SECTION 6E - 4JX1-TC 3.0L ENGINE

DRIVEABILITY AND EMISSIONS

Specification

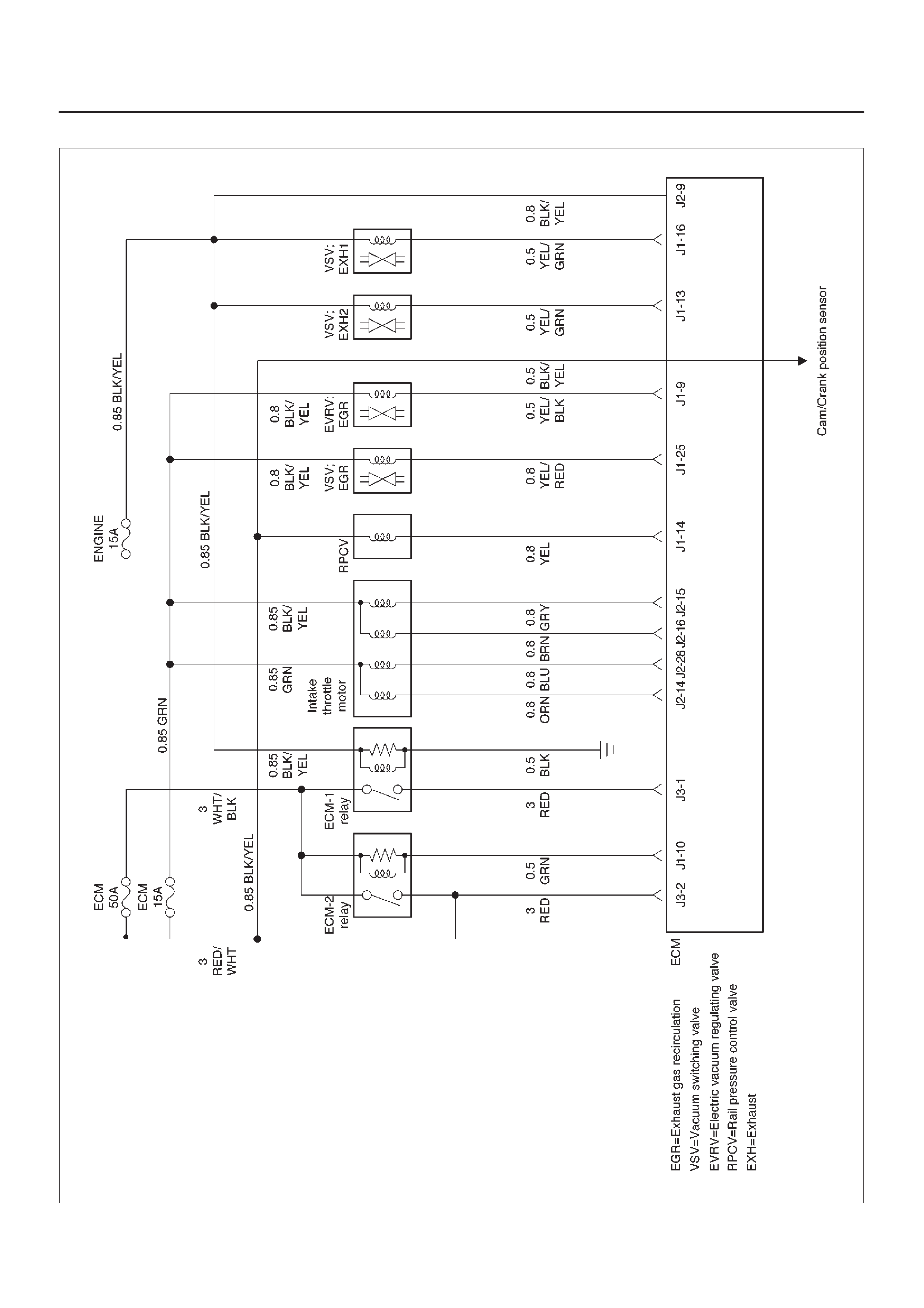

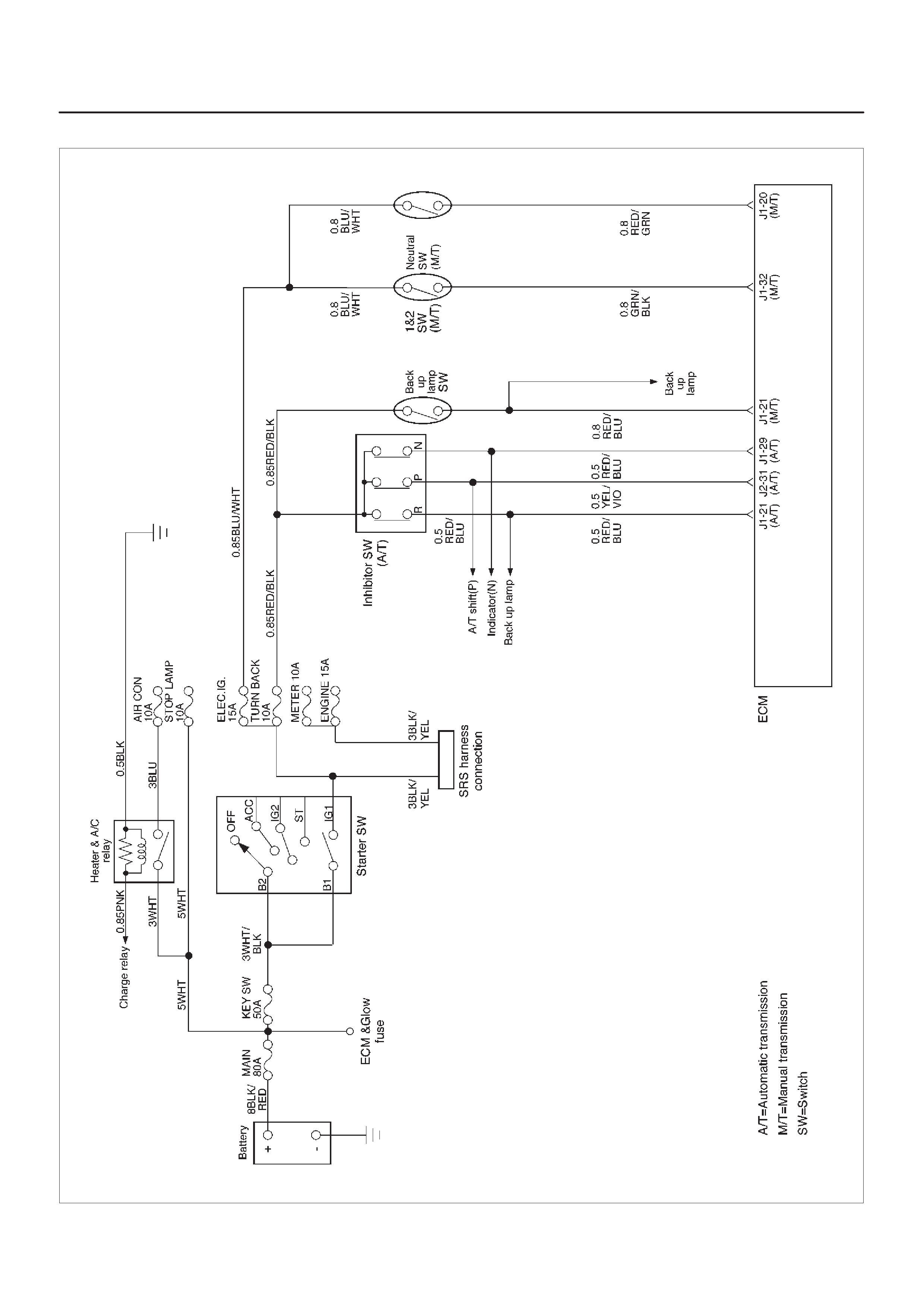

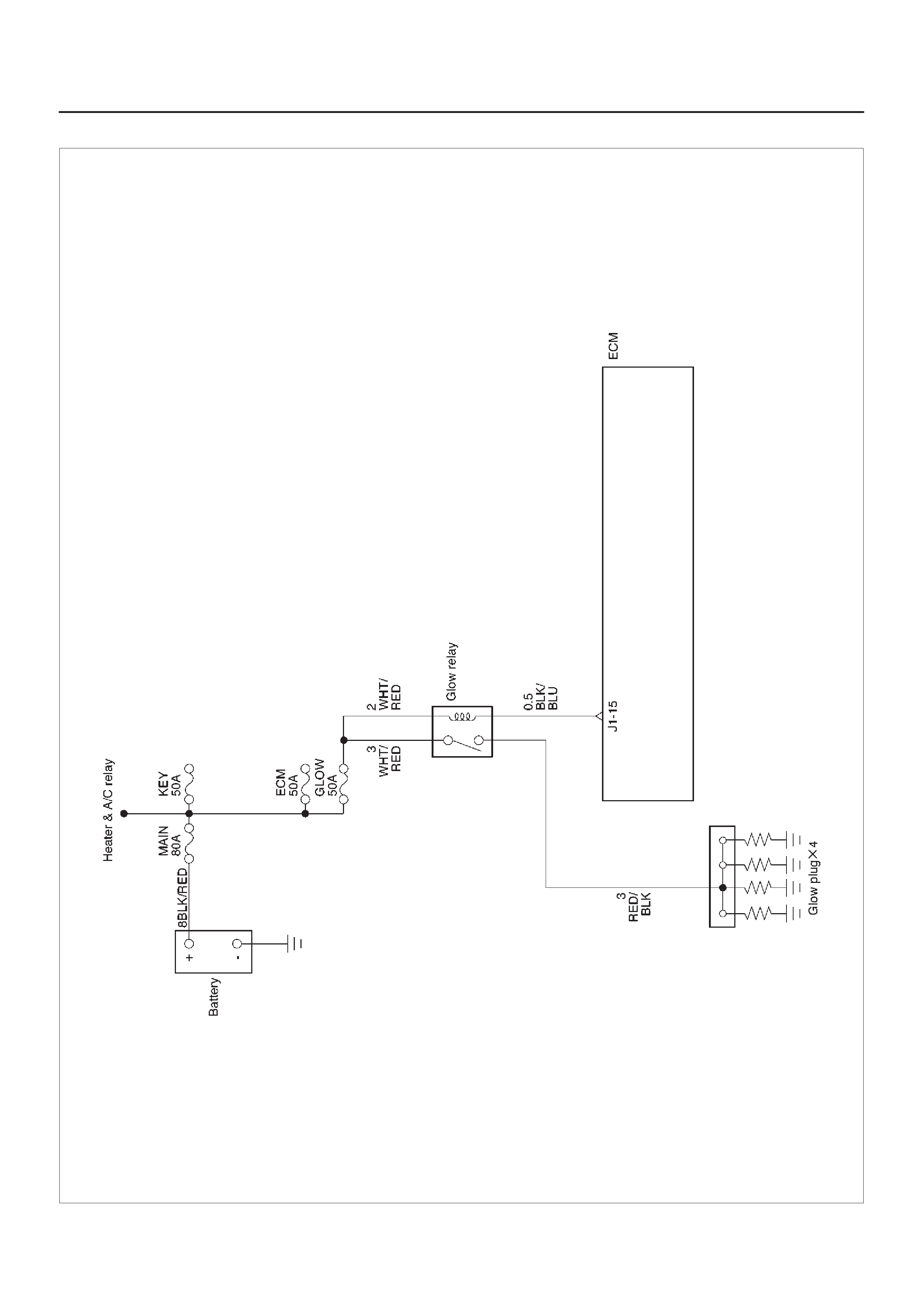

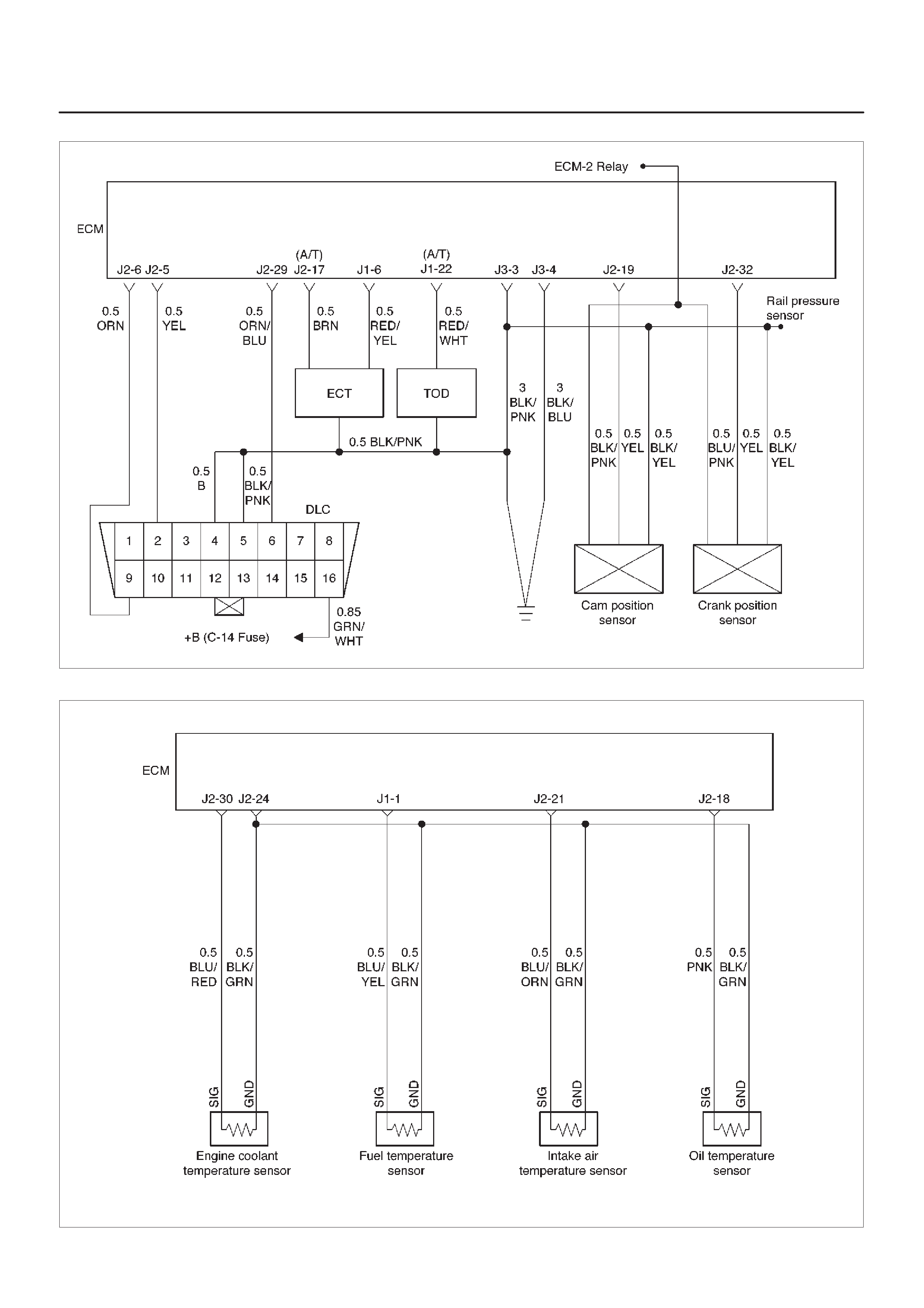

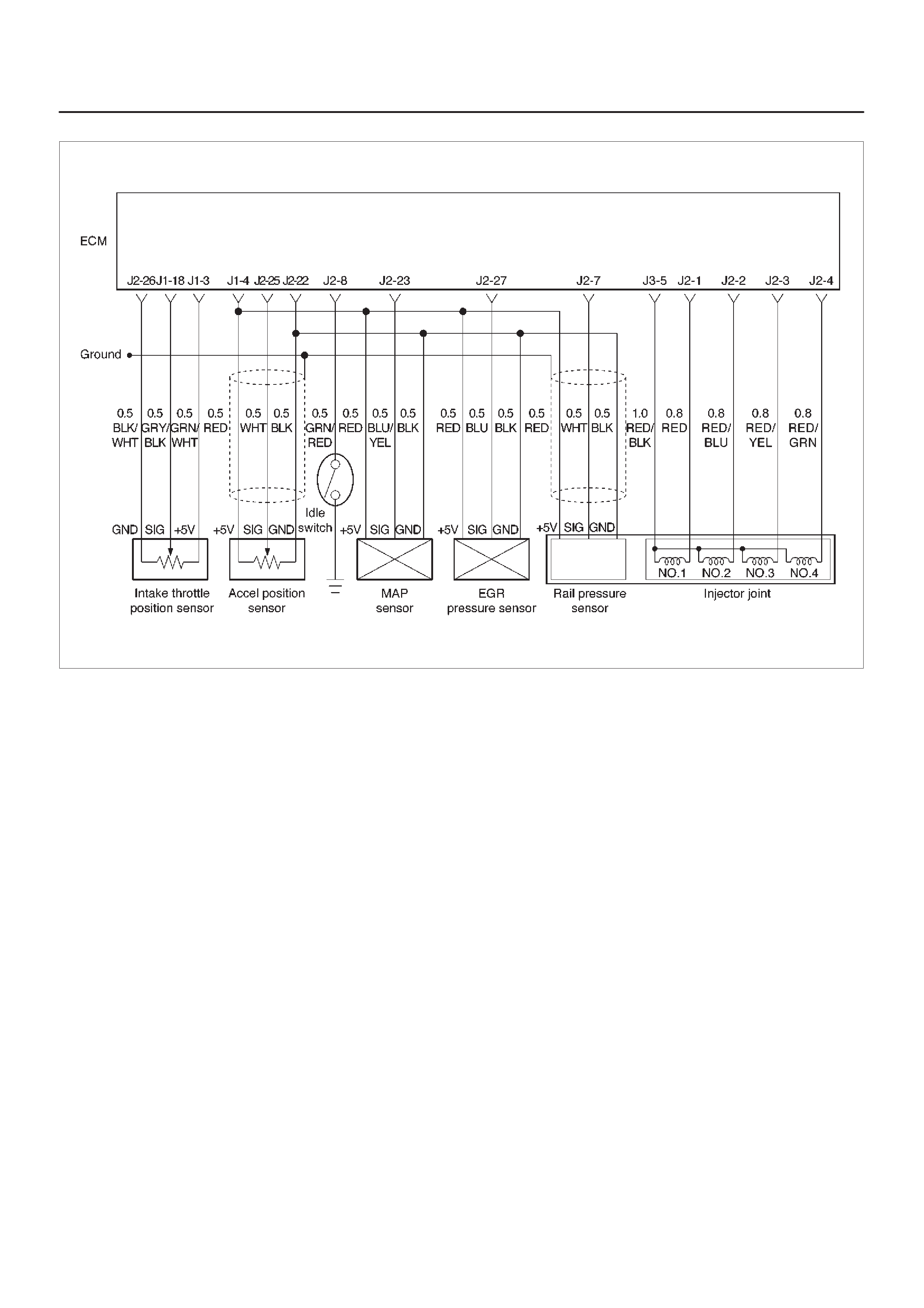

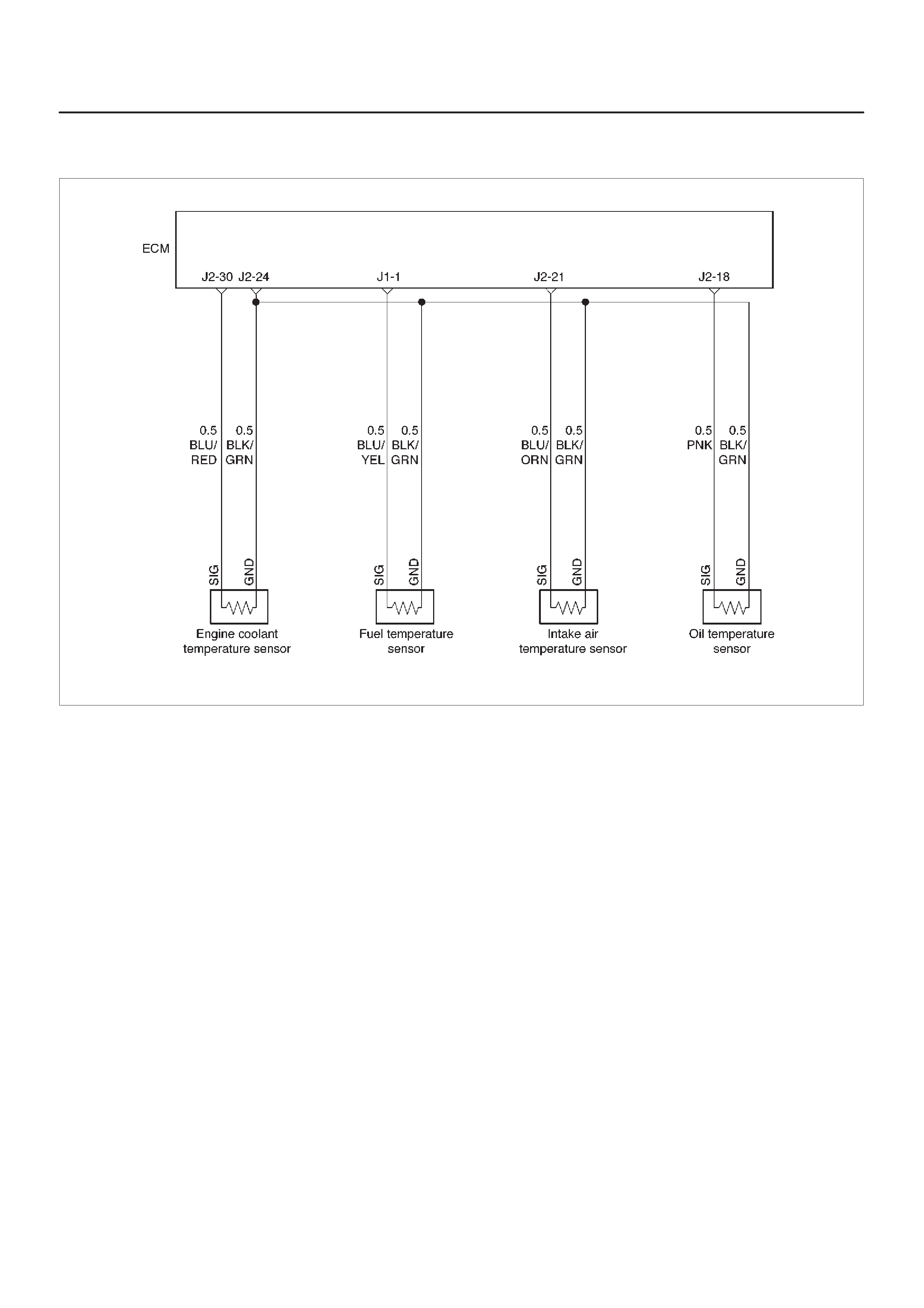

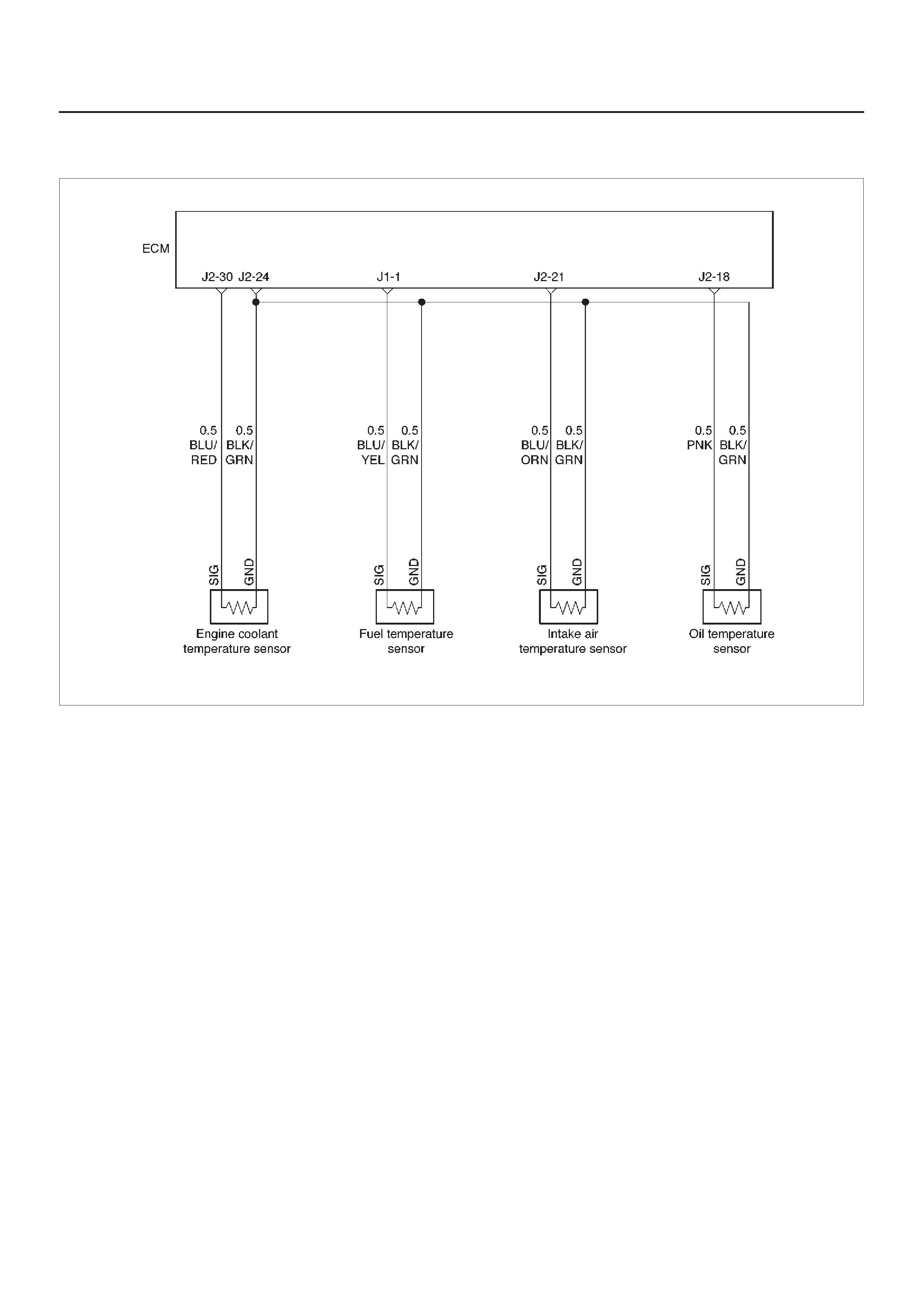

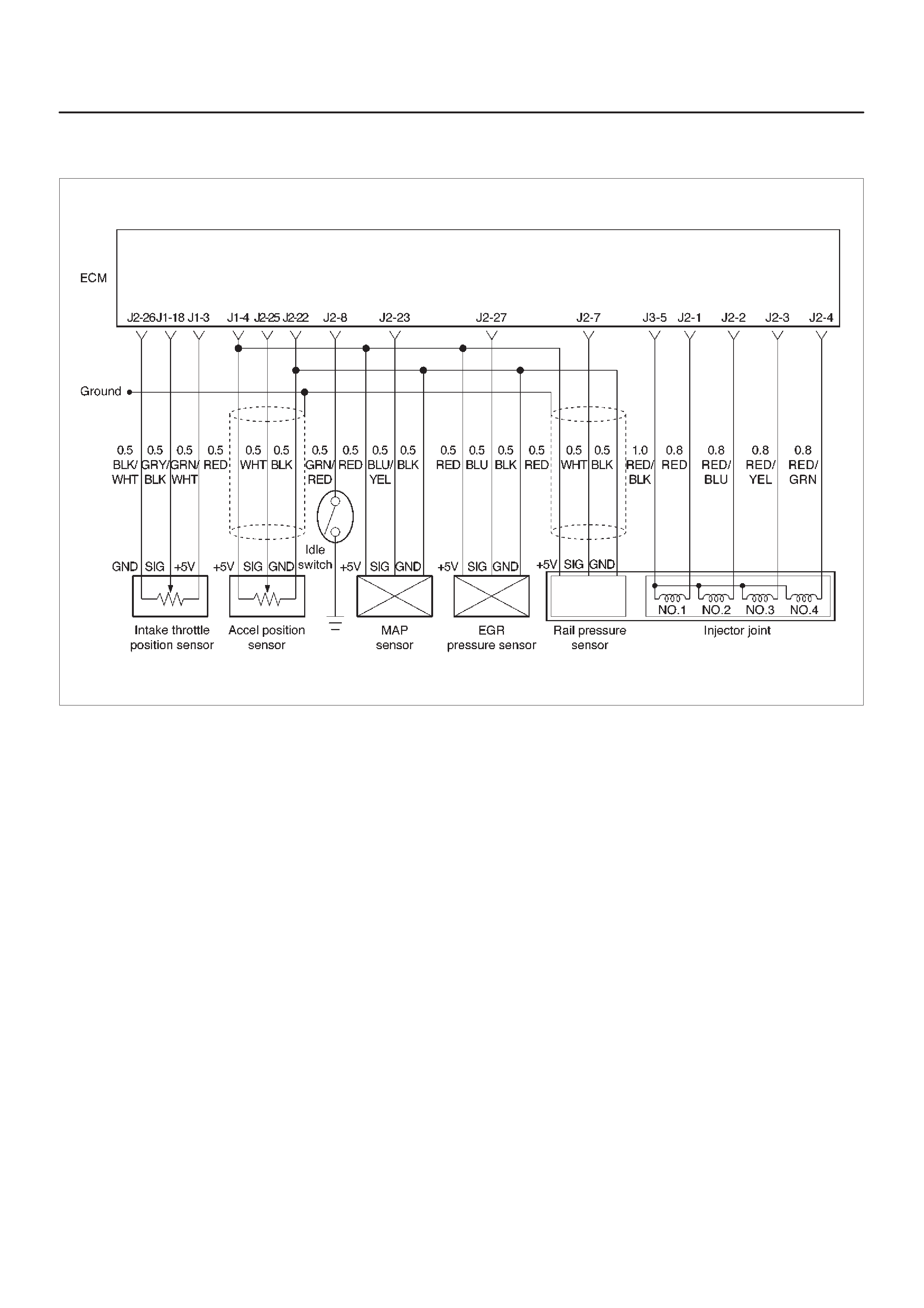

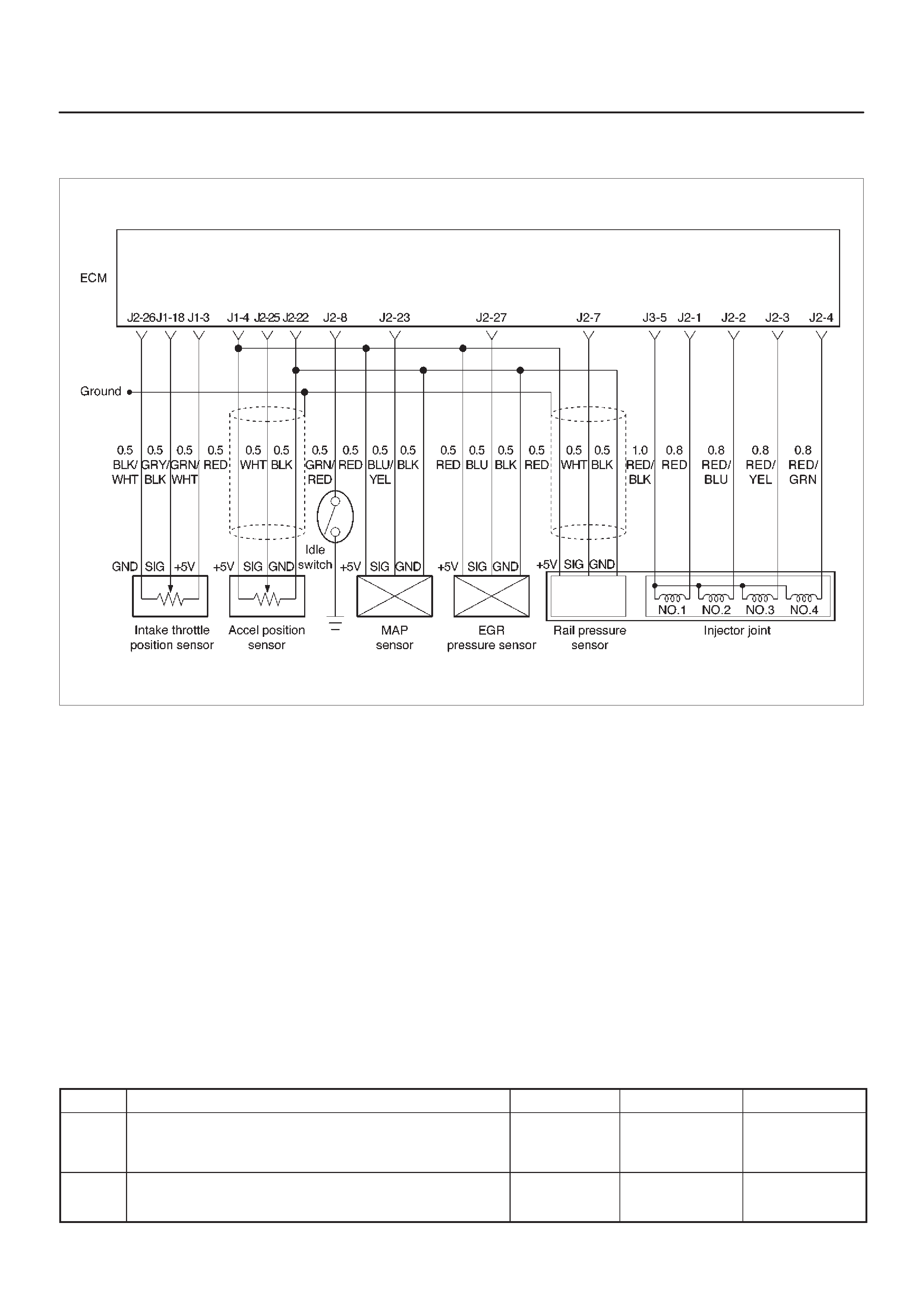

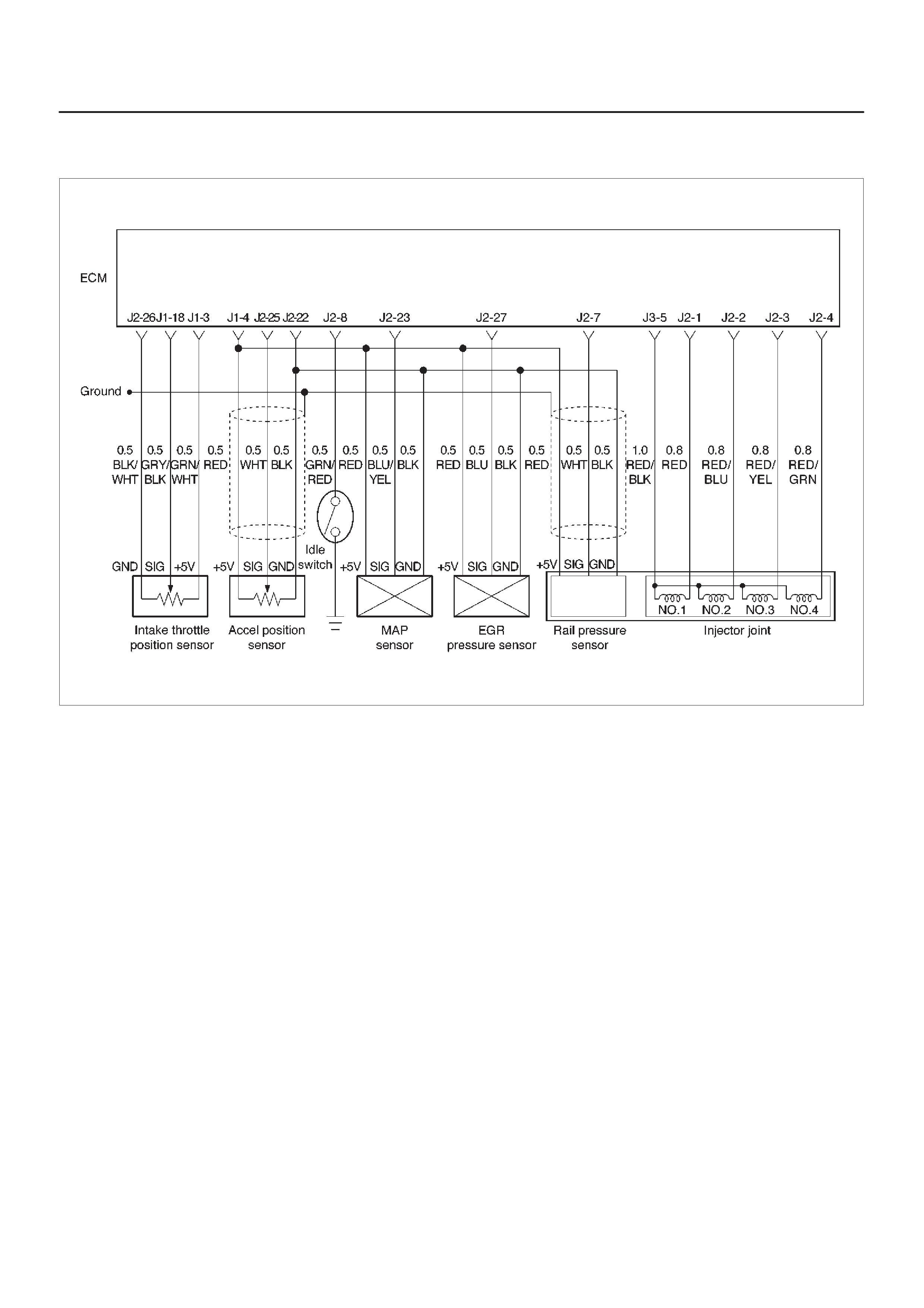

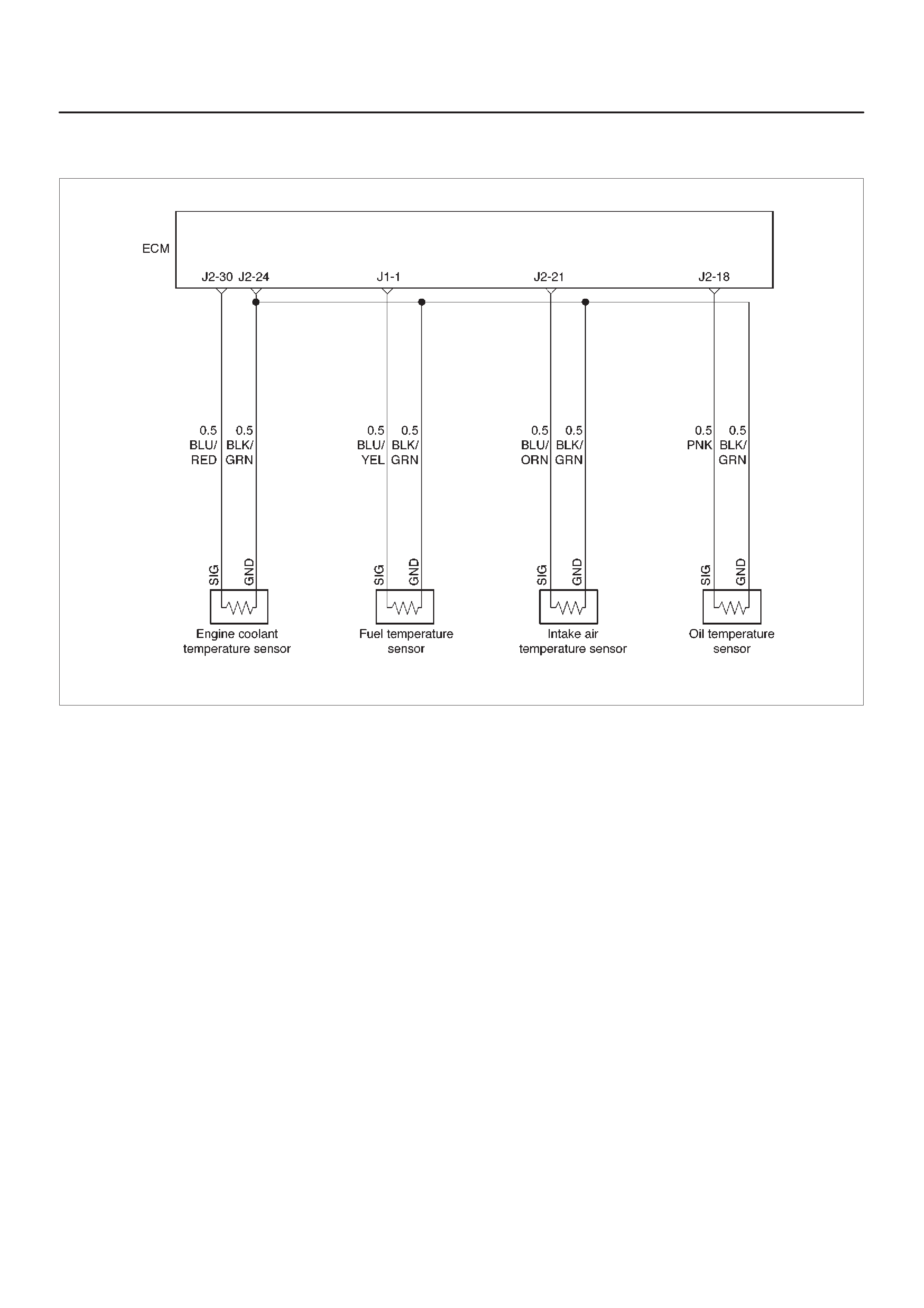

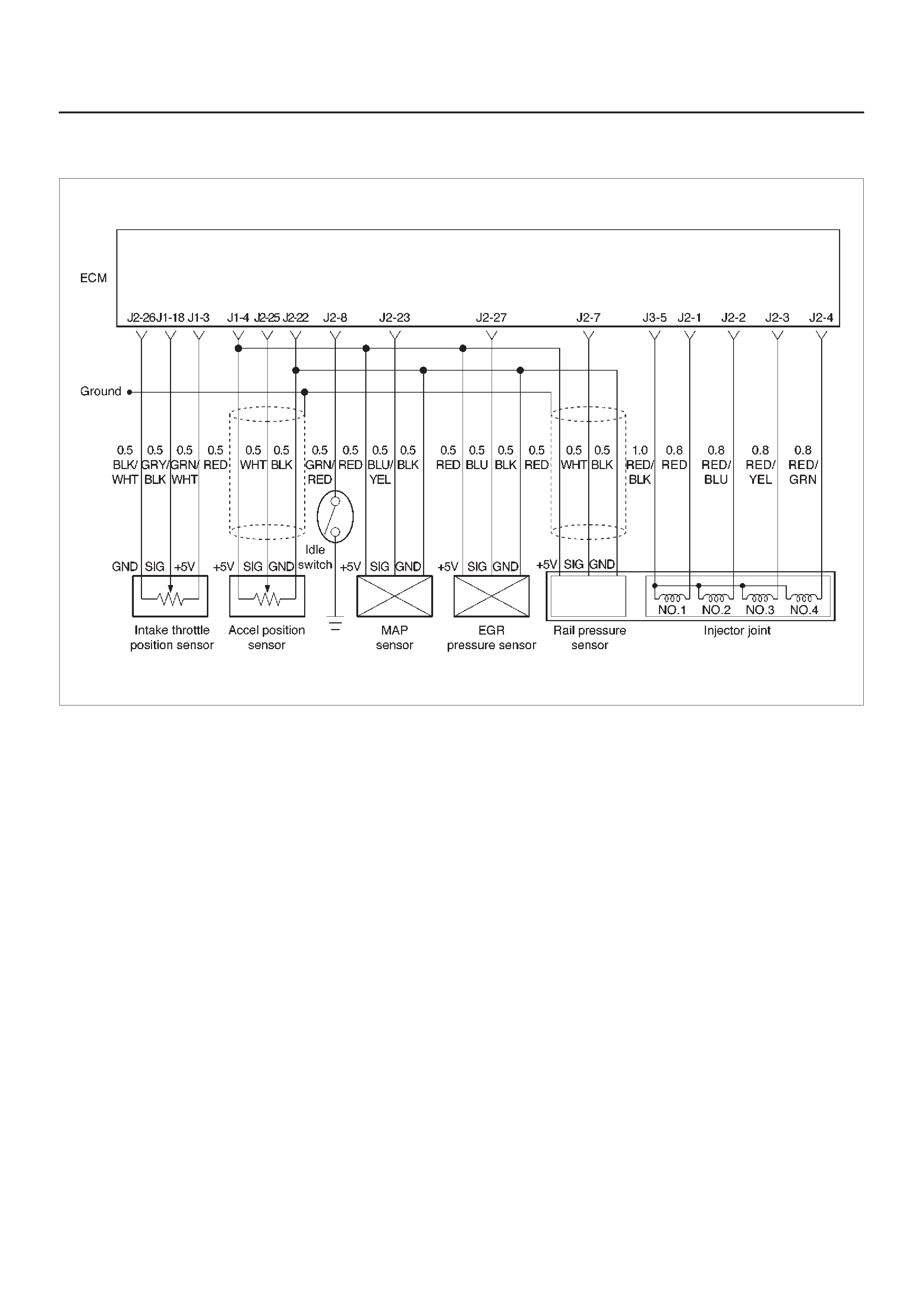

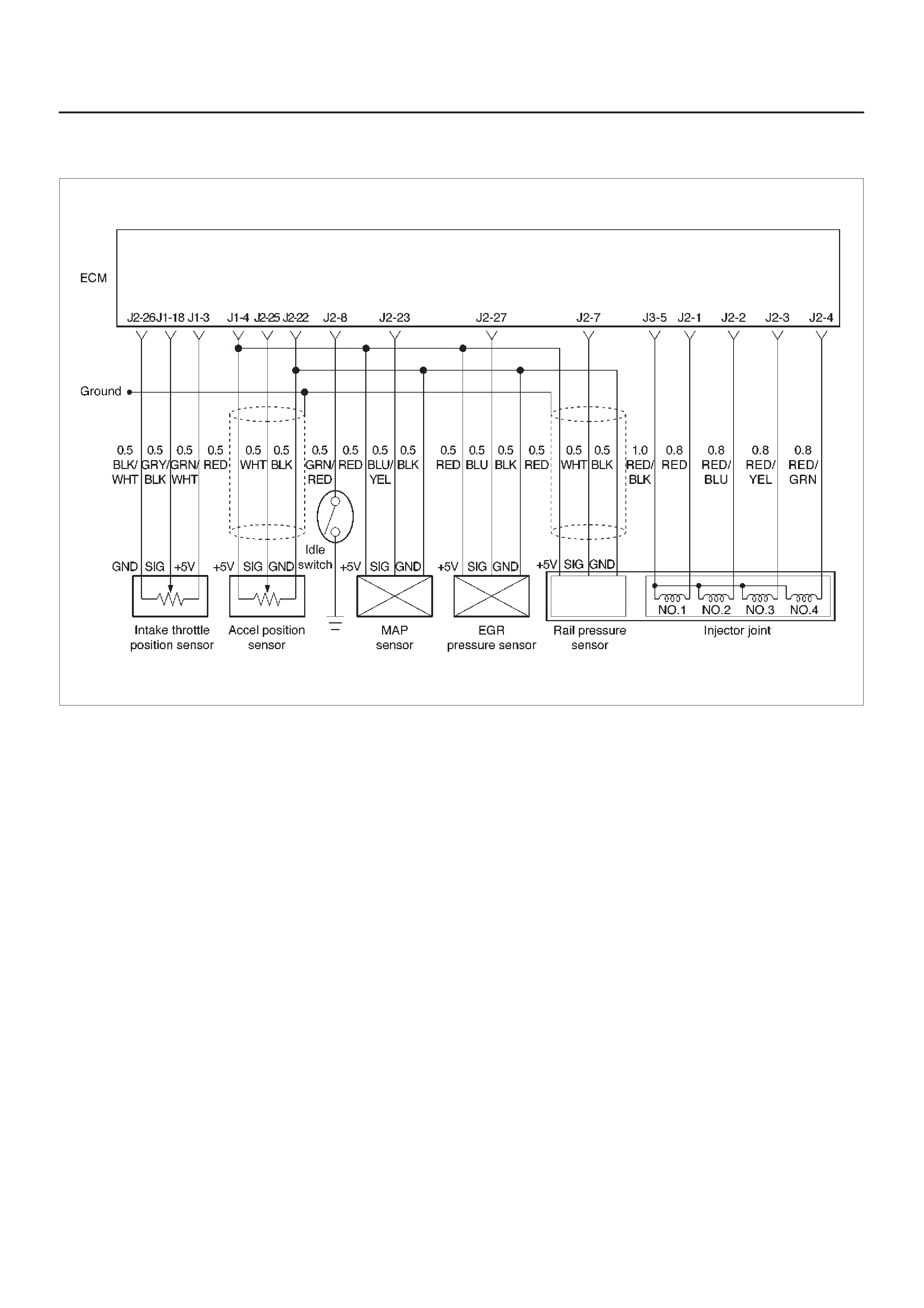

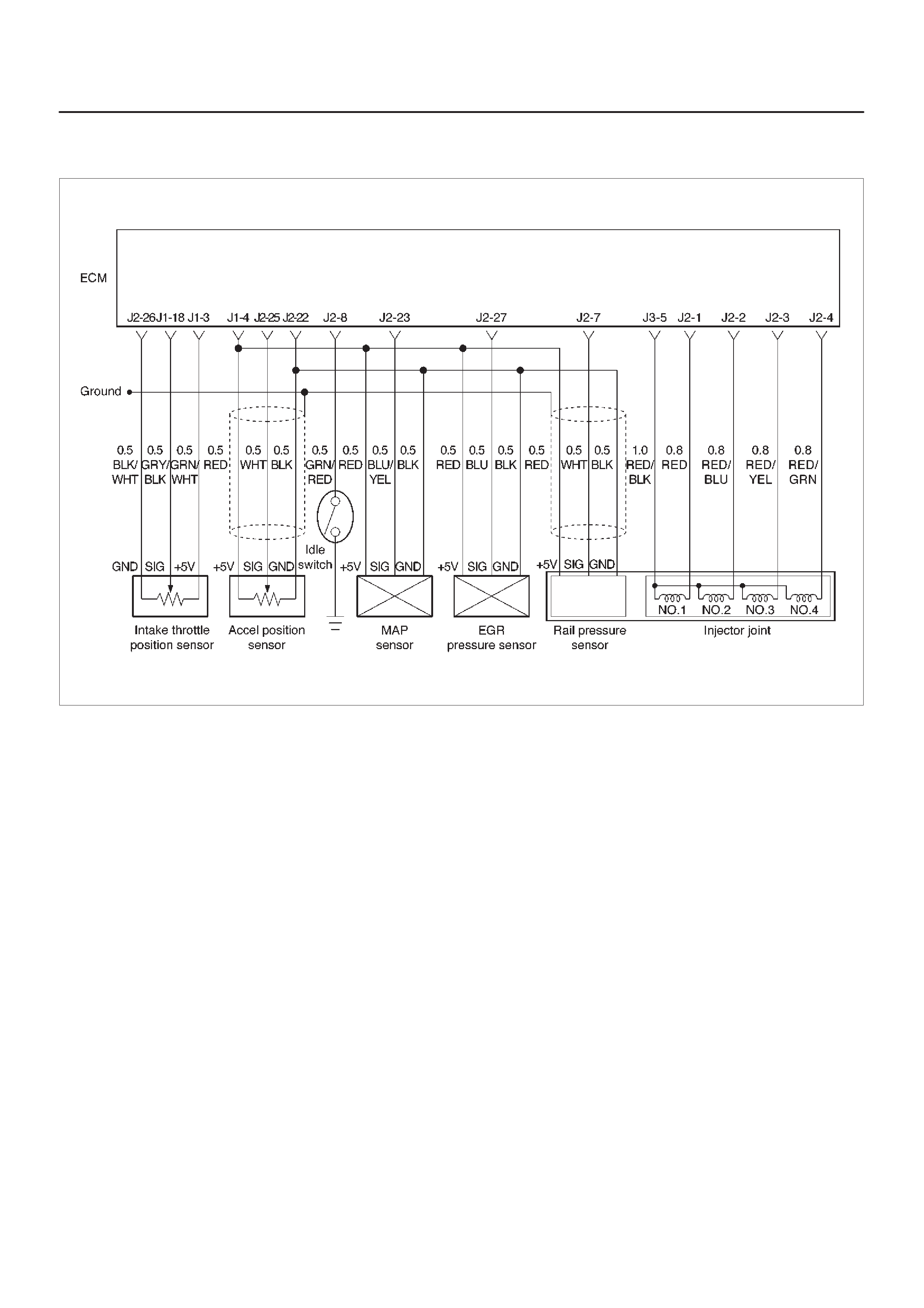

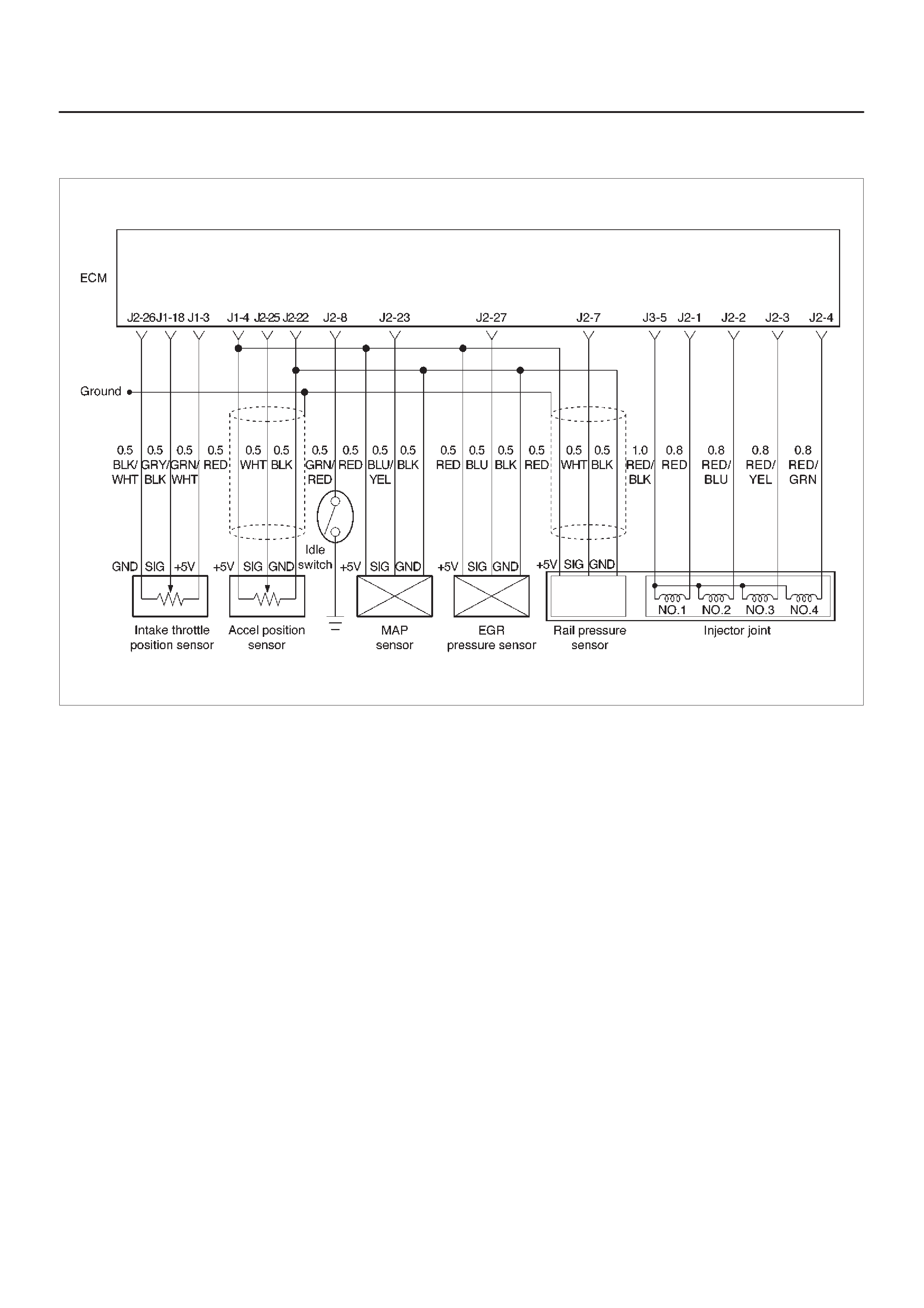

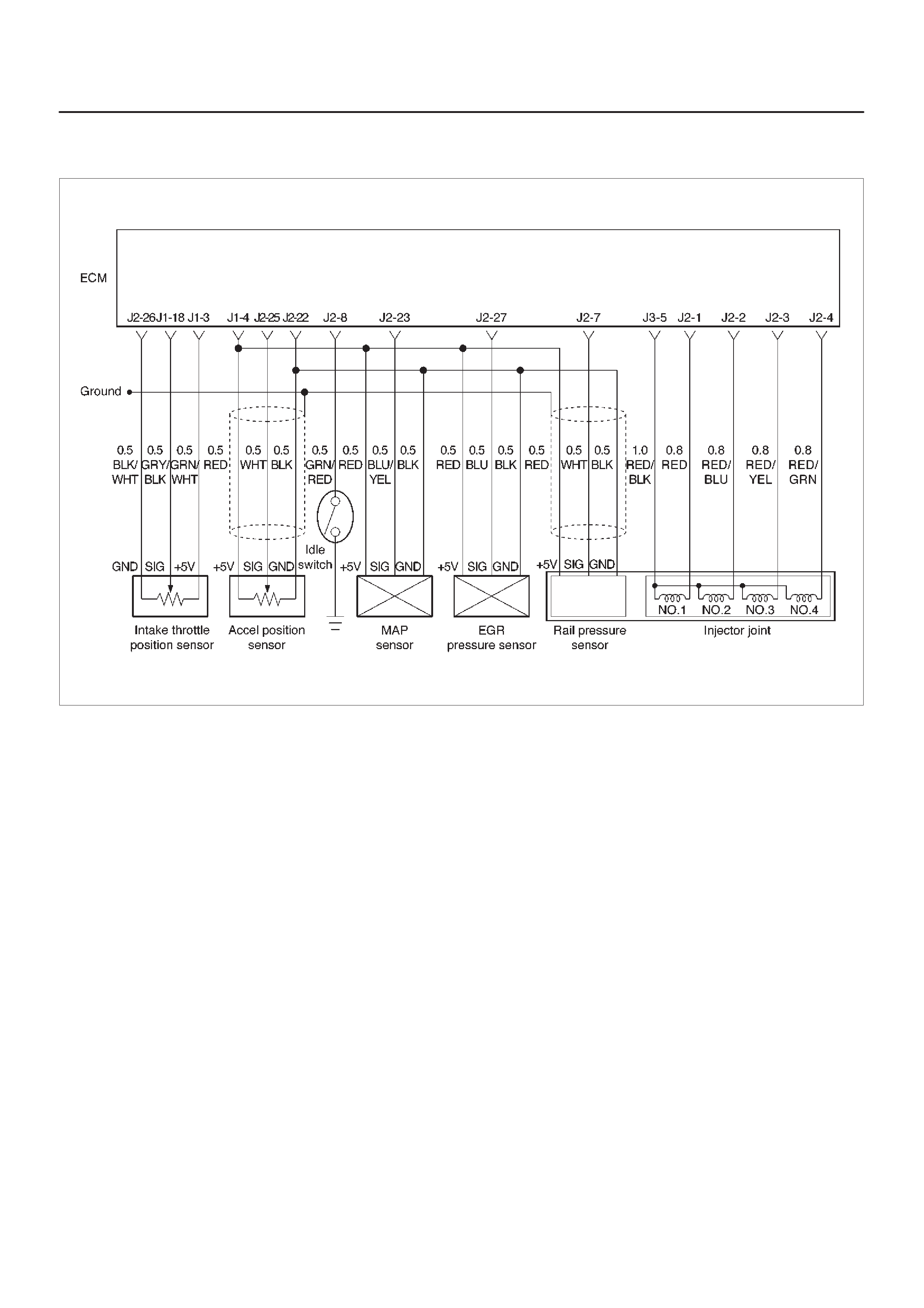

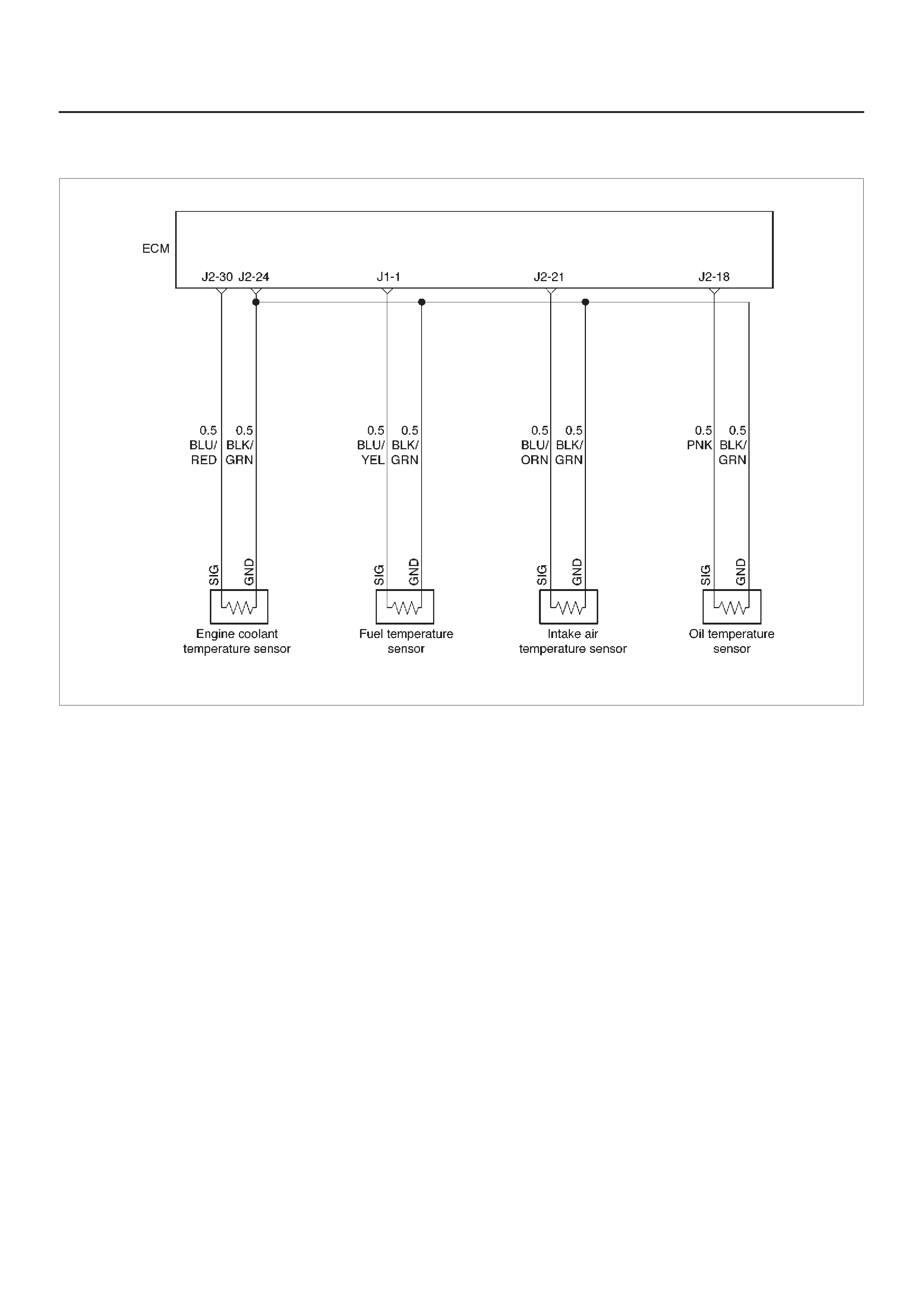

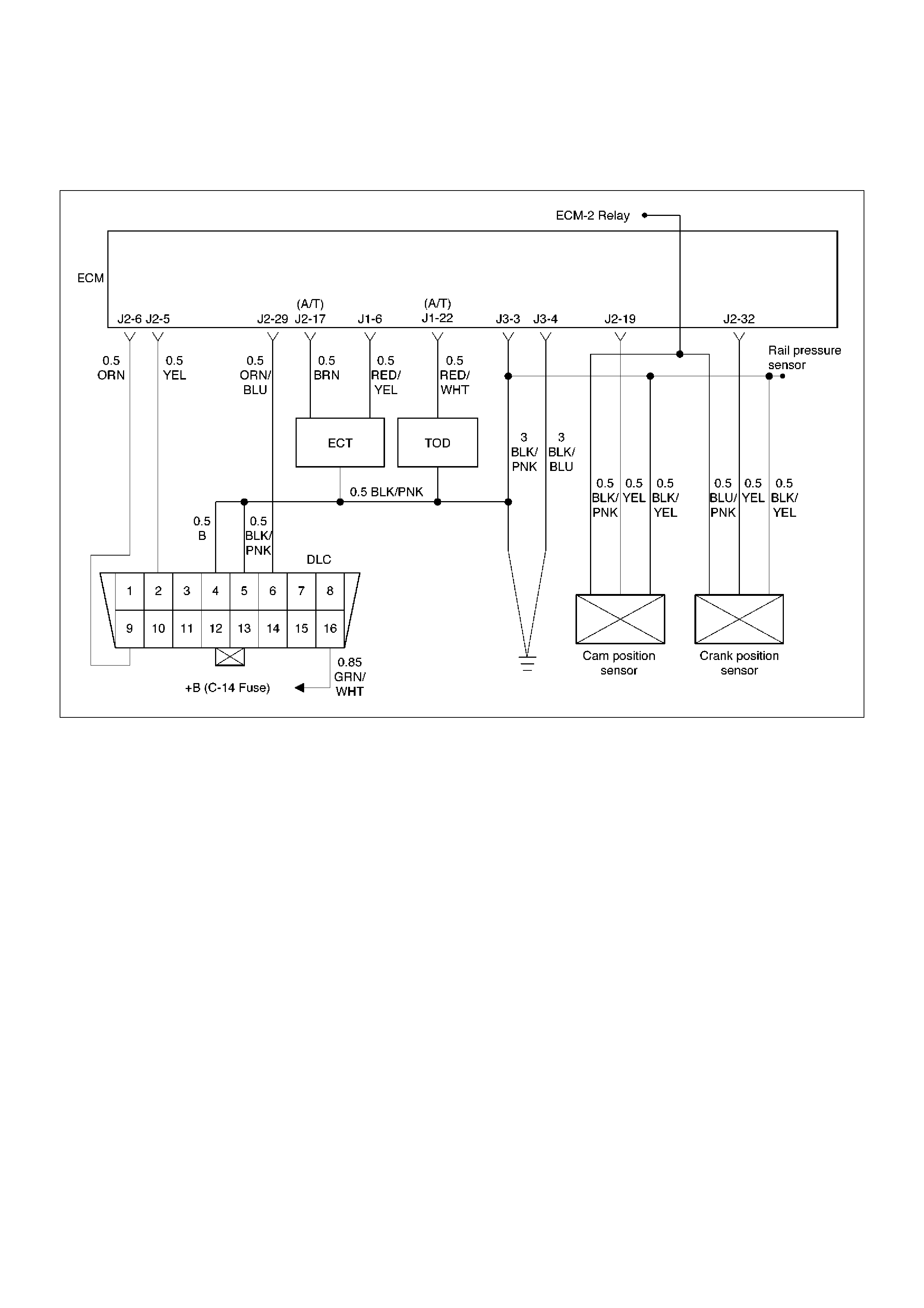

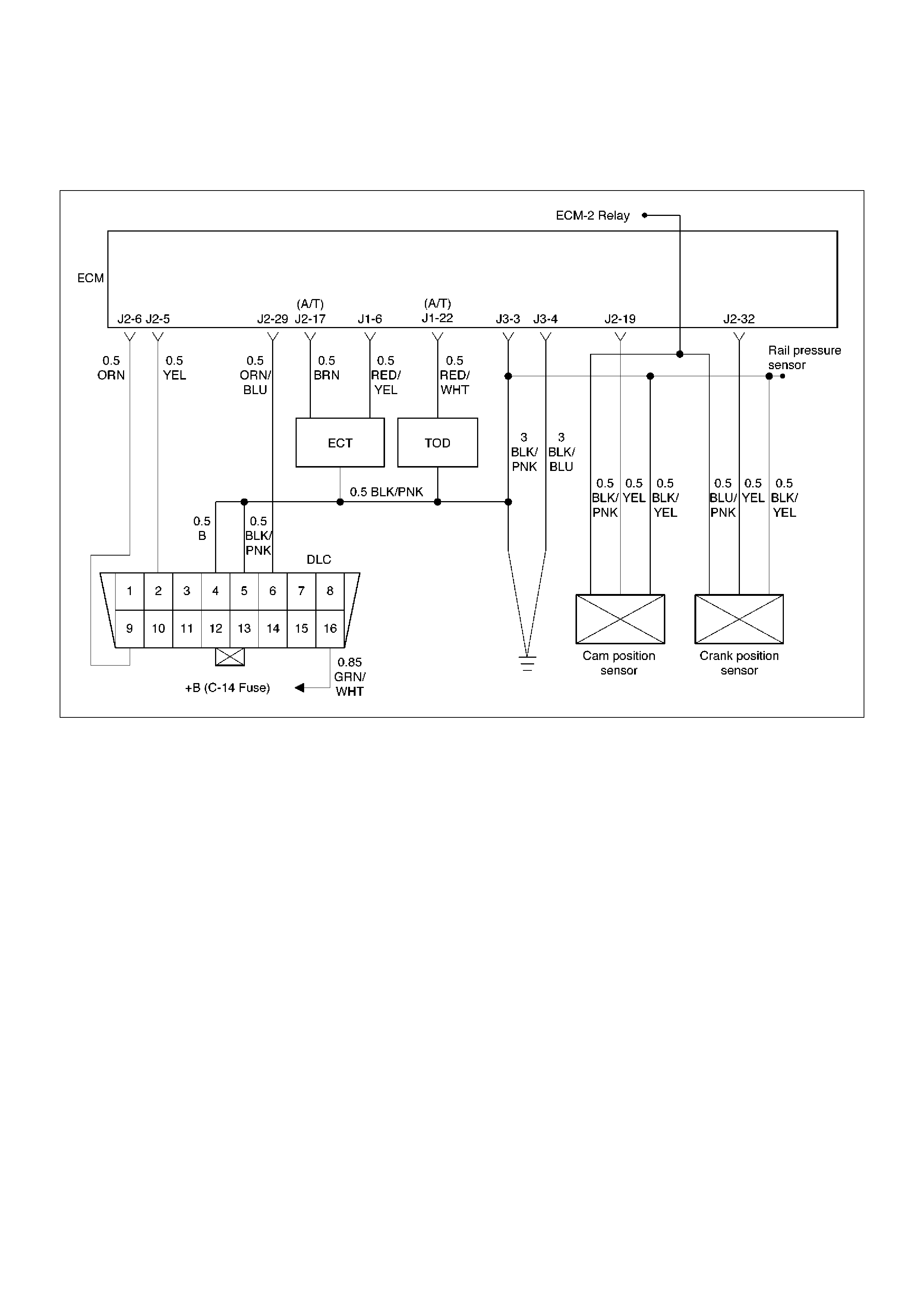

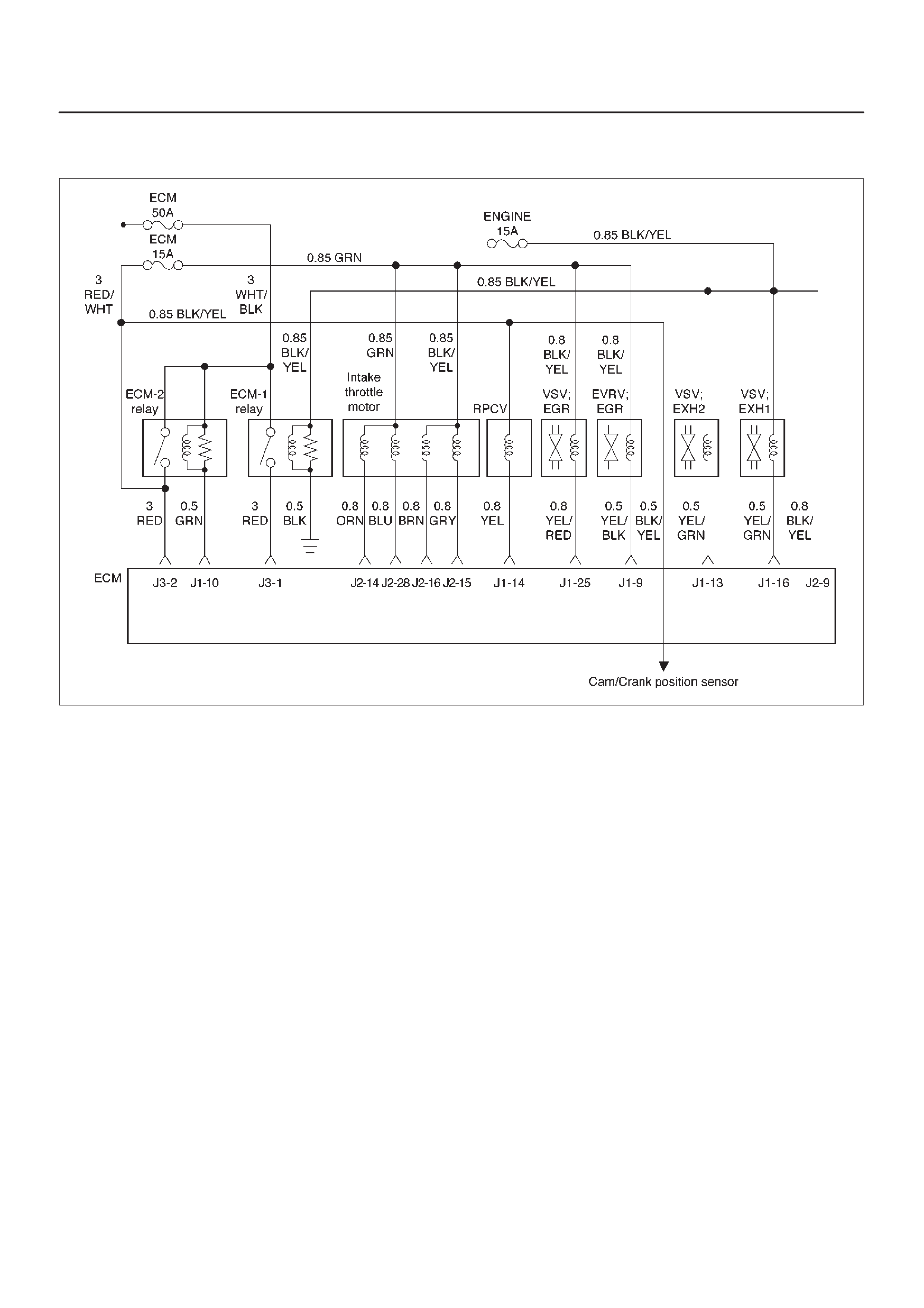

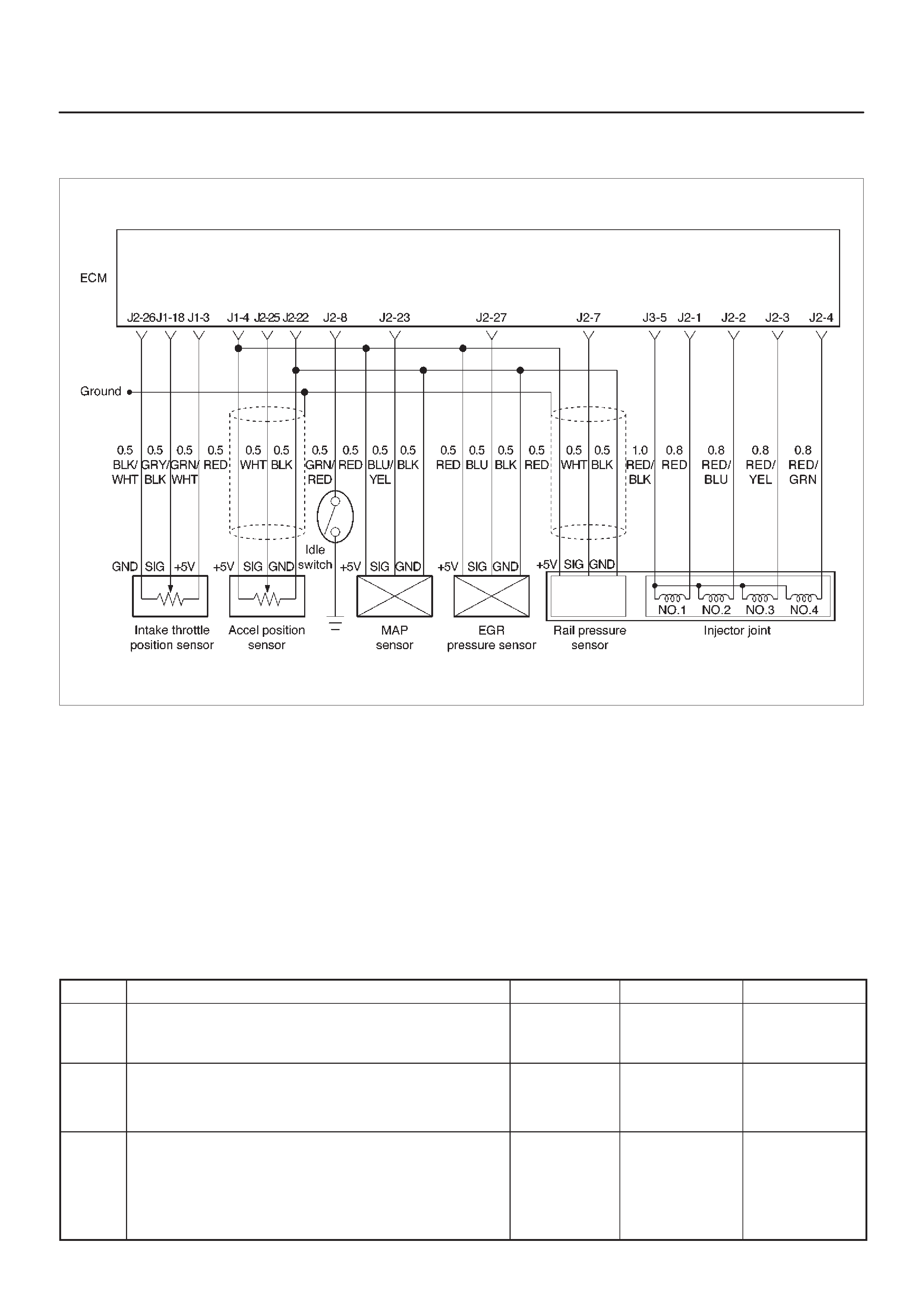

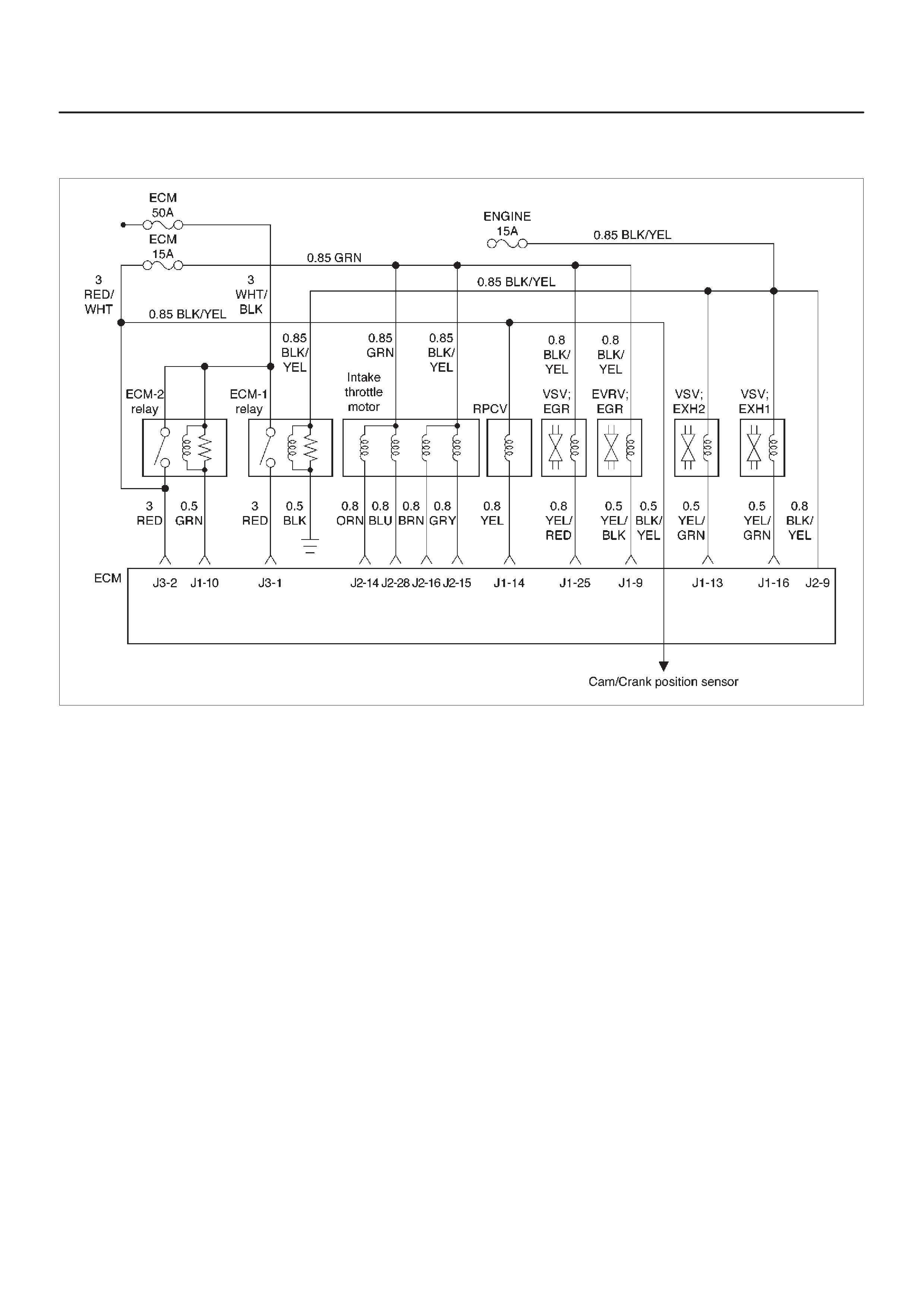

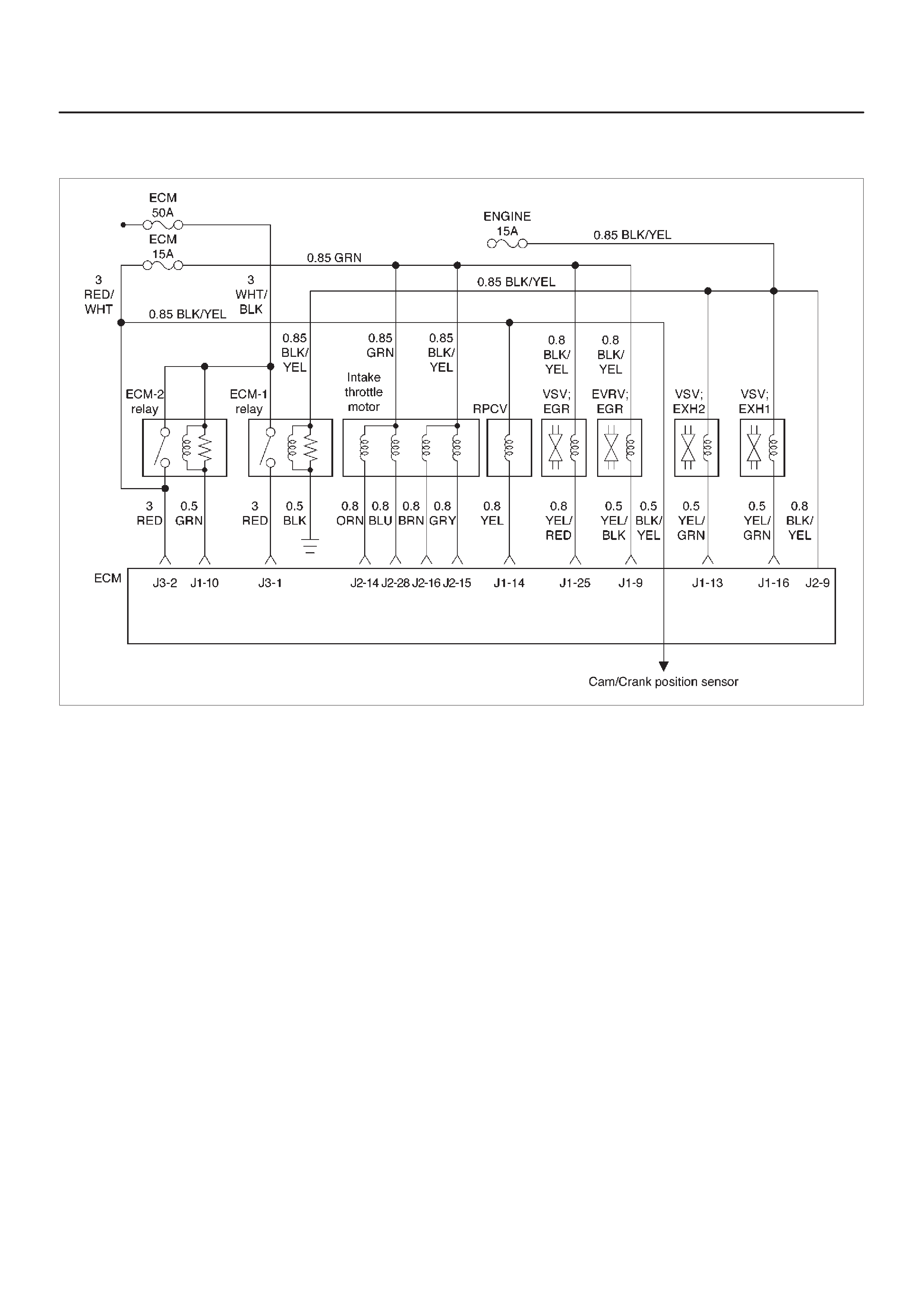

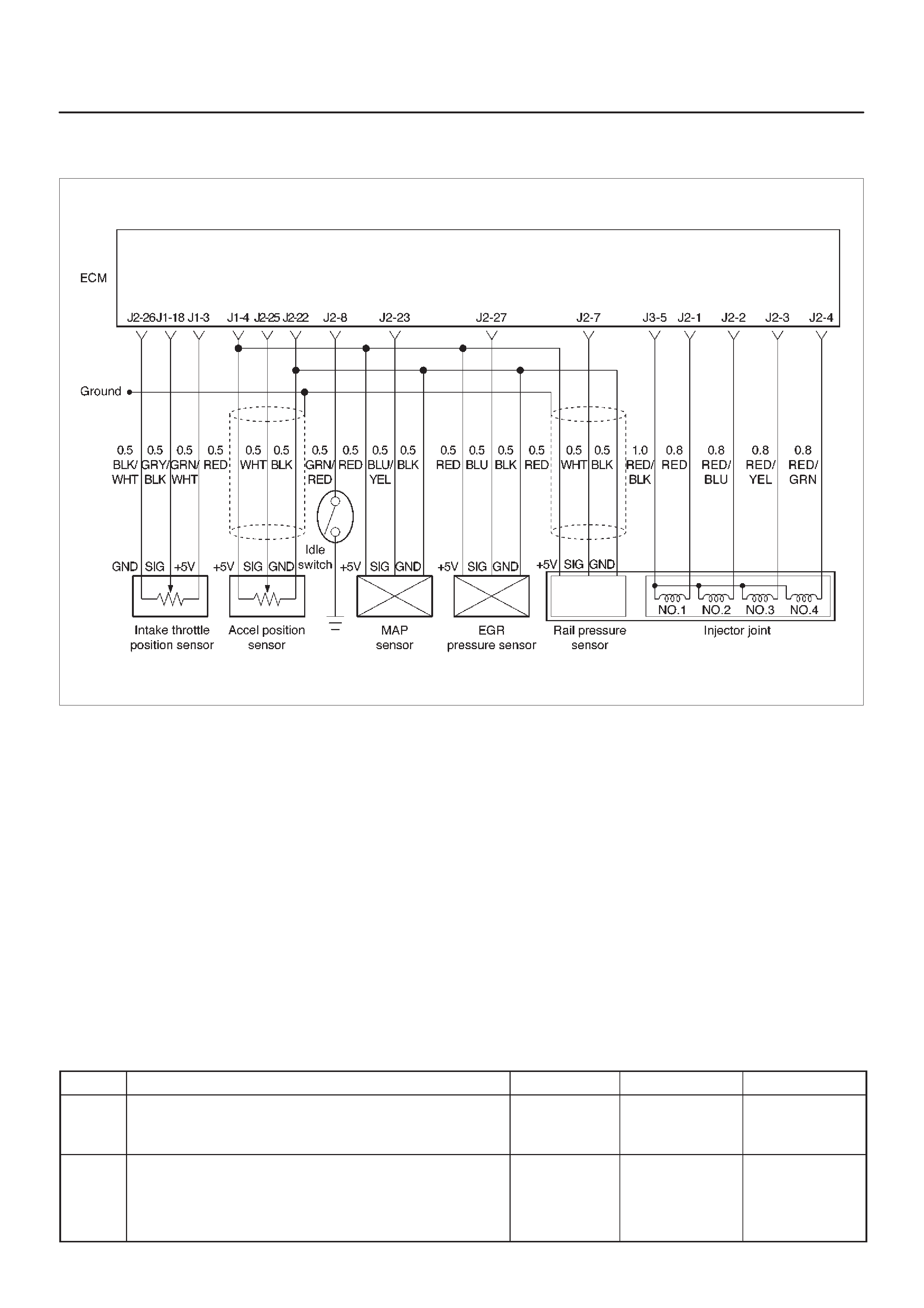

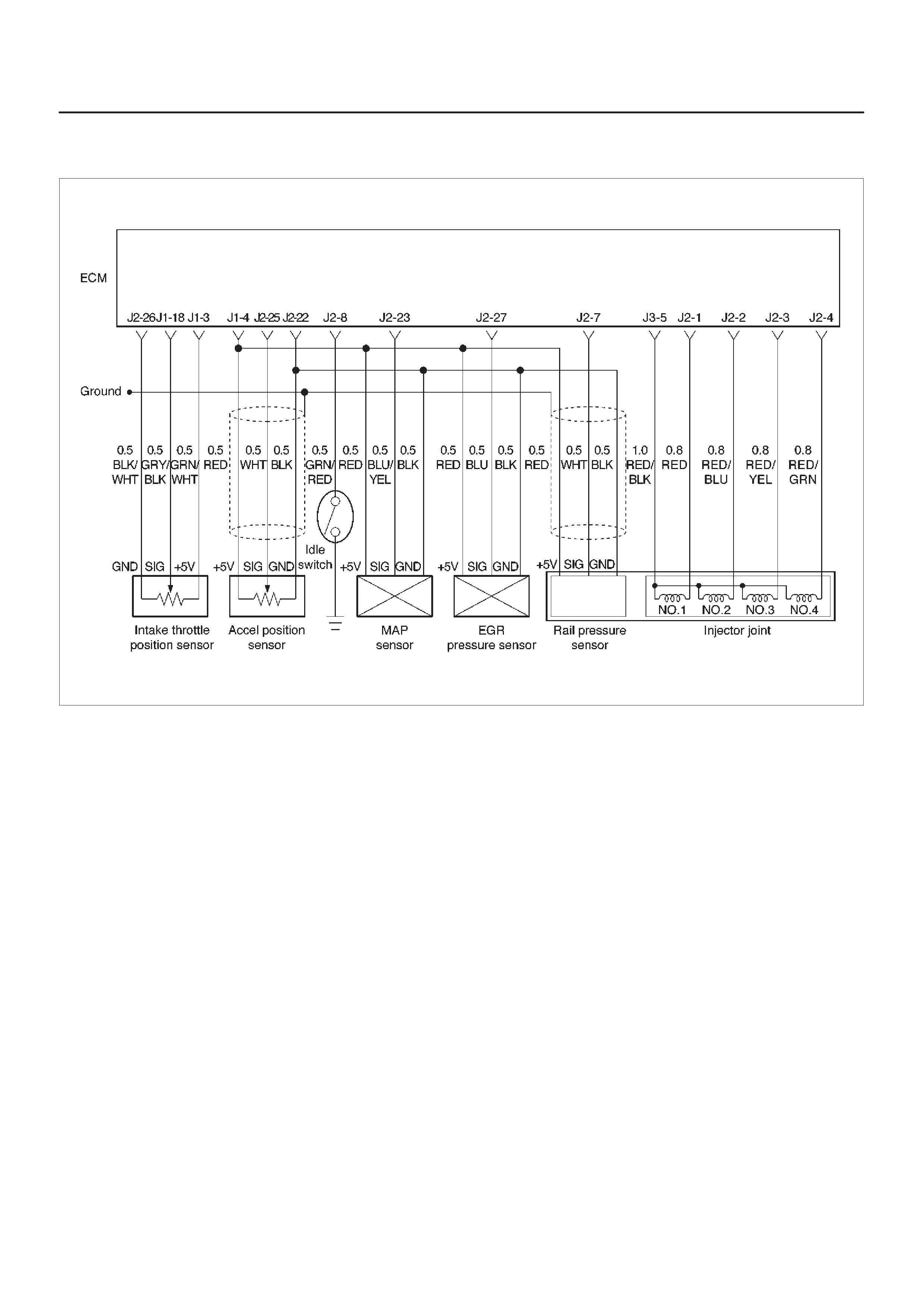

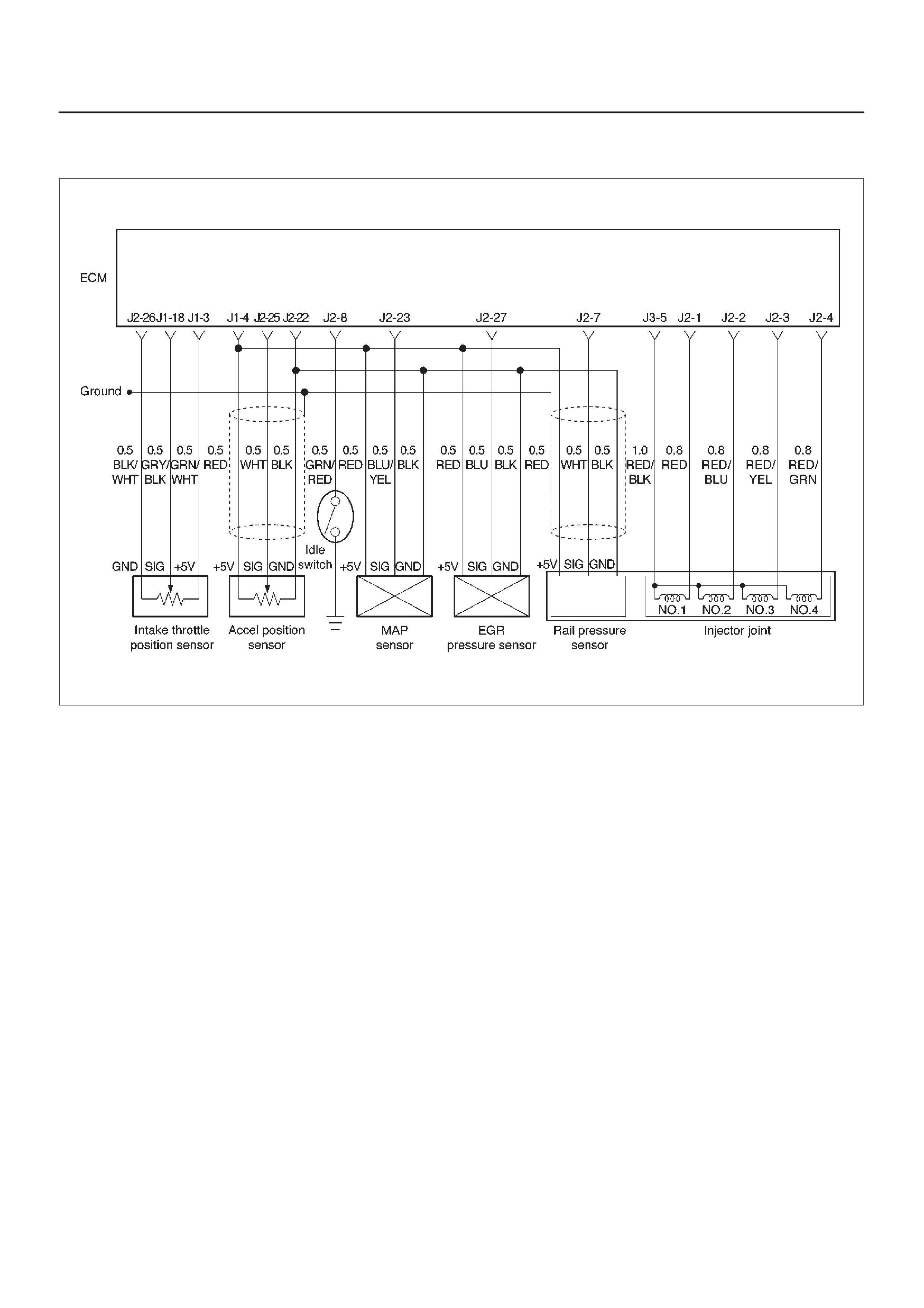

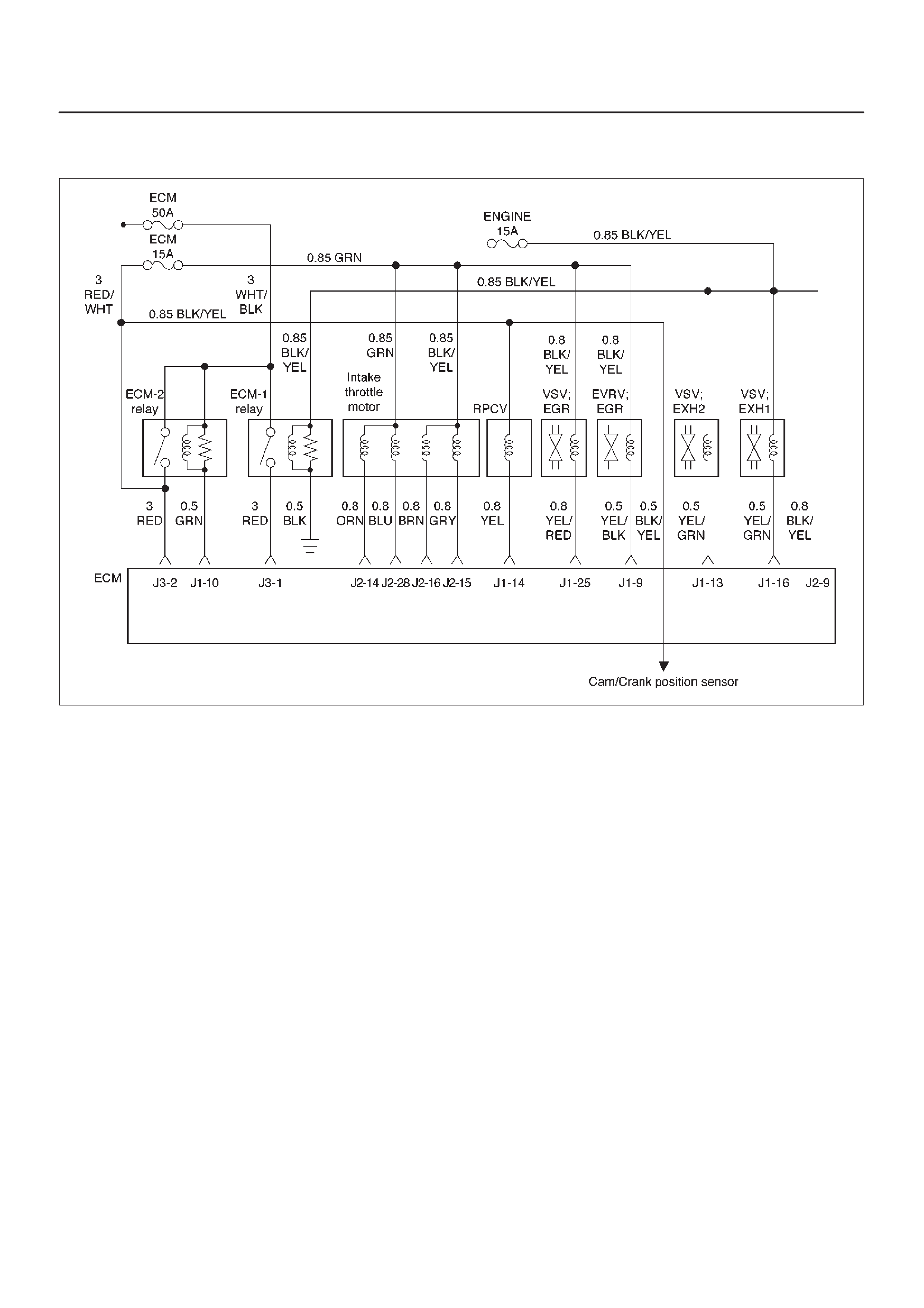

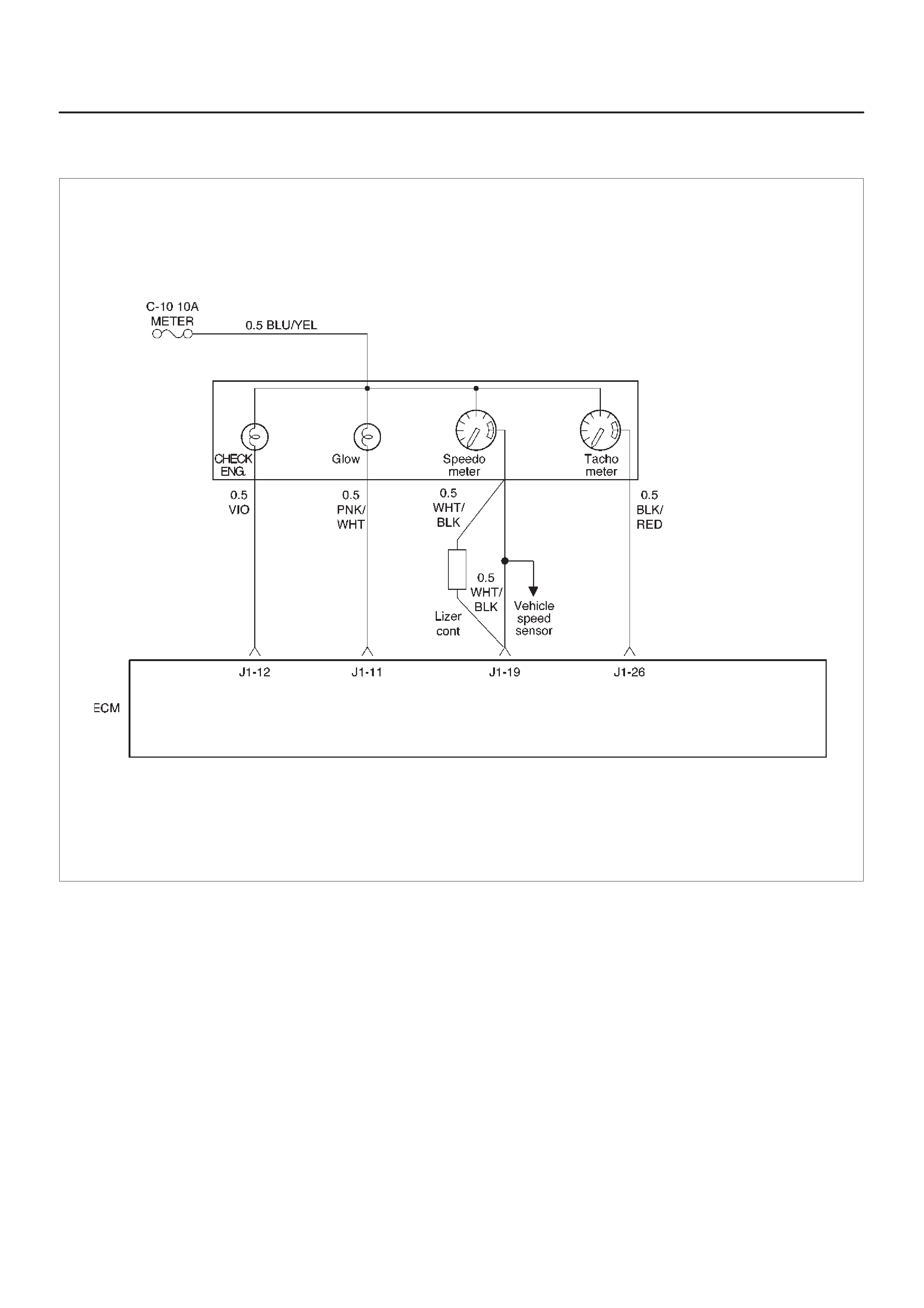

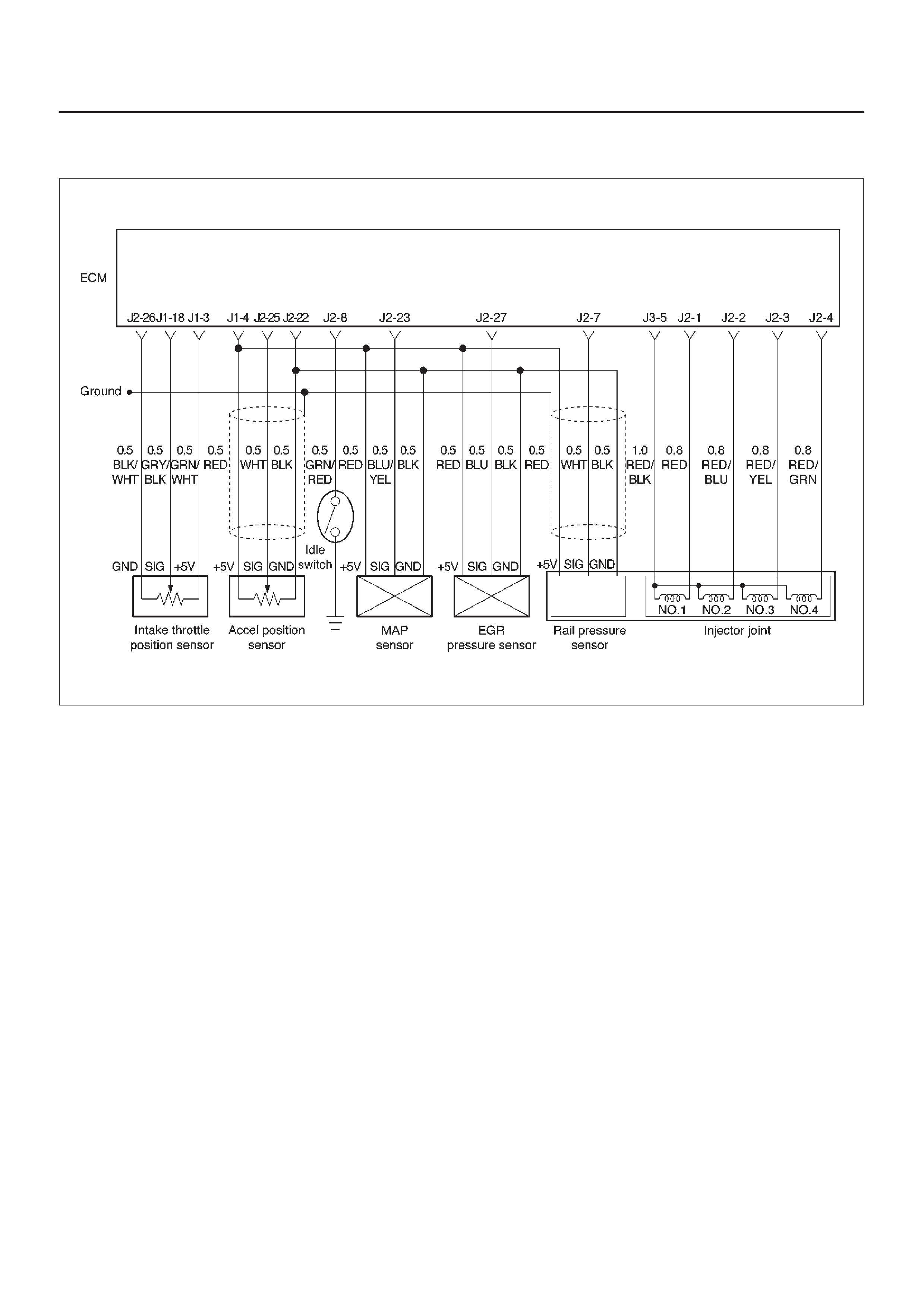

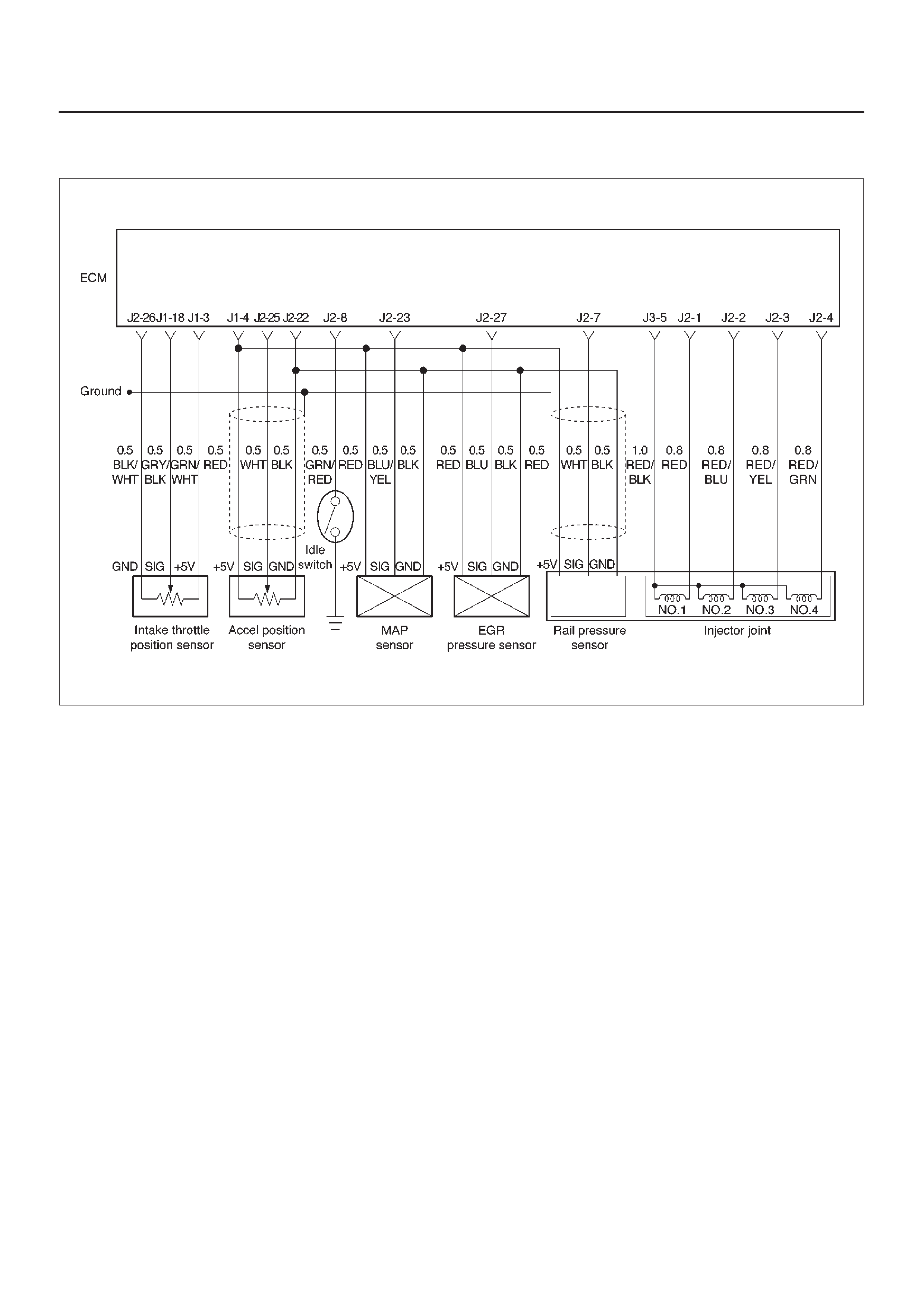

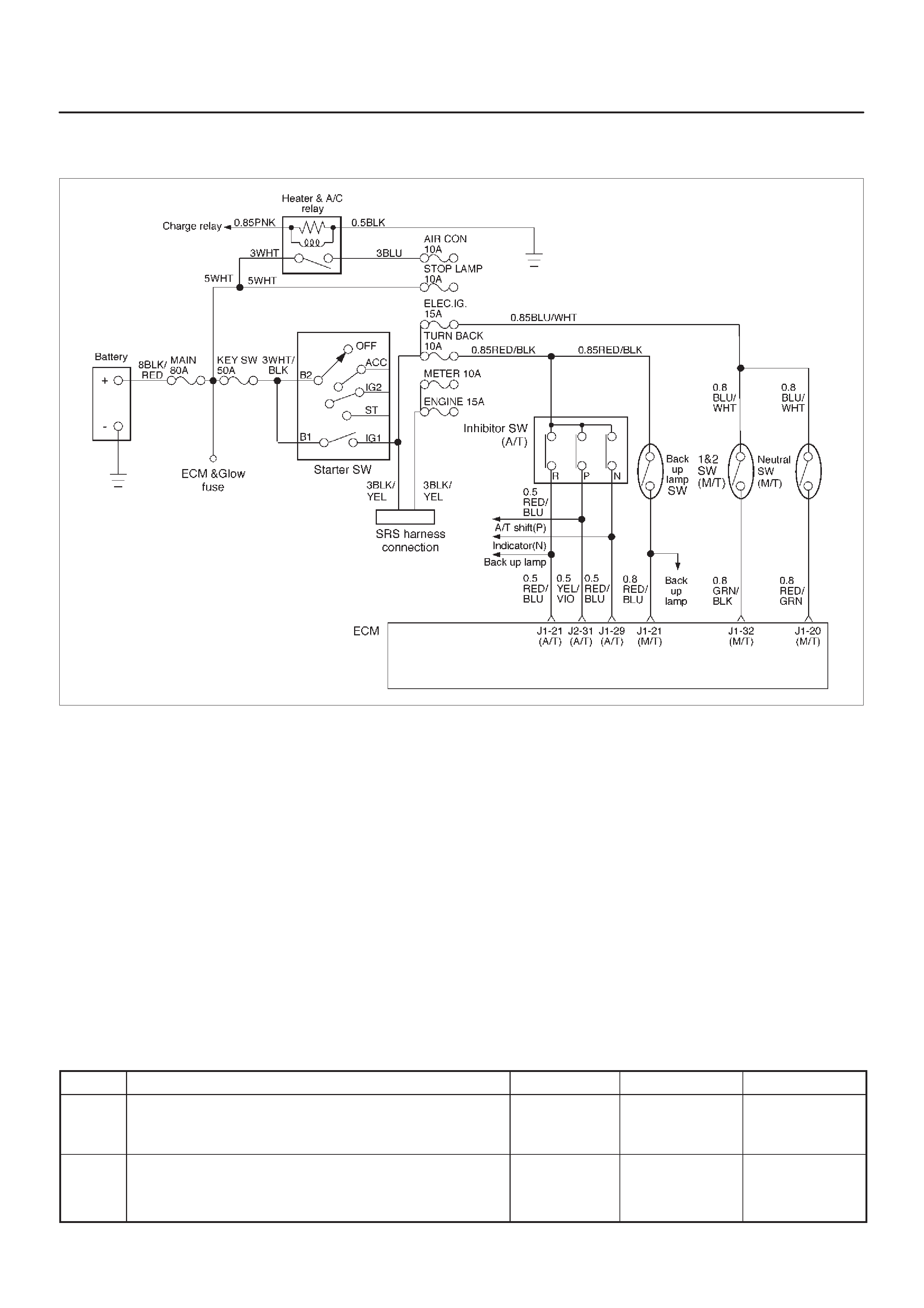

Diagrams and Schematics

ECM Wiring Diagram

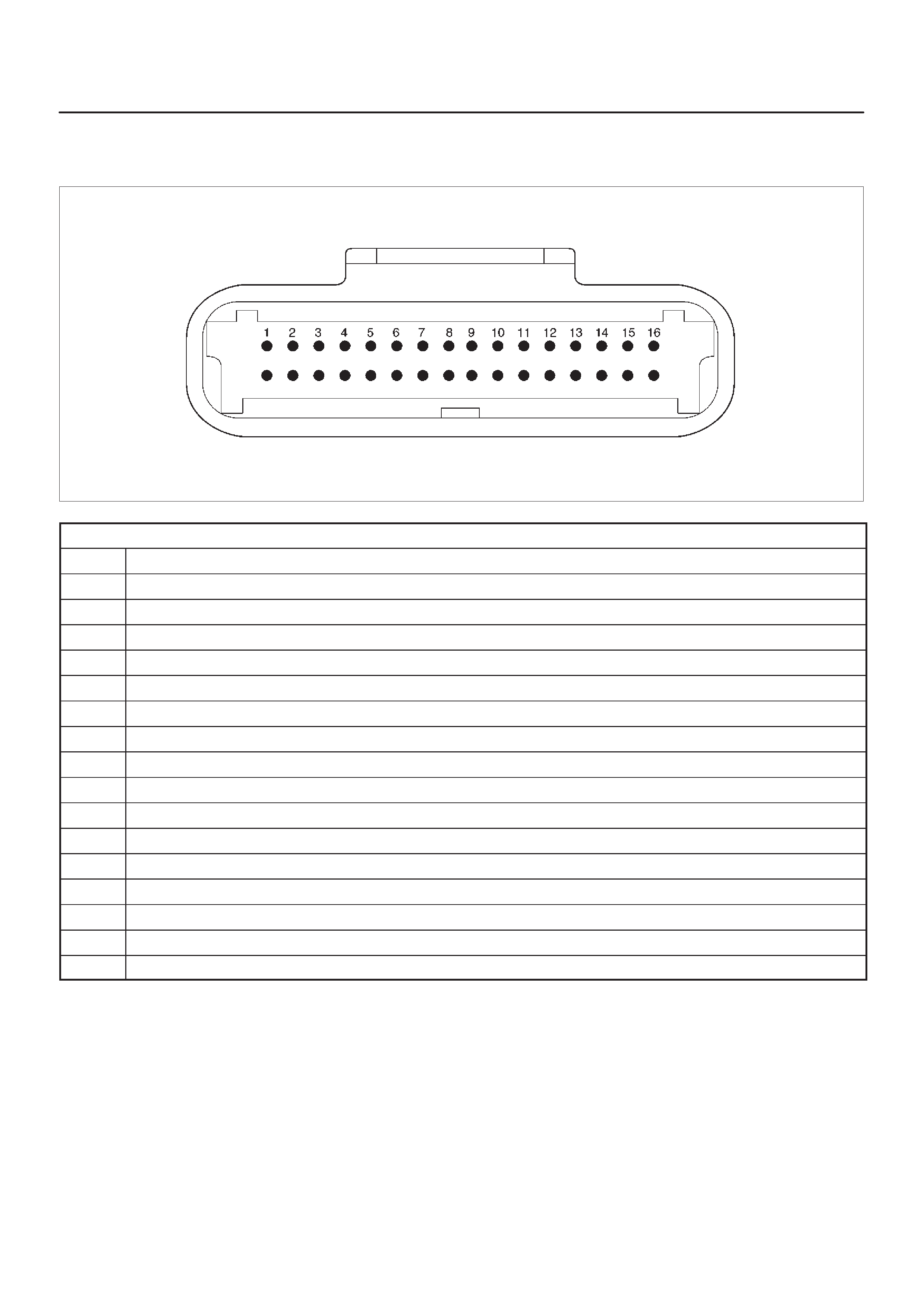

ECM Pinouts

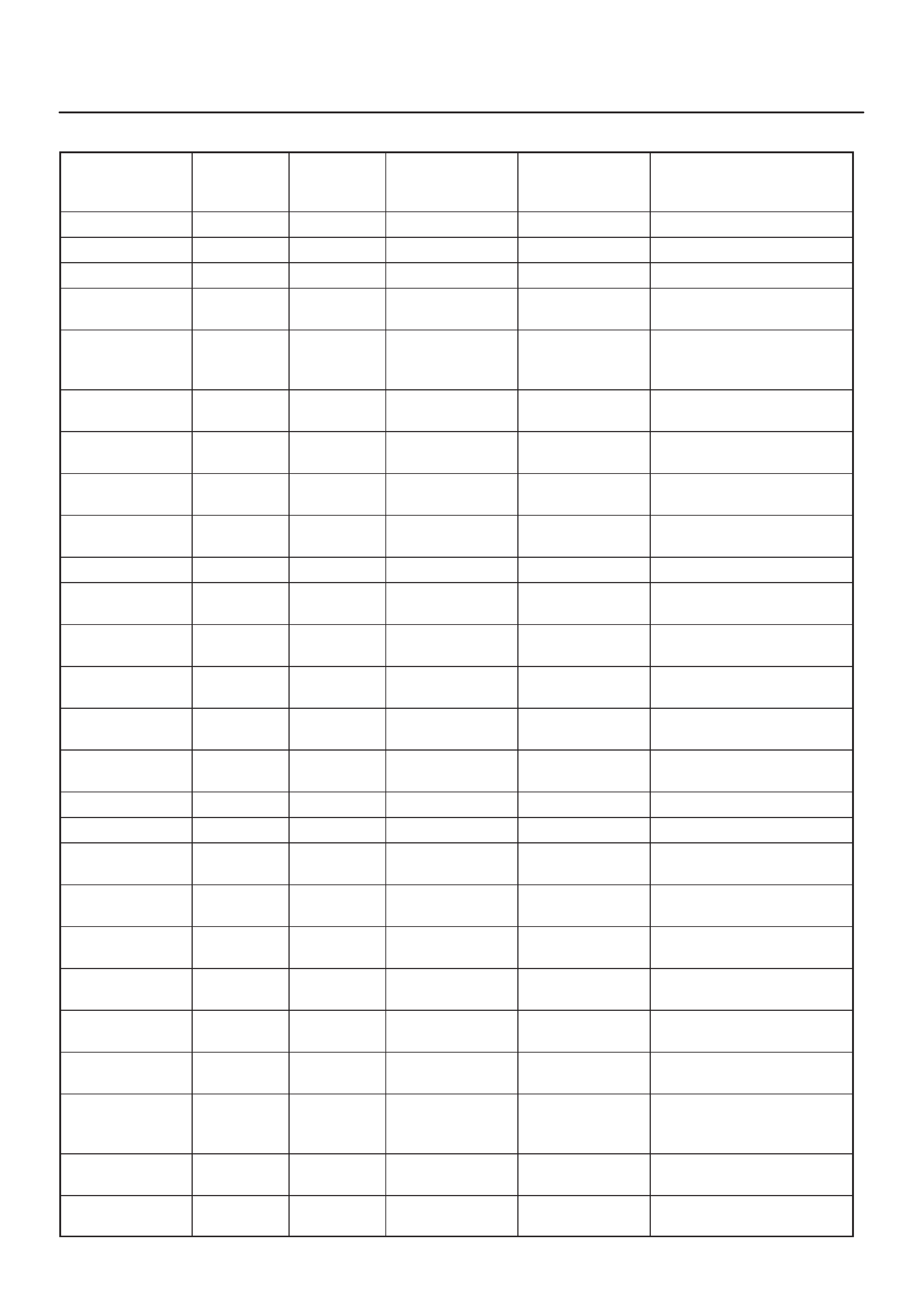

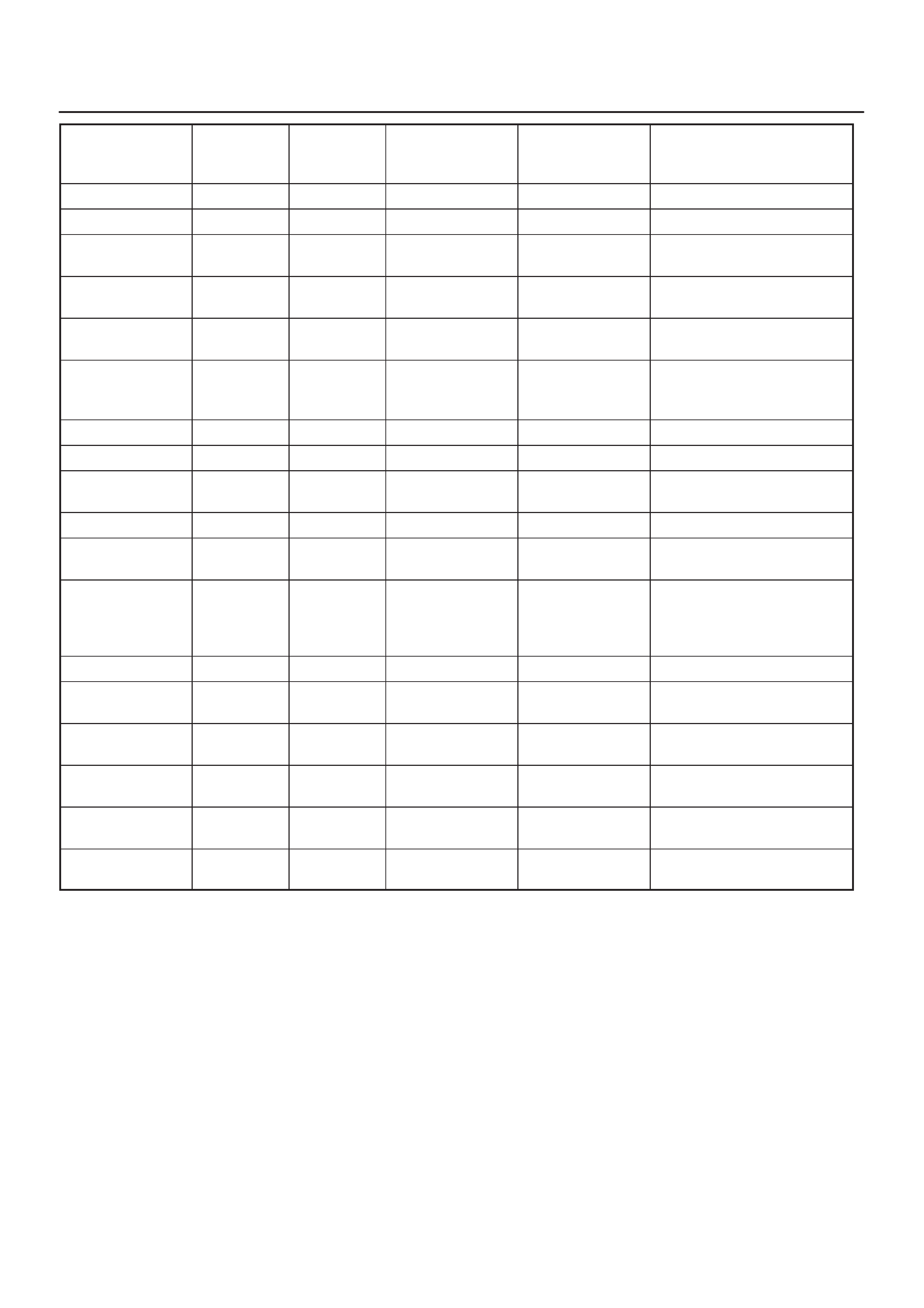

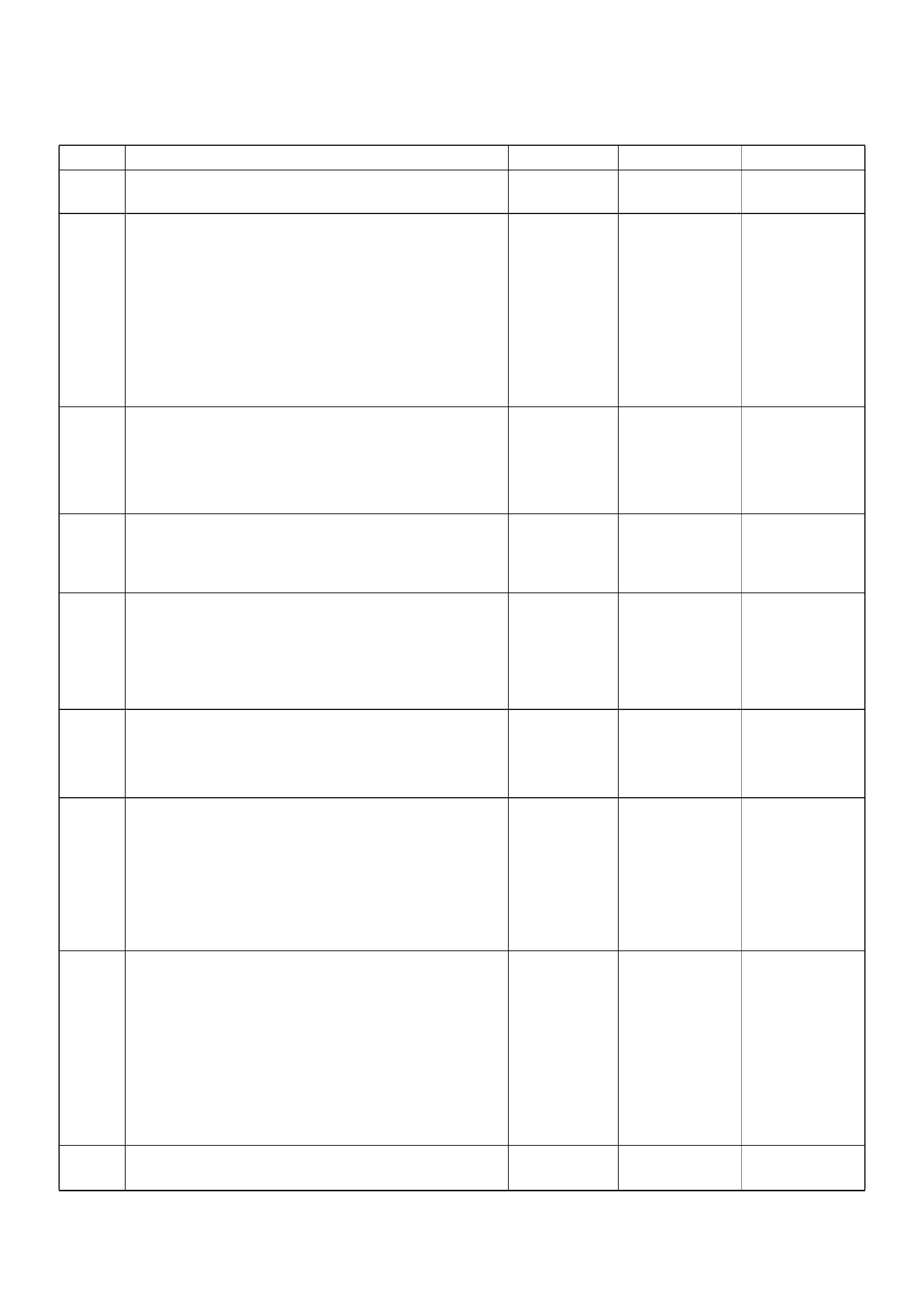

ECM Pinout Table, 32-Way Connector -

J1 RED - Upper

ECM Pinout Table, 32-Way Connector -

J1 RED - Lower

ECM Pinout Table, 32-Way Connector -

J2 BLUE - Upper

ECM Pinout Table, 32-Way Connector -

J2 BLUE - Lower

ECM Pinout Table, 5-Way Connector - J3

Component Locator

Abbreviations Charts

Diagnosis

Strategy-Based Diagnostics

DTC Stored

No DTC

No Matching Symptom

Intermittents

No Trouble Found

Verifying Vehicle Repair

General Service Information

Serviceability Issues

Visual/Physical Engine Compartment Inspection

Basic Knowledge of Tools Requir ed

Serial Data Communications

Class II Serial Data Communications

On-Board Diagnostic (OBD)

On-Board Diagnostic Tes ts

Comprehensive Component Monitor Diagnostic

Operation

Common OBD Terms

The Diagnostic Executiv e

DTC Types

Verifying Vehicle Repair

Reading Flash Diagnostic Trouble Co des

Reading Diagnostic Trouble Codes

Using a TECH 2

Tech 2 Scan Tool

Getting Started

DTC Modes

DTC Information Mode

Injector Test

EGR Valve Test

Rail Pressure Control Valve Test

Injector Balance Test

Data Programming in Case of ECM Change

Rail Pressure Sensor Programming

Injector Group Sign Programming

(Injector Change)

On-Board Diagnostic (OBD) System Check

Engine Control Module ECM Diagnosis

Multiple ECM Information Sensor DTCS Set

EGR (Exhaust Gas Recirculation) Diagnosis

Tech 2 Data Definitions and Rang es

Typical Scan Data Values

No Malfunction Indicator Lamp (MIL)

Malfunction Indicator Lamp (MIL) “ON” Steady

Engine Cranks But Will Not Run

Exhaust Gas Recirculation (EGR) System Check

ECM Diagnostic Trouble Codes

Diagnostic Trouble Code (DTC) P0 107 (Flash

DTC 34 ) MAP Sensor Circuit Low Voltage

Diagnostic Trouble Code (DTC) P0 108 (Flash

DTC 34) MAP Sensor Circuit High Voltage

Diagnostic Trouble Code (DTC) P0 112 (Flash

DTC 23) IAT Sensor Circuit Lo w Voltage

Diagnostic Trouble Code (DTC) P0 113 (Flash

DTC 23) IAT Sensor Circuit High Voltage

Diagnostic Trouble Code (DTC) P0 117 (Flash

DTC 14) ECT Sensor Low Voltage

Diagnostic Trouble Code (DTC) P0 118 (Flash

DTC 14) ECT Sensor High Voltage

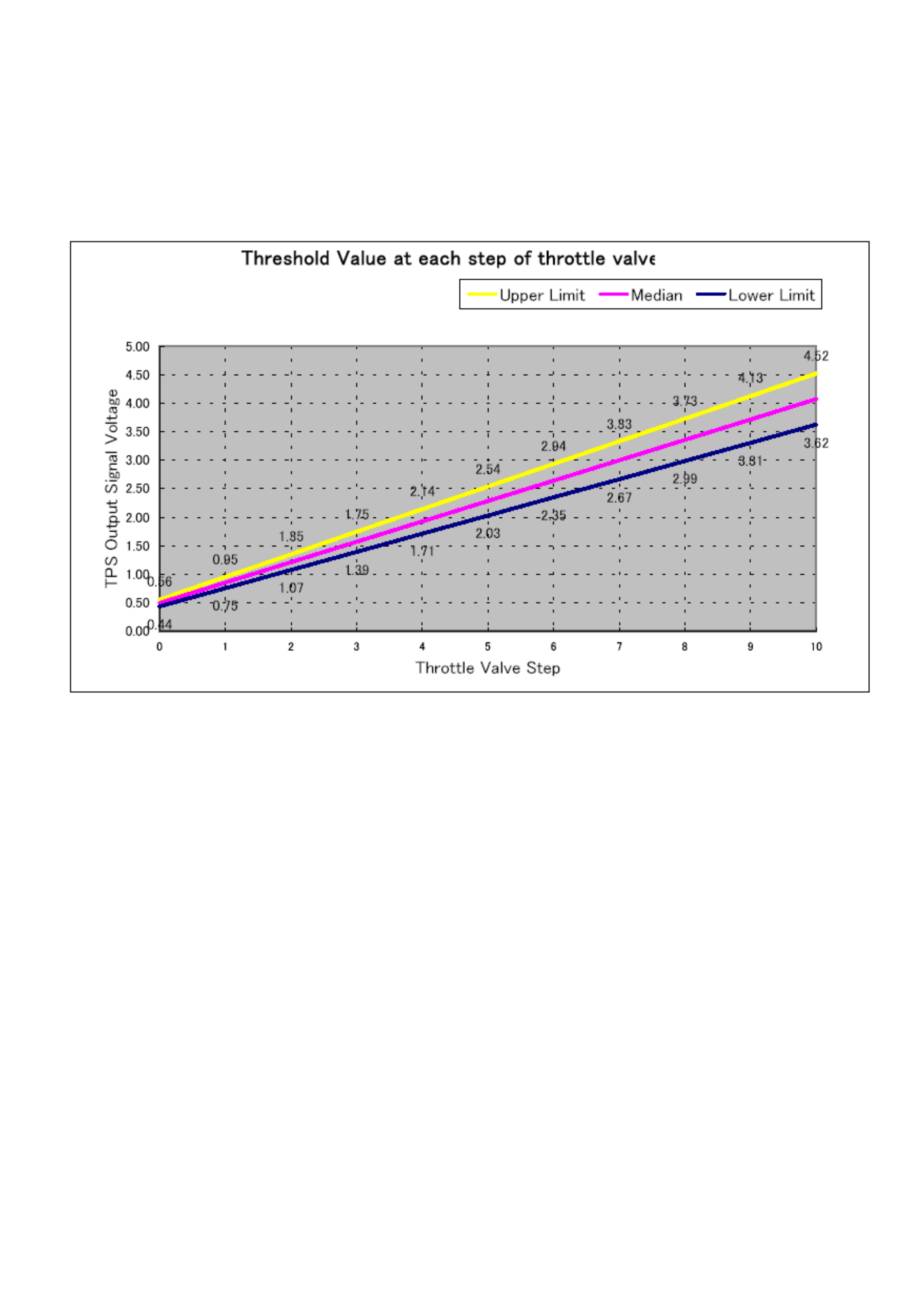

Diagnostic Trouble Code (DTC) P0 121 (Flash

DTC 33) AP Sensor Rationality

Diagnostic Trouble Code (DTC) P0 122 (Flash

DTC 21) AP Sensor Low Voltage

Diagnostic Trouble Code (DTC) P0 123 (Flash

DTC 21) AP Sensor High Voltage

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Diagnostic Trouble Code (DTC) P0 182 (Flash

DTC 15) FT Sensor Low Voltage

Diagnostic Trouble Code (DTC) P0 183 (Flash

DTC 15) FT Sensor High Voltage

Diagnostic Trouble Code (DTC) P0 192 (Flash

DTC 63) Rail Pressure Sensor Low Voltage

Diagnostic Trouble Code (DTC) P0 193 (Flash

DTC 63) Rail Pressure Sensor High Voltage

Diagnostic Trouble Code (DTC) P1 193 (Flash

DTC 64) RPCV Circuit Open/Short

Diagnostic Trouble Code (DTC) P1 194 (Flash

DTC 61) Rail Pressure System Low Voltage

Diagnostic Trouble Code (DTC) P1 195 (Flash

DTC 61) Rail Pressure System High Voltage

Diagnostic Trouble Code (DTC) P1 196 (Flash

DTC 62) Rail Pressure System High Warning

Diagnostic Trouble Code (DTC) P0 197 (Flash

DTC 16) Oil Temp Sensor Low Voltage

Diagnostic Trouble Code (DTC) P0 198 (Flash

DTC 16) Oil Temp Sensor High Voltage

Diagnostic Trouble Code (DTC) P0 201 (Flash

DTC 51) Injector # 1 Circuit Fault

Diagnostic Trouble Code (DTC) P0 202 (Flash

DTC 52) Injector # 2 Circuit Fault

Diagnostic Trouble Code (DTC) P0 203 (Flash

DTC 52) Injector # 3 Circuit Fault

Diagnostic Trouble Code (DTC) P0 204 (Flash

DTC 54) Injector # 4 Circuit Fault

Diagnostic Trouble Code (DTC) P0 217 (Flash

DTC 22) High Coolant Temp Waring

Diagnostic Trouble Code (DTC) P1 217 (Flash

DTC 36) High Oil Temp Warning

Diagnostic Trouble Code (DTC) P0 219 (Flash

DTC 11) Engine Ov er Speed Warning

Diagnostic Trouble Code (DTC) P0 336

(Flash DTC 43) CKP (Crank Position) Sensor

Out of Synchro

Diagnostic Trouble Code (DTC) P0 337

(Flash DTC 43) CKP (Crank Position)

Sensor No Signal

CKP (Crank Position) Sensor No Signal

(MY1999 - MY2002 VEHICLES ONLY)

Diagnostic Trouble Code (DTC) P0 341

(Flash DTC 41) CMP (Cam Position)

Sensor Out of Sy nchro

Diagnostic Trouble Code (DTC) P0 342 (Flash

DTC 41) CMP (Cam Posi tion) Sensor No Signal

CMP (Cam Position) Sensor No Signal

(MY1999 - MY2002 VEHICLES ONLY)

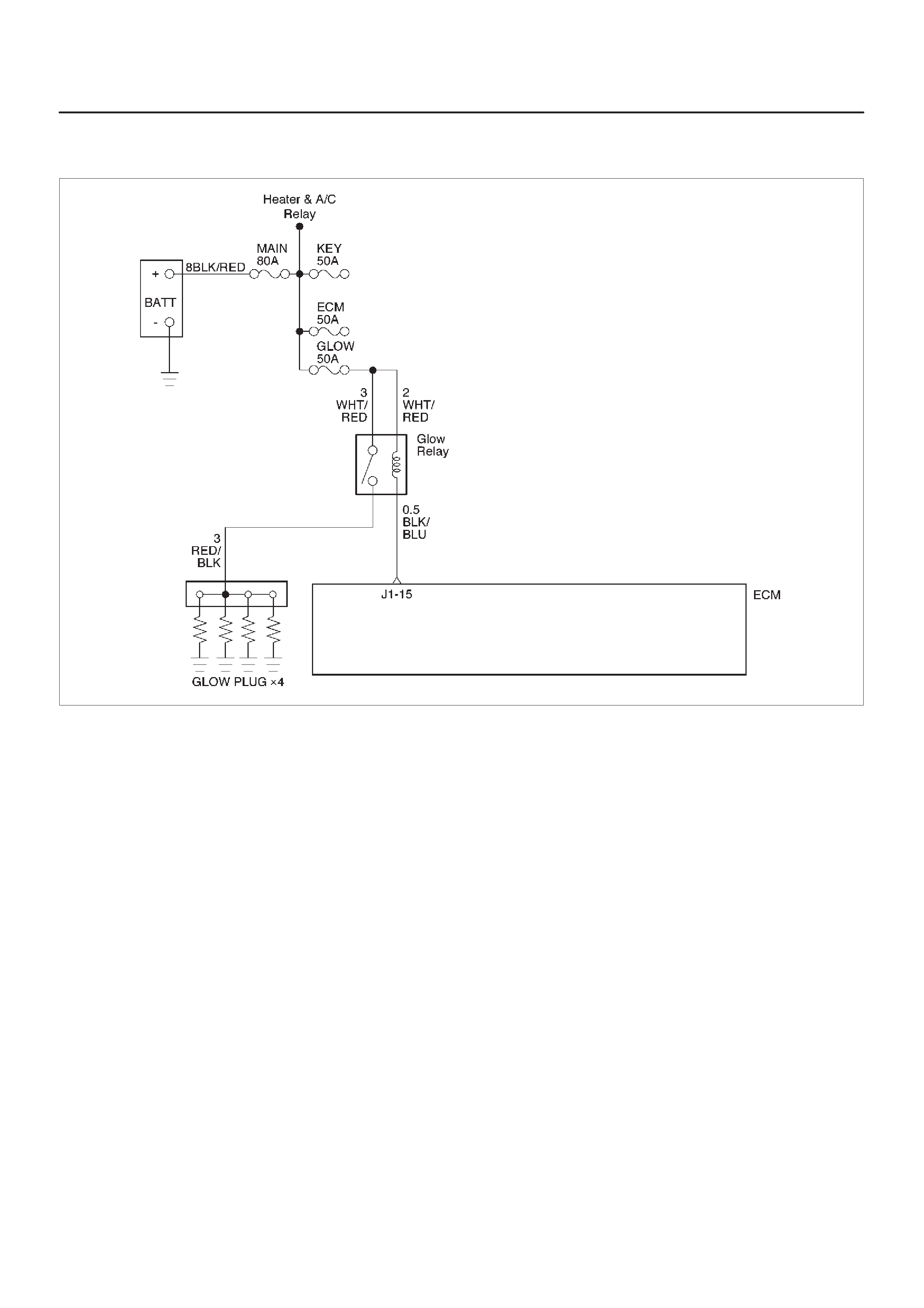

Diagnostic Trouble Code (DTC) P0 380 (Flash

DTC 66) Glow Relay Circuit Open/Short

Diagnostic Trouble Code (DTC) P0 381 (Flash

DTC 67) Glow Lamp Circuit Open/Sh ort

Diagnostic Trouble Code (DTC) P1 403

(Flash DTC 32) EGR EVRV Fault

Diagnostic Trouble Code (DTC) P1 404

(Flash DTC 31) EGR VSV Circuit

Diagnostic Trouble Code (DTC) P0 405

(Flash DTC 26) EGR Pressure Sensor

Diagnostic Trouble Code (DTC) P1 405 (Flash

DTC 37) EGR EVRV Circuit Open/Short

Diagnostic Trouble Code (DTC) P0 406 (Flash

DTC 26) EGR Pressure Sensor High Voltage

Diagnostic Trouble Code (DTC) P0 475

(Flash DTC 71) EXH #1 VSV Circuit

Diagnostic Trouble Code (DTC) P1 475 (Flash

DTC 71) EXH #2 VSV Circuit Open/Short

Diagnostic Trouble Code (DTC) P1 485 (Flash

DTC 74) ITP (Intake Thorottle Positio n)

Sensor Low Voltage

Diagnostic Trouble Code (DTC) P1 486 (Flash

DTC 74) ITP (Intake Throttle Position)

Sensor High Voltage

Diagnostic Trouble Code (DTC) P1 487

(Flash DTC 73) Intake Thr ottle System

Circuit Open/Start

Diagnostic Trouble Code (DTC) P1 488

(Flash DTC 72) Intake Thr ottle Motor

Control Circuit Signal Gap

Diagnostic Trouble Code (DTC) P0 502 (Flash

DTC 24) VSS (Vehicle Speed Sensor) No Signal

Diagnostic Trouble Code (DTC) P0 510 (Flash

DTC 75) Idle SW Malfunction, Open Circuit

Diagnostic Trouble Code (DTC) P1 510 (Flash

DTC 75) Idle SW Malfunction Short Circuit

Diagnostic Trouble Code (DTC) P0 562

(Flash DTC 35) System Voltage Too Low

Diagnostic Trouble Code (DTC) P1 562 (Flash

DTC 35) System Voltage Too Low at Cranking

Diagnostic Trouble Code (DTC) P1 587

(Flash DTC 25) Brake SW Malfunction

Diagnostic Trouble Code (DTC) P1 588

(Flash DTC 25) Brake SW Malfunction

Diagnostic Trouble Code (DTC) P0 601

(Flash DTC 55) ECM Checksum Error

Diagnostic Trouble Code (DTC) P1626 -

No Response From Immobiliser

Diagnostic Trouble Code (DTC) P1631 -

Received Response Was Not Correct

Diagnostic Trouble Code (DTC) P1648 -

Received Incorrect Security Code

Diagnostic Trouble code (DTC) P1 649 - Security

Code & Security Key Not Programmed

Diagnostic Trouble Code (DTC) P0 650 (Flash

DTC 77) Check Engine Lam Circuit Open/Short

Diagnostic Trouble Code (DTC) P0 654 (Flash

DTC 27) Tachometer Circuit Open/Short

Diagnostic Trouble Code (DTC) P1 655 (Flash

DTC 17) Thermo Relay Circuit Open/Short

Diagnostic Trouble Code (DTC) P1 657 (Flash

DTC 76) ECM Main Relay Circuit Open/Short

Diagnostic Trouble Code (DTC) P1 589 (Flash

DTC 47) Transmission SW Circui t Open/Short

Symptom Diagnosis

Default Matrix Table

On-Vehicle Service

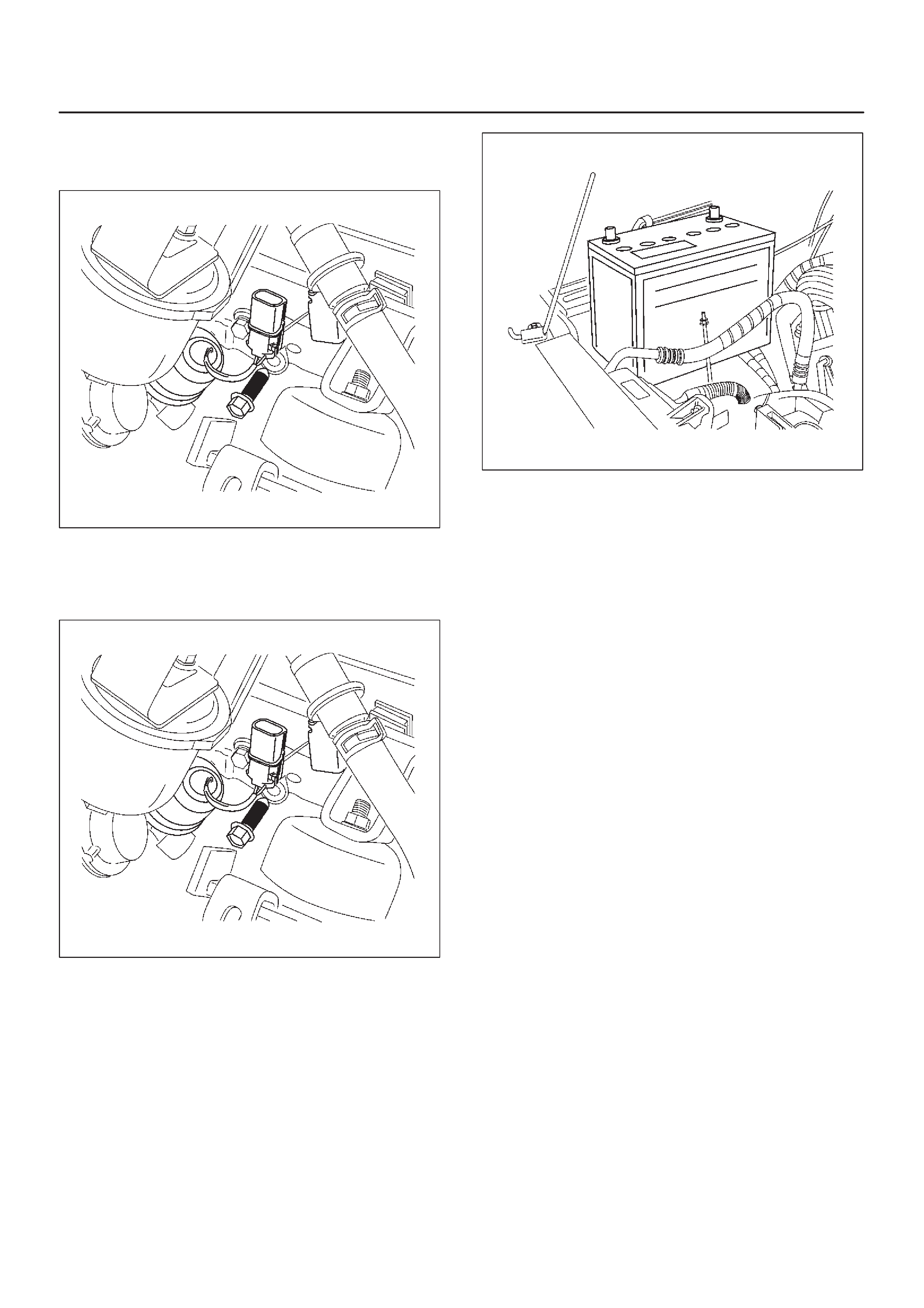

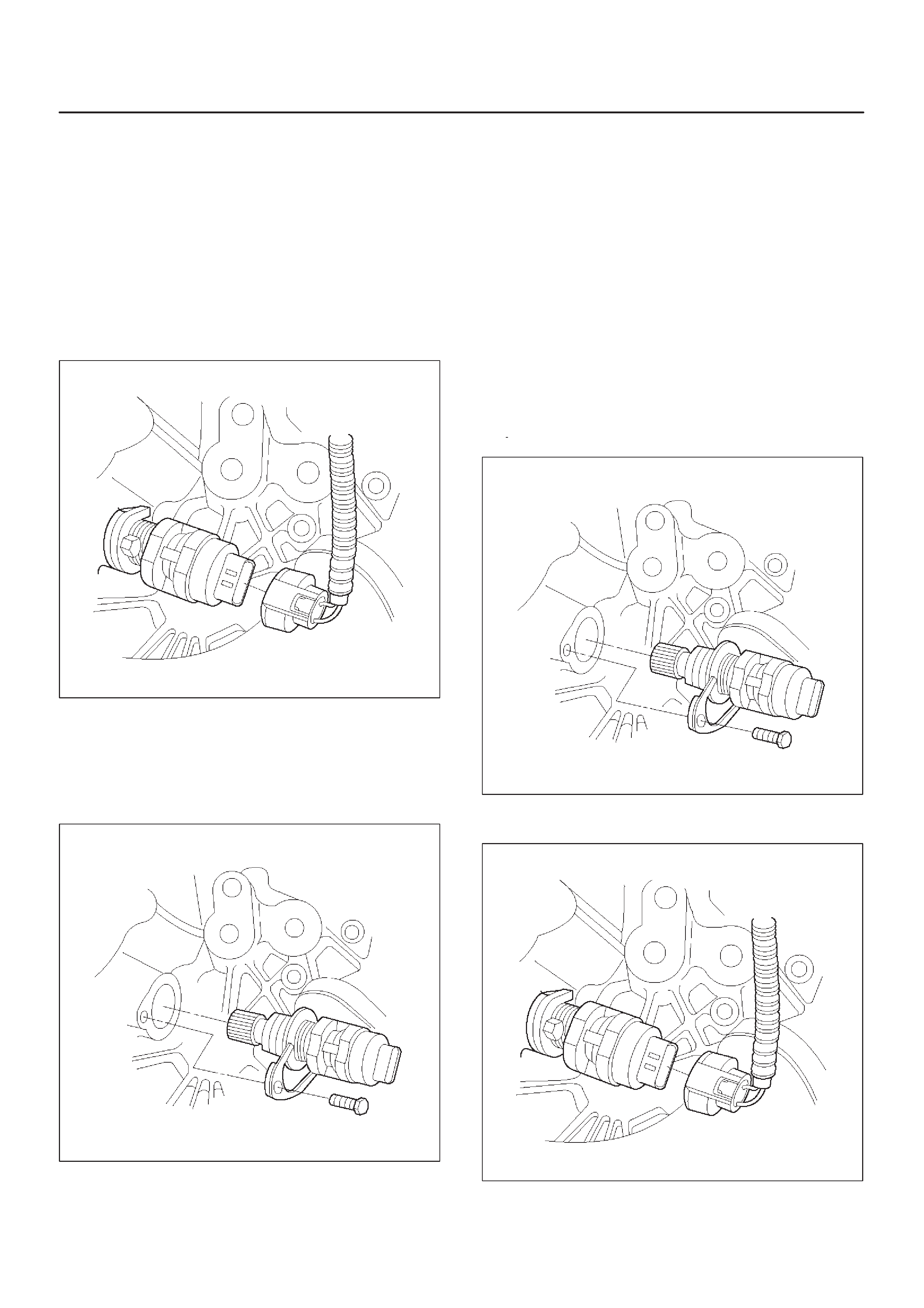

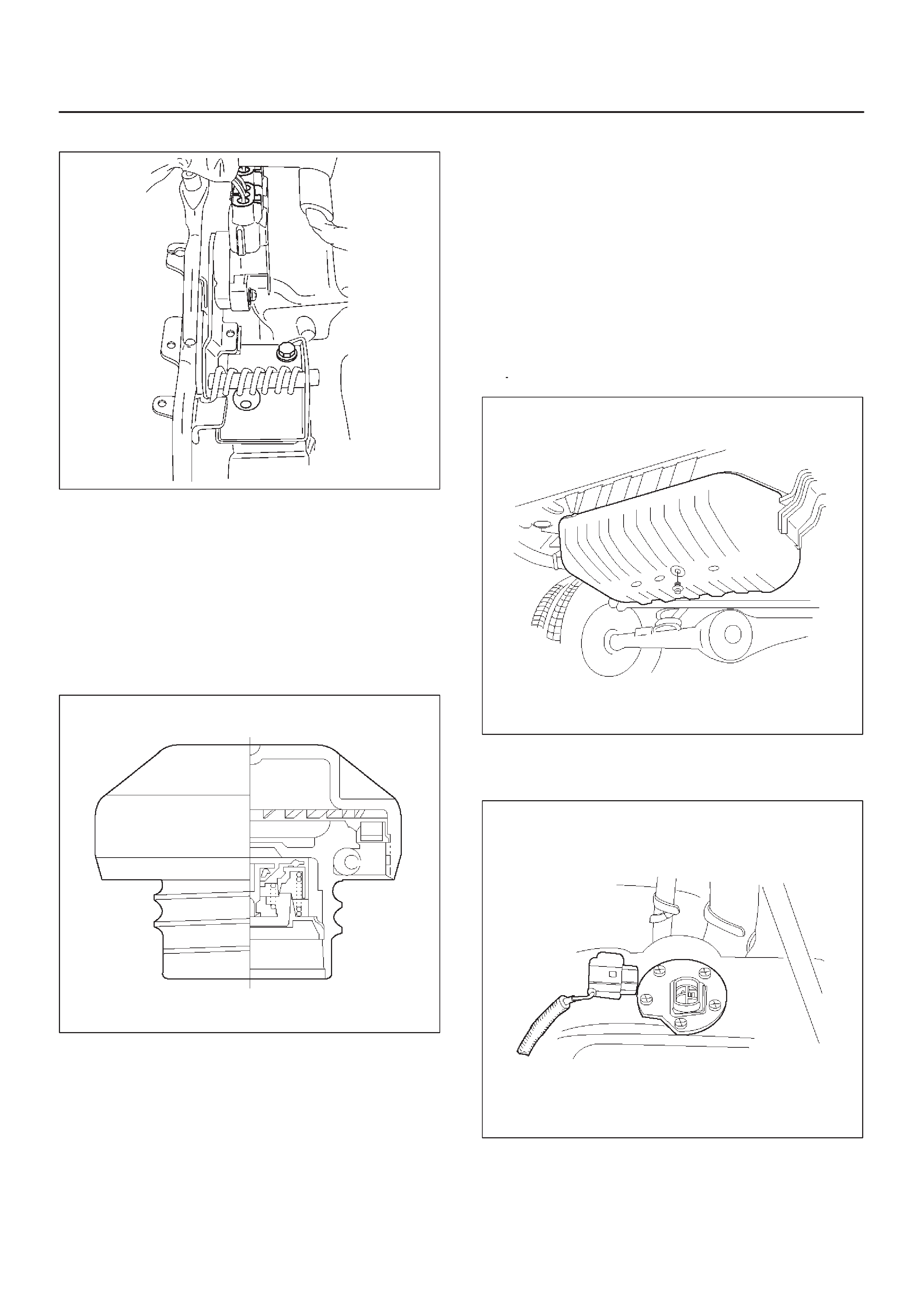

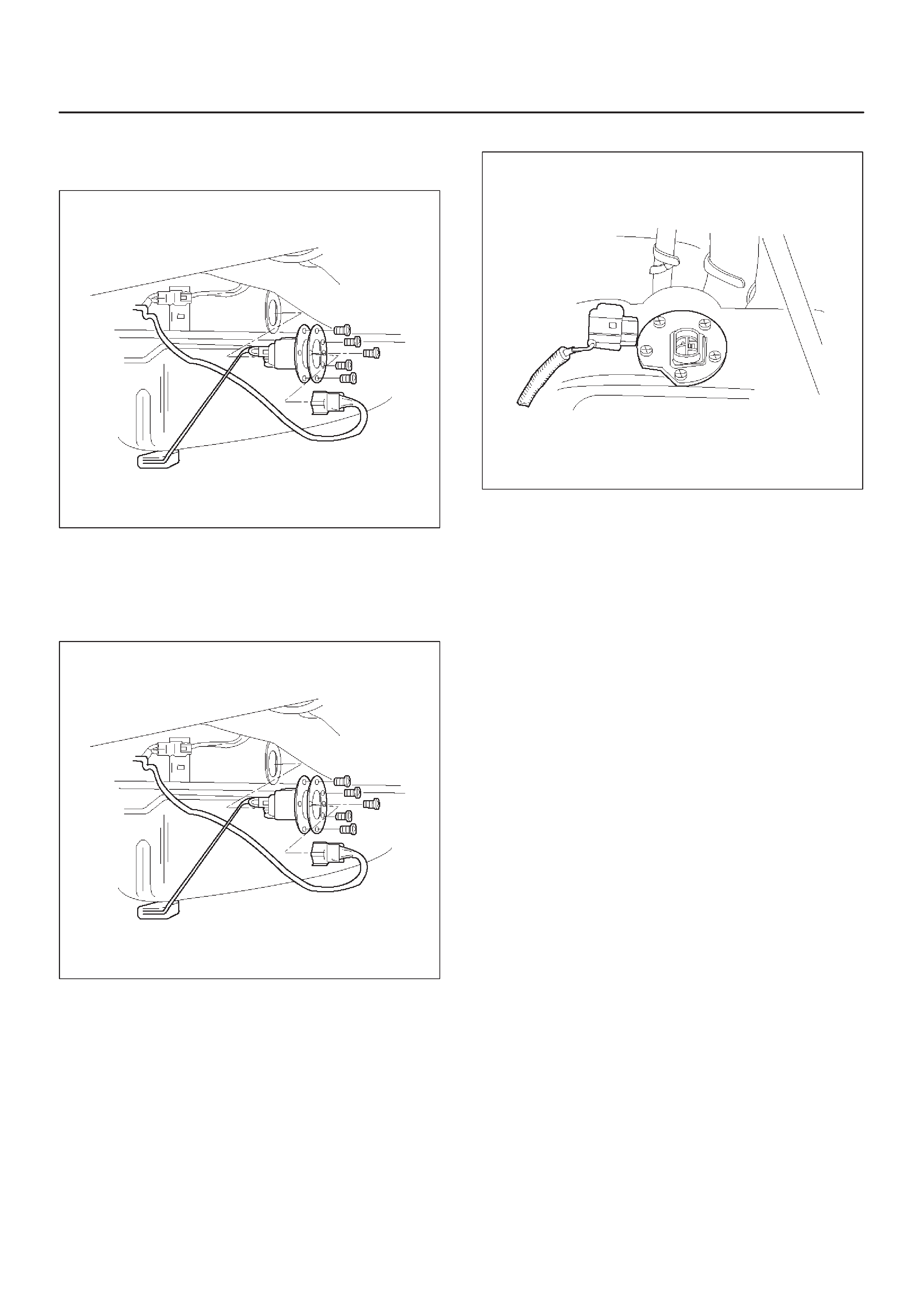

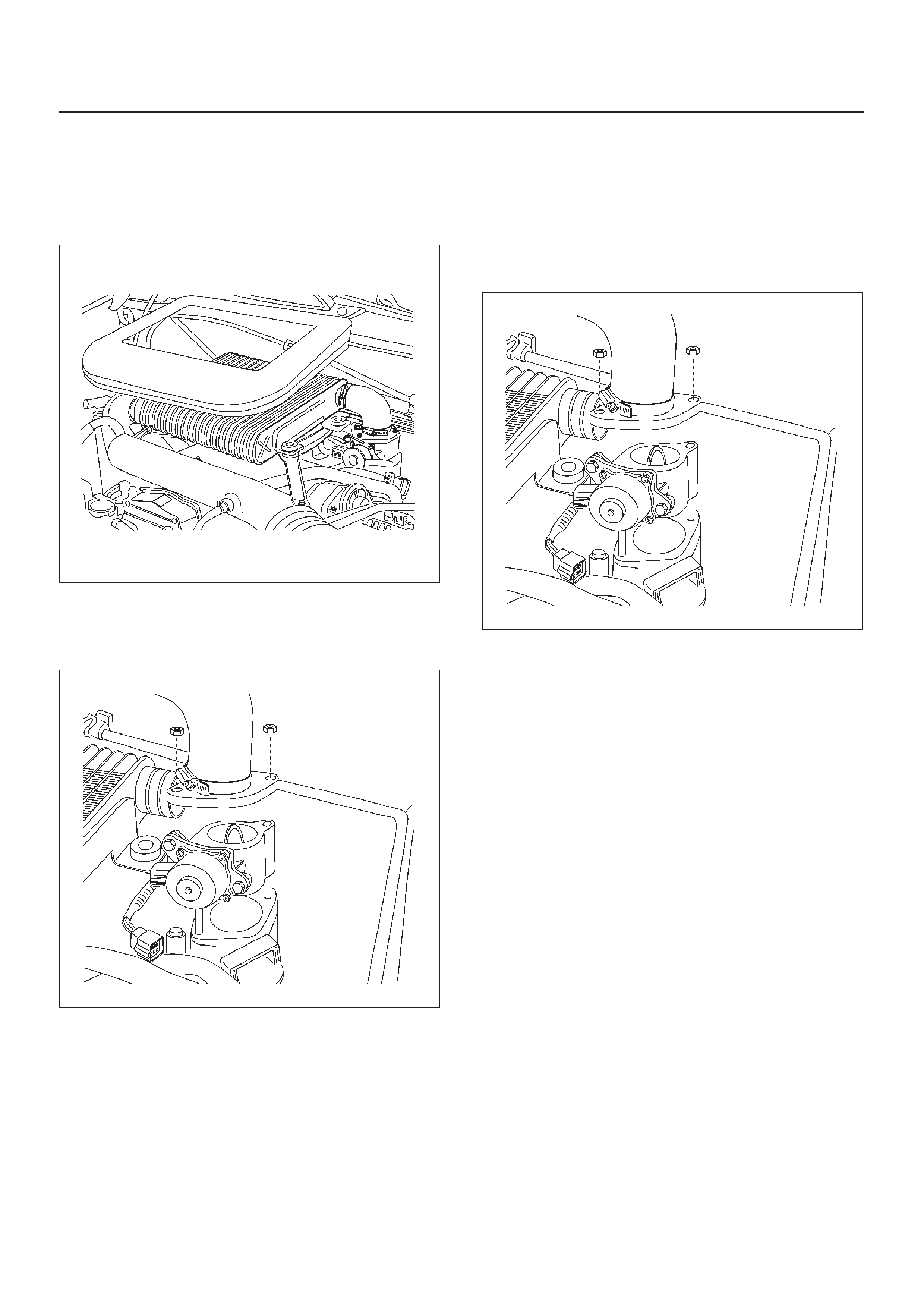

Camshaft Position (CMP) Sensor

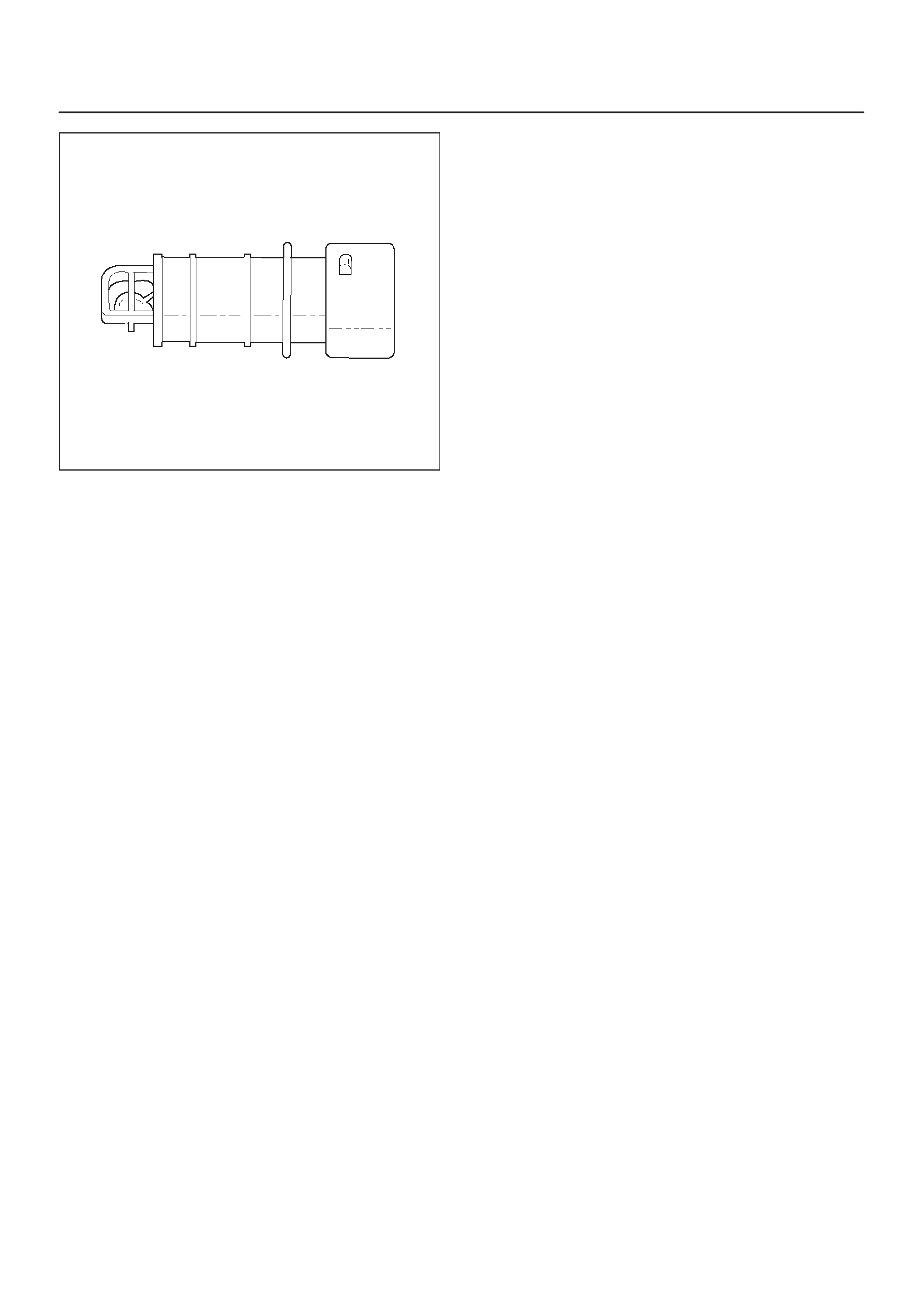

Crankshaft Position (CK P) Sensor

Engine Coolant Temperature (ECT) Sensor

Intake Air Temperature (IAT) Sensor

Manifold Absolute Pressure (M AP) Sensor

Oil Temperature (OT) Sensor

Malfunction Indicator Lamp (MIL)

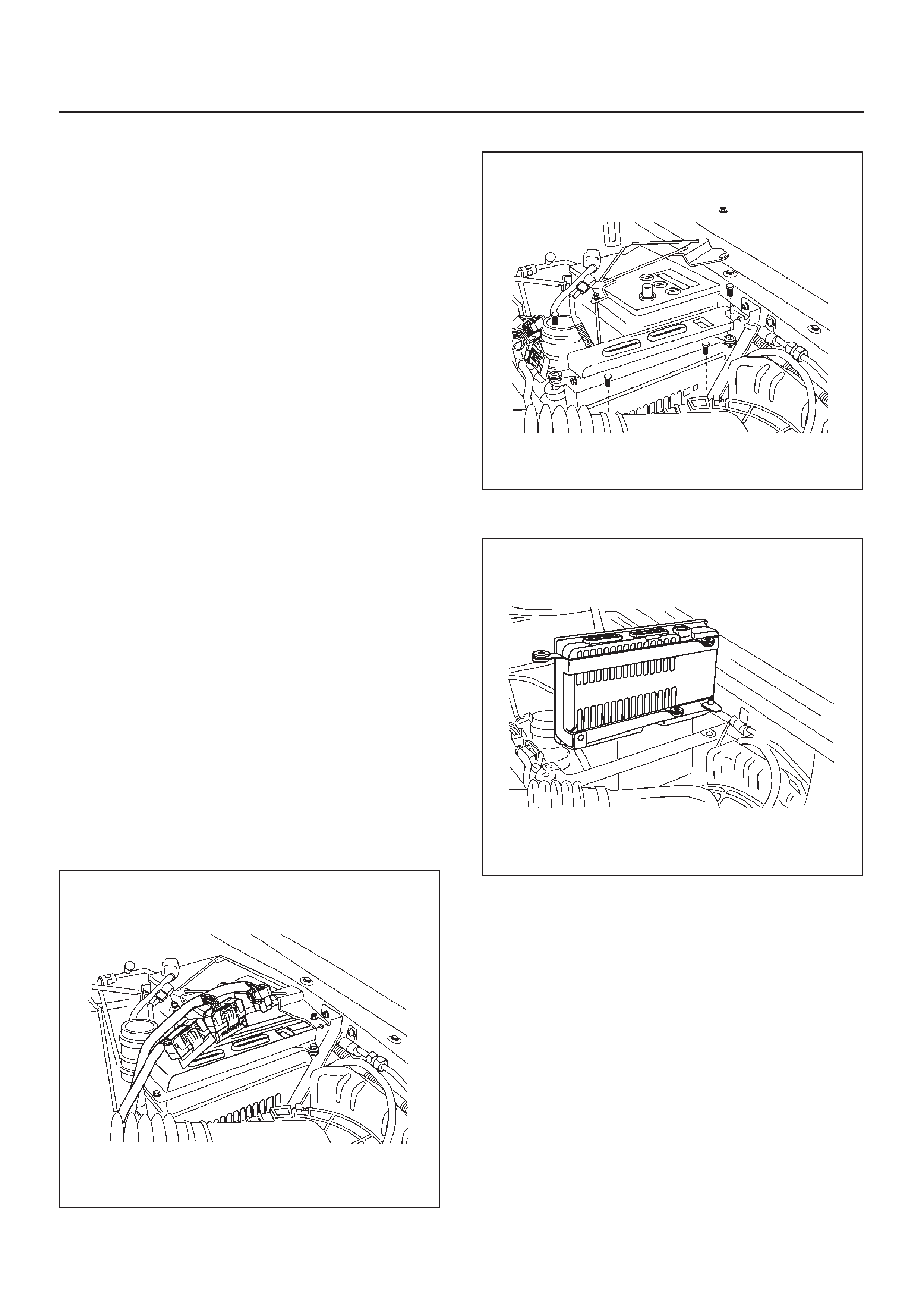

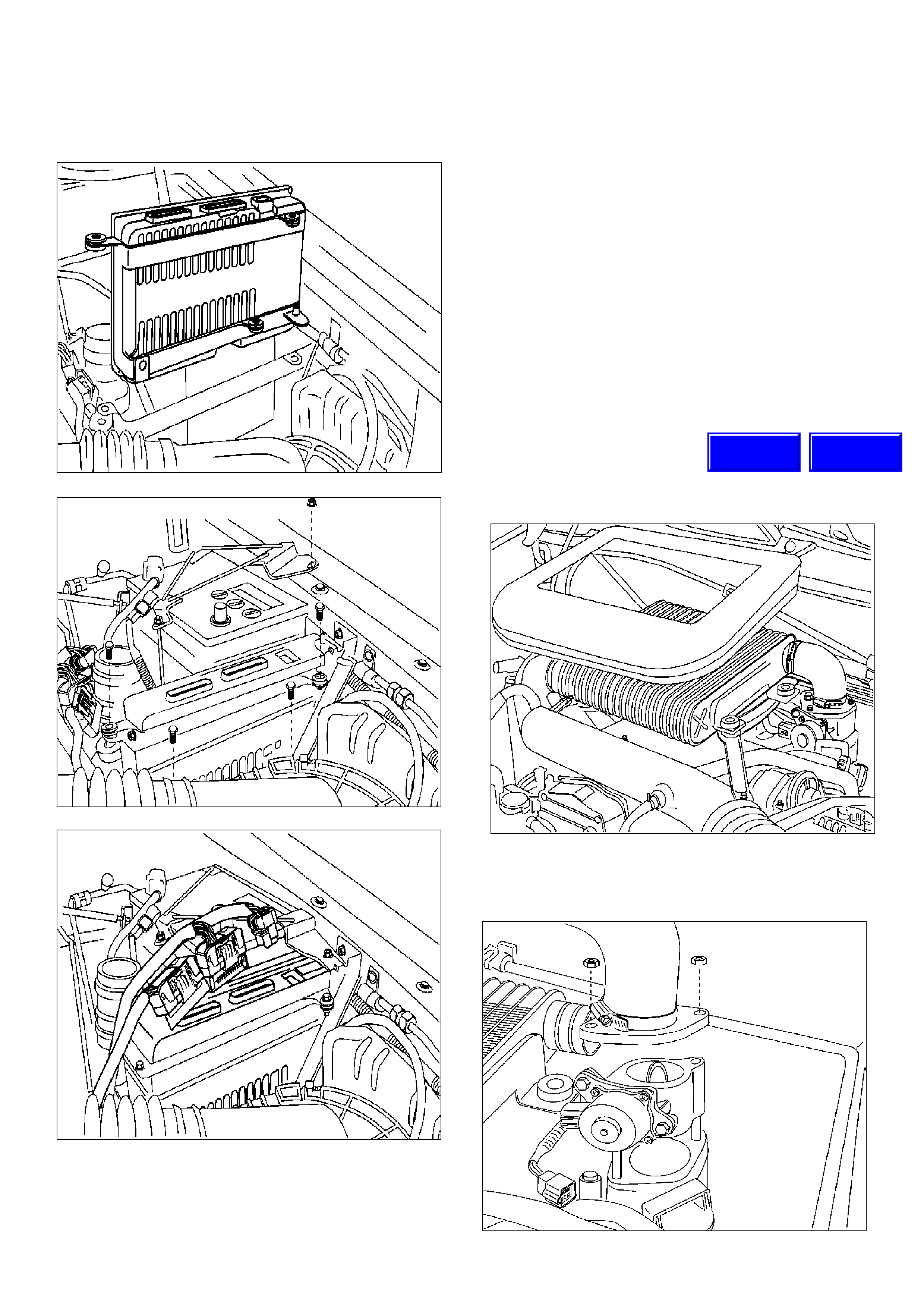

Engine Control Module (ECM)

EEPROM

Intake Throttle Position (ITP) Sensor

Vehicle Speed Sensor (VSS)

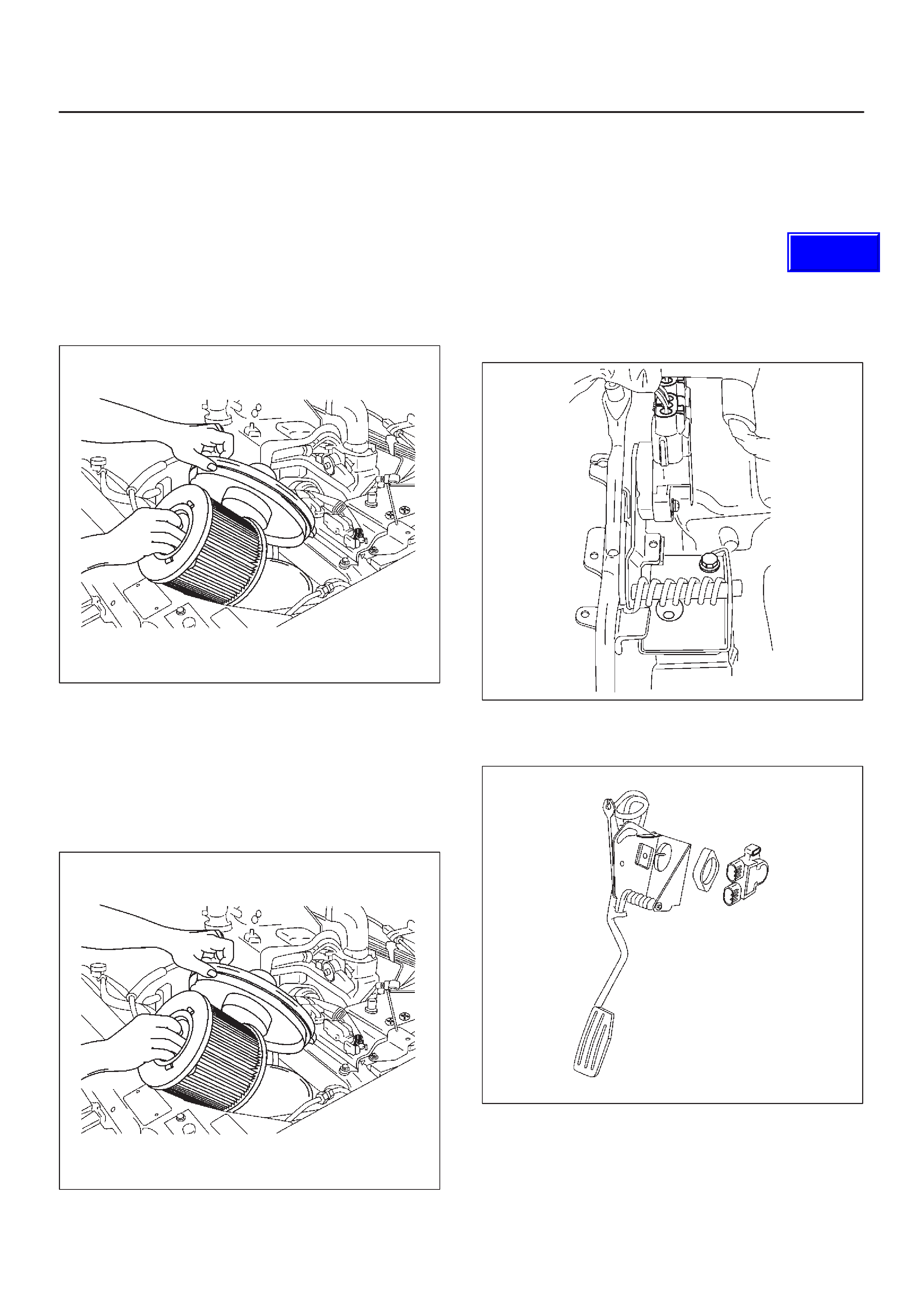

Air Cleaner/Air Filter

Accel Position (AP) Sensor

Accelerator Pedal Replacement

Fuel Filter Cap

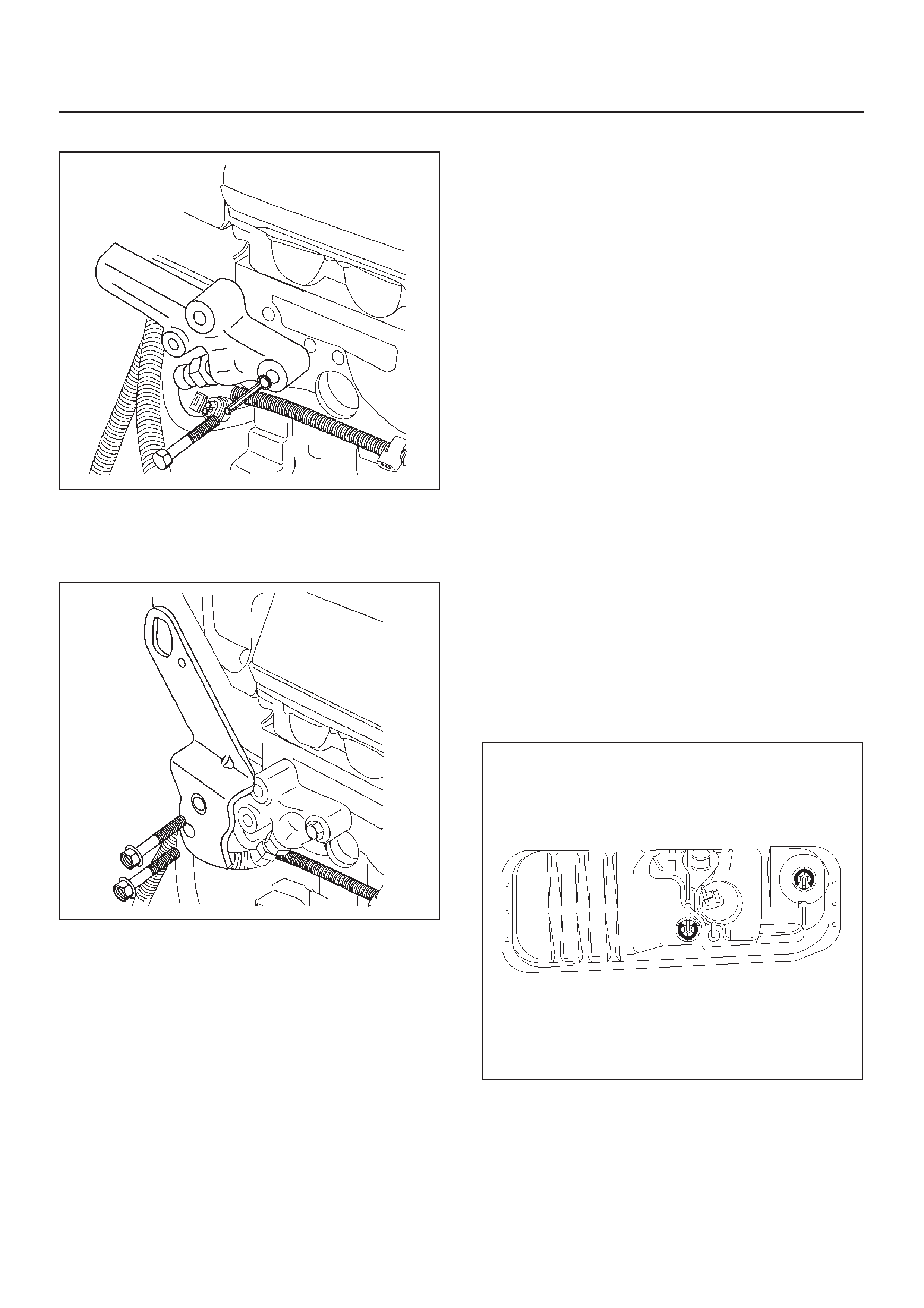

Fuel Filter

Fuel Gauge Unit

Fuel Injectors

Fuel Temperature Sensor

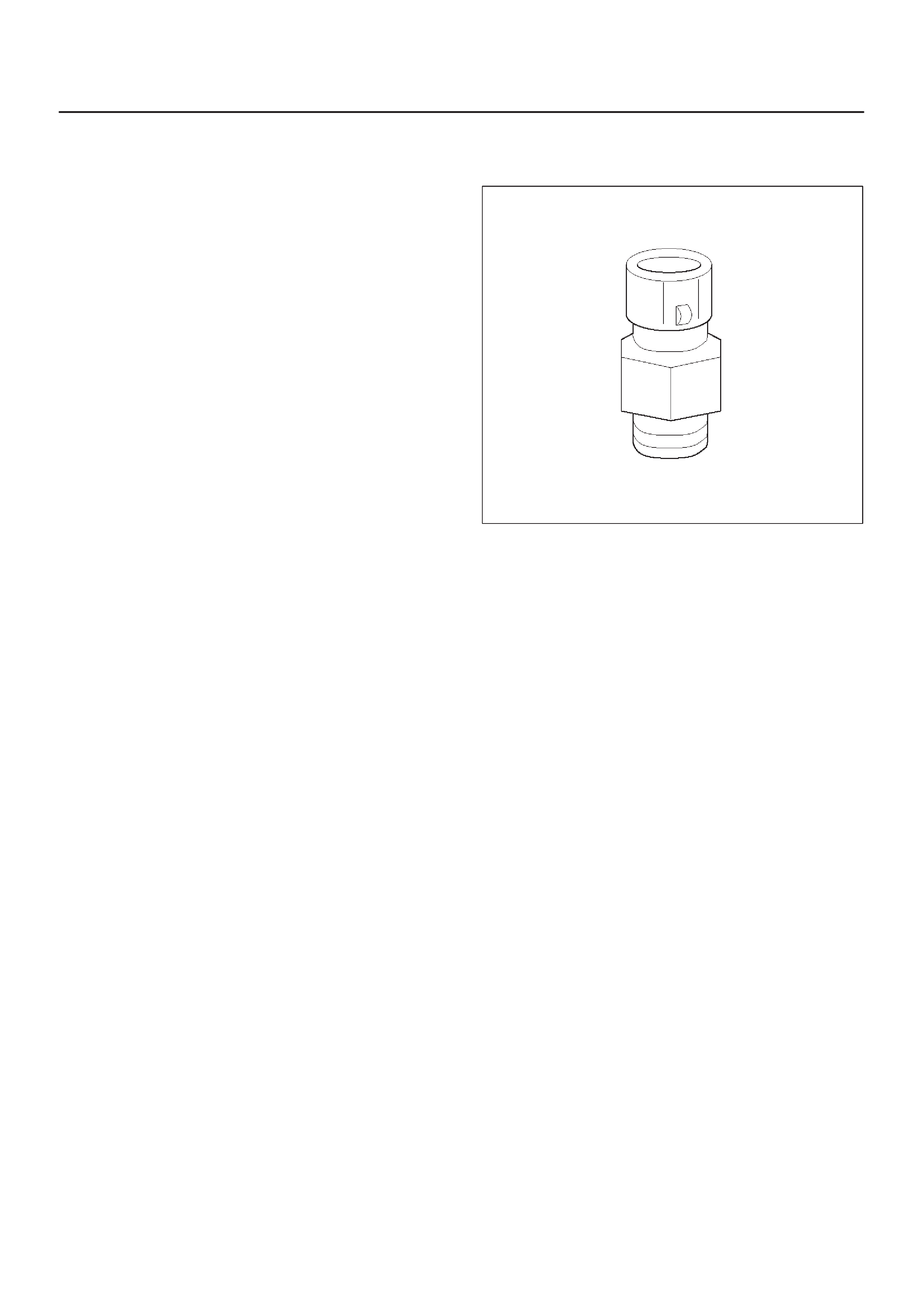

Rail Pressure (RP) Sensor

Fuel Tank

Throttle Body (TB)

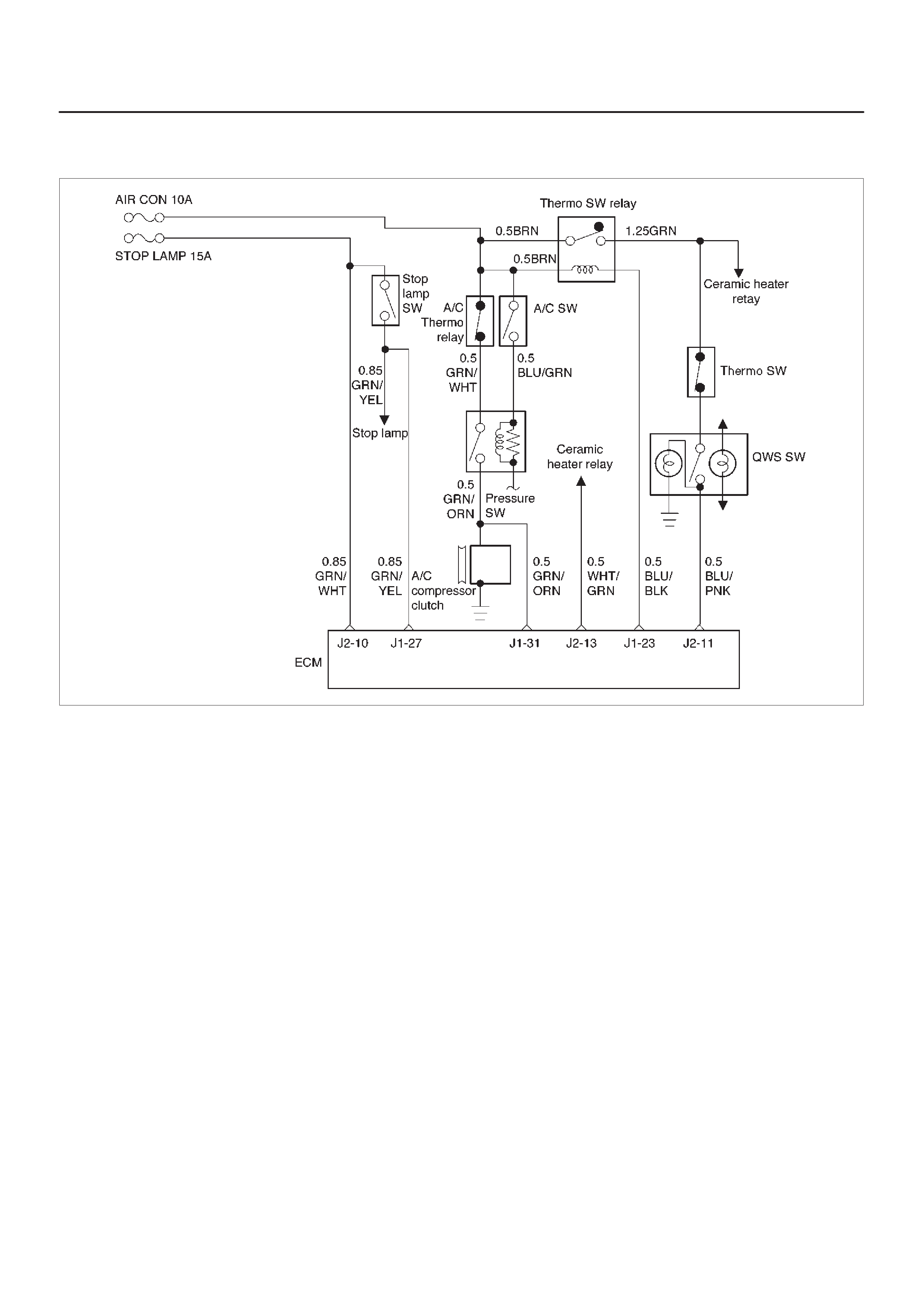

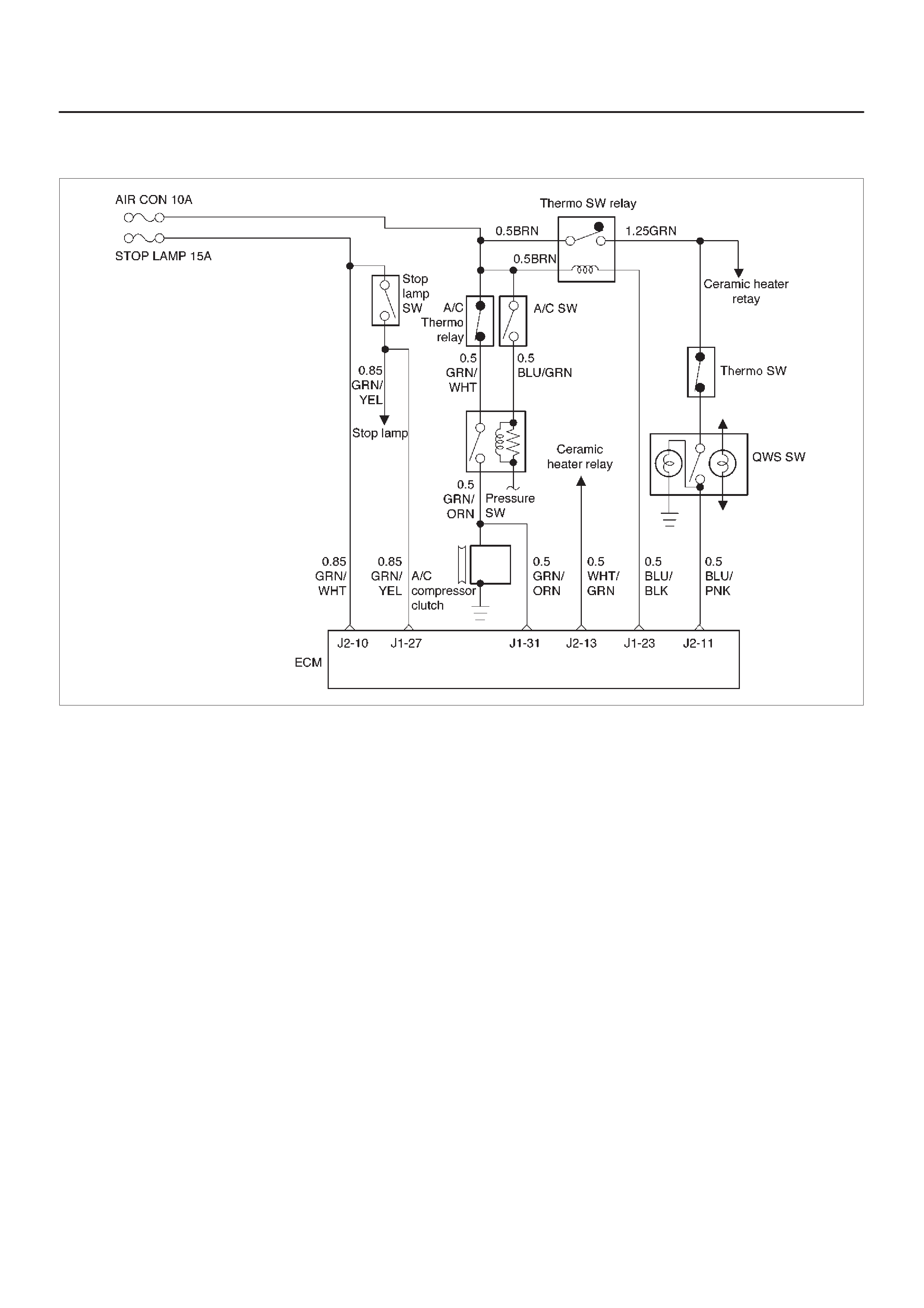

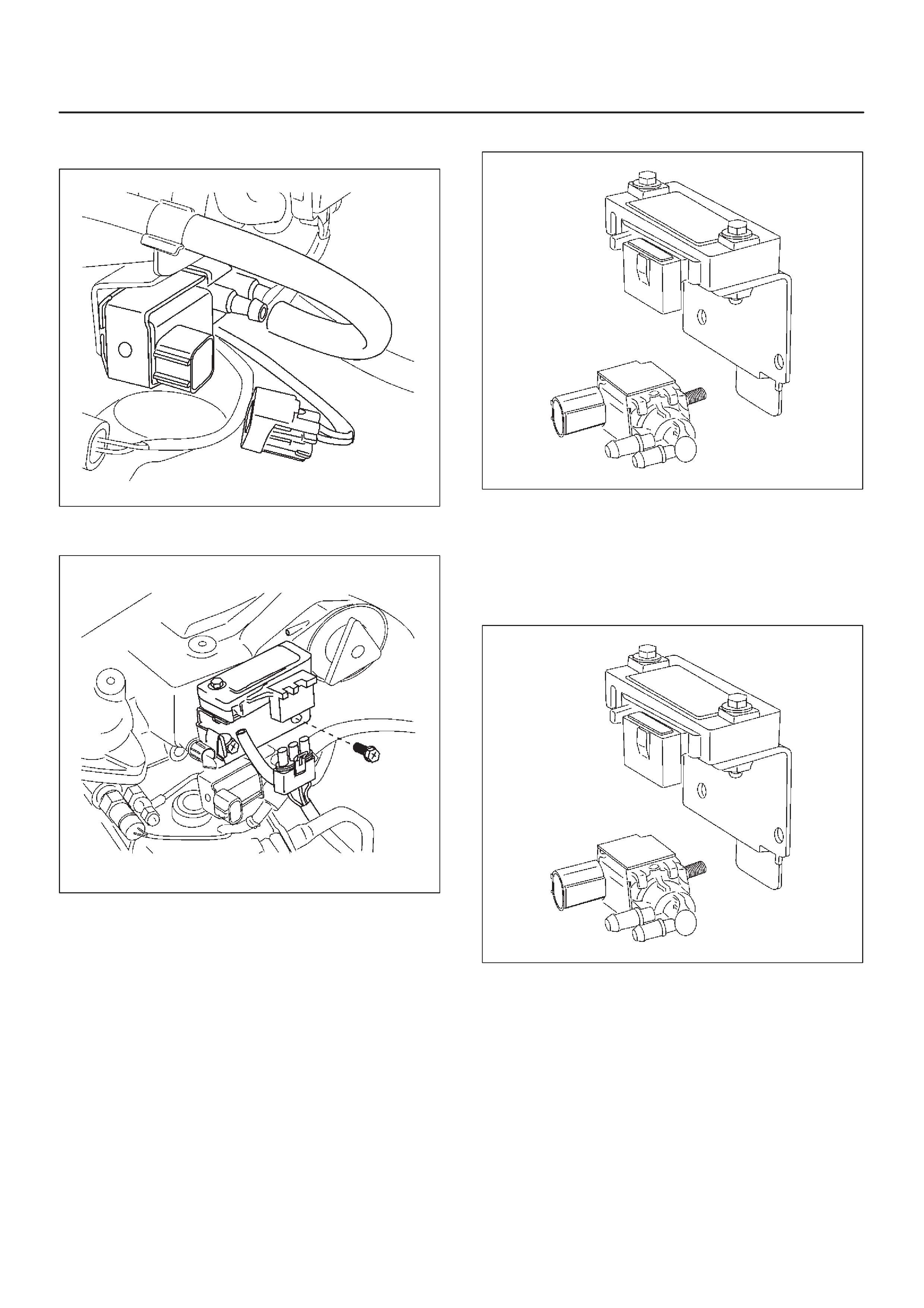

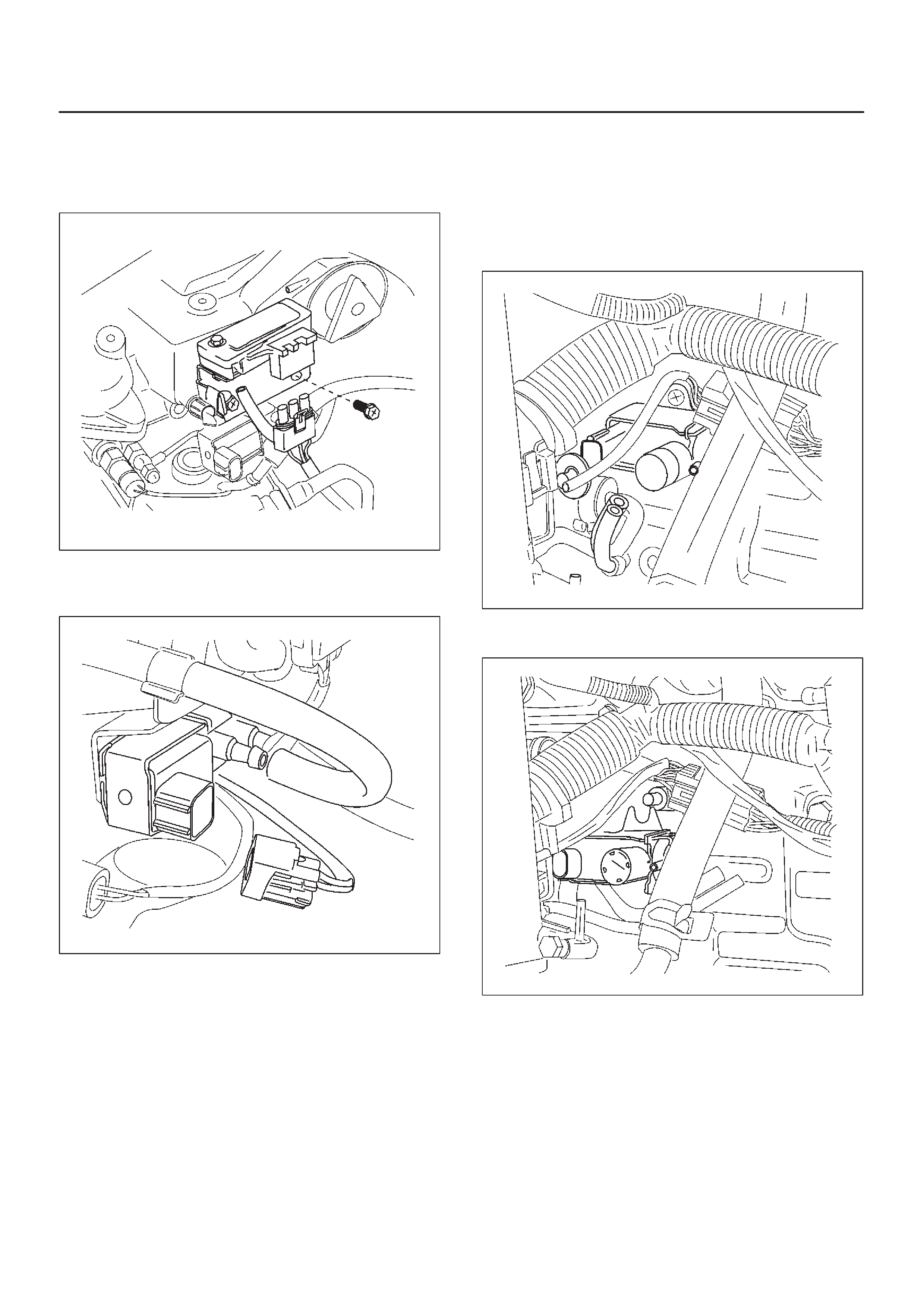

Air Conditioning (A/C) Relay

Exhaust Gas Recirculation (EGR)

Vacuum Switch Valve (VSV)

Electronic Vacuum Regurating Valve (EVRV)

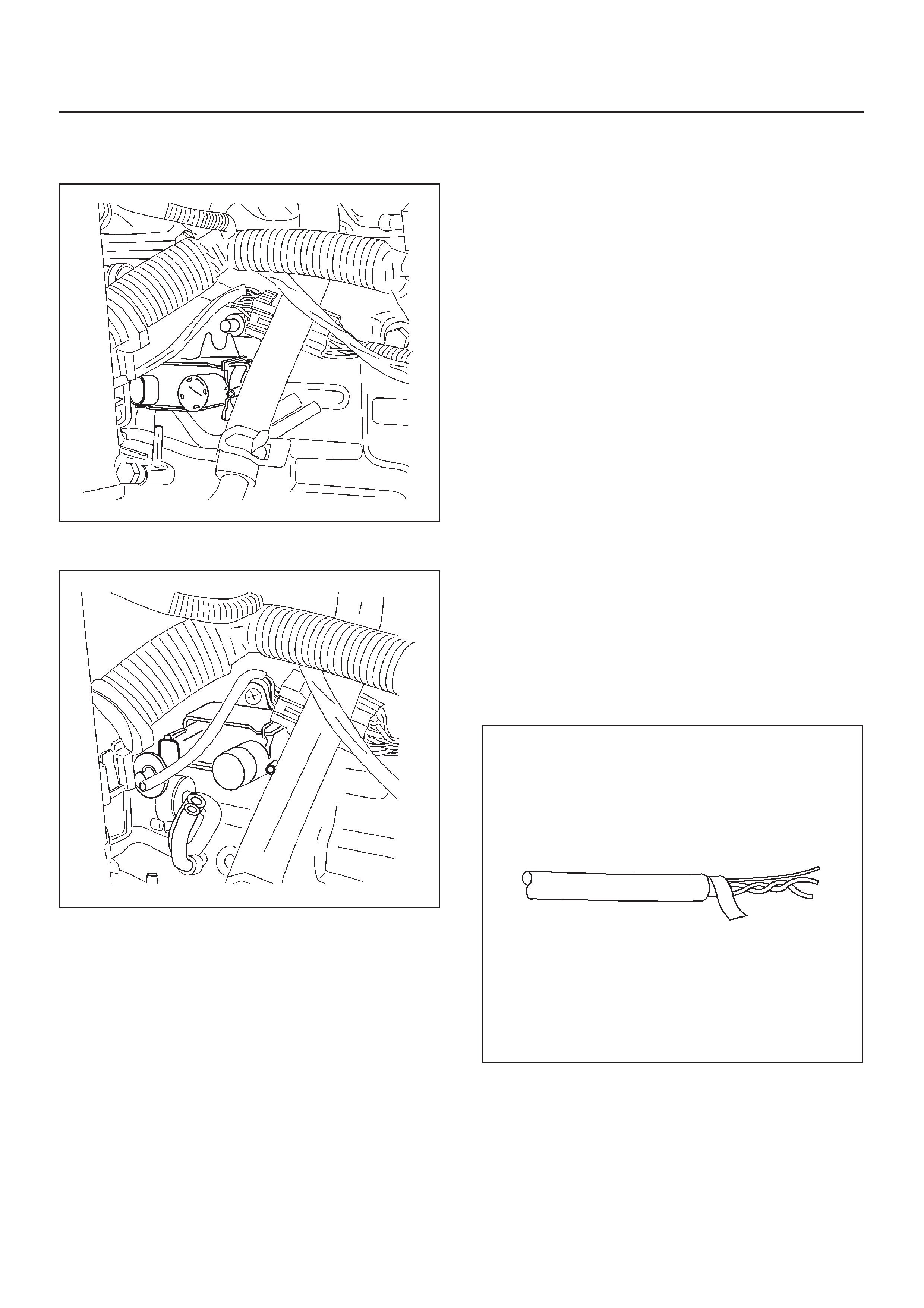

Wiring and Connectors

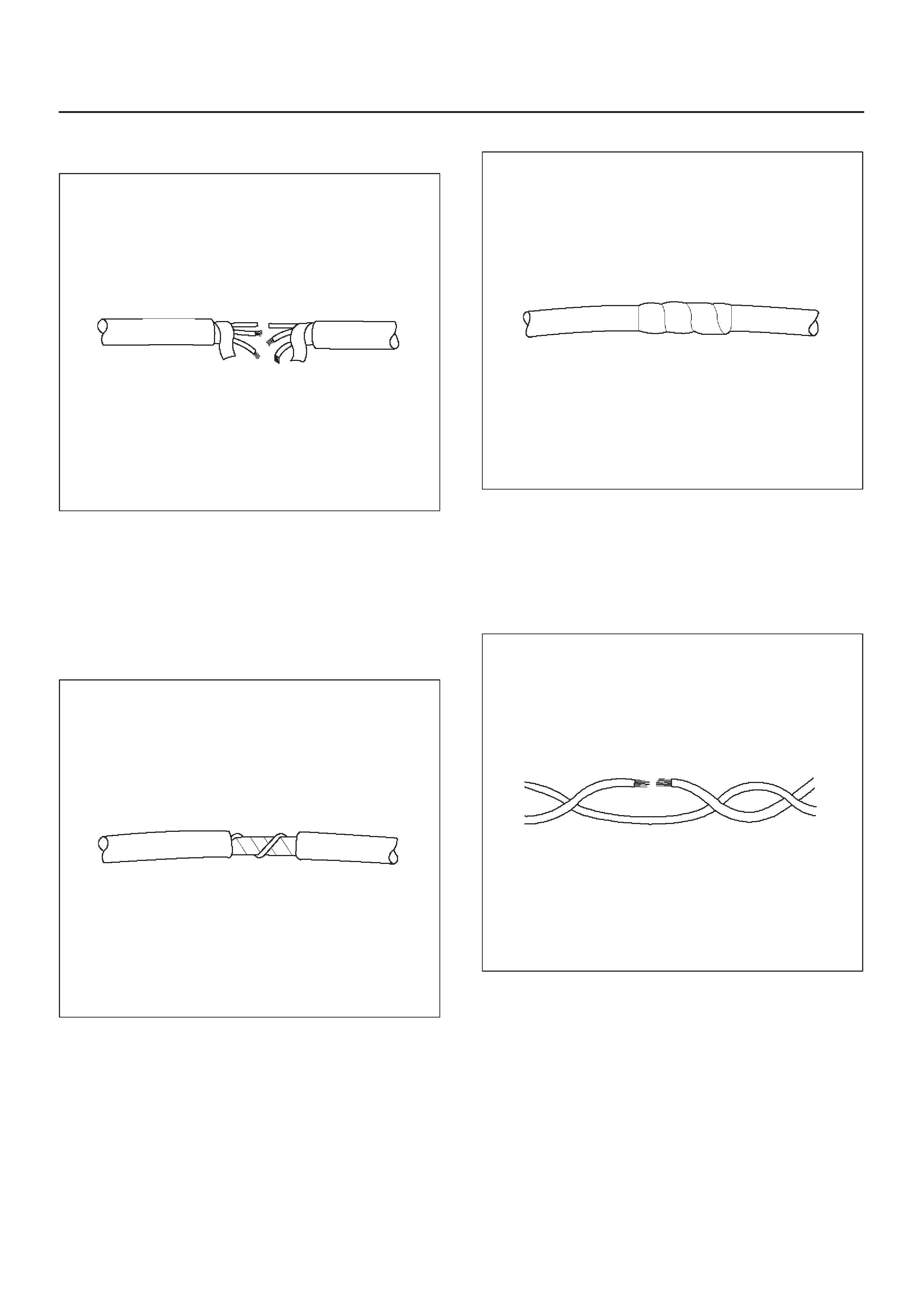

Wire Harness Repair: Twisted Shielded Cable

Twisted Leads

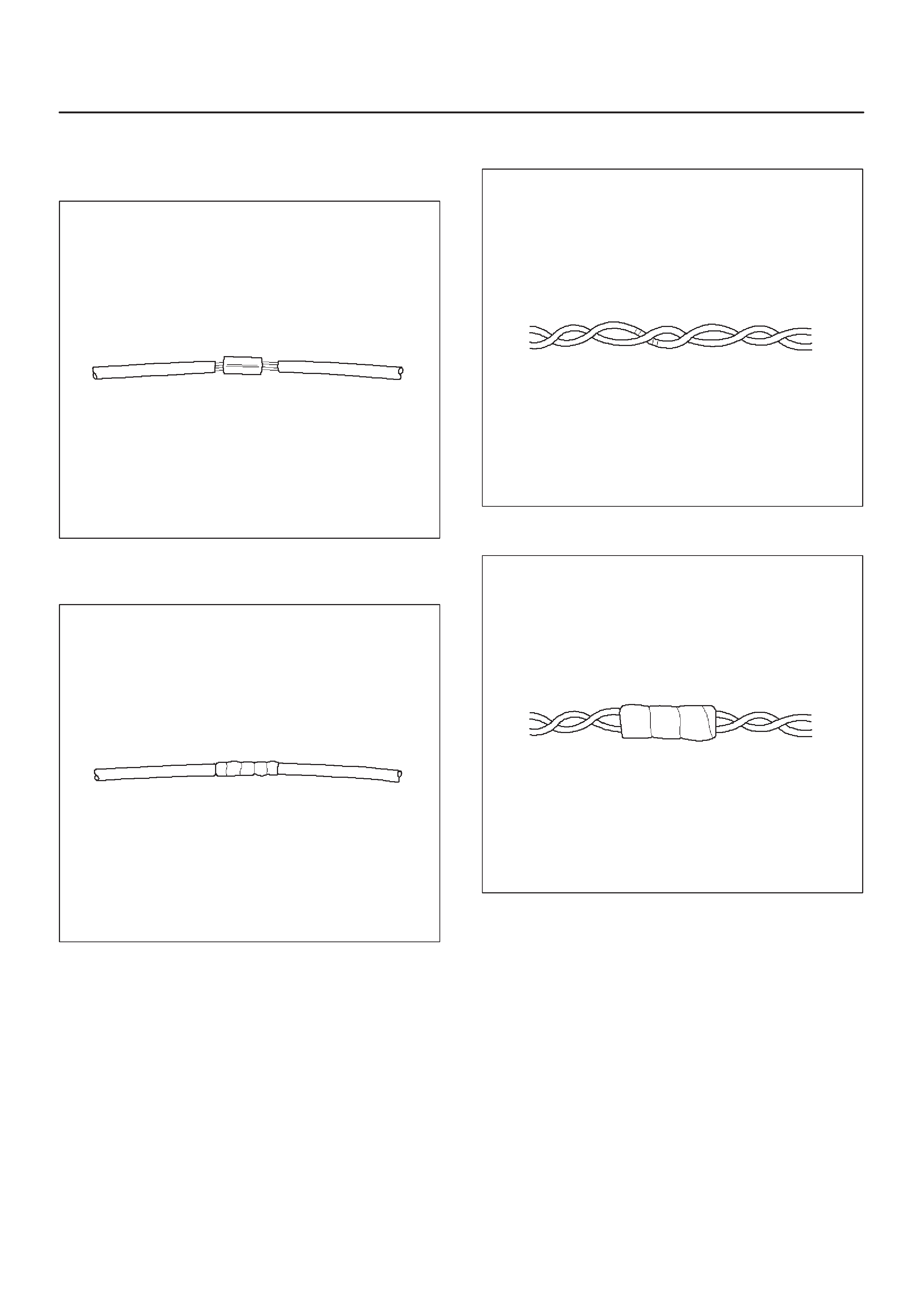

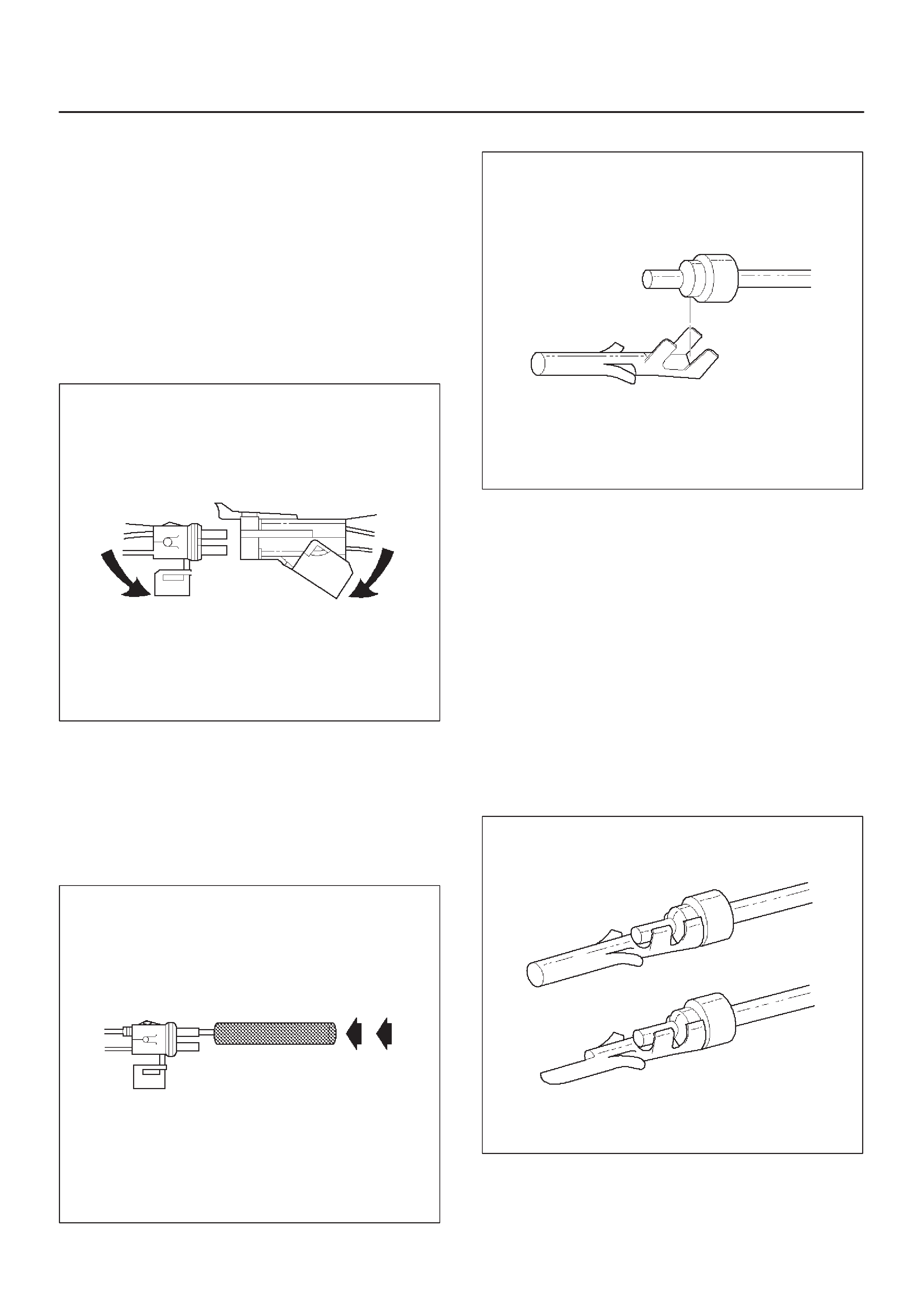

Weather-Pack Connector

Com-Pack III

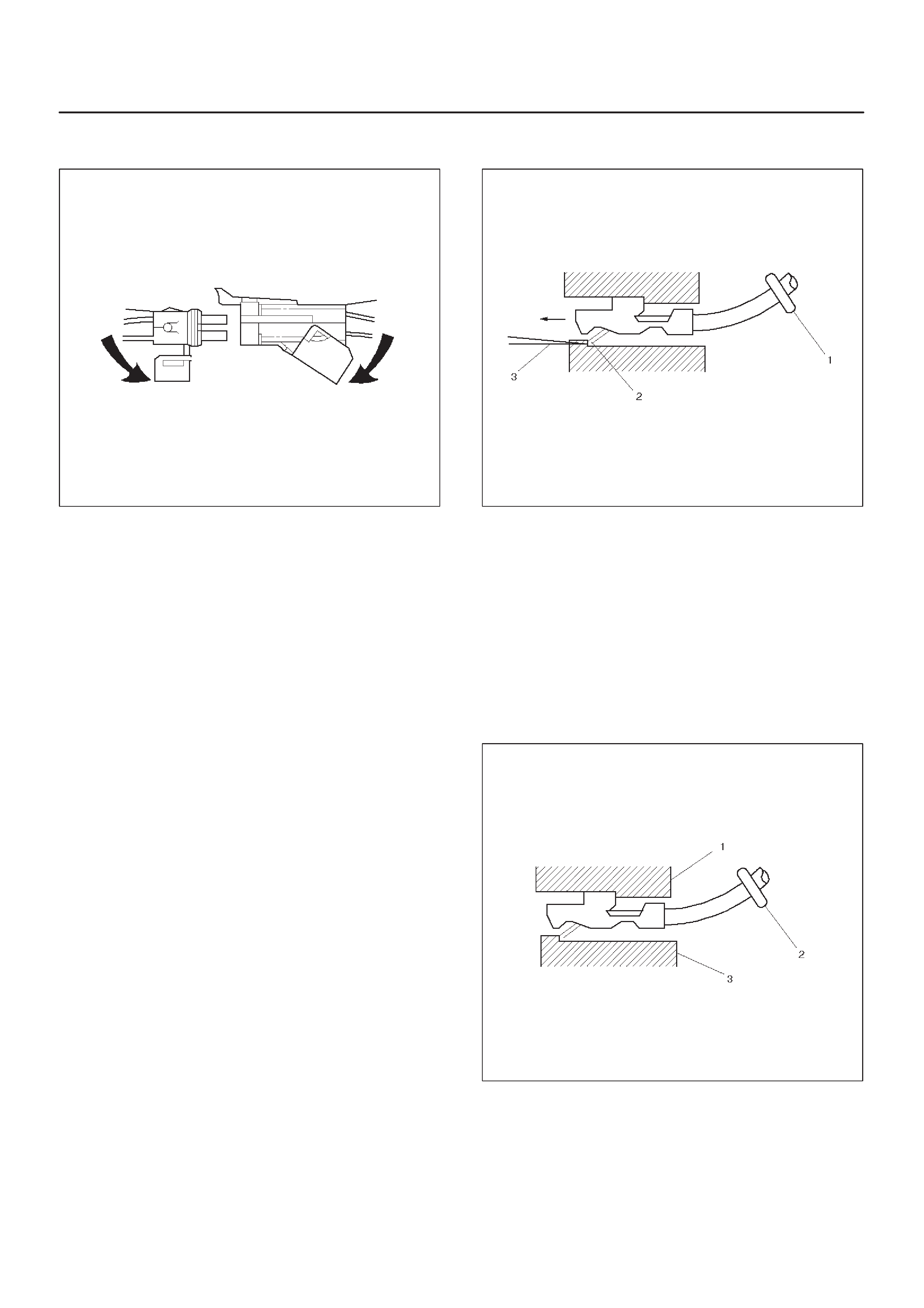

Metri-Pack

General Description (ECM and Sensors)

57X Reference ECM Input

A/C Request Signal

Crankshaft Position (CK P) Sensor

Camshaft Position (CMP) Sensor and Signal

Engine Coolant Temperature (ECT) Sensor

Electrically Erasable Programmable

Read Only Memory (EEPROM)

Intake Air Temperature (IAT) Sensor

Manifold Absolute Pressure (M AP) Sensor

Engine Control Module (ECM)

ECM Function

ECM Components

ECM Voltage Description

ECM Input/Outputs

ECM Service Precautions

Intake Throttle Position (ITP) Sensor

Transmission Range S witch

Accelerator Position Sensor (AP)

Aftermarket Electrical and Vacuum Equipment

Electrostatic Discharge Damage

General Description (Air Induction)

Air Induction System

General Description (Fuel Metering)

Deceleration Mode

Fuel Injector

Fuel Metering System Components

A/C Clutch Diagnosis

A/C Request Signal

General Description Exhaust Gas

Recirculation (EGR) System

EGR Purpose

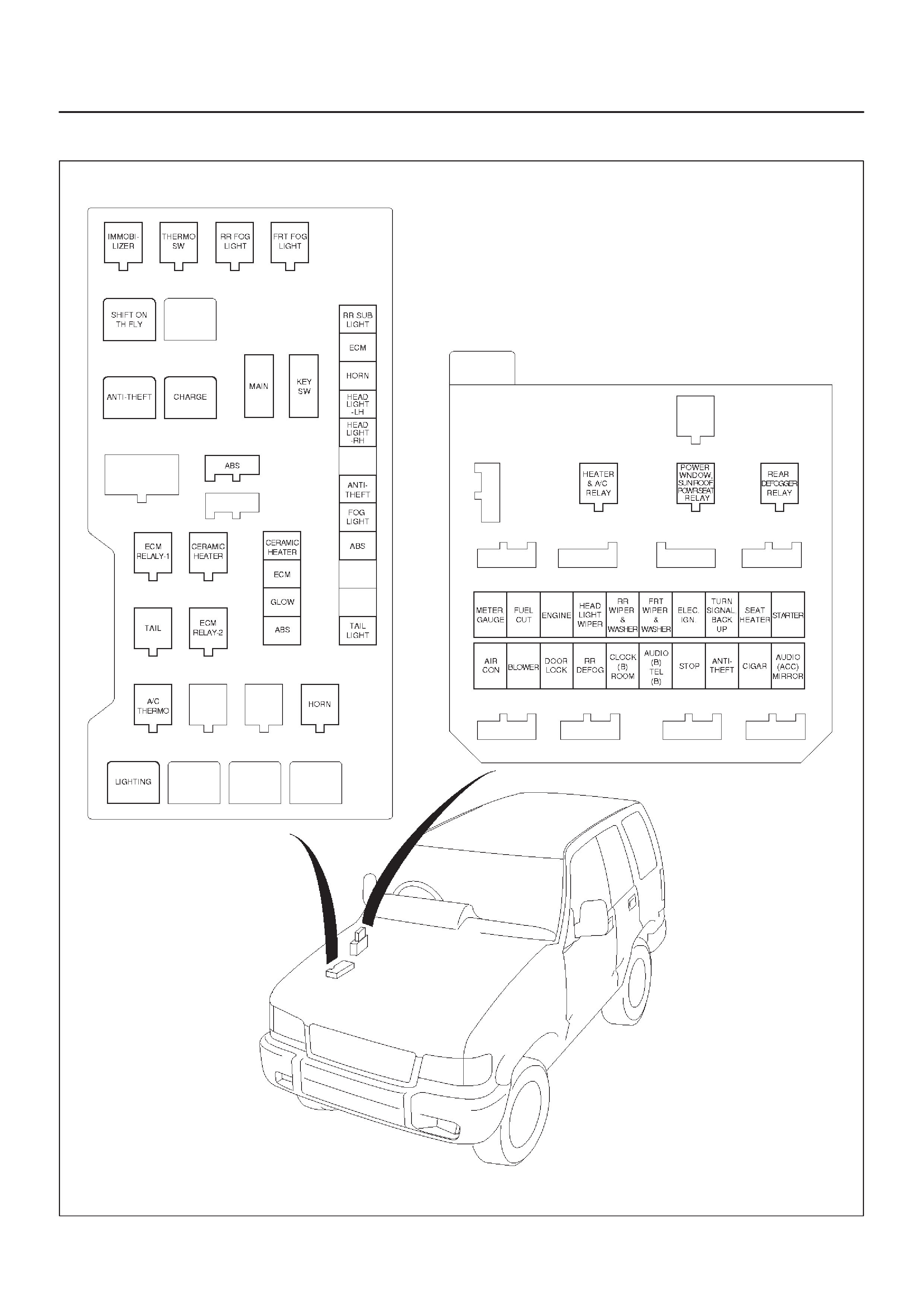

Fuse and Relay Panel (Underhood

Electrical Center)

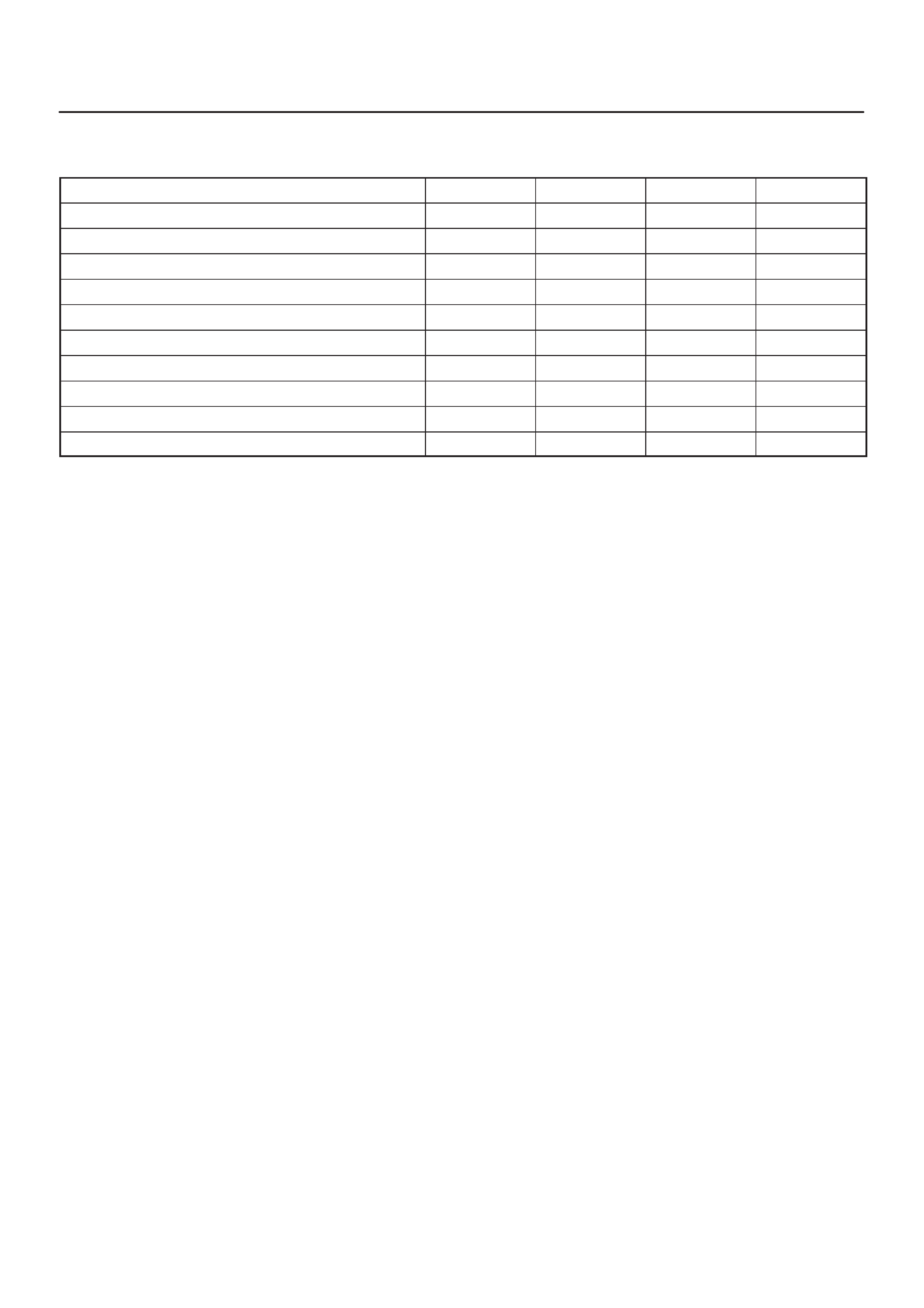

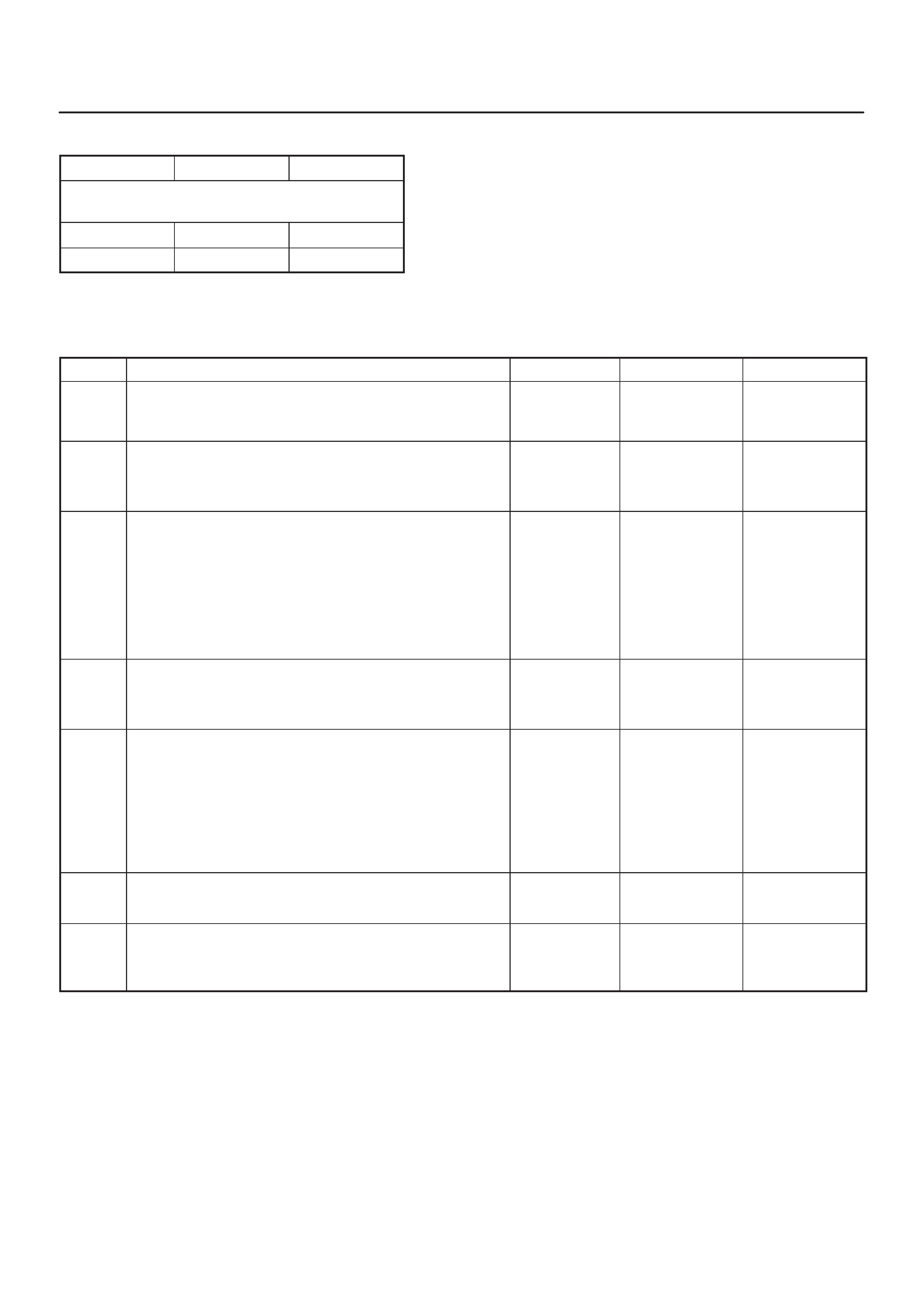

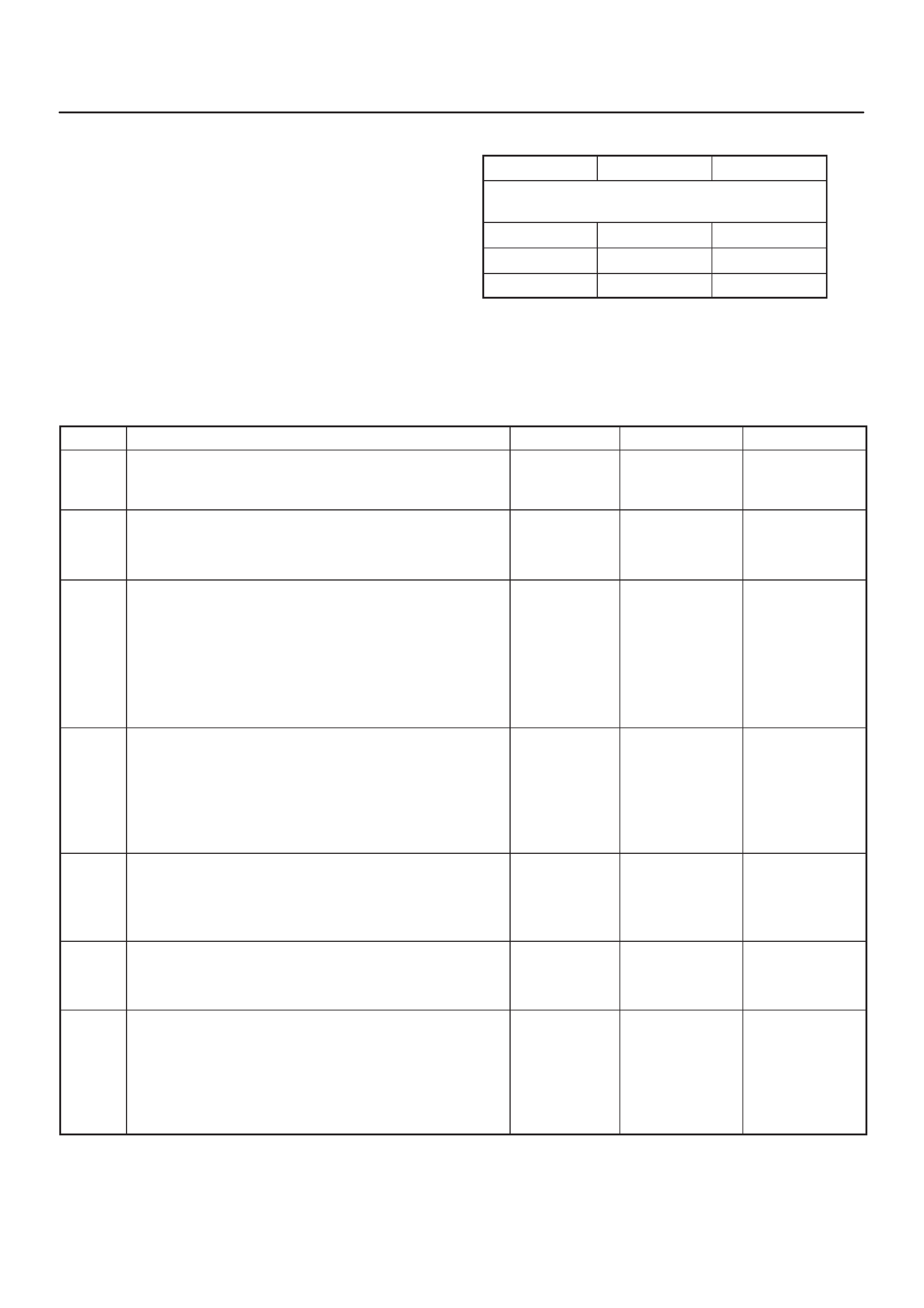

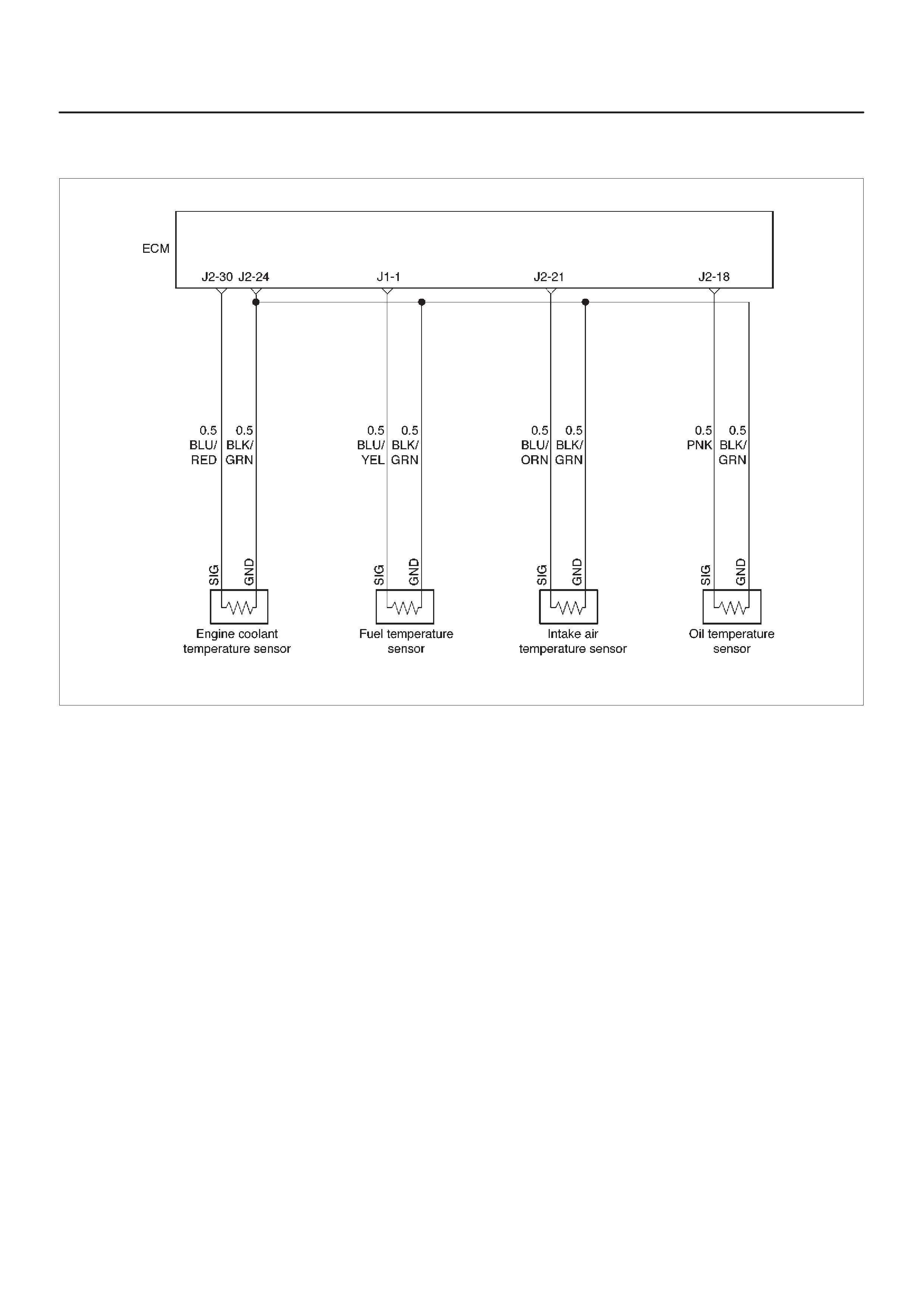

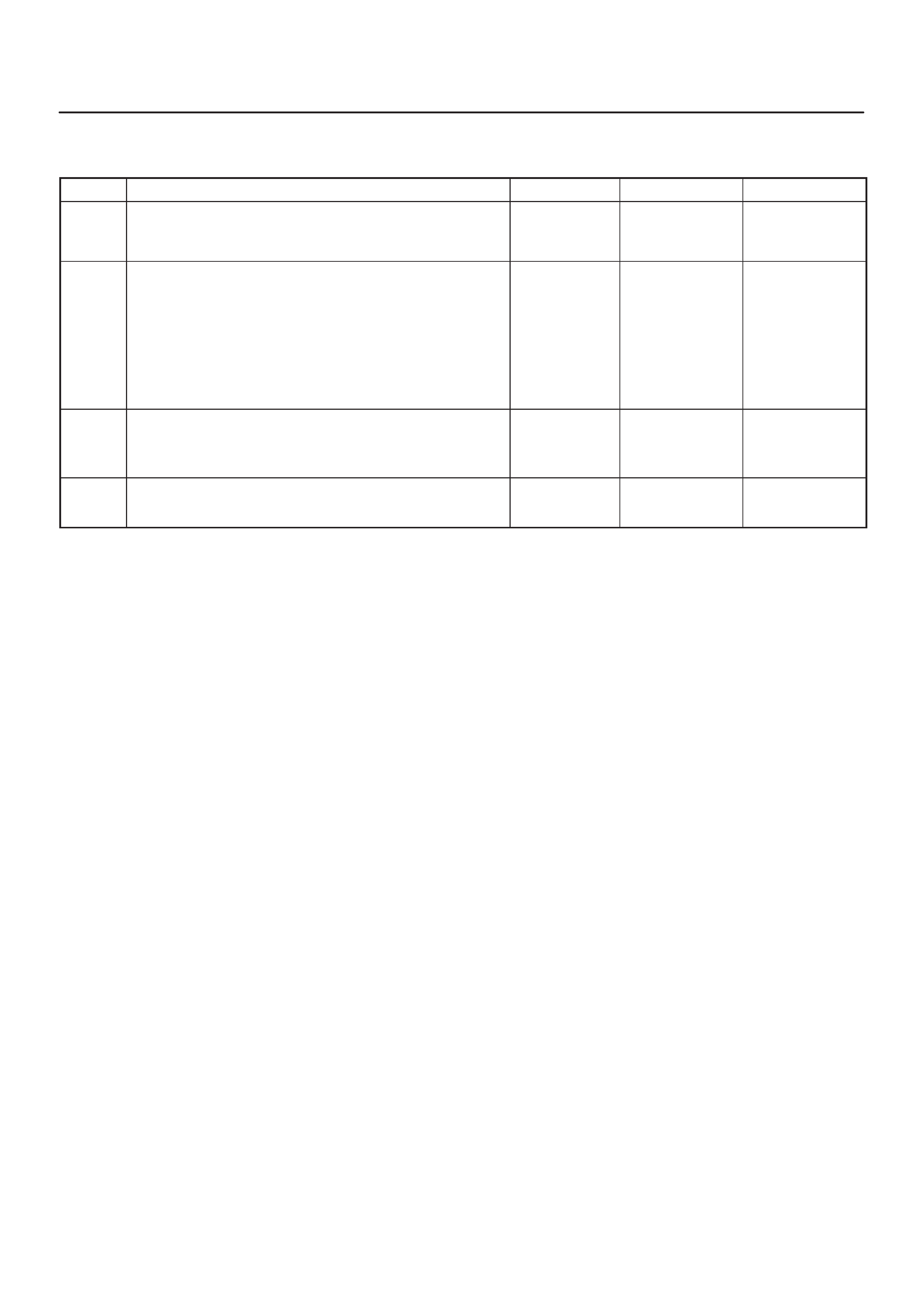

Specification

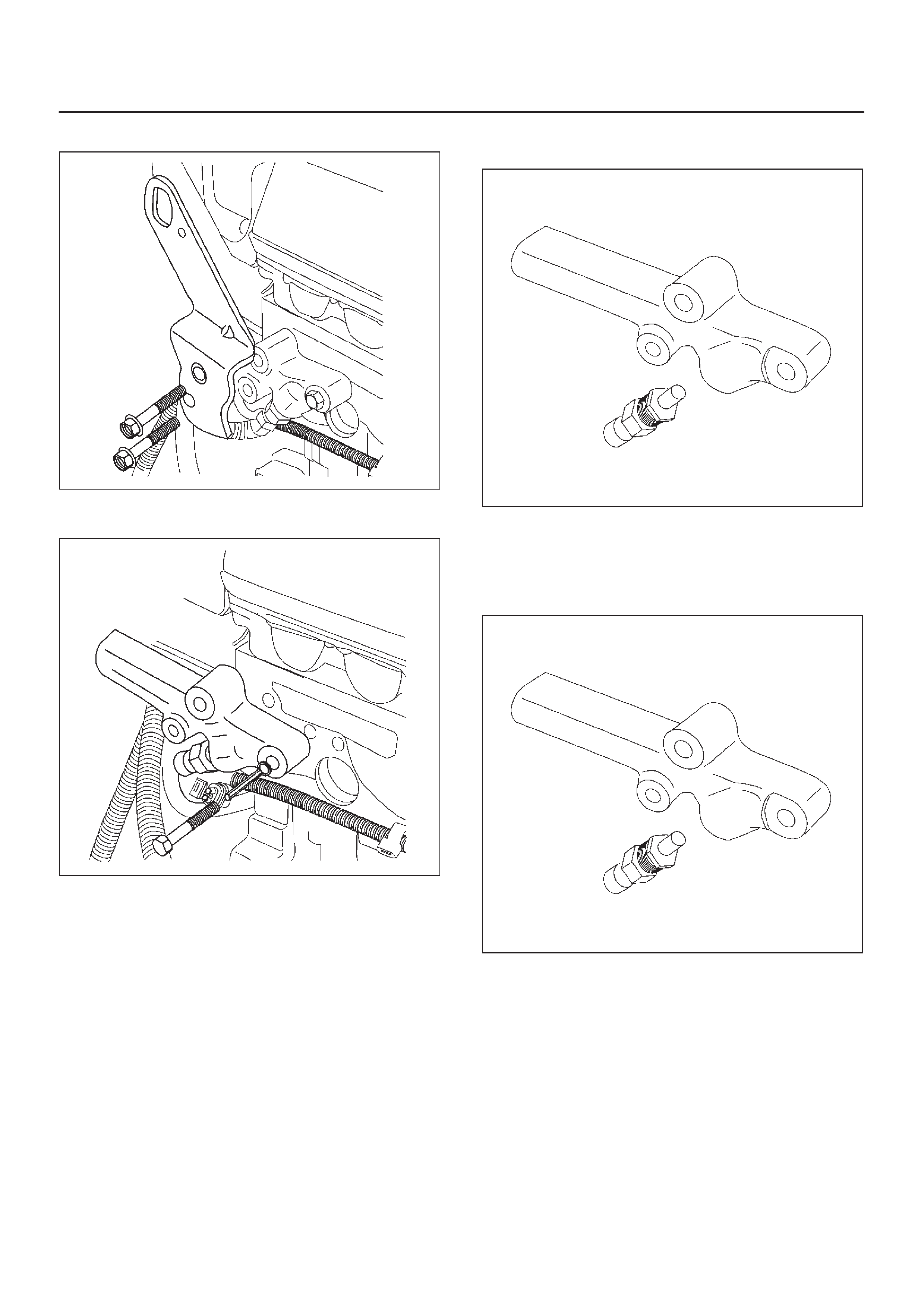

Tightening Specifications

Application N·m Kg·m Lb Ft. Lb In.

Camshaft Position Sensor Retaining Screw 9 0.9 — 78

Crankshaft Position Sensor Mounting Bolt 9 0.9 — 78

Engine Coolant Temperature Sensor 19 1.9 14 —

Throttle Body Mounting Nuts 20 2.0 14 —

VSS Retaining Bolt 16 1.6 12 —

MAP Sensor Screw 4 0.4 — 35

EGR VSV Bolts 8 0.8 — 69

Fuel Temp Sensor 19 1.9 14 —

Oil Temp Sensor Bolt 19 1.9 14 —

Rail Pressure Sensor Bolt 20 2.0 14 —

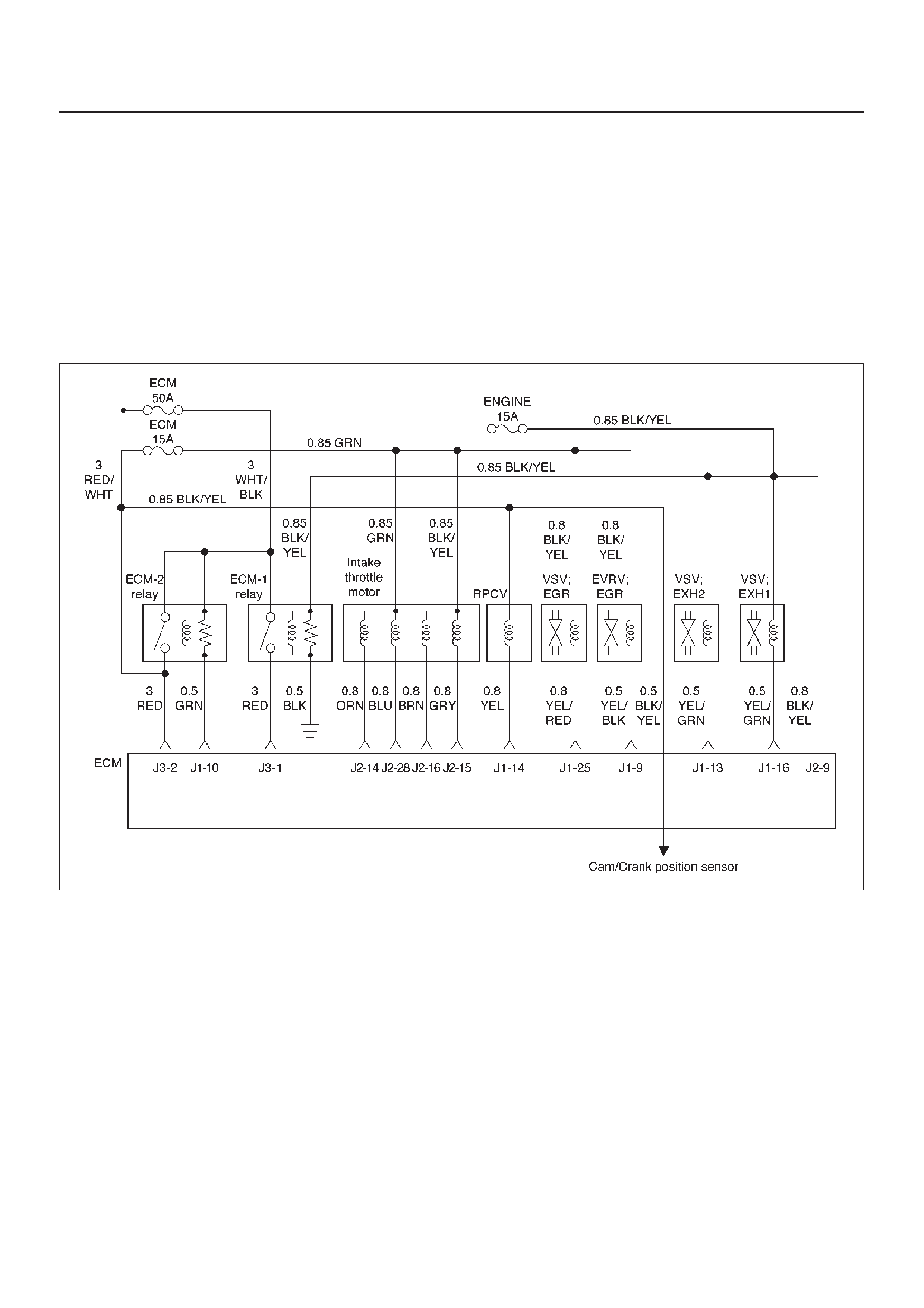

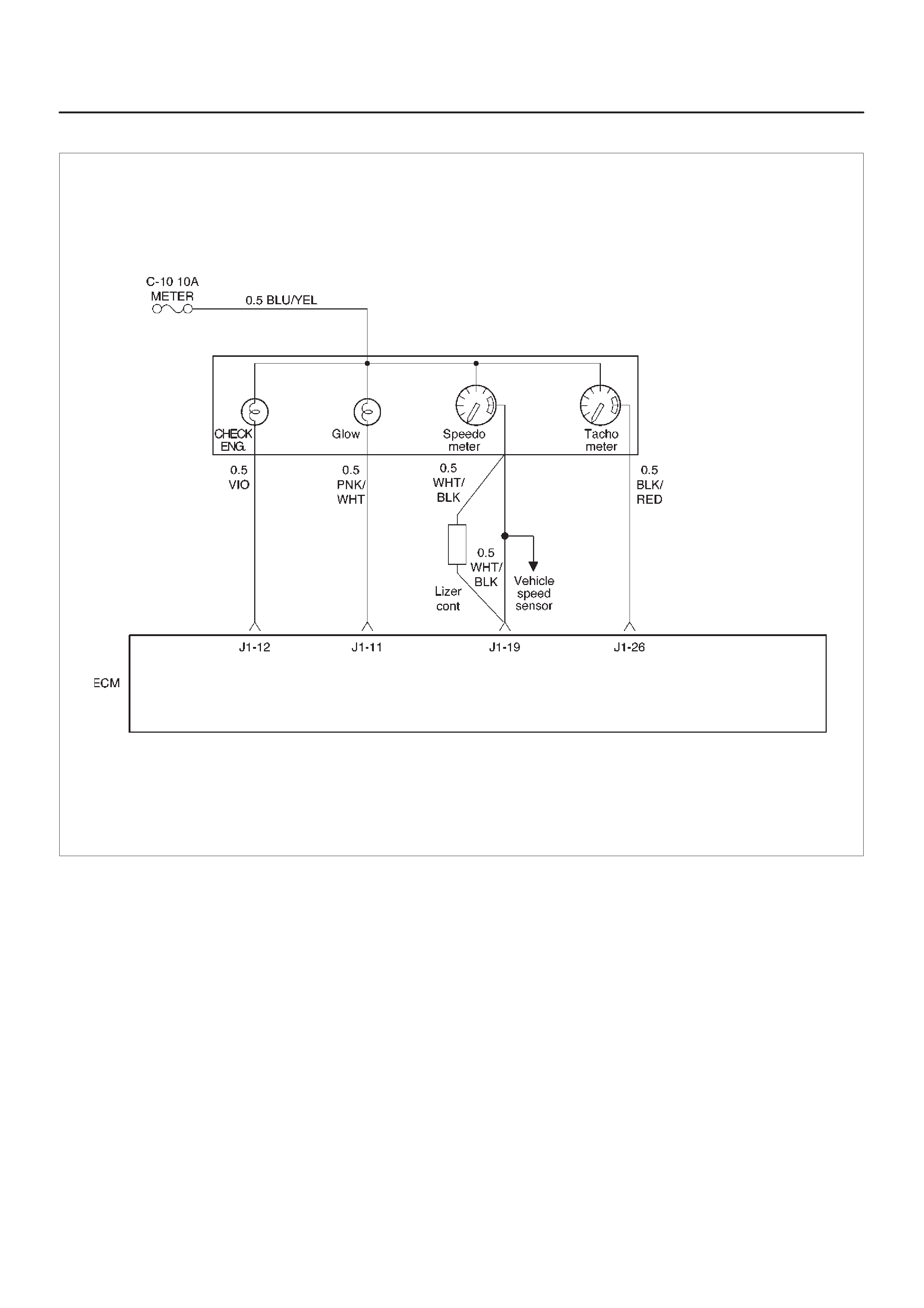

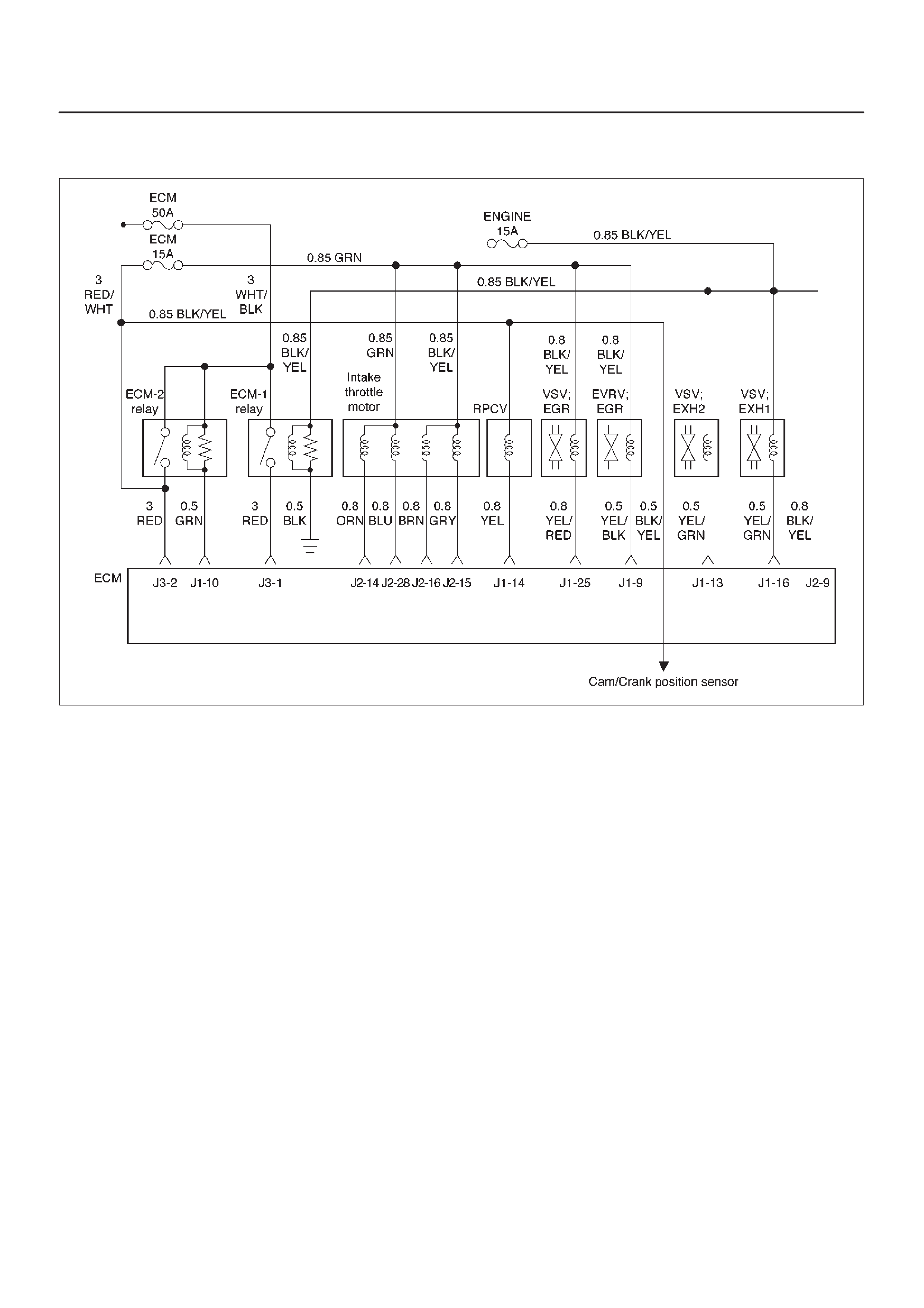

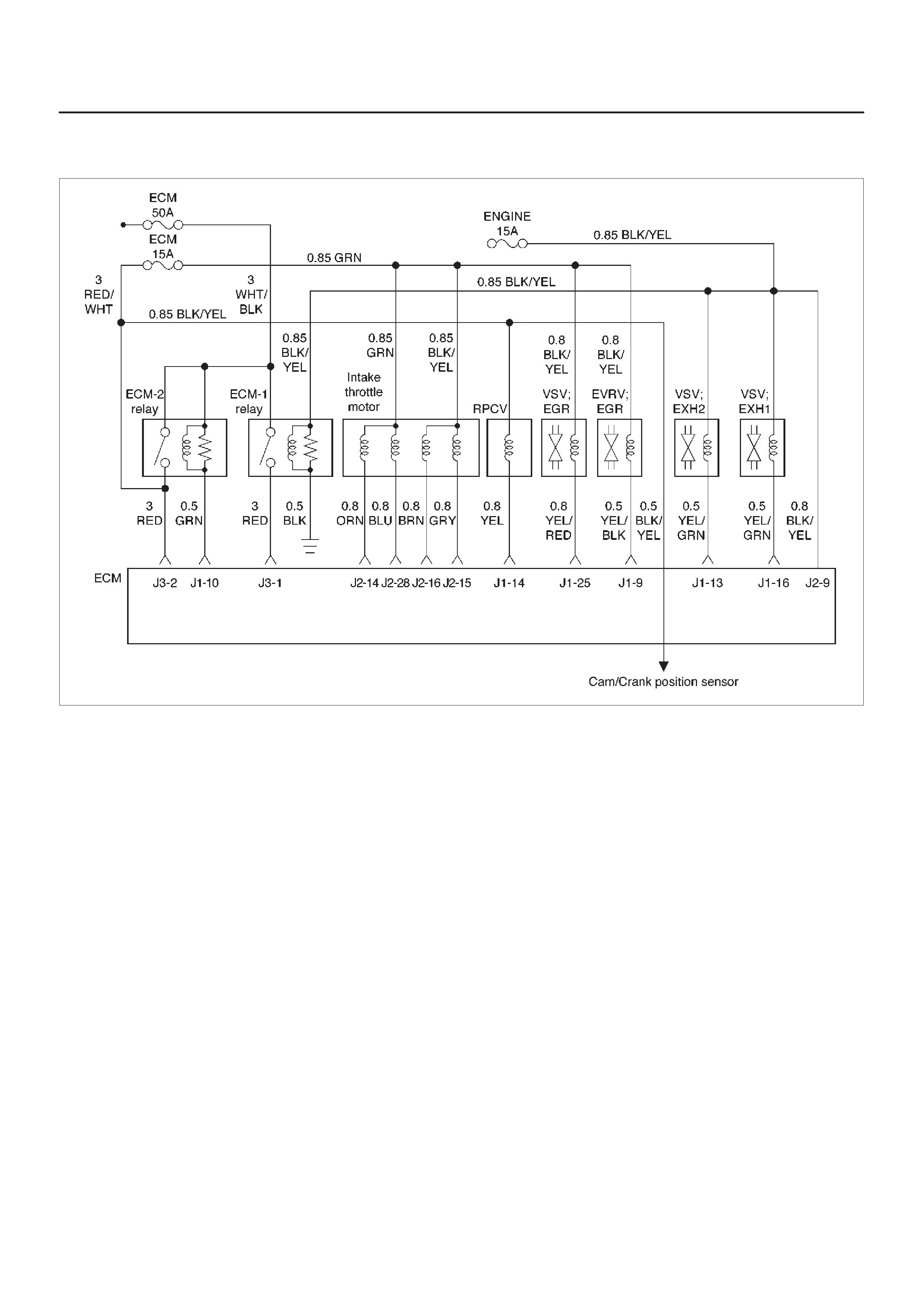

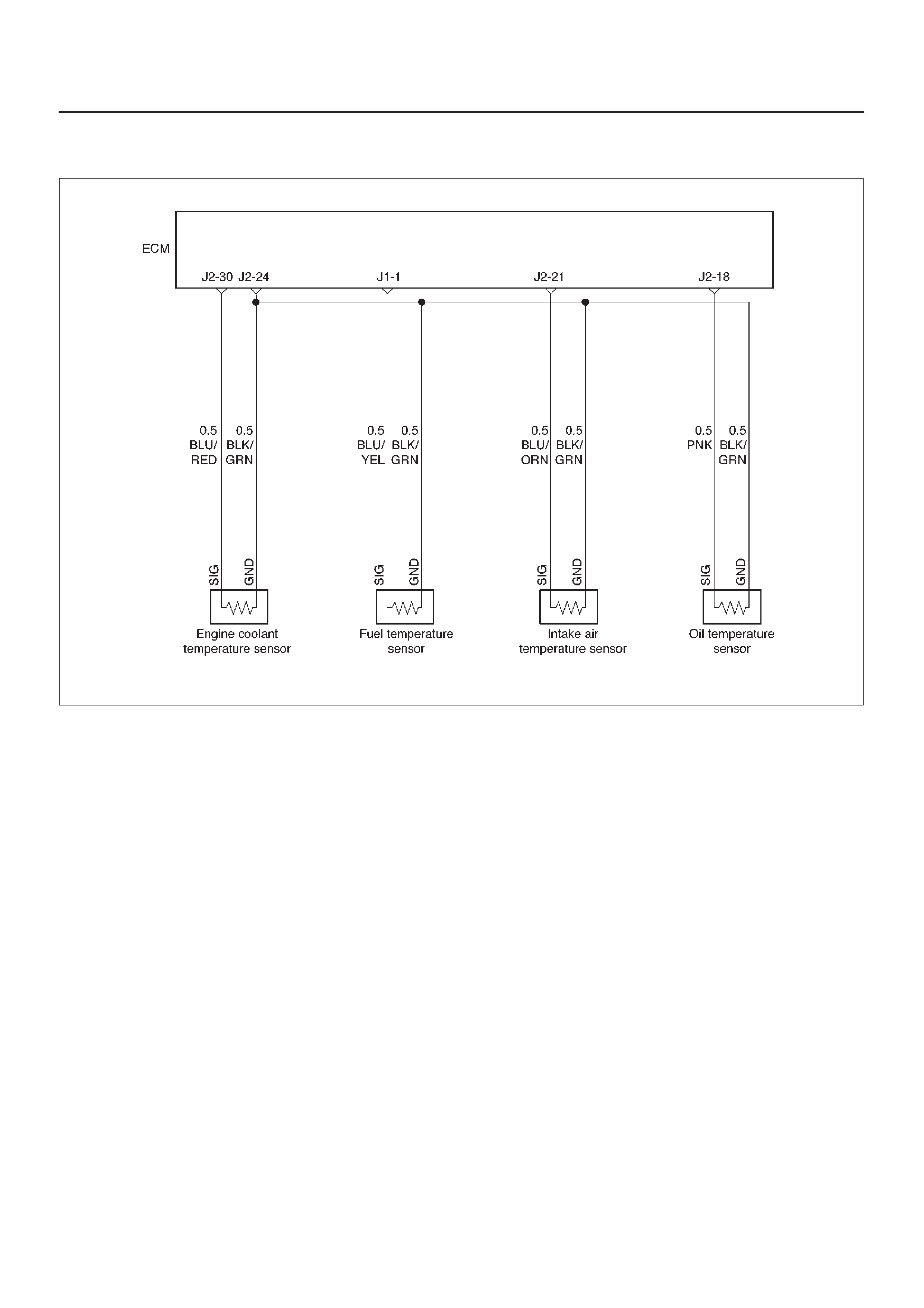

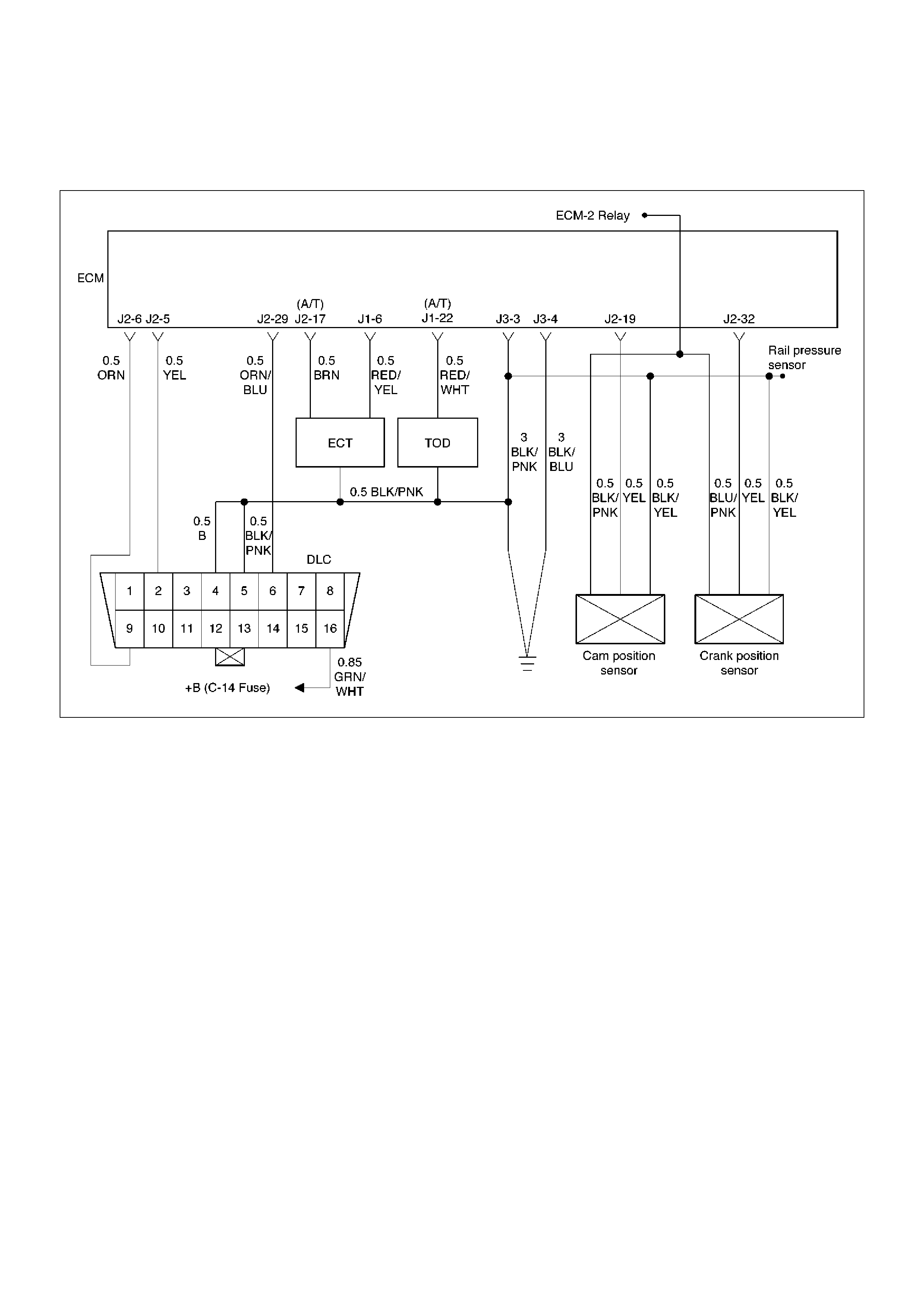

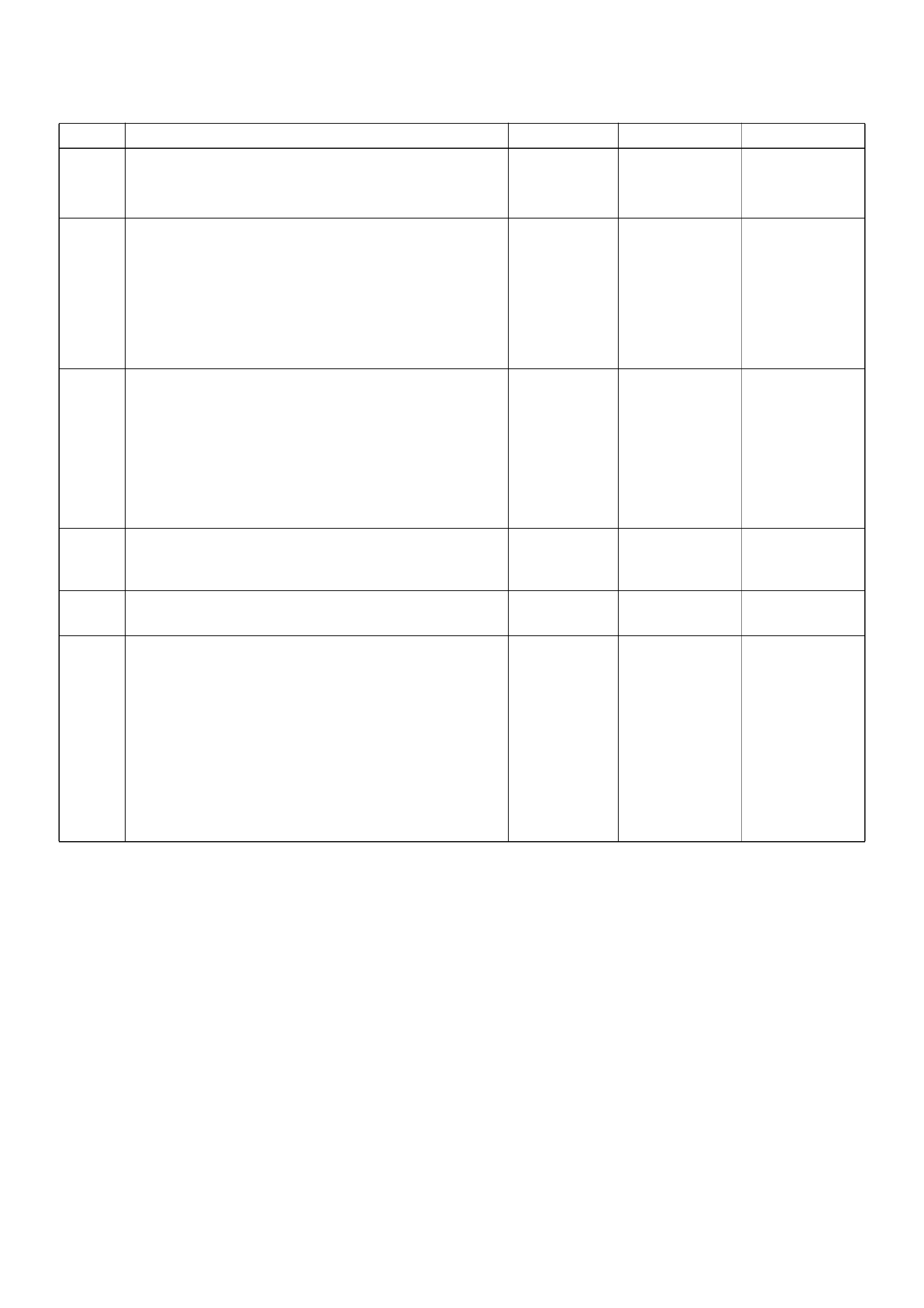

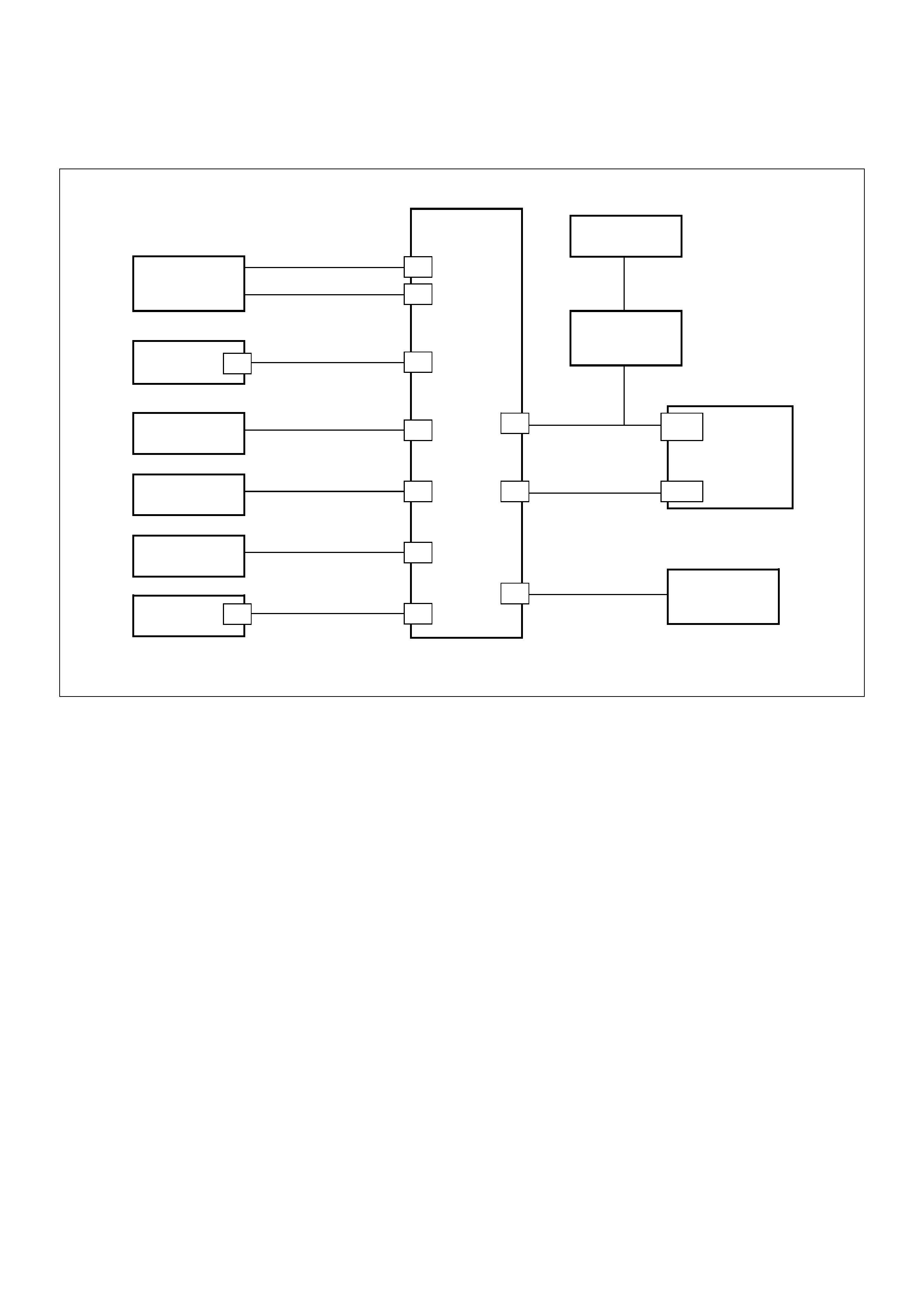

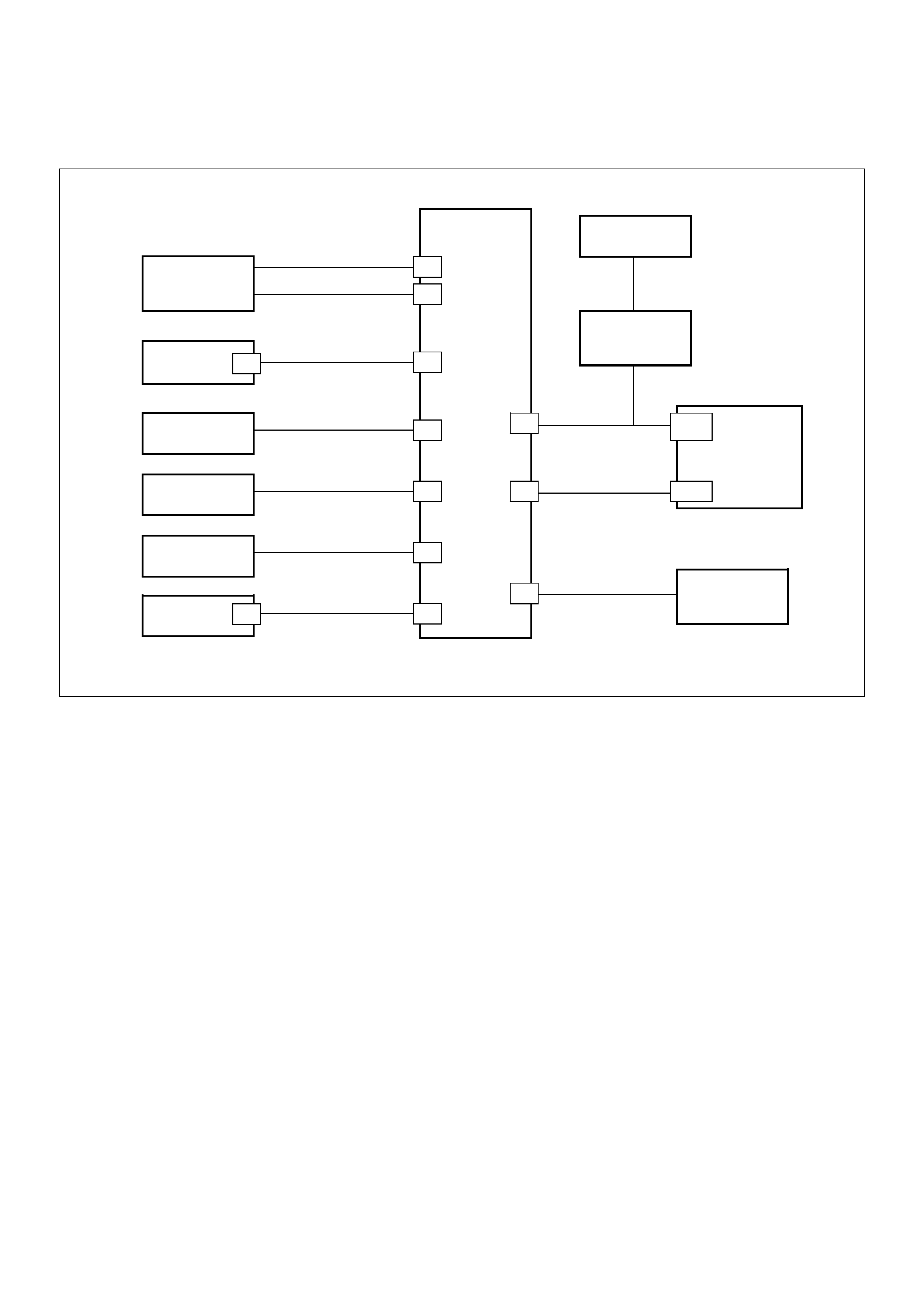

Diagrams and Schematics

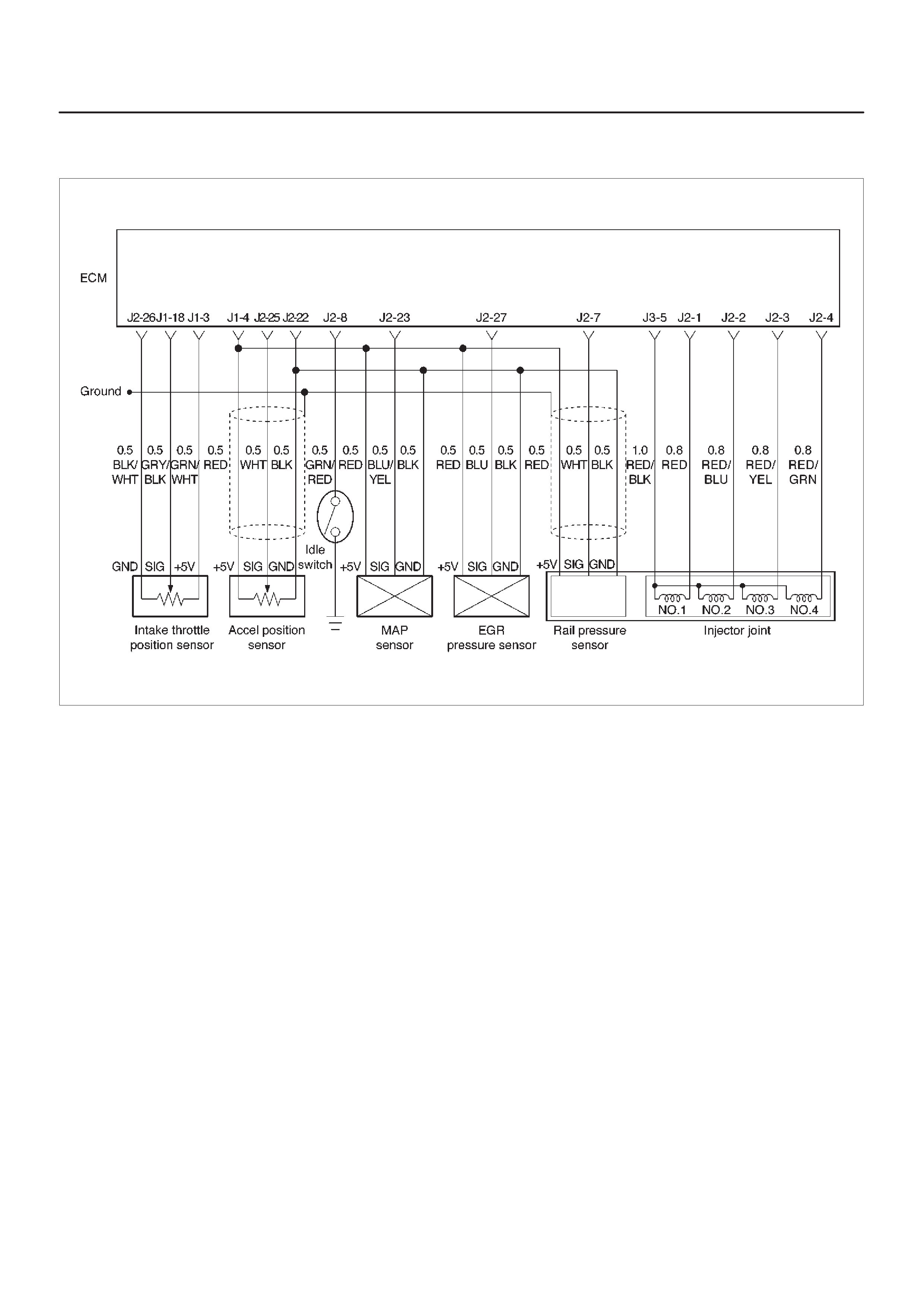

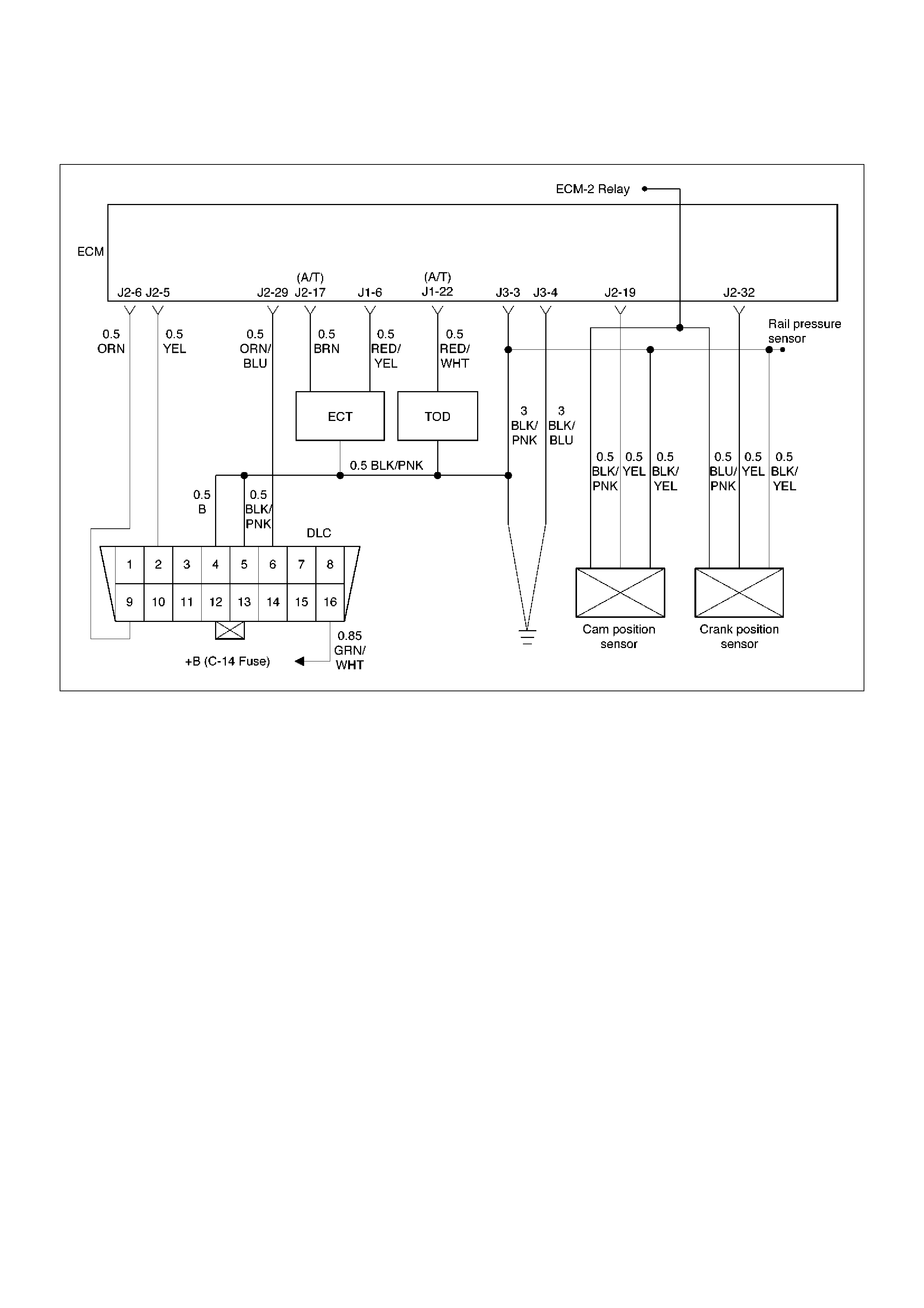

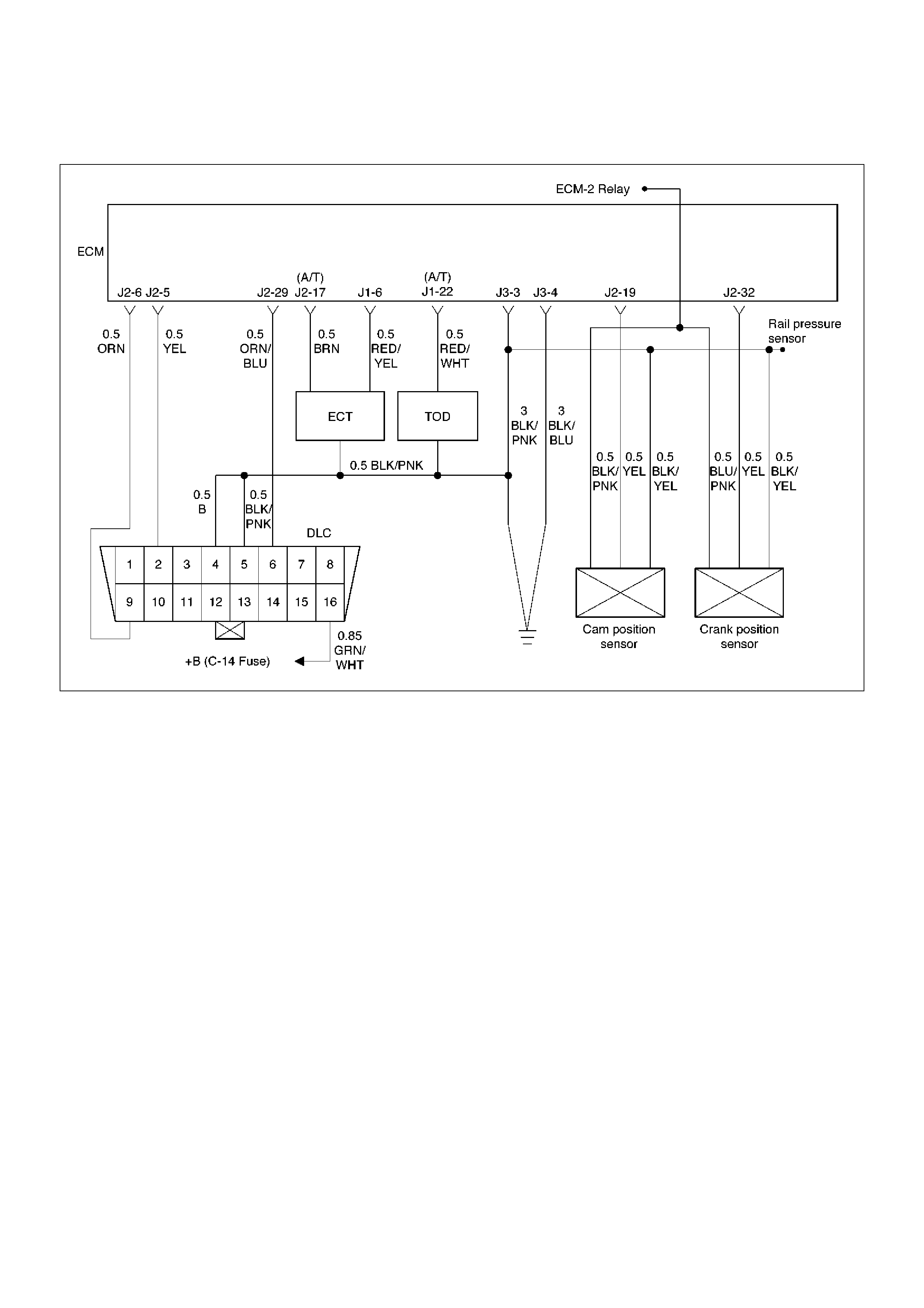

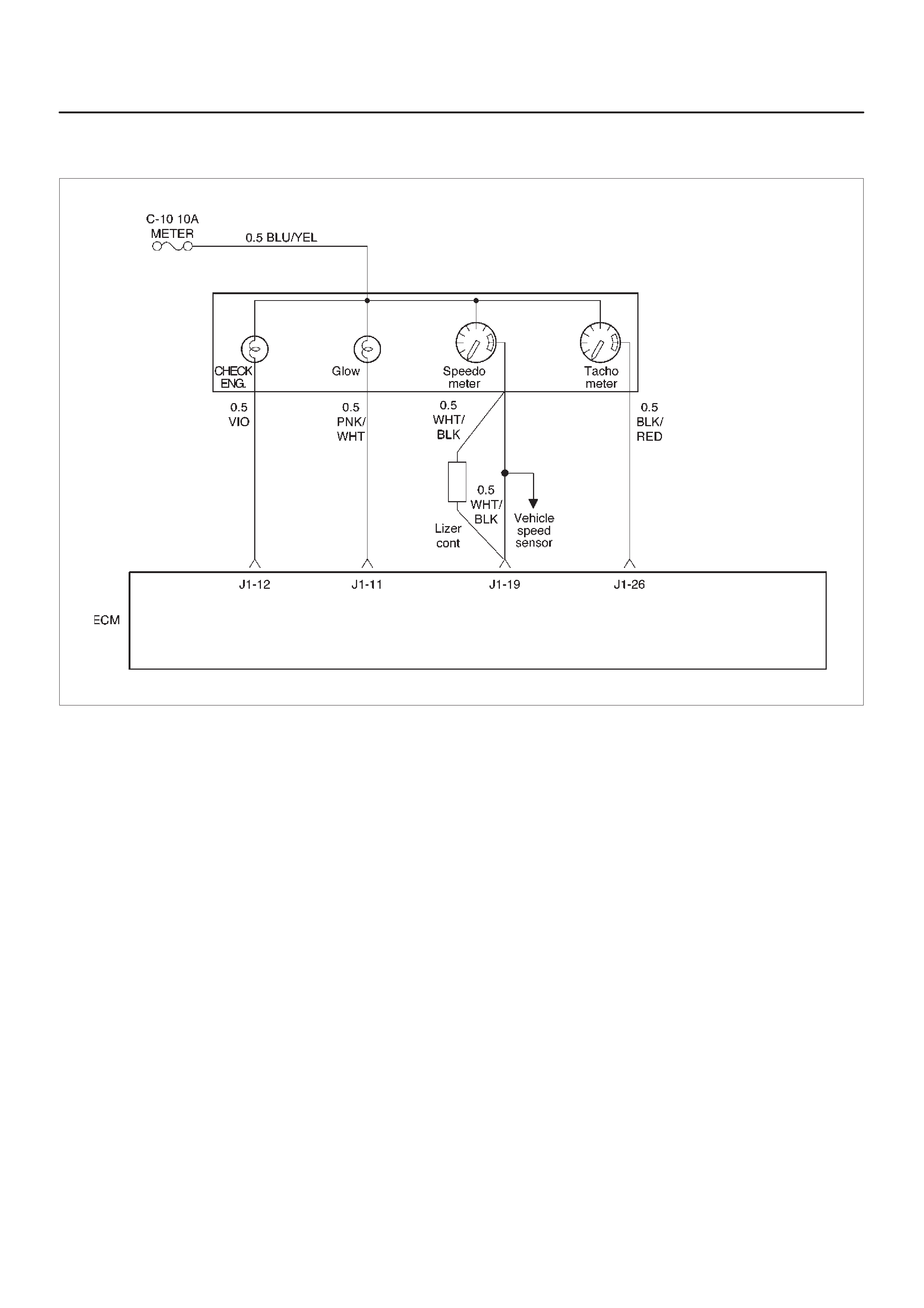

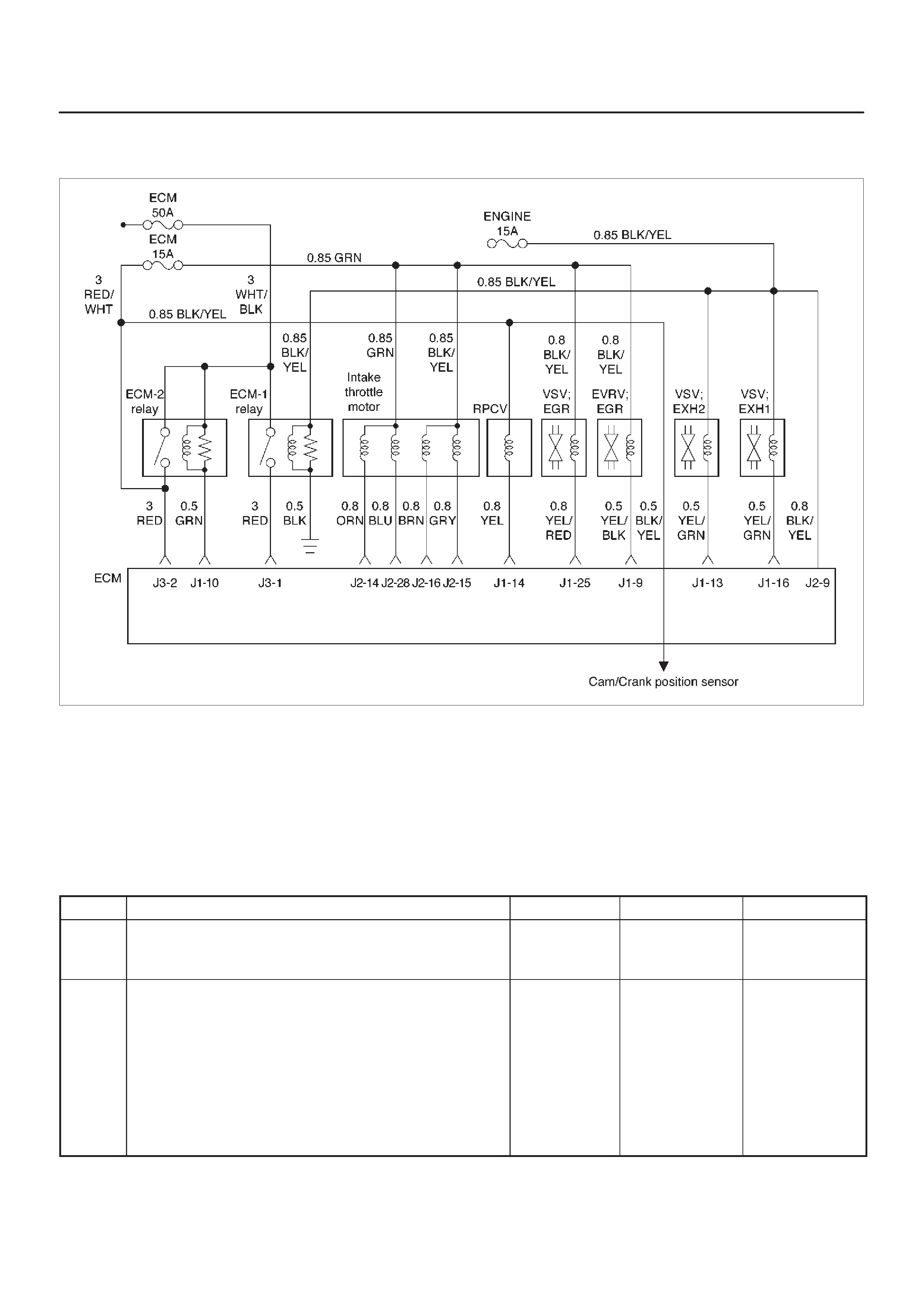

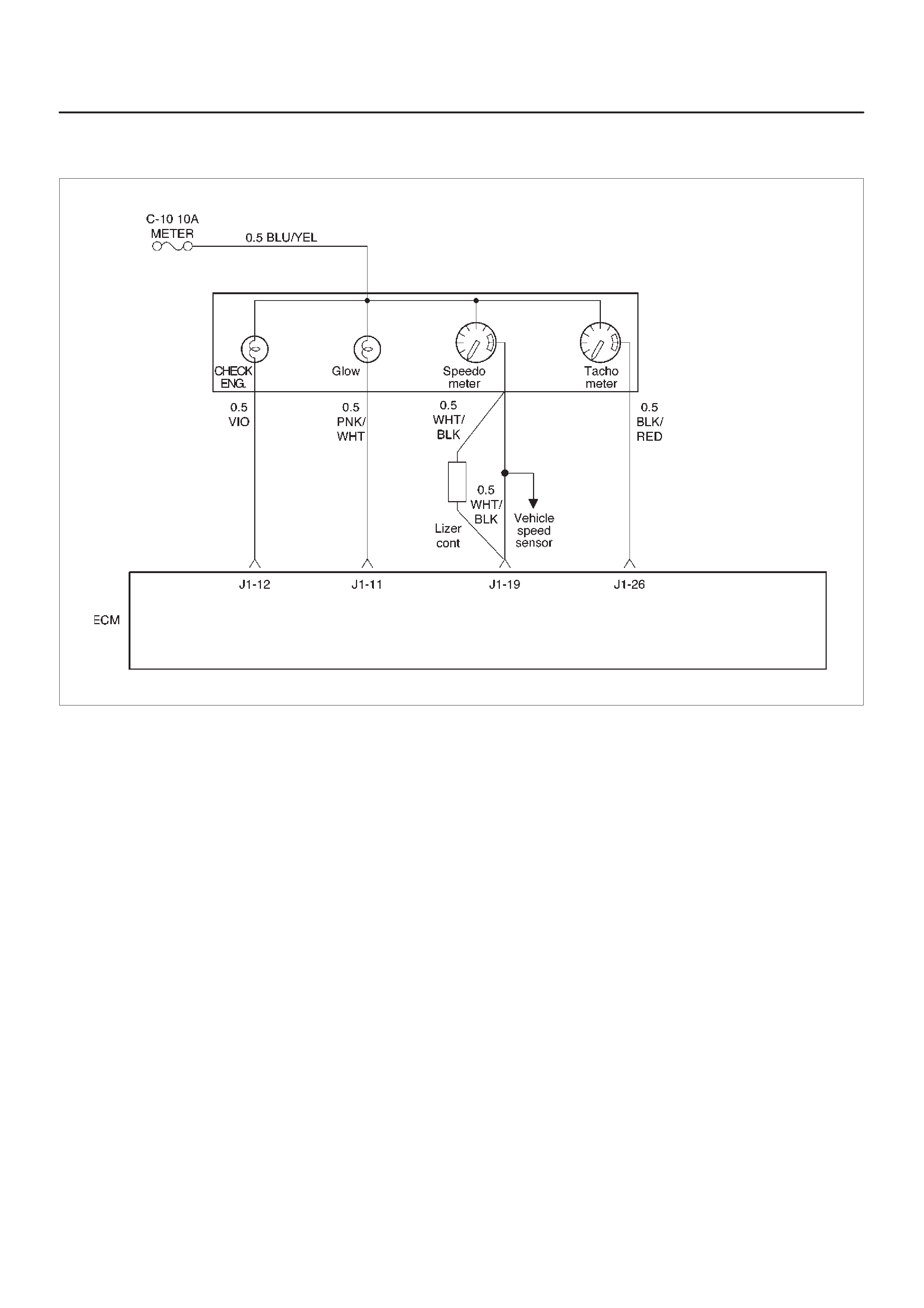

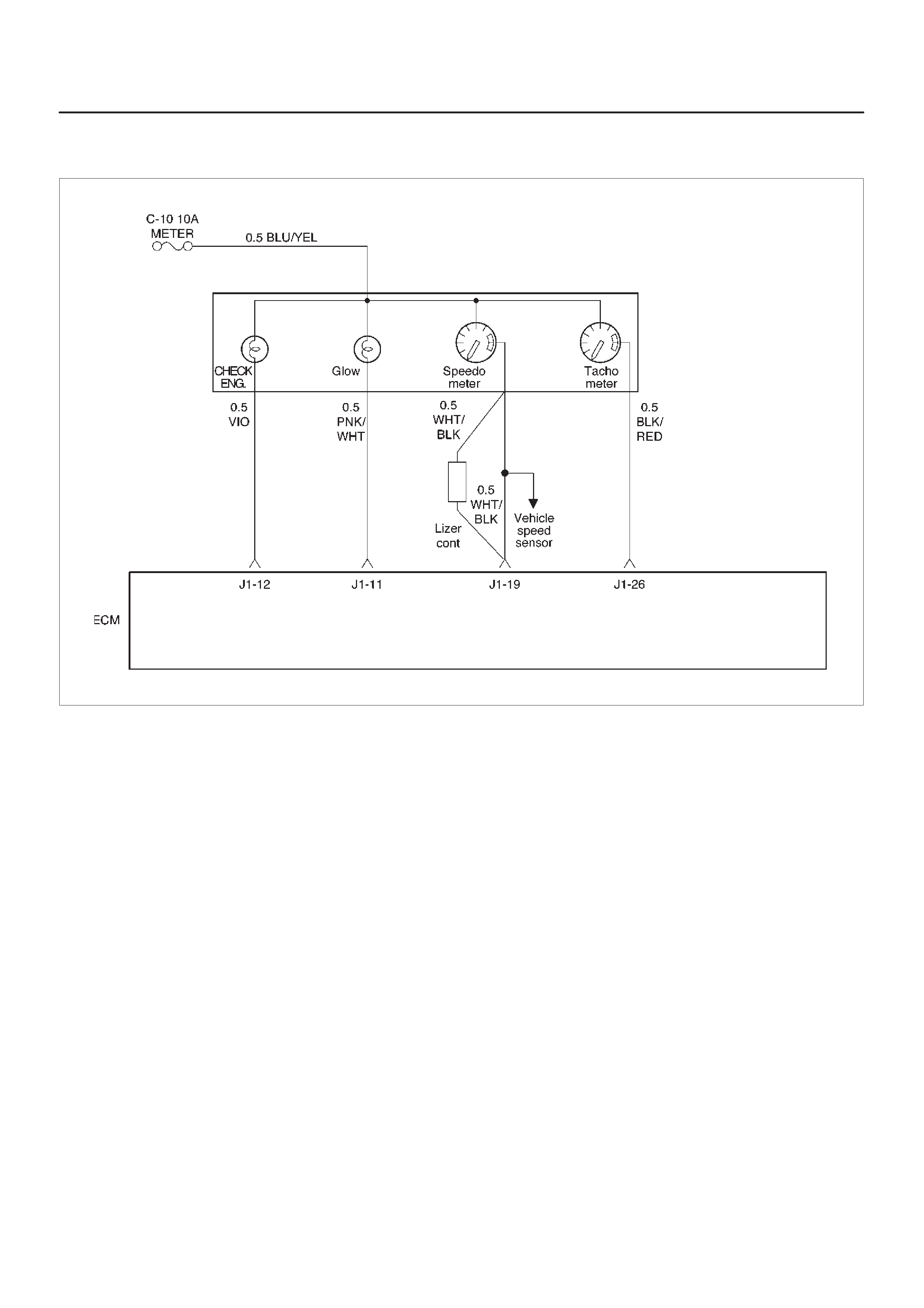

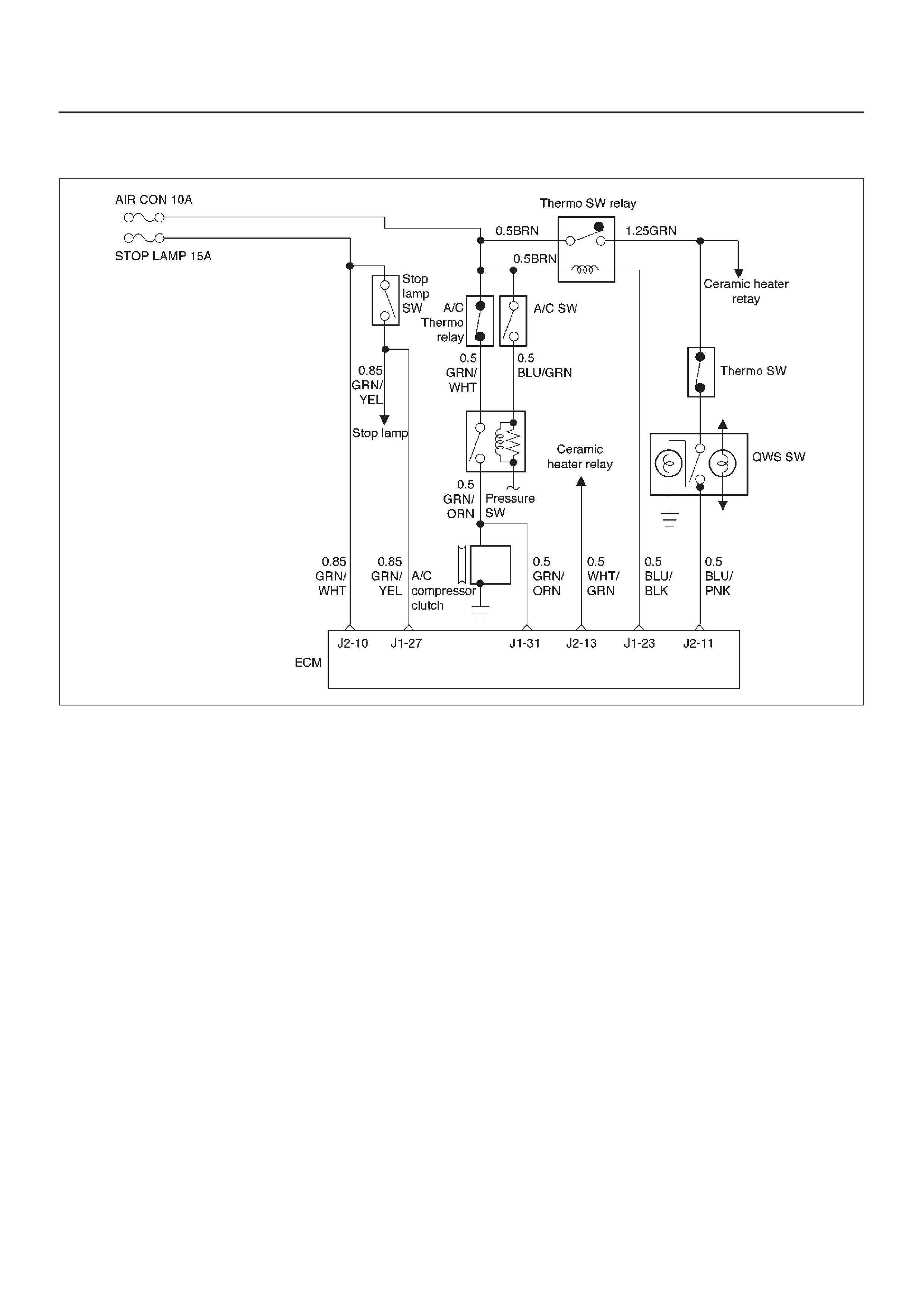

ECM Wiring Diagram (1 of 6)

060RW127

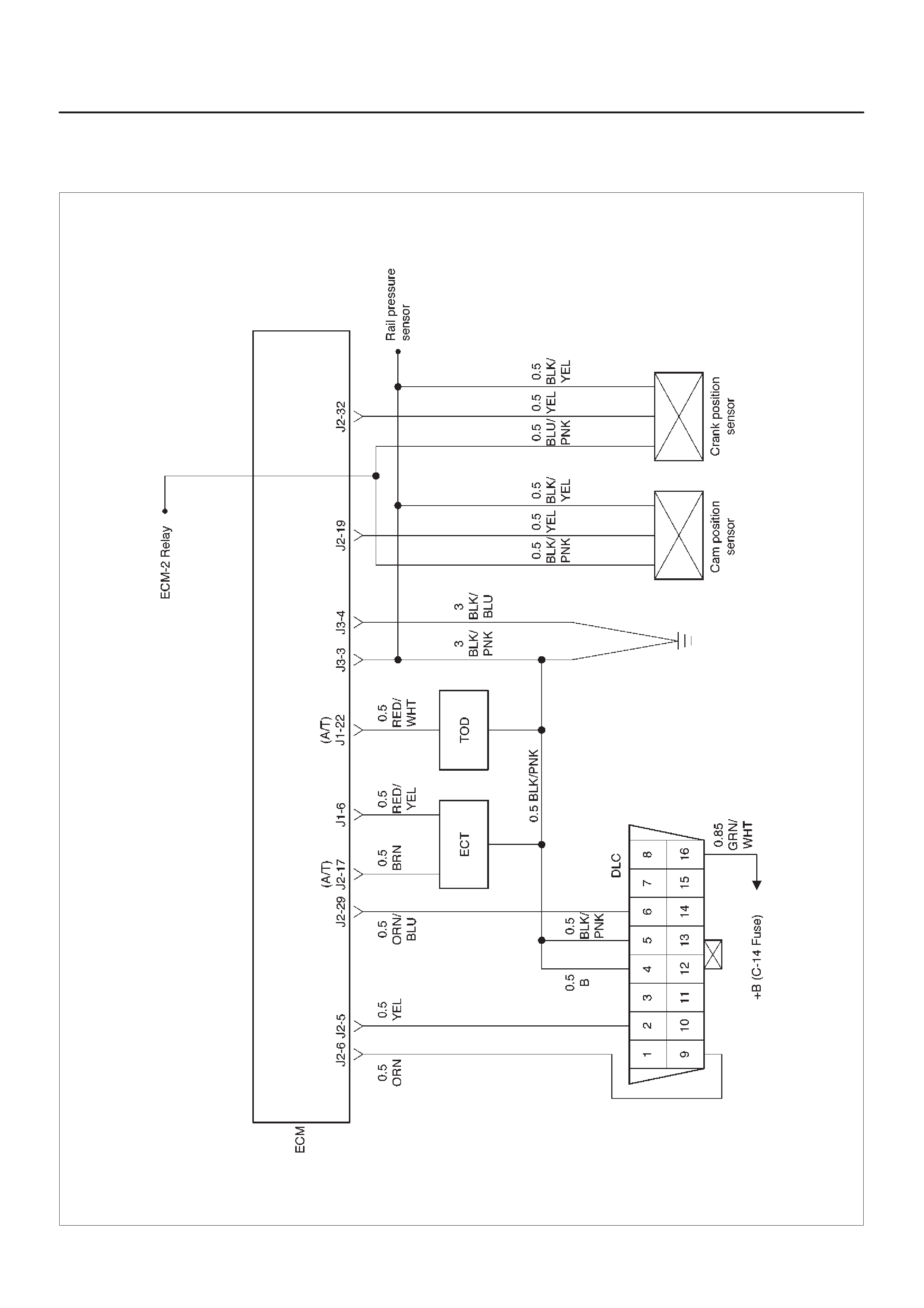

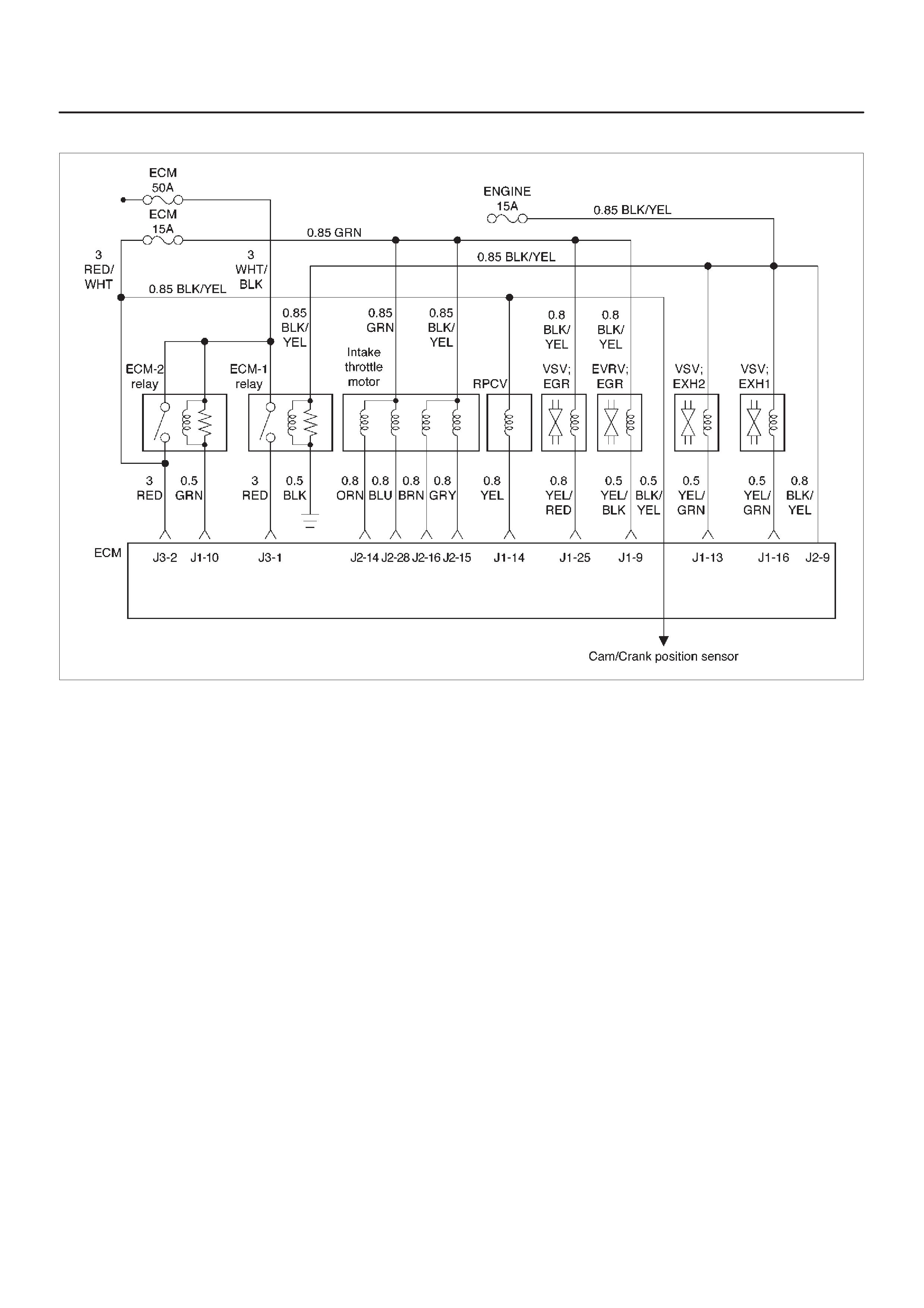

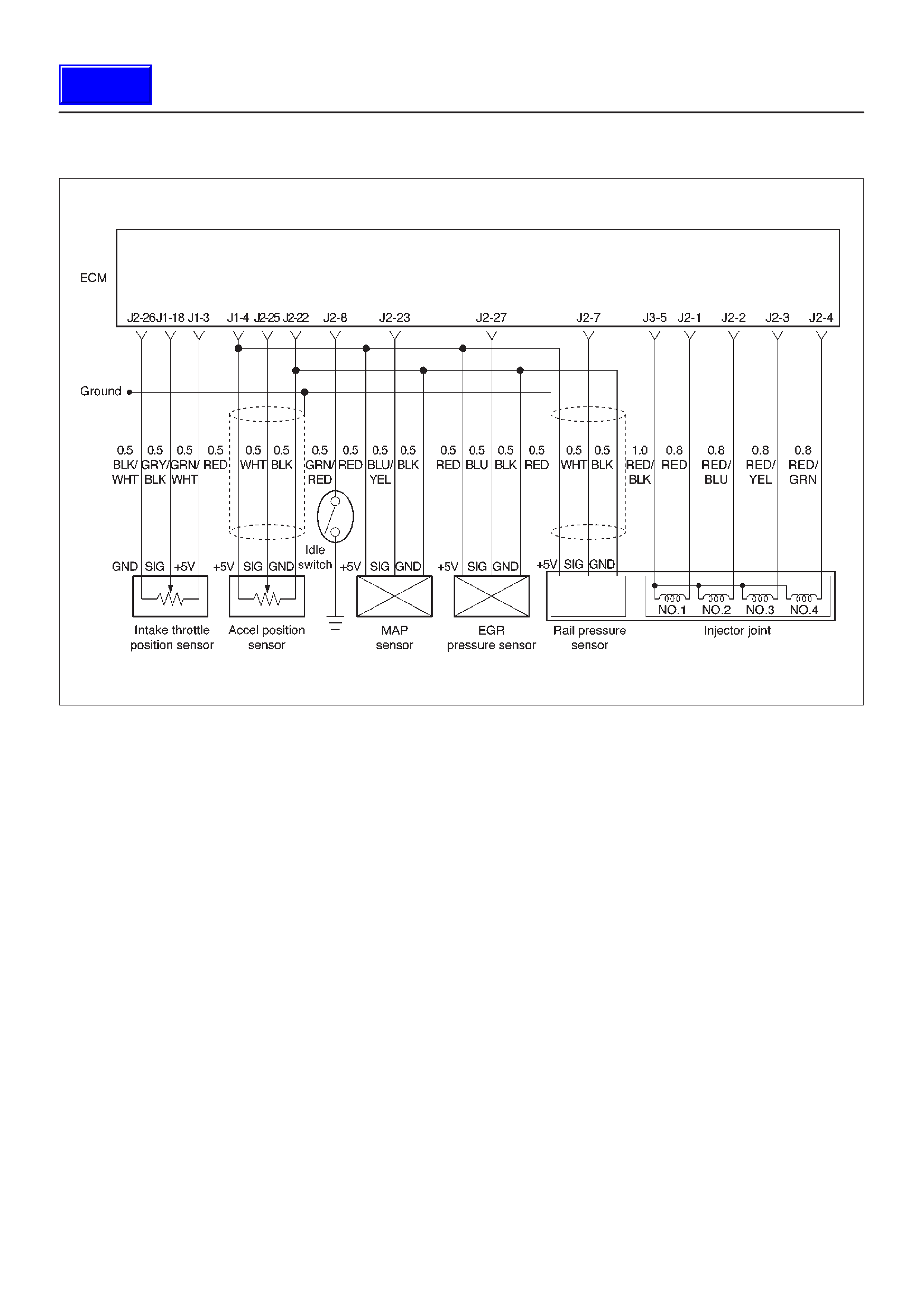

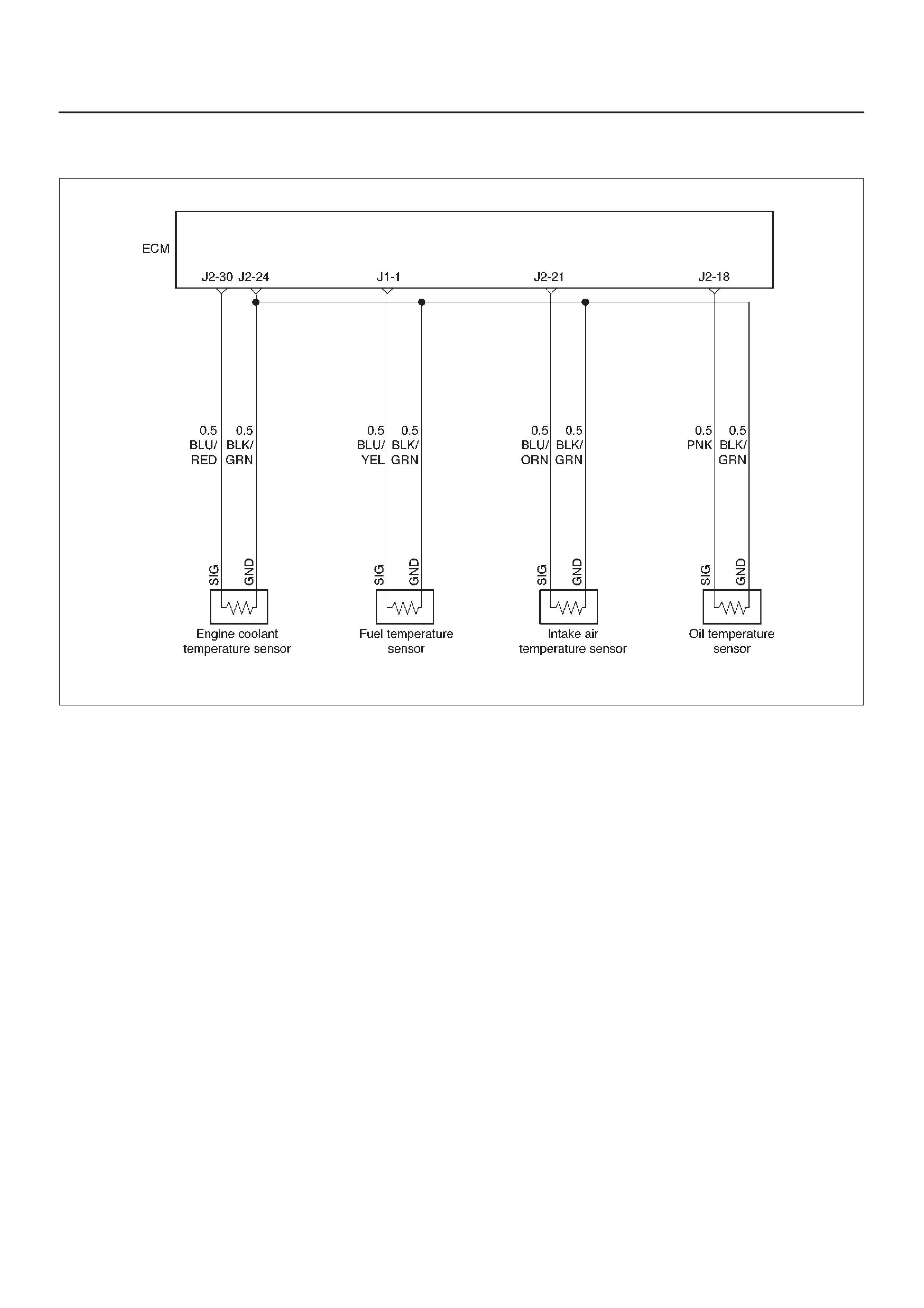

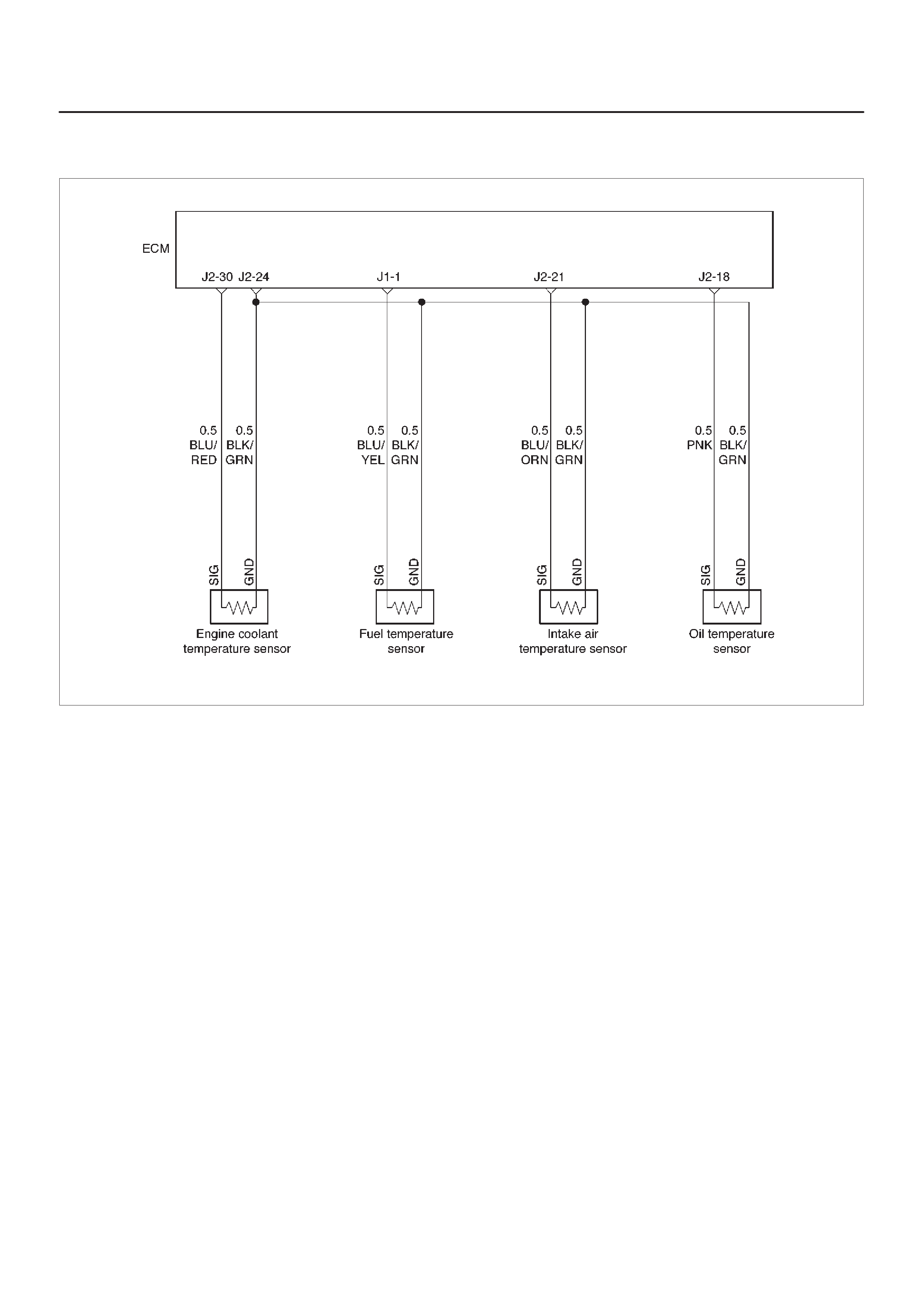

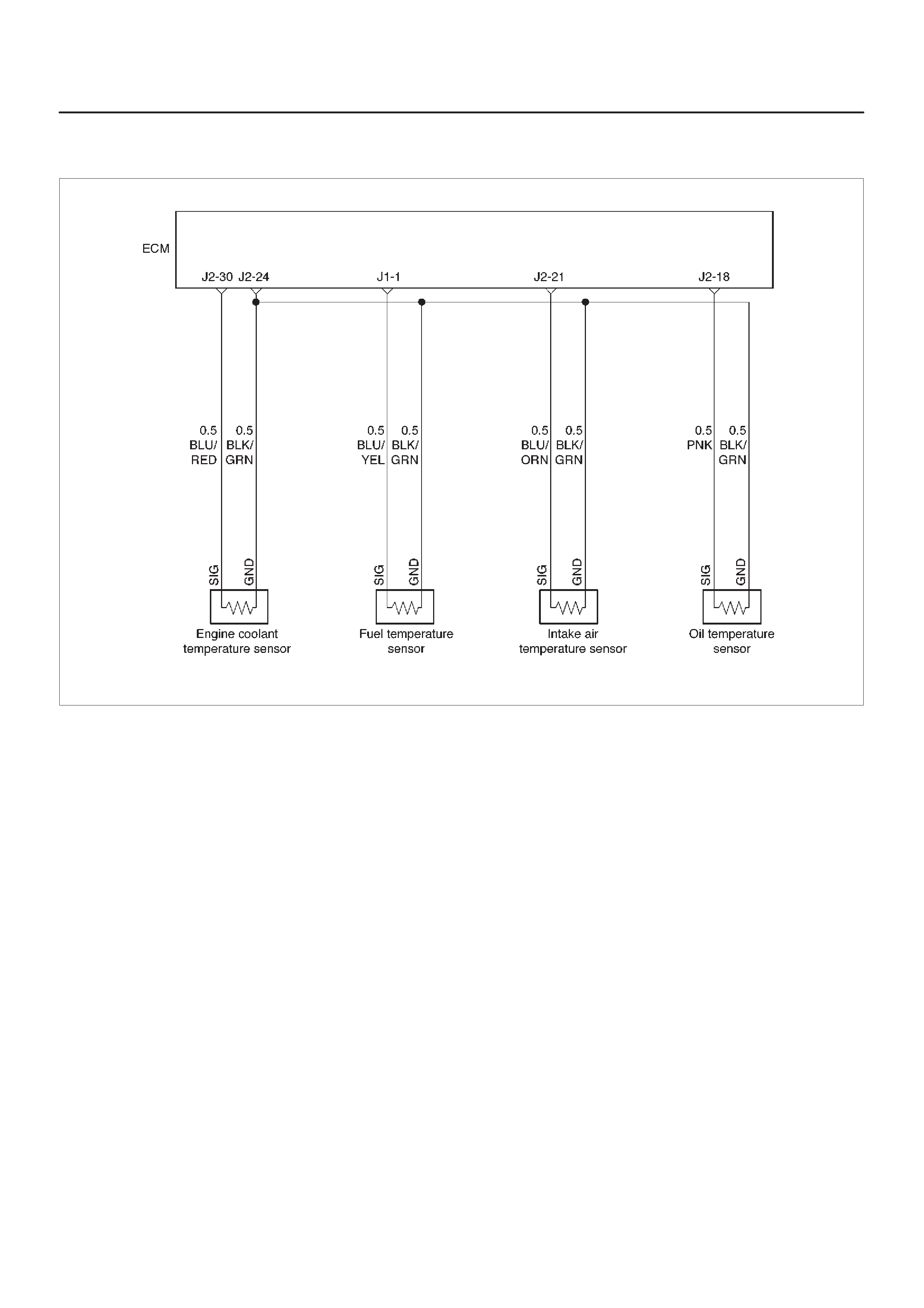

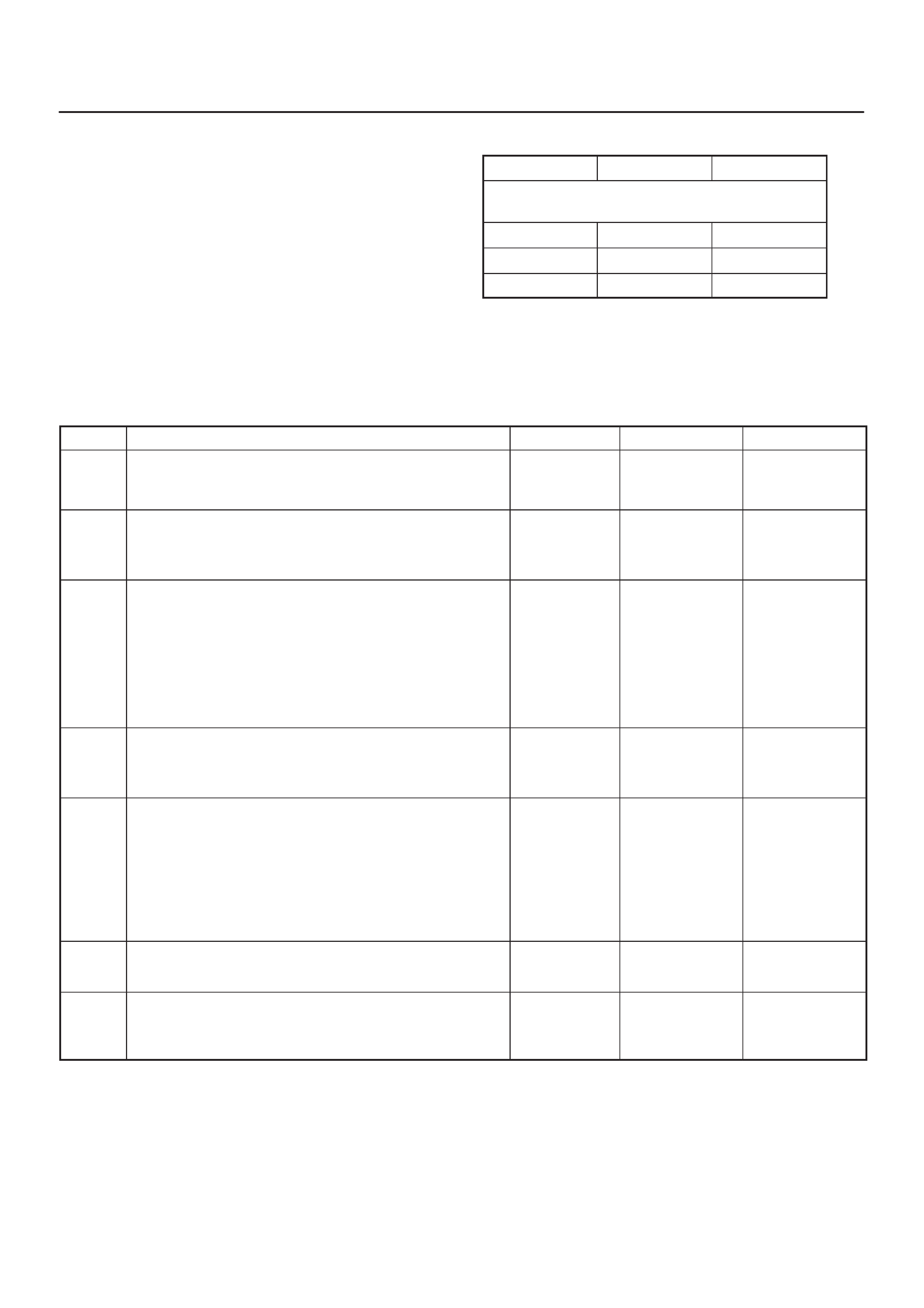

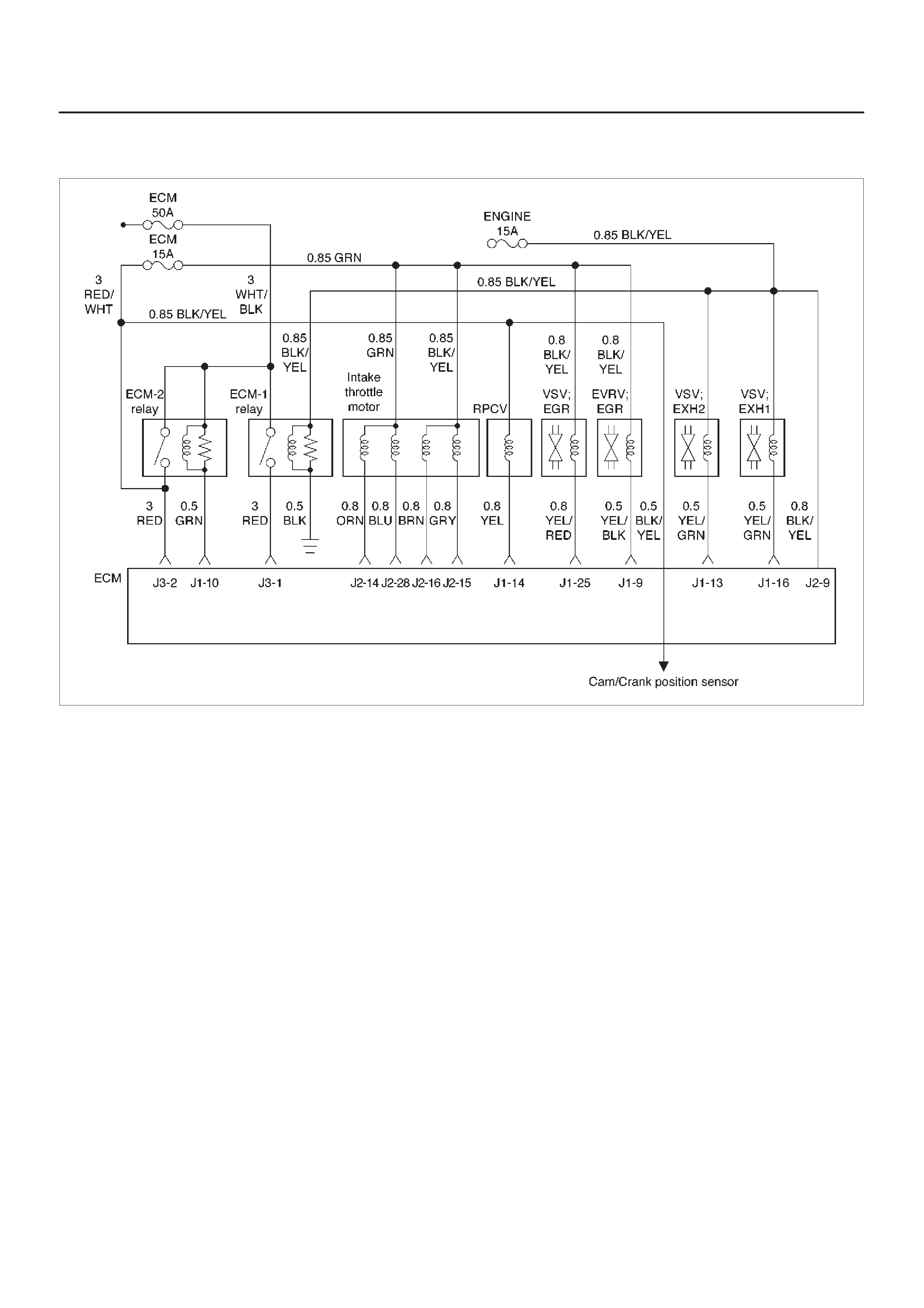

ECM Wiring Diagram (2 of 6)

060RW125

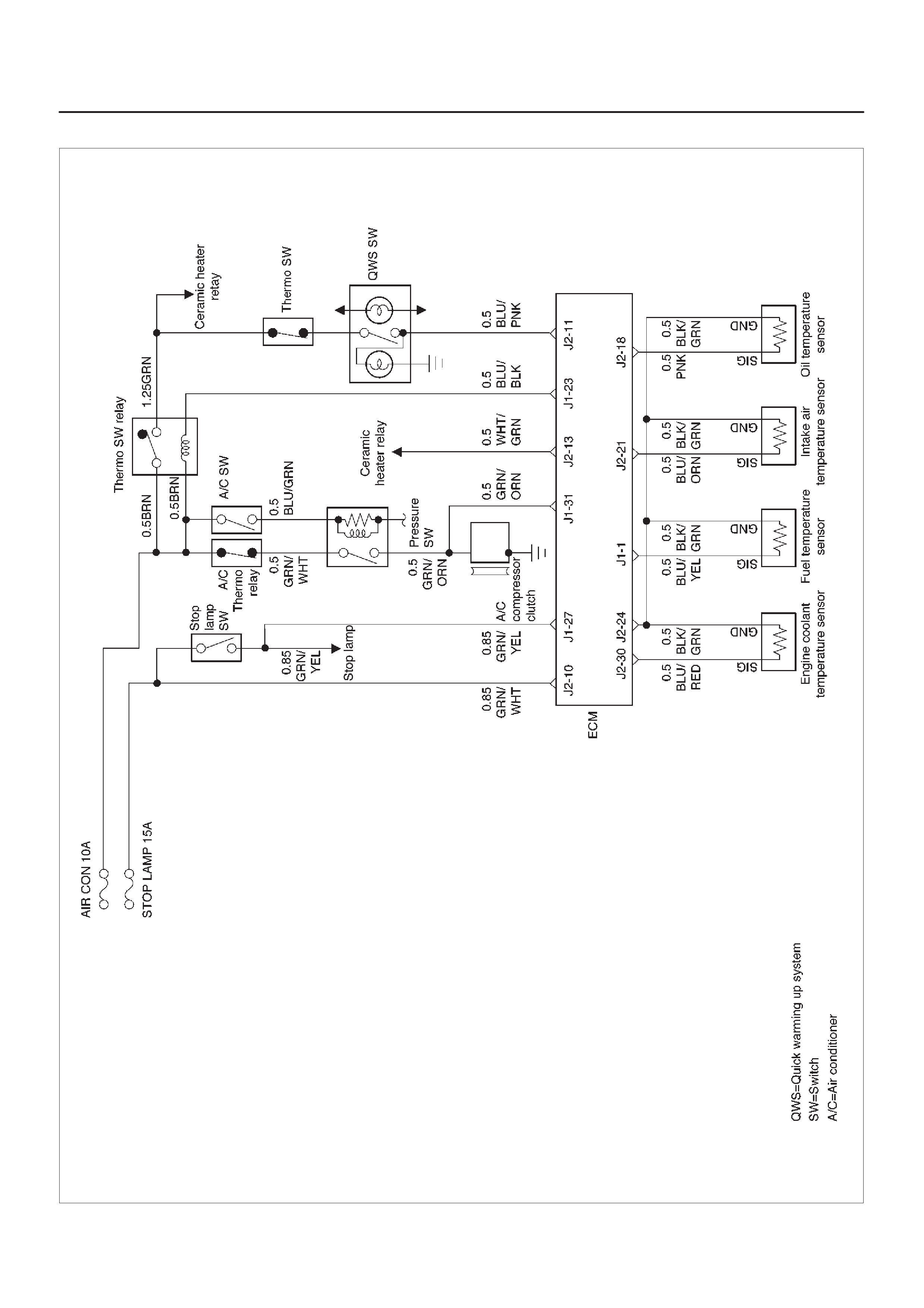

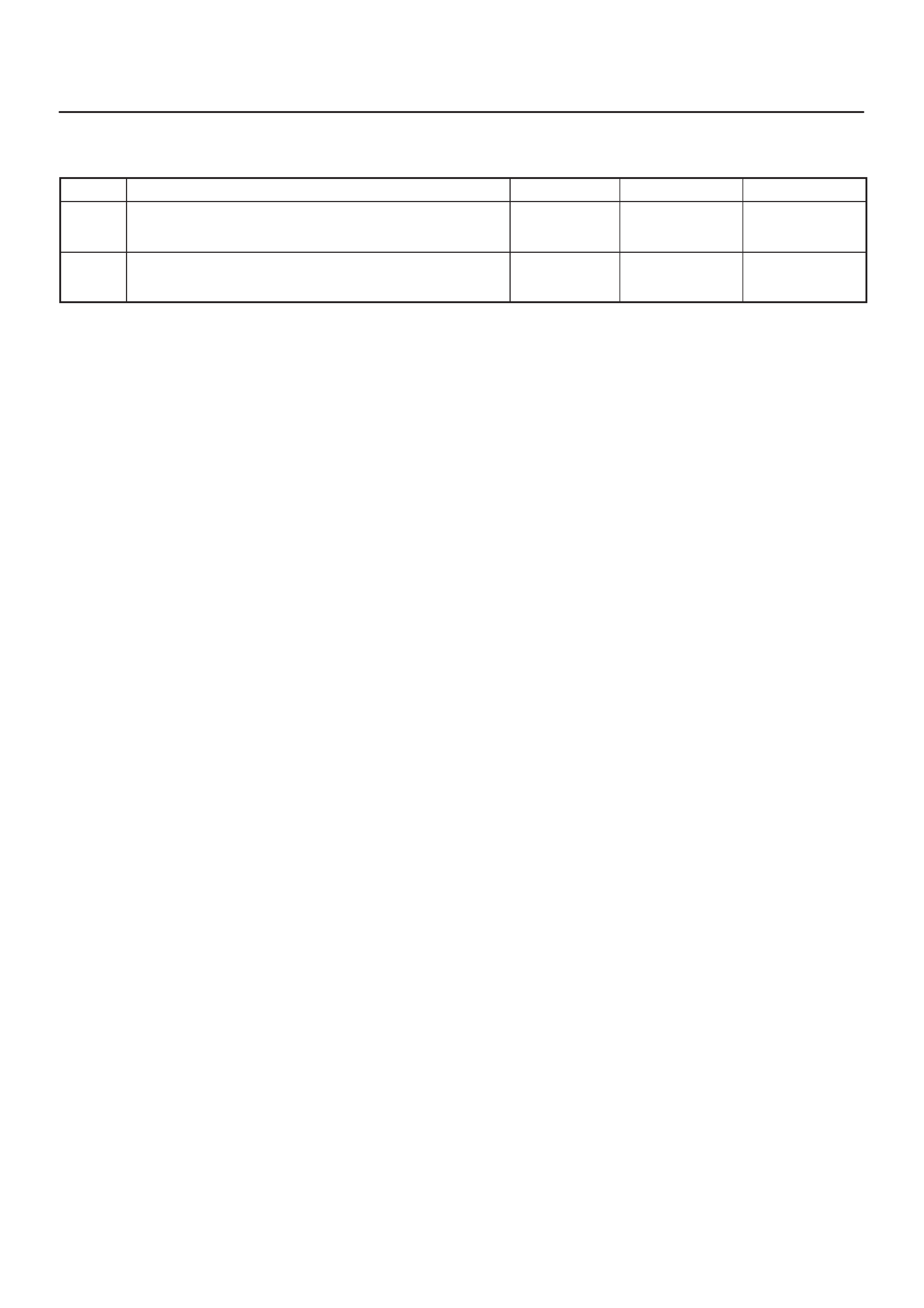

ECM Wiring Diagram (3 of 6)

060RW126

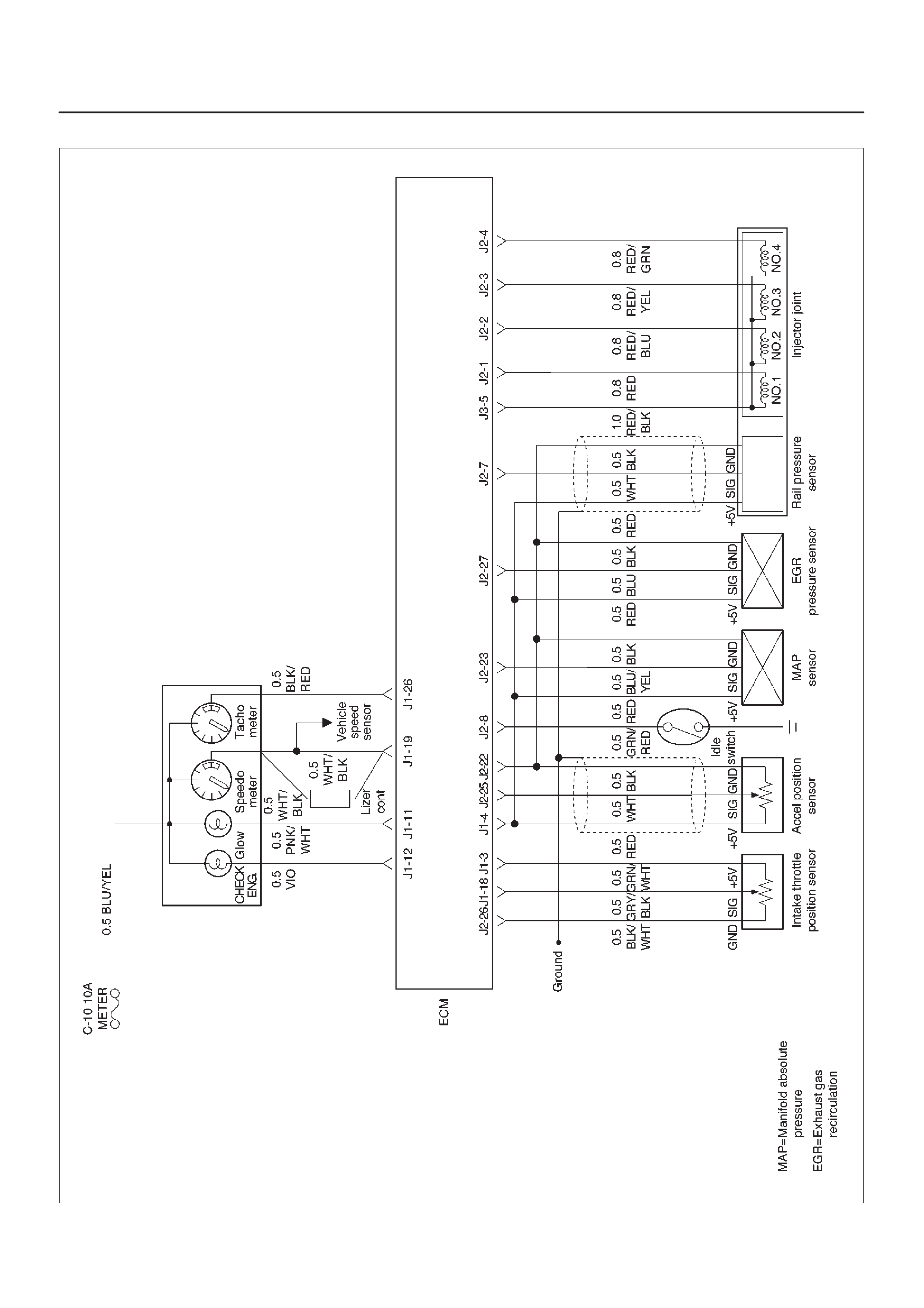

ECM Wiring Diagram (4 of 6)

060RW128

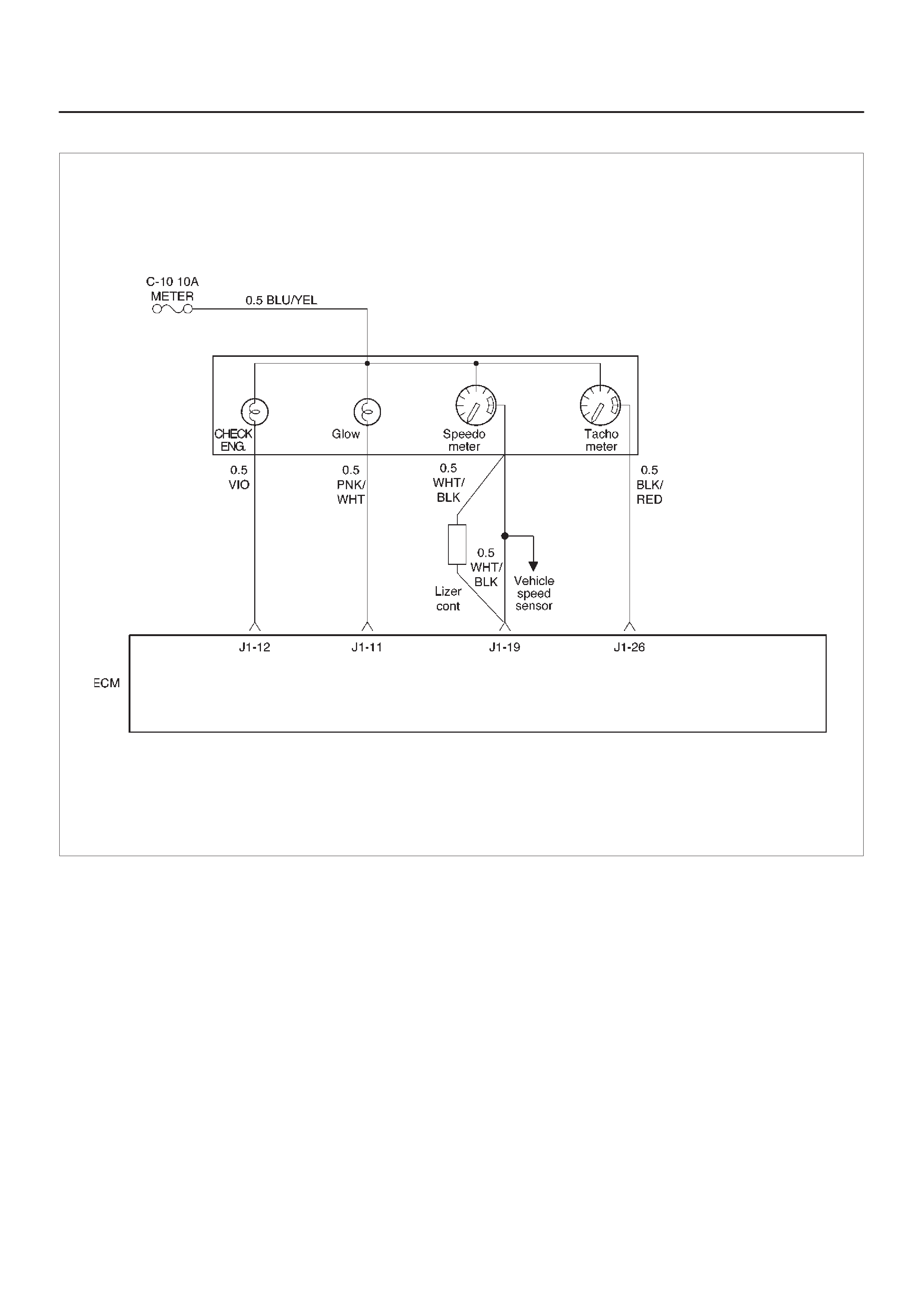

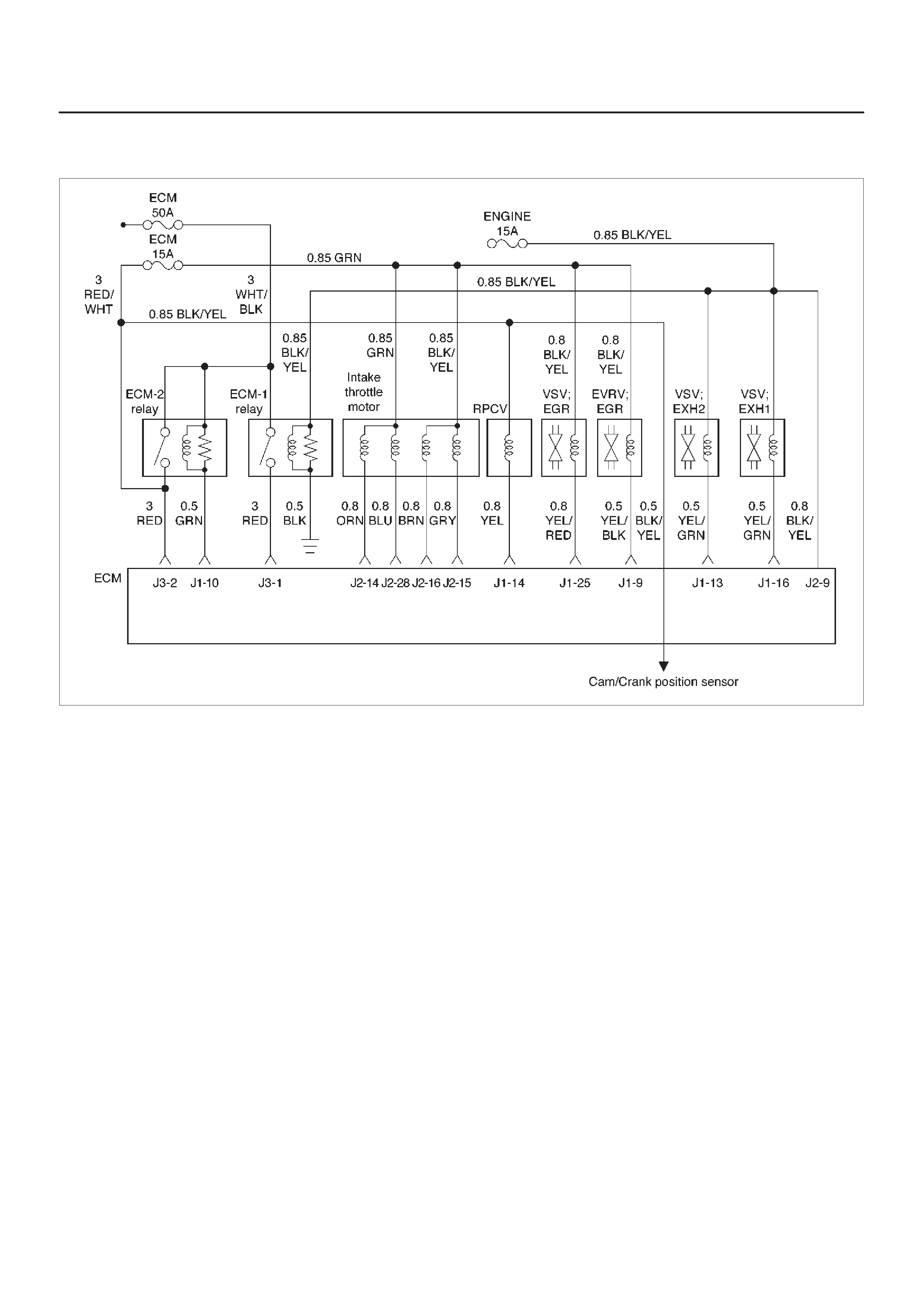

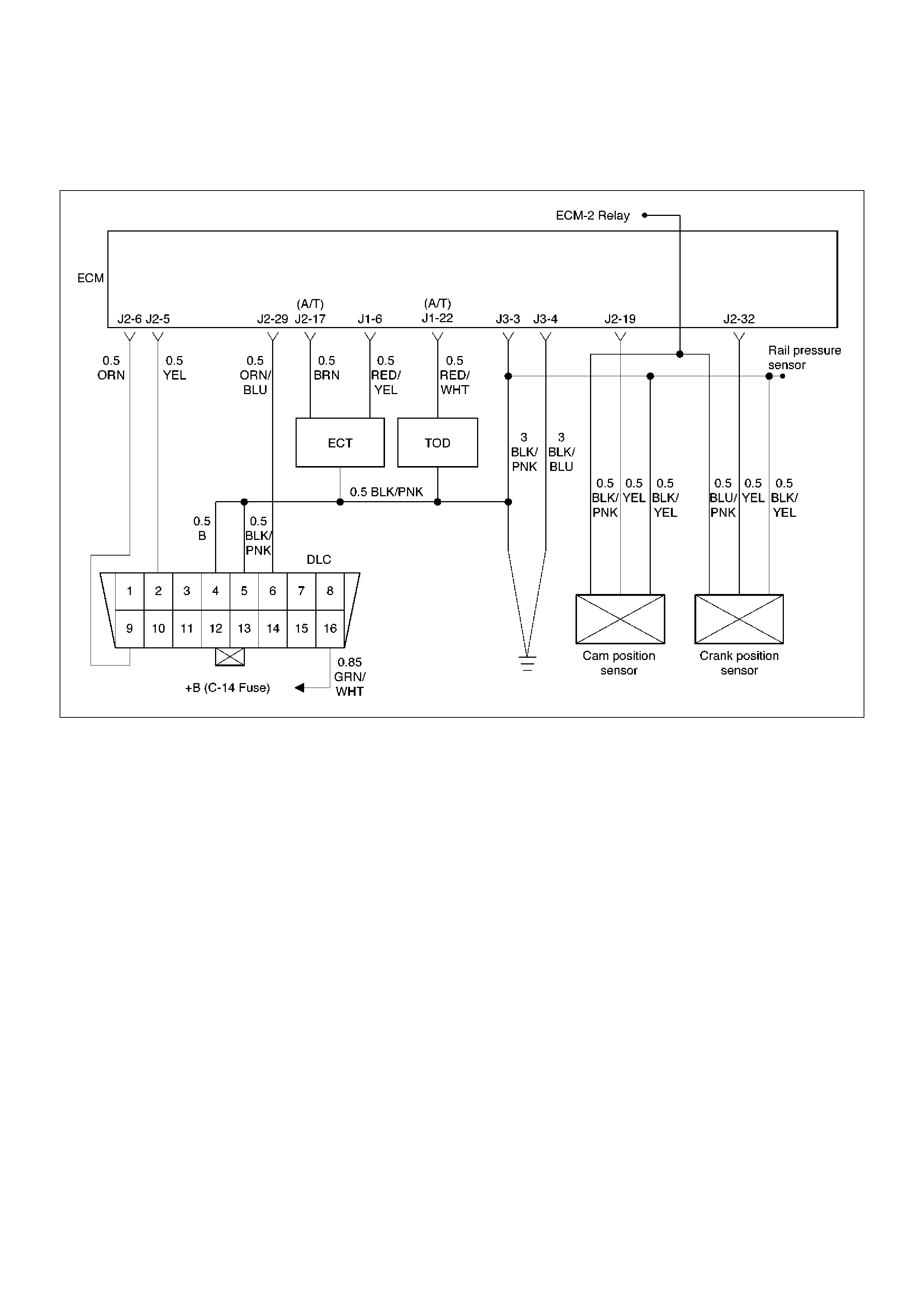

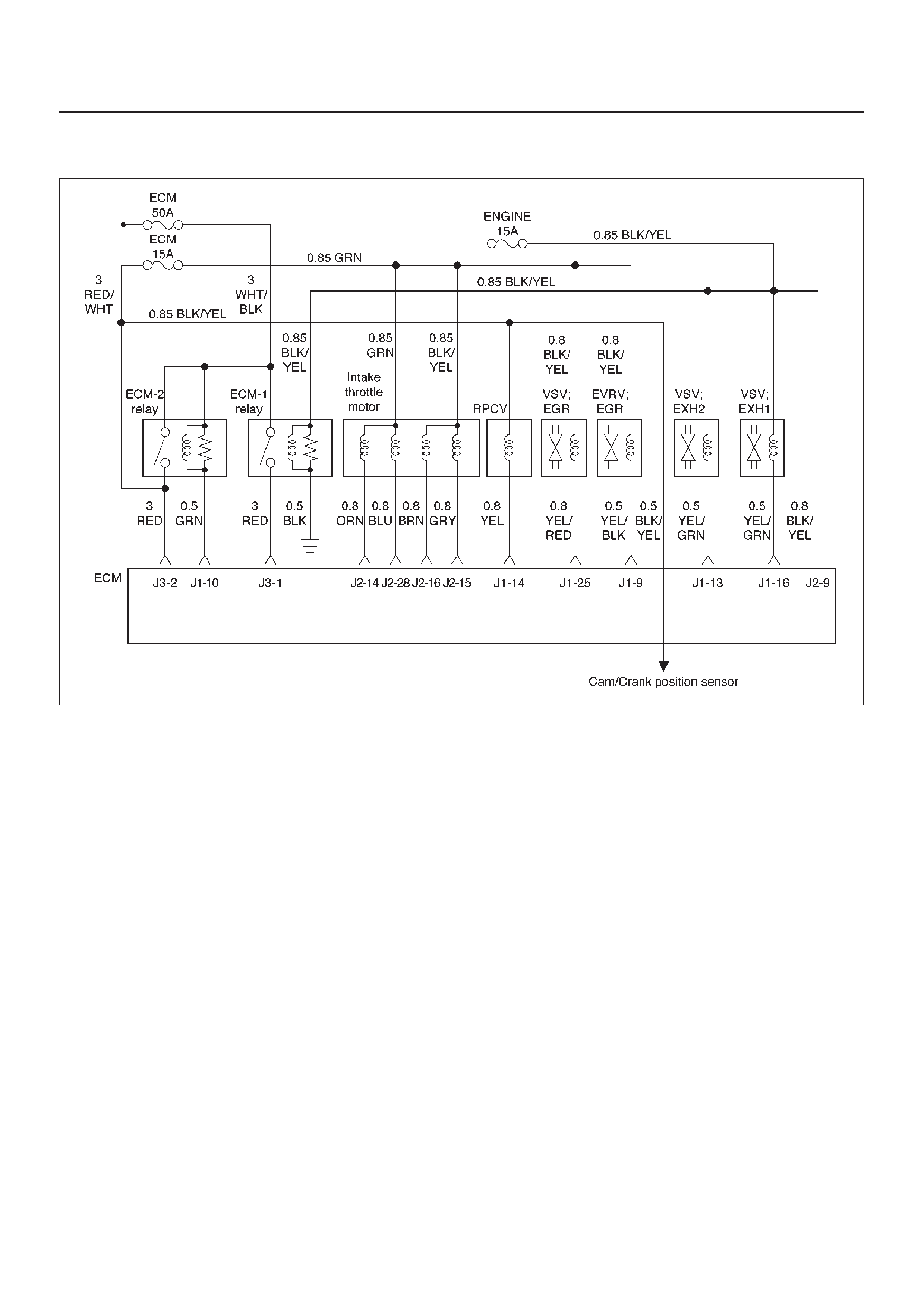

ECM Wiring Diagram (5 of 6)

060RW123

ECM Wiring Diagram (6 of 6)

060RW124

ECM Pinouts

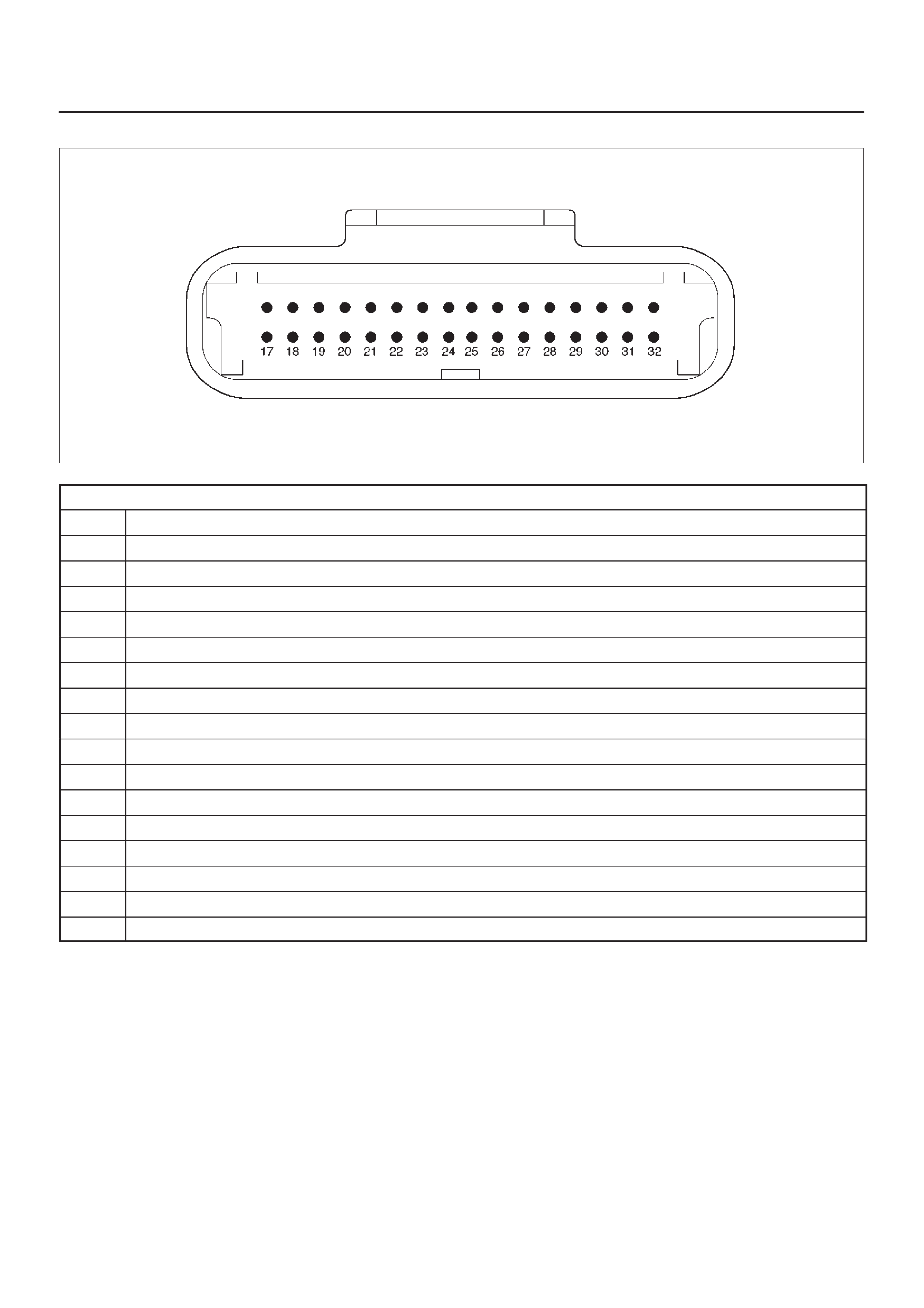

ECM Pinout Table, 32-Way Connector – J1 RED – Upper

060RW138

J1 – RED

PIN SIGNAL

1FUEL TEMPERATURE

2SPARE ANALOG 1

3 +5VB1

4 +5VB2

5SPARE ANALOG 3

6ACCEL POS OUT 1

7NOT USED

8SPARE OUT 2 (TCC)

9EVR V (EGR)

10 IGN RELAY

11 GLOW PLUG LAMP

12 DIAGNOSTIC LAMP

13 VSV (EXHAUST #2)

14 RAIL PRESS CNTRL VALVE

15 GLOW PLUG RELAY

16 VSV (EXHAUST #1)

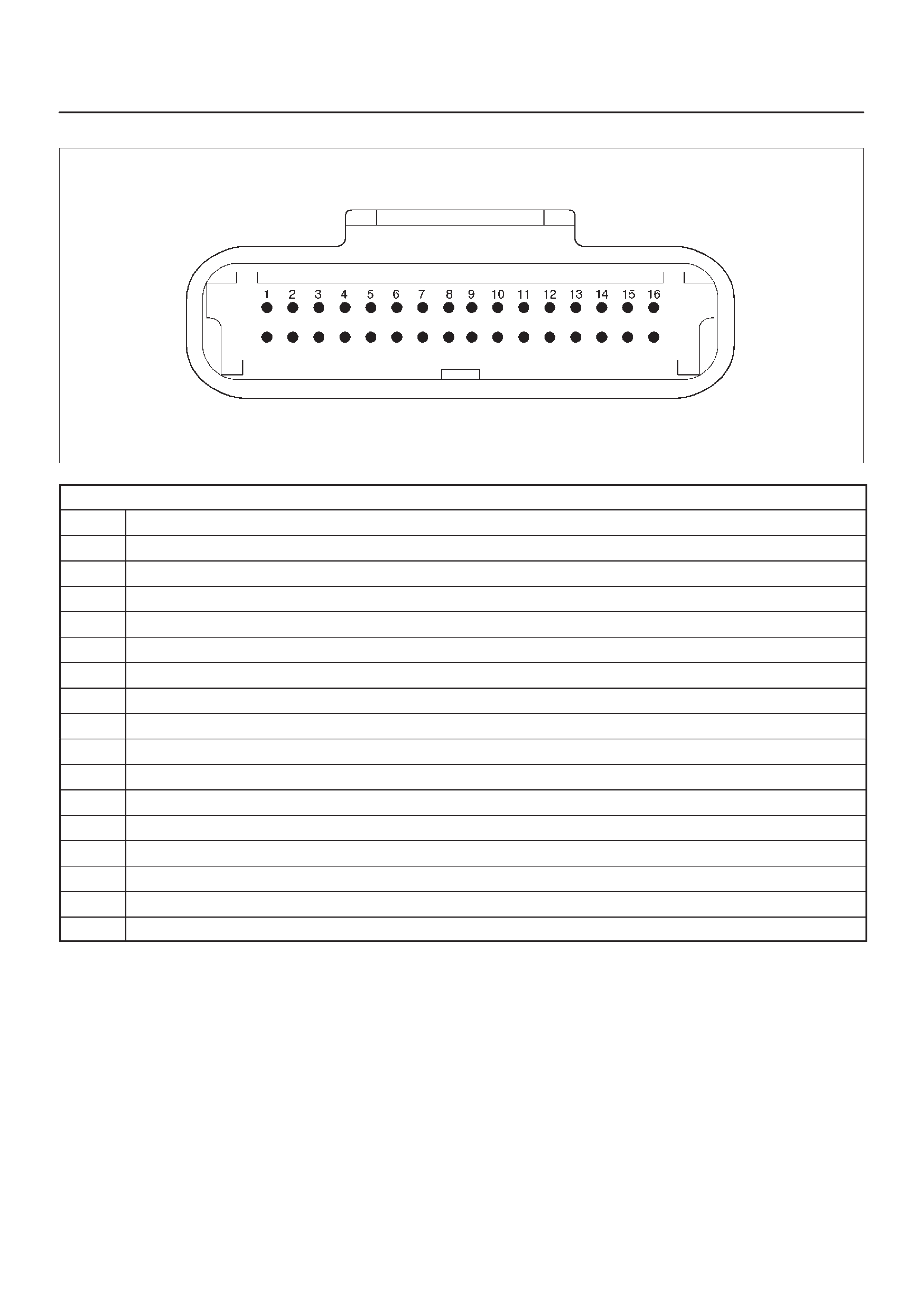

ECM Pinout Table, 32-Way Connector – J1 RED – Lower

060RW137

J1 – RED

PIN SIGNAL

17 SPARE ANALOG 4

18 INTAKE SM POSITION

19 VEHICLE SPEED

20 MT NEUTRAL

21 REVERSE SW

22 ACCEL POS OUT 2

23 THERMO SW RELAY

24 SPARE OUT 3 (TURBO)

25 VSV (EGR)

26 TACHOMETER 1

27 BRAKE SW 1

28 NOT USED (BRAKE 2)

29 A/T NEUTRAL SW

30 NO CONNECTION

31 AC REQUEST SW

32 AT SOLENOID

ECM Pinout Table, 32-Way Connector – J2 BLUE – Upper

060RW138

J2 – BLUE

PIN SIGNAL

1INJECT OR A RTN

2INJECT OR B RTN

3INJECTOR C RTN

4INJECTOR D RTN

5CLASS 2

6 SDATA

7RAIL OIL PRESSURE

8IDLE SW

9IGN SW

10 BATTERY

11 QUICK WARM REQ. SW

12 PAR TIAL IDLE SW

13 CERAMIC HTR REQUEST SW

14 INTAKE SW S2B

15 INTAKE SW S1T

16 INTAKE SW S1B

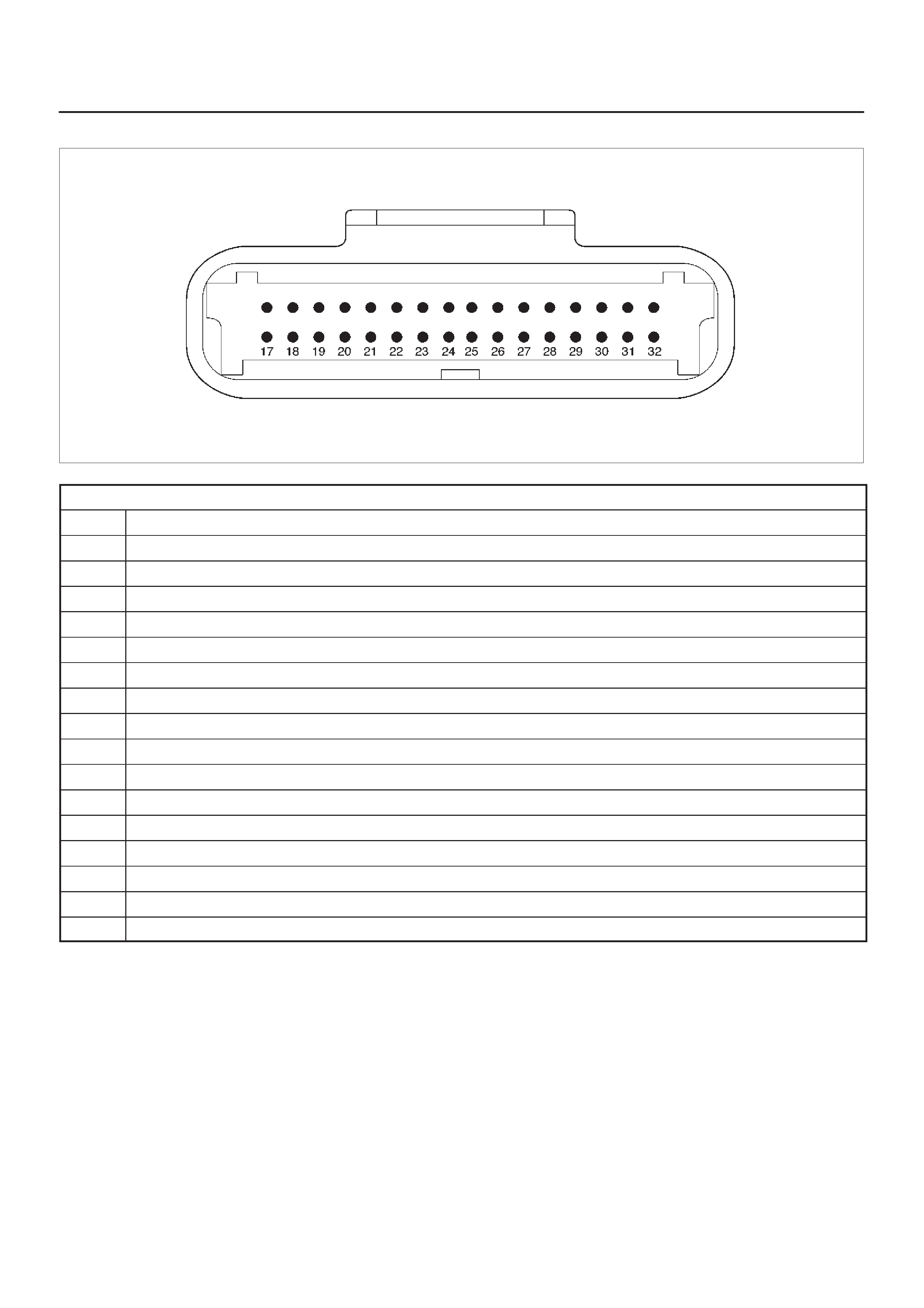

ECM Pinout Table, 32-Way Connector – J2 BLUE – Lower

060RW137

J2 – BLUE

PIN SIGNAL

17 COOLANT TEMP OUT

18 OIL TEMPERATURE

19 TDC/CAM

20 SPARE ANALOG 2

21 INTAKE AIR TEMPERATURE

22 +5VRTN2

23 BOOST/INLET PRESSURE

24 +5VRTN3

25 ACCELERATOR POSITION

26 +5VRTN1

27 EGR VACUUM PRESSURE

28 INTAKE SM S2T

29 DIAGNOSTIC REQUEST SW

30 COOLANT TEMPERATURE

31 A/T PARK SW

32 CRANKSHAFT

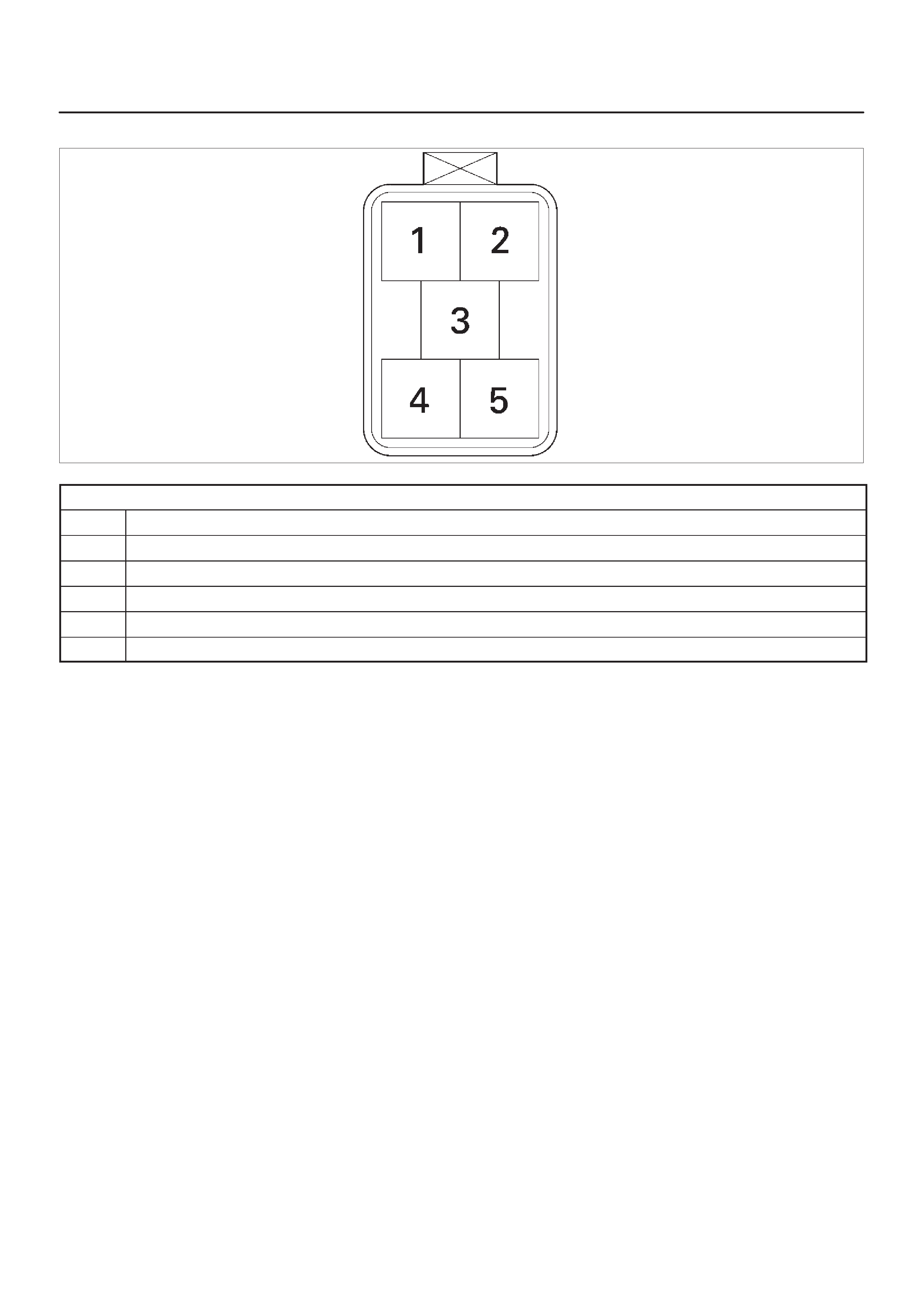

ECM Pinout Table, 5-Way Connector – J3

060RW139

J3

PIN SIGNAL

1 IGNITION

2 IGNITION

3PWR GND

4PWR GND

5INJECTOR H1

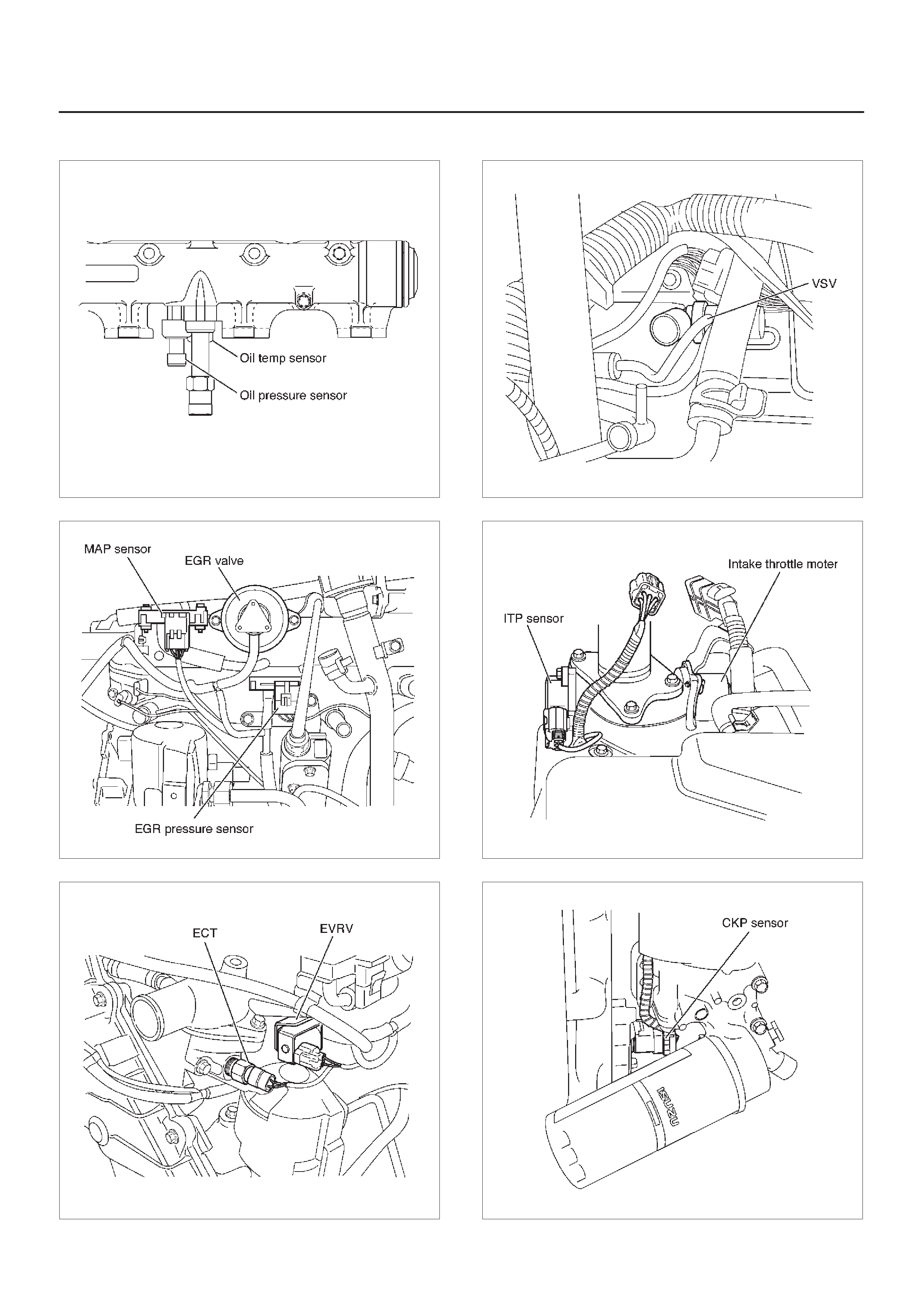

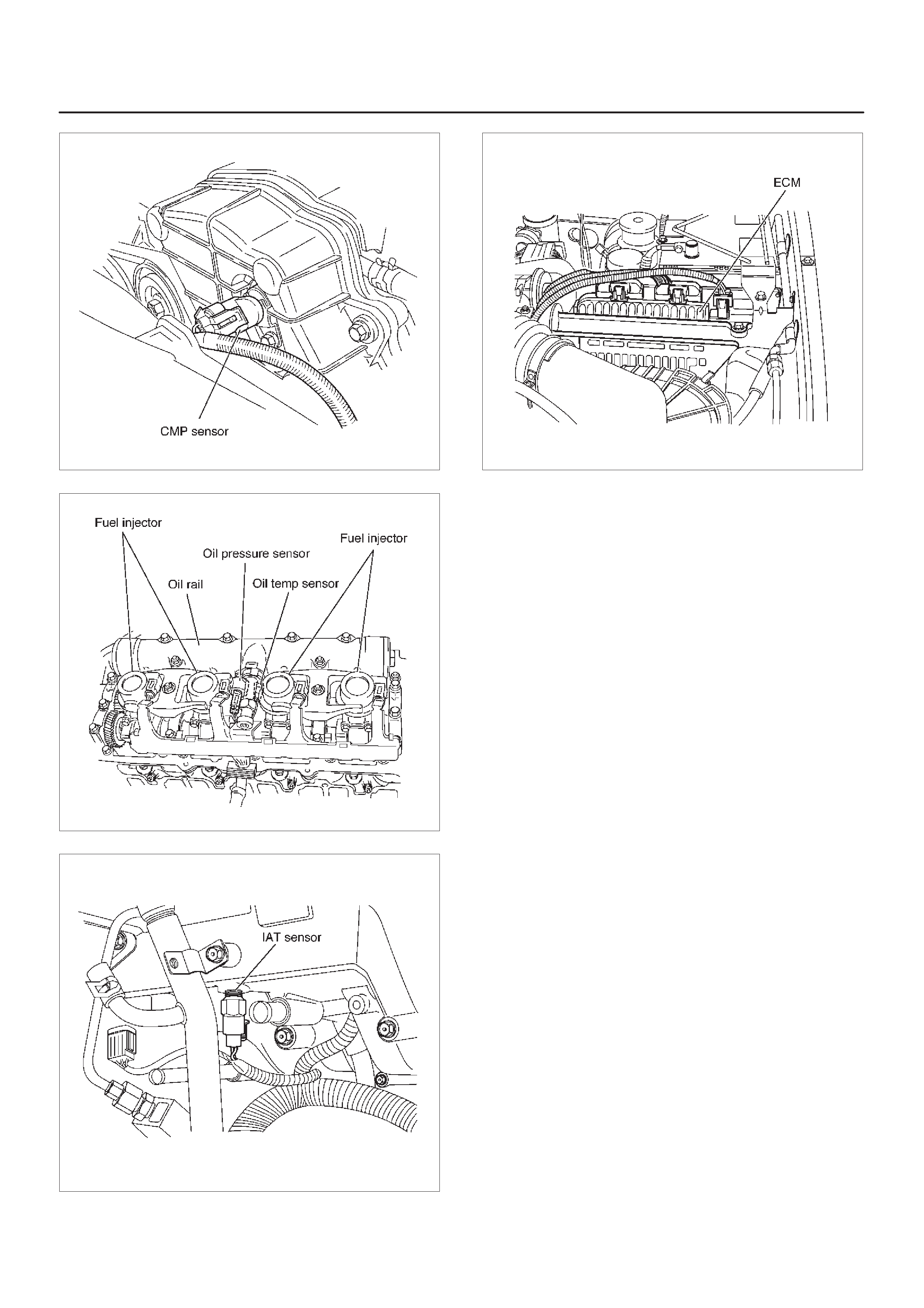

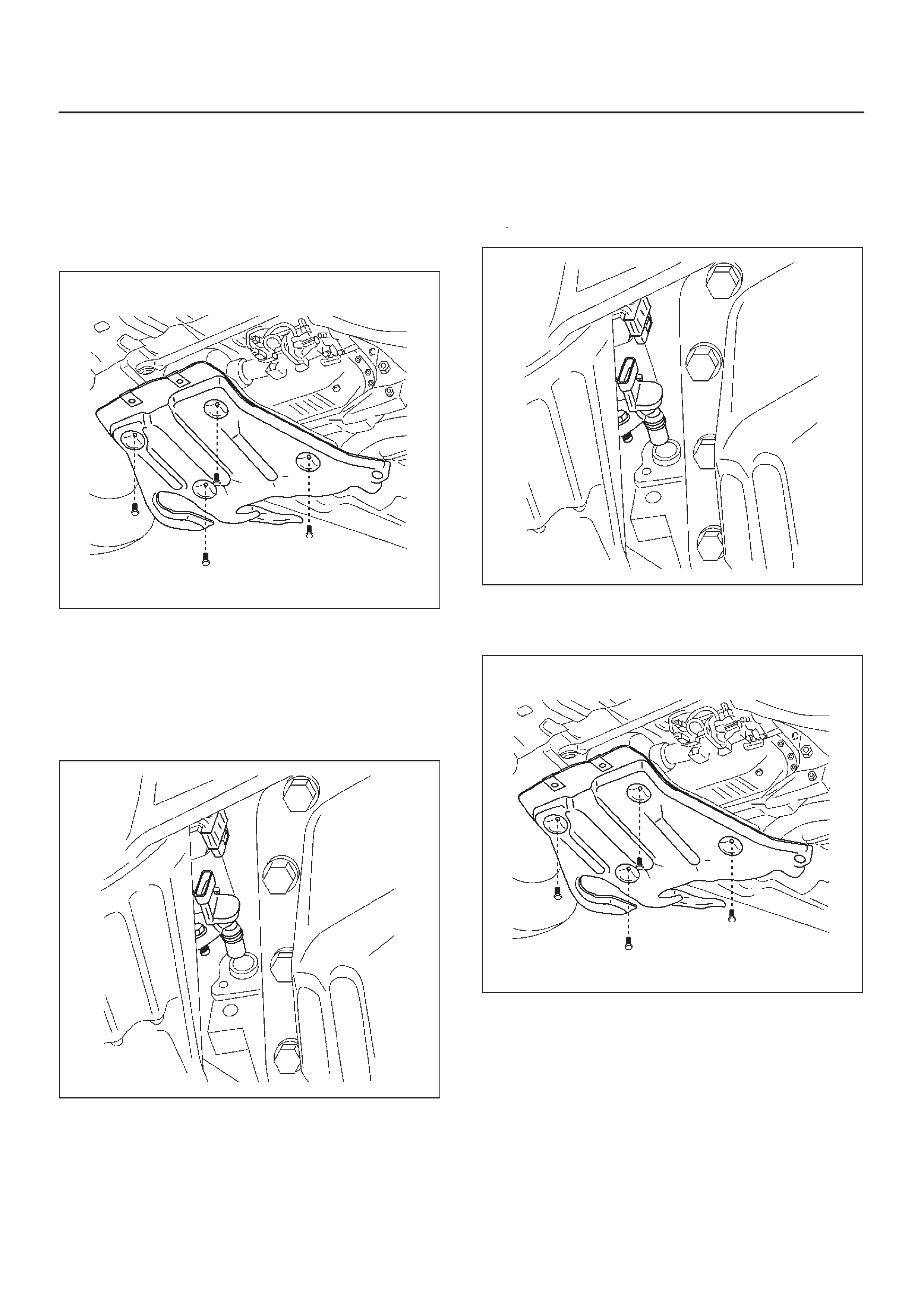

Component Locator

Engine Component Locator Table

F06RW051

Number Name Location

1AP (Accelerator Pedal Position) Sensor AP Bracket

2CKP (Crankshaft Position) Sensor Inside the right front flywheel Housing

3Oil Rail Mounted on the camshaft carrier

4Oil (Rail) Pressure Sensor Mounted on the Oil Rail

5 OT (Oil Temperature) Sensor Mounted on the Oil Rail

6Fuel Injector In the Cylinder Head Cover

7Fuel Return Orifice Inside the Cylinder Head

8 FT (Fuel Temperature) Sensor Fuel Return Adaptor

9 Intercooler On the Cylinder Head Cover

10 Intake Throttle Motor Behind the Intake Manifold

11 Intake Throttle Behind the Intake Manifold

12 2 Way Check Valve Below the Intake Manifold

13 VSV (Vacuum Switching Valve) At the left Cylinder Body

14 EGR Pressure Sensor Below the Intake Manifold

15 Fuel Filter At the left Engine Room

16 CMP (Camshaft Position) Sensor On the forward of Timing Gear Case

17 IAT (Intake Air Temperature) Sensor Below the Intake Manifold

18 ECT (Engine Coolant Temperature) Thermostat Housing

19 High Pressure Oil Pump On the back Timing Gear Case

Number Name Location

20 Rail Pressure Control Valve In the High Pressure Oil Pump

21 Fuel Pump In the High Pressure Oil Pump

22 EVR V On the Intake Manifold

23 MAP (Manifold Absolute Pressure) Sensor On the Intake Manifold

24 EGR Valve On the Intake Manifold

25 Air Cleaner At the left Engine Room

26 ECM Behind the Air Cleaner

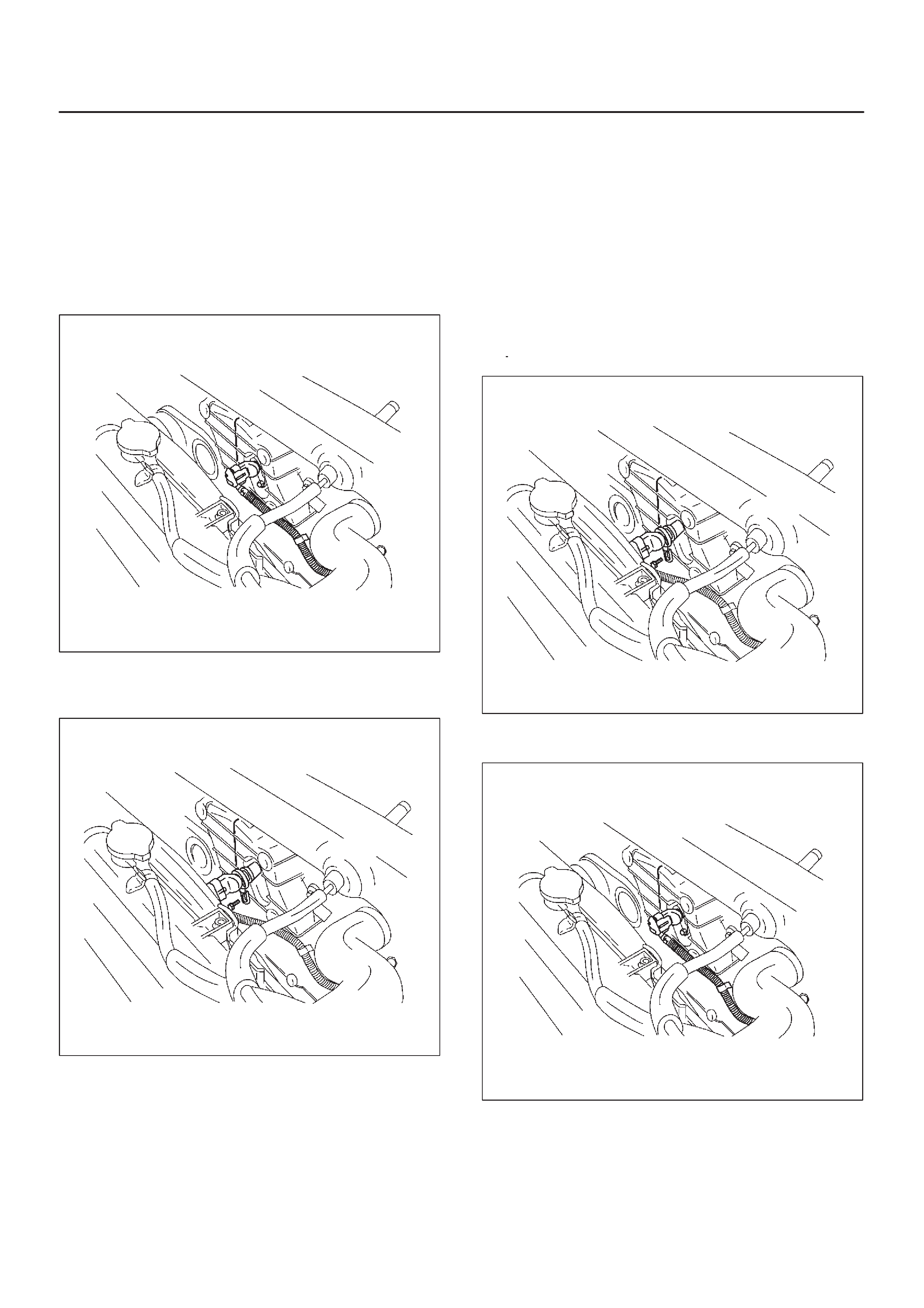

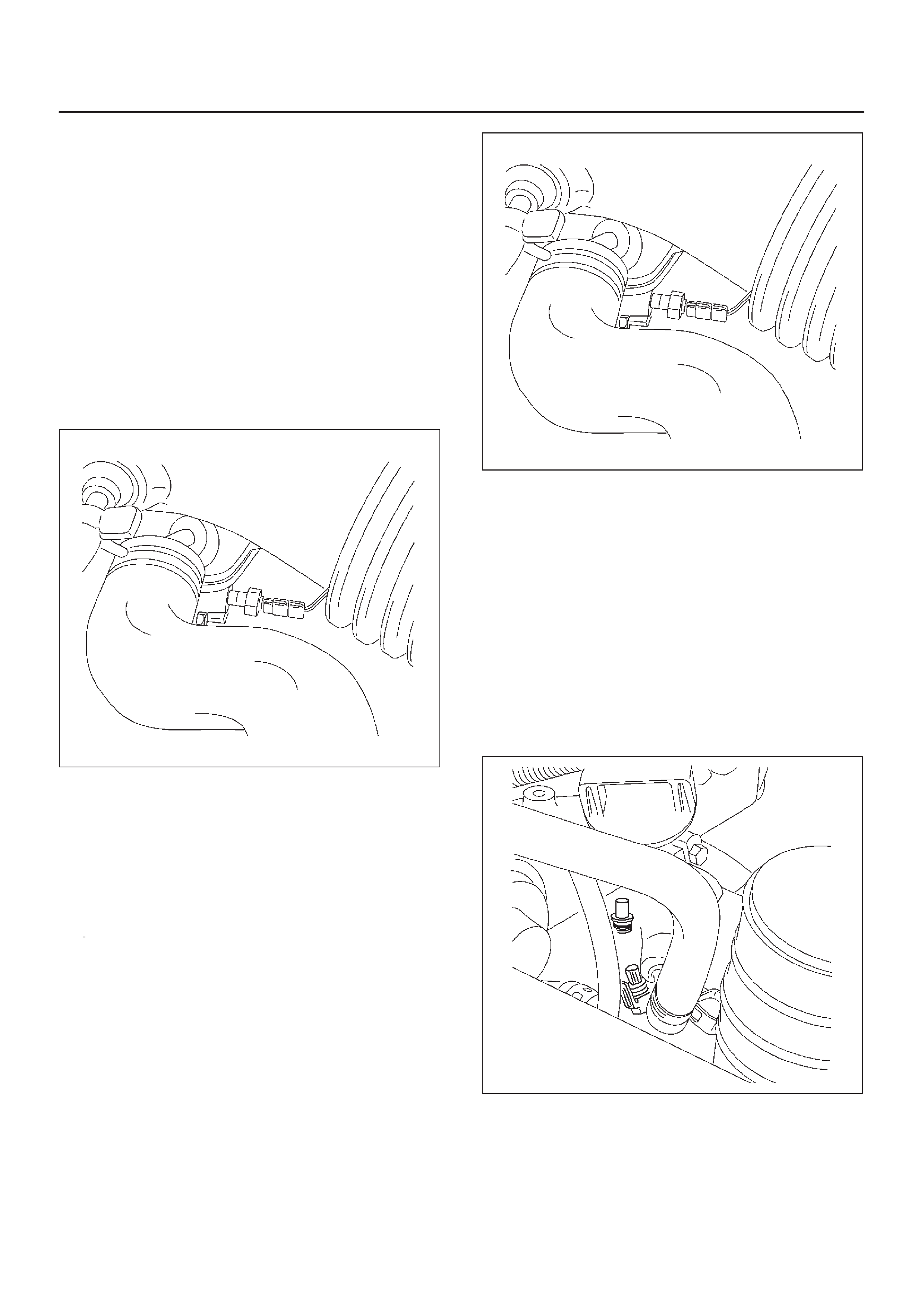

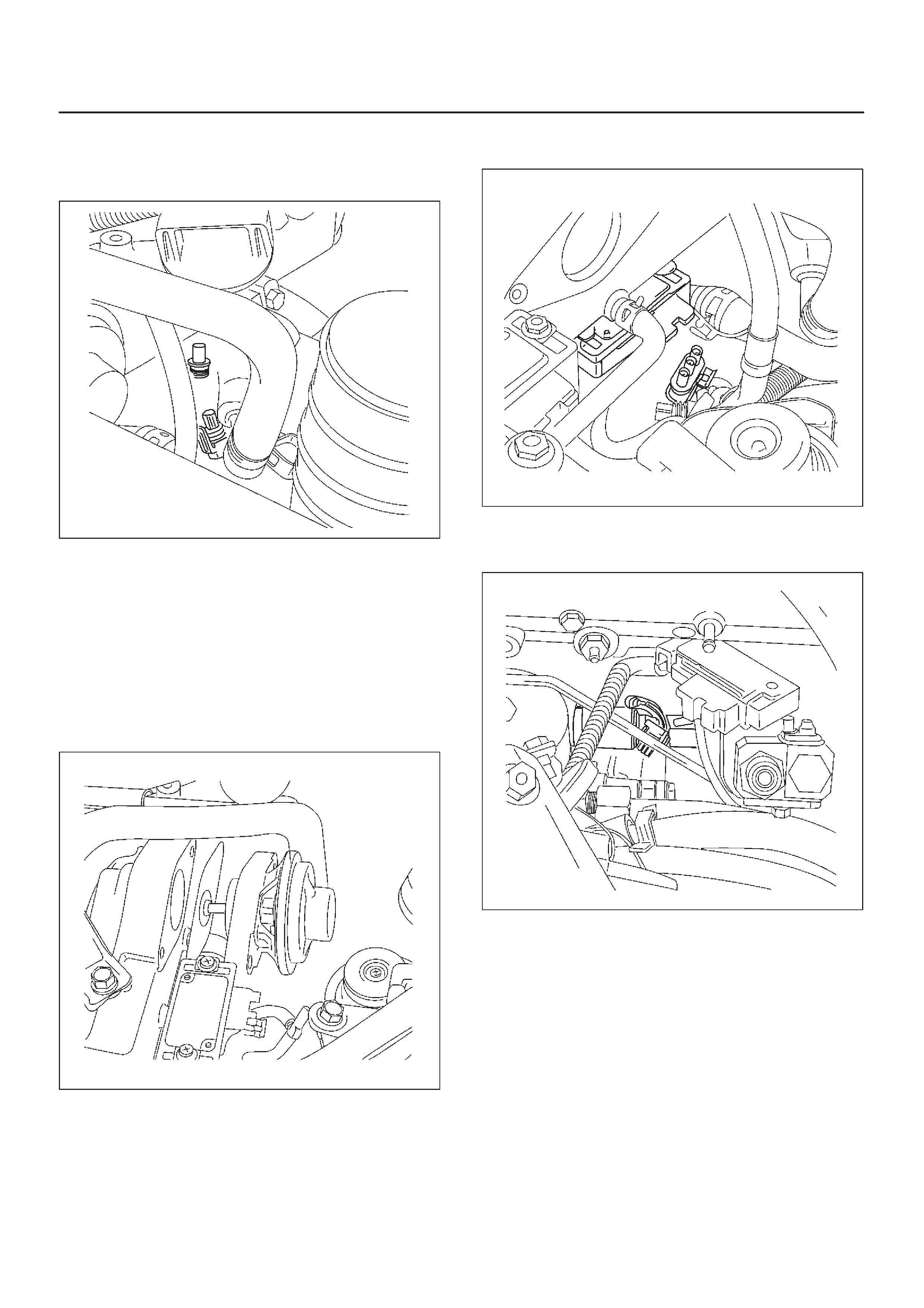

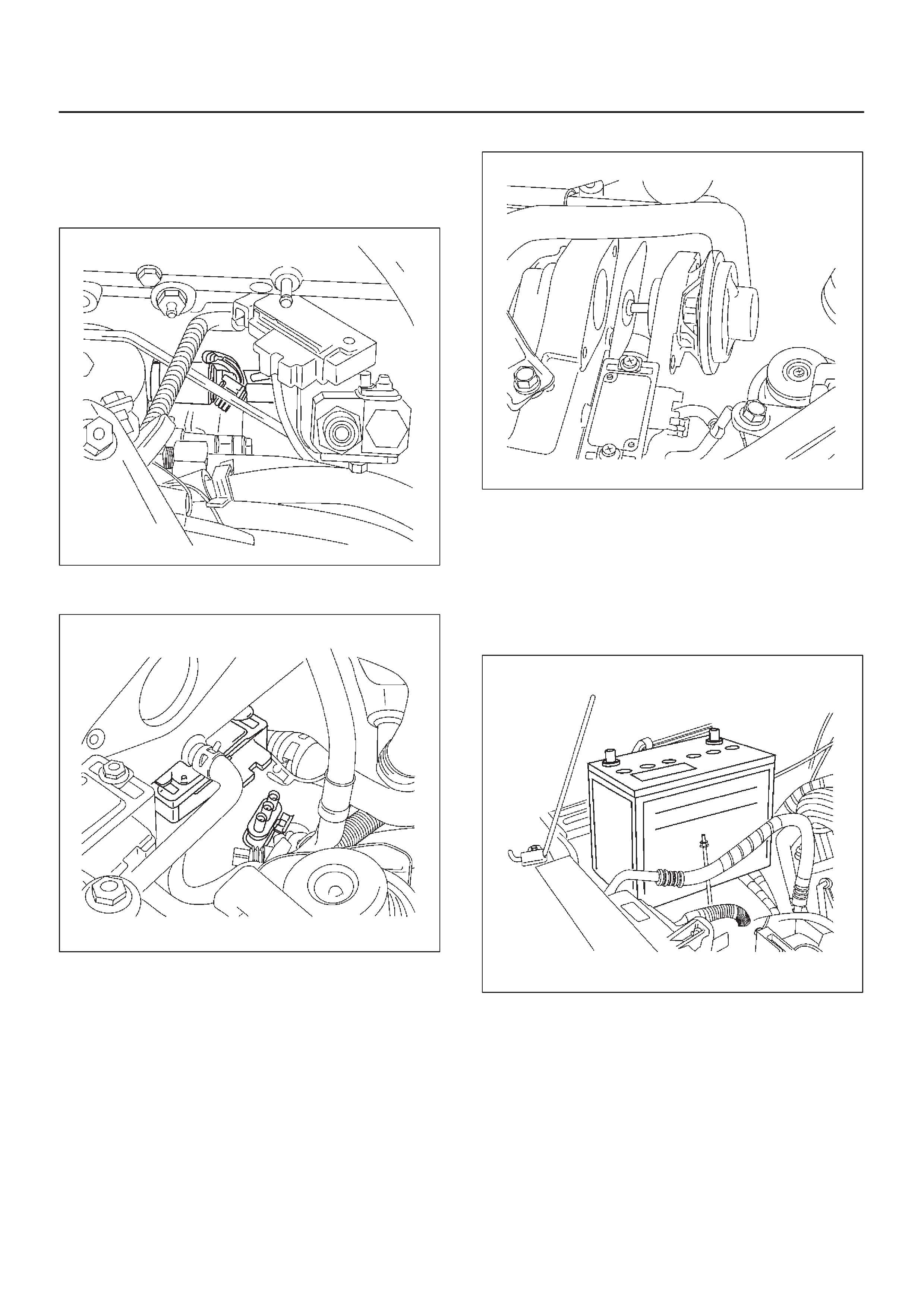

Sensors and Miscellaneous Component Locators

035RW115

035RW117

060RW179

035RW118

035RW119

035RW120

035RW121

035RW122

035RW116

035RW107

Abbreviations Charts

List of abbreviations which may be used in this section.

Abbreviations Term Abbreviations Term

A/C Air Conditioner BLK Black

A/T Automatic Transmission BLU Blue

ACC Accessory BRN Brown

AP Accel Position GRN Green

ASM Assembly GRY Gray

CKP Crank Position LT BLU Light Blue

CMP Cam Position LT GRN Light Green

DLC Data Link Connector ORN Orange

DTC Diagnosis Trouble Code PNK Pink

DVM Digital Volt Meter RED Red

ECM Engine Control Module VIO Violet

ECT Engine Coolant Temperature WHT White

EGR Exhaust Gas Recircuration YEL Yellow

EVRV Electric Vacuum Regulating Valve

EXH Exhaust

FT Fuel Temperature

IAT Intake Air Temperature

IG Ignition

ITP Intake Throttle Position

M/T Manual Transmission

MAP Manifold Absolute Pressure

MIL Mulfunction Indicator Lamp

OBD On-Board Diagnostic

OT Oil Temperature

QOS Quick on Start System

QWS Quick Warming-Up System

RP Rail Pressure

RPCV Rail Pressure Control Valve

SRS Supplemental Restraint System

ST Start

SW Switch

TEMP Temperature

TOD Torque on Demand

VSS Vehicle Speed Sensor

VSV Vacuum Switching Valve

HEUI Hydraulically Actuated Electronically Controlled Unit

Injector

I

n

j

ec

t

or

Diagnosis

Strategy-Based Diagnostics

Strategy-Based Diagnostics

The strategy-based diagnostic is a uniform approach to

repair all Electrical/Electronic (E/E) systems. The

diagnostic flow can always be used to resolve an E/E

system problem and is a starting point when repairs are

necessary. The following steps will instruct the technician

how to proceed with a diagnosis:

1.Verify the customer complaint.

DTo verify the customer complaint, the technician

should know the normal operation of the system.

2.Perform preliminary checks.

DConduct a thorough visual inspection.

DReview the service history.

DDetect unusual sounds or odors.

DGather diagnostic trouble code information to

achieve an effective repair.

3.Check bulletins and other service information.

DThis includes videos, newsletters, etc.

4.Refer to service information (manual) system

check(s).

D“System checks” contain information on a system

that may not be supported by one or more DTCs.

System checks verify proper operation of the

system. This will lead the technician in an

organized approach to diagnostics.

5.Refer to service diagnostics.

DTC Stored

Follow the designated DTC chart exactly to make an

effective repair.

No DTC

Select the symptom from the symptom tables. Follow the

diagnostic paths or suggestions to complete the repair.

You may refer to the applicable component/system check

in the system checks.

No Matching Symptom

1.Analyze the complaint.

2.Develop a plan for diagnostics.

3.Utilize the wiring diagrams and the theory of

operation.

Call technical assistance for similar cases where repair

history may be available. Combine technician knowledge

with efficient use of the available service information.

Intermittents

Conditions that are not always present are called

intermittents. To resolve intermittents, perform the

following steps:

1.Observe history DTCs, DTC modes, and freezeframe

data.

2.Evaluate the symptoms and the conditions described

by the customer.

3.Use a check sheet or other method to identify the

circuit or electrical system component.

4.Follow the suggestions for intermittent diagnosis

found in the service documentation.

Most scan tools, such as the Tech 2 and the DVM, have

data-capturing capabilities that can assist in detecting

intermittents.

No Trouble Found

This condition exists when the vehicle is found to operate

normally. The condition described by the customer may

be normal. Verify the customer complaint against another

vehicle that is operating normally. The condition may be

intermittent. Verify the complaint under the conditions

described by the customer before releasing the vehicle.

1.Re-examine the complaint.

When the complaint cannot be successfully found or

isolated, a re-evaluation is necessary. The complaint

should be re-verified and could be intermittent as

defined in

Intermittents

, or could be normal.

2.Repair and verify.

After isolating the cause, the repairs should be made.

Validate for proper operation and verify that the

symptom has been corrected. This may involve road

testing or other methods to verify that the complaint

has been resolved under the following conditions:

DConditions noted by the customer.

DIf a DTC was diagnosed, verify a repair by

duplicating conditions present when the DTC was

set as noted in the Failure Records or Freeze

Frame data.

Verifying Vehicle Repair

Verification of the vehicle repair will be more

comprehensive for vehicles with OBD system

diagnostics. Following a repair, the technician should

perform the following steps:

IMPORTANT:Follow the steps below when you verify

repairs on OBD systems. Failure to follow these steps

could result in unnecessary repairs.

1.Review and record the Failure Records and the

Freeze Frame data for the DTC which has been

diagnosed (Freeze Frame data will only be stored for

the MIL (“Check Engine” lamp) has been requested).

2.Clear the DTC(s).

3.Operate the vehicle within conditions noted in the

Failure Records and Freeze Frame data.

4.Monitor the DTC status information for the specific

DTC which has been diagnosed until the diagnostic

test associated with that DTC runs.

General Service Information

Serviceability Issues

Non-OEM Parts

All of the OBD diagnostics have been calibrated to run

with OEM parts. Accordingly , if commercially sold sensor

or switch is installed, it makes a wrong diagnosis and turn

on the MIL (“Check Engine” lamp).

Aftermarket electronics, such as cellular phones,

stereos, and anti-theft devices, may radiate EMI into the

control system if they are improperly installed. This may

cause a false sensor reading and turn on the MIL (“Check

Engine” lamp).

Poor Vehicle Maintenance

The sensitivity of OBD diagnostics will cause the MIL

(“Check Engine” lamp) to turn on if the vehicle is not

maintained properly. Restricted oil filters, fuel filters, and

crankcase deposits due to lack of oil changes or improper

oil viscosity can trigger actual vehicle faults that were not

previously monitored prior to OBD. Poor vehicle

maintenance can not be classified as a “non-vehicle

fault”, but with the sensitivity of OBD diagnostics, vehicle

maintenance schedules must be more closely followed.

Related System Faults

Many of the OBD system diagnostics will not run if the

ECM detects a fault on a related system or component.

Visual/Physical Engine Compartment

Inspection

Perform a careful visual and physical engine

compartment inspection when performing any diagnostic

procedure or diagnosing the cause of an emission test

failure. This can often lead to repairing a problem without

further steps. Use the following guidelines when

performing a visual/physical inspection:

DInspect all vacuum hoses for punches, cuts,

disconnects, and correct routing.

DInspect hoses that are difficult to see behind other

components.

DInspect all wires in the engine compartment for proper

connections, burned or chafed spots, pinched wires,

contact with sharp edges or contact with hot exhaust

manifolds or pipes.

Basic Knowledge of Tools Required

NOTE: Lack of basic knowledge of this powertrain when

performing diagnostic procedures could result in an

incorrect diagnosis or damage to powertrain

components. Do not attempt to diagnose a powertrain

problem without this basic knowledge.

A basic understanding of hand tools is necessary to effec-

tively use this section of the Service Manual.

Serial Data Communications

Class II Serial Data Communications

This vehicle utilizes the “Class II” communication system.

Each bit of information can have one of two lengths: long

or short. This allows vehicle wiring to be reduced by

transmitting and receiving multiple signals over a single

wire. The messages carried on Class II data streams are

also prioritized. If two messages attempt to establish

communications on the data line at the same time, only

the message with higher priority will continue. The device

with the lower priority message must wait.

On this vehicle the Tech 2 displays the actual values for

vehicle parameters. It will not be necessary to perform

any conversions from coded values to actual values.

On-Board Diagnostic (OBD)

On-Board Diagnostic Tests

A diagnostic test is a series of steps, the result of which is

a pass or fail reported to the diagnostic executive. When

a diagnostic test reports a pass result, the diagnostic

executive records the following data:

DThe diagnostic test has been completed since the last

ignition cycle.

DThe diagnostic test has passed during the current

ignition cycle.

DThe fault identified by the diagnostic test is not

currently active.

When a diagnostic test reports a fail result, the diagnostic

executive records the following data:

DThe diagnostic test has been completed since the last

ignition cycle.

DThe fault identified by the diagnostic test is currently

active.

DThe fault has been active during this ignition cycle.

DThe operating conditions at the time of the failure.

Comprehensive Component Monitor

Diagnostic Operation

Comprehensive component monitoring diagnostics are

required to operate engine properly.

Input Components:

Input components are monitored for circuit continuity and

out-of-range values. This includes rationality checking.

Rationality checking refers to indicating a fault when the

signal from a sensor does not seem reasonable. Accel

Position (AP) sensor that indicates high throttle position

at low engine loads or MAP voltage. Input components

may include, but are not limited to the following sensors:

DIntake Air Temperature (IAT) Sensor

DCrankshaft Position (CKP) Sensor

DIntake throttle Position (ITP) Sensor

DEngine Coolant Temperature (ECT) Sensor

DCamshaft Position (CMP) Sensor

DManifold absolute Pressure (MAP) Sensor

DAccel Position Sensor

DFuel Temp Sensor

DRail Pressure Sensor

DOil Temp Sensor

DEGR Pressure Sensor

DVehicle Speed Sensor

Output Components:

Output components are diagnosed for proper response to

control module commands. Components where

functional monitoring is not feasible will be monitored for

circuit continuity and out-of-range values if applicable.

Output components to be monitored include, but are not

limited to, the following circuit:

DEGR VSV

DEGR EVRV

DElectronic Transmission controls

DInjector

DIntake throttle

DGlow plug

DMIL control

Refer to ECM and Sensors in General Descriptions.

Passive and Active Diagnostic Tests

A passive test is a diagnostic test which simply monitors a

vehicle system or component. Conversely , an active test,

actually takes some sort of action when performing

diagnostic functions, often in response to a failed passive

test.

Intrusive Diagnostic Tests

This is any on-board test run by the Diagnostic

Management System which may have an effect on

vehicle performance or emission levels.

Warm-Up Cycle

A warm-up cycle means that engine at temperature must

reach a minimum of 70°C (160°F)

and

rise at least 22°C

(40°F) over the course of a trip.

Freeze Frame

Freeze Frame is an element of the Diagnostic

Management System which stores various vehicle

information at the moment an emissions-related fault is

stored in memory and when the MIL is commanded on.

These data can help to identify the cause of a fault. Refer

to

Storing And Erasing Freeze Fame Data

for more

detailed information.

Failure Records

Failure Records data is an enhancement of the OBD

Freeze Frame feature. Failure Records store the same

vehicle information as does Freeze Frame, but it will store

that information for any fault which is stored in on-board

memory, while Freeze Frame stores information only for

emission-related faults that command the MIL on.

Common OBD Terms

Diagnostic

When used as a noun, the word diagnostic refers to any

on-board test run by the vehicle’s Diagnostic

Management System. A diagnostic is simply a test run on

a system or component to determine if the system or

component is operating according to specification. There

are many diagnostics, shown in the following list:

DEGR

Dengine speed

Dvehicle speed

DECT

DMAP

DVSV

DIAT

DITP

DAP

DFT (Fuel Temp)

DRP (Rail Pressure)

DOT (Oil Temp)

DEGR EVRV

DIdle SW

DBrake SW

The Diagnostic Executive

The Diagnostic Executive is a unique segment of

software which is designed to coordinate and prioritize

the diagnostic procedures as well as define the protocol

for recording and displaying their results. The main

responsibilities of the Diagnostic Executive are listed as

follows:

DCommanding the MIL (“Check Engine” lamp) on and

off

DDTC logging and clearing

DFreeze Frame data for the first emission related DTC

recorded

DCurrent status information on each diagnostic

Diagnostic Information

The diagnostic charts and functional checks are designed

to locate a faulty circuit or component through a process

of logical decisions. The charts are prepared with the

requirement that the vehicle functioned correctly at the

time of assembly and that there are not multiple faults

present.

There is a continuous self-diagnosis on certain control

functions. This diagnostic capability is complemented by

the diagnostic procedures contained in this manual. The

language of communicating the source of the malfunction

is a system of diagnostic trouble codes. When a

malfunction is detected by the control module, a

diagnostic trouble code is set and the Malfunction

Indicator Lamp (MIL) (“Check Engine” lamp) is

illuminated.

Malfunction Indicator Lamp (MIL)

The Malfunction Indicator Lamp (MIL) looks the same as

the MIL you are already familiar with “Check Engine”

lamp.

Basically, the MIL is turned on when the ECM detects a

DTC that will impact the vehicle emissions.

DWhen the MIL remains “ON” while the engine is

running, or when a malfunction is suspected due to a

driveability or emissions problem, a Powertrain

On-Board Diagnostic (OBD) System Check must be

performed. The procedures for these checks are

given in On-Board Diagnostic (OBD) System Check.

These checks will expose faults which may not be

detected if other diagnostics are performed first.

DTC Types

Characteristic of Code

DNon-Emissions related

DDose not request illumination of any lamp

DStores a History DTC on the

first trip

with a fail

DStores Fail Record when test fails

DUpdates the Fail Record each time the diagnostic test

fails

Storing and Erasing Freeze Frame Data and Failure

Records

The data captured is called Freeze Frame data. The

Freeze Frame data is very similar to a single record of

operating conditions. Whenever the MIL is illuminated,

the corresponding record of operating conditions is

recorded to the Freeze Frame buffer.

Data from these faults take precedence over data

associated with any other fault. The Freeze Frame data

will not be erased unless the associated history DTC is

cleared.

Each time a diagnostic test reports a failure, the current

engine operating conditions are recorded in the

Failure

Records

buffer. A subsequent failure will update the

recorded operating conditions. The following operating

conditions for the diagnostic test which failed

typically

include the following parameters:

DEngine Speed

DEngine Load

DEngine Coolant Temperature

DVehicle Speed

DIntake Throttle Position

DMAP

DInjector Base Pulse Width

DLoop Status

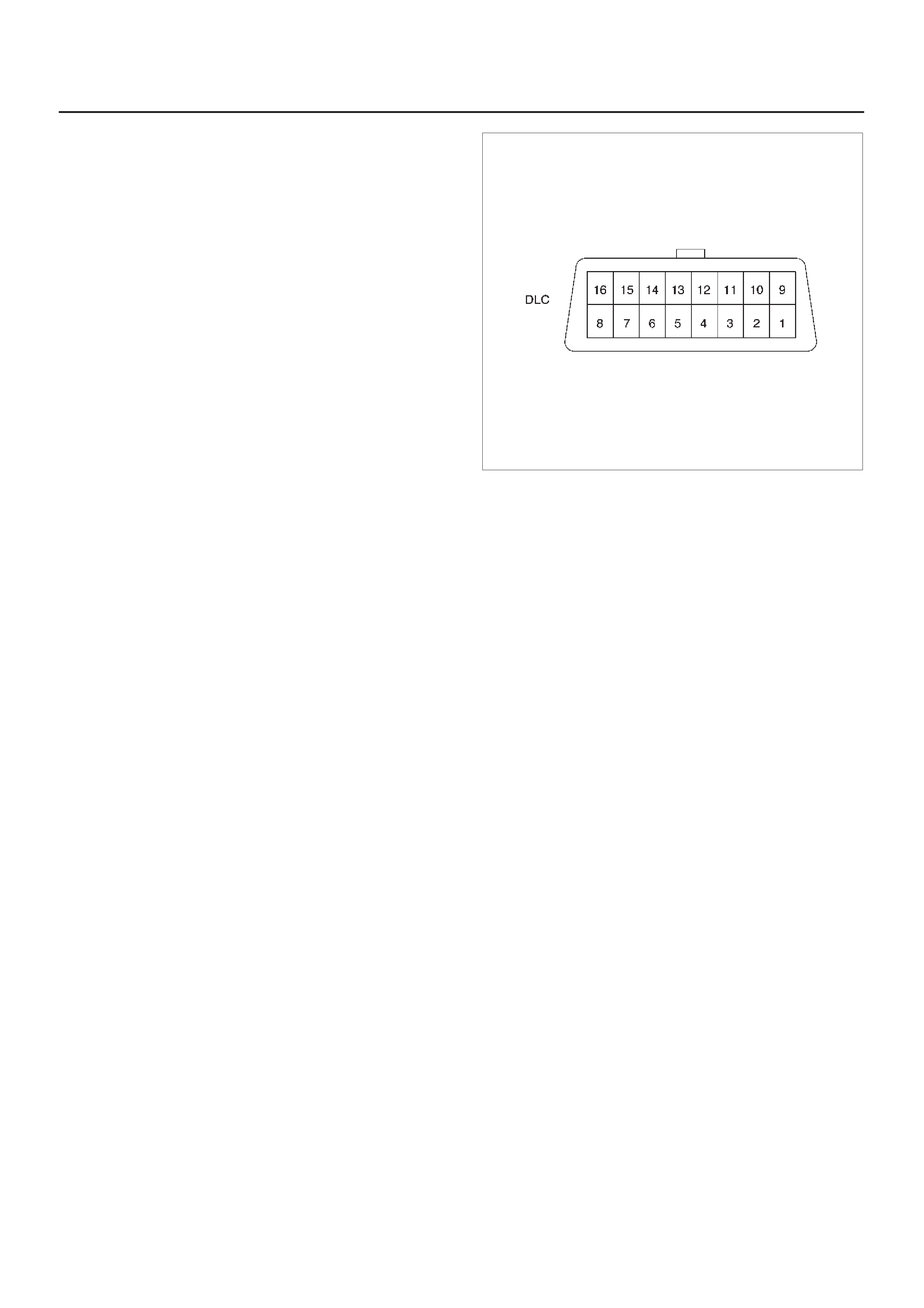

Data Link Connector (DLC)

The provision for communication with the contorl module

is the Data Link Connector (DLC). It is located at behind

the lower front instrument panel. The DLC is used to

connect to a Tech 2. Some common uses of the Tech 2

are listed below:

DIdentifying stored Diagnostic T rouble Codes (DTCs).

DClearing DTCs.

DPerforming out put control tests.

DReading serial data.

060RW046

Verifying Vehicle Repair

Verification of vehicle repair will be more comprehensive

for vehicles with OBD system diagnostic. Following a

repair , the technician should perform the following steps:

1.Review and record the Fail Records and/or Freeze

Frame data for the DTC which has been diagnosed.

2.Clear DTC(s).

3.Operate the vehicle within conditions noted in the Fail

Records and/or Freeze Frame data.

4.Monitor the DTC status information for the specific

DTC which has been diagnosed until the diagnostic

test associated with that DTC runs.

Following these steps are very important in verifying

repairs on OBD systems. Failure to follow these steps

could result in unnecessary repairs.

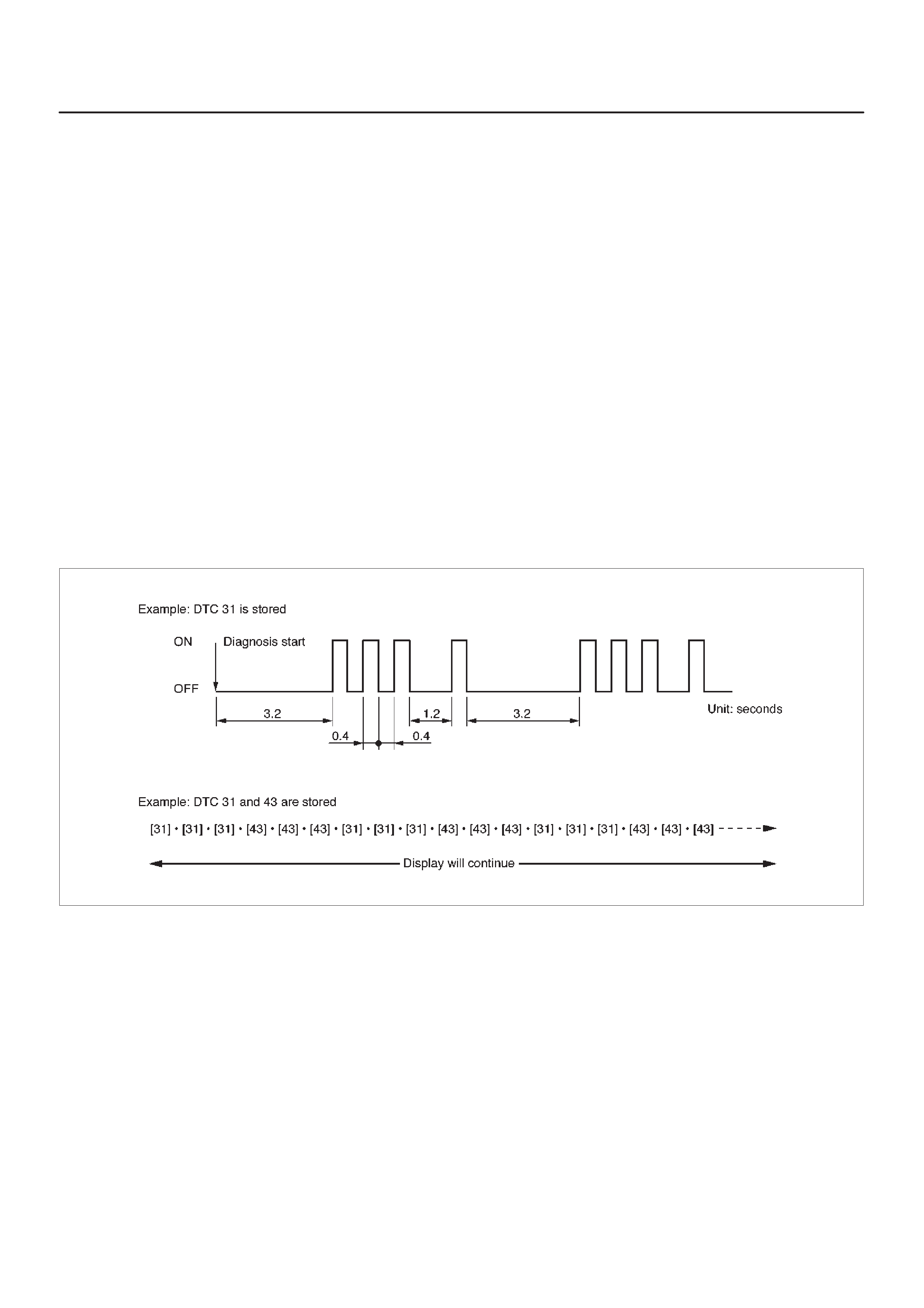

Reading Flash Diagnostic Trouble Codes

The provision for communicating with the Engine Control

Module (ECM) is the Data Link Connector (DLC). The

DLC is located in the front console box. It is used in the

assembly plant to receive information in checking that the

engine is operating properly before it leaves the plant.

The diagnostic trouble code(s) (DTCs) stored in the

ECM’s memory can be read either through a hand-held

diagnostic scanner plugged into the DLC or by counting

the number of flashes of the “Check Engine” Malfunction

Indicator Lamp (MIL) when the diagnostic test terminal of

the DLC is grounded. The DLC terminal “6” (diagnostic

request) is pulled “Low” (grounded) by jumpering to DLC

terminal “4”, which is a ground wire.

This will signal the ECM that you want to “flash” DTC(s), if

any are present. Once terminals “4” and “6” have been

connected, the ignition switch must be moved to the “ON”

position, with the engine not running.

The “Check Engine”MIL will indicate a DTC three times if

a DTC is present. If more than one DTC has been stored

in the ECM’s memory, the DTC(s) will be output from the

lowest to the highest, with each DTC being displayed

three times.

The DTC display will continue as long as the DLC is

shorted.

Reading Diagnostic Trouble Codes Using

a TECH 2

The procedure for reading diagnostic trouble code(s) is to

used a diagnostic Tech 2. When reading DTC(s), follow

instructions supplied by Tech 2 manufacturer.

For the 1998 model year, Isuzu dealer service

departments will continue to use Tech 2.

Clearing Diagnostic Trouble Codes

IMPORTANT:Do not clear DTCs unless directed to do

so by the service information provided for each diagnostic

procedure. When DTCs are cleared, the Freeze Frame

and Failure Record data which may help diagnose an

intermittent fault will also be erased from memory.

If the fault that caused the DTC to be stored into memory

has been corrected, the Diagnostic Executive will begin to

count the “warm-up” cycles with no further faults

detected, the DTC will automatically be cleared from the

ECM memory.

To clear Diagnostic T rouble Codes (DTCs), use the Tech

2 “clear DTCs” or “clear information” function. When

clearing DTCs follow instructions supplied by the Tech 2

manufacturer.

When a Tech 2 is not available, DTCs can also be cleared

by disconnecting

one

of the following sources for at least

thirty (30) seconds.

NOTE: To prevent system damage, the ignition key must

be “OFF” when disconnecting or reconnecting battery

power.

DThe power source to the control module. Examples:

fuse, pigtail at battery ECM connectors etc.

DThe negative battery cable. (Disconnecting the

negative battery cable will result in the loss of other

on-board memory data, such as preset radio tuning).

060RW169

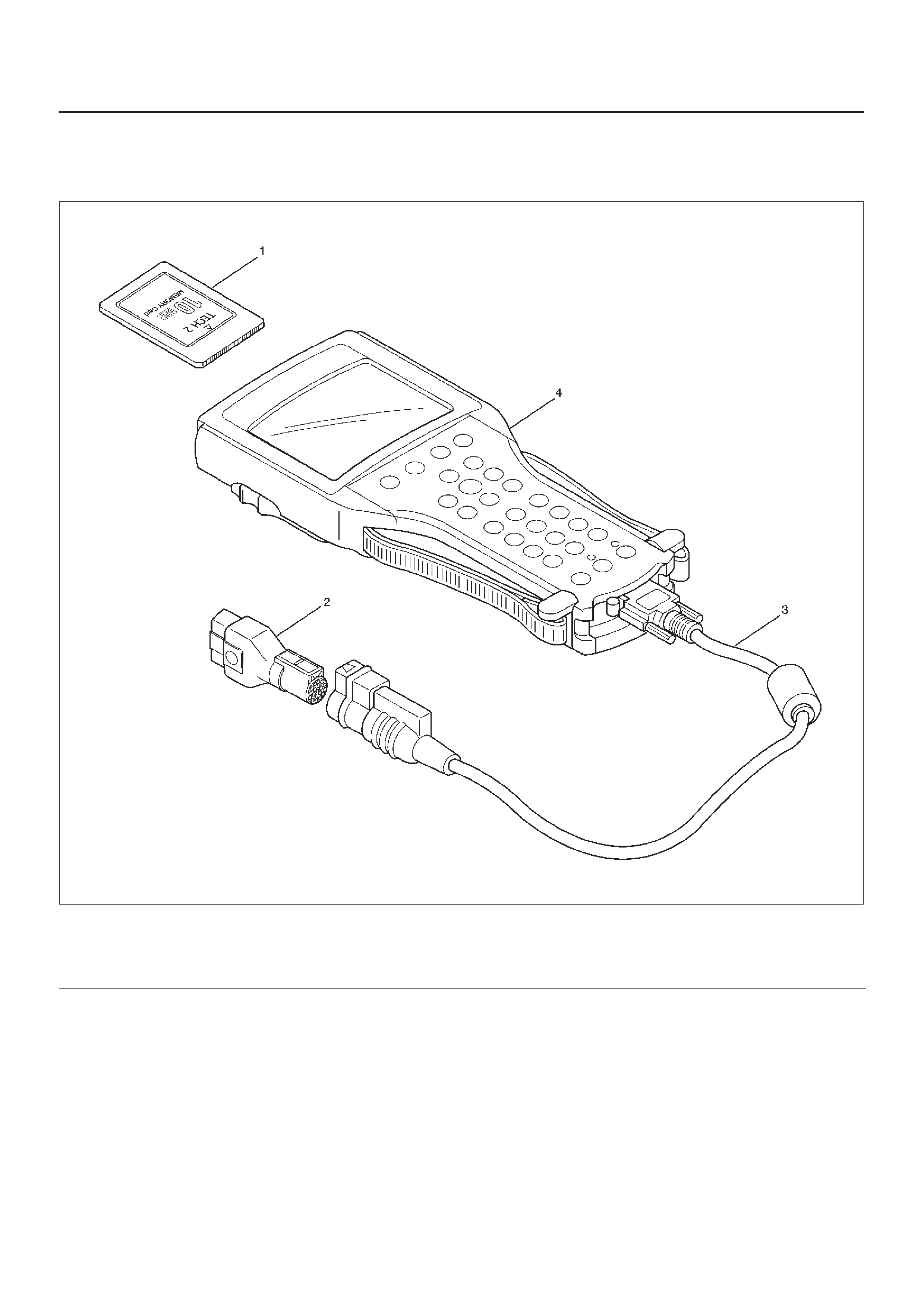

Tech 2 Scan Tool

From 98 MY, Isuzu dealer service departments are

recommended to use Tech 2. Please refer to Tech 2 user

guide.

901RW257

Legend

(1) PCMCIA Card

(2) SAE 16/19 Adaptor

(3) DLC Cable

(4) Tech–2

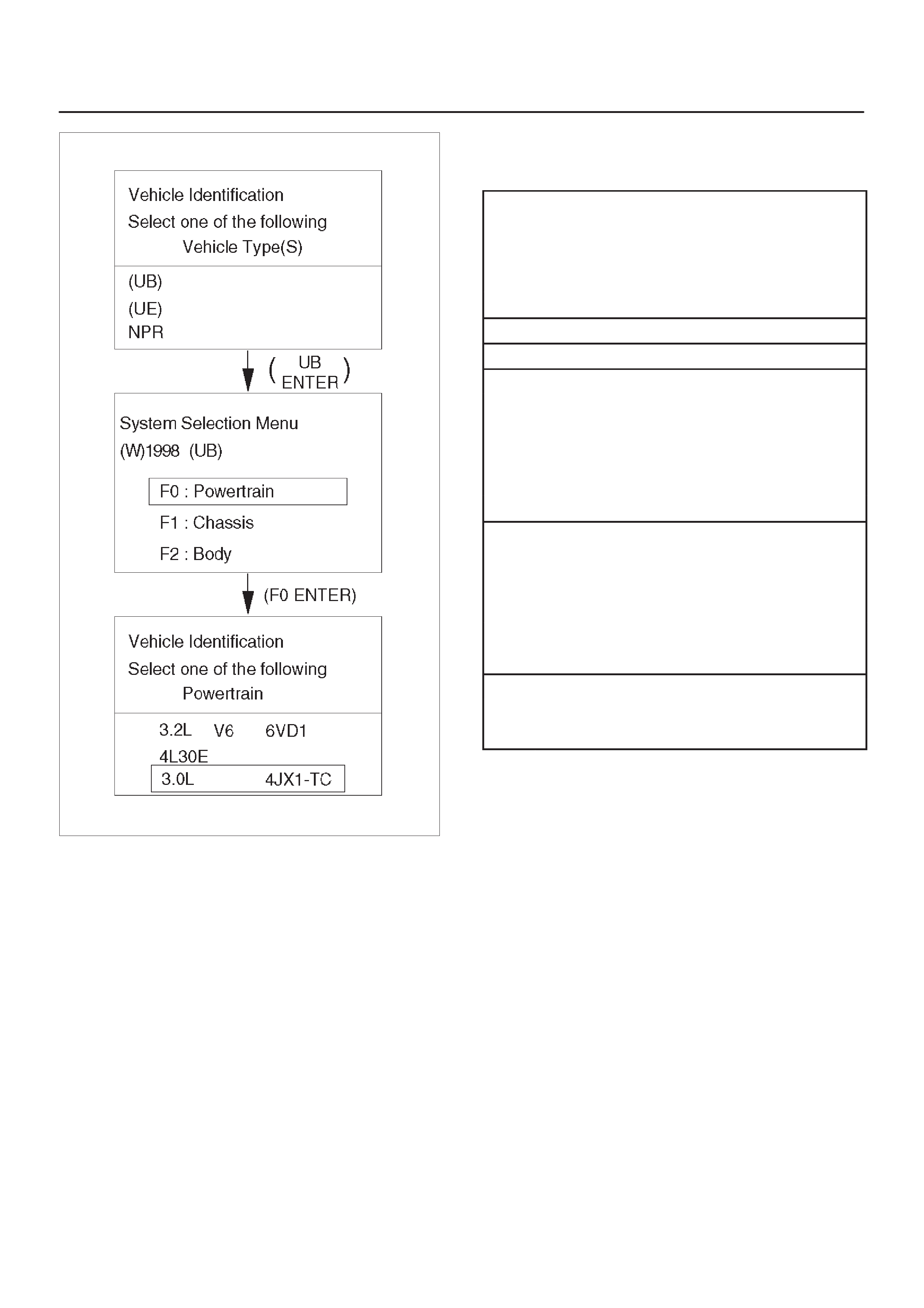

Getting Started

DBefore operating the Isuzu PCMCIA card with the

Tech 2, the following steps must be performed:

1.The Isuzu 98 System PCMCIA card (1) inserts into

the Tech 2 (5).

2.Connect the SAE 16/19 adapter (3) to the DLC cable

(4).

3.Connect the DLC cable to the Tech 2 (5)

4.Make sure the vehicle ignition is off.

5.Connect the Tech 2 SAE 16/19 adapter to the vehicle

DLC.

6.The vehicle ignition turns on.

7.Verify the Tech 2 power up display.

012RW105

NOTE: The RS232 Loop back connector is only to use for

diagnosis of Tech 2 and refer to user guide of the Tech 2.

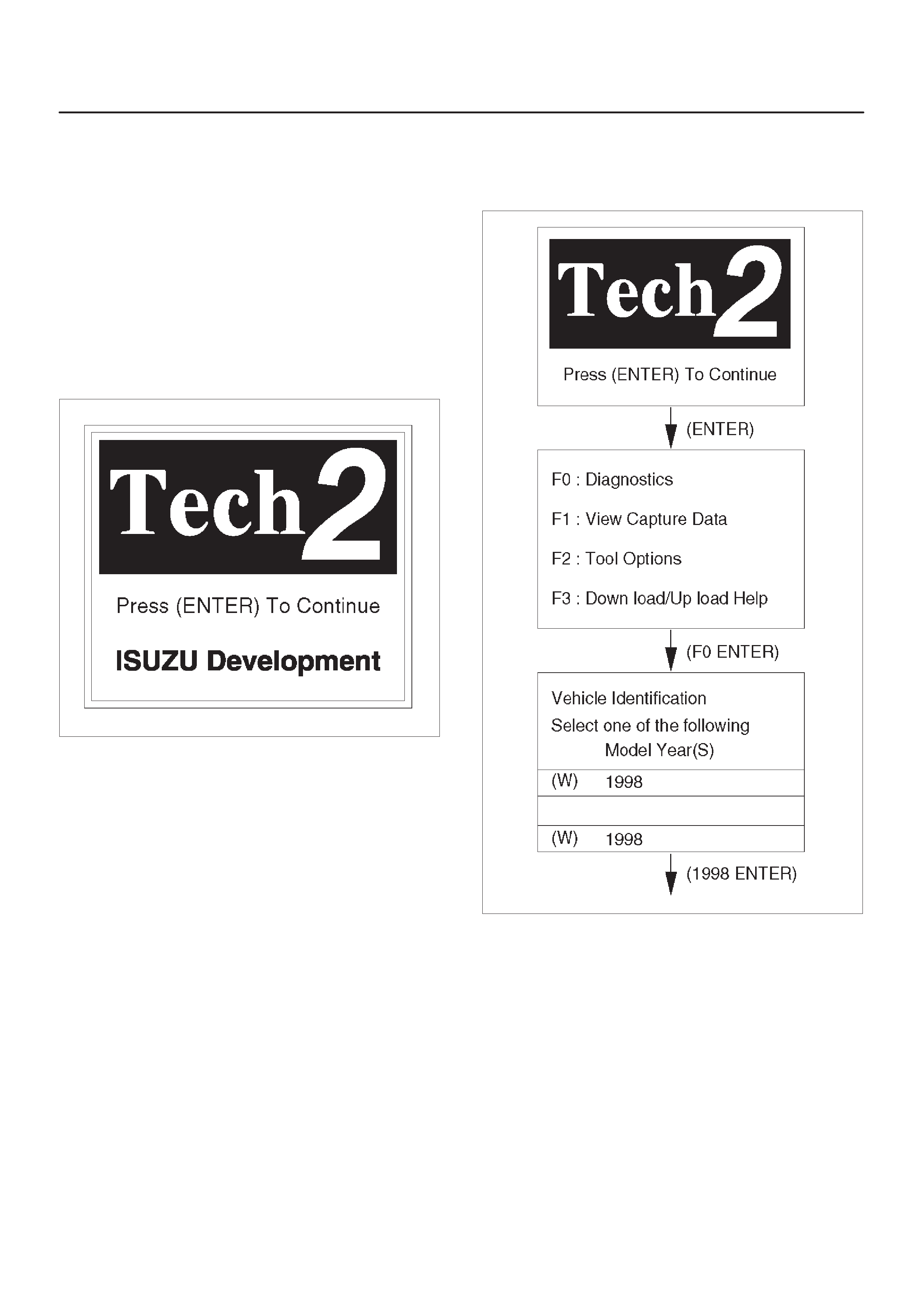

Operating Procedure

The power up screen is displayed when you power up the

tester with the Isuzu systems PCMCIA card. Follow the

operating procedure below.

060RW014

060RW120

Menu

DThe following table shows, which functions are used

the available equipment versions.

F0: Diagnostic Trouble Codes

F0: Read DTC Info Ordered By Priority

F1: Read DTC Info As Stored By ECU

F2: Clear DTC Information

F3: Freeze Frame / Failure Records

F1: Data Display

F2: Snapshot

F3: Actuator Tests

F0: Checklight

F1: Glow Time Lamp

F2: EGR Switching Valve

F3: Exhaust Switching Valve 1

F4: Exhaust Switching Valve 2

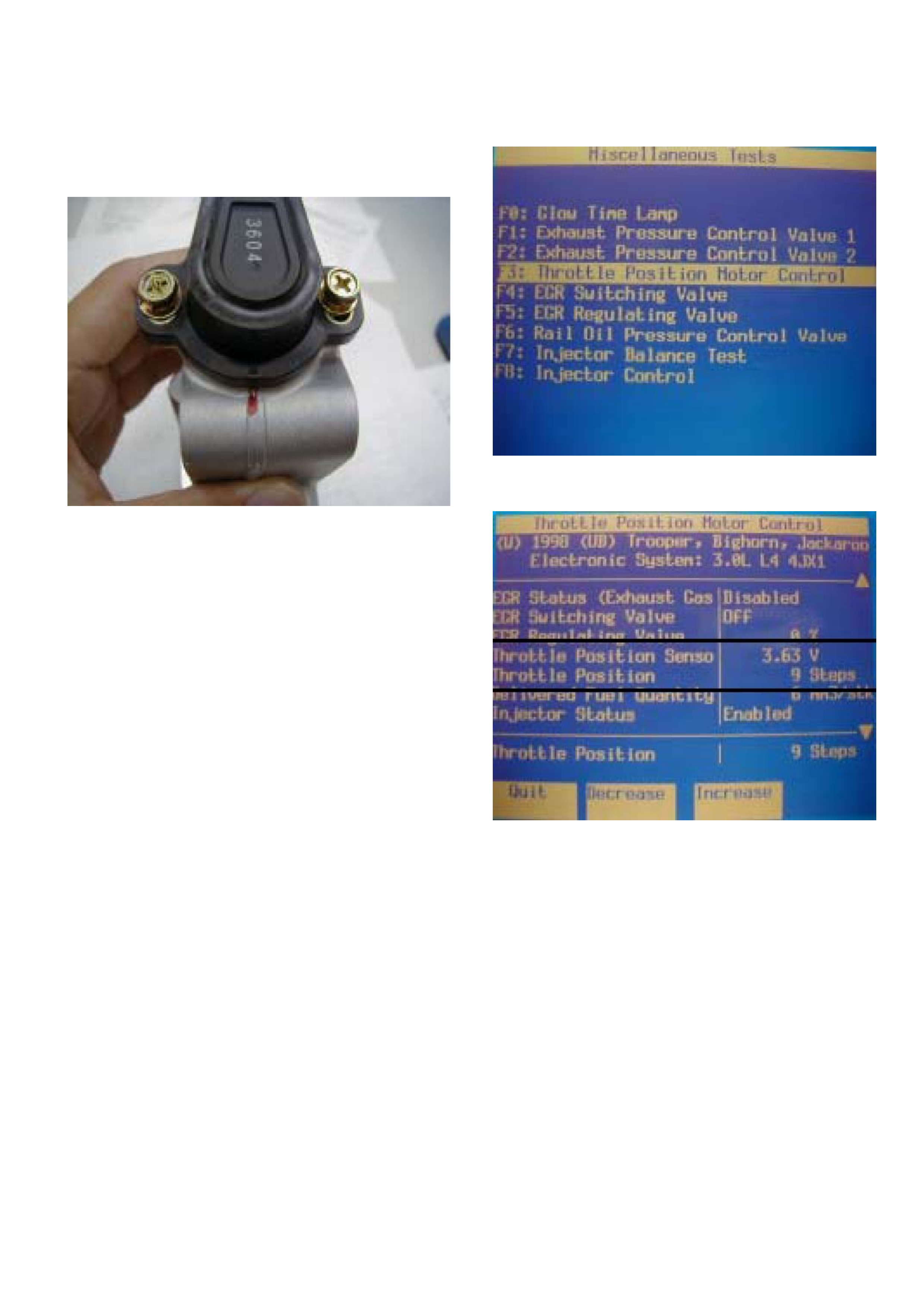

F4: Miscellaneous Tests

F0: Throttle Motor Control

F1: Rail Pressure Control

F2: EGR Regulating Valve Control

F3: Rail Pressure Control Valve

F4: Injector Balance Test

F5: Programming

F0: Injector Calibration

(F1: Rail Pressure Calibration)

DTC Modes

There are three options available in the Tech 2 DTC mode

to display the enhanced information available. A

description of the new modes, DTC Info, follows. After

selecting DTC, the following menu appears:

DDTC Info

DClear Info

DRead DTC Info Ordered By Priority

The following is a brief description of each of the sub

menus in DTC Info. The order in which they appear here is

alphabetical and not necessarily the way they will appear

on the Tech 2.

DTC Information Mode

Use the DTC info mode to search for a specific type of

stored DTC information.The service manual may instruct

the technician to test for DTCs in a certain manner.

Always follow published service procedures.

Fail This Ignition

This selection will display all DTCs that have failed during

the present ignition cycle.

History

This selection will display only DTCs that are stored in the

ECM’s history memory. It will not display Type B DTCs

that have not requested the MIL (“Check Engine” lamp). It

will display all type A and B DTCs that have requested the

MIL and have failed within the last 40 warm-up cycles. In

addition, it will display all type C and type D DTCs that

have failed within the last 40 warm-up cycles.

MIL SVC or Message Requested

This selection will display only DTCs that are requesting

the MIL. Type C and type D DTCs cannot be displayed

using this option. This selection will report type B DTCs

only after the MIL has been requested.

Test Failed Since Code Cleared

This selection will display all active and history DTCs that

have reported a test failure since the last time DTCs were

cleared.

Injector Test

This test is conducted to make it sure that appropriate

electric signals are being sent to injectors Nos. 1 – 4.

Tech–2 must be used for this test.

Test Procedure:

1.Connect Tech–2 to the vehicle DLC.

2.Set Ignition Switch to the “ON” position.

3.Select Control Test.

4.Select Injector Test.

5.Send instructions to each injector(Switch on), making

sure of injector working noise.

NOTE:If injector working noise (Clink) can hardly be

confirmed, remove the engine head cover noise

insulation.

Refer to Section 6A.

6.In the injector whose working noise has been

confirmed, its electric circuit can be regarded as

normal.

As for the injector whose working noise has not been

confirmed, its electric circuit or the injector proper is

faulty.

EGR Valve Test

This test is conducted to check EGR valve for its working.

This test needs Tech–2.

Test Procedure

1.Connect Tech–2 to vehicle DLC.

2.Switch on the engine.

3.Select “DIAGNOSIS” from the main menu.

4.Select Miscellaneous Test.

5.Select EGR Valve.

6.Instruct EGR Valve to check a data list.

7.If change in the data list shows a normal valve, the

working of EGR Valve can be judged to be normal.

Rail Pressure Control Valve Test

This test is conducted to check RPC valve for its working.

This test needs Tech–2.

Test Procedure

1.Connect Tech–2 to vehicle DLC.

2.Switch on the engine.

3.Select “DIAGNOSIS” from the main menu.

4.Select Miscellaneous Test.

5.Select Rail Pressure Control Valve.

6.Instruct RPC Valve to check a data list.

7.If change in the data list shows a normal valve, the

working of RPC Valve can be judged to be normal.

Injector Balance Test

This test is conducted to make it sure that appropriate

electric signals are being sent to injectors Nos. 1-4, when

the engine is idling.

This test needs Tech–2.

Test Procedure

1.Connect Tech–2 to vehicle DLC.

2.The engine is running at idling condition.

3.Select “DIAGNOSIS” from the main menu.

4.Select Miscellaneous Test.

5.Select the injector Balance Test.

6.Send instructions to each injector(Switch On),

making sure change of the engine vibration.

7.In the injector whose change of the vibration has been

confirmed, it’s electric circuit can be regarded as

normal.

Data Programming in Case of ECM Change

When replacing ECM, it is necessary to confirm and

record the group sign of injector beforehand. For this

confirmation.

Techline

Tech–2 must be used. After ECM change, the recorded

group sign should be programmed. Oil pressure sensor

data also should be programmed.

DGroup Sign Confirmation Procedure

1 Connect Tech–2 to vehicle DLC.

2 Turn Ignition Switch to the “ON” position.

3 Select “DIAGNOSIS” from the main menu.

4 Select programming.

5 Select Read/store Trim Data.

6 Confirm and record the group sign of injector.

DECM Change

DProgramming Procedure for Injector Group Sign

1 Connect Tech–2 to vehicle DLC.

2 Turn Ignition Switch to the “ON” position.

3 Select “DIAGNOSIS” from the main menu.

4 Select programming.

5 Select ECM change.

6 Select cylinder.

7 Program Injector Group Sign.

8 Confirm the completion of Injector programming.

DProgramming Procedure for Oil Pressure Sensor

1 Connect Tech–2 to vehicle DLC.

2 Turn Ignition Switch to the “ON” position.

3 Select “DIAGNOSIS” from the main menu.

4 Select programming.

Rail Pressure Sensor Programming

Rail pressure sensor replacement must be programmed.

This programming needs Tech–2.

Programing Procedure

1.Connect Tech–2 to vehicle DLC.

2.Turn Ignition Switch to the “ON” position.

3.Select “DIAGNOSIS” from the main menu.

4.Select Programming.

5.Select Oil Pressure Sensor change.

6.Execute Oil Pressure Sensor Program.

7.Confirm the completion of Oil Pressure Sensor

Program.

Injector Group Sign Programming (Injector

Change)

In case of Injector change, injector group sign must be

programmed.

This programming needs Tech–2.

Programing Procedure

1.Connect Tech–2 to vehicle DLC.

2.Turn Ignition Switch to the “ON” position.

3.Select “DIAGNOSIS” from the main menu.

4.Select Programming.

5.Select Injector change.

6.Select the cylinder changed.

7.Appoint and select Injector Group Sign.

8.Confirm the completion of Injector programming.

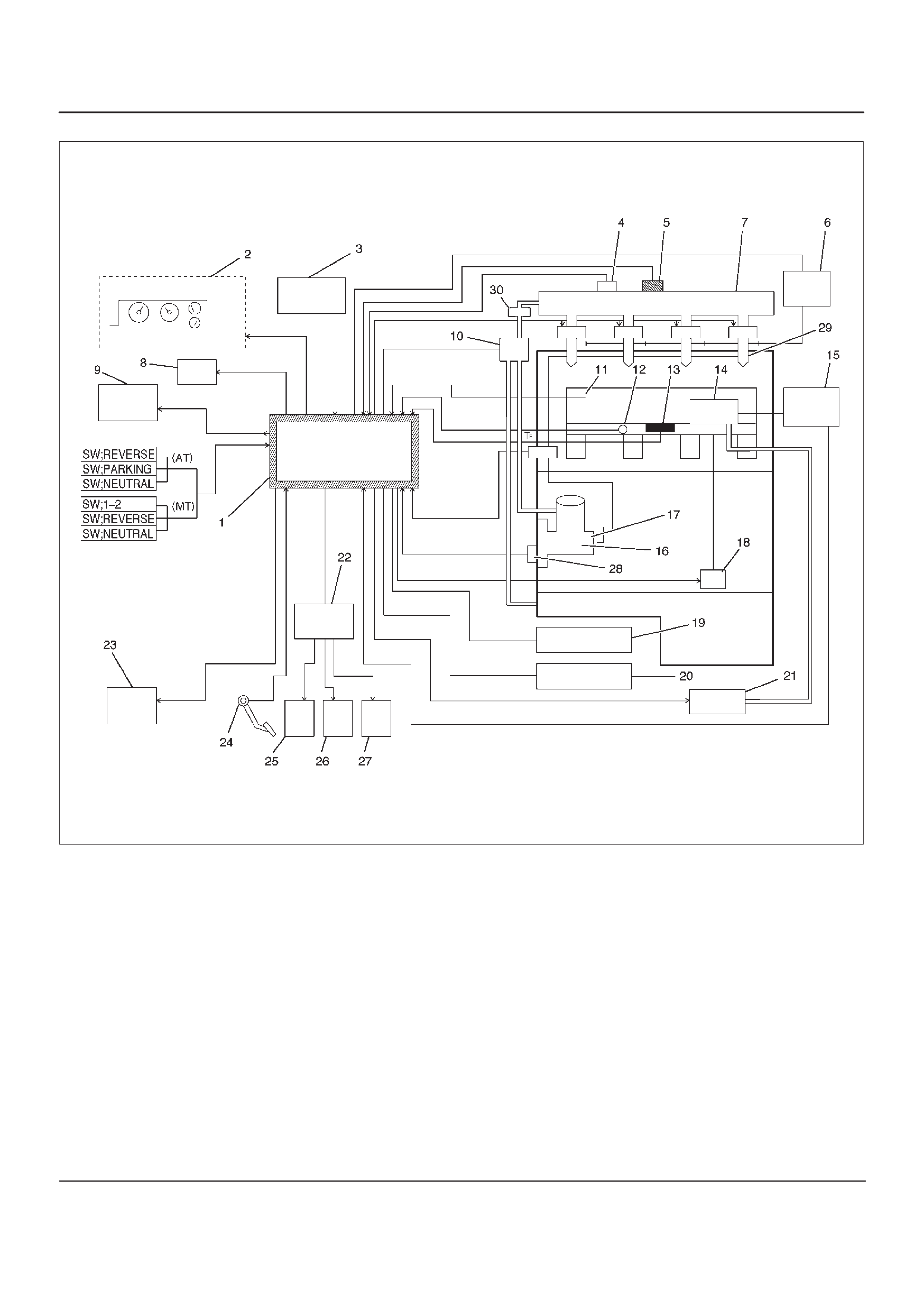

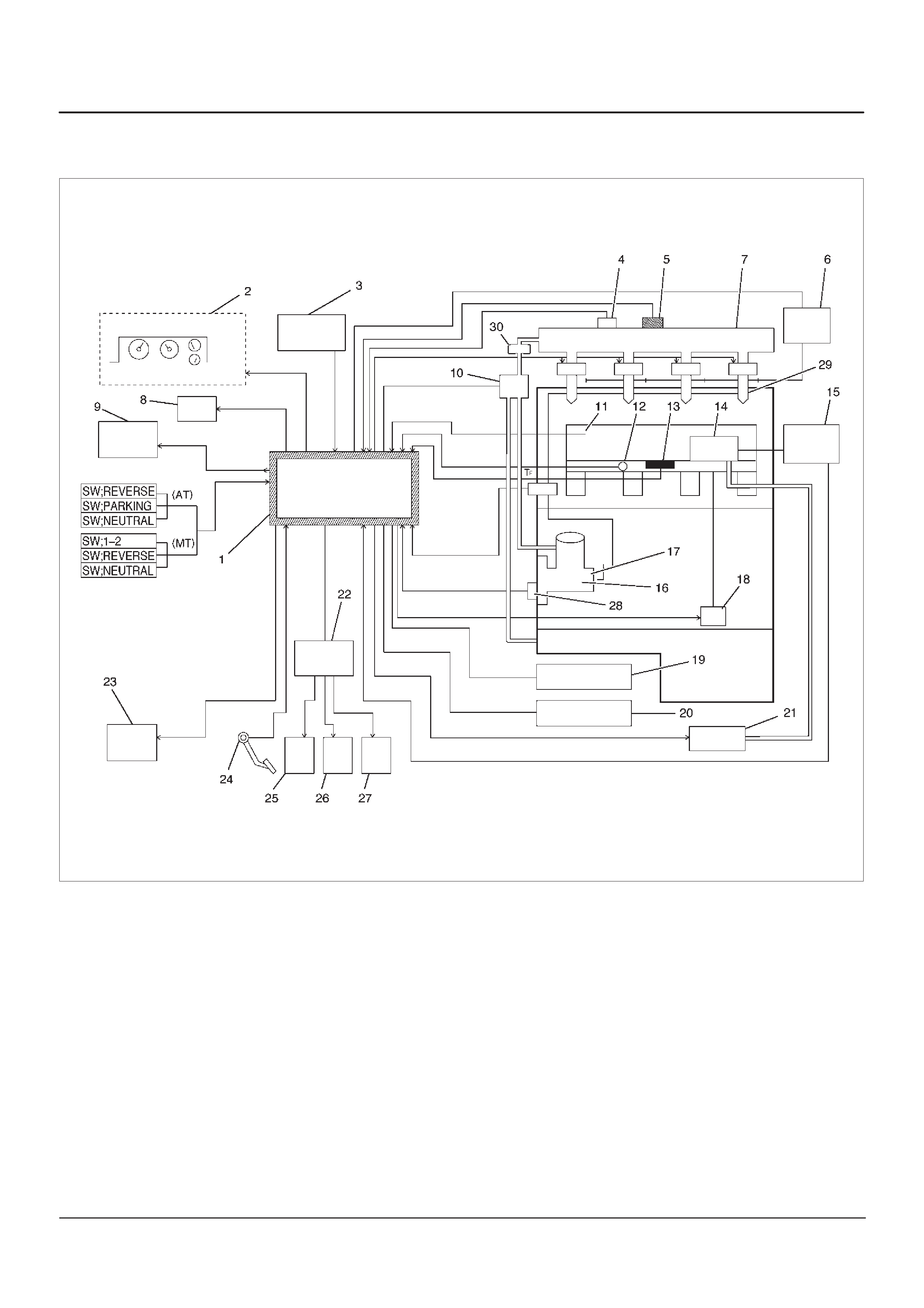

Fuel Injection System

060RW178

Legend

(1) ECM

(2) Meter Panel

(3) Battery

(4) Oil Temp Sensor

(5) Rail Pressure Sensor

(6) Glow Relay

(7) Oil Rail

(8) Tech–2

(9) A/C Comp Relay

(10) RPCV

(11) Intake Air Temp Sensor

(12) Engine Coolant Temp Sensor

(13) MAP Sensor

(14) EGR Valve

(15) EGR Pressure Sensor

(16) High Pressure Oil Pump

(17) Fuel Pump

(18) VSV

(19) EXH Throttle VSV1

(20) EXH Throttle VSV2

(21) EVRV

(22) Engine Harness Connector

(23) QWS Relay

(24) APS

(25) T.O.D

(26) ECT

(27) OBD

(28) TDC

(29) Injector

(30) Edge Filter

Guid to the System

DFuel Injection system is an HEUI (Hydraulically

Actuated, Electronically Controlled, Unit, Injector)

type. In this type of injector system, the oil

pressurized by means of High Pressure Oil Pump

(16) is fed through Rail Pressure Control Valve (10)

and Oil Rail (7) to Injector (29) from which fuel is

injected under this oil pressure.

For diagnosis, therefore, the Rail Pressure as well as

the Electric Circuit must be inspected.

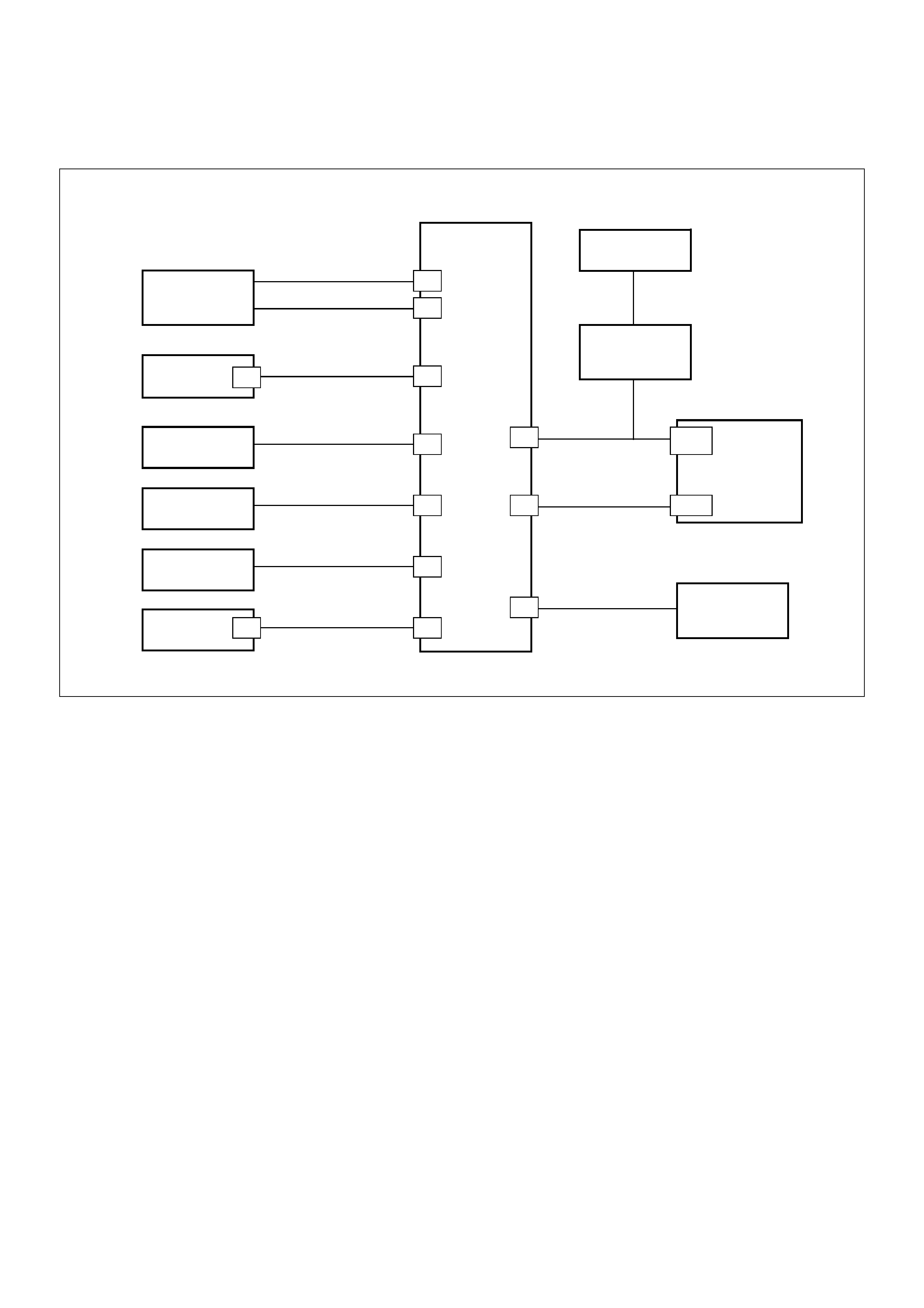

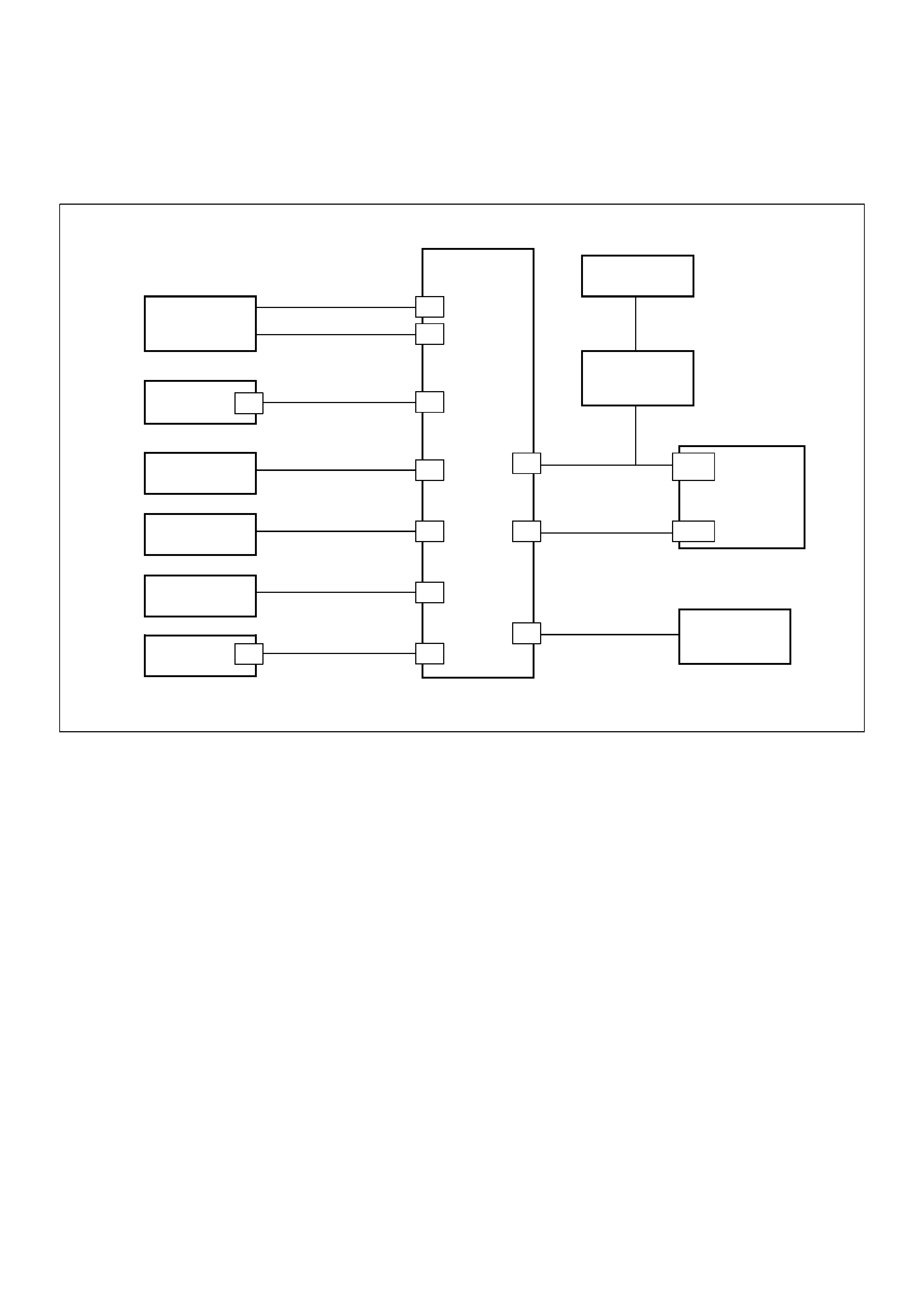

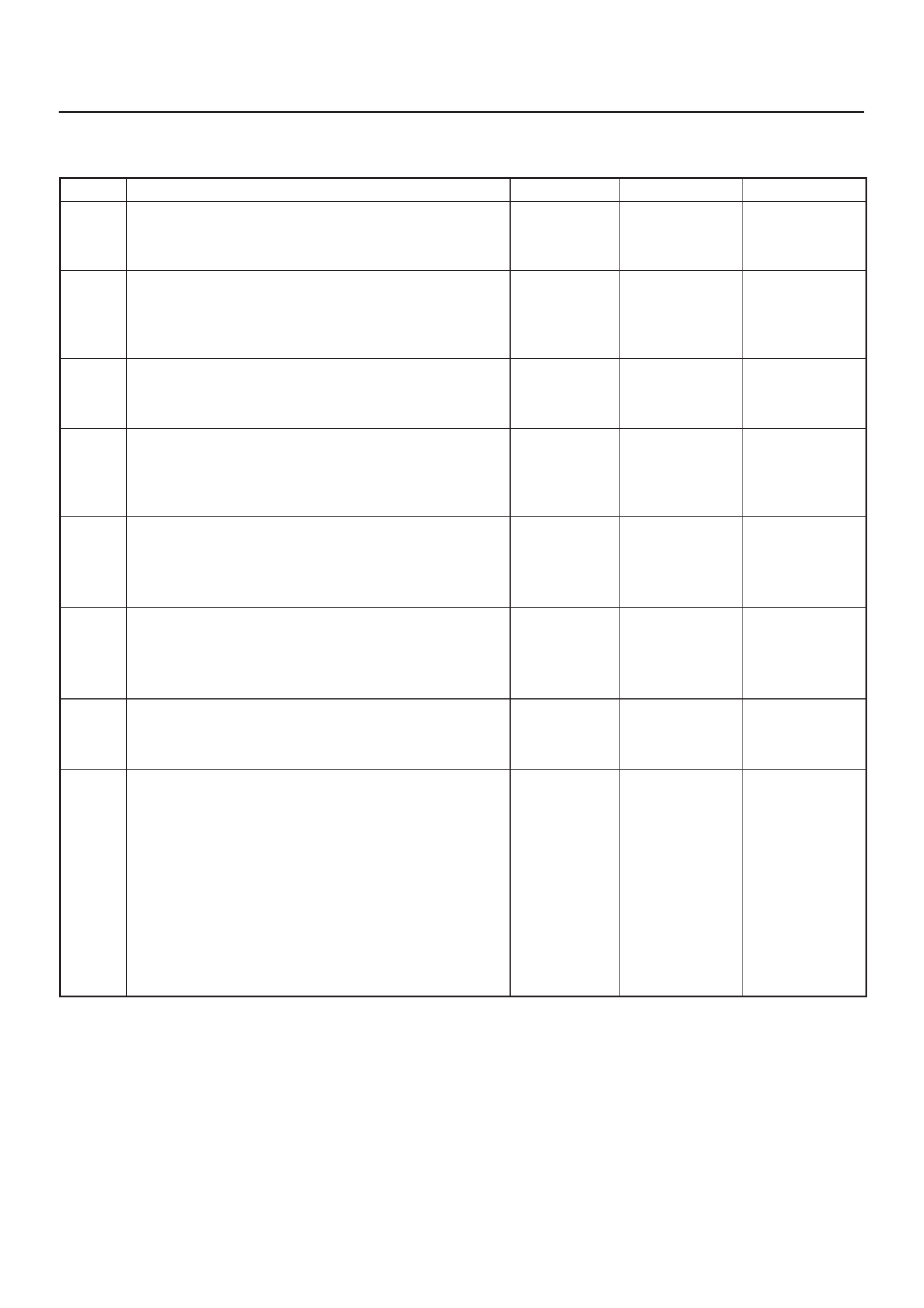

On-Board Diagnostic (OBD) System Check

A Group

060RW135

B Group

060RW133

C Group

060RW129

D Group

060RW134

Circuit Description

The on-board diagnostic system check is the starting

point for any driveability complaint diagnosis. Before

using this procedure, perform a careful visual/physical

check of the ECM and engine grounds for cleanliness and

tightness.

The on-board diagnostic system check is an organized

approach to identifying a problem created by an

electronic engine control system malfunction.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed-through wire insulation or a wire broken inside the

insulation. Check for poor connections or a damaged

harness. Inspect the ECM harness and connector for

improper mating, broken locks, improperly formed or

damaged terminals, poor terminal-to-wire connection,

and damaged harness.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

1. The MIL (“Check Engine” lamp) should be “ON”

steady with the ignition “ON”/engine “OFF.” If not,

Chart A-1 should be used to isolate the malfunction.

2. Checks the Class 2 data circuit and ensures that the

ECM is able to transmit serial data.

3. This test ensures that the ECM is capable of

controlling the MIL (“Check Engine” lamp) and the

MIL (“Check Engine” lamp) driver circuit is not

shorted to ground.

4. If the engine will not start, the

Cranks But Will Not

Run

chart should be used to diagnose the condition.

7. A Tech 2 parameter which is not within the typical

range may help to isolate the area which is causing

the problem.

9. When the ECM is replaced, the characteristic data of

injector and rail pressure sensor should be inputted.

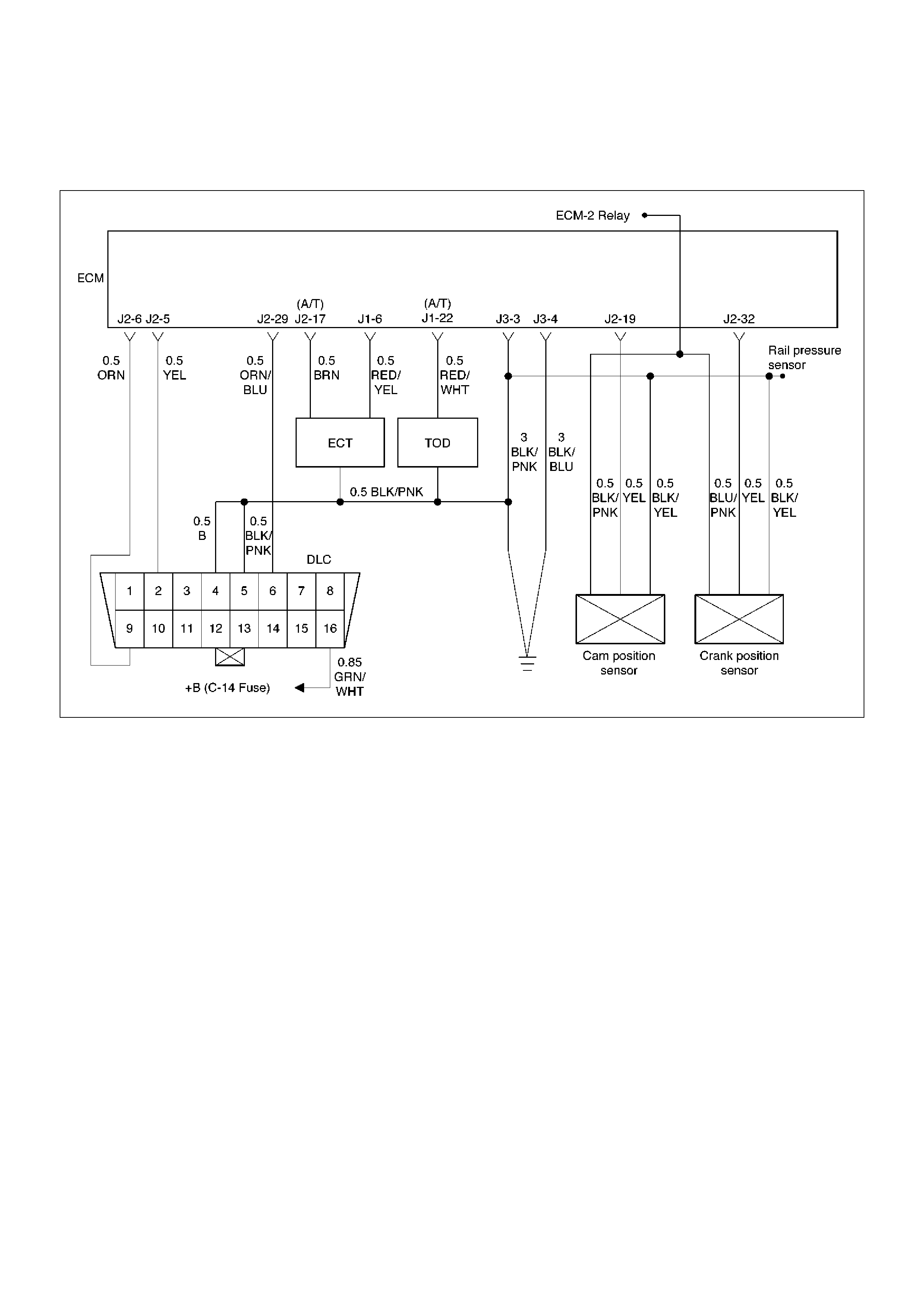

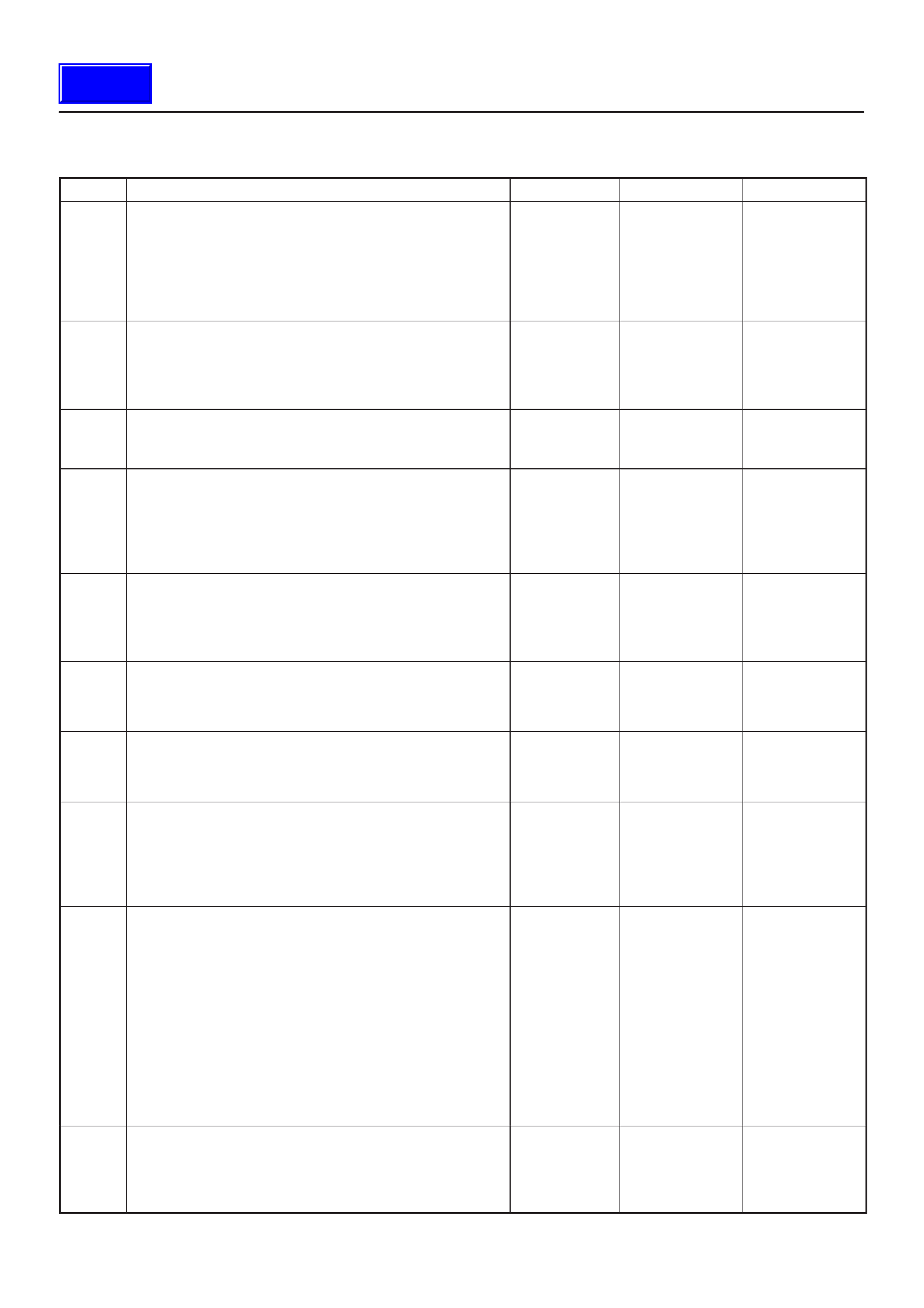

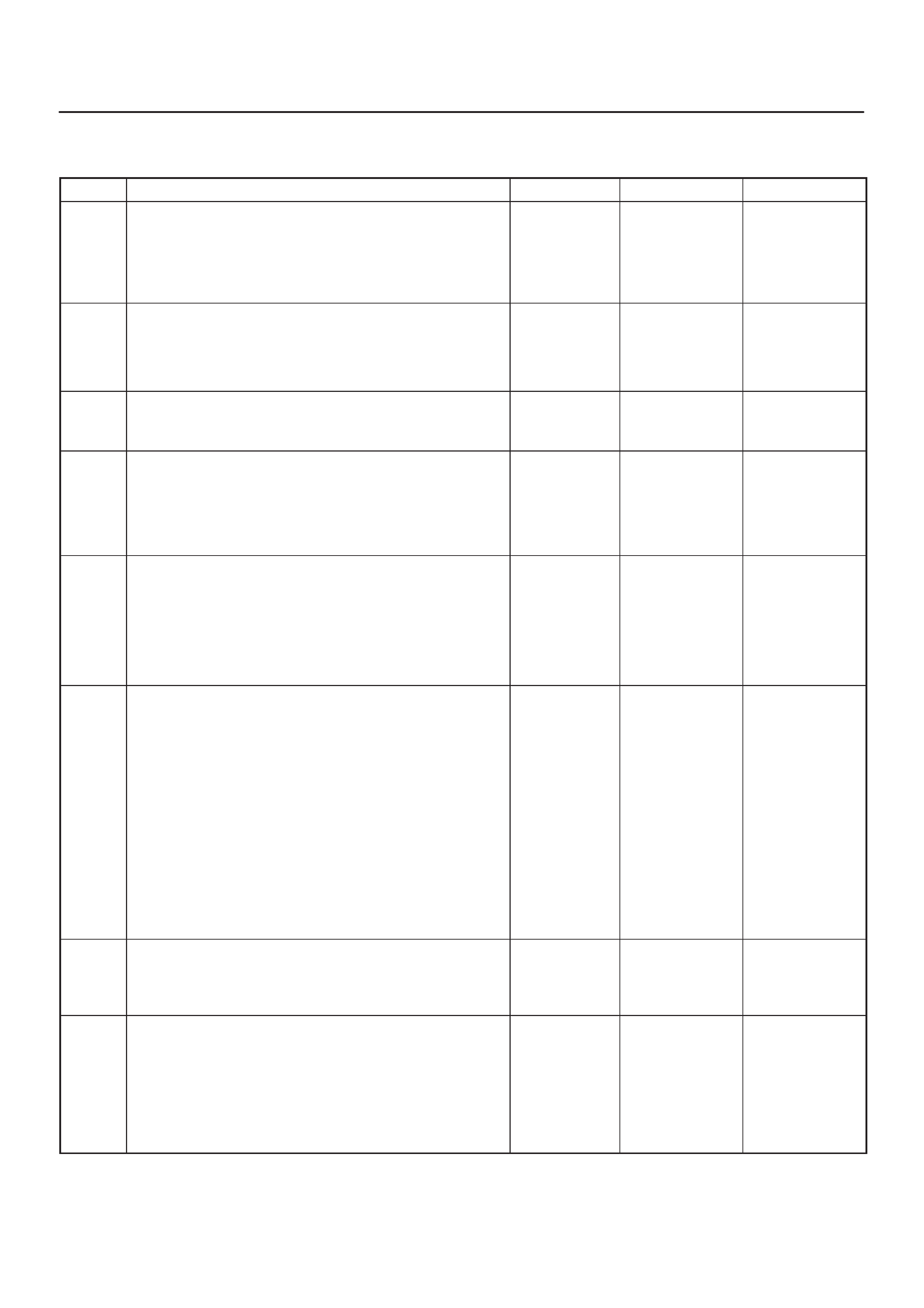

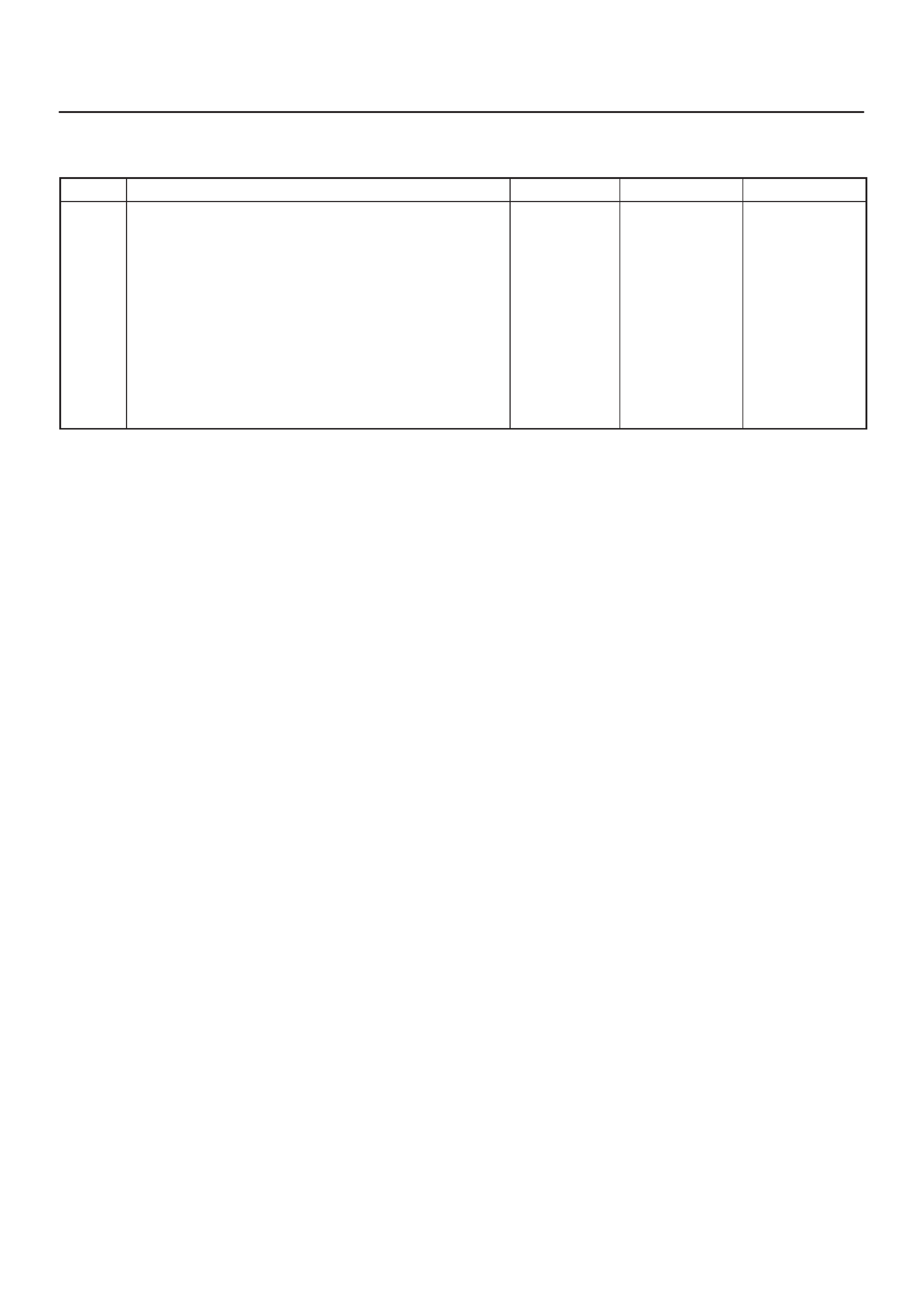

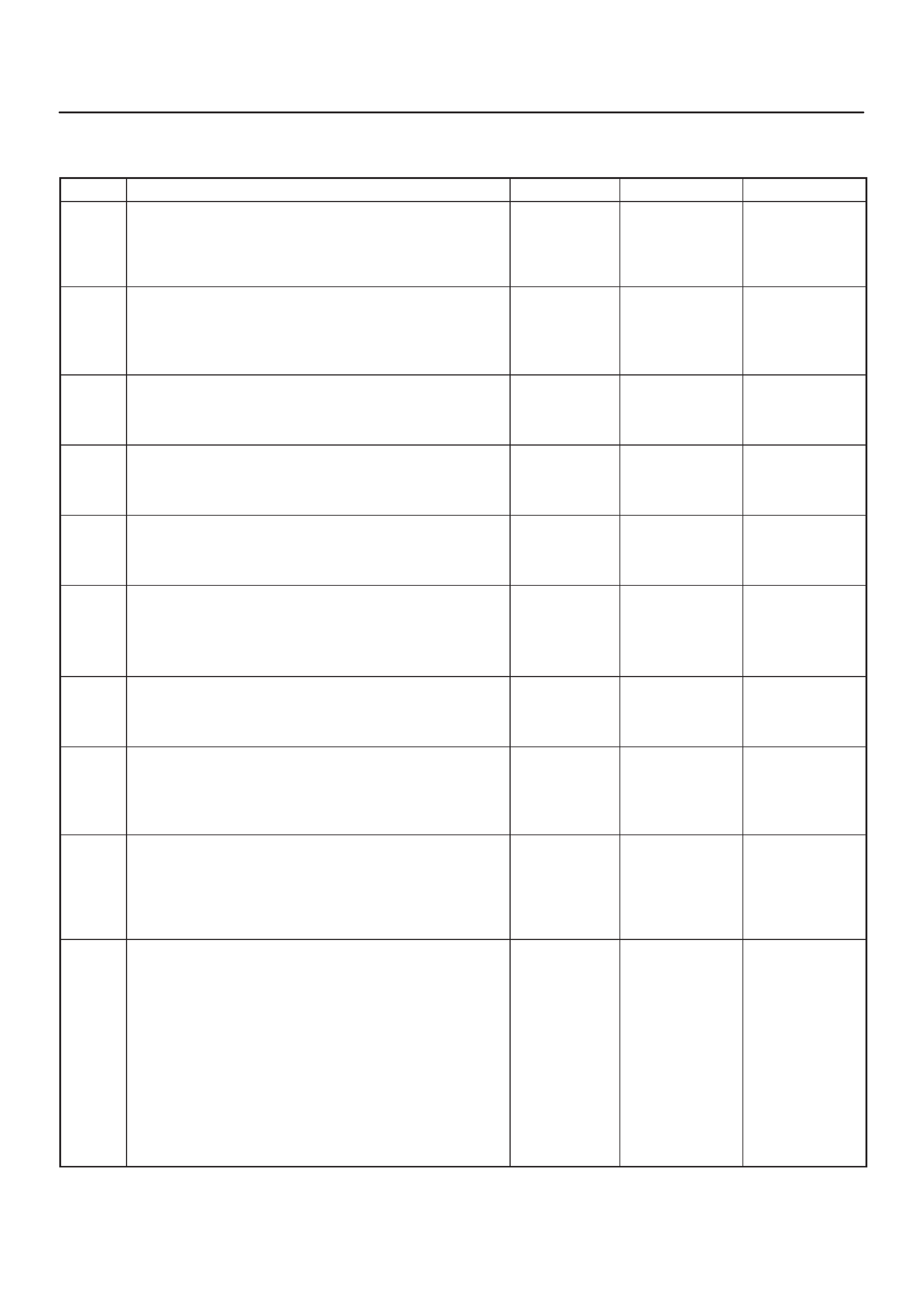

On- Board Diagnostic (OBD) System Check

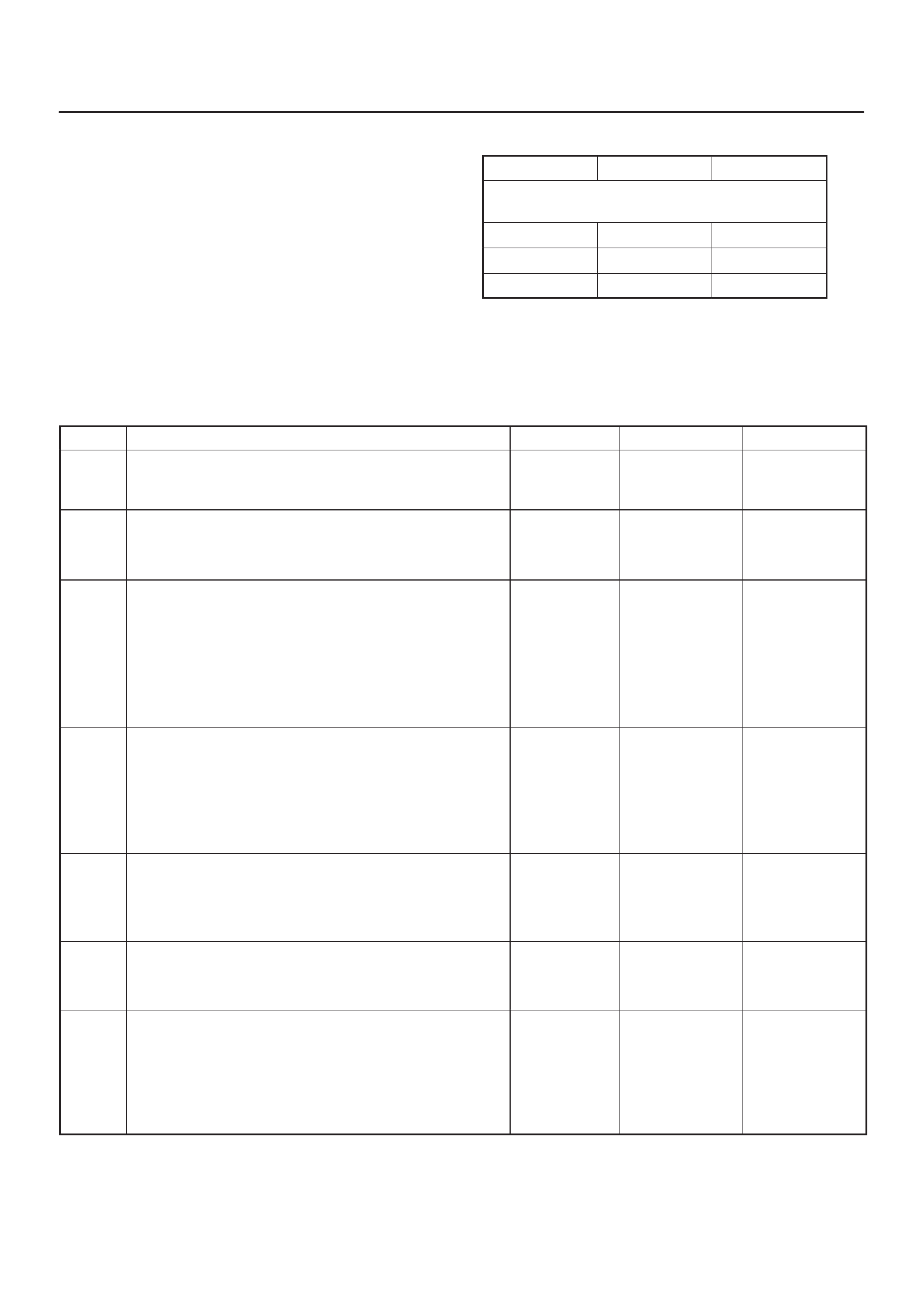

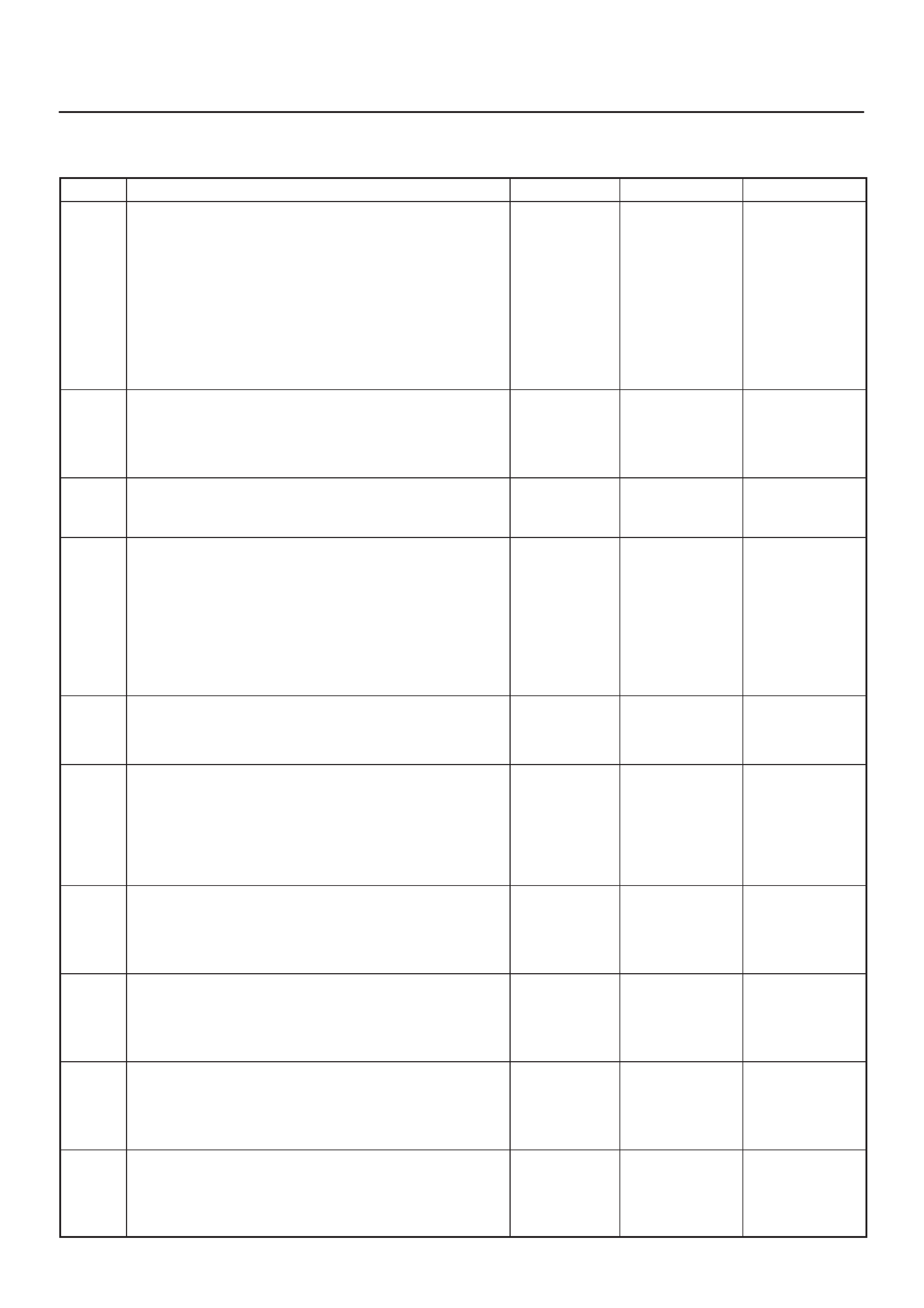

Step Action Value(s) Yes No

1 1. Ignition “ON,” engine “OFF.”

2. Observe the malfunction indicator lamp (MIL or

“Check Engine” lamp).

Is the MIL (“Check Engine” lamp)“ON?” —Go to

Step 2

Go to

No MIL

(“Check

Engine” lamp)

21. Ignition “OFF.”

2. Install a Tech 2.

3. Ignition “ON.”

4. Attempt to display ECM engine data with the T ech 2.

Does the Tech 2 display ECM data? —Go to

Step 3

Go to

Step 8

31. Using the Tech 2 output tests function, select MIL

(“Check Engine” lamp) dash lamp control and

command the MIL (“Check Engine” lamp) “OFF.”

2. Observe the MIL (“Check Engine” lamp).

Did the MIL (“Check Engine” lamp) turn “OFF?” —Go to

Step 4

Go to

MIL

(“Check

Engine” lamp)

On Steady

4Attempt to start the engine.

Did the engine start and continue to run? —Go to

Step 5

Go to

Cranks

But Will Not

Run

5Select “Display DTCs” with the Tech 2.

Are any DTCs stored? —Go to

Step 6

Go to

Step 7

6Are two or more of the following DTCs stored?

A Group; P0337, P0342, P1193, P1404, P1405,

P1488

B Group; P0337, P0342

C Group; P0112, P0117, P0182, P0197

D Group; P0107, P0405, P1194, P1485 —

Go to

Chart

,

“Multiple

ECM

Information

Sensor DTCs

Set”

Go to

applicable

DTC table

7Compare ECM data values displayed on the Tech 2 to

the typical engine scan data values.

Are the displayed values normal or close to the typical

values? — Go to

Step 8

Refer to

indicated

Component

System

Checks

81. Ignition “OFF,” disconnect the ECM.

2. Ignition “ON,” engine “OFF.”

3. Check the Class 2 data circuit for an open, short to

ground, or short to voltage. Also, check the DLC

ignition feed circuit for an open or short to ground

and the DLC ground circuit for an open.

4. If a problem is found, repair as necessary.

Was a problem found? —Go to

Step 2

Go to

Step 9

9Check the Tech 2 on other vehicle.

Was Tech 2 abnormal? —Go to

Step 11

Go to

Step 10

10 Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete? —Go to

Step 2

—

11 Repair the Tech 2 or prepare another Tech 2.

Is the action complete? —Go to

Step 2

—

Engine Control Module ECM

Diagnosis

To read and clear diagnostic trouble codes, use a Tech 2.

IMPORTANT:Use of a Tech 2 is recommended to clear

diagnostic trouble codes from the ECM memory.

Diagnostic trouble codes can also be cleared by turning

the ignition “OFF” and disconnecting the battery power

from the ECM for 30 seconds. Turning off the ignition and

disconnecting the battery power from the ECM will cause

all diagnostic information in the ECM memory to be

cleared. Therefore, all the diagnostic tests will have to be

re-run.

Since the ECM can have a failure which may affect only

one circuit, following the diagnostic procedures in this

section will determine which circuit has a problem and

where it is.

If a diagnostic chart indicates that the ECM connections

or the ECM is the cause of a problem, and the ECM is

replaced, but this does not correct the problem, one of the

following may be the reason:

DThere is a problem with the ECM terminal

connections. The terminals may have to be removed

from the connector in order to check them properly.

DThe problem is intermittent. This means that the

problem is not present at the time the system is being

checked. In this case, refer to the

Symptoms

portion

of the manual and make a careful physical inspection

of all components and wiring associated with the

affected system.

DThere is a shorted solenoid, relay coil, or harness.

Solenoids and relays are turned “ON” and “OFF” by

the ECM using internal electronic switches called

drivers. A shorted solenoid, relay coil, or harness will

not damage the ECM but will cause the solenoid or

relay to be inoperative.

Multiple ECM Information Sensor

DTCS Set

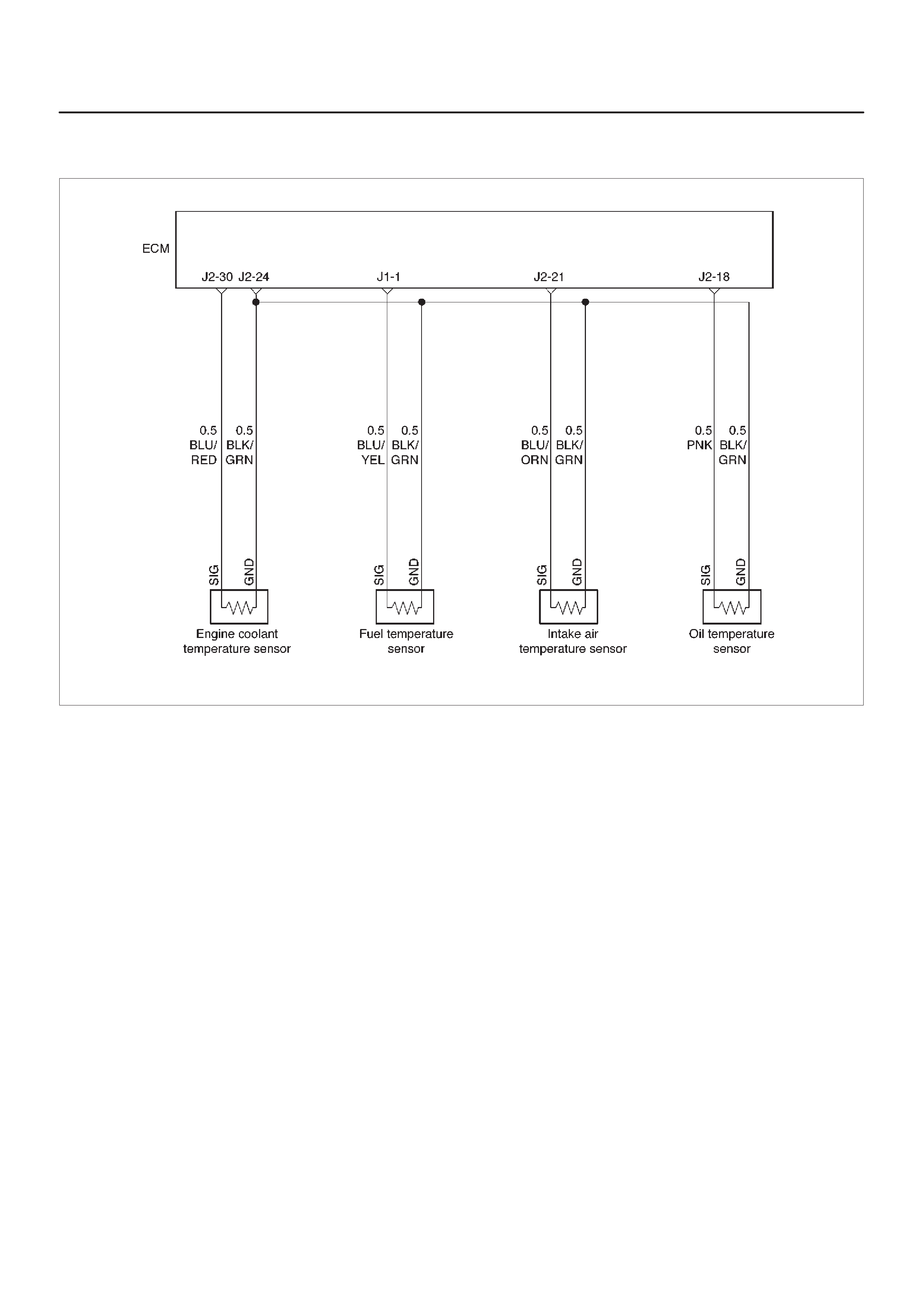

Circuit Description

The Engine Control Module ECM monitors various

sensors to determine the engine operating conditions.

The ECM controls fuel delivery, spark advance,

transmission operation, and emission control device

operation based on the sensor inputs.

The ECM provides a sensor ground to all of the sensors.

The ECM applies 5 volts through a pull-up resistor, and

determines the status of the following sensors by

monitoring the voltage present between the 5-volt supply

and the resistor:

DThe fuel temperature (FT) sensor

DThe engine coolant temperature (ECT) sensor

DThe Intake air temperature (IAT) sensor

The ECM provides the following sensors with a 5-volt

reference and a sensor ground signal:

DThe Intake throttle position sensor

DThe manifold absolute pressure sensor

DThe rail pressure sensor

DThe accelerator position sensor

DThe oil temperature sensor

DThe camshaft position sensor

DThe crankshaft position sensor

DThe EGR pressure sensor

The ECM monitors the signals from these sensors in

order to determine their operating status.

Diagnostic Aids

IMPORTANT:Be sure to inspect ECM and engine

grounds for being secure and clean.

A short to voltage in one of the sensor input circuits may

cause one or more of the following DTCs to be set:

DP0337

DP0342

DP1193

DP1404

DP1405

DP1488

IMPORTANT:If a sensor input circuit has been shorted

to voltage, ensure that the sensor is not damaged. A

damaged sensor will continue to indicate a high or low

voltage after the affected circuit has been repaired. If the

sensor has been damaged, replace it.

An open in the sensor ground circuit between the ECM

and the splice will cause one or more of the following

DTCs to be set:

DP0337

DP0342

DP0117

A short to ground in the 5-volt reference A or B circuit will

cause one or more of the following DTCs to be set:

DP0112

DP0117

DP0182

DP0197

An open in the 5-volt reference circuit A, between the

ECM and the splice will cause one or more of the following

DTCs to be set:

DP0107

DP0405

DP1194

DP0122

An open in the 5-volt reference circuit B, between the

ECM and the splice will cause one or more of the following

DTCs to be set:

DP1485

Check for the following conditions:

DPoor connection at ECM. Inspect the harness

connectors for backed-out terminals, improper

mating, broken locks, improperly formed or damage

terminals, and a poor terminal-to-wire connection.

DDamaged harness. Inspect the wiring harness for

damage. If the harness is not damaged, observe an

affected sensor’s displayed value on the Tech 2 with

the ignition “ON” and the engine “OFF” while you

move the connectors and the wiring harnesses

related to the following sensors:

DECT Sensor

DMAP Sensor

DCMP Sensor

DCKP Sensor

DEGR Pressure Sensor

DEGR VSV

DRPCV

DIAT Sensor

DIntake Throttle Motor

DFuel Temperature Sensor

DOil Temperature Sensor

DRail Pressure Sensor

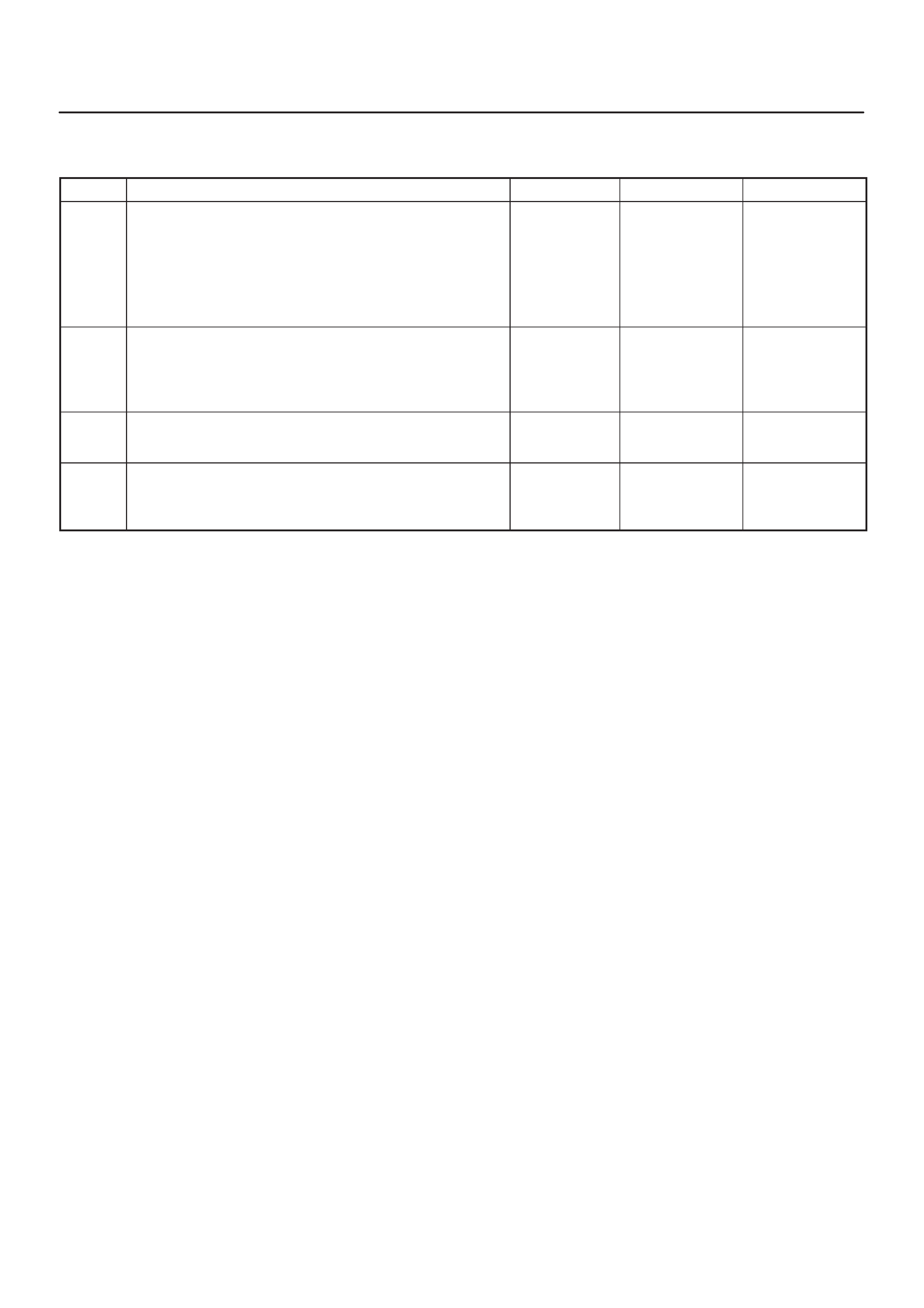

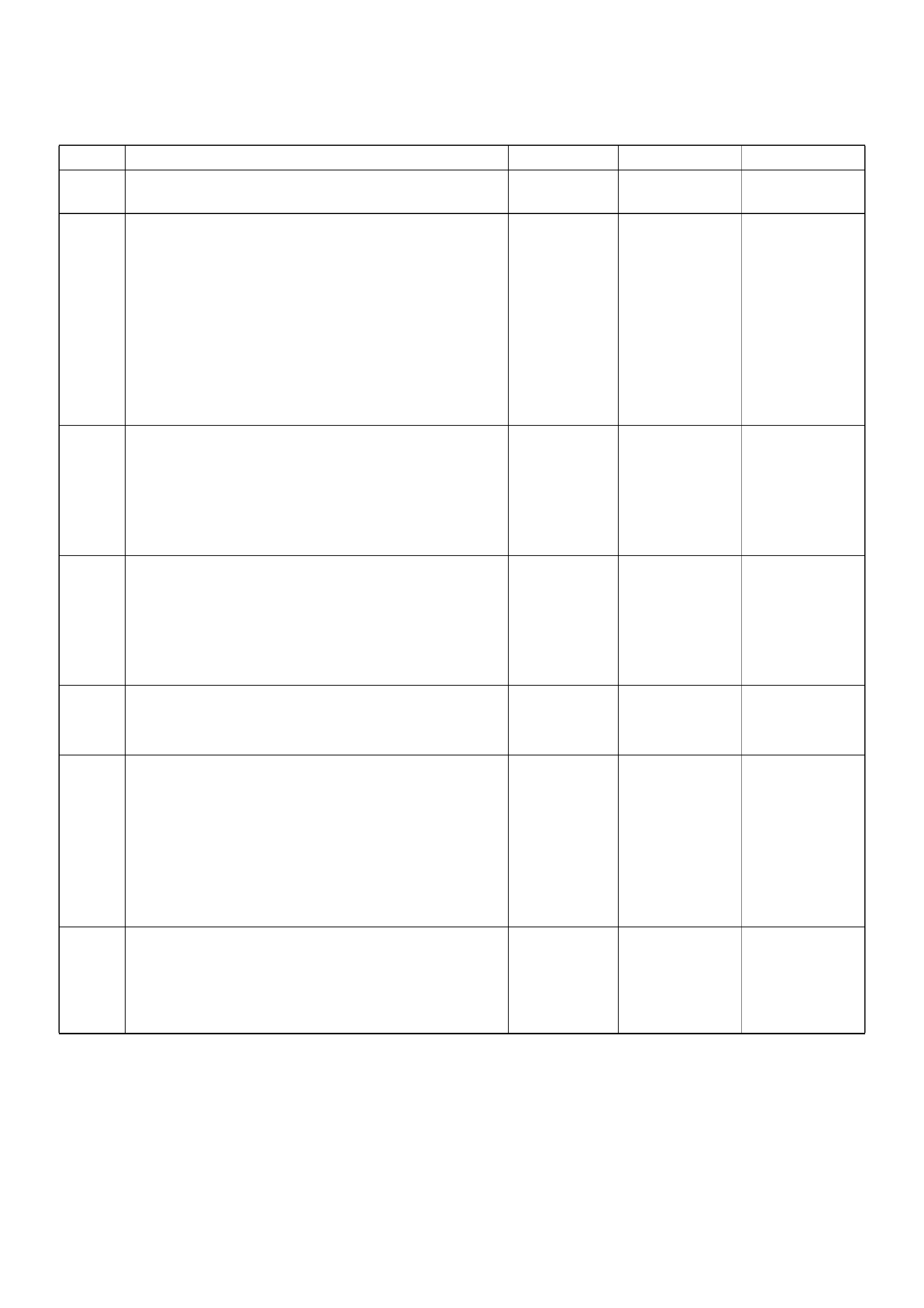

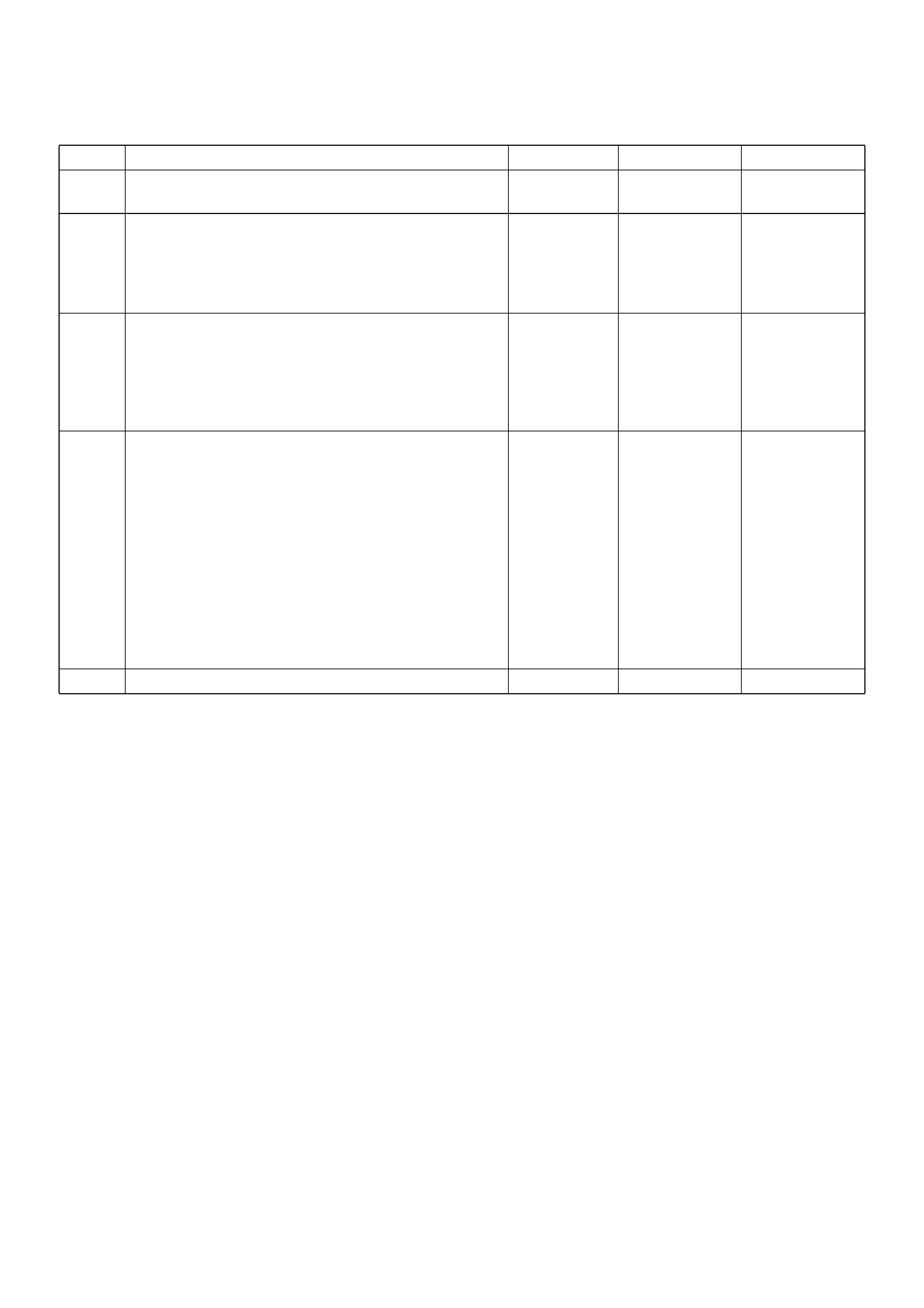

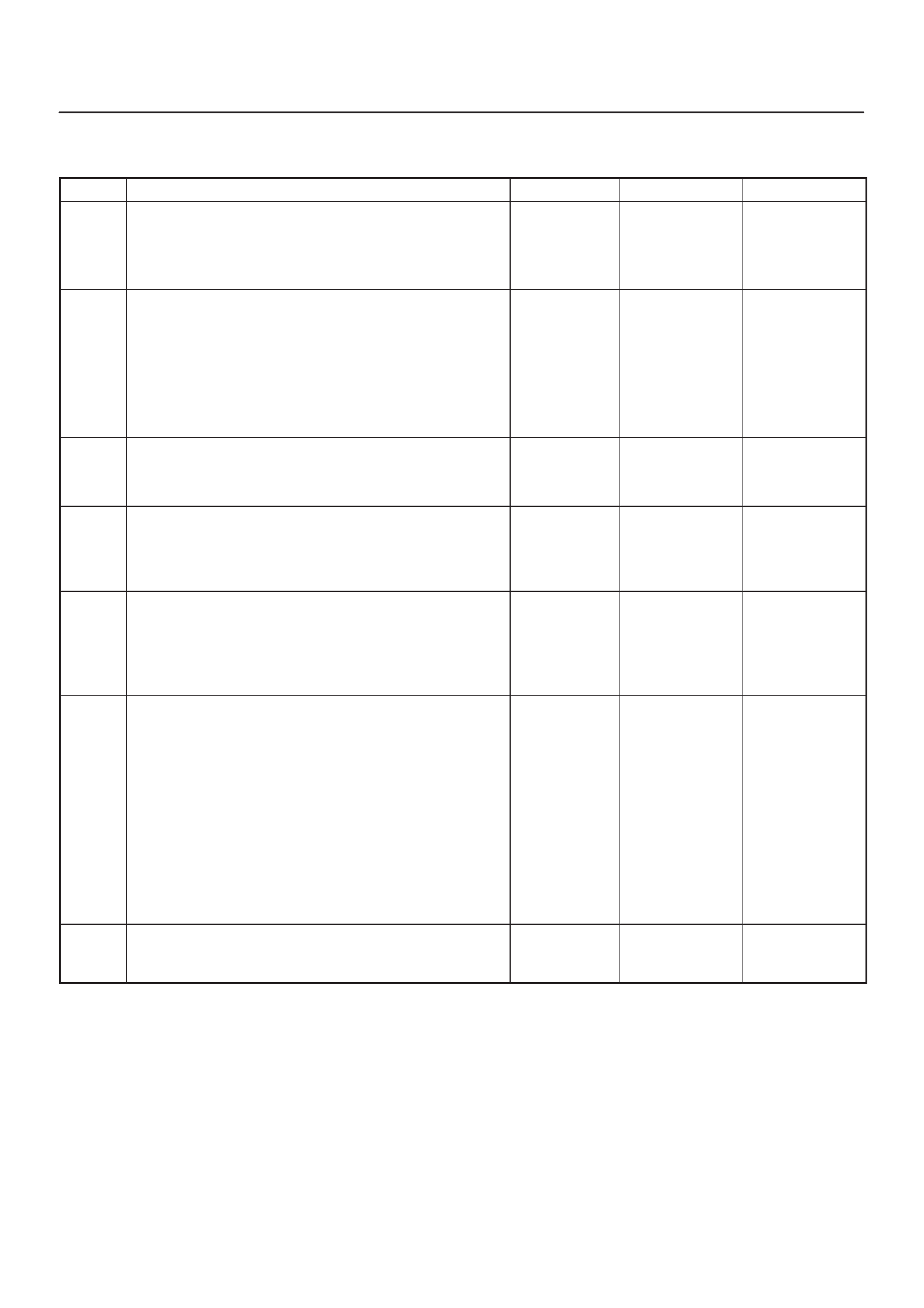

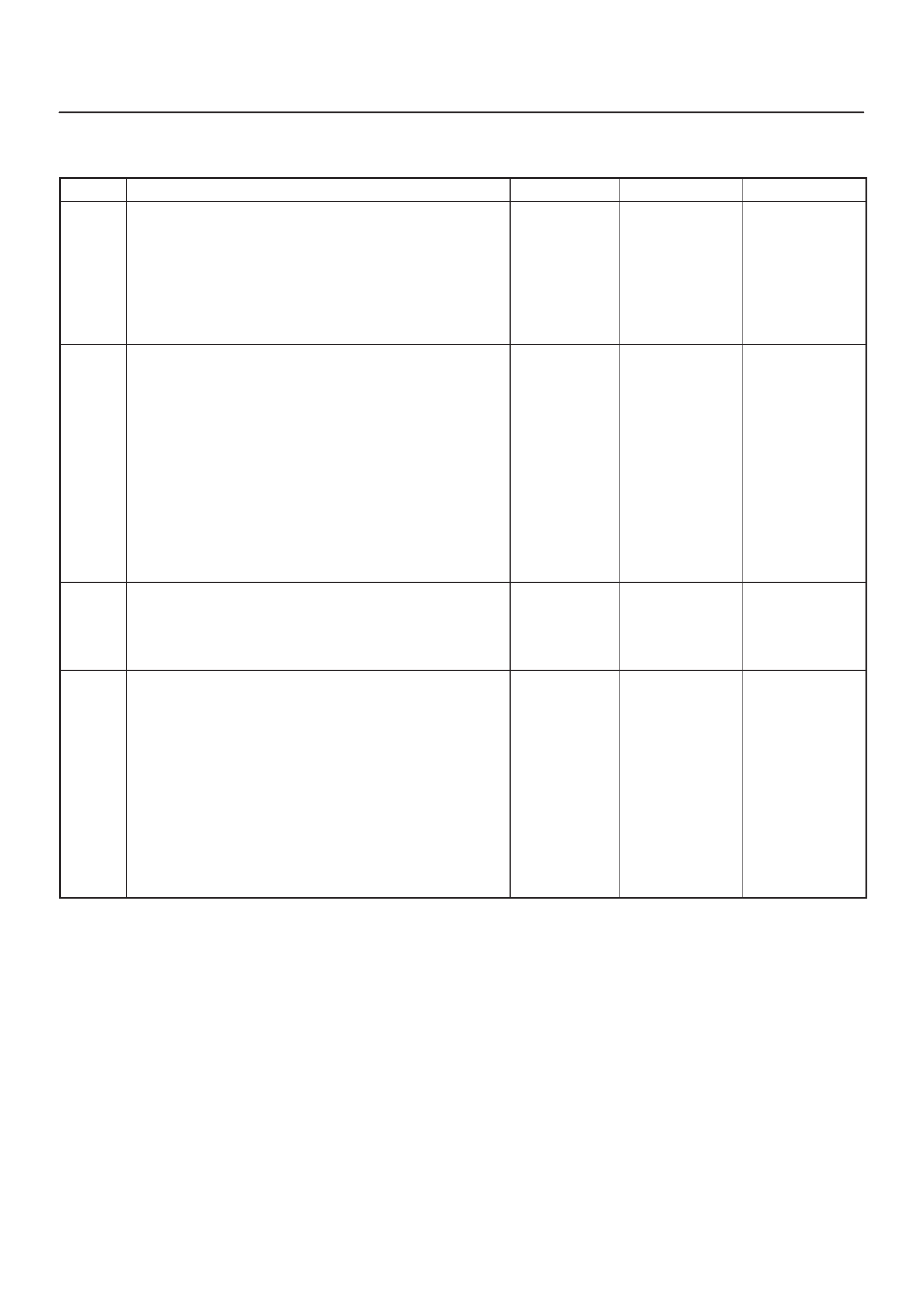

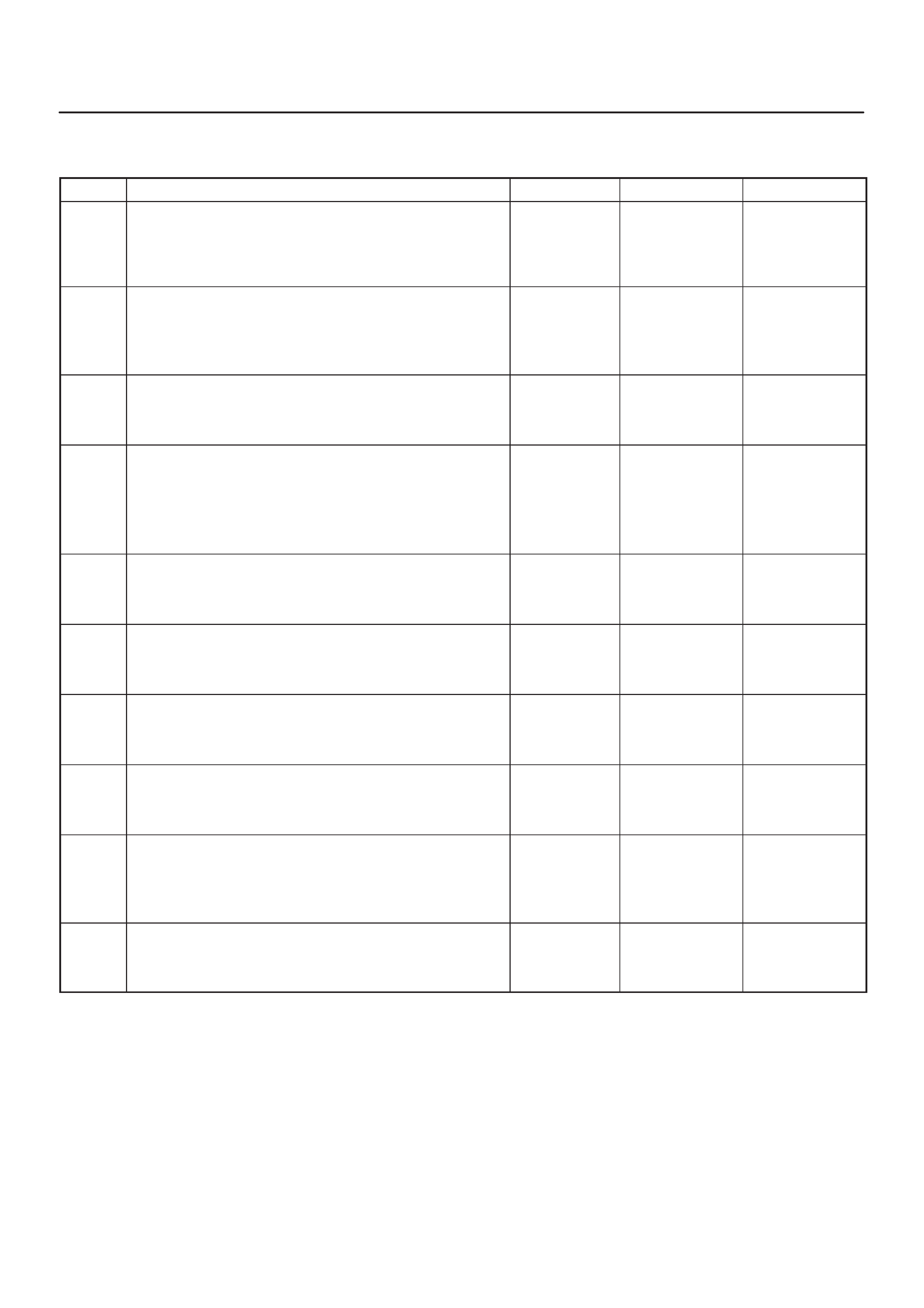

Multiple ECM Information Sensor DTCs Set

Step Action Value(s) YesNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed? —Go to

Step 2

Go to

OBD

System

Check

21. Turn the ignition “OFF,” disconnect the ECM.

2. T urn the ignition “ON,” check the 5 volt reference D

circuit for the following conditions:

DD poor connection at the ECM.

DAn open between the ECM connector and the

splice.

DD short to ground.

DD short to voltage.

Is there an open or short? —Go to

Step 3

Go to

Step 4

3Repair the open or short.

Is the action complete? — Verify repair —

4Check the sensor ground circuit for the following

conditions:

DA poor connection at the ECM or the affected

sensors.

DAn open between the ECM connector and the

affected sensors.

Is there an open or a poor connection? —Go to

Step 5

Go to

Step 6

5Repair the open or the poor connection.

Is the action complete? — Verify repair Go to

Step 6

6Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete? —

Go to

OBD

System

Check

—

EGR (Exhaust Gas Recirculation)

Diagnosis

DA diagnosis of the EGR system is covered by DTC

P1403.

DEGR VSV circuit diagnosis is covered by DTC P1404.

DEGR pressure sensor diagnosis is covered by DTC

P405 and/or P406.

DEGR EVRV circuit diagnosis is covered by DTC

P1405. Refer to the DTC charts.

Tech 2 Data Definitions and Ranges

A/C CLUTCH–Tech 2 Displays ON or OFF–

Indicates whether the A/C has commanded the A/C

clutch ON.

MAP kPa — Tech 2 Range 10-105 kPa/0.00-5.00

Volts —

The manifold absolute pressure reading is determined

from the MAP sensor signal monitored during key up and

wide open throttle (WOT) conditions. The manifold

absolute pressure is used to compensate for altitude

differences and is normally displayed around “61-104”

depending on altitude and manifold absolute pressure.

CMP ACT. COUNTER –Cam Position

DESIRED IDLE — Tech 2 Range 0-3187 RPM —

The idle speed that the ECM is commanding. The ECM

will compensate for various engine loads based on engine

coolant temperature, to keep the engine at the desired

speed.

ECT — (Engine Coolant Temperature) Tech 2

Range –40°C to 151°C (–40°F to 304°F) —

The engine coolant temperature (ECT) is mounted in the

coolant stream and sends engine temperature

information to the ECM. The ECM applies 5 volts to the

ECT sensor circuit. The sensor is a thermistor which

changes internal resistance as temperature changes.

When the sensor is cold (high resistance), the ECM

monitors a high signal voltage and interprets that as a cold

engine. As the sensor warms (decreasing resistance),

the voltage signal will decrease and the ECM will interpret

the lower voltage as a warm engine.

ENGINE RUN TIME — Tech 2 Range

00:00:00-99:99:99 Hrs:Min:Sec —

Indicates the time elapsed since the engine was started.

If the engine is stopped, engine run time will be reset to

00:00:00.

ENGINE SPEED — Range 0-9999 RPM —

Engine speed is computed by the ECM from the 57X

reference input. It should remain close to desired idle

under various engine loads with engine idling.

Air Intake Valve meter POSITION — Tech 2 Range

0-100 % —

IAT (INTAKE AIR TEMPERATURE)— Tech 2 Range

–40°C to 151°C (–40°F to 304°F) —

The ECM converts the resistance of the intake air

temperature sensor to degrees. Intake air temperature

(IAT) is used by the ECM to adjust fuel delivery and spark

timing according to incoming air density.

MAP — Tech 2 Range 10-105 kPa (0.00-4.97 Volts)—

The manifold absolute pressure (MAP) sensor measures

the change in the boost pressure.

MIL — Tech 2 Displays ON or OFF —

Indicates the ECM commanded state of the malfunction

indicator lamp.

AP — Tech 2 Range 0%-100% —

AP (Accelerator position) angle is computed by the ECM

from the AP sensor voltage. AP angle should display

“0%” at idle and “100%” at wide open throttle.

AP SENSOR — Tech 2 Range 0.00-5.00 Volts —

The voltage being monitored by the ECM on the AP

sensor signal circuit.

VEHICLE SPEED—Tech 2 Range 0-255 km/h (0-155

mph)–

The vehicle speed sensor signal is converted into km/h

and mph for display.

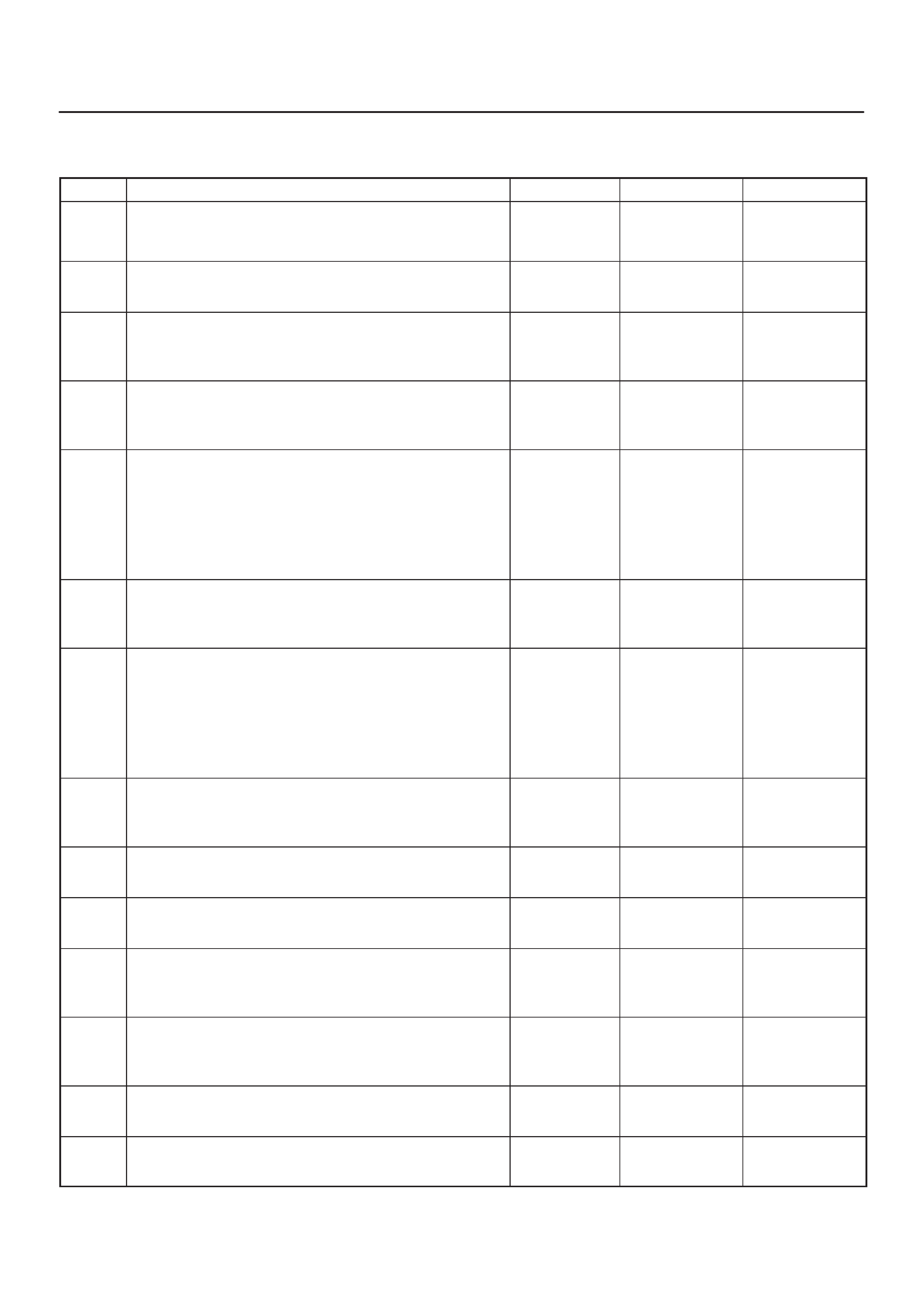

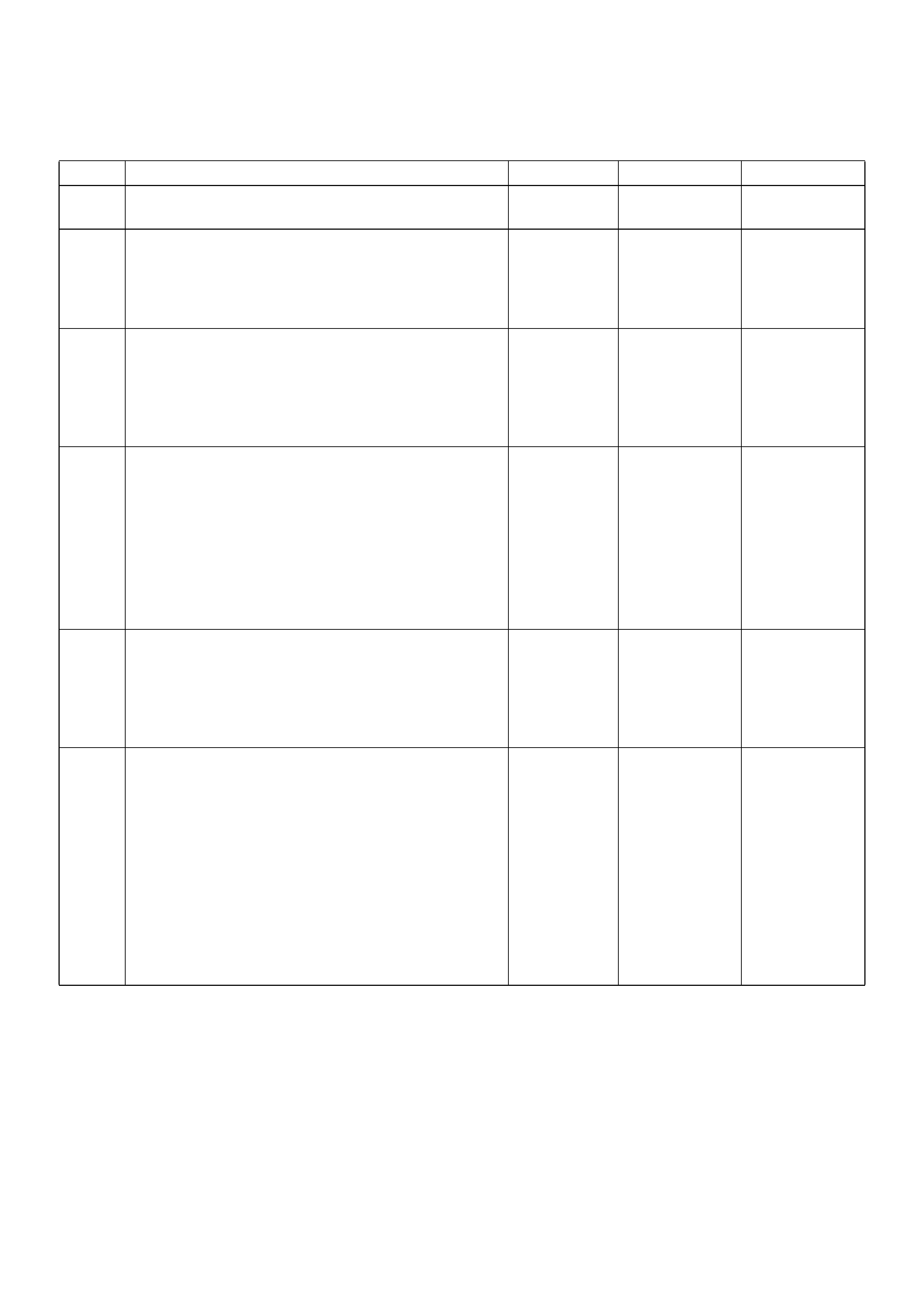

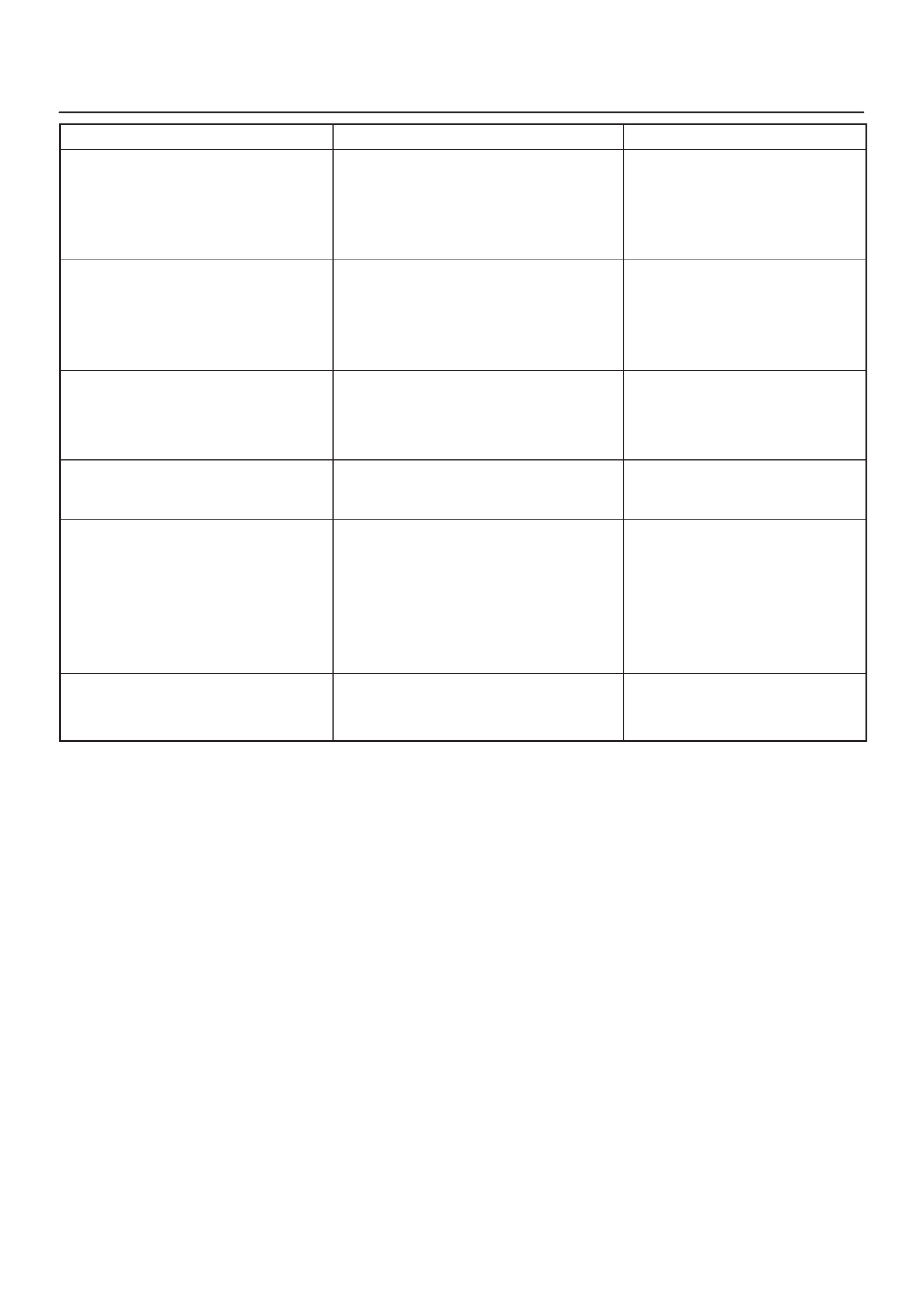

Typical Scan Data Values

Use the Typical Scan Data Values Table only after the

On-Board Diagnostic System Check has been

completed, no DTC(s) were noted, and you have

determined that the on-board diagnostics are functioning

properly. Tech 2 values from a properly-running engine

may be used for comparison with the engine you are

diagnosing. The typical scan data values represent

values that would be seen on a normally-running engine.

NOTE:A Tech 2 that displays faulty data should not be

used, and the problem should be reported to the Tech 2

manufacturer. Use of a faulty Tech 2 can result in

misdiagnosis and unnecessary replacement of parts.

Only the parameters listed below are referred to in this

service manual for use in diagnosis. For further

information on using the Tech 2 to diagnose the ECM and

related sensors, refer to the applicable reference section

listed below. If all values are within the typical range

described below, refer to the

Symptoms

section for

diagnosis.

Test Conditions

Engine running, lower radiator hose hot, transmission in

park or neutral, accessaries off, brake not applied and air

conditioning off.

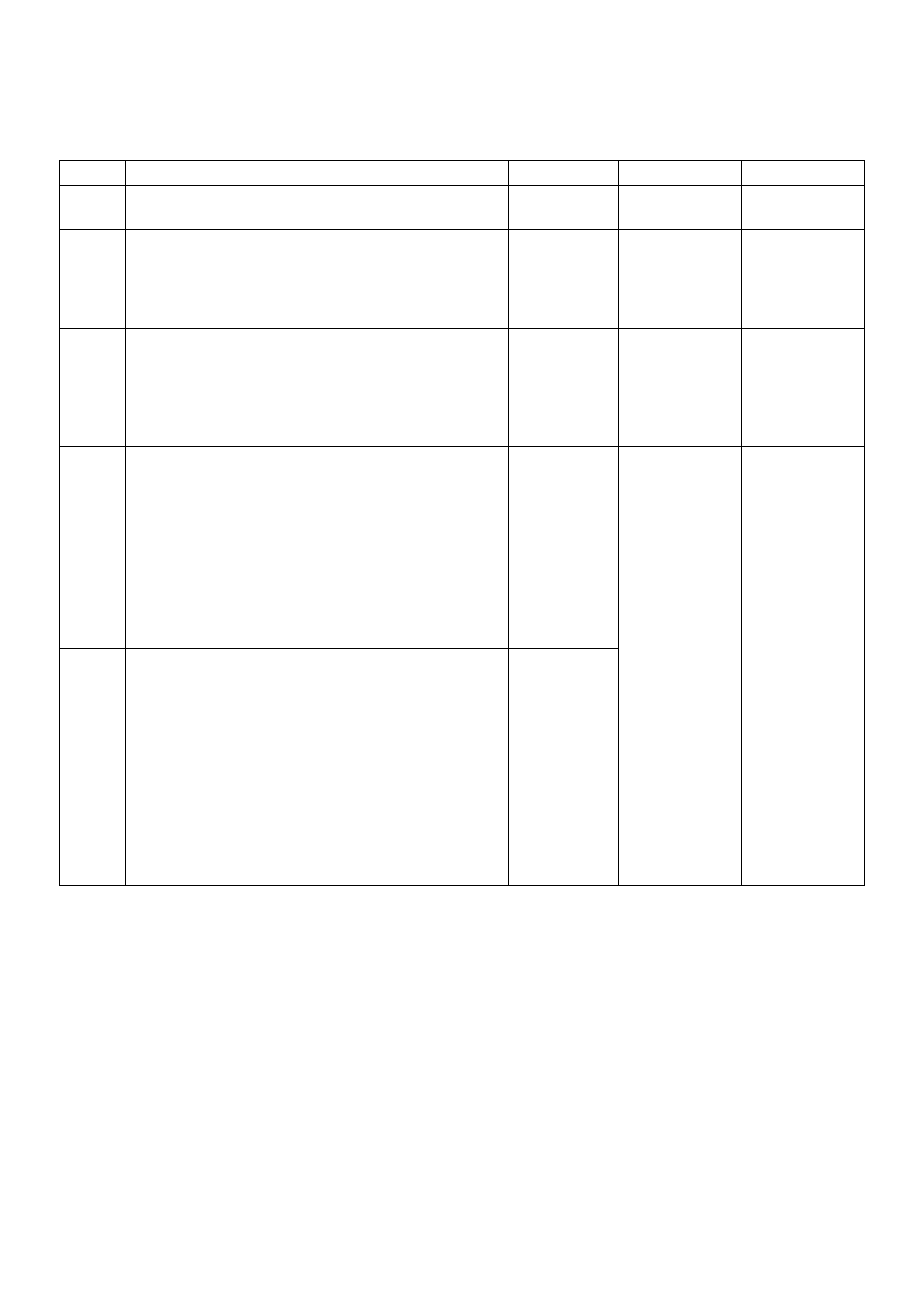

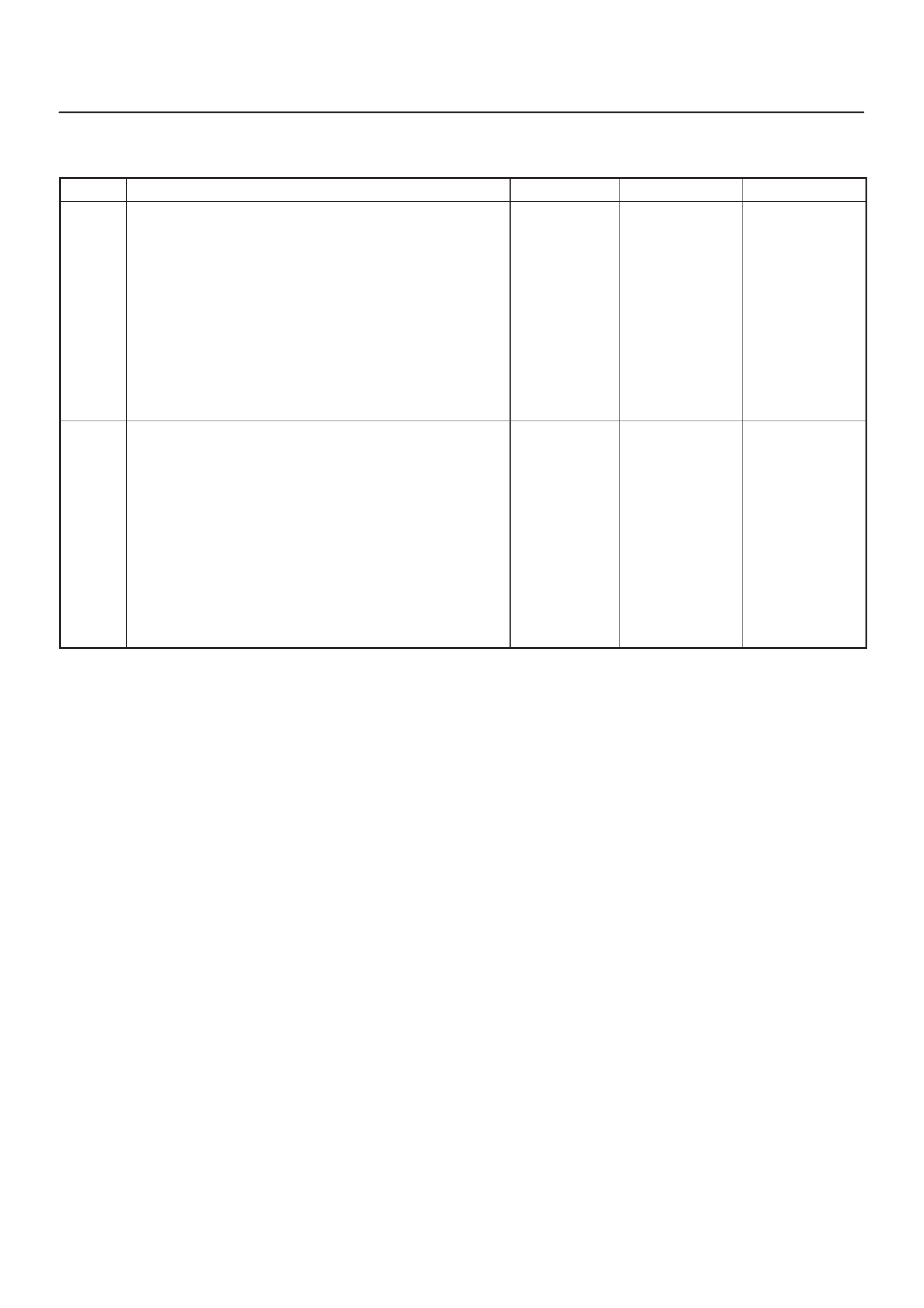

4JX1-TC Engine (Automatic and Manual Transmission)

Tech 2

Parameter Data List Units

Displayed Typical Data

Values (IDLE) Typical Data

Values

(2500 RPM)

Refer To

Battery Voltage Engine Volts 12.5 ∼ 14.5 13 ∼ 15 General Description

Ignition Status Engine On/Off On On General Description

Ignition Relay2Engine On/Off On On General Description

Idle Switch Engine Inactive/

Active — — DTC P0510, P1510

Manifold

Absolute

Pressure

Engine KPa 96 ∼ 106 110 ∼ 150 General Description

DTC P0107, P0108

Rail Oil

Pressure Engine MPa 3.5 ∼ 5 4.5 ∼ 10 General Description

DTC P0192, P0193

Desired Rail Oil

Pressure Engine MPa 4 ∼ 5 5 ∼ 9 General Description

DTC P0192, P0193

Fuel

Temperature Engine °C (°F) 75 ∼ 85 75 ∼ 85 DTC P0182, P0183

Quick Warming

Switch Engine On/Off Off Off DTC P0380

Thermo Relay Engine On/Off — — DTC P1655

Actual EGR

Pressure Engine KPa 58 ∼ 60 M/T 63 ∼ 66

A/T 95 ∼ 105 DTC P0405, P0406

Barometric

Pressure Engine KPa 98 ∼ 102 98 ∼ 102 General Description

Relative EGR

Pressure Engine KPa –38 ∼ –45 M/T –34 ∼ –37

A/T 0 General Description

Desired EGR

Pressure Engine KPa –43 ∼ –40 M/T 36

A/T 0 General Description

Brake Switch Engine Inactive/

Active — — DTC P1588

Gear Engine — — — —

Vehicle Speed Engine Km/h 0 0 Transmission Diagnosis

Rail Pressure

Control Valve Engine % 17 ∼ 22 18 ∼ 27 DTC P1193

EGR Status Engine Disable/

Enable Enable M/T Enable

A/T Disable General Description

EGR Switching

Valve Engine On/Off — — General Description

Throttle Motor

Position Sensor Engine Volts 3.1 ∼ 3.9 0.2 ∼ 0.9 DTC P1485, P1486,

P1487

Throttle Motor

Position Engine Steps 0 ∼ 1.0 0 ∼ 1.0 DTC P1488

Delirered Fuel

Quantity Engine mm 3/st 6 ∼ 10 6 ∼ 12 General Description

Injector Status Engine Disable/

Enable Enable Enable DTC P0201, P0202,

P0203, P0204, General

Description

Injector Pulse

Width Engine ms 0.9 ∼ 1.25 0.7 ∼ 1.1 General Description

Injector Start

Offset Engine °CA — — General Description

Tech 2

Parameter Data List Units

Displayed Typical Data

Values (IDLE) Typical Data

Values

(2500 RPM)

Refer To

Exhaust VSV1 Engine On/Of f Off Off DTC P0475

Exhaust VSV2 Engine On/Of f Off Off DTC P1475

Decelevation

Fuel Cut Off Engine Inactive/

Active — — General Description

Glow Time

Lamp Engine On/Off Off Off DTC P0381

Glow Time

Relay Engine On/Off Off Off DTC P0380

Diagnostic

Request Engine Inactive

12V/

Active 0V

— — General Description

A/C Clutch Engine On/Off Off Off General Description

Desired Idle Engine RPM 720 —General Description

ECT (Engine

Coolant Temp) Engine °C (°F) 80 ∼ 90 80 ∼ 90 General Description

ECT

Engine Speed Engine RPM 720 2500 DTC P0219

MAT (Intake Air

Temp) Engine °C (°F) 65 ∼ 80 65 ∼ 80 DTC P0112, P0113

MAP KPa

(Manifold

Absolute

Pressure)

Engine Kilopascals — — General Description

DTC P0107, P0108

MIL Engine On/Off Off Off General Description

AP (Accel

Position) Engine Percent 0 8 ∼14 DTC P0121, P0122,

P0123

AP (Accel

Position) Engine Volts 0.25 ∼ 0.45 0.8 ∼ 1.0 DTC P0121, P0122,

P0123

Rail Oil

Temperature Engine °C (°F) — — DTC P0197, P0198

Desired Throttle

Motor Position Engine Steps — — —

Learned Idle

Fuel Quantity Engine mm 3/st — — —

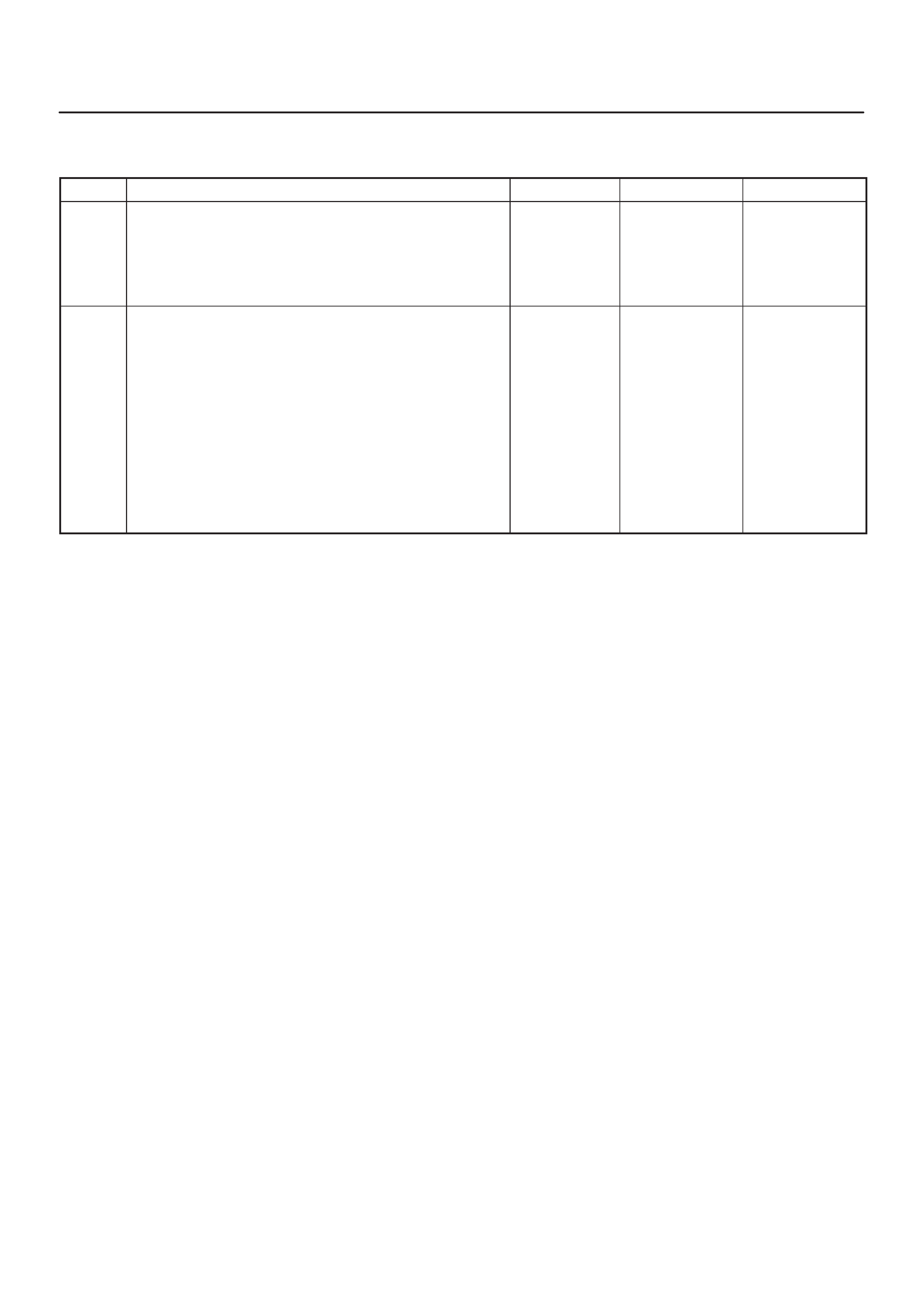

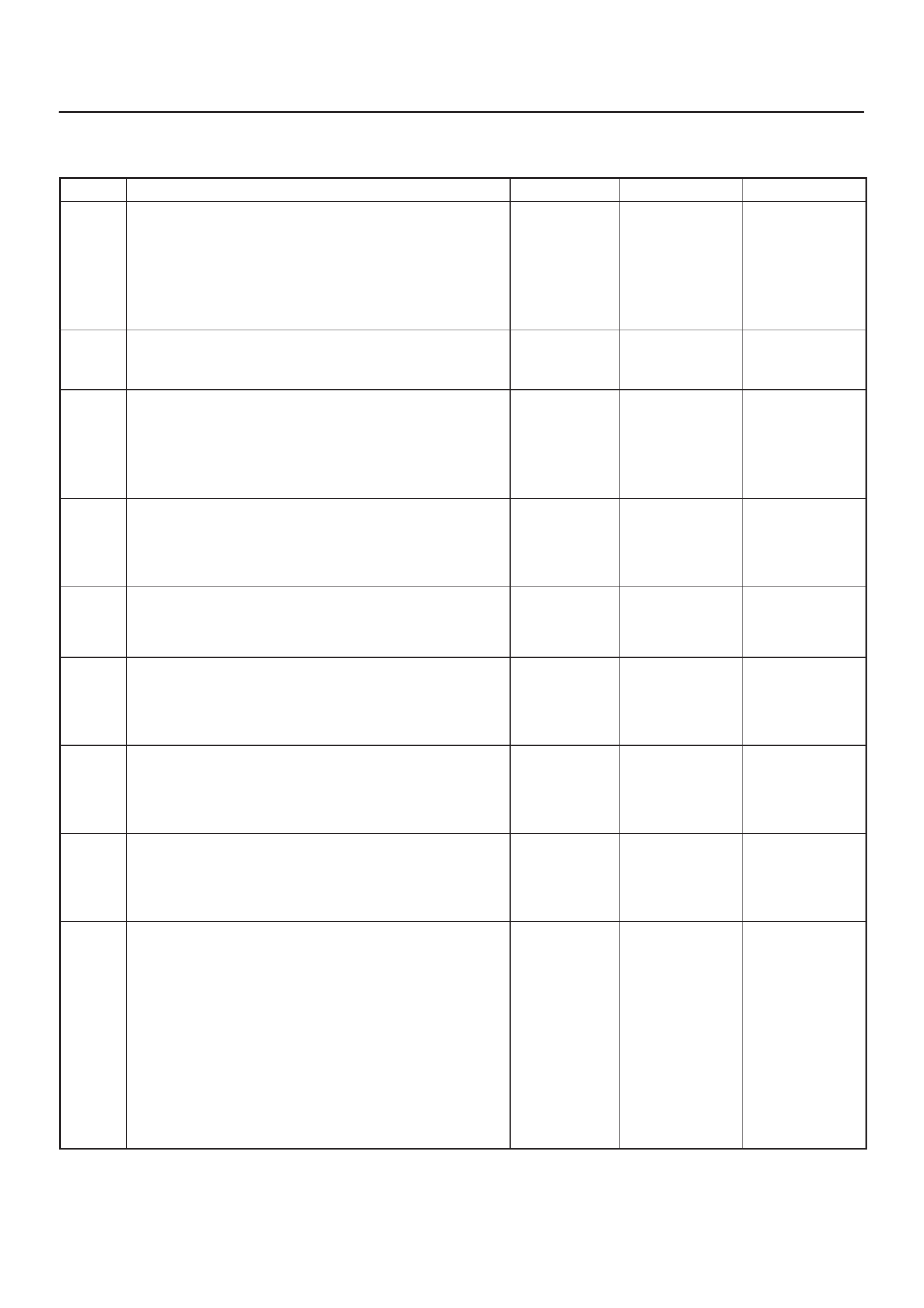

No Malfunction Indicator Lamp (MIL)

060RW136

Circuit Description

The “Check Engine” lamp (MIL) should always be

illuminated and steady with the ignition “ON” and the

engine stopped. Ignition feed voltage is supplied to the

MIL bulb through the meter fuse. The Engine Control

Module ECM turns the MIL “ON” by grounding the MIL

driver circuit.

Diagnostic Aids

An intermittent MIL may be cause by a poor connection,

rubbed-through wire insulation, or a wire broken inside

the insulation. Check for the following items:

DInspect the ECM harness and connections for

improper mating, broken locks, improperly formed or

damaged terminals, poor terminal-to-wire

connection, and damaged harness.

DIf the engine runs OK, check for a faulty light bulb, an

open in the MIL driver circuit, or an open in the

instrument cluster ignition feed.

DIf the engine cranks but will not run, check for an open

ECM ignition or battery feed, or a poor ECM to engine

ground.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. A “No MIL” condition accompanied by a no-start

condition suggests a faulty ECM ignition feed or

battery feed circuit.

9. Using a test light connected to B+, probe each of the

ECM ground terminals to ensure that a good ground

is present. Refer to

ECM Terminal End View

for

terminal locations of the ECM ground circuits.

12.In this step, temporarily substitute a known good

relay for the ECM relay. The horn relay is nearby,

and it can be verified as “good” simply by honking

the horn. Replace the horn relay after completing

this step.

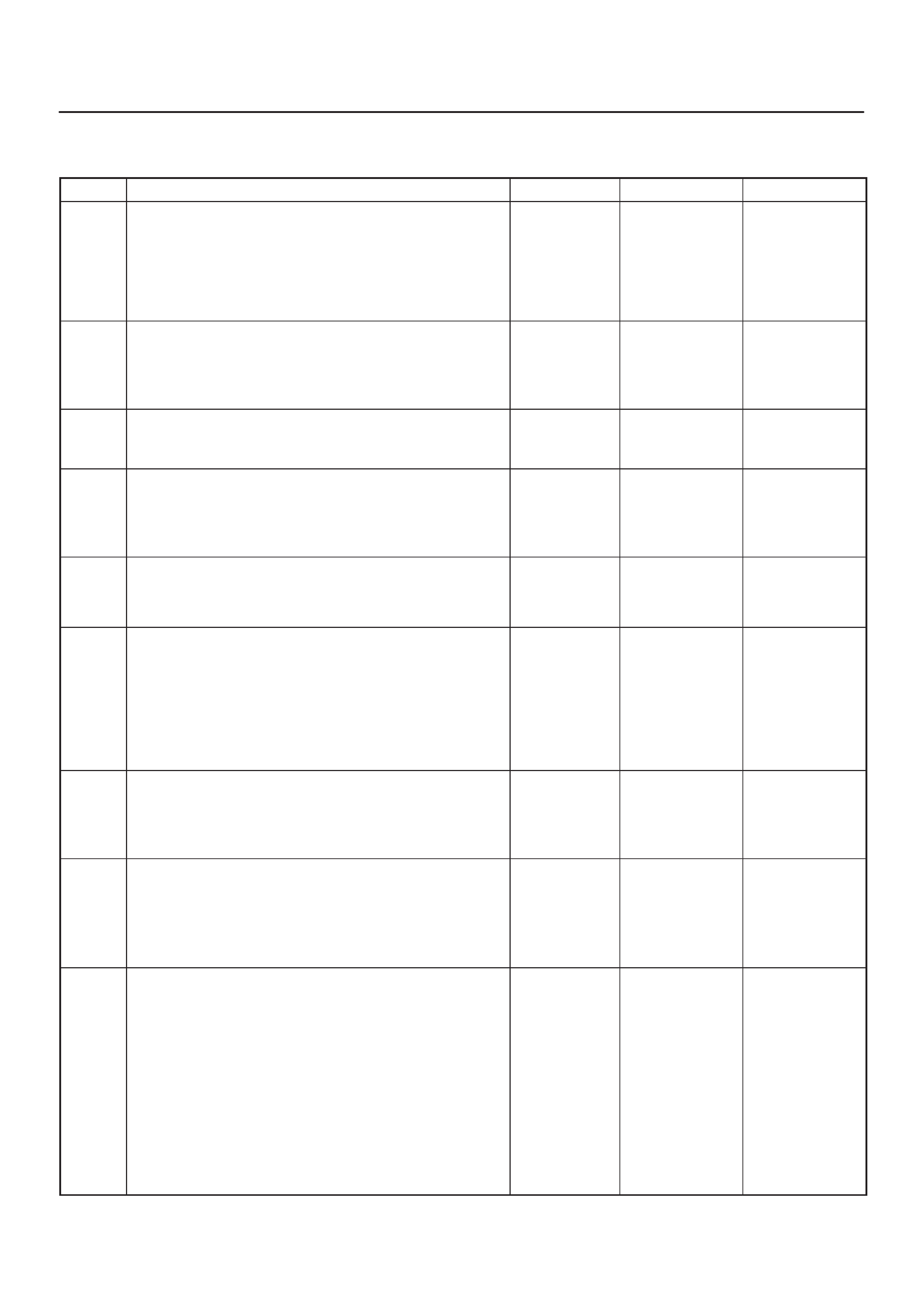

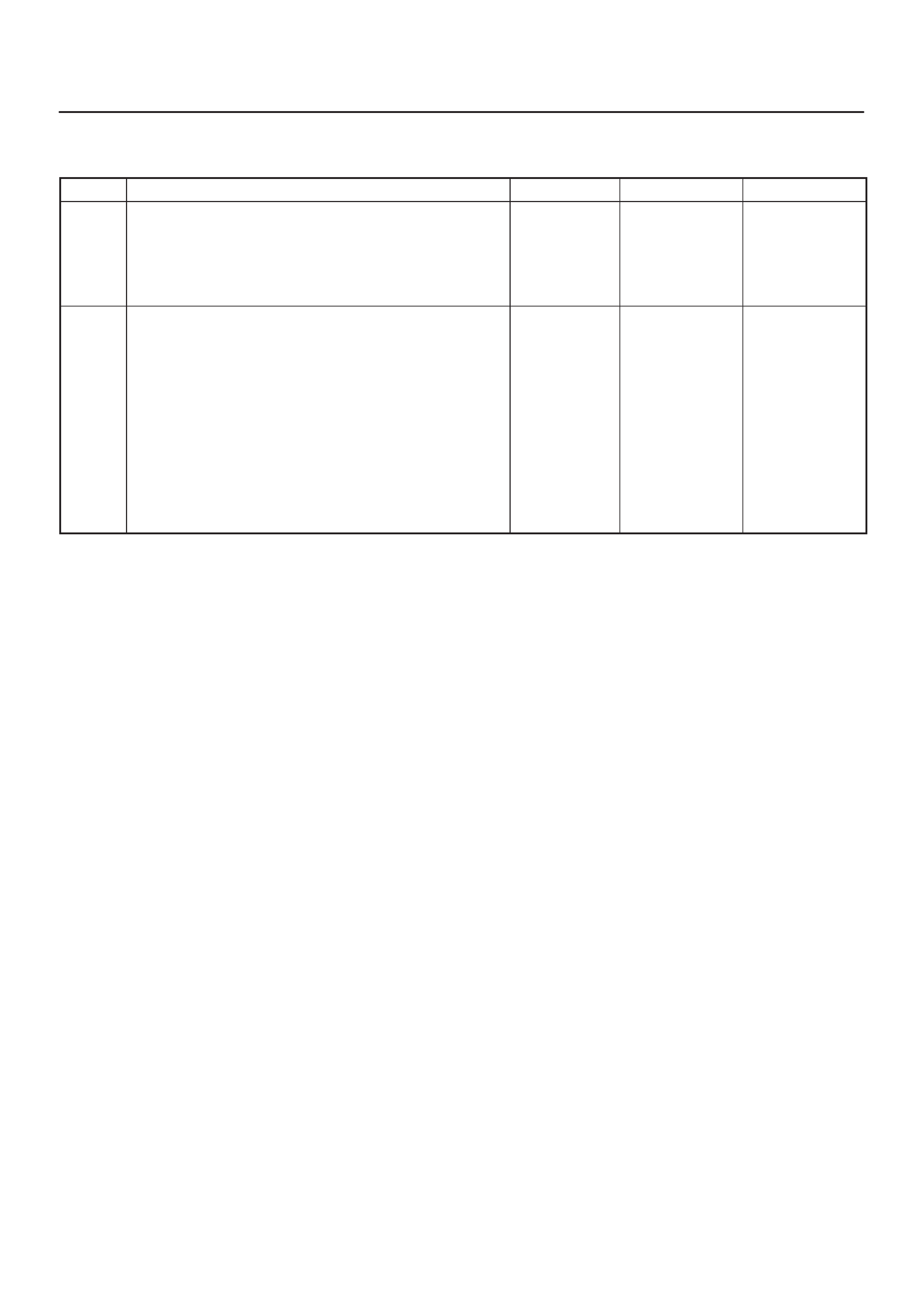

No Malfunction Indicator Lamp (MIL)

Step Action Value(s) YesNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed? —Go to

Step 2

Go to

OBD

System

Check

2Attempt to start the engine.

Does the engine start? —Go to

Step 3

Go to

Step 6

3Check the meter fuse for the instrument cluster ignition

feed circuit.

Is the fuse OK? —Go to

Step 4

Go to

Step 16

4Ignition “ON,” probe the ignition feed circuit at the

cluster connector with a test light to ground.

Is the test light “ON?” —Go to

Step 5

Go to

Step 13

51. Ignition “OFF.”

2. Disconnect the ECM.

3. Jumper the MIL driver circuit at the ECM connector

to ground.

4. Ignition “ON.”

Is the MIL “ON?” —Go to

Step 10

Go to

Step 11

6Check the ECM ignition feed and battery feed fuses (15

A engine fuse and 15 A ECM fuse).

Are both fuses OK? —Go to

Step 7

Go to

Step 15

71. Ignition “OFF.”

2. Disconnect the ECM.

3. Ignition “ON.”

4. Probe the ignition feed circuit at the ECM harness

connector with a test light to ground.

Is the test light “ON?” —Go to

Step 8

Go to

Step 12

8Probe the battery feed circuit at the ECM harness

connector with a test light to ground.

Is the test light “ON?” —Go to

Step 9

Go to

Step 14

9Check for a faulty ECM ground connection.

Was a problem found? — Verify repair Go to

Step 10

10 Check for damaged terminals at the ECM.

Was a problem found? — Verify repair Go to

Step 17

11 Check for an open MIL driver circuit between the ECM

and the MIL.

Was a problem found? — Verify repair Go to

Step 18

12 Substitute a known “good” relay for the ECM main

relay.

Was the malfunction fixed? — Verify repair Go to

Step 13

13 Repair the open in the ignition feed circuit.

Is the action complete? — Verify repair —

14 Locate and repair the open ECM battery feed circuit.

Is the action complete? — Verify repair —

No Malfunction Indicator Lamp (MIL) (Cont'd)

Step NoYesValue(s)Action

15 Locate and repair the short to ground in the ECM

ignition feed circuit or ECM battery feed circuit.

Is the action complete? — Verify repair —

16 Locate and repair the short to ground in the ignition

feed circuit to the instrument cluster, and replace the

fuse.

Is the action complete? — Verify repair —

17 Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete? — Verify repair —

18 Check the MIL driver circuit for a poor connection at the

instrument panel connector.

Was a problem found? — Verify repair

Go to

Instrument

Panel

in

Electrical

Diagnosis

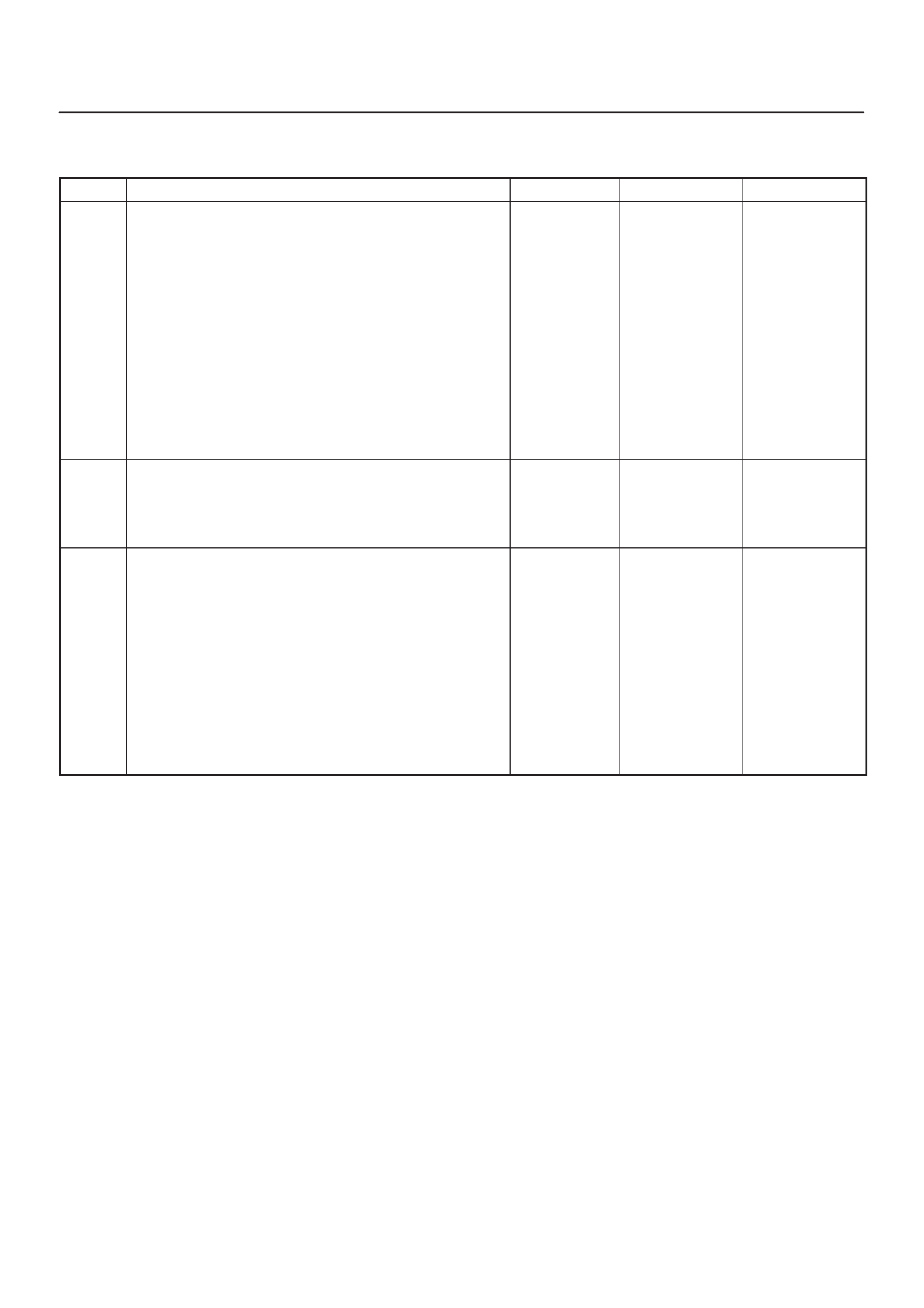

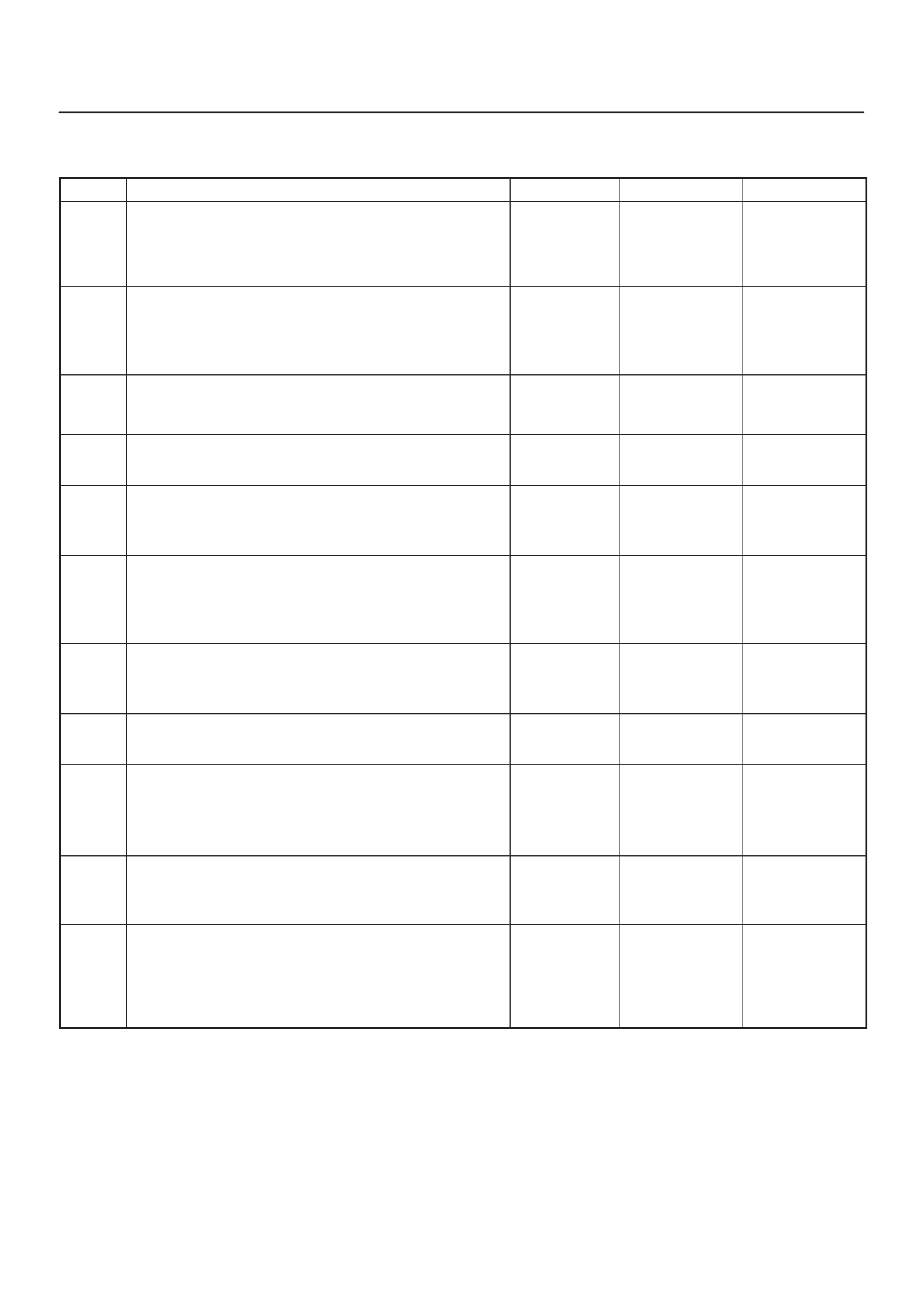

Malfunction Indicator Lamp (MIL) “ON” Steady

060RW136

Circuit description

The “Check Engine” lamp (MIL) should always be

illuminated and steady with ignition “ON” and the engine

stopped. Ignition feed voltage is supplied directly to the

MIL indicator . The Engine Control Module ECM turns the

MIL “ON” by grounding the MIL driver circuit.

The MIL should not remain “ON” with the engine running

and no DTC(s) set. A steady MIL with the engine running

and no DTC(s) suggests a short to ground in the MIL

driver circuit.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed–through wire insulation, or a wire broken inside

the insulation. Check for the following items:

DPoor connection or damaged harness – Inspect the

ECM harness and connectors for improper mating,

broken locks, improperly formed or damaged

terminals, poor terminal-to-wire connection, and

damaged harness.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. If the MIL does not remain “ON” when the ECM is

disconnected, the MIL driver wiring is not faulty.

3. If the MIL driver circuit is OK, the instrument panel

cluster is faulty.

Malfunction Indicator Lamp (MIL) “ON” Steady

Step Action Value(s) YesNo

1Was the “On-Board diagnostic (OBD) System Check”

performed? — Go to

Step 2

Go to

OBD

System

Check

21. Ignition “OFF,” disconnect ECM.

2. Ignition “ON,” observe the MIL (CHECK ENGINE

lamp).

Is the MIL “ON?” —Go to

Step 3

Go to

Step 5

31. Ignition “OFF,” disconnect the instrument panel

cluster.

2. Check the MIL driver circuit between the ECM and

the instrument panel cluster for a short to ground.

3. If a problem is found, repair as necessary.

Was the MIL driver circuit shorted to ground? —

Go to

OBD

System

Check

Go to

Step 4

4Replace the instrument panel cluster.

Is the action complete? —

Go to

OBD

System

Check

—

51. Ignition “OFF,” reconnect the ECM.

2. Ignition “ON,” reprogram the ECM. Refer to

On-Vehicle Service

in

Engine Control Module and

Sensor

for procedures.

3. Using the Tech 2 output controls function, select

MIL dash lamp control and command the MIL

“OFF.”

Did the MIL turn “OFF?” —

Go to

OBD

System

Check

Go to

Step 6

6Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete? —

Go to

OBD

System

Check

—

Engine Cranks But Will Not Run

Circuit Description

In this type of injector system, the Engine Control Module

(ECM) triggers the correct driver inside the injector, which

then triggers the correct injector based on the 57X signal

received from the crankshaft position sensor (CKP).

During crank, the ECM monitors the CKP 57X signal. The

CKP signal is used to determine which cylinder will fire

first. After the CKP 57X signal has been processed by the

ECM, it will command all four injectors to allow a priming

shot of fuel for all the cylinders. After the priming, the

injectors are left “OFF” during the next four 57X reference

pulses from the CKP. This allows each cylinder a chance

to use the fuel from the priming shot. During this waiting

period, a camshaft position (CMP) signal pulse will have

been received by the ECM. The CMP signal allows the

ECM to operate the injectors sequentially based on

camshaft position. If the camshaft position signal is not

present at start-up, the ECM will begin sequential fuel

delivery with a 1-in-4 chance that fuel delivery is correct.

The engine will run without a CMP signal, but will set a

DTC code.

Diagnostic Aids

An intermittent problem may be caused by a poor

connection, rubbed-through wire insulation or a wire

broken inside the insulation. Check for the following

items:

DPoor connection or damaged harness – Inspect the

ECM harness and connectors for improper mating,

broken locks, improperly formed or damaged

terminals, poor terminal-to-wore connection, and

damaged harness.

DFaulty engine coolant temperature sensor – Using a

Tech 2, compare engine coolant temperature with

manifold air temperature on a completely cool engine.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

4. An obvious cause of low fuel pressure would be an

empty fuel tank.

5. The engine will easily start and run if a few injectors

are disabled. It is not necessary to test all injectors

at this time since this step is only a test to verify that

all of the injectors have not been disabled by fuel

contamination.

8.If there is an open or shorted driver circuit, DTCs

0201-0204 should be set.

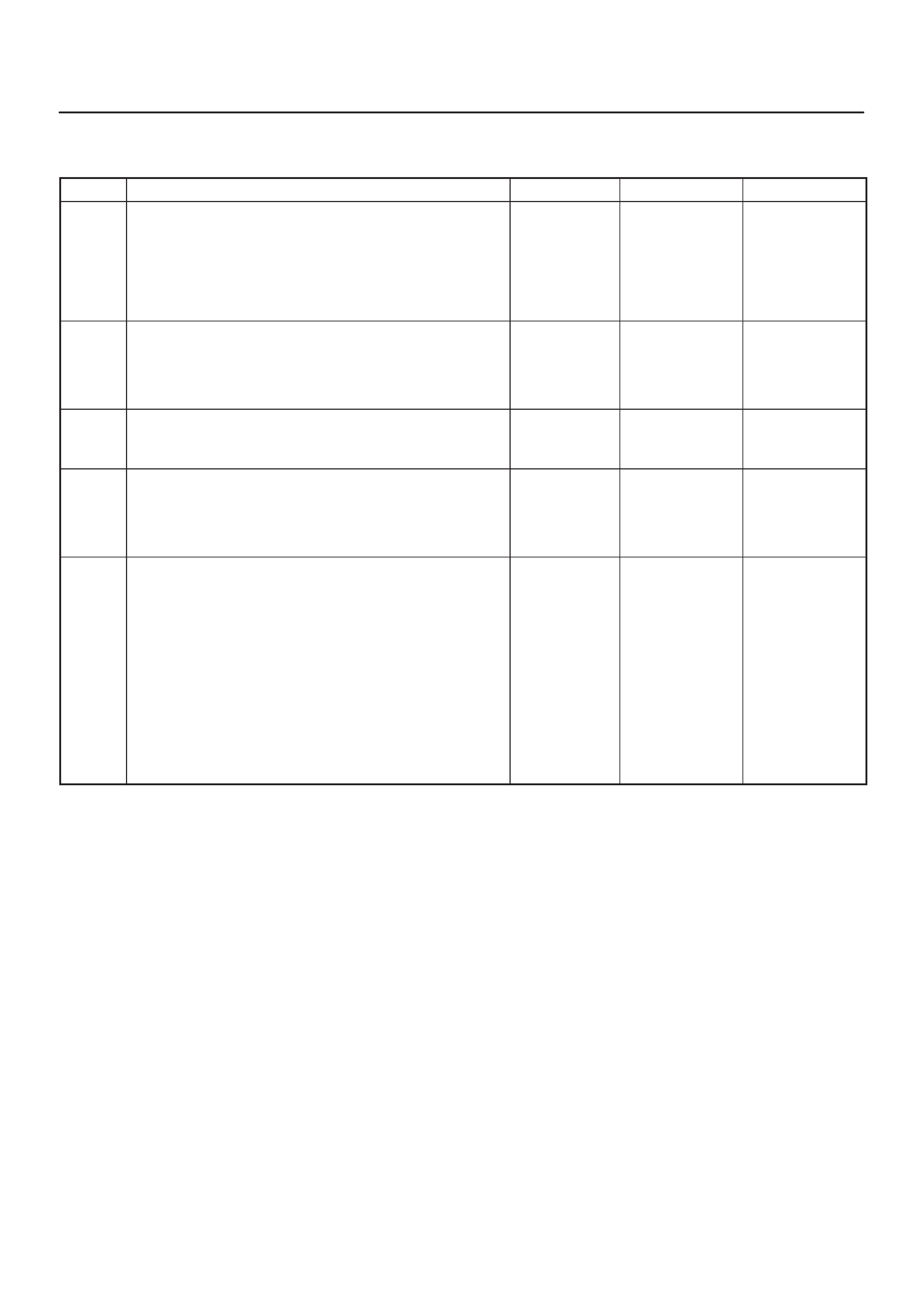

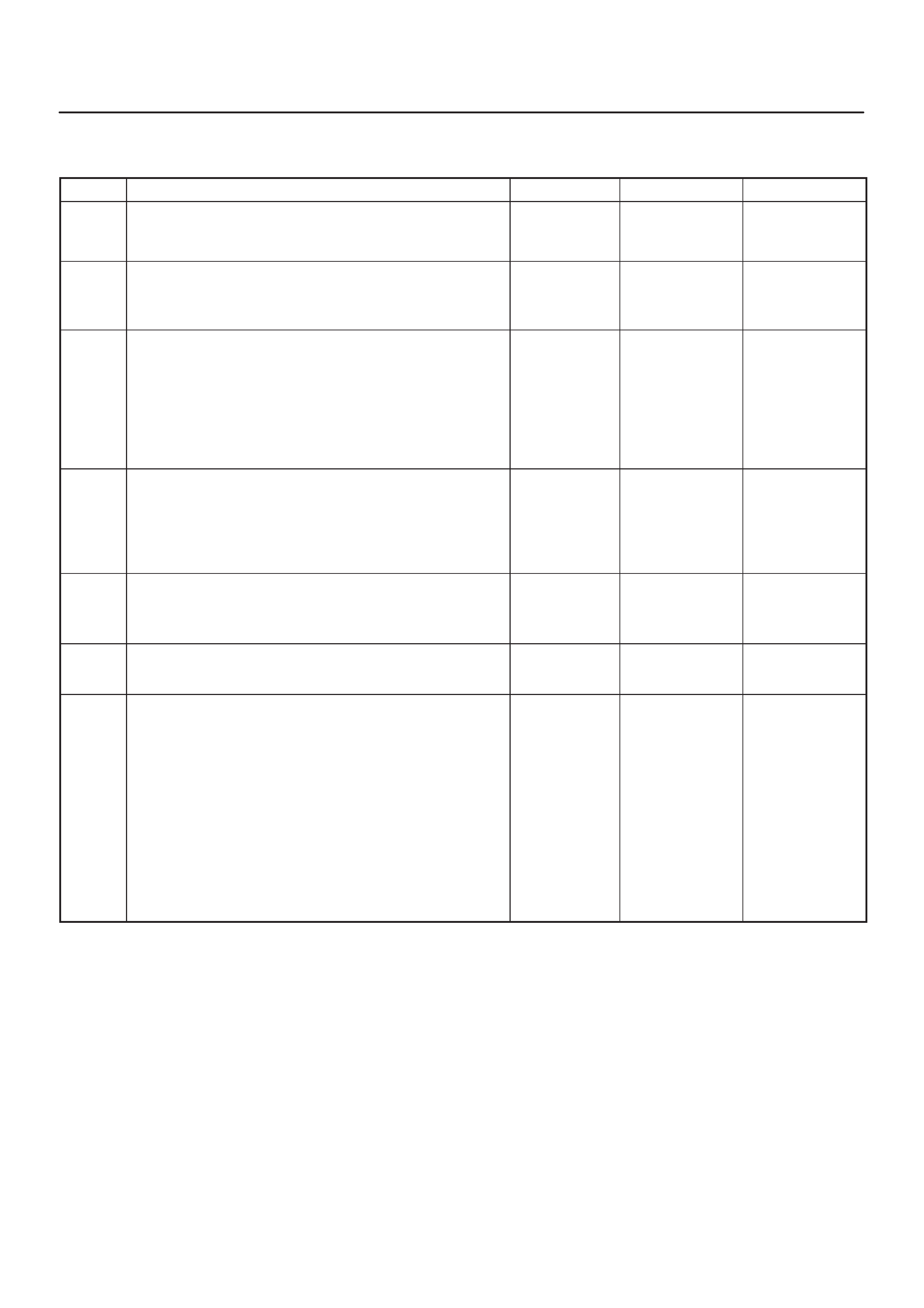

Engine Cranks But Will Not Run

Step Action Value(s) YesNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed? —Go to

Step 2

Go to

OBD

System

Check

2Check the 15 A injector fuse, the 15 A engine device

fuse, and the 15A ECM fuse.

Was a fuse blown? —Go to

Step 3

Go to

Step 4

3Check for a short to ground and replace the fuse.

Is the action complete? — Verify repair —

4Is fuel tank empty? —Fill the fuel

tank Go to

Step 5

5Is the right fuel using? —Go to

Step 6

Replace the

fuel

6Is the right engine oil using? —Go to

Step 7

Replace the

engine oil

7Using the Tech–2.

Is DTC P0192 or P0193 set? (Check rail pressure

system) —

Go to

DTC

P0192 or

DTC P0193

Go to

Step 8

8Using the Tech–2.

Is DTC P0201 – P0204 set? (Check inject circuit fault) —

Go to

DTC

P0201 –

P0204

Go to

Step 9

9Using the Tech–2.

Is DTC P1657 set? (Check ECM Main relay) —Go to

DTC

P1657

Go to

Step 10

Techline

Techline

Engine Cranks But Will Not Run (Cont'd)

Step NoYesValue(s)Action

10 Refer to

Engine Mechanical Diagnosis

to diagnose the

following conditions:

DFaulty camshaft drive belts

DLeaking or sticky valves or rings

DExcessive valve deposits

DWeak valve springs

DIncorrect valve timing

DLeaking head gasket

Is the action complete? — Verify repair Go to

Step 11

11 Observe the “Engine Speed” data display on the T ech 2

while cranking the engine.

Is the engine RPM indicated? (If the Tech 2 is normally

powered from the cigarette lighter socket, and if the

Tech 2 display goes blank while cranking the engine, it

will be necessary to power the Tech 2 directly from the

vehicle battery.) —Go to

Step 12

Go to

Step 17

12 1. At the ECM (female) side of the connector

mentioned in step, connect a test light between the

ignition + terminal and one of the injector driver

circuits at the same connector.

2. Ignition “ON.”

3. Observe the test light, and repeat the test for each

injector driver circuit by oscilloscope.