SECTION 7B - AR-5 MANUAL TRANSMISSION

Service Precaution

General Description

Diagnosis

Manual Transmission Assembly

Transmission and Associated Parts

Removal

Installation

Rear Oil Seal (Transfer Adapter)

Removal

Installation

Transmission (AR-5)

Disassembled View

Disassembly

Inspection

Reassembly

Main Data and Specifications

General Specifications

Torque Specifications

Special Tools

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE

SRS WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

Techline

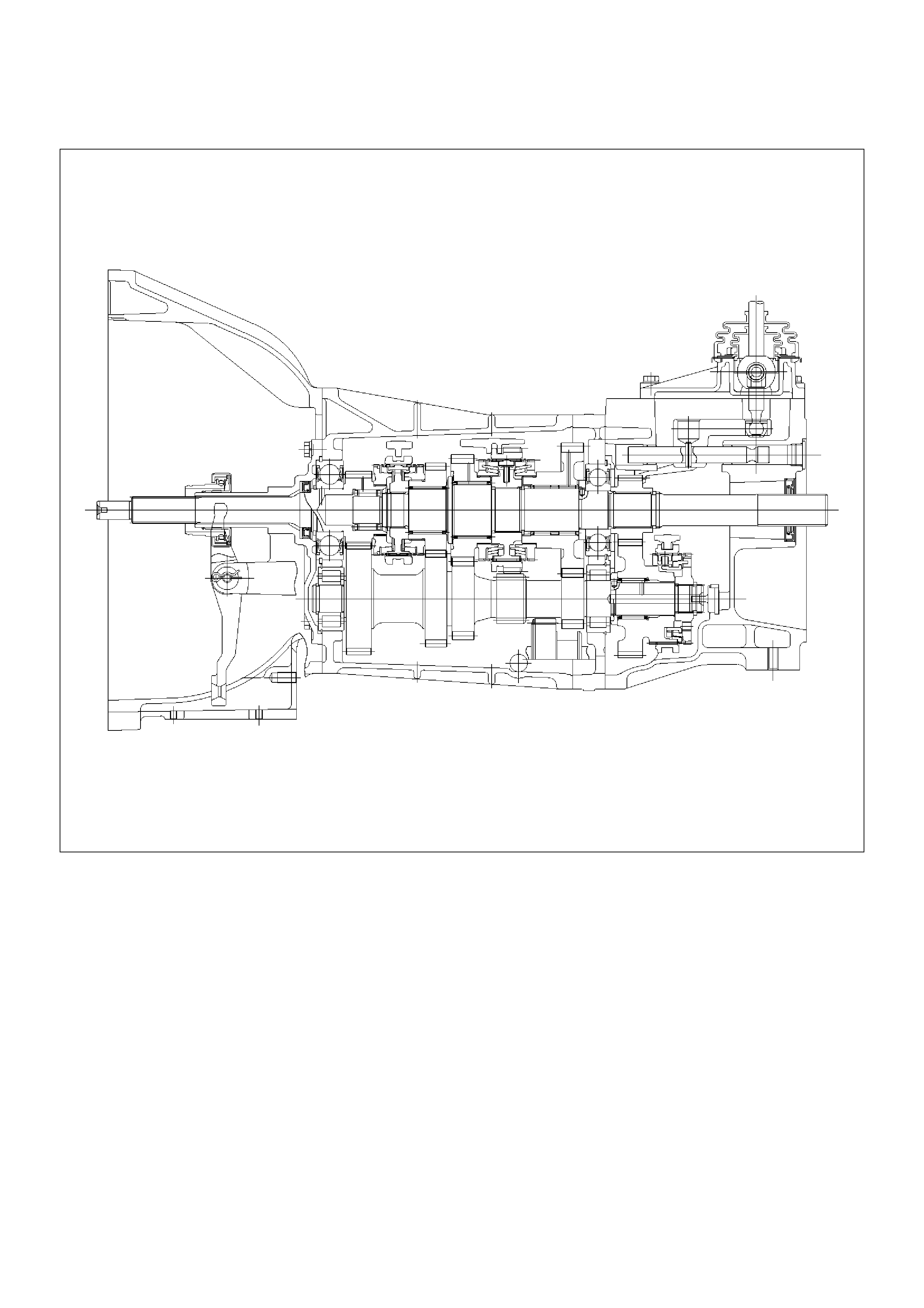

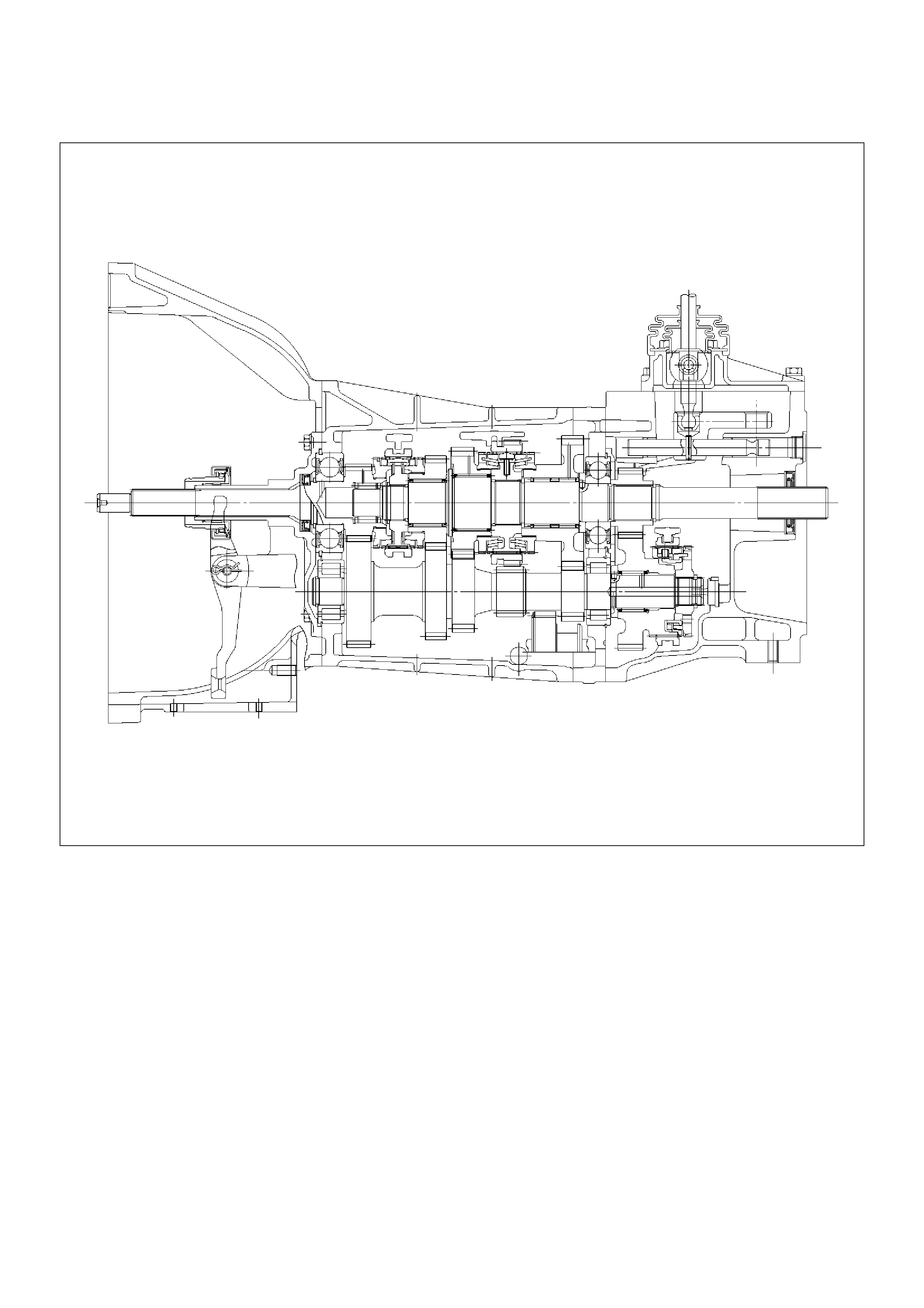

General Description (6VE1)

A07RW044

(4JX1)

A07RW043

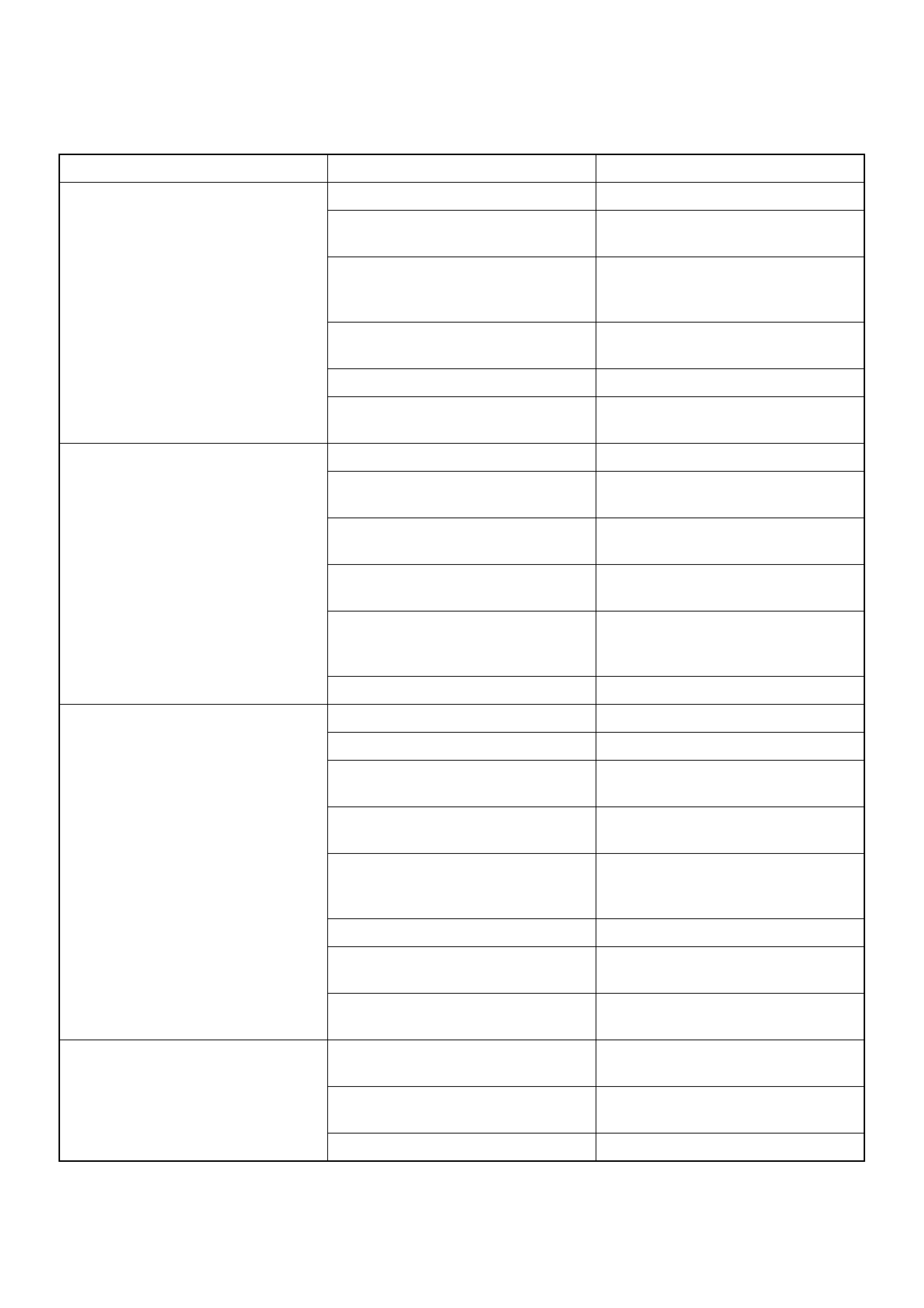

Diagnosis

Condition Possible Cause Correction

Abnormal noise Flywheel pilot bearing worn Replace

Bearings worn or broken (Mainshaft,

counter shaft, and transfer shaft)

Replace

Gear tooth contact surfaces worn or

scuffed (Mainshaft, counter shaft,

reverse idler gear and transfer gears)

Replace

Splines worn (Mainshaft,

synchronizer clutch hub)

Replace

Gear or bearing thrust face seized Replace

Lack of backlash between meshing

gears

Replace

Hard Shifting Improper clutch pedal free play Readjust

Change lever sliding portions worn Repair or replace

Regrease

Shift block, shift rod and/or control

box sliding faces worn

Replace

Shift arm and synchronizer sleeve

groove worn

Replace worn parts

Thrust washer, collar, and/or gear

thrust faces worn (Mainshaft and

counter shaft thrust play)

Replace worn parts

Synchronizer parts worn Replace

Walking or Jumping out of gear Detent ball worn Replace

Detent spring weakened or broken Replace

Shift rod and/or control box sliding

faces worn

Replace

Shift arm and synchronizer sleeve

groove worn

Replace worn parts

Thrust washer, collar, and/or gear

thrust faces worn (Mainshaft and

counter shaft thrust play)

Replace worn parts

Bearings worn or broken Replace

Splines worn (Mainshaft,

synchronizer hub)

Replace

Synchronizer spring weakened or

broken

Replace

Oil leakage Loose drain plug(s) and/or filler

plug(s)

Tighten

Replenish oil

Defective or improperly installed

gasket(s)

Replace

Oil seal worn or scratched Replace

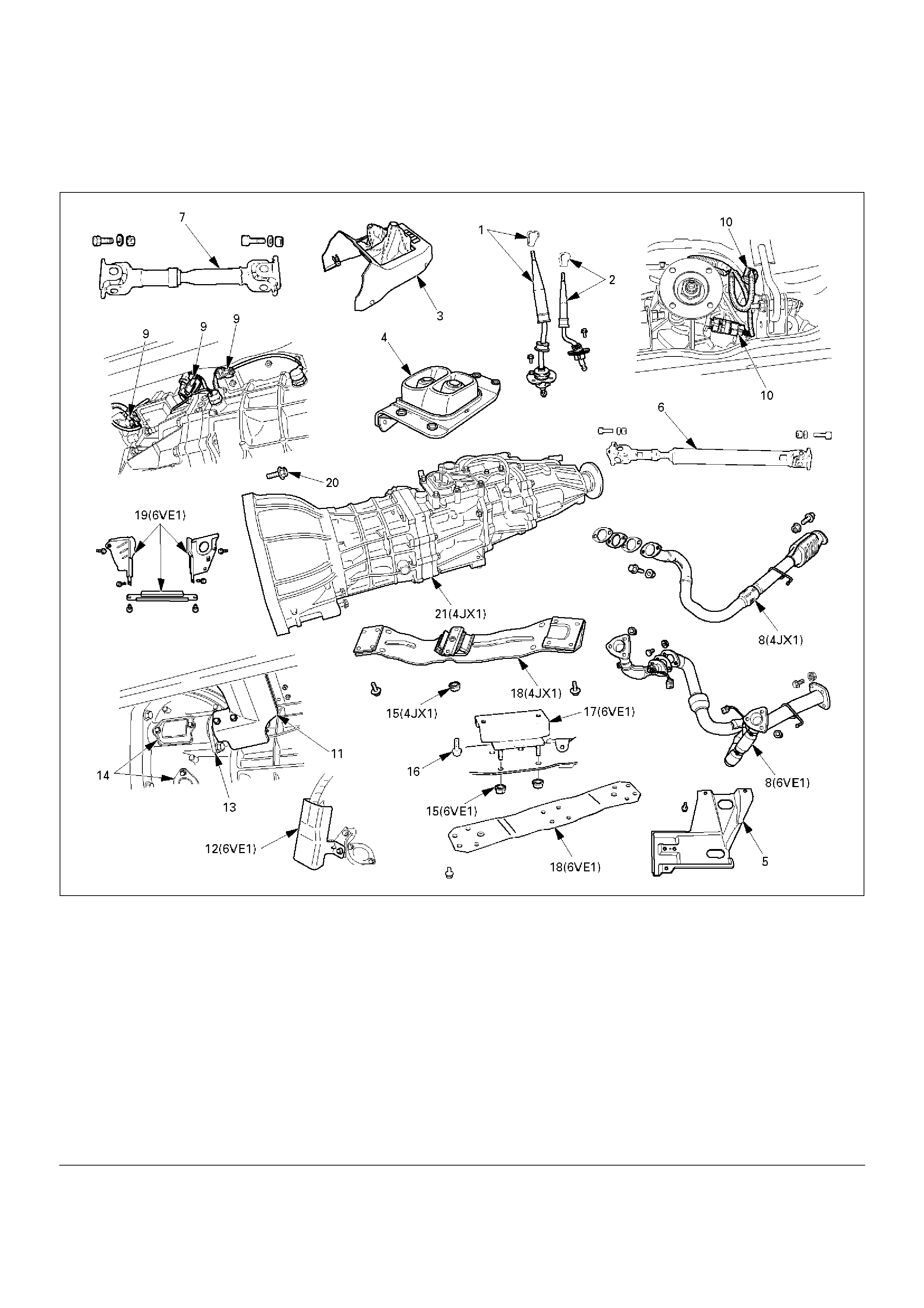

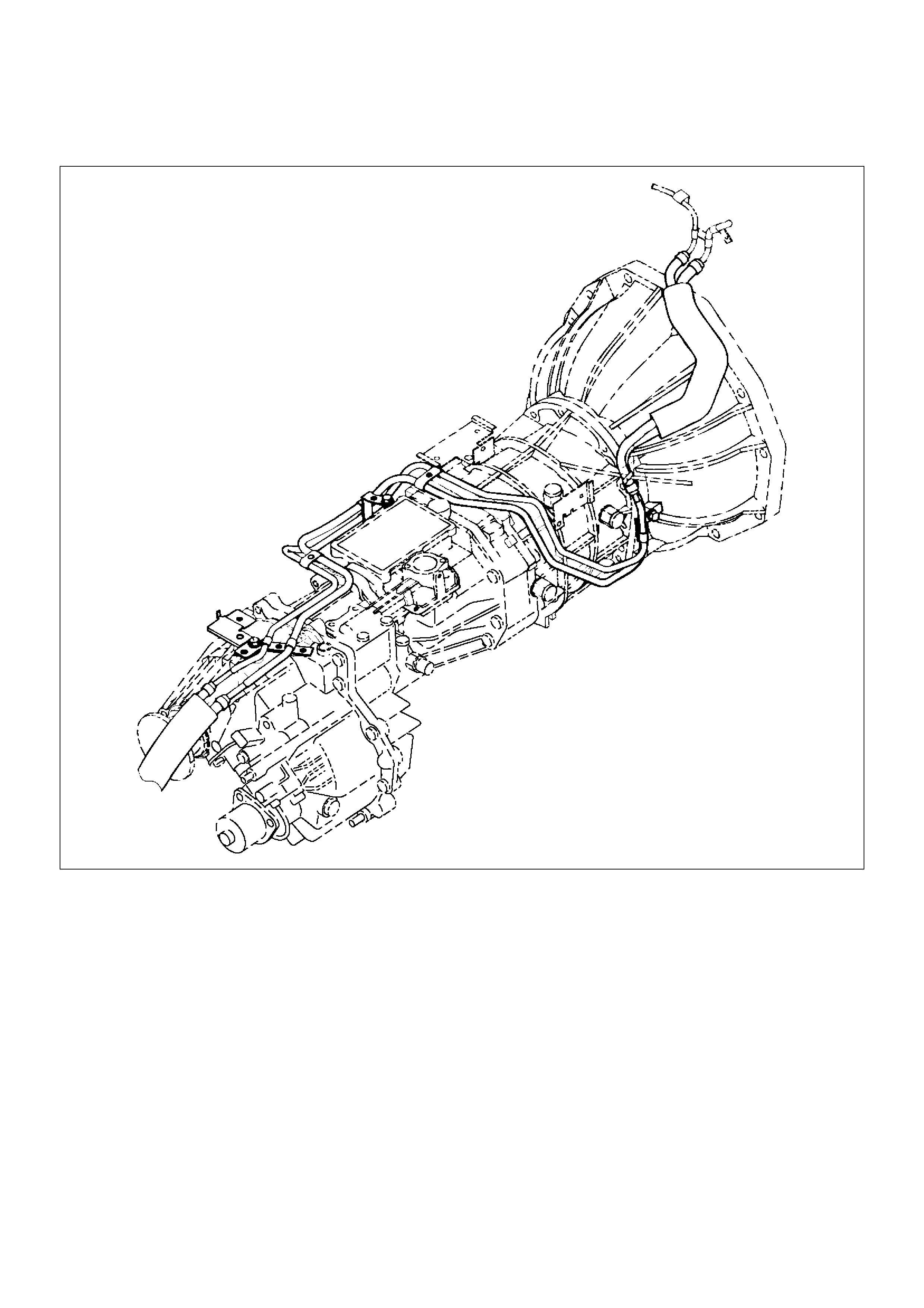

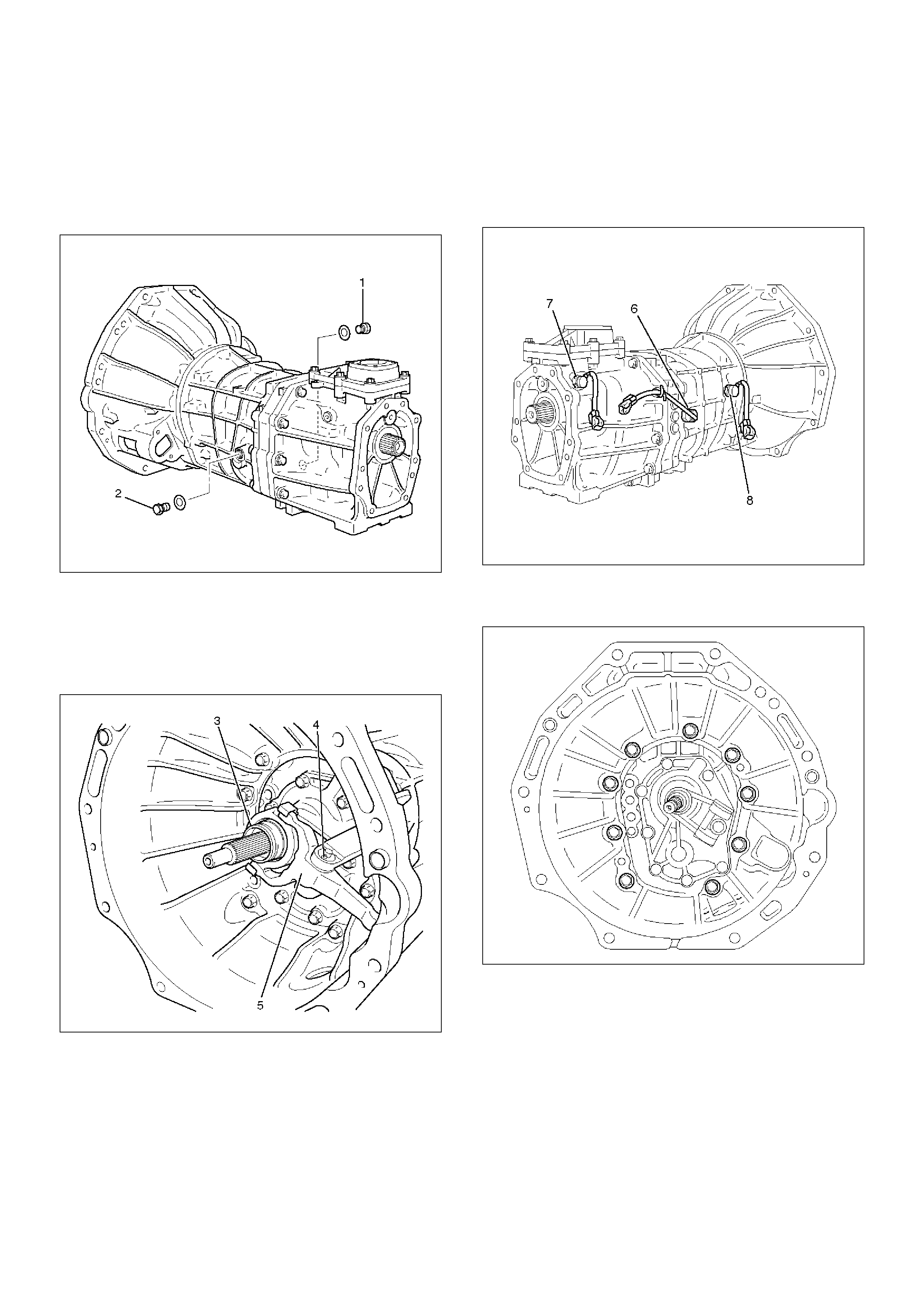

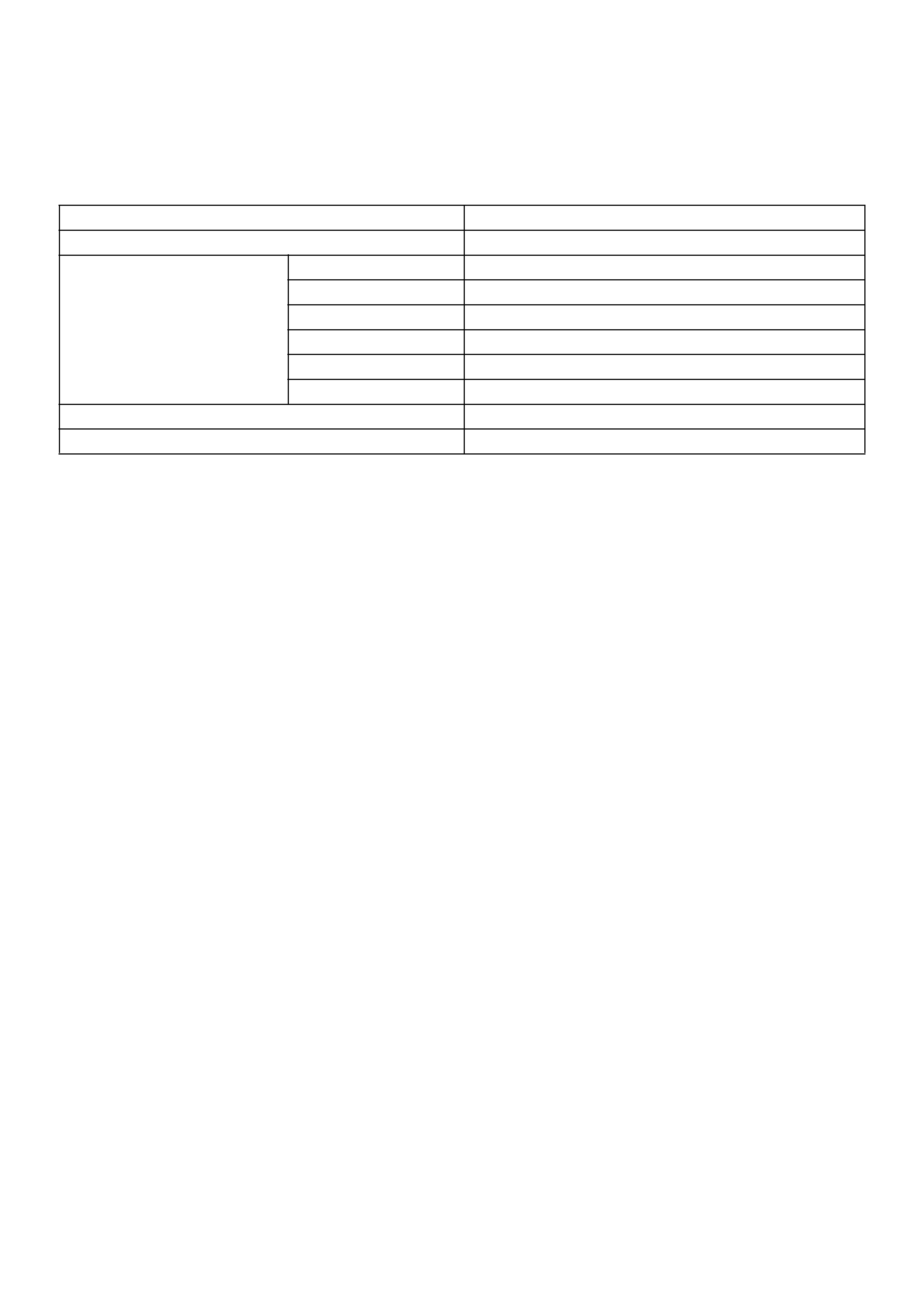

Manual Transmission Assembly

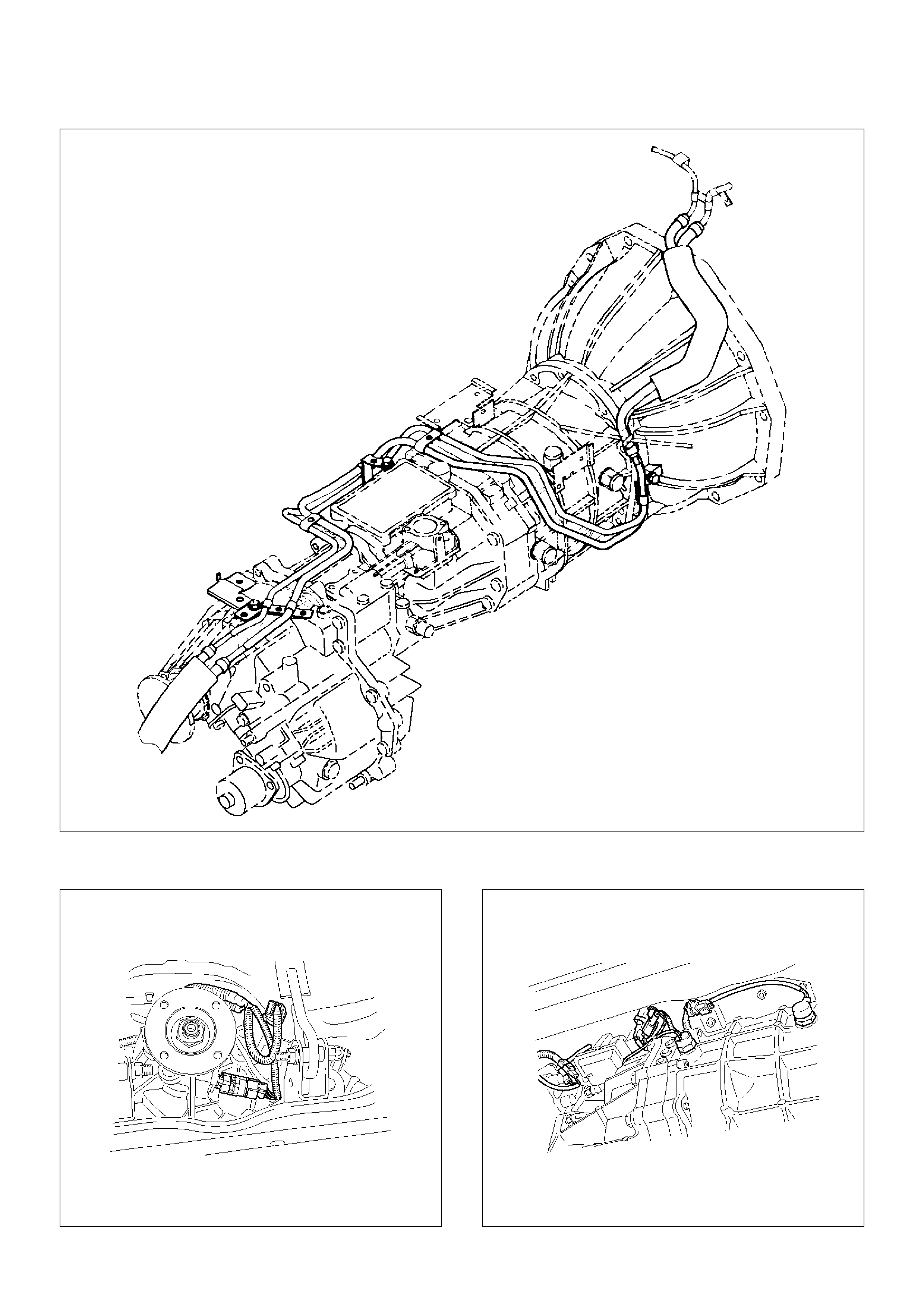

Transmission and Associated Parts

220RW108

EndOFCallout

Legend

(1) Gear Control Lever and Knob

(2) Transfer Control Lever and Knob

(3) Front Console Assembly

(4) Grommet Assembly

(5) Transfer Protector

(6) Rear Propeller Shaft

(7) Front Propeller Shaft

(8) Exhaust Pipe

(9) Backup Lamp, 4WD Indicator, and 1–2

Indicator Switch Harness Connector

(10) Speedometer Sensor and 2WD–4WD Actuator

Harness Connector

(11) Slave Cylinder Heat Protector

(12) Harness Heat Protector

(13) Slave Cylinder

(14) Dust Cover

(15) Engine Rear Mount Nut

(16) Engine Rear Mount Bolt

(17) Engine Rear Mount

(18) Third Crossmember

(19) Flywheel Under Cover

(20) Transmission Retaining Bolt

(21) Transmission Assembly with Transfer Case

Removal

NOTE: Before remove the transmission and transfer

assembly from the vehicle, change the transfer mode to

2WD using push button on dash panel.

1. Remove engine hood.

2. Disconnect battery ground cable.

3. Remove the gear control lever knob.

4. Remove the front console assembly.

5. Remove the grommet assembly.

6. Remove the transmission control lever and transfer

control lever.

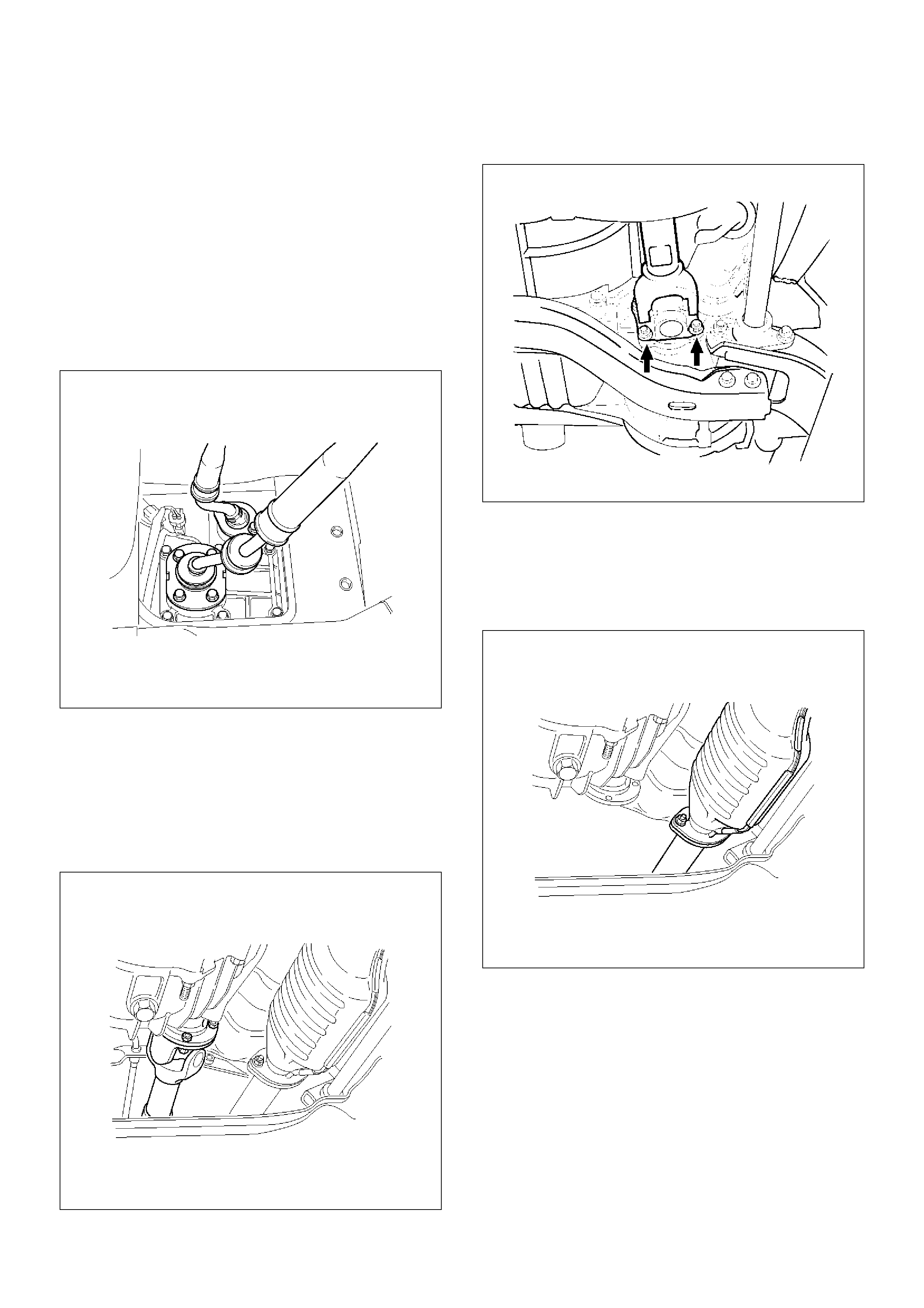

235RW014

7. Raise and support the vehicle with suitable jack

stand.

8. Remove transfer protector.

9. Remove the rear propeller shaft.

NOTE: Apply alignment marks on the flange at the both

front and rear side.

(4JX1)

401RW060

10. Remove the front propeller shaft.

NOTE: Apply alignment marks on the flange at both the

front and rear sides.

401RS003

11. Disconnect two oxygen sensor connectors from the

transmission harness (6VE1).

12. Remove the front and 3 way exhaust pipe (6VE1).

Remove the exhaust pipe with catalytic converter

(4JX1).

(4JX1)

150RW041

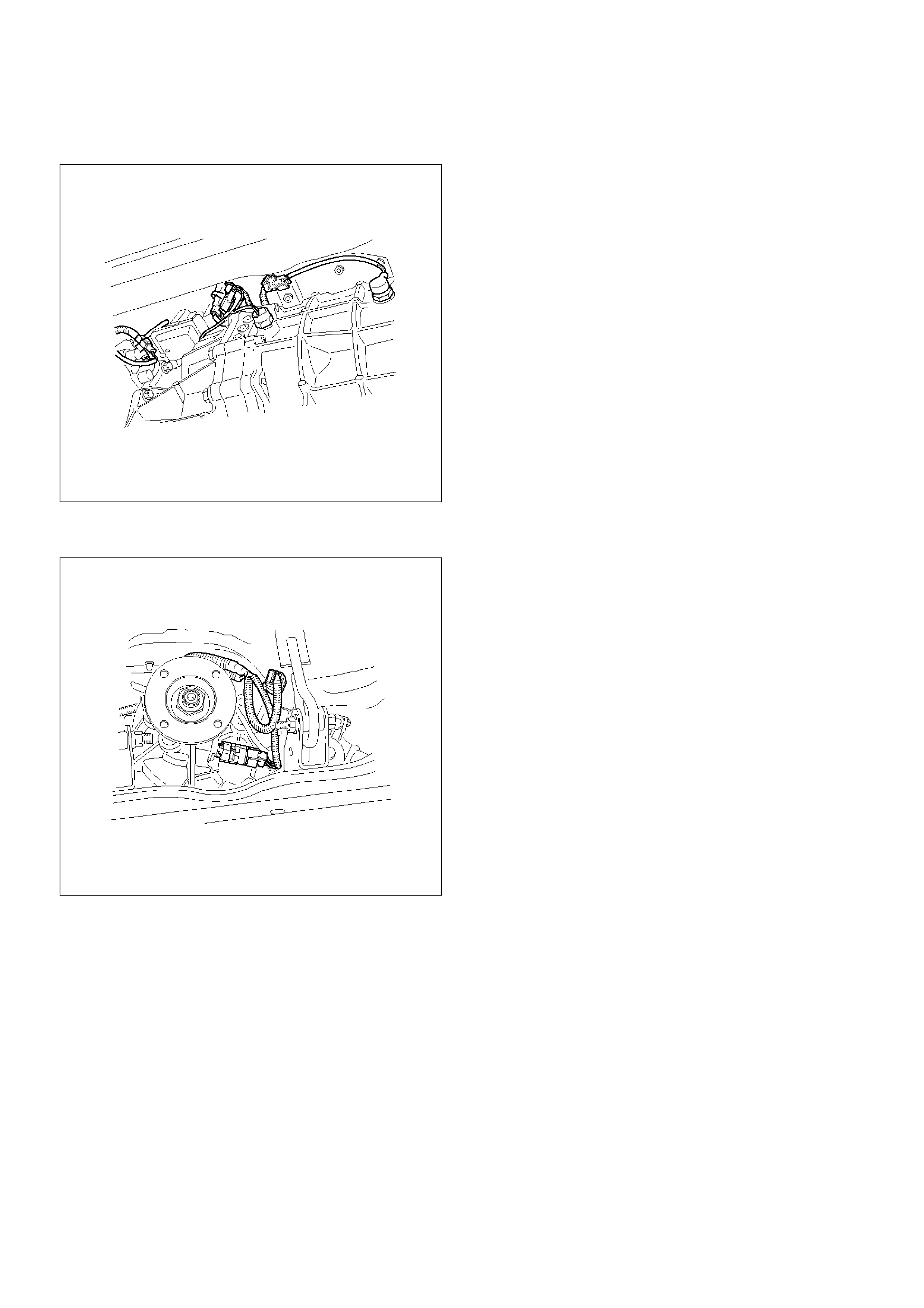

13. Disconnect the backup lamp switch, 4WD indicator

switch and 1–2 indicator switch harness connectors.

826RW023

14. Disconnect the speedometer sensor and 2WD-4WD

actuator harness connectors.

826RW024

15. Remove four fuel pipe bracket from the

transmission case (6VE1).

141RW024

16. Remove the slave cylinder heat protector.

17. Remove the harness heat protector (6VE1).

(6VE1)

225RW006

18. Remove two transmission harness clamps and

bracket (6VE1).

19. Remove the slave cylinder.

206RW002

20. Remove the two dust cover from transmission case.

21. Support the transfer case with a jack.

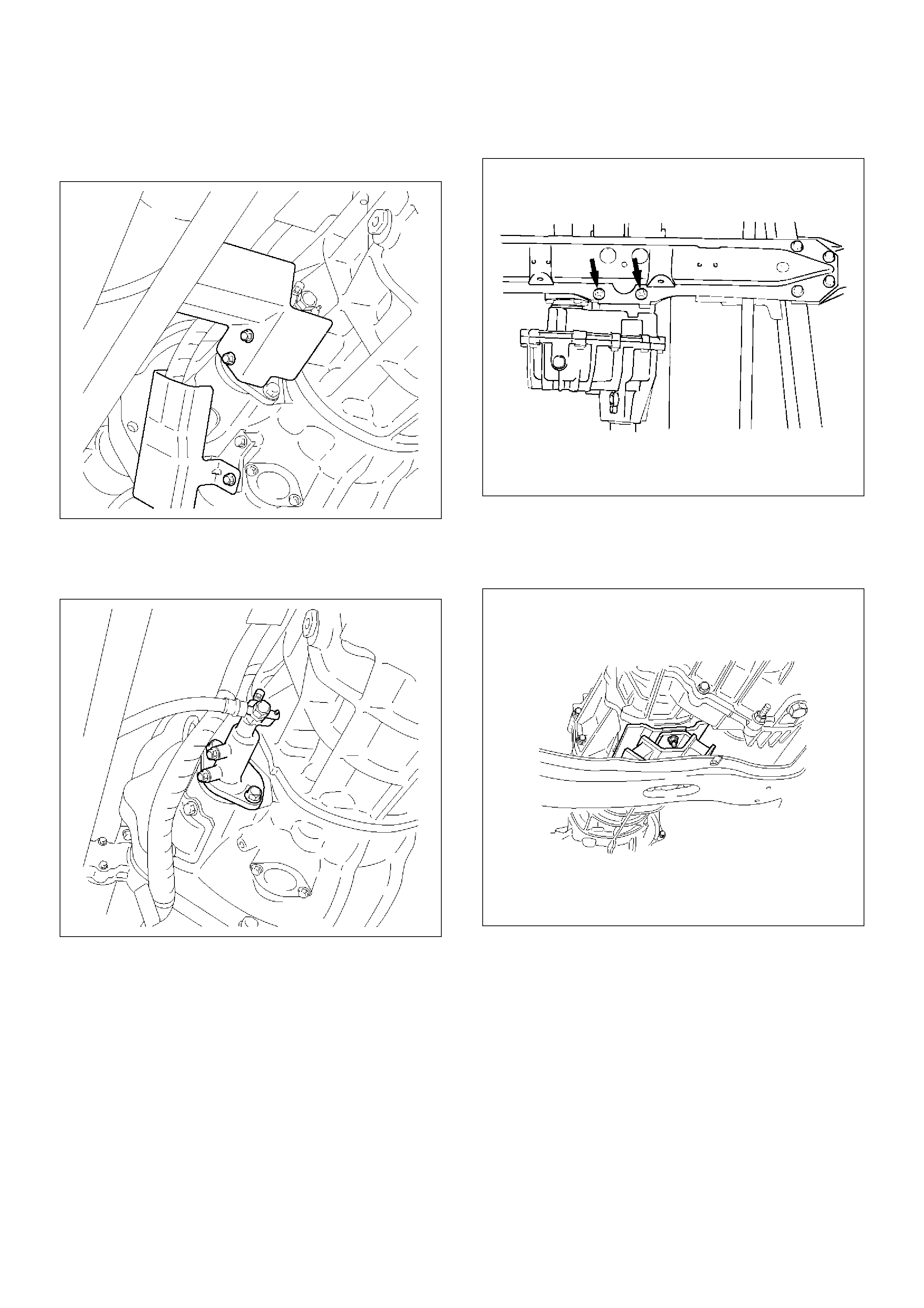

22. Remove two engine rear mount nuts.

(6VE1)

022RT002

23. Remove third crossmember (6VE1).

24. Remove third crossmember with rear mount rubber

(4JX1).

(4JX1)

022RW013

25. Remove two engine rear mount bolts (6VE1).

26. Remove the rear mount from the transmission

(6VE1).

27. Remove three flywheel under cover (6VE1).

28. Support the transmission with a transmission jack

and then remove jack from the transfer case side.

220RS001

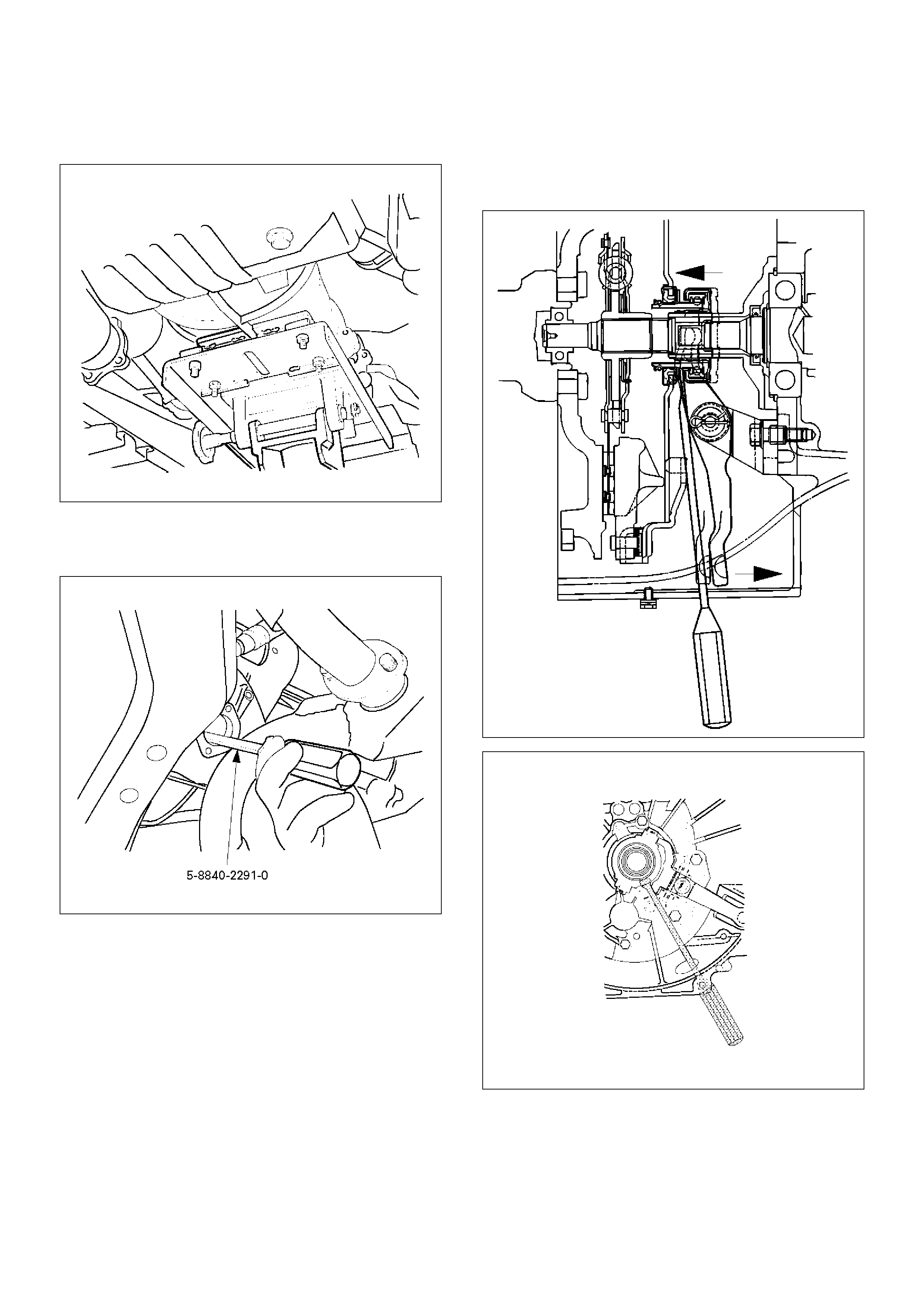

29. Use the clutch release bearing remover 5–8840–

2291–0 (J–39207) to disconnect the clutch release

bearing from the clutch pressure plate.

220RW109

Release bearing disconnection

1. Pull the shift fork toward the transmission to

press the clutch release bearing against the

clutch.

2. Insert the clutch release bearing remover

between the wedge collar and the release

bearing.

3. Turn the remover to separate the release

bearing.

NOTE: Be sure not to insert the remover between the

wedge collar and the clutch.

220RW063

220RW064

220RW119

EndOFCallout

30.Remove the transmission retaining nuts and bolts.

31.Remove the transmission assembly with transfer

case from the vehicle.

NOTE: Remove the transfer case from the

transmission assembly if the transmission disassembly

required.

Refer to Transfer Case in Drive Line/Axle section.

Installation

1. Apply a thin coat of molybdenum disulfide grease to

the top gear shaft spline.

2. Slowly operate the transmission jack until the front

of transmission is aligned with the rear of the

engine.

The slope of the engine and the transmission must

be the same.

3. Align the top gear shaft spline with the clutch driven

plate spline.

220RS005

4. Install the transmission to the engine.

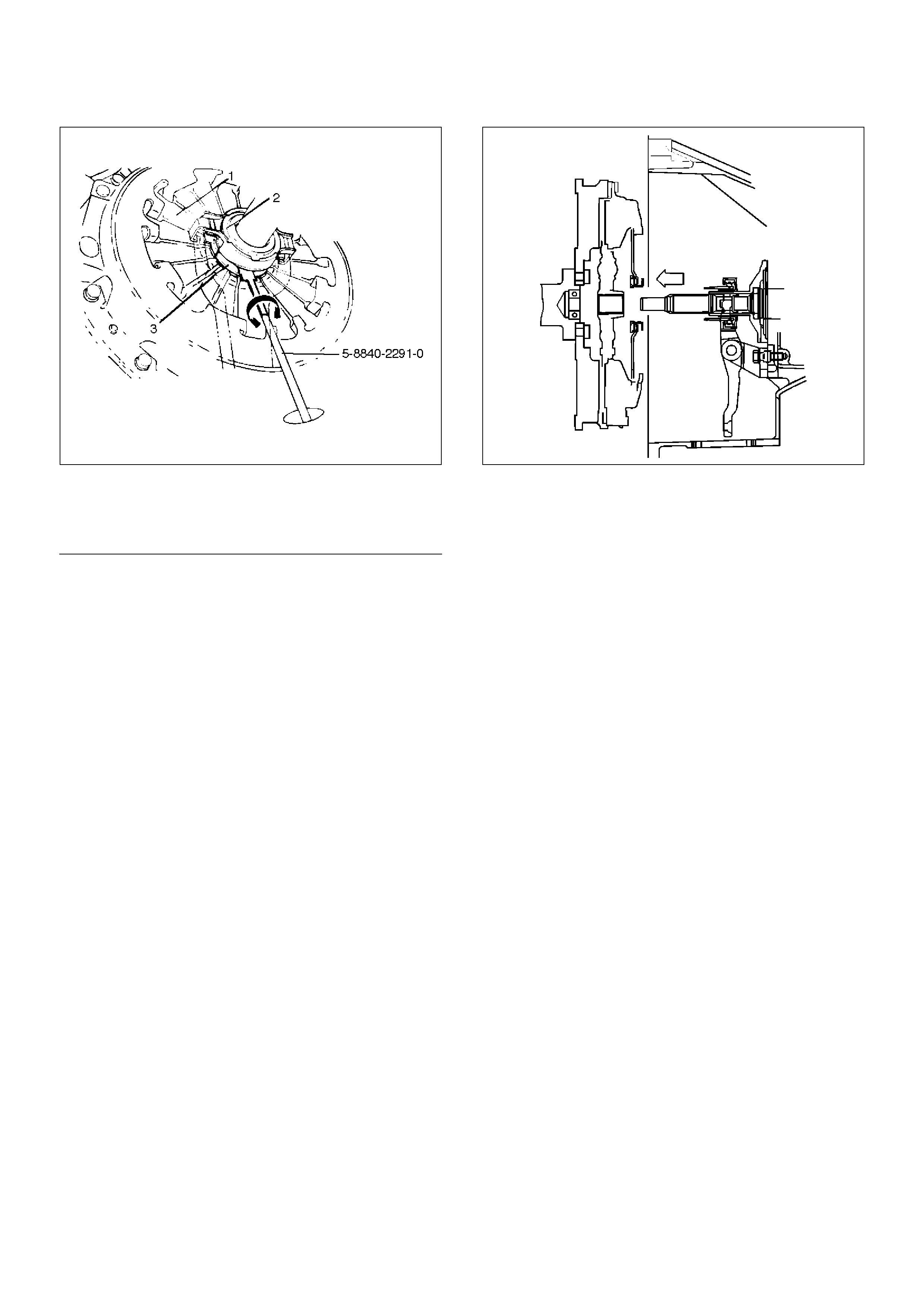

Tighten the transmission retaining nuts and bolts.

Legend

(1) Pressure Plate Assembly

(2) Release Bearing

(3) Wedge Collar

(6VE1)

225RW019

(4JX1)

225RW020

5. Apply a force of about 113N(26Ib) to the tip of the

shift fork in the direction of the transmission to

engage the clutch pressure plate and release

bearing.

NOTE: A clicking sound is heard when the release

bearing and the tip of the diaphragm spring engage

each other.

Check to see if they are securely engaged by pushing

the tip of the shift fork toward the engine while applying

a force of about 25 N (5.5 lb). If the shift fork will not

move, then they are securely engaged.

220RS006

6. Install three flywheel under cover (6VE1).

7. Install the engine rear mount to the transmission

case and tighten the fixing bolts specified torque

(6VE1).

Torque: 41 N·m (4.2kg·m/30 Ibft)

8. Install the third crossmember to the frame and

tighten the fixing bolts specified torque.

Torque: 50 N·m (5.1kg·m/37 Ibft)

9. Tighten the engine rear mount nuts specified torque.

Torque: 50 N·m (5.1kg·m/37 Ibft)

10. Remove the transmission jack.

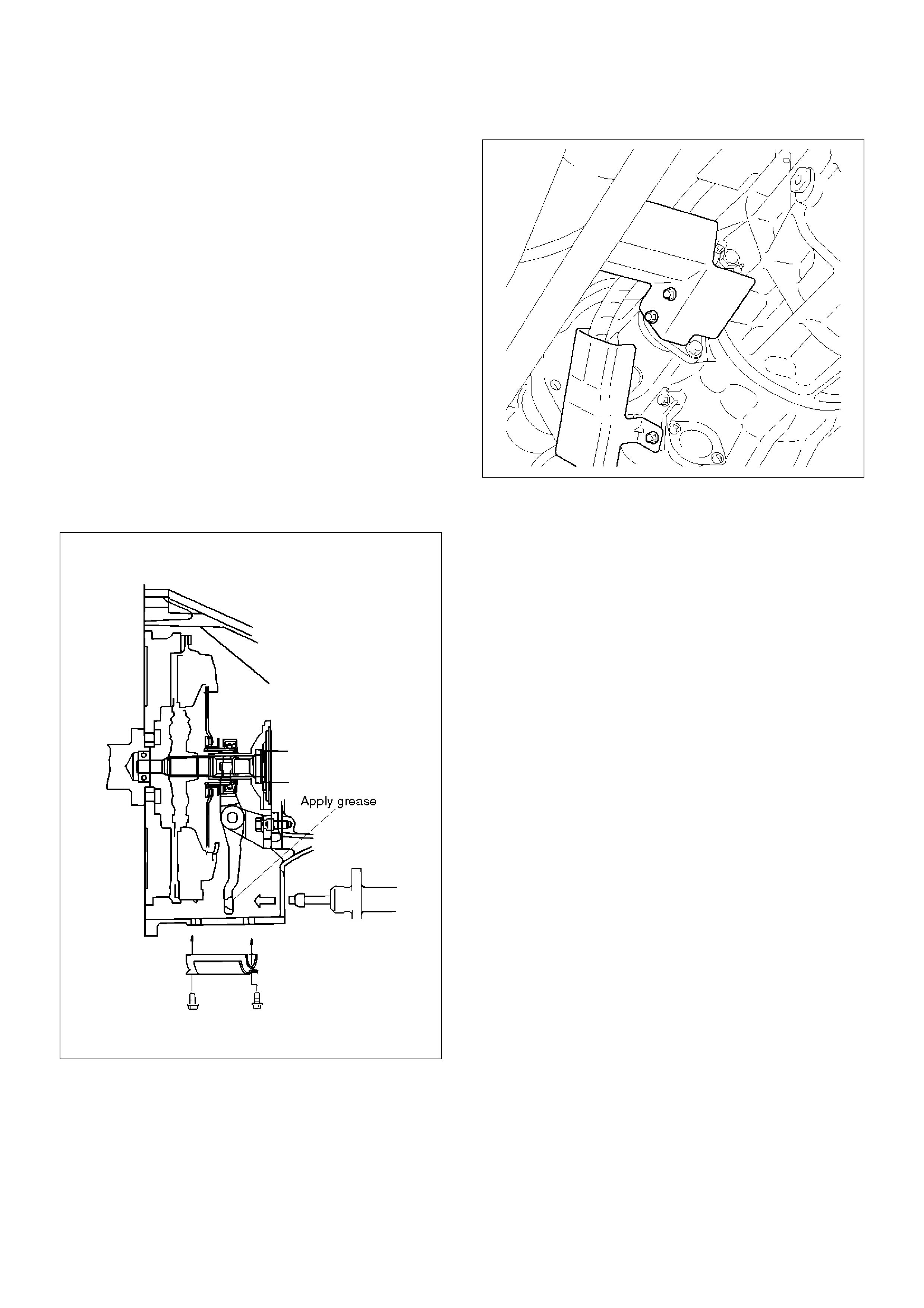

11. Apply the grease to top hole portion of the shift fork.

12. Install the slave cylinder and tighten the fixing bolts

specified torque.

Torque: 43 N·m (4.4kg·m/32 Ibft)

13. Install the clutch dust cover to the clutch housing

and tighten the fixing bolts specified torque.

Torque: 8 N·m (0.8kg·m/69Ibin)

220RS007

14. Install the slave cylinder heat protector to the slave

cylinder.

15. Install bracket and two transmission harness clamps

to the transmission case (6VE1).

16. Install harness heat protector (6VE1).

(6VE1)

225RW006

17. Install four fuel pipe bracket (6VE1).

141RW024

18. Connect the speedometer sensor and 2WD–4WD

actuator harness connector.

826RW024

19. Connect the backup lamp switch, 4WD indicator

switch, and 1-2 indicator switch harness connectors.

826RW023

20. Install the front and 3 way exhaust pipe (6VE1).

Install the exhaust pipe with catalytic converter

(4JX1).

Torque:

Exhaust pipe to exhaust manifold:

67 N·m (6.8kg·m/49 Ibft)

Exhaust pipe flange bolt:

43 N·m (4.4kg·m/32 Ibft)

(4JX1)

150RW041

21. Connect two oxygen sensor connectors to the

transmission harness (6VE1).

22. Install the front propeller shaft and tighten the fixing

bolts and nuts specified torque.

Torque: 63 N·m (6.4 kg·m/46Ib ft)

23. Install the rear propeller shaft and tighten the fixing

bolts and nuts specified torque.

Torque: 63 N·m (6.4 kg·m/46Ib ft)

24. Install transfer protector and tighten the fixing bolts

specified torque.

Torque: 37 N·m (3.8 kg·m/27Ib ft)

25. Install the transmission control lever and transfer

control lever.

235RW014

26. Install the grommet assembly.

27. Install the front console assembly.

28. Install the gear control lever knob.

29. Connect battery ground cable.

30. Install engine hood.

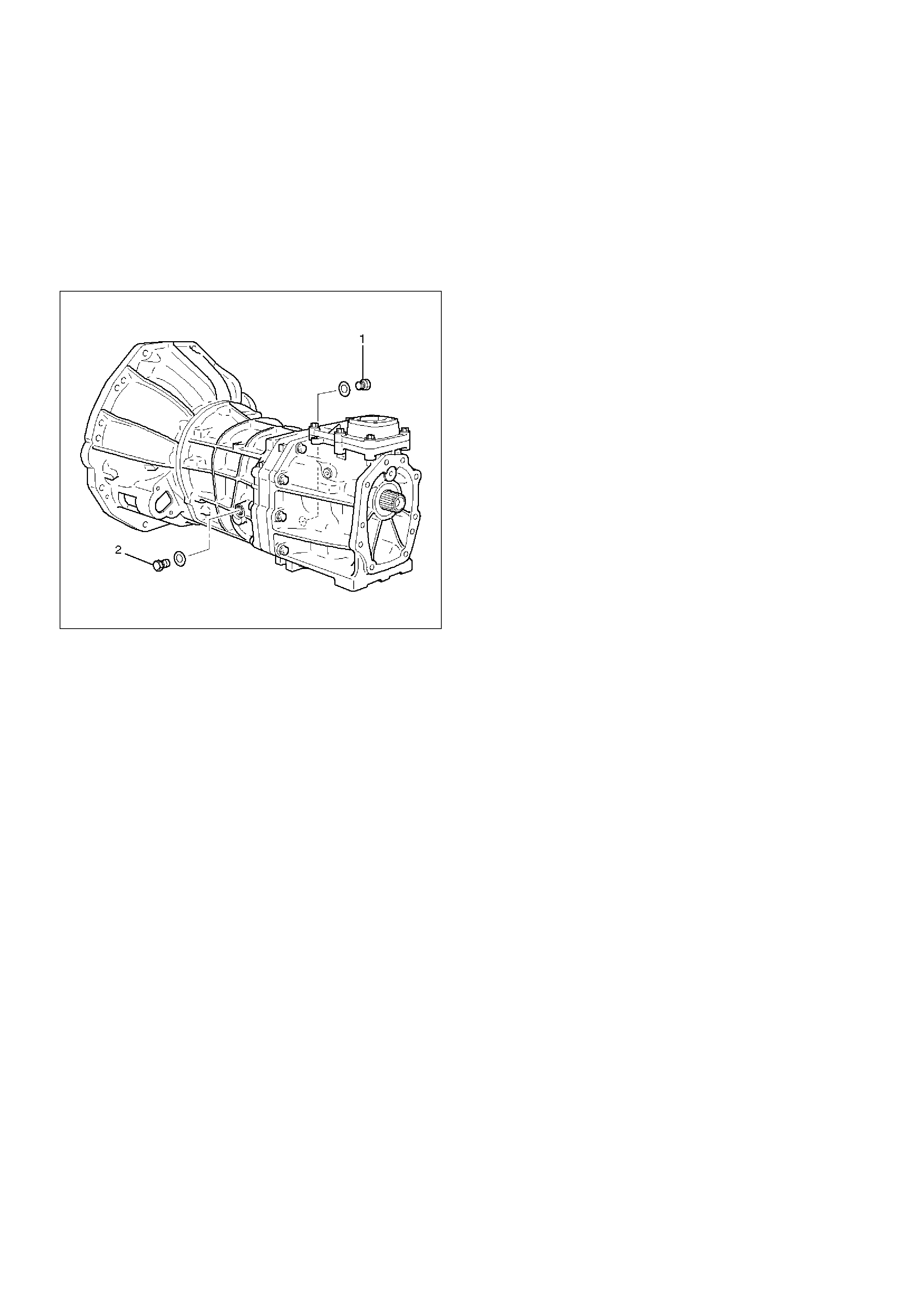

Rear Oil Seal (Transfer Adapter)

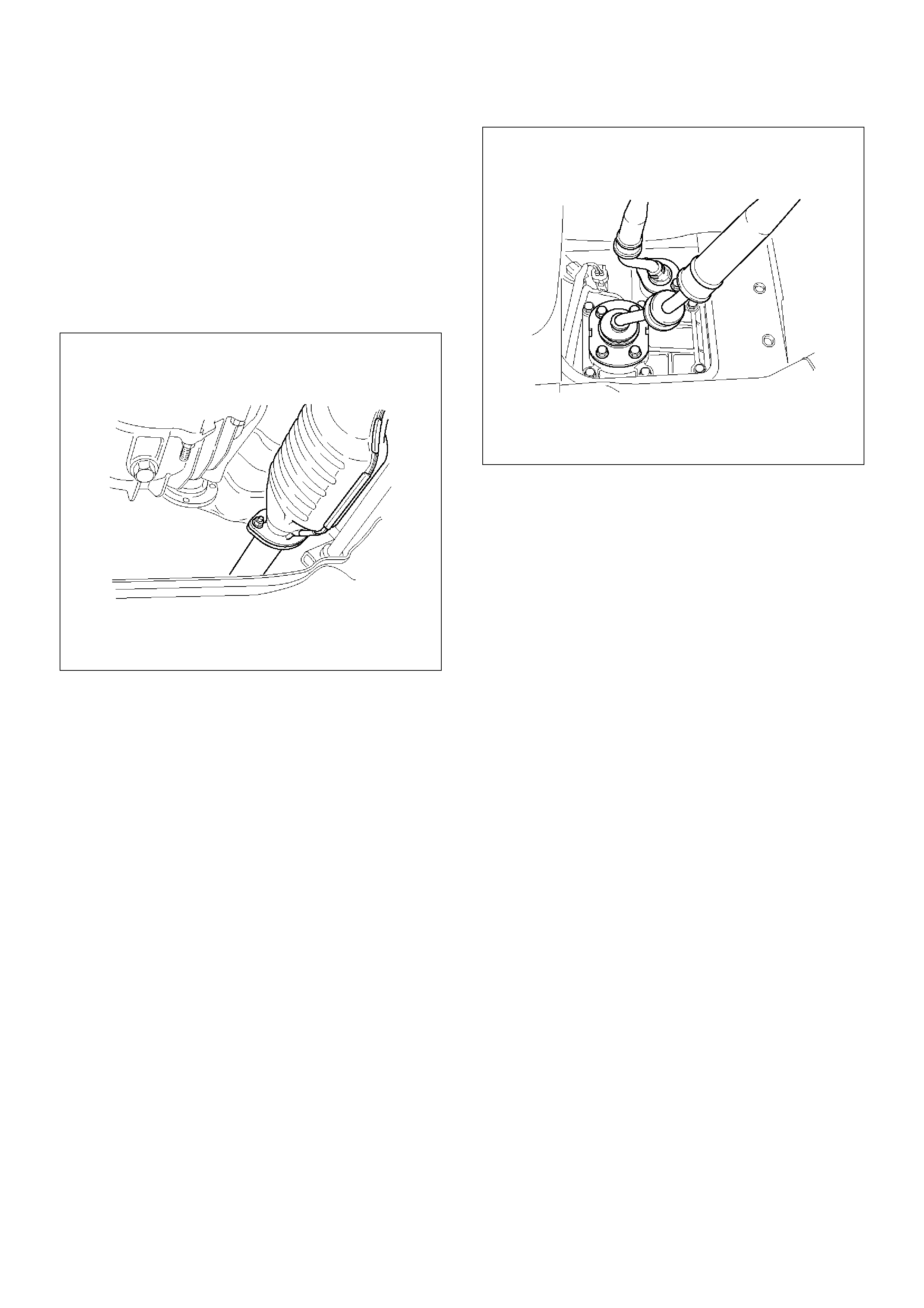

Removal

1.Remove the transfer case assembly from the

vehicle.

Refer to Transfer Case in Drive Line/Axle section.

2.Remove the rear oil seal from the transfer adapter.

220RW090

Installation

1.Use 5–8840–2558–0 (J–42802) transfer adapter oil

seal installer, and install the rear oil seal to the

transfer adapter.

2.Apply grease to the oil seal lip.

3.Install the transfer case assembly to the vehicle.

Refer to Transfer Case in Drive Line/Axle section.

220RW115

Transmission (AR-5)

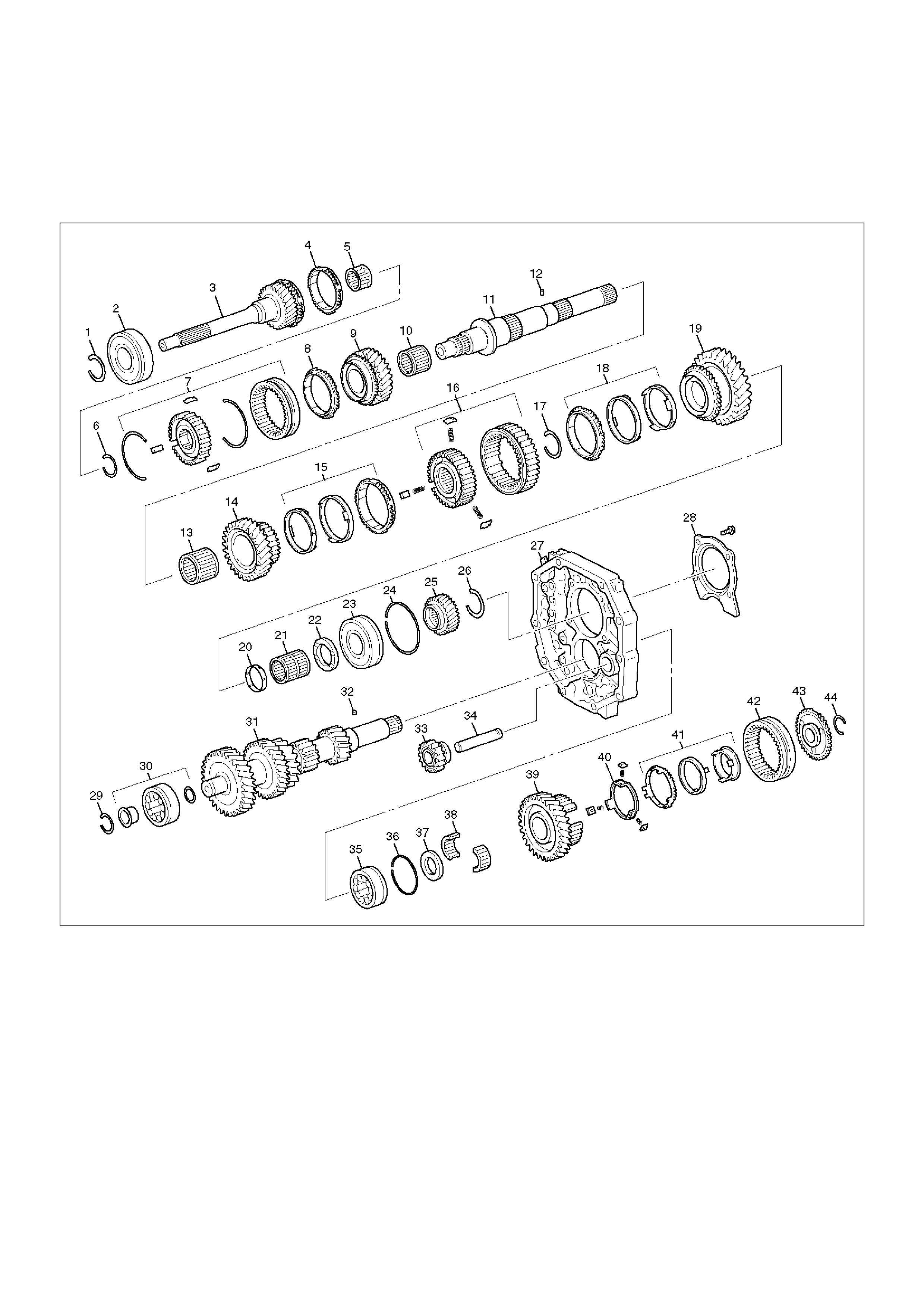

Disassembled View

226RW182

Legend

(1) Snap Ring

(2) Bearing

(3) Top Gear Shaft

(4) Block Ring

(5) Roller Bearing

(6) Snap Ring

(7) Clutch Hub No.2 Assembly

(8) 3rd Block Ring

(9) 3rd Gear

(10) 3rd Gear Needle Roller Bearing

(11) Mainshaft

(12) Thrust Washer Pin

(13) 2nd Gear Needle Roller Bearing

(14) 2nd Gear

(15) Synchronizer Assembly

(16) Clutch Hub No.1 Assembly

(17) Snap Ring

(18) Synchronizer Assembly

(19) 1st Gear

(20) 1st Gear Bearing Spacer

(21) 1st Gear Needle Roller Bearing

(22) 1st Gear Thrust Washer

(23) Mainshaft Bearing

(24) Snap Ring

(25) 5th Gear

(26) Snap Ring

(27) Intermediate Plate

(28) Bearing Retainer

(29) Snap Ring

EndOFCallout

226RW00001

EndOFCallout

(30) Front Bearing Assembly

(31) Counter Gear Shaft

(32) Thrust Washer Pin

(33) Reverse Idle Gear

(34) Reverse Idle Gear Shaft

(35) Counter Gear Shaft Center Bearing

(36) Snap Ring

(37) Thrust Washer

(38) Roller Bearing

(39) Counter 5th Gear

(40) Reverse Block Ring

(41) Synchronizer Assembly

(42) Hub Sleeve No.3

(43) 5th Gear Spline Piece

(44) Snap Ring

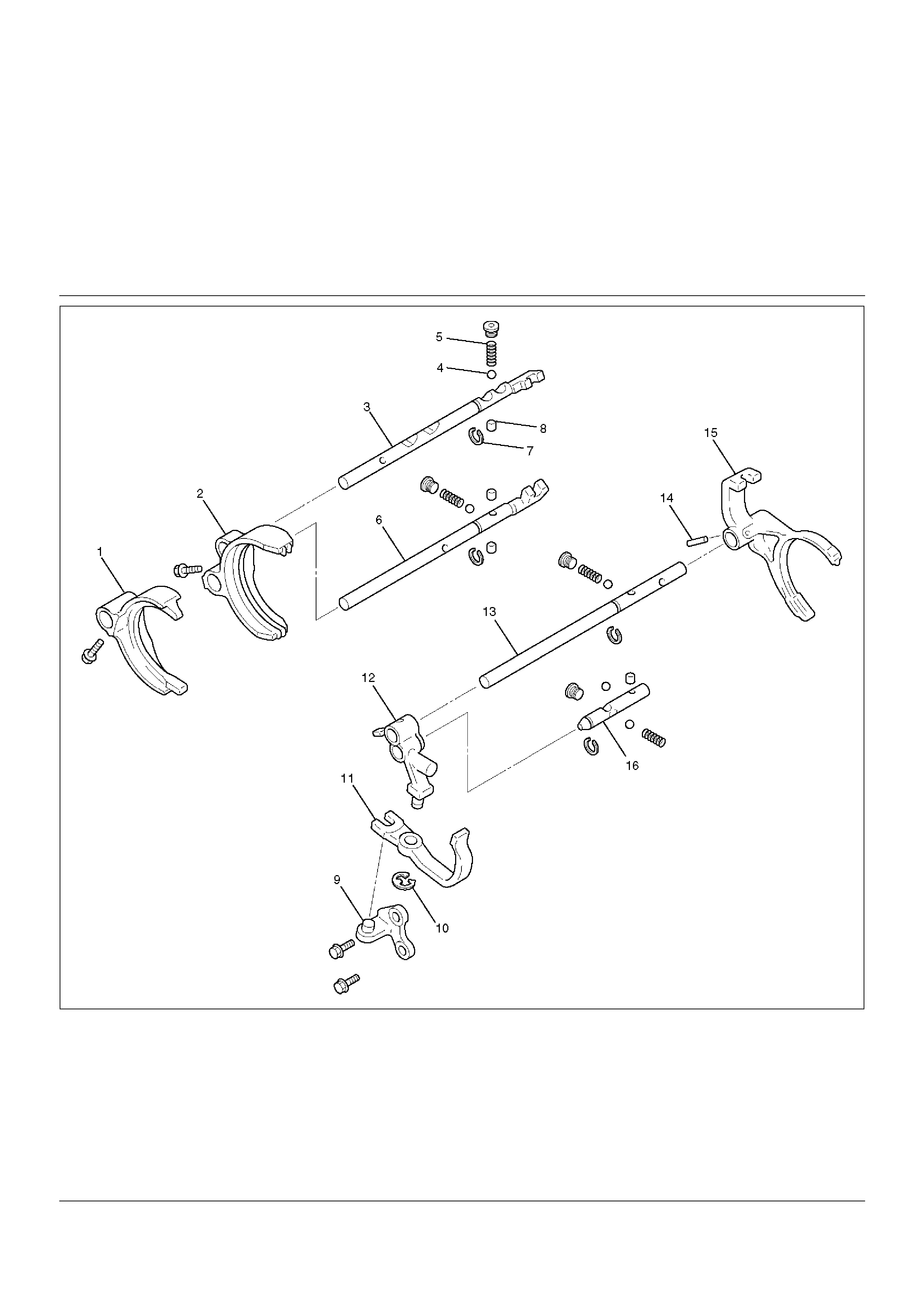

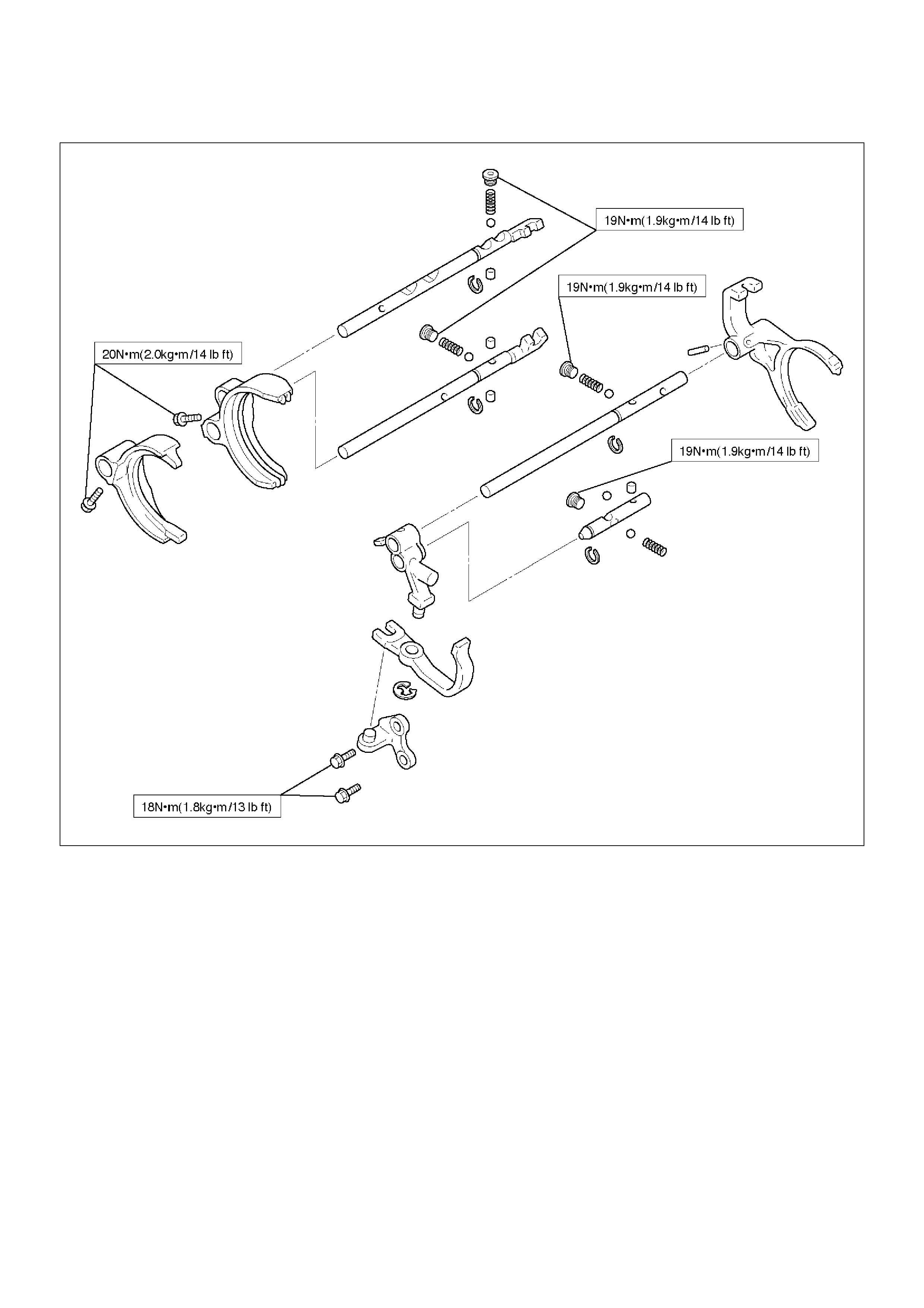

Legend

(1) 3rd-4th Shift Arm

(2) 1st-2nd Shift Arm

(3) 3rd-4th Shift Rod

(4) Ball

(5) Spring

(6) 1st-2nd Shift Rod

(7) Snap Ring

(8) Interlock Pin

(9) Reverse Shift Arm Bracket

(10) E–Ring

(11) Reverse Shift Arm No.2

(12) Reverse Shift Arm No.1

(13) 5th Reverse Shift Rod

(14) Spring Pin

(15) 5th Shift Arm

(16) Reverse Shift Rod

220RW095

EndOFCallout

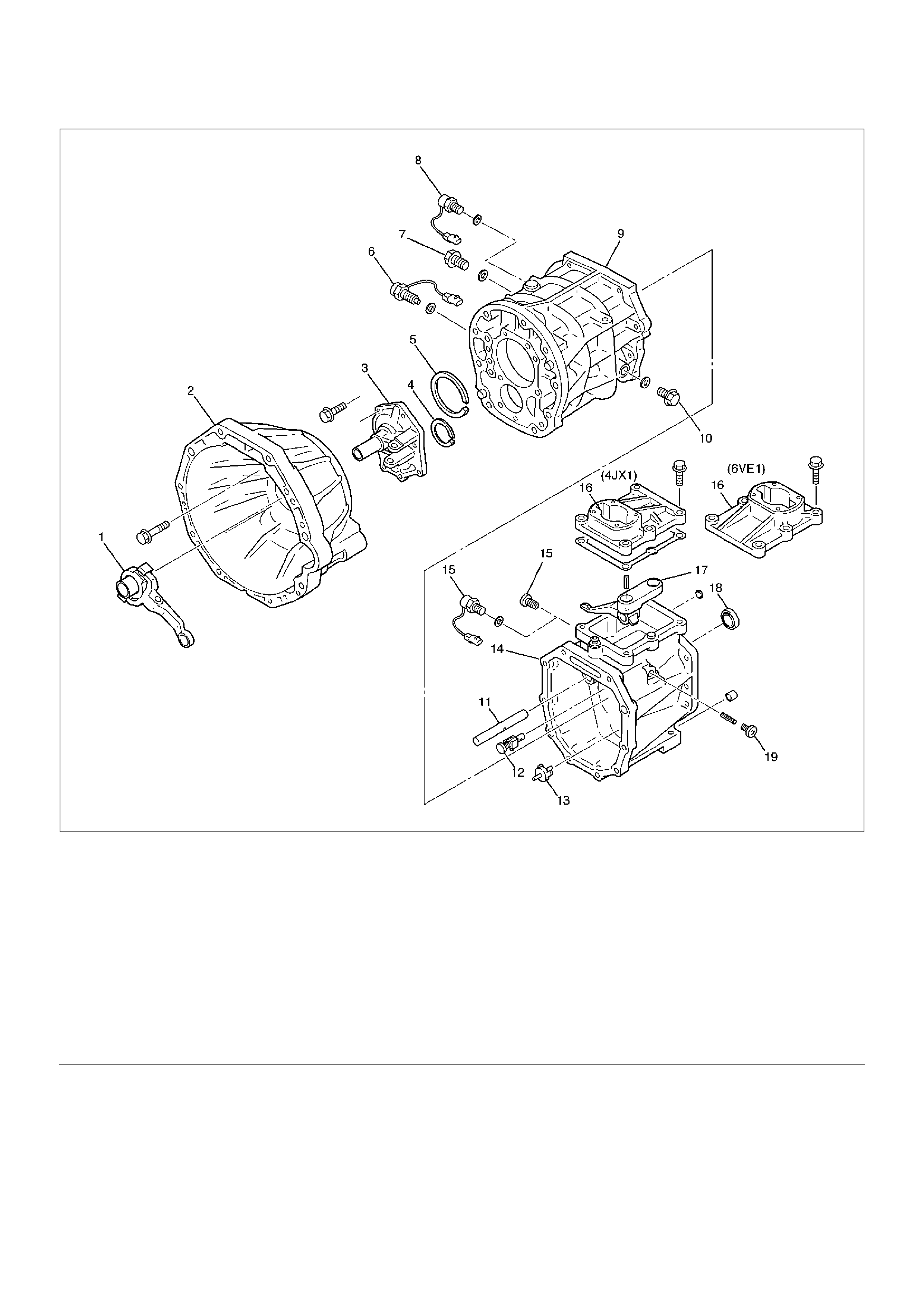

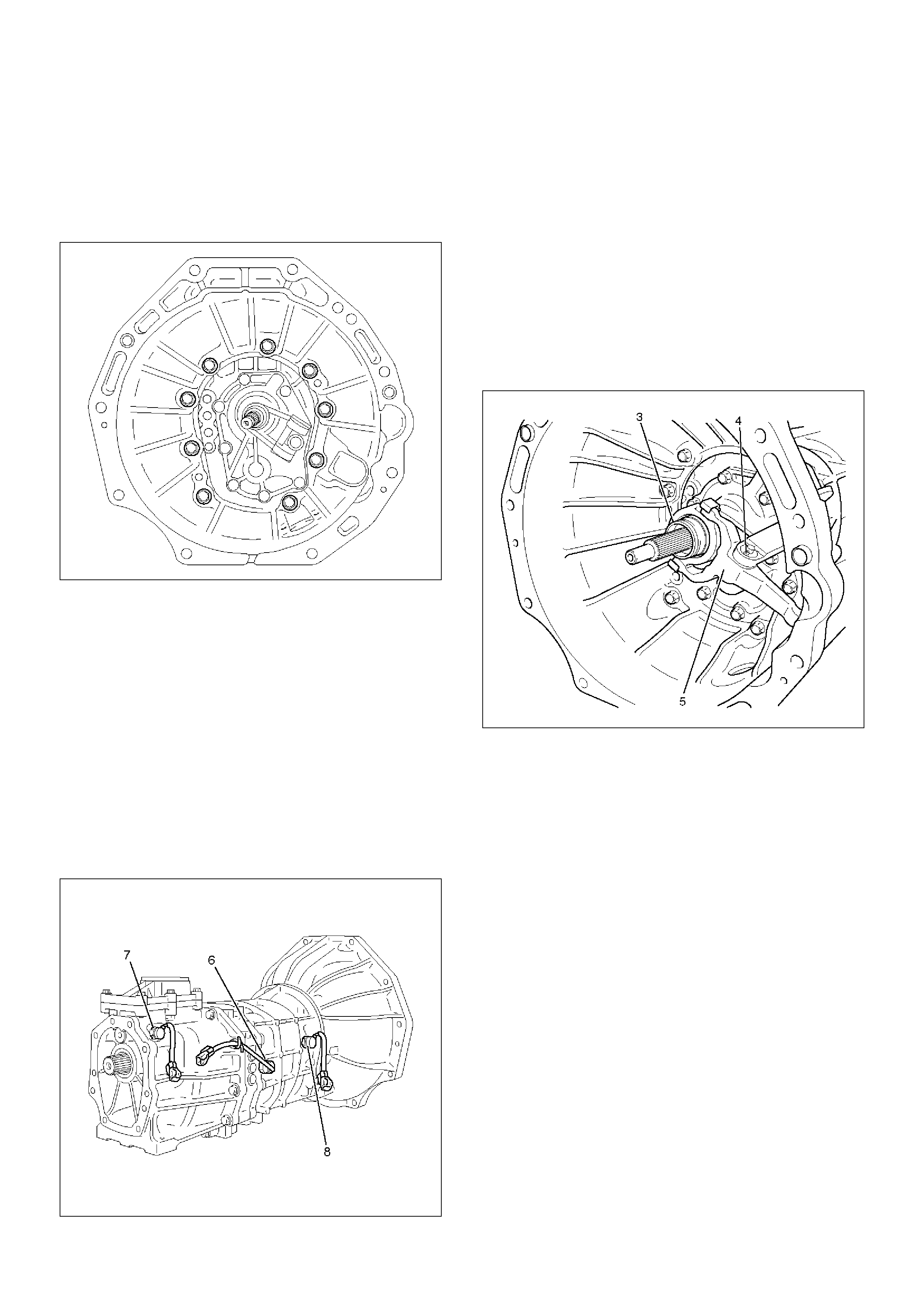

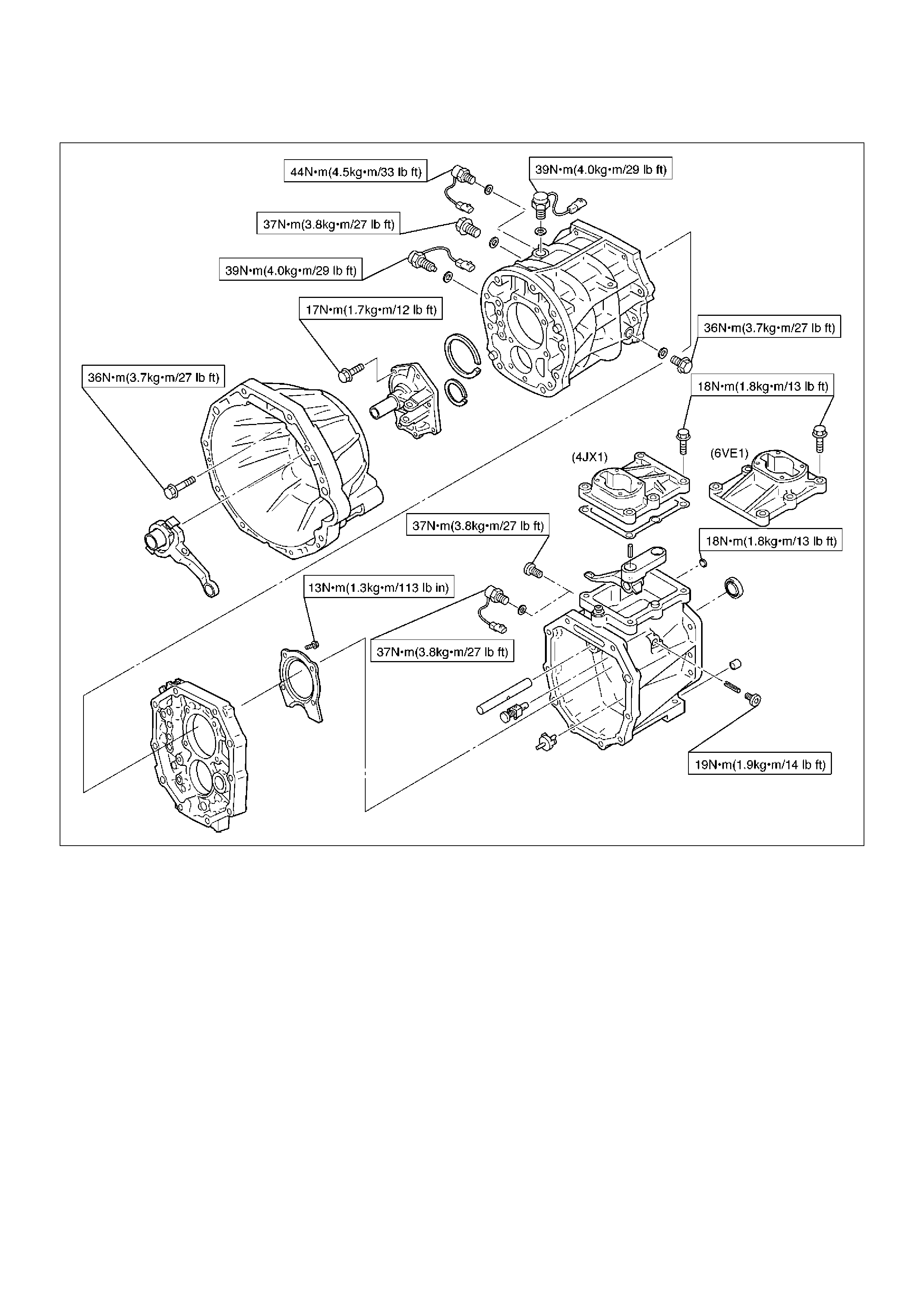

Legend

(1) Release Bearing and Shift Fork

(2) Clutch Housing

(3) Front Cover

(4) Snap Ring

(5) Snap Ring

(6) 1st and 2nd Switch

(7) Drain Plug

(8) Backup Light Switch

(9) Transmission Case

(10) Filler Plug

(11) Gear Control Rod

(12) Reverse Restrict Pin

(13) Oil Receiver Pipe

(14) Transfer Adapter

(15) Plug (6VE1) or Neutral Switch (4JX1)

(16) Gear Control Box

(17) Shift Lever Housing

(18) Oil Seal

(19) Plug

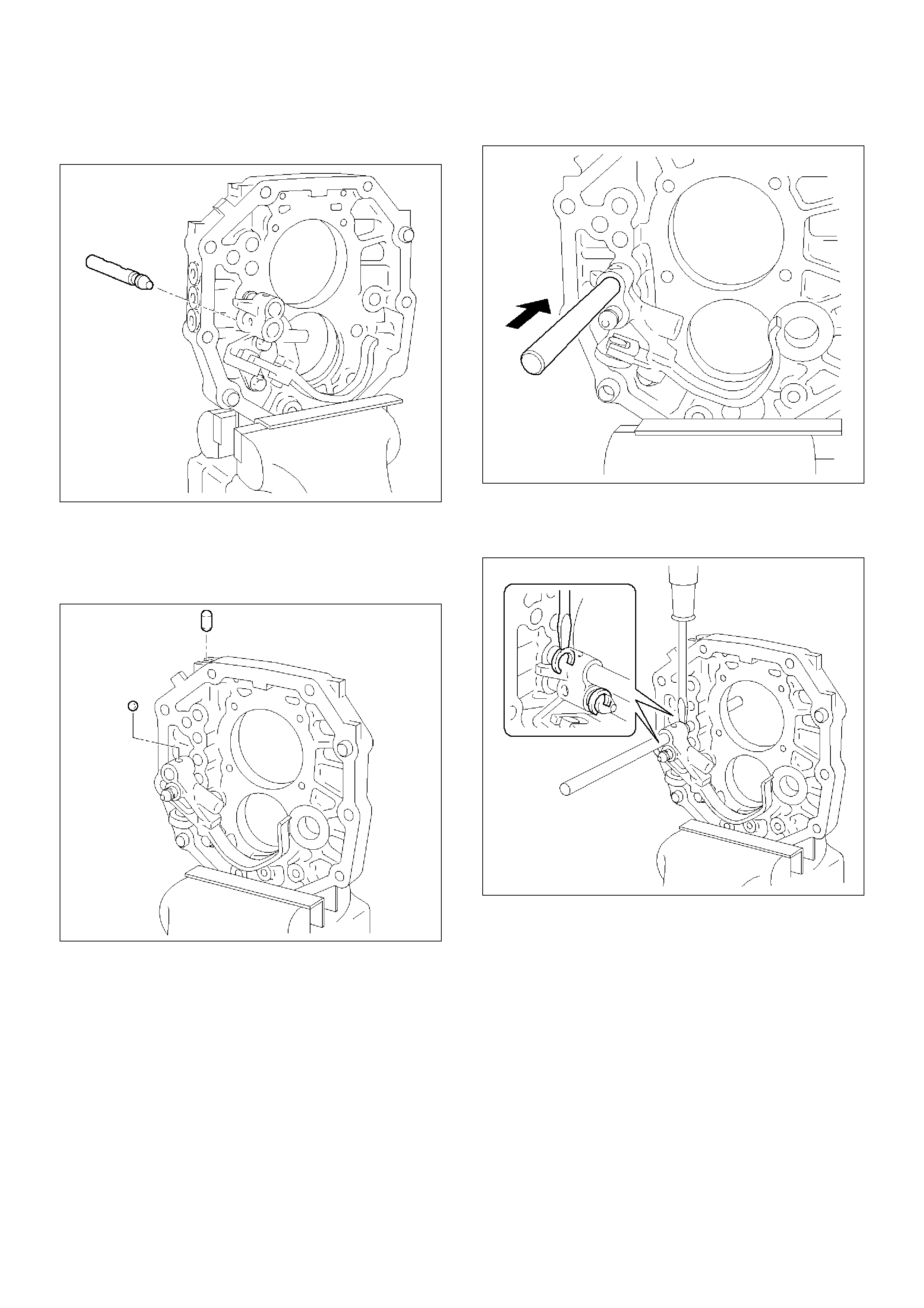

Disassembly

1. Remove the drain plug and filler plug.

1. Remove the drain plug (1) and gasket.

2. Remove the filler plug (2) and gasket.

(6VE1)

220RW007

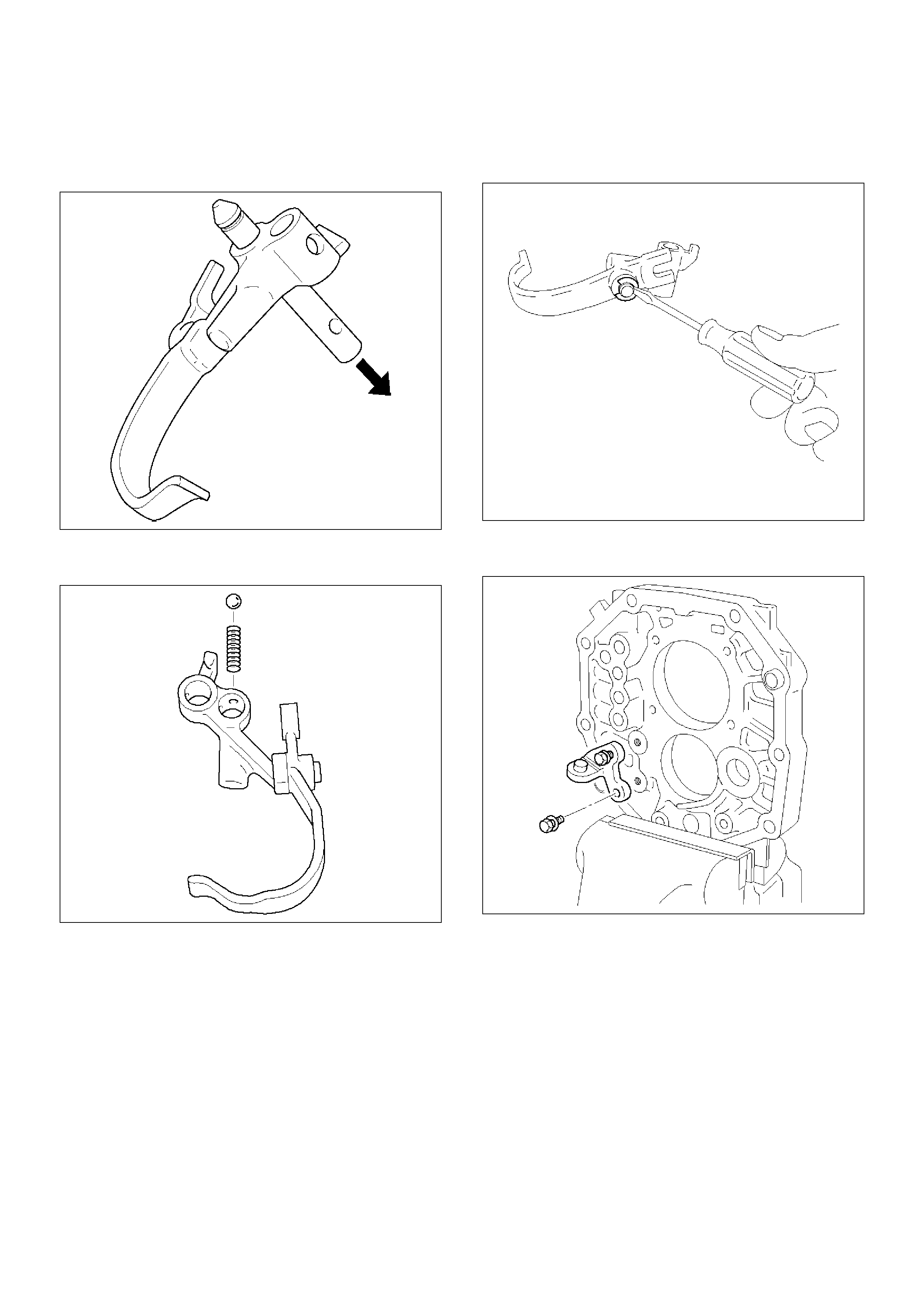

2. Remove the clutch release bearing and shift fork.

1. Remove the clutch release bearing (3) from the

front cover.

2. Remove the split pin (4). Remove the shaft from

the under. Remove the shift fork (5).

220RW086

3. Remove the switch.

1. Remove backup light switch (6) and gasket.

2. Remove neutral switch (7) and gasket (4JX1).

3. Remove 1st and 2nd switch (8) and gasket.

(4JX1)

220RW093

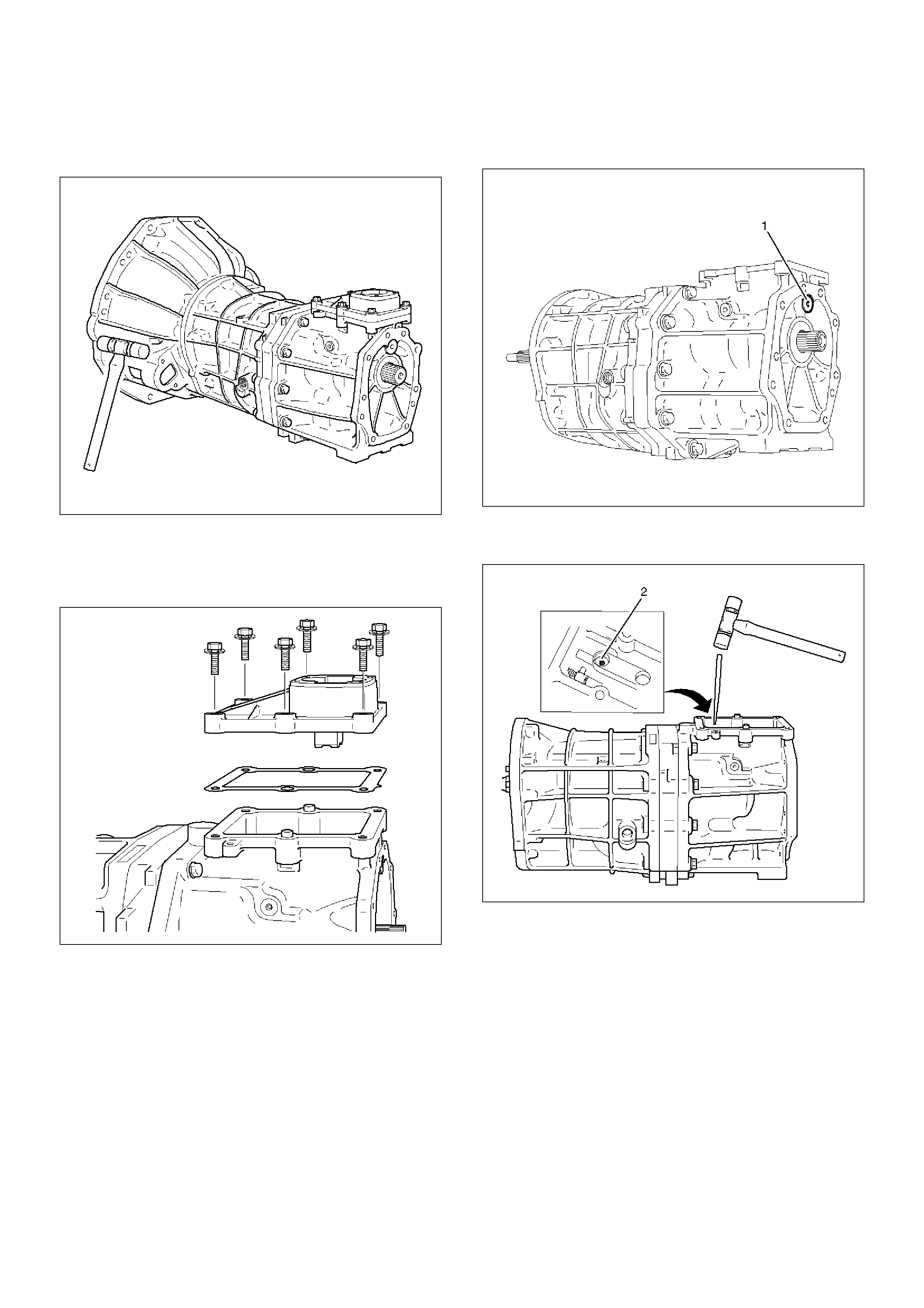

4. Remove the clutch housing.

1. Remove the 9 bolts.

241RW001

2. Using a plastic hammer, carefully tap the clutch

housing.

(6VE1)

220RW008

5. Remove gear control box and gasket.

1. Remove the 6 bolts, gear control box and

gasket.

(6VE1)

230RW001

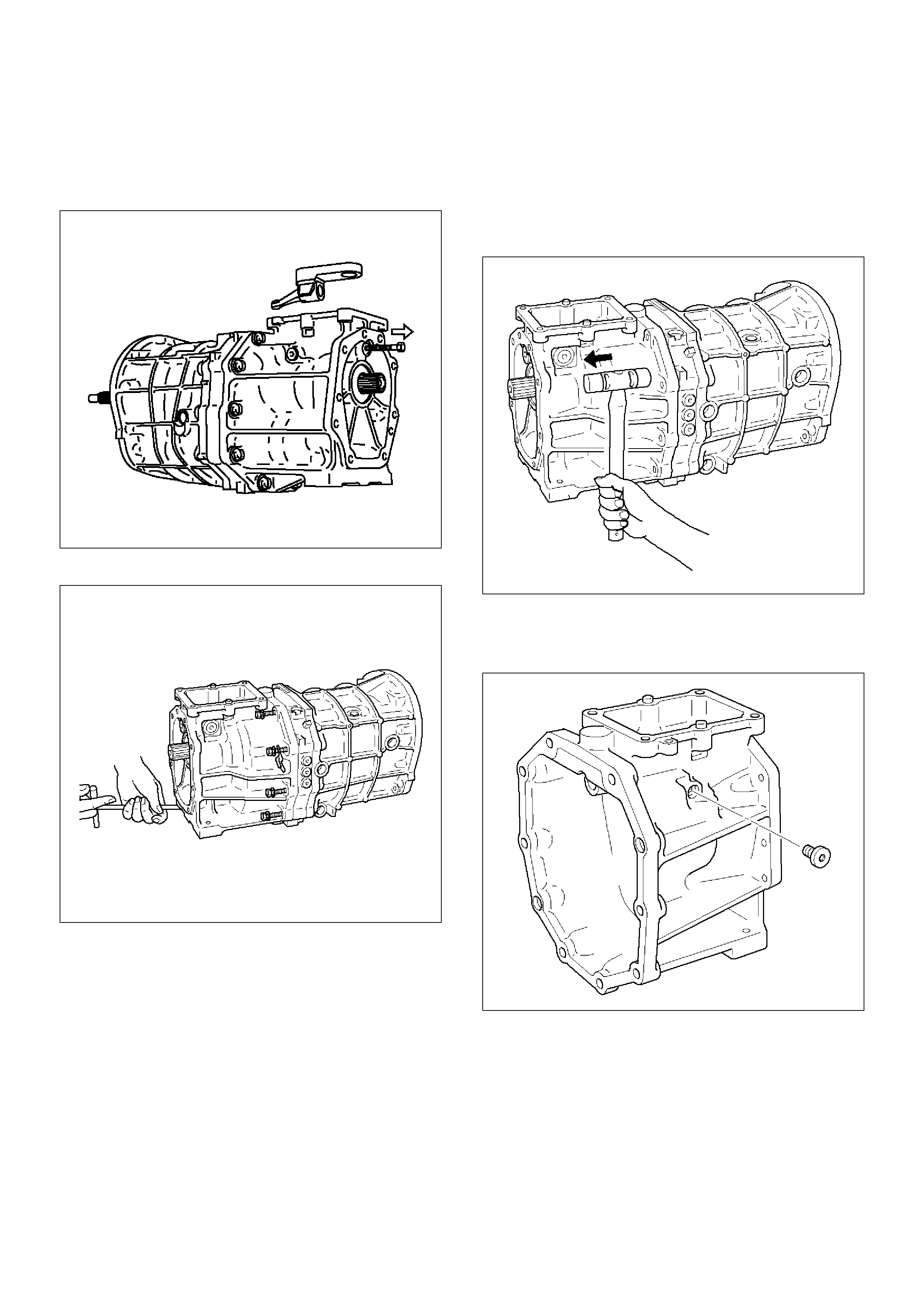

6. Remove transfer adapter.

1. Using a hexagon wrench, remove the plug (1).

220RW010

2. Using a pin punch and hammer, drive out the

slotted spring pin (2).

230RW002

3. Using the M8 ´ 1.25 bolt, remove the gear

control rod and the shift lever hausing.

NOTE: Turn the M8 bolt a few times, before remove the

gear control rod.

220RW098

4. Remove the 10 bolts and clamp.

220RW016

5. Using a plastic hammer, tap the transfer

adapter.

NOTE:

• Be careful not to lose the pin.

• Cover the mainshaft splines with adhesive tape.

This will prevent damage to the oil seal lip.

220RW015

7. Disassemble the transfer adapter assembly.

1. Using a torx socket wrench(T40), remove the

plug.

220RW013

2. Using a pin punch and hammer, drive out the

slotted spring pin. Remove the reverse restrict

pin.

220RW012

3. Remove the oil receiver pipe.

220RW011

4. Remove the oil seal.

5. Using socket hexagon wrench, remove the plug.

220RW014

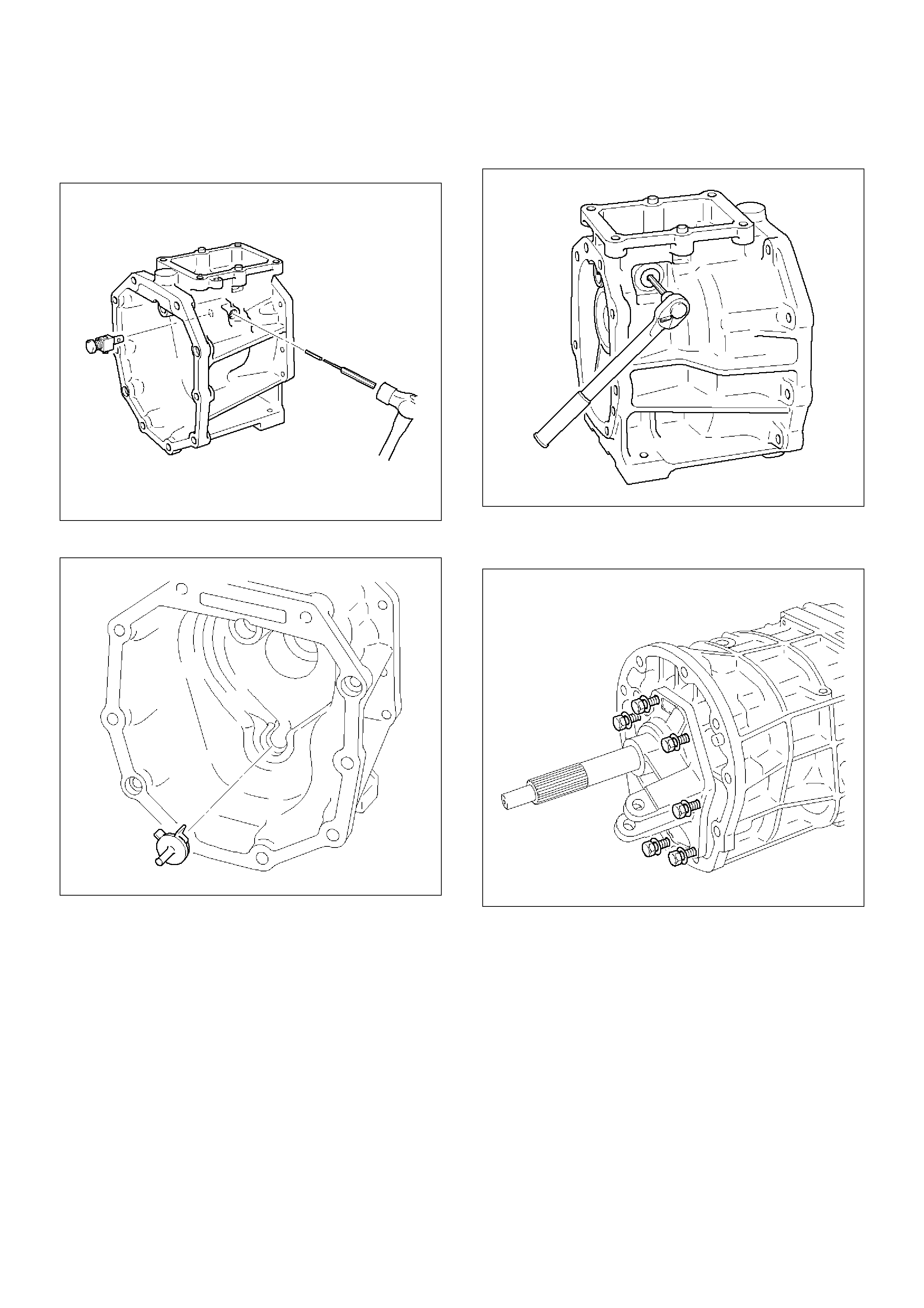

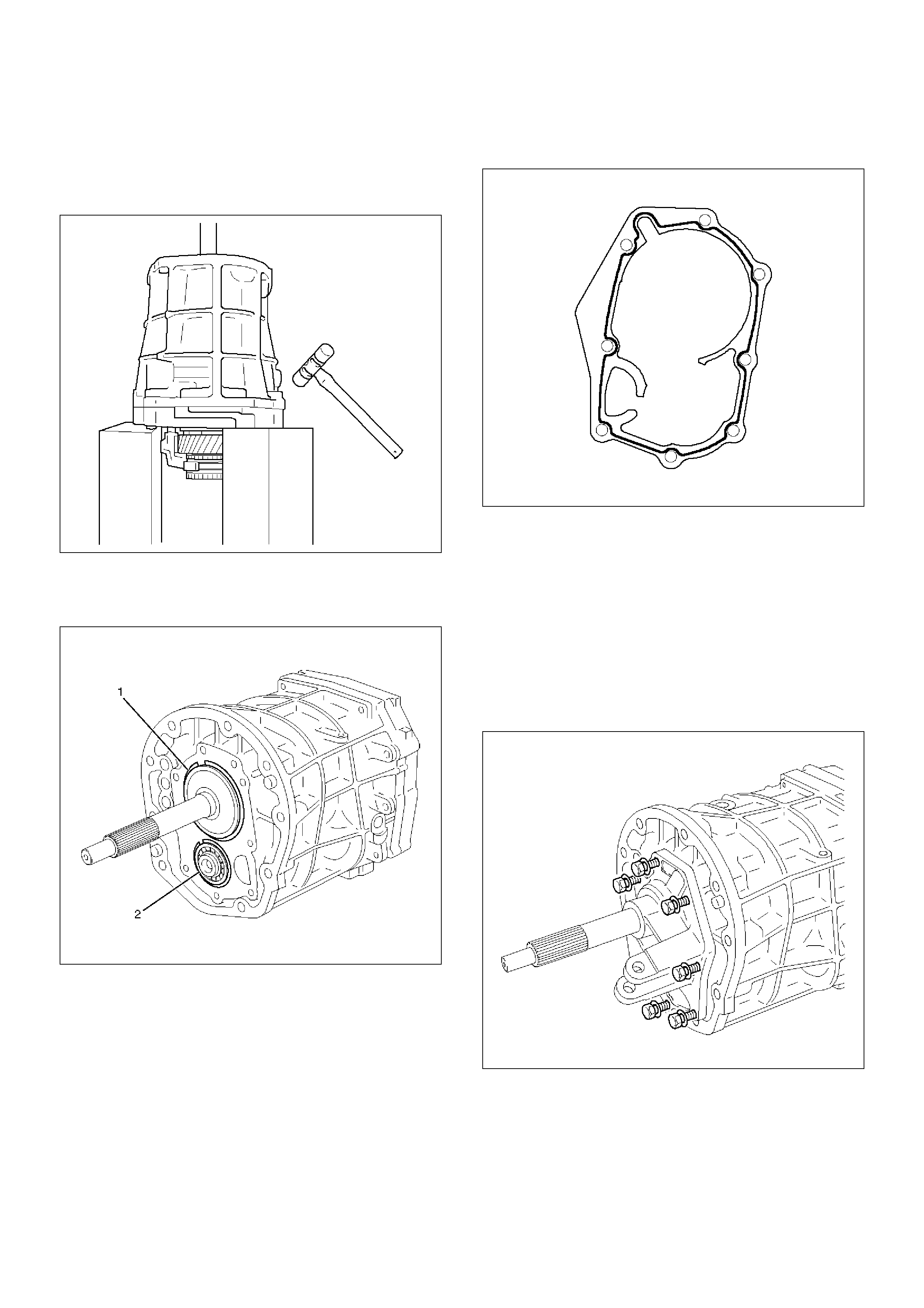

8. Remove the front cover.

1. Remove the 8 bolts.

220RW018

2. Using a plastic hammer, carefully tap the front

cover.

220RW017

9. Remove the front cover oil seal.

1. Mount the front cover through the aluminum

plate in a vise.

2. Using screwdriver, remove oil seal (1).

220RW019

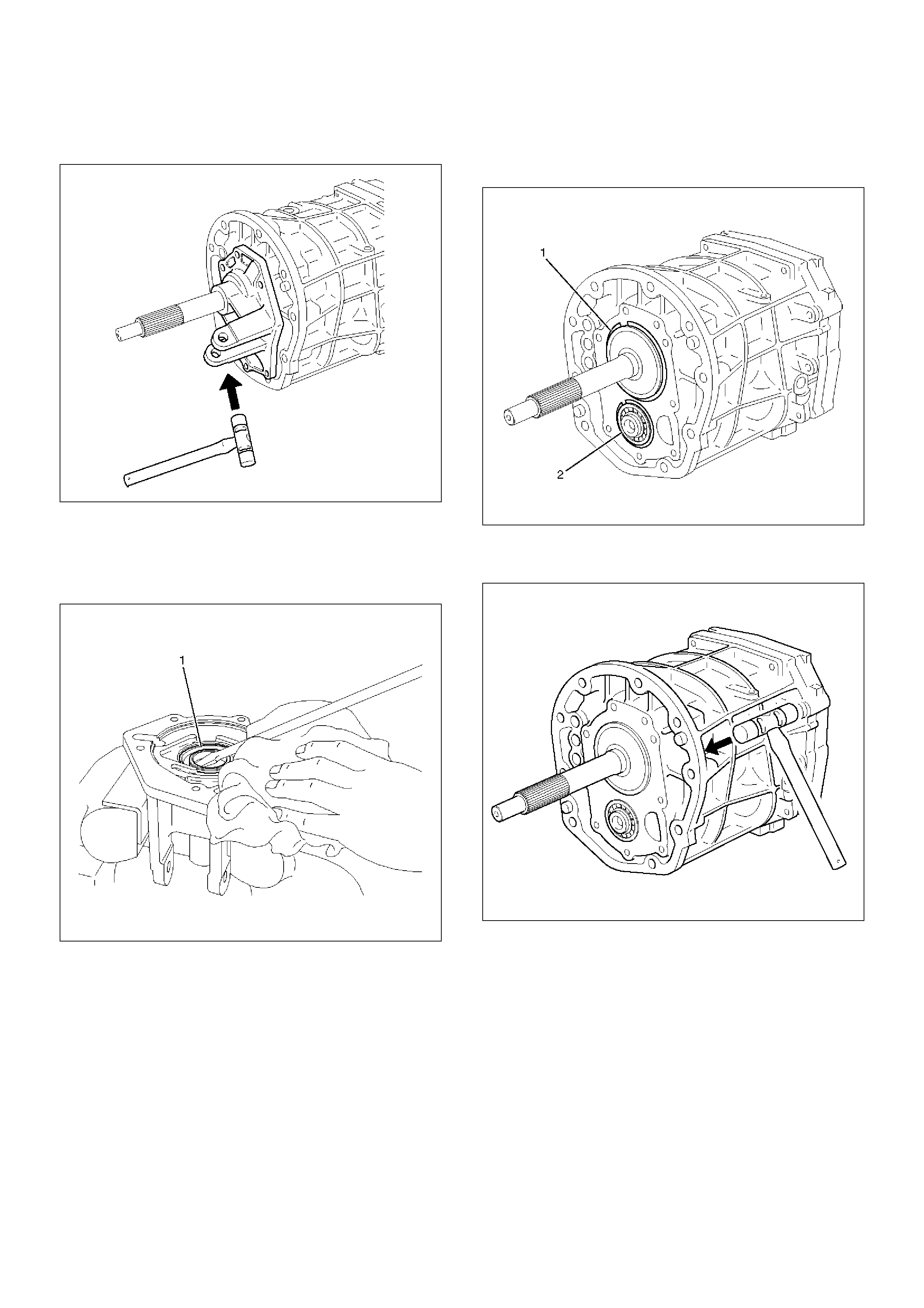

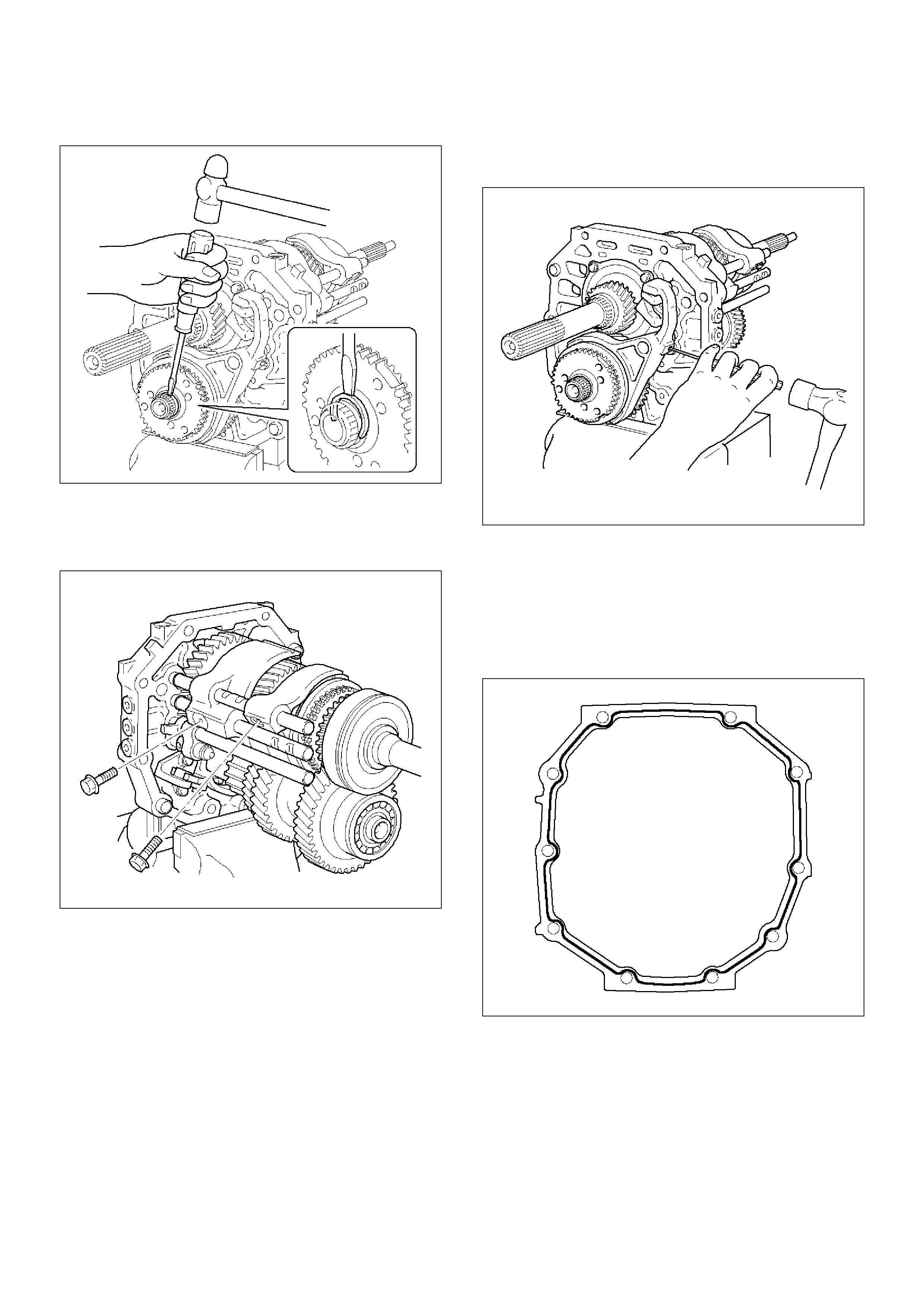

10. Remove the transmission case.

1. Using a snap ring expander, remove the 2 snap

rings (1)(2).

226RW004

2. Using a plastic hammer, carefully tap the

transmission case.

220RW020

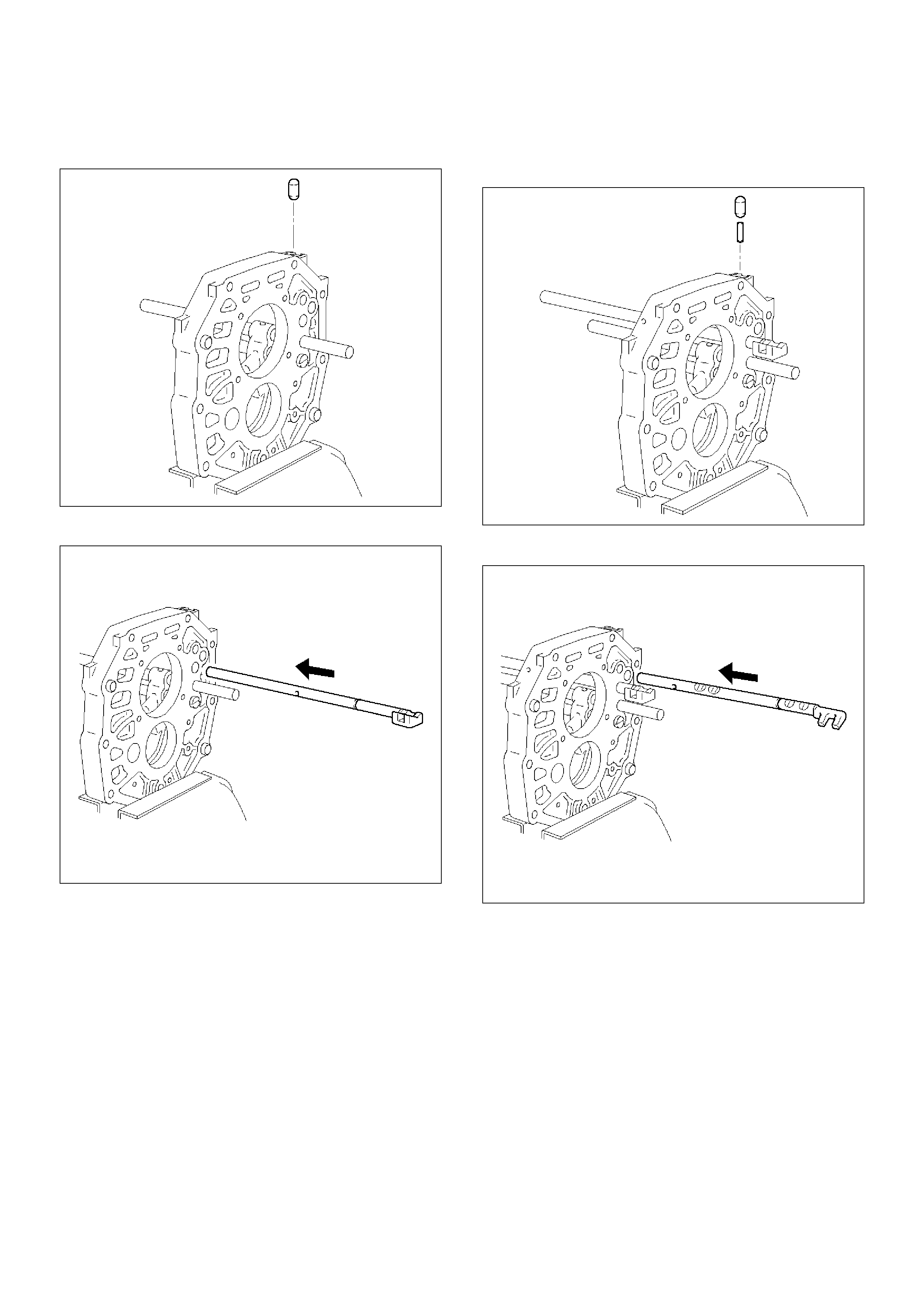

11. Mount the intermediate plate.

1. Mount the intermediate plate through the

aluminum plate in a vise.

226RW005

12. Remove the slotted spring pin.

1. Using a pin punch and hammer, drive out the pin

from the arm.

226RW025

13. Remove the shift arm set bolt.

1. Remove the 2 bolts from the shift arm.

226RW023

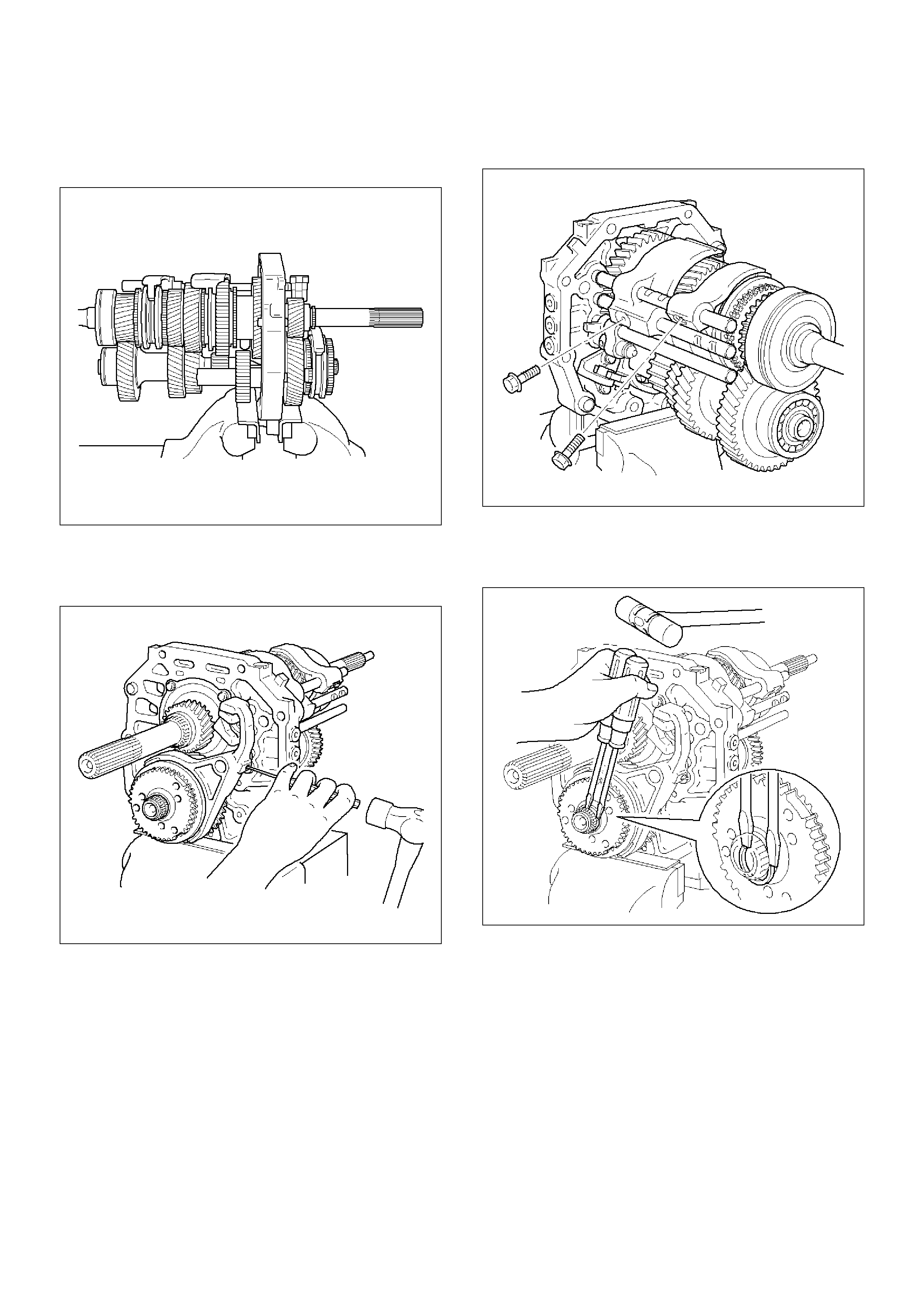

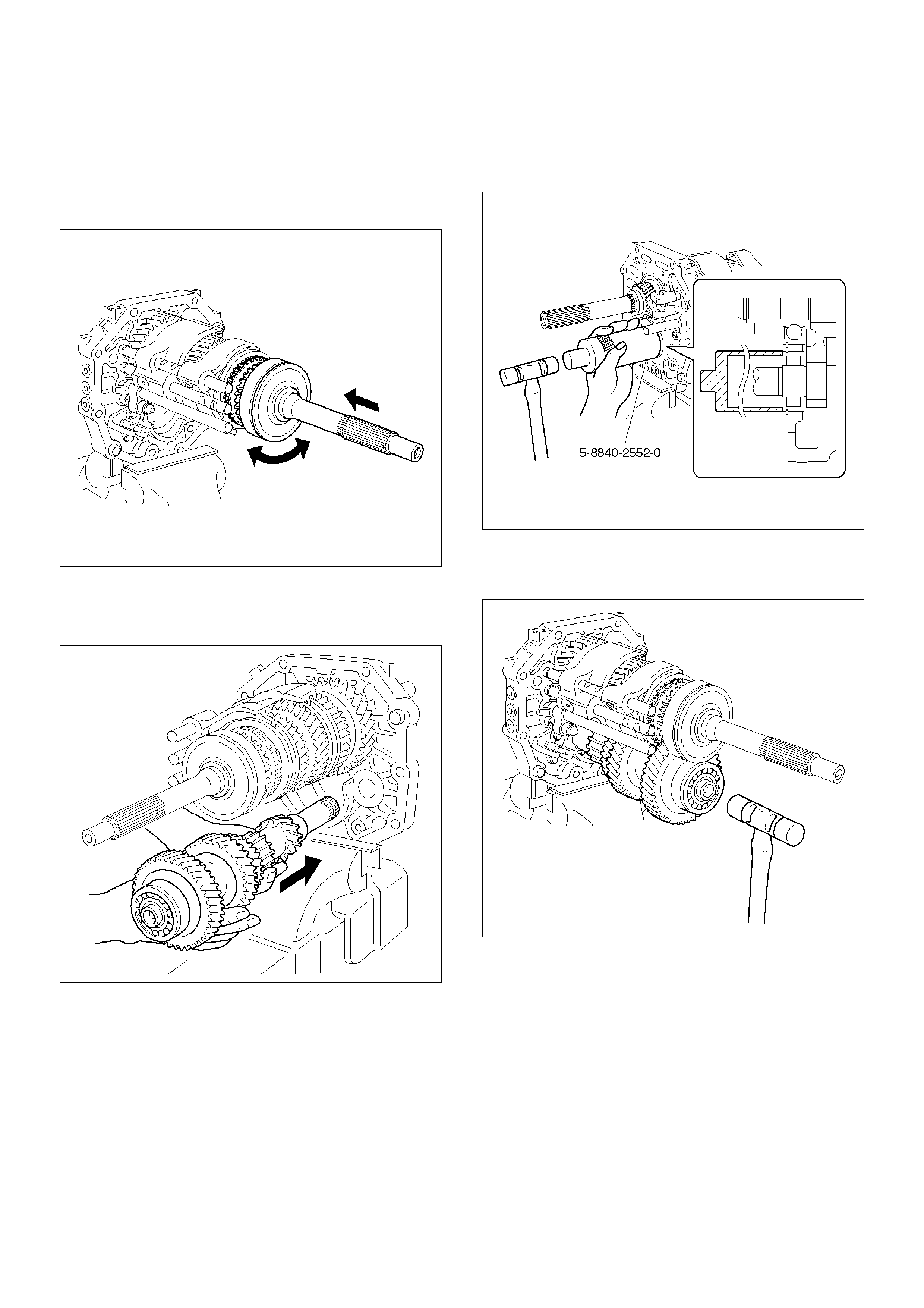

14. Remove the counter 5th gear.

1. Using 2 screwdrivers and hammer, tap out the

snap ring.

226RW024

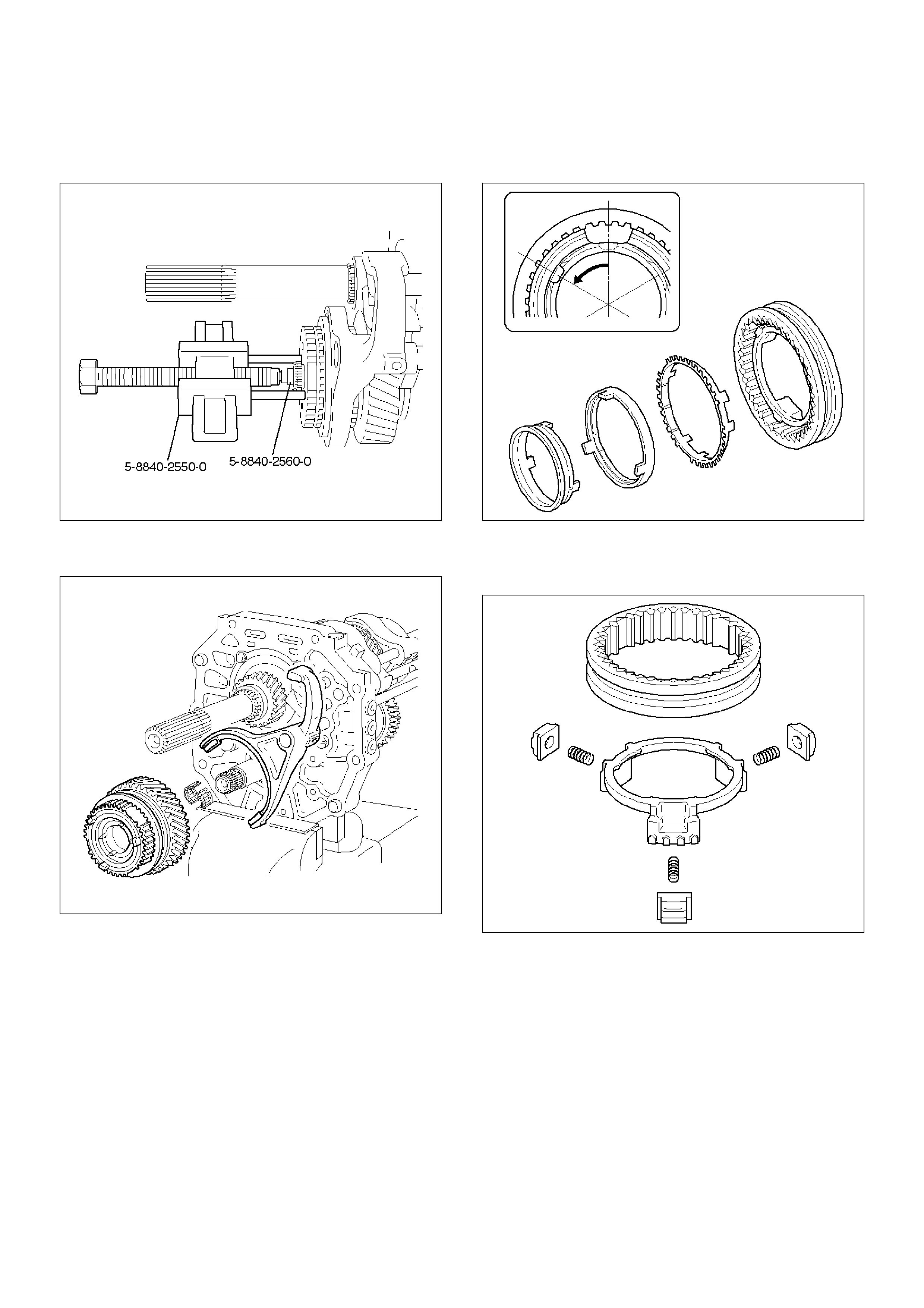

2. Using remover 5–8840–2550–0 (J–42794) and

attachment 5–8840–2560–0 (J–42988), remove

the 5th gear spline piece.

226RW201

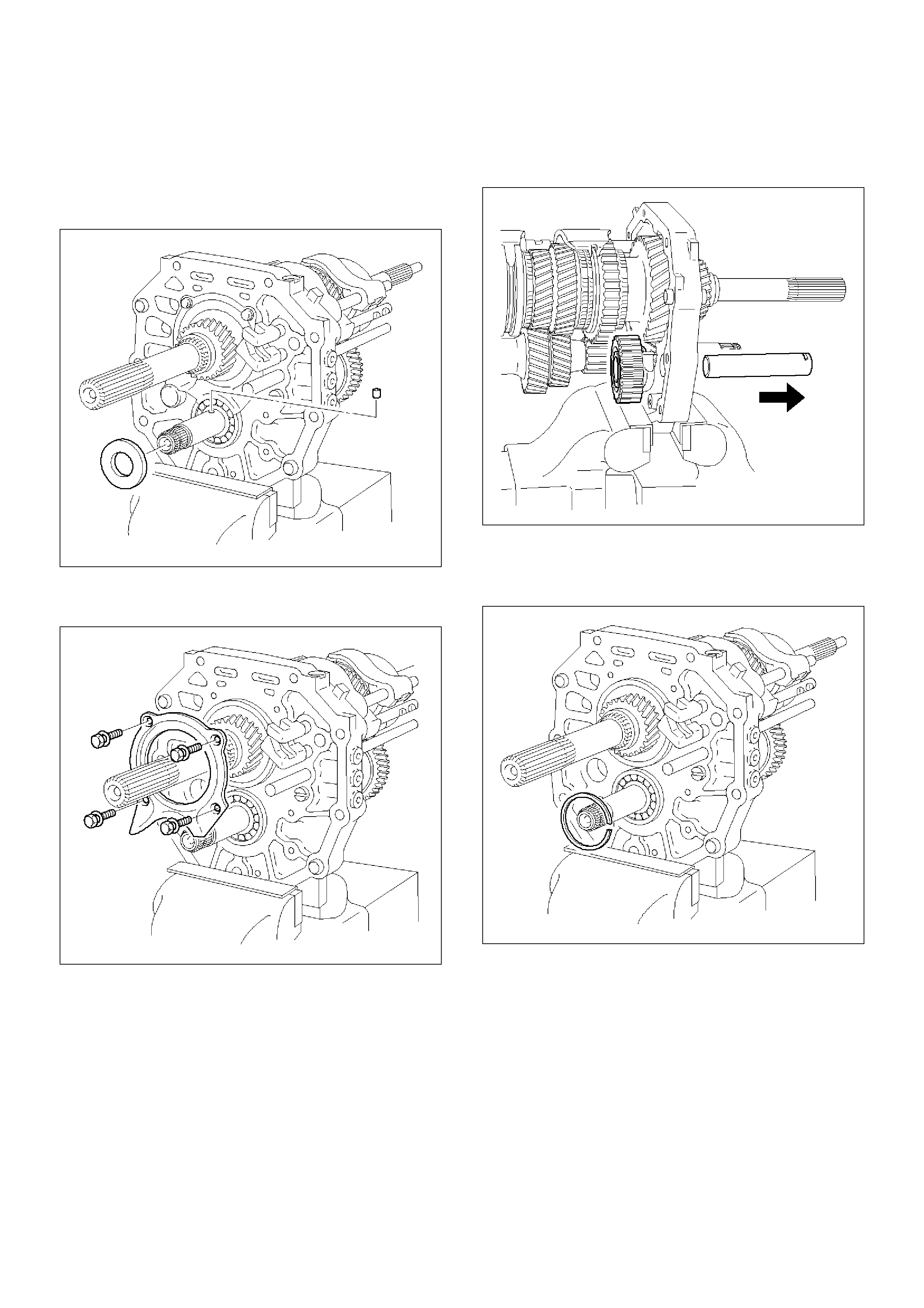

3. Remove the hub sleeve No.3, block ring set,

counter 5th gear, bearing and 5th shift arm.

220RW101

4. Remove the synchronizer pull ring, synchronizer

cone ring, and synchronizer outer ring from hub

sleeve No.3.

226RW066

5. Remove the reverse block ring from the hub

sleeve No.3. Remove the 3 inserts and 3

compression springs.

226RW067

15. Remove the thrust washer.

1. Remove the thrust washer from counter gear

shaft.

2. Remove the thrust washer pin from counter gear

shaft.

226RW018

16. Remove the bearing plate.

1. Remove the 4 bolts and bearing retainer.

226RW016

17. Remove the reverse idle gear.

1. Pull out the shaft foward the rear and remove

the reverse idle gear.

226RW020

18. Remove the counter gear shaft.

1. Using snap ring plier, remove counter gear shaft

center bearing snap ring.

226RW015

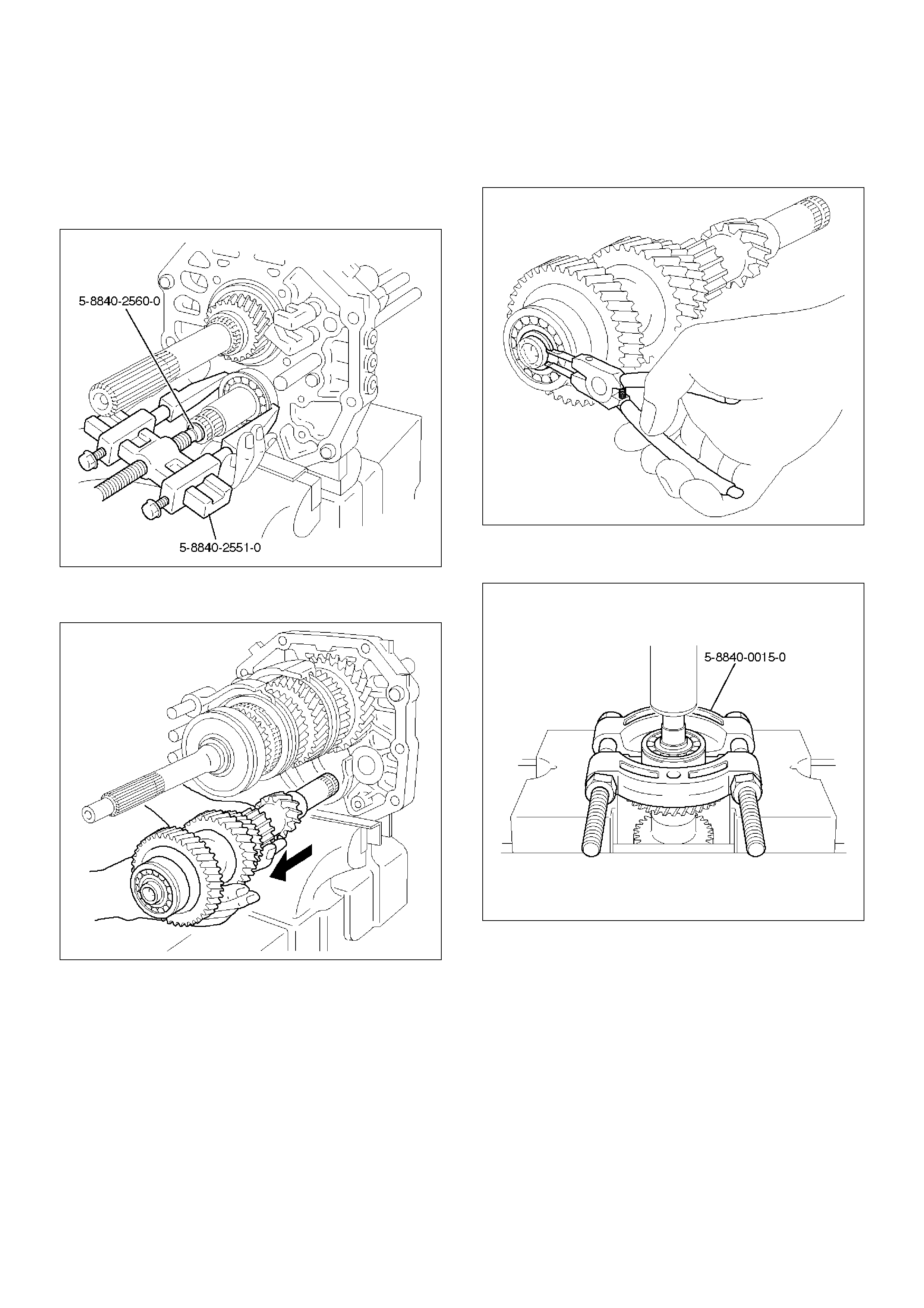

2. Using remover 5–8840–2551–0 (J–42795) and

attachment 5–8840–2560–0 (J–42988), remove

counter gear shaft center bearing.

NOTE: Be careful not to drop the counter gear, when

removing the bearing.

226RW199

3. Remove the counter gear from intermediate

plate.

226RW030

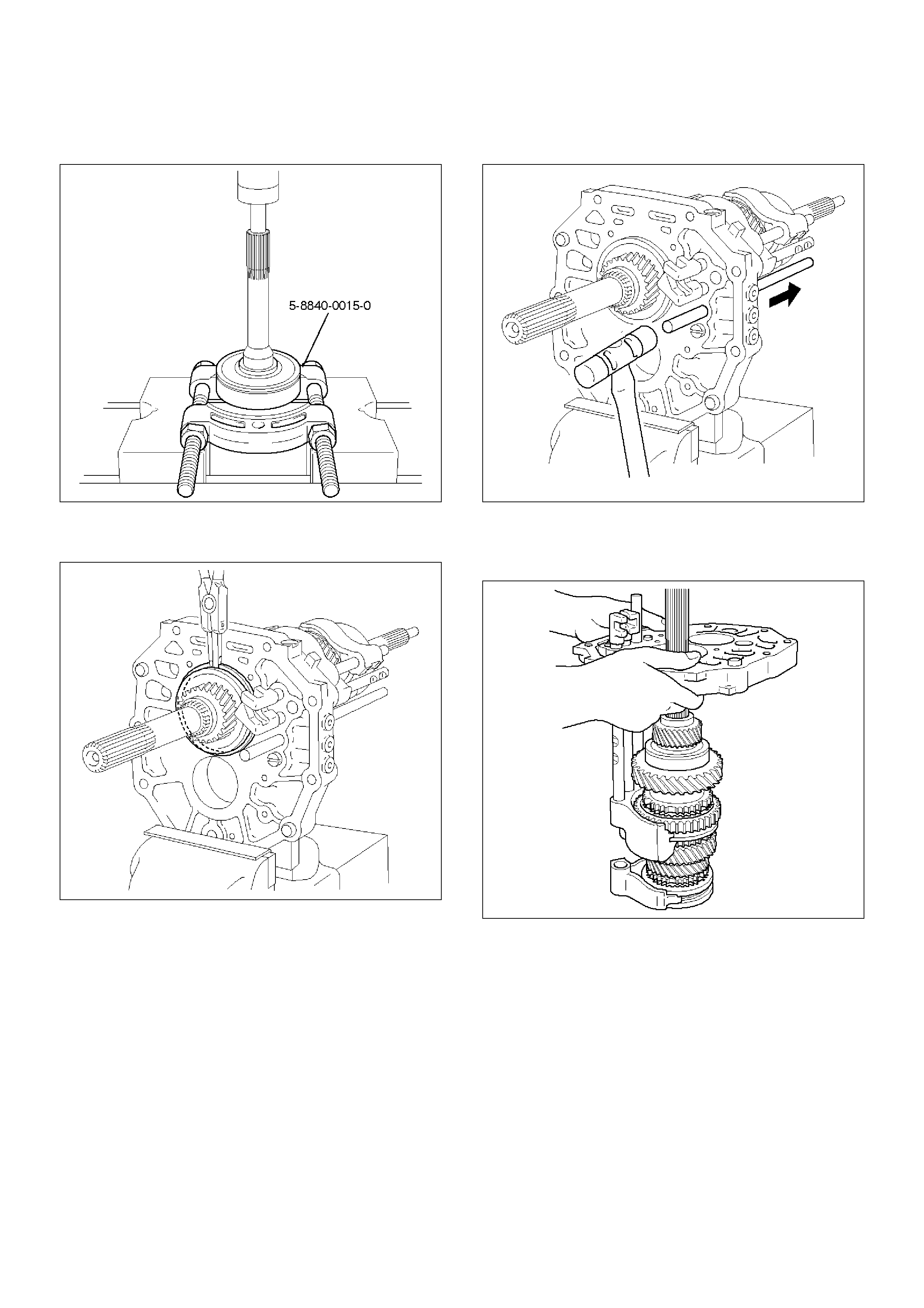

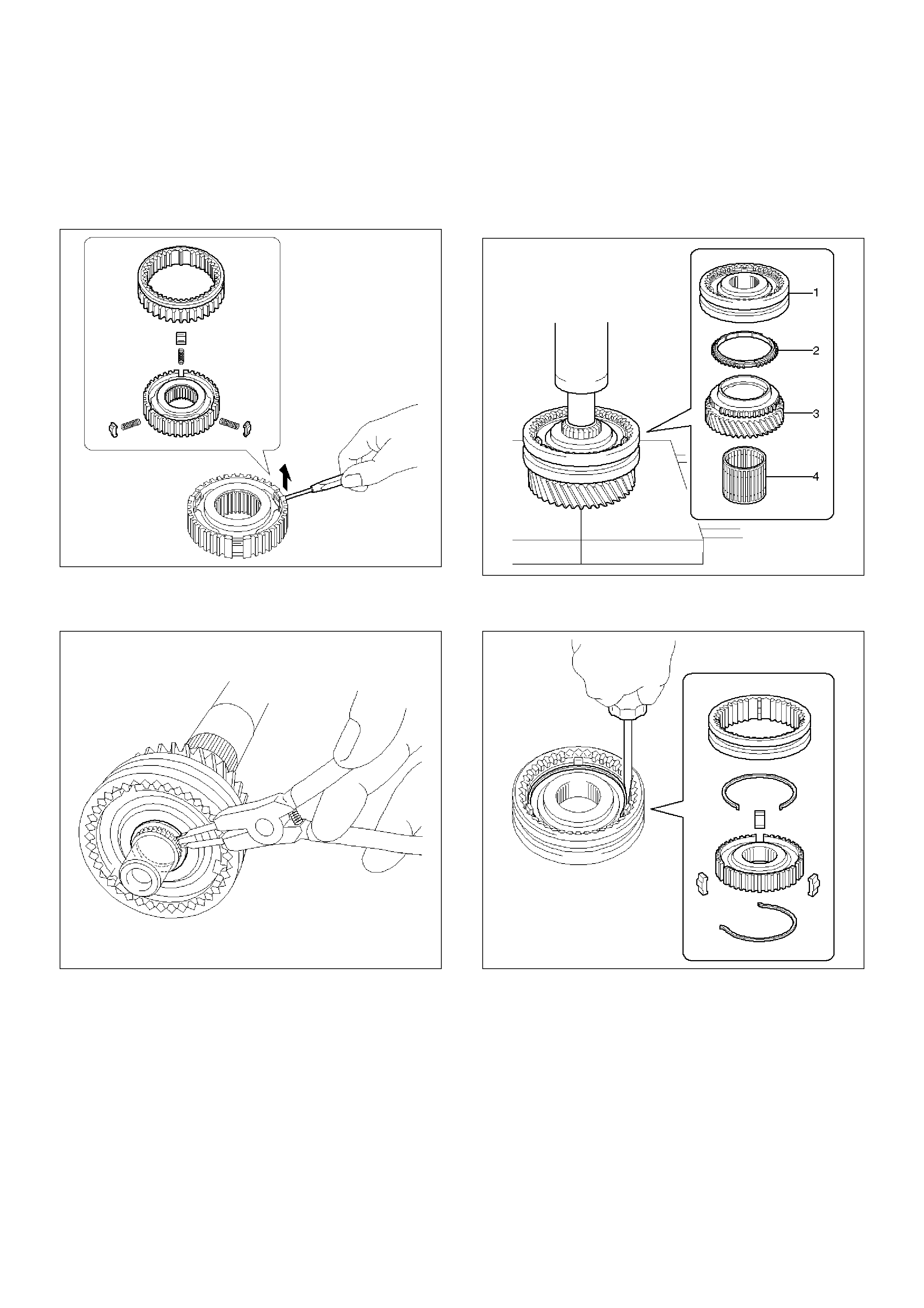

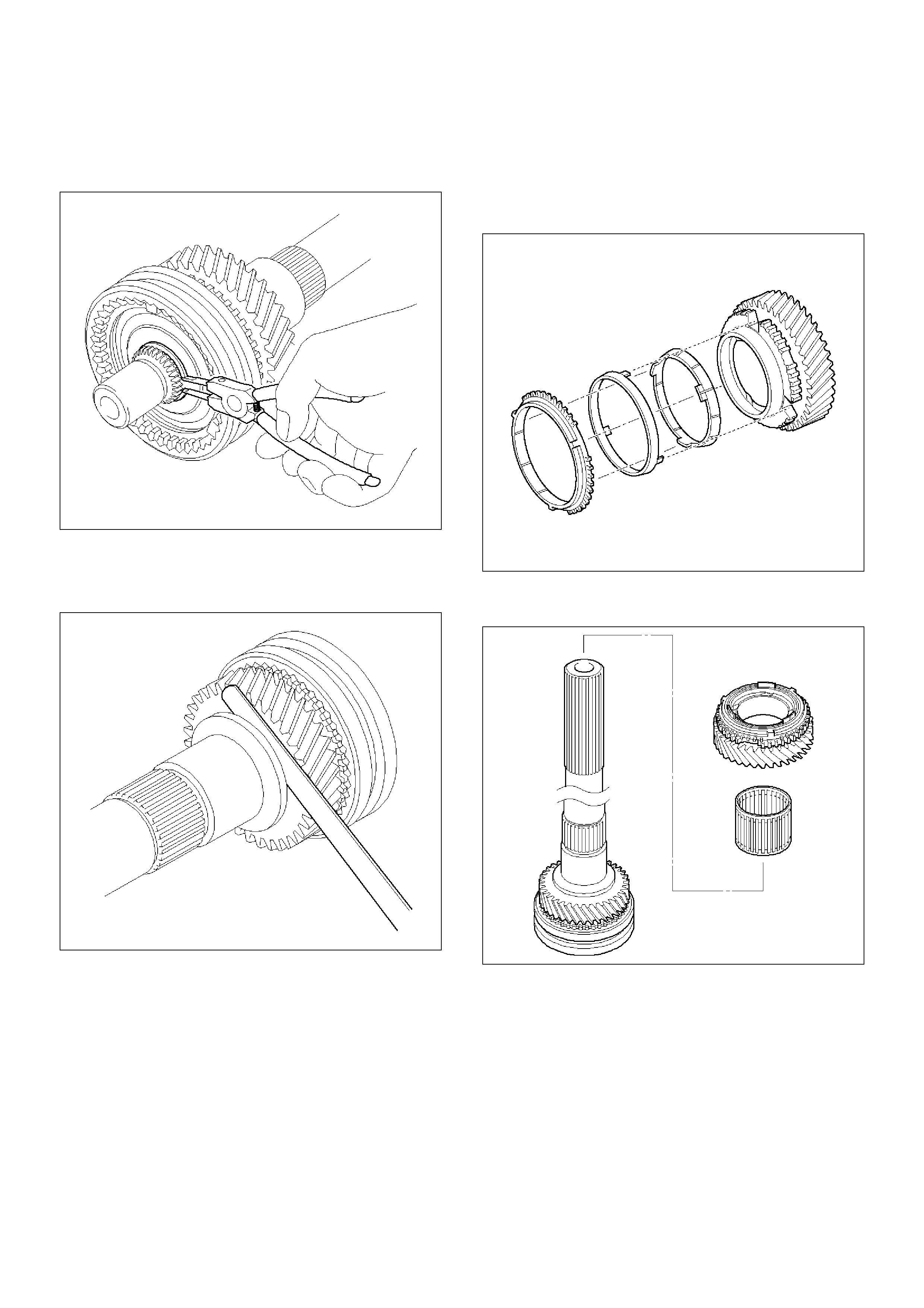

19. Disassemble the counter gear shaft assembly.

1. Using snap ring pliers, remove the counter gear

shaft front bearing snap ring.

226RW065

2. Using bearing separator 5–8840–0015–0 (J–

22912–01) and a press, remove the bearing.

226RW200

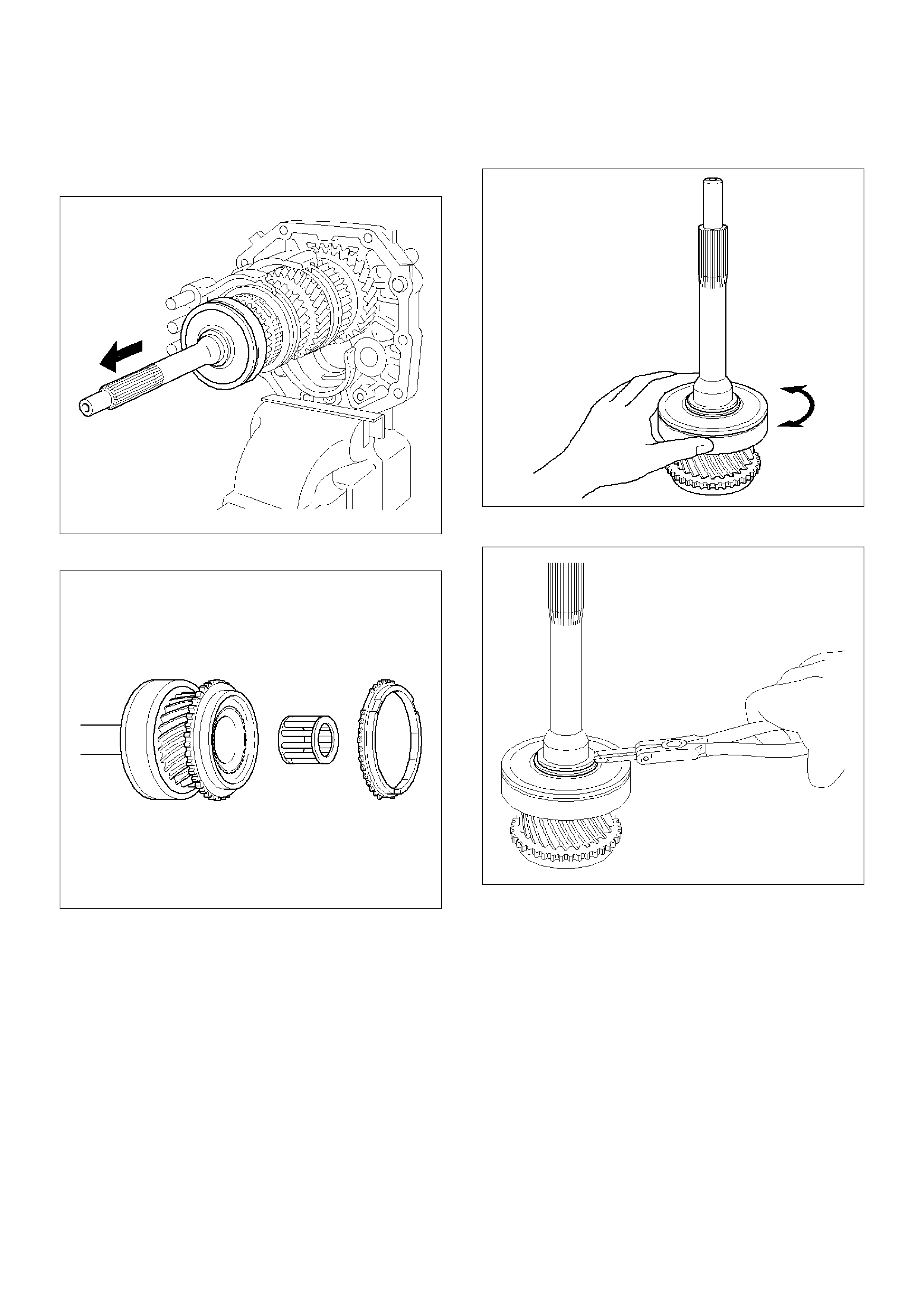

20. Remove the top gear shaft.

1. Remove the top gear shaft from mainshaft.

NOTE: Don't fall needle roller bearing.

226RW029

2. Remove the 4th block ring and roller bearing.

226RW031

21. Disassemble the top gear shaft assembly.

1. Check for wear or damage.

226RW033

2. Remove the front bearing shaft snap ring.

226RW062

3. Using bearing separator 5–8840–0015–0 (J–

22912–01) and a press, remove the bearing.

226RW202

22. Remove the mainshaft.

1. Remove mainshaft bearing snap ring.

226RW035

2. Using a plastic hammer, tap the 5th-reverse shift

rod at the reverse shift side.

226RW034

3. Remove the intermediate plate from a vise.

4. Remove the mainshaft, 1st-2nd shift arm and

3rd-4th shift arm.

226RW014

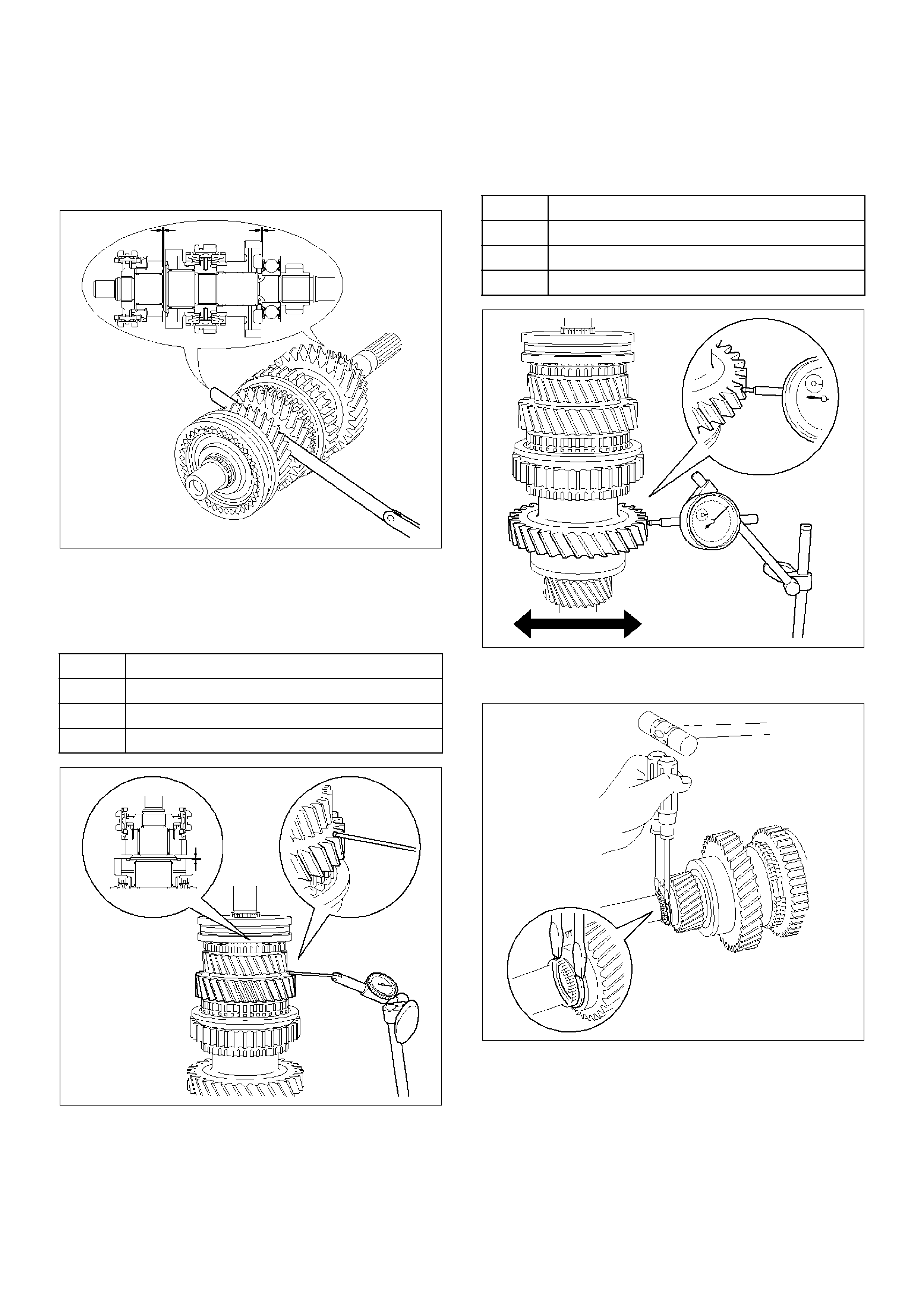

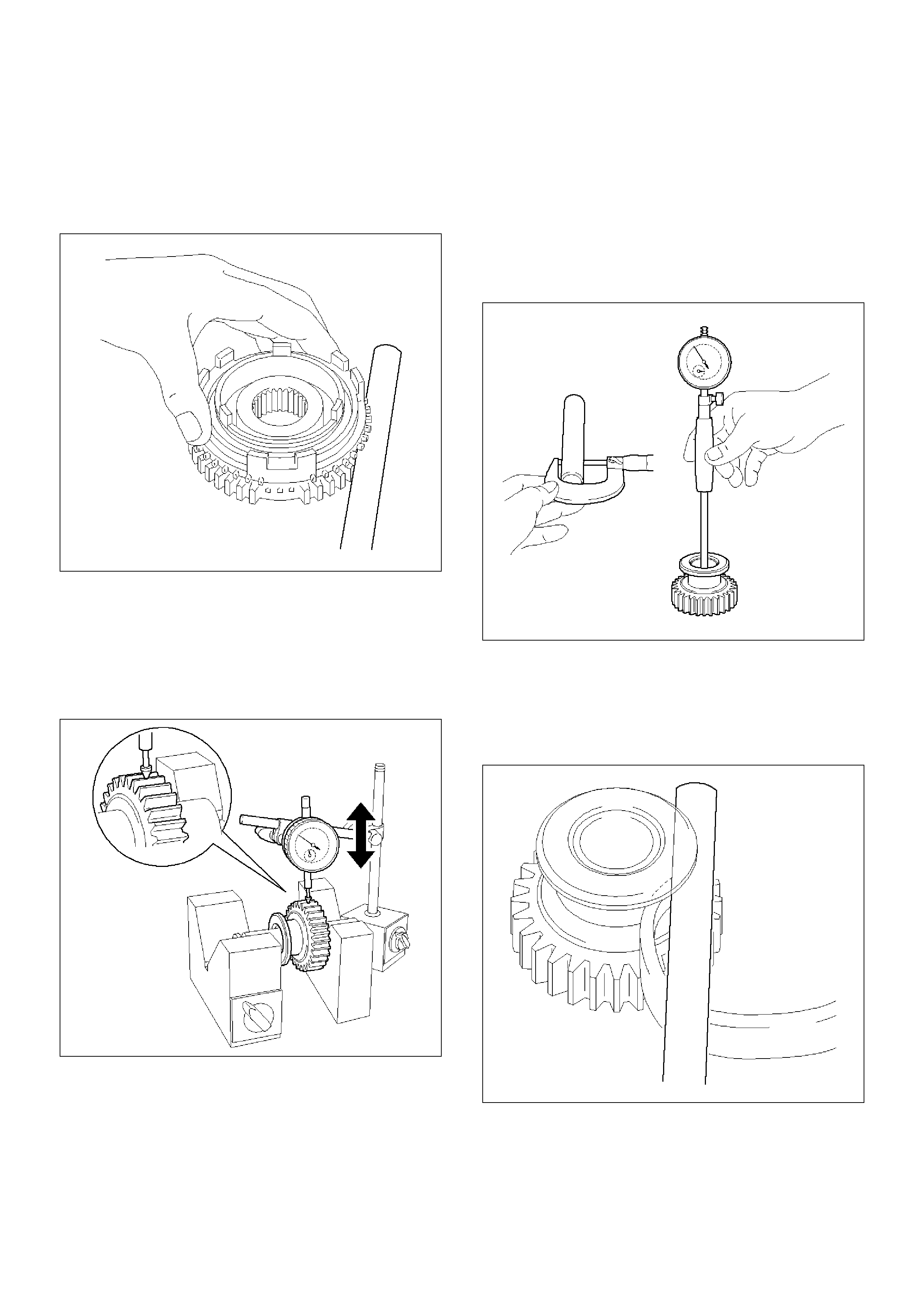

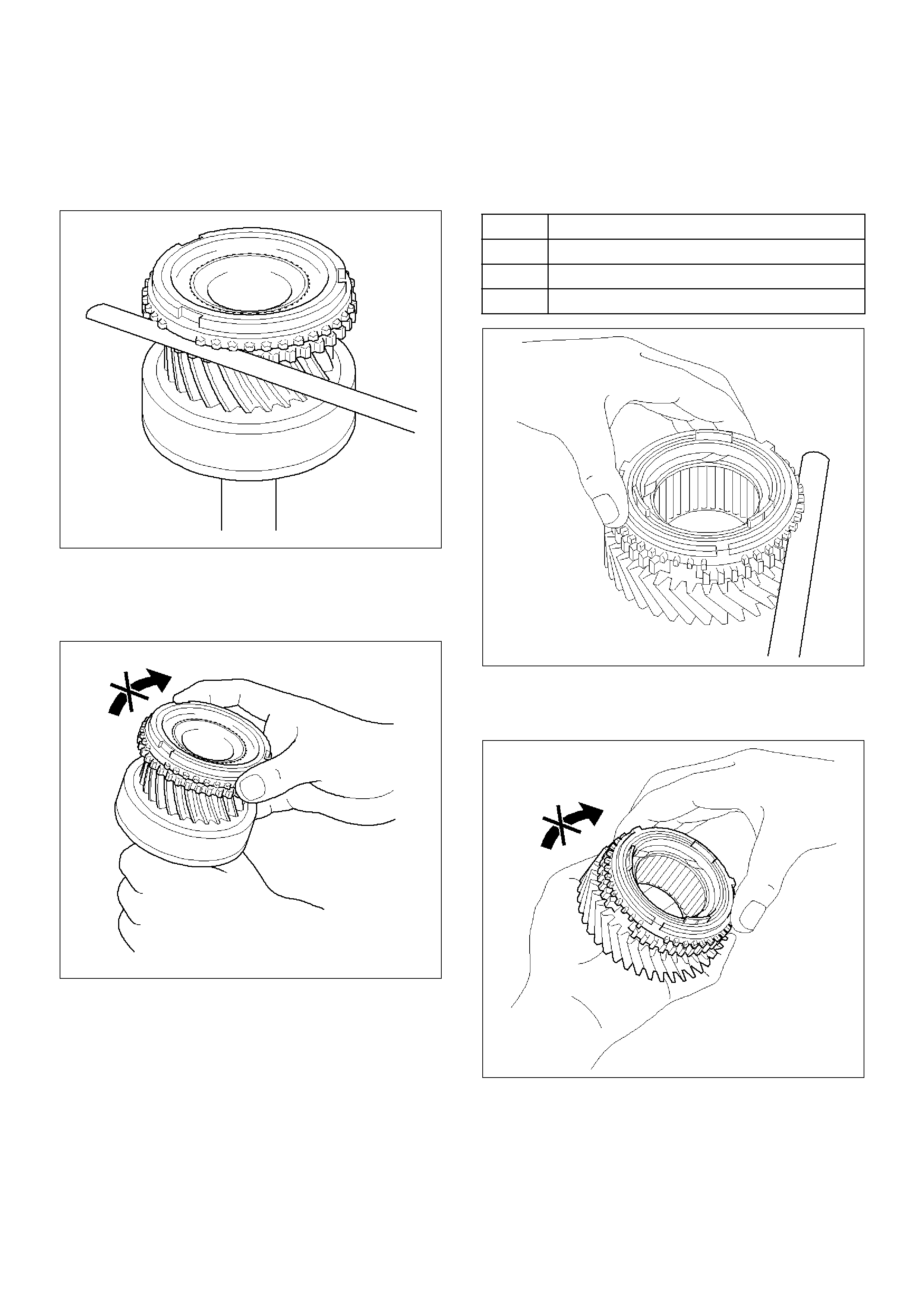

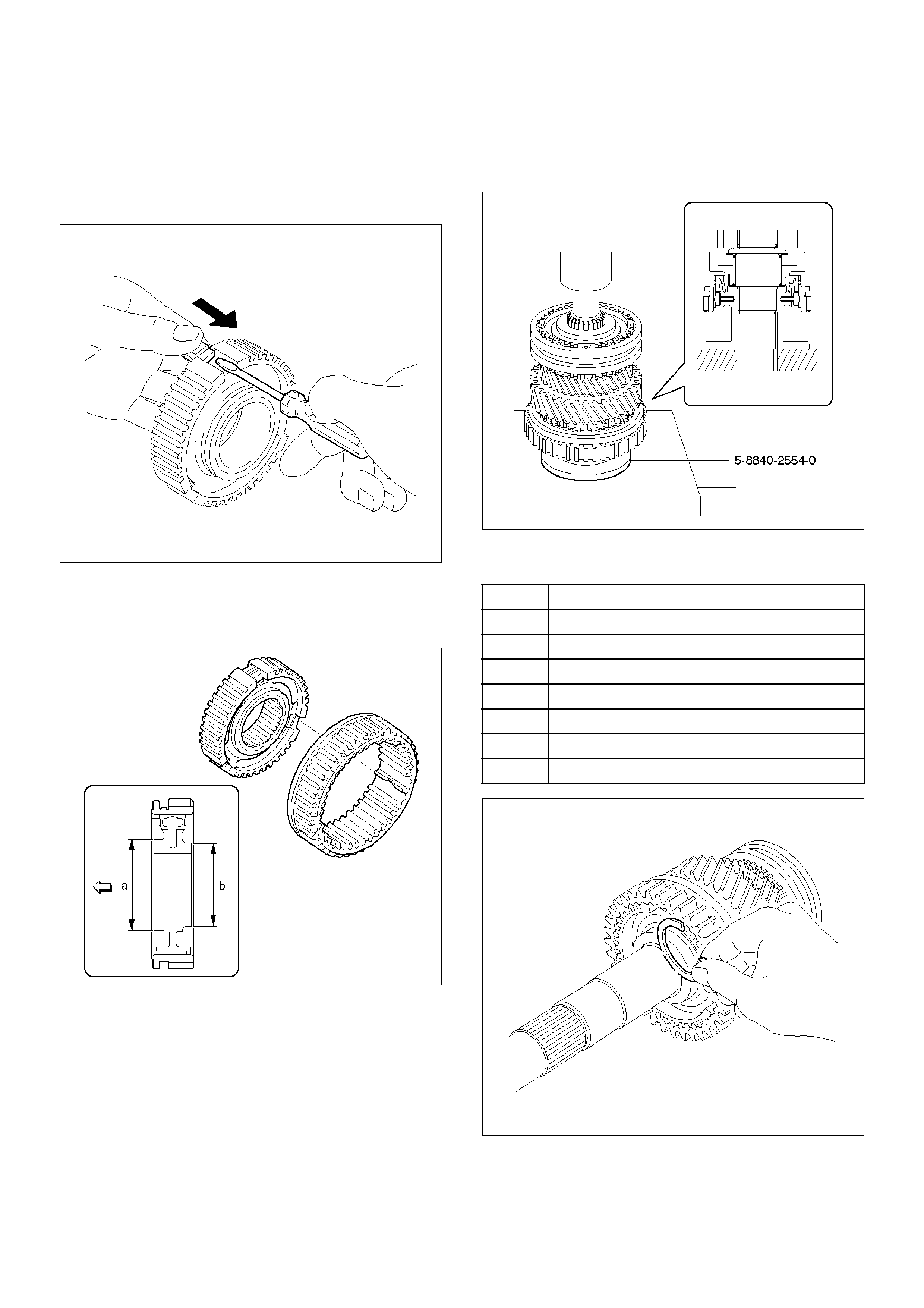

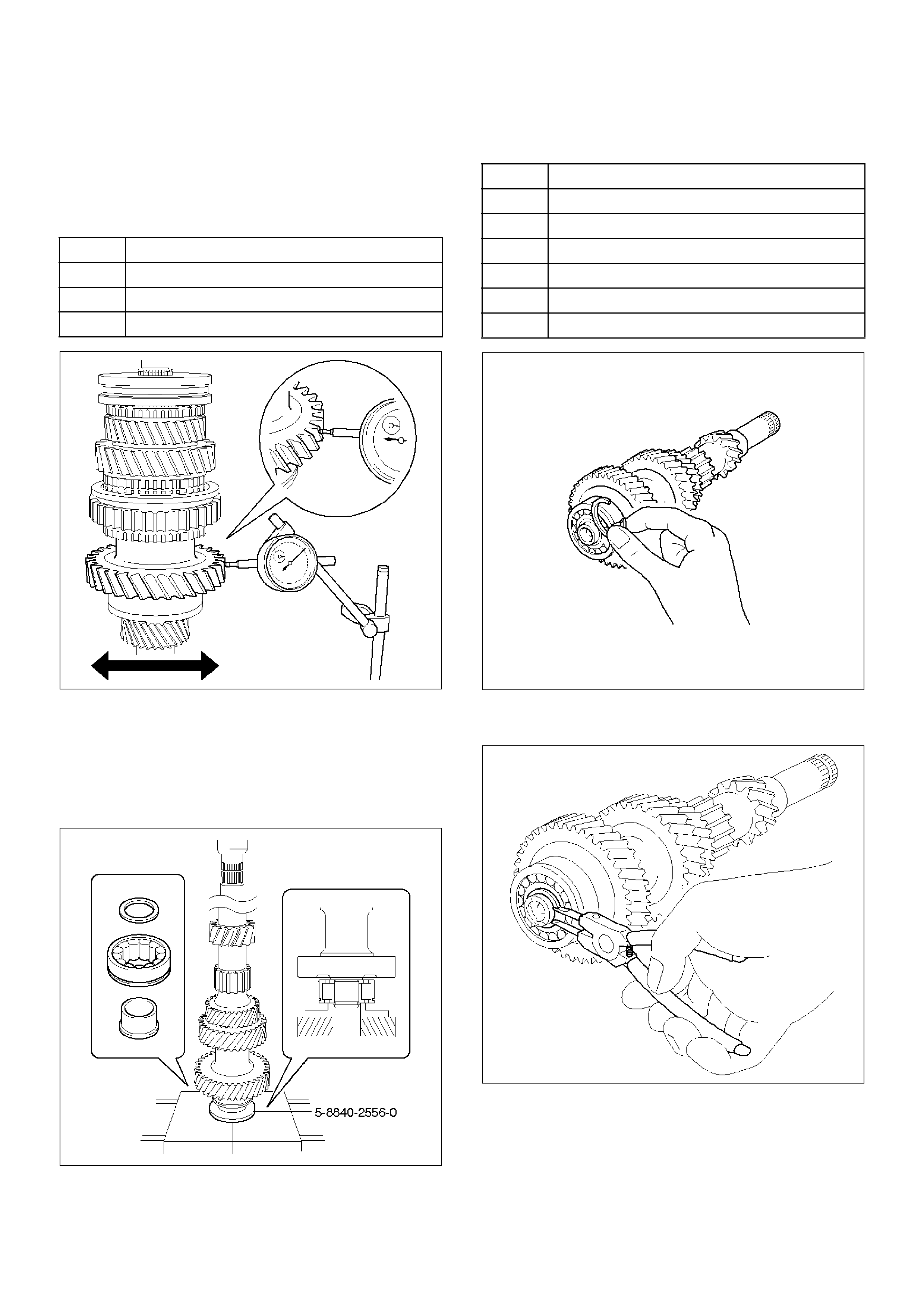

23. Disassemble the mainshaft assembly.

1. Inspect each gear thrust clearance.

1. Using thickness gauge, inspect thrust

clearance (1st gear, 3rd gear).

226RW077

2. Mount the mainshaft through the aluminum

plate in a vise.

3. Using a dial indicator, measure each gear

thrust clearance.

226RW070

2. Inspect each gear radial clearance

1. Using a dial indicator, measure the radial

clearance of each gear.

226RW071

3. Using 2 screwdrivers and hammer, tap out the

snap ring.

226RW053

Gear Standard Clearanse

1st 0.15–0.45mm (0.0059–0.0177 in)

2nd 0.10–0.25mm (0.0039–0.0098 in)

3rd 0.10–0.25mm (0.0039–0.0098in)

Gear Standard Clearanse

1st 0.020–0.074mm (0.00078–0.00291in)

2nd 0.015–0.068mm (0.00059–0.00268in)

3rd 0.015–0.068mm (0.00059– 0.00268 in)

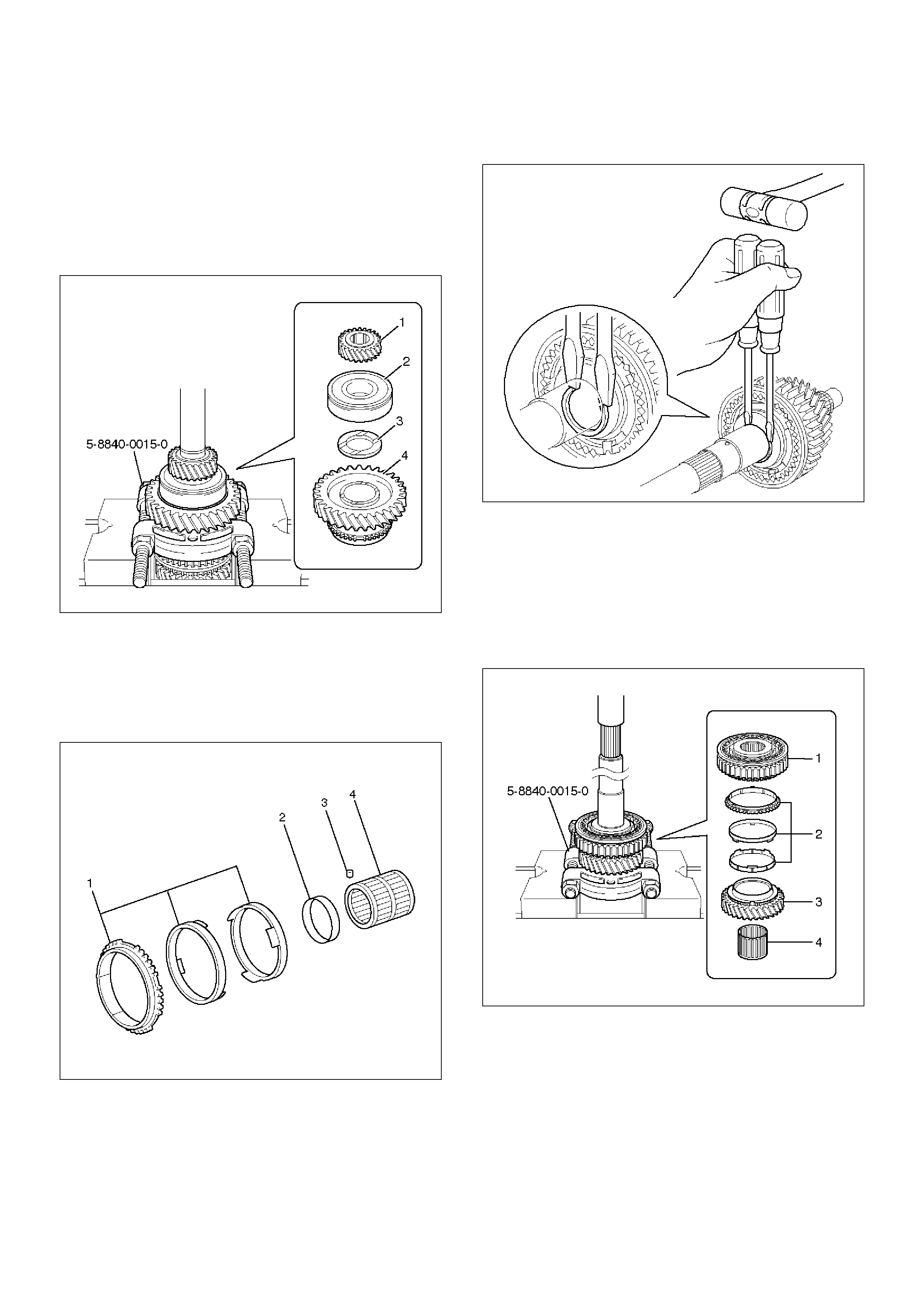

4. Using bearing separator 5–8840–0015–0 (J–

22912–01) and a press, remove the following

parts.

1. 5th gear (1).

2. Mainshaft bearing (2).

3. 1st gear thrust washer (3).

4. 1st gear (4).

226RW197

5. Remove following parts from mainshaft.

1. Synchronizer assembly (1).

2. 1st gear thrust washer pin (3).

3. 1st gear needle roller bearing (4).

4. 1st gear bearing spacer (2).

226RW146

6. Using 2 screwdrivers and hammer, tap out snap

ring.

226RW073

7. Using bearing separator 5–8840–0015–0 (J–

22912–01) and a press, remove the following

parts.

1. Clutch hub No.1 assembly (1).

2. Synchronizer assembly (2).

3. 2nd gear (3).

4. 2nd gear needle roller bearing (4).

226RW198

8. Remove the reverse gear from clutch hub No.1.

9. Remove the 3 inserts and 3 compression

springs.

• When removing the inserts, push the insert

spring with a screwdriver.

226RW075

10. Remove the snap ring.

NOTE: Don't damage the bearing surface.

226RW076

11. Using a press, remove following parts.

1. Clutch hub No.2 assembly (1).

2. 3rd block ring (2).

3. 3rd gear (3).

4. 3rd gear needle roller bearing (4).

226RW091

12. Using screwdriver, remove the 2 insert springs,

hub sleeve No.2, clutch hub No.2 and 3 inserts.

226RW090

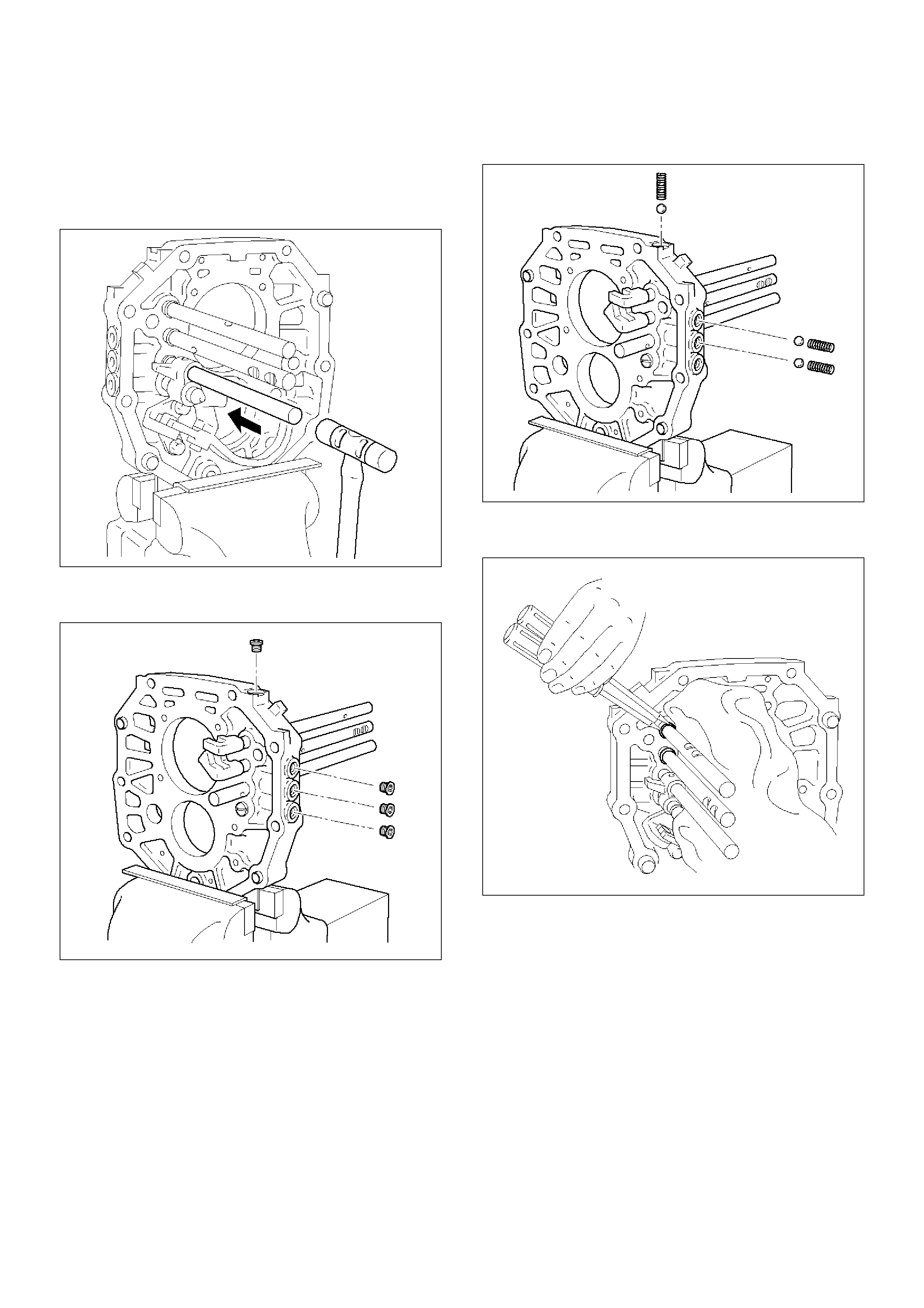

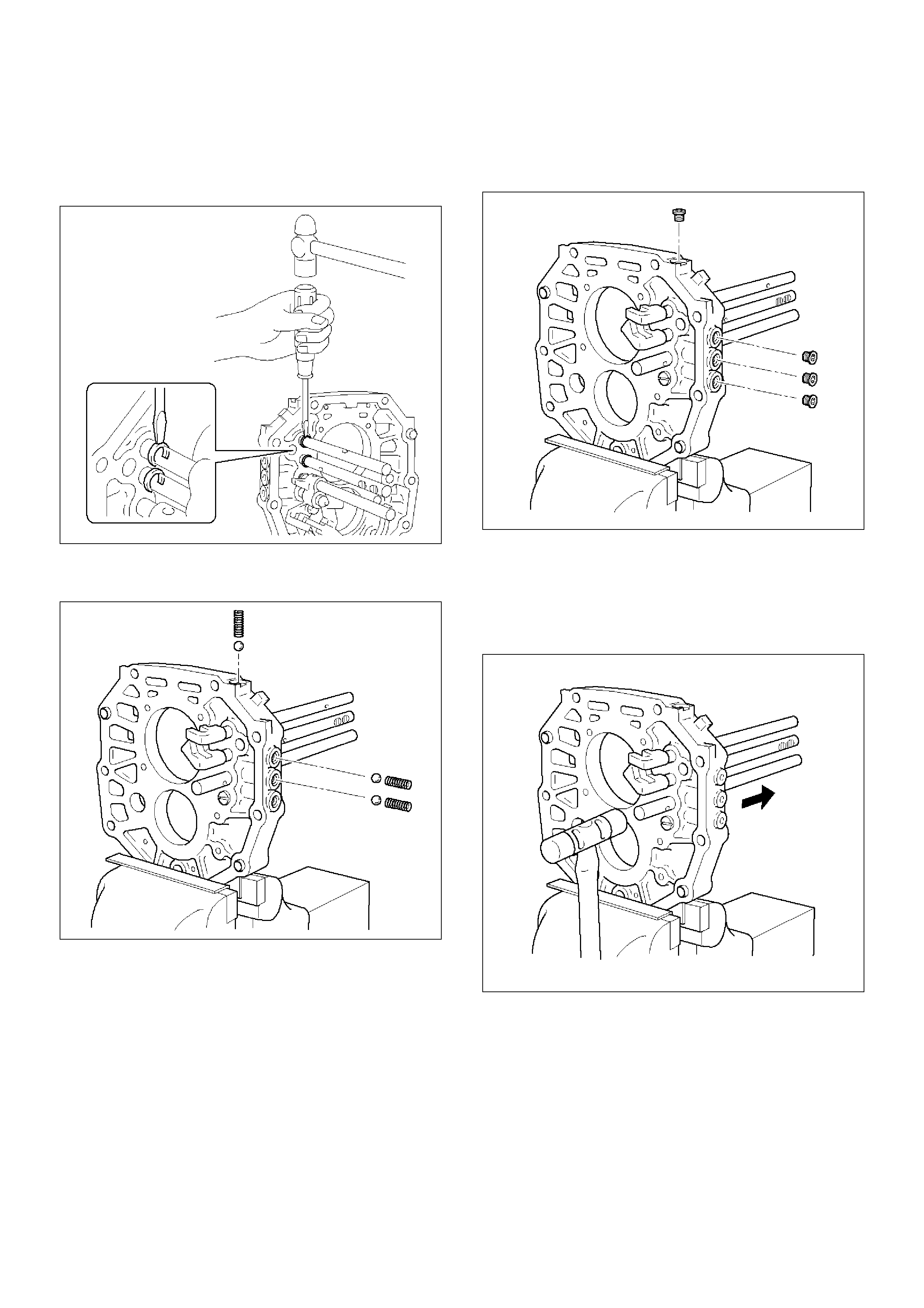

24. Remove the shift parts and interlock parts.

1. Mount the intermediate plate through the

aluminum plate in a vise.

2. Using a plastic hammer, tap the 5th shift rod on

the neutral.

226RW052

3. Using a torx socket wrench(T40), remove the 4

plugs.

226RW050

4. Using a magnetic finger, remove 3 springs and

balls.

226RW049

5. Using 2 screwdrivers and a hammer, remove 2

snap rings from each shift fork rod.

226RW048

6. Pull out the 3rd–4th shift rod at the rear.

226RW047

7. Using a magnetic finger, remove the interlock

pin and straight pin.

226RW043

8. Pull out the 1st–2nd shift rod at the rear.

226RW045

9. Using a magnetic finger, remove the interlock

pin.

226RW042

10. Using 2 screwdrivers and a hammer, remove 2

snap rings.

226RW041

11. Pull out the 5th-reverse shift rod at the front.

226RW040

12. Using a magnetic finger, remove the interlock

pin from the intermediate plate. Remove the

ball from the reverse shift arm No.1.

226RW039

13. Pull out at the rear reverse shift rod, reverse

shift arm No.1 and reverse shift arm No.2 at the

same time.

226RW038

14. Pull out reverse shift rod from reverse shift arm

No.1.

NOTE: Be sure remove at the rear.

226RW055

15. Using a magnetic finger, remove the ball and

spring from reverse shift arm No.1.

226RW056

16. Remove the reverse shift arm No.2 E–ring.

Remove the reverse shift arm No.2 from reverse

shift arm No.1.

226RW089

17. Remove the 2 bolts and reverse shift arm

bracket.

226RW054

Inspection

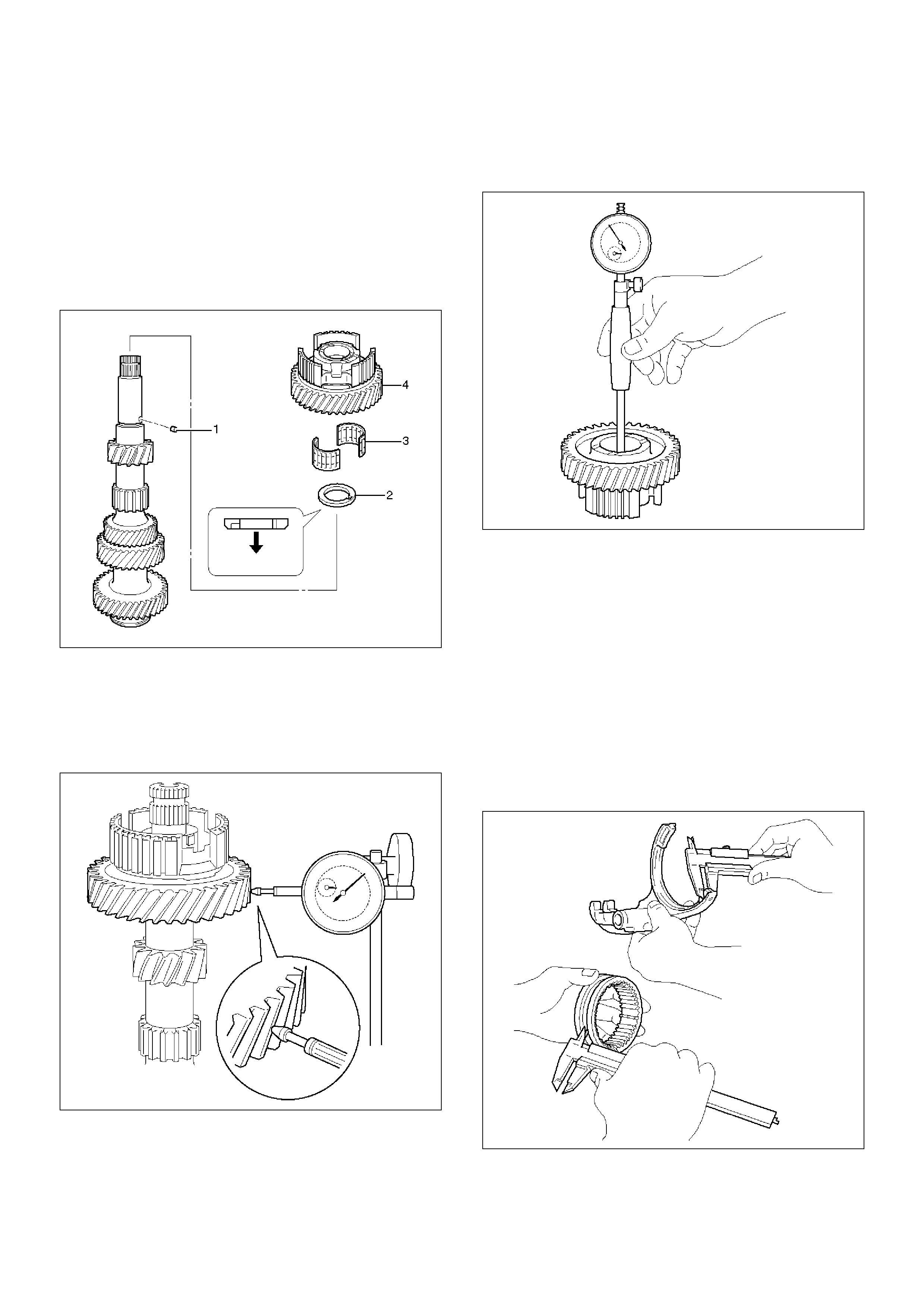

1. Counter 5th gear radial clearance.

1. Install the following parts to the counter gear

shaft.

1. Counter 5th gear thrust washer pin (1).

2. Counter 5th gear thrust washer (2).

3. Counter 5th gear needle bearing( 3).

4. Counter 5th gear (4).

226RW088

2. Mount the counter gear shaft through the

aluminum plate in vise.

3. Using a dial indicator, measure the counter 5th

gear radial clearance.

Standard: 0.015– 0.068mm (0.00059 –0.00268in)

226RW183

4. Using a inside dial indicator, measure the gear

inside diameter.

Standard: 38.015–38.040mm (1.49665– 1.49763 in)

226RW085

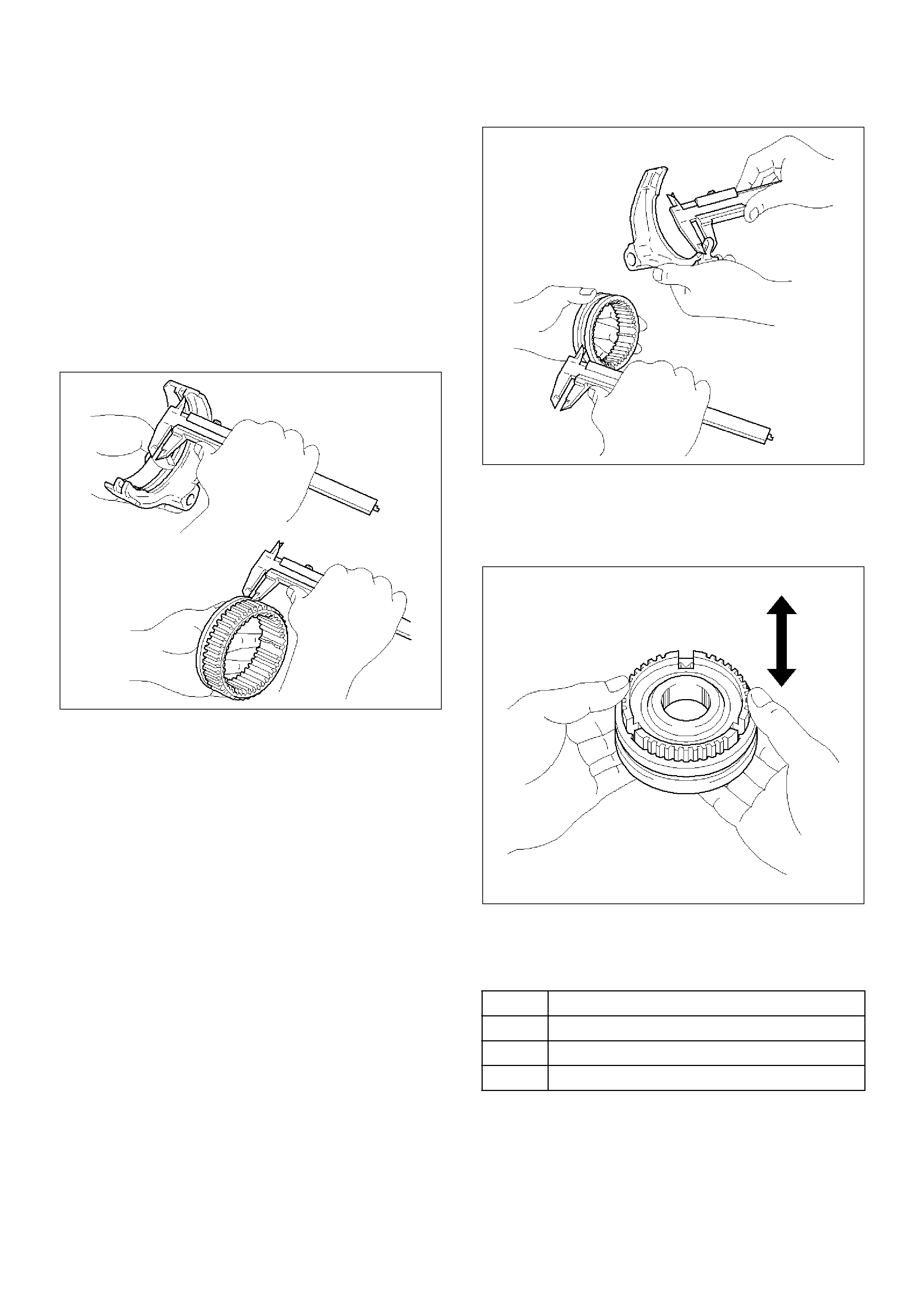

2. 5th-reverse shift arm and hub sleeve No.3

clearance.

1. Using a vernier caliper, measure the 5th-reverse

shift arm thickness.

Reference: 10.2 mm(0.402in)

2. Using a vernier caliper, measure the center

groove of hub sleeve No.3. Calculate the

clearance between the hub sleeve No.3 and

shift arm.

Standard: 0.26–0.84mm (0.0102–0.0331in)

Reference: Center groove dimension 10.5mm

(0.413in)

226RW086

3. Reverse block ring set.

1. Using a thickness gauge, measure the

clearance between the counter 5th gear spline

piece and reverse block ring.

Standard: 0.7–1.7mm (0.028–0.067in)

226RW084

4. Reverse idle gear and reverse idle gear shaft.

1. Mount the reverse idle gear and reverse idle

gear shaft in a vise.

2. Using a dial indicator, measure the reverse idle

gear radial clearance.

Standard: 0.040– 0.082mm (0.0016 –0.0032in)

226RW083

3. If the clearance exceeds the maximum,

measure the gear inside diameter and shaft

diameter.

Standard

Shaft Diameter: 23.979–24.000mm (0.94405–

0.94488in)

Gear Diameter: 24.040–24.061mm (0.94645–

0.94728in)

226RW082

5. Reverse shift arm No.2 thrust clearance.

1. Using a thickness gauge, measure the

clearance between the reverse idle gear and

shift arm No.2.

Standard: 0.05–0.35mm (0.002–0.014in)

226RW081

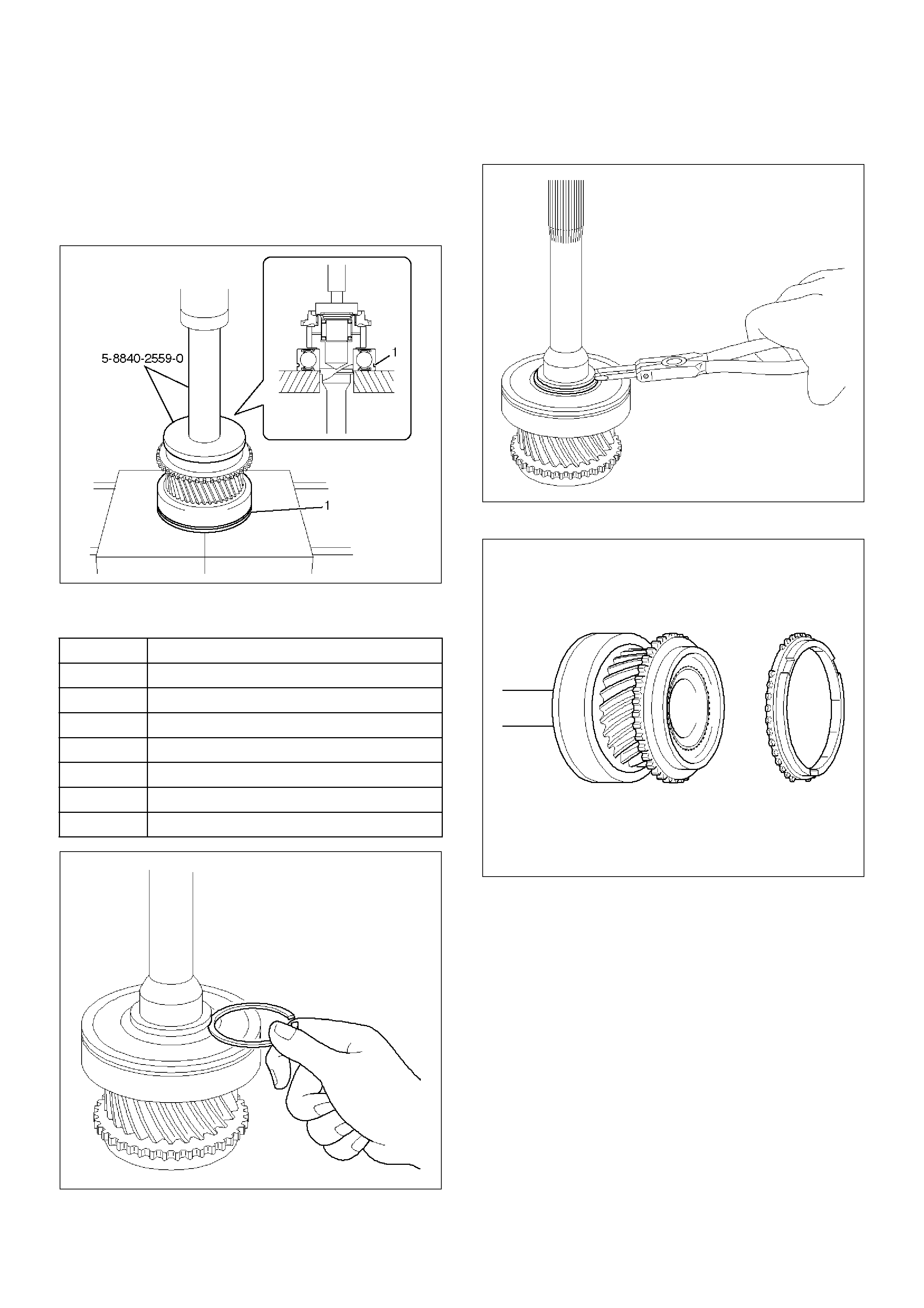

Reassembly

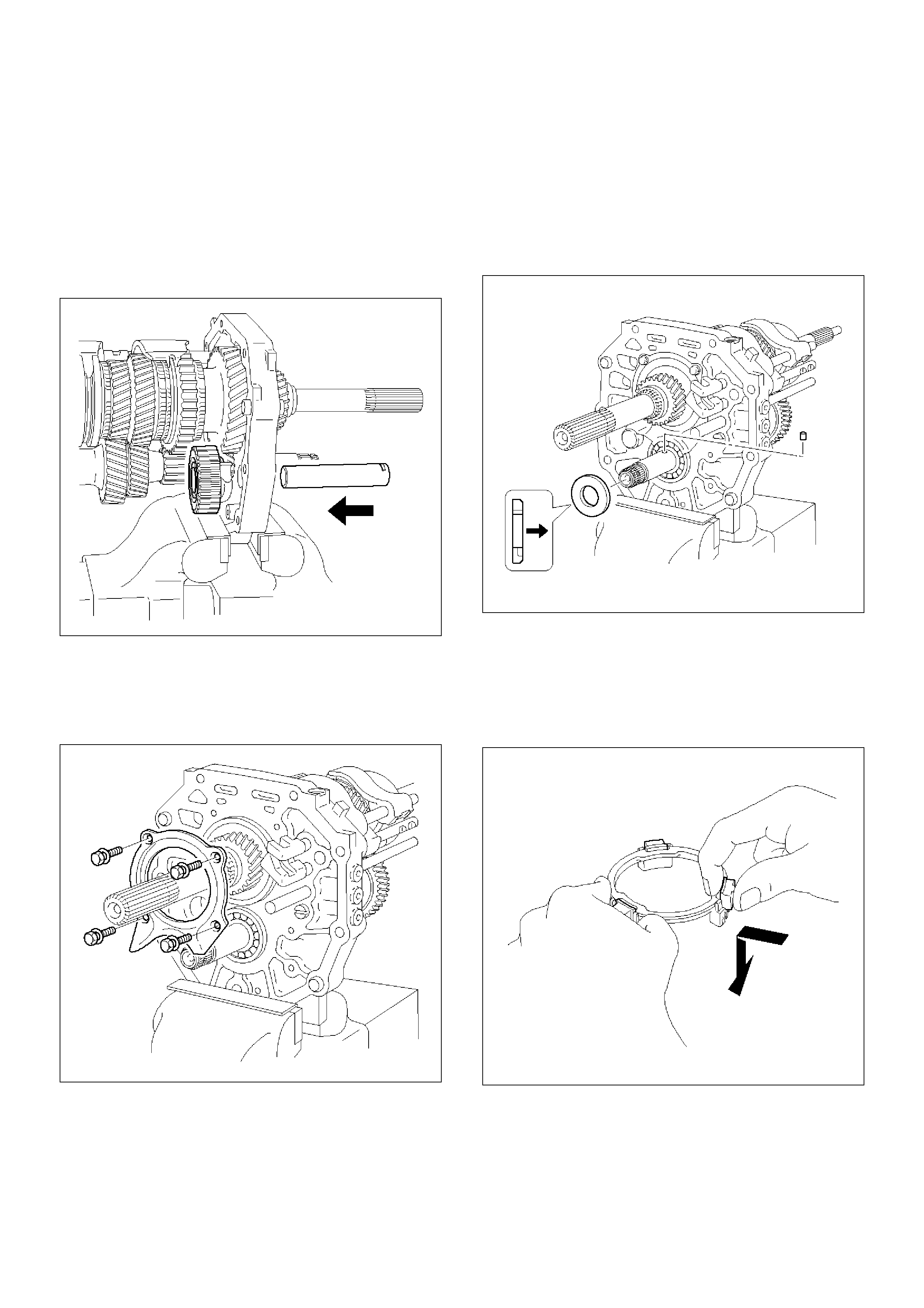

1. Install the top gear shaft assembly.

1. Using installer 5–8840–2559–0 (J–42904) and a

press, install a new bearing.

NOTE: Outer race snap ring groove (1) toward front.

226RW196

2. Select a snap ring that will allow minimum axial

play.

226RW061

3. Using a snap ring expander, install the new snap

ring.

226RW062

4. Install the 4th block ring.

226RW063

Mark Thickness

A 2.10–2.15mm (0.083–0.085in)

B 2.15–2.20mm (0.085–0.087in)

C 2.20–2.25mm (0.087–0.089in)

D 2.25–2.30mm (0.089–0.091in)

E 2.30–2.35mm (0.091–0.093in)

F 2.35–2.40mm (0.093–0.095in)

G 2.40–2.45mm (0.095–0.097in)

5. Using a thickness gauge, measure the

clearance between the 4th block ring back and

gear spline end.

Standard: 0.75– 1.65mm (0.030–0.065in)

226RW064

6. Check the braking effect of the block ring. Turn

the block ring in one direction while pushing it to

the gear cone. Check that the ring locks. If it

does not lock, replace the block ring.

226RW060

7. Install the needle roller bearing.

2. Reassemble the mainshaft assembly.

NOTE: Apply all parts with engine oil before installing

them.

3. Inspect block ring

1. Using a thickness gauge, measure the

clearance between the synchronizer ring back

and gear spline end.

226RW105

2. Turn the synchronizer ring in one direction while

pushing it to the gear cone. Check that the ring

locks.

226RW106

Gear Standard Clearanse

1st 0.80–1.60mm (0.032–0.063 in)

2nd 0.65–1.75mm (0.026–0.069 in)

3rd 0.75–1.65mm (0.030–0.065in)

4. Inspect hub sleeve and shift arm.

1st–2nd shift arm

1. Using a vernier caliper, measure center groove

of the 1st–2nd shift arm.

Reference: 5.28 mm (0.208in)

2. Using a vernier caliper, measure flange of the

reverse gear. Calculate the clearance between

the reverse gear and shift arm.

Reference: Reverse gear flange thickness 5.0

mm. (0.197in)

Standard: 0.15– 0.41mm (0.006–0.016in)

226RW093

3rd–4th shift arm

1. Using a vernier caliper, measure tip of the shift

arm thickness.

Reference: 10.0mm (0.39in)

2. Using a vernier caliper, measure center groove

of the hub sleeve No.2. Calculate the

clearance between the hub sleeve No.2 and

shift arm.

Reference: Center groove dimension 10.2mm

(0.402in)

Standard: 0.15– 0.35mm (0.006–0.014in)

226RW095

5. Inspect clutch hub and hub sleeve.

1. Check for wear or damage.

2. Install the hub sleeve to the clutch hub, and

check sliding smoothly.

226RW094

6. Inspect gear inside diameter.

1. Using a inside dial indicator, measure the gear

inside diameter.

Gear Standard Diameter

1st 46.015–46.040mm (1.8116–1.8126in)

2nd 53.015–53.040mm (2.0872 –2.0882 in)

3rd 44.015–44.040mm (1.7329–1.7339 in)

226RW096

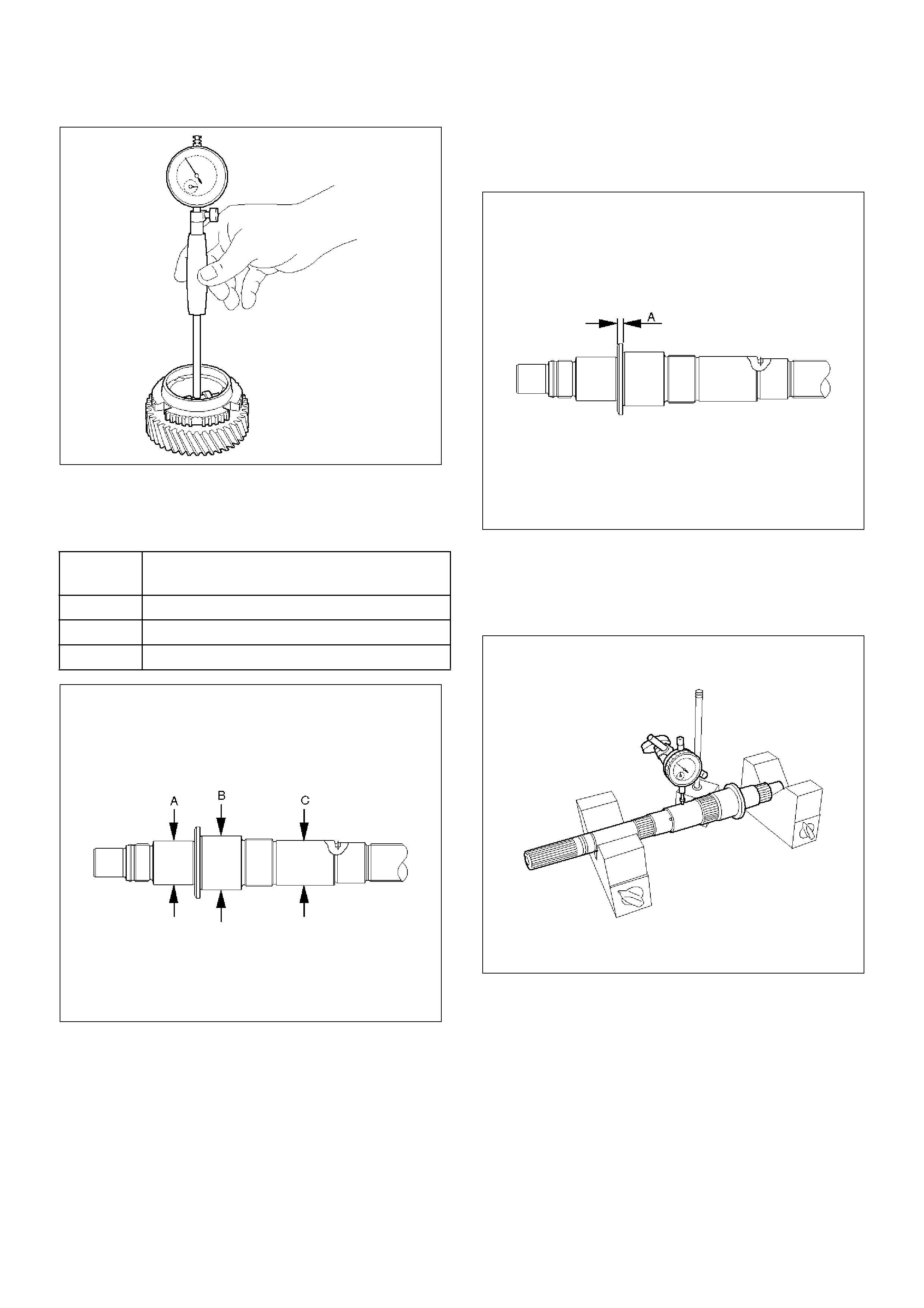

7. Inspect mainshaft.

1. Using a micrometer, measure the outer

diameter of the mainshaft journal.

226RW078

2. Using a micrometer, measure the mainshaft

flange thickness.

Standard: 5.0mm (0.197in)

226RW079

3. Install the mainshaft to V-blocks.

4. Use a dial indicator to measure the mainshaft

central portion run-out.

Standard: less than 0.015mm (0.0006in)

226RW097

Measure

Position Standard

A 37.984–38.000mm (1.4954–1.4961 in)

B 46.984–47.000mm (1.8498–1.8504 in)

C 38.979–38.995mm (1.5346–1.5352 in)

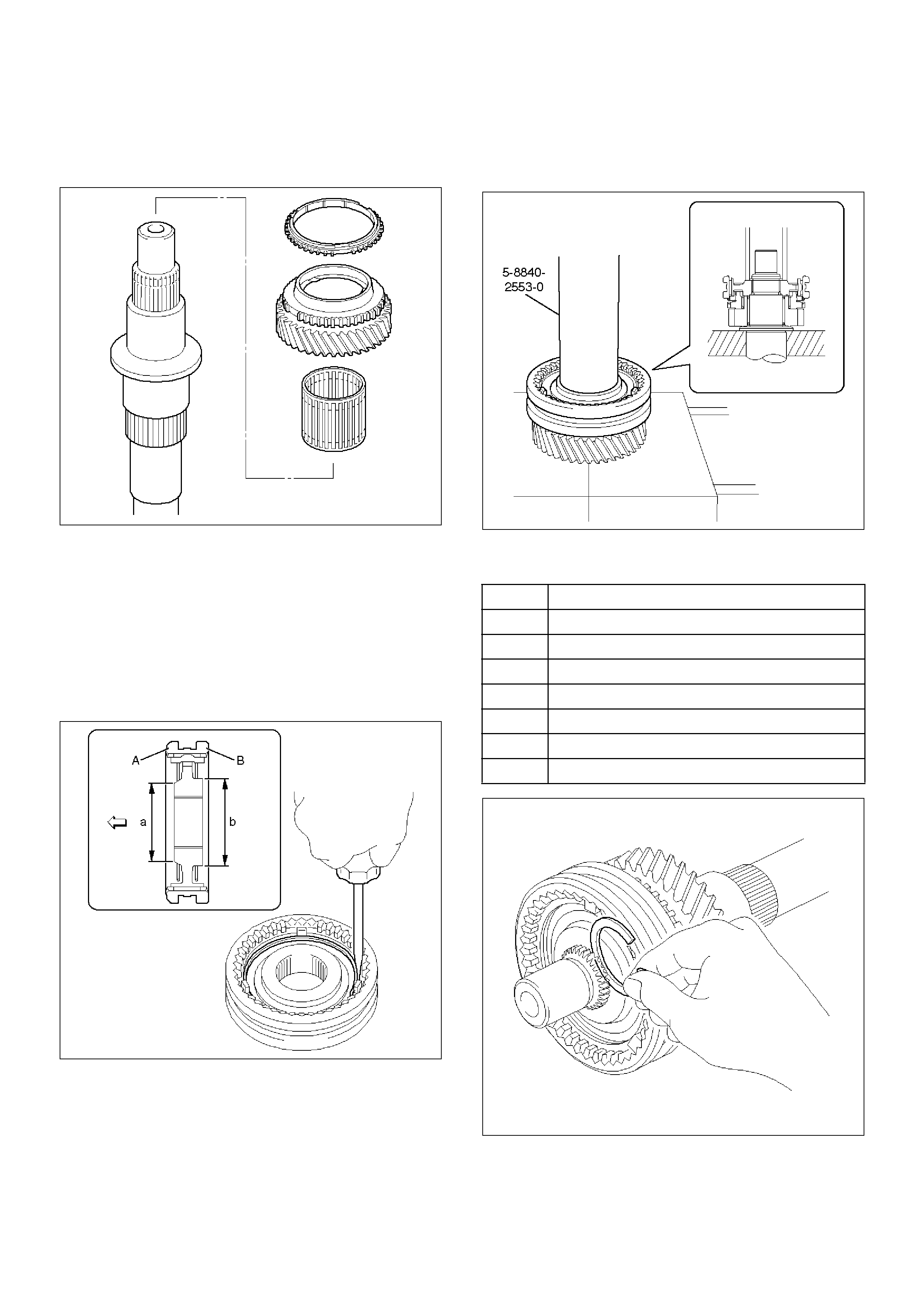

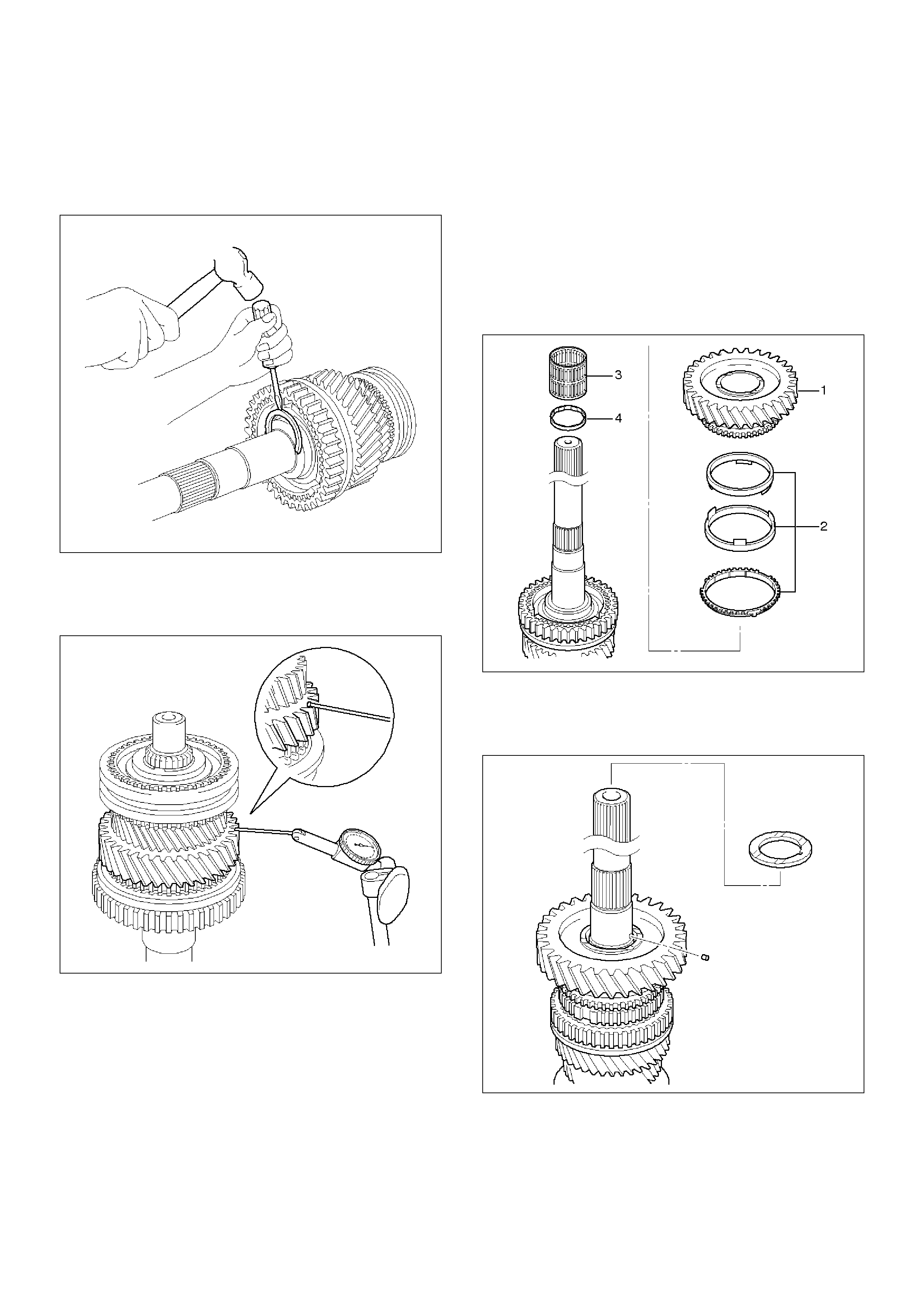

8. Install 3rd gear.

1. Install the 3rd gear needle bearing, 3rd gear and

3rd block ring to the mainshaft.

226RW098

9. Install the clutch hub No.2.

1. Install the clutch hub No.2 and hub sleeve No.2.

NOTE: Be careful the direction of the clutch hub No.2,

as shown.

2. Using a screwdriver, install 3 inserts and 2

springs.

NOTE: Position the insert springs so that their end

gaps are not in line.

226RW099

3. Using installer 5–8840–2553–0 (J–42797) and a

press, install the clutch nob No.2 and hub

sleeve No.2 to the mainshaft.

NOTE:

• Align the brock ring slots with the inserts.

• Check that the gear rotates smoothly.

226RW206

4. Select a snap ring that will allow minimum axial

play.

226RW102

Mark Thickness

A 1.80–1.85mm (0.071–0.073in)

B 1.85–1.90mm (0.073–0.075in)

C 1.90–1.95mm (0.075–0.077in)

D 1.95–2.00mm (0.077–0.079in)

E 2.00–2.05mm (0.079–0.081in)

F 2.05–2.10mm (0.081–0.083 in)

G 2.10–2.15mm (0.083–0.085in)

5. Using a snap ring expander, install the new snap

ring.

NOTE: Be careful not to damage the bearing surface.

226RW101

6. Using a thickness gauge, inspect the 3rd gear

thrust clearance.

Standard: 0.10– 0.25mm (0.004–0.010in)

226RW103

10. Install the 2nd gear.

1. Install the synchronizer ring set No.1 to the 2nd

gear.

NOTE: Align the nail of middle ring with gear spline

slots.

226RW104

2. Install the needle roller bearing, 2nd gear and

2nd gear block ring set to the mainshaft.

226RW107

11. Install the clutch hub No.1.

1. Install the 3 inserts and 3 insert springs to the

clutch hub No.1.

Reference: While pushing the insert spring

with a screwdriver, install the inserts.

226RW108

2. Install the clutch hub No.1 to the reverse gear.

NOTE: Check the clutch hub No.1 installing direction,

as shown.

226RW109

3. Using installer 5–8840–2554–0 (J–42798) and a

press, install the hub No.1 by retaining the

reverse gear.

NOTE:

• Align the projection of inner ring with hub No.1 slots.

• Check that the gear rotates smoothly.

226RW205

4. Select a snap ring that will allow minimum axial

play.

226RW111

Mark Thickness

A 2.30–2.35mm (0.091–0.093in)

B 2.35–2.40mm (0.093–0.095in)

C 2.40–2.45mm (0.095–0.097in)

D 2.45–2.50mm (0.097–0.098in)

E 2.50–2.55mm (0.098–0.100in)

F 2.55–2.60mm (0.100–0.102 in)

G 2.60–2.65mm (0.102–0.104in)

5. Using a screwdriver and hammer, install the

snap ring.

NOTE: Be careful not to damage the bearing surface.

6. Check that the gear rotates smoothly.

226RW112

7. Using a dial indicator, measure the 2nd gear

thrust clearance.

Standard: 0.10– 0.25mm (0.004–0.010in)

226RW113

12. Install the 1st gear.

1. Install the following parts:

1. 1st gear bearing spacer (4).

2. 1st gear needle roller bearing (3).

3. Synchronizer assembly (2).

4. 1st gear (1).

NOTE:

• Align the projection of inner ring with hub No.1 slots.

• Check that the gear rotates smoothly.

226RW114

2. Install the 1st gear thrust washer pin and 1st

gear thrust washer to the mainshaft.

NOTE: Align the straight pin with the thrust washer slot.

226RW115

13. Install the mainshaft center bearing.

1. Using installer 5–8840–2555–0 (J–42799) and a

press, install the mainshaft center bearing.

NOTE: Center bearing snap ring groove toward rear.

226RW195

2. Using a thickness gauge, measure 1st gear

thrust clearance.

Standard: 0.10– 0.45mm (0.004–0.018in)

226RW118

14. Install the 5th gear.

1. Using installer 5–8840–2555–0 (J–42799) and a

press, install the 5th gear.

2. Select a snap ring that will allow minimum axial

play.

226RW203

3. Using a screwdriver and hammer, install the

new snap ring.

226RW127

Mark Thickness

C 2.75–2.80mm (0.108–0.110in)

D 2.80–2.85mm (0.110–0.112in)

E 2.85–2.90mm (0.112–0.114in)

F 2.90–2.95mm (0.114– 0.116in)

G 2.95–3.00mm (0.116–0.118in)

H 3.00–3.05mm (0.118–0.120in)

J 3.05–3.10mm (0.120–0.122in)

K 3.10–3.15mm (0.122–0.124in)

L 3.15–3.20mm (0.124–0.126in)

M 3.20–3.25mm (0.126–0.128in)

N 3.25–3.30mm (0.128–0.130in)

P 3.30–3.35mm (0.130–0.132in)

15. Inspect each gear radial clearance.

1. Mount the mainshaft through the aluminum

plate in a vise.

2. Using a dial indicator, measure the radial

clearance of each gear.

226RW071

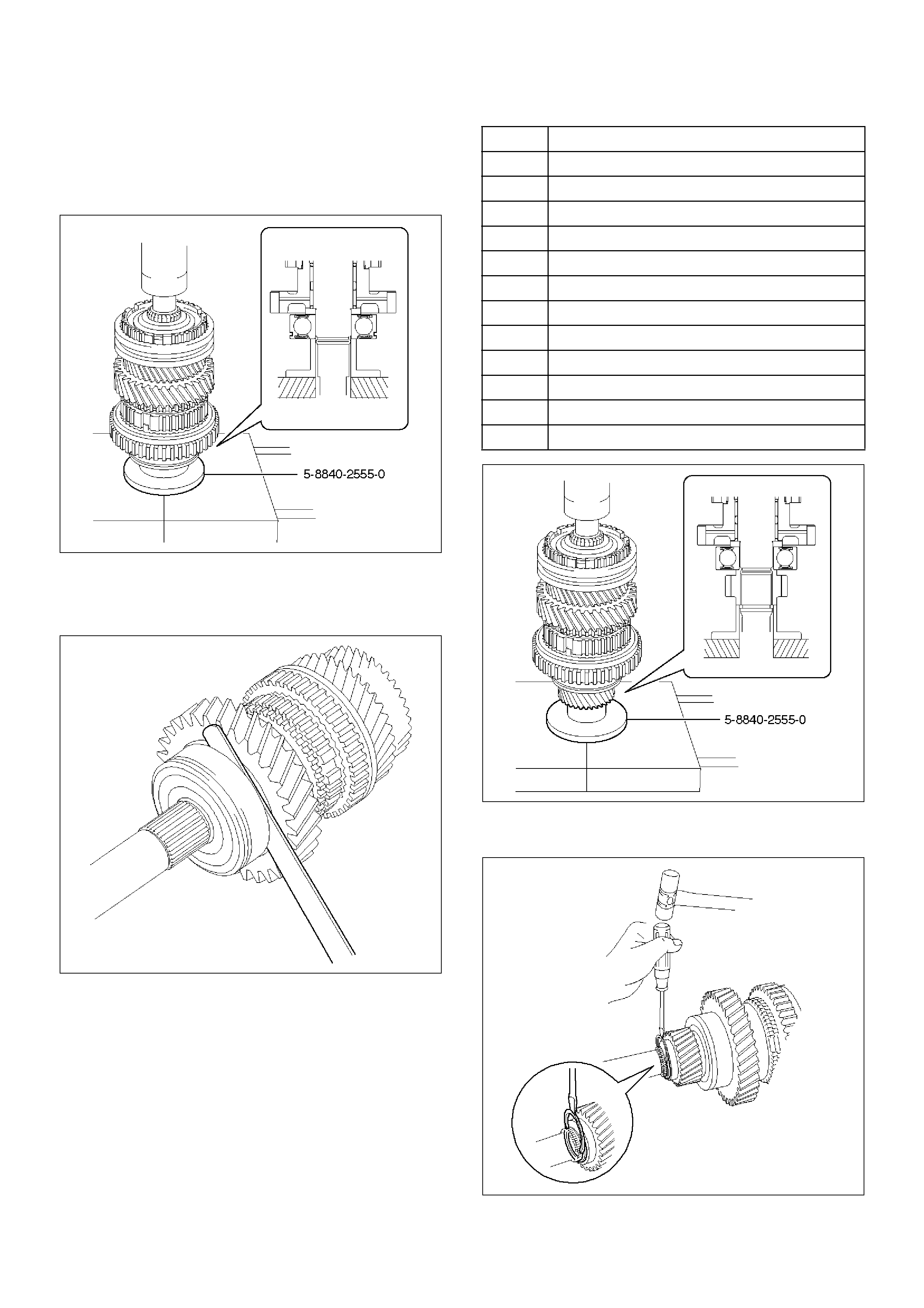

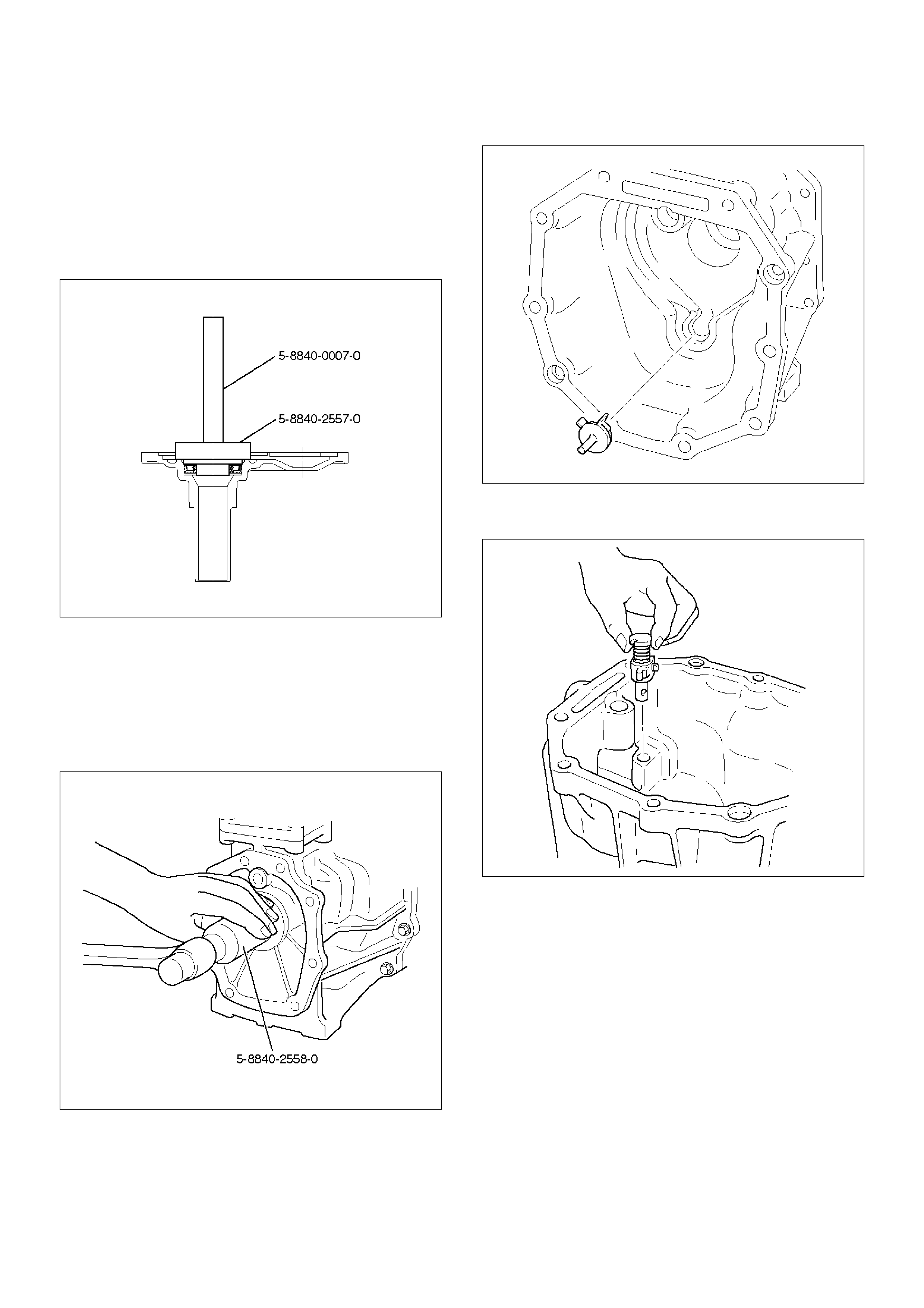

16. Install the counter gear shaft.

1. Check the new counter front bearing inner race

and the side race, as shown.

2. Using installer 5–8840–2556–0 (J–42800) and a

press, install the counter gear shaft front

bearing.

226RW194

3. Select a snap ring that will allow minimum axial

play.

226RW128

4. Using a snap ring expander, install the new snap

ring.

226RW129

Gear Standard Clearanse

1st 0.020–0.073mm (0.0008–0.0029in)

2nd 0.015–0.068mm (0.0006–0.0027 in)

3rd 0.015–0.068mm (0.0006 –0.0027 in)

Mark Thickness

A 2.00–2.05mm (0.079–0.081in)

B 2.05–2.10mm (0.081–0.083in)

C 2.10–2.15mm (0.083–0.085in)

D 2.15–2.20mm (0.085–0.087in)

E 2.20–2.25mm (0.087–0.089in)

F 2.25–2.30mm (0.089–0.091 in)

17. Install the front cover.

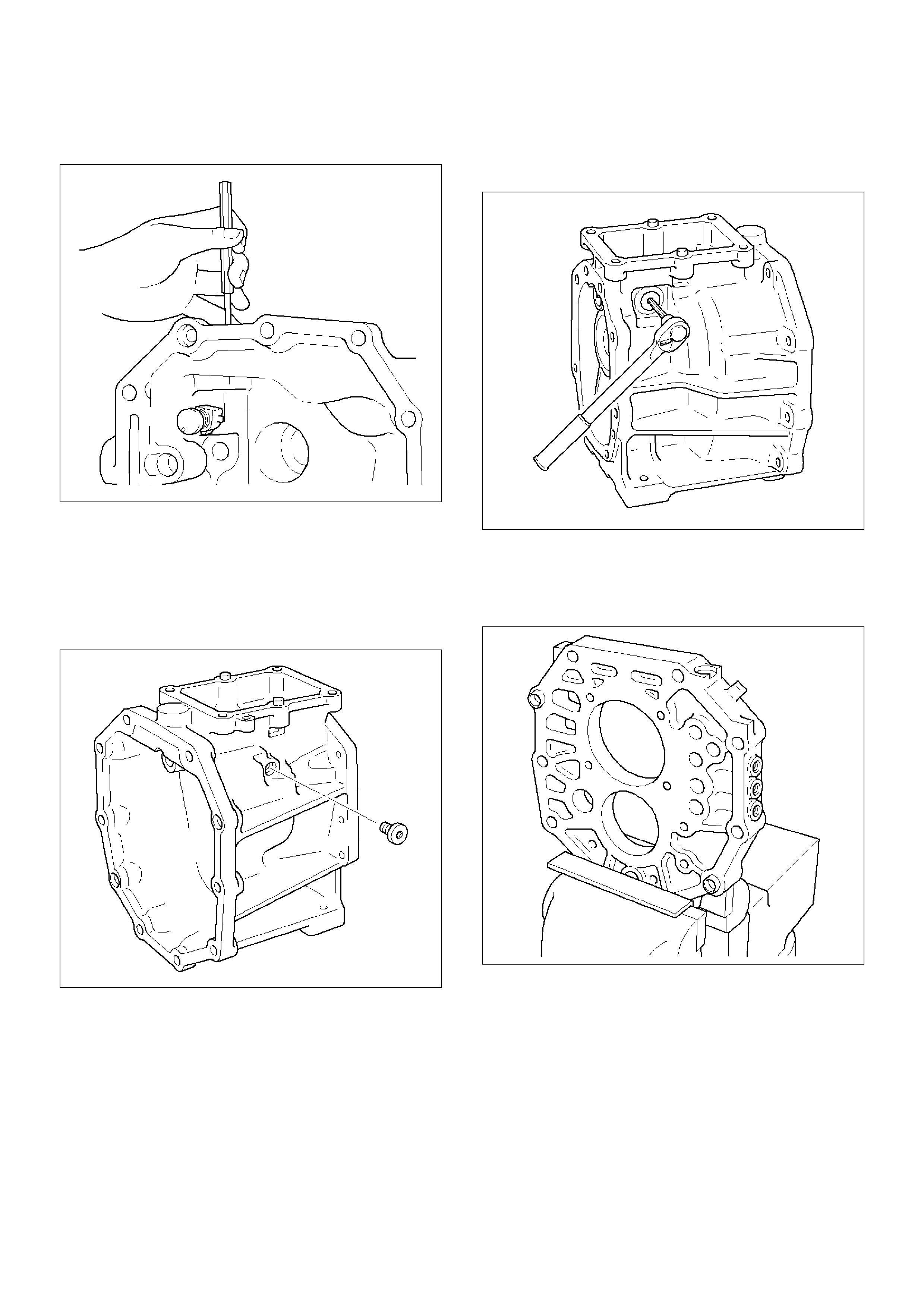

1. Using installer 5–8840–2557–0 (J–42801), grip

5–8840–0007–0 (J–8092) and a hammer, drive

in a new oil seal.

Drive in depth (from cover end): 11.7±0.5mm

(0.46±0.02in)

2. Apply grease to the seal lip.

220RW113

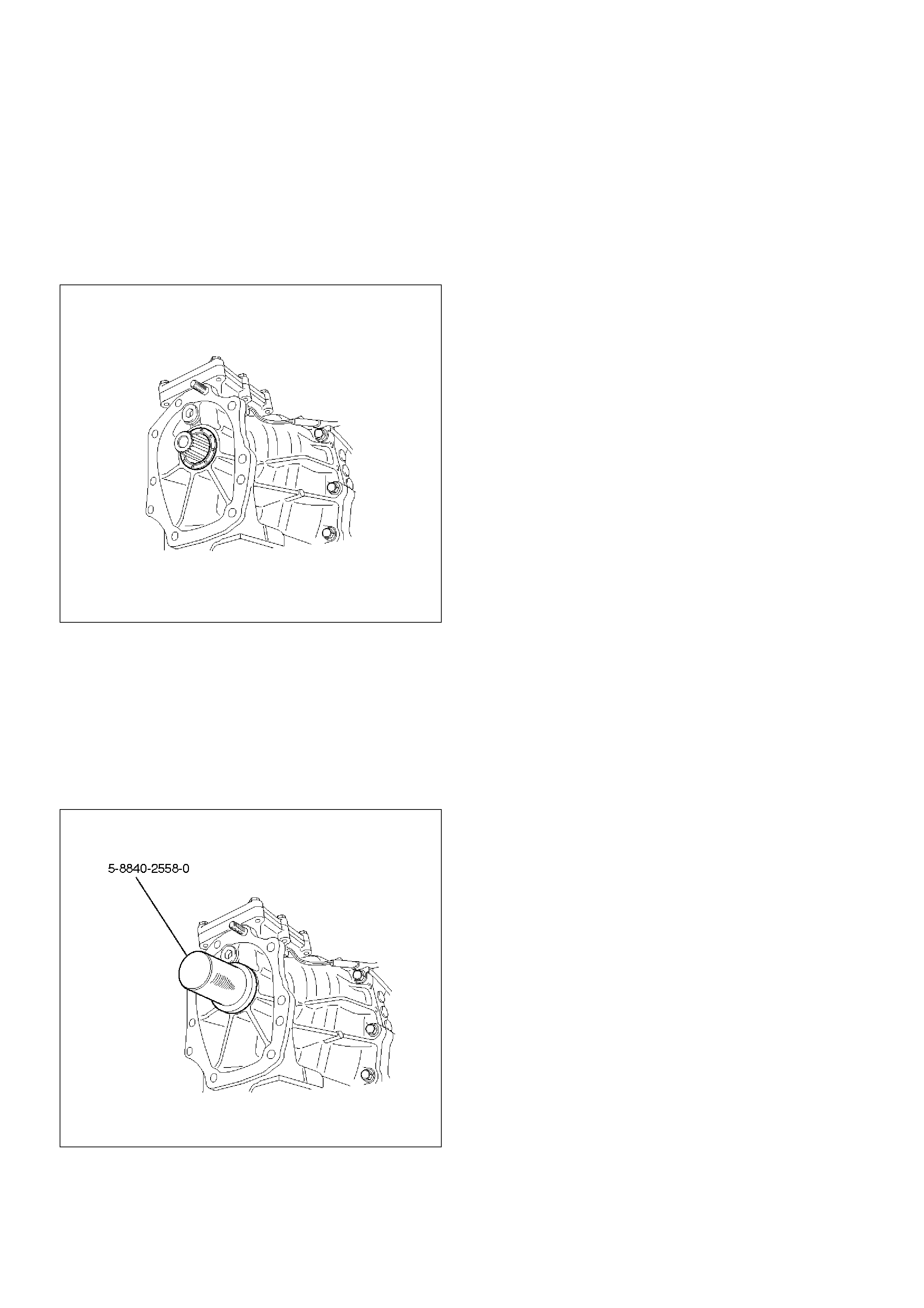

18. Install the transfer adapter.

1. Using installer 5–8840–2558–0 (J –42802), and

a hammer drive in a new oil seal.

Drive in depth (from transfer adapter):

10.95±0.5mm (0.431 ±0.02in)

2. Apply grease to the oil seal lip.

220RW114

3. Install the oil receiver pipe.

220RW011

4. Install the reverse restrict to the transfer

adapter.

226RW059

5. Using a pin punch and hammer, drive in the

slotted spring pin.

226RW058

6. Clean up the plug and plug hole.

7. Apply sealant to the plug threads. (THREE

BOND 1344 or equivalent)

8. Using a torx socket wrench(T40), install and

torque the plug.

Torque: 19N·m (1.9kg·m/14lbft)

220RW013

9. Using hexagon wrench, install and torque the

plug.

Torque: 37N·m (3.8kg·m/27lbft)

220RW014

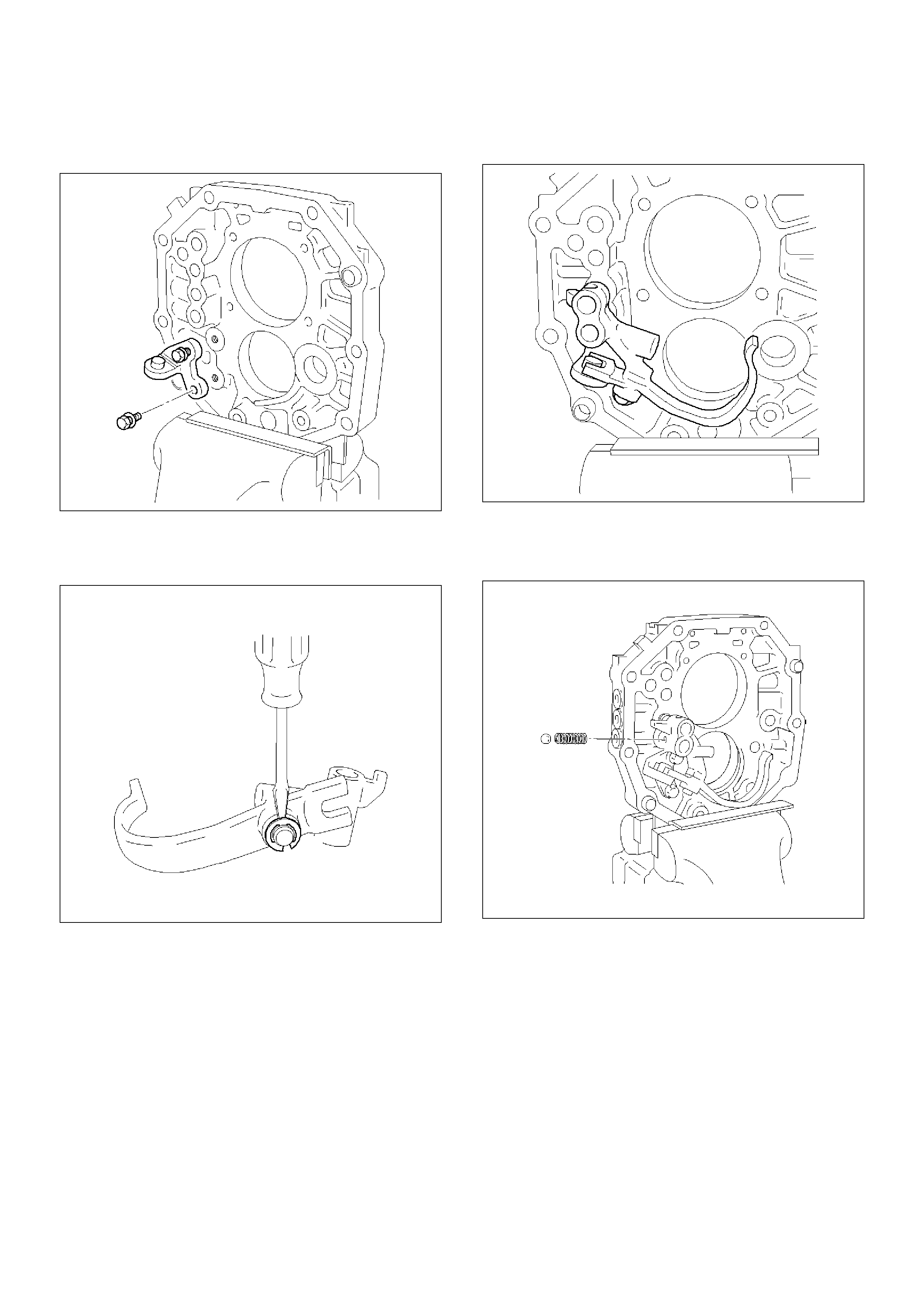

19. Install the reverse shift arm No.1 and reverse shift

arm No.2.

1. Mount the intermediate plate through the

aluminum plate in a vise.

226RW057

2. Using 2 bolts, install reverse shift arm bracket.

Torque: 18N·m (1.8kg·m/13lbft)

226RW054

3. Install reverse shift arm No.2 to the reverse shift

arm No.1. Using screwdriver and a hammer,

install the new E-ring.

226RW138

4. Install reverse shift arm No.2 to the reverse shift

arm bracket.

226RW012

20. Install the reverse shift rod.

1. Install the reverse shift arm No.1 compression

spring and ball to the reverse shift arm No.1.

226RW125

2. Install the reverse shift rod from the rear side by

pushing the ball on using a screwdriver.

226RW126

21. Install the reverse-5th shift rod.

1. Install the reverse shift arm No.1 lock ball to the

reverse shift arm No.1.

2. Install the interlock pin to the intermediate plate.

226RW039

3. Put in the reverse-5th shift rod from the front.

226RW011

4. Using a screwdriver and a hammer, install the 2

new shift rod snap rings to the 5th-reverse shift

rod and reverse shift rod.

226RW037

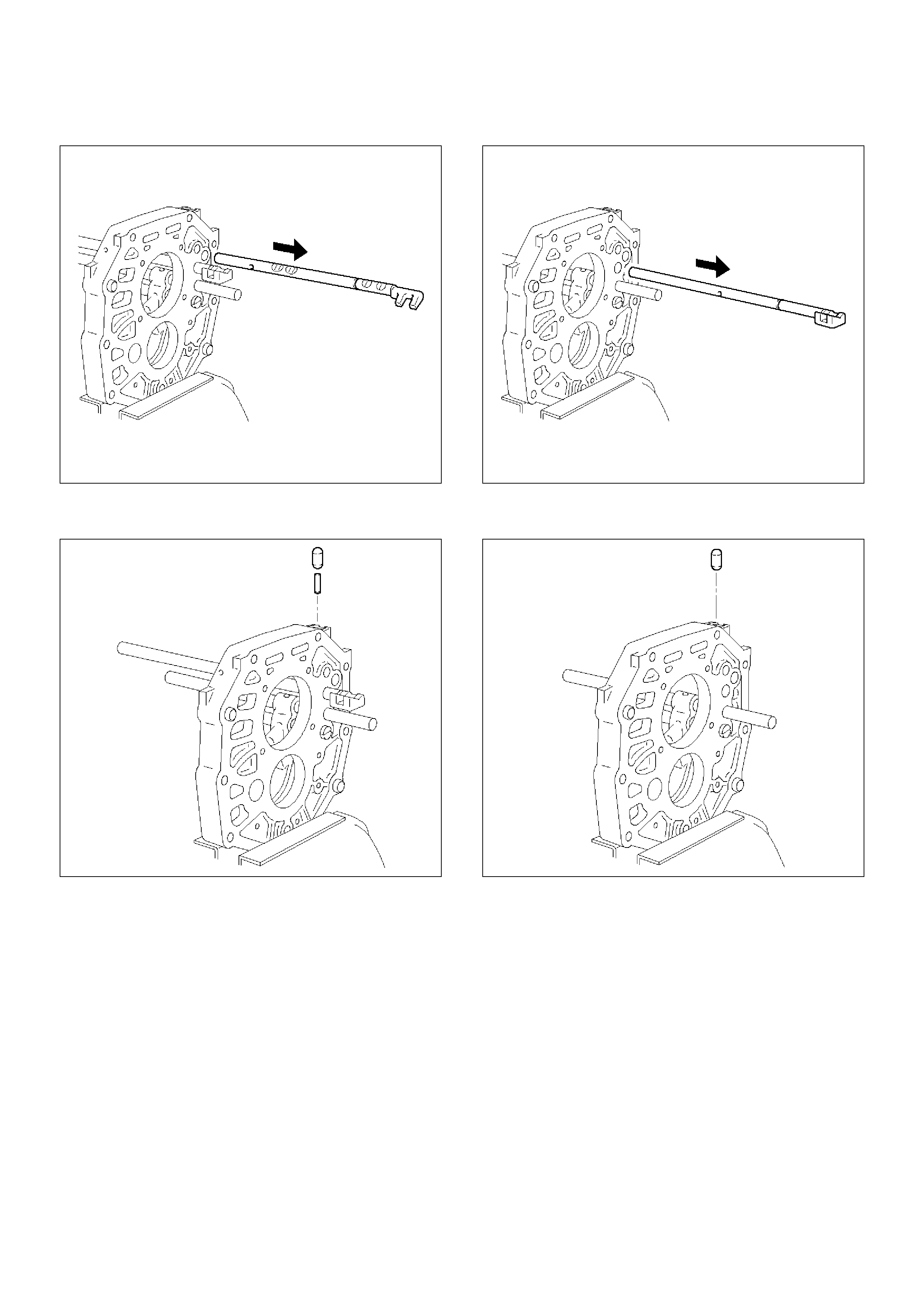

22. Install 1st–2nd shift rod.

1. Install the interlock pin to the intermediate plate.

226RW042

2. Put in the 1st–2nd shift rod from the rear.

226RW044

23. Install 3rd–4th shift rod.

1. Install the straight pin and interlock pin to the

intermediate plate.

226RW043

2. Put in the 3rd–4th shift rod from the rear.

226RW046

24. Install the interlock parts.

1. Using a screwdriver and hammer, 2 new shift

rod snap rings to the 1st–2nd and 3rd–4th shift

rod.

226RW051

2. Install the 3 shift detent ball and springs to the

intermediate plate.

226RW049

3. Clean up the plug hole.

4. Apply sealant to the plug threads.

sealant: THREE BOND 1344 or equivalent

5. Using a torx socket wrench(T40), install and

torque the 4 plugs.

Torque: 19N·m (1.9kg·m/14lbft)

226RW050

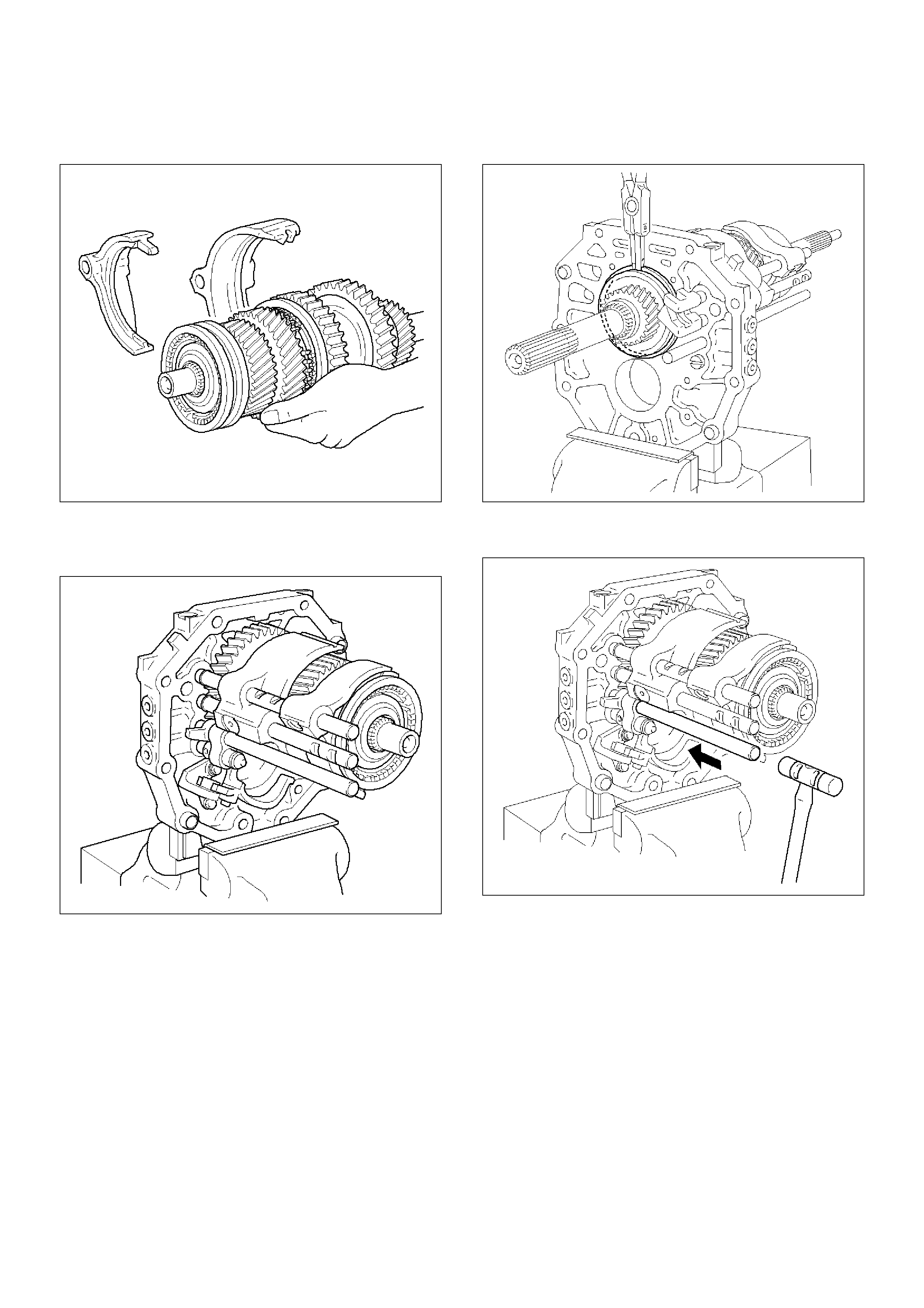

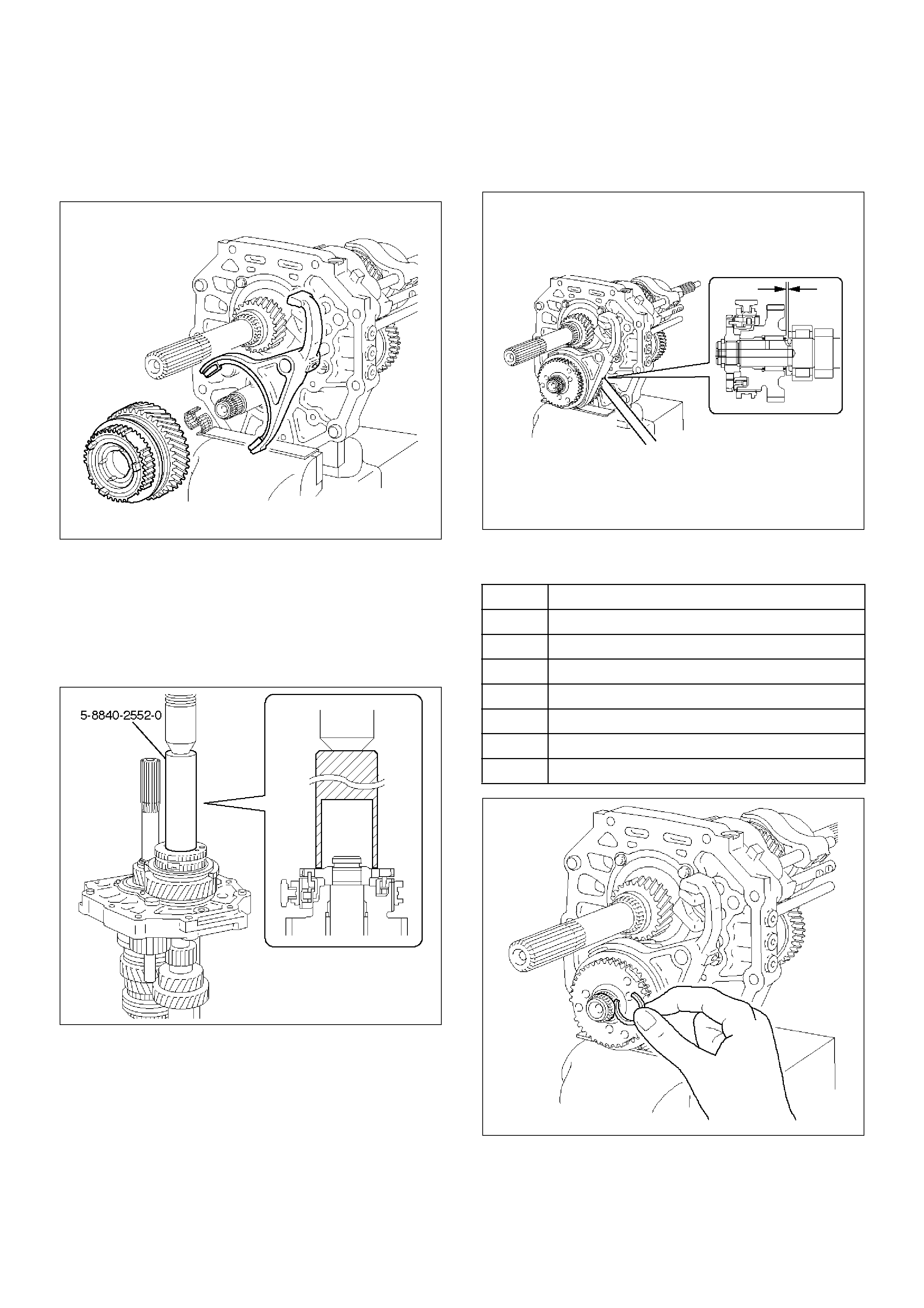

25. Install mainshaft assembly.

NOTE: Coat all parts with gear oil before installing

them.

1. Using a plastic hammer, tap the 5th-reverse shift

rod at the reverse shift.

226RW180

2. Install the shift arm No.1 and No.2 to the

mainshaft.

226RW010

3. Using a plastic hammer, tap the intermediate

plate and install the mainshaft. Through the

shift arm No.1 and No.2 to the shift rod.

226RW009

4. Using a snap ring expander, install the snap

ring.

226RW035

5. Using a plastic hammer, tap the 5th-reverse shift

rod at the neutral shift.

226RW008

26. Install the top gear shaft.

1. Align the projection of the hub No.2 with the

synchronizer ring slots, and install the top gear

shaft assembly to the mainshaft.

2. Check that the gear rotates smoothly.

226RW006

27. Install the counter gear shaft.

1. Temporarily install the counter gear shaft to the

intermediate plate.

226RW028

2. Using installer 5–8840–2552–0 (J–42796) and a

hammer, drive in the center bearing as shown.

NOTE: Outer race snap ring groove toward rear.

226RW192

Reference: Drive in the counter rear bearing

by tapping on the front end of the counter

shaft.

226RW022

28. Install the reverse idle gear.

1. Install the reverse idle gear and reverse idle

gear shaft.

NOTE:

• Insert the reverse idle gear shaft with the slot toward

rear.

• Install the reverse idle gear with the reverse shift arm

No.2.

226RW019

29. Install the bearing plate.

1. Align the bearing plate to groove of the reverse

idle gear shaft.

Torque: 13N·m (1.3kg·m/113lbin)

226RW016

30. Install the 5th gear thrust washer.

1. Install the 5th gear thrust washer pin to the

counter gear shaft.

2. Install the 5th gear thrust washer to the counter

gear shaft.

NOTE: Thrust washer must be assembled with the

chamfered face of the washer toward the front.

226RW185

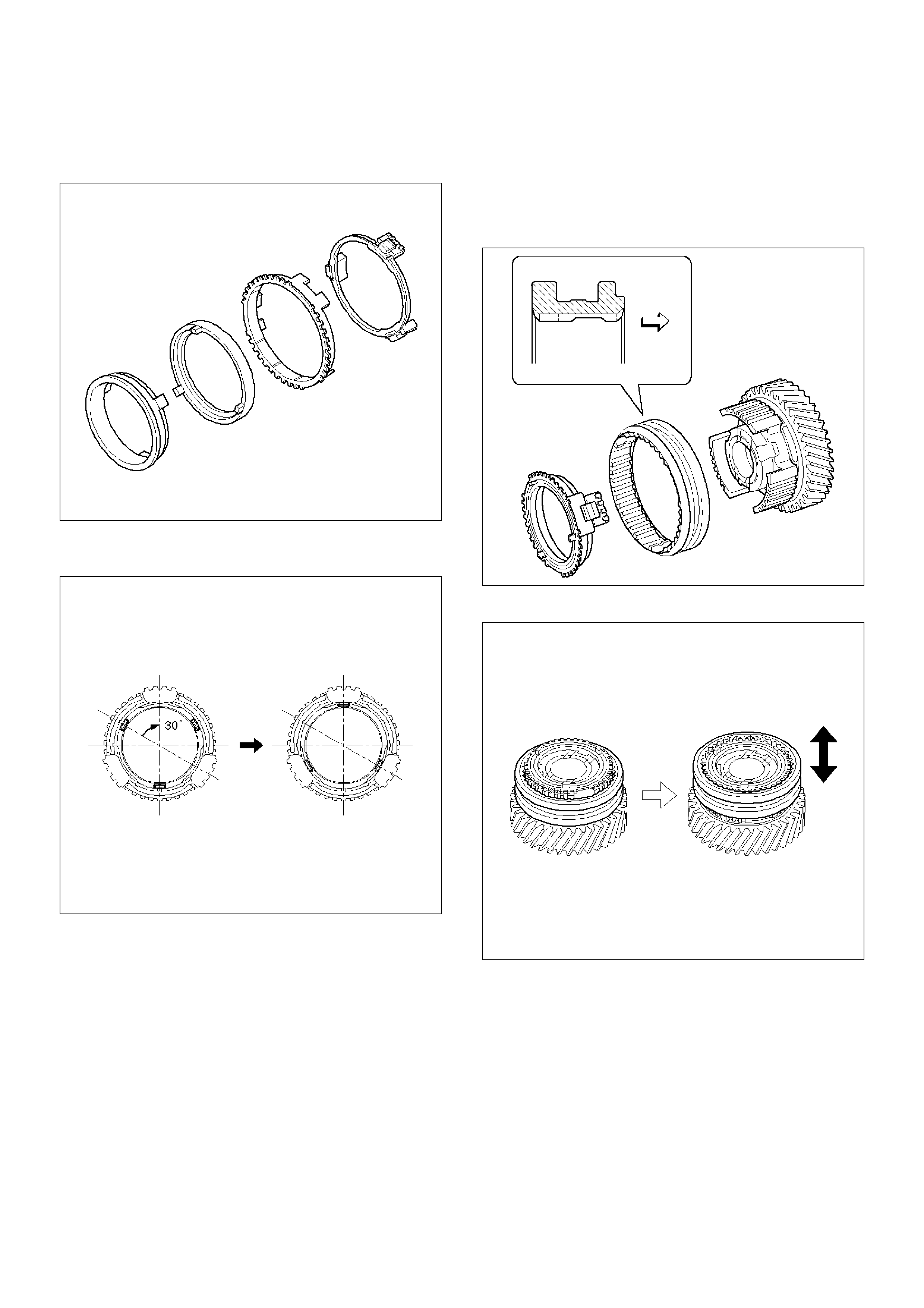

31. Install the counter 5th gear.

1. Install the 3 inserts and 3 compression springs

to the reverse block ring.

Reference: Push the 3 inserts with the 3

compression springs to the reverse

synchronizer ring.

226RW120

2. Install the synchronizer outer ring, synchronizer

cone ring, and synchronizer pull ring to the

reverse block ring.

226RW121

3. Turn to 30 degree the reverse synchronizer pull

ring.

226RW080

4. Install the hub sleeve No.3 and reverse block

ring set to the counter 5th gear.

NOTE: Check the hub sleeve No.3 direction, as shown.

Reference: While pushing the 3 inserts,

install the synchronizer ring assembly to the

hub sleeve No.3.

226RW184

5. Slide the hub sleeve No.3.

226RW123

6. Install the counter 5th gear bearing, counter 5th

gear and reverse block ring set to the counter

gear shaft, through the 5th reverse shift arm to

the 5th reverse shift rod.

220RW101

7. Using installer 5–8840–2552–0 (J–42796) and a

press, install counter 5th gear spline piece.

NOTE:

• Align the projection of the cone ring to the holes of

the 5th gear spline piece.

• Check that the gear rotates smoothly.

226RW193

8. Using thickness gauge, measure the counter

5th gear thrust clearance.

Standard: 0.10–0.35mm (0.004–0.014in)

220RW100

9. Select a snap ring that will allow minimum axial

play.

226RW027

Mark Thickness

A 2.80–2.85 (0.110–0.112in)

B 2.85–2.90 (0.112–0.114in)

C 2.90–2.95 (0.114–0.116in)

D 2.95–3.00 (0.116–0.118in)

E 3.00–3.05 (0.118– 0.120 in)

F 3.05 – 3.10 (0.120 –0.122in)

G 3.10–3.15 (0.122–0.124in)

10. Install the new snap ring.

226RW026

32. Install the shift arm bolts.

1. Install and torque the 2 shift arm bolts.

Torque: 20N·m (2.0kg·m/14lbft)

226RW023

33. Install the shift arm slotted pin.

1. Using a pin punch and a hammer, drive in the

slotted pin to the shift arm.

226RW025

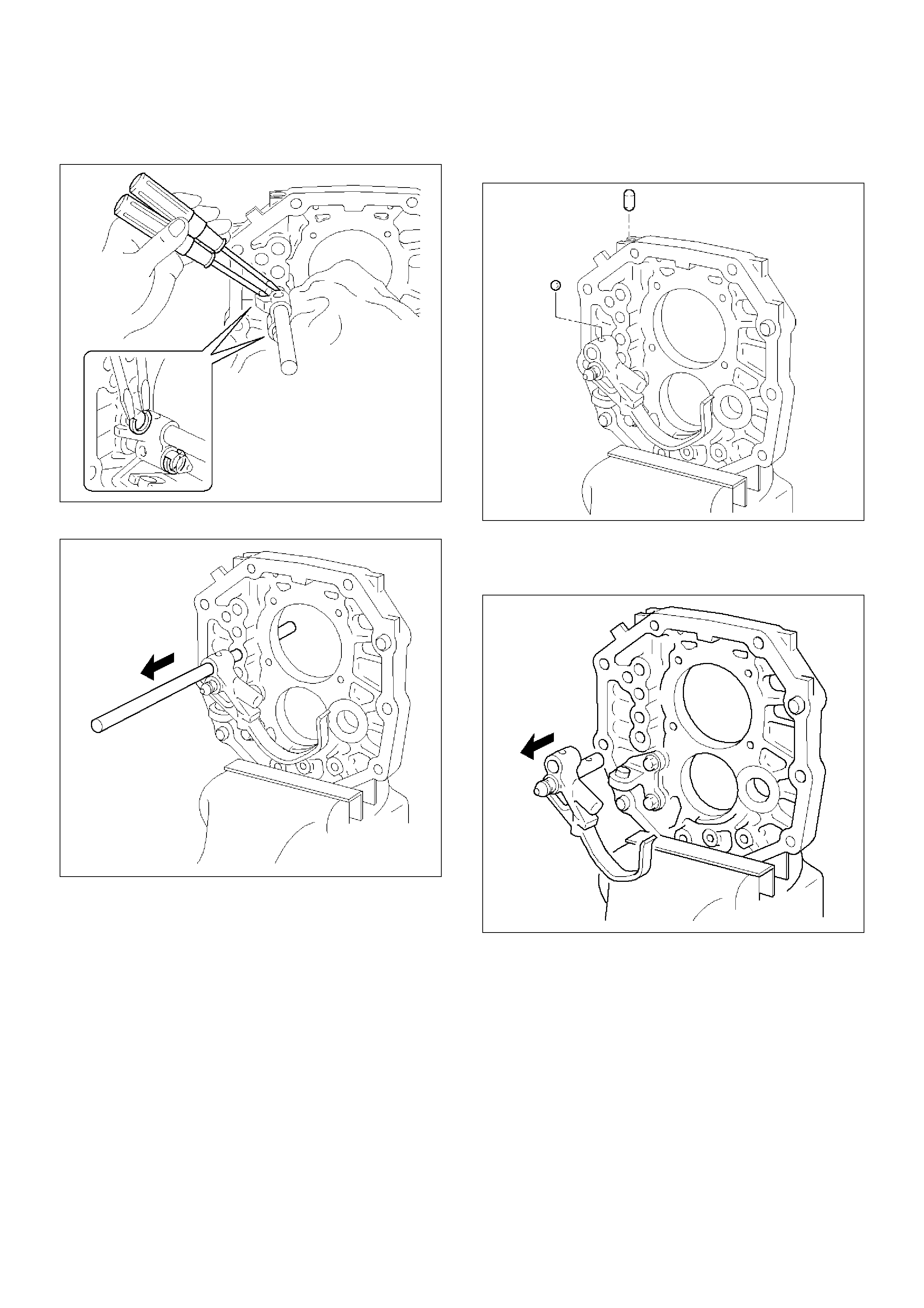

34. Install the transmission case.

1. Clean up the fitting surface.

2. Apply recommended liquid gasket (THREE

BOND 1281 or equivalent), as shown.

NOTE:

• Don't dry the liquid gasket.

220RW024

3. Stand the transmission by the wood blocks.

4. Using a plastic hammer, tap the transmission

case and attach it to the intermediate plate.

NOTE: Be careful not to add over force to bearing.

220RW022

5. Using a snap ring expander, install the front

bearing shaft snap ring (1) and counter gear

shaft bearing snap ring (2).

226RW004

6. Turn over the transmission.

35. Install the front cover.

1. Clean up the fitting surface.

2. Apply recommended liquid gasket (THREE

BOND 1281 or equivalent), as shown.

NOTE:

• Don't dry the liquid gasket.

220RW025

3. Clean up and dry the bolts.

4. Apply thread sealant (THREE BOND 1344 or

equivalent) to the 8 bolts.

5. Using 8 bolts, install the front cover to the

transmission case.

Torque: 17N·m (1.7kg·m/12lbft)

NOTE:

• Tighten the all bolts evenly.

• Be careful not to damage the oil seal.

220RW018

6. Check that the top gear shaft and mainshaft

rotate.

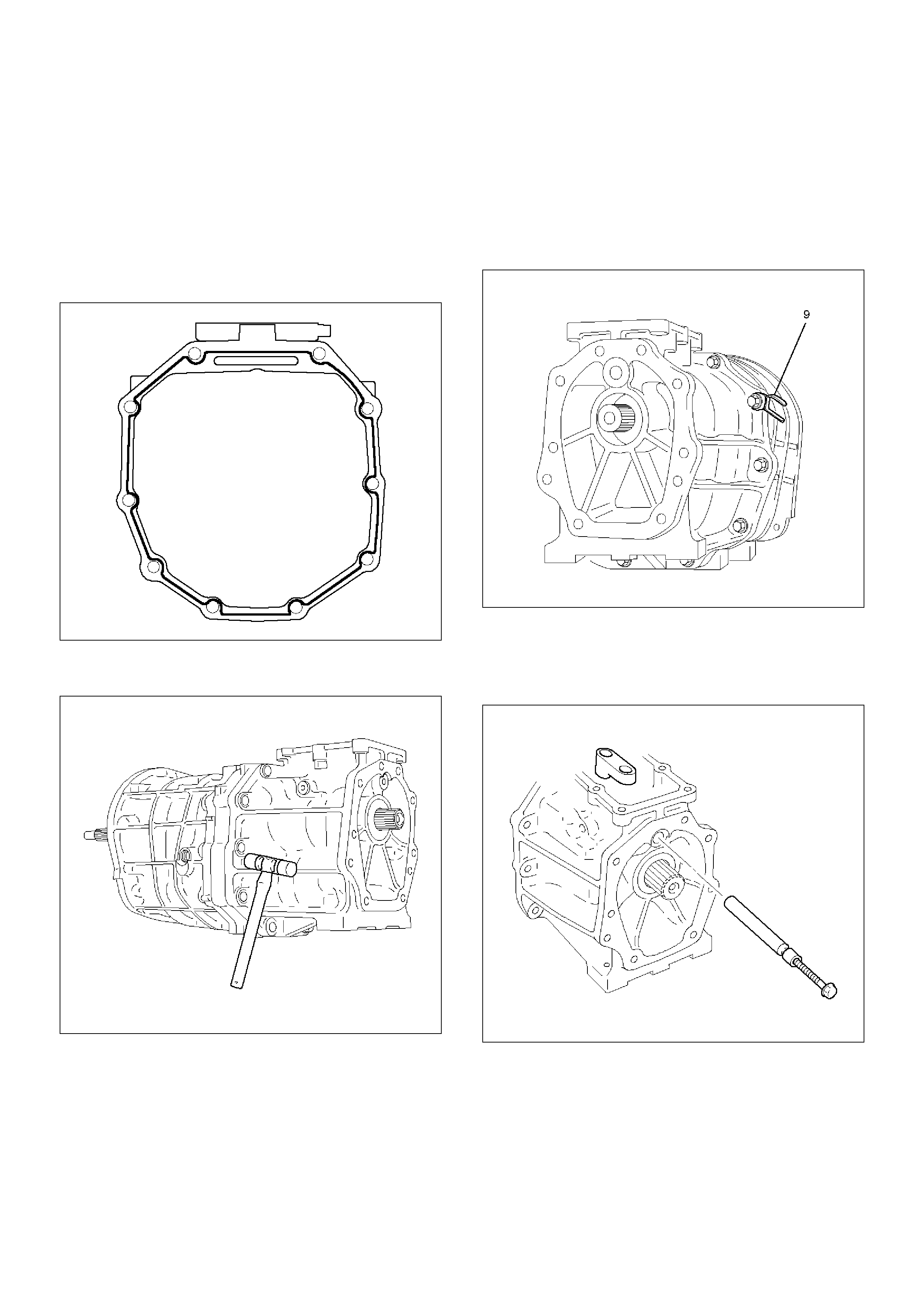

36. Install the transfer adapter.

1. Clean up the fitting surface.

2. Apply recommended liquid gasket (THREE

BOND 1281 or equivalent), as shown.

NOTE:

• Don't dry the liquid gasket.

220RW026

3. Using a plastic hammer, tap the transfer adapter

and attach it to the intermediate plate.

220RW034

4. Using 10 bolts, install the transfer adapter.

Torque: 37N·m (3.8kg·m/27lbft)

NOTE:

• Tighten the all bolts evenly.

• Don't damage the lip of the oil seal.

• Install the wire clamp (9) to the transfer adapter.

220RW083

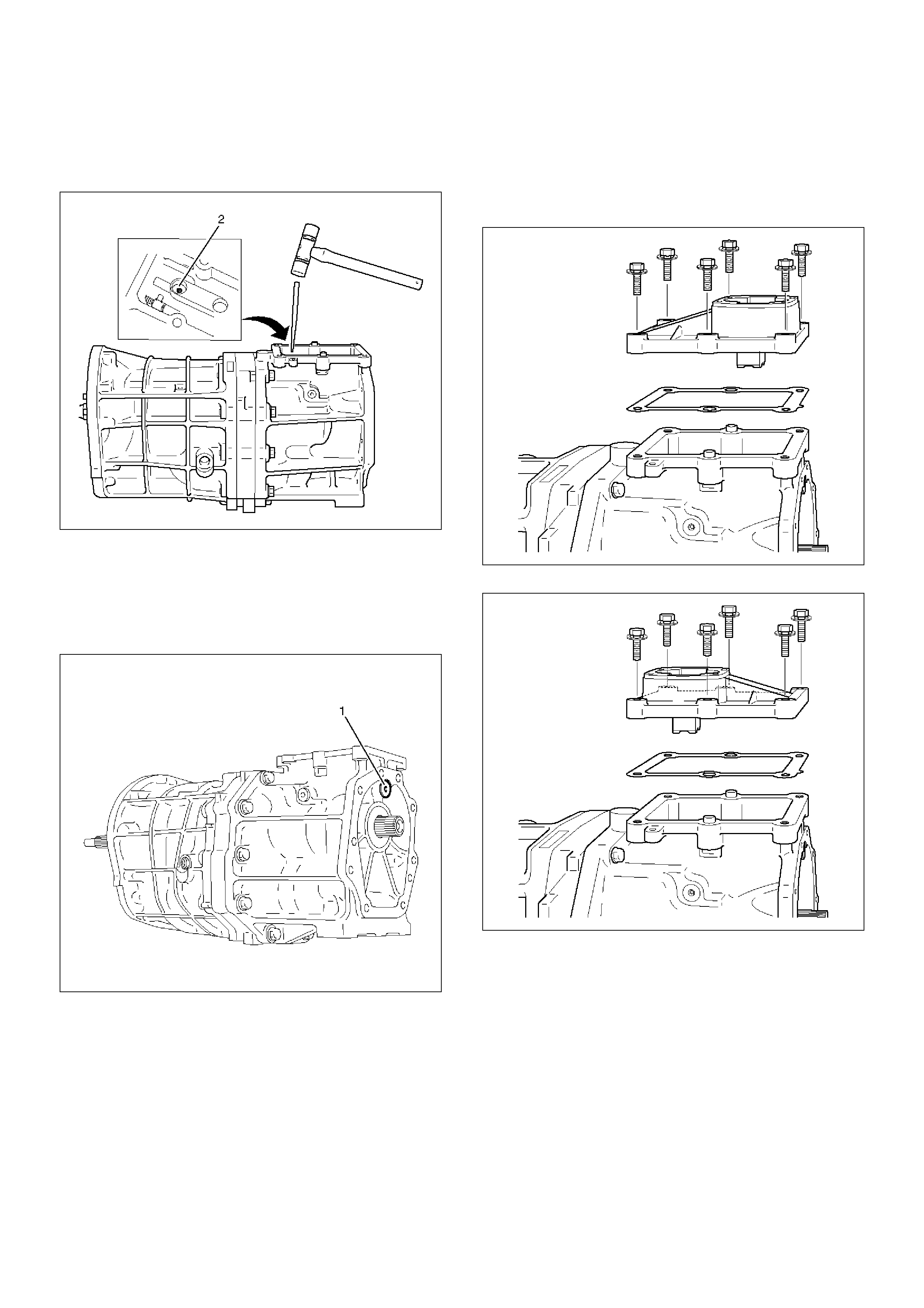

37. Install the gear control box.

1. Align the projection of the shift lever housing to

the shaft rod groove, and install the gear control

rod.

230RW003

2. Using a pin punch and hammer, drive in the

slotted spring pin (2) to the shift lever housing.

NOTE: Be carefull not to drop the slotted spring pin.

230RW002

3. Apply sealant (THREE BOND 1344 or

equivalent) to the plug (1) thread.

4. Using hexagon wrench, install and torque the

plug (1).

Torque: 18N·m (1.8kg·m/13lbft)

220RW010

5. Clean up the bolts and bolt hole.

6. Using 6 bolts, install the gear control box

through the gasket.

Torque 18N·m (1.8kg·m/13lbft)

(6VE1)

230RW001

(4JX1)

220RW097

38. Install clutch housing.

1. Install the clutch housing to the transmission

case.

Torque: 36N·m (3.7kg·m/27lbft)

NOTE: Tighten the all bolts evenly.

241RW001

39. Install the switches.

1. Install the new gasket to the 1st and 2nd switch.

2. Install the 1st and 2nd switch assembly (8).

Torque: 39N·m (4.0kg·m/29lbft)

3. Install the new gasket to the backup light switch.

4. Install the backup light switch assembly (6).

Torque: 44N·m (4.5kg·m/33lbft)

5. Install the new gasket to the neutral switch.

6. Install the neutral switch (7) to the transfer

adapter (4JX1).

Torque: 37N·m (3.8kg·m/27lbft)

(4JX1)

220RW093

40. Install the clutch release bearing (3) and clutch shift

fork (5).

1. Apply the clutch release grease.

1. Fitting surface of the cylinder push rod.

2. Fitting surface of the release bearing hub.

3. The hole of the fork split pin (4).

2. Apply the clutch release grease.

1. The spline surface of the top gear shaft.

3. Install the clutch shift fork (5).

4. Install the snap pin.

5. Install the clutch release bearing (3) to the

clutch shift fork (5).

220RW086

41. Install the drain plug and filler plug.

1. Install the drain plug (1) through the new gasket.

Torque: 37N·m (3.8kg·m/27lbft)

2. Install the filler plug (2) through the new gasket.

Reference: Plug after the gear oil fill in.

Torque: 37N·m (3.8kg·m/27lbft)

(6VE1)

220RW007

Main Data and Specifications

General Specifications

Transmission type Fully synchronized forward and reverse gears

Control method Direct control with the gear shift lever on the floor

Gear ratio 1st 3.954

2nd 2.330

3rd 1.436

4th 1.000

5th 0.788

Rev 3.918

Oil capacity lit (US qt) 2.7 (2.86)

Type of lubricant Engine oil : Refer to the chart in “SECTION 0B”

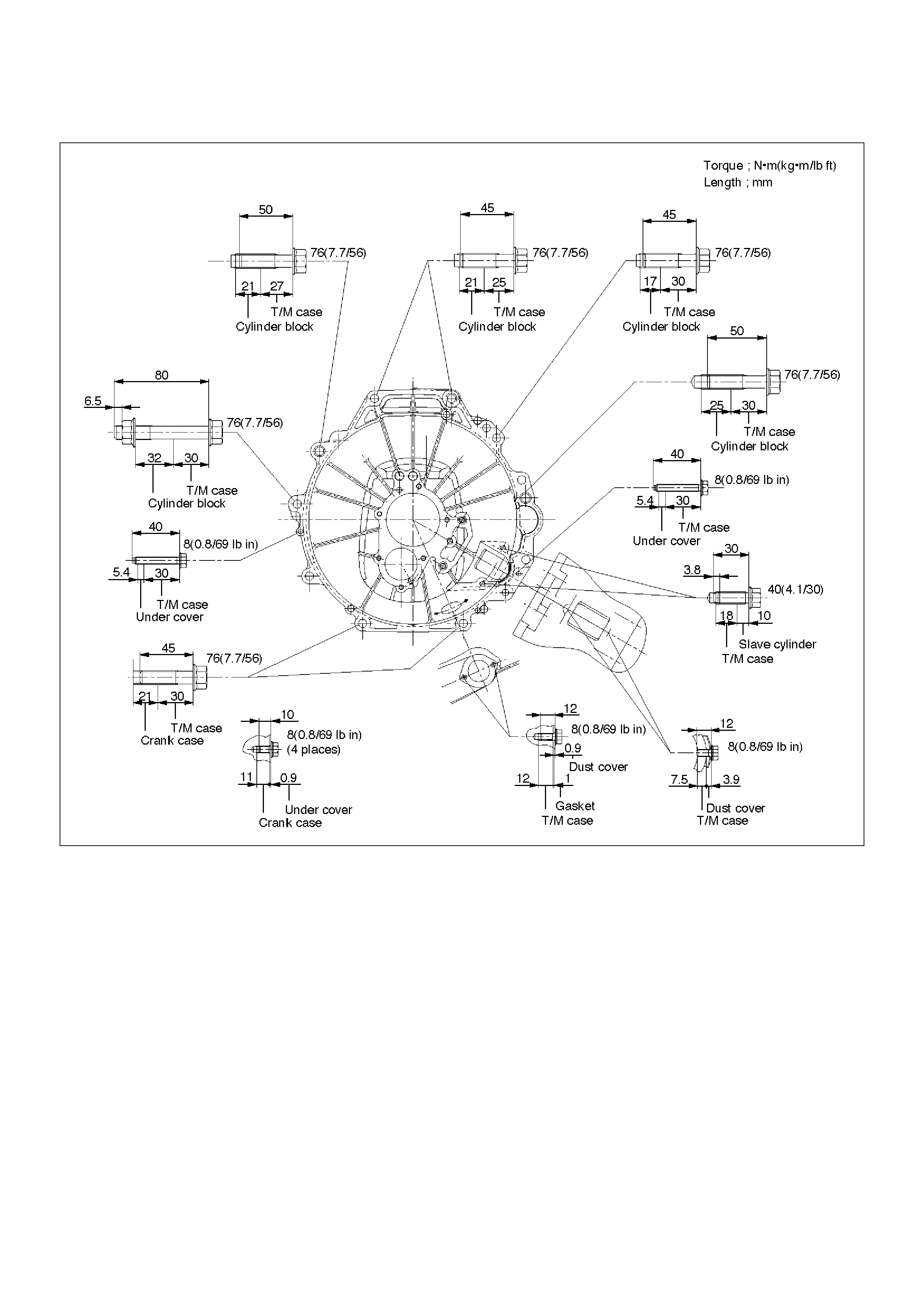

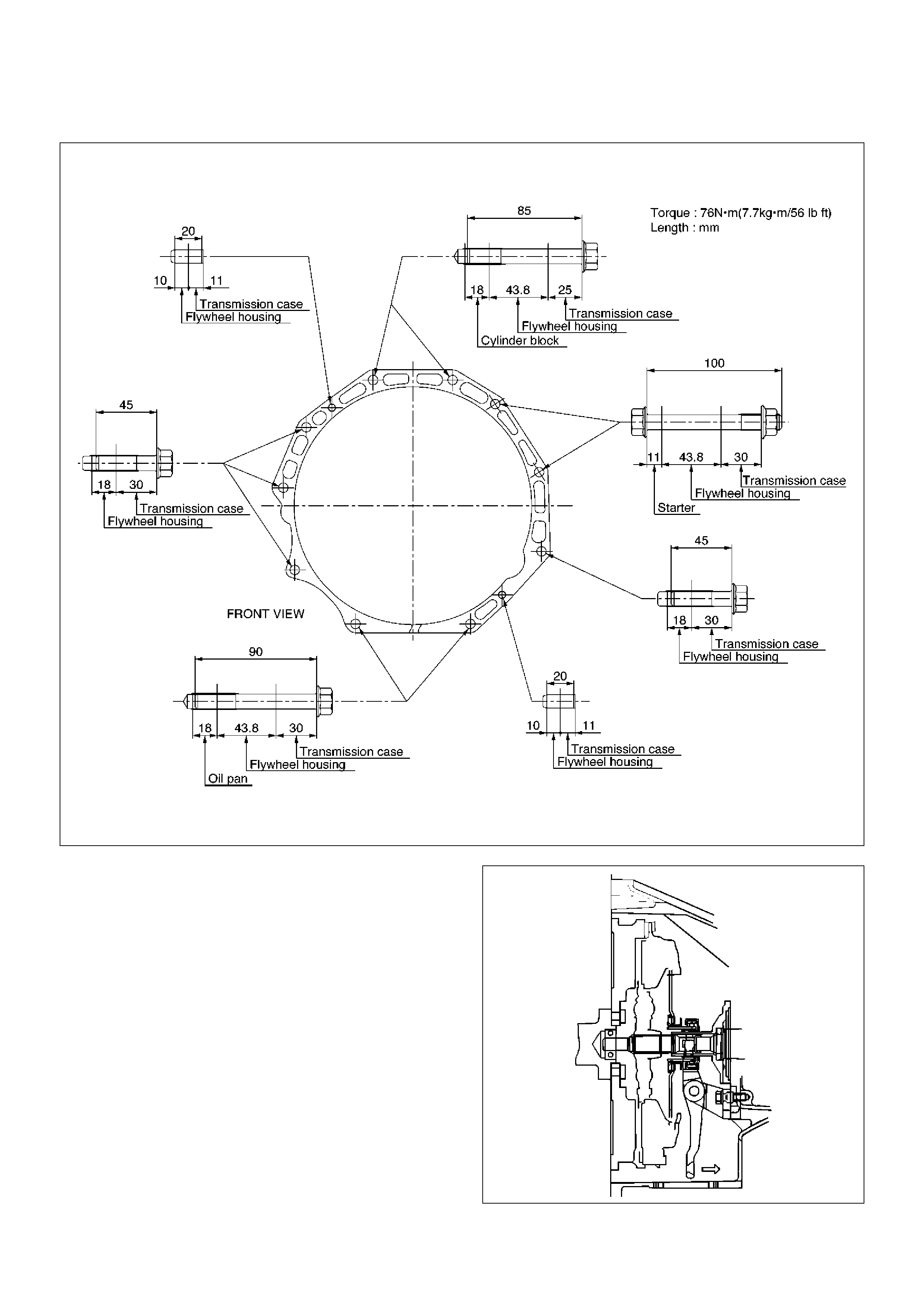

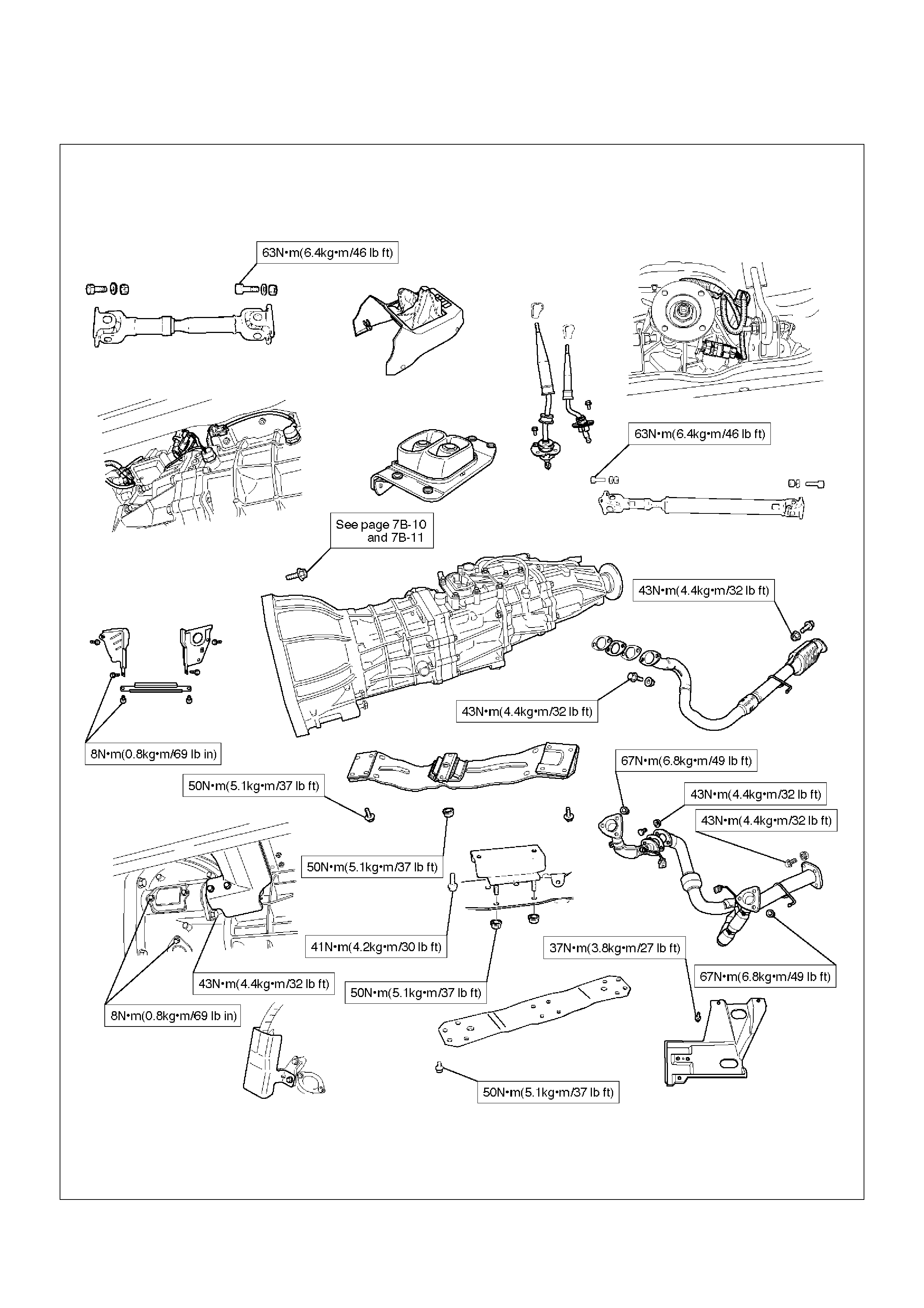

Torque Specifications

E07RW049

Torque Specifications (Cont'd)

E07RW050

Torque Specifications (Cont'd)

E07RW051

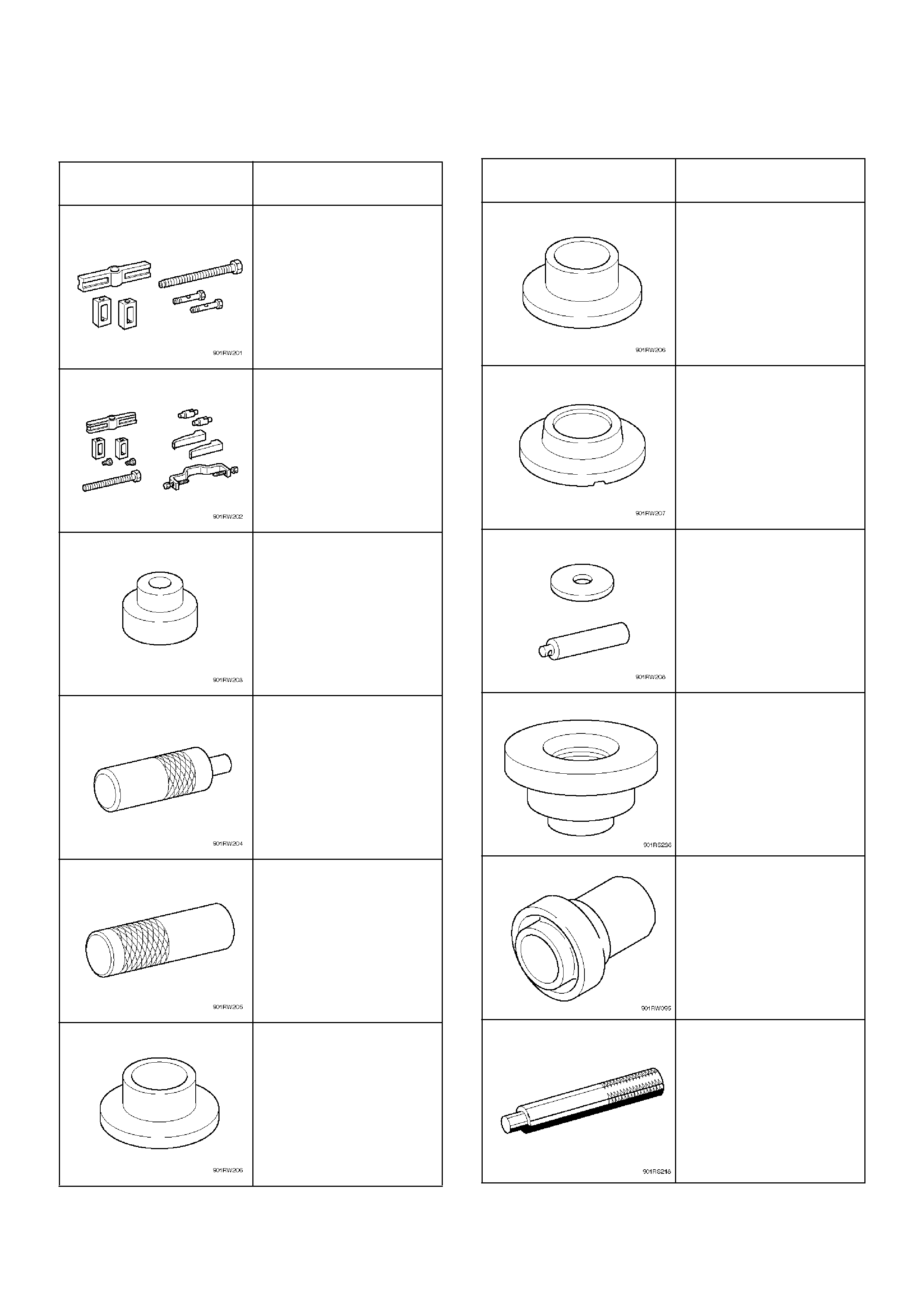

Special Tools

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–2550–0

(J–42794)

Gear spline pieace

remover

5–8840–2551–0

(J–42795)

Center bearing remover

5–8840–2560–0

(J–42988)

Attachment

5–8840–2552–0

(J–42796)

Counter gear shaft center

bearing installer

5–8840–2553–0

(J–42797)

Clutch hub (No.2)

installer

5–8840–2554–0

(J–42798)

Clutch hub (No.1)

installer

5–8840–2555–0

(J–42799)

Installer

5–8840–2556–0

(J–42800)

Counter gear shaft front

bearing installer

5–8840–2559–0

(J–42904)

Top gear shaft front

bearing installer

5–8840–2557–0

(J–42801)

Front rerainer oil seal

installer

5–8840–2558–0

(J–42802)

Transfer adapter oil seal

installer

5–8840–0007–0

(J–8092)

Driver handle

ILLUSTRATION TOOL NO.

TOOL NAME

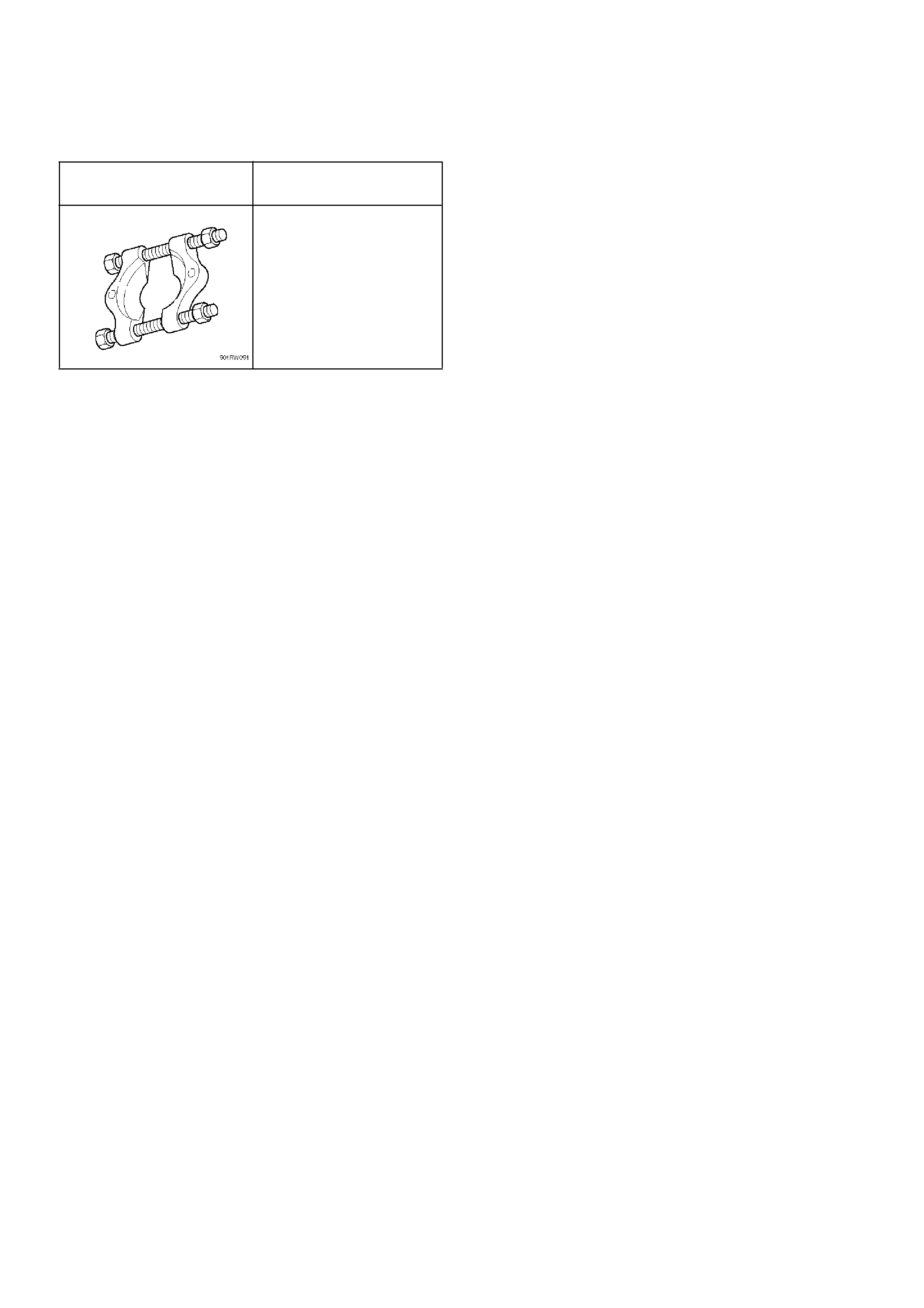

Special Tools (Cont'd)

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–0015–0

(J–22912–01)

Bearing separator