Fuel and Exhaust Systems Page G-1

Page G-1

Section G

Fuel And Exhaust Systems

ATTENTION:

HSV vehicles are equipped with a Supplemental Restraint System (SRS). An SRS consists of seat belt pre-

tensioners (fitted to all front seats), a driver’s-side air bag , a passenger’s-side air bag and right and left hand

side air bags. Refer to CAUTIONS, Section 12M, in Volume 12 of the Holden V2 Series Coupe Service Manual

before performing any service operation on or around SRS components, the steering mechanism or wiring.

Failure to follow the CAUTIONS could result in personal injury or unnecessary SRS system repairs.

1 Purpose...................................................................................................................................................3

1.1 General Information............................................................................................................................................... 3

1.2 Service Operations ................................................................................................................................................ 4

2 Fuel Tank.................................................................................................................................................6

2.1 General Information............................................................................................................................................... 6

Modular Fuel Pump And Sender Assembly......................................................................................................... 9

Fuel Pump .............................................................................................................................................................. 9

Fuel Flow Through The Modular Fuel Pump And Sender Assembly .............................................................. 10

Fuel Limiter Vent Valve........................................................................................................................................ 10

Fuel Tank Pressure Sensor................................................................................................................................. 10

Pressure Regulator.............................................................................................................................................. 10

Fuel Strainer......................................................................................................................................................... 11

Fuel Filter Assembly............................................................................................................................................ 11

Fuel Level Sender Assembly............................................................................................................................... 11

2.2 System Components ........................................................................................................................................... 12

2.3 Fuel Pipe Arrangement........................................................................................................................................ 13

3 Service Operations...............................................................................................................................15

3.1 Quick-Connect Fittings ....................................................................................................................................... 15

3.2 Fuel Tank Siphon Procedure.............................................................................................................................. 16

3.3 Fuel Tank Barrier ................................................................................................................................................. 18

3.4 Fuel Tank Assembly ............................................................................................................................................ 20

Remove................................................................................................................................................................. 20

Reinstall................................................................................................................................................................ 27

3.5 Fuel Filler Neck Assembly................................................................................................................................... 28

3.6 Modular Fuel Pump And Sender Assembly....................................................................................................... 29

Remove................................................................................................................................................................. 29

Test ....................................................................................................................................................................... 31

Disassemble......................................................................................................................................................... 32

Reassemble.......................................................................................................................................................... 35

Reinstall................................................................................................................................................................ 35

Fuel and Exhaust Systems Page G-2

Page G-2

3.7 Fuel Level Sender Assembly............................................................................................................................... 37

3.8 Modular Fuel Pump And Strainer Assembly...................................................................................................... 38

Remove................................................................................................................................................................. 38

Reinstall................................................................................................................................................................ 39

3.9 Fuel Filter Assembly............................................................................................................................................ 40

3.10 Fuel Pressure Regulator ..................................................................................................................................... 41

Remove................................................................................................................................................................. 41

Reinstall................................................................................................................................................................ 41

3.11 Modular Fuel Pump And Sender Assembly O-Rings........................................................................................ 42

3.12 Fuel Tank Pressure Sensor................................................................................................................................. 43

Remove................................................................................................................................................................. 43

Reinstall................................................................................................................................................................ 43

3.13 Fuel Fill Limiter Vent Valve Assembly (FLVV)................................................................................................... 44

Remove................................................................................................................................................................. 44

Reinstall................................................................................................................................................................ 44

3.14 Fuel Filler Cap...................................................................................................................................................... 45

Remove................................................................................................................................................................. 45

Reinstall................................................................................................................................................................ 45

4 Specifications.......................................................................................................................................46

5 Torque Wrench Specifications ...........................................................................................................47

6 Special Tools .................................................................................................................. ......................48

Fuel and Exhaust Systems Page G-3

Page G-3

1 Purpose

The purpose of this supplement is to provide information on the fuel and exhaust systems fitted to the HSV Coupe 4

models. This information is designed to supplement that given in the Holden V2 Coupe Series Service Information, and

details are given where differences occur between the HSV models, and standard Holden models. A series of instruction

drawings detail the design changes and indicate specific part numbers, fitting instructions and relevant notes for vehicle

servicing.

NOTE:

If specific technical data on a HSV model is not

contained in this supplement, obtain data for that

model from the relevant Holden V2 Coupe

Service Manual Supplement. References are

made throughout this section to Holden Service

Manuals, to assist in providing information for

specific service operations.

When hoisting (or jacking) HSV models,

ensure that the liftin g head of the hoist lifts on

the chassis before the arm of the hoist

contacts the side-skirt

1.1 General Information

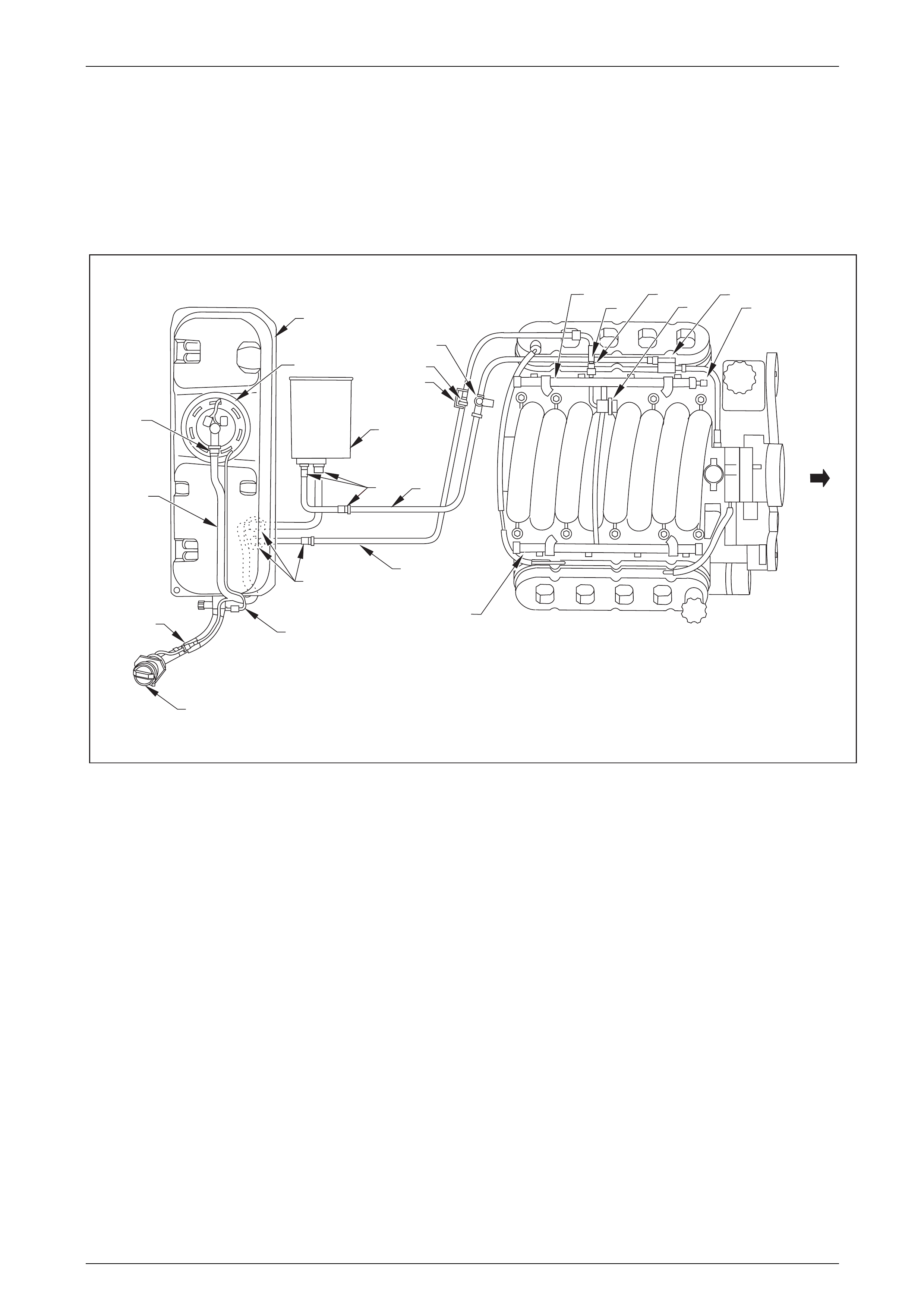

The fuel system fitted to HSV Coupe 4 models is similar to Holdens US Export GTO models with the exception of the

EVAP Canister Vent System, which is not fitted on non Electronic Throttle Control (ETC) Coupe 4 Models.

All information on non ETC Coupe 4 fuel systems is contained in this section.

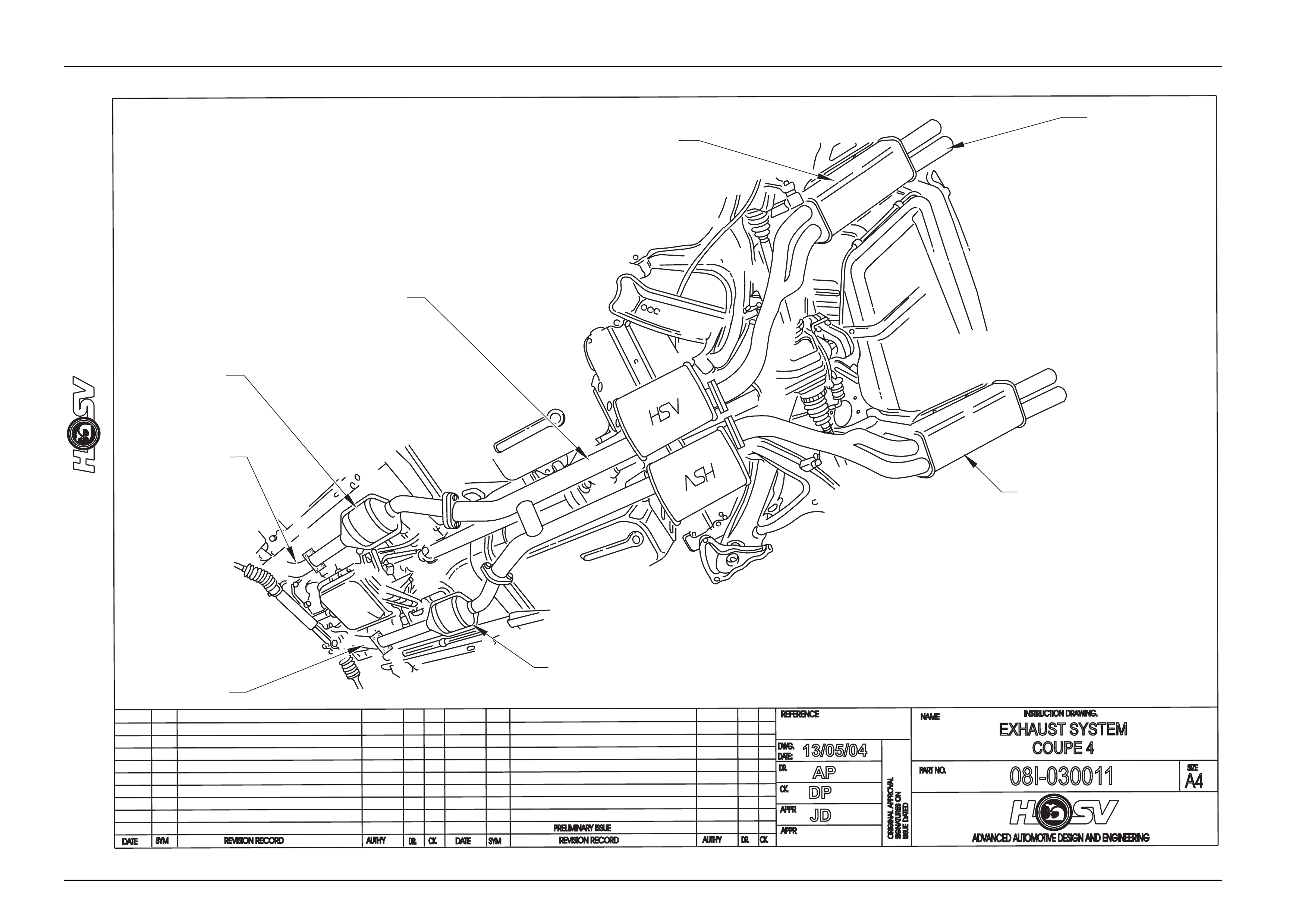

The exhaust system as fitted to the HSV Coupe 4 model is a unique design.

The exhaust system is a “Twin System” including new design headers and intermediate muffler feeding into dual rear

mufflers which have dual outlets with alloy tips.

Fuel and Exhaust Systems Page G-4

Page G-4

1.2 Service Operations

All service operations for the fuel system fitted to HSV Coupe 4 models carry over from Holden V2 Series 3 models.

For information relating to service operations on the fuel tank fitted to HSV Coupe 4 models refer to

Section 8A1 Fuel Tank in the Holden V2 Series 3 models Service Information.

For all service operations for the exhaust system fitted to the HSV Coupe 4 models refer to drawing 08I-030011

Fuel and Exhaust Systems Page G-5

Page G-5

DATE

ISSUEDA

TED

AUTH'Y

CK.

SYM

AUTH'Y

REVISION RECORD

DATE

SYM

SIGNATURES ON

ORIGINAL APPROVAL

DR.

ADVANCED AUTOMOTIVE DESIGN AND ENGINEERING

08I-030011

INSTRUCTION DRAWING.

A4

SIZE

EXHAUST SYSTEM

COUPE 4

REVISION RECORD

PRELIMINARY ISSUE

CK.

NAME

PART NO.

CK.

REFERENCE

DWG.

DR.

DATE:

APPR

APPR

DR.

13/05/04

AP

JD

DP

HEADER LH

08C-032701

CAT CONVERTER-LH

08C-032703

INTERMEDIATE MUFFLER

08C-043301

REAR MUFFLER LH

08C-043303

EXHAUST

EXTENSION

08C-043305

(4 PLACES)

REAR MUFFLER RH

08C-043304

CAT CONVERTER-RH

08C-032704

HEADER RH

08C-032702

Fuel and Exhaust Systems Page G-6

Page G-6

2 Fuel Tank

ATTENTION:

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

2.1 General Information

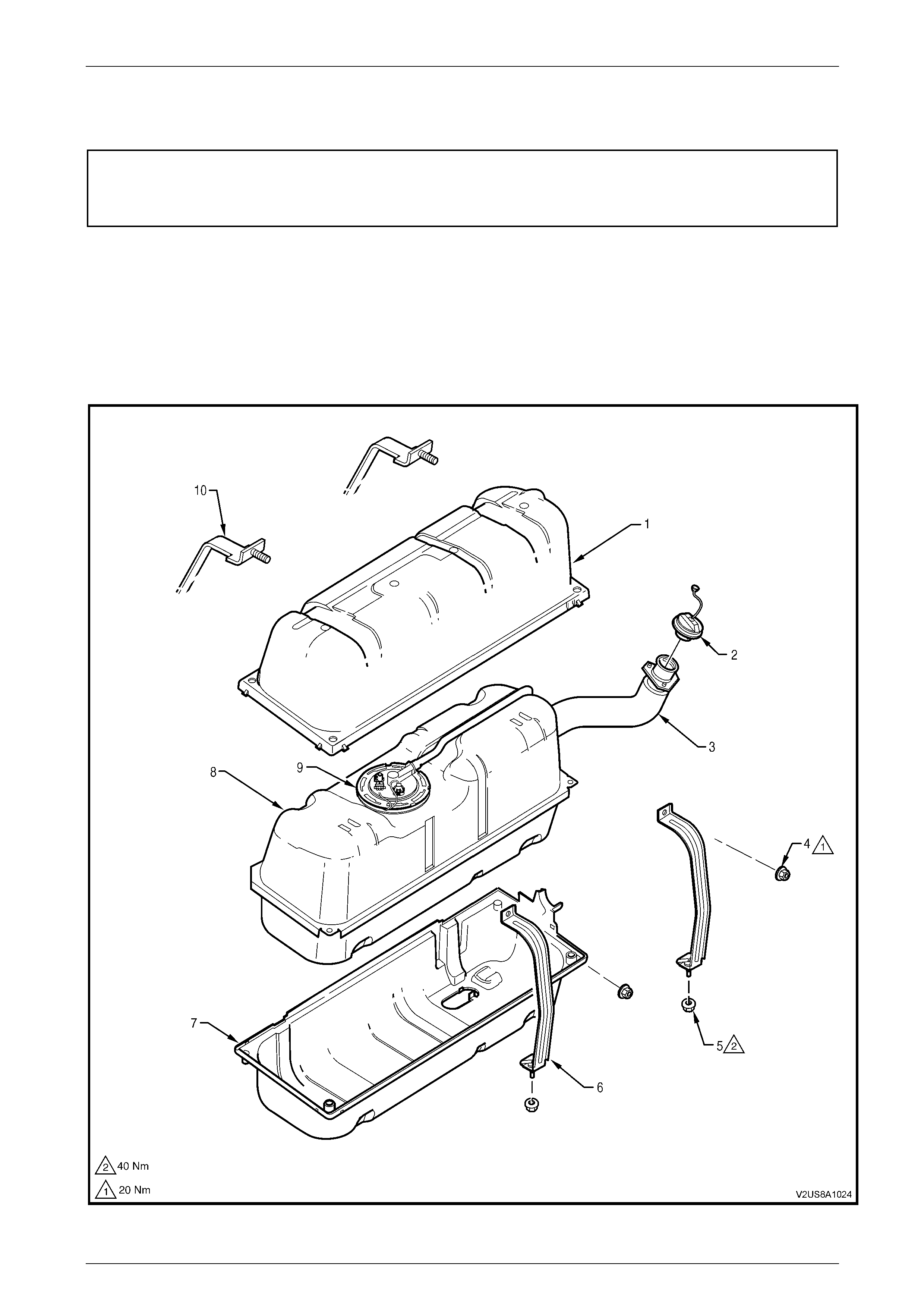

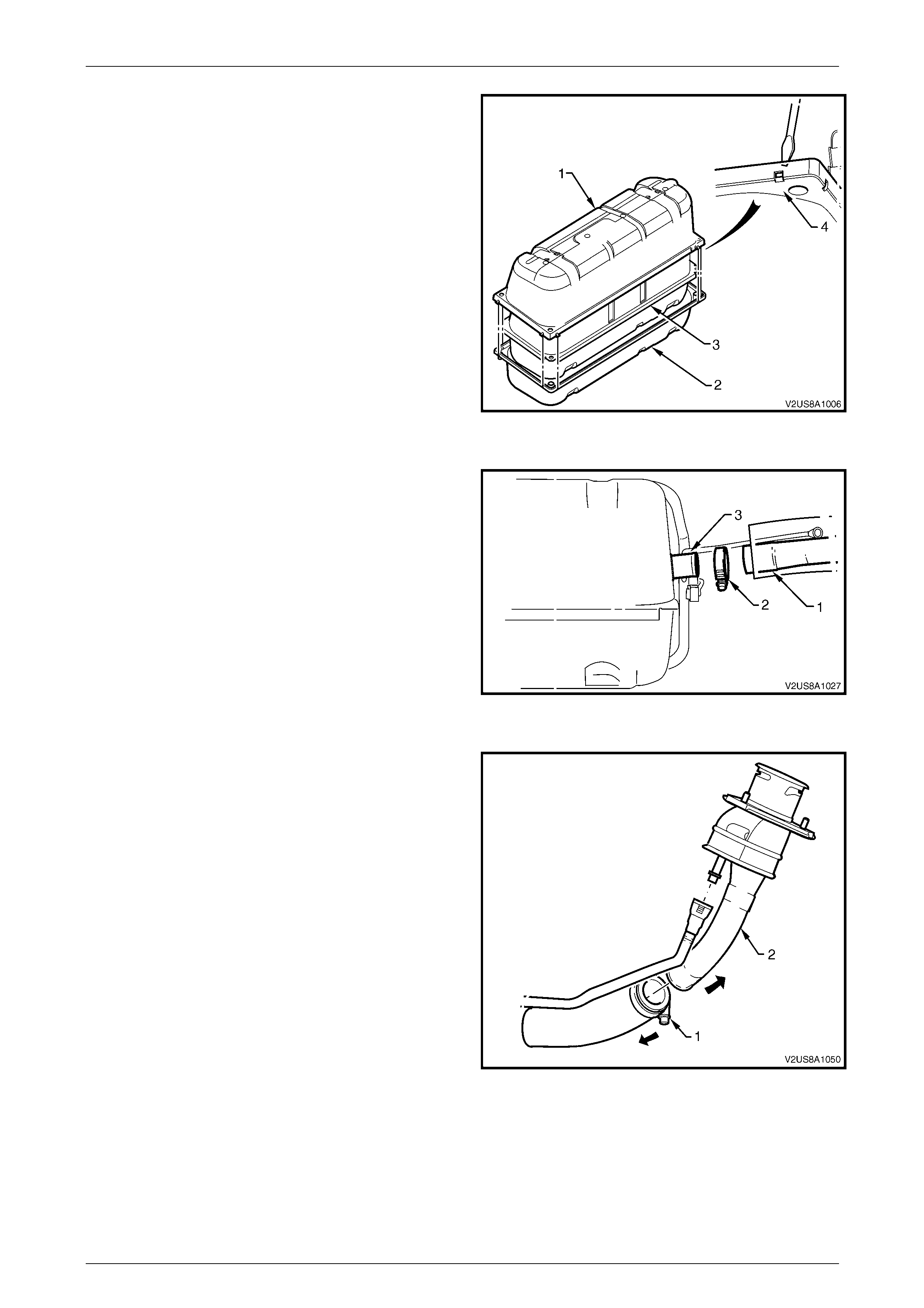

The 70-litre fuel tank fitted to the MY 2004 HSV Coupe 4 is a pressed steel construction. Refer to Figure 8A1 – 1 for the

following. A two piece high density polyethylene shell encapsulates the fuel tank. The fuel tank is fitted immediately

behind the rear seat and is accessed through the rear compartment. The fuel tank is held in place by two mounting straps

and the fuel filler neck is attached to the vehicle body at the fuel filler opening, located in the rear right-hand quarter

panel, with three fastening nuts.

The fuel tank itself is not repairable and if damaged must be replaced.

Figure 8A1 – 1

Fuel and Exhaust Systems Page G-7

Page G-7

Legend

1. Fuel Tank Shell - Upper

2. Fuel Filler Cap

3. Fuel Filler Neck Assembly

4. Mounting Strap Nut - Upper (2 places)

5. Mounting Strap Nut - Lower (2 places)

6. Fuel Tank Mounting Strap (rear facing)

7. Fuel Tank Shell - Lower

8. Fuel Tank

9. Modular Fuel Pump and Sender Assembly

10. Fuel Tank Mounting Strap (front facing)

An in-tank modular fuel pump and sender assembly is attached from the top of the fuel tank and incorporates a modular

fuel pump assembly, a fuel strainer and fuel filter, a reservoir, fuel level sender assembly, pressure regulator and

reservoir jet pump. A fuel fill limiter vent valve (FLVV) and fuel tank pressure sensor is incorporated into the modular fuel

pump and sender cover assembly. The following items of the modular fuel pump and sender assembly are serviceable

items:

• fuel pump and strainer assembly

• fuel filter

• fuel level sender assembly

• fuel pressure regulator

• fuel fill limiter vent valve

• fuel tank pressure sensor

• fuel tank to modular fuel pump and sender assembly seal

• modular fuel pump and sender assembly shaft circlip

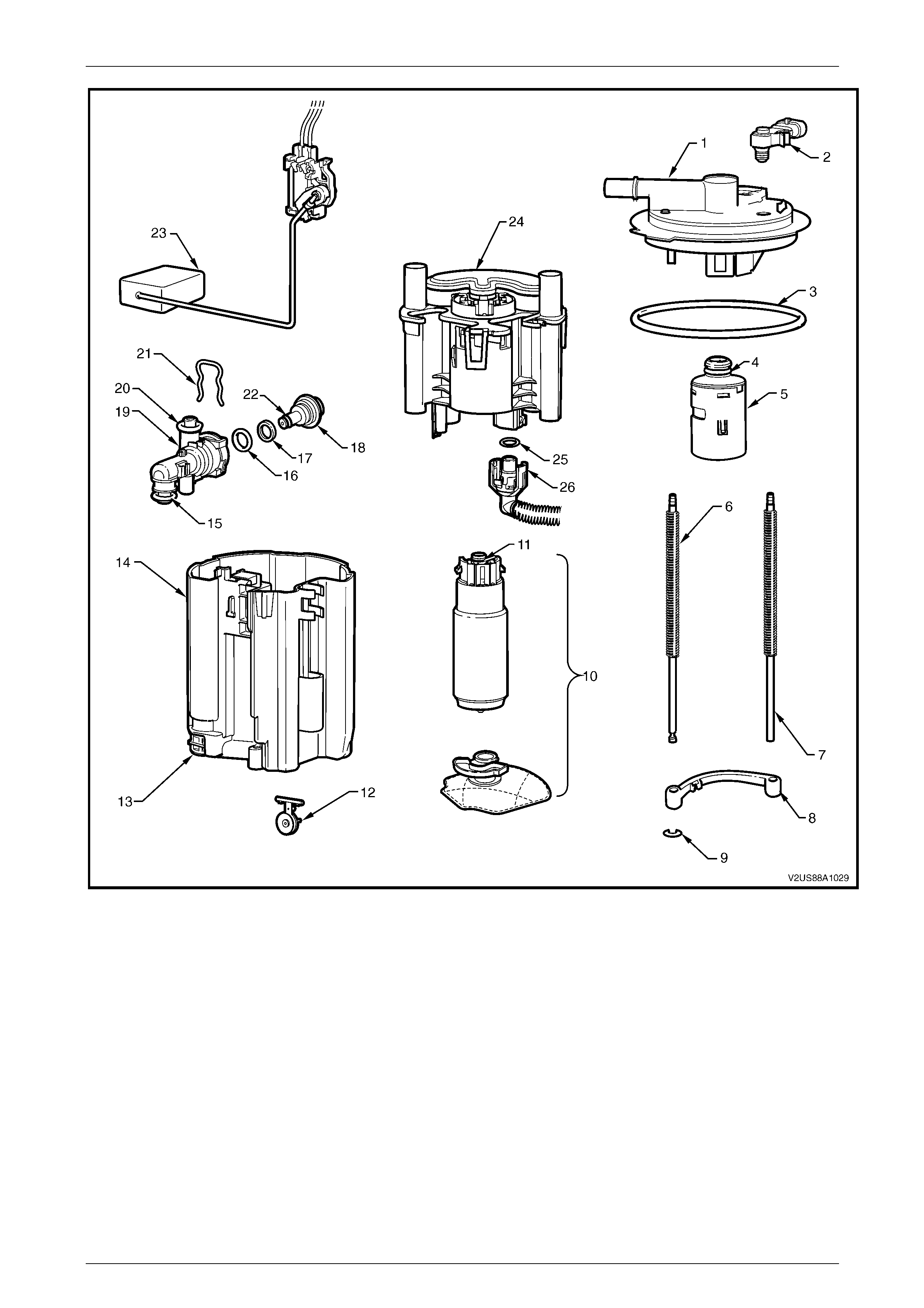

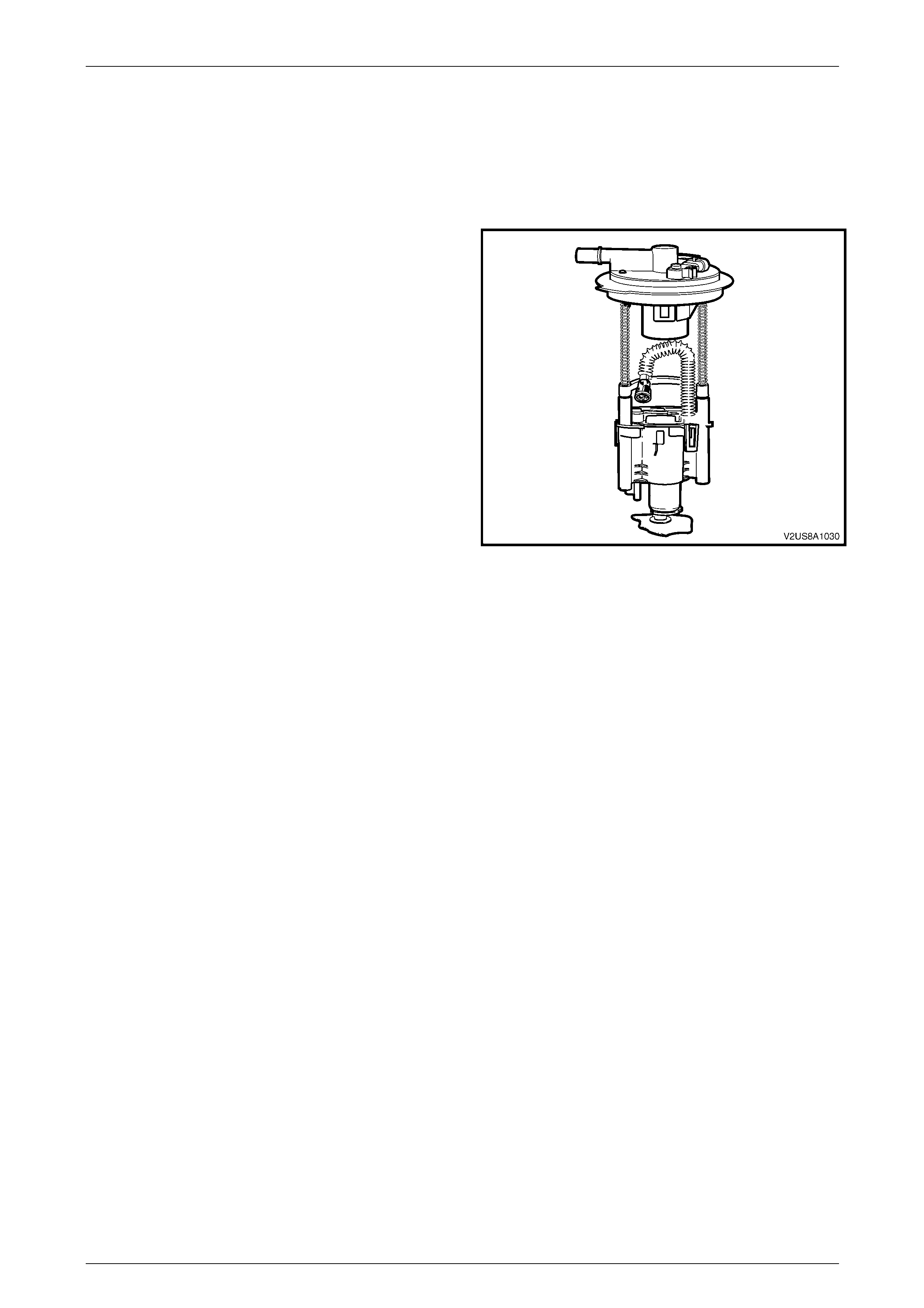

Refer to Figure 8A1 – 2 for an exploded view of the modular fuel pump and sender assembly.

Fuel and Exhaust Systems Page G-8

Page G-8

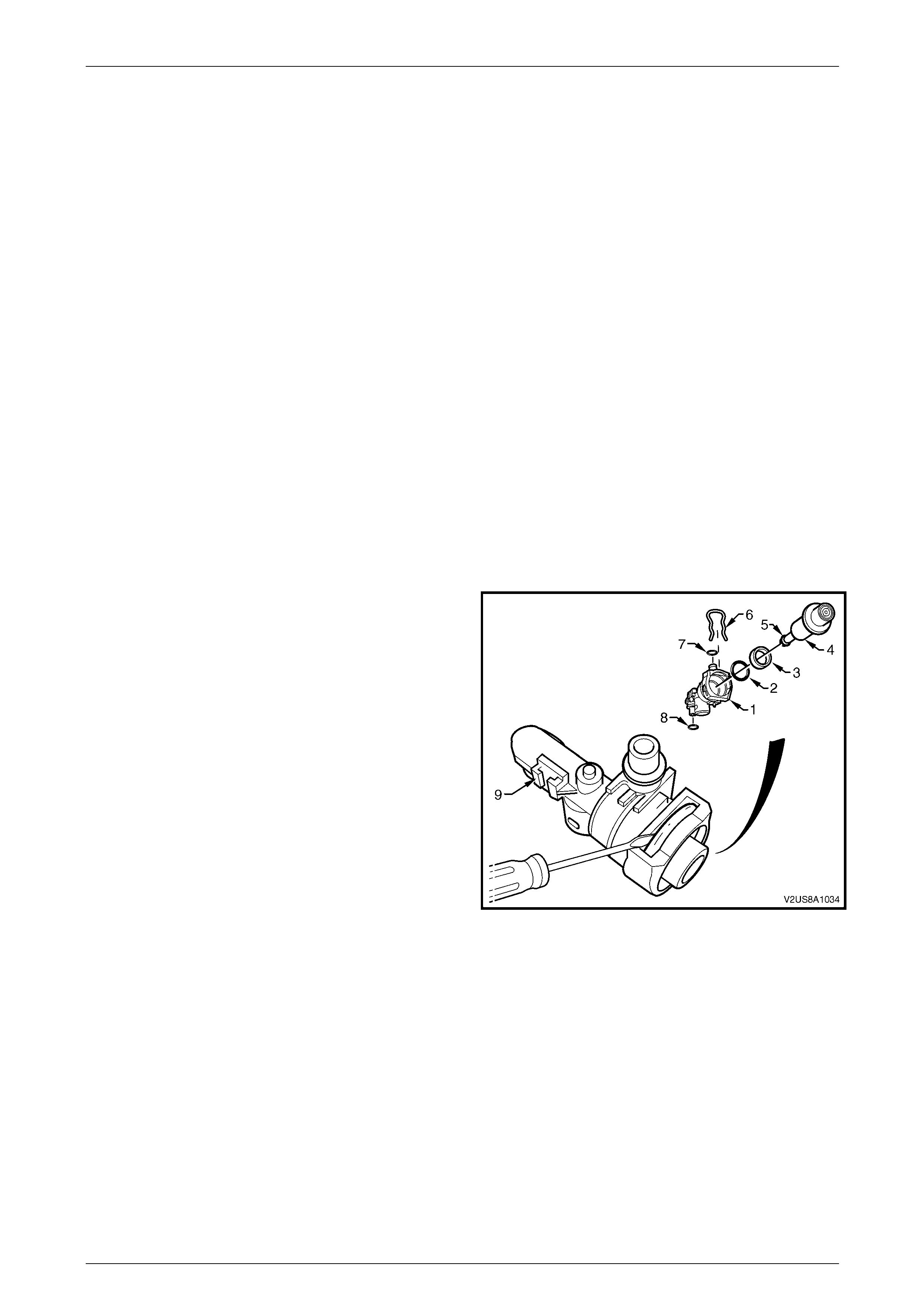

Figure 8A1 – 2

Legend

1. Modular Fuel Pump and Sender

Assembly Cover

2. Fuel Tank Pressure Sensor

3. Seal

4. O-ring

5. Fuel Fill Limiter Vent Valve (FLVV)

6. Spring (2 places)

7. Shaft (2 places)

8. Wiring Earthing Bridge

9. Circlip

10. Fuel Pump and Strainer Assembly

11. O-ring

12. Flapper Valve

13. Reservoir Jet Pump

14. Reservoir

15. O-ring

16. O-ring

17. Nylon Spacer

18. Fuel Pressure Regulator

19. Regulator Holder

20. O-ring

21. Retaining Clip

22. O-ring

23. Fuel Level Sender Assembly

24. Fuel Filter Assembly

25. O-ring

26. Fuel Outlet Connector

Fuel and Exhaust Systems Page G-9

Page G-9

Modular Fuel Pump And Sender Assembly

The modular fuel pump and sender assembly maintains an optimum fuel level in the reservoir. This ensures a continuous

fuel flow under all fuel level conditions and vehicle attitudes. The modular fuel pump and sender assembly also provides

an accurate means of measuring the fuel level within the fuel tank.

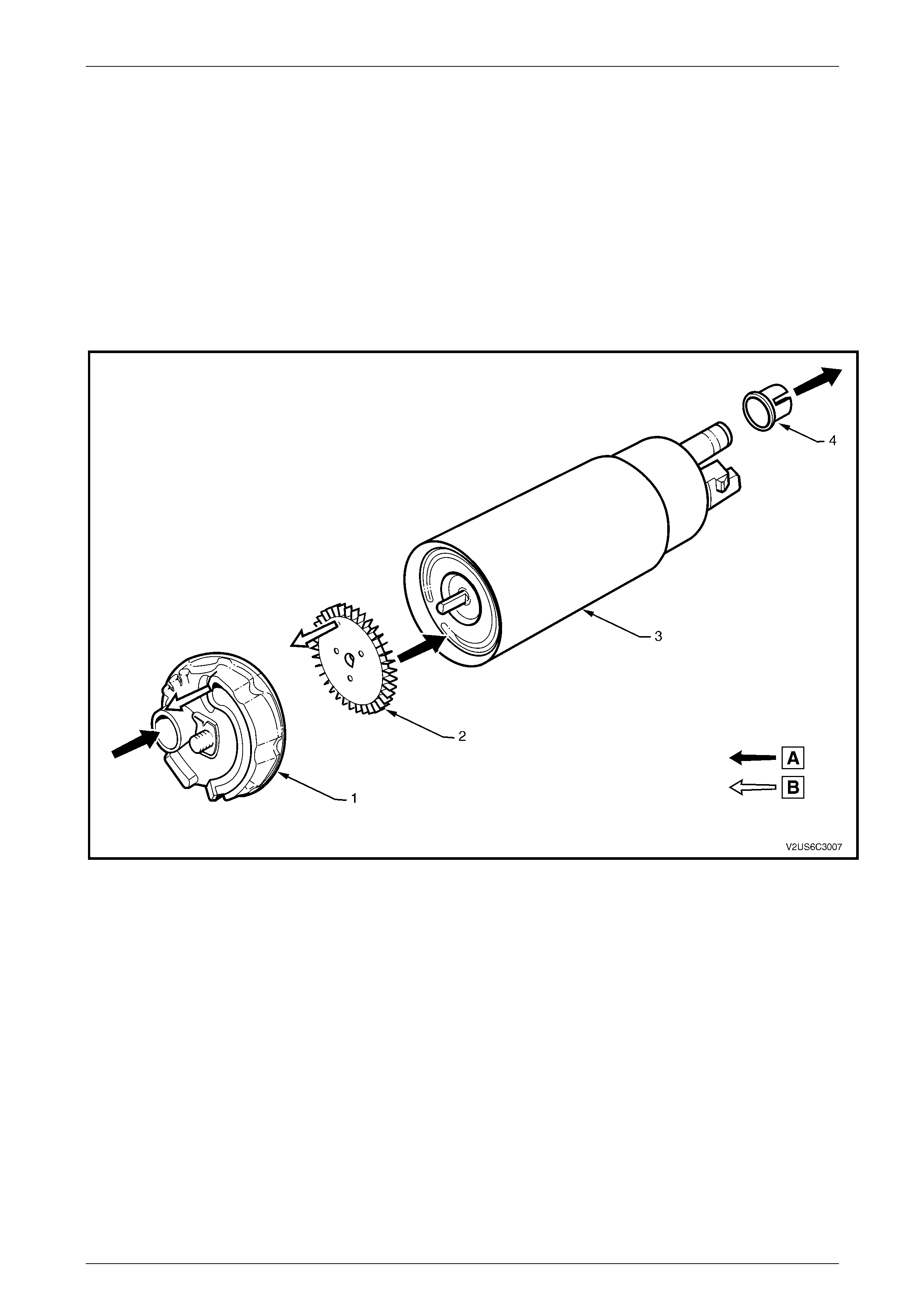

Fuel Pump

Figure 8A1 – 3 details fuel flow through the fuel pump. The fuel pump is incorporated into the design of the modular fuel

sender assembly inside the fuel tank and is an electric, high pressure, single turbine design. The fuel pump provides fuel

to the fuel rail assembly at a specified flow and pressure.

The fuel pump delivers a constant flow of fuel to the engine, even during low fuel conditions or aggressive vehicle

manoeuvres. The PCM controls the electric fuel pump operation through the fuel pump relay.

Figure 8A1 – 3

Legend

A Fuel

B Vapor Out 1. End Cap

2. Impeller

3. Electric Motor Housing Assembly

4. Pump Outlet O-ring Collar

Fuel and Exhaust Systems Page G-10

Page G-10

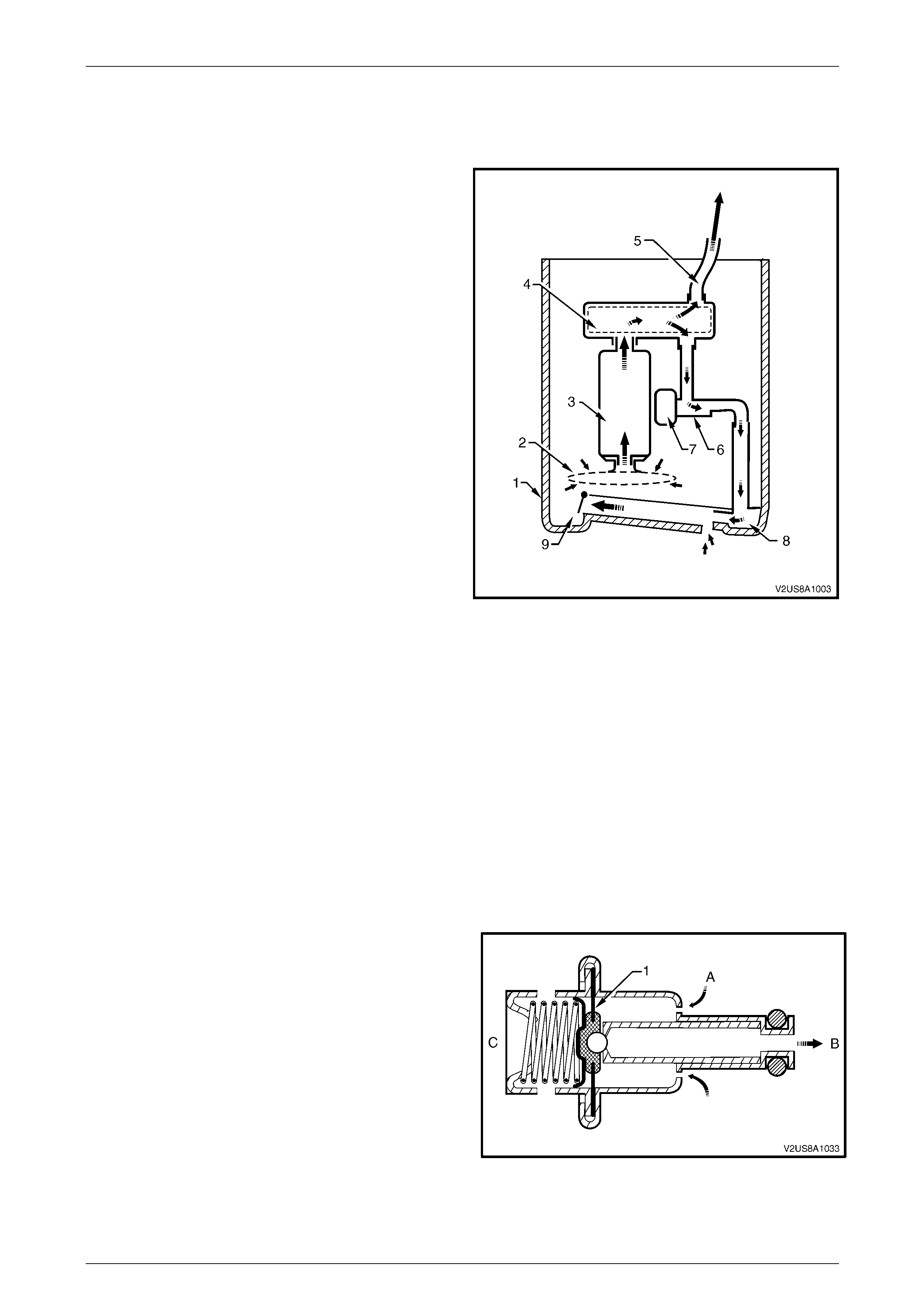

Fuel Flow Through The Modular Fuel Pump And Sender Assembly

This section provides a general description of fuel flow through the modular fuel pump and sender assembly.

Fuel is pumped from the fuel tank to the engine via the

modular fuel pump and sender assembly.

Fuel in the reservoir (1) is drawn through the fuel strainer (2)

and into the single turbine fuel pump (3) which is driven by a

constant-speed motor. Fuel is then forced through the motor

and out, under pressure, into the fuel filter canister and

through the fuel filter (4). There are two fuel filter exit ports,

one runs into a flexible pipe which connects to the engine fuel

feed line (5) within the fuel tank, and the other provides the

connection port to which the fuel pressure regulator holder

and port assembly (6) is connected.

When the engine is operating, fuel is continuously forced to

flow through the ported pressure regulator holder assembly

which has an extended moulding to enable mounting and

provide the fuel exit port. The fuel pressure regulator (7) is

attached to one side of the holder. The exit port directs fuel

into the reservoir jet pump (8), which is moulded integral to

the reservoir assembly. This pump forces extra fuel into the

reservoir through a one way flapper valve (9) connected at

the base of the reservoir.

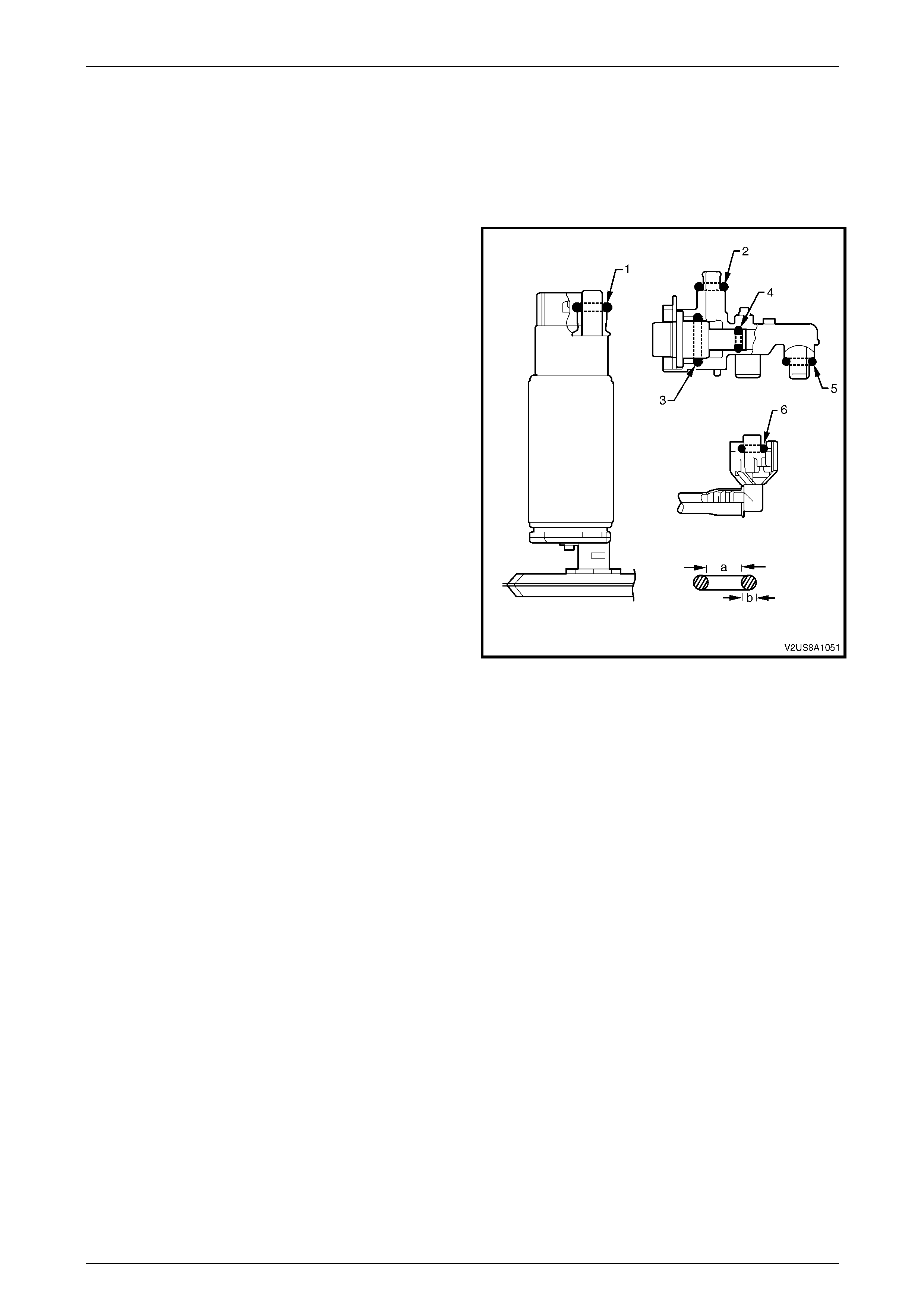

Figure 8A1 – 4

Fuel Limiter Vent Valve

A fuel limiter vent valve is incorporated into the modular fuel pump and sender cover assembly. This valve controls the

fuel tank fill level by closing the primary vent from the fuel tank and prevents fuel from exiting the fuel tank via the EVAP

vapor pipe to the canister. The valve also provides fuel spillage protection in the event of a vehicle rollover by closing the

vapor path from the fuel tank to the EVAP canister.

Fuel Tank Pressure Sensor

A fuel tank pressure sensor is mounted to the cover of the modular fuel tank and sender assembly. When the Powertrain

Control Module (PCM) commands a vacuum into the fuel system to check for leaks, a potential voltage is induced by the

sensor and this voltage will fluctuate according to the pressure change in the fuel tank. The change in voltage is

monitored by the PCM through a circuit carried through the body wiring harness and fuel tank wiring harness.

Pressure Regulator

The fuel pressure regulator is a diaphragm-operated relief

valve located in the modular fuel pump and sender assembly.

Its principal function is to maintain a controlled pressure at

the injectors at all times by regulating fuel flow into the fuel

feed line.

Fuel flows from the fuel pump, into the fuel filter and is

allowed to exit the filter into the fuel feed line or the fuel

pressure regulator entry port. From here, fuel flows under

pressure into the pressure regulator at location A. When fuel

pressure builds in the fuel feed line, the diaphragm and

valve (1) inside the fuel pressure regulator is progressively

pushed out, allowing fuel to exit through the regulator port at

location B. The valve is otherwise held closed by mechanical

spring pressure applied from side C. Fuel exiting the

regulator is directed into the reservoir jet pump to provide

continuous fuel circulation.

Figure 8A1 – 5

Fuel and Exhaust Systems Page G-11

Page G-11

Fuel Strainer

The fuel strainer connects onto the fuel pump inlet port on the end cap of the fuel pump assembly and consists of a finely

woven plastic filter. A metal compression ring is fitted around the plastic strainer to fuel pump feed port and the complete

fuel strainer assembly is fastened to the fuel pump end cap with a metal speed clip fastener.

The strainers function is to filter fuel contaminants from within the fuel reservoir and also act to wick the fuel. The fuel

strainer is serviced as part of the complete fuel pump and strainer assembly. Fuel stoppage at the strainer indicates an

abnormal amount of sediment in the fuel tank which should be removed before reinstallation of the fuel tank into the

vehicle, refer to 3.4 Fuel Tank Assembly.

Fuel Filter Assembly

The fuel filter assembly is contained within the modular fuel pump and sender assembly reservoir and forms the

containment housing for the fuel pump. The filter comprises a paper element which traps particles in the fuel that may

damage the fuel injection system. The fuel filter is made to withstand maximum fuel system pressure, changes in

temperature and exposure to fuel additives.

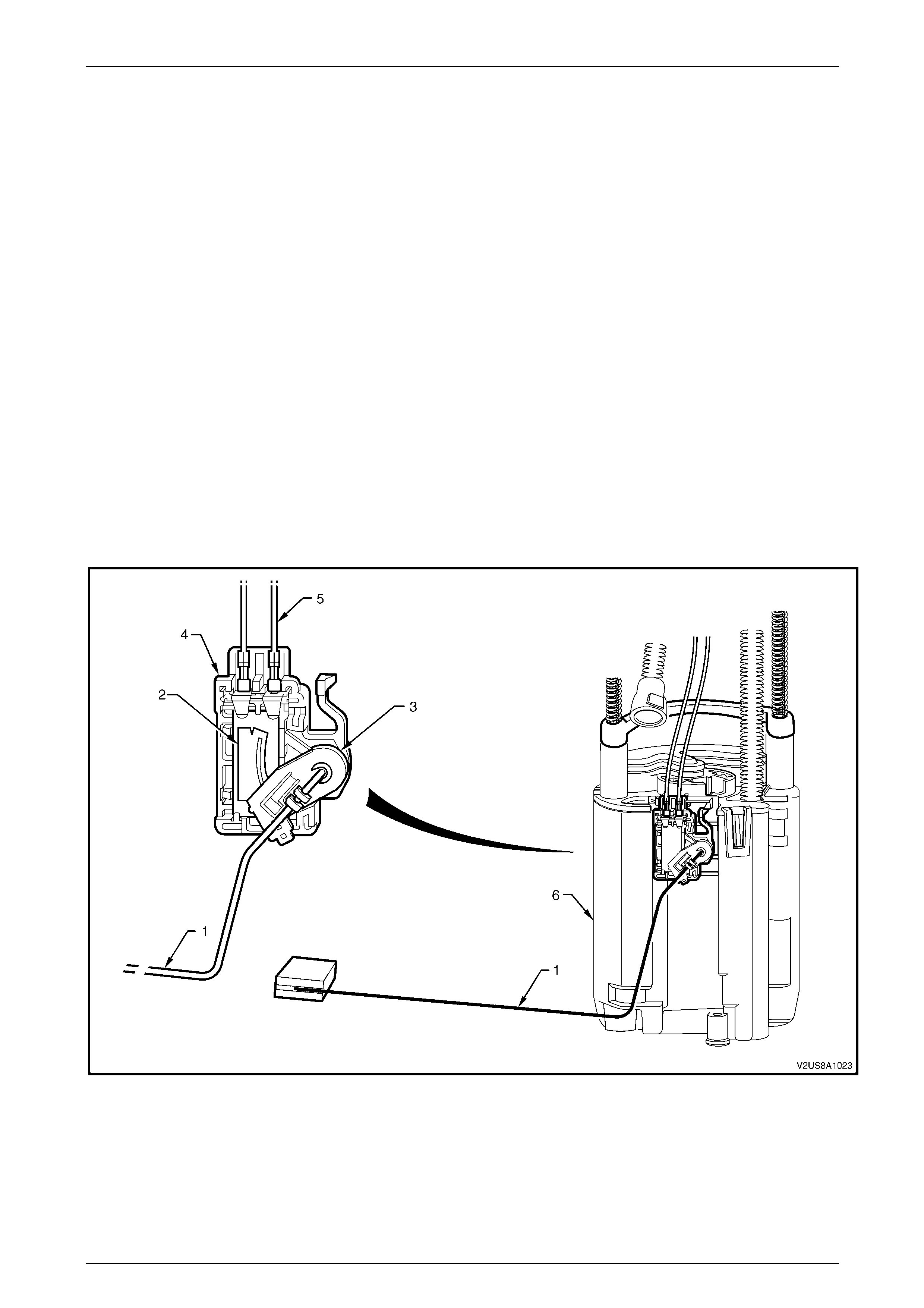

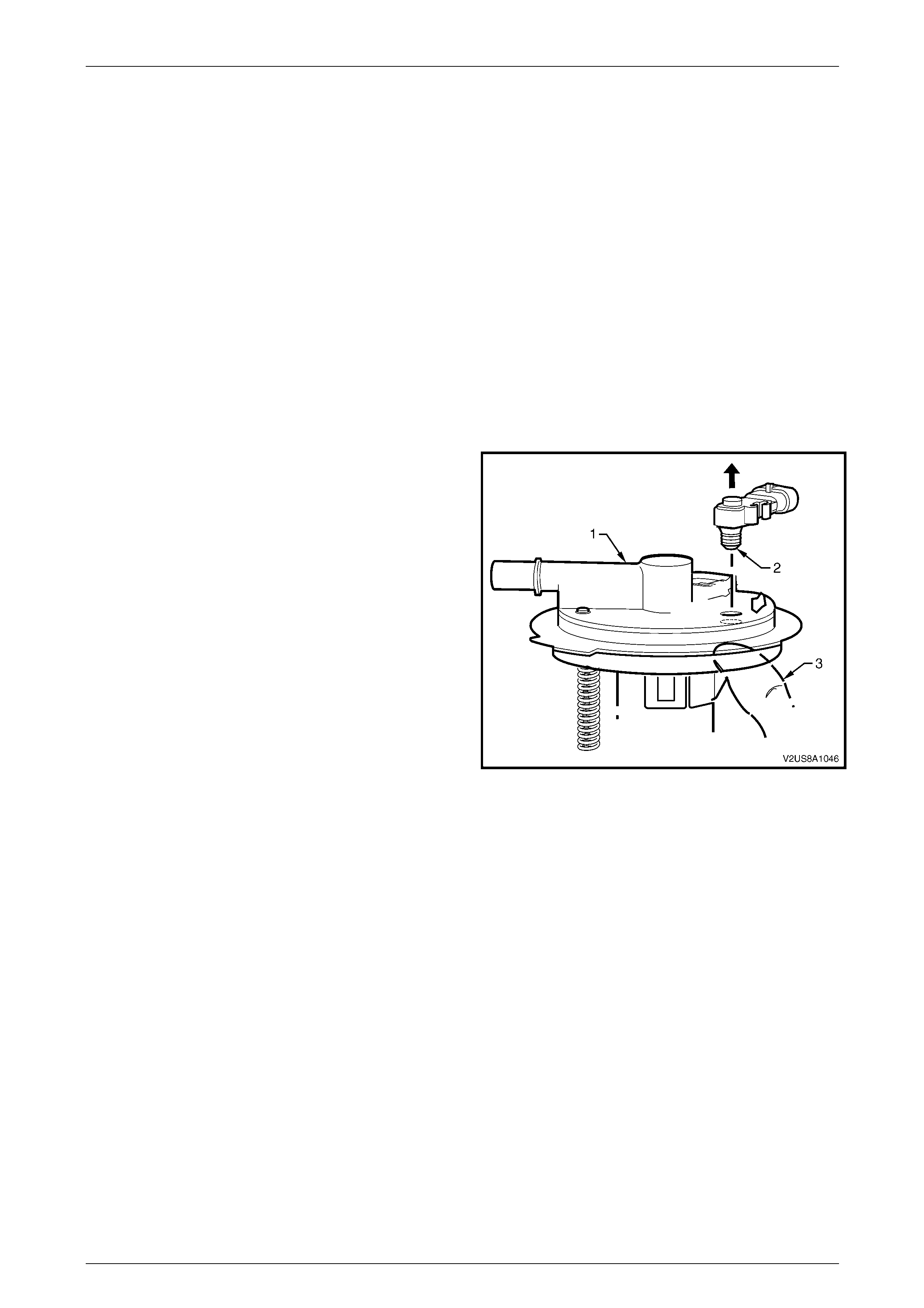

Fuel Level Sender Assembly

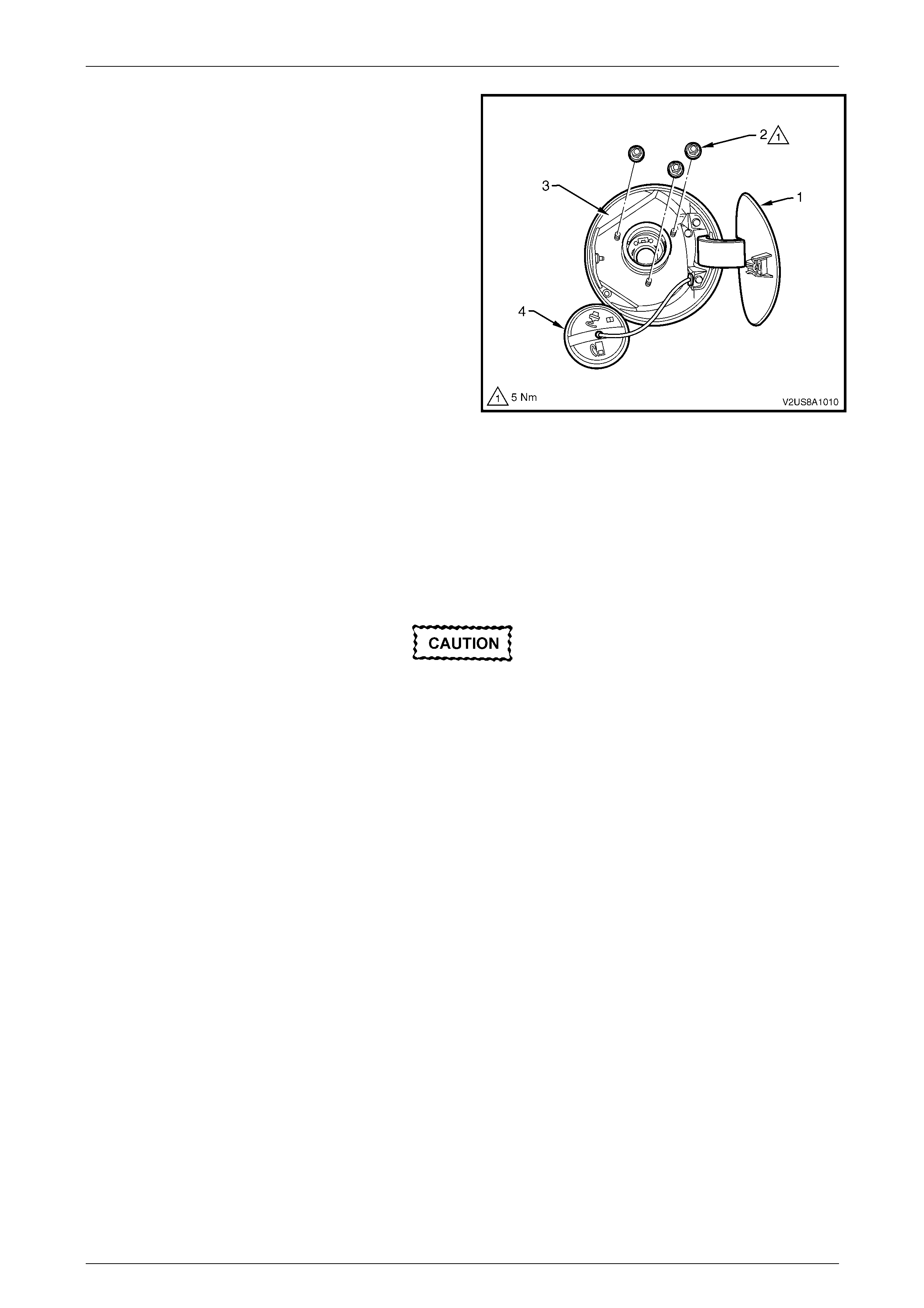

Refer to Figure 8A1 – 6 for details of the fuel level sender assembly. The fuel level sender assembly comprises of a fuel

level float and wire arm assembly (1), a ceramic variable resistor card assembly (2), and a detachable nylon wiper (3).

The ceramic resistor card is attached to a plastic card holder (4) which attaches to the reservoir (6). A metal contact fork

with brushes is connected to the detachable nylon wiper. This assembly provides a variable circuit resistance to the

Powertrain Control Module (PCM) depending on wiper contact position. Two circuit wires (5) run from the resistor card

and extend up to connect with the modular fuel pump to cover assembly wiring connector on the underside of the

modular fuel pump and sender assembly cover. The Powertrain Control Module (PCM) averages out any slosh variation

in the fuel tank and sends this signal to the fuel level indicator on the instrument panel fuel gauge.

Figure 8A1 – 6

Legend

1. Fuel Level Float and Wire Arm Assembly

2. Ceramic Variable Resistor Card

3. Nylon Wiper

4. Card Holder

5. Circuit Wires

6. Reservoir

Fuel and Exhaust Systems Page G-12

Page G-12

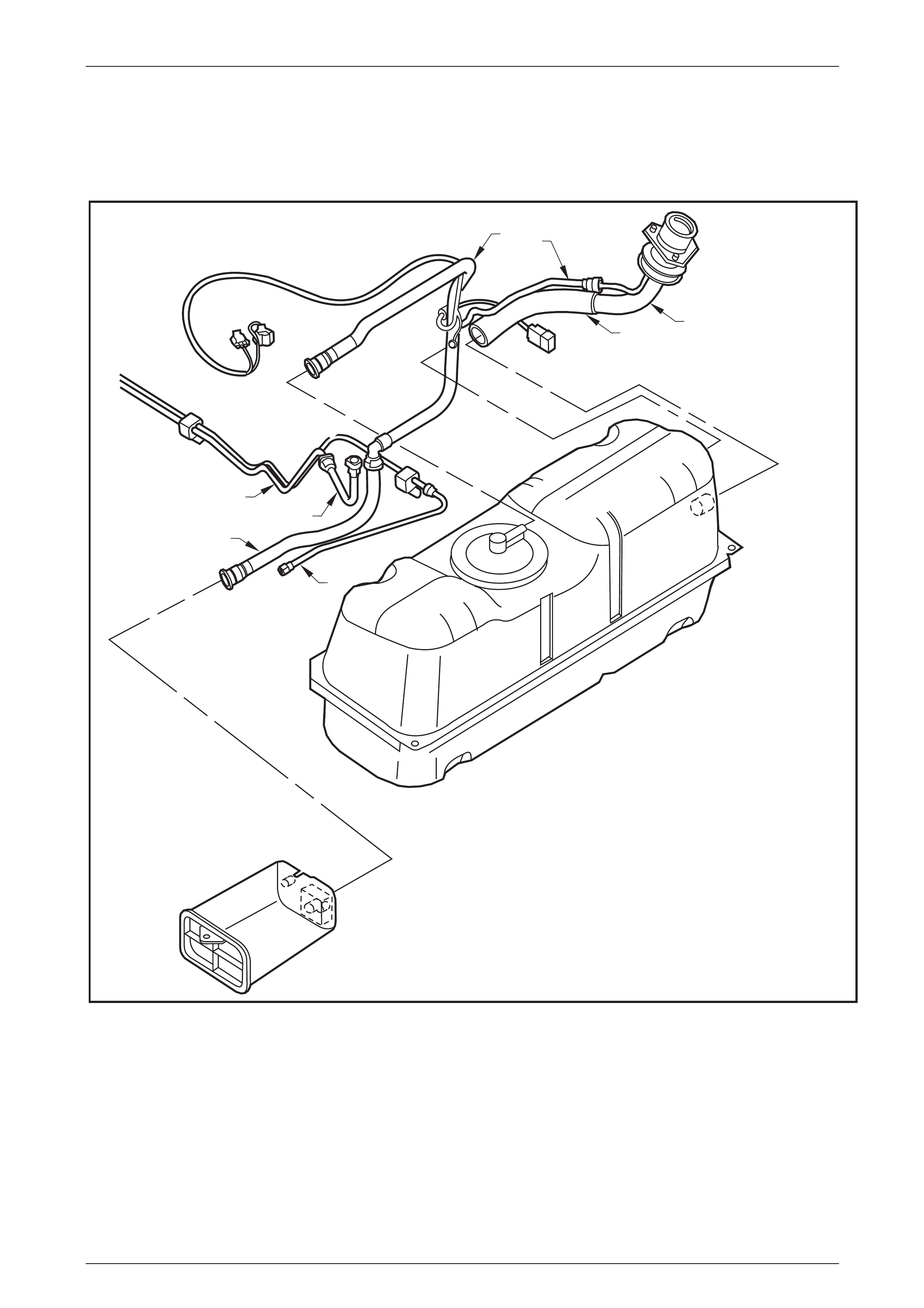

2.2 System Components

Refer to Figure 8A1 – 7 for general components of the fuel control systems. A 2.1L three port vapor canister is mounted

with a bracket onto the underneath the vehicle. The canister cannot be repaired and is serviced only as a complete

assembly. The canister is designed to store vapor from the fuel tank via the tank vent line and release it to the engine via

the canister purge line. A purge line service port is attached along the purge line within the engine bay. Various styles of

quick-connect fittings are used at most fuel line connections, including the modular fuel pump and sender assembly, fuel

vapor canister, fuel filter and fuel feed line, at both the fuel tank and engine ends.

1

2

3

4

5

6

7

89

10 11

12

13

14

15

1617

18

19

20

21

22

Figure 8A1 – 7

Legend

1. Fuel tank

2. Modular Fuel Pump and Sender Assembly

3. Body Wiring Harness to Fuel Tank Wiring Harness Connector

4. Fuel Tank Fill Cap

5. Fuel Fill Neck Vapor Recirculation Line and Quick Connect Fitting

6. Fuel Tank to EVAP Canister Vapor Vent Hose

7. Quick Connect Fitting

8. Quick Connect Fittings

9. Fuel Feed Line to Fuel Rail

10. Quick Connect Fittings

11. Vapor Purge Pipe to Purge Solenoid

12. EVAP Canister

13. Secondary Clip

14. Quick Connect Fitting

15. Service Port and Quick Connect Assembly

16. Fuel Rail, Bank 1

17. Secondary Clip

18. Quick Connect Fitting

19. Fuel Pulse Dampener

20. EVAP Canister Purge Solenoid

21. Fuel Pressure Check Schrader Valve

22. Fuel Rail, Bank 2

Fuel and Exhaust Systems Page G-13

Page G-13

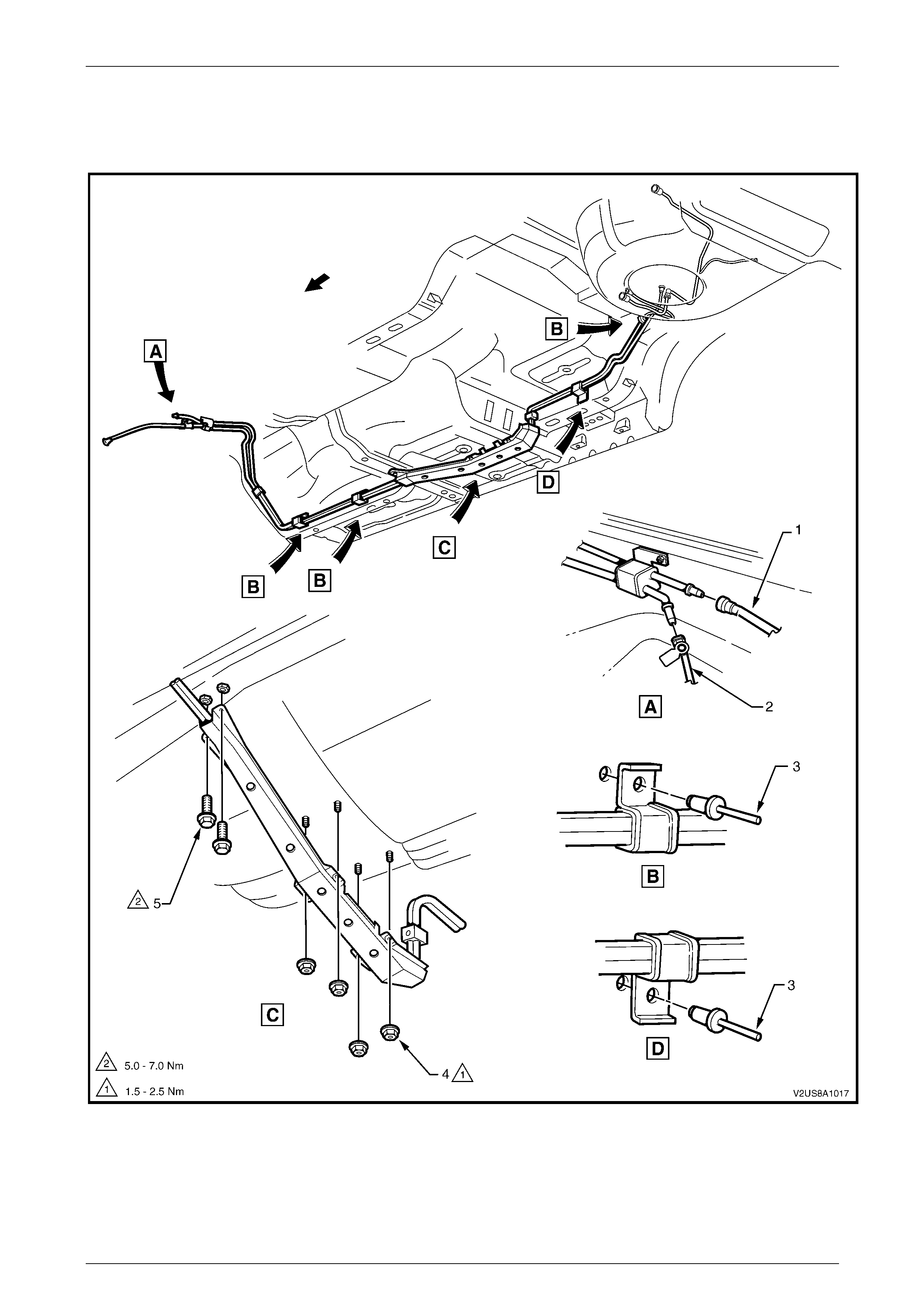

2.3 Fuel Pipe Arrangement

Figure 8A1 – 8 and Figure 8A1 – 9 illustrate the fuel pipe layout and location of other fuel tank related items.

Figure 8A1 – 8

Legend

1. Fuel Feed to Engine Line

2. EVAP Purge to Engine Line 3. Fuel Line Bracket Pop Rivet

4. Stone Guard Securing Nut (4 places) 5. Stone Guard Securing Bolt (2 places)

Fuel and Exhaust Systems Page G-14

Page G-14

NOTE

Refer to Figure 8A1 – 8, if necessary, use special

tool 7371 to remove the fuel feed to engine line

quick-connect fitting (1), refer to

3.1 Quick-Connect Fittings in this Section.

12

3

4

5

6

7

8

Figure 8A1 – 9

Legend

1. EVAP Vapor Line (upstream)

2. EVAP Vapor Recirculation Line

3. Fuel Filler Neck

4. Fuel Filler Hose

5. Fuel Feed Line

6. Fuel Feed Line Extension Elbow

7. EVAP Vapor Line (downstream)

Fuel and Exhaust Systems Page G-15

Page G-15

3 Service Operations

3.1 Quick-Connect Fittings

For information on correct servicing procedures of quick-connect fittings, refer to Section 6C3-3 Service Operations

(GEN III V8 Engine), 3.15 Fuel Hose/Pipes (Rear Pipes) in the MY2003 VY & V2 II Series Service Information.

Fuel and Exhaust Systems Page G-16

Page G-16

3.2 Fuel Tank Siphon Procedure

The fuel system will contain fuel in the

modular fuel pump and sender assembly and

fuel lines that can be spilled during service

operations. Ensure no naked flames or other

ignition sources are nearby. Ensure all mobile

phones (and transmission devices that may

cause any metal objects to become

unintentional receiving antennas) are

switched off.

Place a dry chemical (Class B) fire

extinguisher nearby before performing any

on-vehicle service procedures. Failure to

follow these precautions may result in

personal injury.

For a general exploded view of fuel tank components, refer to Figure 8A1 – 1.

1. Relieve the fuel system pressure. Refer to Section 6C3-3 Service Operations (GEN III V8 Engine),

3.7 Fuel Pressure Relief Procedure in the MY2003 VY & V2 II Series Service Information.

2. Reinstall the fuel pump relay R16, refer to Refer to Section 6C3-3 Service Operations (GEN III V8 Engine),

3.6 Fuel Pump Relay in the MY2003 VY & V2 II Series Service Information.

3. Disconnect the negative battery terminal.

NOTE

Disconnection of the battery affects certain

vehicle electronic systems. Refer to Section 00,

Cautions, 5 Battery Disconnection Procedures, in

the MY2004 VY & V2 Series Service Information

before disconnecting the battery.

4. Remove the fuel filler cap.

Fuel and Exhaust Systems Page G-17

Page G-17

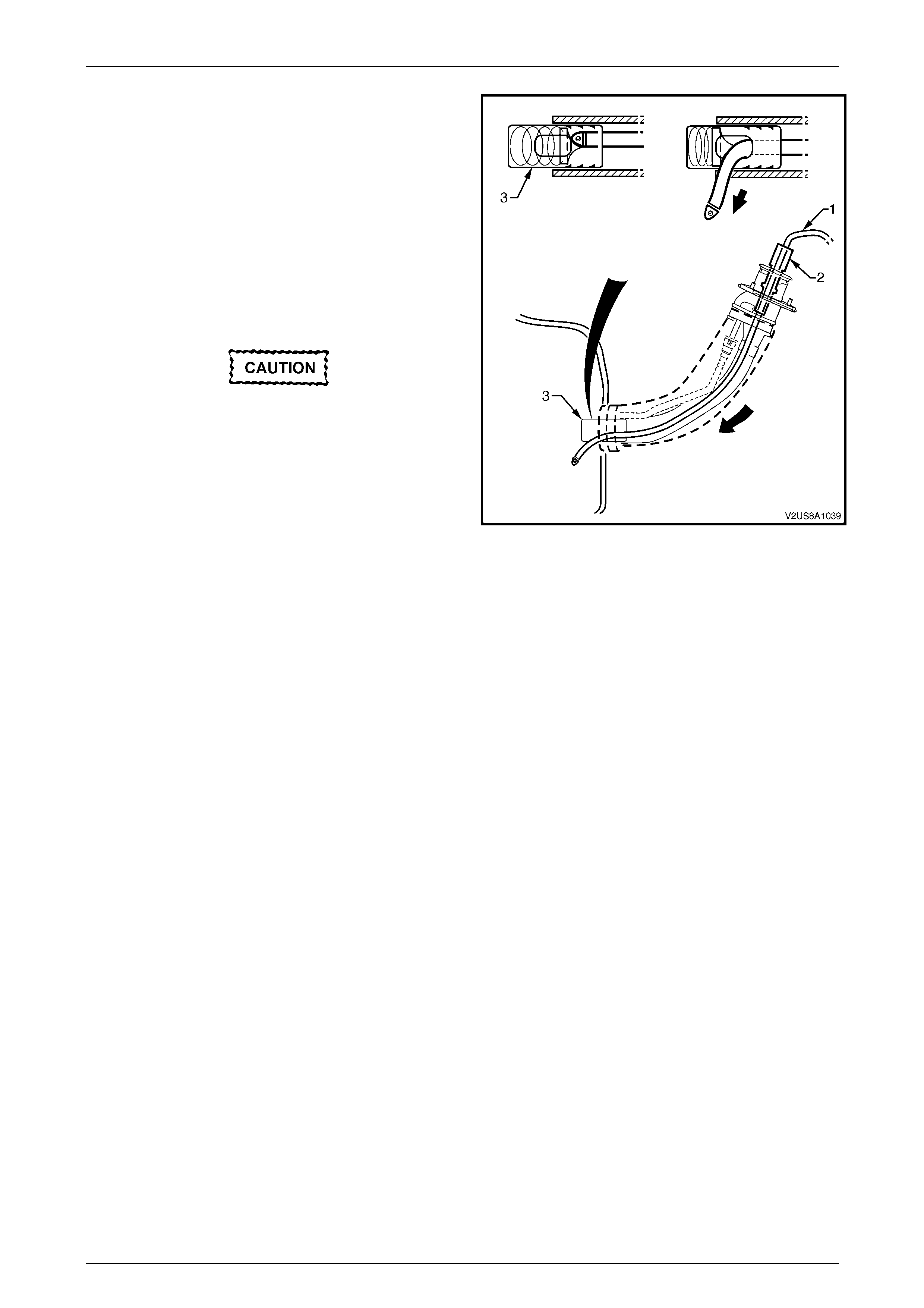

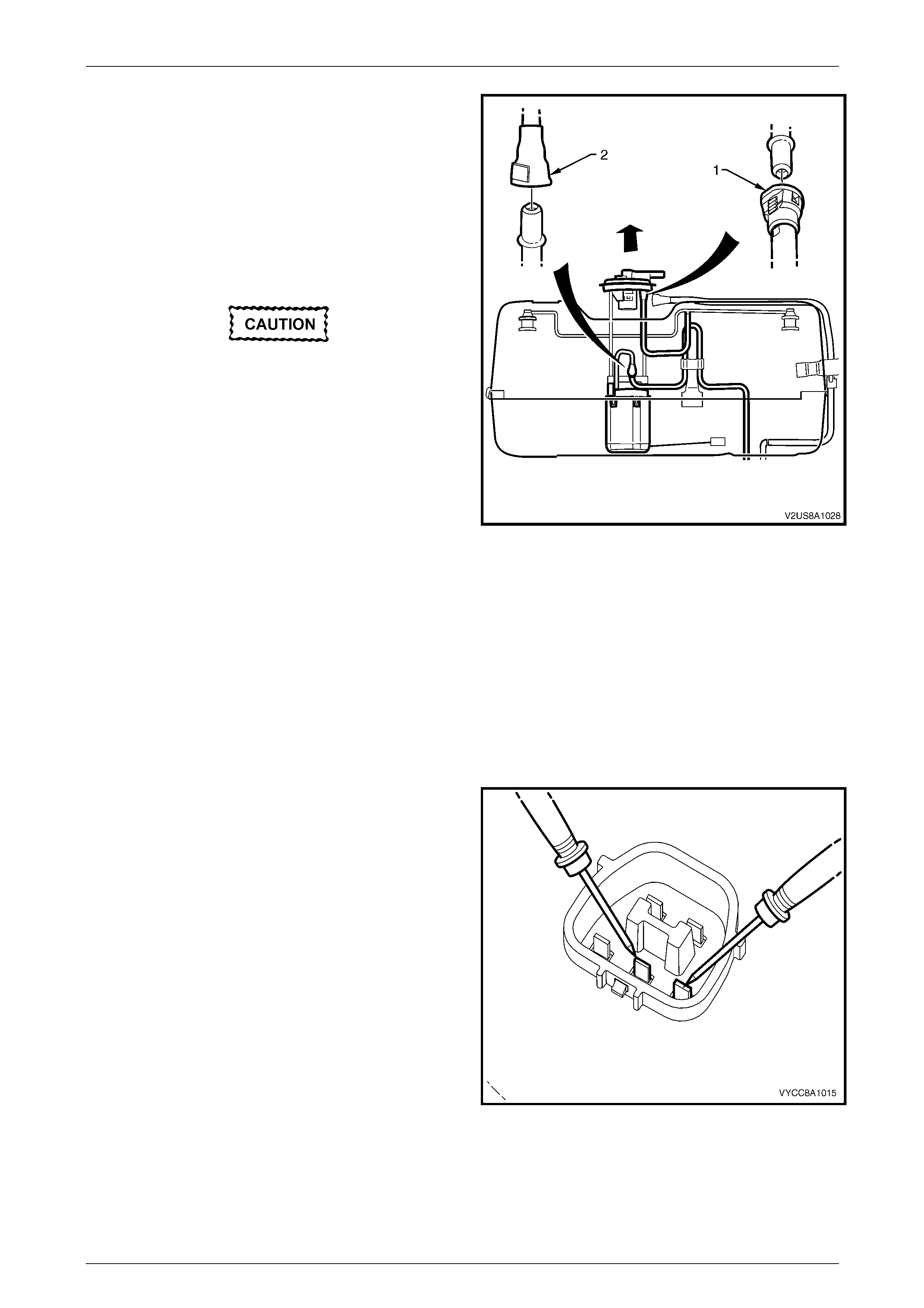

5. Install J44284–2 flapper door holder (2) into the fuel filler

neck in order to hold the door open.

NOTE

Lubricate the fuel siphon hose with J36850

Transjel Transmission Assembly Lubricant or

equivalent to aid hose insertion. Do not use an

unapproved lubricant.

6. Insert the J45004-1 fuel tank siphon hose (1) into the fuel

tank filler neck and gradually twist it around until the tip of

the hose meets the fuel tank check valve (3) and

continues to the bottom of the fuel tank.

7. Use a hand or air operated pump device in order to

siphon as much fuel through the fuel fill pipe as possible.

Never siphon or store fuel into an open

container. Always use and approved fuel

storage container in order to reduce the

chance of fire, explosion or con t amin atio n.

Figure 8A1 – 10

NOTE

Never use excessive force when removing the

siphon hose from the fuel filler neck. If the fuel

siphon hose gets stuck upon removal, gently twist

and tug the hose back and forth until it releases.

NOTE

If fuel does not siphon from the fuel tank, the fuel

hose may have entered the fuel tank through a

roof facing opening of the check valve. If

necessary, repeat step 6 above but twist the hose

by 90 degrees as it is sliding down the filler neck.

This will enable the siphon hose to enter into the

fuel tank through a floor facing check valve

opening.

NOTE

The siphon procedure will not remove all fuel

from the fuel tank. If necessary, fuel remaining in

the fuel tank may be siphoned out through the top

of the fuel tank, once the modular fuel pump and

sender assembly is removed from the tank, refer

to 3.6 Modular Fuel Pump And Sender

Assembly.

Fuel and Exhaust Systems Page G-19

Page G-19

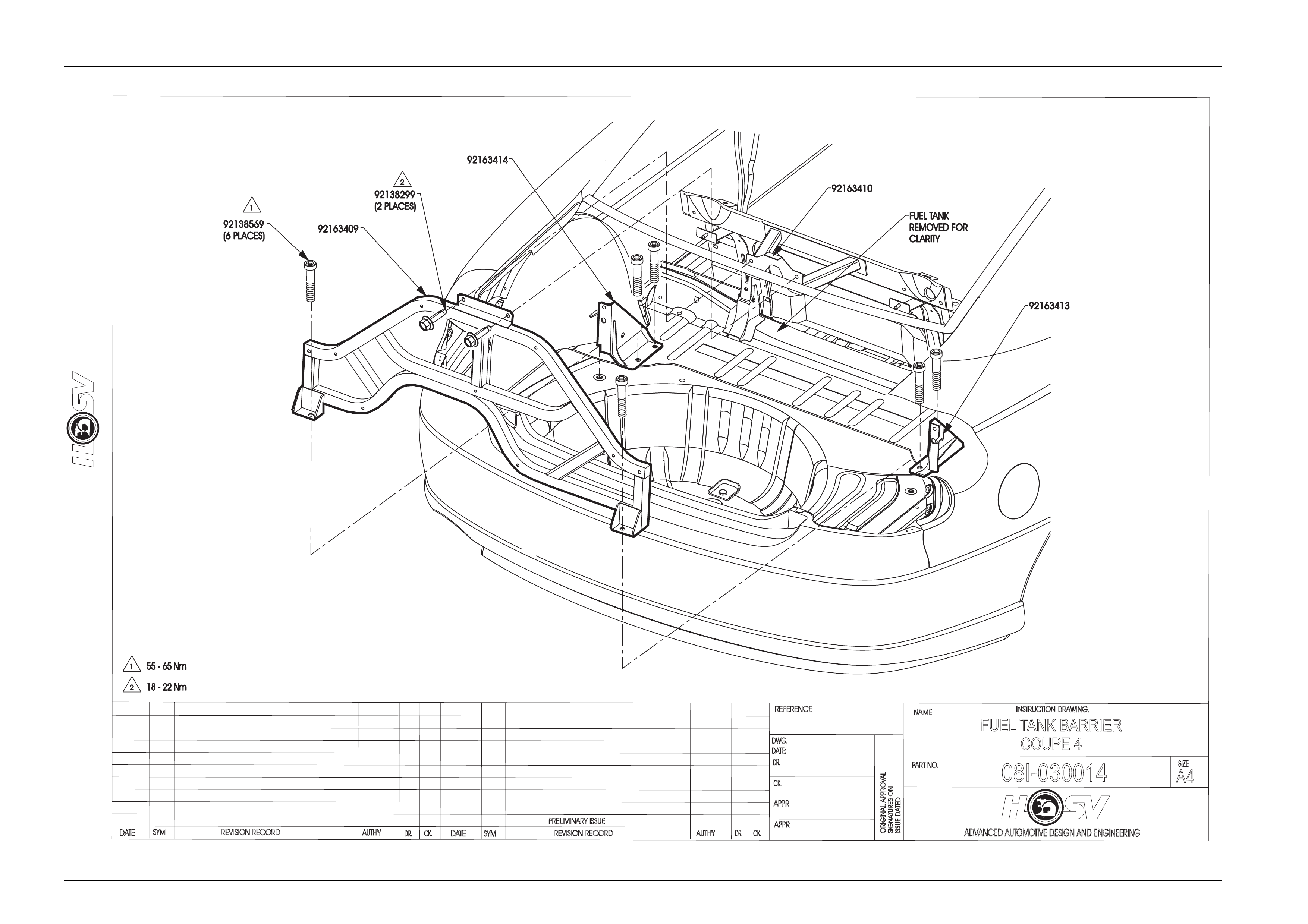

DATE

ISSUE DATED

AUTH'Y

CK.

SYM

AUTH'Y

REVISION RECORD

DATE

SYM

SIGNATURES ON

ORIGINAL APPROVAL

DR.

ADVANCED AUTOMOTIVE DESIGN AND ENGINEERING

08I-030014

INSTRUCTION DRAWING.

A4

SIZE

FUEL TANK BARRIER

COUPE 4

REVISION RECORD

PRELIMINARY ISSUE

CK.

NAME

PART NO.

CK.

REFERENCE

DWG.

DR.

DATE:

APPR

APPR

DR.

02/07/04

AP

DP

JS

Fuel and Exhaust Systems Page G-20

Page G-20

3.4 Fuel Tank Assembly

Remove

The fuel system will contain fuel in the

modular fuel pump and sender assembly and

fuel lines that can be spilled during service

operations. Ensure no naked flames or other

ignition sources are nearby. Ensure all mobile

phones (and transmission devices that may

cause any metal objects to become

unintentional receiving antennas) are

switched off.

Place a dry chemical (Class B) fire

extinguisher nearby before performing any

on-vehicle service procedures. Failure to

follow these precautions may result in

personal injury.

For a general exploded view of fuel tank components, refer to Figure 8A1 – 1.

1. Siphon as much fuel as possible from the fuel tank, refer to 3.2 Fuel Tank Siphon Procedure.

2. Remove the fuel tank brace to gain access to the fuel tank, refer to Drawing 08I-030014 Fuel Tank Brace.

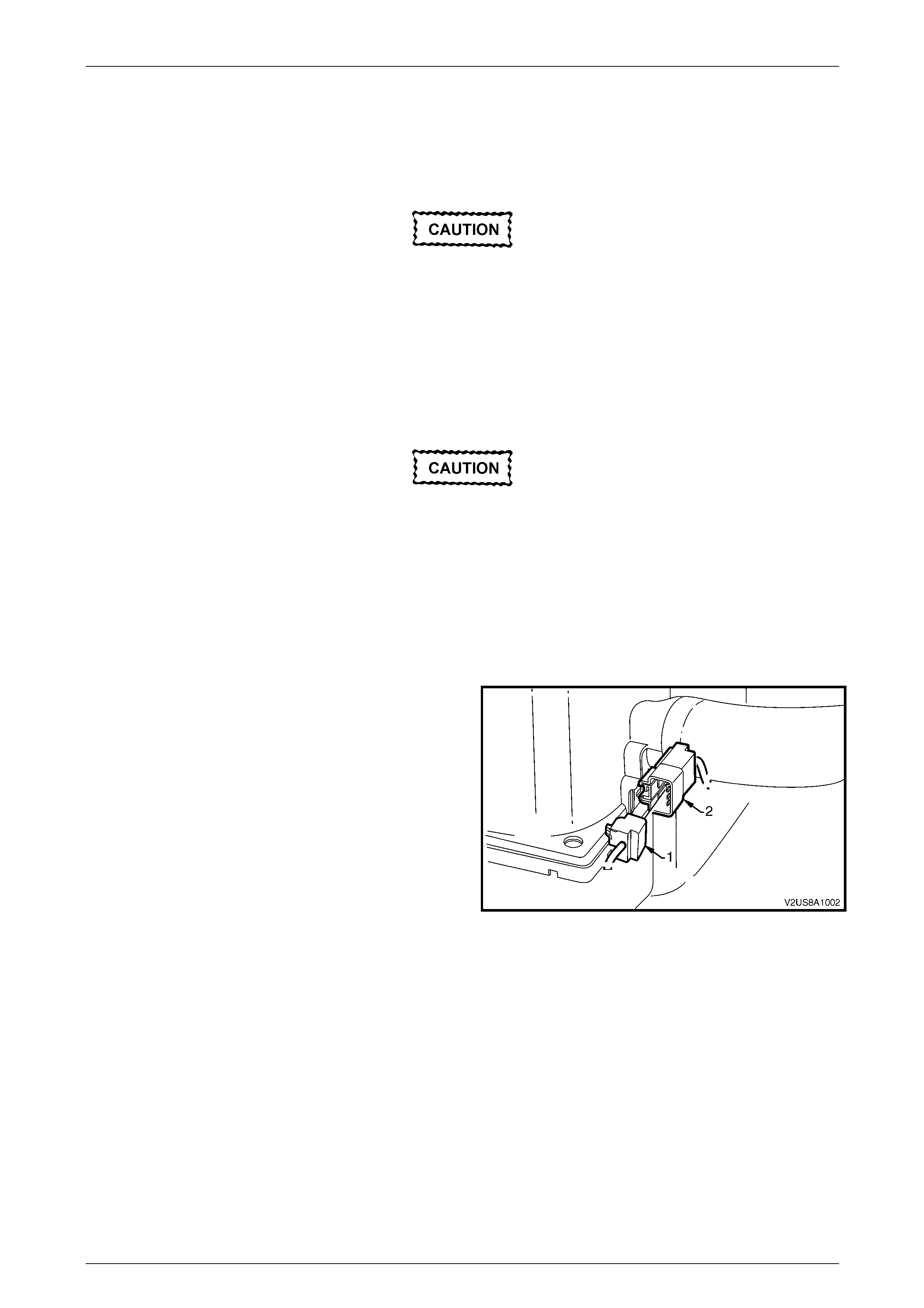

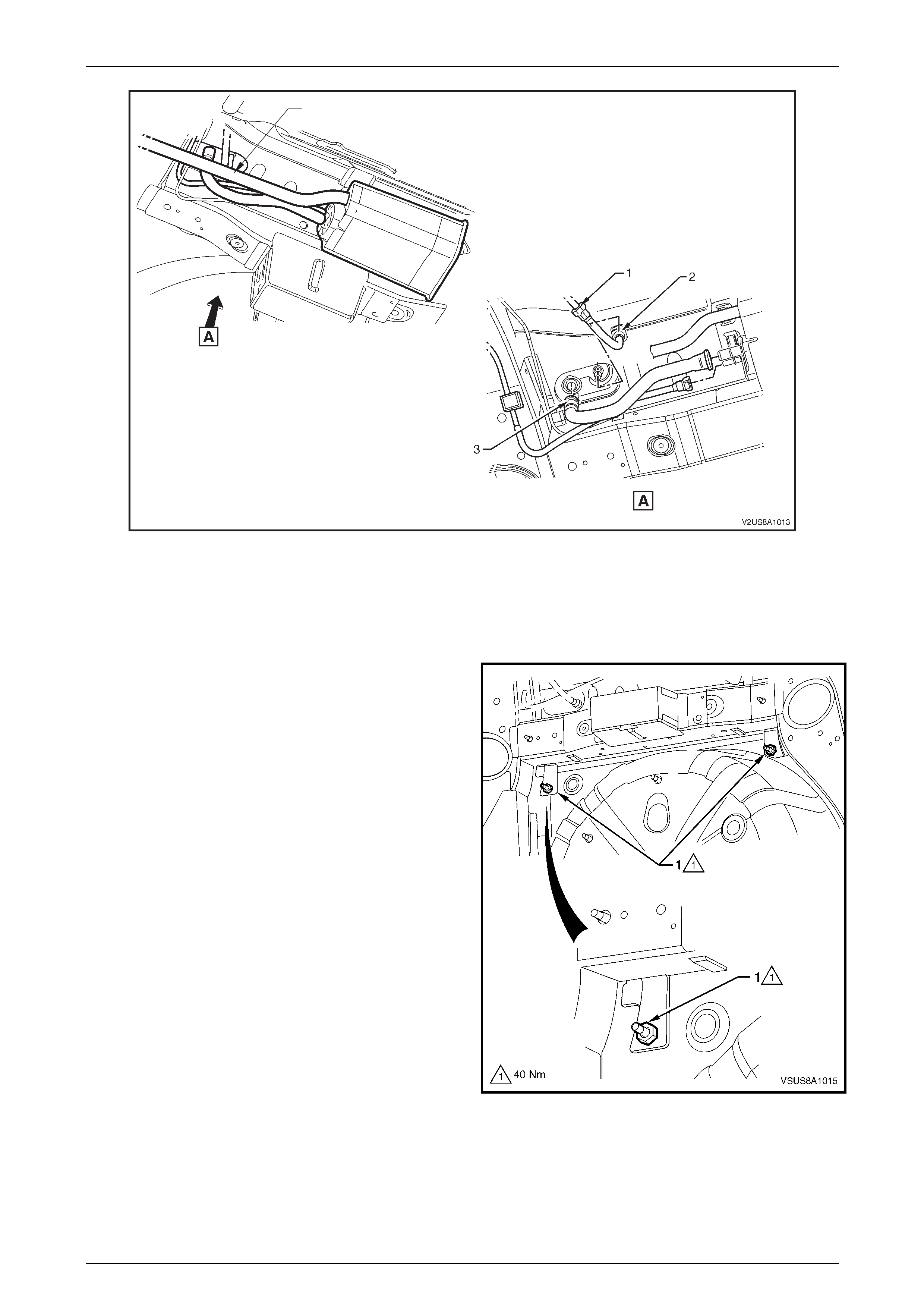

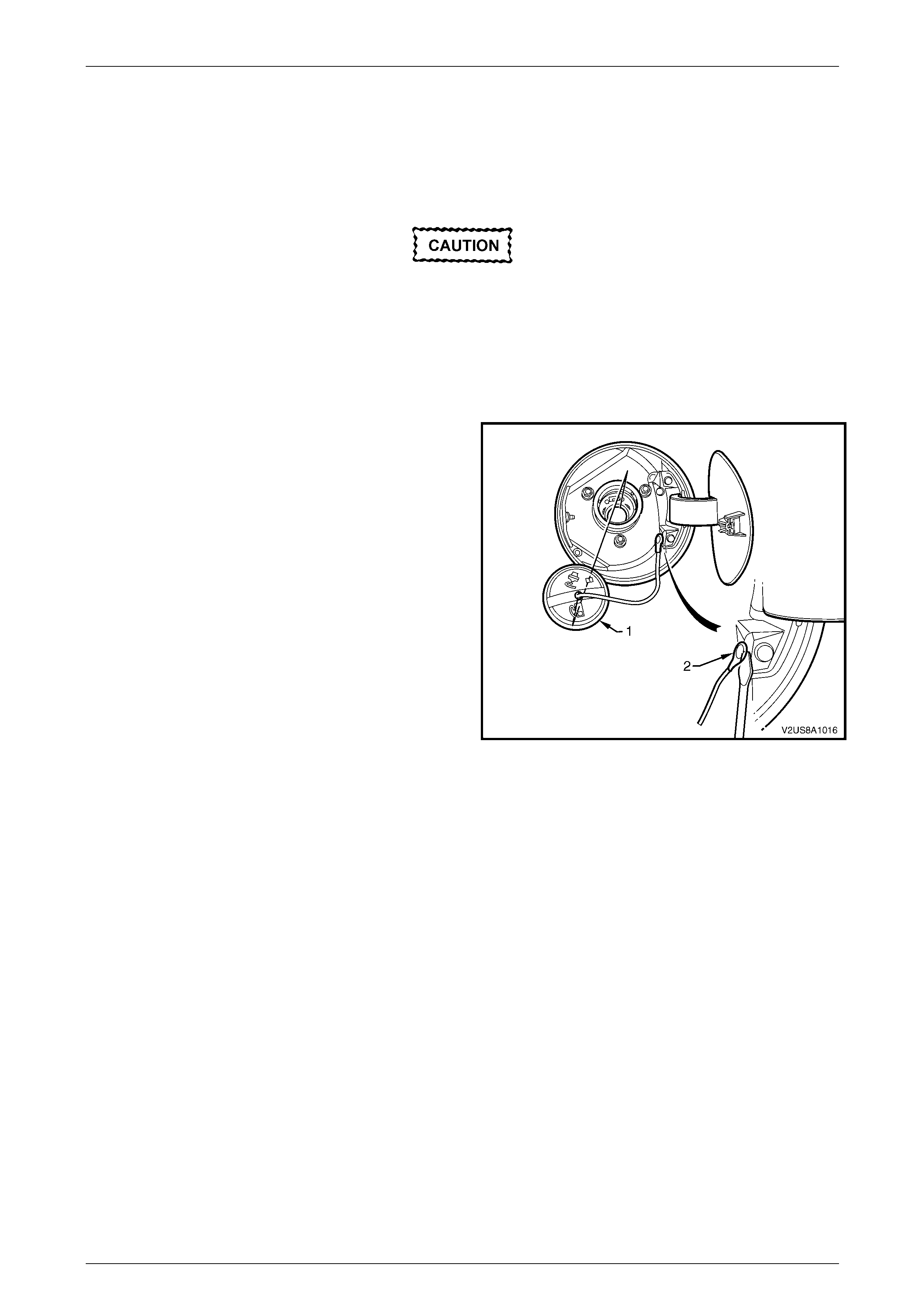

3. Disconnect the body wiring harness to fuel tank harness

connector (1) by depressing the release tang on the

inboard facing face of the connector and pulling the

connector out from the fuel tank harness connector (2).

Figure 8A1 – 11

Fuel and Exhaust Systems Page G-21

Page G-21

4. From behind the fuel filler door (1), unscrew the fuel filler

cap (4) and cover the end of the fuel filler neck with a

suitable material to prevent foreign objects from entering.

5. Remove the three nuts (2) securing the fuel filler neck to

the filler pocket (3).

Figure 8A1 – 12

6. Refer to Figure 8A1 – 13 for the following:

From underneath the vehicle:

a. Disconnect the fuel feed line quick connect fitting (1)

b. Disconnect the fuel tank to fuel feed line quick connect fitting (2) and place feed line to one side.

c. Remove the fuel tank vent line quick connect fitting (2).

Even though the fuel system may have been

de-pressurised, the fuel filter and lines will

contain fuel that will be spilled during this

service operation. Therefore, ensure that no

naked flames or other ignition sources are in

the immediate area.

NOTE

Upon removal of the fuel tank vent line quick

connect fitting (1), it may be necessary to tug the

vent line hose downwards to clear the quick

connect fitting from the underbody panelling. This

will enable enough room to disconnect the quick

connect fitting.

NOTE

For general information on correct servicing

procedures of quick-connect fittings, refer to

Section 6C3-3 Service Operations

(GEN III V8 Engine), 3.10 Quick Connect Fittings

(Plastic Collar), in the MY2003 VY & V2 II Series

Service Information.

NOTE

On non Electronic Throttle Control (ETC) Coupe

4 models the EVAP Canister Vent System (4) is

not used.

Fuel and Exhaust Systems Page G-22

Page G-22

4

Figure 8A1 – 13

Legend

1. Fuel Feed Line Quick Connect Fitting

2. Fuel Tank to Fuel Feed Line Quick Connect Fittings 3. Fuel Tank Vent Line Quick Connect Fitting

d. If required, remove the necessary rear underbody

air deflector to vehicle fasteneing bolts and nuts to

allow the deflector to be pulled down; allowing

improved access to the lower fuel tank mounting

strap nuts (1), refer to Section 1A1 Body,

5.2 Rear Underbody Air Deflector.

NOTE

The underbody air deflector is shown fully

removed for visual purposes only. Full removal of

the air deflector is not essential for this procedure.

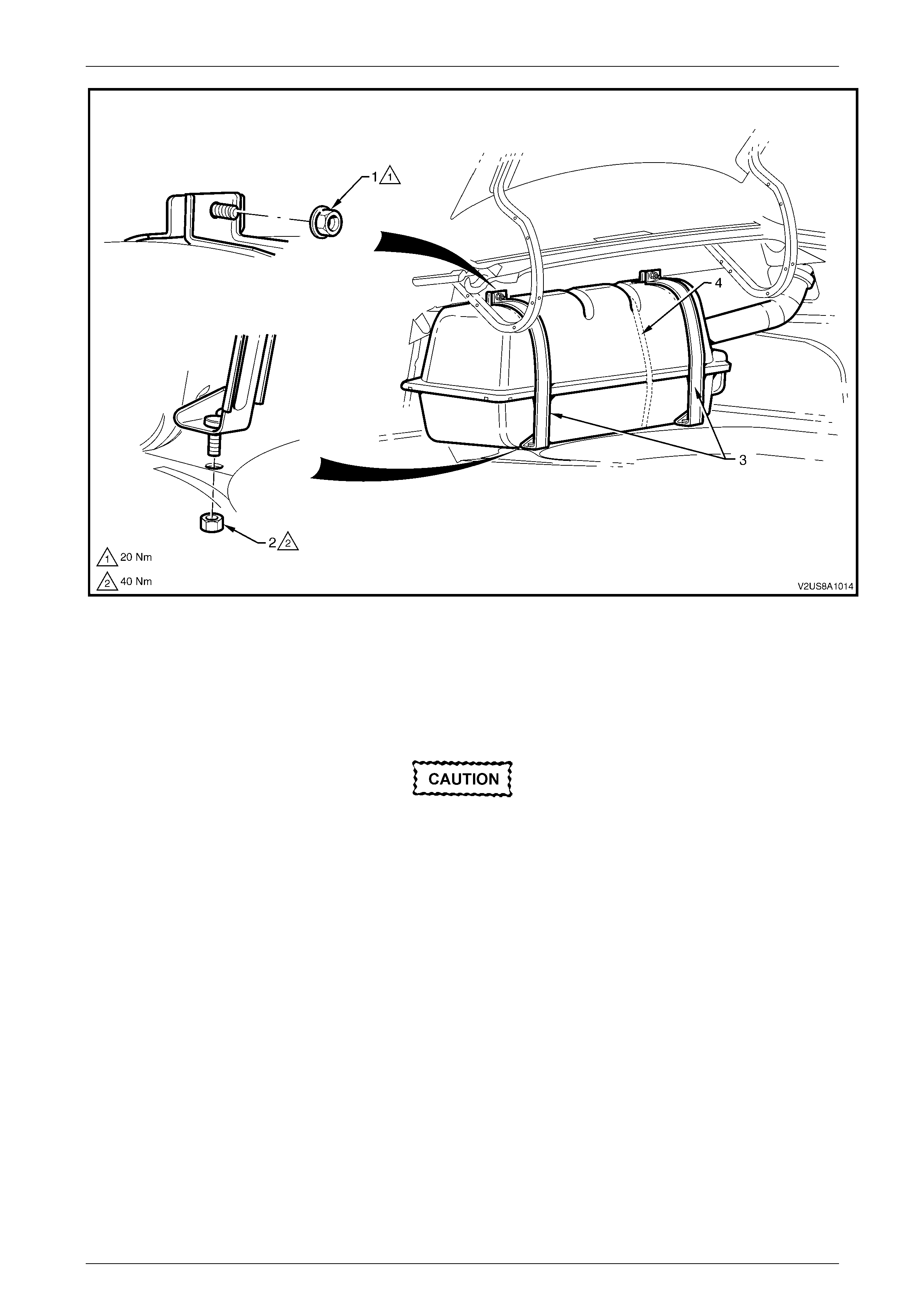

7. Lower the vehicle and from within the rear

compartment, remove the two fuel tank upper mounting

strap nuts (1) and remove each of the mounting

straps (3), refer to Figure 8A1 – 15.

Figure 8A1 – 14

Fuel and Exhaust Systems Page G-23

Page G-23

Figure 8A1 – 15

Legend

1. Mounting Strap Upper Fastening Nut (2 places)

2. Mounting Strap Lower Fastening Nut (2 places) 3. Mounting Strap

4. Shipping Strap

The fuel tank w ill still contain fuel and may be

heavy. Ensure proper workshop lifting

practices are used during removal of the fuel

tank.

8. With the assistance of another person, remove the fuel tank and filler neck assembly from the vehicle.

9. If installed, cut and dispose of the shipping strap.

NOTE

The shipping strap is used for fuel tank shipping

purposes only and does not require reinstallation.

Fuel and Exhaust Systems Page G-24

Page G-24

10. Unclip the fuel tank to body wiring harness connector

(1) from its mounting clip (2) which connects onto the

lower plastic fuel tank shell.

Figure 8A1 – 16

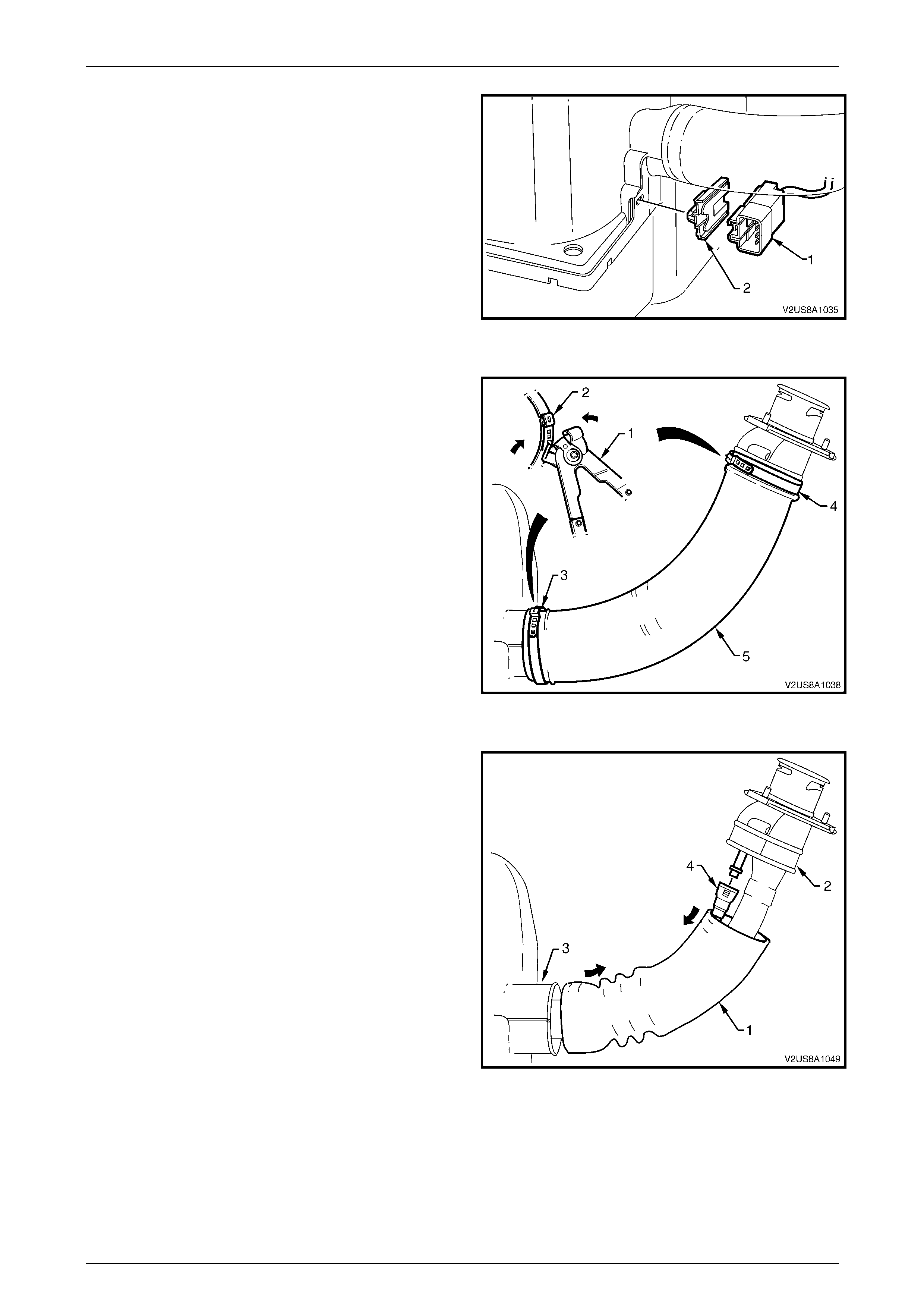

11. Using keystone clamp pliers J22610 (1), position the

jaws across the clamp ear (2) and cut through to

release both clamps (3 and 4). Dispose of the used

clamp.

Figure 8A1 – 17

12. Manipulate the santoprene hose (1) off from around the

filler neck flange moulding (2) and down along the fuel

filler neck.

13. Disconnect the fuel tank vapor recirculation line quick

connect fitting (4). If necessary, use special tool AU533

to assist disconnection of quick connect fitting.

14. Manipulate the santoprene hose off from around the

fuel tank cover flange (3).

Figure 8A1 – 18

Fuel and Exhaust Systems Page G-25

Page G-25

15. Wedge a large flat blade screwdriver in between the

side skirting of each of the upper and lower plastic fuel

tank shells (1 and 2), and pull each of the eight clipping

points (4) free to separate and remove the upper plastic

fuel tank shell as indicated.

16. Lift and remove the fuel tank (3) from the lower plastic

fuel tank shell.

Figure 8A1 – 19

17. If removal of the fuel filler neck assembly is required,

loosen off the fuel tank filler neck throat to fuel filler

neck flexible hose hose-clamp (2) and prise the flexible

hose (1) off from around the fuel tank filler neck

throat (3). Place the fuel filler neck assembly,

santoprene hose and hose-clamp to one side.

18. Plug the fuel tank filler neck throat with a suitable

material to prevent the possibility of foreign objects

entering the fuel tank.

Figure 8A1 – 20

19. If disassembly of the fuel filler neck assembly is

necessary, loosen off the flexible hose to filler neck pipe

hose clamp and pull the flexible hose and filler neck

apart to separate.

20. Cover the fuel tank opening with a suitable material to

prevent foreign objects from entering.

Figure 8A1 – 21

Fuel and Exhaust Systems Page G-26

Page G-26

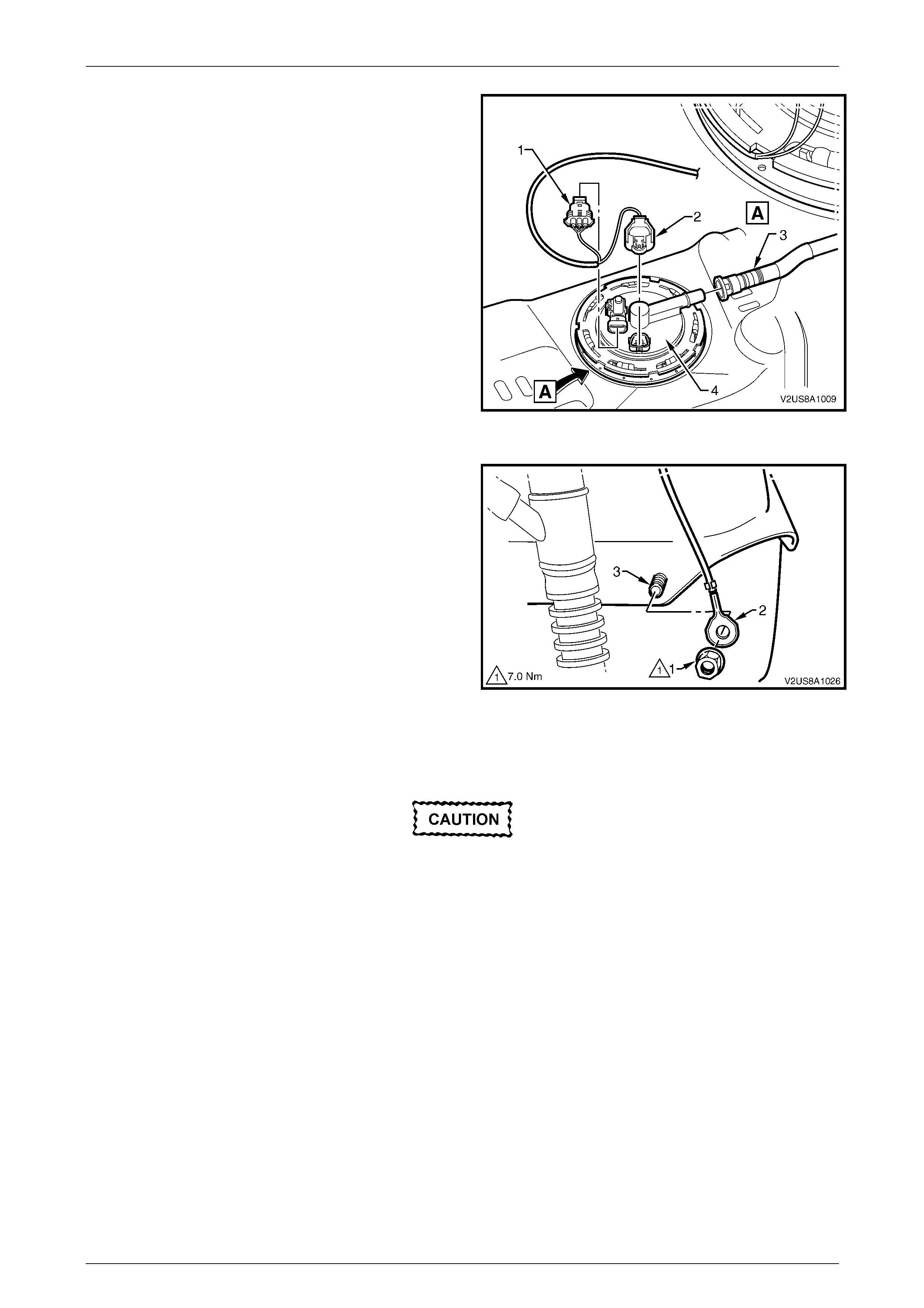

21. Disconnect the fuel tank pressure sensor connector (1),

the fuel pump connector (2) and the EVAP vapor hose

quick connector (3) from the modular fuel pump and

sender assembly cover (4).

22. Cover the EVAP vapor hose quick connect fitting with a

suitable material to prevent foreign objects from

entering.

Figure 8A1 – 22

23. Remove the flanged nut (1) securing the modular fuel

pump and sender assembly earthing terminal (2) to the

fuel tank flange stud (3) and remove the fuel tank wiring

harness.

Figure 8A1 – 23

24. Where necessary, remove the modular fuel pump and sender assembly, refer to

3.6 Modular Fuel Pump And Sender Assembly in this Section.

Fuel vapor remains in the tank even when

completely empty. Seal all openings in the

fuel tank using a suitable plug. Ensure no

naked flames or other ignition sources are

nearby. Ensure all mobile phones and

transmission devices that may cause any

metal objects to become unintentional

receiving antennas are switched off.

Fuel and Exhaust Systems Page G-27

Page G-27

Reinstall

The installation procedure for the fuel tank is the reverse of the removal procedure, noting the following:

1. Tighten the fuel pump and sender assembly earthing terminal nut to the correct torque specification.

Fuel Pump And Sender Assembly

Earthing Terminal Nut

Torque Specification ............................................7.0 Nm

2. When installing the fuel tank assembly into the lower plastic cover, ensure that the EVAP vapor recirculation line

outlet is positioned through the slot provided in the lower cover.

3. Fit each end of the santoprene hose over the fuel tank cover flange and the filler neck flange and locate new ear-

type clamps at each end. Use special service tool keystone clamp pliers J22610 to crimp the clamp ears to fasten.

4. Tighten each of the fuel tank mounting strap upper fastening nuts to the correct torque specification.

Fuel Tank Mounting Strap

Upper Fastening Nut

Torque Specification .............................................20 Nm

5. Tighten each of the fuel tank mounting strap lower fastening nuts to the correct torque specification.

Fuel Tank Mounting Strap

Lower Fastening Nut

Torque Specification .............................................40 Nm

6. If required, tighten the underbody air deflector to vehicle fastening bolts and nuts to the correct torque specification.

Fuel Filler Neck To Filler

Pocket Fastening Nut

Torque Specification ...............................................5 Nm

7. Tighten the three nuts securing the fuel filler neck to the fuel filler pocket to the correct torque specification.

Fuel Filler Neck To Filler

Pocket Fastening Nut

Torque Specification ...............................................5 Nm

8. Fully install the fuel filler cap onto the fuel filler neck.

Fuel and Exhaust Systems Page G-28

Page G-28

3.5 Fuel Filler Neck Assembly

To avoid the possibility of fuel spillage in the rear compartment, removal of the fuel filler neck assembly on its own is not

recommended. Removal and disassembly of the fuel filler neck assembly from the fuel tank forms part of the fuel tank

removal procedure, refer to 3.4 Fuel Tank Assembly, in this Section.

Fuel and Exhaust Systems Page G-29

Page G-29

3.6 Modular Fuel Pump And Sender

Assembly

Remove

Ensure no naked flames or other ignition

sources are nearby. Ensure mobile phones

(and transmission devices that may cause any

metal objects to become unintentional

receiving antennas) are switched off.

Wear safety glasses when using compressed

air. Do not blow compressed air directly onto

any body part.

NOTE

Before proceeding with removal of the modular

fuel pump and sender assembly, clean all traces

of dirt and other foreign material from the top of

the fuel tank, near the modular fuel pump and

sender assembly. Also, use compressed air to

ensure that all dirt and foreign materials are

removed from all relevant fuel system connectors

before disconnection.

NOTE

Full removal of the fuel tank from the vehicle is

recommended for this service procedure so as to

reduce the risk of fuel spillage within the rear

luggage compartment.

Fuel and Exhaust Systems Page G-30

Page G-30

1. Remove the fuel tank assembly from the vehicle to gain

access to the modular fuel pump and sender assembly

and remove the top fuel tank shell, refer to

3.4 Fuel Tank Assembly, in this Section.

2. Disconnect the fuel tank pressure sensor connector, the

fuel pump connector and the EVAP vapor hose quick

connector from the modular fuel pump and sender

assembly cover, refer to

3.4 Fuel Tank Assembly, in this Section.

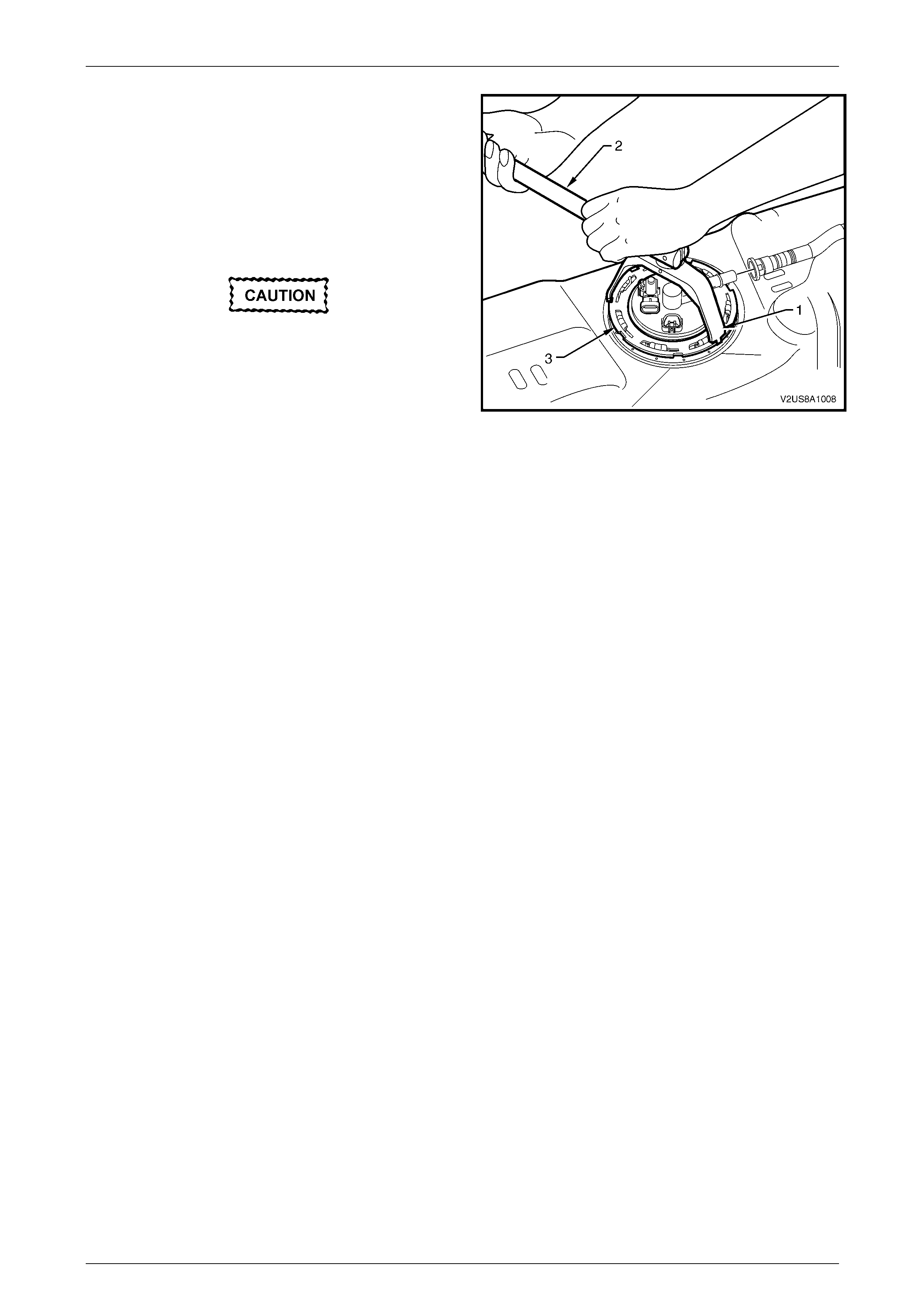

The modular fuel pump and sender assembly

cover springs up when the retainer is

removed.

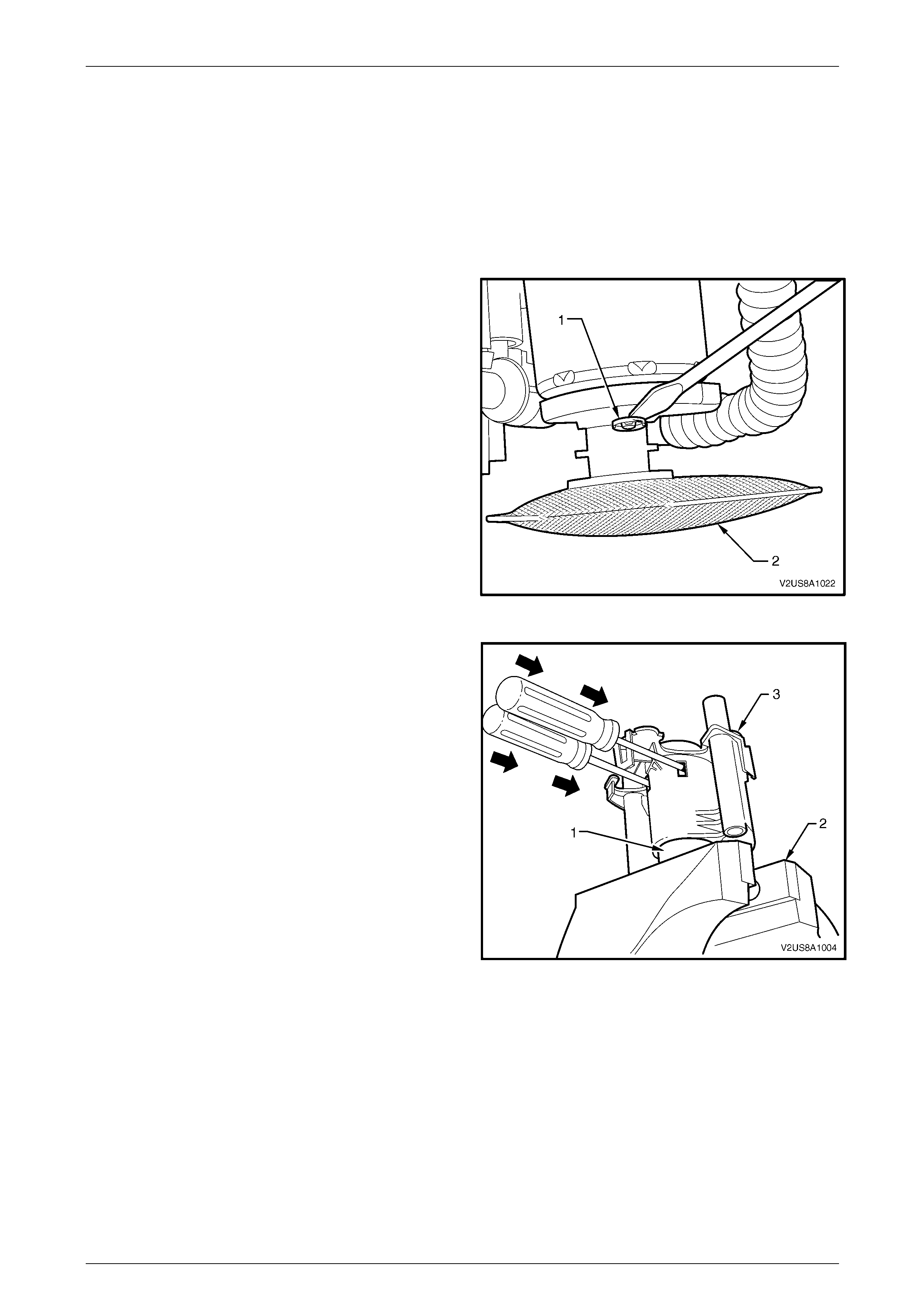

3. Using the lock ring removal tool J45722 (1) and a half-

inch breaker bar (2), remove the cover retainer lock

ring (3) by turning in an anti-clockwise direction.

NOTE

Ensure that the lock ring removal tool is correctly

installed onto the lock ring as significant removal

torque is required to overcome the positive

locking feature of the lock ring. Where necessary,

use a breaker bar extension to aid removal.

NOTE

Assistance will be required to hold the tank in

position during this procedure.

Figure 8A1 – 24

Fuel and Exhaust Systems Page G-31

Page G-31

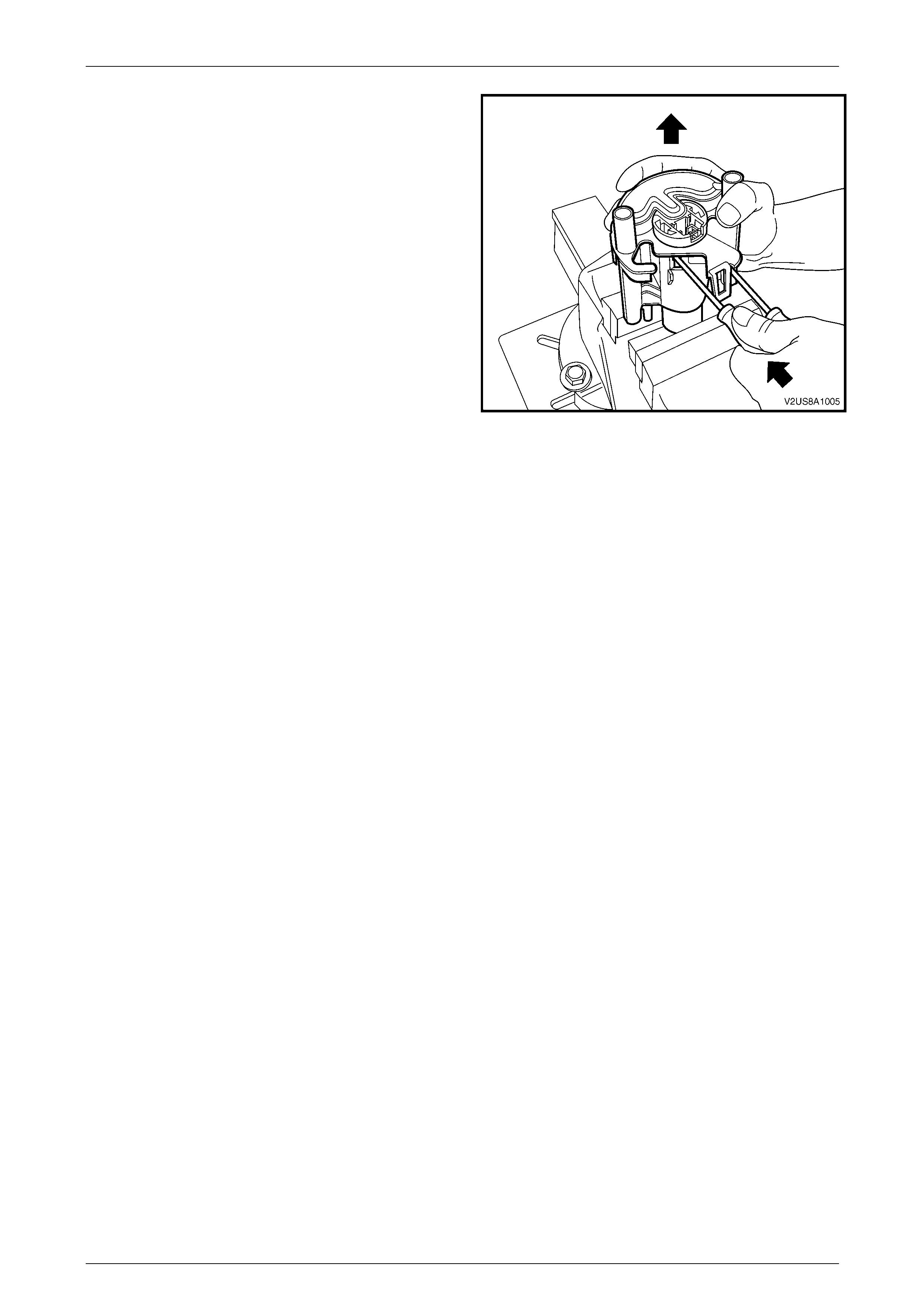

4. Partially lift the modular fuel pump and sender

assembly away from the fuel tank, taking care not to

damage the fuel level sender assembly. Disconnect the

fuel tank EVAP vapor line quick connector (1) from the

underside of the modular fuel pump and sender

assembly cover. If necessary, use special service tool

AU533 to assist disconnection.

5. Insert hand into the fuel tank opening and disconnect

the fuel feed line quick connector (2).

6. Remove the modular fuel pump and sender assembly.

The reservoir will be full of fuel. When the

modular fuel pump and sender assembly is

removed from the fuel tank, pour any

remaining fuel in the reservoir into a suitable

container. Never siphon or store fuel into an

open container, due to the possibility of fire or

explosion.

NOTE

Fuel vapor remains in the tank even when

completely empty. Seal the opening in the fuel

tank using a suitable plug and place a suitable

cover over the plug to prevent any foreign matter

from entering.

7. Remove and discard the modular fuel pump and sender

assembly to fuel tank seal.

8. Check the underside of the reservoir to ensure that

there are three rubber isolator feet attached to the

bottom. If one or more are missing, retrieve each from

within the fuel tank and reinstall.

Figure 8A1 – 25

Test

1. Measure the resistance across the fuel level sender

terminals of the modular fuel pump and sender

assembly cover connector. Take the following

measurements:

a. With the fuel level sender assembly rotated in the

full position, the resistance should be 40 ohms

(+/– 2.5 ohms).

b. With the fuel level sender assembly in the full

position, the resistance should be 248 ohms

(+/- 3.5 ohms).

2. If the fuel level sender assembly resistance for either of

these settings is not as specified, replace the complete

fuel level sender assembly with a serviceable item.

Figure 8A1 – 26

Fuel and Exhaust Systems Page G-32

Page G-32

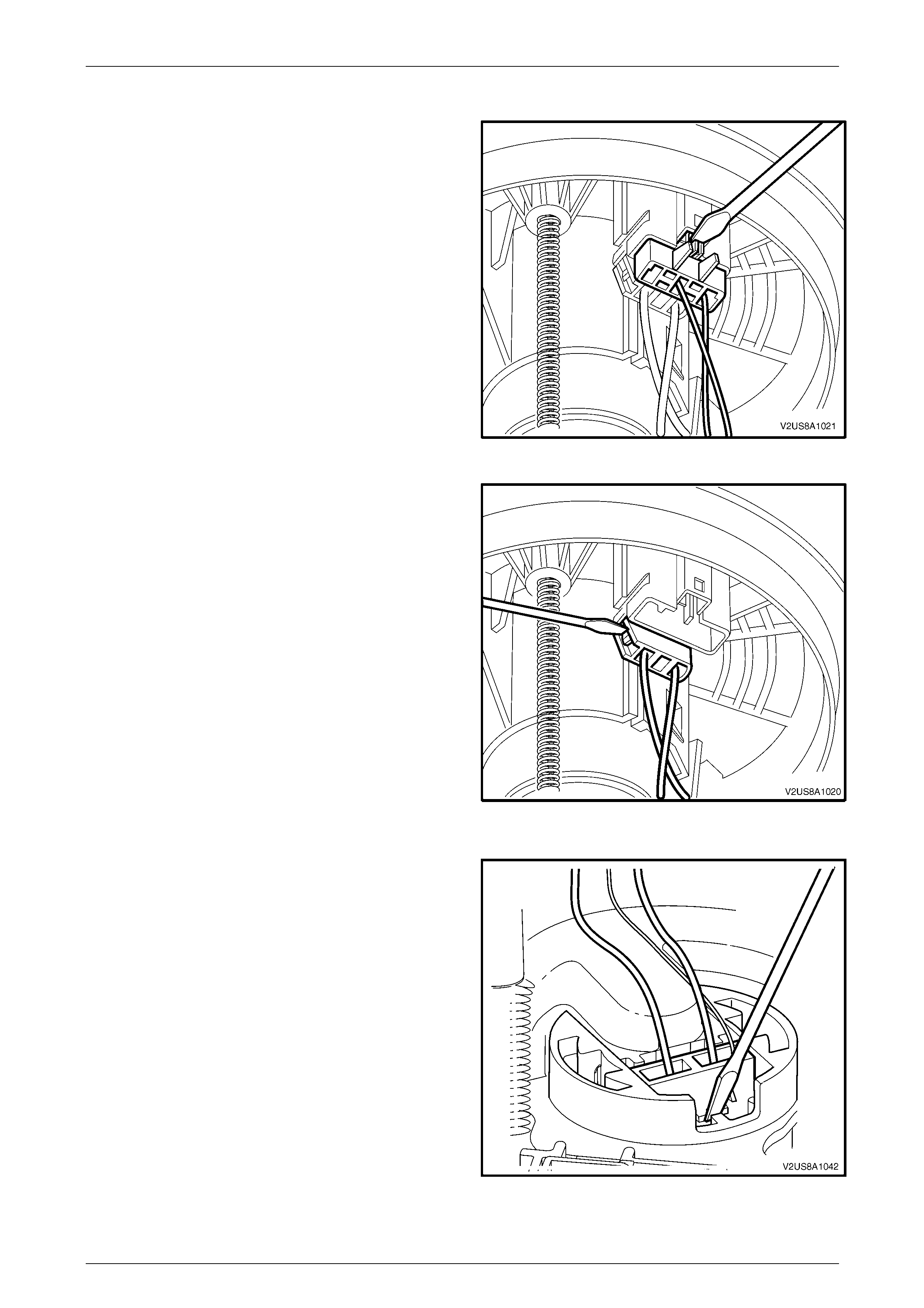

Disassemble

1. Use a flat blade driver to assist removal of the fuel level

sender assembly harness connector from underneath

the modular fuel pump and sender assembly cover as

indicated.

Figure 8A1 – 27

2. Use a flatblade driver to assist removal of the fuel pump

harness connector from underneath the modular fuel

pump and sender assembly cover as indicated.

Figure 8A1 – 28

3. Press in the tang retaining the fuel pump connector on

the fuel pump and filter assembly, then remove the

connector.

Figure 8A1 – 29

Fuel and Exhaust Systems Page G-33

Page G-33

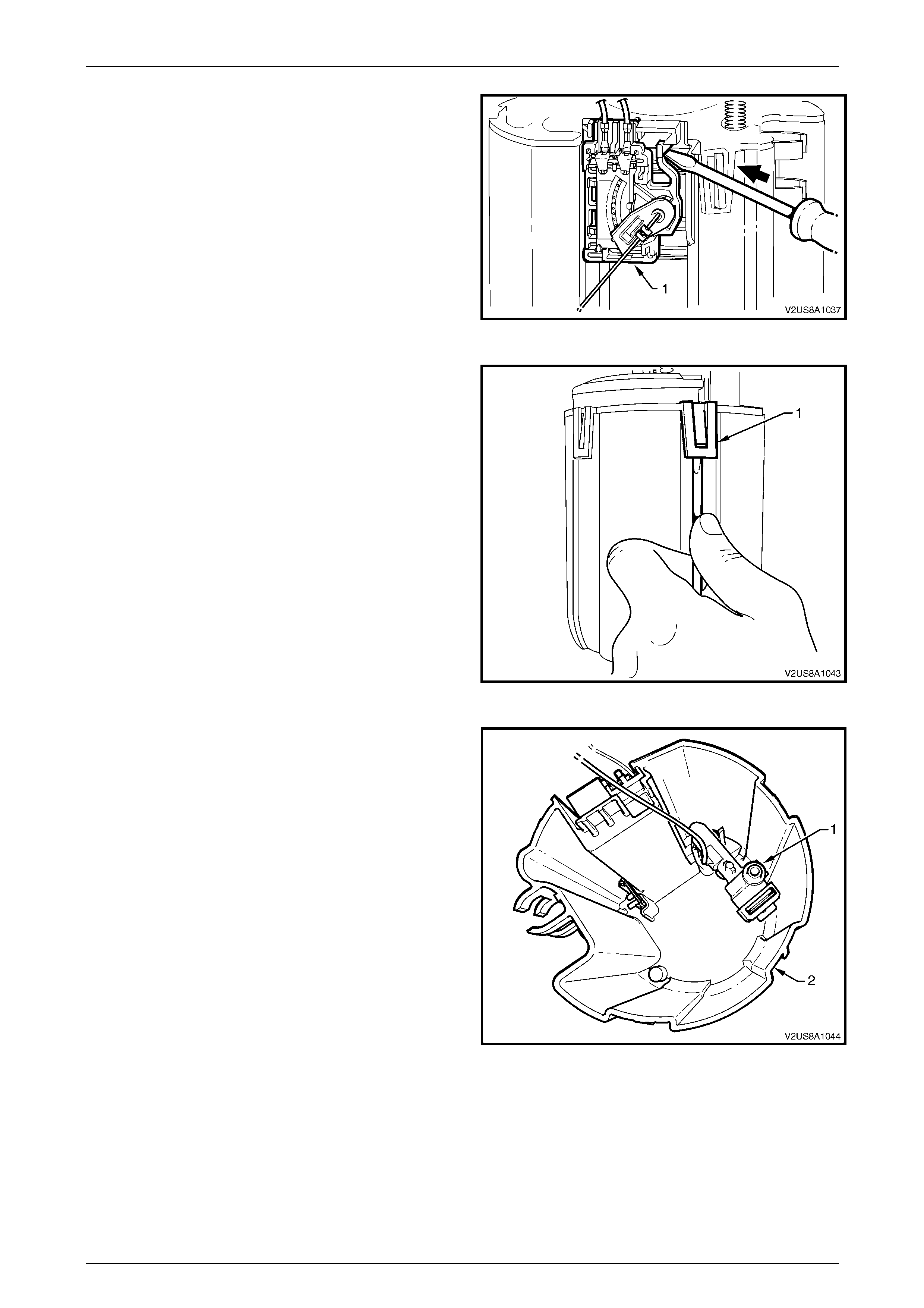

4. Prise the tang open that holds the fuel level sender

assembly (1) to the side of the reservoir, then lift it off

from the reservoir.

Figure 8A1 – 30

5. Prise each of the four tangs (1) with a flat-bladed

screwdriver, then remove the motor and filter assembly,

and cover from the reservoir.

NOTE

Another person may be required to assist in

removing the motor and filter assembly from the

reservoir.

6. Pull the modular fuel pump and sender assembly cover,

motor and filter assembly from the reservoir body.

Figure 8A1 – 31

7. Remove the fuel pressure regulator holder (1) from the

reservoir assembly (2).

NOTE

Some difficulty may be experienced when lifting

these items from the reservoir body due to the

limited space available.

NOTE

Ensure the O-ring is removed from the base of the

reservoir.

Figure 8A1 – 32

Fuel and Exhaust Systems Page G-34

Page G-34

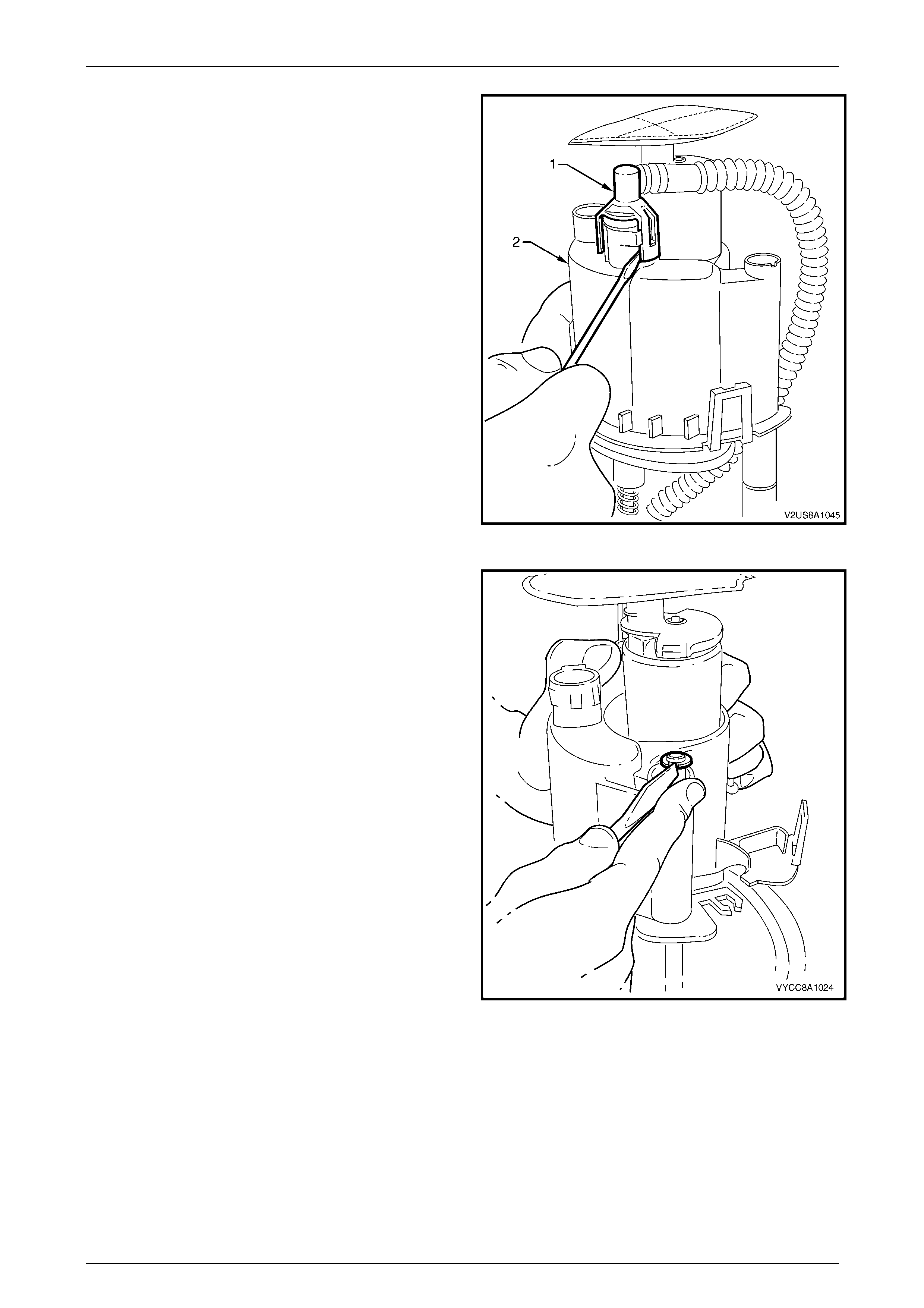

8. Prise open both tangs securing the fuel outlet

connector (1) to the bottom of the motor and filter

assembly (2), then remove the fuel outlet pipe from the

motor and filter assembly.

NOTE

Ensure the O-ring is removed from within the

motor and filter assembly female connector

moulding.

Figure 8A1 – 33

9. Push the motor and filter assembly down the sprung

shafts and remove the circlip (only one shaft is fitted

with a circlip) from the end of the shaft. Place the circlip

in a safe location away from the immediate worksite.

Figure 8A1 – 34

Fuel and Exhaust Systems Page G-35

Page G-35

Reassemble

The procedure for reassembling the modular fuel pump and sender assembly is the reverse of the disassembly

procedure, noting the following:

1. Locate and push the motor and filter assembly down the sprung shafts, then press the circlip into the slot provided

at the tip of one of the shafts.

NOTE

Refer to Figure 8A1 – 35 for the correct

orientation of the motor and filter assembly, and

the cover.

2. Locate and press the fuel outlet connector (1) to its

position on the bottom of the motor and filter assembly

so that it clips firmly into place, refer to Figure 8A1 – 33.

3. Fit a new pressure regulator O-ring (5) into place over

the pressure regulator holders reservoir jet pump port,

refer to Figure 8A1 – 41, and firmly press the pressure

regulator holder into position inside the reservoir, refer to

Figure 8A1 – 32.

4. Position the motor and filter assembly with the cover

attached back into the reservoir and press to clip

together each of the four tangs (1), refer to

Figure 8A1 – 31.

NOTE

Ensure the wires to the fuel level sender

assembly, pressure regulator and both connectors

do not interfere when reassembling the motor and

filter assembly into the reservoir.

5. Locate and press the ceramic variable resistor card and

holder assembly to lock to its position on the reservoir,

refer to Figure 8A1 – 30.

6. Locate and press each of the fuel pump harness

connectors to their positions on the top of the motor and

filter assembly, and on the underside of the modular fuel

pump and sender assembly cover, refer to

Figure 8A1 – 29 and Figure 8A1 – 28 respectively.

7. Locate and press the fuel level sender assembly

harness connector to its position on the underside of

the modular fuel pump and sender assembly cover,

refer to Figure 8A1 – 27.

Figure 8A1 – 35

Reinstall

The procedure for reinstalling the modular fuel pump and sender assembly is the reverse of the removal procedure,

noting the following:

NOTE

Upon installation of the modular fuel pump and

sender assembly, only use the custom sized O-

rings as supplied with modular fuel pump and

sender assembly replacement parts kit. Do not

use off-the-shelf O-rings. Refer to 3.11 Modular

Fuel Pump And Sender Assembly O-Rings for O-

ring specifications.

Fuel and Exhaust Systems Page G-36

Page G-36

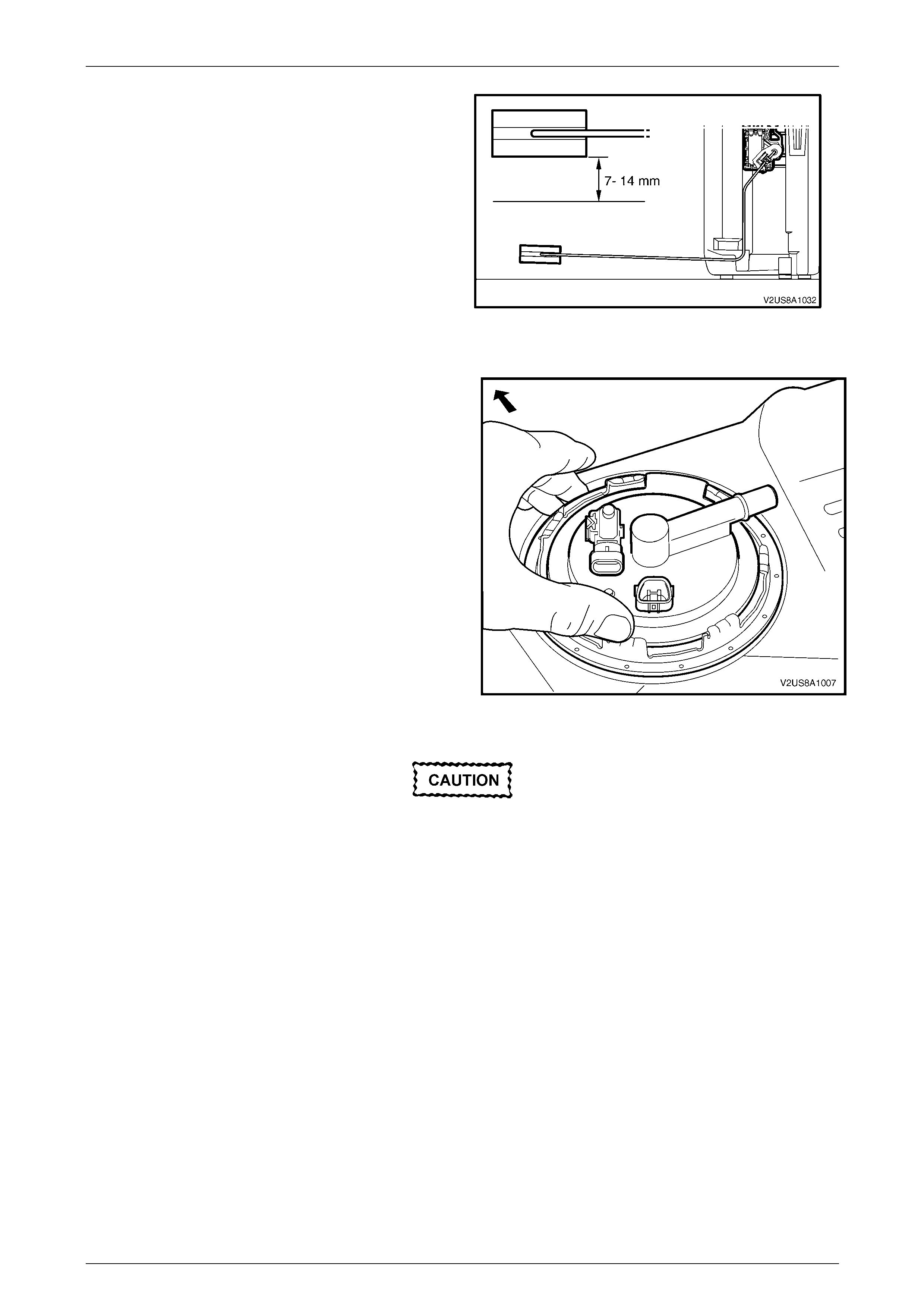

1. Before installation into the fuel tank, check the fuel

sender float position as follows:

a. Stand the assembly upright on a flat surface.

b. Measure the distance between the middle of the fuel

sender float and the flat surface.

c. If required, the float position should be corrected,

through careful adjustment of the float arm, to

achieve a nominal measurement of between 7 mm

and 14 mm.

2. Clean any dirt and foreign materials from the fuel tank

seal recess and position a new seal (3) in the recess,

refer to Figure 8A1 – 2.

3. Install the modular fuel pump and sender assembly into

the fuel tank, taking care not to damage the fuel level

sender float and arm in the process. Figure 8A1 – 36

4. Ensure the locator in the cover engages in the slot in

the tank opening.

Figure 8A1 – 37

Incorrect installation of the modular fuel

pump and sender assembly retainer could

lead to fuel vapor leakage. Take special care

and ensure that the lock ring is installed

correctly.

5. Install the cover retainer lock ring. Use the half-inch breaker bar with special tool J45722 and rotate the retainer in a

clockwise direction until the tangs are engaged.

6. Install the fuel tank pressure sensor connector (1), the fuel pump connector (2) and the EVAP vapor hose quick

connector (3) to the modular fuel pump and sender assembly cover (4), refer to Figure 8A1 – 22.

Fuel and Exhaust Systems Page G-37

Page G-37

3.7 Fuel Level Sender Assembly

The fuel level sender assembly is serviced as a complete assembly and attaches to the side of the modular fuel pump

and sender assembly reservoir. Testing, removal and reinstallation of the fuel level sender assembly are contained within

the modular fuel pump and sender assembly service procedures,

refer to 3.6 Modular Fuel Pump And Sender Assembly.

Fuel and Exhaust Systems Page G-38

Page G-38

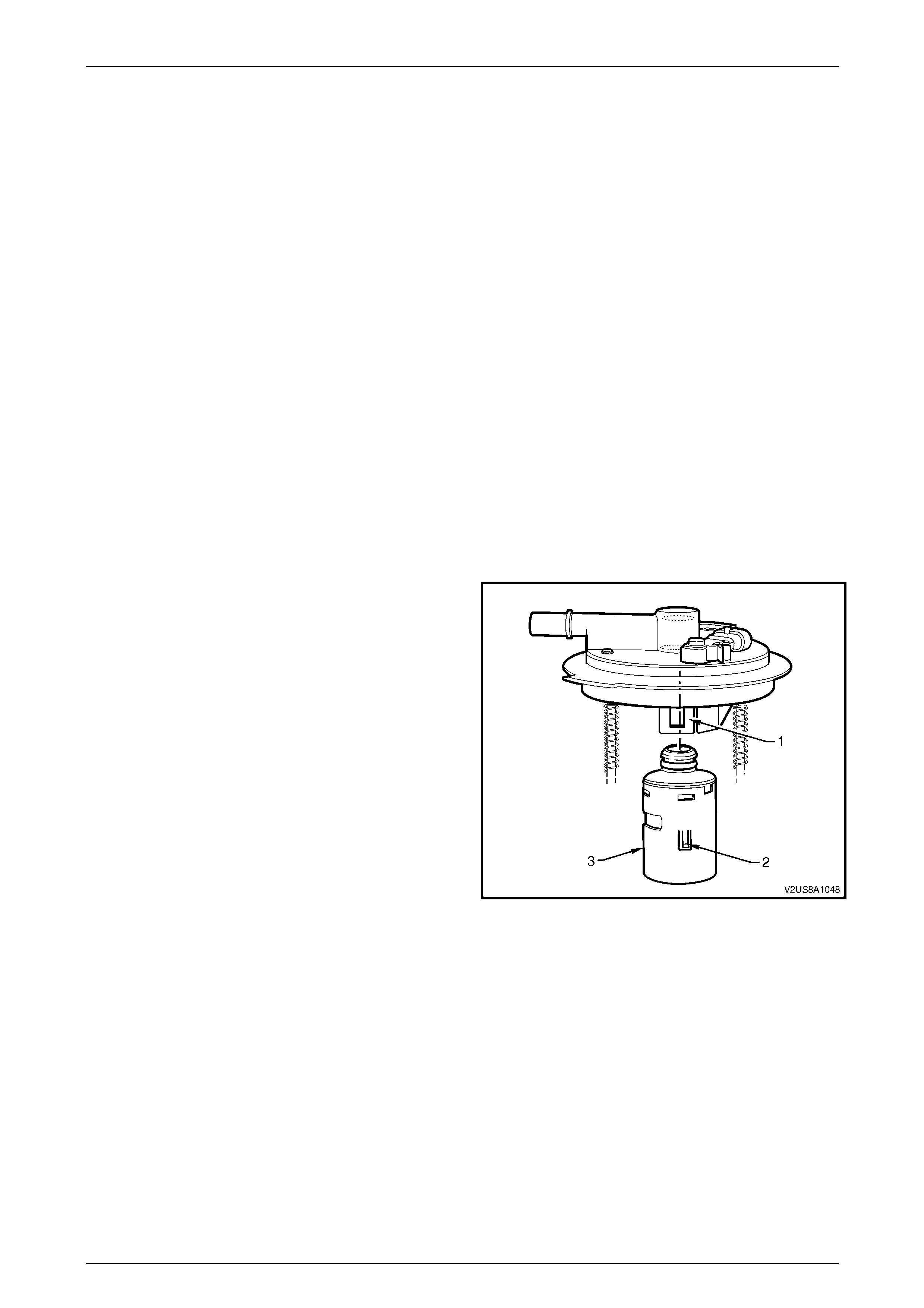

3.8 Modular Fuel Pump And Strainer

Assembly

The modular fuel pump and strainer assembly is contained within the fuel filter assembly.

Remove

1. Remove and disassemble the modular fuel pump and sender assembly to access the fuel pump and strainer

assembly, refer to 3.6 Modular Fuel Pump And Sender Assembly.

2. Using a suitable blade or a flat-bladed screwdriver,

remove the 'easy washer' (1) from the fuel pump end cap

post.

3. Remove the suction filter (2).

Figure 8A1 – 38

NOTE

Do not over tighten the vice grips as this may

damage the fuel pump.

4. Clamp the protruding end of the modular fuel pump (1)

in a soft jawed vice (2) to support the fuel filter and

pump assembly (3) in place.

5. Insert a pair of medium sized flat bladed screwdrivers

through each of the service holes in the fuel filter

assembly and firmly slide the blade between the fuel

pump end cap and the internal fuel filter clips that hold

the fuel pump in place.

Figure 8A1 – 39

Fuel and Exhaust Systems Page G-39

Page G-39

6. Push the screwdrivers in far enough so that the internal

fuel filter clips are deflected just free of each of the fuel

pump end cap retainer shoulders.

7. Whilst holding the screwdrivers in place with one hand,

manipulate the fuel filter assembly in an upward

direction to separate it from the fuel pump.

Figure 8A1 – 40

Reinstall

The procedure for reinstallation of the fuel pump and strainer assembly is the reverse of the removal procedure noting

the following:

NOTE

Check the 'easy washer' for serviceability and

replace if necessary.

NOTE

Upon installation of the modular fuel pump and

strainer assembly, only use the custom sized

O-rings as supplied with fuel pump and strainer

assembly replacement parts kit. Do not use off-

the-shelf O-rings. Refer to 3.11 Modular Fuel

Pump And Sender Assembly O-Rings for O-ring

specifications.

1. Ensure the 'easy washer' is firmly installed along the fuel pump end cap post and firmly pressed up against the

suction filter moulding.

2. Using hands only, locate the fuel pump in its correct orientation into the fuel filter.

3. Push the fuel pump firmly into place and lock the fuel pump into the fuel filter.

Fuel and Exhaust Systems Page G-40

Page G-40

3.9 Fuel Filter Assembly

The fuel filter is contained within the modular fuel pump and sender assembly and forms the moulded housing for the fuel

pump. The fuel filter is accessible upon removal of the modular fuel pump from the modular fuel pump and strainer

assembly, refer to 3.8 Modular Fuel Pump And Strainer Assembly in this Section.

NOTE

Upon installation of the fuel filter assembly, only

use the custom sized O-rings as supplied with

fuel filter assembly replacement parts kit. Do not

use off-the-shelf O-rings. Refer to 3.11 Modular

Fuel Pump And Sender Assembly O-Rings for O-

ring specifications.

Fuel and Exhaust Systems Page G-41

Page G-41

3.10 Fuel Pressure Regulator

Remove

NOTE

Refer to 2.1 General Information in this Section

for O-ring service part specifications.

1. Remove the modular fuel pump and sender assembly from the fuel tank and remove the modular fuel pump and

sender assembly cover from the reservoir to access and remove the fuel pressure regulator holder, refer to the

disassemble procedure within 3.6 Modular Fuel Pump And Sender Assembly.

NOTE

Removal of the fuel pressure regulator can be

achieved without disassembly and removal of the

fuel level sensor assembly or disconnection of the

fuel pump motor or fuel level sensor patch wiring

harness connectors.

NOTE

Do not bend the earthing terminal on the pressure

regulator holder; this can be easily damaged or

broken.

2. Remove the copper earthing terminal attached to the

terminal connector moulding (9) of the pressure

regulator holder using a pair of pointy nose pliers.

3. Remove the retaining clip (6) from the top of the

pressure regulator holder and place in a safe location

away from the immediate worksite.

4. Using a flat-bladed screwdriver, prise the pressure

regulator (4) from the pressure regulator holder (1).

5. If necessary, remove the nylon spacer (3) and remove

and tag the regulator to holder O-ring (2).

6. If necessary, remove and tag the fuel filter to pressure

regulator holder O-ring (7), the pressure regulator

holder to reservoir jet pump O-ring (8) and the fuel

pressure regulator O-ring (5) and place in a safe

location away from the immediate worksite.

Figure 8A1 – 41

Reinstall

The procedure for reinstallation of the pressure regulator is the reverse of the removal procedure noting the following:

NOTE

Upon installation of the fuel pressure regulator,

only use the custom sized O-rings as supplied

with fuel pressure regulator replacement parts kit.

Do not use off-the-shelf O-rings. Refer to

3.11 Modular Fuel Pump And Sender Assembly

O-Rings for O-ring specifications.

Fuel and Exhaust Systems Page G-42

Page G-42

3.11 Modular Fuel Pump And Sender

Assembly O-Rings

O-rings seal various connections in the modular fuel pump and sender assembly and are made of a special material.

Always service the O-ring seals with the correct service part as provided with the service kit. Refer to Figure 8A1 – 42 to

identify O-ring service part specifications.

O-RING SPECIFICATIONS

O-RING a (mm) b (mm)

1 8.20 3.50

2 7.52 3.53

3 15.4 2.90

4 4.25 2.60

5 8.20 3.50

6 8.20 3.50

7 8.20 3.50

Figure 8A1 – 42

Fuel and Exhaust Systems Page G-43

Page G-43

3.12 Fuel Tank Pressure Sensor

The fuel tank pressure sensor is press fitted to the modular fuel tank and sender assembly cover. To access the fuel tank

pressure sensor for service purposes, full removal of the fuel tank from the vehicle is recommended. For information on

fuel tank pressure sensor and fuel tank leak test diagnostics, refer to Section 6C3-2C Functional Checks in the MY2003

VY & V2 II Series Service Information.

Remove

1. Remove the fuel tank assembly from the vehicle and remove the modular fuel pump and sender assembly from the

fuel tank to access the fuel tank pressure sensor, refer to 3.6 Modular Fuel Pump And Sender Assembly.

NOTE

Removal of the fuel pressure regulator can be

achieved without disassembly and removal of the

fuel level sensor assembly or disconnection of the

fuel pump motor or fuel level sensor patch wiring

harness connectors.

NOTE

Do not pull or lever the fuel pressure sensor out

from the connector end as damage the may occur

to the sensor body.

2. Grasp the modular fuel pump and sender assembly

cover (1) in hand and from the underside, apply thumb

pressure (3) to the opening port (2) of the fuel tank

pressure sensor. To aid removal, pull the head of the

sensor body directly outwards from the cover.

Figure 8A1 – 43

Reinstall

Installation of the fuel tank pressure sensor is the reverse of the removal procedure, noting the following:

1. Check the rubber seal around the collar of the pressure sensor opening port (2) for damage and replace complete

pressure sensor assembly if necessary, refer to Figure 8A1 – 43.

2. Align the fuel tank pressure sensor with the opening port and guide support of the modular fuel pump and sender

assembly cover, and press firmly into place.

Fuel and Exhaust Systems Page G-44

Page G-44

3.13 Fuel Fill Limiter Vent Valve Assembly

(FLVV)

The fill limiter vent valve assembly is clipped into the underside of the modular fuel pump and sender assembly cover. To

access the fill limiter vent valve assembly for service purposes, full removal of the fuel tank from the vehicle is

recommended.

NOTE

The fill limiter vent valve assembly is serviced as

a complete assembly, and as such, should not

require further disassembly upon removal from

the modular fuel pump and sender assembly.

Remove

1. Remove the fuel tank assembly from the vehicle and remove the modular fuel pump and sender assembly from the

fuel tank to access the fill limiter vent valve, refer to 3.6 Modular Fuel Pump And Sender Assembly.

NOTE

Removal of the fill limiter vent valve can be

achieved without disassembly and removal of the

fuel level sender assembly or disassembly of the

fuel pump motor or fuel level sender patch wiring

harness connectors.

2. Lever each of the two modular fuel pump and sender

assembly cover tangs (1) clear of the vent valve

locators (2) whilst pulling the fill limiter vent valve

assembly (3) out to remove. If necessary, use a flat

blade screwdriver to assist leverage of the tangs.

Figure 8A1 – 44

Reinstall

Installation of the fuel limiter vent valve assembly is the reverse of the removal procedure, noting the following:

1. Align the fill limiter vent valve into the modular fuel pump and sender assembly cover and press firmly to click into

place.

Fuel and Exhaust Systems Page G-45

Page G-45

3.14 Fuel Filler Cap

The fuel filler cap is a 'screw on' type, with an integrated tightening torque limiting mechanism. When installing the cap,

tighten it until a ratcheting (clicking) sound is heard, indicating the cap is properly tightened. The fuel tank filler cap is

tethered to the fuel filler pocket. The fuel tank filler cap requires a quarter of a turn in order to be removed.

If a fuel tank filler cap requires replacement,

use only a fuel tank filler cap with the same

features. Failure to use the correct fuel tank

filler cap can result in a serious malfunction

of the emission control system.

Remove

1. Untwist and remove the fuel filler cap (1) from the fuel

filler neck opening.

2. Use a flat blade screwdriver to prise the fuel filler cap

tether line fastener (2) from its mounting hole.

3. Plug the fuel filler opening with a suitable material to

prevent the possibility of foreign material entering into

the fuel tank.

Figure 8A1 – 45

Reinstall

Installation of the fuel filler cap is the reverse of the removal procedure, noting the following:

NOTE

Check the fuel filler cap for serviceability and

replace where necessary.

Fuel and Exhaust Systems Page G-46

Page G-46

4 Specifications

Fuel Tank Capacity:.............................................................................70 litres

Fuel Tank Material:.............Pressed steel with high density polyethylene shell

Fuel Filler Location:...........................................Right-hand rear quarter panel

Fuel Pump Type:.......................................................................Single Turbine

Pressure Regulator Location: Inside modular fuel pump and sender assembly

Fuel Pump Location:..............Inside modular fuel pump and sender assembly

Fuel Pump Regulated Pressure:.......................................400 kPa (+/– 3 kPa)

Minimum Fuel Pump Flow Capacity

(at regulated pressure):..............................................2.95 L/min @ 13.5 volts

..................................................2.33 L/min @ 12 volts

Fuel Pump Current Draw

(steady state at regulated pressure):..............................11.0 Amps maximum

Fuel and Exhaust Systems Page G-47

Page G-47

5 Torque Wrench Specifications

Fuel Tank Mounting Strap Nut - Upper...............................................20.0 Nm

Fuel Tank Mounting Strap Nut - Lower...............................................40.0 Nm

Canister Mounting Nut.................................................................5.0 – 8.0 Nm

Fuel Filler Neck to Filler Pocket Mounting Nut......................................5.0 Nm

Modular Fuel Pump and Sender Assembly Earthing

Terminal to Fuel Tank Stud Flanged Earthing Nut................................7.0 Nm

Stone Guard Securing Bolt..........................................................5.0 – 7.0 Nm

Stone Guard Securing Nut ..........................................................1.5 – 2.5 Nm

Fuel and Exhaust Systems Page G-48

Page G-48

6 Special Tools

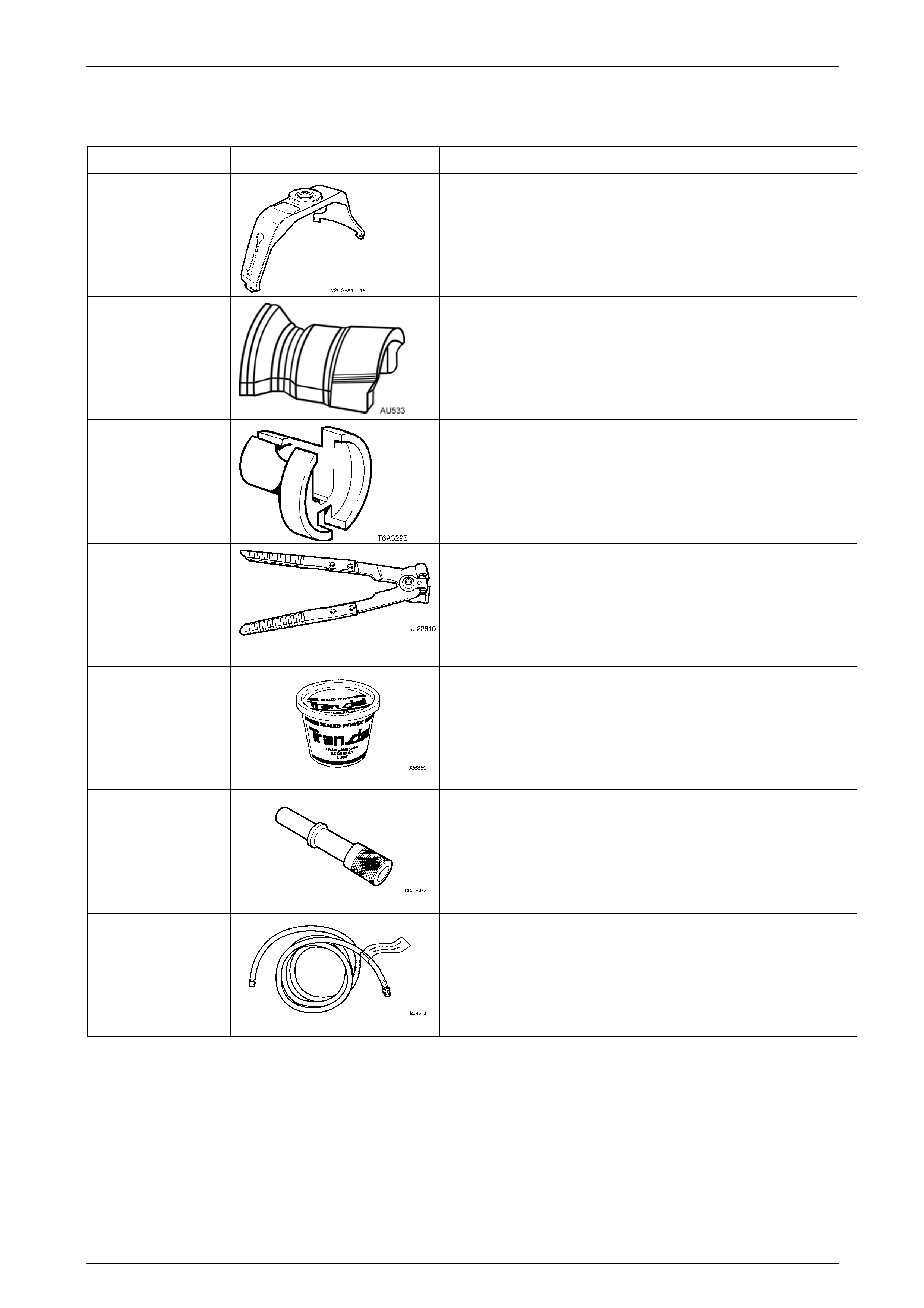

TOOL NUMBER ILLUSTRATION DESCRIPTION CLASSIFICATION

J45722

MODULAR FUEL PUMP AND

SENDER ASSEMBLY LOCKING RING

REMOVE AND INSTALL TOOL

Used to provide positive holding of fuel

tank lock ring for removal and

installation with 1/2 inch breaker bar.

Mandatory

AU533

QUICK-CONNECT FITTI NG RELEASE

TOOL

Released in two sizes; Red for

5/16-inch fittings and Blue for 3/8-inch

fittings.

Also available commercially

Desirable

7371 QUICK-CONNECT RELEASE TOOL –

3/8-INCH

Used for releasing fuel hose quick

connects at the dash panel and fuel rail

connections, after the fuel system has

been depressurised.

Mandatory

J22610 KEYSTONE CLAMP PLIERS

Used to remove and fasten ear-type

clamps.

Available

J36850

TRANSJEL LUBRICANT

Used to lubricate fuel tank siphon hose

during fuel tank drain/siphon

procedures.

Desirable

J44284-2

FUEL FLAPPER DOOR HOLDER

Holds open fuel filler neck flapper door

to allow fuel tank siphon hose to be fed

down into fuel filler neck.

Mandatory

J45004-1

FUEL TANK SIPHON HOSE

Flexible fuel siphoning hose with

earthing wire and threaded vacuum

pump fitting.

Mandatory