the fog light switch.

2. Turn the switch on.

Is there continuity between the switch terminal 3 and 4? —Go to Step 13

Repair or

replace the

switch

13 Is there continuity between harness side connector I–5

terminal 4 and connector I–34 terminal 1? —Go to Step 14 Repair an

open circuit

14 Is there continuity between harness side connector I–5

terminal 3 and connector X–2 terminal 2? —Replace the

tail relay Repair an

open circuit

(While Headlight Is On In Low–Beam) Fog Light On the Left (or Right) Side Inoperative

Step Action Value(s) Yes No

1Is the fog light bulb on the left or right side normal? —Go to Step 2 Replace the

bulb

2Is C–16 or C–36 grounder securely? —Go to Step 3 Ground it

Securely

3Disconnect the fog light connector C–22 or C–17.

Is there continuity between the fog light harness side

connector terminal 2 and the ground? —Go to Step 4 Repair an

open circuit

4Repair an open circuit between fog light relay

connector X–2 terminal 1 and fog light connector

terminal 1.

Is the action complete? — Verify repair —

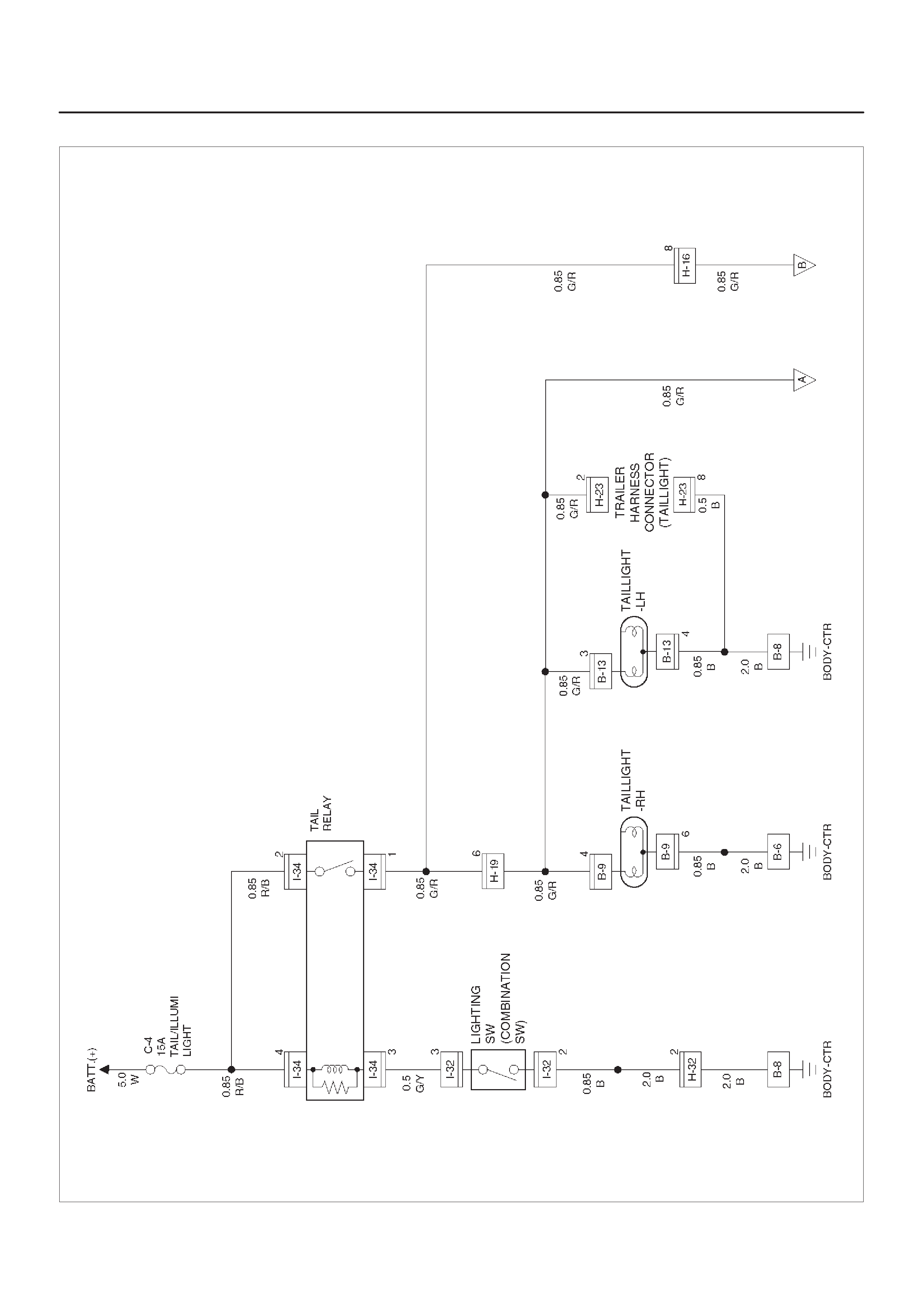

Clearance Light, Tail Light and License Plate Light

General Description

The circuit consists of lighting switch, clearance light, tail

light and license plate light.

All these lights come on when lighting switch is turned on

with the switch to either parking or headlight position.

Circuit Diagram–1

D08RX193

Circuit Diagram–2

D08RX194

Parts Location

D08RWD04

Legend

(1) C–36

(2) H–19, H–32

(3) Lighting Switch

(4) I–32

(5) B–9

(6) Tail Light – RH

(7) G–8

(8) License Plate Light (Bumper Type)

(9) G–3 (Tailgate Type)

(10) G–2 (Tailgate Type)

(11) H–22

(12) Tail Light – LH

(13) B–13

(14) H–27

(15) H–25

(16) H–16

(17) C–16

(18) C– 49

(19) Clearance Light – LH

(20) C–20

(21) Clearance Light – RH

(22) B–6, B–8

Diagnosis

Both Tail Lights Inoperative

Step Action Value(s) Yes No

1Repair an open circuit between the tail relay and the

taillights.

Is the action complete? — Verify repair —

Tail Light On The Left (or Right) Side Inoperative

Step Action Value(s) Yes No

1Remove the taillight bulb on the left or right side.

Is the bulb normal? —Go to Step 2 Replace the

bulb

2Disconnect the taillight connector B–9 or B–13.

Is the battery voltage applied between harness side

connector B–9 or B–13 terminal 4 or 3 and the ground? Approx. 12V Go to Step 4 Go to Step 3

3Repair an open circuit between the tail relay and the

taillight on the left or right side.

Is the action complete? — Verify repair —

4Repair an open circuit between the taillight on the left or

right side and the ground.

Is the action complete? — Verify repair —

Clearance Light Inoperative

Step Action Value(s) Yes No

1Repair an open circuit between the tail relay and the

taillights.

Is the action complete? — Verify repair —

Clearance Light On The Left (or Right) Side Inoperative

Step Action Value(s) Yes No

1Remove the clearance light bulb on the left or right side.

Is the bulb normal? —Go to Step 2 Replace the

bulb

2Disconnect the clearance light connector C–49 or

C–50.

Is the battery voltage applied between harness side

connector C–49, or C–50 terminal 4 and the ground? Approx. 12V Go to Step 4 Go to Step 3

3Repair an open circuit between the tail relay and the

clearance light on the left or right side.

Is the action complete? — Verify repair —

4Repair an open circuit between the clearance light and

the ground?

Is the action complete? — Verify repair —

License Plate Light Inoperative

Step Action Value(s) Yes No

1Do the taillights come on? —Go to Step 2 Go to Step 6

2Remove the license plate light bulb.

Is the bulb normal? —Go to Step 3 Replace bulb

31. Disconnect the license plate light connector G–8.

2. Turn the lighting switch on.

Is the battery voltage applied between harness side

connector G–8 terminal 1 and the ground? Approx. 12V Go to Step 5 Go to Step 4

4Repair an open circuit between connector H–19

terminal 6 and the license plate light.

Is the action complete? — Verify repair —

5Repair an open circuit between the license plate light

and the ground B–8.

Is the action complete? — Verify repair —

6Refer to the diagnosis procedure for “Both Taillight

Inoperative” in this section.

Is the action complete? — Verify repair —

Interior Illumination Light

General Description

The circuit consists of lighting switch, tail relay, and

illumination lights.

All these lights come on when lighting switch is turned on

with the switch to either parking or headlight position.

Circuit Diagram–1

D08RX195

Circuit Diagram–2

D08RX196

Circuit Diagram–3

D08RX197

Parts Location

D08RX198

Legend

(1) H–19, H–32

(2) I–19

(3) I–6

(4) I–5

(5) Lighting Switch

(6) I–2

(7) I–9

(8) I–27

(9) I–16

(10) I–17

(11) I–11

(12) I–33

(13) B–24

(14) H–25

(15) B–8

(16) I–15

(17) I–40

(18) I–3

(19) I–32

(20) I–1

(21) Relay & Fuse Box (I–34)

Diagnosis

Interior Illumination Lights Inoperative

Step Action Value(s) Yes No

1Turn the light switch to clearance light position.

Do the exterior light come on? —Go to Step 3 Go to Step 2

2Refer to the diagnosis procedure in Clearance Light,

Taillight and License Plate Light section.

Is the action complete? — Verify repair —

3Repair an open circuit between tail relay harness side

connector I–34 terminal 1 and interior lights.

Is the action complete? — Verify repair —

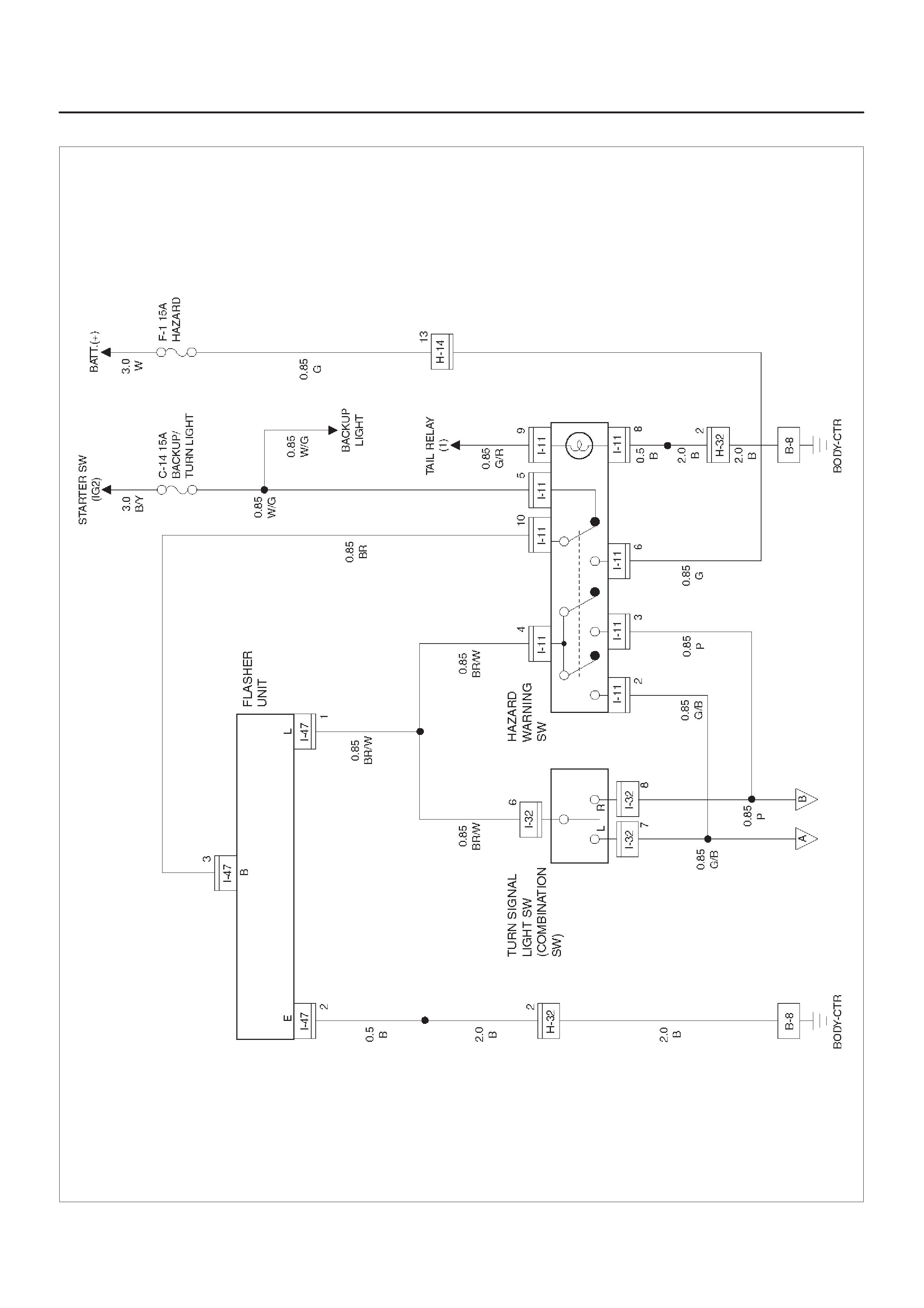

Turn Signal Light, Hazard Warning Light

General Description

The circuit consists of turn signal/light switch

(combination switch) turn signal light, hazard warning

switch and flasher unit. When turn signal light switch is

turned on with starter switch on, turn signal light will

operate. When turn signal light is flashing, indicator light

in meter also starts flashing. When hazard warning switch

is turned on, current flows to flasher unit through hazard

warning switch to cause hazard warning light to flash

independent of position of starter switch. At the same

time, indicator lights in meter also start flashing.

Circuit Diagram–1

D08RX199

Circuit Diagram–2

D08RX200

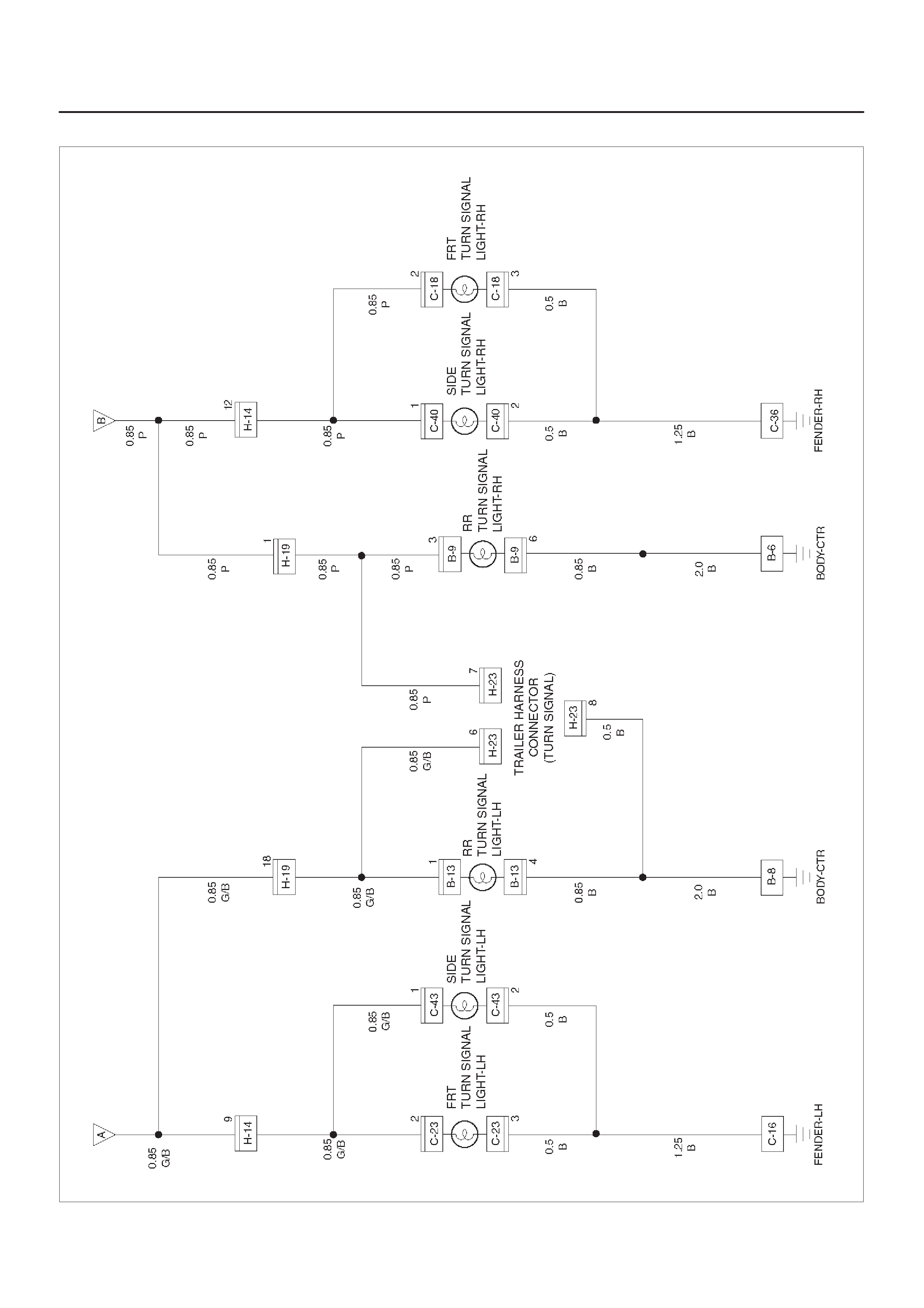

Parts Location

D08RX201

Legend

(1) C–40

(2) C–36

(3) H–14, H–19, H–32

(4) Relay & Fuse Box

(5) Turn Signal light Switch

(6) I–32, I–47

(7) H– 23 (2Door Model)

(8) B–9

(9) Rear Turn Signallight – RH

(10) I–11

(11) C–16

(12) Rear Turn Signallight – LH

(13) B–13

(14) H–23 (4Door Model)

(15) C– 43

(16) C–23

(17) Front Turn Signallight – LH

(18) B– 8

(19) C–18

(20) Front Turn Signallight – RH

Diagnosis

Turn Signal Light Does Not Flash

Step Action Value(s) Yes No

1Is fuse C–14 normal? —Go to Step 2 Replace the

fuse

21. Turn the hazard warning switch off.

2. Disconnect the switch connector I–11.

Is there continuity between switch side connector I–11

terminal 5 and 10? —Go to Step 3

Replace or

replace the

switch

3Turn the starter switch on.

Is the battery voltage applied between harness side

connector I–11 terminal 5 and the ground? Approx. 12V Go to Step 5 Go to Step 4

4Repair an open circuit between the fuse C–14 and the

hazard warning switch.

Is the action complete? —Go to Step 3 —

51. Reconnect the connector I–11 with the hazard

warning switch.

2. Disconnect the flasher unit connector I–47.

Is the battery voltage applied between harness side

connector I-47 terminal 3 and the ground? Approx. 12V Go to Step 7 Go to Step 6

6Repair an open circuit between connector I–11 terminal

10 and connector I–47 terminal 3.

Is the action complete? —Go to Step 5 —

7Is there continuity between harness side connector

I-47 terminal 2 and the ground B–8? —Go to Step 9 Go to Step 8

8Repair an open circuit between connector I–47

terminal 2 and the ground B–8.

Is the action complete? —Go to Step 7 —

91. Reconnect the flasher unit connector I–47.

2. Disconnect the turn signal light switch connector

I–32.

Is there continuity between switch side connector

terminal 6 and 7 with the switch turned to the left

position, and terminal 6 and 8 with the switch turned to

the right position? —Go to Step 10

Repair or

replace the

switch

10 Is there continuity between harness side connector

I–47 terminal 1 and harness side connector I–32

terminal 6? —Go to Step 12 Go to Step 11

11 Repair an open circuit between connector I–47

terminal 1 and connector I–32 terminal 6.

Is the action complete? — Verify repair —

12 Replace the flasher unit.

Is the action complete? — Verify repair —

Turn Signal Light Flashes Too Quickly

Step Action Value(s) Yes No

1Do all of turn signal lights flash? —Go to Step 2 Go to Step 3

2Replace the flasher unit.

Is the action complete? — Verify repair —

3Is the bulb of turn signal light that does not work

normal? —Go to Step 4 Replace the

bulb

4Repair an open circuit between the turn signal light

switch and the turn signal light.

Is the action complete? — Verify repair —

Stoplight

General Description

The circuit consists of stoplight, high mounted stoplight

and stoplight switch.

With brake pedal depressed, stoplight switch is turned to

on to illuminate stoplight.

Stoplight switch controls not only the operation of

stoplight but also the input of cruise cancel signals to

cruise control unit.

Circuit Diagram

D08RX202

Parts Location (2Door Model)

D08RX203

Legend

(1) H–19

(2) Relay & Fuse Box

(3) I–18

(4) B–9

(5) Stoplight – RH

(6) G–4

(7) High Mounted Stoplight

(8) H–37

(9) Stoplight – LH

(10) B–13

(11) B–8

(12) B–6

Parts Location (4Door Model)

D08RX203

Legend

(1) H–19

(2) Relay & Fuse Box

(3) I–18

(4) B–9

(5) Stoplight – RH

(6) H–21

(7) G–10, G–11

(8) High Mounted Stoplight

(9) Stoplight – LH

(10) B–13

(11) B–8

(12) B–6

Diagnosis

Both Stoplights Inoperative

Step Action Value(s) Yes No

1Is the fuse C–6 normal? —Go to Step 2 Replace the

fuse

2Dieconnect the stoplight switch connector I–18.

Is there continuity between connector I–18 terminal 1

and 4 with the brake pedal depressed? —Go to Step 3

Replace or

replace the

switch

3Is the battery voltage applied between harness side

connector I–18 terminal 1 and the ground? Approx. 12V Go to Step 5 Go to Step 4

4Repair an open circuit between the fuse C–6 and

connector I–18 terminal 1.

Is the action complete? — Verify repair —

5Repair an open circuit between stoplight switch and the

stoplight.

Is the action complete? — Verify repair —

Stoplight On The Left (or Right) Side Inoperative

Step Action Value(s) Yes No

11. Disconnect the stoplight connector B–9 or B–13.

2. Depress the brake pedal.

Is the battery voltage applied between stoplight

harness side connector terminal 2 and the ground? Approc. 12V Go to Step 2 Go to Step 3

2Repair an open circuit between the stoplight and the

ground.

Is the action complete? — Verify repair —

3Repair an open circuit between the stoplight switch and

the stoplight.

Is the action complete? — Verify repair —

High Mounted Stoplight Inoperative

Step Action Value(s) Yes No

1Depress the brake pedal.

Do the stoplight come on? —Go to Step 3 Go to Step 2

2Refer to the diagnosis procedure for “Both Stoplights

inoperative” in this section.

Is the action complete? — Verify repair —

3Is B–6 grounded securely? —Go to Step 4 Ground it

securely

41. Disconnect the high mounted stoplight connector.

2. Depress the brake pedal.

Is the battery voltage applied between harness side

connector G–1 1 terminal 1 or connector G–4 terminal 2

and the ground? Appprox. 12V Go to Step 6 Go to Step 5

5Repair an open circuit between connector H–19

terminal 10 and the high mounted stoplight.

Is the action complete? —Go to Step 4 —

6Is there continuity between high mounted stoplight side

connector terminals? —Go to Step 7

Repair or

replace the

light

7Repair an open circuit between the high mounted

stoplight and the ground B–6.

Is the action complete? — Verify repair —

Backup Light

General Description

The circuit consists of backup light switch (M/T), mode

switch (A/T) and backup light.

When shift lever is set to “R” position, backup light switch

(M/T) or mode switch (A/T) is activated to illuminate

backup light.

Circuit Diagram

D08RX204

Parts Location

D08RWD19

Legend

(1) B–9

(2) Backup Light – RH

(3) Backup Light – LH

(4) B–13

(5) H–15, H–16

(6) B–8

(7) B–6

(8) H–9, H–10, (6VD1 M/T)

(9) M–8, M–9 (X22SE)

(10) H–10, (6VD1 A/T)

(11) M–16

(12) Relay & Fuse Box

Diagnosis

Both Backup Lights Inoperative

Step Action Value(s) Yes No

1Is the fuse C–14 normal? —Go to Step 2 Replace the

fuse

2Are B–6 and B–8 ground securely? —Go to Step 3 Ground then

securely

31. Disconnect the mode switch connector M–16 or

backup light switch connector M–8 and M–9.

2. Turn the starter switch on.

Is the battery voltage applied between harness side

connector M-16 terminal 5 and the ground, or harness

side connector M–8 terminal 1 and the ground? Approx. 12V Go to Step 5 Go to Step 4

4Repair an open circuit between the fuse C–14 and

connector M–16 terminal 5 or connector M–8 terminal

1.

Is the action complete? —Go to Step 3 —

5Set the transmission gear to the reverse position.

Is there continuity between mode switch side

connector terminal 2 and 5, or backup light switch side

connector terminals? —Go to Step 6

Repair or

replace the

switch

61. Reconnect the mode switch connector M–16 or

backup light switch connector M–8 and M–9.

2. Disconnect the backup light connector B–9 or B–13.

Is the battery voltage applied between the backup light

harness side connector terminal 5 and the ground? Approx. 12V Go to Step 8 Go to Step 7

7Repair an open circuit between the mode switch or

backup light switch and the backup lights.

Is the action complete? — Verify repair —

8Repair an open circuit between backup lights and the

ground.

Is the action complete? — Verify repair —

Backup Light On The Left (or Right) Side Inoperative

Step Action Value(s) Yes No

1Remove the backup light bulb on the left or right side.

Is the bulb normal? —Go to Step 2 Replace the

bulb

21. Set the transmission gear to the reverse position.

2. Turn the starter switch on.

Is the battery voltage applied between backup light

harness side connector B–9 or B–13 terminal 5 and the

ground? Approx. 12V Go to Step 4 Go to Step 3

3Repair an open circuit between connector H–15

terminal 12 and the backup light on the left or right side.

Is the action complete? — Verify repair —

4Repair an open circuit between the backup light on the

left or right side and the ground.

Is the action complete? — Verify repair —

Backup Lights Remain On

Step Action Value(s) Yes No

1Repair or replace the mode switch or the backup light

switch.

Is the action complete? — Verify repair —

Horn

General Description

The circuit consists of horn (high note), horn (low note),

horn relay (alarm & relay control unit) and horn switch.

When horn switch is pushed, (independent of position of

starter switch) horn relay is activated to sound horns.

Circuit Diagram

D08RX205

Parts Location

D08RWD18

Legend

(1) H–14

(2) SRS Coil ASM

(3) Horn Switch

(4) I–41, I–42

(5) I–32

(6) Horn (Low note)

(7) C–14

(8) C–12

(9) Horn (High note)

Diagnosis

Horn Do Not Sound

Step Action Value(s) Yes No

1Is the fuse F–2 normal? —Go to Step 2 Replace the

fuse

2Disconnect the alarm & relay control unit connector

I–41 and I–42.

Is the battery voltage applied between harness side

connector I–41 terminal 2 or 3 (6VD1), connector I–42

terminal 12 (X22SE) and the ground? Approx. 12V Go to Step 4 Go to Step 3

3Repair an open circuit between the fuse F–2 and the

alarm & relay control unit.

Is the action complete? — Verify repair —

4Disconnect the horn switch connector.

Is there continuity between harness side connector

I–32 terminal 12 and connector I–42 terminal 20, 23 or

14? —Go to Step 6 Go to Step 5

5Repair an open circuit between the alarm & relay

control unit and the horn switch.

Is the action complete? — Verify repair —

6Press the horn switch.

Is there continuity between switch side connector I–32

terminal 12 and the ground? —Go to Step 7

Repair or

replace the

switch

71. Disconnect the horn connector.

2. Connect the battery positive terminal to the horn

side connector terminal 1.

Does the horn work? —Go to Step 8 Replace the

horn

8Is there continuity between harness side connector

terminal between the horn and the alarm & relay control

unit? —Go to Step 9 Go to Step 10

9Replace the alarm & relay control unit.

Is the action complete? — Verify repair —

10 Repair an open circuit between the horn and the alarm

& relay control unit.

Is the action complete? — Verify repair —

Horn Do Not Stop Sounding

Step Action Value(s) Yes No

1Disconnect the horn switch connector I–32.

Do the horn stop sounding? —

Repair or

replace the

horn switch Go to Step 2

2Disconnect the alarm & relay control unit connector

I–42.

Is there continuity between harness side connector

terminal 20 (23 or 14) and the ground? —Repair short

circuit

Replace the

alarm & relay

control unit

Dome Light, Luggage Room Light, Courtesy Light, Map Light, Seat

Belt Switch and Warning Buzzer

General Description

The circuit consists of door switch, dome light, luggage

room light, courtesy light, map light tail relay , key cylinder

switch and alarm & relay control unit.

Dome light comes on with dome light switch turned to

door position and any door open.

The buzzer sounds when starter switch is turned to either

“ACC” or “OFF” position and FRT door–RH, is opened

with lighting switch on.

The buzzer also sounds when FRT door–RH is opened

with starter key left in starter switch key cylinder.

These functions are controlled by alarm & relay control

unit.

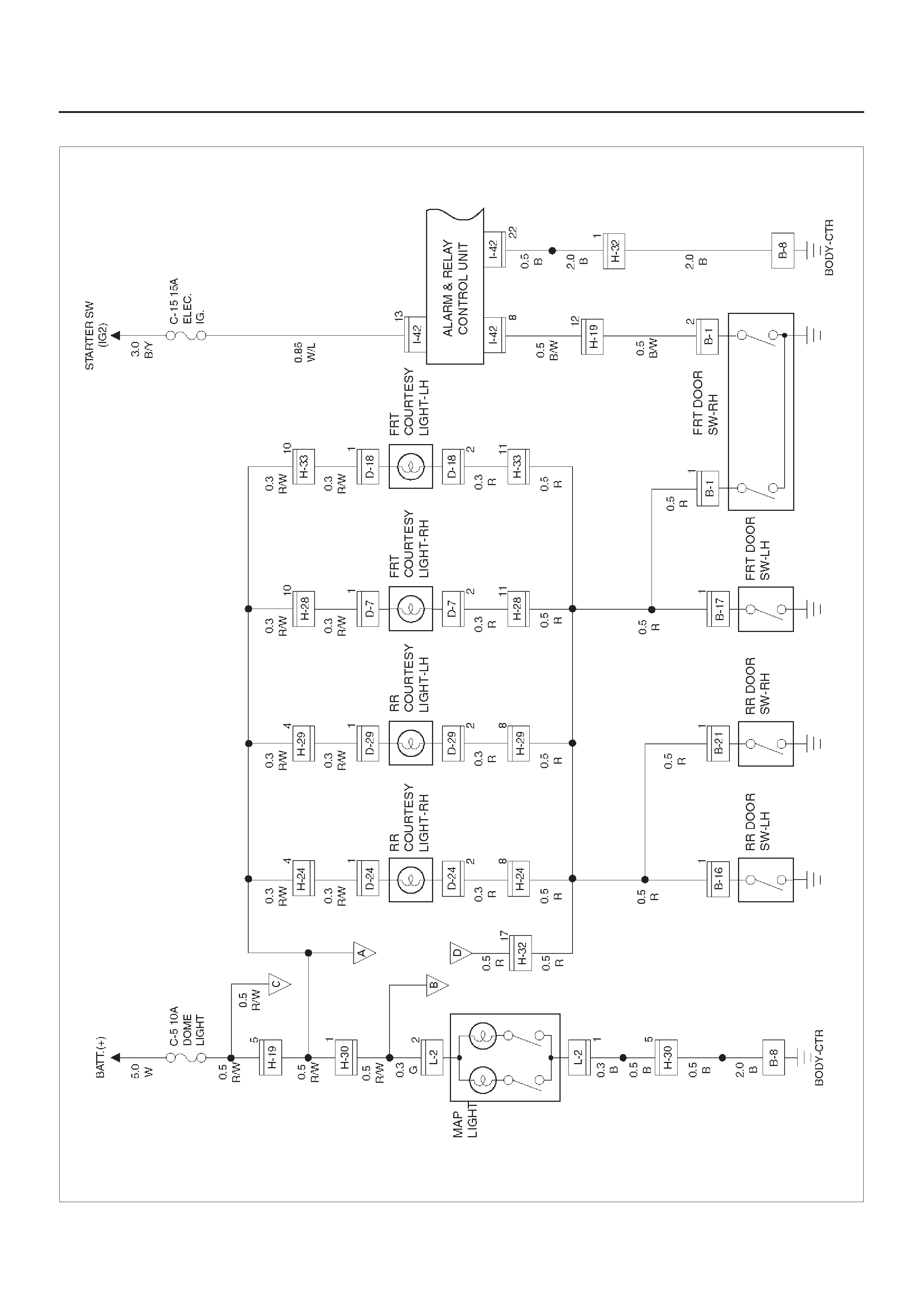

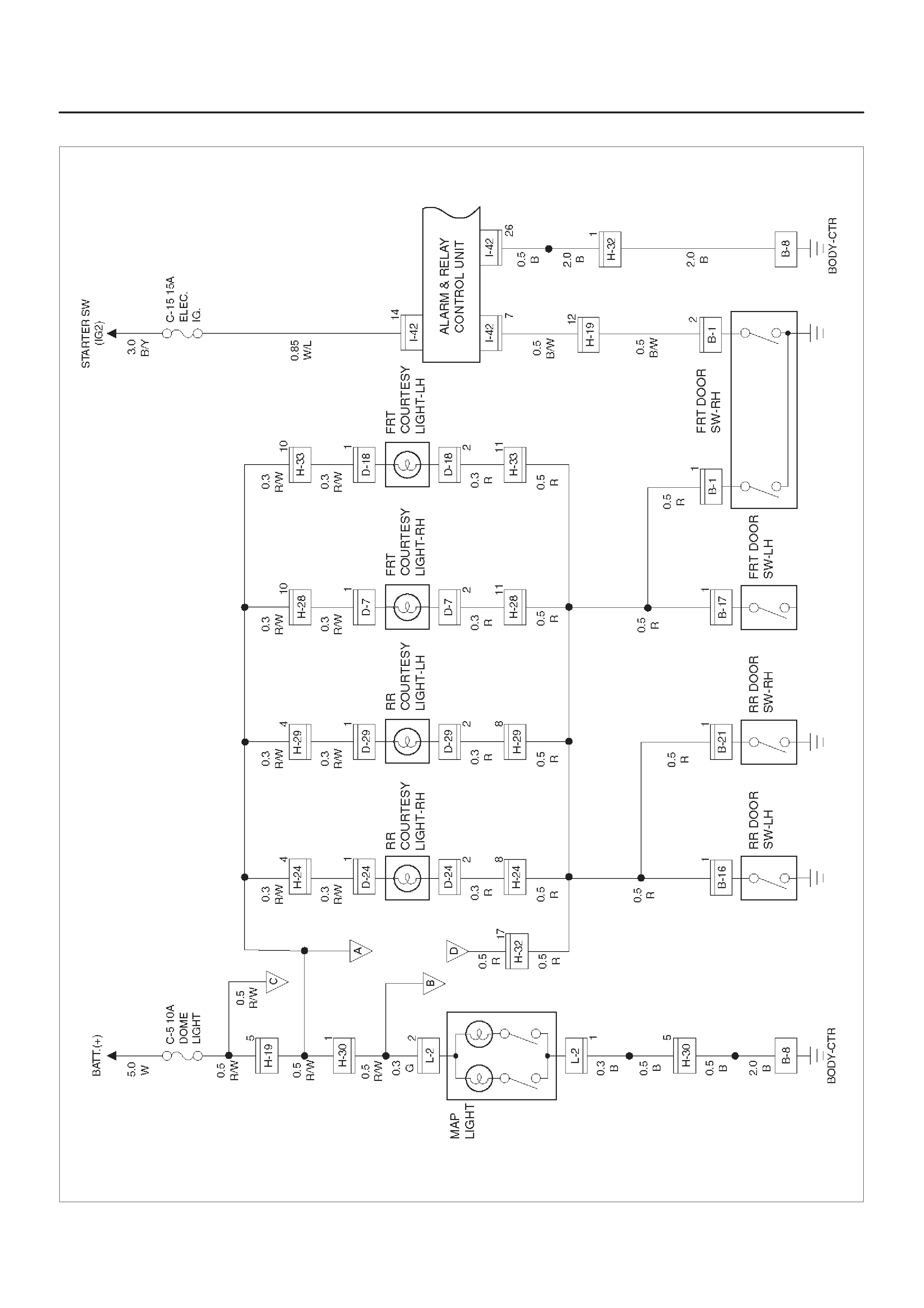

Circuit Diagram–1 (6VD1 M/T)

D08RX208

Circuit Diagram–1 (6VD1 A/T)

D08RX210

Circuit Diagram–1 (X22SE)

D08RX206

Circuit Diagram–2 (6VD1 M/T)

D08RX209

Circuit Diagram–2 (6VD1 A/T)

D08RX211

Circuit Diagram–2 (X22SE)

D08RX207

Parts Location

D08RWD17

Legend

(1) Relay & Fuse Box

(2) FRT Door SW–RH

(3) B–1

(4) D–24

(5) RR Courtesy–Light–RH

(6) B–21

(7) RR Door SW–RH

(8) Map Light

(9) L–2

(10) Dome Light

(11) L–3

(12) B–11 (4Door Model)

(13) Luggage Room Light

(14) G–13 (2Door Model)

(15) G–1

(16) H–37

(17) Tailgate Switch

(18) B–20

(19) H–22

(20) RR Door SW–LH

(21) B–16

(22) RR Courtesy–Light–LH

(23) H–29

(24) FRT Door SW–LH

(25) H–30

(26) FRT Courtesy–Light–LH

(27) D–18

(28) H–33

(29) I–26

(30) I–41, I–42

(31) B–8

(32) H–24

(33) FRT Courtesy–Light–RH

(34) D–7

(35) H–28

(36) I–46

(37) H–19, H–32

Diagnosis

Dome Light Inoperative

Step Action Value(s) Yes No

1Remove the dome light bulb.

Is the bulb normal? —Go to Step 2 Replace the

bulb

21. Reinstall the bulb.

2. Disconnect the dome light connector L–3.

3. Set the dome light switch to door position.

Is there continuity between the dome light side

connector terminal 1 and 3? —Go to Step 3

Repair or

replace the

dome light

3Is the battery voltage applied between harness side

connector L–3 terminal 3 and the ground? Approx. 12V Go to Step 4 Go to Step 5

4Repair an open circuit between the fuse C–5 and the

dome light.

Is the action complete? — Verify repair —

5Repair an open circuit between the dome light and the

door switch or the tail gate switch.

Is the action complete? — Verify repair —

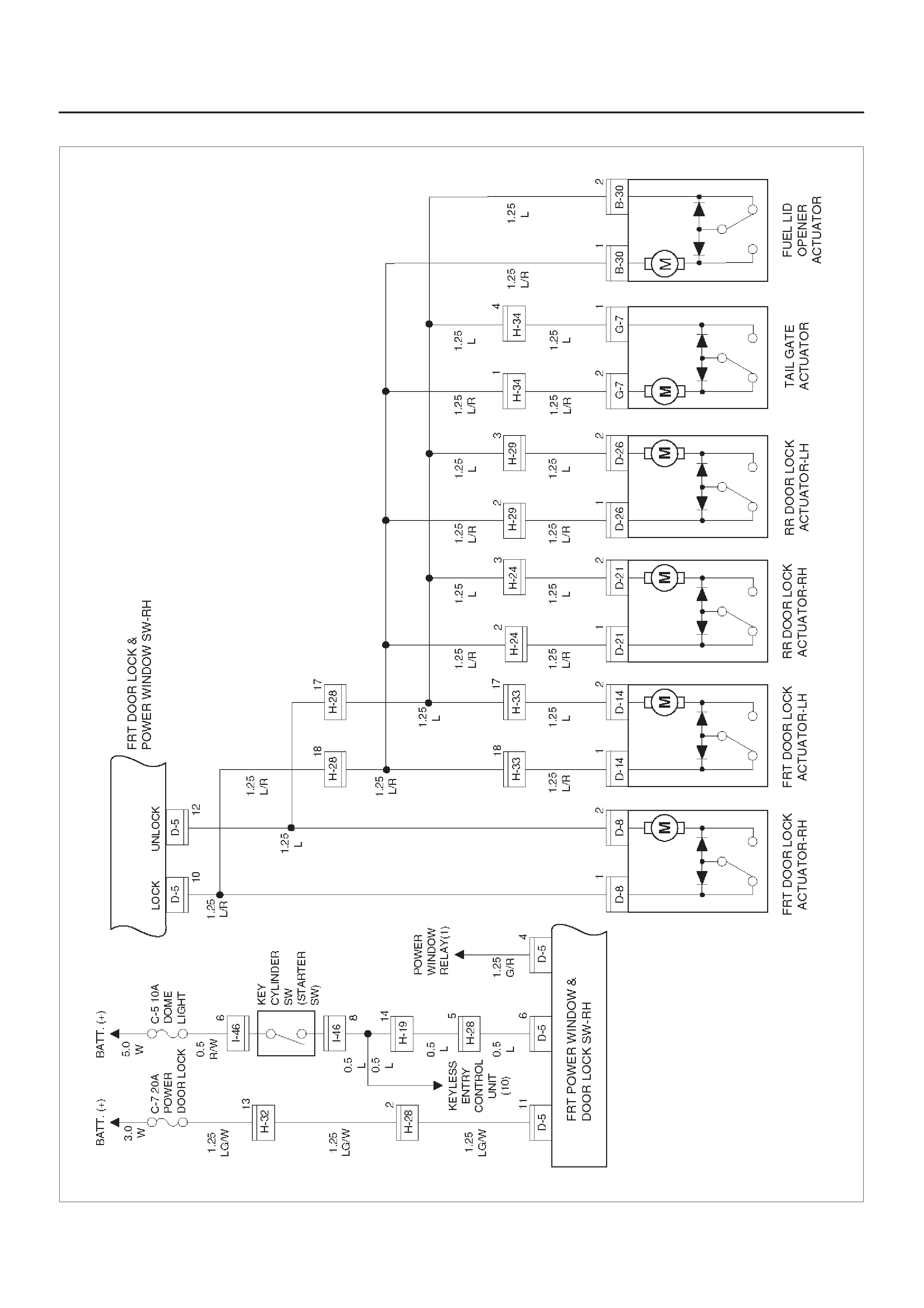

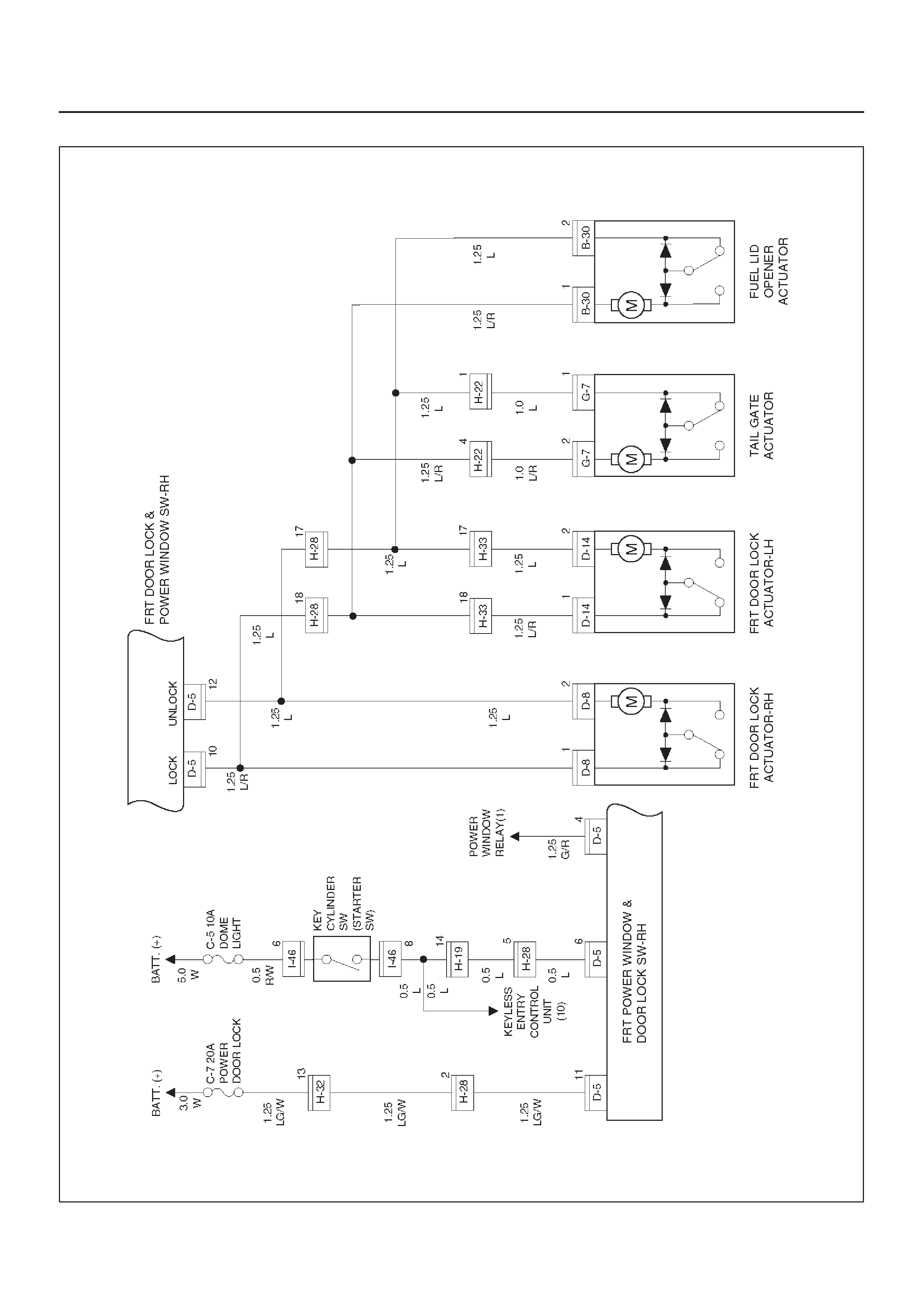

Power Door Lock

General Description

The door lock system consists of door lock switch keyless

entry control unit and door lock actuator . Door lock switch

on driver’s side can actuate the door lock mechanism.

Locking or unlocking the lock switch on the driver side

causes the door lock mechanism to be locked or

unlocked.

At this time, the current flows for approx. 1 second from

door lock switch on driver’s side to door lock actuator to

run the motor.

When the key is in the key cylinder , Door Lock can not be

done.

Circuit Diagram–1 (4Door Model)

D08RX243

Circuit Diagram–1 (2Door Model)

D08RX295

Circuit Diagram–2

D08RX242

Parts Location

D08RWD15

Legend

(1) H–28

(2) H–19, H–32

(3) D–8

(4) FRT Door Lock Actuator–RH

(5) H–24

(6) FRT Door Lock Switch–RH

(7) D–6, D–5

(8) D–23

(9) RR Door Lock Actuator–RH

(10) I–26

(11) FRT Door Lock Actuator–LH

(12) D–14

(13) RR Door Lock Actuator–LH

(14) B –30

(15) D–28

(16) H–29

(17) D–17

(18) FRT Door Lock Switch–LH

(19) H–33

(20) B–8

(21) Relay & Fuse Box (Instrument Panel)

(22) H–34, H–22 (2Door Model)

(23) G–7

Diagnosis

All The Doors Do Not Lock And Unlock By Door Lock SW–RH

Step Action Value(s) Yes No

1Is the fuse C–7 normal? —Go to Step 2 Replace the

fuse

2Disconnect the front power window & door lock

SW–RH connector D–5.

Is the battery voltage applied between harness side

connector D–5 terminal 11 and the ground? Approx. 12V Go to Step 4 Go to Step 3

3Repair an open circuit between the fuse C–7 and the

switch.

Is the action complete? — Verify repair —

4Disconnect the FRT door lock actuator–RH connector

D–8.

Is there continuity between harness side connector

D–5 terminal 10 and connector D–8 terminal 1 (or

connector D–5 terminal 12 and connector D–8 terminal

2)? —Go to Step 5 Go to Step 6

5Replace the FRT power window & door lock SW–RH.

Is the action complete? — Verify repair —

6Repair an open circuit between the FRT power window

& door lock SW–RH and door lock actuator.

Is the action complete? — Verify repair —

All The Doors Do Not Lock and Unlock by FRT Door Lock SW–LH

Step Action Value(s) Yes No

1Disconnect the FRT power window & door lock

SW–RH and –LH connector D–5 and D–17.

Is there continuity between harness side connector

D–5 terminal 13 and connector D–17 terminal 6 (or

connector D–5 terminal 14 and connector D–17

terminal 7)? —Go to Step 2 Go to Step 3

2Replace the FRT power window & door lock SW–LH.

Is the action complete? — Verify repair —

3Repair an open circuit between the FRT power window

& door lock SW–RH and –LH.

Is the action complete? — Verify repair —

All the Doors Do Not Not Lock and Unlock by Door Lock Key SW

Step Action Value(s) Yes No

1Is B–8 grounded securely? —Go to Step 2 Ground it

securely

2Disconnect the door lock key SW connector D–6.

Is there continuity between harness side connector

D–6 terminal 2 and the ground? —Go to Step 4 Go to Step 3

3Repair an open circuit between connector D–6 terminal

2 and the ground B–8.

Is the action complete? — Verify repair —

4Is there continuity between the switch side connector

terminal 1 and 2 when the switch is turned to lock

position, and terminal 2 and 3 when the switch is turned

to unlock position? —Go to Step 5

Repair or

replace the

switch

5Repair an open circuit between the door lock key SW

and FRT power window & door lock SW–RH.

Is the action complete? — Verify repair —

Power Window

General Description

The power window system consists of power window

switches, power window motors and power window relay .

With the starter switch in “ON” position, the battery

voltage is supplied through power window relay to the

power window switches Selection of up or down switch

changes over the motor rotating direction to open or close

the window.

When the lock switch on the switch panel on the driver

side is pressed, the power window switch is in open state.

As a result, the power source to the other switches are cut

off, and the power window motors do not run.

Circuit Diagram–1

D08RX213

Parts Location

D08RWD14

Legend

(1) H–28

(2) D–2

(3) H–32

(4) Relay & Fuse Box

(5) Power Window Motor (FRT RH)

(6) Power Window SW (FRT RH)

(7) D–5

(8) Power Window Motor (RR RH)

(9) D–20

(10) D–22

(11) Power Window SW (RR RH)

(12) Power Window SW (FRT LH)

(13) Power Window SW (RR LH)

(14) D–27

(15) D–25

(16) Power Window Motor (RR LH)

(17) H–29

(18) D–17

(19) D–11

(20) Power Window Motor (FRT LH)

(21) H–33

(22) B–8

(23) H–24

Diagnosis

All Window Do Not Operate

Step Action Value(s) Yes No

1Is the fuse C–15 normal? —Go to Step 2 Replace the

fuse

2Is the circuit breaker C–21 normal?

—Go to Step 3

Replace the

circuit

breaker

3Is B–8 grounded securely? —Go to Step 4 Ground it

securely

4Disconnect the power window relay connector I–35.

Is the battery voltage applied between harness side

connector I–35 terminal 2 and the ground? Approx. 12V Go to Step 6 Go to Step 5

5Repair an open circuit between the circuit breaker

C–21 and connector I–35 terminal 2.

Is the action complete? —Go to Step 4 —

6Turn the starter switch on.

Is the battery voltage applied between harness side

connector I-35 terminal 4 and the ground? Approx. 12V Go to Step 8 Go to Step 7

7Repair an open circuit between the fuse C–15 and

connector I–35 terminal 4.

Is the action complete? —Go to Step 6 —

8Is there continuity between harness side connector

I–35 terminal 3 and the ground B–8? —Replace the

relay Go to Step 9

9Repair an open circuit between connector I–35

terminal 3 and the ground B–8.

Is the action complete? — Verify repair —

Window On The Driver’s Side Does Not Operate

Step Action Value(s) Yes No

1Turn the starter switch on.

Is the battery voltage applied between harness side

connector D–5 terminal 4 and the ground? Approx. 12V Go to Step 3 Go to Step 2

2Repair an open circuit between connector I–35

terminal 1 and connector D–5 terminal 4.

Is the action complete? —Go to Step 1 —

3Connect the battery position terminal with harness side

connector D–5 terminal 3 or 5, and the negative

terminal with harness side connector D–5 terminal 5 or

3.

Does the motor operate? —

Replace the

front power

window &

door lock

switch–RH Go to Step 4

41. Disconnect the front power window motor–RH

connector D–2.

2. Connect the battery position terminal with the motor

side connector D–2 terminal 1 or 2, and connect the

battery negative terminal with the motor side

connector D–2 terminal 2 or 1.

Does the motor operate? —Go to Step 5 Replace the

motor

5Repair an open circuit between the front power window

and door lock switch–Rh and the front power window

motor–RH.

Is the action complete? — Verify repair —

Window On The Front Passenger’s Side Does Not Operate

Step Action Value(s) Yes No

1Is B–8 grounded securely? —Go to Step 2 Ground it

securely

2Disconnect the front power window and door lock

switch–LH connector D–17.

Is there continuity between harness side connector

D–17 terminal 3 and the ground B–8? —Go to Step 4 Go to Step 3

3Repair an open circuit between connector D–17

terminal 3 and the ground B–8.

Is the action complete? —Go to Step 2 —

4Turn the starter switch on.

Is the battery voltage applied between harness side

connector D–17 terminal 2 and the ground? Approx. 12V Go to Step 6 Go to Step 5

5Repair an open circuit between connector I–35