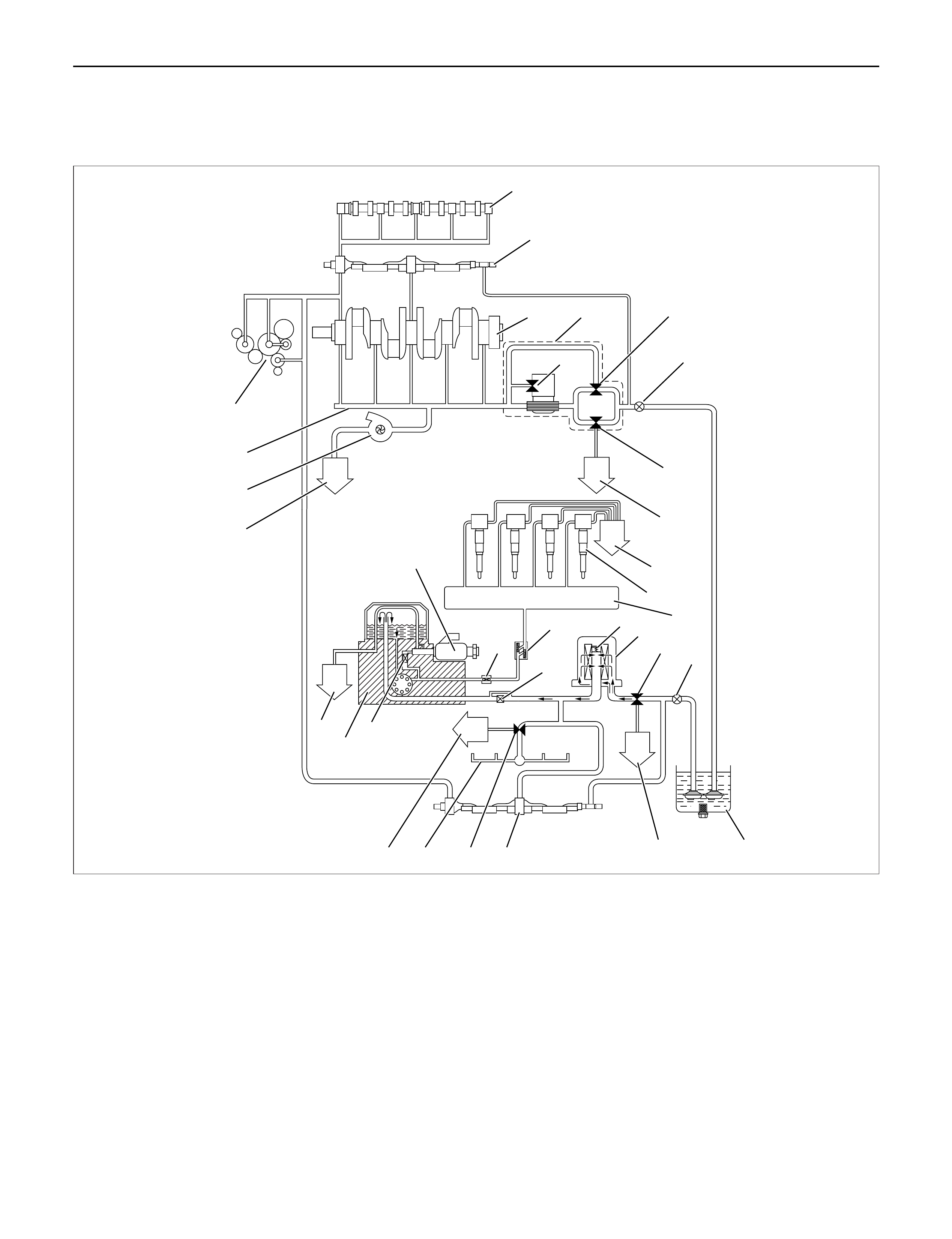

GENERALDESCRIPTION

LUBRICATION CHART

33

32

31

30

1

2

34

5

6

8

9

7

10

11 12

13 14

23

29

25

28 27 26

24

15 16

1718

19202122

Legend

(1) Camshaft

(2) Balance Shaft

(3) Crankshaft

(4) Oil Cooler and Oil Filter Assembly

(5) Oil Filter Relief Valve 98 Kpa (1 kg/cm2/14.2 Psi)

(6) Oil Cooler Relief Valve 245 Kpa (2.5 kg/cm2/

36 Psi)

(7) First Oil Pump

(8) Main Oil Relief Valve 588 Kpa (6 kg/cm2/ 85 Psi)

(9) To Oil Pan

(10) To Oil Pan

(11) Injector

(12) Oil Rail

(13) Sub Oil Filter Relief Valve 98 Kpa (1 kg/cm2/

14.2 Psi)

(14) Sub Oil Filter

(15) Relief Valve 588 Kpa (6 kg/cm2/ 85 Psi)

(16) Second Oil Pump

(17) Oil Pan

(18) To Oil Pan

(19) Balance Shaft

(20) Cooling Jet Relief Valve 245 Kpa (2.5 kg/cm2/

36 Psi)

(21) Cooling Jet

(22) To Oil Pan

(23) Two Way Check Valve

(24) Nipple Filter

040RW018

To meet the requirements of the 4JX1-TC HUEI

fuel injection system, two engine oil pumps have

been provided to ensure adequate oil flow.

The first oil pump serves mainly to lubricate the engine

parts, while the second mainly serves the fuel injectors

and partially cools the pistons.

The oil cooler is provided on the first oil pump side and

uses engine coolant.

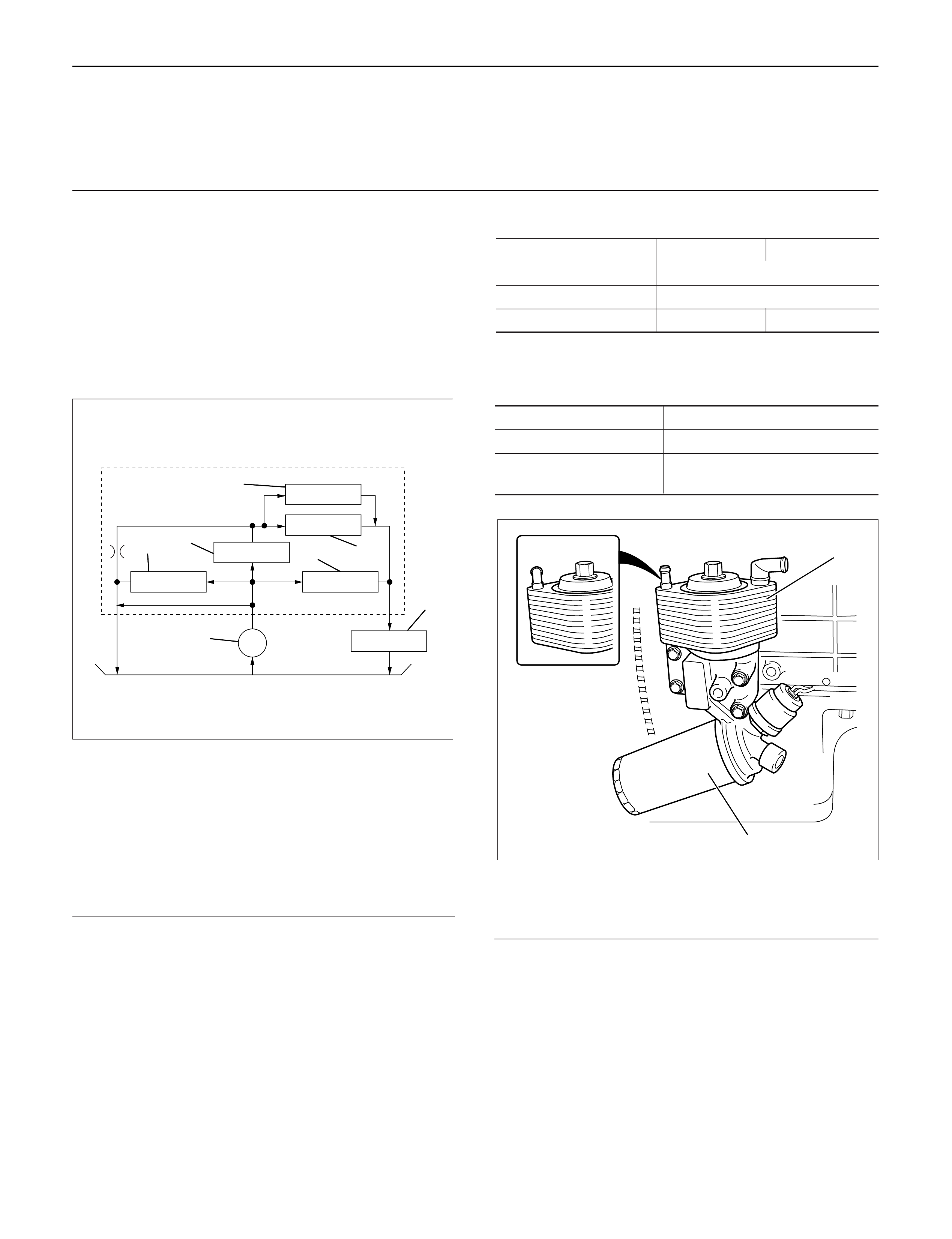

OILFLOW

Legend

(1) Oil Pump

(2) Regulator Valve

(3) Oil Cooler

(4) Oil Filter Relief Valve

(5) Full Flow Filter

(6) Oil Cooler Relief Valve

(7) Gallery

OILPUMPSPECIFICATIONS

First Second

Pump Revolution 8800 rpm

Delivery Pressure 392 Kpa (4.0 kg/cm2/57 psi)

Delivery Capacity >48.8 l/min >37.1 l/min

OILFILTER SPECIFICATIONS

Filtration MethodFull flow Paper

Filtration Area 0.32 m2

Relief Valve opening

981 Kpa (10 kg/cm2/142 psi)

pressure

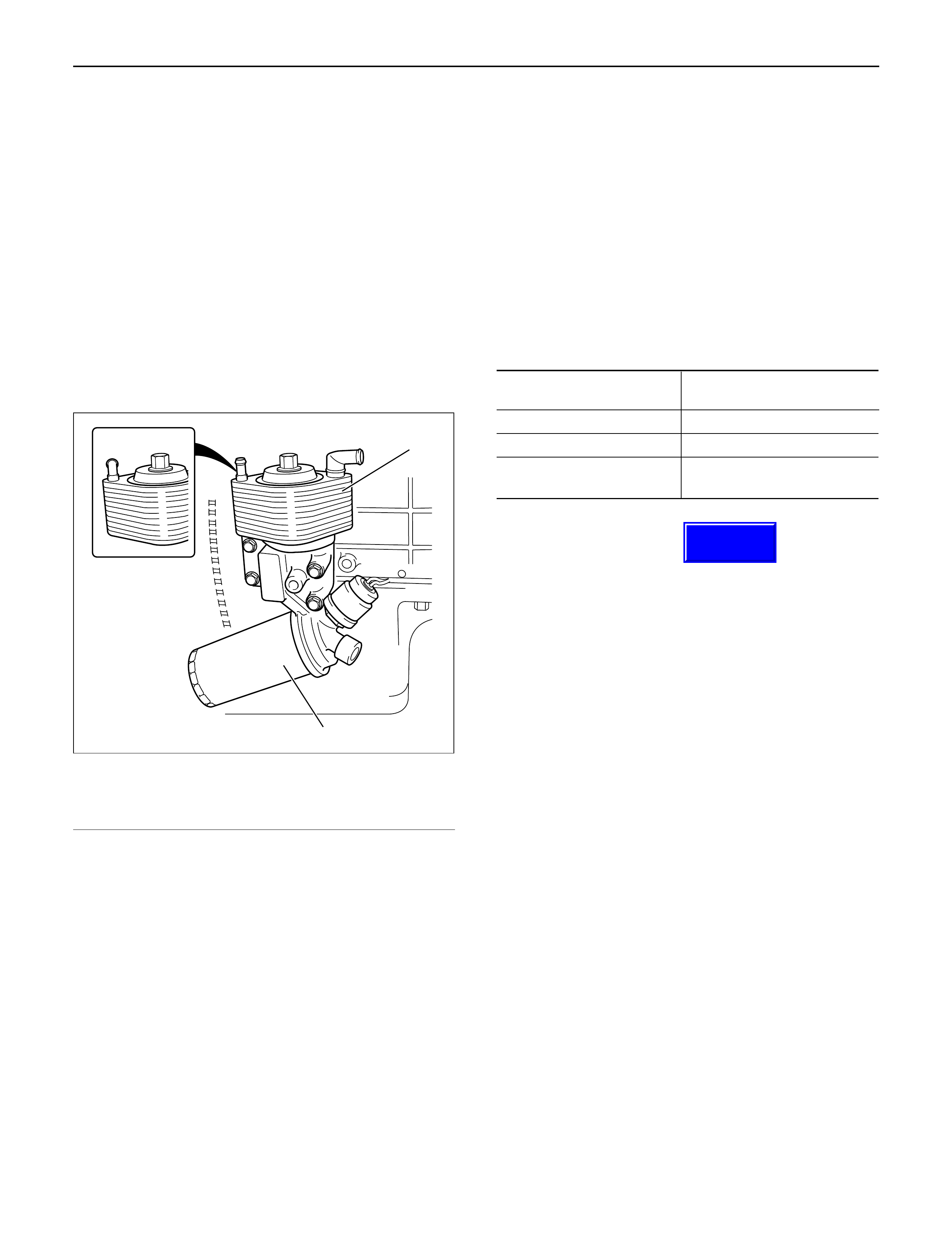

Legend

(1) Oil cooler assembly

(2) Oil filter assembly

(25) Edge Filter

(26) Edge Filter

(27) High Pressure Oil Pump Assembly

(28) To Oil Pan

(29) Pressure Control Valve

(30) To Oil Pan

(31) Turbocharger

(32) Oil Gallery

(33) Timing Gear Train

1

7

65

4

3

2

050RW010

MY2003 Euro-3 1

2

050R200001

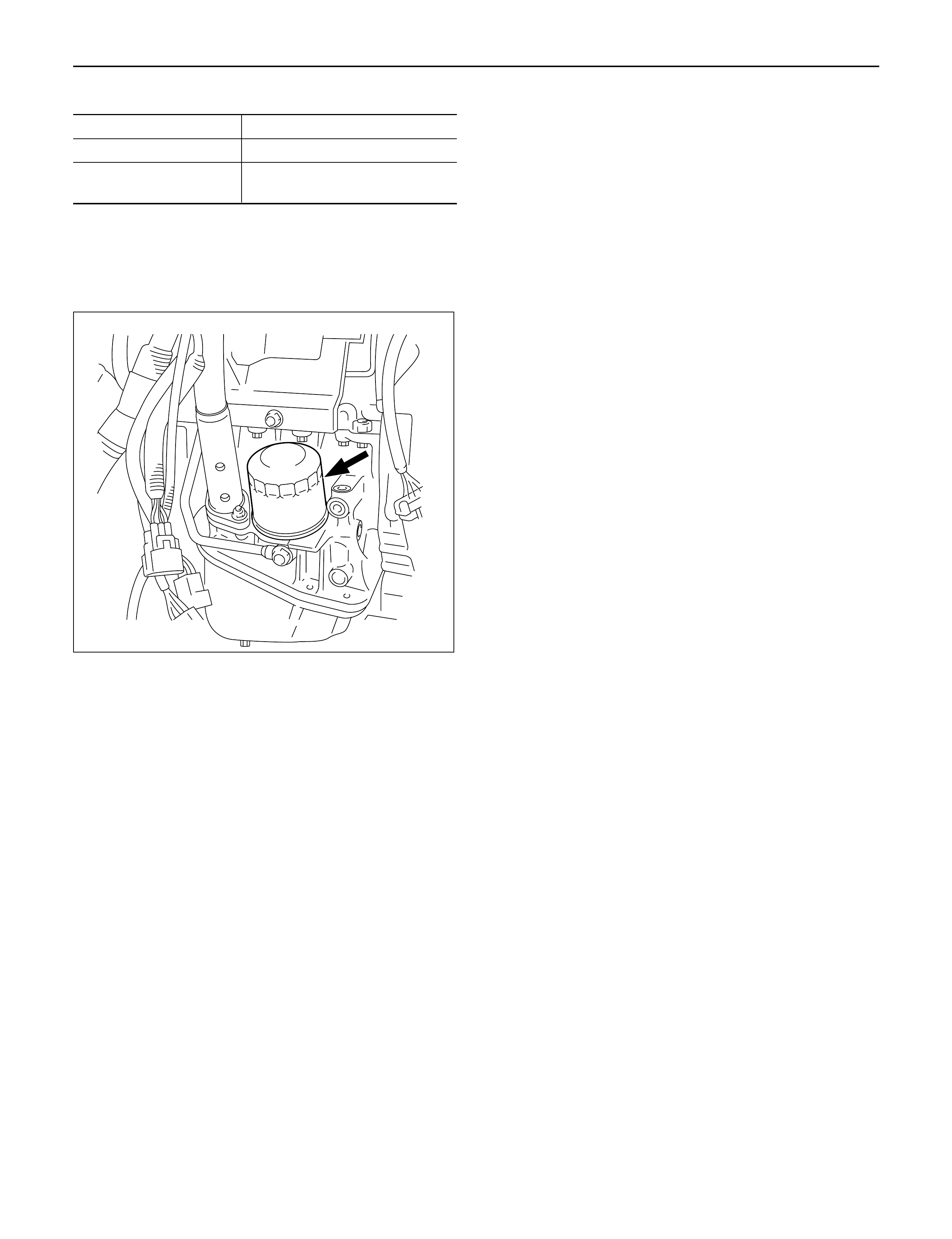

SUB OILFILTER SPECIFICATIONS

Filtration Method Full flow Paper

Filtration Area 0.12 m2

Relief Valve opening

981 Kpa (10 kg/cm2/142 psi)

pressure

The sub oil filter requires replacement after every

20,000km of engine operation.

It is recommended to check and replace the sub filter

whenever the engine is being overhauled.

442RW004

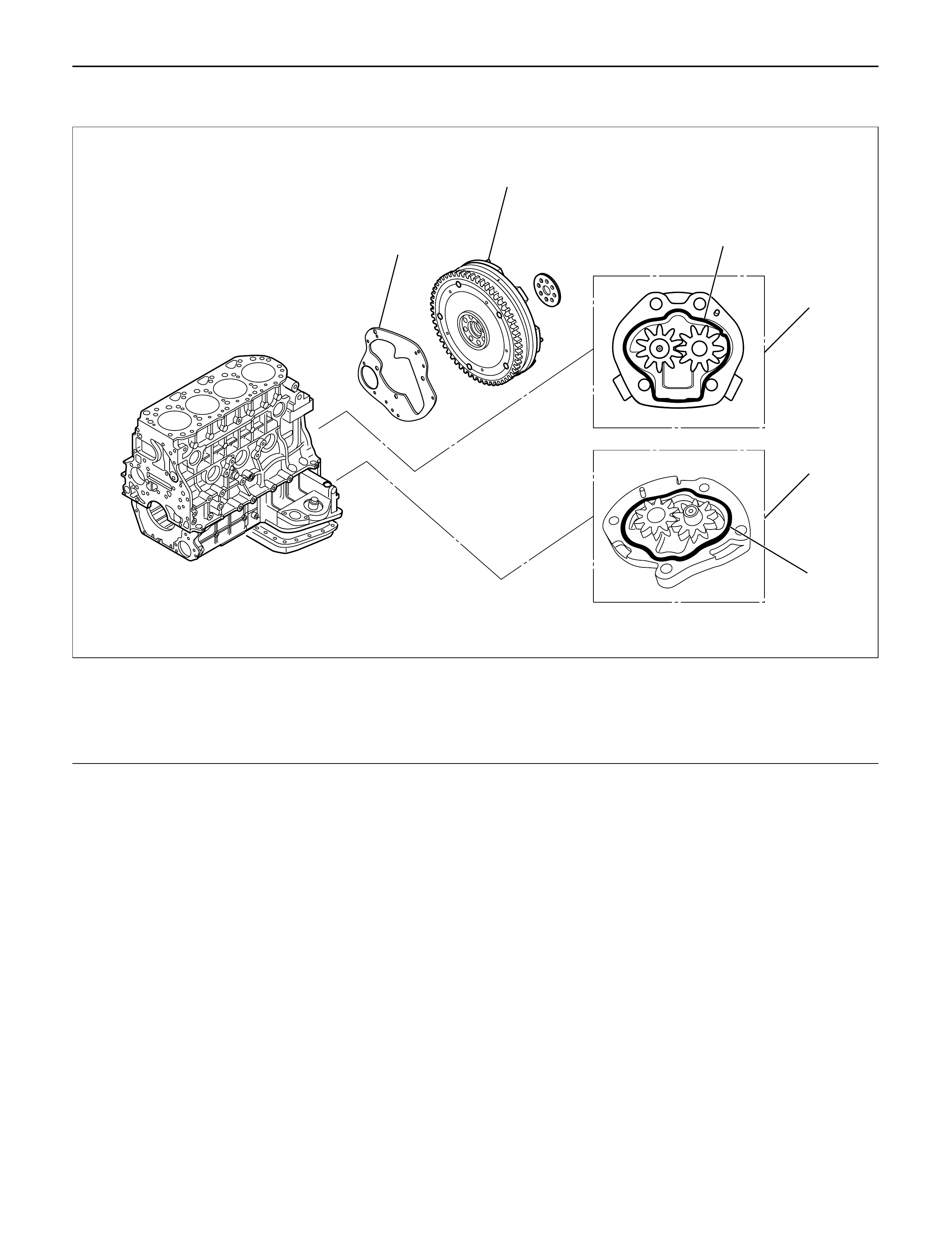

OILPUMP

REMOVAL

1. Remove battery ground cable.

2 Raise the vehicle and support with suitable safety

stand.

3. Drain engine oil.

4. Remove flywheel assembly.

5. Remove rear plate (For A/T) or flywheel housing

(For MT).

6. Remove first oil pump assembly from cylinder block

and second oil pump assembly from crank case.

INSPECTION AND REPAIR

1. Inspect flaws and/or wear on the teeth surface.

2. Inspect abnormal wear journal on the gear and in

the drive spline.

3. If problem is found during inspection, the worn parts

must be replaced.

INSTALLATION

1. Install first oil pump.

1) Set O-ring to oil pump.

2) Install oil pump drive gear to the end of

balance shaft RH.

3) Apply engine oil to oil pump gear and install

gear to the end surface of cylinder block.

Torque: 20 N·m (2.0 kg·m / 14 lb ft)

2. Install second oil pump.

1) Set O-ring to oil pump.

2) Install oil pump drive gear to the end of

balance shaft LH.

3) Apply engine oil to oil pump gear and install

gear to the end surface of crankcase.

Torque: 20 N·m (2·0 kg.m / 14 lb ft)

2

1

5

6

3

4

Legend

(1) Flywheel

(2) Rear Plate

(3) First Oil Pump

(4) Second Oil Pump

(5) O-ring (For 1st oil pump)

(6) O-ring (For 2nd oil pump)

012RW097

OILCOOLER ASSEMBLY

REMOVAL

1. Disconnect battery ground cable.

2. Drain engine coolant.

3. Remove front exhaust pipe.

4. Remove heat protector.

5. Remove exhaust valve assembly.

6. Oil cooler assembly.

1) Remove water hose from water inlet and outlet

side.

2) Cloth should be put under the oil cooler to

prevent oil from flowing out.

3) Loosen fixing bolt then remove oil cooler

assembly.

Legend

(1) Oil cooler assembly

(2) Oil filter assembly

INSPECTION AND REPAIR

1. Inspect for corrosion, wear, and breaks on the oil

cooler core.

2. If a problem is found on the oil cooler core, the oil

cooler assembly must be replaced.

INSTALLATION

1. Oil cooler assembly

1) Tighten oil cooler fixing bolt to the specified

torque and install water hoses.

Torque: 29 N·m (3.0 kg·m / 22 lb ft)

2. Install exhaust valve assembly to turbocharger

assembly and tighten to the specified torque.

Torque: 27 N·m (2.8 kg·m / 20 lb ft)

3. Install front exhaust pipe to the exhaust valve.

Torque:

67 N·m (6.8 kg·.m / 49 lb ft)

(At exhaust valve side)

43 N·m (4.4 kg·m / 32 lb ft)

(At center exhaust pipe side)

4. Install heater protector.

5. Fill engine coolant.

6. Connect battery ground cable.

7. Start engine and carefully check for leakage of oil

and coolant.

OILCOOLER SPECIFICATIONS

Cooling method Water cooled

Multi plate type

Heat exchange Area 0.323 m2

Heat exchange capacity >11,300 kcl/h

Relief Valve opening

245 Kpa (2.5 kg/cm2/36 psi)

pressure

OILFILTER

REMOVAL

1. Put container under the oil filter to prevent oil from

the oil filter from flowing out.

2. Use filter wrench to remove oil filter.

Filter wrench: 5-8840-0203-0

INSTALLATION

1. Apply engine oil thinly to oil filter O-ring.

2. Tighten oil filter by hand until O-ring comes in

contact with the sealing surface.

3. Use filter wrench to tighten oil filter one turn and 1/8

turn.

4. Start engine and carefully check for oil leakage from

oil filter.

SUB OILFILTER

The sub oil filter requires replacement after every

20,000km of engine operation.

It is recommended to check and replace the sub oil filter

when the engine is being overhauled.

MY2003 Euro-3 1

2

050R200001

Techline