Brakes Page D-1

Page D-1

Section D

Brakes

ATTENTION

HSV vehicles are equipped with a Supplemental Restraint System (SRS). An SRS consists of seat belt pre-

tensioners (fitted to all front seats), a driver’s-side air bag, a passenger’s-side air bag and right and left hand

side air bags. Refer to CAUTIONS, Section 12M, of the Holden WK Service Information before performing any

service operation on or around SRS components, the steering mechanism or wiring. Failure to follow the

CAUTIONS could result in personal injury or unnecessary SRS system repairs.

1 Purpose................................................................................................................................................... 2

2 Brakes..................................................................................................................................................... 3

2.1 General Information...............................................................................................................................................3

2.2 Service Operations.................................................................................................................................................4

Pad Replacement ...................................................................................................................................................4

Calliper Overhaul....................................................................................................................................................4

Brake Discs.............................................................................................................................................................5

2.3 Service Parts...........................................................................................................................................................6

Front Callipers........................................................................................................................................................6

Rear Callipers.........................................................................................................................................................7

Brakes Page D-2

Page D-2

1 Purpose

The purpose of this section is to provide information on the Brake Systems fitted to HSV WK model. Details are given

where differences occur between the HSV models and standard Holden models. A series of instruction drawings

describe the design changes and indicate specific part numbers, fitting instructions and relevant notes for vehicle

servicing.

NOTE

If specific technical data on a HSV model is not

contained in this supplement, obtain data for that

model from Section 5A – Standard Brakes of the

WK Service Information. References are made

throughout this section to Holden Service

Information to assist in providing information for

specific serv ice operati ons .

When hoisting (or jacking) HSV models,

ensure that the lifting head of the hoist lifts on

the chassis before the arm of the hoist

contacts the side-skirt

Brakes Page D-3

Page D-3

2 Brakes

2.1 General Information

Brake systems fitted to HSV WK model employ the vacuum boosted, four-wheel-disc concept operating through a

tandem master cylinder. This tandem arrangement provides separate braking systems to the front and rear wheels which

in turn, provides adequate braking (to the front or rear wheels) if a fault occurs in either system. HSV W K model is also

equipped with the BOSCH Anti-lock Braking System (ABS) as standard. Inspection, replacement and testing of the ABS

must be carried out in accordance with the procedures detailed in the relevant Holden Service Information.

Whenever any component of the ABS is

disturbed during service operations, it is vital

that the complete ABS is checked using the

procedure detailed in the relevant Holden

Service Information.

Model Premium Performance

GRANGE --- S

Table D-1 Brake System

Brakes Page D-4

Page D-4

2.2 Service Operations

Although HSV brake systems have different fittings and components, the general service principles are the same as

those which apply to Holden standard brake systems. The important differences between Holden brake systems and

HSV systems are the component parts and the specified wear limits for those parts. Drawings of specific HSV brake

systems and component part numbers are included in this section and wear limits have also been specified where

required.

Pad Replacement

Refer to appropriate drawings in this section or in Holden Service Information. Ensure that the following important notes

are observed and replace brake pads in accordance with the procedures in the Holden WK Series Service Information.

Important Notes On Brake Pad Replacement

• Do not remove mounting brackets unless damaged or for disc servicing.

• Pads should be replaced if there is less than 3mm of lining material remaining or if pads are damaged.

• Pads must be replaced as a full set of 4. Ensure pad material is correct specification. Do not mix pad material front

to rear. Use genuine HSV replacement parts to ensure correct pad material is used.

• Before fitting new pads check that all pads are fitted with insulating material.

When replacing pads in Performance brakes, ensure that shims and spring are fully clipped into position so that they are

clear of the rotor. Carefully lower the body over the pads and bracket ensuring the pads are engaged with spring so that

they are free to slide. Ensure Piston Boot is not caught between the Piston and the inner pad. Fit new guide bolt through

the lower hole and tighten to a torque of 30-34 Nm.

Callip er Ov erhau l

Refer to appropriate drawings in this section or in Holden Service Information. Ensure that the following important notes

are observed and overhaul callipers as detailed in Section 5A-Standard Brakes of the W K series Service Information.

Notes On Calliper Overhaul

• Do not remove the mounting brackets unless damaged or for disc servicing.

• Remove the pistons by directing light air pressure into the brake hose port, and progressively increase until piston

is forced out of bore .

Caution is necessary to avoid physical

injury—Piston may be ejected with

considerable force due to air pressure. Use

packing to prevent piston damaging body of

calliper.

Brakes Page D-5

Page D-5

Brake Discs

Refer to appropriate drawings in this section or in Holden Service Information. Ensure that important notes are observed

and overhaul discs as detailed in Section 5A-Standard Brakes.

Do not remove mounting bracket from the

brake calliper unless the bracket requires

service. It is critical for safety that the bolts

holding the mounting bracket to the calliper if

removed, are correctly reinstalled.

Refer Drawing No. 041-030003 for assembly

requirements.

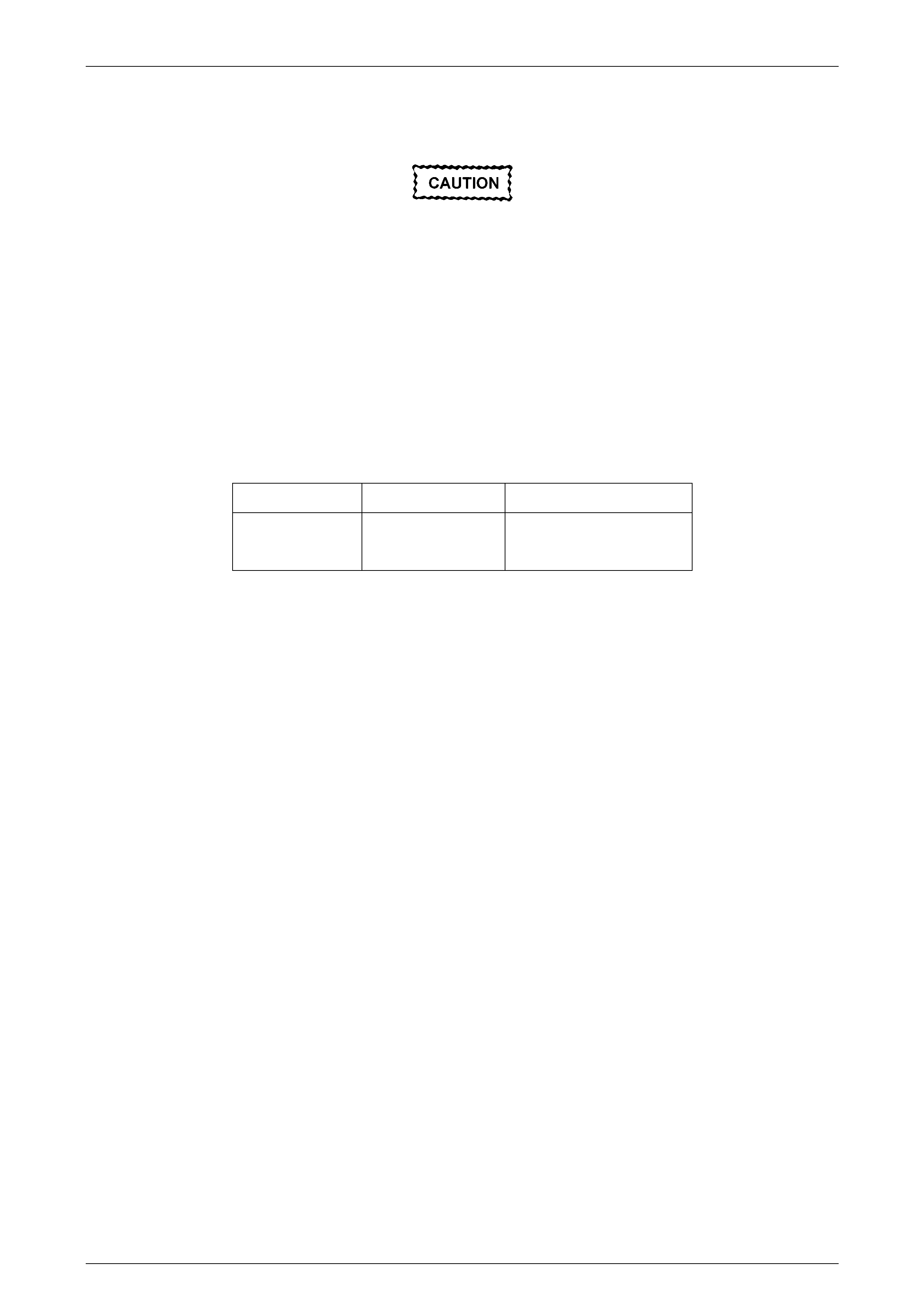

Brake Disc Wear Limits.

The minimum thickness for discs fitted to standard Holden brakes is cast in the hub of the disc and is specified in

Section 5A – Standard Brakes in the Holden Service Information. The minimum thickness for brake discs fitted to HSV

brake systems is stamped into the edge of the disc. For information, the new and minimum thicknesses of discs

used in HSV brake systems are tabulated below.

Disc Location New Thickness Minimum Thickness

FRONT

REAR

32.0 mm

18.0 mm

30.0 mm

16.0 mm

Brakes Page D-6

Page D-6

2.3 Service Parts

It is essential that genuine replacement parts be fitted to HSV brake assemblies. This is particularly important when

replacing brake pads because of the various types of lining material used. Complete brake assemblies, front and rear

discs, callipers and attachment parts have also been identified as replacement parts and these items are available from

HSV. These parts are listed in the following paragraphs or referenced in enclosed drawings.

Front Callipers

05A-970730 FRONT HYDRAULIC REPAIR KIT COMPRISING

2 OFF SEALING RINGS

2 OFF PISTON BOOT

1 OFF BLEED SCREW PROTECTION COVER

2 OFF GUIDE PIN BOOT

05A-030702 FRONT CALLIPER HOUSING ASSEMBLY RH COMPRISING

1 OFF CALLIPER BODY RH

1 OFF ABUTMENT BODY

2 OFF PAD ABUTMENT SHIM

2 OFF SEALING RING

2 OFF PISTON BOOT

2 OFF PISTON

1 OFF BLEED SCREW PROTECTOR COVER

1 OFF BLEED SCREW

1 OFF ANTI RATTLE SPRING

2 OFF GUIDE PIN BOOT

2 OFF GUIDE PIN

2 OFF GUIDE PIN BOLT

05A-030701 FRONT CALLIPER HOUSING ASSEMBLY LH COMPRISING

1 OFF CALLIPER BODY RH

1 OFF ABUTMENT BODY

2 OFF PAD ABUTMENT SHIM

2 OFF SEALING RING

2 OFF PISTON BOOT

2 OFF PISTON

1 OFF BLEED SCREW PROTECTOR COVER

1 OFF BLEED SCREW

1 OFF ANTI RATTLE SPRING

2 OFF GUIDE PIN BOOT

2 OFF GUIDE PIN

2 OFF GUIDE PIN BOLT

05A-970733 PISTON BRAKE

05A-970734 BLEED SCREW

05A-970735 PAD ABUTMENT SHIM

05A-970736 ANTI RATTLE SPRING

05A-970737 GUIDE PIN

05A-970738 GUIDE PIN BOLT

05A-990704 BRAKE PAD KIT JBI NF42 COMPRISING

2 OFF OUTER PAD ASSEMBLY JBI NF42

2 OFF INNER PAD ASSEMBLY JBI NF42

4 OFF GUIDE PIN BOLT

Brakes Page D-7

Page D-7

Rear Callipers

Servicing procedures and servicing kits for the WK Performance Rear Caliper are exactly the same as for the standard

WK Holden Rear Caliper. Therefore, when servicing the WK rear caliper, refer to the procedures in the Section 5A-

Standard Brakes.

HSV Performance Rear Calipers use unique brake pads, with a thinner pad to suit HSV’s wider ventilated disc.

05B-020710 REAR CALLIPER HOUSING ASSY RH COMPRISING

1 OFF CALLIPER BODY

1 OFF SEALING RING

1 OFF CALLIPER PISTON

1 OFF DUSTBOOT

1 OFF BLEED SCREW

1 OFF BLEED SCREW DUST CAP

05B-020709 REAR CALLIPER HOUSING ASSY LH COMPRISING

1 OFF CALLIPER BODY

1 OFF SEALING RING

1 OFF CALLIPER PISTON

1 OFF DUSTBOOT

1 OFF BLEED SCREW

1 OFF BLEED SCREW DUST CAP

05B-970704 REAR BRAKE PAD KIT (BM962) COMPRISING

4 OFF BRAKE PAD (BM962)

4 OFF RETAINING BOLTS

Brakes Page D-8

Page D-8

advanced automotive design and engineeringadvanced automotive design and engineering

RELEASE

REVISION RECORD

REVISION RECORD

SYM

DATE

INSTRUCTION DRAWING.INSTRUCTION DRAWING.

advanced automotive design and engineeringadvanced automotive design and engineering

SIGNATURES ONSIGNATURES ON

ISSUE DATEDISSUE DATED

ORIGINAL APPROVALORIGINAL APPROVAL

AUTH'YAUTH'Y CK.

DR.

-

APPR

VY

L.H

D.P

22.04.03

APPR

CK.

DR.

MODEL :

MODEL :

DWG.DWG.

DATE:

REFERENCE :

REFERENCE :

PART NO.

04I-030003

-

NAME

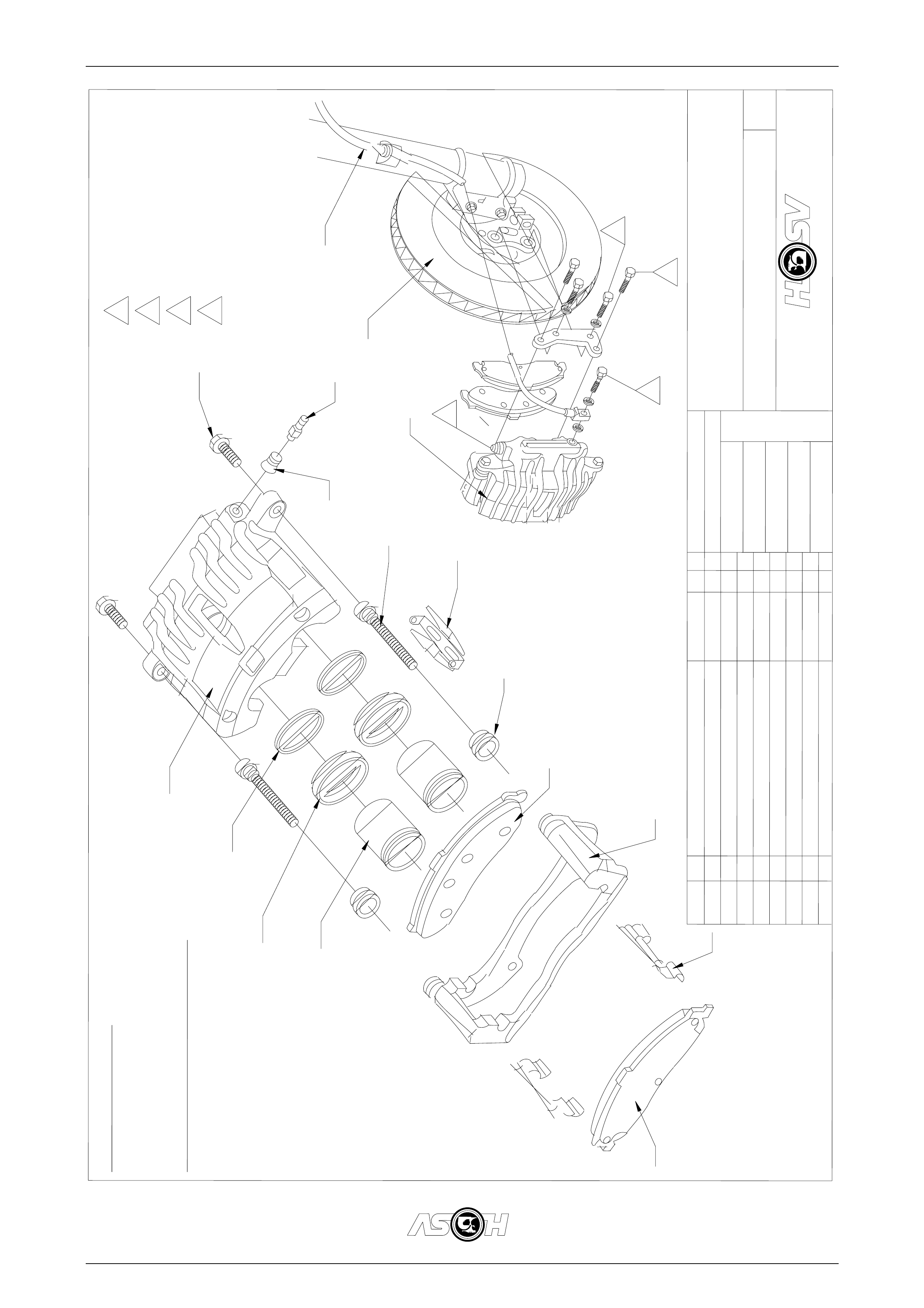

PERFORMANCE BRAKE

SYSTEM -

SYSTEM -FRONT

A4

SIZE

11.07.02 ECN. O1186.03

ECN. O1186.03

M.B

MAJOR ASSEMBLIES

1. 05A-970705/61. 05A-970705/6

2. 05A-9707012. 05A-970701

3. 05F-970701/23. 05F-970701/2

CALIPER ASM FRT. RH/LHCALIPER ASM FRT. RH/LH

DISC FRONT PERFORMANCEDISC FRONT PERFORMANCE

HOSE FRONT RH/LHHOSE FRONT RH/LH

COMPONENTS / SERVICE PARTSCOMPONENTS /SERVICE PARTS

4. ABUTMENT BRACKET4. ABUTMENT BRACKET

5. PAD ABUTMENT SHIM5. PAD ABUTMENT SHIM

6. OUTER PAD ASM6. OUTER PAD ASM

7. INNER PAD ASM7. INNER PAD ASM

8. BLEED SCREW COVER8. BLEED SCREW COVER

9. BLEED SCREW9. BLEED SCREW

10. ANTI RATTLE SPRING10. ANTI RATTLE SPRING

11. GUIDE PIN BOOT11. GUIDE PIN BOOT

12. CALIPER BODY12. CALIPER BODY

13. SEALING RING13. SEALING RING

14. PISTON BOOT14. PISTON BOOT

15. GUIDE PIN BOLT15. GUIDE PIN BOLT

16. GUIDE PIN16. GUIDE PIN

17. PISTON17. PISTON

2

1

3

4

#

#

1

2

3

4

5

6

7

89

10

11

12

13

14

15

16

17

3

2

1

32-37Nm

32 -37 Nm

180 - 190 Nm180 -190 Nm

80 - 90 Nm THEN 45° TURN80 -90 Nm THEN 45° TURN

412 - 14 Nm THEN 90° TURN

12 -14 Nm THEN 90° TURN

APPLY LOCTITE 243APPLY LOCTITE 243

#

BEFORE INSTALLATIONBEFORE INSTALLATION

Brakes Page D-9

Page D-9

advanced automotive design and engineeringadvanced automotive design and engineering

RELEASE

REVISION RECORD

REVISION RECORD

SYM

DATE

INSTRUCTION DRAWING.INSTRUCTION DRAWING.

advanced automotive design and engineeringadvanced automotive design and engineering

SIGNATURESON

SIGNATURES ON

ISSUE DATEDISSUE DATED

ORIGINAL APPROVALORIGINAL APPROVAL

AUTH'Y CK.

DR.

-

APPR

VY

L.H

D.P

22.04.03

APPR

CK.

DR.

MODEL :

MODEL :

DWG.

DATE:

REFERENCE :

REFERENCE :

PART NO.

04I-030004

-

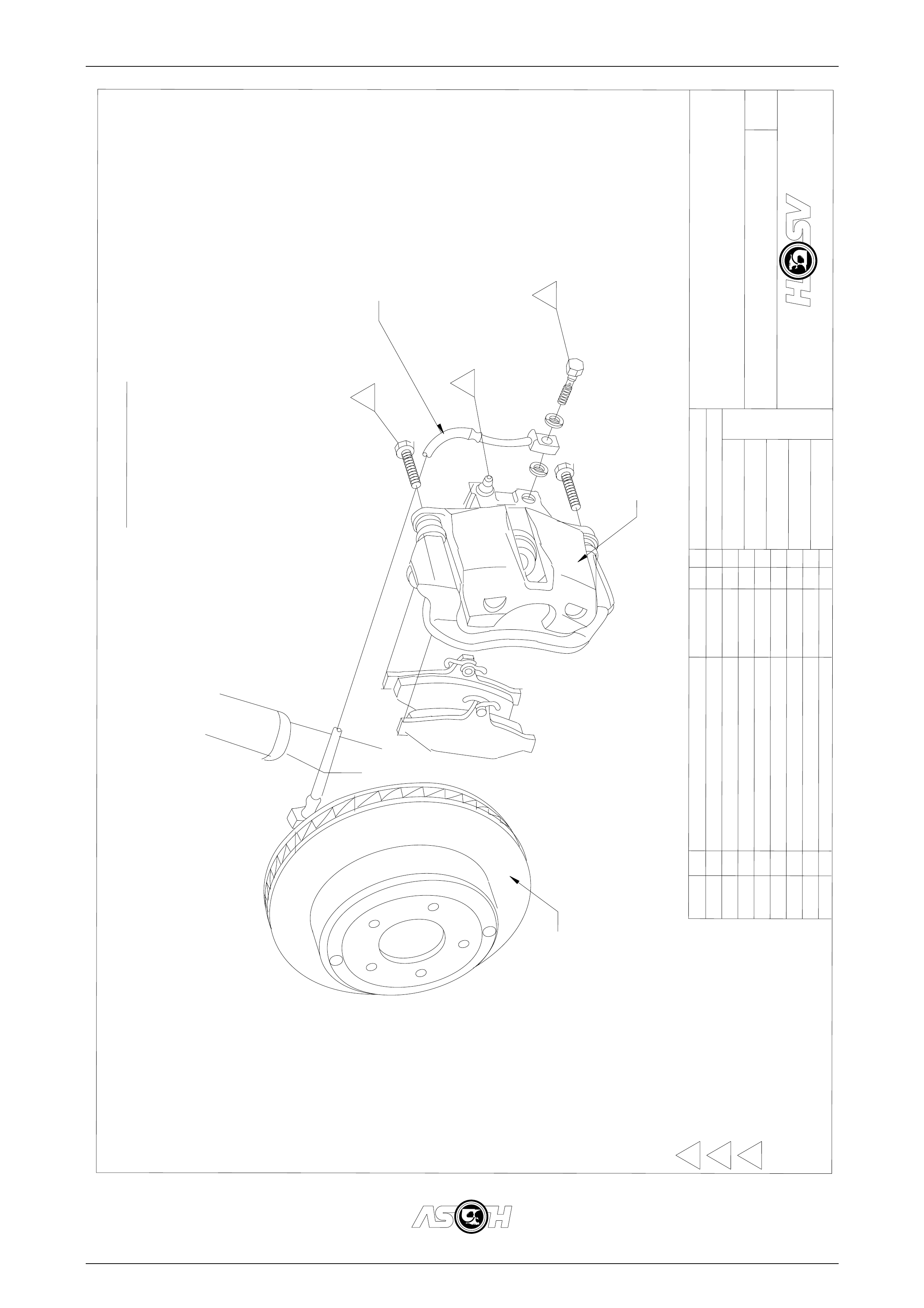

NAME

PERFORMANCE BRAKE

SYSTEM - REAR

SYSTEM -REAR

A4

SIZE

11.07.02 ECN. O1186.03

ECN. O1186.03

M.B

3

2

1

70 - 100 Nm

70 - 100 Nm

32-37Nm32 - 37 Nm

12-14Nm12 - 14 Nm

APPLY LOCTITE 243APPLY LOCTITE 243

#

1

2

3

3

#

1

2

BEFORE INSTALLATIONBEFORE INSTALLATION

MAJOR ASSEMBLIES

1. 05B-970705/61. 05B-970705/6

2. 05B-9707012. 05B-970701

3. 05F-9707033. 05F-970703

CALIPER ASM RR RH/LHCALIPER ASM RR RH/LH

DISC REAR PERFORMANCEDISC REAR PERFORMANCE

HOSE REAR BRAKE PERFORMANCEHOSE REAR BRAKE PERFORMANCE