Wheels, Tyres and Steering Wheel Page H-1

28-OCT-2003 Page H-1

Section H

Wheels, Tyres and Steering Wheel

ATTENTION

HSV vehicles are equipped with a Supplemental Restraint System (SRS). An SRS consists of seat belt pre-

tensioners (fitted to all front seats), a driver’s-side air bag , a passenger’s-side air bag and left and right hand

side airbags. Refer to CAUTIONS, Section 12M of the Holden WK Service Information before performing any

service operation on or around SRS components, the steering mechanism or wiring. Failure to follow the

CAUTIONS could result in personal injury or unnecessary SRS system repairs.

1 Purpose................................................................................................................................................... 2

2 Wheels And Tyres.................................................................................................................................. 3

2.1 General Description...............................................................................................................................................3

2.2 Service Operations.................................................................................................................................................4

Wheel and Tyre Balancing.....................................................................................................................................4

HSV Wheel and Tyre Combinations......................................................................................................................4

Wheels, Tyres and Steering Wheel Page H-2

28-OCT-2003 Page H-2

1 Purpose

The purpose of this section is to provide information on the wheels, tyres and steering wheels fitted to the HSV WK

model. The information is designed to supplement that given in the Holden W K Service Information and details are given

where differences occur between the HSV models and standard Holden models. A series of instruction drawings

describe the design changes and indicate specific part numbers, fitting instructions and relevant notes for vehicle

servicing.

NOTE

If specific technical data on a HSV model is not

contained in this supplement, obtain data for that

model from the relevant Holden WK Service

Information. References are made throughout

this section to Holden Service Information, to

assist in providing information for specific service

operations.

When hoisting (or jacking) HSV models,

ensure that the lifting head of the hoist lifts on

the chassis before the arm of the hoist

contacts the side-skirt

Wheels, Tyres and Steering Wheel Page H-3

28-OCT-2003 Page H-3

2 Wheels And Tyres

2.1 General Description

The HSV W K model is fitted with alloy wheels developed specifically for HSV application.

NOTE

Nuts are fitted with a plastic dress cap, which

must be removed prior to undoing the wheel nuts.

HSV WK wheels do not have a steel insert and

therefore require wheel nuts with a flanged

seat as per the VT, VT2 and WK wheel nuts,

10B-970304. Do not use VS wheels nuts on

HSV WK wheels.

Wheels, Tyres and Steering Wheel Page H-4

28-OCT-2003 Page H-4

2.2 Service Operations

Alloy wheels fitted to HSV vehicles are to be serviced in accordance with the procedures detailed in the relevant Holden

Service Information. In addition, particular care should be taken with the surface finish of alloy wheels. The manufacturer

recommends that alloy surfaces be treated the same as high-gloss painted services to prevent corrosion and general

deterioration.

Wheel and Tyre Balancing

In order to balance the HSV Design wheels and tyre assemblies, refer to the relevant Holden Series Service Information

Supplement.

HSV Wheel and Tyre Combinations

The following HSV wheel and tyre combinations are fitted to WK Grange:

STANDARD 18” x 8.0” (48P) using 235/40 R18 Bridgestone S03

OPTIONAL 19” x 8.0” (48P) using 245/35 R19 Pirelli Pzero Rosso

Wheels, Tyres and Steering Wheel Page H-5

28-OCT-2003 Page H-5

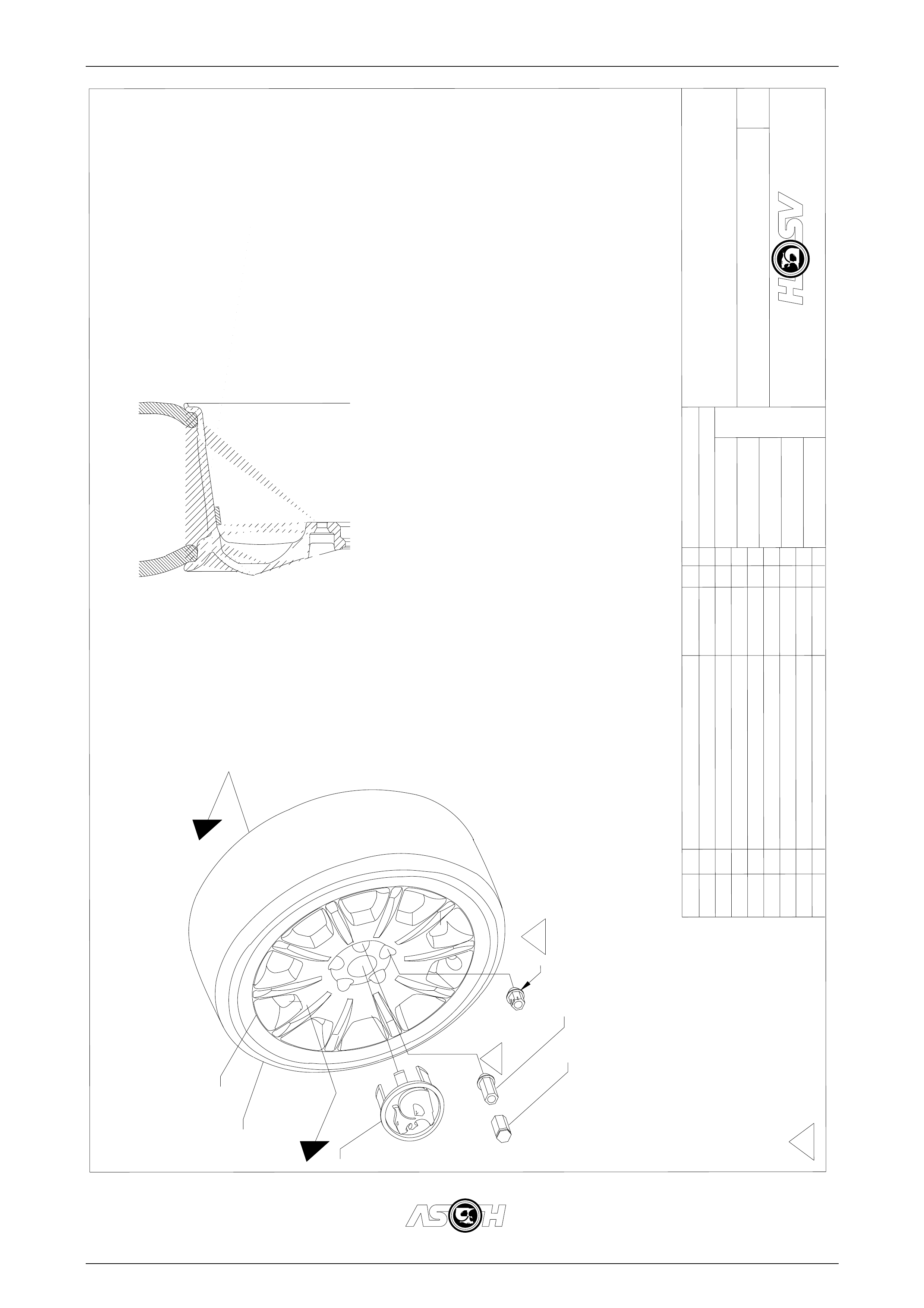

A-A

100 - 125 Nm100 -125 Nm

NOTE: BREAKAWAY TORQUENOTE: BREAKAWAY TORQUE

OF WHEEL NUTS TO BEOF WHEEL NUTS TO BE

100 Nm MINIMUM100 Nm MINIMUM

SECTION

advanced automotive design and engineeringadvanced automotive design and engineering

RELEASE

1

INSTRUCTION DRAWING.INSTRUCTION DRAWING.

advanced automotive design and engineeringadvanced automotive design and engineering

M.B

SIGNATURES ONSIGNATURES ON

ISSUE DATEDISSUE DATED

ORIGINAL APPROVALORIGINAL APPROVAL

APPR

VY

T.K

D.P

20.05.02

APPR

CK.

DR.

MODEL :

DWG.

DATE:

REFERENCE :

REFERENCE :

PART NO.

10I-020003

-

NAME

ALLOY WHEELALLOY WHEEL

SENATORSENATOR

A4

SIZE

REVISION RECORDREVISION RECORD

SYM

DATE AUTH'Y CK.

DR.

-

A. LUBRICATE TYRE BEADS BOTH SIDES FULL CIRCUMFERANCE

A. LUBRICATE TYRE BEADS BOTH SIDES FULL CIRCUMFERANCE

FOR A DISTANCE SHOWN WITH TYRE MOUNTING LUBRICANT IN ACCORDANCE WITHFOR A DISTANCE SHOWN WITH TYRE MOUNTING LUBRICANT IN ACCORDANCE WITH

HN-1162.TYRE INSTALATION MUST BE MADE BEFORE LUBRICANTHN-1162.TYRE INSTALATION MUST BE MADE BEFORE LUBRICANT

IS DRY TO ENSURE SATISFACTORY BEAD SEATING. TYRE IS TO BE INFLATED TOIS DRY TO ENSURE SATISFACTORY BEAD SEATING. TYRE IS TO BE INFLATED TO

280 kPa ON INITIAL ASSEMBLY.280 kPa ON INITIAL ASSEMBLY.

TYRE WHEN ASSEMBLED TO WHEEL IS NOT TO EXCEEDTYRE WHEN ASSEMBLED TO WHEEL IS NOT TO EXCEED

A DYNAMIC IMBALANCE OF 1.5 kg/mm AFTER BALANCINGA DYNAMIC IMBALANCE OF 1.5 kg/mm AFTER BALANCING

AND THE WEIGHT USED TO BE BALANCE IS NOT TO EXCEEDAND THE WEIGHT USED TO BE BALANCE IS NOT TO EXCEED

120 gm TOTAL AND 60 gm PER WHEEL FLANGE.120 gm TOTAL AND 60 gm PER WHEEL FLANGE.

B. WITH CONCEALED BALANCE WEIGHTS FITTED AS SHOWNB. WITH CONCEALED BALANCE WEIGHTS FITTED AS SHOWN

SET THE BALANCE AS 17" x 8" WHEEL.SET THE BALANCE AS 17" x 8" WHEEL.

C. POSITION WHEEL BALANCE WEIGHT AS CLOSE AS POSSIBLEC. POSITION WHEEL BALANCE WEIGHT AS CLOSE AS POSSIBLE

TO SPOKE EDGE (MAXIMUM 5 mm) TO ENSURE SUFFICIENTTO SPOKE EDGE (MAXIMUM 5mm) TO ENSURE SUFFICIENT

CLEARANCE BETWEEN THE WHEEL WEIGHT AND BRAKE CALIPER.CLEARANCE BETWEEN THE WHEEL WEIGHT AND BRAKE CALIPER.

1. 10B-101919 CAP WHEEL NUT 5 PLACES1. 10B-101919 CAP WHEEL NUT 5 PLACES

2. 10B-970219 WHEEL NUT 4 PLACES2. 10B-970219 WHEEL NUT 4 PLACES

3. 10B-970309 CAP & BADGE ASM WHEEL3. 10B-970309 CAP & BADGE ASM WHEEL

4. WHEEL ALLOY 10B-0208014. WHEEL ALLOY 10B-020801

5. TYRE 235/40 ZR185. TYRE 235/40 ZR18

1

2

1

3

4

5

A

A

6. LOCKNUTS SPZ-3001686. LOCKNUTS SPZ-300168

61

Wheels, Tyres and Steering Wheel Page H-6

28-OCT-2003 Page H-6

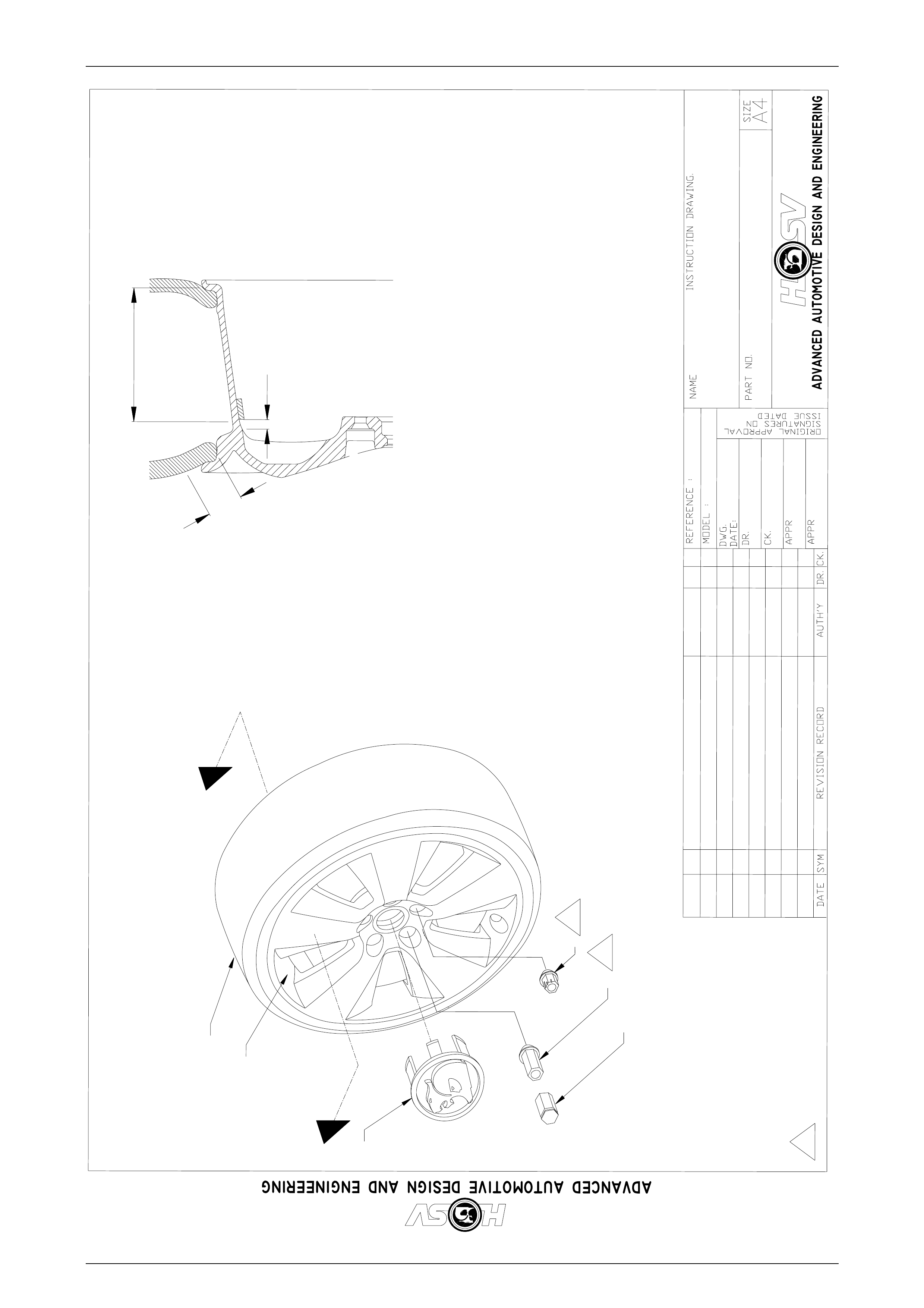

100 - 125 Nm100 -125 Nm

NOTE: BREAKAWAY TORQUENOTE: BREAKAWAY TORQUE

OF WHEEL NUTS TO BEOF WHEEL NUTS TO BE

100 Nm MINIMUM100 Nm MINIMUM

SEC A-A

RELEASE

1M.B

VY

T.K

D.P

20.05.02

10I-020005

-ALLOY WHEELALLOY WHEEL

SENATOR - 19"SENATOR - 19"

-

A. LUBRICATE TYRE BEADS BOTH SIDES FULL CIRCUMFERANCE

A. LUBRICATE TYRE BEADS BOTH SIDES FULL CIRCUMFERANCE

FOR A DISTANCE SHOWN WITH TYRE MOUNTING LUBRICANT IN ACCORDANCE WITHFOR A DISTANCE SHOWN WITH TYRE MOUNTING LUBRICANT IN ACCORDANCE WITH

HN-1162.TYRE INSTALATION MUST BE MADE BEFORE LUBRICANTHN-1162.TYRE INSTALATION MUST BE MADE BEFORE LUBRICANT

IS DRY TO ENSURE SATISFACTORY BEAD SEATING. TYRE IS TO BE INFLATED TOIS DRY TO ENSURE SATISFACTORY BEAD SEATING. TYRE IS TO BE INFLATED TO

280 kPa ON INITIAL ASSEMBLY.280 kPa ON INITIAL ASSEMBLY.

TYRE WHEN ASSEMBLED TO WHEEL IS NOT TO EXCEEDTYRE WHEN ASSEMBLED TO WHEEL IS NOT TO EXCEED

A DYNAMIC IMBALANCE OF 1.5 kg/mm AFTER BALANCINGA DYNAMIC IMBALANCE OF 1.5 kg/mm AFTER BALANCING

AND THE WEIGHT USED TO BE BALANCE IS NOT TO EXCEEDAND THE WEIGHT USED TO BE BALANCE IS NOT TO EXCEED

120 gm TOTAL AND 60 gm PER WHEEL FLANGE.120 gm TOTAL AND 60 gm PER WHEEL FLANGE.

B. WITH CONCEALED BALANCE WEIGHTS FITTED AS SHOWNB. WITH CONCEALED BALANCE WEIGHTS FITTED AS SHOWN

SET THE BALANCE AS 18" x 8" WHEEL.SET THE BALANCE AS 18" x8"WHEEL.

C. POSITION WHEEL BALANCE WEIGHT AS CLOSE AS POSSIBLEC. POSITION WHEEL BALANCE WEIGHT AS CLOSE AS POSSIBLE

TO SPOKE EDGE (MAXIMUM 5 mm) TO ENSURE SUFFICIENTTO SPOKE EDGE (MAXIMUM 5mm) TO ENSURE SUFFICIENT

CLEARANCE BETWEEN THE WHEEL WEIGHT AND BREAK CALIPER.CLEARANCE BETWEEN THE WHEEL WEIGHT AND BREAK CALIPER.

1. 10B-101919 CAP WHEEL NUT 5 PLACES1. 10B-101919 CAP WHEEL NUT 5 PLACES

2. 10B-970219 WHEEL NUT 4 PLACES2. 10B-970219 WHEEL NUT 4 PLACES

3. 10B-970309 CAP & BADGE ASM WHEEL3. 10B-970309 CAP & BADGE ASM WHEEL

4. WHEEL ALLOY 10B-0208044. WHEEL ALLOY 10B-020804

5. TYRE 245/35 ZR195. TYRE 245/35 ZR19

2

6

1

1

3

4

5

A

A

B

A

C

6. LOCKNUTS SPZ-3001686. LOCKNUTS SPZ-300168

1