SECTION 3A - JR & JS SERIES VECTRA BODY KITS

1. GENERAL INFORM ATION

This Section of the Holden By Design Service Infor mation Supplem ent describes the rem oval and installation of

the aerodynamic id body styling kit components available for JR & JS Vectra Series Vehicles.

The id body styling kit consists of a front spoiler, side skirts and unique rear spoilers for Sedan and Hatch

variants. The rear spoilers include an integral LED type high mount stop lamp.

Alloy wheels, id badging and a Holden By Design identification plate are also included as part of the package.

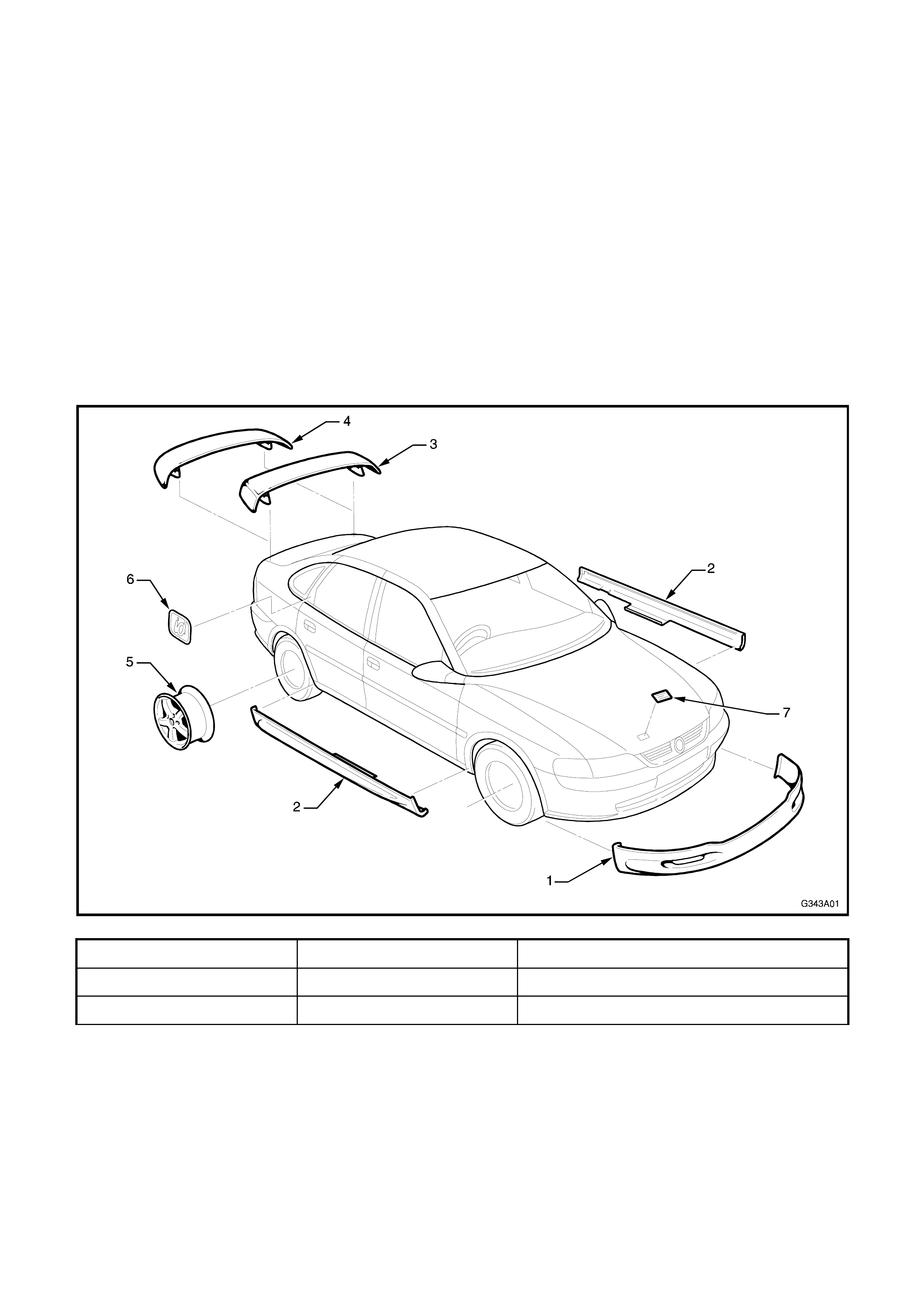

Figure 3A-1 illustrates the Vectra id body kit major components.

NOTE: Vehicles can be supplied with only one or several of the c omponents. In this c ase no Holden By Design

identification or badging is included.

For inf orm ation not contained in this Supplem ent, ref er to Gr oup A in Volum e 1 of the J R Series Service Manual

or TIS CD-ROM, Vectra B.

1.1 MAJOR COMPONENTS

Figure 3A-1

1. Front spoiler 4. Rear spoiler - Hatch 7. Holden By Design identification plate

2. Side skirts 5. Alloy wheel

3. Rear spoiler - Sedan 6. id emblem

2. FRONT SPOILER

The front spoiler is attached to the bumper facia with

adhesive, retainers and screws.

Front bumper facia removal is not required for front

spoiler removal and installation.

NOTE: T he front spoiler is painted in the vehicle’s body

colour. The painting procedures are relatively straight

forward providing the correct steps for refinishing PUR-

RIM material are followed. Refer to your paint supplier if

further information is required.

REMOVE

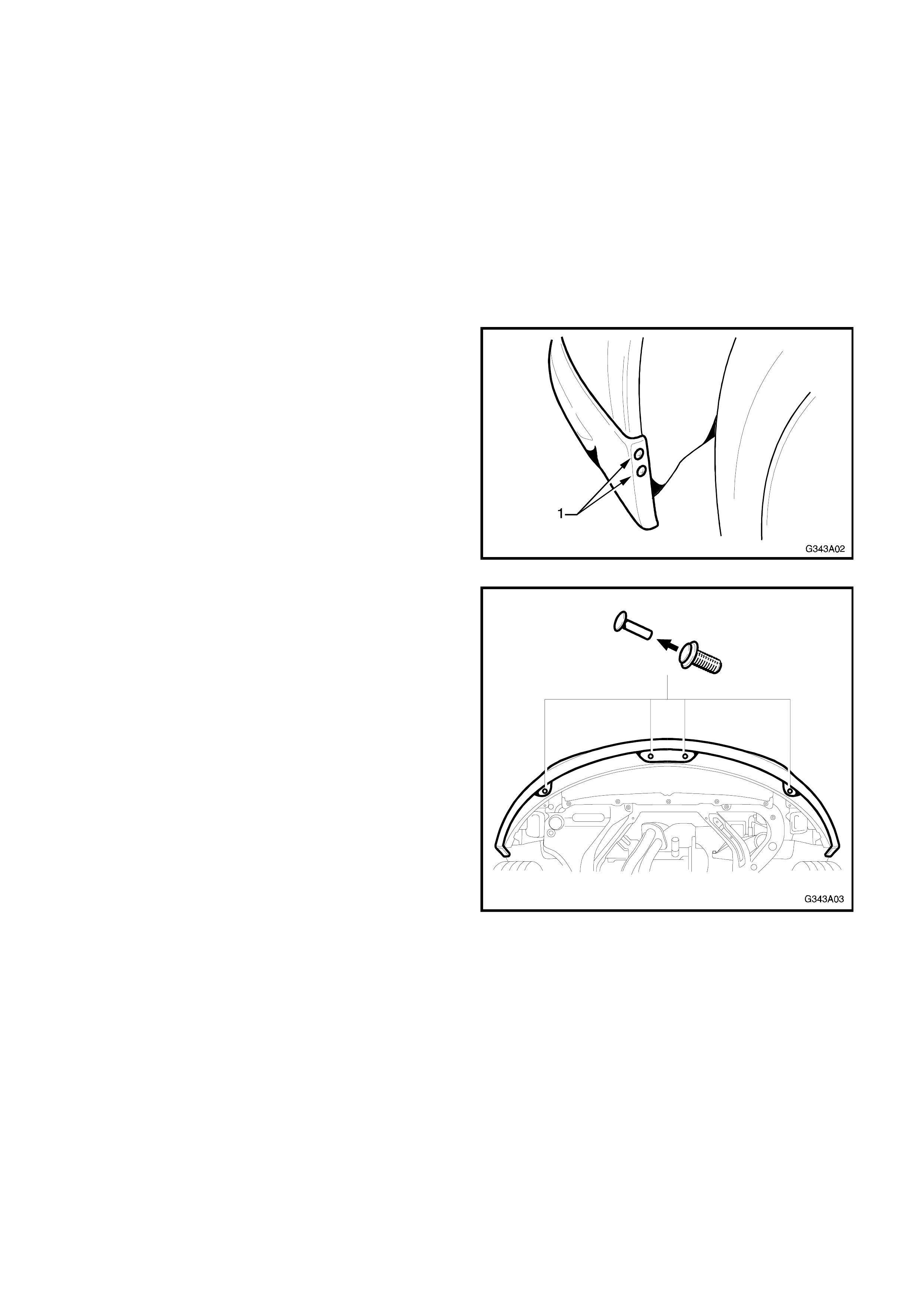

1. Remove the s crews (1) attac hing each end of the

spoiler to the bumper facia at the wheel arch

openings.

Figure 3A-2

2. From underneath the spoiler, remove the four

retainers attaching the spoiler to the bum per fac ia

by removing the centre pin from the retainer.

NOTE: The f ront spoiler m ay be attached with s crivets

as shown in Fig. 3A-3 or self tapping screws.

Figure 3A-3

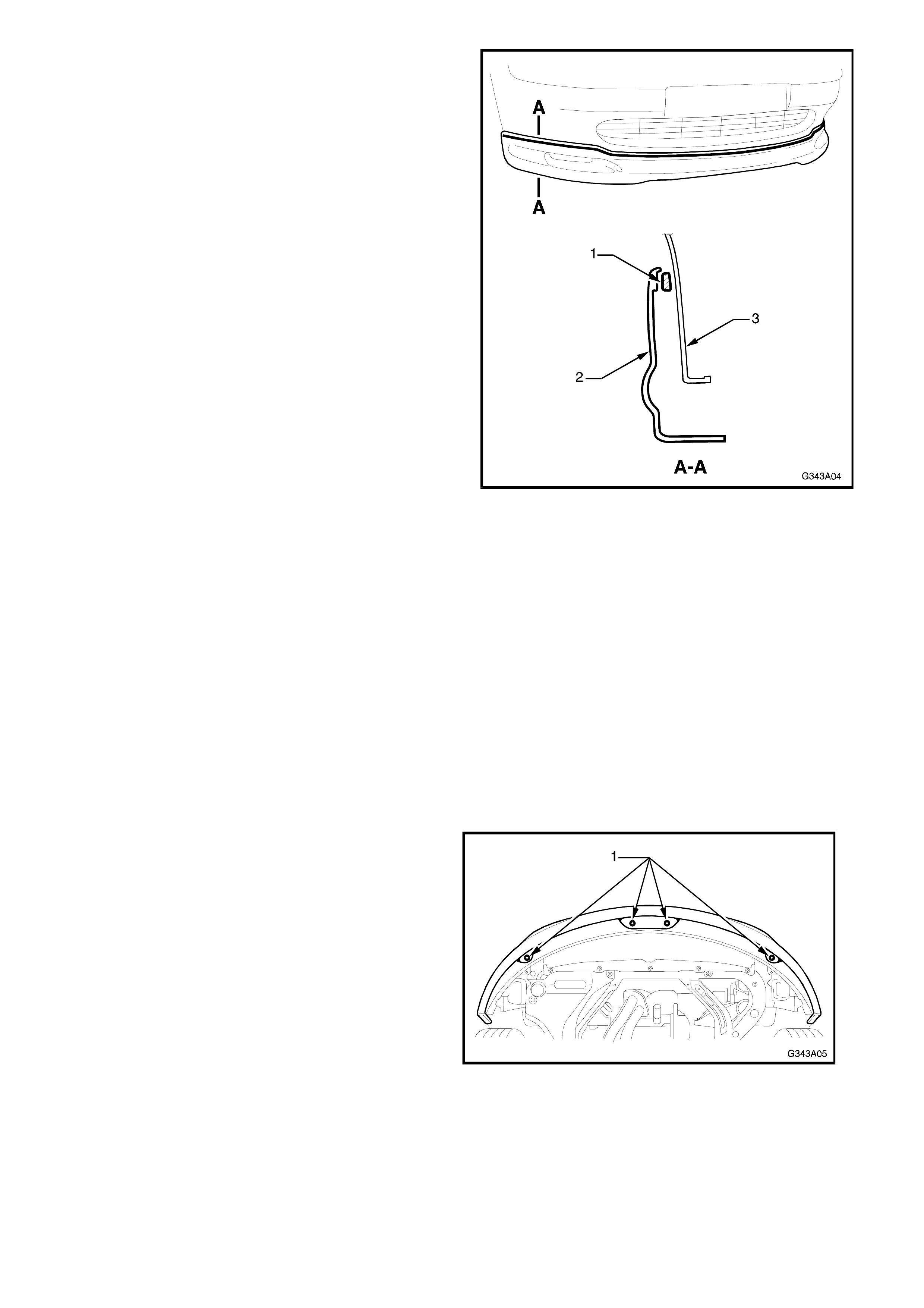

3. Using a sharp knife, cut the adhesive (1) from

behind the upper edge of the spoiler (2). This may

be made easier by applying gentle force to the

spoiler while cutting, pulling it away from the facia

(3).

NOTE: Take care not to cut into the bumper facia.

4. Remove spoiler.

5. If the bumper facia will not be replaced, clean off

the remaining adhesive.

Figure 3A-4

INSTALL

NOTE 1: The vehic le m ust not be dr iven for at least five

hours, or washed for at least 24 hours after installation

to allow the adhesive to cure. Refer to the directions

supplied with the adhesive.

NOTE 2: If the bumper facia has not been replaced,

proceed to Step 5.

NOTE 3: If scrivets were used to attach the spoiler in

the positions shown in Fig. 3A-5, dis card these and use

self tapping screws when installing the spoiler.

1. With the aid of an assistant, temporarily fit the

spoiler to the bumper facia ensuring correct

alignment.

2. From underneath, drill through the spoiler and

bumper facia with the four spoiler retainer holes

(1) with a 3 mm drill bit.

Figure 3A-5

3. Remove the spoiler.

4. W here the adhesive is to be applied, remove all

paint and primer from the spoiler and clean the

bumper facia and spoiler with the correct

urethane adhesive cleaner.

NOTE: Refer to the directions supplied with the

adhesive for further information.

6. Apply a bead of urethane adhesive (1) such as

Betalink K1 or equivalent to the spoiler (2) as

shown in Fig. 3A-6.

NOTE: Directions enclosed with the adhesive must

be fully read and followed.

Figure 3A-6

7. Carefully fit the spoiler to the bumper facia.

8. Install four self tapping screws in the positions

shown in Fig. 3A-5.

9. Attach several lengths of mas king tape ( 1) along

the spoiler (2) to temporarily hold it in position.

Blocks (3) placed under the tape against the

upper edge of the s poiler m ay aid in achieving a

flush fit of the upper surface.

NOTE: The masking tape should not be removed

until the adhesive has cured.

Figure 3A-7

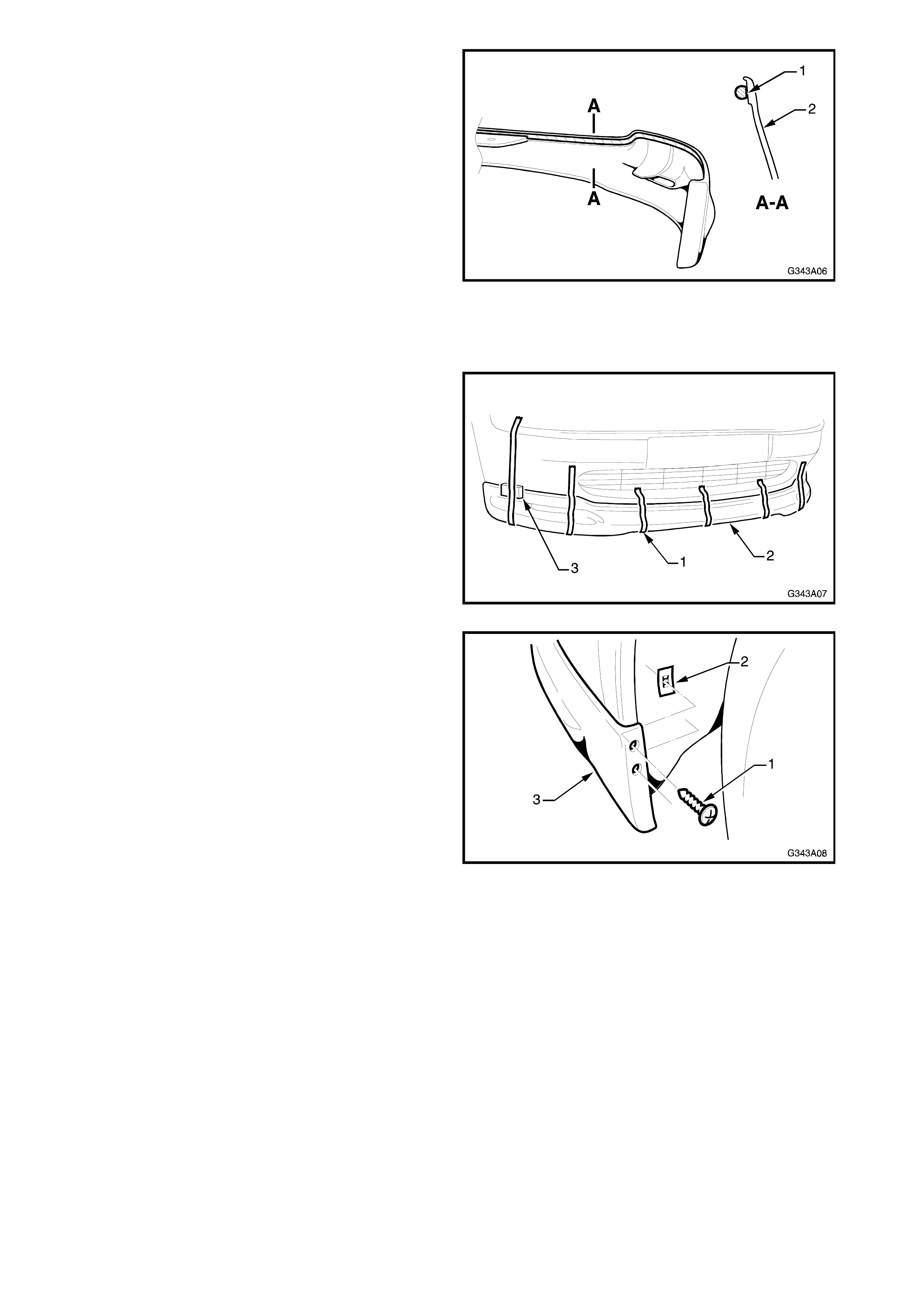

10. Drill two screw holes at each end of the spoiler,

through the bumper facia, at each wheel arch

opening with a 4 mm drill bit. Install the screws

(1) with speed nuts (2) behind at each end of the

spoiler (3) in the wheel arch opening.

Figure 3A-8

3. SIDE SKIRTS

The Holden By Design side skirt assemblies are

mounted to the existing sill panel.

A length of aluminium angle is attached to the sill with

screws and is used to support the upper surface of the

skirt. Two beads of adhesive and four clips secure the

side skirt to the sill panel.

NOTE: The side skirts are painted in the vehicle’s body

colour. The painting procedures are relatively straight

forward providing the correct steps for refinishing PUR-

RIM material are followed. Refer to your paint supplier if

further information is required.

REMOVE

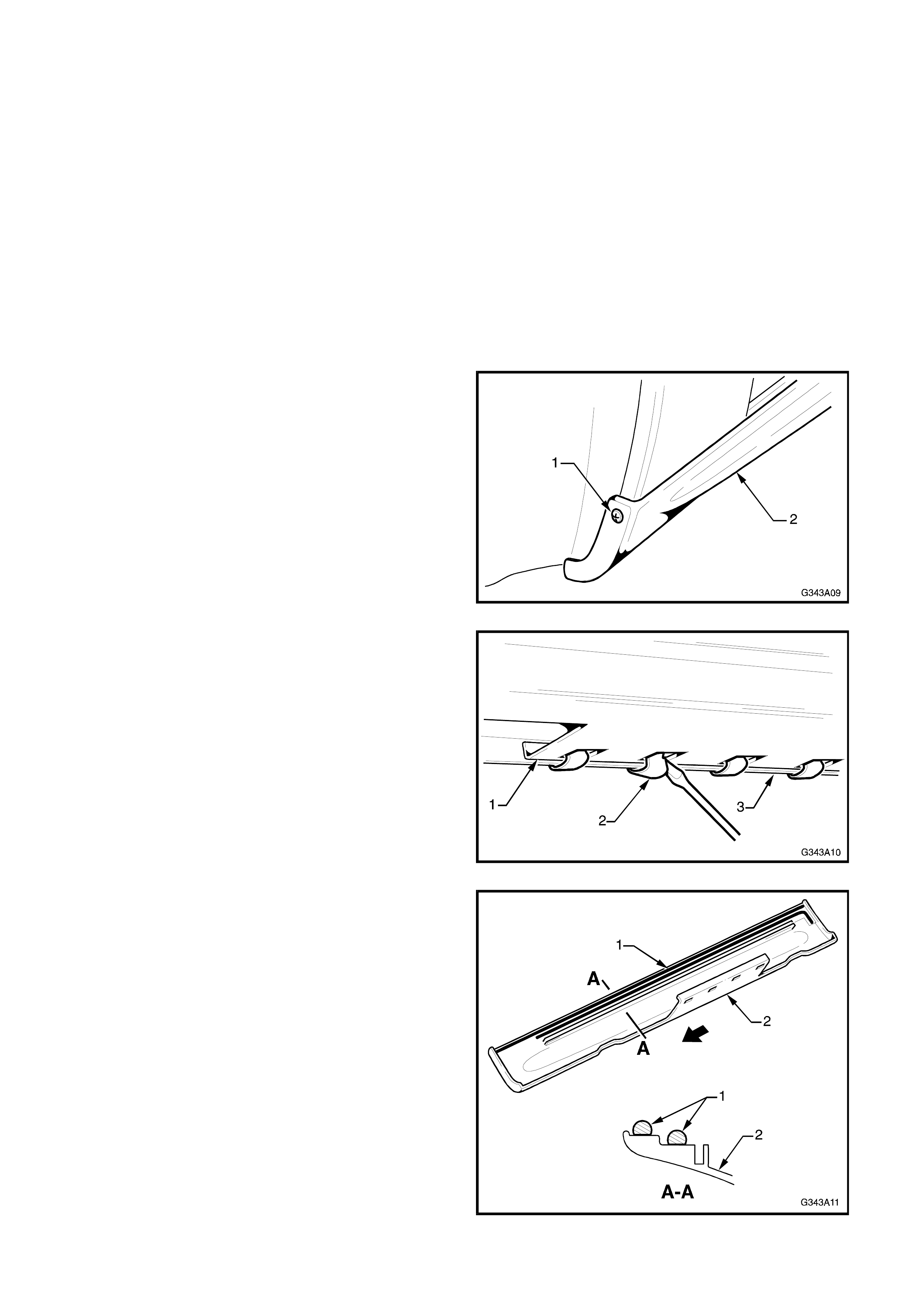

1. Remove the screw (1) attaching the front edge

of the skirt (2) to the front guard wheel arch

opening.

Figure 3A-9

2. From underneath the skir t (1), us e a scr ewdriver

to rem ove the four clips (2) attac hing the s kirt to

the sill panel (3).

Figure 3A-10

3. Starting at the front, use a sharp k nife to cut the

beads of adhesive (1) from behind the upper

and rear edges of the skirt (2). This may be

made eas ier by applying gentle f orce to the sk irt

while cutting, pulling it away from the sill.

Figure 3A-11

4. Remove the skirt.

5. If required, remove the nine screws attaching

the aluminium angle to the sill panel.

6. Using a screwdriver, gently prise the nine screw

plugs from the sill panel.

7. If the sill panel is not to be replaced, clean off

the excess adhesive.

INSTALL

N

O

TE

1

: The vehicle m ust not be driven or washed

f

or at least

f

ive hours a

f

ter installation to allow the

adhesive to cure. Re

f

er to the directions su

pp

lied

with the adhesive.

NOTE 2: If the aluminium angle was not removed,

proceed to Step 13.

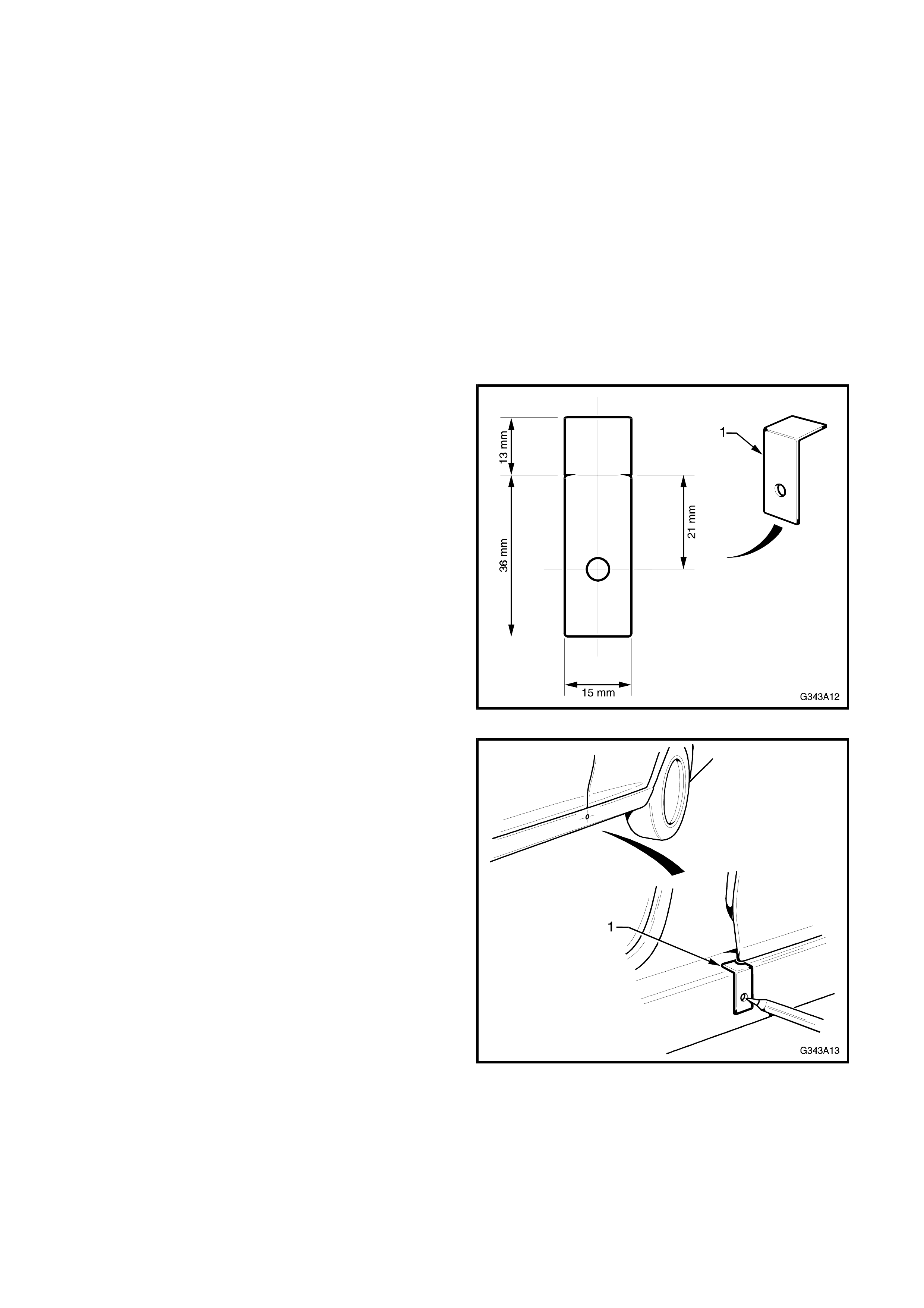

1. Construct a drilling template from light card

using the dimensions shown in Fig. 3A-12.

Figure 3A-12

2. Place the template (1) on the sill in alignment

with the door gap between the front and rear

doors, as shown in Fig. 3A-13. Mark the hole.

Figure 3A-13

3. Drill a 5 m m hole into the s ill panel and coat the

bare metal with primer.

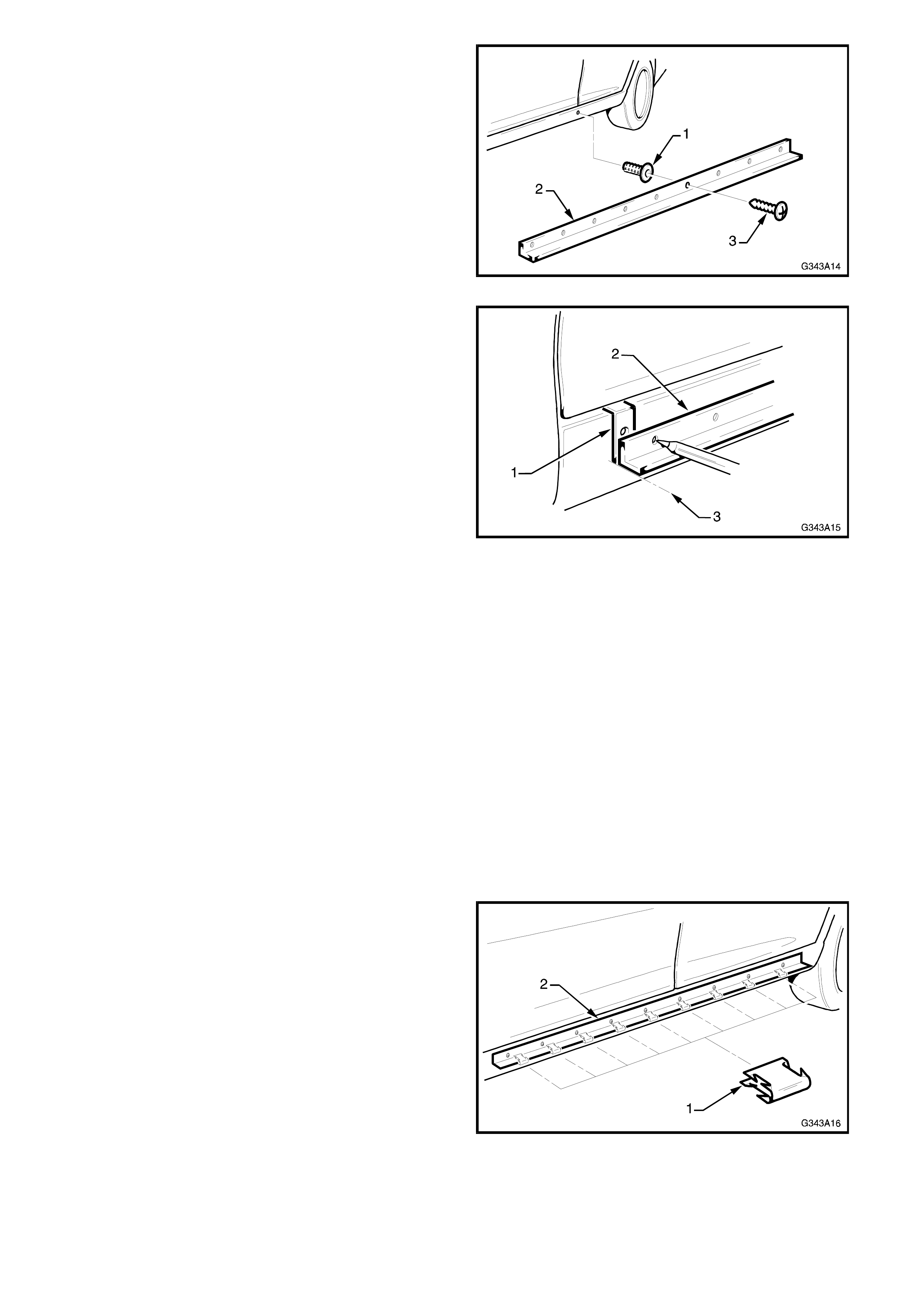

4. Insert a screw plug (1) and temporarily install the

aluminium angle (2). Ensure the screw (3) is

placed in the fourth hole from the rear of the

angle.

Figure 3A-14

5. U sing the drilling tem plate (1), place it on the sill

and align the front lower corner of the angle (2)

with the front lower corner of the template as

shown (3) in Fig. 3A-15. Mark the front hole in

the angle.

Figure 3A-15

6. Repeat Step 4 at the rear, aligning the rear

lower corner of the angle with the rear lower

corner of the template. Mark the rear hole in the

angle.

NOTE: The angle should be straight with no undue

force required to align the front and rear points.

7. Drill a 5 mm hole at the front and rear marks

and coat the bare metal with primer.

8. Ins ert a scr ew plug in each hole and tem porarily

install the front and rear screws through

aluminium angle.

9. Mark the r emaining six s crew holes and rem ove

the aluminium angle.

10. Drill the remaining holes and coat the bare metal

with primer.

11. Insert the screw plugs in the remaining holes

and install the aluminium angle.

12. Place the nine clips (1) evenly spaced onto the

aluminium angle (2) as shown in Fig. 3A-16.

Figure 3A-16

13. W here the adhesive is to be applied, remove all

paint and primer from the side skirt and clean

the sill panel and side skirt with the correct

urethane adhesive cleaner.

NOTE: Refer to the directions supplied with the

adhesive for further information.

14. Apply two beads of urethane adhesive such as

Betalink K1 or equivalent to the area shown in

Fig. 3A-11.

NOTE: Directions enclosed with the adhesive must

be fully read and followed.

15. Install the side skirt, ensuring the aluminium

angle is correctly located within the slot in the

side skirt. Tap it home with an open hand.

NOTE: At this point it may be advisable to secure

the skirt with tape, clean off any excess adhesive,

then continue when the adhesive has cured, as

continuing may open a gap along the upper edge of

the skirt. Blocks placed under the tape against the

upper edge will assist in achieving a flush fit.

16. Install the four clips attaching the side skirt to

the sill panel as shown in Fig. 3A-10.

17. Drill a 2.5 mm hole thr ough the front edge of the

side skirt and the wheel arch opening of the

front guard. Refer Fig 3A-9.

18. Prime the bare metal and install the screw.

4. REAR SPOILER

The Holden By Design Vectra Series rear spoilers are

unique for sedan and hatch variants.

Each spoiler inc ludes a LED type high m ount stop lam p

that replaces the operation of the standard high mount

stop lamp.

Removal and installation procedures differ for each

variant.

NOTE 1: If a new spoiler kit is supplied, several

electrical items are included which are not used by

HBD.

NOTE 2: The rear spoiler is painted in the vehicle’s

body colour. The painting procedures are relatively

straight forward providing the correct steps for

refinishing PU-Hard material are followed. Refer your

paint supplier if further information is required.

4.1 SEDAN

NOTE 1: W here a deck lid spoiler is fitted, the deck lid

assist s prings are upgr aded to compens ate f or the ex tra

weight. This must be taken into consideration if

replacing the springs.

NOTE 2: T he r ear hook on eac h spr ing is to be ins talled

into the rearmost hole.

REMOVE

1. O pen the deck lid and remove the dec k lid inner

trim if fitted. Refer Group A, in the JR Series

Service Manual or TIS CD-ROM.

2. Disconnect the high mount stop lamp wiring

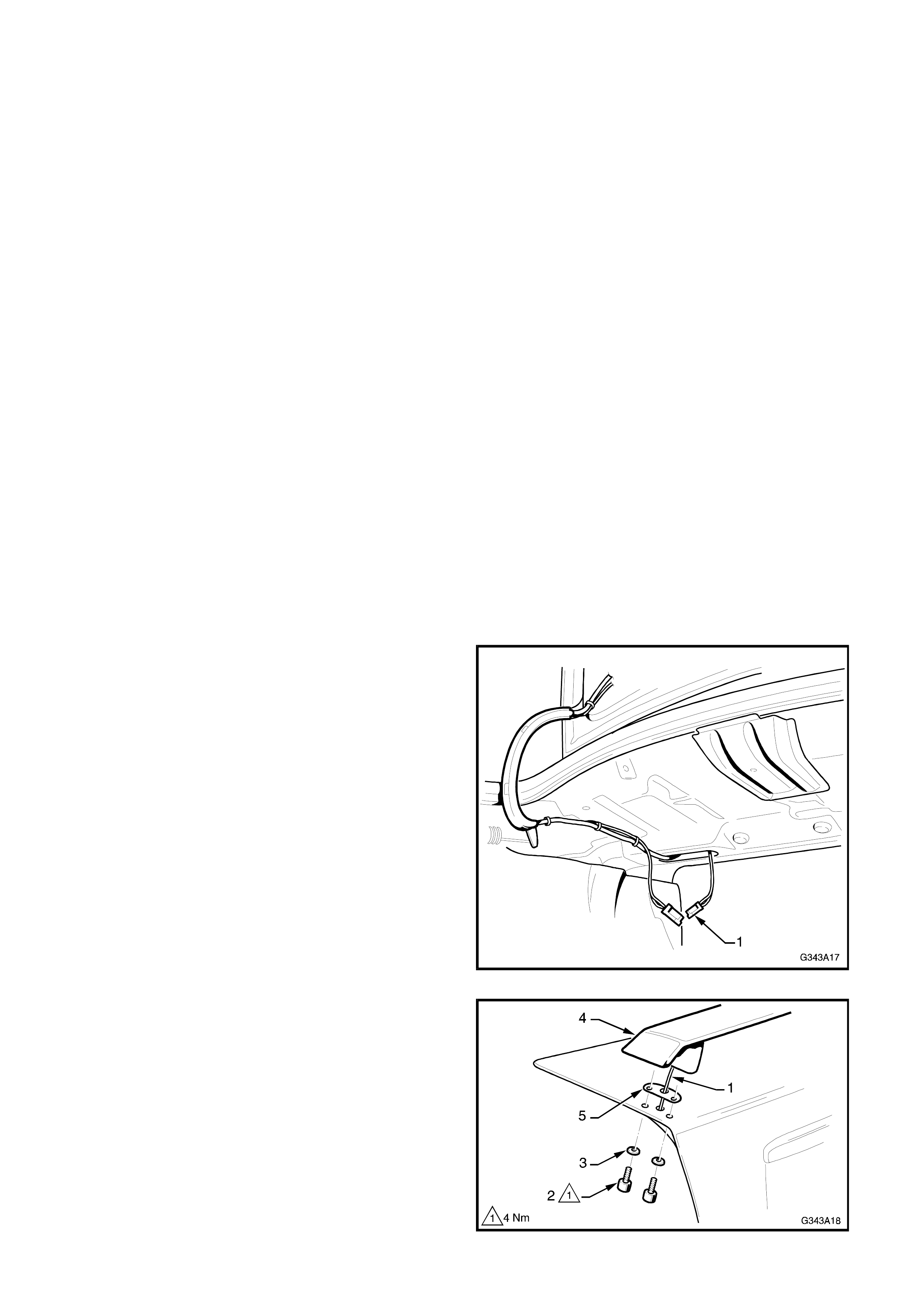

connector (1) from under the parcel shelf.

Figure 3A-17

3. Unclip the high mount stop lamp harness (1)

and pass it through the deck lid inner frame.

4. Remove the two screws (2) and washers (3)

each side attaching the rear spoiler (4) to the

deck lid. Remove the spoiler and seal (5).

Figure 3A-18

5. If required, remove and disassemble the high

mount stop lam p assembly as shown in Fig 3A-

19.

Remove the screw (1) from each side and

disconnect the wiring connec tor ( 2) . Remove the

screw (3) and washer (4) from three places.

Separate the stop lam p (5) f rom the lower cover

(6).

NOTE: Once removed the high mount stop lamp to

spoiler attaching screws (1) must be discarded and

replaced with new ones.

Figure 3A-19

INSTALL

NOTE 1: Correct installation of the spoiler has the

high mount stop lamp harness routed through the

LH side of the deck lid. Some installations may find

it on the RH side. Regardless, the harness must

route through the conduit on the LH hinge.

NOTE 2: If the deck lid has not been replaced

proceed to Step 10.

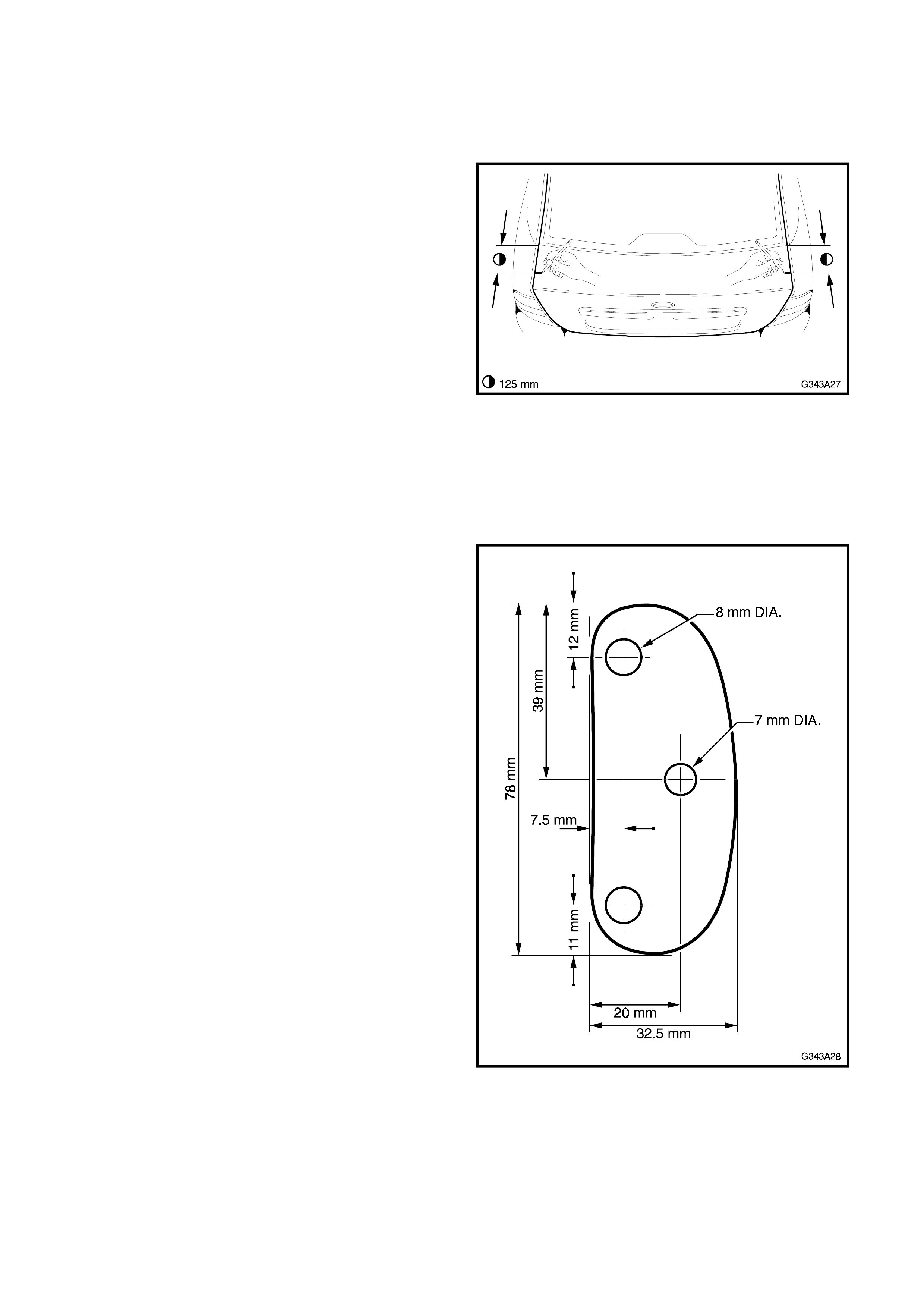

1. Mark the deck lid on each side, 450 mm from

the front corner of the deck lid.

2. W ith the aid of an as sistant, place the spoiler on

the deck lid, aligning the rear of the s poiler pos ts

with the marks on the deck lid.

3. Ensure the spoiler is evenly spaced from each

side of the deck lid and mark around the posts.

4. Remove the spoiler

Figure 3A-20

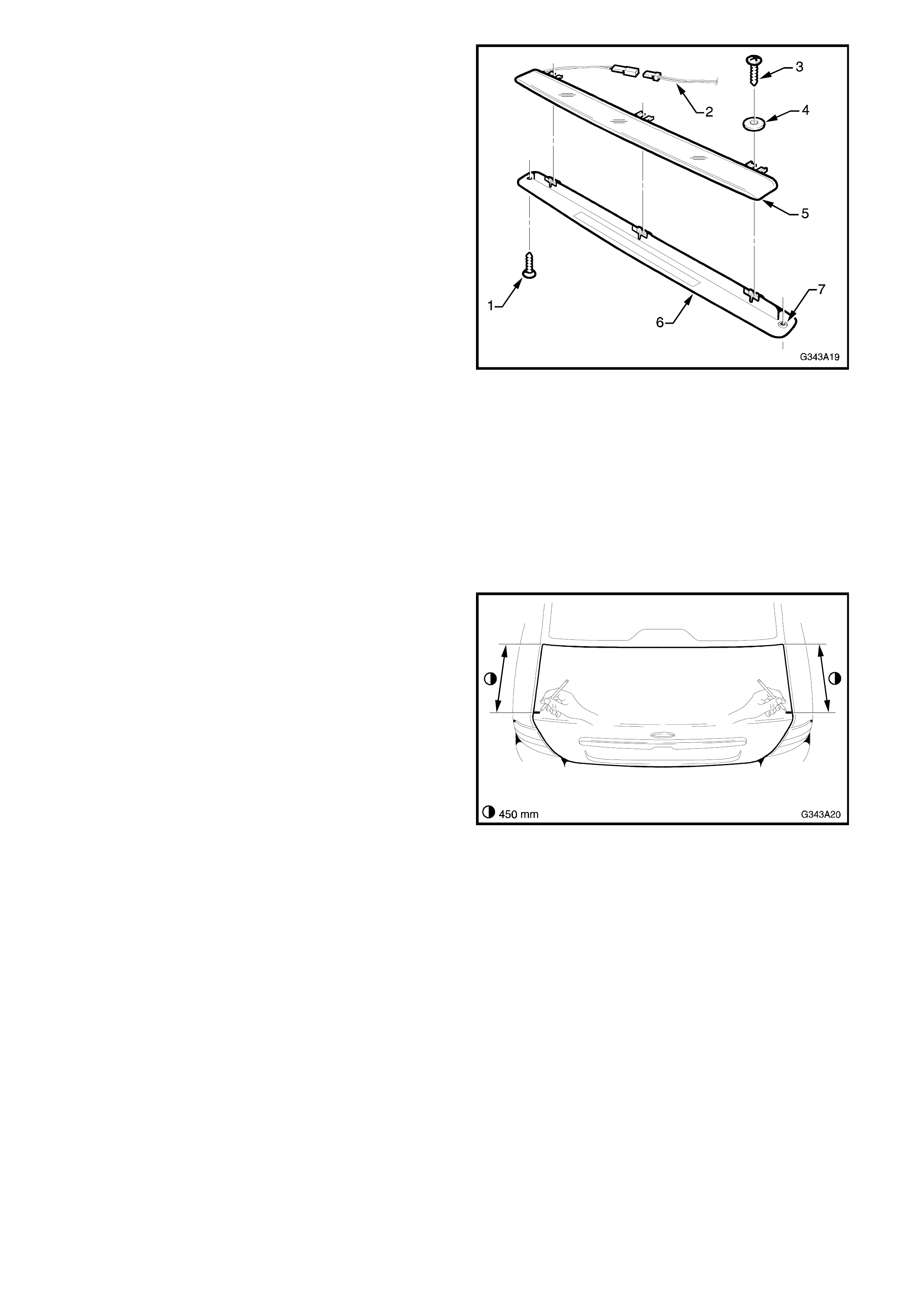

5. Construct a drilling template from light card

using the dimensions shown in Fig. 3A-21.

Figure 3A-21

6. Place the template on the deck lid, aligning it

with the marks.

7. Mark the spoiler mounting holes and on the LH

side only, the high mount stop lamp harness

hole.

8. Initially drill 3 m m holes, f ollowed by 8 mm holes

for the mounting holes and 7 mm for the

harness hole.

IMPORTANT: Drill the high mount stop lamp

harness hole through the outer panel only.

9. Debur the drill holes and apply primer to the

bare metal.

10. Fit the rubber gromm et (1) to the wiring harness

hole in the deck lid (2).

Figure 3A-22

11. Assemble the high mount stop lamp to the

spoiler, ensuring the high mount stop lamp

harness is routed to the LH spoiler post.

NOTE: If a new part is supplied, r emove the s tep (7)

from the screw hole in the high mount stop lamp

lower cover (6) as shown in Fig. 3A-19. This allows

a better fit of the stop lamp in the spoiler cavity.

12. Fix the spoiler post seals to the spoiler posts,

use contact adhesive if required.

13. Fit the spoiler to the deck lid, routing the high

mount stop lamp harness through the grommet

in the deck lid.

14. Install the four Allen head screws and washers

and tighten. Refer Fig 3A-18.

15. Route the high mount stop lamp harness (1)

through the deck lid (2), along the LH hinge

conduit (3) and under the parcel shelf as shown

in Fig. 3A-23.

16. Connect the high mount stop lamp wiring to the

stop lamp wiring connector as shown in Fig. 3A-

17. Check the operation of the high mount stop

lamp.

17. Refit deck lid trim if required.

Figure 3A-23

4.2 HATCH

NOTE: W here a rear spoiler is fitted, the gas struts are

upgraded to compensate f or the extr a weight. This must

be taken into consideration if replacing the struts.

REMOVE

1. Open the tailgate and remove the inner trim.

Refer Group 1 in the JR Series Service Manual

or TIS CD-ROM, Vectra B.

2. Disconnect the high mount stop lamp wiring

connector (1) from within the tailgate cavity.

Figure 3A-24

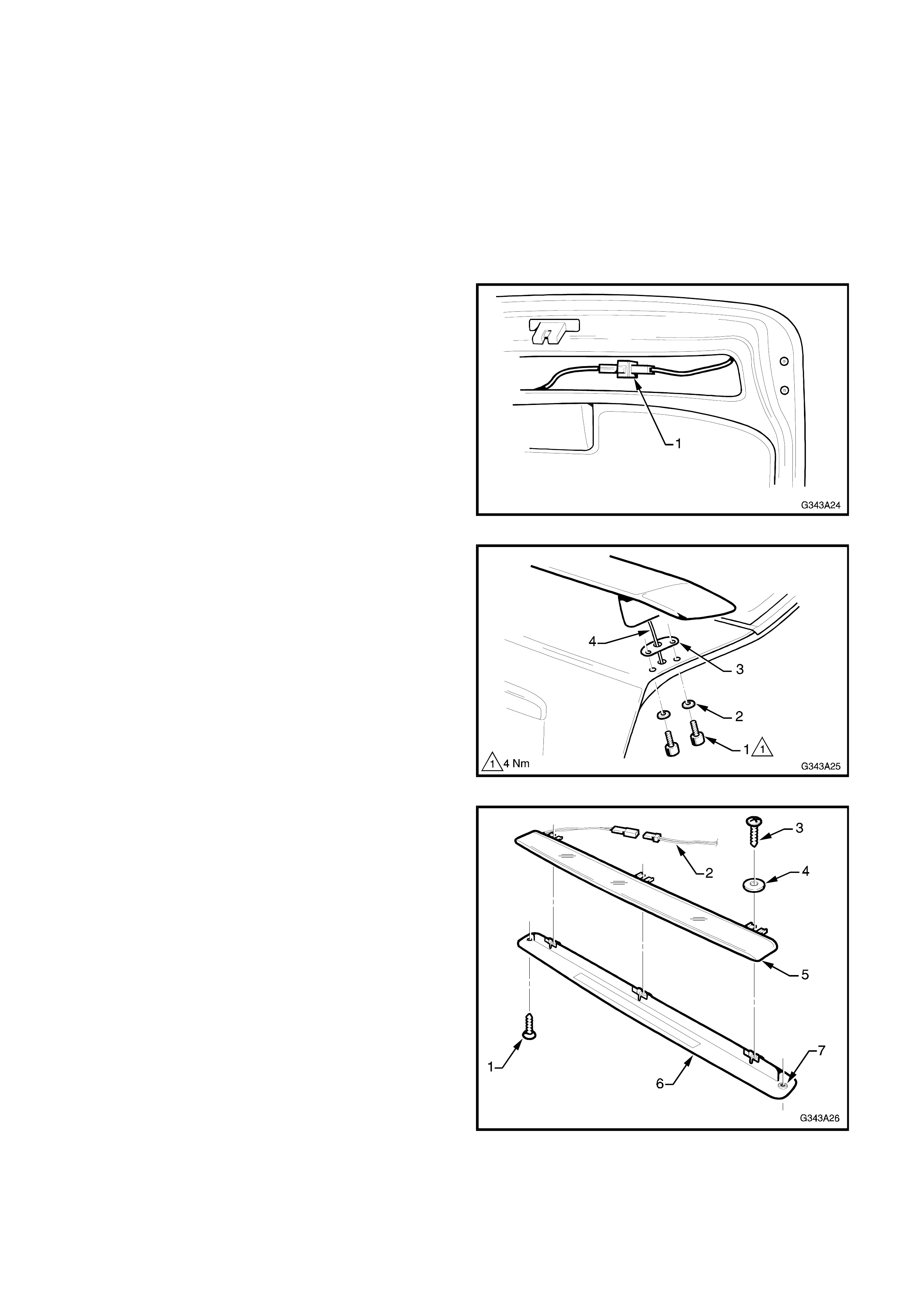

3. Remove the two screws (1) and washers (2)

attaching the rear spoiler to the tailgate.

Remove the spoiler and seal (3), carefully

pulling the wiring harness (4) through the

grommet hole.

Figure 3A-25

4. If required, remove and disassemble the high

mount stop lam p assembly as shown in Fig 3A-

26.

Remove the screw (1) from each side and

disconnect the wiring connec tor ( 2) . Remove the

screw (3) and washer (4) from three places.

Separate the stop lam p (5) f rom the lower cover

(6).

NOTE: Once removed the high mount stop lamp to

spoiler attaching screws (1) must be discarded and

replaced with new ones.

Figure 3A-26

INSTALL

NOTE: If the tailgate has not been r eplaced pr oc eed

to Step 10.

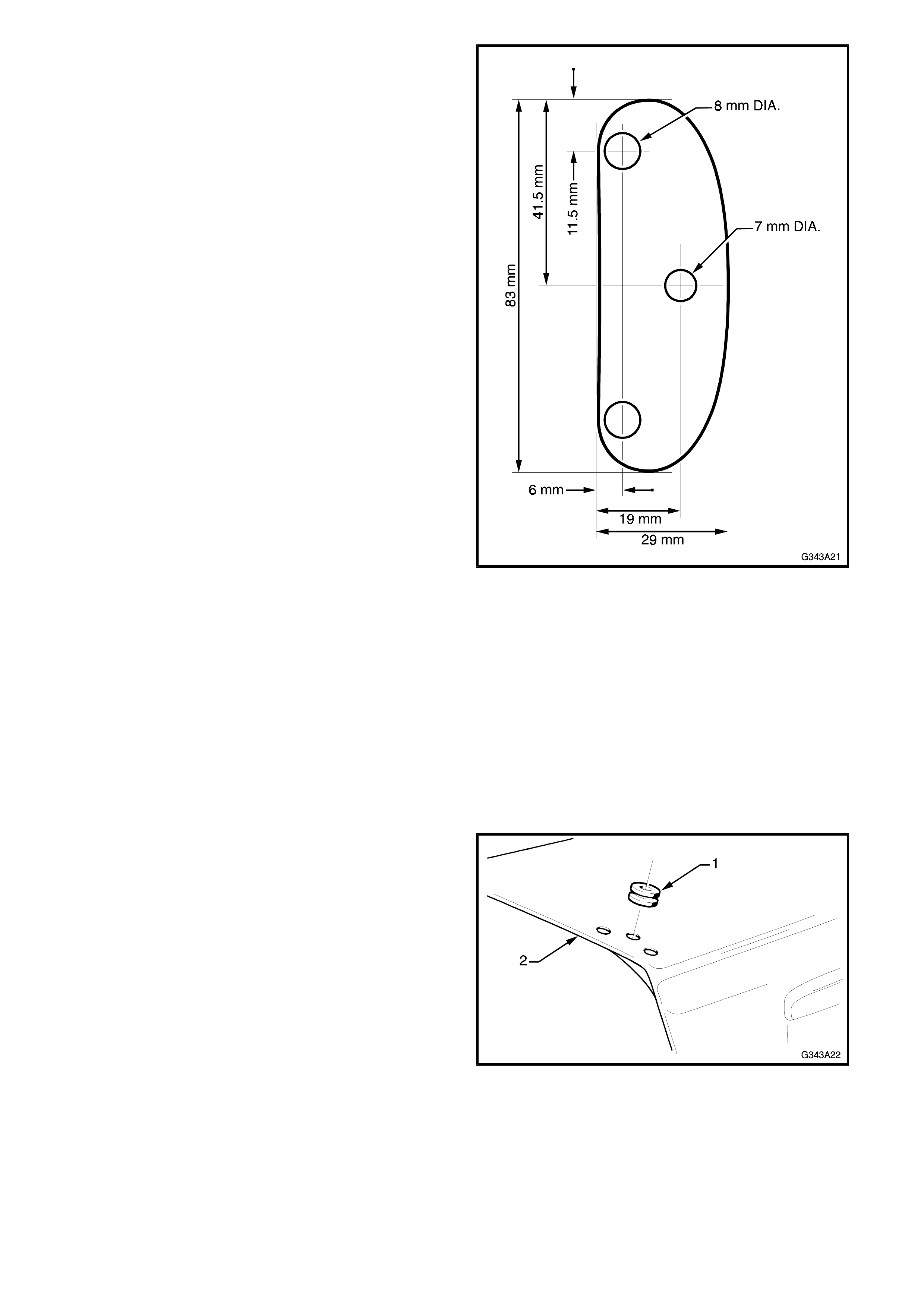

1. Mark the tailgate on each side, 125 mm from the

corner of the rear window moulding.

Figure 3A-27

2. W ith the aid of an as sistant, place the spoiler on

the tailgate, aligning the front of the spoiler posts

with the marks on the deck lid.

3. Ensure the spoiler is evenly spaced from each

side of the tailgate and mark around the posts.

4. Remove the spoiler

5. Construct a drilling template from light card

using the dimensions shown in Fig. 3A-28.

Figure 3A-28

6. Place the template on the tailgate, aligning it

with the marks.

NOTE: Ensure the correct side of the template is

used.

7. Mark the spoiler mounting holes and on one

side only, the high mount stop lamp harness

hole.

8. Initially drill 3 m m holes, f ollowed by 8 mm holes

for the mounting holes and 7 mm for the

harness hole.

IMPORTANT: Drill the high mount stop lamp

harness hole through the outer panel only.

9. Debur the drill holes and apply primer to the

bare metal.

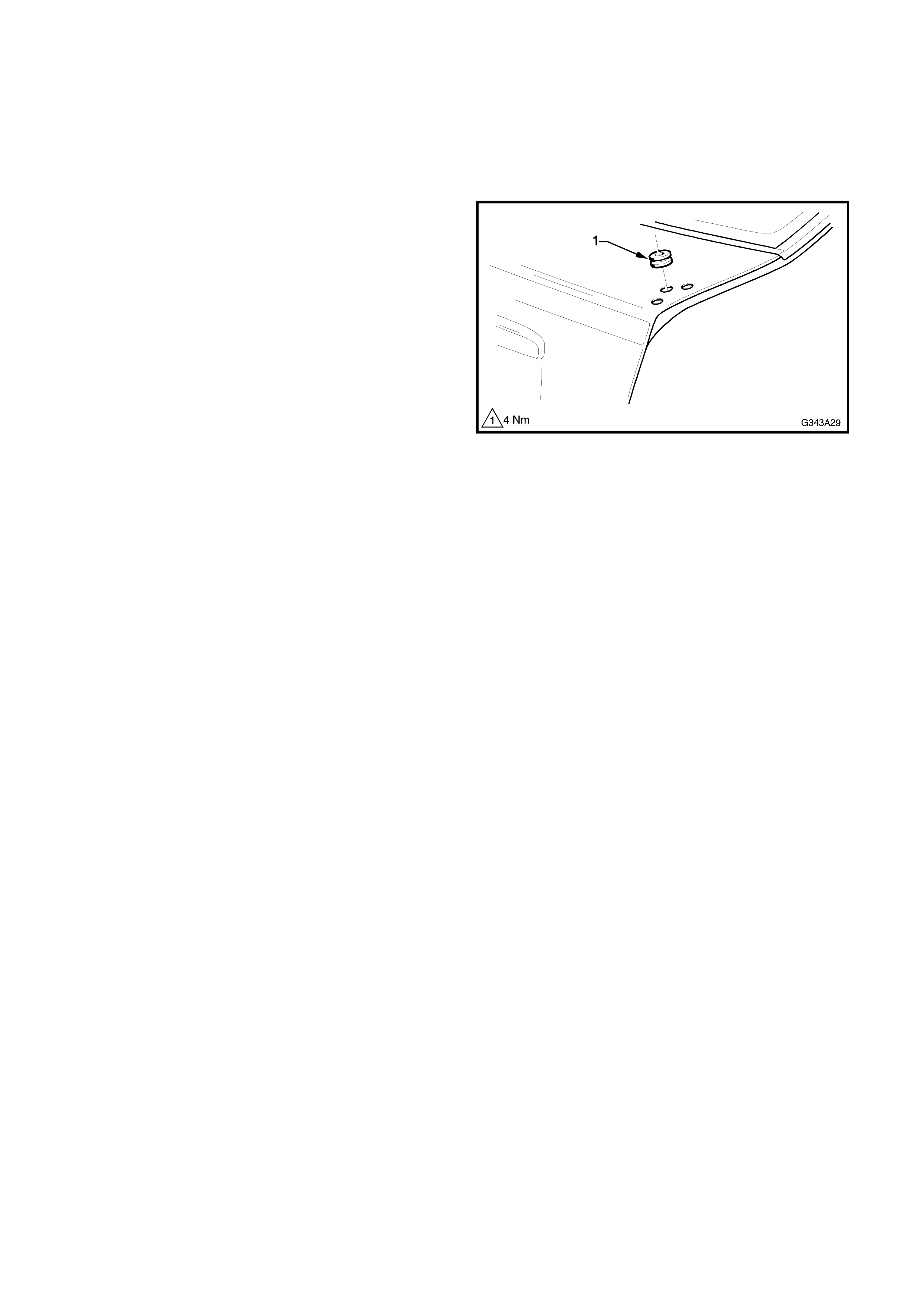

10. Fit the rubber gromm et (1) to the wiring harness

hole.

Figure 3A-29

11. Assemble the high mount stop lamp to the

spoiler.

NOTE: If a new part is supplied, r emove the s tep (7)

from the screw hole in the high mount stop lamp

lower cover (6) as shown in Fig. 3A-26. This allows

a neater fit of the stop lamp in the spoiler cavity

12. Fix the spoiler post seals to the spoiler posts,

use contact adhesive if required.

13. Fit the spoiler to the tailgate, routing the high

mount stop lamp harness through the grommet

in the tailgate.

14. Install the four Allen head screws and washers

and tighten. Refer Fig 3A-25.

15. Connect the high mount stop lamp connector

within the tailgate cavity as shown in Fig 3A-24.

16. Close the tailgate and check the oper ation of the

high mount stop lamp.

17. Refit tailgate trim.

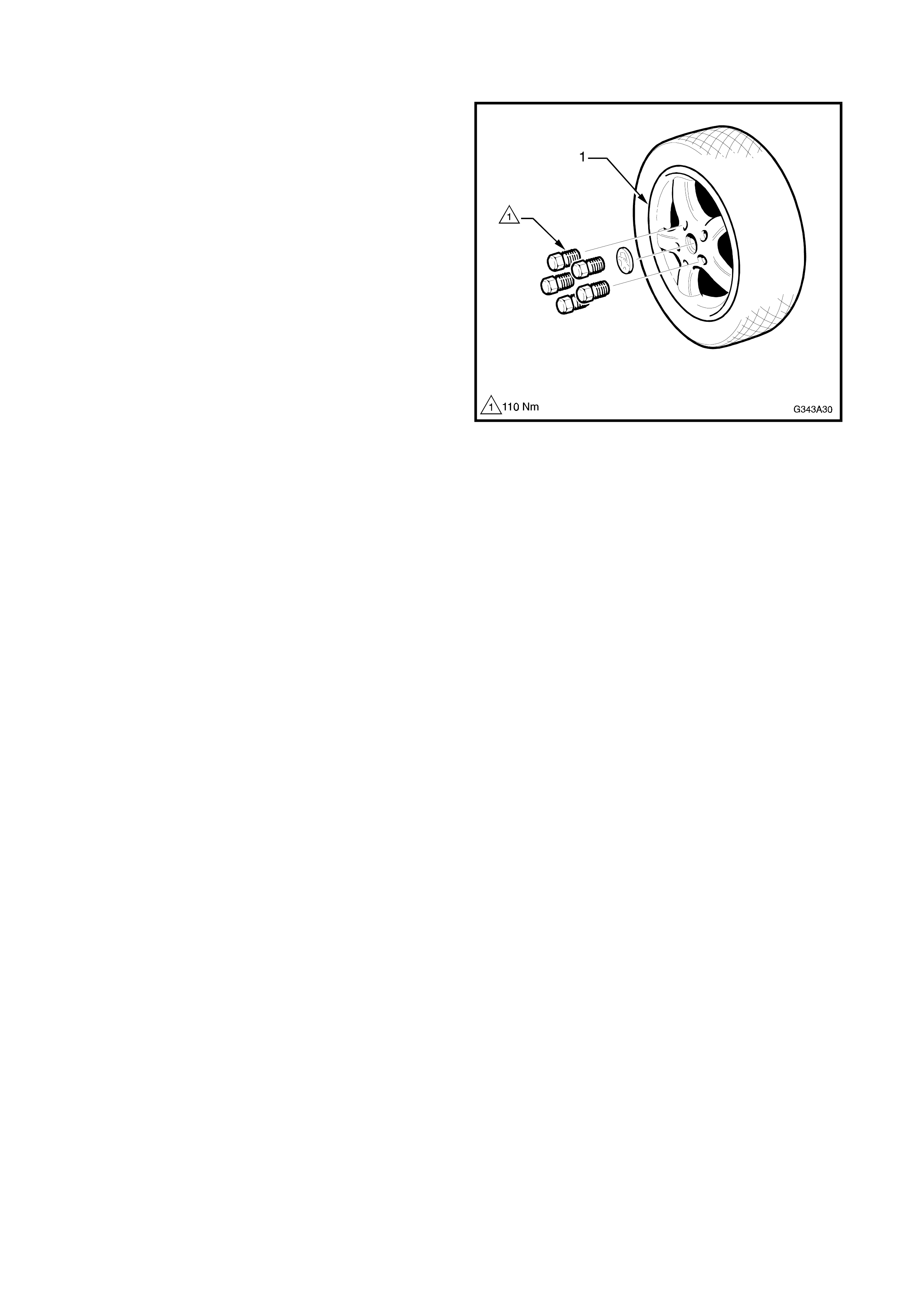

5. ALLOY WHEELS

A unique 15” x 6” 5 spoke alloy wheel is available

for the Holden By Design Vectr a Vehicles, as either

part of the id package or individually. The existing

tyres are r etained as is the standar d steel rim spare

wheel.

This Section of the Holden By Design Service

Information Supplement illustrates the wheel type

only. For the inf orm ation requir ed to servic e wheels,

refer to Group E, in Volume 2 of the JR Series

Service Manual or TIS CD-ROM, Vectra B.

Figure 3A-30

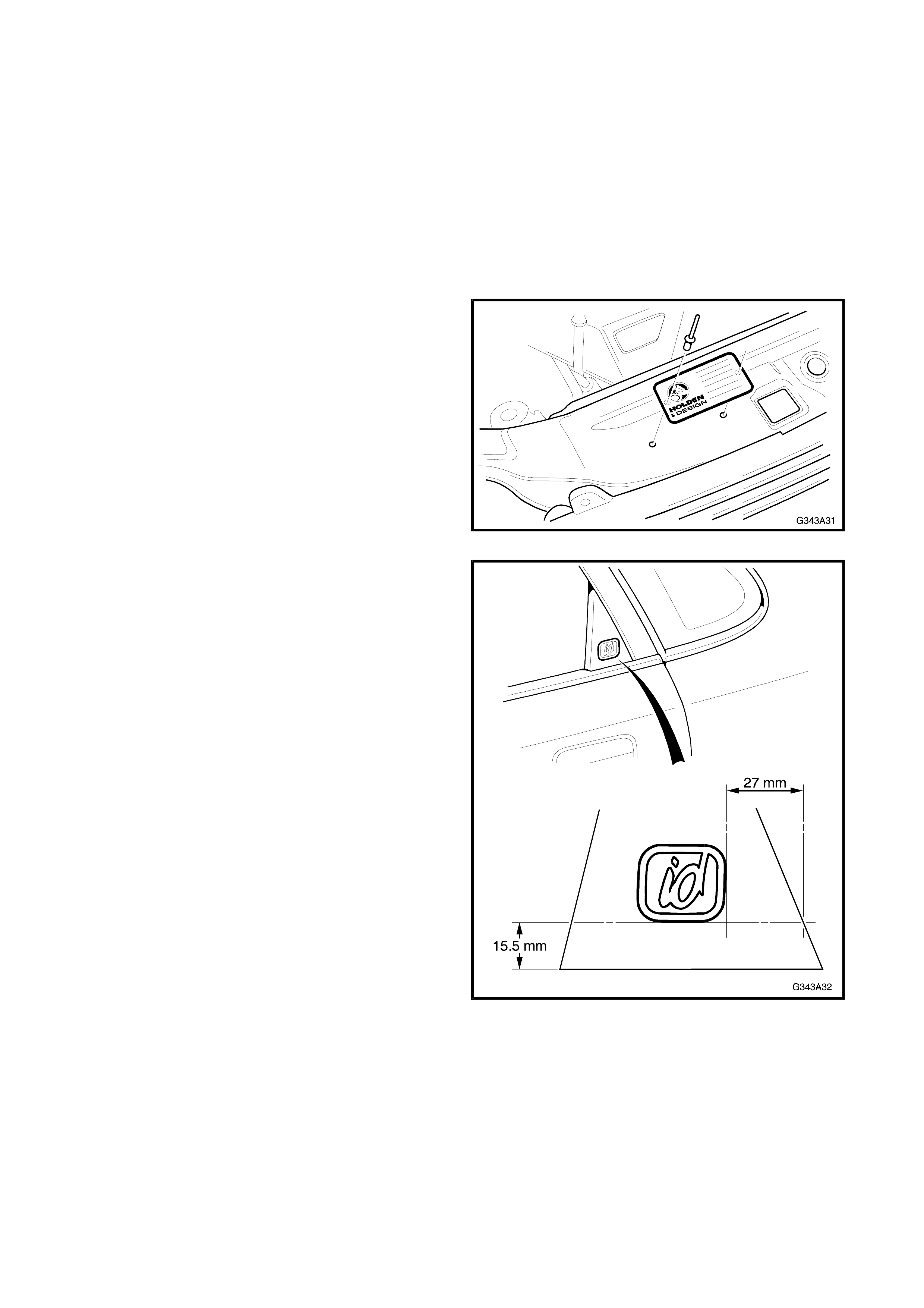

6. IDENTI FICATION & BADGING

W her e a full Holden By Design id kit has been ins talled,

a HBD identification plate is installed onto the radiator

support panel with pop-rivets.

Holden By Design id emblems are affixed onto each

rear door window filler plate with double sided adhesive

tape.

NOTE: The HBD identification plate replaces the air-

conditioning label, which is relocated to the lower, left

side of the bonnet frame.

Figure 3A-31 shows the location of the HBD

identification plate. The existing holes in the radiator

support panel are used.

Figure 3A-31

Figure 3A-32 shows the location of the id emblem and

the positioning measurements on the rear door

window filler plate.

Figure 3A-32