SECTION 4B - FRONT AXLE & DIFFERENTIAL

Service Precaution

Front Drive Axle

Diagnosis

Pinion Shaft Oil Seal

Pinion Shaft Oil Seal and Associated Parts

Removal

Inspection and Repair

Installation

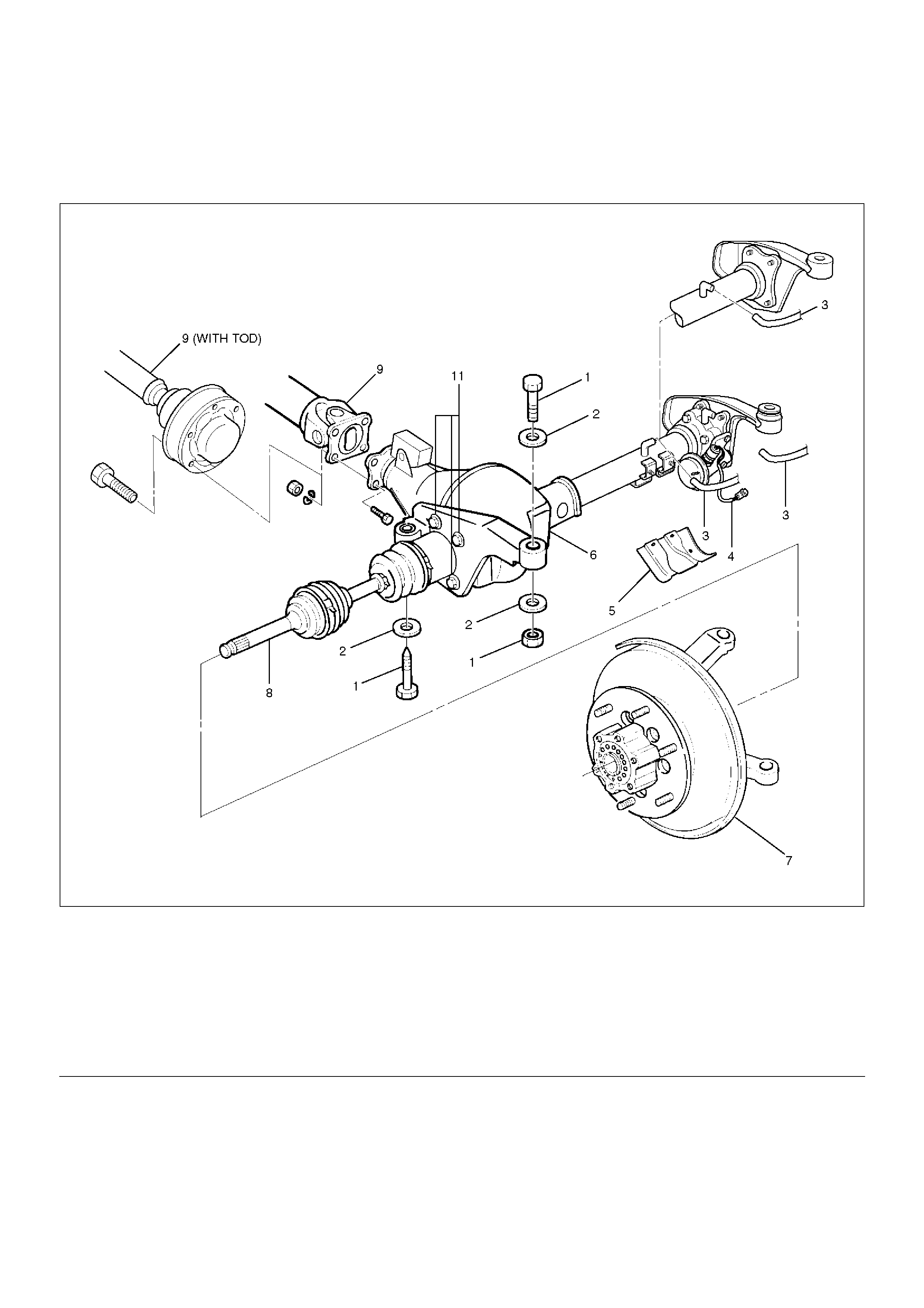

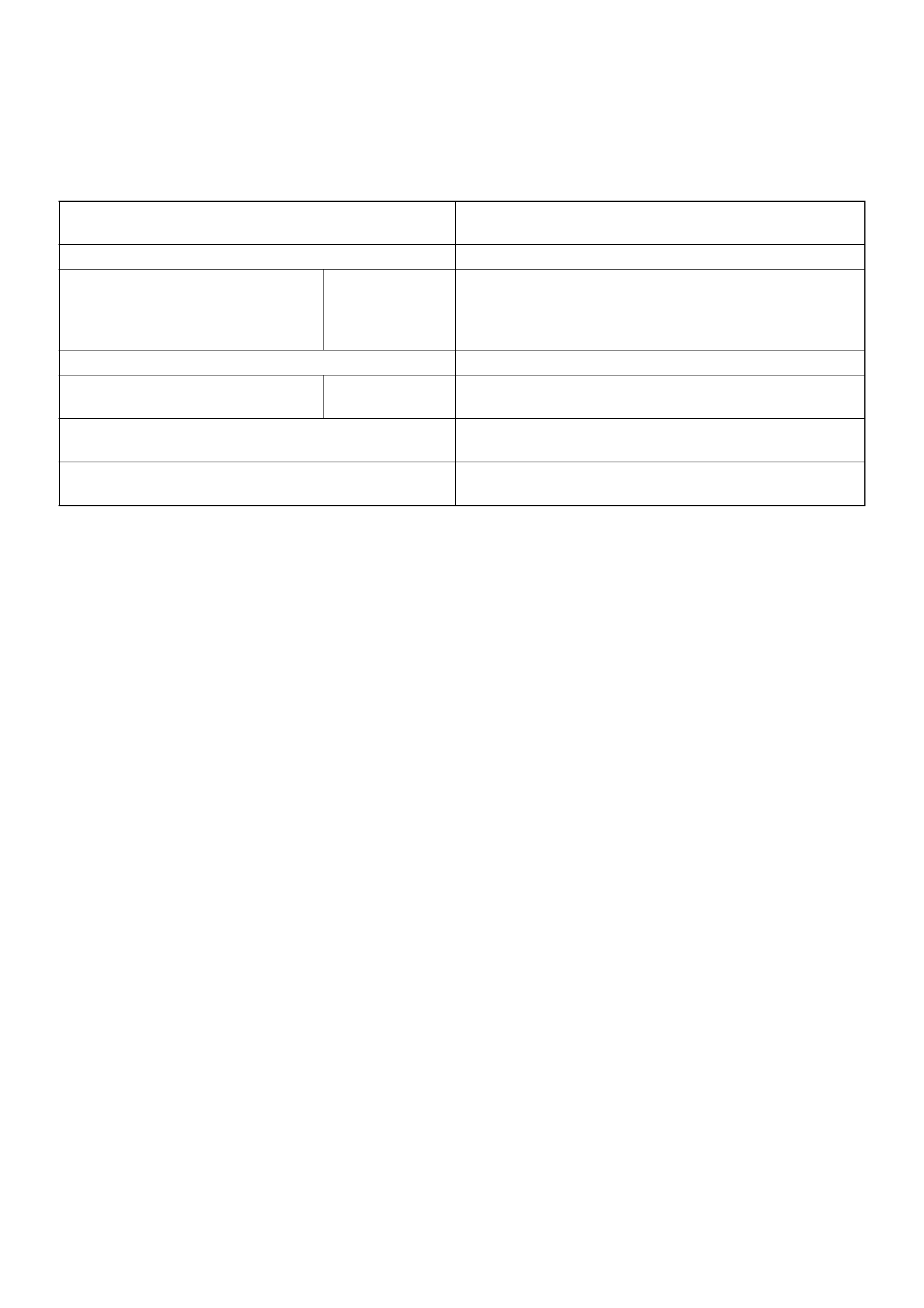

Front Drive Axle Assembly

Front Drive Axle Assembly and Associated Parts

Removal

Installation

Differential Assembly

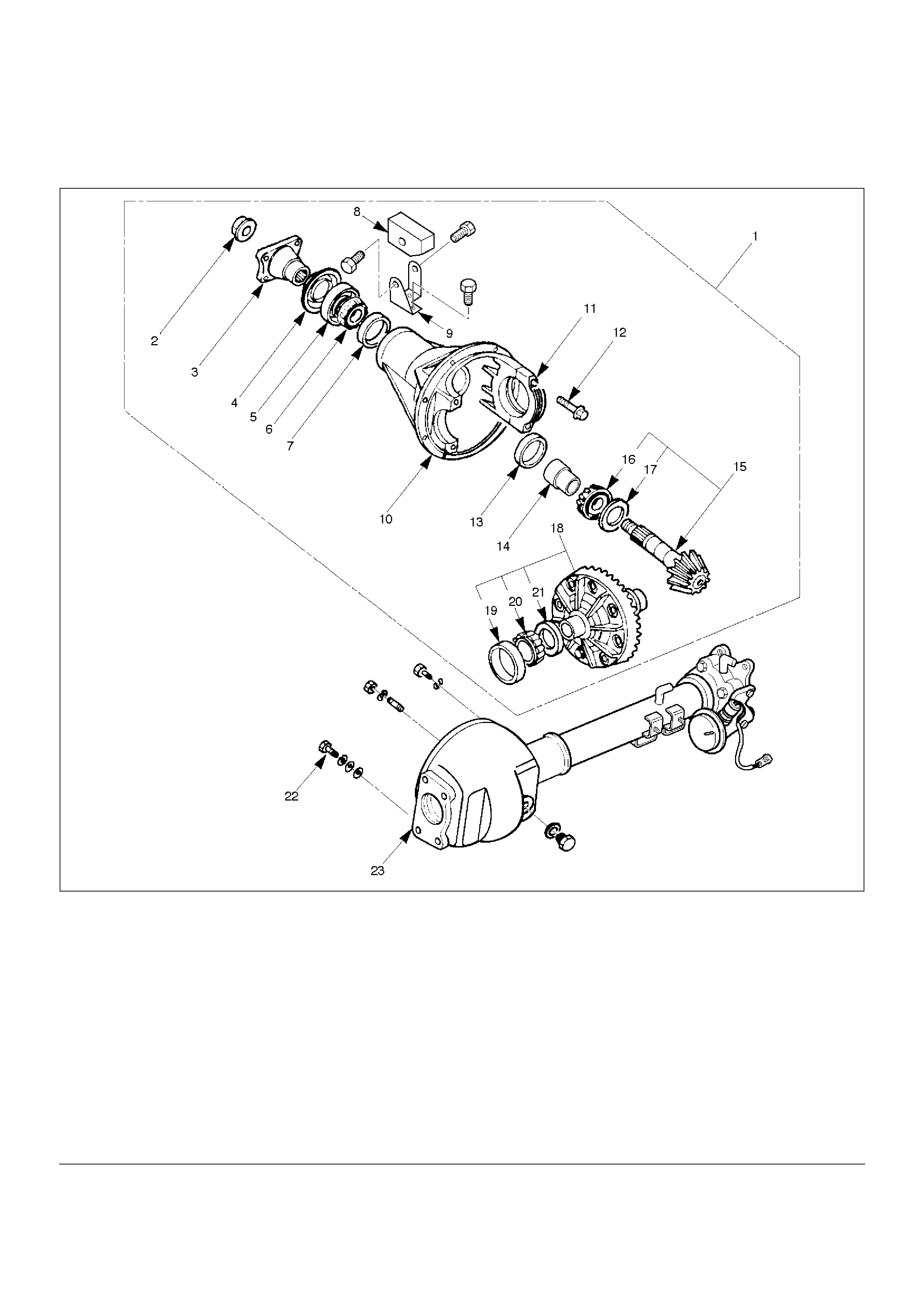

Disassembled View

Disassembly

Reassembly

Differential Cage Assembly

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

General Specifications

Torque Specifications

Special Tools

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE REFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED ,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specification.

Following these instructions can help you avoid

damage to parts and systems.

Techline

Front Drive Axle

Diagnosis

Condition Possible Cause Correction

Oil Leak At Front Axle Worn or defective oil seal. Replace the oil seal.

Front axle housing cracked. Repair or replace.

Oil Leak At Pinion Shaft Too much gear oil. Correct the oil level.

Oil seal worn or defective. Replace the oil seal.

Pinion flange loose or damaged. Tighten or replace.

Noises In Front Axle Drive Shaft

Joint

Broken or worn drive shaft joints and

bellows (BJ and DOJ).

Replace the drive shaft joints and

bellows.

“Clank”When Accelerating From

“Coast”

Loose drive shaft joint to output shaft

bolts.

Tighten.

Damaged inner drive shaft joint. Replace.

Shudder or Vibration During

Acceleration

Excessive drive shaft joint angle. Repair.

Worn or damaged drive shaft joints. Replace.

Sticking spider assembly (inner drive

shaft joint).

Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint).

Lubricate or replace.

Vibration At Highway Speeds Out of balance or out of round tires. Balance or replace.

Front end out of alignment. Align.

Noises in Front Axle Insufficient gear oil. Replenish the gear oil.

Wrong or poor grade gear oil. Replace the gear oil.

Drive pinion to ring gear backlash

incorrect.

Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear.

Replace the ring gear, pinion gear or

side gear.

Pinion shaft bearing worn. Replace the pinion shaft bearing.

Wheel bearing worn. Replace the wheel bearing.

Differential bearing loose or worn. Tighten or replace.

Wanders and Pulls Wheel bearing preload too tight. Adjust the wheel bearing preload.

Incorrect front alignment. Adjust the front alignment.

Steering linkage loose or worn. Tighten or replace.

Steering gear out of adjustment. Adjust or replace the steering gear.

Tire worn or improperly inflated. Adjust the inflation or replace.

Front or rear suspension parts loose

or broken.

Tighten or replace.

Front Wheel Shimmy Wheel bearing worn or improperly

adjusted.

Adjust or replace.

Incorrect front alignment. Adjust the front alignment.

Worn ball joint or bush. Replace the ball joint or bush.

Steering linkage loose or worn. Tighten or replace.

Steering gear out of adjustment. Tighten or replace.

Tire worn or improperly inflated. Replace or adjust the inflation.

Shock absorber worn. Replace the shock absorber.

Condition Possible Cause Correction

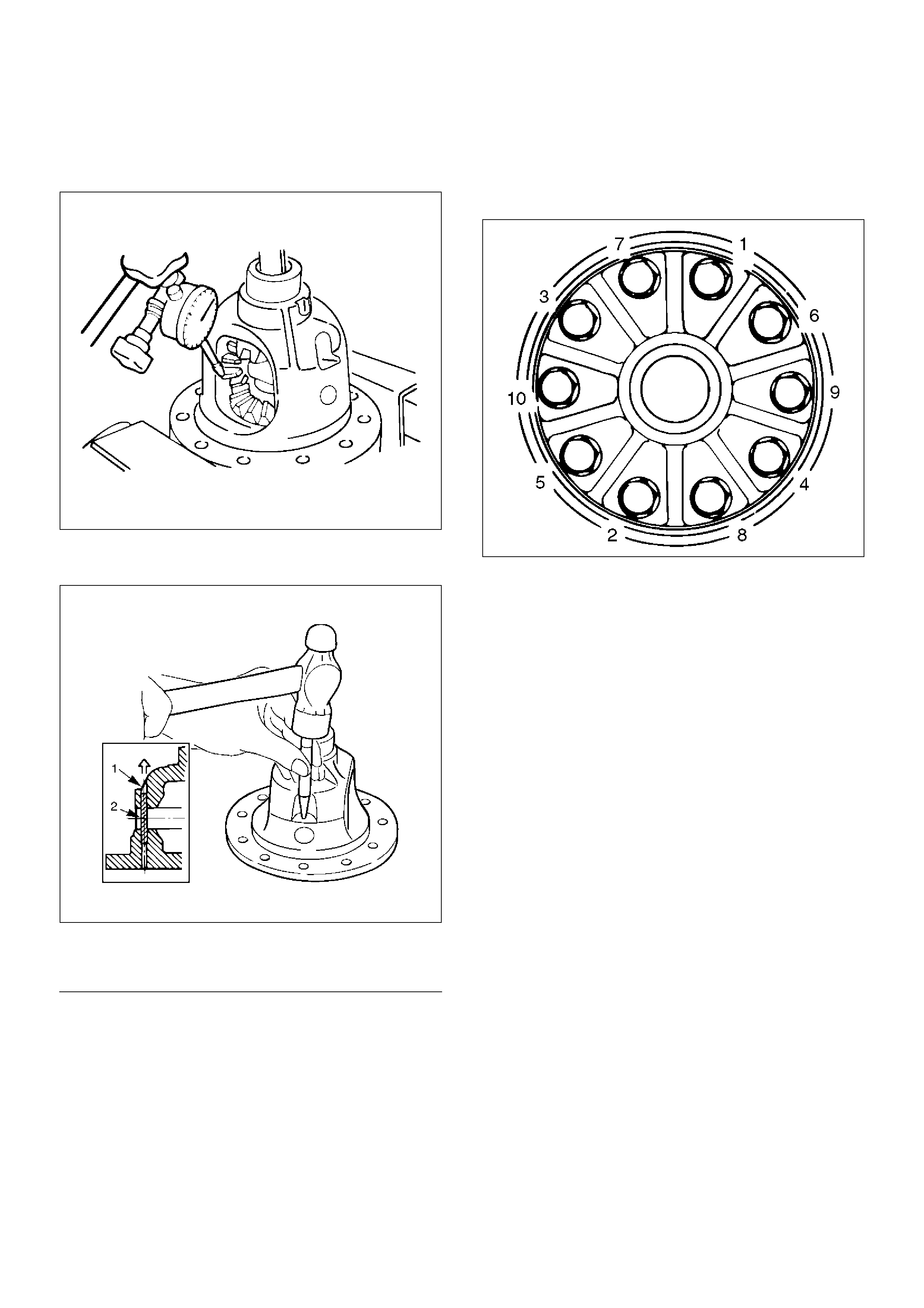

Pinion Shaft Oil Seal

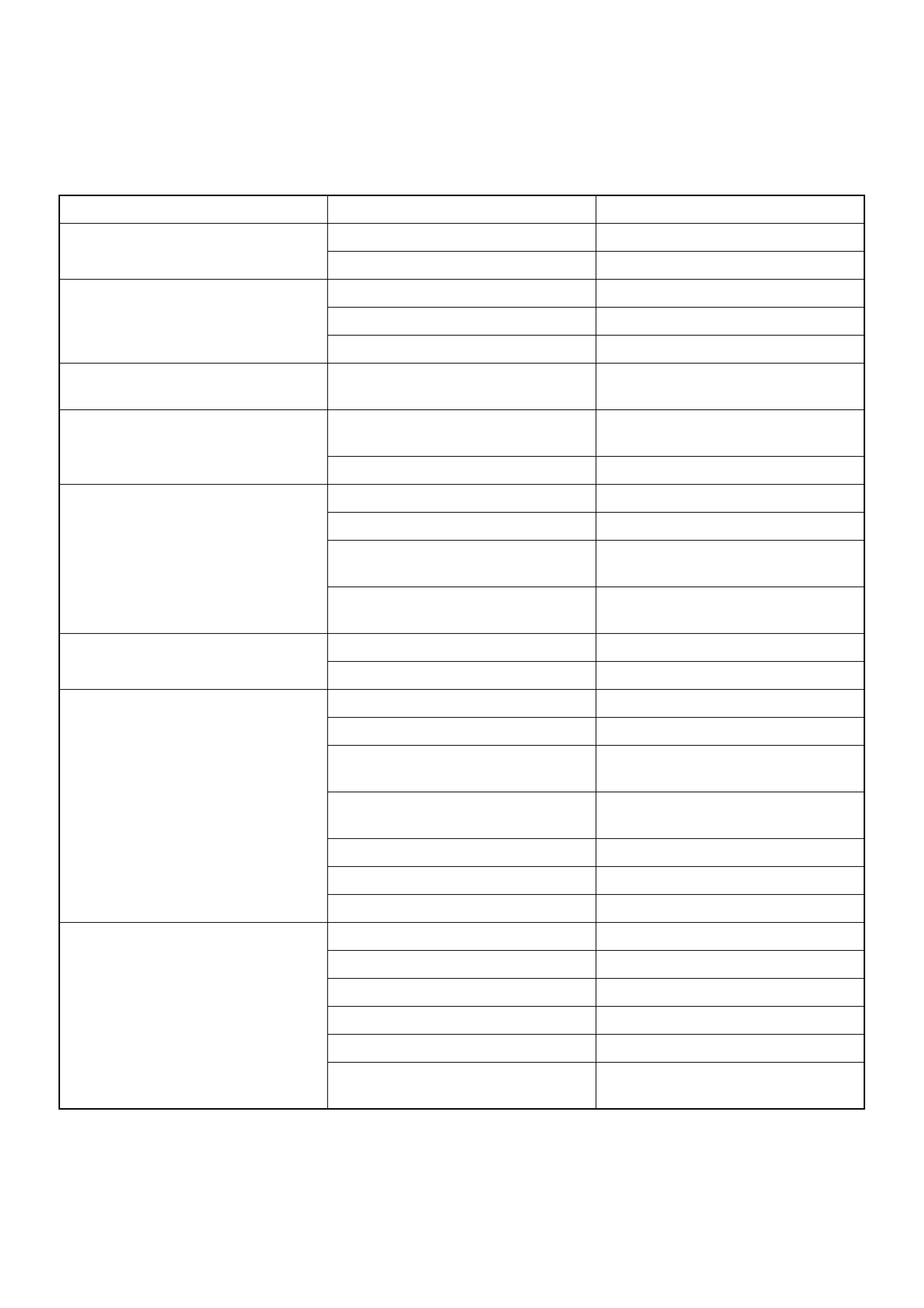

Pinion Shaft Oil Seal and Associated Parts

415RW015

EndOFCallout

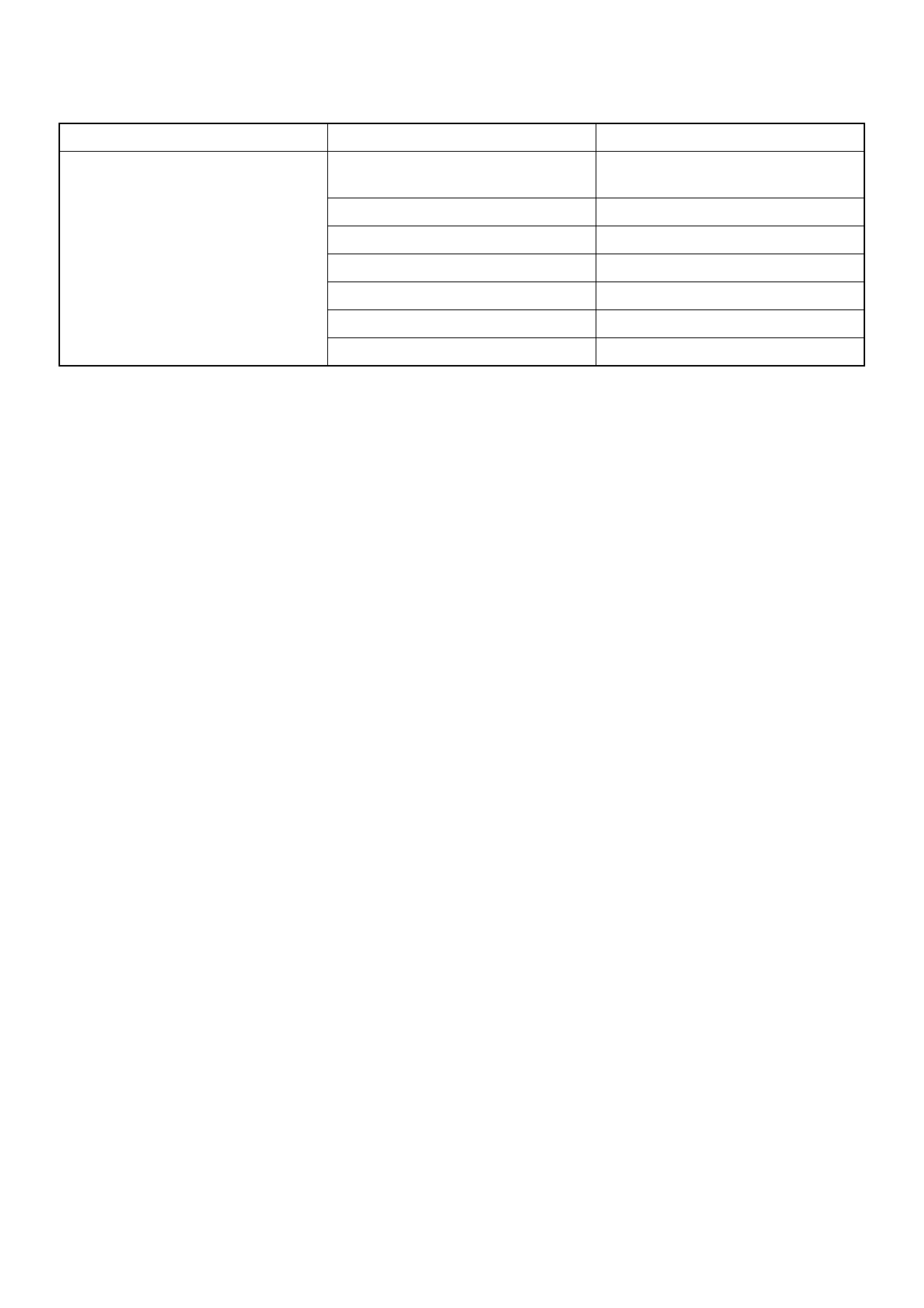

Removal

1. Raise the vehicle and support it at the frame.

The hoist must remain under the front axle housing.

2. Drain the front axle oil by loosening the drain

plug(1).

412RS001

Legend

(1) Flange Nut

(2) Flange

(3) Oil Seal

(4) Outer Bearing

(5) Collapsible Spacer

3.Remove the front propeller shaft. Refer to Front

Propeller Shaft in this section.

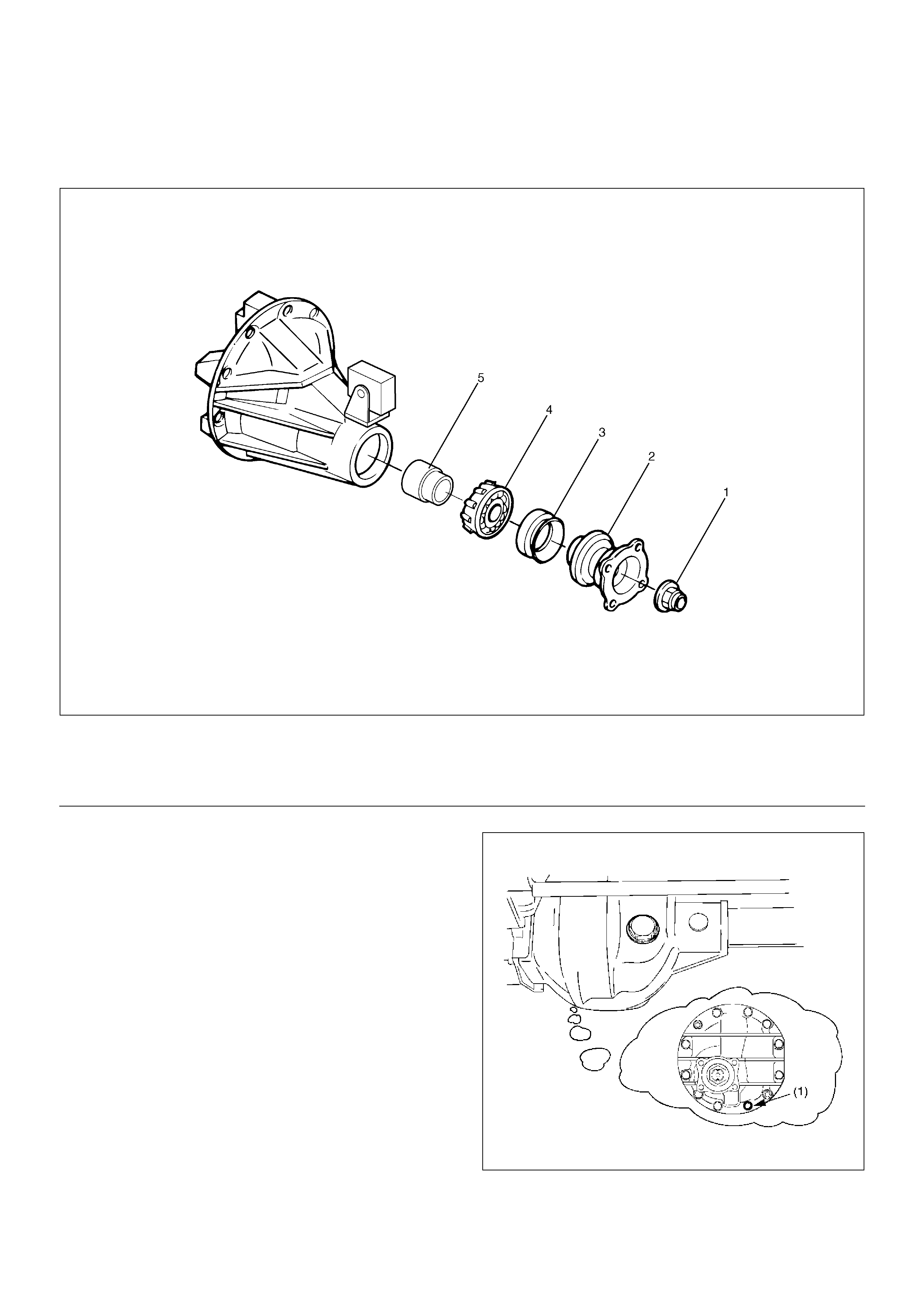

4.Remove flange nut by using pinion flange holder 5–

8840–2157–0.

425RW045

5.Remove flange.

6.Remove oil seal.

7.Remove outer bearing by using remover 5–8840–

2323–0.

415RW022

8.Remove collapsible spacer.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

1.Seal surface of the pinion.

2.Cage bore for burns.

Installation

1.Install collapsible spacer. Discard the used

collapsible spacer and install a new one.

2.Install outer bearing.

NOTE: Do not drive in, but just temporarily set in the

outer bearing by hand, which should be indirectly

pressed in finally by tightening the flange nut.

3.Install oil seal, use oil seal installer 9–8522–1275–0

to install a new oil seal that has been soaked in axle

lubricant.

415RW021

4.Install flange.

5.Install flange nut, refer to Differential Assembly for

flange nut reassembly in this section.

NOTE: Discard the used nut and install a new one.

Front Drive Axle Assembly

Front Drive Axle Assembly and Associated Parts

412RY00001

EndOFCallout

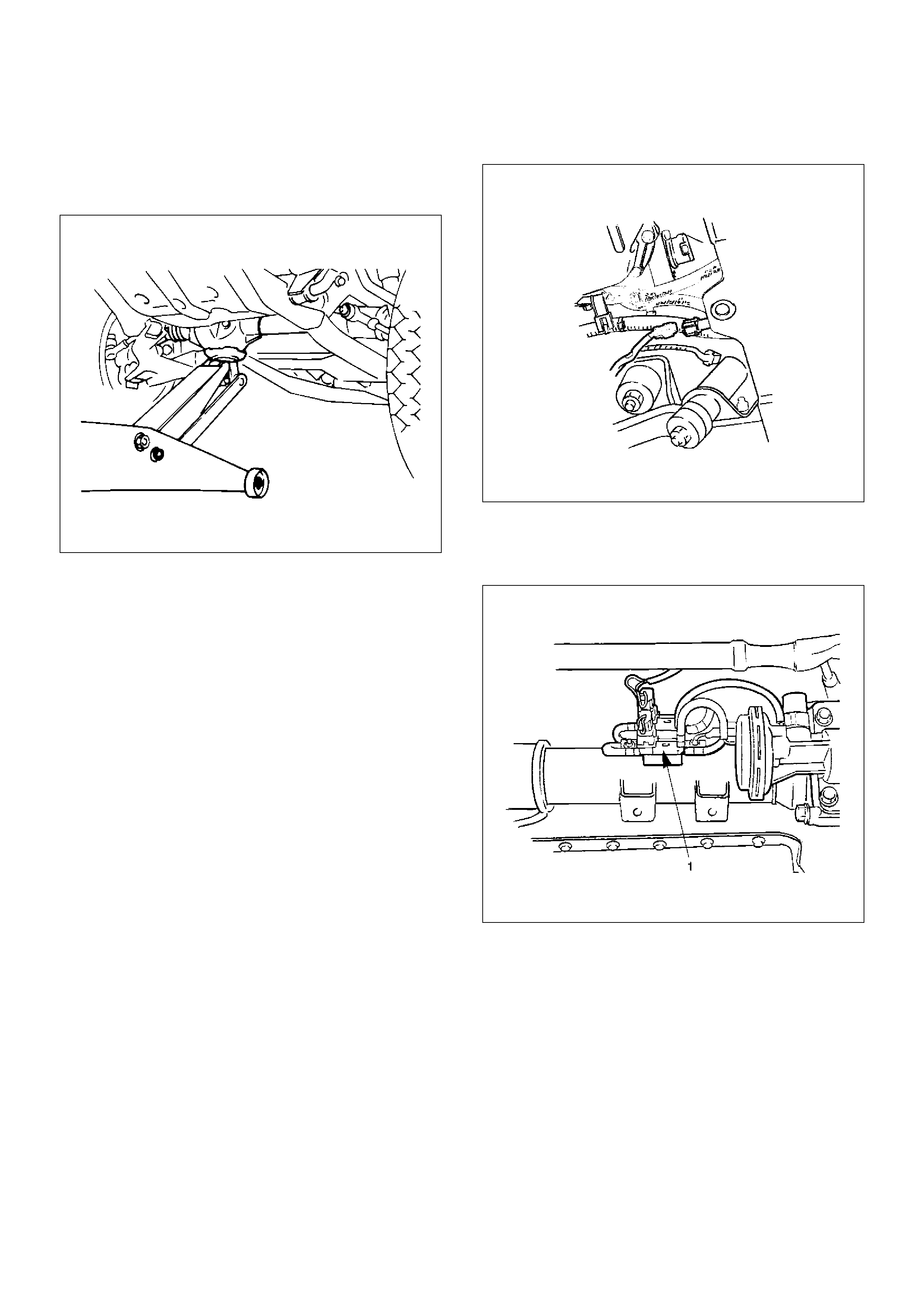

Removal

1. Jack up the vehicle and support it using jack stands.

2. Remove the tire and wheel.

Legend

(1) Mounting Bolt and Nut

(2) Washer and Spacer

(3) Breather Hose

(4) Shift Switch Connector (with Shift on the Fly)

(5) Protector (with Shift on the Fly)

(6) Front Axle Case Assembly and Front Drive

Shaft Assembly (LH side)

(7) Hub Assembly (Disc, Back Plate and Knuckle)

(8) Front Drive Shaft Assembly (RH side)

(9) Propeller Shaft

(10) Bolt

3.Remove the drain bolt to drain differential oil.

NOTE:

aDuring the work, be sure that the diff case is

supported by the jack.

412RS003

bRemove the brake caliper fixing bolt and hang the

caliper. Refer to Front Disc Brake Caliper Assembly

in Brake section.

cRemove the antilock brake system speed sensor (if

equipped). Refer to Front Wheel Speed Sensor in

Brakes section.

4.Remove the hub assembly (Disc, back plate and

knuckle), refer to Front Hub and Disc in this section.

5.Disconnect the knuckle and the suspension arm.

Refer to Suspension section.

6.Remove steering link and arm assembly, refer to

Steering Linkage in Steering section.

7.Remove suspension crossmember.

8.Remove propeller shaft, refer to Front Propeller

Shaft in this section.

9. Remove protector (Shift on the fly model).

10. Remove the hose clip.

11. Disconnect breather hose from front drive axle tube.

(and disconnect housing : Shift on the fly model).

12. Disconnect vacuum hose from actuator (Shift on the

fly model).

13. Disconnect shift switch connector (Shift on the fly

model).

412RS031

14. Remove VSV assembly (1) (Shift on the fly model).

NOTE: Be sure not to remove hose and connector from

VSV asm.

412RW002

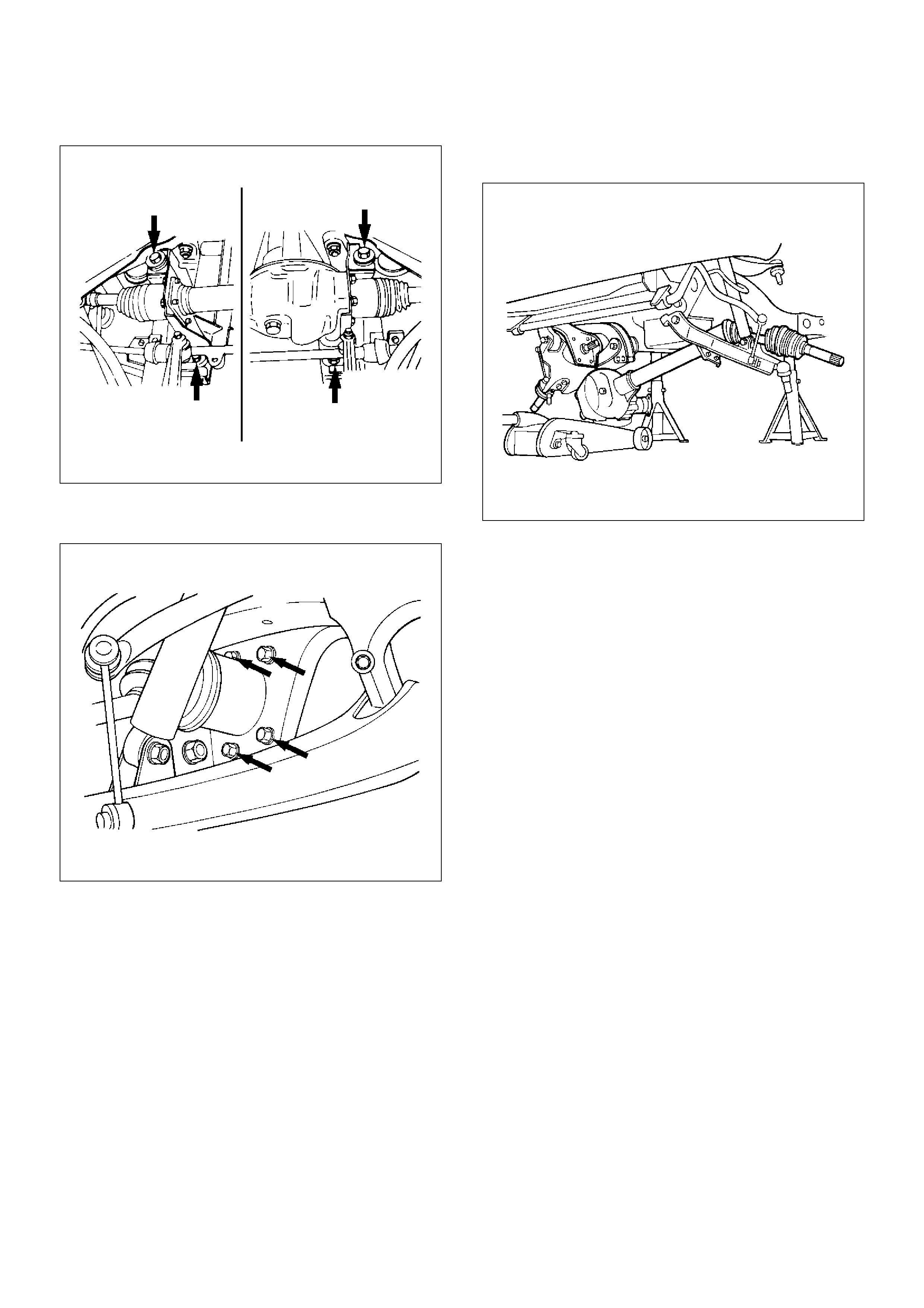

15. Remove mounting bolt and nut.

412RS004

16. Remove washer and spacer.

17. Remove the mounting bracket fixing bolt.

412RS005

18. Lower the vehicle and disconnect the RH front drive

shaft assembly, then remove the front axle case

assembly and front drive shaft assembly (LH).

412RS006

19. Remove front drive shaft assembly (RH).

Installation

1. Install front drive shaft assembly (RH) and lay the

assembly on the lower arm.

2. Install front axle case assembly and front drive shaft

assembly (LH) and place the axle case on the jack,

connect to the front drive shaft assembly (RH)

before installing to the vehicle.

3. Install bolt and tighten the mounting bracket fixing

bolt to the specified torque.

Torque:116N·m (11.8kg·m/85 lbft)

4. Install washer and spacer.

5.Tighten the mounting bolt and nut to the specified

torque.

Torque:152N·m (15.5kg·m/112lbft)

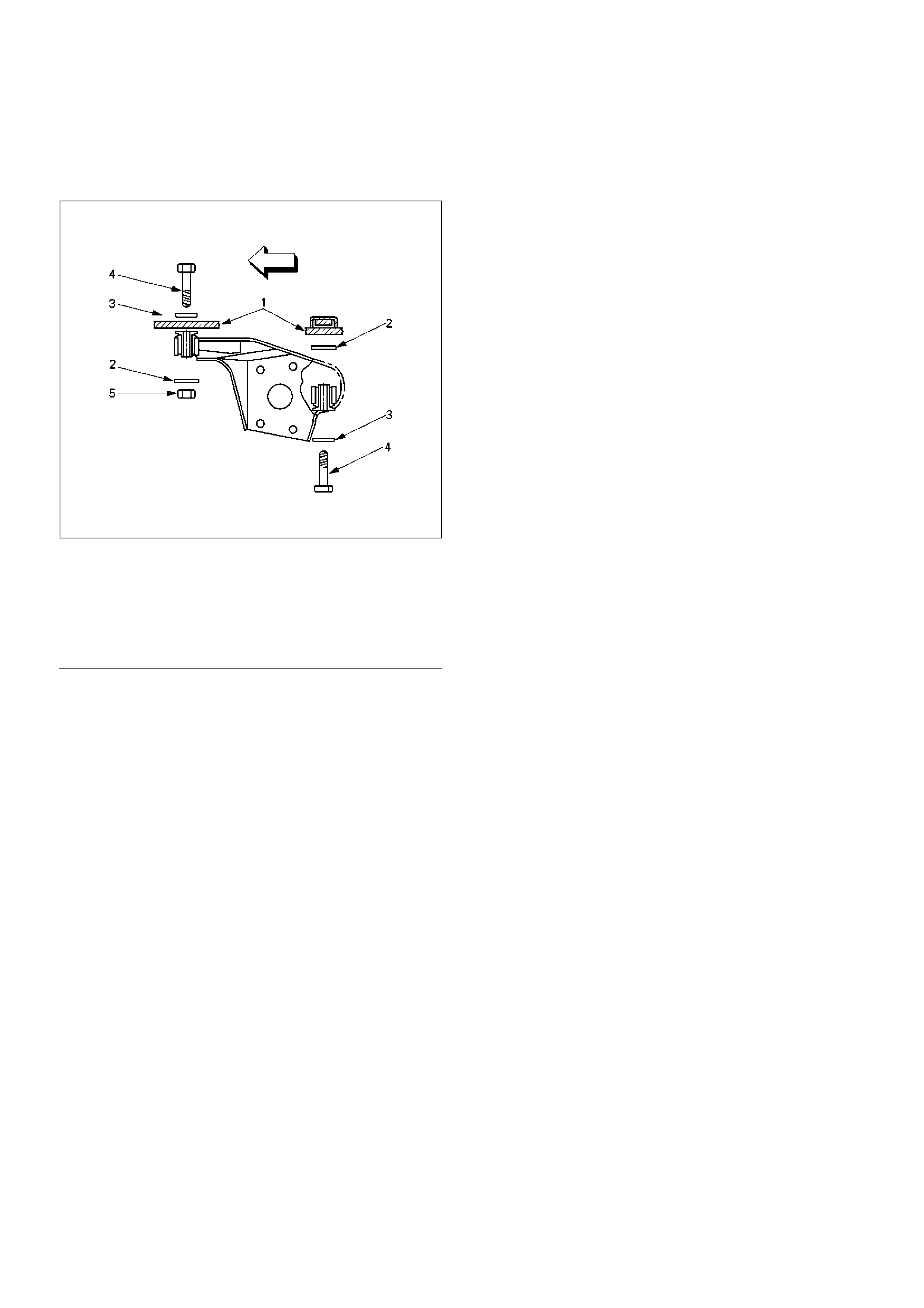

412RW005

EndOFCallout

6. Install VSV assembly and tighten nuts to specified

torque (Shift on the fly model).

Torque:8N·m (0.8kg·m/69lbin)

7. Install the shift switch connector (Shift on the fly

model).

NOTE: Be careful not to permit the entry of dust into

the connector.

8. Install the actuator side of vacuum hose (Shift on

the fly model).

NOTE: Be careful not to permit the entry of dust into

the hose.

9.Connect breather hose and install the hose clip.

10.Install protector and tighten bolts to specified torque

(Shift on the fly model).

Torque:26N·m (2.7kg·m/20lbft)

11.Install propeller shaft, refer to Front Propeller Shaft

in this section.

12. Install suspension crossmember.

13.Steering link and arm assembly, refer to Steering

Linkage in Steering section.

14. Install hub assembly (Disc, back plate and knuckle),

refer to Front Hub and Disc in this section.

Legend

(1) Frame

(2) Spacer

(3) Washer

(4) Bolt

(5) Nut

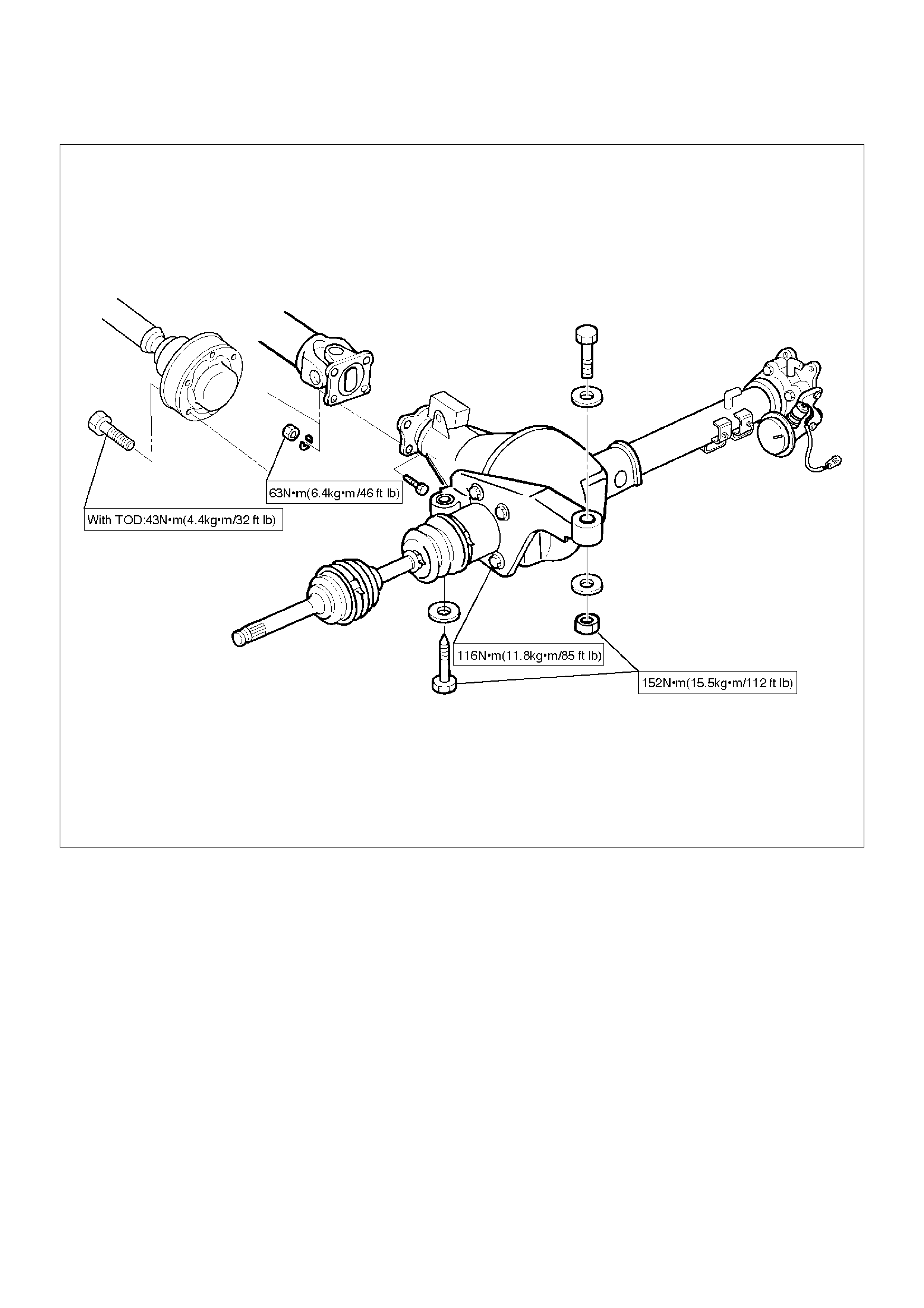

Differential Assembly

Disassembled View

415RW001

EndOFCallout

Legend

(1) Differential Assembly

(2) Flange Nut

(3) Flange

(4) Dust Cover

(5) Oil Seal

(6) Outer Bearing

(7) Outer Bearing Outer Race

(8) Damper

(9) Bracket

(10) Differential Carrier

(11) Bearing Cap

(12) Bolt

(13) Inner Bearing Outer Race

(14) Collapsible Spacer

(15) Pinion Gear

(16) Inner Bearing

(17) Adjust Shim

(18) Diff Cage Assembly

(19) Side Bearing Outer Race

(20) Side Bearing

(21) Adjust Shim

(22) Bolt

(23) Axle Case

Disassembly

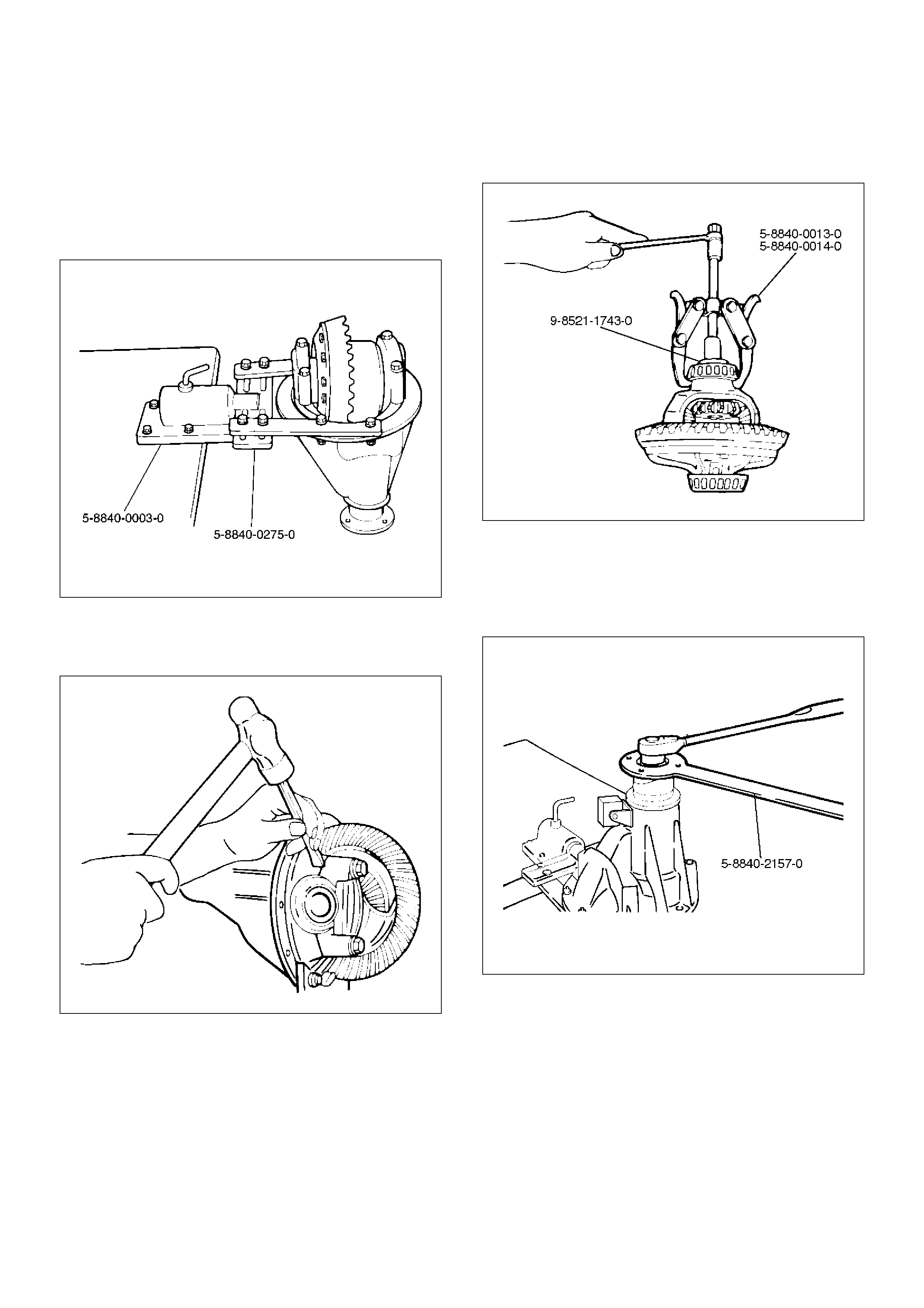

1. Remove differential carrier fixing bolt.

2. Remove differential assembly.

3. Using holding fixture 5–8840–0275–0 and holding

fixture base 5–8840–0003–0, fix the differential

assembly to the bench.

425RW046

4. Remove bearing cap bolt.

5. Apply a setting mark to the side bearing cap and the

differential carrier then remove bearing cap.

425RS009

6. Remove differential cage assembly.

7. Remove side bearing outer race, after removal,

keep the right and left hand side bearing assemblies

separate to maintain inner and outer race

combinations.

8. Remove side bearing, using remover 5–8840–

0013–0, 5–8840–0014–0 and adapter 9–8521–

1743–0.

415RW023

9. Remove adjust shim, note the thickness and

position of the shims removed.

10. Remove the flange nut using holding wrench 5–

8840–2157–0 after raising up its staked parts

completely.

425RW047

11. Remove flange.

12. Remove dust cover.

13. Remove the drive pinion assembly using a soft

metal rod and a hammer.

425RW041

14. Remove collapsible spacer.

15. Remove the inner bearing using a separator 5–

8840–0015–0 and a press.

415RW033

16. Remove adjust shim.

17. Remove inner bearing outer race.

18. Remove oil seal.

19. Remove outer bearing.

20. Remove the inner bearing outer race (1) and the

outer bearing outer race (2) by using a brass bar

and a hammer.

425RS014

425RS015

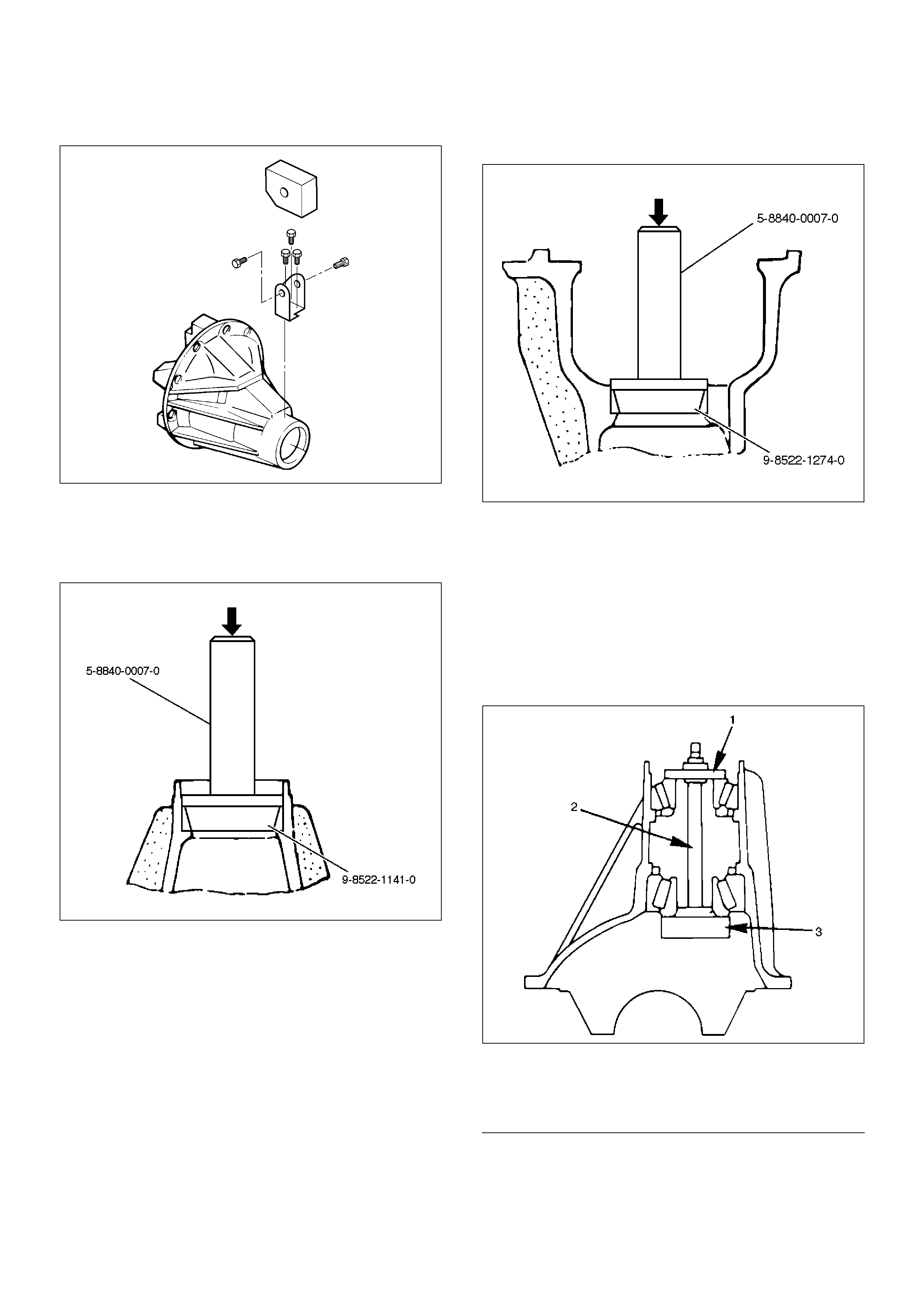

21. Remove damper and bracket.

425RW042

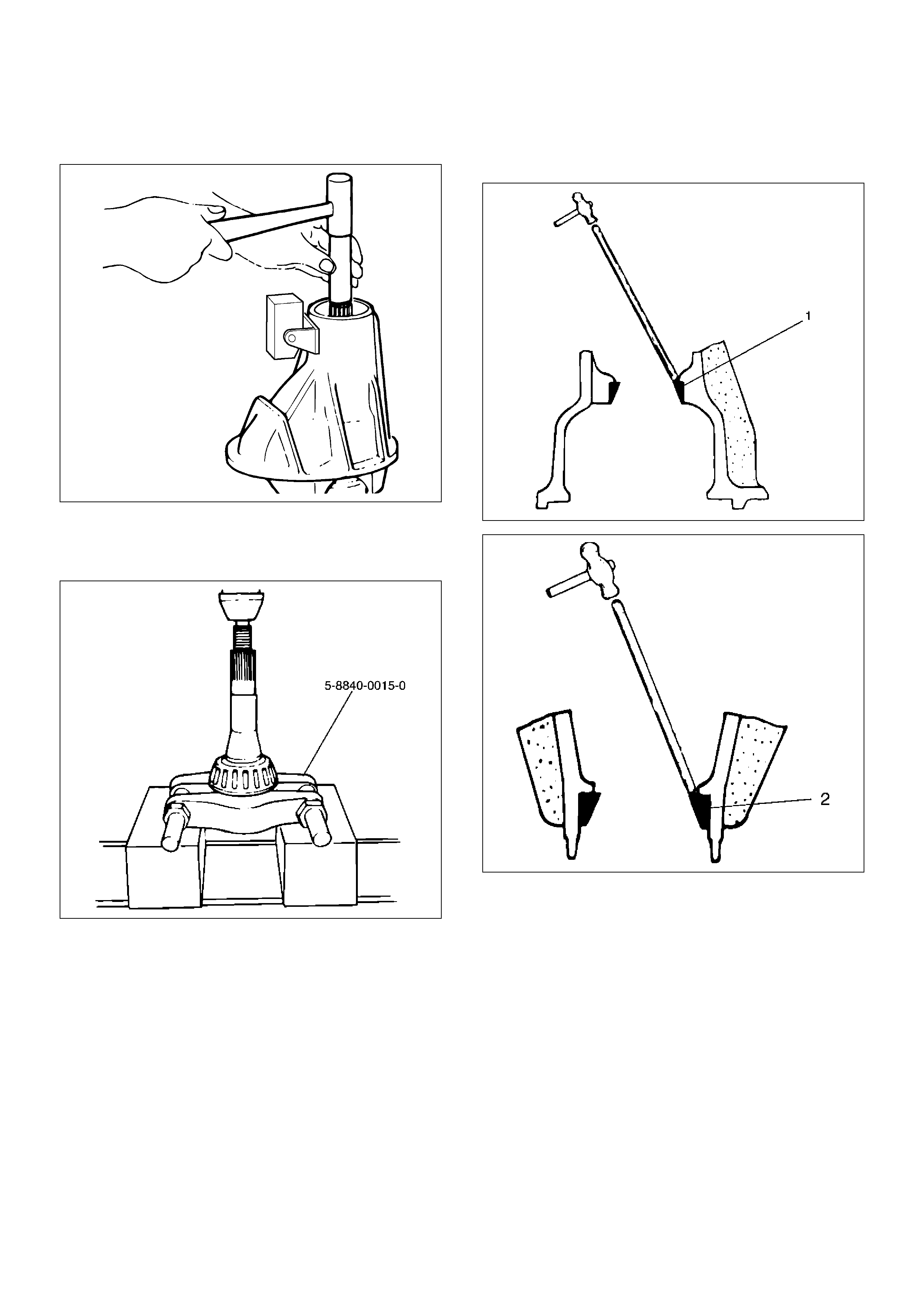

Reassembly

1. Using installer 9–8522–1141–0 and grip 5–8840–

0007–0, install outer bearing outer race.

415RW018

2. Using installer 9–8522–1274–0 and grip 5–8840–

0007–0, install Inner bearing outer race.

415RW017

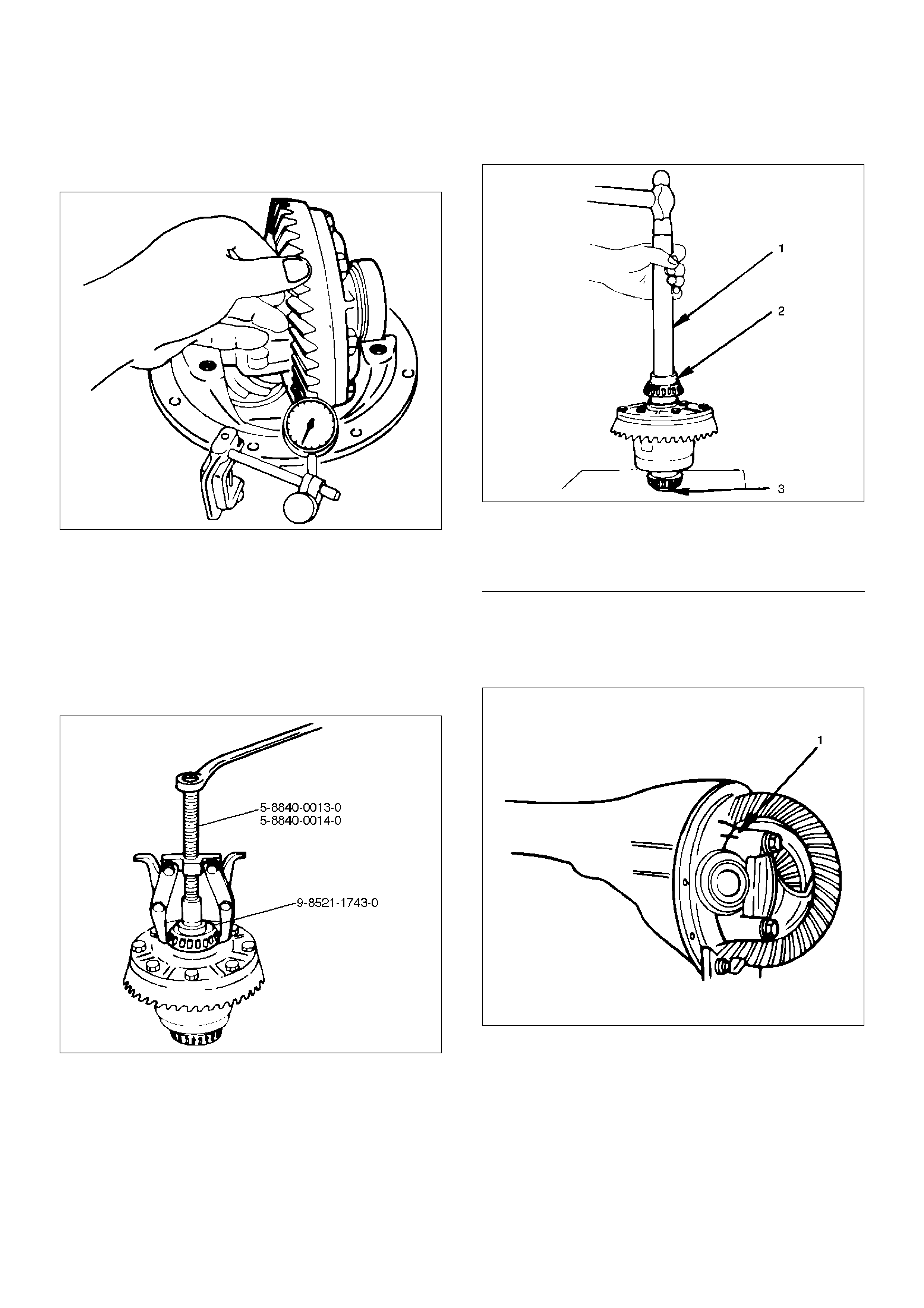

3. Install adjust shim and adjust drive pinion mounting

distance

1. Apply gear oil to the inner and outer drive pinion

bearing.

Clean the pinion setting gauge set.

Then install the gauge set together with the

inner and outer bearings.

2. Tighten the nut to the specified torque.

Torque:2.3N·m (0.23kg·m/20lbin)

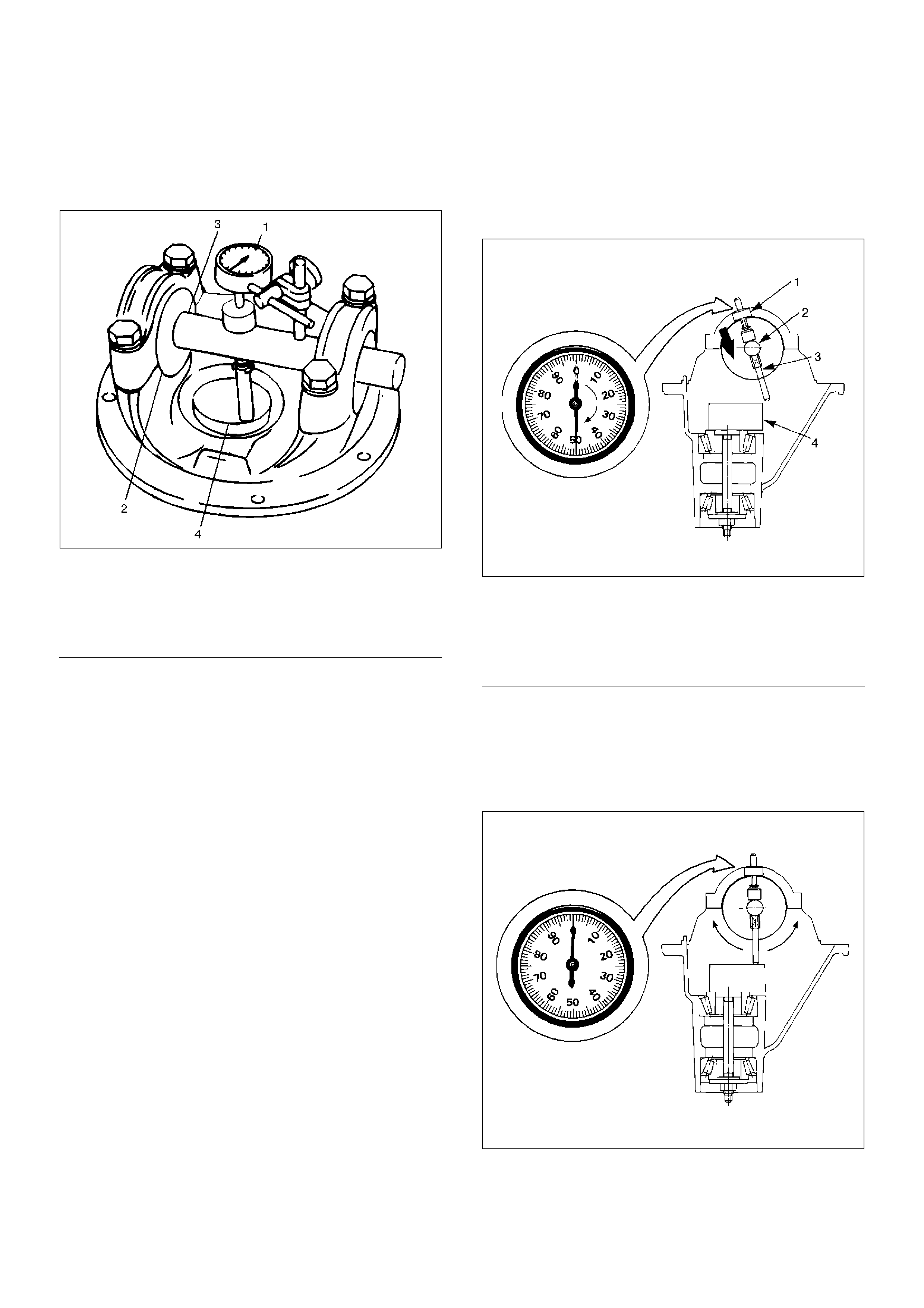

415RS009

EndOFCallout

Legend

(1) Pilot : 5–8840–2085–0

(2) Nut and Bolt : 5–8840–2089–0

(3) Gauge Plate : 5–8840–2087–0

3. Clean the side bearing bores. Install the dial

indicator with the discs and arbor. Install and

tighten the bearing caps to the specified torque.

Torque:98N·m (10kg·m/72lbft)

415RS010

EndOFCallout

4. Set the dial indicator to“0”. Place it on the

mounting post of the gauging arbor with the

contact button touching the indicator pad. Force

the dial indicator downward until the needle has

made a half turn clockwise. Tighten down the

dial indicator in this position.

425RS020

EndOFCallout

5. Position the plunger on the gauge plate. Move

the gauging arbor slowly back and forth and

locate the position at which the dial indicator

shows the greatest defection. At this point, once

again set the dial indicator to“0”.

Repeat the procedure to verify the “0” setting.

425RS021

Legend

(1) Dial Indicator: 5–8840–0126–0

(2) Disc (2 pcs.): 5-8840-2088-0

(3) Arbor: 5–8840–0128–0

(4) Gauge Plate: 5–8840–2087–0

Legend

(1) Dial Indicator

(2) Gauging Arbor

(3) Plunger

(4) Gauge Plate

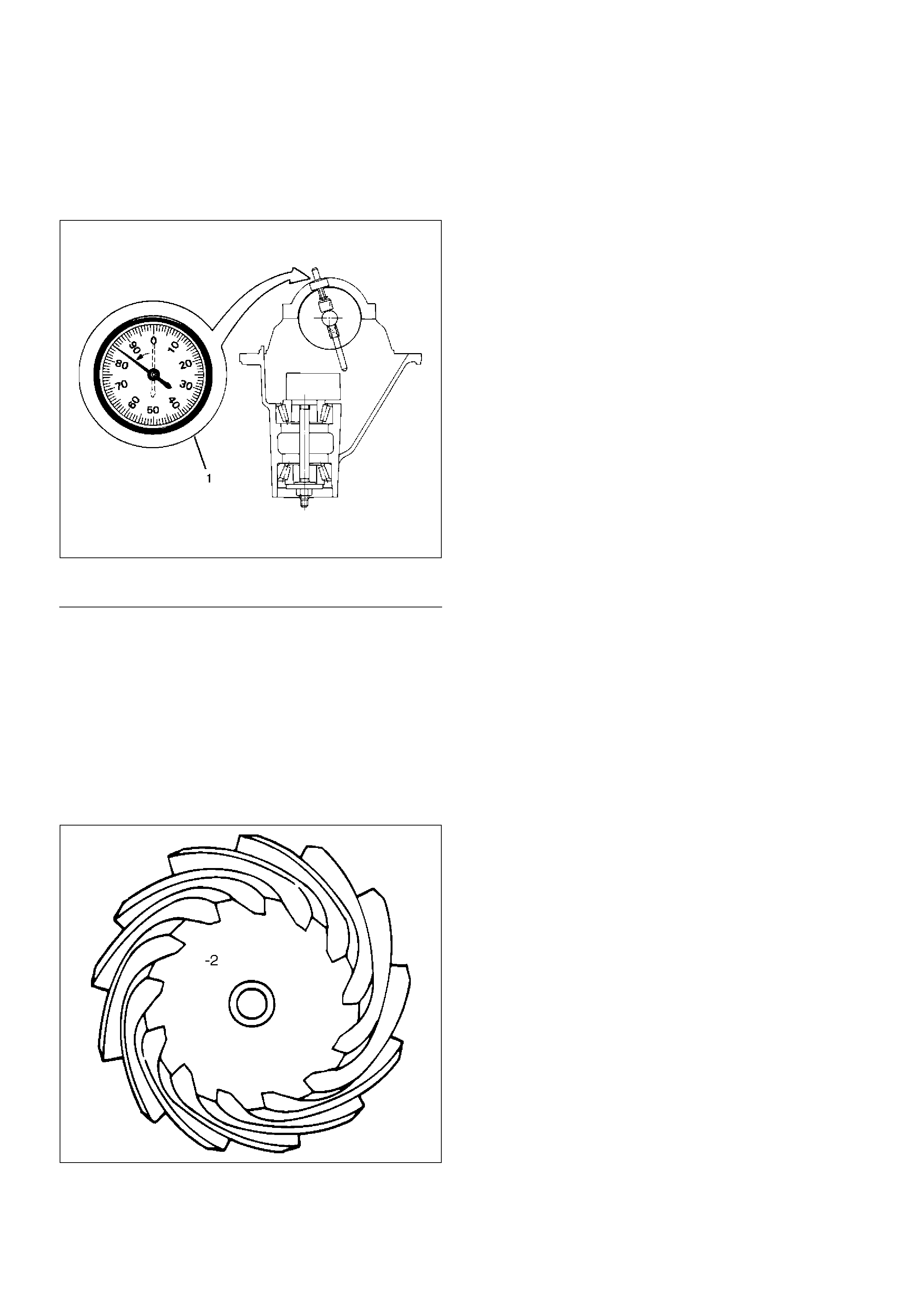

6. After the ZERO setting is obtained, rotate the

gauging arbor until the dial indicator rod does

not touch the gauging plate.

Record the number the dial indicator needle

points to.

425RS022

EndOFCallout

7. Record the pinion depth code on the head of

the drive pinion.

The number indicates a necessary change in

the pinion mounting distance. A plus number

indicates the need for a greater mounting

distance (which can be achieved by decreasing

the shim thickness). A minus number indicates

the need for a smaller mounting distance (which

can be achieved by increasing the shim

thickness). If examination reveals pinion depth

code“0”, the pinion is“nominal”.

425RS023

Legend

(1) Example=Dial indicator reading of 0.085

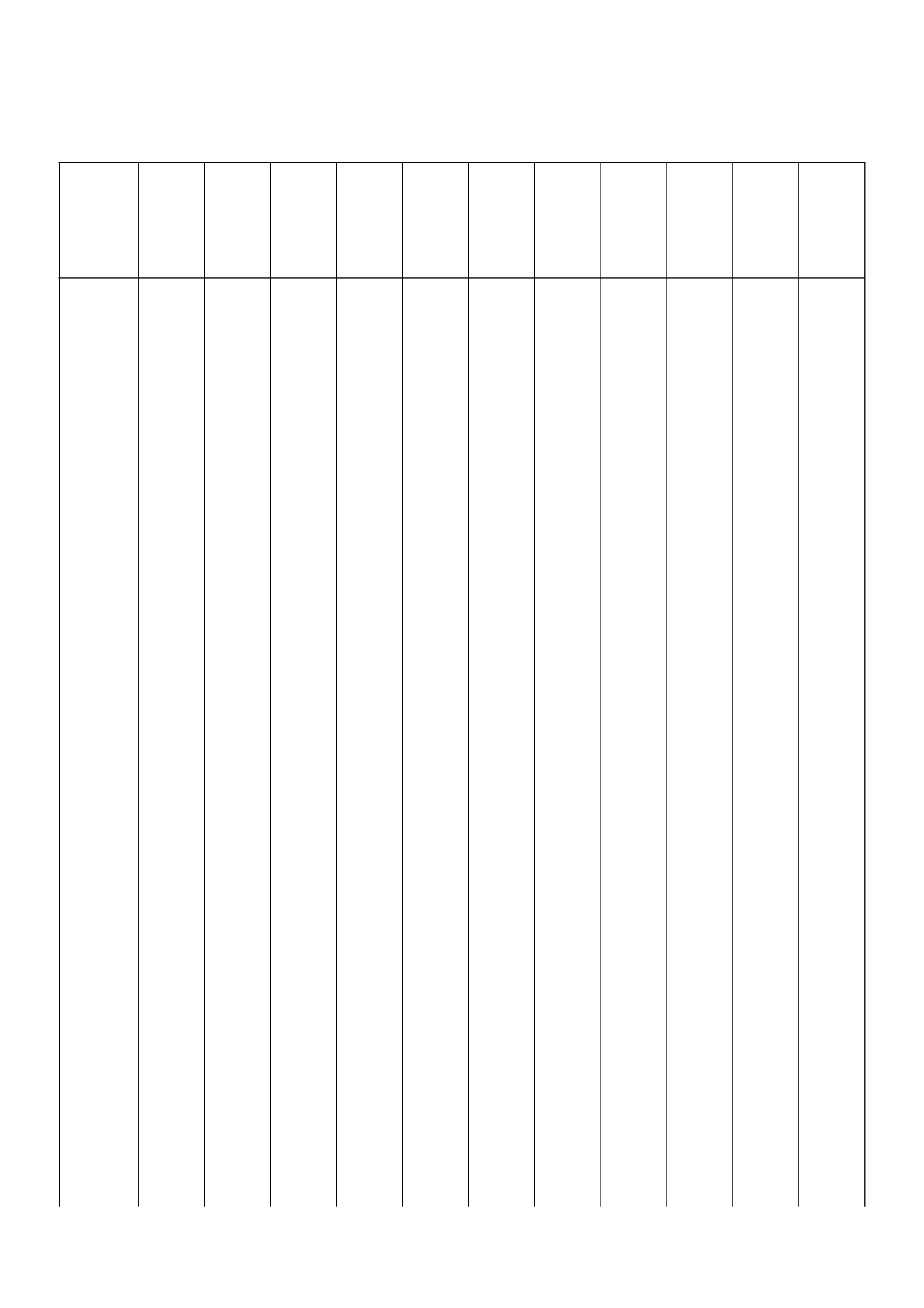

8. Select the shim using the chart;

Pinion

marking +10 +8 +6 +4 +2 0 –2 –4 –6 –8 –10

Dial

indicator

reading

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

0.081 2.18

(0.0858)

0.082 2.18

(0.0858)

2.20

(0.0866)

0.083 2.18

(0.0858)

2.20

(0.0866)

2.23

(0.0882)

0.084 2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

0.085 2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

0.086 2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

0.087 2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

0.088 2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

0.089 2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

0.090 2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

0.091 2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

0.092 2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

0.093 2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

0.094 2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

0.095 2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

0.096 2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0.097 2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0.098 2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0.099 2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

02.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0.001 2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0.002 2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0.003 2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

NOTE: When ordering shims, find the part number in

the parts catalog by using the thickness of shims listed

in the above table.

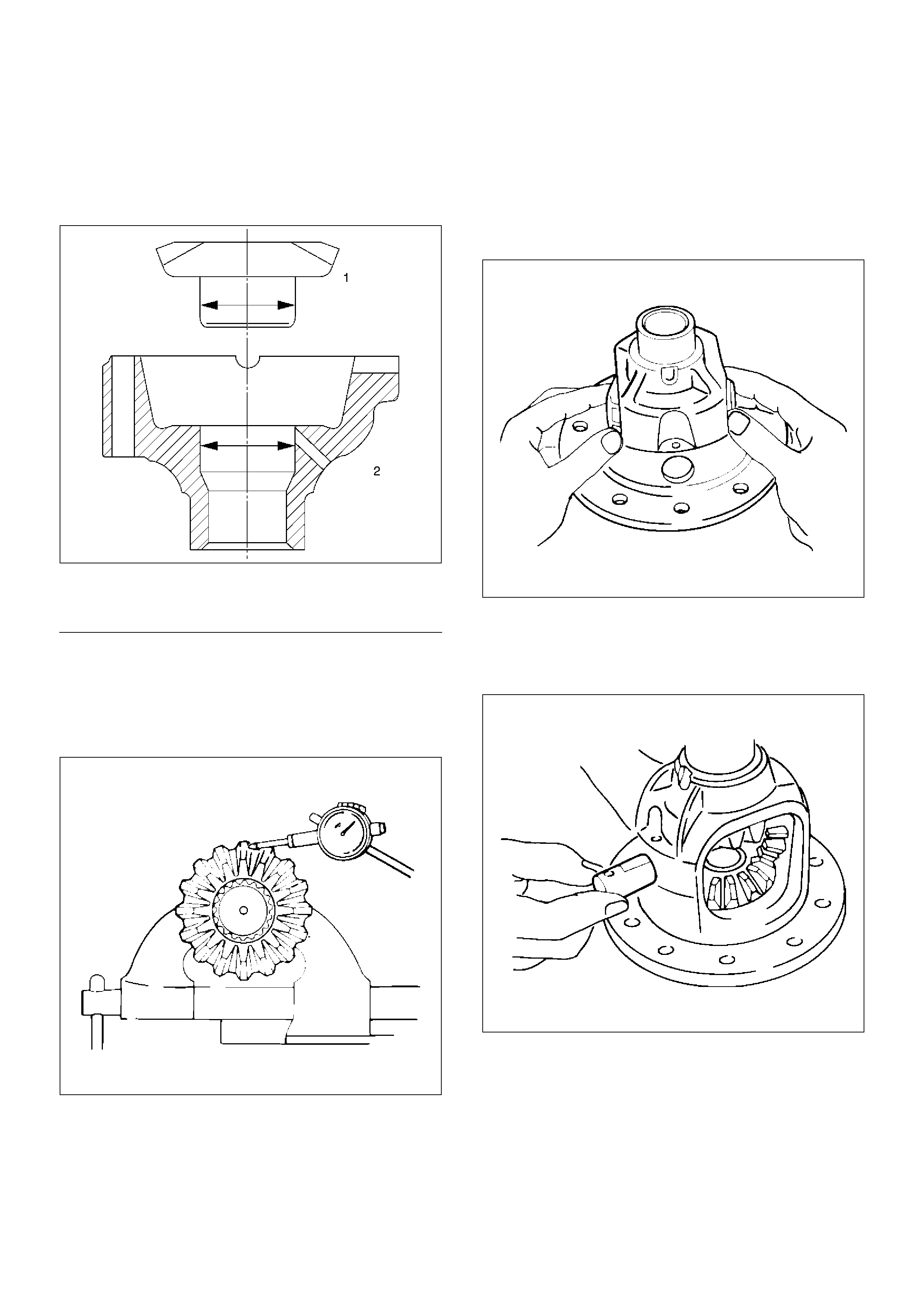

4. Place the shim on the drive pinion, with the

chamfered side turned towards the pinion head then

install the inner bearing onto the pinion using an

installer 9–8522–1165–0 and a press.

0.004 2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0.005 2.54

(0.1000)

2.56

(0.1008)

0.006 2.56

(0.1008)

Pinion

marking +10 +8 +6 +4 +2 0 –2 –4 –6 –8 –10

Dial

indicator

reading

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

NOTE: Do not apply pressure to the roller cage and

apply pressure only to the inner race.

425RW048

5. Discard the used collapsible spacer and install a

new one.

6. Install pinion gear.

7. Install outer bearing.

8. Use oil seal installer 9–8522–1275–0 to install a

new oil seal that has been soaked in rear axle

lubricant.

NOTE: Take care to use a front differential oil seal,

NOT the rear differential oil seal.

415RW024

9. Install dust cover.

10. Install flange.

11. Install flange nut.

1. Apply lubricant to the pinion threads.

2. Tighten the nut to the specified torque using the

pinion flange holder 5–8840–2157–0.

Torque:177–275N·m(18–28kg·m/130–203lbft)

NOTE: Discard used flange nut and install new one

and do not over tighten the flange nut.

425RW047

3. Adjust pinion bearing preload.

a Measure the bearing preload by using a

torque meter. Note the scale reading

required to rotate the flange.

b Continue tightening flange nut until the

specified starting torque is obtained.

Starting torque:

New bearing 0.7–1.1N·m(0.065–0.115kg·m/5.64–

9.98lbin)

Used bearing 0.4–0.5N·m(0.033–0.057kg·m/2.86–

4.94Ibin)

425RS027

4. Using punch 5-8840-2293-0, stake the flange

nut at two points.

NOTE: When staking, be sure to turn the nut to insure

that there is no change in bearing preload. Make sure of

preload again as instructed in 3).

415RW019

EndOFCallout

12. Install adjust shim.

1. Attach the side bearing to the differential

assembly without shims. Support the opposite

side using a pilot to prevent bearing damage.

425RS029

EndOFCallout

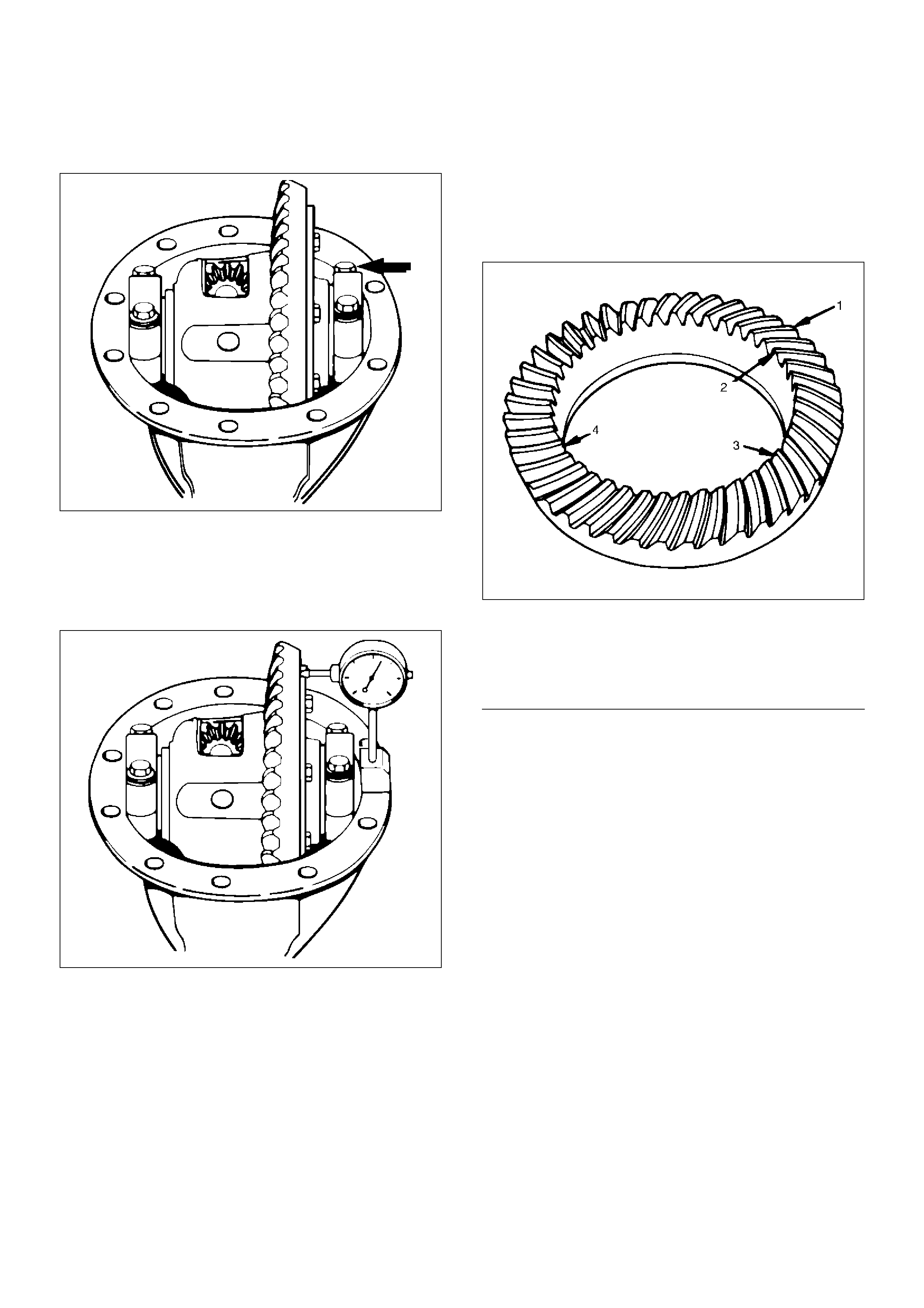

2. Insert the differential cage assembly with

bearing outer races into the side bearing bores

of the carrier.

425RS030

3. Using two sets of feeler gauges, insert a feeler

stock of sufficient thickness between each

bearing outer race and the carrier to remove all

end play. Make certain the feeler stock is

pushed to the bottom of the bearing bores.

Mount the dial indicator 5–8840–0126–0 on the

carrier so that the indicator stem is at right

angles to a tooth on the ring gear.

425RW049

Legend

(1) 1.3mm or less

Legend

(1) Drive handle:5–8840–0007–0

(2) Installer:9–8522–1164–0

(3) Pilot:9–8521–1743–0

4. Adjust feeler gauge thickness from side to side

until ring gear backlash is in the specified range.

Backlash:0.13–0.18mm(0.005 –0.007in)

425RS032

With zero end play and correct backlash

established, remove the feeler gauge packs,

determine the thickness of the shims required

and add 0.05 mm (0.002 in) to each shim pack

to provide side bearing preload. Always use new

shims.

5. Use bearing remover 5–8840–0013–0 and 5–

8840–0014–0 and pilot 9–8521–1743–0 to

remove side bearing.

415RW020

13. Install the side bearings together with the selected

shims.

425RS029

EndOFCallout

14. Install side bearing outer race.

15. Install differential cage assembly.

16. Install bearing cap then align the setting marks(1)

applied at disassembly.

425RS035

Legend

(1) Drive Handle:5–8840–0007–0

(2) Installer: 9–8522–1164–0

(3) Pilot: 9–8521–1743–0

17. Tighten the cap bolt to the specified torque.

Torque:98N·m (10kg·m/72lbft)

425RS036

1. Measure the amount of run–out of the ring gear

at its rear face.

Standard:0.02mm (0.001in)

Limit:0.05mm(0.002in)

425RS037

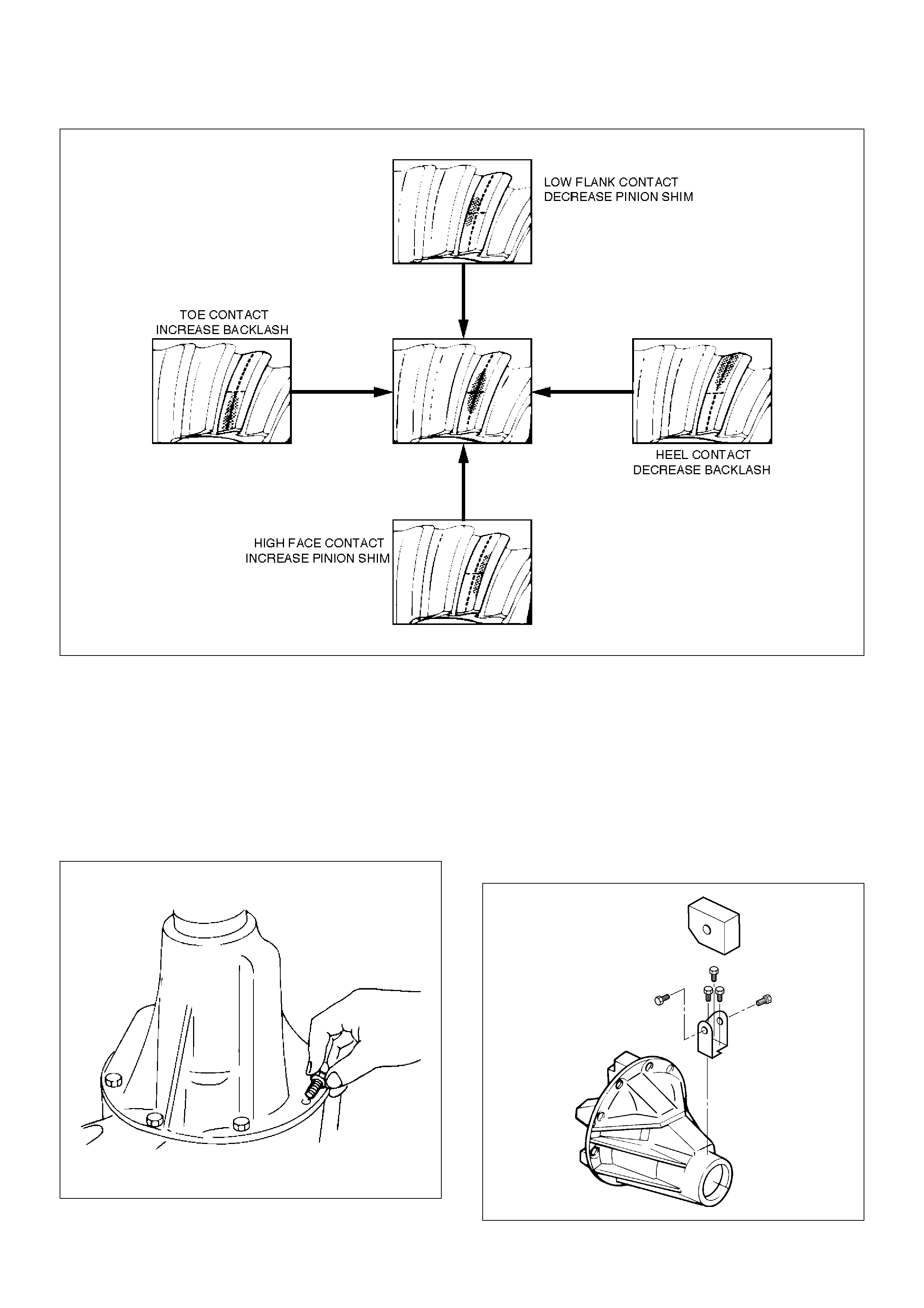

Gear Tooth Contact Pattern Check and Adjustment

1. Apply a thin coat of prussian blue or

equivalent to the faces of the 7–8 teeth of

the ring gear. Check the impression of

contact on the ring gear teeth and make

necessary adjustment as described in

illustration if the contact is abnormal.

425RS038

EndOFCallout

Legend

(1) Heel

(2) Toe

(3) Concave Side(Coast)

(4) Convex Side(Drive)

425RS039

18. Install differential assembly.

1. Clean the faces of the front axle case and

differential carrier.

Apply Three Bond TB1215 or equivalent to the

sealing side of the axle case and the carrier.

2. Attach the differential case and the carrier

assembly to the front axle case and tighten the

nuts and bolts.

Torque:25N·m(2.5kg·m/19lbft)

415RS014

3. Fill the axle case with hypoid gear lubricant, to

just below the filler hole.

Lubricant capacity:1.4liter(1.2Impqt/1.5USqt)

19. Install damper.

1. Clean the faces and bolt thread hole of

differential carrier.

2. Install the bracket with new bolts.

3. Install the damper to the bracket with new bolts.

Torque:25N·m(2.5kg·m/19lbft)

425RW042

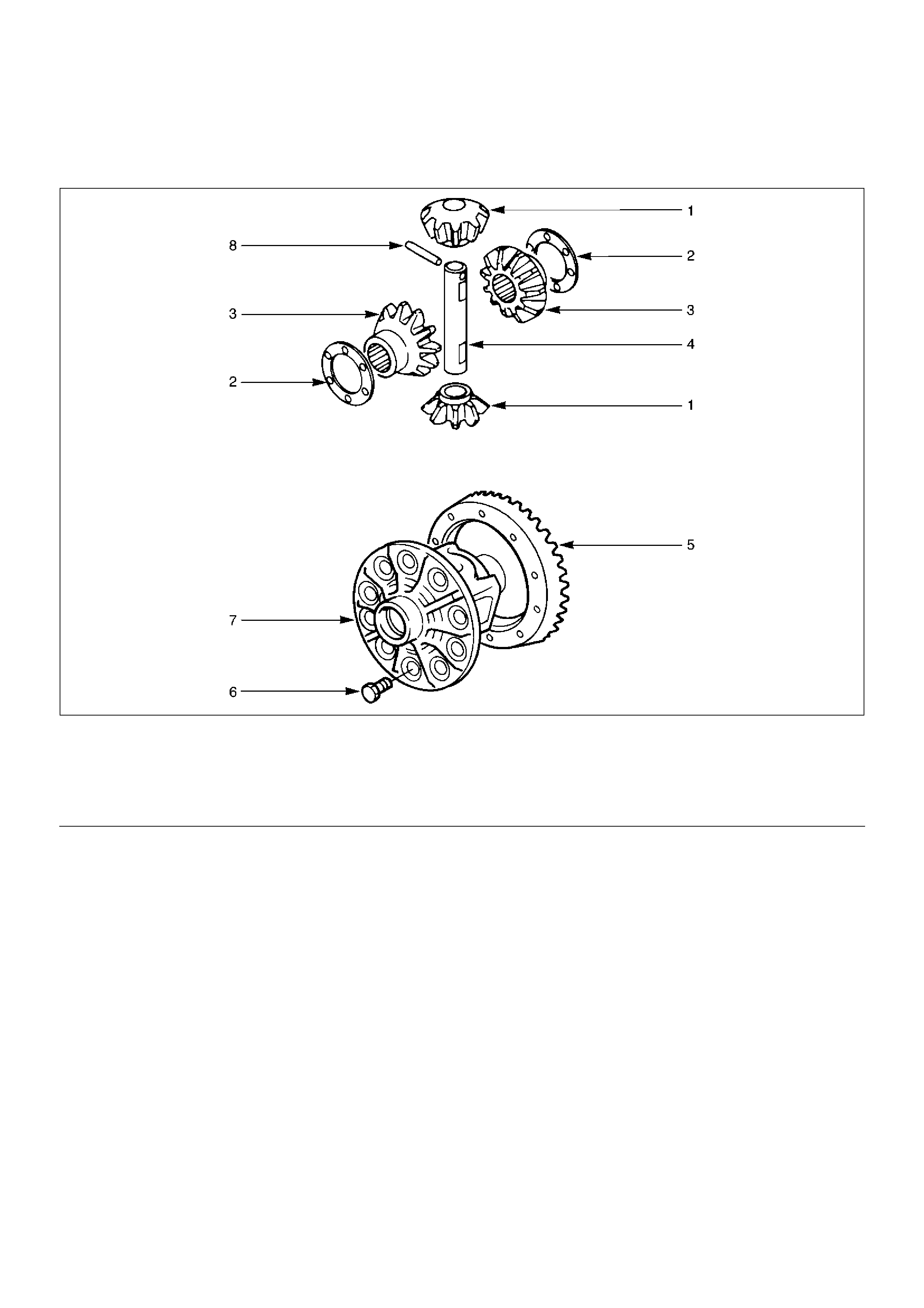

Differential Cage Assembly

Disassembled View

415RS015

EndOFCallout

Disassembly

1. Remove bolt.

2. Remove ring gear.

Legend

(1) Pinion Gear

(2) Thrust Washer

(3) Side Gear

(4) Cross Pin

(5) Ring Gear

(6) Bolt

(7) Differential Cage

(8) Lock Pin

3. Remove lock pin, break staking on the lock pin,

using a 5 mm (0.20 in) diameter drill.

425RS042

4. Remove the cross pin, using a soft metal rod and a

hammer.

425RS043

5. Remove pinion gear.

6. Remove side gear.

7. Remove thrust washer.

Inspection and Repair

Make necessary correction or parts replacement if

wear, damage, corrosion or any other abnormal

conditions are found through inspection.

Check the following parts:

1. Ring gear, pinion gear

2. Bearing

3. Side gear, pinion gear, cross pin

4. Differential cage, carrier

5. Thrust washer

6. Oil seal

Ring gear replacement:

1. The ring gear should always be replaced with the

drive pinion as a set.

2. Clean the ring gear threaded holes to remove the

locking agent.

3. When installing the ring gear, apply LOCTITE 271 or

equivalent to all the threaded area and half of the

unthreaded area of the bolt.

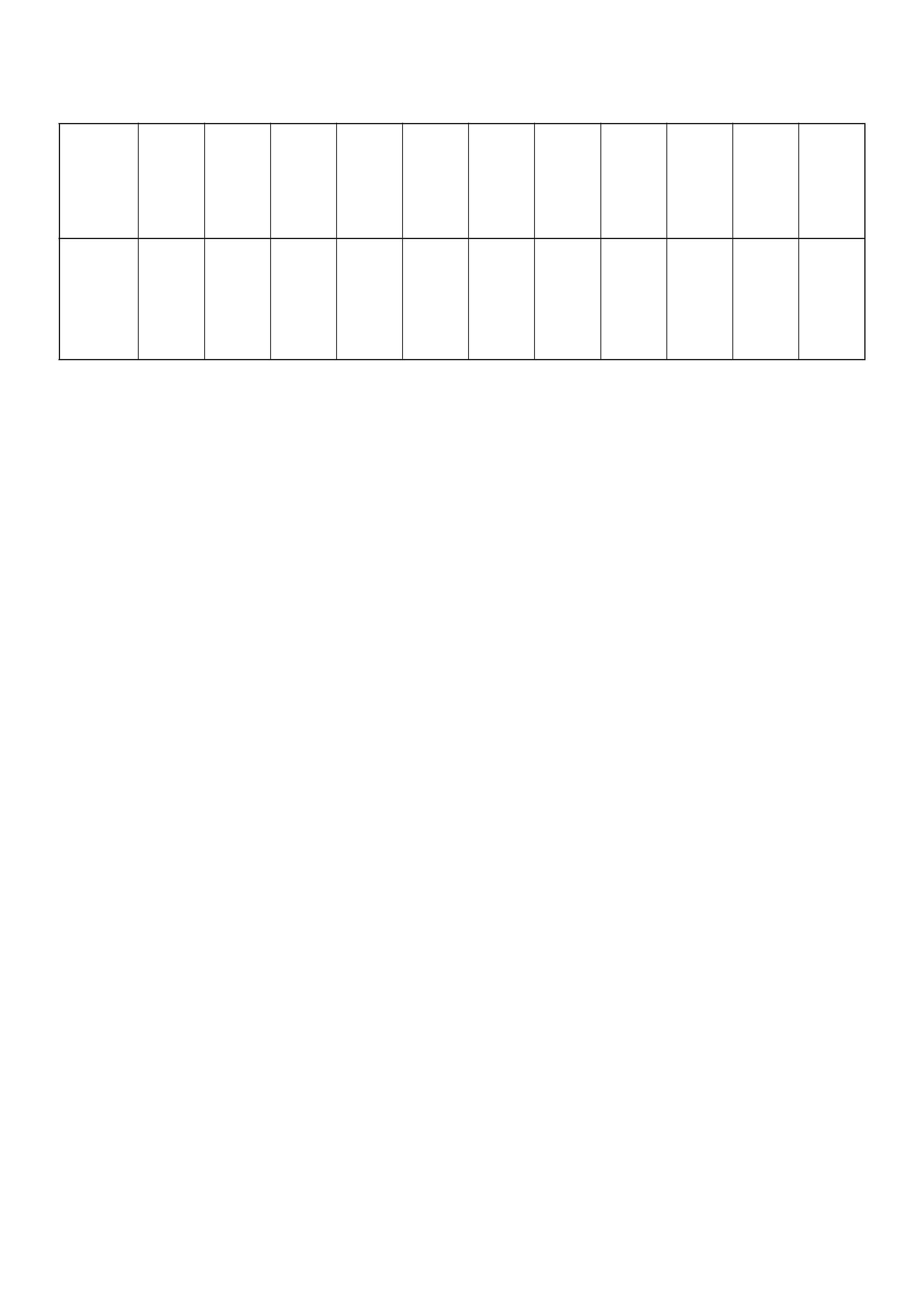

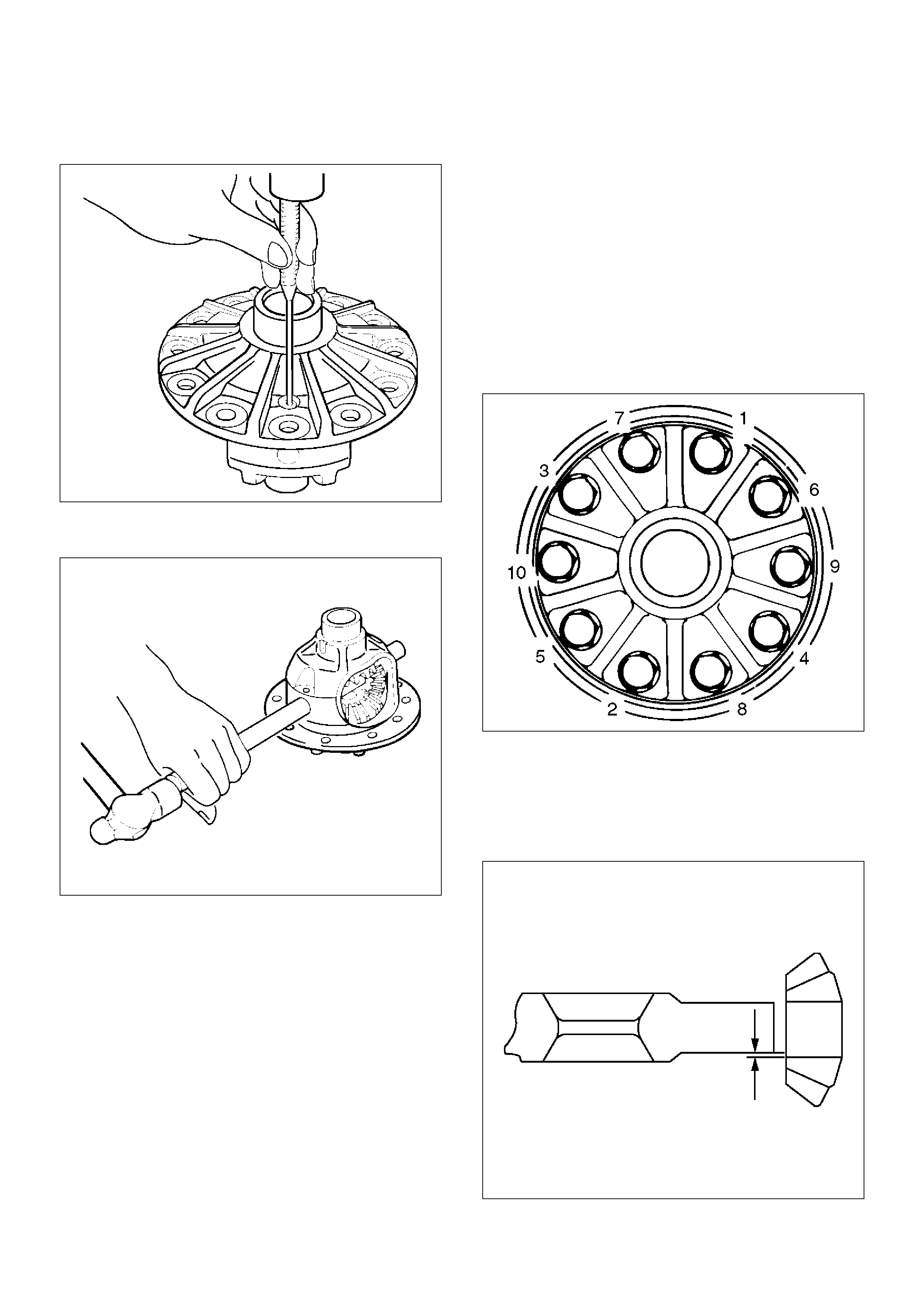

4. Discard used bolts and install new ones.

Torque:108N·m(11kg·m/80lbft)

5. Tighten the fixing bolts in a diagonal sequence as

illustrated.

415RS016

Clearance between the differential pinion

and the cross pin measurement:

Standard:0.06 – 0.12mm (0.002–0.005in)

Limit:0.2mm(0.008in)

425RS045

Clearance between the side gear and the

differential box:

Standard:0.03–0.10mm (0.001–0.004in)

Limit:0.15mm(0.006in)

425RS046

EndOFCallout

Play in splines between the side gear and

the axle shaft:

Standard:0.08–0.36mm(0.003 –0.014 in)

Limit:0.5m (0.02in)

425RS047

Reassembly

1. Install thrust washer.

2. Install side gear.

3. Install the pinion gear by engaging it with the side

gears while turning both pinion gears

simultaneously in the same direction.

425RS048

4. Install cross pin.

1. Be sure to install the cross pin so that it is in

alignment with the lock pin hole in the differential

cage.

425RS049

2. Adjust the backlash between the side gear and

the pinion gear.

Backlash:0.03 – 0.08mm (0.001– 0.003in)

Legend

(1) Side Gear

(2) Differential Box

Thickness of thrust washers available:

1.00mm, 1.05mm, 1.10mm(0.039in, 0.041in,

0.043in)

425RS050

5. Install lock pin. After lock pin installation, stake the

cage to secure the lock pin.

425RS051

EndOFCallout

6. Clean the ring gear threaded holes to remove the

locking agent. When installing the ring gear, apply

LOCTITE 271 or equivalent to all the threaded area

and half of the unthreaded area of the bolt.

7. Tighten the bolts in diagonal sequence as

illustrated.

Torque:108N·m(11kg·m/80lbft)

NOTE: Discard used bolts and install new ones.

415RS016

Legend

(1) Staked Portion

(2) Lock Pin

Main Data and Specifications

General Specifications

Axle tube Type It consists of the duct, a cast iron housing and the axle

tube.

Gear type Hypoid

Gear ratio (to 1) 4.100(6VE1)

4.300(4JX1, 6VE1)

4.555(4JG2–TC, 6VD1)

4.777(4JG2)

Differential type Two pinion

Oil capacity liter (Imp qt/US

qt)

1.4 (1.2/1.5) (Differential)

0.12 (0.11/0.13) (Actuator Housing: Shift on the fly)

Type of lubricant 75W–90 GL–5 (Multi grade type)

Refer to General Information

Axle shaft type Constant velocity joint (Birfield joint type and double offset

joint)

Torque Specifications

E04RW014

E04RW015

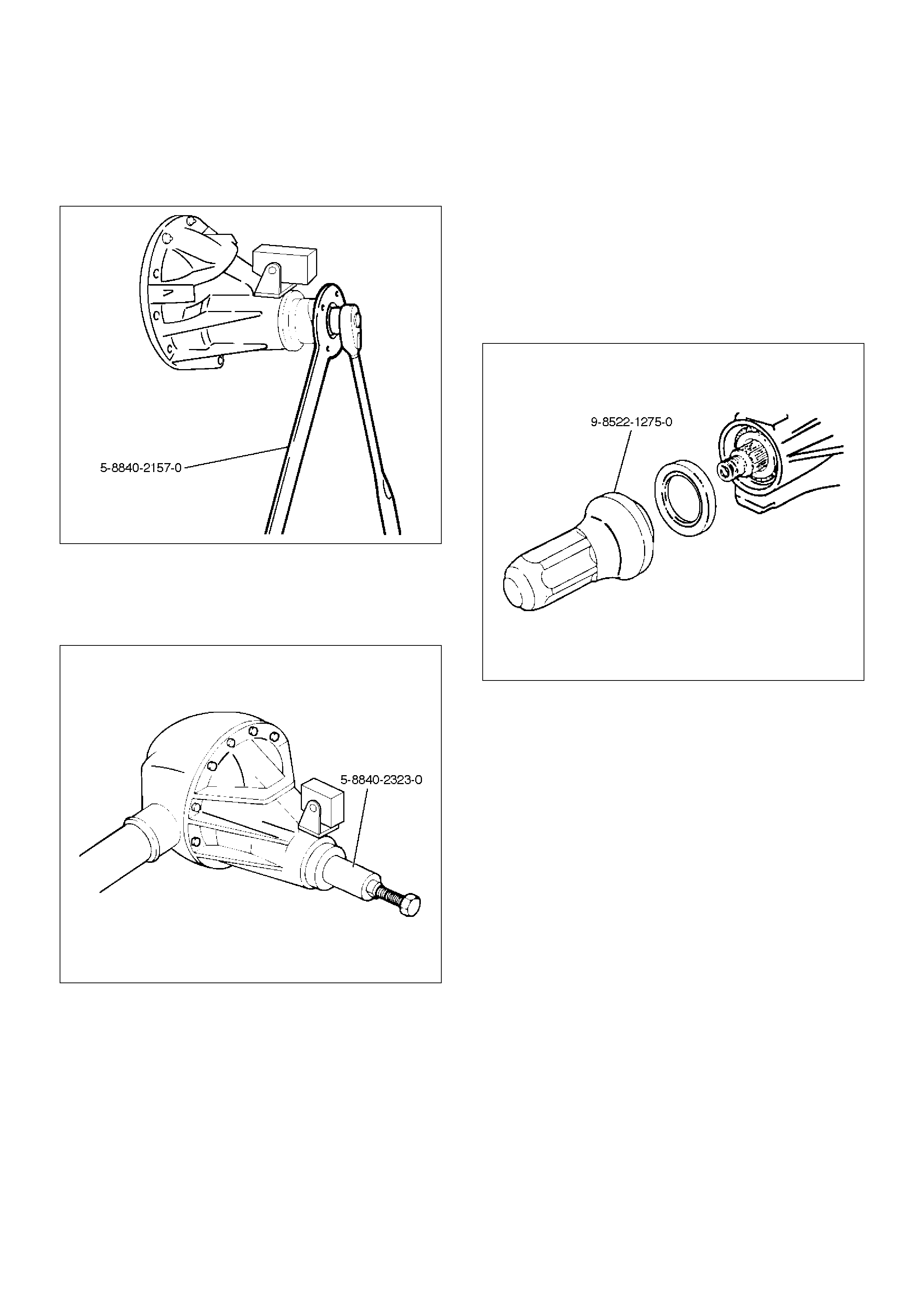

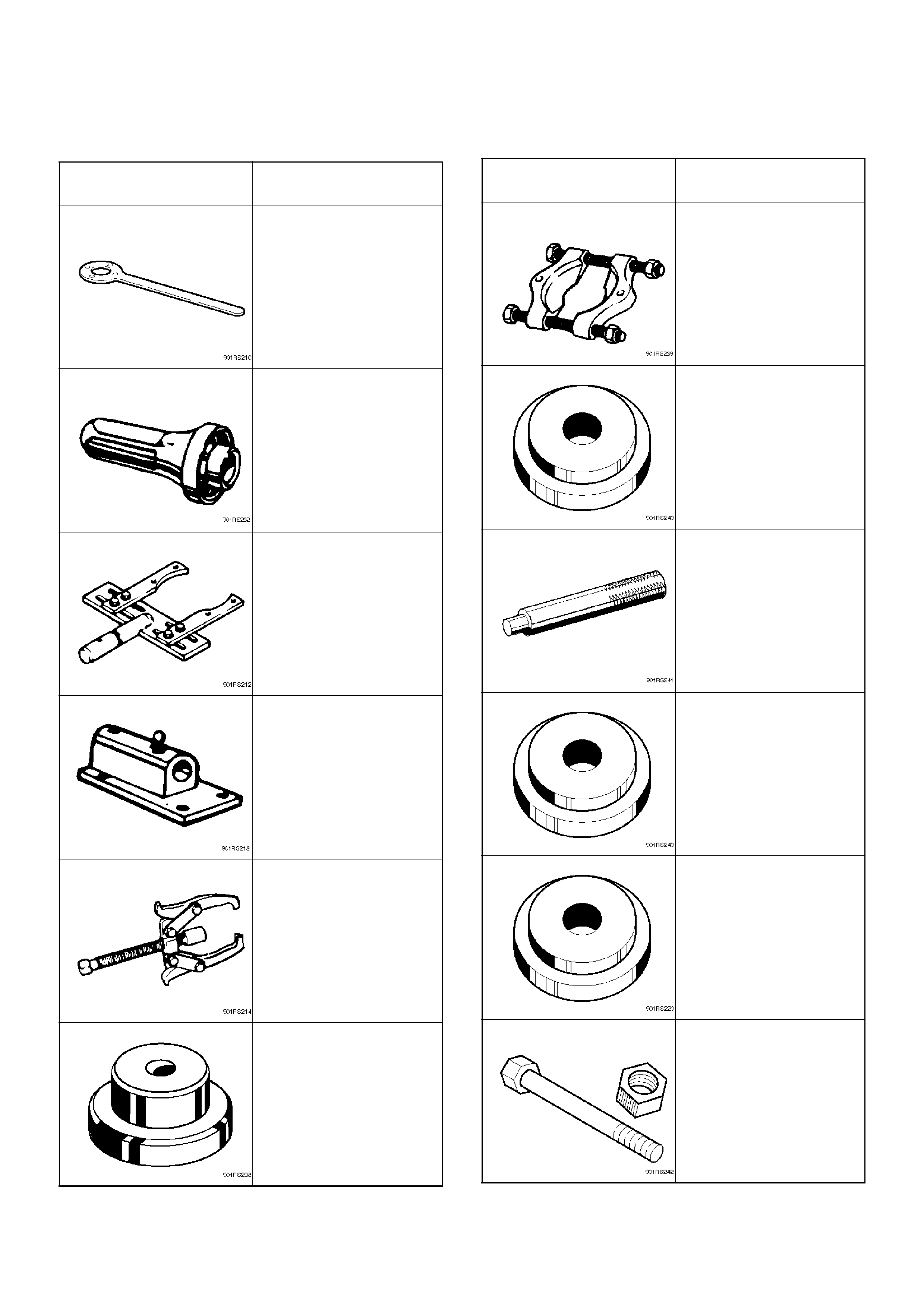

Special Tools

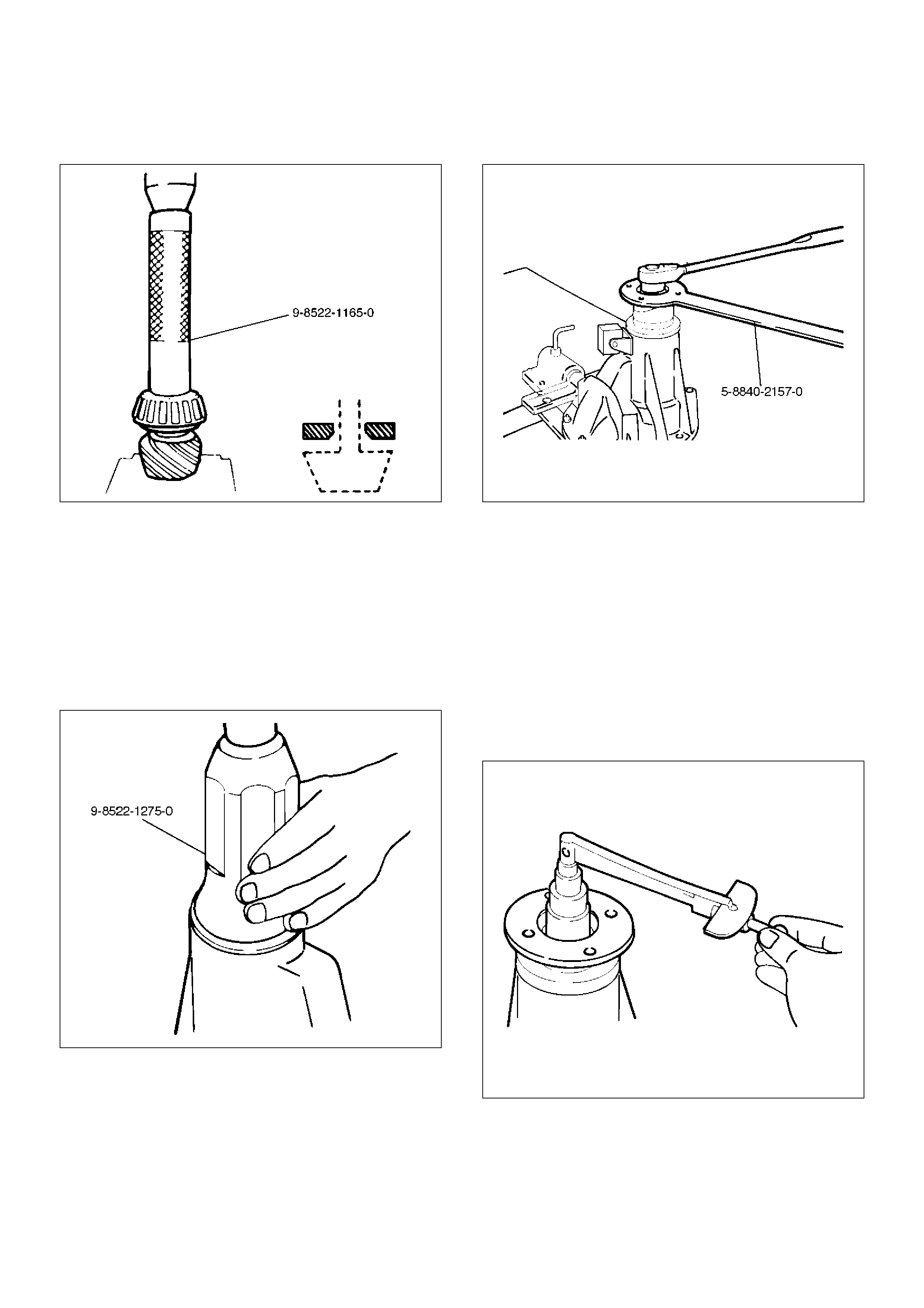

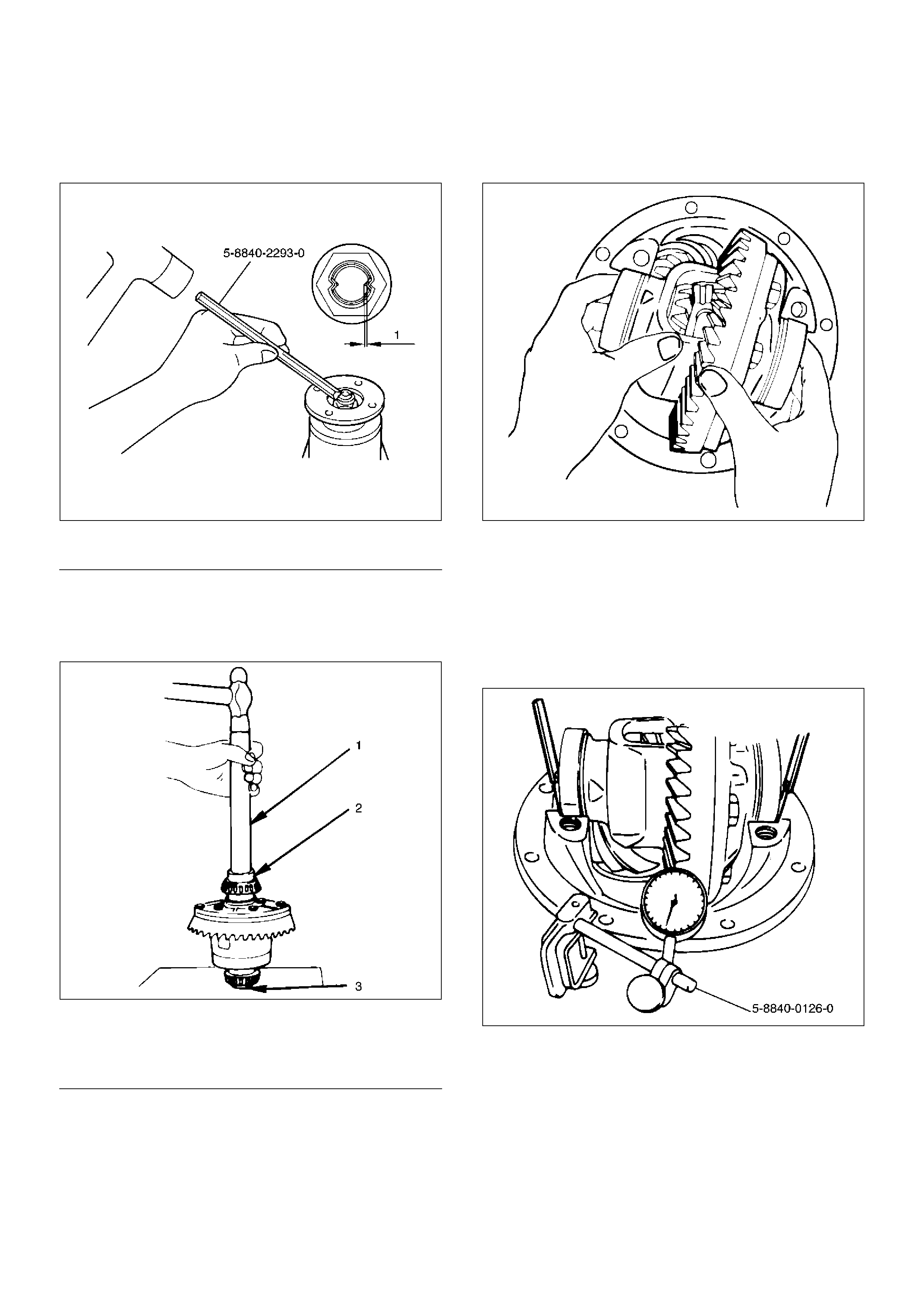

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–2157–0

(J–37221)

Holder; Pinion flange

9–8522–1275–0

(J–24250)

Installer; Oil seal

5–8840–0275–0

(J–37264)

Differential holding fixture

(Use with 5–8840–0003–

0 base)

5–8840–0003–0

(J–3289–20)

Holding fixture base

5–8840–0013–0

5–8840–0014–0

(J–22888)

Puller; Side bearing

9–8521–1743–0

(J–8107–2)

Adapter; Side bearing

plug

5–8840–0015–0

(J–22912–01)

Separator

9–8522–1141–0

(J–24256)

Installer; Outer bearing

outer race

5–8840–0007–0

(J–8092)

Driver handle

9–8522–1274–0

(J–24252)

Installer; Inner bearing

outer race

5–8840–2085–0

(J–21777–42)

Pilot

5–8840–2089–0

(J–23597–9)

Nut and bolt

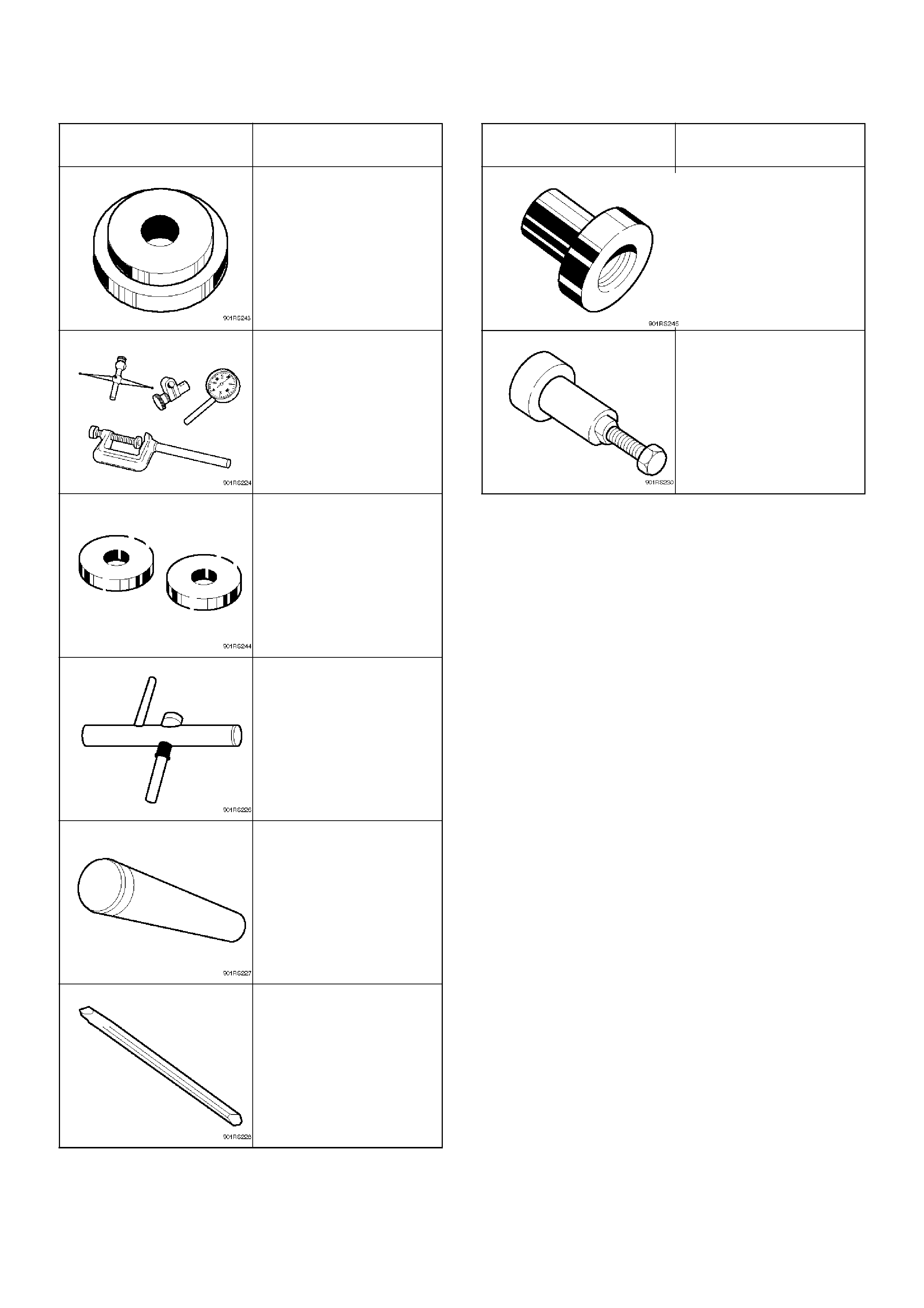

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–2087–0

(J–23597–7)

Gauge plate

5–8840–0126–0

(J–8001)

Dial indicator

5–8840–2088–0

(J–23597–8)

Disc

5–8840–0128–0

(J–23597–1)

Arbor

9–8522–1165–0

(J–6133–01)

Installer; Pinion bearing

5–8840–2293–0

(J–39209)

Punch; End nut lock

ILLUSTRATION TOOL NO.

TOOL NAME

9–8522–1164–0

(J–24244)

Installer; Side bearing

5–8840–2323–0

(J–39602)

Remover; Outer bearing

ILLUSTRATION TOOL NO.

TOOL NAME