Wheels, Tyres and Steering Wheel Page H-1

Section H

Wheels, Tyres And Steering Wheel

ATTENTION

HSV vehicles are equipped with a Supplemental Restraint System (SRS). An SRS consists of seat belt pre-

tensioners (fitted to all front seat s), a driver’s-side air bag, a passeng er’s-side air bag and left and right han d

side airbags. Refer to CAUTIONS, Section 12M, of the Holden series Adventra AWD Service Information

before performing any service operation on or around SRS components, the steering mechanism or wiring.

Failure to follow the C AUTIONS cou ld result in personal injury or unnecessar y SRS system repairs.

1 Purpose...................................................................................................................................................2

2 Wheels And Tyres ..................................................................................................................................3

2.1 General Description............................................................................................................................................... 3

2.2 Service Operations................................................................................................................................................ 4

2.3 Wheel and Tyre Balancing .................................................................................................................................... 5

2.4 Tyre Placard And Pressures................................................................................................................................. 6

3 Steering Wheel........................................................................................................................................8

Page H-1

Wheels, Tyres and Steering Wheel Page H-2

1 Purpose

The purpose of this section is to provide information on the wheels, tyres and steering wheels fitted to the HSV

Avalanche AWD model. The informatio n is d esigned to supplement that given in the Holden Adventra AWD series

Service Information and details are give n where differences occur between the HSV models and standard Hol den

models. A series of instruction drawings describe the d esi gn changes and indicate specific part numbers, fitting

instructions and relevant notes for vehicle se rvicing.

NOTE

If specific technical data on a HSV model is not

contained in this supplement, obtain data for that

model from the relevant Holden Adventra AWD

series Information Supplement. References are

made throughout this section to Holden Service

Information, to assist in providing information for

specific service operations.

When hoisting (or jacking) HSV models,

ensure that the lifting h ead of the hoist lifts on

the chassis before the arm of the hoist

contacts the side-skirt

Page H-2

Wheels, Tyres and Steering Wheel Page H-3

2 Wheels And Tyres

2.1 General Description

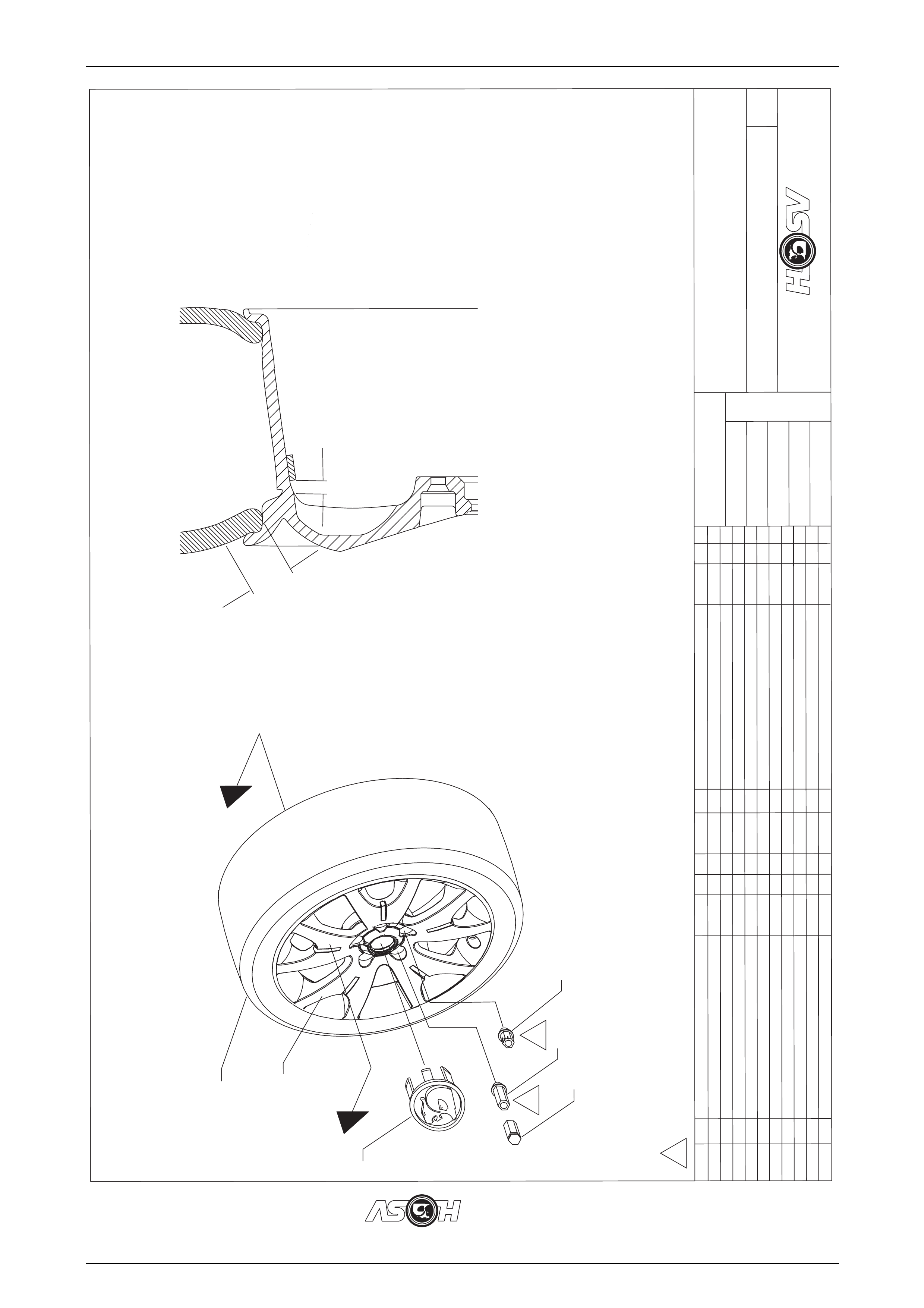

HSV Avalanche AWD models are fitted with alloy wheels developed specifically for HSV application. Each wheel is

manufactured from a single-piece alloy casting.

NOTE

Specific wheel nuts are used to attach alloy

wheels to the vehicle. T hese nuts are fitted with a

plastic dress cap which must be removed prior to

undoing the wheel nuts.

HSV Avalanche AWD wheels do not have a

steel insert and therefore require wheel nuts

with a flang ed seat as per the VT, VT2 and VX

wheel nuts, 10B-970304. Do not use VS

wheels nuts on HSV Avalanche AWD wheels.

Page H-3

Wheels, Tyres and Steering Wheel Page H-4

2.2 Service Operations

Alloy wheels fitted to all HSV vehicl es are to be serviced in accordance with the procedures detailed in the relevant

Holden Service Information, refer to Section 10 – Wheels And Tyres. In addition, particular care should be taken with the

surface finish of alloy wheels. The manufacturer recommends that allo y surfaces be treated the same as high-gloss

painted services to prevent corrosion and genera l deteriorat ion.

Page H-4

Wheels, Tyres and Steering Wheel Page H-6

2.4 Tyre Placard And Pressures

The HSV Tyre Placard is posit ioned on the opening of the right hand door. The Tyre Placard details important

information on the tyre pressures recomme nded for the HSV Avalanche AWD Series Models. If carrying load, or

travelling at high speed, the t yre pressur es n eed to be increased as detailed on the placard. This is very important for

tyre wear and also to ensure that the tyres have sufficient load carrying capac ity.

Page H-6

Wheels, Tyres and Steering Wheel Page H-7

DATE

ISSUE DATED

ISSUE DATED

AUTH'Y

CK.

SYM

AUTH'Y

RELEASE

REVISION RECORD

REVISION RECORD

DATE

SYM

SIGNATURES ON

SIGNATURES ON

ORIGINAL APPROVAL

ORIGINAL APPROVAL

DR.

14.07.00

ADVANCED AUTOMOTIVE DESIGN AND ENGINEERING

ADVANCED AUTOMOTIVE DESIGN AND ENGINEERING

10I-020006

INSTRUCTION DRAWING.

INSTRUCTION DRAWING.

A4

SIZESIZE

ALLOY WHEEL

AVALANCHE

ALLOY WHEEL

AVALANCHE

REVISION RECORD

REVISION RECORD

PRELIMINARY ISSUE

PRELIMINARY ISSUE

CK.

NAME

PART NO.

PART NO.

CK.

REFERENCE

DWG.

DR.

DATE:

APPR

APPR

DR.

22.01.04

AP

DP

MB

A. LUBRICATE TYRE BEADS BOTH SIDES FULL CIRCUMFERANCE WITH TYRE

MOUNTING LUBRICANT IN ACCORDANCE WITH HN - 1162. TYRE INSTALLATION

MUST BE MADE BEFORE LUBRICANT IS DRYTO ENSURE SATISFACTORY BEAD

SEATING, TYRE IS TO BE INFLATED TO 280kPa ON INITIAL ASSEMBLY

.

A. LUBRICATE TYRE BEADS BOTH SIDES FULL CIRCUMFERANCE WITH TYRE

MOUNTING LUBRICANT IN ACCORDANCE WITH HN -1162. TYRE INSTALLATION

MUST BE MADE BEFORE LUBRICANT IS DRYTO ENSURE SATISFACTORY BEAD

SEATING,TYRE IS TO BE INFLATED TO 280kPa ON INITIAL ASSEMBLY

.

B. POSITION STICK-ON WHEEL WEIGHT AS CLOSE AS POSSIBLE TO SPOKE EDGE

(MAXIMUM 5mm) AND ENSURE SUFFICIENT CLEARANCE BETWEEN THE WHEEL

WEIGHT AND BRAKE CALIPER EXISTS.

B. POSITION STICK-ON WHEEL WEIGHT AS CLOSE AS POSSIBLE TO SPOKE EDGE

(MAXIMUM 5mm) AND ENSURE SUFFICIENT CLEARANCE BETWEEN THE WHEEL

WEIGHT AND BRAKE CALIPER EXISTS.

SEC A-A

NOTES :

A

B

NOTE: BREAKAWAY TORQUE

NOTE: BREAKAWAY TORQUE

OF WHEEL NUTS TOBE

OF WHEEL NUTS TO BE

100 Nm MINIMUM

100 Nm MINIMUM

110-140 Nm

110-140 Nm

1

1. 10B-101919 CAP WHEEL NUT 5 PLACES

1. 10B-101919 CAP WHEEL NUT 5PLACES

2. 10B-970219 WHEEL NUT 4 PLACES

2. 10B-970219 WHEEL NUT 4 PLACES

3. 10B-970309 CAP &BADGE ASM WHEEL

3. 10B-970309 CAP & BADGE ASM WHEEL

4. WHEEL ALLOY 10B-032701

4. WHEEL ALLOY 10B-032701

5. TYRE 245/45 ZR18

5. TYRE 245/45 ZR18

6. LOCKNUTS SPZ-300168

6. LOCKNUTS SPZ-300168

A

A

1

1

16

3

4

5

2

Page H-7

Wheels, Tyres and Steering Wheel Page H-8

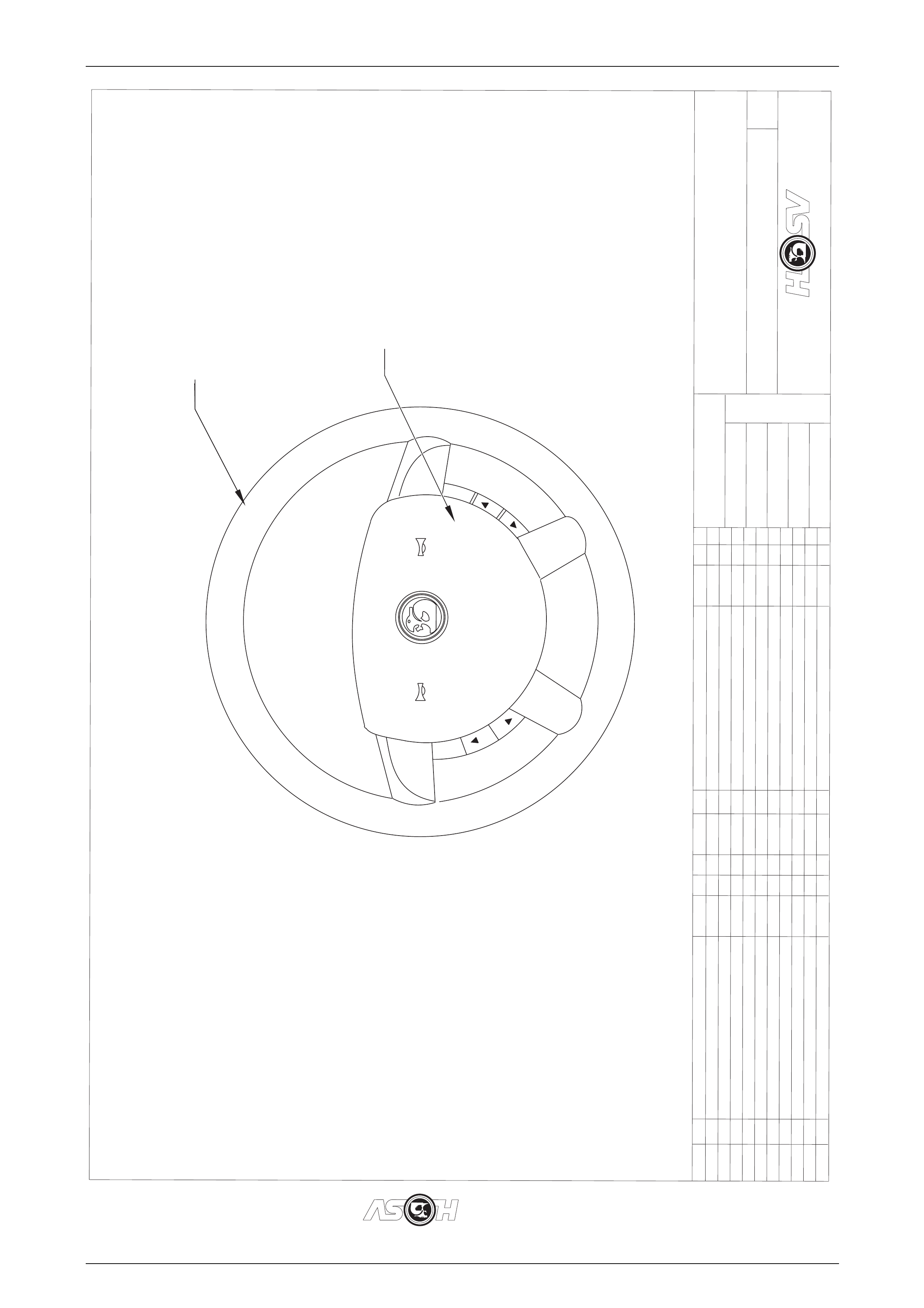

3 Steering Wheel

ATTENTION

HSV Avalanche AWD vehicles are equipped with AIR BAGS. An AIR BAG is a Supplemental Restraint System

(SRS). Refer to CAUTIONS, Section 12M, of the Holden Adventra AWD series Service Information Supplement

before performing any service operation on or around SRS components, the steering mechanism or wiring.

Failure to follow the CAUTIONS could result in air bag deployment, resulting in possible personal injury or

unnecessary SRS syst em repairs.

The steering wheel assembly fitted to HSV Avalanche AWD models incorporates a HSV-design central horn pad

complete with HSV logo (see Drawing 09I-030004). The central horn pad also incorporates the driver’s-side air bag. All

other components, fixtures and fasteners are identical to standard Holden parts and therefore, any service operations on

the assembly should be carried out in accordance with the relevant Holden Service Information Supplement, refer to

Section 9A – Steering of the Adventra AWD Series Service Information.

Page H-8

Wheels, Tyres and Steering Wheel Page H-9

DATE

DATE

ISSUEDATED

ISSUEDATED

AUTH'Y

AUTH'Y

CK.

CK.

SYM

SYM

AUTH'Y

AUTH'Y

REVISIONRECORD

REVISIONRECORD

DATE

DATE

SYM

SYM

SIGNATURESO

N

SIGNATURESON

ORIGINAL APPROVAL

ORIGINAL APPROVAL

DR.

DR.

ADVANCEDAUTOMOTIVE DESIGNA

N

DENGINEERINGADVANCEDAUTOMOTIVE DESIGNANDENGINEERING

09I-030004

09I-030004

INSTRUCTIONDRAWING.

INSTRUCTIONDRAWING.

A4

SIZE

SIZE

STEERINGWHEEL

AVALANCHE AWD.

STEERINGWHEEL

AVALANCHE AWD.

REVISIONRECORD

REVISIONRECORD

PRELIMINARYI

SSUE

PRELIMINARYISSUE

CK.

CK.

NAME

PARTN

O.

PARTNO.

CK.

CK.

REFERENCE

REFERENCE

DWG.

DWG.

DR.

DR.

DATE:

DATE:

APPR

APPR

APPR

APPR

DR.

DR.

26.02.04

AP

DP

GD

SRS

AIRBAG

AIRBAG

VOL

VOL

VOL

VOL

MUTE

MUTE

NEXT

NEXT

NEXT

NEXT

MODE

MODE

STEERING WHEEL

92163207

AIR BAG

92117622

Page H-9