SECTION 4D - HUBS, AXLES & DRIVE SHAFTS

Service Precaution

General Description

Diagnosis

Rear Axle Shaft

Rear Axle Shaft and Associated Parts

Removal

Inspection and Repair

Oil Seal Replacement

Installation

Special Tools

Front Hub and Disc (with Shift on the Fly)

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Front Hub and Disc with Manual Locking Hub

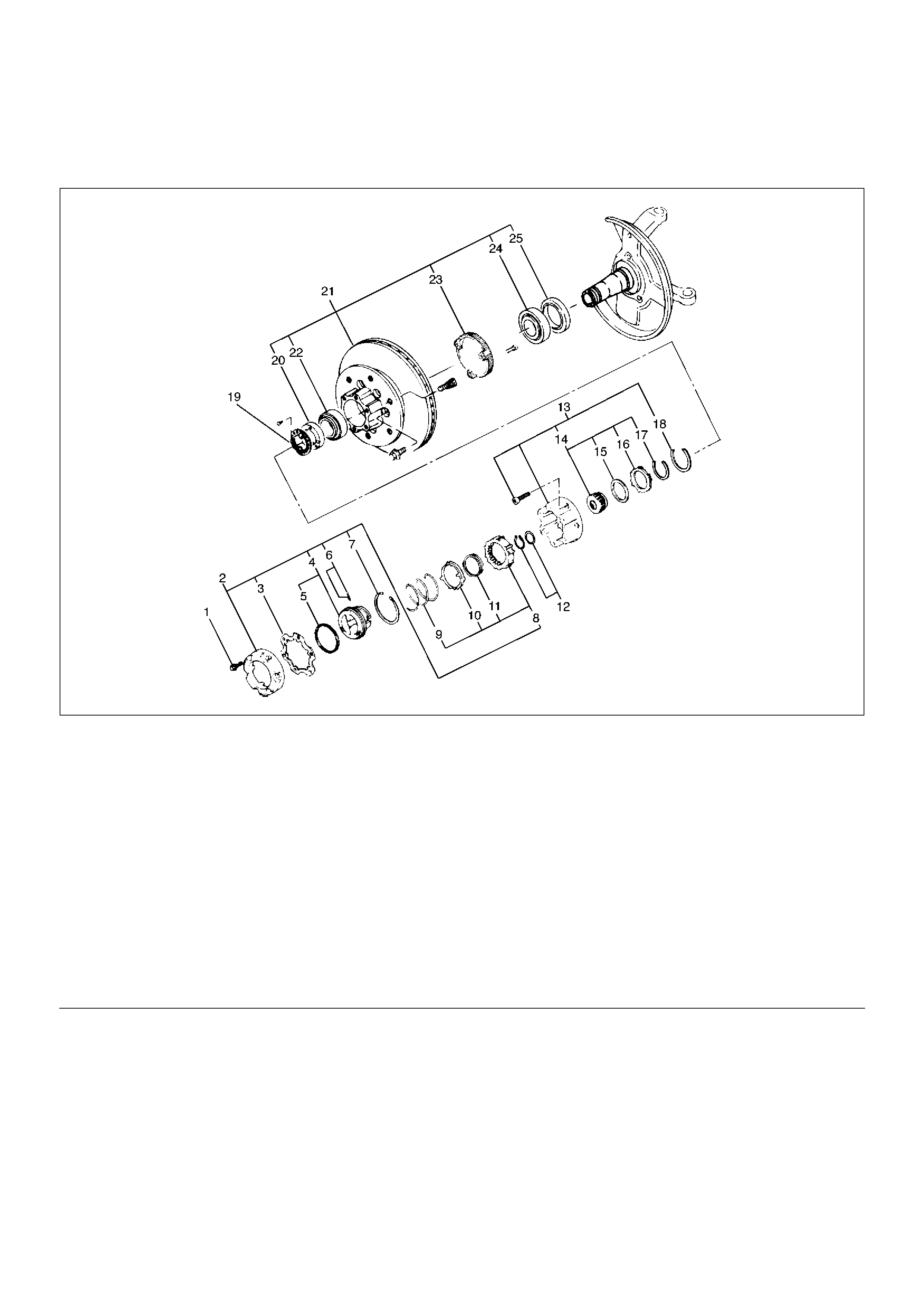

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

Torque Specifications

Special Tools

Front Drive Shaft Joint

Front Drive Shaft Joints Replacement

Front Axle Drive Shaft

Front Axle Drive Shaft and Associated Parts

Disassembly

Inspection and Repair

Bushing Replacement

Reassembly

Shift On The Fly System

Shift On The Fly System and Associated Parts

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

General Specifications

Torque Specifications

Special Tools

Front Propeller Shaft

General Description

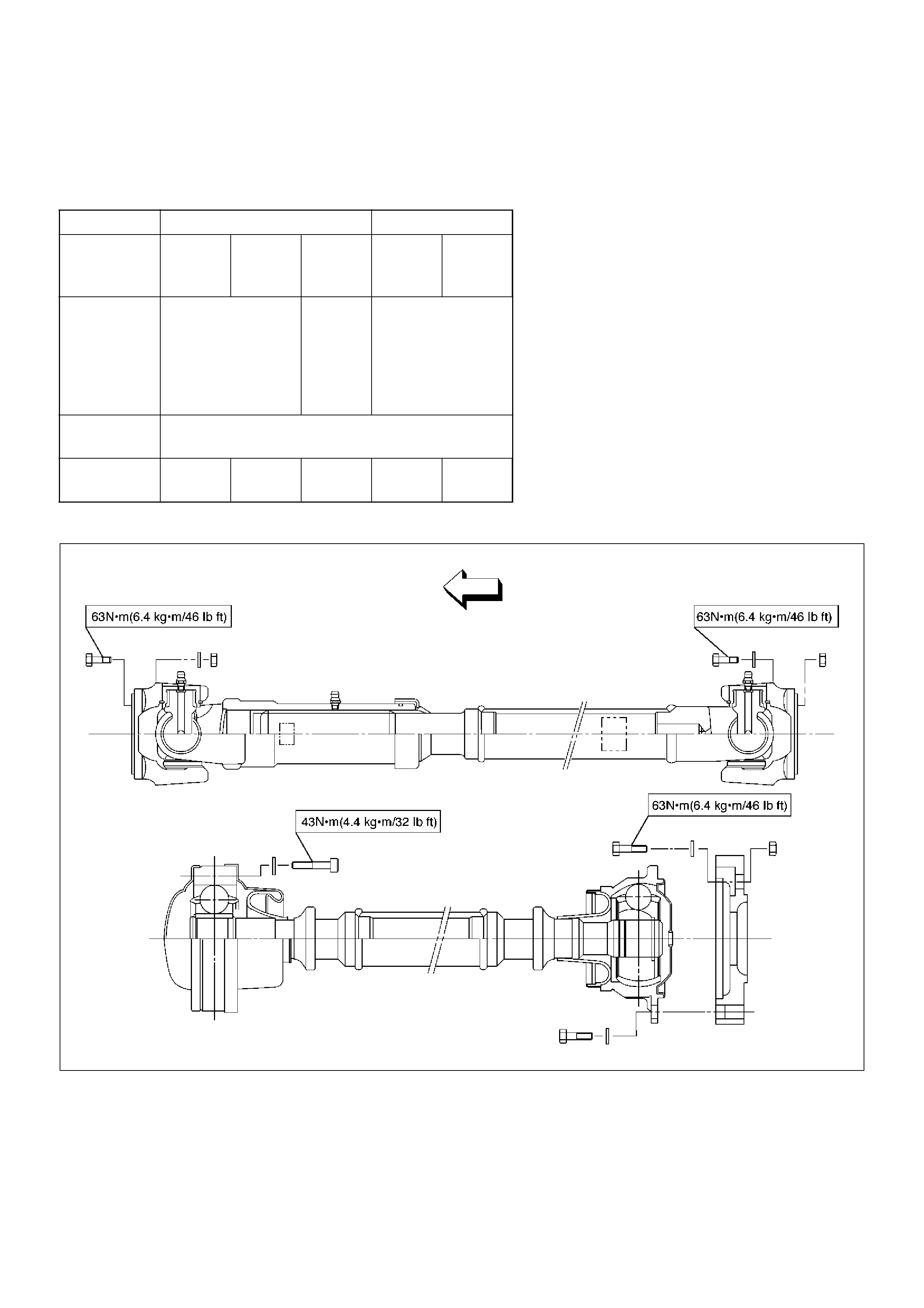

Front Propeller Shaft and Associated Parts

Removal

Installation

Disassembly (Except TOD 4x4)

Universal Joint Disassembly

Inspection and Repair

Universal Joint Reassembly

Reassembly (Except TOD 4x4)

Main Data and Specifications

General Specifications

Torque Specifications

Rear Propeller Shaft

General Description

Rear Propeller Shaft and Associated Parts

Removal

Installation

Disassembly

Universal Joint Disassembly

Inspection and Repair

Universal Joint Reassembly

Reassembly

Main Data and Specifications

General Specifications

Torque Specifications

Techline

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE

SRS WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED ,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

General Description

This publication contains essential removal, installation,

adjustment and maintenance procedures.

The front axle utilizes a central disconnect type front

axle/transfer case system.

The drive axles are completely flexible assemblies,

consisting of inner and outer constant velocity (CV)

drive shaft joints connected by an axle shaft.

For description of propeller shaft and universal joint,

refer to Front / Rear Propeller Shaft in this section.

Diagnosis

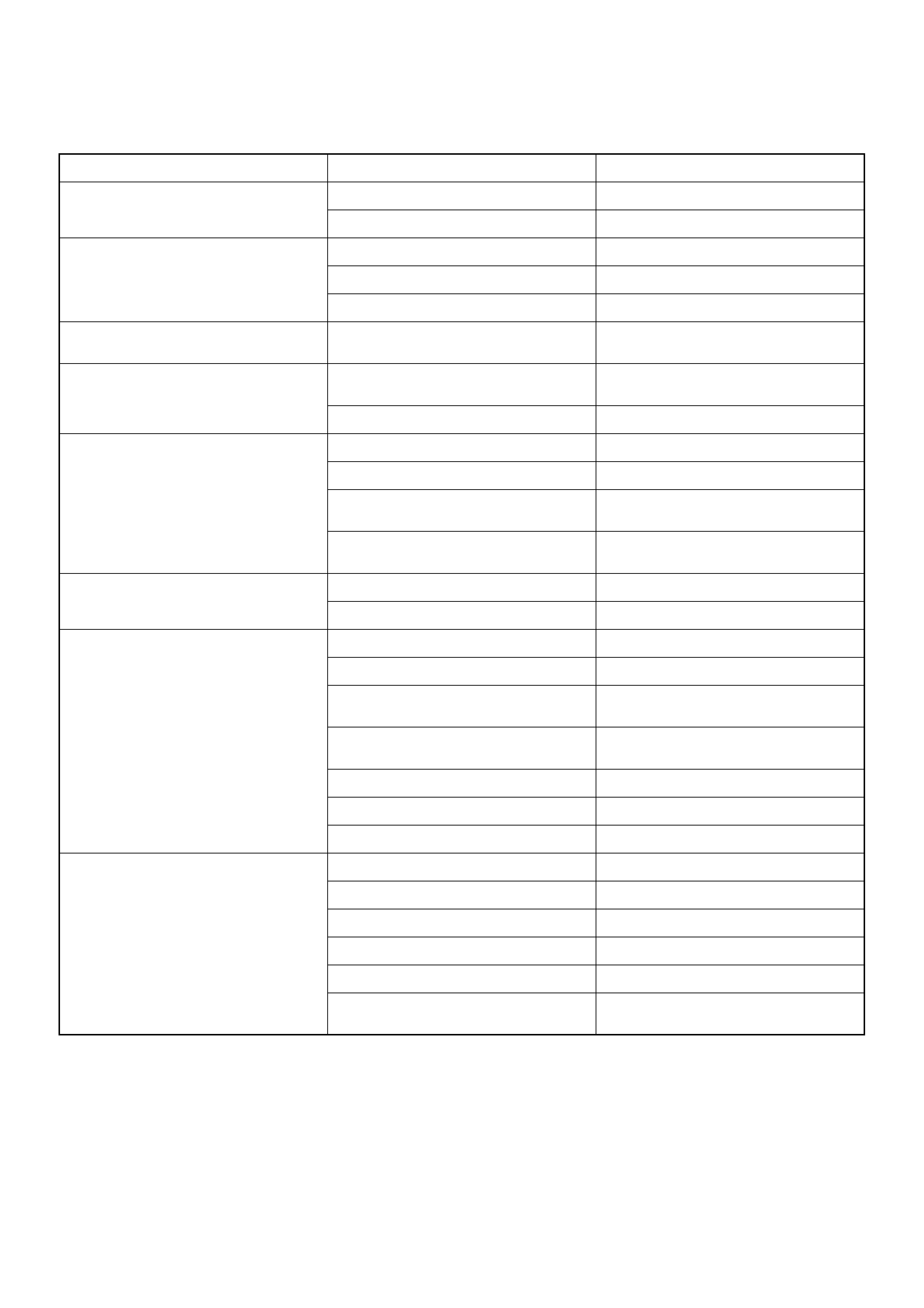

Condition Possible Cause Correction

Oil Leak At Front Axle Worn or defective oil seal. Replace the oil seal.

Front axle housing cracked. Repair or replace.

Oil Leak At Pinion Shaft Too much gear oil. Correct the oil level.

Oil seal worn or defective. Replace the oil seal.

Pinion flange loose or damaged. Tighten or replace.

Noises In Front Axle Drive Shaft Joint Broken or worn drive shaft joints and

bellows (BJ and DOJ). Replace the drive shaft joints and

bellows.

“Clank”When Accelerating From

“Coast” Loose drive shaft joint to output shaft

bolts. Tighten.

Damaged inner drive shaft joint. Replace.

Shudder or Vibration During

Acceleration Excessive drive shaft joint angle. Repair.

Worn or damaged drive shaft joints. Replace.

Sticking spider assembly (inner drive

shaft joint). Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint). Lubricate or replace.

Vibration At Highway Speeds Out of balance or out of round tires. Balance or replace.

Front end out of alignment. Align.

Noises in Front Axle Insufficient gear oil. Replenish the gear oil.

Wrong or poor grade gear oil. Replace the gear oil.

Drive pinion to ring gear backlash

incorrect. Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear. Replace the ring gear, pinion gear or

side gear.

Pinion shaft bearing worn. Replace the pinion shaft bearing.

Wheel bearing worn. Replace the wheel bearing.

Differential bearing loose or worn. Tighten or replace.

Wanders and Pulls Wheel bearing preload too tight. Adjust the wheel bearing preload.

Incorrect front alignment. Adjust the front alignment.

Steering linkage loose or worn. Tighten or replace.

Steering gear out of adjustment. Adjust or replace the steering gear.

Tire worn or improperly inflated. Adjust the inflation or replace.

Front or rear suspension parts loose

or broken. Tighten or replace.

Front Wheel Shimmy Wheel bearing worn or improperly

adjusted. Adjust or replace.

Incorrect front alignment. Adjust the front alignment.

Worn ball joint or bush. Replace the ball joint or bush.

Steering linkage loose or worn. Tighten or replace.

Steering gear out of adjustment. Tighten or replace.

Tire worn or improperly inflated. Replace or adjust the inflation.

Shock absorber worn. Replace the shock absorber.

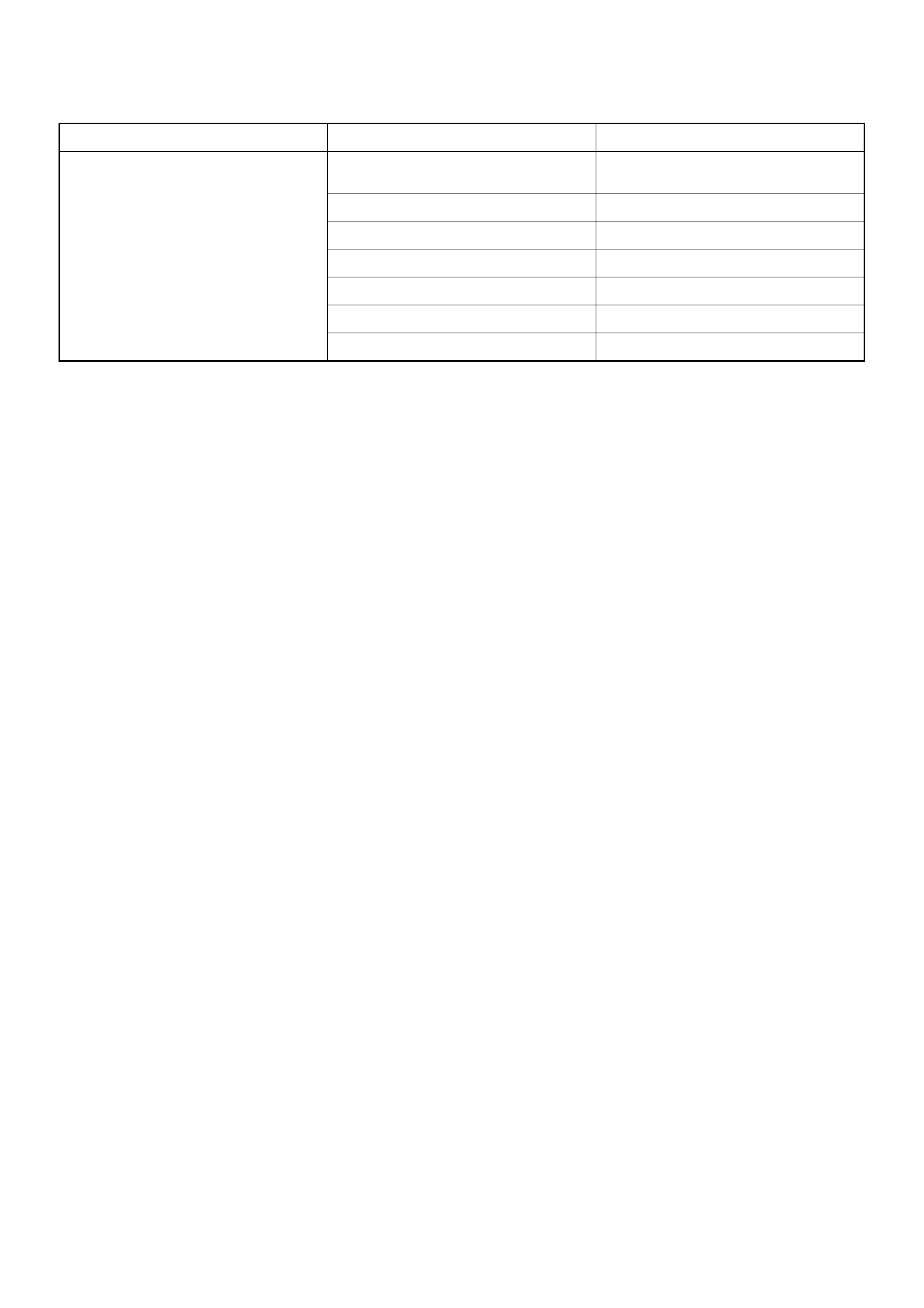

Condition Possible Cause Correction

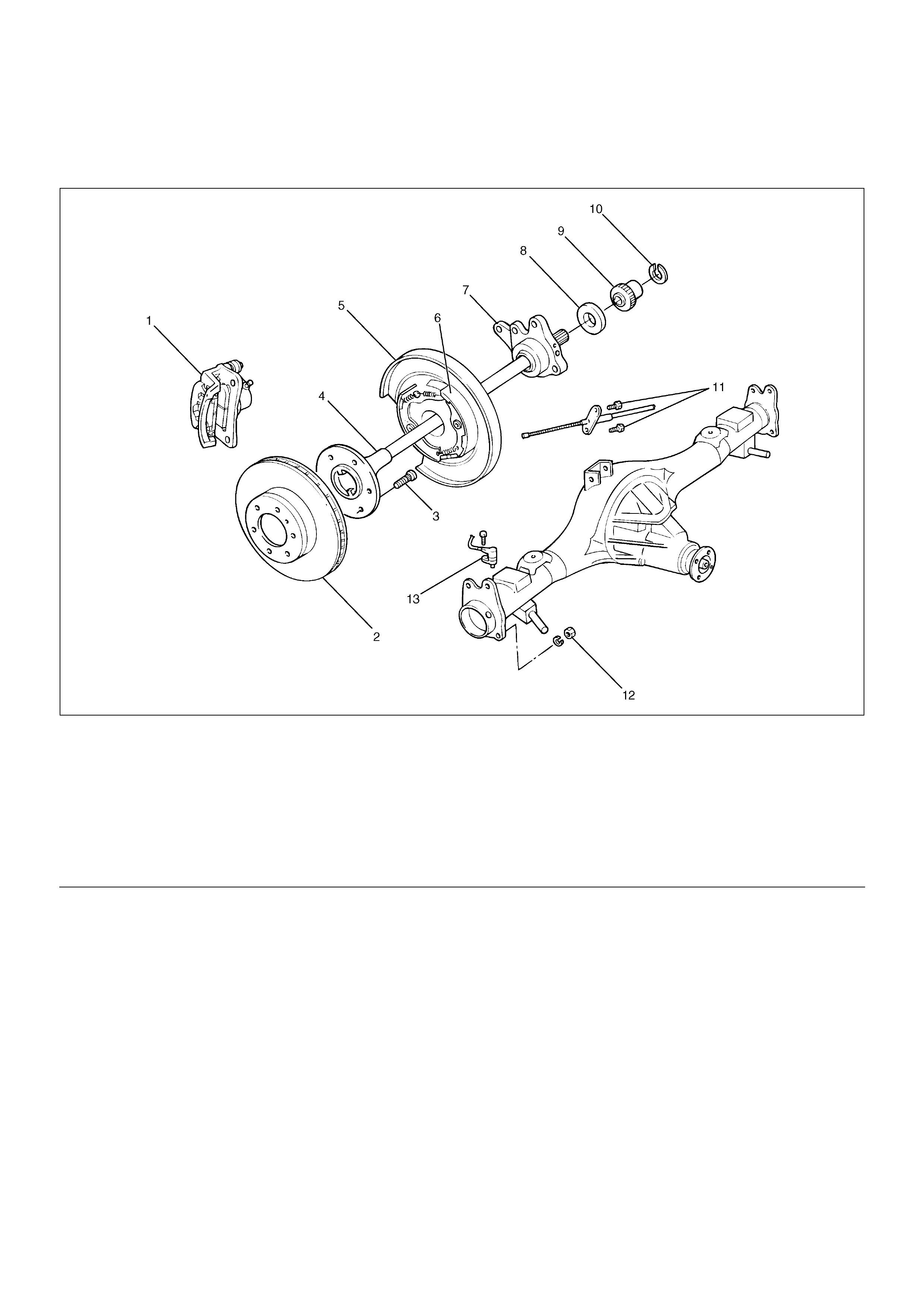

Rear Axle Shaft

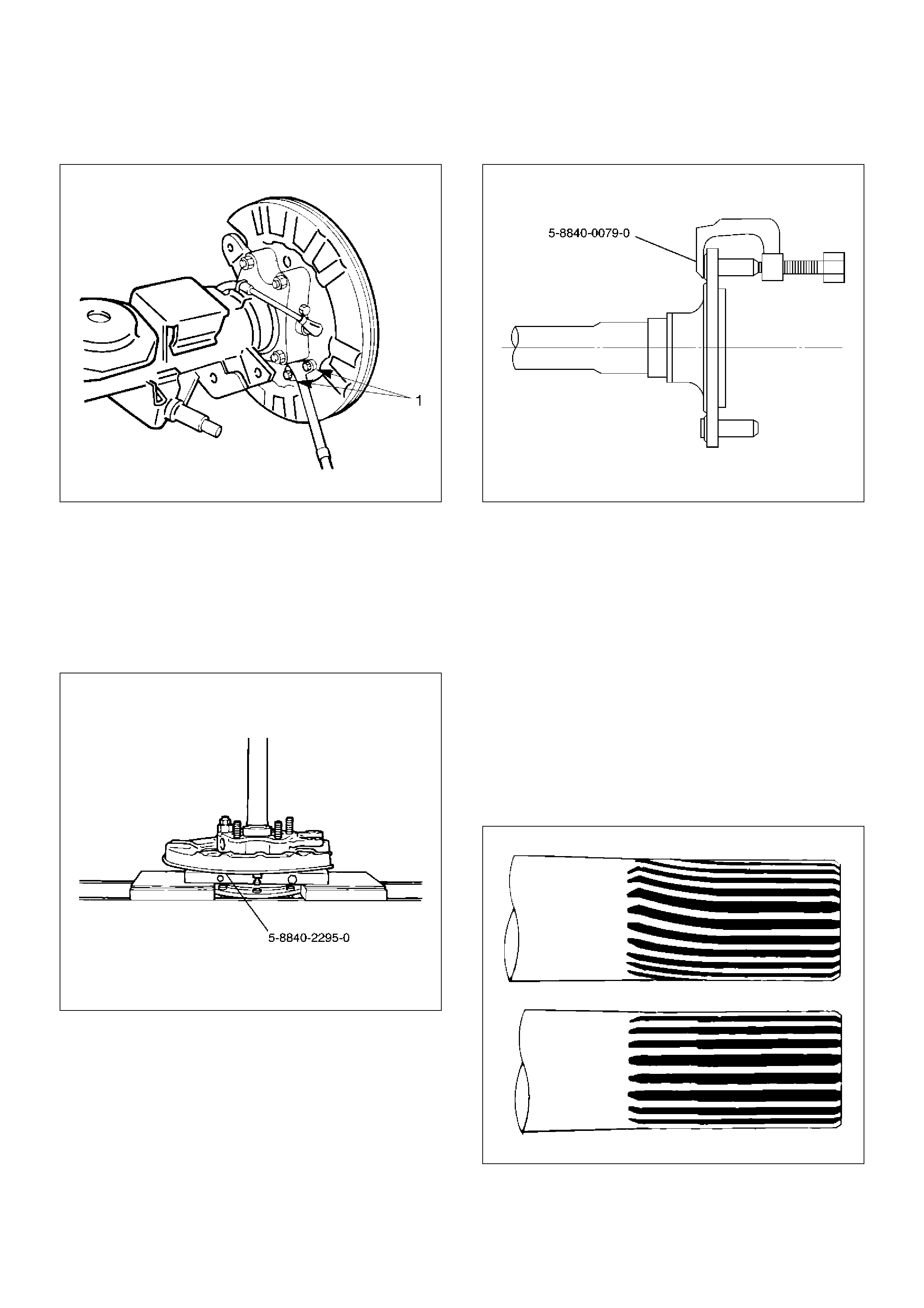

Rear Axle Shaft and Associated Parts

420RW014

EndOFCallout

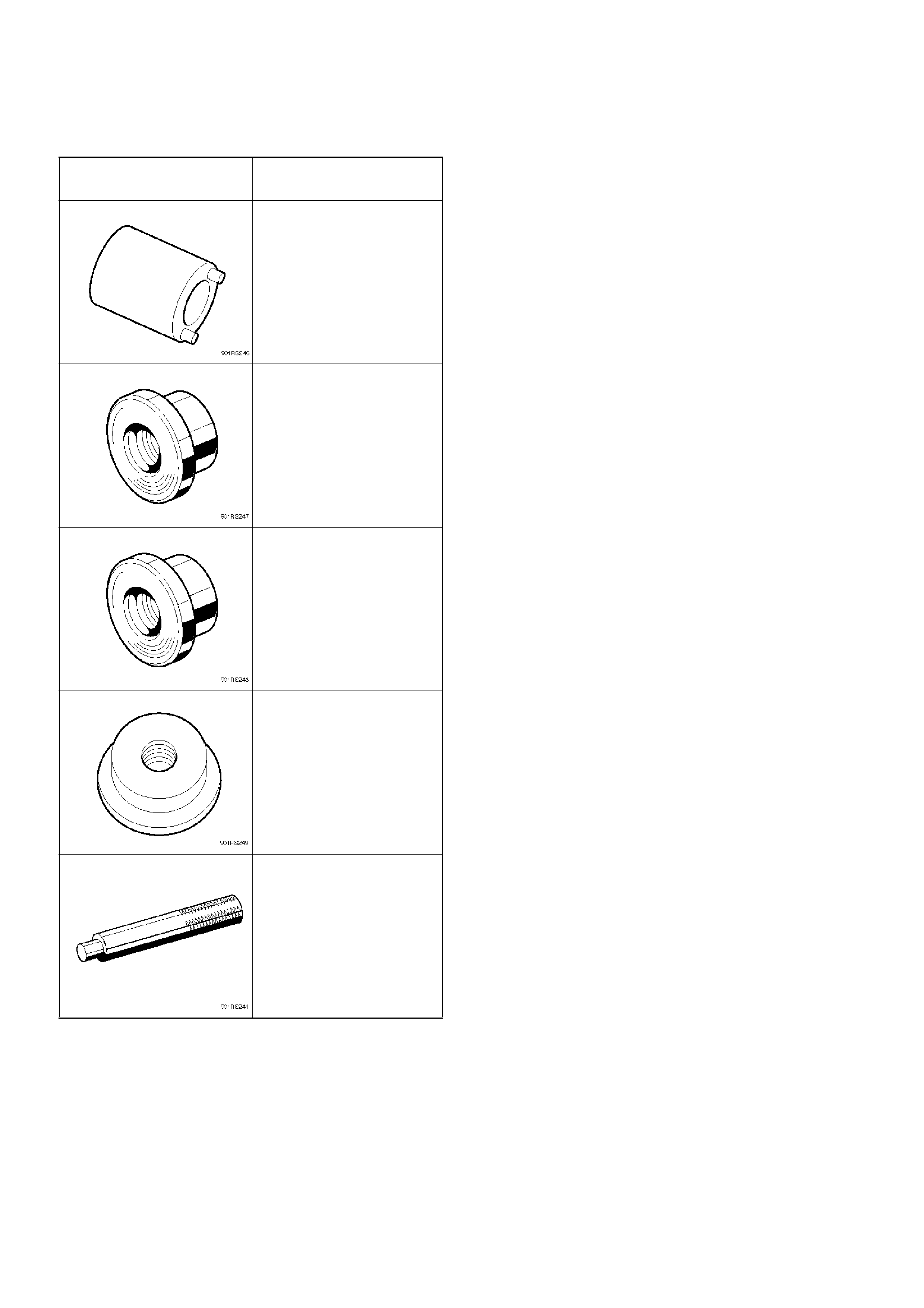

Removal

1.Raise the vehicle.

2.Remove tires and wheels. Refer to Wheel in

Steering section.

3.Remove brake caliper. Use a wire to attach the

brake caliper to the frame. Refer to Disc Brakes in

Brake section.

4. Remove brake disc.

5. Remove ABS sensor (if so equipped).

6.Remove Parking brake assembly. Refer to Parking

Brakes in Brake section.

Legend

(1) Brake Caliper

(2) Brake Disc

(3) Wheel Pin

(4) Axle Shaft Assembly

(5) Back Plate

(6) Parking Brake Assembly

(7) Bearing Holder

(8) Bearing

(9) Retainer

(10) Snap Ring

(11) Bolt

(12) Nut

(13) Antilock Brake System (ABS) Speed Sensor (if

so equipped)

7. Remove the parking brake cable mounting

bolts(Behind the back plate)(1).

311RS001

8. Remove the bearing holder mounting nuts.

9. Remove axle shaft assembly.

NOTE: Be sure not to damage the oil seal.

10. Remove snap ring.

11. Using a bearing remover 5–8840–2295–0 and

press, remove retainer together with the bearing

holder.

420RW024

12. Remove bearing.

13. Remove bearing holder.

14. Remove back plate.

15. Remove the wheel pins using a remover 5–8840–

0079–0.

420RW023

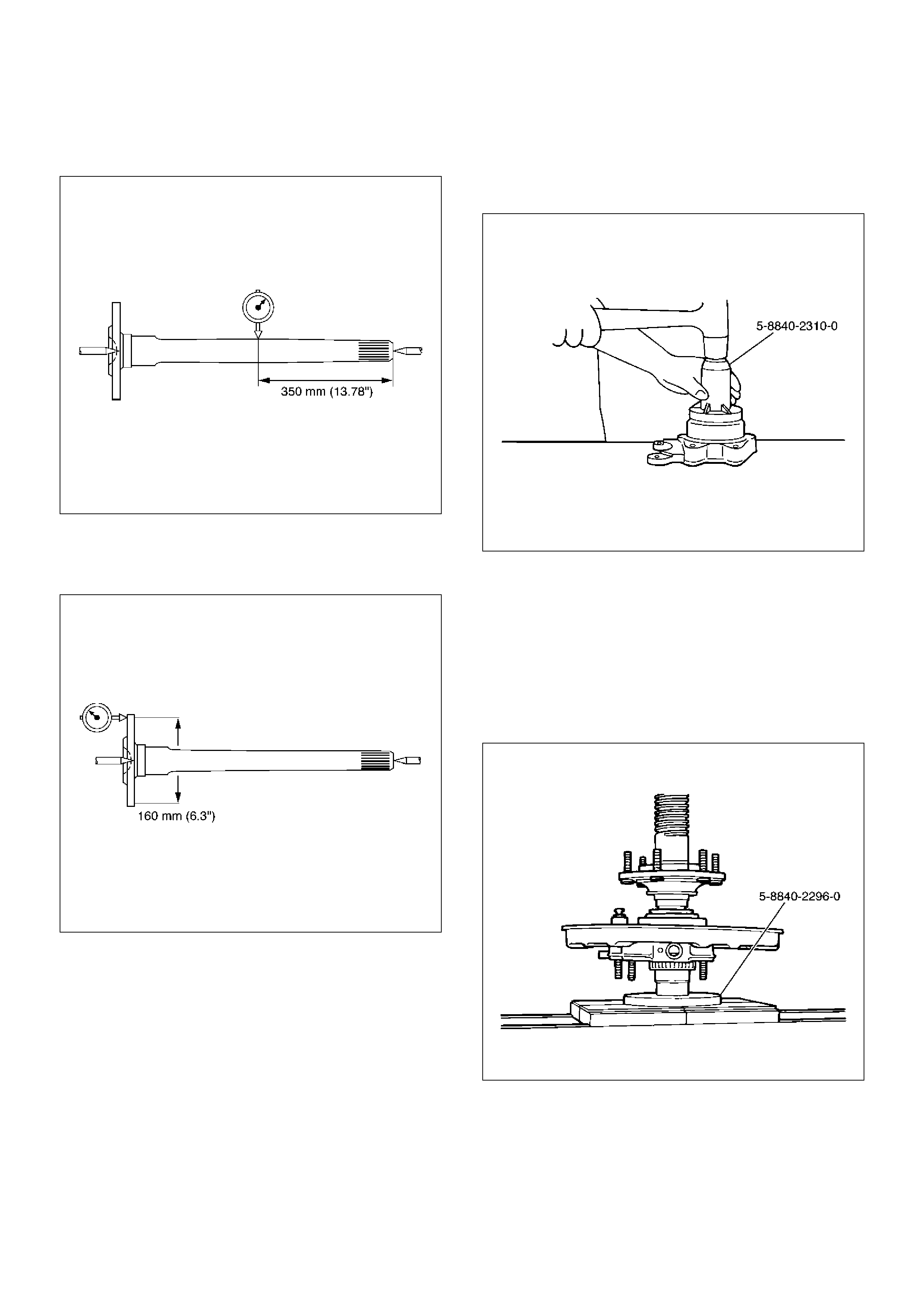

Inspection and Repair

Make necessary correction or parts replacement if wear,

corrosion or any other abnormal conditions are found

through inspection.

Visual Check:

Check the following parts for wear, damage, noise or

any other abnormal conditions:

1. Axle shaft

2. Bearing

When checking the axle shaft, pay special attention to

the splined portions and replace the shaft if distortion or

step wear is noticeable. Correct slight step wear with a

grinder.

420RS008

Axle Shaft Run–out

Limit: 1.0 mm (0.039 in)

420RW025

Axle Shaft Flange Run–out

Limit: 0.08 mm (0.003 in)

420RS010

Oil Seal Replacement

Remove the oil seal carefully not to damage the bearing

holder bore .

When installing, use oil seal installer 5–8840–2310–0.

420RW026

Installation

1. Install wheel pin.

2. Install back plate.

3. Install bearing holder.

4. Install bearing.

5. Install retainer by using a bearing installer 5–8840–

2296–0, press fit together with the bearing.

420RW027

6. Install snap ring.

7. Install axle shaft assembly.

NOTE: Be sure not to damage the oil seal.

8. Tighten the bearing holder mounting nut to the

specified torque.

Torque: 74N·m (7.5kg·m/54 Ib ft)

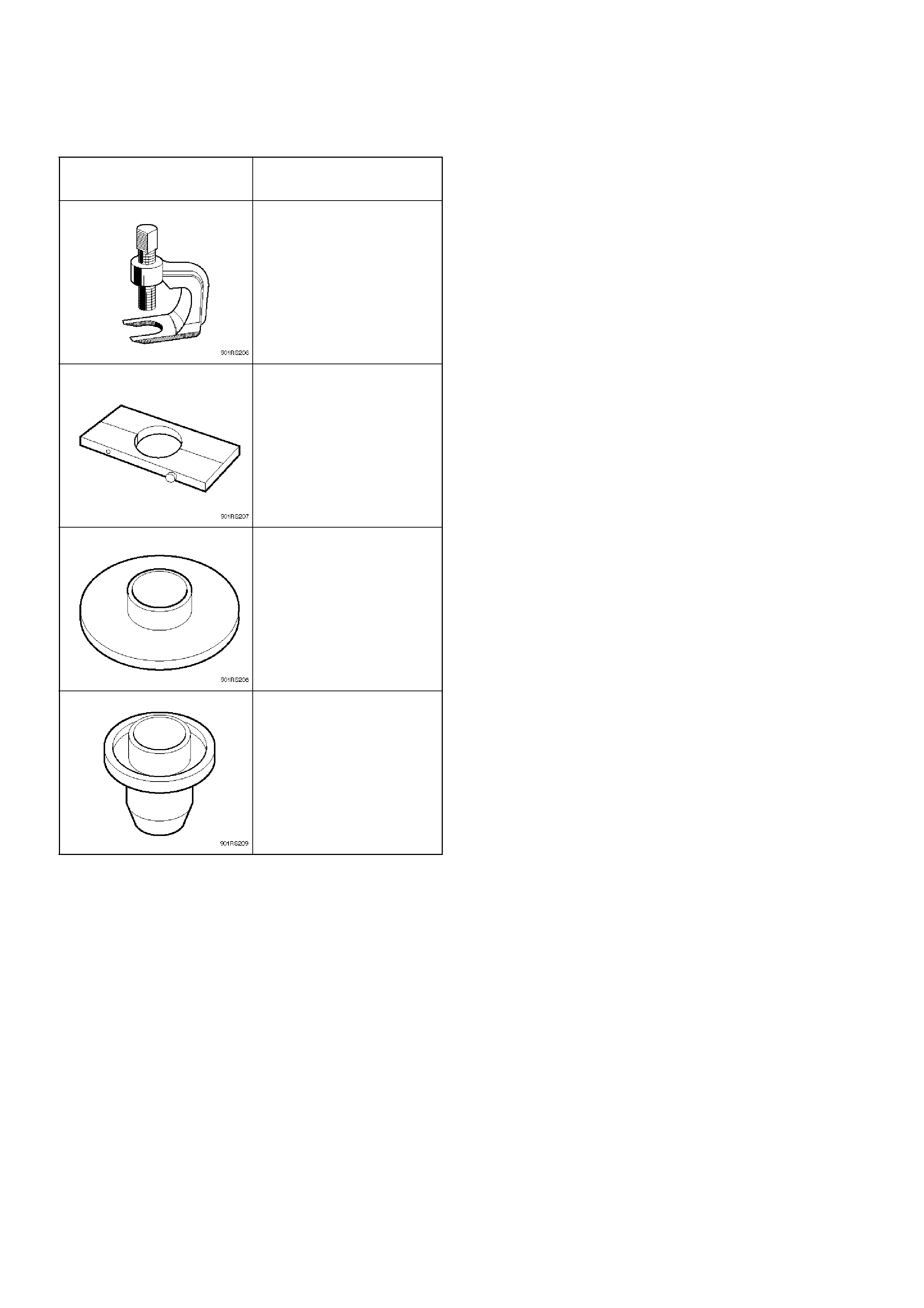

Special Tools

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–0079–0

(J–6627–A)

Wheel pin remover

5–8840–2295–0

(J–39211)

Remover; Axle shaft

bearing

5–8840–2296–0

(J–39212)

Installer; Axle shaft

bearing

5–8840–2310–0

(J–39379)

Installer; Outer axle seal

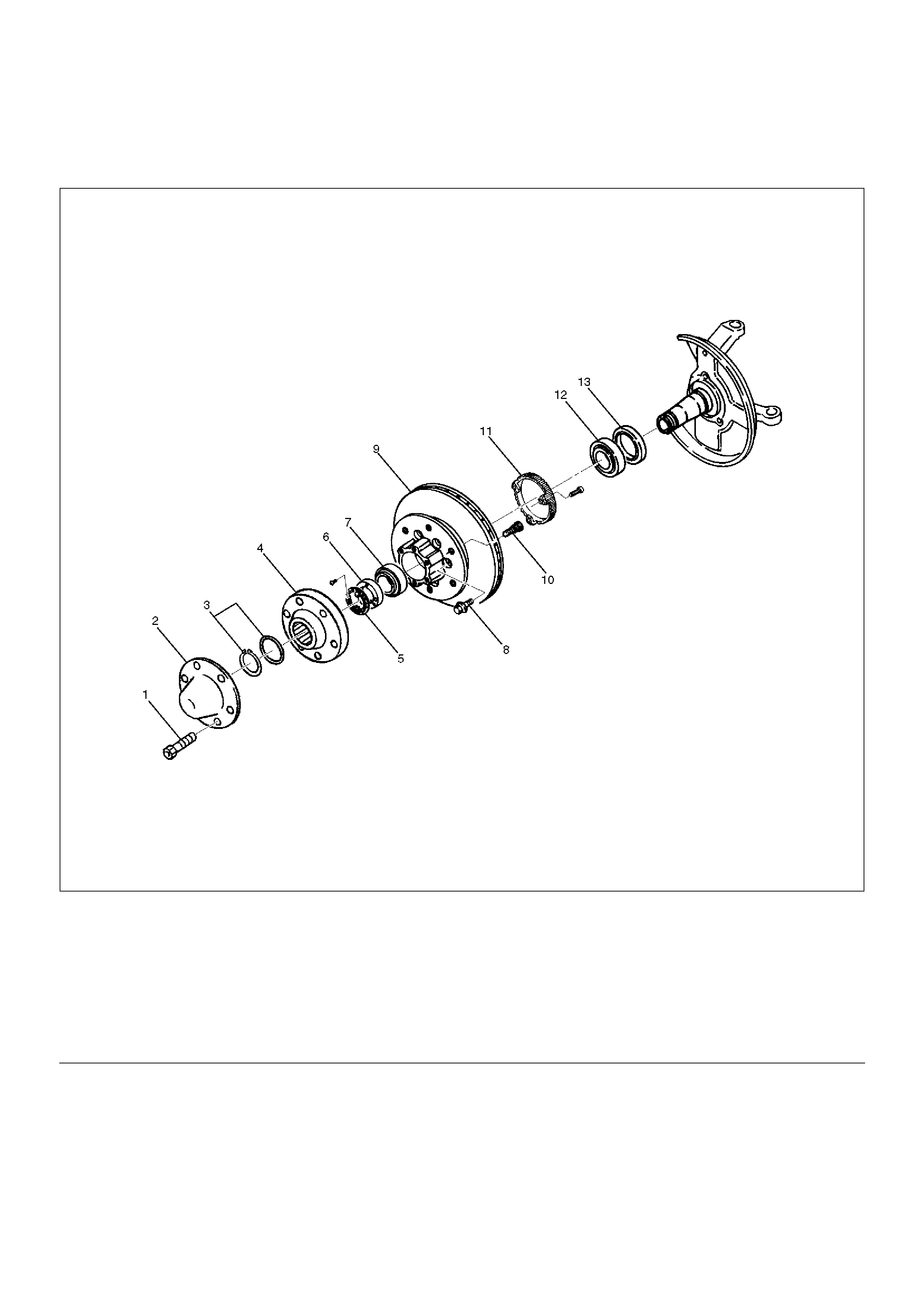

Front Hub and Disc (with Shift on the Fly)

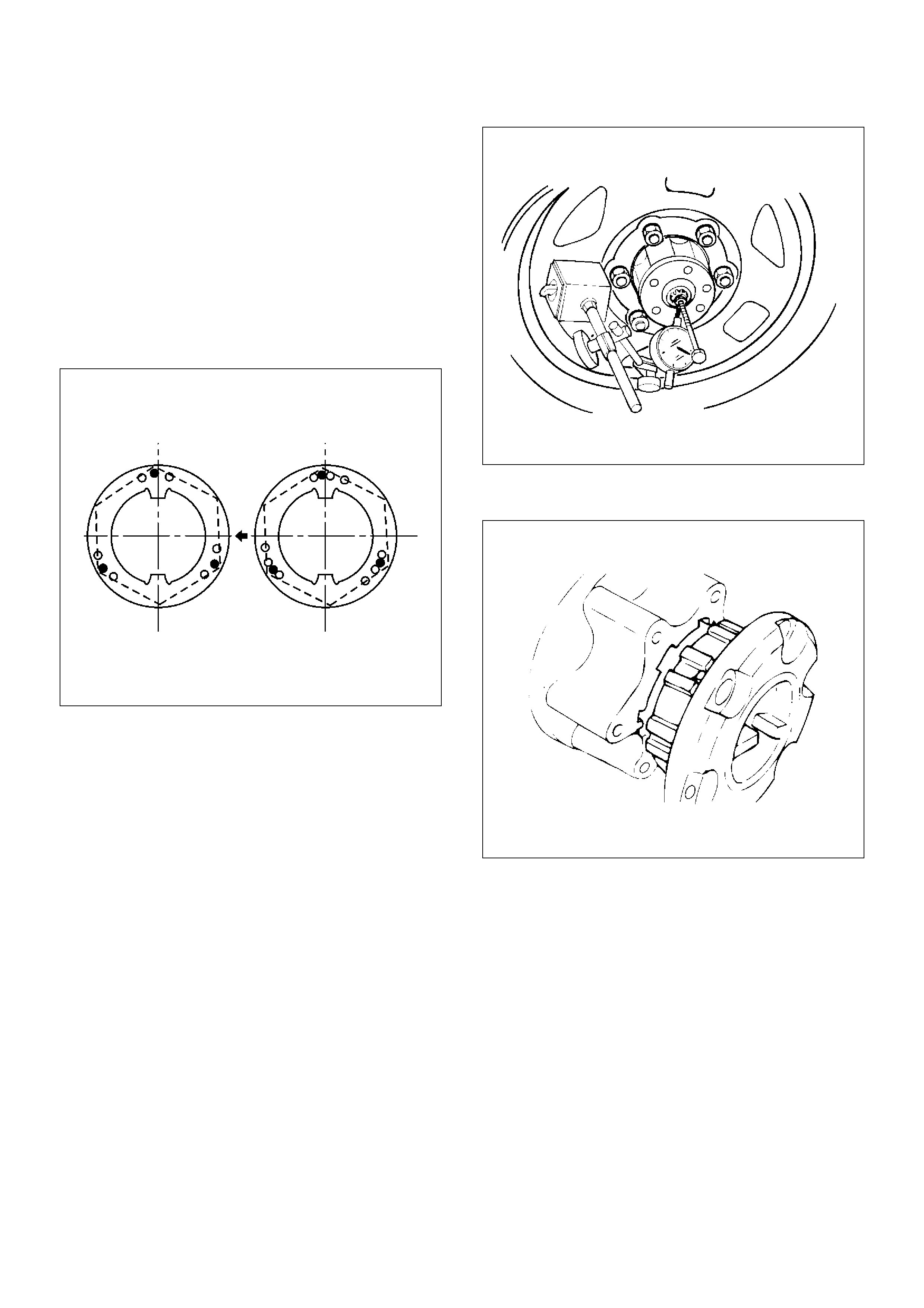

Disassembled View

411RW001

EndOFCallout

Disassembly

1.Before disassembly, select the 2WD position.

2.Jack up the front of vehicle and support frame with

jack stands.

3.Remove the disc brake caliper assembly and hang it

on the frame with wires. Refer to Front Disc Brake

Caliper Assembly in Brakes section.

4. Remove bolt.

5. Remove cap.

6. Remove snap ring and shim.

7. Remove hub flange.

Legend

(1) Bolt

(2) Cap

(3) Snap Ring and Shim

(4) Hub Flange

(5) Lock Washer and Lock Screw

(6) Hub Nut

(7) Outer Bearing

(8) Bolt

(9) Hub and Disc Assembly

(10) Wheel Pin

(11) ABS Sensor Ring (If equipped)

(12) Inner Bearing

(13) Oil Seal

8.Remove lock washer and lock screw.

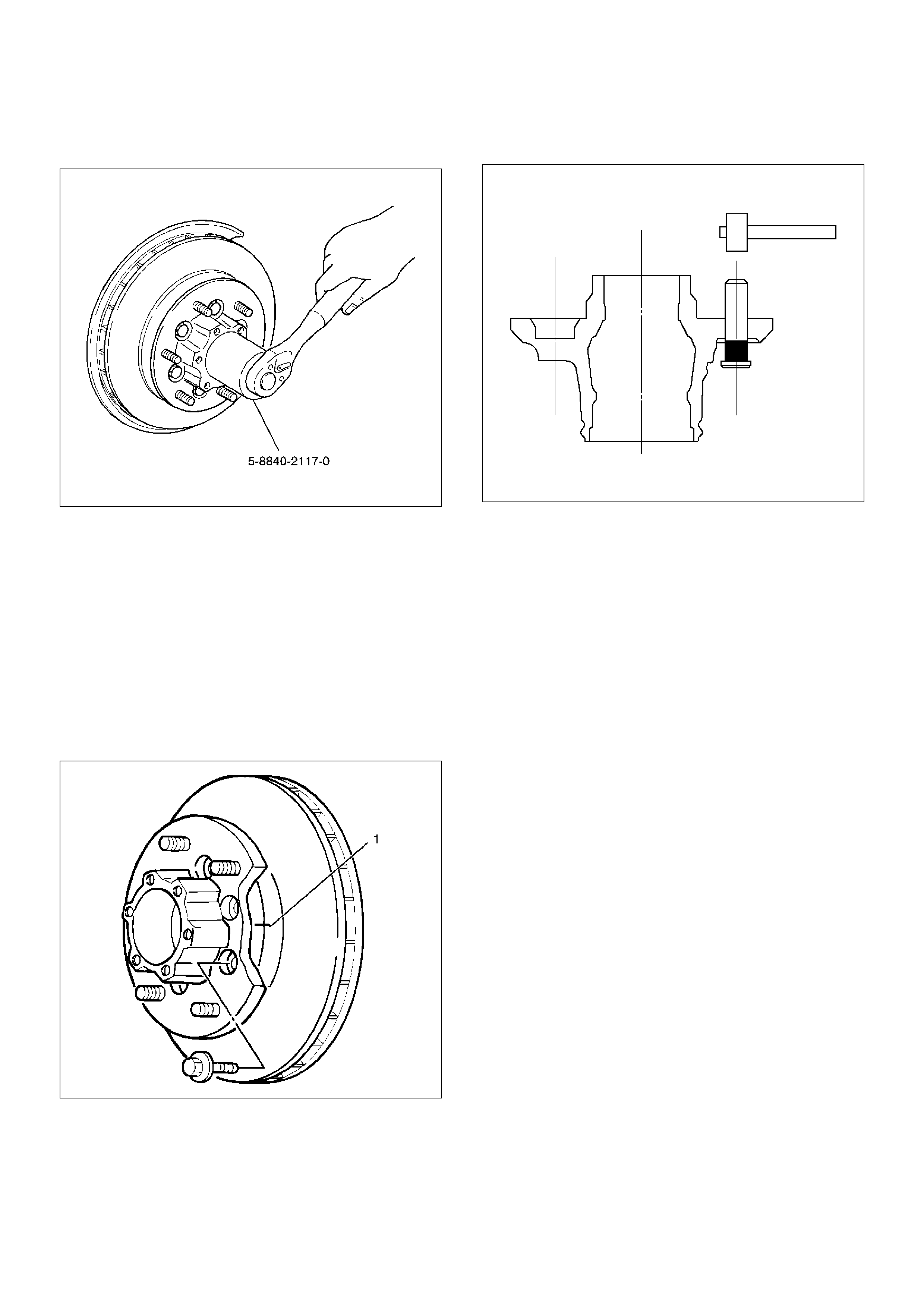

9.Use wrench 5–8840–2117–0, remove hub nut.

411RW005

10.Remove hub and disc assembly.

11.Remove ABS sensor ring (If equipped).

12.Remove outer bearing.

13.Remove oil seal.

14.Remove inner bearing.

15.Remove bolt , if necessary, replace the wheel pin in

the following manner.

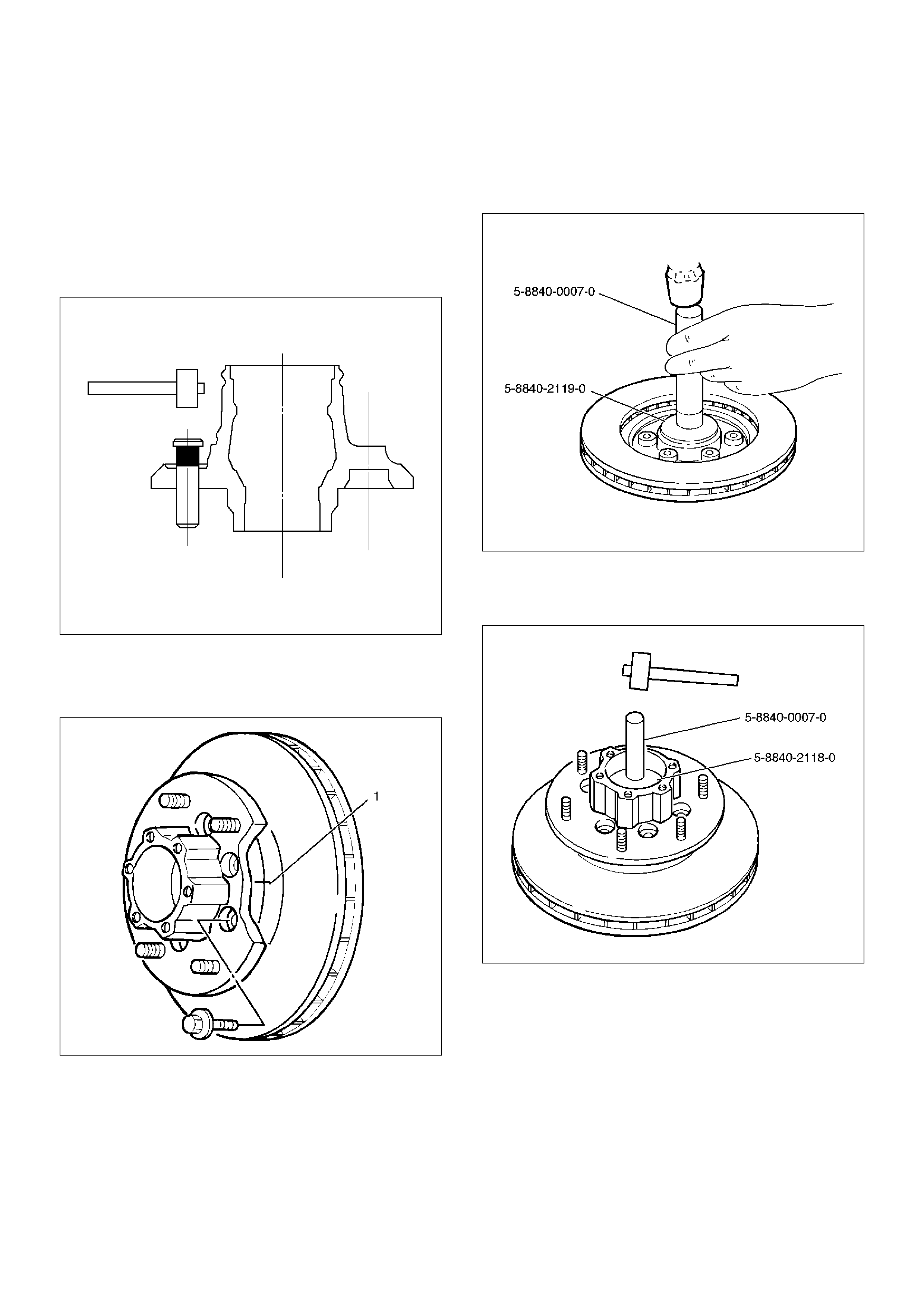

•Apply a scribe mark(1) to disc to hub.

•Clamp the hub and disc assembly in a vise, using

protective pads. Remove the 6 disc–to–hub

retaining bolts.

411RS003

•Place hub on a suitable work surface and remove

the studs by using a hammer.

411RS004

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

•Hub

•Hub bearing oil seal

•Knuckle spindle

•Disc

•Caliper

•Shift on the fly system parts (Cap, Hub flange, Shim,

Snap ring)

•ABS sensor ring (If equipped)

For inspection and servicing of disc caliper and related

parts, refer to Brakes section.

Reassembly

1. Install wheel pin.

• Place the hub on a wood workbench or a block of

wood approx. 6" by 6" to protect the wheel stud

ends and threads.

• Insert a wheel stud using a hammer.

Be sure the wheel stud is started squarely and

seats completely.

411RS005

2. Align scribe marks(1) and attach the hub to the disc,

then tighten the bolts to the specified torque.

Torque: 103N·m(10.5kg·m/76lbft)

411RS003

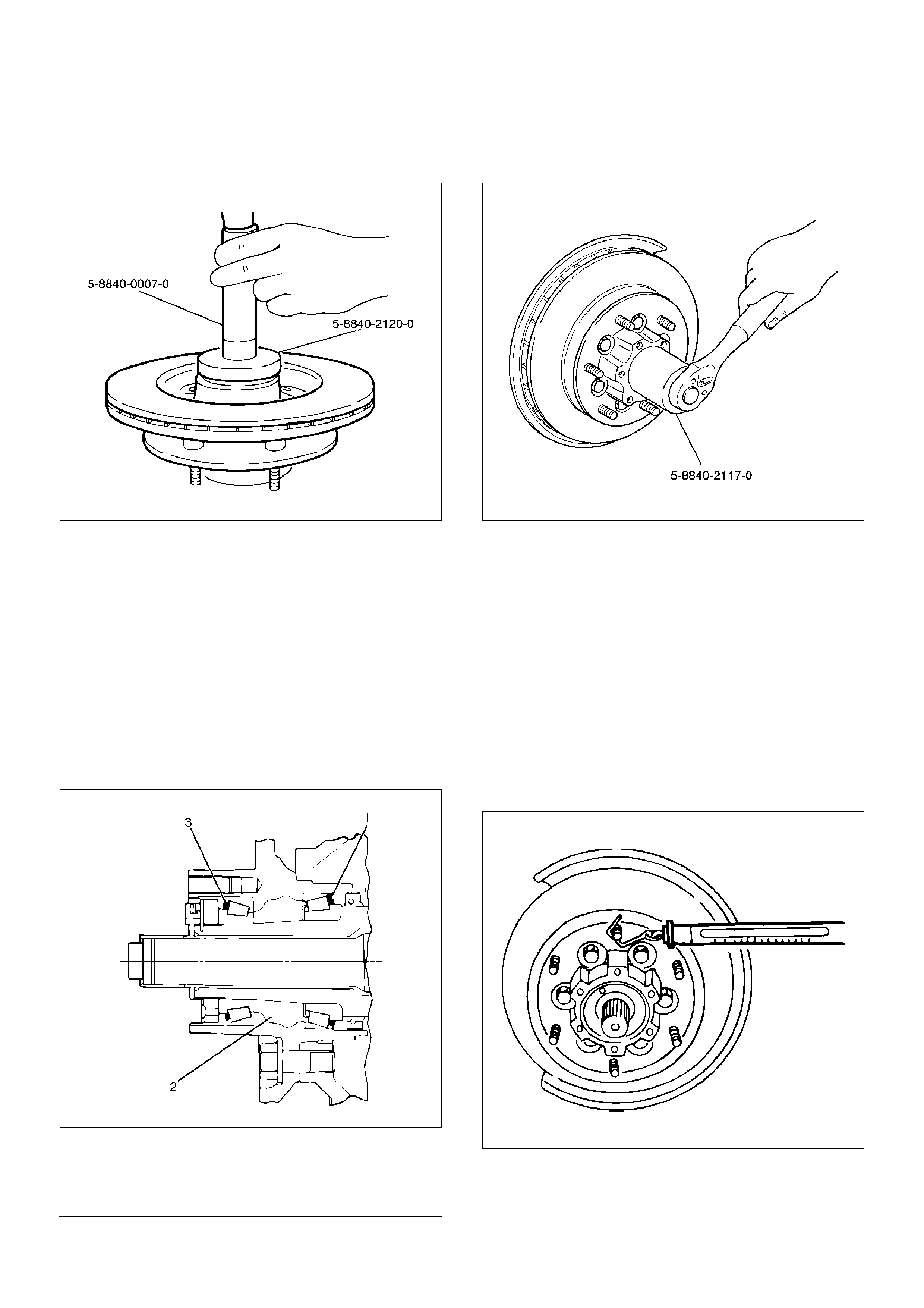

3. Use installer 5–8840–2119–0 and grip 5–8840–

0007–0, then install the inner bearing by driving it

into the hub.

411RW006

4. Use installer 5–8840–2118–0 and grip 5–8840–

0007–0, then install the outer bearing by driving it

into the hub.

411RW007

5. Apply grease (NLGI No.2 or equivalent) to the lip

portion, then install oil seal by using installer 5–

8840–2120–0 and grip 5–8840–0007–0.

411RW008

6. Install ABS sensor ring, then tighten the bolts to the

specified torque.

Torque: 18N·m (1.8kg·m/13lbft)

7. Install hub and disc assembly.

• Apply grease in the hub.

• Apply wheel bearing type grease NLGI No. 2 or

equivalent to the outer and inner bearing.

Grease Amount

Hub: 35 g (1.23oz)

Outer bearing: 10g (0.35oz)

Inner bearing: 15g (0.53oz)

411RS009

EndOFCallout

8. Install hub nut. Turn the place where there is a

chamfer in the tapped hole to the outer side, then

attach the nut by using front hub nut wrench 5–

8840–2117–0.

411RW005

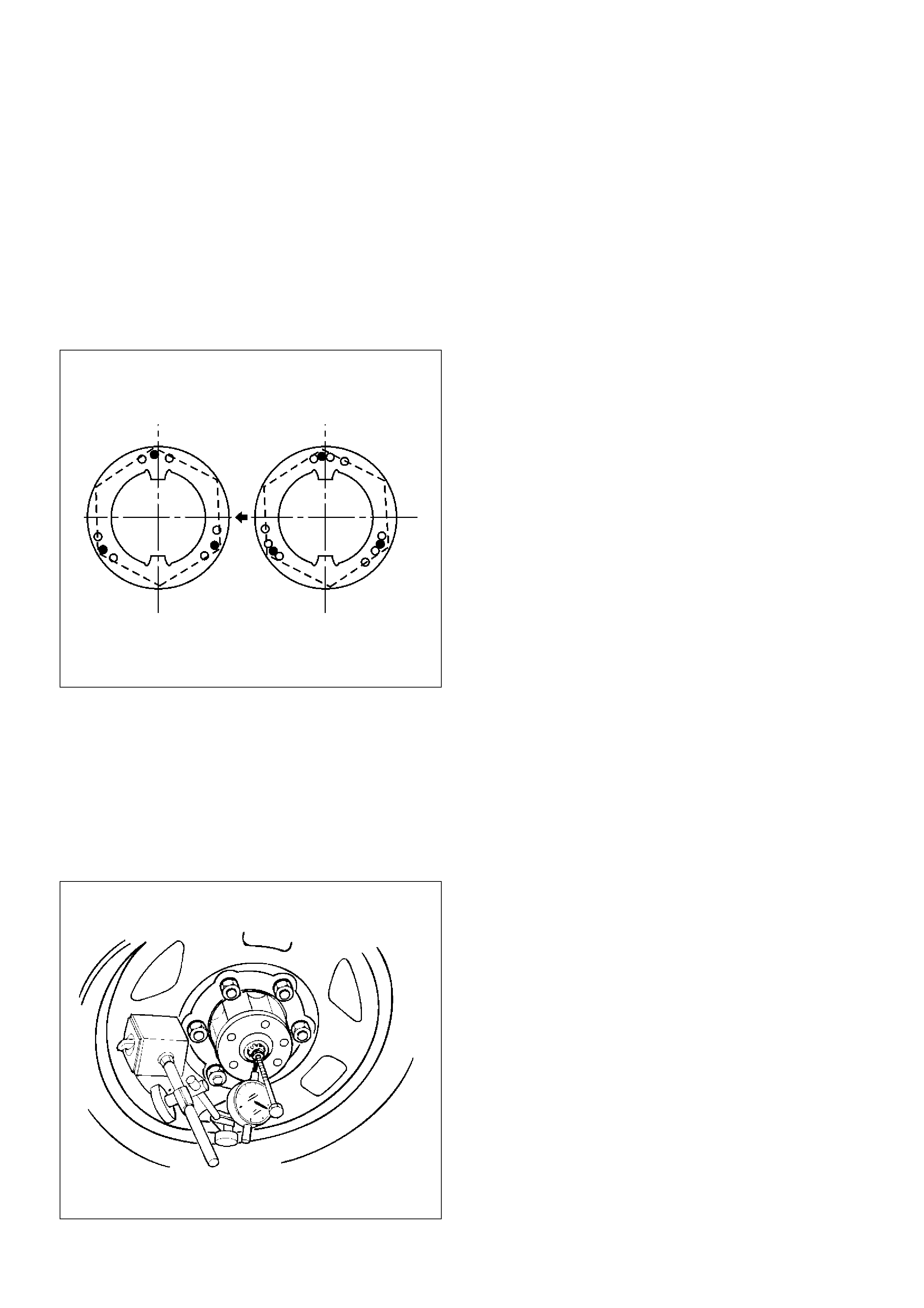

Preload Adjustment

1. Tighten the hub nut to 29 N·m (3.0kg·m/22lbft),

then fully loosen the nut.

2. Tighten the hub nut to the value given below,

using a spring scale on the wheel pin.

New bearing and New oil seal

Bearing Preload: 20 – 25N (2.0–2.5kg/4.4– 5.5lb)

Used bearing and New oil seal

Bearing Preload: 12 – 18N (1.2–1.8kg/2.6– 4.0lb)

If the measured bearing preload is outside the

specifications, adjust it by loosening or tightening

the bearing nut.

411RS011

Legend

(1) Inner Bearing

(2) Hub

(3) Outer Bearing

9. Install lock washer and lock screw in the following

manner.

• Turn the side with larger diameter of the tapered

bore to the vehicle outer side, then attach the

washer.

• If the bolt holes in the lock plate are not aligned

with the corresponding holes in the nut, reverse

the lock plate.

• If the bolt holes are still out of alignment, turn in

the nut just enough to obtain alignment.

• Screw is to be fastened tightly so its head may

come lower than the surface of the washer.

411RS012

10. Apply adhesive (LOCTITE 515 or equivalent) to

both joining flange faces then install hub flange.

11. Install snap ring and shim.

• Adjust the clearance between the free wheeling

hub body and the snap ring.

Clearance: 0mm–0.3mm (0in–0.012in)

Shims Available: 0.2mm, 0.3mm, 0.5mm, 1.0mm

(0.008in, 0.012in, 0.020in, 0.039in)

411RW002

12. Install hub cap.

13. Tighten the bolts to the specified torque.

Torque: 59N·m (6.0kg·m/43lbft)

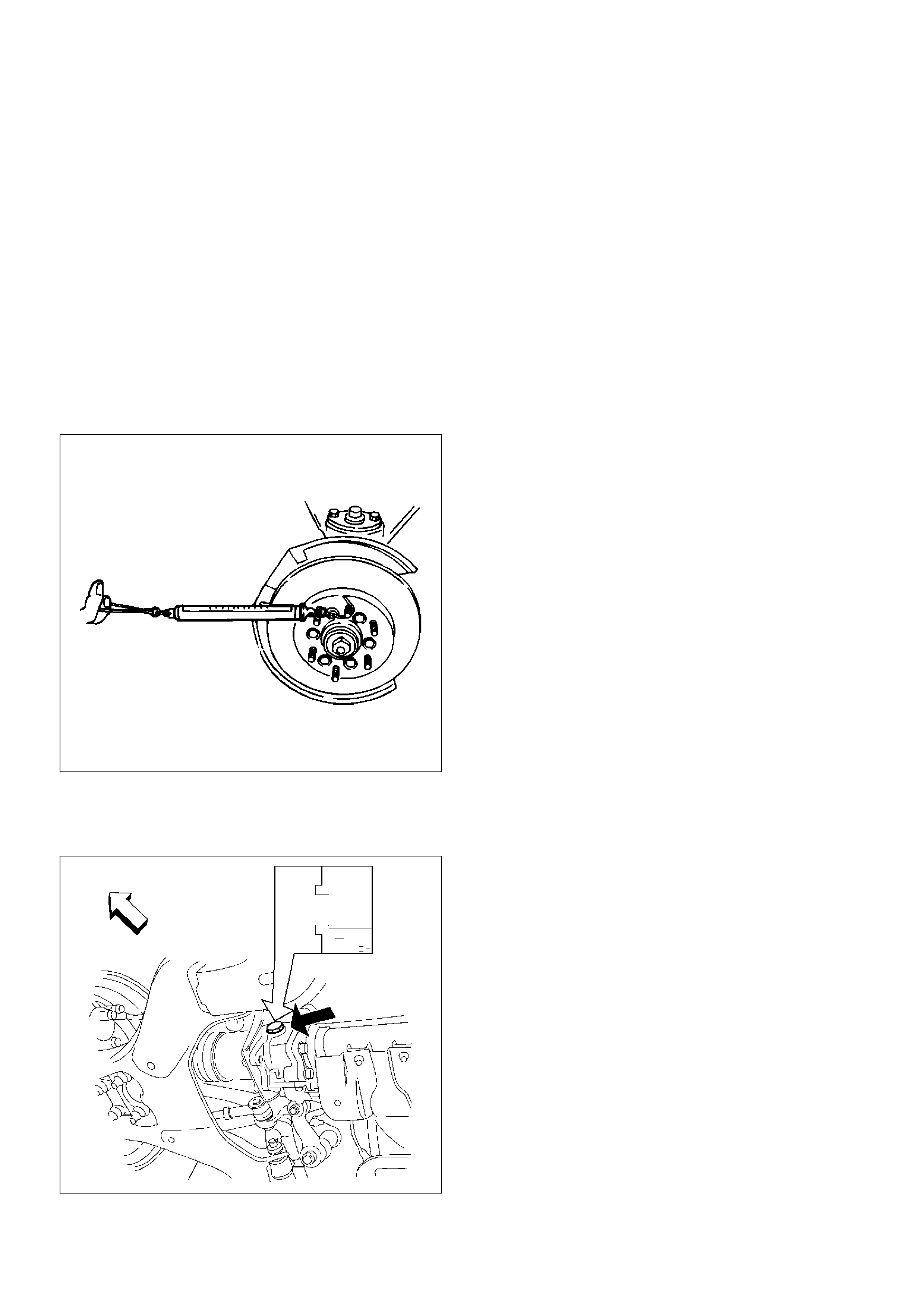

Front Hub and Disc with Manual Locking Hub

Disassembled View

411RW009

EndOFCallout

Disassembly

1.Before disassembly, jack up the front of vehicle and

support frame with jack stands.

2.Remove the disc brake caliper assembly and hang it

on the frame with wires. Refer to Front Disc Brake

Caliper Assembly in Brakes section.

Legend

(1) Bolt

(2) Cover Assembly

(3) Gasket

(4) Knob

(5) X–ring

(6) Detent Ball and Spring

(7) Snap Ring

(8) Clutch Assembly

(9) Compression Spring

(10) Follower

(11) Retaining Spring

(12) Snap Ring and Shim

(13) Body Assembly

(14) Inner Assembly

(15) Spacer

(16) Ring

(17) Snap Ring

(18) Snap Ring

(19) Lock Washer and Lock Screw

(20) Hub Nut

(21) Hub and Disc Assembly

(22) Outer Bearing Outer Race

(23) ABS Sensor Ring (if so equipped)

(24) Inner Bearing Outer Race

(25) Oil Seal

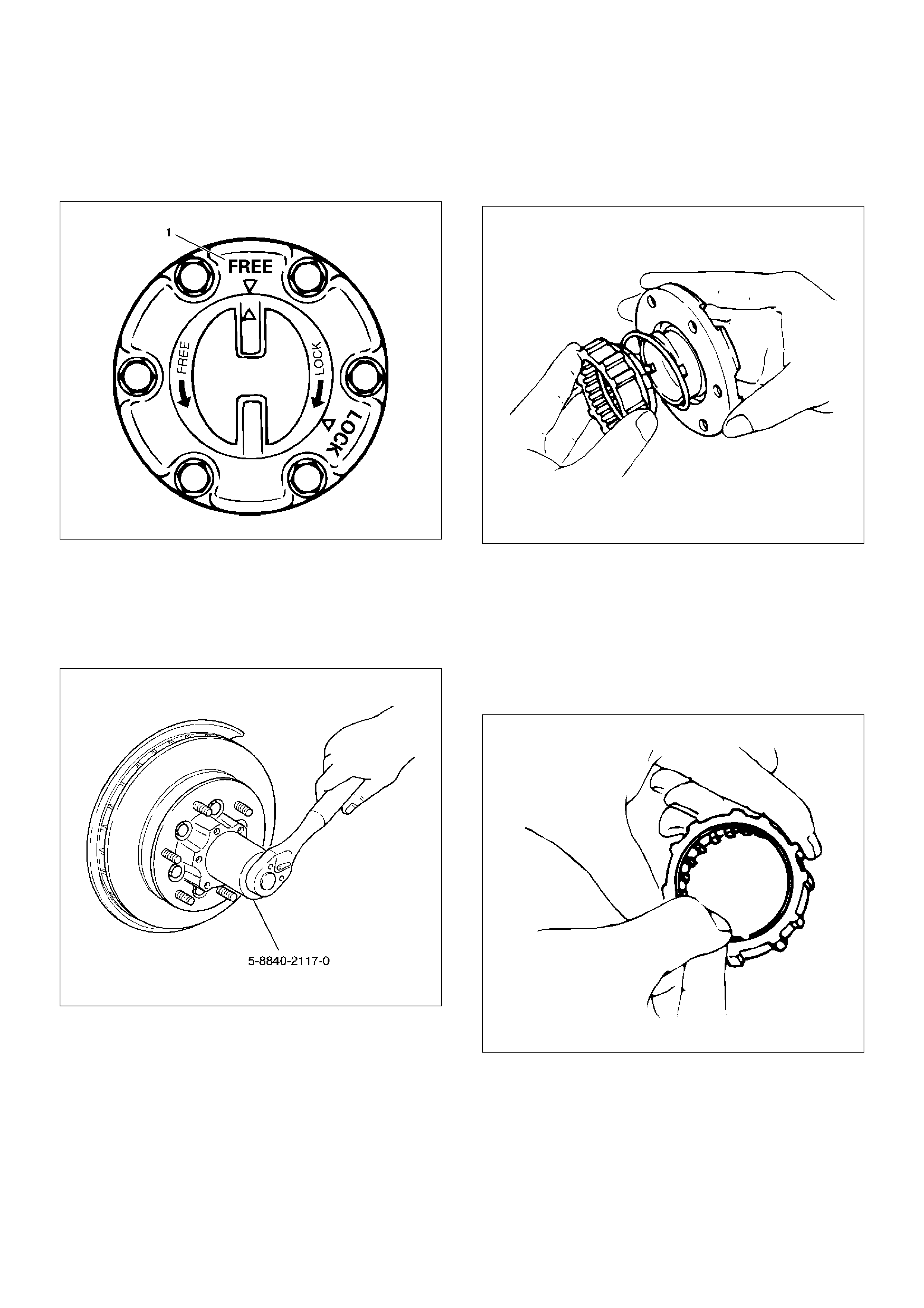

3. Remove bolt.

Before removal, shift transfer lever into “2H”

position, set free wheeling hub knob into “FREE”

position (1), and run the vehicle about 50m (160 ft).

411RW010

4. Remove cover assembly.

5. Remove snap ring and shim.

6. Remove body assembly.

7. Remove lock washer and lock screw.

8. Remove hub nut by using wrench 5–8840–2117–0.

411RW005

9. Remove hub and disc assembly.

10. Remove ABS sensor ring (If equipped).

11. Remove outer bearing outer race.

12. Remove oil seal.

13. Remove inner bearing outer race.

14. While pushing follower knob against cover, turn

clutch assembly clockwise and then remove clutch

assembly from knob.

411RW011

15. Remove gasket.

16. Remove snap ring.

17. Remove knob.

18. Remove compression spring.

19. Remove follower.

20. Remove retaining spring from clutch assembly by

turning it counterclockwise.

411RW012

21. Remove dedent ball and spring.

22. Remove X–ring.

23. Remove snap ring.

24. Remove inner assembly.

25. Remove snap ring.

26. Remove ring.

27. Remove spacer.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition are

found through inspection.

Check the following parts.

•Hub

•Hub bearing, oil seal

•Knuckle spindle

•Disc

•Caliper

•Free wheeling hub parts (Clutch, knob, follower,

inner, ring and spring)

•ABS sensor ring (if so equipped)

For inspection and servicing of disc caliper, and relative

parts, refer to Brakes section.

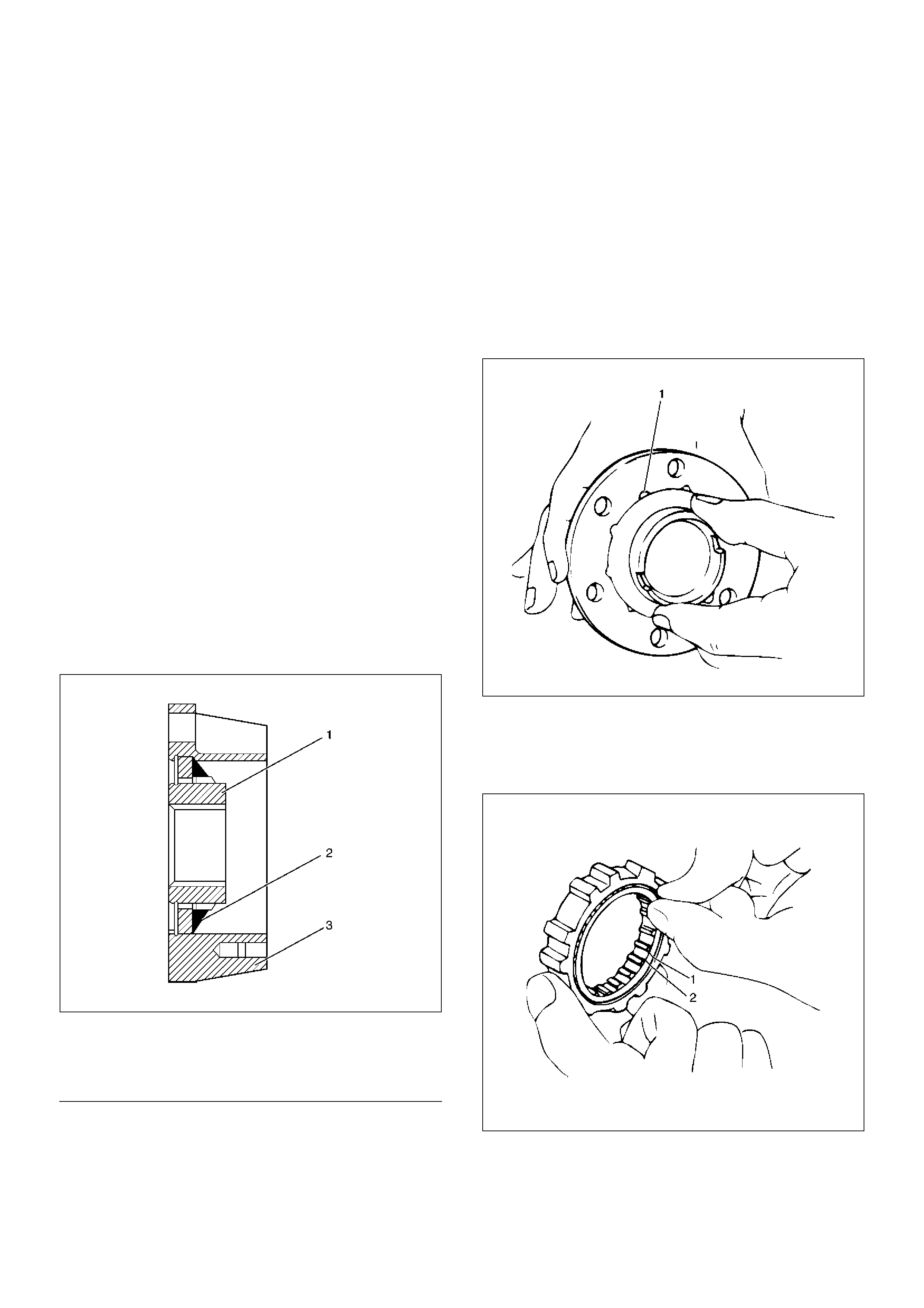

Reassembly

1. Install spacer.

Apply about 1 g wheel bearing grease to both face

of spacer.

2. Install ring.

Apply about 3 g wheel bearing grease to inside face

of ring.

3. Install snap ring

Assembly with grease surplus being left unwiped up

as illustrated.

411RW013

EndOFCallout

4. Install inner assembly.

Apply grease to splined portion of body.

5. Install snap ring.

6. Install X–ring.

Apply wheel bearing grease to hub lock ring and fit it

in knob paying attention to mounting direction.

NOTE: After fitting, make sure that the hub lock ring is

not twisted.

7. Apply wheel bearing grease to ball and spring and

fit them in knob.

8. Install knob.

1. Apply grease to outer circumference of knob

and inner circumference of cover.

2. Align detent ball (1) to a groove cut in the cover.

411RW014

9. Install snap ring.

Turn the smoother face to knob side.

10. Align the end of retaining spring (1) with clutch

spring groove (2) and fit in the spring.

411RW015

Legend

(1) Inner Assembly

(2) Apply Grease

(3) Body

11. Install follower to clutch so that follower nails (large)

(1) will come closer to the bent portion of retaining

spring by aligning follower stopper nail with outer

teeth of clutch. Then, fit in with follower's nails

(small) (2) caught in spring.

411RW016

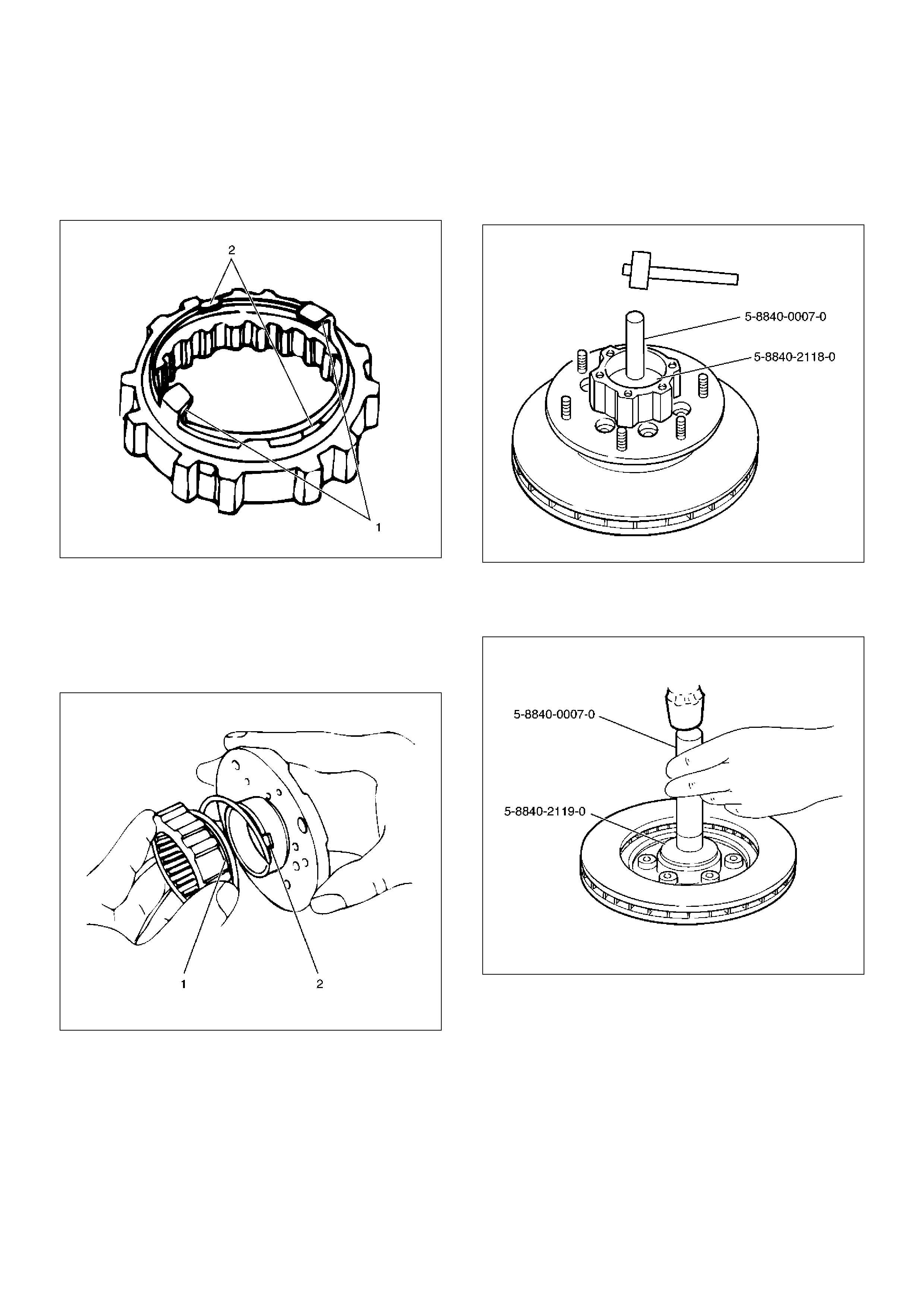

12. Install compression ring.

Turn the smaller diameter side toward follower and

fit spring in clutch.

13. Align follower nail (1) to handle groove (2). and then

assemble clutch with knob by pushing and turning

clutch counterclockwise to knob.

411RW017

14. Install gasket.

Make sure that there is no breakage, etc.

15. Install outer bearing outer race by driving it into the

hub, by using installer 5–8522–2118–0 and grip 5–

8840–0007–0.

411RW007

16. Install inner bearing outer race by driving it into the

hub, by using installer 5–8840–2119–0 and grip 5–

8840–0007–0.

411RW006

17. Install oil seal by using installer 5–8840–2120–0

and grip 5–8840–0007–0.

Apply grease (NLGI No.2 or equivalent) to the lip

portion.

411RW008

18. Install ABS sensor ring (if so equipped).

Tighten the bolts to the specified torque.

Torque:18N·m (1.8 kg·m/13 lbft)

19. Install hub and disc assembly.

1. Apply grease in the hub.

2. Apply wheel bearing type grease NLGI No.2 or

equivalent to the outer and inner bearing.

Grease Amount

Hub: 35 g (1.23oz)

Outer bearing: 10g (0.35oz)

Inner bearing: 15g (0.53oz)

20. Install hub nut.

1. Turn the place where there is a chamfer in the

tapped hole to the outer side, and attach the nut

by using wrench 5–8840–2117–0.

411RW005

Preload Adjustment

Tighten the hub nut to 29N·m (3.0kg·m/22lb·ft), then

fully loosen the nut.

Tighten the hub nut to the value given below, using a

spring scale on the wheel pin.

Bearing Preload

New bearing and New oil seal:

20-25N (2-2.5kg/4.4-5.5lb)

Used bearing and New oil seal:

12-18N (1.2-1.8kg/2.6-4.0lb)

If the measured bearing preload is outside the

specifications, adjust it by loosening or tightening the

bearing nut.

411RS011

21. Install lock washer and lock screw in the following

manner.

• Turn the side with larger diameter of the tapered

bore to the vehicle outer side, and attach the

washer.

• If the bolt holes in the lock plate are not aligned

with the corresponding holes in the nut, reverse

the lock plate.

• If the bolt holes are still out of alignment, trun in

the nut just enough to obtain alignment.

• Screw is to be fastened tightly so its head may

come lower than the surface of the washer.

411RS012

22. Install body assembly.

• Apply adhesive (LOCTITE 515 or equivalent) to

both joining faces.

• Tighten the bolts to the specified torque.

Torque:59N·m (6.0 kg·m/43 lbft)

23. Install snap ring and shim.

Adjust the clearance between the free wheeling hub

body and the snap ring.

Clearance:

0-0.3mm (0-0.012in)

Shims Available:

0.2mm, 0.3mm, 0.5mm, 1.0mm, (0.008in, 0.012in,

0.020in, 0.039in)

411RW002

24. Install cover assembly.

Align stopper nails (1) to grooves of body (2).

411RW019

25. Tighten the cover bolts to the specified torque.

Torque:12N·m (1.2 kg·m/104lbin)

Main Data and Specifications

Torque Specifications

E04RW022

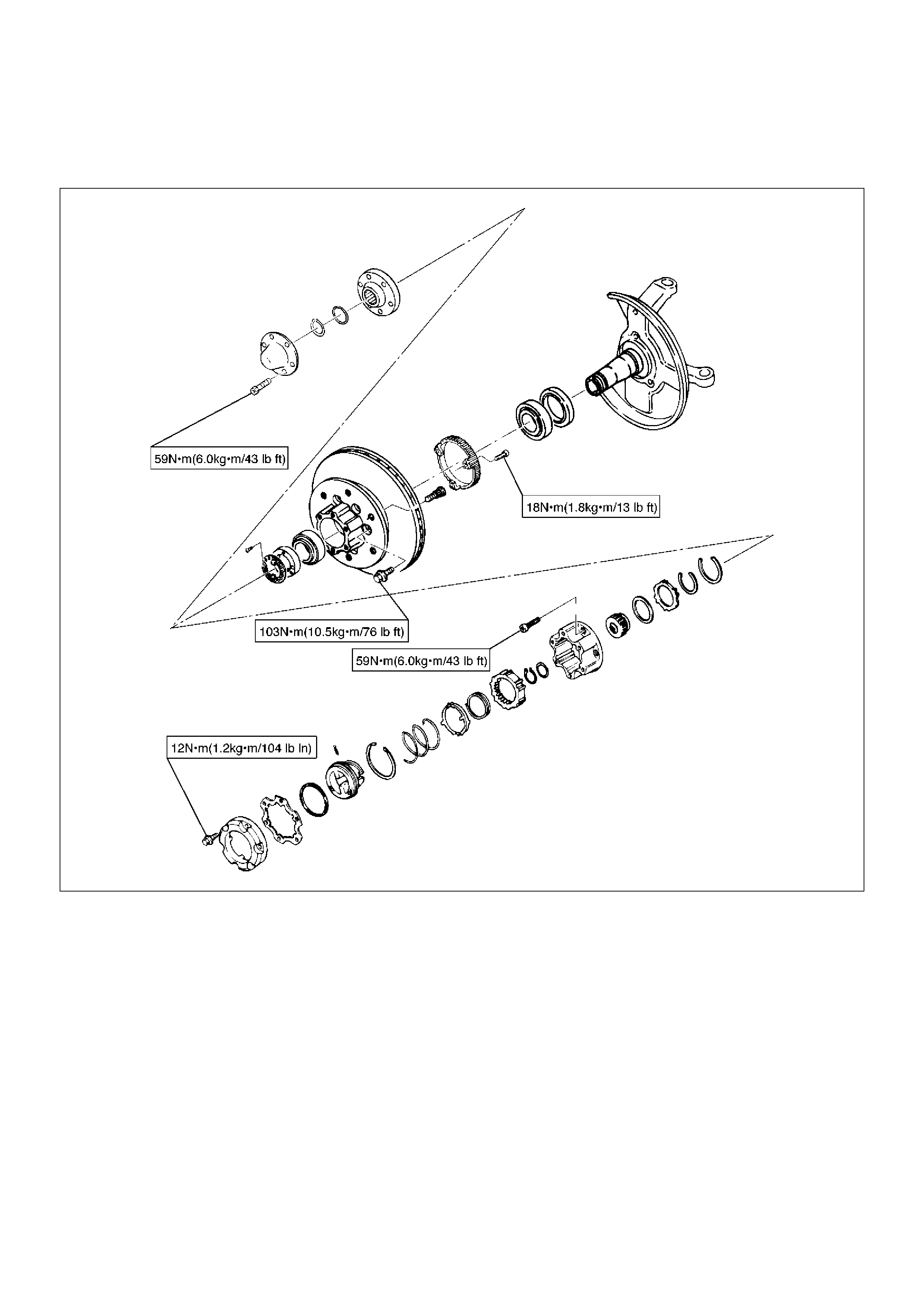

Special Tools

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–2117–0

(J–36827)

Wrench; Hub nut

5–8840–2119–0

(J–36829)

Installer; Inner bearing

5–8840–2118–0

(J–36828)

Installer; Outer bearing

5–8840–2120–0

(J–36830)

Installer; Oil seal

5–8840–0007–0

(J–8092)

Grip

Front Drive Shaft Joint

Front Drive Shaft Joints Replacement

•Refer to Front Drive Axle Assembly Replacement in

this section, and refer to Front Hub and Disc in

Suspension section.

Front Hub Bearing Preload Check

Check the hub bearing preload at the wheel pin.

New bearing and New oil seal

Preload: 20 – 25N (2.0 – 2.5 kg/4.4–5.5 lb)

New bearing and New oil seal

Preload: 12 –18N (1.2 – 1.8kg/2.6–4.0 lb)

411RS001

Inspection Of Shift On The Fly System Gear

Oil

412RT002

1. Open filler plug and make sure that the oil is up to

the plug port.

If the level oil is low, replenish with gear oil GL–5

grade.

2. Tighten the filler plug to specified torque.

Torque:7.8N·m (7.9kg·cm/58lbin)

Front Axle Drive Shaft

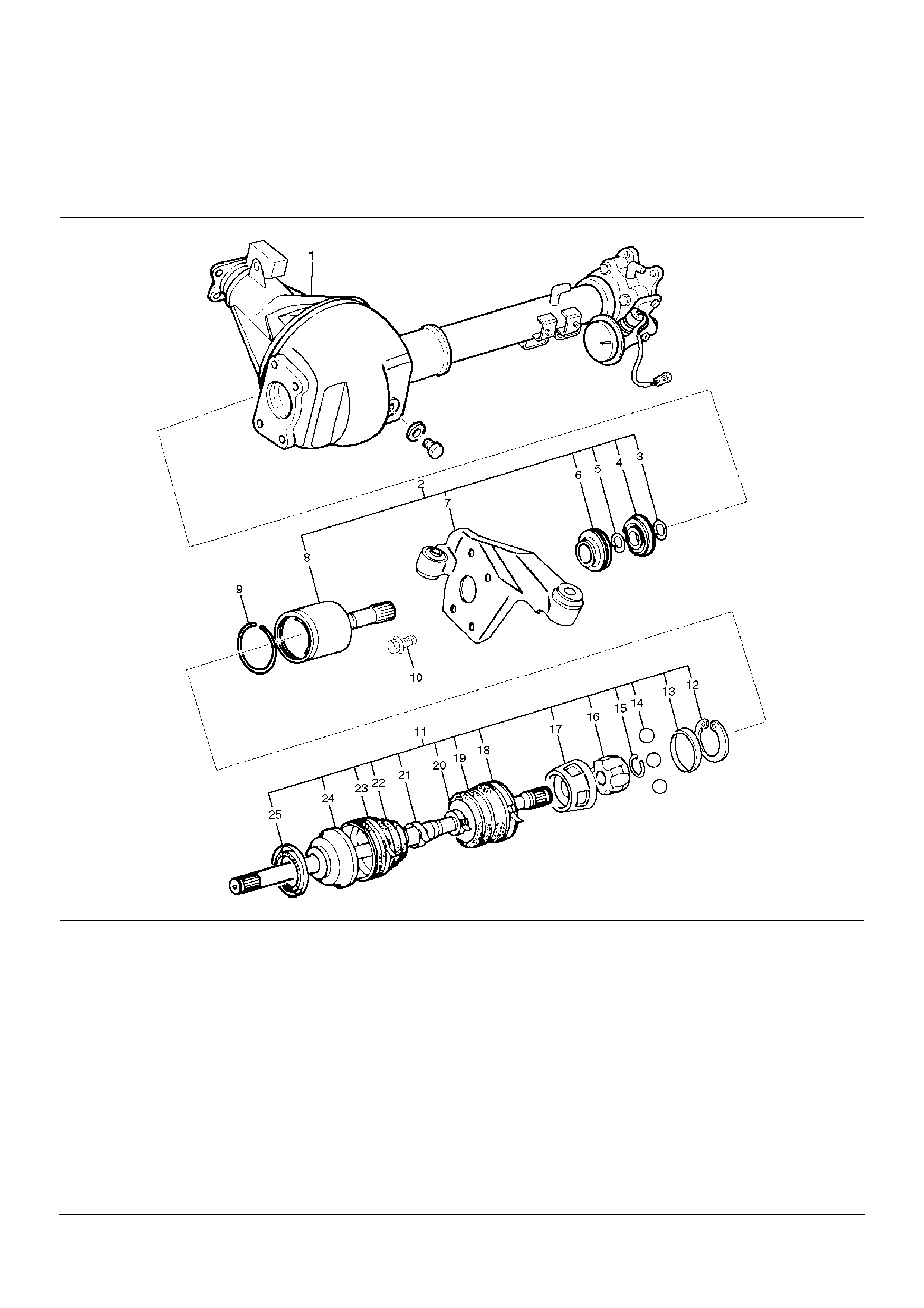

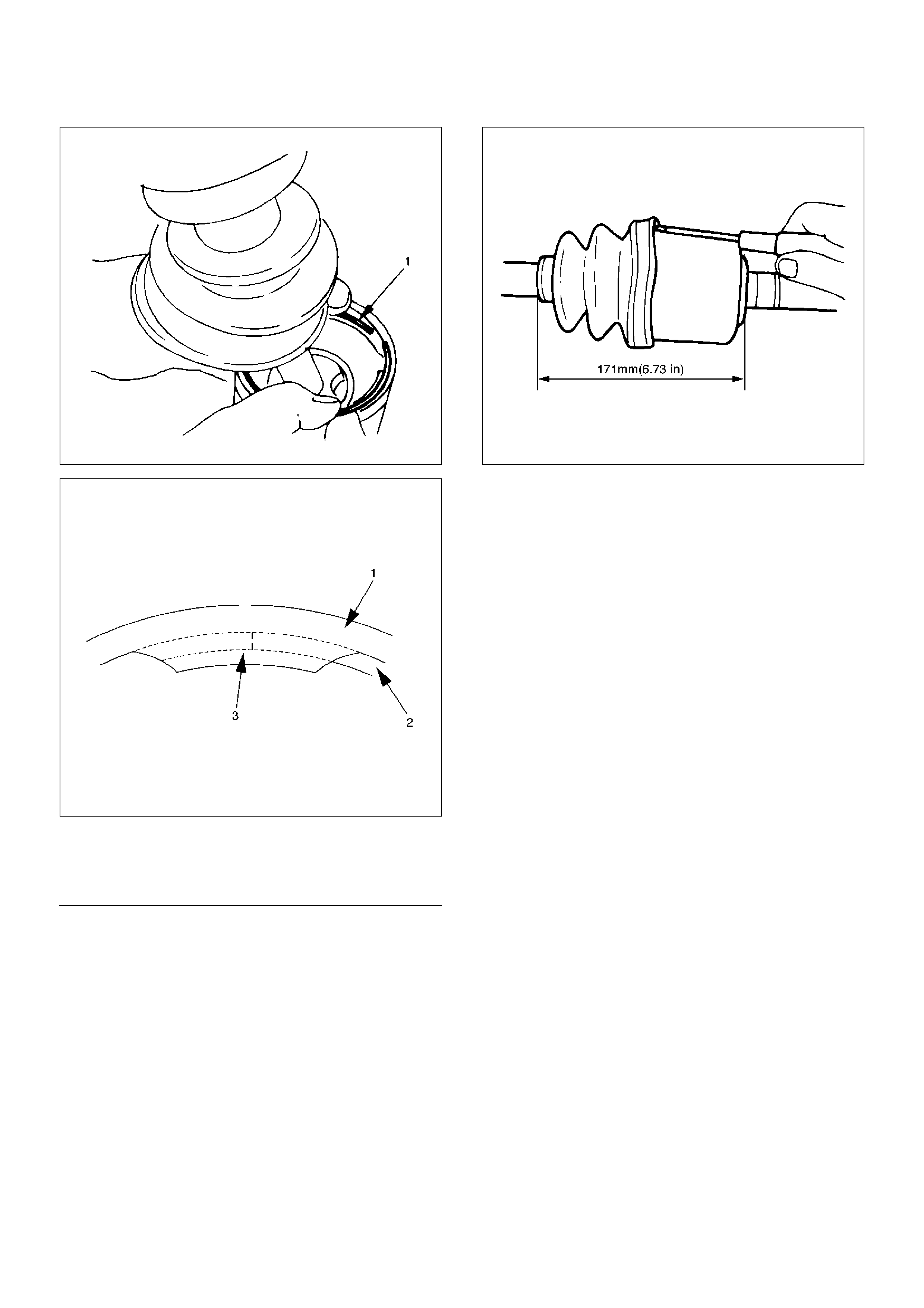

Front Axle Drive Shaft and Associated Parts

This illustration is based on the model equipped with shift on the fly system.

412RW003

EndOFCallout

Leg

end

(1) Axle Case and Differential

(2) DOJ Case Assembly

(3) Snap Ring

(4) Bearing

(5) Snap Ring

(6) Oil Seal

(7) Bracket

(8) DOJ Case

(9) Circlip

(10) Bolt

(11) Drive Shaft Joint Assembly

(12) Snap Ring

(13) Spacer

(14) Ball

(15) Snap Ring

(16) Ball Retainer

(17) Ball Guide

(18) Band

(19) Bellows

(20) Band

(21) Band

(22) Bellows

(23) Band

(24) BJ Shaft

(25) Dust Seal

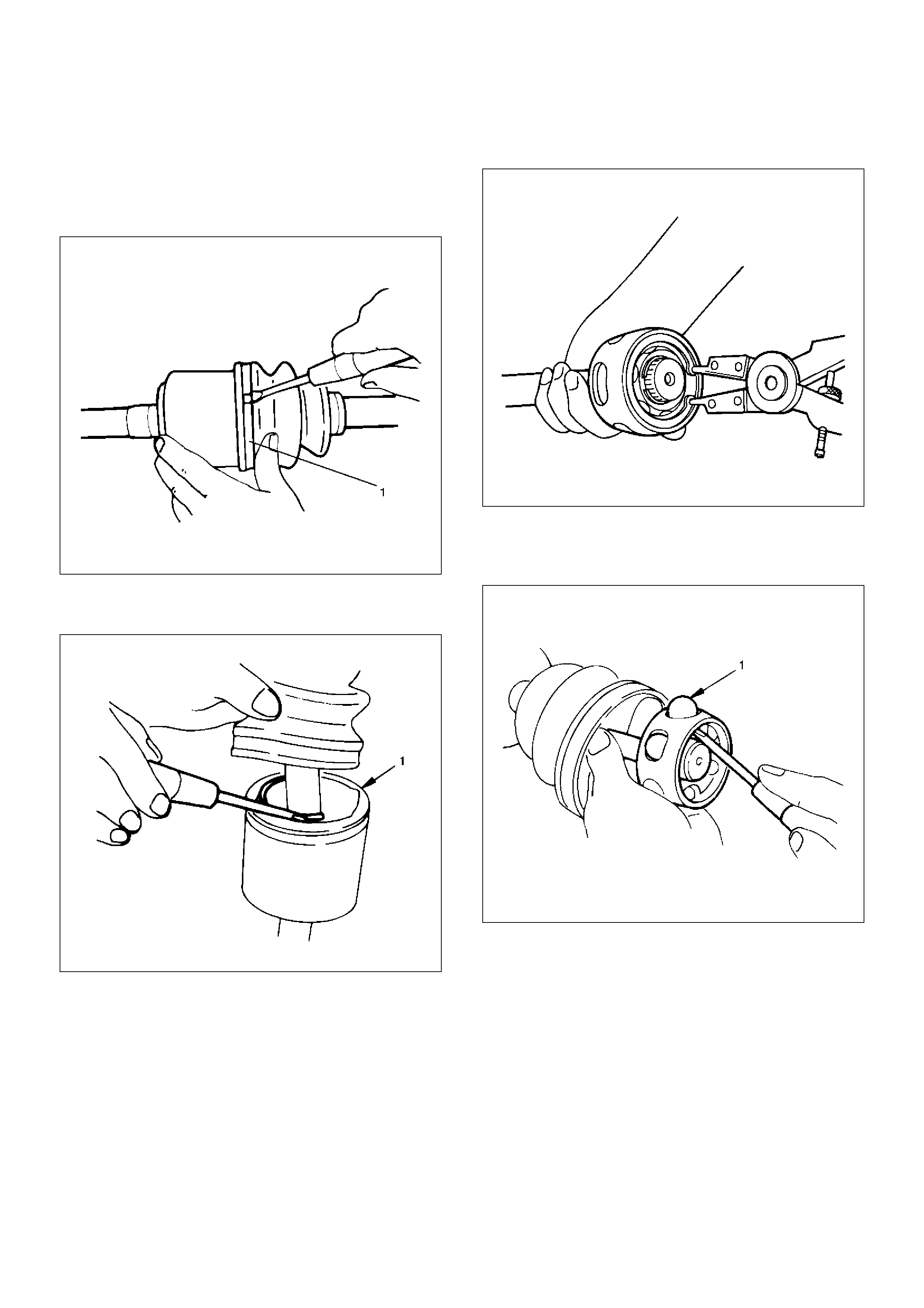

Disassembly

NOTE: For the left side, follow the same steps as right

side.

1. Raise the hooked end of the band (1) with a

screwdriver or equivalent.

412RS009

2. Remove band.

3. Pry off circlip (1) with a screwdriver or equivalent.

412RS010

4. Remove drive shaft joint assembly.

5. Using snap ring pliers, remove the snap ring.

412RS011

6. Remove spacer.

7. Remove the six balls (1) with a screwdriver or

equivalent.

412RS012

8. Using snap ring pliers, remove the snap ring (1)

fastening the ball retainer to the center shaft.

412RS013

9. Remove ball retainer, ball guide and bellows.

10. Raise the hooked end of the band (1) with a

screwdriver or equivalent.

412RS014

11. Remove band.

12. Remove bellows.

13. Remove dust seal.

14. Remove BJ shaft assembly.

15. Remove the mounting bracket fixing bolts, and then

remove DOJ case assembly from the axle ca se.

16. Remove snap ring and bearing.

17. Remove snap ring and oil seal.

18. Remove bracket.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

1. Drive shaft joint assembly

2. DOJ case, ball, ball guide, ball retainer

3. Bellows

4. Bearing

5. Dust seal, oil seal

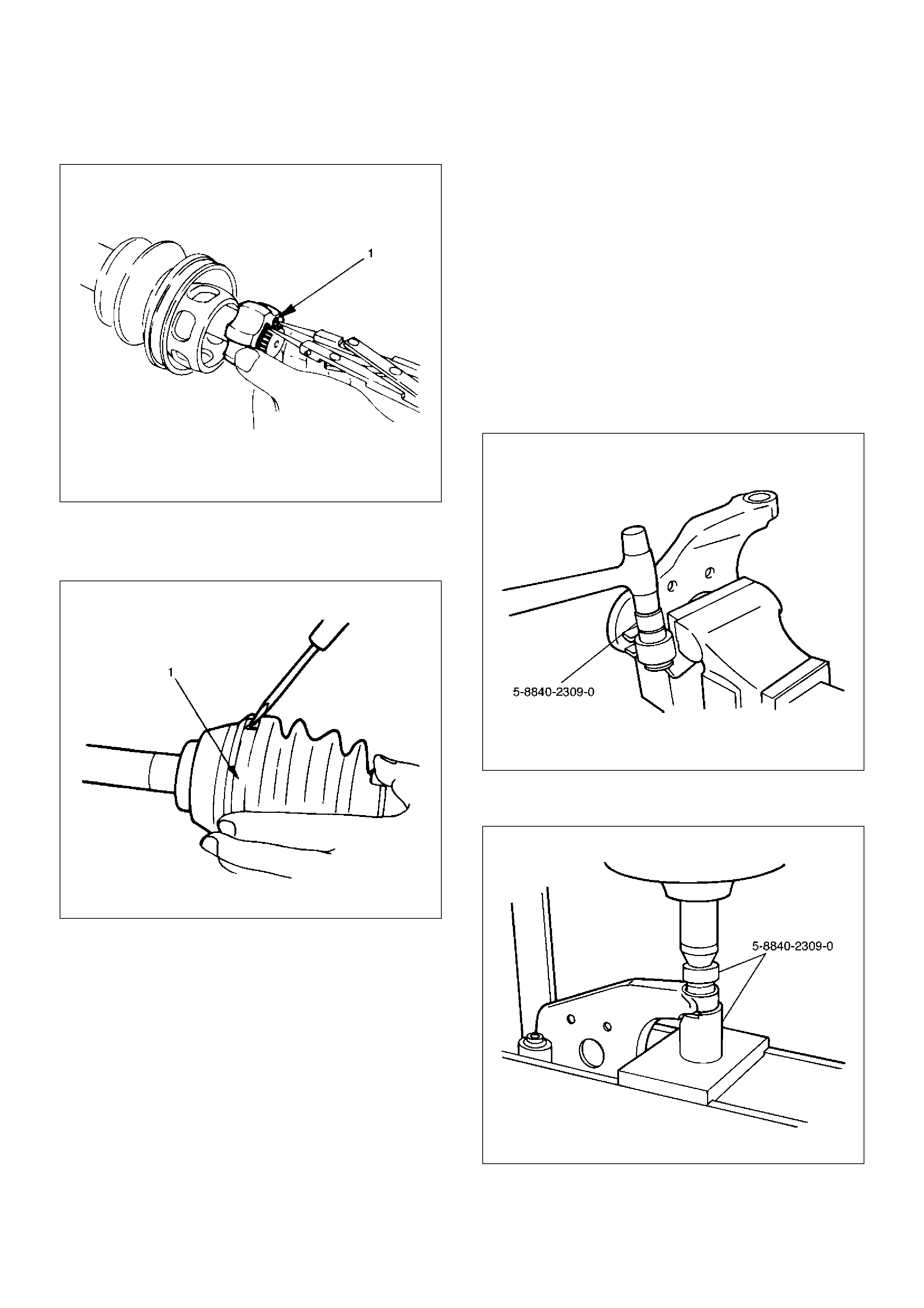

Bushing Replacement

• Remove the bushings using a remover 5–8840–

2309–0 and hammer.

412RW051

• By using installer and base 5–8840–2309–0, press

fit the bushings into the bracket.

412RW052

Reassembly

1. Install DOJ case to bracket.

2. Install oil seal and fix snap ring.

3. Install bearing and fix snap ring.

4. Install bracket to axle case. Tighten the bracket bolt

to the specified torque.

Torque:116N·m (11.8kg·m/85lbft)

5. Apply 150g of the specified grease in BJ .

6. Install dust seal .

7. Apply a thin coat of grease to the shaft for smooth

installation then install bellows.

8. Install band. Note the setting direction. After

installation, check that the bellows is free from

distortion.

412RS017

9. Install another bellows and fix band.

10. Install the ball guide with the smaller diameter side

ahead onto the shaft.

11. Install ball retainer.

12. Using snap ring pliers, install the snap ring (1)

securing the ball retainer to the shaft.

412RS013

13. Align the track on the ball (1) retainer with the

window in the cage, and install the six balls into

position.

412RS018

14. Install spacer.

15. Install snap ring.

16. Enclose 150g of the specified grease in DOJ case,

then install drive shaft joint assembly. After

reassembly, move the DOJ longitudinally several

times to get to fit.

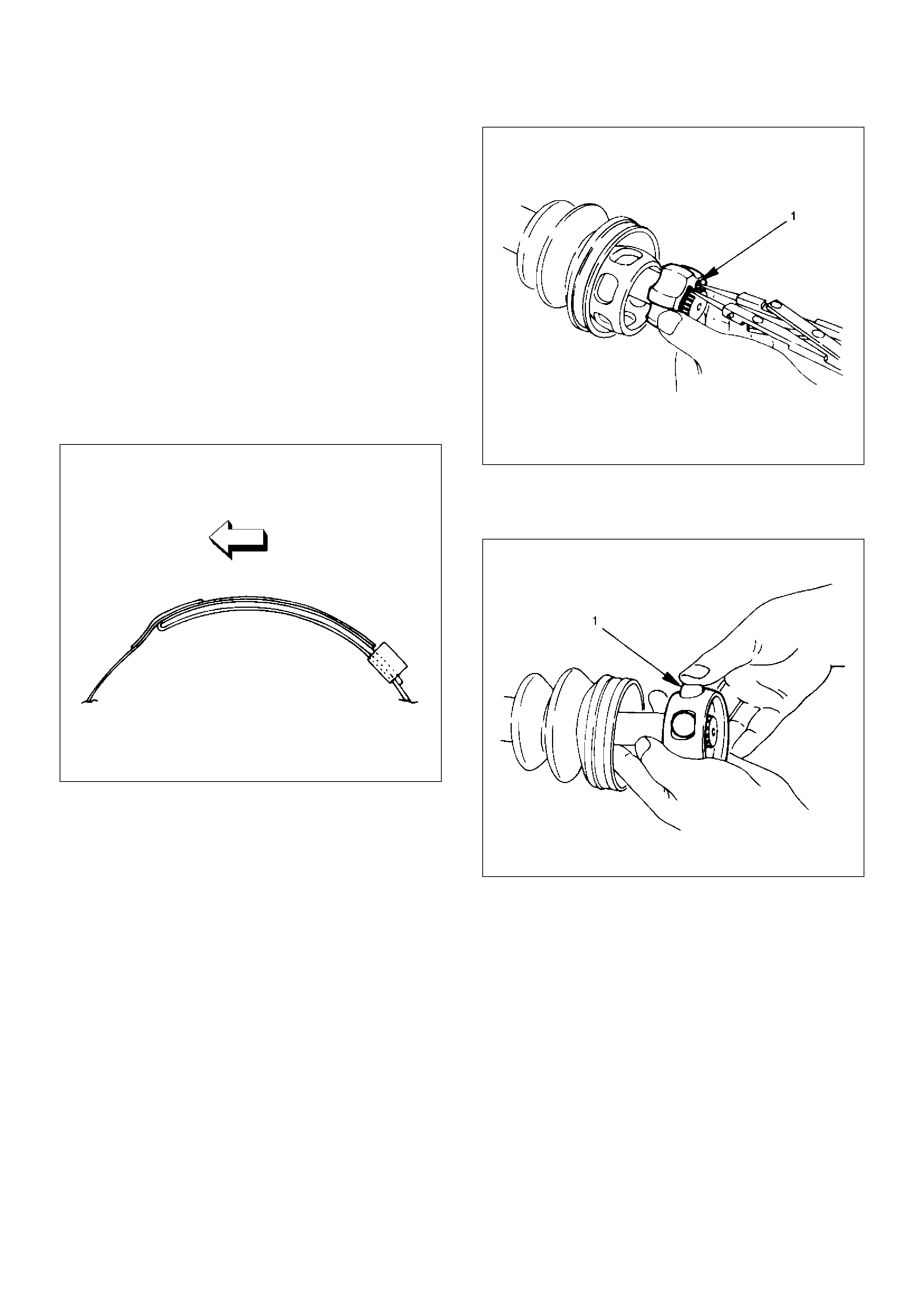

17. Install the circlip (1) so that open ends are

positioned away from the ball groove.

412RS019

412RS020

EndOFCallout

18. Install bellows. Adjust the air pressure within the

bellows by inserting a screwdriver or equivalent, so

that it equals atmospheric pressure.

412RW053

19. Install Band. After installation, check that the

bellows is free from distortion.

Legend

(1) Outer Case

(2) Circlip

(3) Open Ends

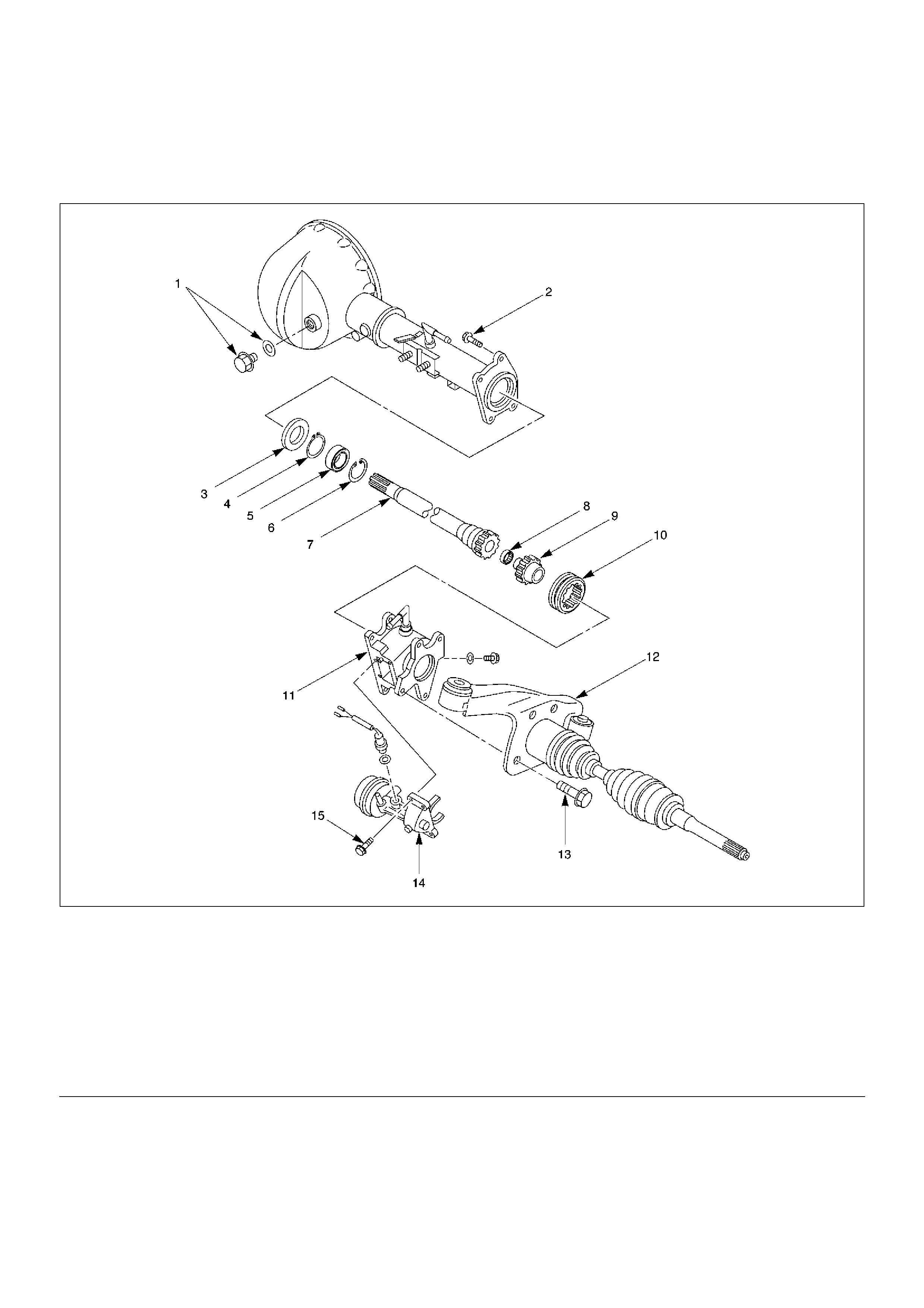

Shift On The Fly System

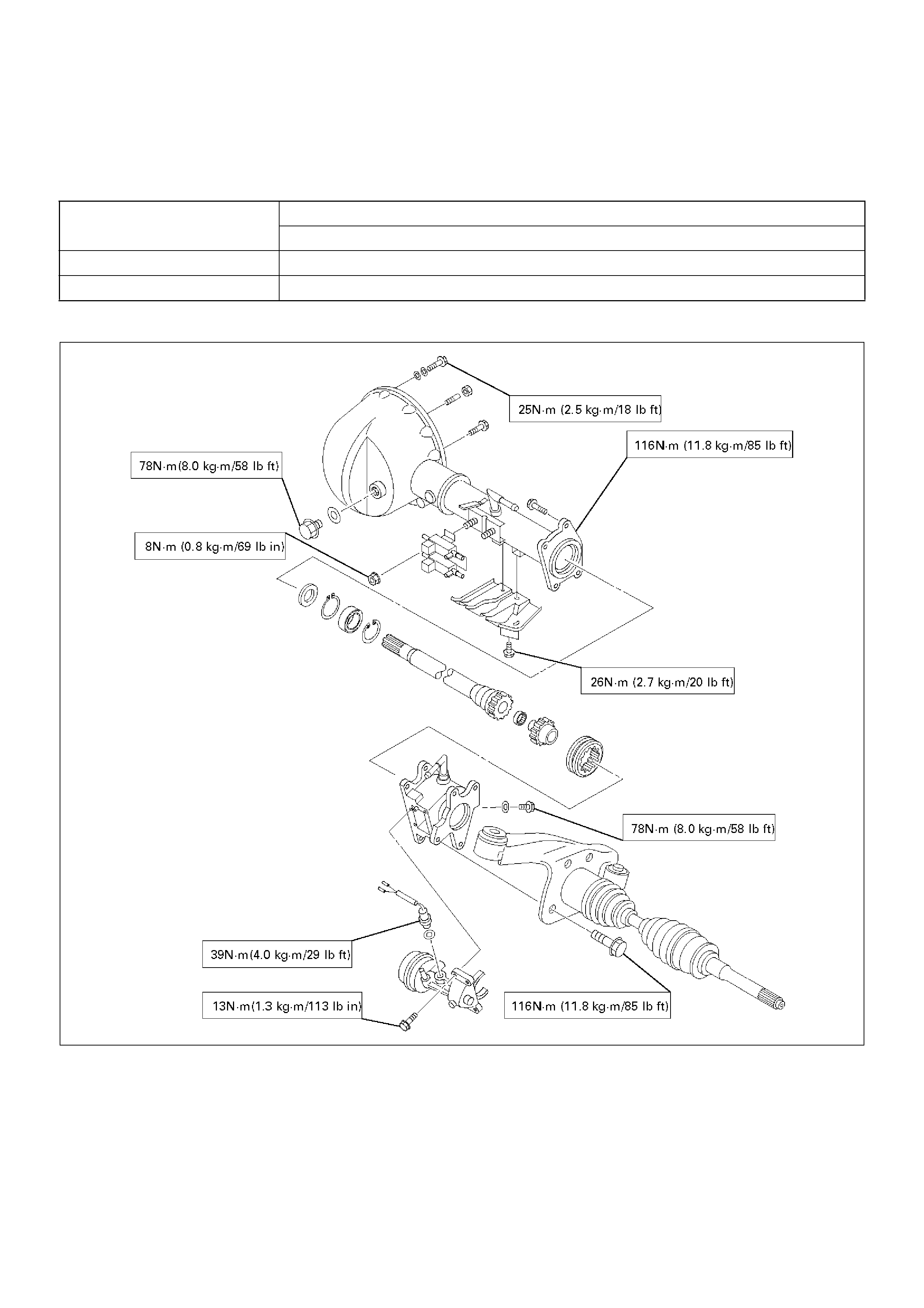

Shift On The Fly System and Associated Parts

412RW004

EndOFCallout

Disassembly

1. Remove filler plug and gasket, drain oil.

2. Loosen mounting bracket fitting bolts and remove

front axle drive shaft from front axle case.

3. Remove Actuator Assembly and draw out actuator

ASM.

4. Remove housing.

5. Remove sleeve.

6. Remove clutch gear.

Leg

end

(1) Filler Plug

(2) Bolt

(3) Oil Seal

(4) Snap Ring(External)

(5) Inner Shaft Bearing

(6) Snap Ring(Internal)

(7) Inner Shaft

(8) Needle Bearing

(9) Clutch Gear

(10) Sleeve

(11) Housing

(12) Front Axle Drive Shaft (LH side) with Bracket

(13) Bolt

(14) Actuator Assembly

(15) Bolt

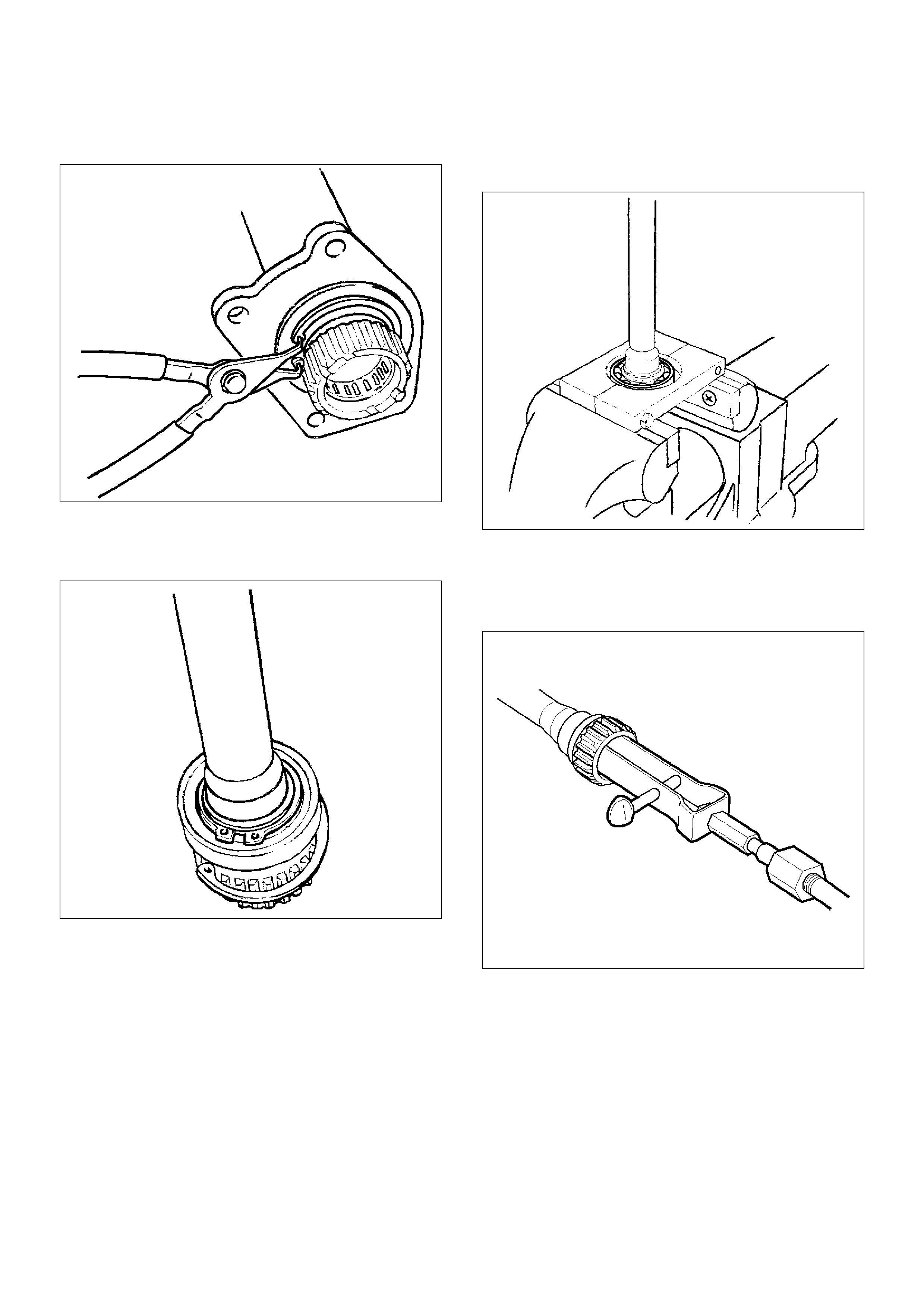

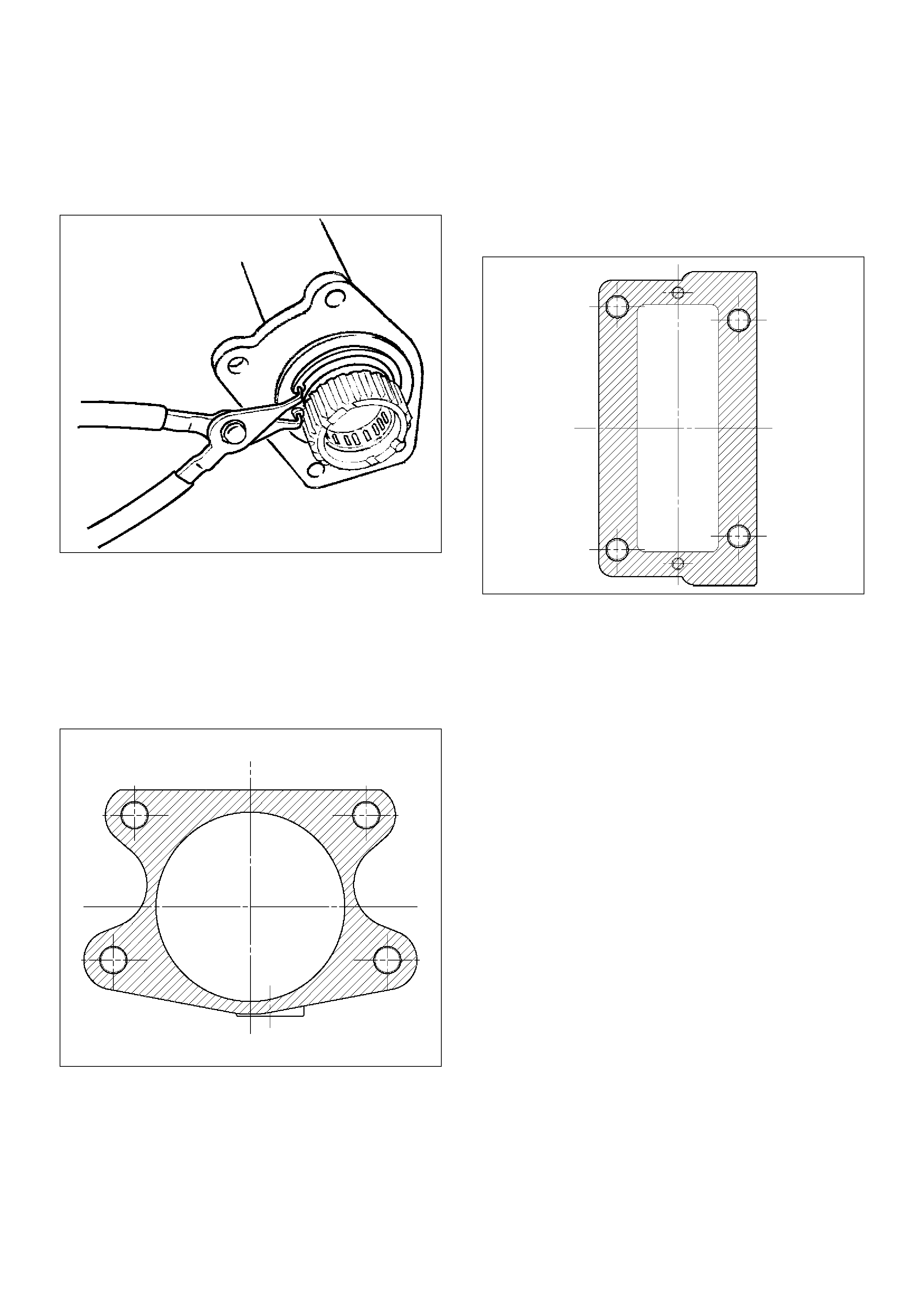

7. Remove snap ring from front axle case by using

snap ring pliers.

412RW017

8. Take out inner shaft from front axle case.

9. Remove snap ring from inner shaft by using snap

ring pliers.

412RW016

10. Remove inner shaft bearing by using a remover 5–

8840–2197–0 and press.

NOTE: Be careful not to damage the shaft.

412RW015

11. Remove needle bearing from inner shaft by using a

remover 5–8840–0027–0 and sliding hammer 5–

8840–0084–0.

NOTE: Be careful not to damage the shaft.

412RS045

12. Remove oil seal from front axle case.

NOTE: Be careful not to damage the front axle case.

Inspection and Repair

Inspect the removed parts. If there are abnormalities

such as wear and damage, take corrective action or

replace.

Visual Check

1. Check and see if the inner shaft has any

abnormalities such as wear and damage.

412RW014

2. When inspecting the inner shaft, be sure to check

and see if its splined part is twisted, worn, or

cracked. If so, replace with a new shaft. In case of

an abnormality in its gear part (a slide with sleeve),

replace the shaft.

420RS008

Inner Shaft Run–Out

With both end centers supported, rotate the shaft slowly

and measure deflection with a dial gauge.

Limit:0.5mm (0.02in) max.

NOTE: Do not heat the shaft to correct its bend.

412RS026

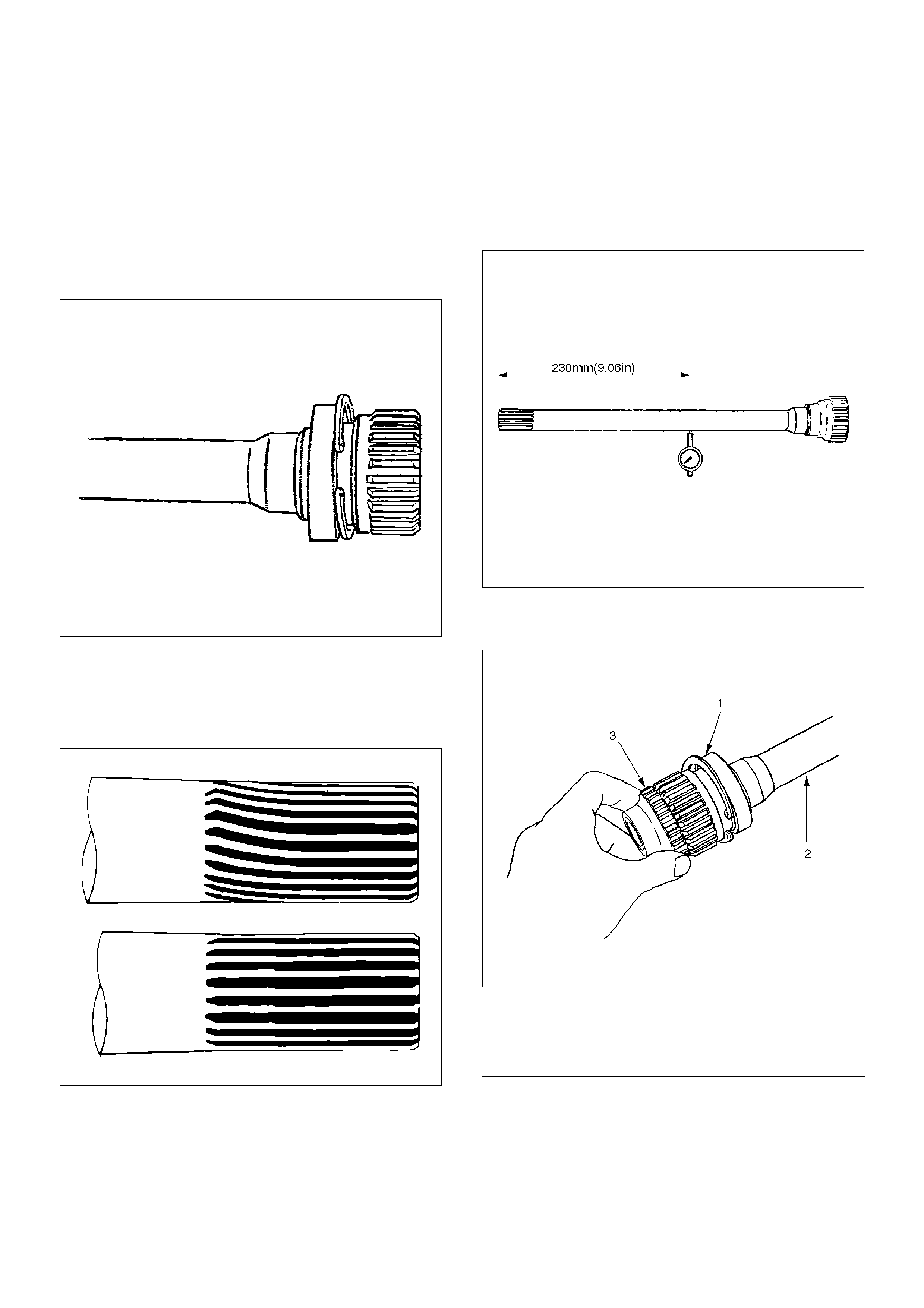

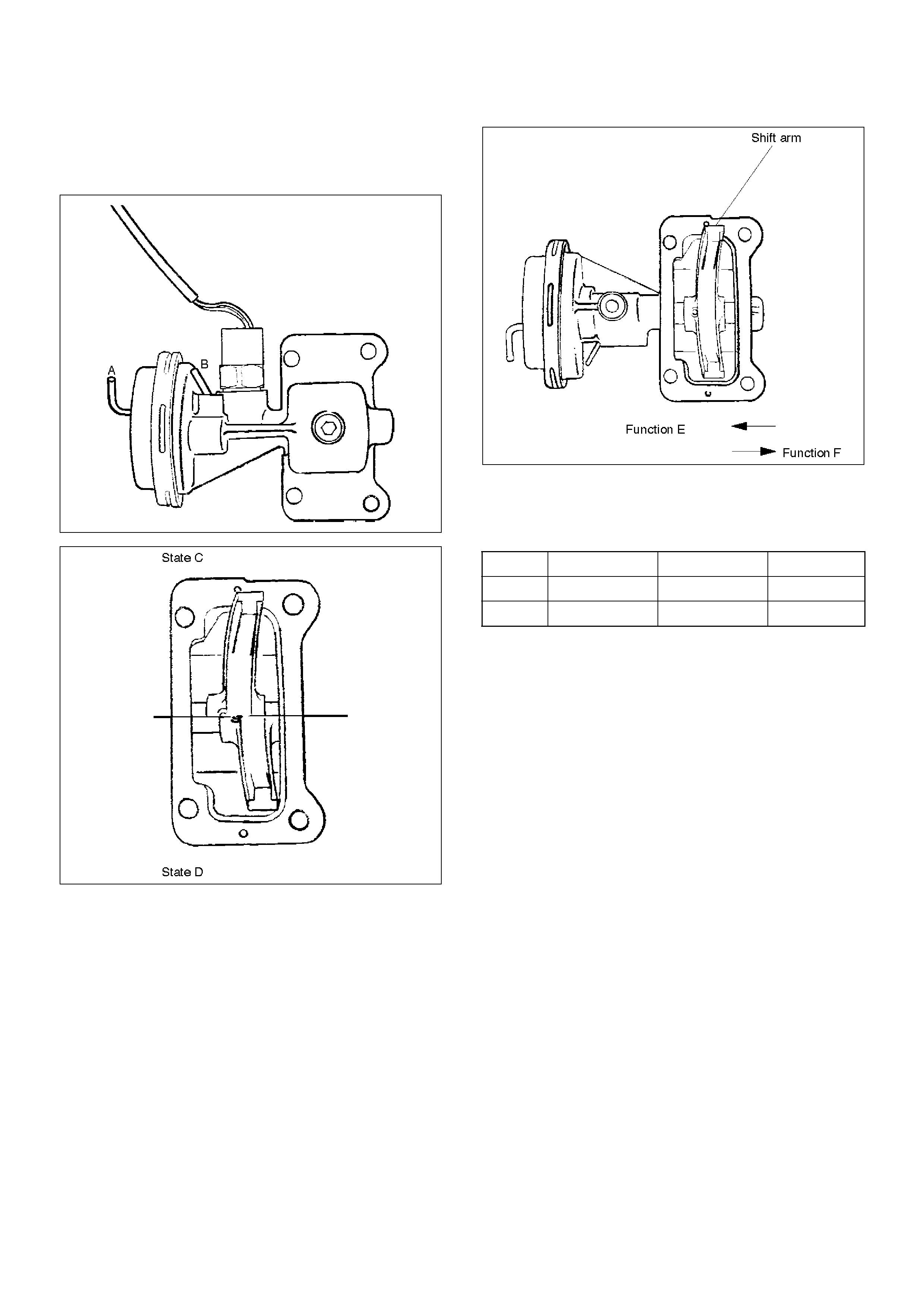

Inner Shaft Bearing

412RW006

EndOFCallout

1. Inspect the state of inner shaft bearing. If any

abnormality such as roughness is found, replace

with a new inner shaft bearing.

2. Insert a clutch gear and check the state of needle

bearing.

3. If there is an abnormality such as roughness,

replace the needle bearing.

Legend

(1) Inner Shaft Bearing

(2) Inner Shaft

(3) Clutch Gear

Sleeve Condition

Check and see that there is no wear, damage, or

cracking in the sleeve.

NOTE: Close inspection of the groove and inner gear

are required because those are important parts.

Sleeve Function

412RW011

Operate the sleeve with the inner shaft combined with

the clutch gear. If roughness is felt, replace the sleeve.

NOTE: Gear oil should be applied to the contact

surface of gear.

Check the width of sleeve center groove.

Limit:7.1mm (0.28in) max.

412RW022

Clutch Gear Condition

Check and see that there is no wear, damage, cracking,

or any other abnormality in the clutch gear.

Clutch Gear Function

412RW010

If there is an abnormality such as roughness when

operated in combination with sleeve, replace the clutch

gear.

NOTE: When inspecting, gear oil should be applied to

the contact surface of gear.

Clutch Gear Journal Diameter

Make sure of the size illustrated.

Limit:36.98mm (1.456 in) min.

412RW009

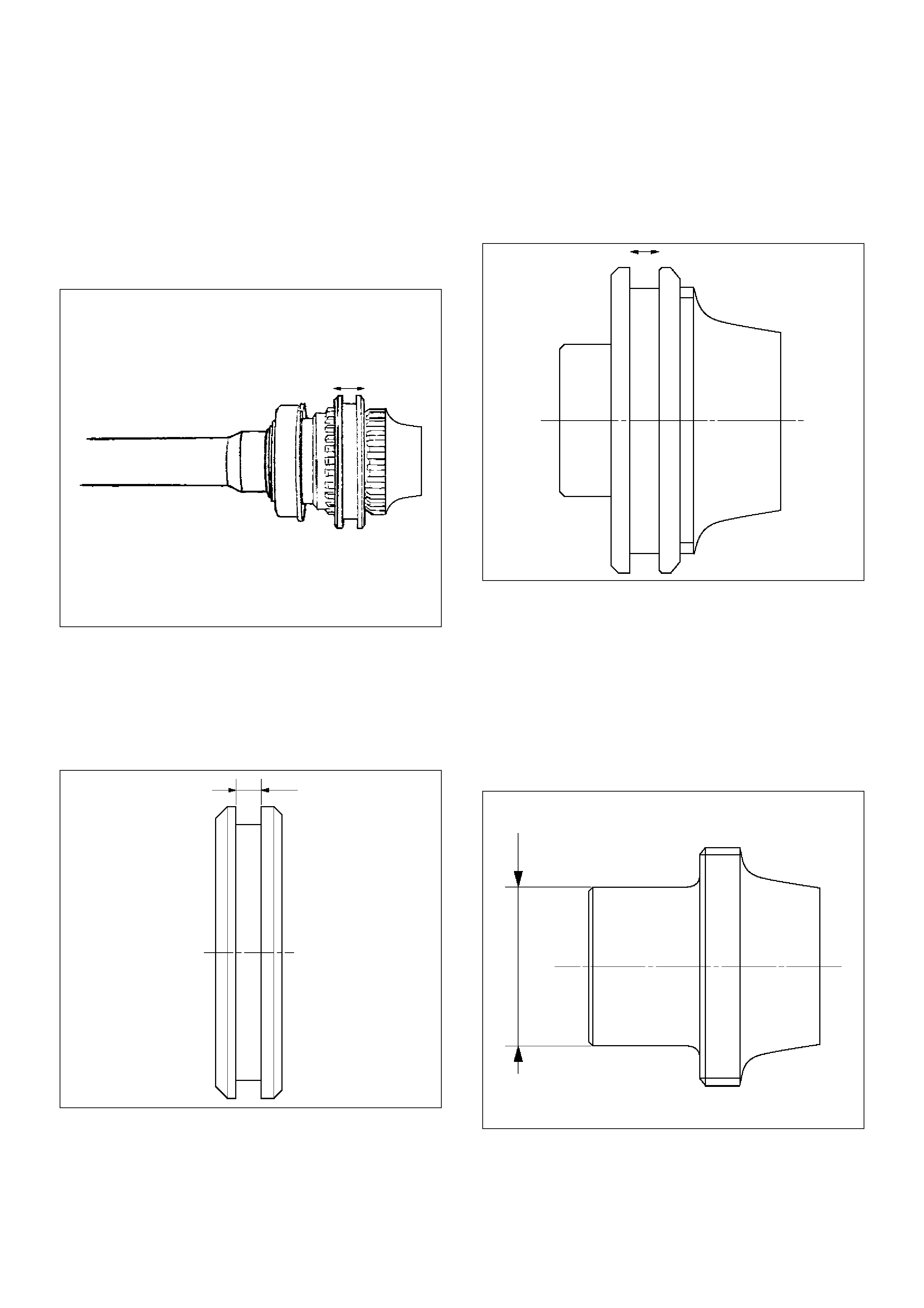

Actuator

Check and see that there is no damage, cracking, or

other abnormality.

Functional Check

412RW021

412RW013

412RW007

Disconnect the shift position switch and make sure of

function with a vacuum of –400 mmHg applied to Ports

A and B, in accordance with the table below.

If there is an abnormality, replace the actuator as an

assembly.

NOTE:

1. If the actuator works under –400mmHg or less,

there is no functional problem.

2. Be careful not to permit the entry of water or dust

into the ports of the actuator.

Dimensional Check

Measure illustrated sizes 1, 2, and 3.

Limit

1=64.3mm (2.53in) max.

2=6.7mm (0.26in) min.

3=6.7mm (0.26in) min.

State Port A Port B Function

C –400 mmHg A/P E

D A/P –400 mmHg F

412RS037

Reassembly

1. Install the new oil seal which has been immersed in

differential gear oil, by using an oil seal installer 5–

8840–2407–0 and grip 5–8840–0007–0.

412RS043

2. Force a new needle bearing into inner shaft by

using a installer 5–8840–2408–0 and grip 5–8840–

0007–0.

412RS051

3. Place a new snap ring(internal) in inner shaft.

Force a new inner shaft bearing into the inner shaft

by using a installer 5–8840–2197–0 and press.

412RS044

4. Install snap ring(external).

NOTE: Be careful not to damage the inner shaft.

5. Clean the housing contact surface of the front axle

case and insert inner shaft assembly into the front

axle case.

NOTE: Be careful not to damage seal.

6. Install snap ring (internal) in the groove of front axle

case.

NOTE: Be sure to install the snap ring properly.

412RW017

7. Apply differential gear oil to clutch gear, then install

clutch gear.

8. Apply differential gear oil to sleeve, then install

sleeve.

9. Clean contact surface with the front axle and

actuator mounting surface. Apply liquid gasket to

the contact surface on the front axle case, then

install in the housing.

412RW023

10. Tighten bolts to specified torque.

Torque:116N·m (11.8kg·m/85lbft)

11. Clean the actuator contact surface with the housing

then Install and tighten shift position switch to

specified torque.

Torque:39N·m (4.0kg·m/29lbft)

12. Apply liquid gasket to the contact surface on the

actuator side.

412RW012

13. Align shift arm with the groove of sleeve and install

the actuator.

14. Tighten bolts to specified torque.

Torque:13N·m (1.3kg·m/113lbin)

15. Install front axle drive shaft and mounting bracket.

Tighten fitting bolts to specified torque.

Torque:116N·m (11.8kg·m/85lbft)

16. Pour specified amount of differential gear oil to filler

plug.

Front Differential

Oil Capacity: 1.4lit(1.23Imp qt/1.48US qt)

Actuator Housing

Oil Capacity: 0.12lit(0.10Imp qt/0.13US qt)

17. Install filler plug through gasket and tighten to

specified torque.

Torque:78N·m (58lbft)

Main Data and Specifications

General Specifications

Torque Specifications

E04RW020

Front drive axle oil capacity 1.4 liter (1.23Imp qt/1.48US qt)(Differential)

0.12 liter (0.10Imp qt/0.13US qt)(Actuator Housing:Shift on the fly)

Type of lubricant Refer to chart in General Information

Axle shaft type Constant velocity joint(Birfield joint type and double offset joint)

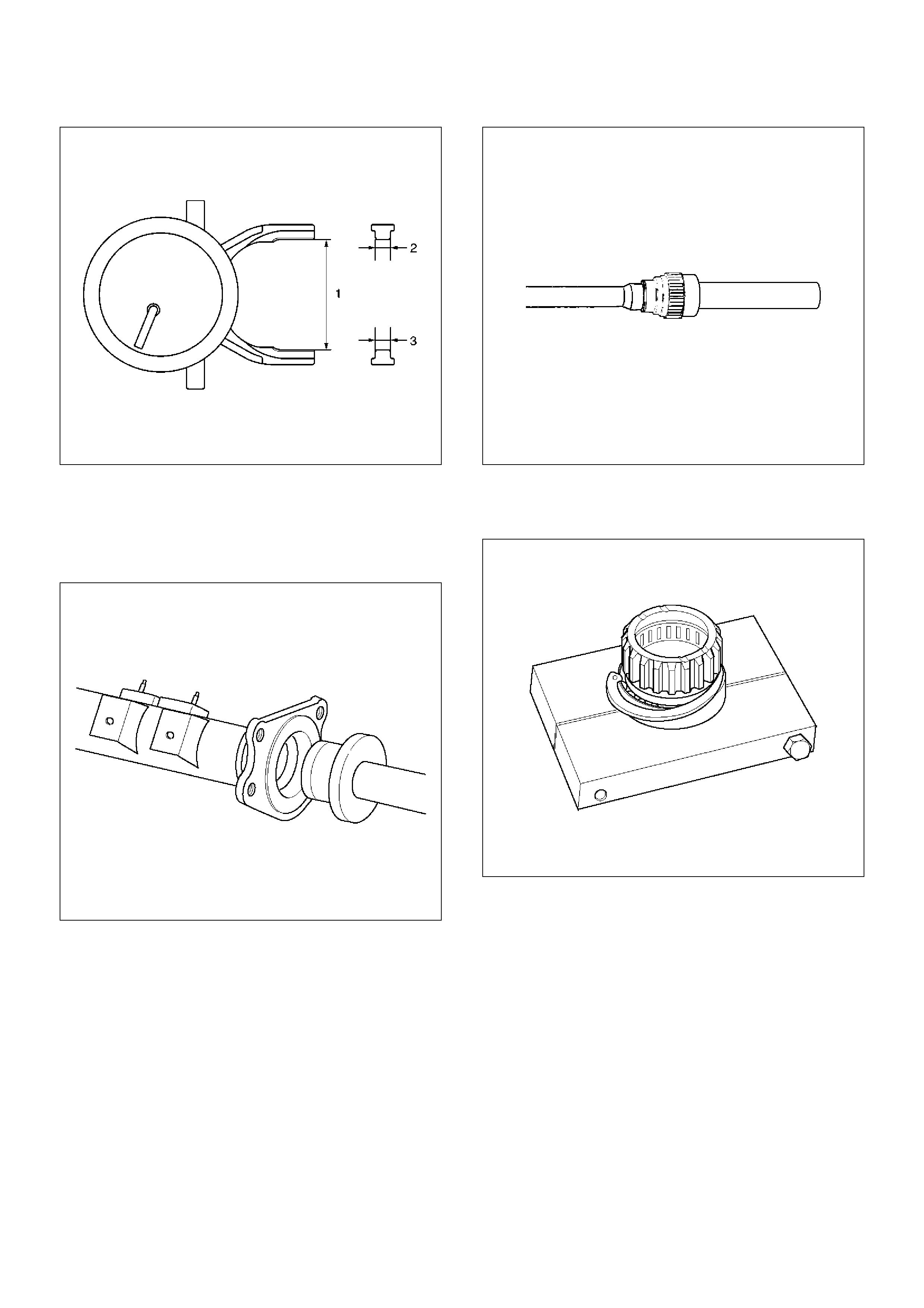

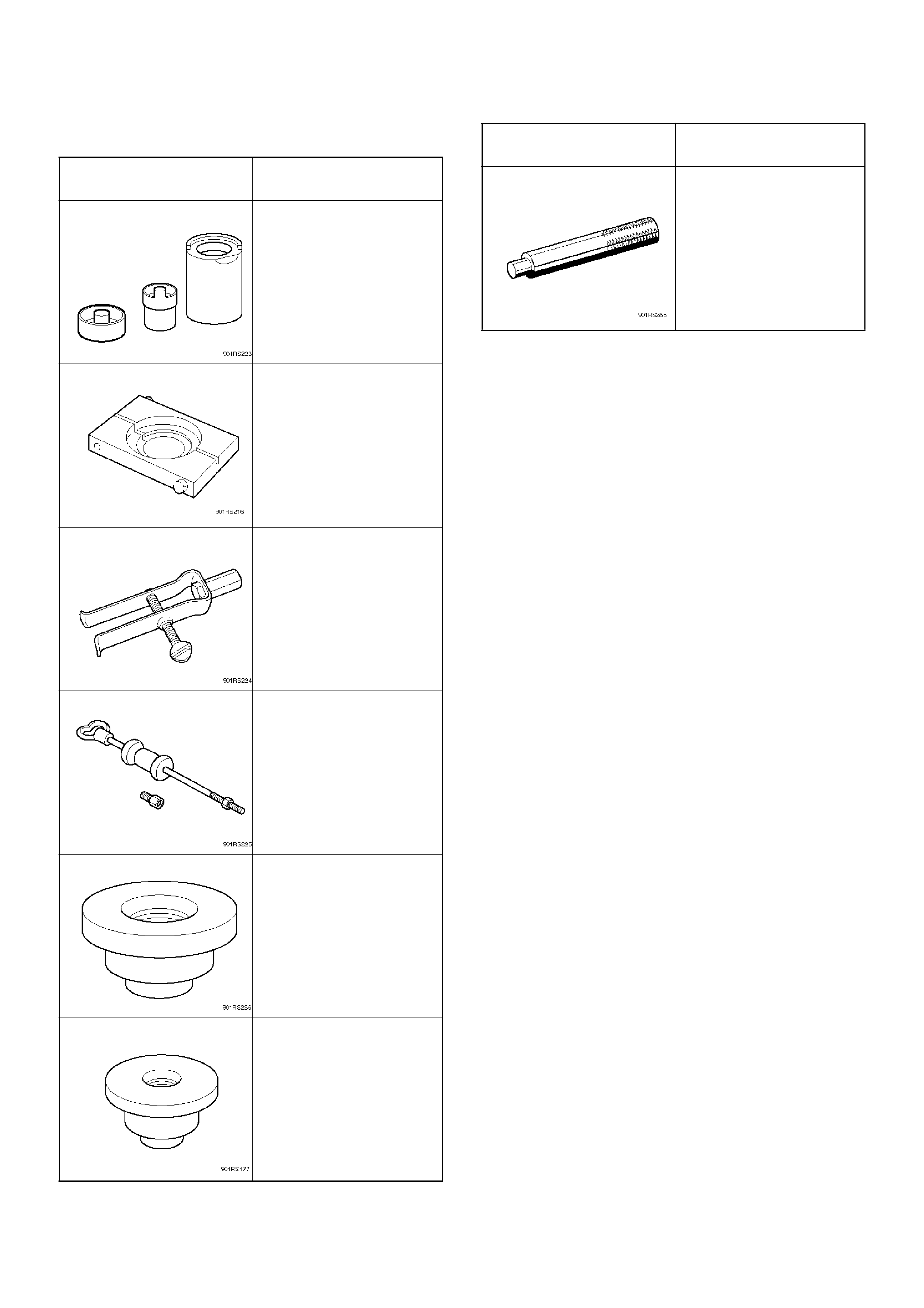

Special Tools

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–2309–0

(J–39378)

Remover and Installer;

Front Axle mount bushing

5–8840–2197–0

(J–37452)

Remover and Installer;

Inner shaft bearing

5–8840–0027–0

(J– 26941)

Remover;Bearing needle

5–8840–0084–0

(J–2619–01)

Hammer; Sliding

5–8840–2407–0

(J–41693)

Installer; Oil seal

5–8840–2408–0

(J–41694)

Installer; Bearing needle

5–8840–0007–0

(J–8092)

Grip

ILLUSTRATION TOOL NO.

TOOL NAME

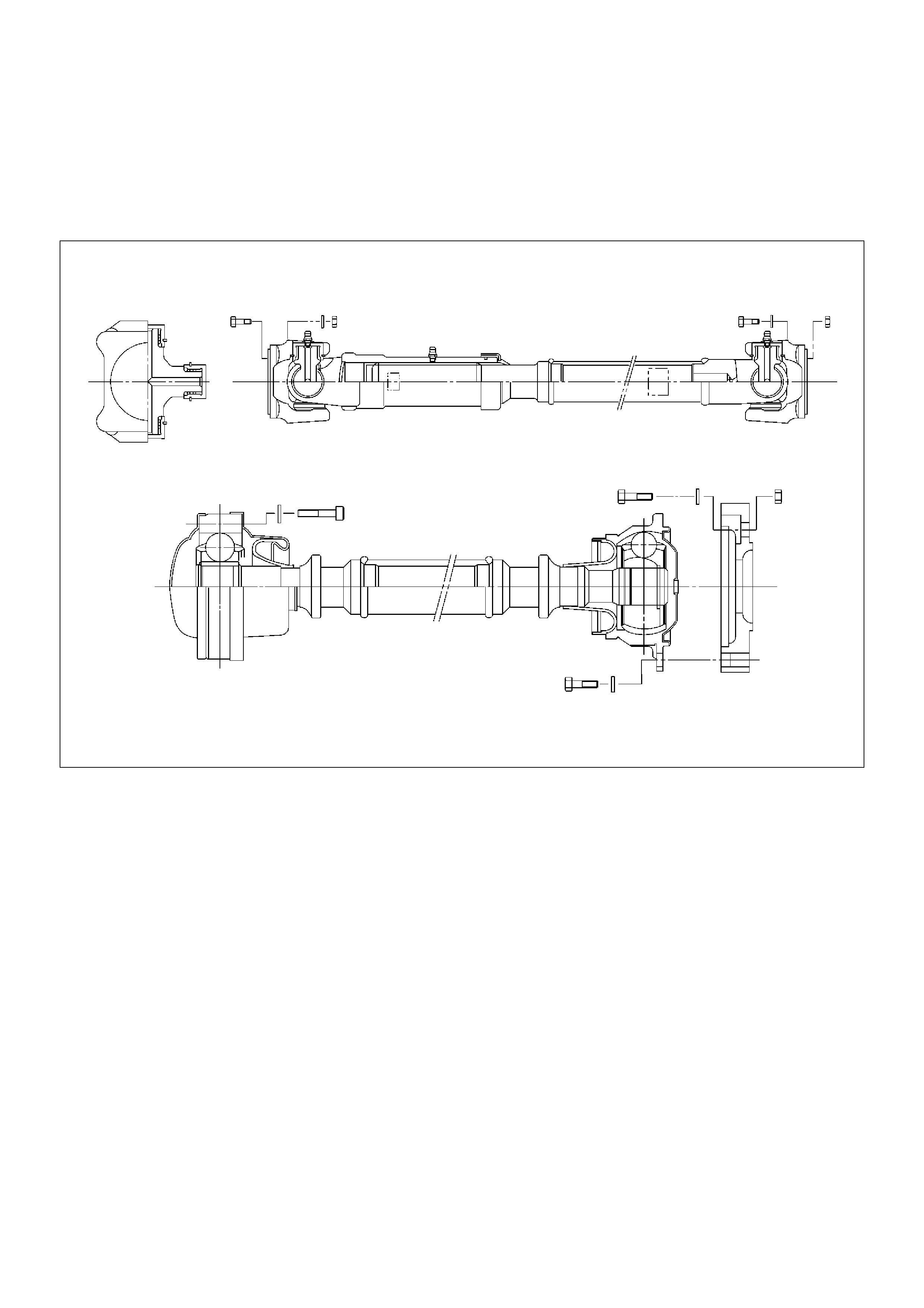

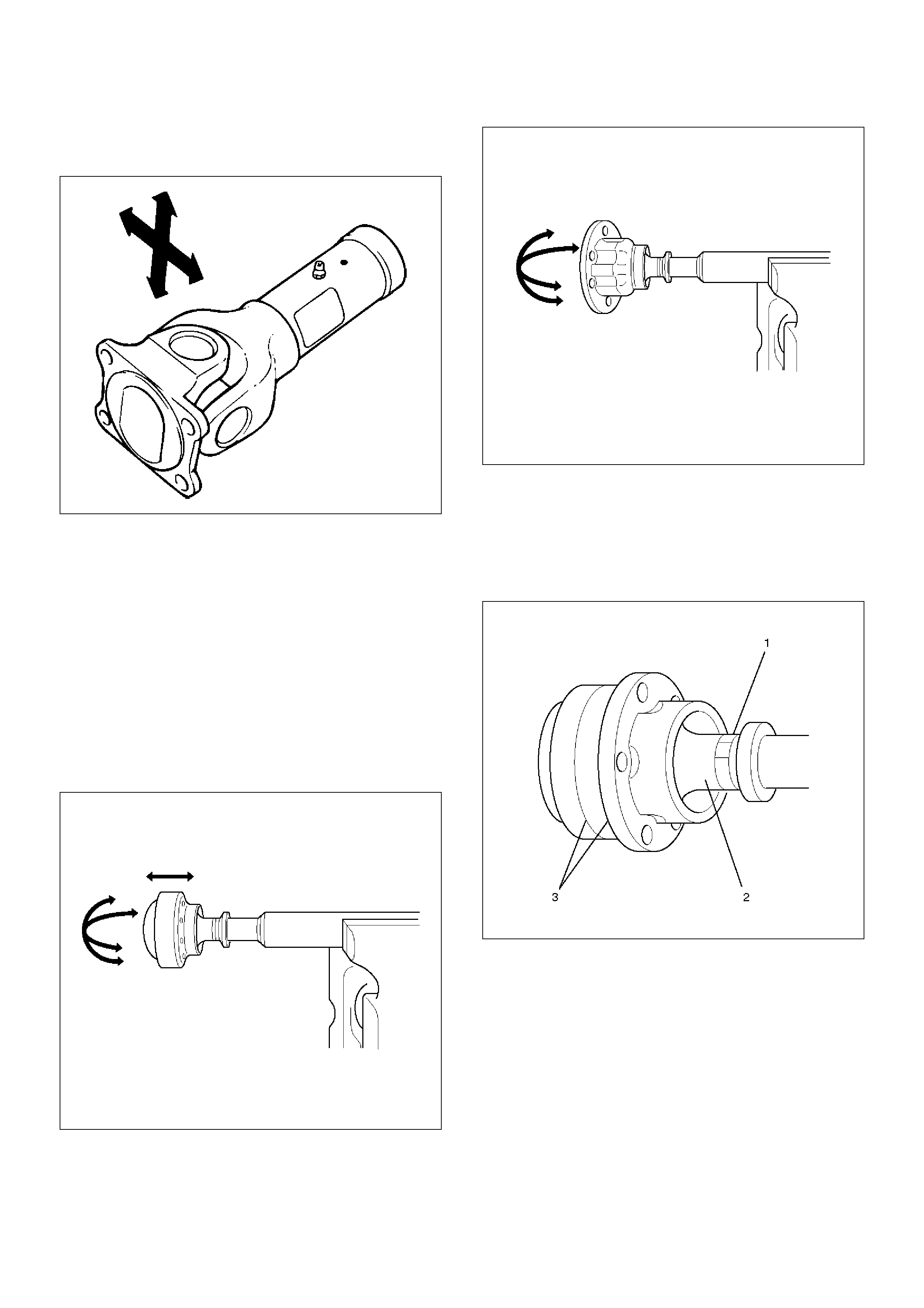

Front Propeller Shaft

General Description

Since the propeller shaft is balanced carefully, welding

or any other modifications are not permitted.

Alignment marks should be applied to each propeller

shaft before removal.

401RW002

Front Propeller Shaft and Associated Parts

401RW058

EndOFCallout

Removal

1. Jack up the vehicle and support it on the chassis

stands.

2. Gear shift lever should be placed in neutral position

and parking brake released.

3. Remove the exhaust and transfer protectors.

NOTE: Apply alignment marks on the flange at the front

propeller shaft both front and rear side.

401RS020

Legend

(1) Bolt, Nut and Washer (Front Axle Side)

(2) Front Propeller Shaft

(3) Bolt, Nut and Washer (Transfer Side)

(4) Front Propeller Shaft (with TOD)

(5) Coupling

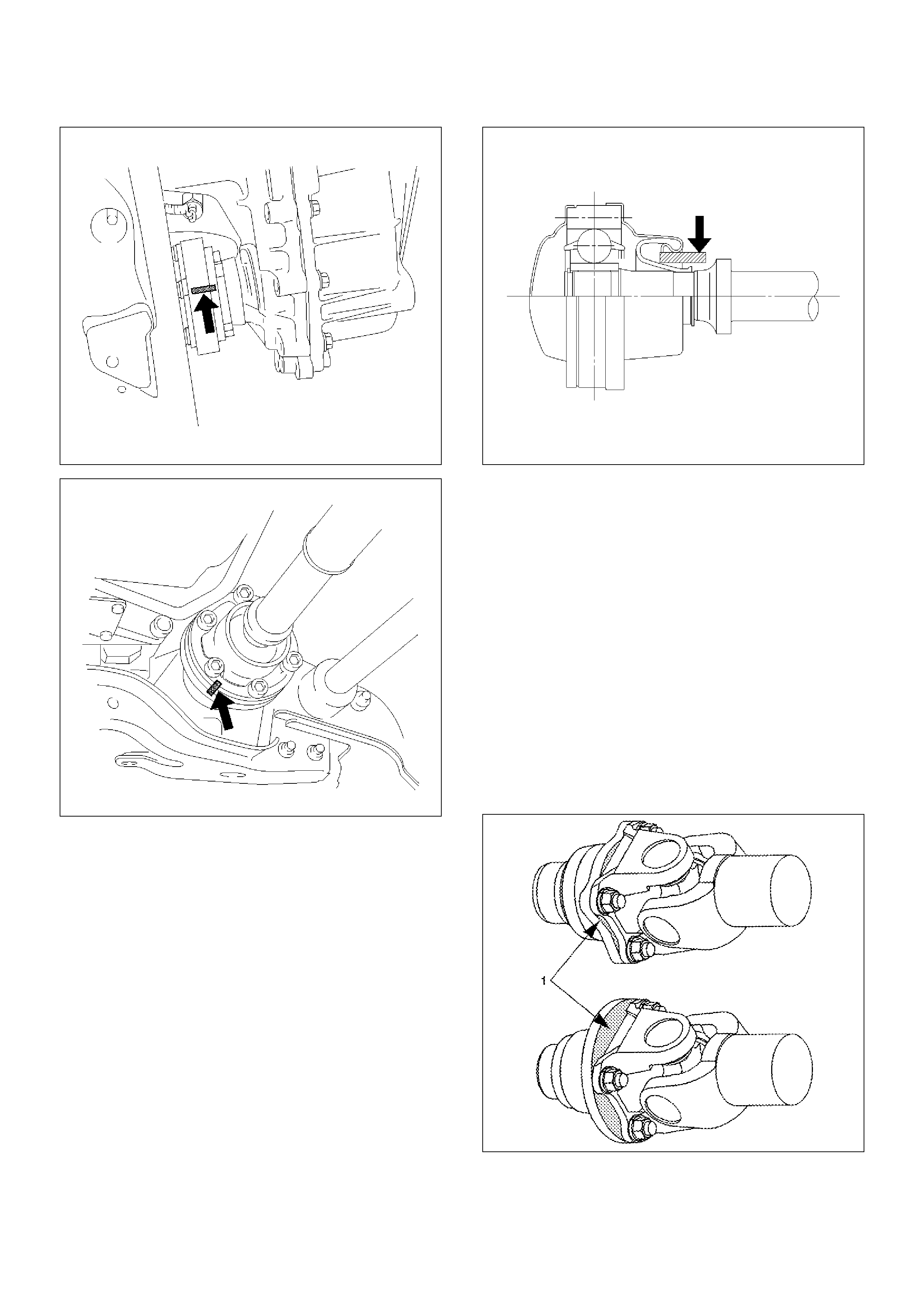

(6) LJ Constant Velocity Joint

(7) BJ Constant Velocity Joint

401RW053

401RW052

4. Remove bolt, nut and washer (Front axle side).

5. Remove bolt, nut and washer (Transfer side).

6. Remove front propeller shaft.

NOTE: If equipped with torque on demand (TOD),

when removing, installing or carring for front propeller

shaft, be sure to wind a piece of cloth round the part of

the boot with which fittings may interfere so that the

boot can be protected. The boot may be damaged if

bending force is applied to the constant velocity joint of

the shaft.

401RW051

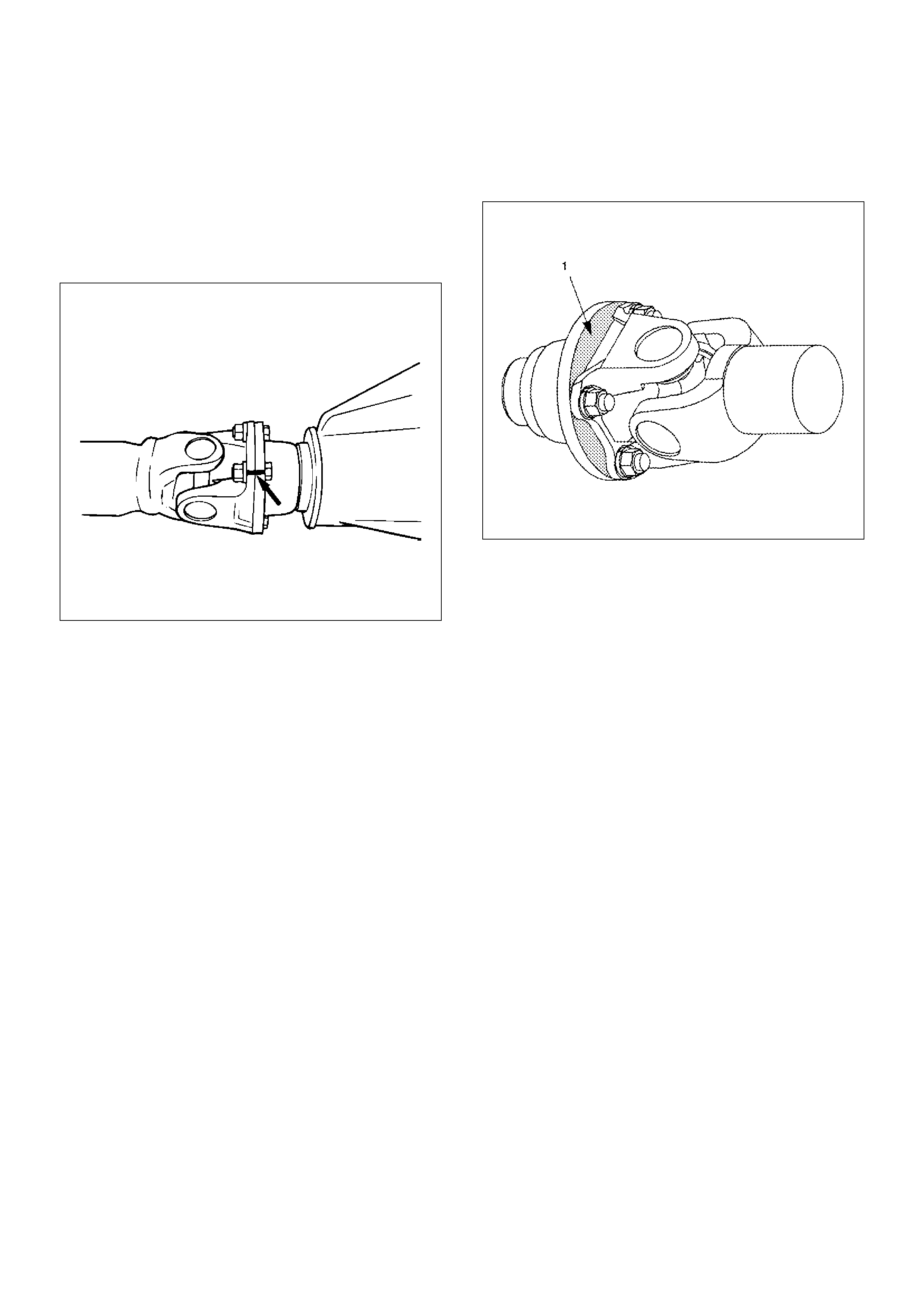

Installation

NOTE: Never install the shaft assembly backwards.

Completely remove the black paint from the connecting

surface of flange coupling on each end of propeller

shaft. Clean so that no foreign matter will be caught in

between.

1. Align the mark which was applied at removal. Install

front propeller shaft and tighten the bolts to the

specified torque.

Torque:63N·m (6.4kg·m/46 lbft)

2. Install the exhaust and transfer protectors.

3. After installing the propeller shaft, be sure to apply

black paint (1) to exposed area (other than

connecting surface) of the entire surface of flange

coupling .

401RS019

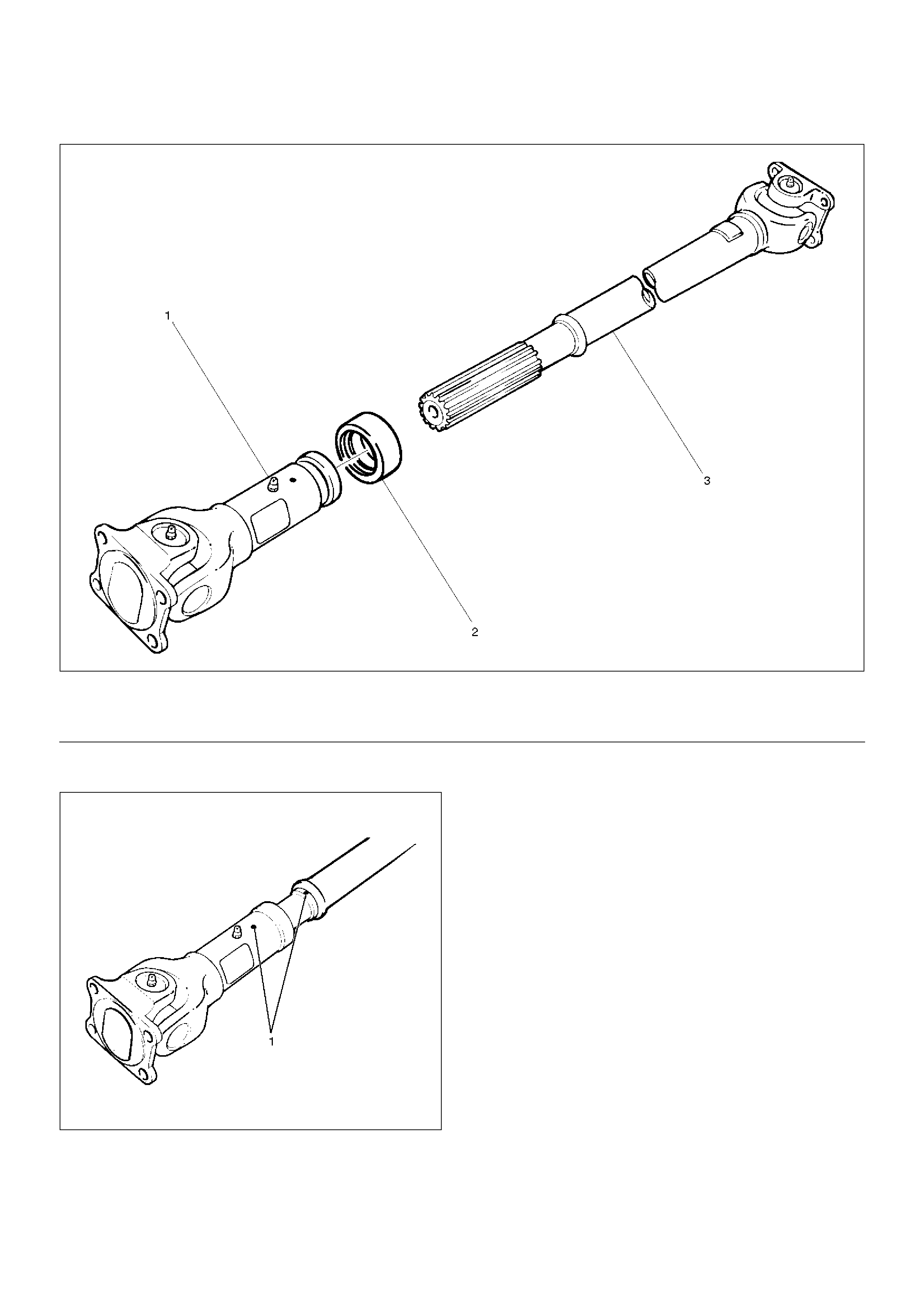

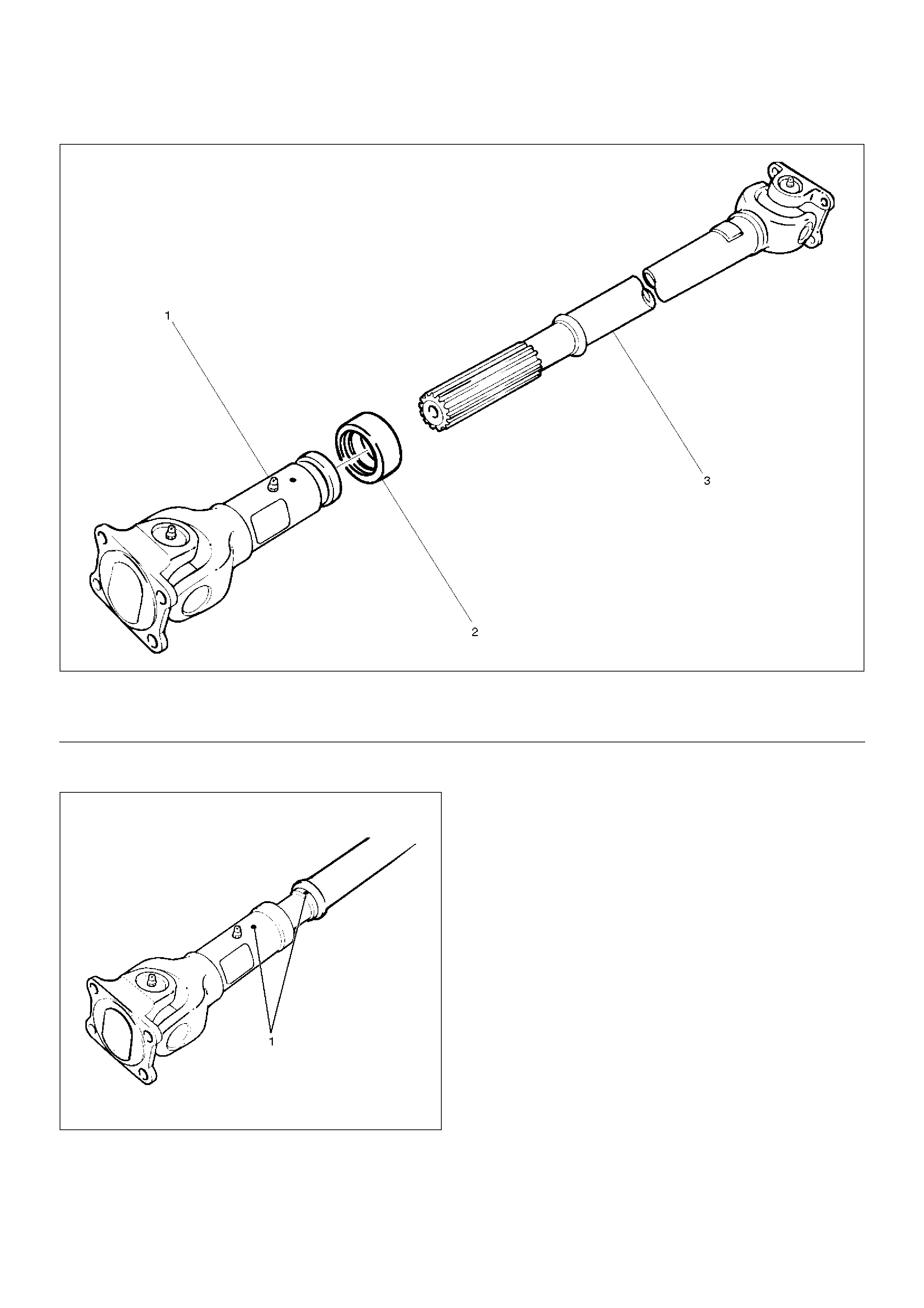

Disassembly (Except TOD 4´4)

401RW057

EndOFCallout

1. Apply alignment marks (1) on the sleeve yoke and

tube assembly then remove sleeve yoke.

401RW056

2. Remove seal.

3. Remove tube assembly.

Legend

(1) Sleeve Yoke

(2) Seal

(3) Tube Assembly

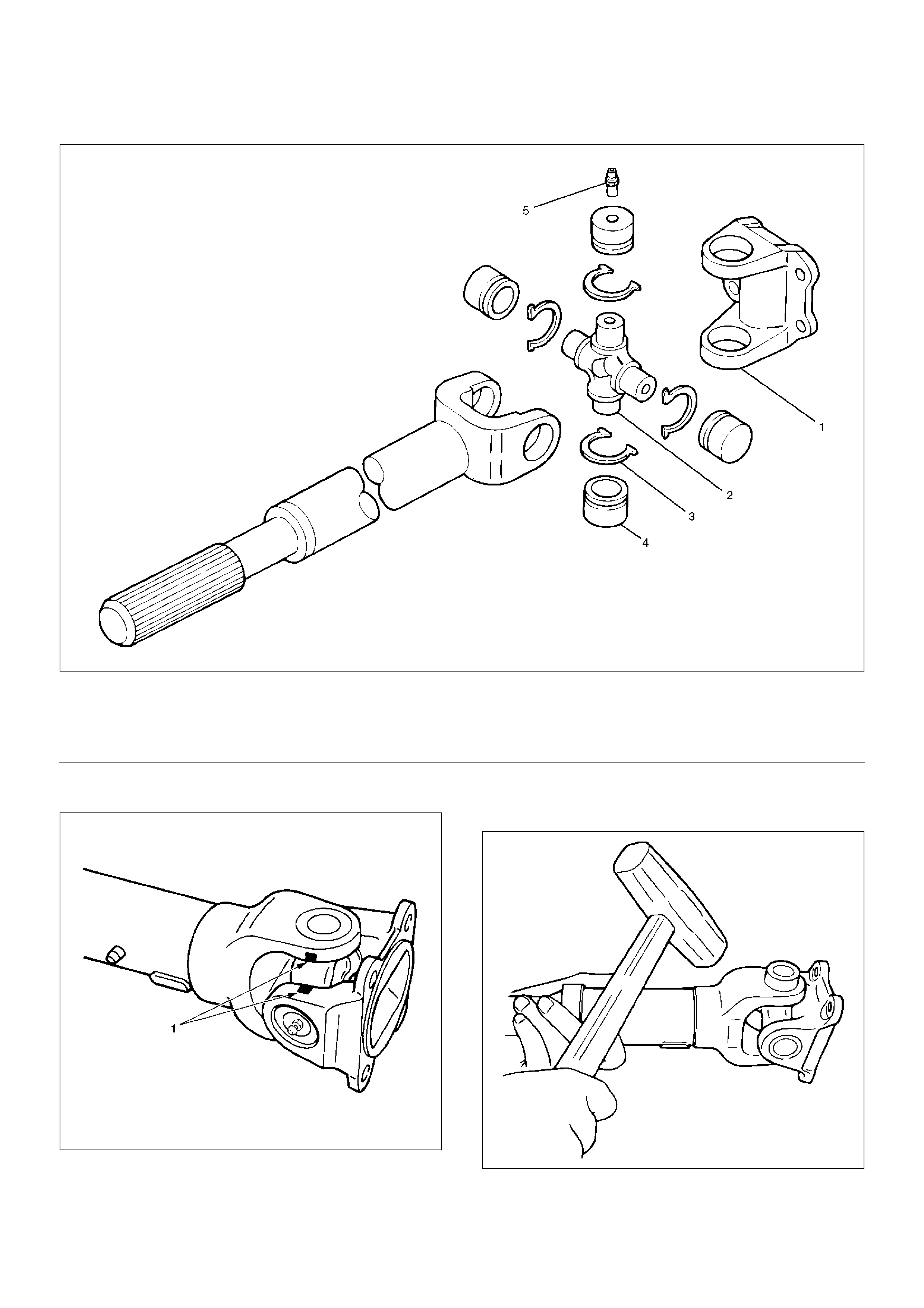

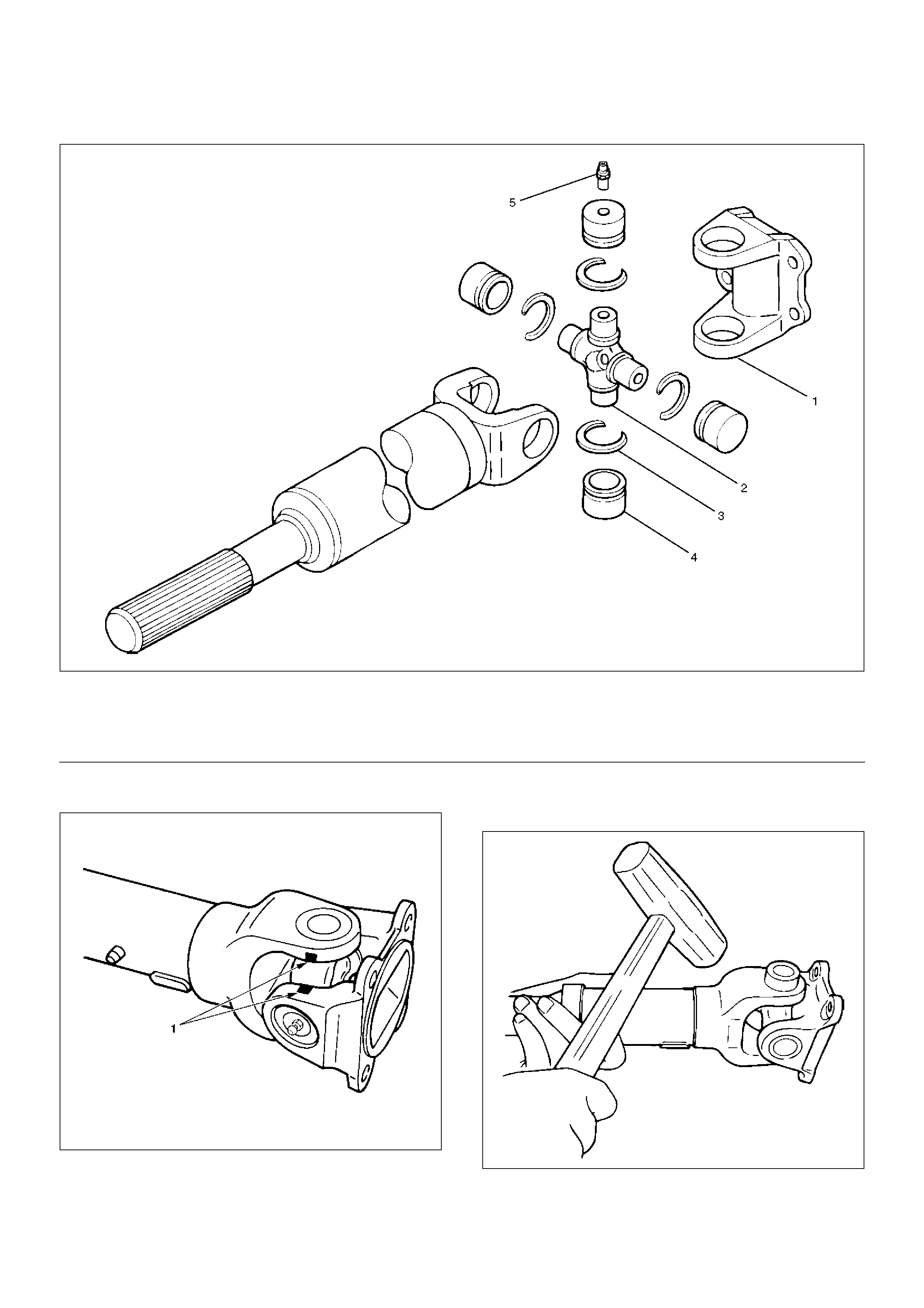

Universal Joint Disassembly

401RW055

EndOFCallout

1. Apply alignment marks (1) on the yokes of the

universal joint, then remove snap ring.

401RS028

2. Tap out the needle roller bearing by gently striking

the shoulder of the yoke, using a mallet or a copper

hammer.

401RS006

Legend

(1) Flange Yoke

(2) Spider

(3) Snap Ring

(4) Needle Roller Bearing

(5) Grease Fitting

3. Make sure of proper position for reinstallation by

applying setting marks, then remove spider .

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition is

found through inspection.

NOTE: When any part of the journal assembly (spider,

needle roller bearing) requires replacement, be sure to

replace the entire assembly.

Check the following parts for wear, damage, noise or

any other abnormal conditions:

1. Spider

2. Needle roller bearing

3. Yoke

4. Flange

5. Constant velocity joint

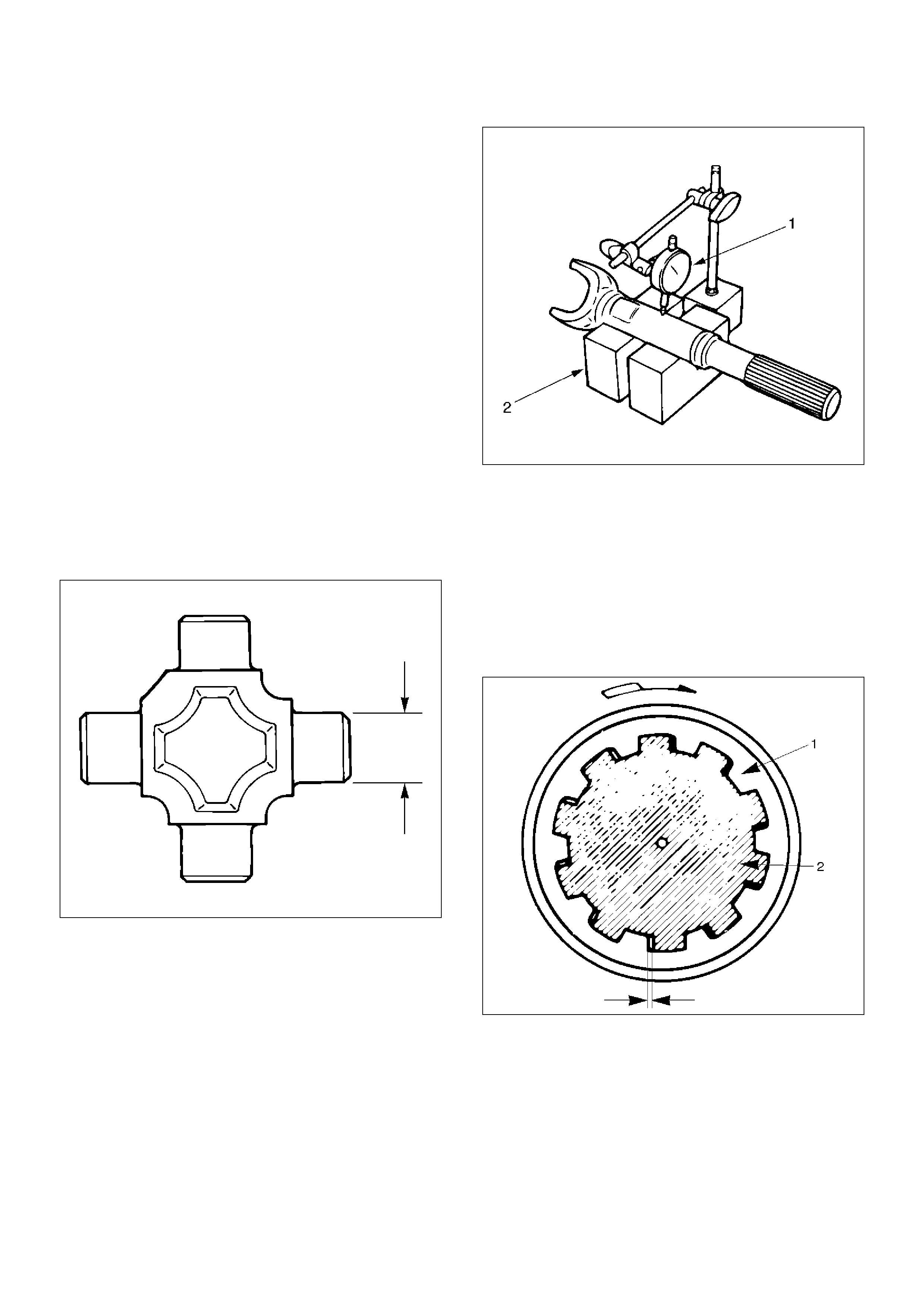

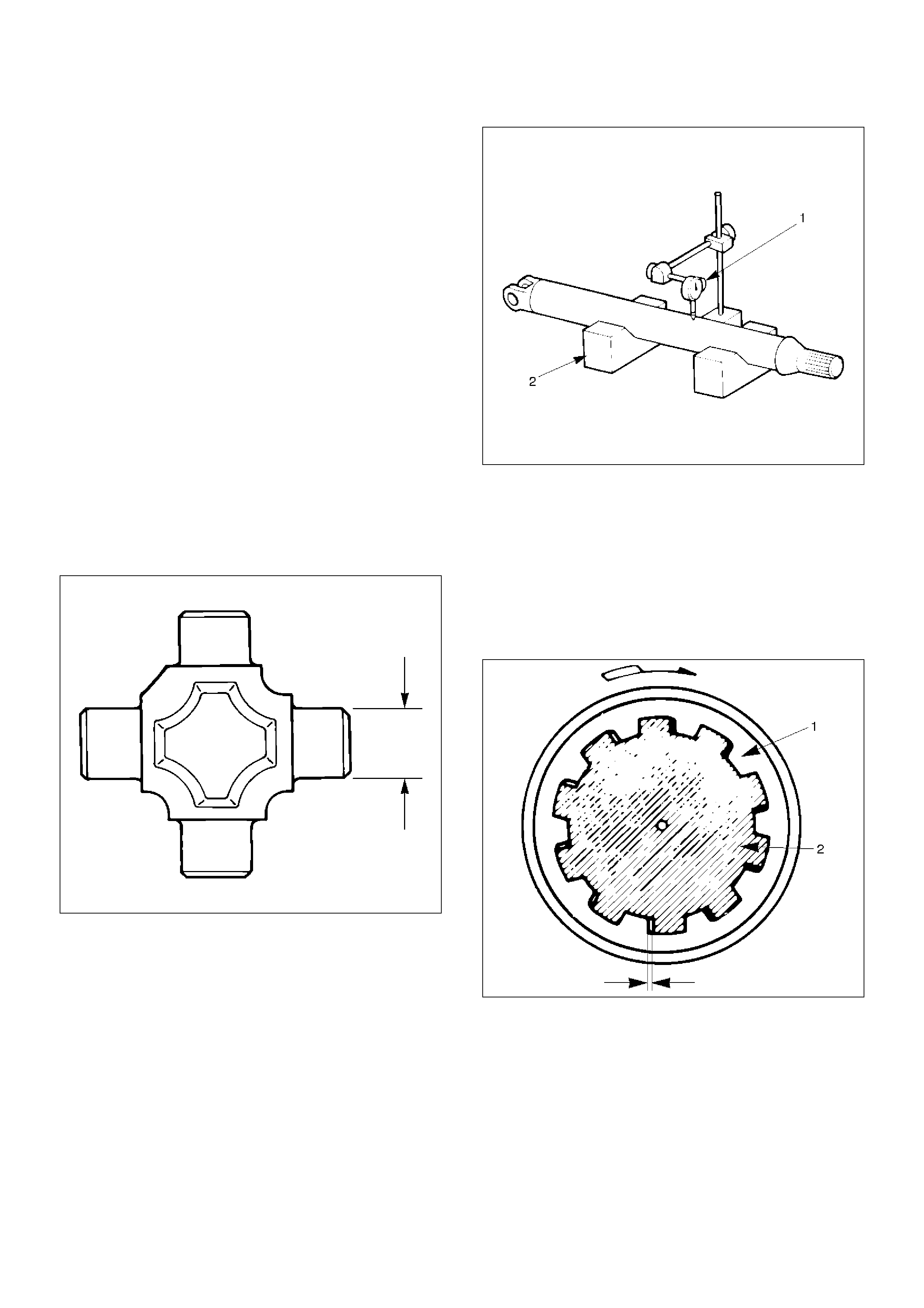

Outside Diameter of Spider Pin

Standard:17.00mm (0.669in)

Limit:16.90mm (0.665in)

401RS007

Propeller Shaft Run–out

Support the ends of the propeller shaft on V-blocks (2)

and check for run–out by holding the probe of a dial

indicator (1) in contact with the center part of the shaft. If

the amount of run–out is beyond the standard value for

assembly, correct with a bench press or replace the

shaft with a new propeller shaft assembly.

Standard:0.3mm (0.012in)

Limit:0.5mm (0.02in)

401RS027

Play in Splines in Normal Direction of

Rotation

Check the amount of play between the sleeve yoke (1)

and the propeller shaft spline (2) in the direction of

rotation, using a pointed feeler gauge.

Standard:0.073 – 0.156mm (0.003 – 0.006in)

Limit:0.3mm (0.012in)

401RS009

Play in Universal Joint

Limit:Less than0.1mm (0.004in)

401RS010

Constant Velocity Joint

NOTE: LJ and BJ constant velocity joints are

unremovable types. Check the joint for play and the

boot for damage, wear, and leak of grease. If

abnormality is found, replace propeller shaft as an

assembly.

Play in Constant Velocity Joint

Fix the shaft in a vise throrgh pieces of wood, and try to

move the joint vertically, right and left, and back and

forth to make sure of smooth motions and no

remarkable play.

401RW050

401RW049

Boot of Constant Velocity Joint

Check the boot (2) for crack, damage and grease leak,

and the boot band (1) for loosening and damage. Check

the both sides of the joint and make sure that there is no

leak of grease from the cover press-in parts(3).

401RW048

401RW047

Front Axle Flange Run-out

1. Set a dial gage at right angle near the outer

circumference of the flange face and check the

run-out of the flange face.

Limit:0.15mm (0.006in)

401RW046

2. Set a dial gage at right angle near the inner

circumference and check the run-out of the flange.

Limit:0.15mm (0.006in)

401RW045

3. If vibration is felt during the 4H AUTO drive,

disconnct the propeller shaft at the front axle.

Reinstall the propeller shaft at 60°, 120°, 180°, 240°,

and 300° and conduct test drive in each position

and check if there is vibration.

401RW044

Universal Joint Reassembly

1.Install spider to flange yoke. Be sure to install the

spider by aligning the setting marks made during

disassembly.

2.Apply a molybdenum–disulfide grease or a multi–

purpose type grease NLGI No. 2 to inside of the

bearing cap.

Grease Amount:Approx.1.2g (0.042oz)

401RS011

3.Using either a mallet (or copper hammer) or a

press, install the needle roller bearing into the yoke

so that the snap ring can be installed in its groove.

CAUTION: The needle roller bearing cannot be

installed smoothly if it is set at an incorrect angle

with the flange and excessive hammering will

damage the needle roller bearing.

401RS012

4. Align setting marks (1) and join the yokes.

401RS028

5. Install snap ring.

NOTE: Discard used snap rings and install new ones.

When the bearing cap is in position, select and attach a

snap ring of suitable thickness so that the end play of

the spider pin is held within 0.1 mm (0.004 in).

Snap ring thickness and Identification color

1.5mm (0.059in);Blue

1.53mm (0.060in);White

1.59mm (0.063in);Yellow

1.62mm (0.064in);Green

1.68mm (0.066in);Not colored

NOTE: Be sure to use snap rings of the same thickness

on both sides.

Reassembly (Except TOD 4´4)

401RW057

EndOFCallout

1. Discard used seal and install new one.

2. Align the alignment marks and install tube assembly

to sleeve yoke.

Legend

(1) Sleeve Yoke

(2) Seal

(3) Tube Assembly

Main Data and Specifications

General Specifications

Torque Specifications

E04RW021

Engine 6VE1 (3.5L) 4JX1 (3.0L)

Transmission

M/T A/T

A/T

with

TOD

M/T A/T

Construction

Hollow steel tube

with yoke and

spider type

universal joint

Hollow

steel

tube with

constant

velocity

joints

Hollow steel tube

with yoke and

spider type

universal joint

Outside

diameter 40.0mm (1.57 in)

Length 559mm

(22.01in)

559mm

(22.01in)

577mm

(22.72in)

627mm

(24.69in)

627mm

(24.69in)

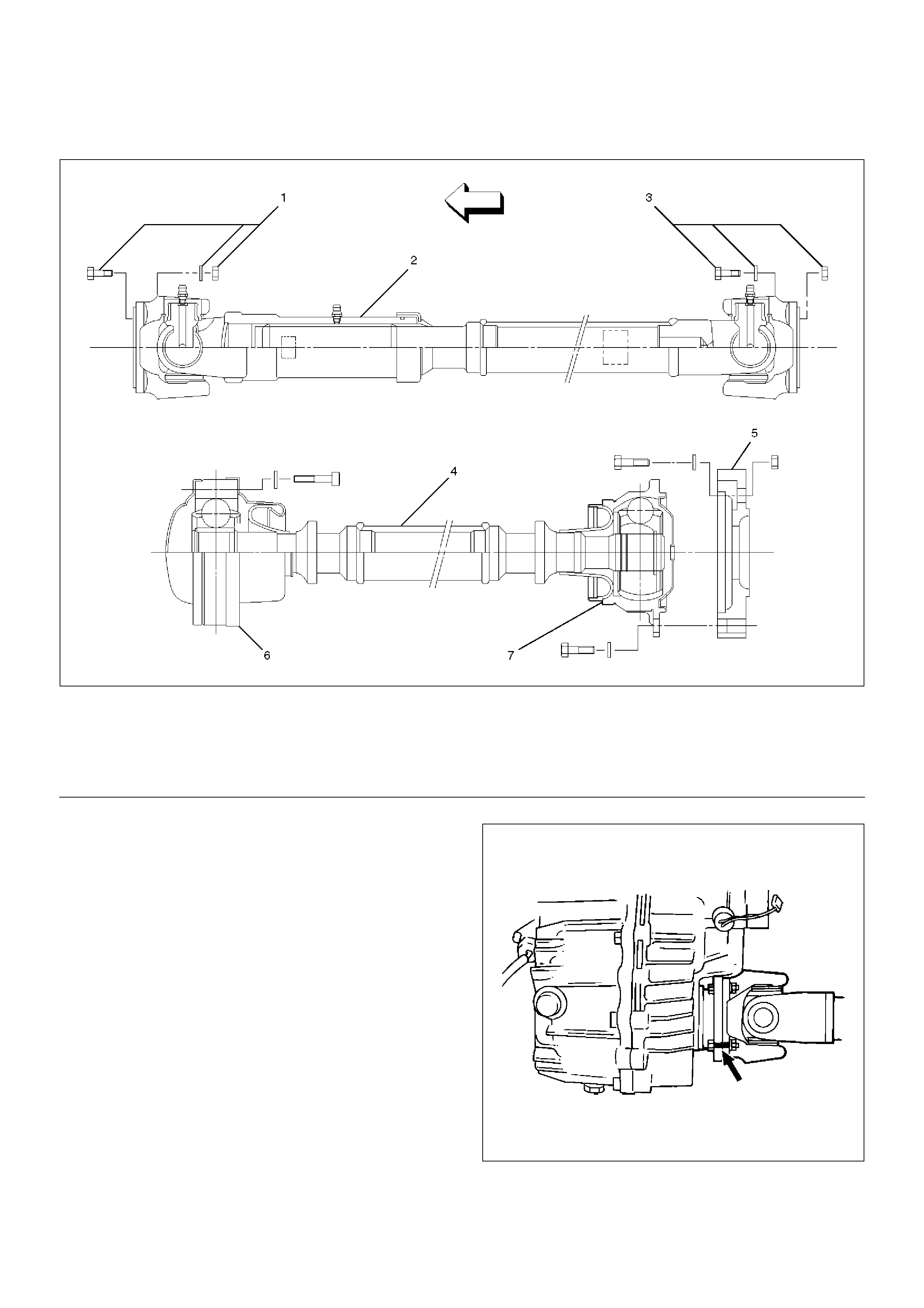

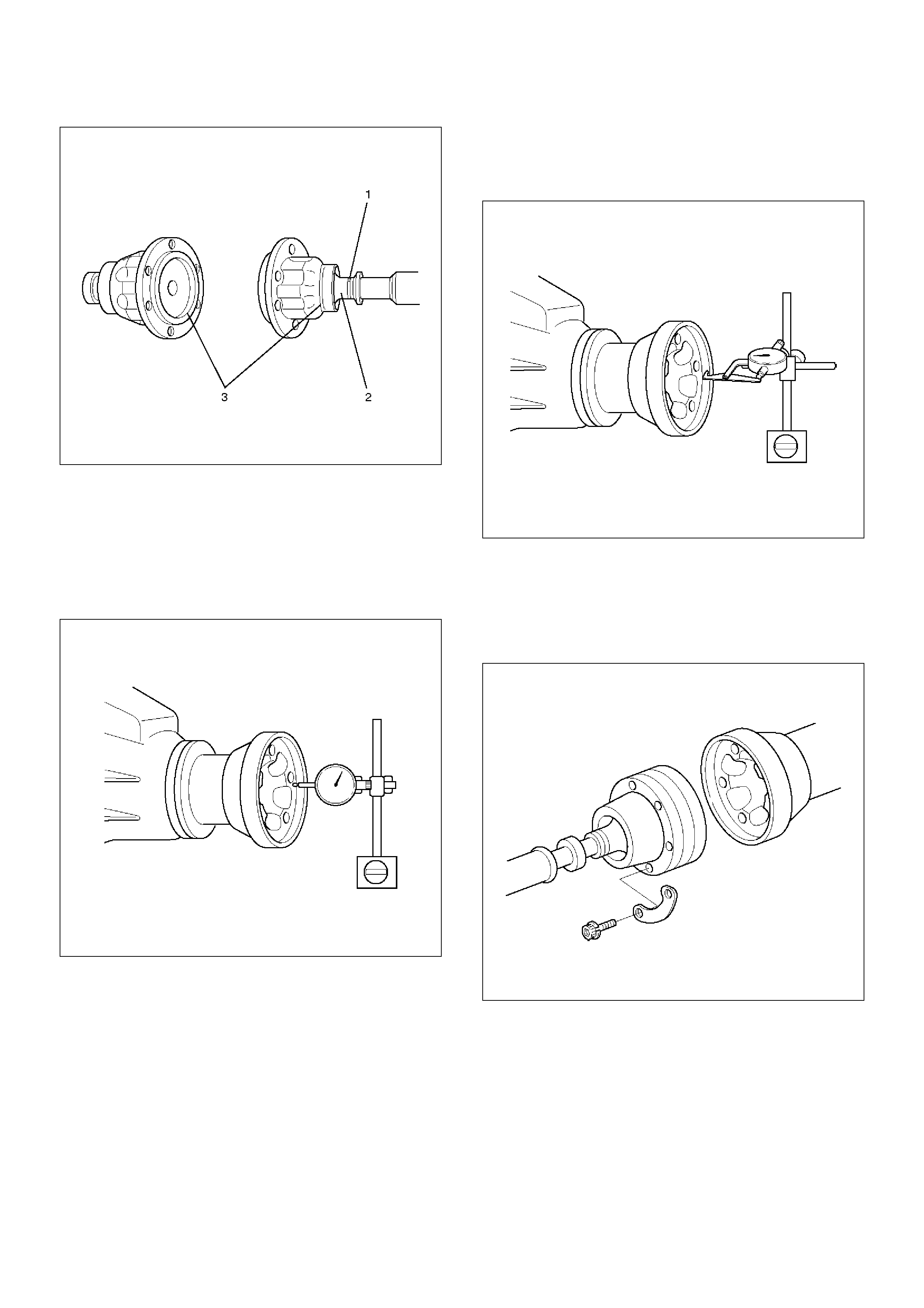

Rear Propeller Shaft

General Description

Since the propeller shaft is balanced carefully, welding

or any other modifications are not permitted.

Alignment marks should be applied to each propeller

shaft before removal.

401RW003

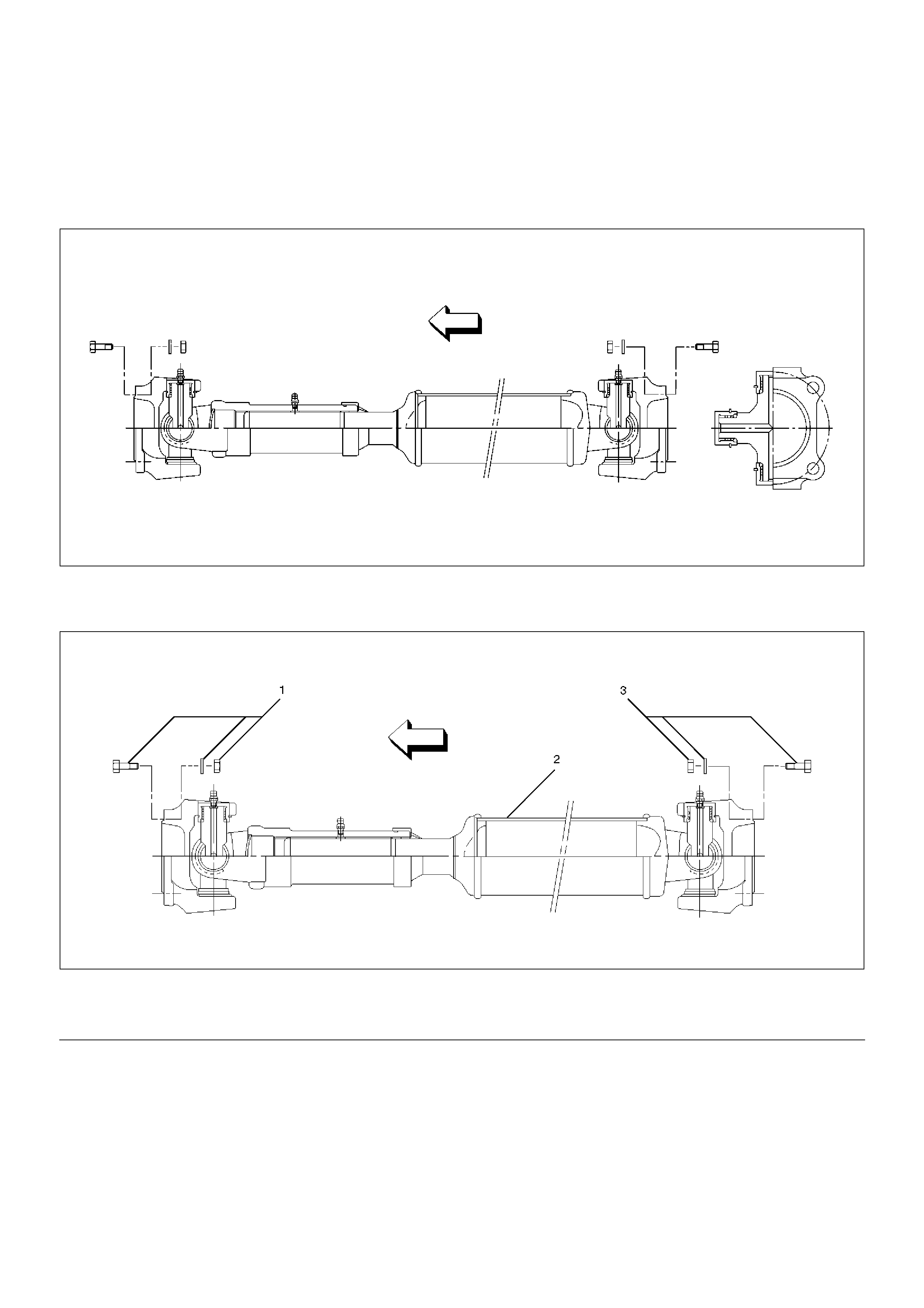

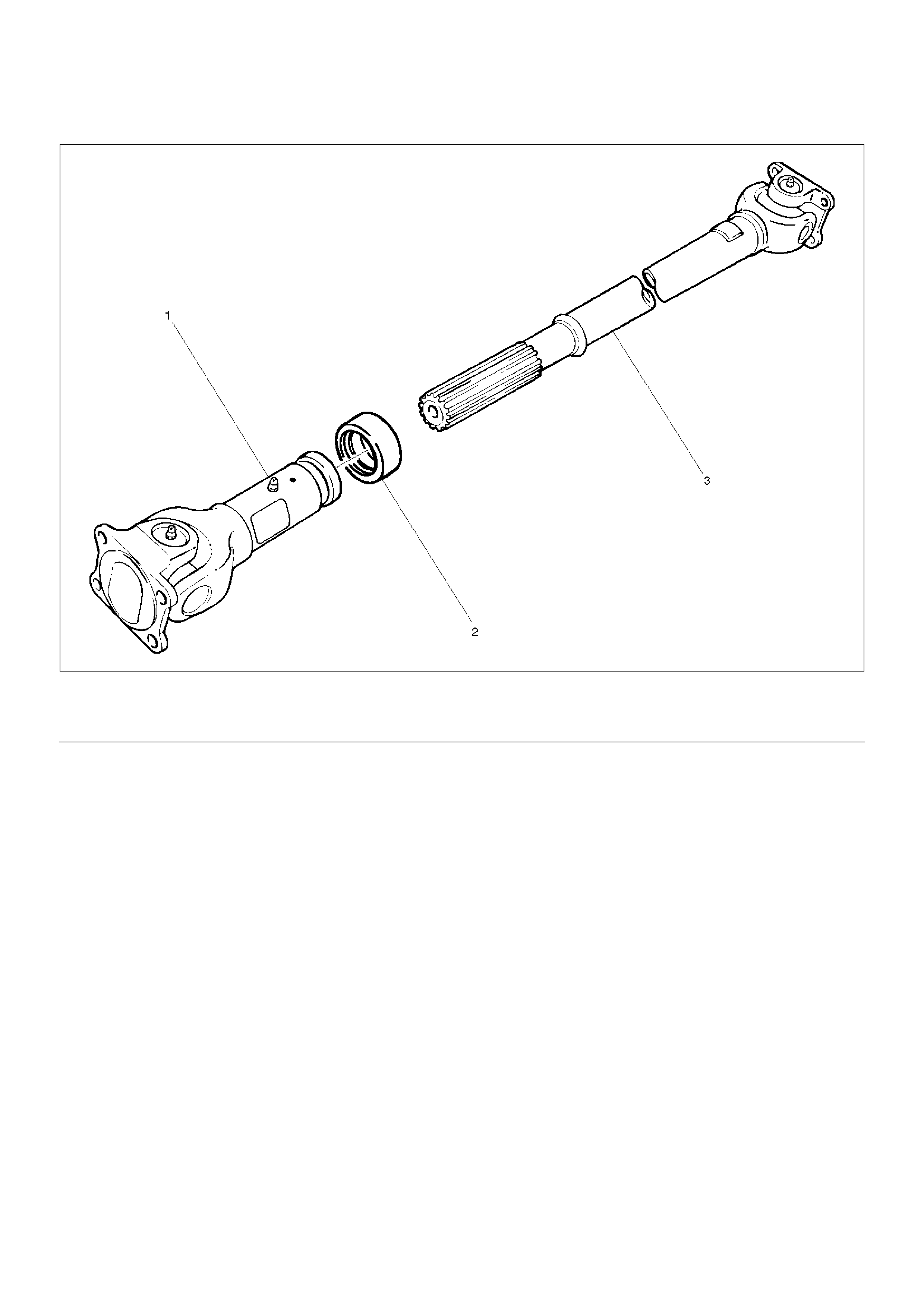

Rear Propeller Shaft and Associated Parts

401RW059

EndOFCallout

Legend

(1) Bolt, Nut and Washer

(2) Rear Propeller Shaft

(3) Bolt, Nut and Washer

Removal

1. Jack up the vehicle and support it on the chassis

stands.

2. Gear shift lever should be placed in neutral position

and parking brake released.

NOTE: Apply alignment marks on the flange at the rear

propeller shaft both front and rear side.

401RS023

3. Remove bolt, nut and washer (Rear axle side).

4. Remove bolt, nut and washer (Transfer side).

5. Remove rear propeller shaft.

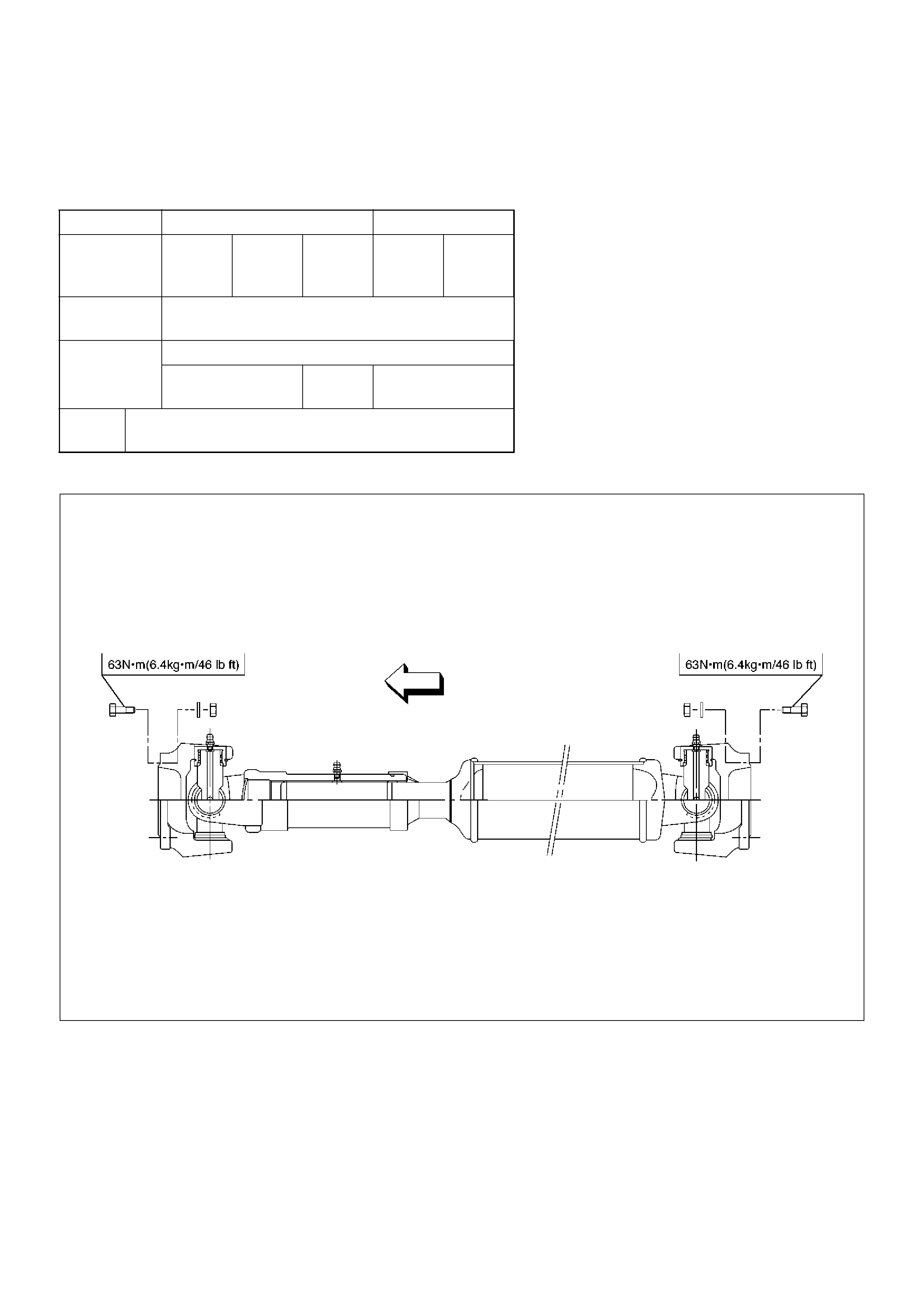

Installation

NOTE: Never install the shaft assembly backwards.

1. Completely remove the black paint from the

connecting surface of flange coupling on each end

of propeller shaft. Clean so that no foreign matter

will be caught in between.

2. Align the mark which is applied at removal .

Install rear propeller shaft and tighten the bolts to

the specified torque.

Torque:63N·m (6.4kg·m/46lbft)

3. After installing the propeller shaft, be sure to apply

black paint (1) to exposed area (other than

connecting surface) of the entire surface of flange

coupling .

401RS022

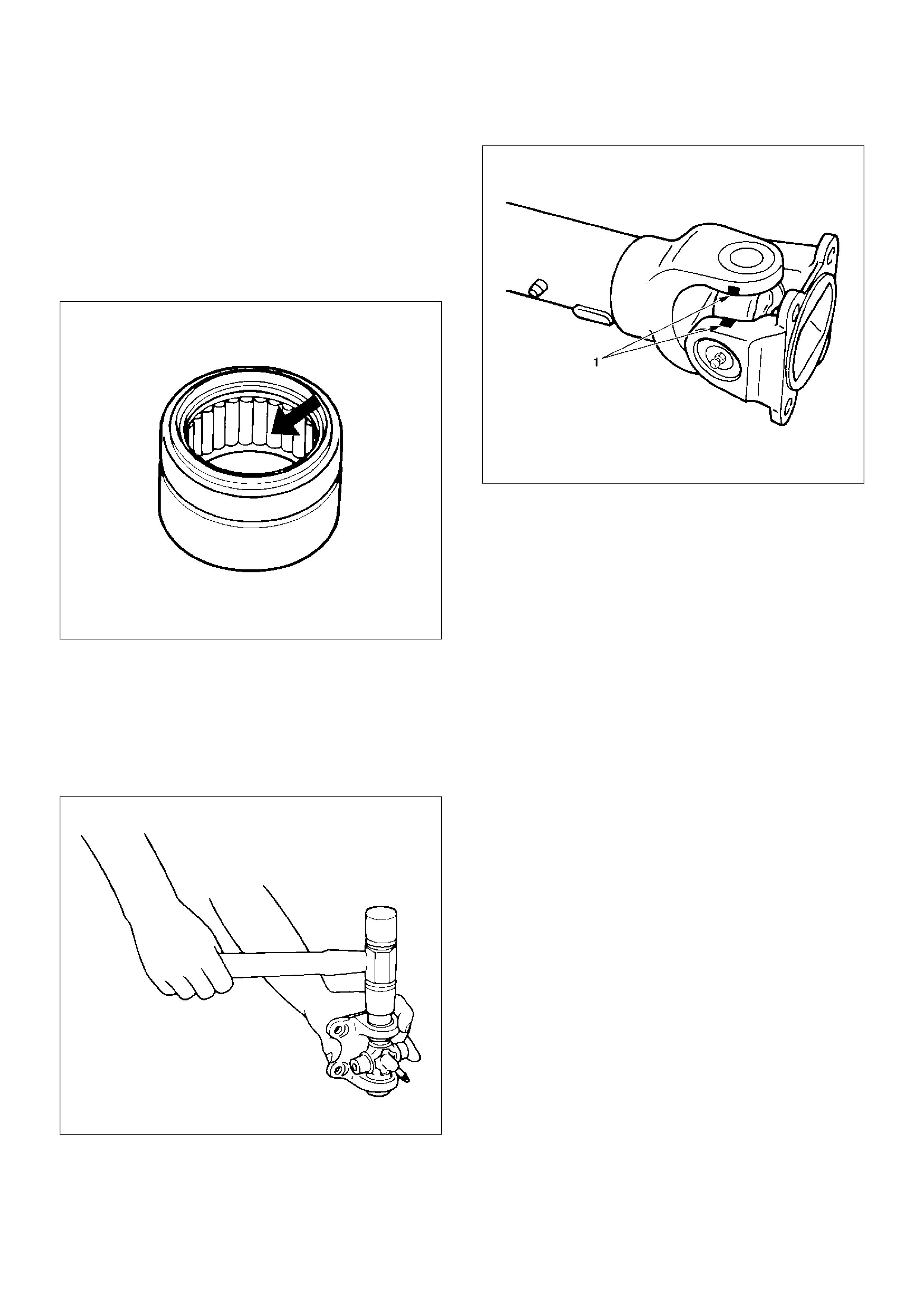

Disassembly

401RW057

EndOFCallout

1. Apply alignment marks (1) on the sleeve yoke and

tube assembly then remove sleeve yoke.

401RW056

2. Remove seal.

3. Remove tube assembly.

Legend

(1) Sleeve Yoke

(2) Seal

(3) Tube Assembly

Universal Joint Disassembly

401RW054

EndOFCallout

1. Apply alignment marks (1) on the yokes of the

universal joint, then remove snap ring.

401RS028

2. Tap out the needle roller bearing by gently striking

the shoulder of the yoke, using a mallet or a copper

hammer.

401RS006

Legend

(1) Flange Yoke

(2) Spider with Grease Fitting

(3) Snap Ring

(4) Needle Roller Bearing

(5) Grease Fitting

3. Make sure of proper position for reinstallation by

applying setting marks, then remove spider with

grease fitting.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition is

found through inspection.

NOTE: When any part of the journal assembly (spider,

needle roller bearing, grease fitting) requires

replacement, be sure to replace the entire assembly.

Check the following parts for wear, damage, noise or

any other abnormal conditions:

1. Spider

2. Needle roller bearing

3. Yoke

4. Flange

Outside Diameter of Spider Pin

Standard:17.00mm (0.669in)

Limit:16.90mm (0.665in)

401RS007

Propeller Shaft Run-out

Support the ends of the propeller shaft on V-blocks (2)

and check for run-out by holding the probe of a dial

indicator (1) in contact with the center part of the shaft.

If the amount of run-out is beyond the standard value for

assembly, correct with a bench press or replace the

shaft with a new propeller shaft assembly .

Standard:0.3mm (0.012in)

Limit:0.5mm (0.02in)

401RS008

Play in Splines in Normal Direction of

Rotation

Check the amount of play between the sleeve yoke (1)

and the propeller shaft spline (2) in the direction of

rotation, using a pointed feeler gauge.

Standard:0.073 – 0.156mm (0.003 – 0.006in)

Limit:0.3mm (0.012in)

401RS009

Play in Universal Joint

Limit:Less than0.1mm (0.004in)

401RS010

Universal Joint Reassembly

1.Install spider to flange yoke. Be sure to install the

spider by aligning the setting marks made during

disassembly.

2.Before installing needle roller bearing, apply a

molybdenum–disulfide grease or a multi–purpose

type grease NLGI No. 2 to inside of the bearing cap.

Grease Amount:Approx.1.2g (0.042oz)

401RS011

3.Using either a mallet (or copper hammer) or a

press, install the needle roller bearing into the yoke

so that the snap ring can be installed in its groove.

CAUTION: The needle roller bearing cannot be

installed smoothly if it is set at an incorrect angle

with the flange and excessive hammering will

damage the needle roller bearing.

401RS012

4. Align setting marks (1) and join the yokes.

NOTE: Assemble the spider and spline yoke so that

their grease fittings are arranged on the same side.

401RS028

5. Install snap ring.

NOTE: Discard used snap rings and install new ones.

When the bearing cap is in position, select and attach a

snap ring of suitable thickness so that the end play of

the spider pin is held within 0.1 mm (0.004 in).

Snap ring thickness and identification color

1.5mm (0.059in):Blue

1.545mm (0.061in):White

1.59mm (0.063in):Yellow

1.635mm (0.064in):Green

1.68mm (0.066in):Not colored

NOTE: Be sure to use snap rings of the same thickness

on both sides.

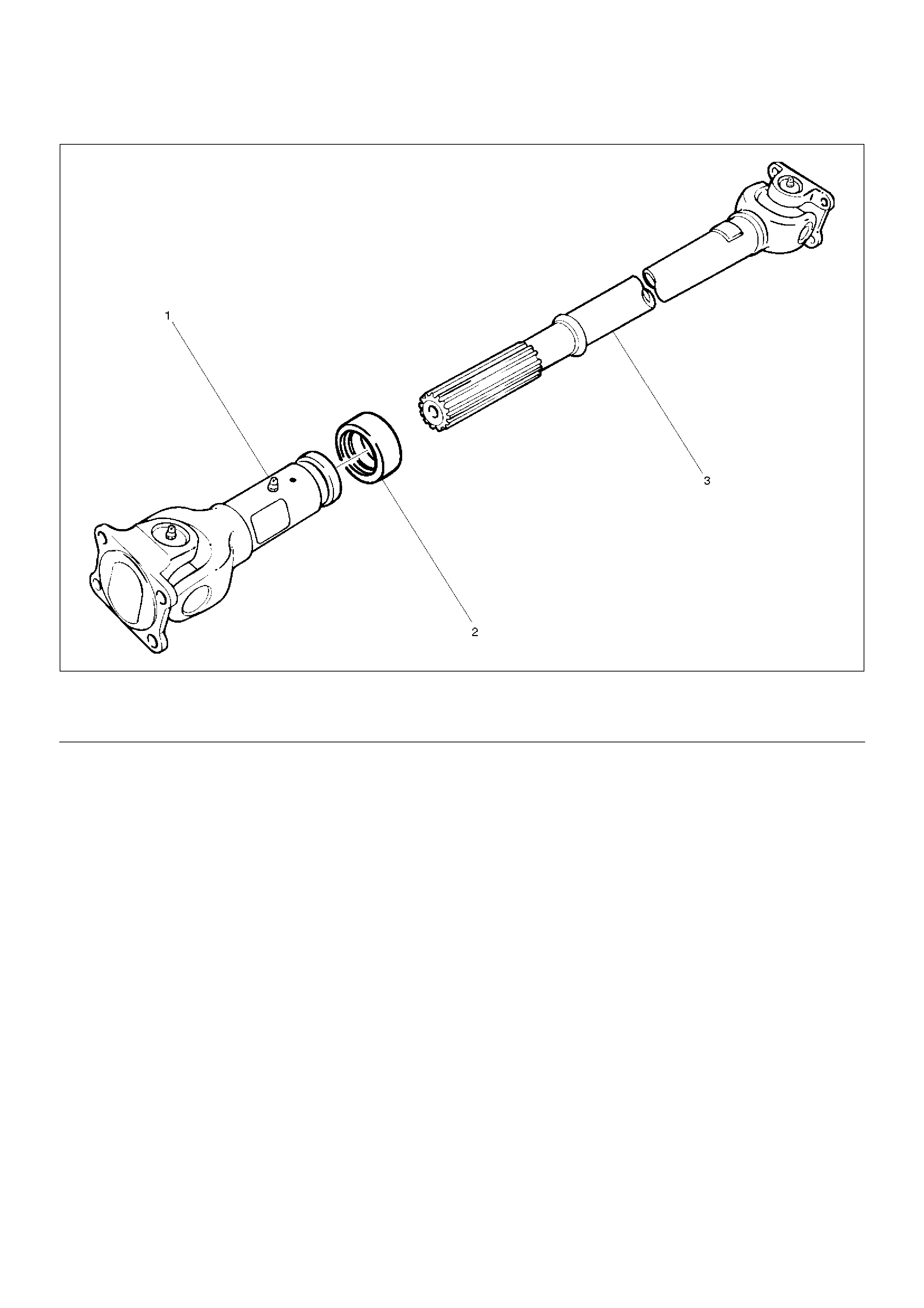

Reassembly

401RW057

EndOFCallout

1. Discard used seal and install new one.

2. Align the alignment marks and install tube assembly

to sleeve yoke.

Legend

(1) Sleeve Yoke

(2) Seal

(3) Tube Assembly

Main Data and Specifications

General Specifications

Torque Specifications

E04RW023

Engine 6VE1 (3.5L) 4JX1 (3.0L)

Transmission

M/T A/T

A/T

with

TOD

M/T A/T

Construction Hollow steel tube with yoke and spider type

universal joint

Length

1093mm (43.03in) 1075mm

(42.32in) 1029mm (40.51in)

Outside

diameter 68.9mm (2.71in)