SECTION 8A - VX SERIES BODY KIT &

ALLOY WHEELS

1.0 GENERAL INFORM ATION

This Section of the Holden By Design Service Supplement describes the service procedures for the aerodynamic

body styling kit components and alloy wheels available for VX Series vehicles.

The body styling kit consists of:

- Radiator grille insert for Level 1 vehicles,

- Two front aprons; one for Level 1 vehicles and one for Level 2 and Level 3 vehicles, the later requiring a

modification where fog lamps are fitted,

- Unique side skirts,

- Two rear aprons; one for Level 1 vehicles and one for Level 2 and 3 vehicles,

- Three decklid spoilers, Types 1, 2 or 3 depending on customer option and,

- Exhaust extension for Level 2 and 3 vehicles.

A choice of four uniquely styled alloy w heels are available:

- 17” x 8” X-series 8 spoke alloy wheels fitted with 235/45 V-rated tyres,

- 17” x 8” C-series 5 spoke alloy wheels fitted with 235/45 V-rated tyres,

- 17” x 8” RT-series 5 spoke alloy wheels fitted with 235/45 V-rated tyres,

- 16” x 7.5” T-series multi spoke alloy wheels fitted with 225/50 V-rated tyres.

W hen a complete package is fitted, a Holden By Design identification plate and decals are included as part of the

package.

NOTE: Vehicles can be supplied with only one or several of the components. In this case no Holden By Design

badging is included.

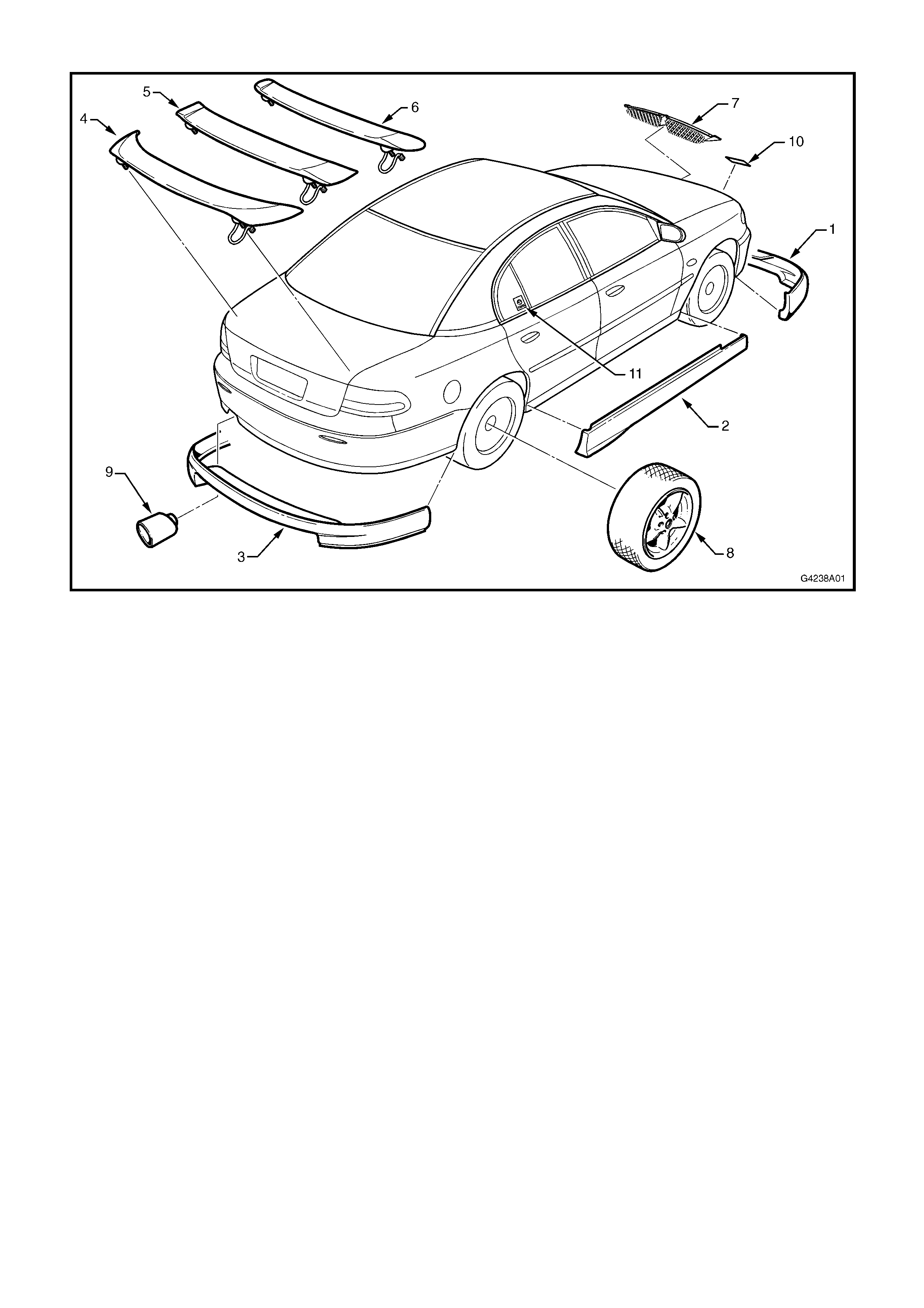

Figure 8A- 1 illustrates the VX Series body kit maj or com ponents and alloy wheels. For inform ation not contained in

this Section, refer to Section 1 BODY in the VX Series Service Information.

1.1 MAJOR COMPONENTS

Figure 8A-1

Legend

1. Front apron - Level 1 / Level 2 & 3 8. Alloy Wheel: - 17” x 8” X-series 8 spoke

2. Side skirt - 17” x 8” C-series 5 spoke

3. Rear apron - Level 1 / Level 2 & 3 - 17” x 8” RT-series 5 spoke

4. Type 3 rear spoiler - 16” x 7.5” T-series multi spoke

5. Type 2 rear spoiler 9. Exhaust extension - Level 2 & 3

6. Type 1 rear spoiler 10. Holden By Design plate

7. Radiator grille insert - Level 1 11. Holden By Design Label

2.0 RADIATOR GRILLE INSERT

The radiator grille insert replaces the standard Level one VX Series twin grille inserts. If the front bumper

facia is being replaced, the new facia will require modifying to accommodate the grille insert. Refer to

Section 1D, BUMPER BARS in the VX Series Service Information for the bumper facia removal procedure.

NOTE: The radiator grille insert is painted in the vehicle’s body colour. The painting procedures are relatively

straight f orward, pr oviding the cor r ect s teps are followed for PUR polyurethane. Refer to your paint manuf ac turer for

further information.

REMOVE

1. Remove the front bumper facia, refer

Section 1D BUMPER BARS in the VX Series

Service Information.

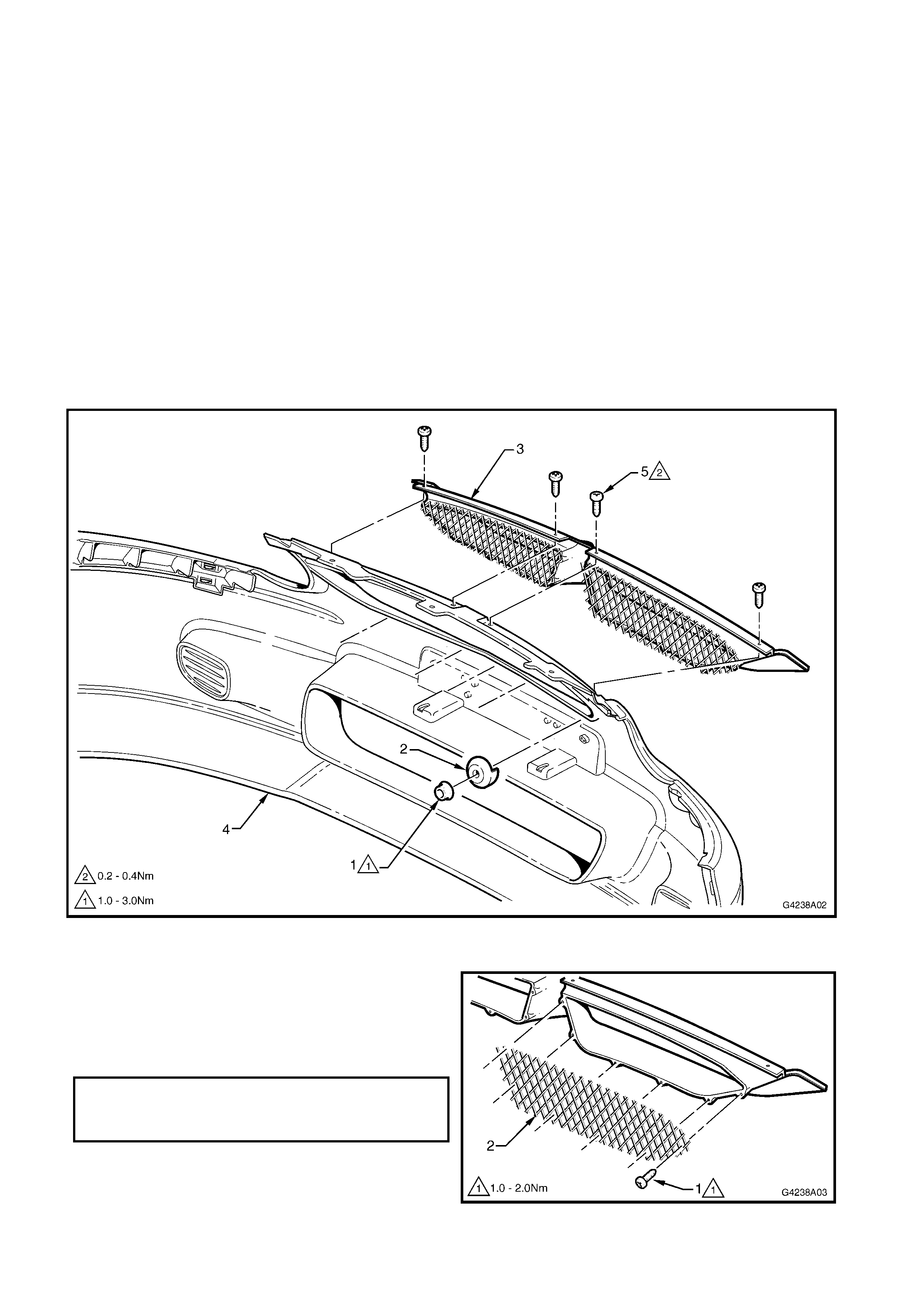

2. Remove the f ive nuts (1) and spacers (2) securing

the grille insert (3) to the bumper facia (4), refer

Fig. 8A-2.

3. Remove the four screws (5) securing the grille

insert to the bumper facia.

4. Remove the grille insert.

Figure 8A-2

DISASSEMBLE

1. Remove the screw (1) 6 places, attaching the

radiator grille insert mesh (2) to the grille insert.

2. Installation is the reverse of remove. Tighten the

screws to the specified torque.

Figure 8A-3

RADIATOR GRILLE INSERT

MESH ATTACHING SCREW 1.0 – 2.0Nm

TORQUE SPECIFICATION

INSTALL

1. If the existing bum per facia is being used, proceed

to step 15.

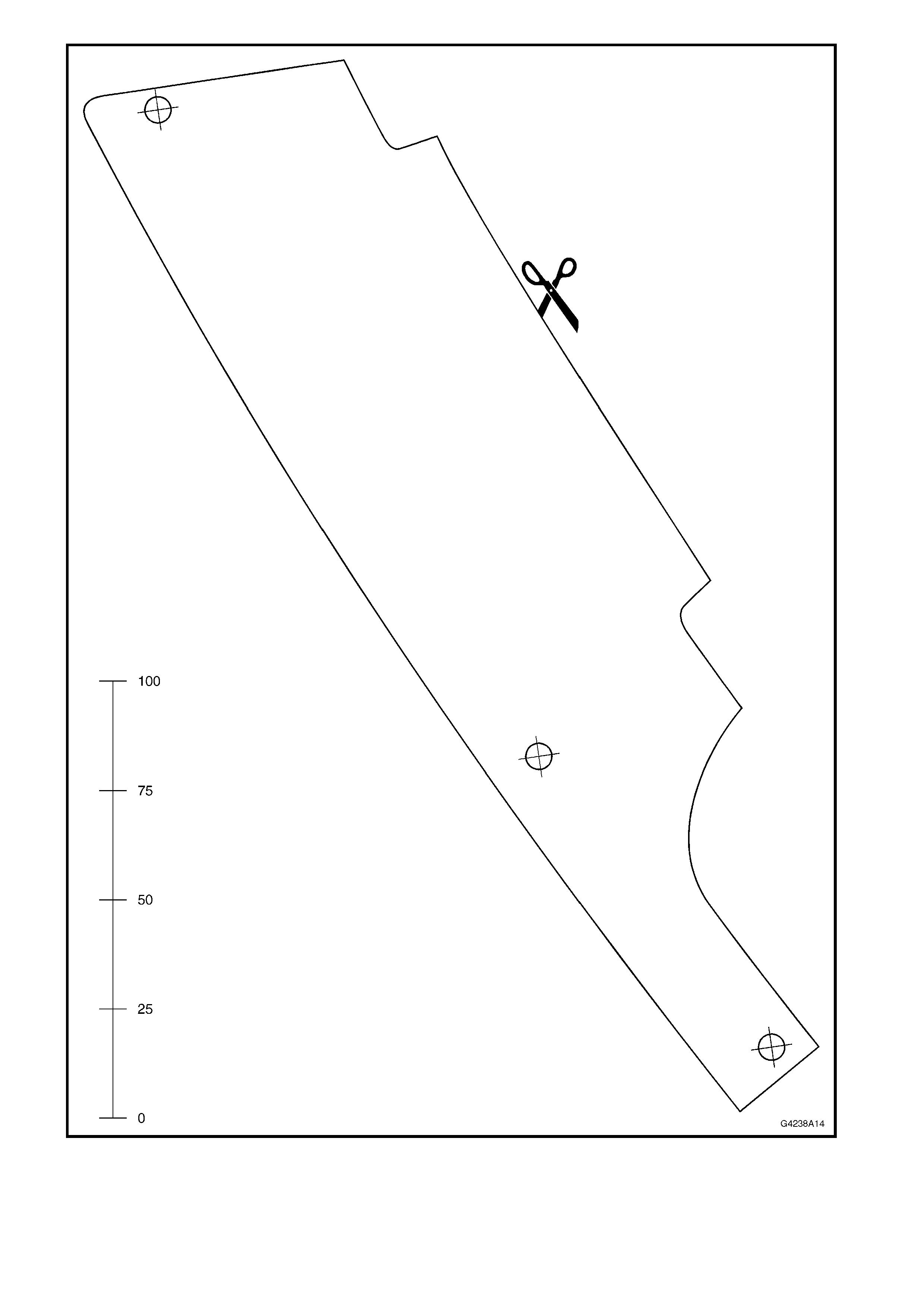

2. Print the template provided in Fig. 8A-8.

NOTE: Ensure the template prints the correct size by

comparing the scale.

3. Cut out the template and attach it to the bumper

facia with tape as shown (1).

4. Pin-punc h the centre of the grille insert centre hole

(2) and the outer holes (3).

5. Carefully remove the template, turn it over and

attach it to the the opposite side. The centre hole

should align with the punch mark.

6. Pin-punch the two outer holes and remove the

template.

7. Drill the five punch marks with a 6 mm drill.

8. Mar k a horizontal line (1), 10 m m above the centr e

of the middle hole, refer Fig. 8A-5.

9. Continue each end of the line directly to the outer

grille insert slots (2).

10. Continue each end of the line to the upper corner

at the rear edge (3).

Figure 8A-4

Figure 8A-5

11. Mark a horizontal line (1) across the recess at the

top of the centre section of the facia.

12. Contiue each end of the line downward at an angle

and rearward.

Figure 8A-6

13. Cut the section from the bumper facia.

14. Test fit the grille insert. Adjust the holes as

required.

15. Fit the grille insert, install the four upper screws

and carefully tighten to the specified torque, refer

Fig. 8A-2.

16. Fit a spacer and nut to each of the lower studs.

17. Beginning with the middle nut, tighten the nuts to

the specified torque.

Figure 8A-7

RADIATOR GRILLE INSERT

ATTACHING SCREW 0.2 – 0.4Nm

TORQUE SPECIFICATION

RADIATOR GRILLE INSERT

ATTACHING ATTACHING NUT 1.0 – 3.0Nm

TORQUE SPECIFICATION

Figure 8A-8

3.0 FRONT APRON

The Holden By Design front apron is attached to the bumper fac ia with screws and urethane adhesive. Two aprons

are available, one for Level 1 vehicles and one for Level 2 & 3 vehicles. For Level 3 vehicles with fog lamps, the

Level 2 & 3 apron requires modifying prior to installation.

NOTE 1: The front bumper facia must be removed prior to the apron. This is required to allow access to the

attaching screws. Refer to Section 1D, BUMPER BARS in the VX Series Service Information for this procedure.

NOTE 2: The front apron is painted in the vehicle’s body colour. The painting procedures are relatively straight

forward, providing the correct steps are followed for PUR (polyurethane). Refer to your paint manufacturer for

further information.

LEVEL 1

REMOVE

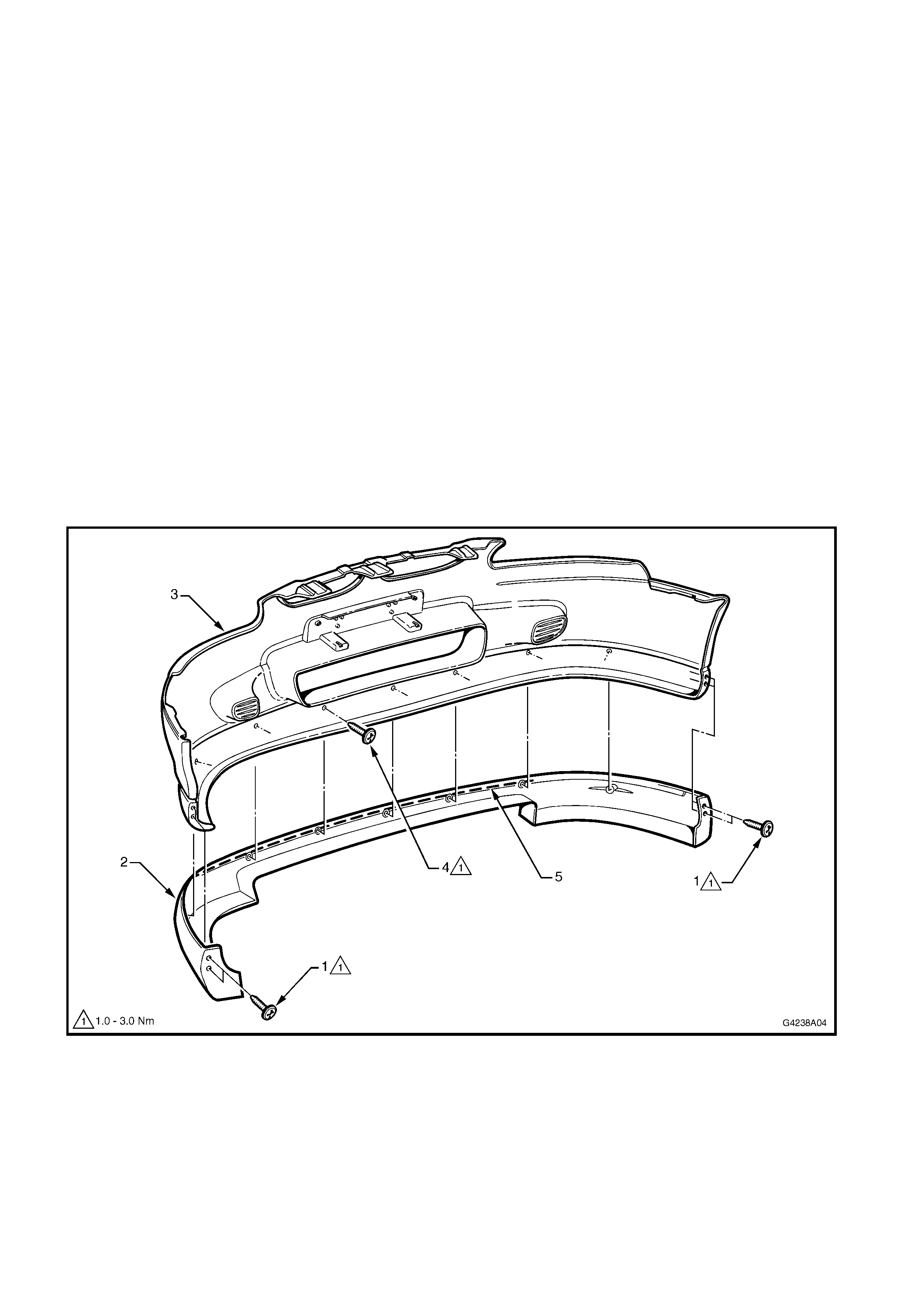

1. Place the bumper facia assembly upside down on

a clean, soft surface.

2. Remove the two screws (1) securing each end of

the front apron (2) to the front bumper facia (3).

Refer Fig. 8A-9.

3. Remove the seven screws (4) from the rear side of

the bumper facia.

4. Remove the apron.

NOTE: A bead of urethane adhesive (5) is applied to

the front of the apron. Carefully pulling on the apron

will break the bond.

Figure 8A-9

INSTALL

1. If the bumper facia has not been replaced,

proceed to Step 11.

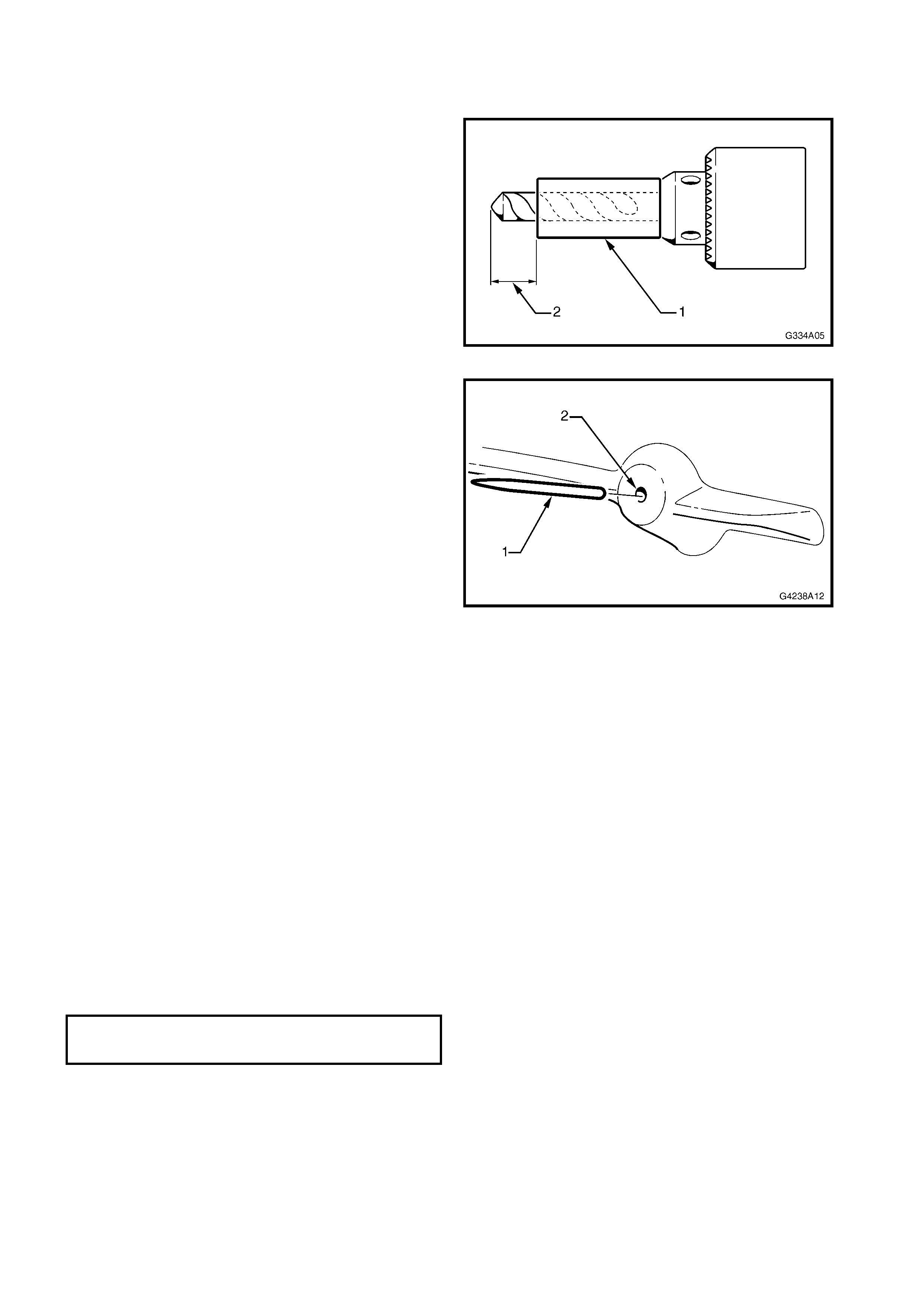

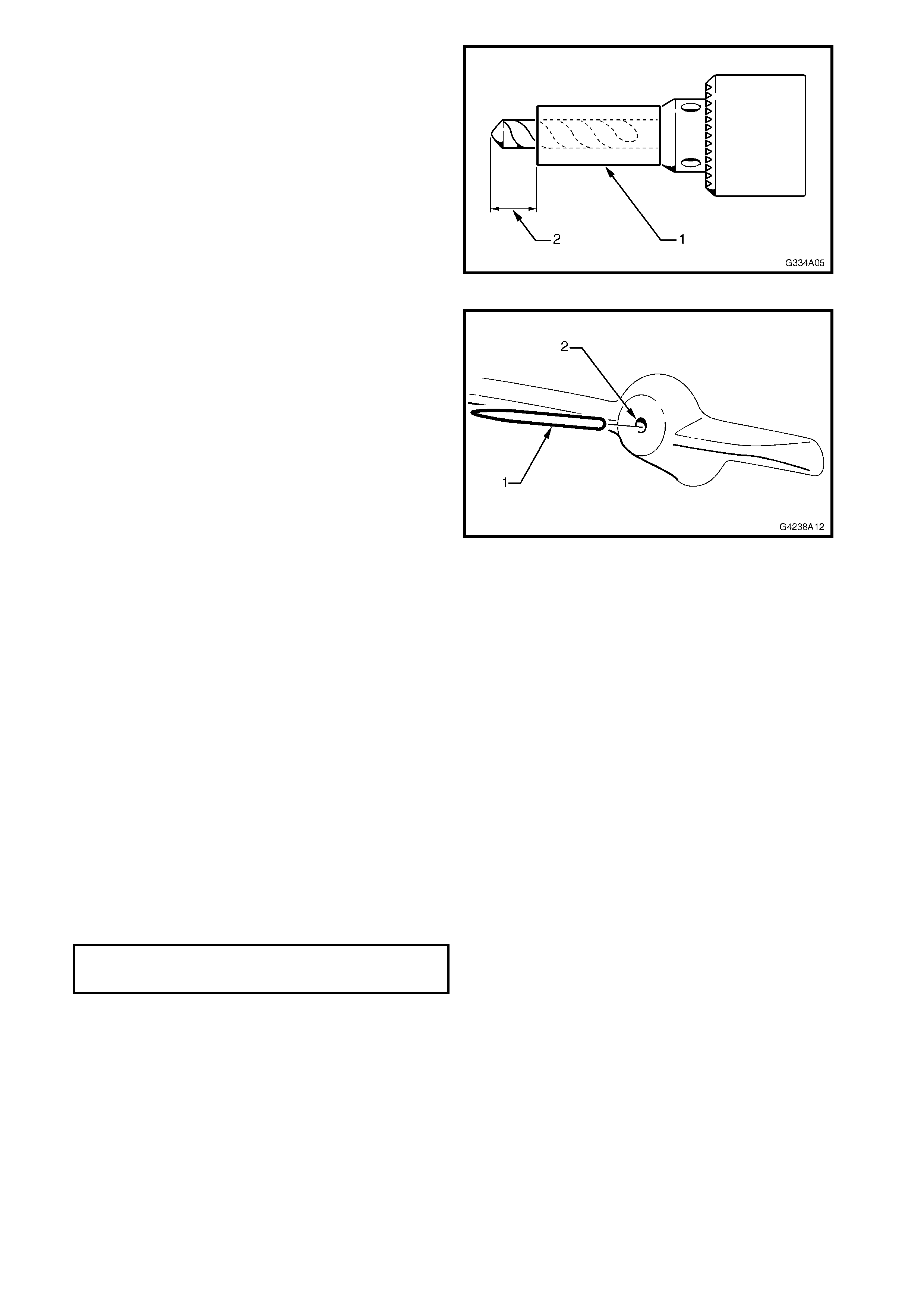

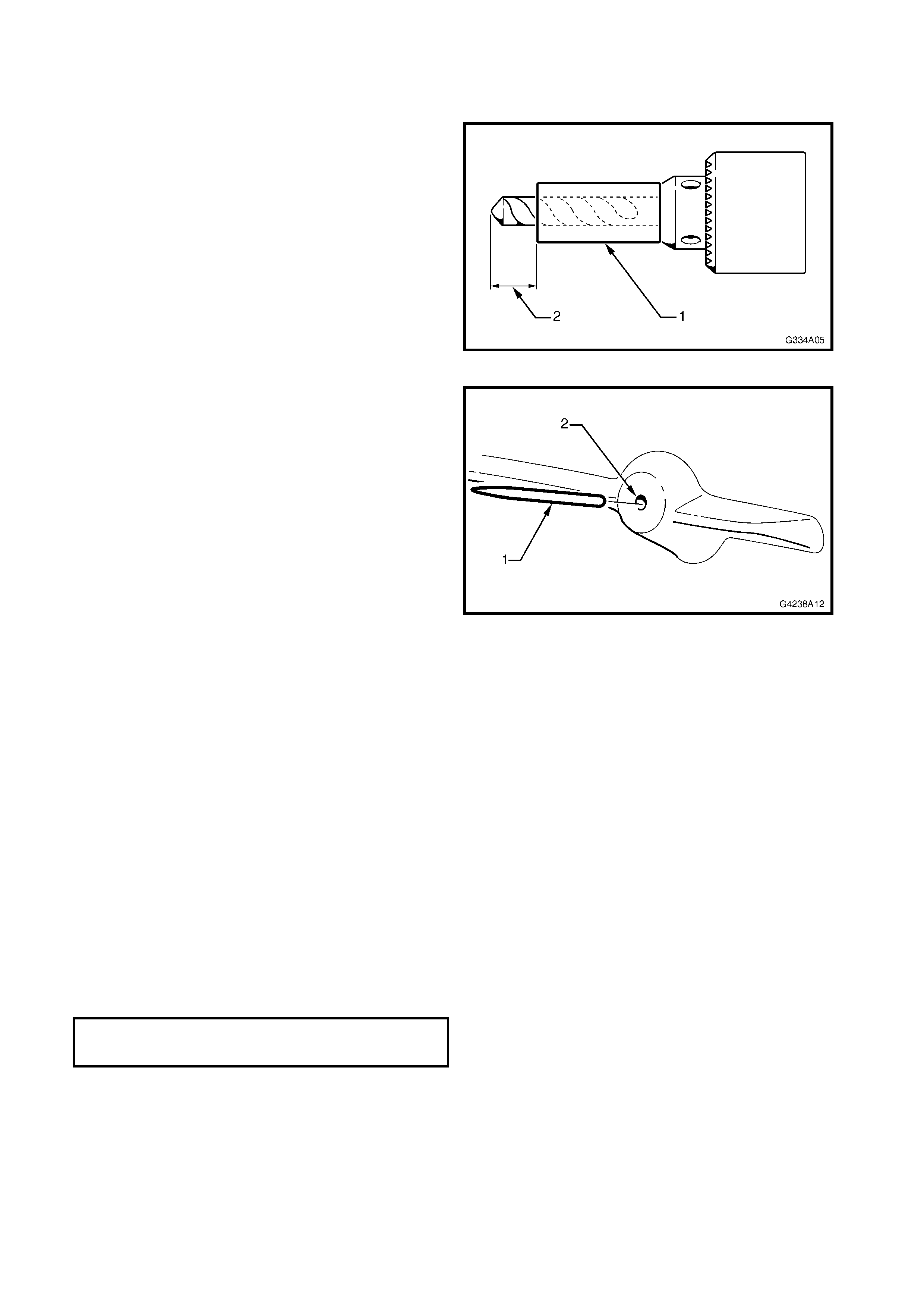

2. Cut a length of tube (1) to fit over a drill-bit to

restrict drill tip depth. The size of the drill-bit is to

be the same diameter as the pins that will be

manufactured in the nex t s tep. T he length f r om the

top of the tube to the end of the drill-bit (2) is to be

8mm.

NOTE: As an alternative, tape can be used.

Figure 8A-10

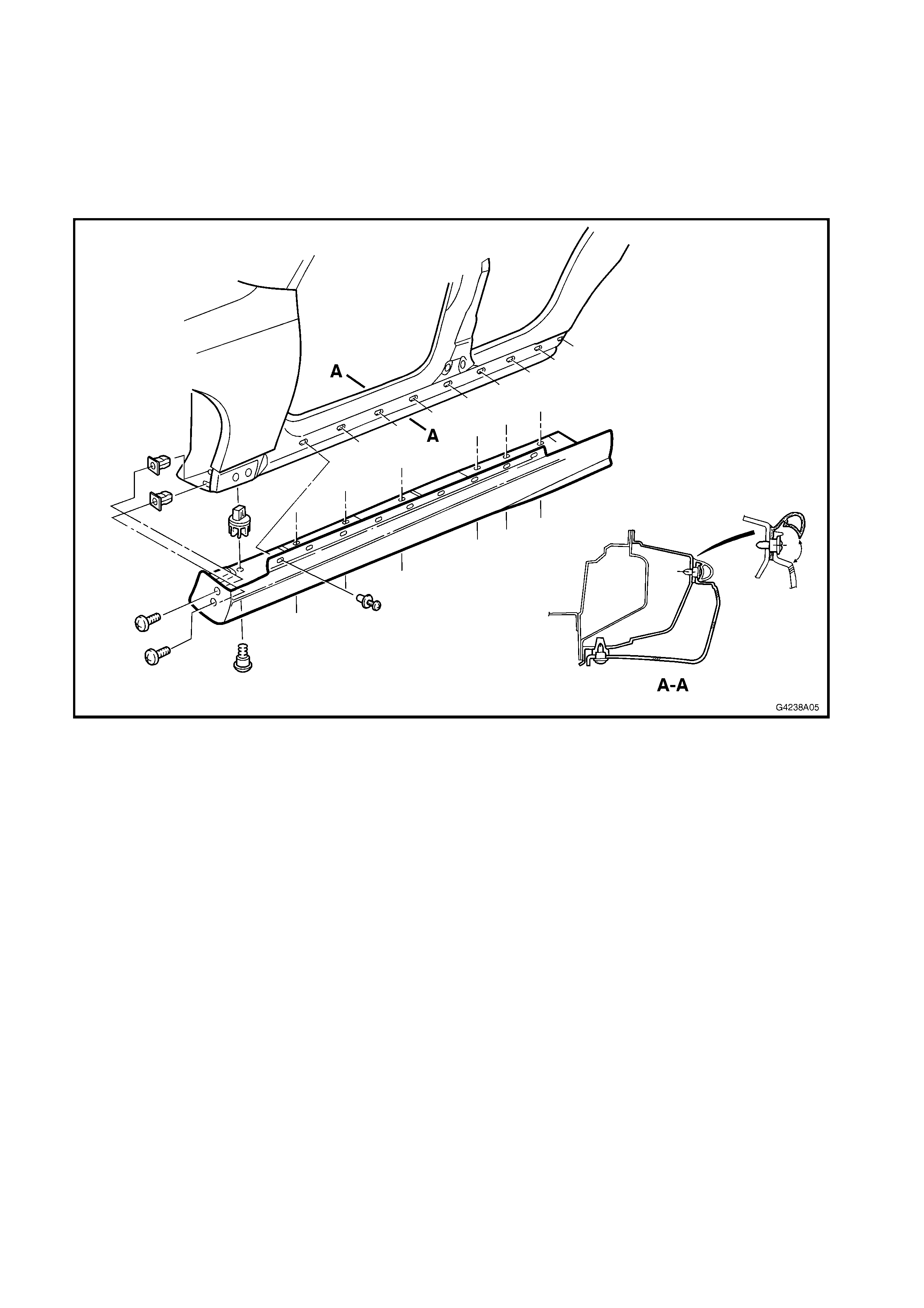

3. Manufacture the required number of pins (1) from

a length of bronze welding rod or sim ilar. The pins

are to be between 9 to 10mm in length. Sharpen

one end on a grinder.

4. Drill a hole (2) the size of the pins, centrally in each

screw boss on the rear side of the apron.

NOTE: Ensure the dr ill depth is 8m m and the diam eter

no greater than 2.5mm.

5. Insert the pins into the holes. Ensure the end of

the pin is protruding 1 – 2mm.

6. With the aid of an assistant carefully fit the apron

onto the bumper facia.

7. At each screw boss, tap on the apron and facia to

ensure each pin clearly marks the facia.

8. Remove the apron.

9. Drill the facia with the screw holes, 5mm in

diameter.

10. Remove the pins and if required, dr ill out the apr on

pilot holes to 2.5mm.

NOTE: Fit a length of tube or tape to the drill-bit to

ensure the drill depth is no more than 8mm.

Figure 8A-11

11. Apply a bead of urethane adhesive to the front

edge of the apron, refer (5) Fig. 8A-9.

12. Fit the apron onto the bumper facia.

13. From the rear of the f acia, install the s even screws

and tighten to the specified torque.

14. Install the two screws each end of the apron and

tighten to the specified torque.

15. Reinstall the bumper facia as described in

Section 1D, BUMPER BARS in the VX Series

Service Information.

FRONT APRON ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0Nm

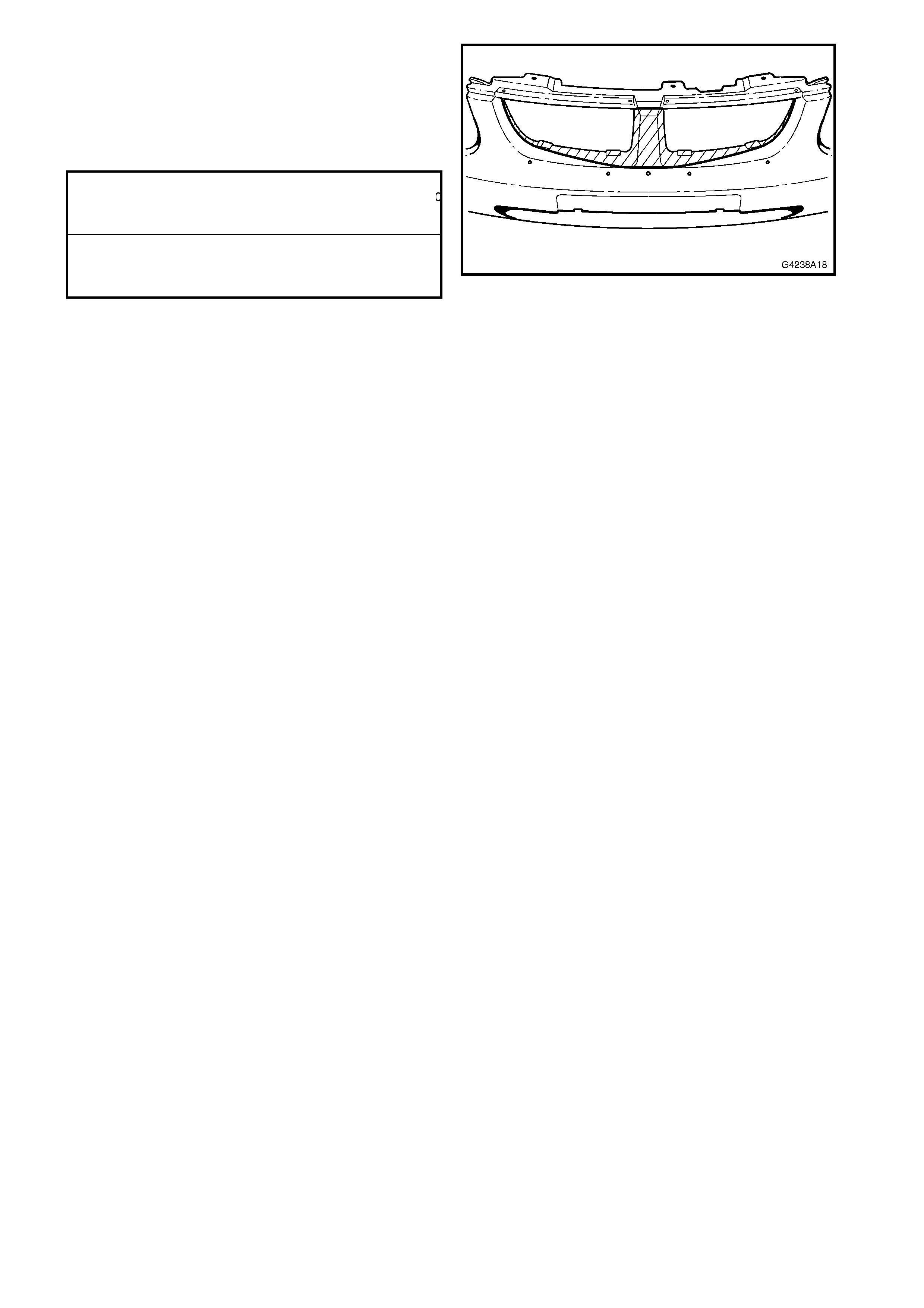

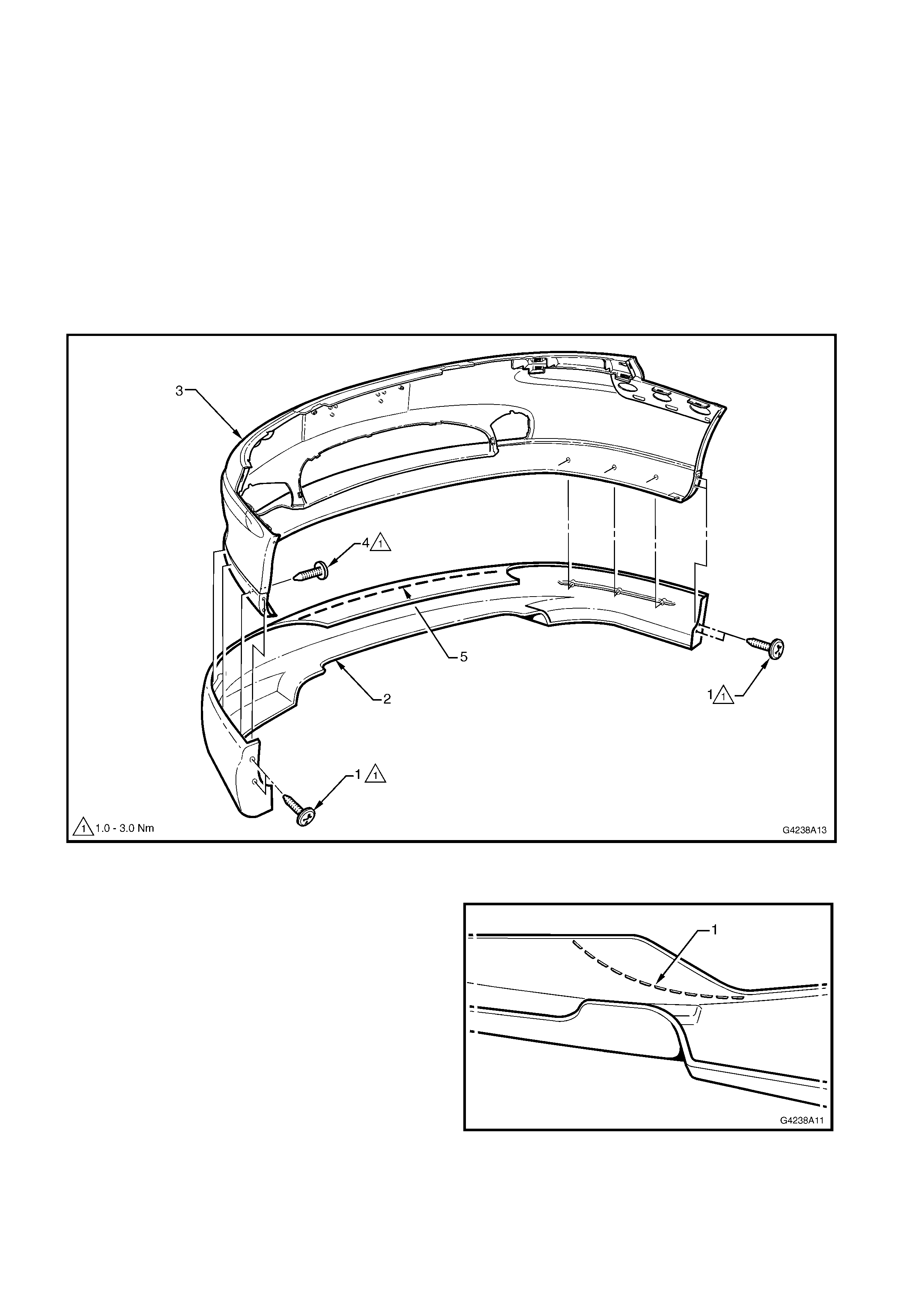

LEVEL 2 & 3

REMOVE

1. Place the bumper facia assembly upside down on

a clean, soft surface.

2. Remove the two screws (1) securing each end of

the front apron (2) to the front bumper facia (3).

Refer Fig. 8A-12.

3. Remove the six screws (4) from the rear side of

the bumper facia.

4. Remove the apron.

NOTE: A bead of urethane adhesive (5) is applied to

the front of the apron. Carefully pulling on the apron

will break the bond.

Figure 8A-12

INSTALL

1. If the apron is to be fitted to a Level 3 vehicle with

fog lamps, remove the section shown by cutting

along the line (1) moulded into the apron.

2. Clean up the edge with fine sandpaper.

3. If the bumper facia has not been replaced,

proceed to Step 13.

Figure 8A-13

4. Cut a length of tube (1) to fit over a drill-bit to

restrict drill tip depth. The size of the drill-bit is to

be the same diameter as the pins that will be

manufactured in the next s tep. T he length f r om the

top of the tube to the end of the drill-bit (2) is to be

8mm.

NOTE: As an alternative, tape can be used.

Figure 8A-14

5. Manufacture the required number of pins (1) from

a length of bronze welding rod or sim ilar. The pins

are to be between 9 to 10mm in length. Sharpen

one end on a grinder.

6. D rill a hole ( 2) the size of the pins centrally in each

screw boss on the rear side of the apron.

NOTE: Ensure the dr ill depth is 8m m and the diam eter

no greater than 2.5mm.

7. Insert the pins into the holes. Ensure the end of

the pin is protruding 1 – 2mm.

8. With the aid of an assistant carefully fit the apron

onto the bumper facia.

9. At each screw boss, tap on the apron and facia to

ensure each pin clearly marks the facia.

10. Remove the apron.

11. Drill the facia with the screw holes, 5mm in

diameter.

12. Remove the pins and if r equir ed, drill out the apr on

pilot holes to 2.5mm.

NOTE: Fit a length of tube or tape to the drill-bit to

ensure the drill depth is no more than 8mm.

Figure 8A-15

13. Apply a bead of urethane adhesive to the front

edge of the apron, refer (5) Fig. 8A-12.

14. Fit the apron onto the bumper facia.

15. From the rear of the facia, install the six screws

and tighten to the specified torque.

16. Install the two screws each end of the apron and

tighten to the specified torque.

17. Reinstall the bumper facia as described in

Section 1D, BUMPER BARS in the VX Series

Service Information.

FRONT APRON ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0Nm

4.0 SIDE SKIRTS

The Holden By Design side skirt assemblies replace the existing rocker panel skirts. The procedure for their

rem oval is the sam e as the standar d skir t. Refer to Sect ion 1A9, EXTERIOR O RNAMENTATION in the VX Series

Service Information for this procedure.

NOTE: The side skirts are painted in the vehicle’s body colour. The painting procedures are relatively straight

forward providing the c or rec t s teps are f ollowed f or PUR ( polyurethane). Refer to your paint manufac turer for fur ther

information.

Figure 8A-16

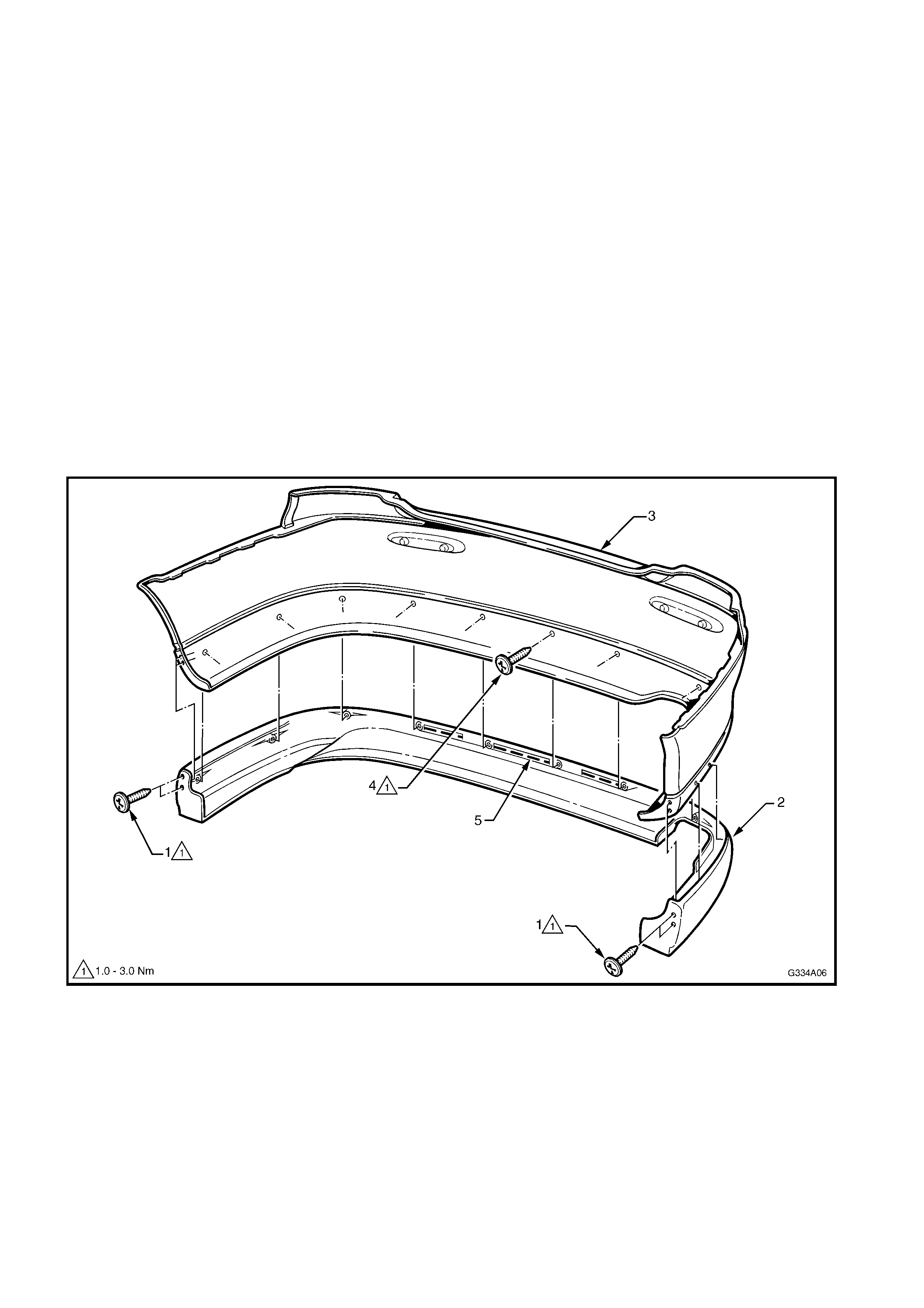

5.0 REAR APRON

The Holden By Design rear apron is attached to the rear bumper facia with screws and urethane adhesive. Although

there are physical differences between Level 1 and Level 2 & 3 aprons, the service procedures are the same.

NOTE 1: The rear bumper facia must be removed prior to the apron. This is required to allow access to the

attaching screws. Refer Section 1D, BUMPER BARS in the VX Series Service Information for this procedure.

NOTE 2: The rear apron is painted in the vehicle’s body colour. The painting procedures are relatively straight

forward providing the c or rec t s teps are f ollowed f or PUR ( polyurethane). Refer to your paint manufac turer for fur ther

information.

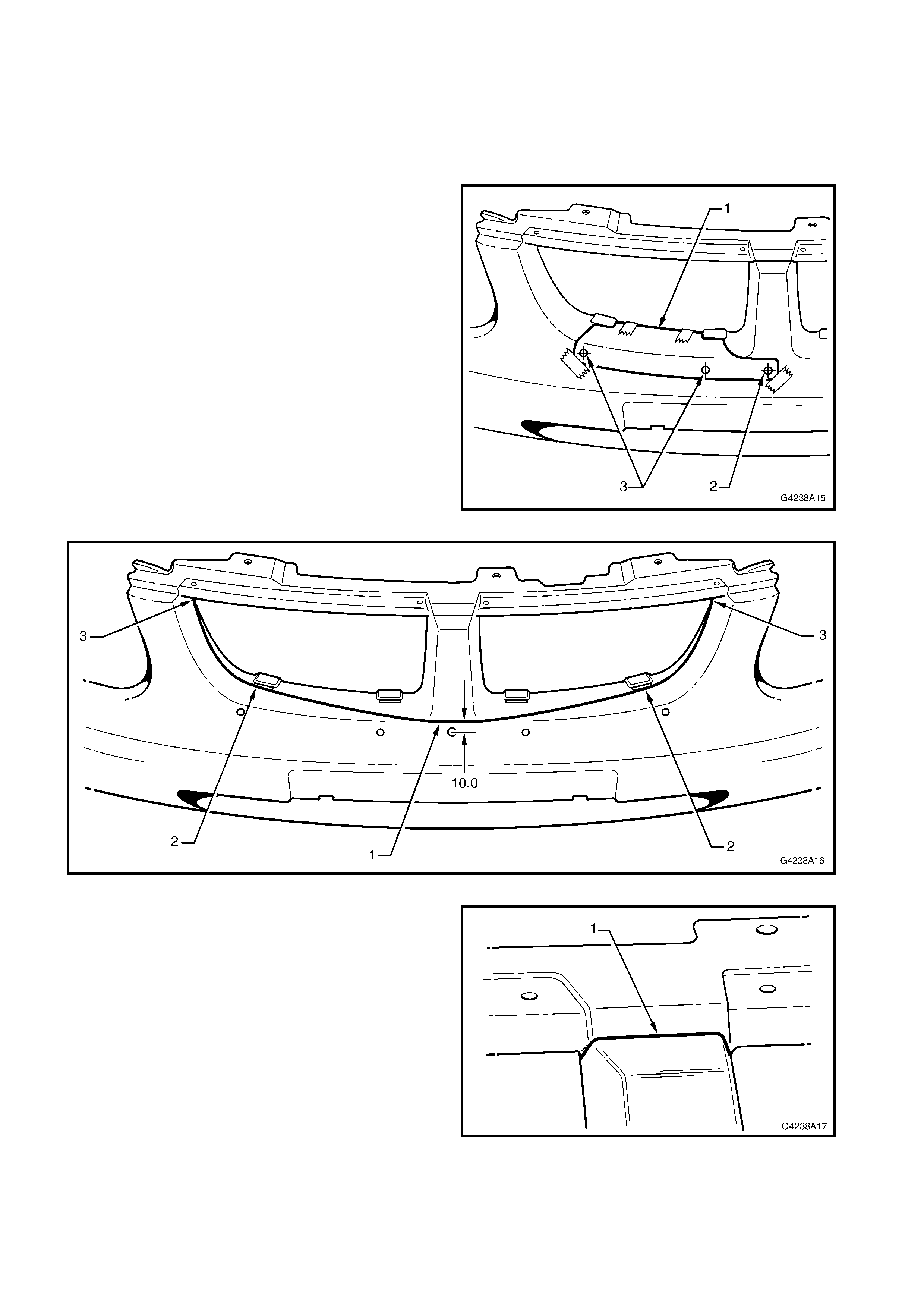

REMOVE

1. Place the bumper facia assembly upside down on

a clean, soft surface.

2. Remove the two screws (1) securing each end of

the rear apron (2) to the rear bumper facia (3).

Refer Fig. 8A-17.

3. Remove the 10 screws (4) from the rear side of

the bumper facia.

4. Remove the apron.

NOTE: A bead of urethane adhesive (5) is applied to

the the apron. Carefully pulling on the apron will break

the bond.

Figure 8A-17

INSTALL

1. If the bumper facia has not been replaced,

proceed to Step 11.

2. Cut a length of tube (1) to fit over a drill-bit to

restrict drill tip depth. The size of the drill-bit is to

be the same diameter as the pins that will be

manufactured in the next s tep. T he length f r om the

top of the tube to the end of the drill-bit (2) is to be

8mm.

NOTE: As an alternative, tape can be used.

Figure 8A-18

3. Manufacture the required number of pins (1) from

a length of bronze welding rod or sim ilar. The pins

are to be between 9 to 10mm in length. Sharpen

one end on a grinder.

4. Drill a hole (2) centrally in each screw boss on the

rear side of the apron, the size of the pins.

NOTE: Ensure the dr ill depth is 8m m and the diam eter

no greater than 2.5mm.

5. Insert the pins into the holes. Ensure the end of

the pin is protruding 1 – 2mm.

6. With the aid of an assistant carefully fit the apron

onto the bumper facia.

7. At each screw boss, tap on the apron and facia to

ensure each pin clearly marks the facia.

8. Remove the apron.

9. Drill the facia with the screw holes, 5mm in

diameter.

10. Remo ve the pins and drill out the apron pilot holes

to 2.5mm, if required.

NOTE: Fit a length of tube or tape to the drill-bit to

ensure the drill depth is no more than 8mm.

Figure 8A-19

11. Apply a bead of urethane adhesive to the front

edge of the apron, refer (5) Fig. 8A-9.

12. Fit the apron onto the bumper facia.

13. From the rear of the facia, install the 10 screws

and tighten to the specified torque.

14. Install the two screws each end of the apron and

tighten to the specified torque.

15. Reinstall the bumper facia as described in

Section 1D, BUMPER BARS in the VX Series

Service Information.

REAR APRON ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0Nm

6.0 DECKLID SPOILERS

Three Holden By Design decklid spoilers are available. Each is attached to the decklid with screws and nuts, no

adhesive is used.

Although different in style, the servicing of the three spoilers is the same and they share common mounting holes.

NOTE: The s poilers are painted in the vehic le’s body colour. The painting procedures are relatively straight forward

providing the correct steps are followed for PUR (polyurethane with rigid structure foam core material). Refer to your

paint manufacturer for further information.

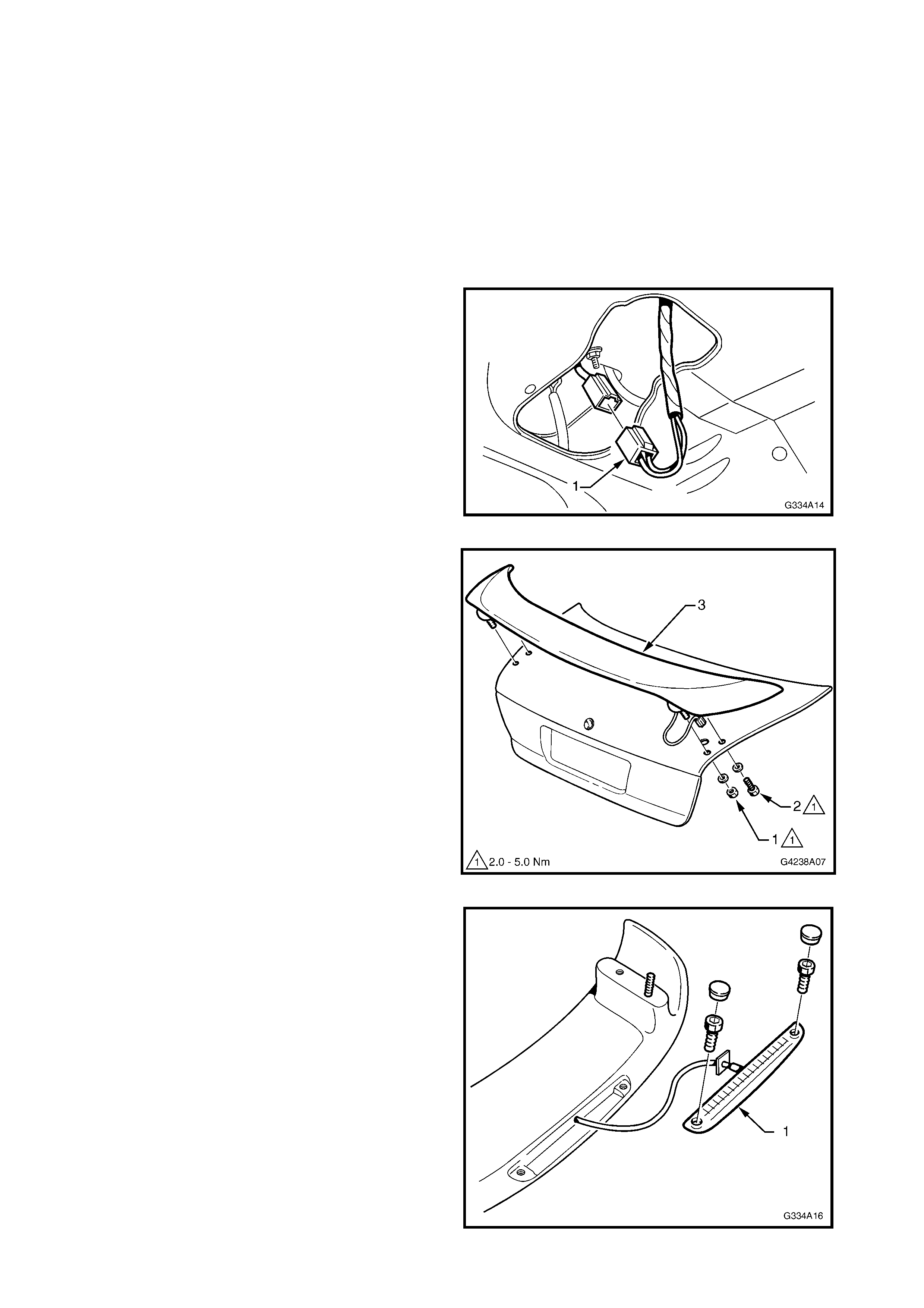

REMOVE

1. Open the deck lid and r emove the dec k lid inner trim,

if fitted. Refer to Section 1 BODY in the VX Ser ies

Service Information.

2. Remove each wiring terminal from the spoiler

harness connector body (1) by inserting a scribe or

like into the front side of the connector cavity and

depressing the tab to release the terminal from the

connector body.

Figure 8A-20

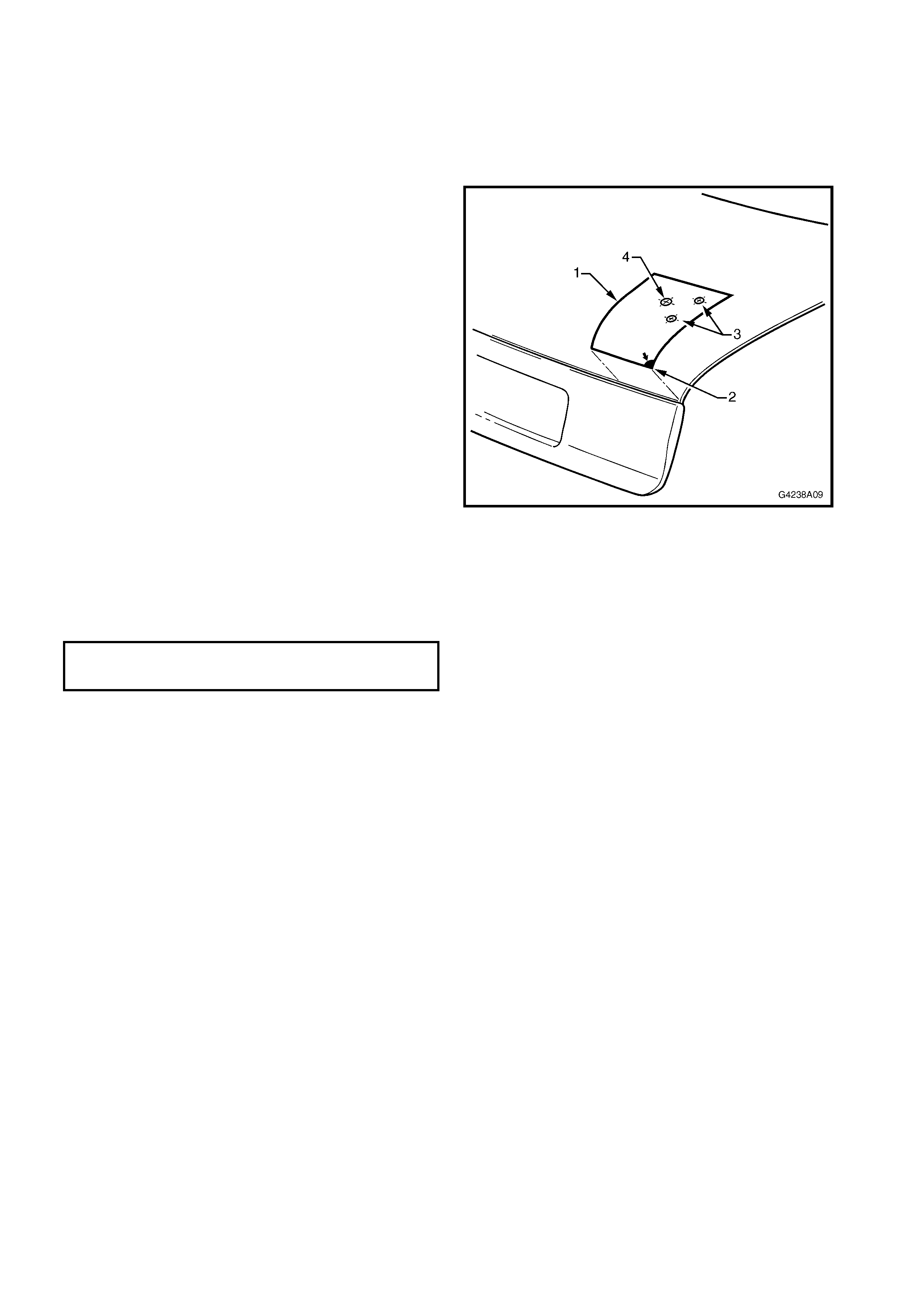

3. From the underside of the decklid, remove the nut

(1), screw (2) and washers attaching the spoiler (3).

4. Remove the s poiler, withdrawing the wiring harness

from the RH side.

Figure 8A-21

5. If required, remove the high mount stop lamp

assembly (1).

Figure 8A-22

INSTALL

1. If the decklid has not been replaced, proceed to

Step 8.

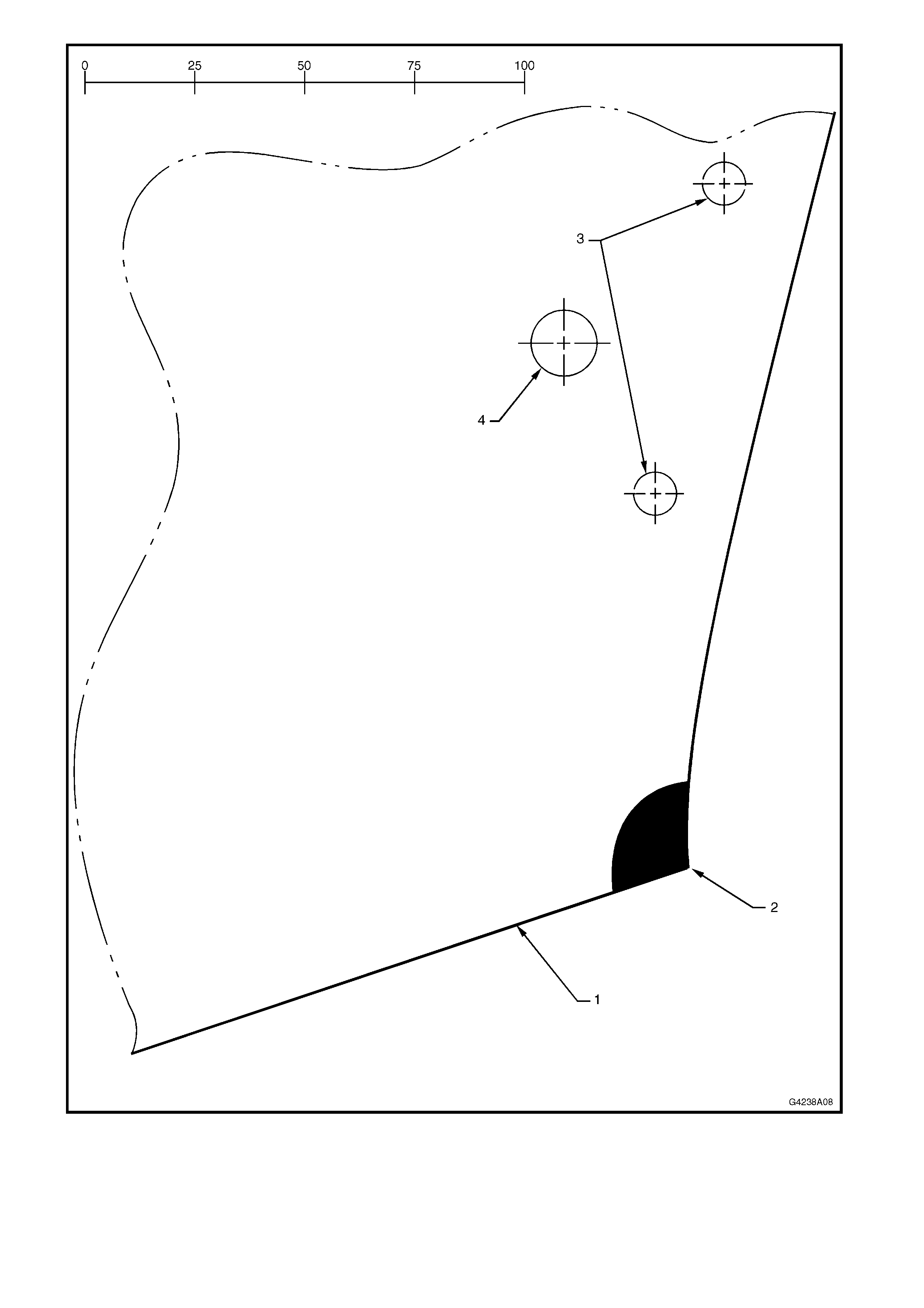

2. Print the drilling template provided in Fig. 8A-24.

NOTE: Ensure the tyemplates prints the correct size

by comparing the scale.

3. Cut out the template (1) and place on the RH side

of the decklid. The arrow (2) is to align with the

corner of the decklid as shown.

4. Mark the mounting holes (3) and for the RH side

only, the wiring harness hole (4).

5. T urn the template over and place it on the LH side

of the decklid. Mark the mounting holes only.

6. Sit the spoiler on the decklid and ensure the

mounting studs align with the marks. Adjust as

required.

7. Carefully drill the mounting holes. Initially drill 3

mm holes, followed by 10 mm holes.

8. Carefully drill the wiring harness hole on the RH

side only. Initially drill a 3mm hole, then drill out to

15mm.

9. Debur the drill holes and apply primer to the bare

metal.

10. Install the high m ount stop lamp onto the spoiler if

required, refer Fig. 8A-22.

11. Fit the spoiler to the decklid, feeding the high

mount stop lamp harness through its hole in the

decklid, refer Fig. 8A-21.

12. Fit the screw, nuts and washers to the studs and

hand tighten.

13. Check alignment of spoiler on decklid and tighten

the screw and nuts to the specified torque.

Figure 8A-23

14. Fit the high mount stop lamp connector pins into

the connector body and join the wiring connector

within the decklid cavity as shown in Fig. 8A-20.

15. Check high mount stop lamp operation.

16. Refit decklid inner trim, if removed.

DECKLID SPOILER ATTACHING SCREW

& NUT TORQUE SPECIFICATION 2.0 – 5.0Nm

Figure 8A-24

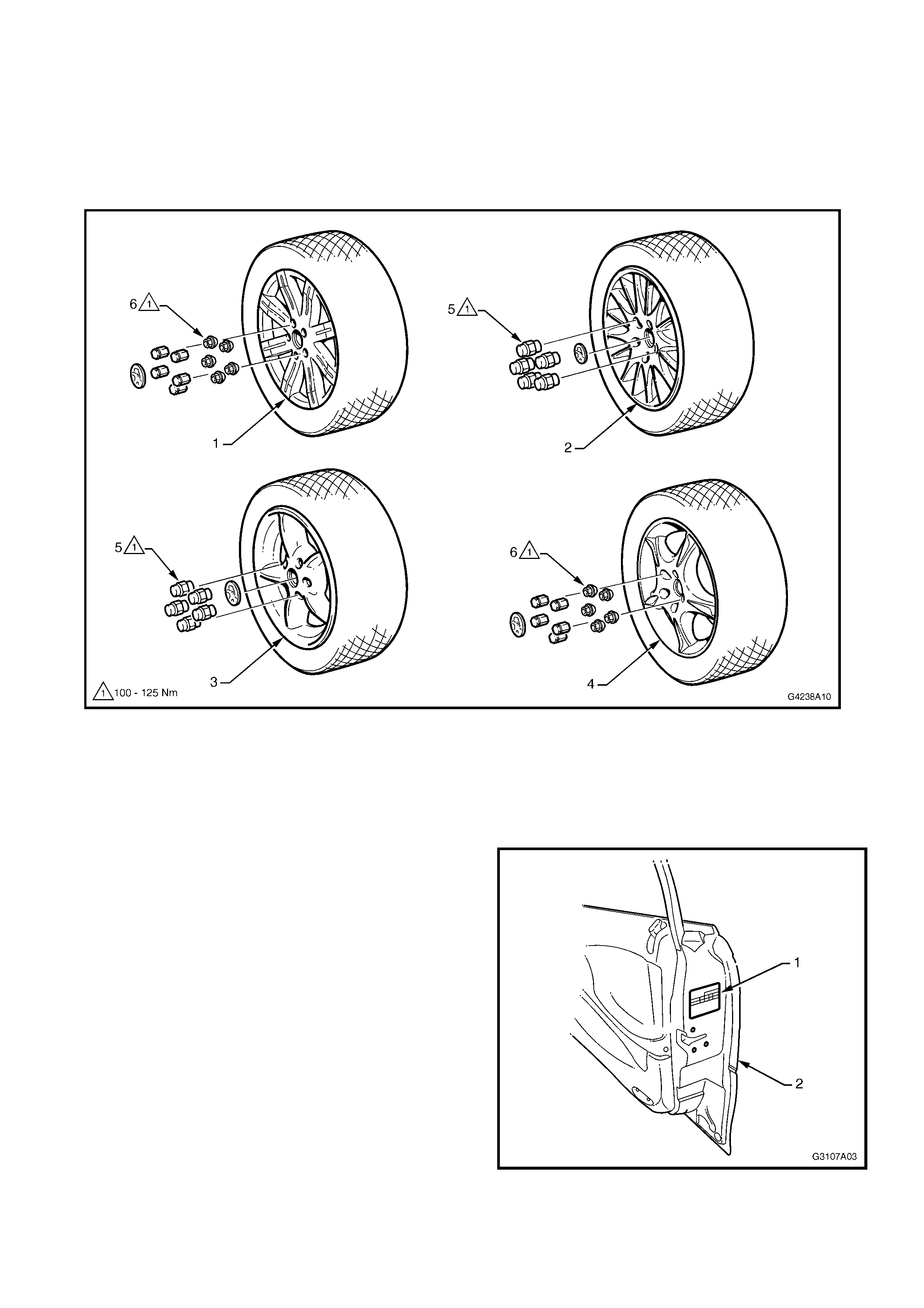

7.0 ALLOY WHEELS

Four alloy wheel styles are available for Holden By Design VX Series vehicles. Each has its own unique styling,

diameter and width. The standard steel rim spare wheel remains fitted.

This Section of the Holden By Design Service Manual Supplement illustrates the wheel types available. For the

information required to service wheels for VX Series vehicles, refer to Section 10 WHEELS & TYRES in the VX

Series Service Information.

Figure 8A-25

Legend

1. X - Series 8-spoke alloy wheel 17” x 8” 4. C - Series 5-spoke alloy wheel 17” x 8”

2. T - Series Multi-spoke alloy wheel 16” x 7.5” 5. Alloy wheel nut

3. RT - Series 5-spoke alloy wheel 17” x 8” 6. Wheel nut with cap

When a Holden By Design alloy wheel and tyre

pack age is fitted, the standar d tyre placard (1); located

on the end surface of the right-hand front door (2), is

replaced with a new placard.

Figure 8A-26

The tyre placard provides information on the specific

tyre and wheel package fitted to the vehicle.

Figure 8A-27

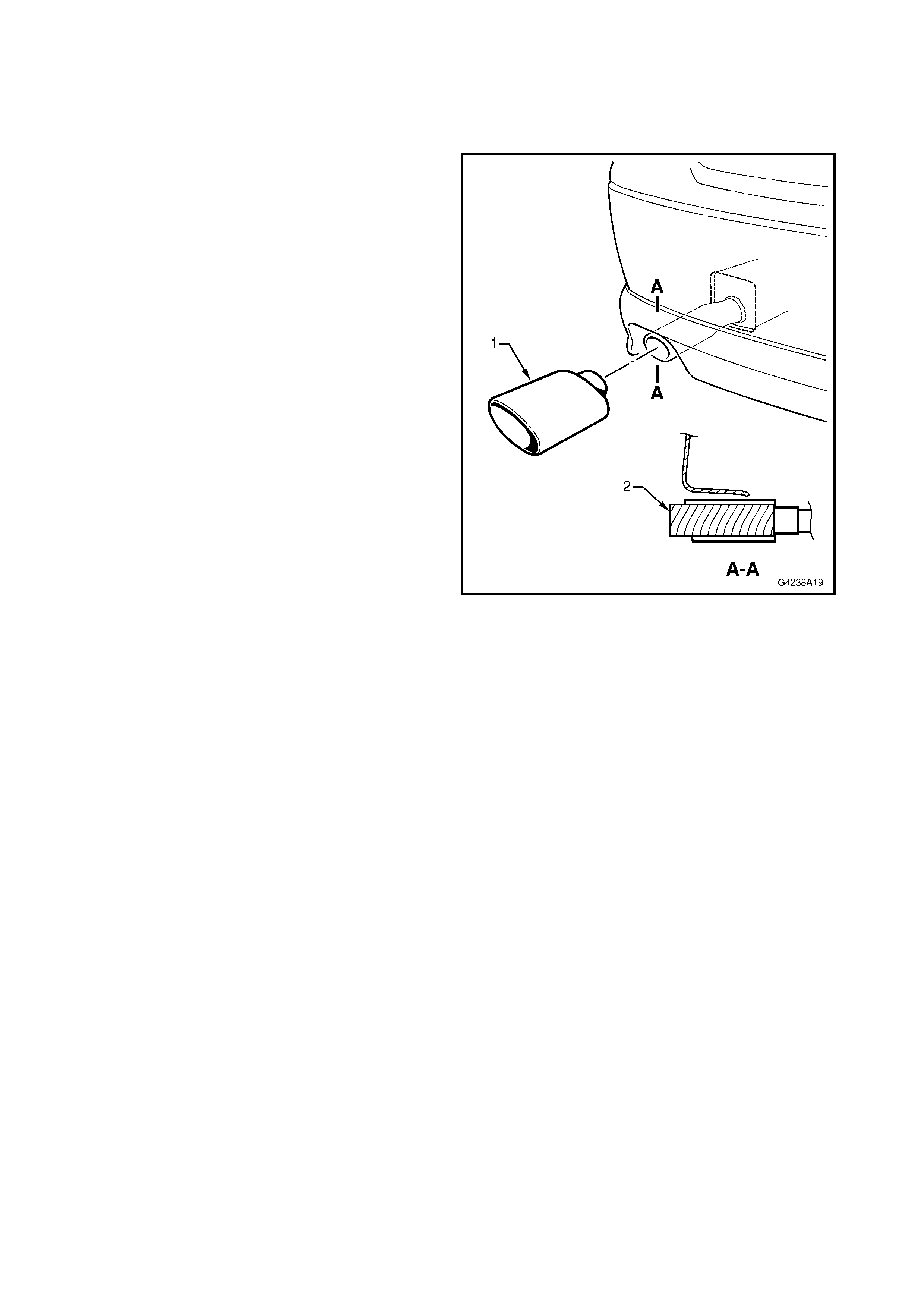

8.0 EXHAUST EXTENSION

W her e a f ull Holden By Design body kit has been installed, a c hrom e finished exhaus t extension is f itted to Level 2

and 3 vehicles.

REMOVE

1. Using a hammer and bloc k of wood seated against

the front edge of the extension(1), knock the

extension off the exhaust pipe.

INSTALL

1. Seat the extension on to the exhaust pipe.

2. Place a block of wood (2) within the extension,

seated against the front wall.

3. Knock the extension onto the exhaust pipe with a

hammer until it is level with the rear apron.

Figure 8A-28

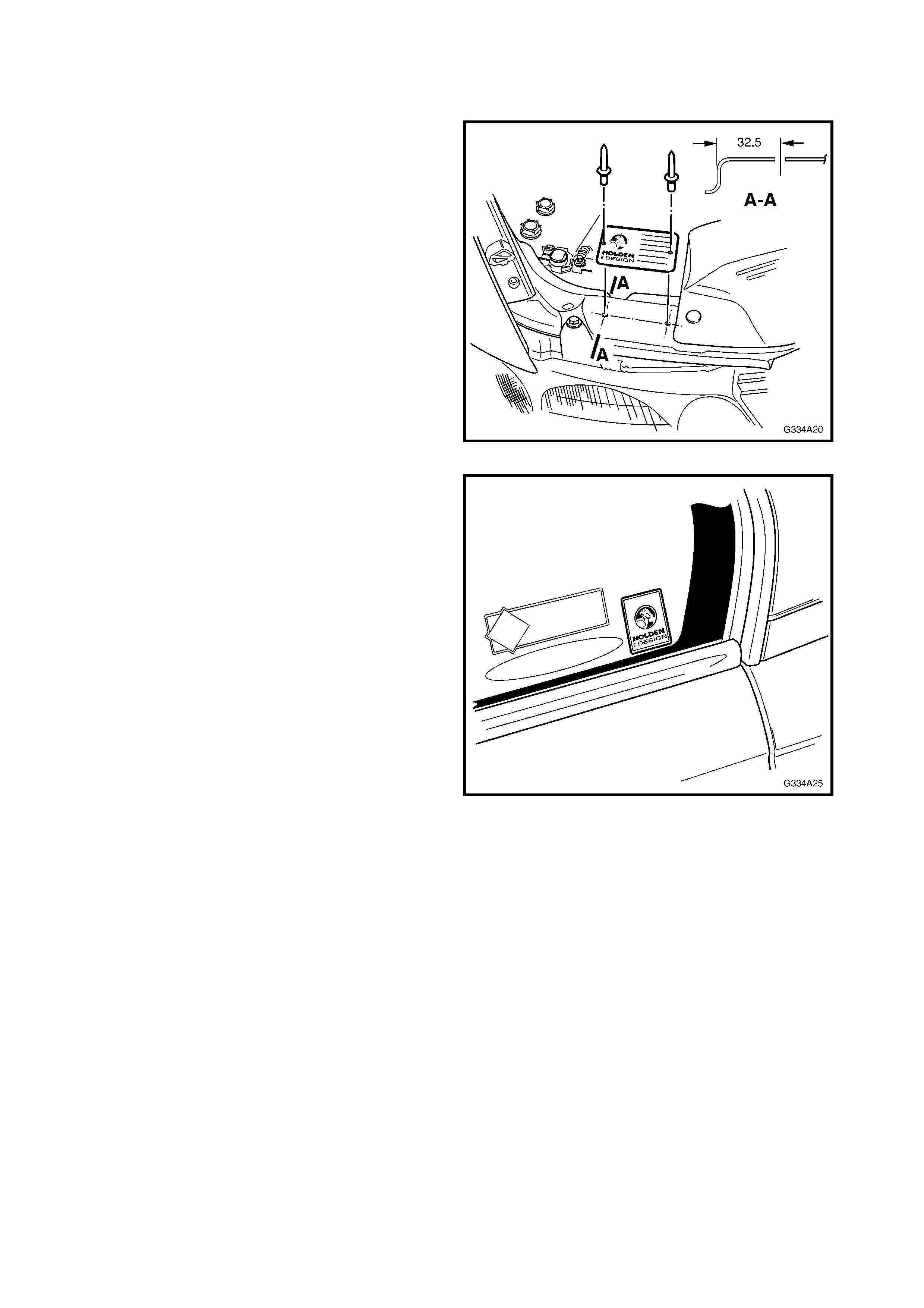

9.0 IDENTI FICATION & DECALS

Where a full Holden By Design body kit has been installed, a HBD identification plate is installed in the engine

compartment on the front upper panel. Holden By Design labels are also placed on each rear door fixed glass.

1. Drill 3 mm holes to the dimensions shown into the

front panel upper.

2. Affix the identification plate with pop-rivets.

Figure 8A-29

The Holden By Design decal is affixed to the inside of

each rear door fixed window as shown.

NOTE: Ensure the surface is clean and dry before

applying the decal.

Figure 8A-30

10.0 TORQUE WRENCH SPECIFICATIONS

Radiator grille insert mesh attaching screw .......................................................................................1.0 – 2.0 Nm

Radiator grille insert attaching screw .................................................................................................0.2 – 0.4 Nm

Radiator grille insert attaching nut......................................................................................................1.0 – 3.0 Nm

Front apron attaching screw...............................................................................................................1.0 – 3.0 Nm

Rear apron attaching screw ...............................................................................................................1.0 – 3.0 Nm

Decklid spoiler attaching screw..........................................................................................................2.0 – 5.0 Nm

Decklid spoiler attaching nut ..............................................................................................................2.0 – 5.0 Nm

Alloy wheel attaching nut............................................................................................................110.0 – 140.0 Nm