SECTION 9A - VU SERIES HBD PACKAGES

1.0 GENERAL INFORM ATION

This Section of the Holden By Design Service Information Supplement describes the service procedures for the

hard tonneau cover, which is part of the Holden By Design packages available for VU Series utility vehicles.

The other pac k ages available are als o fitted to other vehic les; theref ore ref erenc e should be made to the applicable

Service Information Sections as described in 1.1 VU Series HBD Package References.

The hard tonneau c over is painted in the vehicle’s body colour and is hinged at the f ront. Gas struts aid in opening

the tonneau cover and support it while open. Two keyed locks secure the tonneau cover when closed and provide

security for items stored in the load compartment.

Painting procedures for the hard tonneau cover are not provided in this Supplement, as the products used in the

refinish industry vary significantly. The hard tonneau is manufactured from fibreglass; therefore the correct

procedures for refinishing this material, as specified by the paint manufacturer, must be followed.

1.1 VU SERIES HBD PACKAGE REFERENCES

Package Refer

Hard Tonneau This Supplement

Alloy Wheels:

16 x 7.5 T-Series Multi-spoke Wheel & 225/50 B530 Tyre

17 x 8 C-Series 5 Spoke Wheel & 235/45 V Tyre

17 x 8 RT-Series 5 Spoke Wheel & 235/45 V Tyre

17 x 8 X-Series 8 Spoke Wheel & 235/45 V Tyre

Section 8A, VX Series Body Kit & Alloy Wheels in the

Holden By Design Service Information Supplement

Brakes (Only with 17” Wheels):

Performance Brakes

Premium Brakes

Section D, Brakes in the VX Series Holden Special

Vehicles Service Information Supplement

Holden By Design Radiator Grille Insert (Except SS) Section 8A, VX Series Body Kit & Alloy Wheels in the

Holden By Design Service Information Supplement

Country Roo Bar (Except SS) Section 4F, VT Series Country Driving & Load

Management in the Holden By Design Service

Information Supplement

Cruise Control (Except S & SS) VT Commodore cruise control accessories fitting

instructions for the applicable motor on this Service

Information Package, together with Section 12E Cruise

Control in the VU Series Service Information

Audible Alarm VT Commodore Series II anti-theft alarm package

accessories fitting instructions on this Service

Information Package, together with Section 12F Theft

Deterrent in the VU Series Service Information

Leather Bound Steering Wheel Section 4E, VT Series Comfort, Security &

Convenience in the Holden By Design Service

Information Supplement together with Section 9A

Steering in the VU Series Service Information

Power Antenna Section 4E, VT Series Comfort, Security &

Convenience in the Holden By Design Service

Information Supplement together with Section 12D

Audio System in the VT Series Service Information

2.0 HARD TONNEAU

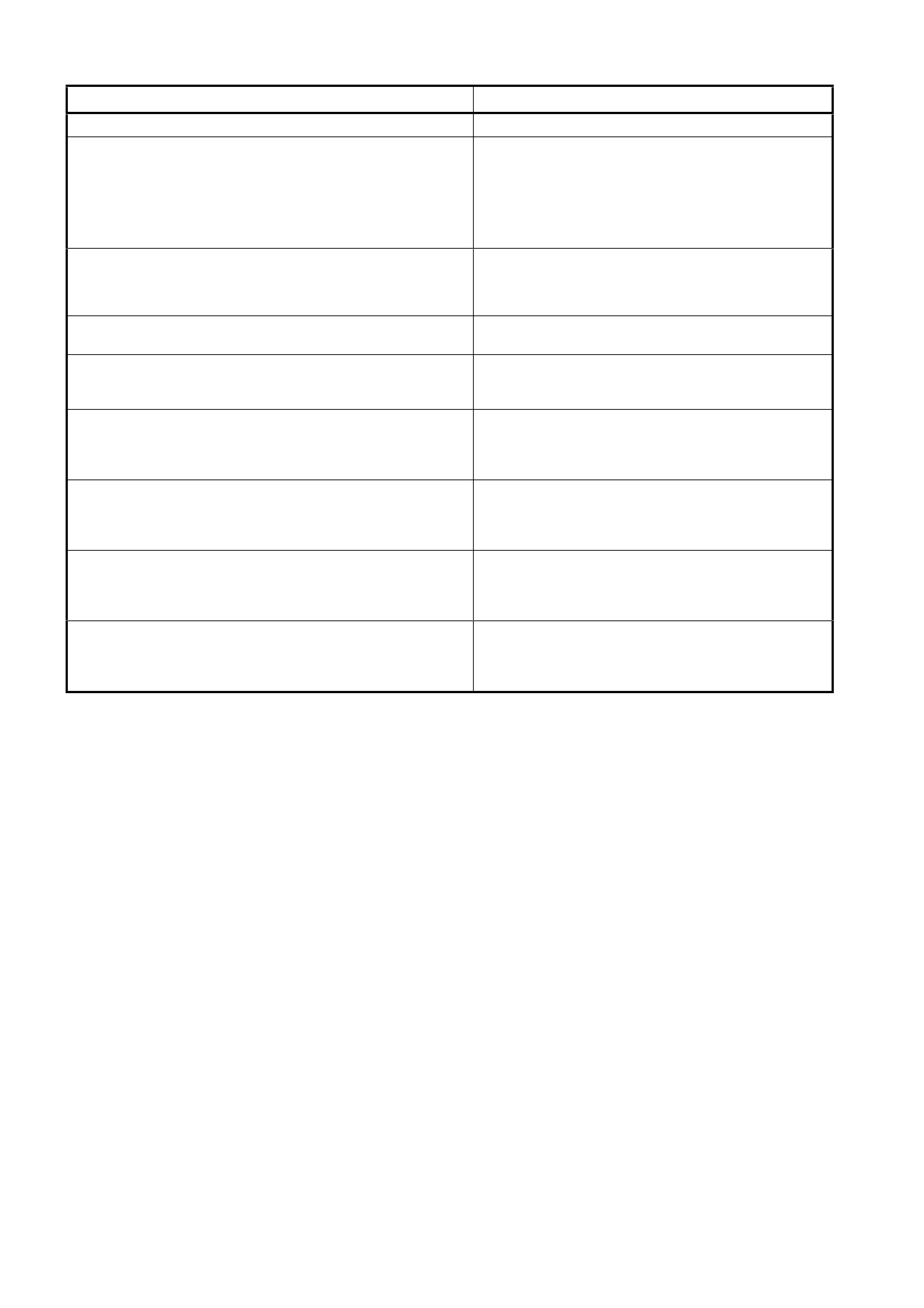

Figure 9A-1

Legend

1. Tonneau Cover Assembly 7. Seal Plate Washer 13. Seal - Drain *

2. Front Upper Panel Seal 8. Seal Plate 14. Seal - Cap *

3. Hinge Slot Plate 9. Gas Strut 15. Seal - Endgate *

4. Hinge Slot Plate Screw 10. Gas Strut Ball Screw 16. Nutsert - Centre Roof Rear Cap #

5. L-Shaped Foam Pad 11. Gas Strut Ball Screw Wa sher 17. Adhesive Tape - Roof Rear Cap #

6. Seal Plate Screw 12. Lock Plate

* Part of load compartment area seal kit, sold separately.

# Part of centre roof rear cap repair kit, sold separately.

2.1 TONNEU COVER ASSEMBLY

REMOVE

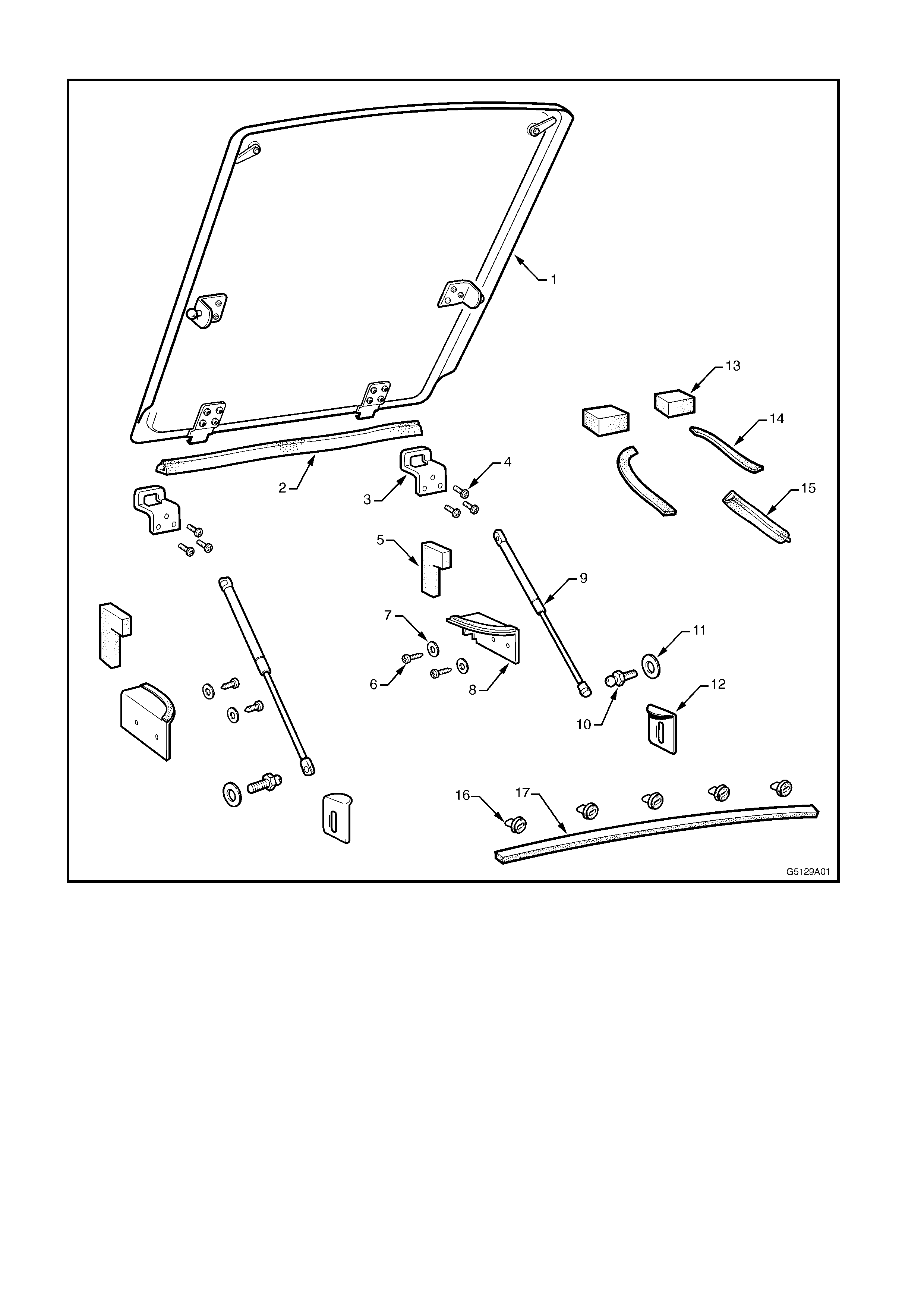

1. Open the tonneau cover and have an assistant

support the opposite side.

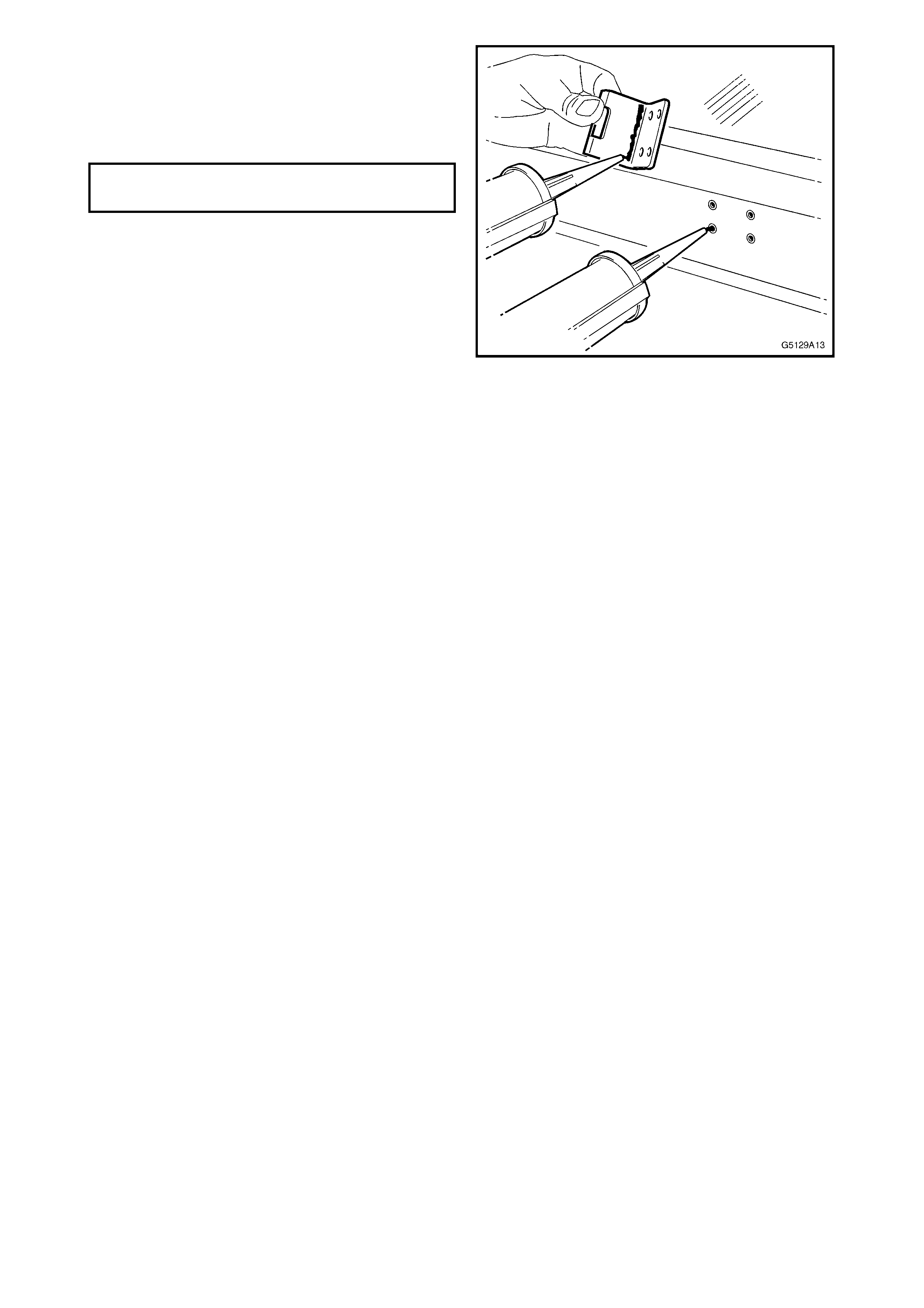

2. Insert a small flat blade screwdriver under the

spring clip ( 1) on the strut end and pris e the clip

outward: Do not remove.

3. Lever the strut from the strut bracket. Repeat

for the opposite side.

4. Carefully raise the tonneau cover to nearly 90

degrees and withdraw the hinge tongues from

the hinge slots, refer Fig. 9A-3.

5. Store the tonneau cover in a safe place.

Figure 9A-2

Figure 9A-3

DISASSEMBLE

1. Carefully place the tonneau cover upside down

on a soft surface.

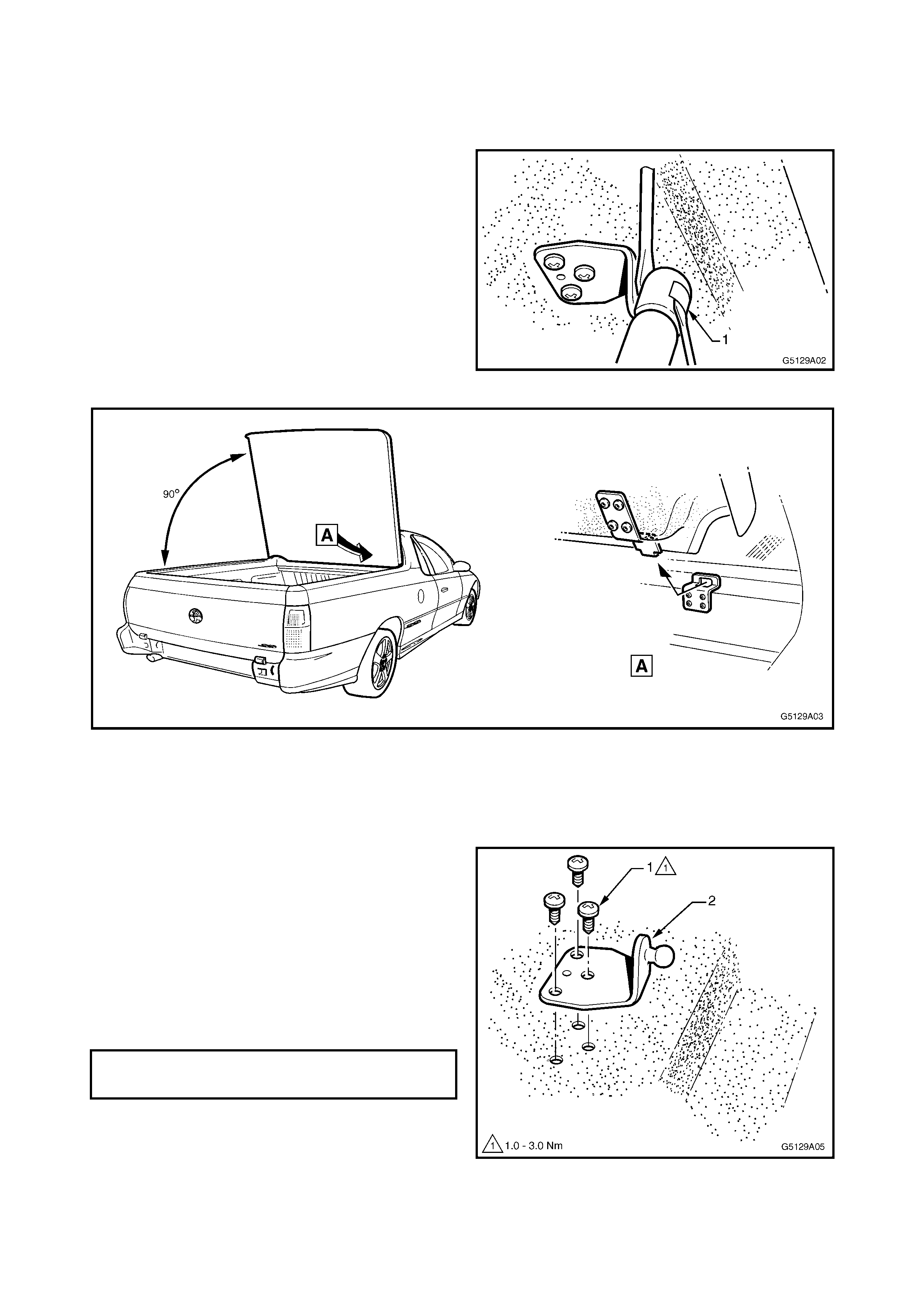

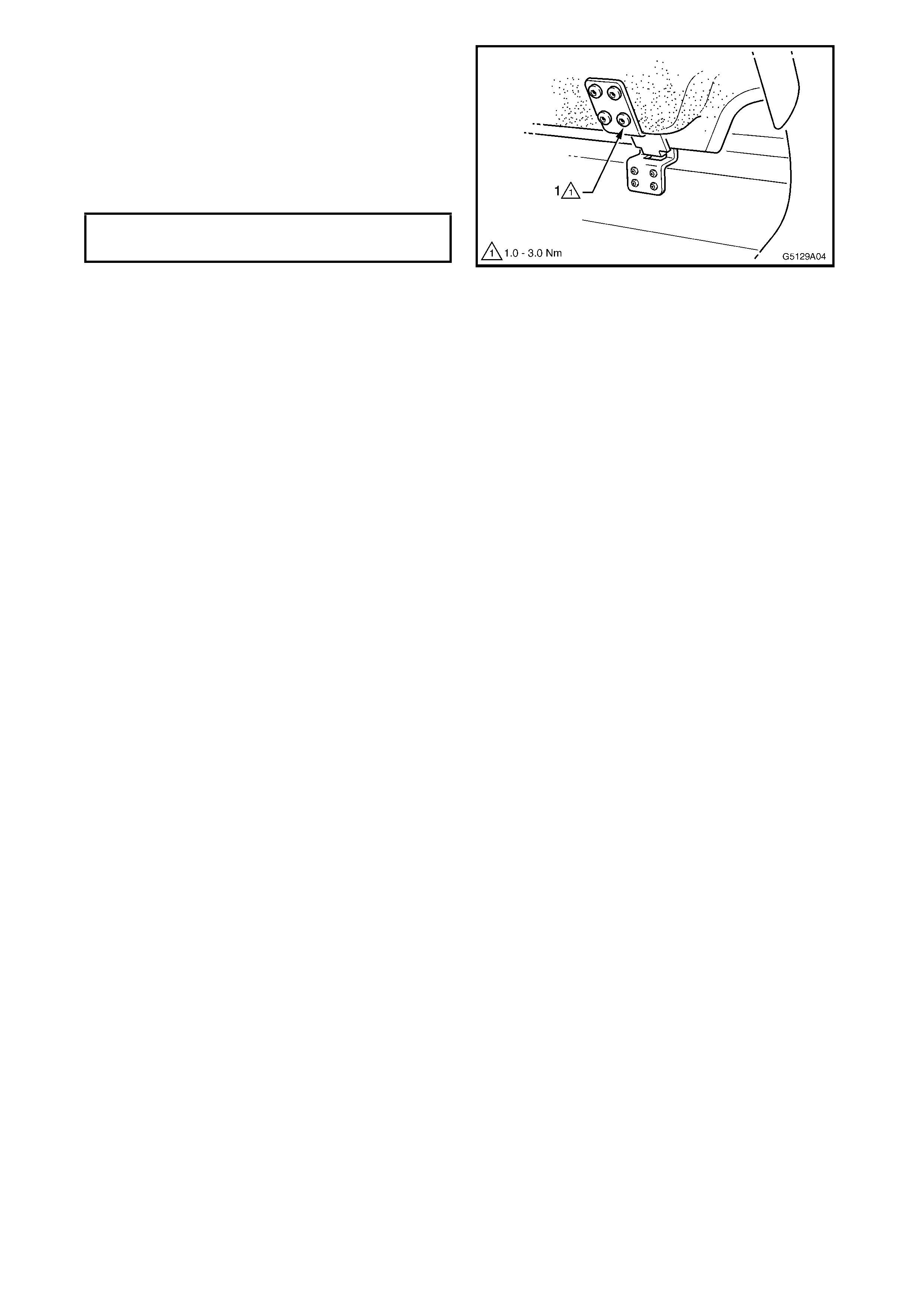

REMOVE – GAS STRUT BRACKET

1. Remove the three screws (1) attaching the gas

strut bracket (2) and remove the bracket.

REINSTALL – GAS STRUT BRACKET

1. Place the bracket in position ensuring correct

orientation.

2. Install the three screws and tighten to the

specified torque.

Figure 9A-4

GAS STRUT BRACKET ATTACHING

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

REMOVE – HINGE TONGUE PLATE

1. Remove the four screws (1) attac hing the hinge

tongue plate (2) and remove the plate.

REINSTALL – HINGE TONGUE PLATE

1. Place the hinge tongue plate in position, install

the screws and tighten to the specified torque.

Figure 9A-5

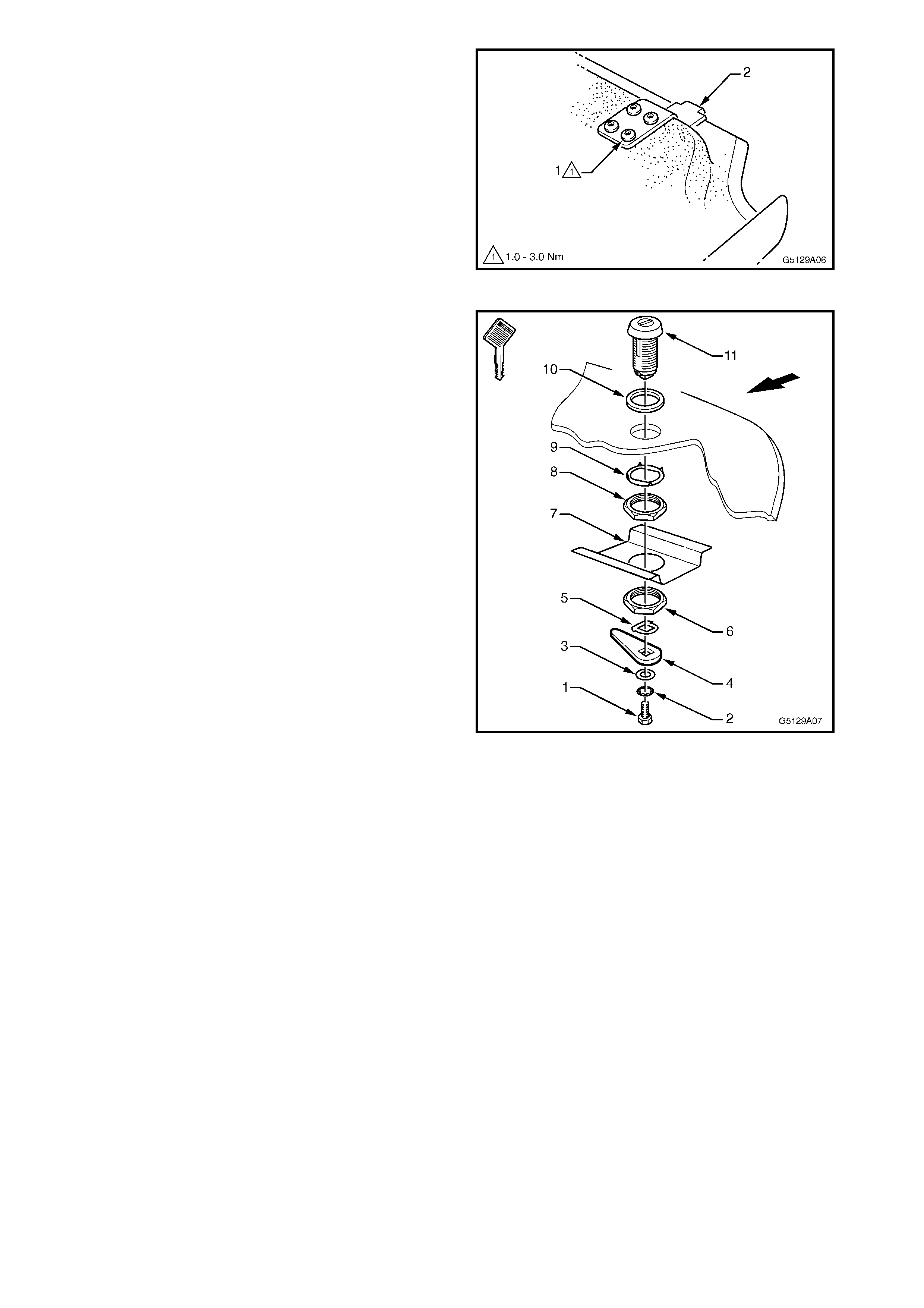

REMOVE – LOCK ASSEMBLY

1. Remove the screw (1) shake proof washer (2)

and flat washer (3) attaching the latch plate (4).

2. Remove the latch plate and locating plate (5).

3. Remove the nut (6) and support plate (7).

4. Remove the nut (8) and anti-rotation ring (9)

and withdraw the lock barrel (11) and seal ring

(10) from the tonneau cover.

REINSTALL – LOCK ASSEMBLY

1. Reinstall the components in the correct order

ensuring their correct orientation. The locating

plate lug at the base of the loc k barr el should be

facing forward.

2. Tighten the nuts and screw tightly.

3. Chec k for c orrec t operation. T he key slot should

be parallel to the vehicle when the lock is in the

open and closed positions.

Figure 9A-6

REINSTALL

1. If not done so, install all seals for the hard

tonneau cover, refer 2.5 SEALS.

2. With the aid of an assistant, install the tonneau

cover by r aising its r ear to near 90 degrees and

insert the hinge tongue plates into the hinge

slots, refer Fig. 9A-3.

NOTE: Tak e care not to dam age the tonneau c over

or vehicle.

3. Lower the tonneau to allow the gas struts to be

attached to the strut brackets. A 'click' will be

heard when the strut is seated correctly.

NOTE 1: Ensure the hinge tongues are fully inserted

into the hinge slots.

NOTE 2: Ensure the cylinder end of the strut is up.

4. Close the tonneau carefully and check its

alignment around each side and the rear.

5. If adjustment is required, open the tonneau and

disconnect the gas struts from the tonneau by

inserting a small screwdriver under the spring

clip on the strut end and prise the clip outward:

do not remove. Remove the strut.

6. Loosen the screws (1) attaching each hinge to

the tonneau cover with a 5mm Allen key. Open

the endgate and have an as sistant lie in the tr ay

on their back with the Allen key.

7. Close the tonneau and manoeuvre it into the

correct position. When correctly aligned each

side and rear, have the assistant tighten the

hinge screws to the specified torque.

8. While the assistant is in the rear compartment,

check the seal plates are in contact with the

tonneau. Adjust as required.

9. Open the tonneau cover and reconnect the gas

struts.

10. Close the tonneau and check the locking action

each side. Adjust the lock plates as required,

refer 2.2 LOCK PLATE.

Figure 9A-7

TONNEAU COVER HINGE TONGUE

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

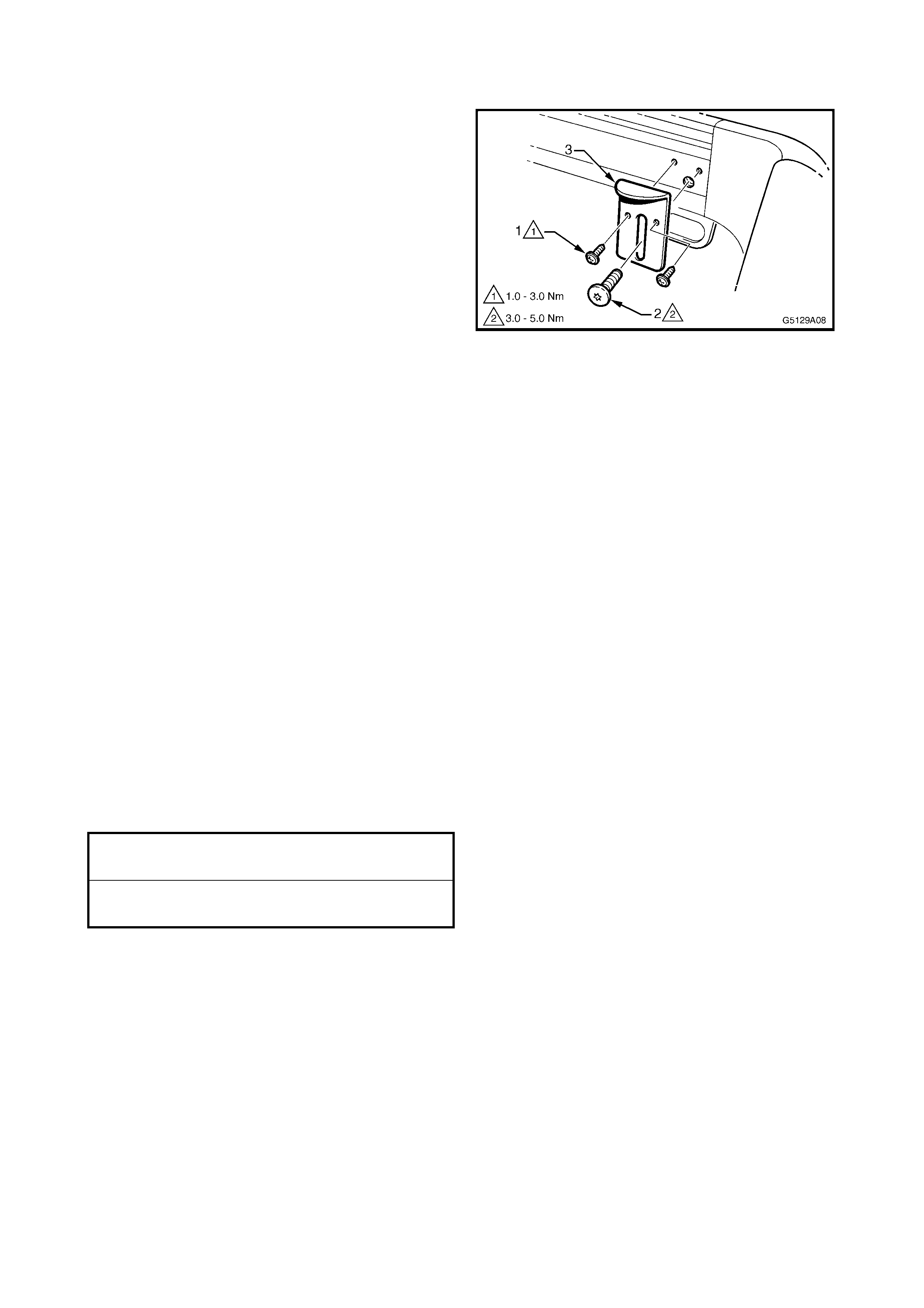

2.2 LOCK PLATE

REMOVE

1. Remove the lock plate lock-screws (1), 2

places.

2. Using a T40 Torx head bit, remove the screw

(2) and remove the lock plate (3).

Figure 9A-8

REINSTALL

1. Place the lock plate in position and install the

Torx-head screw.

2. Close the tonneau and check the locking action.

3. Raise or lower the lock plate until slight

pressur e on the tonneau is required for the lock

to be operated.

4. Tighten the Torx head screw to the specified

torque.

5. If the exis ting lock plate is us ed, install the lock -

screws.

NOTE: The lock-screws are used to maintain the

lock plate in its factory set position. If this position is

now diff erent, new holes will be required adjacent to

the existing holes.

6. If a new loc k plate is being f itted, install the lock

screws level with the top of the slot.

NOTE 1: The screws are self-drilling.

NOTE 2: If attaching the plate to the existing rail

cap, install the screws either 5 mm higher or lower

to avoid interfering with the original holes.

7. Tighten the screws to the specified torque.

LOCK PLATE ATTACHING SCREW

TORQUE SPECIFICATION 3.0 – 5.0 Nm

LOCK PLATE LOCK-SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

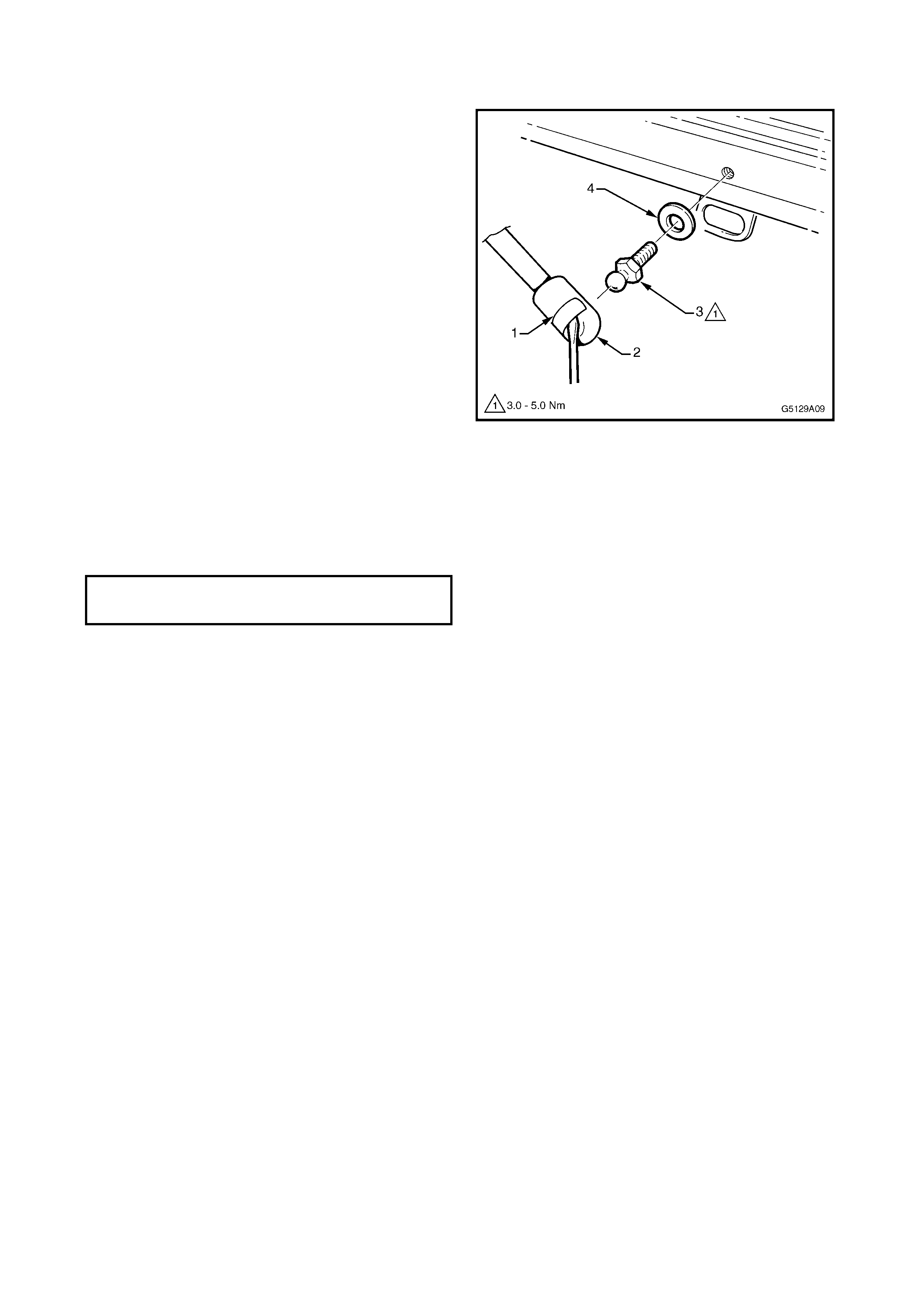

2.3 GAS STRUT BALL SCREW

REMOVE

1. Insert a small flat blade screwdriver under the

spring clip (1) on the strut end (2) and prise the

clip outward. Do not remove.

2. Lever the strut from the ball screw (3).

3. Remove the ball screw and washer (4).

Figure 9A-9

REINSTALL

1. Install the washer and ball sc rew. Tighten to the

specified torque.

2. Reconnect the gas strut.

GAS STRUT BALL SCREW

TORQUE SPECIFICATION 3.0 – 5.0 Nm

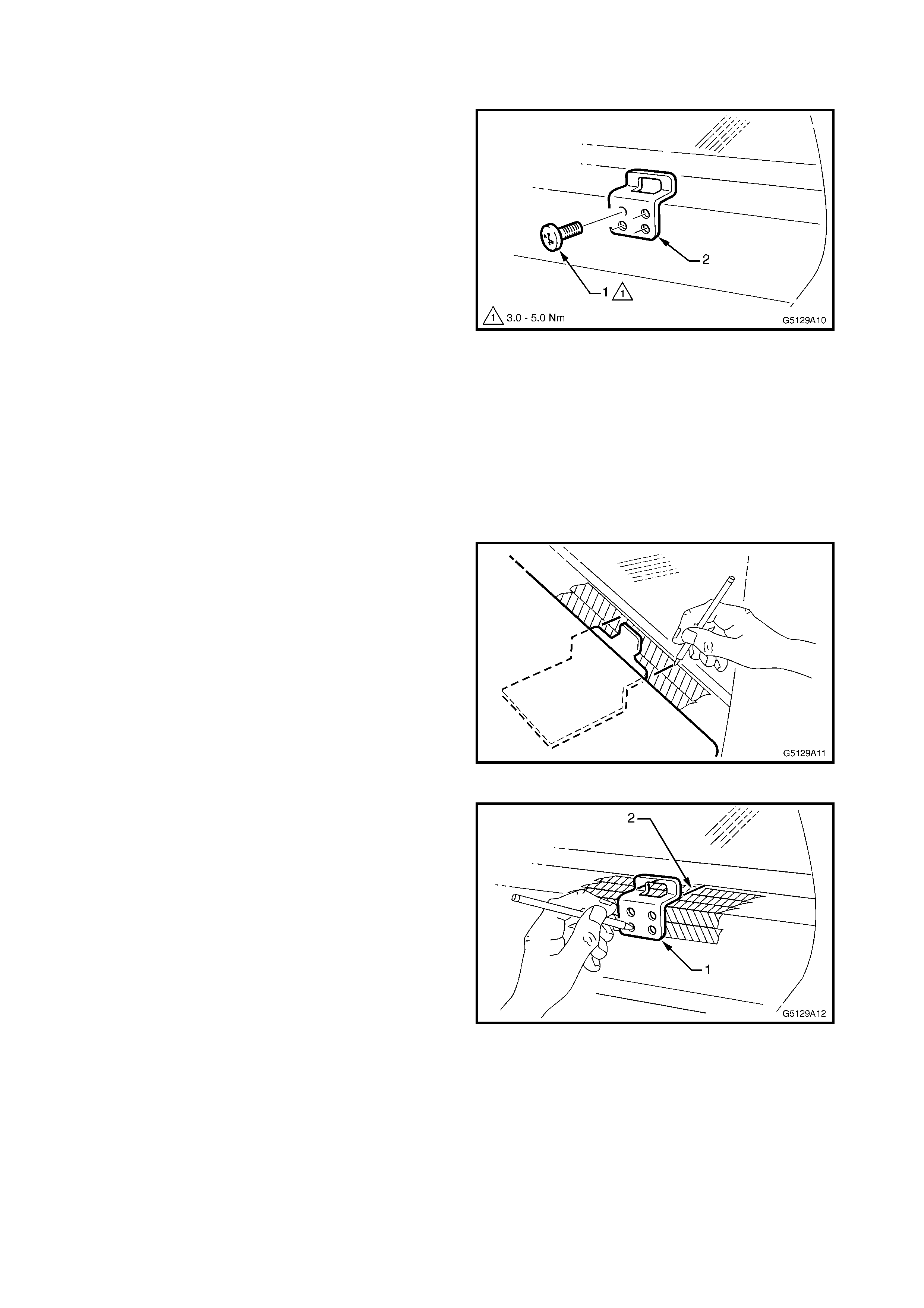

2.4 HINGE SLOT PLATE

REMOVE

1. Remove the pan-head screw (1), four places

attaching the hinge slot plate (2) to the vehicle.

Figure 9A-10

REINSTALL

NOTE: If the nutserts have not been removed,

proceed to step 13.

1. To avoid paint damage, place masking tape on

the panel where each hinge will be.

2. With the aid of an assistant, place the hard

tonneau in position on the vehicle and

centralise.

3. Mark a line on the load compartment front upper

panel, each side of the hinge.

4. As required, repeat for the opposite hinge.

5. Remove the tonneau cover from the vehicle.

Figure 9A-11

6. Align the hinge slot plate (1) with the marks on

the load compartment front upper panel (2).

7. Using the hinge slot as a template, mark the

screw hole positions.

8. Dill four 6 mm pilot holes.

9. Drill the pilot holes out to 9.5 mm.

10. Remove the masking tape.

11. Vacuum up any swarf and paint the holes with

corrosion protection primer.

12. Using a commercially available nutsert tool,

insert a M6 nutsert in each hole.

Figure 9A-12

13. Apply silicone or butyl sealer to the mounting

surface of the hinge slot plate and on each

screw hole.

14. Install the hinge slot plate and pan-head screws.

Tighten to the specified torque.

Figure 9A-13

HINGE SLOT PLATE SCREW

TORQUE SPECIFICATION 3.0 – 5.0 Nm

2.5 SEALS

L-SHAPED FOAM PAD

REMOVE

NOTE: The L-shaped foam pad (1) is adhesive

backed and removal may damage the pad, which

must then be replaced.

1. Insert a narr ow scraper or knife under the lower

edge of the pad and car efully prise the pad from

the vehicle.

REINSTALL

1. Clean the surface of the vehicle where the pad

is to be fitted.

2. If a new pad is being fitted, remove the backing

paper. If the existing undamaged pad is being

fitted, apply contact adhesive such as Quick-

Grip or equivalent to the back of the pad.

3. Install the pad as shown.

Figure 9A-14

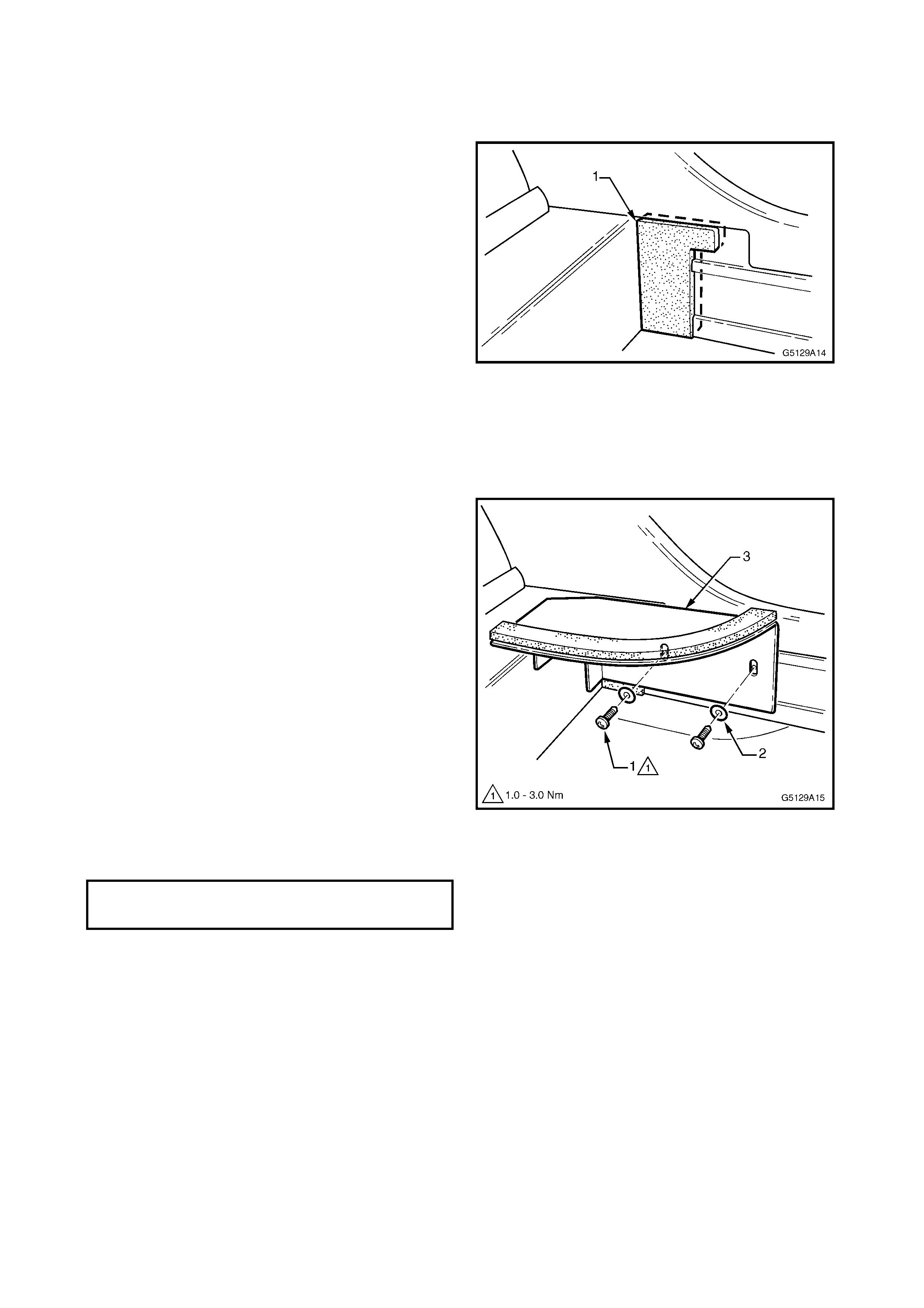

SEAL PLATE

REMOVE

1. Remove the two screws (1) and washers (2)

attaching the seal plate (3) to the vehicle and

remove.

REINSTALL

1. Fit the seal plate in position against the load

compartment front upper panel. Ensure the top

surface of the plate is sitting on the panel.

2. Install the screws and washers in the middle

position in each slot. Do not tighten.

NOTE: The screws are self-drilling if the existing

holes no longer exist.

3. If removed, install the tonneau cover as

described in Section 2.1 TONNEAU COVER.

4. Open the endgate and close the tonneau cover.

5. From within the rear compartment, adjust the

seal plate so that it is in contact with the

tonneau cover.

6. Tighten the screws to the specified torque.

Figure 9A-15

SEAL PLATE SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

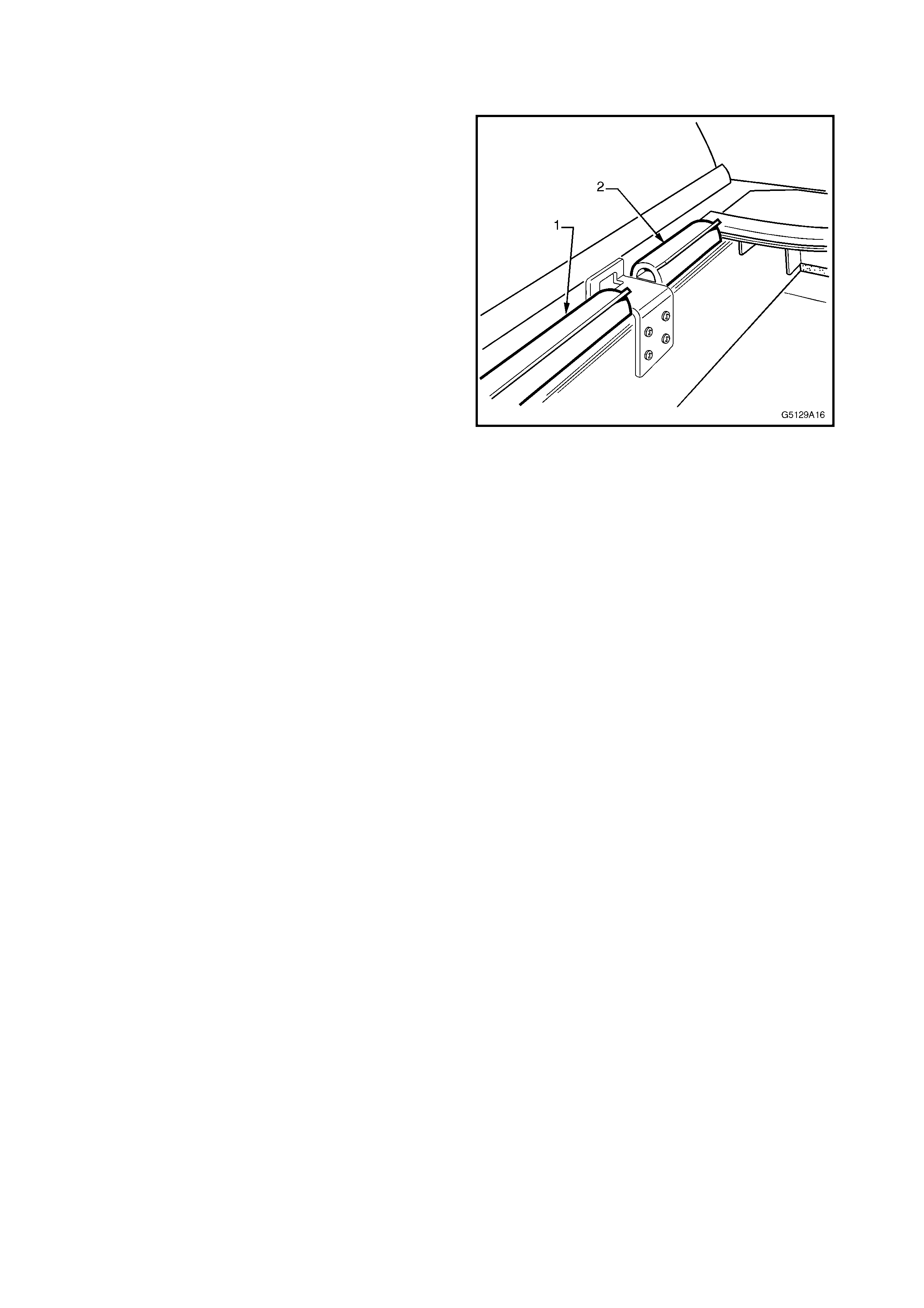

FRONT UPPER PANEL SEALS

REMOVE

NOTE: The front upper panel seals are adhesive

backed and removal may damage the seal, which

must then be replaced.

1. Carefully prise the front upper panel seal -

centre (1) or outer (2) from the vehicle, taking

care not to damage the seal or paintwork.

REINSTALL

NOTE: New seals are supplied in the one piece,

which is to be cut to length as required.

1. Clean the surface of the vehicle where the

seal(s) are to be fitted.

2. If a new seal is being f itted, cut it to length. The

centre seal is to f it between the hinge slot plates

and the two outer seals are to fit between the

hinge slot plate and seal plate each side.

3. Remove the backing paper, or if an existing

undamaged seal is being fitted, apply contact

adhesive such as Quick-Grip or equivalent to

the back of the seal.

4. Install the seal as shown, noting that the lip of

the seal is facing rearward.

Figure 9A-16

CAP SEAL & DRAIN SEAL

NOTE 1: The cap and drain seals are part of the

load compartment area seal kit, available

separately.

NOTE 2: The cap and drain seals are adhesive

backed. Removal may damage the seals, which

must then be replaced.

NOTE 3: The centre roof rear cap is affixed to the

vehicle with retainers inserted into nutserts and

double-sided tape. On removal of the cap, the

double-sided tape will be destr oyed and some of the

nutserts m ay be damaged. If required, a centre roof

rear cap repair kit is available which includes these

parts.

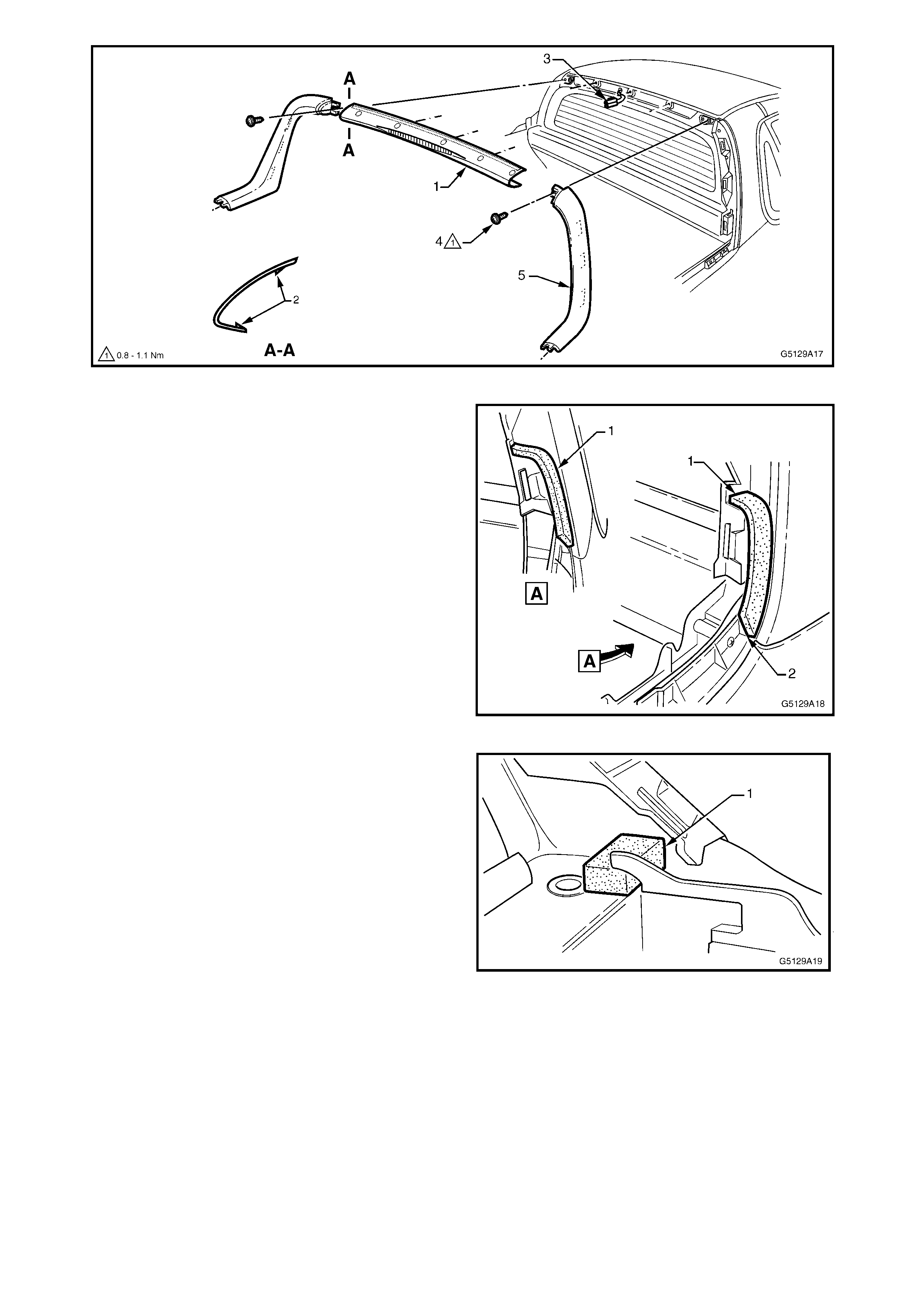

REMOVE

1. Remove the c entre roof rear c ap (1) by carefully

spreading each end of the cap to disengage the

locking tabs (2), refer Fig. 9A-17.

2. Insert a flat blade screwdriver and clean shop

rag between the lower edge of the centre roof

rear cap and the rear window.

3. Ensuring the lock ing tabs are disengaged, prise

the cap off in an upward and rearward direction.

NOTE: The upper edge of the cap is attached with

double sided tape.

4. Where fitted, disconnect the high mount stop

lamp connector (3) and remove the cap.

5. Remove the screw (4) attaching the side roof

rear cap (5).

6. Rotate the cap rearward to disengage the three

clips and ease the lower end of the c ap forward

to disengage the cap from the side rail capping.

Figure 9A-17

7. Peel the cap seal (1) from the quarter panel

upper moulding.

8. Clean off any residual adhesive as required.

Figure 9A-18

9. Peel the drain seal (1) from the front upper

panel.

10. Clean off any residual adhesive as required.

REINSTALL

1. Clean the surfaces with wax and grease

remover such as Prepsol or equivalent.

2. If the existing seal(s) are being used, apply

contact adhesive such as Quick-Grip or

equivalent to the seal, or remove the backing

paper if a new seal(s) is being fitted.

3. Install the drain seal as shown in Fig. 9A-19,

ensuring it is seated against the side panel.

4. Install the cap seal as shown in Fig. 9A-18,

ensuring the upper end is seated aganst the

quarter panel upper m oulding and the lower end

is seated on the rib (2).

NOTE: It is important the seal is applied in such a

way that it is not visible when the cap is fitted.

5. Installation of the roof rear caps is the reverse

of removal.

NOTE: Replace the double-sided tape and nutserts

as r equired using the centre roof rear cap repair k it,

available seperately. Follow the instructions supplied

with the kit.

Figure 9A-19

ENDGATE SEALS

NOTE 1: The endgate seals are part of the load

compartment area seal kit, available separately.

NOTE 2: The endgate seals are adhesive backed.

Removal may damage the seals, which must then

be replaced.

REMOVE

1. Open the endgate.

2. Carefully peel the endgate seal (1) from the load

compartment rail end cap.

3. Remove any residual adhesive as required.

REINSTALL

1. Clean the surface of the load compartment rail

end cap with wax and grease remover such as

Prepsol or equivalent.

2. If a new seal is being fitted from the load

com partment area s eal kit, cut the new endgate

seal in half.

3. Remove the backing paper or, if the old seal is

being used, carefully apply contact adhesive

such as Quick-Grip.

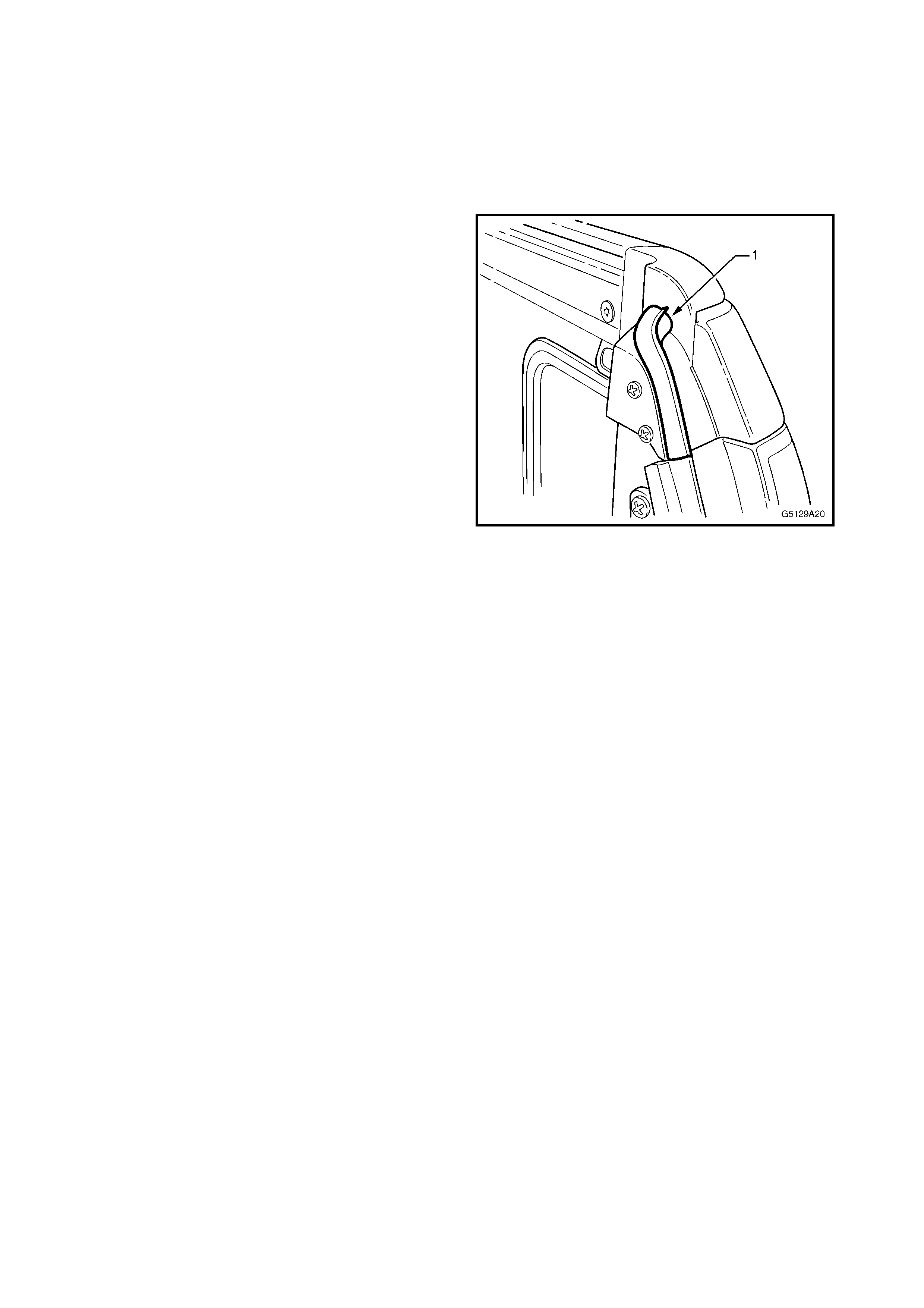

4. Fit the seal in position ensuring the lip is facing

rearward and the ends are seated against the

end cap and existing seal, refer Fig. 9A-20.

Figure 9A-20

3.0 TORQUE WRENCH SPECIFICATIONS

Gas strut bracket attaching screw...............................................................................................1.0 – 3.0 Nm

Hinge tongue plate attaching screw............................................................................................1.0 – 3.0 Nm

Tonneau cover hinge tongue screw............................................................................................1.0 – 3.0 Nm

Lock plate attaching screw..........................................................................................................3.0 – 5.0 Nm

Lock plate lock-screw..................................................................................................................1.0 – 3.0 Nm

Gas strut ball screw.....................................................................................................................3.0 – 5.0 Nm

Hinge slot plate screw.................................................................................................................3.0 – 5.0 Nm

Seal plate screw..........................................................................................................................1.0 – 3.0 Nm