SECTION 6A1 - ENGINE MECHANICAL

Service Precaution

General Description

Engine Diagnosis

Cylinder Head Cover LH

Removal

Installation

Cylinder Head Cover RH

Removal

Installation

Common Chamber

Removal

Installation

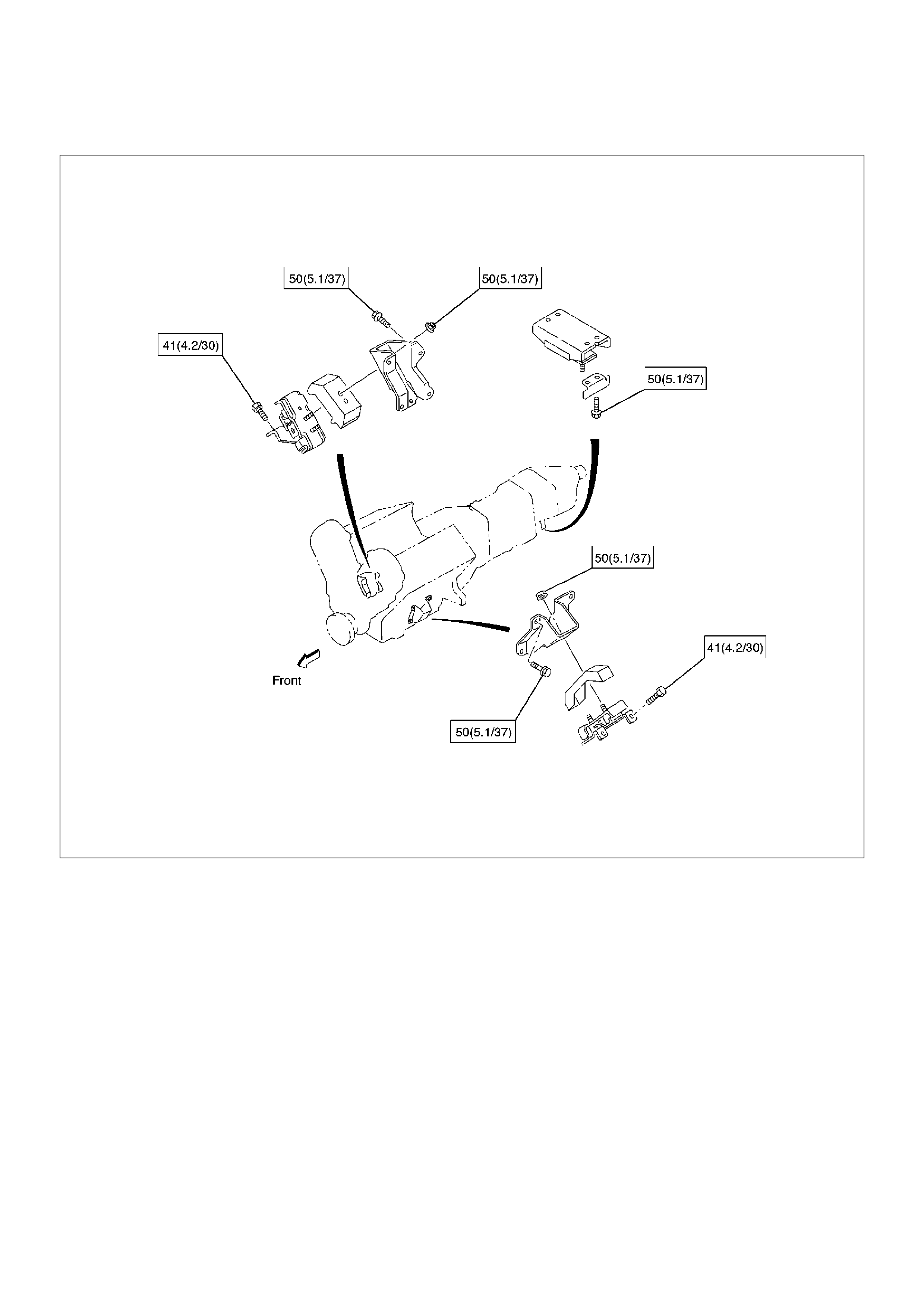

Exhaust Manifold LH

Removal

Installation

Exhaust Manifold RH

Removal

Installation

Crankshaft Pulley

Removal

Installation

Timing Belt - Broken Belt

Removal

Installation

Timing Belt Replacement - Service Operation

Removal

Installation

Installation

Camshaft

Removal

Installation

Cylinder Head

Removal

Installation

Valve Stem Oil Controller , Valve Spring and Valve

Guide

Removal

Installation

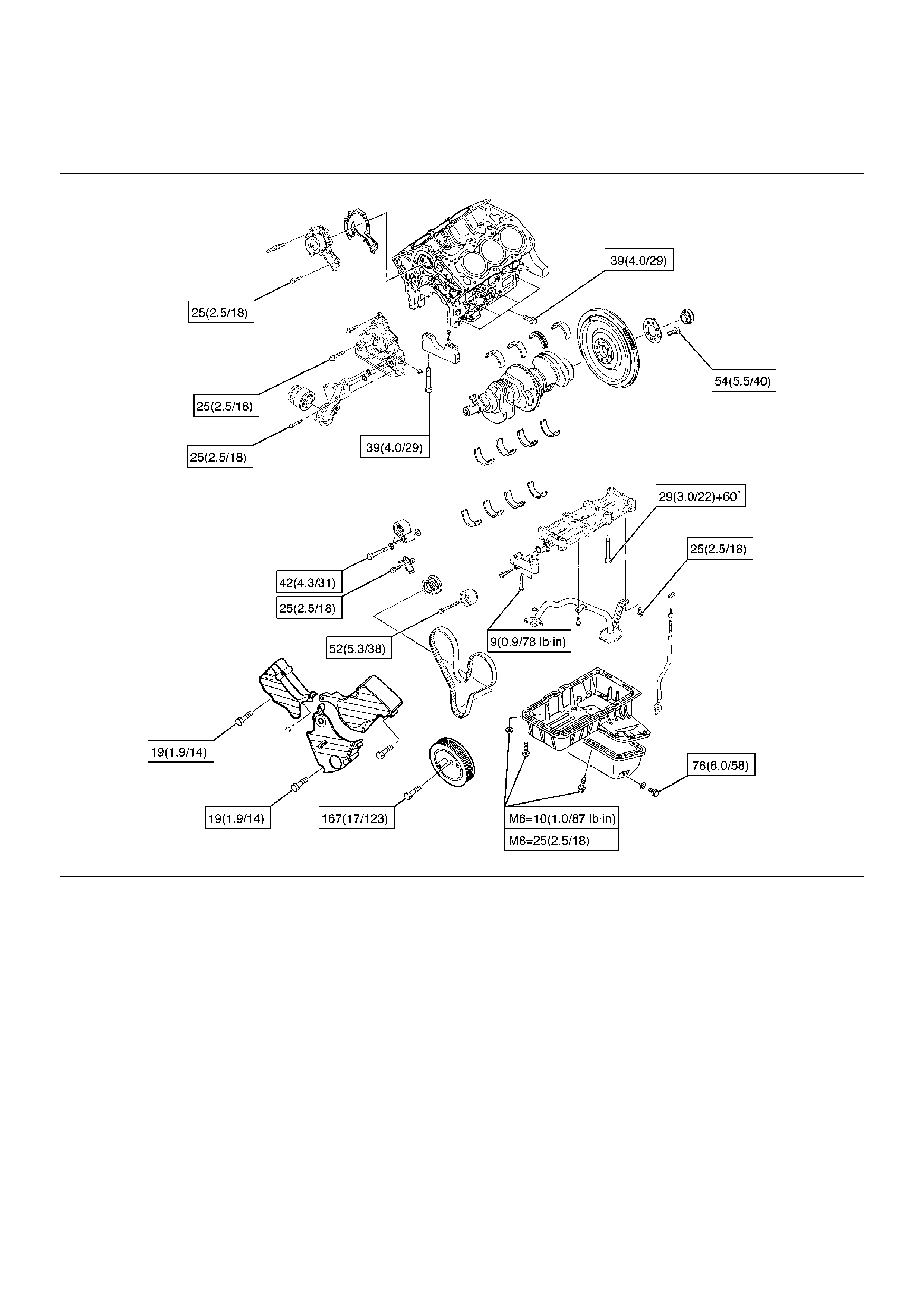

Piston, Piston Ring and Connecting Rod

Removal

Installation

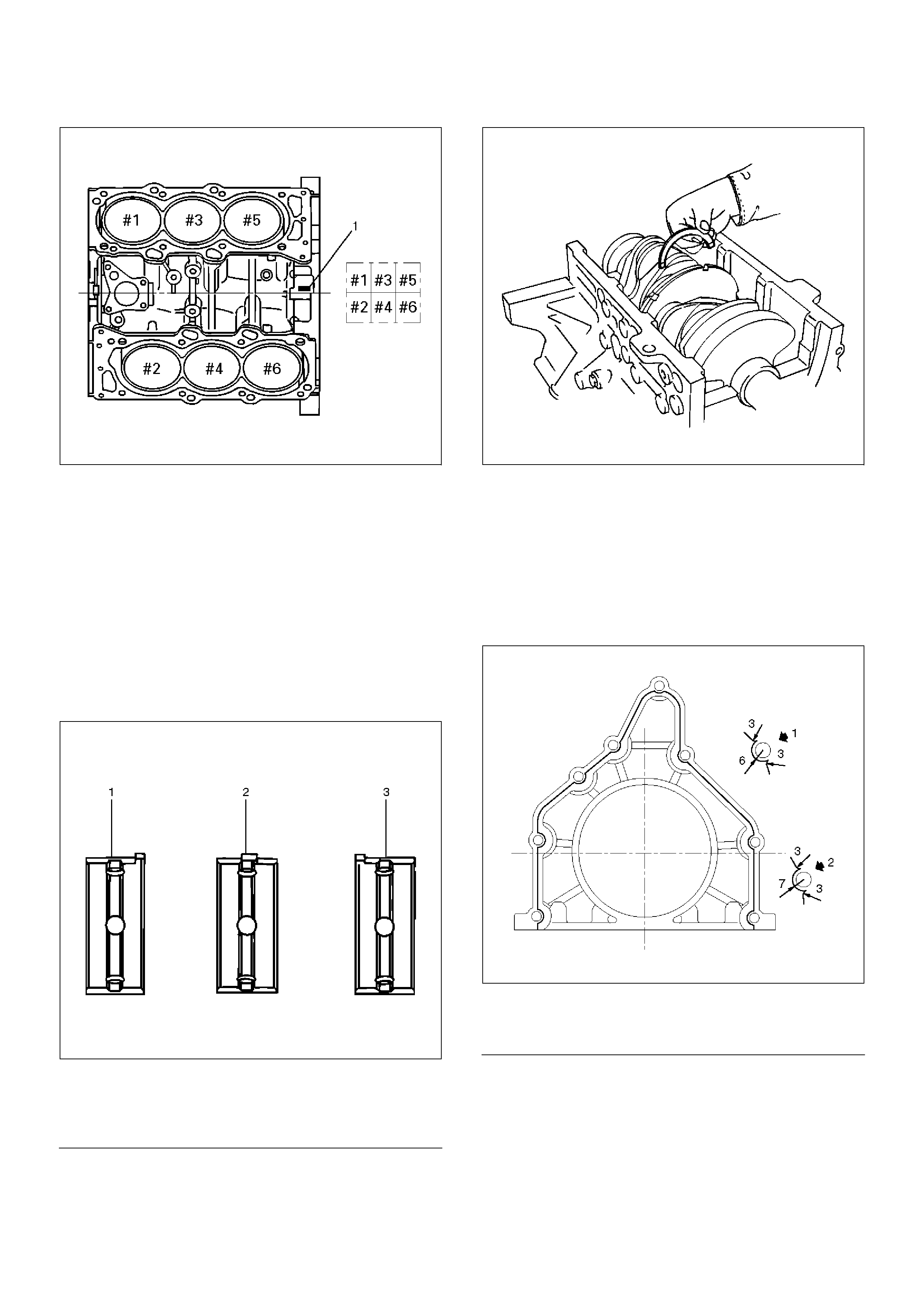

Crankshaft and Main Bearings

Removal

Installation

Rear Oil Seal

Removal

Installation

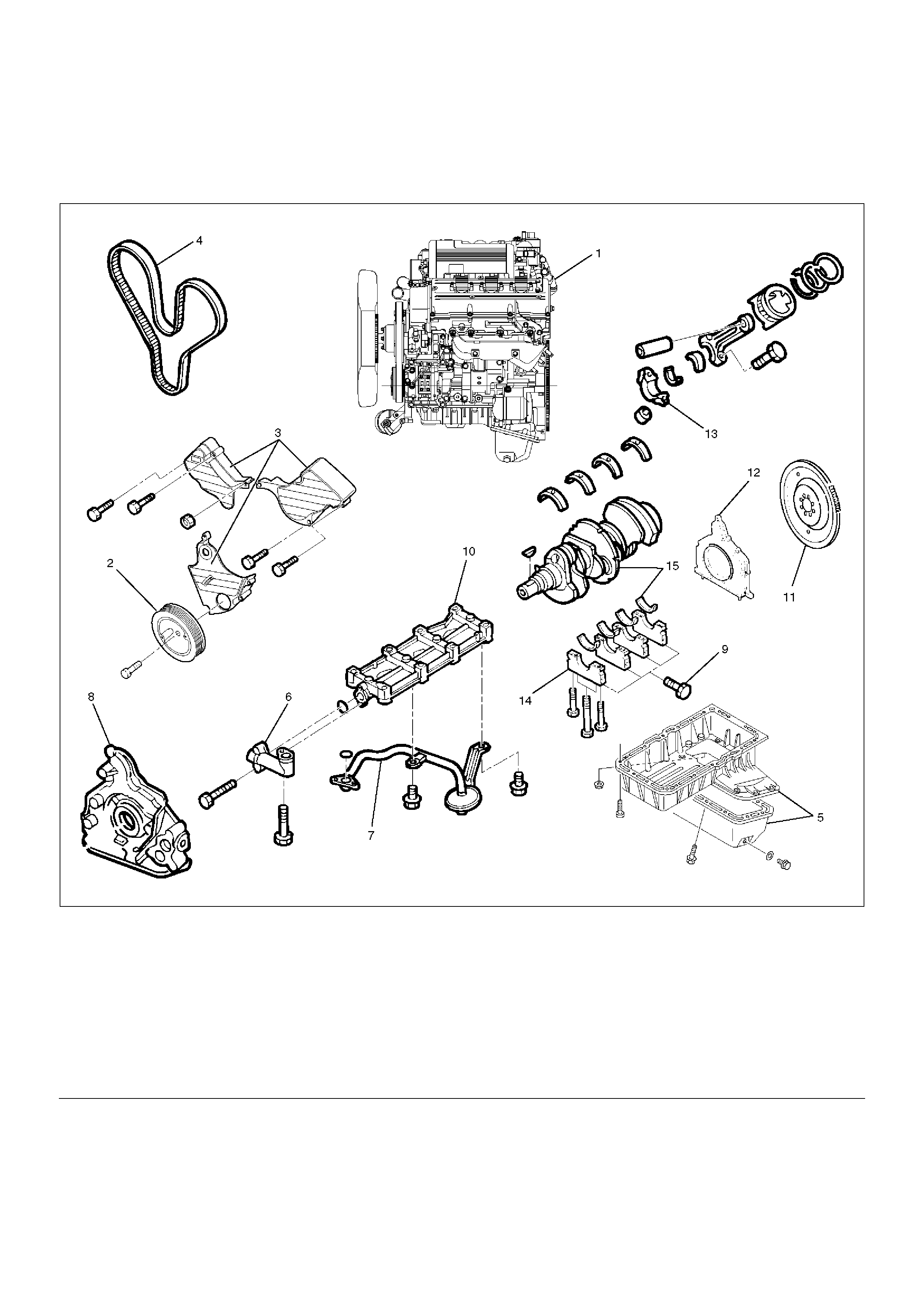

Engine Assembly

Removal

Installation

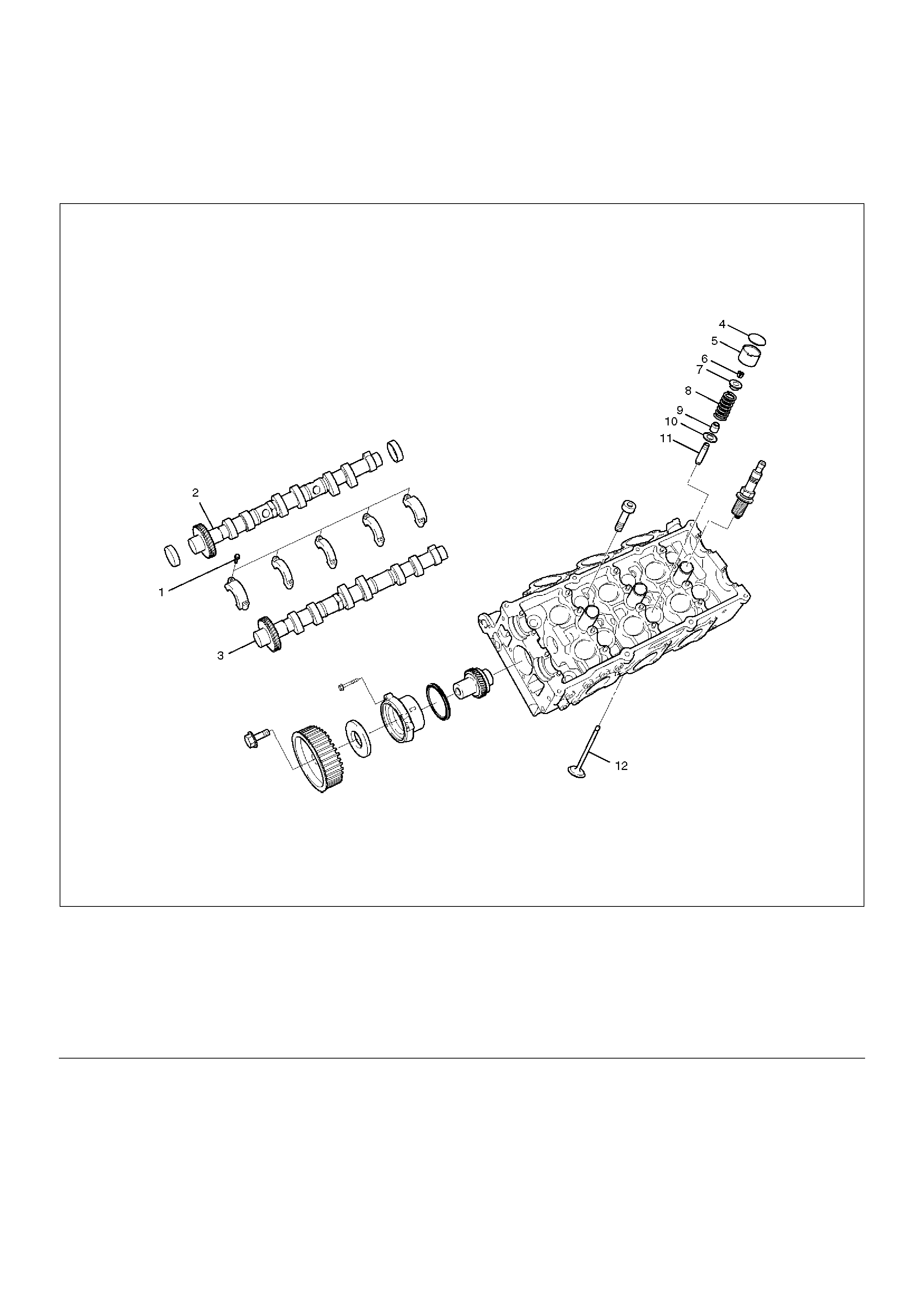

Cylinder Head

Cylinder Head and Associated Parts

Disassembly

Clean

Inspection and Repair

Reassembly

Valve Spring, Oil Controller, Valve, Valve Guide

Valve Spring, Oil Controller, Valve, Valve Guide and

Associated Parts

Disassembly

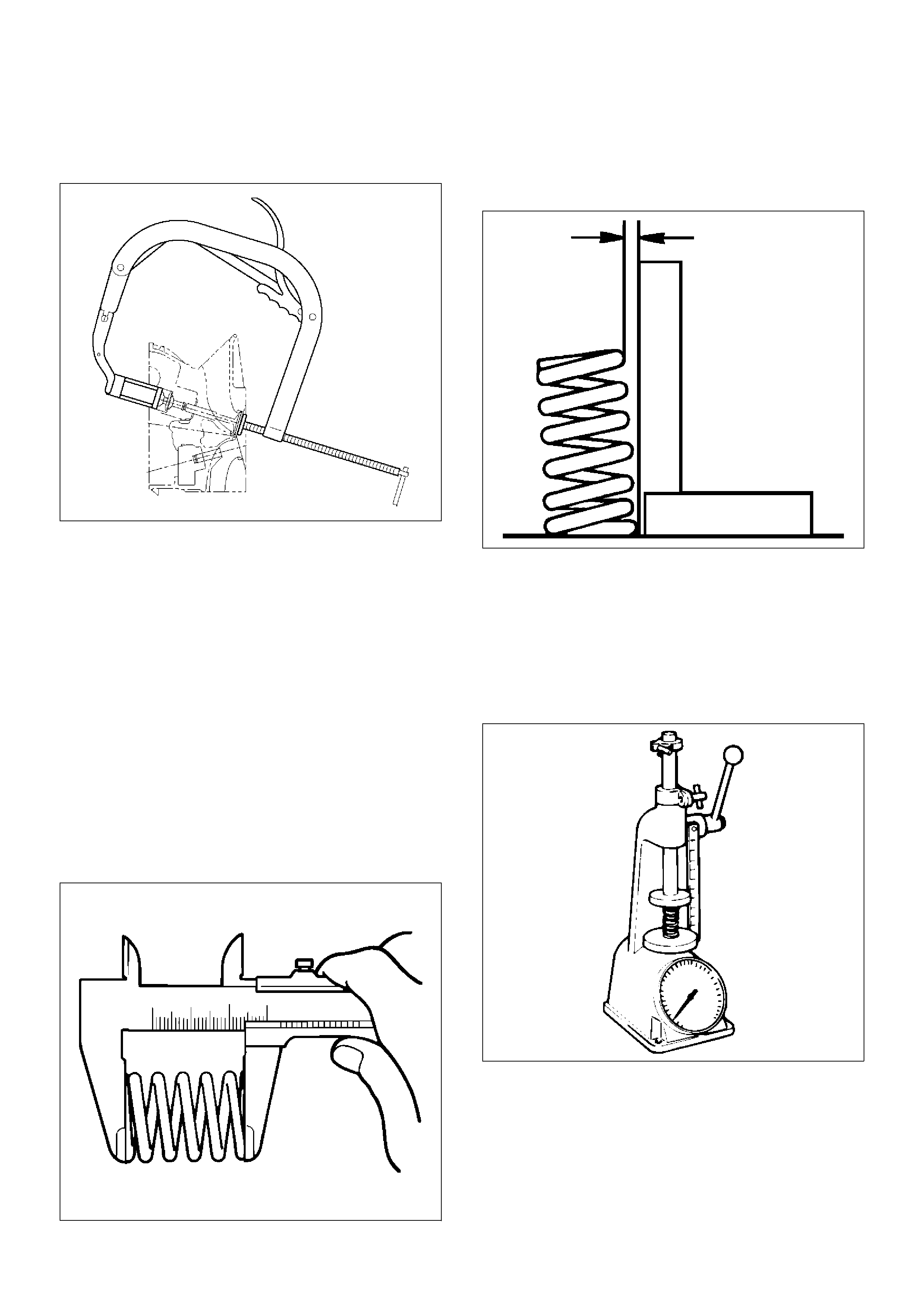

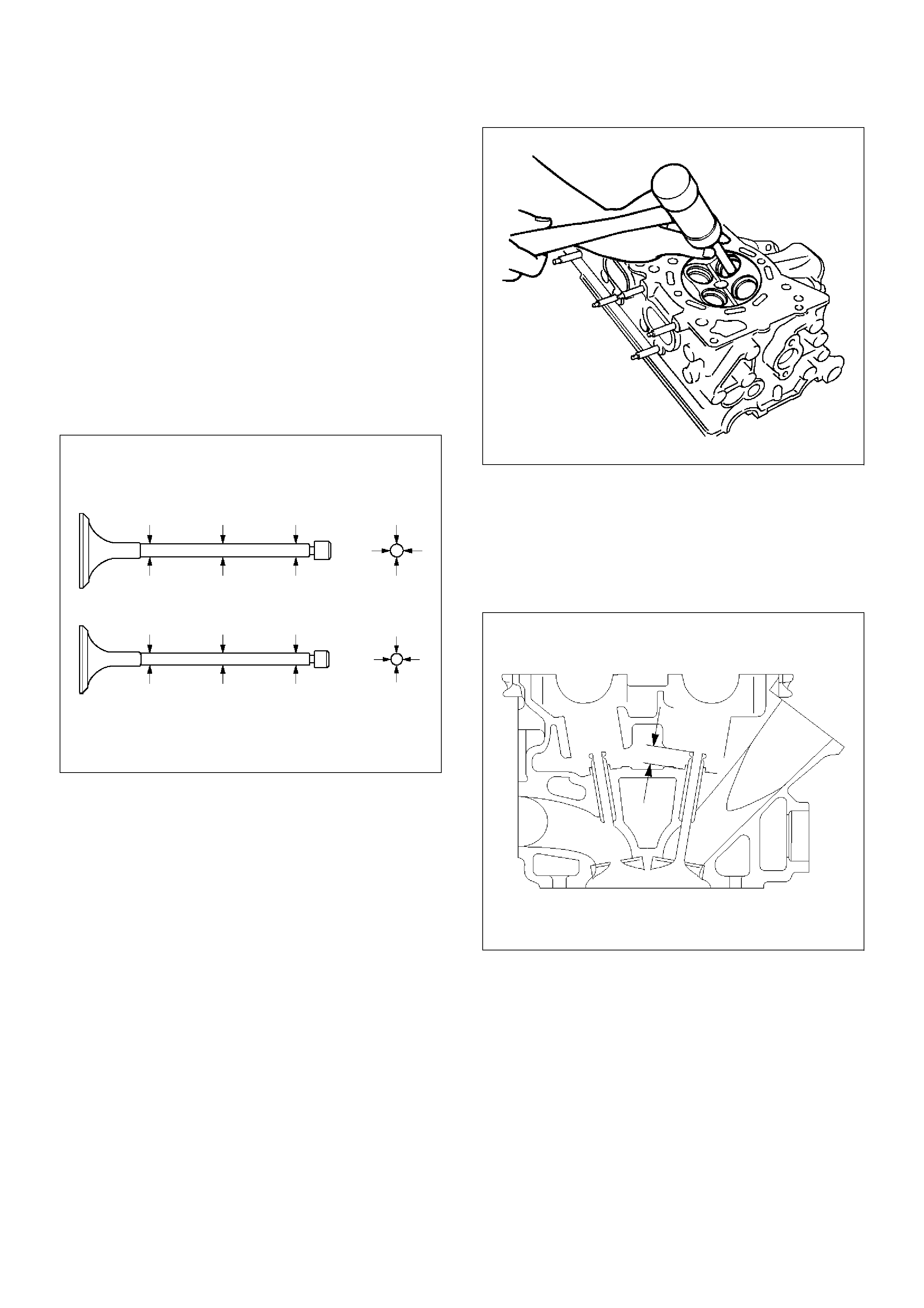

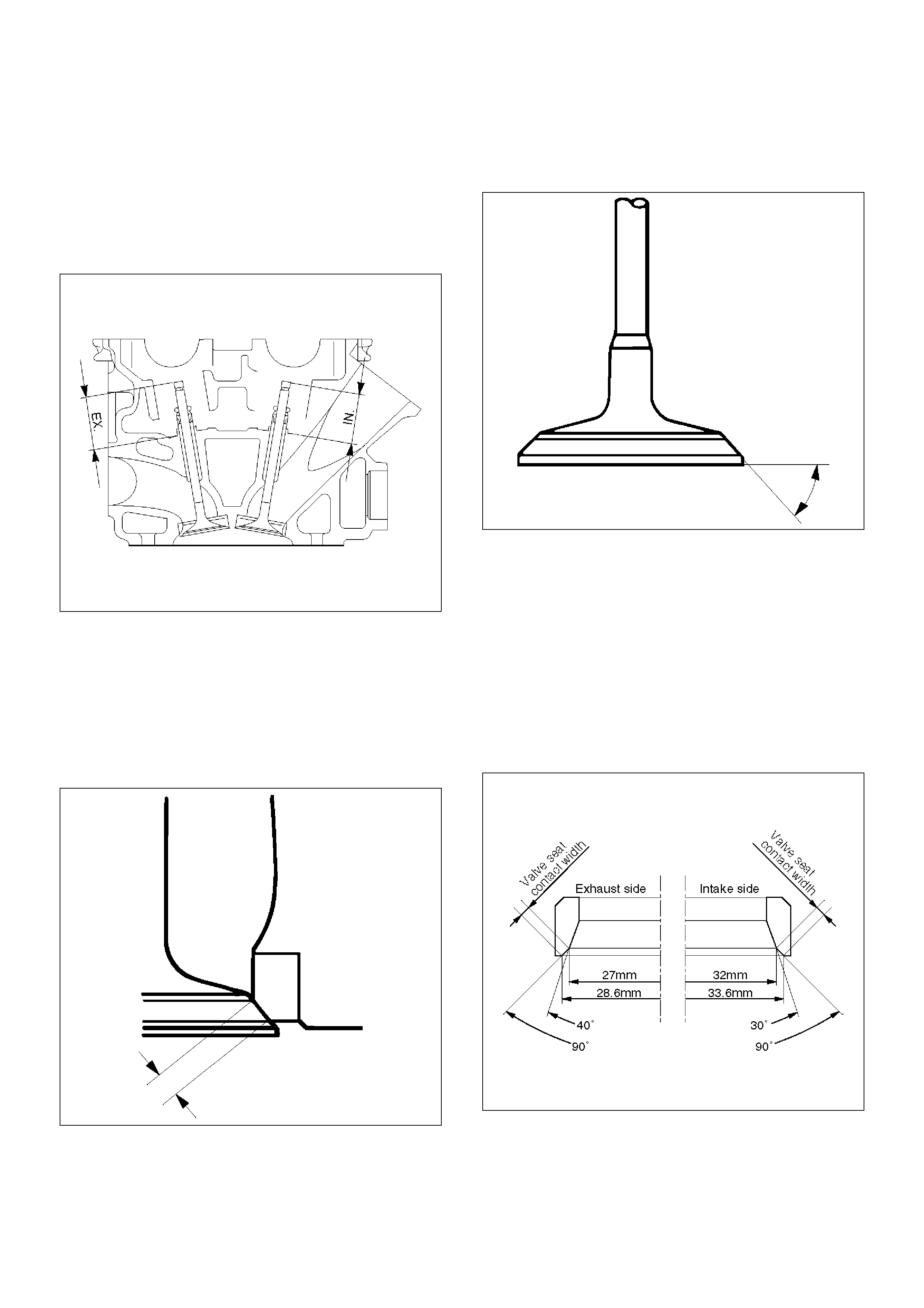

Inspection and Repair

Reassembly

Valve Clearance Adjustments

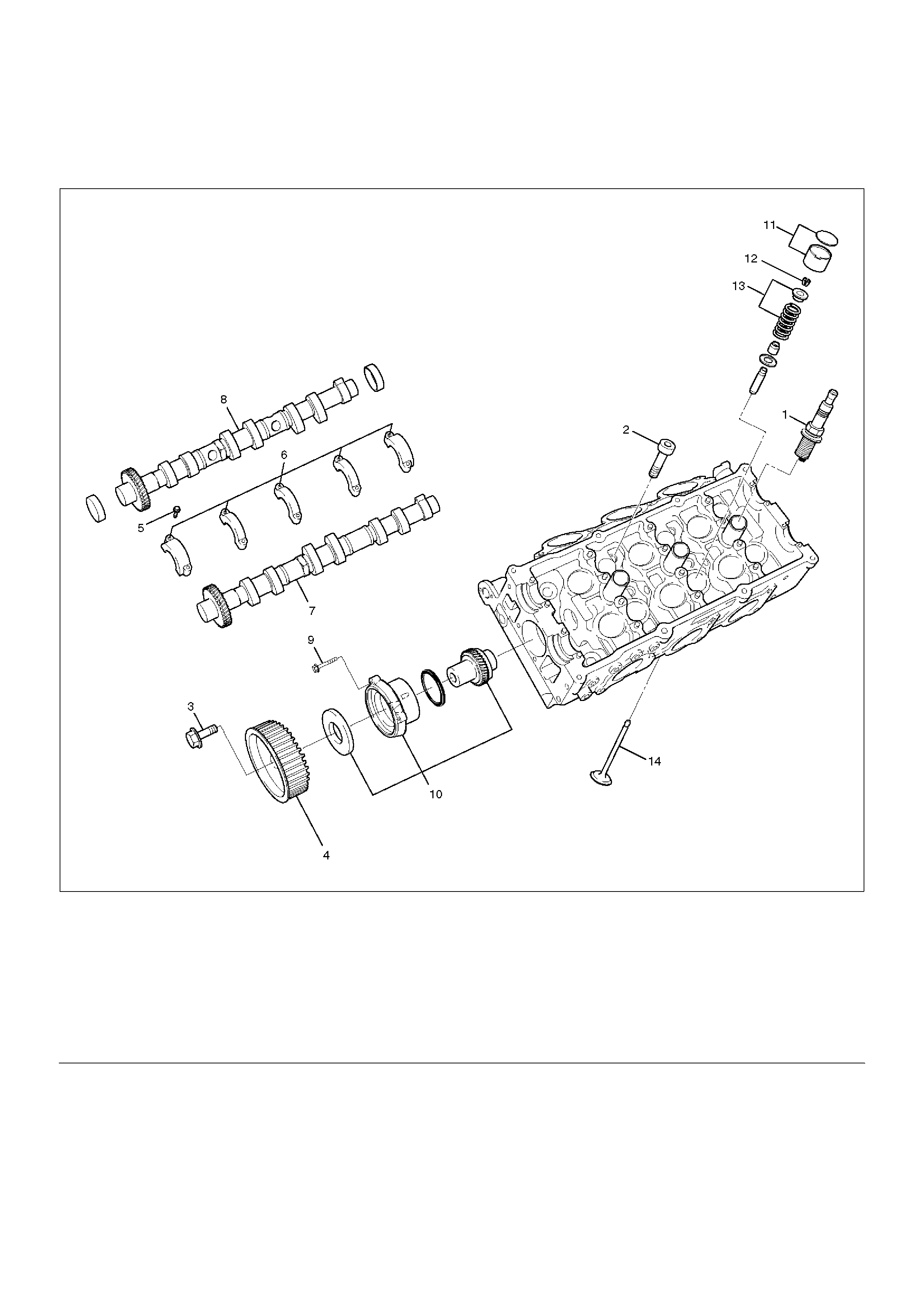

Camshaft

Camshaft and Associated Parts

Disassembly

Inspection and Repair

Reassembly

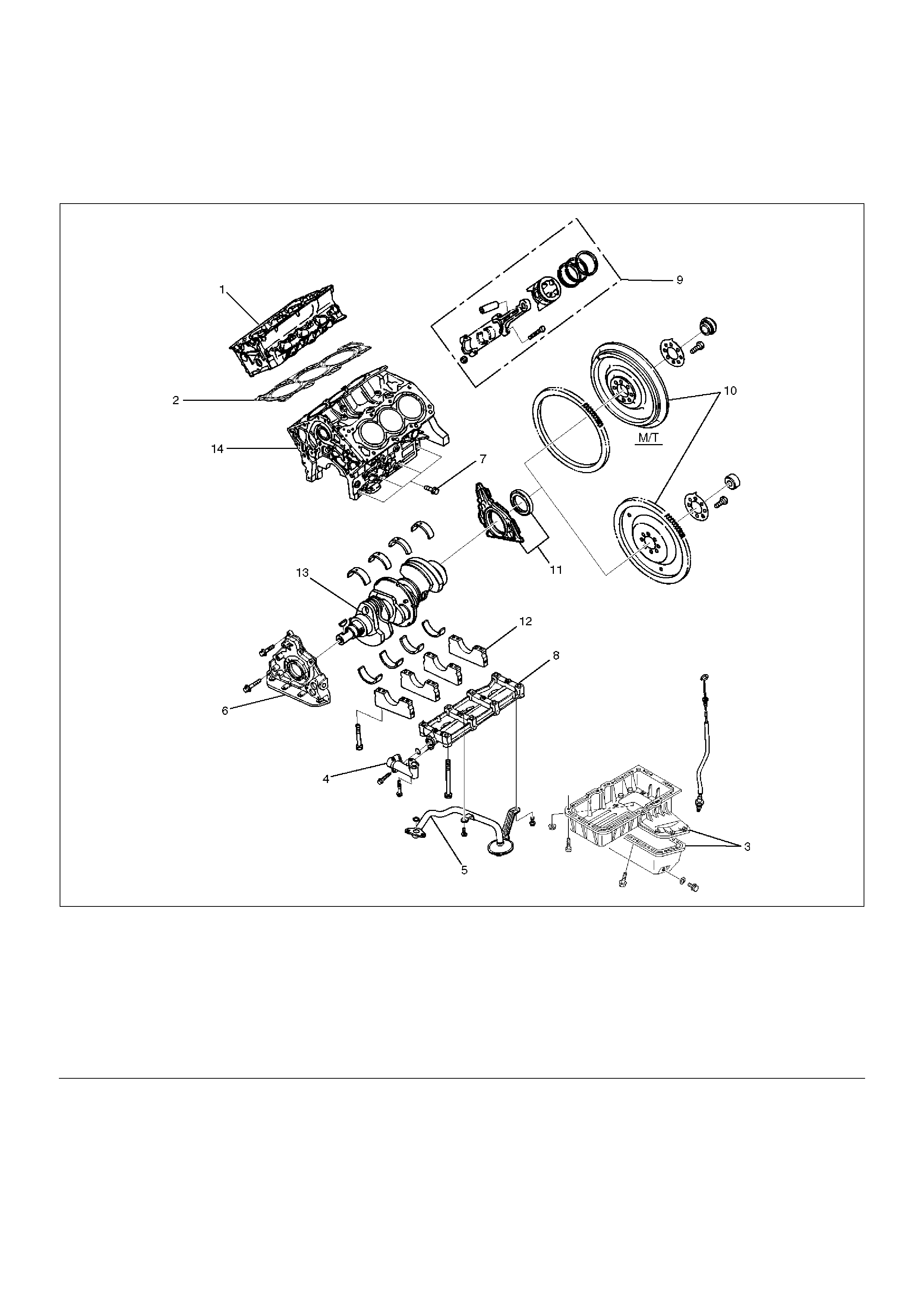

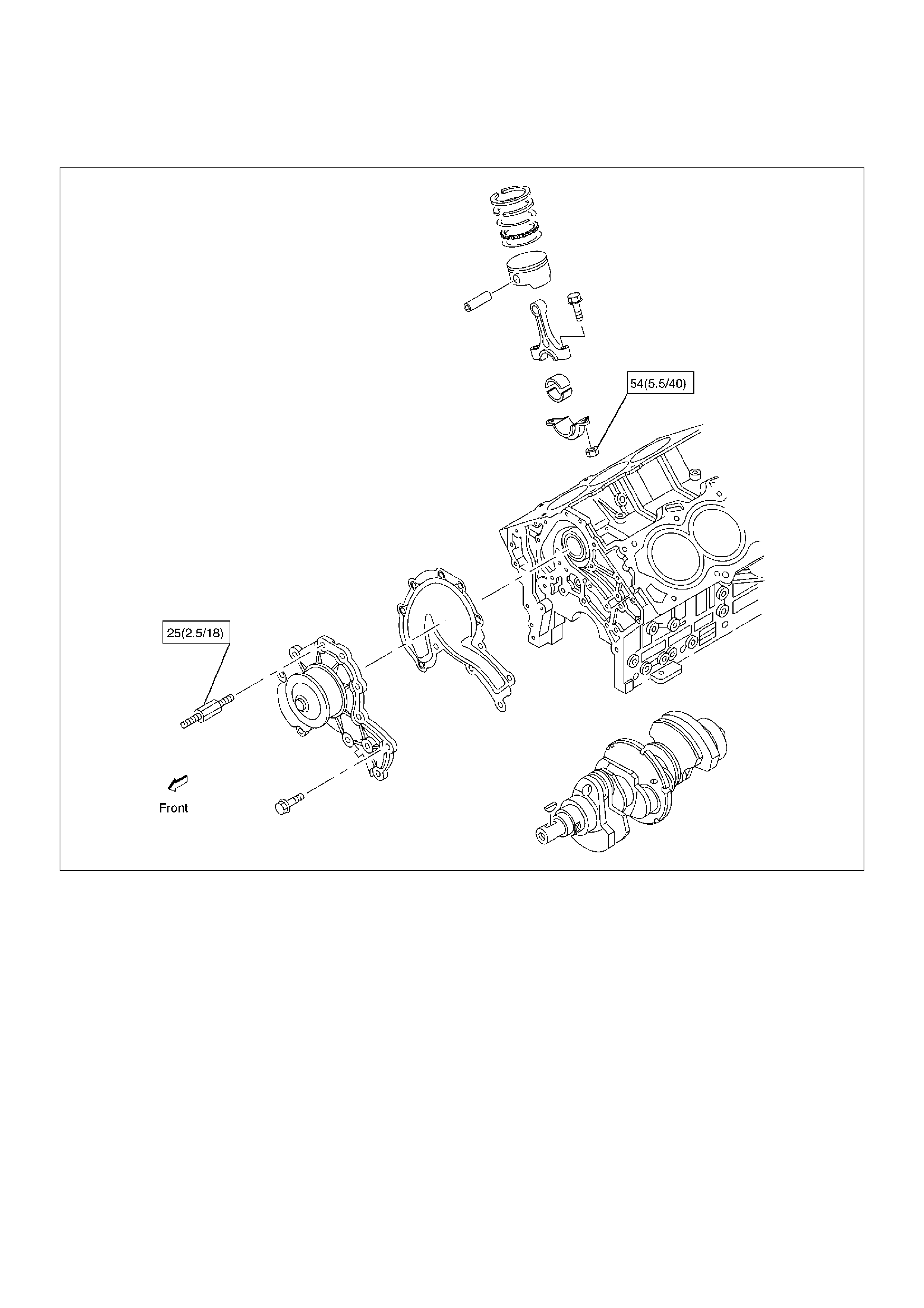

Crankshaft

Crankshaft and Associated Parts

Disassembly

Inspection and Repair

Inspection and Repair

Reassembly

Piston and Connecting Rod

Piston, Connecting Rod and Associate Parts

Disassembly

Inspection and Repair

Reassembly

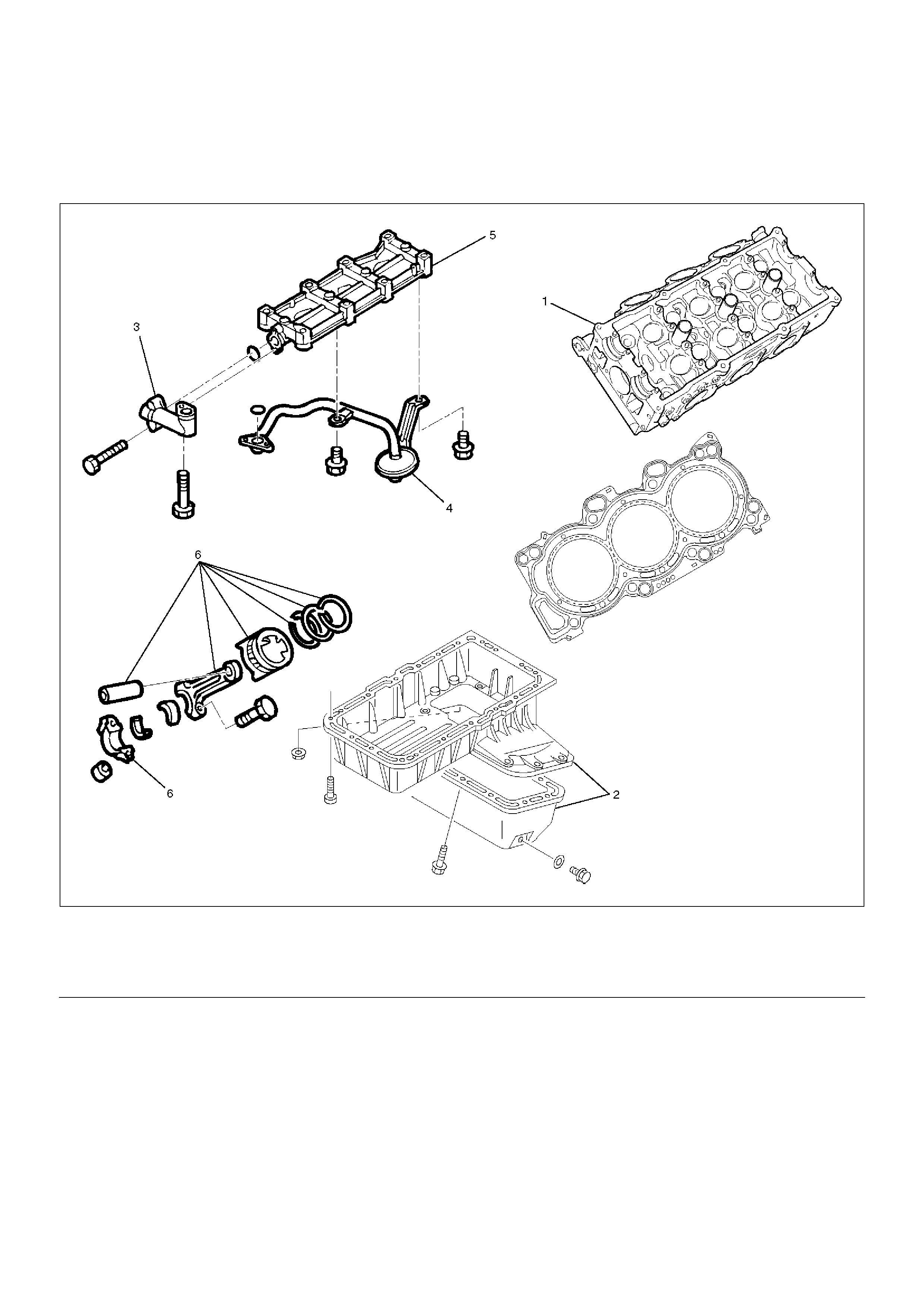

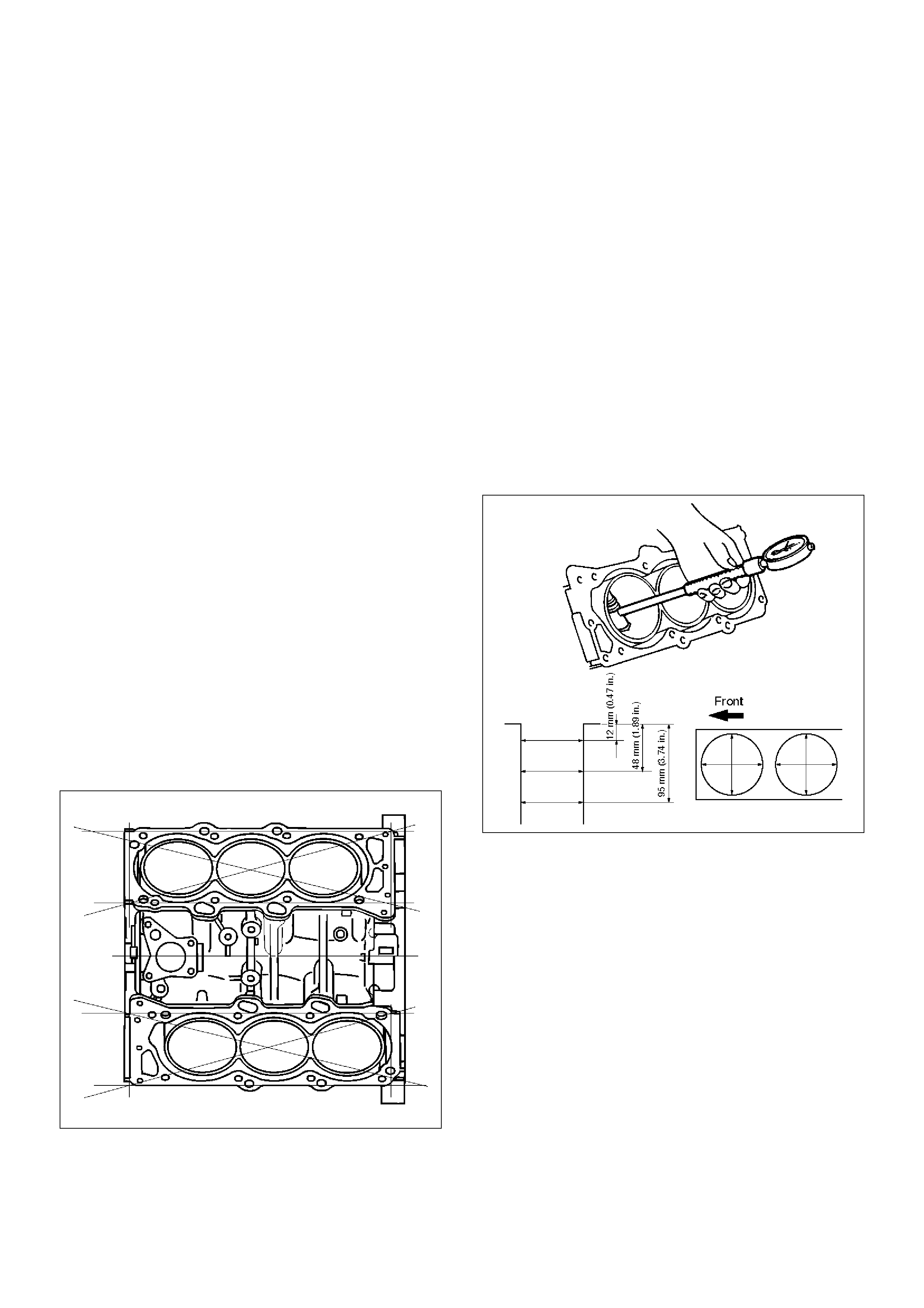

Cylinder Block

Cylinder Block and Associated Parts

Disassembly

Inspection and Repair

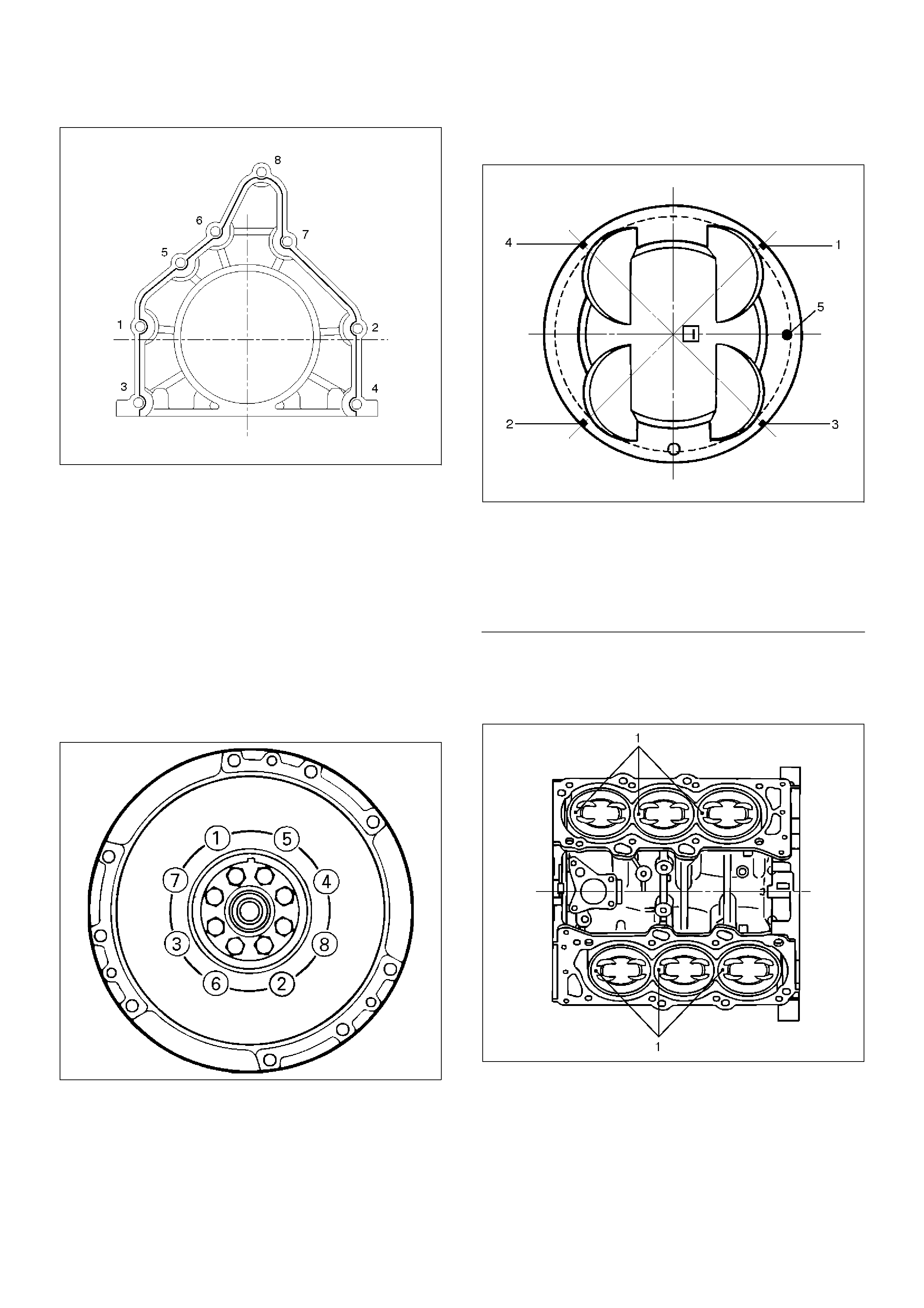

Reassembly

Main Data and Specification

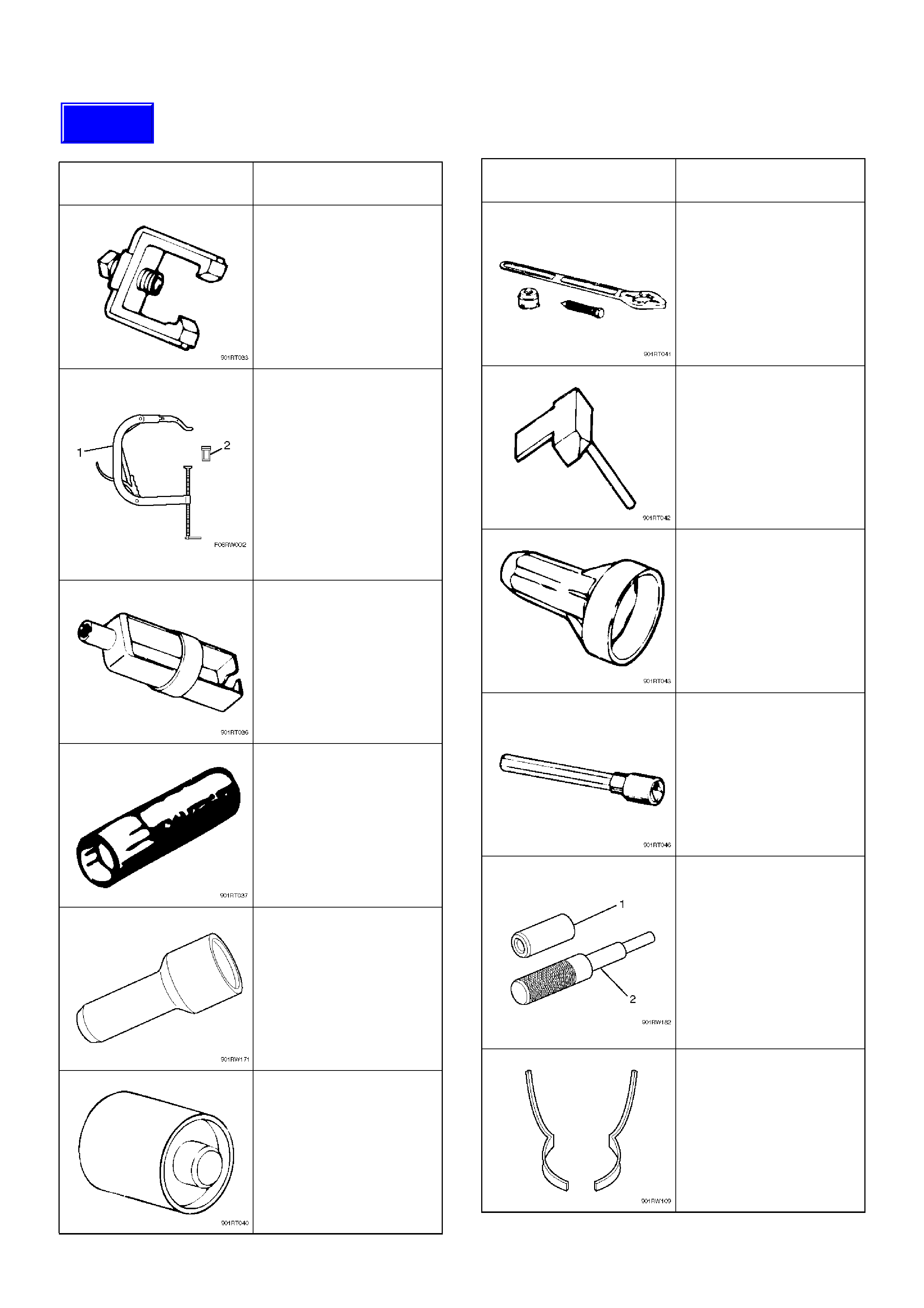

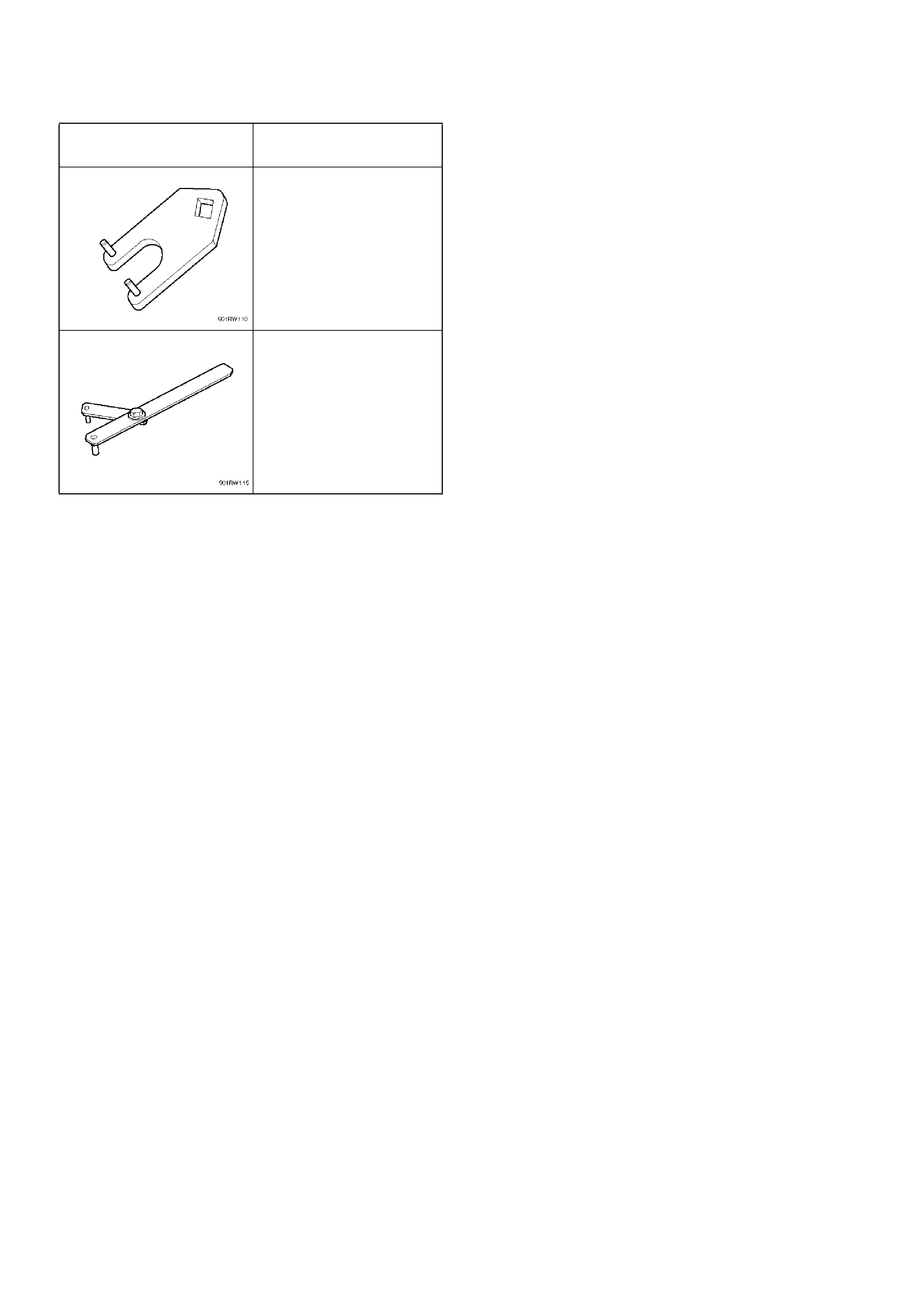

Special Tool

Techline

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE

SRS WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

General Description

Engine Cleanliness And Care

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousandths of a

millimeter (ten thousandths of an inch). Accordingly,

when any internal engine parts are serviced, care and

cleanliness are important. Throughout this section, it

should be understood that proper cleaning and

protection of machined surfaces and friction areas is

part of the repair procedure. This is considered standard

shop practice even if not specifically stated.

• A liberal coating of engine oil should be applied to all

friction areas during assembly to protect and lubricate

the surfaces on initial operation.

• Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

• At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

• Battery cables should be disconnected before any

major work is performed on the engine. Failure to

disconnect cables may result in damage to wire

harness or other electrical parts.

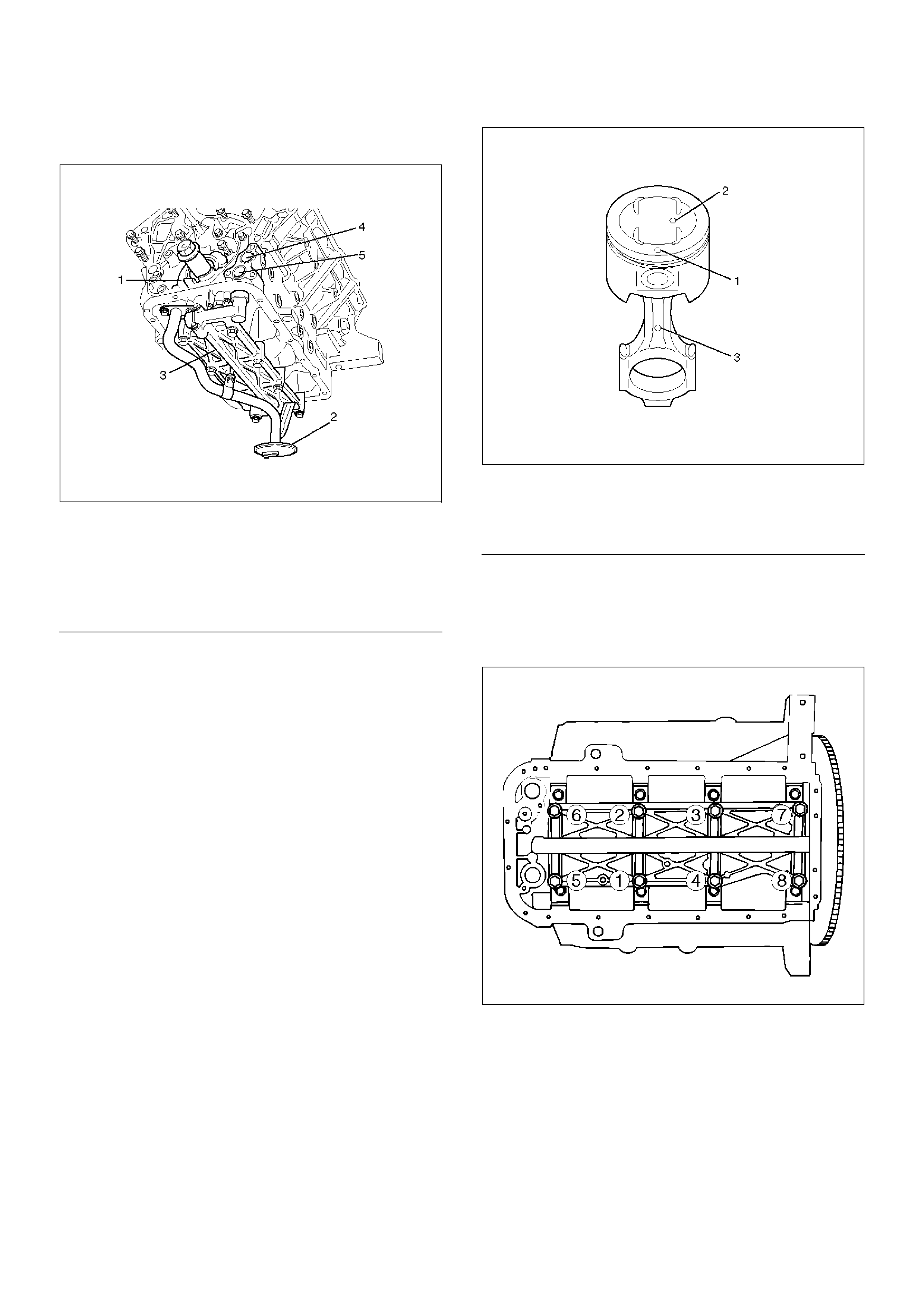

• The six cylinders of this engine are identified by

numbers; Right side cylinders 1, 3 and 5, Left side

cylinders 2, 4 and 6, as counted from crankshaft

pulley side to flywheel side.

General Information on Engine Service

The following information on engine service should be

noted carefully, as it is important in preventing damage

and contributing to reliable engine performance:

• When raising or supporting the engine for any

reason, do not use a jack under the oil pan. Due to

the small clearance between the oil pan and the oil

pump strainer, jacking against the oil pan may cause

damage to the oil pick–up unit.

• The 12–volt electrical system is capable of damaging

circuits. When performing any work where electrical

terminals could possibly be grounded, the ground

cable of the battery should be disconnected at the

battery.

• Any time the intake air duct or air cleaner is removed,

the intake opening should be covered. This will

protect against accidental entrance of foreign

material into the cylinder which could cause

extensive damage when the engine is started.

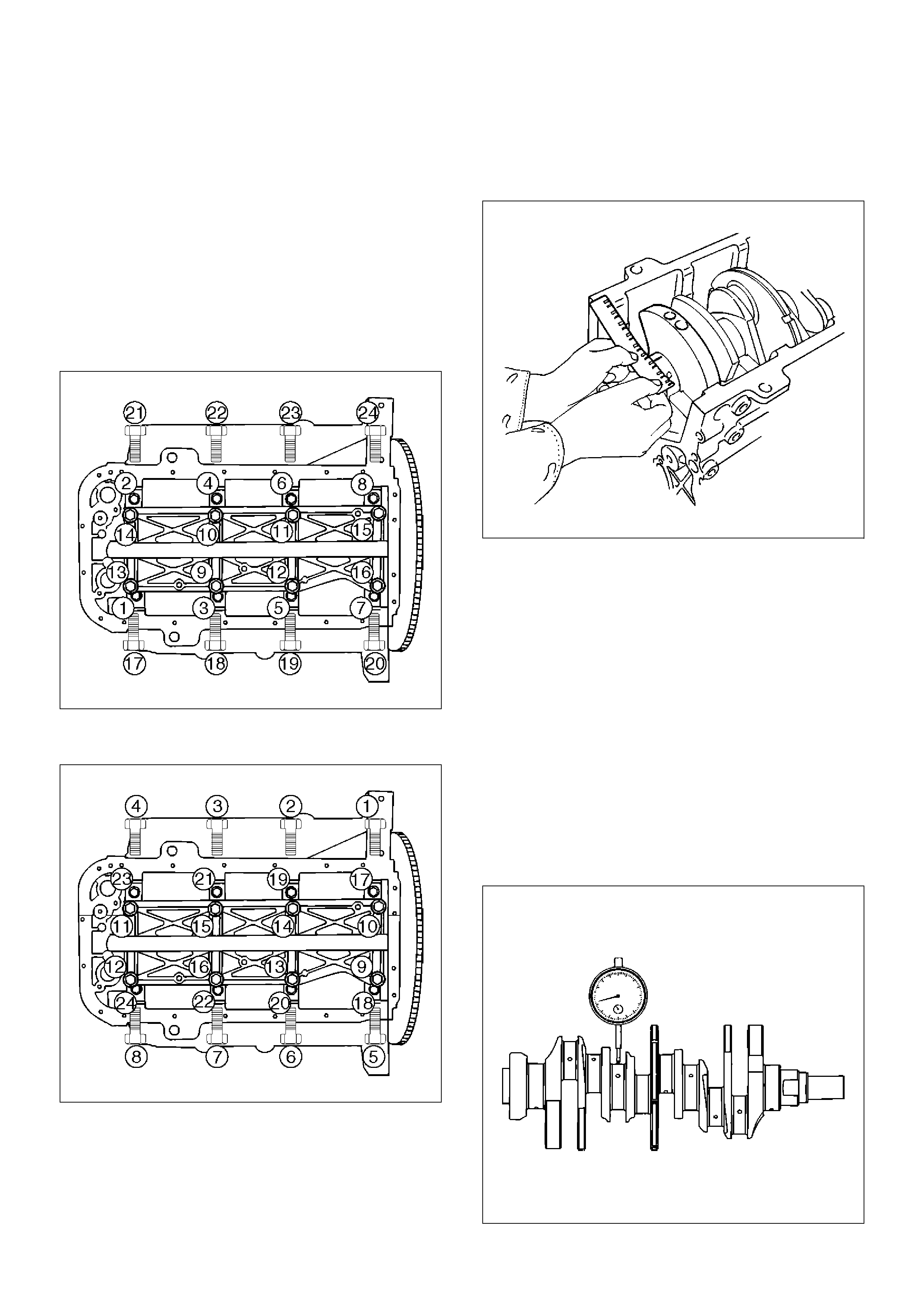

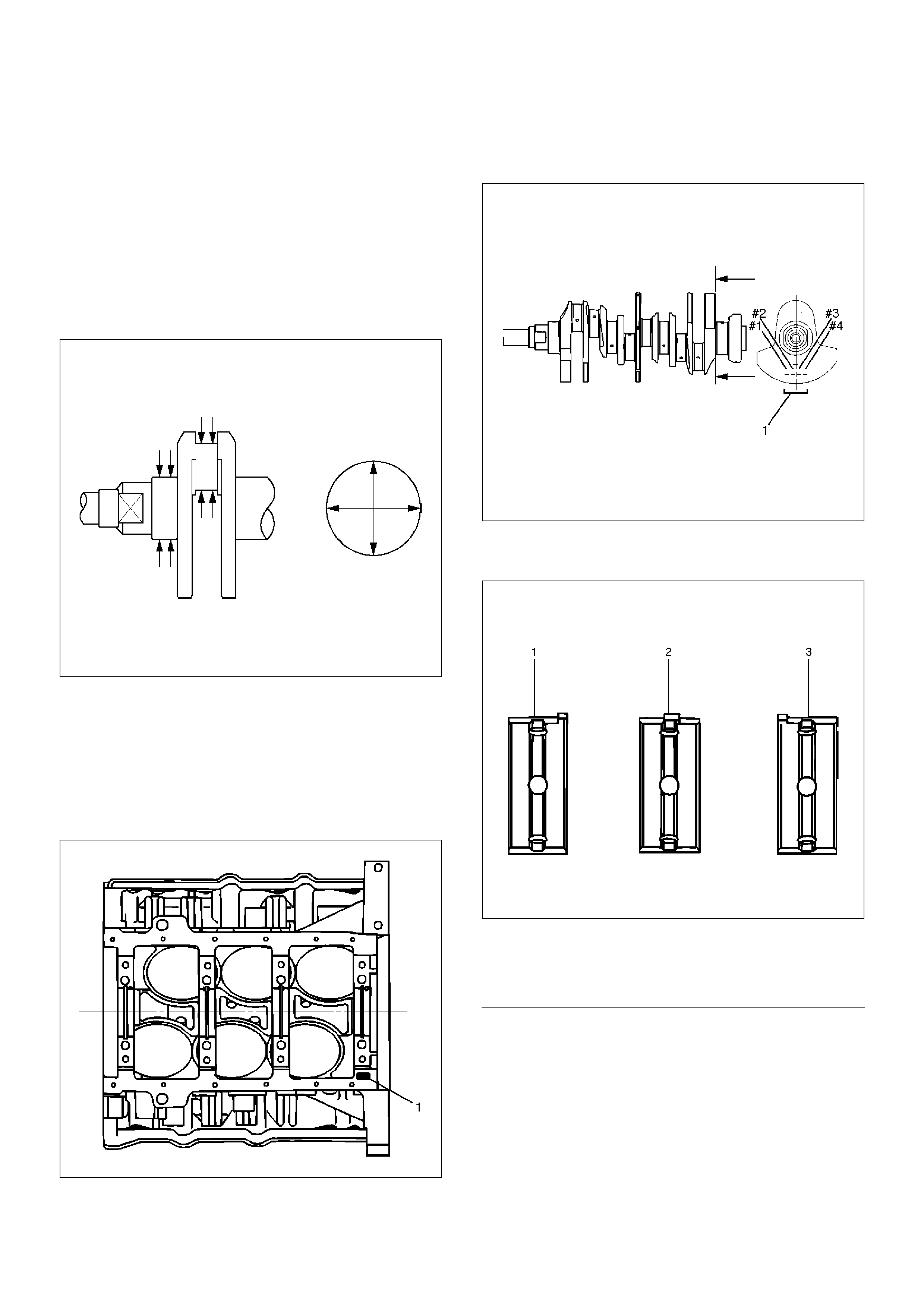

Cylinder Block

The cylinder block is made of aluminum die–cast

casting for 75°V–type six cylinders. It has a rear plate

integrated structure and employs a deep skint. The

cylinder liner is cast and the liner inner diameter and

crankshaft journal diameter are classified into grades.

The crankshaft is supported by four bearings of which

width of No.3 bearing on the body side is different in

order to support the thrust bearing. The bearing cap is

made of nodular cast iron and each bearing cap uses

four bolts and two side bolts.

Cylinder Head

The cylinder head, made of aluminum alloy casting

employs a pent–roof type combustion chamber with a

spark plug in the center. The intake and exhaust valves

are placed in V–type design. The ports are cross–flow

type.

Valve Train

Intake and exhaust camshaft on the both side of banks

are driven through an camshaft drive gear by timing

belt. The valves are operated by the camshaft and the

valve clearance is adjusted to select suitable thickness

shim.

Intake Manifold

The intake manifold system is composed of the

aluminum cast common chamber and intake manifold

attached with six fuel injectors.

Exhaust Manifold

The exhaust manifold is made of nodular cast iron.

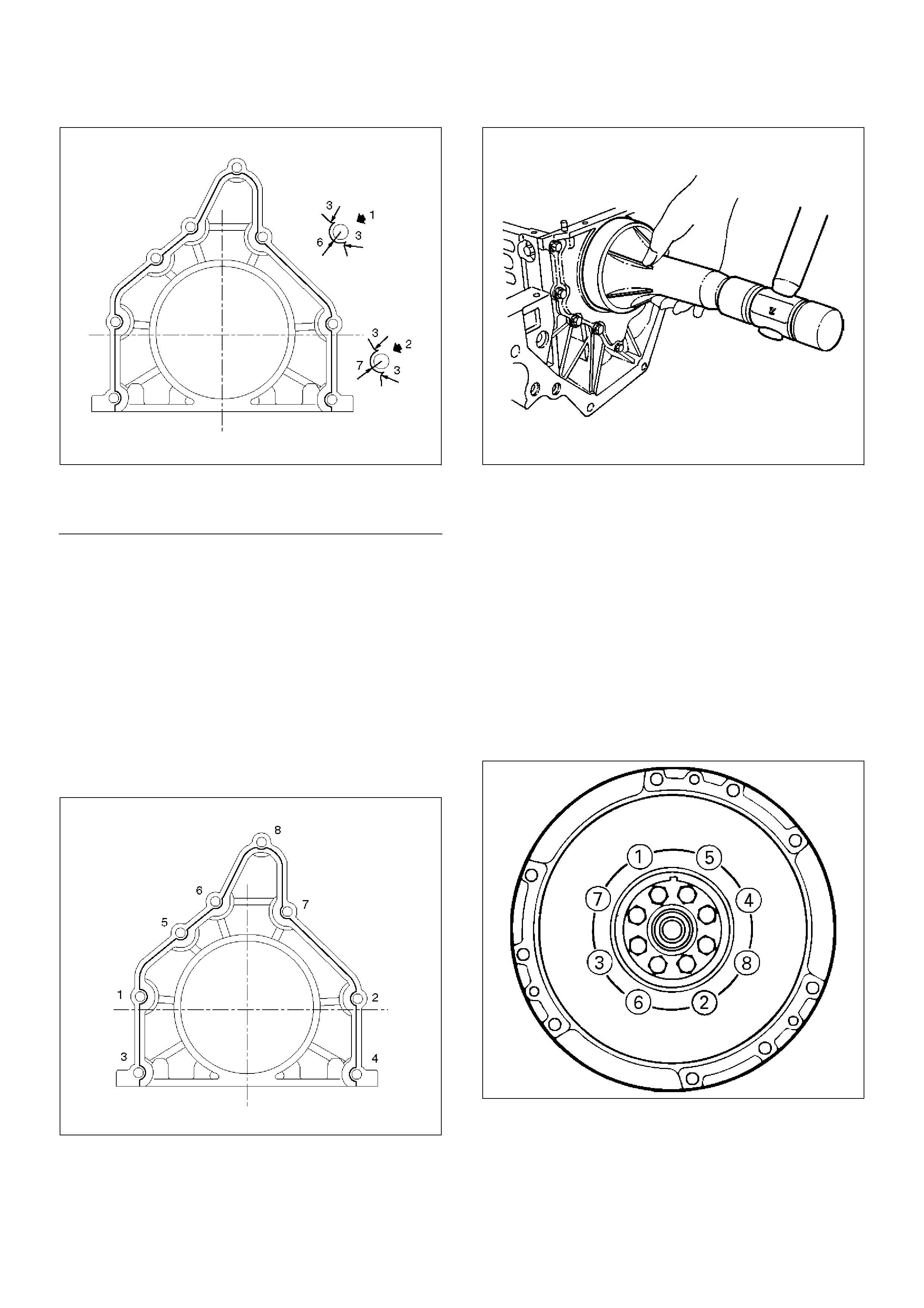

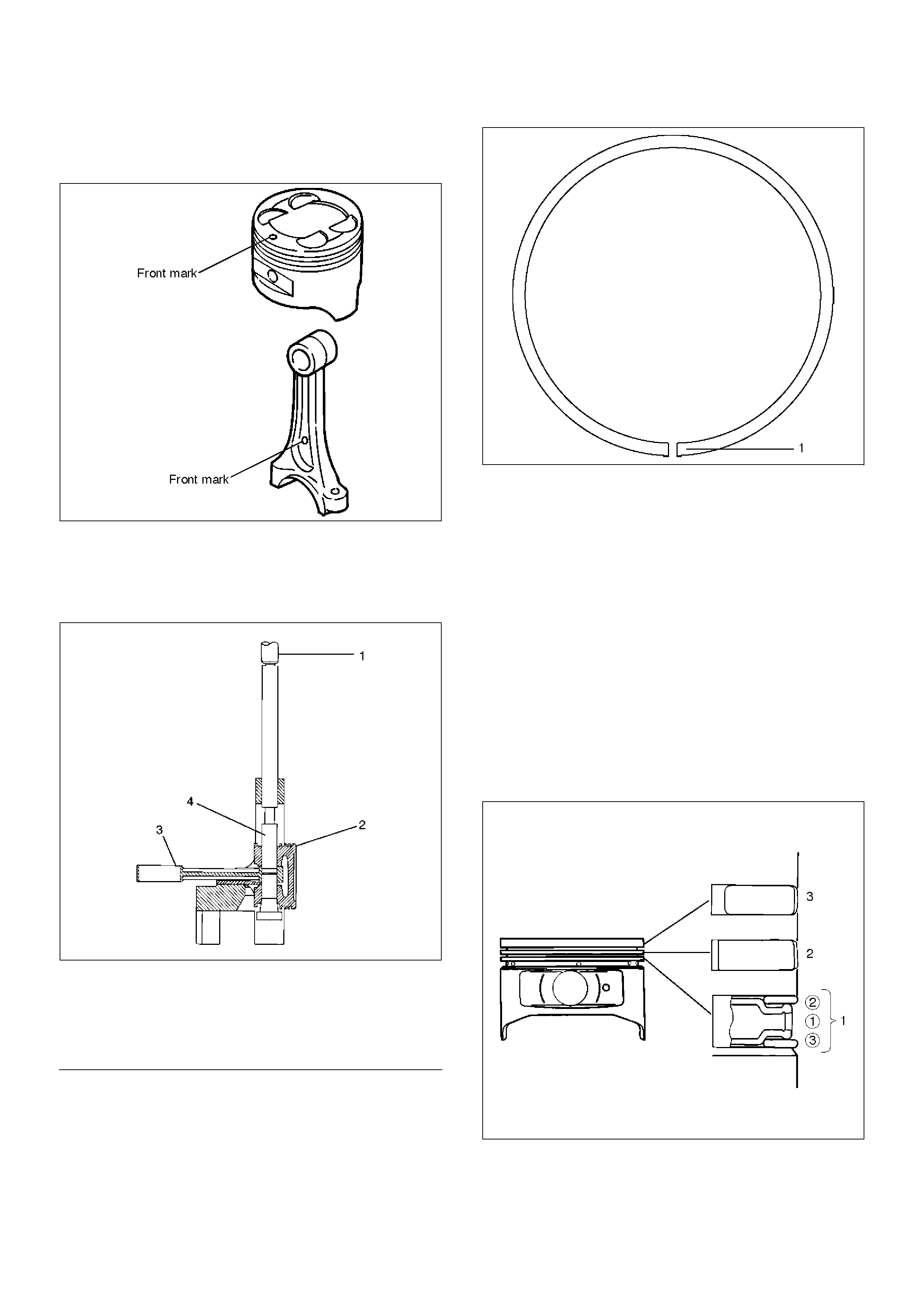

Pistons and Connecting Rods

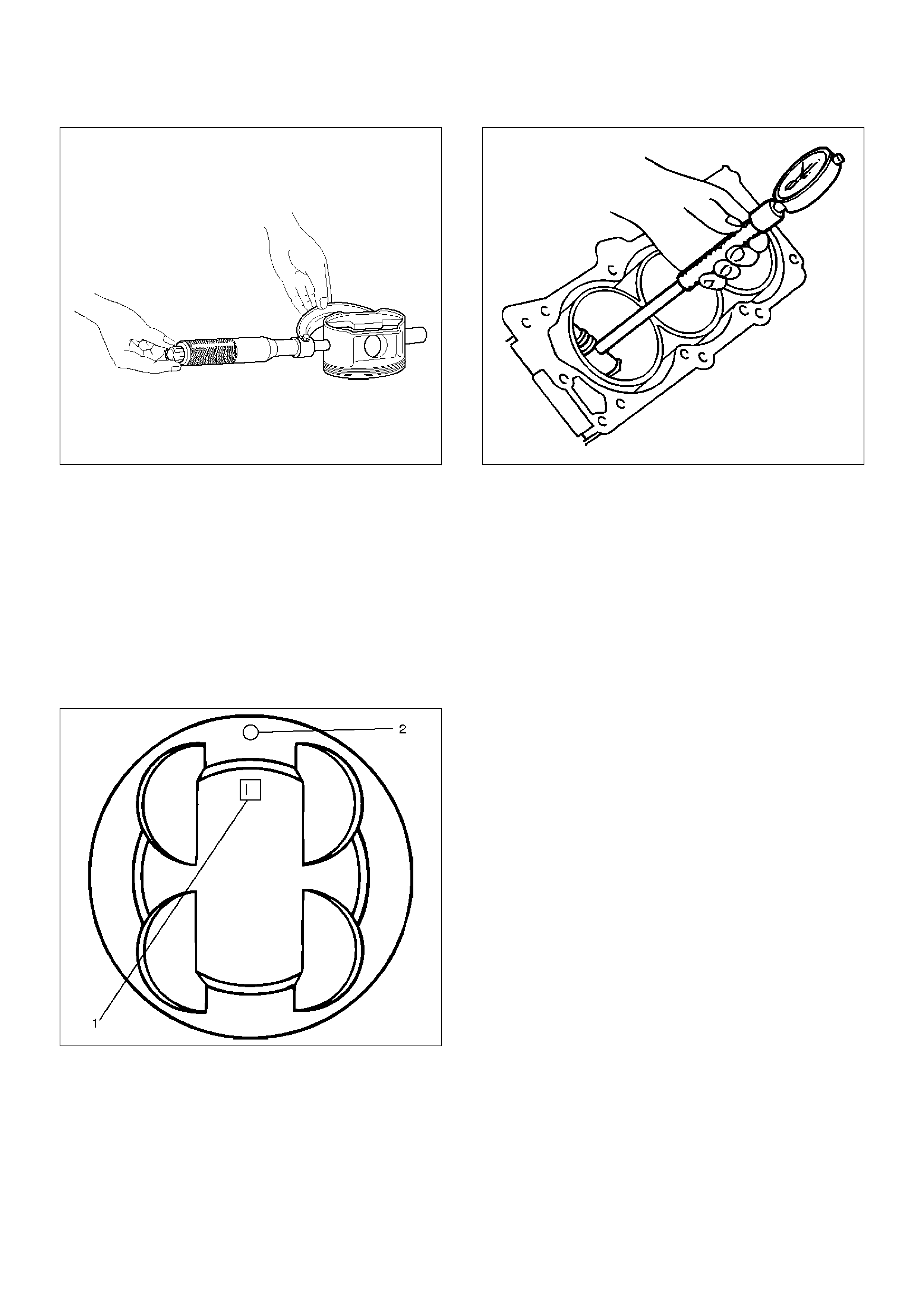

Aluminum pistons are used after selecting the grade

that meets the cylinder bore diameter. Each piston has

two compression rings and one oil ring. The piston pin is

made of chromium steel is offset 1mm toward the thrust

side, and the thrust pressure of piston to the cylinder

wall varies gradually as the piston travels. The

connecting rods are made of forged steel. The

connecting rod bearings are graded for correct seze

selection.

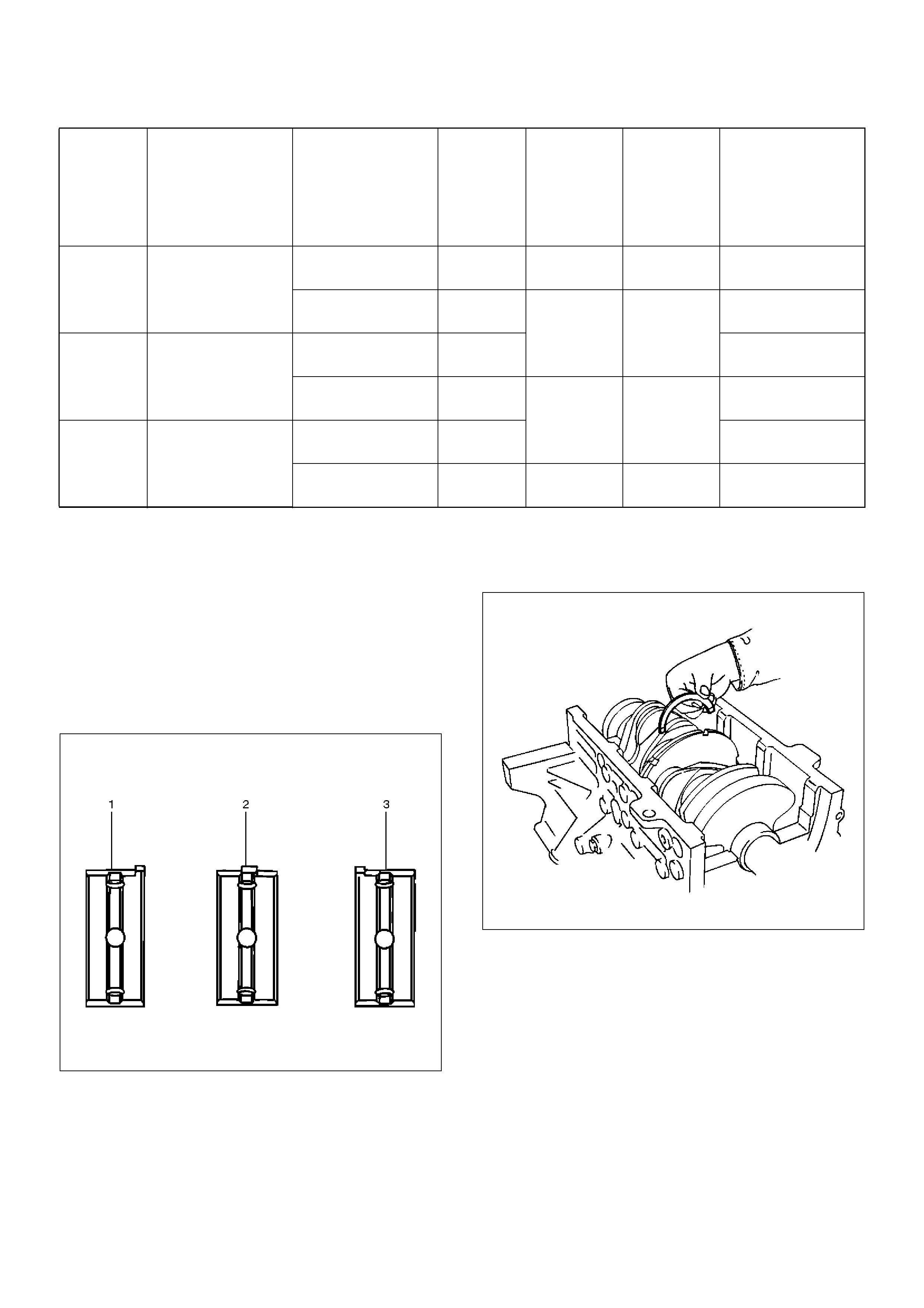

Crankshaft and Bearings

The crankshaft is made of Ductile cast–iron. Pins and

journals are graded for correct size selection for their

bearing.

Engine Lubrication

The oil discharged by a trochoid–type oil pump driven

by the crankshaft is fed through full–flow oil filter and to

the oil gallery provided under the crankshaft bearing

cap. The oil is then led to the crankshaft journals and

cylinder head. The crank pins are lubricated with oil

from crankshaft journals through oil holes. Also, an oil

jet is fed to each cylinder from crankshaft juornals on

the connecting rod for piston cleaning. The oil pan

flange is dealed with liquid packing only; do not deform

or damage the flange surface during removal or

installation.

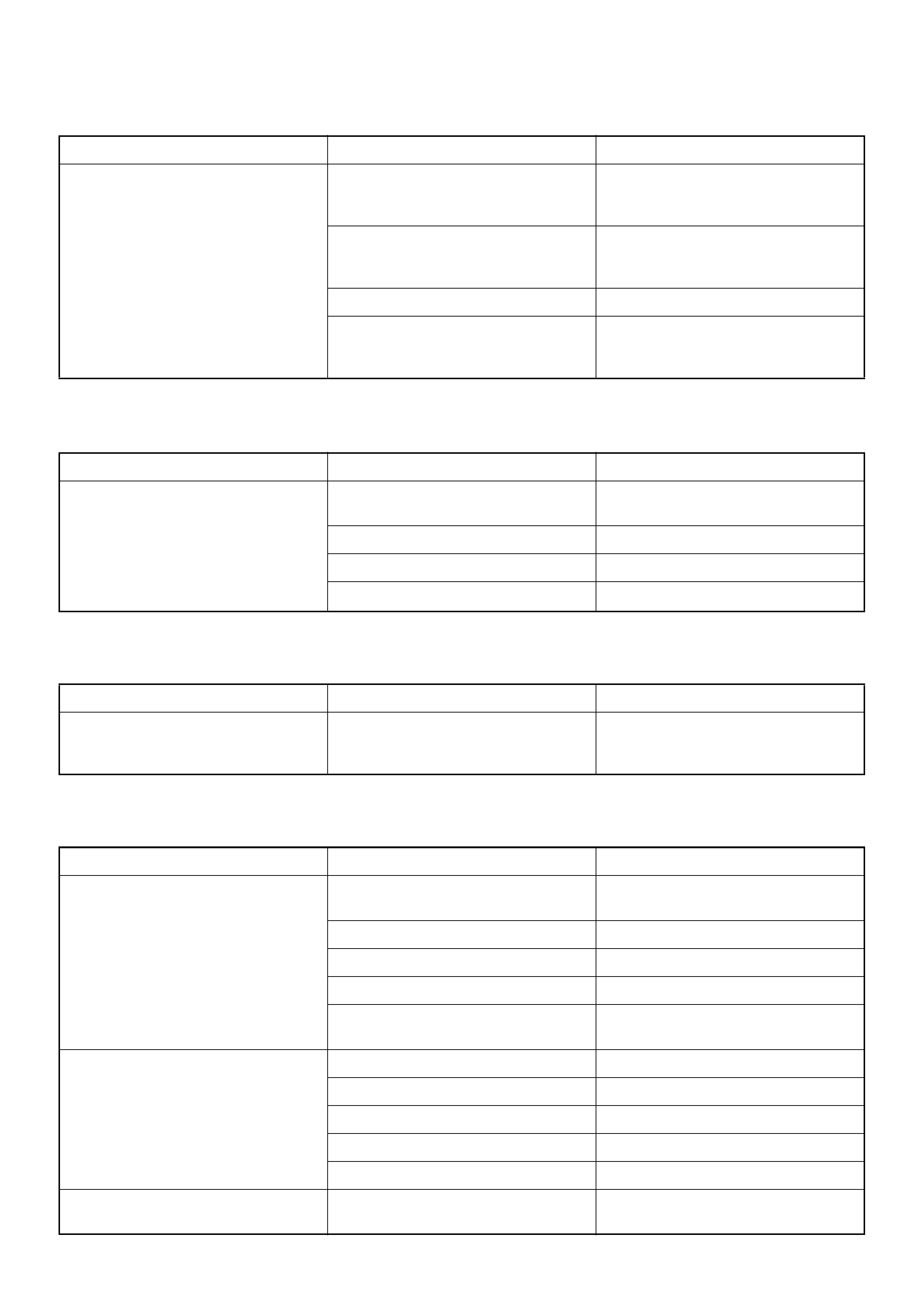

Engine Diagnosis

Hard Starting

1. Starting Motor Does Not Turn Over

Troubleshooting Procedure

Turn on headlights and starter switch.

2. Ignition Trouble — Starter Motor Turns Over But Engine Does Not Start

Spark Test

Disconnect an igniton coil from any spark plug. Connect

the spark plug tester 5–8840–0607–0, start the engine,

and check if a spark is generated in the spark plug

tester. Before starting the engine, make sure that the

spark plug tester is properly grounded. To avoid

electrical shock, do not touch the part where insulation

of the igniton coil is broken while the engine is running.

3. Fuel System Fault

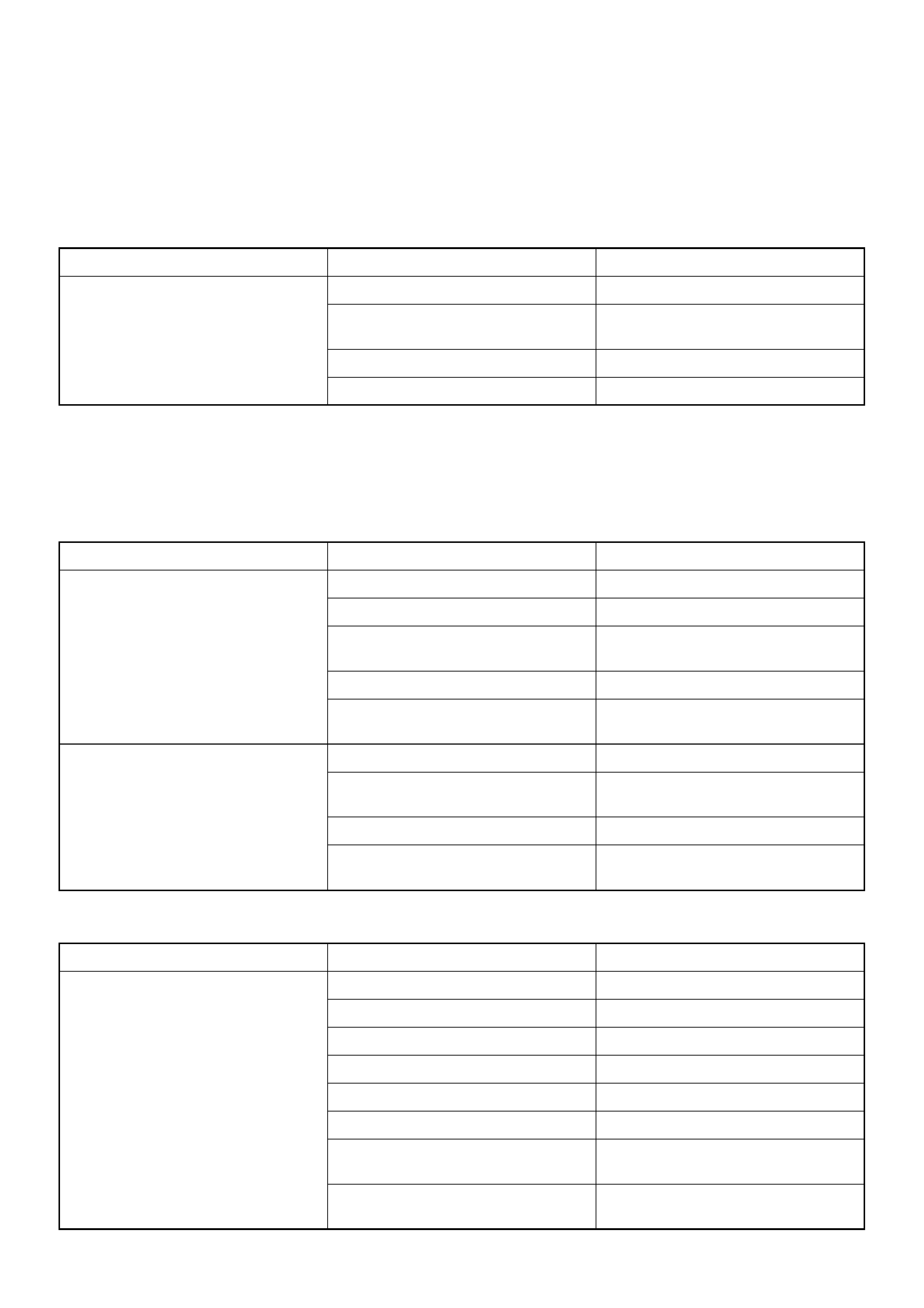

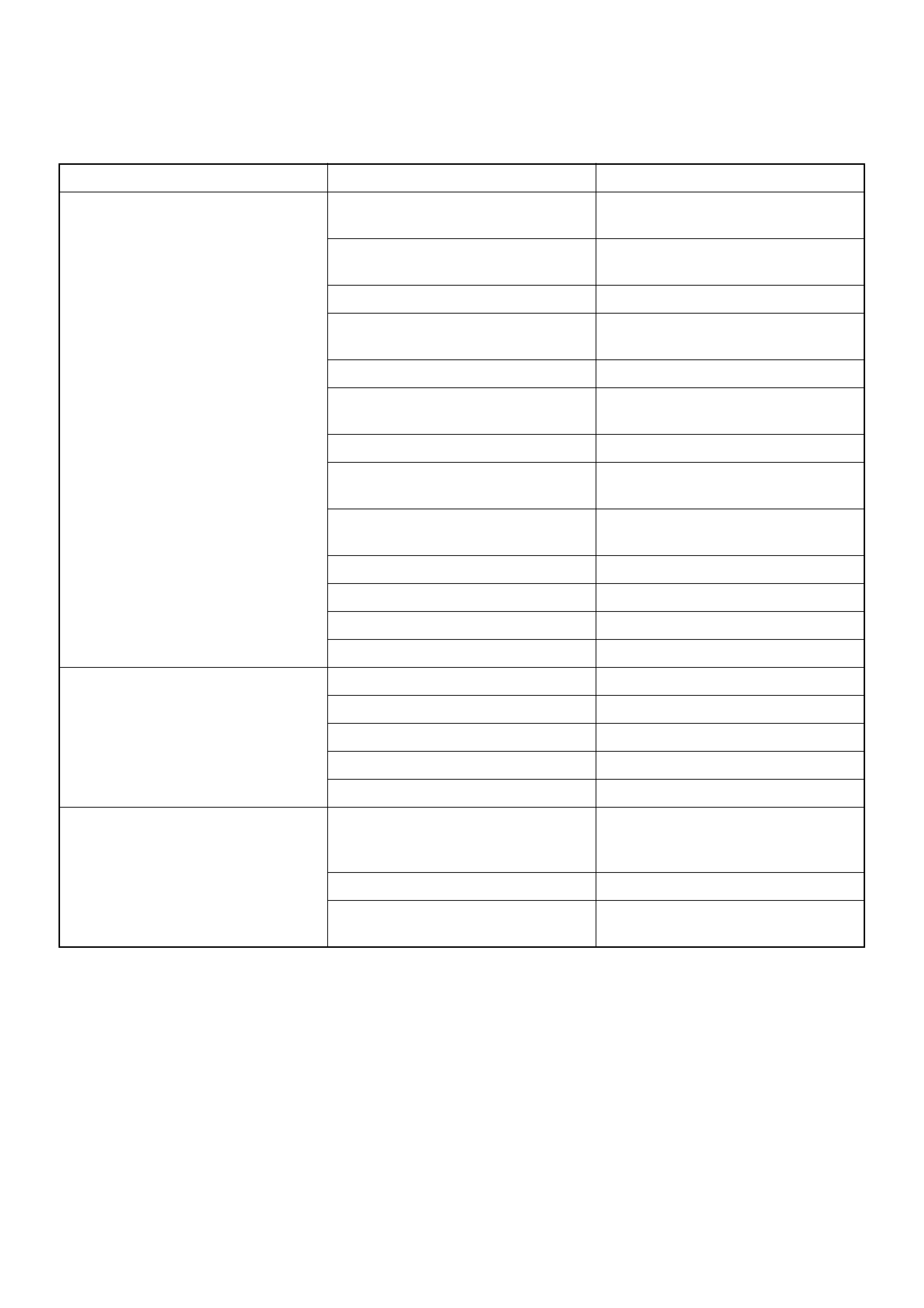

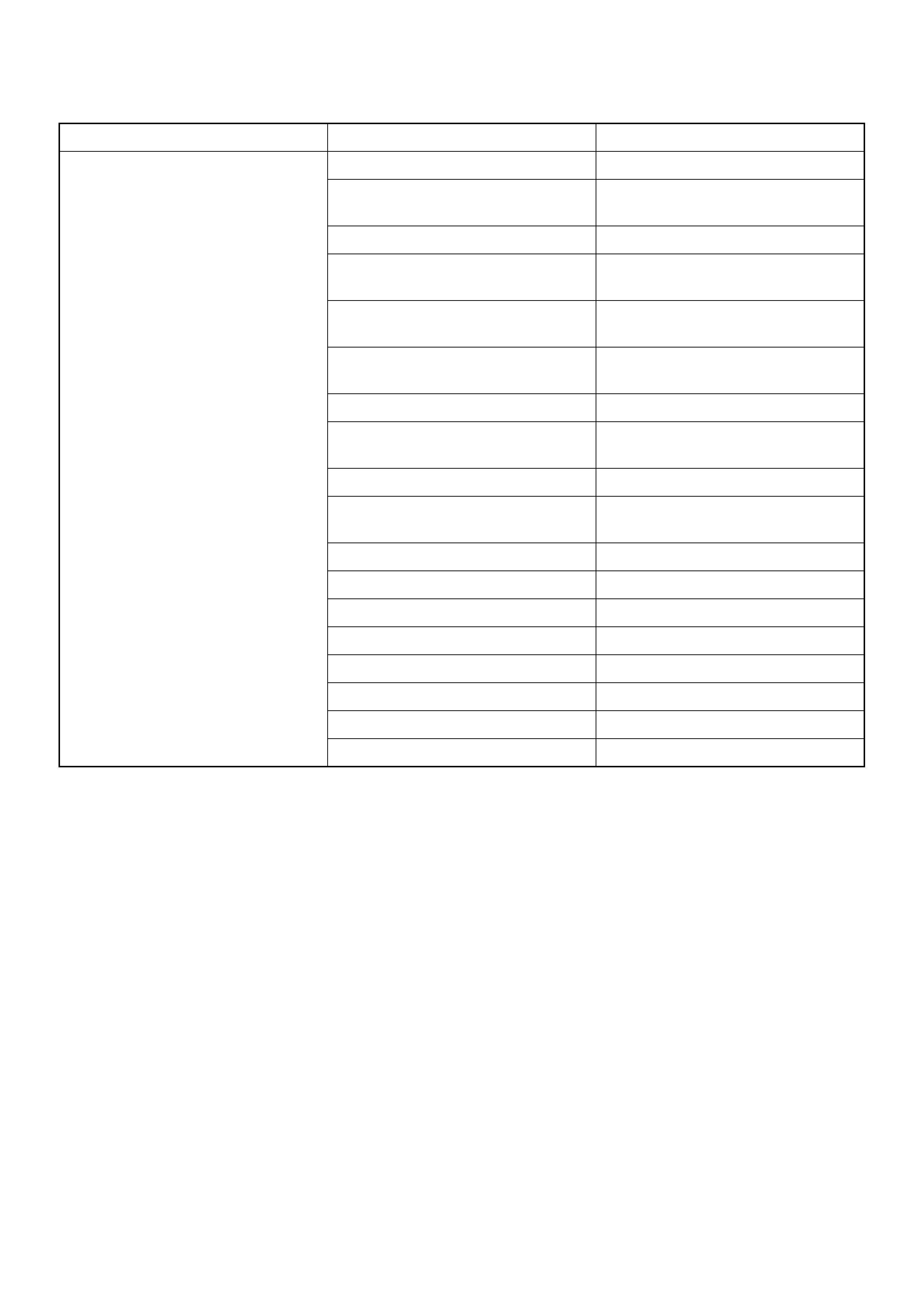

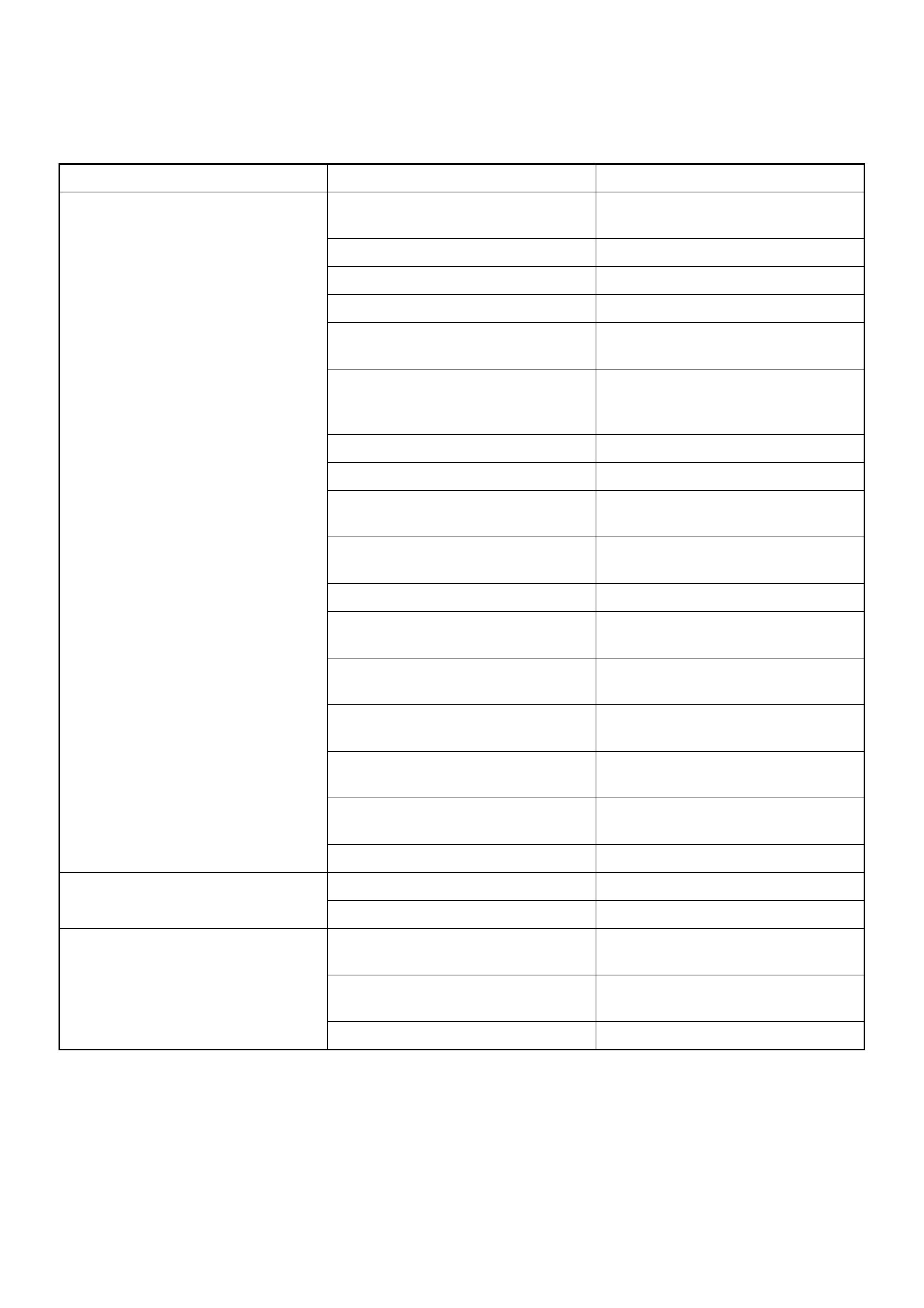

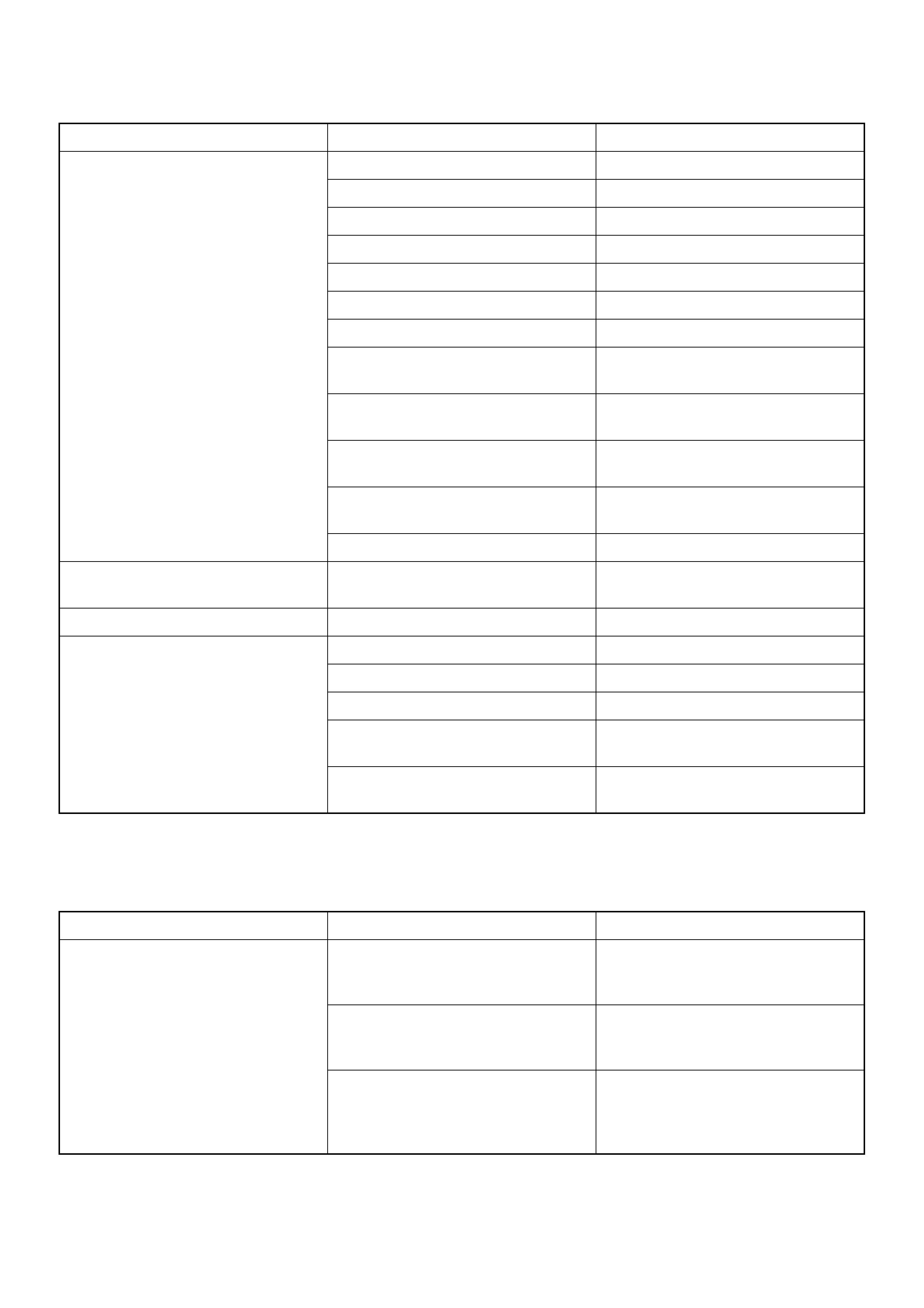

Condition Possible Cause Corrction

Headlights go out or dim

considerably

Battery run down or under charged Recharge or replace battery

Terminals poorly connected Clean battery posts and terminals

and connect properly

Starting motor coil circuit shorted Overhaul or replace

Starting motor defective Overhaul or replace

Condition Possible Cause Correction

Spark jumps across gap Spark plug defective Clean, adjust spark gap or replace

Ignition timing incorrect Refer to Ignition System

Fuel not reaching fuel injector(s) or

engine

Refer to item 3 (Trouble in fuel

system)

Valve timing incorrect Adjust

Engine lacks compression Refer to item 4 (Engine lacks

compression)

No sparking takes place Ignition coil disconnected or broken Connect properly or replace

Electronic Ignition System with

module

Replace

Poor connections in engine harness Correct

Powertrain Control Module cable

disconnected or defective

Correct or replace

Condition Possible Cause Correction

Starter motor turns over and spark

occurs but engine does not start.

Fuel tank empty Fill

Water in fuel system Clean

Fuel filter clogged Replace filter

Fuel pipe clogged Clean or replace

Fuel pump defective Replace

Fuel pump circuit open Correct or replace

Evaporative Emission Control

System circuit clogged

Correct or replace

Multiport Fuel Injection System faulty Refer to “Electronic Fuel Injection”

section

4. Engine Lacks Compression

Engine Compression Test Procedure

1. Start and run the engine until the engine reaches

normal operating temperature.

2. Turn the engine off.

3. Remove all the spark plugs.

4. Remove ignition coil fuse (15A) and disable the

ignition system.

5. Remove the fuel pump relay from the relay and fuse

box.

6. Engage the starter and check that the cranking

speed is approximately 300 rpm.

7. Install cylinder compression gauge into spark plug

hole.

8. With the throttle valve opened fully, keep the starter

engaged until the compression gage needle

reaches the maximum level. Note the reading.

9. Repeat the test with each cylinder.

If the compression pressure obtained falls below the

limit, engine overhaul is necessary.

Limit; 1000 kPa (145 psi)

Condition Possible Cause Correction

Engine lacks compression Spark plug loosely fitted or spark plug

gasket defective

Tighten to specified torque or replace

gasket

Valve timing incorrect Adjust

Cylinder head gasket defective Replace gasket

Valve incorrectly seated Lap valve

Valve stem seized Replace valve and valve guide

Valve spring weakened or broken Replace

Cylinder or piston rings worn Overhaul engine

Piston ring seized Overhaul engine.

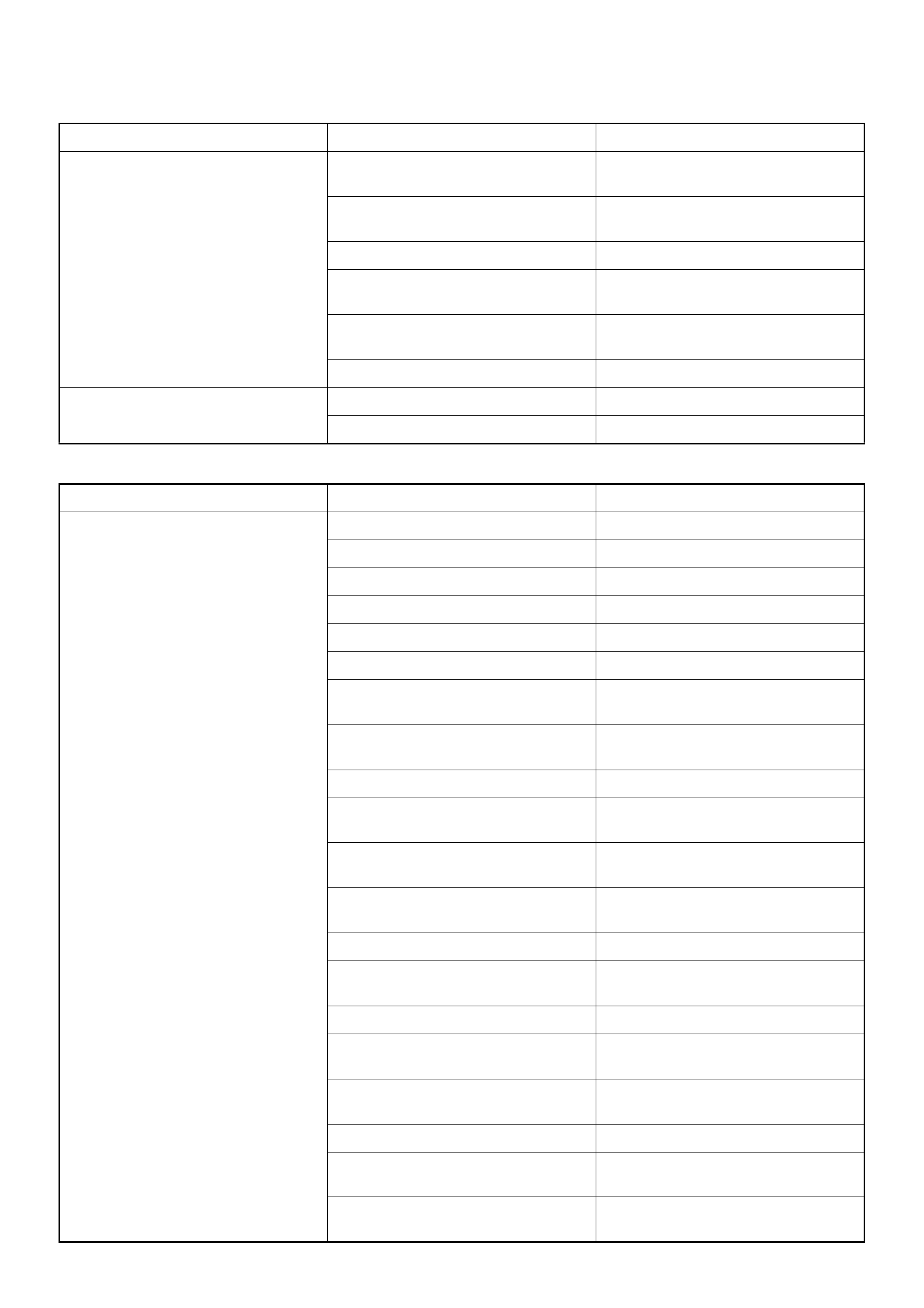

Rough Engine Idling or Engine Stalling

Condition Possible Cause Correction

Fuel injection system failure Idle air control valve defective Replace

Throttle shutting off incomplete Correct or replace

Throttle position sensor circuit open

or shorted

Correct or replace

Fuel injector circuits open or shorted Correct or replace

Fuel injectors damaged Replace

Fuel pump relay defective Replace

Mass Airflow Sensor circuit open or

poor connections

Correct or replace

Mass Airflow Sensor defective Replace

Manifold Absolute Pressure Sensor

circuit open or poor connections

Correct or replace

Manifold Absolute Pressure Sensor

defective

Replace

Engine Coolant Temperature Sensor

circuit open or poor connections

Correct or replace

Engine Coolant Temperature Sensor

defective

Replace

Intake Air Temperature sensor circuit

open or poor connections

Correct or replace

Intake Air Temperature sensor

defective

Replace

Knock Sensor (KS) cable broken or

poor connections

Correct or replace

KS defective Replace

KS Module circuits open or ground Correct or replace

KS Module defective Replace

Vehicle Speed Sensor circuit open or

shorted

Correct or replace

Vehicle Speed Sensor defective Replace

Emission control system failure Powertrain Control Module defective Replace

Exhaust Gas Recirculation Valve

circuit open or poor connections

Correct or replace

Exhaust Gas Recirculation Valve

faulty

Replace

Canister purge valve circuit open or

poor connections

Correct or replace

Canister purge valve defective Replace

Evaporative Emission Canister Purge

control valve defective

Replace

Trouble in ignition system Refer to “Hard Start”

Rough Engine Running

Others Engine lacks compression Refer to “Hard Start”

Valve incorrectly seated Lap valve

Air Cleaner Filter clogged Replace filter element

Valve timing incorrect Readjust

Idle air control valve broken Replace

Fast idle solenoid defective Replace

Positive Crankcase Ventilation valve

defective or clogged

Replace

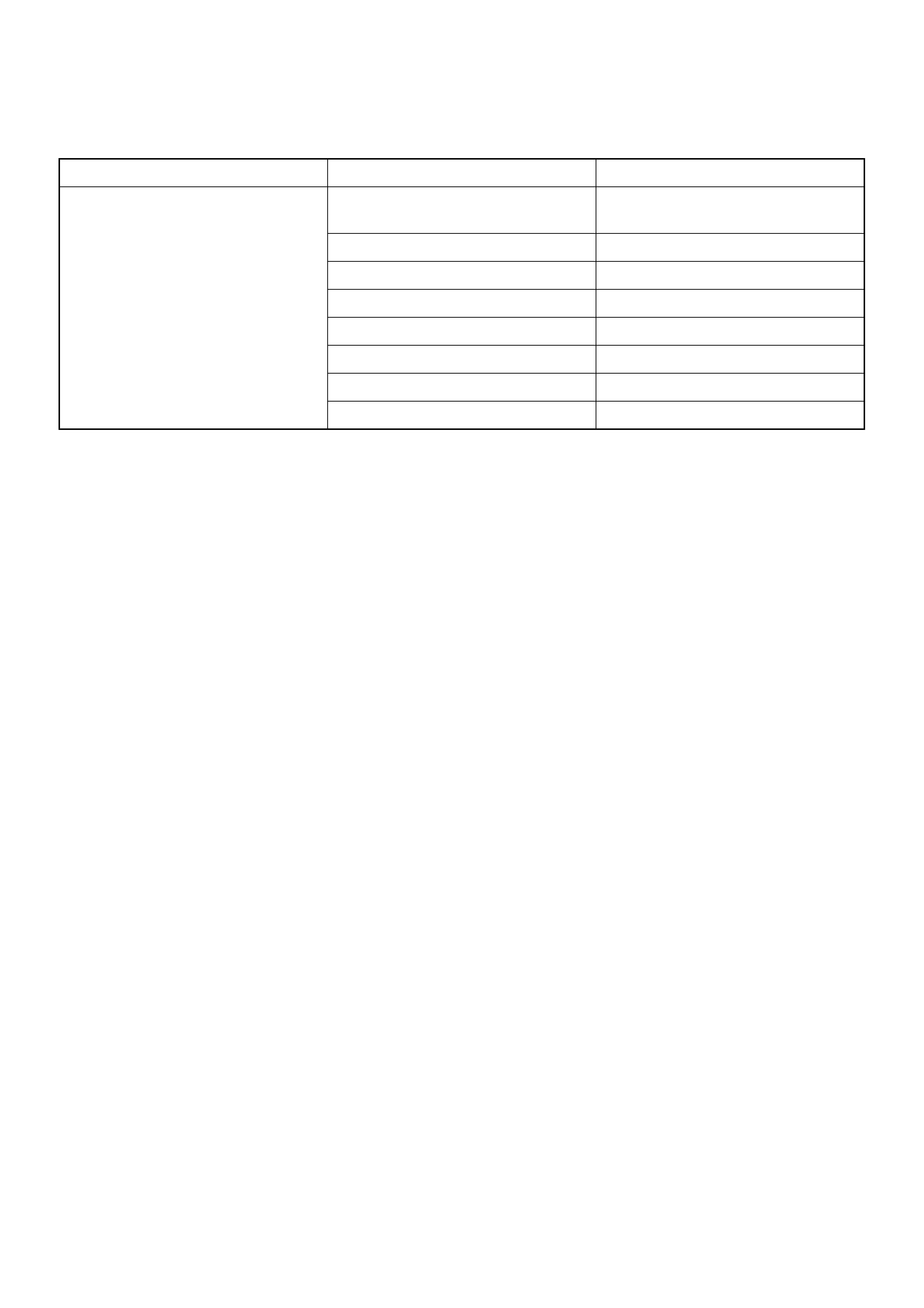

Condition Possible Cause Correction

Condition Possible Cause Correction

Engine misfires periodically Ignition coil layer shorted Replace

Spark plugs fouling Clean or install hotter type plug

Spark plug(s) insulator nose leaking Replace

Fuel injector(s) defective Replace

Powertrain control module faulty Replace

Engine knocks periodically Spark plugs running too hot Install colder type spark plugs

Powertrain control module faulty Replace

Engine lacks power Spark plugs fouled Clean

Fuel injectors defective Replace

Mass Airflow Sensor or Intake Airflow

Sensor circuit defective

Correct or replace

Manifold Absolute Pressure (MAP)

Sensor or Manifold Absolute

Pressure Sensor circuit defective

Correct or replace

Engine Coolant Temperature Sensor

or Engine Coolant Temperature

Sensor circuit defective

Correct or replace

Powertrain Control Module faulty Replace

Intake Air Temperature Sensor or

Intake Air Temperature Sensor circuit

defective

Correct or replace

Throttle Position Sensor or Throttle

Position Sensor circuit defective

Correct or replace

Knock Sensor or Knock Sensor

circuits defective

Correct or replace

Knock Sensor Module or Knock

Sensor Module circuits defective

Correct or replace

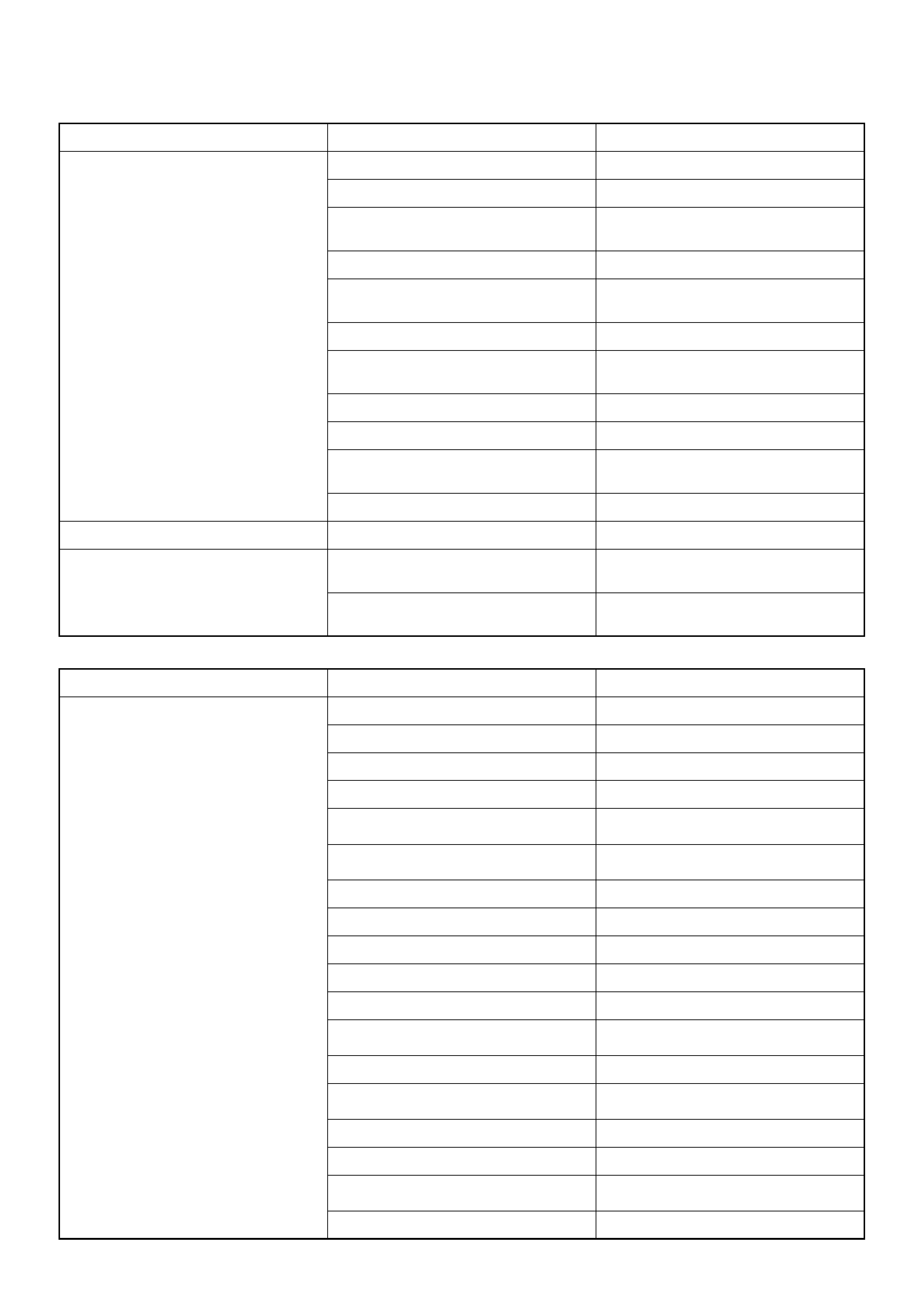

Hesitation

Condition Possible Cause Correction

Hesitation on acceleration Throttle Position Sensor adjustment

incorrect

Replace throttle valve assembly

Throttle Position Sensor circuit open

or shorted

Correct or replace

Excessive play in accelerator linkage Adjust or replace

Mass Airflow Sensor circuit open or

poor connections

Correct or replace

Mass Airflow Sensor defective Replace

Manifold Absolute Pressure (MAP)

Sensor circuit open or shorted

Correct or replace

MAP Sensor defective Replace

Intake Air Temperature (IAT) Sensor

circuit open or shorted

Correct or replace

Knock Sensor (KS) Circuit open or

poor connections

Correct or replace

KS defective Replace

KS Module circuits open or shorted Correct or replace

KS Module defective Replace

IAT Sensor defective Replace

Hesitation at high speeds

(Fuel pressure too low)

Fuel tank strainer clogged Clean or replace

Fuel pipe clogged Clean or replace

Fuel filter clogged Replace

Defective fuel pump system Check and replace

Fuel Pressure Control Valve leaking Replace

Hesitation at high speeds

(Fuel injector not working normally)

Power supply or ground circuit for

Multiport Fuel Injection System

shorted or open

Check and correct or replace

Fuel Injector defective Replace

Fuel Injection System circuit open or

poor connections

Correct or replace

Hesitation at high speeds Powertrain Control Module defective Replace

Throttle Position Sensor cable

broken or poor connections

Correct or replace

Throttle Position Sensor defective Replace

Engine Coolant Temperature Sensor

circuit open or shorted

Correct or replace

Engine Coolant Temperature Sensor

defective

Replace

Mass Airflow Sensor circuit open or

poor connections

Correct or replace

Mass Airflow Sensor defective Replace

MAP Sensor cable broken or poor

connections

Correct or replace

MAP Sensor defective Replace

IAT Sensor circuit open or poor

connections

Correct or replace

IAT Sensor defective Replace

KS circuit open or poor connections Correct or replace

KS defective Replace

KS Module circuit open or shorted Correct or replace

KS Module defective Replace

Throttle valve not fully opened Check and correct or replace

Air Cleaner Filter clogged Replace filter element

Power supply voltage too low Check and correct or replace

Condition Possible Cause Correction

Engine Lacks Power

Condition Possible Cause Correction

Fuel system fault Fuel Pressure Control Valve not

working normally

Replace

Fuel injector clogged Clean or replace

Fuel pipe clogged Clean

Fuel filter clogged or fouled Replace

Fuel pump drive circuit not working

normally

Correct or replace

Fuel tank not sufficiently breathing

due to clogged Evaporative Emission

Control System circuit

Clean or replace

Water in fuel system Clean

Inferior quality fuel in fuel system Use fuel of specified octane rating

Powertrain Control Module supplied

poor voltage

Correct circuit

Throttle Position Sensor cable

broken or poor connections

Correct or replace

Throttle Position Sensor defective Replace

Mass Airflow Sensor not working

normally

Replace

Manifold Absolute Pressure Sensor

not working normally

Replace

Intake Air Temperature Sensor not

working normally

Replace

Engine Coolant Temperature Sensor

circuit open or shorted

Correct or replace

Engine Coolant Temperature Sensor

defective

Replace

Powertrain Control Module defective Replace

Trouble in intake or exhaust system Air Cleaner Filter clogged Replace filter element

Air duct kinked or flattened Correct or replace

Ignition failure ———— Refer to Hard Start Troubleshooting

Guide

Heat range of spark plug inadequate Install spark plugs of adequate heat

range

Ignition coil defective Replace

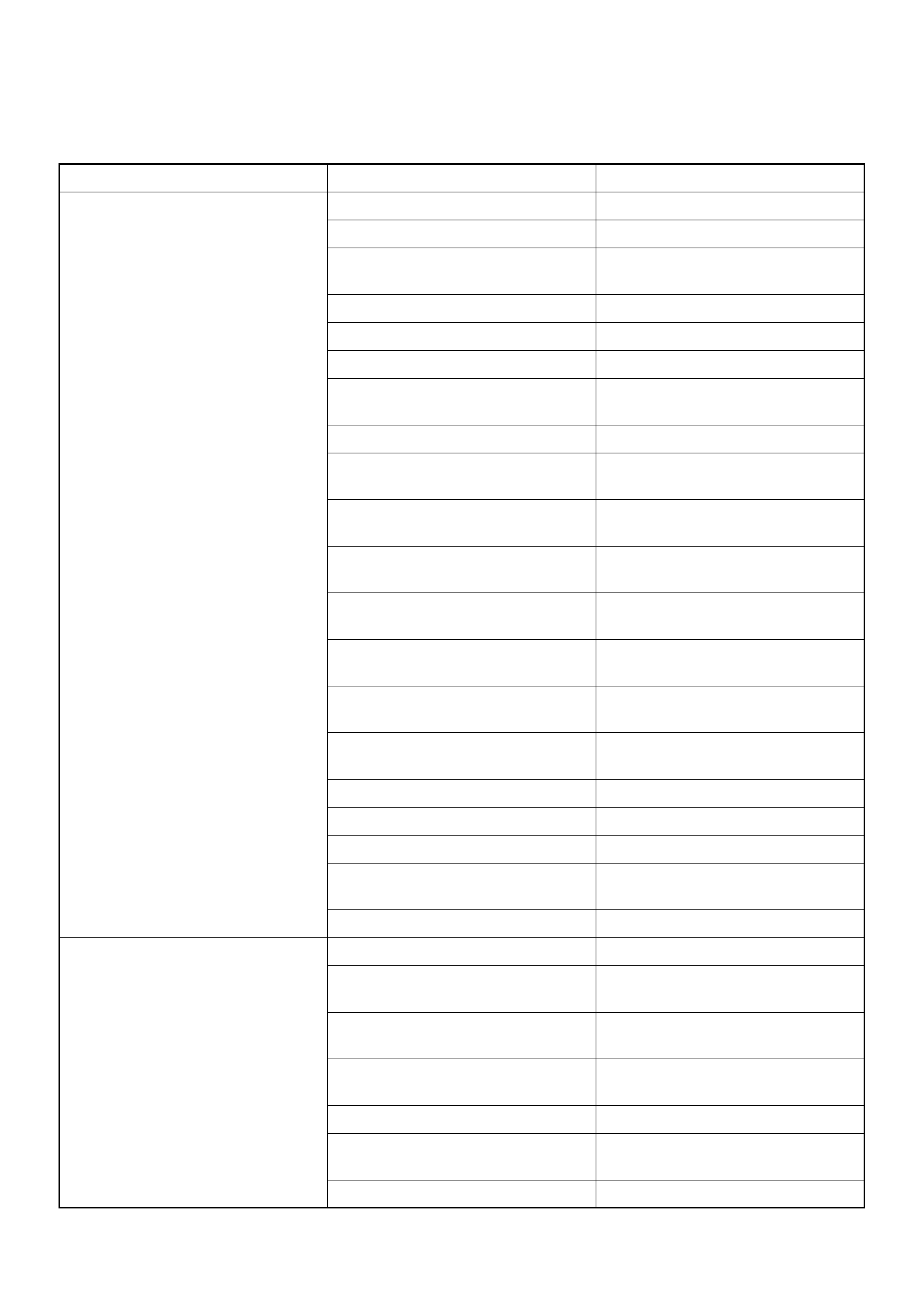

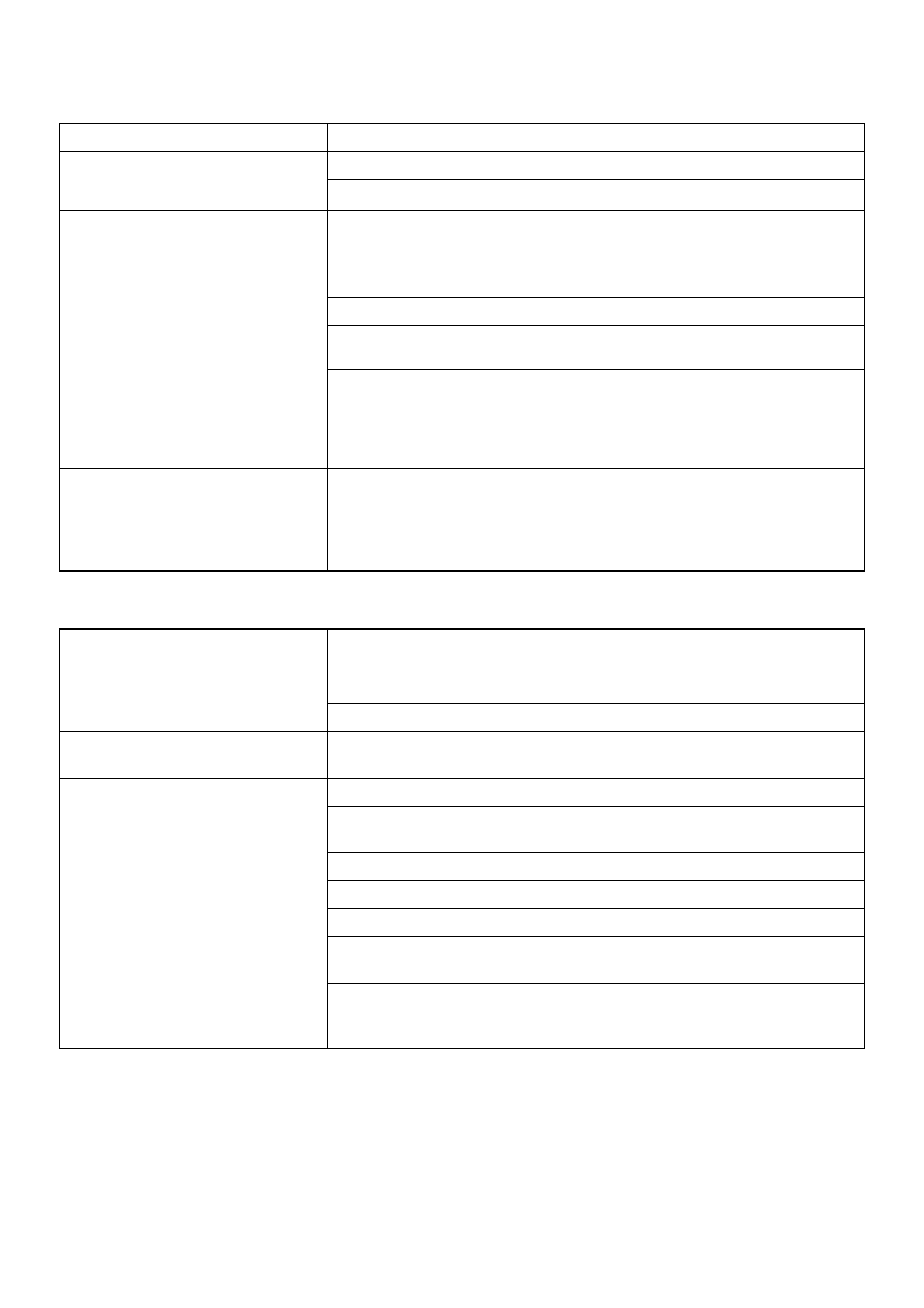

Engine Noisy

Abnormal engine noise often consists of various noises

originating in rotating parts, sliding parts and other

moving parts of the engine. It is, therefore, advisable to

locate the source of noise systematically.

Troubleshooting Procedure

Short out each spark plug in sequence using insulated

spark plug wire removers. Locate cylinder with defective

bearing by listening for abnormal noise that stops when

spark plug is shorted out.

Engine overheating Level of Engine Coolant too low Replenish

Fan clutch defective Replace

Incorrect fan installed Replace

Thermostat defective Replace

Engine Coolant pump defective Correct or replace

Radiator clogged Clean or replace

Radiator filler cap defective Replace

Level of oil in engine crankcase too

low or wrong engine oil

Change or replenish

Resistance in exhaust system

increased

Clean exhaust system or replace

defective parts

Throttle Position Sensor adjustment

incorrect

Replace with Throttle Valve ASM

Throttle Position Sensor circuit open

or shorted

Correct or replace

Cylinder head gasket damaged Replace

Engine overcooling Thermostat defective Replace (Use a thermostat set to

open at 82

°

C (180

°

F))

Engine lacks compression ———— Refer to Hard Start

Others Tyre inflation pressure abnormal Adjust to recommended pressures

Brake drag Adjust

Clutch slipping Adjust or replace

Level of oil in engine crankcase too

high

Correct level of engine oil

Exhaust Gas Recirculation Valve

defective

Replace

Condition Possible Cause Correction

Condition Possible Cause Correction

Noise from crank journals or from

crank bearings

(Faulty crank journals and crank

bearings usually make dull noise that

becomes more evident when

accelerating)

Oil clearance increased due to worn

crank journals or crank bearings

Replace crank bearings and

crankshaft or regrind crankshaft and

install the undersize bearing

Crankshaft out of round Replace crank bearings and

crankshaft or regrind crankshaft and

install the undersize bearing

Crank bearing seized Crank bearing seized. Replace crank

bearings and crankshaft or regrind

crankshaft and install the undersize

bearing

Troubleshooting Procedure

Abnormal noise stops when the spark plug on the

cylinder with defective part is shorted out.

Troubleshooting Procedure

Short out each spark plug and listen for change in

engine noise.

Troubleshooting Procedure

The slapping sound stops when spark plug on bad

cylinder is shorted out.

Condition Possible Cause Correction

Noise from connecting rods or from

connecting rod bearings

(Faulty connecting rods or

connecting rod bearings usually

make an abnormal noise slightly

higher than the crank bearing noise,

which becomes more evident when

engine is accelerated)

Bearing or crankshaft pin worn Replace connecting rod bearings and

crankshaft or regrind crankshaft pin

and install the undersize bearing

Crankpin out of round Replace connecting rod bearings and

crankshaft or regrind crankshaft pin

and install the undersize bearing

Connecting rod bent Correct or replace

Connecting rod bearing seized Replace connecting rod bearings and

crankshaft or regrind crankshaft pin

and install the undersize bearing

Condition Possible Cause Correction

Piston and cylinder noise

(Faulty piston or cylinder usually

makes a combined mechanical

thumping noise which increases

when engine is suddenly

accelerated but diminishes gradually

as the engine warms up)

Piston clearance increased due to

cylinder wear

Replace piston and cylinder body

Piston seized Replace piston and cylinder body

Piston ring broken Replace piston and cylinder body

Piston defective Replace pistons and others

Condition Possible Cause Correction

Piston pin noise

(Piston makes noise each time it

goes up and down)

Piston pin or piston pin hole worn Replace piston, piston pin and

connecting rod assy

Condition Possible Cause Correction

Timing belt noise Timing belt tension is incorrect Replace pusher or adjust the tension

pulley or replace timing belt

Tensioner bearing defective Replace

Timing belt defective Replace

Timing pulley defective Replace

Timing belt comes in contact with

timing cover

Replace timing belt and timing cover

Valve noise Valve clearance incorrect Replace adjusting shim

Valve and valve guide seized Replace valve and valve guide

Valve spring broken or weakened Replace

Valve seat off–positioned Correct

Camshaft worn out Replace

Crankshaft noise Crankshaft end play excessive (noise

occurs when clutch is engaged)

Replace thrust bearing

Abnormal Combustion

Engine knocking Preignition due to use of spark plugs

of inadequate heat range

Install Spark Plugs of adequate heat

range

Carbon deposits in combustion

chambers

Clean

Fuel too low in octane rating Replace fuel

Wide Open Throttle enrichment

system failure

Refer to Section 6E

Selection of transmission gear

incorrect

Caution operator of incorrect gear

selection

Engine overheating Refer to “Engine Lacks Power”

Others Water pump defective Replace

Drive belt slipping Replace auto tentioner or drive belt

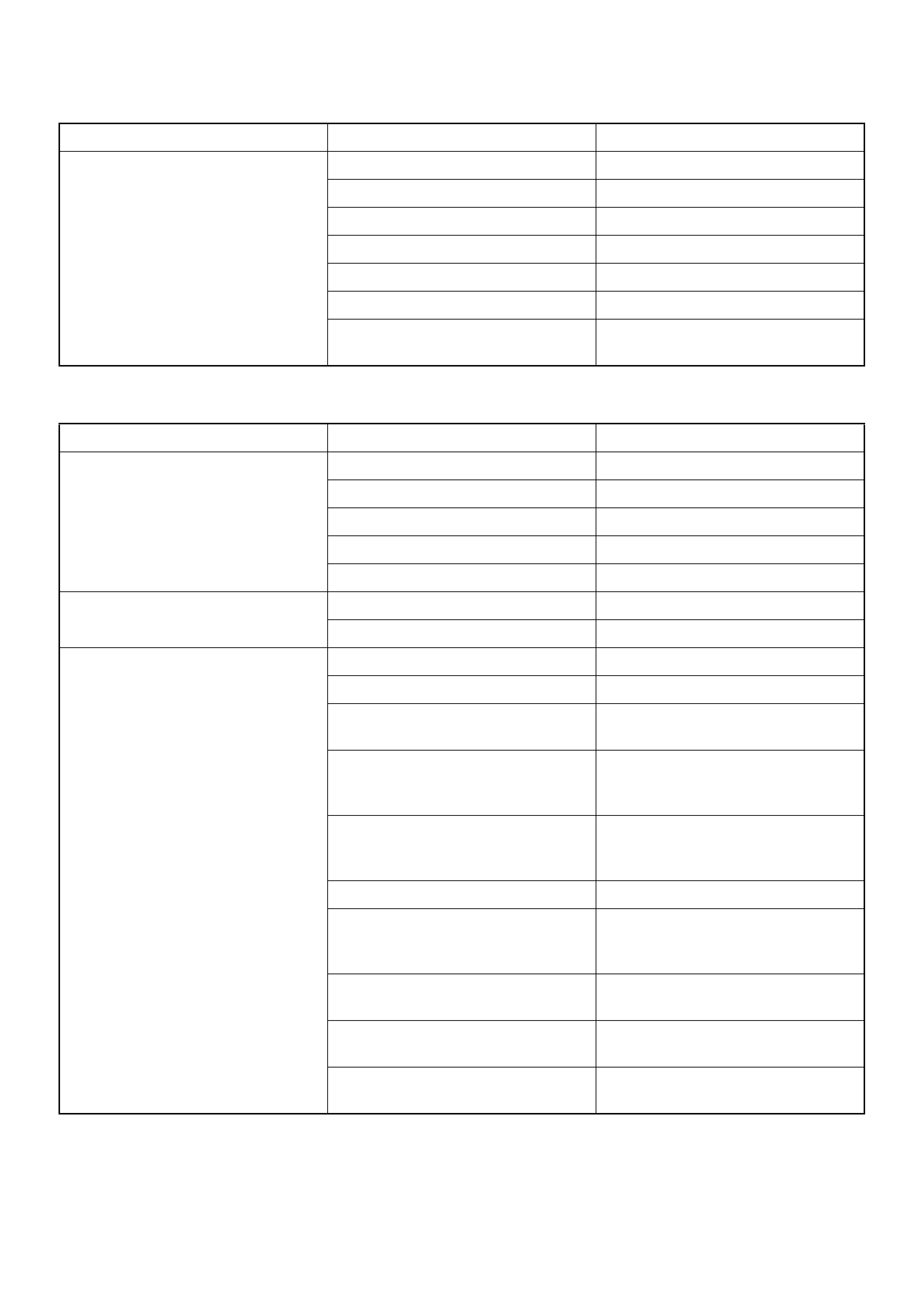

Condition Possible Cause Correction

Condition Possible Cause Correction

Trouble in fuel system Fuel pressure control valve defective Replace

Fuel filter clogged Replace

Fuel pump clogged Clean or replace

Fuel tank or fuel pipe clogged Clean or replace

Fuel injector clogged Clean or replace

Fuel pump relay defective Replace

Power supply cable for fuel pump

broken or poor connections

Reconnect, correct or replace

Mass Airflow (MAF) sensor circuit

open or defective

Correct or replace

MAF Sensor defective Replace

Manifold Absolute Pressure Sensor

circuit open or shorted

Correct or replace

Manifold Absolute Pressure Sensor

defective

Replace

Engine Coolant Temperature (ECT)

Sensor circuit open or shorted

Correct or replace

ECT Sensor defective Replace

Throttle Position Sensor adjustment

incorrect

Readjust

Throttle Position Sensor defective Replace

Throttle Position Sensor connector

poor connections

Reconnect

Vehicle Speed Sensor cable poor

connections or defective

Correct or replace

Vehicle Speed Sensor loosely fixed Fix tightly

Vehicle Speed Sensor in wrong

contact or defective

Replace

Powertrain Control Module cable

poor connections or defective

Correct or replace

Engine Oil Consumption Excessive

Trouble in emission control system Heated Oxygen Sensor circuit open Correct or replace

Heated Oxygen Sensor defective Replace

Signal vacuum hose loosely fitted or

defective

Correct or replace

EGR Valve circuit open or shorted Correct or replace

Exhaust Gas Recirculation Valve

defective

Replace

ECT Sensor circuit open or shorted Correct or replace

Canister Purge Valve circuit open or

shorted

Correct or replace

Canister Purge Valve defective Replace

ECT Sensor defective Replace

Positive Crankcase Ventilation (PCV)

valve and hose clogged

Correct or replace

Evaporator system Refer to Section 6E

Trouble in ignition system ———— Refer to “Engine Lacks Power”

Trouble in cylinder head parts Carbon deposits in combustion

chamber

Remove carbon

Carbon deposit on valve, valve seat

and valve guide

Remove carbon

Condition Possible Cause Correction

Condition Possible Cause Correction

Oil leaking Oil pan drain plug loose Retighten or replace gasket

Crankcase fixing bolts loosened Retighten

Oil pan setting bolts loosened Retighten

Oil pan gasket broken Replace gasket

Front cover retaining bolts loose or

gasket broken Retighten or replace gasket

Head cover fixing bolts loose or

gasket broken Retighten or replace gasket

Oil cooler adapter cracked Replace

Oil cooler center bolt loose Retighten

Oil cooler O–ring broken Replace

Oil cooler piping loose or broken Retighten or replace

Oil filter adapter cracked Replace

Oil filter attaching bolt loose or rubber

gasket broken Retighten or replace oil filter

Oil cooler broken Replace

Crankshaft front or rear oil seal

defective Replace oil seal

Oil pressure unit loose or broken Retighten or replace

Blow–by gas hose broken Replace hose

Positive Crankcase Ventilation Valve

clogged Clean

Engine/Transmission coupling failed Replace oil seal

Fuel Consumption Excessive

Oil leaking into combustion

chambers due to poor seal in valve

system

Valve stem oil seal defective Replace

Valve stem or valve guide worn Replace valve and valve guide

Oil leaking into combustion

chambers due to poor seal in cylinder

parts

Cylinders and pistons worn

excessively

Replace cylinder body assembly and

pistons

Piston ring gaps incorrectly

positioned

Correct

Piston rings set with wrong side up Correct

Piston ring sticking Replace cylinder body assembly and

pistons

Piston ring and ring groove worn Replace pistons and others

Return ports in oil rings clogged Clean piston and replace rings

Positive Crankcase Ventilation

System malfunctioning

Positive Crankcase Ventilation Valve

clogged

Clean

Others Improper oil viscosity Use oil of recommended S.A.E.

viscosity

Continuous high speed driving and/or

severe usage such as trailer towing

Continuous high speed operation

and/or severe usage will normally

cause increased oil consumption

Condition Possible Cause Correction

Suspect System Possible Cause Correction

Fuel system Mixture too rich or too lean due to

trouble in fuel injection system

Refer to “Abnormal Combustion”

Fuel cut function does not work Refer to “Abnormal Combustion”

Ignition system Misfiring or abnormal combustion

due to trouble in ignition system

Refer to “Hard Start” or “Abnormal

Combustion”

Others Engine idle speed too high Reset Idle Air Control Valve

Returning of accelerator control

sluggish

Correct

Fuel system leakage Correct or replace

Clutch slipping Correct

Brake drag Correct

Selection of transmission gear

incorrect

Caution operator of incorrect gear

selection

Excessive Exhaust Gas Recirculation

flow due to trouble in Exhaust Gas

Recirculation system

Refer to “Abnormal Combustion”

Lubrication Problems

Engine Oil Pressure Check

1.Check for dirt, gasoline or water in the engine oil.

aCheck the viscosity of the oil.

bChange the oil if the viscosity is outside the

specified standard.

cRefer to the “Maintenance and Lubrication”

section of this manual.

2. Check the engine oil level.

The level should fall somewhere between the “ADD”

and the “FULL” marks on the oil level dipstick.

If the oil level does not reach the “ADD” mark on the

oil level dipstick, engine oil must be added.

3. Remove the oil pressure unit.

4. Install an oil pressure gauge.

5. Start the engine and allow the engine to reach

normal operating temperature (About 80°C).

6. Measure the oil pressure.

Oil pressure should be:

392–550 kPa (56.9–80.4 psi) at 3000 rpm.

7. Stop the engine.

8. Remove the oil pressure gauge.

9. Install the oil pressure unit.

10. Start the engine and check for leaks.

Condition Possible Cause Correction

Oil pressure too low Wrong oil in use Replace with correct engine oil

Relief valve sticking Replace

Oil pump not operating properly Correct or replace

Oil pump strainer clogged Clean or replace strainer

Oil pump worn Replace

Oil pressure gauge defective Correct or replace

Crankshaft bearing or connecting rod

bearing worn

Replace

Oil contamination Wrong oil in use Replace with correct engine oil

Oil filter clogged Replace oil filter

Cylinder head gasket damage Replace gasket

Burned gases leaking Replace piston and piston rings or

cylinder body assembly

Oil not reaching valve system Oil passage in cylinder head or

cylinder body clogged

Clean or correct

Malfunction Indicator Lamp

The instrument panel “CHECK ENGINE” Malfunction

Indicator Lamp (MIL) illuminates by self diagnostic

system when the system checks the starting of engine,

or senses malfunctions.

Condition Possible Cause Correction

“CHECK ENGINE” MIL does not

illuminate at the starting of engine

Bulb defective Replace

MIL circuit open Correct or replace

Command signal circuit to operate

self diagnostic system shorted

Correct or replace

Engine Control Module (PCM) cable

loosely connected, disconnected or

defective

Correct or replace

PCM defective Replace

“CHECK ENGINE” MIL illuminates,

and stays on

Deterioration of heated oxygen

sensor internal element

Replace

Heated oxygen sensor connector

terminal improper contact

Reconnect properly

Heated oxygen sensor lead wire

shorted

Correct

Heated oxygen sensor circuit open Correct or replace

Deterioration of engine coolant

temperature sensor internal element

Replace

Engine coolant temperature sensor

connector terminal improper contact

Reconnect properly

Engine coolant temperature sensor

lead wire shorted

Correct

Engine coolant temperature sensor

circuit open

Correct or replace

Throttle position sensor open or

shorted circuits

Correct or replace

Deterioration of crankshaft position

sensor

Replace

Crankshaft position sensor circuit

open or shorted

Correct or replace

Vehicle speed sensor circuit open Correct or replace

Manifold absolute pressure sensor

circuit open or shorted

Correct or replace

Intake air temperature sensor circuit

open or shorted

Correct or replace

Fuel injector circuit open or shorted Correct or replace

PCM driver transistor defective Replace PCM

Malfunctioning of PCM RAM

(Random Access Memory) or ROM

(Read Only Memory)

Replace PCM

Cylinder Head Cover LH

Removal

1. Disconnect battery ground cable.

2. Drain engine coolant from faucet bottom of radiator.

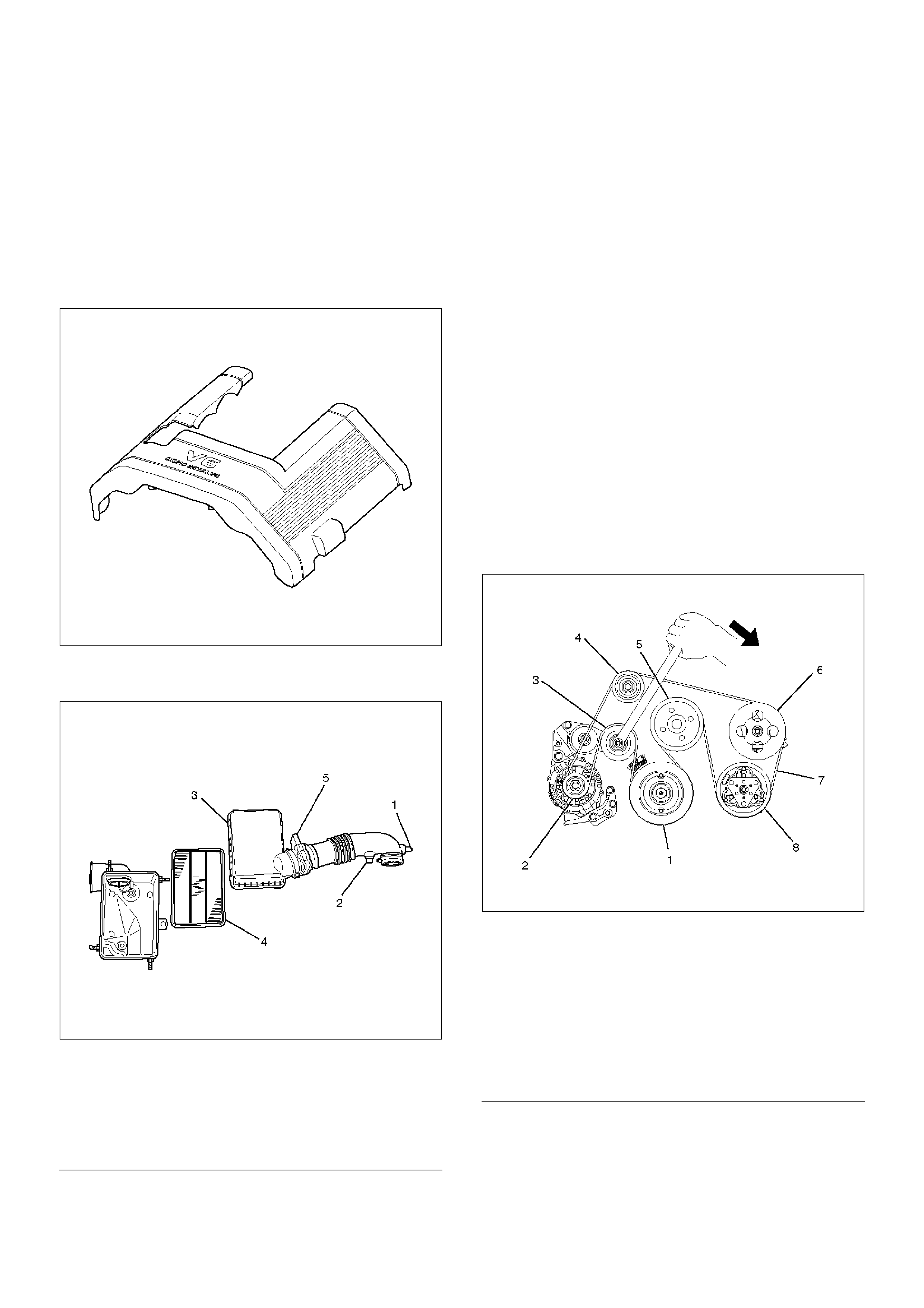

3. Remove engine cover from the dowels on the

common chamber.

F06RW018

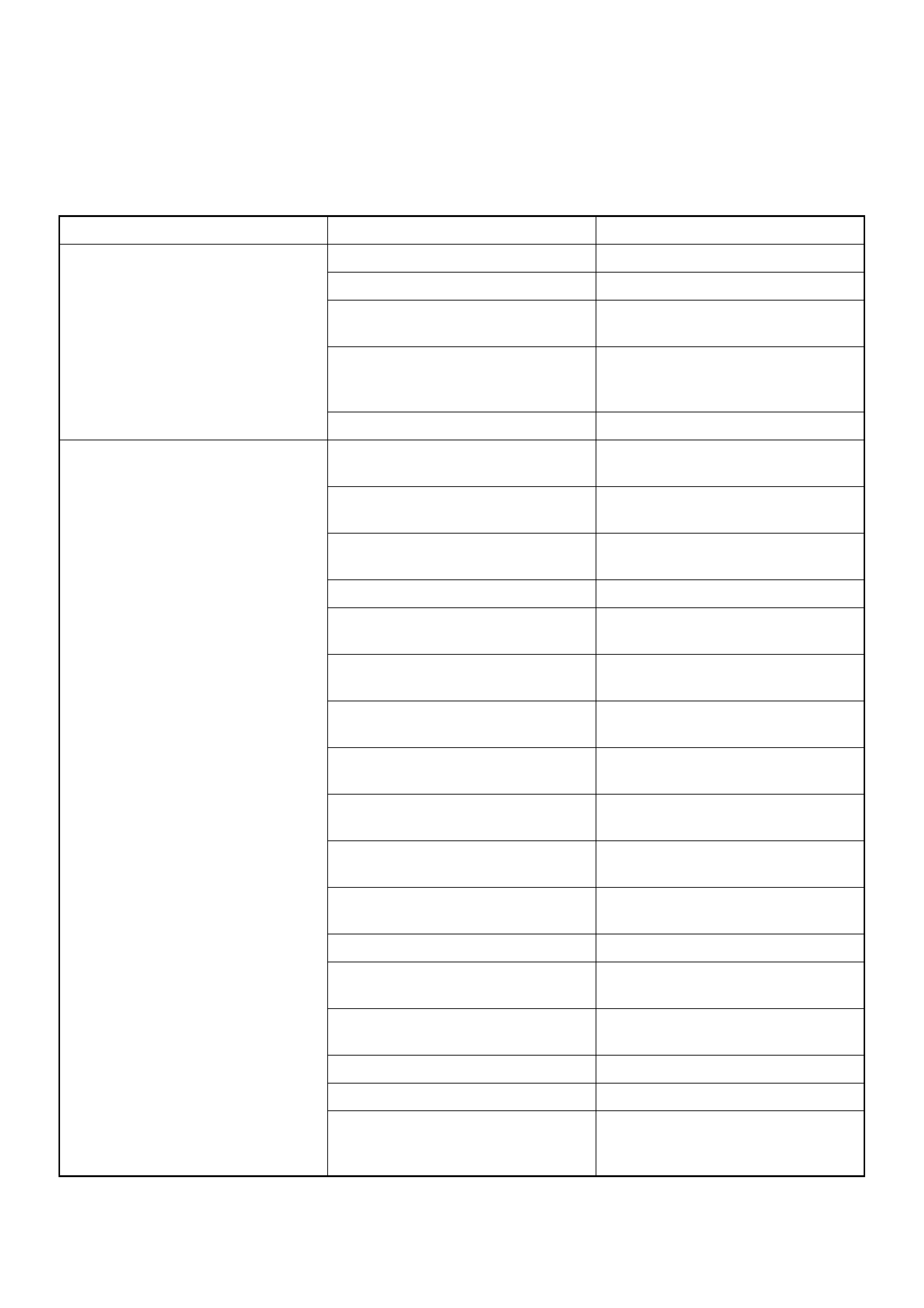

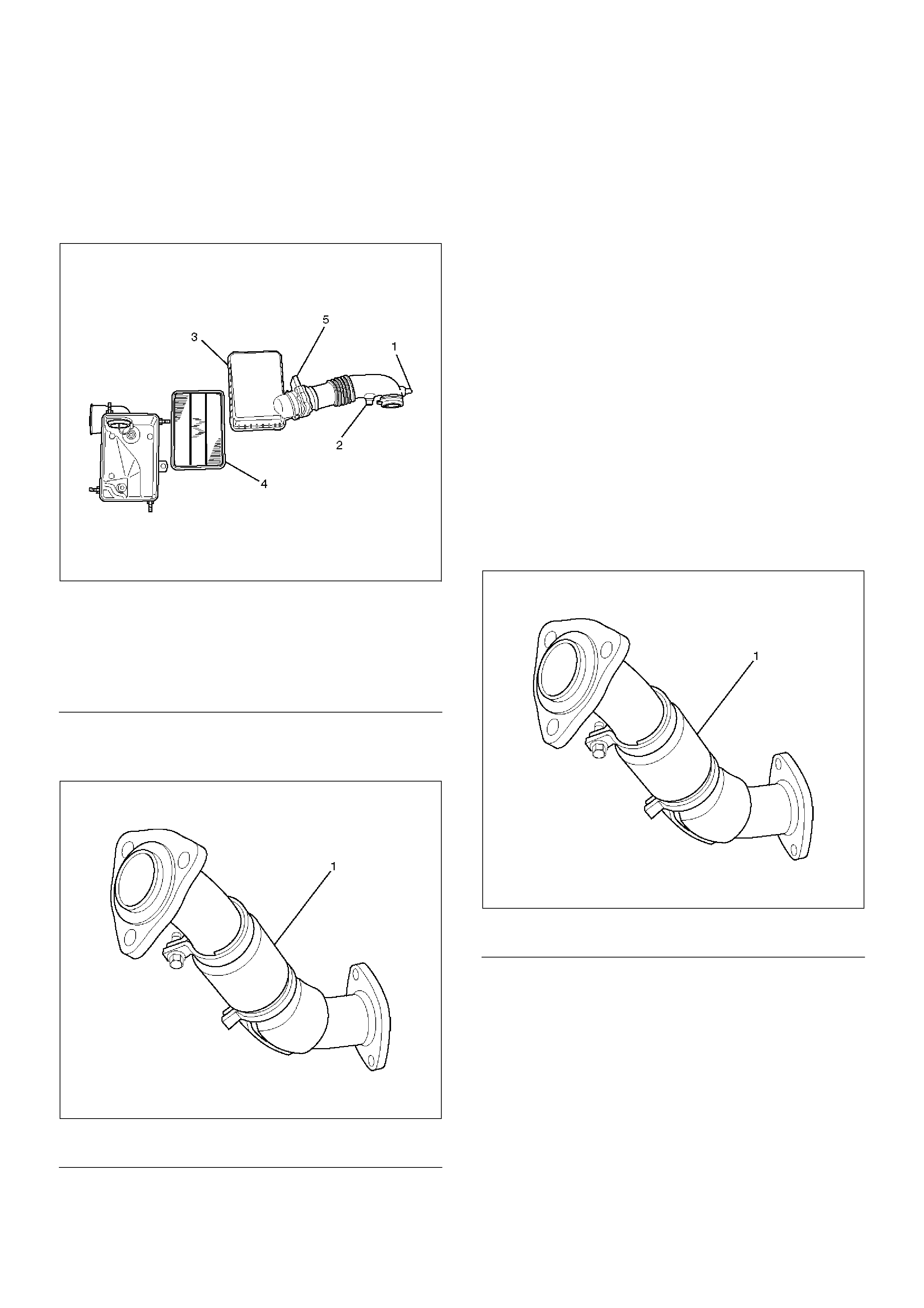

4. Remove air cleaner duct assembly (3) and air

cleaner element (4).

130RW001

EndOFC allout

NOTE: Disconnect the mass air flow (MAF) sensor

connector, intake air temperature (IAT) sensor

connector, and positive crankcase ventilation (PCV)

hose before hand the air cleaner duct assembly is

removed.

5. Disconnect following wiring connectors and bonding

cable:

• Manifold Absolute Pressure (MAP) sensor

• Vacuum Switching Valve (VSV) for Induction Air

Control Valve (IACV) actuator

• Ignition coils for left bank

• Fuel injectors for left bank

• Idle air control (IAC) valve

• Throttle position sensor (TPS)

• Bonding cable

• Others as necessitated

6. Disconnect following vacuum hoses:

• Brake master VAC

• Canister

• VSV for IACV actuator

• Duty solenoid valve

•PCV

7. Disconnect radiator upper and lower hoses

8. Remove engine harness from the cylinder head

cover.

9. Remove the upper fan guide.

10. Remove cooling fan and clutch assembly.

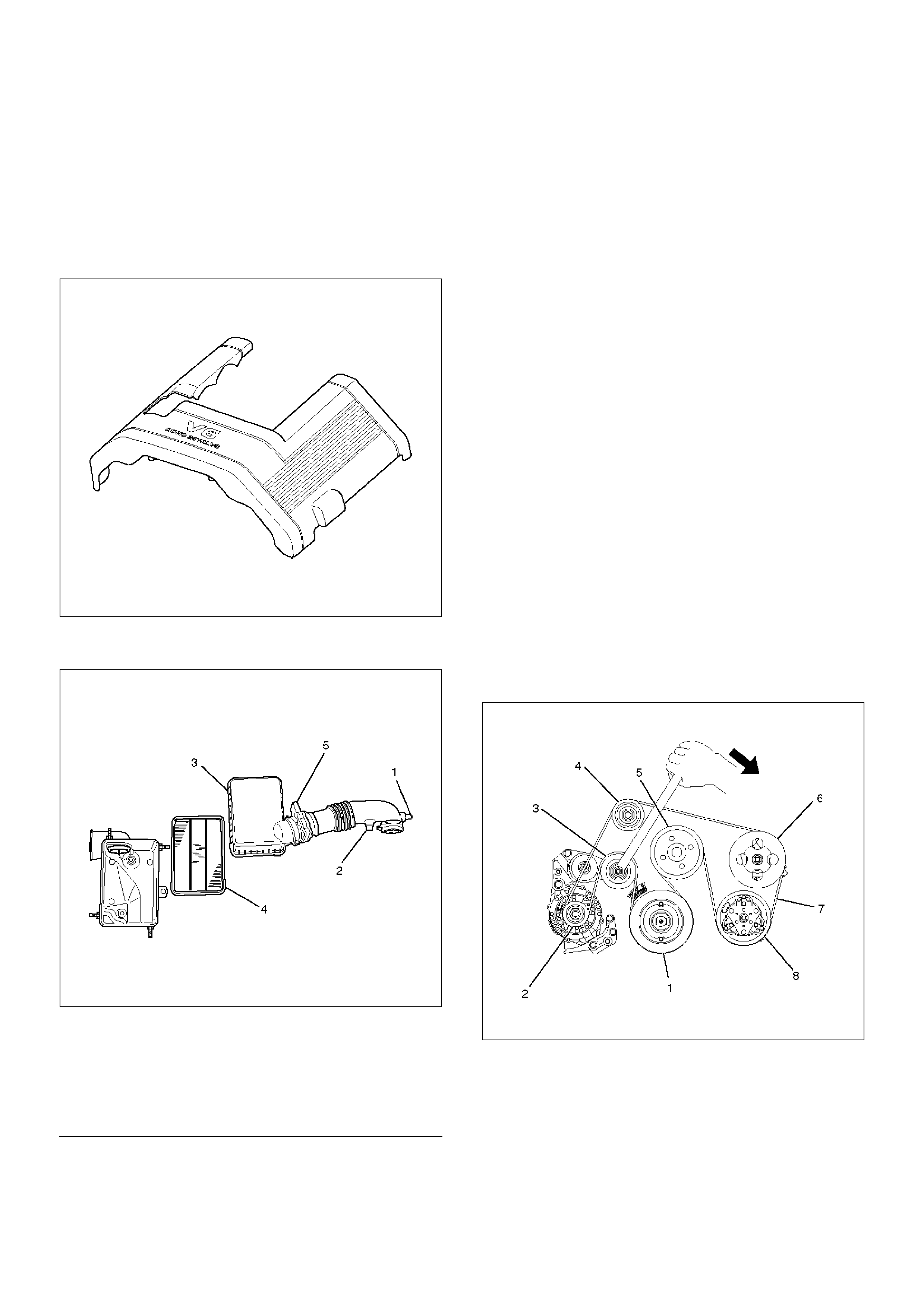

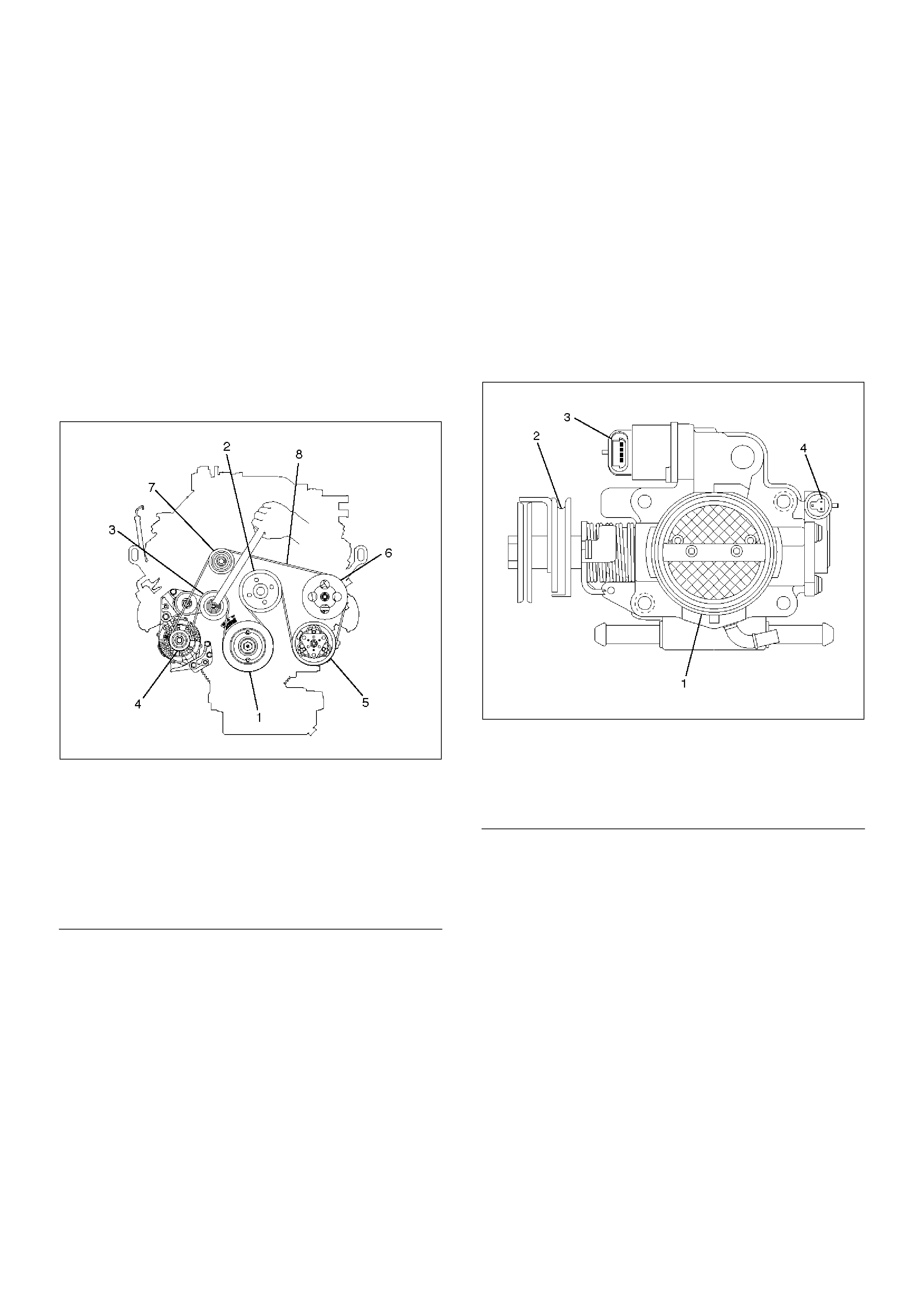

11. Remove drive belt by pushing down the auto

tensioner using spanner as illustrated.

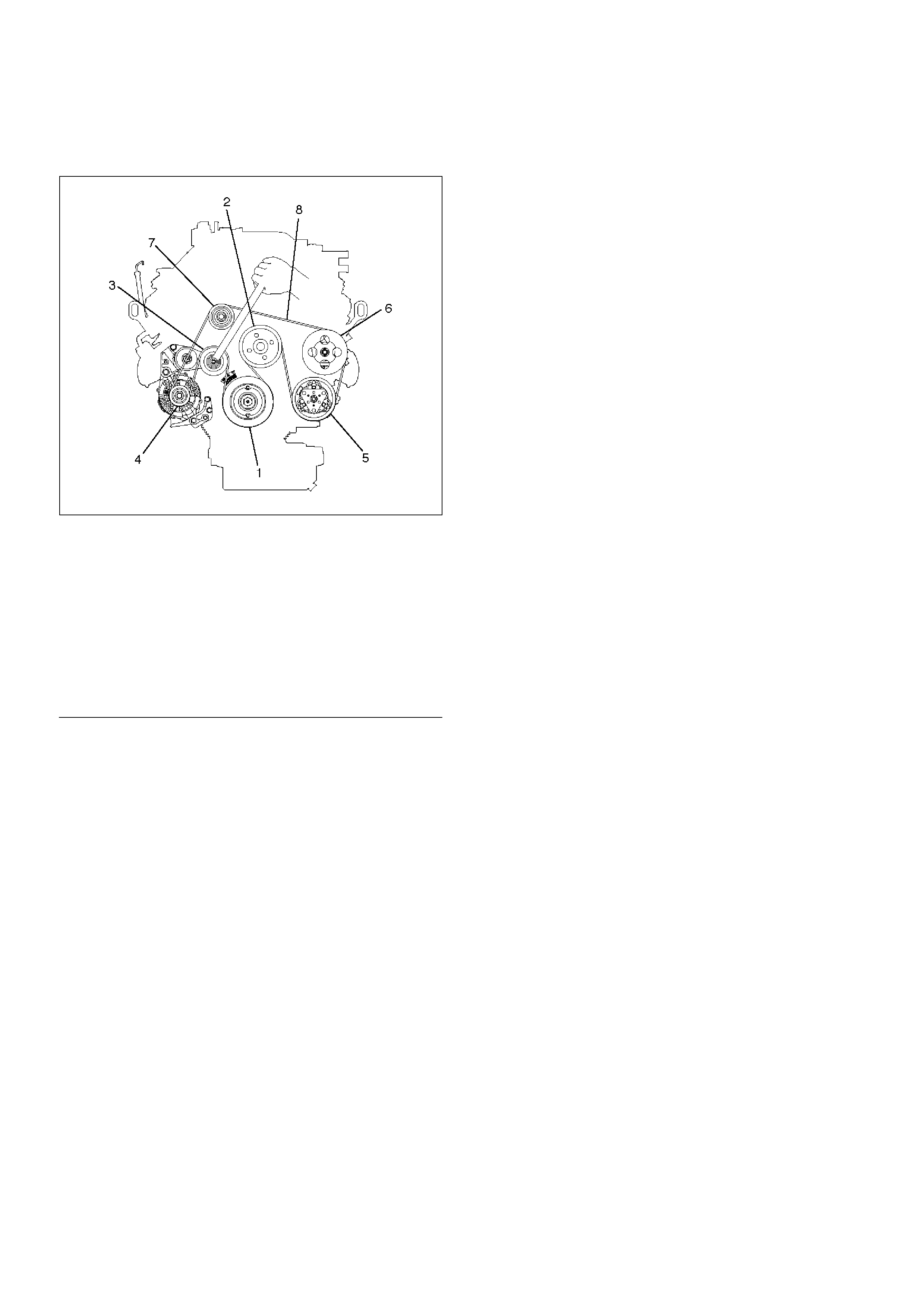

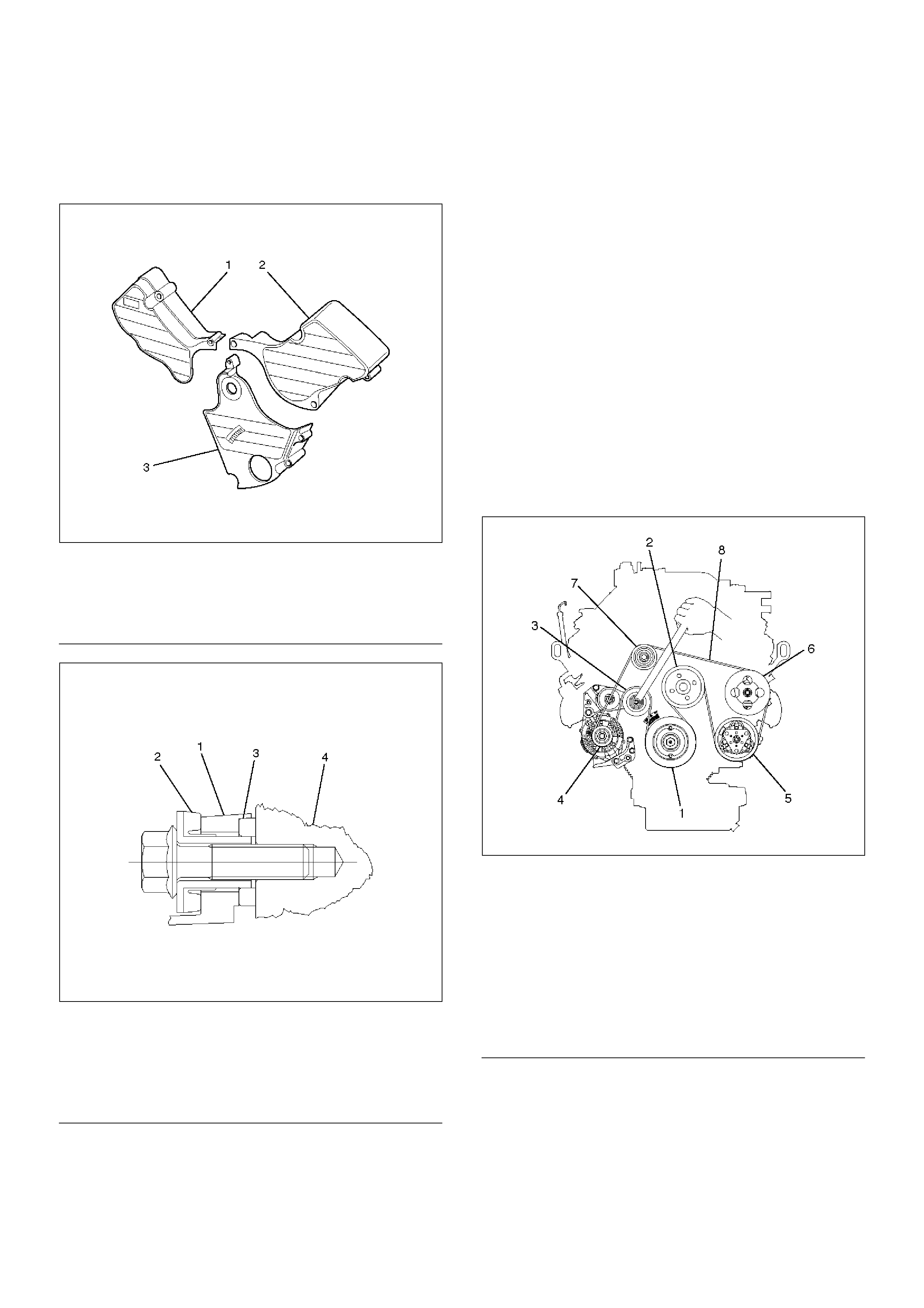

F06RW019

Legend

(1) Positive Crankcase Ventilation Hose Connector

(2) Intake Air Temperature Sensor

(3) Air Cleaner Duct Assembly

(4) Air Cleaner Element

(5) Mass Air Flow Sensor

EndOFC allout

12. Remove power steering oil pump pulley.

13. Remove fan pulley and bracket assembly.

14. Remove idle pulley assembly.

15. Remove auto tensioner assembly.

16. Remove crankshaft pulley using 5–8840–0133–0

crankshaft holder.

17. Remove timing belt covers from the right bank side

to the left bank side in order.

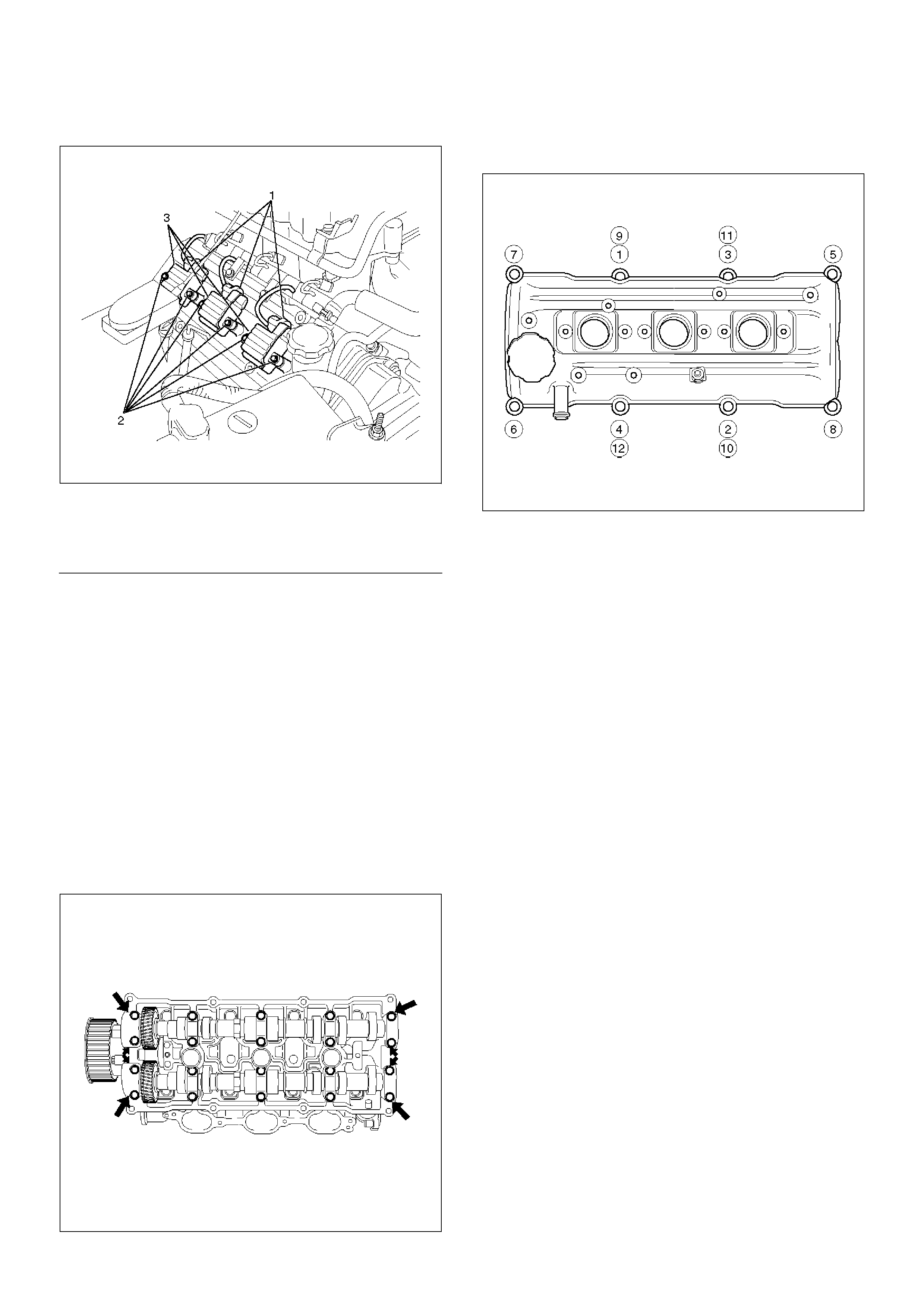

18. Remove ignition coil assemblies for the left side

bank.

060RW018

EndOFC allout

19. Remove cylinder head cover assembly.

Installation

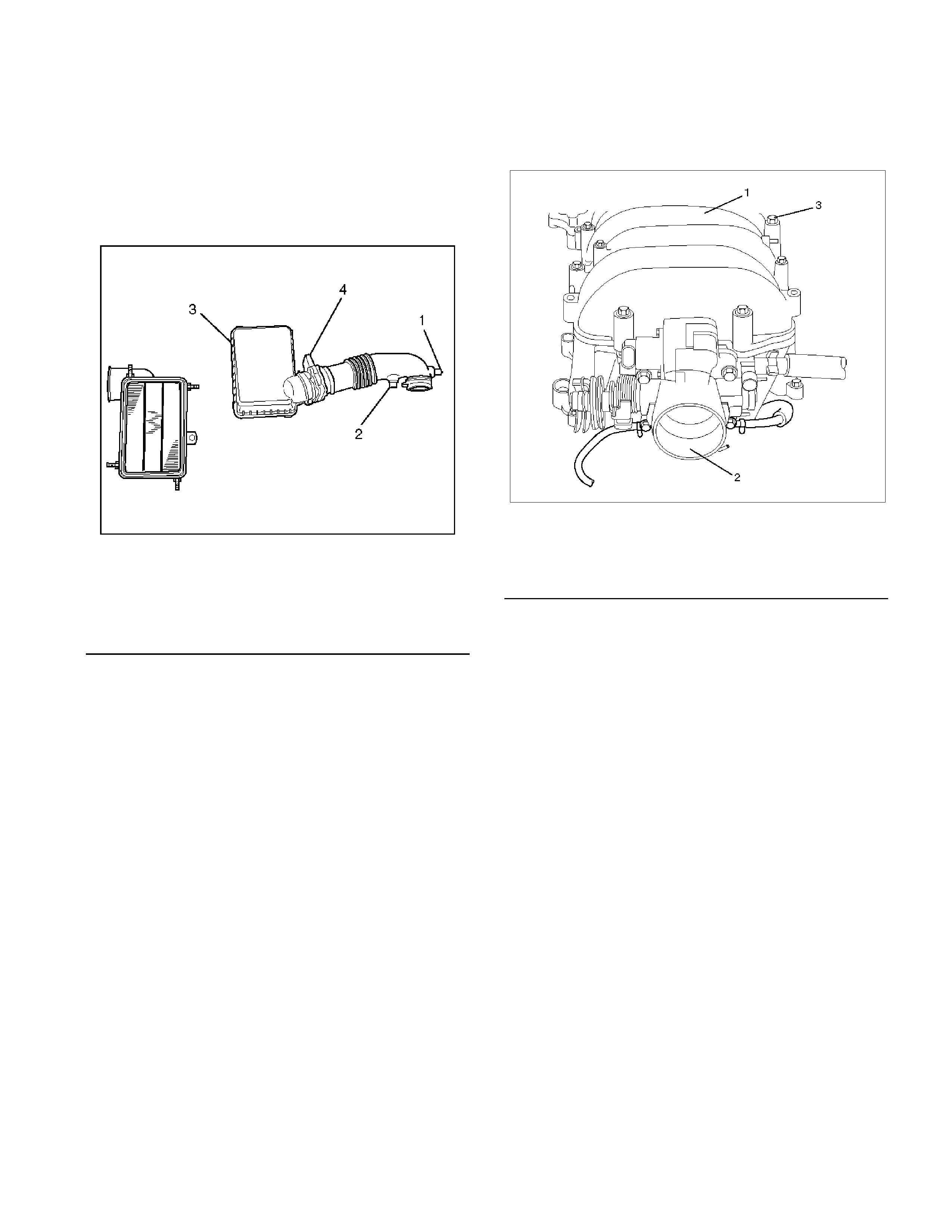

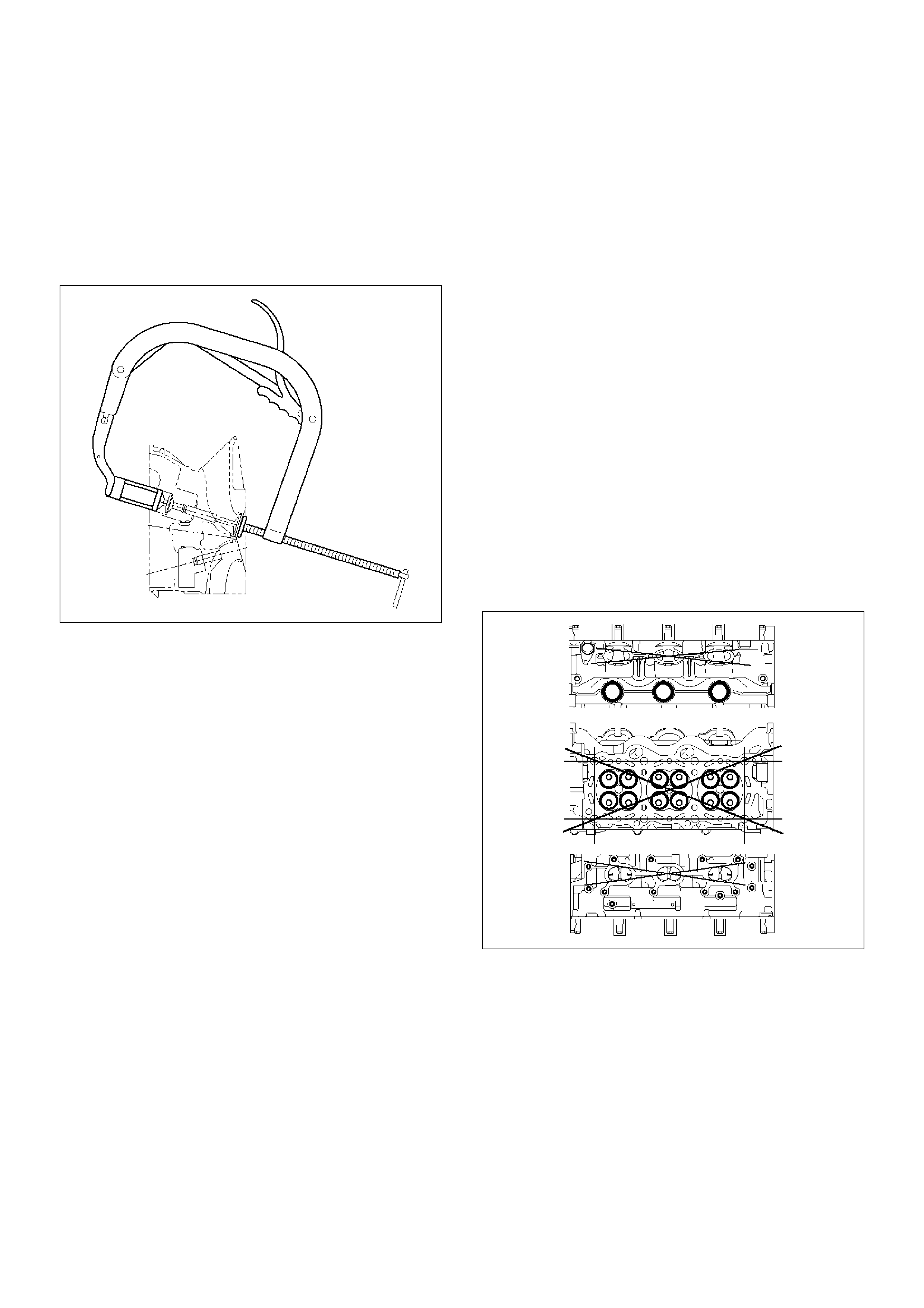

1. Install cylinder head cover.

• Clean the sealing surface of cylinder head and

cylinder head cover to remove oil and sealing

materials completely.

• Apply sealant (TB-1207B or equivalent) of bead

diameter 2-3 mm at eight place of arched area of

camshaft bracket on front and rear sides.

• The cylinder head cover must be installed within

5 minutes after sealant application to prevent

premature hardening of sealant.

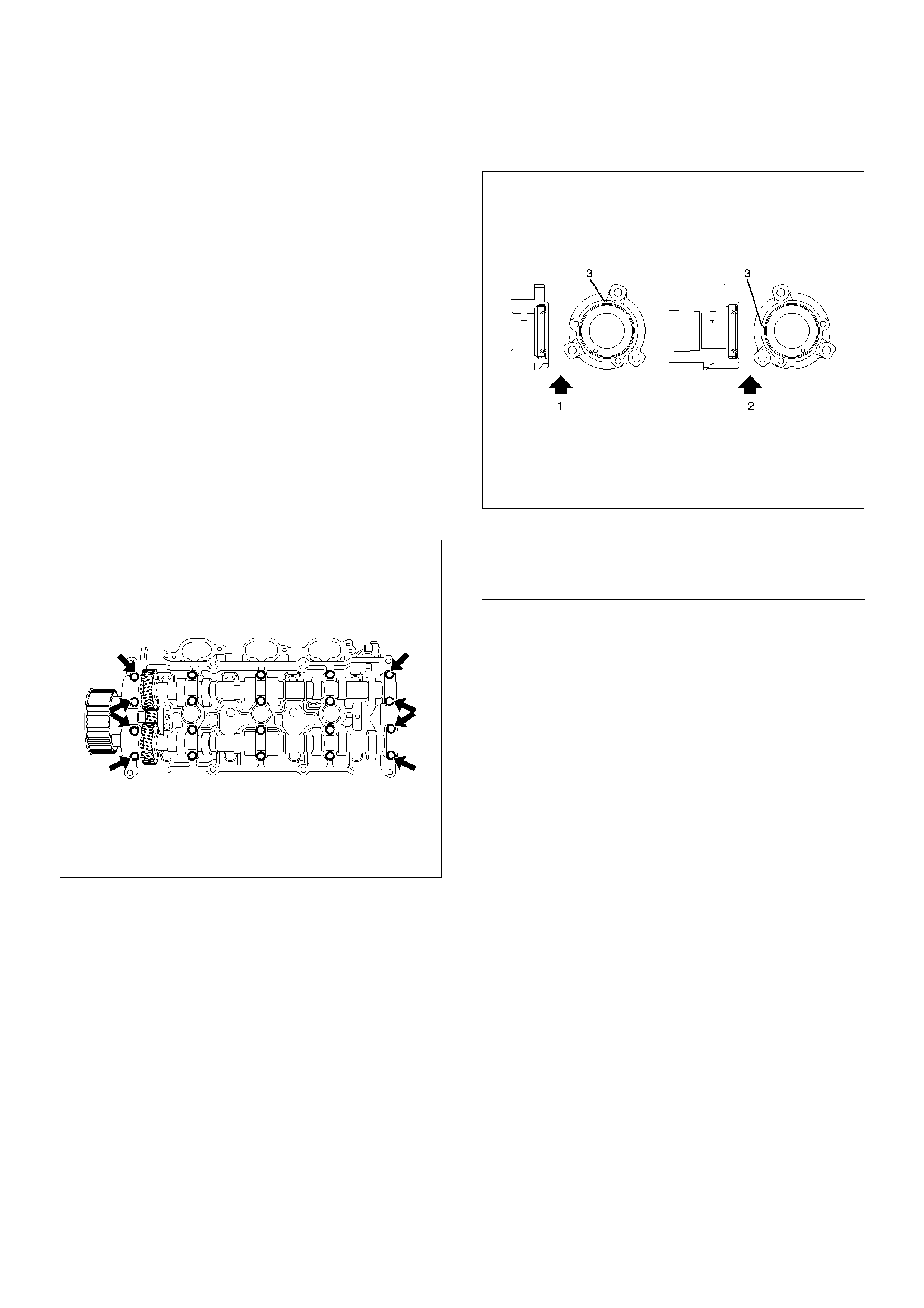

014RW144

• Tighten bolts to the specified torque.

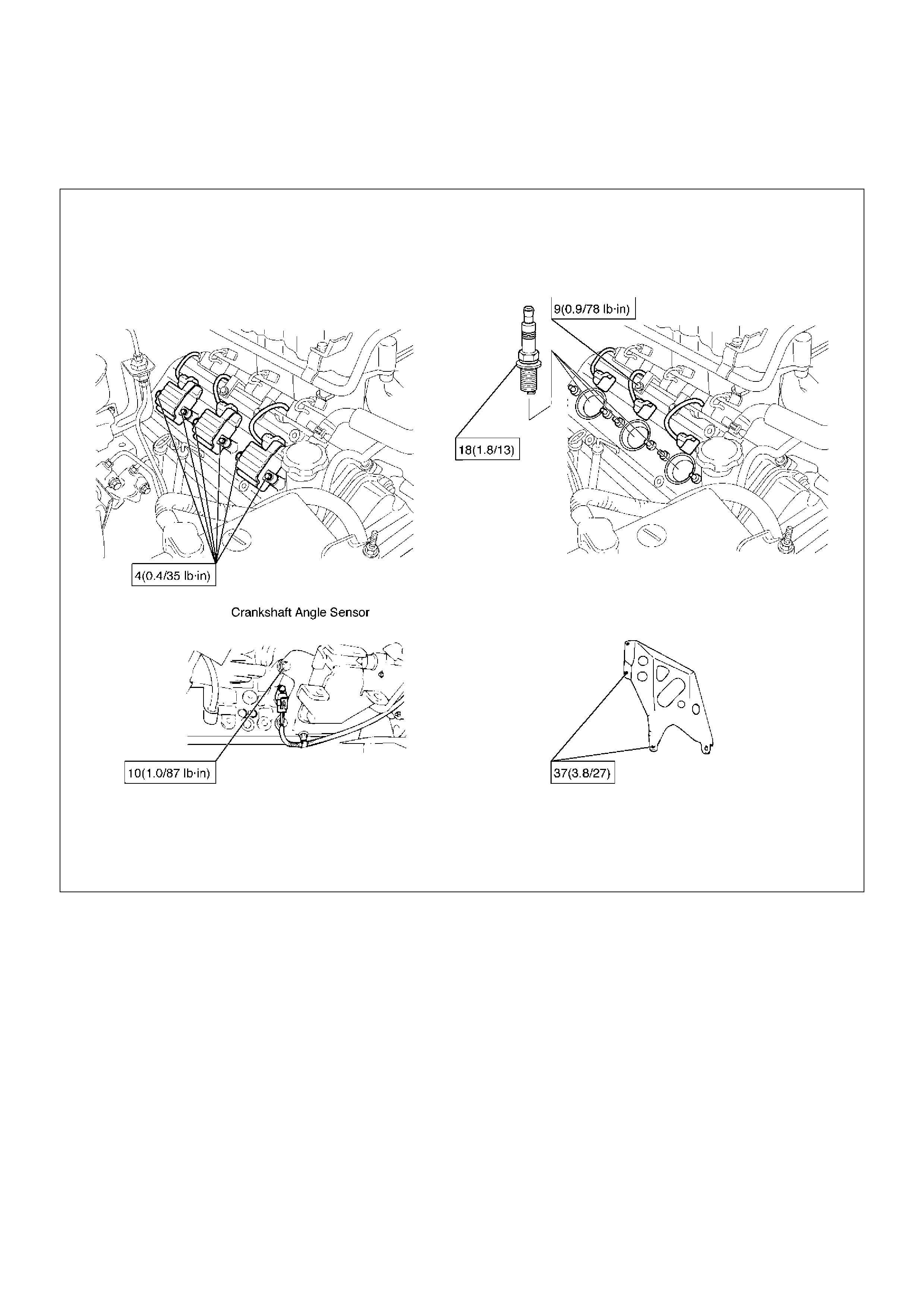

Torque : 9 N·m (0.9 Kg·m/78 lb in)

010RW008

2. Install ignition coil assemblies and tighten the fixing

bolts to the specified torque.

Torque : 4 N·m (0.4 Kg·m/35 lb in)

3. Install timing belt covers from left bank side to right

bank side, and tighten the fixing bolts and nut to the

specified torque.

Torque : 19 N·m (1.9 Kg·m/14 lb ft)

4. Install crankshaft pulley and tighten the fixing bolt

using 5–8840–0133–0 crankshaft holder to the

specified torque.

Torque : 167 N·m (17.0 Kg·m/123 lb ft)

Legend

(1) Crankshaft Pulley

(2) Generator

(3) Auto Tensioner

(4) Idle Pulley

(5) Cooling Fan Pulley

(6) Power Steering Oil Pump

(7) Drive Belt

(8) Air Conditioner Compressor

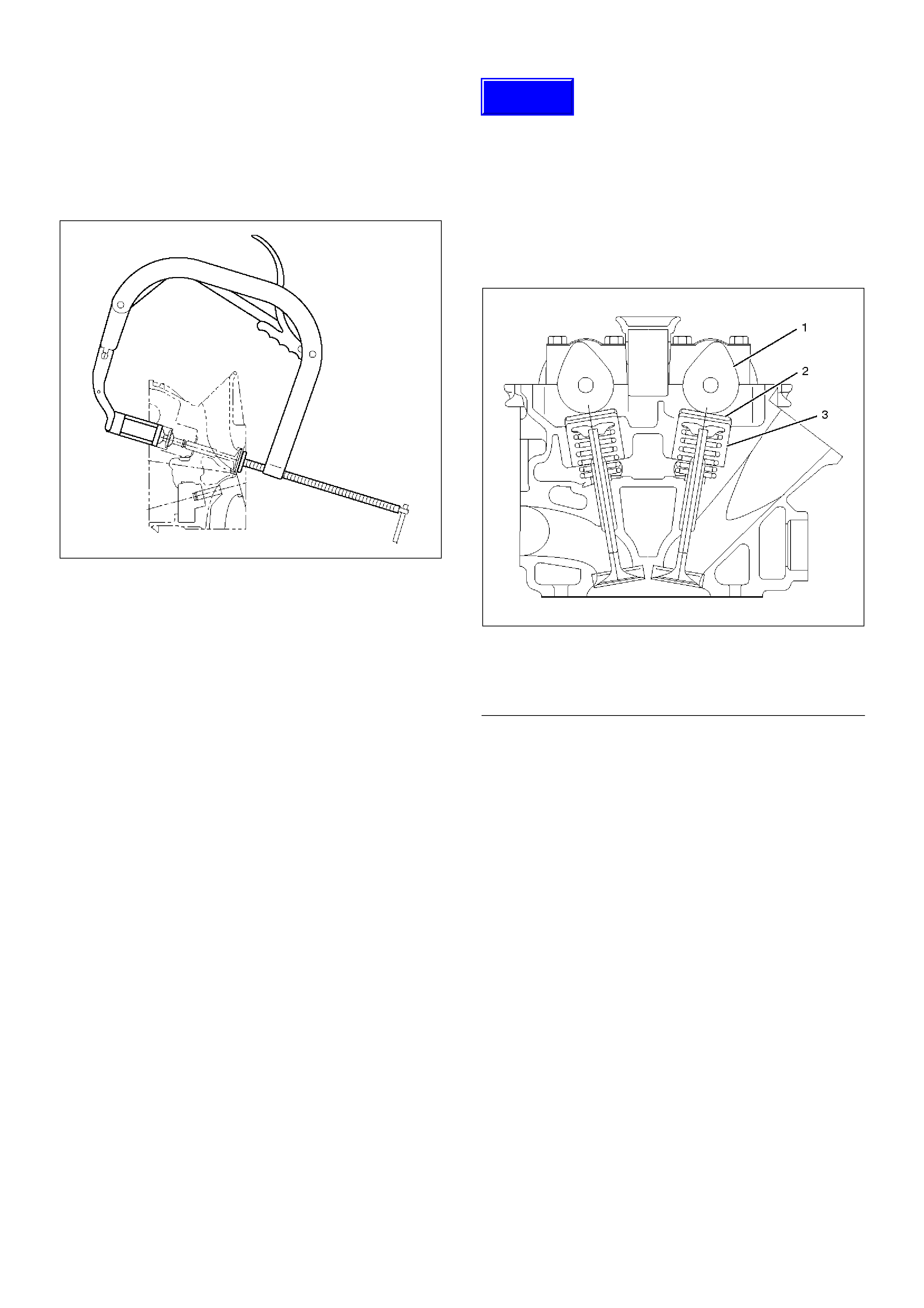

Legend

(1) Ignition Coil Connectors

(2) Bolts

(3) Ignition Coil Assemblies

5. Install auto tensioner assembly and tighten the

fixing bolts to the specified torque.

Torque :

Shorter Bolt : 20 N·m (2.0 Kg·m/14 lb ft)

Longer Bolt : 39 N·m (4.0 Kg·m/29 lb ft)

6. Install idle pulley and bracket assembly and tighten

the fixing bolt to the specified torque.

Torque : 52 N·m (5.3 Kg·m/38 lb ft)

7. Install fan pulley and bracket assembly and tighten

the fixing bolts and nut to the specified torque.

Torque : 22 N·m (2.2 Kg·m/16 lb ft)

8. Install power steering oil pump pulley and tighten

the fixing bolt to the specified torque.

Torque : 78 N·m (8.0 Kg·m/58 lb ft)

9. Install drive belt by pushing down the auto tensioner

using spanner as shown in the removal step of drive

belt.

10. Install cooling fan and clutch assembly and tighten

the fixing bolts to the specified torque.

Torque : 10 N·m (1.0 Kg·m/87 lb in)

11. Install upper fan guide and clip both side and tighten

the fixing bolts to the specified torque.

Torque : 4 N·m (0.4 Kg·m/35 lb in)

12. Install engine harness and tighten the fixing bolts of

the retaining clip and bracket to the specified torque.

Torque : 4 N·m (0.4 Kg·m/35 lb in)

13. Connect radiator upper and lower hoses and clip

them securely.

14. Connect vacuum hoses of those which were

disconnected in the removal step.

15. Connect wiring connectors and bonding cable of

those which were disconnected in the removal step.

16. Install air cleaner element and air cleaner duct

assembly, and clip the both end securely.

17. Connect MAF sensor connector, IAT sensor

connector and PCV hose.

18. Install engine cover mating with the dowels.

Cylinder Head Cover RH

Removal

1. Disconnect battery ground cable.

2. Remove battery from the vehicle.

3. Drain engine coolant from faucet bottom of radiator.

4. Remove engine cover from the dowels on the

common chamber.

F06RW018

5. Remove air cleaner duct assembly (3) and air

cleaner element (4).

130RW001

EndOFC allout

NOTE: Disconnect the mass air flow (MAF) sensor

connector, intake air temperature (IAT) sensor

connector, and positive crankcase ventilation (PCV)

hose before hand the air cleaner duct assembly is

removed.

6. Disconnect following wiring connectors and bonding

cable:

• Exhaust Gas Recirculation (EGR) valve

• Fuel injectors for right bank

• Ignition coils for right bank

• Bonding cable

• Othres as necessitated

7. Disconnect radiator upper and lower hoses.

8. Remove engine harness from the cylinder head

cover.

9. Remove the upper fan guide.

10. Remove cooling fan and clutch assembly.

11. Remove drive belt by pushing down the auto

tensioner using spanner as illustrated.

F06RW019

EndOFC allout

12. Remove fan pulley and bracket assembly.

13. Remove idle pulley assembly.

14. Remove auto tensioner assembly.

15. Remove crankshaft pulley using 5–8840–0133–0

crankshaft holder.

16. Remove timing belt covers for right bank side.

Legend

(1) Positive Crankcase Ventilation Hose Connector

(2) Intake Air Temperature Sensor

(3) Air Cleaner Duct Assembly

(4) Air Cleaner Element

(5) Mass Air Flow Sensor

Legend

(1) Crankshaft Pulley

(2) Generator

(3) Auto Tensioner

(4) Idle Pulley

(5) Cooling Fan Pulley

(6) Power Steering Oil Pump

(7) Drive Belt

(8) Air Conditioner Compressor

17. Remove timing belt covers for right bank side.

060RW001

EndOFC allout

18. Remove ignition coil assemblies for the right side

bank.

19. Remove cylinder head cover assembly.

Installation

1. Install cylinder head cover.

• Clean the sealing surface of cylinder head and

cylinder head cover to remove oil and sealing

materials completely.

• Apply sealant (TB-1207B or equivalent) of bead

diameter 2-3 mm at eight place of arched area of

camshaft bracket on front and rear sides.

• The cylinder head cover must be installed within

5 minutes after sealant application before the

sealant hardens.

014RW143

• Tighten bolts in turn to the specified torque.

Torque : 8.8 N·m (0.9 Kg·m/78 lb in)

010RW007

2. Install ignition coil assemblies and tighten the fixing

bolts to the specified torque.

Torque : 4 N·m (0.4 Kg·m/35 lb in)

3. Install timing belt cover and tighten the fixing bolts

and nut to the specified torque.

Torque : 19 N·m (1.9 Kg·m/14 lb ft)

4. Install crankshaft pulley and tighten the fixing bolt

using 5–8840–0133–0 crankshaft holder to the

specified torque.

Torque : 167 N·m (17 Kg·m/123 lb ft)

5. Install auto tensioner assembly and tighten the

fixing bolts to the specified torque.

Torque :

Shorter Bolt : 20 N·m (2.0 Kg·m/14.8 lb ft)

Longer Bolt : 39 N·m (4.0 Kg·m/28.8 lb ft)

6. Install idle pulley assembly and tighten the fixing

bolt to the specified torque.

Torque : 52 N·m (5.3 Kg·m/38.4 lb ft)

7. Install fan pulley and bracket assembly and tighten

the fixing bolts and nut to the specified torque.

Torque : 22 N·m (2.2 Kg·m/16.2 lb ft)

8. Install drive belt by pushing down the auto tensioner

using spanner as shown in the removal step of drive

belt.

9. Install cooling fan clutch assembly and tighten the

fixing bolts to the specified torque.

Torque : 10 N·m (1.0 Kg·m/88.5 lb in)

10. Install upper fan guide and clip both side and tighten

the fixing bolts to the specified torque.

Torque : 4 N·m (0.4 Kg·m/35.4 lb in)

Legend

(1) Ignition Coil Connectors

(2) Bolts

(3) Ignition Coil Assemblies

11. Install engine harness and tighten the fixing bolts of

the retaining clip and brackets to the specified

torque.

Torque : 4 N·m (0.4 Kg·m/35.4 lb in)

12. Connect radiator upper and lower hoses and clip

them securely.

13. Connect wiring connectors and bonding cable of

those which were disconnected in the removal step.

14. Install air cleaner element and air cleaner duct

assembly, and the clip both end securely.

15. Connect MAF sensor connector, IAT sensor

connector and PCV hose.

16. Install engine cover mating with the dowels.

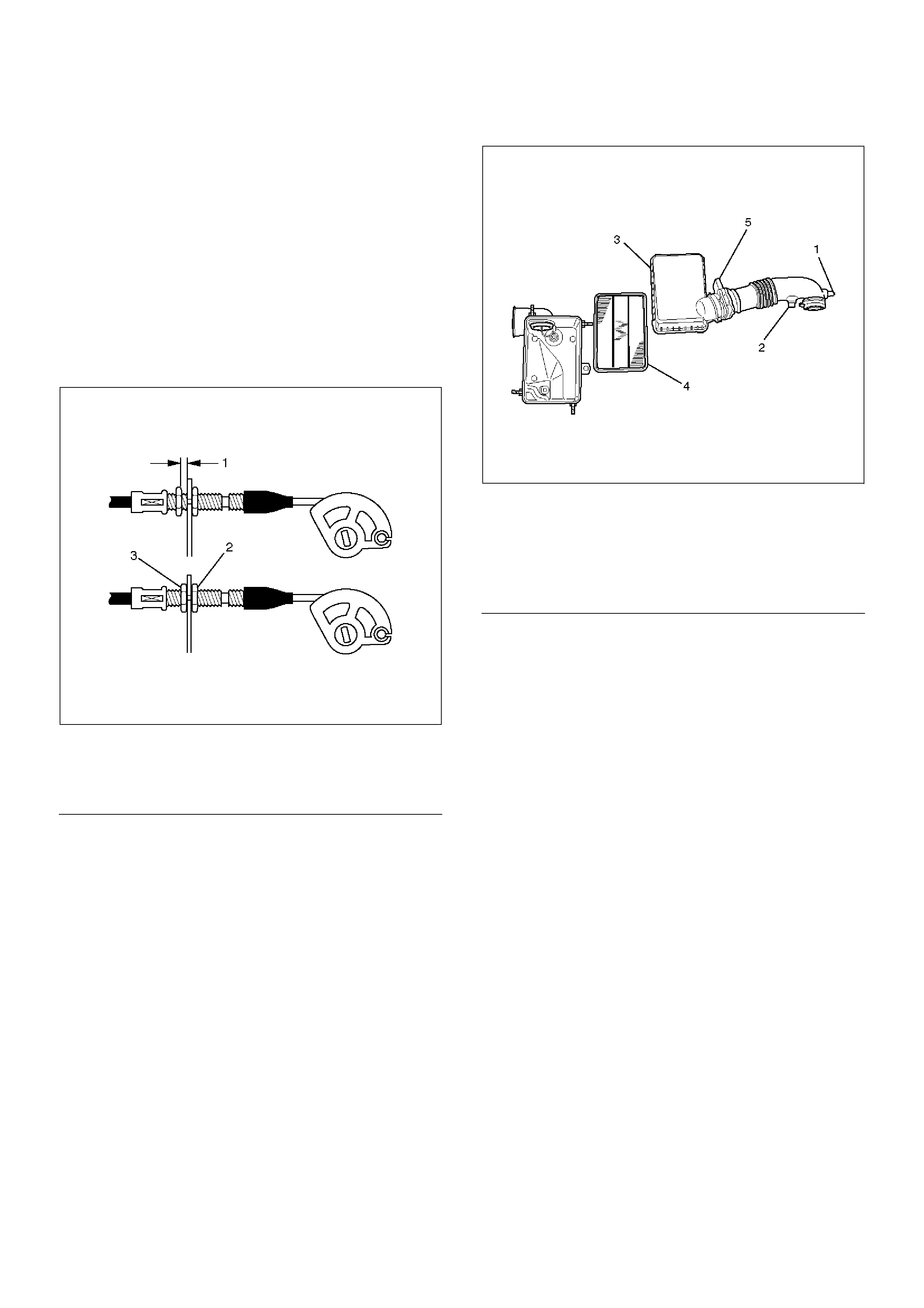

Common Chamber

Removal

1. Disconnect battery ground cable.

2. Remove the air cleaner duct assembly.

013RY00001

Legend

(1) Positive Crankcase Ventilation Hose Connector

(2) Intake Air Temperature Sensor

(3) Air Cleaner Duct As sembly

(4) Air Flow Sensor

3. Disconnect accelerator pedal cable from throttle

body and cable bracket.

4. Disconnect vacuum booster hose from common

chamber.

5. Disconnect connector from manifold absolute

pressure sensor, idle air control valve, throttle

position sensor, solenoid valve, electric vacuum

sensing valve, and EGR valve.

6. Disconnect vacuum hose on canister VSV and

positive crankcase ventilation hose, fuel rail

assembly with pressure control valve bracket.

7. Remove ventilation hose from throttle valve and

intake duct and remove water hose.

8. Remove the four throttle body fixing bolts.

9. Remove exhaust gas recirculation valve assembly

fixing bolt and nut on common chamber and

remove EGR valve assembly.

10. Remove two bolts from co mmon chamber rear

side for remove fuel hose bracket.

11. Remove common chamber four bolts and four nuts

then remove the common chamber.

025RW001

Legend

(1) Common Chamber

(2) Throttle Valve Assembly

(3) Bolt

Installation

1. Install throttle body and tighten bolts to the

specified torque.

Torque : (Bolt size M8)

25 N.m (2.6 kg·m/18 lb ft)

2. Install fuel hose bracket and tighten bolts to

specified torque.

Torque : 10 N.m (1.0 kg·m/89 lb in)

3. Install common chamber and tighten bolts and

nuts to the specified torque.

Torque :

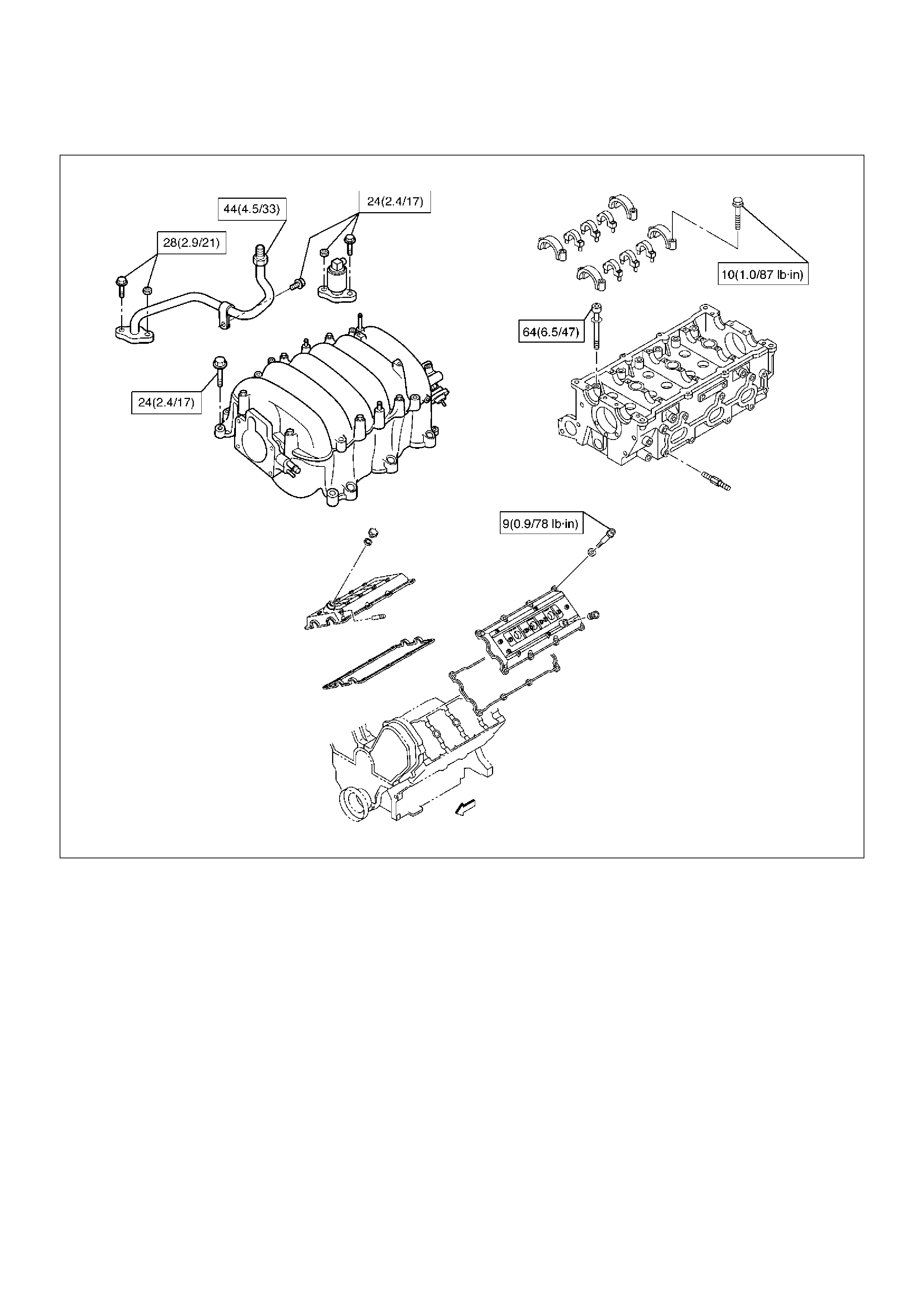

Bolt : 18 N.m (1.8 kg-m/13 lb ft.)

Nut : 18 N.m (1.8 kg·m/13 lb ft)

4. Install ventilating hose to throttle valve and intake

duct.

5. Install exhaust gas recirculation valve assembly

and tighten bolt and nut to specified torque.

Torque : 25 N.m (2.5 kg·m/18 lb ft)

6. Connect vacuum hoses on canister VSV and

positive crankcase ventilation valve. Tighten bolts

for fuel rail assembly with pressure control valve

bracket to specified torqu e.

Torque : 25 N.m (2.5 kg·m/18 lb ft)

7. Connect each connector without fail.

8. Connect vacuum booster hose.

9. Connect accelerator pedal cable.

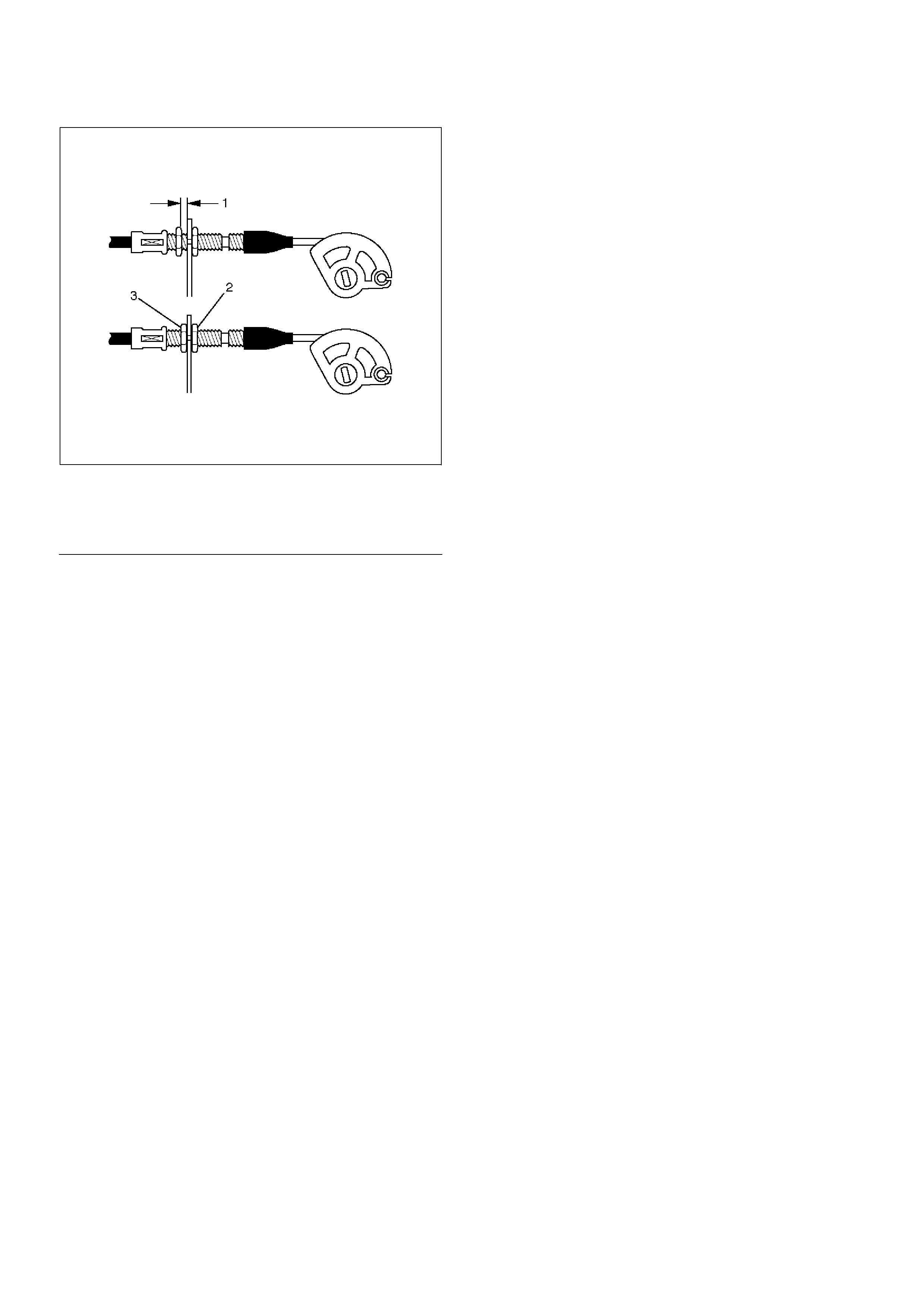

Accelerator pedal cable adjustment

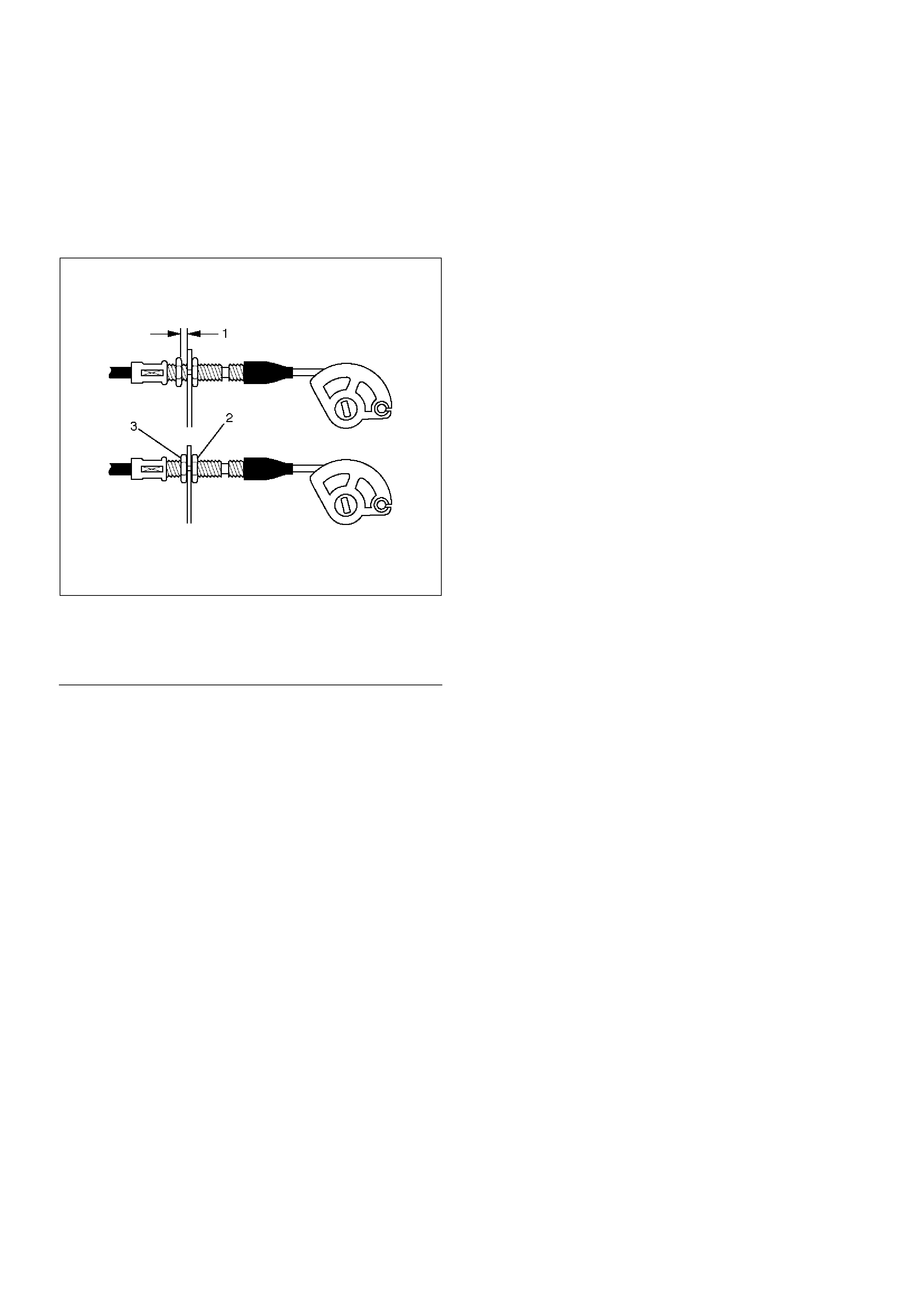

1. Loosen the adjusting nut and screw cap.

2. Pull outer cable while fully closing the throttle

valve.

3. Tighten adjusting nut and lock nut temporarily.

4. Loosen adjusting nut by three turns and tighten

lock nut.

Then manually operating the throttle valve,

make sure that the valve lever returns up to the

stopper screw.

If it does not reach the stopper screw, repeat

from step 1.

035RW004

EndOFC allout

10. Install air cleaner duct assembly.

130RW001

EndOFC allout

Legend

(1) Clearance

(2) Lock Nut

(3) Adjusting Nut

Legend

(1) Positive Crankcase Ventilation Hose Connector

(2) Intake Air Temperature Sensor

(3) Air Cleaner Duct Assembly

(4) Air Cleaner Element.

(5) Mass Air Flow Sensor

Exhaust Manifold LH

Removal

1. Disconnect battery ground cable.

2. Remove air cleaner duct assembly.

130RW001

EndOFC allout

3. Remove exhaust front pipe three stud nuts from

exhaust side and two nuts from rear end of exhaust

front pipe.

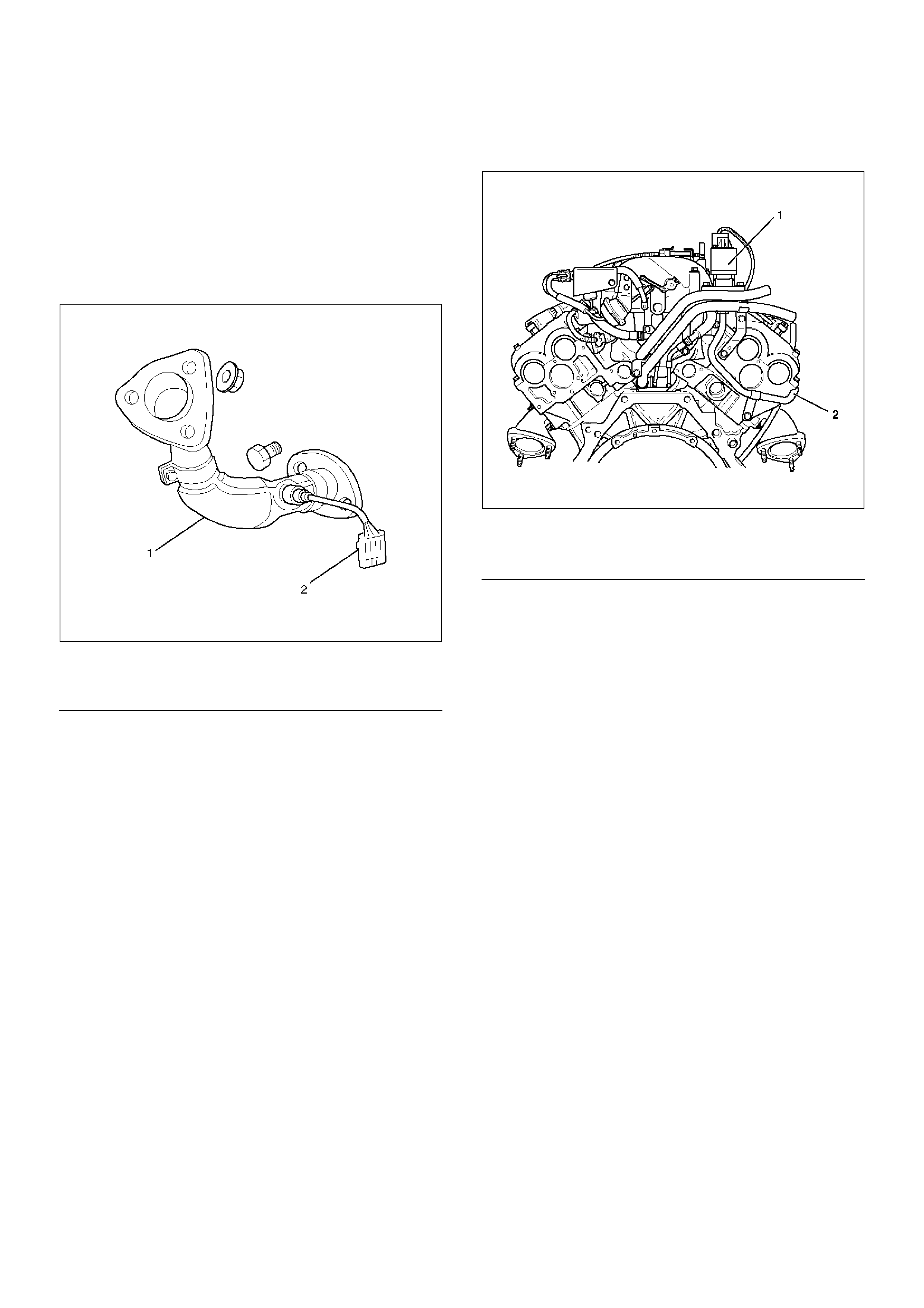

150RW062

EndOFC allout

4. Remove heat protector two fixing bolts then the heat

protector.

5. Remove a bolt on engine LH side for air conditioner

(A/C) compressor bracket and loosen two bolts for

A/C compressor then move A/C compressor to front

side.

6. Remove exhaust manifold eight fixing nuts and

remove exhaust manifold from the engine.

Installation

1. Install exhaust manifold and tighten exhaust

manifold fixing nuts to the specified torque with new

nuts.

Torque: 57 N·m (5.8 Kg·m/42 lb ft)

2. Install heat protector.

3. Install exhaust front pipe and tighten three stud nuts

and two nuts to the specified torque.

Torque :

Stud nuts: 67 N·m (6.8 Kg·m/49 lb ft)

Nuts: 43 N·m (4.4 Kg·m/32 lb ft)

150RW062

EndOFC allout

4. Set A/C compressor to normal position and tighten

two bolts and a bolt to the specified torque.

Torque : 40 N·m (4.1 Kg·m/30 lb ft)

5. Install air cleaner duct assembly.

Legend

(1) Positive Crankcase Ventilation Hose Connector

(2) Intake Air Temperature Sensor

(3) Air Cleaner Duct Assembly

(4) Air Cleaner Element

(5) Mass Air Flow Sensor

Legend

(1) Exhaust Front Pipe LH

Legend

(1) Exhaust Front Pipe LH

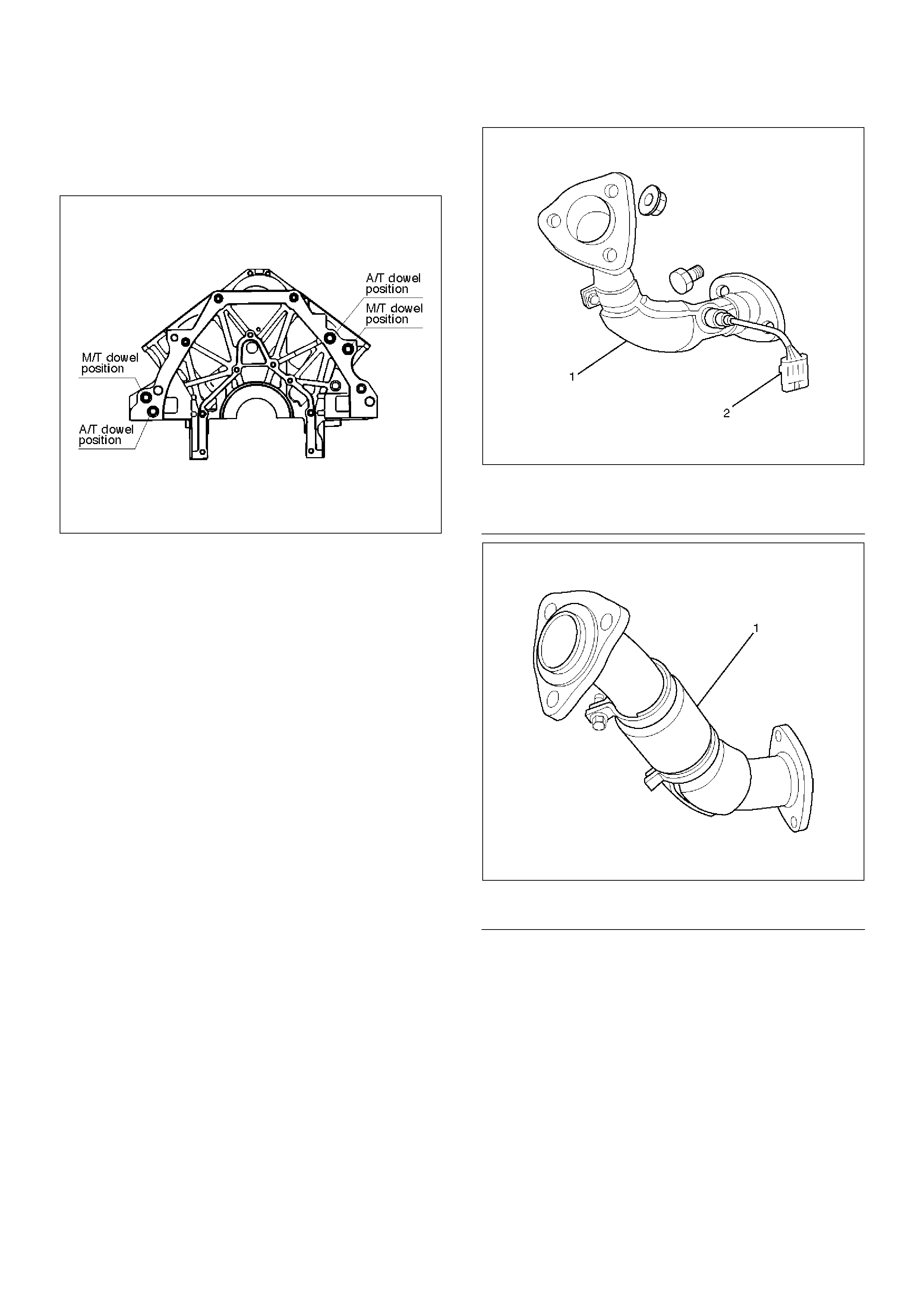

Exhaust Manifold RH

Removal

1.Disconnect battery ground cable.

2.Remove torsion bar. Refer to removal procedure in

Front Suspension section.

3.Remove exhaust front pipe three stud nuts and two

nuts then disconnect exhaust front pipe.

150RW061

EndOFCallout

4.Remove heat protector two fixing bolts then the heat

protector.

5.Remove exhaust gas recirculation (EGR) pipe fixing

bolt and nut from exhaust manifold, remove a nut

from EGR valve and a bolt from rear side of cylinder

head for bracket of EGR pipe then remove the EGR

pipe.

056RW001

EndOFCallout

6.Remove exhaust manifold eight fixing nuts then the

exhaust manifold.

Installation

1.Install exhaust manifold and tighten bolts to the

specified torque.

Torque : 57 N·m (5.8 Kg·m/42 lb ft)

2.Install the EGR pipe, tighten bolt and nut on exhaust

manifold to specified torque.

Torque : 28 N·m (2.9 Kg·m/21 lb ft)

Tighten nut to EGR valve to the specified torque.

Torque : 44 N·m (4.5 Kg·m/33 lb ft)

Tighten the bolt for EGR pipe bracket to specified

torque.

Torque : 25 N·m (2.5 Kg·m/18 lb ft)

3.Install heat protector

4.Install exhaust front pipe and tighten three stud nuts

and two nuts to the specified torque.

Torque:

Stud nuts: 67 N·m (6.8 Kg·m/49 lb ft)

Nuts: 43 N·m (4.4 Kg·m/32 lb ft)

5.Install the torsion bar and readjust the vehicle

height. Refer to installation and vehicle height

adjustment procedure for Front Suspension.

Legend

(1) Exhaust Front Pipe RH

(2) O2 Sensor (for IGM)

Legend

(1) Exhaust Gas Recirculation (EGR) Valve

(2) EGR Pipe

Crankshaft Pulley

Removal

1. Disconnect battery ground cable.

2. Remove air cleaner assembly.

130RW001

EndOFC allout

3. Remove radiator upper fan shroud from radiator.

4. Move serpentine belt tensioner to loose side using

wrench then remove serpentine belt.

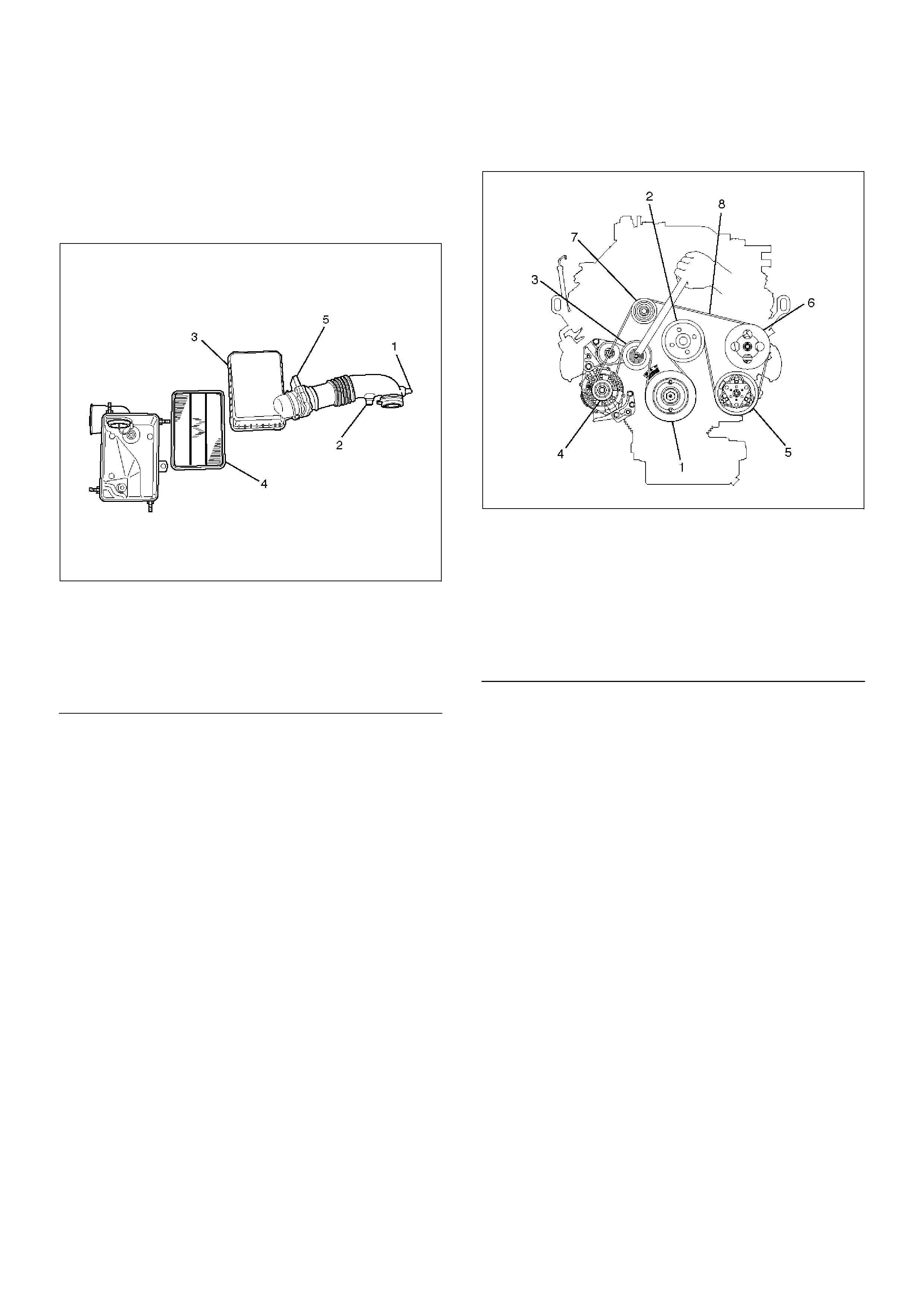

850RW001

EndOFC allout

5. Remove cooling fan assembly four fixing nuts, then

the cooling fan assembly.

6. Remove crankshaft pulley assembly using

J-8614-01 crankshaft holder, hold crankshaft pulley

then remove center bolt and pulley.

Installation

1. Install crankshaft pulley using J-8614-01 crankshaft

holder, hold the crankshaft pulley and tighten center

bolt to the specified torque.

Torque : 167 N·m (17.0 Kg·m/123 lb ft)

2. Install cooling fan assembly and tighten bolts/nuts to

the specified torque.

Torque : 22 N·m (2.2 Kg·m/16 lb ft) for fan pulley

and fan bracket.

Torque : 10 N·m (1.0 Kg·m/88.5 lb in) for fan and

clutch assembly.

3. Move serpentine belt tensioner to loose side using

wrench, then install serpentine belt to normal

position.

4. Install radiator upper fan shroud.

5. Install air cleaner assembly.

Legend

(1) Positive Crankcase Ventilation Hose Connector

(2) Intake Air Temperature Sensor

(3) Air Cleaner Duct Assembly

(4) Air Cleaner Element

(5) Mass Air Flow Sensor

Legend

(1) Crankshaft Pulley

(2) Cooling Fan Pulley

(3) Tensioner

(4) Generator

(5) Air Conditioner Compressor

(6) Power Steering Oil Pump

(7) Serpentine Belt

Timing Belt - Broken Belt

Removal

1. Disconnect battery ground cable.

2. Remove air cleaner assembly.

3. Remove radiator upper fan shroud from radiator.

4. Move drive belt tensioner to loose side using

wrench then remove drive belt.

850RW001

EndOFCallout

5. Remove cooling fan assembly four nuts, then the

cooling fan assembly.

6. Remove cooling fan drive pulley assembly.

7. Remove idle pulley assembly.

8. Remove serpentine belt tensioner assembly.

9. Remove power steering pump assembly.

10. Remove crankshaft pulley assembly using 5–8840–

0133–0 crankshaft holder, hold crankshaft pulley

remove center bolt, then the pulley.

11. Remove right side timing belt cover then left side

timing belt cover.

12. Remove lower timing belt cover

13. Remove timing belt tensioner.

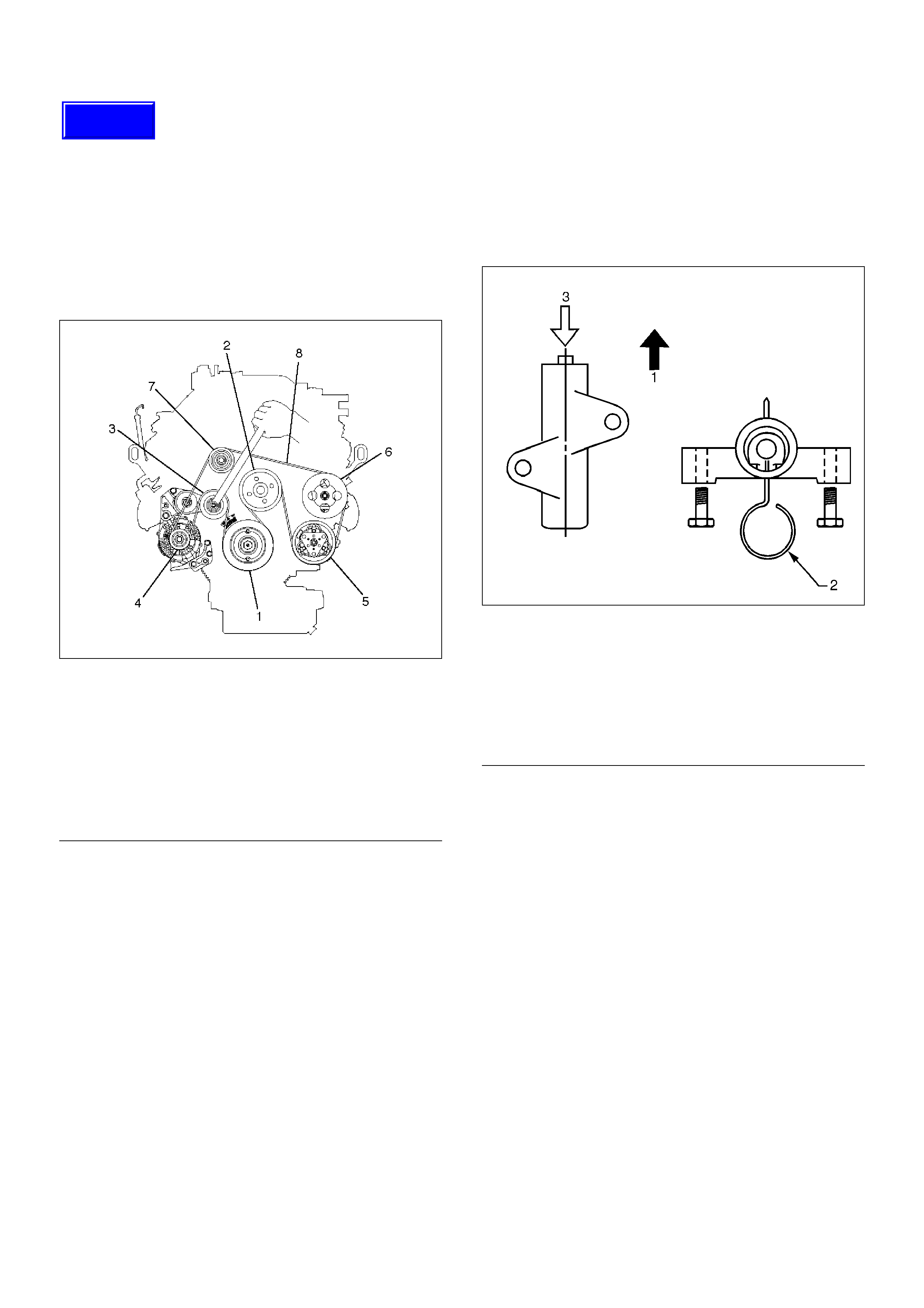

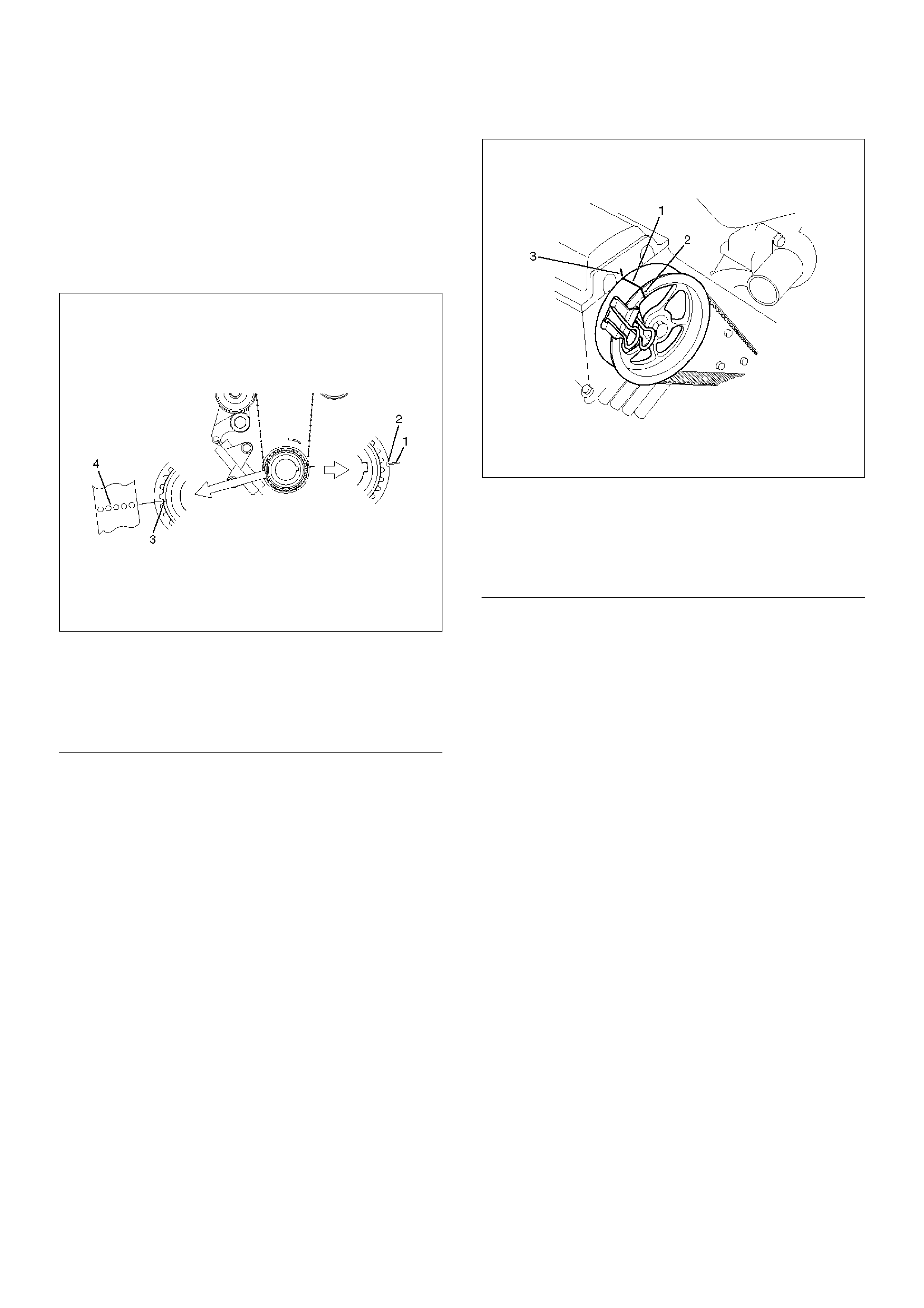

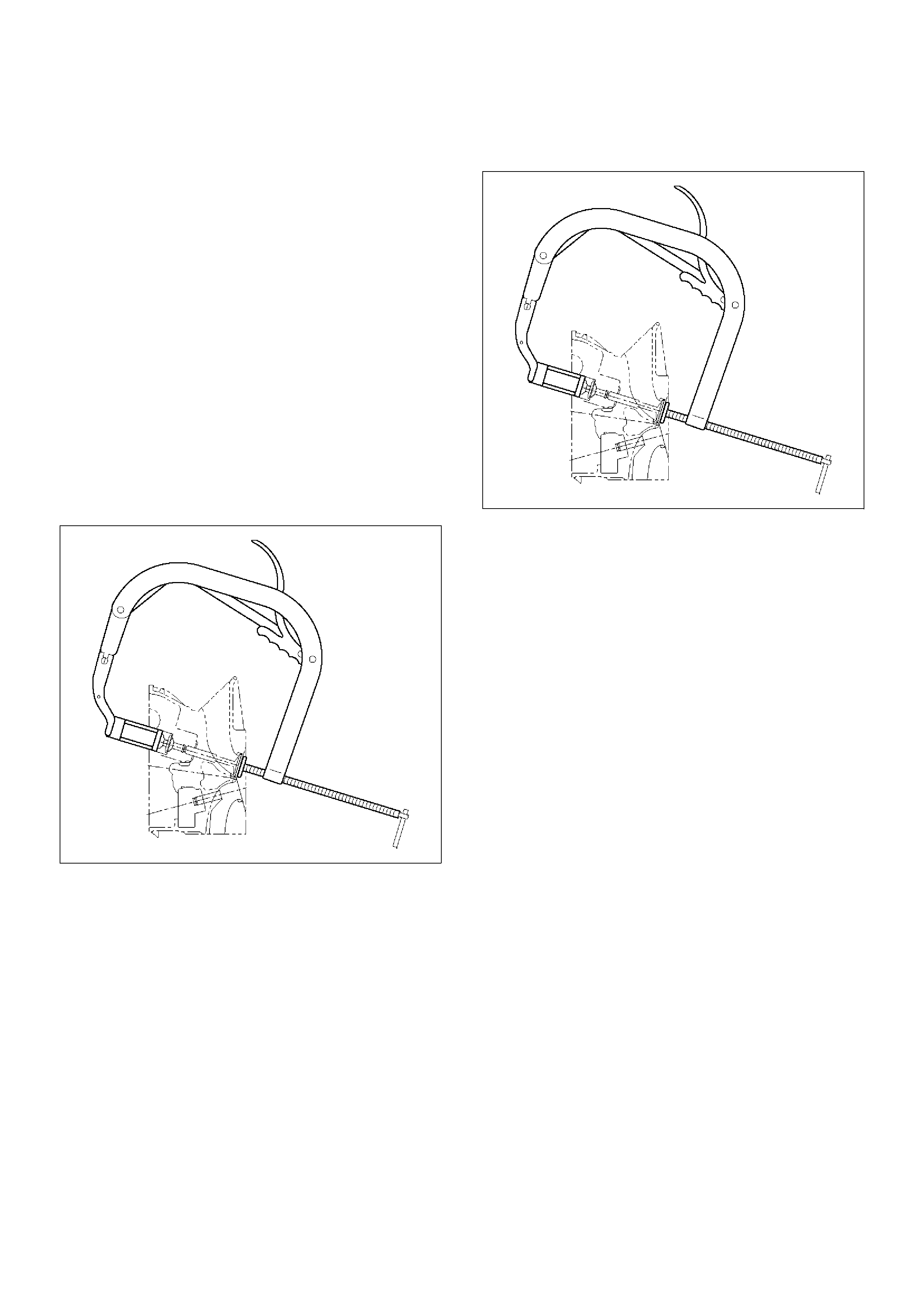

CAUTION: The prevent air entering the oil chamber.

The tensioner must be stored with the rod facing

upward.

014R100020

EndOFCallout

14. Remove broken timing belt.

15.Remove the cylinder head covers - refer to 6A-24

NOTE: NEW BELT CARE

1. Do not bend or twist the new belt, otherwise its

core could be damaged. The belt should not be

bent at a radius less than 30 mm.

2. Do not allow oil or other chemical substances to

come in contact with the belt. They will shorten

the life.

3. Do not attempt to pry or stretch the belt with a

screw driver or any other tool during

installation.

4. Store timing belt in a cool and dark place. Never

expose the belt to direct sunlight or heat.

Legend

(1) Crankshaft Pulley

(2) Cooling Fan Pulley

(3) Tensioner

(4) Generator

(5) Air Conditioner Compressor

(6) Power Steering Oil Pump

(7) Drive Belt

Legend

(1) Up Side

(2) Down Side

(3) Direction For Installation

(4) Locking Pin

(5) Apply a force of 980 N (220 lb) when

compressing the pusher rod.

Techline

Installation

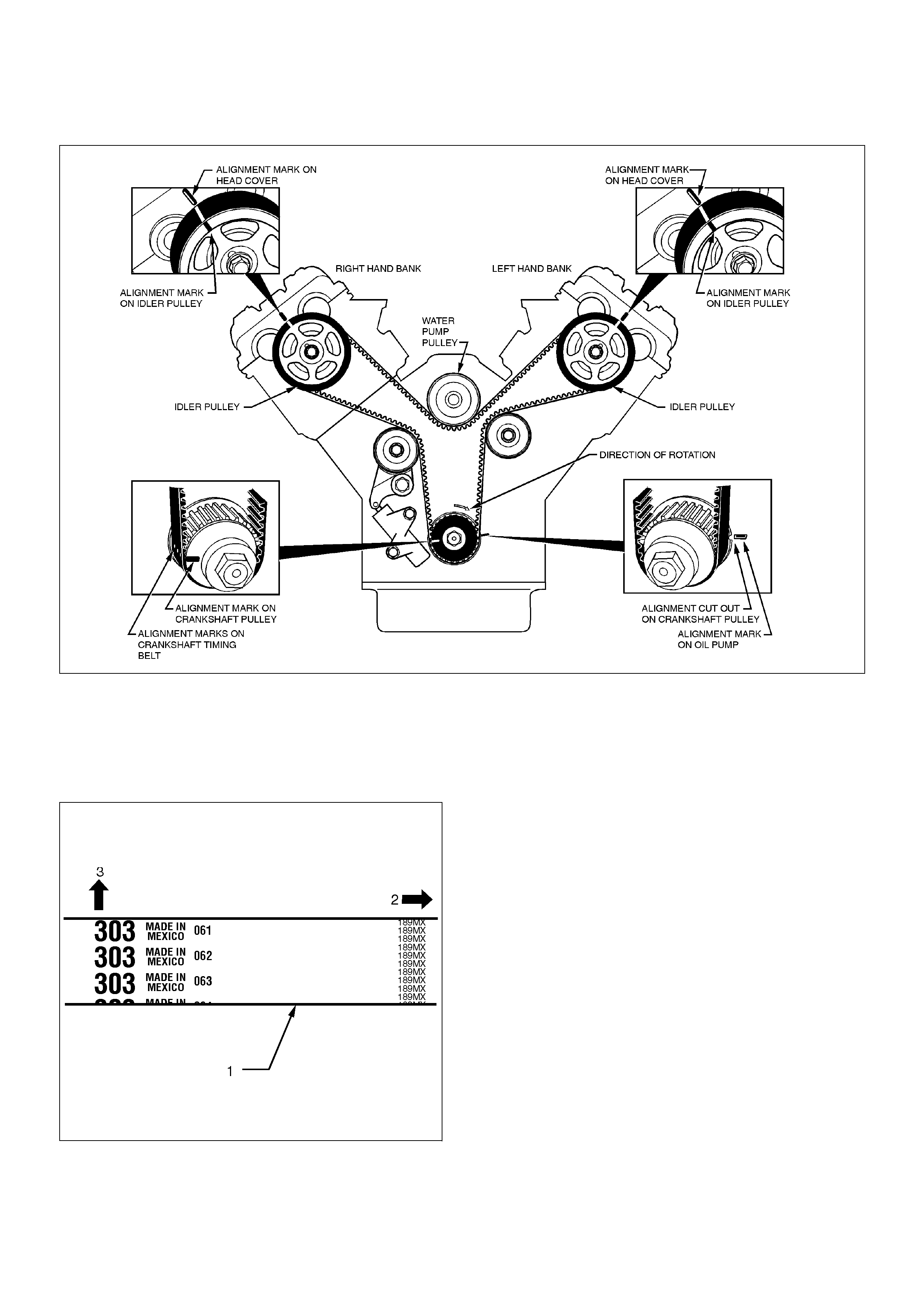

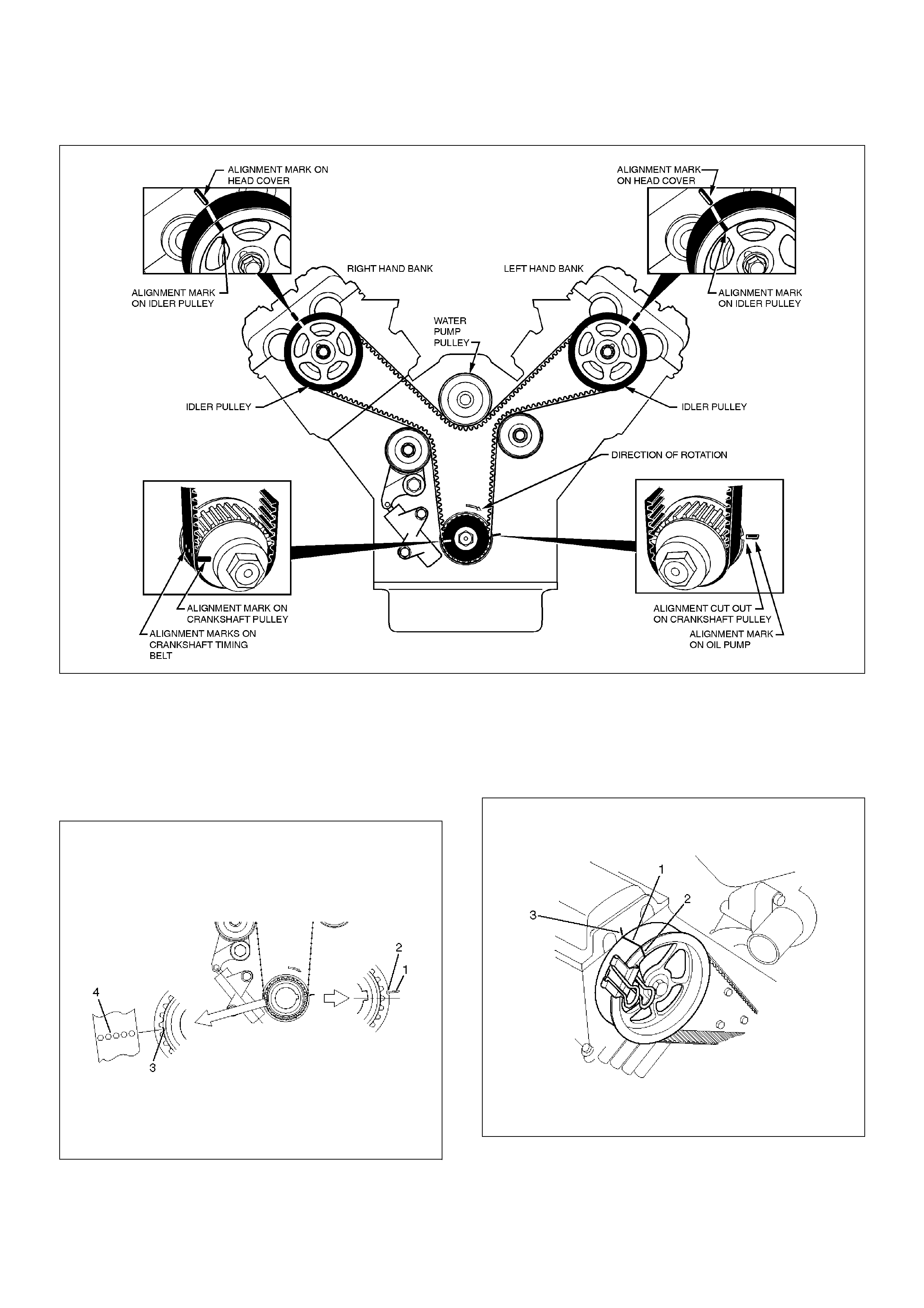

014R100015

NOTE: For correct belt installation, the lettering on

the belt must be able to be read as viewed from the

front of the vehicle. Any attempt to use belts with

different markings will void these service

procedures.

014RW006

Legend

(1) Timing Belt

(2) Engine Rotation Direction

(3) Cylinder Head Side

1. Install timing belt.

a Align the mark (notch) of crankshaft timing

pulley (2) with mark on oil pump (1).

Align the mark (groove) on the crankshaft timing

pulley (3) with alignment mark (white dots line)

on the timing belt (4).

When timing marks are aligned, No.2 piston will

be on Top Dead Center.

014RW003

EndOFCallout

b Rotate the camshaft drive gear pulley on the

right-hand bank to position the cam lobes for #1

cylinder as shown in the diagram on page xxx-

The alignment mark on the Camshaft Drive

Gear pulley should be at the 12o’clock position

relative to the cylinder head-block mounting

face.

c Align the alignment mark (white line) on the

timing belt (1) with alignment mark on the RH

bank camshaft drive gear pulley (2) (on the left

side as viewed from the front of the vehicle) and

put the timing belt on the camshaft drive gear

pulley.

Secure the belt with a double clip or equivalent

clip.

014RW00004

EndOFCallout

d Rotate the camshaft drive gear pulley on the

left-hand bank to position the cam lobes for #2

cylinder as shown in the diagram on page xxx-

The alignment mark on the Camshaft Drive

Gear pulley should be at the 12o’clock position

relative to the cylinder head-block mounting

face.

e Align the alignment mark (white line) on the

timing belt (1) with alignment mark on the RH

bank camshaft drive gear pulley (2) (on the left

side as viewed from the front of the vehicle) and

put the timing belt on the camshaft drive gear

pulley.

Secure the belt with a double clip or equivalent

clip.

f When aligning the timing marks, use a wrench

to turn the camshaft drive gear pulley, then set

the timing mark between timing belt and

camshaft drive gear pulley and put the timing

belt on the camshaft drive gear pulley.

Secure the belt with a double clip or equivalent

clip.

Legend

(1) Alignment Mark on Oil Pump

(2) Groove on Crankshaft Timing Pulley

(3) Alignment Mark on Crankshaft Timing Pulley

(4) Alignment Mark on Timing Belt

Legend

(1) Alignment Mark on Timing Belt (White line).

(2) Alignment Mark on Camshaft Drive Gear

Pulley.

(3) Alignemnt Mark on Cylinder Head Cover RH.

NOTE: It is recommended for easy installation that the

belt be secured with a double clip or equivalent clip after

it is installed the timing belt to each pulley.

014RW00005

EndOFCallout

g Install crankshaft pulley temporarily and tighten

center bolt by hand (do not use a wrench).

Turn the crankshaft pulley clockwise to give

some belt slack between the crankshaft timing

pulley and the RH bank camshaft drive gear

pulley.

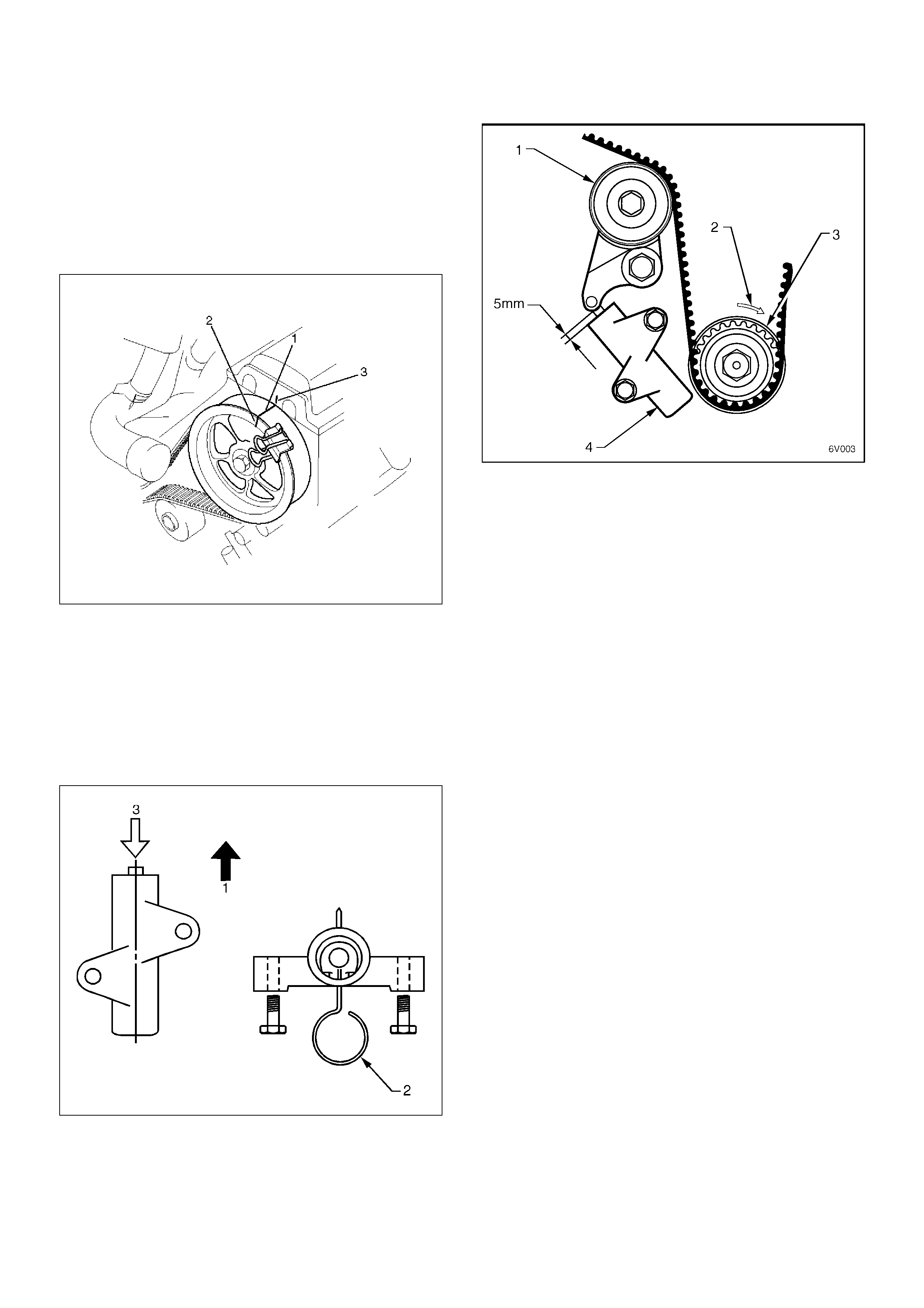

NOTE: When reusing the tensioner, compress the

tensioner rod with approximately 980N force and

insert a holding pin (1.4 mm piano wire).

2. Install timing belt tensioner and tighten bolt to the

specified torque.

Torque : 25 N·m

a Install the tensioner while pushing the tension

pulley to the belt.

b Pull out pin from the tensioner.

NOTE: After release the push rod from the locking

pin, the rod projection is approximate 5 mm.

014R100020

dOFCallout

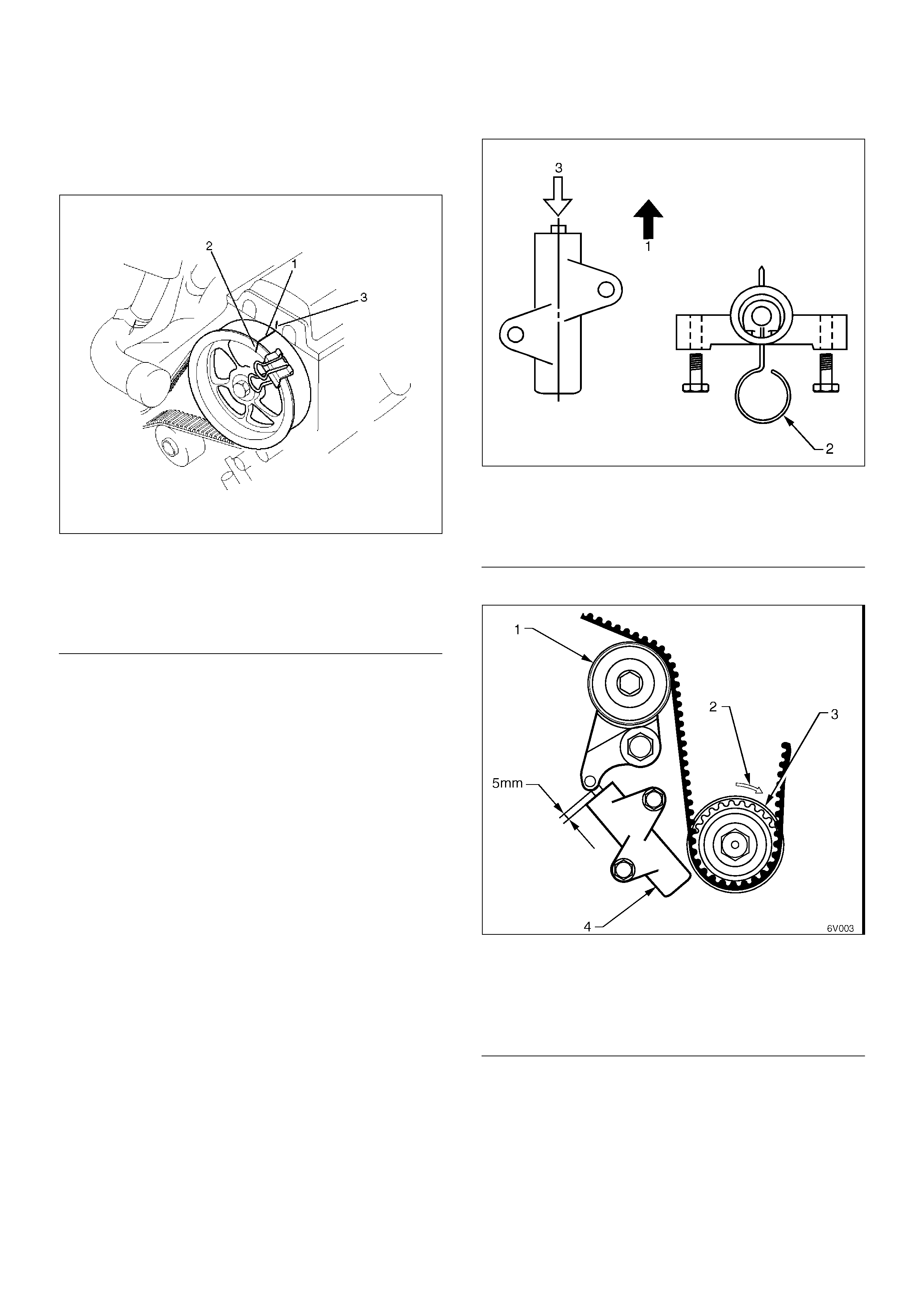

014R100032

EndOFCallout

c Remove double clips or equivalent clips, from

timing belt pulleys.

Turn the crankshaft pulley by six turns and

check for timing mark alignment.

NOTE: The crankshaft pulley timing mark, oil pump

cover timing mark and camshaft lobes will be in

their timing setting positions every six (6)

crankshaft revolutions.

Legend

(1) Alignment Mark on Timing Belt (White line).

(2) Alignment Mark on Camshaft Drive Gear

Pulley.

(3) Alignemnt Mark on Cylinder Head Cover LH.

Legend

(1) Direction for Installation

(2) Locking Pin

(3) Apply 980 N to compress the tensioner rod

Legend

(1) Tensioner Pulley

(2) Crankshaft Pulley Rotation Direction

(3) Crankshaft Pulley

(4) Tension Assembly

NOTE: The markings on the timing belt are for

installation only and will not realign every six turns.

3. Install timing belt covers

Remove crankshaft pulley that was installed in step

1 item 5.

Tighten bolts to the specified torque.

Torque: 19 N·m

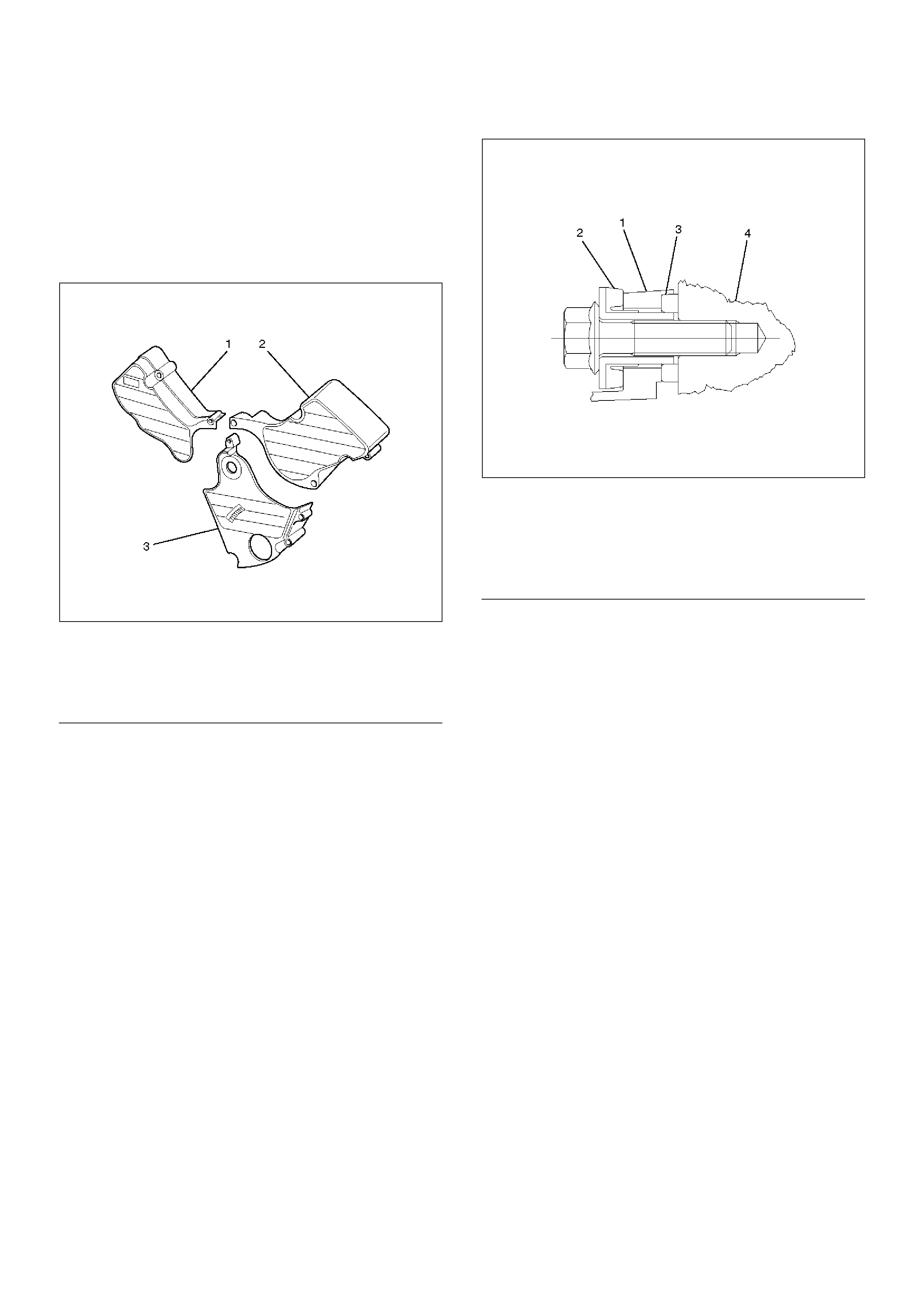

020RW004

EndOFCallout

020RW003

EndOFCallout

4. Install crankshaft pulley using 5–8840–0133–0, hold

the crankshaft pulley and tighten center bolt to the

specified torque.

Torque : 167 N·m

5. Install fan pulley bracket and tighten fixing bolts to

the specified torque.

Torque : 22 N·m

6. Install power steering pump assembly and tighten to

the specified torque.

Torque :

M8 bolt : 22 N·m

M10 bolt : 46 N·m

7. Install cooling fan assembly and tighten bolts/nuts to

the specified torque.

Torque : 22 N·m for fan pulley and fan bracket.

Torque : 10 N·m for fan and clutch assembly.

Legend

(1) Timing Belt Cover RH

(2) Timing Belt Cover LH

(3) Timing Belt Cover Lower

Legend

(1) Timing Belt Cover

(2) Rubber Bushing

(3) Sealing Rubber

(4) Cylinder Body

8. Move drive belt tensioner to loose side using

wrench, then install drive belt to normal position.

850RW001

EndOFCallout

9. Install radiator upper fan shroud.

10. Install air cleaner assembly.

Legend

(1) Crankshaft Pulley

(2) Cooling Fan Pulley

(3) Auto Tensioner

(4) Generator

(5) Air Conditioner Compressor

(6) Power Steering Oil Pump

(7) Idle Pulley

(8) Drive Belt

Timing Belt Replacement - Service Operation

Removal

1.Follow steps 1) through to 12) of the Timing Belt

Replacement - Broken Belt procedure - refer 6A-34

2. Rotate the crankshaft until the following marks are

aligned:

• The mark (notch) of crankshaft timing pulley (2) with

mark on oil pump (1).

• The alignment mark on the RH bank camshaft drive

gear pulley (2) to the alignment mark of the cylinder

head cover RH (3).

• The alignment mark on the LH bank camshaft drive

gear pulley (2) to the alignment mark of the cylinder

head cover LH (3).

NOTE: It It may require up to three revolutions of

the crankshaft to achieve alignment of all marks.

3. Remove the timing belt tensioner and carefully

remove the timing belt, ensuring the Camshaft

Drive Gear Pulleys do not turn.

Installation

NOTE:

1. Do not bend or twist the belt, otherwise its core

could be damaged. The belt should not be bent

at a radius less than 30 mm.

2. Do not allow oil or other chemical substances to

come in contact with the belt.

3. Do not attempt to pry or stretch the belt with a

screw driver or any other tool during

installation.

4. Store timing belt in a cool and dark place. Never

expose the belt to direct sunlight or heat.

NOTE:

For correct belt installation, the lettering on the

belt must be able to be read as viewed from the

front of the vehicle.

Any attempt to use belts with different markings to

those shown below will void these service

procedures.

014RW006

.

Legend

(1) Timing Belt

(2) Engine Rotation Direction

(3) Cylinder Head Side

Techline

Installation

014R100015

1. Ensure that the alignment marks on the crankshaft

and camshaft drive gear pulleys are aligned with

their respective marks as shown above.

2. Align the mark (groove) on the crankshaft timing

pulley (3) with alignment mark (white dots line) on

the timing belt (4)

3. Align the alignment mark (white line) on the timing

belt (1) with alignment mark on the RH bank

camshaft drive gear pulley (2) and put the timing

belt on the camshaft drive gear pulley. Secure the

belt with a double clip or equivalent clip.

4. Align the alignment mark (white line) on the timing

belt (1) with the alignment mark on the LH bank

camshaft drive gear pulley (2).

5. When aligning the timing marks, use a wrench to

turn the camshaft drive gear pulley, and put the

timing belt on the camshaft drive gear pulley.

Secure the belt with a double clip or equivalent clip.

6. Install crankshaft pulley temporarily and tighten

center bolt by hand (do not use a wrench).

7. Turn the crankshaft pulley clockwise to give some

belt slack between the crankshaft timing pulley and

the RH bank camshaft drive gear pulley.

8. Compress and pin the timing belt tensioner push

rod, then install timing belt tensioner and tighten bolt

to the specified torque.

Torque : 25 N·m

9. Remove the timing belt tensioner push rod locking

pin, and ensure that the push rod projection is about

5 mm., as shown above.EndOFCallout

10. Remove double clips or equivalent clips, from timing

belt pulleys.

11. Turn the crankshaft pulley by three turns and check

for timing mark alignment.

NOTE: The timing marks on the belt are for initial

installation only. Due to the gear ratio between the

camshaft drive gear pulley and the camshaft driven

gear, the belt markings cannot be used to recheck

timing accuracy.

Legend

(1) Direction for Installation

(2) Locking Pin

(3) Apply 980 N to compress the tensioner rod

Legend

(1) Tensioner Pulley

(2) Crankshaft Pulley Rotation Direction

(3) Crankshaft Pulley

(4) Tensioner Assembly

12. Install timing belt cover. and tighten bolts to the

specified torque.

Torque: 19 N·m (1.9 kg·m/14 lb ft)

020RW004

EndOFCallout

020RW003

EndOFCallout

13. Install crankshaft pulley using 5–8840–0133–0, hold

the crankshaft pulley and tighten center bolt to the

specified torque.

Torque : 167 N·m (17.0 kg·m/123 lb ft)

14. Install fan pulley bracket and tighten fixing bolts to

the specified torque.

Torque : 22 N·m (2.2 kg·m/16 lb ft)

15. Install power steering pump assembly and tighten to

the specified torque.

Torque :

M8 bolt : 22 N·m (2.2 kg·m/16 lb ft)

M10 bolt : 46 N·m (4.7 kg·m/34 lb ft)

16. Install cooling fan assembly and tighten bolts/nuts to

the specified torque.

Torque : 22 N·m (2.2 kg·m/16 lb ft) for fan pulley

and fan bracket.

Torque : 10 N·m (1.0 kg·m/87 lb in) for fan and

clutch assembly.

17. Move drive belt tensioner to loose side using

wrench, then install drive belt to normal position.

850RW001

EndOFCallout

18. Install radiator upper fan shroud.

19. Install air cleaner assembly.

Legend

(1) Timing Belt Cover RH

(2) Timing Belt Cover LH

(3) Timing Belt Cover Lower

Legend

(1) Timing Belt Cover

(2) Rubber Bushing

(3) Sealing Rubber

(4) Cylinder Body

Legend

(1) Crankshaft Pulley

(2) Cooling Fan Pulley

(3) Auto Tensioner

(4) Generator

(5) Air Conditioner Compressor

(6) Power Steering Oil Pump

(7) Idle Pulley

(8) Drive Belt

Camshaft

Removal

1.Disconnect battery ground cable.

2.Remove crankshaft pulley.

•Refer to removal procedure for Crankshaft Pulley

in this manual.

3.Remove timing belt.

•Refer to removal procedure for Timing Belt in this

manual.

4. Remove cylinder head cover LH.

•Refer to removal procedure for Cylinder Head

Cover LH in this manual.

5. Remove cylinder head cover RH.

•Refer to removal procedure for Cylinder Head

Cover RH in this manual.

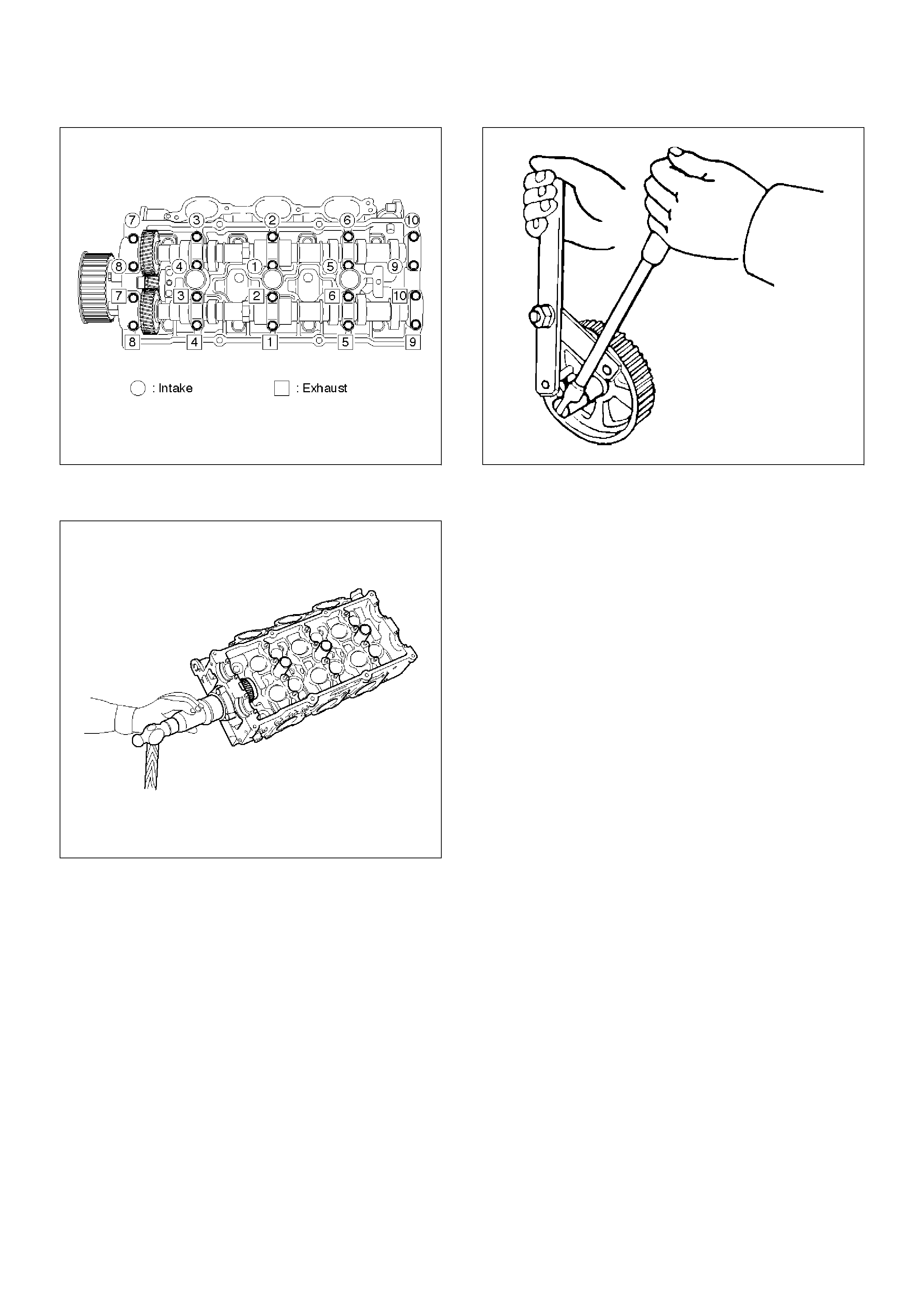

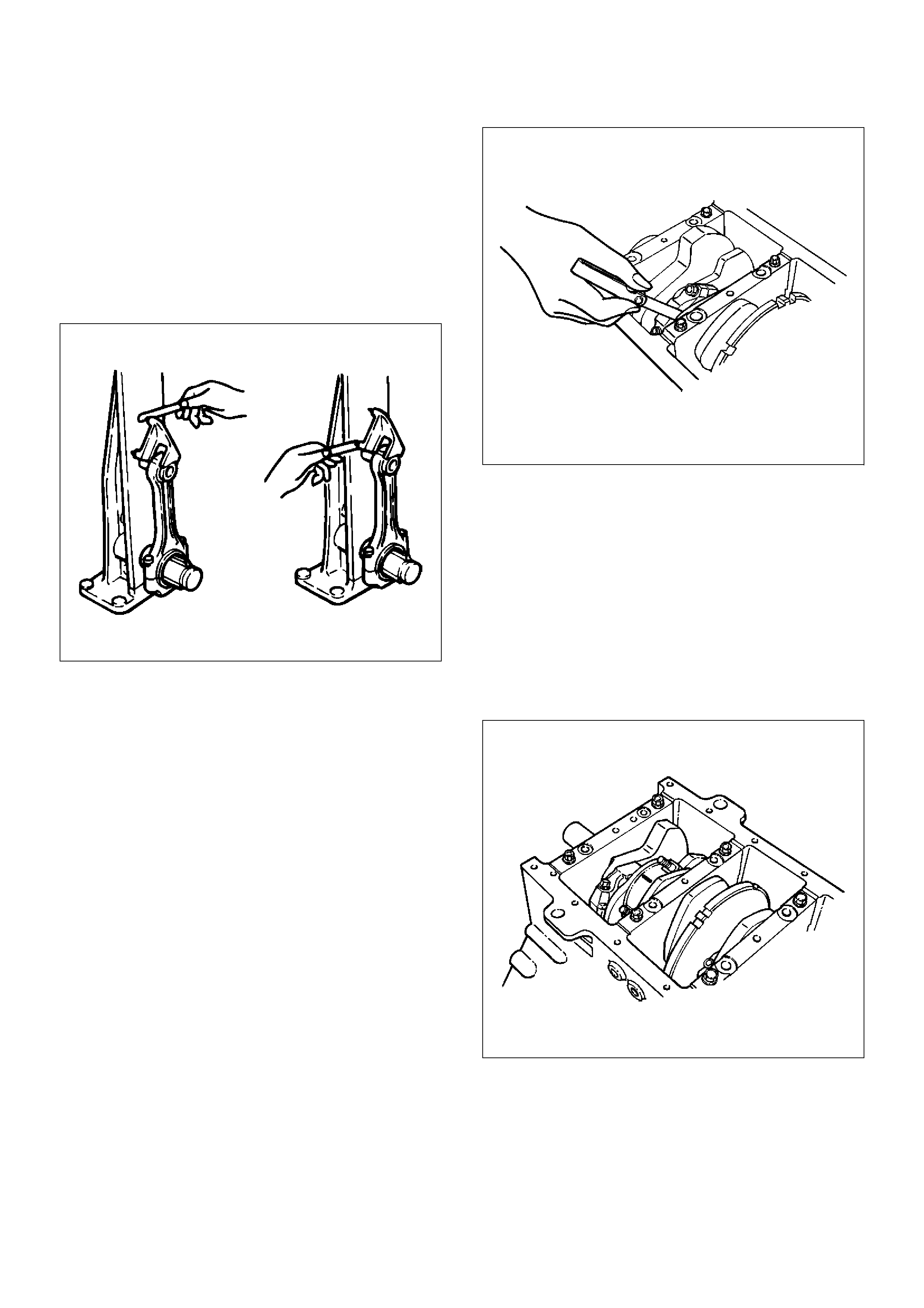

6. Remove twenty fixing bolts from inlet and exhaust

camshaft bracket on one side bank, then camshaft

brackets.

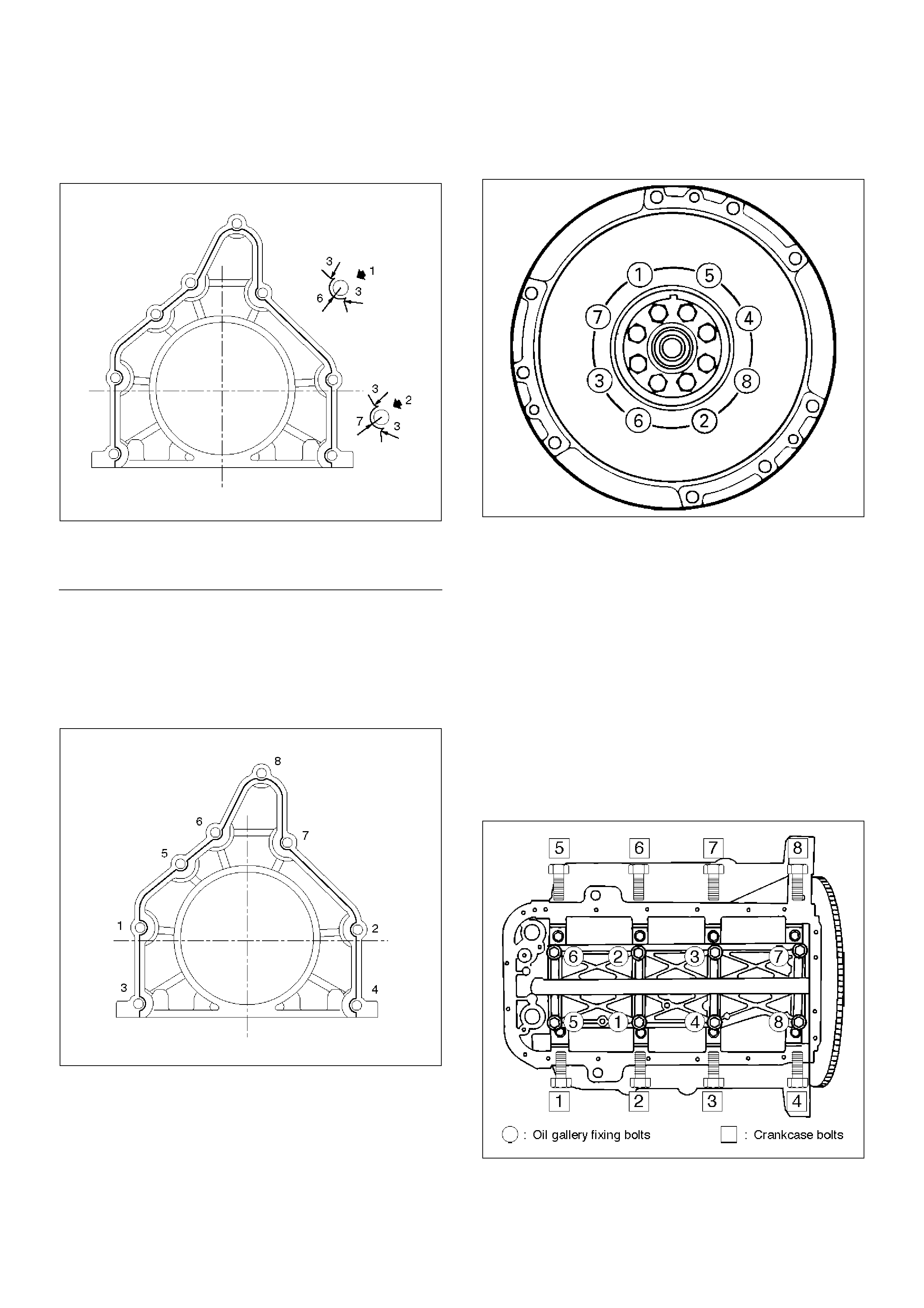

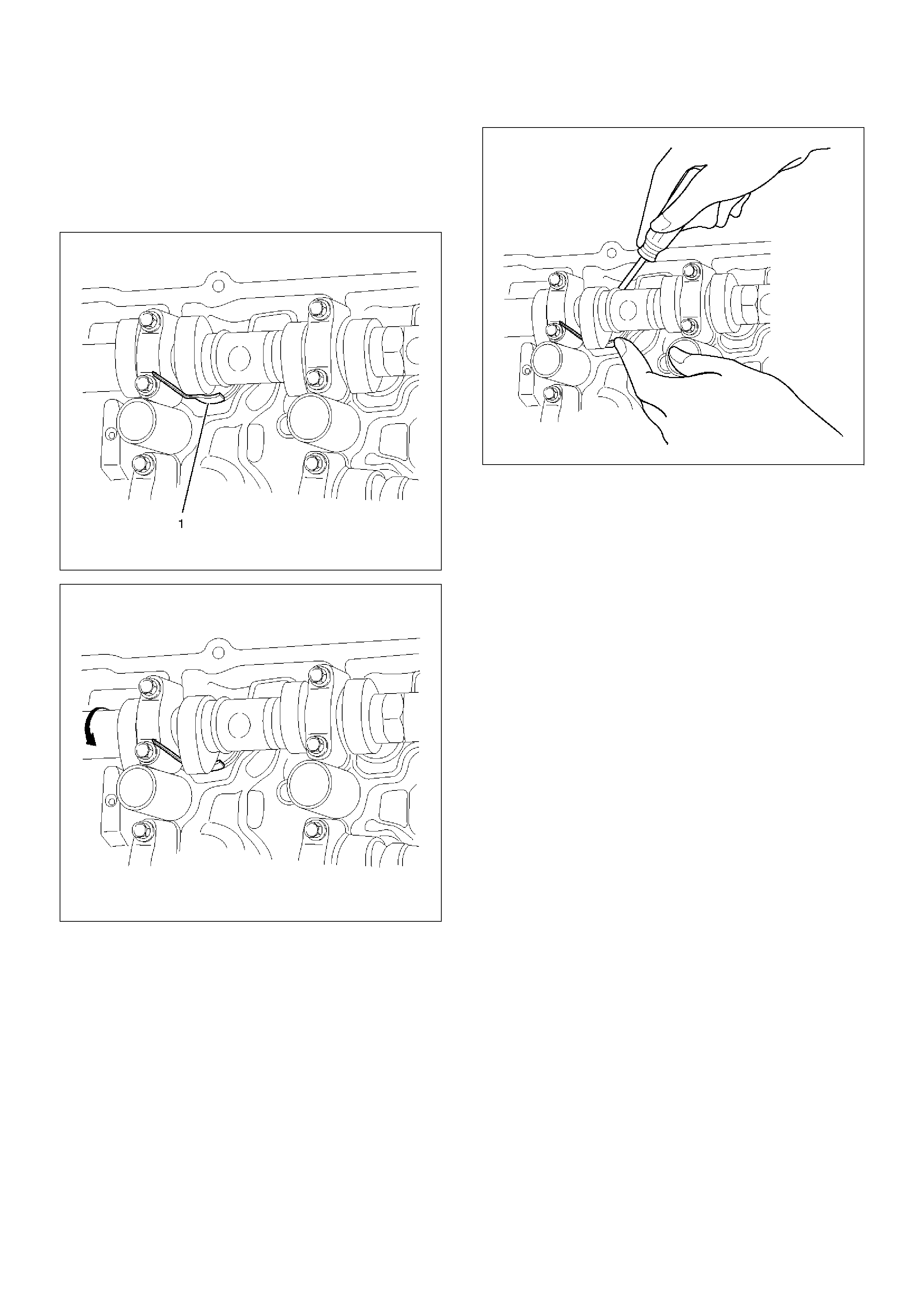

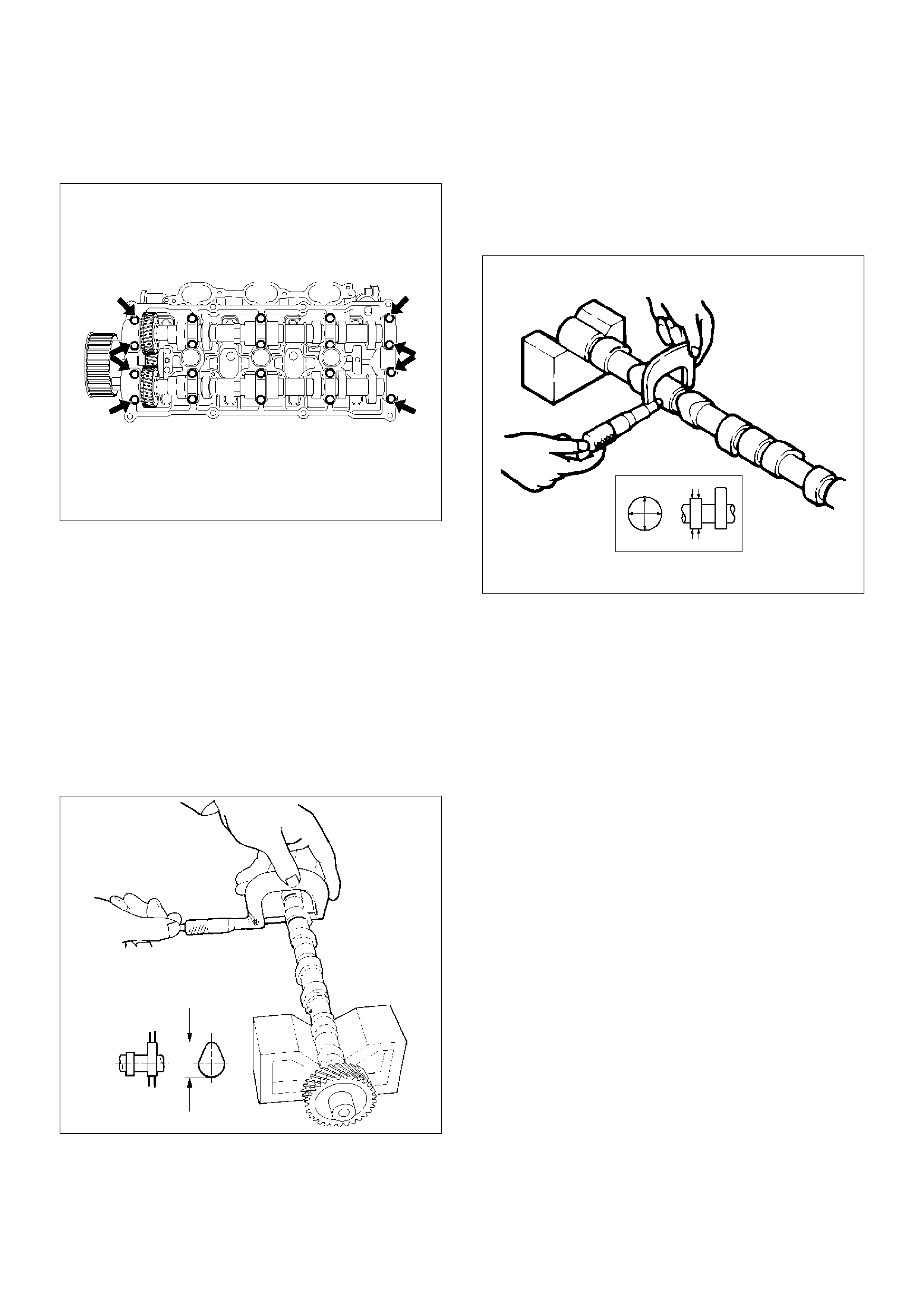

014RW027

7. Remove camshaft assembly.

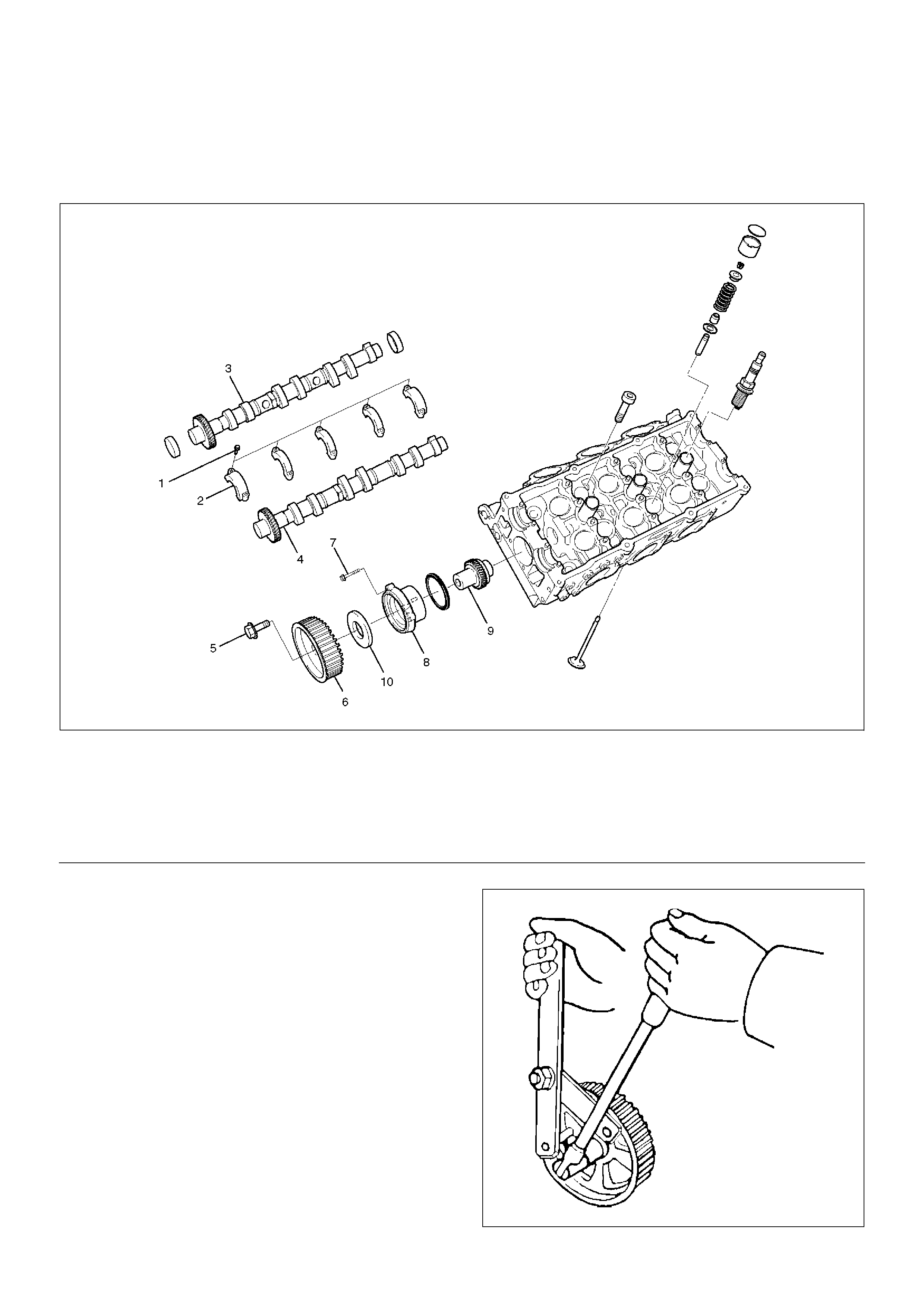

8. Remove fixing bolt for camshaft drive gear pulley.

9. Remove three fixing bolts from camshaft drive gear

retainer, then camshaft drive gear assembly.

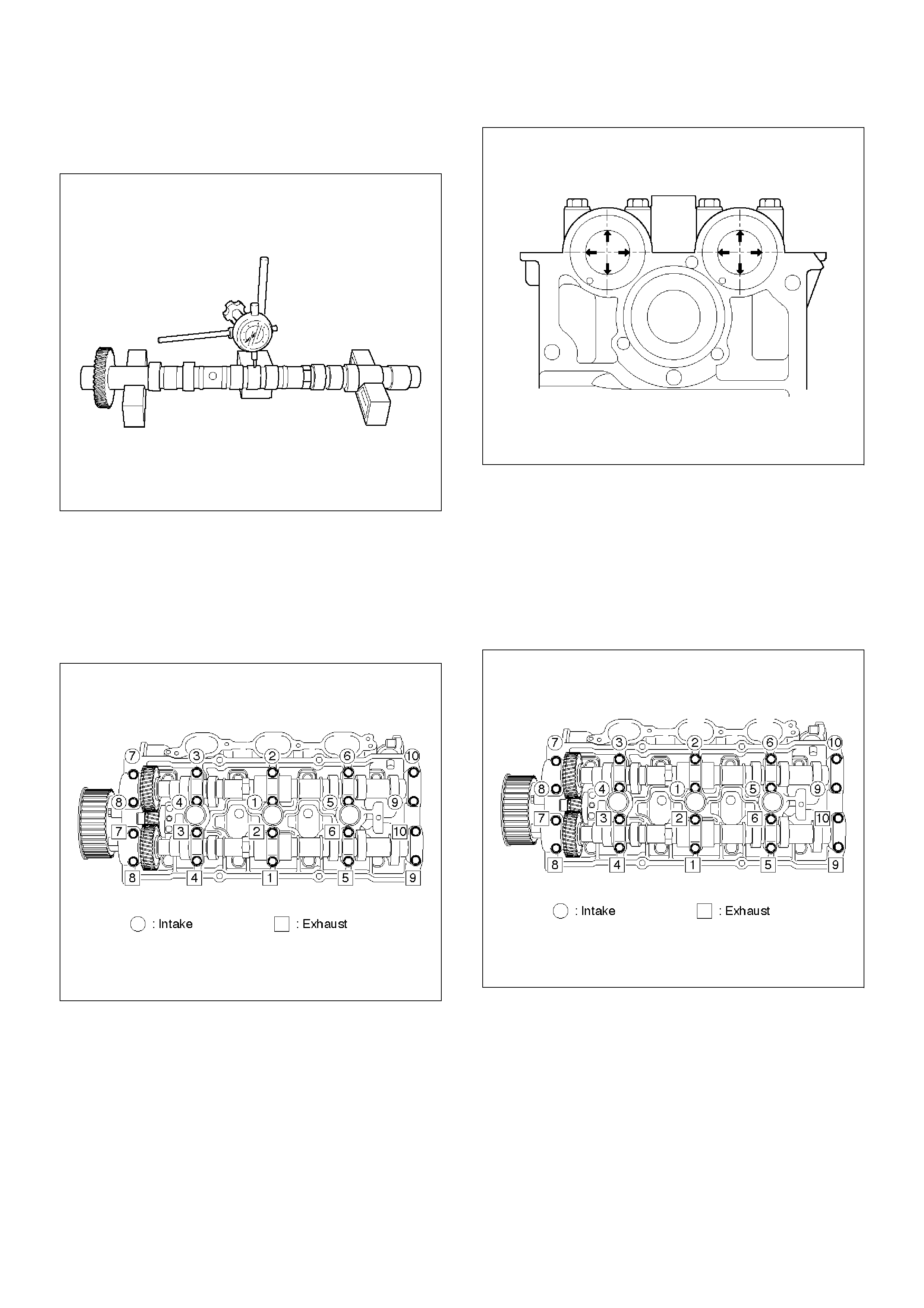

014RW026

EndOFC allout

Installation

1. Install camshaft drive gear assembly and tighten

three bolts to the specified torque.

Torque : 10 N·m (1.0 Kg·m/89 lb in)

2. Tighten bolt for camshaft drive gear assembly pulley

to the specified torque.

Torque : 98 N·m (10.0 Kg·m/72 lb ft)

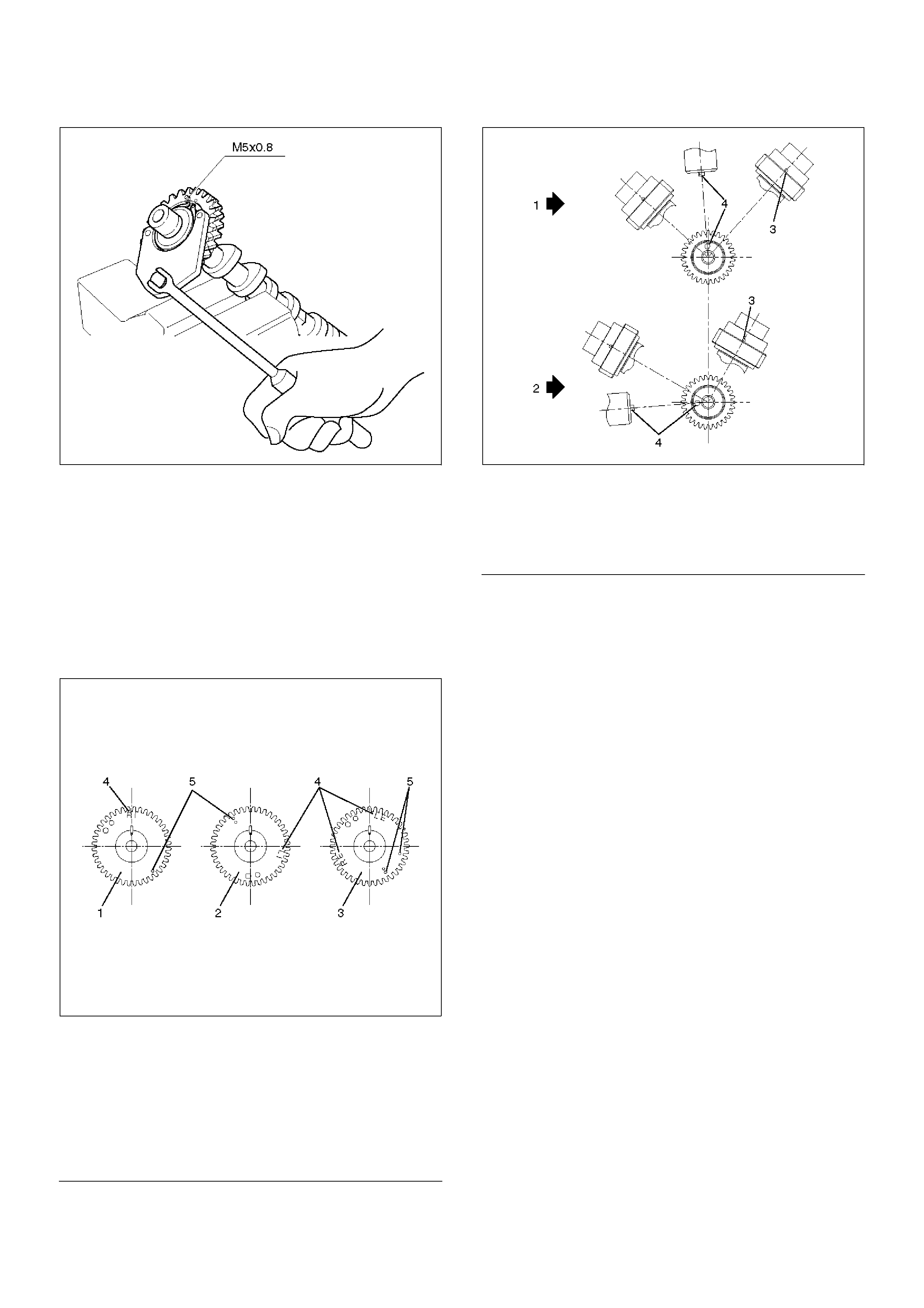

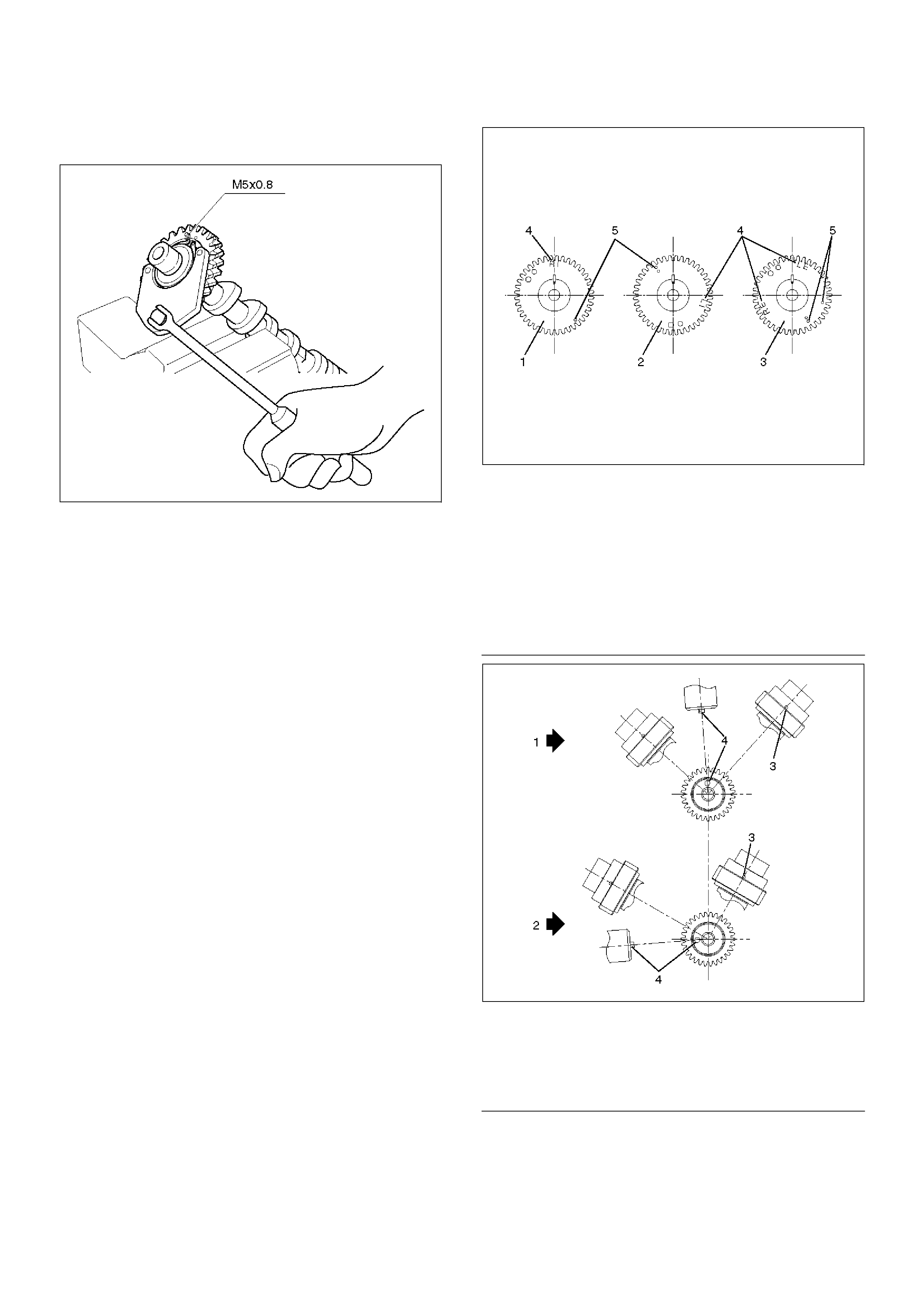

3. Tighten sub gear setting bolt.

1. Use the 5–8840–2443–0 gear spring lever to

turn sub gear to right direction until it aligns with

the M5 bolt hole between camshaft driven gear

and sub gear.

2. Tighten the M5 bolt to a suitable torque to

prevent the sub gear from moving.

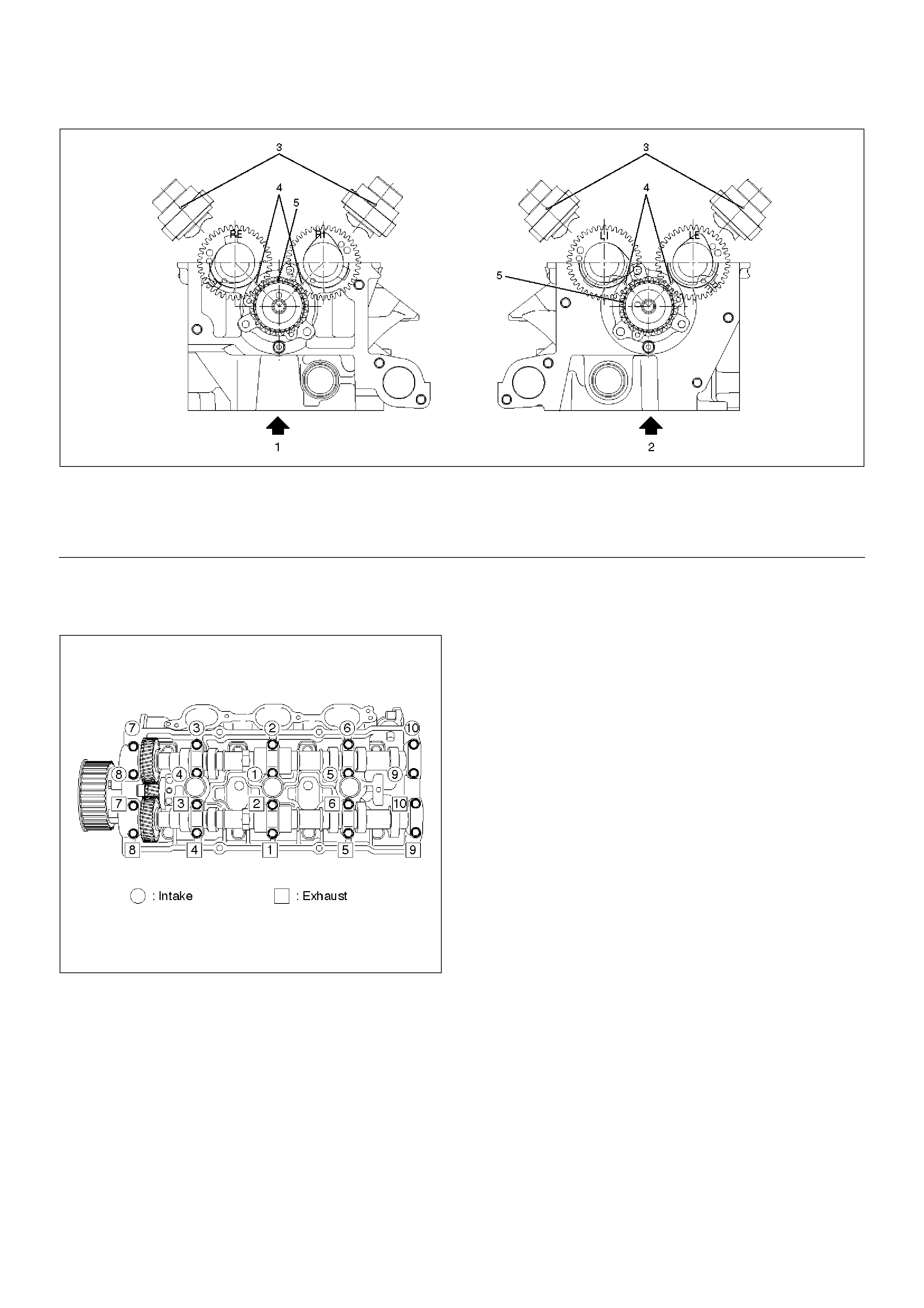

Legend

(1) Right Bank

(2) Left Bank

(3) Timing Mark on Retainer

014RW041

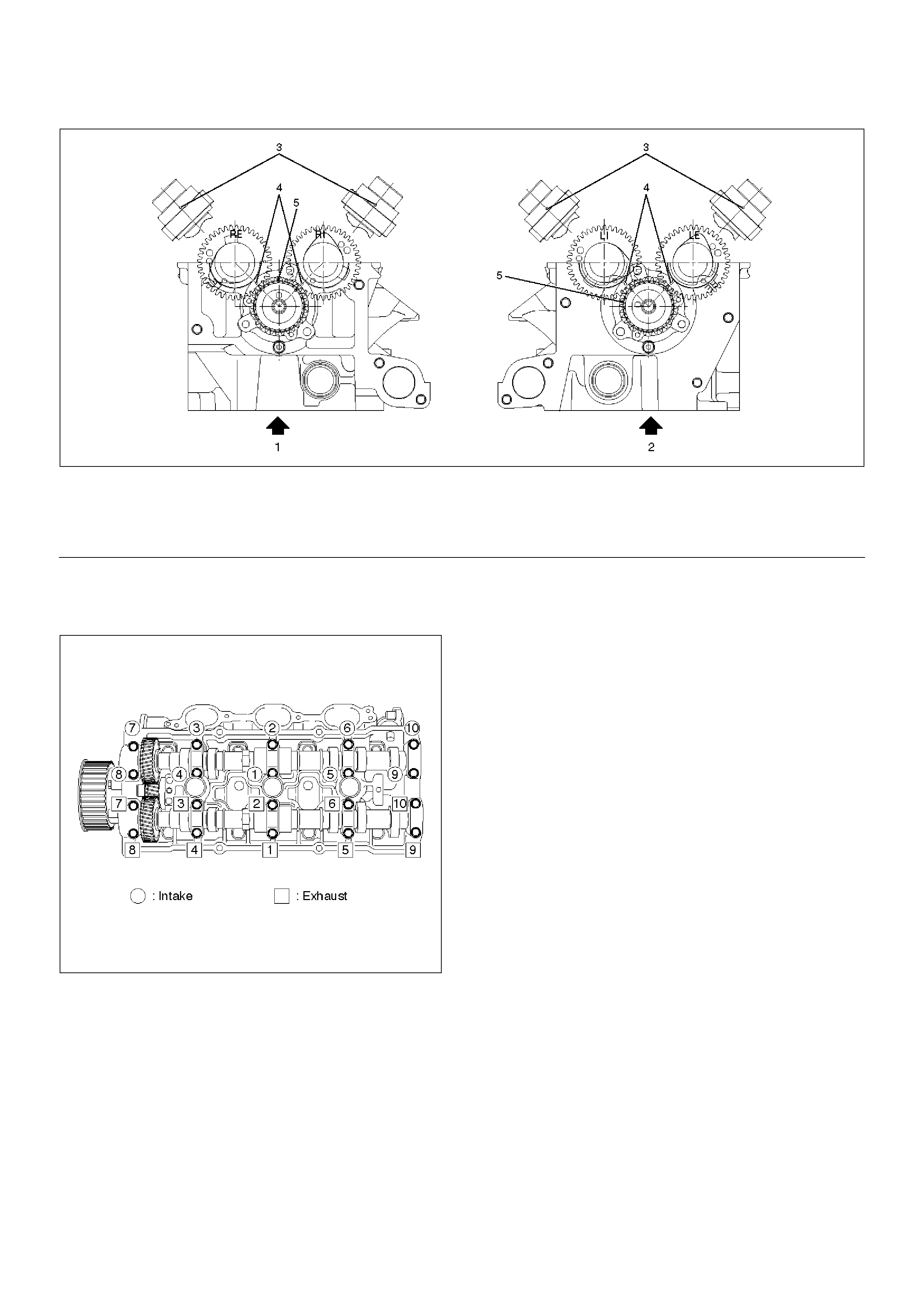

4. Install camshaft assembly and camshaft brackets,

tighten twenty bolts on one side bank to the

specified torque.

1. Apply engine oil to camshaft journal and bearing

surface of camshaft bracket.

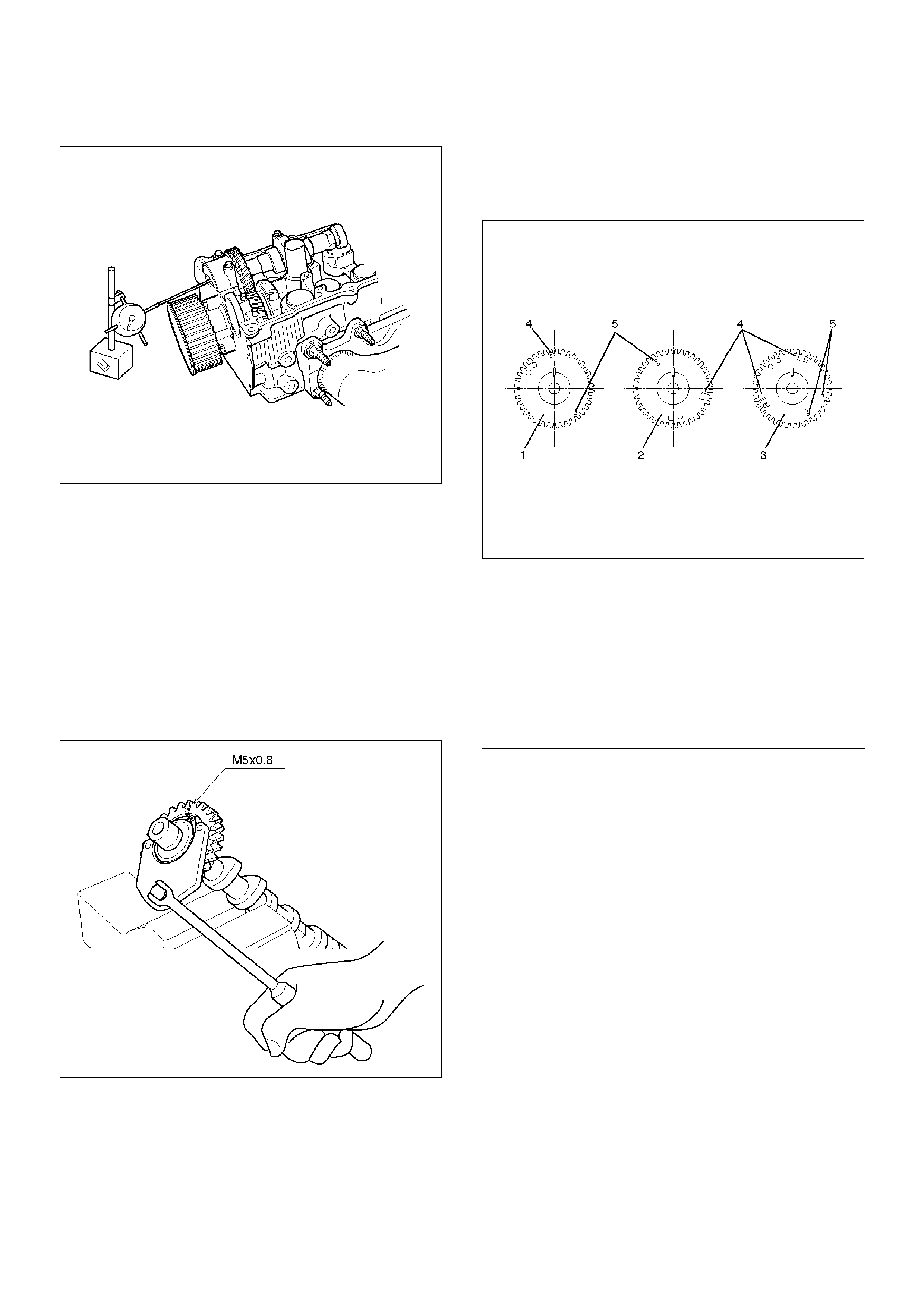

2. Align timing mark on intake camshaft (one dot

for right bank, two dot for left bank) and exhaust

camshaft (one dot for right bank, two dots for

left bank) to timing mark on camshaft drive gear

(one dot).

014RW020

EndOFC allout

014RW023

EndOFC allout

Legend

(1) Intake Camshaft Timing Gear for Right Bank

(2) Intake Camshaft Timing Gear for Left Bank

(3) Exhaust Camshaft Timing Gear

(4) Discrimination Mark

(LI: Left bank intake, RI: Right bank intake)

(LE: Left bank exhaust, RE: Right bank

exhaust)

Legend

(1) Right Bank Camshaft Drive Gear

(2) Left Bank Camshaft Drive Gear

(3) Timing Mark on Drive Gear

(4) Dowel Pin

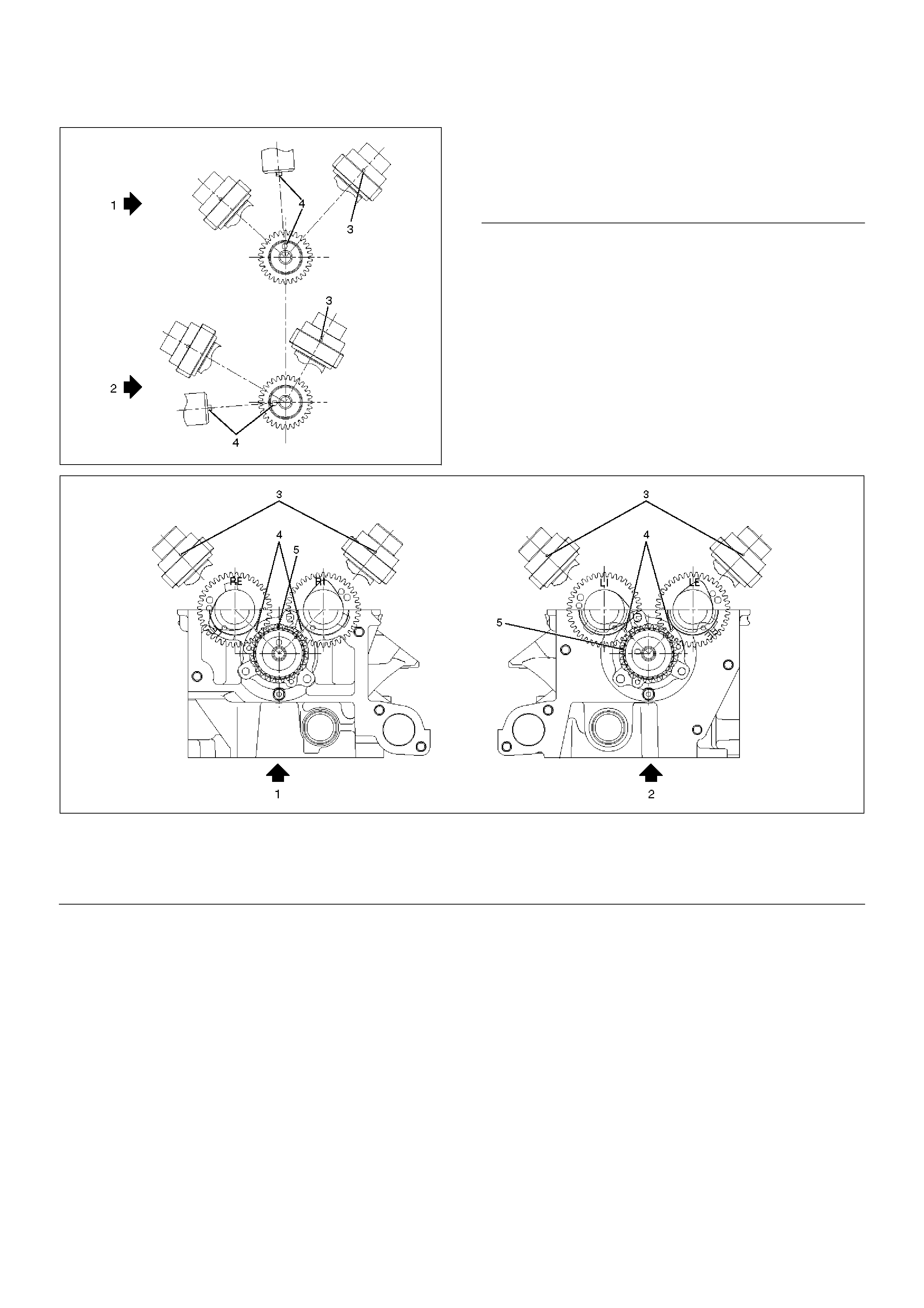

014RW024

EndOFCallout

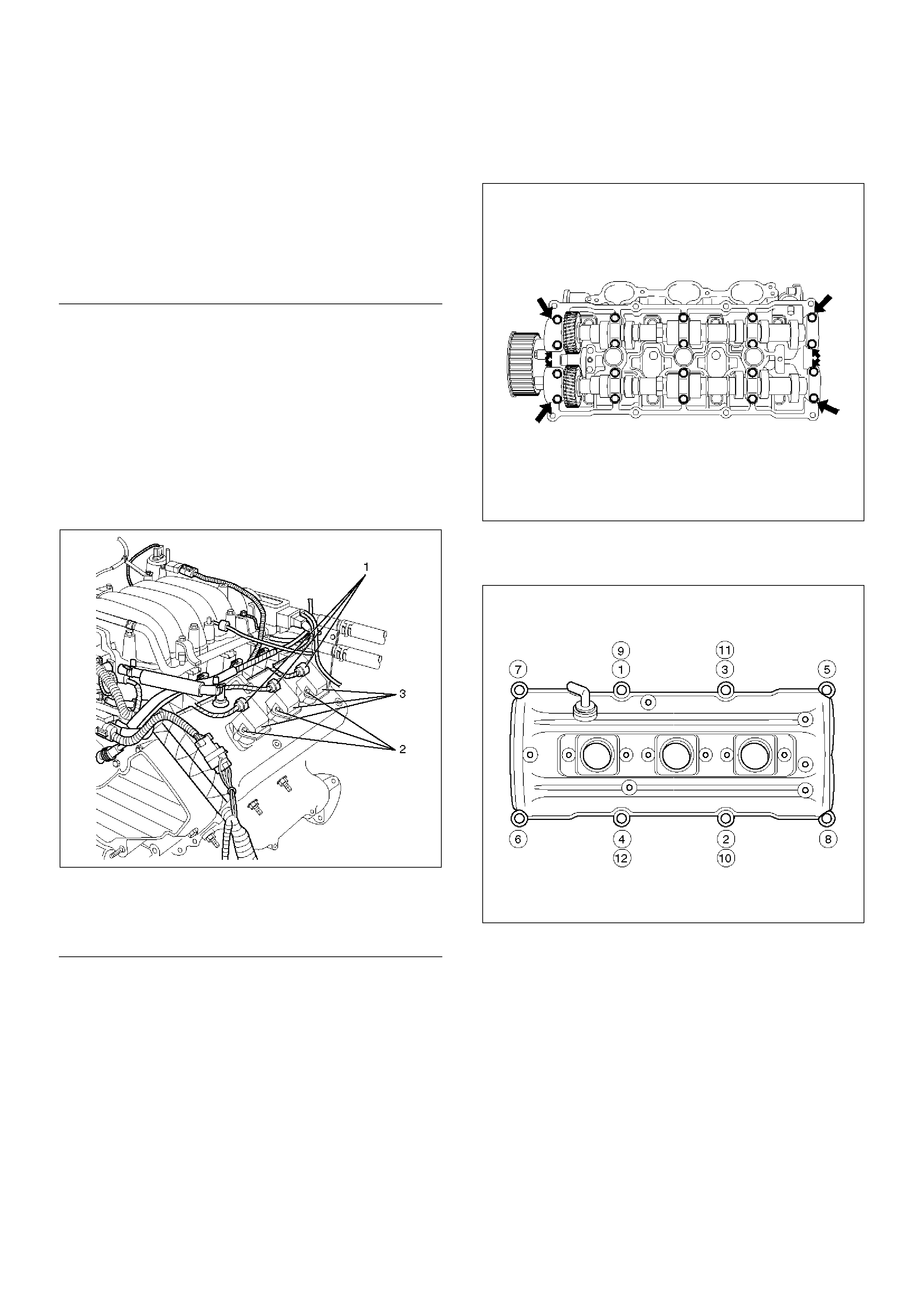

3.Tighten twenty bolts on numerical order an one

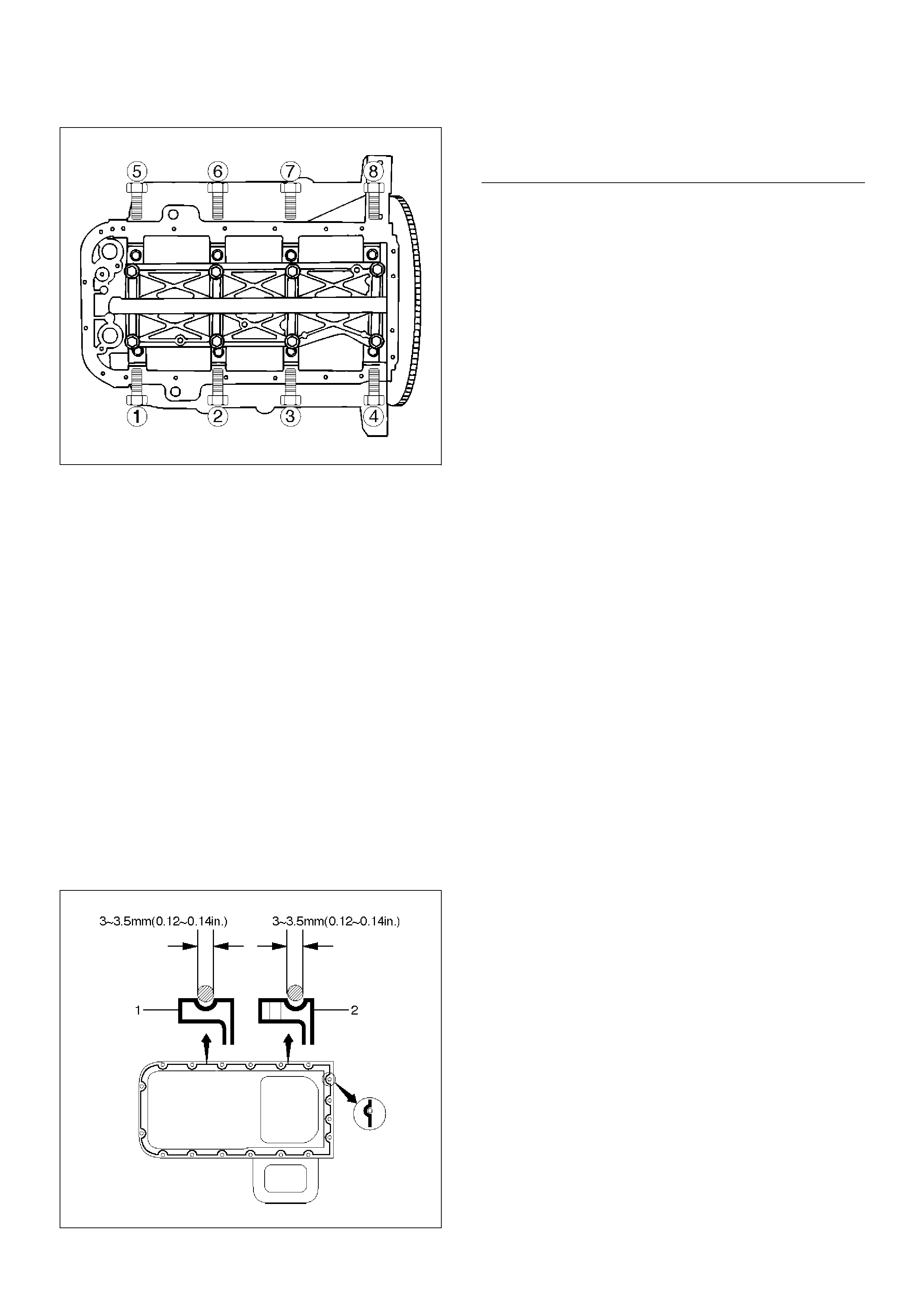

side bank as shown in the illustration.

Torque : 10 N·m (1.0 Kg·m/89 lb in)

014RW031

5.Install cylinder head cover RH.

•Refer to installation procedure for CYLINDER

HEAD COVER RH in this manual.

6.Install cylinder head cover LH.

•Refer to installation procedure for CYLINDER

HEAD COVER LH in this manual.

7.Install timing belt.

•Refer to installation procedure for TIMING BELT

in this manual.

8.Install crankshaft pulley.

•Refer to installation procedure for CRANKSHAFT

PULLEY in this manual.

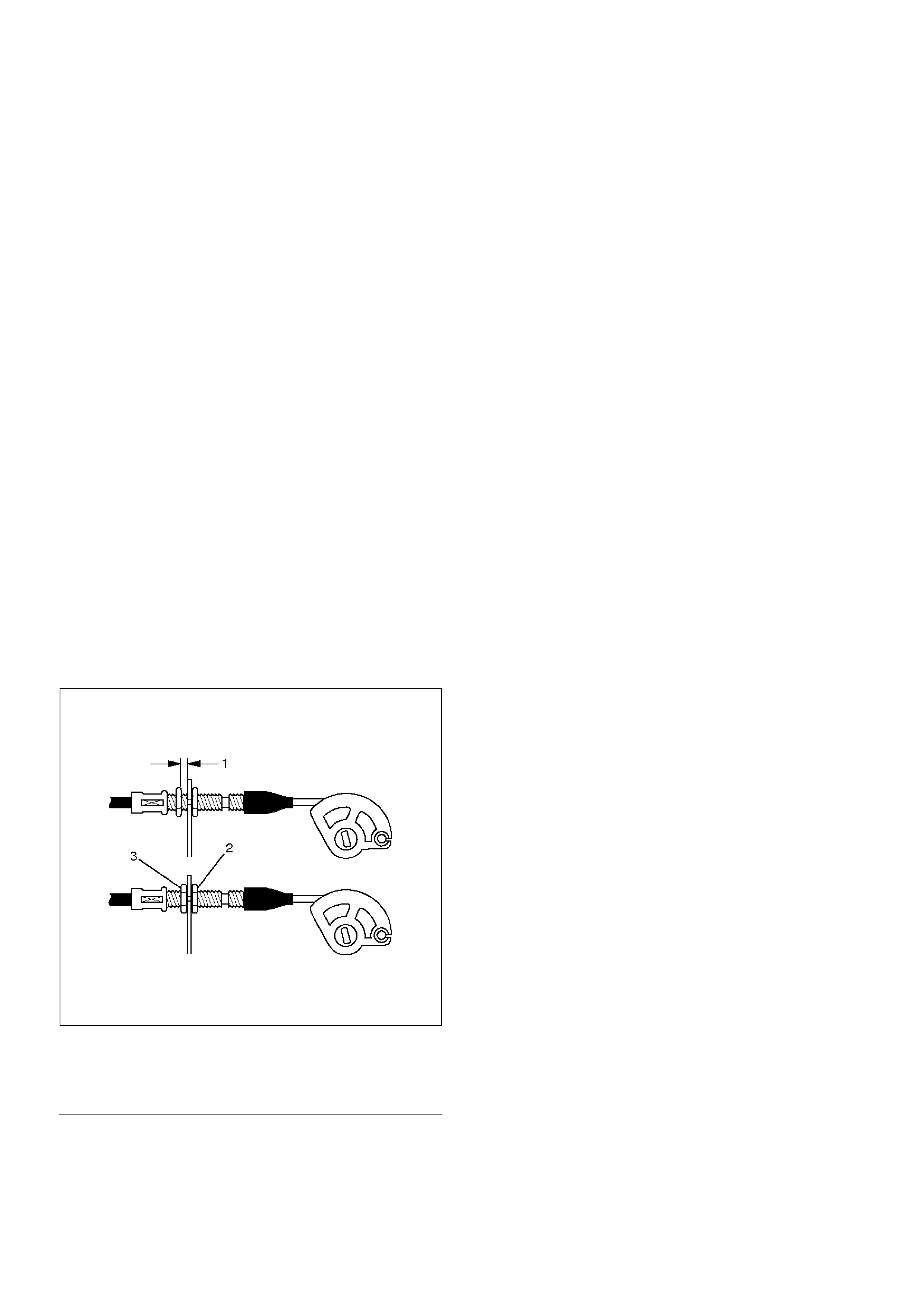

Accelerator pedal cable adjustment

1. Loosen adjusting nut and lock nut.

2. Pull outer cable while closing fully the throttle

valve.

3. Tighten adjusting nut and lock nut temporarily.

Legend

(1) Right Bank

(2) Left Bank

(3) Alignment Mark on Camshaft Drive Gear

(4) Alignment Mark on Camshaft

(5) Alignment Mark on Retainer

4. Loosen adjusting nut by three turns and tighten

lock nut.

Then, manually operating the throttle valve,

make sure that the valve lever returns up to the

stopper screw.

If it does not reach the stopper screw, repeat

from step 1.

035RW004

EndOFC allout

Legend

(1) Clearance

(2) Lock Nut

(3) Adjusting Nut

Cylinder Head

Removal

1.Remove engine hood.

2.Disconnect battery ground cable.

3.Drain radiator coolant.

4.Drain engine oil.

5.Remove crankshaft pulley.

•Refer to removal procedure for Crankshaft Pulley

in this manual.

6. Remove timing belt.

•Refer to removal procedure for Timing Belt in this

manual.

7. Remove cylinder head cover LH.

•Refer to removal procedure for Cylinder Head

Cover LH in this manual.

8. Remove cylinder head cover RH.

•Refer to removal procedure for Cylinder Head

Cover RH in this manual.

9. Remove common chamber.

•Refer to removal procedure for Common

Chamber in this manual.

10. Remove cylinder head assembly.

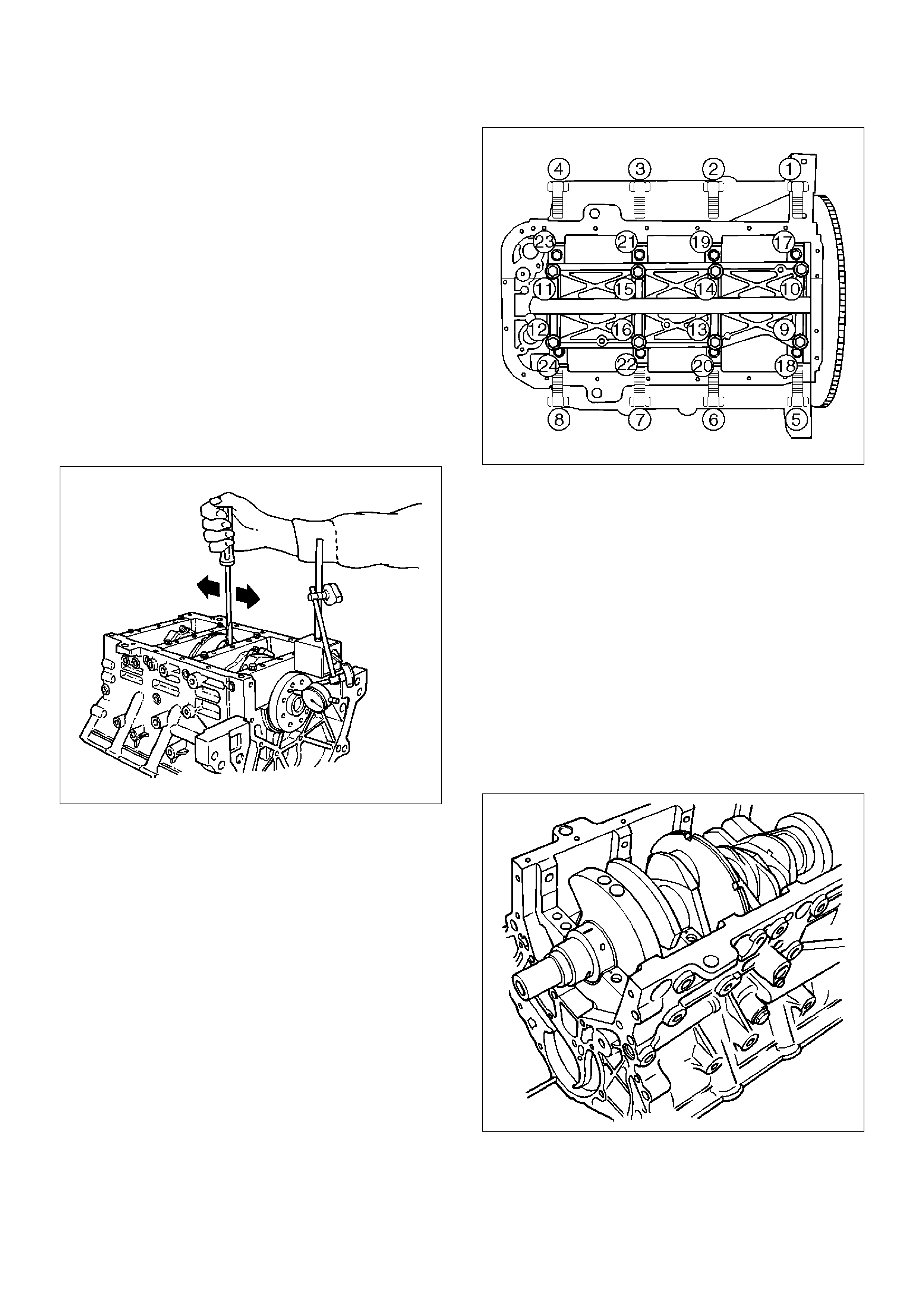

1. Loosen eights bolts for tight cylinder head.

2. Remove cylinder head assembly.

014RW028

EndOFC allout

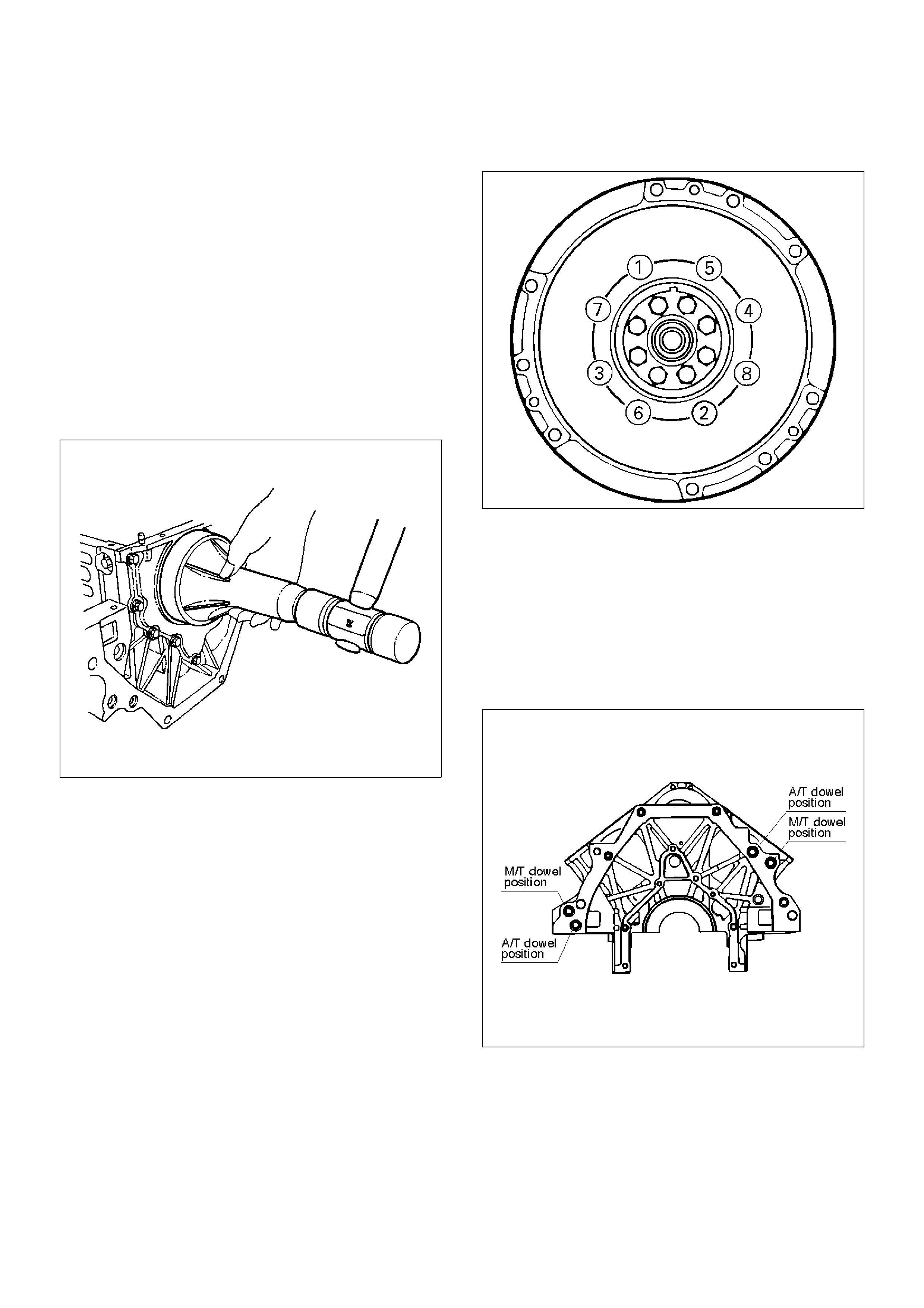

Installation

1. Install cylinder head assembly to cylinder block.

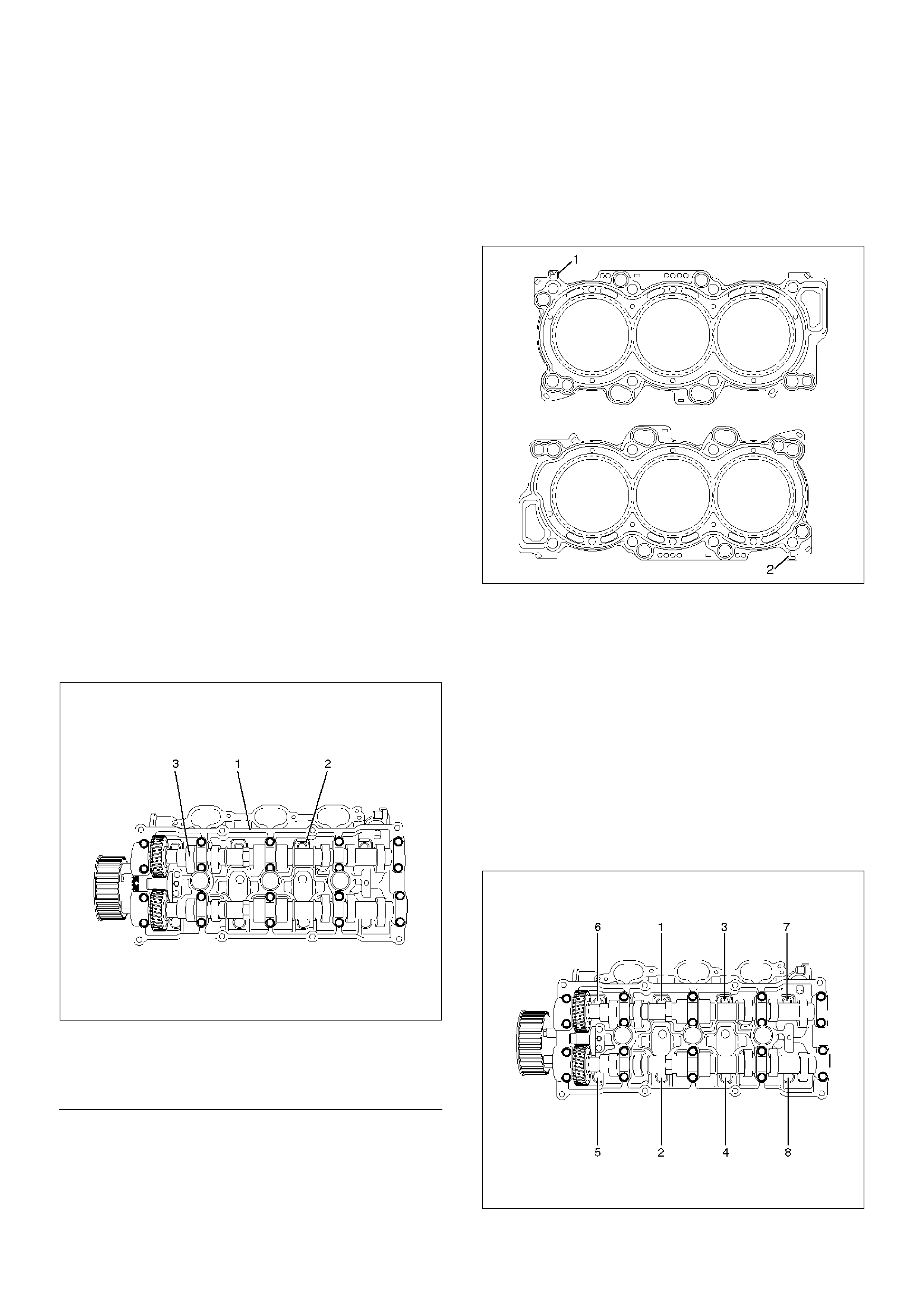

1. Put cylinder head gasket on the cylinder block.

NOTE: There is discrimination mark “R” for right bank

and “L” for left bank on the cylinder head gasket as

shown in the illustration.

Do not reuse cylinder head gasket.

011RW005

2. Align dowel pin hole to dowel pin on the cylinder

block.

3. Tighten two bolts temporarily by hand to prevent

the cylinder head assembly from moving.

4. Using 9–8511–4209–0 cylinder head bolt

wrench, tighten bolts in numerical order as

shown in the illustration to the specified torque.

NOTE: Do not reuse cylinder head bolts.

Do not apply any lubricant to the cylinder head bolts.

Torque :

Temporary : 29 N·m (3.0 Kg·m/21 lb ft)

Final : 64 N·m (6.5 Kg·m/47 lb ft)

014RW029

Legend

(1) Cylinder Head

(2) Cylinder Head Bolt

(3) Camshaft

2.Install common chamber.

•Refer to installation procedure for Common

Chamber in this manual.

3. Install cylinder head cover RH.

•Refer to installation procedure for Cylinder Head

Cover RH in this manual.

4. Install cylinder head cover LH.

•Refer to installation procedure for Cylinder Head

Cover LH in this manual.

5. Install timing belt.

•Refer to installation procedure for Timing Belt in

this manual.

6. Install crankshaft pulley.

•Refer to installation procedure for Crankshaft

Pulley in this manual.

Accelerator pedal cable adjustment

1. Loosen adjusting nut and lock nut.

2. Pull outer cable while closing fully the throttle

valve.

3. Tighten adjusting nut and lock nut temporarily.

4. Loosen adjusting nut by three turns and tighten

lock nut.

Then, manually operating the throttle valve,

make sure that the valve lever returns up to the

stopper screw.

If it does not reach the stopper screw, repeat

from step 1.

035RW004

EndOFC allout

Legend

(1) Clearance

(2) Lock Nut

(3) Adjusting Nut

Valve Stem Oil Controller , Valve Spring and Valve Guide

Removal

1.Disconnect battery ground cable.

2.Drain engine oil.

•Drain engine coolant.

3.Remove cylinder head assembly.

•Refer to removal procedure for Cylinder Head in

this manual.

4.Remove camshaft.

•Refer to removal procedure for Camshaft in this

manual.

5.Remove tappets with shim.

NOTE: Do not damage shim surface.

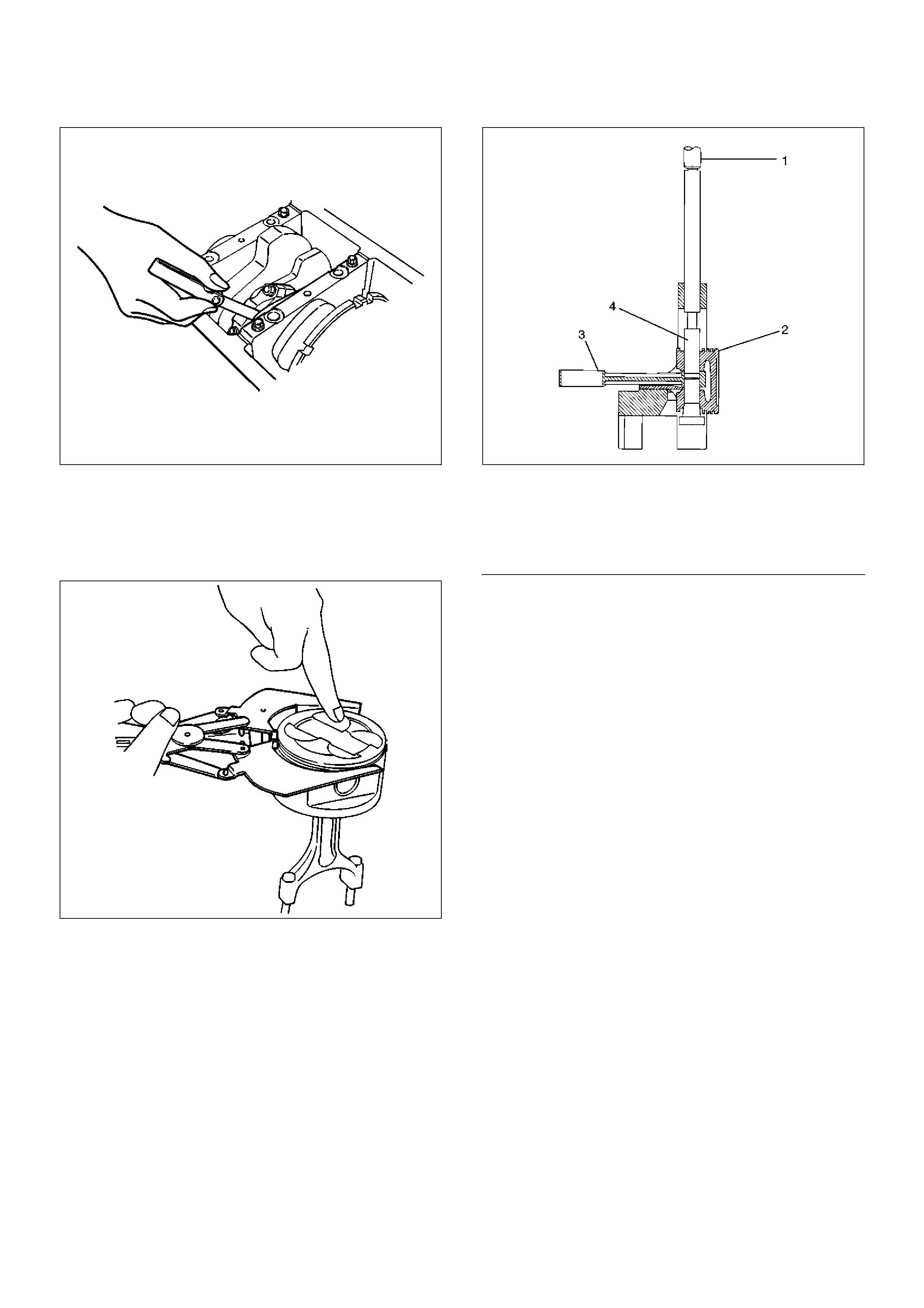

6.Remove valve springs using 5–8840–2446–0 valve

spring compressor and 5–8840–2547–0 valve

spring compressor adapter then remove upper

valve spring seat and lower seat.

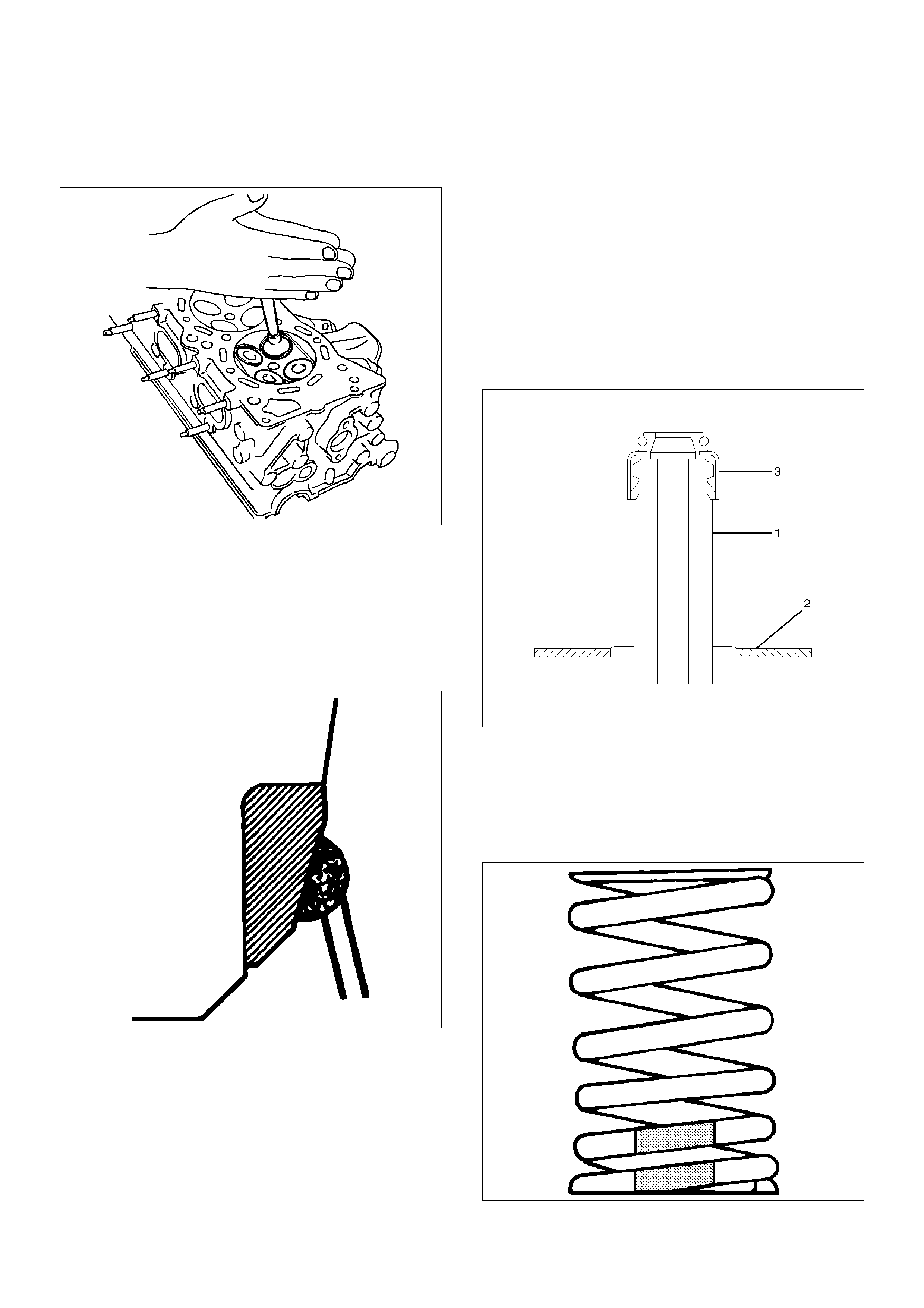

014RW042

7.Remove oil controller using 5–8840–0623–0 oil

controller remover, remove each valve stem oil

controller.

8.Remove valve guide using 5–8840–2549–0 valve

guide replacer.

Installation

1.Install valve guide using 5–8840–2442–0 valve

guide installer.

2.Install oil controller using 5–8840–0624–0 oil

controller installer.

3.Install lower valve spring seat, valve spring and

upper valve spring seat then put split collars on the

upper spring seat, using 5–8840–2446–0 valve

spring compressor and 5–8840–2547–0 valve

spring compressor adapter to install the split collars.

014RW042

4.Install tappet with shim.

5. Install camshaft assembly.

•Refer to installation procedure for Camshaft in

this manual.

6. Install cylinder head assembly.

•Refer to installation procedure for Cylinder Head

in this manual.

7. Fill engine oil until full level.

8. Fill engine coolant.

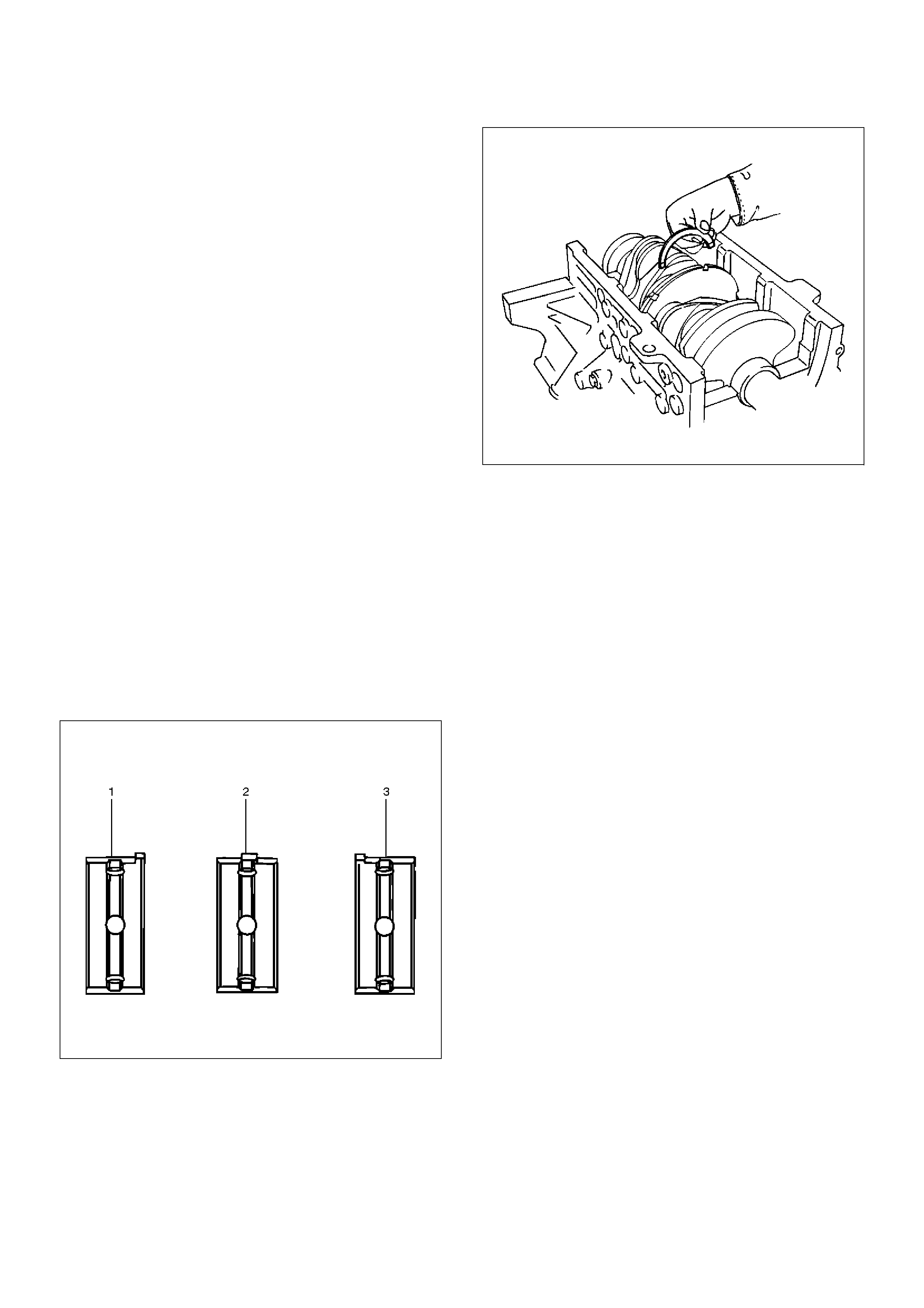

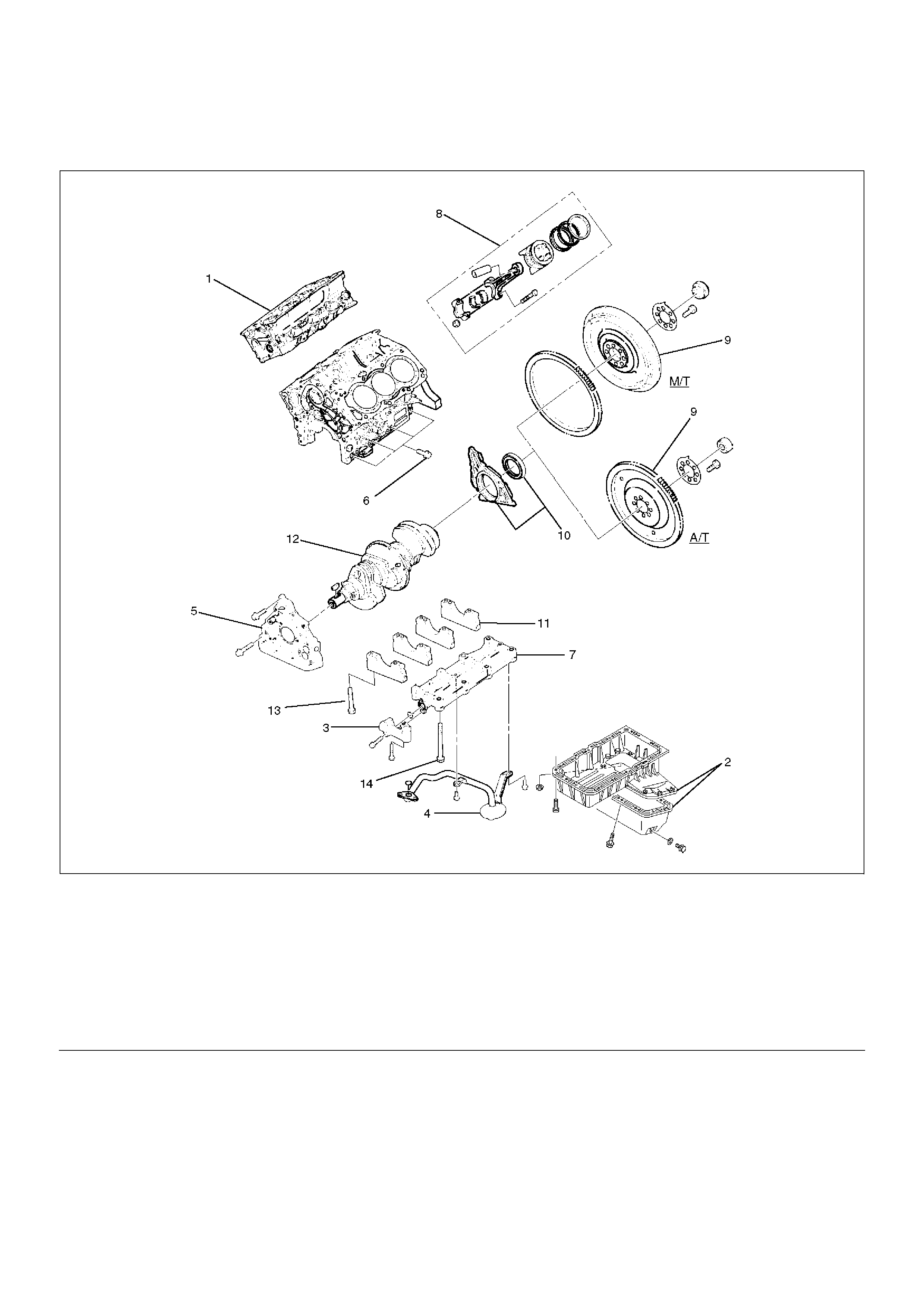

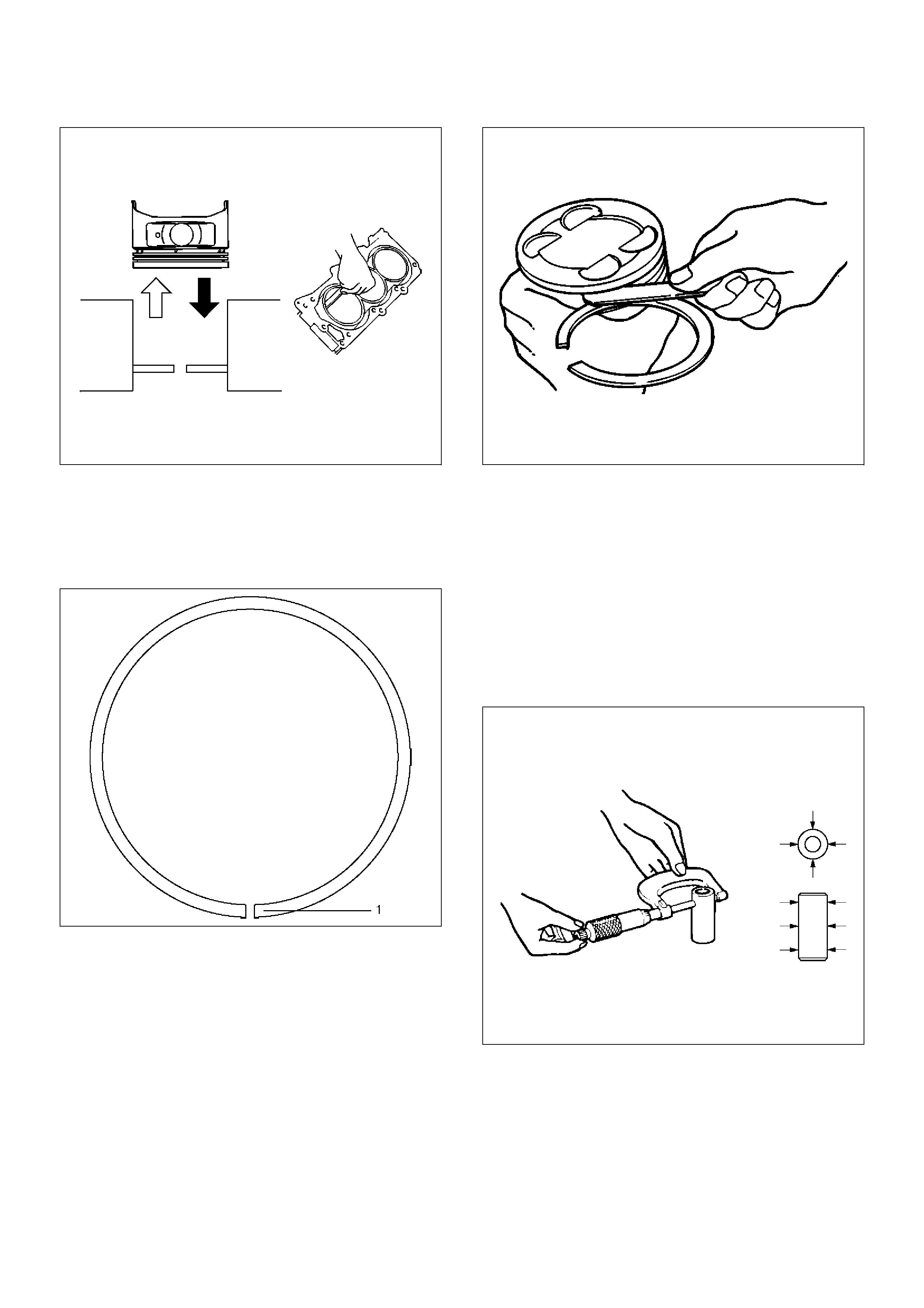

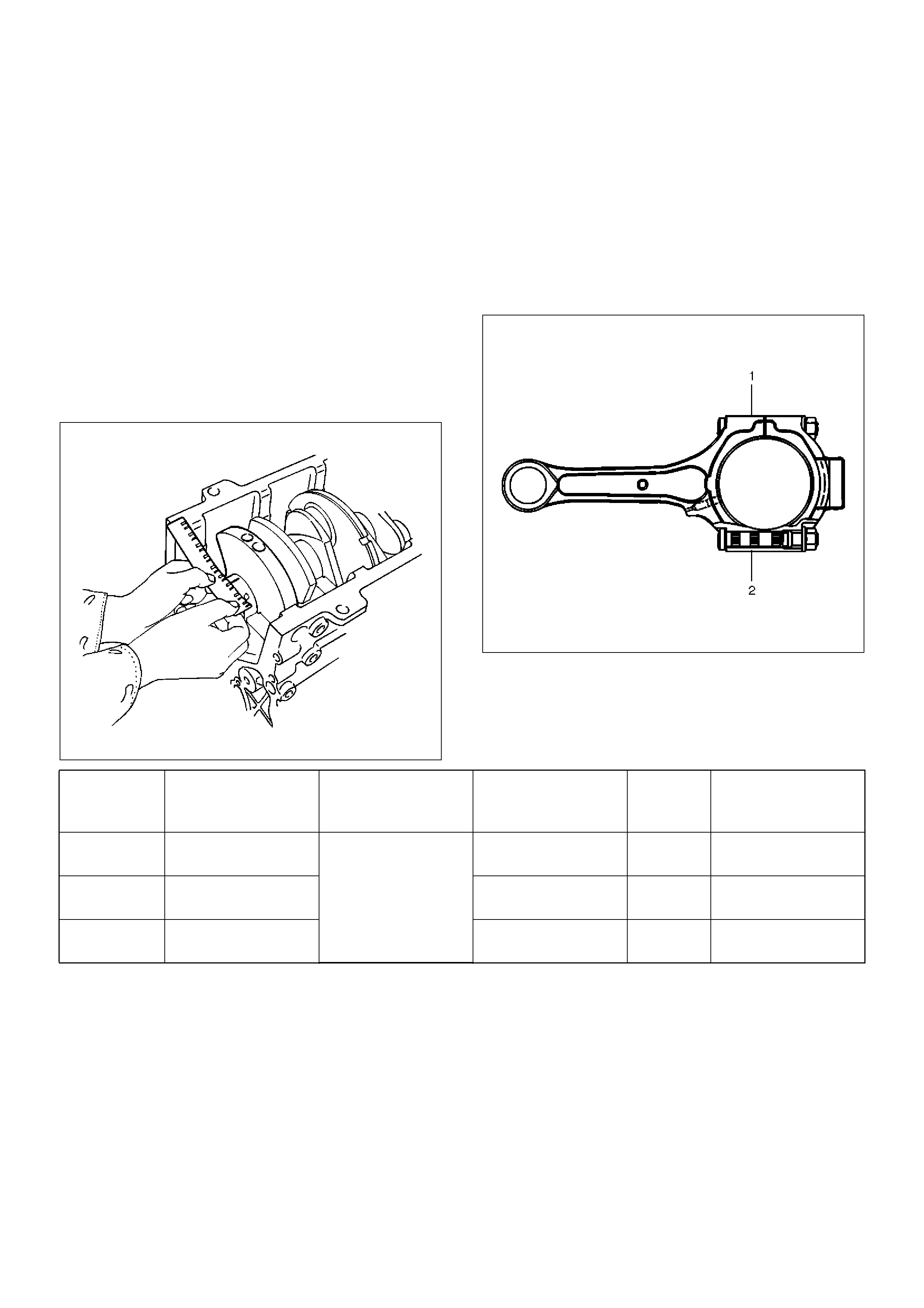

Piston, Piston Ring and Connecting Rod

Removal

F06RW011

EndOFCallout

1.Remove cylinder head assembly.

•Refer to removal procedure for Cylinder Head in

this manual.

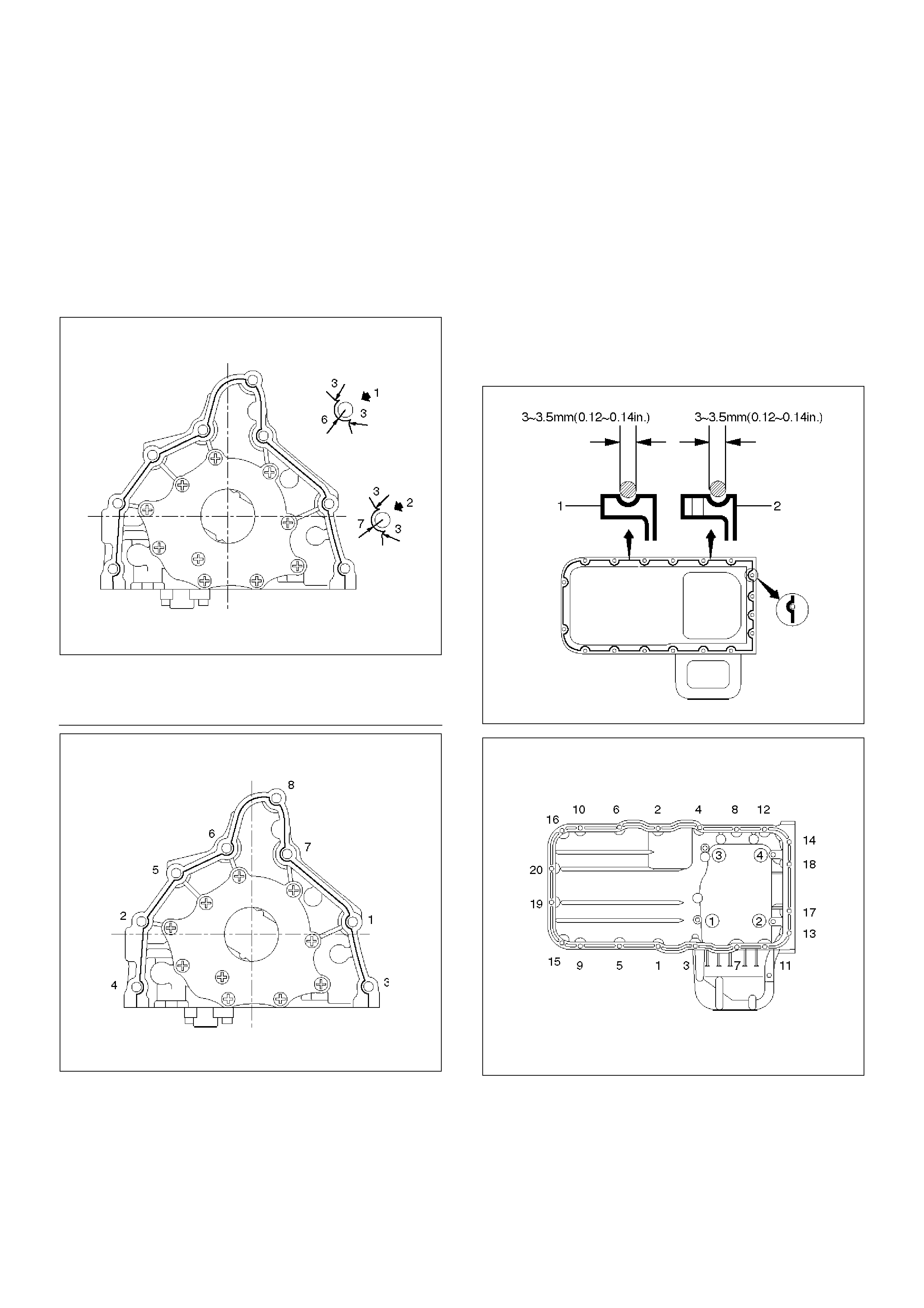

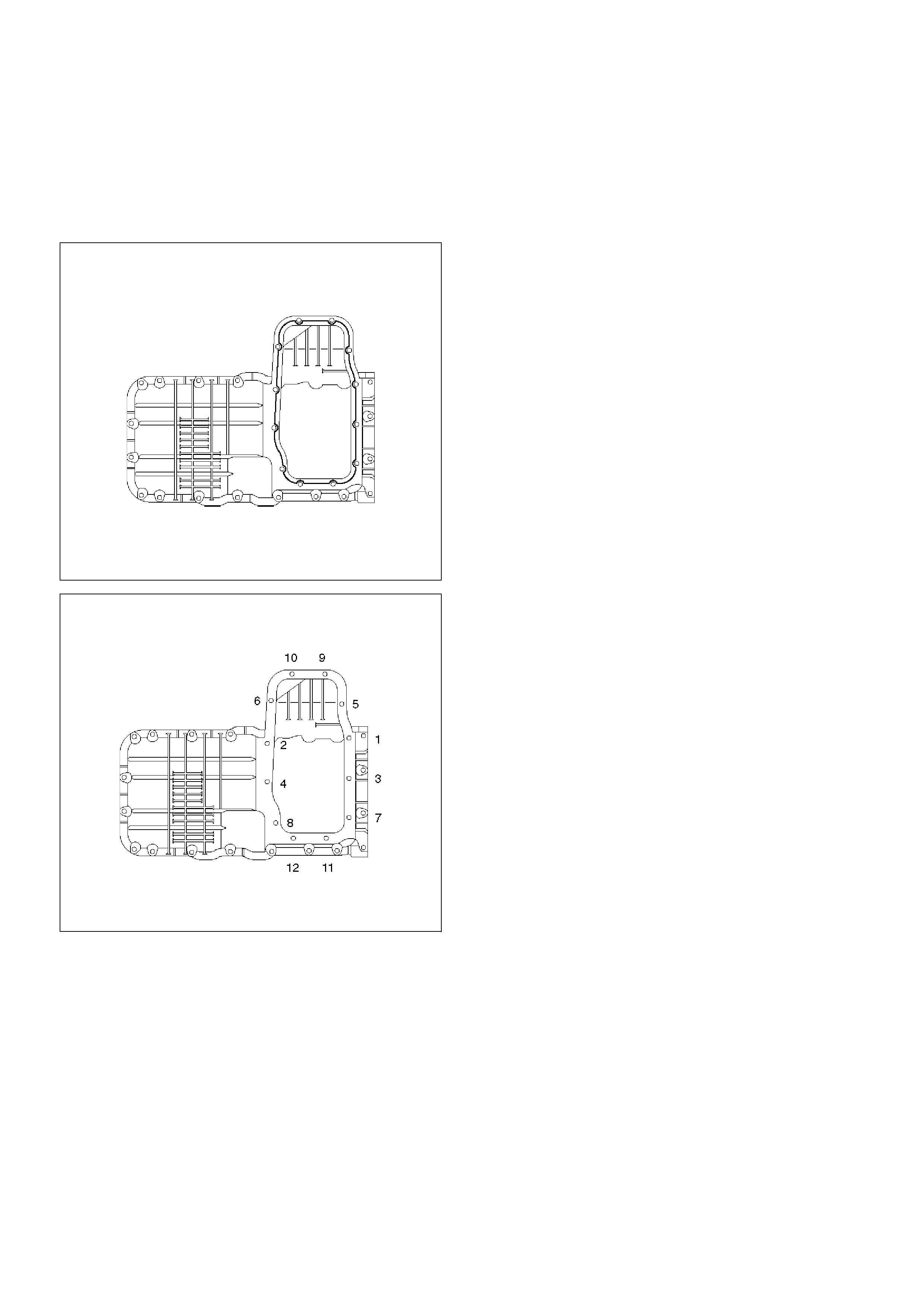

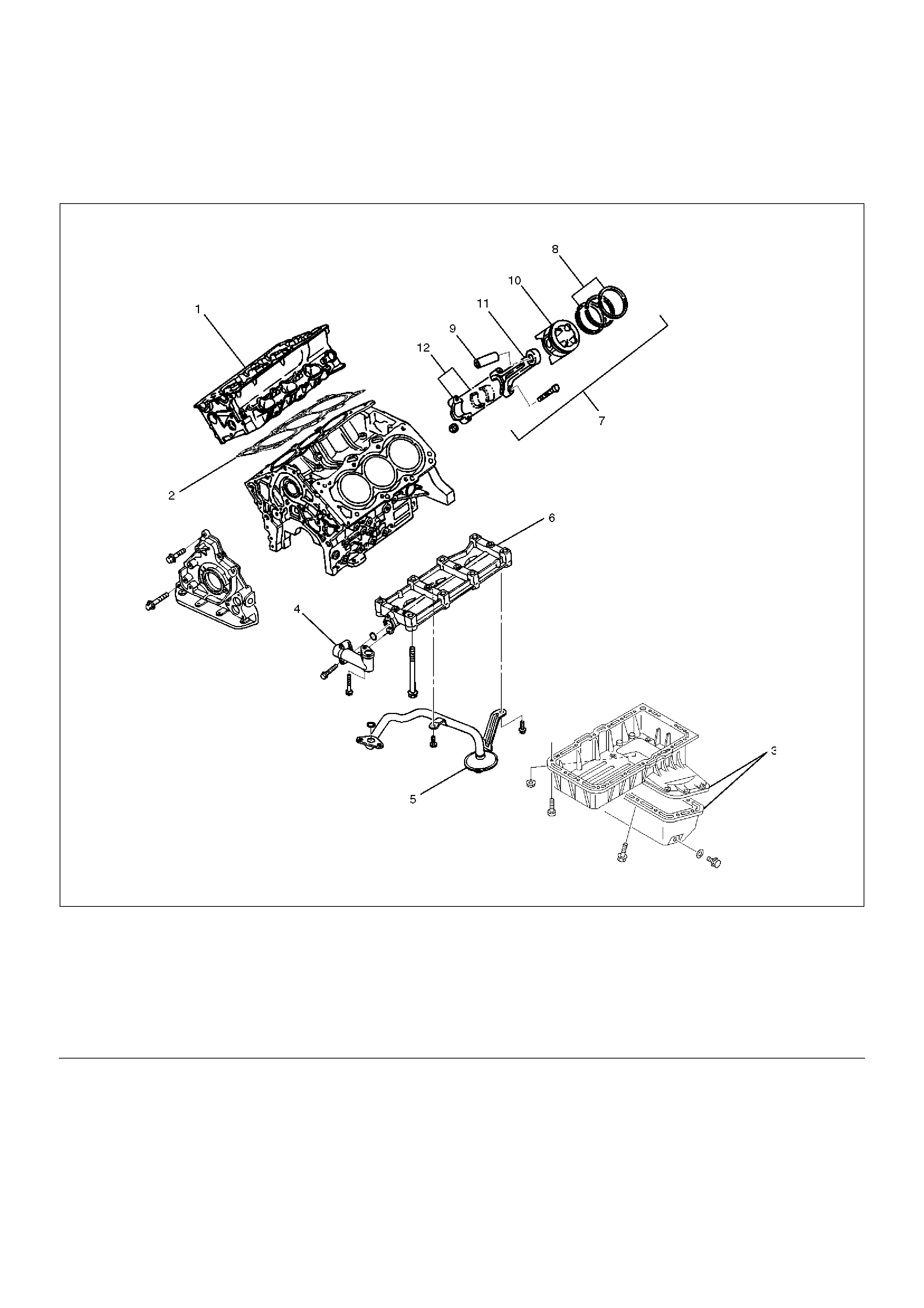

2. Remove crankcase with Oil Pan.

•Refer to removal procedure for Oil Pan and

Crankcase in this manual.

Legend

(1) Cylinder Head

(2) Crankcase with Oil Pan

(3) Oil Pipe

(4) Oil Strainer

(5) Oil Gallery

(6) Piston with Connecting Rod Assembly

3.Remove oil strainer fixing bolts, remove oil strainer

assembly with O-ring.

050RW002

EndOFCallout

4.Remove three fixing bolts, oil pipe with O-ring.

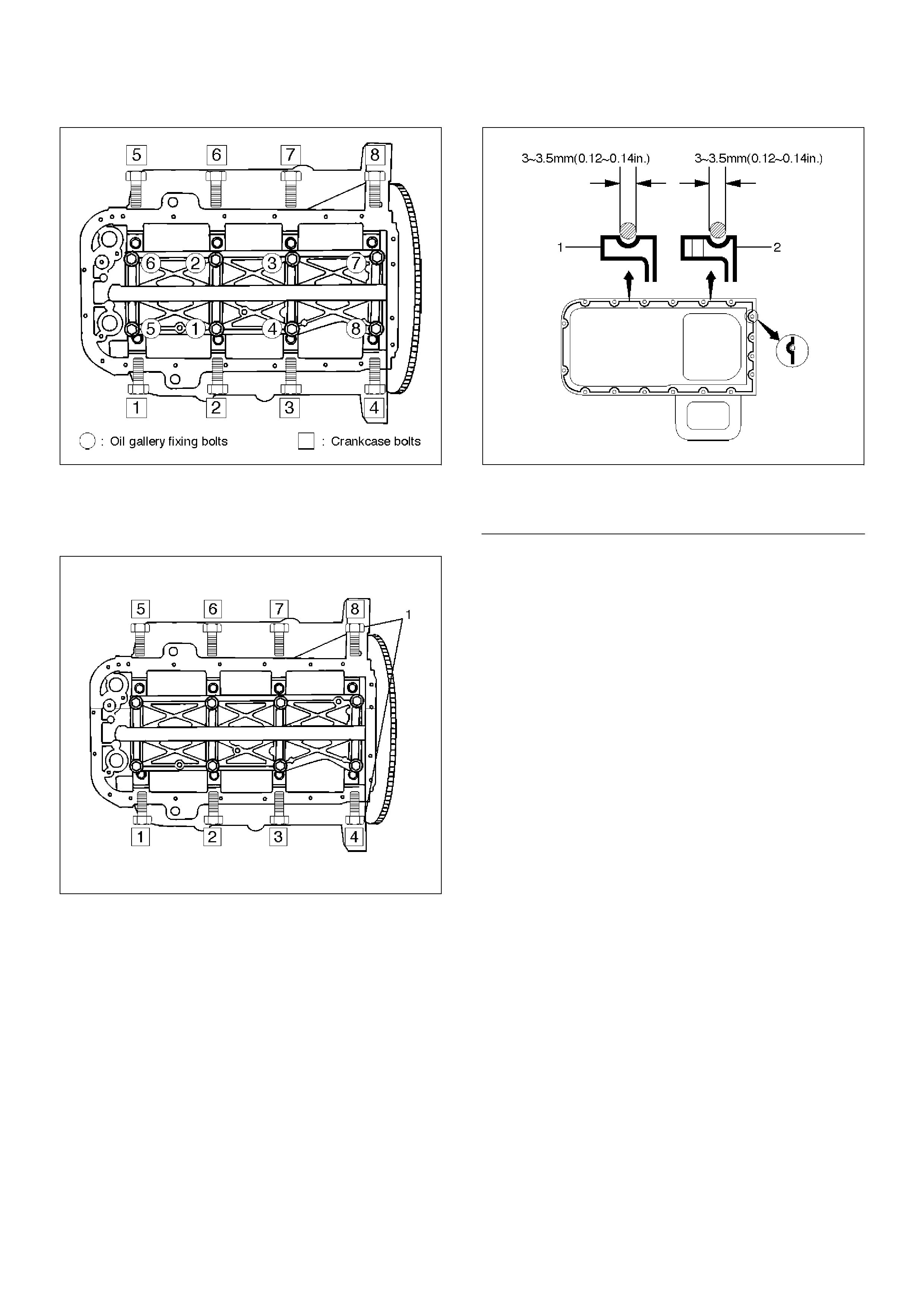

5.Remove eight fixing bolts, oil gallery.

6.Remove piston with connecting rod assembly,

before removing the bearing cap, remove carbon on

the top of cylinder bore and push piston with

connecting rod out from the top of cylinder bore.

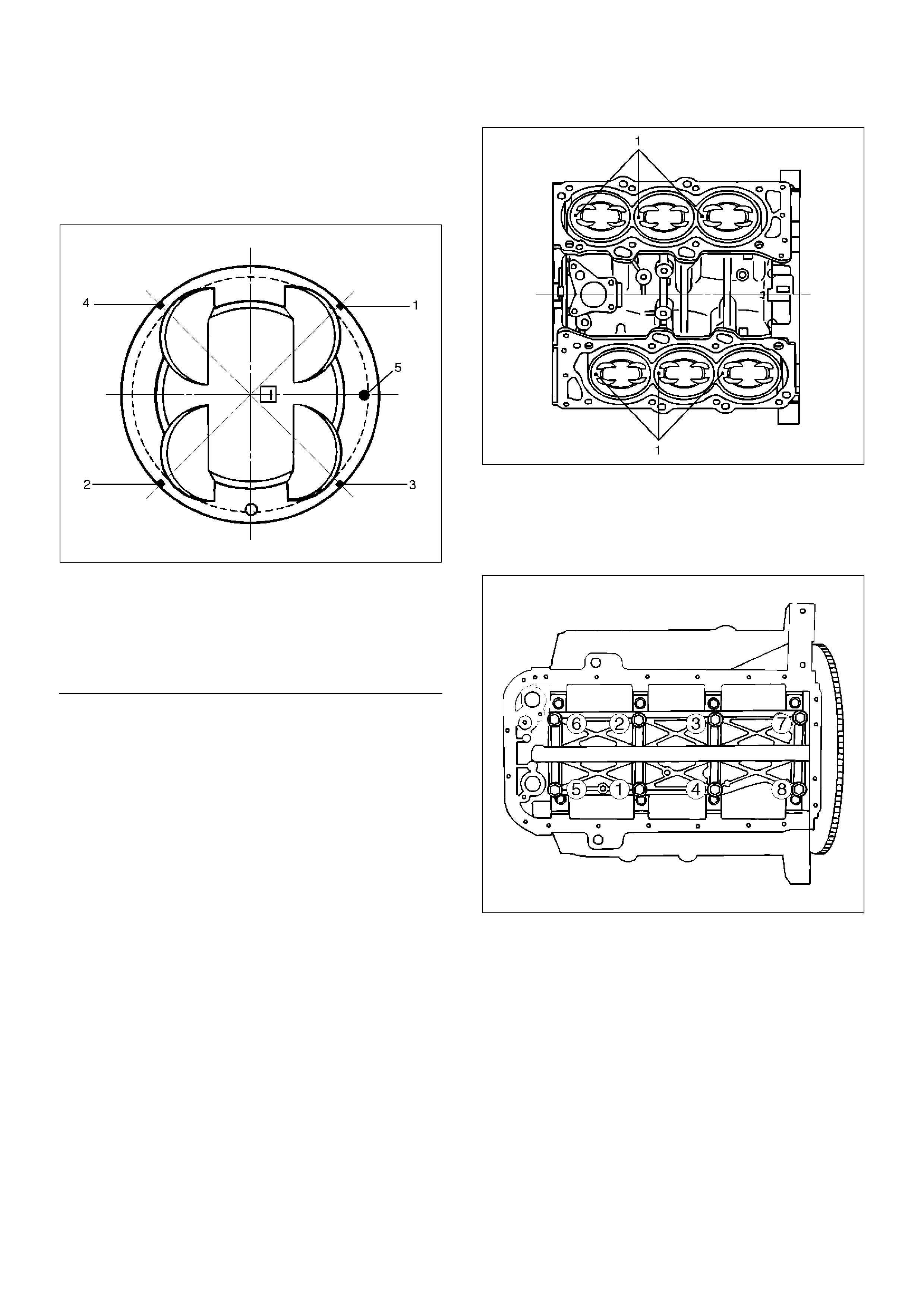

Installation