SECTION 6E1 - CHARGING SYSTEM

Service Precaution

Charging System

General Description

General On–Vehicle Inspection

Generator

Removal

Inspection

Installation

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Bench Test

Main Data and Specifications

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

Charging System

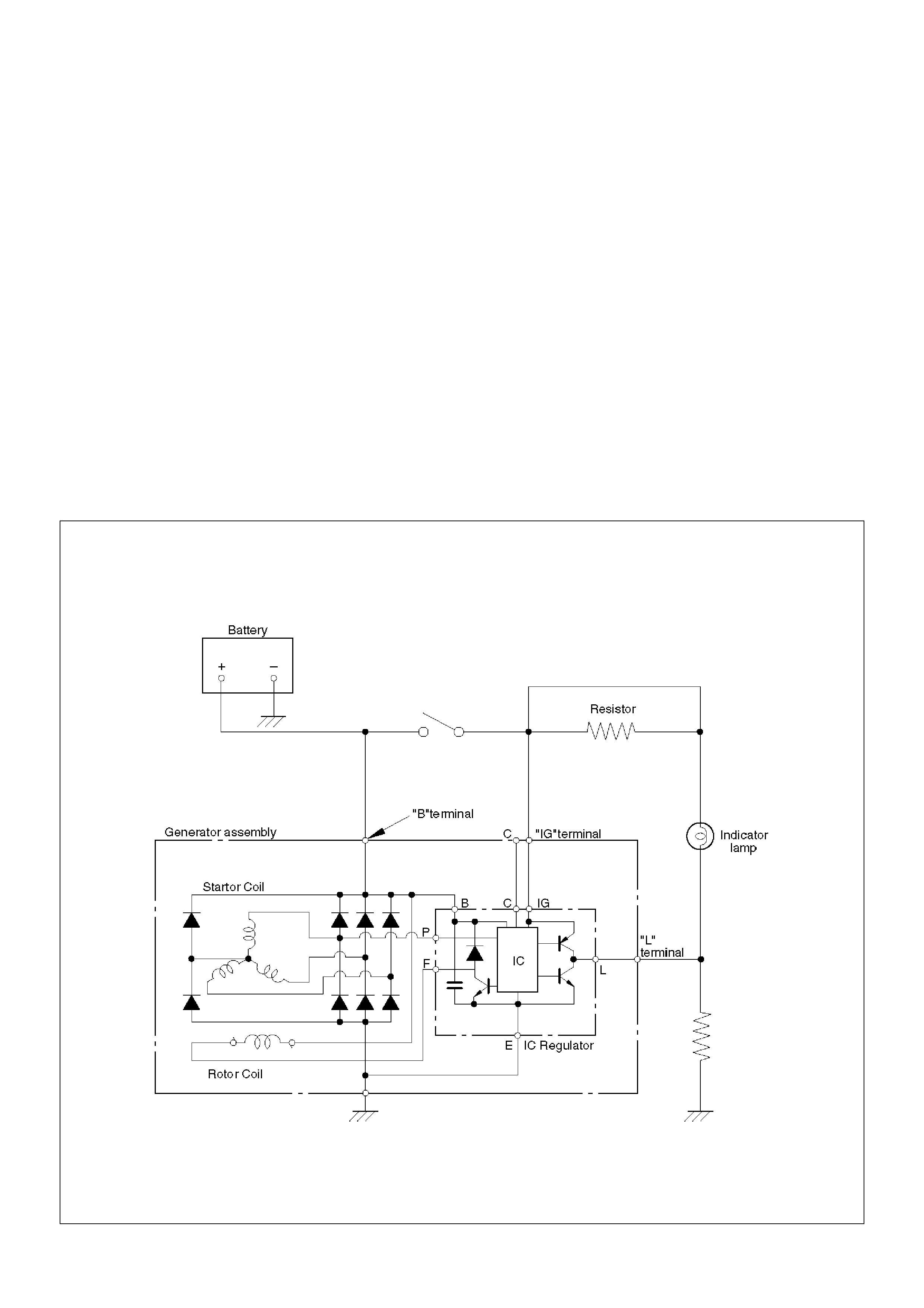

General Description

The IC integral regulator charging system and its main

components are connected as shown in the illustration.

The regulator is a solid state type and it is mounted

along with the brush holder assembly inside the

generator installed on the rear end cover.

The generator does not require particular maintenance

such as voltage adjustment.

The rectifier connected to the stator coil has eight

diodes to transform AC voltage into DC voltage.

This DC voltage is connected to the output terminal of

generator.

General On–Vehicle Inspection

The operating condition of charging system is indicated

by the charge warning lamp. The warning lamp comes

on when the starter switch is turned to “ON” position.

The charging system operates normally if the lamp goes

off when the engine starts.

If the warning lamp shows abnormality or if

undercharged or overcharged battery condition is

suspected, perform diagnosis by checking the charging

system as follows:

1. Check visually the belt and wiring connector.

2. With the engine stopped, turn the stator switch to

“ON” position and observe the warning lamp.

If lamp does not come on:

Disconnect wiring connector from generator, and

ground the terminal “L” on connector side.

If lamp comes on:

Repair or replace the generator.

F06RW009

Generator

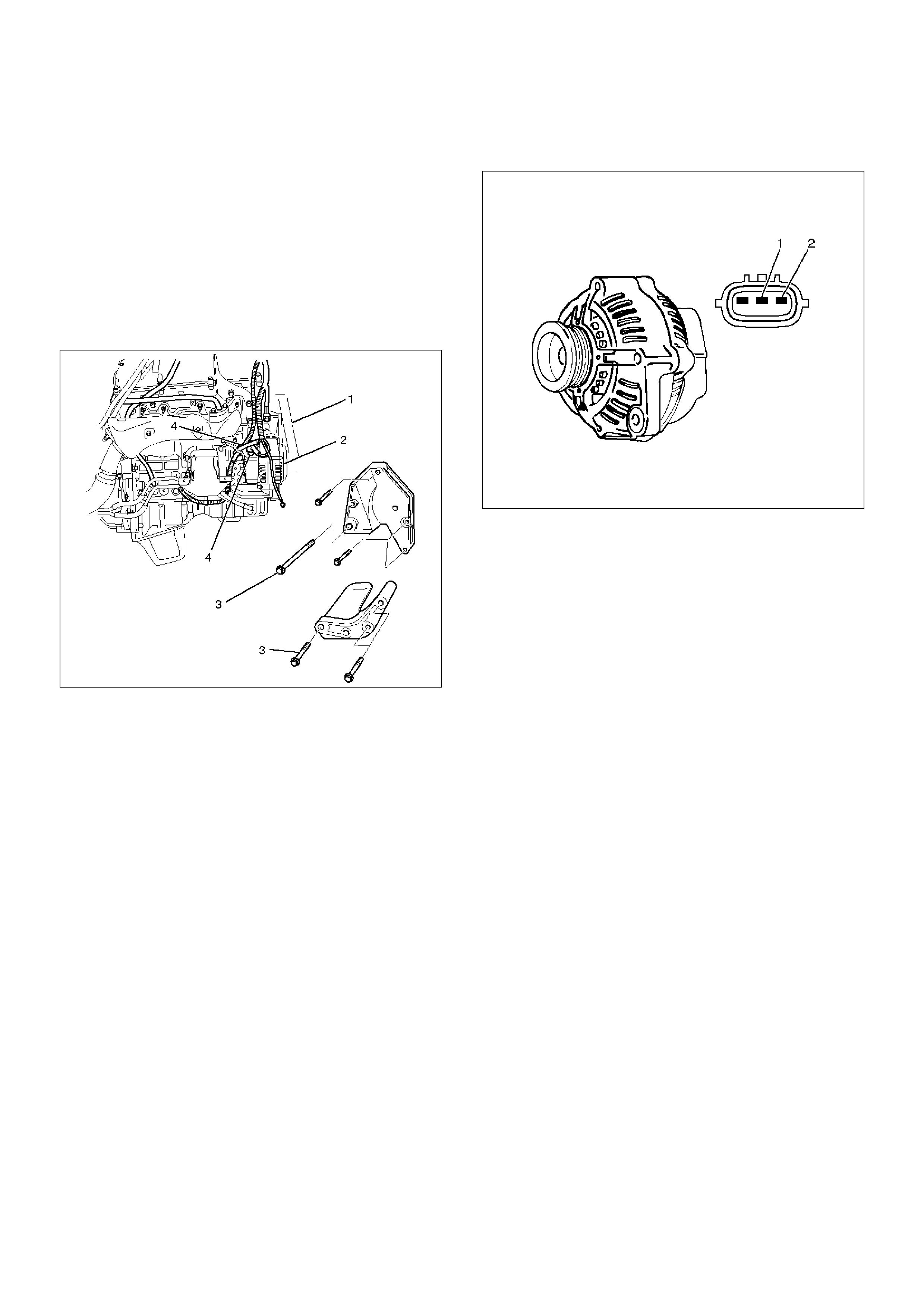

Removal

1. Disconnect battery ground cable.

2. Move drive belt tensioner to loose side using

wrench then remove drive belt (1).

3. Disconnect the wire from terminal “B” and

disconnect the connector (4).

4. Remove generator fixing bolt (3).

5. Remove generator assembly (2).

060RW002

Inspection

1. Disconnect the wiring connector from generator.

2. With the engine stopped, turn starter switch to “ON”

and connect a voltmeter between connector

terminal L (2) and ground or between terminal IG (1)

and ground.

066RW001

If voltage is not present, the line between battery

and connector is disconnected and so requires

repair.

3. Reconnect the wiring connector to the generator,

run the engine at middle speed, and turn off all

electrical devices other than engine.

4. Measure battery voltage. If it exceeds 16V, repair or

replace the generator.

5. Connect an ammeter to output terminal of

generator, and measure output current under load

by turning on the other electrical devices (eg., head

lights). At this time, the voltage must not be less

than 13V.

Installation

1. Install generator assembly to the position to be

installed.

2. Install generator assembly and tighten the fixing

bolts to the specified torque.

Torque:

M10 bolt: 41 N·m (4.2 Kg·m/30 lb ft)

M8 bolt: 21 N·m (2.1 Kg·m/15 lb ft)

3. Connect wiring harness connector and direct

terminal“B”.

4. Move drive belt tensioner to loose side using

wrench, then install drive belt to normal position.

5. Reconnect battery ground cable.

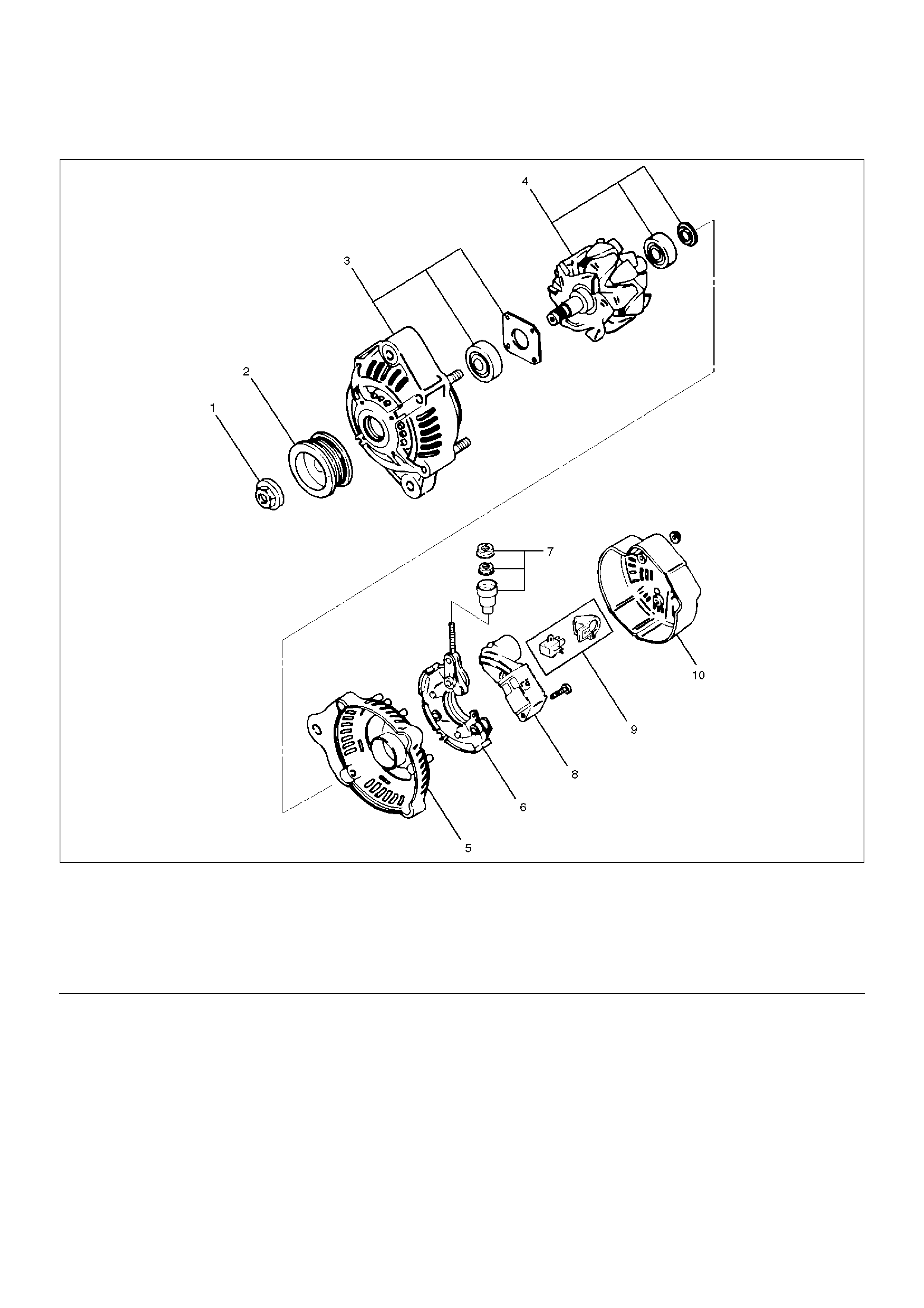

Disassembled View

066RW007

EndOFCallout

Legend

(1) Pulley Nut

(2) Pulley

(3) Front Cover Assembly

(4) Rotor Assembly

(5) Rear End Cover

(6) Rectifier

(7) Terminal Insulator and Nut

(8) Regulator Assembly

(9) Brush Holder Assembly

(10) Rear Cover

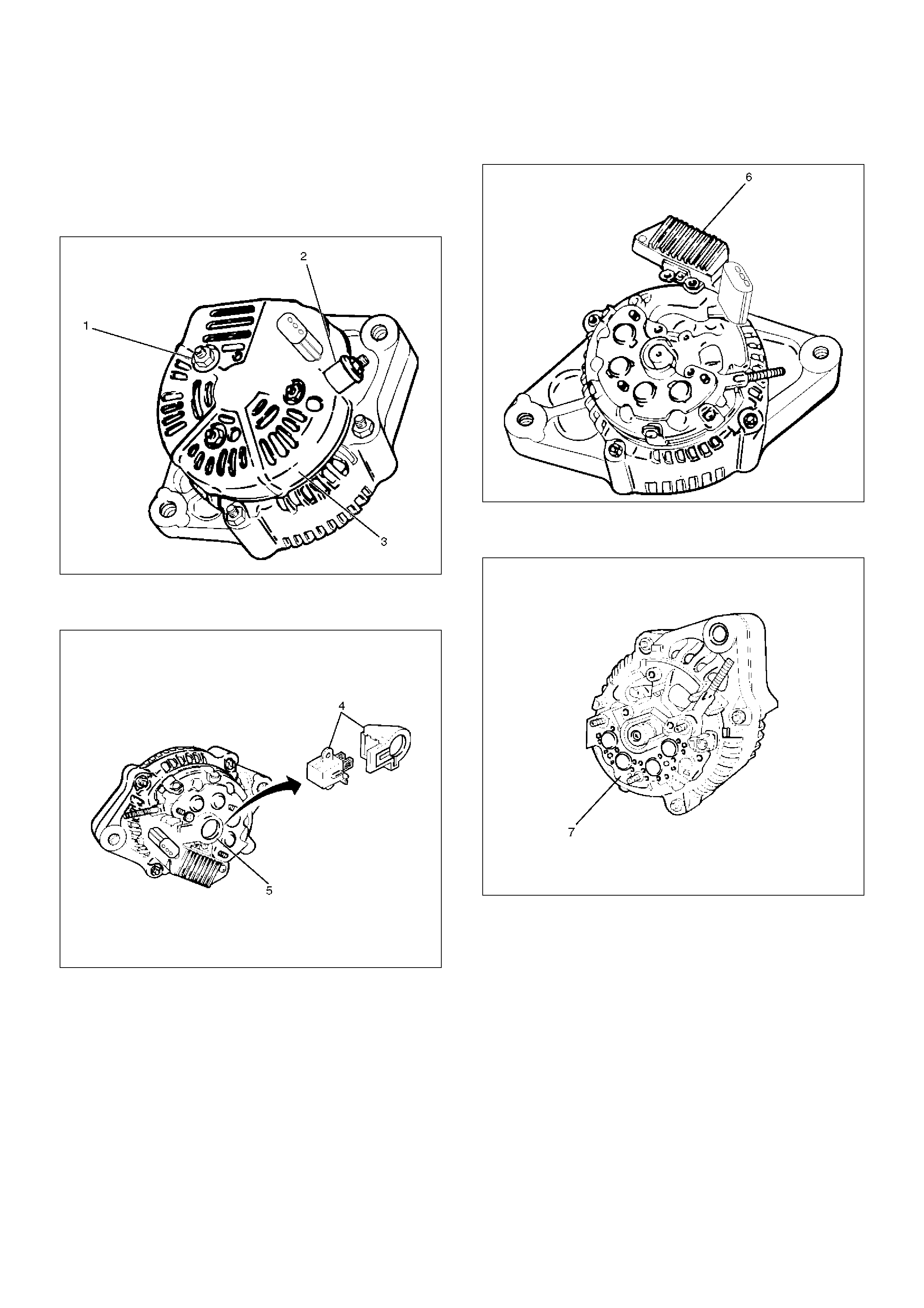

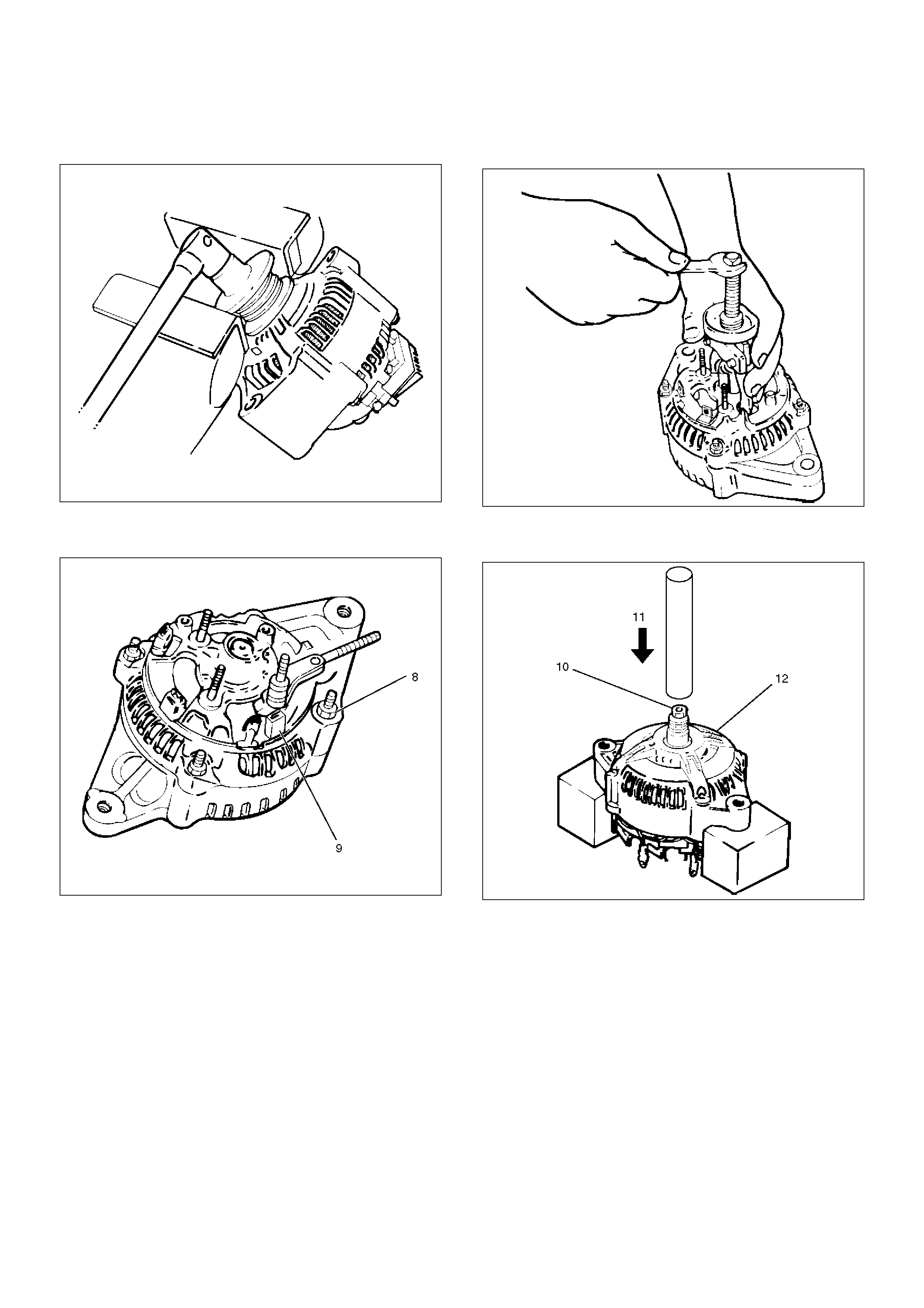

Disassembly

1. Terminal insulator and nut(2).

2. Remove three nuts(1) on the rear cover and a nut

on terminal B and insulator, then remove the rear

cover(3).

060RW005

3. Remove two screws that fix the brush holder(5) and

rectifier, then remove the brush holder assembly(4).

060RW004

4. Remove three screws on the IC regulator, then the

IC regulator assembly(6).

060RW003

5. Remove four screws that fix rectifier(7) and stator

lead wires.

066RW004

6. Secure the pulley directly in the vise between two

copper plates, and remove the nut and pulley.

066RS010

7. Remove four nuts(8) that secure the front cover

assembly and rear end cover, and an insulator(9).

066RW005

8. Use the puller to remove the rear end cover.

9. Rotor assembly

066RS012

10. Pull the rotor assembly(10) off the front cover

assembly(12) using a bench press(11).

066RW006

Inspection and Repair

Repair or replace necessary parts if extreme wear or

damage is found during inspection.

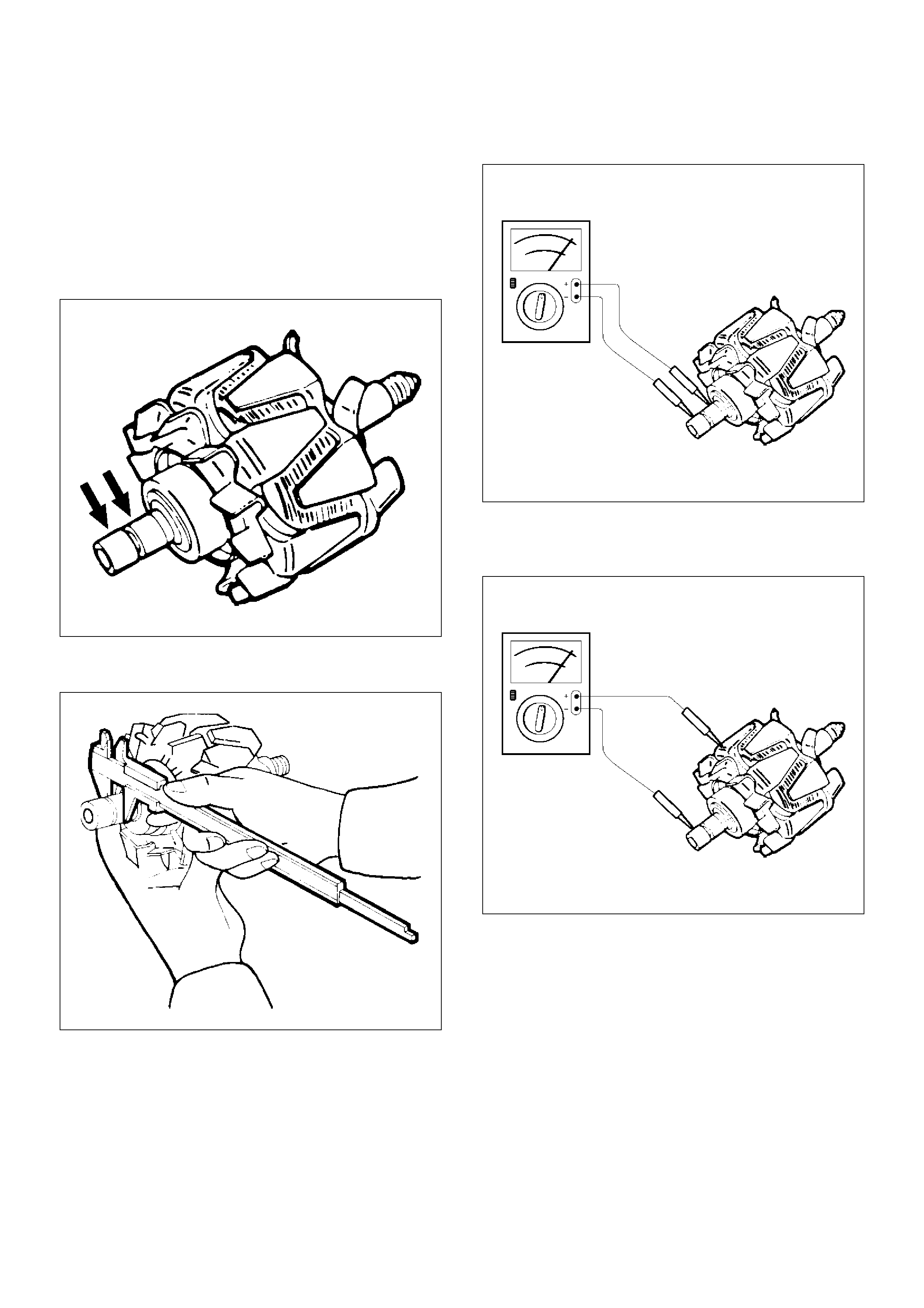

Rotor Assembly

1. Check the rotor slip ring surfaces for contamination

and roughness. If rough, polish with #500—600

sandpaper.

066RS014

2. Measure the slip ring diameter, and replace if it

exceeds the limit.

066RS015

3. Check resistance between slip rings, and replace if

there is no continuity.

066RS016

4. Check for continuity between slip ring and rotor

core.

In case of continuity, replace the rotor assembly.

066RS017

Stator Coil

1. Measure resistance between respective phases.

2. Measure insulation resistance between stator coil

and core with a mega–ohmmeter.

If less than standard, replace the coil.

066RS018

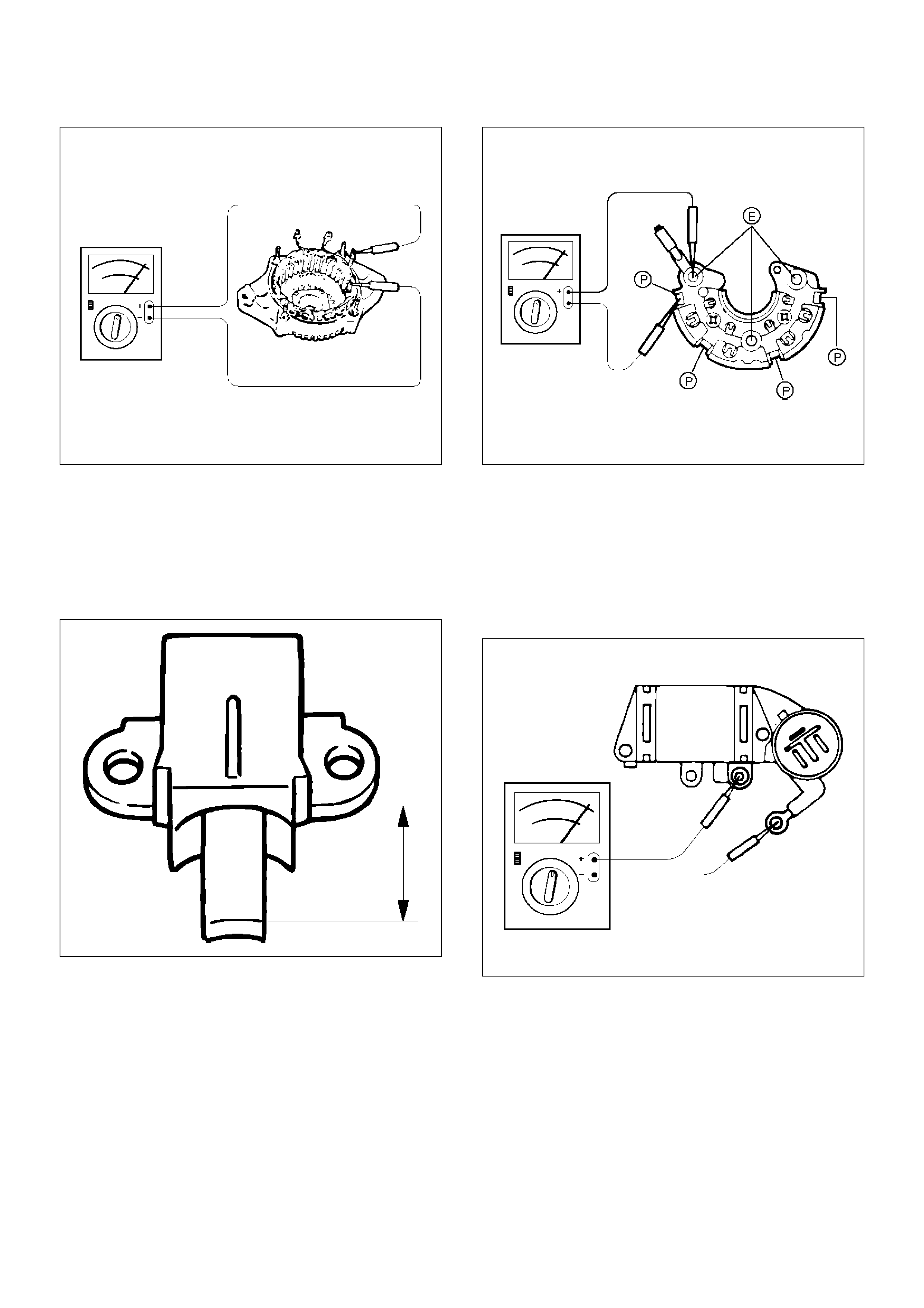

Brush

Measure the brush length.

If more than limit, replace the brush.

Standard: 10.mm (0.4134 in)

Limit: 8.4.mm (0.3307 in)

066RS019

Rectifier Assembly

Check for continuity across “P” and “E” in the ´ 100W

range of multimeter.

066RW002

Change polarity, and make sure that there is continuity

in one direction, and not in the reverse direction. In

case of continuity in both directions, replace the rectifier

assembly.

IC Regulator Assembly

Check for continuity across “B” and “F” in the ´ 100W

range of multimeter.

066RS021

Change polarity, and make sure that there is continuity

in one direction, and not in the reverse direction. In

case of continuity in both directions, replace the IC

regulator assembly.

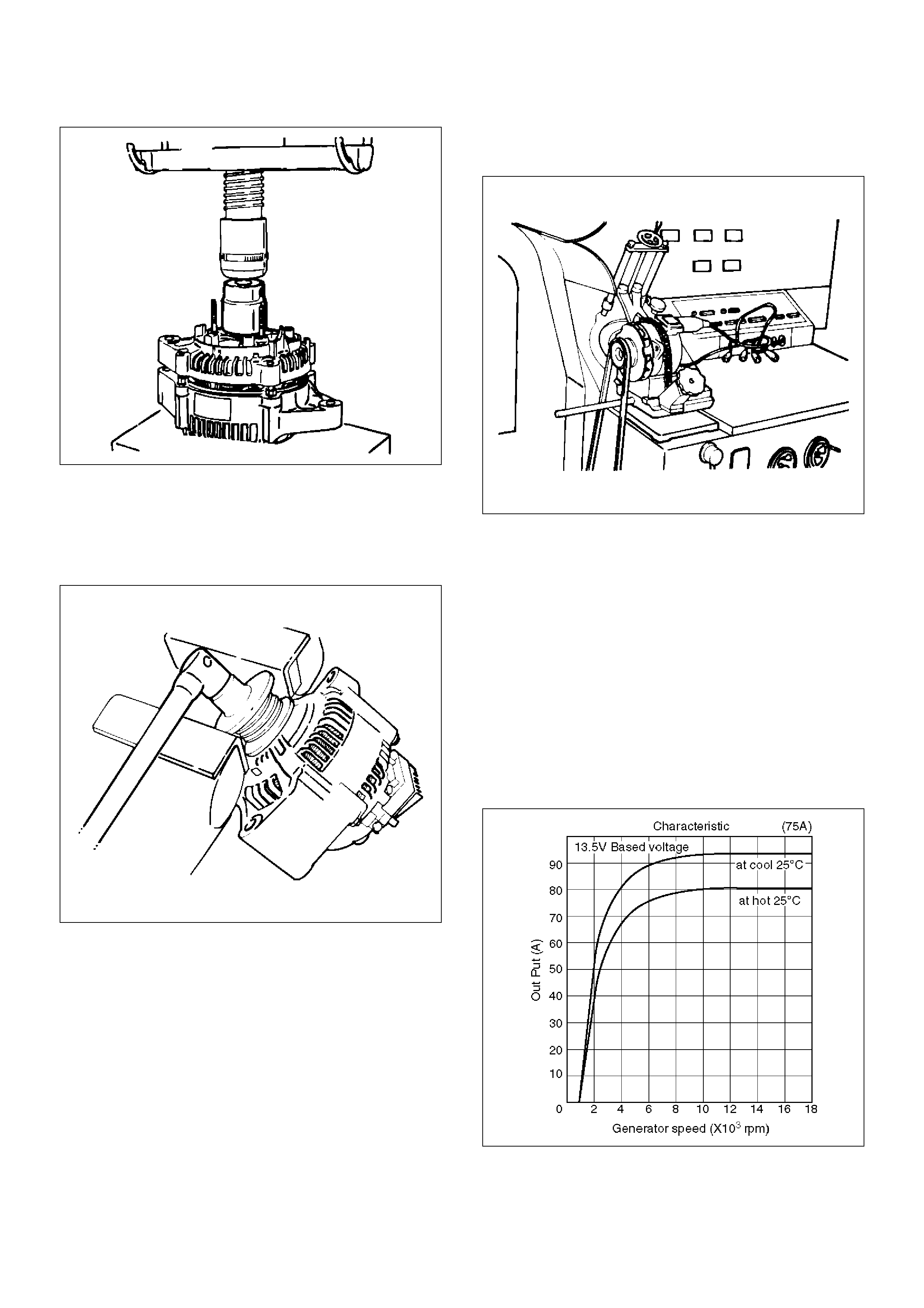

Reassembly

To reassemble, follow the disassembly steps in the

reverse order, noting the following points:

1. Using a press with a socket wrench attached,

reassemble rotor and rear end cover assembly in

the front cover.

066RS022

2. Install pulley on the rotor.

Secure the pulley directly in the vise between two

copper plates, and tighten nut to the specified

torque.

Torque: 111 N·m (11.3 Kg·m/82 lb ft)

066RS010

Bench Test

Conduct a bench test of the generator.

066RS023

Preparation

Remove generator from the vehicle (see“Generator

removal”).

1. Secure generator to the bench test equipment and

connect wires.

Terminal “IG” for energization

Terminal “L” for neutral (warning lamp)

Terminal “B” for output

2. Conduct the generator characteristic test.

Characteristics of generator are shown in

illustration.

Repair or replace the generator if its outputs are

abnormal.

B06RW001

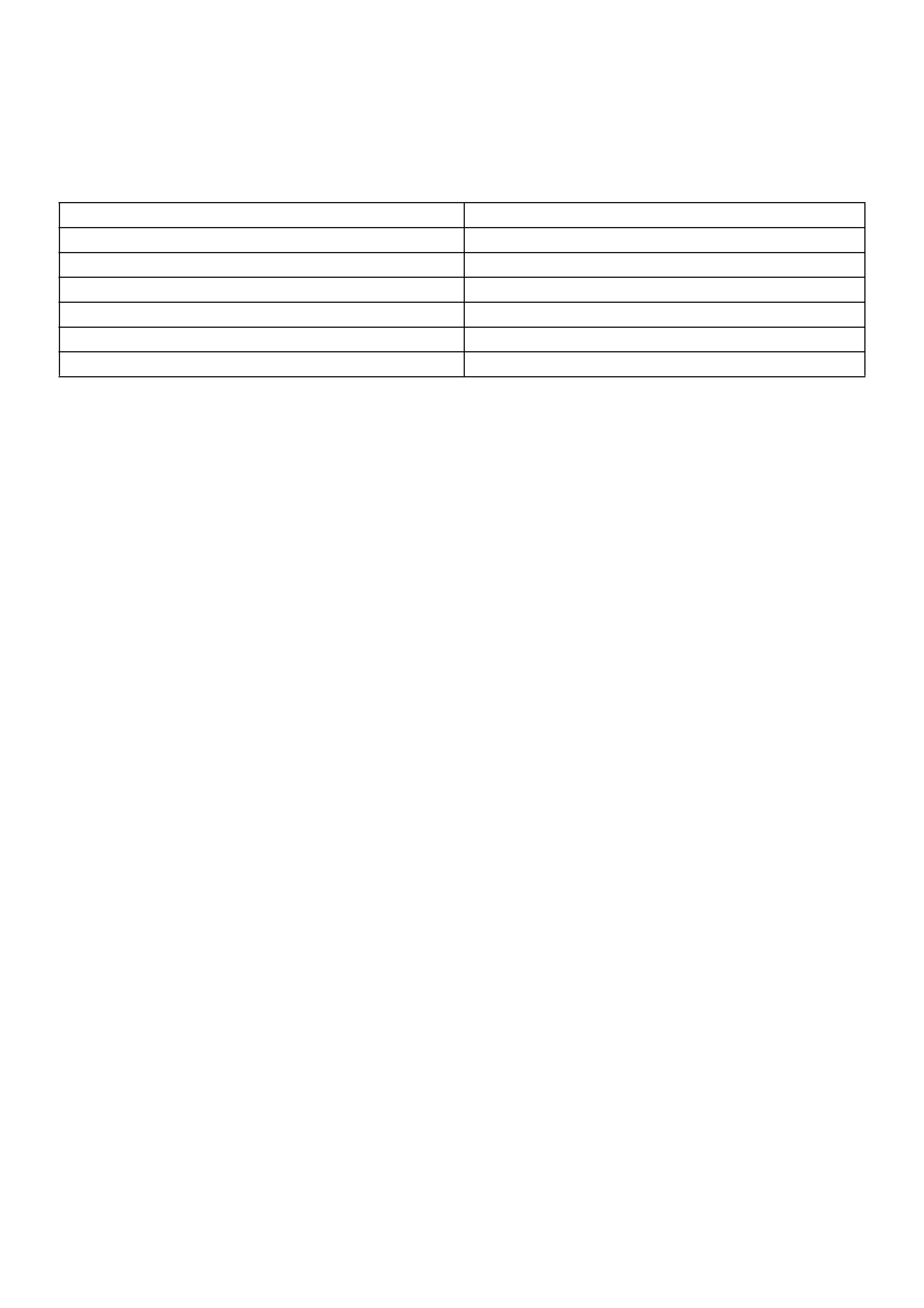

Main Data and Specifications

General Specifications

Parts Number (Nippon denso) 102211—5030

Model ACHD04

Rated voltage 12 V

Rated output 75 A

Rotating direction (As viewed from pulled) Clockwise

Pulley effective diameter 50 mm (1.97 in)

Weight 44 N (33 lb)