SECTION 7A3 - CLUTCH (4JX1 ENIGNE)

Service Precaution

General Description

Diagnosis

Clutch Assembly

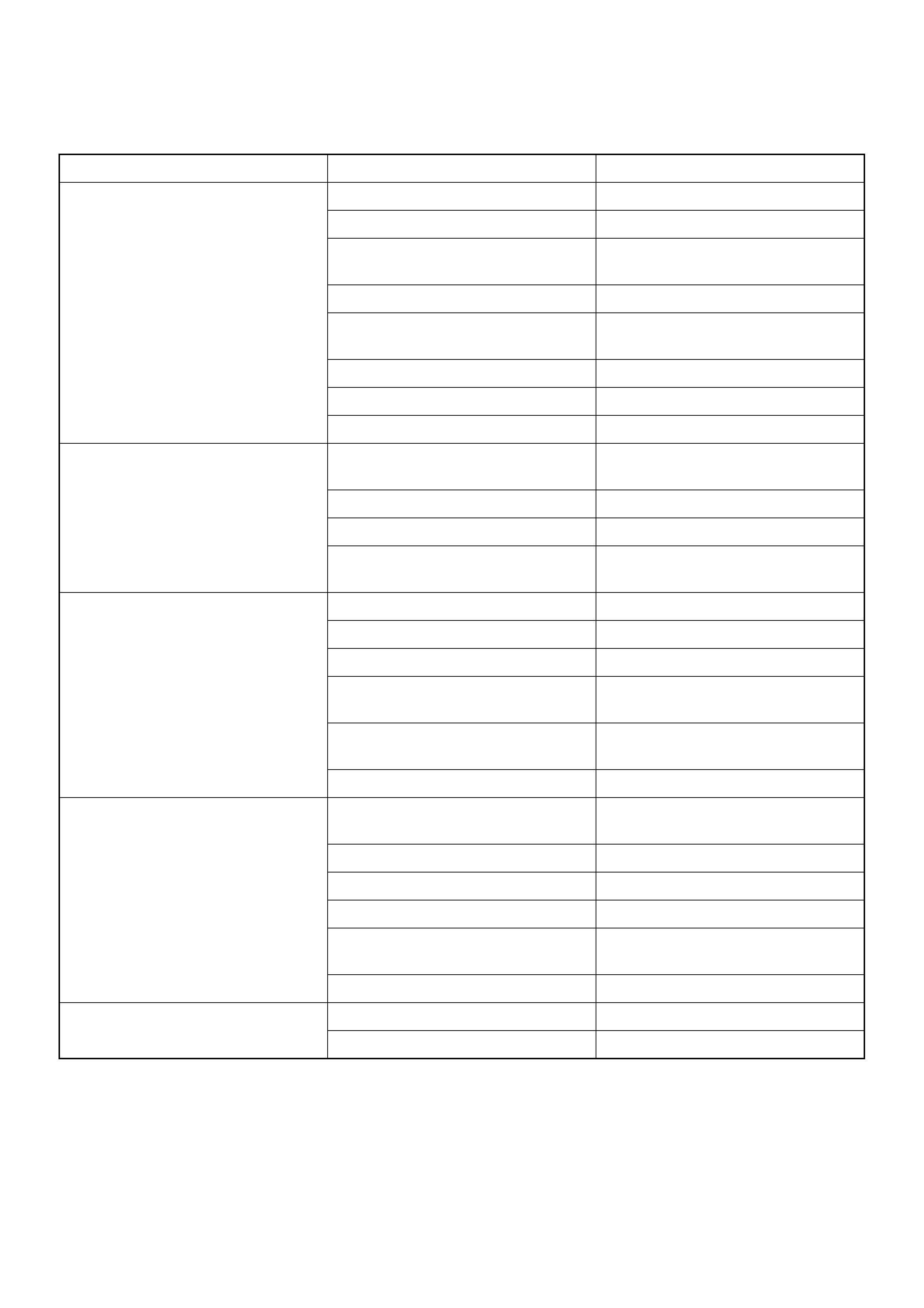

Clutch Assembly and Associated Parts

Removal

Inspection and Repair

Installation

Clutch Control

Clutch Control Parts

Removal

Inspection and Repair

Installation

Adjustment

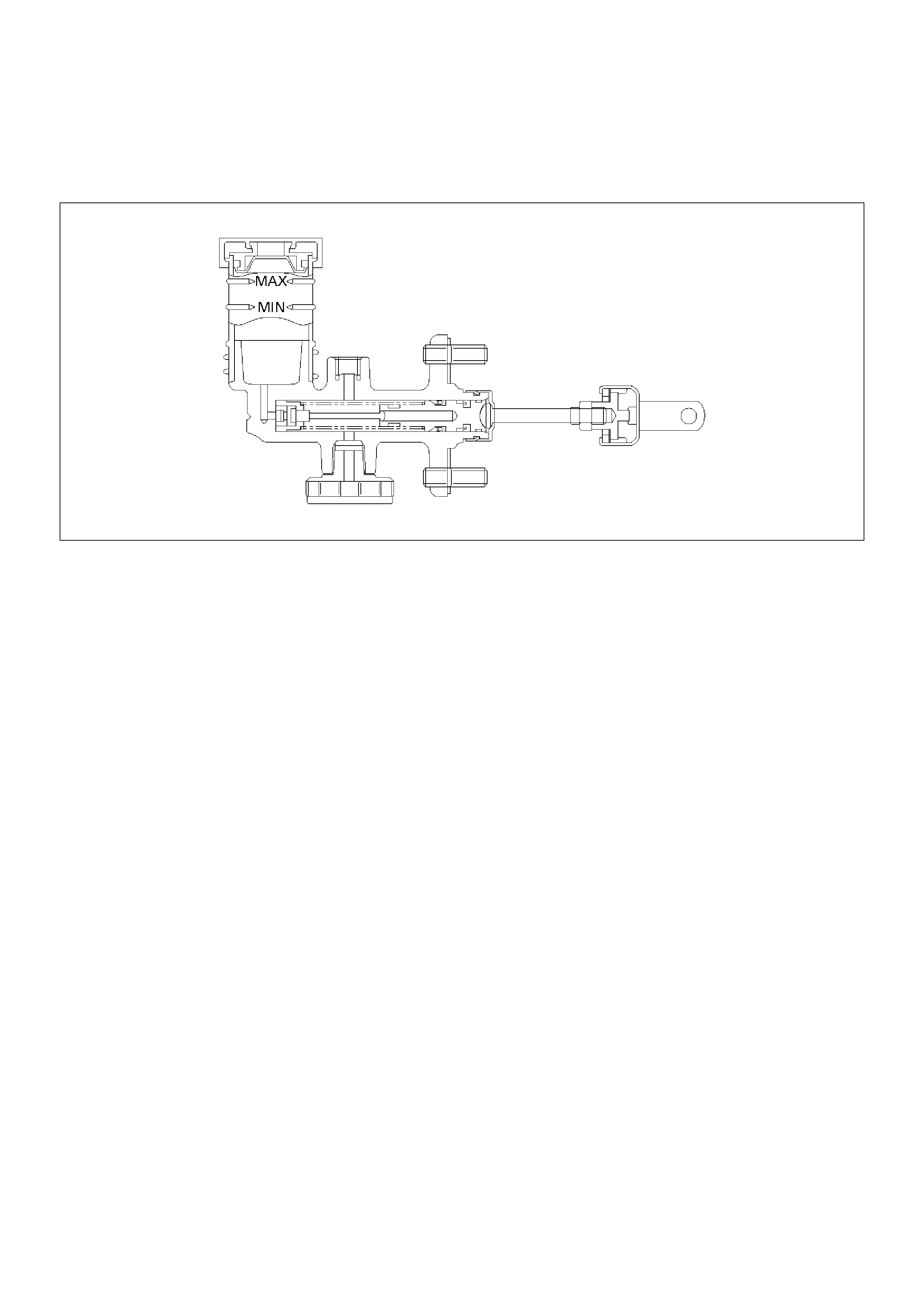

Master Cylinder

Disassembled View

Disassembly

Inspection and Repair

Reassembly

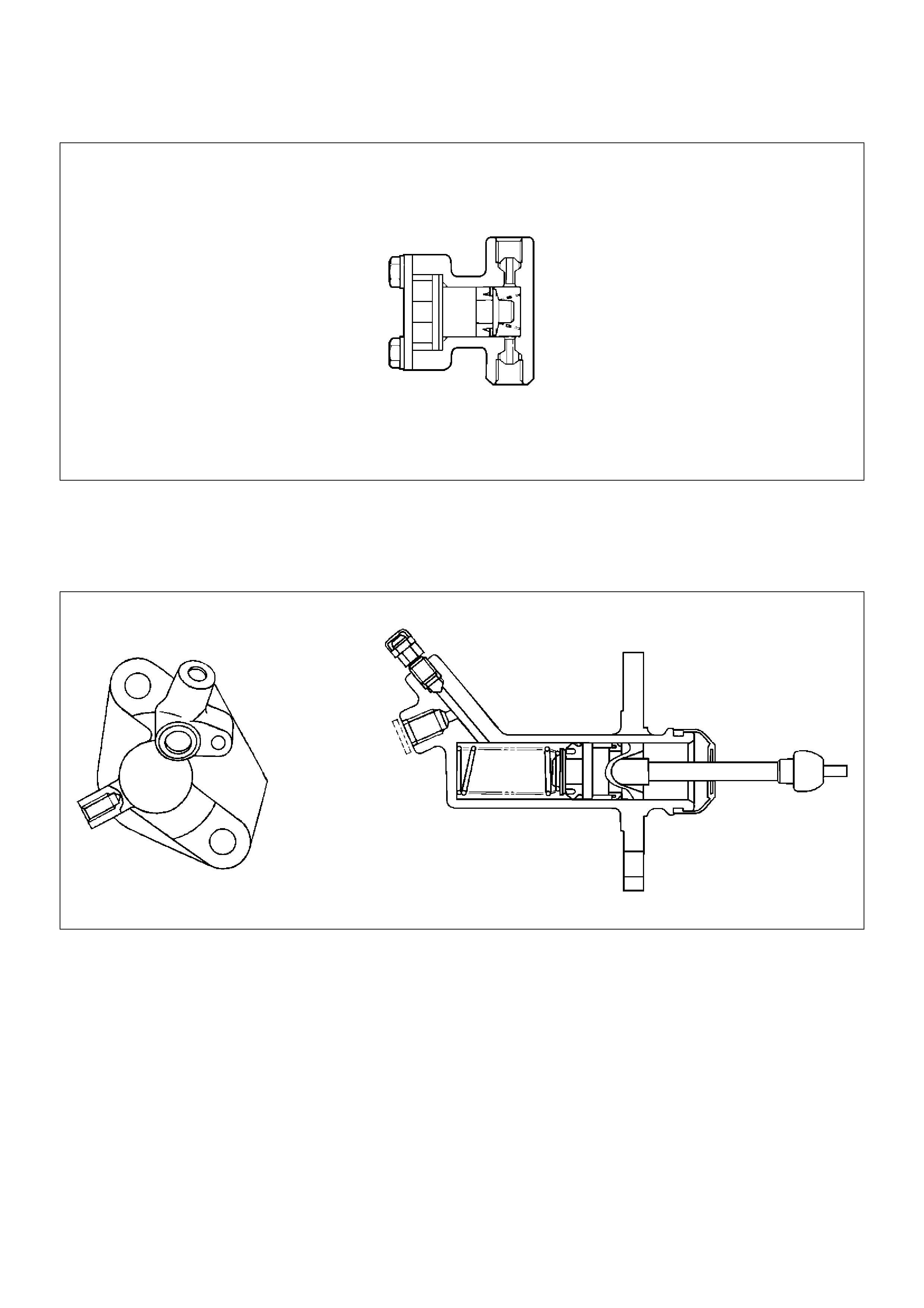

Slave Cylinder

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Damper Cylinder

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

General Specifications

Torque Specifications

Special Tools

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFOMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED ,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

General Description

Clutch

A07RW046

For 4JX1 (3.0L) engine models, the pull-type clutch is

employed. The pull-type clutch is disengaged by

pulling the release lever (release bearing) to disengage

the pressure plate.

Master Cylinder

A07RW066

4JX1

A07RW067

Damper Cylinder

A07RS004

In order to improve the operation of the clutch hydraulic system, a damper cylinder is used in the hydraulic line

between the master cylinder and the slave cylinder.

Slave Cylinder

A07RS005

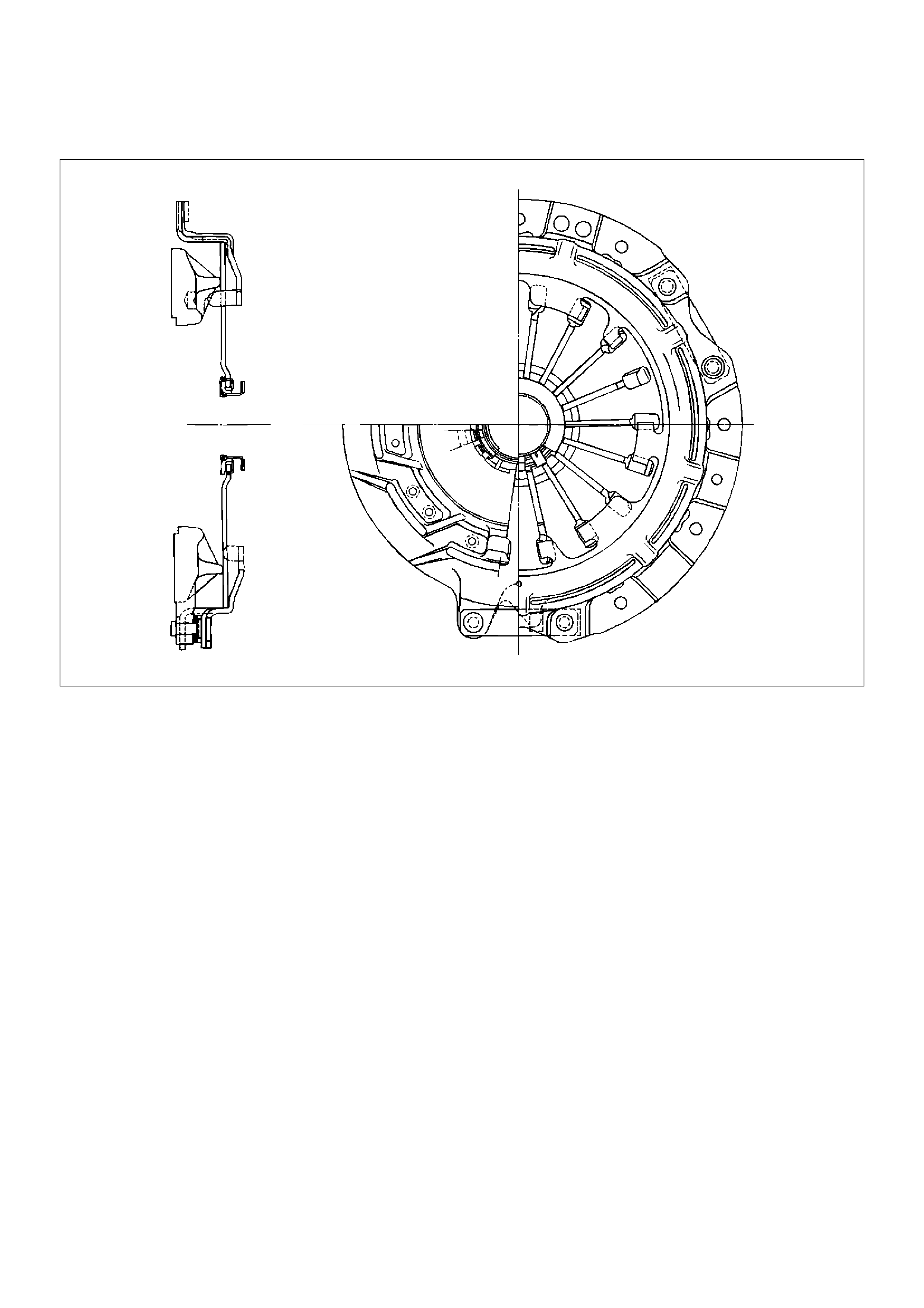

Pressure Plate Assembly

A07RS006

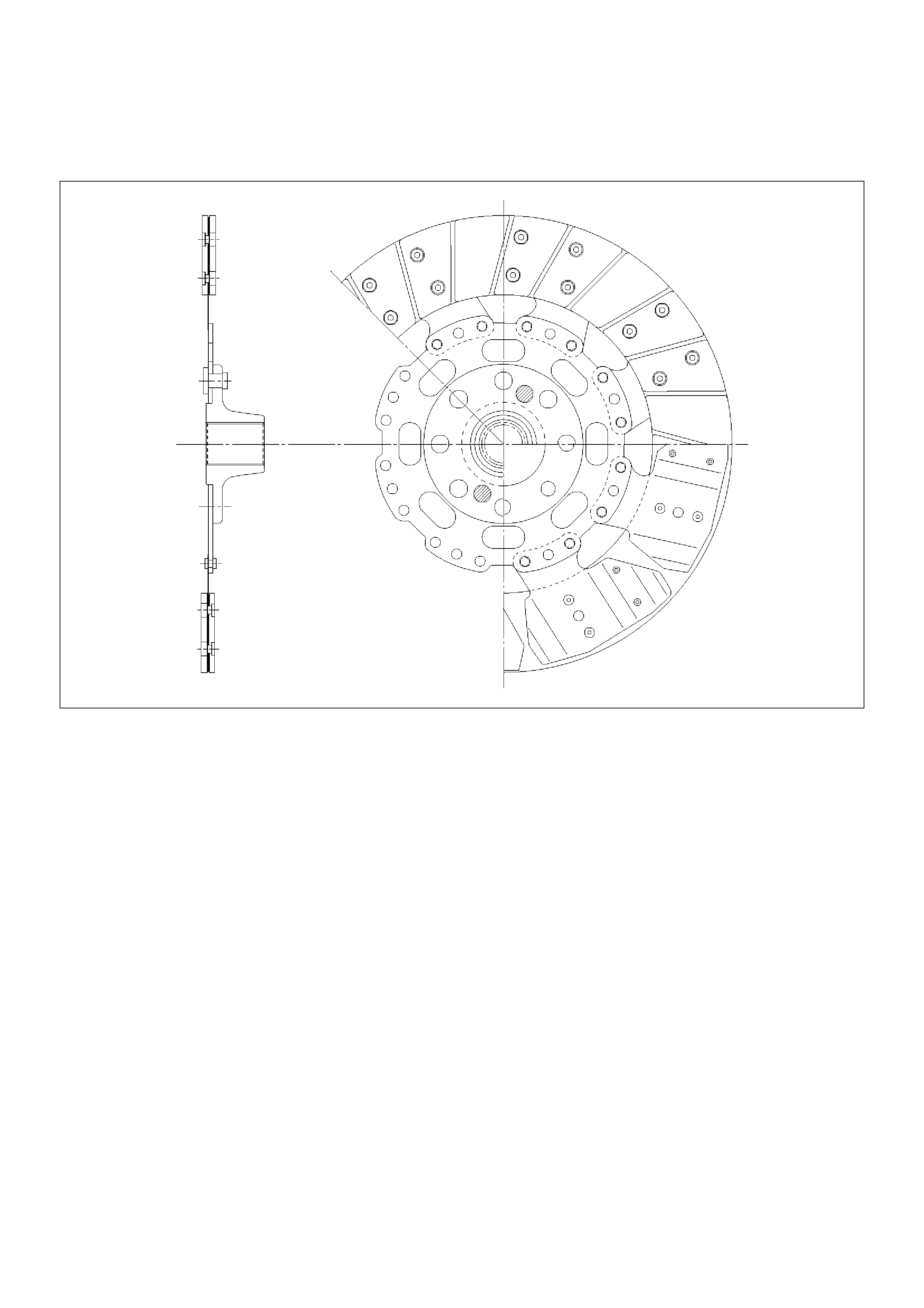

Driven Plate Assembly

A07RS007

4JX1

A07RW045

Diagnosis

Condition Possible Cause Correction

Dragging Fluid leakage. Repair

Air in hydraulic line. Bleed

Master cylinder and slave cylinder

seals worn.

Replace master cylinder.

Replace slave cylinder seals.

Driven plate warped. Replace driven plate.

Diaphragm spring weakened or tip of

fingers worn.

Replace pressure plate

Driven plate sticking on splines. Lubricate with grease or replace.

Clutch spline worn. Repair

Release bearing worn or damaged. Replace release bearing.

Slipping Driven plate facing worn or oil–

soaked.

Replace driven plate and check for

leaks.

Diaphragm spring weakened. Replace pressure plate.

Pressure plate or flywheel warped. Correct or replace.

Master cylinder and slave cylinder

seals worn.

Replace master cylinder.

Replace slave cylinder seals.

Chattering Engine mounts loose or damaged. Tighten or replace.

Driven plate facing warped. Replace driven plate.

Surface of facing hardened. Replace driven plate

Driven plate facing oil soaked. Replace driven plate and check for

leaks.

Damper springs weakened or

broken.

Replace.

Pressure plate or flywheel warped. Correct or replace.

Noisy Replace bearing binding. Correct, or replace if damaged, and

lubricate.

Replace bearing worn or damaged. Replace release bearing.

Release bearing poorly lubricated. Lubricate.

Pilot bearing worn. Replace pilot bearing.

Damper springs weakened or

broken.

Replace driven plate.

Rivets of driven plate exposed. Replace driven plate.

Replace driven plate. Hydraulic line blocked. Clean out or replace.

Master or slave cylinders binding. Repair or replace as needed.

Clutch Assembly

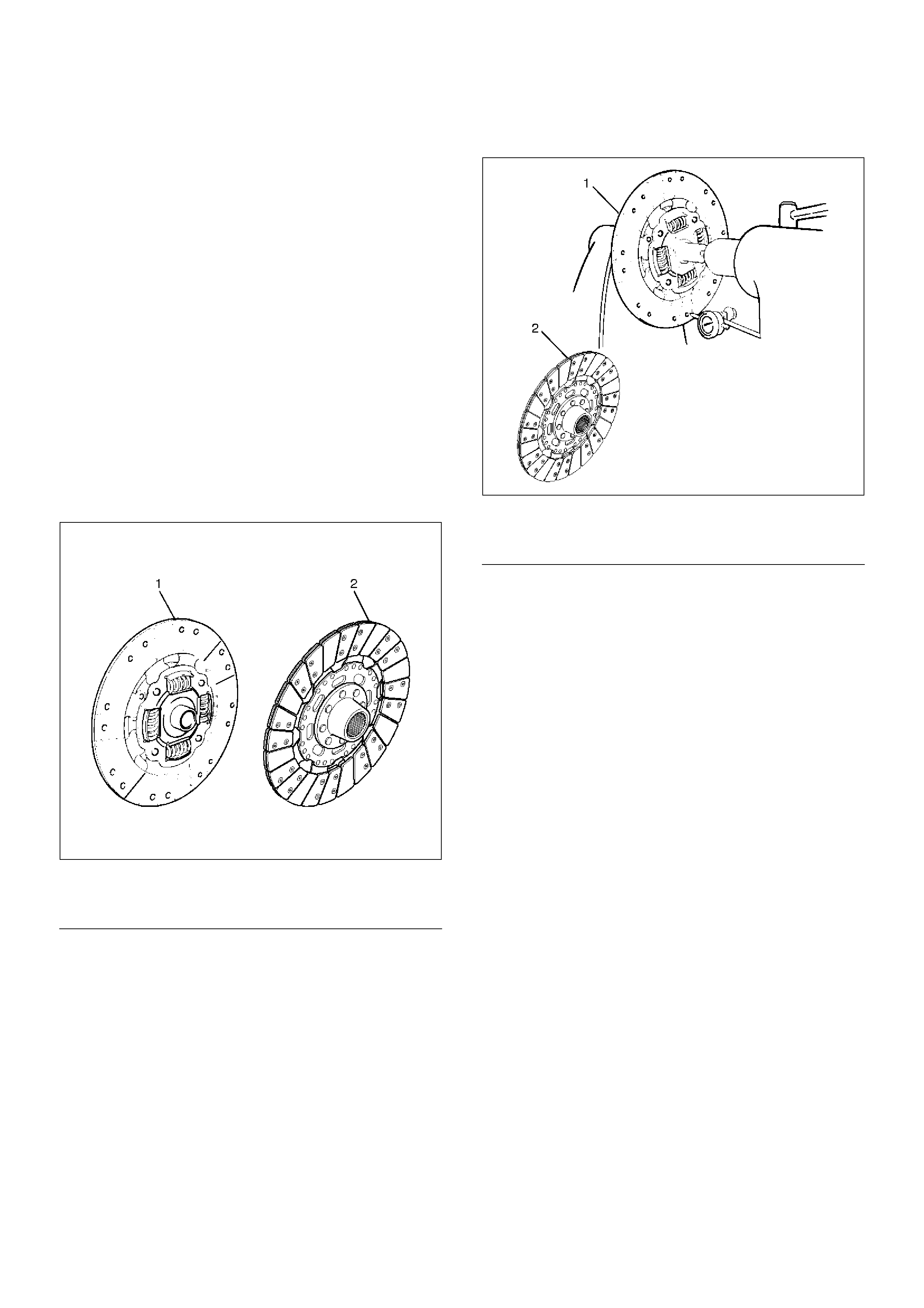

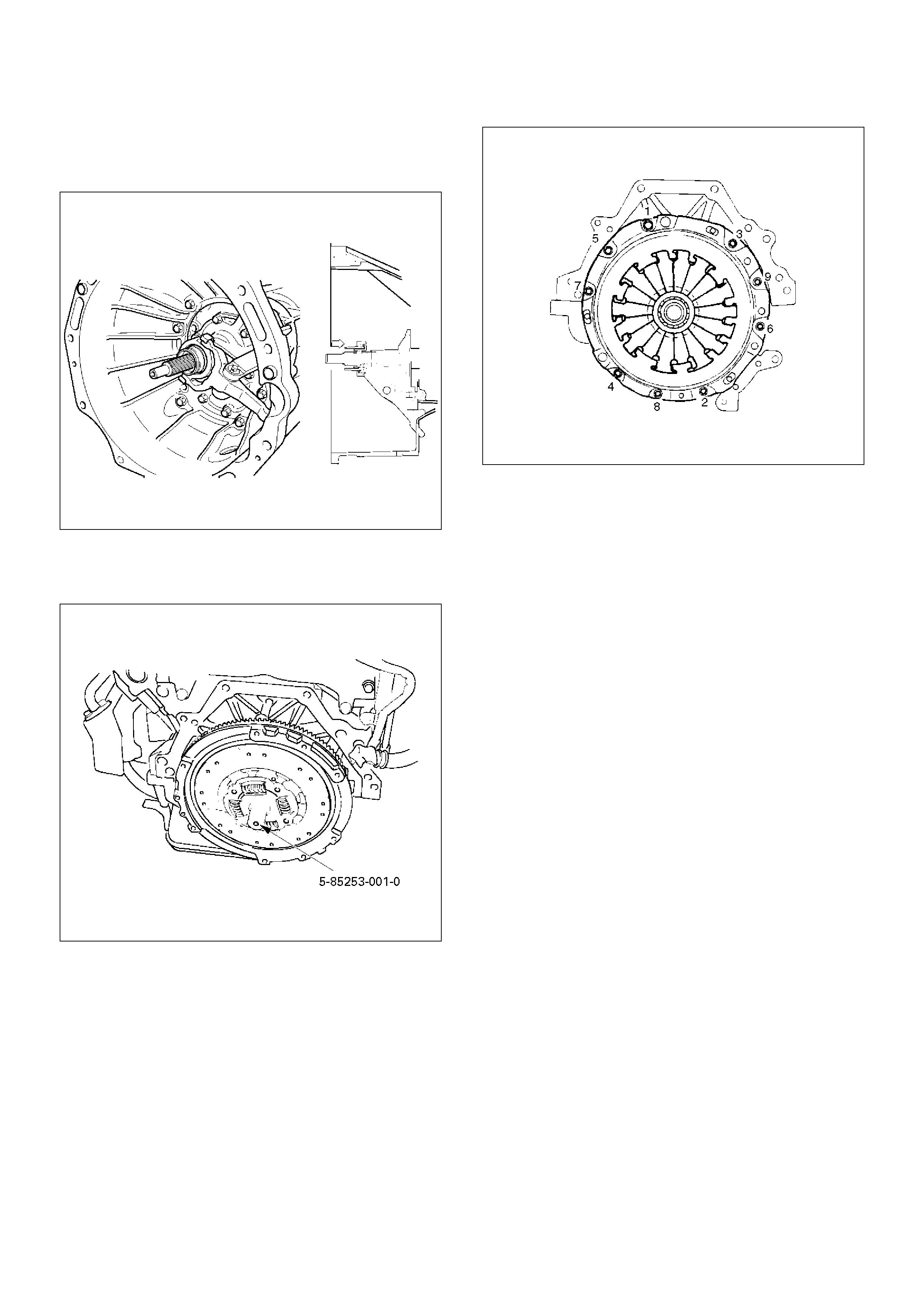

Clutch Assembly and Associated Parts

201RW029

EndOFCallout

Removal

1.Remove transmission assembly, refer to "MANUAL

TRANSMISSION" of Section 7B for "Removal AND

INSTALLATION" procedure.

2. Mark the flywheel, clutch cover and pressure plate

lug for alignment when installing.

3. Remove pressure plate assembly (3).

Legend

(1) Flywheel Assembly and Crankshaft Bearing

(2) Driven Plate Assembly (6VE1)

(3) Driven Plate Assembly (4JX1)

(4) Pressure Plate Assembly

(5) Transmission Assembly

(6) Front Cover

(7) Shift Fork

(8) Release Bearing

Techline

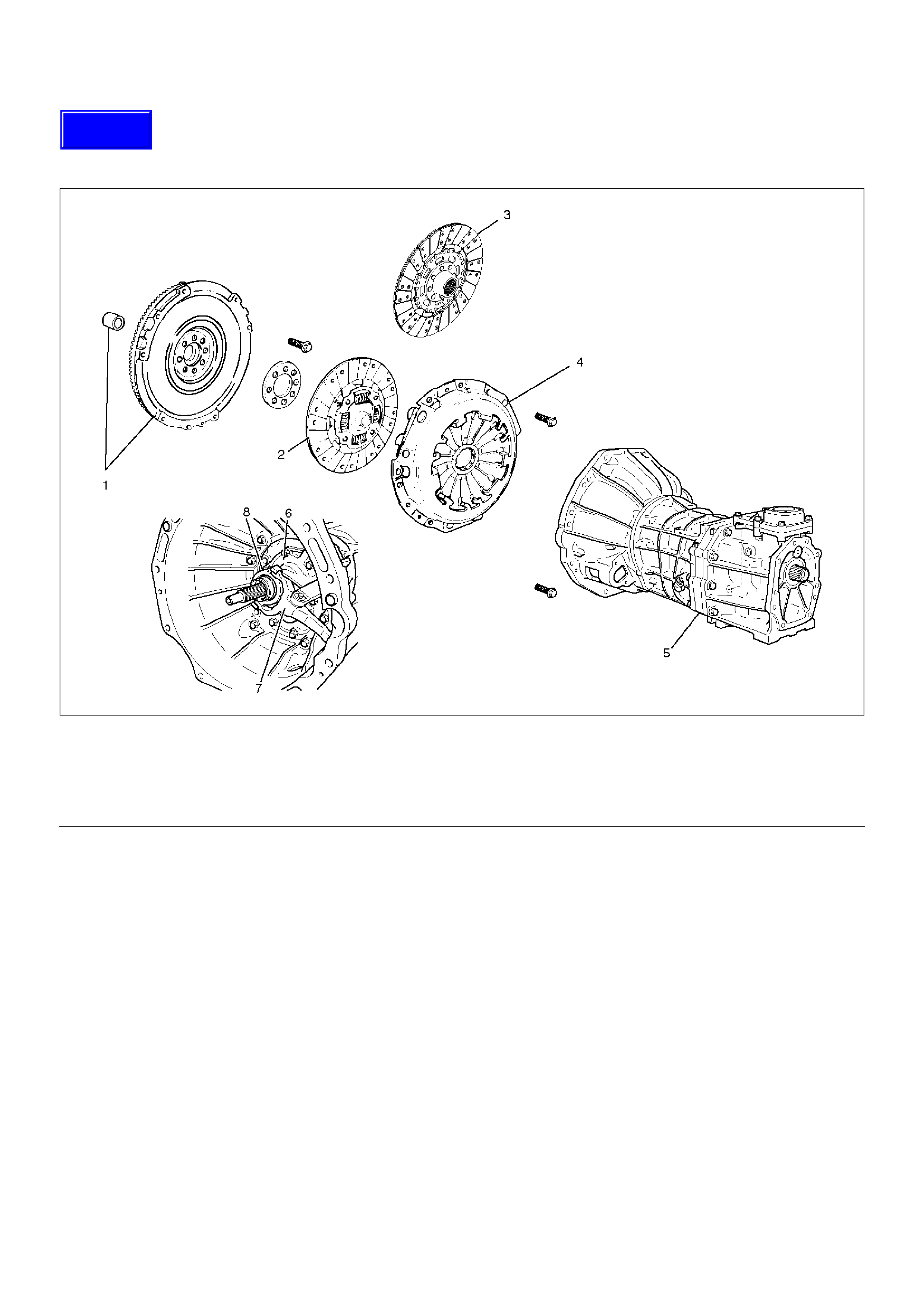

4. Remove driven plate assembly (1) or (2). Use the

pilot aligner 5-85253-001-0 (J-24547) to prevent the

driven plate assembly from falling free.

201RW031

5. Mark the flywheel, clutch cover and pressure plate

lug for alignment when installing.

6. Remove the release bearing (3) from the

transmission case .

7. Remove the shift fork snap pin.

8. Remove the shift fork pin and shift fork (4) from the

front cover.

9. Remove the front cover bolts.

10. Remove the front cover (5) from the transmission

case.

220RW088

11. Remove flywheel assembly and crankshaft bearing.

Do not remove except for replacement.

12. Use the remover 5–8840–2000–0 (J–5822) and

sliding hammer 5–8840–0019–0 (J–23907) to

remove the crankshaft bearing

015RW053

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, or any other abnormal condition are found

through inspection.

Pressure Plate Assembly

201RS002

1. Visually check the pressure plate friction surface for

excessive wear and heat cracks.

2. If excessive wear or deep heat cracks are present,

the pressure plate must be replaced.

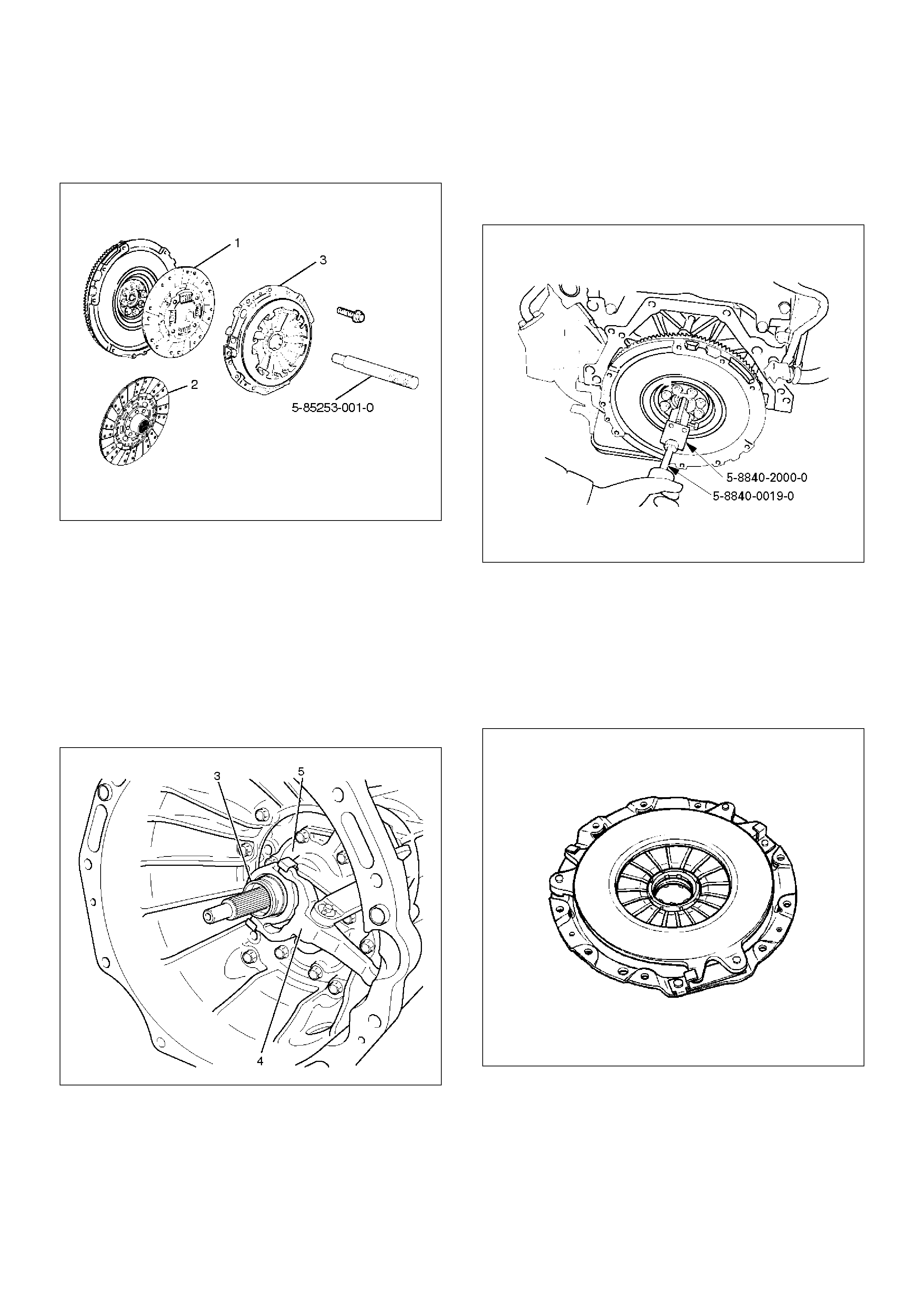

Pressure Plate Warpage

201RS003

1. Use a straight edge and a feeler gauge to measure

the pressure plate friction surface flatness in four

directions.

2. If any of the measured values exceeds the specified

limit, the pressure plate must be replaced.

Pressure Plate Warpage

Limit: 0.3mm (0.012in)

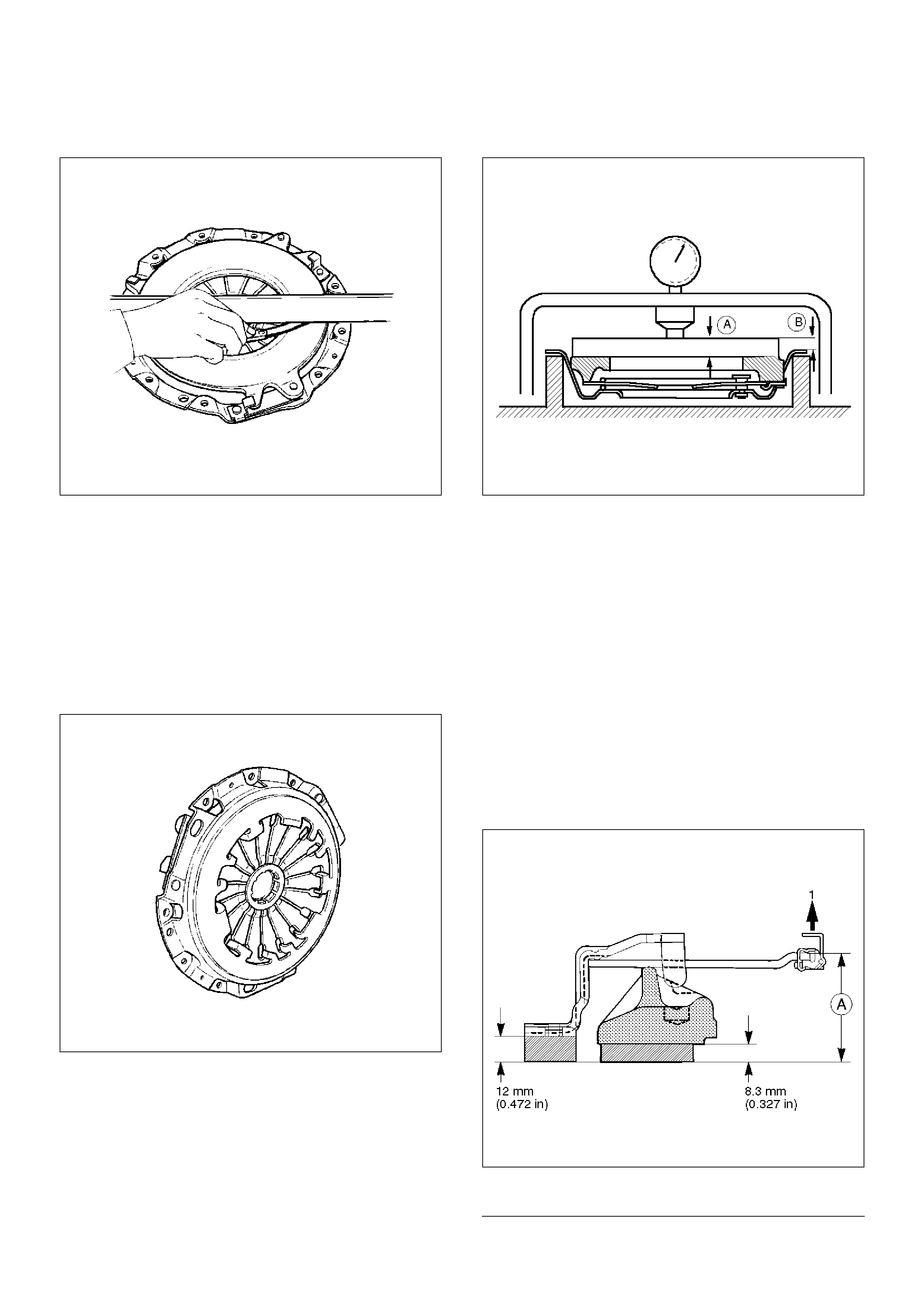

Clutch Cover

201RS004

1. Visually check the entire clutch cover for excessive

wear, cracking, and other damage.

2. The clutch cover must be replaced if any of these

conditions are present.

Clutch Set Force

201RS005

1. Invert the pressure plate assembly.

2. Place a new driven plate over the pressure plate. A

metal sheet with “A” thickness of 8.3mm (0.327in)

may be used in place of the driven plate.

3. Compress the pressure plate assembly until the

distance “B” becomes 12mm (0.472 in).

4. Note the pressure gauge reading.

5. If the measured value is less than the specified limit,

the pressure plate assembly must be replaced.

Clutch Set Force

Standard: 7208N ( 1621lb)

Limit: 6468N (1454 lb)

Diaphragm Spring Finger Height

201RW009

EndOFC allout

Legend

(1) Release Side

1. Place a new driven plate or a 8.3mm (0.327in)

spacer beneath the pressure plate.

2. Fully compress the pressure plate and diaphragm

spring.

3. There are two ways to do this.

4. Use a bench press to press down on the assembly

from the top.

5. Tighten the fixing bolts.

NOTE: Preload on diaphragm spring finger must be 49

– 98 N (11 – 22lb) in direction of release, when clutch

cover assembly is bolted to the flywheel.

6. Measure the spring height from base to spring

tip“A”. If the measured value exceeds the specified

limit, the pressure plate assembly must be replaced.

Diaphragm Spring Finger Height

Standard: 49.9mm – 51.9mm (1.965in – 2.043 in)

Driven Plate Assembly

201RW033

EndOFCallout

1. Visually check the torsion spring for looseness,

breakage, and weakening.

2. If any of these conditions are discovered, the driven

plate assembly must be replaced.

3. Visually check the facing surfaces for cracking and

excessive scorching.

4. Visually inspect the facing surfaces for the presence

of oil or grease.

5. If any of these conditions are discovered, the facing

must be cleaned or replaced.

6. Check that the driven plate moves smoothly on the

transmission top gear shaft spline.

7. Minor ridges on the top gear shaft spline may be

removed with an oil stone.

Driven Plate Warpage

201RW034

EndOFC allout

1. Insert the clutch pilot aligner into the driven plate

splined hub.

2. The clutch pilot aligner J-24547 must be held

perfectly horizontal.

3. Set a dial indicator to the driven plate outside

circumference.

4. Slowly turn the driven plate.

5. Read the dial indicator as you turn the driven plate.

6. If the measured value exceeds the specified limit,

the driven plate assembly must be replaced.

Driven Plate Warpage

Standard: 0.7mm (0.028in)

Limit: 1.0mm (0.039in)

Legend

(1) Driven Plate Assembly (6VE1)

(2) Driven Plate Assembly (4JX1)

Legend

(1) Driven Plate Assembly (6VE1)

(2) Driven Plate Assembly (4JX1)

Driven Plate Splined Hub Spline Wear

201RW032

EndOFCallout

1. Clean the driven plate splined hub.

2. Install the driven plate to the transmission top gear

shaft spline.

3. Set a surface gauge to the driven plate outside

circumference.

4. Slowly turn the driven plate counterclockwise.

5. Measure the spline rotation play as you turn the

driven plate.

6. If the measured value exceeds the specified limit,

the driven plate assembly must be replaced.

Driven Plate Splined Hub Spline Wear

Standard: 0.5mm (0.020in)

Limit: 1.0mm (0.039in)

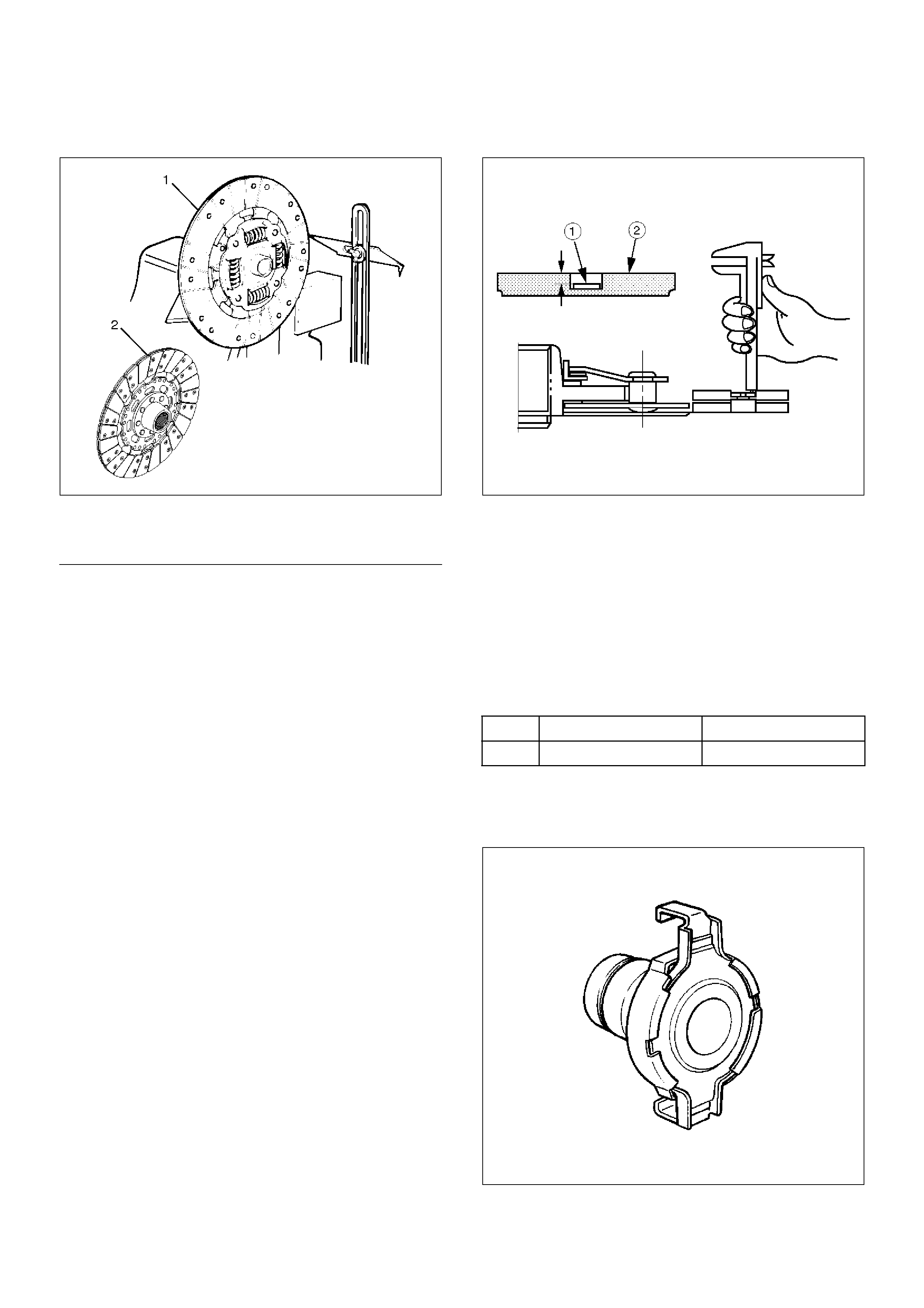

Rivet Head Depression

201RS010

1. Use a depth gauge or a straight edge with steel rule

to measure the rivet head depression 1 from the

facing surface 2.

2. Be sure to measure the rivet head depression on

both sides of the driven plate.

3. If the measured value is less than the specified limit,

the driven plate assembly must be replaced.

Rivet Head Depression

Standard:

Limit: 0.2mm (0.008in)

Release Bearing

201RS011

1. Visually check the release bearing for excessive

play, noise and breakage.

Legend

(1) Driven Plate Assembly (6VE1)

(2) Driven Plate Assembly (4JX1)

Flywheel side Pressure plate side

4JX1 1.60mm(0.063in) 1.60mm(0.063in)

2. If any of these conditions are discovered, the

release bearing must be replaced.

3. When replacing the release bearing, replace both

the wedge collar and wire ring at the same time.

201RW010

EndOFCallout

Wedge Collar

201RS013

1. Visually check the surfaces of the wedge collar

making contact with the release bearing for

excessive wear and damage.

2. Replace any exhibiting excessive wear or damage.

Shift Fork

201RS014

1. Visually check the surfaces of the shift fork making

contact with the release bearing for excessive wear

and damage.

2. Remove any minor stepping or abrasion from shift

fork with an oil stone.

3. Replace any exhibiting excessive wear or damage.

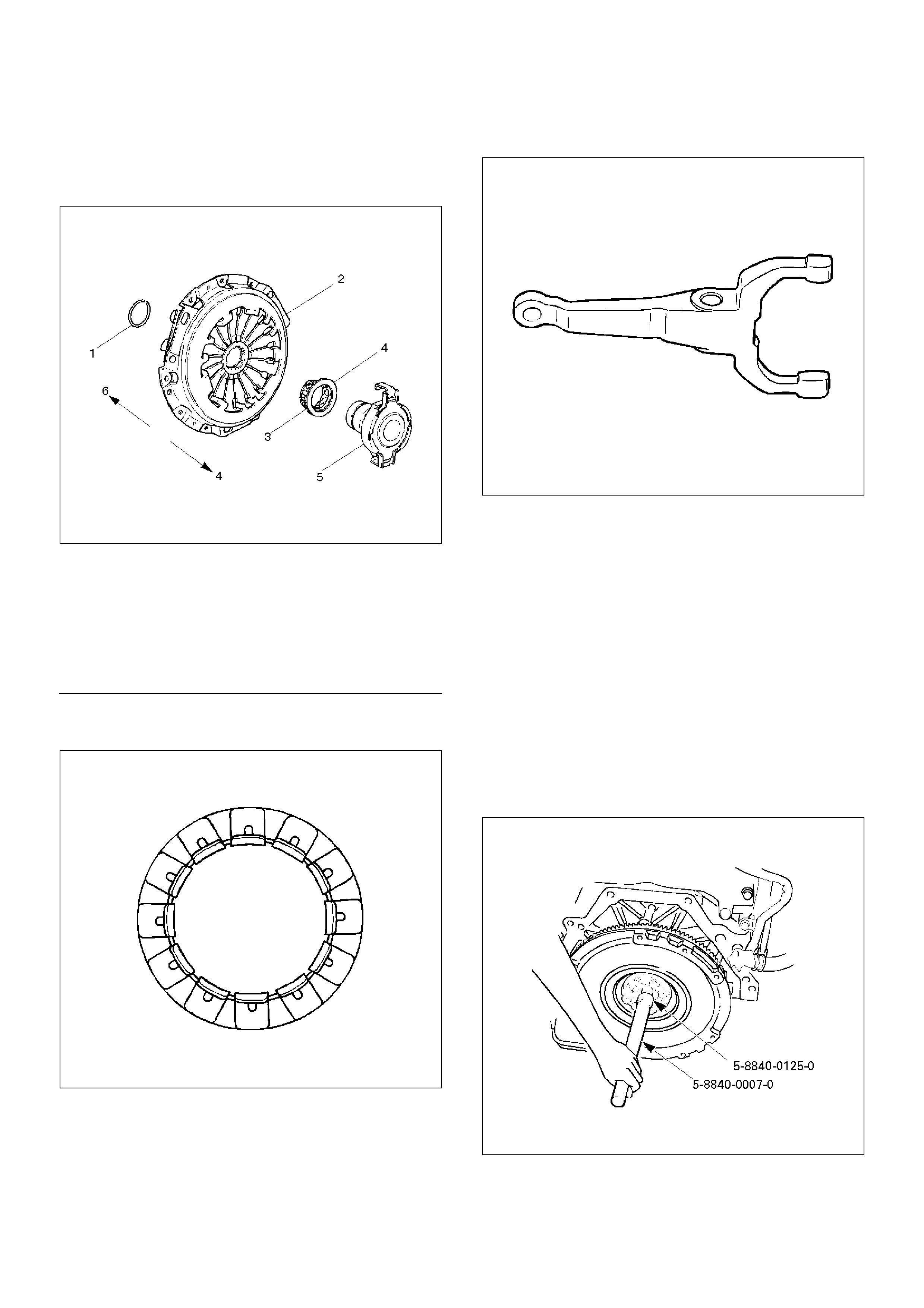

Installation

To install, follow the removal steps in the reverse order,

noting the following points:

1. Install flywheel assembly and crankshaft bearing.

Use the installer 5-8840-0125-0 (J-26516-A) and

driver handle 5-8840-0007-0 (J-8092) to install the

crankshaft bearing then clean and lubricate with

grease.

015RW054

Legend

(1) Wire Ring

(2) Pressure Plate Assembly

(3) Wedge Collar

(4) T/M Side

(5) Release Bearing

(6) Engine Side

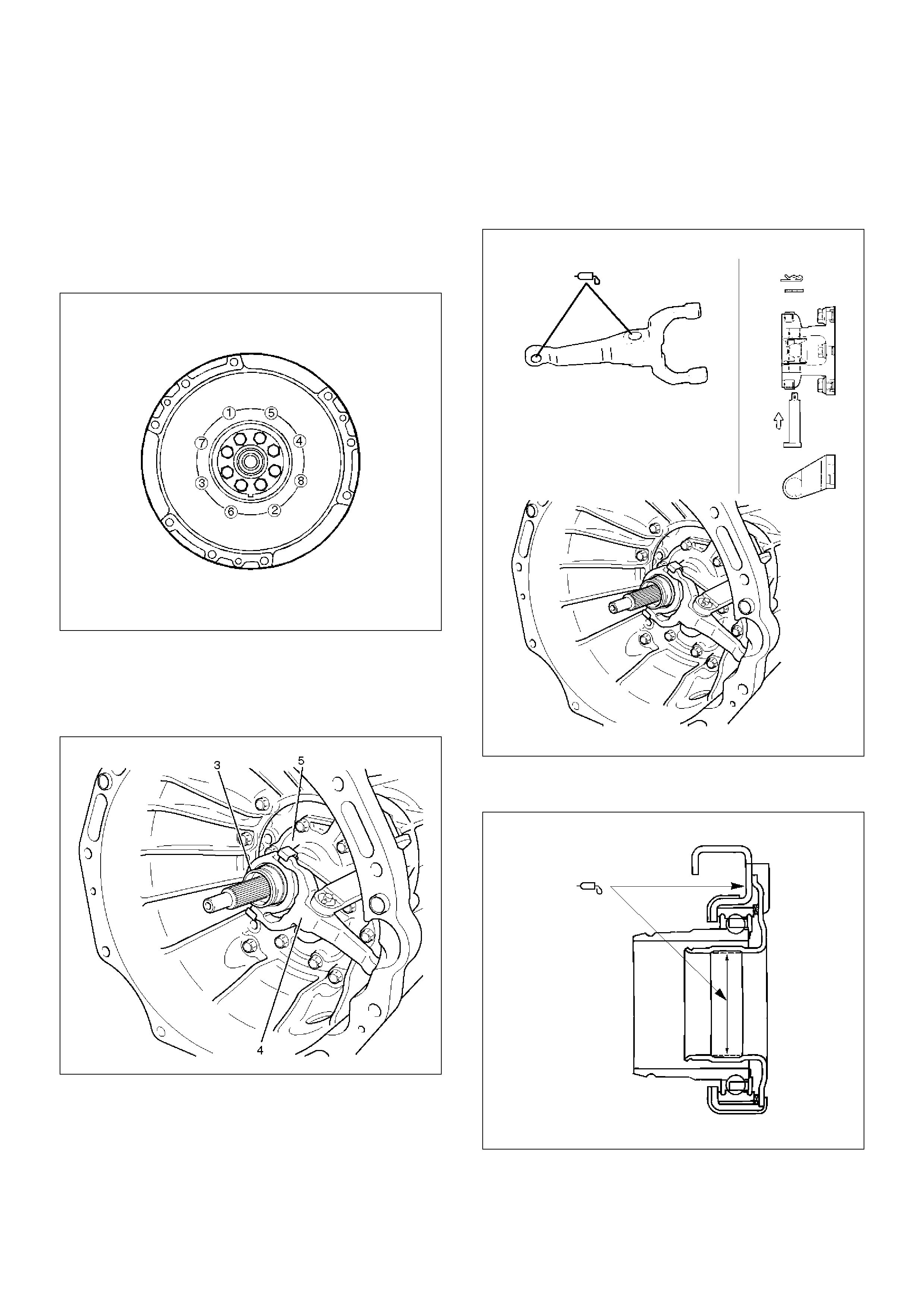

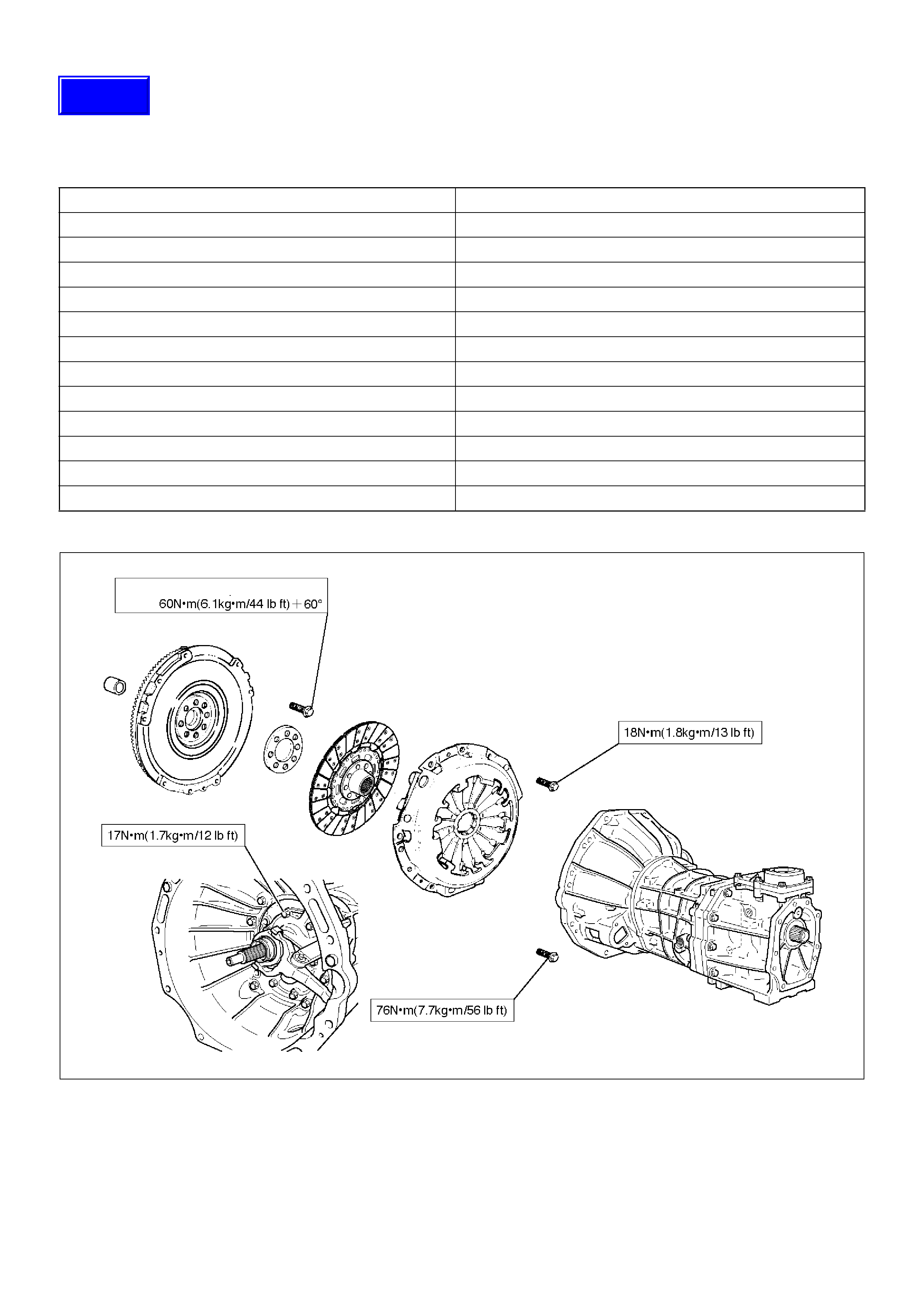

2. Install new flywheel fixing bolts in the order

illustrated and tighten them to the specified torque.

Torque:

6VE1: 54N·m (5.5kg·m/40lbft)

4JX1: 60N·m (6.1kg·m/44lbft)+60°

NOTE: Do not reuse the bolt and do not apply oil or

thread lock to the bolt.

015RS047

3. Install the front cover (5) to the transmission case.

4. Tighten eight front cover bolts to the specified

torque.

Torque: 17N·m (1.7kg·m/12lbft)

220RW088

5. Apply molybednum disulfide type grease to the pin

hole inner circumferences and thrust surfaces.

6. Attach the shift fork to the front cover and insert the

pin from below of the front cover.

7. Install the washer and snap pin.

201RW019

8. Apply molybdenum disulfide type grease to the

areas shown in illustration.

201RW012

9. Install the release bearing in the proper direction.

NOTE: Ensure release bearing is properly positioned

during installation, as shown in illustration.

201RW020

10. Install driven plate assembly. Use the pilot aligner

5-85253-001-0 (J-24547) to install the driven plate

assembly.

201RW027

11. Install pressure plate assembly and tighten the bolts

holding the pressure plate assembly in the order

shown in illustration.

Torque: 18N·m (1.8kg·m/13lbft)

201RS017

12. Remove the aligner.

NOTE: Do not strike the aligner with a hammer to

remove it.

13. Install transmission assembly.

Clutch Control

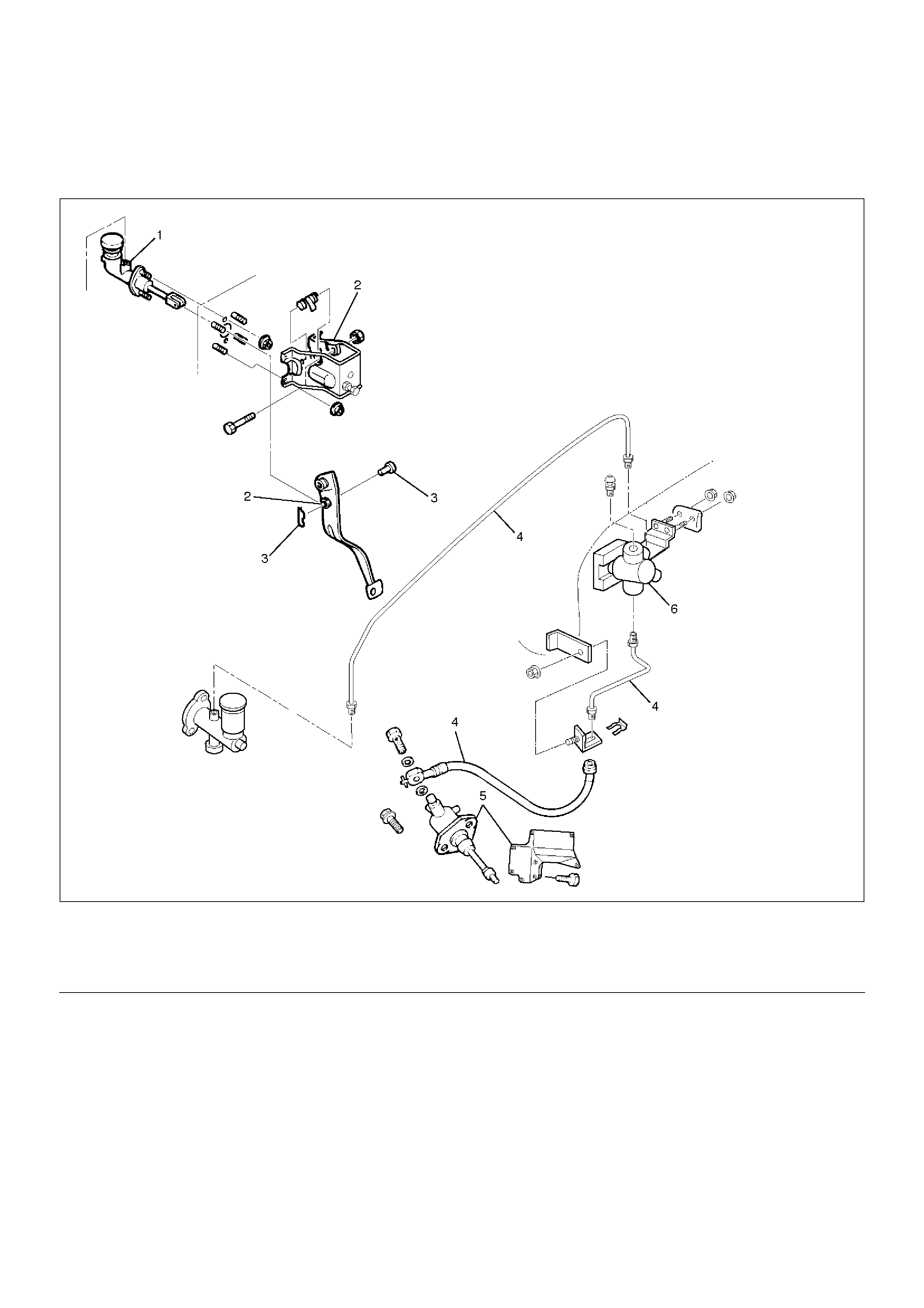

Clutch Control Parts

203RW009

EndOFCallout

Removal

1. Remove pin and jaw joint pin.

2. Remove pedal assembly.

3. Remove oil line pipe.

4. Remove slave cylinder assembly and heat

protector.

5. Remove master cylinder assembly.

6. Remove damper cylinder assembly

Inspection and Repair

Make necessary adjustments, repairs, and part

replacement if wear, damage or other problems are

discovered during inspection.

Legend

(1) Master Cylinder Assembly

(2) Pedal Assembly

(3) Pin and Joint Pin

(4) Oil Line Pipe

(5) Slave Cylinder Assembly and Heat Protector

(6) Damper Cylinder Assembly

Installation

1. Install damper cylinder assembly

2. Install master cylinder assembly.

3. Install slave cylinder assembly and heat protector.

4. Install oil line pipe.

5. Install pedal assembly.

6. Install pin and jaw joint pin.

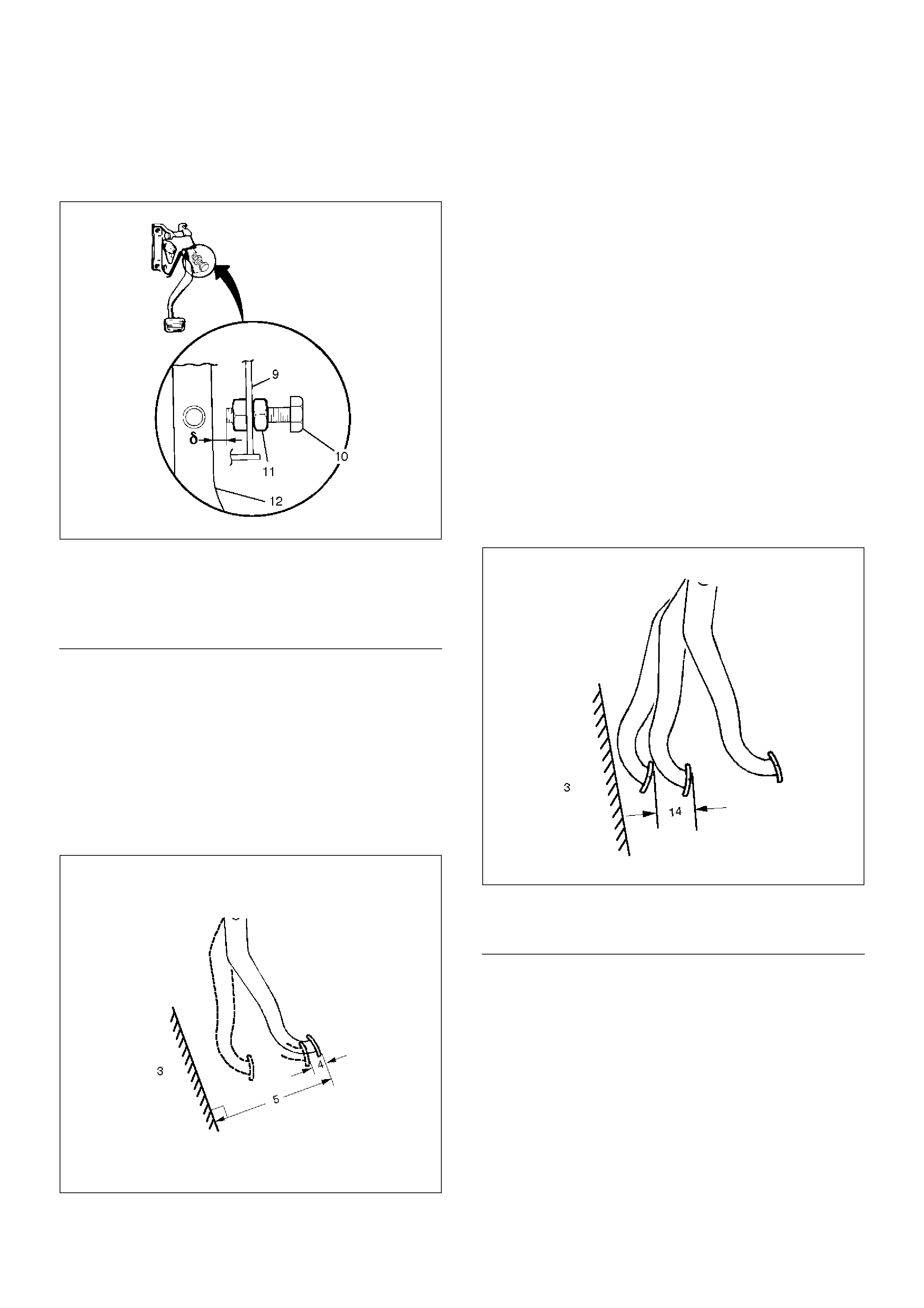

Adjustment

Clutch Pedal Adjustment

1. Loosen the clutch pedal adjusting bolt so that there

is enough gap between the clutch pedal and the

adjusting bolt to allow push rod adjustment.

203RW011

EndOFCallout

2. Loosen clutch master cylinder push rod lock nut.

Turn push rod by hand to set clutch pedal height (5)

to within specification.

Clutch pedal height (5):

231mm – 241mm (9.094in – 9.488in)

203RW004

EndOFCallout

3. Tighten push rod lock nut.

4. Adjusting bolt adjustment.

1. Turn the adjusting bolt until it just touches the

clutch pedal arm.

203RW012

EndOFCallout

Legend

(1) Push Rod

(2) Adjusting Bolt

Legend

(3) Floor Panel

(4) Pedal Free Play

(5) Clutch Pedal Height

Legend

(6) Bracket

(7) Adjusting Bolt

(8) Clutch Pedal Arm

Techline

2. Adjust clutch padel adjusting bolt by backing it

out half a turn, and measure the clearance (d)

between the clutch pedal arm and the adjusting

bolt.

203RW010

EndOFCallout

3. Lock the lock nut.

Clutch Switch and Clutch Pedal Clearance (d)

0.5mm – 1.5mm (0.020 in – 0.059in)

5. After adjusting the clutch pedal height, push the

clutch pedal by hand rightly to check the clutch

pedal free play (4) to within specification.

Pedal Free Play (4)

5mm – 15mm (0.20in – 0.59in)

203RW004

6. Clutch pedal engagement height inspection:

1. Operate the parking brake lever and block the

wheels.

2. Start the engine, fully step on the clutch pedal,

and move the shift lever to 1st position.

3. With the engine idling, release the clutch pedal

slowly and measure its stroke just prior to its

clutching position.

Clutch Pedal Engagement Height (14)

MIN.30mm (1.18in)

7. If the measured value exceeds the specified limit,

check the following points. Repair if necessary:

• Hydraulic circuit for fluid leakage or air in circuit.

• Clutch disc warped.

• Diaphragm spring weakened or tip of fingers

worn.

• Driven plate sticking on sprines.

• Release bearing worn or damaged.

• Master cylinder and slave cylinder worn.

203RW007

EndOFCallout

Legend

(9) Bracket

(10) Clutch Pedal Adjusting Bolt

(11) Lock Nut

(12) Clutch Pedal Arm

Legend

(3) Floor Panel

(14) Clutch Pedal Engagement Height

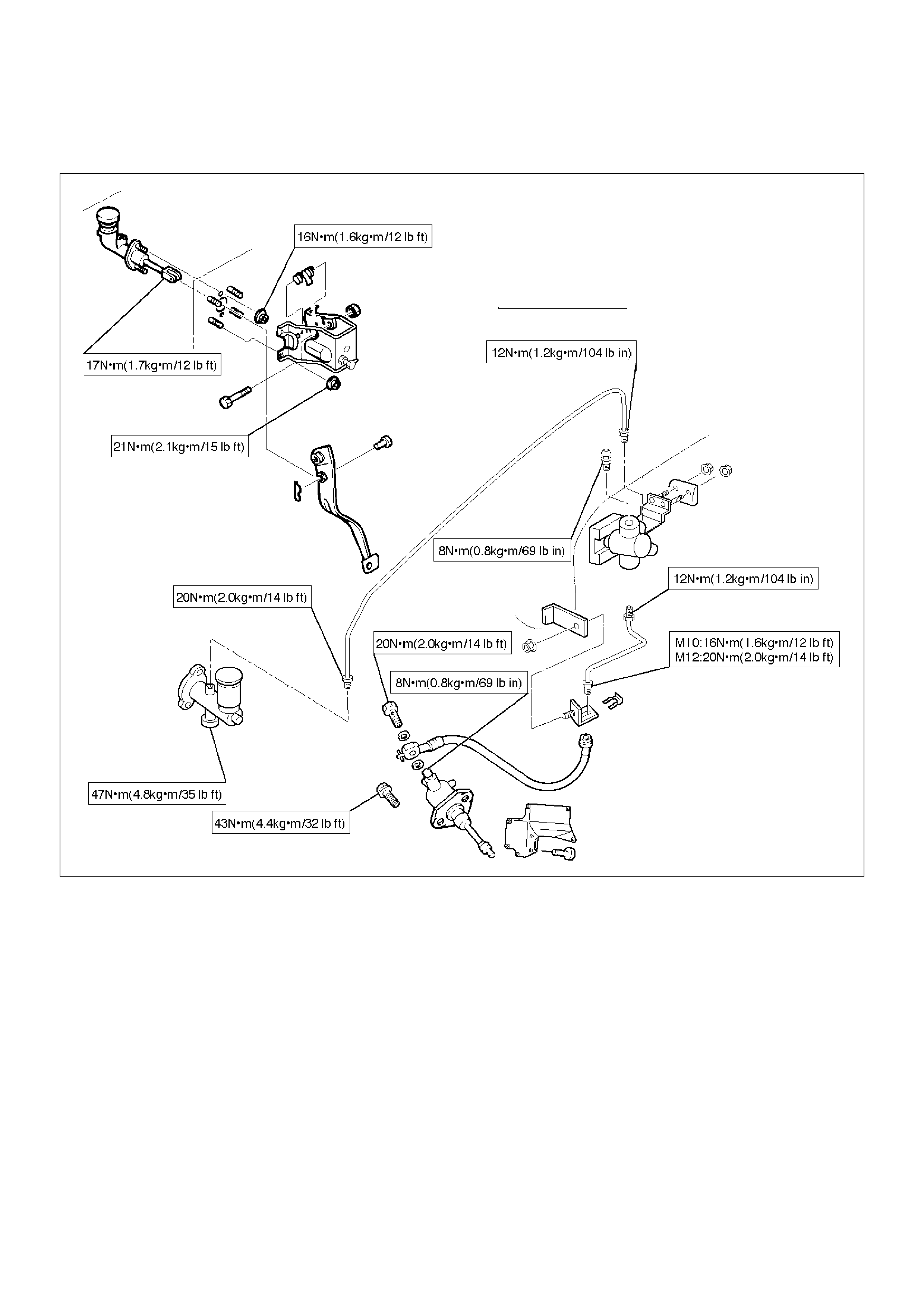

Torque Specifications

• Master cylinder to dash panel

Torque: 16N·m (1.6kg·m/12lbft)

• Clutch pedal to dash panel

Torque: 21N·m (2.1kg·m/15lbft)

• Master cylinder push rod to yoke

Torque: 17N·m (1.7kg·m/12lbft)

• Clutch pipe to master cylinder

Torque: 20 N·m (2.0 kg·m/14lbft)

• Clutch pipe to flex, hose

Torque:

M 10: 16N·m (1.6kg·m/12lbft)

M 12: 20N·m (2.0kg·m/14lbft)

• Slave cylinder to case

Torque: 43N·m (4.4kg·m/32lbft)

• Slave cylinder bleeder screw

Torque: 8N·m (0.8kg·m/69lbin)

• Flexible hose to slave cylinder

Torque: 20N·m (2.0kg·m/14lbft)

• Clutch pipe to damper cylinder

Torque: 12N·m (1.2kg·m/104lbin)

• Damper cylinder bleeder screw

Torque: 8N·m (0.8kg·m/69lbin)

Bleeding

1. Check the level of clutch fluid in the reservoir and

replenish if necessary.

Bleeding the damper cylinder

Remove the rubber cap from the bleeder screw and

wipe clean the bleeder screw. Connect a vinyl tube

to the bleeder screw and insert the other end of the

vinyl tube into a transparent container.

2. Pump the clutch pedal repeatedly and hold it

depressed.

203RS005

3. Loosen the bleeder screw to release clutch fluid with

air bubbles into the container, then tighten the

bleeder screw immediately.

4. Release the clutch pedal carefully. Repeat the

above operation until air bubbles disappear from the

clutch fluid being pumped out into the container.

During the bleeding operation, keep the clutch fluid

reservoir filled to the specified level. Reinstall the

rubber cap.

Bleeding the slave cylinder

5. Repeat step 2 through 5 for bleeding the slave

cylinder.

206RW003

EndOFCallout

Legend

(1) Slave Cylinder

(2) Bleeder Screw

(3) Vinyl Tube

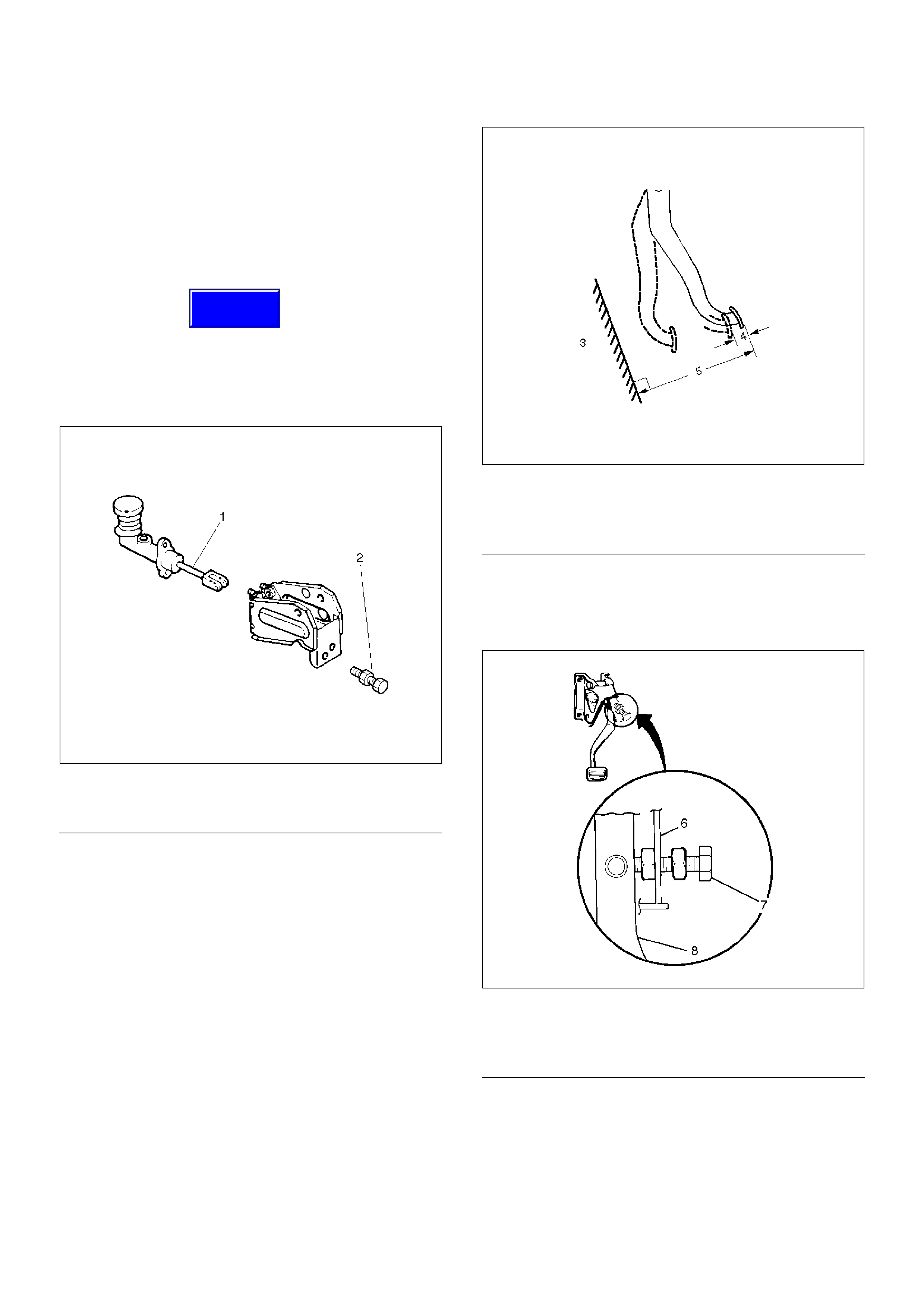

Master Cylinder

Disassembled View

208RW016

EndOFCallout

Legend

(1) Master Cylinder Assembly

(2) Gasket

(3) Damper Cylinder Assembly

(4) Nut

(5) Push Rod Damper

Disassembly

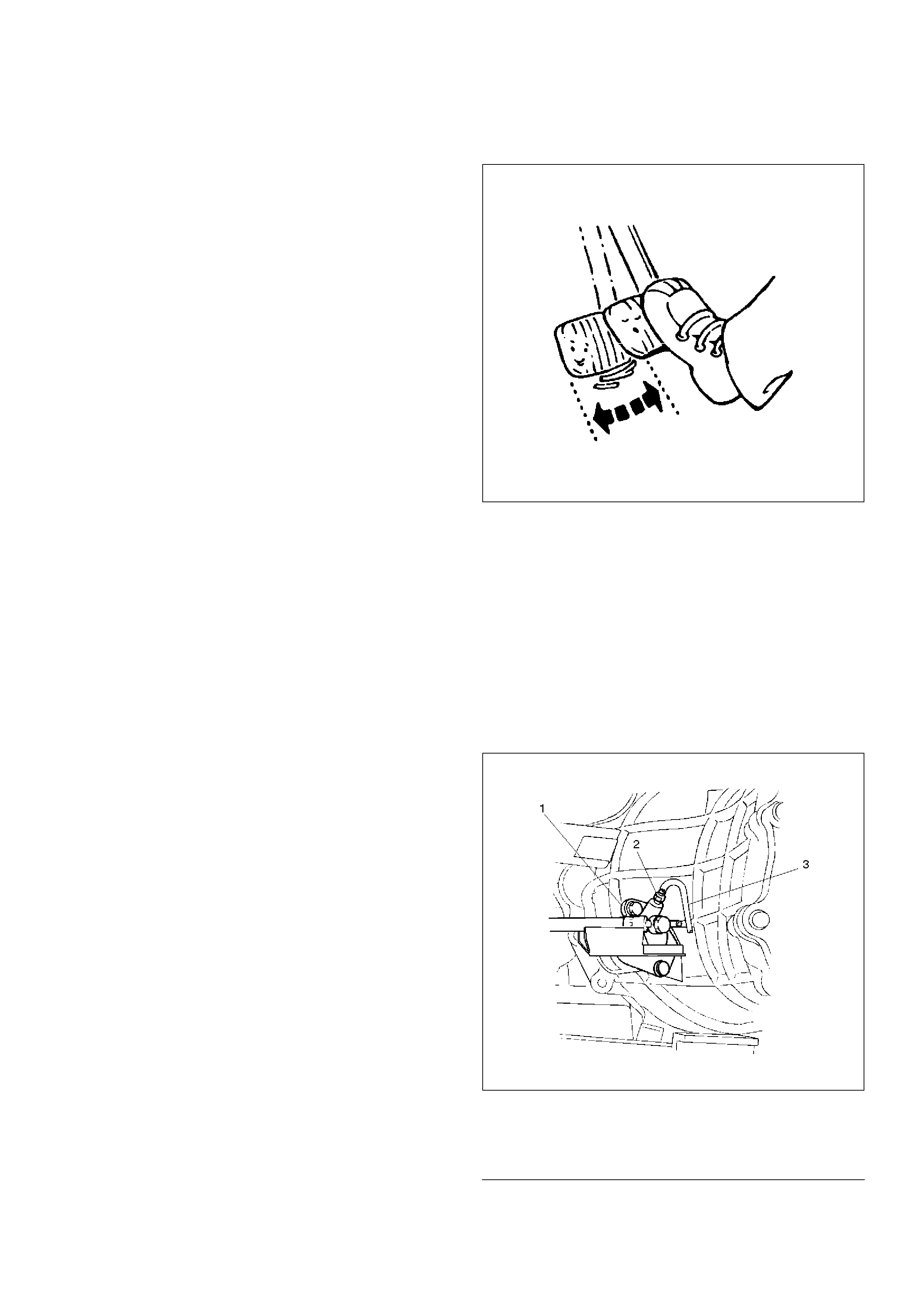

1. Remove damper cylinder assembly and gasket.

2. Remove push rod damper.

NOTE: The master cylinder assembly cannot be

disassembled because of point–staked rod stopper.

Inspection and Repair

Clean and inspect the removed parts.

Make necessary parts replacement if any abnormalities

such as wear, oil leaks or other damage are found

through inspection.

Reassembly

To reassemble, follow the disassembly steps in the

reverse order, noting the following points:

1. Push rod set length

117.5 mm (4.626 in)

2. Push rod nut torque

17 N·m (1.7 kg·m/12 Ib ft)

3. Damper cylinder torque

47 N·m (4.8 kg·m/35 Ib ft)

Slave Cylinder

Disassembled View

206RW004

EndOFCallout

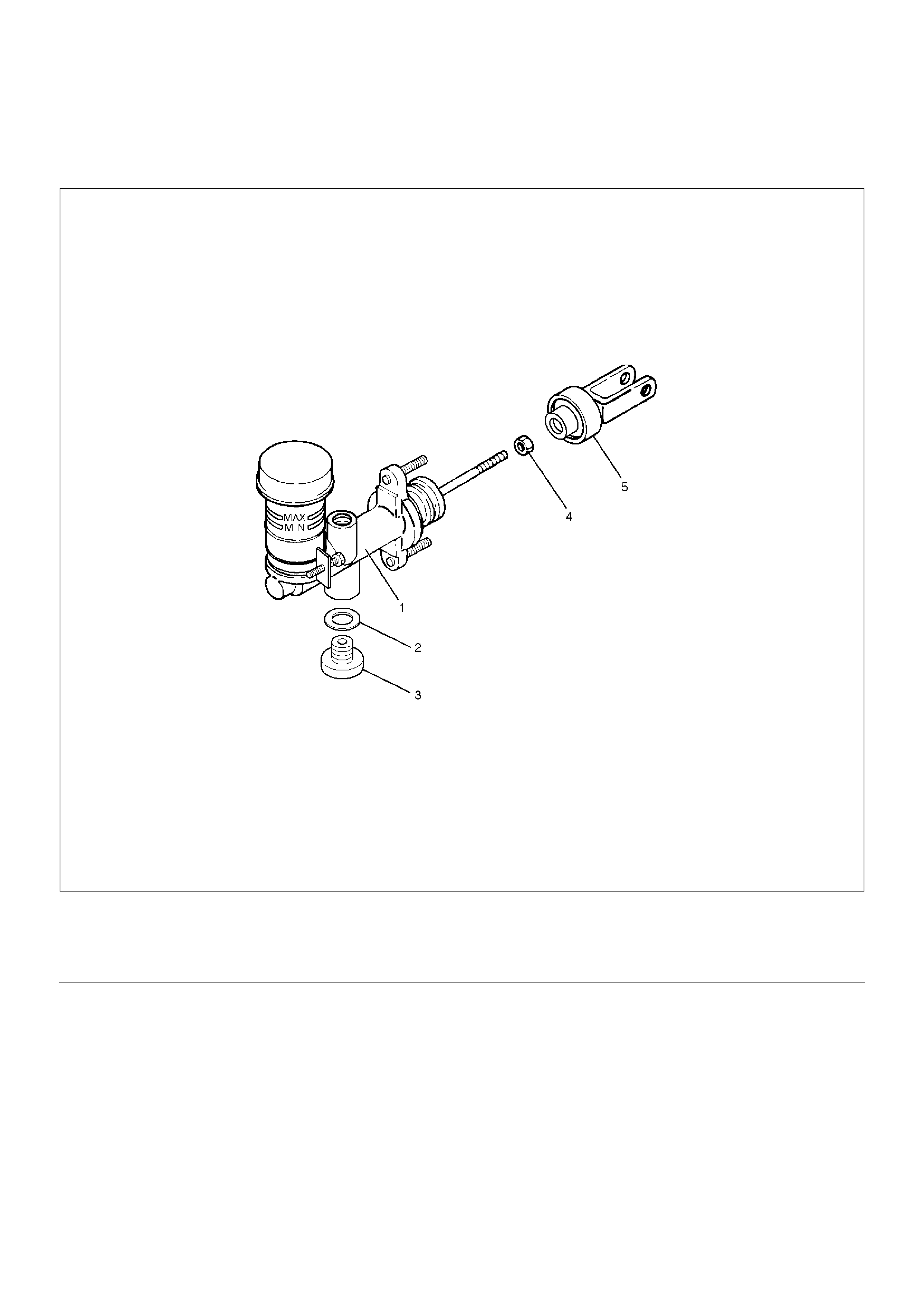

Disassembly

1. Remove boot.

2. Remove push rod.

3. Remove piston and piston cup.

4. Remove spring.

Inspection and Repair

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is

discovered during inspection.

Cylinder Body

206RS003

1. Clean the cylinder body.

2. Check the fluid return port for restrictions and clean

it if necessary.

Legend

(1) Cylinder Body

(2) Spring

(3) Piston and Piston Cup

(4) Boot

(5) Push Rod

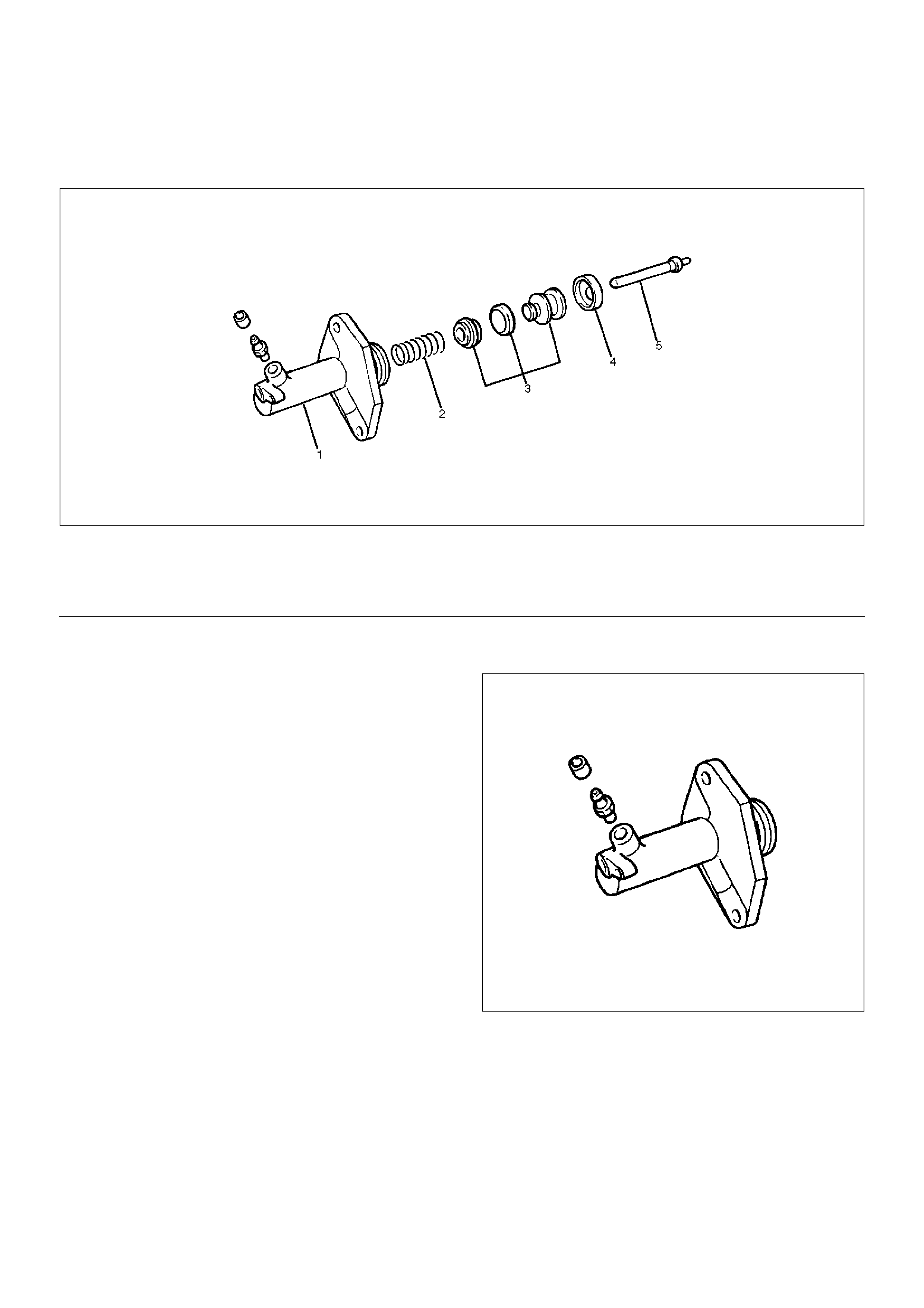

Piston and Piston Cup

1. Visually inspect the disassembled piston and piston

cup for excessive wear and damage.

2. Replace the inner parts with new parts shown in the

illustration.

206RS004

3. Measure the clearance between slave cylinder wall

and piston.

4. If the measured value exceeds the specified limit,

the slave cylinder assembly must be replaced.

Standard: 0.07mm (0.0028 in)

Limit: 0.15mm (0.0059 in)

206RS005

Reassembly

To reassemble, follow the disassembly steps in the

reverse order, noting the following points:

1. Before installing the parts, apply a thin coat of

rubber grease.

2. Install cup in groove in piston with the lip turned to

the front of cylinder. Use care so as not to scratch

the cylinder.

206RS006

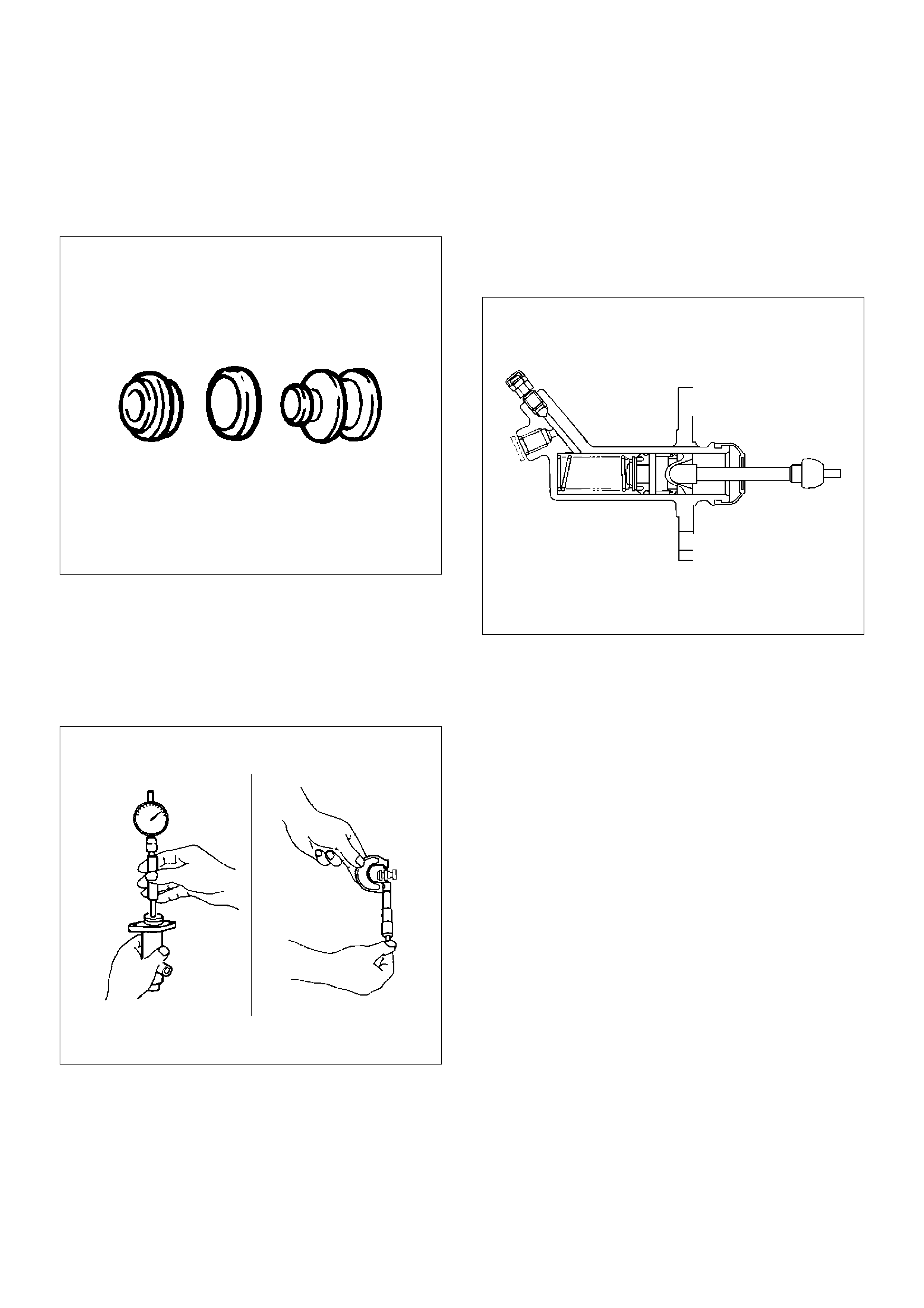

Damper Cylinder

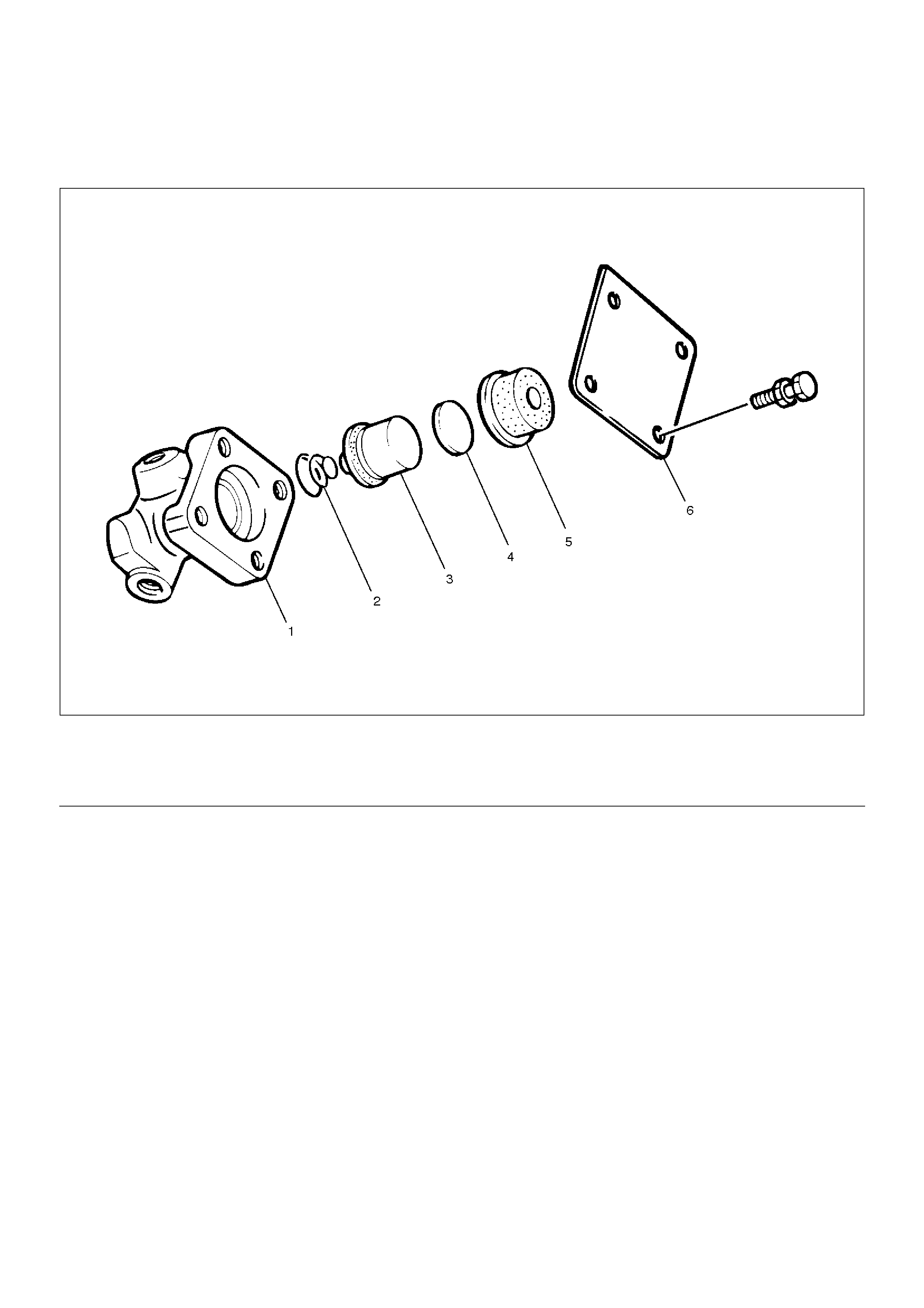

Disassembled View

205RW005

EndOFCallout

Disassembly

1. Remove cover and gasket.

2. Remove damper rubber.

3. Remove spacer.

4. Remove piston assembly.

5. Remove spring.

Inspection and Repair

Check damper rubber and piston cup for cracks,

deformation or damage.

Replace the damper cylinder assembly if necessary.

Reassembly

To assemble, follow the disassembly steps in the

reverse order.

Legend

(1) Cylinder Body

(2) Spring

(3) Piston Assembly

(4) Spacer

(5) Damper Rubber

(6) Cover and Gasket

Main Data and Specifications

General Specifications

Torque Specifications

E07RW053

Type Dry single plate type with diaphragm spring

Size 275mm(10.83in)

Pressure plate Outside diameter 332mm(13.07in)

Pressure plate Clamping force 7208N(1621lb)

Pressure plate Spring finger height 49.9–51.9mm(1.965–2.043in)

Driven plate Outside diameter x inside diameter 275´180 mm(10.83´6.69in)

Thickness Clutch disengaged 8.8mm(0.346in)

Thickness Clutch engaged 8.3mm(0.327in)

Total friction area 339´2cm (52 ´2in )

Clutch control type Hydraulic

Clutch pedal free play 5–15mm(0.20– 0.59in)

Clutch pedal height 231mm – 241mm (9.094in – 9.488in)

Clutch pedal stroke 145–155mm(5.709–6.102in)

Techline

Torque Specifications (Cont'd)

E07RW055

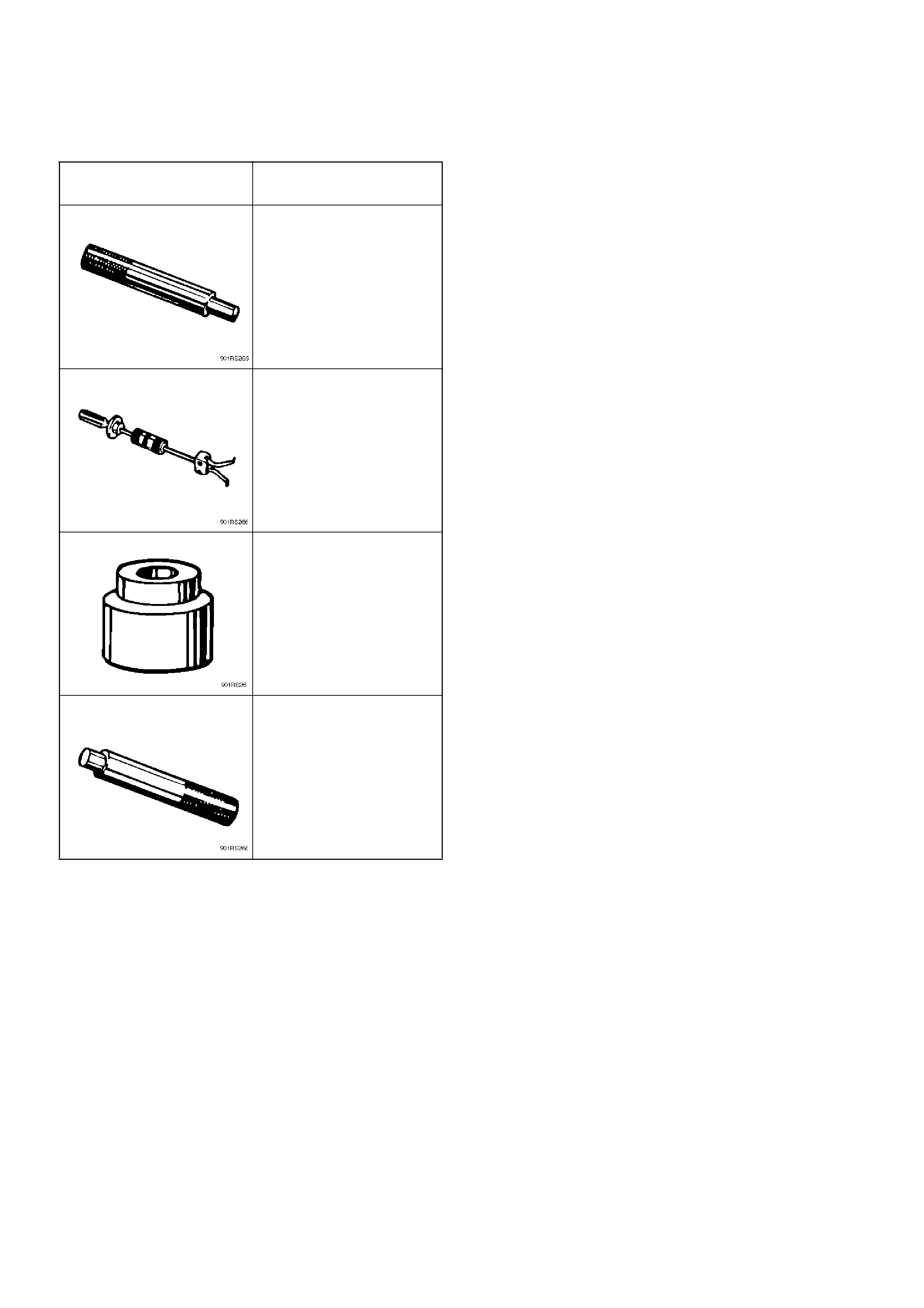

Special Tools

ILLUSTRATION TOOL NO.

TOOL NAME

5-85253-001-0

(J-24547)

Driven plate aligner

5-8840-2000-0 and

5-8840-0019-0

(J-5822 and J-23907)

Pilot bearing remover and

Sliding hammer

5-8840-0125-0

(J-26516-A)

Crankshaft pilot bearing

installer

5-8840-0007-0

(J-8092)

Driver handle