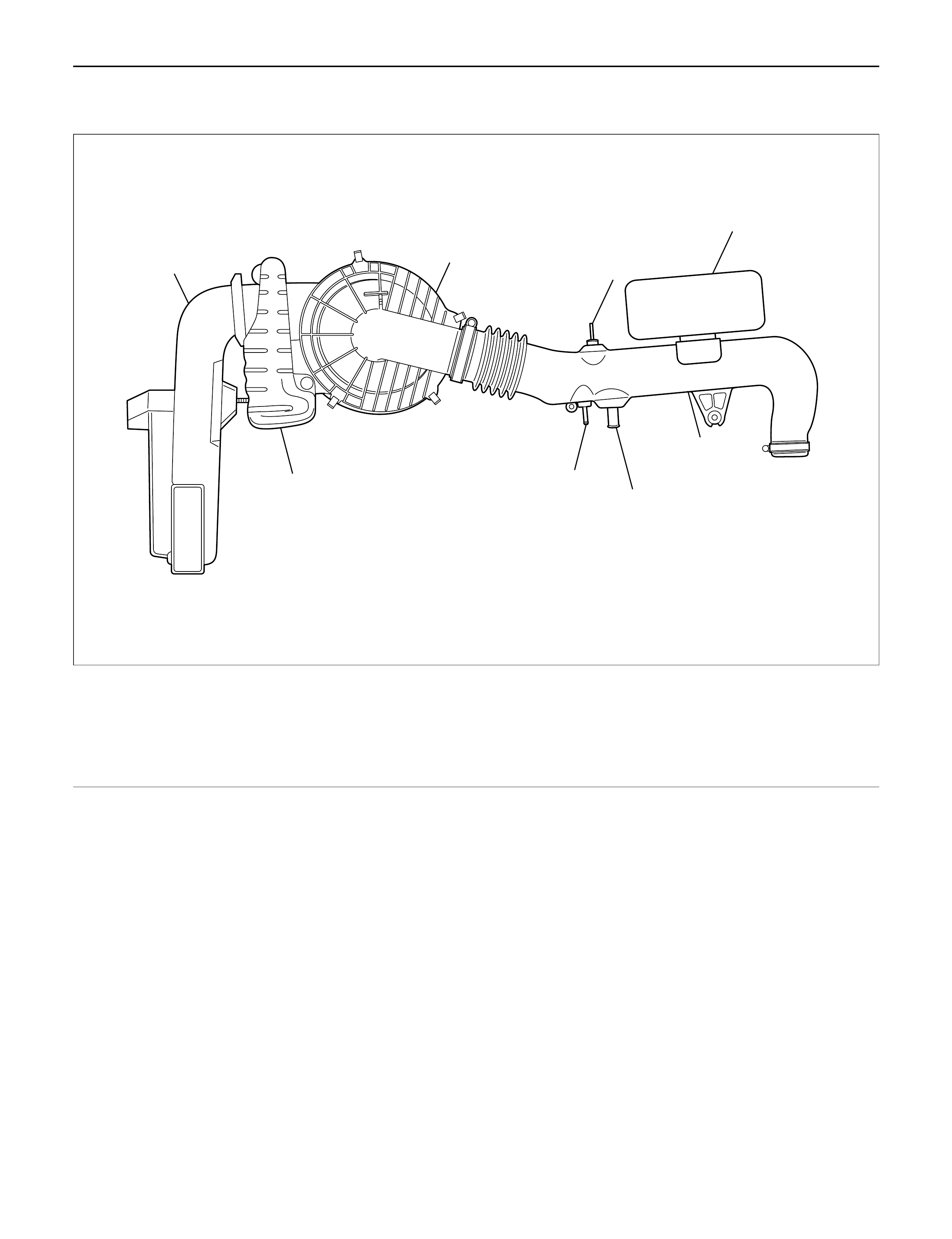

There is a large intake silencer provided at the entrance

of the air cleaner. Air cleaner element is a viscous type

which features high filtration efficiency.

A resonator is used also in the air duct between the air

cleaner and turbocharger to reduce air intake noise.

The air taken in flows through the turbocharger to the

intercooler where the air is cooled and then taken in the

cylinder through the intake manifold.

7

12

3

4

8

5

6

Legend

(1) Air Cleaner

(2) Connector for Fuel Tank Breather Hose

(3) Resonator

(4) Air Duct

(5) Connector for PCV Hose

(6) Connector for EGR VSV Hose

(7) Air Duct

(8) Air Duct

130R200003

GENERALDESCRIPTION

REMOVAL

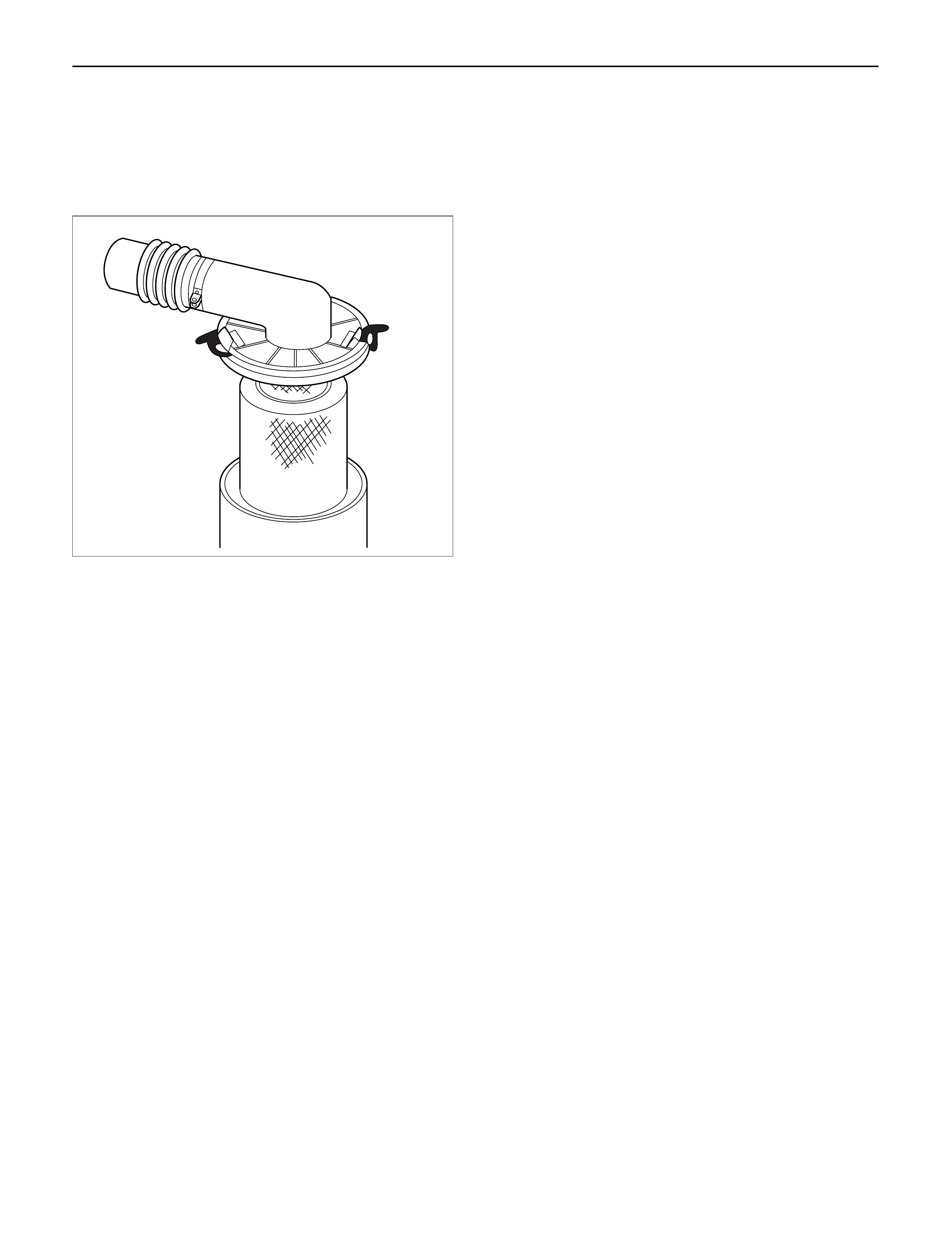

1. Remove air cleaner cover with air duct.

2. Remove air cleaner element.

INSPECTION

Check air cleaner element for clogs, chokes and

breaks, and if any problem is found during inspection,

the element must be replaced.

INSTALLATION

1. Air cleaner element

2. Air cleaner cover with air duct.

1) Put air cleaner cover in original position and

tighten it with the clip.

130RW010

AIR CLEANER

TURBOCHARGER

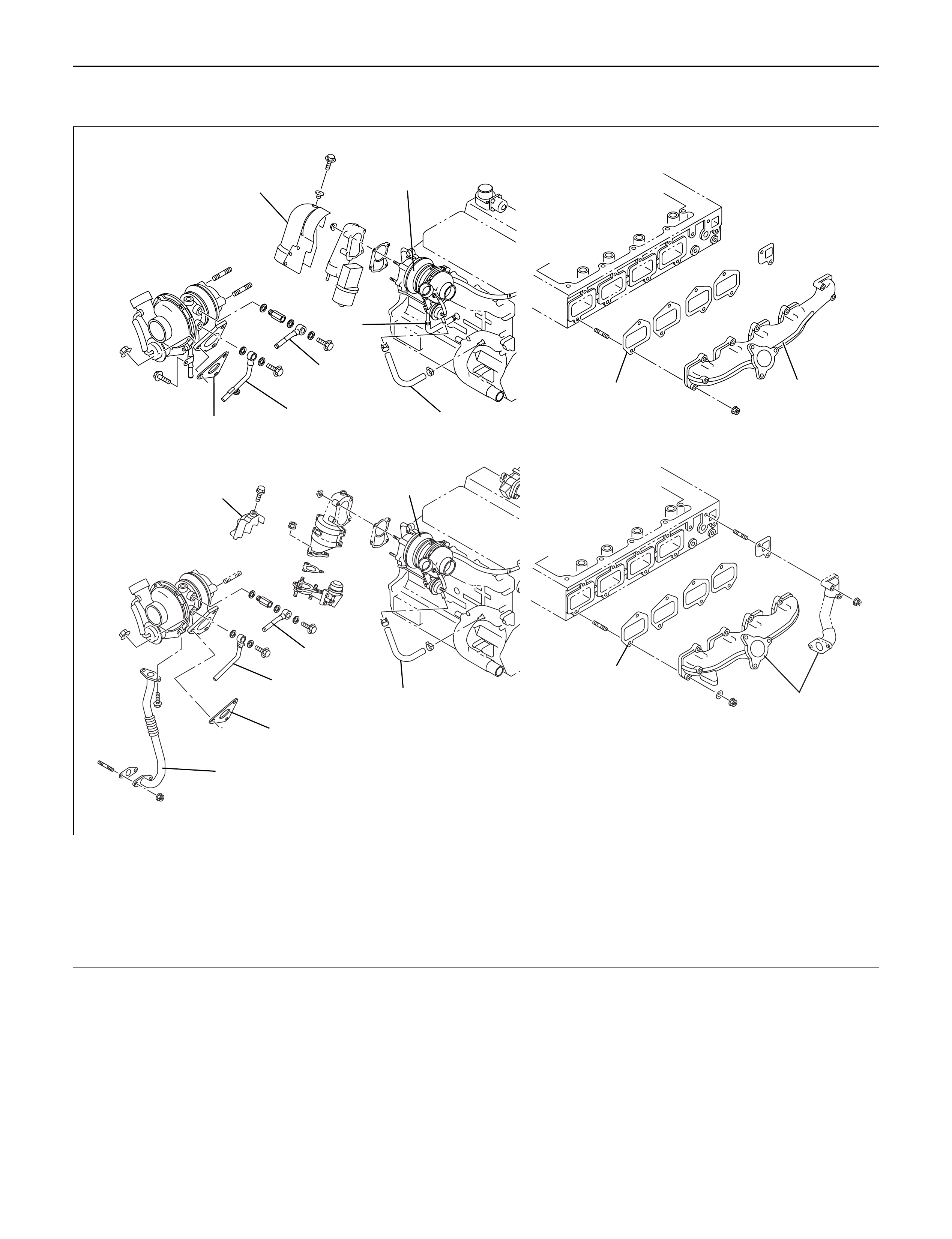

9

5

9

8

MY2003 Euro-3

8

7

5

63

21

4

7

4

2

1

3

6

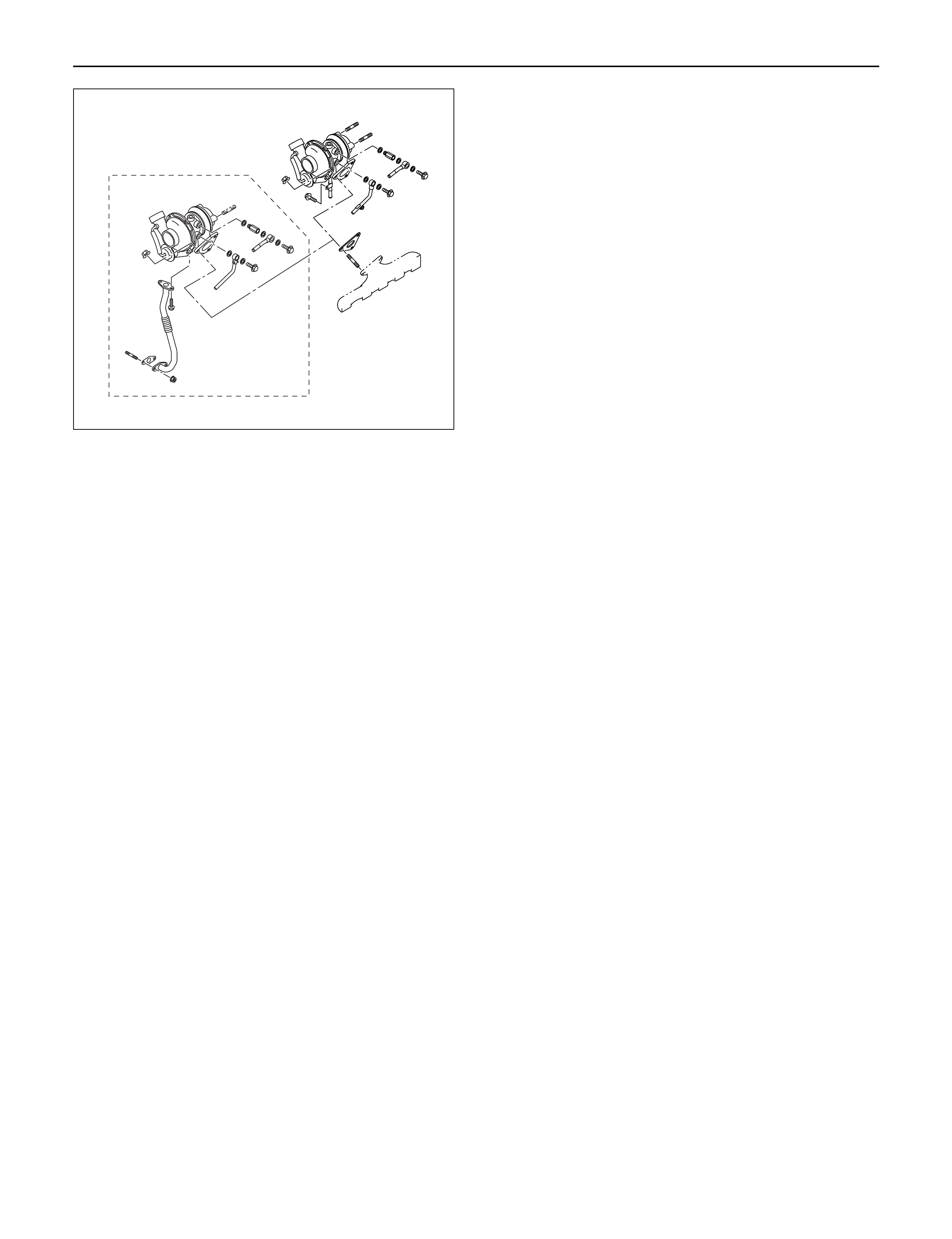

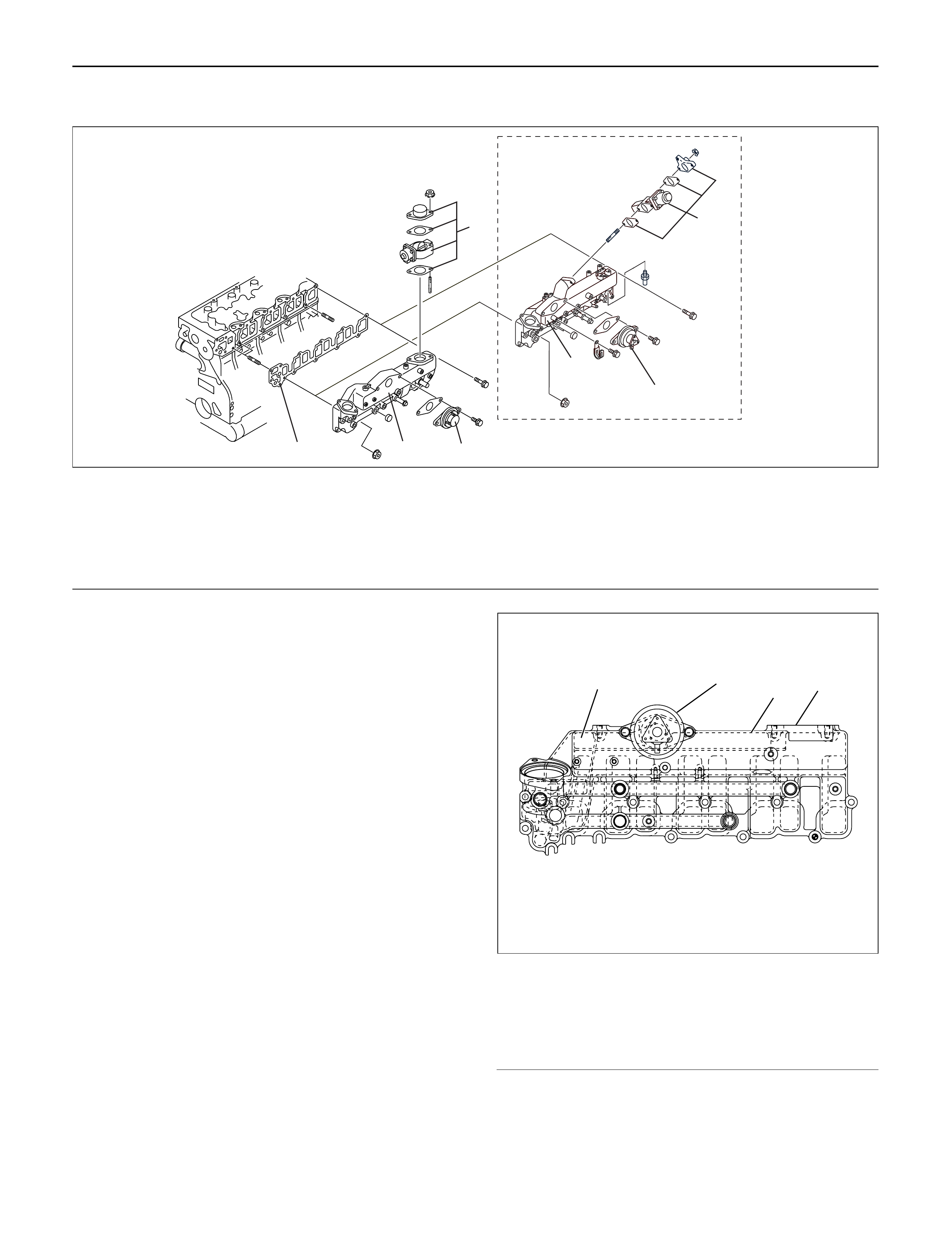

Legend

(1) Exhaust Manifold

(2) Gasket

(3) T urbocharger Assembly

(4) Water Hose

(5) Water Hose

(6) Heat Protector

(7) Oil Pipe

(8) Oil Pipe

(9) Gasket

025R200004

REMOVAL

1.Remove battery.

2.Drain engine coolant.

3.Remove air cleaner cover and air duct.

4.Remove intercooler assembly.

Refer to “Intercooler” in this manual.

5. Remove water pipe from water inlet of

turbocharger.

6. Remove oil pipe.

1) Remove fixing bolts from oil inlet of turbocharger

then remove oil pipe.

2) Plug open port of turbocharger to prevent

foreign materials from entering the turbocharger.

7. Remove oil drain pipe from turbocharger.

8. Remove water outlet pipe from turbocharger.

9. Remove heat protector.

10. Remove exhaust valve assembly.

11. Remove turbocharger fixing nuts from exhaust

manifold then remove turbocharger assembly.

MY2003 Euro-3

025R200006

INSPECTION AND REPAIR

Make the necessary adjustments, repairs and part

replacements if excessive wear or damage is

discovered during inspection.

Minor servicing operations are described in this section.

Contact the nearest IHI SERVICE FACILITY for major

repairs and maintenance.

Refer to IHI SERVICE NETWORK at the end of this

section for the location of your area’s IHI SERVICE

FACILITY.

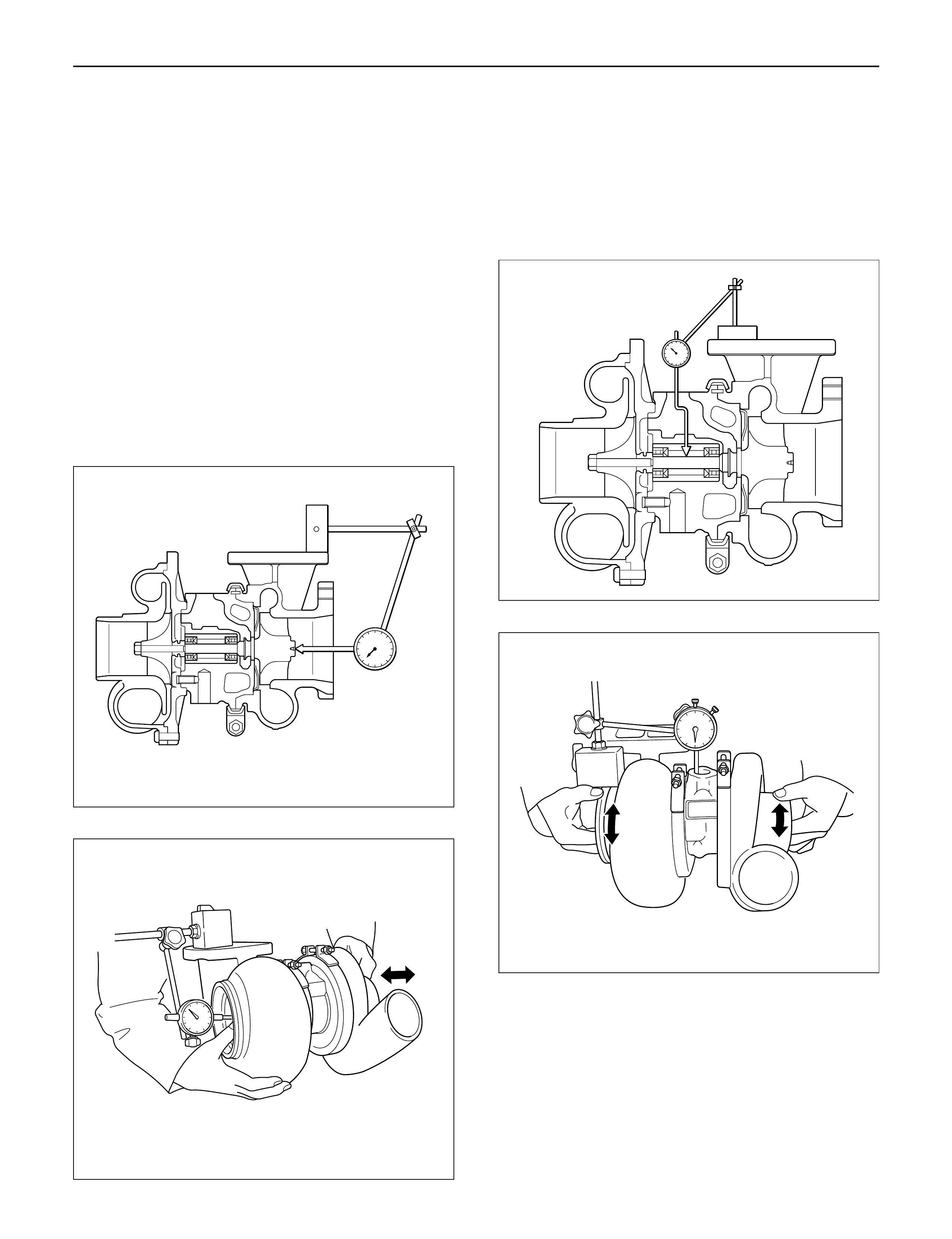

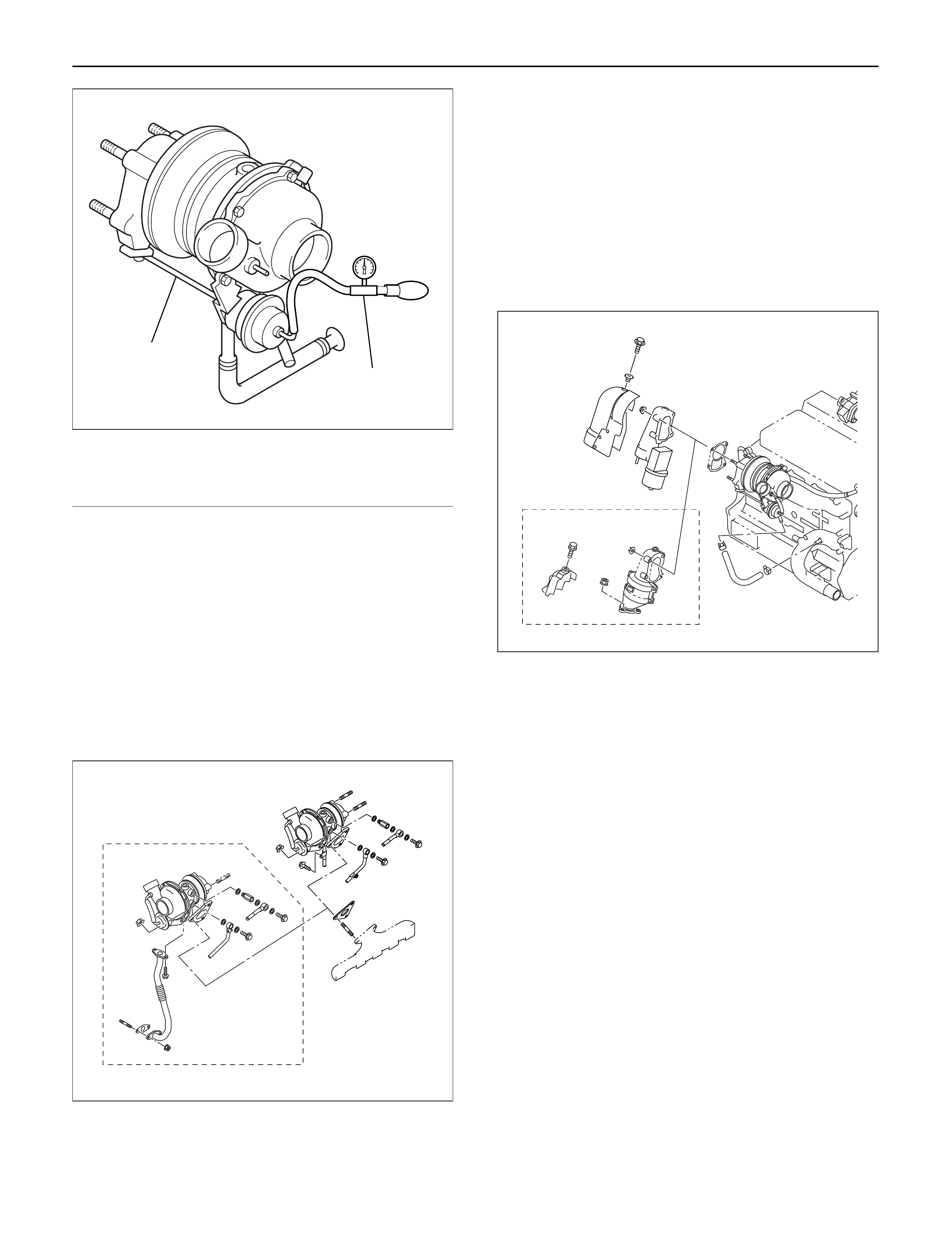

Turbine shaft end play.

1) Set a dial indicator to the turbine shaft end.

2) Apply a force of 11.8 N (1.2 kg / 2.6 lb)

alternately to the compressor wheel and and the

turbine wheel end.

3) Read the dial indicator.

Turbine End Play

Standard: 0.03 – 0.06 mm (0.0012 – 0.0024 in)

Limit: 0.09 mm (0.0035 in)

Turbine shaft and bearing clearance

1) Set a dial indicator to the turbine shaft center

through the center housing oil drain port.

2) Move the turbine shaft from side to side.

3 Read the dial indicator.

Turbine Shaft and Bearing Clearance

Standard: 0.056 - 0.127 mm (0.0022 - 0.0050 in)

Limit: 0.14 mm (0.0055 in)

Waste gate operation

1) Remove hose from waste gate actuator side and

install pressure gauge (1) to the waste gate

actuator.

2) Operate pump of pressure gauge while engine is

stopped.

3) Read pressure at the control rod (2) move 2mm.

Pressure: 106 – 115 kPa

(796 – 862 mmHg/ 15.4 – 16.7 PSi)

036RW008

036RW010

036RW009

036RW007

Legend

(1)Pressure gauge

(2)Waste gate control rod

4)Check for cracks or breaks on the hose, if a

problem is found, the hose must be replaced.

CAUTION: Do not apply more than 120 Kpa (900

mmHg / 18.7 PSi) to waste gate actuator.

INSTALLATION

1. Install turbocharger assembly to exhaust manifold,

tighten to the specified torque.

Torque: 27 N·m (2.8 kg·m / 20 lb ft)

2. Install exhaust valve assembly to outlet of

turbocharger, tighten bolts to the specified torque.

Torque: 27 N·m (2.8 kg·m / 20 lb ft)

3. Install heat protector.

4. Water inlet pipe.

1) Tighten water inlet pipe with new gasket.

Torque: 9 N·m (0.9 kg·m / 78 lb in)

5. Oil drain pipe.

1) Tighten oil drain pipe with new gasket.

Torque: 9 N·m (0.9 kg·m / 78 ib in)

6. Oil inlet pipe.

1) Apply about 100 cc engine oil to turbocharger

housing before installing the oil pipe.

2) Turn the turbine shaft by hand to lubricate the

bearing.

3) Install the oil inlet pipe with a new gasket, tighten

bolt to the specified torque.

Torque: 22 N·m (2.2 kg·m / 16 lb ft) For M10

Torque: 54 N·m (5.5 kg·m / 40 lb ft) For M14

2

1

036RW011

MY2003 Euro-3

025R200007

MY2003 Euro-3

025R200006

7.Water inlet pipe.

1)Install water inlet pipe with a new gasket, tighten

bolts to the specified torque.

Torque: 9 N·m (0.9 kg·m / 78 lb in)

8.Install intercooler assembly.

Refer to “Intercooler” in this manual.

9. Install air cleaner cover with air duct.

10. Fill engine coolant to full level.

11. Install battery and connect battery cable.

MY2003 Euro-3

025R200007

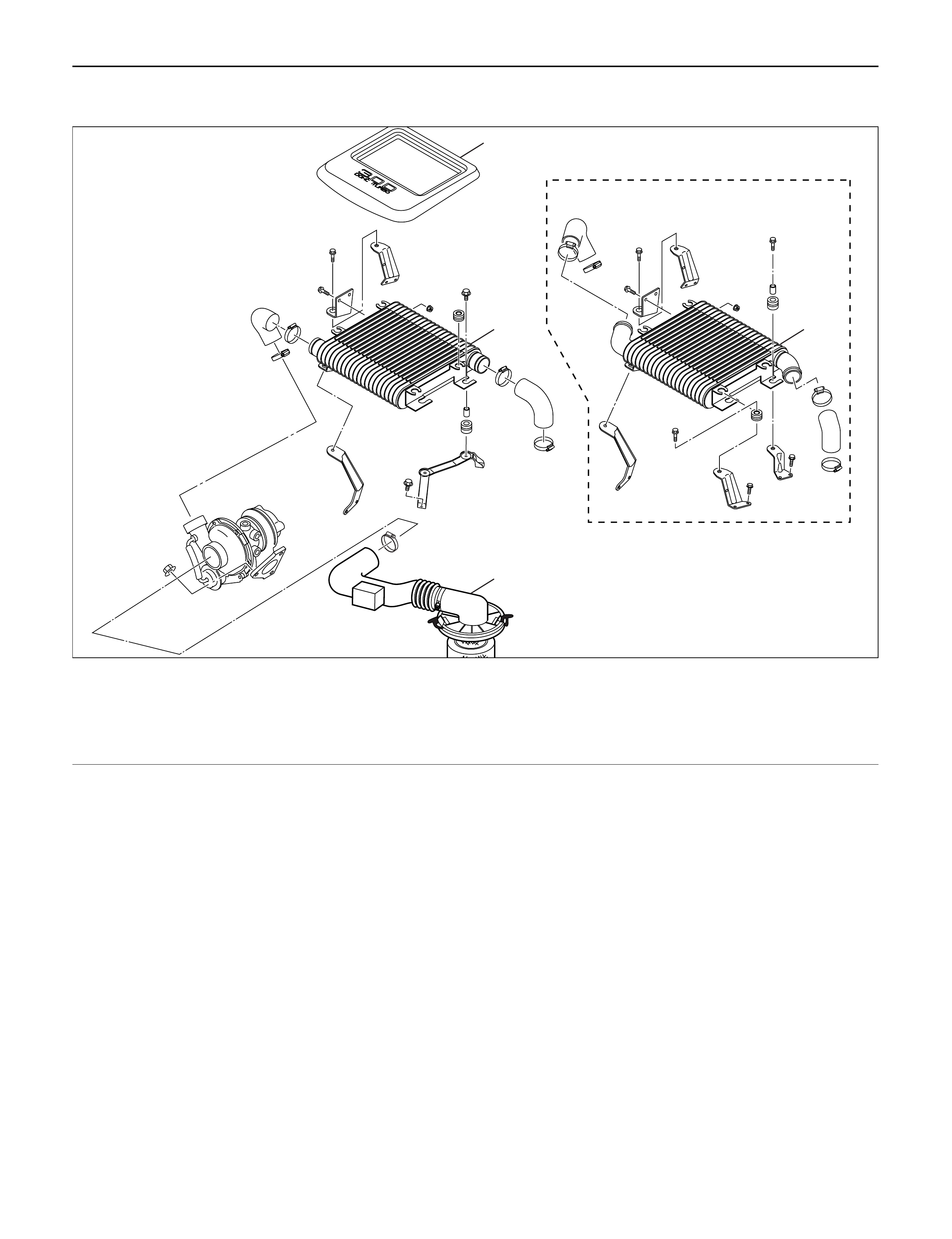

INTERCOOLER

REMOVAL

1. Disconnect battery ground cable.

2. Remove air cleaner cover with air duct.

3. Remove intercooler cover.

4. Intercooler assembly.

1) Remove rubber hose from intercooler outlet

side.

2) Remove rubber hose from intercooler inlet side.

3) Remove four fixing bolts and remove intercooler

assembly.

INSPECTION AND REPAIR

1. Visual check for clogs in the fins.

2. Check for brokens on the tube.

3. If any problem on the intercooler is observed during

inspection, clean or replace the intercooler.

INSTALLATION

1. Intercooler assembly.

1) Connect outlet hose to intake manifold.

Tighten hose clamp to the specified torque.

Torque: 4 N·m (0.4 kg·m / 35 lb in)

2) Connect inlet hose to the turbocharger outlet

side.

Tighten hose clamp to the specified torque.

Torque: 4 N·m (0.4 kg·m / 35 lb in)

3) Install intercooler assembly, tighten fixing bolts

to the specified torque.

Torque: 20 N·m (2.0 kg·m / 14 lb ft)

2. Install intercooler cover.

3. Install air cleaner cover and air duct.

4. Connect battery ground cable.

MY2003 Euro-3

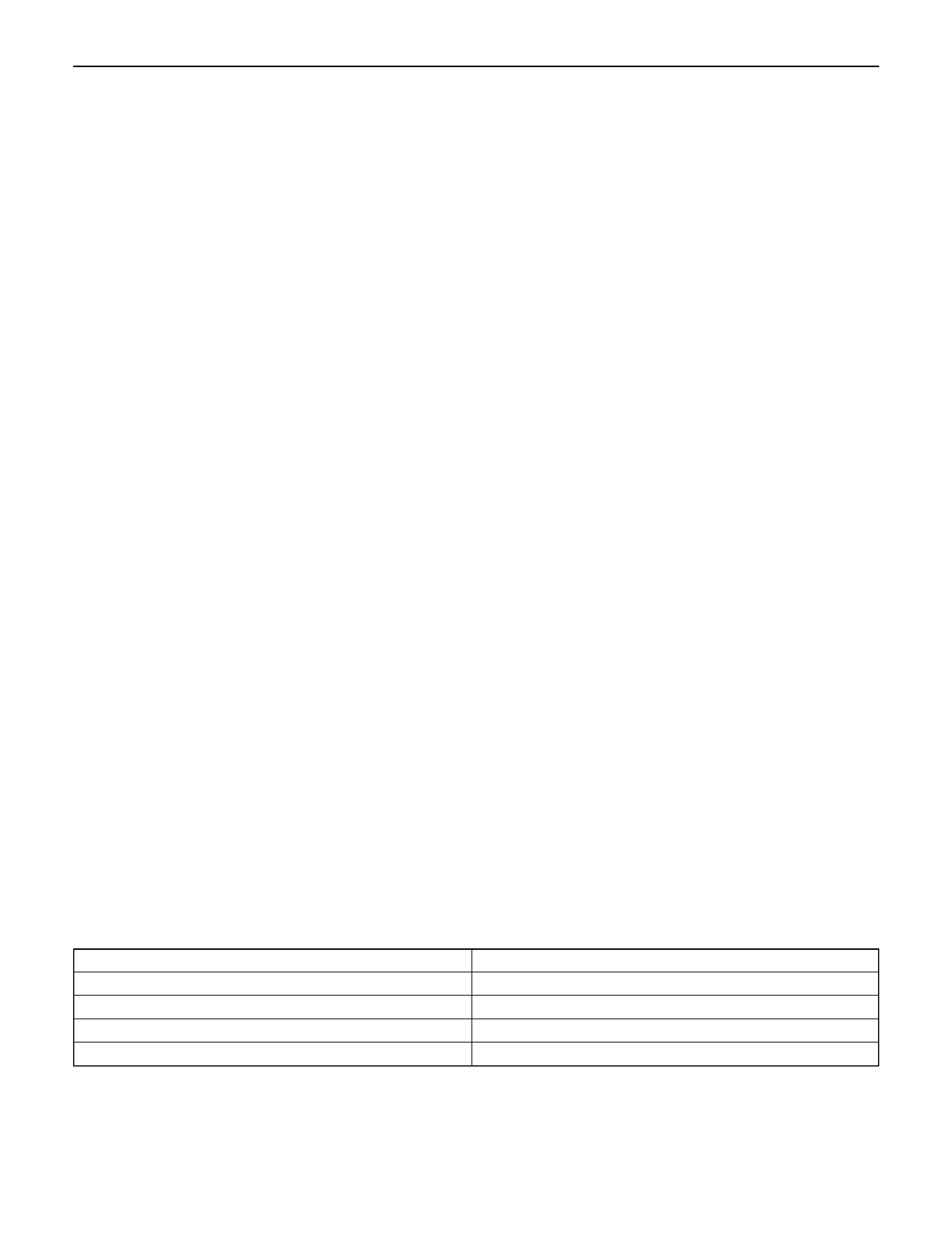

2

3 3

1

Legend

(1) Air Cleaner Cover and Air Duct

(2) Intercooler Cover

(3) Intercooler Assembly

135R200003

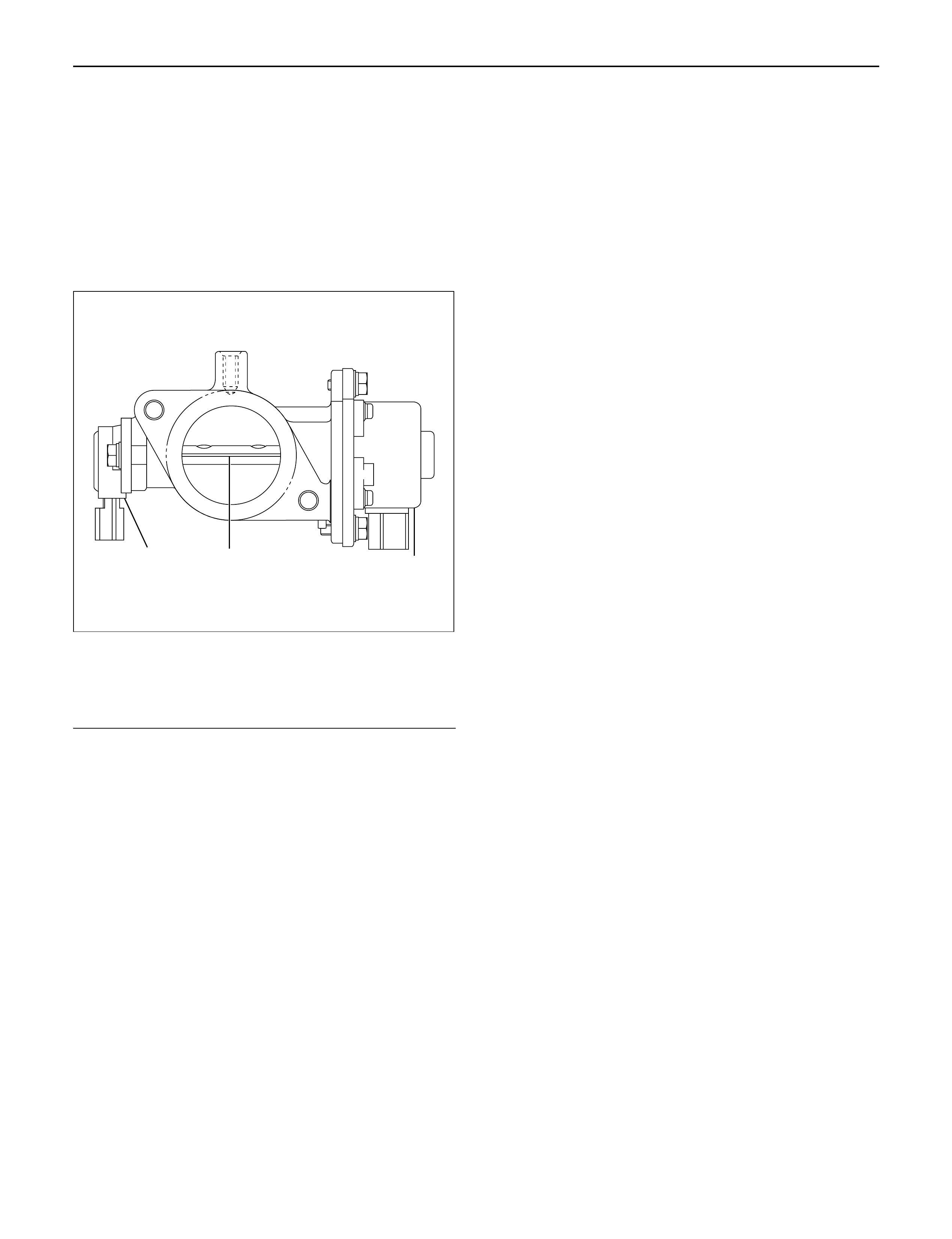

REMOVAL

1.Remove intercooler assembly.

Refer to “Intercooler” in this manual.

2. Remove harness connector from motor and ITP

sensor.

3. Loosen the two fixing nuts and remove the throttle

valve assembly.

Legend

(1) Motor

(2) Intake Throttle Valve

(3) ITP sensor

INSPECTION AND REPAIR

1. Check for catching somwhere on the throttle valve.

2. If some problem is discovered during inspection on

the throttle valve, the throttle valve must replace.

INSTALLATION

1. Put gasket on the intake manifold and install throttle

valve.

2. Tighten nuts to the specified torque.

Torque: 20 N·m (2.0 kg·m / 14 lb ft)

3. Reconnect harness connector to motor and

ITPsensor.

4. Install intercooler assembly.

1

2

3

025RW032

INTAKE THROTTLE VALVE

INTAKE MANIFOLD

REMOVAL

1. Drain engine coolant and remove water hose from

thermostat housing

2. Remove intercooler assembly.

3. Remove bracket fixing bolt of oil level gauge guide

tube.

4. Remove PCV hose.

5. Remove hoses from EGR valve, EGR vacuum

sensor and outlet of heater unit.

6. Disconnect harness connector from MAP sensor,

EGR vacuum sensor, ETC sensor, Water

temperature unit, IAT sensor and EVRV.

7. Remove high pressure oil pipe.

8. Remove two way check valve.

9. Remove fuel pipe.

10. Remove fixing bolts and nuts of intake manifold,

remove intake manifold assembly.

Legend

(1) Intake manifold

(2) Fixing portion of throttle valve

(3) EGR passage

(4) EGR valve

MY2003 Euro-3

2

1

3

3

14

2

Legend

(1) Intake Manifold

(2) Throttle Valve Assembly

(3) EGR Valve

(4) Gasket

025R200005

312

4

025RW031

INSPECTION AND RAPAIR

1.Visually check for cracks/clogs inside intake

manifold.

2.If foreign material is observed, it should be taken

out, and if there are some cracks on the intake

manifold, it must be replaced.

INSTALLATION

1.Install the intake manifold assembly, tighten bolts

and to the specified torque.

Torque: 20 N·m (2.0 kg·m / 14 lb ft) for bolt

Torque: 20 N·m (2.0 kg·m / 14 lb ft) for nut

2.Install fuel pipe.

Torque: 4 N·m (0.4 kg·m / 35 lb in) for M16 nut

(Apply engine oil)

Torque: 13 N·m (1.3 kg·m / 113 lb in) for M10 cap

nut

Torque: 14 N·m(1.4 kg·m / 122 lb in) for M10

(Apply engine oil)

3.Install two way check valve.

Torque: 20 N·m (2.0 kg·m / 14 lb ft)

4.Fill with about 300 cc of engine oil from the high

pressure oil pipe installation port of the oil rail using

an oil filler.

If assembled without filling the oil rail with oil, the

time for engine starting will be longer.

5.Install high pressure oil pipe, then tighten sleeve nut

to the specified torque.

Torque: 29 N·m (3.0 kg·m / 22 lb ft)

6.Reconnect harness connector to MAPsensor, EGR

vacuum sensor, ETC sensor, Water thermo unit,

IATsensor and EVRV sensor.

7.Install hoses to EGR valve, EGR vacuum sensor

and Water outlet of heater.

8.Connect PCV hose.

9.Install oil level gauge guide and fix it.

10.Install intercooler assembly.

Refer to “Intercooler” in this manual.

11. Install water hose to thermostat housing and fill with

engine coolant.

Model of Turbocharger IHI RHF5

Turbine Maximum Speed 180,000 rpm

Maximum Inlet Gas Temperature 800 °C (1472 °F)

Vibration Peak (G) criteria Maximum 4 (G) at Turbine Rotor Speed 140,000 rpm

Tolerance Limit of Compressor Blade Height Less then 0.5 mm (0.0197 in)

MAIN DATAAND SPECIFICATIONS