CAUTION

When fasteners are removed, always

reinstall them at the same location from

which they were removed. If a fastener

needs to be replaced, use the correct part

number fastener for that application. If the

correct part number fastener is not available,

a fastener of equal size and strength (or

stronger) may be used.

Fasteners that are not reused, and those

requiring thread locking compound, will be

called out. The correct torque values must

be used when installing fasteners that

require it. If the above conditions are not

followed, parts or system damage could

result.

SECTION 2A - HEATING AND VENTILATION

General Description

Heater

Control Lever Assembly

Ventilation

Air Select Knob

Air Source Select Lever

Fan Control Knob

Temperature Control Knob

Ceramic Heater

On-Vehicle Service

Heater Unit

Heater Core and/or Mode Door

Heater Mode Control Link Unit

Heater Temperature Control Link Unit

Blower Assembly

Blower Link Unit and/or Mode Door

Blower Motor

Rear Heater Duct, Defroster Nozzle and Ventilation Duct

Center and/or Side Vent

Control Lever Assembly and/or Control Cables

Control Panel Illumination Bulb

Resistor

When the engine warming up, the warmed engine

coolant is sent out into the heater core. The heater

system supplies warm air into the passenger

compartment to warm it up.

Outside air is circulated through the heater core of

the heater unit and then back into the passenger

compartment. By controlling the mixture of outside

air and heater core air, the most comfortable

passenger compartment temperature can be

selected and maintained.

The temperature of warm air sent to the passenger

compartment is controlled by the temperature

control knob. This knob acts to open and close the

air mix door, thus controlling the amount of air

passed through the heater core.

The air select knob, with its different modes, also

allows you to select and maintain the most

comfortable passenger compartment temperature.

The air source select lever is used to select either

“FRESH” for the introduction of the outside air, or

“CIRC” for the circulation of the inside air. When

the lever is set to “FRESH”, the outside air is always

taken into the passenger compartment. When

setting the lever to “CIRC” position, the circulation

of air is restricted only to the inside air with no

introduction of the outside air and the air in the

passenger compartment gets warm quickened.

However, the lever is normally set to “FRESH” to

prevent the windshield from clouding.

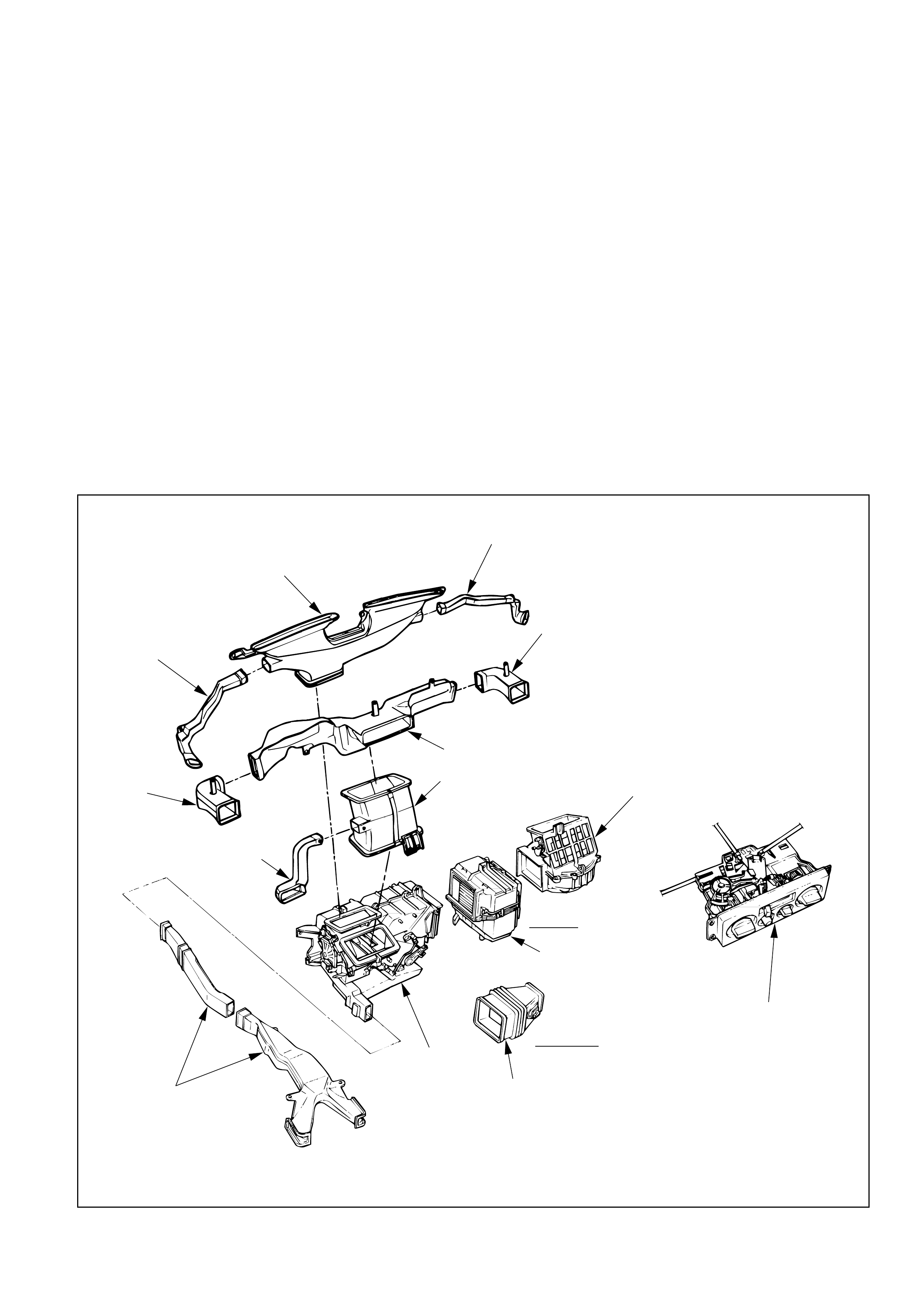

GENERAL DESCRIPTION

HEATER

Side def hose

Vent box

Upper center vent duct

Lower center

vent duct Blower assembly

Control lever assembly

Evaporator

assembly

W/A/C

W/O A/C

Duct

Heater unit

Lap vent nozzle

Vent box

Side def hose

Defroster nozzle

Rear heater duct

A/C - Air Conditioning

This illustration is based on LHD

This illustration is based on LHD

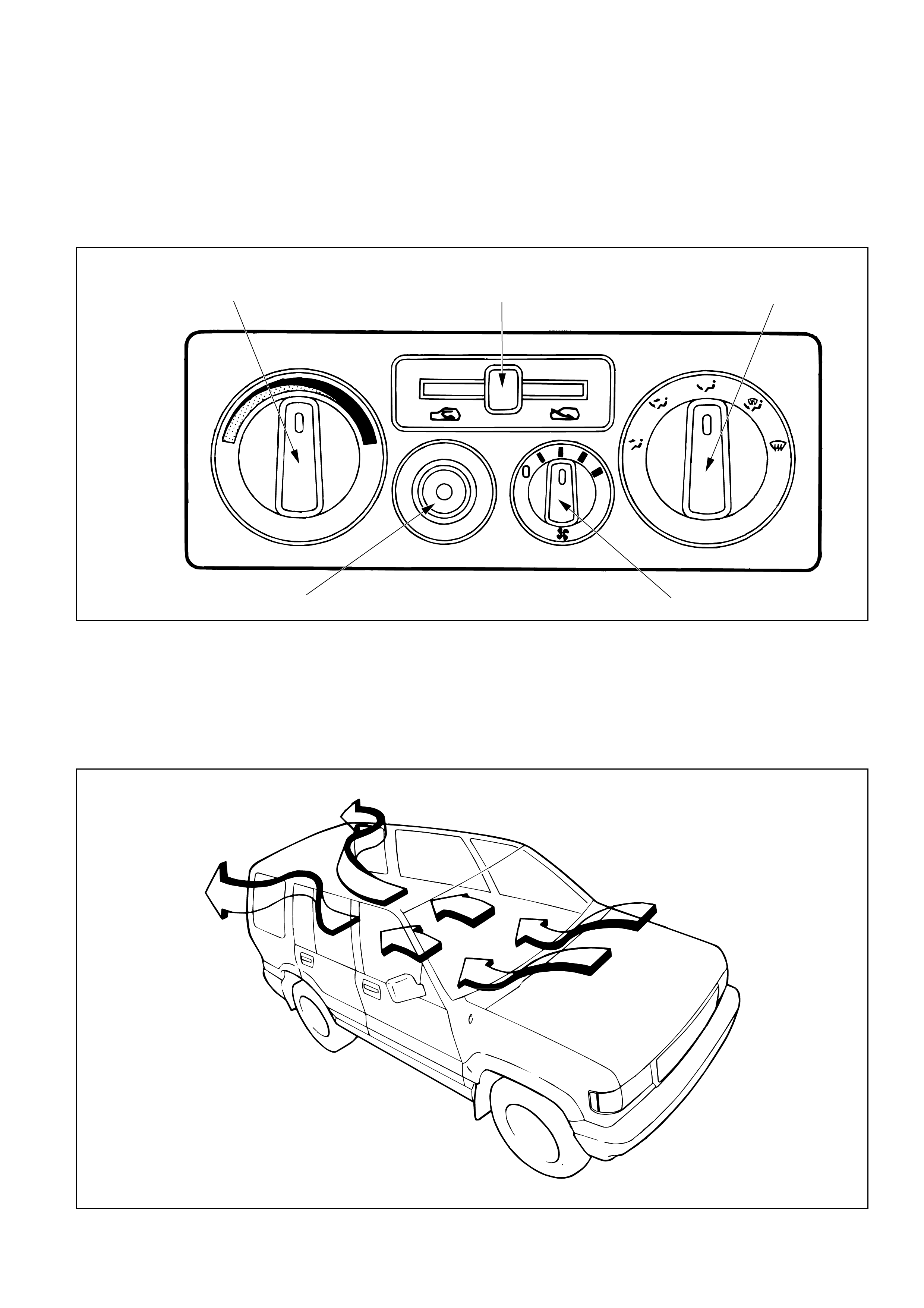

Temperature control knob

A/C switch (W/A/C)

TEMP

A/C

Fan control knob(Fan switch)

Air source select lever Air select knob

The vehicle has cable-control-type to control by

cable the mode and temperature of the heater unit

and the mode door for the air source of the blower

assembly.

The fan control is used to control the amount of air

sent out by the resistor at four levels from “LOW”

to “HIGH”.

CONTROL LEVER ASSEMBLY

VENTILATION

Set “AIR SOURCE SELECT LEVER” to “FRESH”

position and turn on the blower fan. Heating can be

done in this lever position, sending in fresh air from

outside.

The blower fan also serves to deliver fresh outside

air to the vehicle interior to assure adequate

ventilation.

AIR SELECT KNOB

The air selector knob allows you to direct heated air

into the passenger compartment through different

outlets.

1. Vent - In this position, air is discharged from

the upper air outlet. Air quantity is controlled

by the fan control knob.

2. Bi-Level - In this position, air flow is divided

between the upper air outlets and the foot air

outlets, with warmer air delivered to the floor

outlets than the air delivered to the upper air

outlets.

3. Foot - In this position, air flow is delivered to

the foot while sending approx. 30% of total

amount of air to the windshield

4. Def/Foot - In this position, air flow is delivered

to the foot, while sending approx. 40% of total

amount of air to the windshield.

5. Defrost - In this position, most of the air is

delivered to the windshield and a small

amount is delivered to the side windows.

Moving the air source select lever to the “CIRC”

position provides quickest heat delivery by closing

the blower assembly mode door. In this position,

outside air is not delivered to the passenger

compartment.

AIR SOURCE SELECT LEVER

The intake of outside air and the circulation of inside

air are controlled by sliding this lever left or right.

FAN CONTROL KNOB

This knob controls the blower motor speed to

regulate the amount of air delivered to the defrost,

foot, and ventilation ducts:

1. Low

2. Medium Low

3. Medium High

4. High

TEMPERATURE CONTROL KNOB

When the temperature control knob is in the

“COLD” position, the air mix door closes to block

the flow of air to the heater core.

When the temperature control knob is in the

“HOT” position, the air mix door opens to allow air

to pass through the heater core and heat the

passenger compartment.

Placing the knob in an intermediate position will

cause a lesser or greater amount of air to reach the

heater core. In this mode the passenger compart-

ment temperature can be regulated.

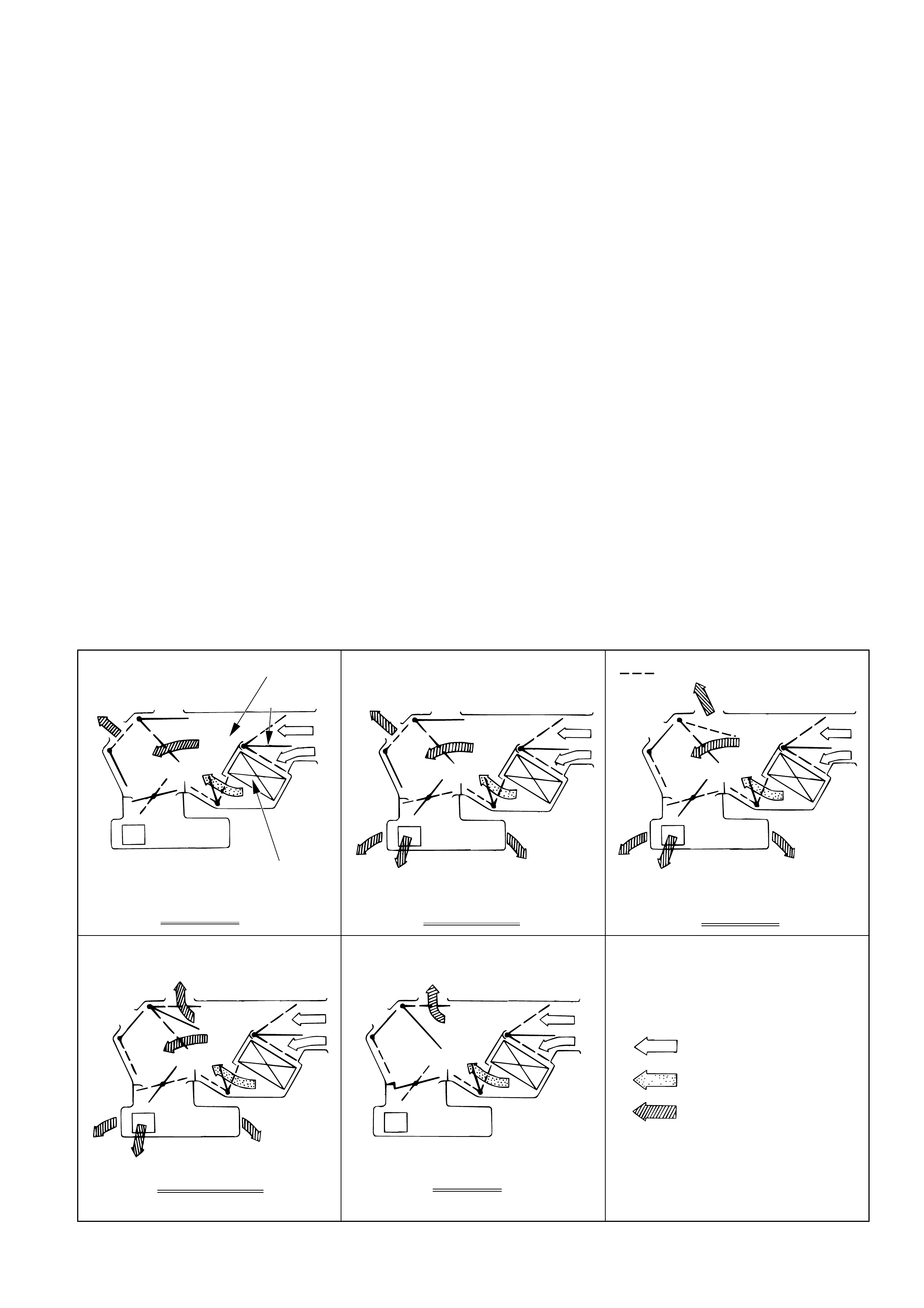

Heater core

Heater unit

TO VENT OUTLET Air mix door

VENT MODE

TO FOOT

TO VENT OUTLET

BI-LEVEL MODE

FOOT MODE

TO FOOT OUTLET

TO DEF OUTLET(LHD)

DEF/FOOT MODE

TO FOOT OUTLET

TO DEF OUTLET

DEF MODE

TO DEF OUTLET

: COLD AIR

: HOT AIR

: TEMP.CONTROLLED AIR

Full hot switch

Ceramic heater

Heater unit

CERAMIC HEATER

When the fan control knob (fan switch) turns on with the temperature control knob set to “FULL HOT” (full

hot switch “ON”), the ceramic heater in the heater unit gets hot, thus causing the heater blow temperature

of diesel vehicle to get high to improve the heating performance (Since the engine coolant temperature of

diesel vehicle is low, its blow temperature is also low.).

Glow plug

Full hot switch

Fan switch

Thermo switch

Less than 80°C (177.8°F)

CERAMIC HEATER

“ON”CERAMIC HEATER

“OFF”

OFF

ON

OFF

OFF

OFF

ON

ON

ON

This illustration is based on RHD

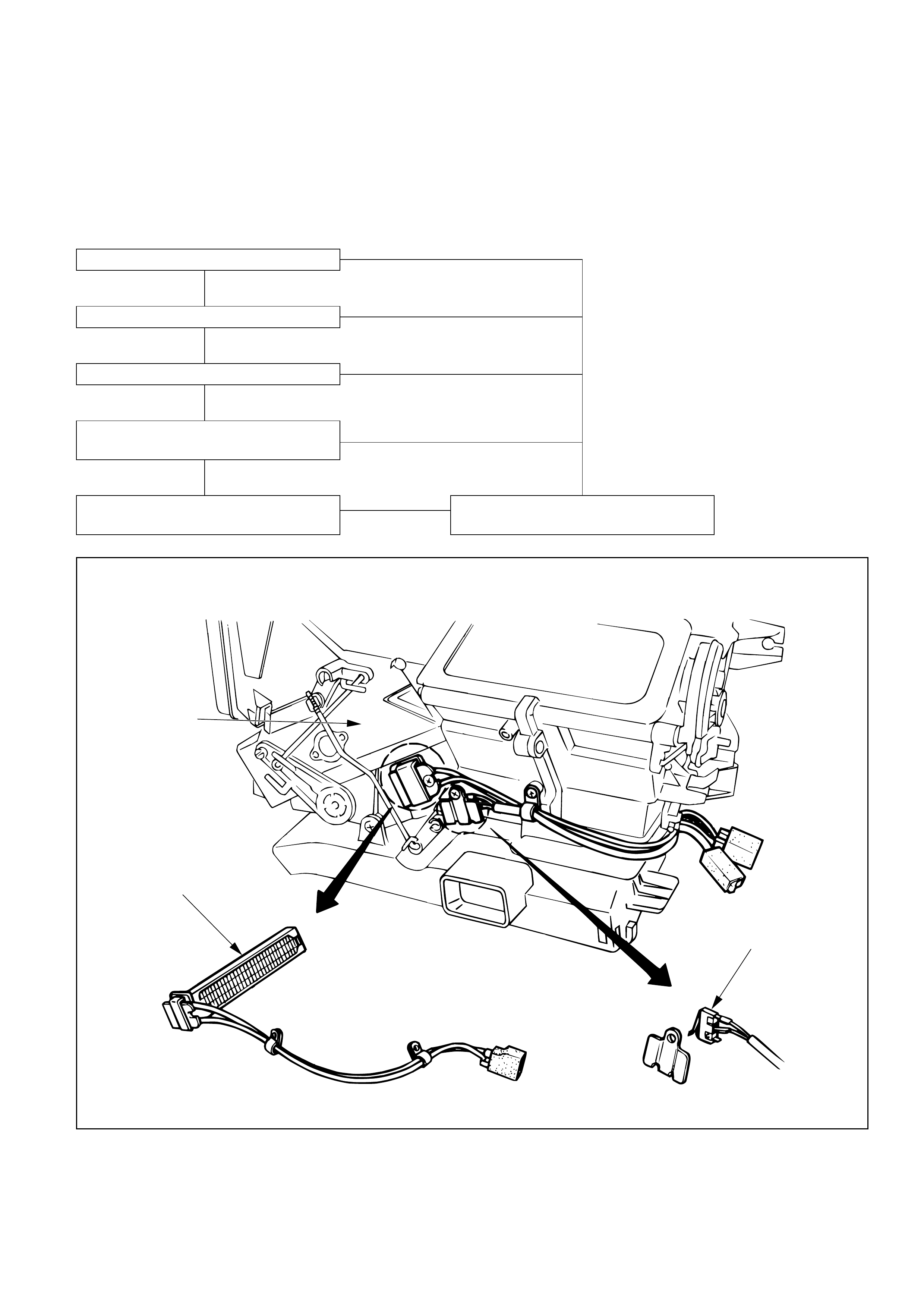

ON-VEHICLE SERVICE

HEATER UNIT

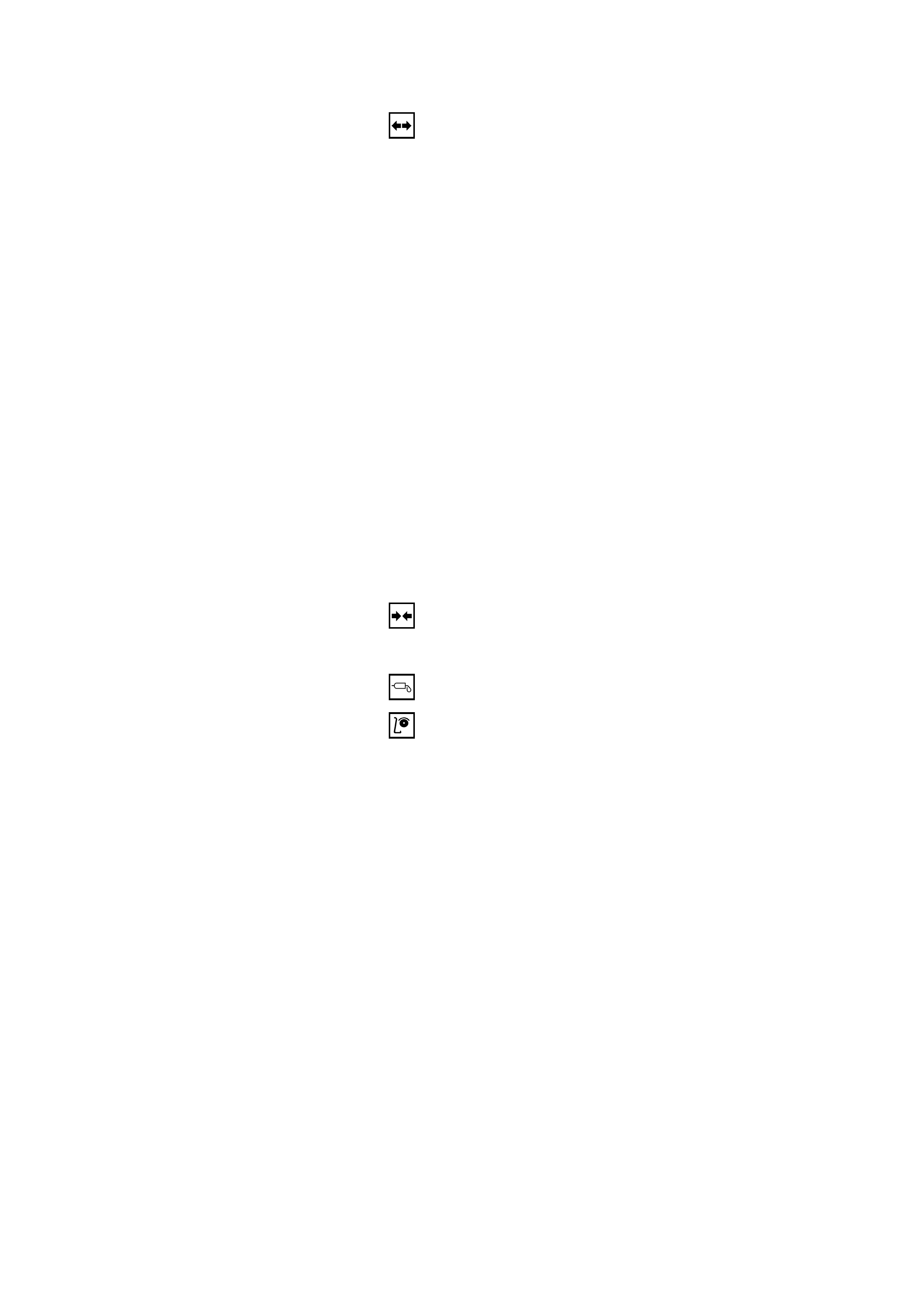

4a

5

3

4

2

6

9

8

7

1

Electro thermo connector (With A/C)

Resistor

Removal Steps

1. Instrument panel assembly

2. Water hose

3. Resistor connector

4. Duct

4a. Evaporator assembly (A/C only)

5. Instrument panel center bracket

6. Rear heater duct

7. Heater unit

8. Lap vent nozzle

9. Center ventilation lower duct

Installation Steps

To install, follow the removal steps in the

reverse order

This illustration is based on LHD

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. When handling the ECM and the control unit, be

careful not to make any improper connection of the

connectors.

2. Adjust control lever assembly cables.

Refer to “CONTROL LEVER ASSEMBLY” installation

steps in this section.

3. When installing the heater unit, defroster nozzle and

center vent duct, be sure that proper seal is made,

without any gap between then.

REMOVAL

Preparation:

• Disconnect the battery ground cable

• Drain engine coolant

• Discharge and recover refrigerant (W/A/C)

(Refer to Section 2B “REFRIGERANT RECOVERY”)

1. Instrument Panel Assembly

Refer to Section 1 “BODY” for INSTRUMENT PANEL

ASSEMBLY removal procedure.

2. Water Hose

Disconnect water hoses at heater unit.

3. Resistor Connector

4. Duct

4a. Evaporator Assembly

Refer to Section 2B “AIR CONDITIONING” for

Evaporator Assembly removal procedure.

5. Instrument panel center bracket

6. Rear Heater Duct

7. Heater Unit

8. Lap vent nozzle

9. Center ventilation lower duct

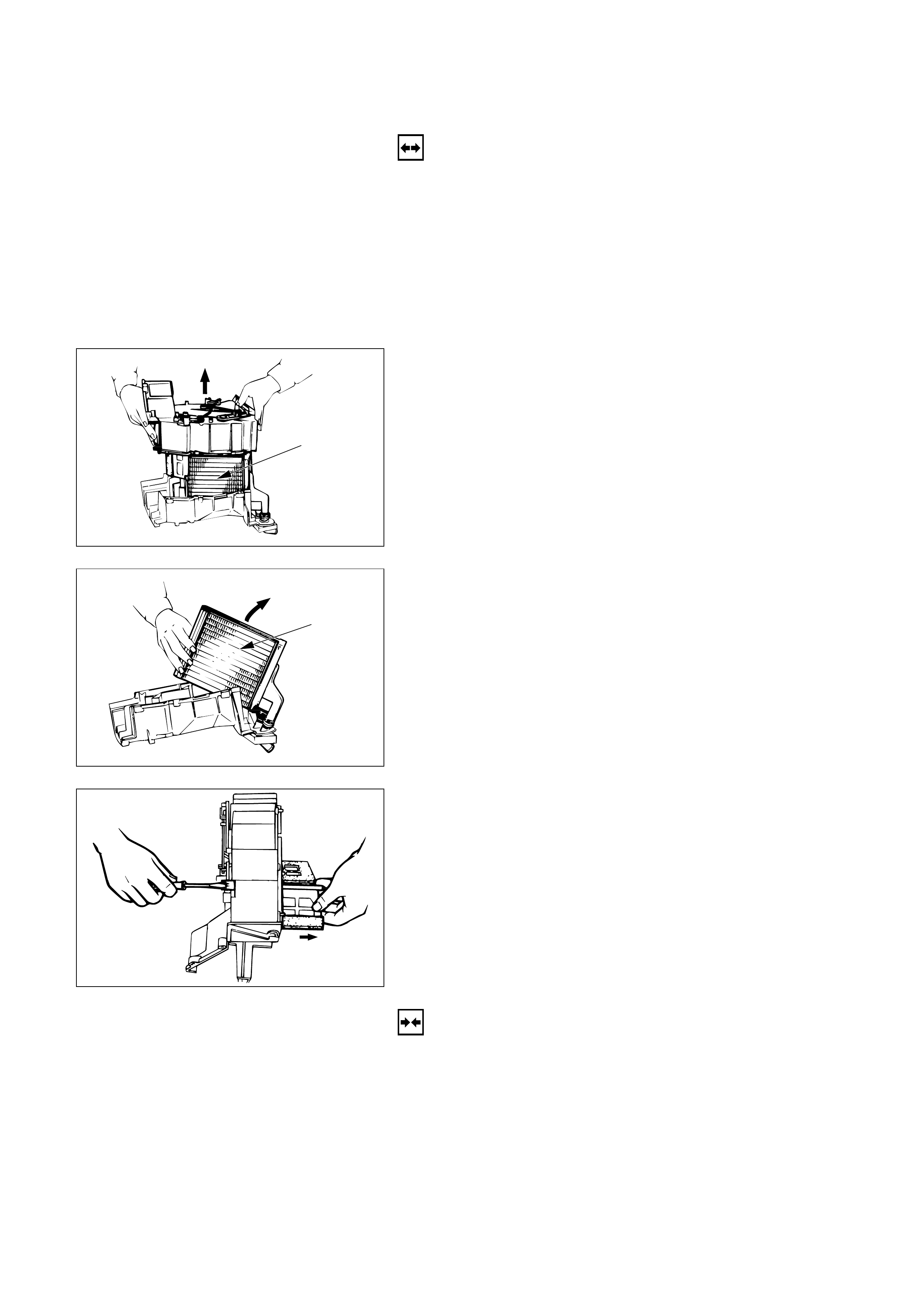

Removal Steps

1. Heater unit

2. Duct

3. Case (Mode control)

4. Case (Temperature control)

5. Heater core

6. Mode door

Installation Steps

To install, follow the removal steps in the

reverse order.

HEATER CORE AND/OR MODE DOOR

4

5

3

2

16

This illustration is based on LHD

REMOVAL

Preparation:

• Disconnect the battery ground cable

• Drain engine coolant

1. Heater Unit

Refer to “HEATER UNIT” removal procedure in this

section.

2. Duct

3. Case (Mode Control)

Do not remove link unit at this step.

4. Case (Temperature Control)

Separate two halves of core case.

Heater core

5. Heater Core

Heater core

6. Mode Door

Pull out the mode door while raising up the catch of

the door lever.

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following point:

1. Check that each mode door operates properly.

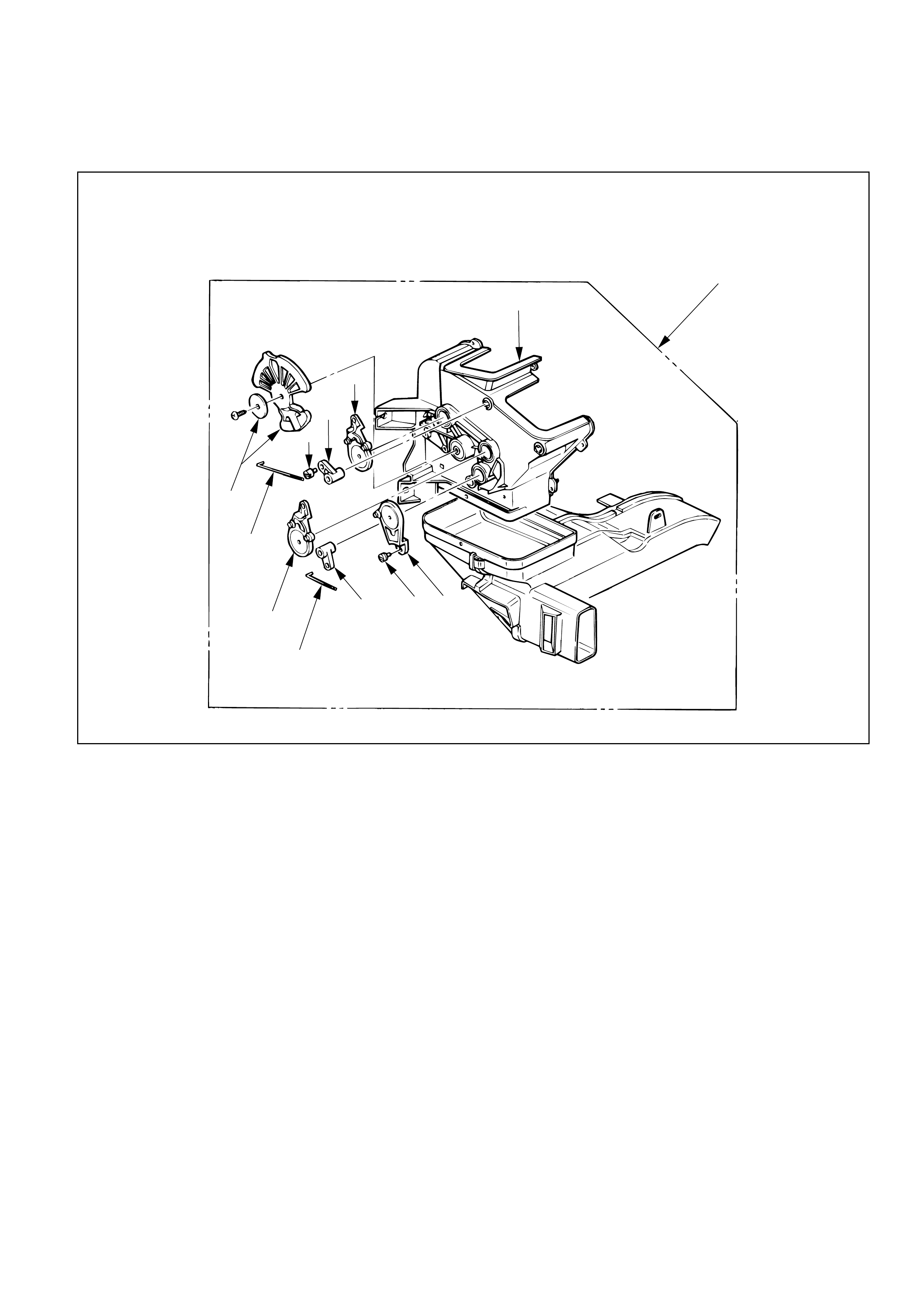

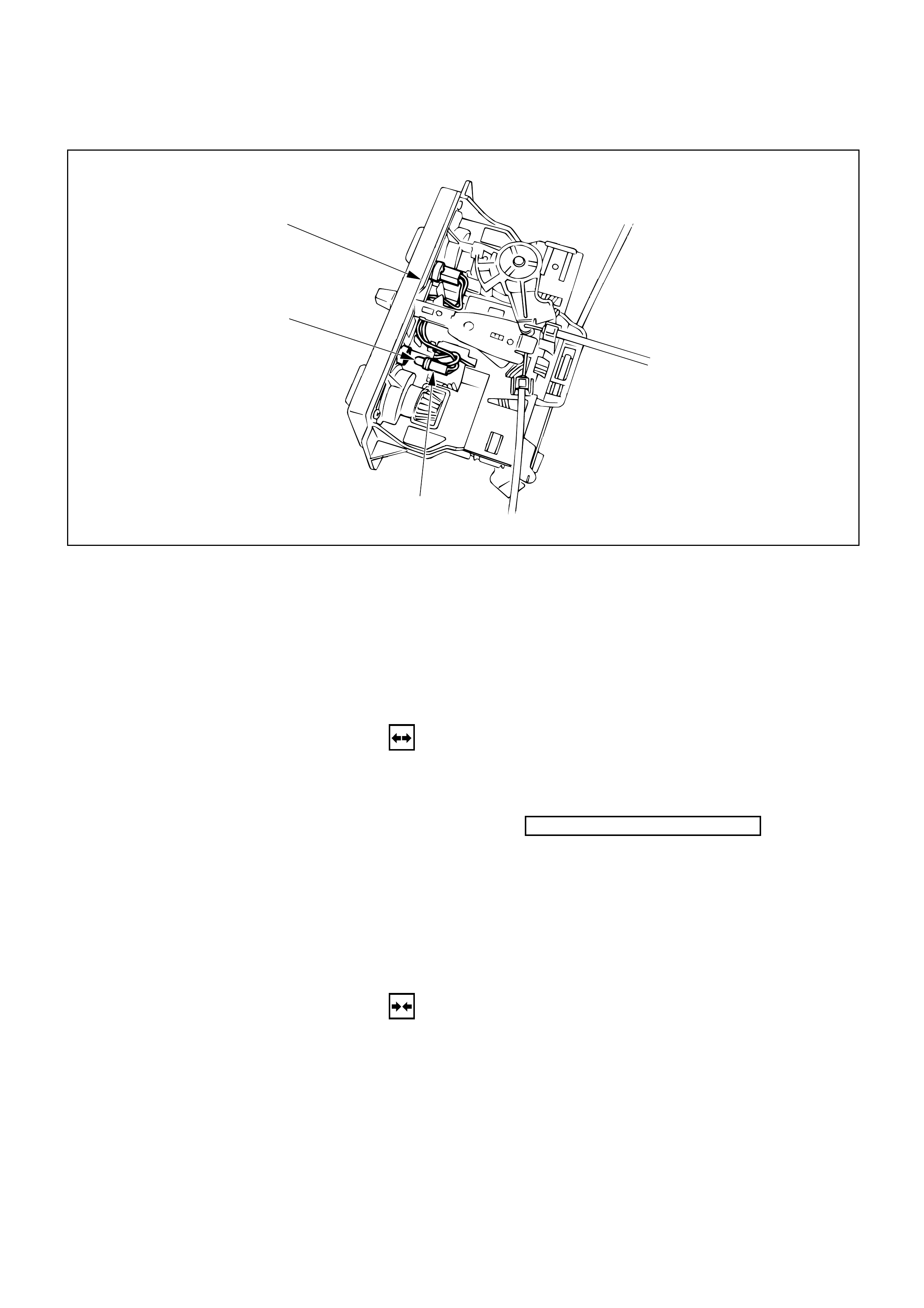

Removal Steps

1. Heater unit

2. Case (Mode control)

3. Washer and mode main lever

4. Rod

5. Mode sub-lever

6. Door lever

7. Clip

Installation Steps

To install, follow the removal steps in the

reverse order.

HEATER MODE CONTROL LINK UNIT

This illustration is based on LHD

1

2

5

6

7

3

4

5

4

675

REMOVAL

Preparation:

• Disconnect the battery ground cable

• Drain engine coolant

1. Heater Unit

Refer to “HEATER UNIT” removal procedure in this

section.

2. Case (Mode Control)

Remove the case (Mode control) from heater unit.

3. Washer and Mode Main Lever

4. Rod

5. Mode Sub-Lever

Press the tab of the sub-lever inward, and take out the

sub-lever.

6. Door Lever

Pull out the door lever while raising up the catch of

the door lever.

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. Apply grease to mode sub-lever and to the abrasive

surface of the heater unit.

2. After installing the link unit, check to see if the link

unit operates correctly.

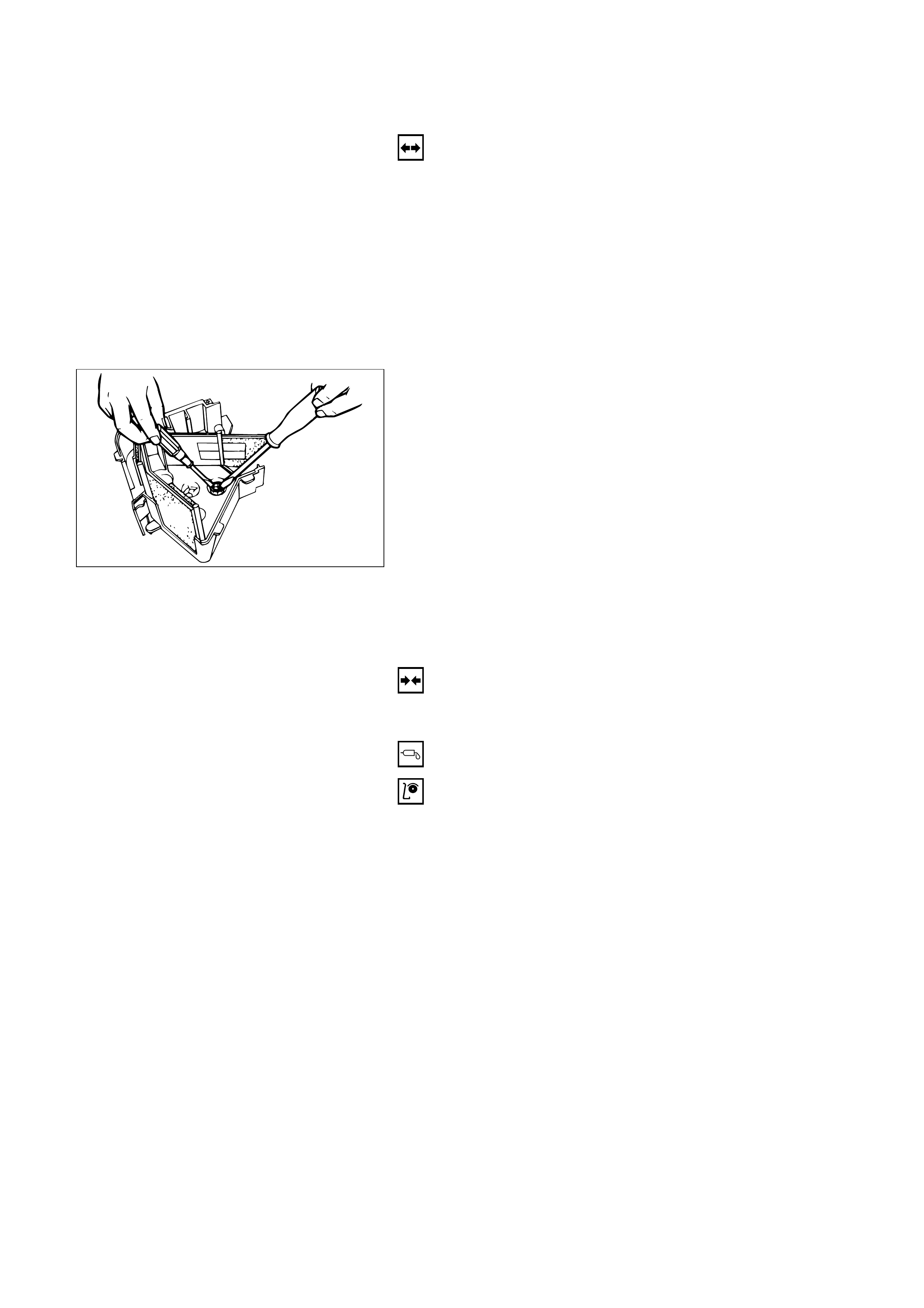

Removal Steps

1. Heater unit

2. Case (Temperature control)

3. Rod

4. Sub-lever

5. Door lever

6. Clip

Installation Steps

To install, follow the removal steps in the

reverse order.

HEATER TEMPERATURE CONTROL LINK UNIT

2

5

6

6

4

51

3

This illustration is based on LHD

REMOVAL

Preparation:

• Disconnect the battery ground cable

• Drain engine coolant

1. Heater Unit

Refer to “HEATER UNIT” removal procedure in this

section.

2. Case (Temperature Control)

Remove the case (Temperature control) from the

heater unit.

3. Rod

4. Sub-Lever

5. Door Lever

Pull out the door lever while raising up the catch of

the door lever.

6. Clip

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. Apply grease to sub-lever and to the abrasive surface

of the heater unit.

2. After installing the link unit, check to see if the link

unit operates correctly.

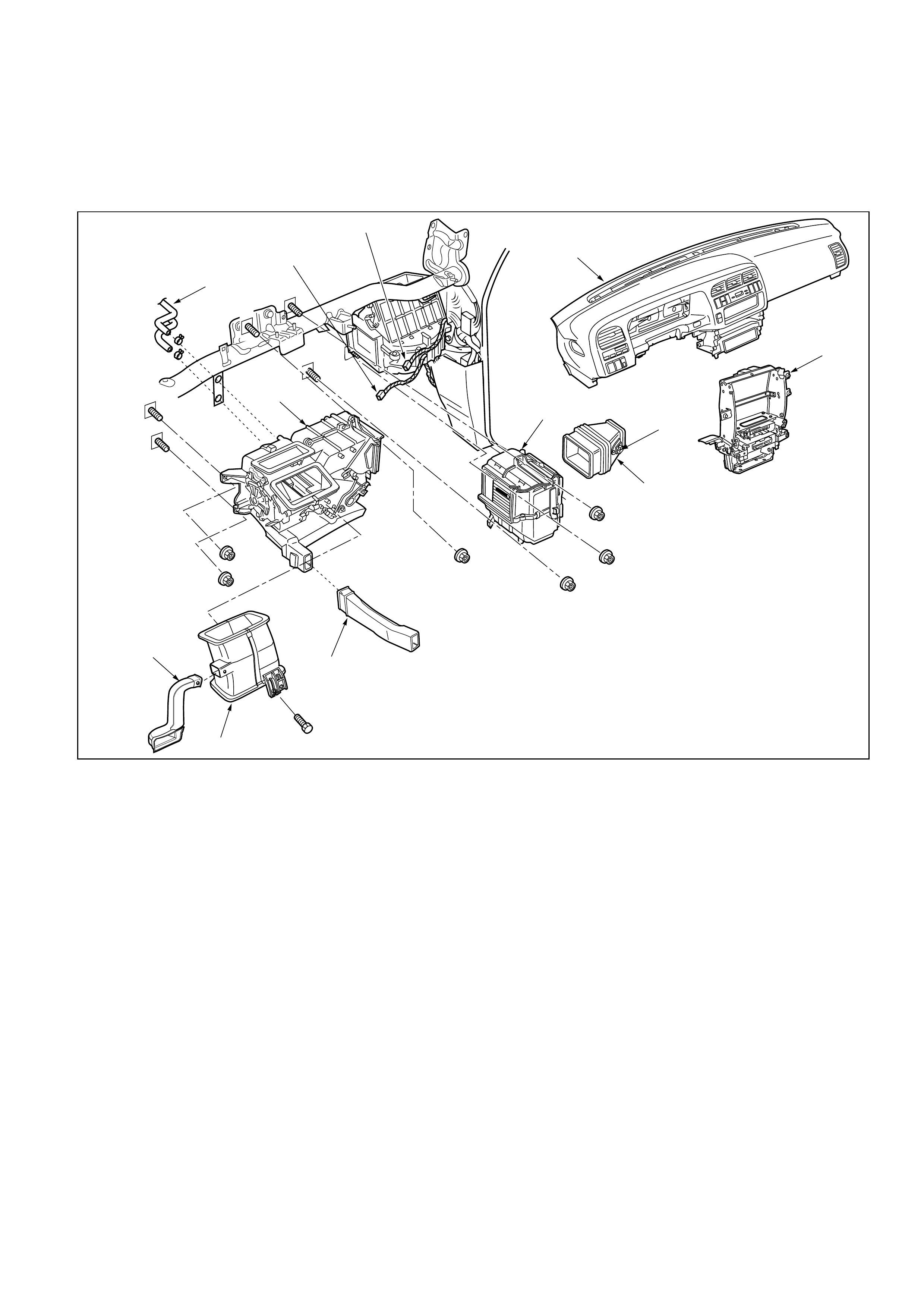

Removal Steps

1. Instrument panel assembly

2. Resistor connector

3. Duct

3a. Evaporator assembly (A/C only)

4. Kick panel

5. Blower motor connector

6. Blower assembly

Installation Steps

To install, follow the removal steps in the

reverse order.

BLOWER ASSEMBLY

2

3a(With A/C)

3

Heater unit

Electro thermo connector

(With A/C)

14

6

5

This illustration is based on LHD

REMOVAL

Preparation:

• Disconnect the battery ground cable

• Discharge and recover refrigerant (W/A/C)

(Refer to Section 2B “REFRIGERANT RECOVERY”)

1. Instrument Panel Assembly

Refer to Section 1 “BODY” for INSTRUMENT PANEL

ASSEMBLY removal procedure.

2. Resistor Connector

3. Duct

3a. Evaporator Assembly (A/C only)

Refer to Section 2B “AIR CONDITIONING” for

EVAPORATOR ASSEMBLY removal procedure.

4. Kick panel

5. Blower Motor Connector

6. Blower Assembly

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following point:

1. Adjust Control Lever Assembly Cables

Refer to “CONTROL LEVER ASSEMBLY” installation

procedure in this section.

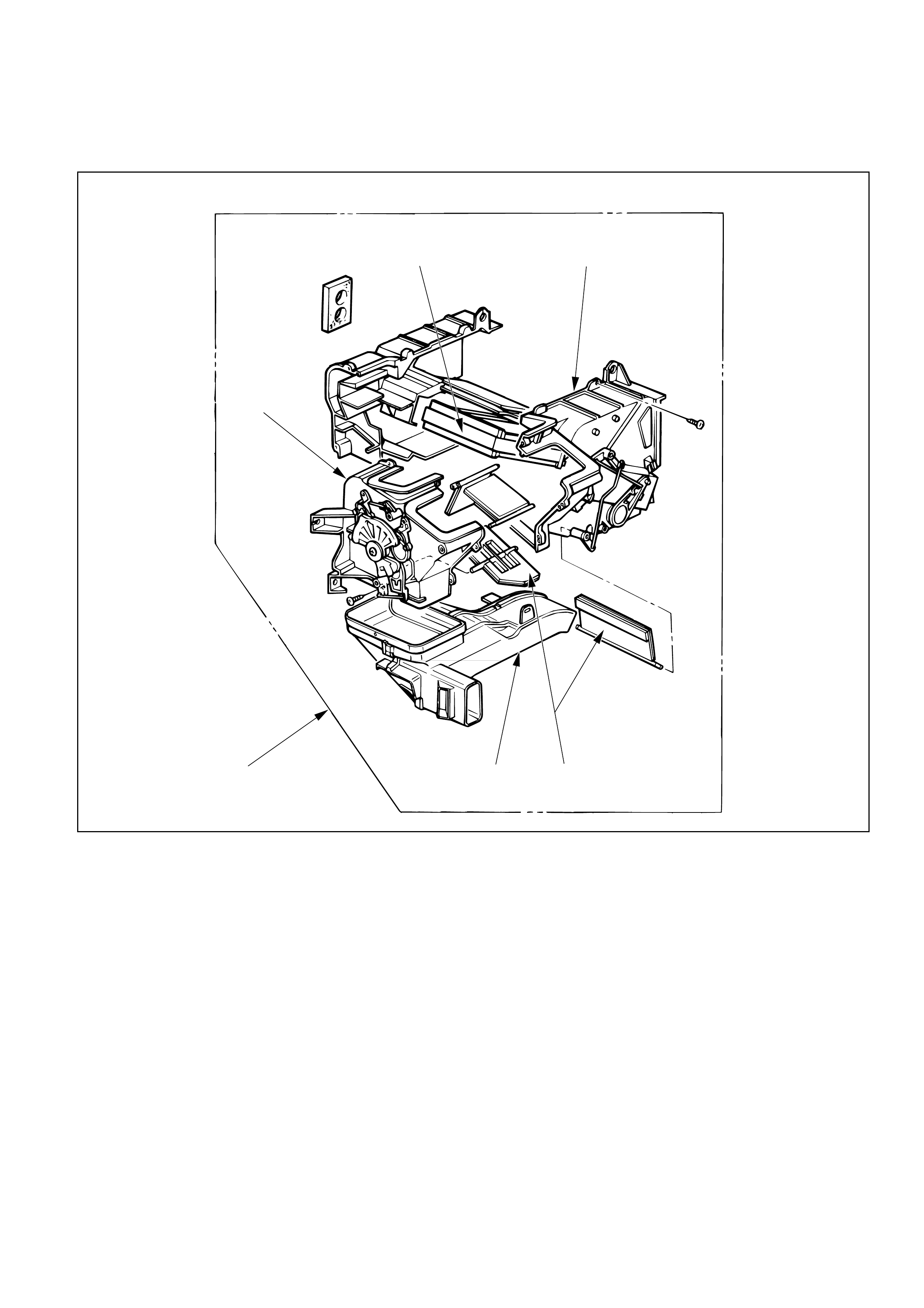

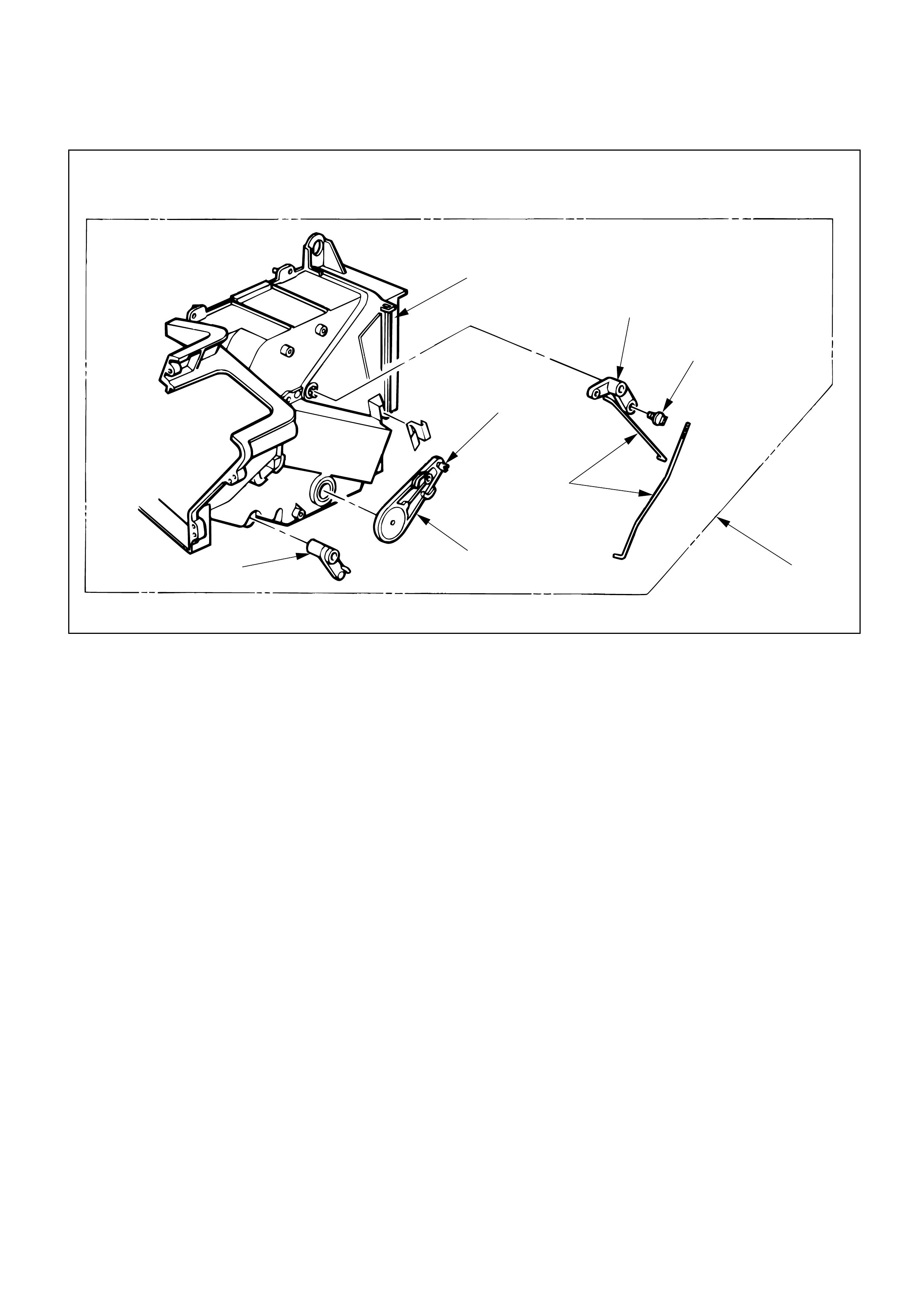

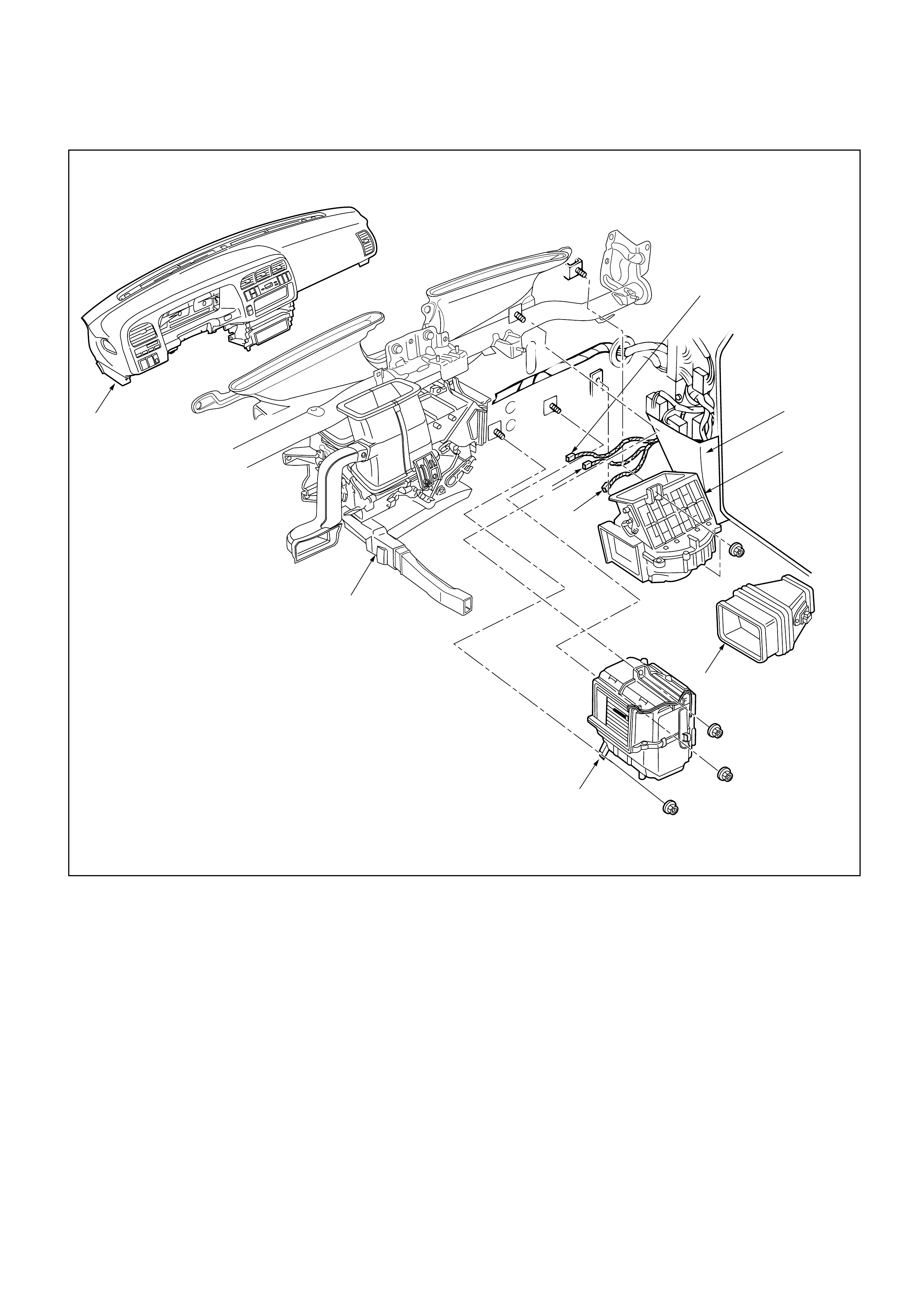

Removal Steps

1. Blower assembly

2. Lower case

3. Upper case

4. Mode door

5. Sub-lever

6. Door lever

Installation Steps

To install, follow the removal steps in the

reverse order.

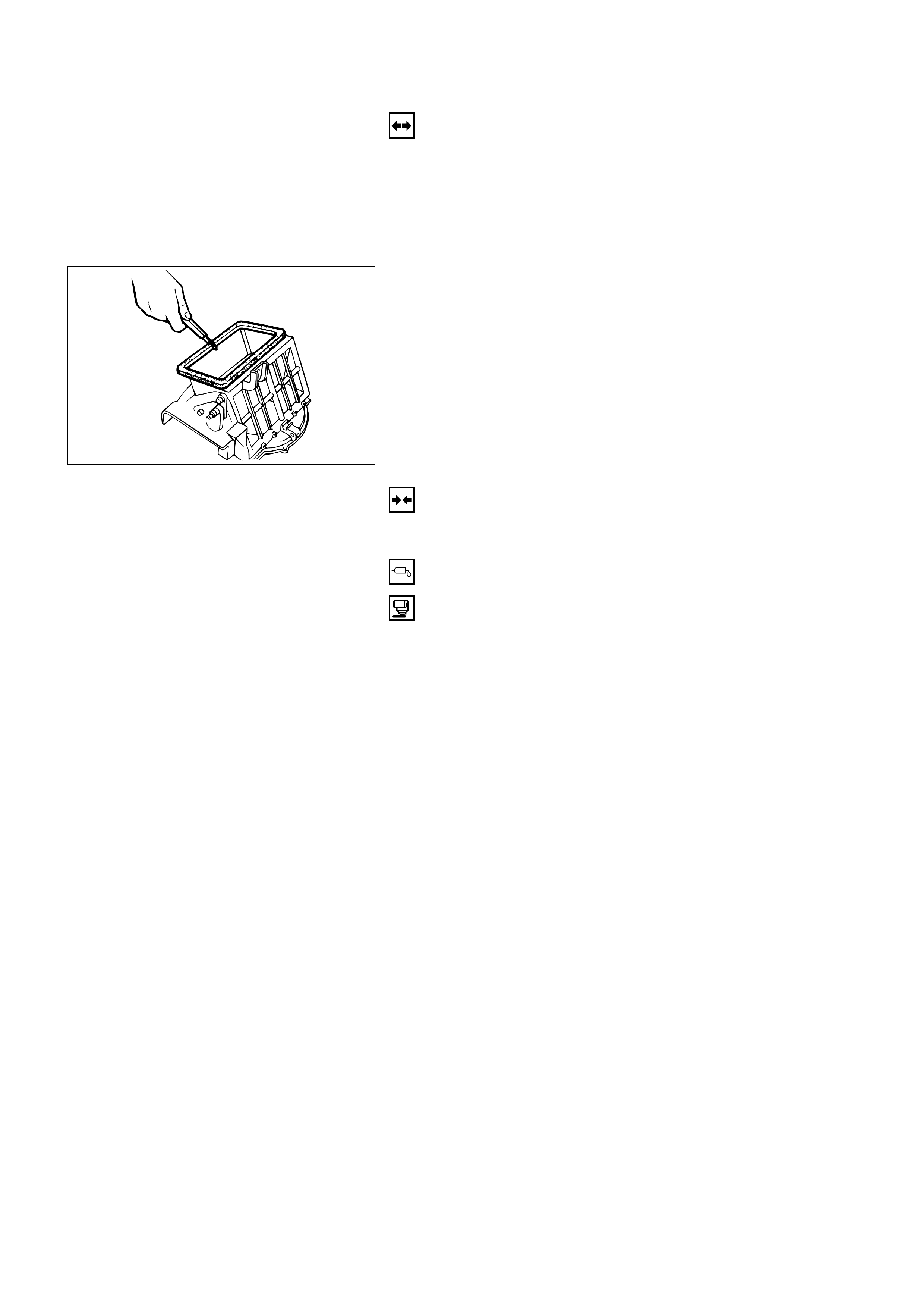

BLOWER LINK UNIT AND/OR MODE DOOR

This illustration is based on LHD

1

3

6

2

4

5

REMOVAL

Preparation:

Disconnect the battery ground cable

1. Blower Assembly

Refer to “BLOWER ASSEMBLY” removal procedure

in this section.

2. Lower Case

3. Upper Case

Separate upper case and slit the lining parting face

with a knife.

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. Apply grease to the door lever and to the abrasive

surface of the upper case.

2. Apply an adhesive to parting face of lining when

assembling upper case.

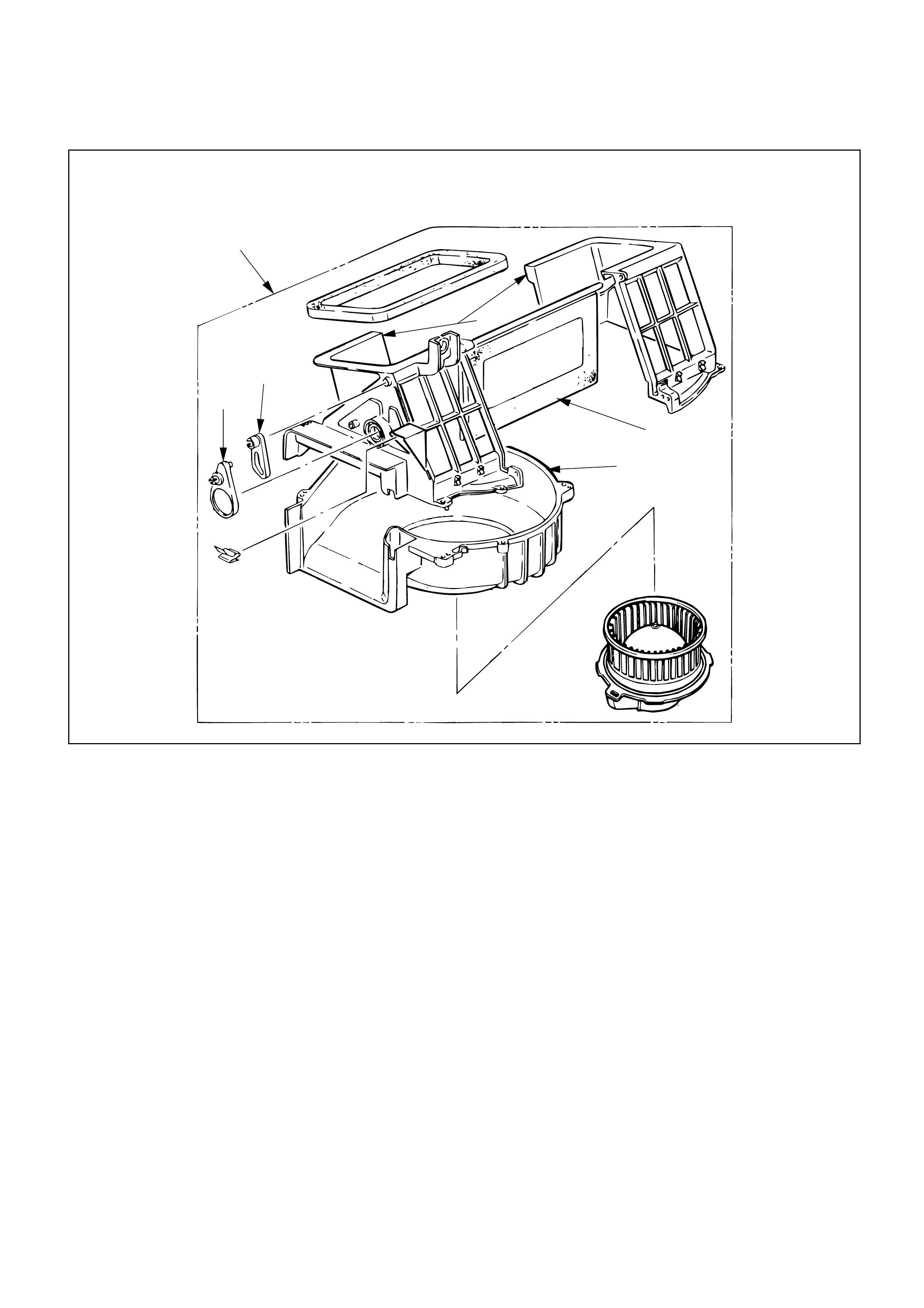

3

4

2

1

5

6

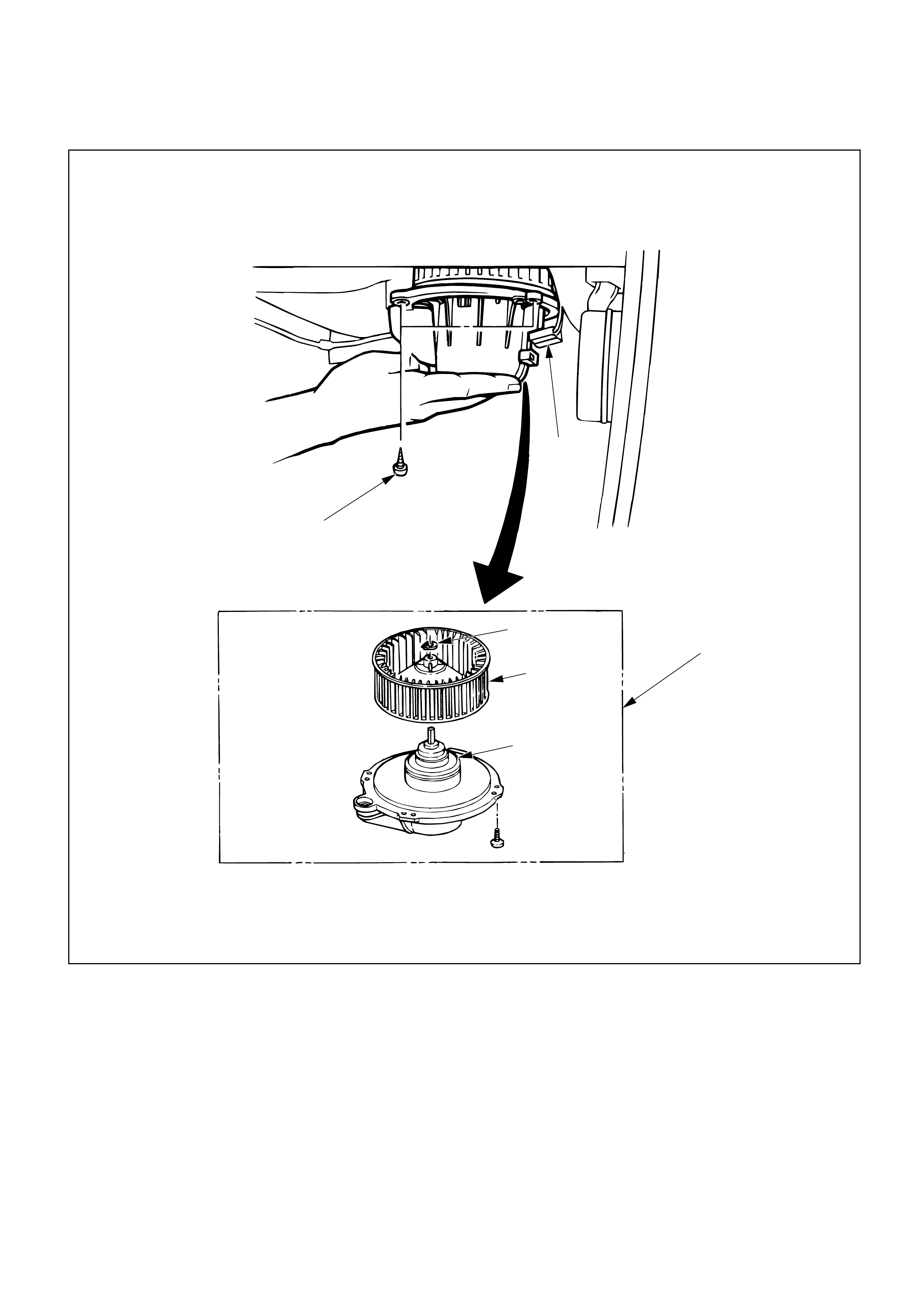

Removal Steps

1. Blower motor connector

2. Attaching screw

3. Blower motor assembly

4. Clip

5. Fan

6. Blower motor

Installation Steps

To install, follow the removal steps in the

reverse order.

BLOWER MOTOR

This illustration is based on LHD

REMOVAL

Preparation:

Disconnect the battery ground cable

1. Blower Motor Connector

2. Attaching Screw

3. Blower Motor Assembly

4. Clip

5. Fan

6. Blower Motor

INSTALLATION

To install, follow the removal steps in the reverse order.

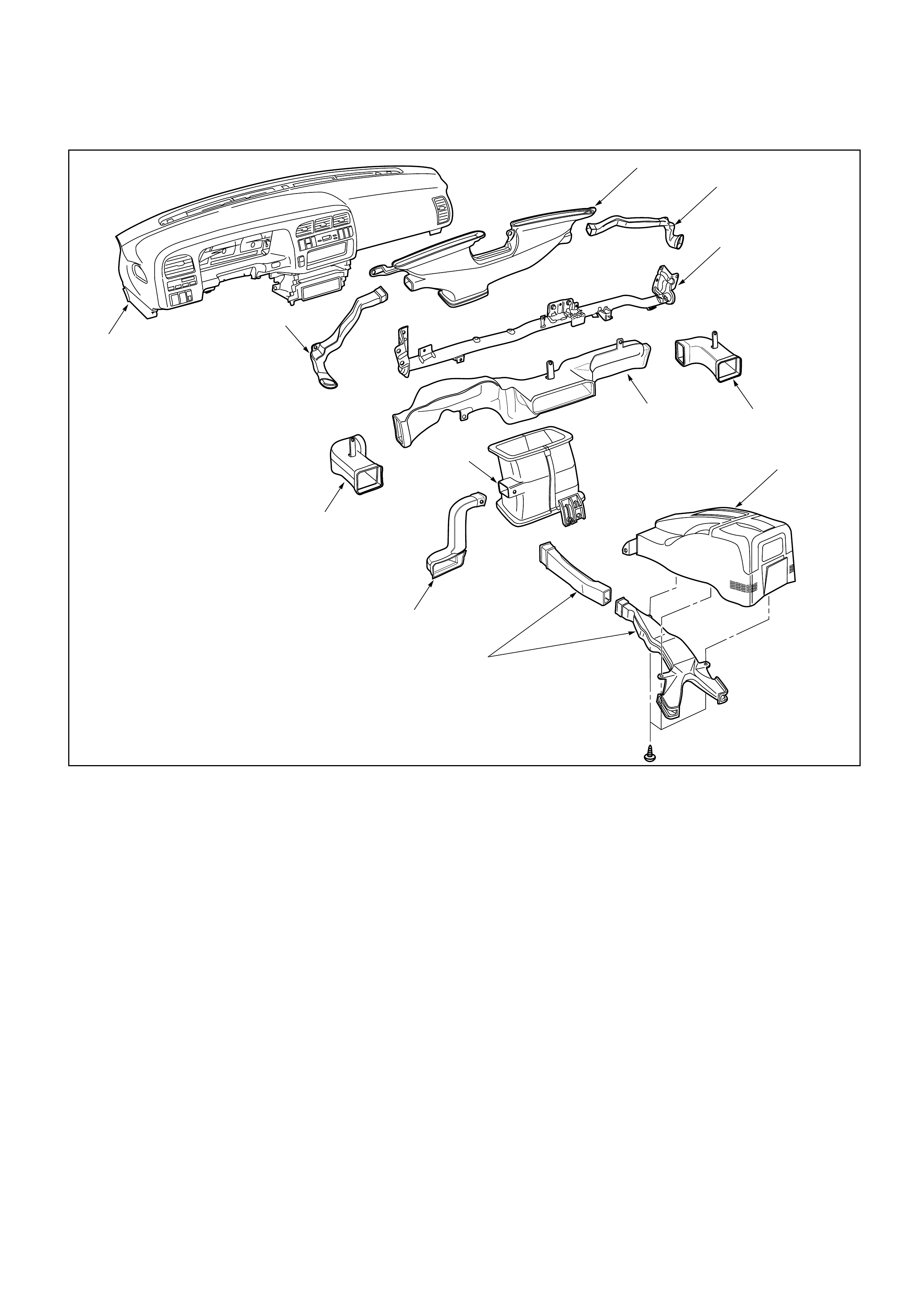

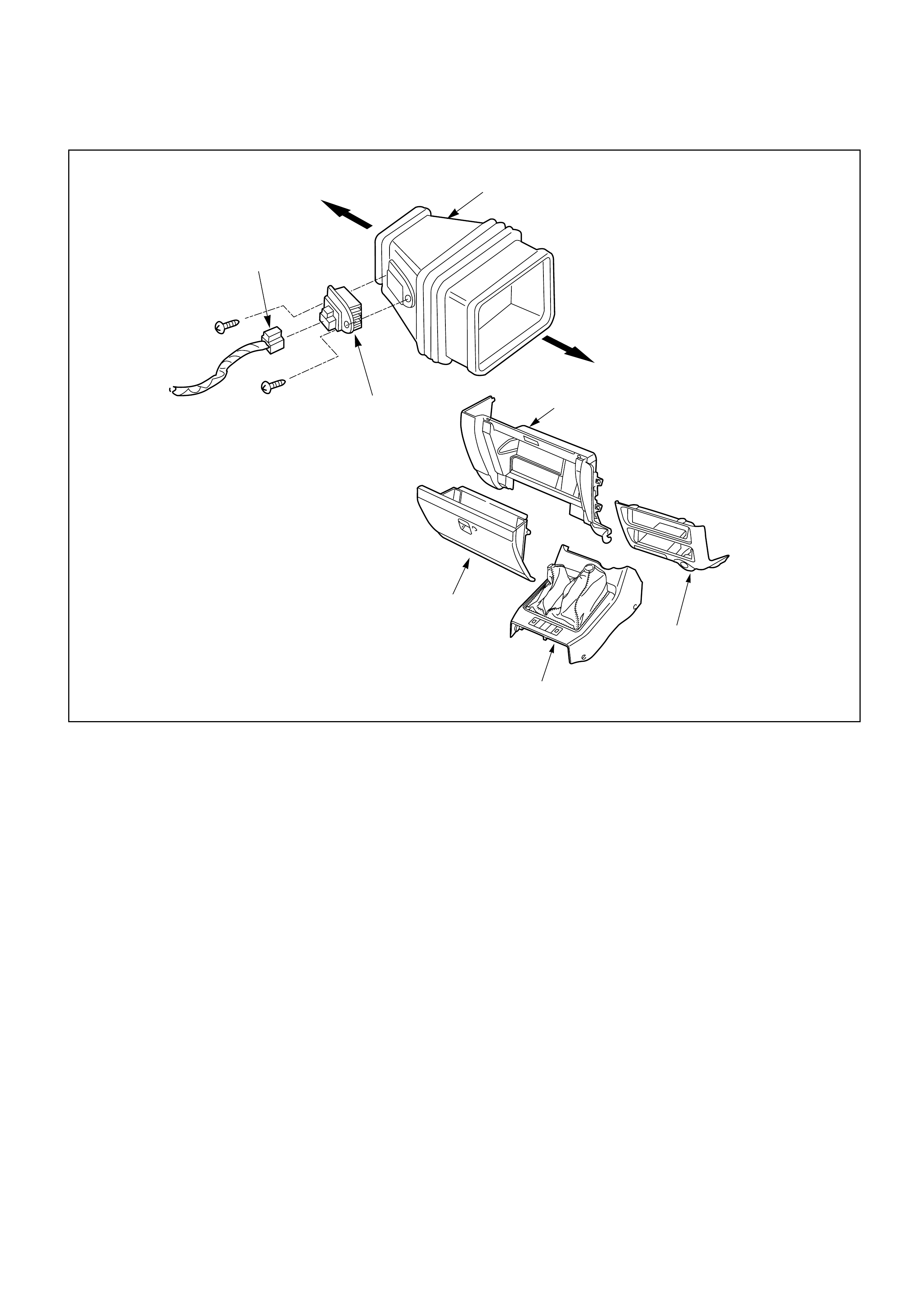

REAR HEATER DUCT, DEFROSTER NOZZLE AND VENTILATION DUCT

Removal Steps

1. Instrument panel assembly

2. Center ventilation upper duct

3. Side ventilation duct

4. Center ventilation lower duct

5. Driver lap duct

6. Center console

7. Rear heater duct

8. Cross beam assembly

9. Side defroster nozzle

10. Center defroster nozzle

Installation Steps

To install, follow the removal steps in the

reverse order.

7

9

9

10

8

6

3

5

1

3

4

2

This illustration is based on LHD

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following point:

1. Connect each duct and nozzle securely leaving no

clearance between them and making no improper

matching.

REMOVAL

Preparation:

Disconnect the battery ground cable

1. Instrument panel assembly

• Refer to Section 1 “BODY” for INSTRUMENT

PANEL ASSEMBLY removal procedure.

2. Center ventilation upper duct

3. Side ventilation duct

4. Center ventilation lower duct

5. Driver lap duct

6. Center console

7. Rear heater duct

• Refer to Section 1 “BODY” for CONSOLES

removal procedure.

8. Cross beam assembly

• Refer to Section 1 “BODY” for CROSS BEAM

ASSEMBLY removal procedure.

9. Side defroster nozzle

10. Center defroster nozzle

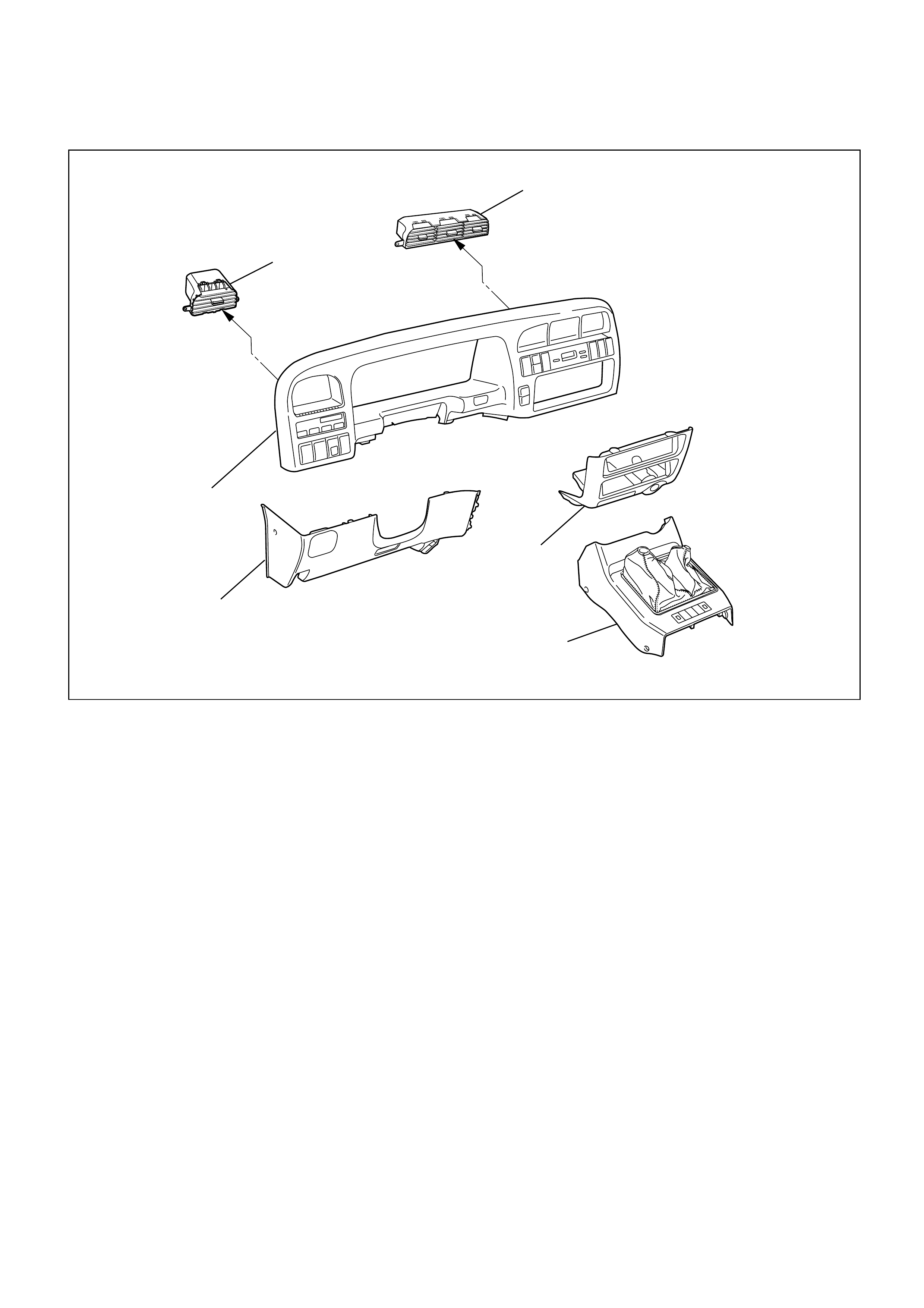

Removal Steps

1. Front console assembly

2. Lower cluster assembly

3. Instrument panel driver lower

cover assembly

4. Meter cluster assembly

5. Center vent

6. Side vent

Installation Steps

To install, follow the removal steps in the

reverse order.

CENTER AND/OR SIDE VENT

6

5

3

1

2

4

This illustration is based on LHD

740RW168

INSTALLATION

To install, follow the removal steps in the reverse order.

REMOVAL

1. Front console assembly

2. Lower cluster assembly

3. Instrument panel driver lower cover assembly

4. Meter cluster assembly

• Refer to Section 1 “BODY” for INSTRUMENT

PANEL ASSEMBLY removal procedure.

5. Center vent

•Remove screws and the center vent from center

cluster while prying up the center vent catch

portions.

6. Side vent

•Remove screws and the side vent from center

cluster while prying up the side vent catch

portions.

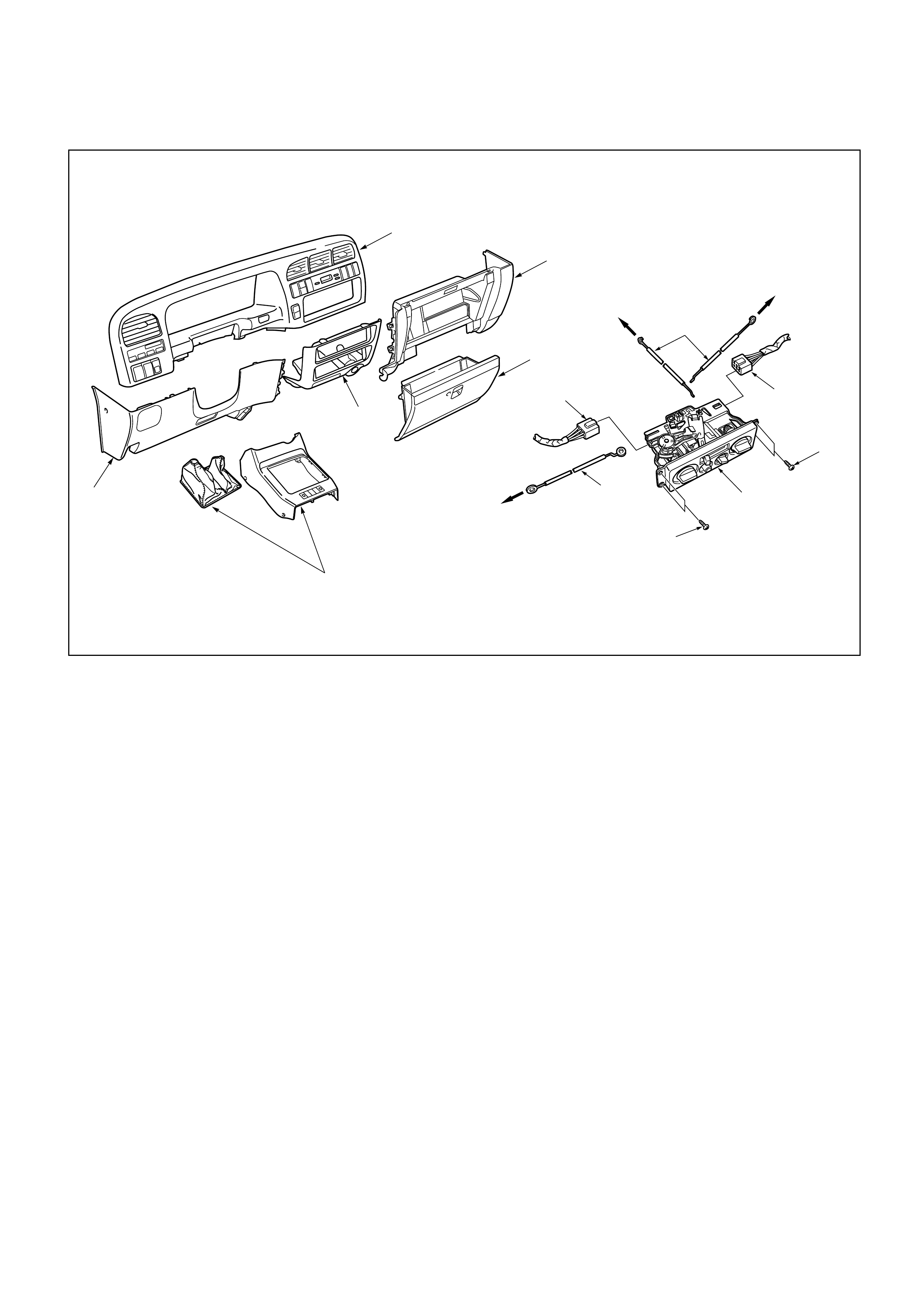

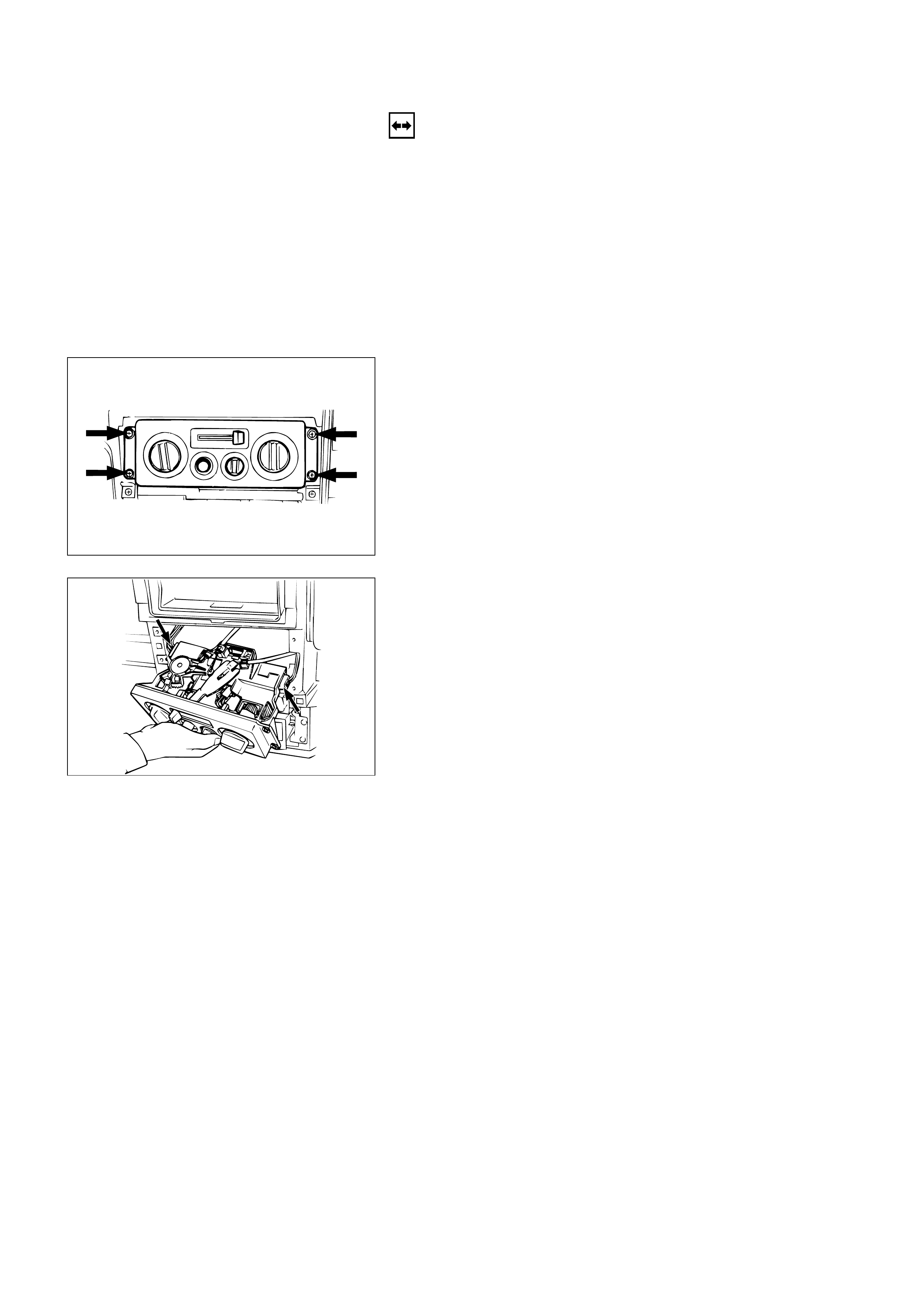

Removal Steps

1. Center console assembly

2. Lower cluster assembly

3. Glove box

4. Instrument panel passenger lower

cover assembly

5. Instrument panel driver lower cover

assembly

6. Meter cluster assembly

7. Attaching screws

8. Fan switch and air conditioning switch

connector

9. Control lever assembly

10. Control cable

CONTROL LEVER ASSEMBLY AND/OR CONTROL CABLES

6

1

5

2

10

7

7

8

8

9

10

To Mode control link

To Temp control link To Blower assembly

4

3

Installation Steps

To install, follow the removal steps in

the reverse order.

This illustration is based on LHD

REMOVAL

Preparation:

Disconnect the battery ground cable

1. Front console assembly

2. Lower cluster assembly

3. Glove box

4. Instrument panel passenger lower cover

5. Instrument panel driver lower cover

6. Meter cluster assembly

Refer to Section 1 “BODY” for INSTRUMENT PANEL

ASSEMBLY removal procedure.

7. Attaching Screws

Remove the 4 attaching screws and disconnect the

control lever cables at heater unit and blower

assembly.

8. Fan Switch and A/C Switch Connector

Pull the control lever assembly out and disconnect

the connectors.

9. Control Lever Assembly

10. Control Cable

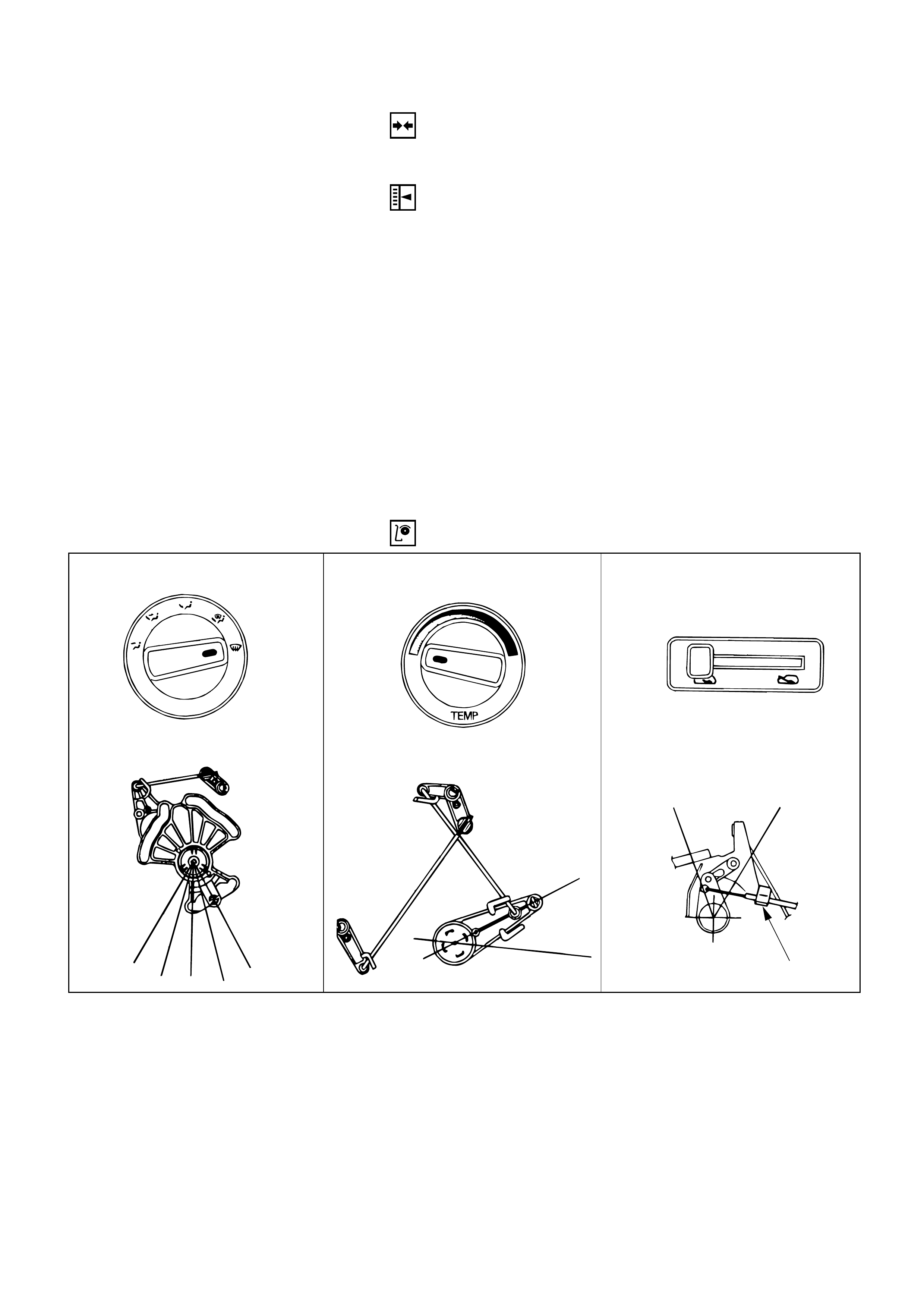

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. Adjust the control cables

Air source control cable

1) Slide the control lever to the left (“CIRC” position).

2) Connect the control cable at the “CIRC” position of

the link unit of blower assembly and fix it with the

clip.

Temperature control cable

1) Turn the control knob to the left (“MAX COLD”

position).

2) Connect the control cable at the “COLD” position

of the temperature control link of the heater unit

and fix it with the clip.

Air select control cable

1) Turn the control knob to the right (“DEFROST”

position).

2) Connect the control cable at the “DEFROST”

position of the mode control link of the heater unit

and fix it with the clip.

2. Check control cable operation.

AIR SELECTOR CABLE

Air selector knob

VENT

BI-LEVEL

FOOT

DEF/FOOT

DEF

(DEF)

TEMPERATURE CONTROL CABLE

Temperature control knob

COLD

HOT

(MAX

COLD)

AIR SOURCE SELECT CABLE

Air source select lever

(CIRC)

CIRC FRESH

Clip

Removal Steps

1. Control lever assembly

2. Bulb socket

3. Illumination bulb

Installation Steps

To install, follow the removal steps in the

reverse order.

CONTROL PANEL ILLUMINATION BULB

2

3

1

REMOVAL

Preparation:

Disconnect the battery ground cable

1. Control Lever AssemblyRefer to “CONTROL LEVER ASSEMBLY” removal

procedure in this section.

2. Bulb Socket

Pull out the socket from the panel by turning it

counterclockwise.

3. Illumination Bulb

Pull the illumination bulb from socket.

INSTALLATION

To install, follow the removal steps in the reverse order.

5

7

6

To Blower unit

To Heater unit

3

4

1

2

Removal Steps

1. Front console assembly

2. Lower cluster assembly

3. Glove box

4. Instrument panel passenger

lower cover

5. Resistor connector

6. Duct (Heater only)

7. Resistor

Installation Steps

To install, follow the removal steps in the

reverse order.

RESISTOR

This illustration is based on RHD

REMOVAL

Preparation:

Disconnect the battery ground cable

1. Front console assembly

2. Lower cluster assembly

3. Glove box

4. Instrument panel passenger lower cover

Refer to “BODY” for INSTRUMENT PANEL

ASSEMBLY removal procedure.

5. Resistor connector

6. Duct (Heater only)

7. Resistor

INSTALLATION

To install, follow the removal steps in the reverse order.