SECTION 5C – VS SERIES III ID UTILITY & 195 KW V8

ENGINE

CAUTION:

This vehicle may be equipped with a driver’s side only or driver’s and front passenger’s side Air

Bags. An AIR BAG is a Supplemental Restraint System (SRS). Refer to CAUTIONS, Section 12M in

Volume 4 of the VS Series Service Manual, before performing any se rvice operation on or around SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS could result in air

bag deployment, resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

This v ehicle may be equipped w ith LPG ( Liquefied Pet roleum Gas). In th e interests of safet y, the LPG

fuel system should be isolated by turning 'OFF' the manual service valve and then draining the LPG

service lines, before any service work is carried out on the vehicle. Refer to the LPG leaflet included

with the Owner's Handbook for details or Volume 6 of the VS Series Service Manual for more specific

servicing information.

1. GENERAL INFORMATION

This Section of the Holden By Design Service Information Supplement provides a detailed summary of the VS

Series III utility id enhancement package and associated components, including the 195 kW engine.

The utility id enhancem ent package c onsists of components designed to enhance and add spor ting character to

the Holden utility. The standard package consists of a unique single opening grille, f ive spoke alloy wheels and

revised suspension.

Where the id enhancement package is optioned on a standard model utility, the bumper bars are painted the

vehicle body colour. A Holden By Design identification plate, decals and id badging complete the package.

In addition, other components can be added or optioned individually to further enhance the vehicle.

The components include:

• Rigid tonneau,

• Cargo liner,

• 195 kW V8 engine,

• Alloy wheels of a different style.

The 195 kW V8 engine was developed by Holden Special Vehicles ( HSV) and incorporates m odifications to the

inlet, exhaust and engine management systems.

Where necessary, the removal and installation procedures for various components of the package have been

included, however for information not contained in this Section, refer to the relevant VS Series Service Manual.

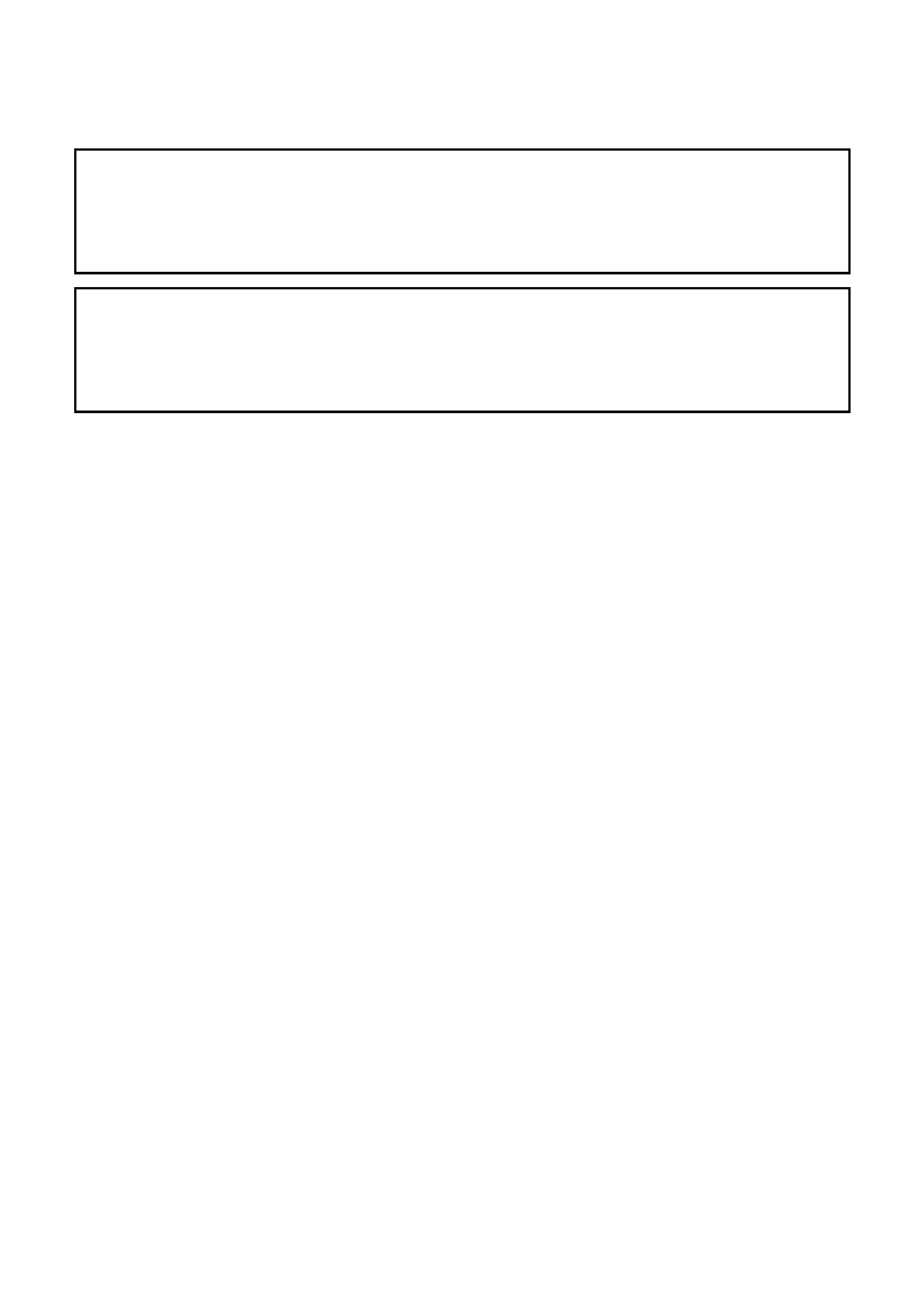

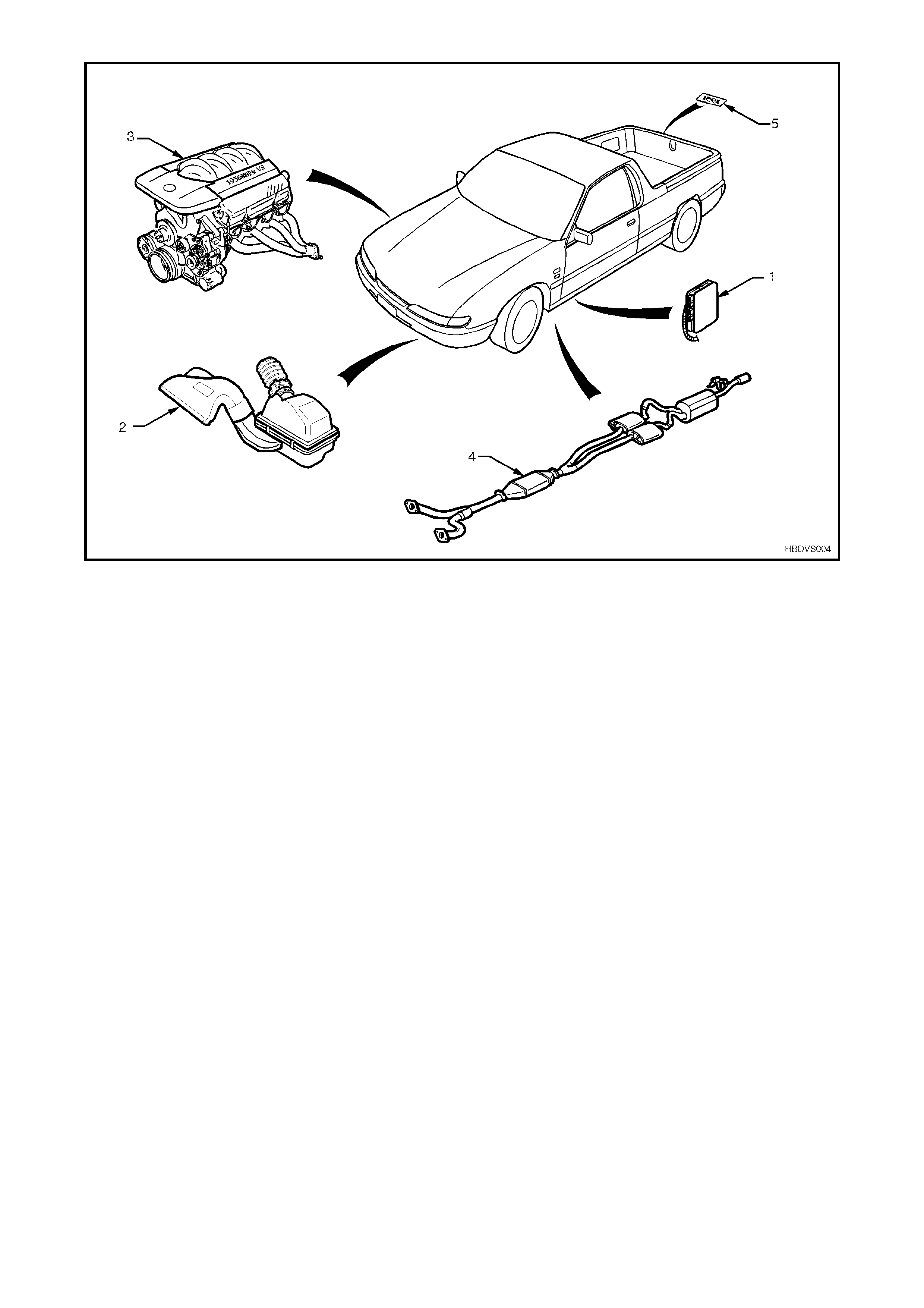

Fig. 5C-1 illustrates the major components available for the VS Series III Utility.

1.1 MAJOR COMPONENTS

Figure 5C-1

1. Cargo liner 7. Rear coil springs 13. Front stabalizer bar

(27mm)

2. Exhaust system 8. Alloy wheels 14. Sports grille

3. 195i emblem 9.id badge 15. 195 kW V8 engine

4. Rigid tonneau 10.PCM 16. HBD identification plate

5. Rear panhard rod 11.Front gas shock absorbers

6. Rear gas shock absorbers 12. Front coil springs

2. ID SPORTS GRILLE

The sports grille fitted to VS Series III Utility Models with the id enhancement package remains unchanged from

earlier VS Utility Model. For all id sports grille information, including removal and installation procedures, refer to

Section 5A VS ID UTILITY in this Service Information Supplement.

3. RIGID TONNEAU

The rigid tonneau cover fitted to VS Series III Utility Models with the id enhancement package remains

unchanged from earlier VS Utility Model. For the removal and installation procedures of the rigid tonneau cover,

refer to Section 5A VS ID UTILITY in this Service Information Supplement.

4. CARGO LINER

The cargo liner fitted to VS Series III Utility Models with the id enhancement package remains unchanged from

earlier VS Utility Model. For the removal and installation procedures of the rigid tonneau cover, refer to Section

5A VS ID UTILITY in this Service Information Supplement.

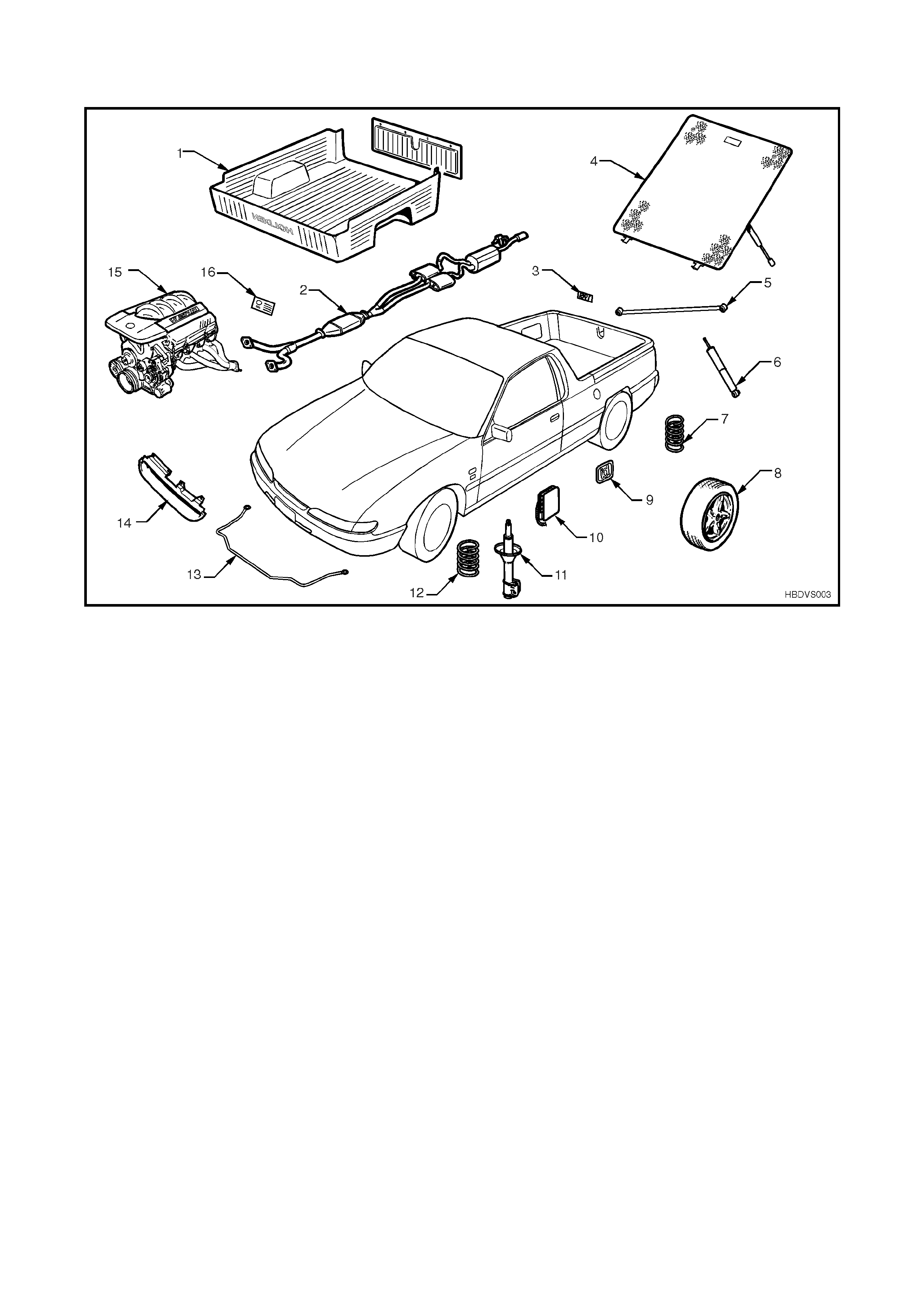

5. ALLOY WHEELS

Two alloy wheel styles are available for Holden By

Design VS Utility Vehicles. Both have a 16” diameter

and are 7” wide.

While wheel nuts designed for use with alloy wheels

are fitted, the wheel studs remain the same as

standard VS Series Vehicles.

The standard spare wheel is not changed and as

such, should be used as a temporary wheel only.

This Section of the Holden By Design Service

Supplement illustrates the wheel types only. For the

information required to service wheels for VS Series

Vehicles, refer to Section 10, WHEELS & TYRES in

Volume 4 of the VS Series Service Information.

Figure 5C-2

6. SUSPENSION

To cater for the increased power and enhance the

overall performance of the vehicle, the suspension has

been revised to include:

• HBD developed progressive rate springs

• HBD recalibrated gas shock absorbers

• HBD developed front stabiliser bar

• HBD developed rear panhard rod

These changes do not effect the Service Operations of

the vehicle, however, specifications have been revised

and published in this Section.

Whenever any Service Operation is performed on the

front or rear suspension of a VS Series III Utility Model

with Production Option XX3, refer to Sections 3 FRONT

SUSPENSION and 4A FIVE LINK REAR SUSPENSION

in the relevant Volumes of the VS and VR Series

Service, while referring to the following specifications.

6.1 SPECIFICATIONS

FRONT

Stabiliser bar

Type......................................................................... Decoupled

Diameter.................................................................. 27.0 mm

Control arm

Type......................................................................... Forged with rubber bushes for attachment to front

crossmember and tension rod. Ball joint is riveted

on to the control arm.

Front wheel bearings

Type......................................................................... Double row ball bearing

Lubricant.................................................................. Sealed for life: non-adjustable

Front strut

Type......................................................................... Oil; gassed – non-serviceable

Piston Diameter....................................................... 30 mm

Capacity................................................................... 310 ml

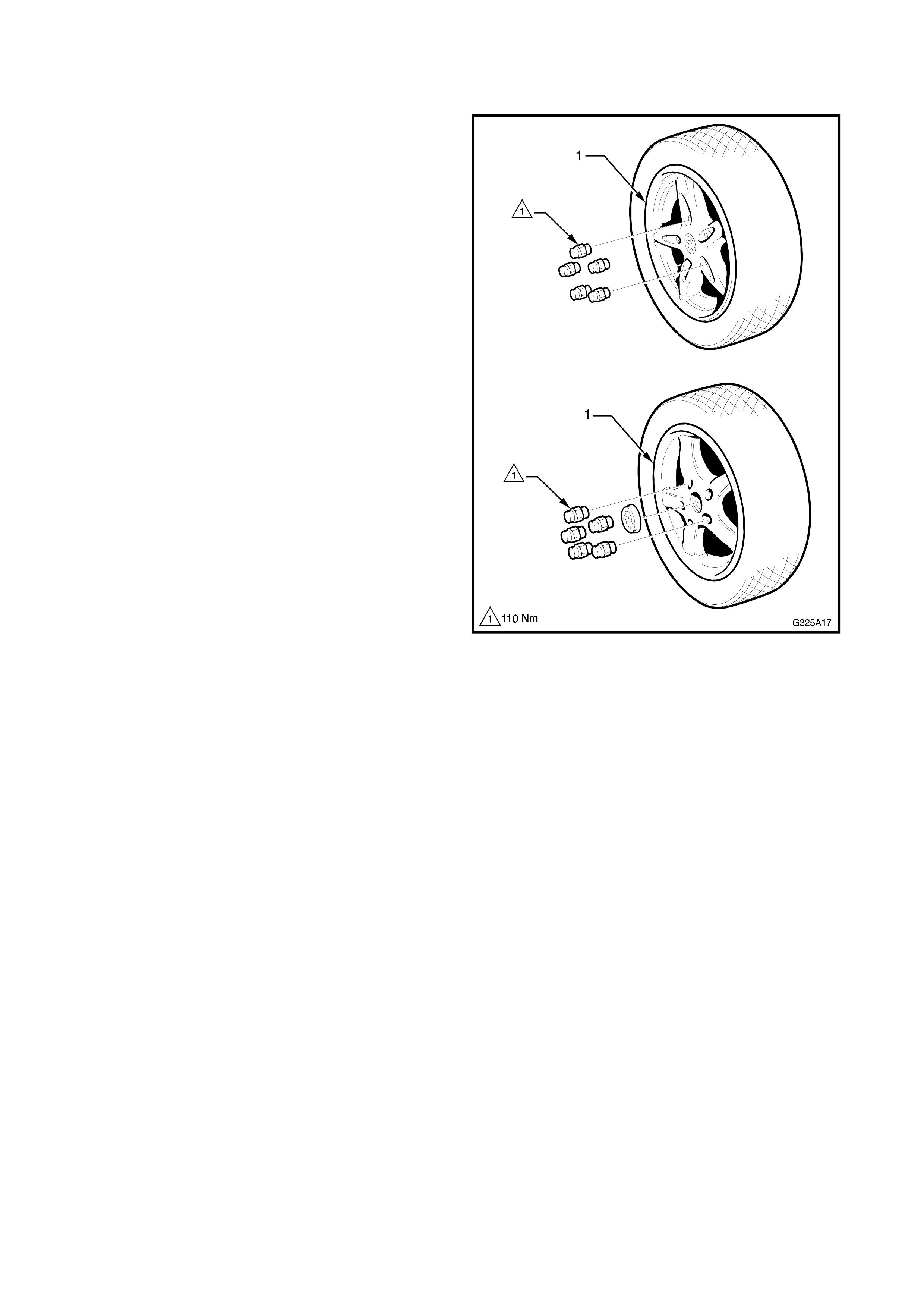

Front spring details

Model:........................ VS Series III with P.O. XX3

Total number coils:.... 5.70

Free length: ............... 348 mm

Outside diameter:...... 165 mm

Production I.D. code:. HT

Spring rate & type:..... Variable 25 – 25 N/mm

(3825 ± 110 N @ 194mm)

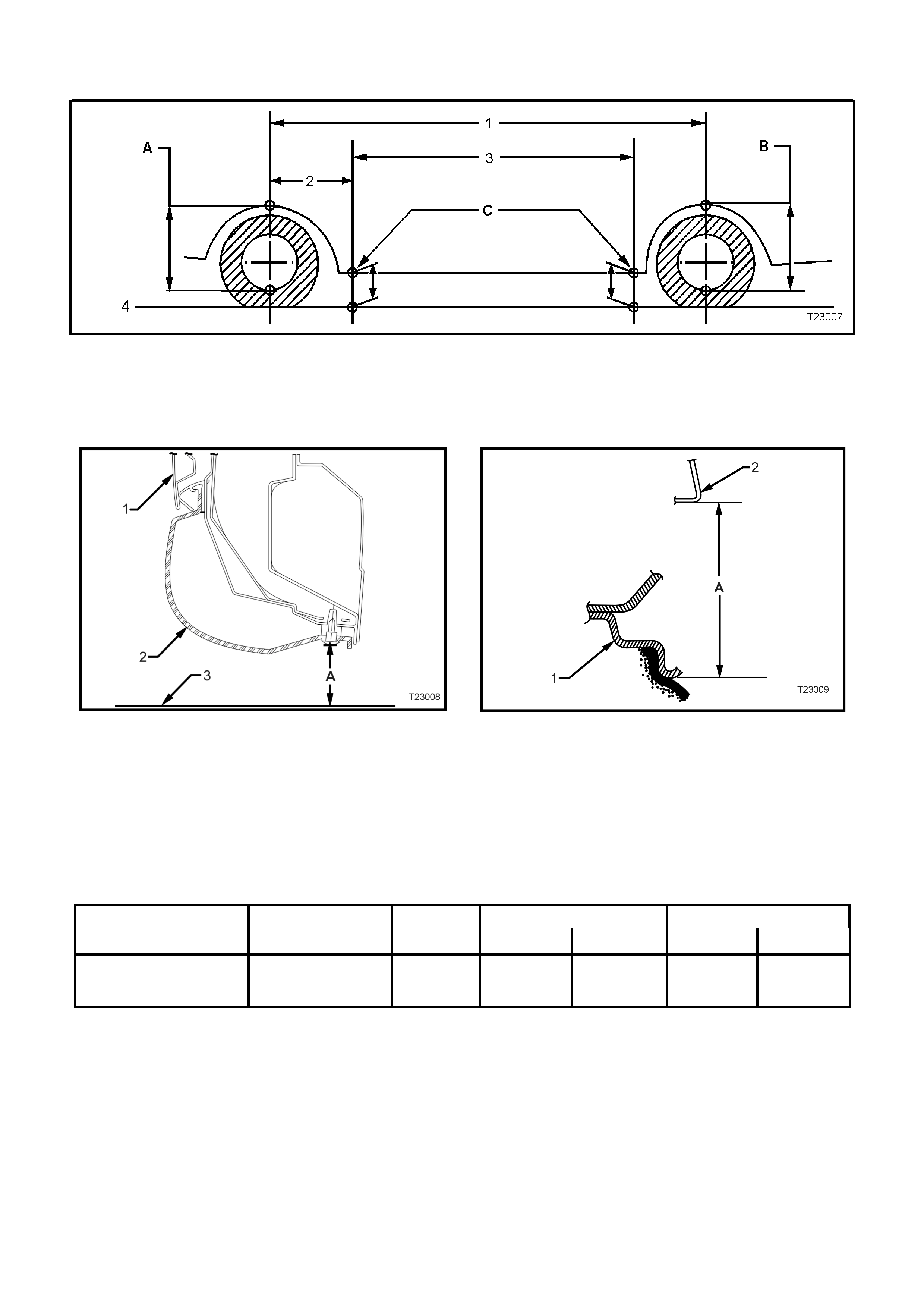

Figure 5C-3

Trim and suspension heights

Figure 3-4

A Front Suspension Height

B Rear Suspension Height

C Trim Height Checking Locations

1. Wheelbase: 2822 mm

2. Reference Point: – 521.25 mm

3. Trim Height Spacing:1800.00 mm

4. Ground Line

Figure 3-5 Rear trim height checking location

(similar location for front)

1. Door

A Trim height

2. Trim

3. Ground line

Figure 3-6 Front and rear suspension checking location

1. Wheel rim

A Suspension height

2. Fender opening

NOTE: The following suspension/trim height dimensions are intended for reference and are intended to

be a guide only (Refer to 2.2 SUSPENSION AND TRIM HEIGHT CHECK, in Section 3 FRONT

SUSPENSION, in Volume 11A of the VR Series Service Information).

SUSPENSION HEIGHT TRIM HEIGHT

VEHICLE

DESCRIPTION TRANSMISSION MODEL FRONT REAR FRONT REAR

VS SERIES III UTILITY

WITH P.O. XX3 Manual or

Automatic Base 610 mm 610 mm 259 mm 298 mm

REAR

Stabilizer bar details

Diameter..................................................................... 16.0 mm

Production I.D. code................................................... AE

Rear spring details

Total number of coils.................................................. 9.06

Free length................................................................. 350 mm (Note: 10mm ring space fitted to RHS)

Inside diameter........................................................... 94.0 mm

Production I.D. code................................................... YA

Spring type & rate....................................................... Variable 49 - 64.1 N/mm

7. 195 KW V8 ENGINE

This Section of the Holden By Design Service Information Supplement describes the components employed in

the 195 kW V8 engine upgrade (Production Option XX3).

Holden Special Vehicles have developed the 195 kW V8 engine, based on the standard Holden 5.0 litre V8

engine. Modified components fitted to this engine, that differ from the standard V8 engine include:

• Cylinder head

• Exhaust valve spring

• Stainless steel valve spring seat

• Exhaust valve

• Fuel rail and throttle body cover (engine dress cover)

• High lift, high duration camshaft (refer specifications in this Section)

• Timing chain and steel sprockets

• Timing chain damper

These modifications are designed to improve the engines breathing and ensure it copes with the power increase.

Accompanying these modified engine components are; a revised air inlet system, a new exhaust system and a

recalibrated powertrain management system (PROM).

Together, these modifications increase the power output to 195 kW @ 4800 rpm and torque output to 430 Nm

@ 3600 rpm.

195 kW V8 engines are identified by the engine option code LB9 & XX3, which is stamped into the vehicle

identification plate. Also, the engine number is prefixed by the letters VN. The engine number is located on the

LH side of the cylinder block above the oil pump housing.

A Holden By Design identification plate and 195i badging completes the package, which is described in 8,

IDENTIFICATION & BADGING in this Section.

All other service procedures for the Holden By Design 195 kW V8 engine are the same as the standard 5.0 litre

V8 engine components. Refer to the relevant Section in Volume 11 of the VS Series Service Information, noting

the following:

Some references in Volume 11 of the VS Series Service manual will refer the reader to Section 6A2 ENGINE

MECHANICAL – V8 ENGINE in Volume 2 of the VT Series Service Information.

Fig. 5C-7 illustrates the 195 kW V8 engine major components.

Figure 5C-7

1. Powertrain Control Module (PCM) &

PROM 4. Exhaust system

2. Air inlet assembly 5. 195i emblem

3. 195 kW engine assembly

CAMSHAFT

195 KW V8 CAMSHAFT SPECIFICATIONS

HSV 195 kW V8 camshaft Part No. 06X-970301

Lobe lift 0.28”

Lobe duration: Inlet

Exhaust268°

268°

Valve timing @ 0.050” valve lift:

Inlet open

close

Exhaust open

close

21° BTDC

67° ATDC

65° BTDC

23° ATDC

Duration @ 0.050” 206°

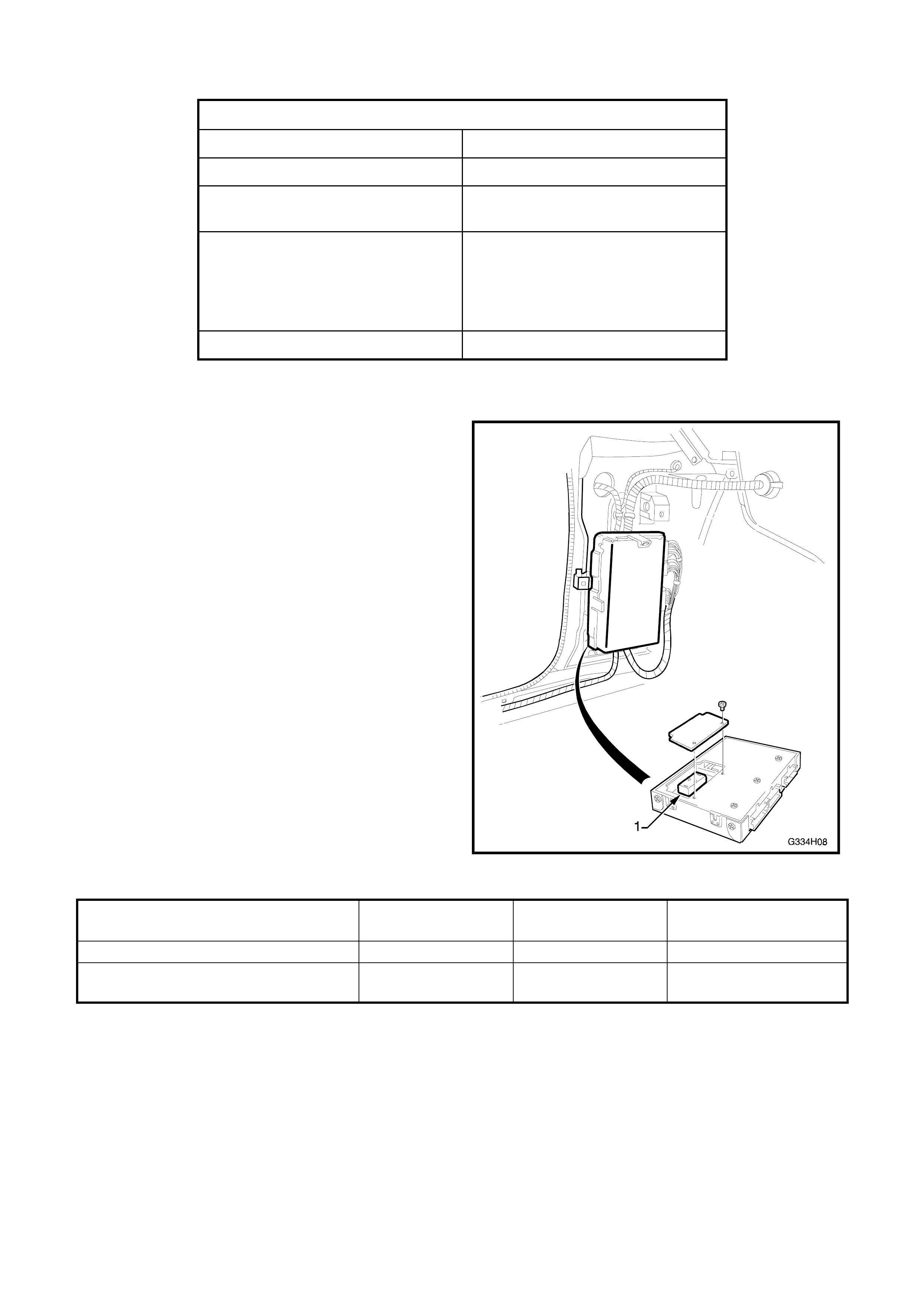

POWERTRAIN MANAGEMENT

Changes to the powertrain management system for

the 195 kW V8 include the fitment of a revised

Powertrain Control Module PROM unit (1).

Service procedures for the Holden By Design 195 kW

V8 powertrain management system are the same as

the standard VS Series V8 powertrain management,

with the exception of the PCM & PROM identifications

as shown in the chart below.

Refer to Section 6C2, POWERTRAIN

MANAGEMENT - V8 ENGINE in Volume 11 of the VS

Series Service Information.

Figure 5C-8

DESCRIPTION HOLDEN PART

No. HSV PART No. BROADCAST CODE

195 kW PROM – Manual transmission 98363158 12F- 990501 CNPC

195 kW PROM – Automatic

transmission 09363168 12F-990502 CNPD

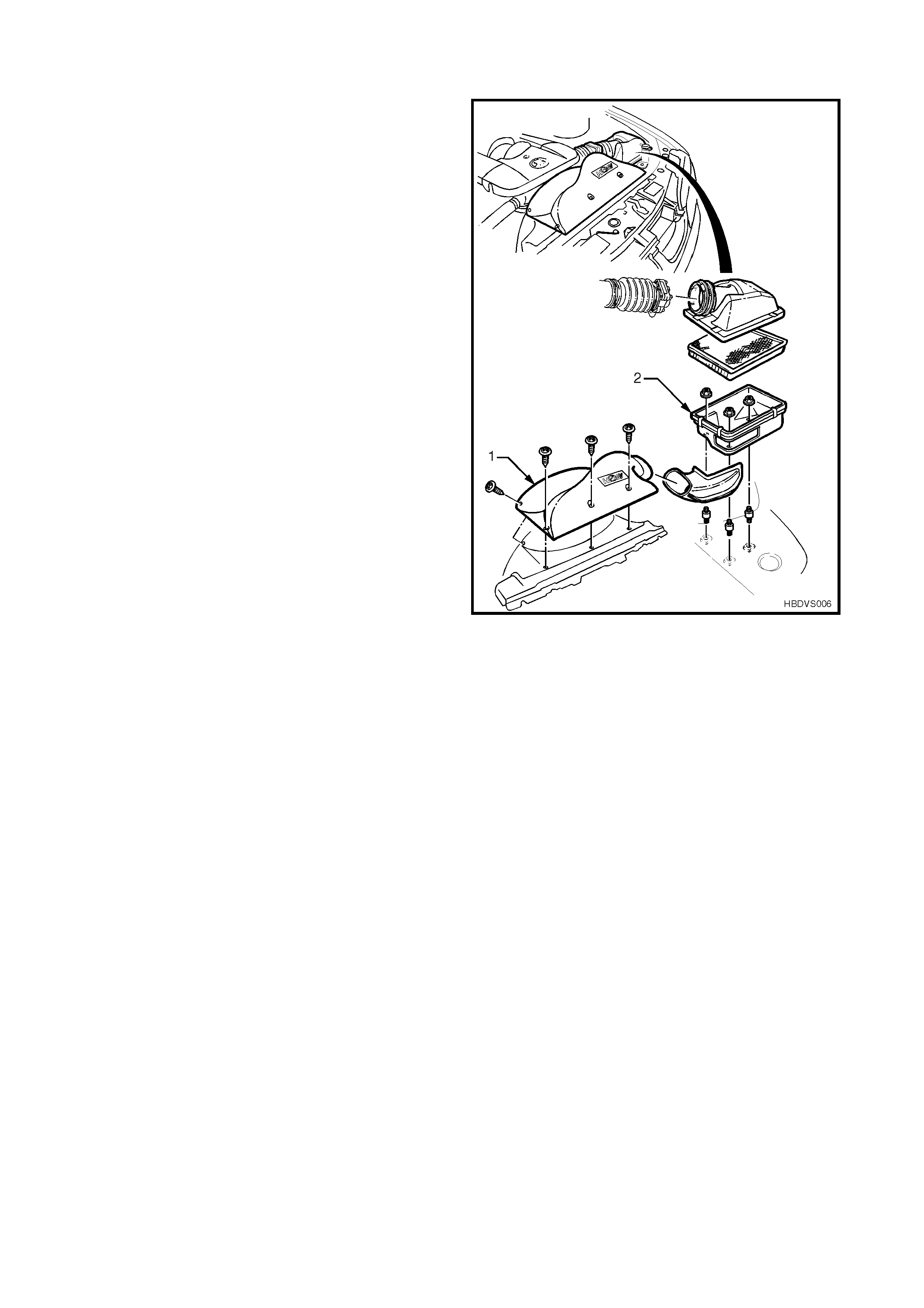

INLET SYSTEM

A newly designed cold-air inlet system, which has

been optimised for the 195 kW engine is fitted.

Changes from the standard air inlet system include a

free flow inlet snorkel (1). All other components,

including the air filter, are standard VS Series III V8

engine (P.O. XT9) components.

Service procedures are the same as the standard V8

engine (with P.O. XT9) inlet system. Refer to Section

6C2, POWERTRAIN MANAGEMENT-V8 ENGINE in

Volume 11 of the VS Series Service Information.

Figure 5C-9

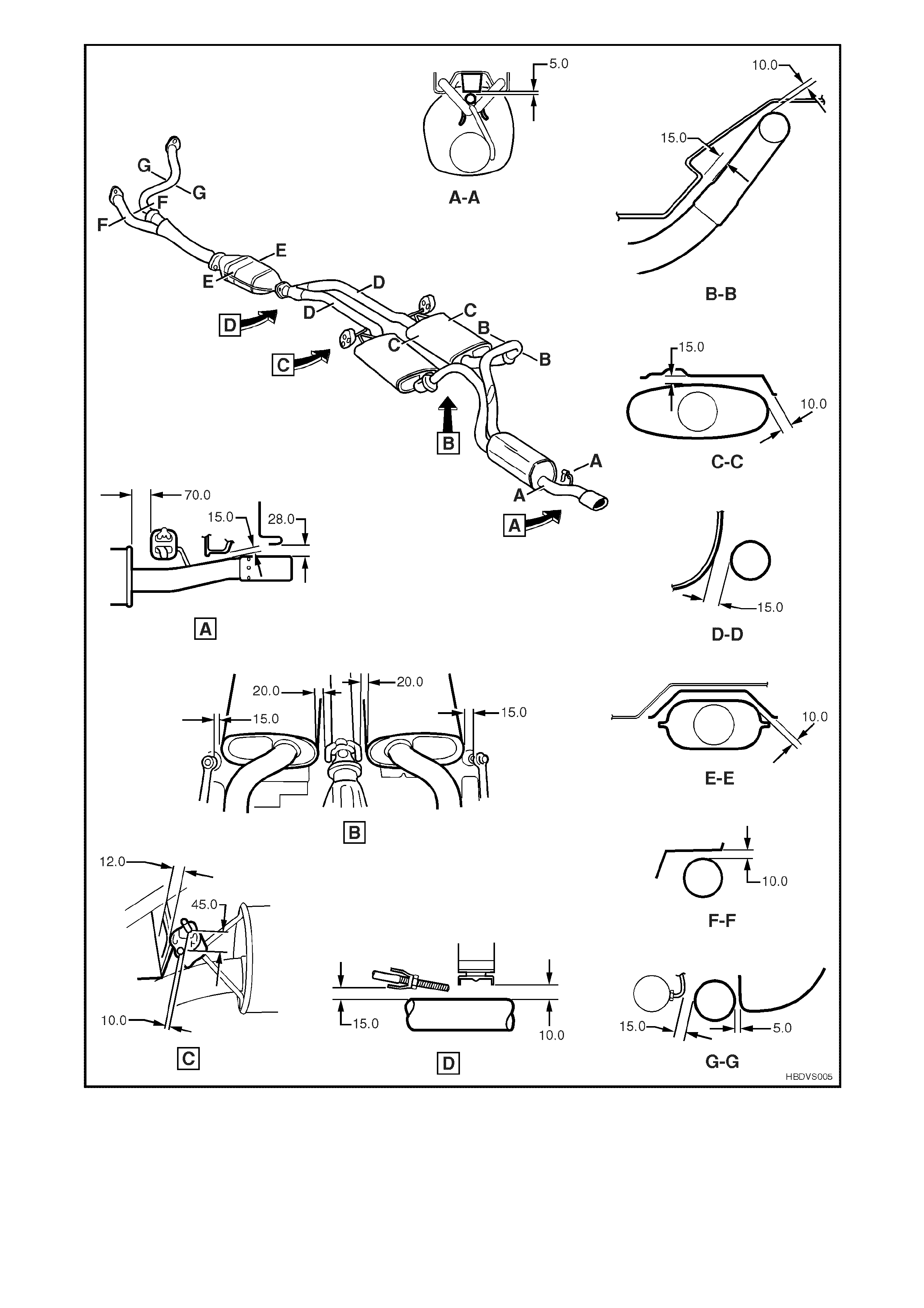

EXHAUST SYSTEM

The Holden By Design 195 kW V8 engine exhaust

system replaces the standard V8 exhaust and is a low

restriction, free flowing design. Although service

procedures are the same as the standard exhaust

system, the clearances differ, which are shown in Fig.

5C-10.

Figure 5C-10

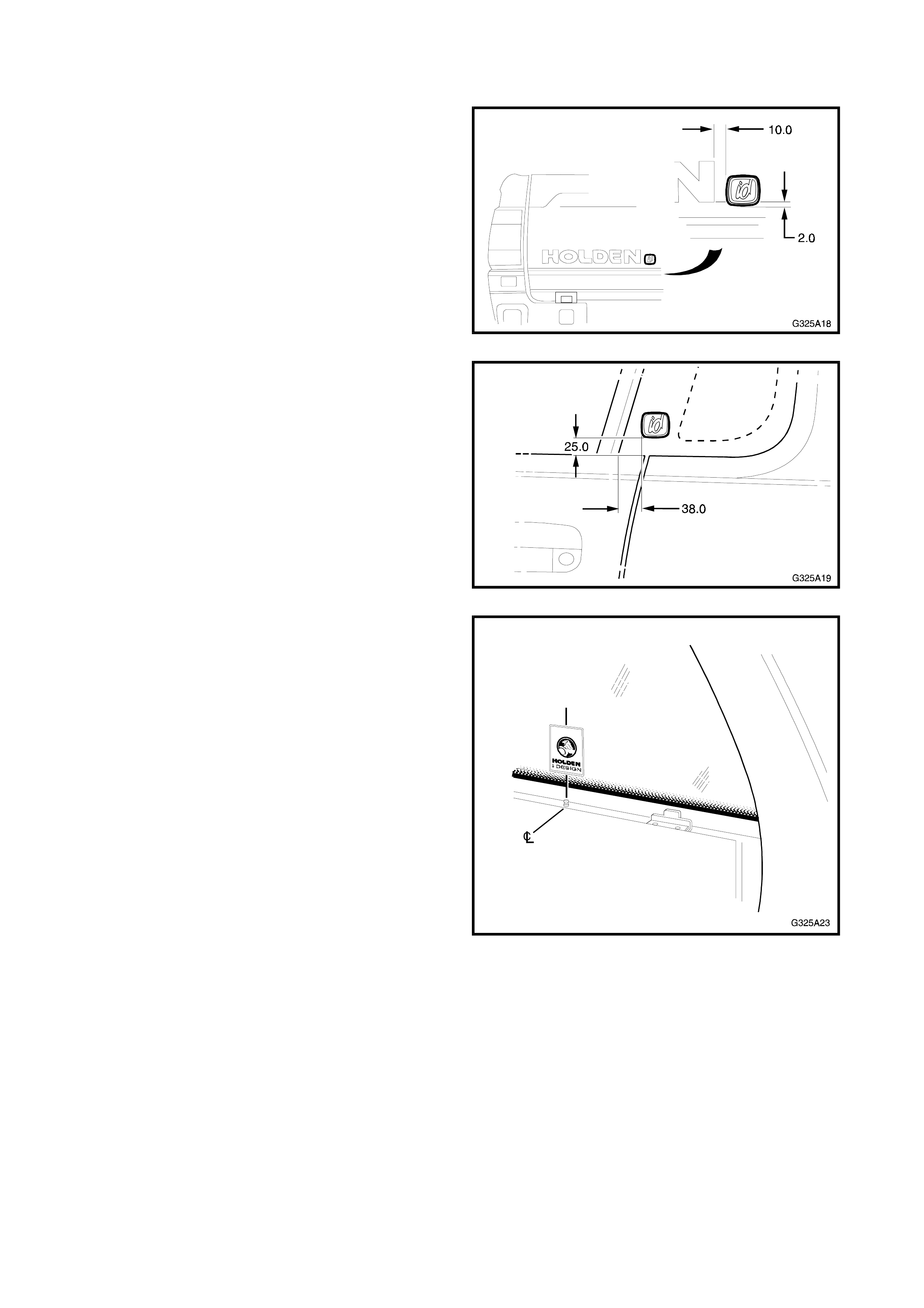

8. IDENTI FICATION & BADGING

All Holden By Design VS Series III id utilities are f itted

with unique id badging which is affixed to the tailgate

and each side quarter glass as shown in Figs. 5C-11

and 5C-12.

Figure 5C-11

Figure 5C-12

A Holden By Design decal is affixed to the rear

window. It is placed just above the edge of the

ceramic band, in line with the third tonneau cover

retainer.

NOTE: Some earlier vehicles had the decal aligned

with the second tonneau cover retainer or rigid

tonneau hinge centre.

Figure 5C-13

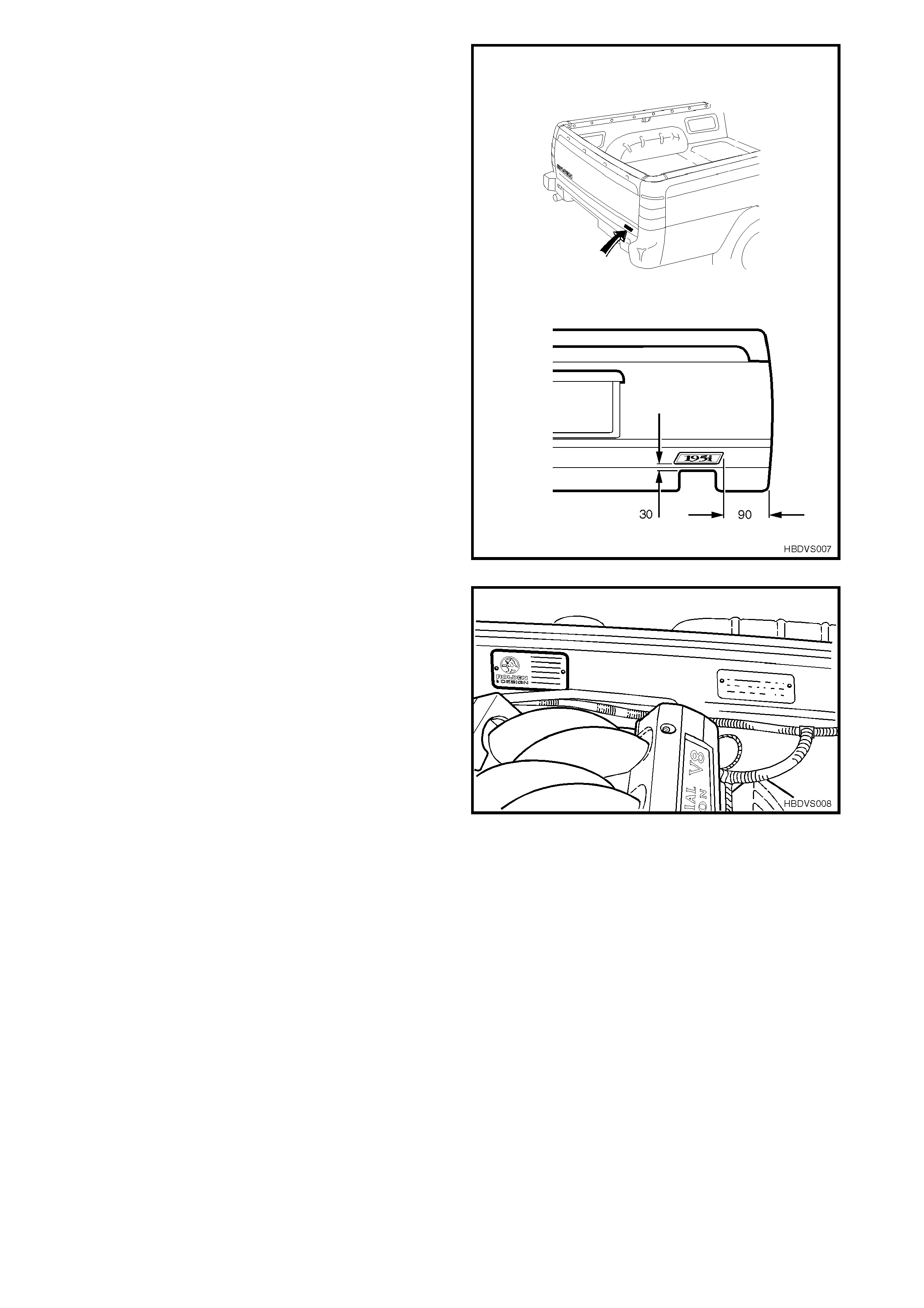

Vehicles fitted with the 195 kW V8 engine, receive a

unique 195i decal, which is affixed to the tailgate as

shown.

Figure 5C-14

A HBD identification plate is installed onto the engine

compartment side of the cockpit module with pop-

rivets.

Figure 5C-15