Engines Page E-1

Page E-1

Section E

Engines

ATTENTION

HSV vehicles are equipped with a Supplemental Restraint System (SRS). An SRS consists of seat belt pre-

tensioners (fitted to all front seats), a driver’s-side air bag, a passenger’s-side air b ag and left and right hand

side air bags. Refer to CAUTIONS, Section 12M, in Volume 12 of the Holden VYII series Service Manual before

performing any service operation on or around SRS components, the steering mechanism or wiring. Failure

to follow the CAUTIONS could result in personal injury or unnecessary SRS system repairs.

1 Purpose...............................................................................................................................................E-2

2 Engines - General Information..........................................................................................................E-3

Engine Dress Covers..........................................................................................................................................E-3

Engine Air Induction System.............................................................................................................................E-3

Specific HSV Engine Components....................................................................................................................E-4

3 Clubsport, R8 And Senator 285 LS1.................................................................................................E-5

3.1 General Description............................................................................................................................................E-5

3.2 Service Operations .............................................................................................................................................E-6

4 GTS 300 C4B LS1 ...............................................................................................................................E-9

4.1 General Description............................................................................................................................................E-9

4.2 Service Operations ..........................................................................................................................................E-11

4.3 Engine Assembly – Service..............................................................................................................................E-12

Techline

Techline

Engines Page E-2

Page E-2

1 Purpose

The purpose of this supplement is to provide information on the various engine packages fitted to the HSV VYII models.

This information is designed to supplement that given in the Holden VYII series Service Manuals, and details are given

where differences occur between the HSV models, and standard Holden models. A series of instruction drawings detail

the design changes and indicate specific part numbers, fitting instructions and relevant notes for vehicle servicing.

NOTE:

If specific technical data on a HSV model is not

contained in this supplement, obtain data for that

model from the relevant Holden VYII series

Service Manual Supplement. References are

made throughout this section to Holden Service

Manuals, to assist in providing information for

specific service operations.

When hoisting (or jacking) HSV models,

ensure that the liftin g head of the hoist lifts on

the chassis before the arm of the hoist

contacts the side-skirt

Engines Page E-3

Page E-3

2 Engines - General Information

VYII sees the carry over of the two Chevrolet Generation 111 engines introduced into the HSV range during VT2.

These engines have both received upgrades to the base engine as manufactured by GM, resulting in improvements over

the VT2 engine.

The 285 LS1 engine is not modified internally by HSV, and uses an HSV specific calibration to optimise the benefits of

the specific HSV exhaust and inlet systems. As part of the development process, these changes have been proven

through extensive testing throughout Australia, as is the case with all engines fitted to HSV models.

The 300kW C4B engine is fitted with unique HSV components, such as camshaft, pistons, valve train and the like. It

should be noted however, that assembly procedures, torque settings, engine diagnosis, valve timing procedures and

other parameters are the same as for the standard GMHA product unless stated otherwise in this supplement. The

various HSV engines are discussed in the following paragraphs.

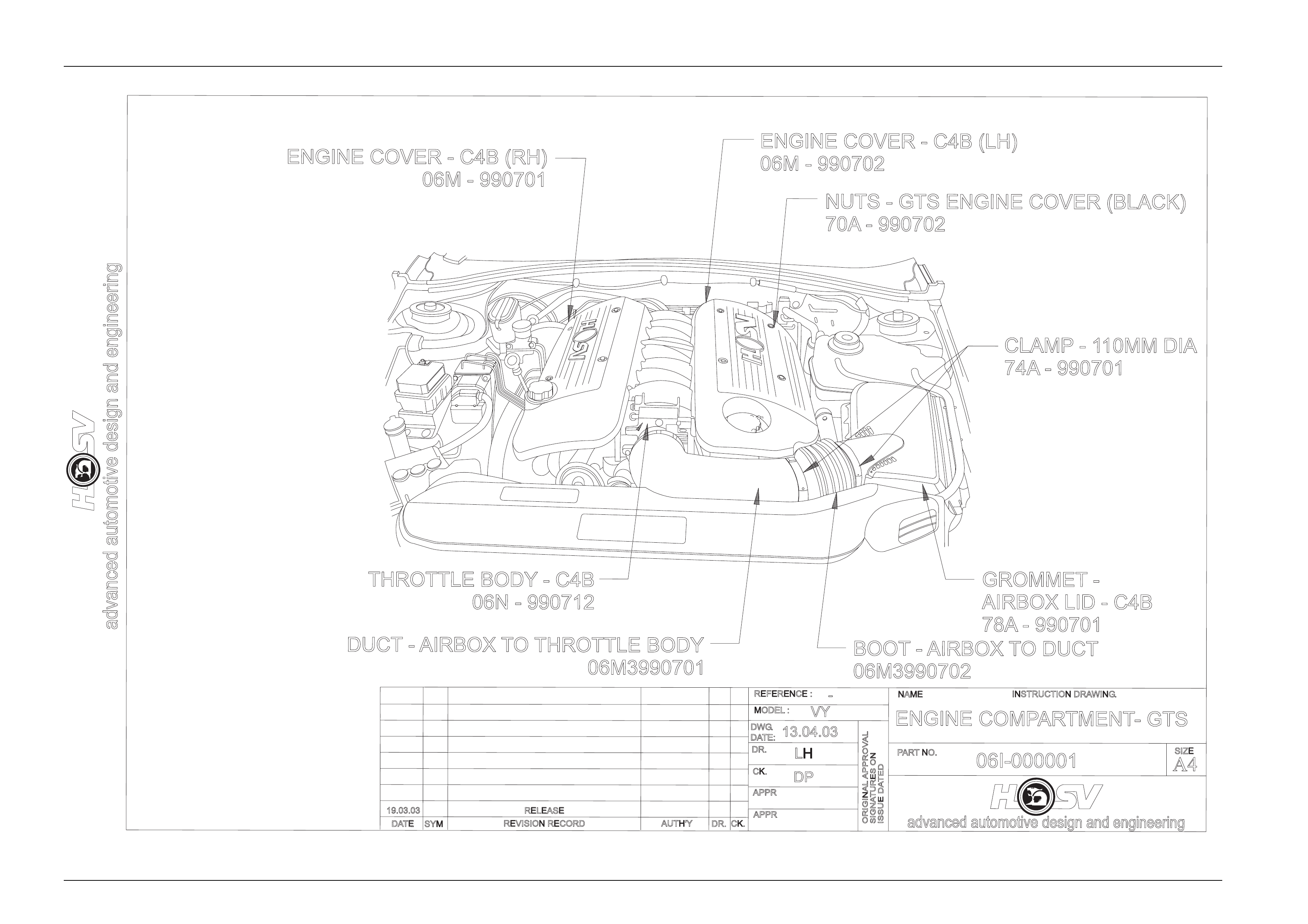

Engine Dress Covers

The HSV LS1 V8 engine is fitted with a specific decorative engine cover. This is a large one piece plastic cover that

encases the fuel rail and coil packs, as well as the inlet manifold and throttle body. The cover includes a moulded-in HSV

Lion and Helmet logo, and is painted black, with silver highlights.

The HSV C4B LS1 V8 engine comes with specifically designed engine covers, that cover the two banks of the engine,

leaving the centre of the inlet manifold exposed. The covers are painted and moulded in a red polypropylene copolymer,

and incorporate HSV logos and 300kW signage.

LS1

06M-990601 COVER ASM: LS-1 ENGINE (SILVER HIGHLIGHT)

C4B LS1

06M-990701 COVER - ENGINE RH-GTS

06M-990702 COVER - ENGINE LH-GTS

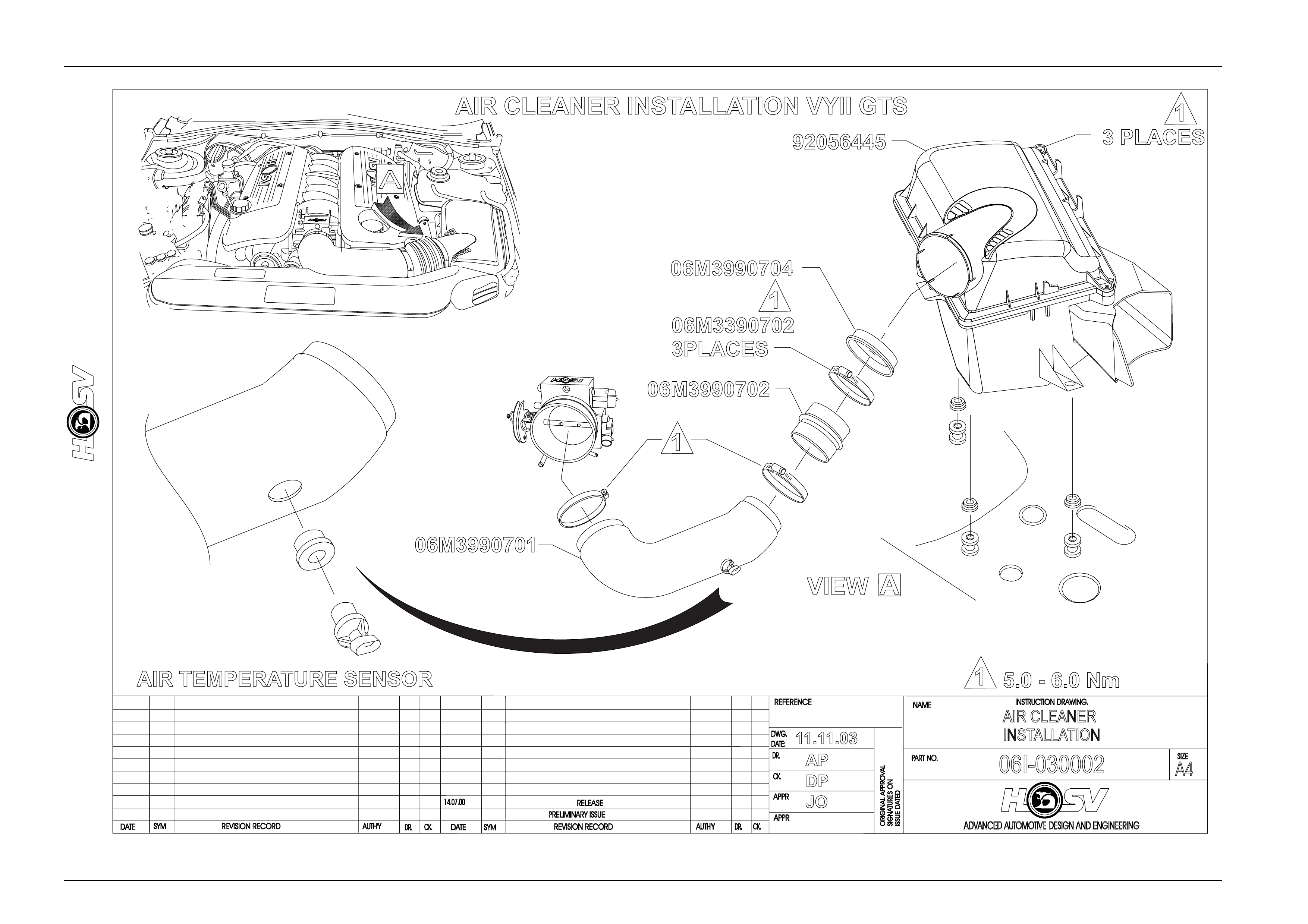

Engine Air Induction System

The air induction system on the HSV C4B LS1(300kw) varies from the standard Holden and HSV 285 kw system, in that

it does not use the original equipment Mass Air Flow (MAF) Sensor. Instead, the engine runs on a speed/density based

calibration system, using a Manifold Absolute Pressure (MAP) Sensor, Intake Air Temperature (IAT) Sensor and engine

rpm to calculate the mass of air entering the engine. Due to this change, the C4B engine uses a specific duct and boot

combination from the airbox to the throttle body. As part of these changes, the IAT sensor is relocated to the inlet duct,

as this gives faster response to changing intake air temperature changes.

The rest of the intake system is common with the 285 LS1 introduced with VYII, and this incorporates much of the

standard Holden system, with the difference being concentrated on ensuring the engine receives as much cold air as

possible. This was found to give the greatest performance advantage, and also helped reduce the performance lost due

to stop start warm weather driving.

The intake system on the HSV LS1 uses the standard Holden air filter element, Mass Air Flow (MAF) Sensor and Inlet Air

Temperature (IAT) sensor. Service requirements for the filter are described in the Holden service manual, and no

adjustment is possible on the MAF sensor.

To remove the HSV inlet duct, it is necessary to release the coolant system surge tank from its locating studs, then pull

the airbox base away from its locating studs, pulling the rear away first, and then away from the inlet duct. To remove the

duct, it is best to take the outboard edge of the duct and rotate it inboard and up to clear bodywork, then pull out.

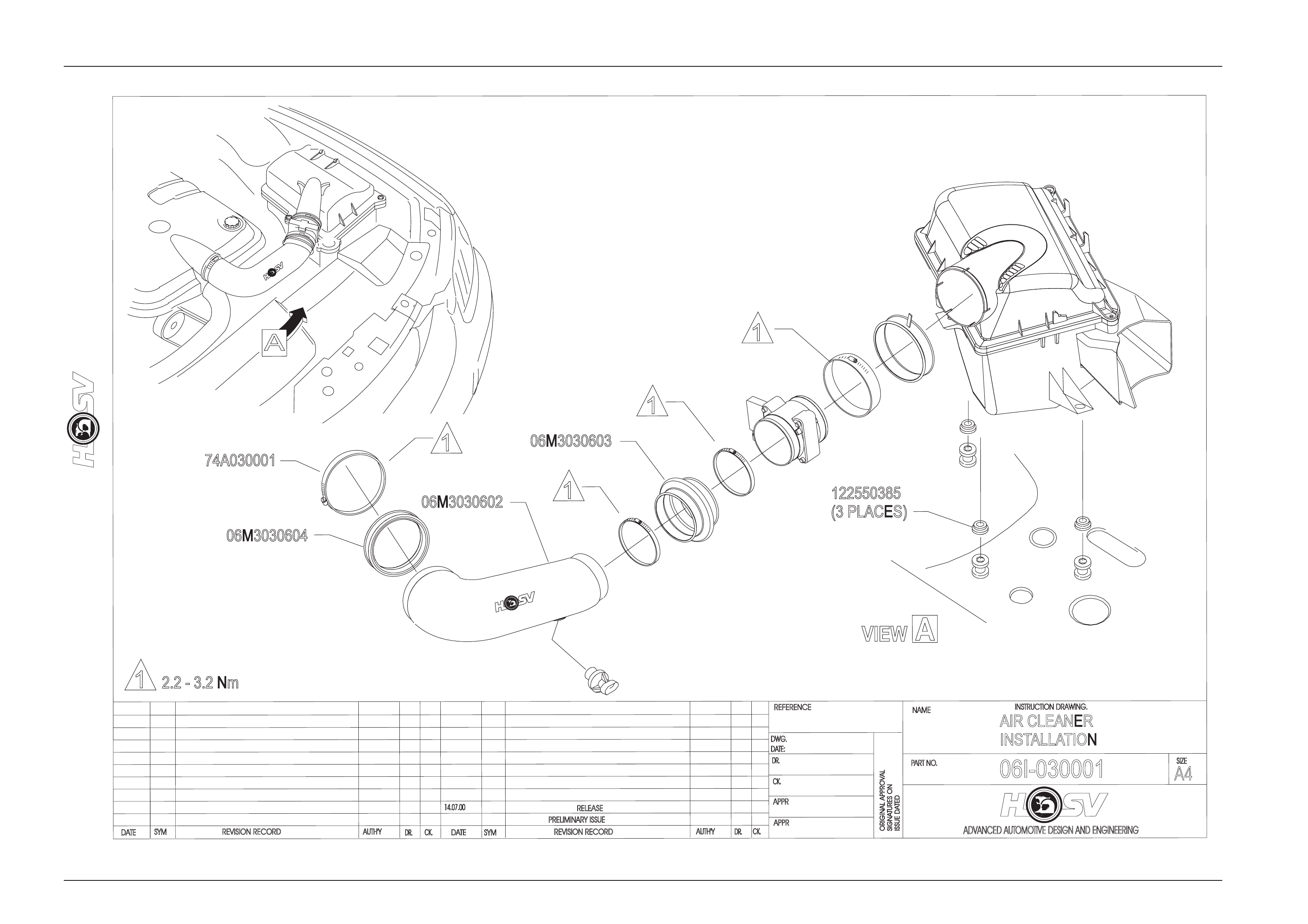

For replacement part numbers see Drawings 06I-030001, 06I-000001, 06I-030002.

Engines Page E-4

Page E-4

Specific HSV Engine Components

As the HSV C4B LS1 engine is a specific assembly for HSV, there are several components that warrant a specific

mention in this section. These components are the specific valve springs, which are of a constant diameter, and made

from an oval formed wire, specific Titanium valve spring retainers to match the springs, and a new, high lift camshaft.

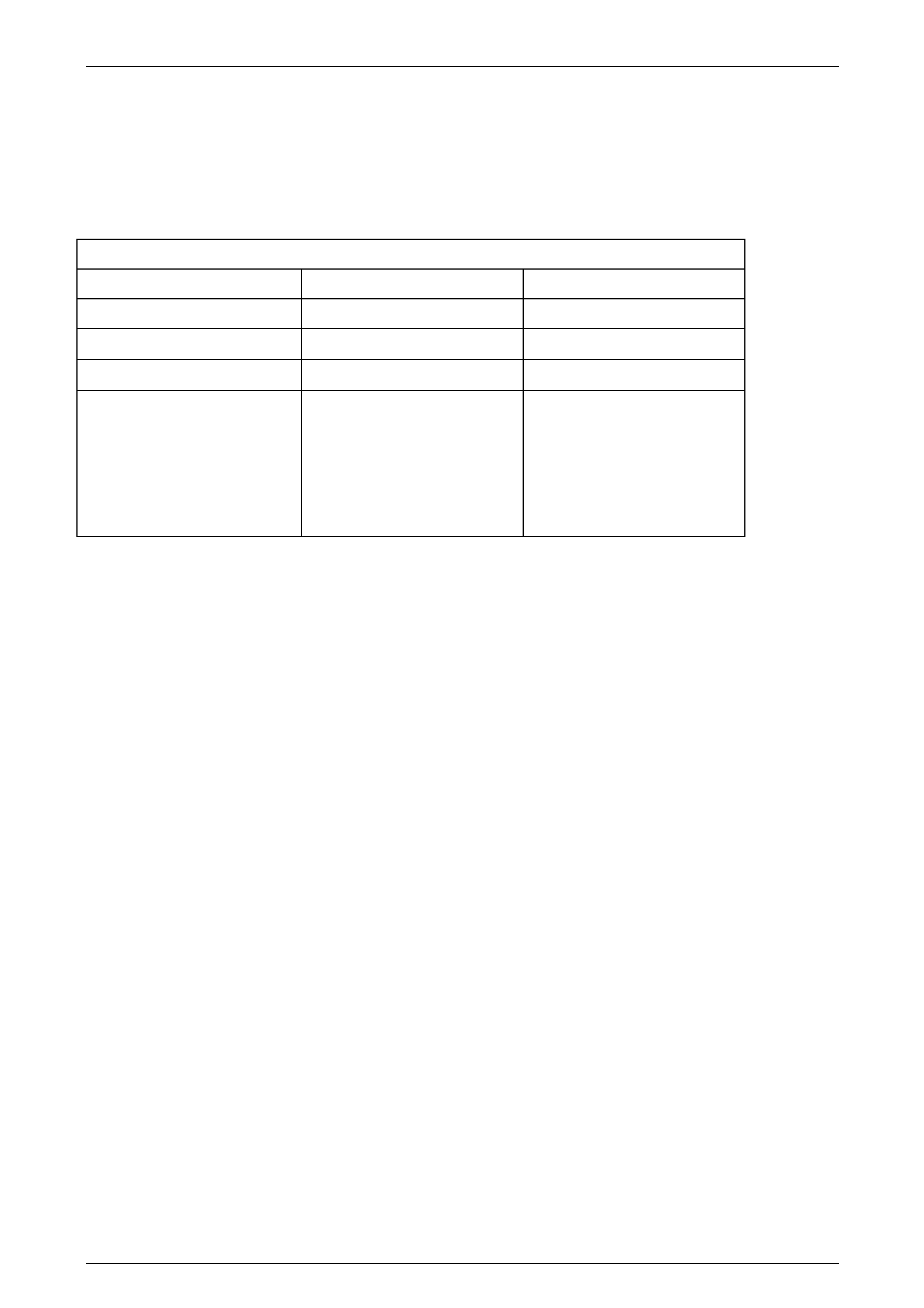

Details of this new camshaft are detailed in the table below:

HSV C4B CAMSHAFT SPECIFICATION

INTAKE EXHAUST

Lobe Lift 8.331mm (0.327”) 8.356mm (0.329”)

Duration at 1.27mm (0.050”) lift 184.7° 189.0°

Duration 278.8° 283.0°

Valve Timing at 1.27mm (0.050”)

lift

-Open

-Close

25.1° ATDC

29.8° ABDC

31.3° BBDC

22.3° BTDC

Engines Page E-5

Page E-5

3 Clubsport, R8 And Senator 285

LS1

3.1 General Description.

All HSV VYII V8 models use the new, Chevrolet developed LS1 engine. This engine is common with the Holden Gen III

V8 engine, and has a capacity of 5667m3, produced by a bore of 99.00mm and a stroke of 92.00 mm. The compression

ratio for this engine is 10.1:1.

The base engine design is that of a 90° V8, two valve per cylinder engine. The engine features an aluminium block and

heads, with cast iron sleeves cast into the block

during manufacture, while the heads have powdered metal valve guides and seats pressed in place.

For more information regarding the LS1 engine, see the relevant section in Holden's VY Service information.

The HSV LS1 engine has an optimised Cold air Induction System, including a

Low Restriction large diameter ‘Zip Tube’,a Low Restriction Exhaust System and an Optimised Engine Management

System. These improvements allow the engine to develop 285kW at 5,800 rpm and 510Nm at 4,800 rpm.

Engines Page E-6

Page E-6

3.2 Service Operations

The HSV LS1 engine fitted to ClubSport,Senator and Maloo models are to be serviced in accordance with the procedures

detailed in the Holden VYII series service information.

Engines Page E-7

Page E-7

DATE

ISSUE DATED

AUTH'Y

CK.

SYM

AUTH'Y

RELEASE

REVISION RECORD

DATE

SYM

SIGNATURES ON

ORIGINAL APPROVAL

DR.

14.07.00

ADVANCED AUTOMOTIVE DESIGN AND ENGINEERING

06I-030001

INSTRUCTION DRAWING.

A4

SIZE

AIR CLEANER

INSTALLATION

06M3030603

06M3030602

06M3030604

2.2 - 3.2 Nm

74A030001

122550385

(3 PLACES)

REVISION RECORD

PRELIMINARY ISSUE

CK.

NAME

PART NO.

CK.

REFERENCE

DWG.

DR.

DATE:

APPR

APPR

DR.

07.11.03

AP

DP

JO

A

A

VIEW

1

1

1

1

1

Engines Page E-8

Page E-8

DATE

ISSUE DATED

AUTH'Y

CK.

SYM

AUTH'Y

RELEASE

REVISION RECORD

DATE

SYM

SIGNATURES ON

ORIGINAL APPROVAL

DR.

14.07.00

ADVANCED AUTOMOTIVE DESIGN AND ENGINEERING

06I-030002

INSTRUCTION DRAWING.

A4

SIZE

AIR CLEANER

INSTALLATION

REVISION RECORD

PRELIMINARY ISSUE

CK.

NAME

PART NO.

CK.

REFERENCE

DWG.

DR.

DATE:

APPR

APPR

DR.

11.11.03

AP

DP

JO

AIR CLEANER INSTALLATION VYII GTS

AIR TEMPERATURE SENSOR 5.0 - 6.0 Nm

3 PLACES

92056445

06M3990704

06M3990702

06M3990701

06M3390702

3PLACES

A

VIEW A

1

1

1

1

Engines Page E-9

Page E-9

4 GTS 300 C4B LS1

4.1 General Description

The HSV GTS is the second tier engine to HSV. With a Holden production option designation of C4B, this engine is

based on the standard LS1 engine common with the 260kW models. The differences over the LS1 engine are related to

cylinder head and camshaft modifications.

The engine hardware was developed in conjunction with Callaway Cars in the USA, and the rest of the vehicle

development and validation carried out by HSV.

The changes included a specific camshaft, upgraded valve springs and titanium valve spring retainers, stainless steel

intake and exhaust valves, revised cylinder head porting and combustion chamber modifications, and a specific, larger

bore machined throttle body. The throttle body is the easiest identifier for the engine, as it is anodised bright red.

Additional marking is also evident on the cylinder heads, where the C4B designation is machined into the head, on the

exhaust port face.

The swept volume of the C4B LS1 engine is unchanged from the LS1 engine, although, due to the combustion chamber

modifications the compression ratio has been lowered slightly to 9.95:1. This gives improved engine performance across

the entire speed range, as it allows more spark advance, due to less knock sensitivity, to be calibrated into the engine,

particularly at low to medium engine speeds.

The HSV C4B LS1 engine uses a high flow induction system, that does not require a Mass Air Flow Meter, and

incorporates this with the optimised Cold air Induction System, a Low Restriction Exhaust System (including a specific,

straight through design rear muffler) and an Optimised Engine Management System. These improvements allow the

engine to develop 300kW at 6,000 rpm and 510 Nm at 4,800 rpm.

Techline

Engines Page E-10

Page E-10

advanced automotive design and engineering

RELEASE

REVISION RECORD

SYM

DATE

INSTRUCTION DRAWING.

advanced automotive design and engineering

SIGNATURES ON

ISSUE DATED

ORIGINAL APPROVAL

AUTH'YCK.

DR.

APPR

VY

LH

13.04.03

APPR

CK.

DR.

MODEL :

DWG.

DATE:

REFERENCE :

PARTNO.

-

NAME

ENGINE COMPARTMENT- GTS

A4

SIZE

19.03.03

06I-000001

DP

DUCT -AIRBOX TOTHROTTLE BODY

06M3990701

THROTTLE BODY - C4B

06N - 990712

BOOT -AIRBOX TO DUCT

06M3990702

GROMMET -

AIRBOX LID - C4B

78A - 990701

CLAMP -1

10MM DIA

74A - 990701

NUTS - GTS ENGINE COVER (BLACK)

70A - 990702

ENGINE COVER - C4B (LH)

06M - 990702

ENGINE COVER - C4B (RH)

06M - 990701

Engines Page E-11

Page E-11

4.2 Service Operations

The HSV C4B LS1 engine fitted to the VY GTS is to be serviced in accordance with the procedures detailed in the VT

Series II Service Information however, due to the deletion of the MAF sensor, the following service bulletin was released

by HSV.

Dealer Bulletin - HSV GTS MAF Sensor Deletion

As part of the modifications made by HSV to achieve the 300kW output of the C4B engine, it was decided to use the less

restrictive Speed/Density calibration system. This allowed HSV to remove the Mass Air Flow (MAF) Sensor from the

intake system, removing the restriction it creates at high engine speeds advance requirements of the engine by using a

software model. This model incorporates inputs from the Manifold Absolute Pressure (MAP) Sensor, along with the Inlet

Air Temperature (IAT) Sensor and the engine rpm to predict airflow rate and volume into the engine, and therefore

fuelling requirements.

One effect of this system is that the engine no longer runs on 2 separate spark maps, resulting in the potential for some

audible knock under certain conditions when using 91 Ron Unleaded. It should be noted that the engine still runs an

advanced knock control, and a level of detonation will not harm the engine.

When carrying out diagnostic work on the HSV VY GTS, it is important that you are aware that the PCM will always log

Diagnostic Trouble Code 0102-Mass Air Flow Sensor Circuit Low Frequency. The calibration has been modified to

prevent the Malfunction Indicator Lamp from illuminating at this DTC the Instrument will also log an fault code in this case

DTC 19, which indicates that the instrument has detected a fault code in the PCM.

HSV GTS vehicles are also fitted with a PCM containing a specific engine calibration. This PCM is serviced in the same

manner as that for the HSV LS1 PCM.

For calibration details use TECH 2 to obtain data from PCM. Connect to TIS 2000, go to Service Program System and

check for calibration update. If vehicle has latest calibration no changes will be permitted

Engines Page E-12

Page E-12

4.3 Engine Assembly - Service

Specific HSV components that have been included in the LS1 C4B 300 engine assembly are detailed below. The part

numbers for these components are listed for servicing requirements.

06Z-030701 ENGINE ASM-LS1 C4B AS SHIPPED

06X-990702 CAMSHAFT-C4B

06X-990703 VALVE SPRING-C4B

06X-990704 RETAINER-VALVE SPRING

06X-990705 SHIM-0.030"

06X-990706 SHIM-0.015"

06X-990707 VALVE-XHAUST-C4B

06X-990708 VALVE-INLET-C4B

06A-990709 CYLINDER HEAD-MACHINED-C4B

06A-990710 CYLINDER HEAD ASM-C4B

06N-020712 THROTTLE BODY-C4B