SECTION 6C ENGINE FUEL

GENERAL DESCRIPTION

General Description

On-Vehicle Service

Fuel Filter Assembly

Fuel Filter Cartridge

Injector

Fuel Pump Pipe

High Pressure Oil Pump

Fuel Tank

Fuel Gauge Unit

Fuel Filler Cap

To ensure the compatibility between low exhaust

emission and high engine output, an HEUI

(Hydraulically actuated Electronically controlled Unit

Injector) system, has been adopted. This system is

comprises of a hydraulic system, fuel system, and

electronic control system, using a high-pressure oil

pump in place of the conventional fuel injection pump.

The oil pressurized by means of this pump and by

signals from the ECM (Electronic Control Module)

actuates the fuel injector provided for each cylinder.

Inside of the fuel injector, fuel pressure is increased due

to the high-pressure oil. The ECM detects the driving

state of the vehicle, forms, signals sent by engine and

other part sensors, which determines the optimum fuel

injection amount and timing, thus controlling the fuel

injectors. Thus high engine output, good fuel economy,

and low exhaust emission are realized.

IMPORTANT

For MY2003, a number of modifications were made to

the engine mechanical design and the engine fuel,

air intake and exhaust systems.

The engine fuel system modifications include the

fitment of revised injectors and a new fuel calibration

for the ECM.

Always ensure the correct components and ECM

calibration are used when conducting any servicing

procedures on the 4JX1-TC engine.

Always refer to the latest issue of Holden Partfinder to

correctly identify replacement part.

When working on the fuel system, there are several

things to keep in mind:

1) Any time the fuel system is being worked on,

disconnect the negative battery cable except for

those tests where battery voltage is required.

2) Always keep a dry chemical (Class B) fire

extinguisher near the work area.

3) Replace all pipes with the same pipe and fittings

that were removed.

Clean and inspect 'O' rings. Replace where

required.

4) Always relieve the line pressure before servicing

any fuel system components.

5) Do not attempt repairs on the fuel system until you

have read the instructions and checked the pictures

relating to that repair.

6) After maintenance work, push priming pump and

send enough fuel to the fuel system before starting

the engine.

NOTE: In comparison with the conventional engine,

the capacity of fuel passage in the 4JX1 engine is

larger. It takes the priming pump more time to fill the

system with fuel. Keep this in mind when servicing the

fuel system.

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

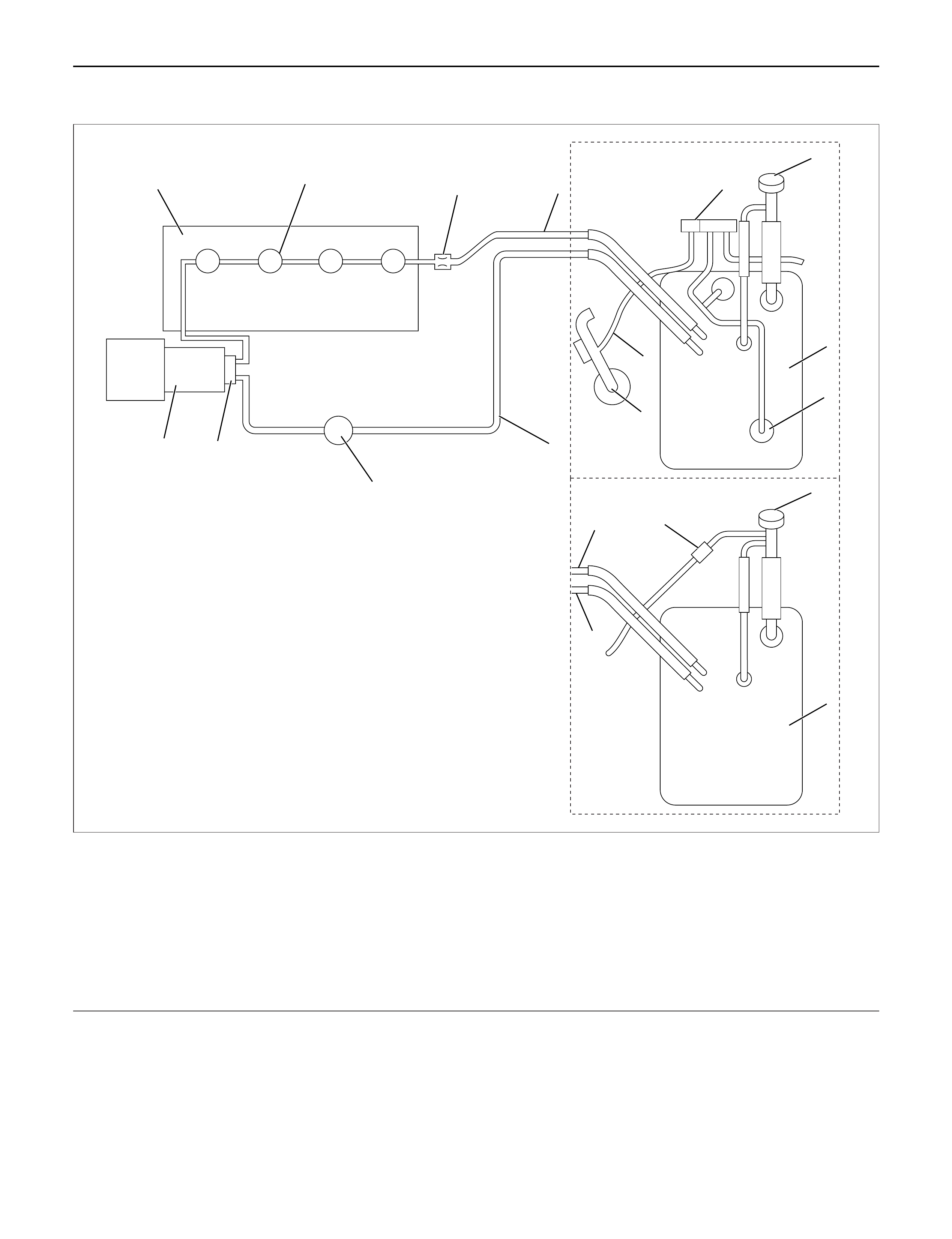

FUEL FLOW

1

14

MY1998-2002 Euro-2

8910 11

1

2

2

4

12

5

6

7

3

13

14

MY2003 Euro-3

11

4

Legend

(1) Fuel Filler Cap

(2) Fuel Tank

(3) Rollover Valve

(4) Fuel Supply Pipe

(5) Fuel Filter with Priming Pump

(6) Fuel Pump

(7) High Pressure Oil Pump

(8) Cylinder Head

(9) Injector

(10) Orifice

(11) Fuel Return Pipe

(12) Fuel Tank Pressure Release Hose

(13) Intake Air Duct

(14) Fuel Tank Pressure Control Valve

040R200001

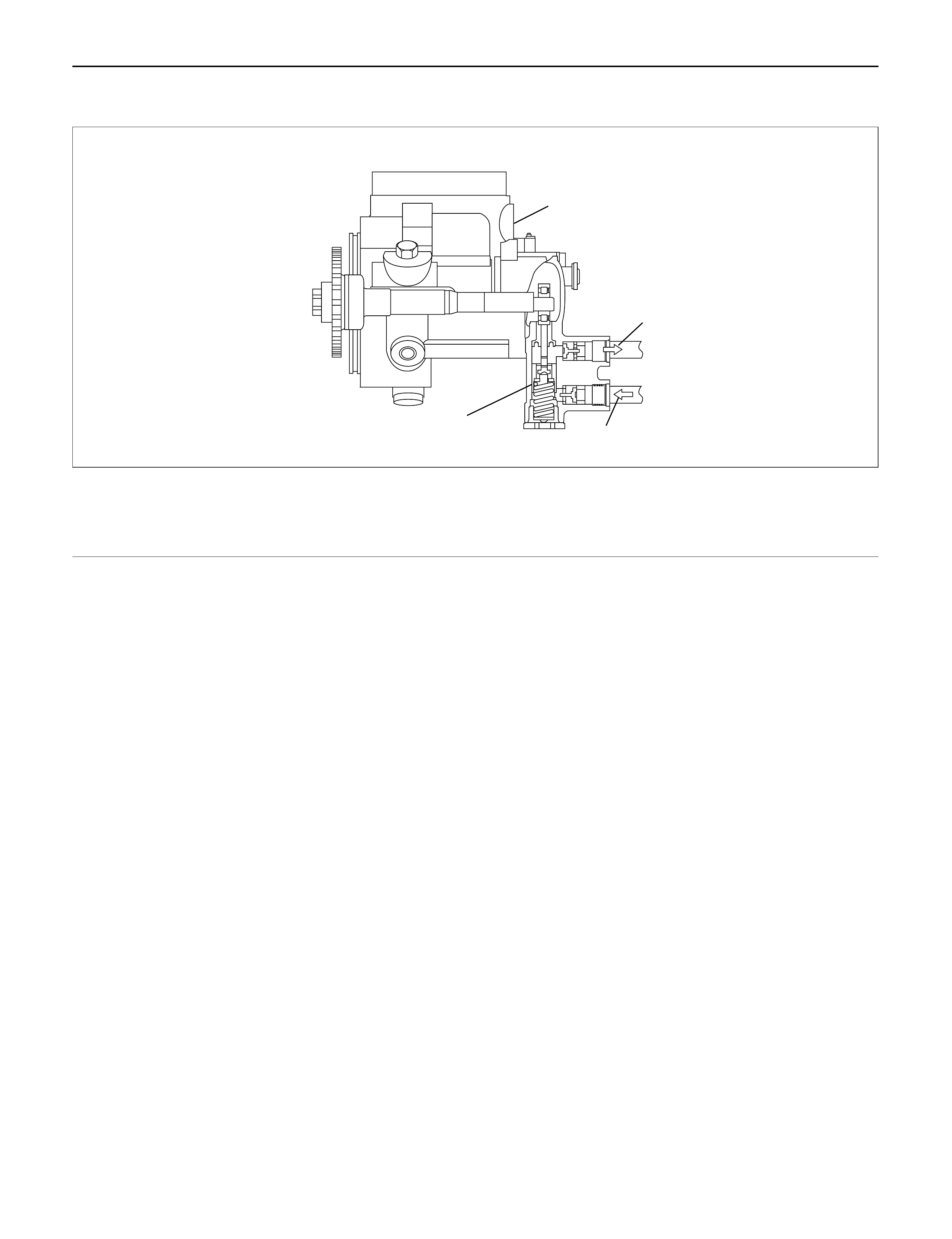

FUELPUMP

1

2

3

4

Legend

(1) High Pressure Oil Pump

(2)Outlet To Injector

(3)Inlet From Fuel Tank

(4) Fuel Pump

140RW041

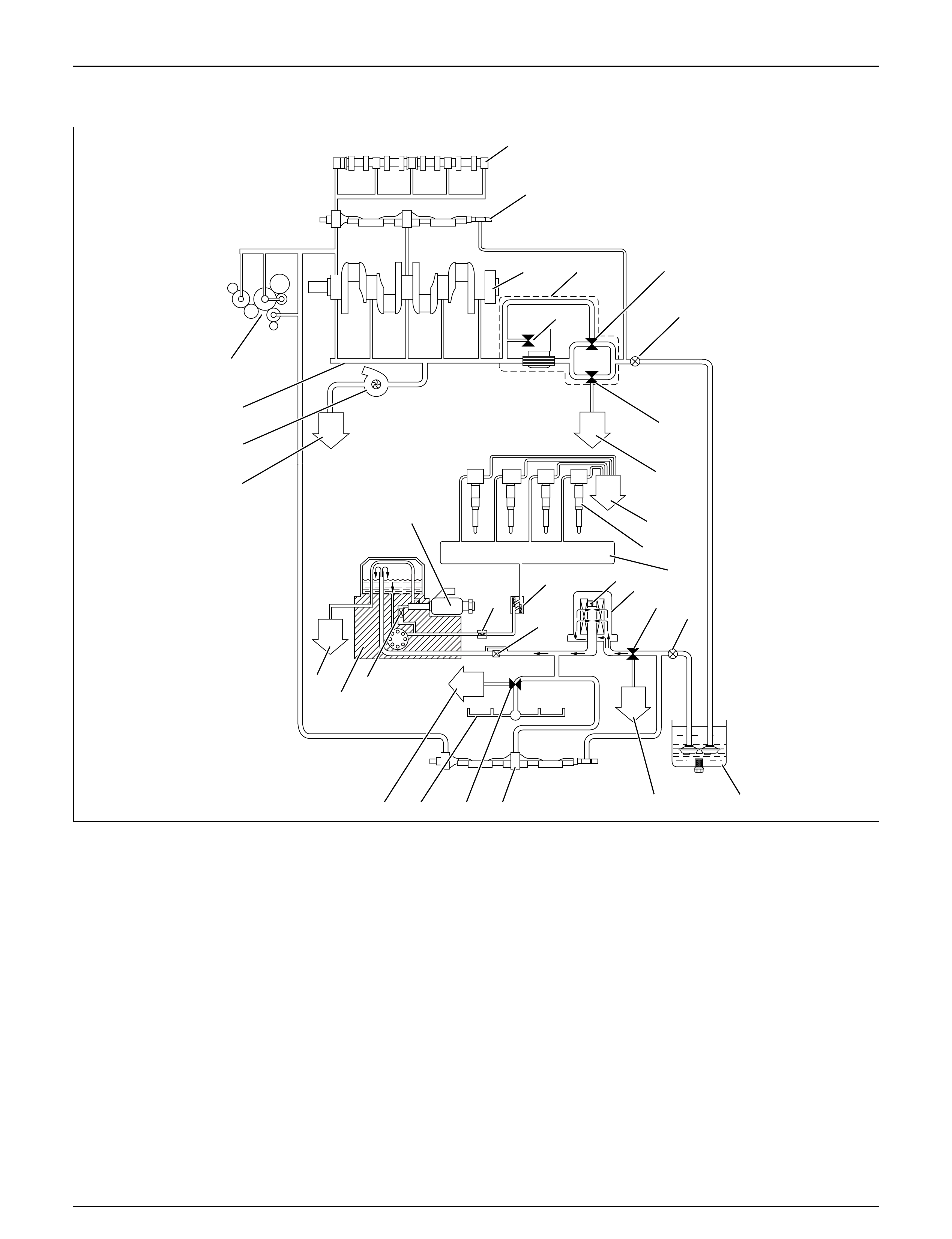

HIGH PRESSURE OIL PUMP, OIL FLOW

33

32

31

30

1

2

34

5

6

8

9

7

10

11 12

13 14

23

29

25

28 27 26

24

15 16

1718

19202122

Legend

(1) Camshaft

(2) Balance Shaft

(3) Crankshaft

(4) Oil Cooler and Oil Filter Assembly

(5) Oil Filter Relief Valve 98 Kpa (1 kg/cm2/14.2 Psi)

(6) Oil Cooler Relief Valve 245 Kpa (2.5 kg/cm2/

36 Psi)

(7) First Oil Pump

(8) Main Oil Relief Valve 588 Kpa (6 kg/cm2/ 85 Psi)

(9) To Oil Pan

(10) To Oil Pan

(11) Injector

(12) Oil Rail

(13) Sub Oil Filter Relief Valve 98 Kpa (1 kg/cm2/

14.2 Psi)

(14) Sub Oil Filter

(15) Relief Valve 588 Kpa (6 kg/cm2/ 85 Psi)

(16) Second Oil Pump

(17) Oil Pan

(18) To Oil Pan

(19) Balance Shaft

(20) Cooling Jet Relief Valve 245 Kpa (2.5 kg/cm2/

36 Psi)

(21) Cooling Jet

(22) To Oil Pan

(23) Two Way Check Valve

(24) Nipple Filter

(25) Edge Filter

(26) Edge Filter

(27) High Pressure Oil Pump Assembly

(28) To Oil Pan

(29) Pressure Control Valve

(30) To Oil Pan

(31) Turbocharger

(32) Oil Gallery

(33) Timing Gear Train

040RW018

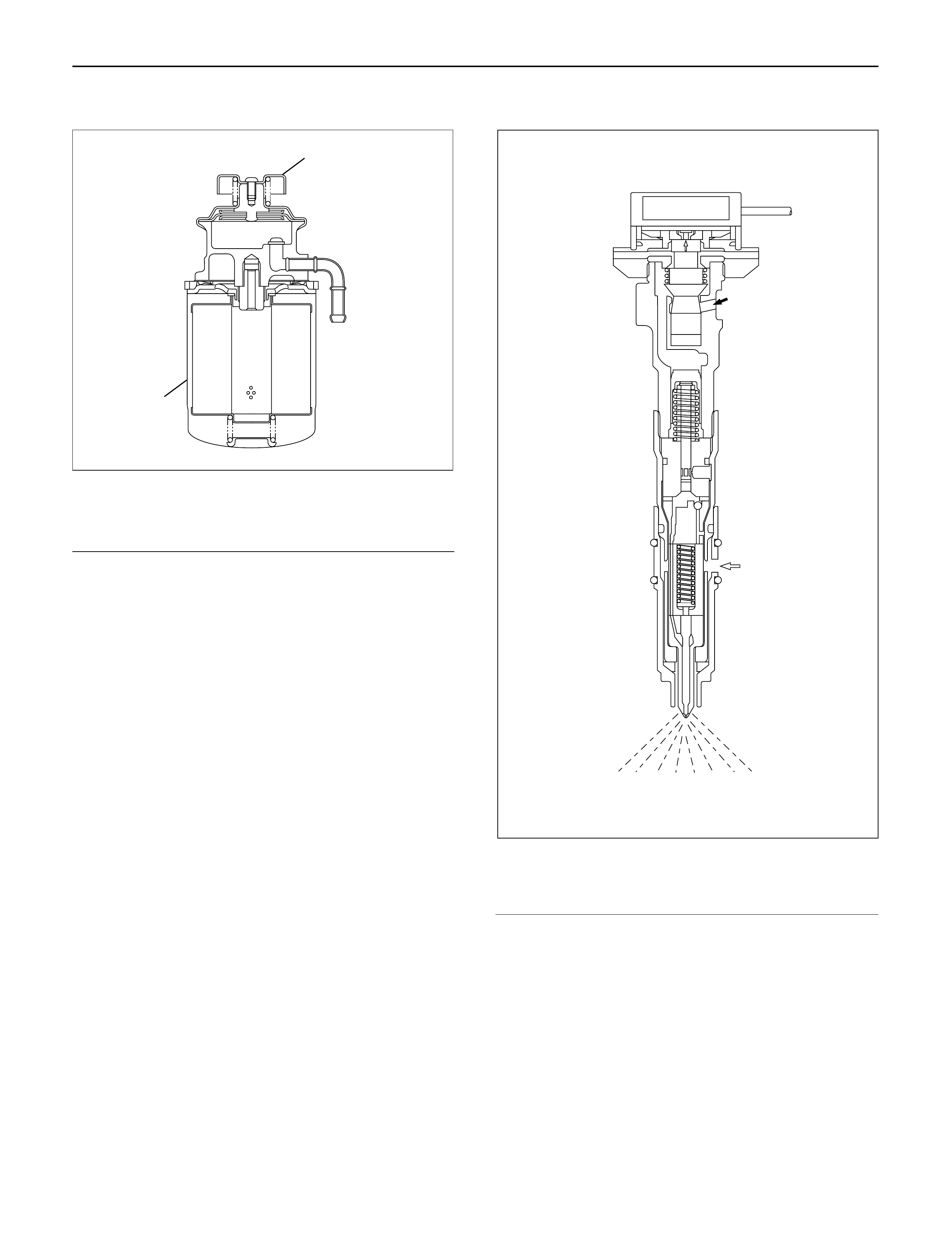

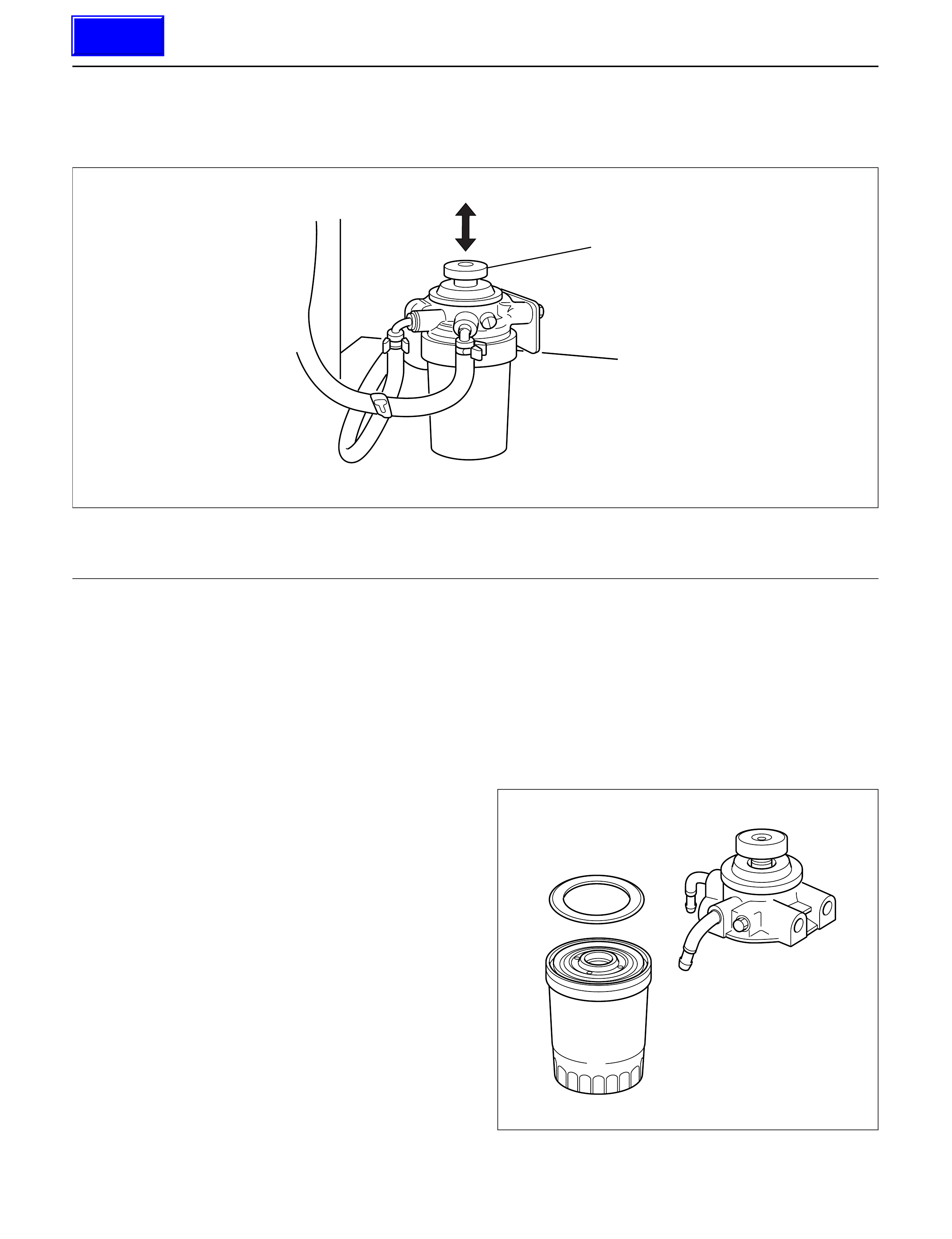

FUEL FILTER

Legend

(1) Priming Pump

(2) Fuel Filter Cartridge

A cartridge type fuel filter is used along with the piston

type fuel pump on the high pressure oil pump.

The fuel filter removes foreign material from the fuel

before it reaches the fuel pump.

Adiaphragm type priming pump is installed at the top of

the fuel filter. It is used during the air bleeding

procedures.

INJECT OR ASSEMBLY

Legend

(1) Oil Passage

(2) Fuel Passage

1.Construction

The fuel injector is comprised of the solenoid

section, hydraulic line, and fuel line. Fuel injection is

controlled by the continuity time signal and

continuity start timing signal sent by the ECM

(Electronic Control Module) to the solenoid.

2.Operation

1)The ECM detects engine operating conditions

from input signals, such as engine speed

accelerator throttle opening, and engine coolant

temperature, sending the optimal signals to the

solenoid.

1

2

041RW017

1

2

055RW018

2)With the current applied to the solenoid, a

poppet valve is opened by means of an

armature to let high-pressure engine oil into the

injector.

3) Under the oil pressure, the piston and plunger

are depressed to compress the fuel. The

pressure of the compressed fuel is increased

over the pressure of high-pressure engine oil by

the ratio (about 7 : 1) of piston top to plunger

base area.

4) The injection nozzle end needle is lifted under

the increased pressure of the fuel for fuel

injection.

5) When the ECM switches the current flow OFF,

the poppet valve closes, and the high-pressure

engine oil is exhausted from the injector.

ON-VEHICLE SERVICE

FUELFILTER ASSEMBLY

REMOVAL

1. Disconnect battery ground cable.

2.Fuel Filter cap

3. Fuel Hose

1) Disconnect fuel hose from filter body.

Plug the hose ends to prevent fuel spillage.

4. Remove the Bolt on Fuel Filter Bracket

5. Remove Fuel Filter Assembly

INSTALLATION

1. Install the fuel filter assembly

2. Tighten the Fuel Filter Bracket Fixing Bolt

3. Fuel Hose

1) Connect hoses to filter body.

4. Fuel Filler Cap

1) Connect the battery ground cable.

2) Feed fuel to the fuel pump by priming, and bleed

the air from fuel system.

FUELFILTER CARTRIDGE

DISASSEMBLY

1. Drain fuel completely from the fuel filter.

2. Protect the filter body with cloth and lightly grip with

a vise.

3. Remove the cartridge using a filter wrench.

Filter wrench: 5-8840-0203-0

1

Legend

(1) Priming Pump

012RW111

012RW112

Techline

REASSEMBLY

1. Clean the cartridge mounting surface of the filter

body so that the cartridge can be secured.

Apply engine oil thinly to new cartridge O-ring.

2. To facilitate bleeding, fill the new cartridge with light

oil.

3. Tighten the cartridge until O-ring comes in contact

with the seal, taking care not to spill the light oil.

4. Retighten 1/3 – 2/3 using a filter wrench.

Filter wrench: 5-8840-0203-0

Bleeding

1. Loosen air bleeding plug.

2. Operate priming pump to bleed the air in the fuel

line.

3. Operate the priming pump until the fuel is overflow

from air bleeding plug.

4. Tighten the air bleeding plug.

5. Start the engine, and if it is not started in 10

seconds or less, repeat the bleeding steps.

6. Make sure of no fuel leakage, and tighten the

priming pump.

Legend

(1) Priming Pump

NOTE: In comparison with the conventional engine,

the capacity of fuel passage in the 4JX1 engine is

larger. It takes the priming pump more time to fill the

engine with fuel.

012RW078

1

012RW111

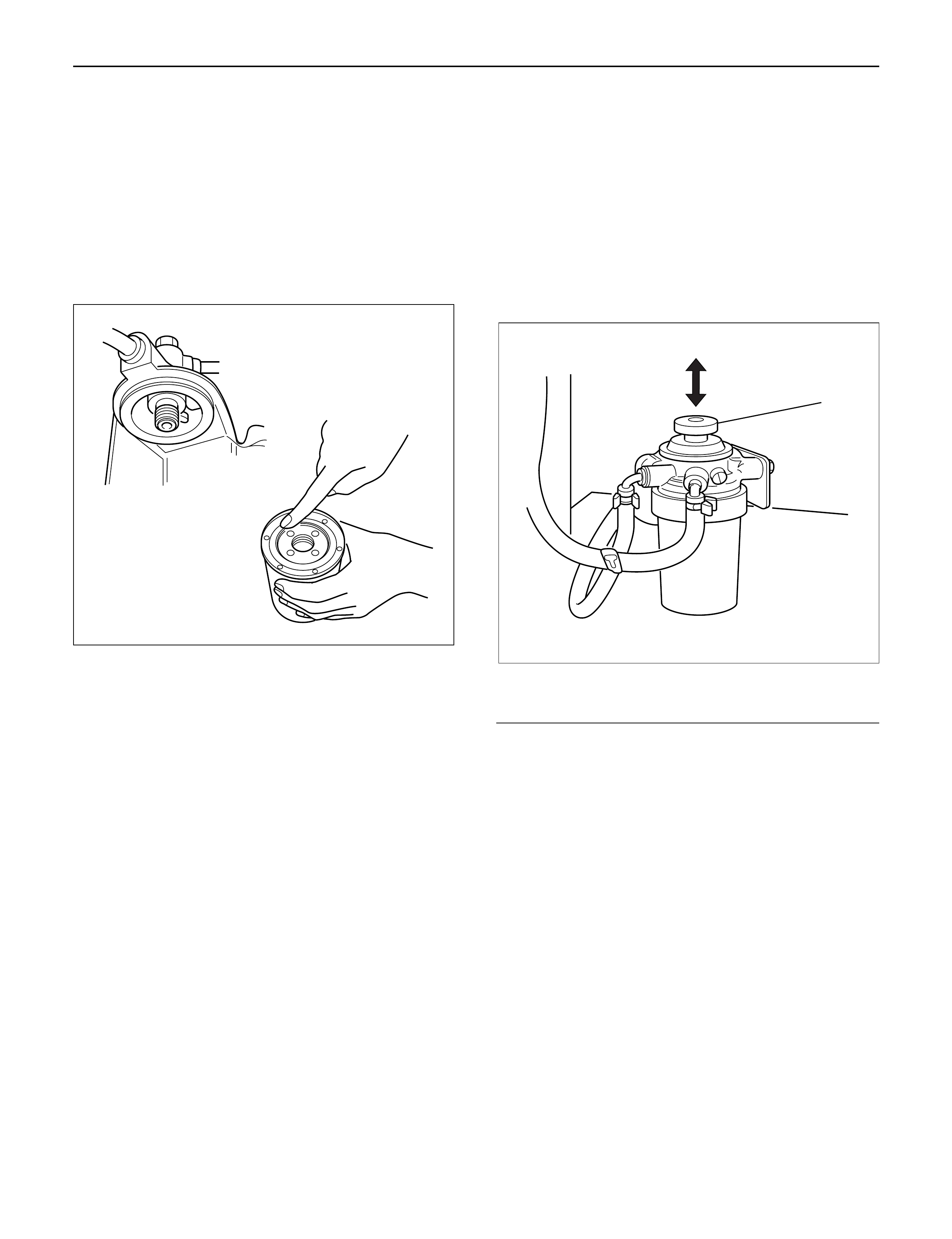

INJECTOR

N.m (kg m/lb ft)

20N.m (2.0kg.m/14 lb.ft)

7N.m (0.7kg.m/61 lb.in)

20N.m (2.0kg.m/14 lb.ft)

Recheck tightening torque

after tightening the oil rail

Apply engine oil to the

stud bolt threads

Tighten 30N.m (3.1kg.m/22lb.ft)

Loosen then tighten again to

25N.m (2.5kg.m/18 lb.ft)

Apply engine oil

to both sides

25N.m (2.5kg.m/18ft.lb) Without

spacer type

E06R200027

With

spacer type

Techline

Techline

Techline

Techline

Techline

Techline

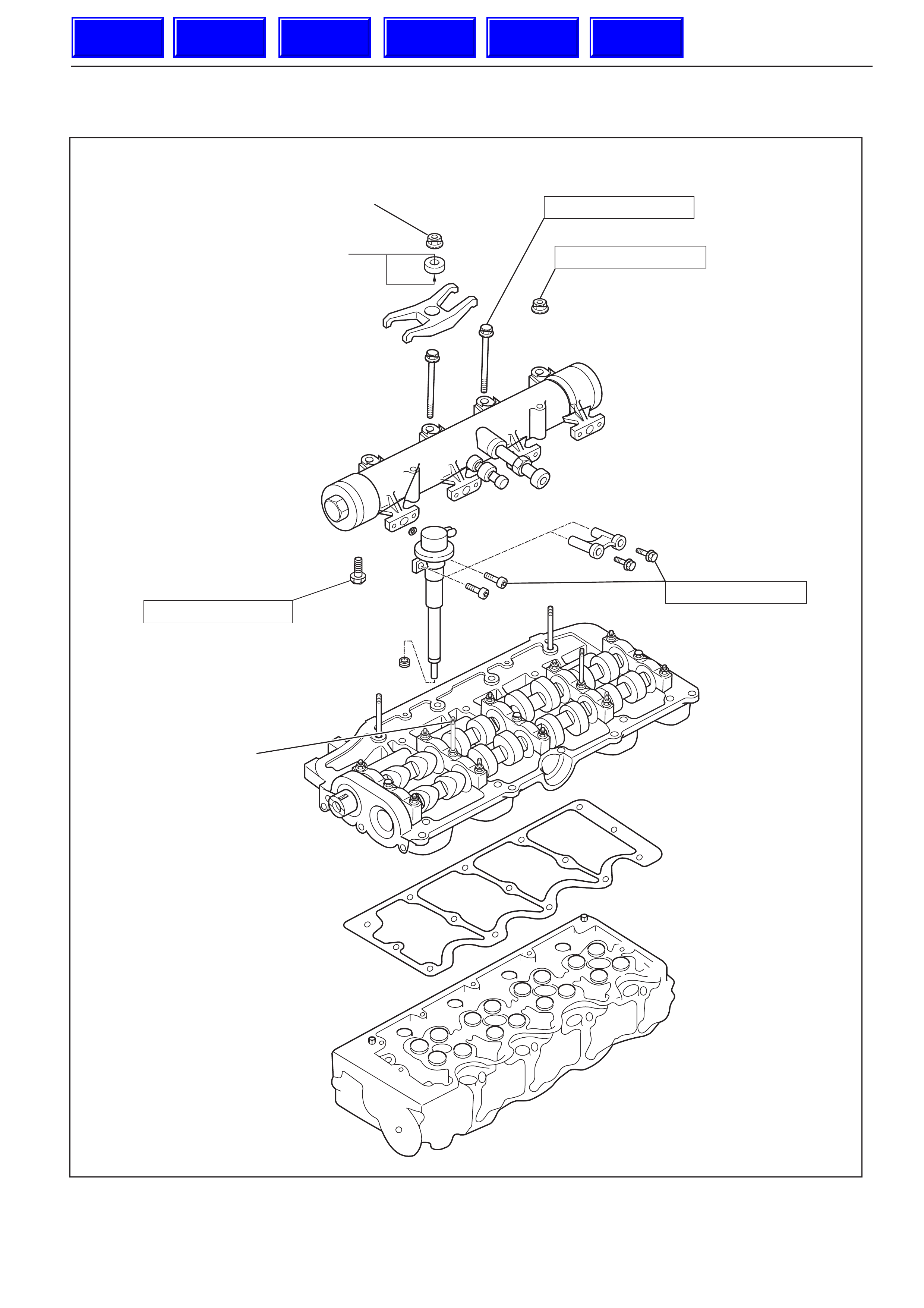

REMOVAL

Prior to removal, be sure to confirm and record the

group code of the injector installed using Tech2.

1.Disconnect battery ground cable.

2.Remove air cleaner cover and air duct.

3.Remove intercooler.

Refer to “Intercooler” in this manual.

4.Remove PCV hose and pipe.

5.Remove cylinder head noise insulator cover.

6.Remove high pressure oil pipe.

CAUTION:

1) Sleeve nut should be loosened with cloth tied

around to prevent oil from spurting due to the

remaining pressure.

2) High oil pressure pipe should be disconnected

with cloth tied around the intake manifold glow

plug to prevent oil from flowing out of the oil

rail.

7. Loosen eye bolt of fuel pipe at fuel pump side.

NOTE: Cloth should be put around the loosened eye

bolt to prevent fuel from flowing out.

8. Remove fuel return hose at chassis side.

9. Remove PCV hose to cylinder head cover.

10. Remove cylinder head cover.

11. Drain the oil from oil rail assembly.

NOTE: Do not drop O-ring

12. Record the grade code of injector for each cylinder

that is indicated on the upper portion of injector.

There are nine kinds of grade code available, one

alphabet letter and one numeral letter.

Grade code

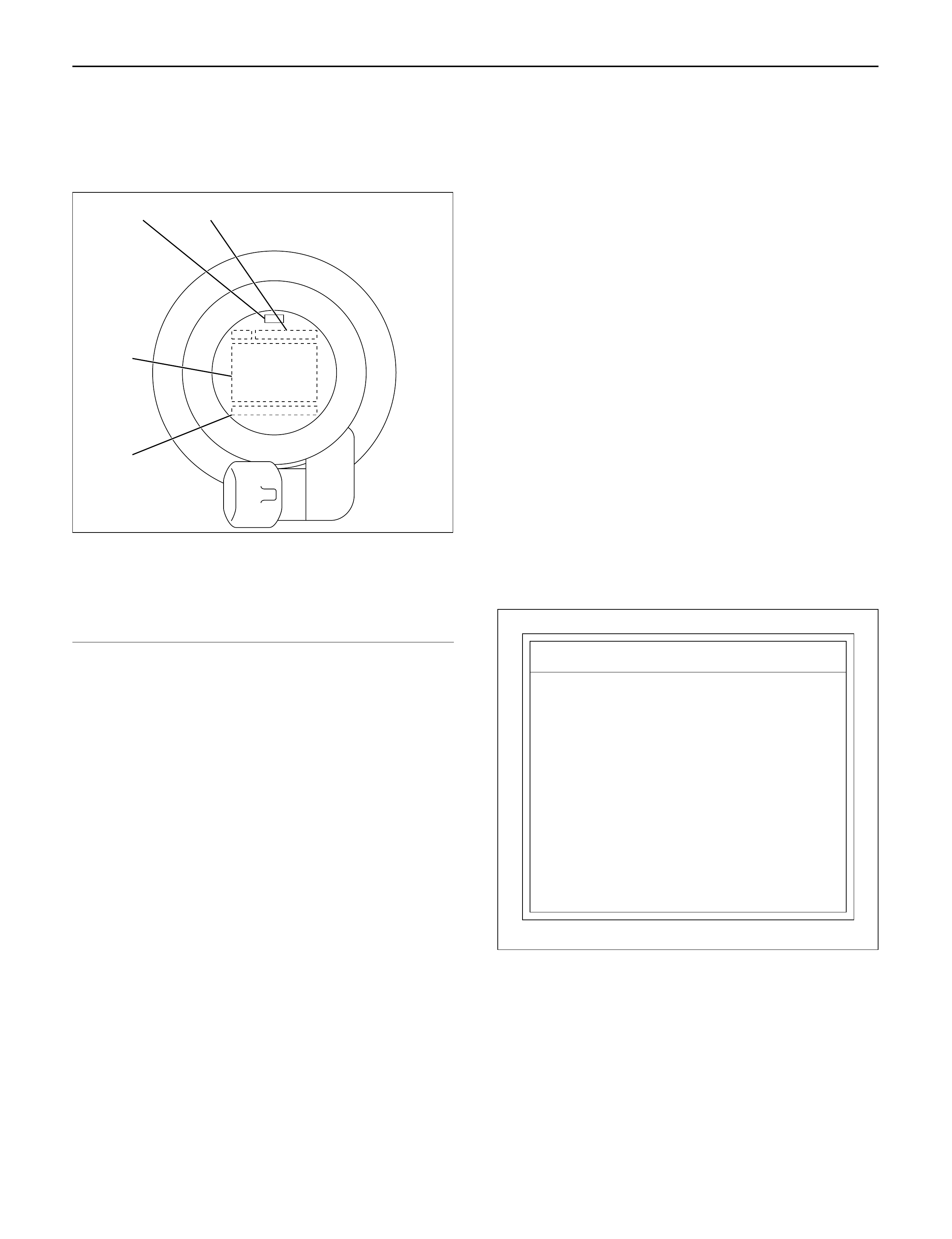

Legend

(1) Part Number

(2) Category Number (Grade code)

(3) Serial Number

(4) Bar Code

13. Remove harness connector from each injector.

14. Loosen nuts and bolts for oil rail.

15. Remove injector fixing bolts.

16. Remove injector clamp.

17. Remove injector assembly.

INSTALLATION

1. Install oil rail, tighten temporarily

2. Install injector assembly.

NOTE:

1) Do not forget to install O-ring between injector and

oil rail.

2) Use new O-ring

3) Clean O-ring groove and fitting surface of parts.

4) Apply engine oil to O-ring.

3. Install injector fixing bolts, tighten temporarily.

4. Install injector clamp, tighten nut temporarily.

· Apply engine oil to washer both side.

5. Tighten injector fixing bolts to the specified torque.

Torque: 7 N·m (0.7 kg·m / 61 lb in)

6. Tighten injector clamp nut to the specified torque

with special method.

Torque: 30 N·m (3.1 kg·m / 22 lb ft) then loosen a

time again tighten as following torque.

Torque: 25 N·m (2.5 kg·m / 18 lb ft)

7. Tighten oil rail to the specified torque.

Torque: 20 N·m (2.0 kg·m / 14 lb ft)

1

4

3

2

055RW00001

Category number

A– 1

A– 2

A– 3

B – 1

B – 2

B – 3

C – 1

C – 2

C – 3

8.Install injector harness assembly, reconnect

harness connecter to injector.

9.Record the identification marking of injector for

each cylinder that is indicated on the upper portion

of injector.

Legend

(1)Part Number

(2)Category Number (Grade code)

(3)Serial Number

(4)Bar Code

10.Install cylinder head assembly.

Refer to “Cylinder Head” in this manual.

11.Fill with about 300cc of engine oil from the high

pressure oil pipe installation port of the oil rail using

an oil filler.

If assembled without filling the oil rail with oil, the

time for engine starting will be longer.

12.Immediately install high pressure oil pipe and

tighten to specified torque.

Torque: 78 N·m (8.0 kg·m / 58 lb ft)

13.Install cylinder head noise insulator cover.

Refer to “Cylinder Head” in this manual.

14.Install intercooler assembly.

Refer to “Intercooler” in this manual.

15.Install air cleaner cover and air duct.

16.Use TECH2 to rewrite injector data to ECM.

For rewriting method refer to section “Data

Programming in Case of ECM Change” of section

6E 4JX1 engine driveability and emissions in this

manual.

NOTE:

1) On completion of servicing, bleed air from the

engine inside fuel passage by means of the priming

pump. (The priming pump should be operated more

times than in the case of conventional engines.)

2) As air is in the oil rail, it takes more time to start the

engine. Rough idling may occur while the air is

being bled completely after engine start, but it does

not indicate trouble.

The air will be bled and normal engine status will be

reached while the vehicle is driven for about 5 km

or engine is operated for about 5 minutes at 1500 to

2000 rpm.

3) The injector spare part will be provided for group

number B1, B2 and B3 only.

Injector Grade code Programming

(Injector Change)

In case of an injector change, the injector grade code

(category number) must be programmed by Tech-2.

Programming Procedure

1. Connect the Tech-2 to the vehicle DLC.

2. Turn the starter switch to the “ON” position.

3. Select the “Diagnosis” from the Main menu.

4. Select the “Programming” from the Application

menu.

1

4

3

2

055RW00001

F0 :

F1 :

F2 :

F3 :

F4 :

035RW00002

5. Select “Programming Trim Date” from

Programming menu.

6. Select the injector change from Programming Trim

Date menu.

7. Select the cylinder number which changed injector.

8. Appoint and select the grade code (Category

number) of injector.

9. Confirm the completion of injector programming.

Note; The injector grade code (category number) is

indicated on the new (service part) injector.

Injector 1

Injector 4

Injector 3

Injector 1

Programming Trim Data

Select cylinder

Injector 2

(W) 1998 (UE) Rodeo/Amigo,Wizard

Electronic System 3.0L L4 4JX1

035RW00003

Injector 1

Programming Trim Data

Do you program trim data in

this cylinder

(W) 1998 (UE) Rodeo/Amigo,Wizard

Electronic System 3.0L L4 4JX1

YesNo

035RW00004

1Category A1

(W) 1998 (UE) Rodeo/Amigo,Wizard

3.0L L4 4JX1

035RW00005

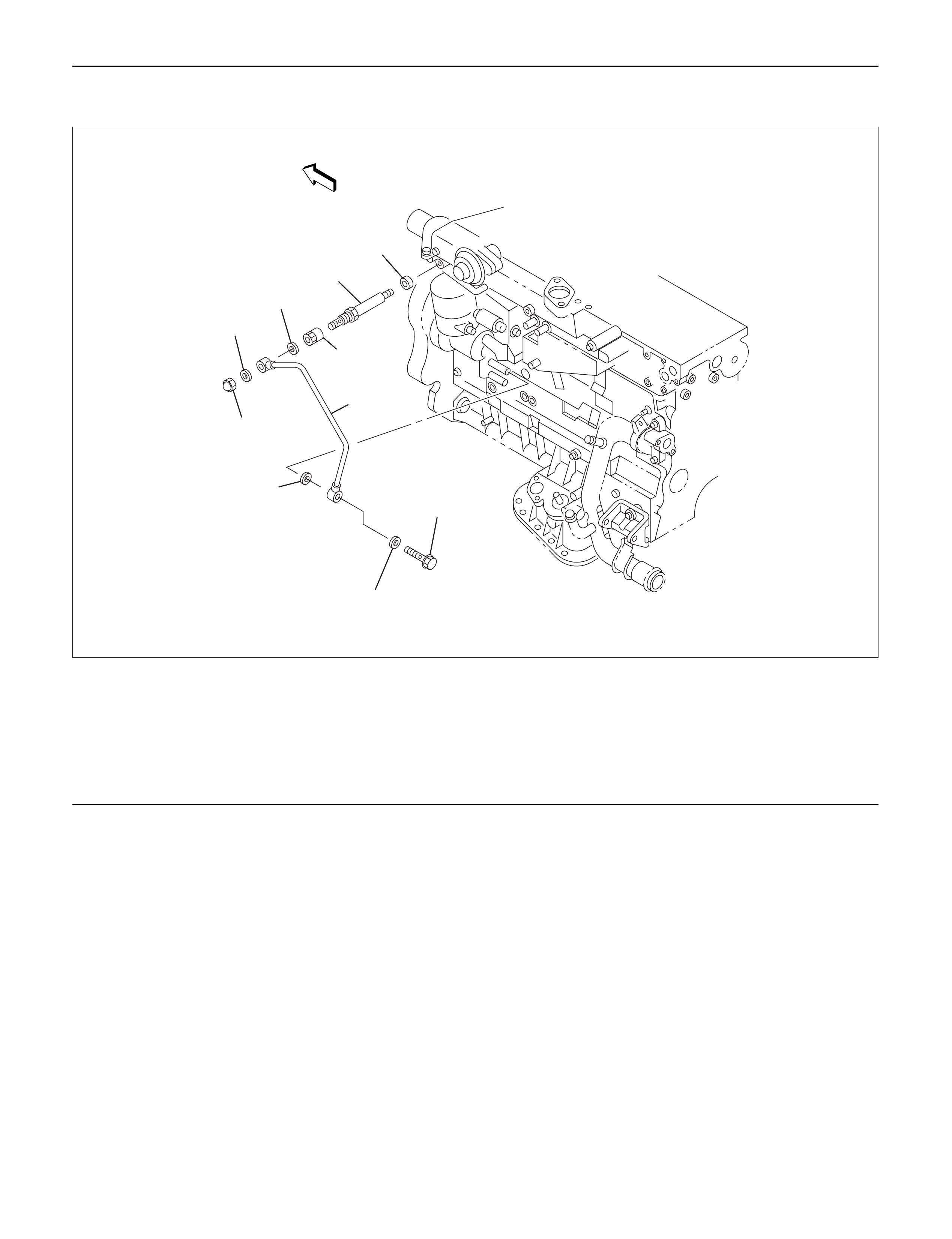

FUELPUMPPIPE

6

2

3

10

9

8

5

4

7

1

Legend

(1) Cap Nut

(2) Gasket

(3) Gasket

(4) Pipe Nut

(5) Adapter

(6) Gasket

(7) Fuel Pump Pipe

(8) Eye Bolt

(9) Gasket

(10) Gasket

040R200002

REMOVAL

1. Remove eye bolt.

2. Remove cap nut.

NOTE: The eye bolt and cap nut should be

disconnected with cloth tied around them to prevent

flowing out of fuel.

3. Remove fuel pump pipe.

4. Remove pipe nut.

5. Remove adapter.

INSTALLATION

1. Apply engine oil to the thread, then install adapter

with new gasket.

Torque : 13 N·m (1.3 kg·m/113 lb in)

NOTE: Be careful not to enter the foreign material.

2. Apply engine oil to the thread, then install pipe nut.

Torque : 14 N·m (1.4 kg·m/122 lb in)

NOTE: Do not apply oil to cap nut side.

3. Install fuel pump pipe, new gaskets and cap nut to

adapter temporarily. Do not tighten the cap nut.

4. Install eye bolt with new gasket then tighten to

specified torque.

Torque : 30 N·m (3.1 kg·m/22 lb ft)

NOTE:

1) Do not apply oil to the eye bolt.

2) Do not bend the fuel pump pipe.

5. Tifhten cap nut to specified torque.

Torque : 13 N·m (1.3 kg·m/113 lb in)

NOTE: Do not apply oil to the cap nut.

6. Start the engine, check that the fuel leakage is not

found.

HIGH PRESSURE OILPUMP

REMOVAL

1. Disconnect battery ground cable.

2. Remove air cleaner cover and air duct

3. Intercooler assembly

Refer to “Intercooler” in this manual.

4. Remove high pressure oil pipe

5. Timing belt cover

Disconnect CMP sensor cable.

Remove CMP sensor bracket.

6. Tensioner

7. Timing Belt

8. Remove high pressure oil pump timing pulley

9. Remove crankshaft damper pulley

10. Remove timing gear case cover

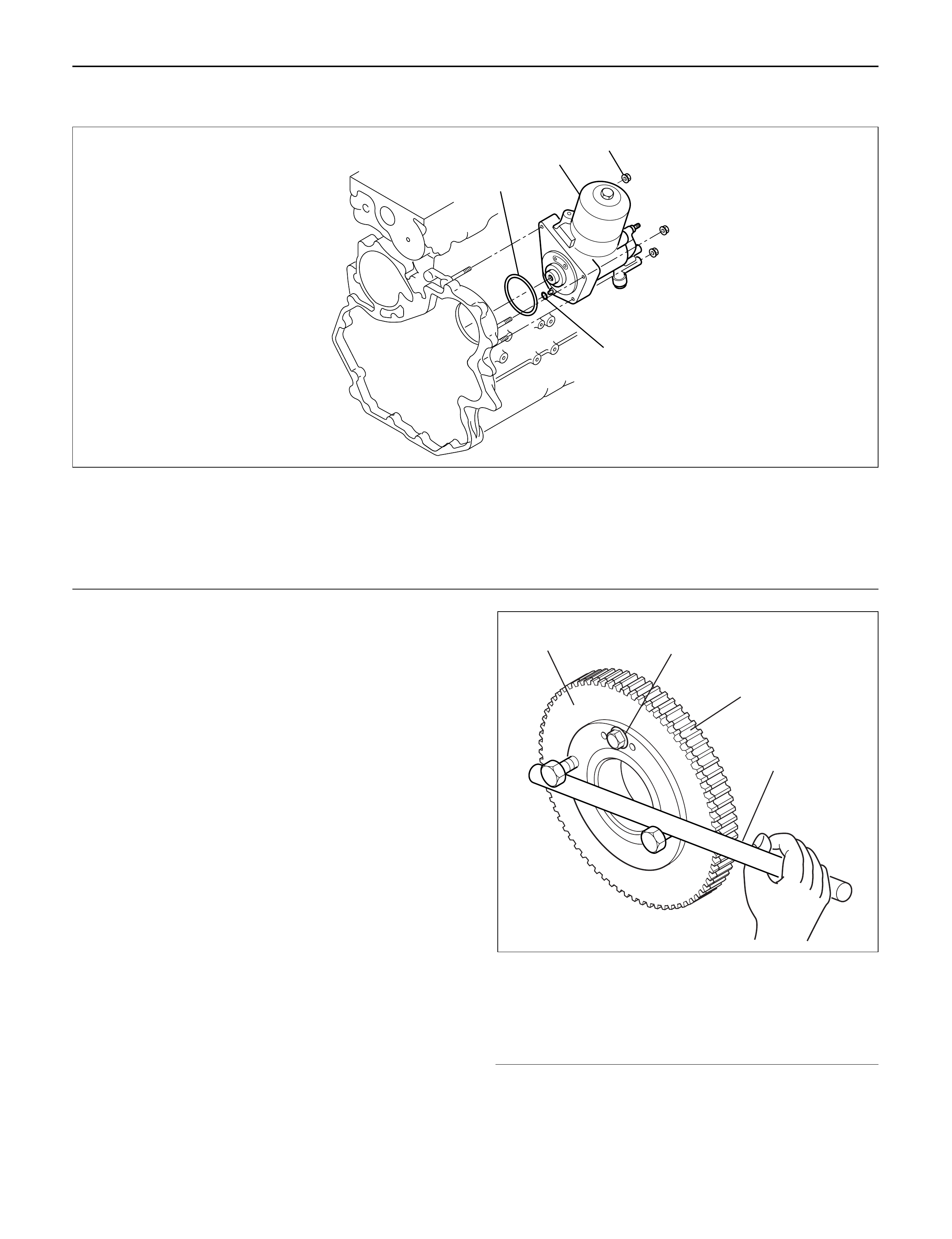

11. Remove idle gear A

Before removing idle gear A, set two bolts to the

sub gear of idle gear A and turn it to align the teeth

of idle gear A main gear.

Then lock them by bolts as shown in the illustration. Legend

(1) Idle gear A sub gear

(2) Idle gear A main gear

(3) Bar

(4) Lock bolt

1

2

4

3

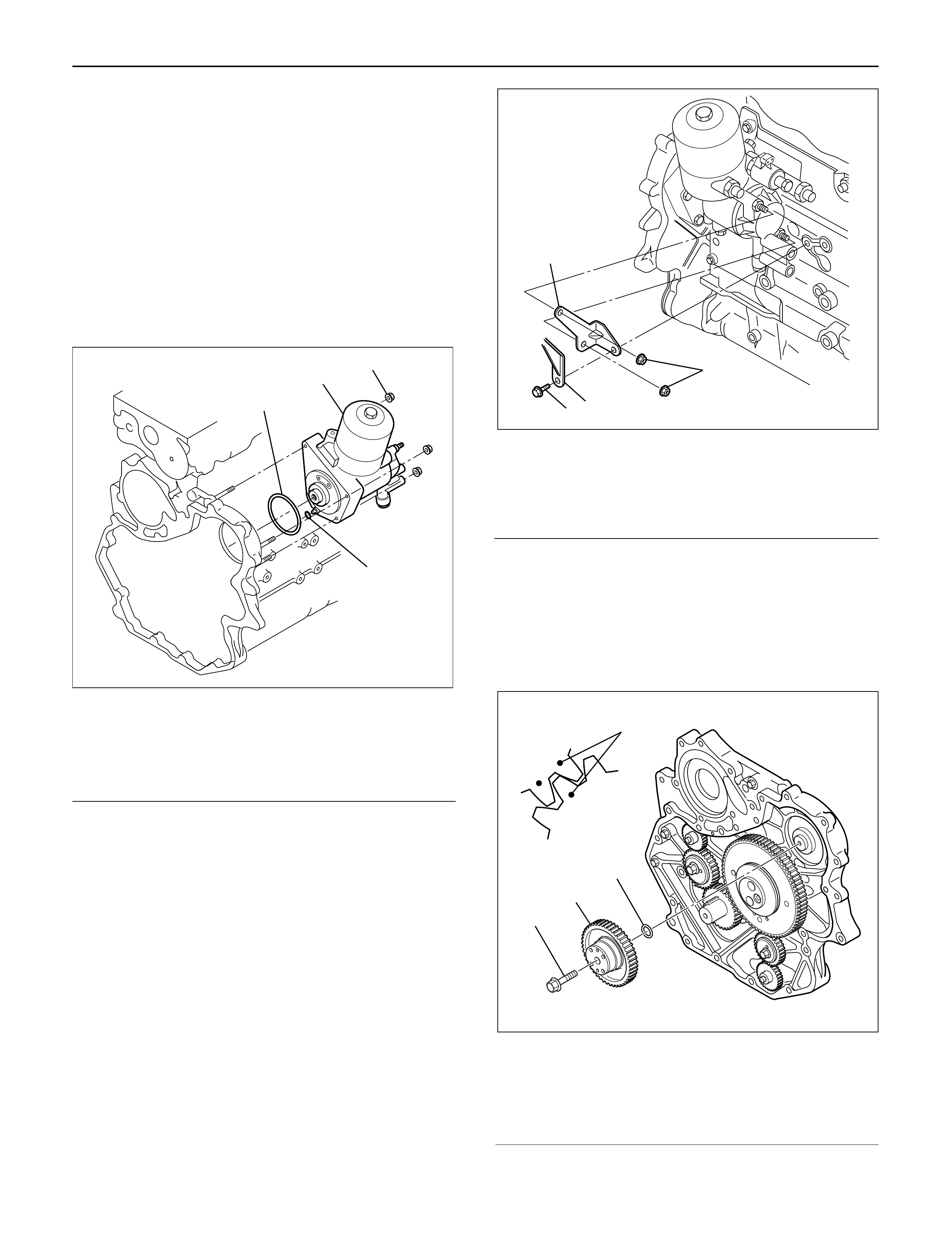

Legend

(1) O-Ring

(2) High Pressure Oil Pump Assembly

(3) Nut

(4) O-Ring

040RW007

4

1

2

3

014RW177

12. Remove high pressure oil pump

13. Remove high pressure oil pump assembly

Legend

(1) O-ring

(2) High pressure oil pump

(3) Nut

(4) O-ring

1

2

4

3

040RW007

INSPECTION AND REPAIR

The high pressure oil pump is made precisely,

therefore, disassembly is not recommended.

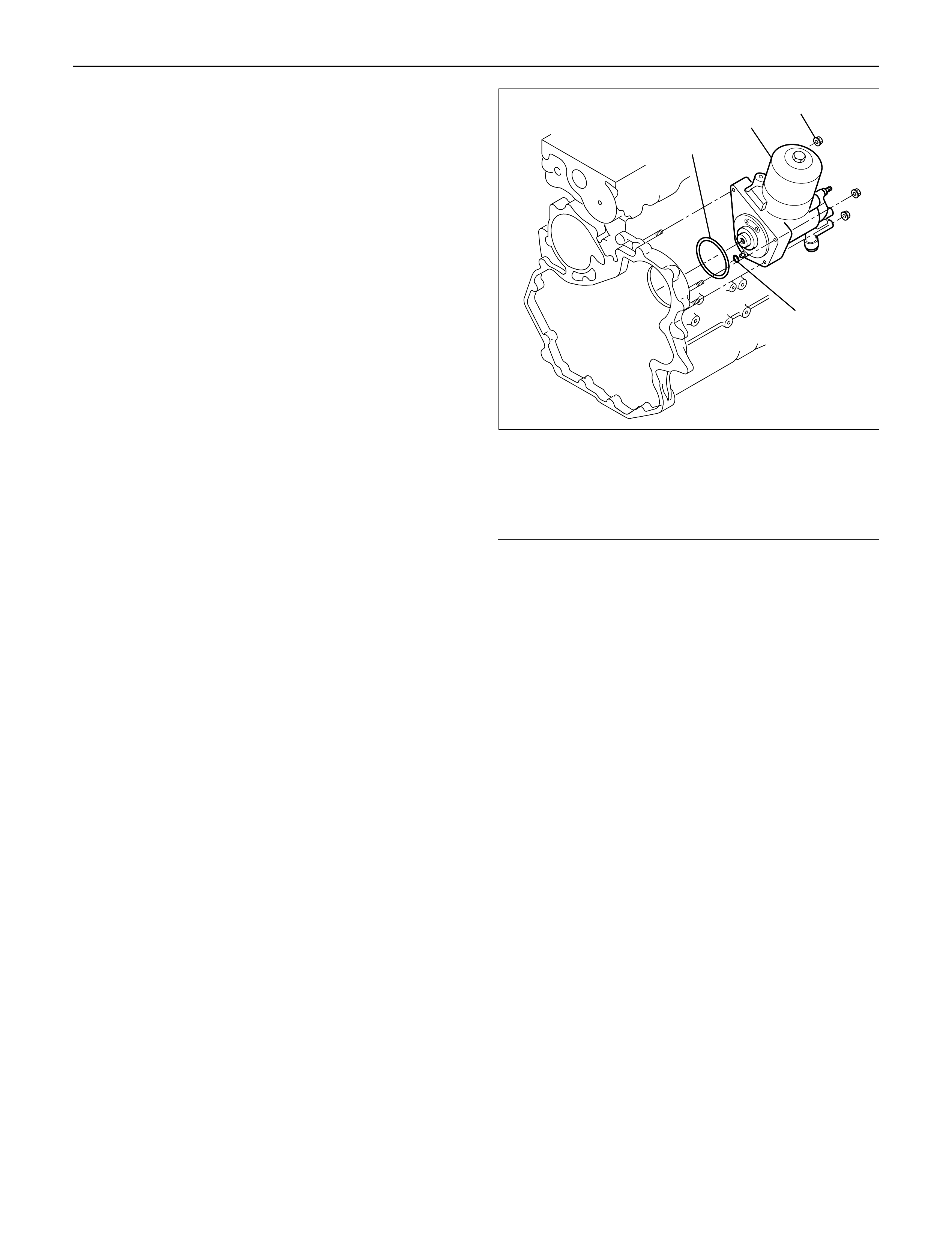

INSTALLATION

1. Set O-ring to high pressure oil pump assembly.

Apply Loctite No. 262 to the stud bolts.

Install the pump assembly into the rear of timing

gear case.

Tighten nut to specified torque.

Torque: 20 N·m (2.0 kg·m/14 lb ft)

Legend

(1) O-ring

(2) High Pressure Oil Pump Assembly

(3) Nuts

(4) O-ring

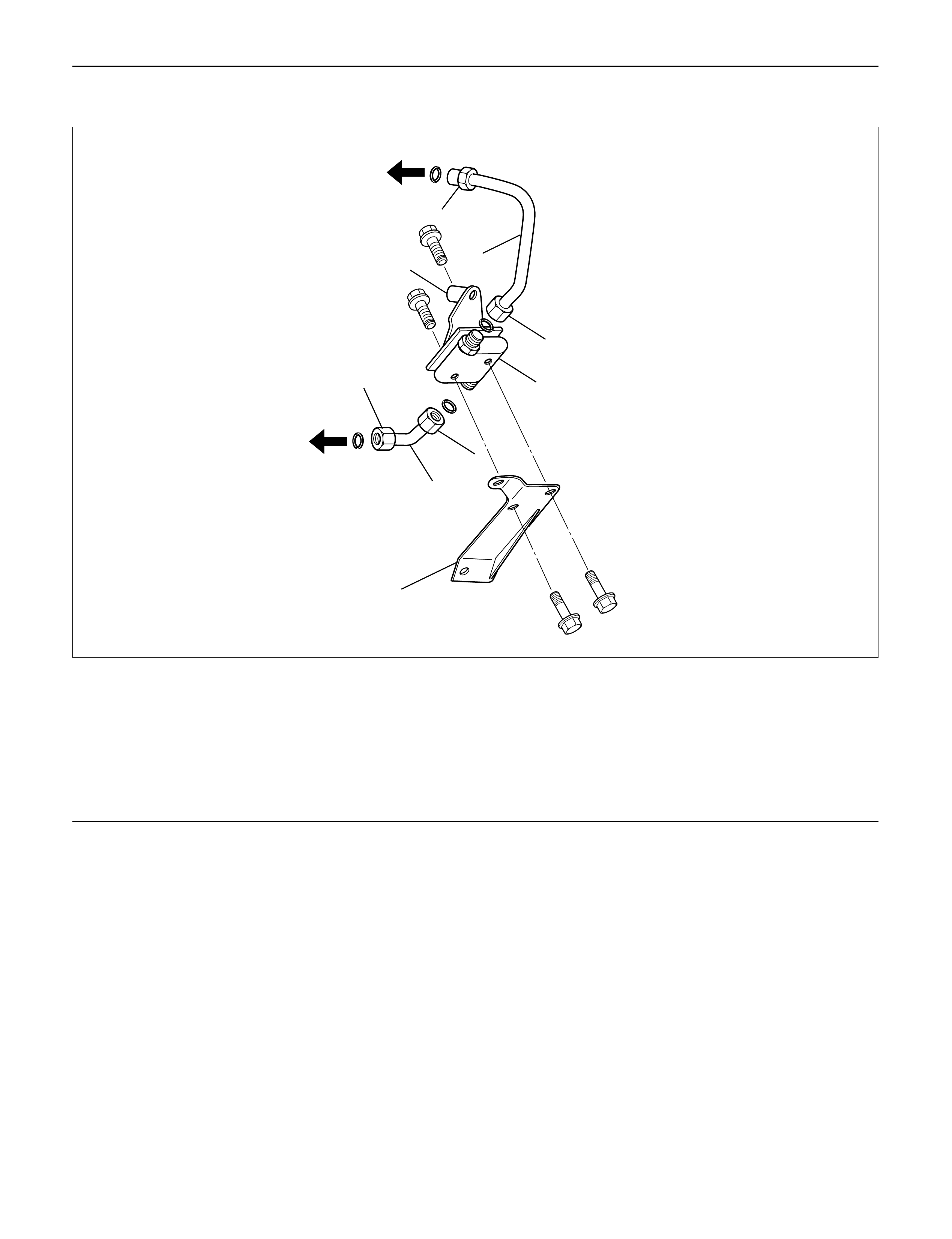

2. Tighten high pressure oil pump assembly bracket

together with two way valve bracket.

Torque: 27 N·m (2.8 kg·m/20 lb ft)

Legend

(1) High Pressure Oil Pump Assembly

(2) Nut

(3) Two Way Valve Bracket

(4) Bolt

3. Install the pump gear to align timing mark with idle

gear A.

Tighten high pressure pump gear fixing bolt to the

specified torque.

Apply engine oil to thread and seat of bolt.

Torque: 75 N·m (7.6 kg·m/55 lb ft)

Legend

(1) O-ring

(2) Pump Gear

(3) Bolt

(4) Timing Mark

1

2

4

3

040RW007

2

3

4

1

040RW006

4

GEAR:O/PUMP

IDLE GEAR A

1

2

3

040RW005

4.Remove lock bolt of idle gear A.

5.Install timing gear case cover.

Refer to “Timing gear” in this manual.

6.Install front plate.

Torque: 20 N·m (2.0 kg·m/14 lb ft)

7.Install timing pulley of high pressure oil pump.

Torque: 10 N·m (1.0 kg·m/87 lb in)

8.Install timing belt and tighten timing belt tensioner

assembly.

Refer to “Cylinder head” in this manual.

Legend

(1)Align Mark

(2)Camshaft Pulley

(3)Timing Belt

(4)High Pressure Oil Pump Pulley

(5)Tensioner Bolt B

(6)Tensioner Assembly

(7)Tensioner Bolt A

(8)Tensioner Spring

9.Install CMPsensor bracket.

Torque: 20 N·m (2.0 kg·m/14 lb ft)

10.Connect CMPsensor cable.

11.Install timing belt cover.

Torque: 9 N·m (0.9 kg·m/78 lb in)

12.Fill with about 300 cc of engine oil from the high

pressure oil pipe installation port of the oil rail using

an oil filler.

If assembled without filling the oil rail with oil, the

time for engine starting will be longer.

13.Immediately install high pressure oil pipe and

tighten to specified torque.

NOTE:

1)Use new O-ring.

2)Clean O-ring groove and fitting surface of parts.

3)Apply engine oil to O-ring.

Torque: 78 N·m (8.0 kg·m/58 lb ft)

14.Install the crankshaft damper pulley with specified

torque.

Torque: 216 N·m (22 kg·m/159 lb ft)

15.Install the intercooler assembly.

Refer to “Intercooler” in this manual.

16. Install air cleaner cover and air duct.

1

2

3

8

6

7

4

5

F06R200006

HIGH PRESSURE OILPIPE INSTALLATION

1. Install upper bracket to two way valve, tighten them

temporarily.

2. Install pipe A to two way valve, tighten pipe A

temporarily with union nut D.

3. Install two way valve assembly to cylinder block,

tighgten with union nut C temporarily.

4. Install pipe B to two way valve, tighten union nut E

and union nut F temporarily.

5. Tighten upper bracket to specified torque.

Torque : 20 N·m (2.0 kg·m/14 lb ft)

6. Tighten union nut in the following order, union nut

C, D, F, and E to the specified torque.

Torque : 78 N·m (8.0 kg·m/58 lb ft)

7. Tighten lower bracket to the specified torque.

Torque : 20 N·m (2.0 kg·m/14 lb ft)

NOTE: Wash inside pipe, inside union nut and O-ring

seal surface to remove engine oil and foreign materials.

6

5

7

9

8

11

4

1

2

3

10

Legend

(1) Union Nut F

(2) Pipe B

(3) Union Nut E

(4) Upper Bracket

(5) Two Way Valve

(6) Union Nut D

(7) Pipe A

(8) Union Nut C

(9) Lower Bracket

(10) To Oil Rail

(11) To High Pressure Oil Pump

052R200001

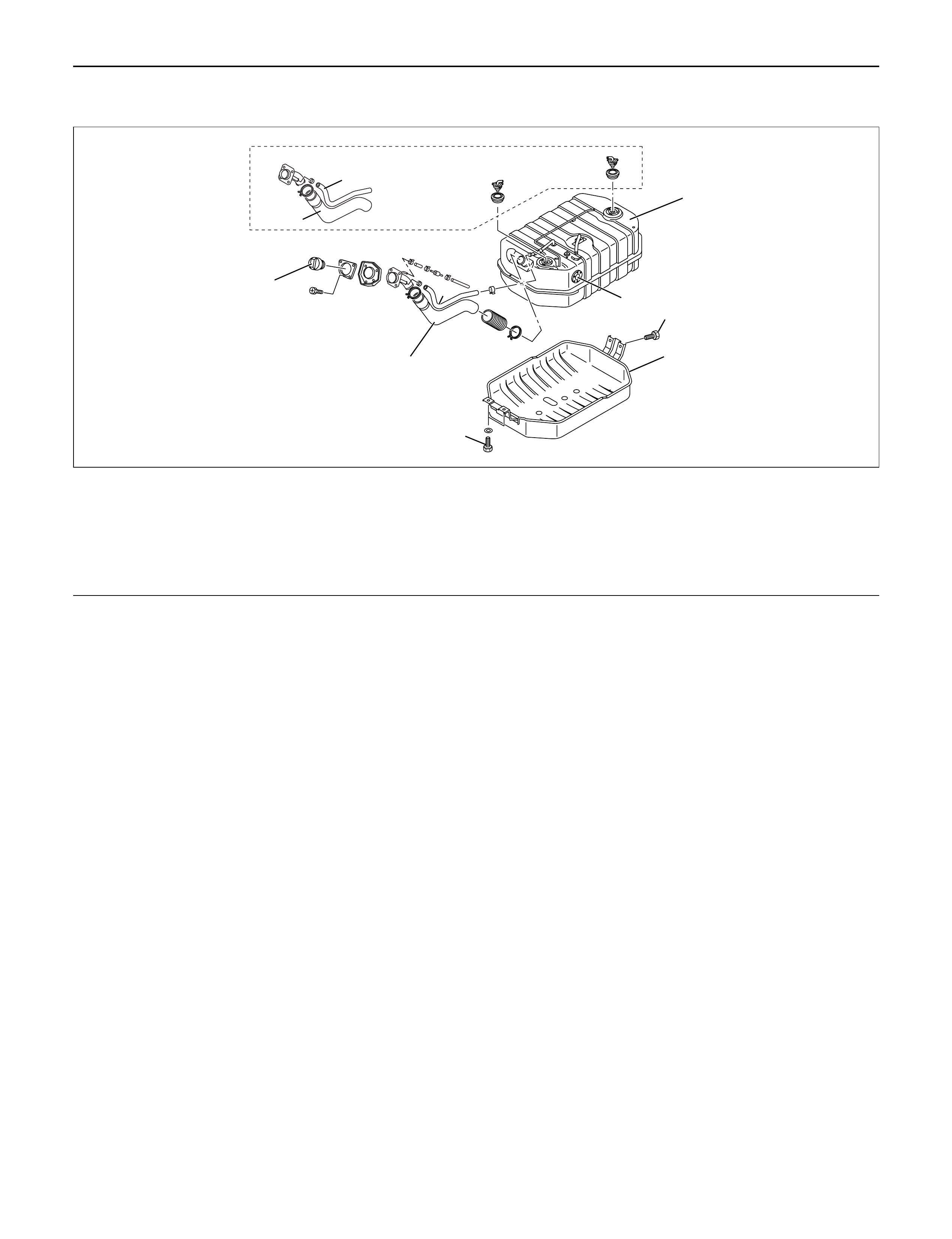

FUELTANK

REMOVAL

1. Disconnect battery ground cable.

2. Remove fuel filler cap.

3. Drain fuel.

After drain the fuel tighten the drain plug with

specified torque.

Torque : 20 N·m (2.0 kg·m/14 lb ft)

4. Remove fuel filler hose and let air pull off hose.

5. Remove breather hose.

6. Remove fuel feed hose and fuel return hose.

7. Disconnect harness connector from fuel gauge unit.

8. Remove under cover.

9. Remove fuel tank assembly.

INSTALLATION

1. Fuel tank assembly.

1) Place a flange on right side of tank on the

bracket.

2) Install a flange to left side of the bracket from the

bottom, and tighten bolts to the specified torque.

Torque : 36 N·m (3.7 kg·m/27 lb ft)

2. Install fuel hose and fuel return hose.

3. Install the breather hose.

4. Reconnect harness connector to fuel gauge unit.

5. Install under cover.

6. Install fuel filler hose and let air pull off hose.

7. Fill fuel tank with fuel and tighten filler cap.

8. Reconnect battery ground cable.

1

2

4

8

6

7

8

MY2003 Euro-3

6

5

3

Legend

(1) Fuel Tank Assembly

(2) Gauge Unit

(3) Bolt

(4) Under Cover

(5) Bolt

(6) Fuel Filler Hose

(7) Fuel Filler Cap

(8) Breather Hose

140R200032

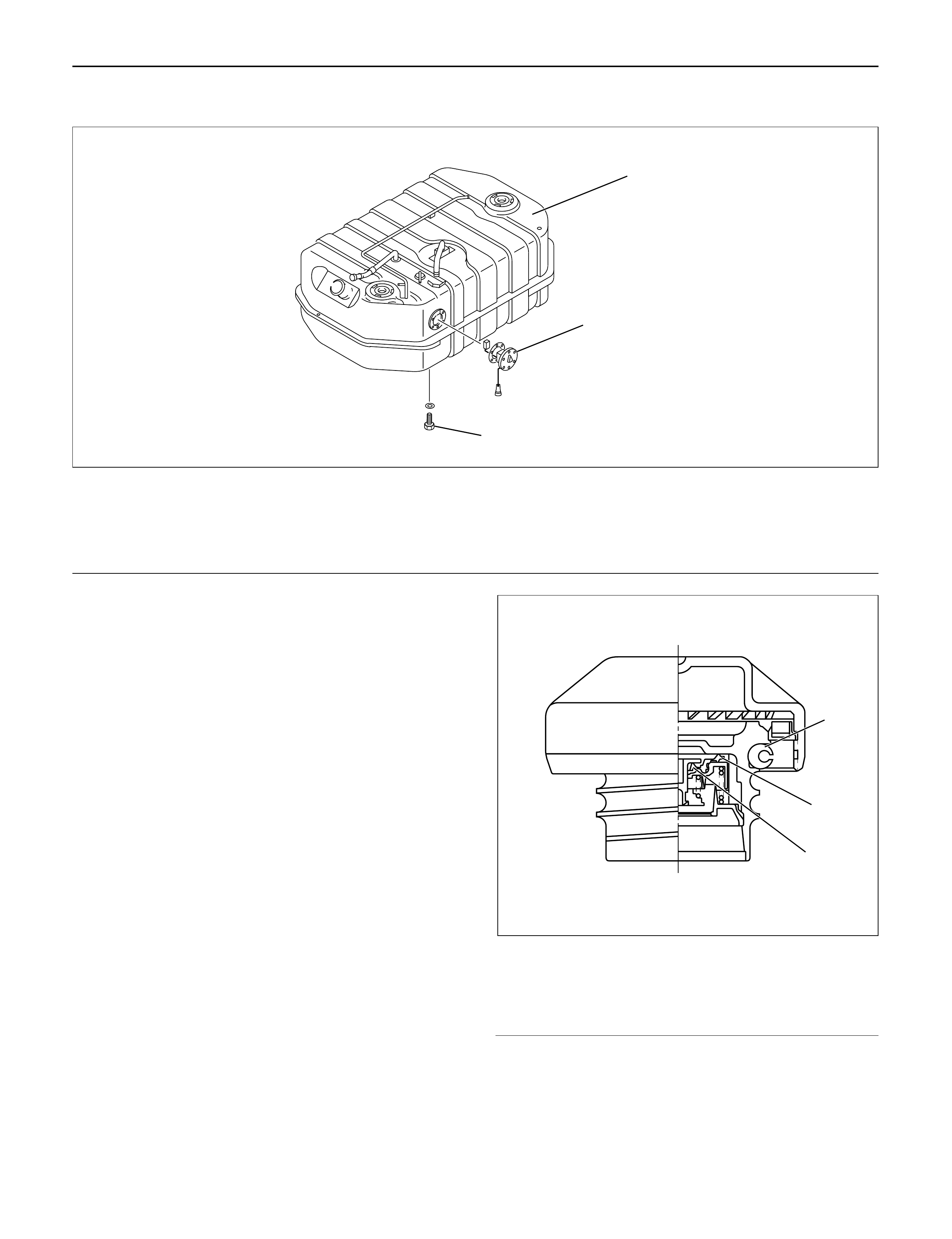

FUELGAUGE UNIT

1

2

3

140R200033

REMOVAL

1. Disconnect battery ground cable.

2. Loosen fuel filler cap.

3. Drain fuel.

After drain the fuel tighten the drain plug with

specified torque.

Torque : 20 N·m (2.0 kg·m/14 lb ft)

4. Disconnect harness connector from fuel gauge unit.

5. Fuel Gauge Unit

1) Remove the fixing screws, then the fuel gauge

unit.

INSTALLATION

1. Fuel Gauge Unit

2. Connect the harness connector to the fuel gage

unit.

3. Fill the tank with fuel and tighten fuel filler cap.

4. Connect battery ground cable.

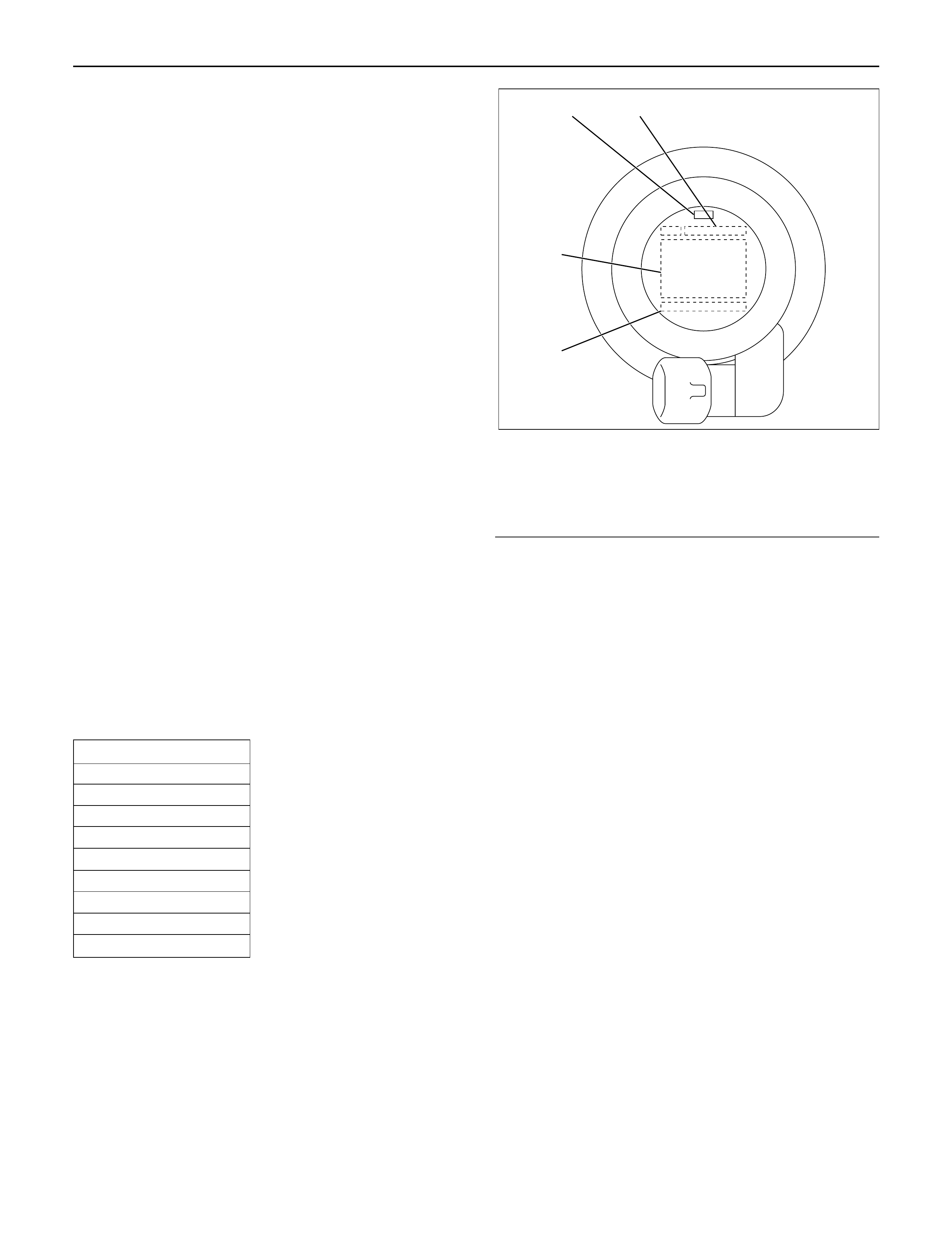

FUELFILLER CAP

The fuel filler cap contains a vacuum valve. If a

negative pressure develops in the fuel tank, the

external valve of the fuel filler cap opens to allow the

fresh air to flow into the fuel tank through the vacuum

valve.

INSPECTION

Check the seal ring in the filler cap for presence of any

abnormality and for seal condition.

Replace the filler cap, if abnormal.

Legend

(1) Vacuum Valve

(2) Pressure Valve

(3) Seal Ring

Legend

(1) Fuel Tank Assembly

(2) Fuel Gauge Unit

(3) Drain Plug

1

3

2

060R200247