CAUTION

When fasteners are removed, always

reinstall them at the same location from

which they were removed. If a fastener

needs to be replaced, use the correct part

number fastener for that application. If the

correct part number fastener is not available,

a fastener of equal size and strength (or

stronger) may be used.

Fasteners that are not reused, and those

requiring thread locking compound, will be

called out. The correct torque values must

be used when installing fasteners that

require it. If the above conditions are not

followed, parts or system damage could

result.

SECTION 2B - HVAC AIR CONDITIONING

General Description

Air Conditioning Refrigerant Cycle Construction

Compressor

Magnetic Clutch

Receiver/Drier

Dual Pressure Switch

Triple Pressure Switch

Expansion Valve

Evaporator

Electronic Thermostat

Refrigerant Line

Service Charge Valve

Air Conditioning Parts

On-Vehicle Service

Precautions For Replacement or Repair of Air Conditioning Parts

Compressor Assembly and Associated Parts

Condenser Assembly (Shown without Condenser Fan)

Condenser Fan Motor

Receiver/Drier

Pressure Switch

Evaporator Assembly

Evaporator Core and/or Expansion Valve

Electronic Thermostat

A/C Switch and Illumination Bulb

Refrigerant Line

Rear Cooler Parts

Techline

Techline

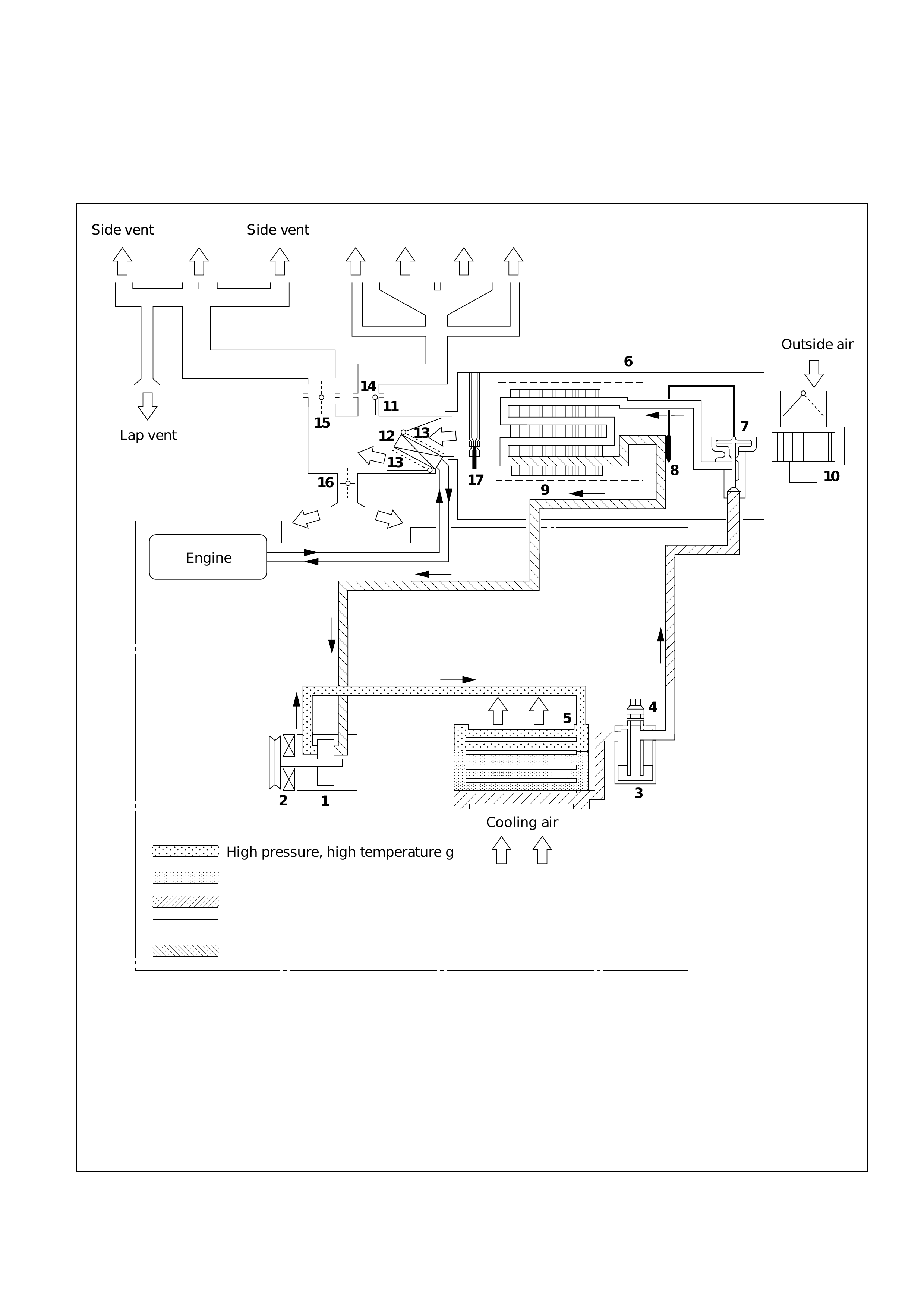

AIR CONDITIONING REFRIGERANT CYCLE CONSTRUCTION

;;

;;

;;

;;;;

;;;;

;;;

;

;;

;;

;;

;;;

;;;

;;;

;;;

;;;;;;;;;

;;;;;;;;;

;;;;;;;;;

;;;;;;;;

;

;;;;;;

;

;;;;;;;;

;;

;

;;;

;

;;;

;;;

;;;;;

;;;;;

;;

;

;

;;

15

14 11

12

13

16

10

17

7

3

4

5

2

1

8

9

6

13

Side vent

Lap vent

Outside air

Engine

Side vent

Cooling air

High pressure, high temperature gas

High pressure, high temperature

mixture of gas and liquid

Low pressure, low temperature

mixture of liquid and gas

Low pressure, low temperature gas

High pressure, medium temperature liquid

Side defrost Side defrostDefrostCenter vent

GENERAL DESCRIPTION

1. Compressor

2. Magnetic clutch

3. Receiver/Drier

4. Dual pressure switch

5. Condenser

6. Evaporator assembly

7. Expansion valve

8. Temperature sensor

9. Evaporator core

10. Blower motor

11. Heater unit

12. Heater core

13. Temp. control door (Air mix door)

14. Mode (DEF) control door

15. Mode (VENT) control door

16. Mode (HEAT) control door

17. Electronic thermostat

The refrigeration cycle includes the following four

processes as the refrigerant changes repeatedly

from liquid to gas and back to liquid while

circulating.

EVAPORATION

The refrigerant is changed from a liquid to a gas

inside the evaporator. The refrigerant mist that

enters the evaporator vaporizes readily. The liquid

refrigerant removes the required quantity of heat

(latent heat of vaporization) from the air around the

evaporator core cooling fins and rapidly vaporizes.

Removing the heat cools the air, which is then

radiated from the fins and lowers the temperature

of the air inside the vehicle.

The refrigerant liquid sent from the expansion valve

and the vaporized refrigerant gas are both present

inside the evaporator and the liquid is converted to

gas.

With this change from liquid to gas, the pressure

inside the evaporator must be kept low enough for

vaporization to occur at a lower temperature.

Because of that, the vaporized refrigerant is sucked

into the compressor.

COMPRESSION

The refrigerant is compressed by the compressor

until it is easily liquefied at normal temperature.

The vaporized refrigerant in the evaporator is

sucked into the compressor. This action maintains

the refrigerant inside the evaporator at a low

pressure so that it can easily vaporize, even at low

temperatures close to freezing point.

Also, the refrigerant sucked into the compressor is

compressed inside the cylinder to increase the

pressure and temperature to values such that the

refrigerant can easily liquefy at normal ambient

temperatures.

CONDENSATION

The refrigerant inside the condenser is cooled by

the outside air and changes from gas to liquid.

The high temperature, high pressure gas coming

from the compressor is cooled and liquefied by the

condenser with outside air and accumulated in the

receiver/drier. The heat radiated to the outside air

by the high temperature, high pressure gas in the

compressor is called heat of condensation. This is

the total quantity of heat (heat of vaporization) the

refrigerant removes from the vehicle interior via the

evaporator and the work (calculated as the quantity

of heat) performed for compression.

EXPANSION

The expansion valve lowers the pressure of the

refrigerant liquid so that it can easily vaporize.

The process of lowering the pressure to encourage

vaporization before the liquefied refrigerant is sent

to the evaporator is called expansion. In addition,

the expansion valve controls the flow rate of the

refrigerant liquid while decreasing the pressure.

That is, the quantity of refrigerant liquid vaporized

inside the evaporator is determined by the quantity

of heat which must be removed at a prescribed

vaporization temperature. It is important that the

quantity of refrigerant be controlled to exactly the

right value.

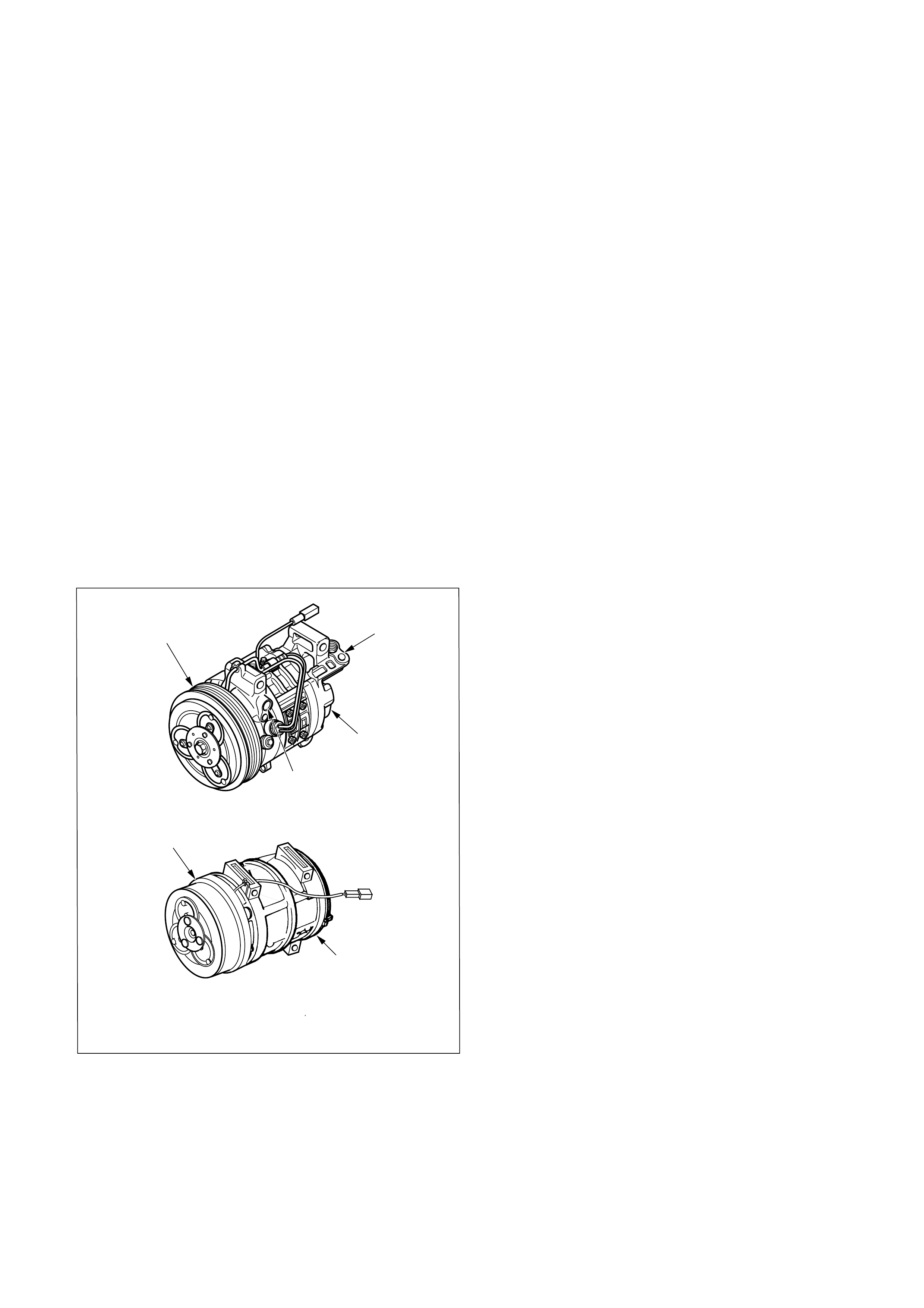

COMPRESSOR

The compressor performs two main functions:

It compresses low-pressure and low-temperature

refrigerant vapor from the evaporator into high-

pressure and high-temperature refrigerant vapor to

the condenser. And it pumps refrigerant and

refrigerant oil through the A/C system.

The compressor sucks and compresses refrigerant

by the rotation of the vane installed to the shaft,

and always discharges a fixed amount of refrigerant

independent of the load of refrigerant.

The thermo sensor is installed to the front head of

the compressor to protect it by stopping its

operation when the refrigerant gas is insufficient or

when the temperature is abnormally high.

OFF ........ 160o C

ON .......... 135oC

Swash plate compressors have a swash (slanted)

plate mounted on the shaft. W hen the shaft turns,

the rotation of the swash plate is converted to

reciprocating piston motion which sucks in and

compresses the refrigerant gas.

Shaft seal (Lip type) is installed between the valve

plate and shaft & cylinder head to prevent

refrigerant gas leaks. A specified amount of

compressor oil is contained in the oil pan.

This oil is supplied to the cylinders, bearings, etc.,

by an oil pump which is connected to the swash

plate shaft.

COMPRESSOR TYPES

6VE1(MY1998-2001) Zexel DKV-14D Rotary

6VE1 (MY2002) Zexel DKV-14G Rotary

4JX1 (MY1998-2002) Zexel DKS -15CH Swash Plate

With some compressors the differential between

the intake pressure and discharge pressure

generated while the compressor is operating is

used for lubrication instead of an oil pump.

The specified amount of the DKV-14D, DKS-15CH

and HD6 compressors oil is 150cc (4.2 Imp fl oz).

Also, compressor oil to be used varies according to

the compressor model. Be sure to avoid mixing

two or more different types of oil.

If the wrong oil is used, lubrication will be poor and

the compressor will seize or malfunction.

The magnetic clutch connector is a waterproof type.

MAGNETIC CLUTCH

The compressor is driven by the drive belt from the

crank pulley of the engine. If the compressor is

activated each time the engine is started, this

causes too much load to the engine. The magnetic

clutch transmits the power from the engine to the

compressor and activates it when the air

conditioning is “ON”. Also, it cuts off the power

from the engine to the compressor when the air

conditioning is “OFF”. (Magnetic clutch repair

procedure can be found in Section 2E.)

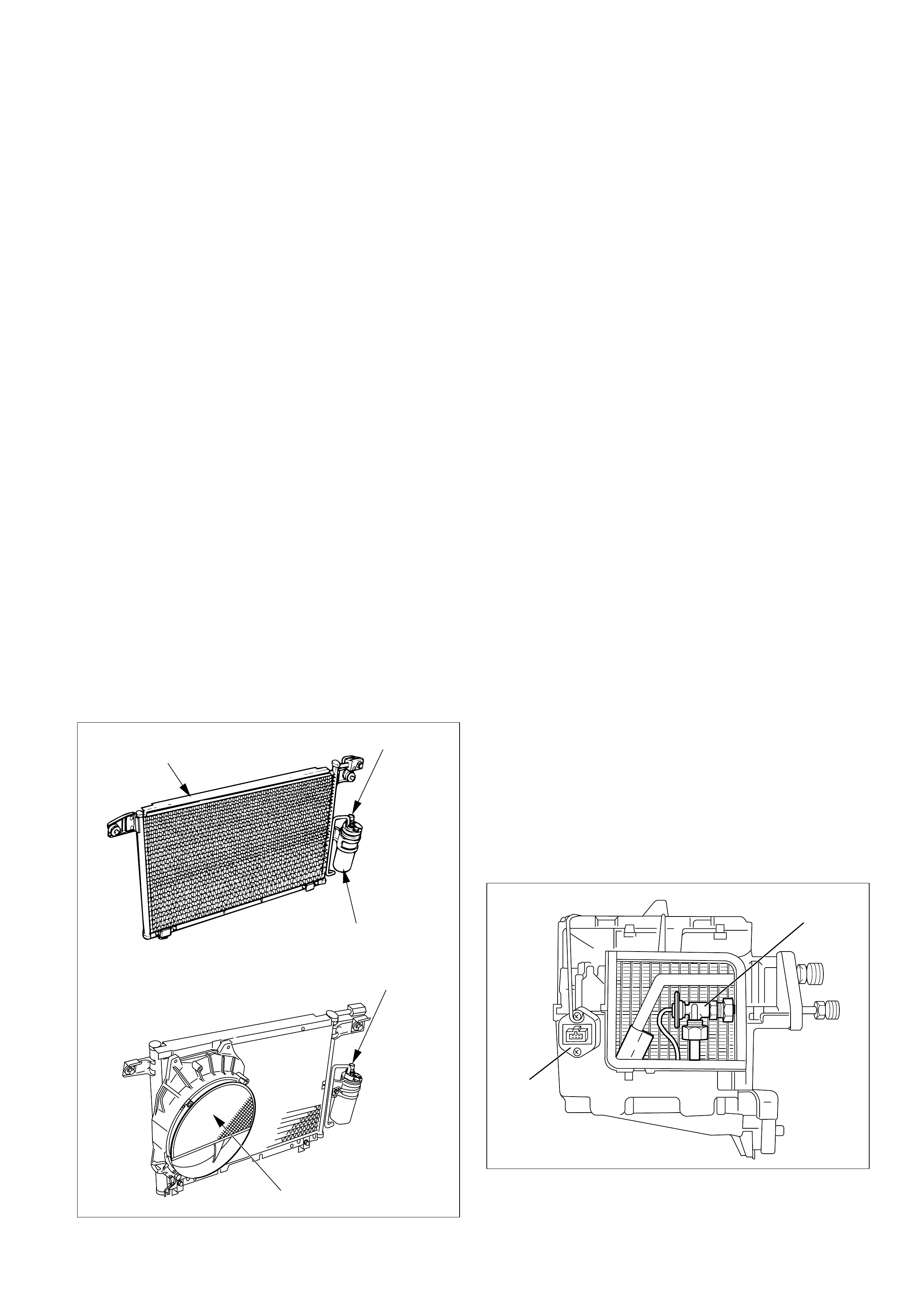

CONDENSER

The condenser assembly in front of the radiator,

which carry the refrigerant and cooling fins to

provide rapid transfer of heat.

Also, it functions to cool and liquefy the high-

pressure and high-temperature vapor sent from the

compressor by the radiator fan or outside air.

A condenser may malfunction in two ways: it may

leak, or it may be restricted. A condenser restriction

will result in excessive compressor discharge

pressure. If a partial restriction is present, the

refrigerant expands after passing through the

restriction.

Thus, ice or frost may from immediately after the

restriction. If air flow through the condenser or

radiator is blocked, high discharge pressures will

result. During normal condenser operation, the

refrigerant outlet line will be slightly cooler than the

inlet line.

The vehicle is equipped with the condenser of the

parallel flow type condenser. A larger thermal

transmission area on the inner surface of the tube

allows the radiant heat to increase and the

ventilation resistance to decrease.

The refrigerant line connection has a bolt at the

block joint, for easy servicing.

RECEIVER/DRIER

The receiver/drier performs four functions;

•As the quantity of refrigerant circulated varies

depending on the refrigeration cycle conditions,

sufficient refrigerant is stored for the refrigera-

tion cycle to operate smoothly in accordance

with fluctuations in the quantity circulated.

•The liquefied refrigerant from the condenser is

mixed with refrigerant gas containing air

bubbles. If refrigerant containing air bubbles is

sent to the expansion valve, the cooling

capacity will decrease considerably. Therefore,

the liquid and air bubbles are separated and

only the liquid is sent to the expansion valve.

•The receiver/drier utilizes a filter and dryer to

remove the dirt and water mixed in the cycling

refrigerant.

•The sight glass, installed atop the receiver/

drier, show the state of the refrigerant.

A receiver/drier may fail due to a restriction inside

the body of the unit. A restriction at the inlet to the

receiver/drier will cause high pressures.

Outlet restrictions will be indicated by low pressure

and little or no cooling. An excessively cold

receiver/ drier outlet may indicate a restriction.

The receiver/drier of this vehicle is made of

aluminum with a smaller tank. It has 300 cc

(8.5 Imp fl oz) refrigerant capacity.

The refrigerant line connection has a bolt at the

block joint, for easy servicing.

DKV-14D TYPE

DKS-15CH TYPE

Magnetic clutch

Compressor

Suction side

Discharge side

Compressor

Magnetic clutch

871RY00012

871RY00011

DUAL PRESSURE SWITCH

The dual pressure switch is installed on the upper

part of the receiver/drier, to detect excessively high

pressure (high pressure switch) and prevent

compressor seizure due to the refrigerant leaking

(low pressure switch), switching the compressor

“ON” or “OFF” as required.

The pressure switch connector is waterproof type.

•Low-pressure control kpa (kg·cm2/ PSI)

Compressor

ON: 205.9 ± 30 (2.1 ± 0.3 / 30 ± 4)

OFF: 176 ± 20 (1.8 ± 0.2 / 26 ± 3)

•High-pressure control

Compressor

ON: 2354 ± 196 (24.0 ± 2.0 / 341 ± 28)

OFF: 2942 ± 196 (30.0 ± 2.0 / 427 ± 28)

TRIPLE PRESSURE SWITCH

Triple pressure switch is installed atop the receiver/

drier. This switch is constructed with a unitized type

of two switches. One of them is a low and high

pressure switch (Dual pressure switch) to switch

“ON” or “OFF” the magnetic clutch as a result of

irregularly high-pressure or low-pressure of the

refrigerant. The other one is a medium pressure

switch (Cycling switch) to switch “ON” or “OFF”

the condenser fan sensing the condenser high side

pressure.

•Low-pressure control kpa (kg·cm2/PSI)

Compressor

ON: 186 ± 30 (1.9 ± 0.3 / 27 ± 4)

OFF: 176 ± 20 (1.8 ± 0.2 / 26 ± 3)

•Medium-pressure control

Condenser fan

ON: 1471 ± 98 (15.0 ± 1.0 / 213 ± 14)

OFF: 1079 ± 98 (11.0 ± 1.0 / 156 ± 14)

•High-pressure control

Compressor

ON: 2354 ± 196 (24.0 ± 2.0 / 341 ± 28)

OFF: 2942 ± 196 (30.0 ± 2.0 / 427 ± 28)

EXPANSION VALVE

This expansion valve (1) is internal pressure type

and it is installed at the evaporator intake port.

The expansion valve converts the high pressure

liquid refrigerant sent from the receiver/drier to a

low pressure liquid refrigerant by forcing it through

a tiny port before sending it to the evaporator (2).

This type of expansion valve consists of a

temperature sensor, diaphragm, ball valve, ball

seat, spring adjustment screw, etc.

The temperature sensor contacts the evaporator

outlet pipe, and converts changes in temperature to

pressure. It then transmits these to the top chamber

of the diaphragm.

The refrigerant pressure is transmitted to the

diaphragms bottom chamber through the external

equalizing pressure tube.

The ball valve is connected to the diaphragm. The

opening angle of the expansion valve is determined

by the force acting on the diaphragm and the spring

pressure.

The expansion valve regulates the flow rate of the

refrigerant. Accordingly, when a malfunction occurs

to this expansion valve, both discharge and suction

pressures get low, resulting in insufficient cooling

capacity of the evaporator.

Pressure switch

Receiver/Drier

Triple pressure switch

Condenser fan

Condenser

1

2

875RY00003

874RY00003

EVAPORATOR

The evaporator cools and dehumidifies the air

before the air enters the vehicle. High-pressure

liquid refrigerant flows through the expansion valve

(1) into the low-pressure area of the evaporator (2).

The heat in the air passing through the evaporator

core is lost to the cooler surface of the core, thereby

cooling the air.

As heat is lost between the air and the evaporator

core surface, moisture in the vehicle condenses on

the outside surface of the evaporator core and is

drained off as water.

When the evaporator malfunctions, the trouble will

show up as inadequate supply of cool air. The

cause is typically a partially plugged core due to

dirt, or a malfunctioning blower motor.

The evaporator core with a laminate louver fin is a

single-sided tank type where only one tank is

provided under the core.

ELECTRONIC THERMOSTAT

The thermostat consists of the thermosensor (1)

and thermostat unit (4) which functions electrically

to reduce the noises being generated while the

system is in operation.

The electronic thermosensor (1) is mounted at the

evaporator core (2) outlet and senses the

temperature of the cool air from the evaporator (3).

Temperature signals are input to the thermostat

unit. This information is compared by the thermo

unit and the results in output to operate the A/C

Thermostat relay and turn the magnetic clutch

“ON” or “OFF” to prevent evaporator freeze-up.

A characteristic of the sensor is that the resistance

decreases as the temperature increases and the

resistance increases as the temperature decreases.

REFRIGERANT LINE

Restrictions in the refrigerant line will be indicated by:

1. Suction line; A restricted suction line will cause

low suction pressure at the compressor, low

discharge pressure and little or not cooling.

2. Discharge line; A restriction in the discharge line

generally will cause the discharge line to leak.

3. Liquid line; A liquid line restriction will be

evidenced by low discharge and suction

pressure and insufficient cooling.

Refrigerant flexible hoses that have a low

permeability to refrigerant and moisture are used.

These low permeability hoses have a special nylon

layer on the inside.

SERVICE CHARGE VALVES

The charging hoses have a quick-joint type fitting,

to reduce refrigerant loss during removal and

installation.

1 2

3

4

Reinforcement layer(Polyester)

Resin layer(Nylon)

Internal rubber layer

External rubber layer

1

2

874RY00003

874RX022

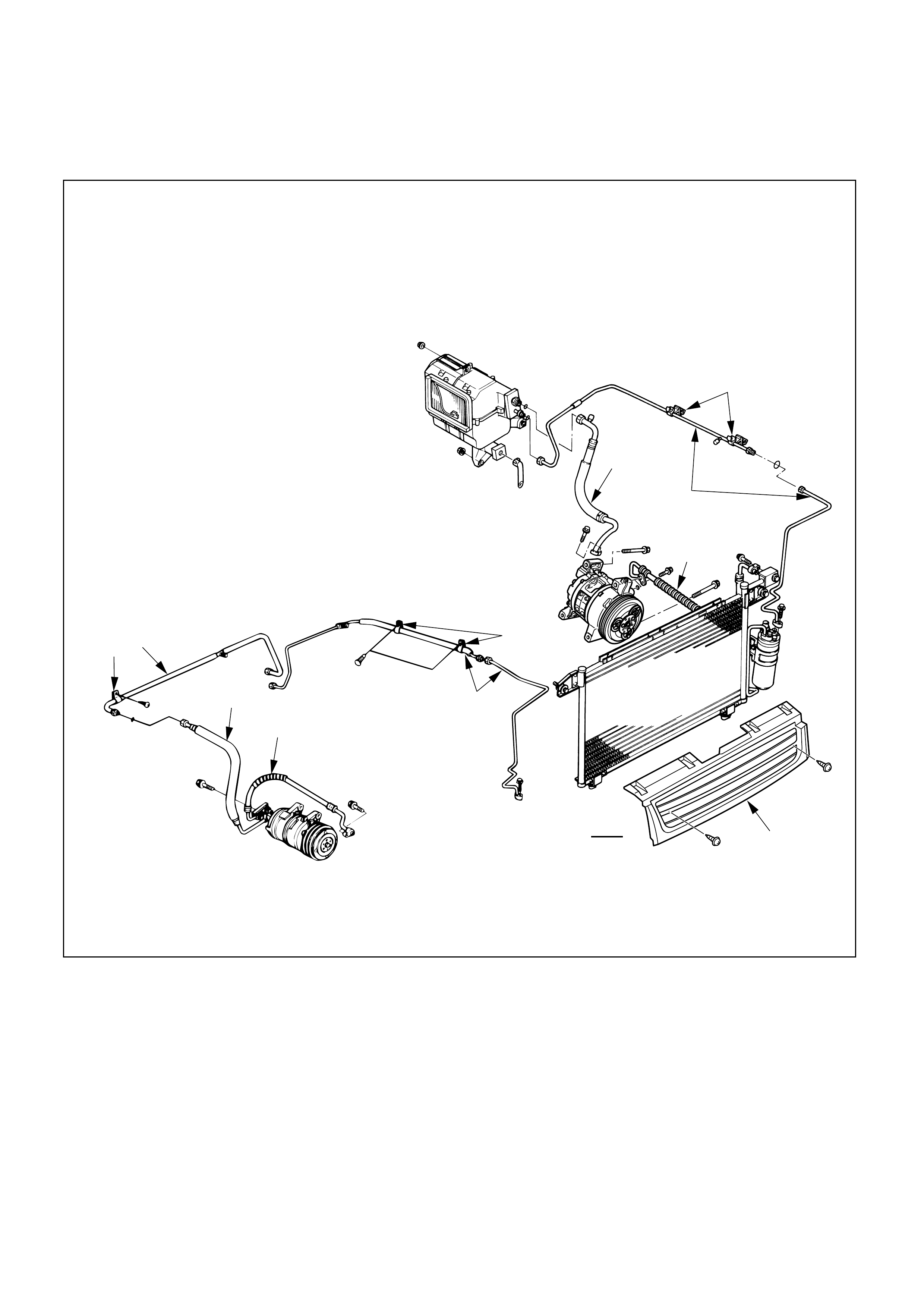

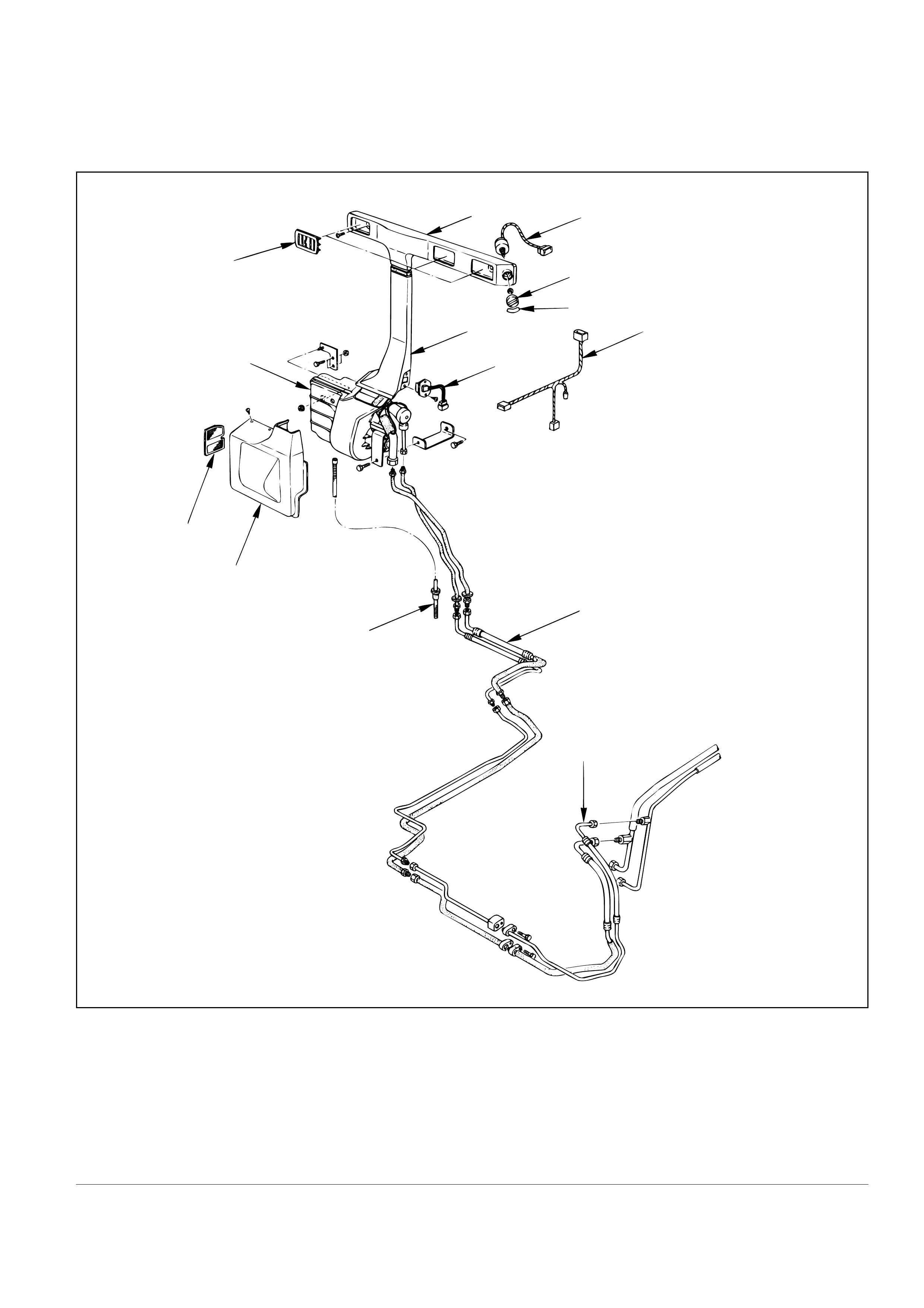

AIR CONDITIONING PARTS

Legend

(1) Liquid Line (High-Pressure Pipe)

(2) Pressure Switch

(3) Receiver Drier

(4) Discharge Line (High-Pressure Hose)

(5) Suction Line (Low-Pressure Hose)

(6) Compressor

(7) Condenser Assembly

(8) Serpentine Belt

(9) Compressor Bracket

(10) Drain Hose

(11) Evaporator Assembly

(12) O-ring

9

6

1

1

4

5

11 12

10

2

3

7

8

6VE1

852RY00006

9

6

12

5

4

11

13

10

14

2

1

3

8

7

852RY00005

4JX1

Legend

(1) Liquid Line (High- Pressure Pipe)

(2) Pressure Switch

(3) Receiver Drier

(4) Compressor Bracket

(5) Discharge Line (High-Pressure Hose)

(6) Suction Line (Low-Pressure Hose)

(7) Compressor

(8) Condenser Assembly

(9) O-ring

(10) Insulator Pipe

(11) Suction Line (Low Pressure Pipe)

(12) Drain Hose

(13) Evaporator Assembly

(14) A/C Switch

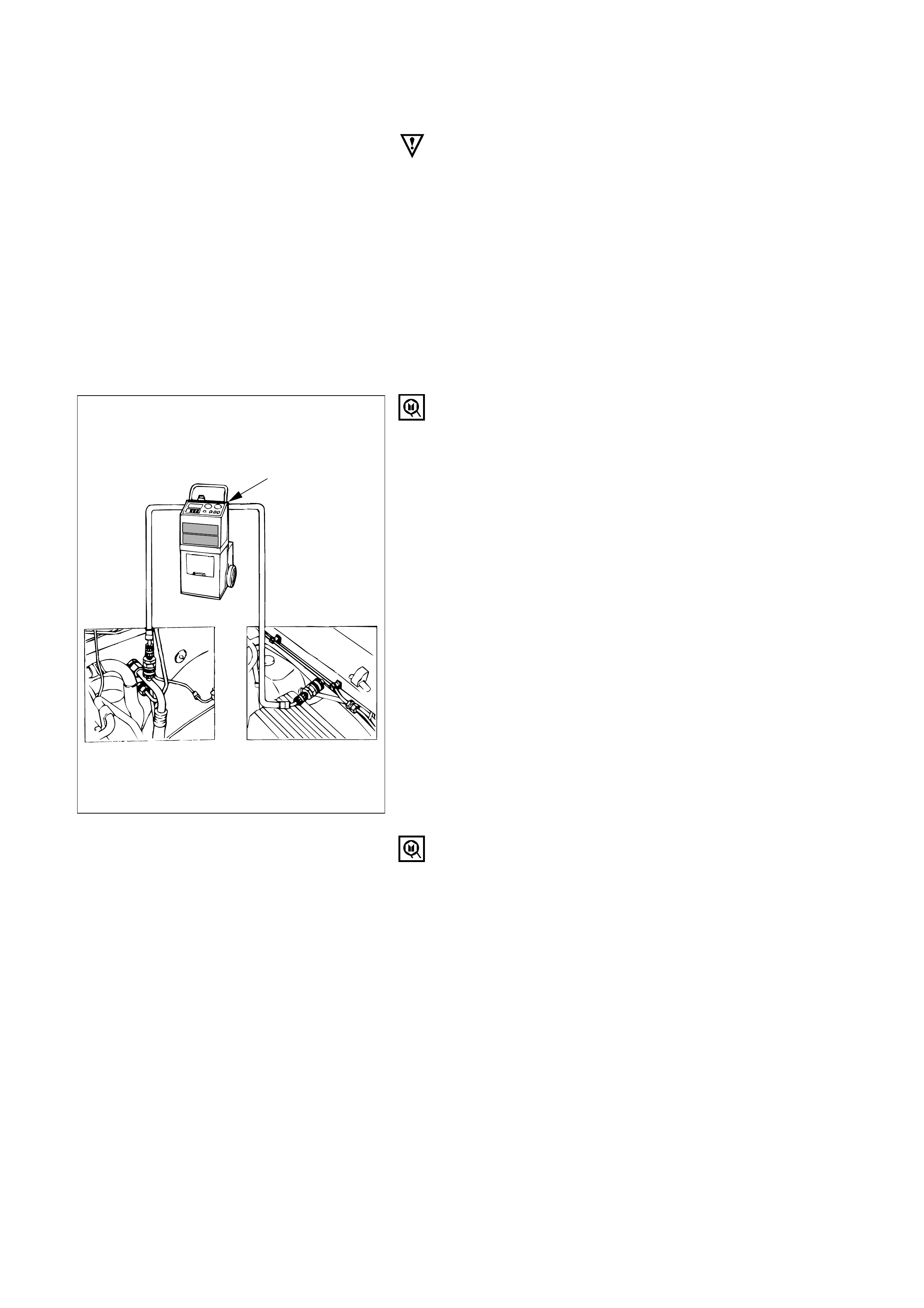

ACR4

1) Using the ACR4

(HFC-134a Refrigerant Recovery/

Recycling/ Recharging/ System) or equivalent to

thoroughly discharge and recover the refrigerant.

ACR4

(115V 60Hz) : 5-8840-0629-0 (J-39500-A)

ACR4

(220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR4

(220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

2) Remove and replace the defective part.

3) After evacuation, charge the air conditioning

system and check for leaks.

PRECAUTIONS FOR REPLACEMENT OR REPAIR OF

AIR CONDITIONING PARTS

There are certain procedure, practices and precautions

that should be followed when servicing air conditioning

systems:

• Keep your work area clean.

• Always wear safety goggle and protective gloves

when working on refrigerant systems.

• Beware of the danger of carbon monoxide fumes

caused by running the engine.

• Beware of discharged refrigerant in enclosed or

improperly ventilated garages.

• Always disconnect the negative battery cable and

discharge and recover the refrigerant whenever

repairing the air conditioning system.

• When discharging and recovering the refrigerant, do

not allow refrigerant to discharge too fast; it will draw

compressor oil out of the system.

• Keep moisture and contaminants out of the system.

When disconnecting or removing any lines or parts,

use plugs or caps to close the fittings immediately.

Never remove the caps or plugs until the lines or

parts are reconnected or installed.

• When disconnecting or reconnecting the lines, use

two wrenches to support the line fitting, to prevent

from twisting or other damage.

• Always install new O-rings whenever a connection is

disassembled.

• Before connecting any hoses or lines, apply new

specified compressor oil to the O-rings.

• When removing and replacing any parts which

require discharging the refrigerant circuit, the

operations described in this section must be

performed in the following sequence:

ON-VEHICLE SERVICE

Techline

REPAIR OF REFRIGERANT LEAKS

Refrigerant Line Connections

Install new O-rings, if required. When disconnecting or

connecting lines, use two wrenches to prevent the

connecting portion from twisting or becoming damaged.

When connecting the refrigerant line at the block joint,

securely insert the projecting portion of the joint portion

into the connecting hole on the unit side and secure with a

bolt.

O-ring

Block joint

Apply specified compressor oil to the O-rings prior to

connecting.

CAUTION:

Compressor (PAG) oil to be used varies according to

compressor model. Be sure to apply oil specified for the

model of compressor.

O-rings must be closely aligned with raised portion of

refrigerant line.

Correct Incorrect Incorrect

1

Insert nut into union. First tighten nut by hand as much as

possible. Then, tighten nut to specified torque.

(Refer to “SERVICE INFORMATION” for Fixing Torque in

section 0A)

12

852RY00014

852RY00015

852RY00016

Techline

COMPRESSOR LEAKS

If leaks are located around the compressor shaft seal or

shell, replace or repair the compressor.

RECOVERY, RECYCLING, EVACUATION AND

CHARGING

Handling Refrigerant-134a (HFC-134a)

Air conditioning systems contain HFC-134a.

This is a chemical mixture which requires special

handling procedures to avoid personal injury.

• Always wear safety goggles and protective gloves.

• Always work in a well-ventilated area. Do not weld or

steam clean on or near any vehicle-installed air

conditioning lines or components.

• If HFC-134a should come in contact with any part of

the body, flush the exposed area with cold water and

immediately seek medical help.

• If it is necessary to transport or carry any container of

HFC-134a in a vehicle, do not carry it in the passenger

compartment.

• If it is necessary to fill a small HFC-134a container

from a large one, never fill the container completely.

Space should always be allowed above the liquid for

expansion.

• Keep HFC-134a containers stored below 40 °C (104°F).

LEAK AT REFRIGERANT LINE CONNECTIONS

1) Check the torque on the refrigerant line fitting and, if

too loose, tighten to the specified torque.

•Use two wrenches to prevent twisting and damage

to the Line.

•Do not over tighten.

2) Perform a leak test on the refrigerant line fitting.

3) If the leak is still present, discharge and recover the

refrigerant from the system.

4) Replace the O-rings.

•O-rings cannot be reused. Always replace with

new ones.

•Be sure to apply specified compressor oil to the

new O-rings.

5) Retighten the refrigerant line fitting to the specified

torque.

•Use two wrenches to prevent twisting and damage

to the line.

6) Evacuate, charge and retest the system.

LEAK IN THE HOSE

If the compressor inlet or outlet hose is leaking, the entire

hose must be replaced. Refrigerant hose must not be cut

or spliced for repair.

1) Locate the leak.

2) Discharge and recover the refrigerant.

3) Remove the hose assembly.

•Cap the open connections at once.

4) Connect the new hose assembly.

•Use two wrenches to prevent twisting or damage

to the hose fitting.

•Tighten the hose fitting to the specified torque.

5) Evacuate, charge and test the system.

WARNING

•SHOULD HFC-134a CONTACT YOUR EYE(S),

CONSULT A DOCTOR IMMEDIATELY.

•DO NOT RUB THE AFFECTED EYE(S). INSTEAD,

SPLASH QUANTITIES OF FRESH COLD WATER

OVER THE AFFECTED AREA TO GRADUALLY

RAISE THE TEMPERATURE OF THE

REFRIGERANT ABOVE THE FREEZING POINT.

•OBTAIN PROPER MEDICAL TREATMENT AS

SOON AS POSSIBLE. SHOULD THE HFC-134a

TOUCH THE SKIN, THE INJURY MUST BE

TREATED THE SAME AS SKIN WHICH HAS

BEEN FROSTBITTEN OR FROZEN.

REFRIGERANT RECOVERY

The refrigerant must be discharged and recovered by

using ACR4(HFC-134a Refrigerant Recovery/ Recycling/

Recharging/ System) or equivalent before removing or

mounting air conditioning parts.

ACR4(115V 60Hz) : 5-8840-0629-0 (J-39500-A)

ACR4(220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR4(220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

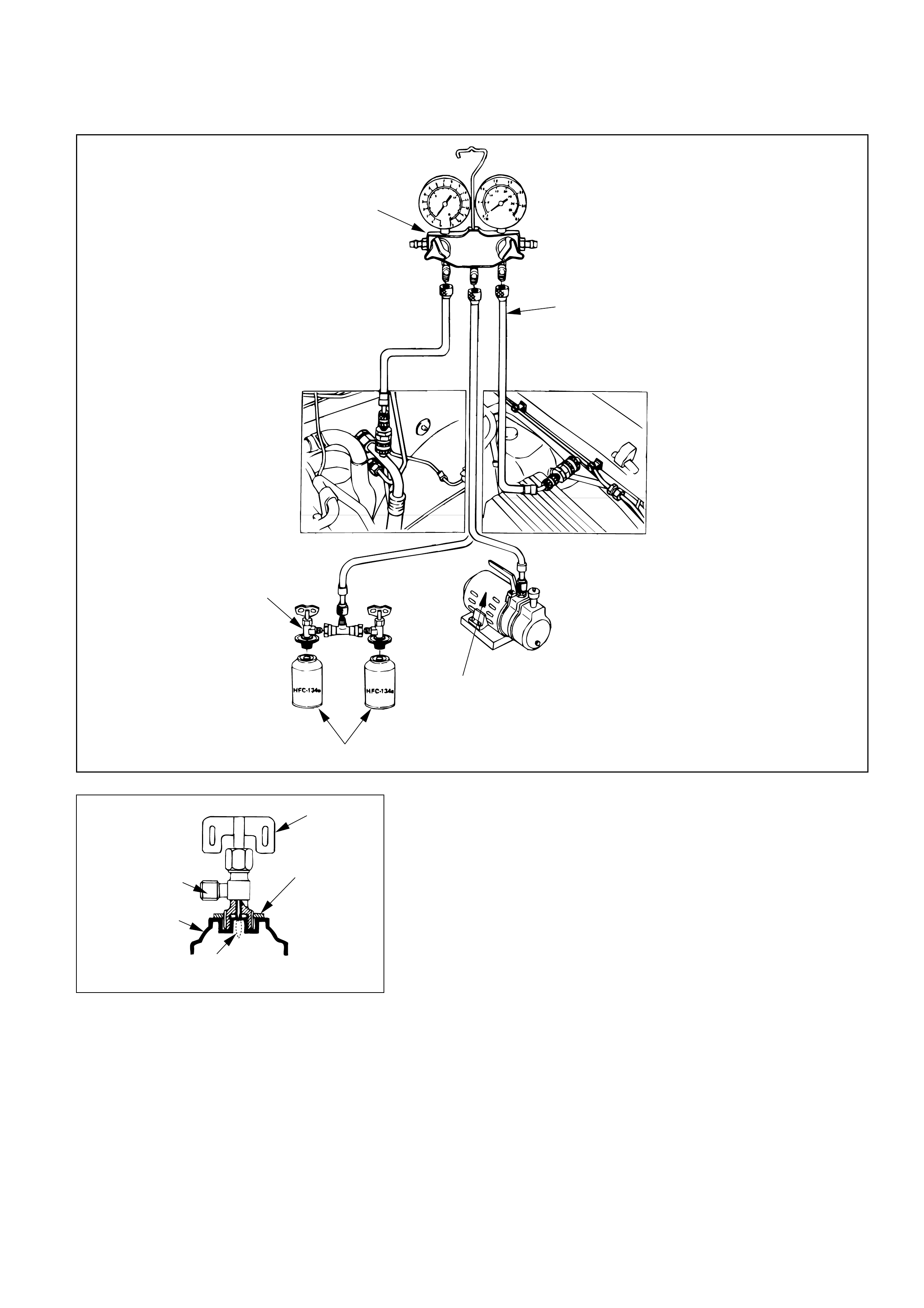

1) Connect the high and low charging hoses of the ACR4

(or equivalent) as shown

2) Recover the refrigerant by following the ACR4

Manufacture’s Instructions.

3) When a part is removed, put a cap or a plug on the

connecting portion so that dust, dirt or moisture

cannot get into it.

ACR4

(Low side) (High side)

HFC 134a

REFRIGERANT RECYCLING

Recycle the refrigerant recovered by ACR4or equivalent.

For the details of the actual operation, follow the steps in

the ACR4Manufacture’s Instructions.

ACR4(115V 60Hz) : 5-8840-0629-0 (J-39500-A)

ACR4(220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR4(220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

7) Check to ensure that the pressure does not change

after 10 minutes or more.

•If the pressure changes, check the system for leaks.

•If leaks occur, retighten the refrigerant line

connections and repeat the evacuation steps.

8) If no leaks are found, again operate the vacuum

pump for 20 minutes or more, After confirming that

the gauge manifold pressure is at 750 mmHg(30

inHg), close both hand valves.

9) Close positive shutoff valve.

Stop the vacuum pump and disconnect the center

hose from the vacuum pump.

Air and moisture in the refrigerant will cause problems in

the air conditioning system.

Therefore, before charging the refrigerant, be sure to

evacuate air and moisture thoroughly from the system.

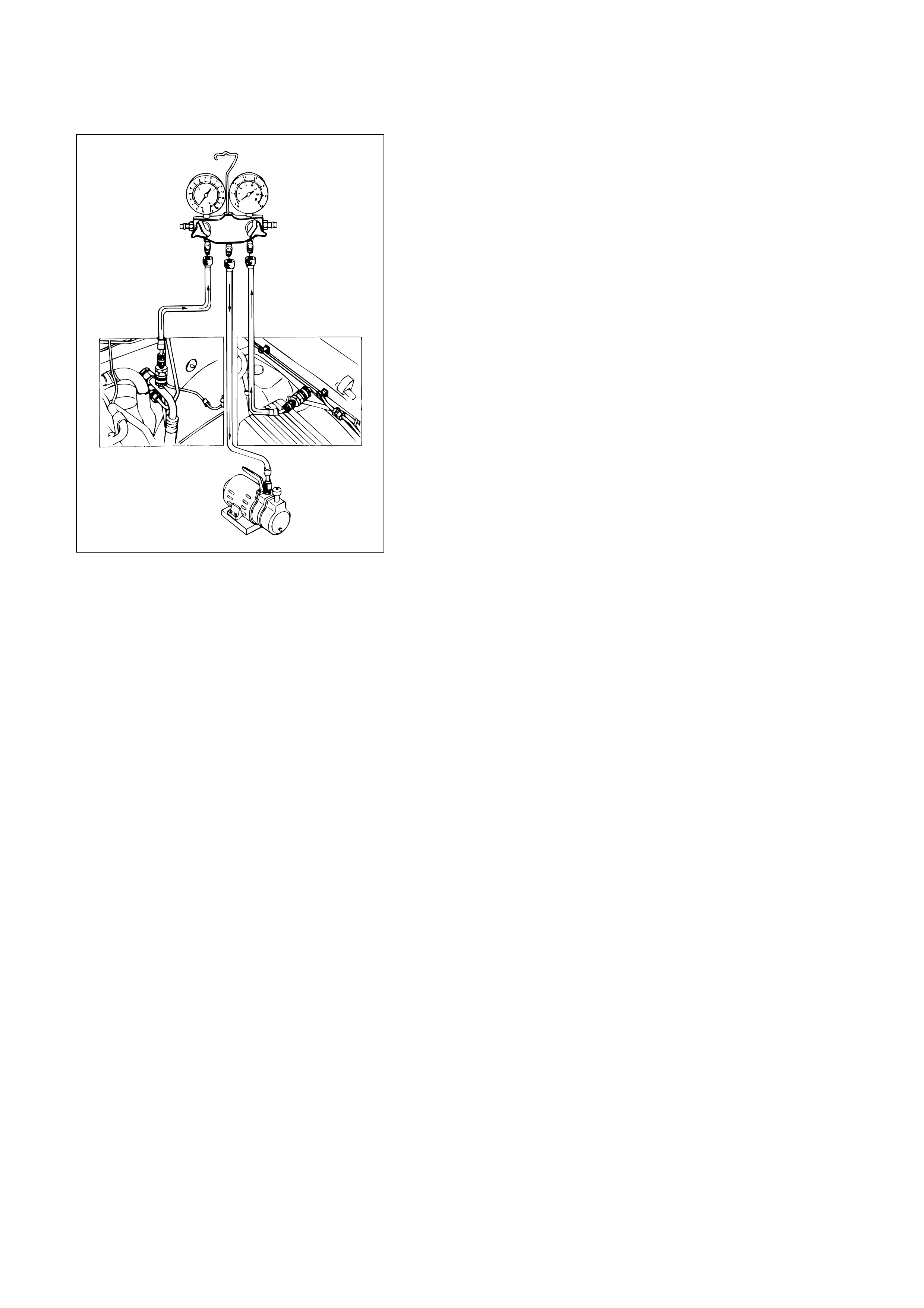

1) Connect the gauge manifold.

•High-pressure valve (HI) – Discharge-side

•Low-pressure valve (LOW) – Suction-side

2) Discharge and recover the refrigerant.

3) Connect the center hose of the gauge manifold set to

the vacuum pump inlet.

4) Operate the vacuum pump, open shutoff valve and

then open both hand valves.

5) When the low-pressure gauge indicates approx. 750

mmHg (30 inHg), continue the evacuation for 5

minutes or more.

6) Close both hand valves and stop the vacuum pump.

EVACUATION OF THE REFRIGERANT SYSTEM

NOTE:

Explained below is a method using a vacuum pump. Refer

to ACR4(or equivalent) manufacture’s instructions when

evacuating the system with ACR4(or equivalent)

(Low side) (High side)

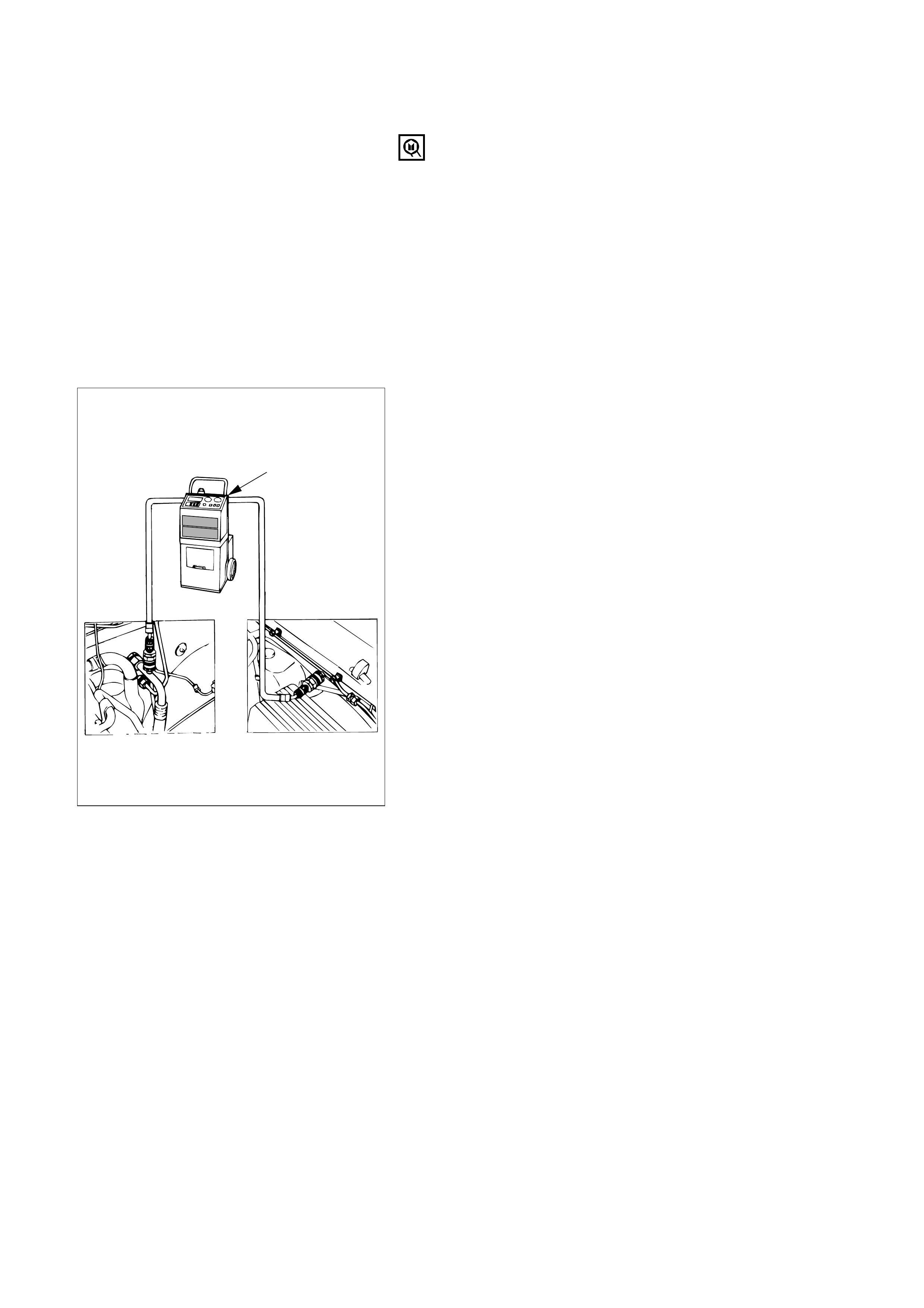

CHARGING THE REFRIGERANT SYSTEM

There are various methods of charging refrigerant into the

air conditioning system.

These include using ACR4(HFC-134a Refrigerant

Recovery/ Recycling/ Recharging/ System) or equivalent

and direct charging with a manifold gauge charging

station.

ACR4(115V 60Hz) : 5-8840-0629-0 (J-39500-A)

ACR4(220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR4(220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

Charging procedure

•ACR4(or equivalent) method

For the charging of refrigerant recovery by ACR4, follow

the manufacture’s instruction.

ACR4

(Low side) (High side)

HFC 134a

•Direct charging with a manifold gauge charging station

method

Handling the charging valve handle when installing

refrigerant container.

1) Before attaching the charge valve to the refrigerant

container, turn the charge valve handle

counterclockwise until the needle is fully retracted.

2) Turn the plate nut counterclockwise until it reaches its

highest position relative to the charge valve.

3) Install the charge valve onto the refrigerant container.

4) Turn the plate nut clockwise and connect the center

hose of the manifold gauge to the charge valve.

5) Tighten the plate nut sufficiently by hand. Then turn

the charge valve handle clockwise to lower the needle

and bore a hole in the refrigerant container.

6) Turn the charge valve handle counterclockwise to

raise the needle. The refrigerant in the refrigerant

container is charged into the air conditioning system

by the operation of the manifold gauge.

•Be absolutely sure not to reuse the emptied

refrigerant container.

Charge valve handle

Plate nut

Needle

Connection

<Charge valve>

Refrigerant container

Charging hose

Manifold gauge

Vacuum pump

Refrigerant container

Charge valve handle

(Low side) (High side)

1) Make sure the evacuation process is correctly

completed.

2) Connect the center-hose of the manifold gauge to the

refrigerant container.

• Turn the charge valve handle counterclockwise to

purge the charging line and purge any air existing

in the center-hose of the manifold gauge.

3) Open the low-pressure hand valve and charge the

refrigerant about 200 g(0.44 lbs.).

• Make sure the high-pressure hand valve is closed.

• Avoid charging the refrigerant by turning the

refrigerant container upside down.

4) Close the low-pressure hand valve of the manifold

gauge.

• Check to ensure that the degree of pressure does

not charge.

5) Check the refrigerant leaks by using a HFC-134a leak

detector.

• If a leak occurs, repair the leak connection, and

start all over again from the first step of

evacuation.

6) If no leaks are found, open the low-pressure hand

valve of the manifold gauge.Then continue charging

refrigerant to the system.

• When charging the system becomes difficult:

(1) Run the engine at Idling and close the all

vehicle doors.

(2) A/C switch is “ON”.

(3) Set the fan control knob (fan switch) to its

highest position.

WARNING

BE ABSOLUTELY SURE NOT TO OPEN THE HIGH-

PRESSURE HAND VALVE. SHOULD THE HIGH-

PRESSURE HAND VALVE BE OPENED, THE HIGH-

PRESSURE REFRIGERANT GAS WOULD FLOW

BACKWARD, AND THIS MAY CAUSE THE

REFRIGERANT CONTAINER TO BURST.

7) When the refrigerant container is emptied, use the

following procedure to replace it with a new

refrigerant container.

(1) Close the low pressure hand valve.

(2) Raise the needle upward and remove the charge

valve.

(3) Reinstall the charge valve to the new refrigerant

container.

(4) Purge any air existing in the center hose of the

manifold gauge.

8) Charge the system to the specified amount and then

close the low-pressure hand valve.

Refrigerant Amount g(lbs.)

750 (1.65)

DELPH1HD6/HT6 g(lbs.)

600 (1.32)

• A fully charged system is indicated by the sight

glass on the receiver/driver being free of any

bubbles(Refer to “Reading Sight Glass”).

•Check the high and low pressure value of the

manifold gauge.

•Check for refrigerant leaks by using a HFC-134a

leak detector.

Immediately after charging refrigerant, both high and low

pressures are slightly high and to the left of the gauge, but

they settle down to the guide pressure valves as shown

below:

•Ambient temperature; 25 ∼30°C (77 ∼86°F)

•Guide pressure

High-pressure side;

Approx. 1373 – 1863 kPa (14 – 19 kg·cm2/ 199 – 270 PSI)

Low-pressure side;

Approx. 147 – 294 kPa (1.4 – 3.0 kg·cm2/ 21 – 43 PSI)

9) Close the low pressure hand valve and charge valve

of the refrigerant container.

10) Stop the air conditioning and the engine.

11) Disconnect the high and low pressure hoses from the

manifold gauge fittings.

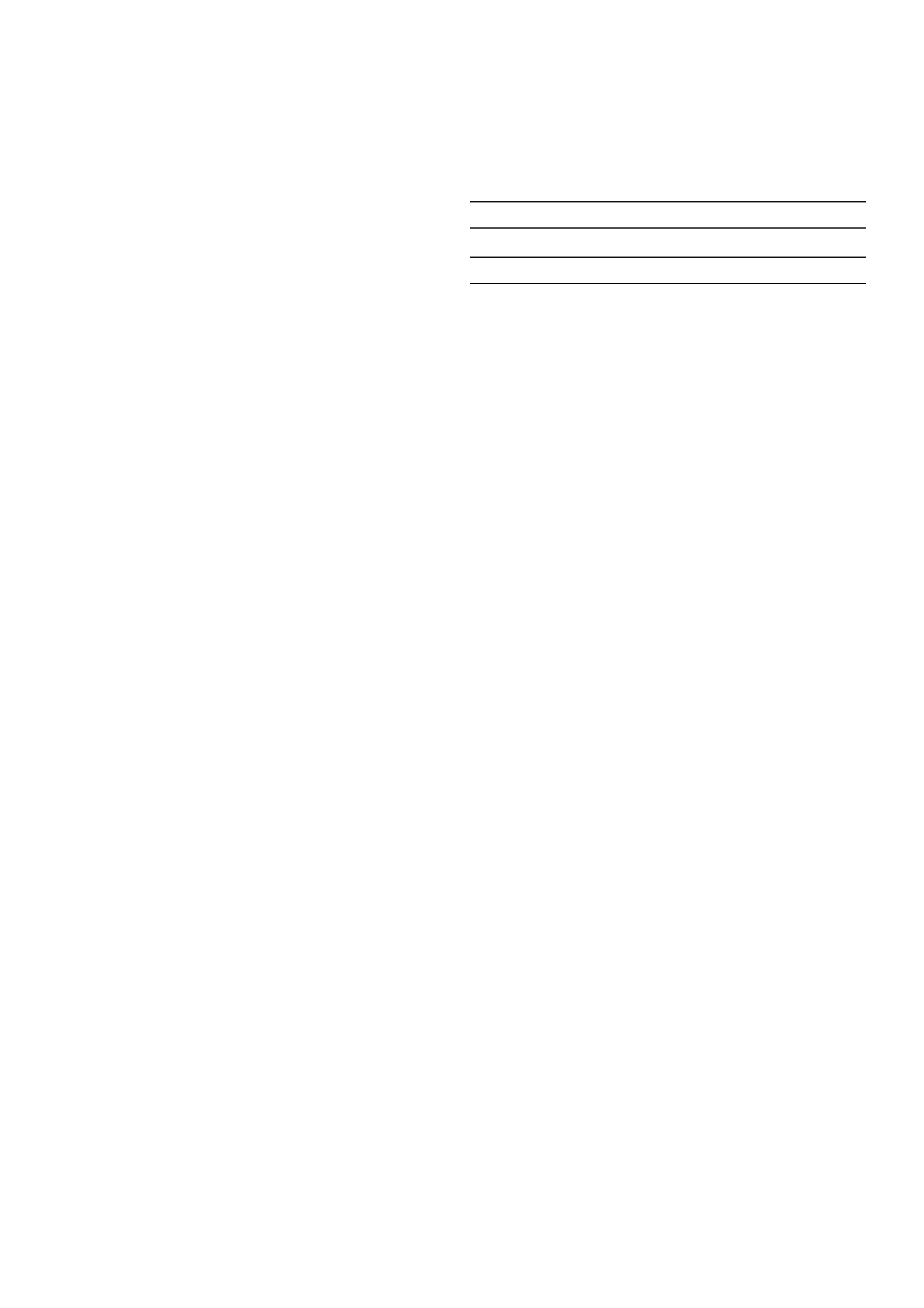

Almost transparent.

A flow of bubbles

can be seen, but

they disappear

when the throttle is

opened.

The sight glass provides accurate diagnosis only under the following conditions.

If the vehicle can be tested under these conditions, check the sight glass appearance and compare to the

chart.

* Engine speed Idling

* A/C switch “ON”

* Blower fan operating at highest speed

* Air source selector lever at “RECIRC”

* Temperature control knob at coldest position

* Ambient temperature below 30°C (86°F) and humidity below 70% (See NOTE 1)

* High side pressure less than 1863 kPa (19 kg·cm2/ 270 PSI) (See NOTE 2)

NOTE 1

If the vehicle cannot be moved to a testing location that meets these specifications, then the sight glass

cannot be used for diagnosis. You must discharge and recover the refrigerant, then recharge the system

with the specified amount of refrigerant. Then continue checking the system performance.

NOTE 2

If the high side pressure is greater than stated, the sight glass cannot be used for diagnosis. You must

discharge and recover the refrigerant, then recharge the system with the specified amount of refrigerant.

Then continue checking system performance.

Reading Sight Glass

High and low

pressure pipe

temperature

Sight glass

condition

Air condi-

tioner cycle

condition

The high pressure

pipe is hot and the

low pressure pipe is

cold. There is a dis-

tinct difference in

temperature bet-

ween them.

OK

The high pressure

pipe is warm and

the low pressure

pipe is cool. There

is no great dif-

ference in tempera-

ture between them.

A flow of bubbles

always can be seen.

It appears some-

times transparent,

and sometimes

frothy.

NG

(Not enough

refrigerant)

There is little dif-

ference in tempera-

ture between the

high pressure pipe

and the low press-

ure pipe.

Something like fog

faintly can be seen.

NG

(Almost no

refrigerant)

The high pressure

pipe is hot and the

low pressure pipe is

slightly warm.

There is a difference

in temperature bet-

ween them.

Even at idle with the

fan at “HI” (with the

window fully open),

the bubbles cannot

be seen.

NG

(Too much

refrigerant)

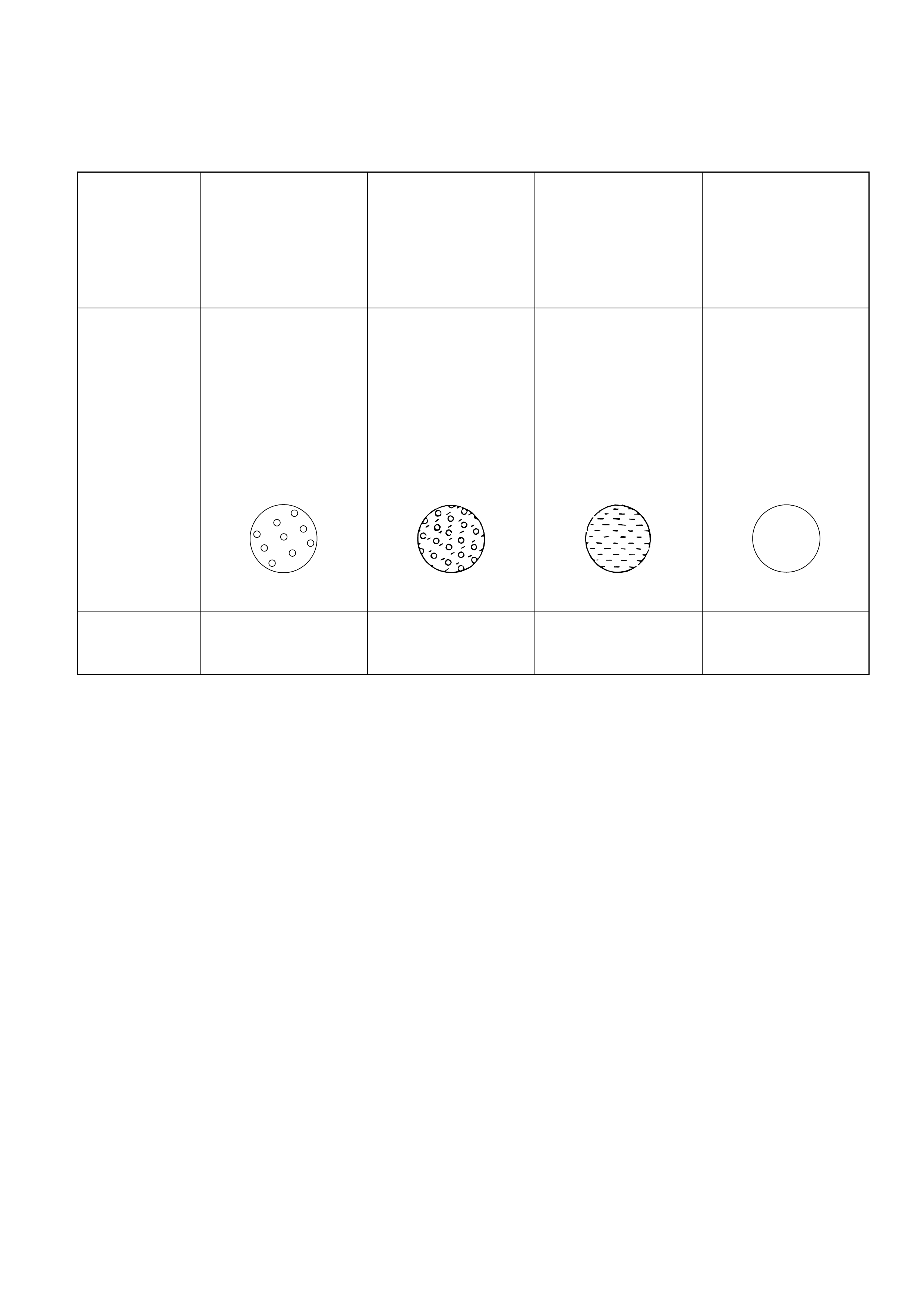

Legend

(1) Magnetic Clutch Harness Connector

(2) To Evaporator

(3) Refrigerant Line Connector

(4) To Condenser

(5) Compressor

(6) Serpentine Belt

(7) Radiator Fan

(8) Radiator Fan Shroud

(9) Compressor Bracket

COMPRESSOR ASSEMBLY AND ASSOCIATED PARTS

6VE1

3

4

2

5

7

8

9

1

6

852RY00007

Removal

1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant.

• Refer to Refrigerant Recovery in this section.

3. Disconnect magnetic clutch harness connector.

4. Remove radiator fan shroud.

5. Remove radiator fan.

•When the fan is removed, be sure to tighten

the fan fixing nuts temporarily to their original

positions.

6. Remove serpentine belt.

•Move serpentine belt tensioner to loose side

using wrench, then remove serpentine belt.

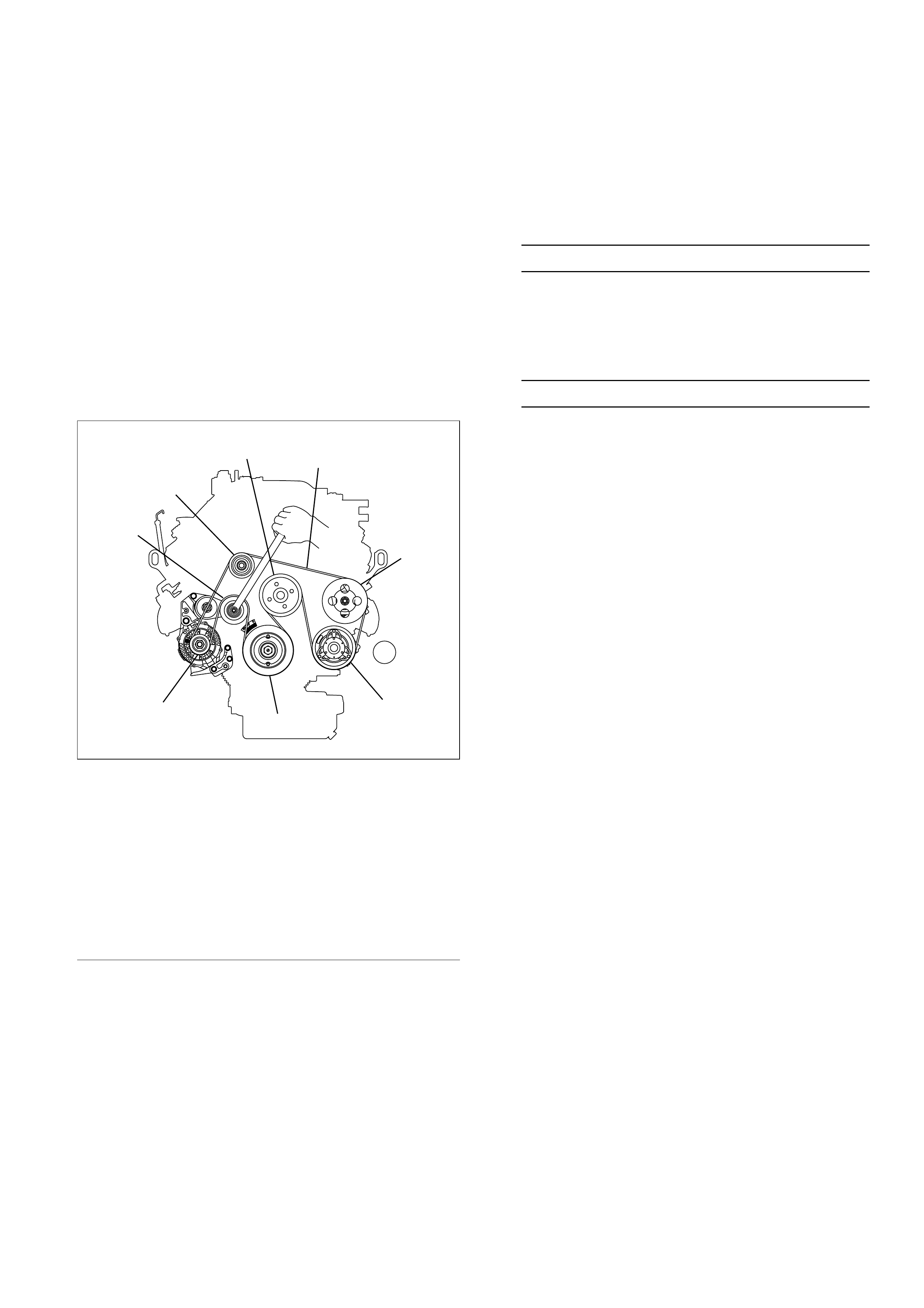

Legend

(1) Tensioner

(2) Idle Pulley

(3) Cooling Fan Pulley

(4) Serpentine Belt

(5) Power Steering Oil Pump

(6) Air Conditioner Compressor

(7) Crankshaft Pulley

(8) Generator

7. Disconnect refrigerant line connector.

•When removing the line connector, the

connecting part should immediately be

plugged or capped to prevent foreign matter

from being mixed into the line.

8. Remove compressor.

Installation

1. Install compressor.

•Tighten the compressor fixing bolts to the

specified torque.

Compressor Fixing Torque N·m (kg·m / lb·ft)

19 (1.9 / 14)

2. Connect refrigerant line connector.

•Tighten the refrigerant line connector fixing

bolts to the specified torque.

Refrigerant Line Bolt Torque N·m (kg·m / lb·ft)

15 (1.5 / 11)

•O-rings cannot be reused. Always replace with

new ones.

•Be sure to apply new compressor oil to the O-

rings when connecting refrigerant lines.

3. Install serpentine belt.

•Move serpentine belt tensioner to loose side

using wrench, then install serpentine belt to

normal position.

4. Install radiator fan.

5. Install radiator fan shroud.

6. Connect magnetic clutch harness connector.

34

2

7

86

1

5

850RX003

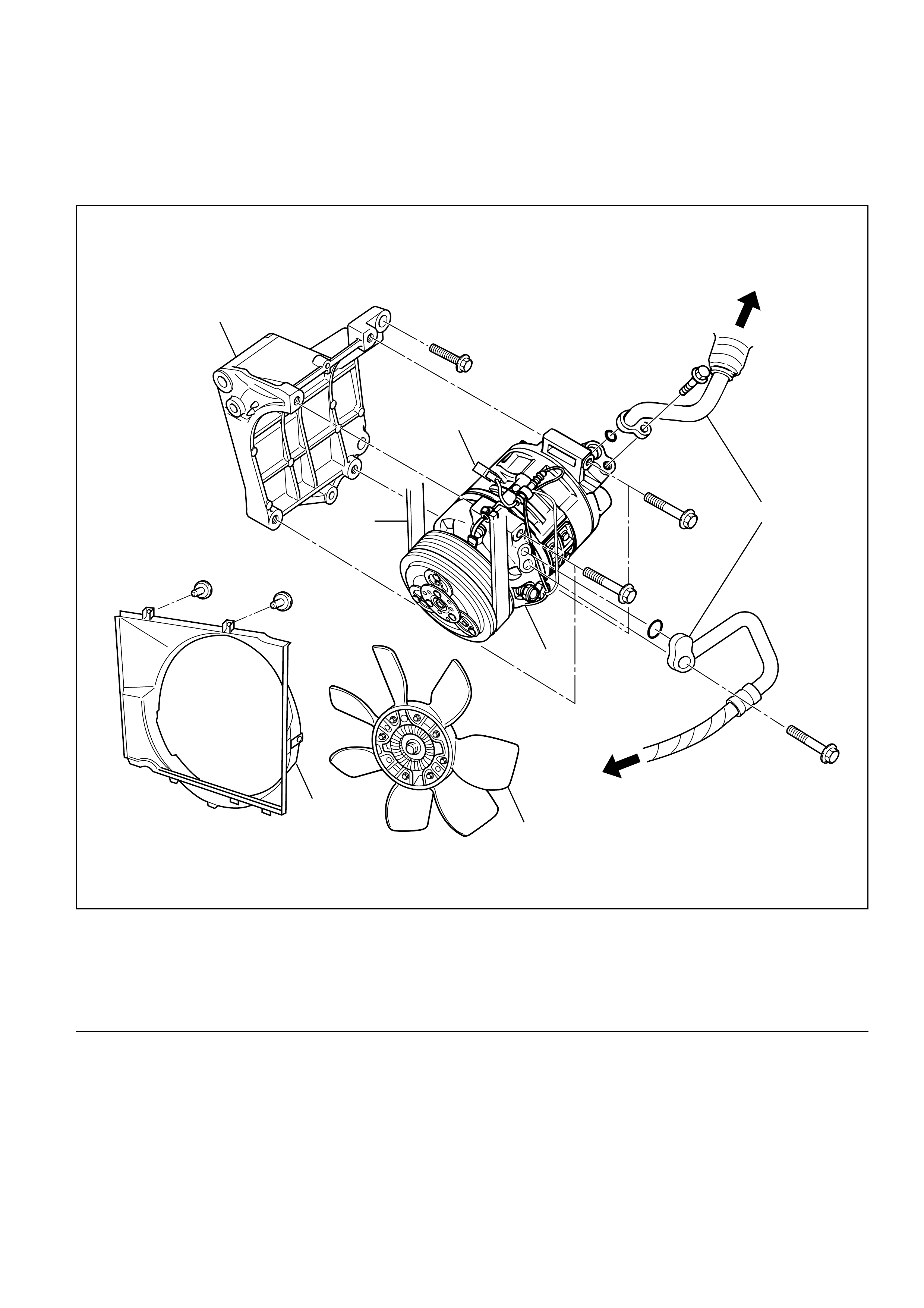

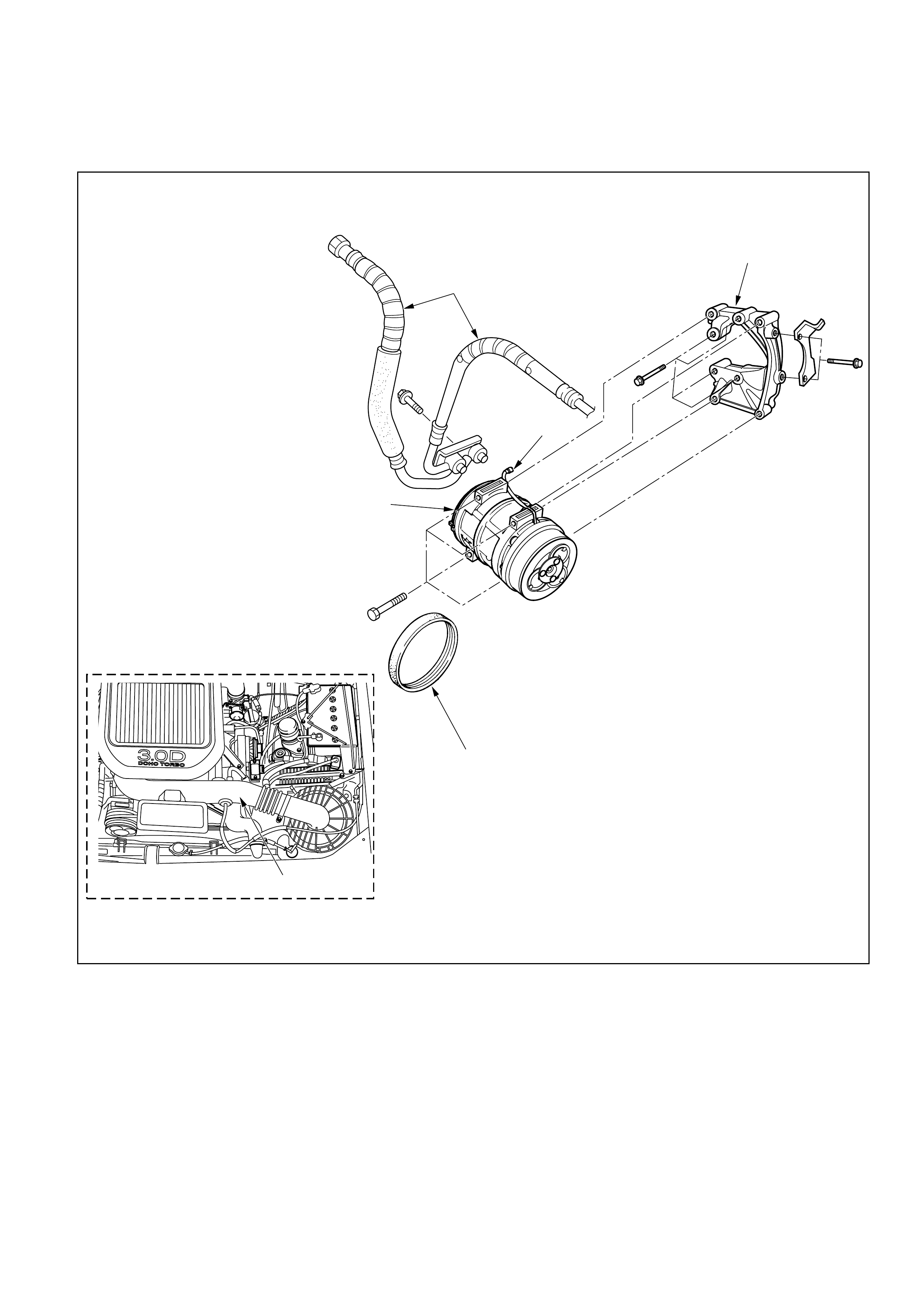

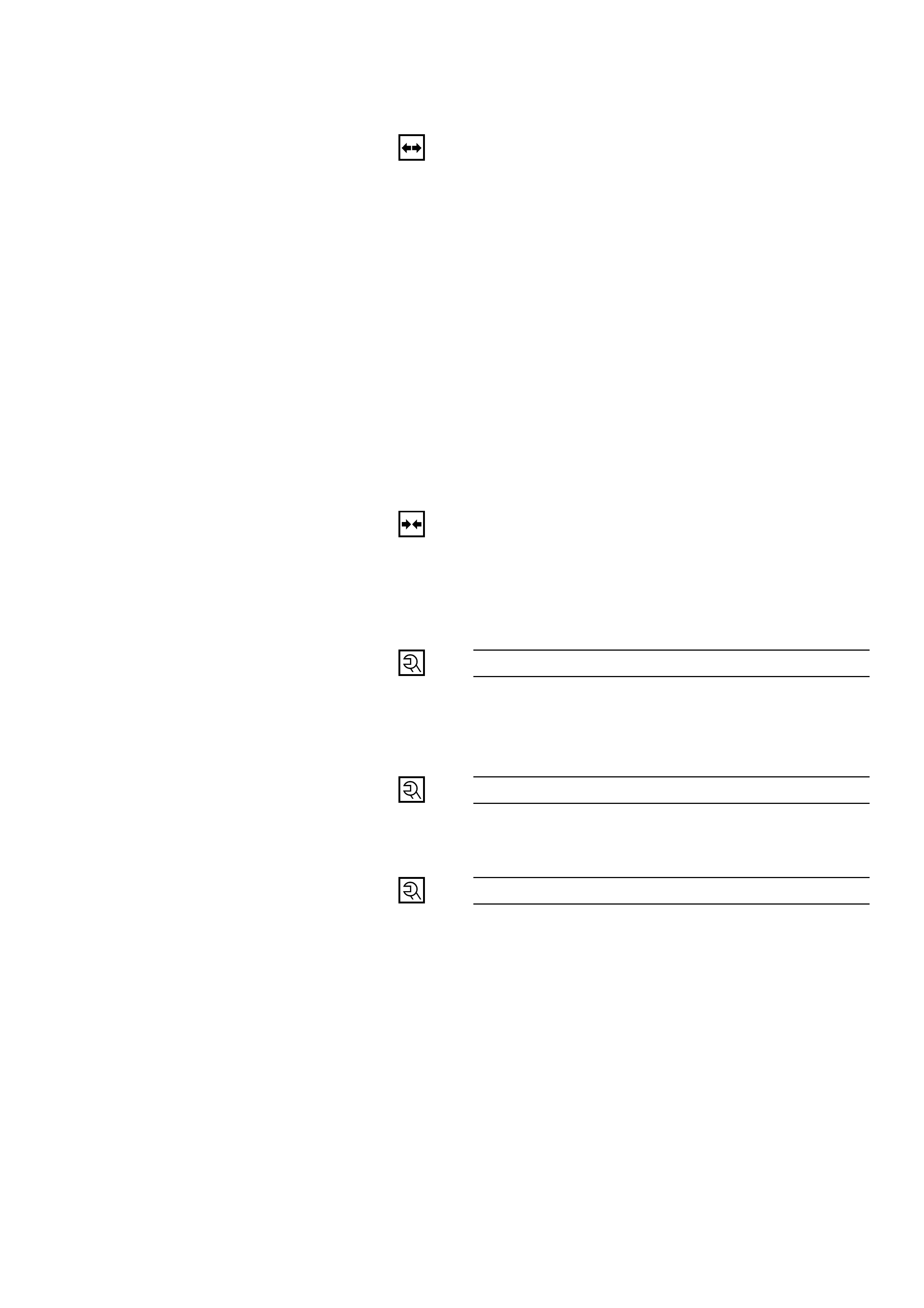

Removal Steps

1. Air duct

2. Compressor bracket

3. Magnetic clutch harness

connector

4. Compressor

5. Drive belt

6. Refrigerant line connector

Installation Steps

To install, follow the removal steps in the

reverse order.

4JX1 ENGINE

1

5

4

6

3

2

852RY00011

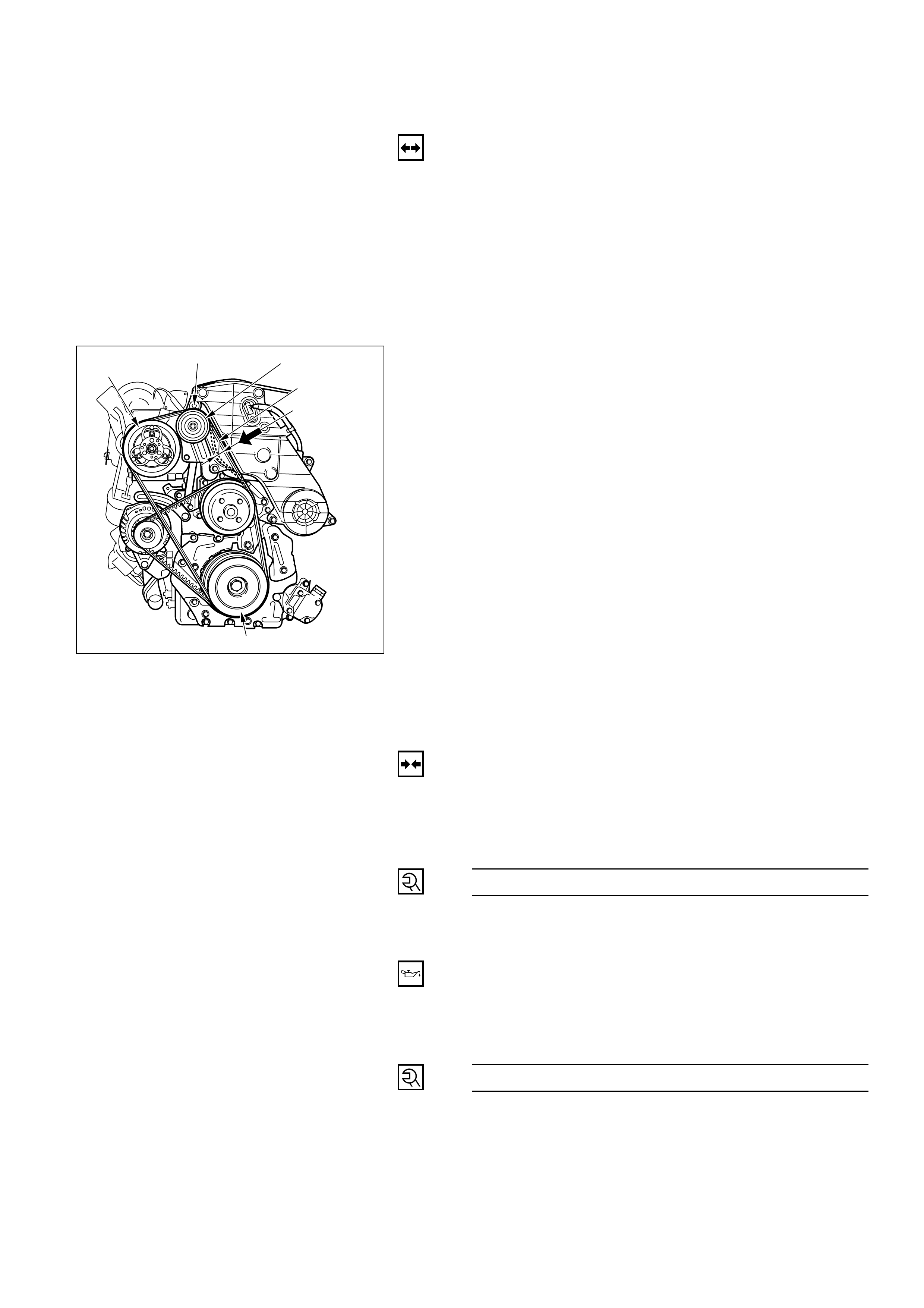

REMOVAL

Preparation:

• Battery ground cable

• Discharge and recover refrigerant (Refer to

“REFRIGERANT RECOVERY” in this section)

1. Air Duct (Turbo to air cleaner)

Cover up the air duct connecting portion to prevent

foreign materials from getting into the turbo and the

air cleaner.

2. Magnetic Clutch Harness Connector

3. Drive Belt

Loosen the power steering pump unit fixing bolts,

then loosen the drive belt adjustment bolt and

remove the drive belt.

4. Refrigerant Line Connector

5. Compressor

Compressor

Tension adjustment bolt Tension pulley

14~17mm

(0.55-0.67in)

98N{10kgf}

Crank shaft pulley

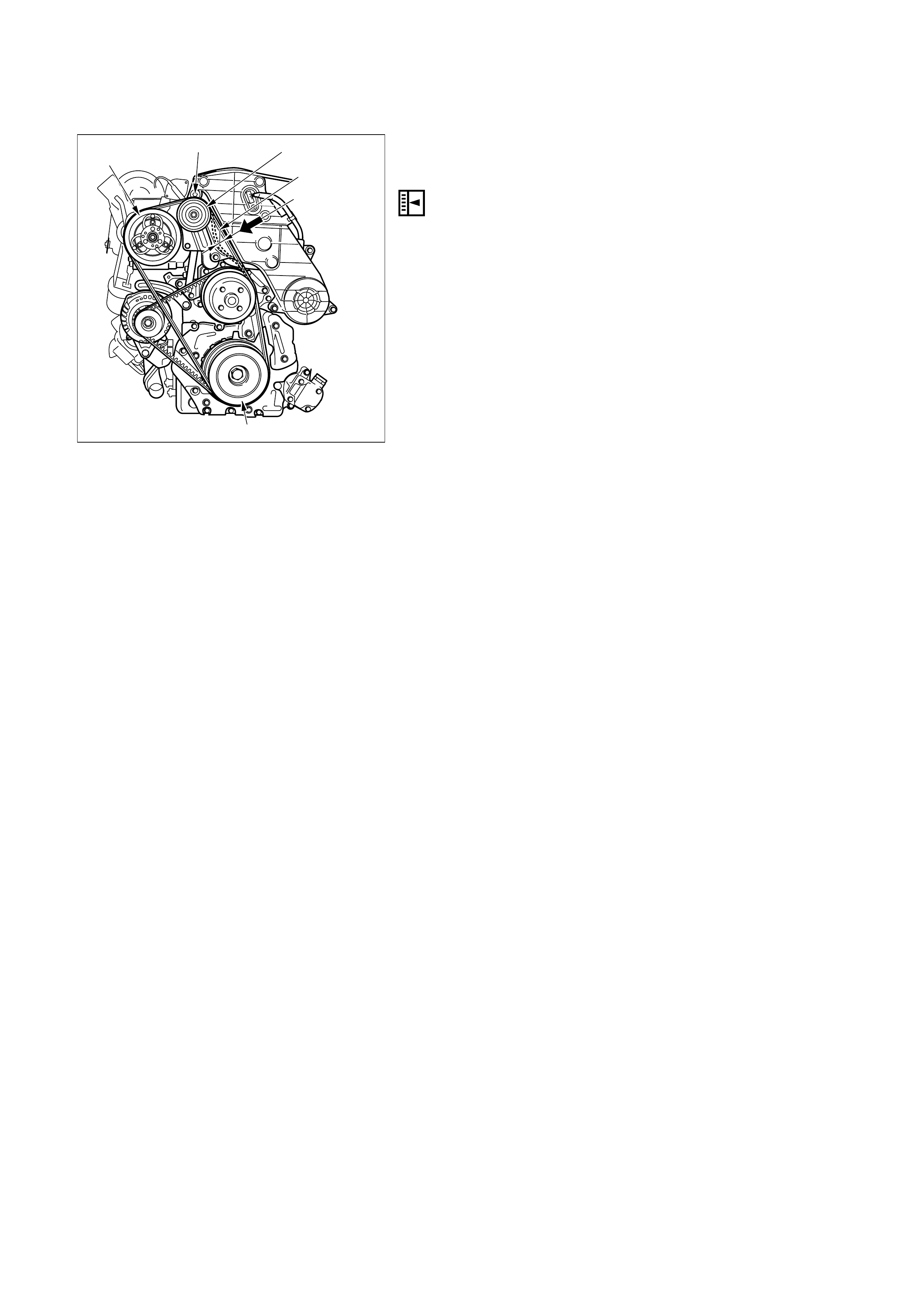

INSTALLATION

5. Compressor

Tighten the compressor fixing bolts to the specified

torque.

Compressor Bolt Torque N·m (kg·m / lb·ft)

40 (4.1 / 30)

4. Refrigerant Line Connector

•O-rings cannot be reused. Always replace with new

ones.

•Be sure to apply new compressor oil to the O-rings

when connecting refrigerant lines.

•Tighten the refrigerant line connector to the

specified torque.

Refrigerant Line Bolt Torque N·m (kg·m / lb·ft)

27 (2.8 / 20)

850RY00007

3. Drive Belt

1) Temporary tighten the power steering pump unit

fixing bolts.

2) Push the drive belt when the force of 98N {10kgf}.,

and adjust the drive belt tension by tightening

drive belt tension adjustment bolt, till the 14 ∼17

mm (0.55 ∼0.67 in) of deflection of the belt is

obtained. Then tighten the power steering pump

fixing bolts.

2. Magnetic Clutch Harness Connector

1. Air Duct (Turbo to air cleaner)

Compressor

Tension adjustment bolt Tension pulley

14~17mm

(0.55-0.67in)

98N{10kgf}

Crank shaft pulley

850RY00007

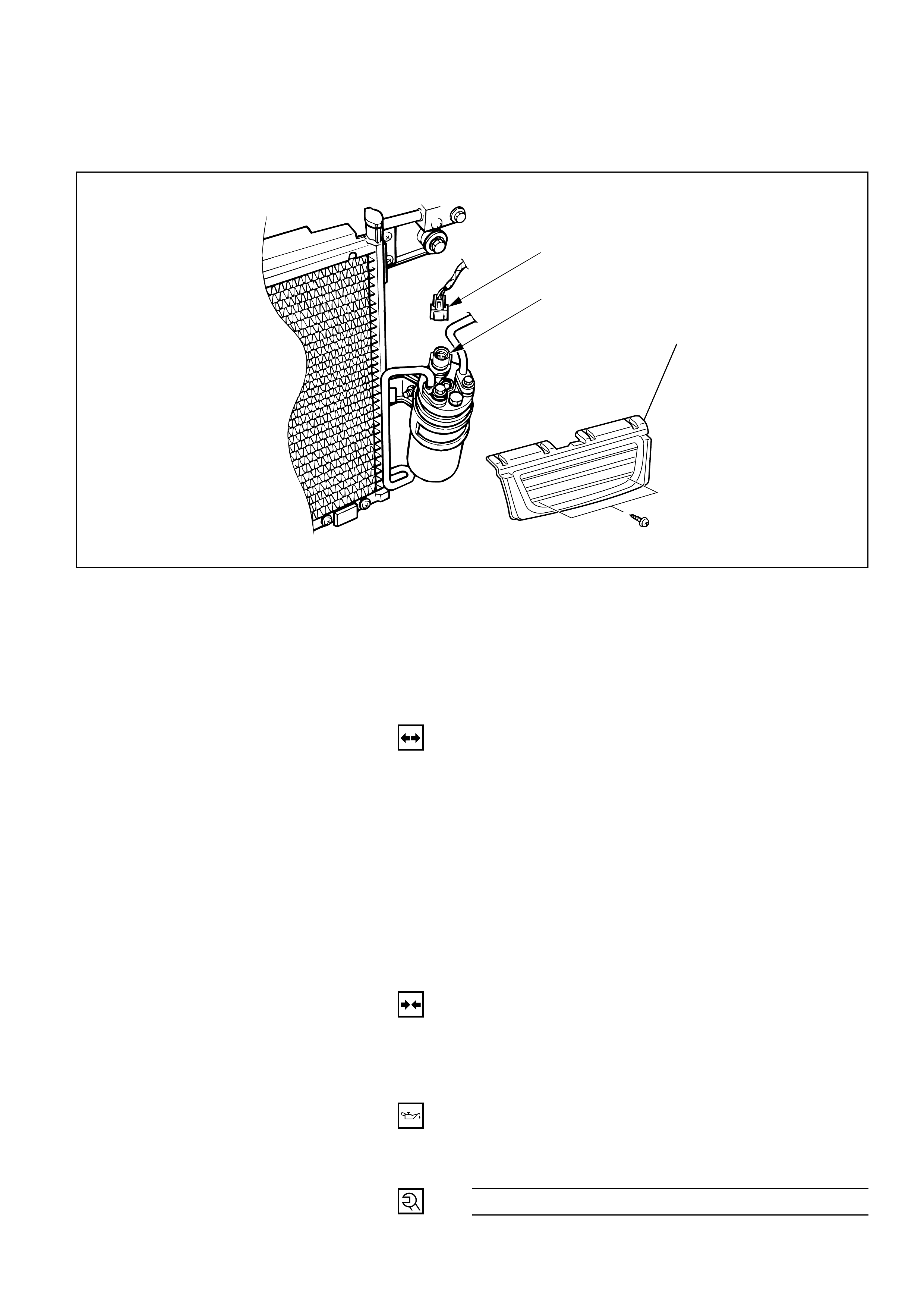

CONDENSER ASSEMBLY (SHOWN WITHOUT CONDENSER FAN)

1

2

1

4

3

5

6

875RW001

Legend

(1) Refrigerant Line

(2) Pressure Switch Connector

(3) Front Bumper Assembly

(4) Radiator Grille

(5) Engine Hood Front End Stay

(6) Condenser Assembly

REMOVAL

1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant.

• Refer to Refrigerant Recovery in this section.

3. Remove radiator grille.4. Remove front bumper assembly.• Refer to Bumpers in Body and Accessories section.5. Remove engine hood front end stay.

6. Disconnect pressure switch connector.

7. Disconnect refrigerant line.

•When removing the line connector, the connecting

part should immediately be plugged or capped to

prevent foreign matter from being mixed into the

line.

8. Remove condenser assembly.

•Handle with care to prevent damaging the

condenser or radiator fin.

•Be sure to apply new compressor oil to the O-rings

when connecting the refrigerant line.

INSTALLATION

1. Install condenser assembly.

•If installing a new condenser, be sure to add 30cc

(1.0 fl. oz.) of new compressor oil to a new one.

•Tighten the condenser fixing bolts to the specified

torque.

Condenser Fixing Torque N·m (kg·m / lb·in)

6 (0.6 / 52)

2. Connect refrigerant line.

•Tighten the inlet line connector fixing bolt to the

specified torque.

Inlet Line Torque N·m (kg·m / lb·ft)

15 (1.5 / 11)

•Tighten the outlet line connector fixing bolt to the

specified torque.

Outlet Line Torque N·m (kg·m / lb·in)

6 (0.6 / 52)

•O-rings cannot be reused. Always replace with new

ones.

•Be sure to apply new compressor oil to the O-rings

when connecting the refrigerant line..

3. Connect pressure switch connector.

4. Install engine hood front end stay.

5. Install front bumper assembly.

6. Install radiator grille.

CONDENSER FAN MOTOR

Removal Steps

(1) Condenser Fan Motor

(2) Fan Motor Shroud

(3) Motor Fan

(4) Condenser Unit Net

(5) Radiator Grille

(6) Condenser Fan Assembly

(7) Shroud Bracket

5

4

3

2

1

76

875RY00002

Removal

1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant.

• Refer to Refrigerant Recovery in this section.

3. Remove radiator grille.

4. Remove condenser fan assembly.

•Disconnect the fan motor connector and

remove the 4 fixing bolts.

5. Remove condenser unit net.

•Remove the 4 fixing screws.

6. Remove motor fan.

7. Remove condenser fan motor.

Installation

To install, follow the removal steps in the reverse

order, noting the following point.

1. Route the fan motor harness in its previous

position and fix it securely with clip and bracket.

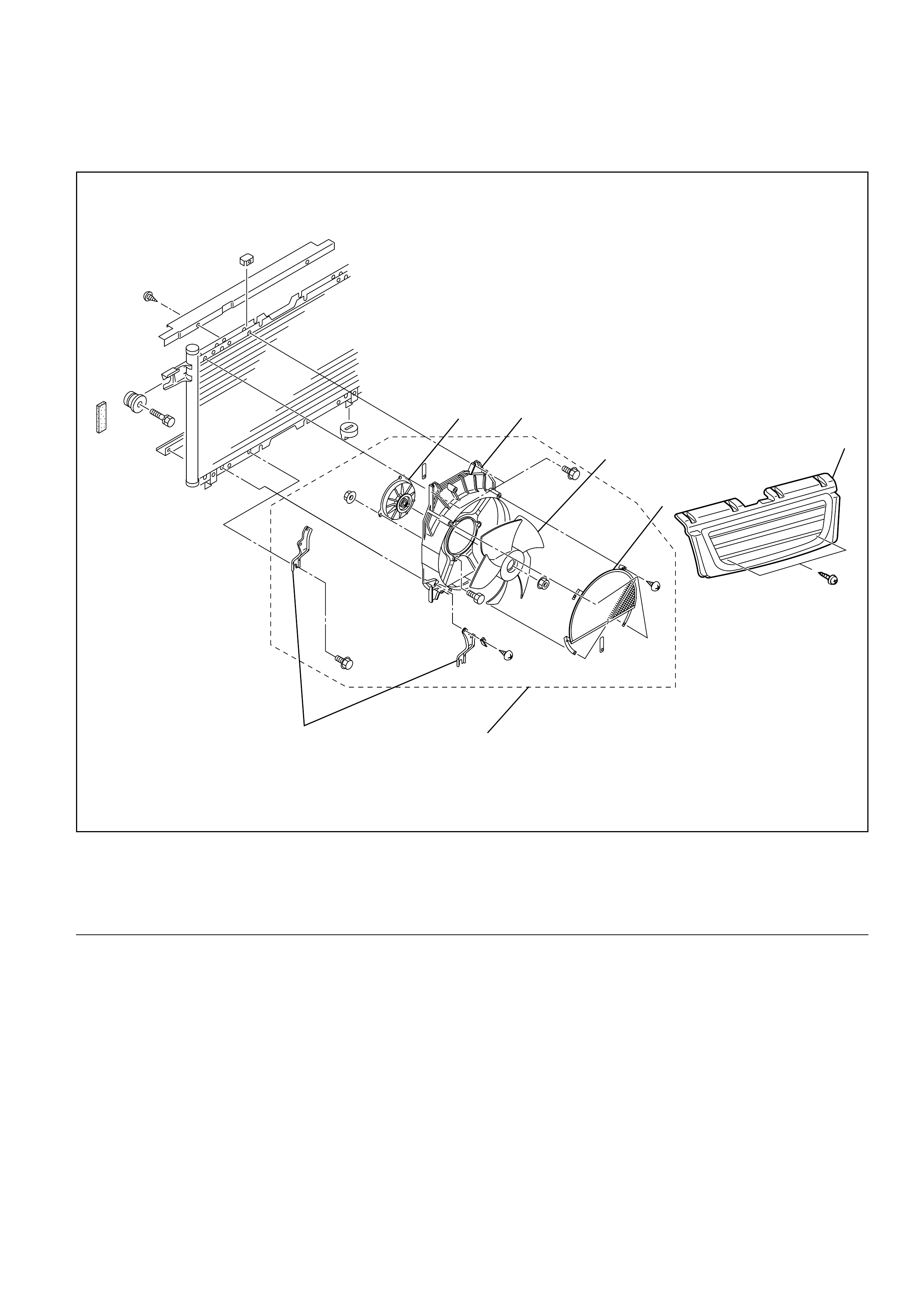

Removal Steps

1. Radiator grille

2. Pressure switch connector

3. Refrigerant line

4. Bracket bolt

5. Receiver/drier

Installation Steps

To install, follow the removal steps in the

reverse order.

RECEIVER/DRIER

3

3

5

2

4

1

REMOVAL

Preparation:

• Disconnect the battery ground cable• Discharge and recover refrigerant (Refer to“REFRIGERANT RECOVERY” in this section.)

1. Radiator Grille

2. Pressure Switch Connector

3. Refrigerant Line

When removing the line connected part, the

connecting part should immediately be plugged or

capped to prevent foreign matter from being mixed

into the line.

4. Bracket Bolt

5. Receiver/Drier

Loosen the bolt, then, using care not to touch or bend

the refrigerant line, carefully pull out the receiver/

drier.

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. If installing a new receiver/drier, be sure to add 30 cc

(0.8 Imp fl oz) of new compressor oil to a new one.

2. Put the receiver/drier in the bracket, and connect with

the refrigerant line. Check that no excessive force is

imposed on the line. Fasten the bracket bolt to the

receiver/drier.

3. Tighten the line to the specified torque.

Refrigerant Line Bolt Torque N·m (kg·m / lb·in)

6 (0.6 / 52)

4. O-rings cannot be reused. Always replace with new

ones.

5. Be sure to apply new compressor oil to the O-rings

when connecting refrigerant line.

Removal Steps

1. Radiator grille

2. Pressure switch connector

3. Pressure switch

Installation Steps

To install, follow the removal steps in the

reverse order.

PRESSURE SWITCH

2

3

1

REMOVAL

Preparation:

• Disconnect the battery ground cable• Discharge and recover refrigerant (Refer to“REFRIGERANT RECOVERY” in this section.)

1. Radiator Grille

2. Pressure Switch Connector

3. Pressure Switch

When removing the switch connected part, the

connecting part should immediately be plugged or

capped to prevent foreign matter from being mixed

into the line.

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. O-ring cannot be reused. Always replace with a new

one.

2. Be sure to apply new compressor oil to the O-ring

when connecting pressure switch.

3. Tighten the pressure switch to the specified torque.

Pressure Switch Torque N·m (kg·m / lb·in)

13 (1.3 / 113)

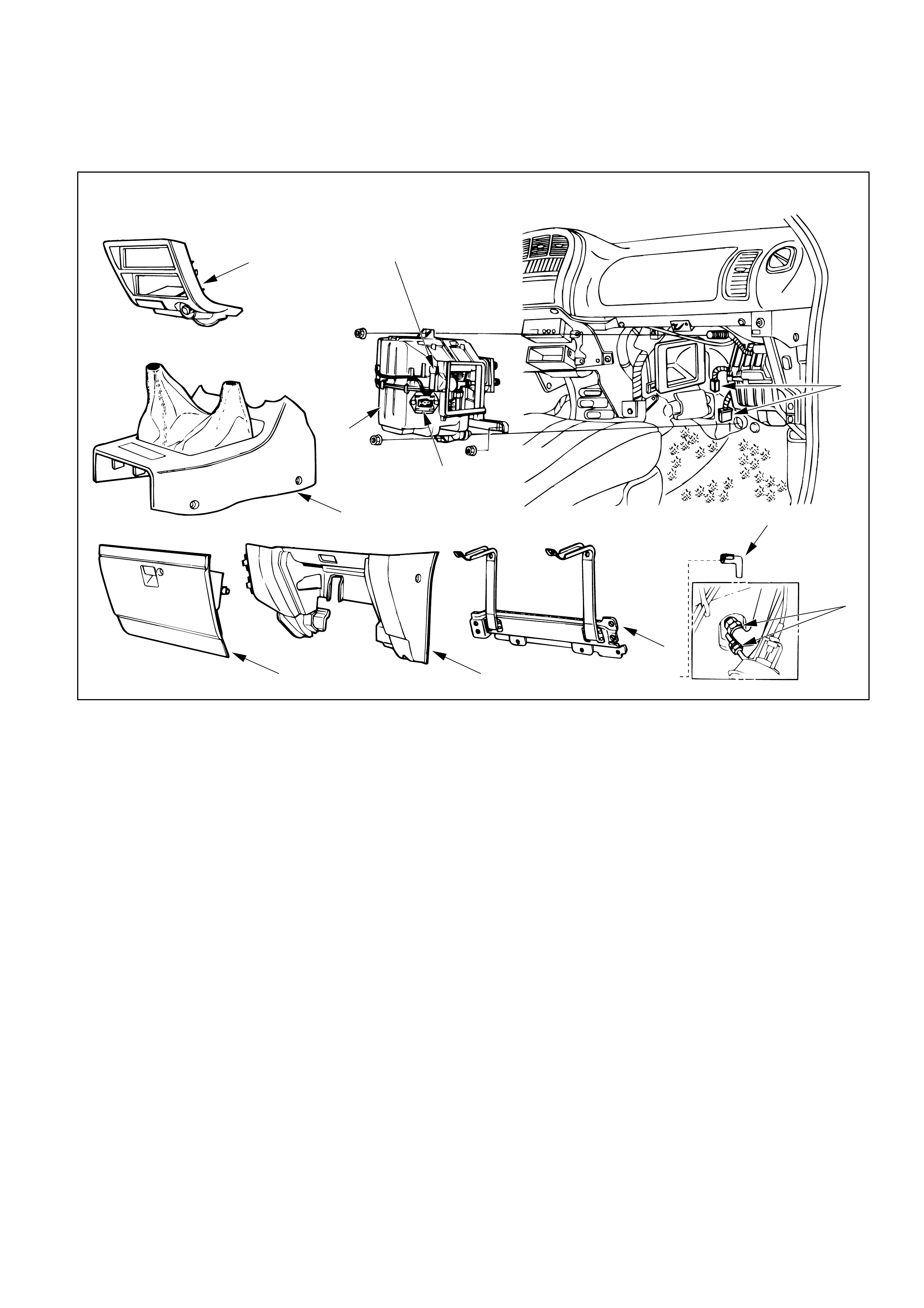

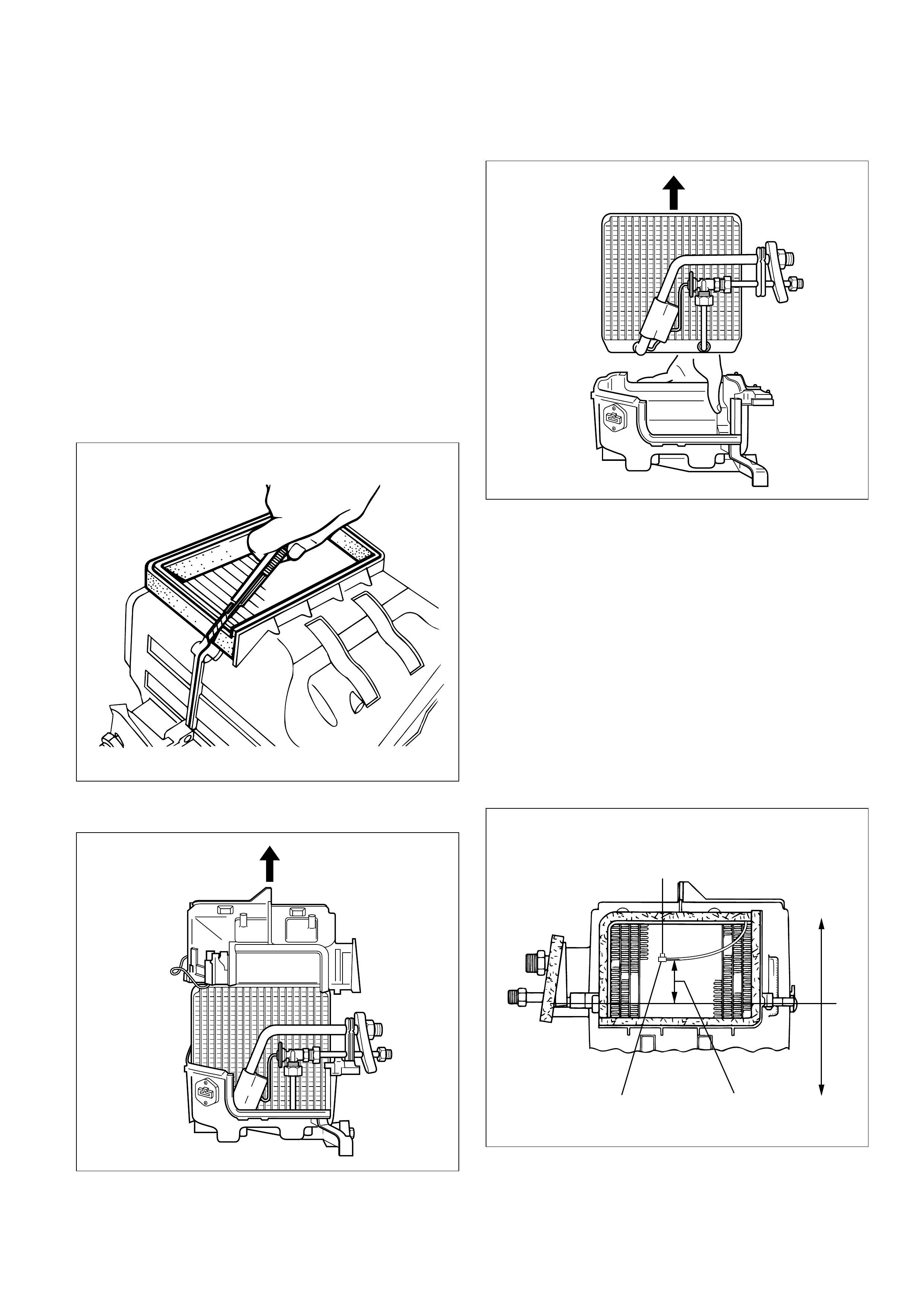

Removal Steps

1. Front console assembly

2. Lower cluster assembly

3. Glove box

4. Instrument panel passenger

lower cover assembly

5. Passenger knee bolster

reinforcement assembly

6. Resistor and electronic

thermostat connector

7. Drain hose

8. Refrigerant line

9. Evaporator assembly

Installation Steps

To install, follow the removal steps in the

reverse order.

EVAPORATOR ASSEMBLY

1

2

34

5

6

7

8

9

This illustration is based on LHD

Electronic thermostat

Resistor

850RW00001

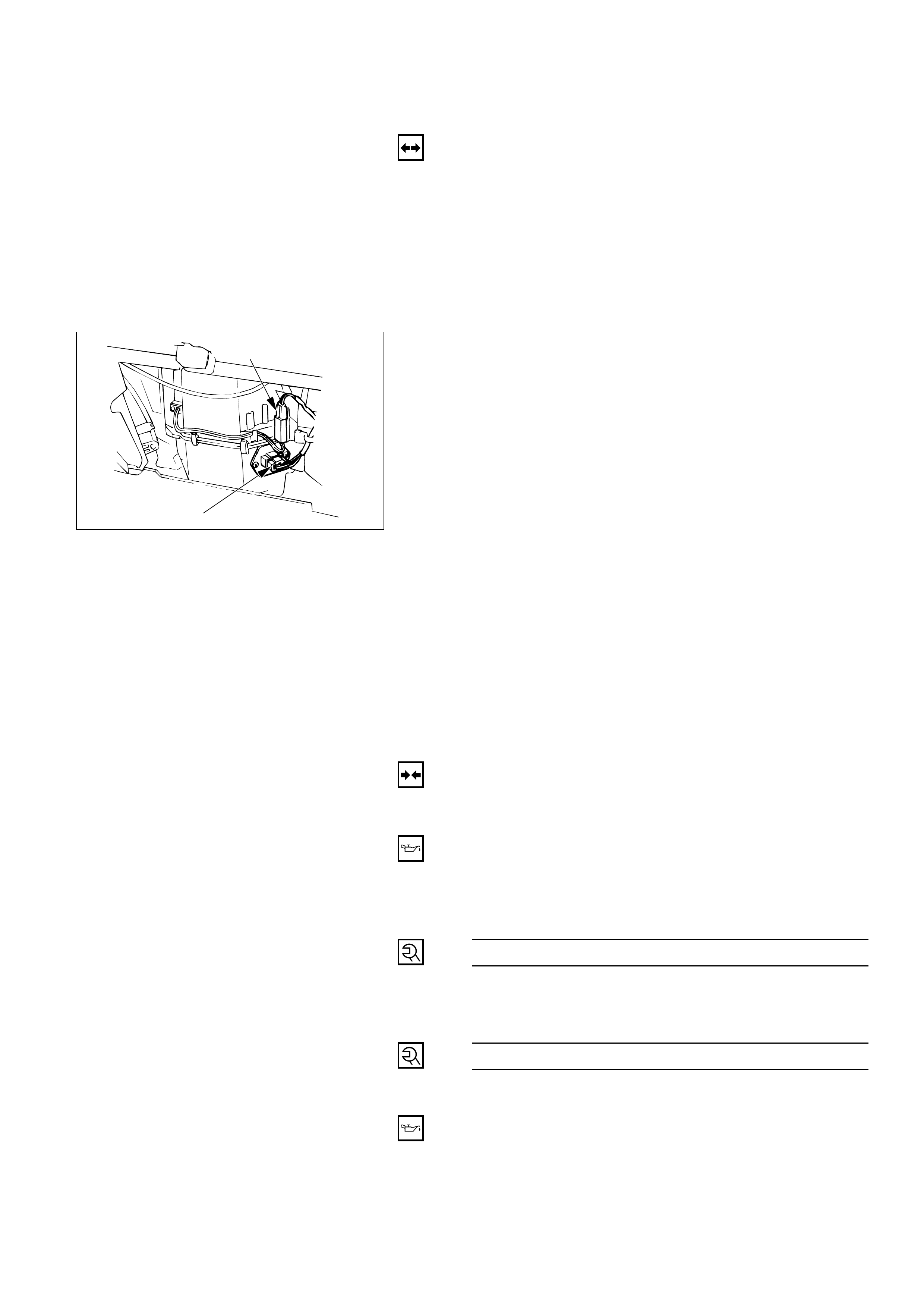

REMOVAL

Preparation:

• Disconnect the battery ground cable

• Discharge and recover refrigerant (Refer to

“REFRIGERANT RECOVERY” in this section.)

1. Front Console Assembly

2. Lower Cluster Assembly

3. Glove Box

4. Instrument Panel Passenger Lower Cover Assembly

5. Passenger Knee Bolster Reinforcement Assembly

• Refer to Section 1 “BODY” for INSTRUMENT

PANEL ASSEMBLY removal procedure.

6. Resistor and Electronic Thermostat Connector

7. Drain Hose

8. Refrigerant Line

•Use a back-up wrench when disconnecting and

reconnecting the refrigerant lines.

•When removing the refrigerant line connected part,

the connecting part should immediately be

plugged or capped to prevent foreign matter from

being mixed into the line.

9. Evaporator Assembly

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. To install a new evaporator assembly, add 50cc

(1.4 Imp fl oz) of new compressor oil to a new core.

2. Tighten the refrigerant outlet line to the specified

torque.

Outlet Line Torque N·m (kg·m / lb·ft)

25 (2.5 / 18)

3. Tighten the refrigerant inlet line to the specified

torque.

Inlet Line Torque N·m (kg·m / lb·ft)

15 (1.5 / 11)

4. O-rings cannot be reused. Always replace with new

ones.

5. Be sure to apply new compressor oil to the O-rings

when connecting lines.

Electronic thermostat

connector

Resistor connector

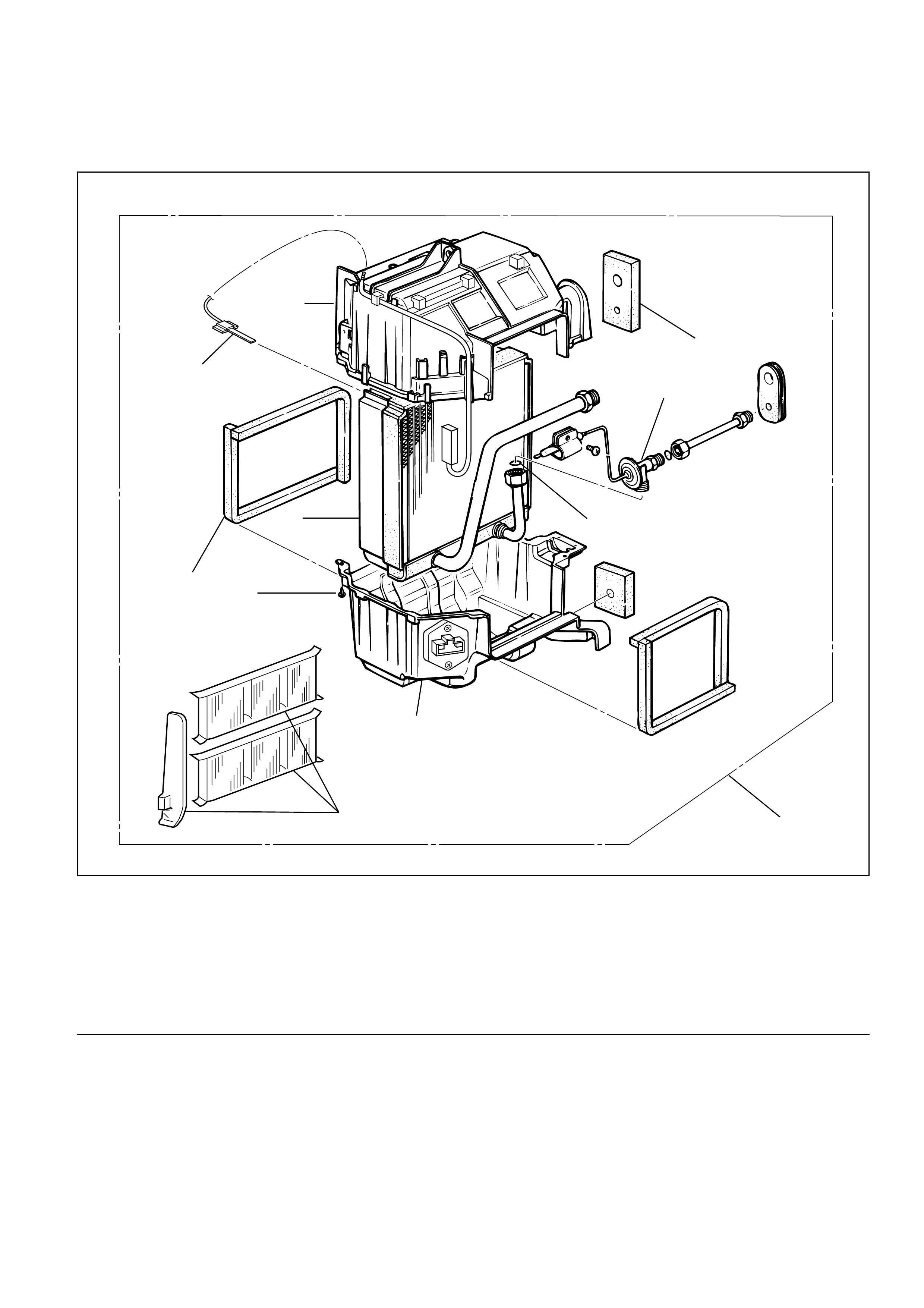

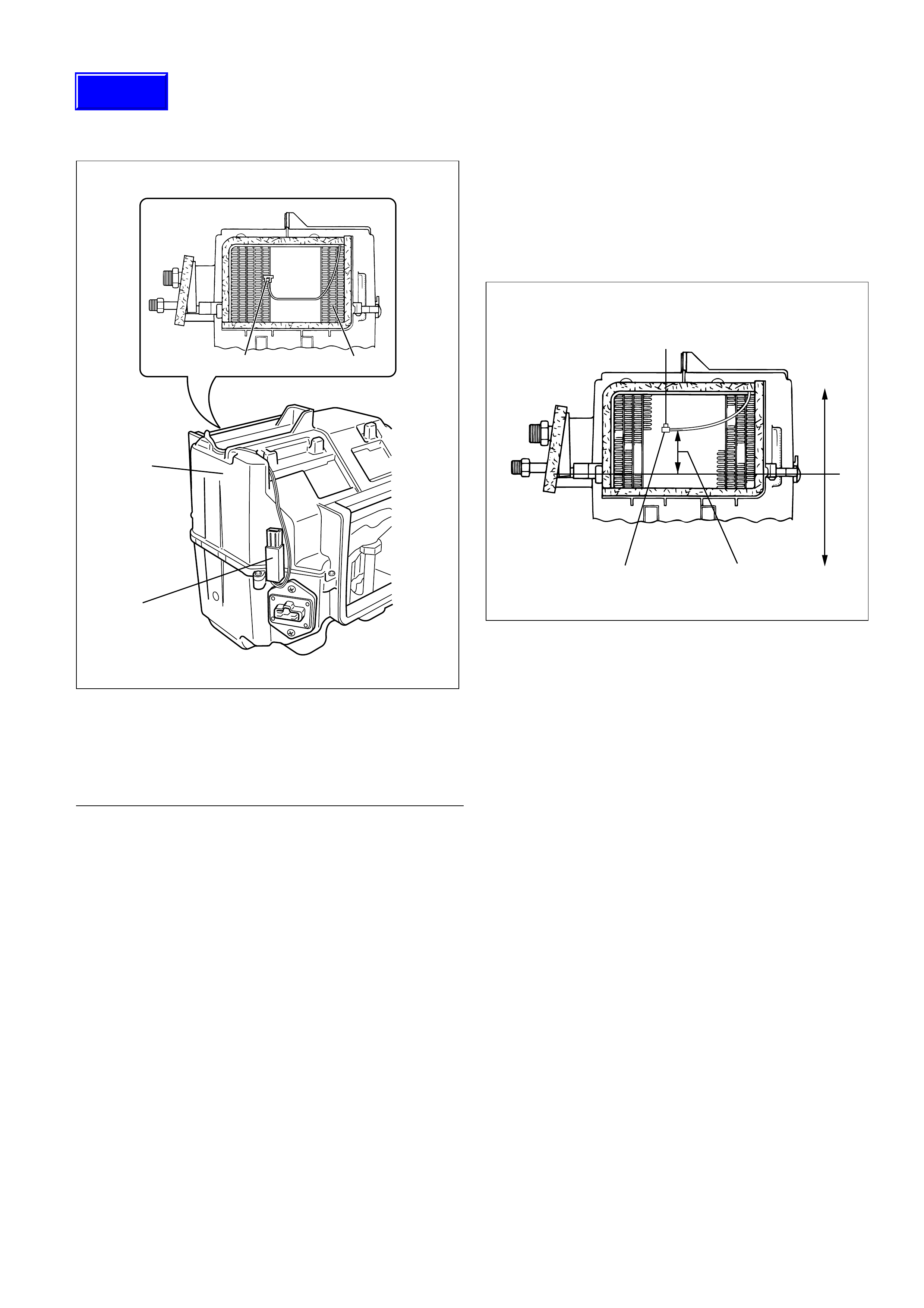

Legend

(1) Lining

(2) Expansion Valve

(3) O-ring

(4) Lower Case

(5) Evaporator Assembly

(6) Pollen Filter

(7) Attaching Screw

(8) Lining

(9) Evaporator Core

(10) Electronic Thermostat

(11) Upper Case

EVAPORATOR CORE AND/OR EXPANSION VALVE

This illustration is based on LHD

8

1

2

3

5

4

6

7

9

11

10

874RY00012

Removal

1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant.

• Refer to Refrigerant Recovery in this section.

3. Remove evaporator assembly.

• Refer to Evaporator Assembly in this section.

4. Remove pollen filter.

5. Pull the sensor from the evaporator assembly.

6. Remove attaching screw.

7. Remove upper case.

8. Remove lower case.

•Slit the case parting face with a knife since the

lining is separated when removing the

evaporator.

•Lift to remove the upper case.

9. Remove evaporator core.

10.Remove expansion valve.

•Tear off the insulator carefully.

•Use a back-up wrench when disconnecting all

refrigerant pipes.

Installation

To install, follow the removal steps in the reverse

order, noting the following points:

1. The sensor is installed on the core with the clip.

2. The sensor must not interfere with the

evaporator core.

3. When installing the new evaporator core, install

the thermo sensor (2) to the evaporator core (1)

specified position with the clip in the illustration.

874RS006

874RY00005

874RY00006

SENSOR TO BE LOCATED

AT 7TH LINE FROM LEFT

57.5mm(2.26 in.)2

1

Lower case Upper case

874RX021

4. O-rings cannot be reused, Always replace with

new ones.

5. Be sure to apply new compressor oil to the O-

rings when connecting lines.

6. Be sure to install the sensor and the insulator on

the place where they were before.

7. To install a new evaporator core, add 50cc (1.7

fl. oz.) of new compressor oil to the new core.

8. Tighten the refrigerant lines to the specified

torque. Refer to Main Data and Specifications for

Torque Specifications in this section.

9. Apply an adhesive to the parting face of the

lining when assembling the evaporator

assembly.

ELECTRONIC THERMOSTAT

Legend

(1) Thermo Sensor(2) Evaporator Core(3) Evaporator(4) Thermostat Unit

Removal1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant.•Refer to Refrigerant Recovery in this section.3. Remove evaporator assembly.

• Refer to Evaporator Assembly removal

procedure in this section.

4. Remove electronic thermostat.

•Pull the sensor from the evaporator assembly.

Installation

To install, follow the removal steps in the reverse

order, noting the following points.

1. Install the thermostat sensor to the evaporator

core specified position with the clip.

2. The sensor is installed on the core with the clip

and it must not interfere with the core.

1 2

3

4

874RX022

SENSOR TO BE LOCATED

AT 7TH LINE FROM LEFT

57.5mm(2.26 in.)2

1

Lower case Upper case

874RX021

Techline

1

2

3

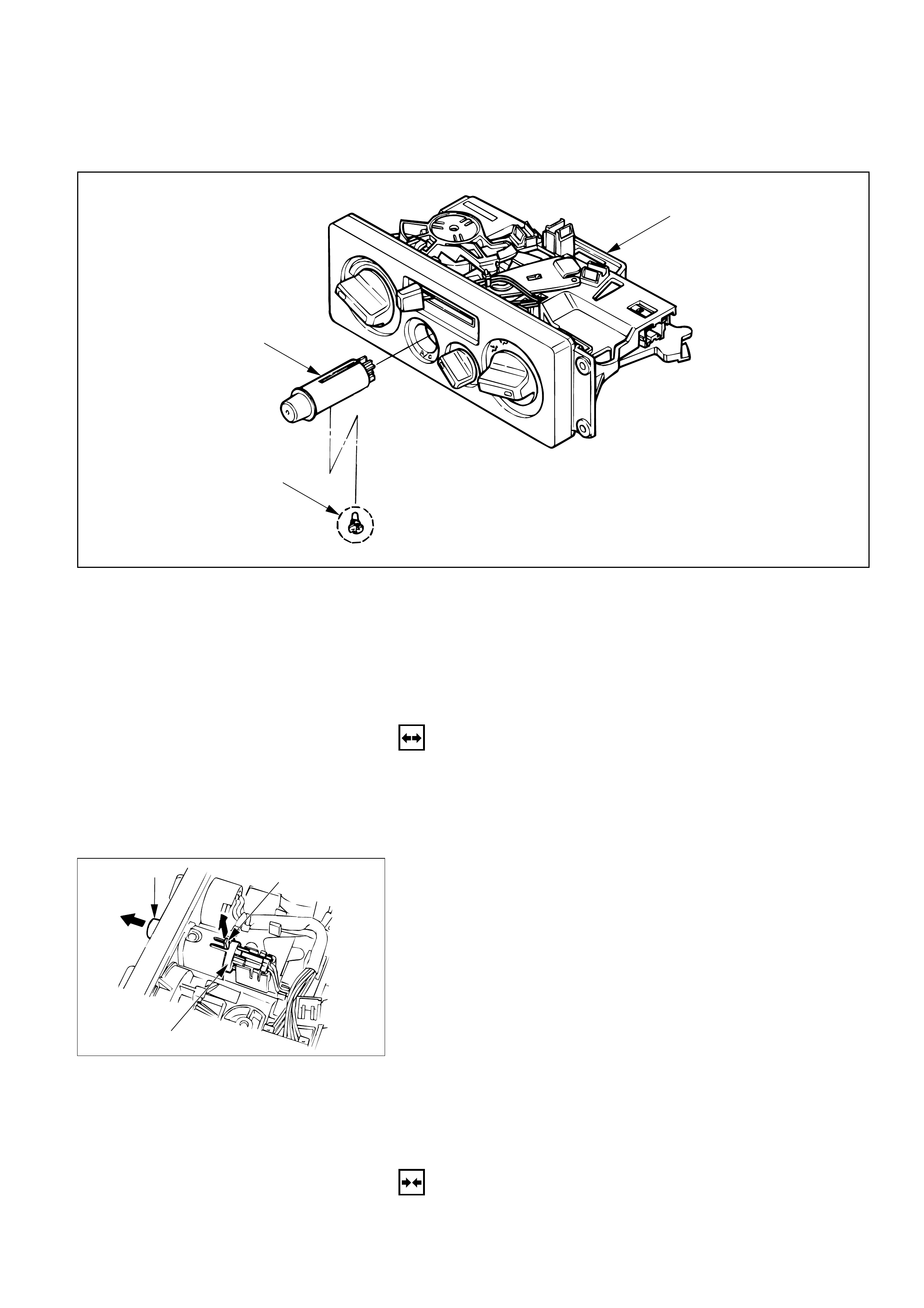

Removal Steps

1. Control lever assembly

2. A/C switch

3. Illumination bulb

Installation Steps

To install, follow the removal steps in the

reverse order.

A/C SWITCH AND ILLUMINATION BULB

REMOVAL

Preparation:

Disconnect the battery ground cable

1. Control Lever Assembly

Refer to Section 2A “CONTROL LEVER ASSEMBLY”

removal procedure.

2. A/C Switch

Raise up the catch portion of the switch and remove

the switch while pushing it toward the outside.

3. Illumination Bulb

Turn the illumination bulb counterclockwise to

remove.

Catch portion

End of switch

A/C switch

INSTALLATION

To install, follow the removal steps in the reverse order.

1

6

7

7

6

5

3

3

3

4

4

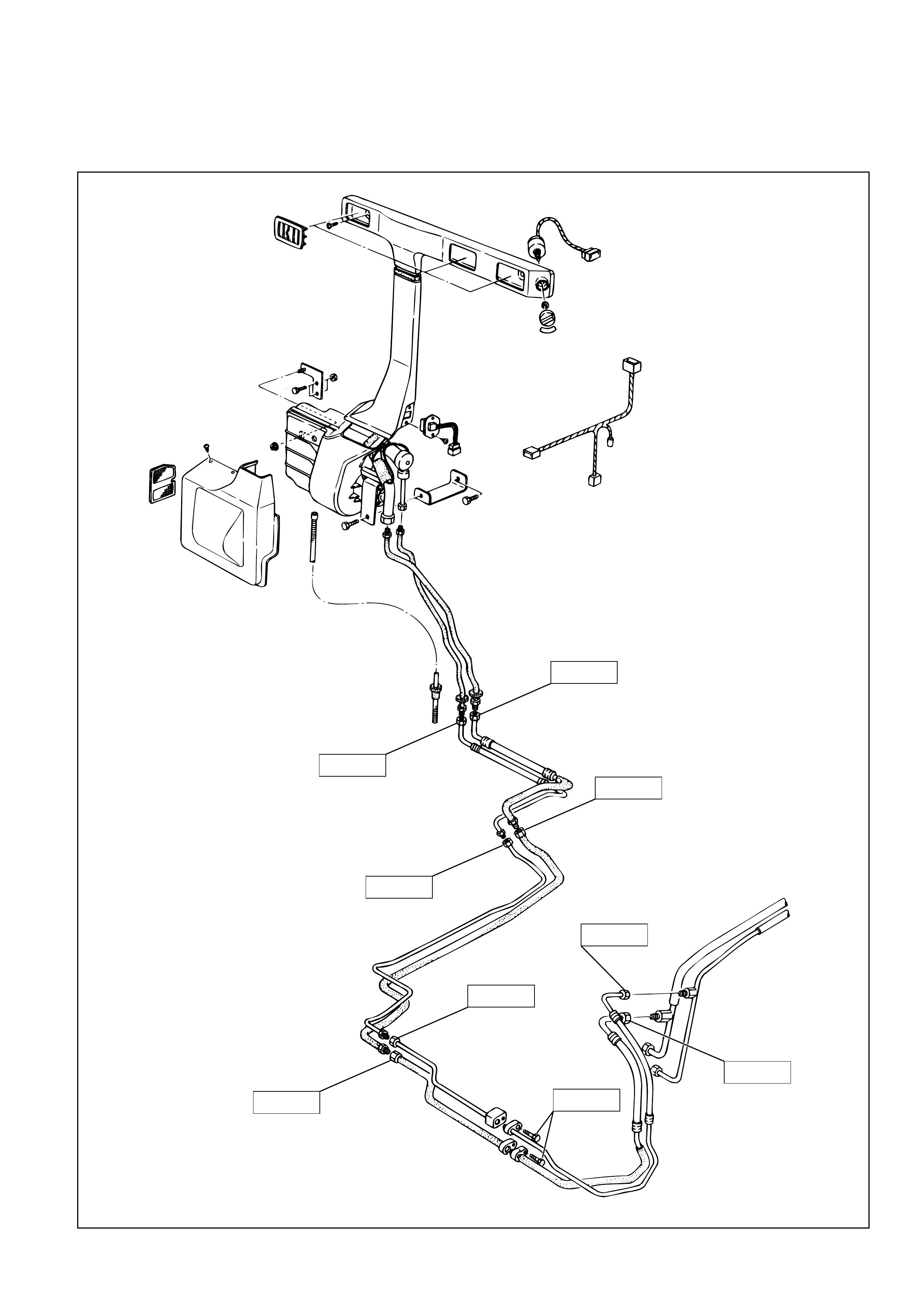

REFRIGERANT LINE

Removal Steps

1. Radiator grille

2. Air cleaner

2a. Dust

2b. Battery and reserver tank

2c. Air cleaner cover

3. Clip and clamp

4. Liquid line (High-pressure pipe)

5. Suction line (Low-pressure pipe)

6. Suction line (Low-pressure hose)

7. Discharge line (High-pressure hose)

Installation Steps

To install, follow the removal steps in the

reverse order.

REMOVAL

Preparation:

• Disconnect the battery ground cable

• Discharge and recover refrigerant (Refer to

“REFRIGERANT RECOVERY” in this section.)

1. Radiator Grille

2. Air Cleaner

2a. Duct

2b. Battery and Reserver Tank

2c. Air Cleaner Cover

3. Clip and Clamp

4. Liquid Line (High-pressure pipe)

5. Suction Line (Low-pressure pipe)

6. Suction Line (Low-pressure hose)

7. Discharge Line (High-pressure hose)

• Use a back-up wrench when disconnecting and

reconnecting the refrigerant lines.

• When removing the refrigerant line connecting

part, the connecting part should immediately be

plugged or capped to prevent foreign matter from

being mixed into the line.

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. O-rings cannot be reused. Always replace new ones.

2. Be sure to apply compressor oil to the O-rings when

connecting refrigerant lines.

3. Tighten the refrigerant line to the specified torque.

(Refer to “SERVICE INFORMATION” for FIXING

TORQUE in section 0A.)

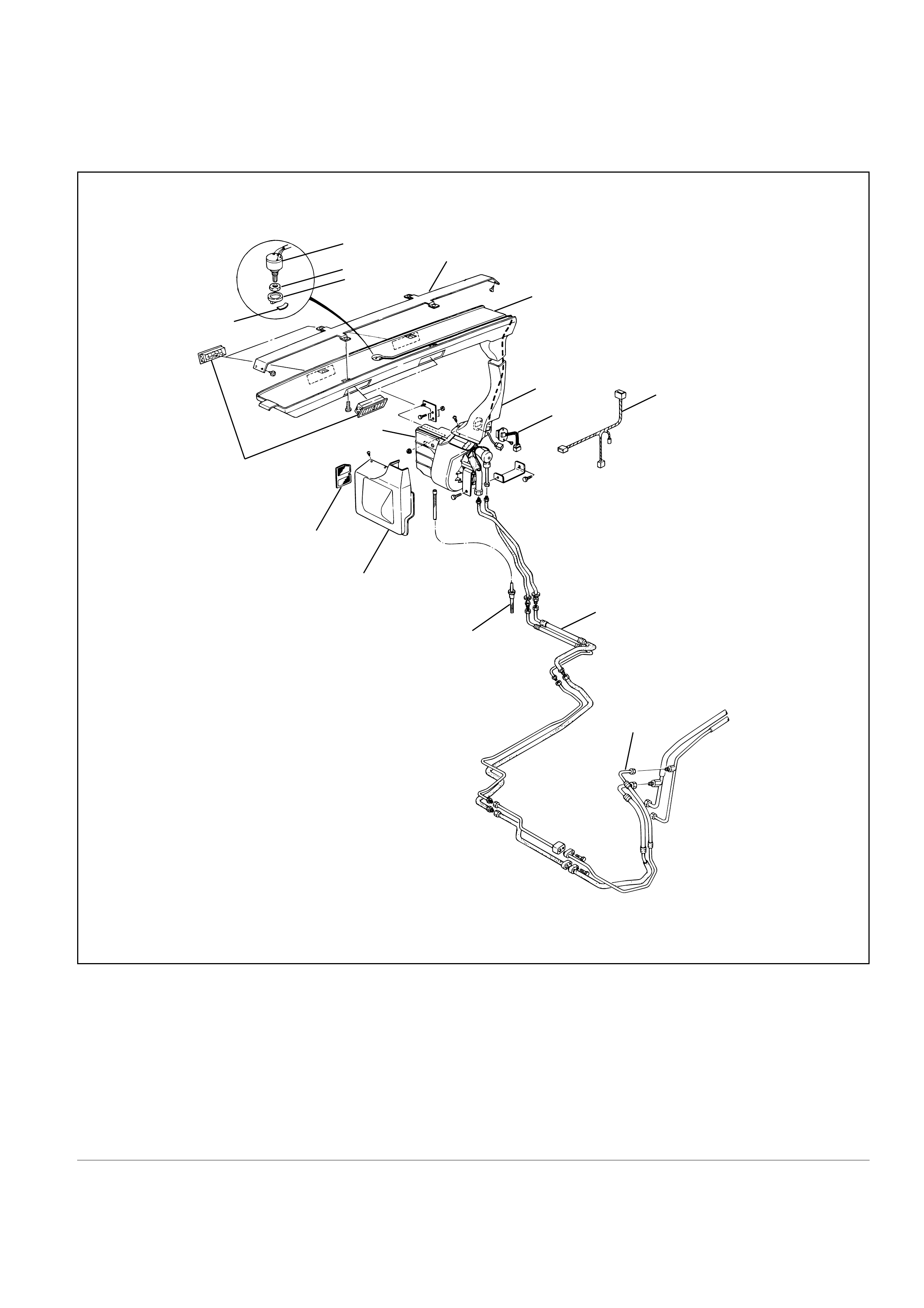

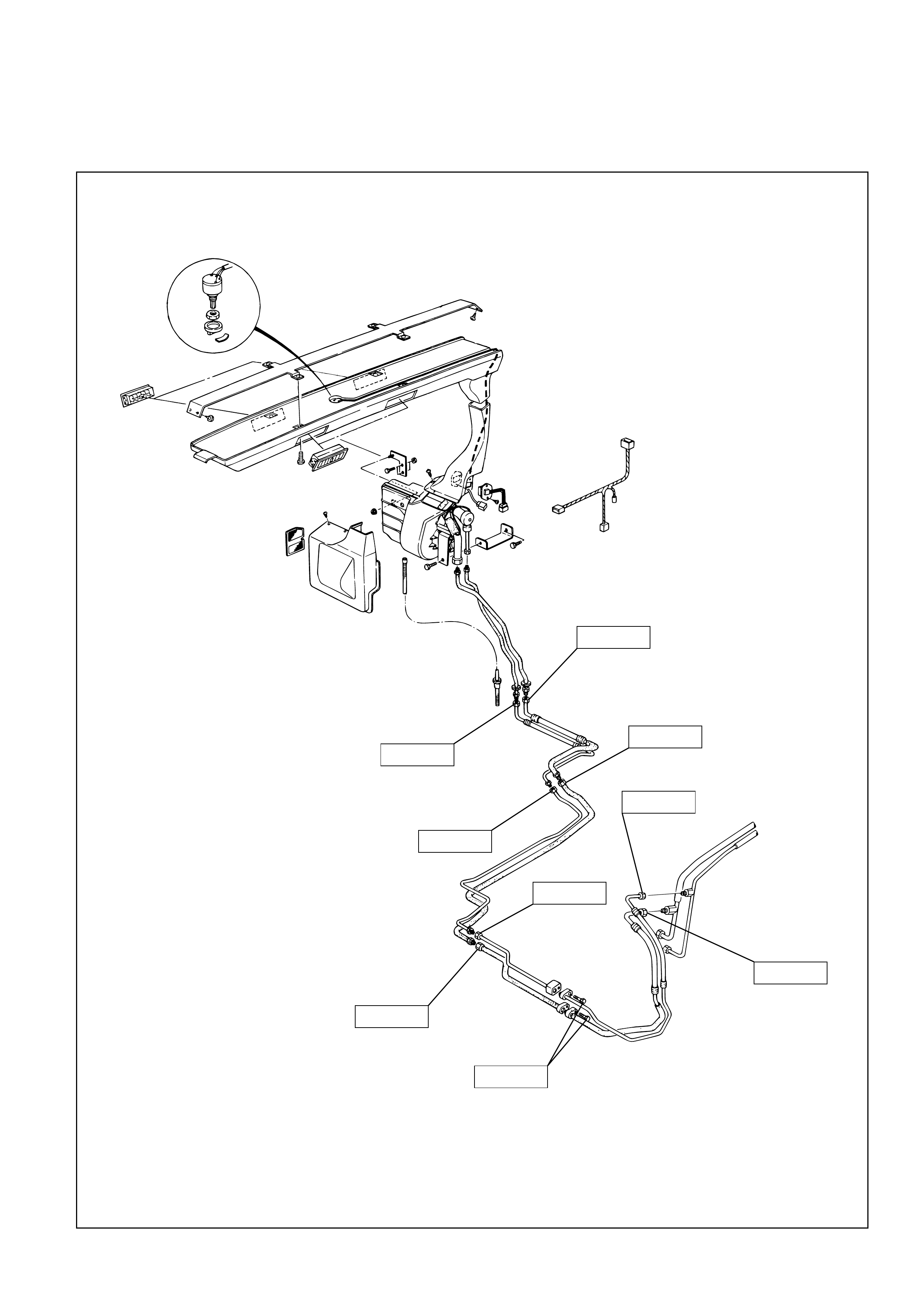

REAR COOLER PARTS

56

7

813

4

9

14

2

12

11

10

3

1

Legend

(1) Liquid Line (high pressure pipe)

(2) Cooling Unit

(3) Suction Line (low pressure pipe)

(4) Duct Assembly

(5) Duct Assembly

(6) Switch

(7) Knob

(8) Panel

(9) Resistor

(10) Drain Hose

(11) Cover Assembly

(12) Filter

(13) Wire Harness

(14) Grille Assembly

855RY00002

REAR COOLER PARTS (ROOF DUCT TYPE)

16

15

14 2

3

45

7

6

1

13

11

12

10

9

8

Legend

(1) Roof Duct Bracket

(2) Roof Duct

(3) Lower Duct

(4) Resistor

(5) Wire Harness

(6) Liquid Line (high pressure pipe)

(7) Suction Line (low pressure pipe)

(8) Drain Hose

(9) Cover Assembly

(10) Filter

(11) Cooling Unit

(12) Grille Assembly

(13) Panel

(14) Knob

(15) Nut

(16) Fan Control Switch

855RY00001

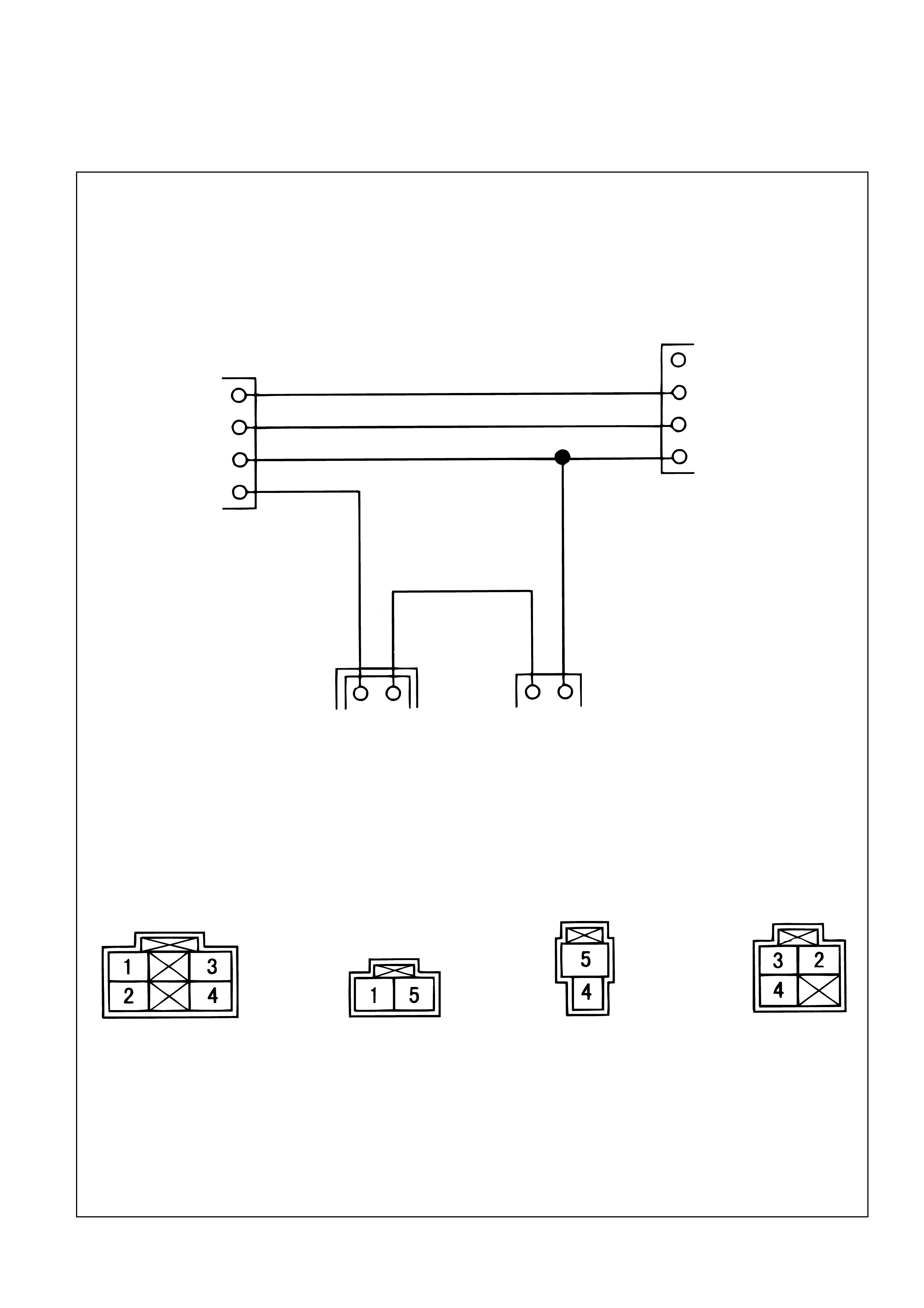

Switch Vehicle Motor Resistor

15 54

(Vehicle) (Motor)

0.85 RW

0.85 B

0.85 RB

(Resistor)(Switch)

0.5 LG

0.85 RG

0.85 WR

2

3

4

1

2 LO

3 MI

4 HI

WIRING DIAGRAM

D08RY00303

E06RY00003

25(2.5/18)

25(2.5/18)

25(2.5/18)

25(2.5/18)

15(1.5/11)

15(1.5/11)

15(1.5/11)

15(1.5/11)

15(1.5/11)

TORQUE SPECIFICATIONS N·m (kg·m/ib·ft)

25 (2.5/18)

25 (2.5/18)

25 (2.5/18)

25 (2.5/18)

15 (1.5/11)

15 (1.5/11)

15 (1.5/11)

15 (1.5/11)

15 (1.5/11)

TORQUE SPECIFICATIONS (ROOF DUCT TYPE) N·m (kg·m/ib·ft)

E06RY00002

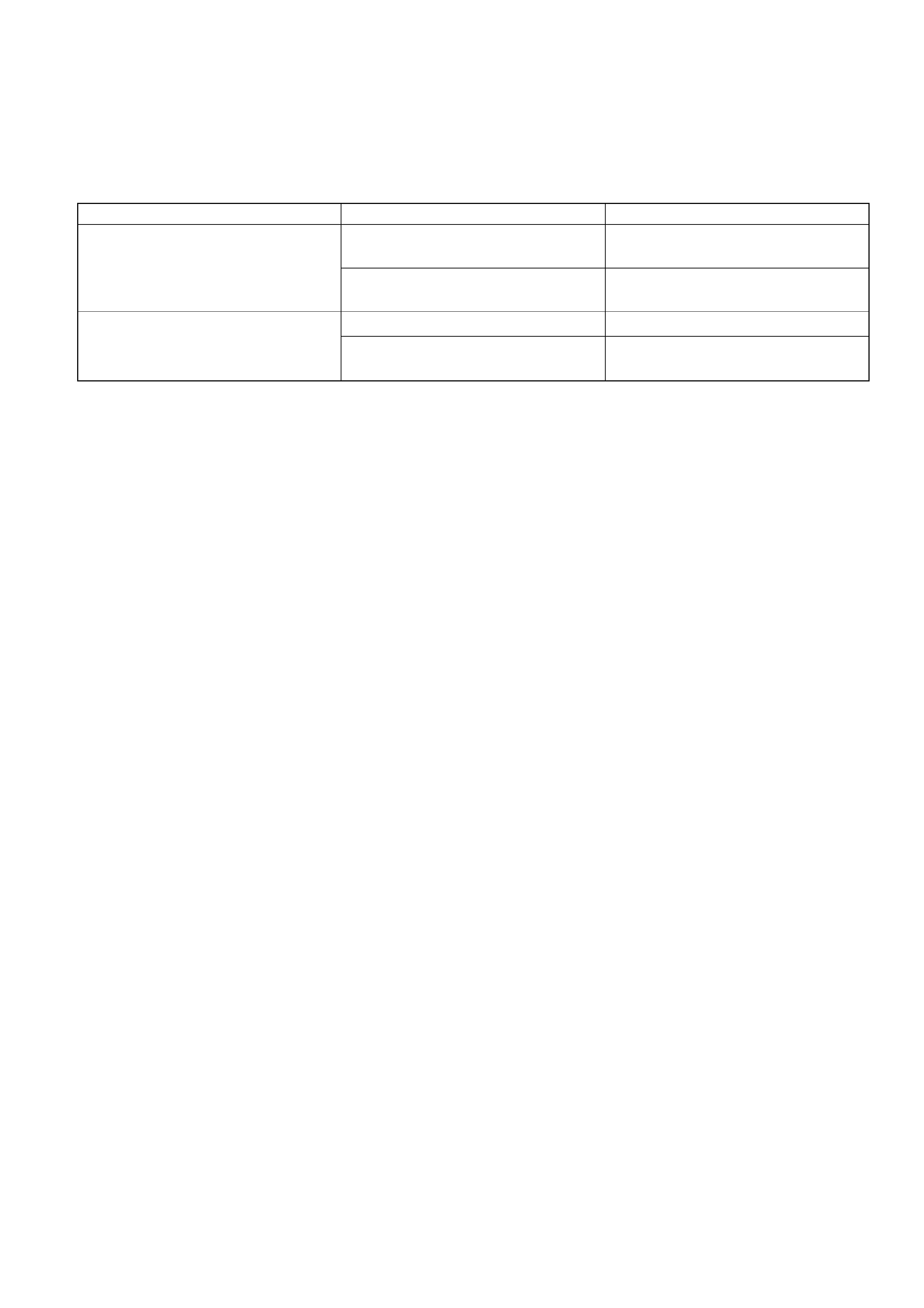

DIAGNOSIS

Rear Air Conditioning Cycle Diagnosis

Condition Possible Cause Correction

No cooling or insufficient cooling

Insufficient velocity of cooling air

Front air conditioner not switched

on.

Other

Clogged filter

Other

Switch front A/C switch ON.

See front air conditioner

workshop manual.

Clean or replace cooling unit filter.

See front air conditioner

workshop manual.

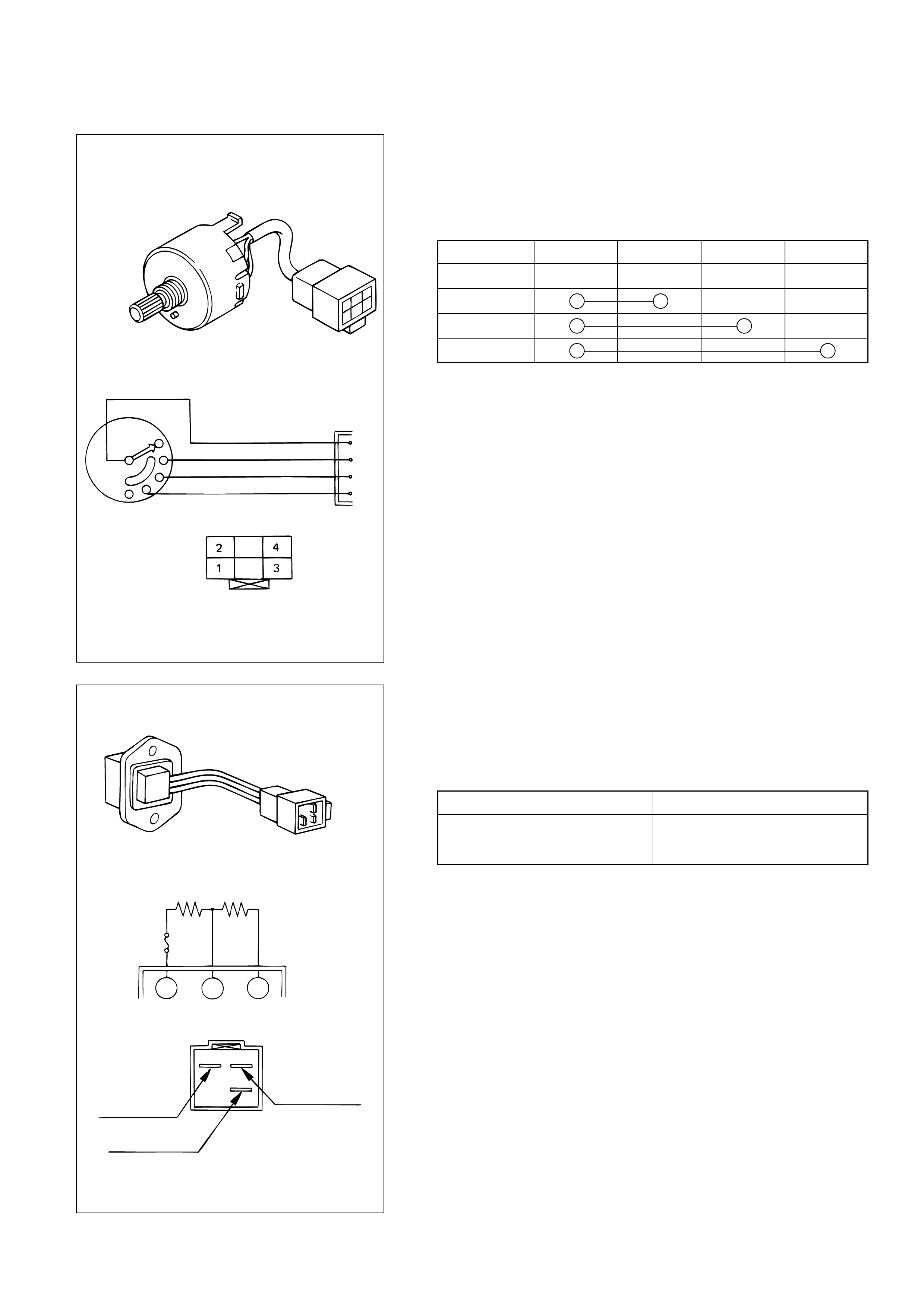

FAN CONTROL SWITCH

Inspection

Using an electric circuit tester, check continuity between

terminals.

If not as specified, replace the switch.

1234

OFF

LOW

MEDIUM

HIGH

Fan control switch

OFF

L 0.5 LG

0.85 Y

0.85 RG

0.85 B

M

H

1

2

3

4

Resistor

0.5Ω1.1Ω

Mo MH ML

0.5 LG(ML)

0.85 WR(Mo)

0.85 RG(MH)

RESISTOR

Inspection

Using an electric circuit tester, check the resistance

between the terminals specified below.

If the resistances are not as specified, replace the resistor.

Terminal Resistance (Ω)

Mo ~ MH 0.5

Mo ~ ML 1.6

825RY00058

826RY00016

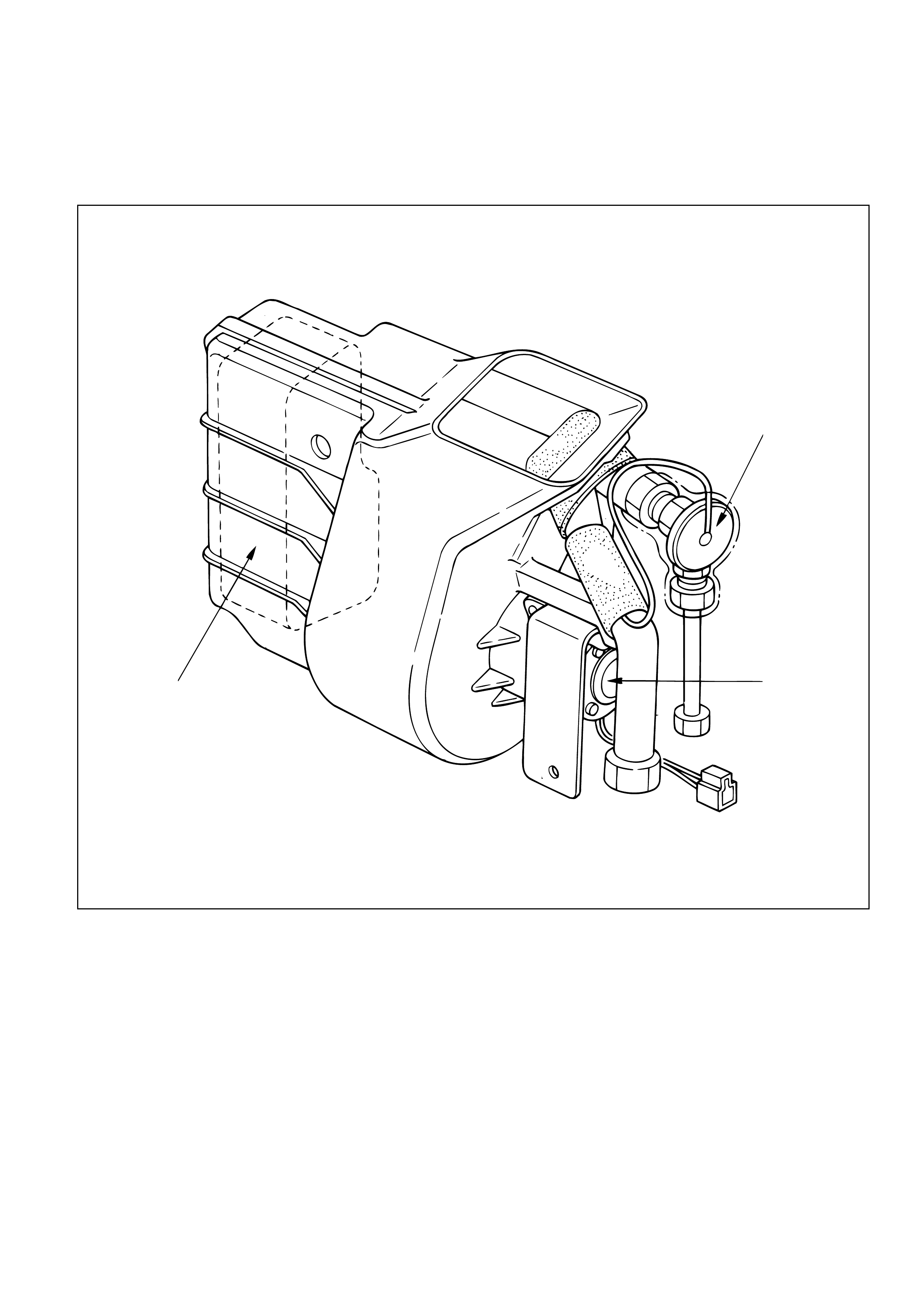

COOLING UNIT

Main Components

2

3

1

Legend

(1) Evaporator Assembly

(2) Expansion Valve

(3) Fan Motor

872RY00001

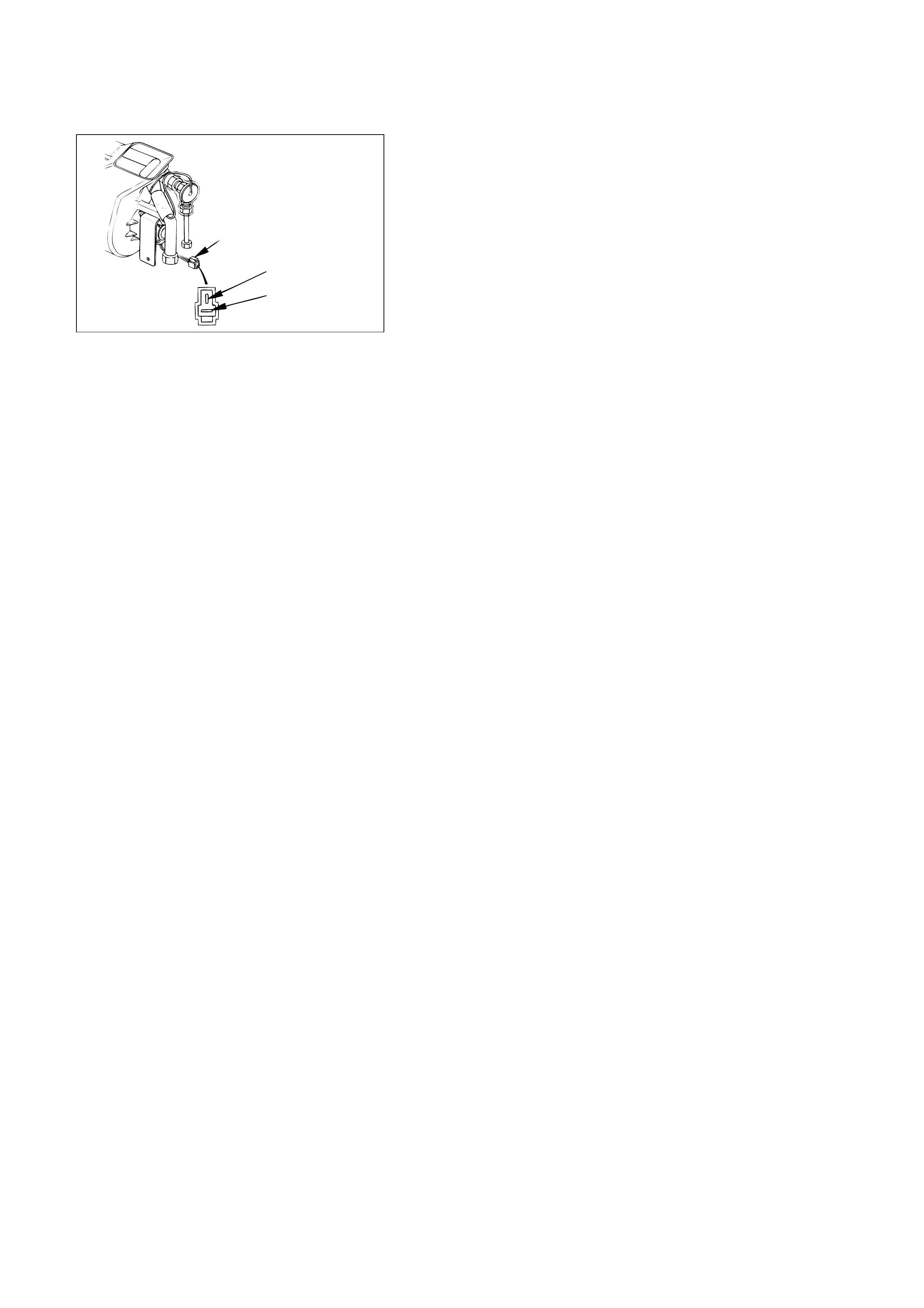

FAN MOTOR

Inspection

1. Disconnect the fan motor connector from the A/C

harness.

2. Connect the battery’s positive terminal to the No.5

terminal of the fan motor and the negative terminal to

the No.4 terminal.

3. Check that the fan motor operates correctly.

Fan motor connector

0.85 B (-) 4

0.85 R (+) 5

872RY00002