SECTION 4J - VT & WH SERIES HAND CONTROL

SYSTEM

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of

either seat belt pre-tension ers and a driver’s air bag , seat belt pre-t ensioners and a driv er’s and front

passenger’s air bag s or seat belt pre-tensio ners, driver’s and fron t passenger’s air bags and left and

right hand side air bags. Depending upon the system fitted, refer to SAFETY PRECAUTIONS, Section

12M Supplemental Restraint System in the VT Series I Service Information, before performing any

service operation on or around any SRS components, the steering mechanism or wiring. Failure to

follow the SAFETY PRECAUTIONS could result in SRS deployment, resulting in possible personal

injury or unnecessary SRS system repairs.

1. GENERAL INFORMATION

This Section of the Holden By Design Service Information Supplement, describes the m aintenance and service

procedures for the Hand Control System available with VT & WH Series vehicles.

Designed and only provided for driver s with special needs , the hand c ontrol s ystem allows brake and acc eler ator

control from a steering column mounted lever, which is operated with the right hand. A steering wheel ‘spinner’

knob and indicator stalk extension allow complete turning of the steering wheel and indicator operation with the

left hand.

The hand control system is available only with automatic transmission vehicles and meets AS 3954, motor

vehicle controls, adaptive systems for people with disabilities.

Most Austr alian States require the driver of a vehicle f itted with a hand control system hold a spec ially endorsed

licence.

NOTE: It is a mandatory requirem ent by licencing authorities f or the steer ing wheel knob to be f itted for dis abled

drivers.

The hand control assembly restricts access to the fuse panel. Section 3.1 provides a simple procedure for

accessing the fuses should servicing be required.

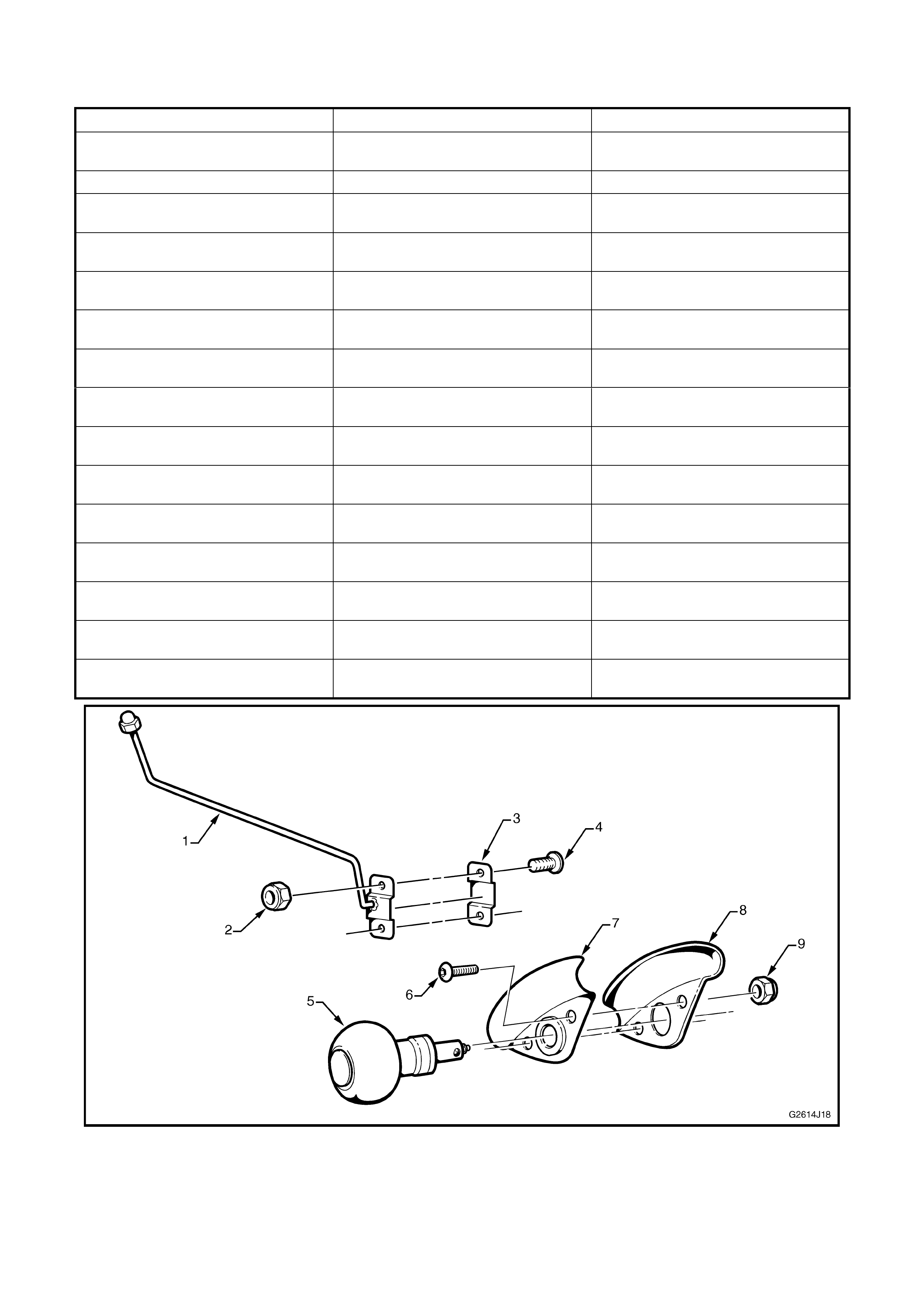

1.1 COMPONENTS

1. Indicator extension arm 17. Hand control assembly 33. Brake pedal clamp, part B

2. Nut – indicator arm mounting (x 2) 18. Pin – lever mounting 34. Spring washer – brake pedal

clamp (x 2)

3. Bracket – indicator arm mounting 19. Screw – lever mounting M8 (x 2) 35. Nut – brake pedal clamp (x 2)

4. Screw – indicator arm mounting

(x 2) 20. Lever assembly 36. Nut – accelerator rod joint, hand

control assembly end

5. Knob – steering wheel spinner 21. Bolt – lever to brake pedal rod

joint M8 37. Spacer – accelerator rod joint,

hand control assembly end

6. Screw – steering wheel knob

mounting (x 2) 22. Spring washer – lever to brake

pedal rod joint 38. Spring washer – accelerator rod

joint, hand control assembly end

7. Bracket, front – steering wheel

knob mounting 23. Nut – lever to brake pedal rod

joint 39. Rose joint – accelerator rod, hand

control assembly end

8. Bracket, rear – steering wheel

knob mounting 24. Rose joint – brake pedal rod,

lever end 40. Rod – accelerator pedal, 100 mm

9. Nut – steering wheel knob

mounting (x 2) 25. Locknut – brake pedal rod upper 41. Rod – accelerator pedal, 50 mm

10. Bolt – steering column mounting

M8 x 35 mm HT (x 2) 26. Rod – brake pedal 42. Rod – accelerator pedal, pedal

end

11. Washer – shake proof, steering

column mounting (x 2) 27. Locknut – brake pedal rod lower

(x 2) 43. Adjusting rod – accelerator pedal

rod

12. Flat washer – steering column

mounting (x 2) 28. Rose joint – brake pedal rod,

pedal end 44. Locknut – accelerator pedal rod

lower (x 3)

13. Mounting bracket 29. Spring washer – rose joint to

brake pedal clamp 45. Rose joint – accelerator pedal,

pedal end

14. Bolt – mounting bracket to hand

control assembly M8 HT (x 2) 30. Nut – rose joint to brake pedal

clamp 46. Spring washer – accelerator pedal

rod, pedal end

15. Spring washer – mounting

bracket to hand control ass’y (x 2) 31. Bolt – brake pedal clamp M8 (x 2) 47. Clamp – accelerator pedal

16. Steering column adjustment lever

stop plate 32. Brake pedal clamp, part A 48. Grub screw – accelerator pedal

clamp (x2)

Figure 4J-1

Figure 4J-2

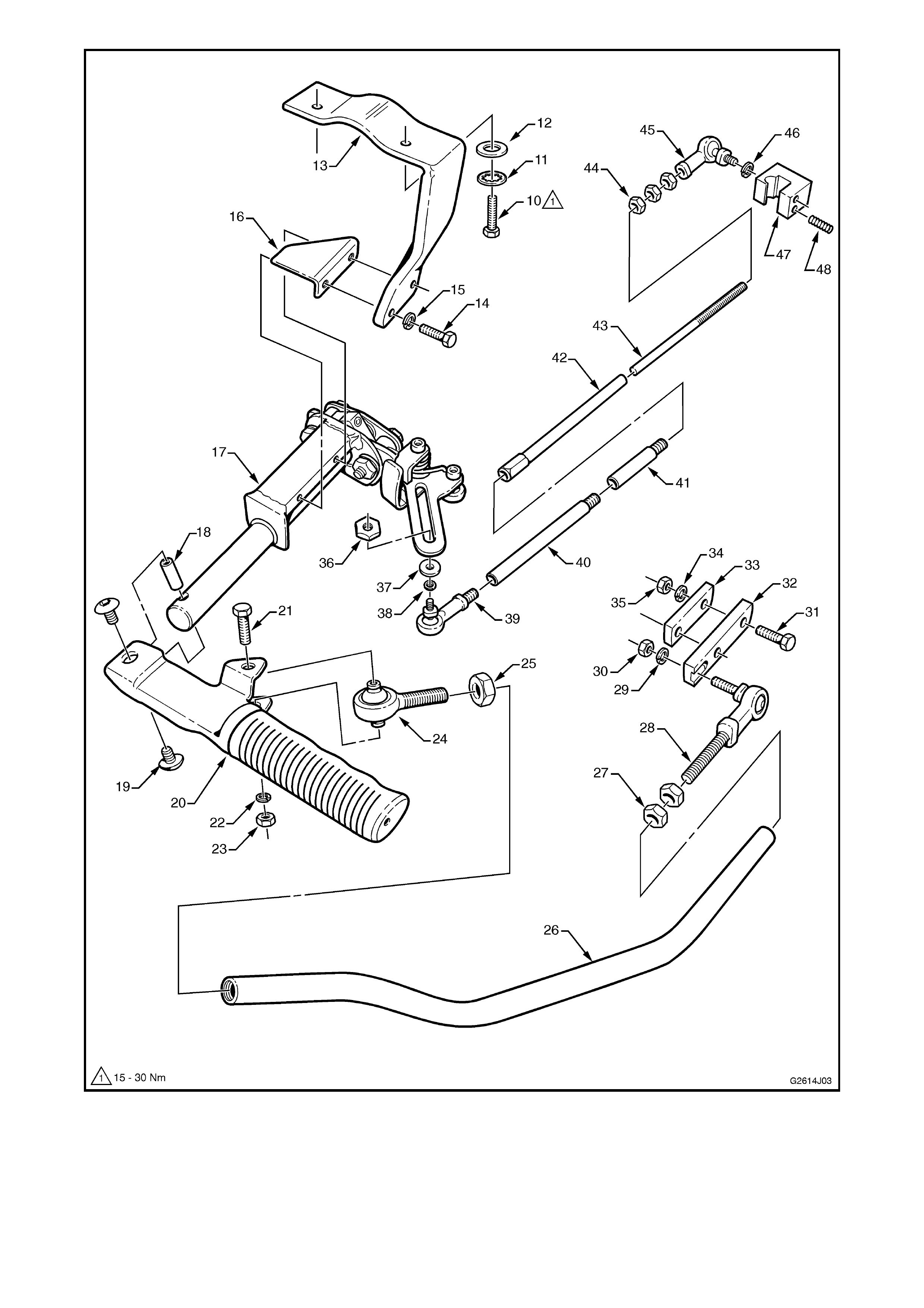

1.2 OPERATION

While operation of the hand control system is

relatively straightforward, familiarisation is required.

Brake application is achieved by pushing the lever

away from you, toward the dash (A). Pushing the

lever downward (B) toward your lap operates the

accelerator.

NOTE: It is recommended that non-authorised

persons do not drive a vehicle fitted with the hand

control system. However, circumstances may

necessitate service personnel drive such a vehicle.

Follow the procedures below and practice

maneuvering the vehicle in an isolated area before

driving the vehicle.

1. Start the engine.

2. W ith the engine at idle, depress the lever to apply

the brakes. Rev the engine slightly several times

to get the feel of the accelerator by pushing the

lever downwards.

3. Release the parking brake and place the

transmission selector in drive (or reverse if

required).

4. Release the brake lever while applying the

accelerator slightly.

5. Reapply the brake to get the feel of the braking

effort required.

6. Repeat as required until you feel confident of the

controls.

Figure 4J-3

2. MAINTENANCE

The Hand Control System has been designed for years of trouble free motoring, providing it is serviced and

inspected every twelve months in accordance with the following table.

ITEM

NO. COMPONENT ACTION SPECIFICATION

1. Hand grip Check for wear and fit Replace as required

2. Idle Speed If incorrect, throttle body return

spring may have lost tension.

Perform Tech II diagnostic

checks.

If OK, replace spring as required.

V6 – 725 ± 50 Auto in

N775 ± 50 Man

5.0 V8 – 700 ± 100 All

GEN III V8 – 650 ± 50

Auto in N 800 ± 50 Man

3. Mounting Bolts Check for looseness Tighten securely as required

4. Pedal Clamps Check for looseness Tighten securely and check

position as required

5. Pivots Check for looseness and/or wear Tighten securely as required

or replace if excessive play

6. Rose joints Check for wear Replace if excessive play

7. Brake pedal linkage Free-play

Position

Operation

Adjust if not approx. 2 mm

Adjust if too high or low

Check for binding, stiffness

8. Accelerator pedal linkage Free-play

Position

Operation

Adjust if not approx. 2 mm

Adjust if too high or low

Check for binding, stiffness

9. Spinner knob Check for looseness

Ensure knob spins freely Tighten securely as required

10. Indicator stalk extension Check for looseness

Ensure correctly positioned Tighten securely as required

Bend as required

11. All components Check for wear or damage Replace as required

3. SERVICE OPERATIONS

The Holden By Design Hand Control System mounts

below the steering column and attaches to the brake

and accelerator pedals. The fuse panel cover is

modified to fit around the steering column mounting

bracket.

3.1 FUSE PANEL ACCESS

The hand control assembly restricts access to the

fuse panel. The following procedure provides the

simplest means for accessing the fuses.

1. Remove the two bolts (1) attaching the hand

control assembly to mounting bracket (2).

2. Lower the hand control assembly to the floor.

NOTE: Steering column adjustment lever stop plate

(3) is also removed with the assembly.

3. Open the fuse panel cover by grasping each top

corner and pulling down. Service the fuses as

required.

4. Close fuse panel cover.

5. Return the steering column adjustment to its

correct position, if it has been moved.

6. Raise the hand control assembly into position at

the mounting bracket and fit the steering column

lever stop plate.

7. Insert bolts and tighten securely.

8. Check correct operation. Figure 4J-4

3.2 HAND CONTROL ASSEMBLY

REMOVE

1. Disconnect battery to disable the SRS air bag

system.

NOTE: Disconnecting the batter y will render the radio

inoperative until the correct security PIN code is

entered. Refer to the audio system operating

instructions provided with the vehicle owner’s

handbook for further information.

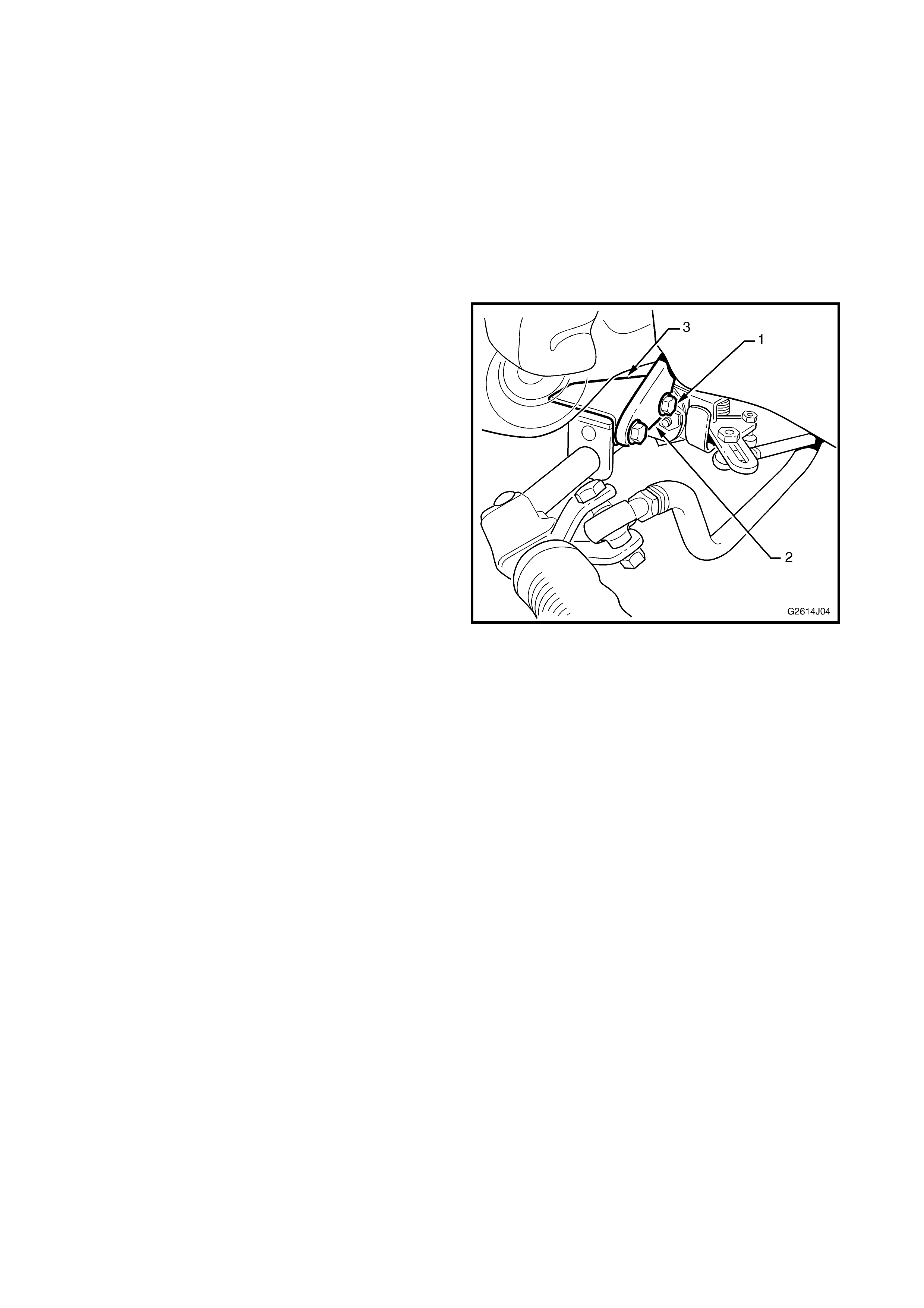

2. Slightly loosen the nut and bolt (1) fr om the brak e

pedal clamp (2).

3. Completely remove the other nut and bolt (3).

4. Remove the clamp from the pedal and rest

linkage on the floor.

Figure 4J-5

5. Either:

• Loosen the two grub screws (1) from the

accelerator clamp (2).

Remove the clamp from the pedal and rest

the linkage on the floor, or

• Once the hand control assembly is lowered,

slide the linkage shaft (3) off the end link.

Figure 4J-6

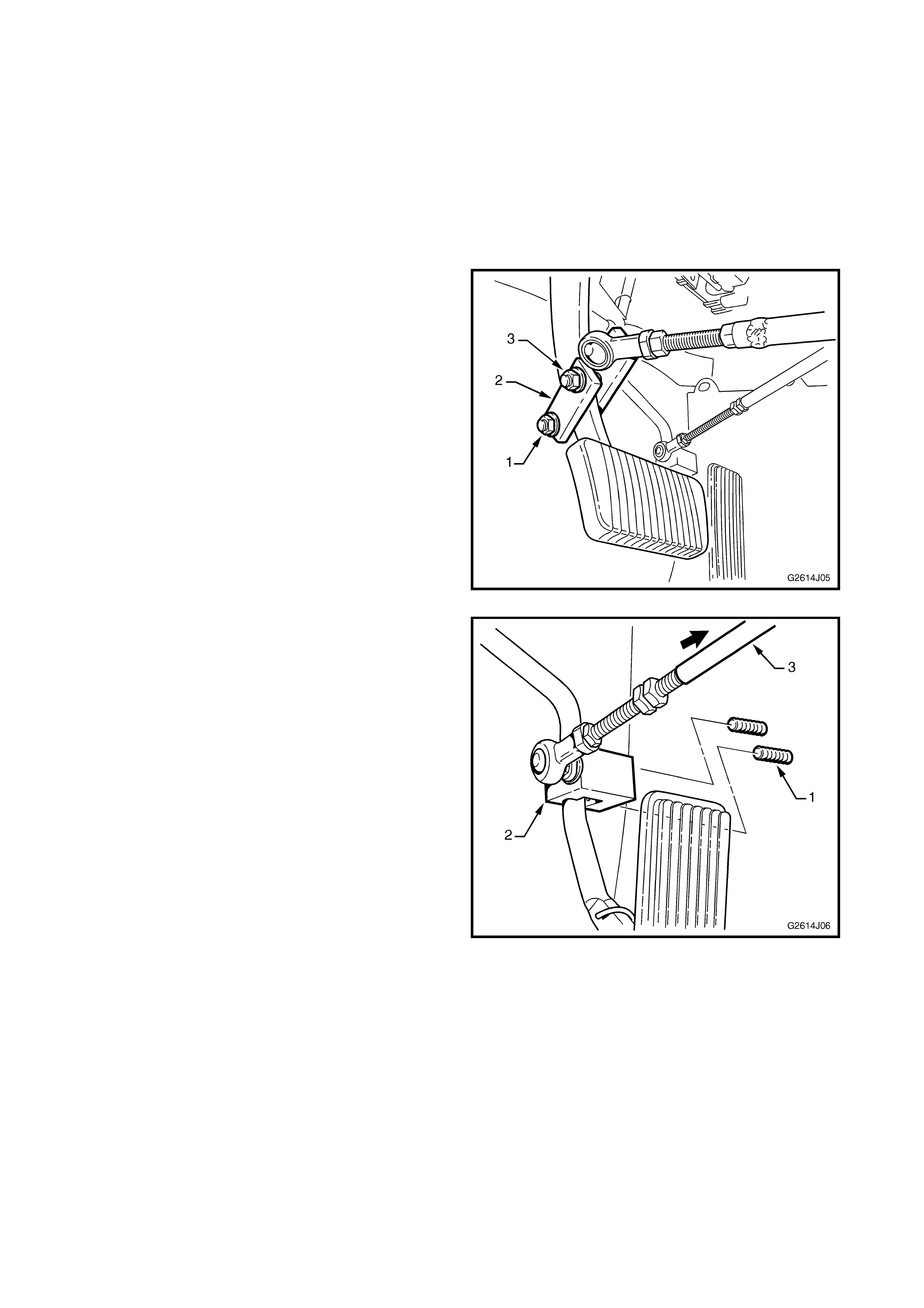

6. Remove the two bolts (1) attaching hand control

assembly to mounting bracket (2).

NOTE: Steering column lever stop plate (3) is also

removed with the assembly.

7. Remove hand control assembly from vehicle.

Figure 4J-7

8. Open the fuse panel cover (1) by grasping each

top corner and pulling down, disengaging the

retainers (2), three places.

9. Remove the pin (3) and slide the fuse cover out of

its mounting.

Figure 4J-8

10. Undo bolt (1) attaching the mount bracket (2) to

the steering colum n m ount, lower the column and

remove the mount bracket.

NOTE: A retainer washer (3) is attached to the bolt

and will hold the bolt in place.

11. To remove mounting bolt, unscrew retainer (3)

and remove the bolt, shake-proof washer (4) and

flat washer (5).

Figure 4J-9

DISASSEMBLE

The components can be further disassembled if

required, refer 1.1 COMPONENTS for view of

components.

NOTE: To assist in assembly and adjustment, note

the position of locknuts, rose joints, etc. on their

threads prior to disassembly.

INSTALL

Mounting Bracket

1. Disconnect battery to disable the SRS air bag

system.

NOTE: Disconnecting the batter y will render the radio

inoperative until the correct security PIN code is

entered. Refer to the audio system operating

instructions provided with the vehicle owner’s

handbook for further information.

2. If not already done, undo bolts attaching steering

column upper mount and lower the steering

column.

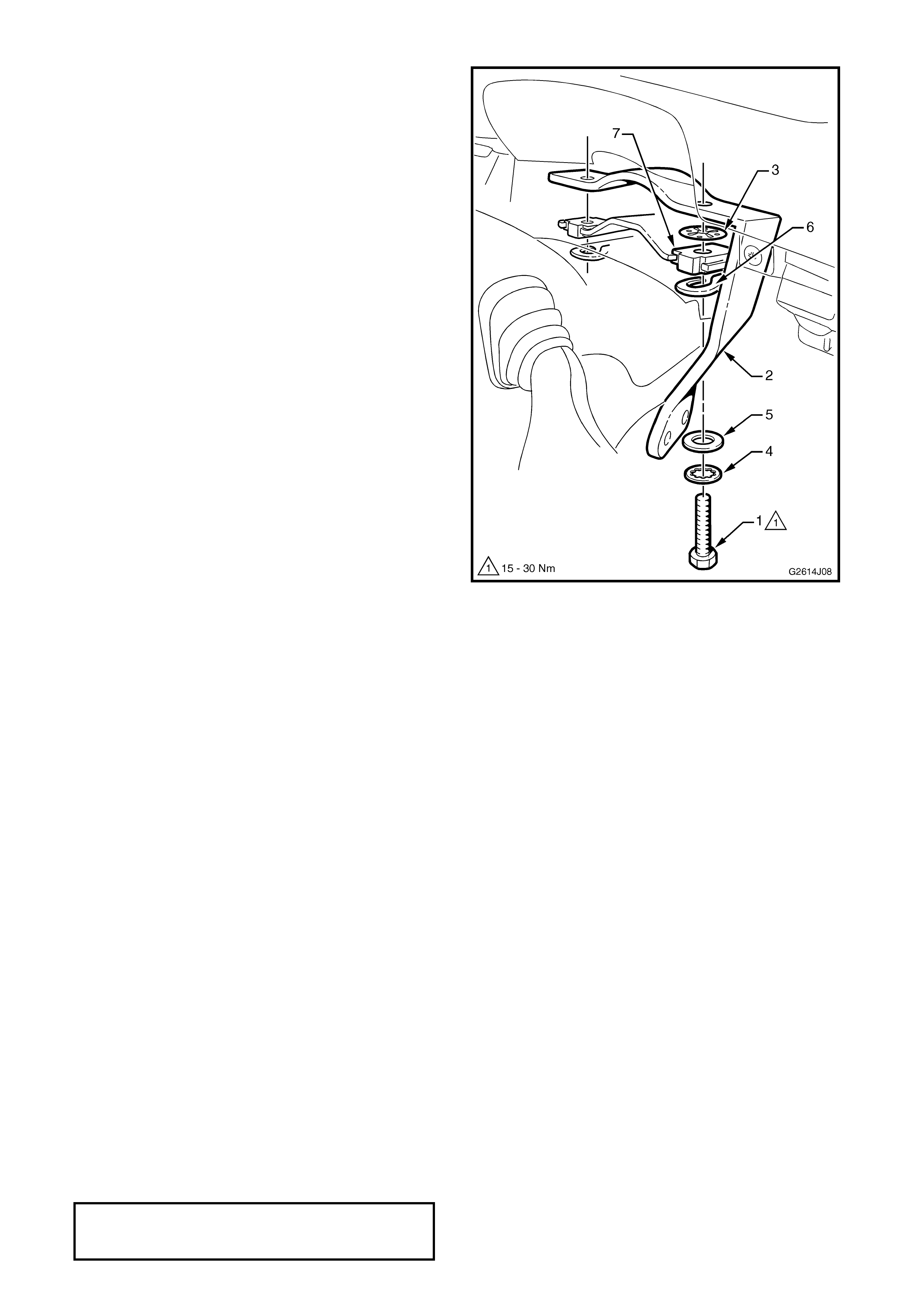

3. If required, f it the bolt (1), shake-pr oof washer (4)

and flat washer (5) through the tilt spring (6) and

steering column upper mount (7). Attach the

retainer (3), refer Fig. 4J-9.

NOTE: The original 25 mm bolts are replaced with

longer 35 mm bolts when the hand control is fitted.

4. Fit the hand control bracket (2) between the

steering column and column mount bracket.

5. Raise the steering column into position and

tighten bolts to the specified torque.

STEERING COLUMN UPPER

MOUNT BOLT

TIGHTENING TORQUE 15 – 30 Nm

Fuse Panel Cover

NOTE: If a new fuse panel cover is supplied it will

require modifying.

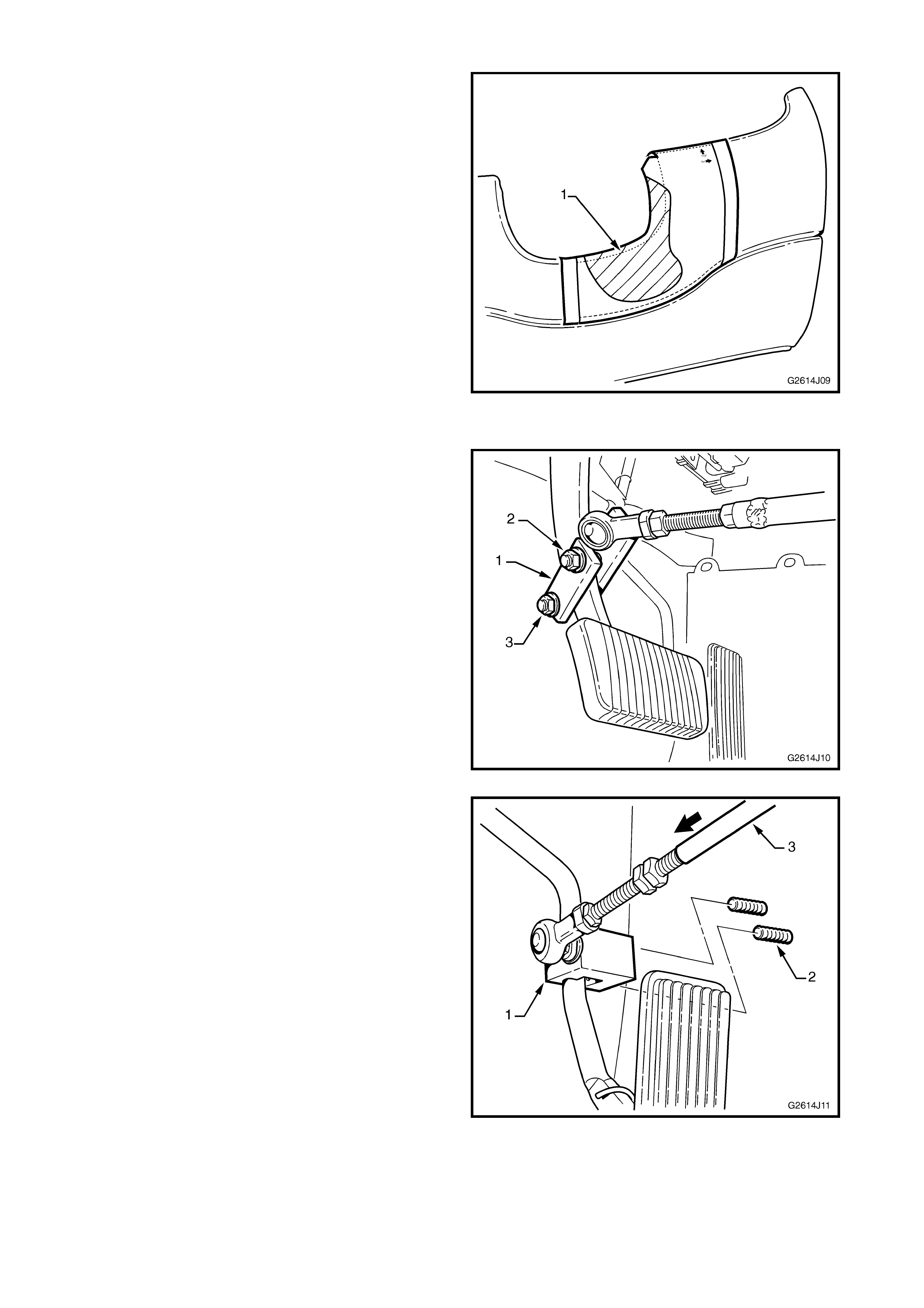

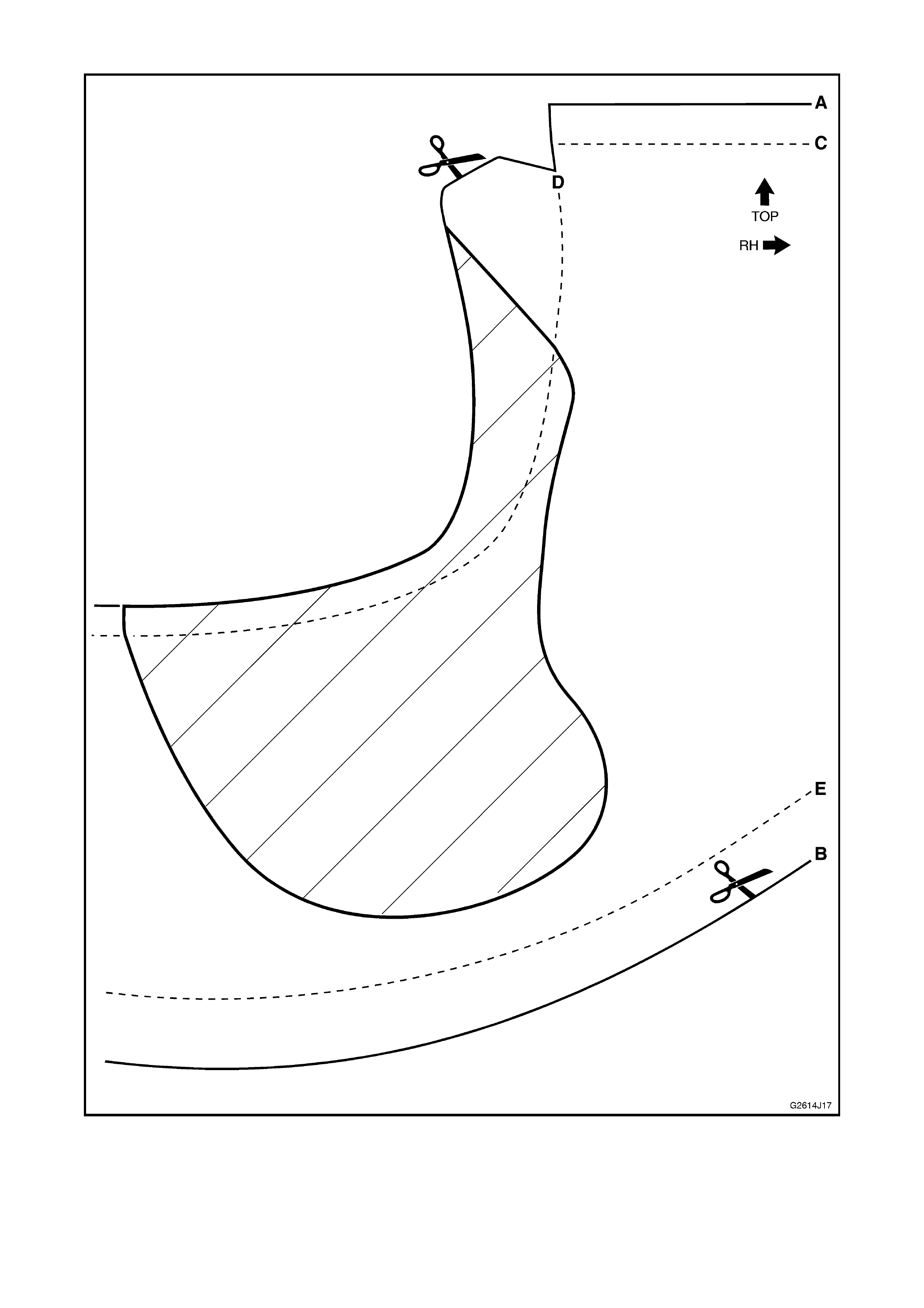

1. Copy the template provided in Fig. 4J-17 and cut

along lines A & B.

2. Fold along lines C, D & E and place it on the fuse

panel cover as shown.

3. Mark around the area to be removed (1) and cut

the fuse panel cover to provide clearance for the

hand control assembly.

4. Fit the fuse panel cover in place and close, refer

Fig. 4J-8.

5. Trim the fuse panel cover as required and smooth

all sharp edges.

Figure 4J-10

Hand Control Assembly

1. Return the steering column adjustment to its

correct position, if it has been moved.

2. Lay hand control assembly on the driver’s floor.

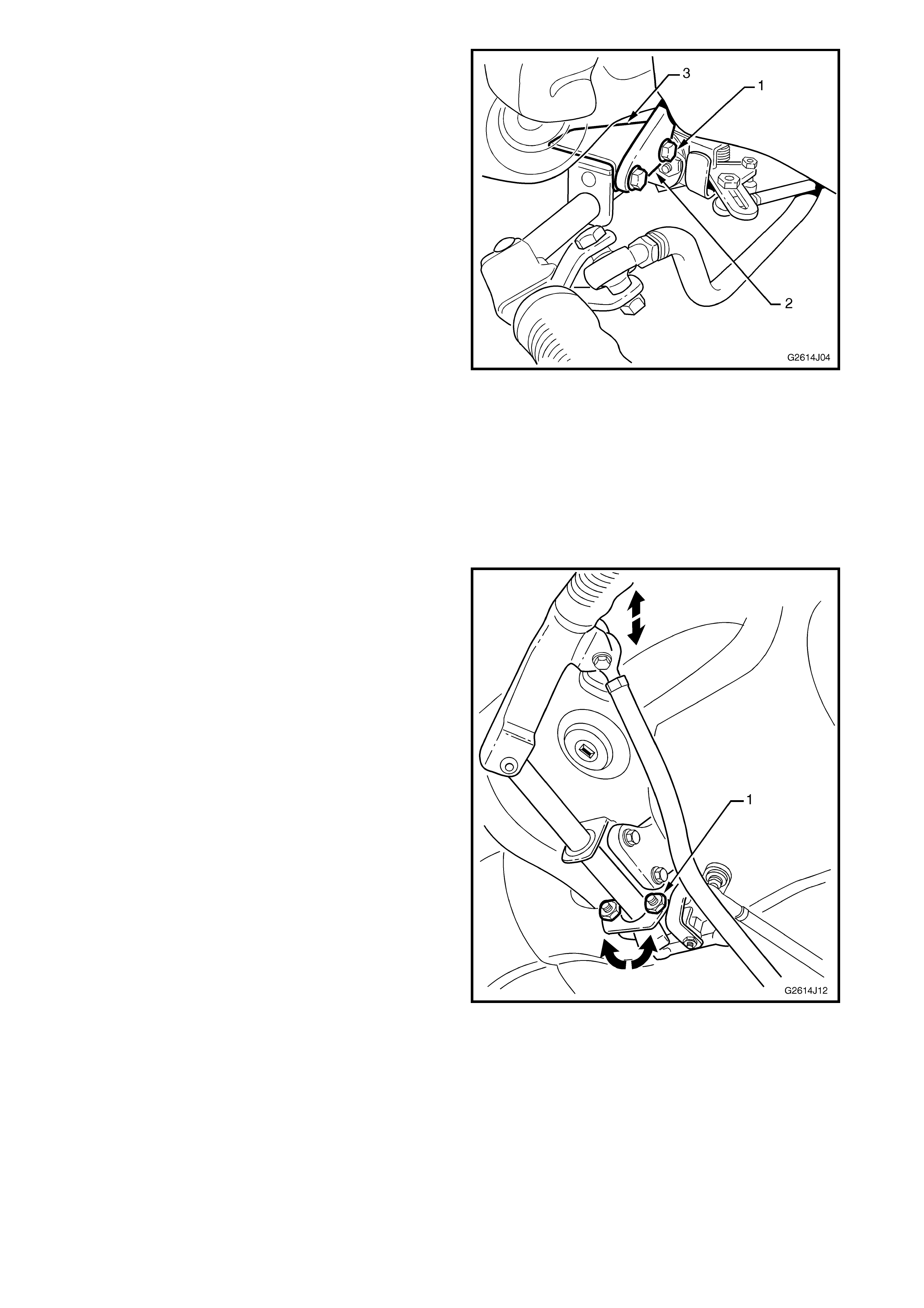

3. Attach brake pedal clamp (1) to the brake pedal

arm, approximately 90 mm above brake pedal

pad.

4. Insert nut, bolt and washer (2).

5. Tighten bolts (2 & 3) securely.

Figure 4J-11

6. Depending on removal method, either:

• Attach the accelerator clamp (1) to the

accelerator pedal arm, as close to the pedal

as possible without interfering in its operation.

Tighten grub screws (2) securely, or

• Slide the linkage shaft (3) on to the end link.

7. Close fuse panel cover, if open.

Figure 4J-12

8. Raise the hand control assembly into position at

the mounting bracket (2) and fit the steering

column lever stop plate (3).

9. Insert bolts (1) and tighten securely.

10. Check correct operation, ensuring upon full travel

of the brake and accelerator pedals the

mechanism clears surrounding components and

the pedal pads. Adjust if required.

Figure 4J-13

ADJUST

Three main adjustments of the hand control are

provided which set the position of the lever. They

must be performed in the following order.

NOTE: The hand control is set to default factory

settings. Minor adjustments may be required to best

suit the driver’s requirements. Adjust only if

necessary.

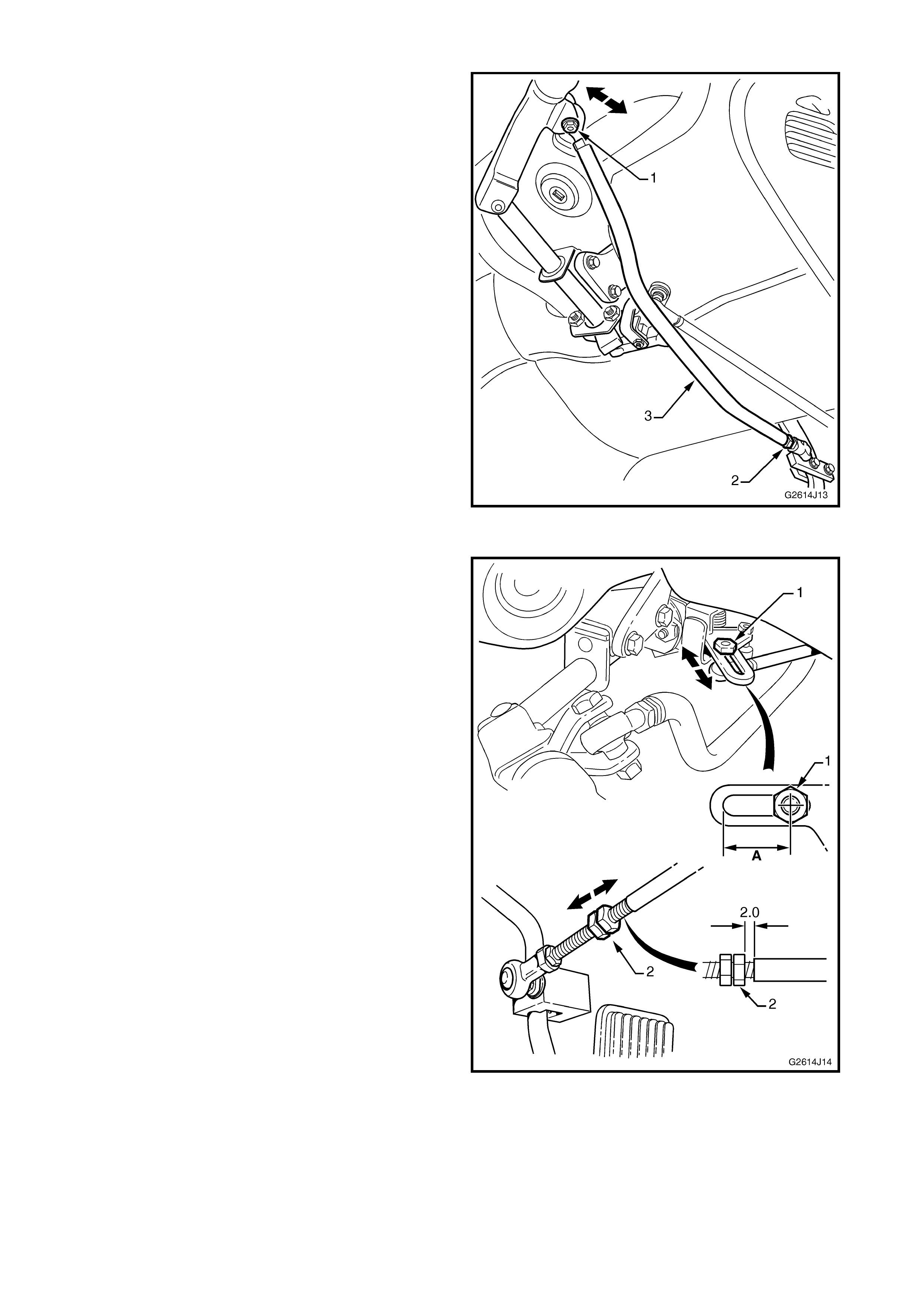

Lever Height

1. Loosening bolt and nut (1), two places will allow

the lever to be rotated up or down as shown.

NOTE: The factory default position is the lever grip

set slightly above horizontal.

2. Retighten the bolts and nuts securely.

Figure 4J-14

Brake Pedal Rod

This adjustment sets the distance of the lever from

the driver.

NOTE: The factory default setting is 50 mm from the

rear of the steering wheel rim.

1. Remove bolt and nut (1) from lever and remove

the brake pedal rod joint.

2. Loosen locknut (2).

3. Rotate the rod (3) to increase or decrease its

length. This will move the control lever closer or

further away from the driver.

NOTE: It may be helpful to have the driver seated in

their normal driving position while performing this

adjustment.

4. When desired lever position (factory default or

driver’s preferred position) is achieved, refit joint,

bolt and nut into lever and tighten securely.

5. Tighten locknut securely.

Figure 4J-15

Accelerator Pedal Rod

These adjustments are performed last and set the

amount of leverage required to operate the

accelerator and freeplay in the rod.

1. Loosen nut (1).

2. Slide the joint along the slot as required.

NOTE 1: Moving the joint closer to the assembly

results in less lever action being required to operate

the accelerator.

NOTE 2: The factory default dimension A is:

VT – 20 mm

WH – 35 mm

3. Tighten nut securely when the desired position is

achieved.

4. Loosen locknuts (2) and adjust until

approxim ately 2 mm freeplay is present when the

pedal is at rest.

5. Tighten locknuts securely.

6. Start vehicle and check for correct idle speed,

refer 2. MAINTENANCE in this Supplement.

Figure 4J-16

Fuse Panel Cover Template

Figure 4J-17

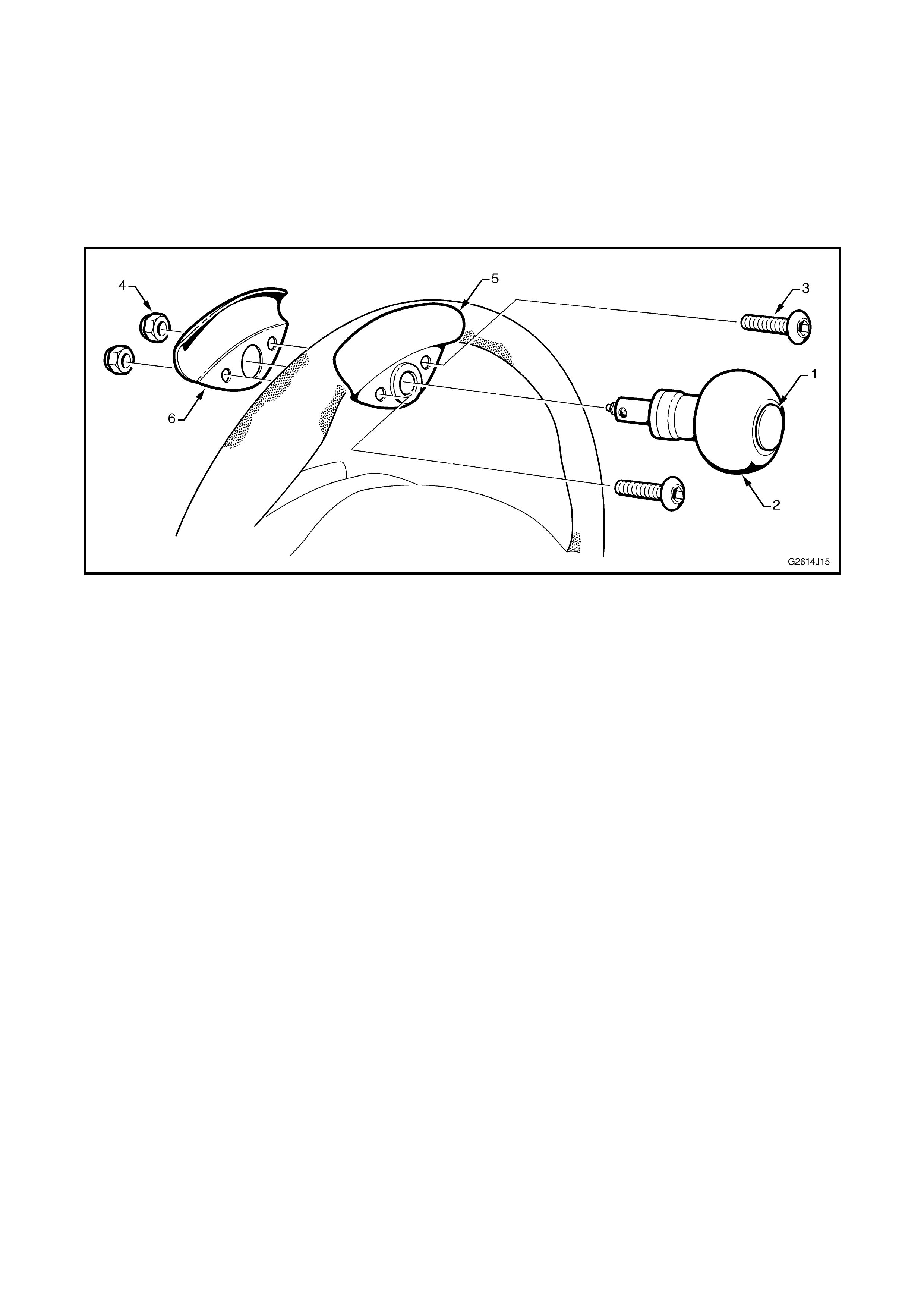

3.3 STEERING WHEEL KNOB

REMOVE

1. Depress button (1) in centre of knob (2) and

remove from mounting bracket.

2. Remove screws (3) and Nyloc nuts (4), two

places.

3. Remove mounting bracket sections (5 & 6).

Figure 4J-18

INSTALL

1. Align steering wheel in the straight-ahead

position.

2. Fit the m ounting brack ets to the steering wheel at

the 10 o’clock position.

NOTE: Ensure the front and rear sections are

positioned correctly and the rubber padding is

correctly seated.

3. Insert screws and Nyloc nuts, two places and

tighten securely.

4. Depress button in centre of k nob and fit the knob

into the mounting bracket.

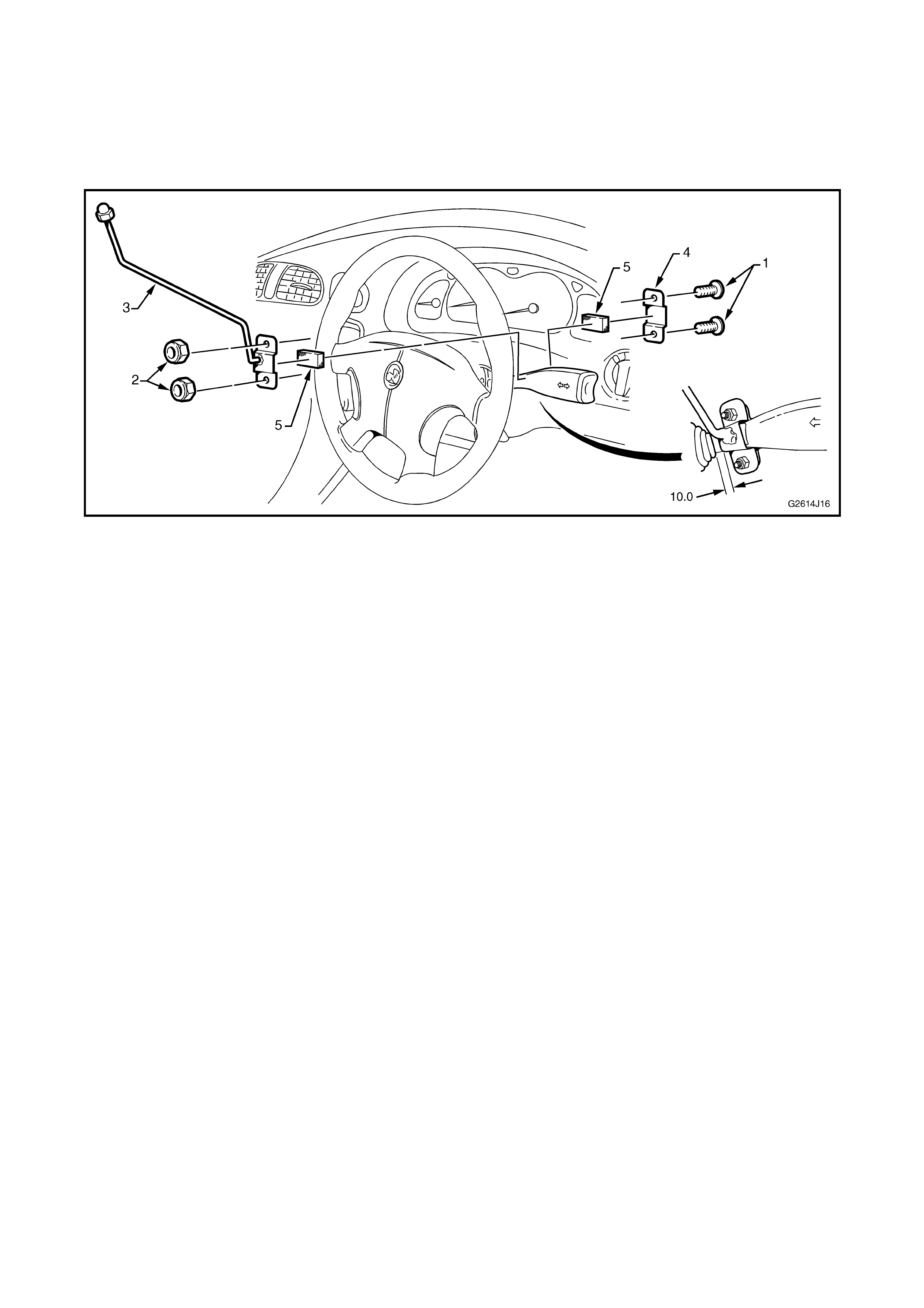

3.4 INDICATOR STALK EXTENSION

REMOVE

1. Remove screws (1) and nuts (2), two places.

2. Remove the extension (3) and bracket (4).

Figure 4J-19

INSTALL

1. Ensure foam-padding (5) is seated in the indicator

stalk extension and bracket.

2. Position the extension on the indicator stalk

approximately 10 mm from the rubber boot.

3. Fit brack et to the ex tens ion and ins ert s c rews and

nuts as shown and tighten nuts securely.

NOTE: Ensure foam is seated correctly on stalk.

4. If required bend the extension to best suit the

driver’s requirements.