Wheels, Tyres And Steering Wheel Page H-1

Page H-1

Section H

Wheels, Tyres And Steering Wheel

ATTENTION

HSV vehicles are equipped with a Supplemental Restraint System (SRS). An SRS consists of seat belt pre-

tensioners (fitted to all front seat s), a driver’s-side air bag, a passeng er’s-side air bag and left and right h and

side airbags. Refer to C AUTIONS, Section 12M, in Volume 12 of the Holden series VYII Ser vice Manual before

performing any service operation on or around SRS components, the steering mechanism or wiring. Failure

to follow the CAUTIONS could result in personal injury or unnecess ary SRS system repairs.

1 Purpose...............................................................................................................................................H-2

2 Wheels And Tyres ..............................................................................................................................H-3

2.1 General Description............................................................................................................................................H-3

3 Service Operations.............................................................................................................................H-4

3.1 Wheel and Tyre Balancing .................................................................................................................................H-4

3.2 HSV Wheel and Tyre Combinations..................................................................................................................H-5

3.3 Tyre Placard And Pressures............................................................................................................................H-11

3.4 Loading The HSV Maloo...................................................................................................................................H-12

3.5 HSV Temporary Spare Tyre..............................................................................................................................H-13

4 Steering Wheel..................................................................................................................................H-14

Techline

Wheels, Tyres And Steering Wheel Page H-2

Page H-2

1 Purpose

The purpose of this section is to provide information on the wheels, tyres and steering wheels fitted to the HSV VYII

model. The information is designed to supplement that given in the Holden VYII series Service Manual and details are

given where differences occur between the HSV models and sta ndard Holden models. A series of i nstruction dra wings

describe the design changes and indicate specific part numbers, fitting instructions and relevant notes for vehicle

servicing.

NOTE

If specific technical data on a HSV model is not

contained in this supplement, obtain data for that

model from the relevant Holden VYII series

Manual Supplement. References are made

throughout this section to Holden Service

Manuals, to assist in providing information for

specific service operations.

When hoisting (or jacking) HSV models,

ensure that the lifting h ead of the hoist lifts on

the chassis before the arm of the hoist

contacts the side-skirt

Wheels, Tyres And Steering Wheel Page H-3

Page H-3

2 Wheels And Tyres

2.1 General Description

HSV VYII models are fitted with alloy wheels dev eloped specifically for e ach HSV application. S everal types and sizes of

wheel are manufactured to suit the various applications and each wheel is manufactured from a single-piece alloy

casting.

NOTE

Specific wheel nuts are used to attach alloy

wheels to the vehicle. These nuts are fitted with

a plastic dress cap which must be removed prior

to undoing the wheel nuts.

HSV VYII wheels do not have a steel insert

and therefore require wheel nuts with a

flanged seat as per the VT, VT2 and VX wheel

nuts, 10B-970304. Do no t use VS wheels nuts

on HSV VY wheels.

Wheels, Tyres And Steering Wheel Page H-4

Page H-4

3 Service Operations

Alloy wheels fitted to all HSV vehicles are to be serviced in accordance with the procedures detailed in the relevant

Holden Service Manual, refer to Section 10 – Wheels And Tyres. In addition, particular care should be taken with the

surface finish of alloy wheels. The manufacturer recommends that alloy surfaces be treated the same as high-gloss

painted services to prevent corrosion and genera l deteriorat ion.

3.1 Wheel and Tyre Balancing

In order to balance the HSV Design wheels and t yre assemblies, refer to the relevant Hol den series Service Information,

refer to Section 10 – WHEELS AND TYRES of the VT Series II Service Information.

NOTE

HSV wheels are balanced with concealed

weights. The lateral distance between these

weights is considerabl y less than the actua l width

of the wheel. To achieve wheel balance within

specification with concealed balance weights, set

the balancing machine for a wheel width of 5.5".

Wheels, Tyres And Steering Wheel Page H-5

Page H-5

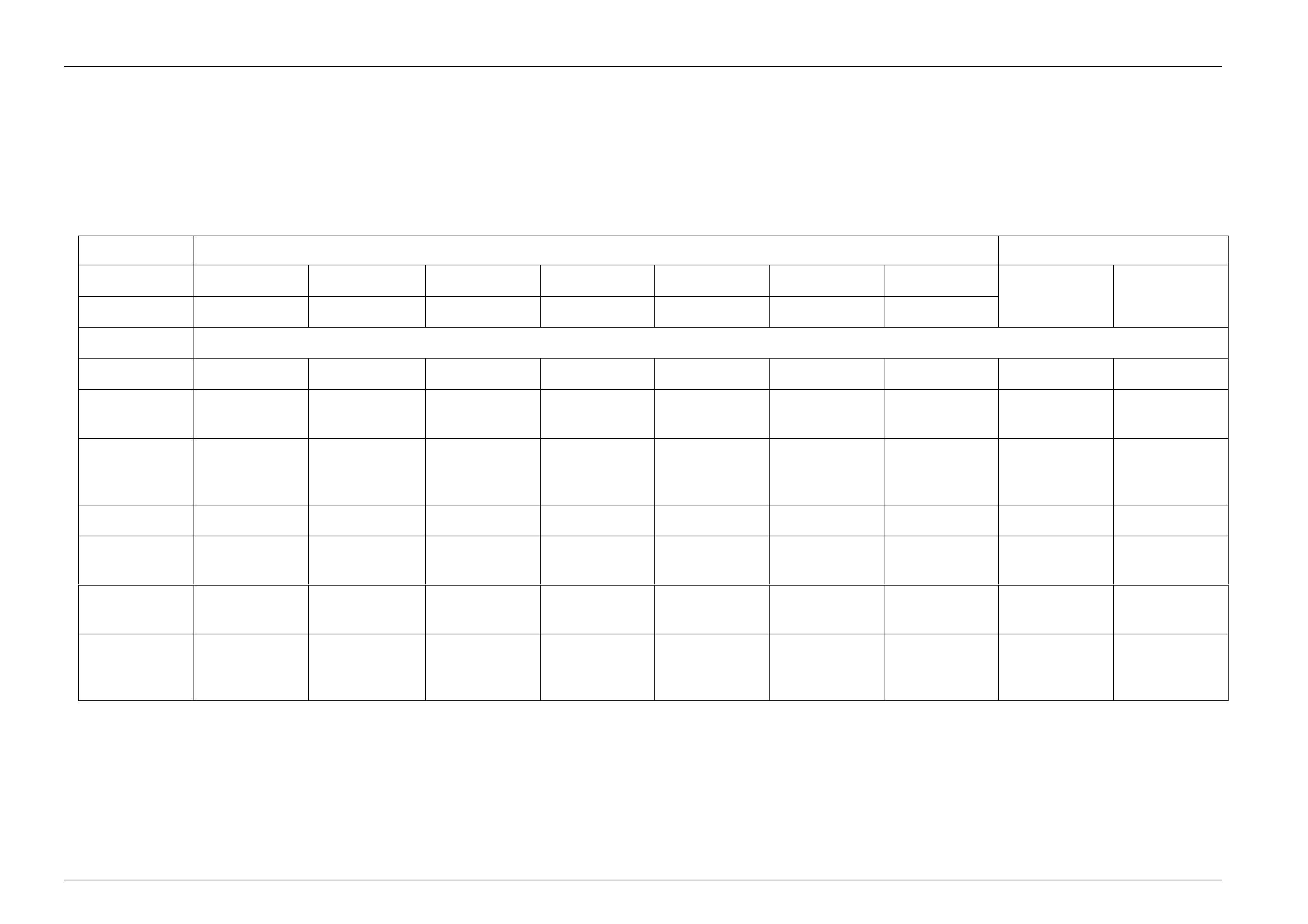

3.2 HSV Wheel and Tyre Combinations

The following HSV Wheels and tyre combination are fitted to VYII.

Refer to drawings 10I-020001, 10I-020002, 10I-020003, 10I-010002, 10I-020005.

VYII WHEEL AND TYRE MATRIX

WHEEL TYRE

WHEEL SIZE 18” X 8.00 19” X 8.00 19” X 8.00 18” X 8.00 19” X 8.00 18” X 8.00 19” X 8.00

PART NO 10B020601 10B000701SS 10B000701 10B020601C 10B020701 10B020801 10B020804 235/40 ZR18 245/35 ZR19

MODEL

VYII GTS S S

VYII

CLUBSPORT S O S O

VYII

CLUBSPORT

R8 S S

VYII MALOO S S

VYII MALOO

R8 S S

VYII

SENATOR O S S O

VYII

SENATOR

SIG O S O

Wheels, Tyres And Steering Wheel Page H-6

Page H-6

SECTION

100 - 125 Nm

A-A

advanced automotive design and engineering

RELEASE

1

INSTRUCTION DRAWING.

advanced automotive design and engineering

M.B

SIGNATURES ON

ISSUE DATED

ORIGINAL APPROVAL

APPR

VY

T.K

D.P

20.05.02

APPR

CK.

DR.

MODEL :

DWG.

DATE:

REFERENCE :

PARTNO.

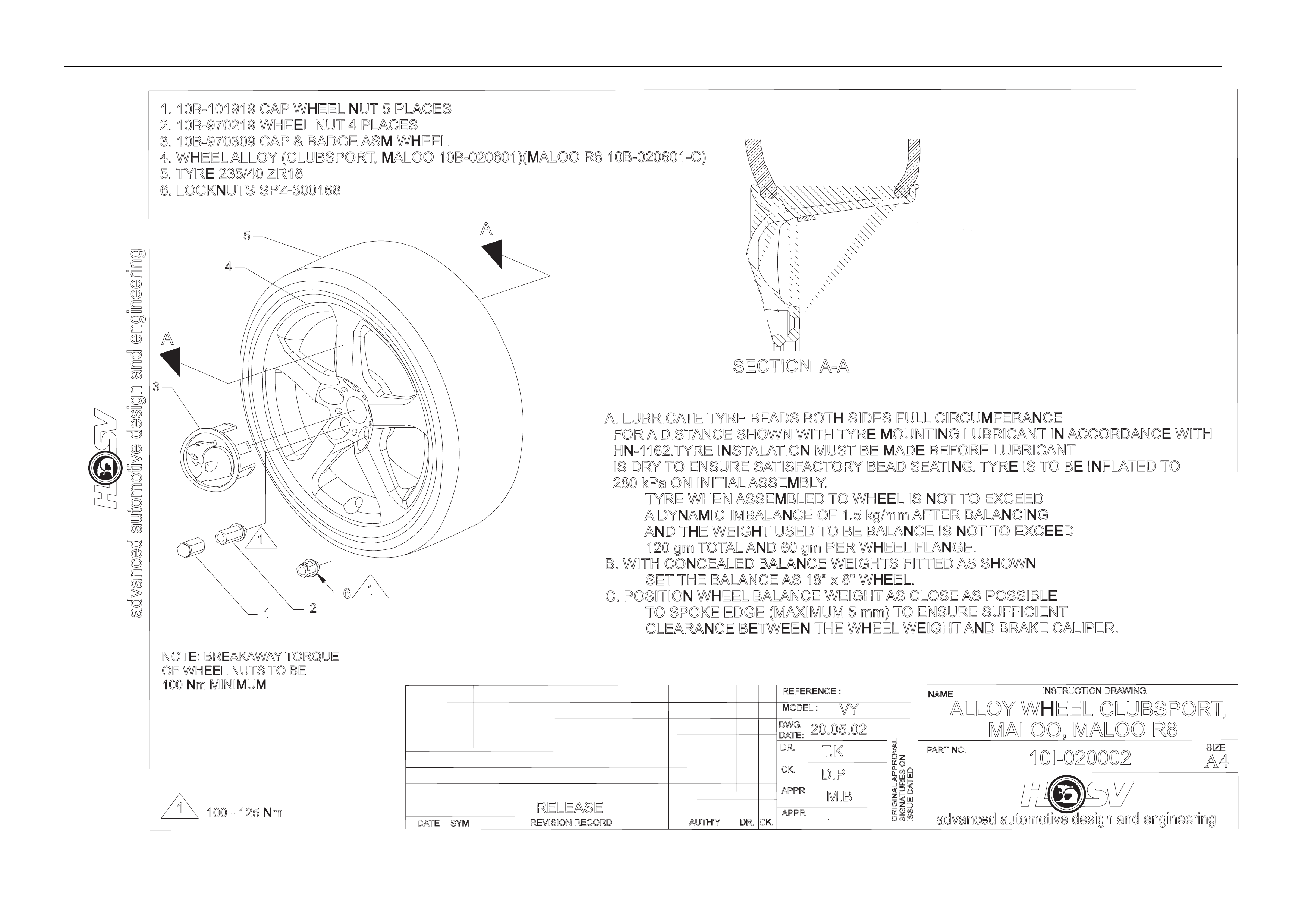

10I-020002

-

NAME

ALLOY WHEEL CLUBSPORT,

MALOO R8

MALOO,

A4

SIZE

REVISION RECORD

SYM

DATE AUTH'Y CK.

DR.

-

A. LUBRICATE TYRE BEADS BOTH SIDES FULL CIRCUMFERANCE

FOR ADISTANCE SHOWN WITH TYRE MOUNTING LUBRICANT IN ACCORDANCE WITH

HN-1162.TYRE INSTALATION MUST BE MADE BEFORE LUBRICANT

IS DRYTO ENSURE SATISFACTORYBEAD SEATING.TYRE IS TO BE INFLATED TO

280 kPa ON INITIAL ASSEMBLY

.

TYRE WHEN ASSEMBLED TO WHEEL IS NOT TO EXCEED

ADYNAMIC IMBALANCE OF 1.5 kg/mm AFTER BALANCING

AND THE WEIGHT USED TO BE BALANCE IS NOT TO EXCEED

120 gm TOTAL AND 60 gm PER WHEEL FLANGE.

B. WITH CONCEALED BALANCE WEIGHTS FITTED AS SHOWN

SET THE BALANCE AS 18" x 8" WHEEL.

C. POSITION WHEEL BALANCE WEIGHT AS CLOSE AS POSSIBLE

TO SPOKE EDGE (MAXIMUM 5 mm) TO ENSURE SUFFICIENT

CLEARANCE BETWEEN THE WHEEL WEIGHT AND BRAKE CALIPER.

NOTE: BREAKAWAYTORQUE

OF WHEEL NUTS TOBE

100 Nm MINIMUM

1

2

1

3

4

5

A

A

1. 10B-101919 CAP WHEEL NUT 5 PLACES

2. 10B-970219 WHEEL NUT 4 PLACES

3. 10B-970309 CAP & BADGE ASM WHEEL

4. WHEEL ALLOY (CLUBSPORT, MALOO 10B-020601)(MALOO R8 10B-020601-C)

5. TYRE 235/40 ZR18

6. LOCKNUTS SPZ-300168

61

Wheels, Tyres And Steering Wheel Page H-7

Page H-7

NOTE: BREAKAWAYTORQUE

OF WHEEL NUTS TOBE

100 Nm MINIMUM

SEC A-A

advanced automotive design and engineering

RELEASE

100-125 Nm

INSTRUCTION DRAWING

.

advanced automotive design and engineering

M.B

SIGNATURES ON

ISSUE DATED

ORIGINAL APPROVAL

APPR

VY

T.K

D.P

20.05.02

APPR

CK.

DR.

MODEL :

DWG.

DATE:

REFERENCE :

PARTNO.

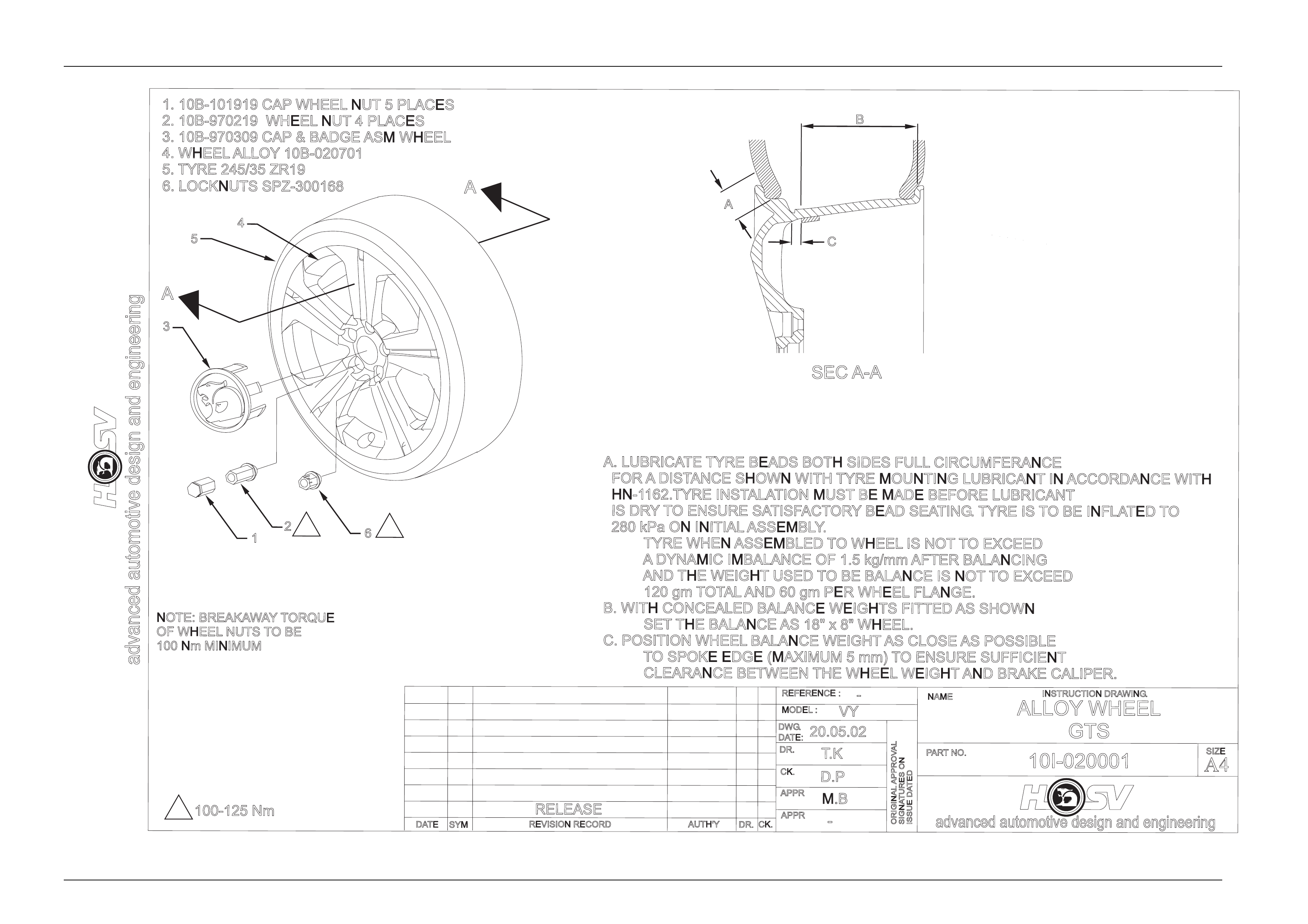

10I-020001

-

NAME

ALLOY WHEEL

GTS

A4

SIZE

REVISION RECORD

SYM

DATE AUTH'YCK.

DR.

-

A. LUBRICATE TYRE BEADS BOTH SIDES FULL CIRCUMFERANCE

FOR ADISTANCE SHOWN WITH TYRE MOUNTING LUBRICANT IN ACCORDANCE WITH

HN-1162.TYRE INSTALATION MUST BE MADE BEFORE LUBRICANT

IS DRYTO ENSURE SATISFACTORYBEAD SEATING.TYRE IS TO BE INFLATED TO

280 kPa ON INITIAL ASSEMBLY

.

TYRE WHEN ASSEMBLED TO WHEEL IS NOT TO EXCEED

ADYNAMIC IMBALANCE OF 1.5 kg/mm AFTER BALANCING

AND THE WEIGHT USED TO BE BALANCE IS NOT TO EXCEED

120 gm TOTAL AND 60 gm PER WHEEL FLANGE.

B. WITH CONCEALED BALANCE WEIGHTS FITTED AS SHOWN

SET THE BALANCE AS 18" x 8" WHEEL.

C. POSITION WHEEL BALANCE WEIGHT AS CLOSE AS POSSIBLE

TO SPOKE EDGE (MAXIMUM 5 mm) TO ENSURE SUFFICIENT

CLEARANCE BETWEEN THE WHEEL WEIGHT AND BRAKE CALIPER.

1. 10B-101919 CAP WHEEL NUT 5 PLACES

2. 10B-970219 WHEEL NUT 4 PLACES

3. 10B-970309 CAP & BADGE ASM WHEEL

4. WHEEL ALLOY 10B-020701

5. TYRE 245/35 ZR19

6. LOCKNUTS SPZ-300168

16

3

4

5

A

A

2

A

C

B

1

11

Wheels, Tyres And Steering Wheel Page H-8

Page H-8

A-A

100 - 125 Nm

NOTE: BREAKAWAYTORQUE

OF WHEEL NUTS TOBE

100 Nm MINIMUM

SECTION

advanced automotive design and engineering

RELEASE

1

INSTRUCTION DRAWING.

advanced automotive design and engineering

M.B

SIGNATURES ON

ISSUE DATED

ORIGINAL APPROVAL

APPR

VY

T.K

D.P

20.05.02

APPR

CK.

DR.

MODEL :

DWG

.

DATE:

REFERENCE :

PARTNO.

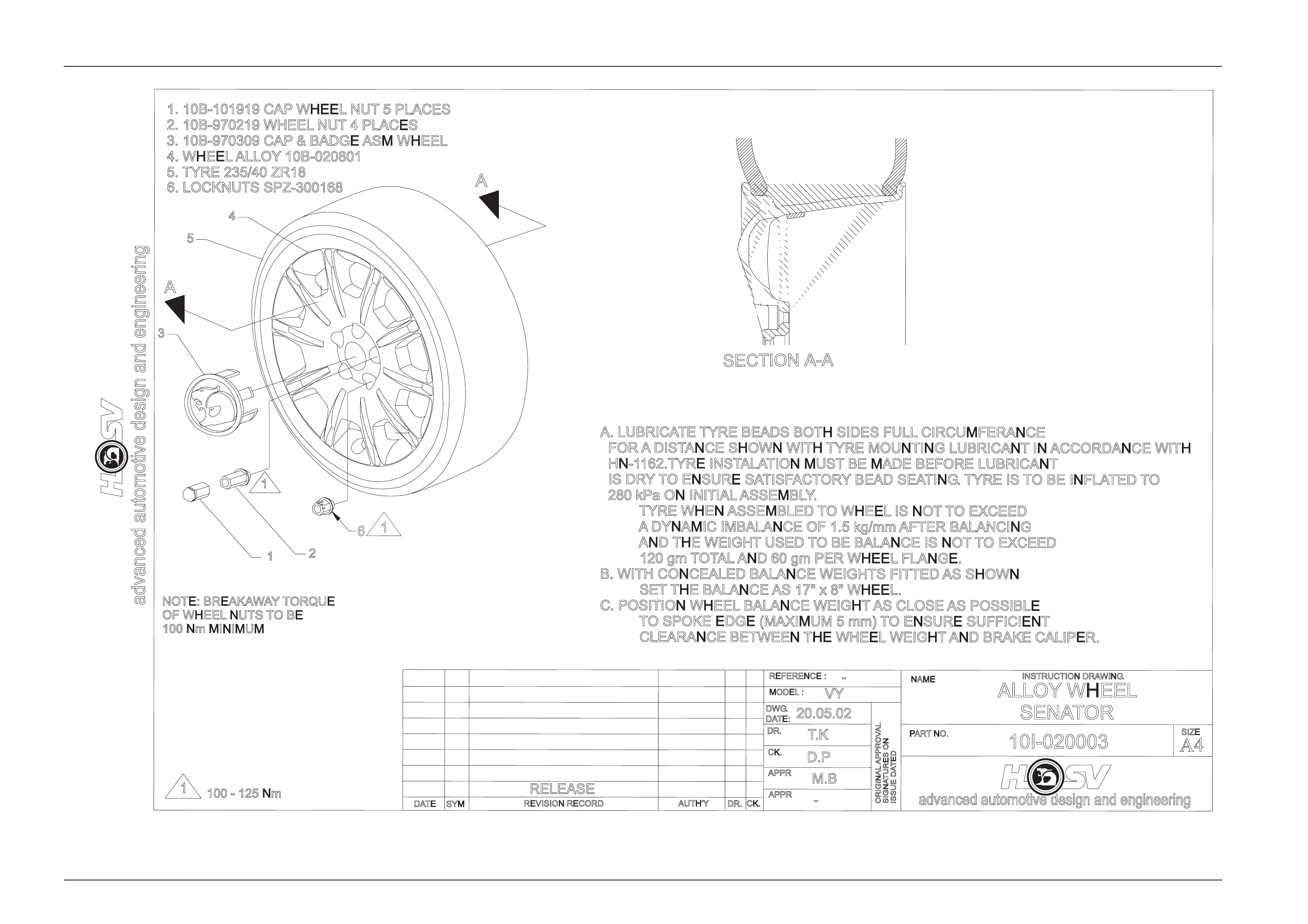

10I-020003

-

NAME

ALLOY WHEEL

SENATOR

A4

SIZE

REVISION RECORD

SYM

DATE AUTH'Y CK.

DR.

-

A. LUBRICATE TYRE BEADS BOTH SIDES FULL CIRCUMFERANCE

FOR ADISTANCE SHOWN WITH TYRE MOUNTING LUBRICANT IN ACCORDANCE WITH

HN-1162.TYRE INSTALATION MUST BE MADE BEFORE LUBRICANT

IS DRYTO ENSURE SATISFACTORYBEAD SEATING.TYRE IS TO BE INFLATED TO

280 kPa ON INITIAL ASSEMBLY

.

TYRE WHEN ASSEMBLED TO WHEEL IS NOT TO EXCEED

ADYNAMIC IMBALANCE OF 1.5 kg/mm AFTER BALANCING

AND THE WEIGHT USED TO BE BALANCE IS NOT TO EXCEED

120 gm TOTAL AND 60 gm PER WHEEL FLANGE.

B. WITH CONCEALED BALANCE WEIGHTS FITTED AS SHOWN

SET THE BALANCE AS 17" x 8" WHEEL.

C. POSITION WHEEL BALANCE WEIGHT AS CLOSE AS POSSIBLE

TO SPOKE EDGE (MAXIMUM 5 mm) TO ENSURE SUFFICIENT

CLEARANCE BETWEEN THE WHEEL WEIGHT AND BRAKE CALIPER.

1. 10B-101919 CAP WHEEL NUT 5 PLACES

2. 10B-970219 WHEEL NUT 4 PLACES

3. 10B-970309 CAP & BADGE ASM WHEEL

4. WHEEL ALLOY 10B-020801

5. TYRE 235/40 ZR18

1

2

1

3

4

5

A

A

6. LOCKNUTS SPZ-300168

61

Wheels, Tyres And Steering Wheel Page H-9

Page H-9

100 - 125 Nm

NOTE: BREAKAWAYTORQUE

OF WHEEL NUTS TOBE

100 Nm MINIMUM

SEC A-A

RELEASE

1M.B

VY

T.K

D.P

20.05.02

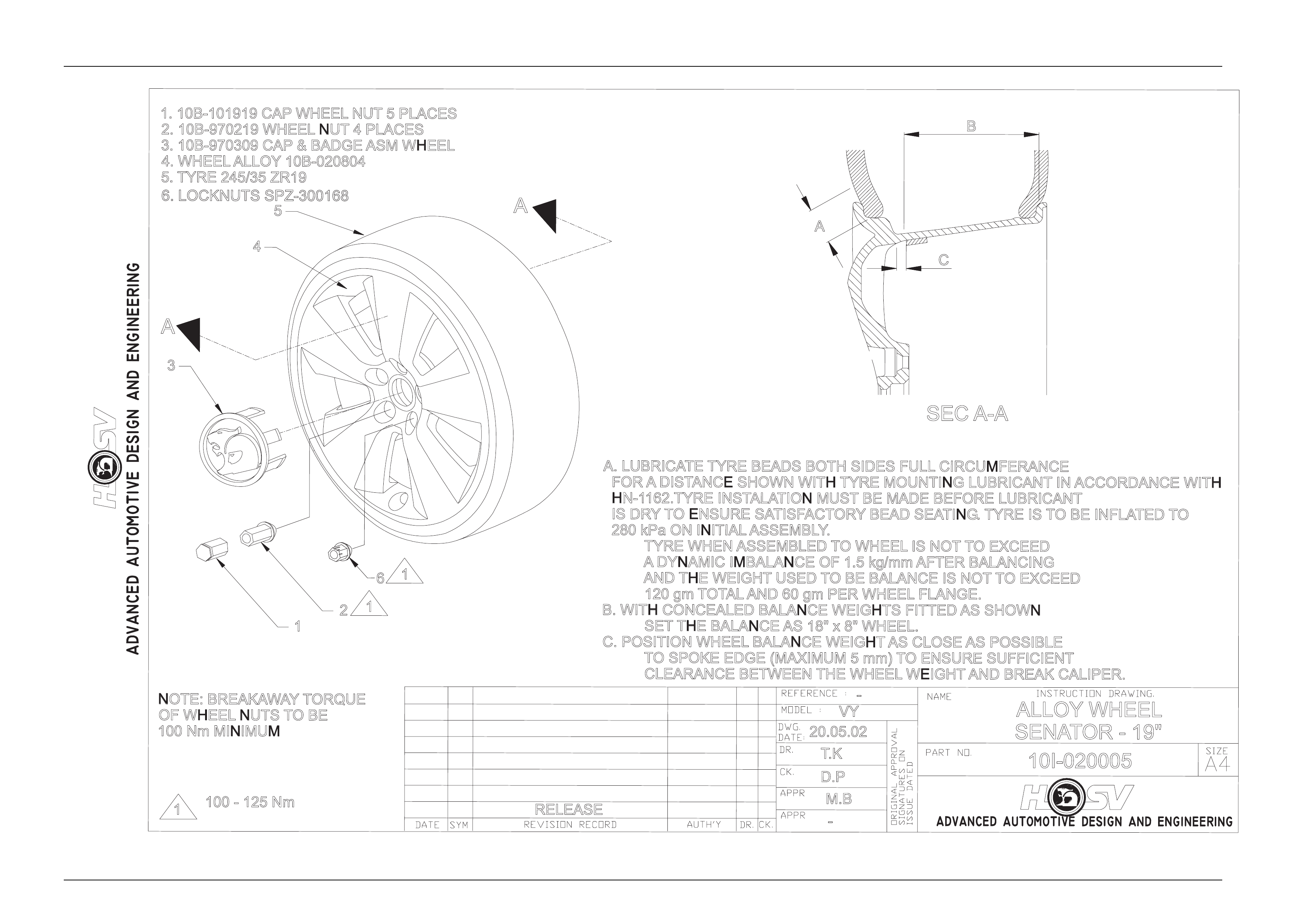

10I-020005

-

ALLOY WHEEL

SENATOR - 19"

-

A. LUBRICATE TYRE BEADS BOTH SIDES FULL CIRCUMFERANCE

FOR ADISTANCE SHOWN WITH TYRE MOUNTING LUBRICANT IN ACCORDANCE WITH

HN-1162.TYRE INSTALATION MUST BE MADE BEFORE LUBRICANT

IS DRYTO ENSURE SATISFACTORYBEAD SEATING.TYRE IS TO BE INFLATED TO

280 kPa ON INITIAL ASSEMBLY

.

TYRE WHEN ASSEMBLED TO WHEEL IS NOT TO EXCEED

ADYNAMIC IMBALANCE OF 1.5 kg/mm AFTER BALANCING

AND THE WEIGHT USED TO BE BALANCE IS NOT TO EXCEED

120 gm TOTAL AND 60 gm PER WHEEL FLANGE.

B. WITH CONCEALED BALANCE WEIGHTS FITTED AS SHOWN

SET THE BALANCE AS 18" x 8" WHEEL.

C. POSITION WHEEL BALANCE WEIGHT AS CLOSE AS POSSIBLE

TO SPOKE EDGE (MAXIMUM 5 mm) TO ENSURE SUFFICIENT

CLEARANCE BETWEEN THE WHEEL WEIGHT AND BREAK CALIPER.

1. 10B-101919 CAP WHEEL NUT 5 PLACES

2. 10B-970219 WHEEL NUT 4 PLACES

3. 10B-970309 CAP & BADGE ASM WHEEL

4. WHEEL ALLOY 10B-020804

5. TYRE 245/35 ZR19

2

6

1

1

3

4

5

A

A

B

A

C

6. LOCKNUTS SPZ-300168

1

Wheels, Tyres And Steering Wheel Page H-10

Page H-10

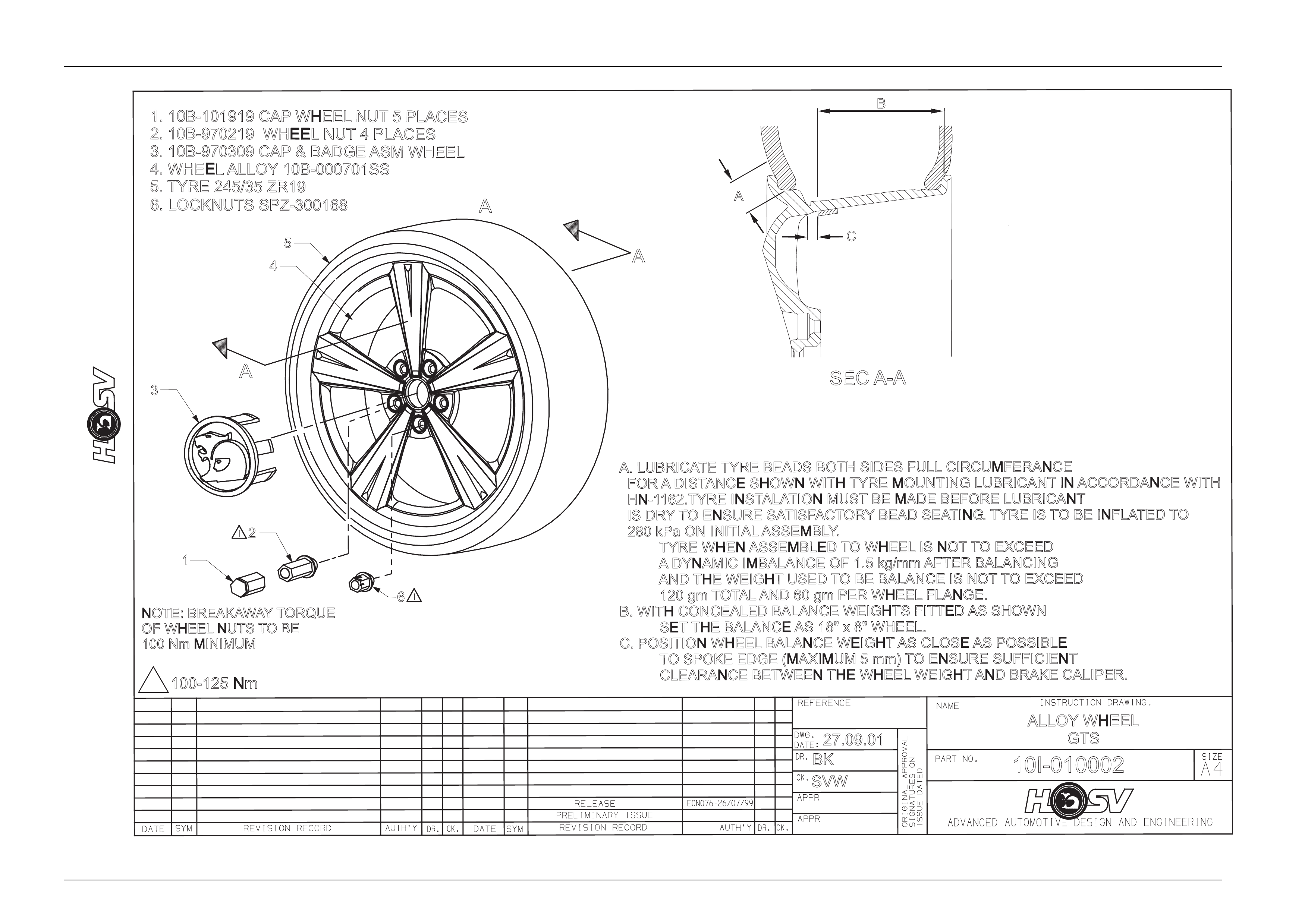

A. LUBRICATE TYRE BEADS BOTH SIDES FULL CIRCUMFERANCE

FOR ADISTANCE SHOWN WITH TYRE MOUNTING LUBRICANT IN ACCORDANCE WITH

HN-1162.TYRE INSTALATION MUST BE MADE BEFORE LUBRICANT

IS DRYTO ENSURE SATISFACTORYBEAD SEATING.TYRE IS TO BE INFLATED TO

280 kPa ON INITIAL ASSEMBLY

.

TYRE WHEN ASSEMBLED TO WHEEL IS NOT TO EXCEED

ADYNAMIC IMBALANCE OF 1.5 kg/mm AFTER BALANCING

AND THE WEIGHT USED TO BE BALANCE IS NOT TO EXCEED

120 gm TOTAL AND 60 gm PER WHEEL FLANGE.

B. WITH CONCEALED BALANCE WEIGHTS FITTED AS SHOWN

SET THE BALANCE AS 18" x 8" WHEEL.

C. POSITION WHEEL BALANCE WEIGHT AS CLOSE AS POSSIBLE

TO SPOKE EDGE (MAXIMUM 5 mm) TO ENSURE SUFFICIENT

CLEARANCE BETWEEN THE WHEEL WEIGHT AND BRAKE CALIPER.

NOTE: BREAKAWAYTORQUE

OF WHEEL NUTS TOBE

100 Nm MINIMUM

100-125 Nm

1

BK

27.09.01

ALLOY WHEEL

GTS

SVW

10I-010002

SECA-A

A

C

B

A

A

4

5

3

2

6

1

1. 10B-101919 CAP WHEEL NUT 5 PLACES

2. 10B-970219 WHEEL NUT 4 PLACES

3. 10B-970309 CAP & BADGE ASM WHEEL

4. WHEEL ALLOY 10B-000701SS

5. TYRE 245/35 ZR19

6. LOCKNUTS SPZ-300168

A

Wheels, Tyres And Steering Wheel Page H-11

Page H-11

3.3 Tyre Placard And Pressures

The HSV Tyre Placard is posit ioned on the opening of the right hand door. The Tyre Placard details important

information on the tyre pressures recomme nded for the HSV VYII Series Models. If carrying load, or travell ing

at high speed, the tyre pressures need to be increased as detailed on the placard. This is very important for

tyre wear and also to ensure that the tyres have sufficient load carrying capac ity.

Wheels, Tyres And Steering Wheel Page H-12

Page H-12

3.4 Loading The HSV Maloo

Also on the right hand door open ing are the HSV Maloo payload details. The Maloo is restricted to a maximum

payload of 490kg, with the driver and passenger in the car, this leaves approximately 350kg load capacity for

the rear tray. The load is restricted by the carr ying capacity of the 235/40 ZR18 t yres. As noted above, it is

important to increase tyre pressures when vehicle load is increased, refer to the tyre placard.

Wheels, Tyres And Steering Wheel Page H-13

Page H-13

3.5 HSV Temporary Spare Tyre

All HSV VYII Models are fitted with a temporary spare wheel/tyre. This temporary use spare is for emergency

use only, do not exceed 80km/h when it is fitted. Refer to the owner’s manual for further details.

All HSV Models fitted with the 19” wheel & tyre option are fitted with a space saver temporary spare wheel &

tyre.

This temporary spare is for emergency use only, do not exceed 80km/h when it is fitted. Refer to the owner’s

manual for further details.

Wheels, Tyres And Steering Wheel Page H-14

Page H-14

4 Steering Wheel

HSV VYII vehicles are equipped with AIR

BAGS. An AIR BAG is a Supplemental

Restraint System (SRS). Refer to CAUTIONS,

Section 12M, in Volume 12 of the Holden VYII

series Service Manual Supplement before

performing any service operation on or

around SRS components, the steering

mechanism or wiring. Failure to follow the

CAUTIONS could result in air bag

deployment, resulting in possible personal

injury or unnecessary SRS system repairs

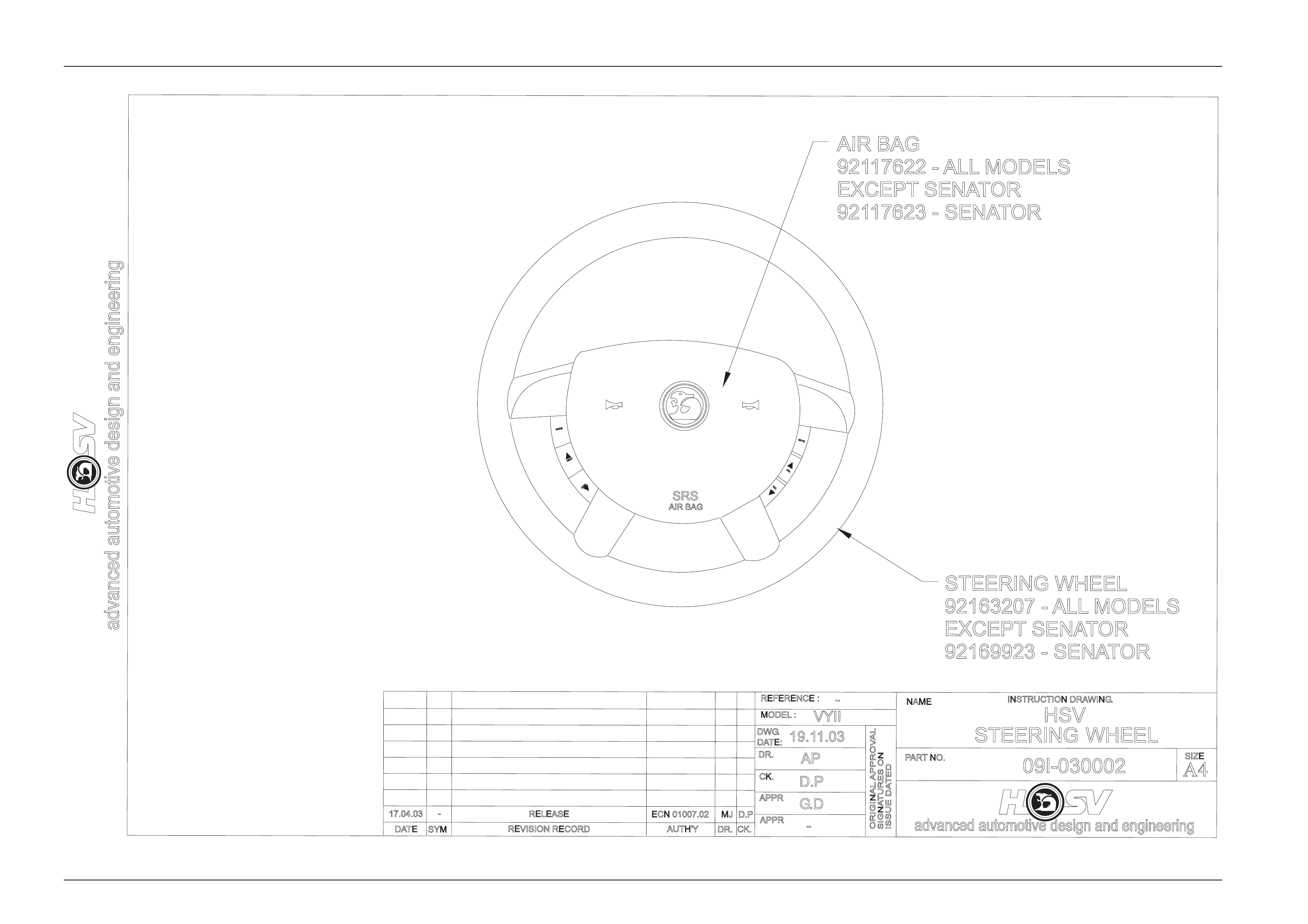

The steering wheel assembly fitted to all HSV VYII models incorporates a HSV-design central horn pad complete with

HSV logo (see Drawing 09I-030002). The central horn pad also incorporates the driver’s-side air bag. All other

components, fixtures and fasteners are identical to standard Holden parts and therefore, any service operations on the

assembly should be carried out in accord ance with the relevant Holden Service Manual S upplement, refer to

Section 9A – STEERING of the VYII Series Service Information.

Wheels, Tyres And Steering Wheel Page H-15

Page H-15

advanced automotive design and engineering

DATE

PARTNO.

NAME

REVISION RECORD

SYM

ORIGINAL APPROVAL

ISSUE DATED

SIGNATURES ON

DR.

AUTH'YCK.

APPR

APPR

-

MODEL :

REFERENCE :

DWG.

CK.

DATE:

DR.

19.11.03

D.P

AP

VYII

-

HSV

STEERING WHEEL

09I-030002

advanced automotive design and engineering

INSTRUCTION DRAWING.

A4

SIZE

RELEASE

AIR BAG

92117622 - ALL MODELS

EXCEPT SENATOR

92117623 - SENATOR

STEERING WHEEL

92163207 - ALL MODELS

EXCEPT SENATOR

92169923 - SENATOR

SRS

AIR BAG

G.D

17.04.03 -ECN 01007.02 MJ D.P

VOL

VOL

MUTE

NEXT

NEXT

MODE