SECTION 7C - AUTOMATIC TRANSMISSION (AW30-40LE)

General Description

Construction

Electronic Control Components

Transmission Control Module (TCM)

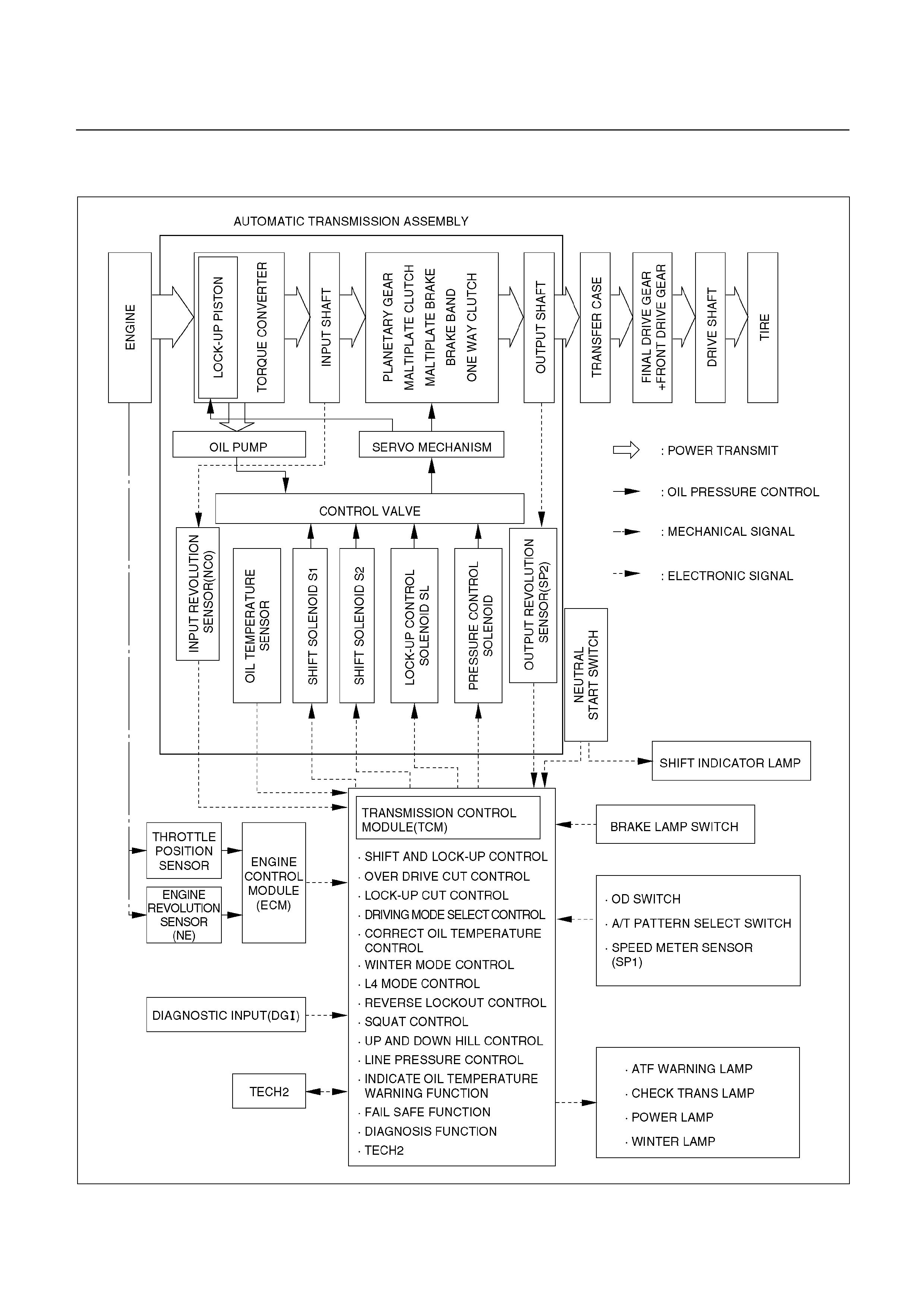

Control System Diagram

Control and Functions

Major Input/Output Components

Location of Clutch, Brake, One-way Clutch and Solenoid

Operation of Clutch, Brake and One-Way Clutch

Speed Change and Lock-up Pattern

Overdrive and Lock-up Operating Conditions

Diagnosis

Basic Troubleshooting

Self Diagnosis

Diagnosis with Tech 2

Using Tech 2 on the Vehicle

Connecting Tech 2 to the Vehicle

Transmission Data

TCC Data

Intermittent Conditions

Identification of Transmission Control Module (TCM)

Diagnostic Trouble Codes (DTC) Check

DTC P0120 (Flashing Code 21) Analog Throttle Signal Failure (VTH) (For UBS)

DTC P0502 (Flashing Code 24) Speed Meter Sensor Failure (SP1)

DTC P0705 (Flashing Code 17) Gear Selector Failure (PRND2L)

DTC P0710 (Flashing Code 16) Oil Temperature Sensor Failure (OT2)

DTC P0717 (Flashing Code 14) Input Revolution Sensor Failure (NC0)

DTC P0722 (Flashing Code 11) Output Revolution Sensor Failure (SP2)

DTC P0727 (Flashing Code 13) Engine Revolution Signal Failure (NE)

DTC P0743 (Flashing Code 33) Torque Converter Clutch Control Lock-up (ON/OFF)

Solenoid Failure (SL)

DTC P0748 (Flashing Code 35) Pressure Control Solenoid Failure (STH)

DTC P0753 (Flashing Code 31) Solenoid 1 Failure (S1)

DTC P0758 (Flashing Code 32) Solenoid 2 Failure (S2)

DTC P1120 (Flashing Code 22) PWM Throttle Signal Failure (TH) (For TFR/S)

DTC P1121 (Flashing Code 23) Analog Throttle Signal Failure (VREF, VGND)

(ForUBS)

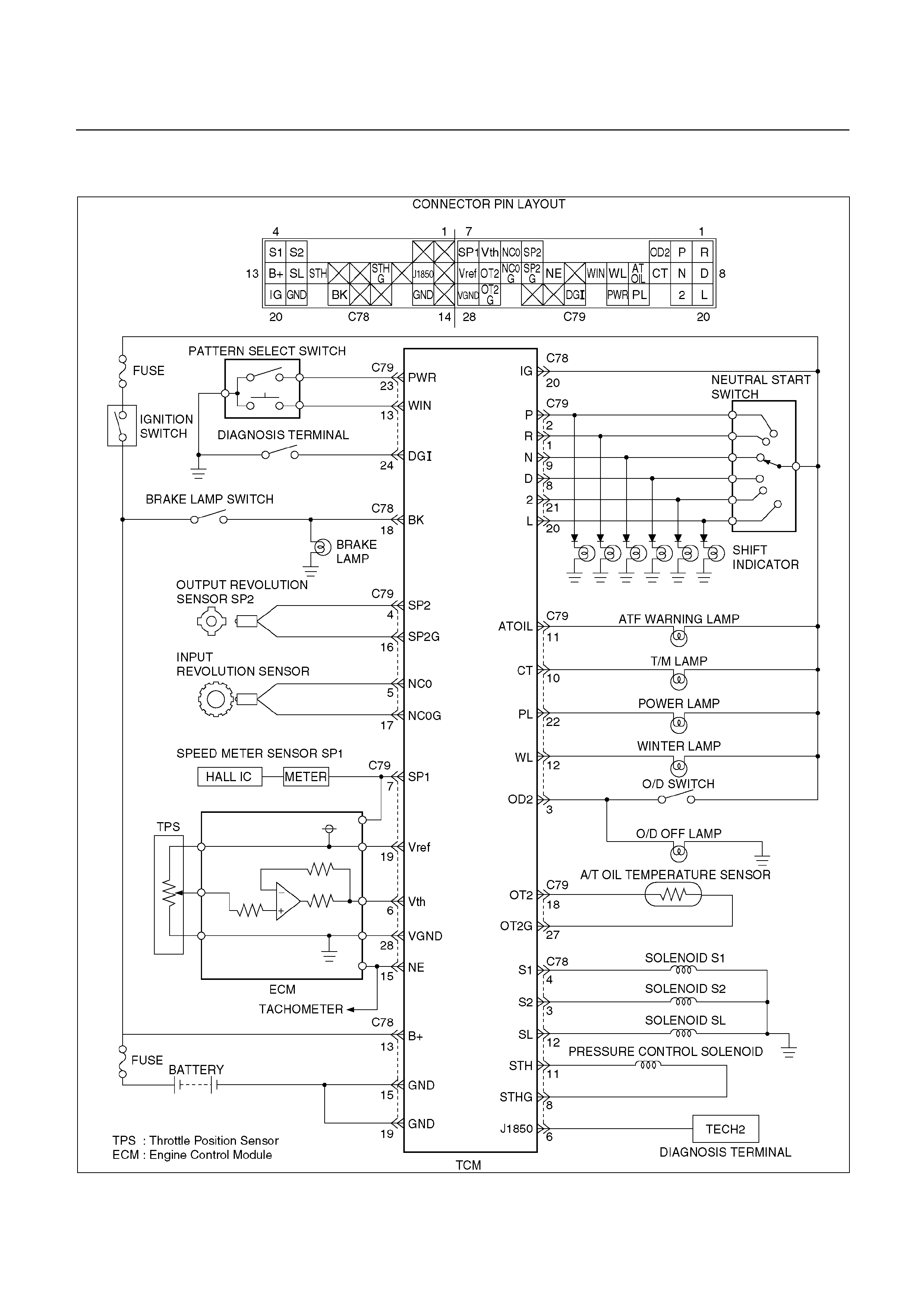

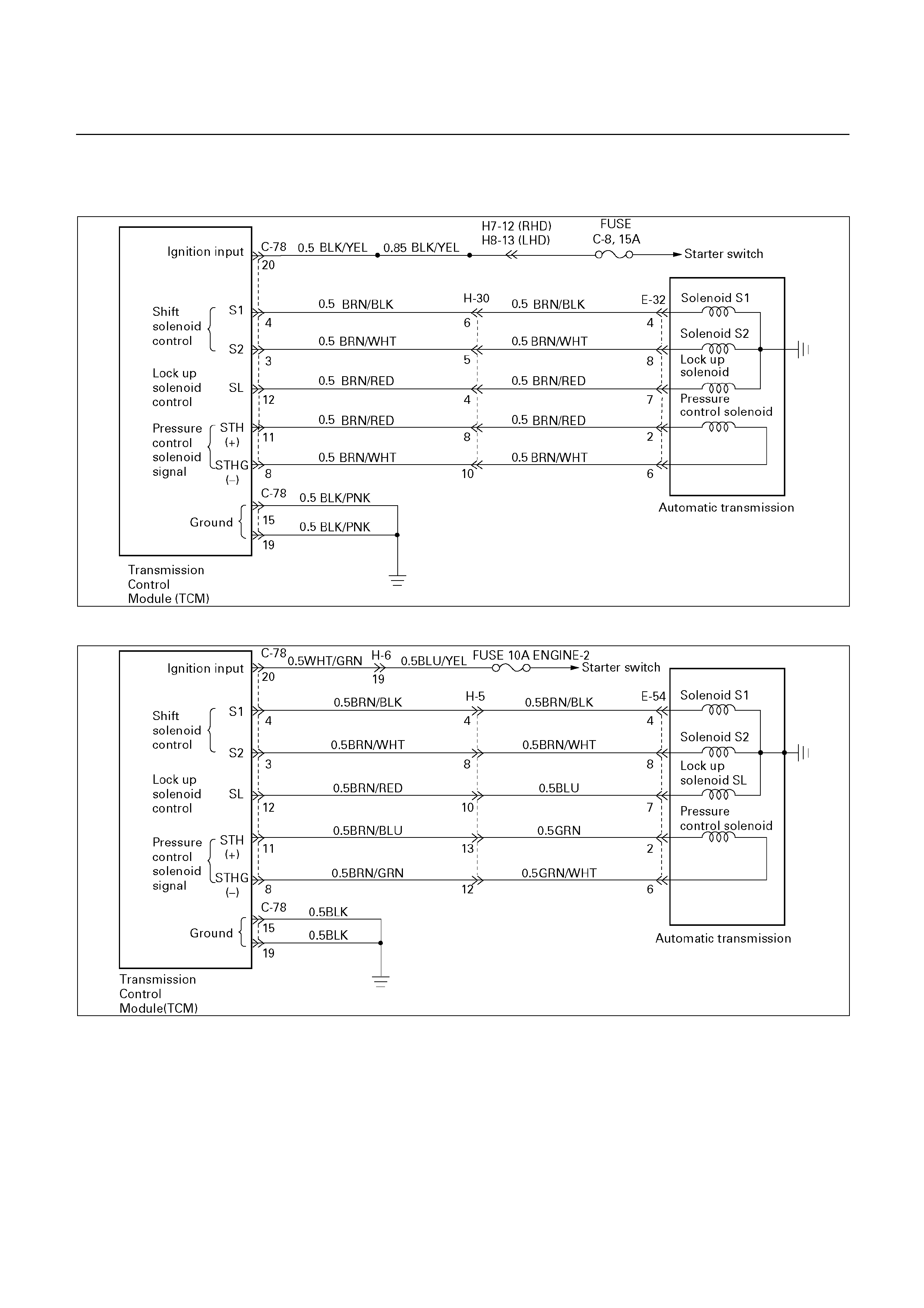

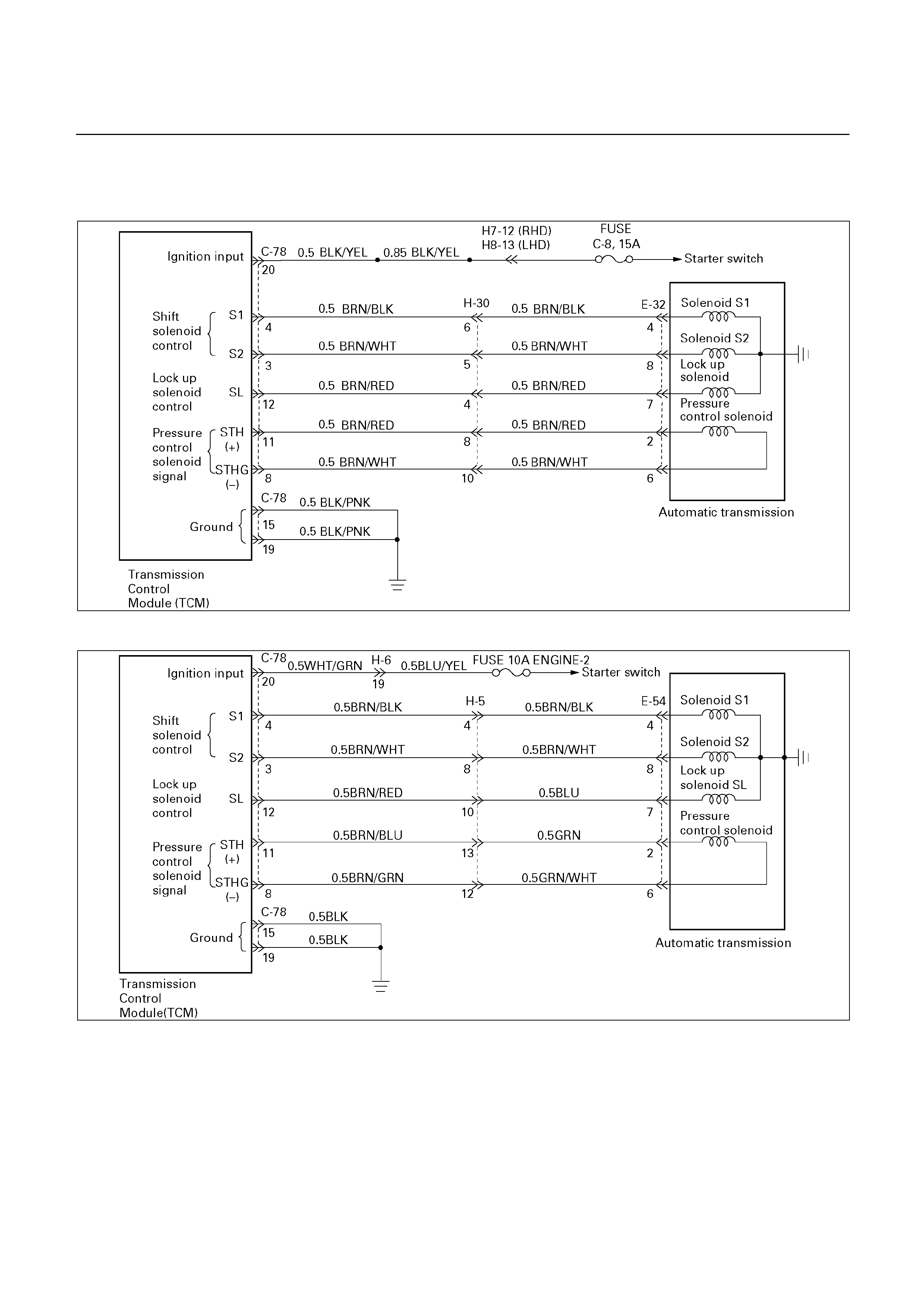

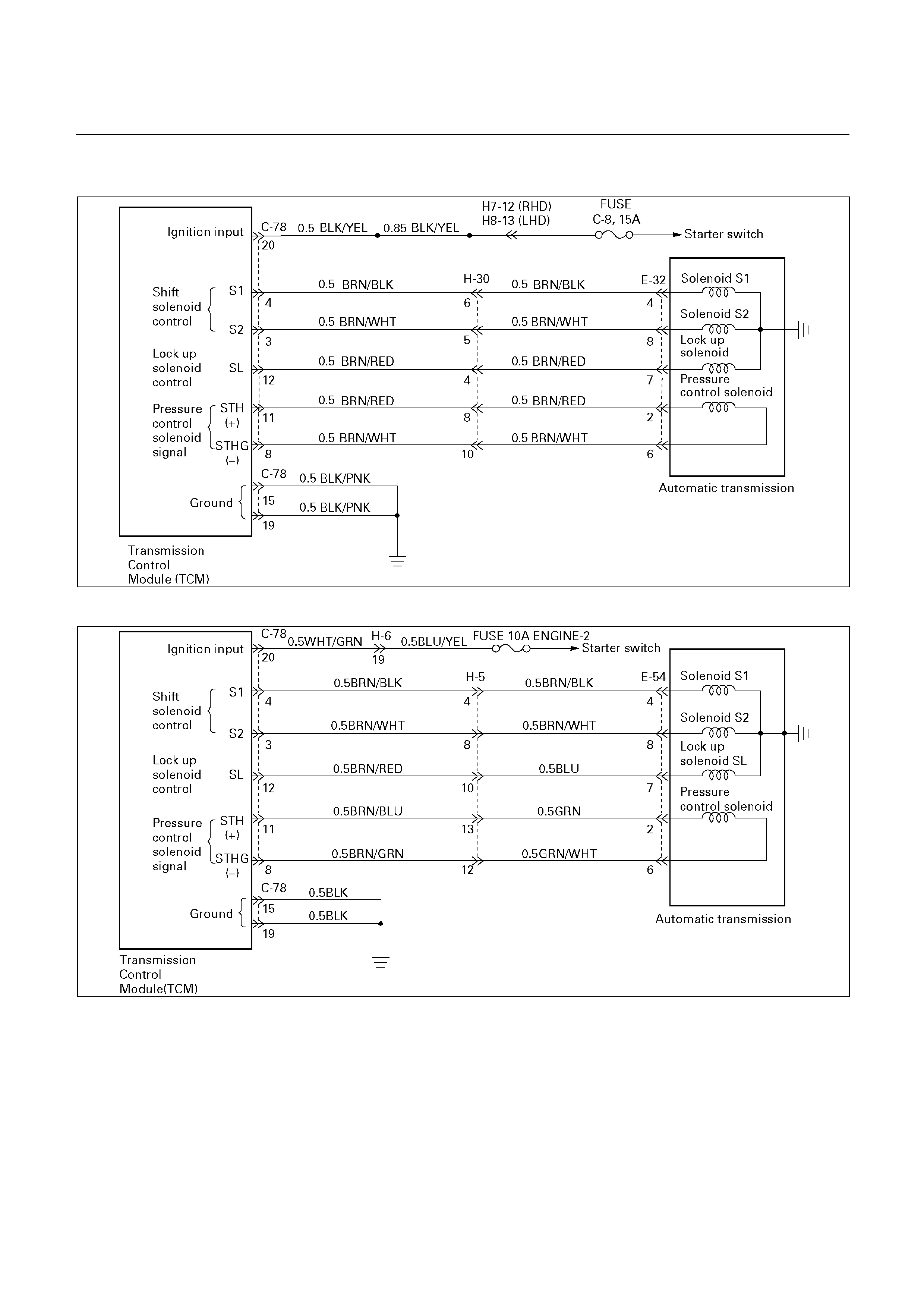

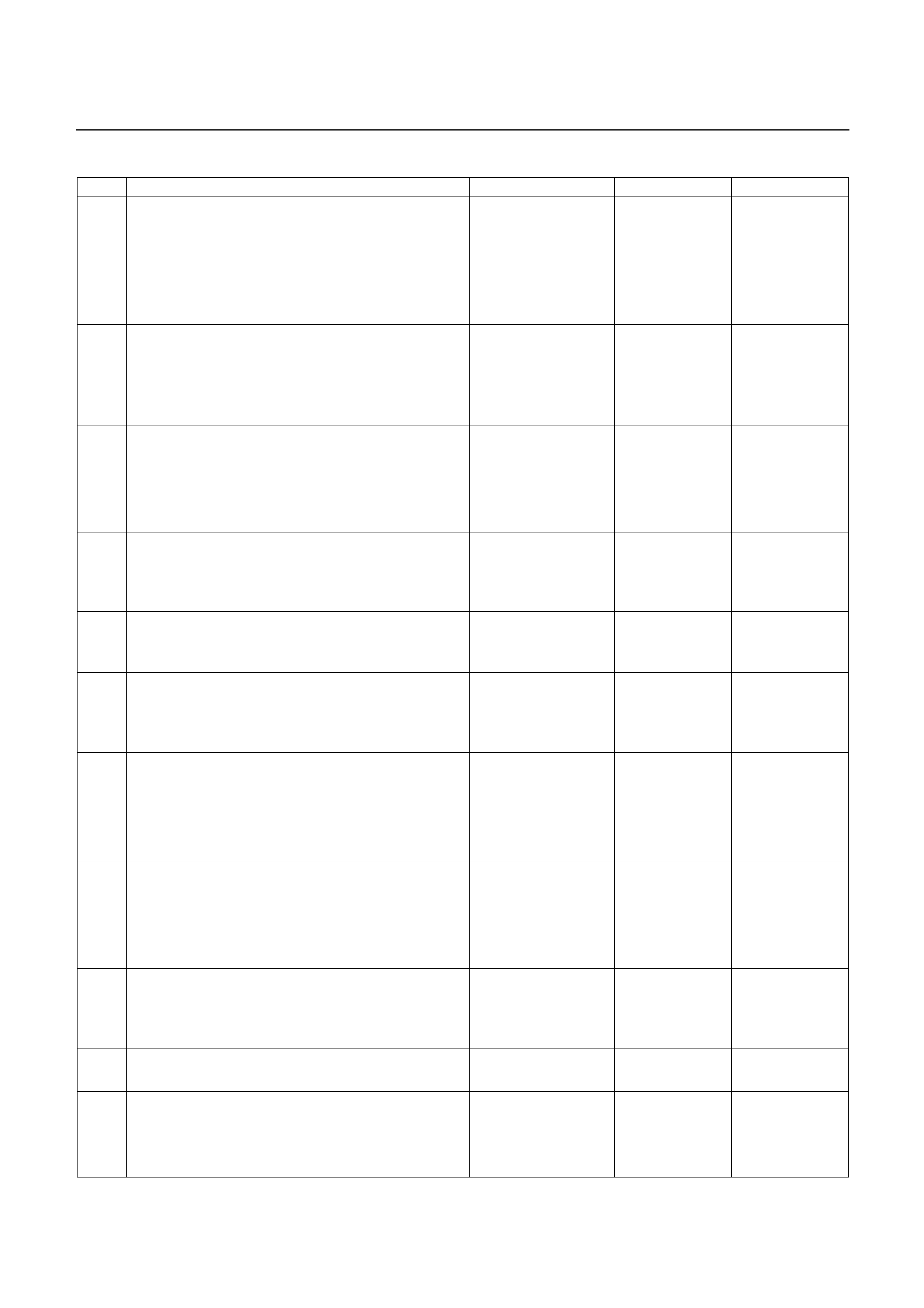

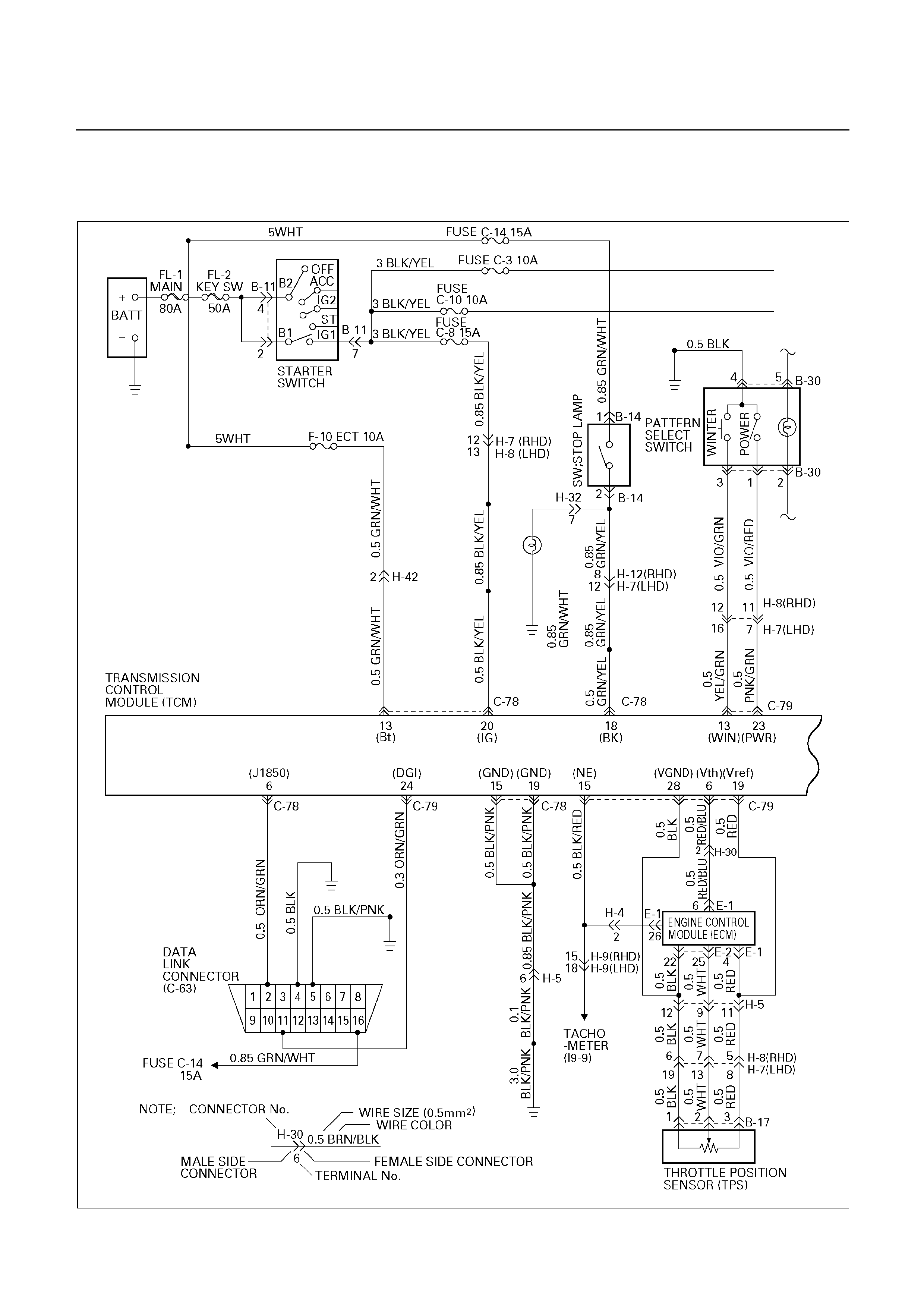

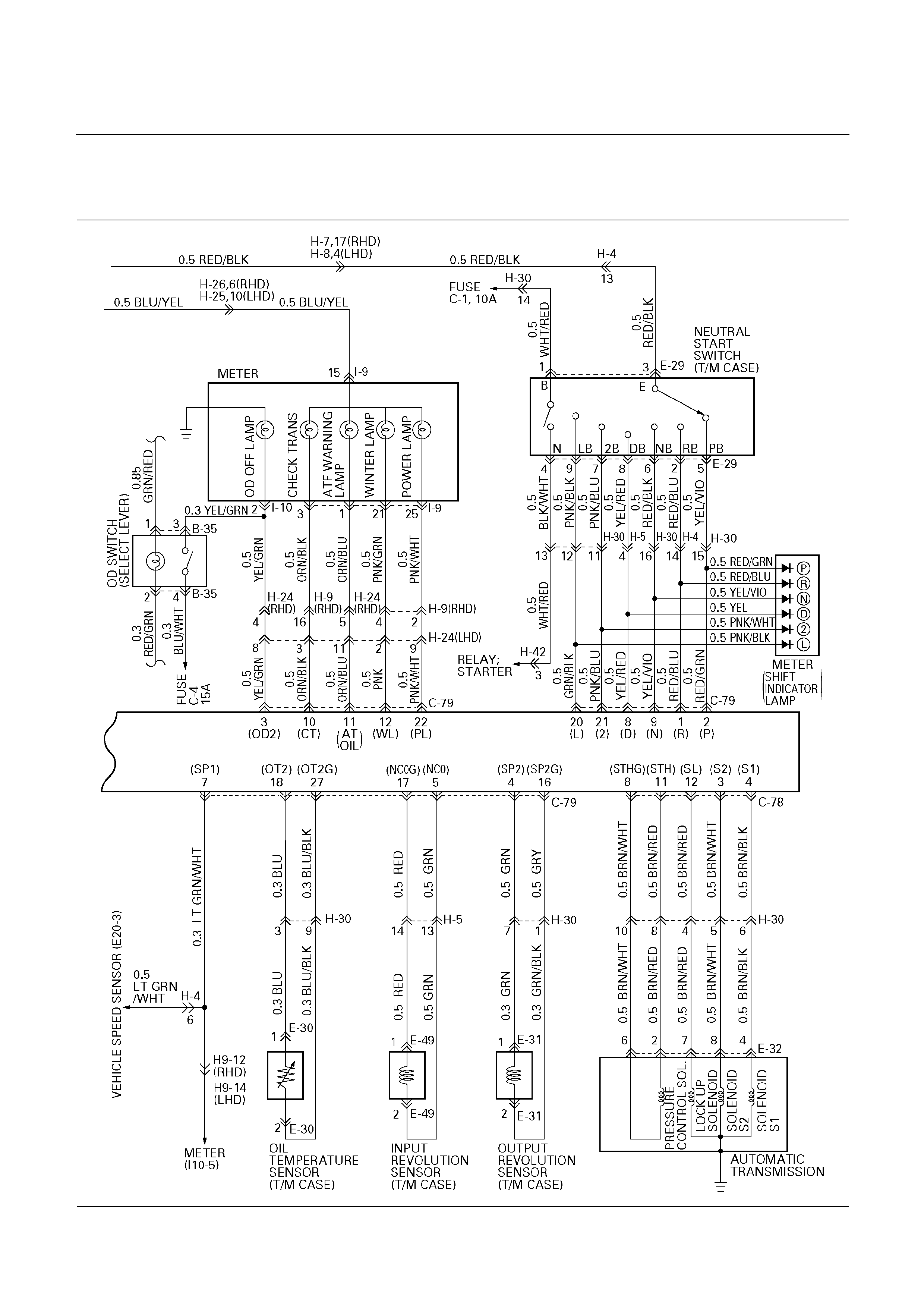

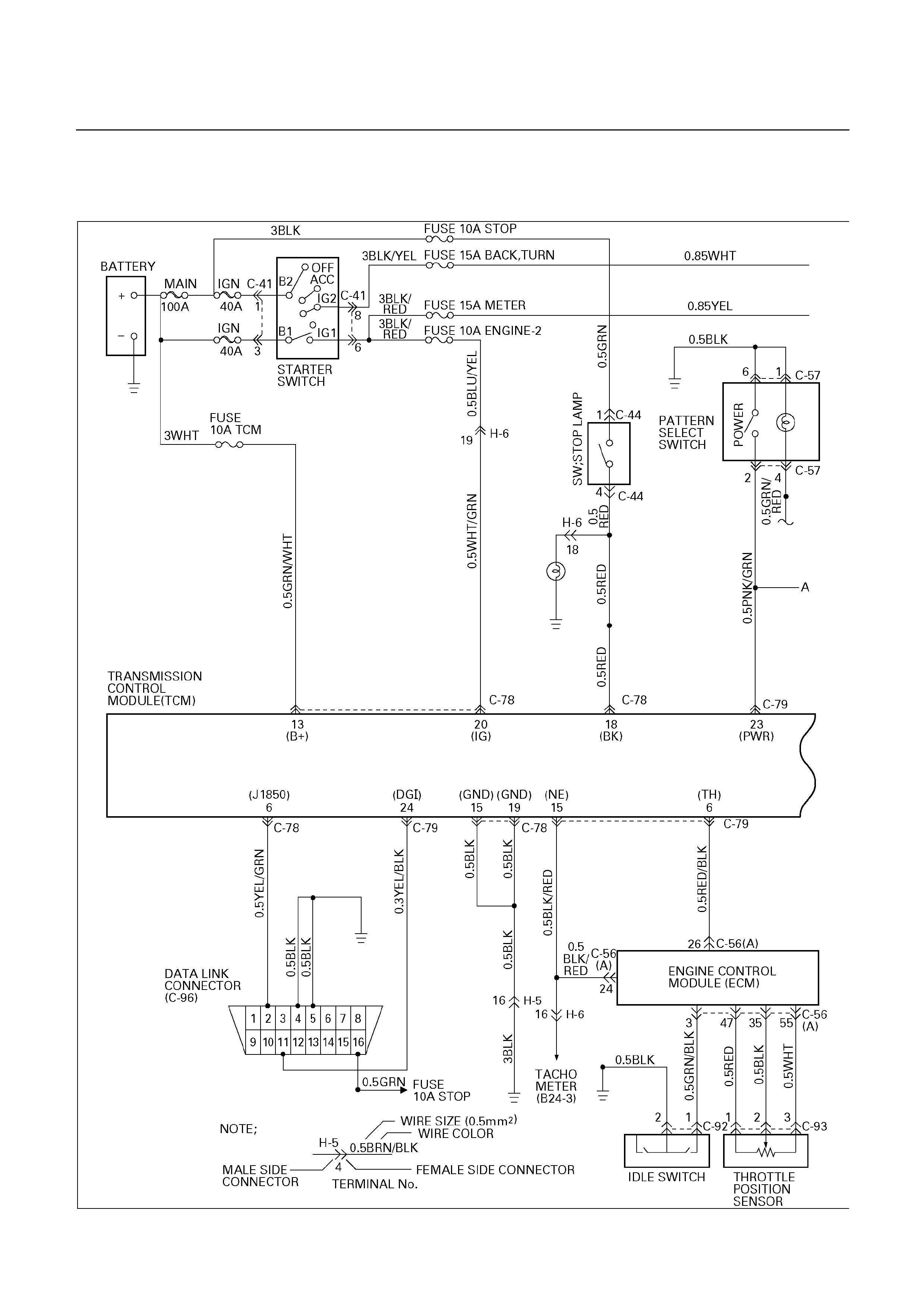

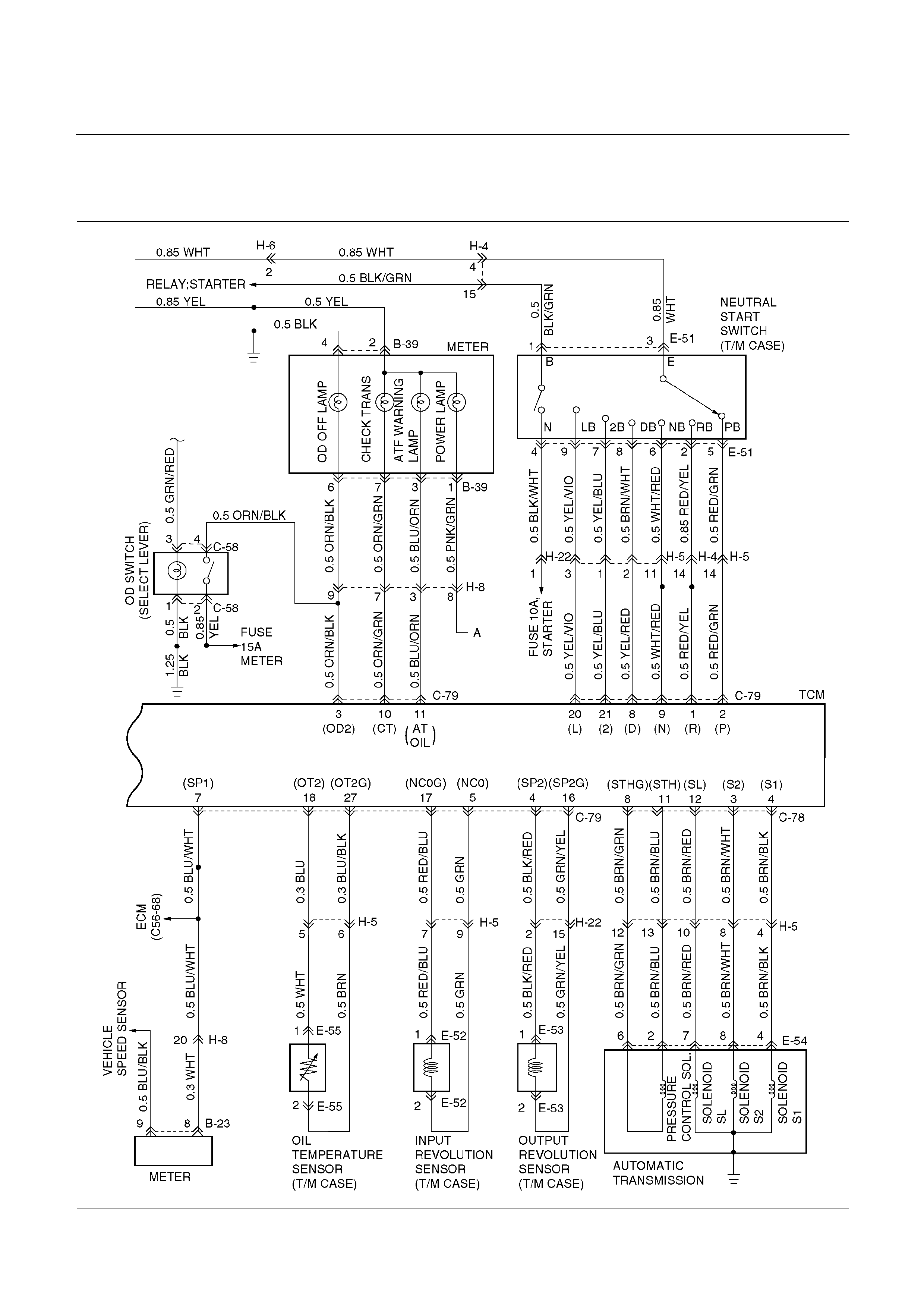

Wiring Diagram

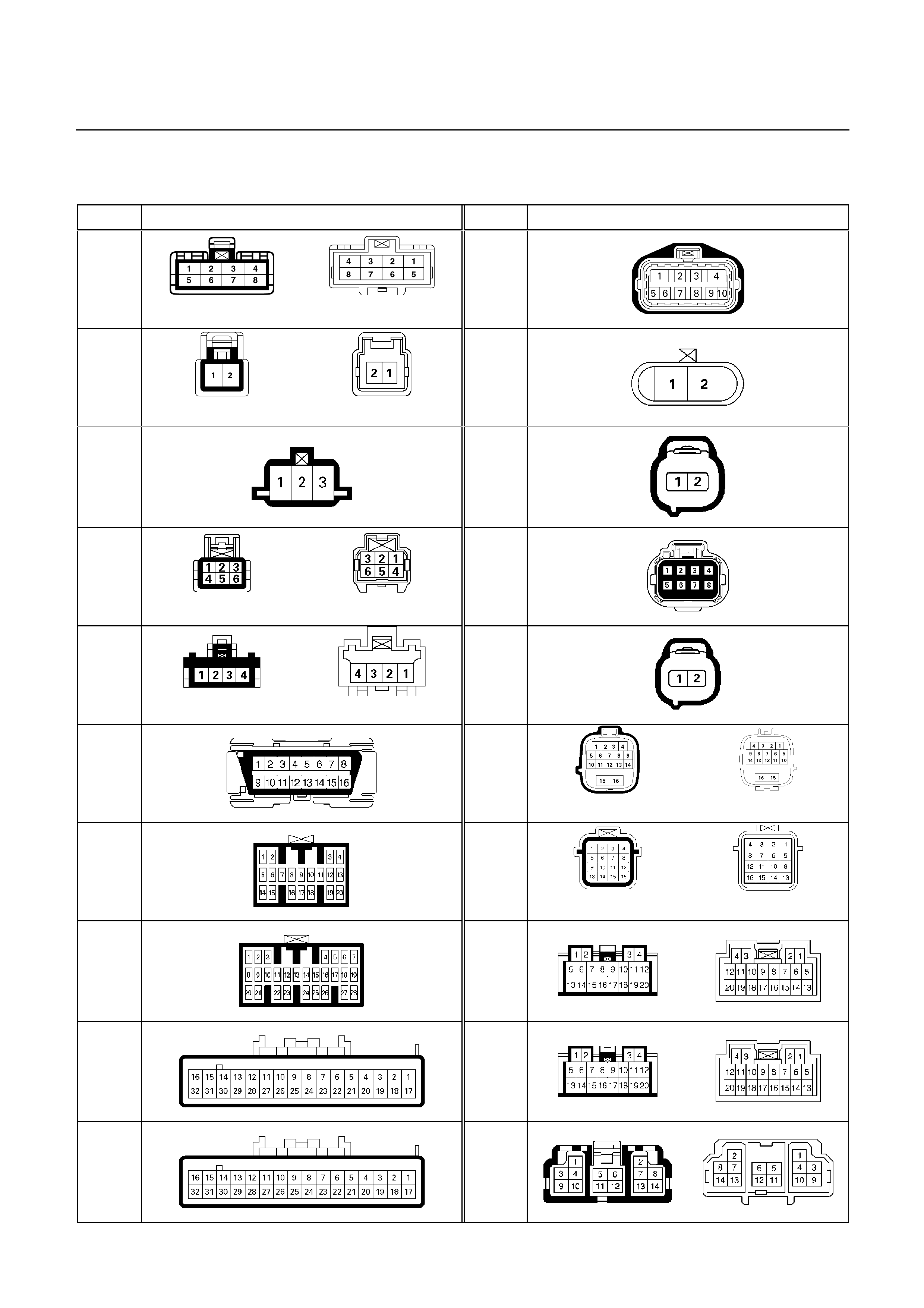

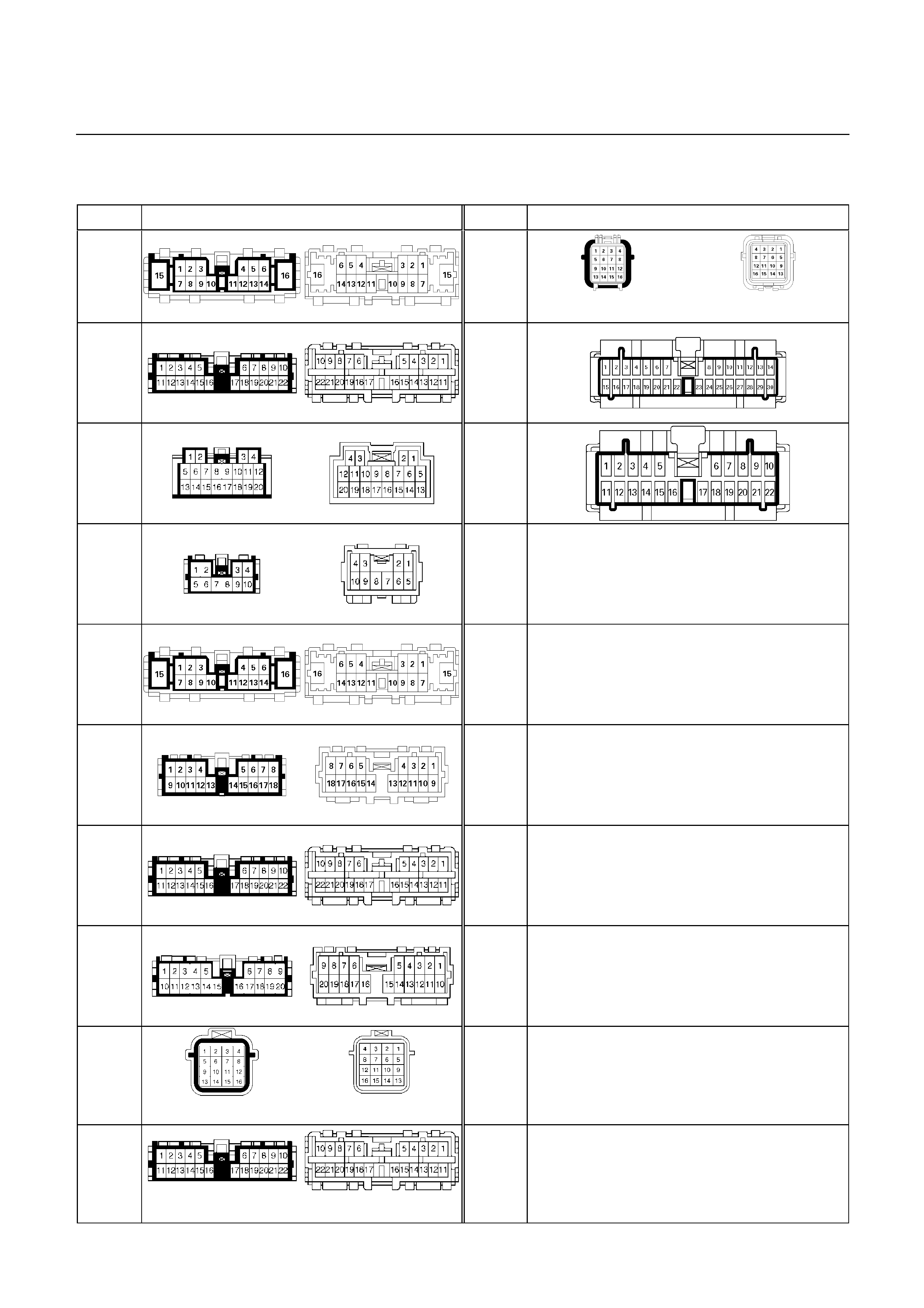

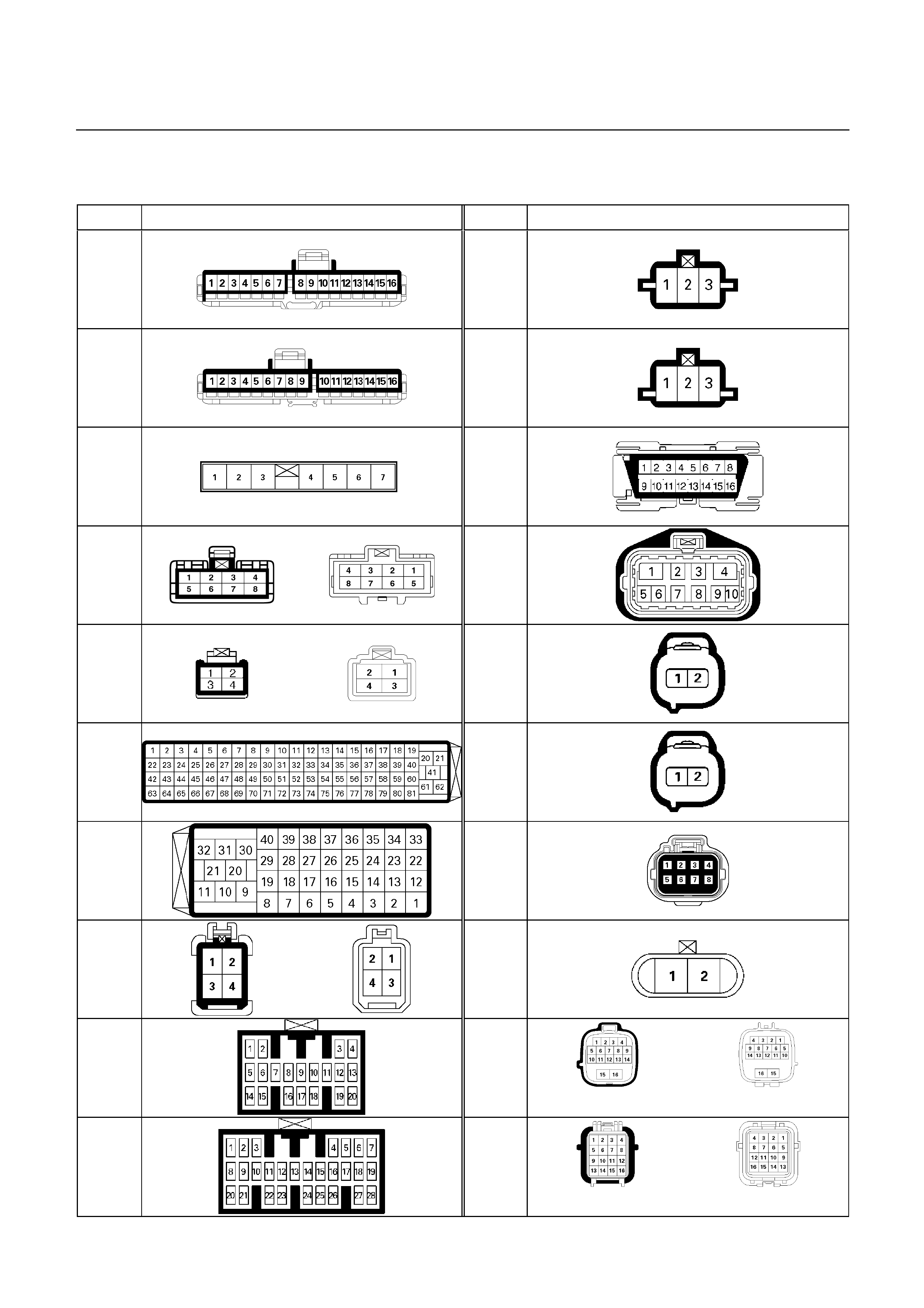

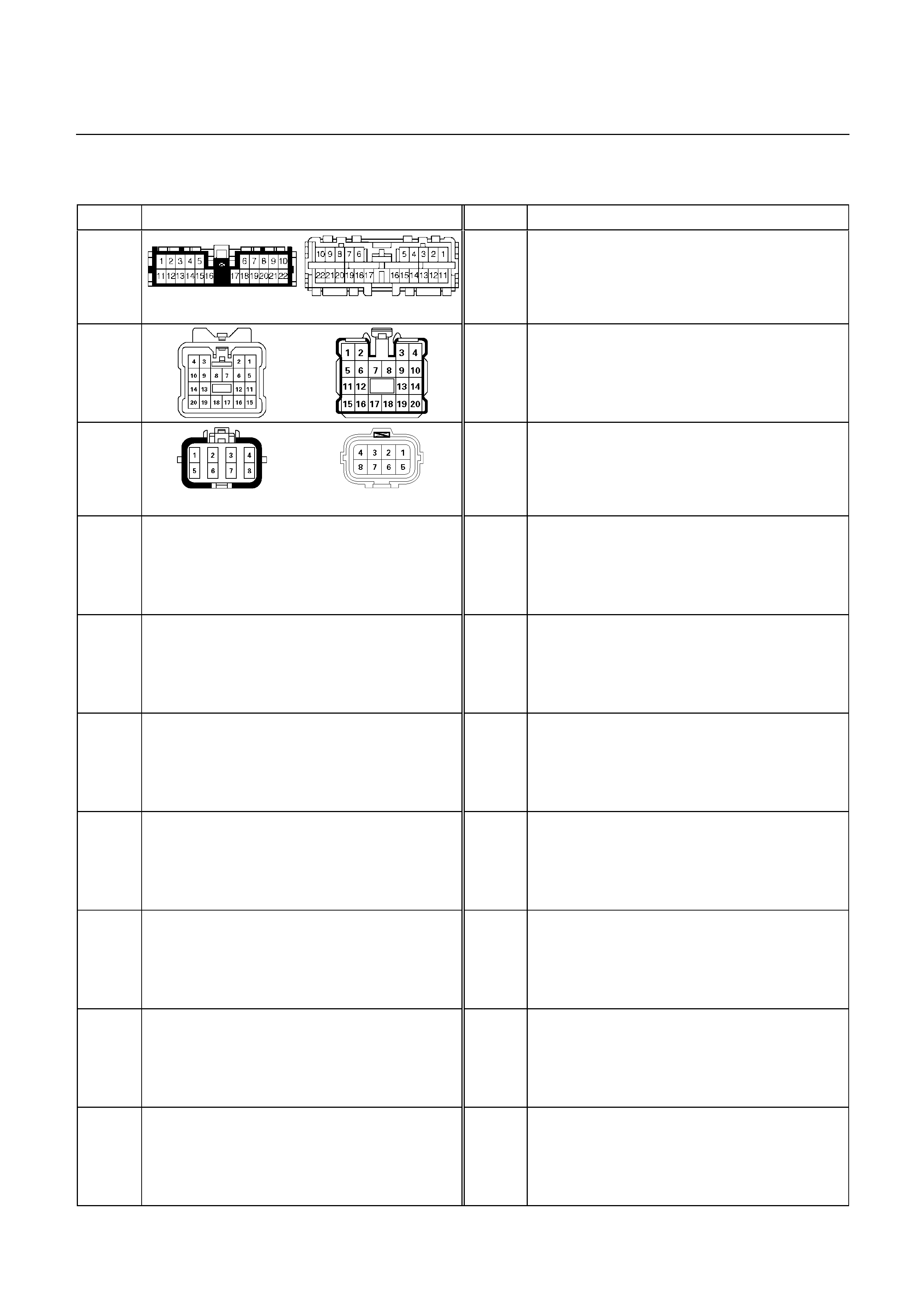

Connector List

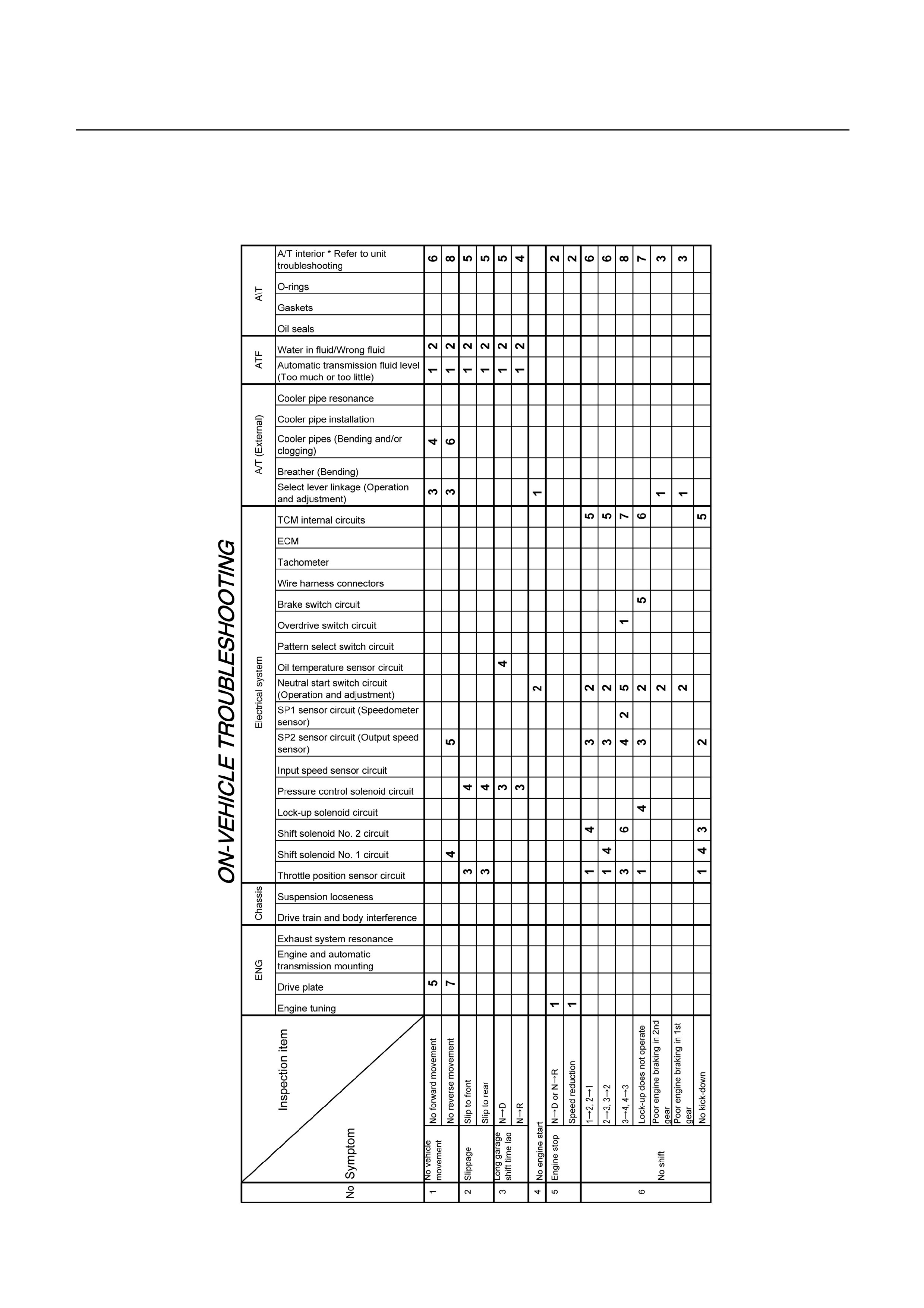

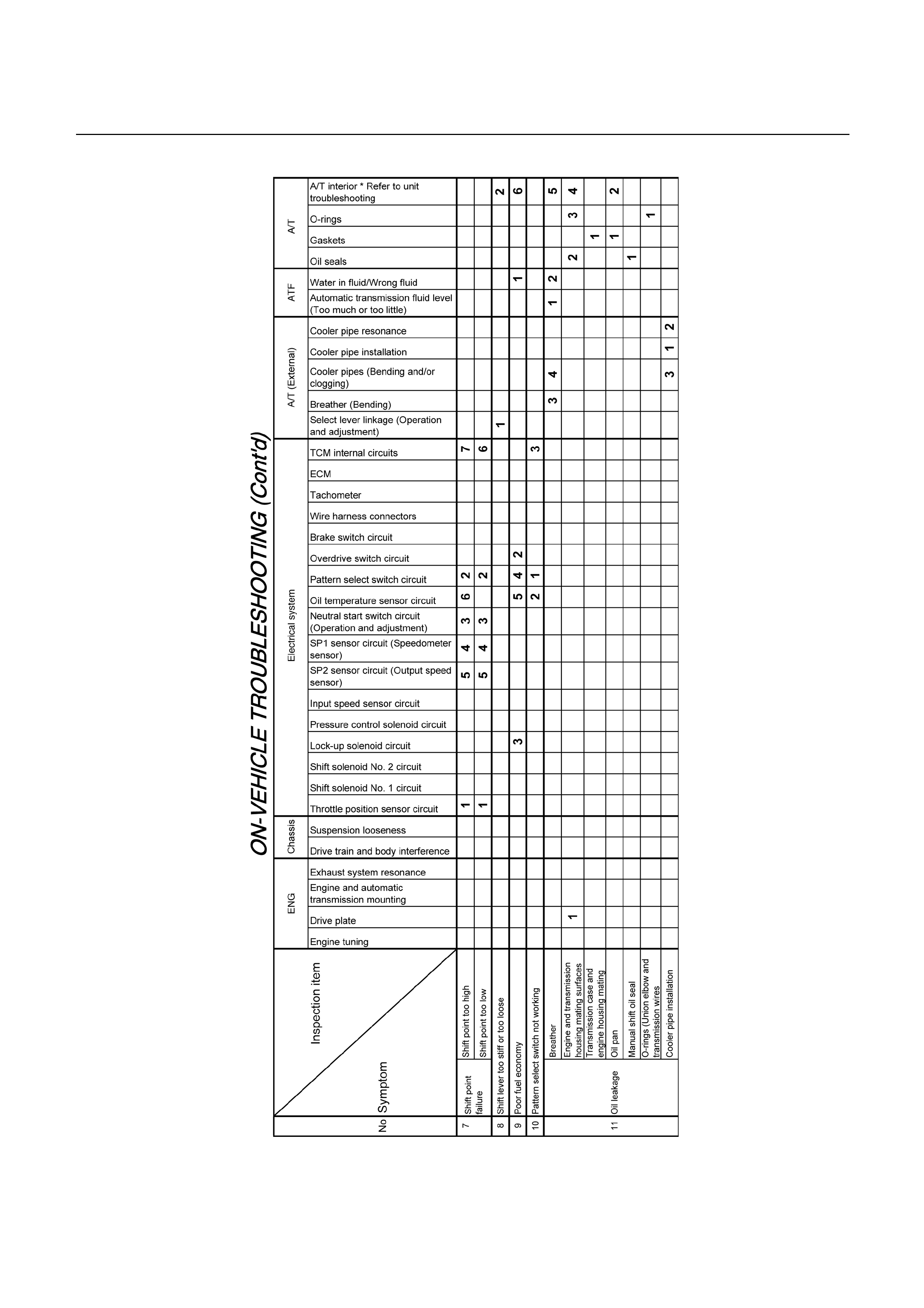

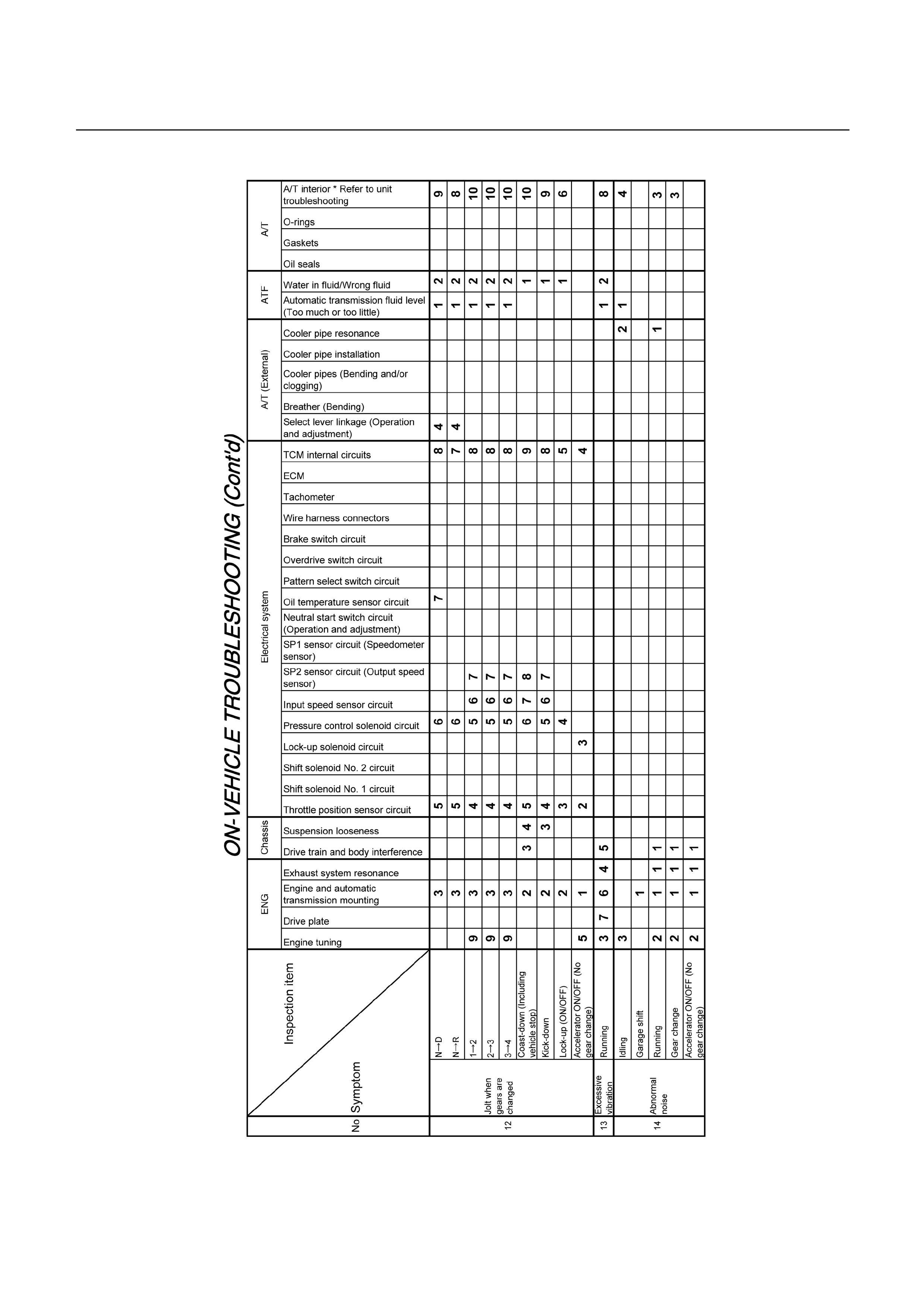

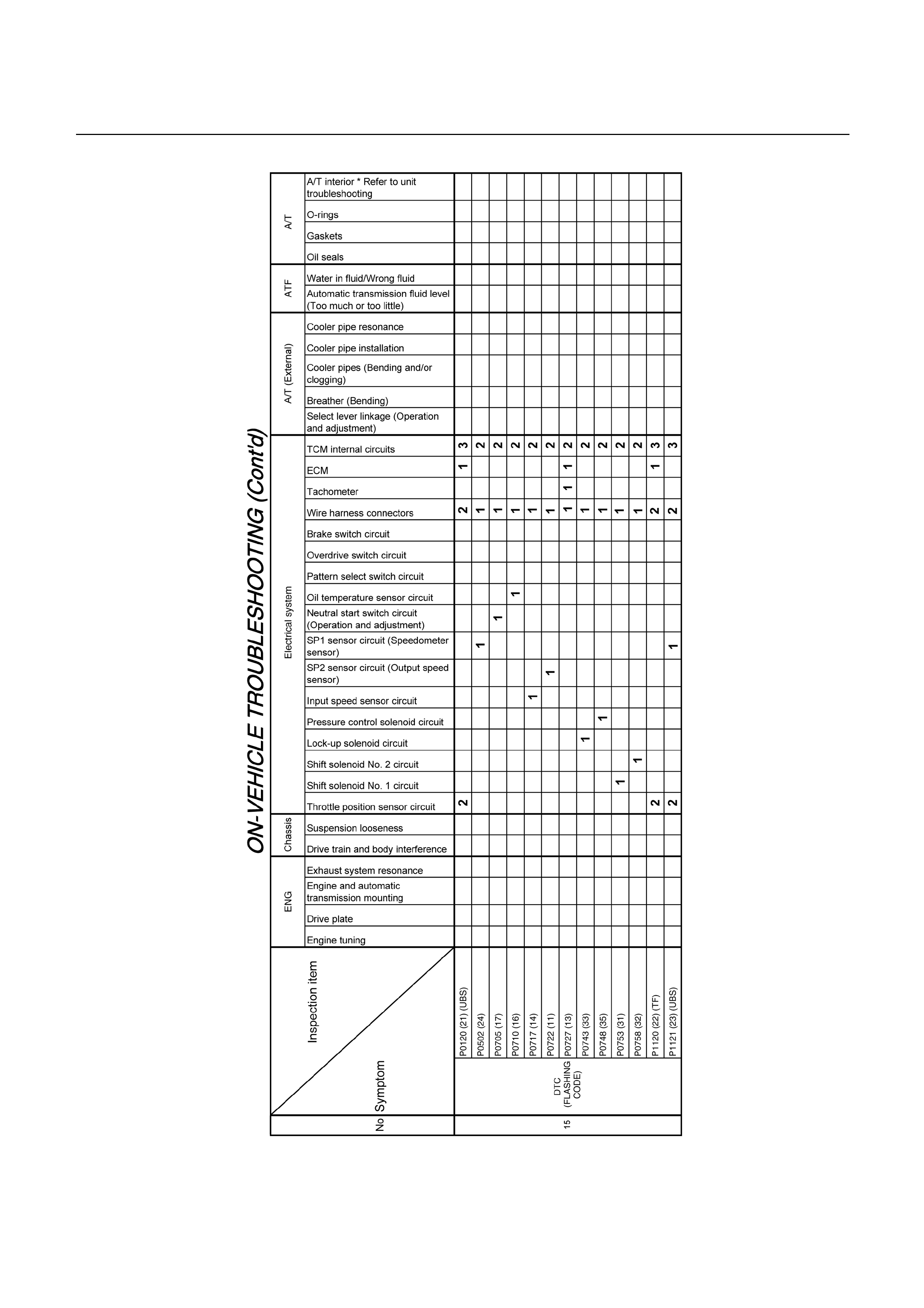

Troubleshooting Chart

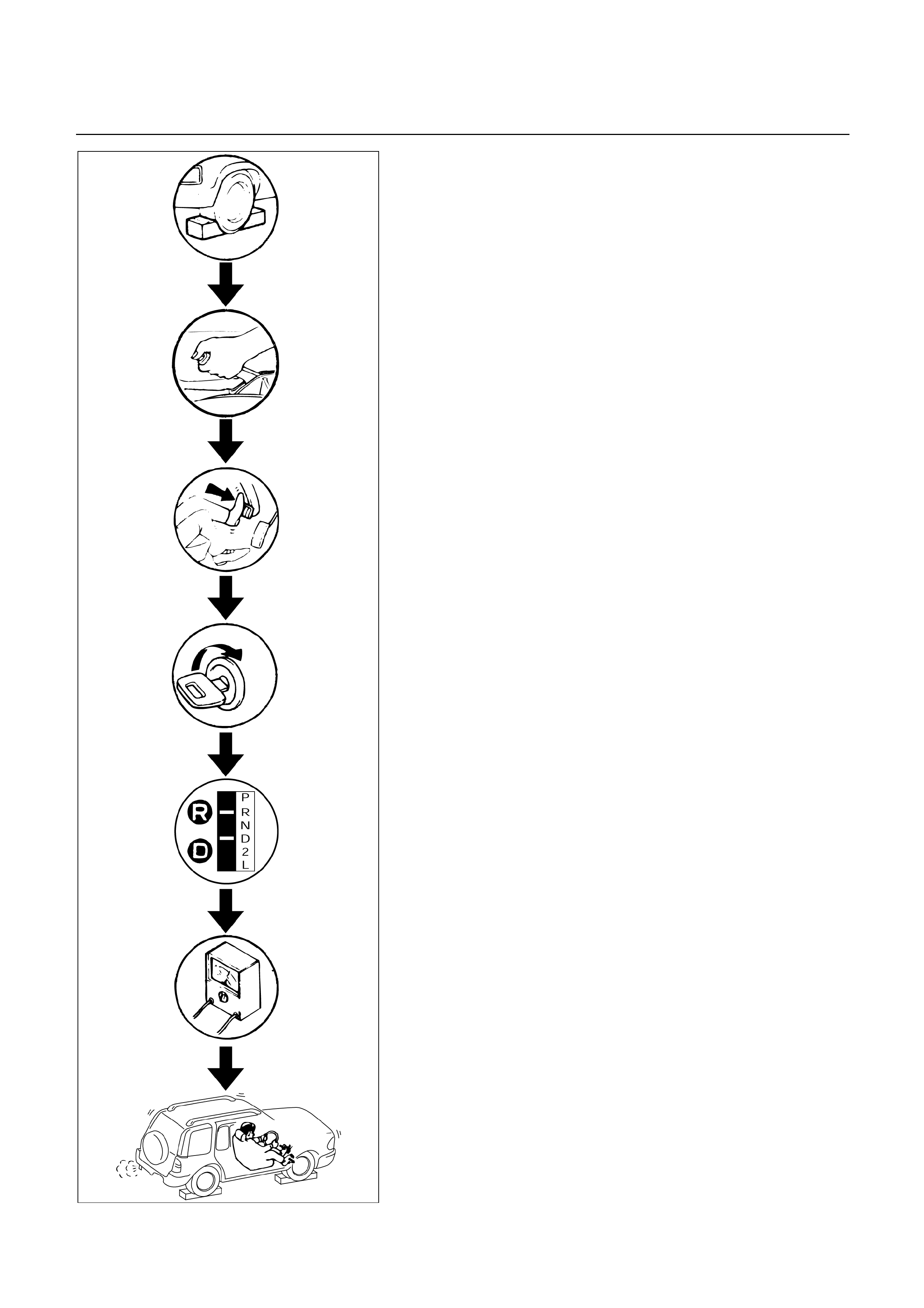

Manual Shifting Test

Stall Test

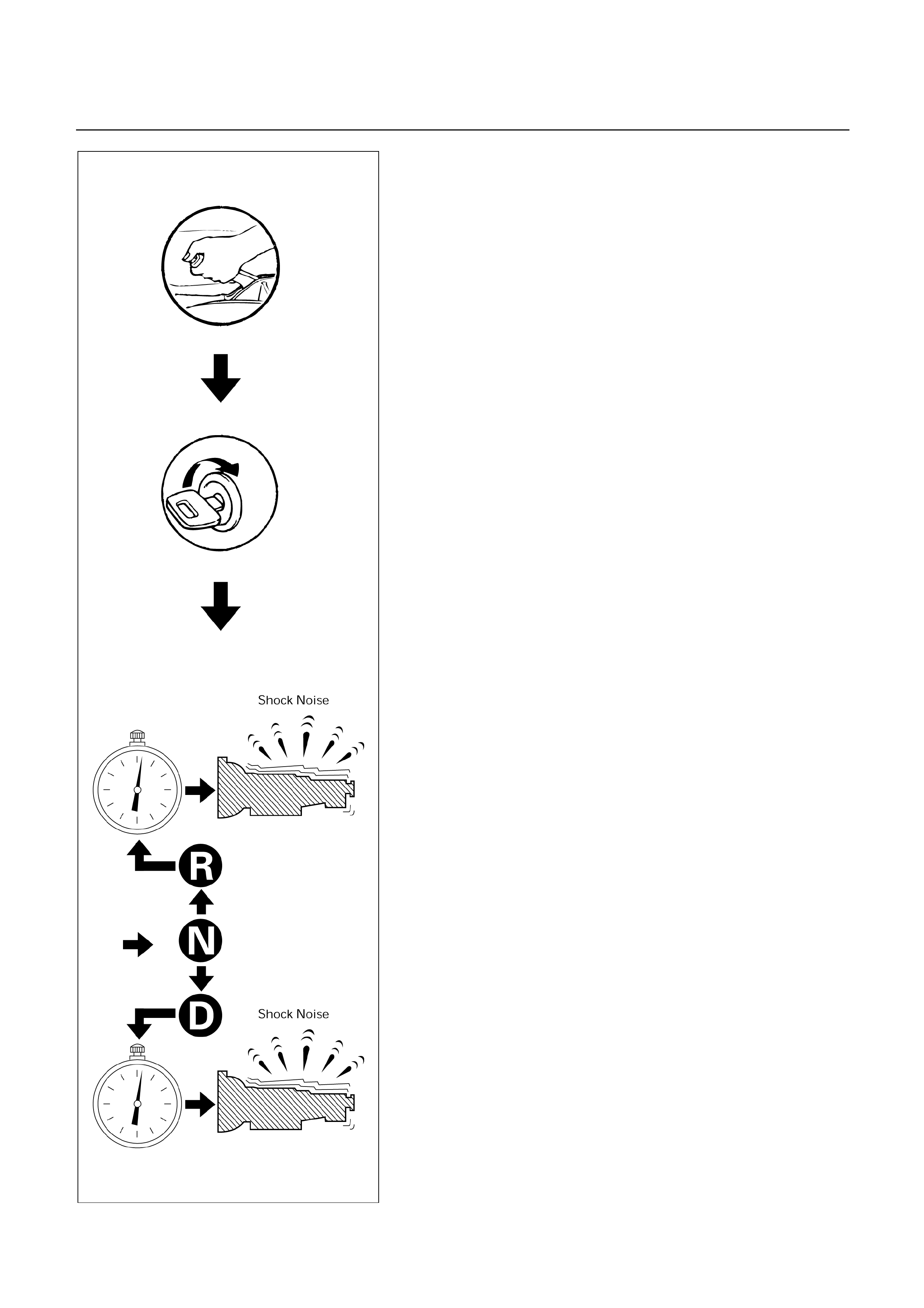

Time Lag Test

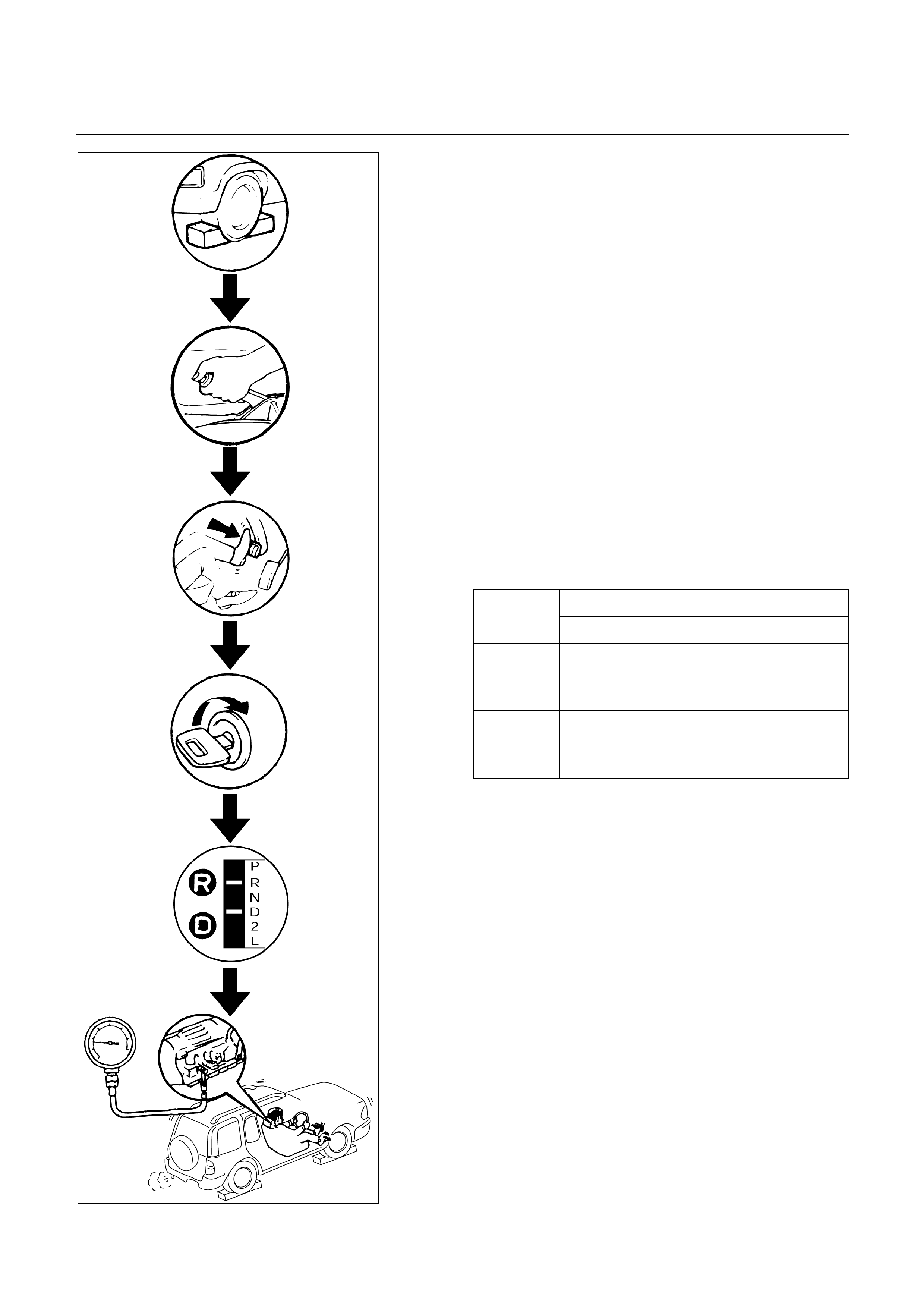

Hydraulic Test

Road Test

Shift Point Chart and Lock-Up Point Chart

TCM Voltage Check

On-Vehicle Service

Transmission Fluid Level and Condition

ATF Replacement

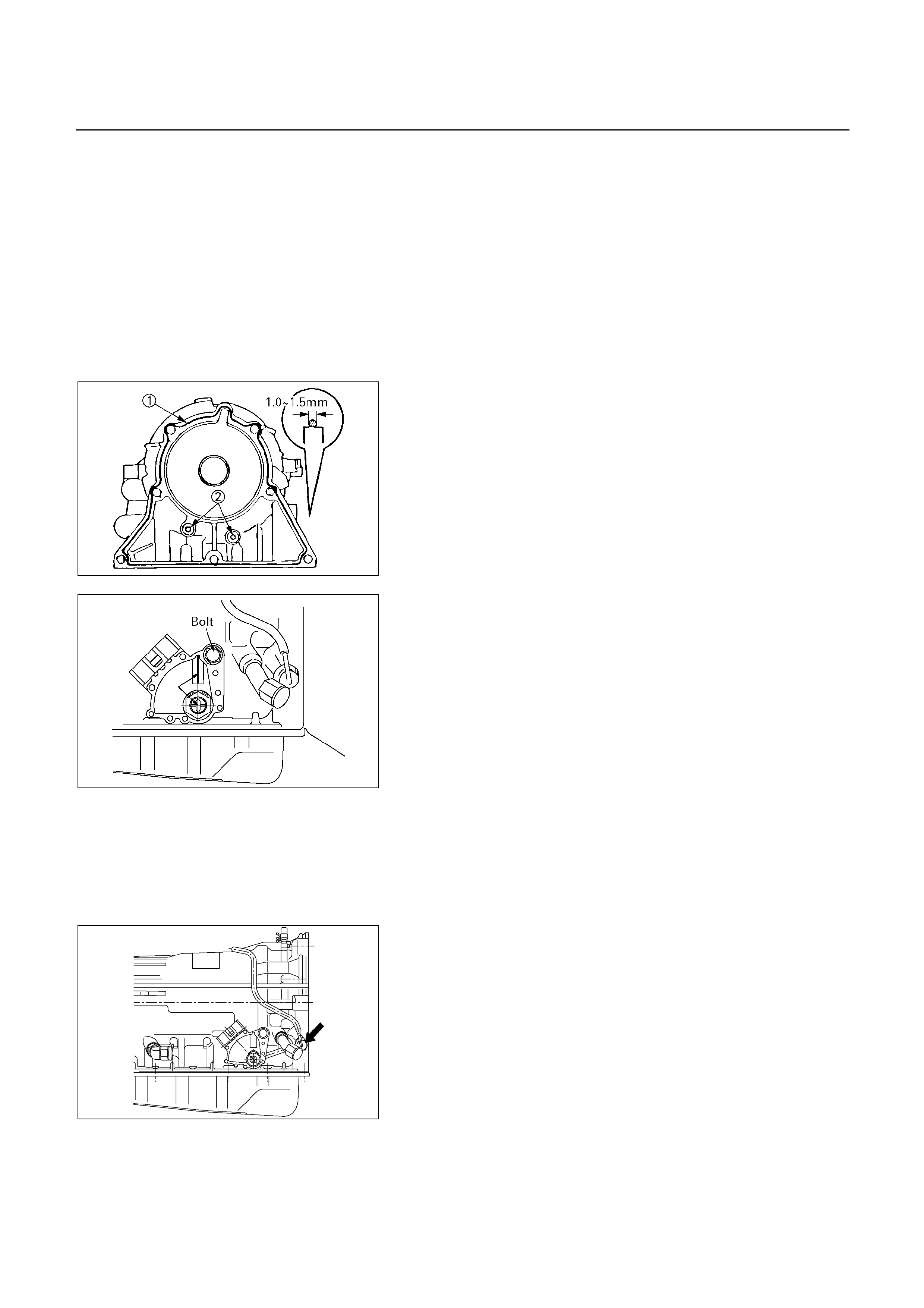

Neutral Start Switch Inspection

Brake Signal Inspection

Vehicle Speed Sensor Inspection

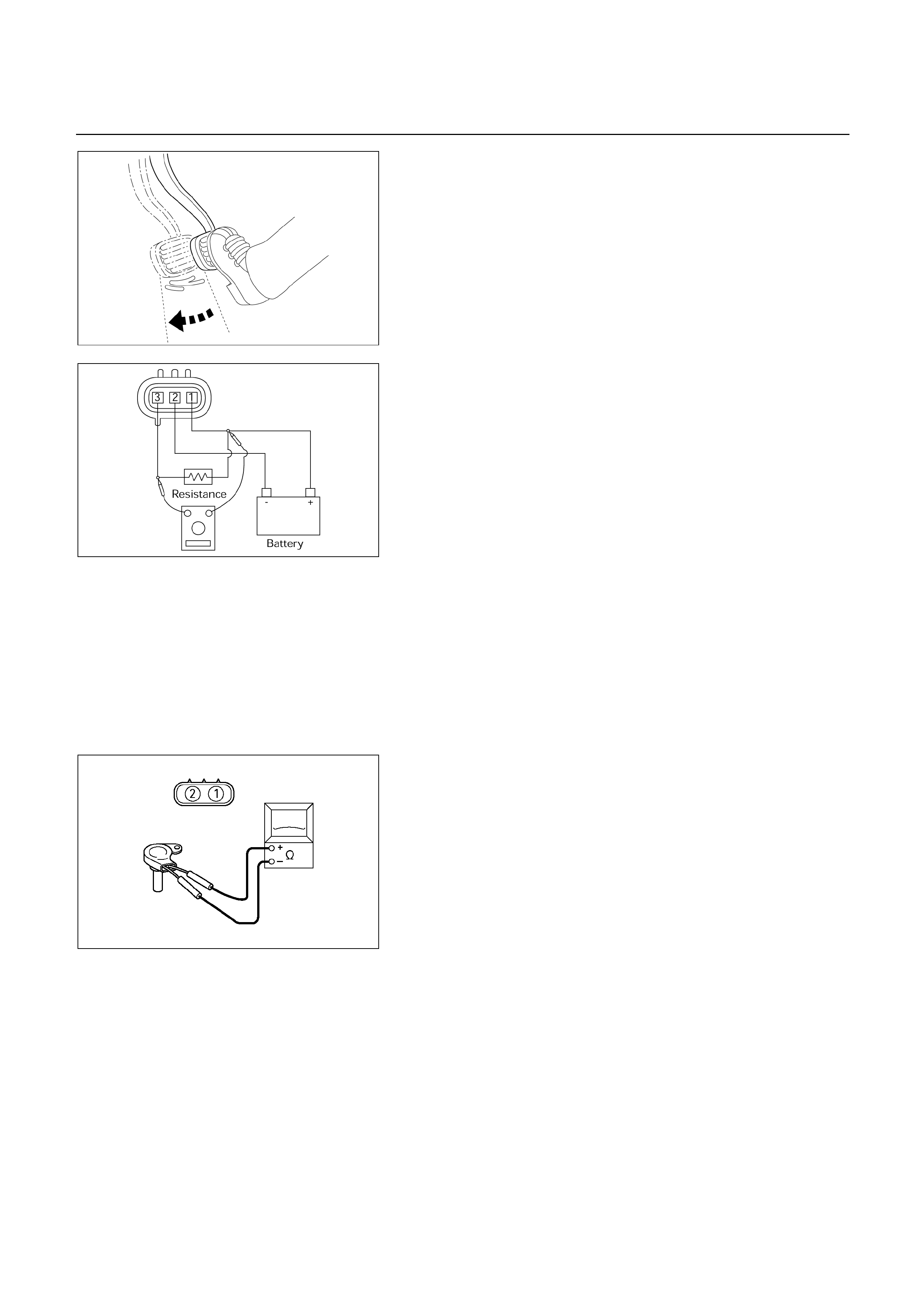

Input and Output Revolution Sensor Inspection

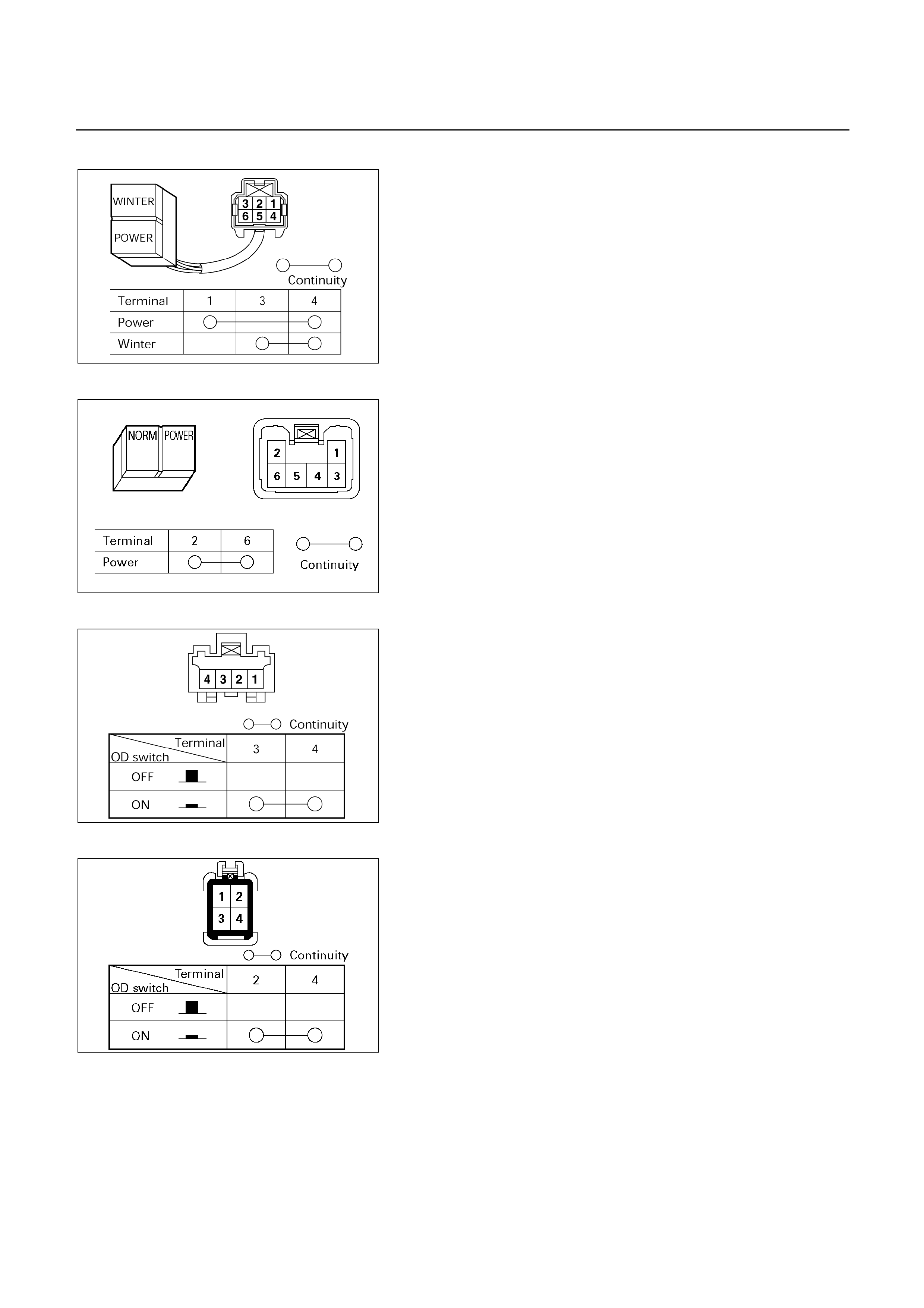

Pattern Select Switch Inspection

Overdrive Switch Inspection

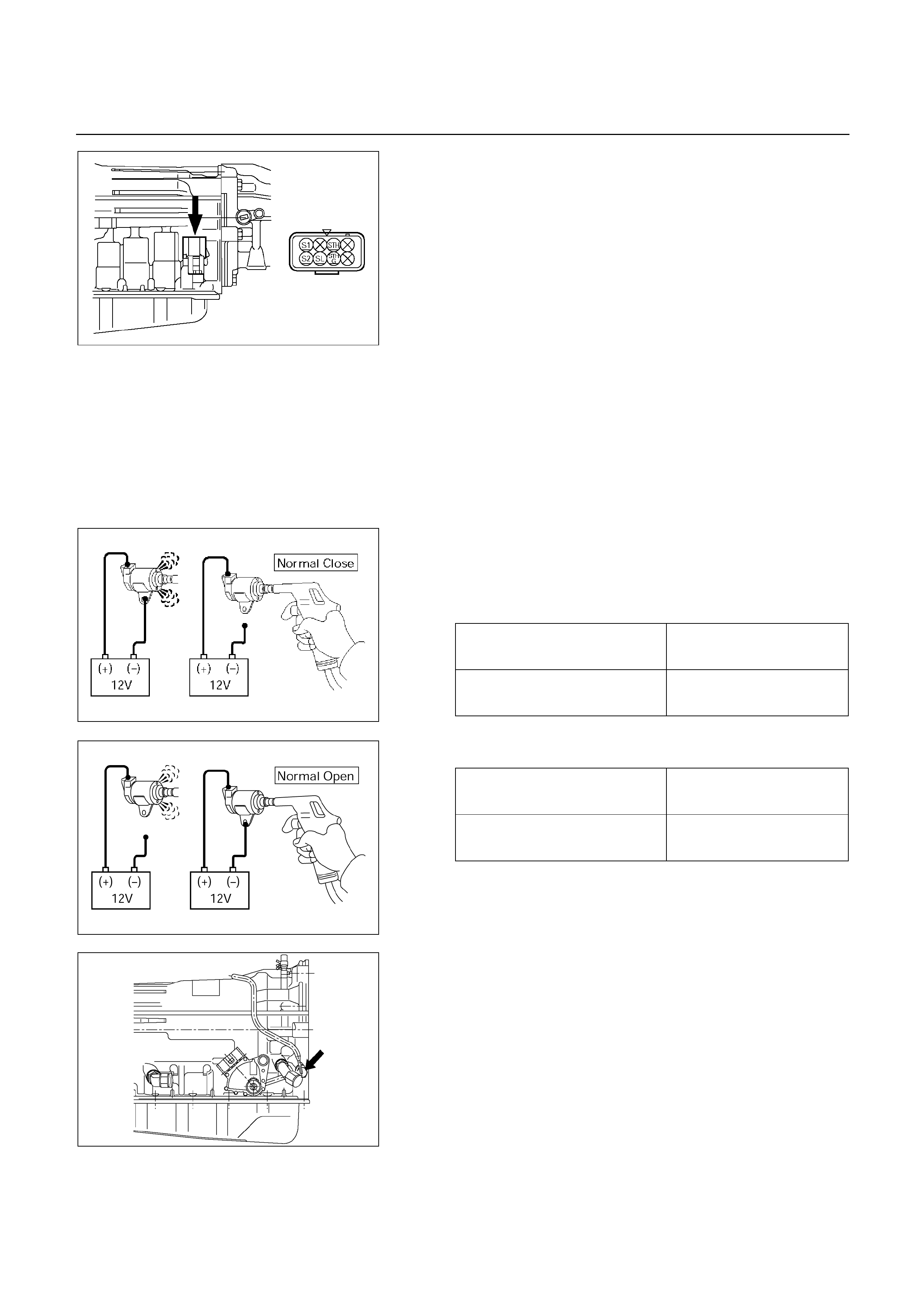

Solenoid Inspection

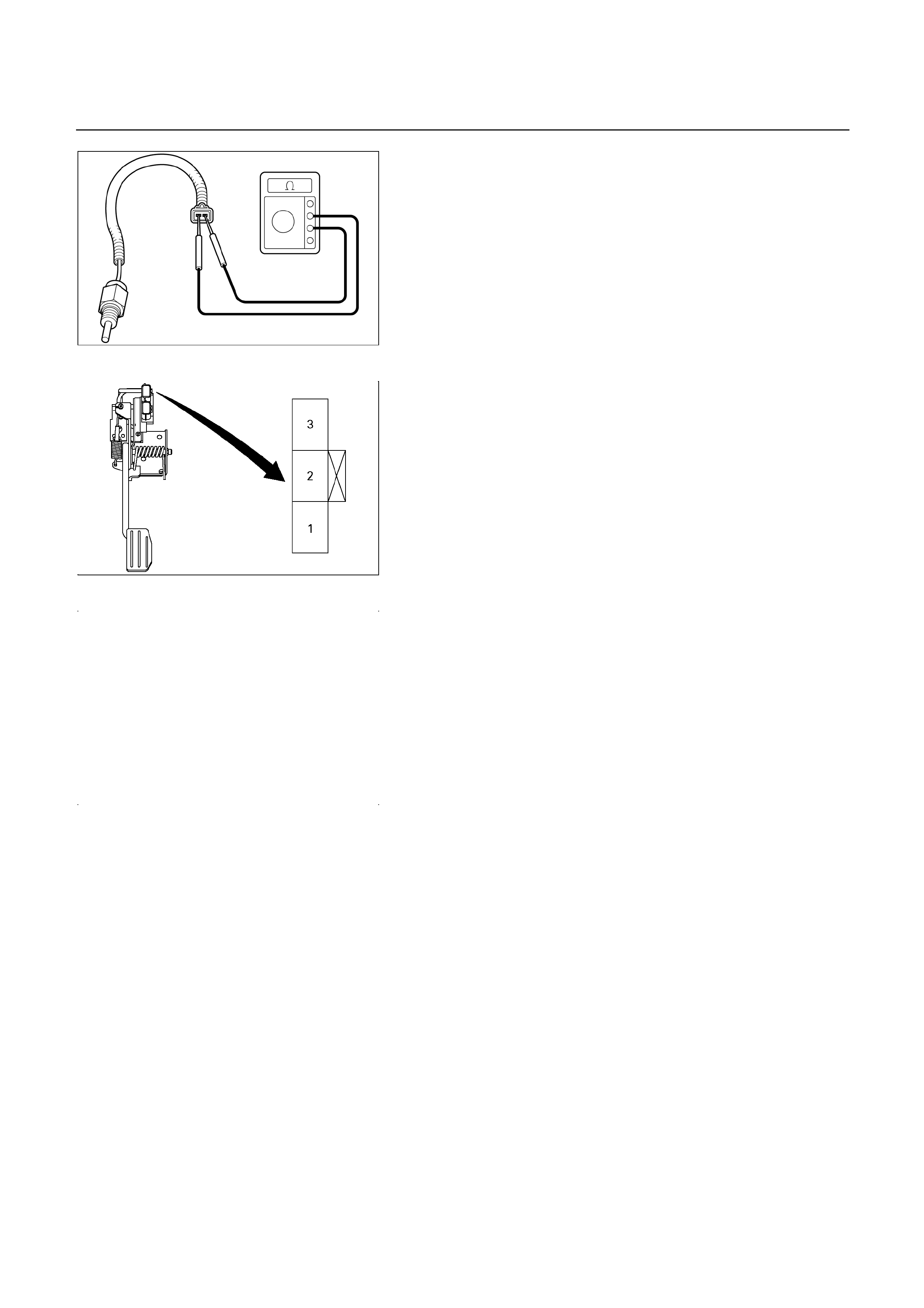

ATF Temperature Sensor Inspection

Throttle Position Sensor Inspection (UBS and TFR/S)

Throttle Position Sensor Inspection (’01 TFR)

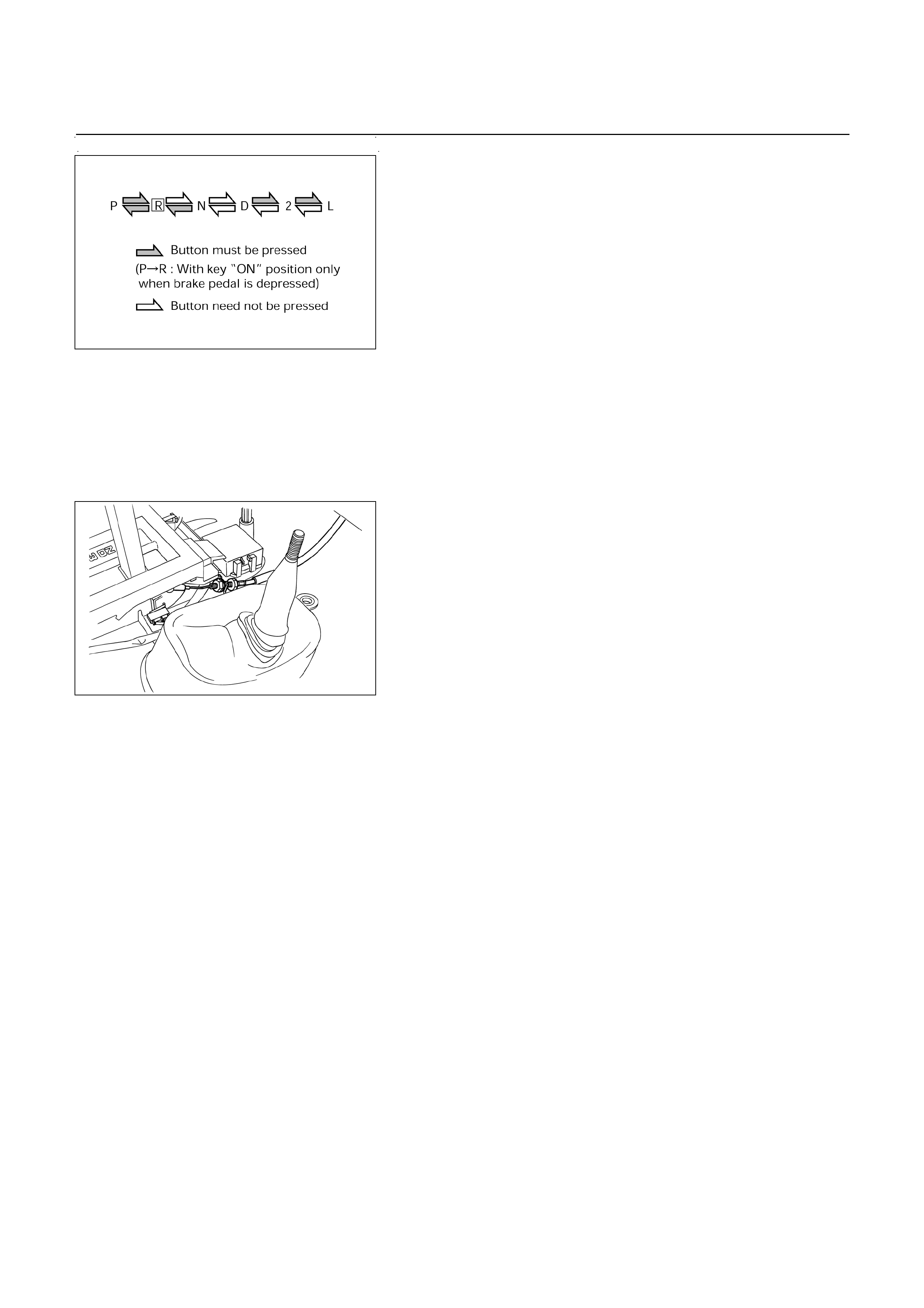

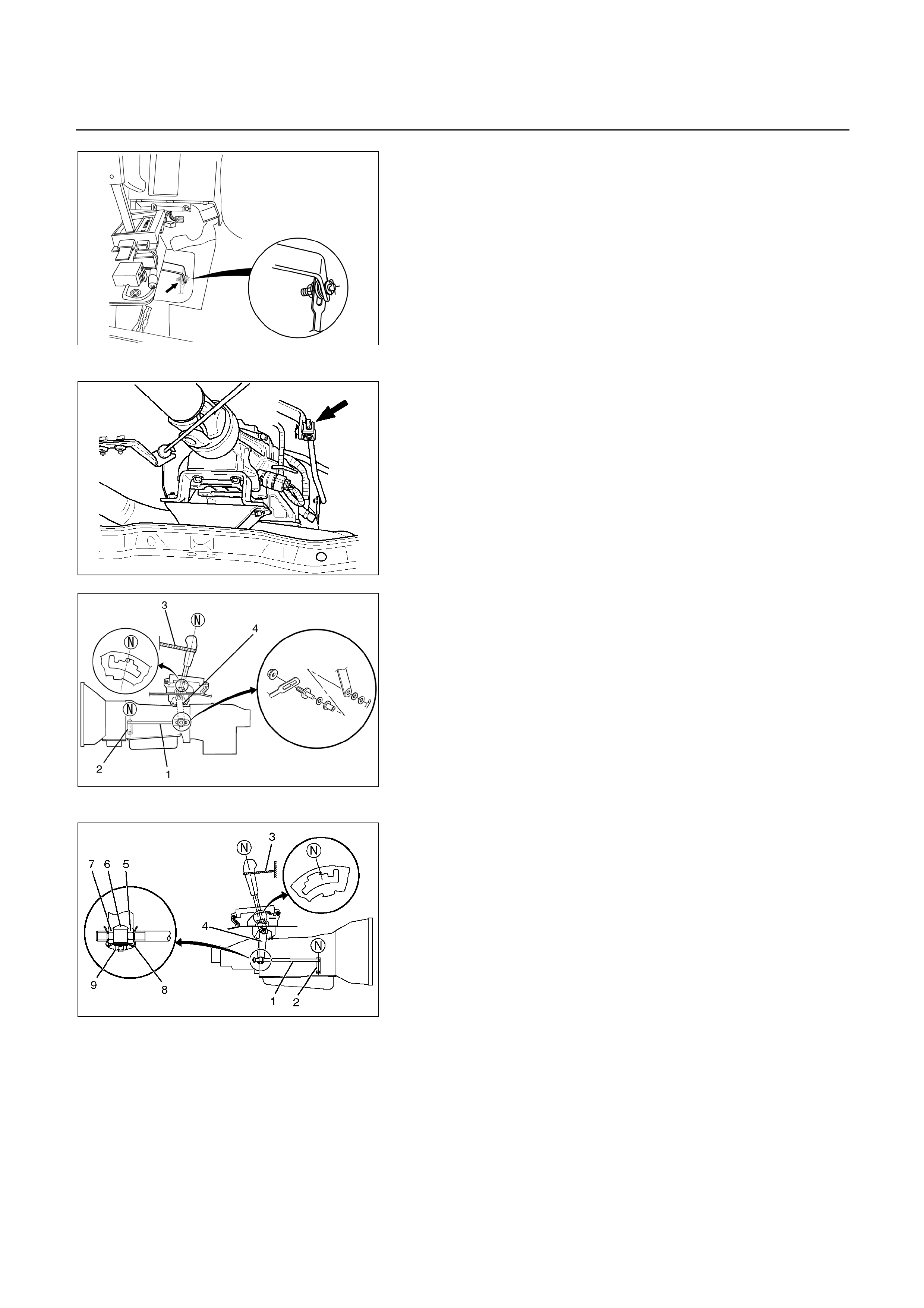

Selector Lever

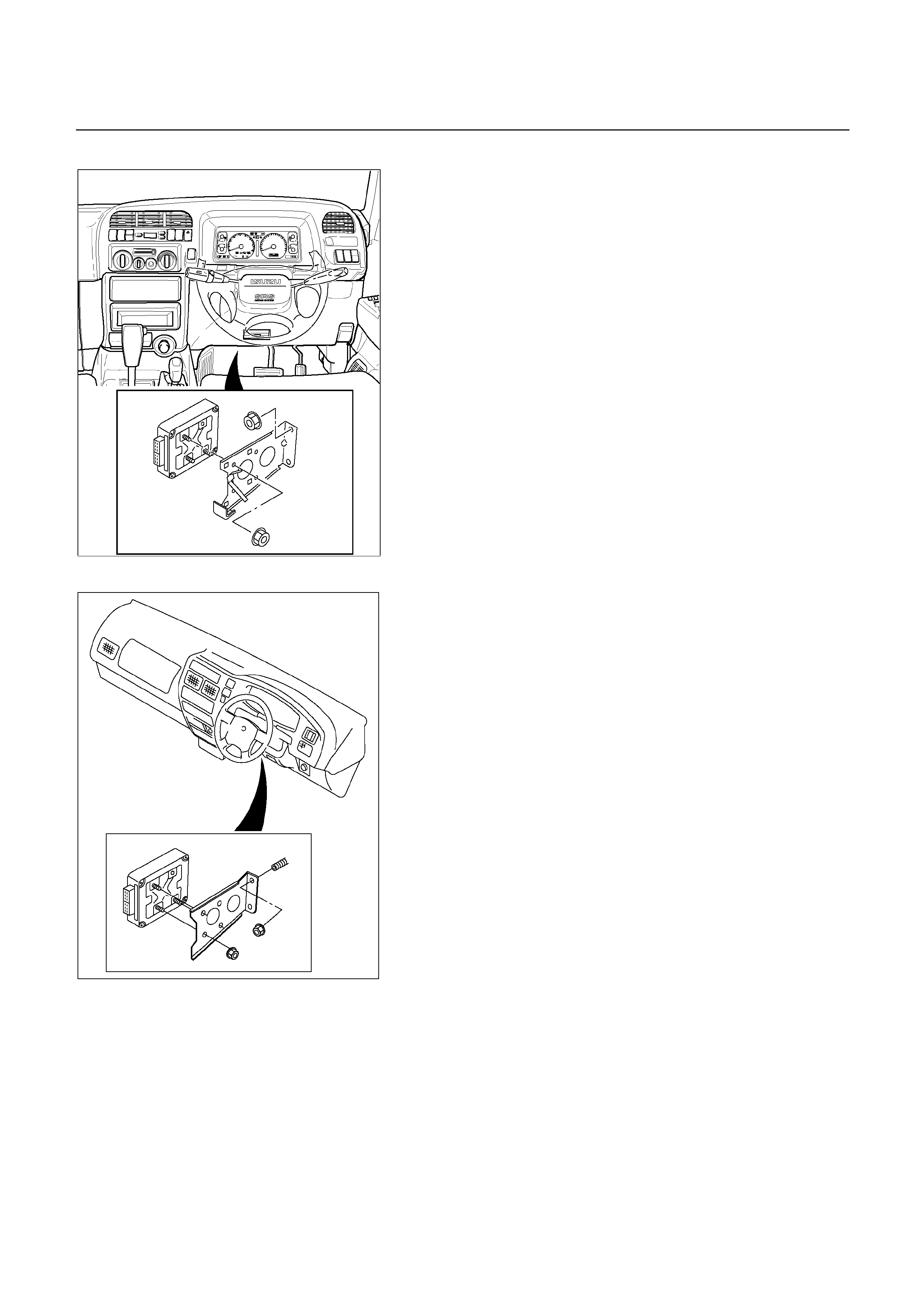

Transmission Control Module (TCM)

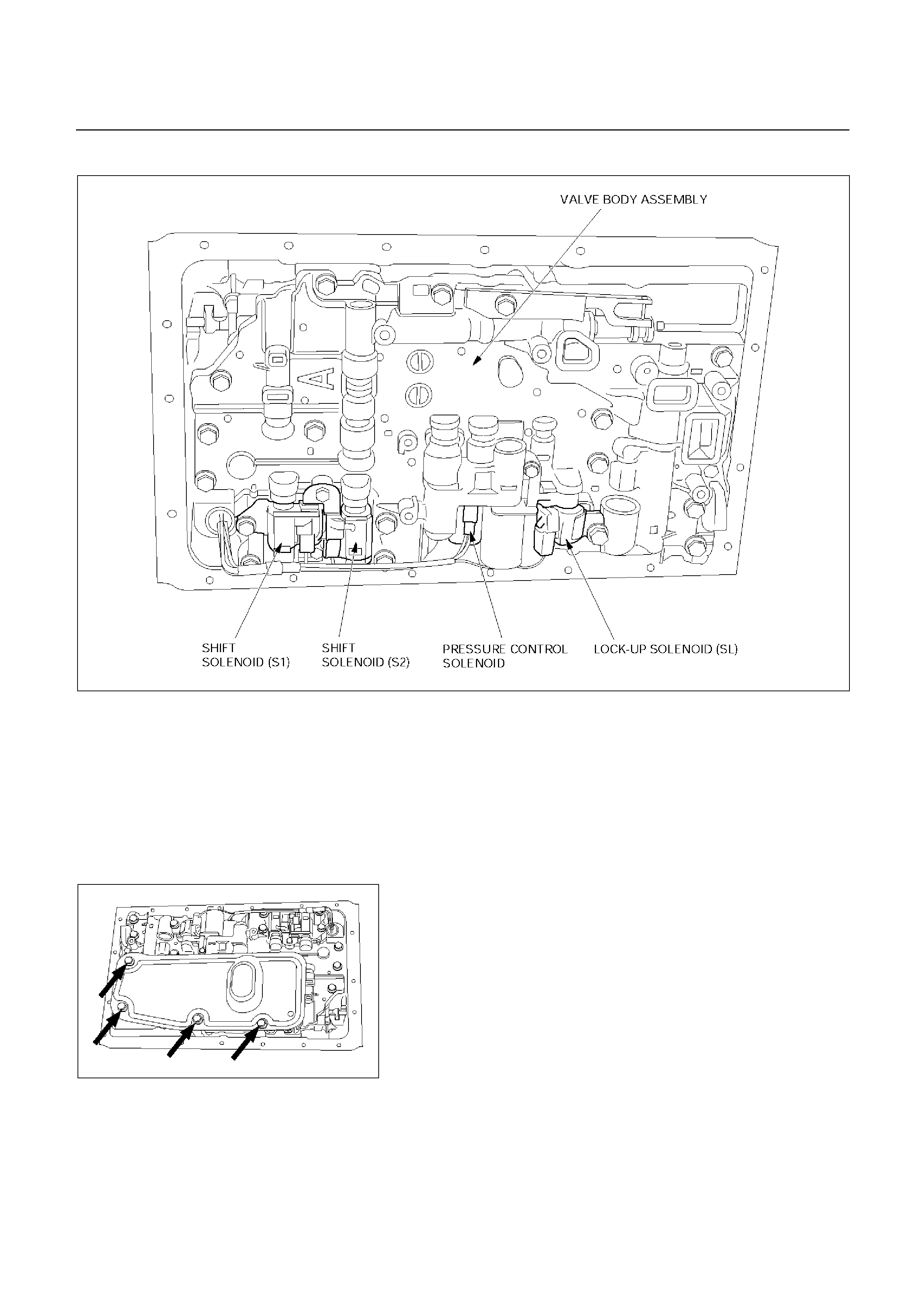

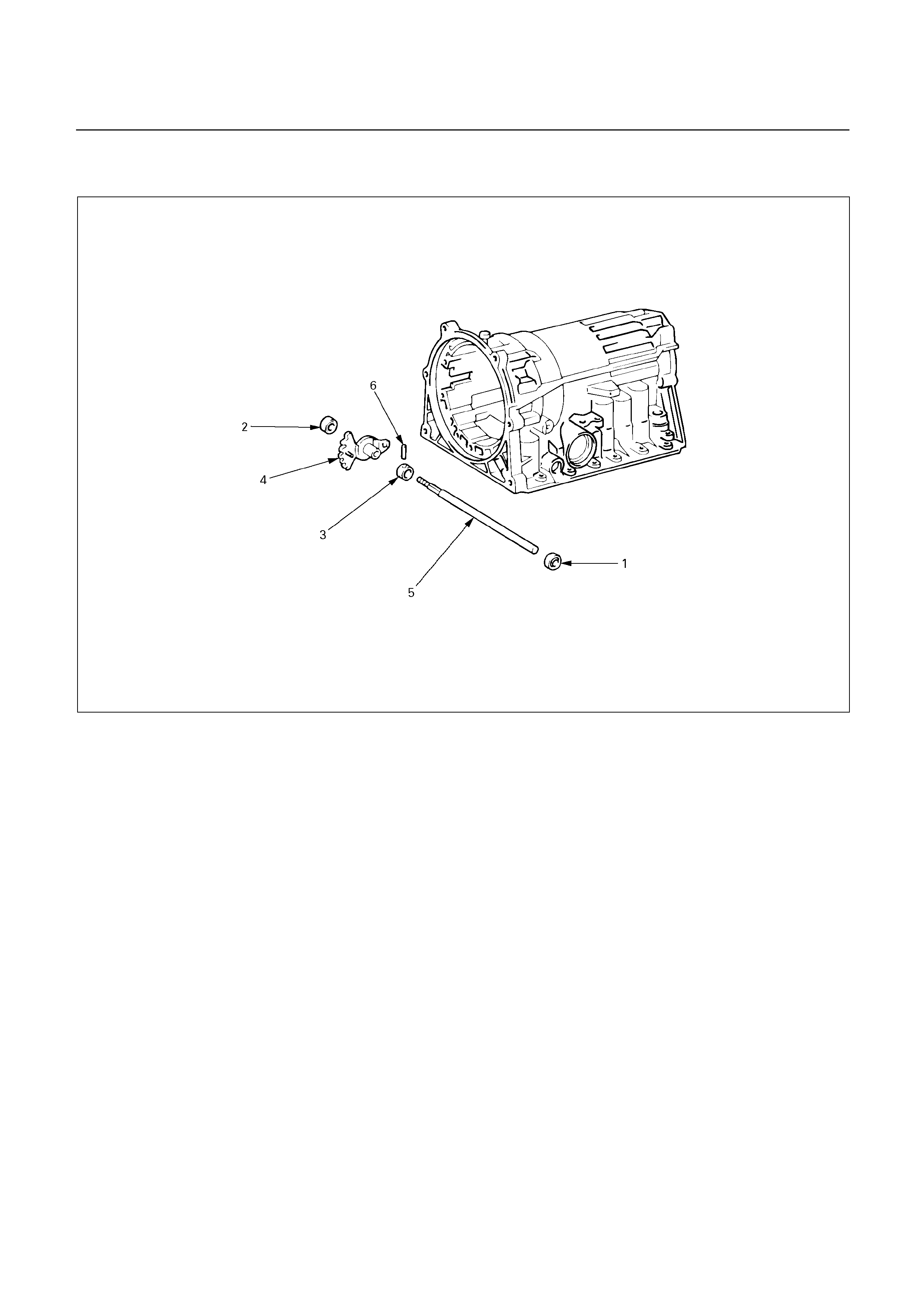

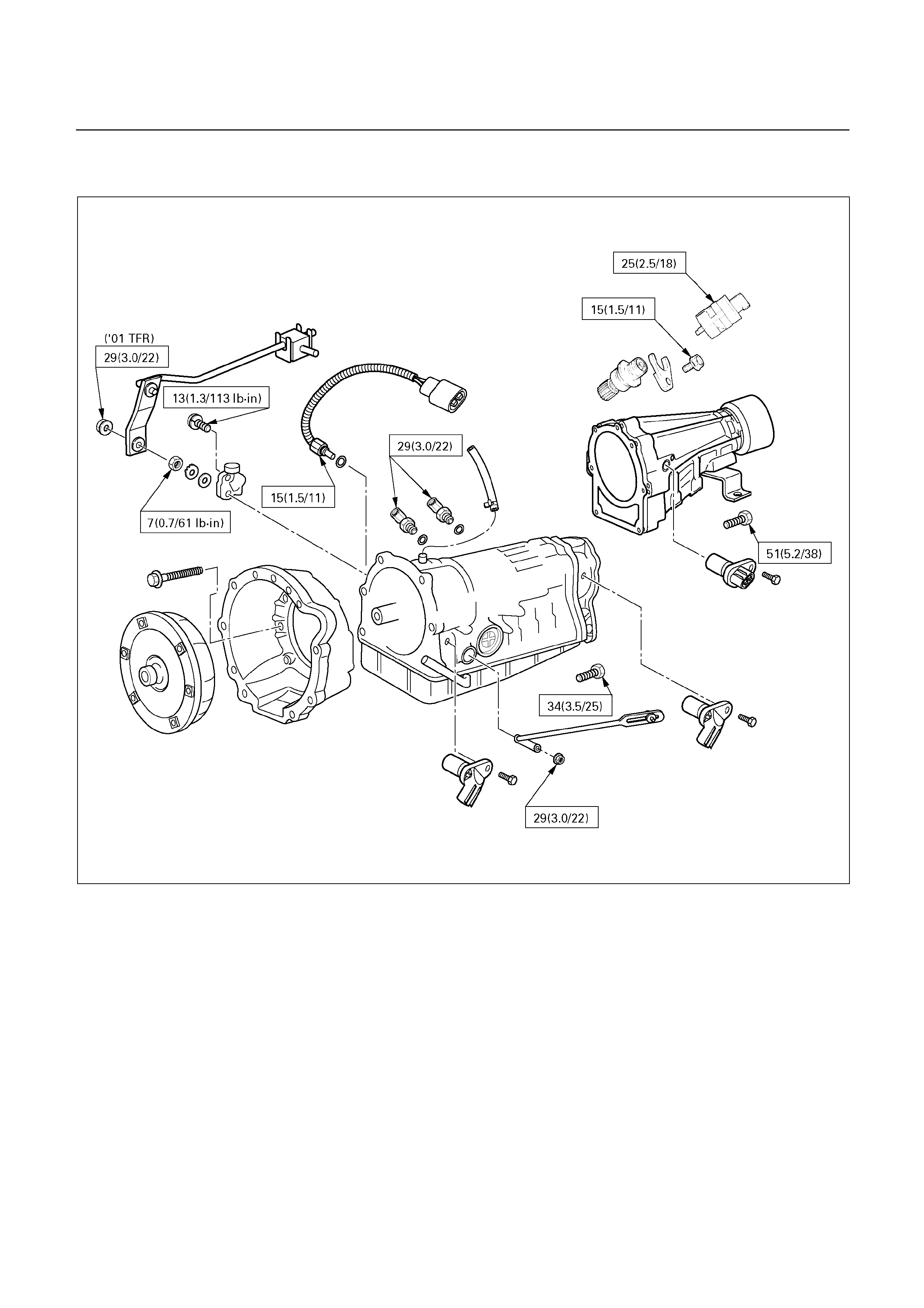

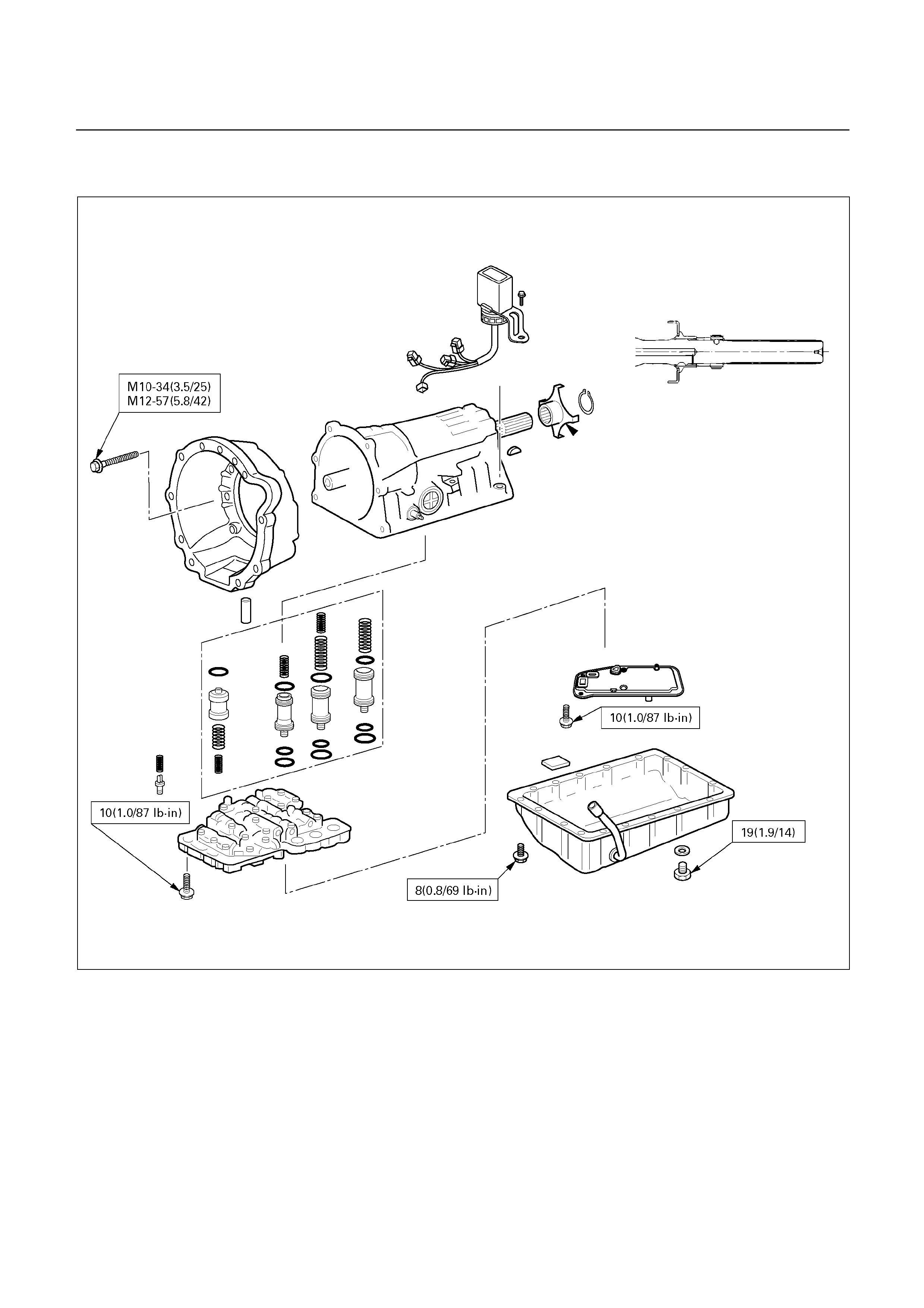

Shift Solenoid and Lock-Up Solenoid

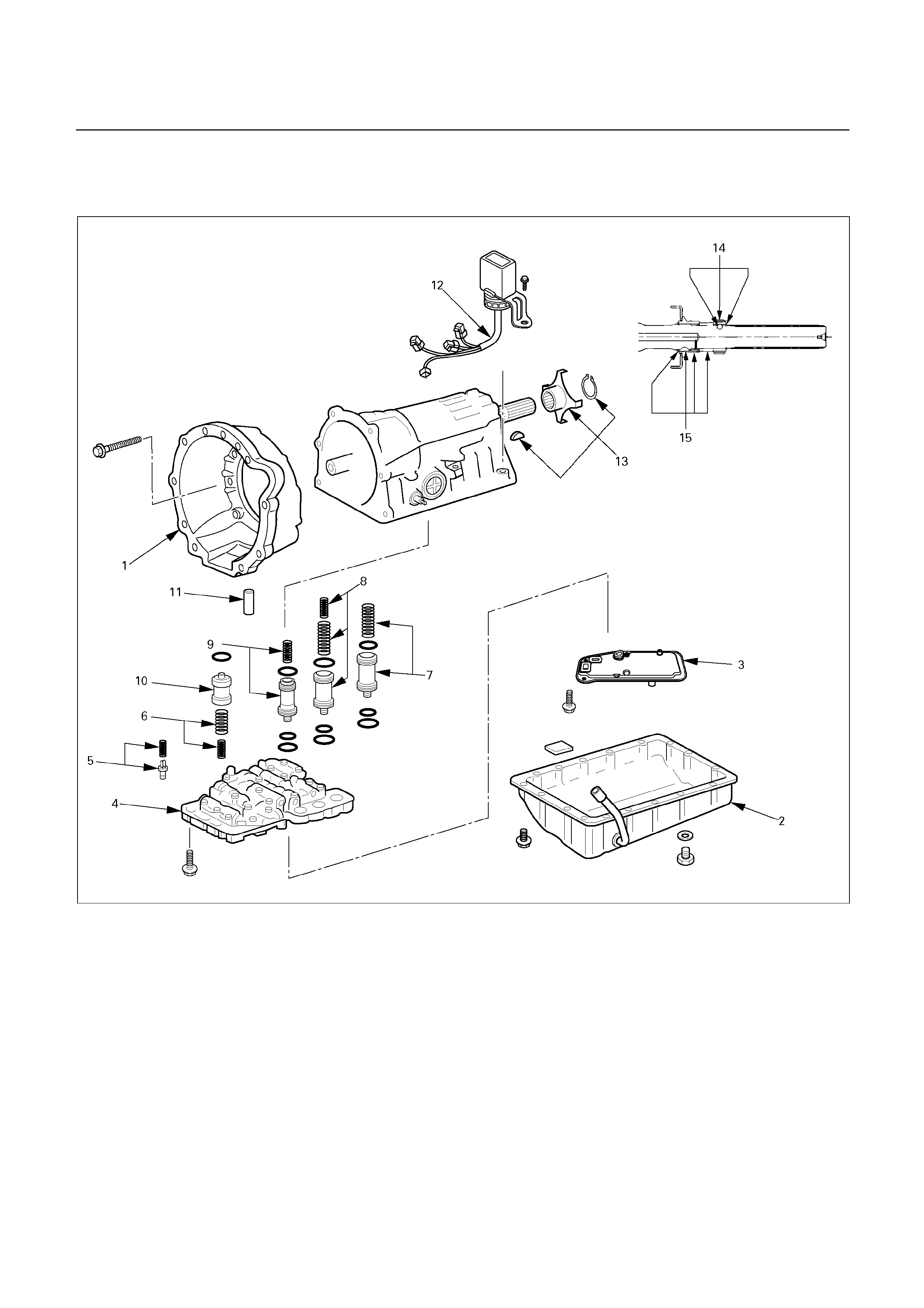

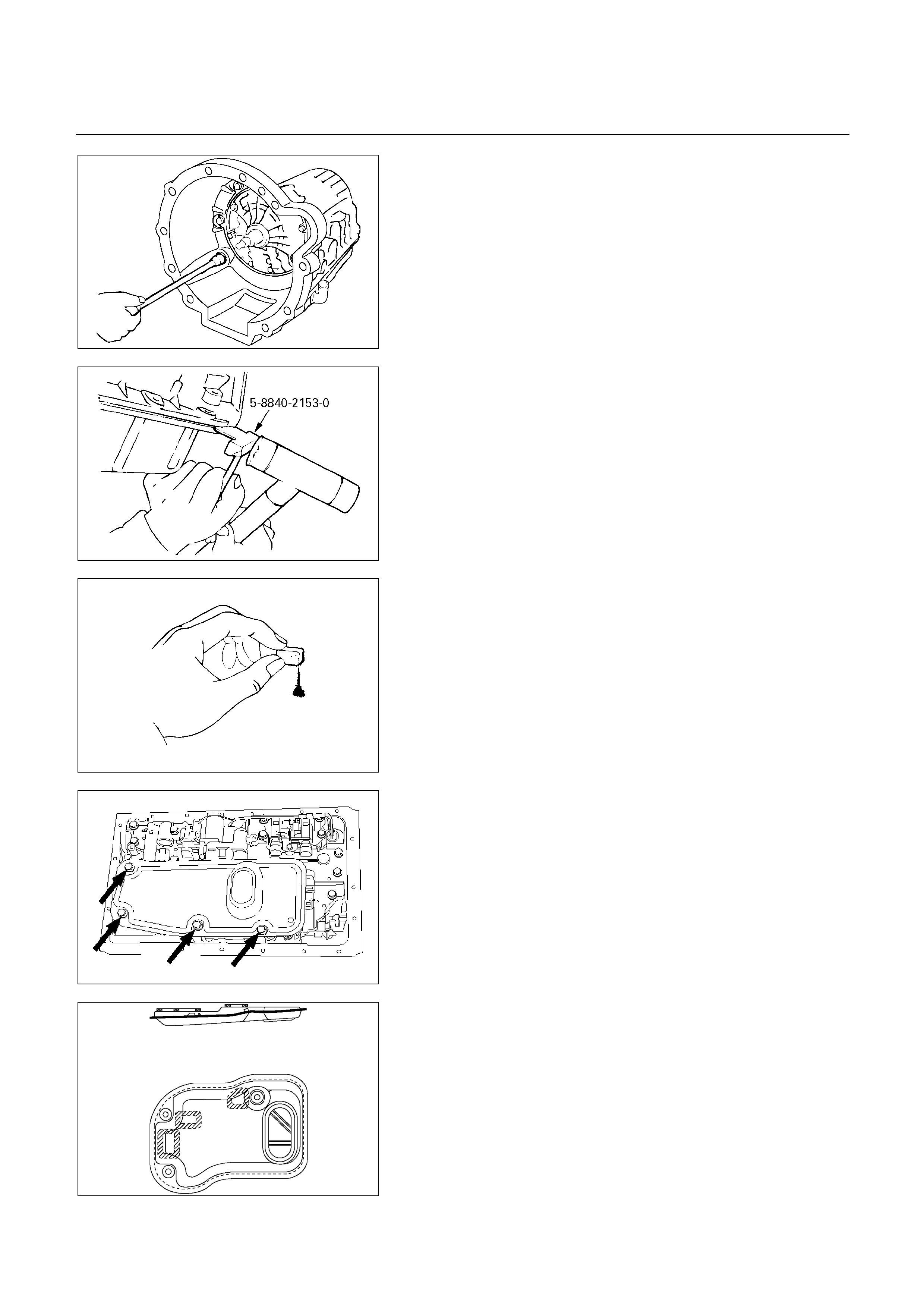

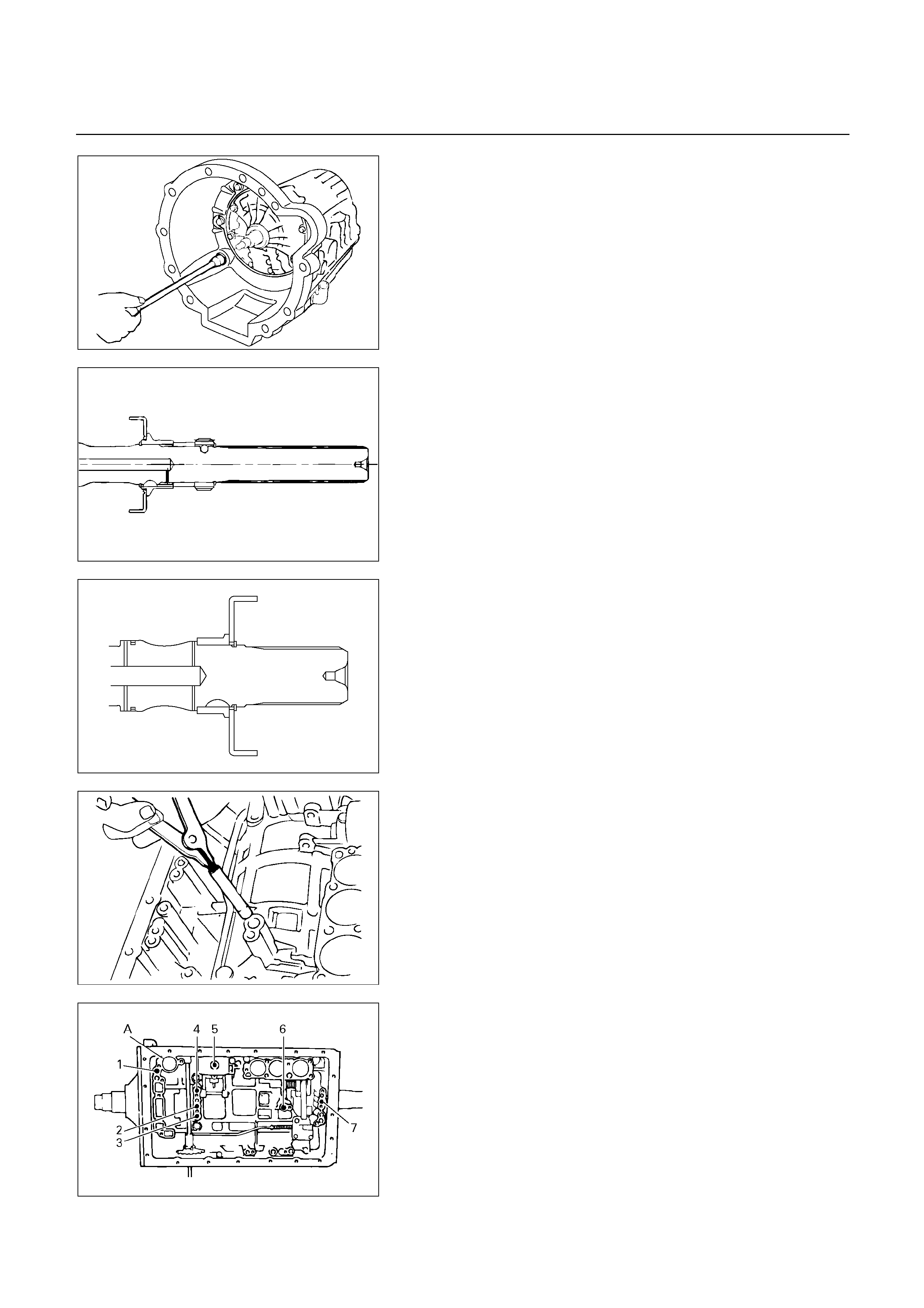

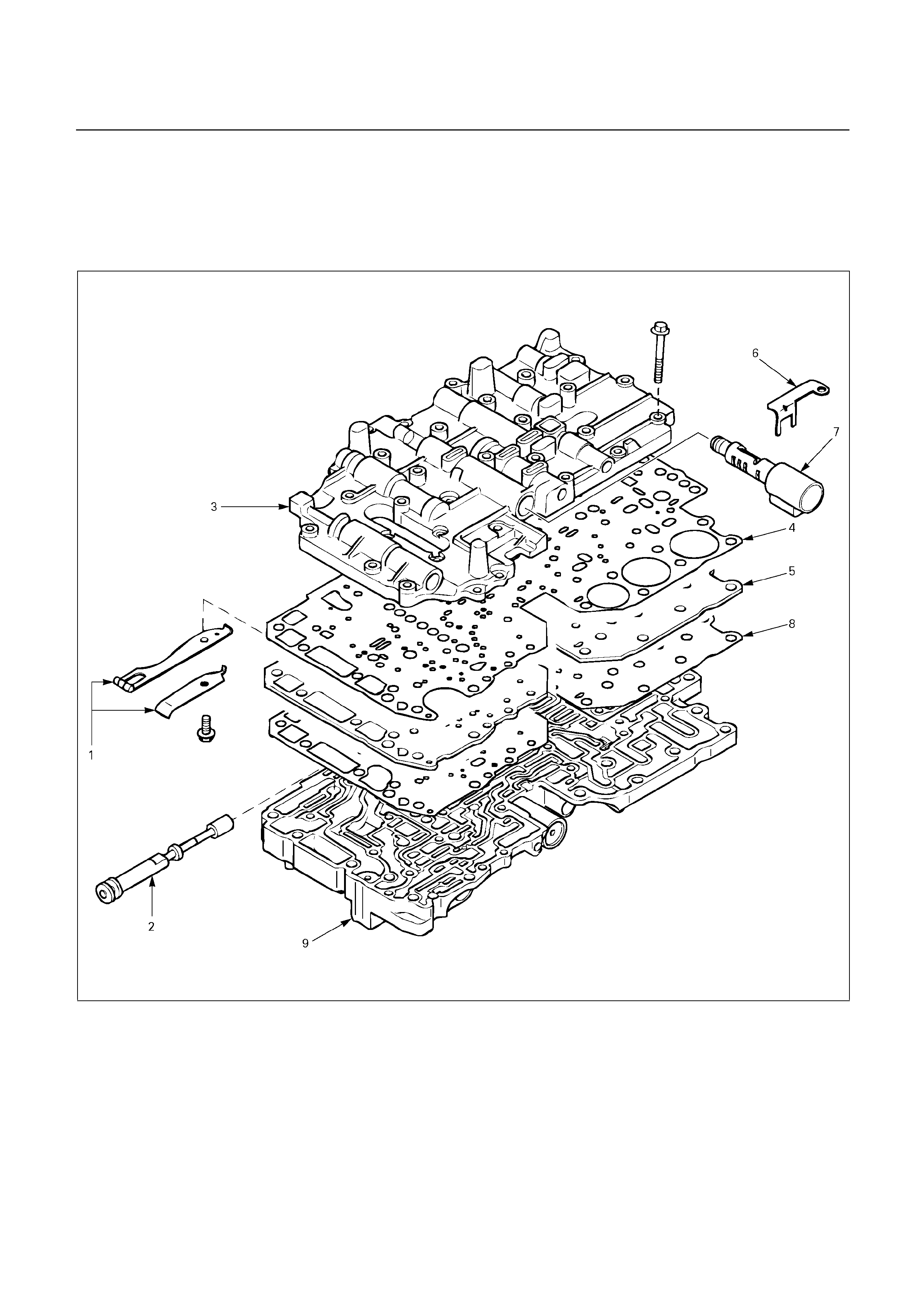

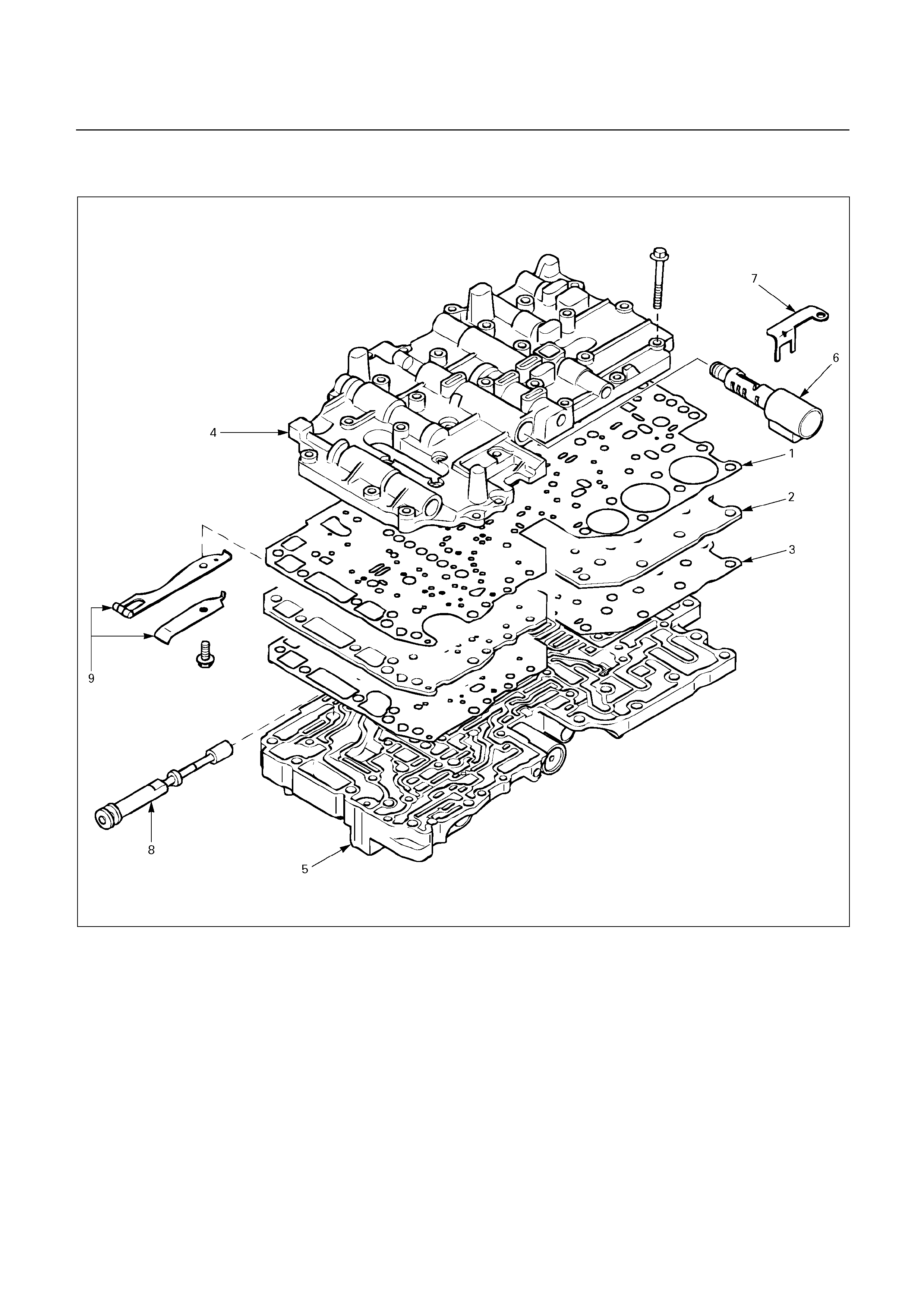

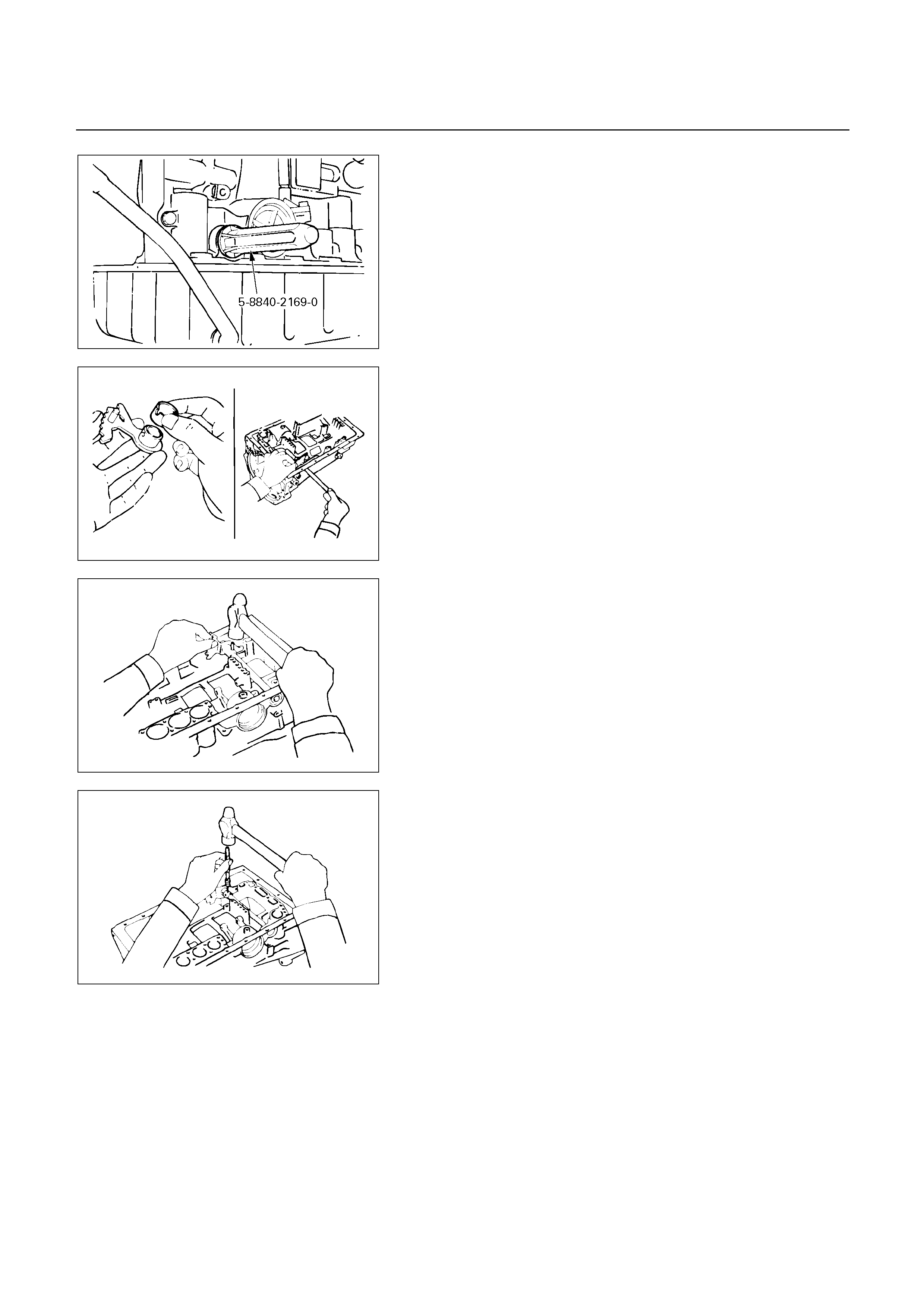

Valve Body Assembly and Pressure Control Solenoid

Rear Oil Seal (Adapter Housing, 44)

Rear Oil Seal (Extension Housing, 42)

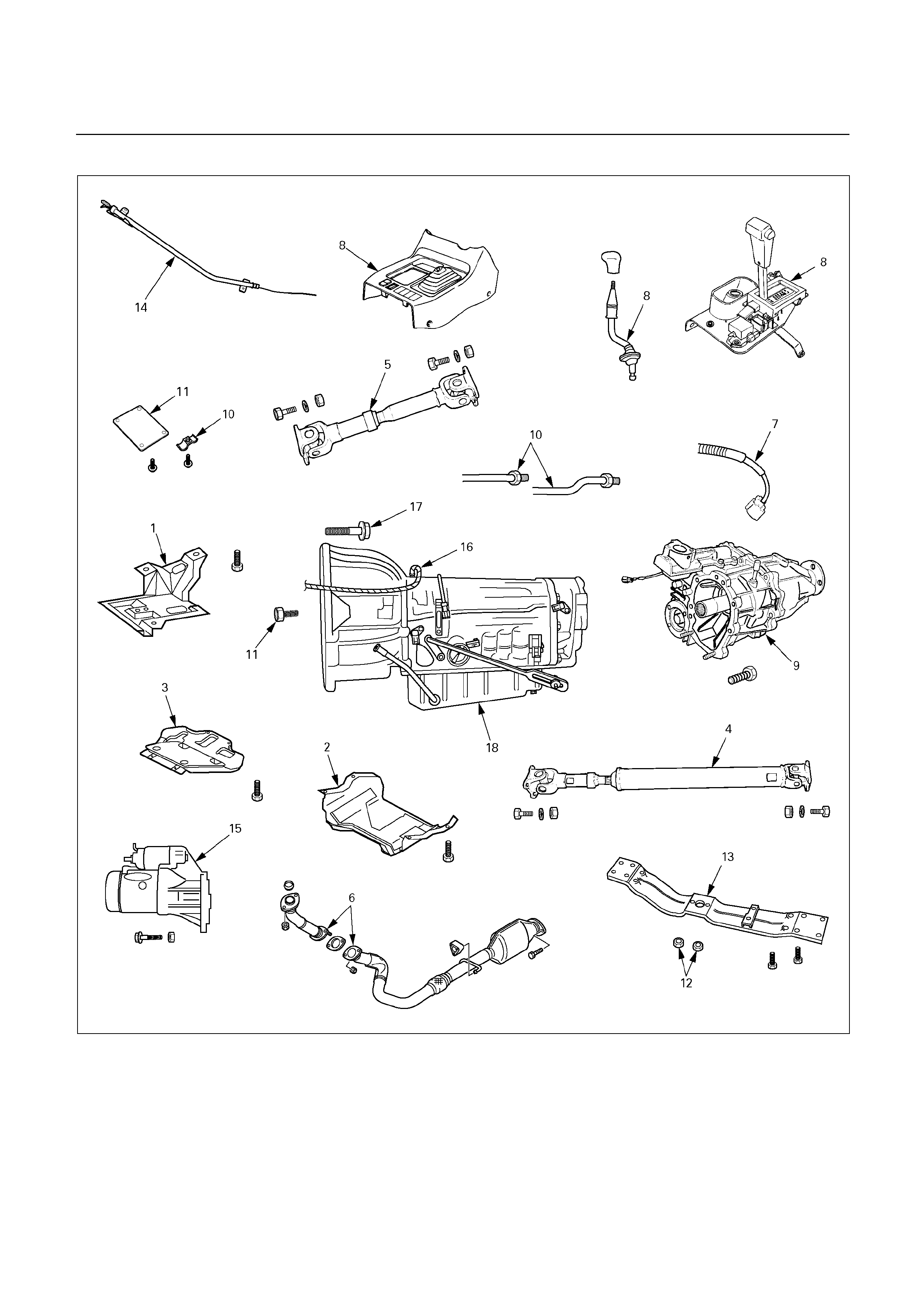

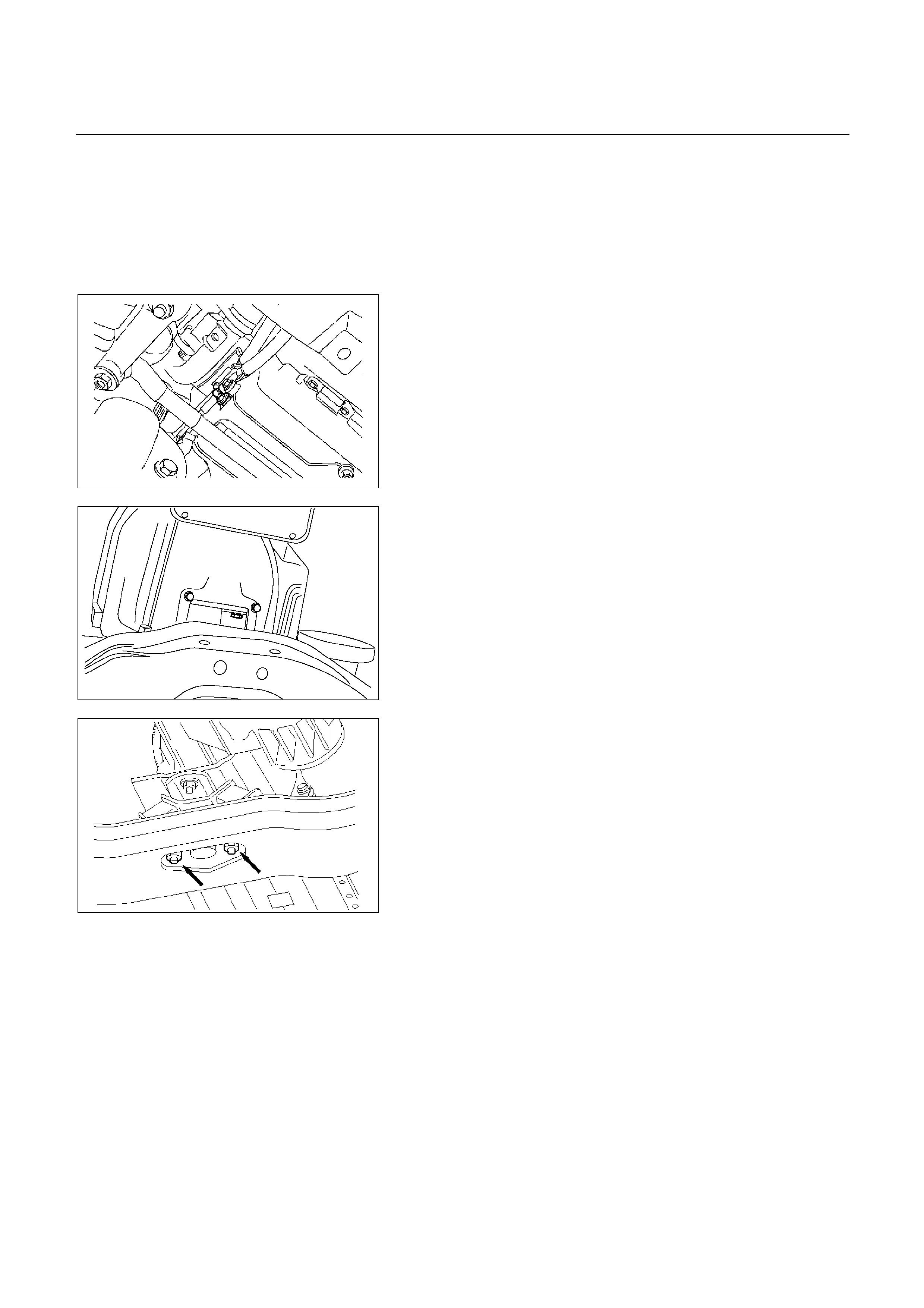

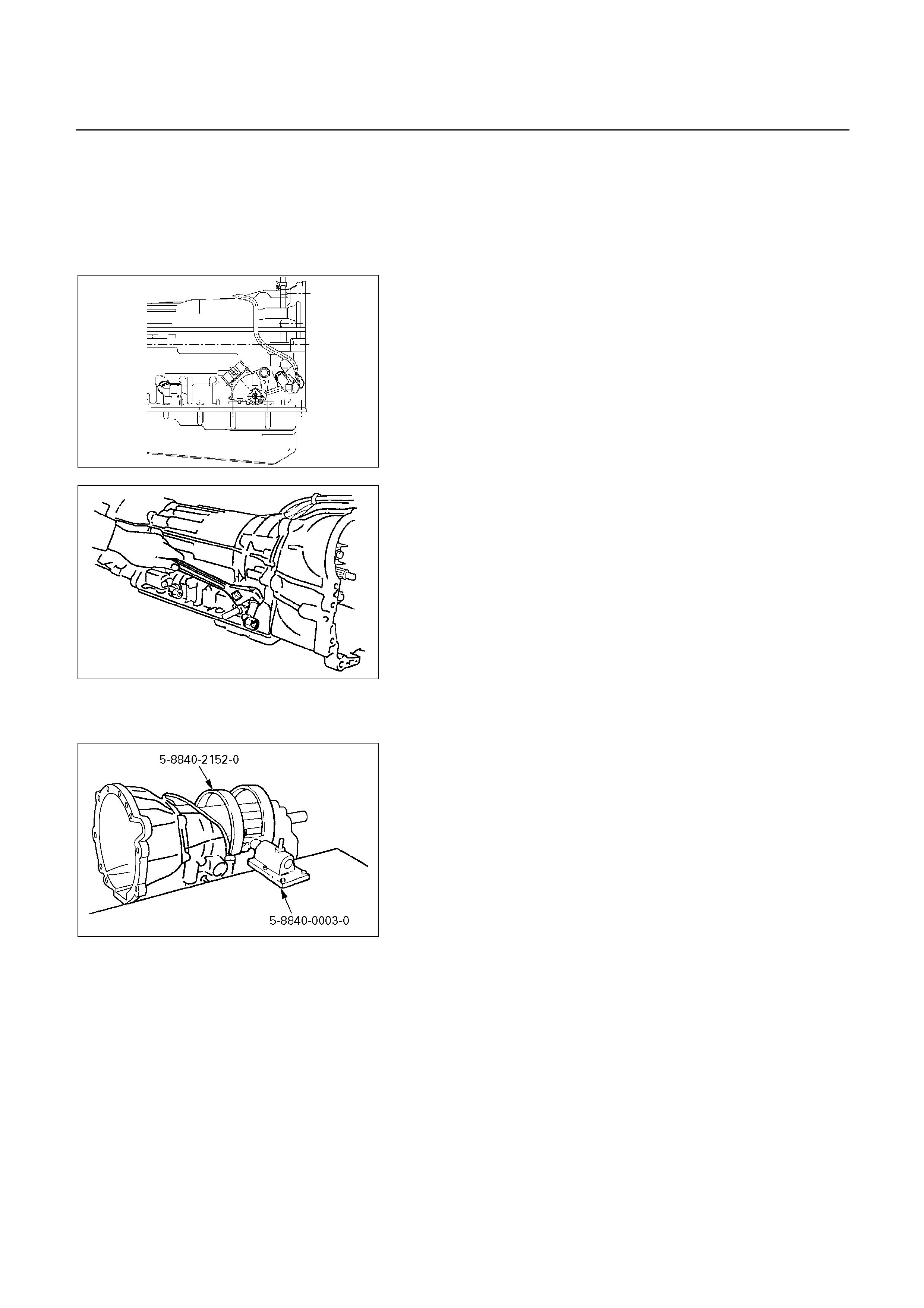

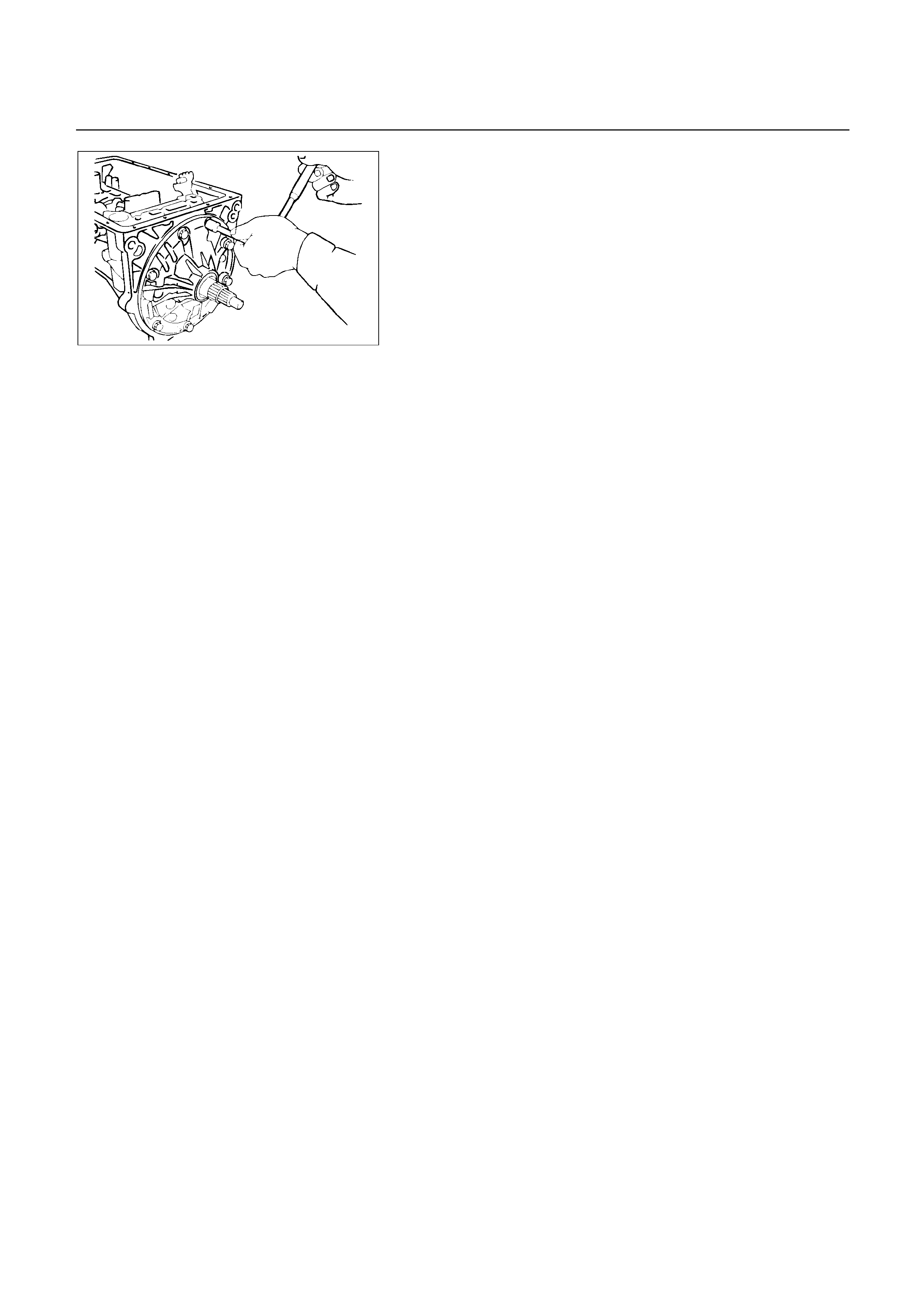

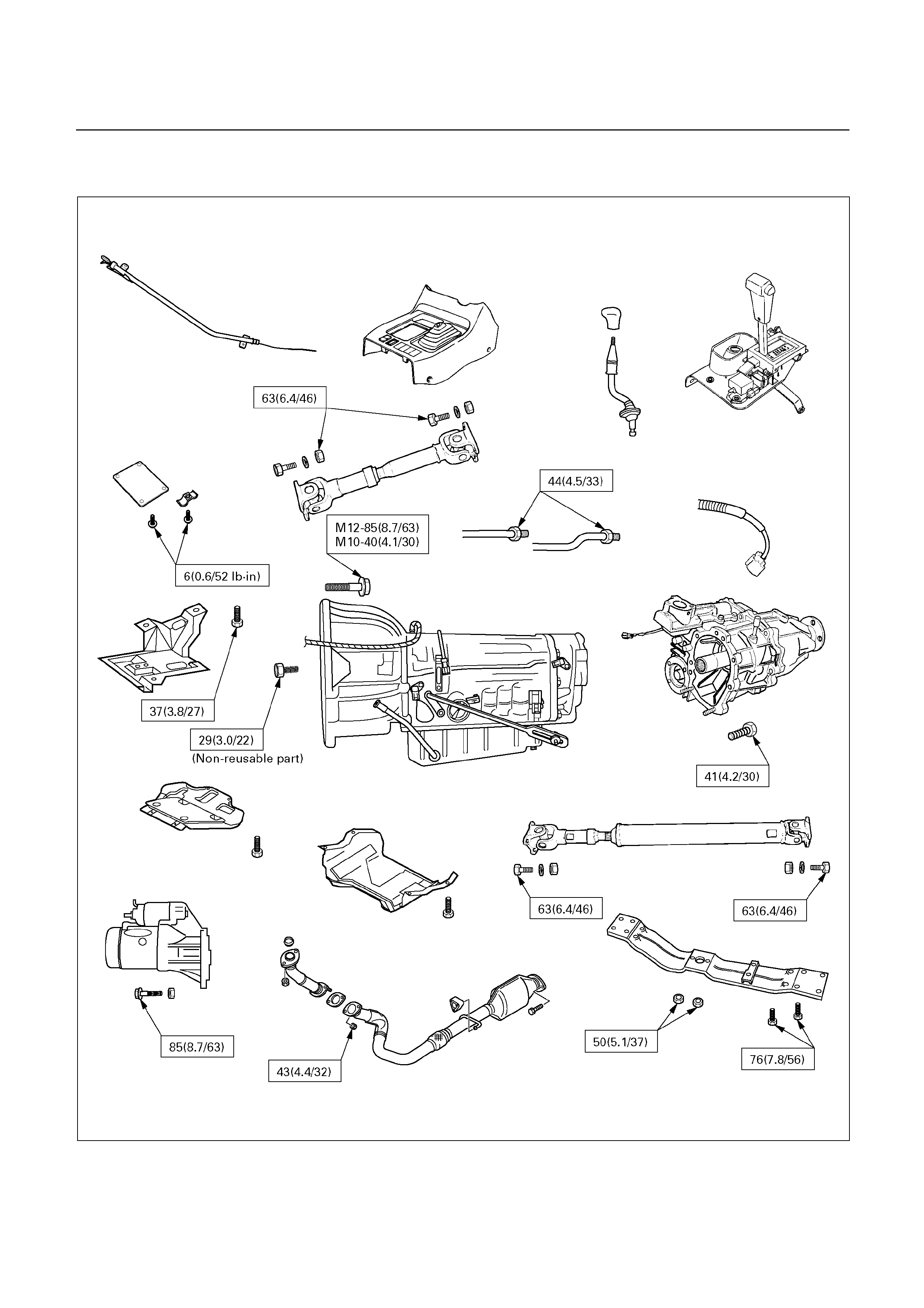

Transmission Removal and Installation (UBS)

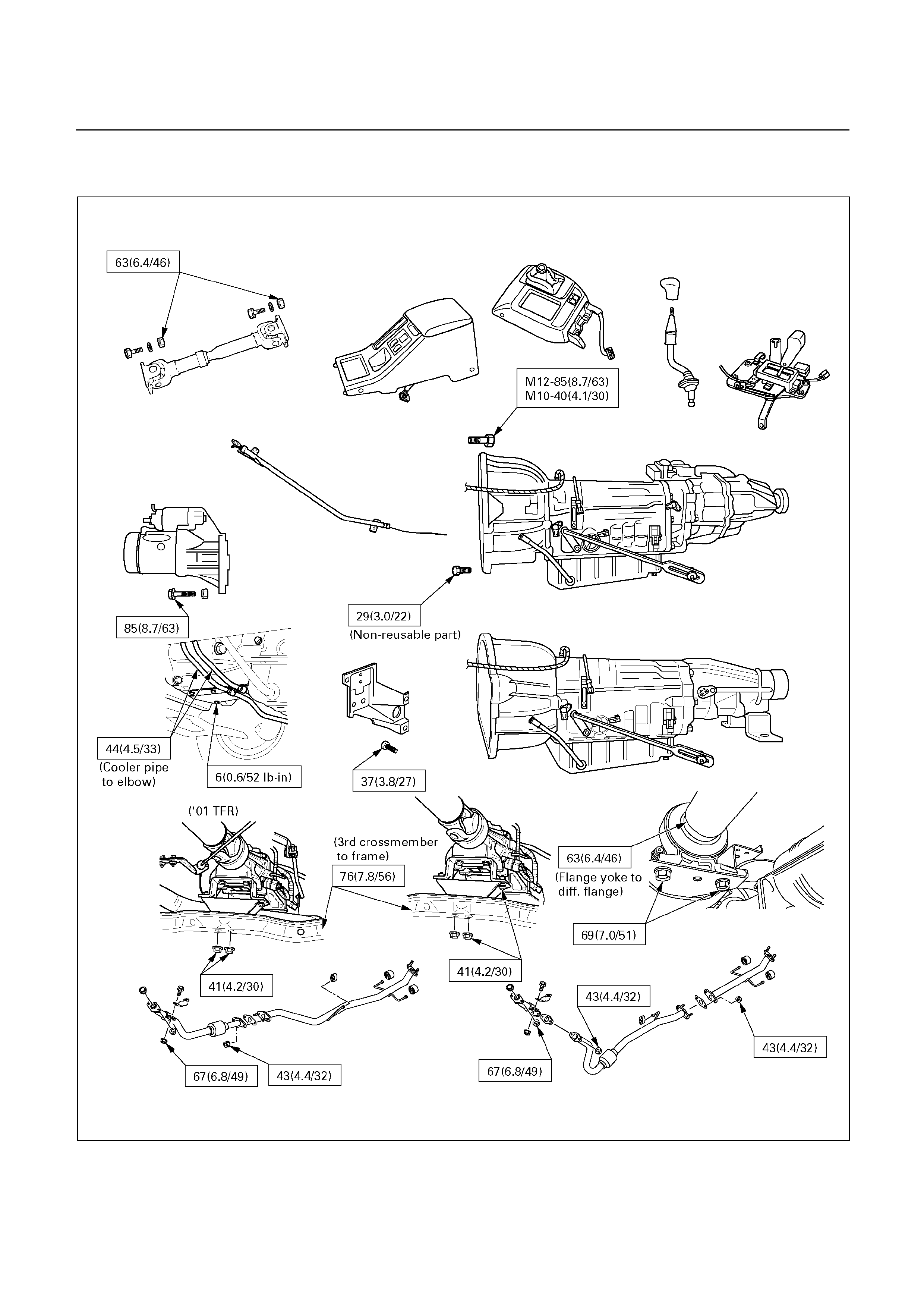

Transmission Removal and Installation (TFR/S)

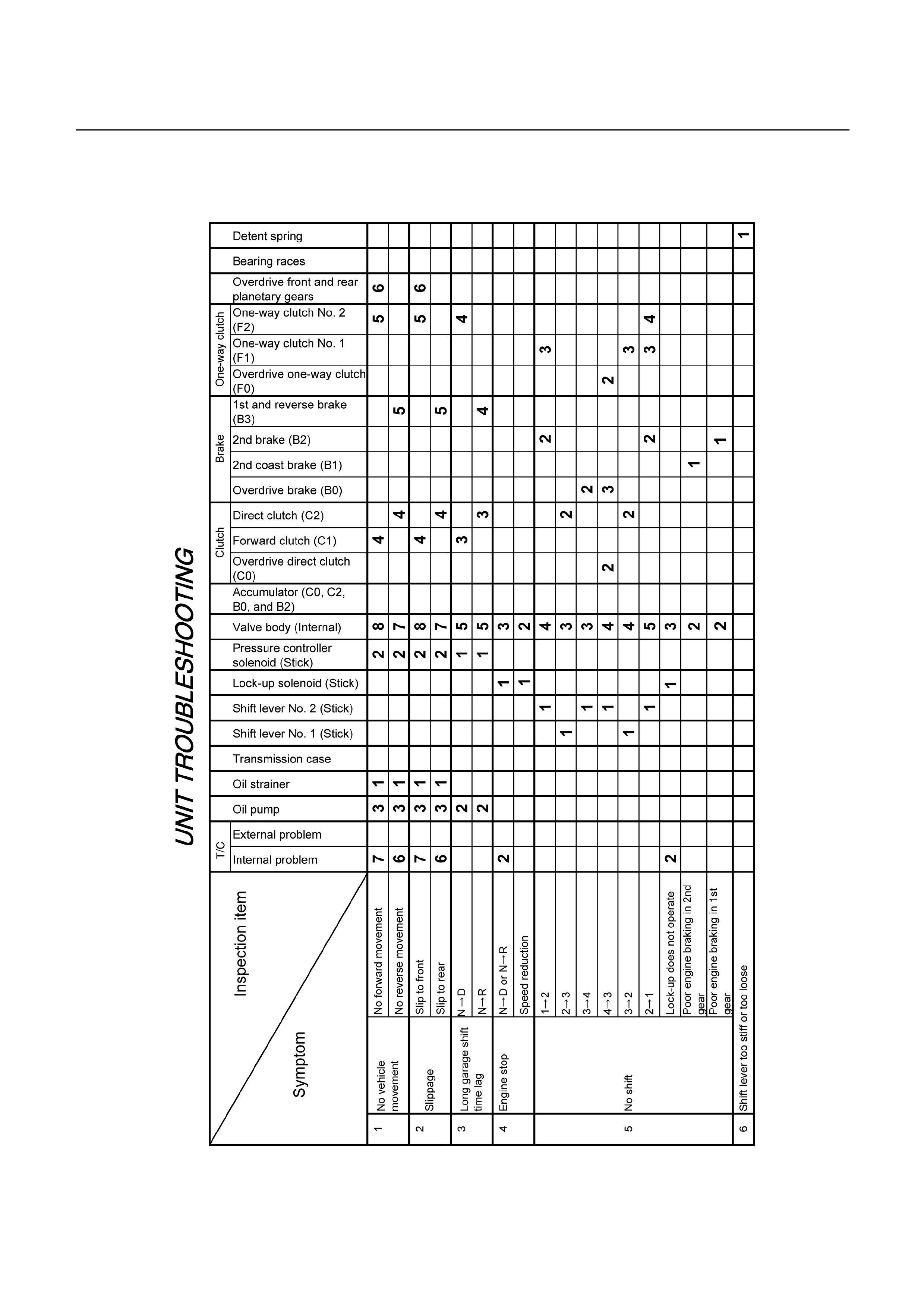

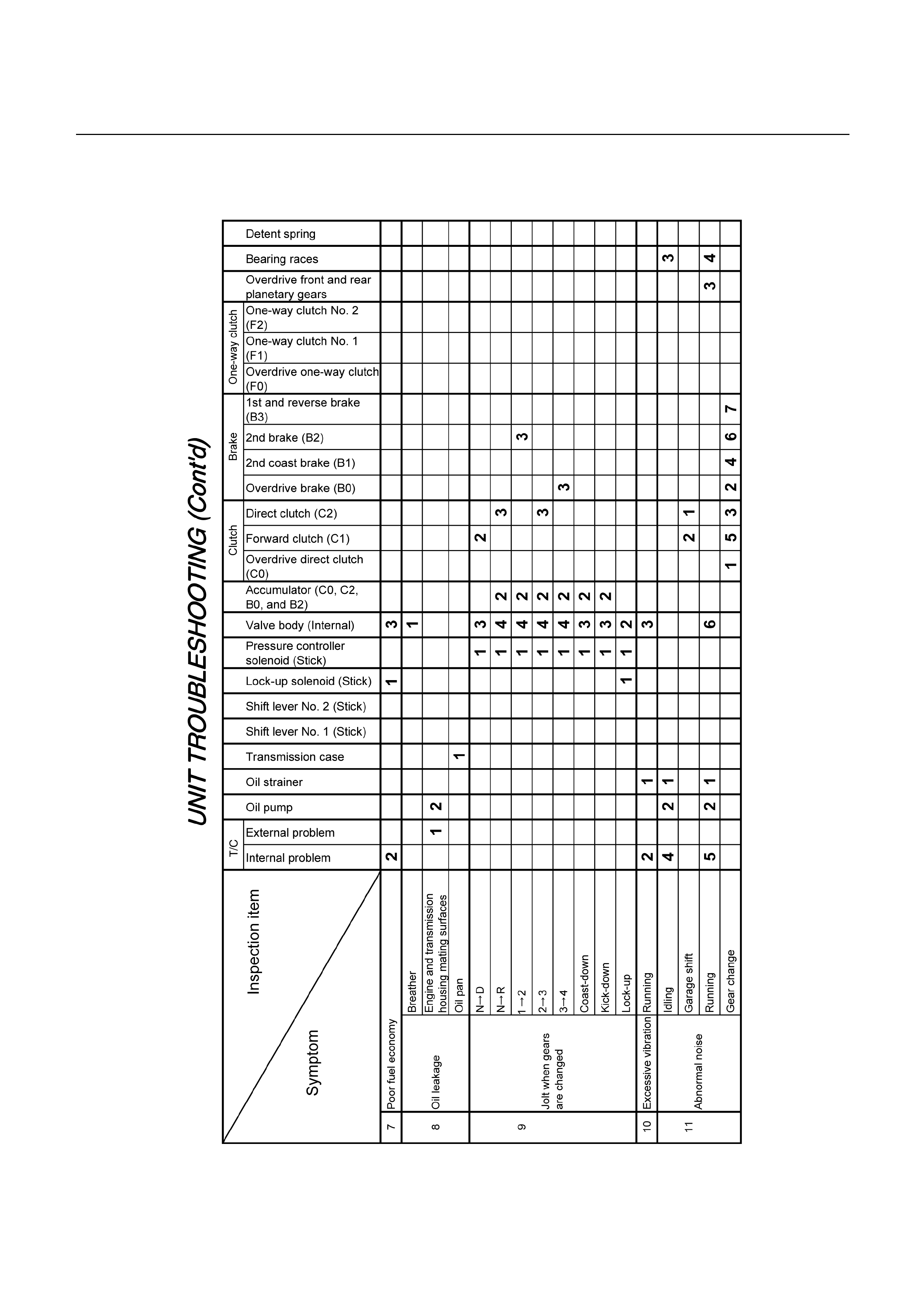

Unit Repair

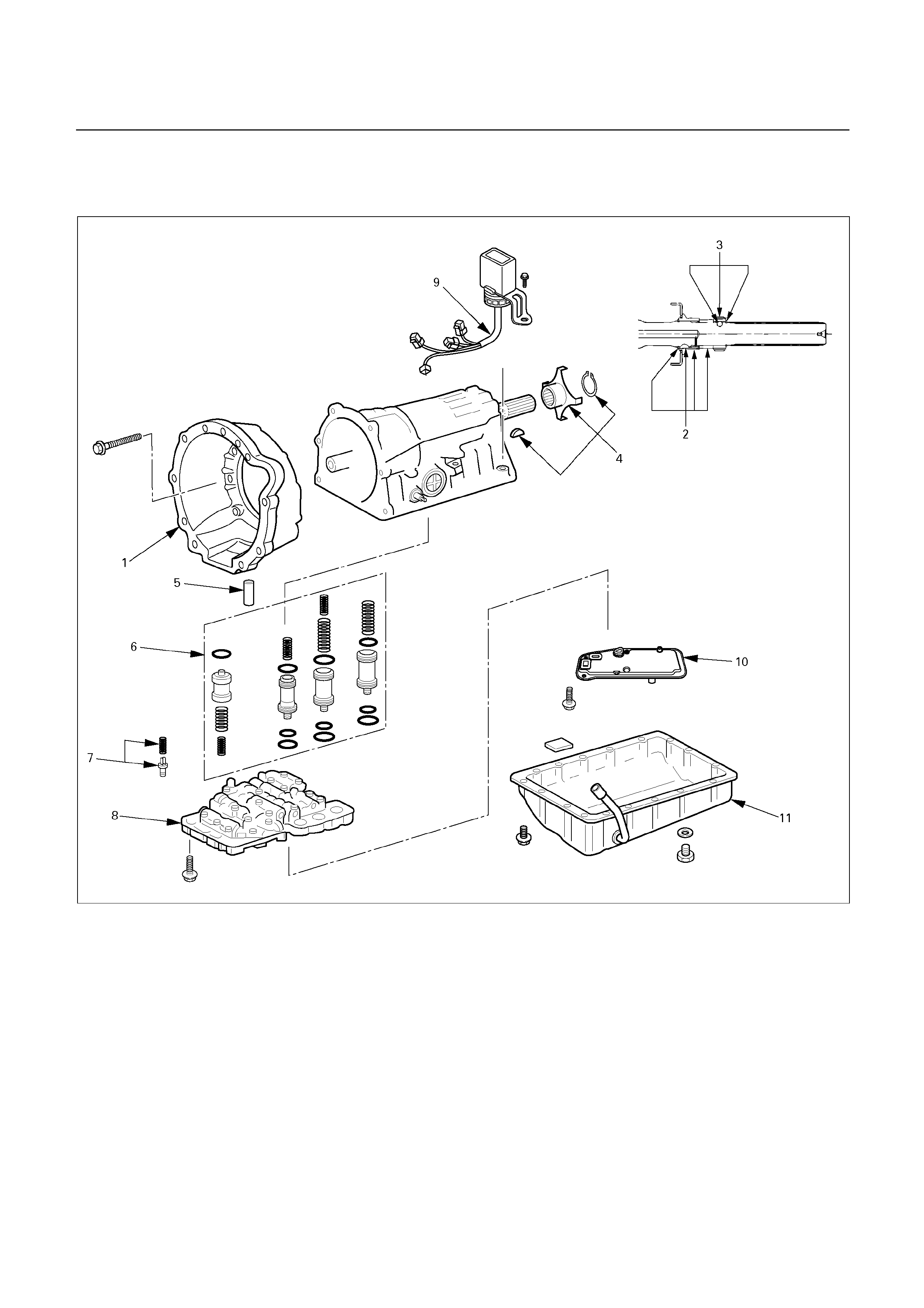

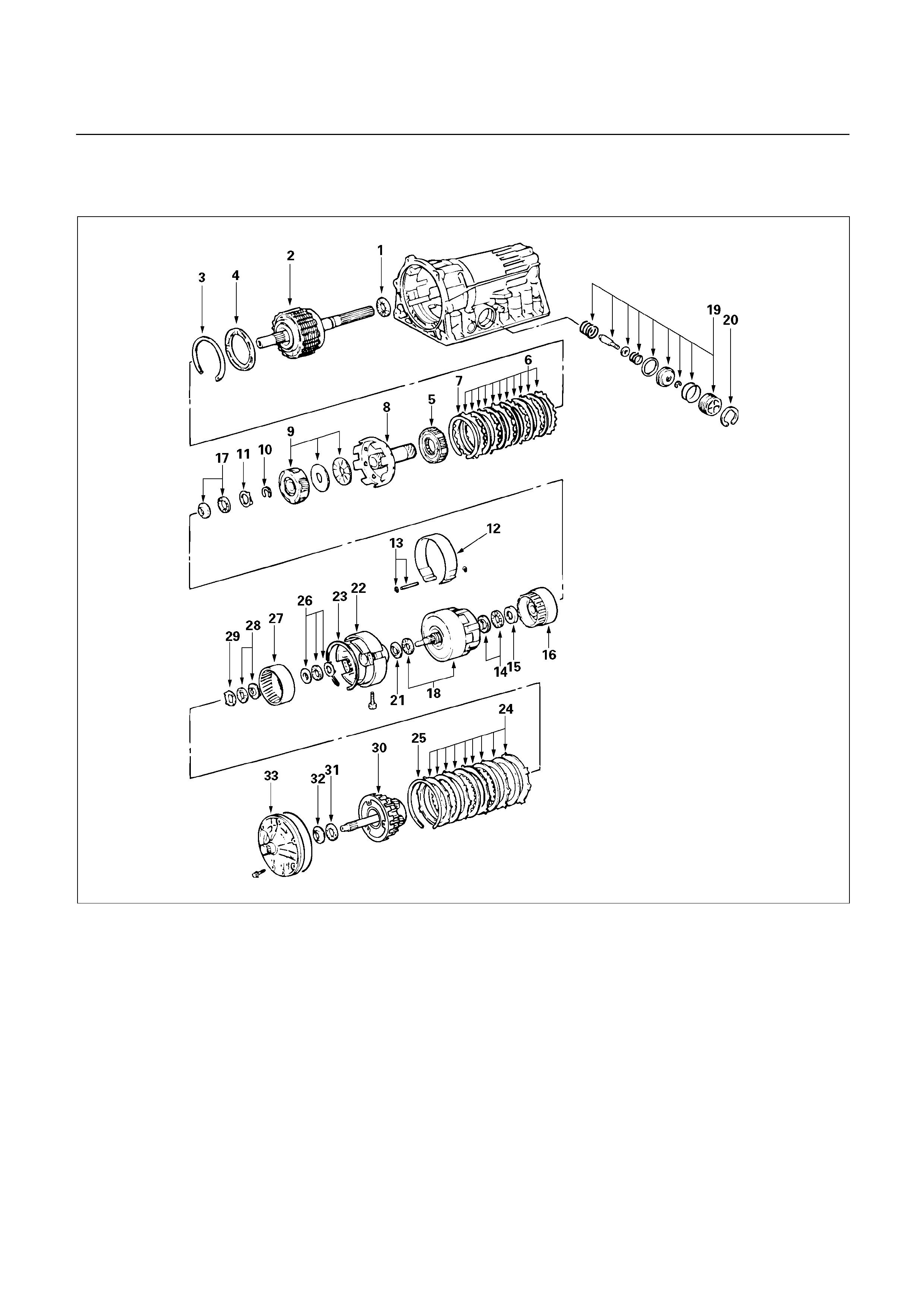

Major Components

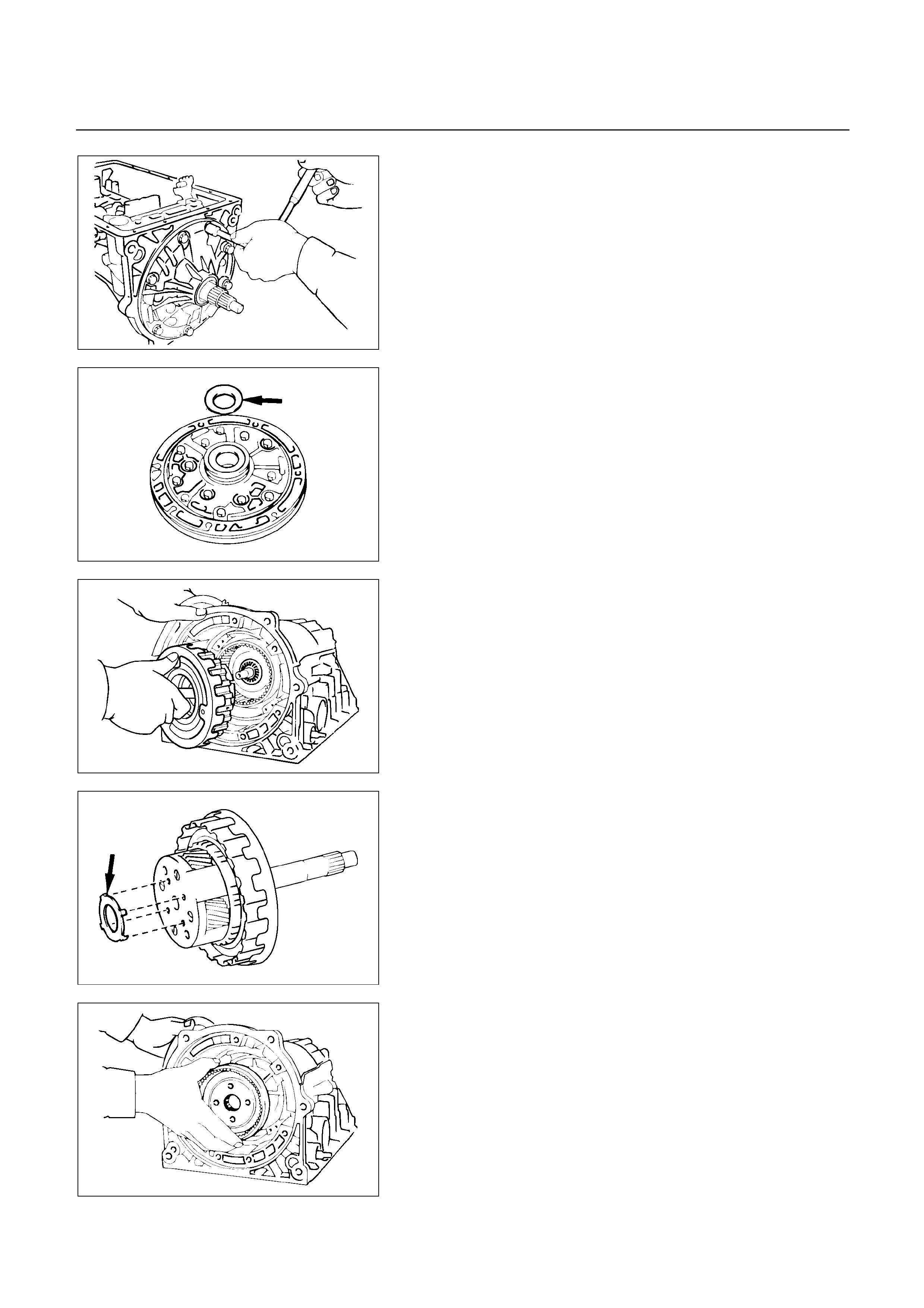

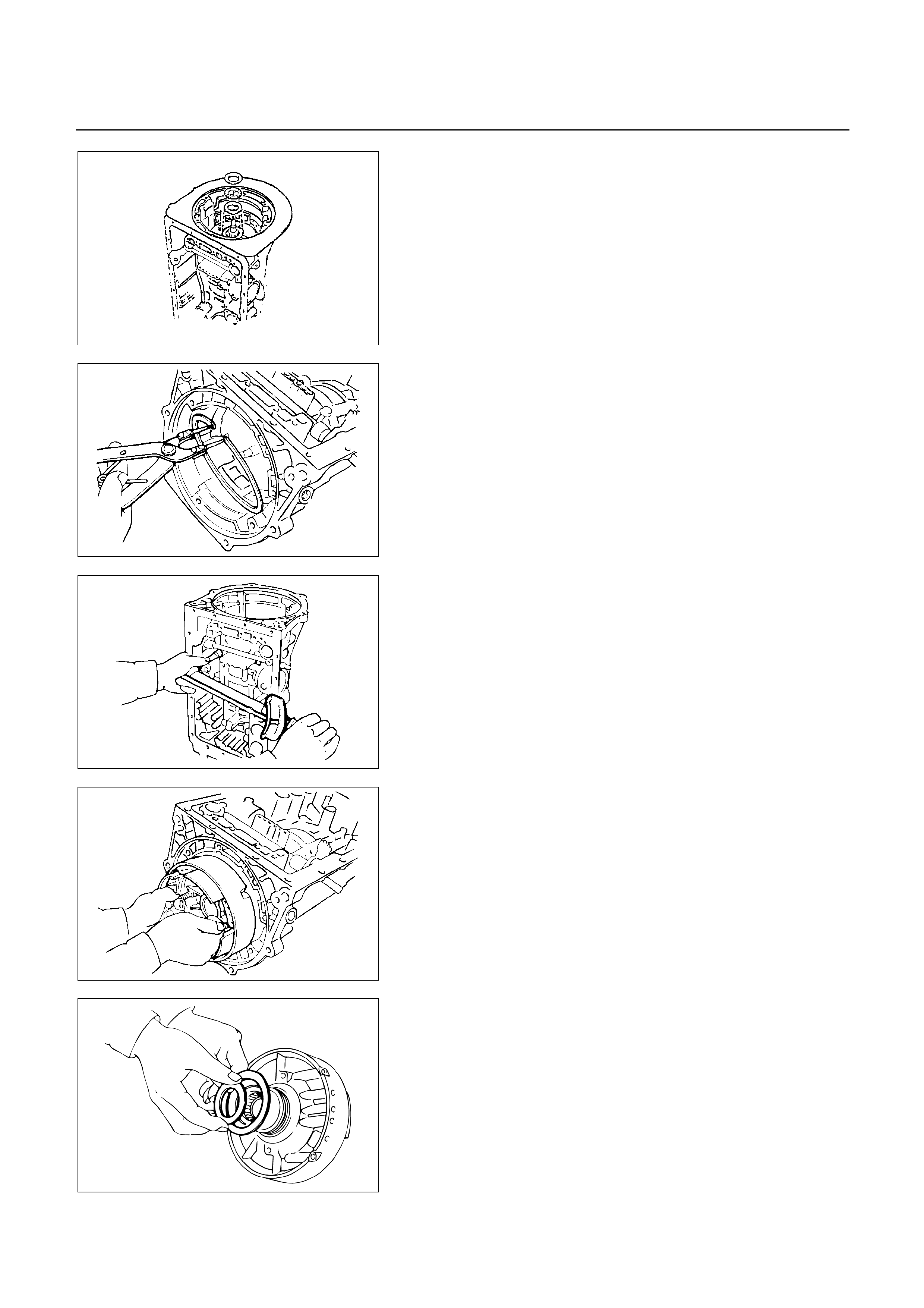

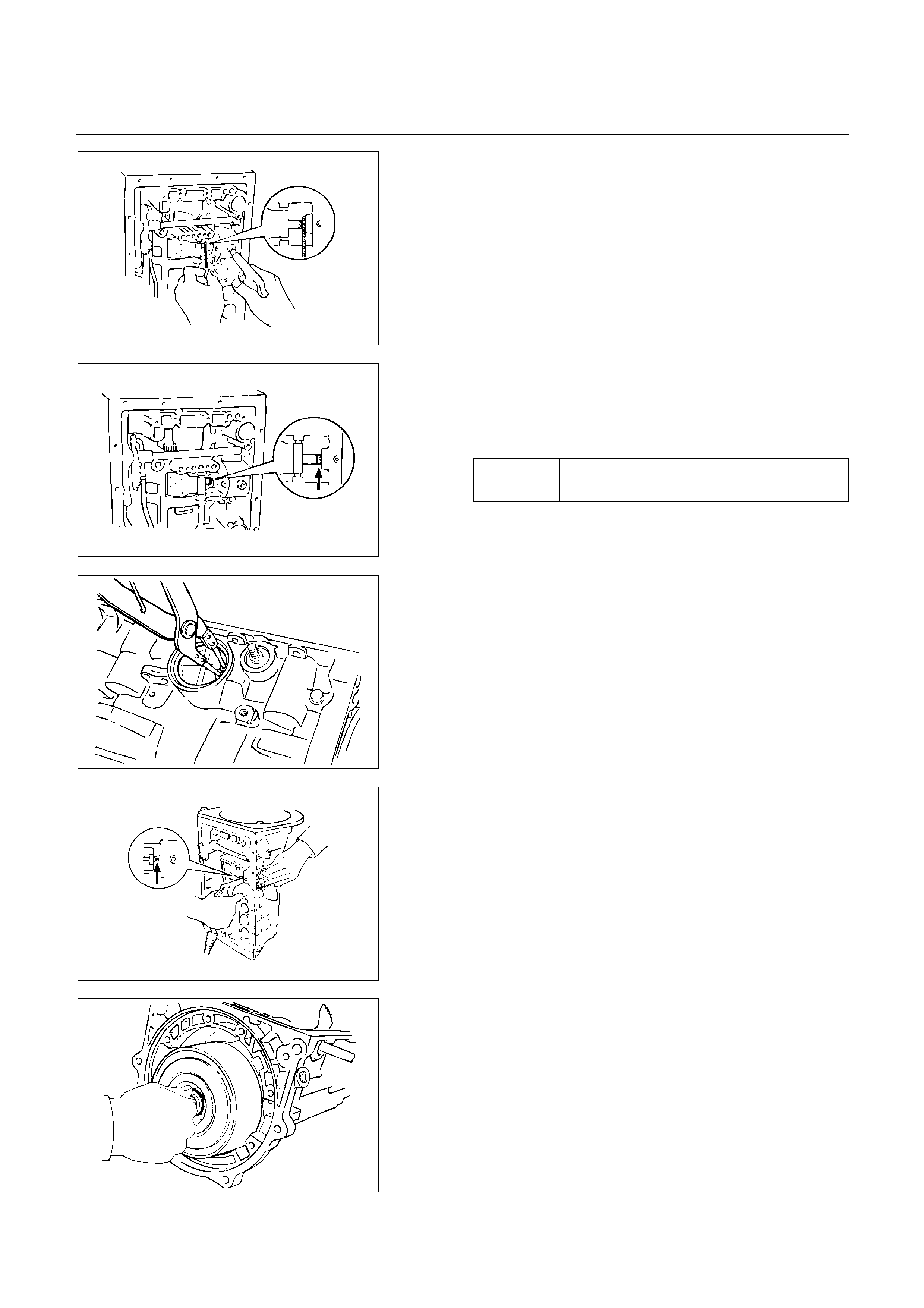

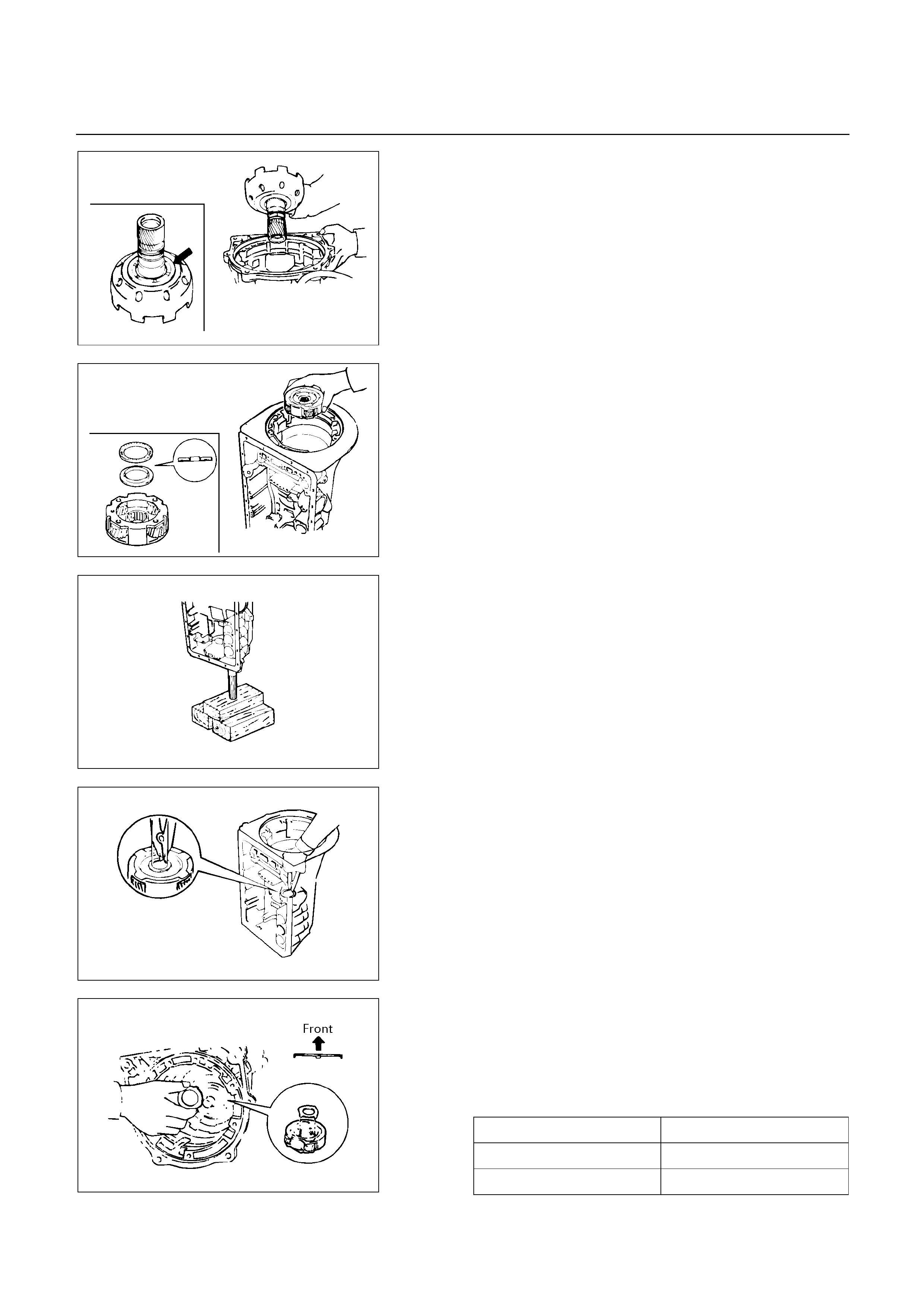

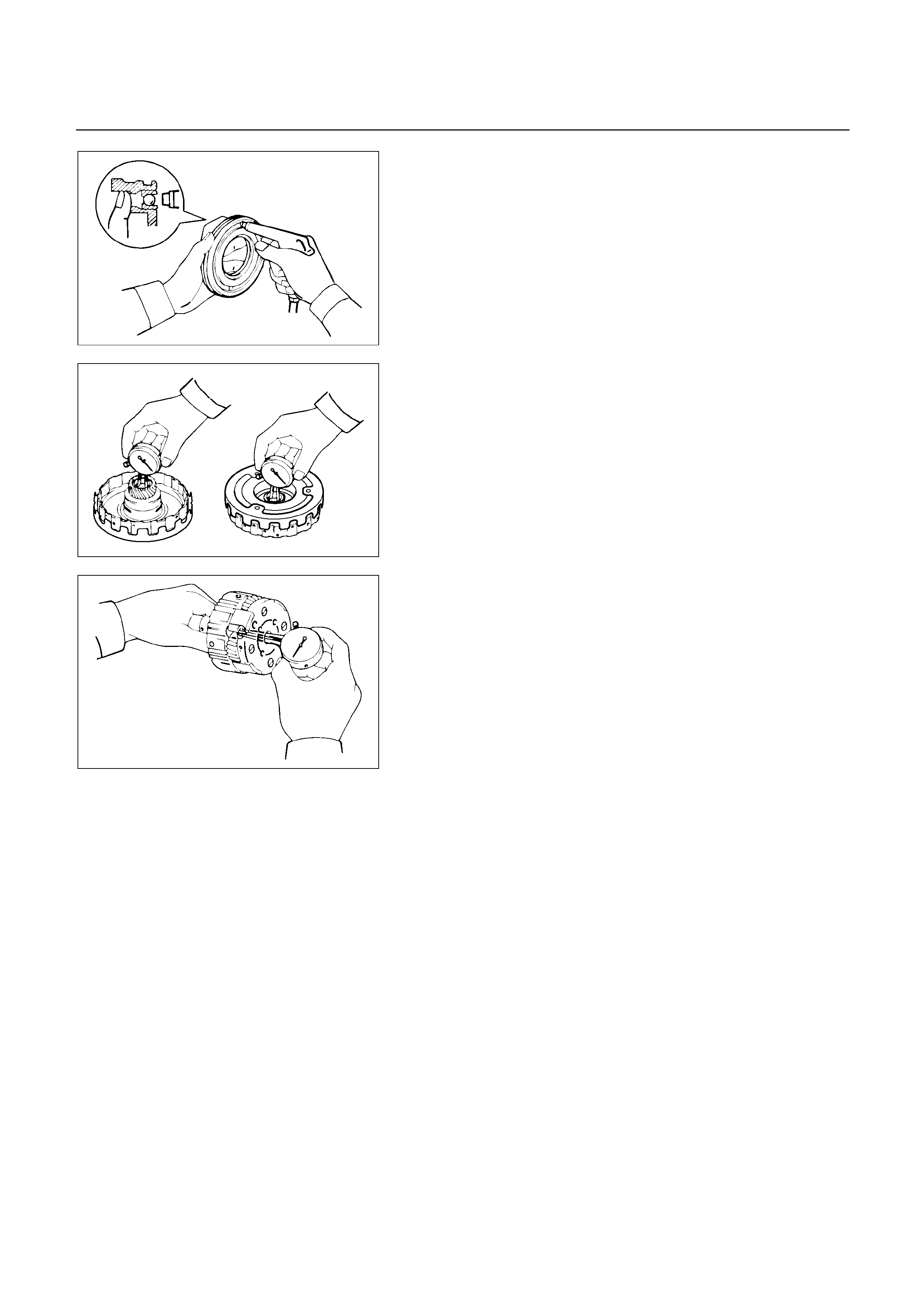

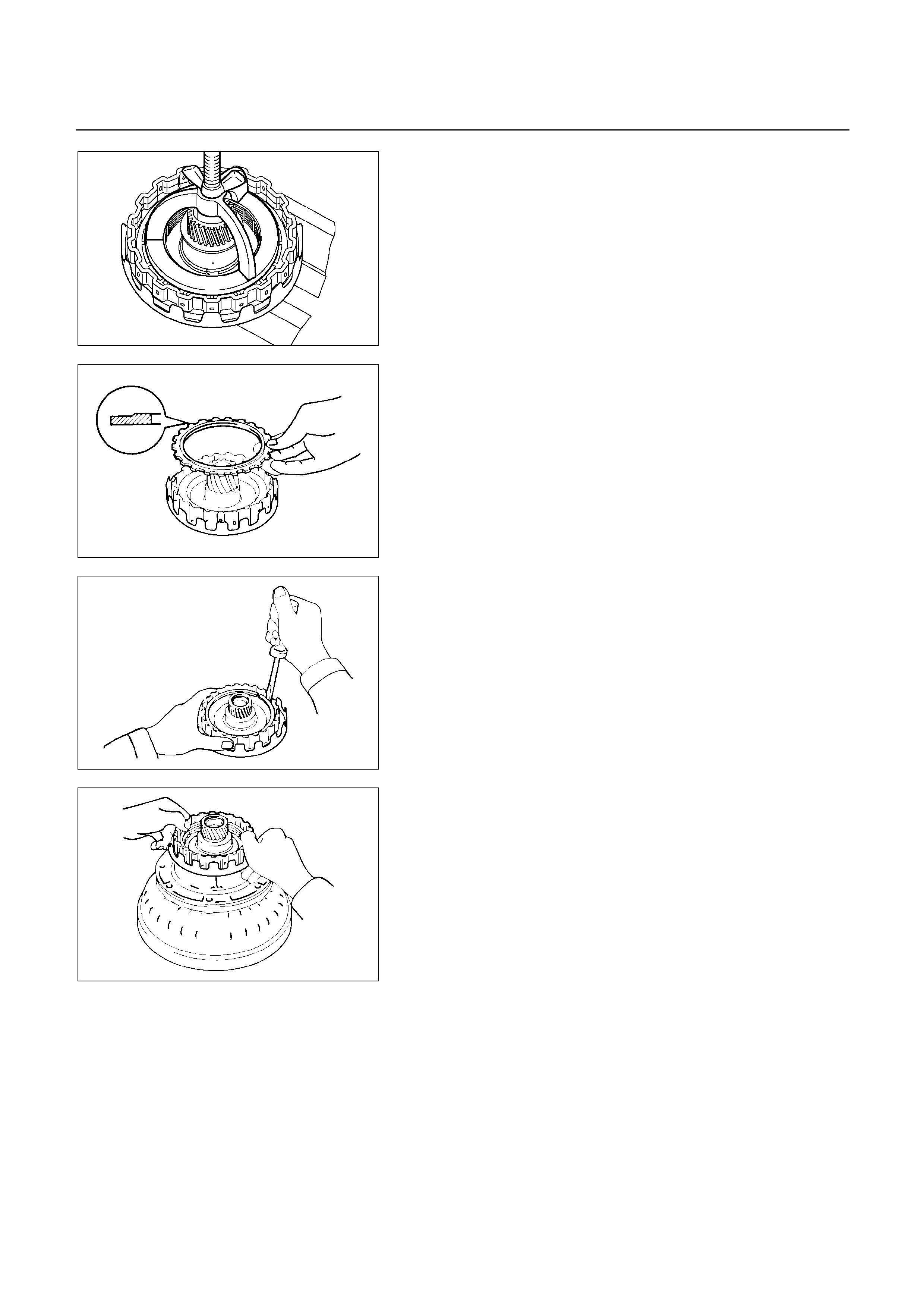

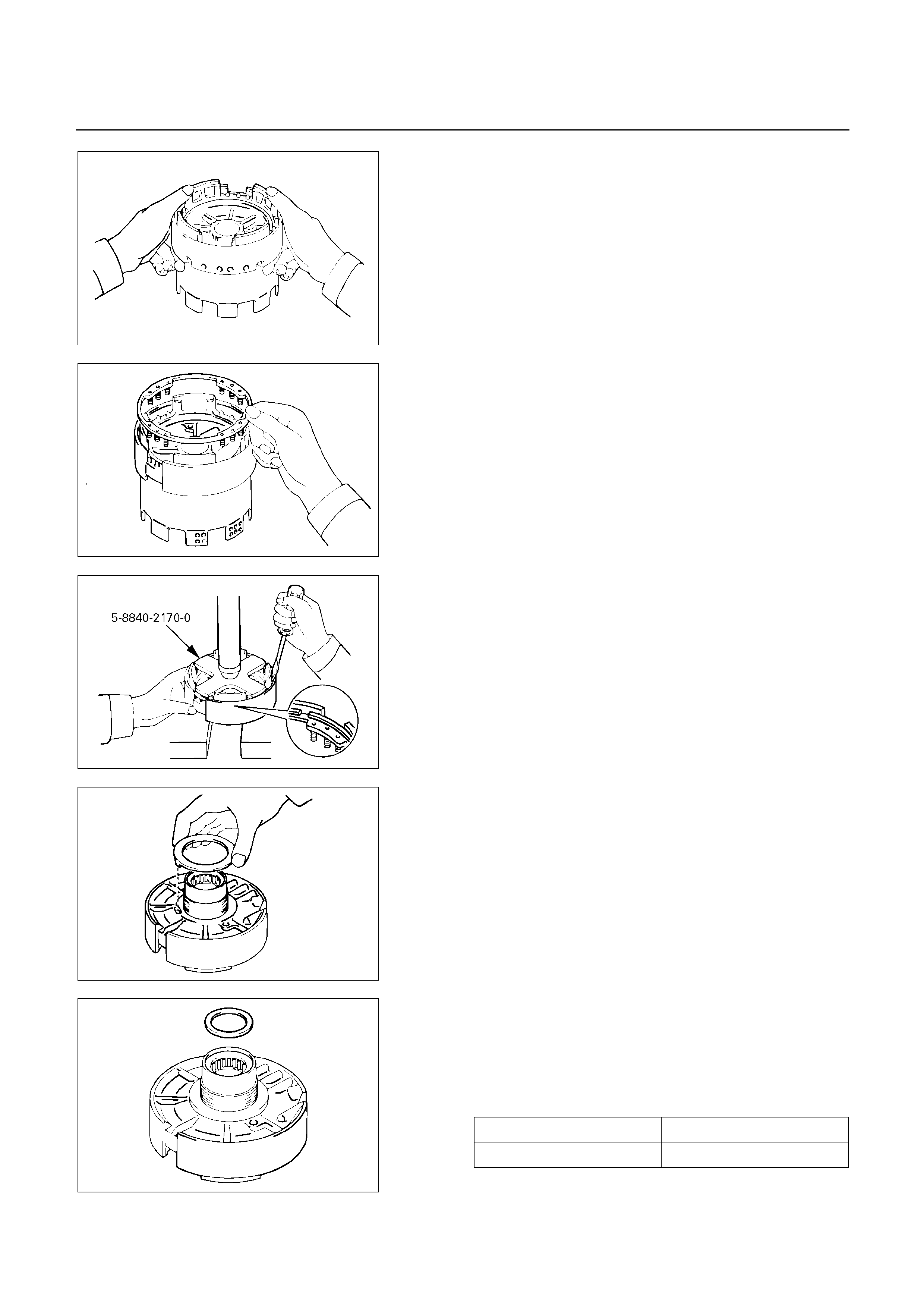

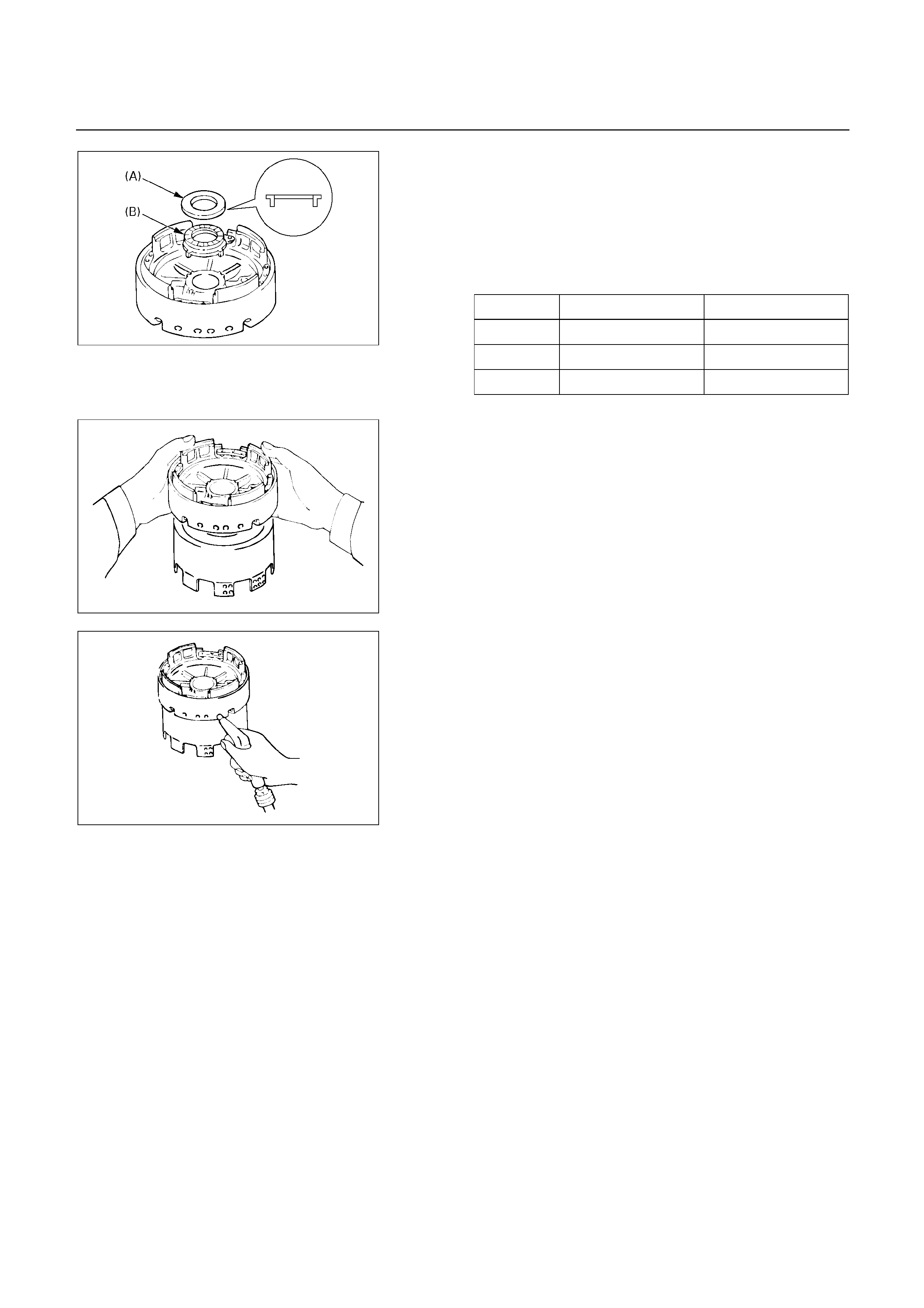

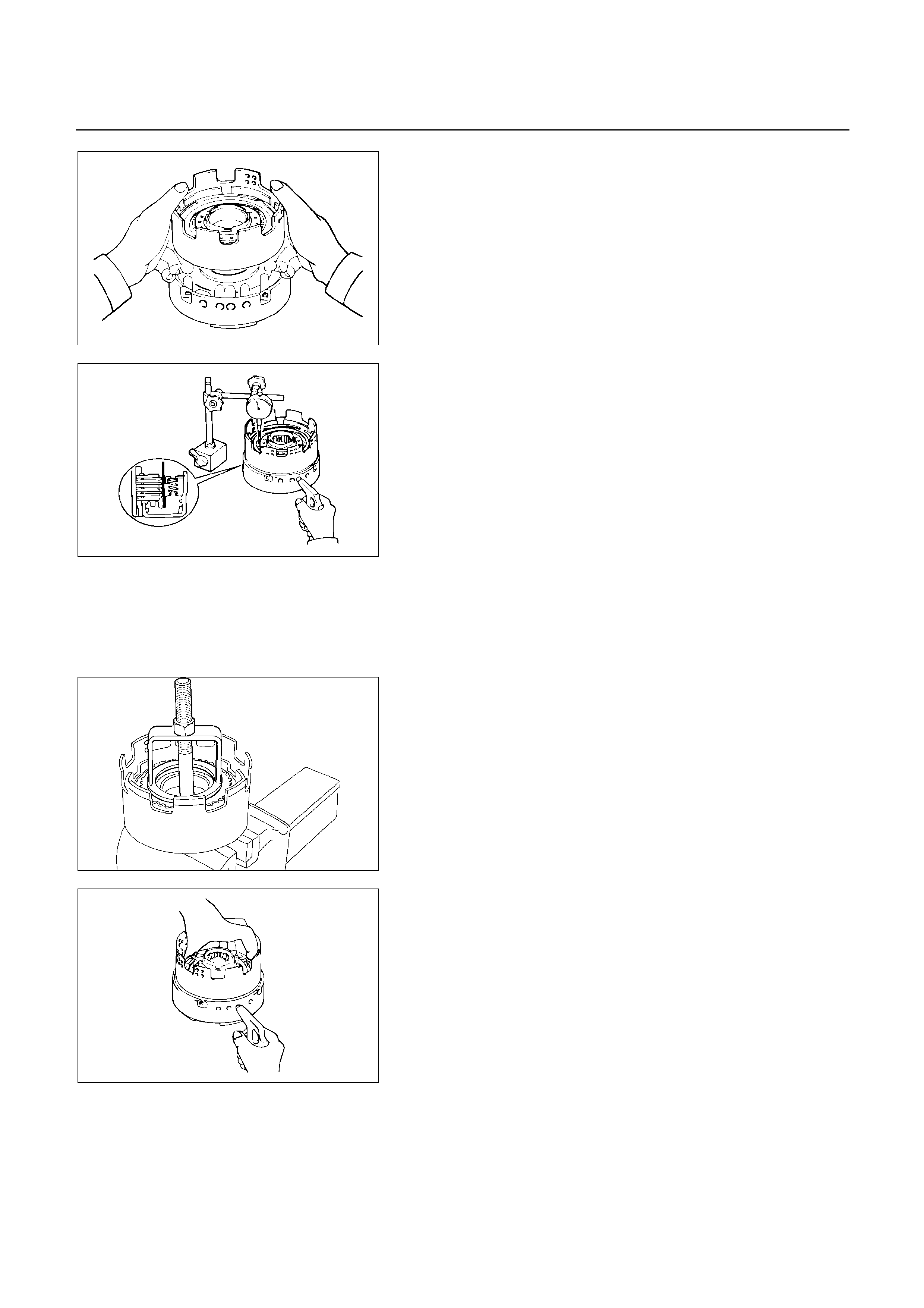

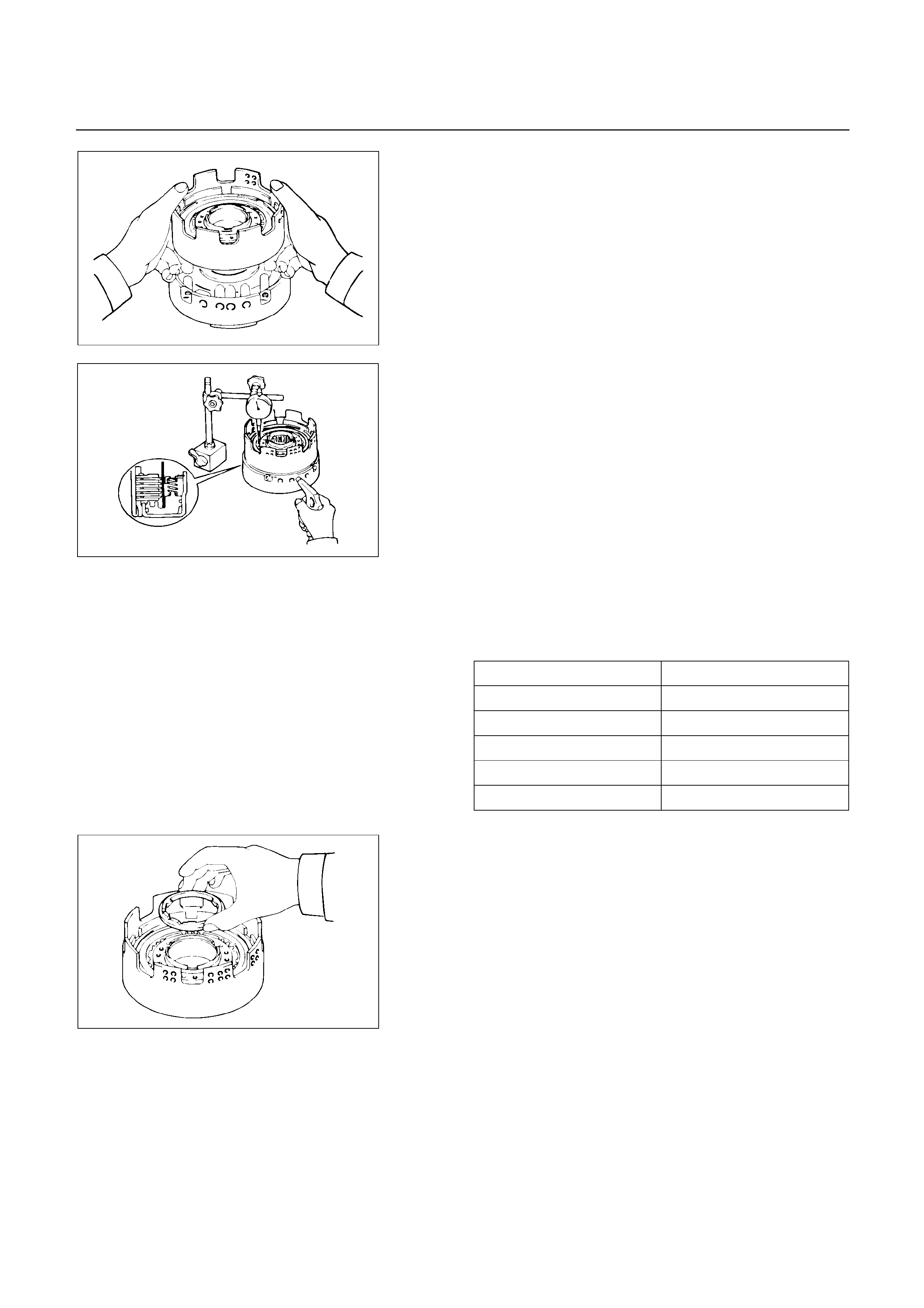

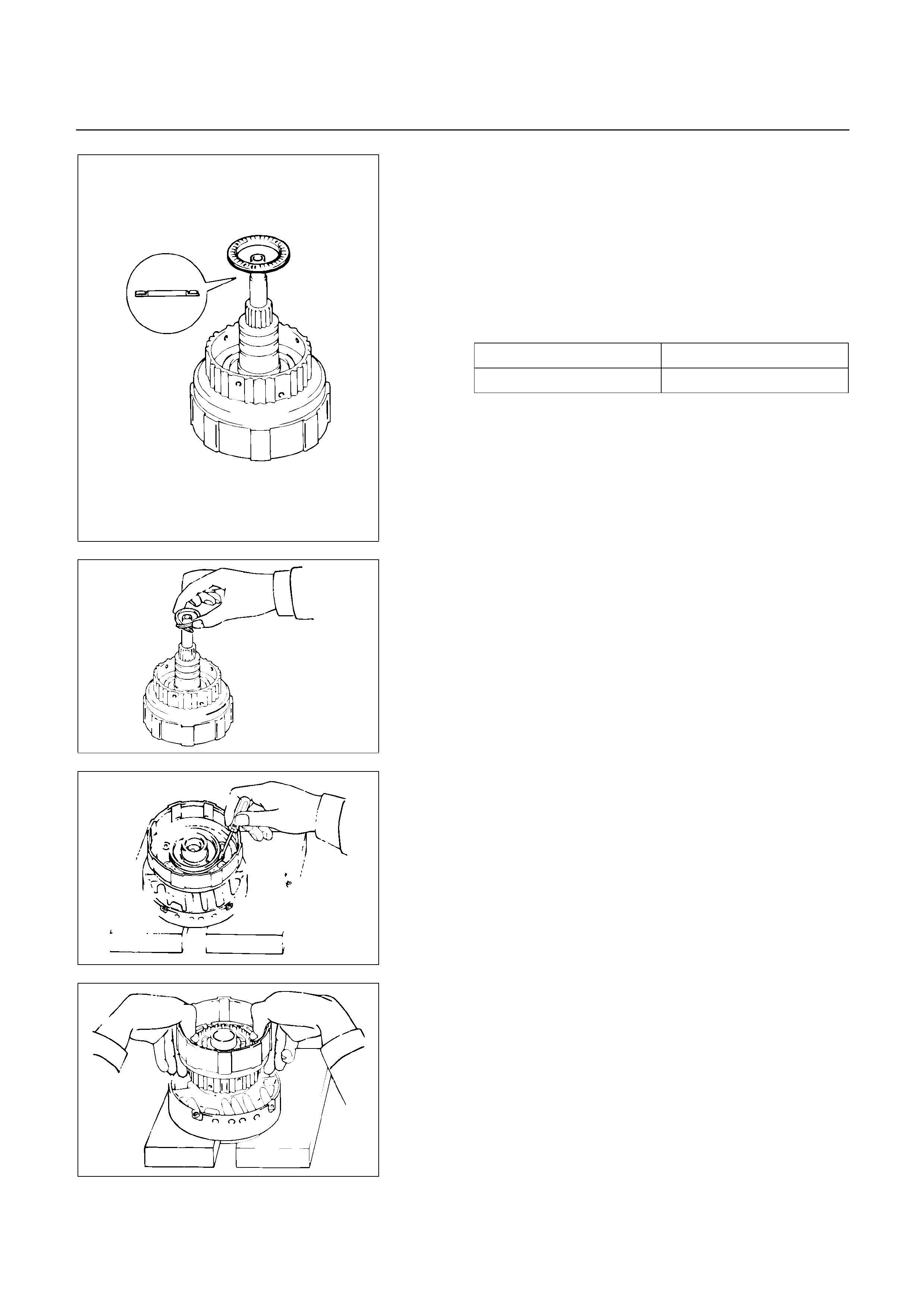

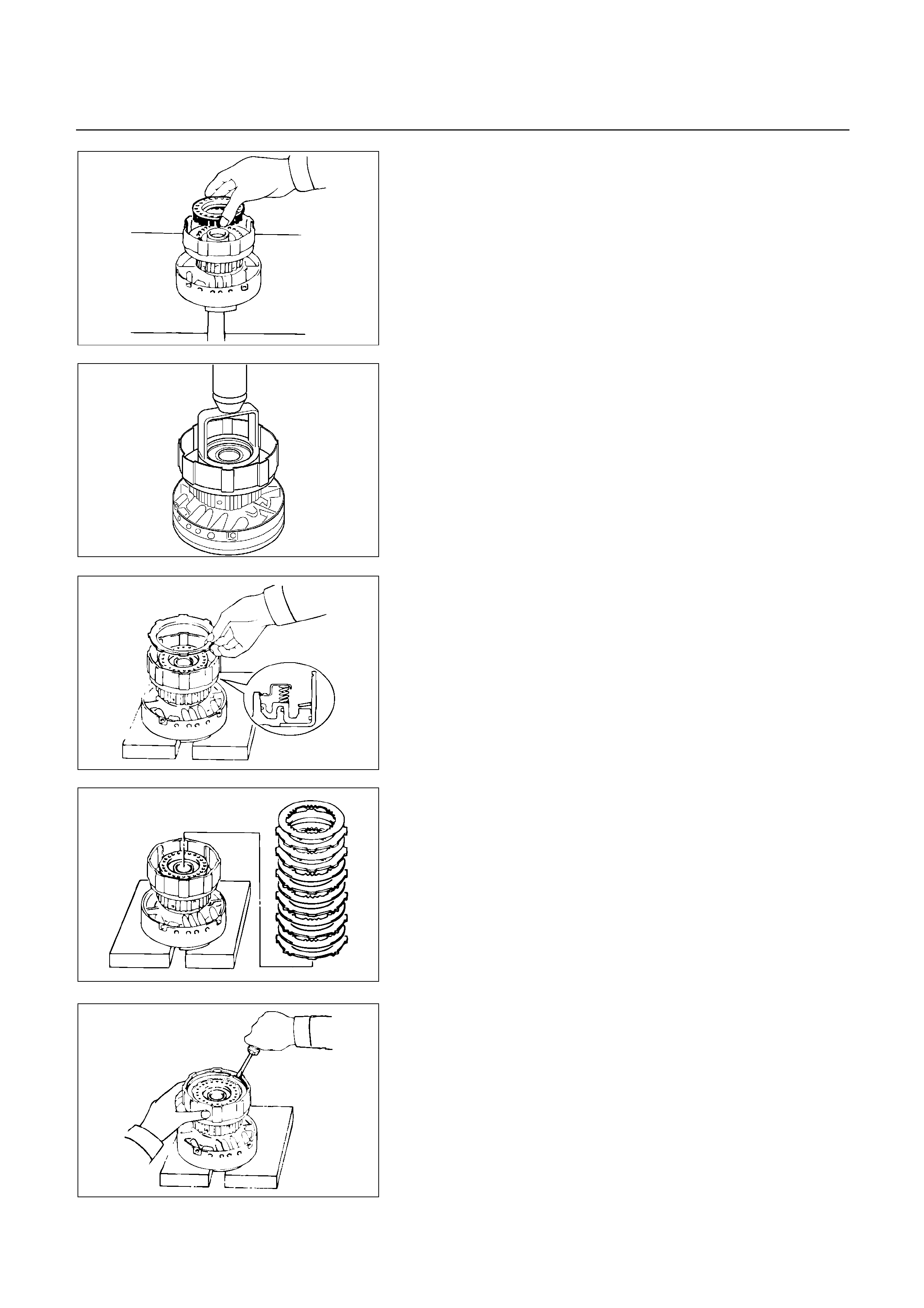

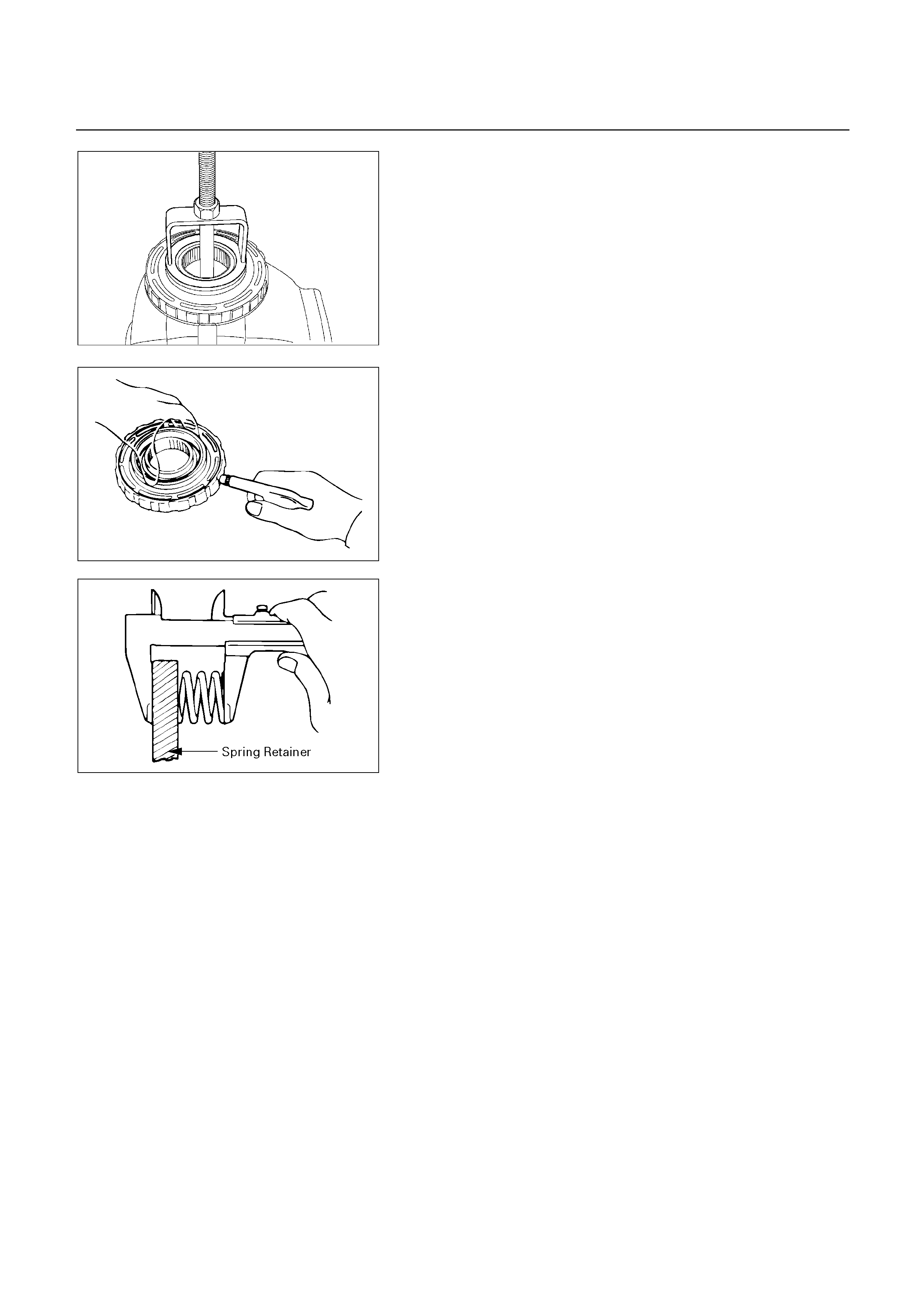

Disassembly of Major Components (1)

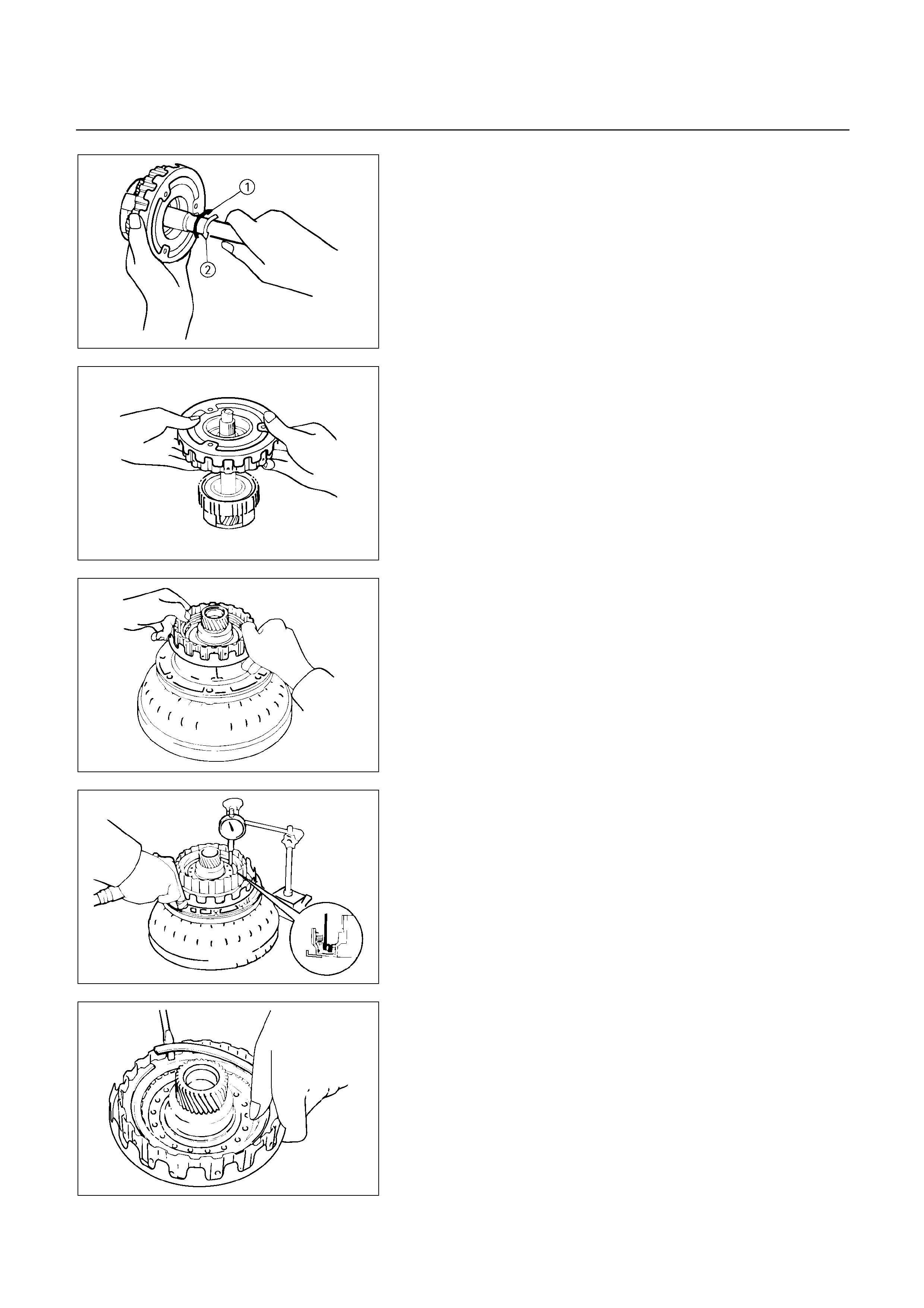

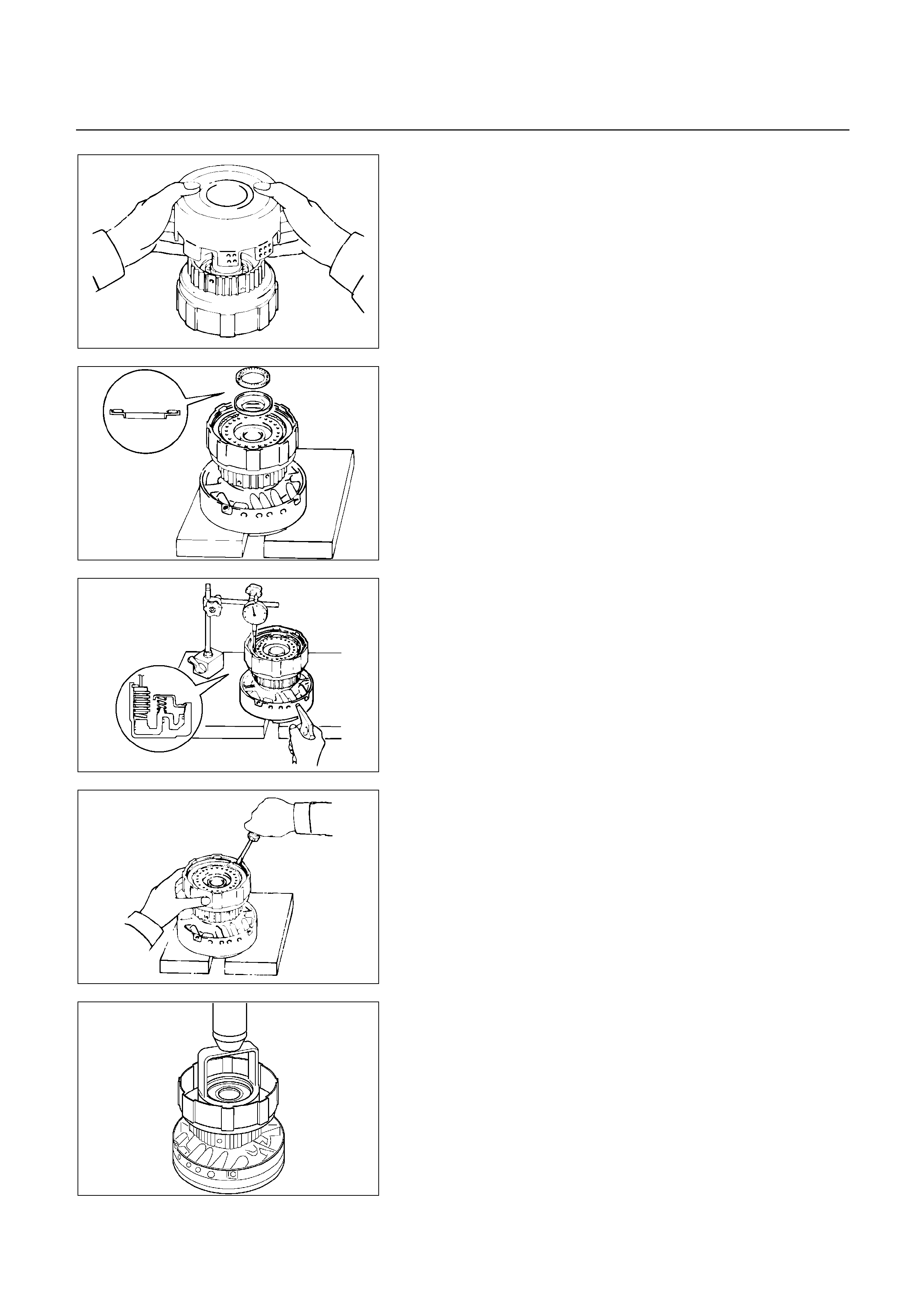

Reassembly of Major Components (1)

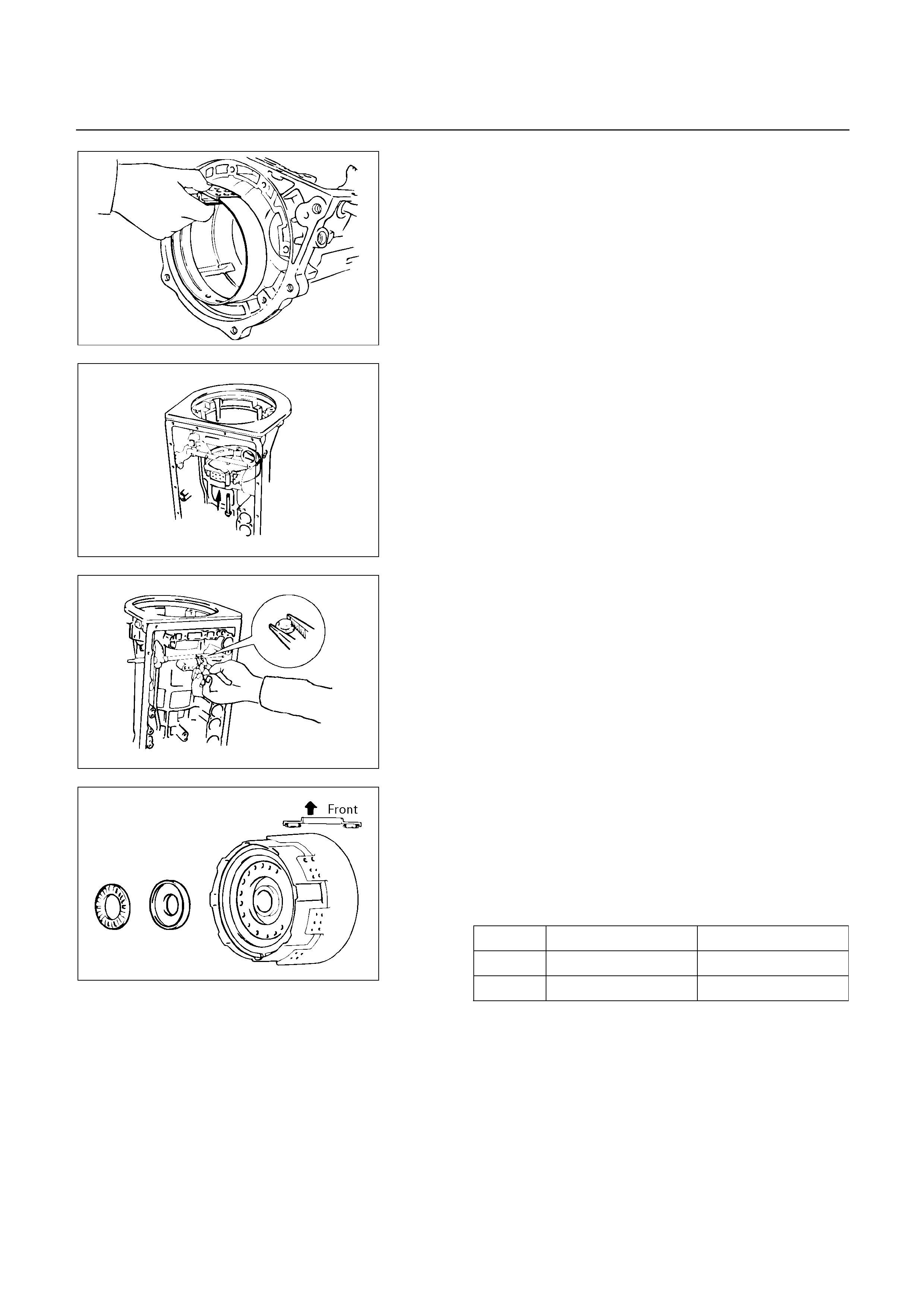

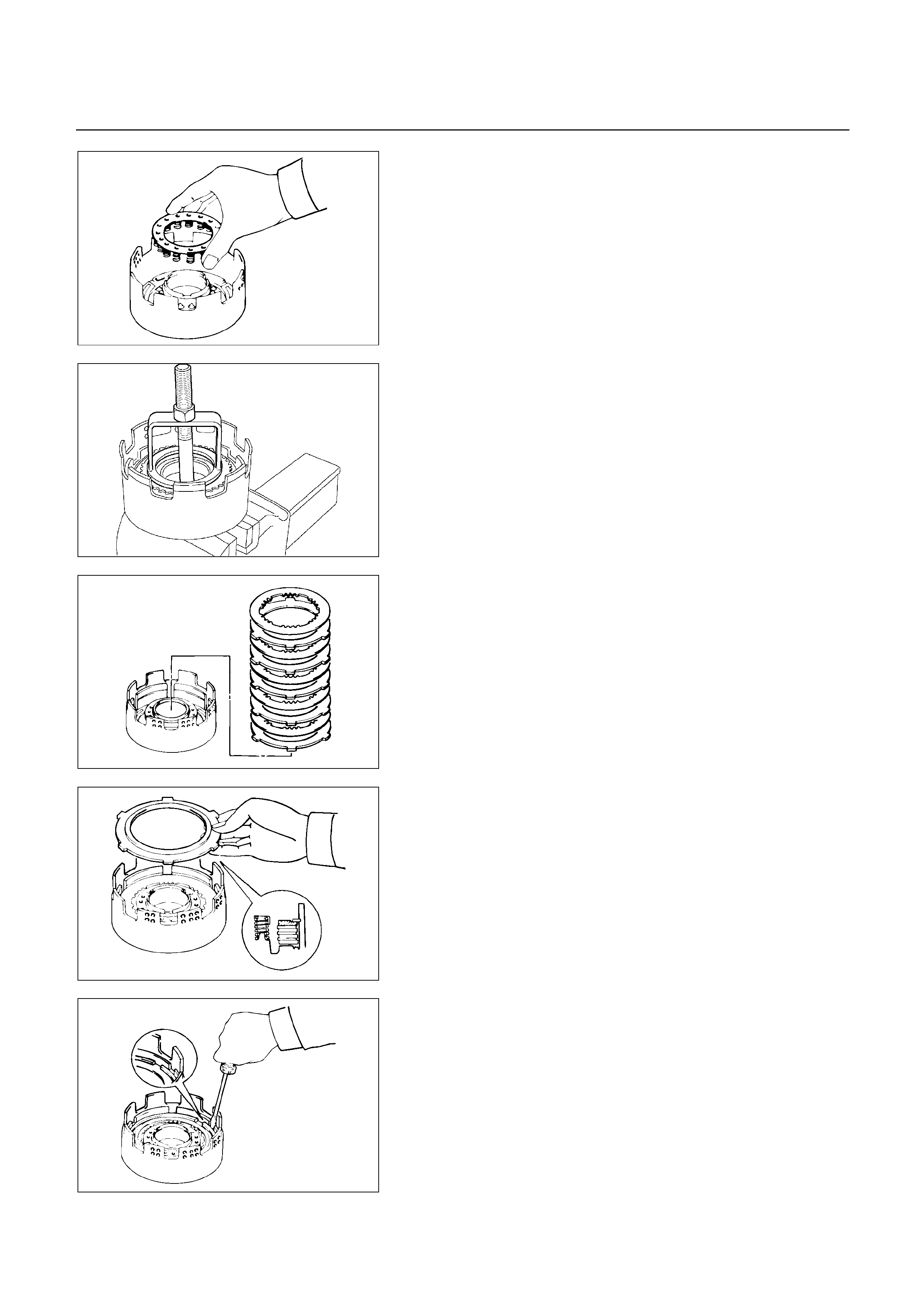

Disassembly of Major Components (2)

Reassembly of Major Components (2)

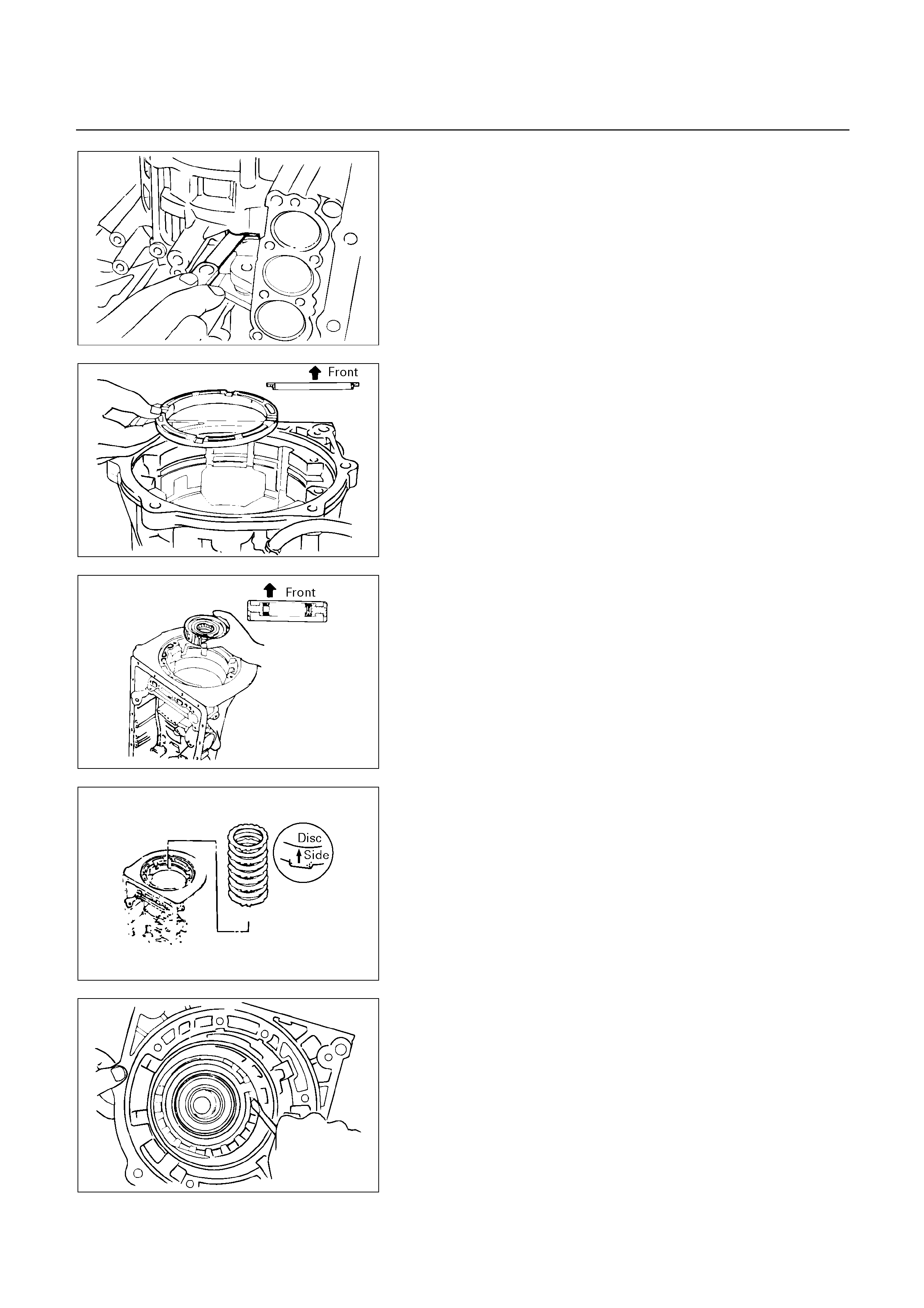

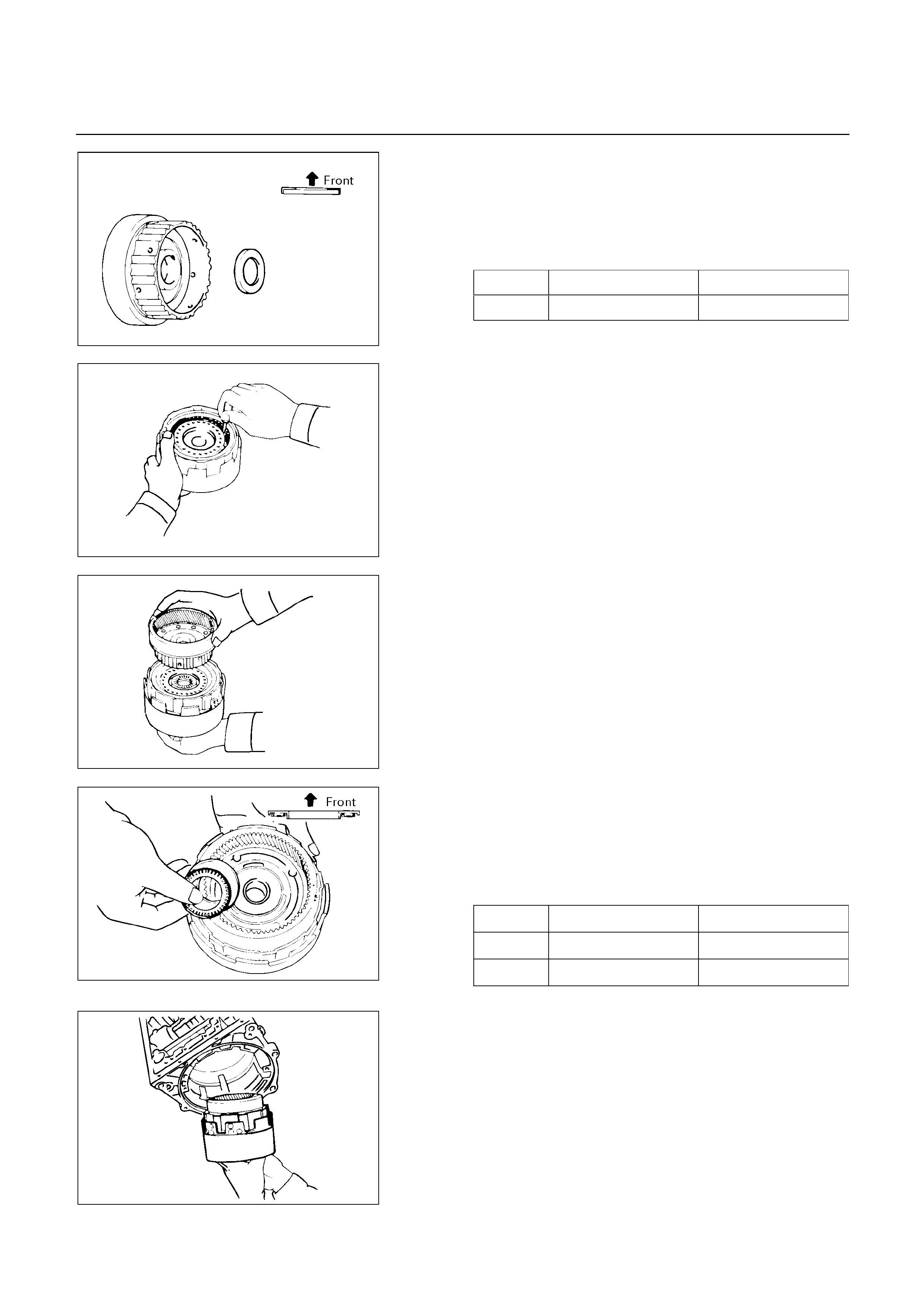

Disassembly of Major Components (3)

Reassembly of Major Components (3)

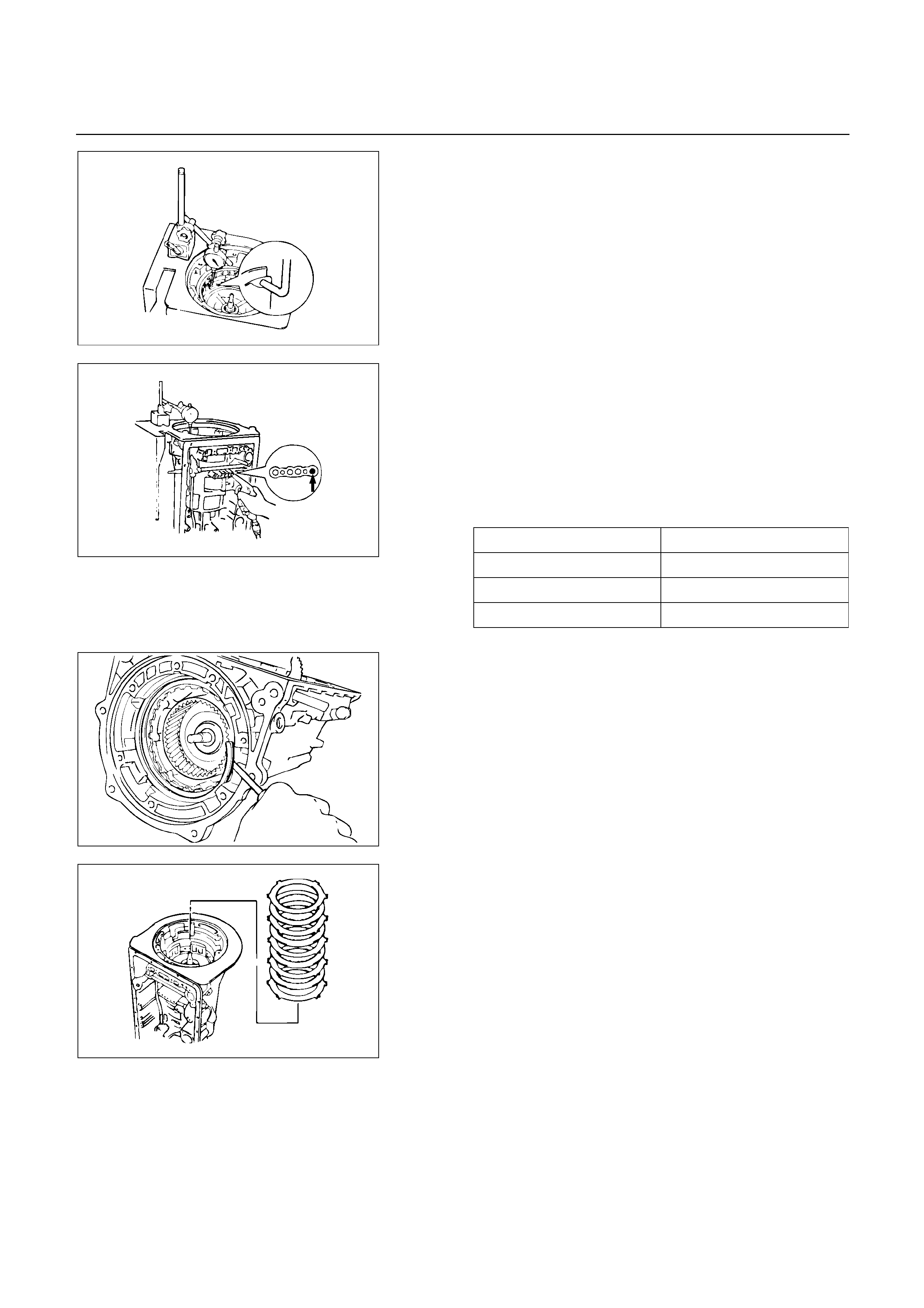

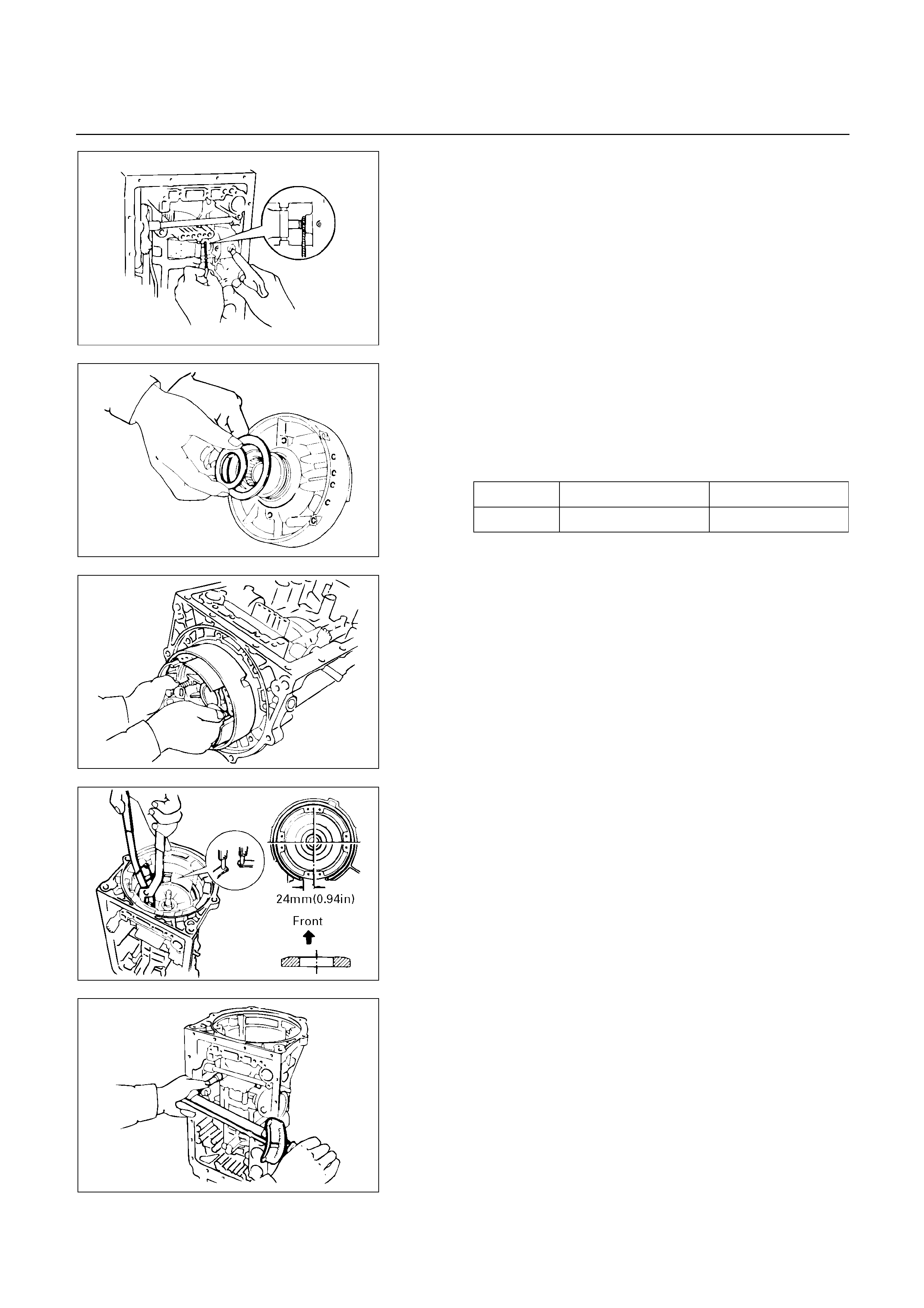

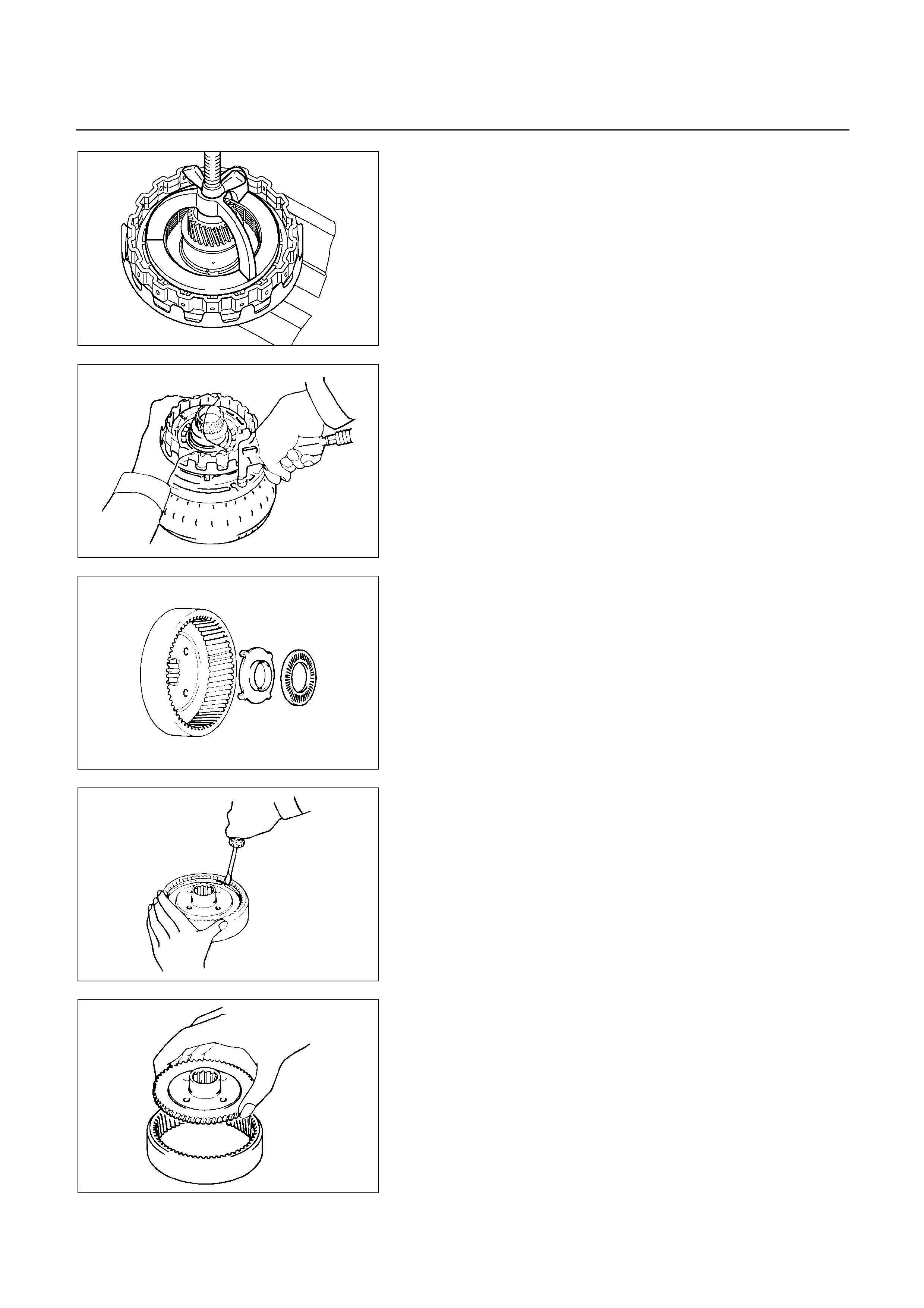

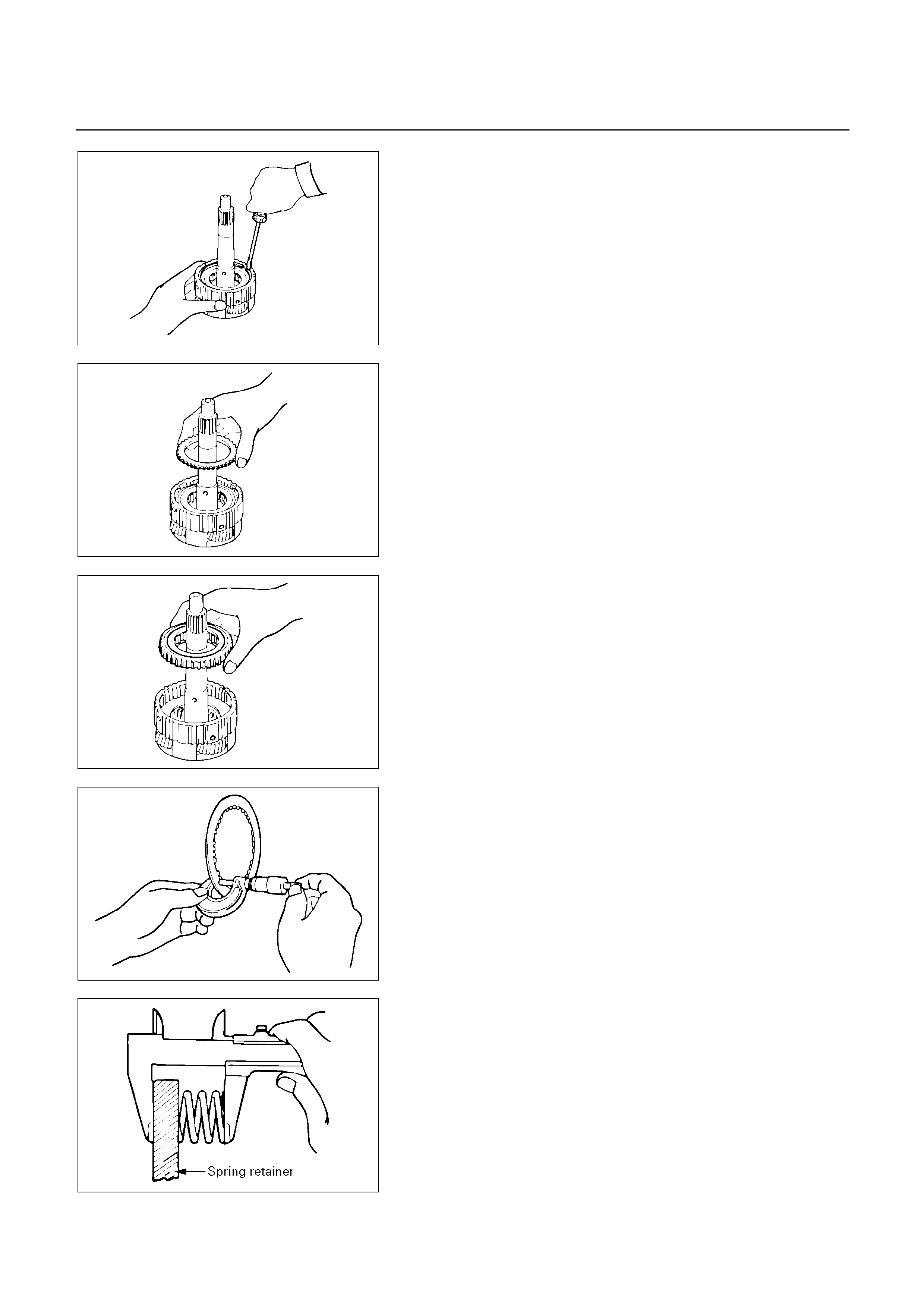

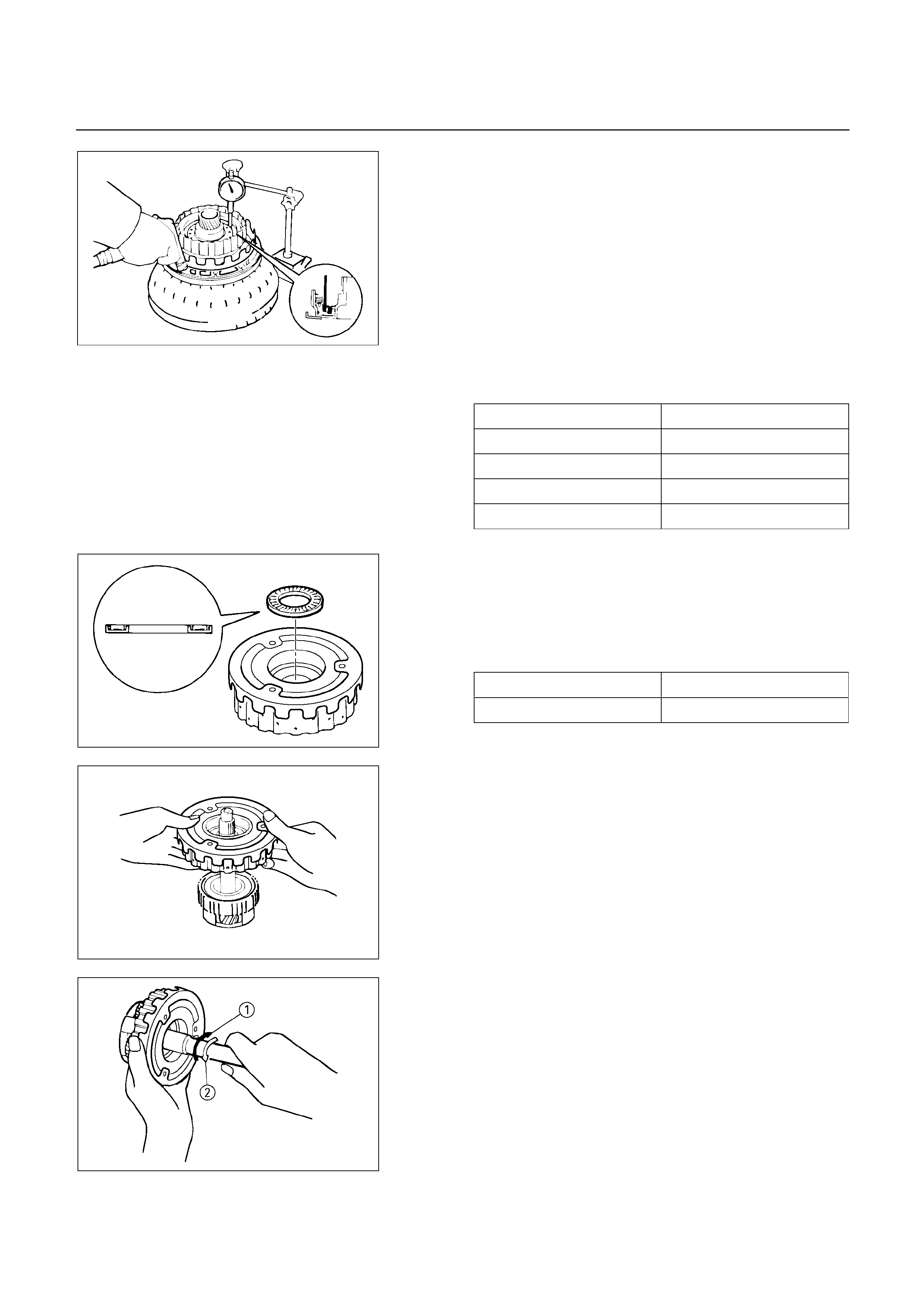

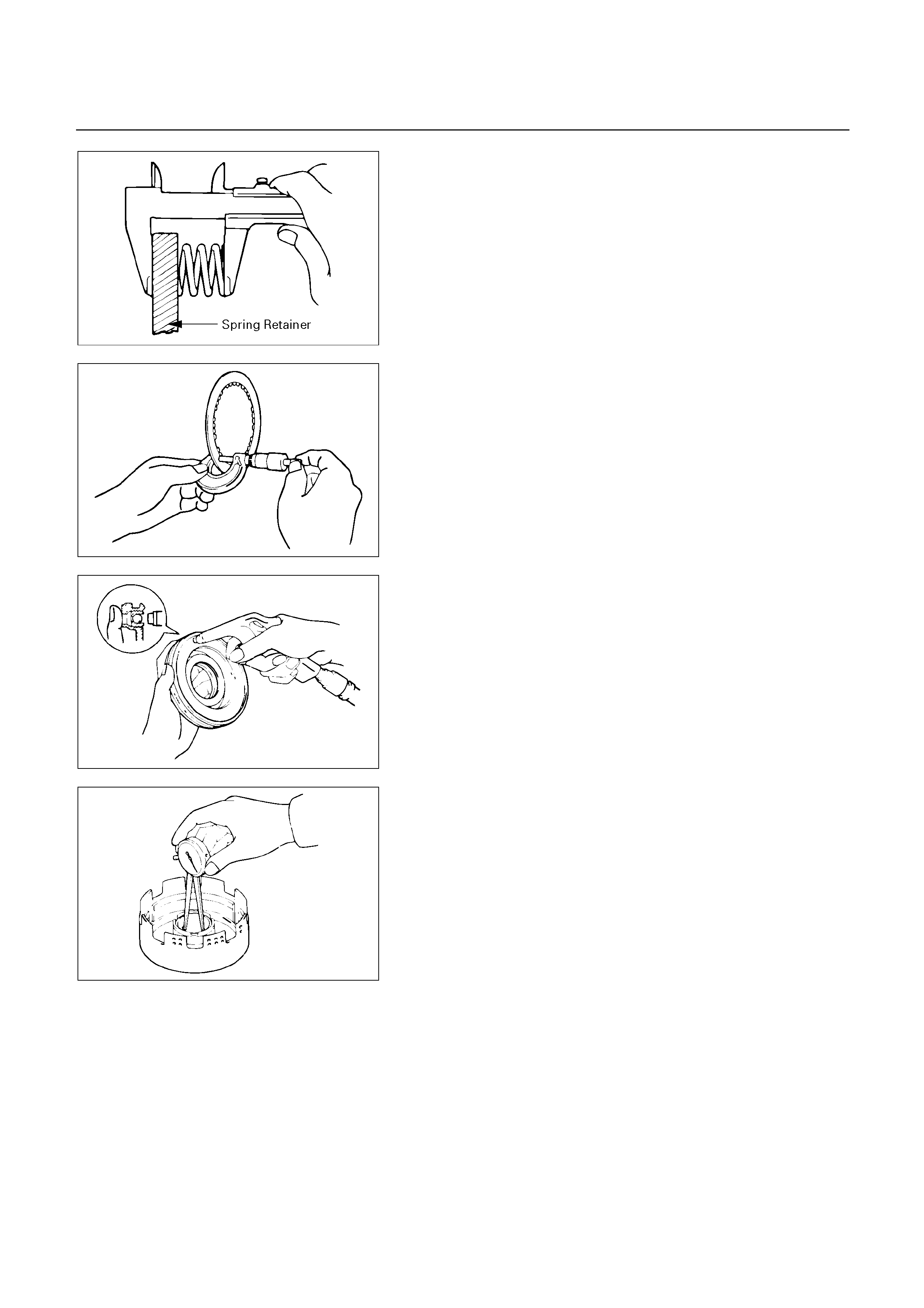

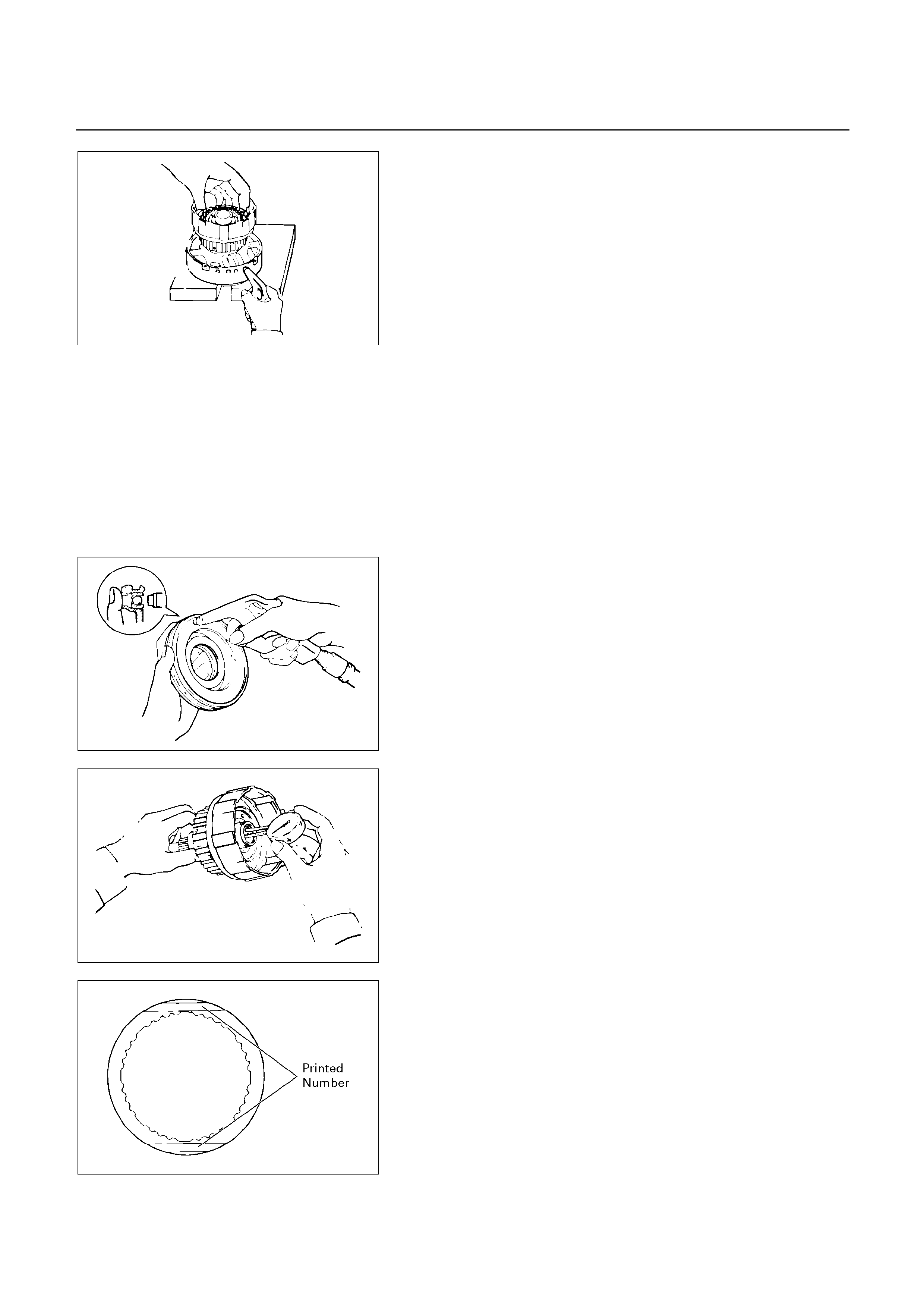

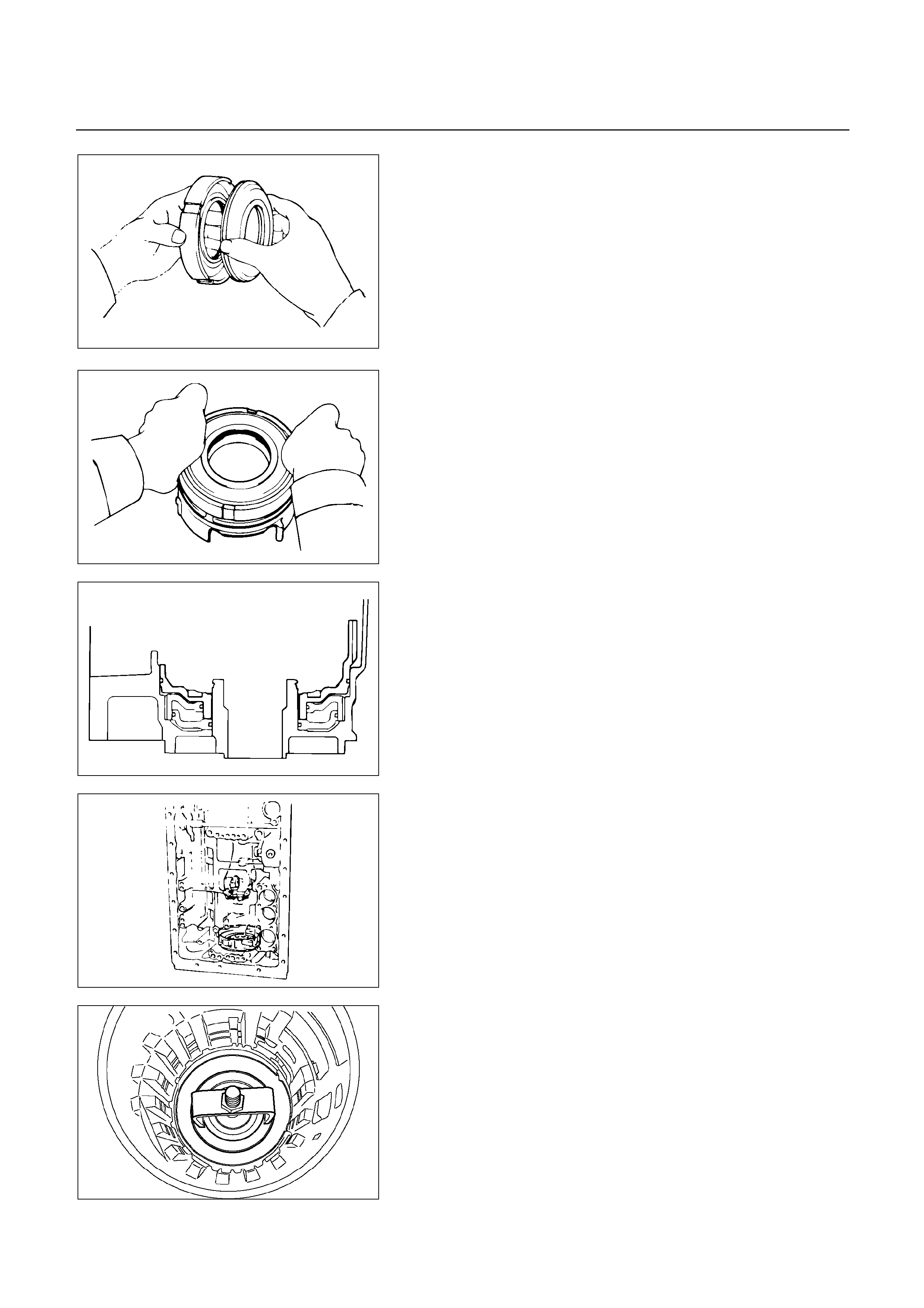

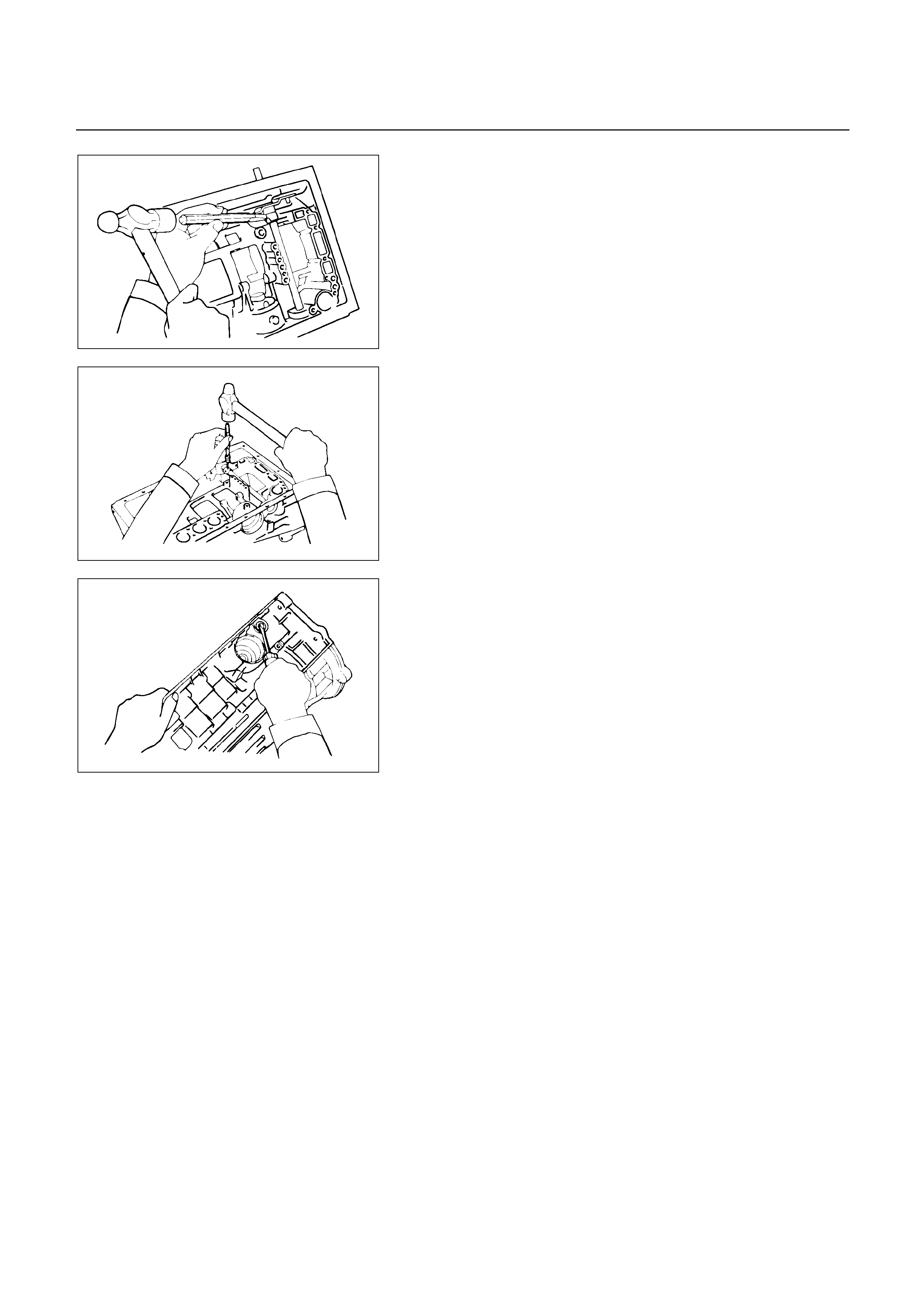

Disassembly, Inspection and Reassembly of Minor Components

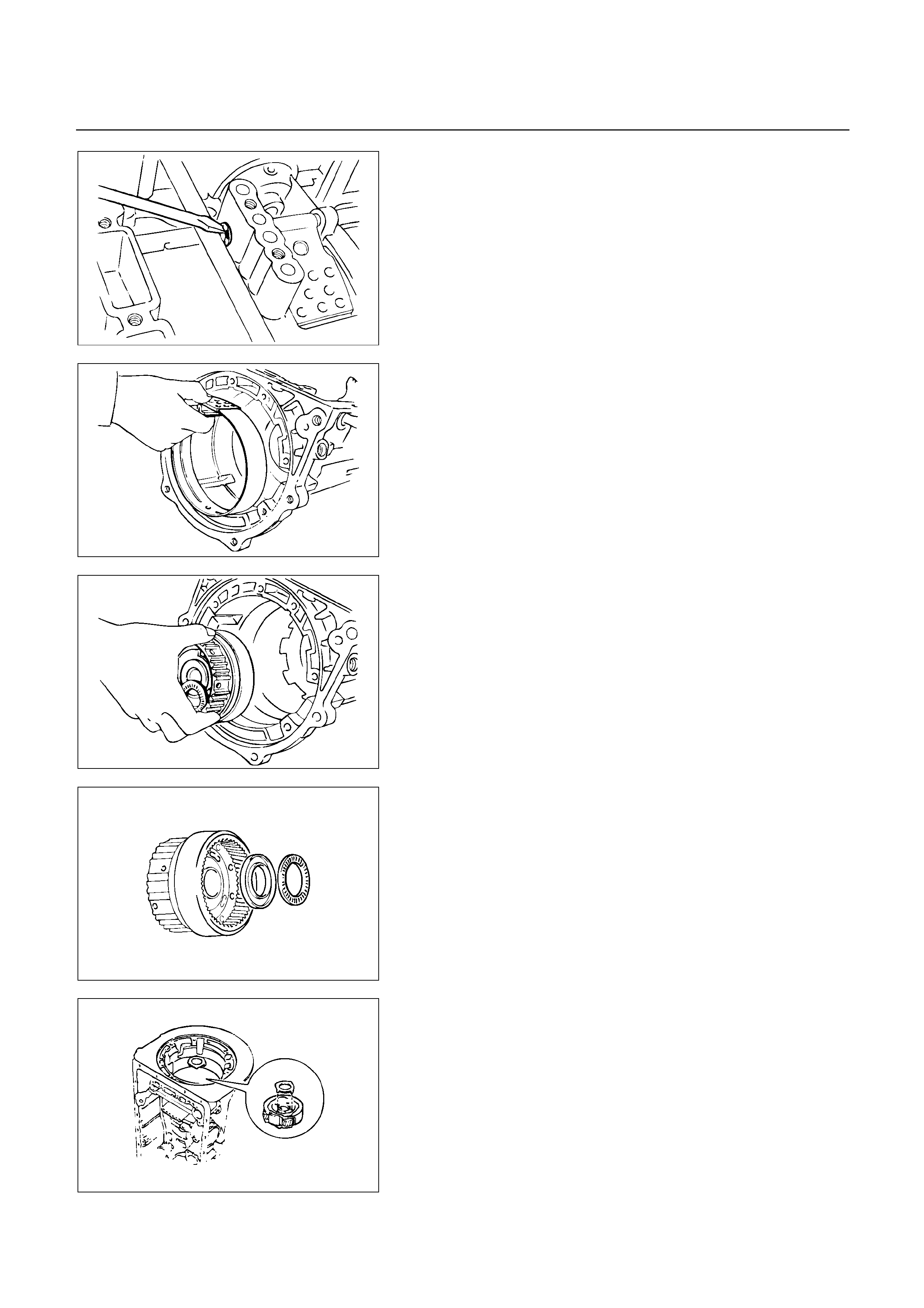

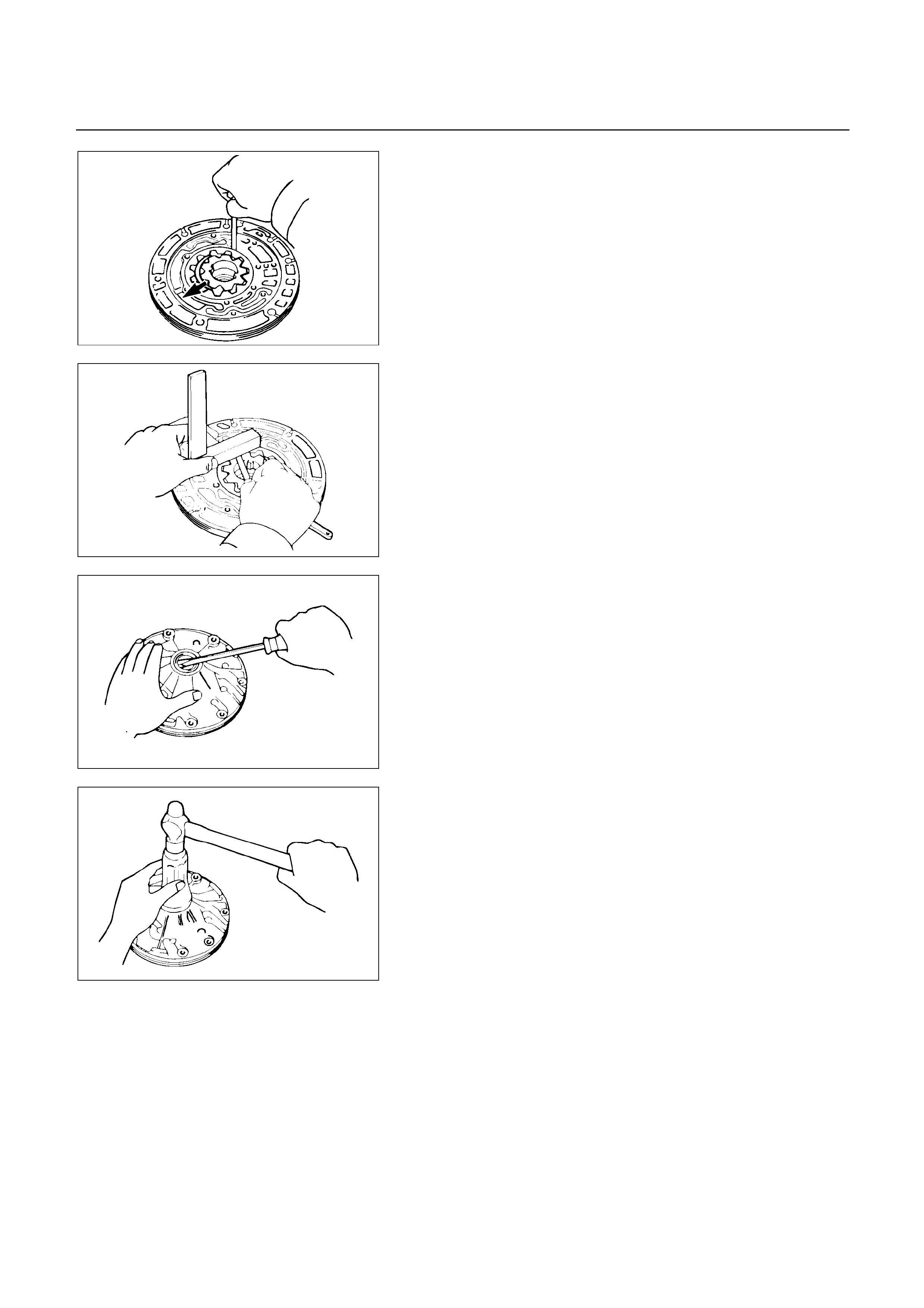

Oil Pump

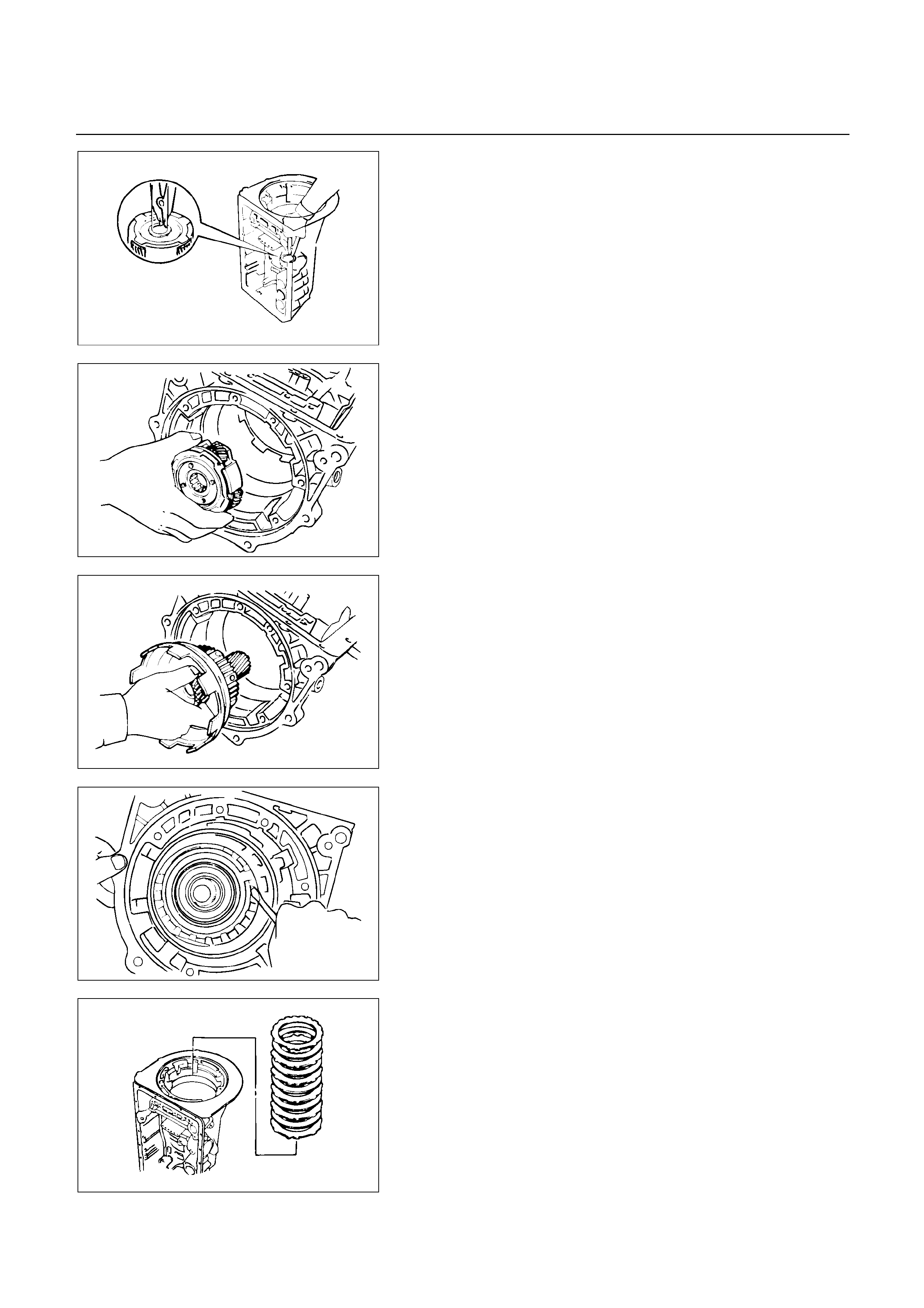

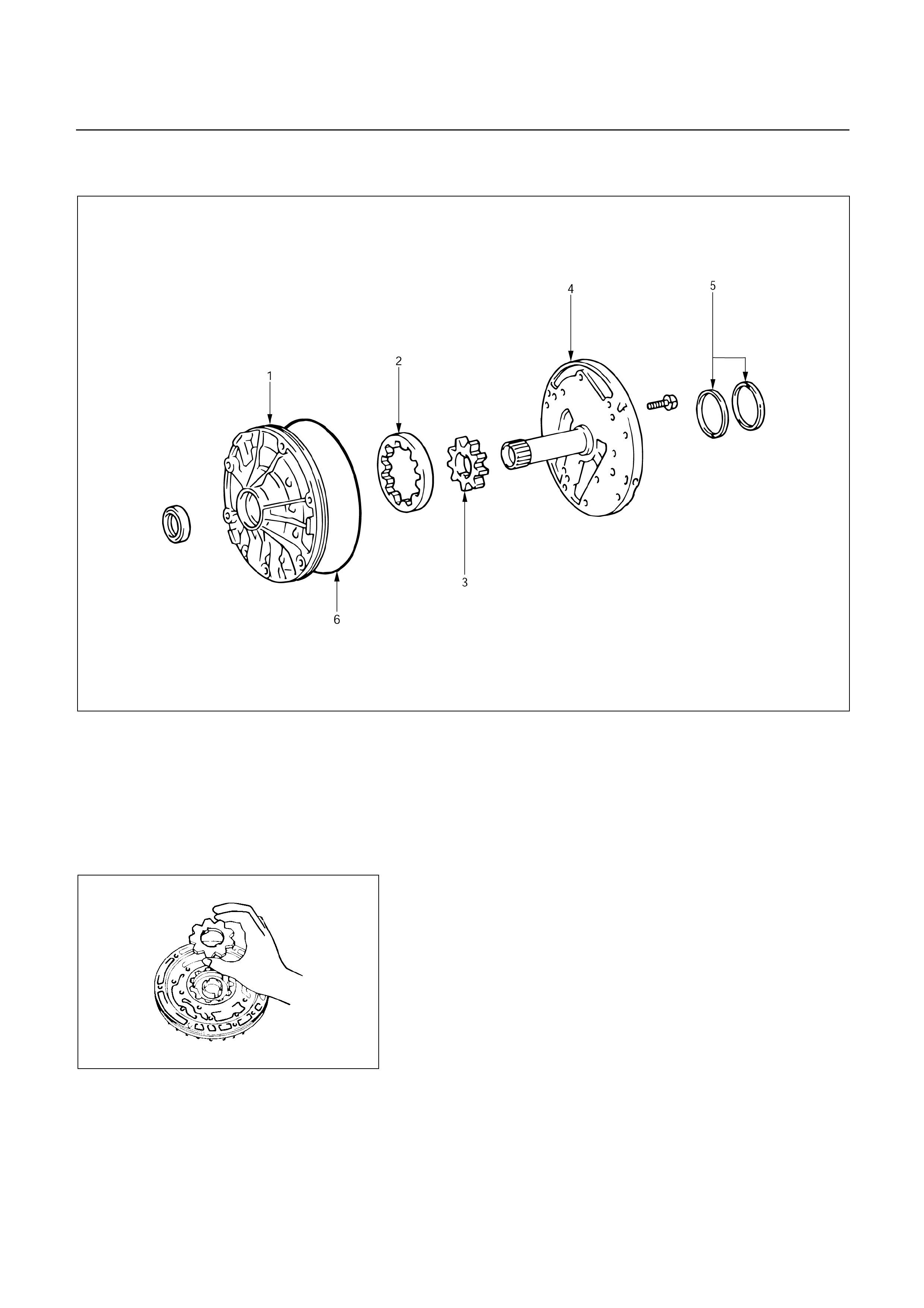

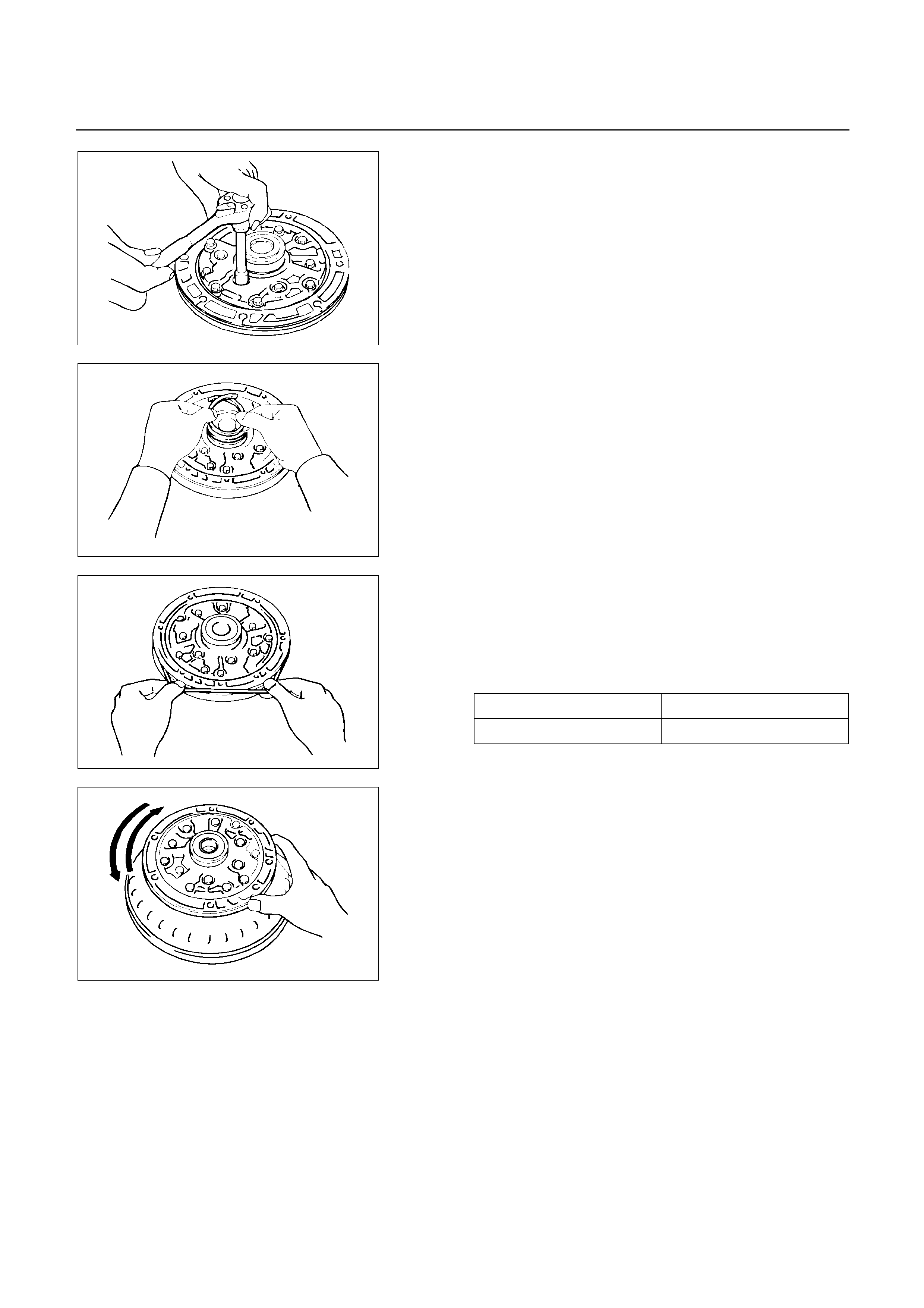

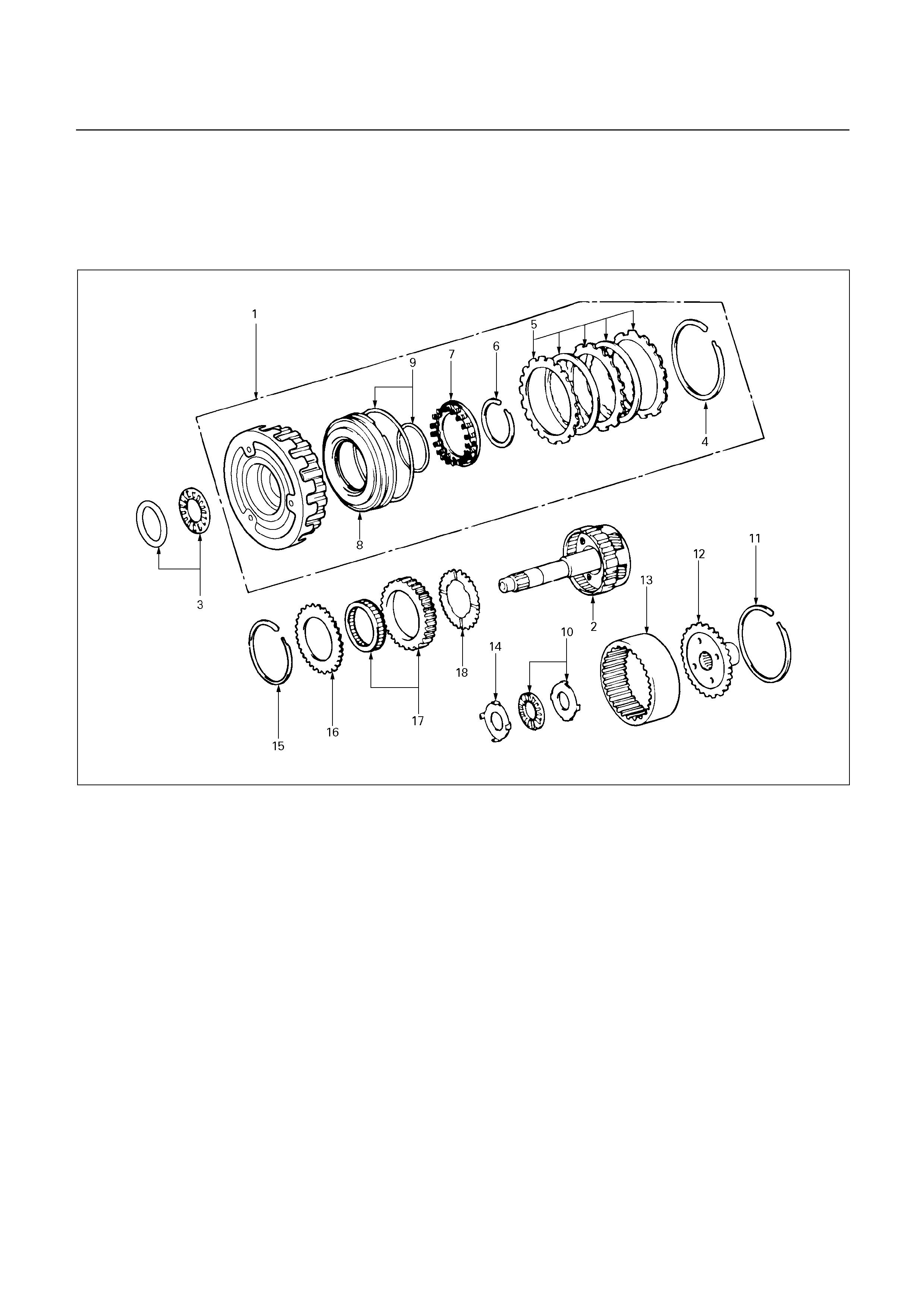

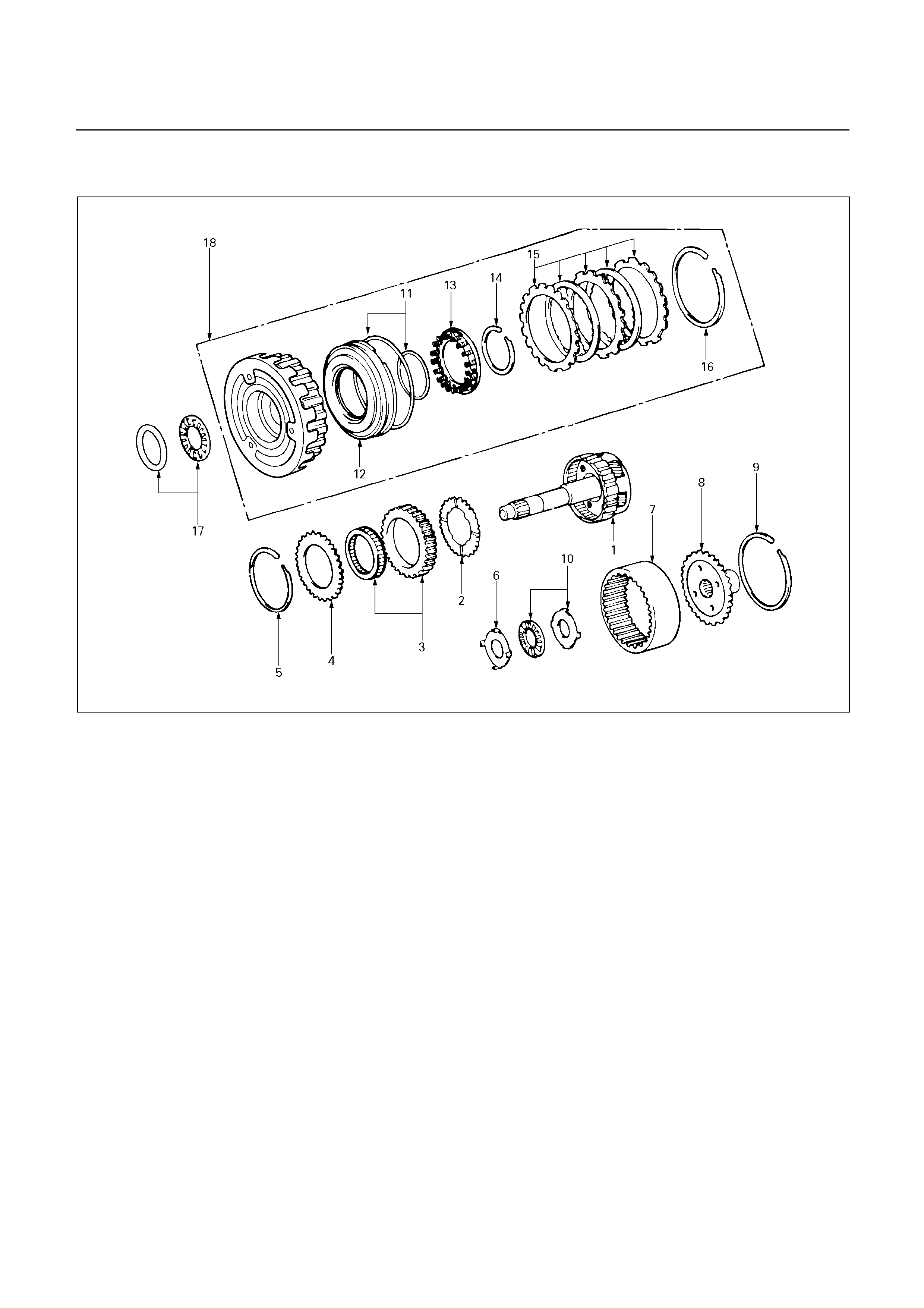

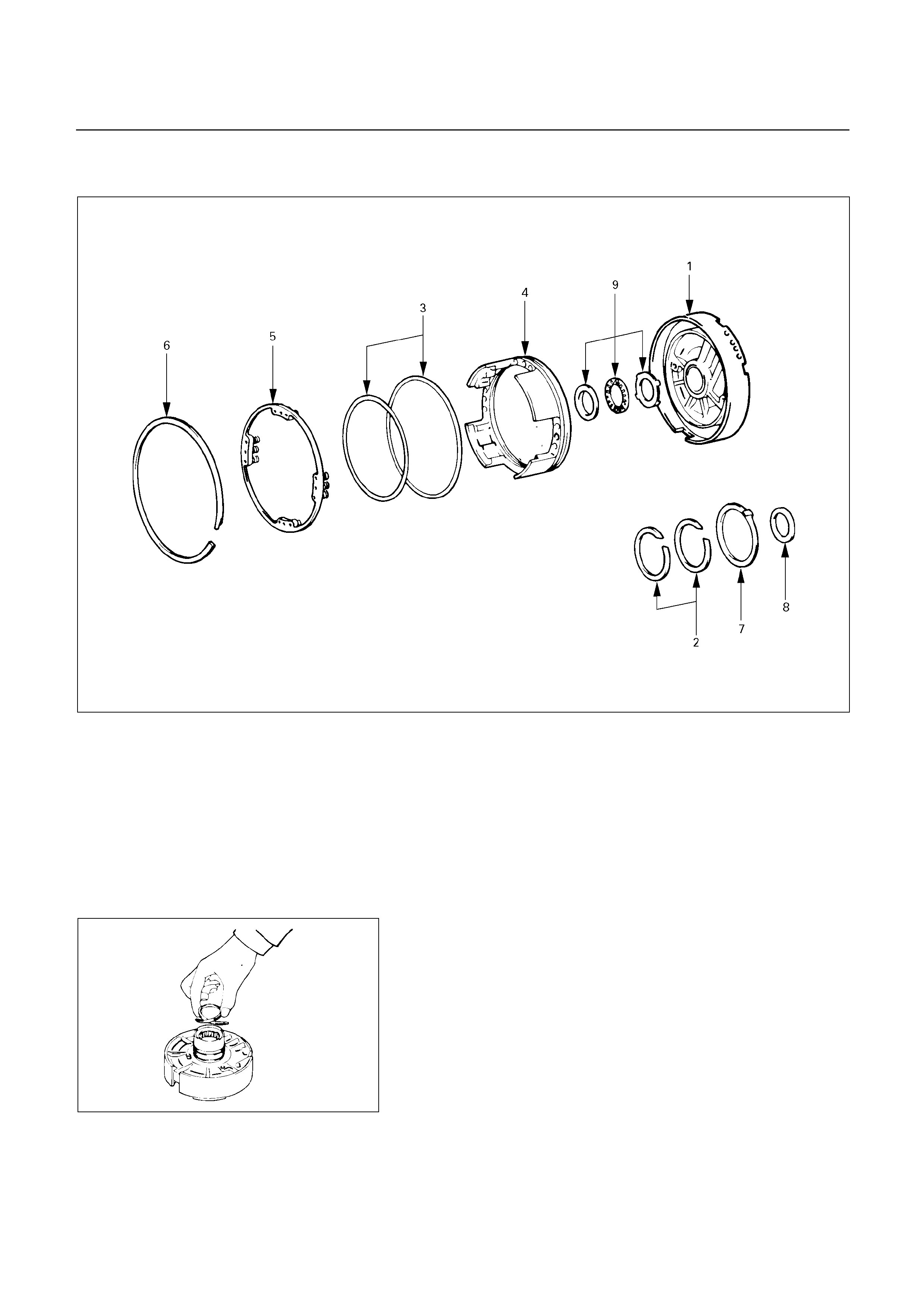

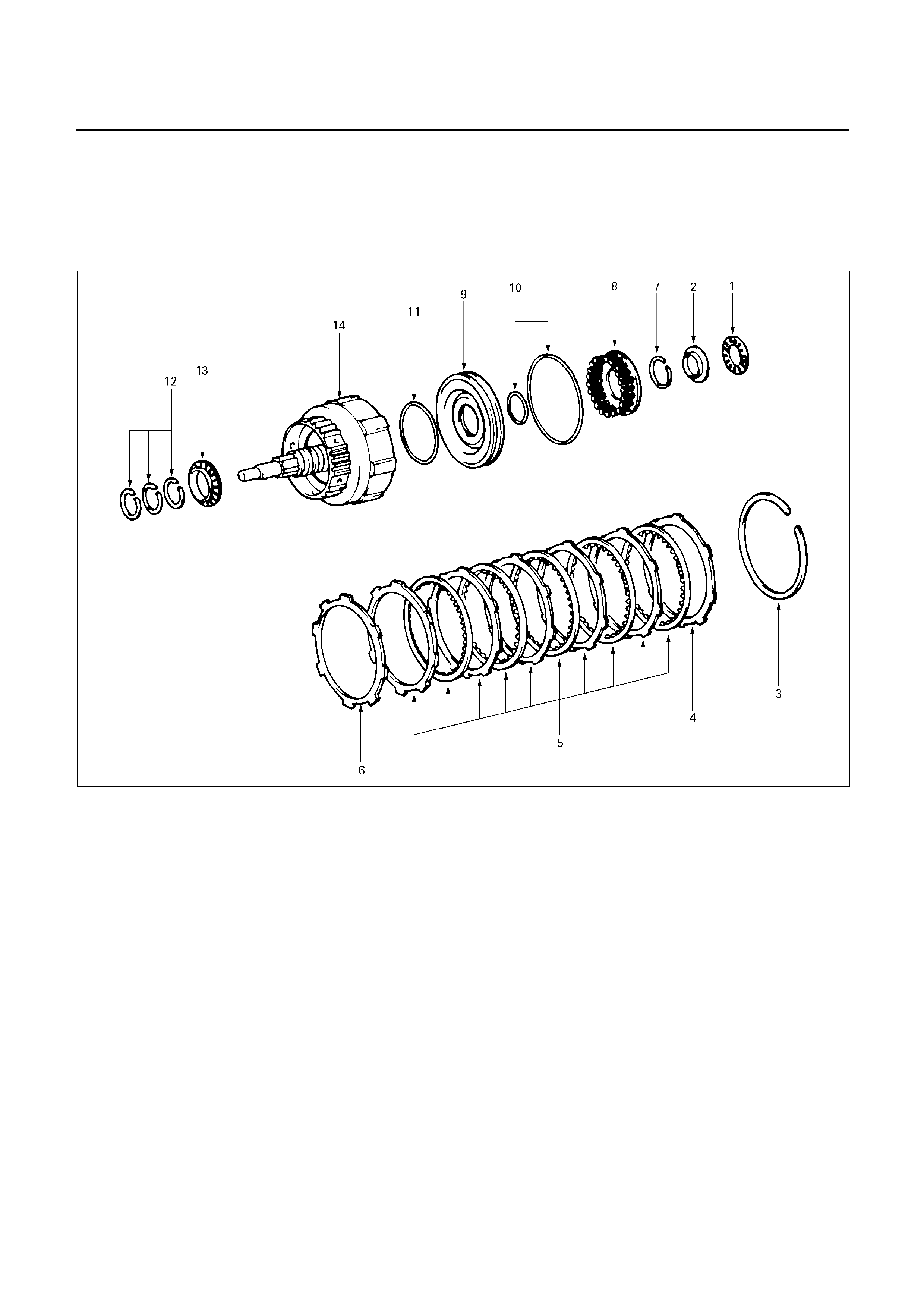

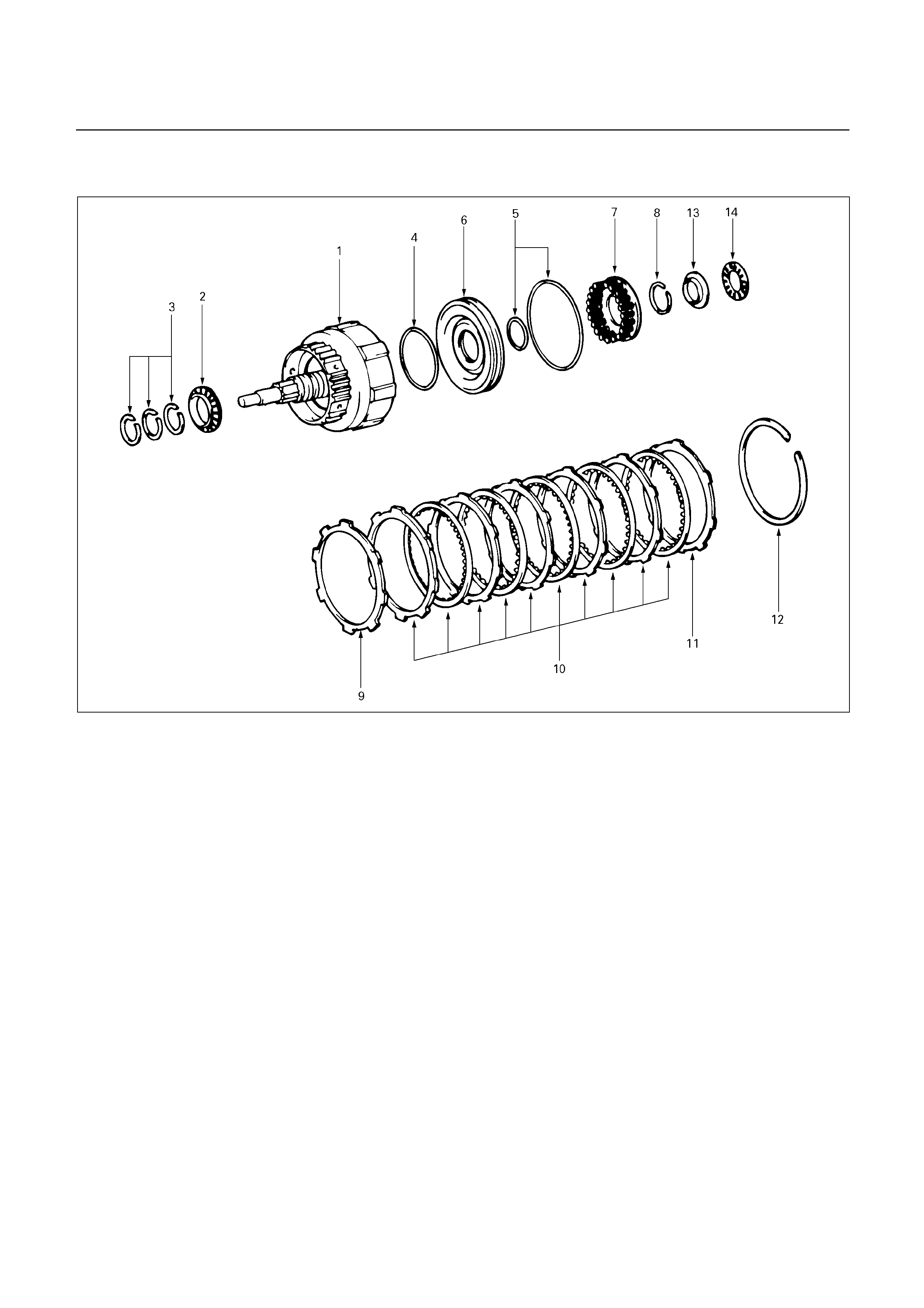

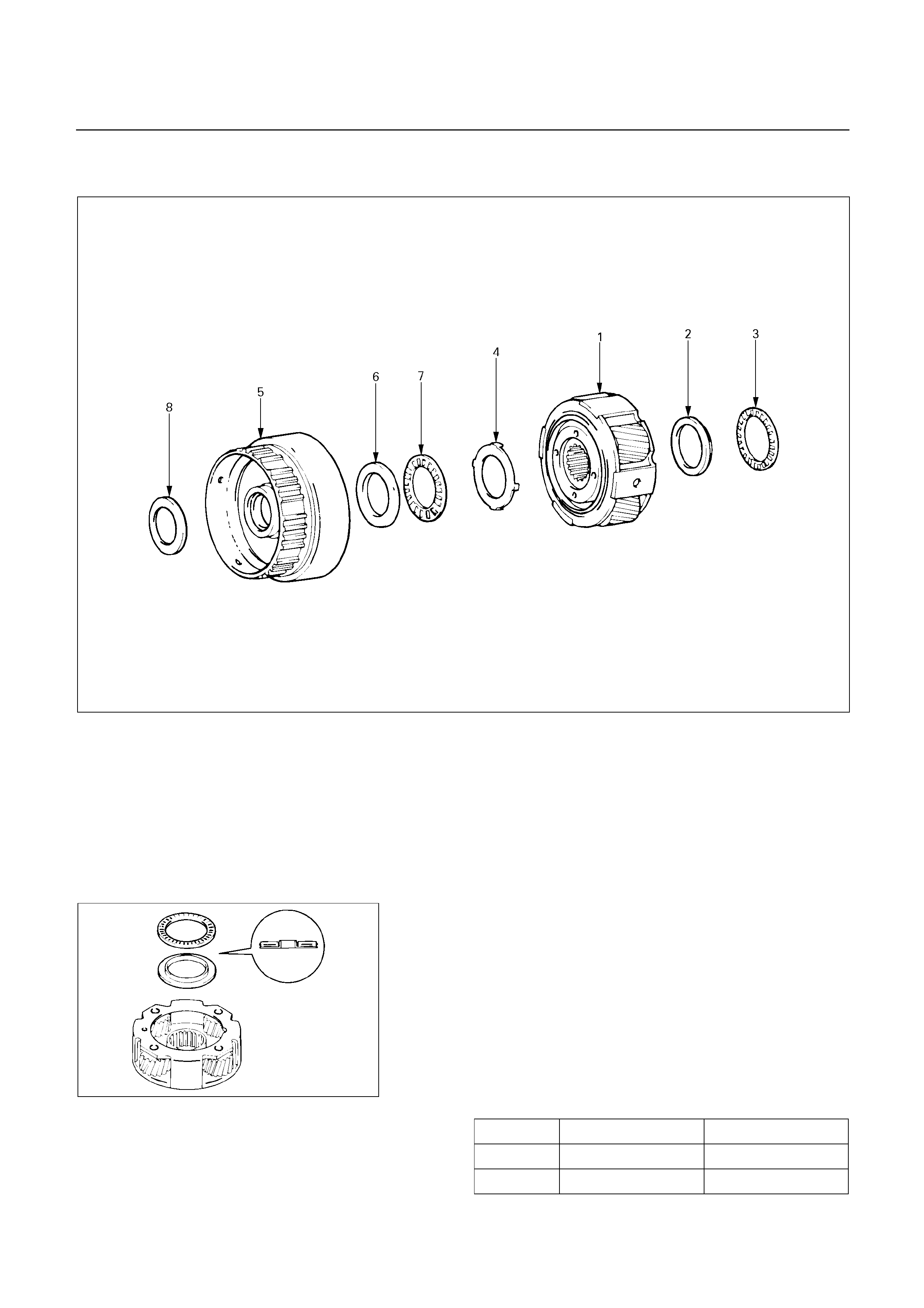

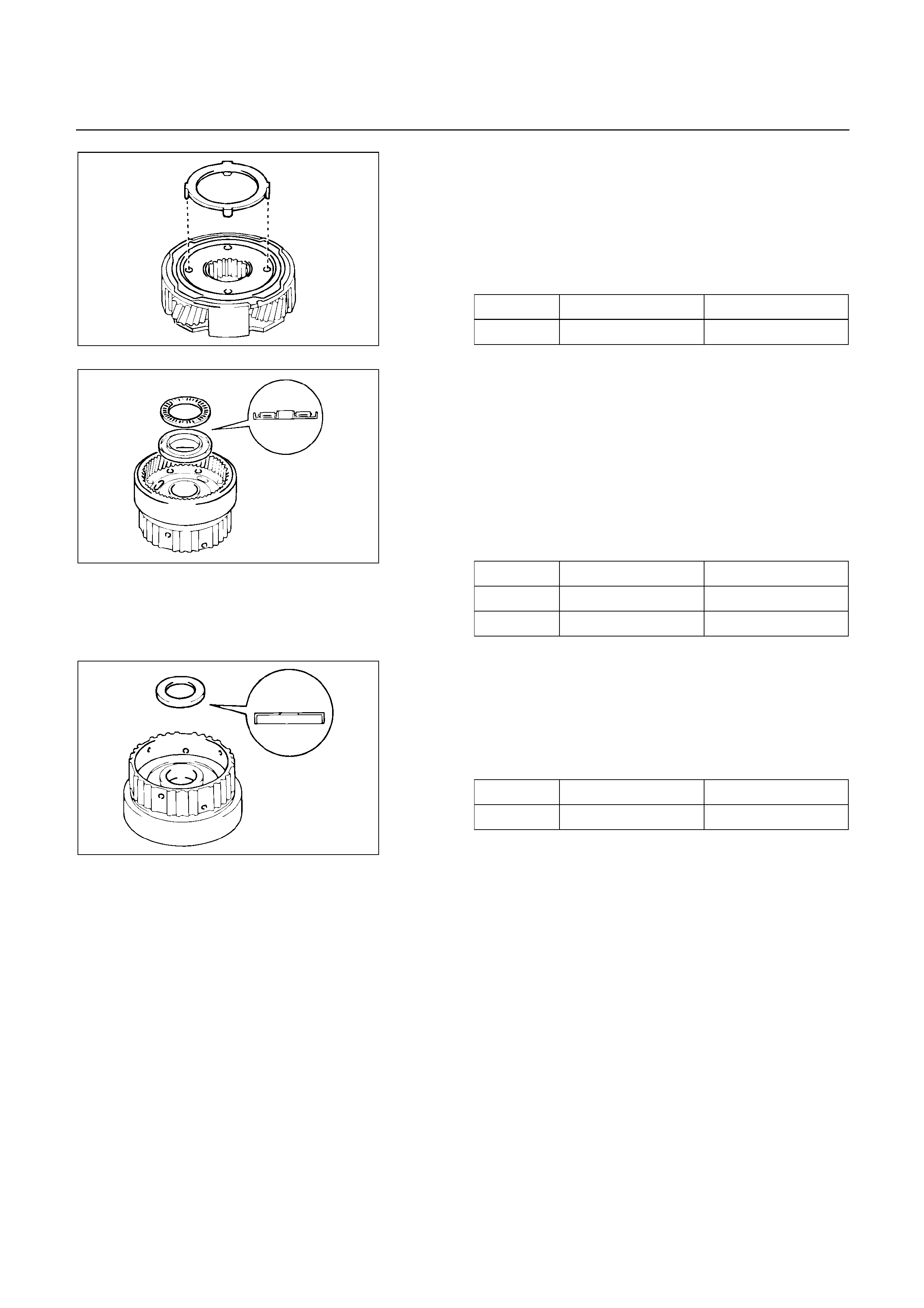

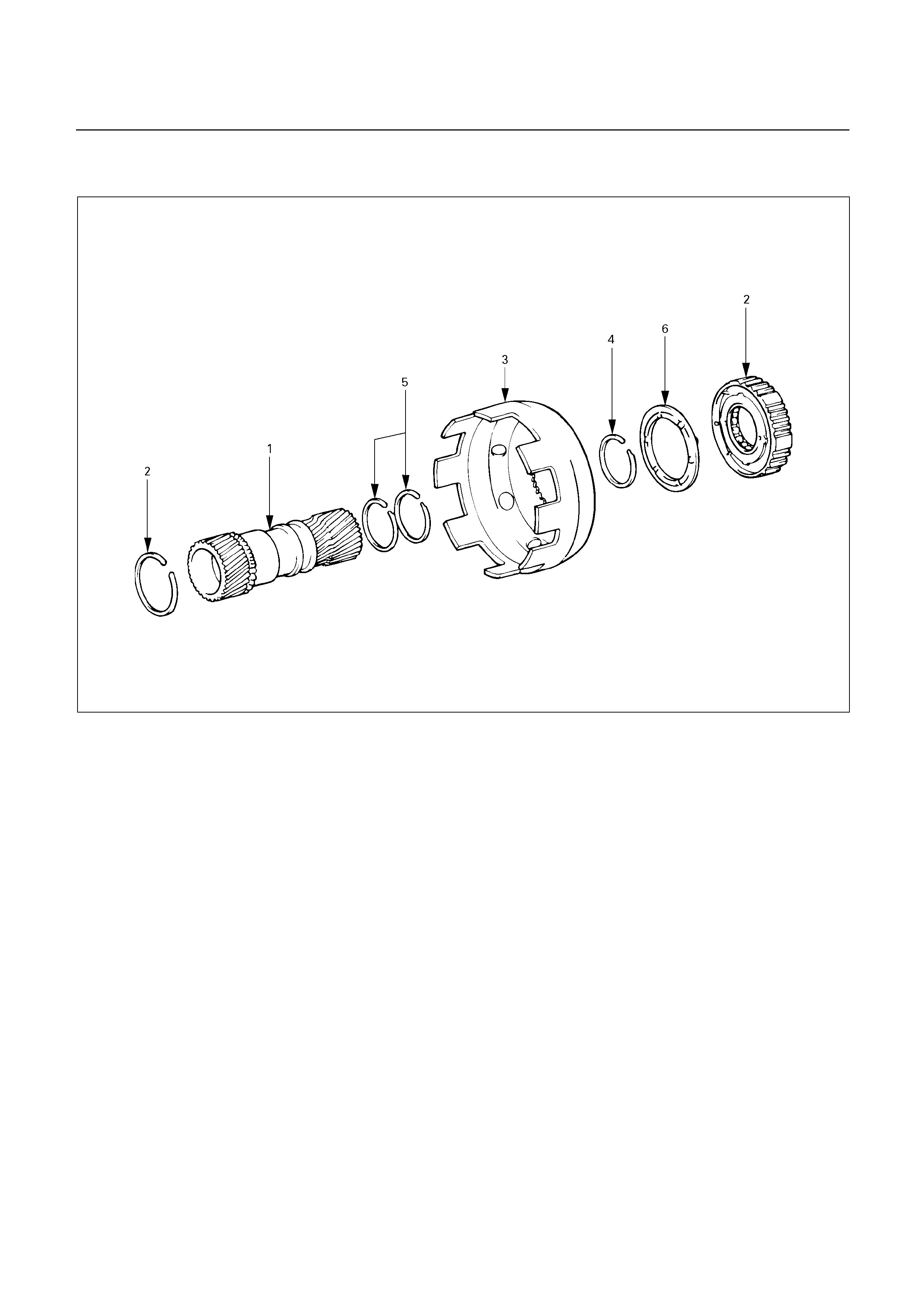

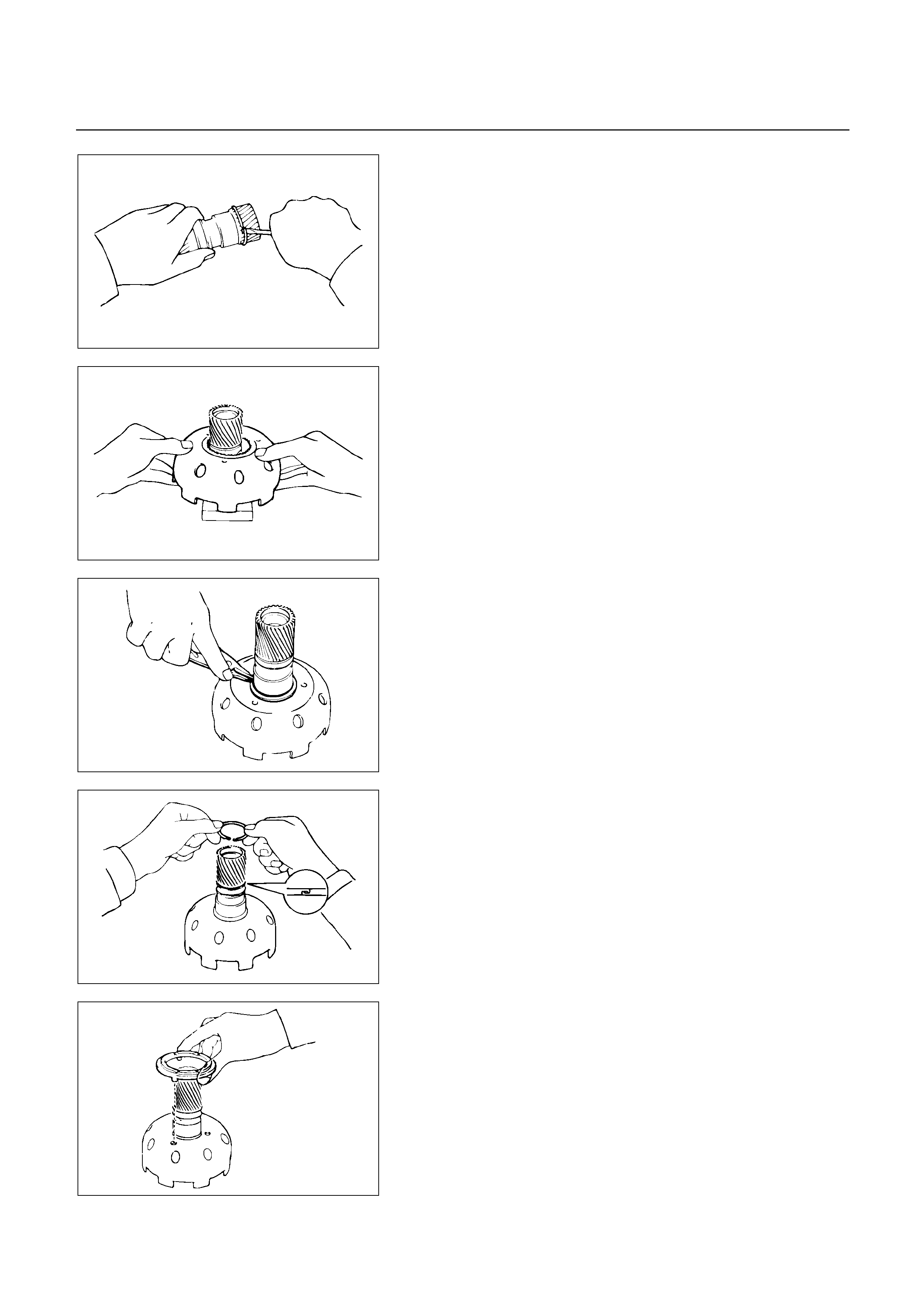

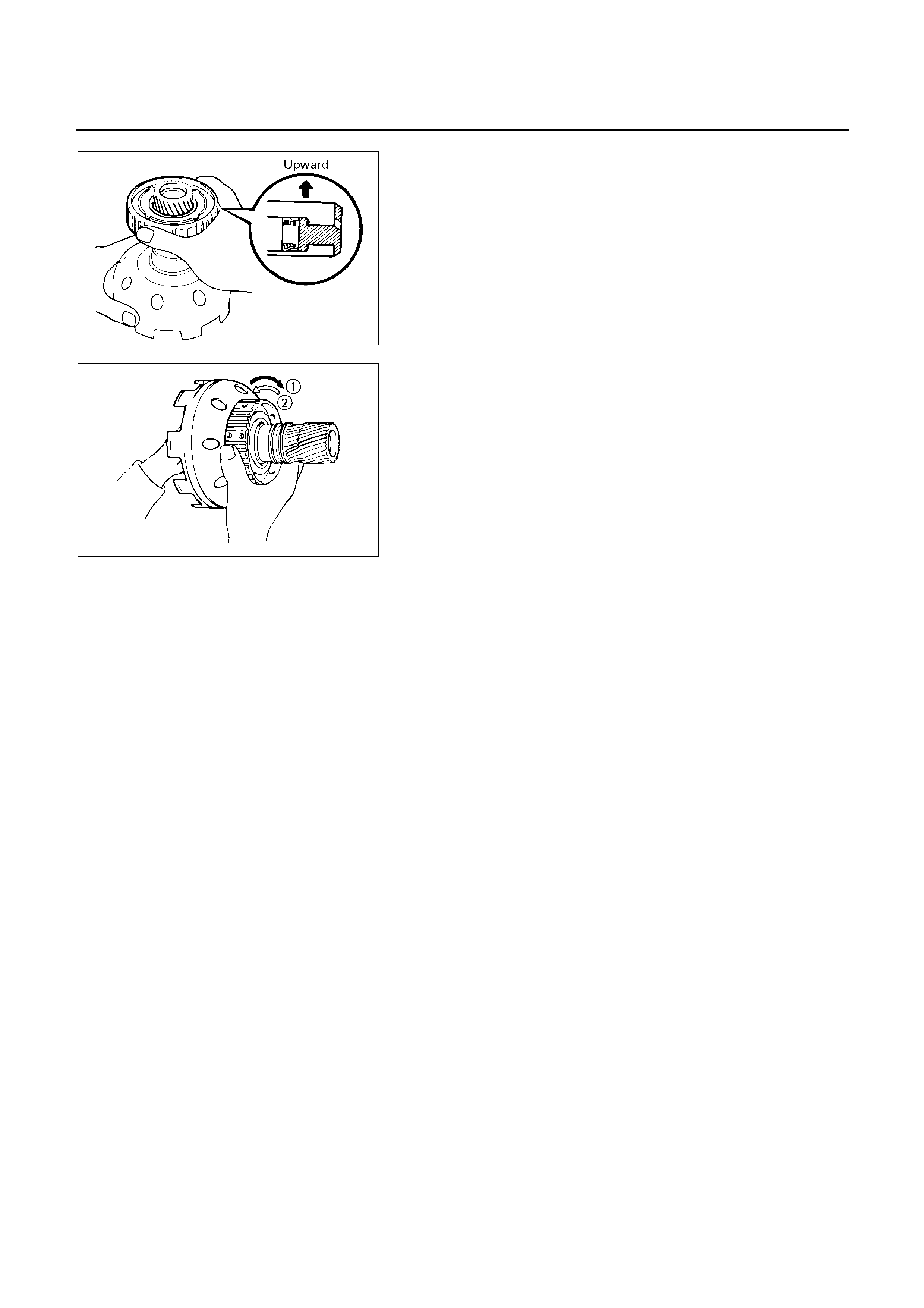

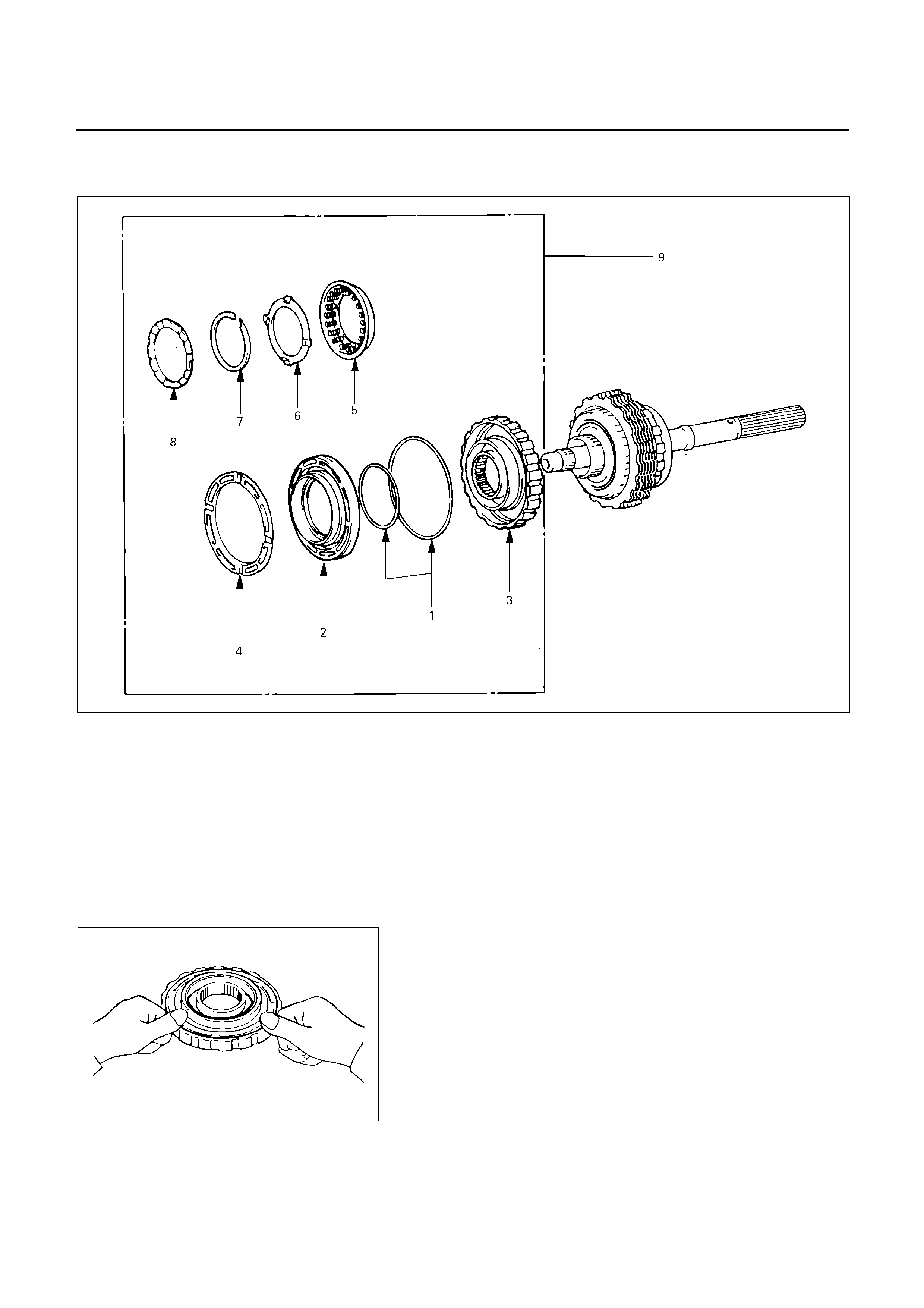

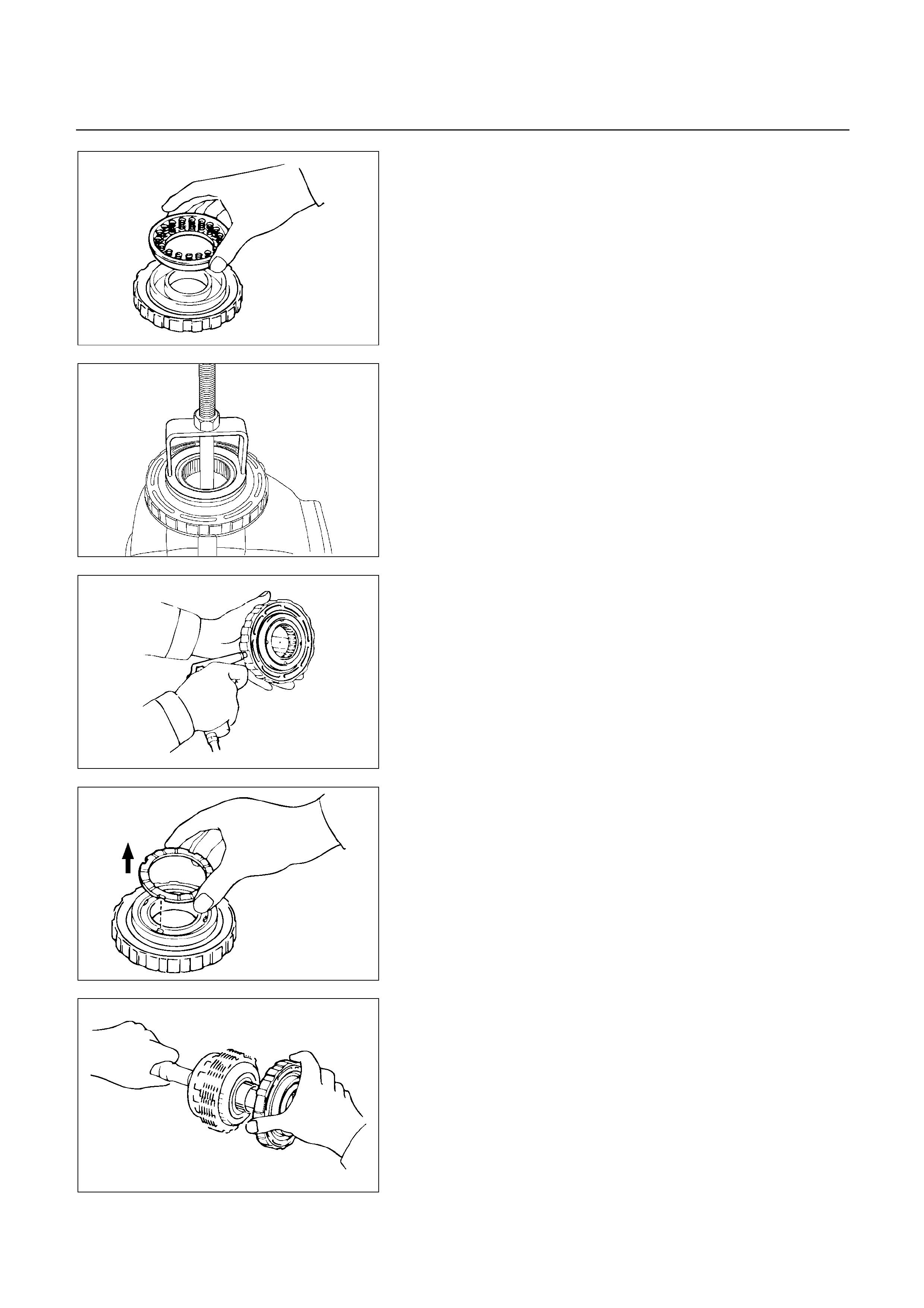

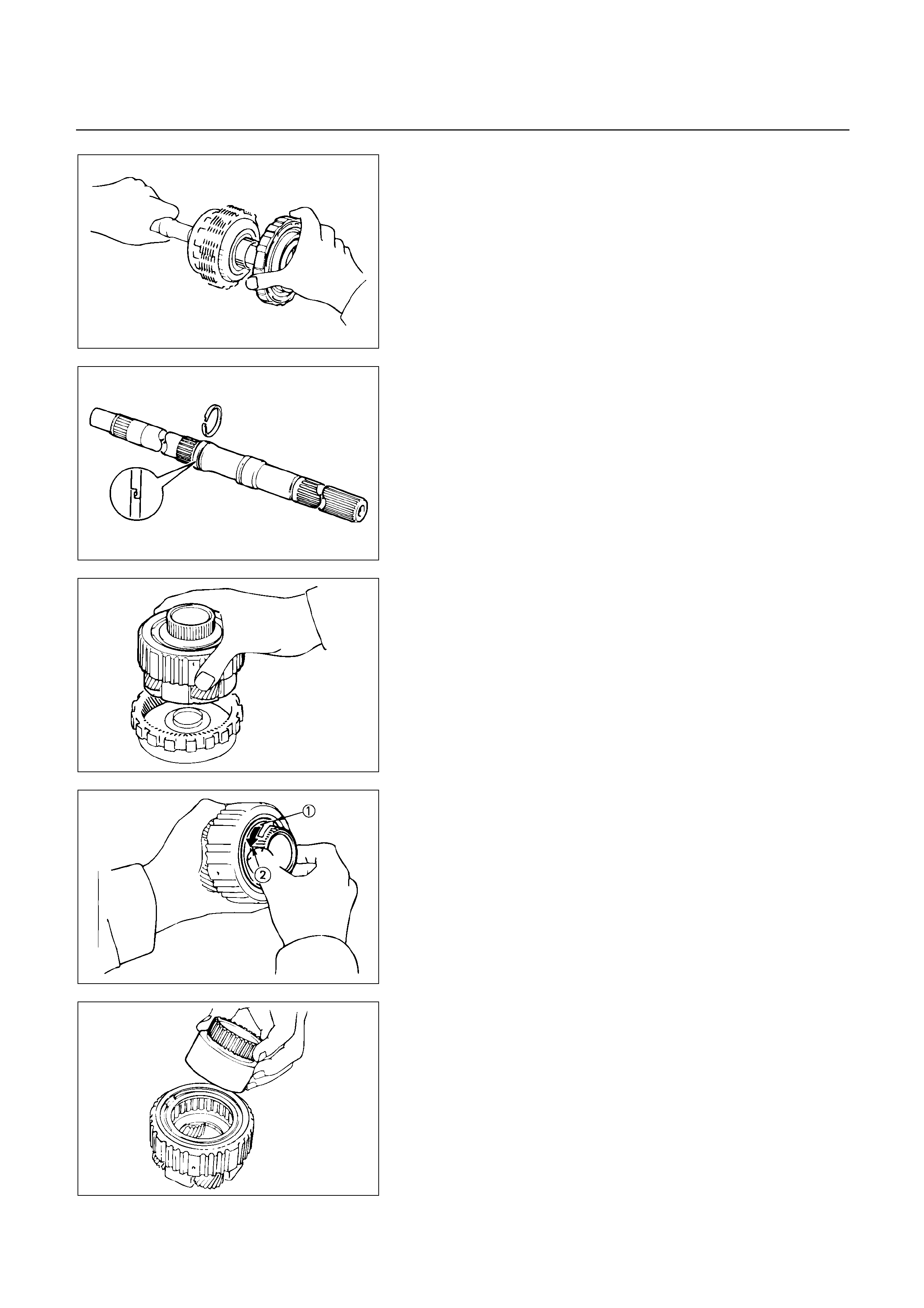

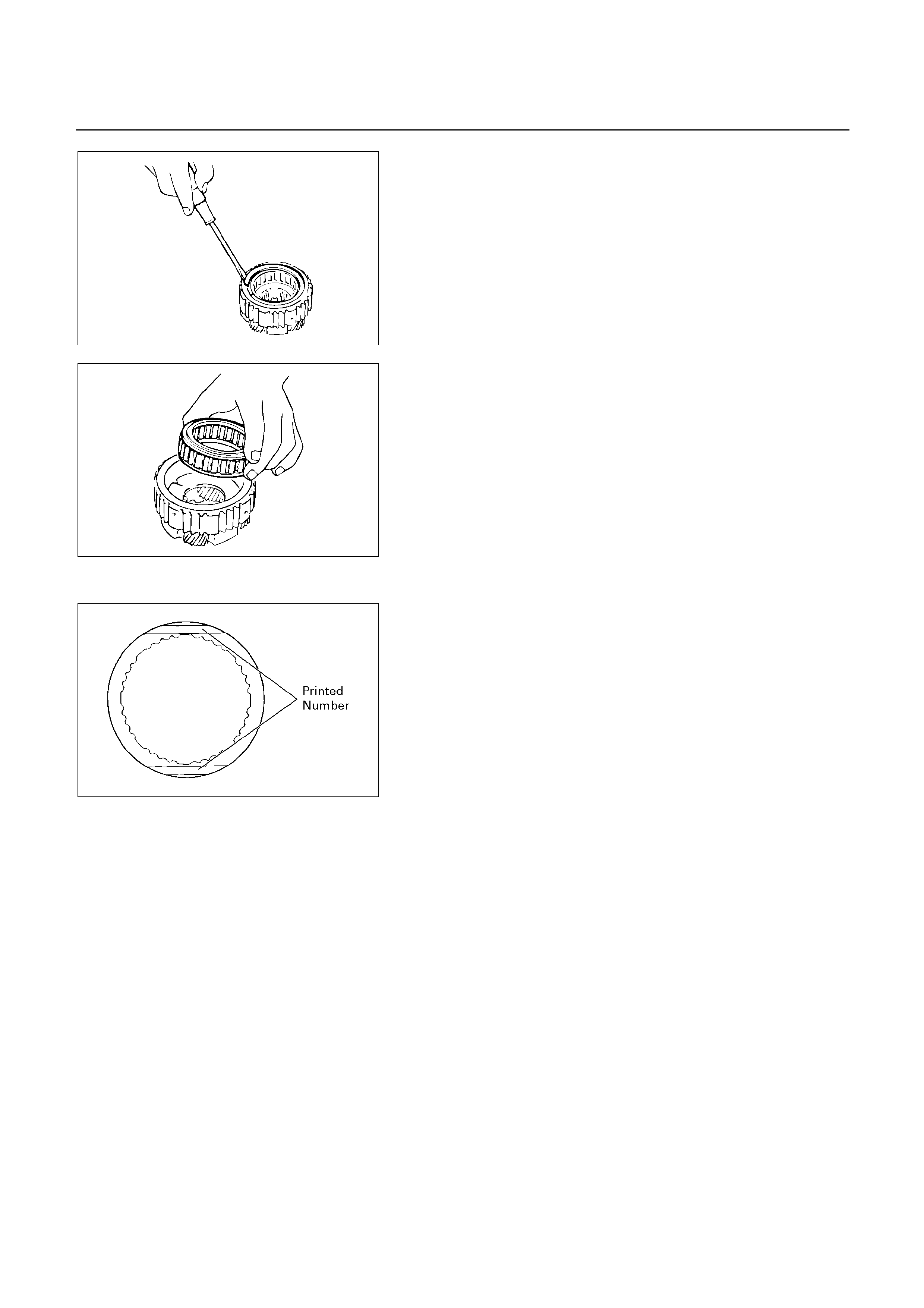

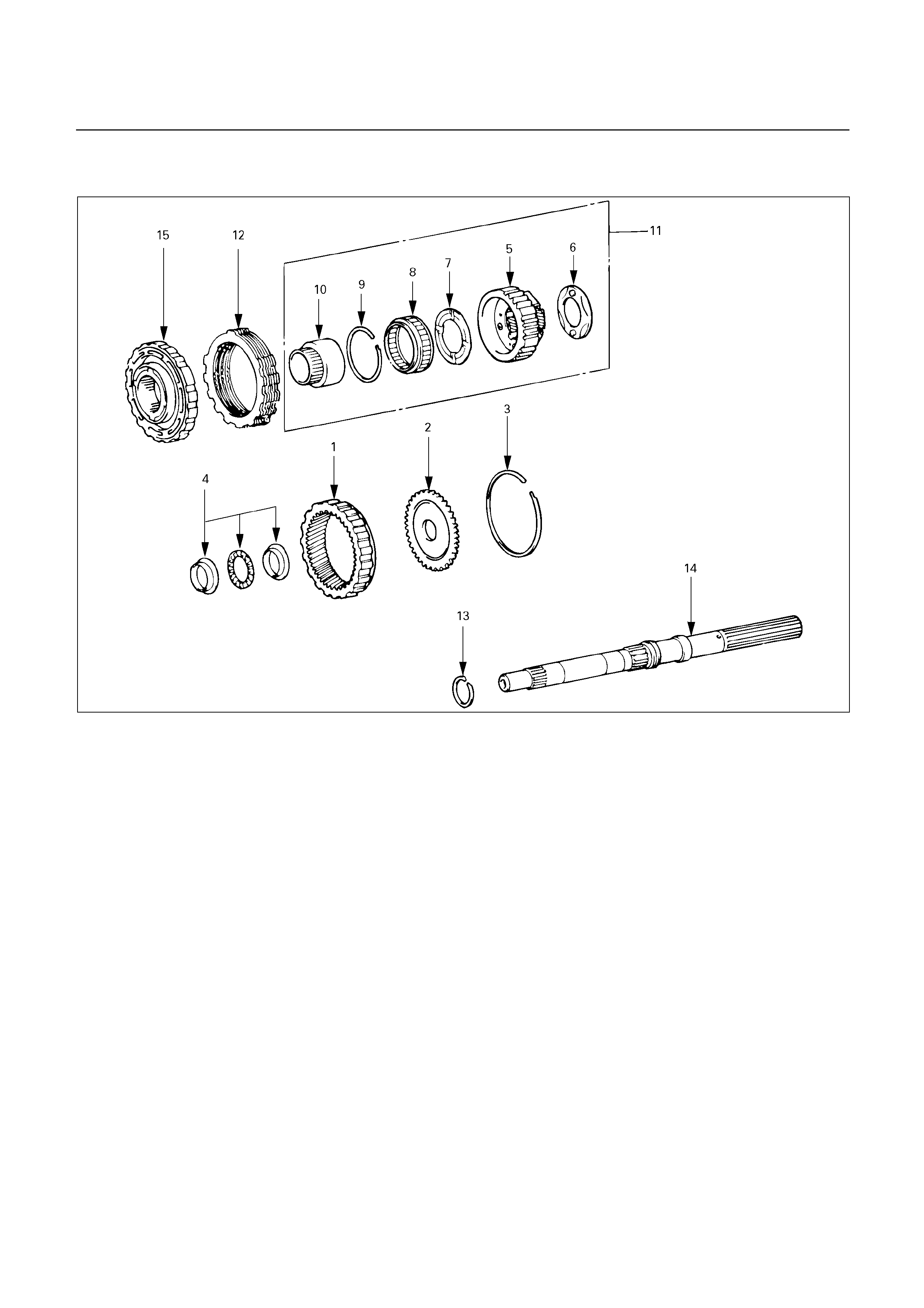

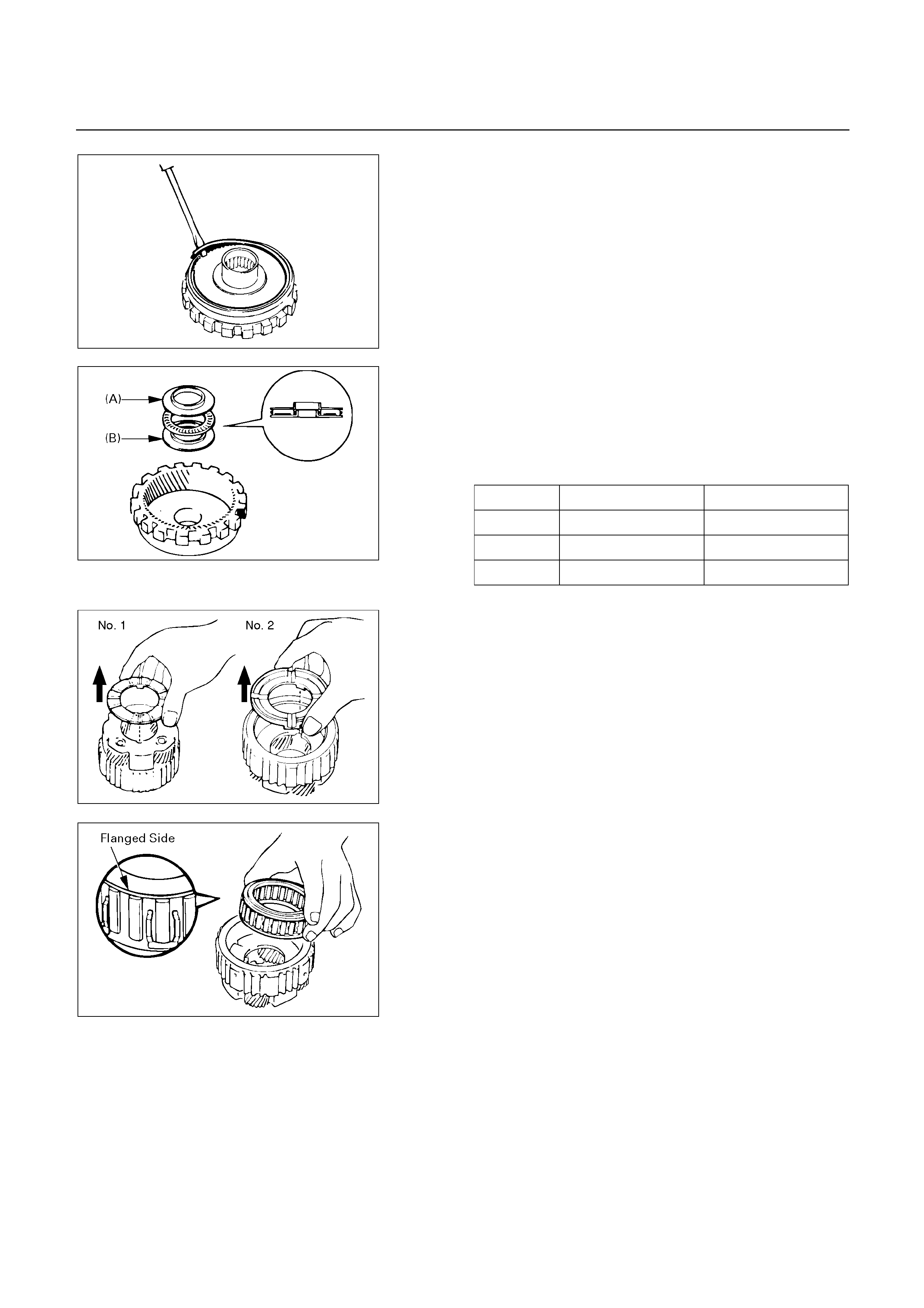

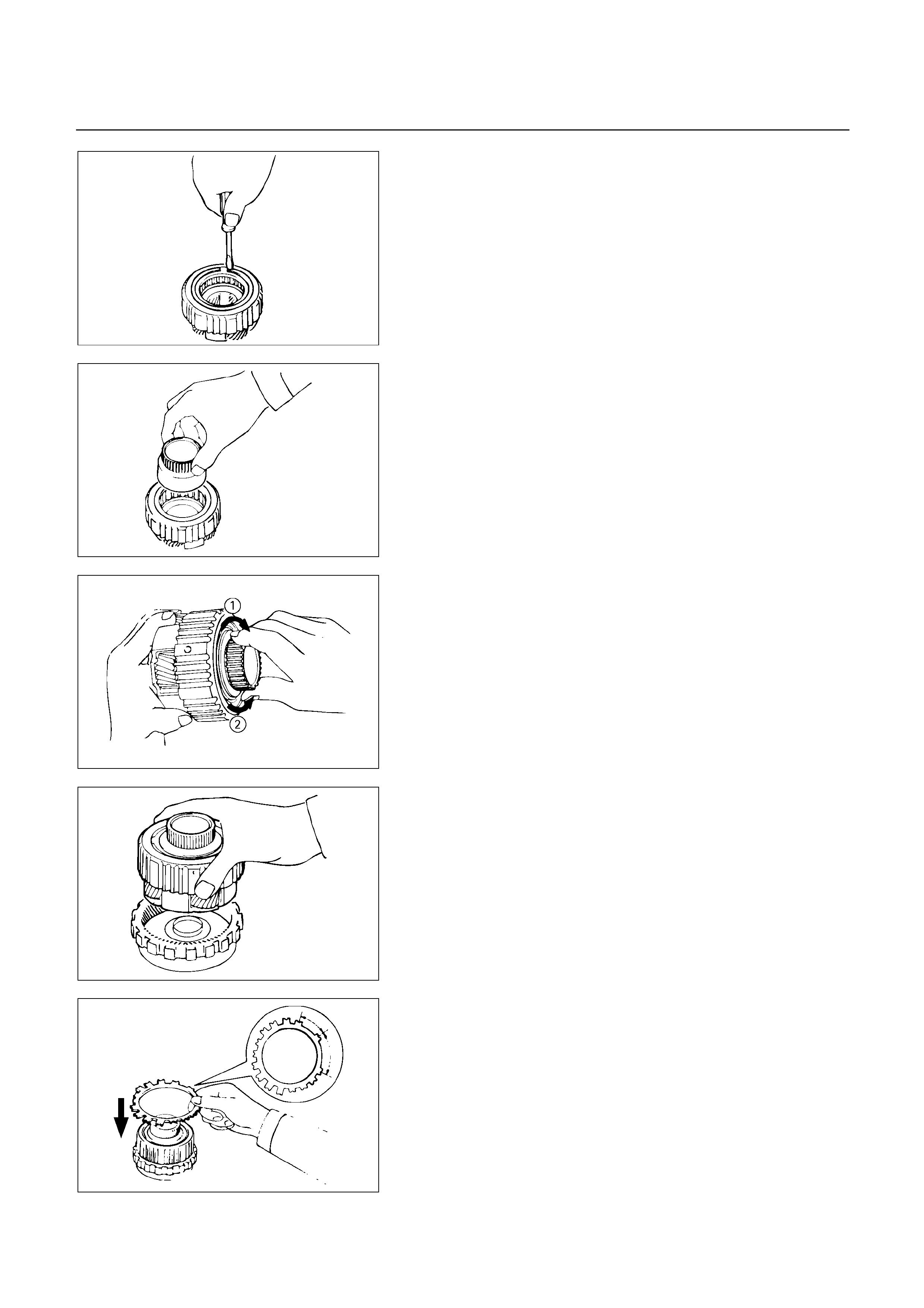

OD Planetary Gear and OD Direct Clutch Assembly (C-0)

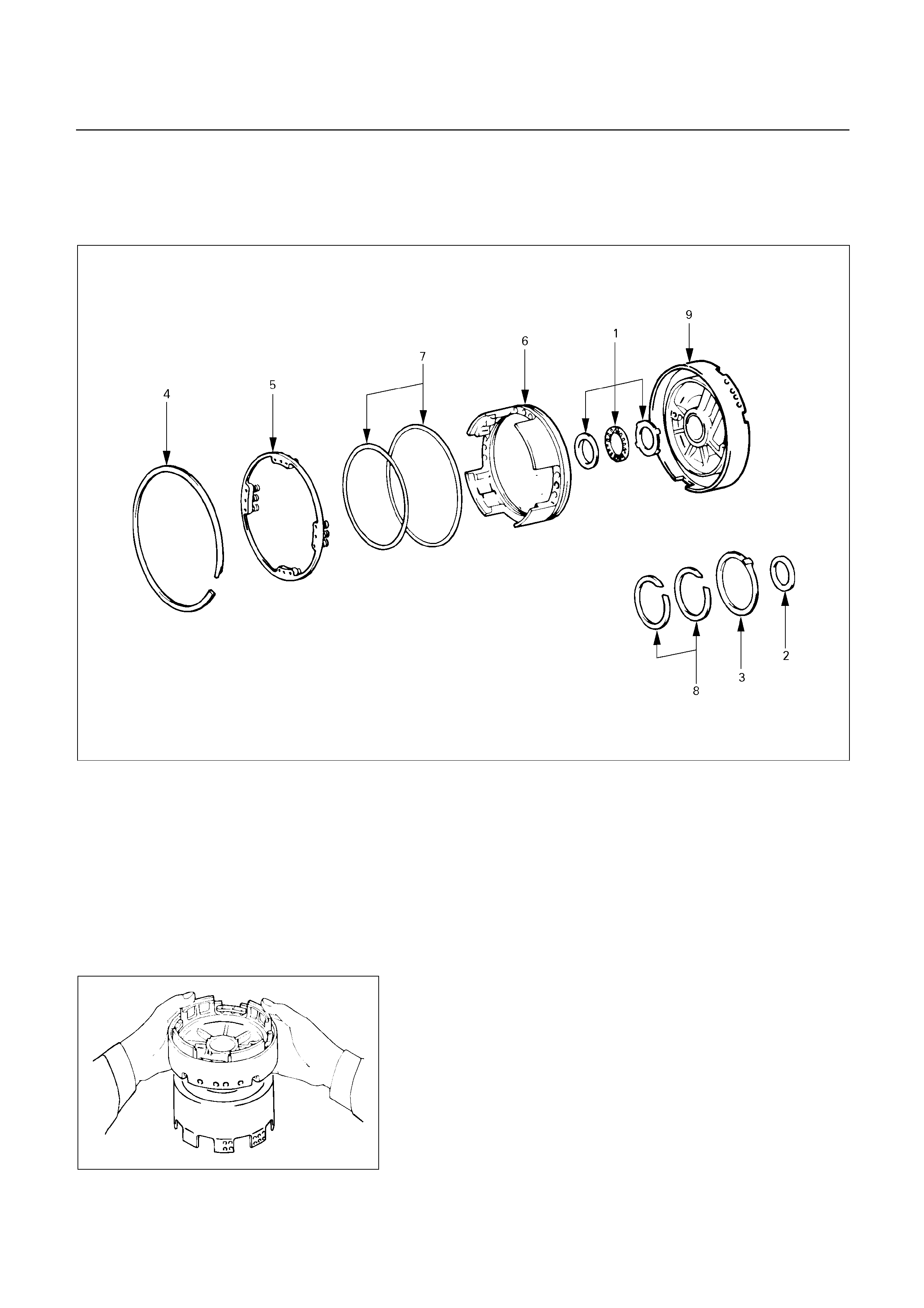

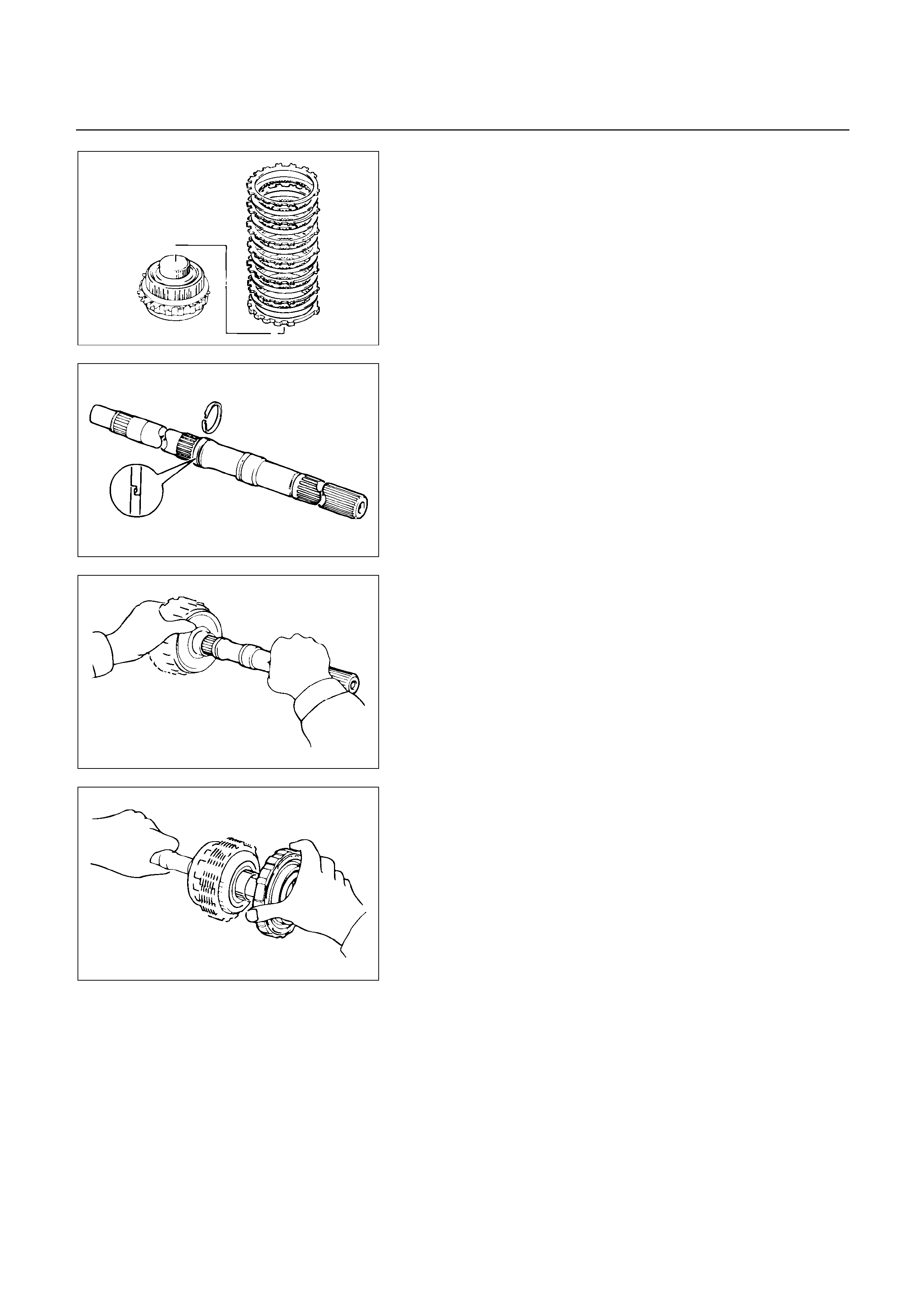

OD Support Assembly

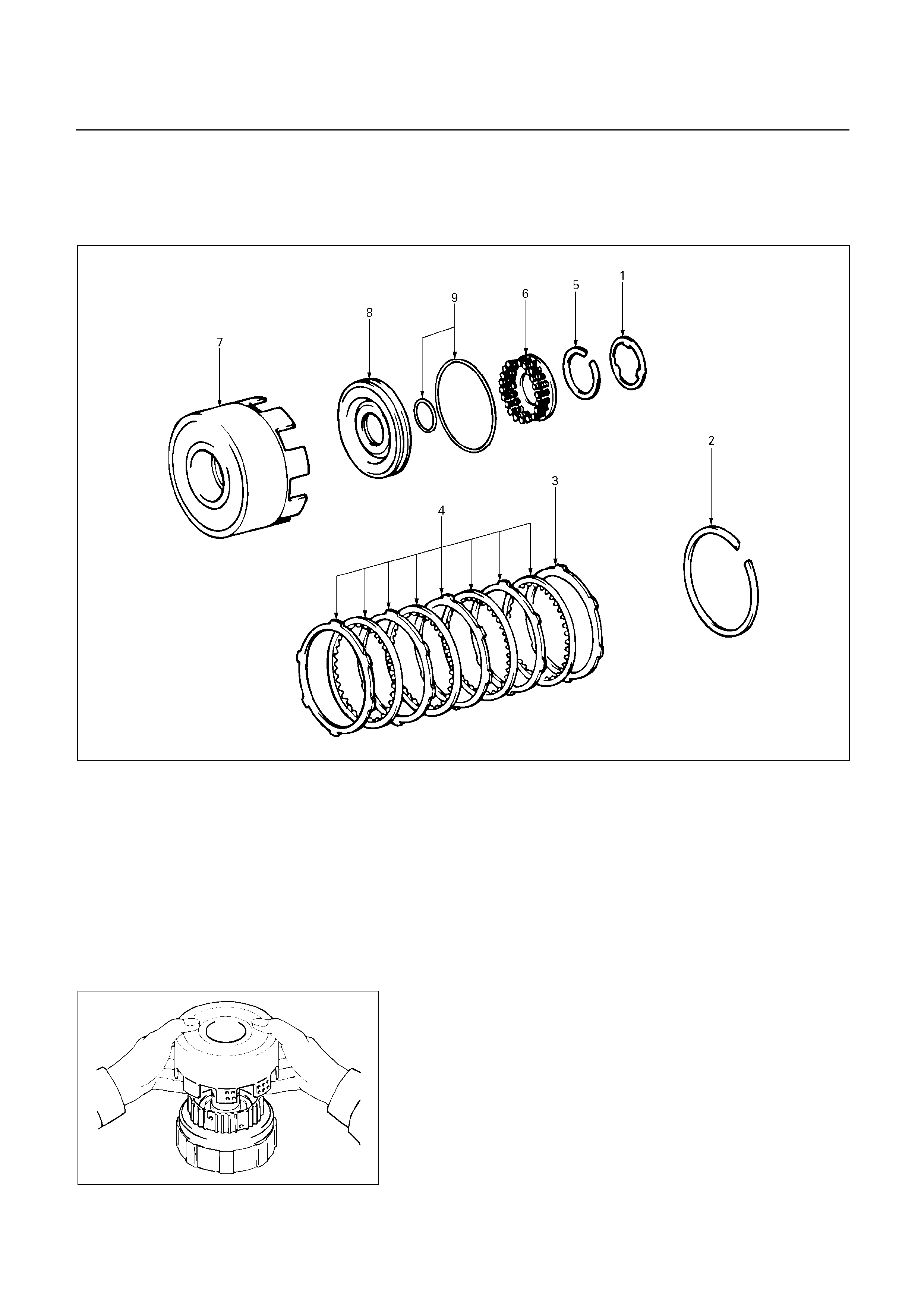

Direct Clutch Assembly (C-2)

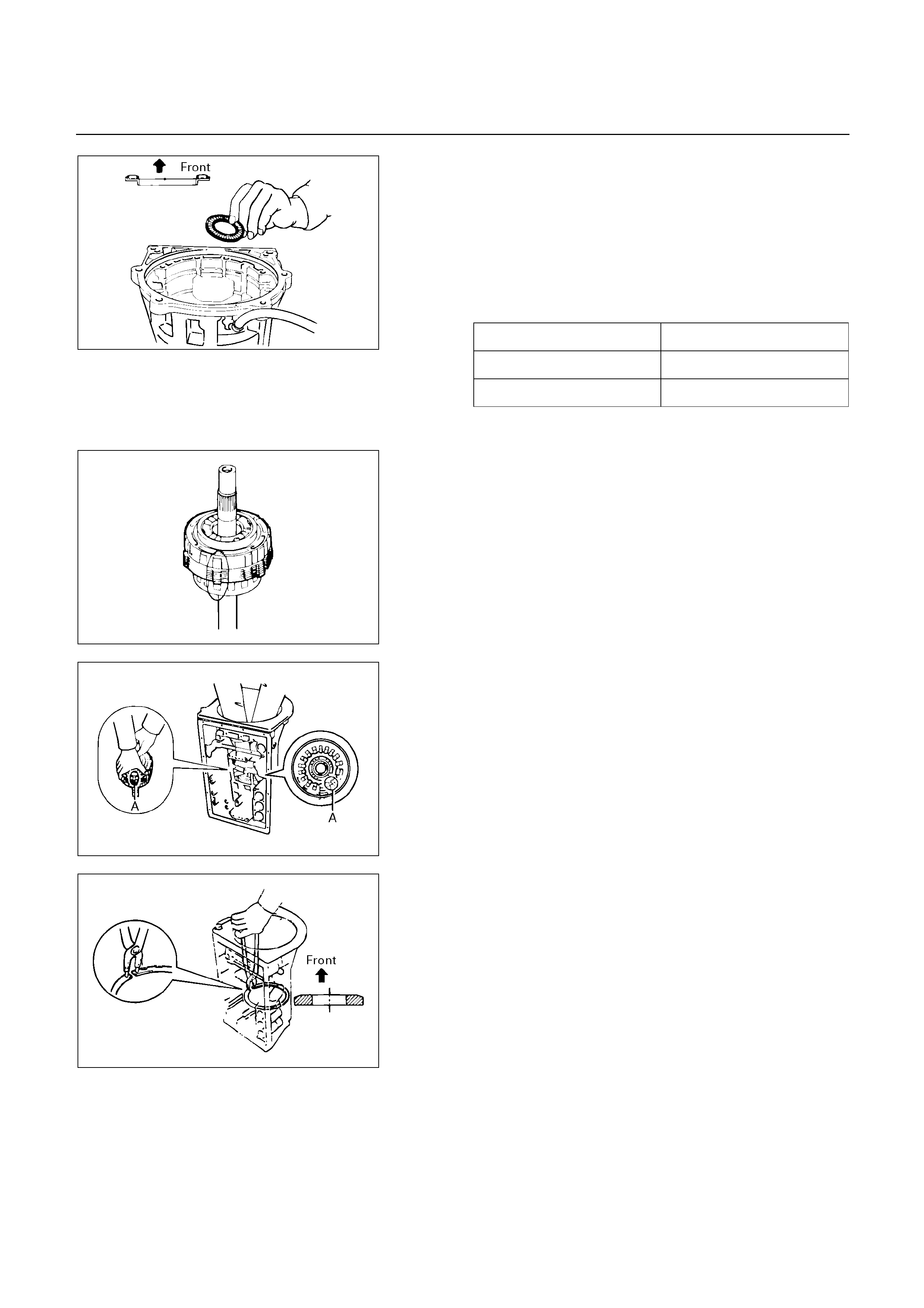

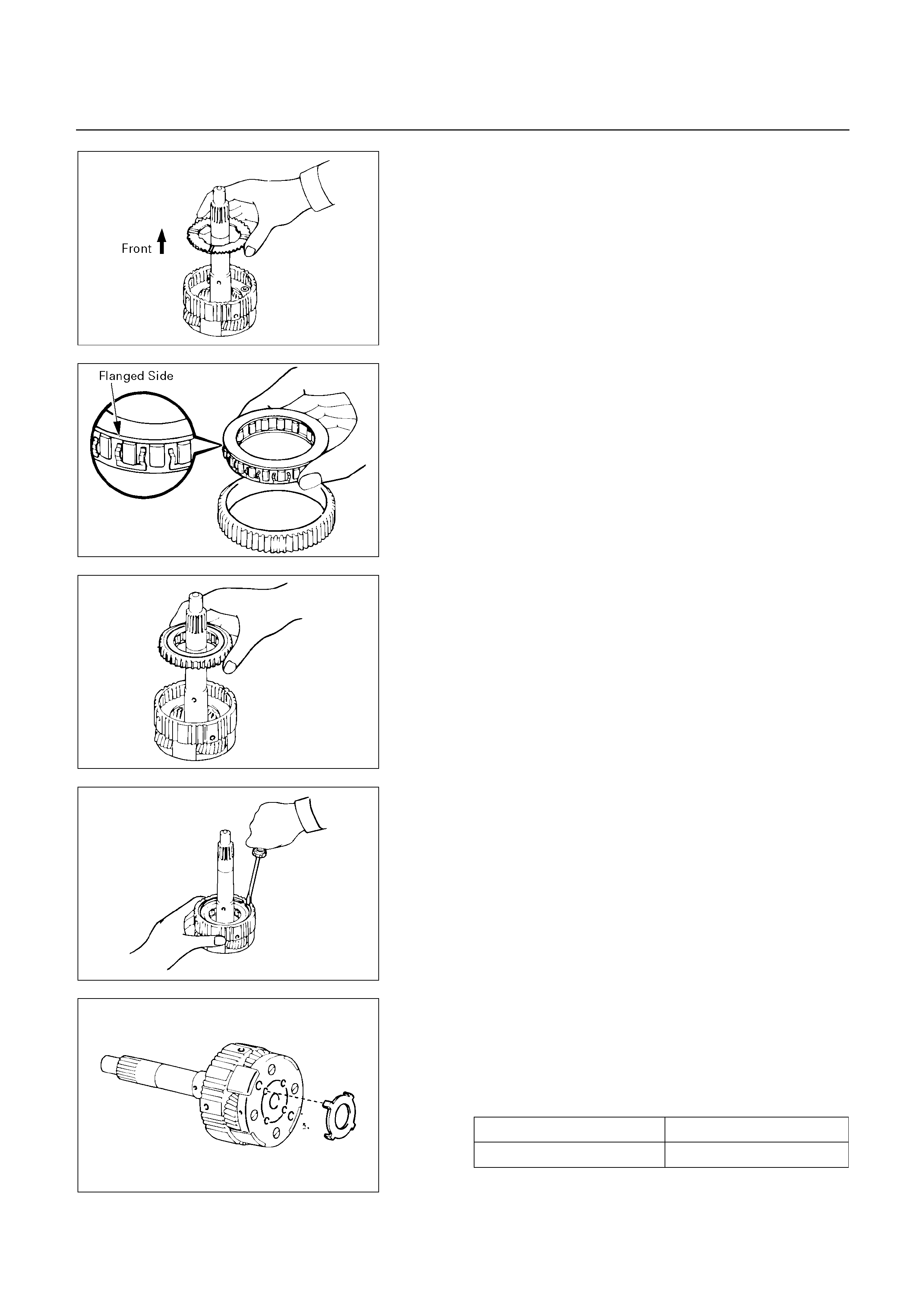

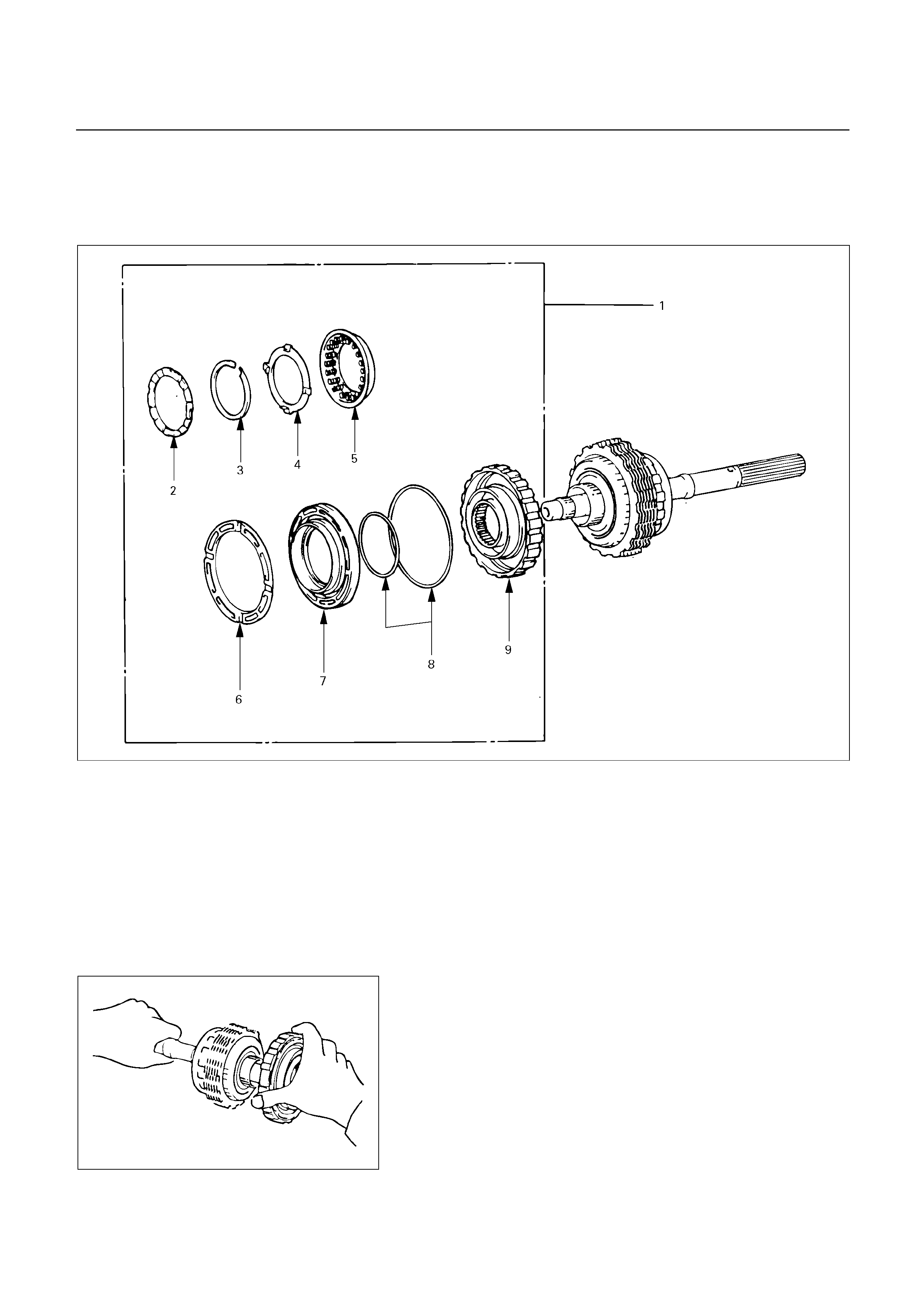

Forward Clutch Assembly (C-1)

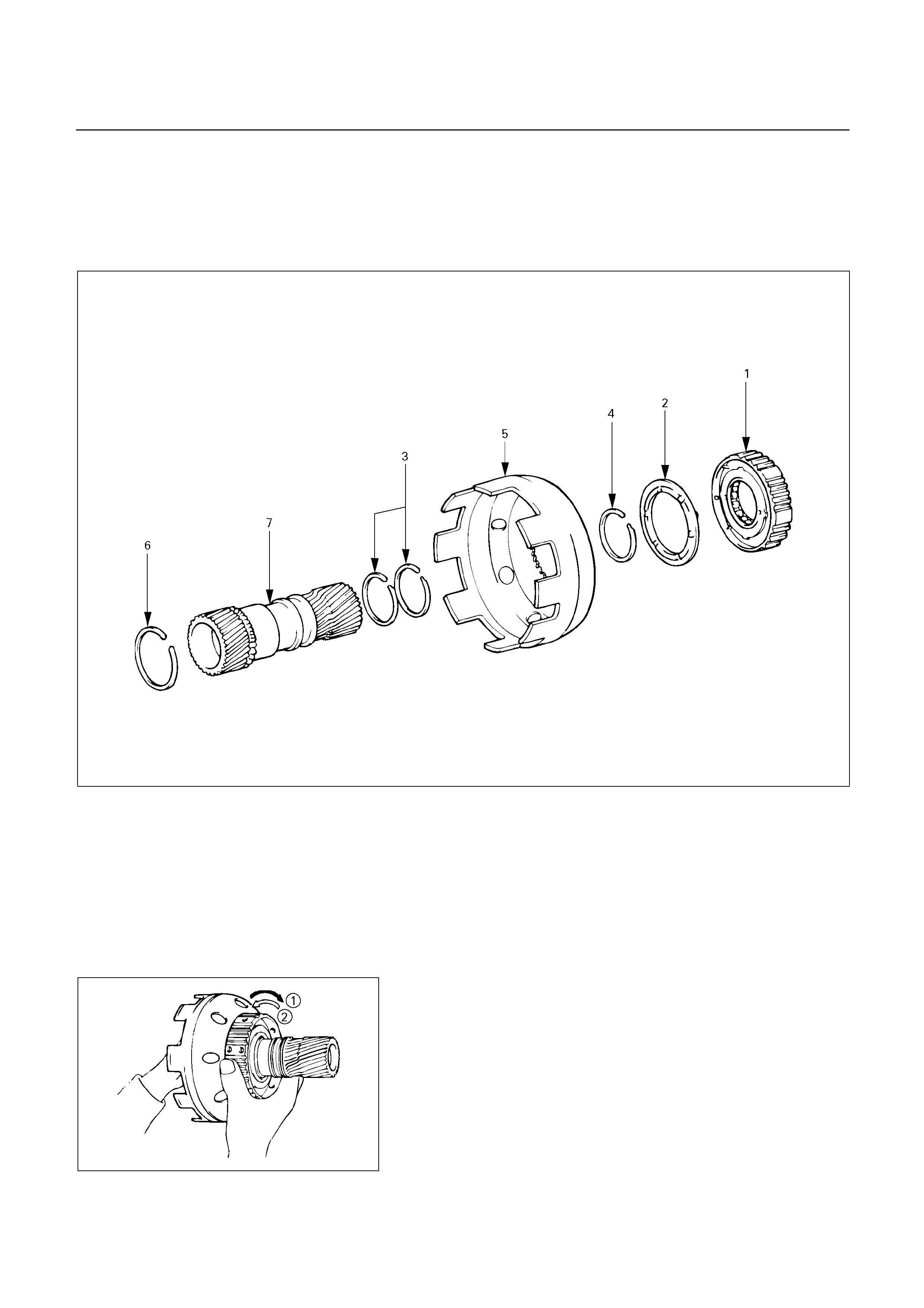

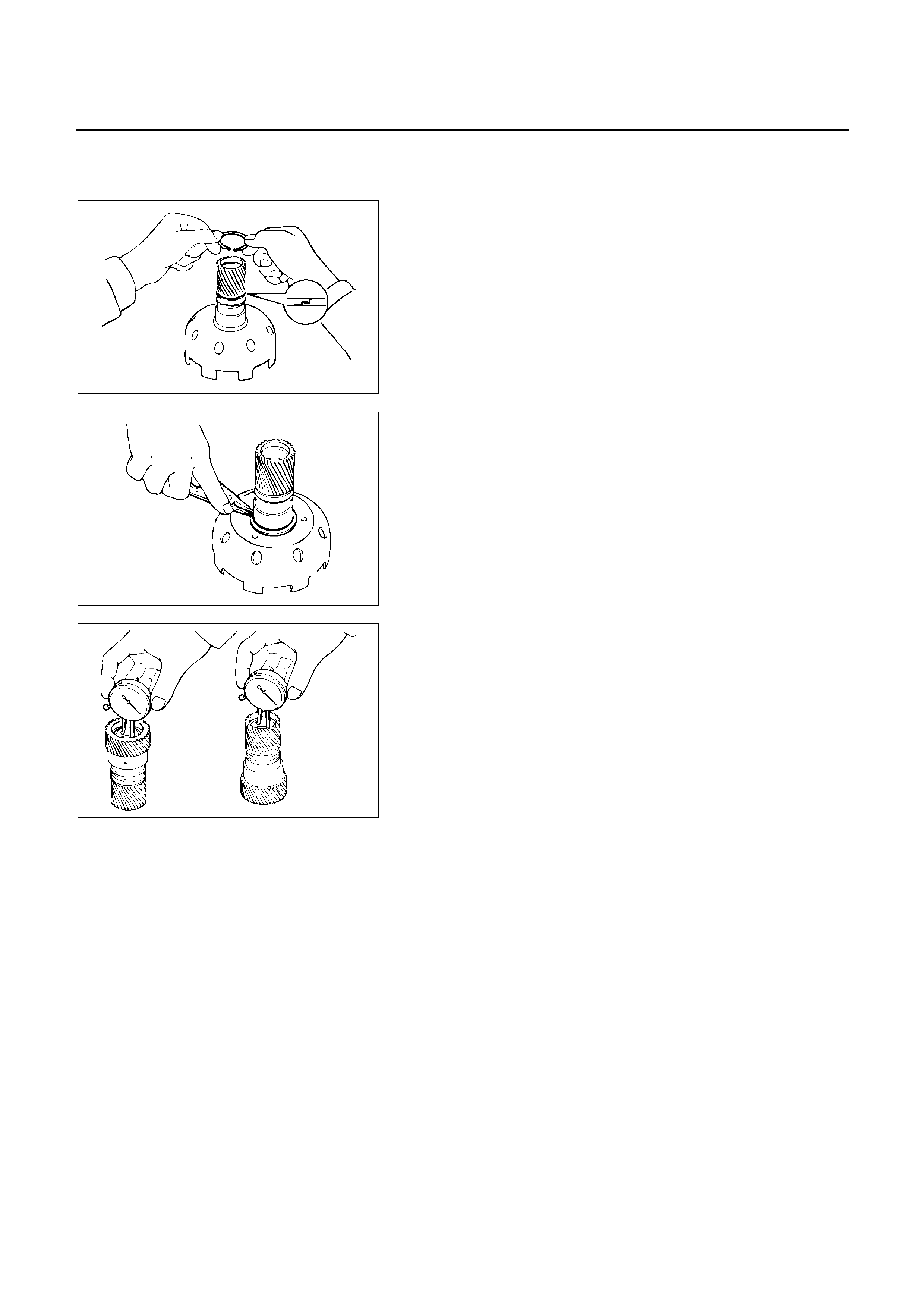

Front Planetary Gear

Planetary Sun Gear and No.1 One-Way Clutch

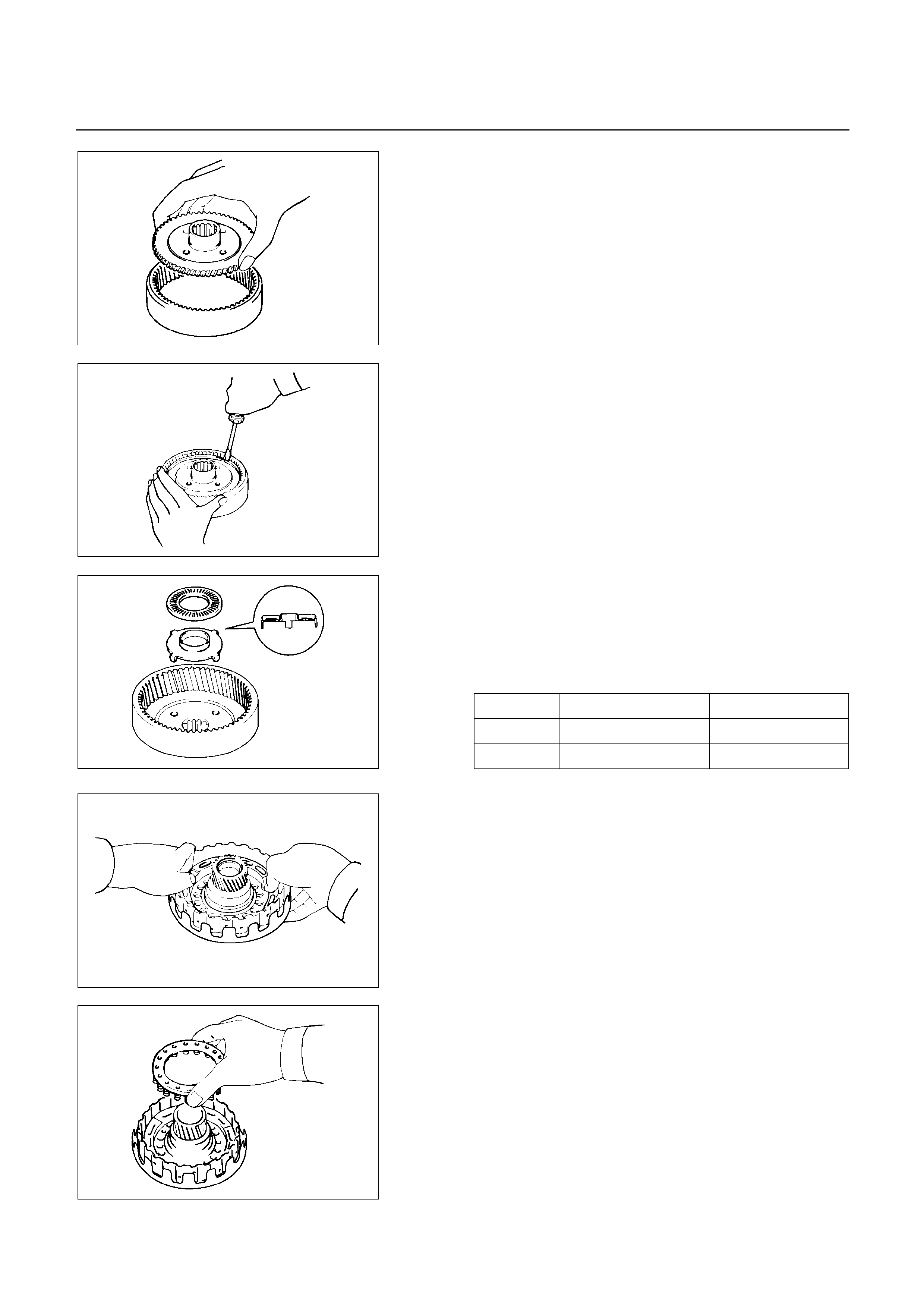

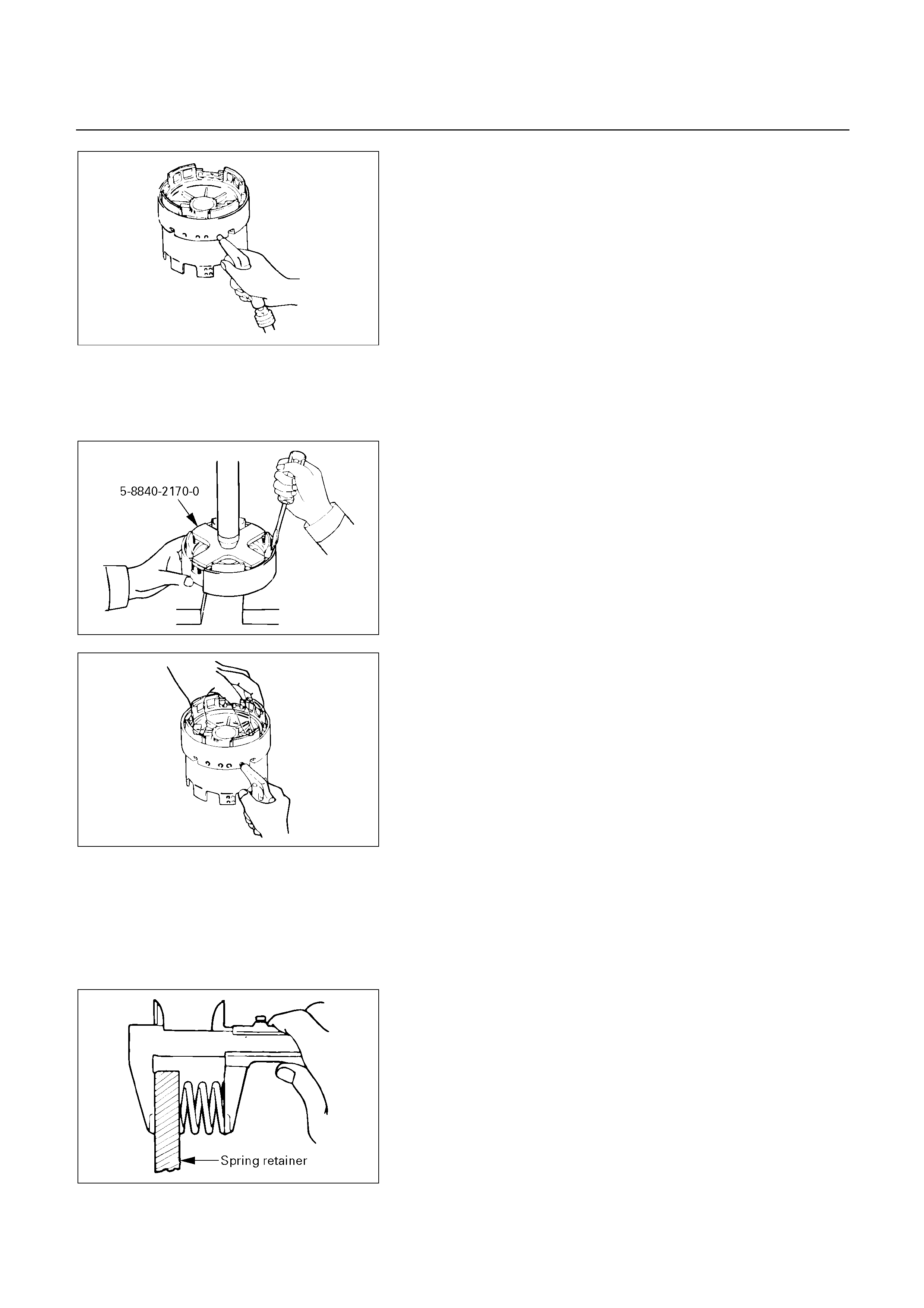

Second Brake Assembly (B-2)

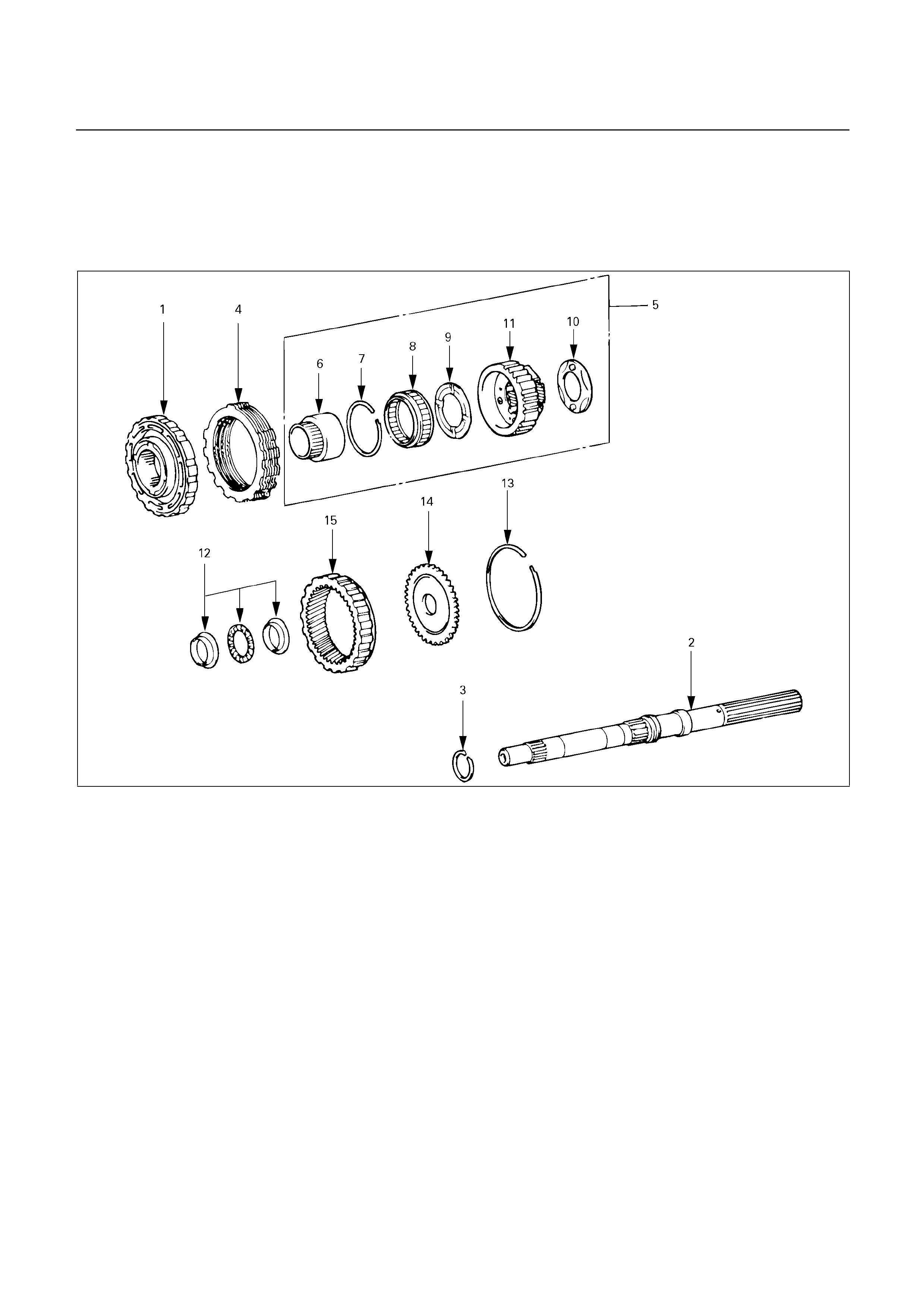

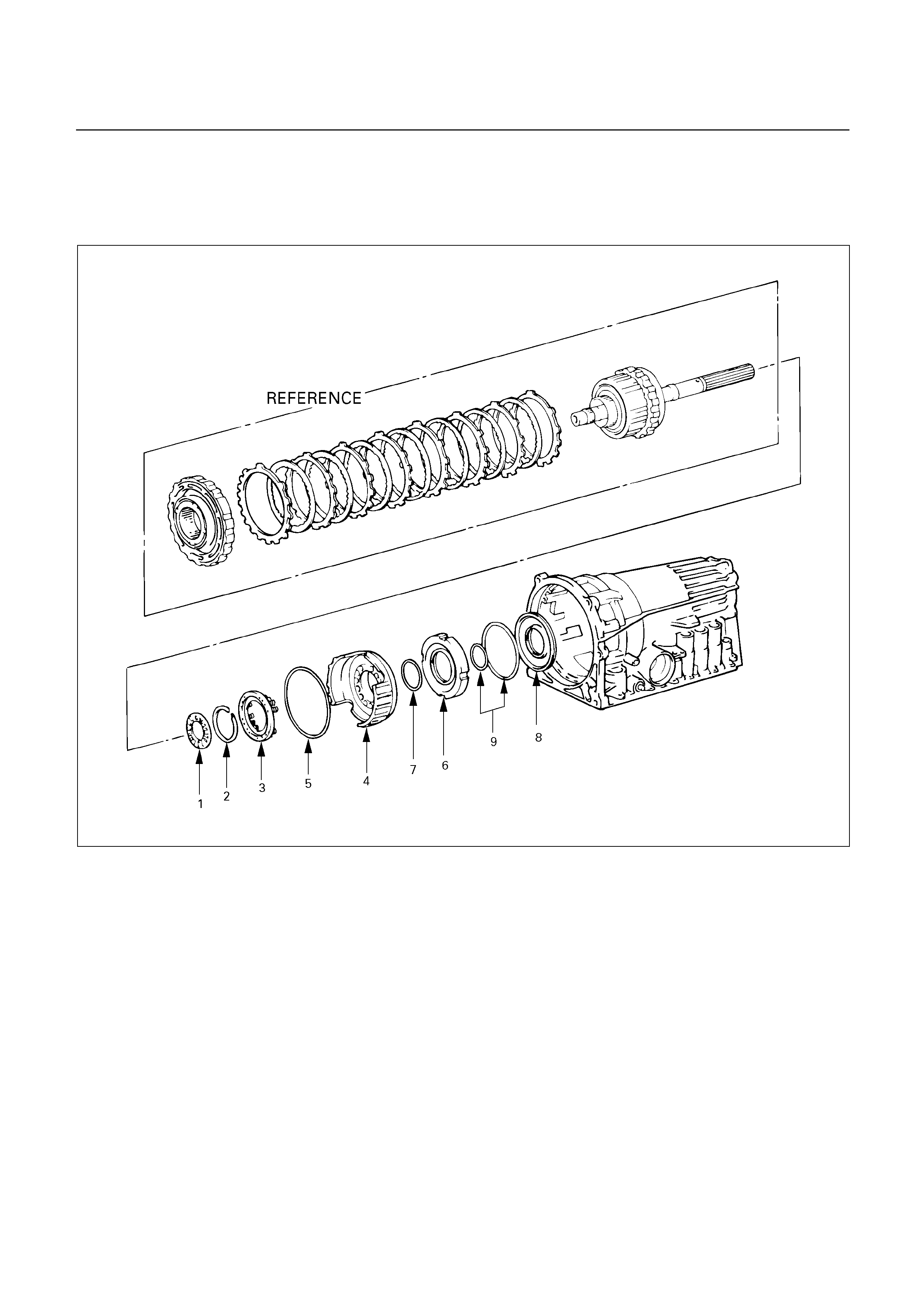

Rear Planetary Gear Assembly and Output Shaft

First and Reverse Brake Assembly (B-3)

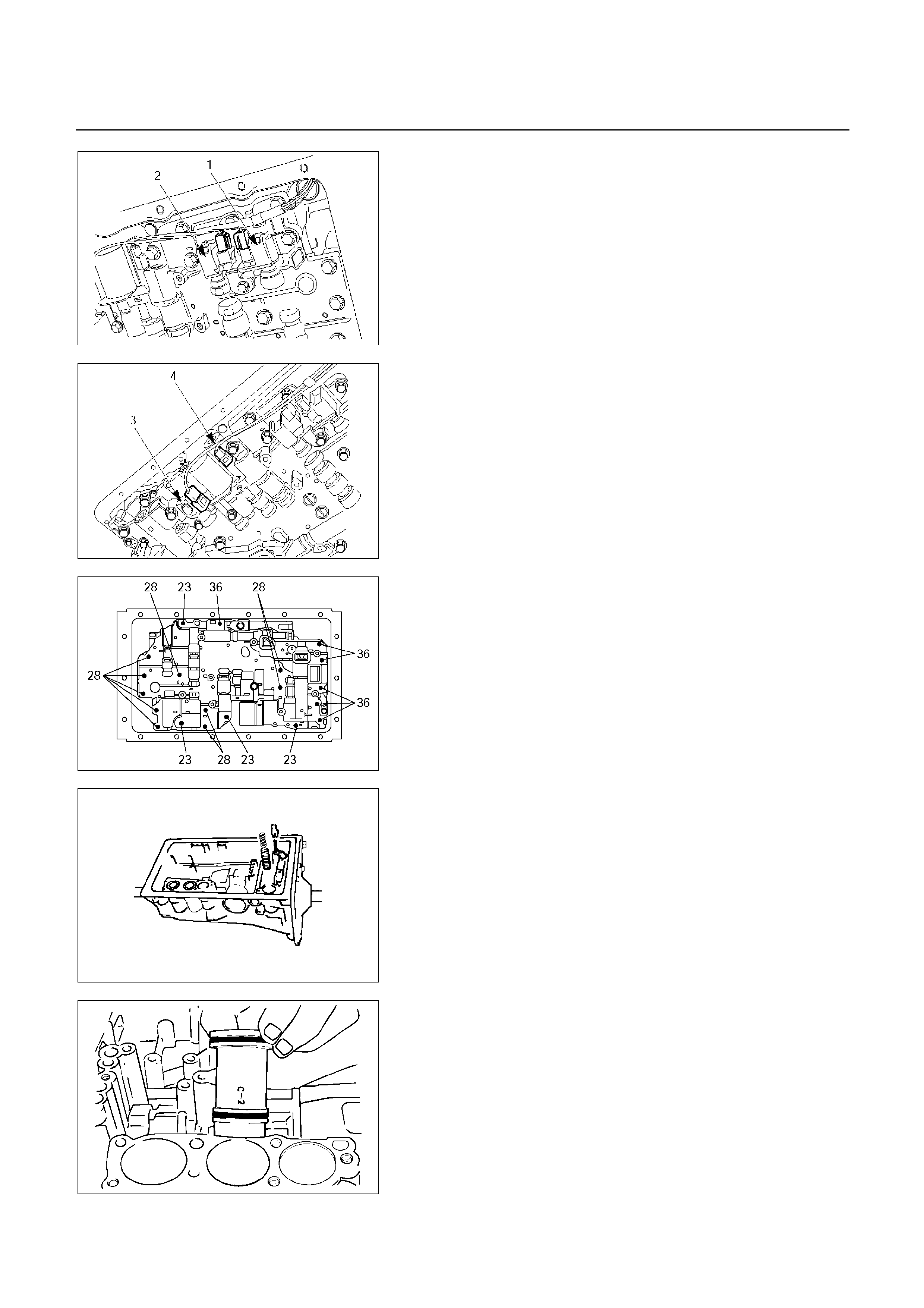

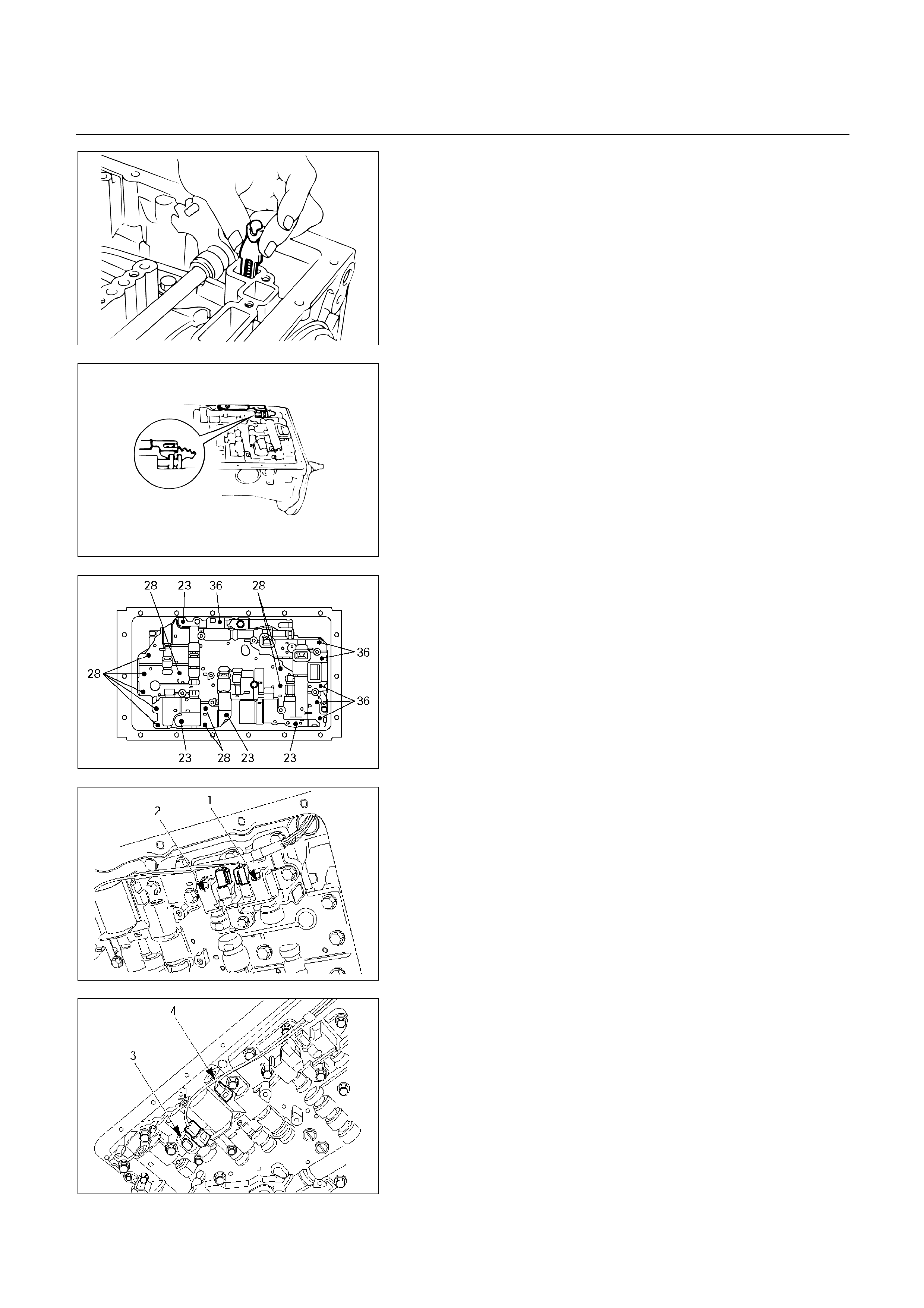

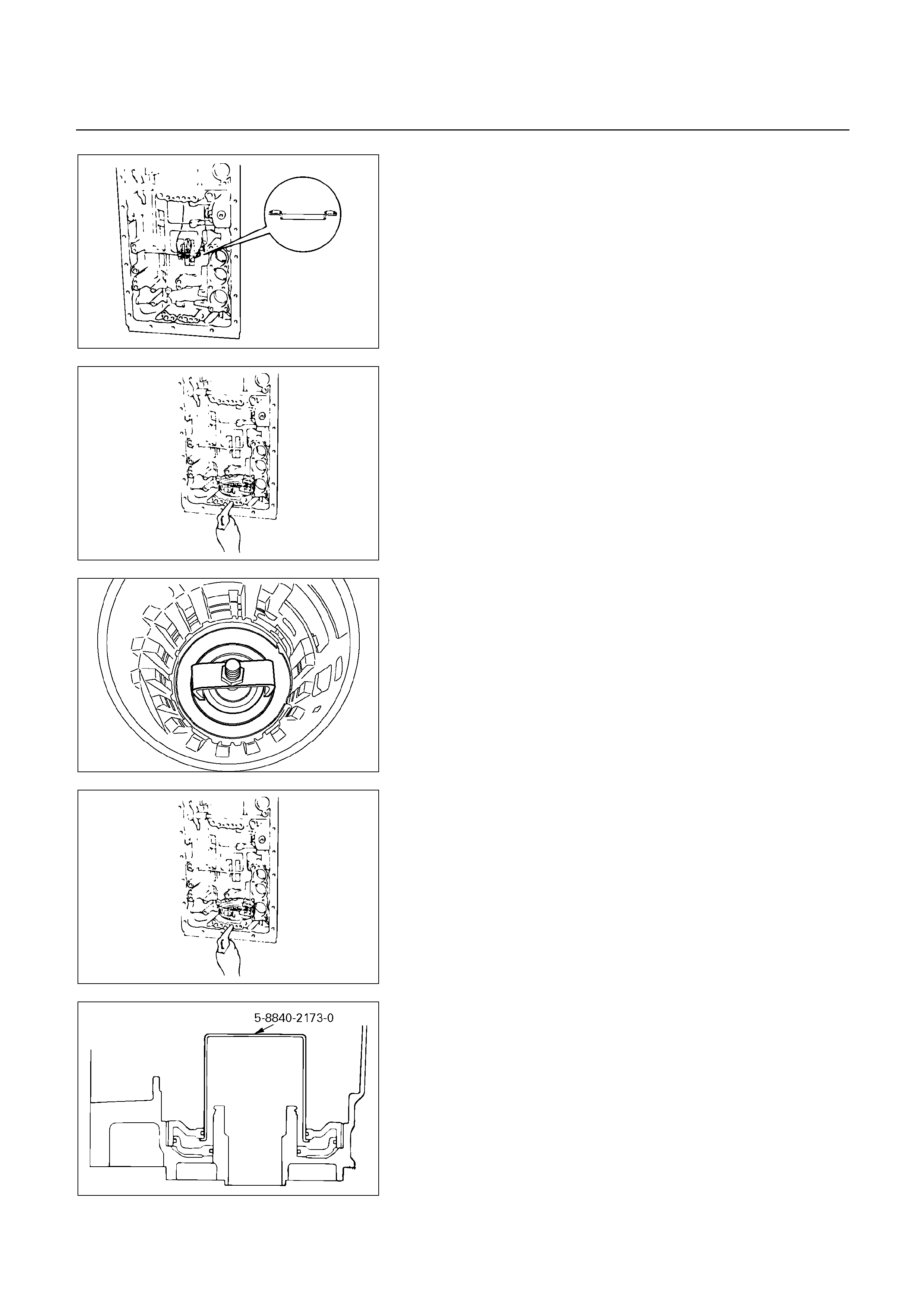

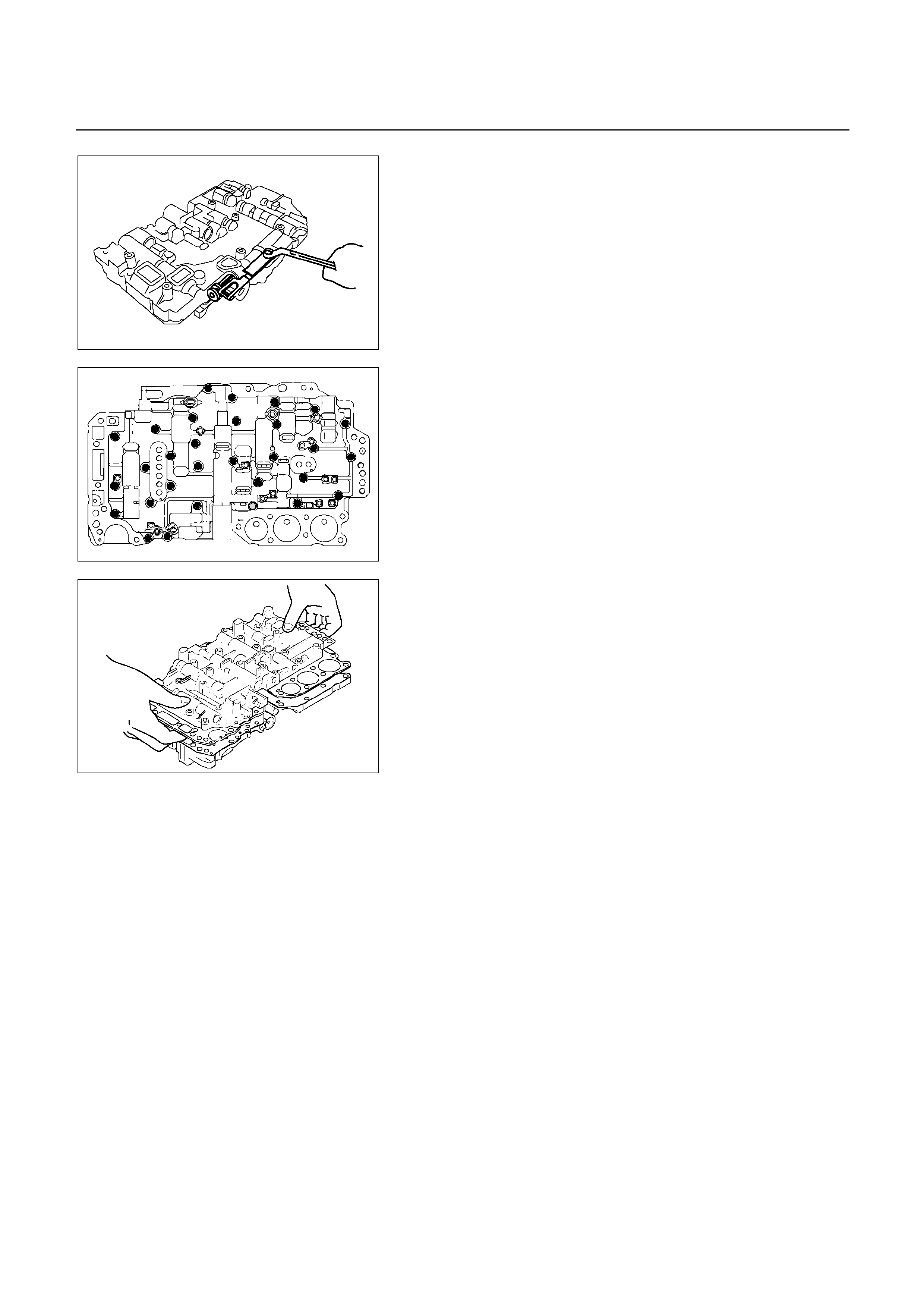

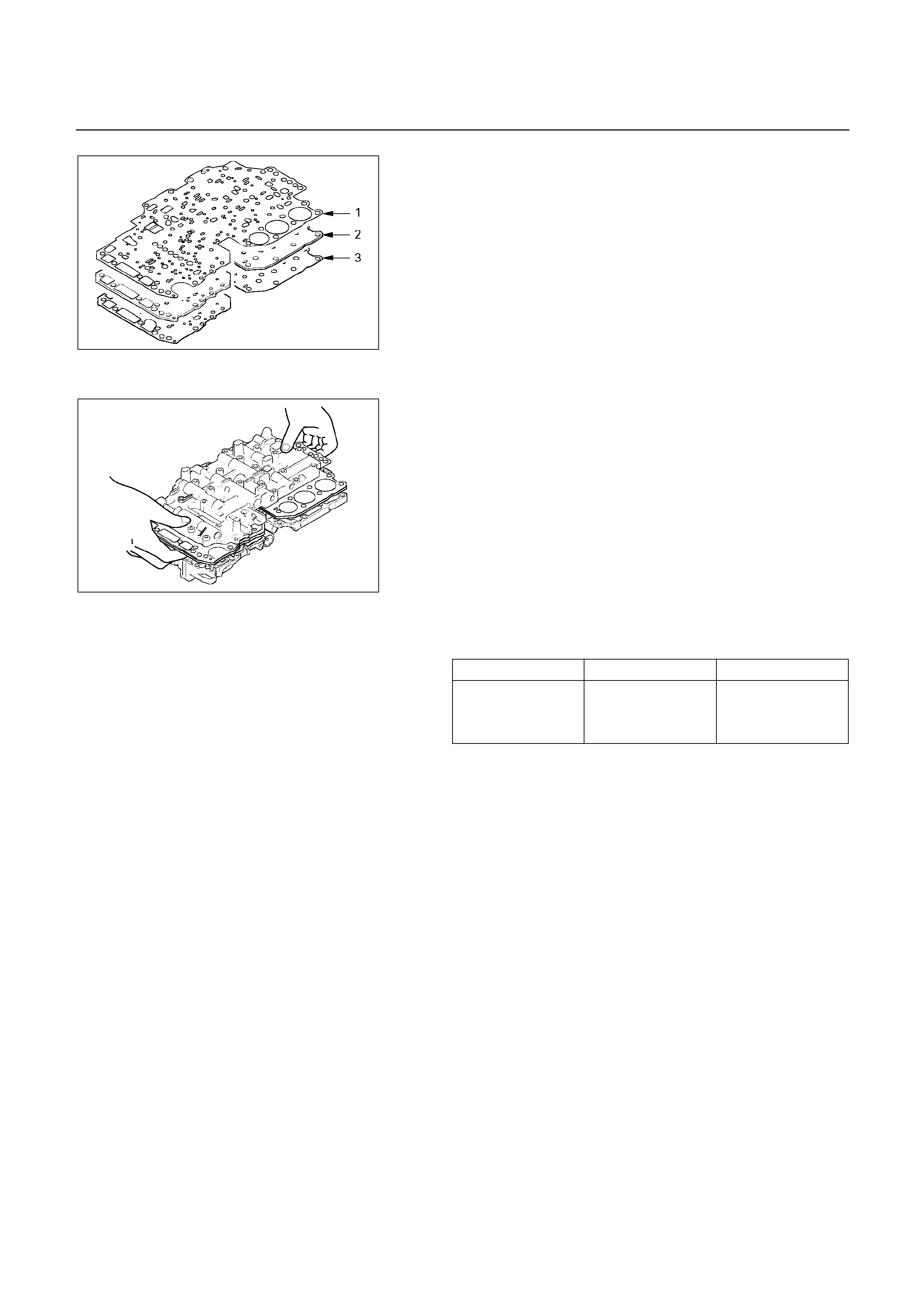

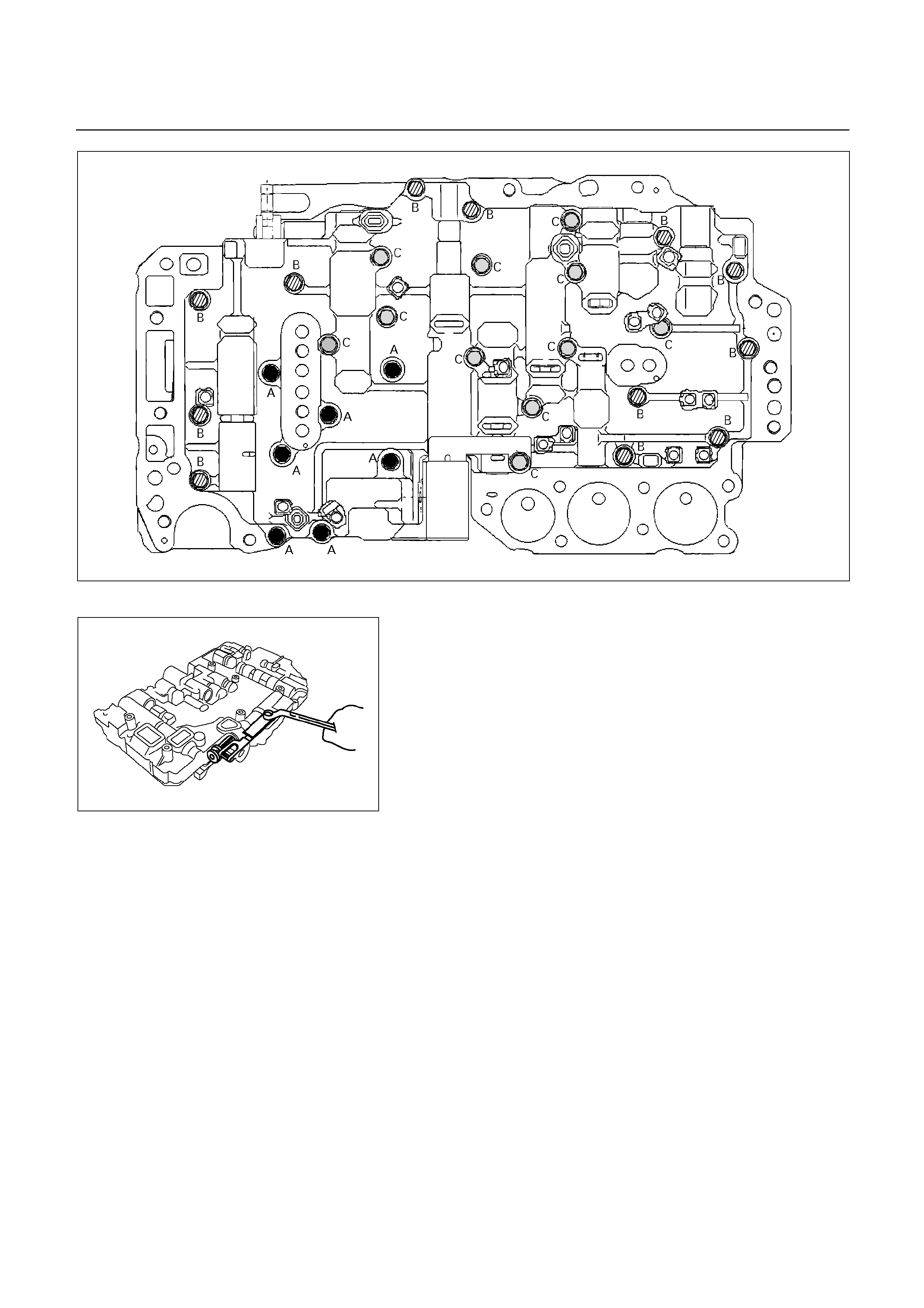

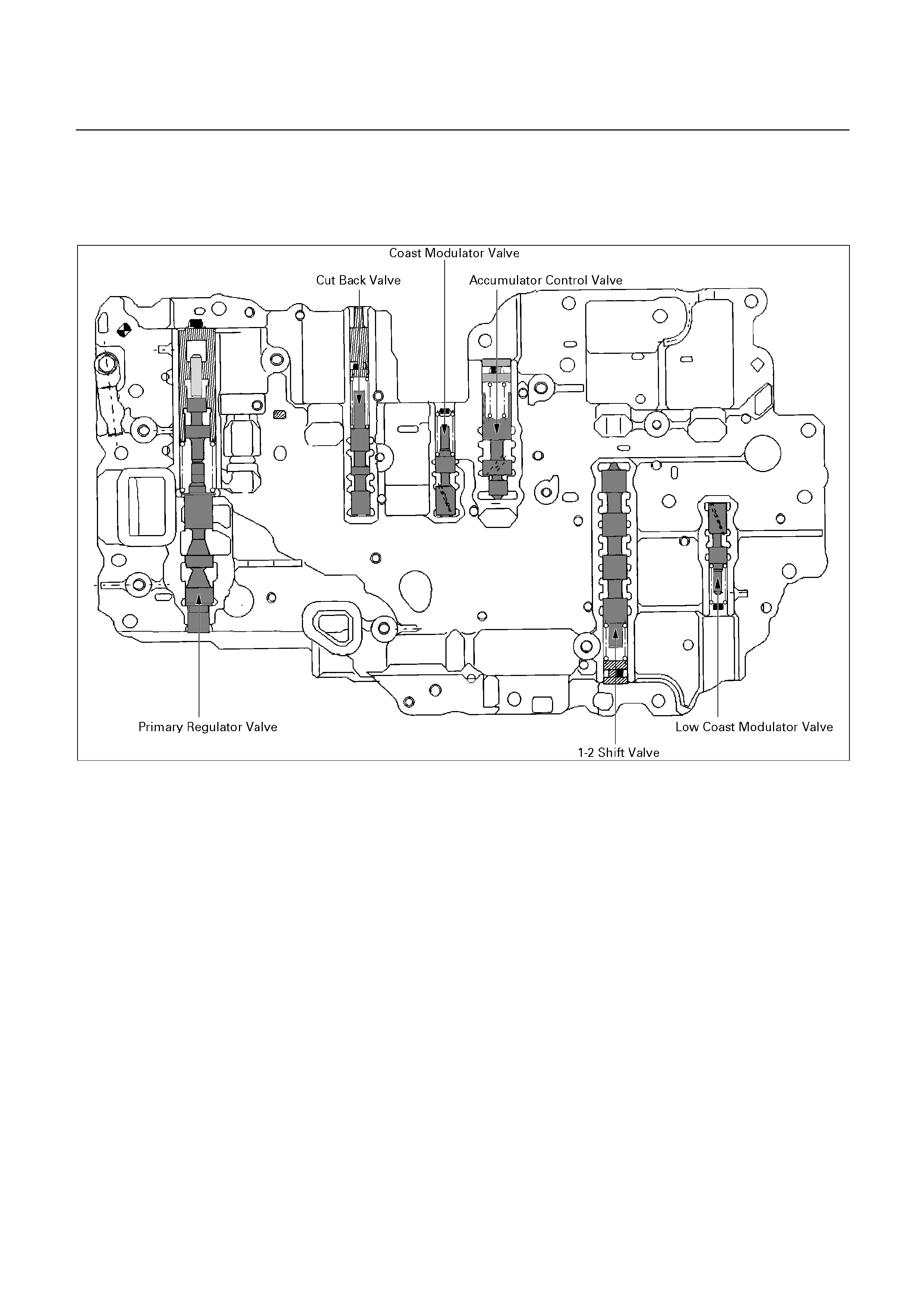

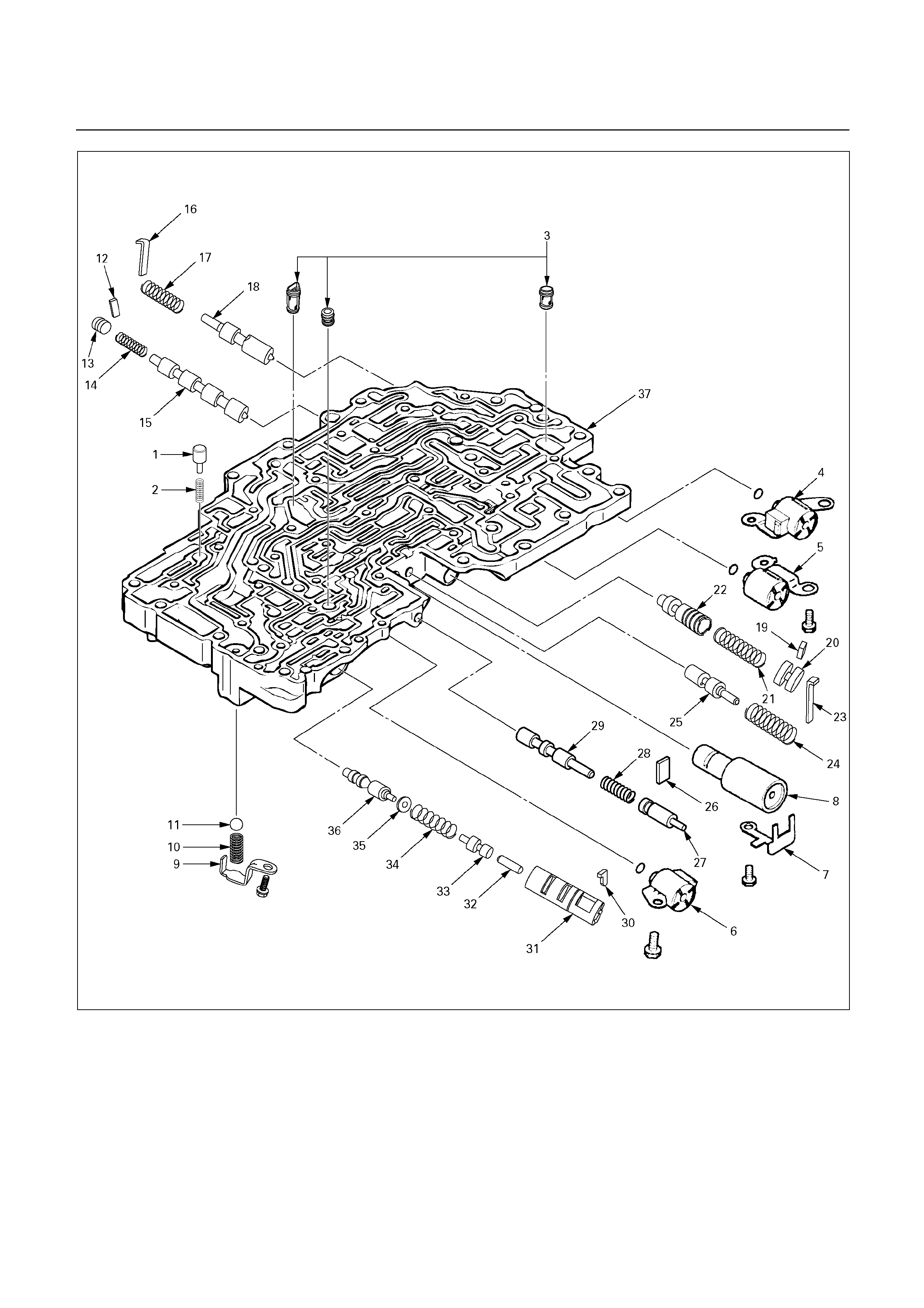

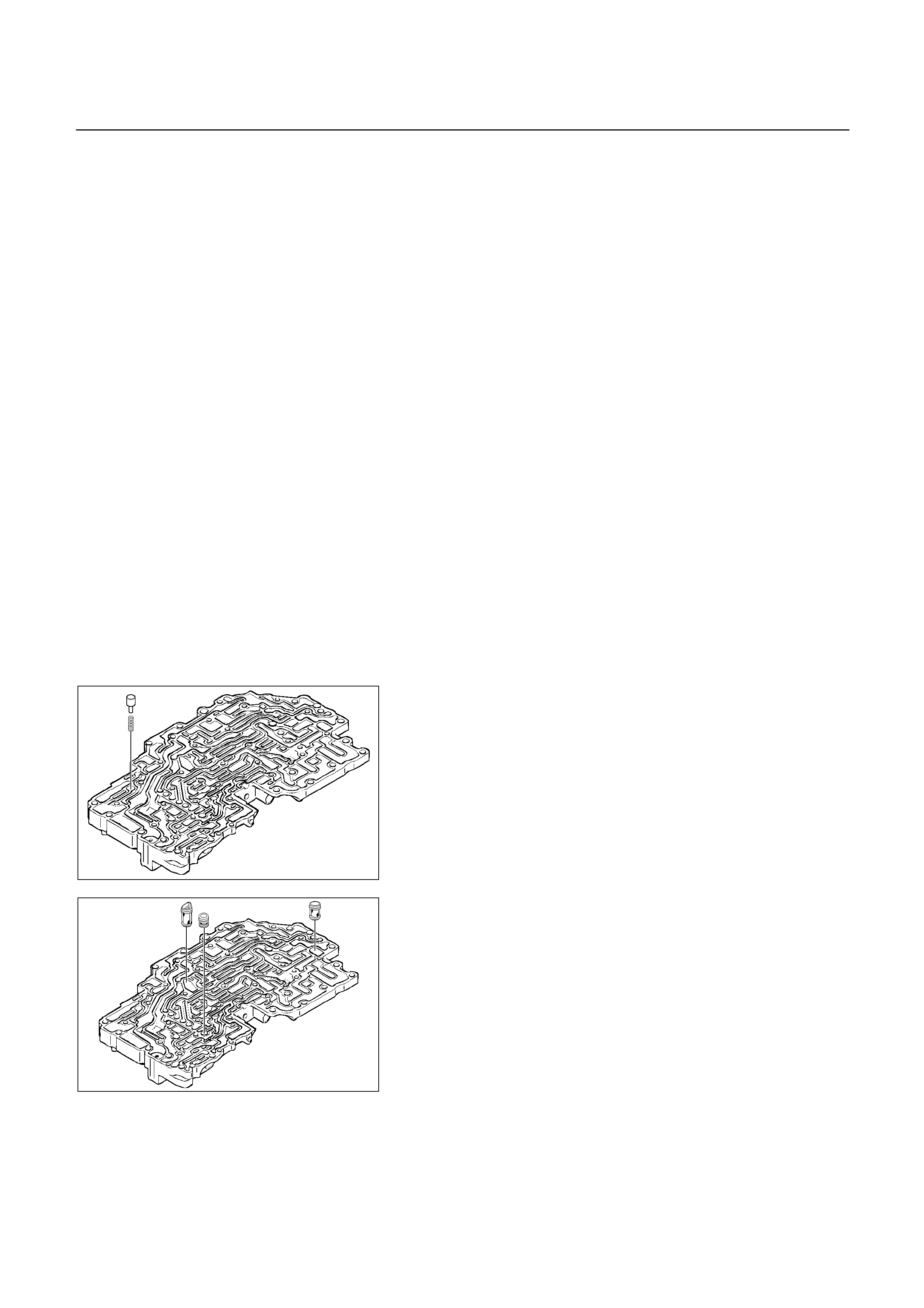

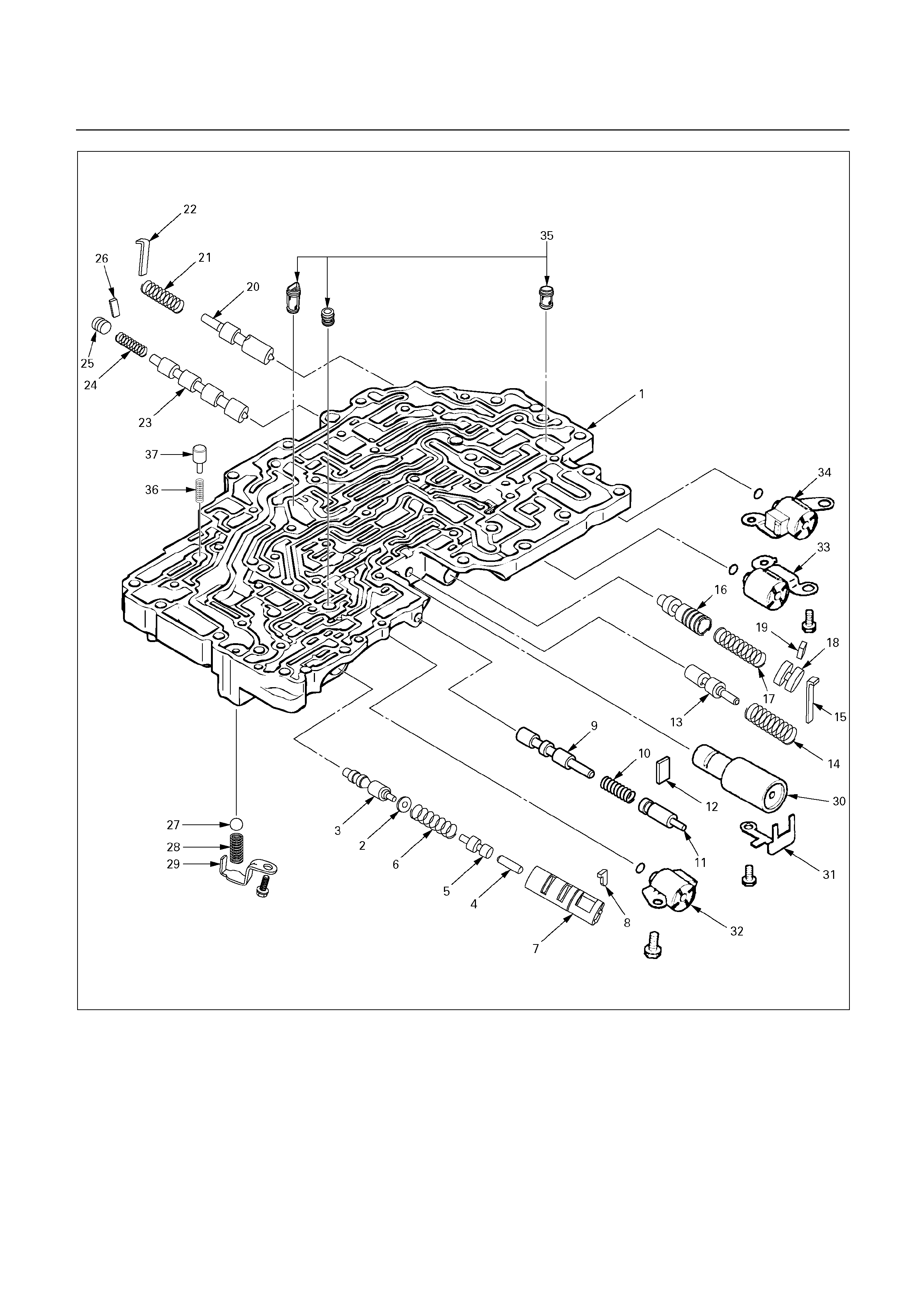

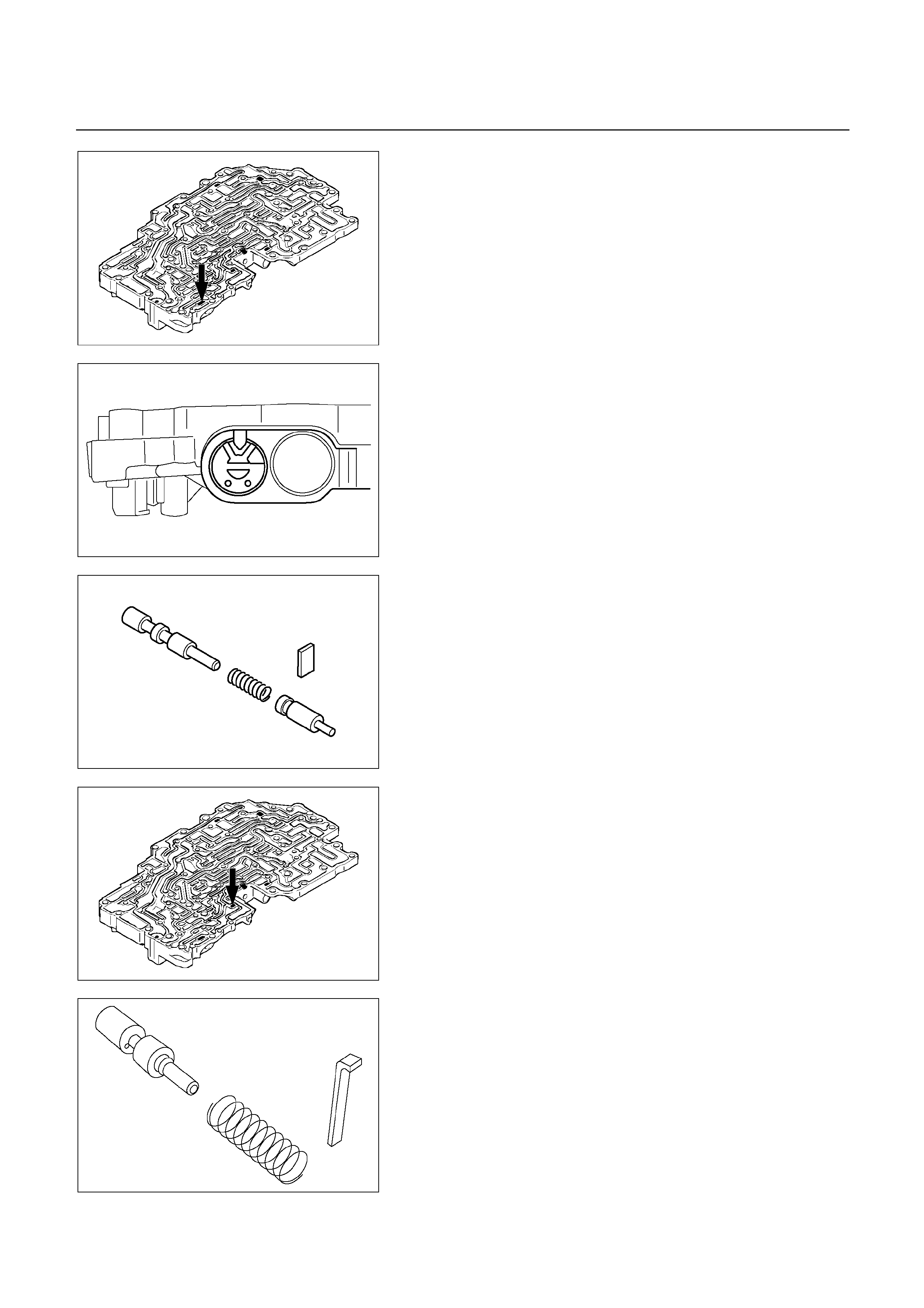

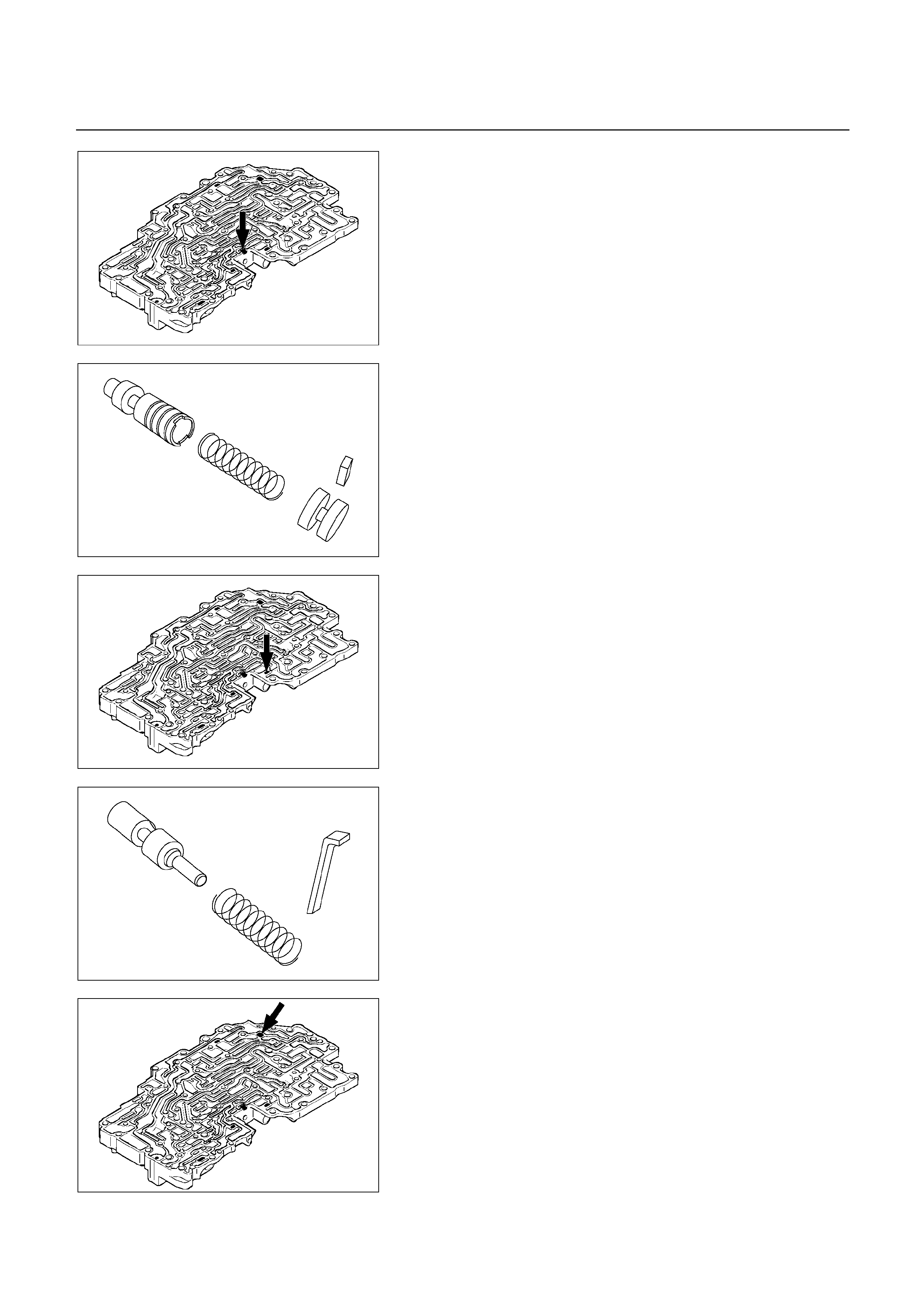

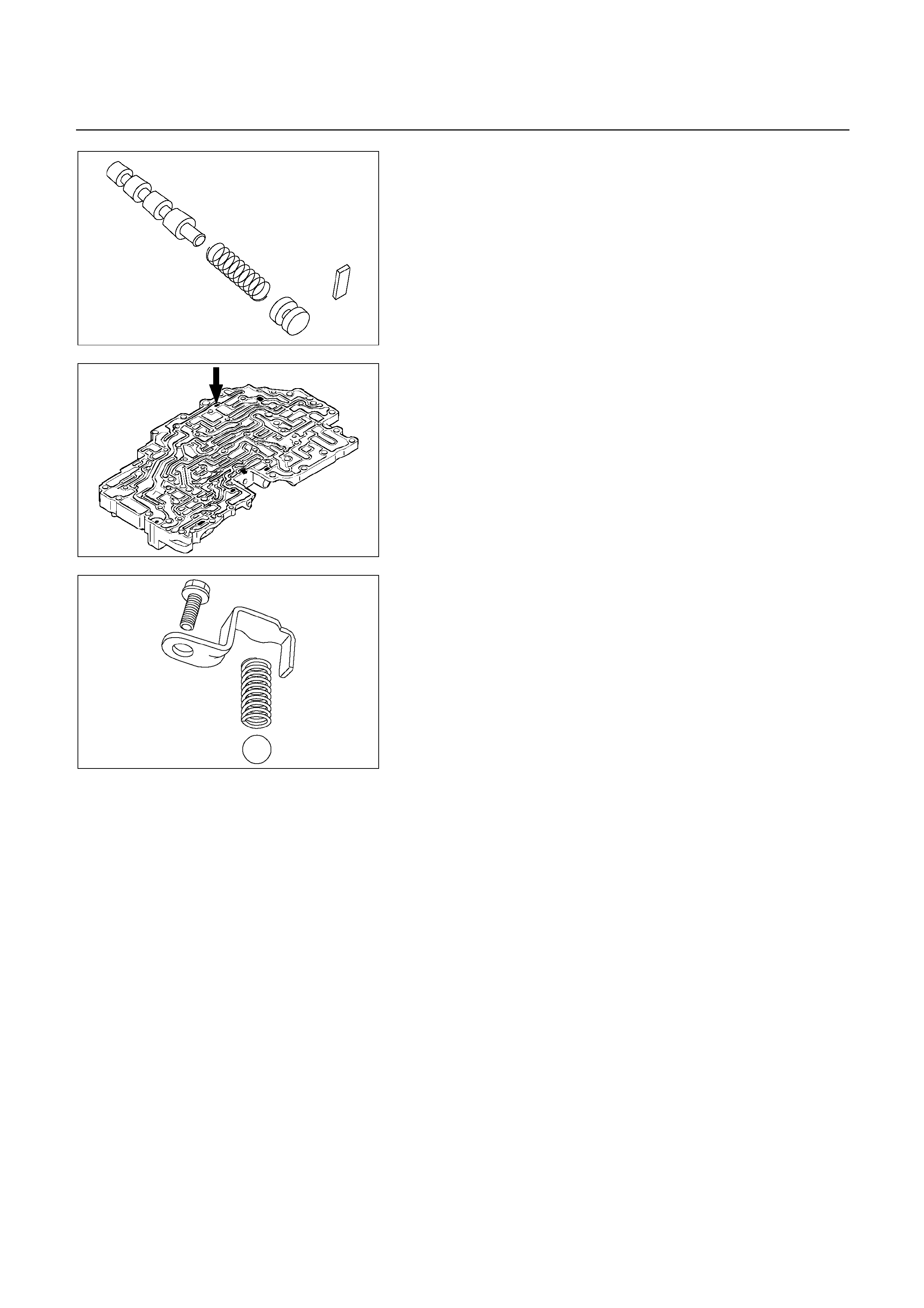

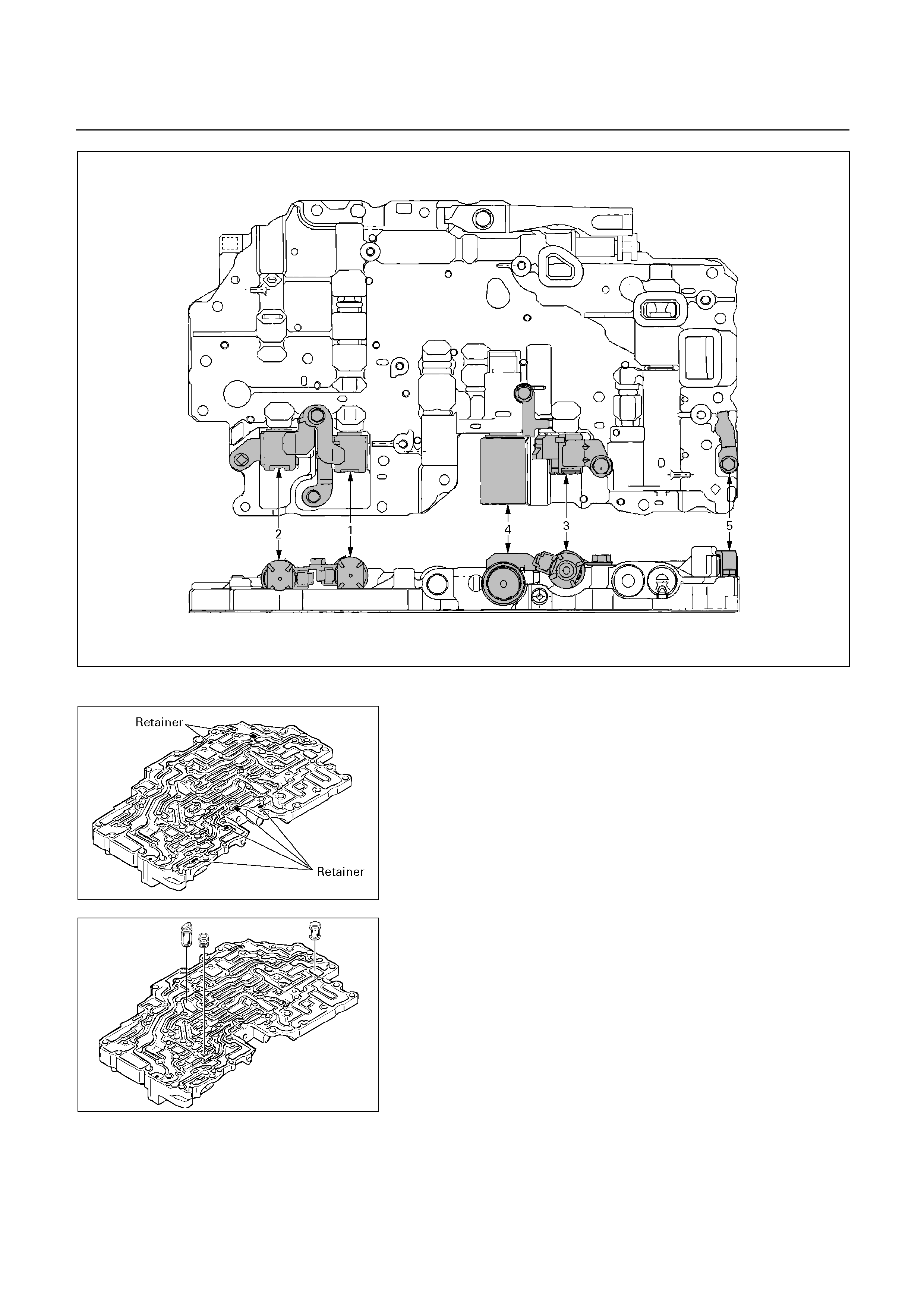

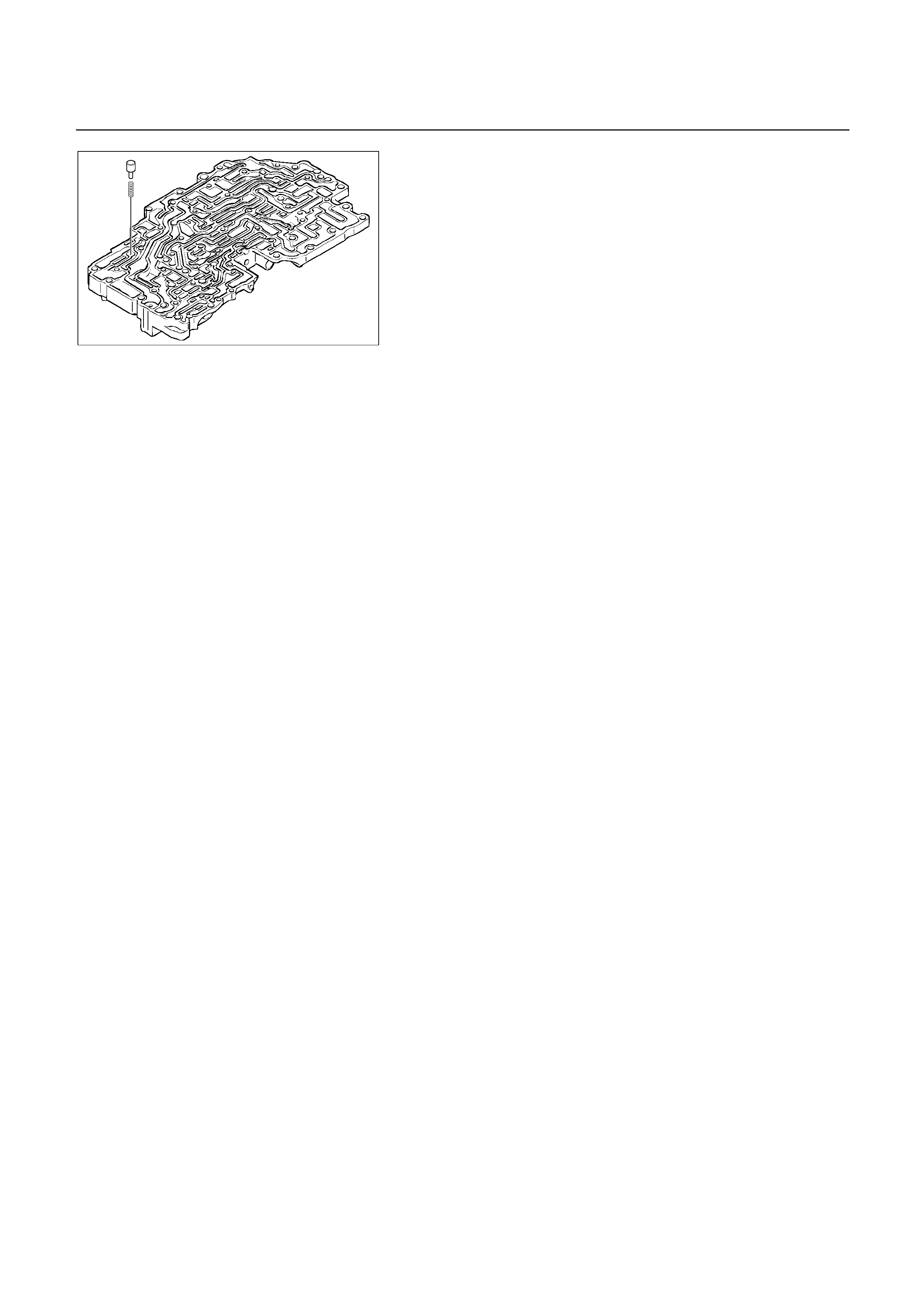

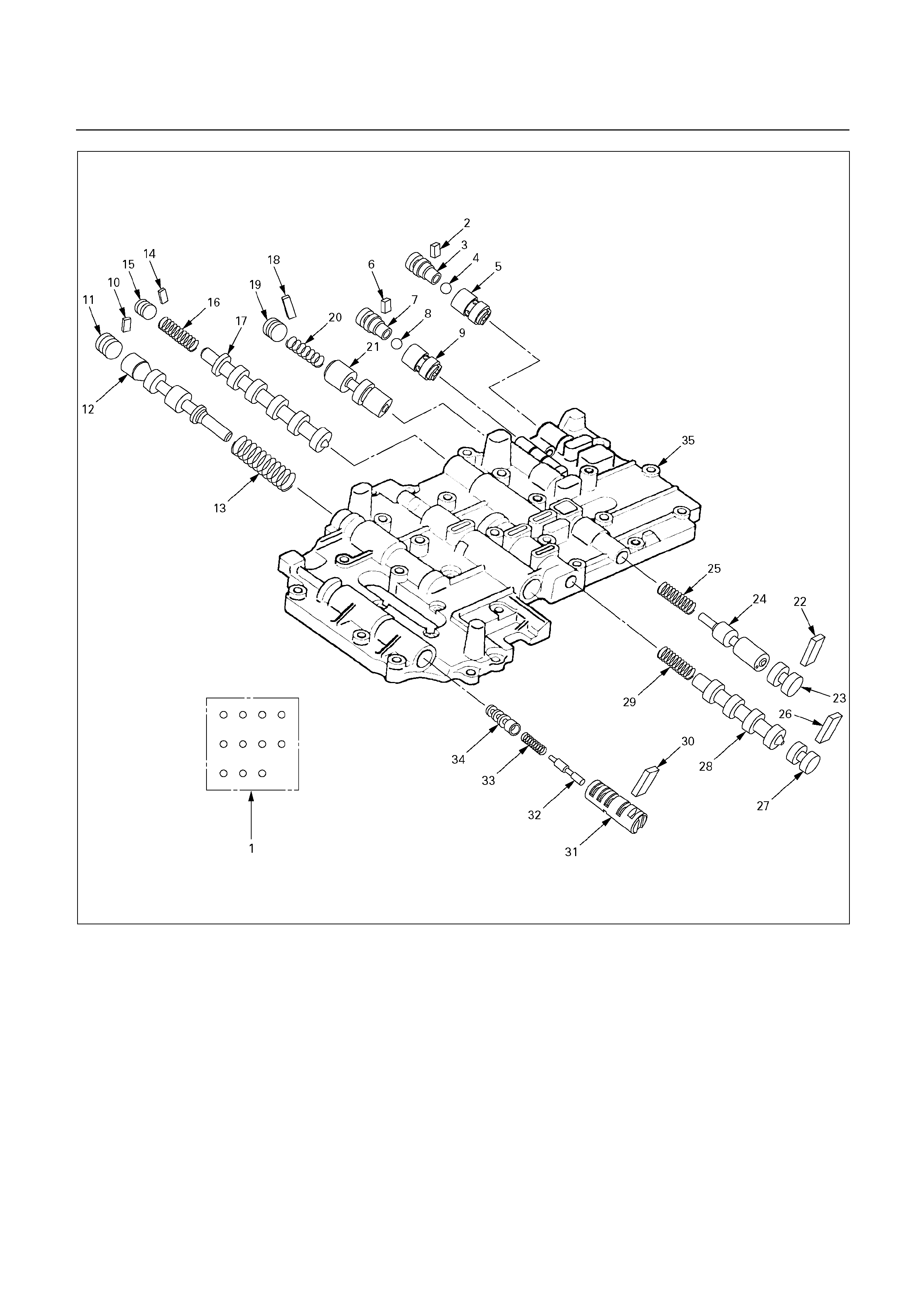

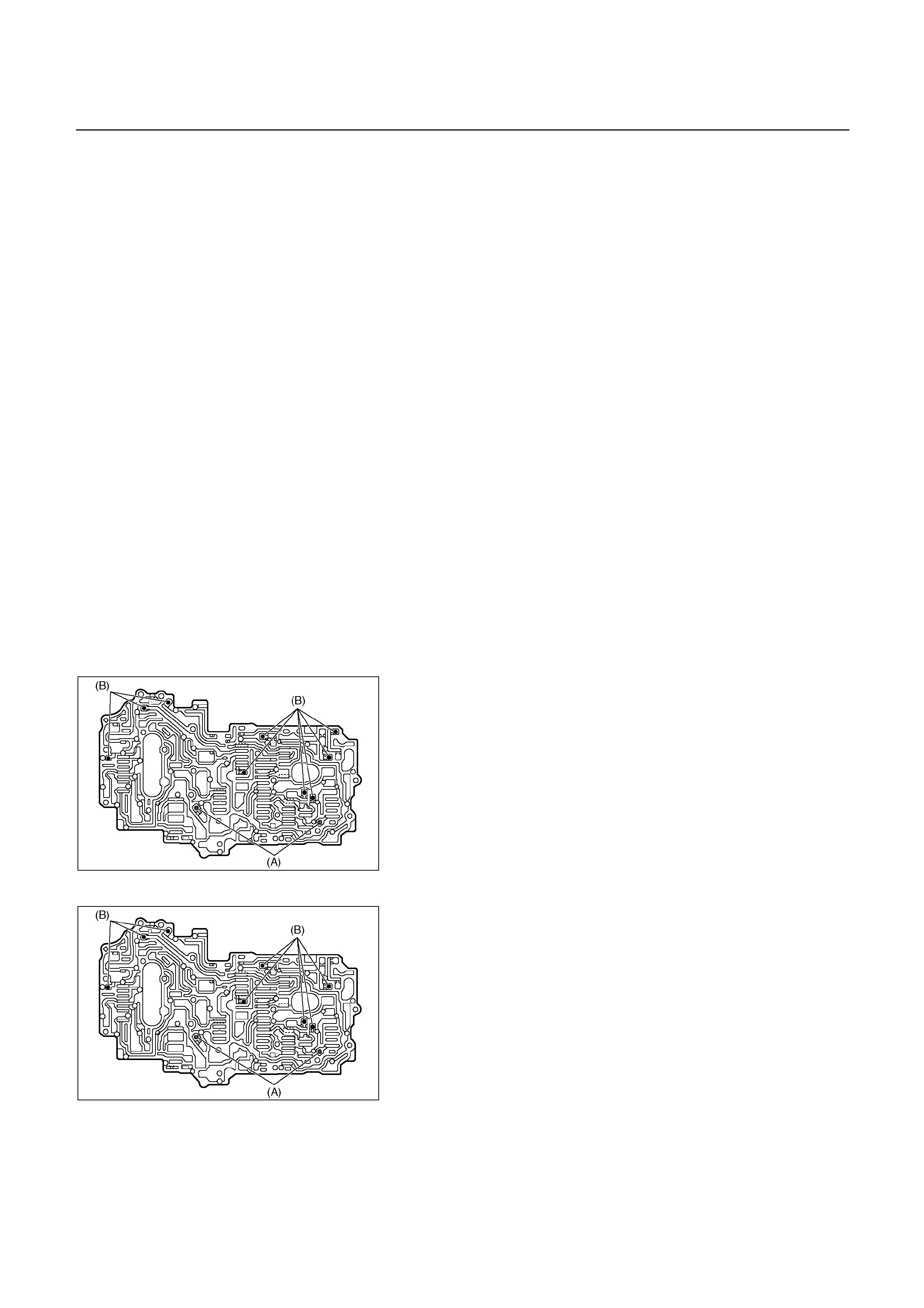

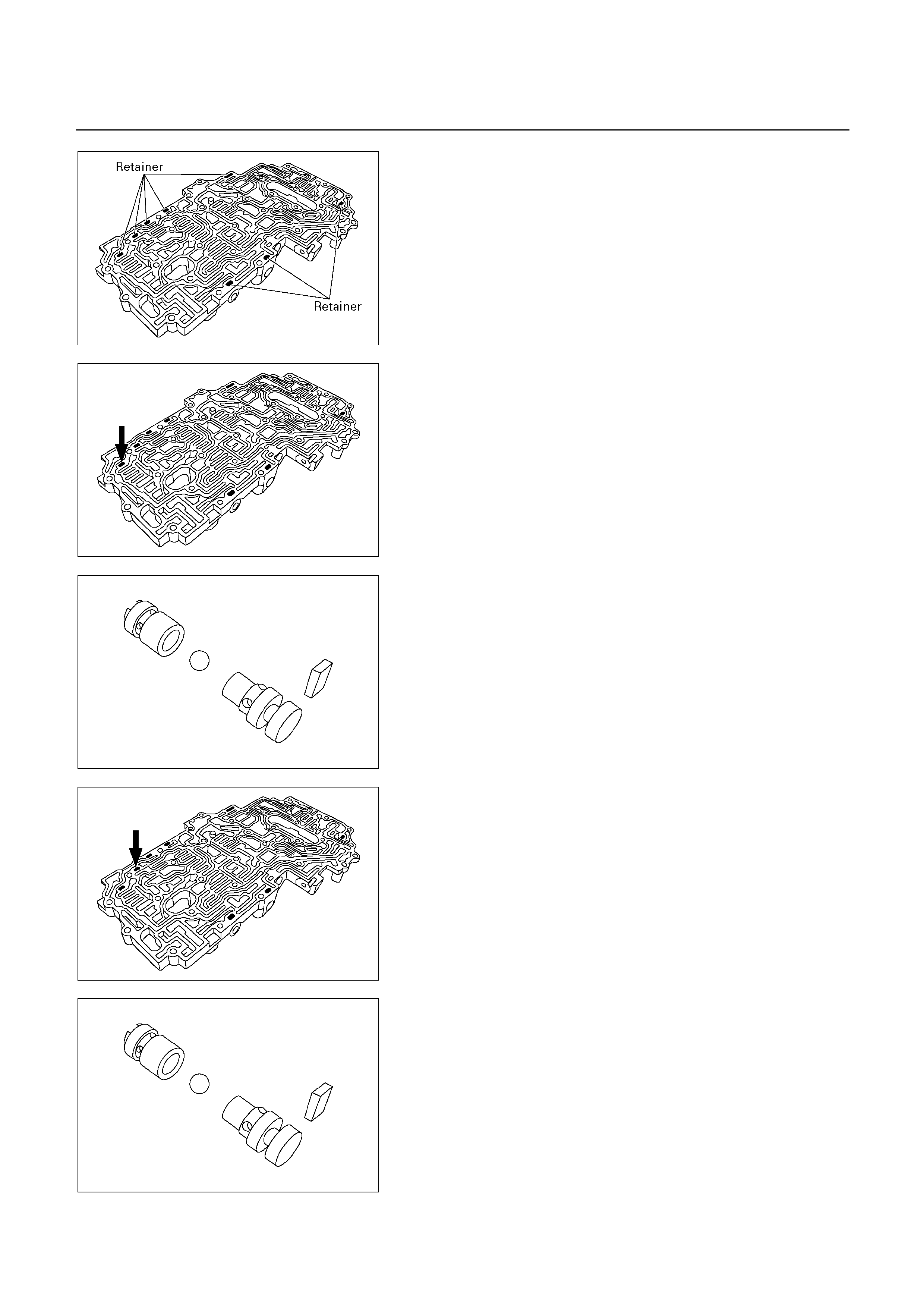

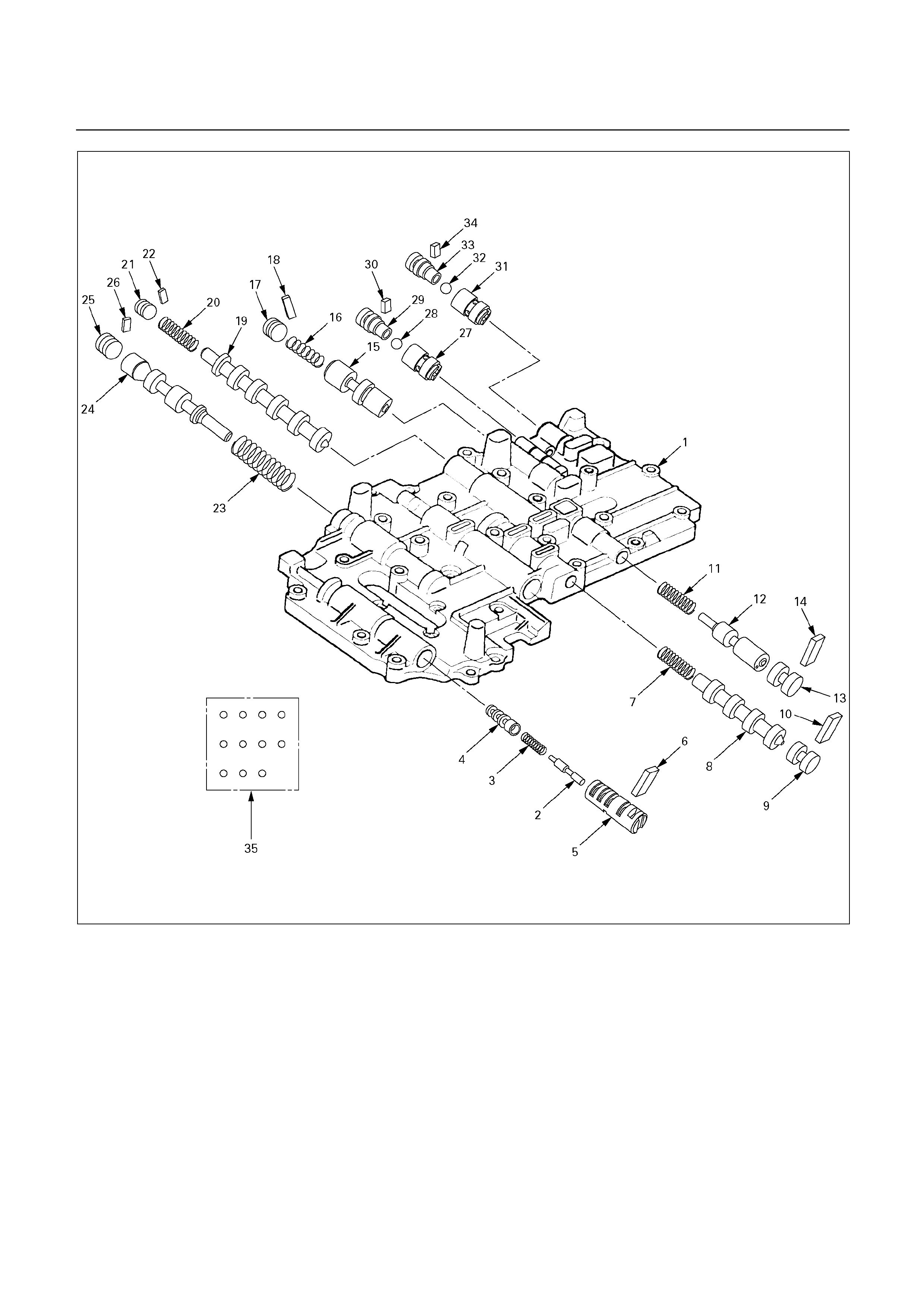

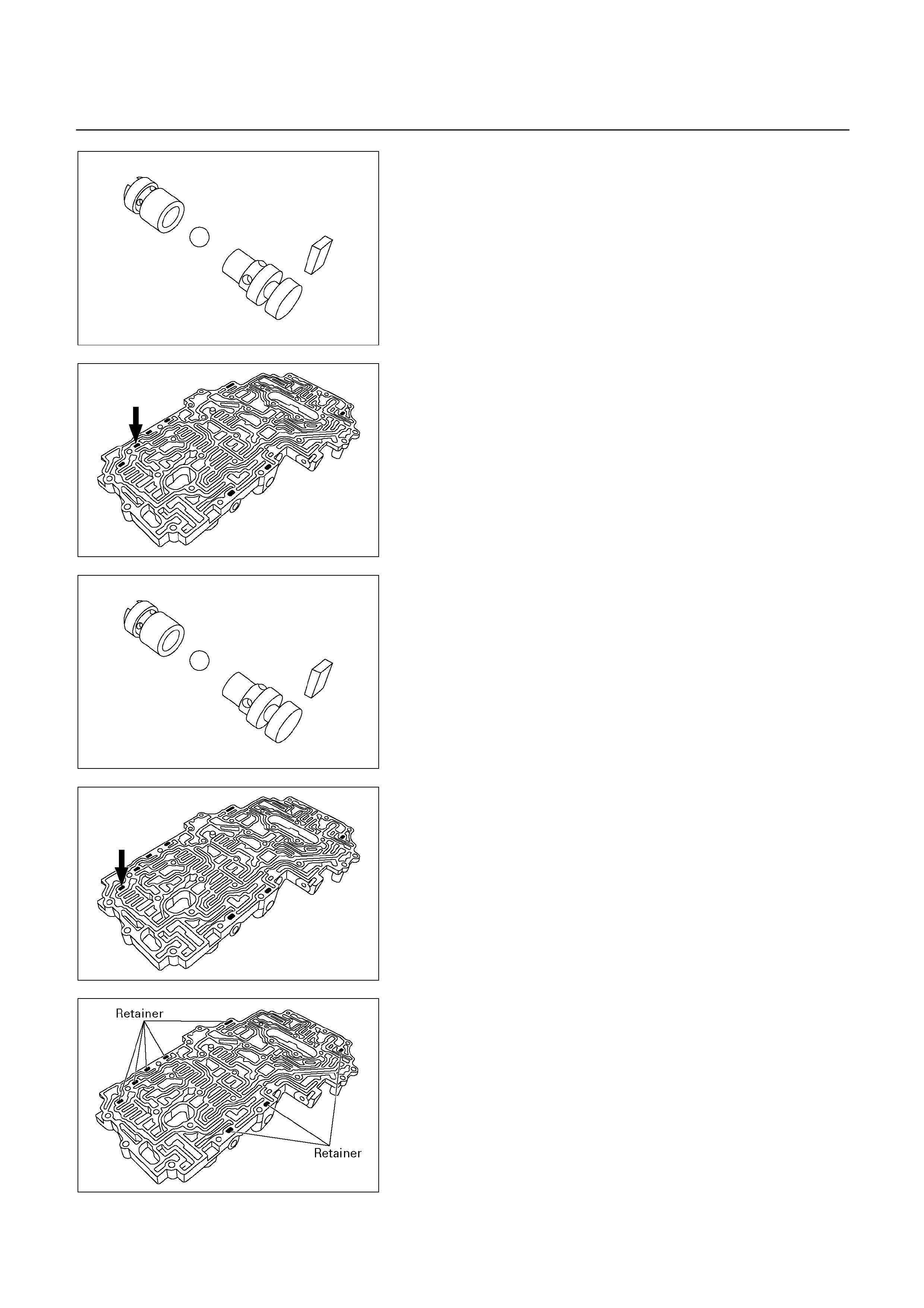

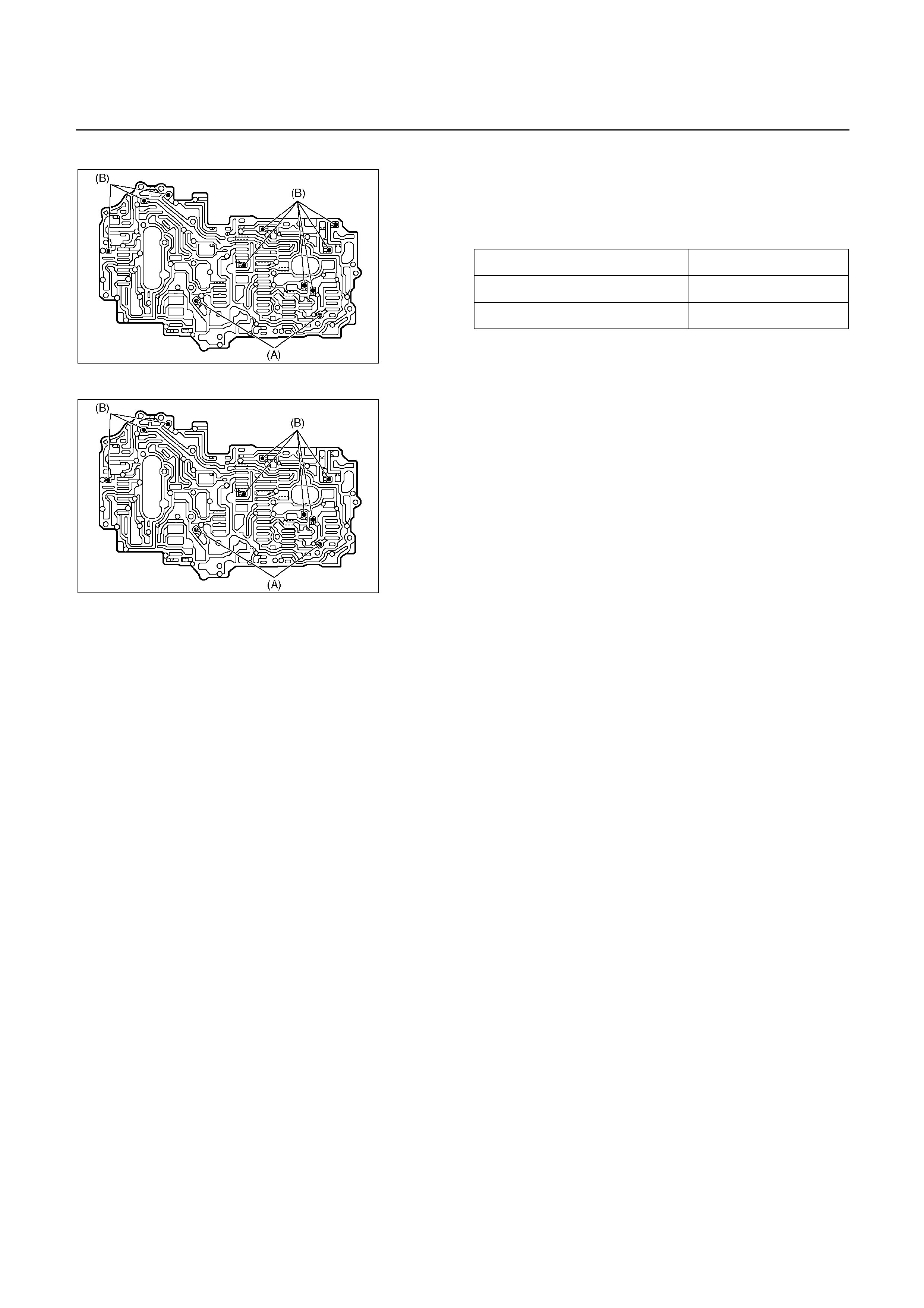

Transmission Valve Body Assembly

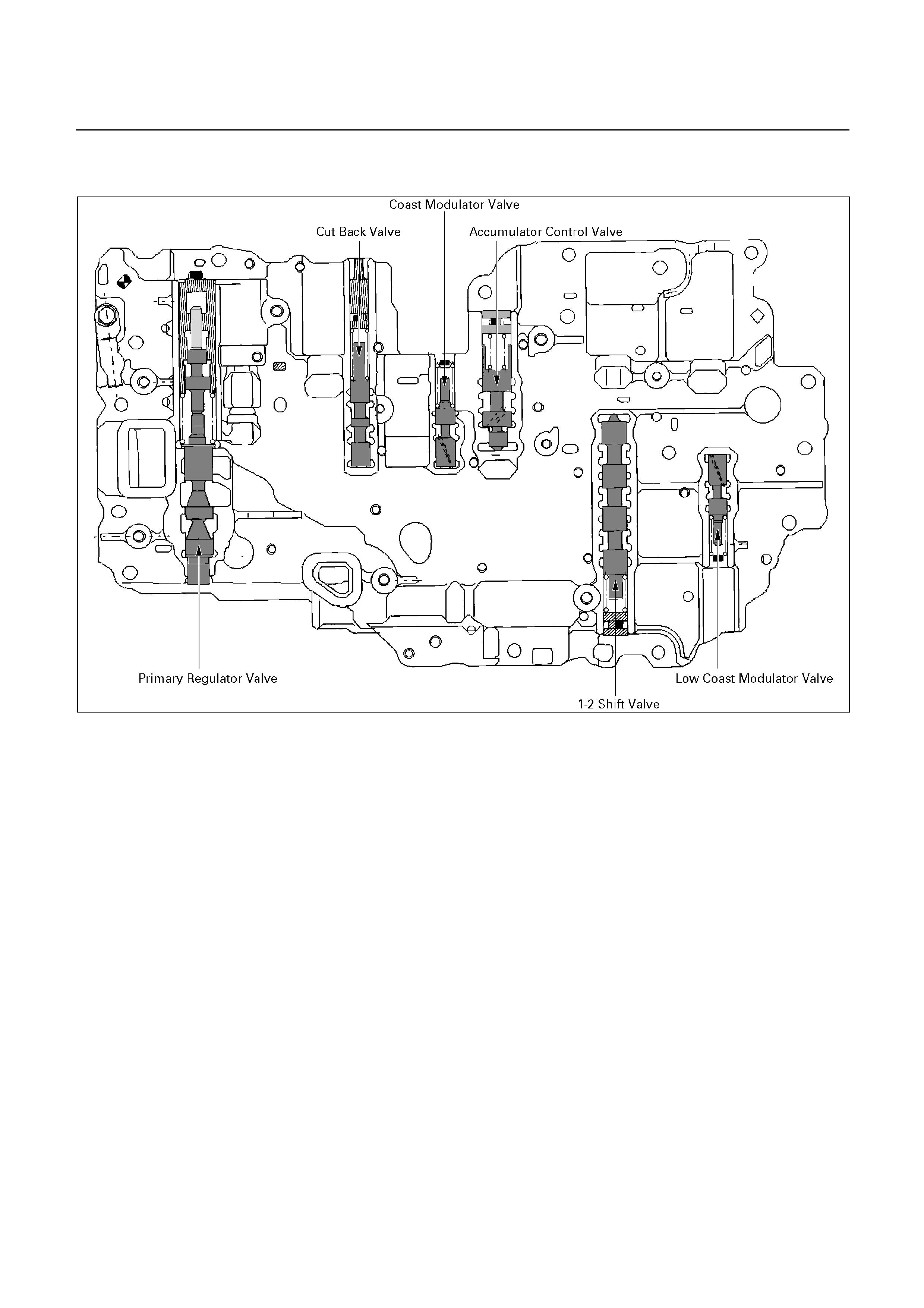

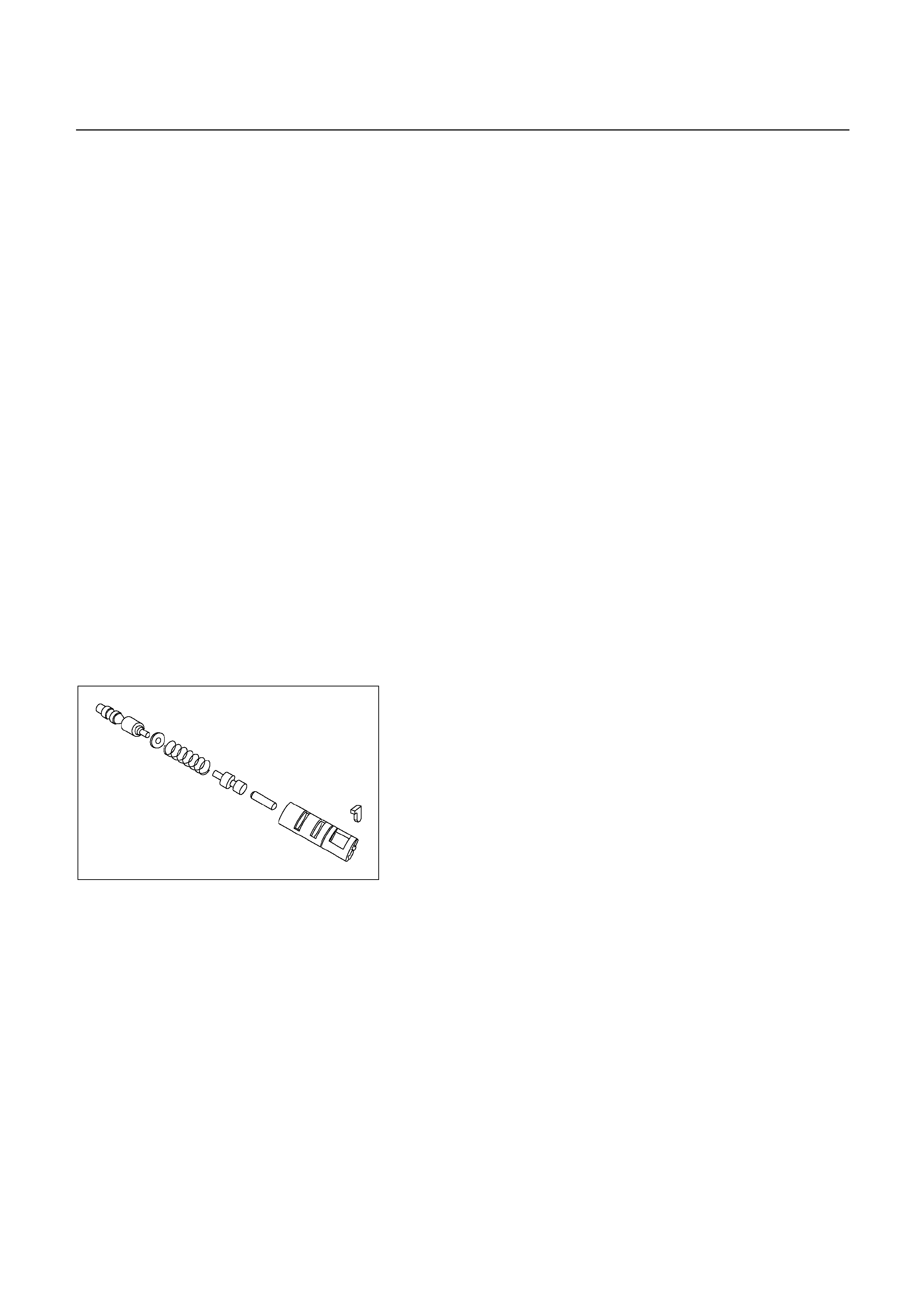

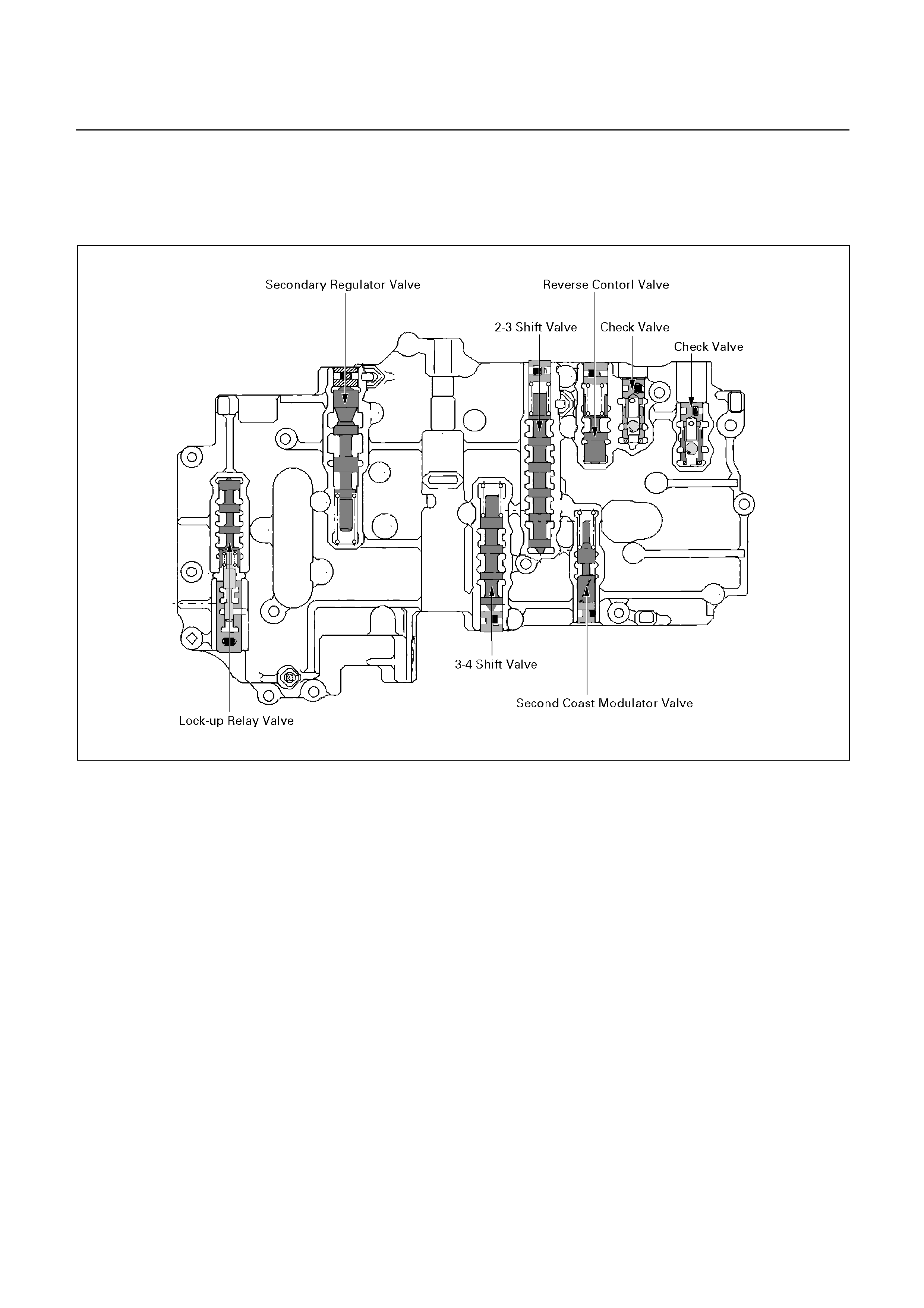

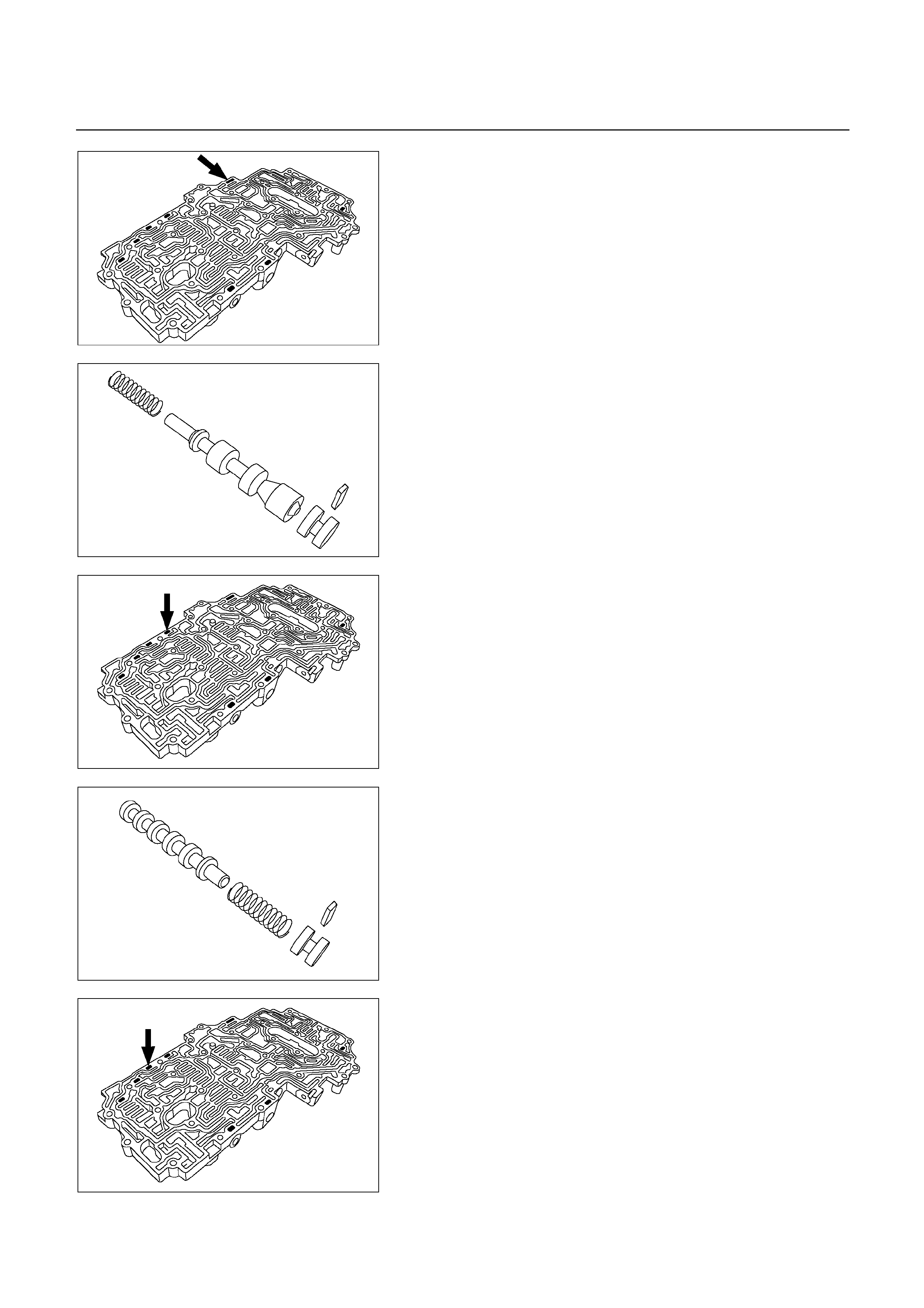

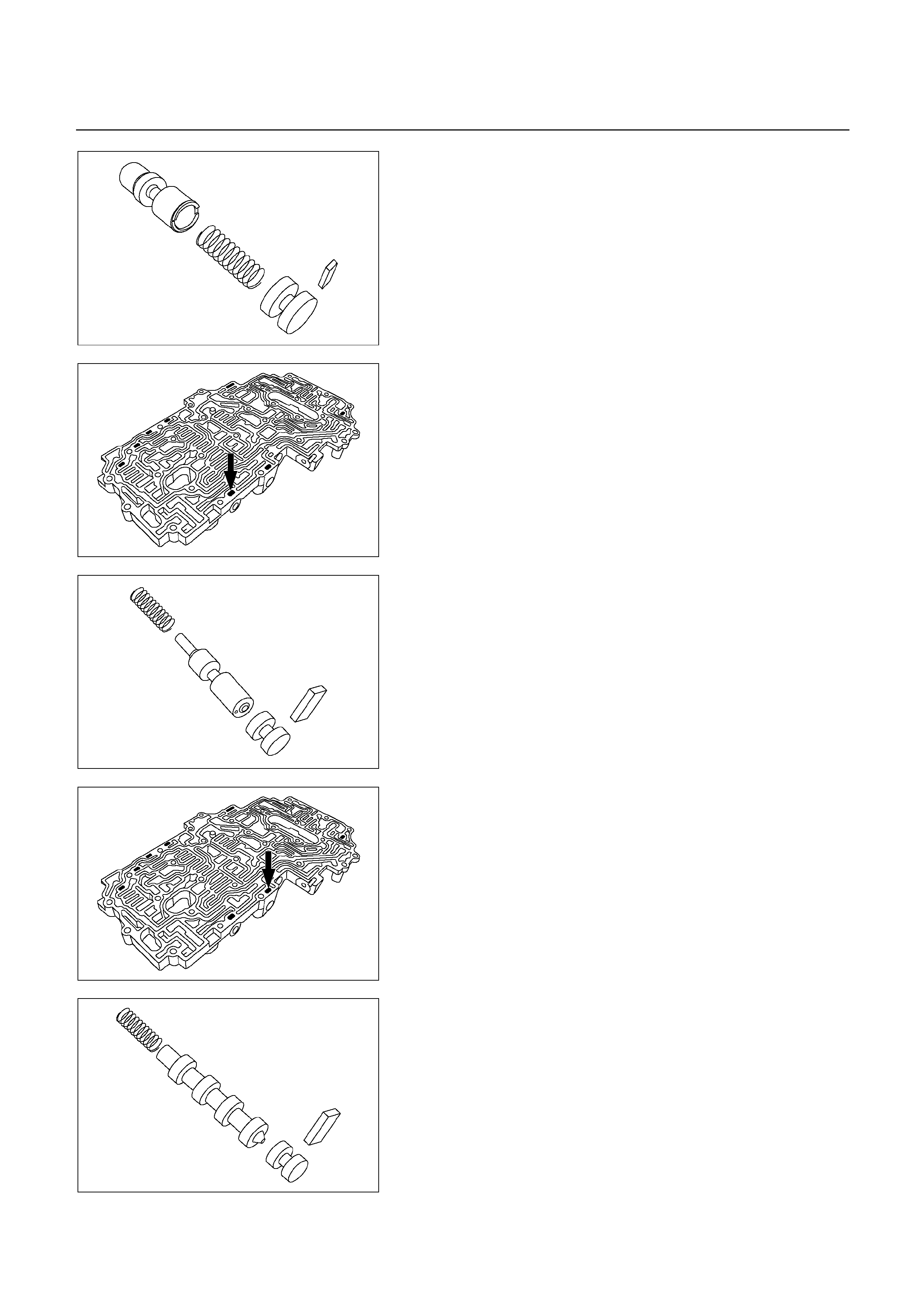

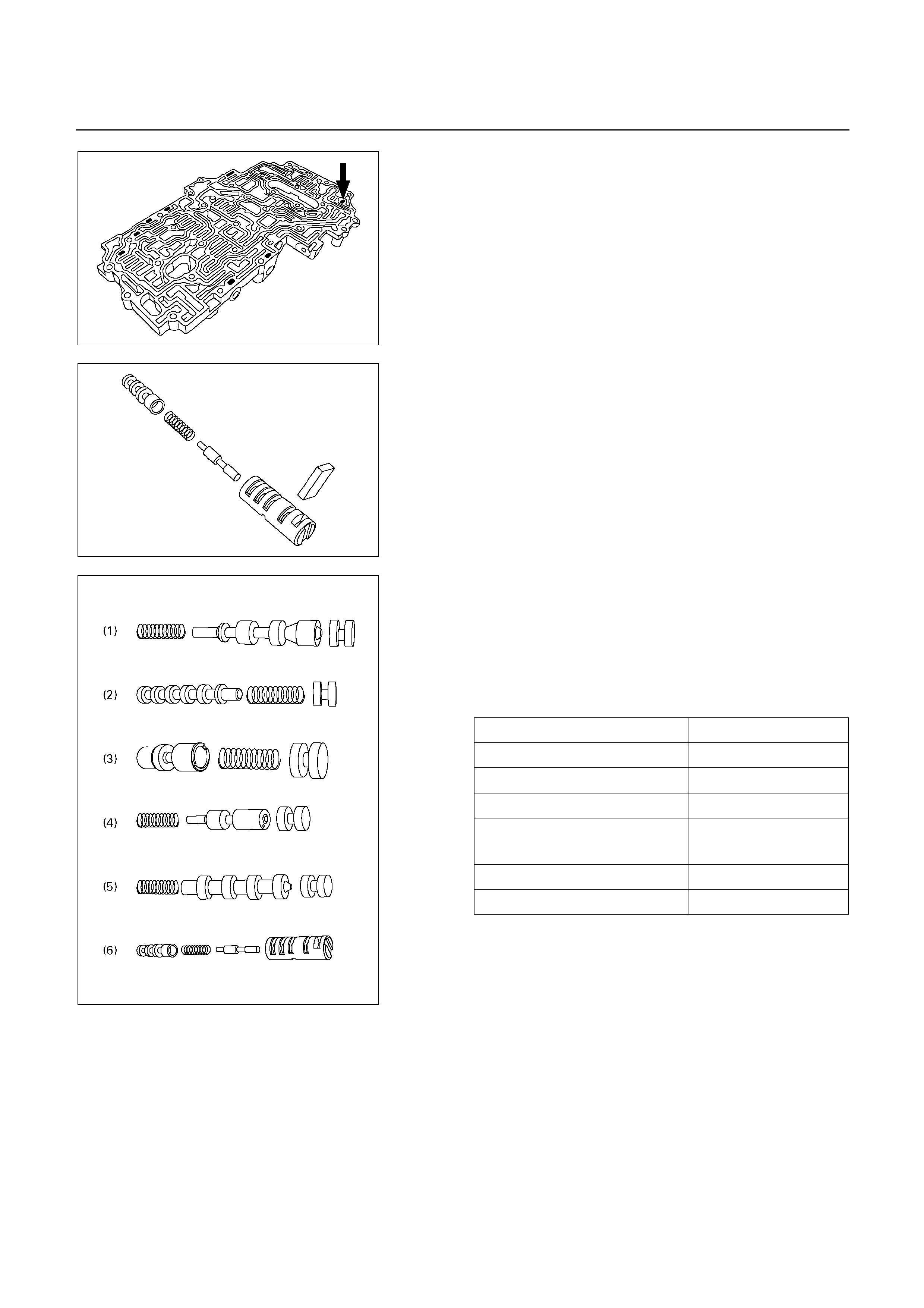

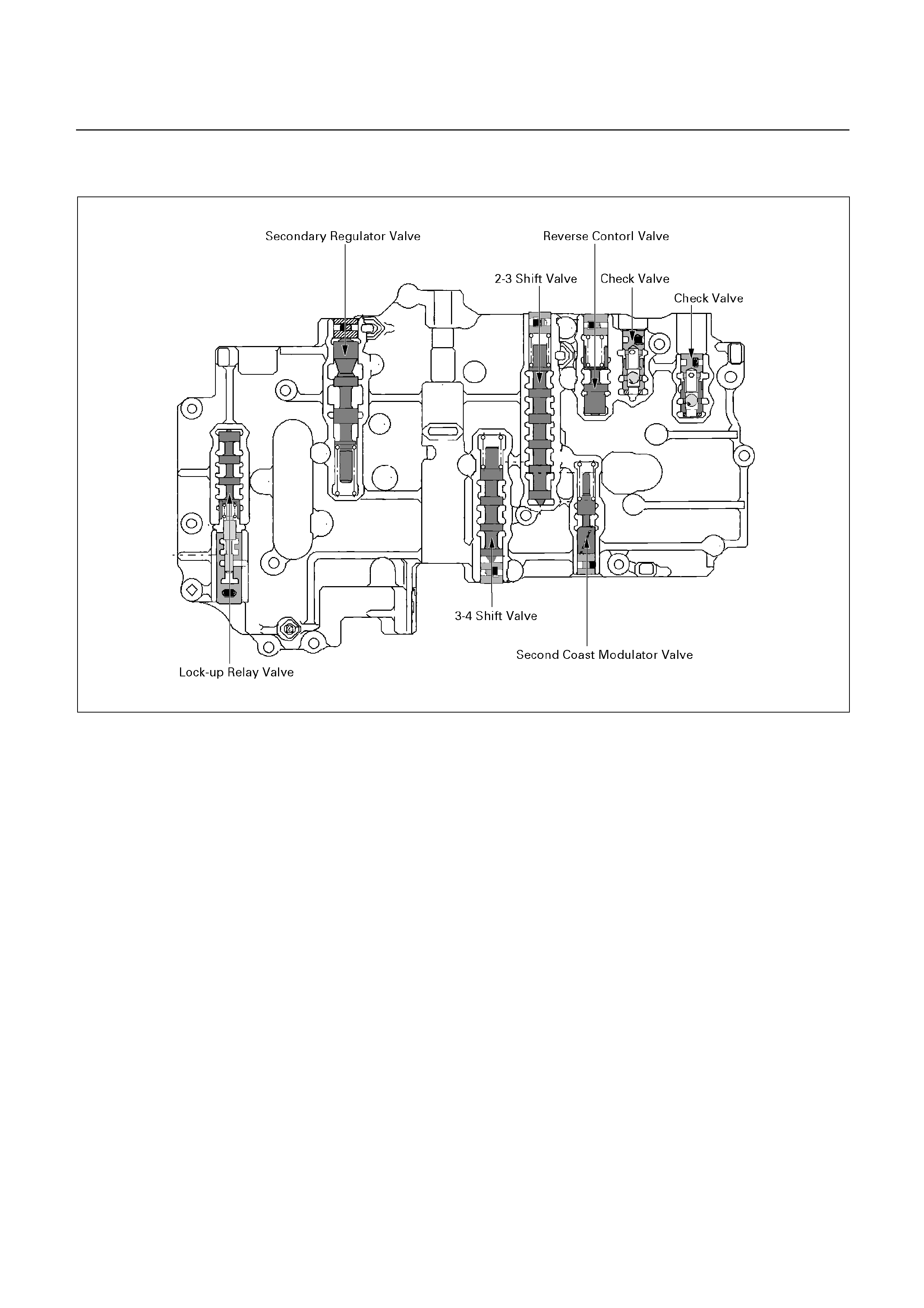

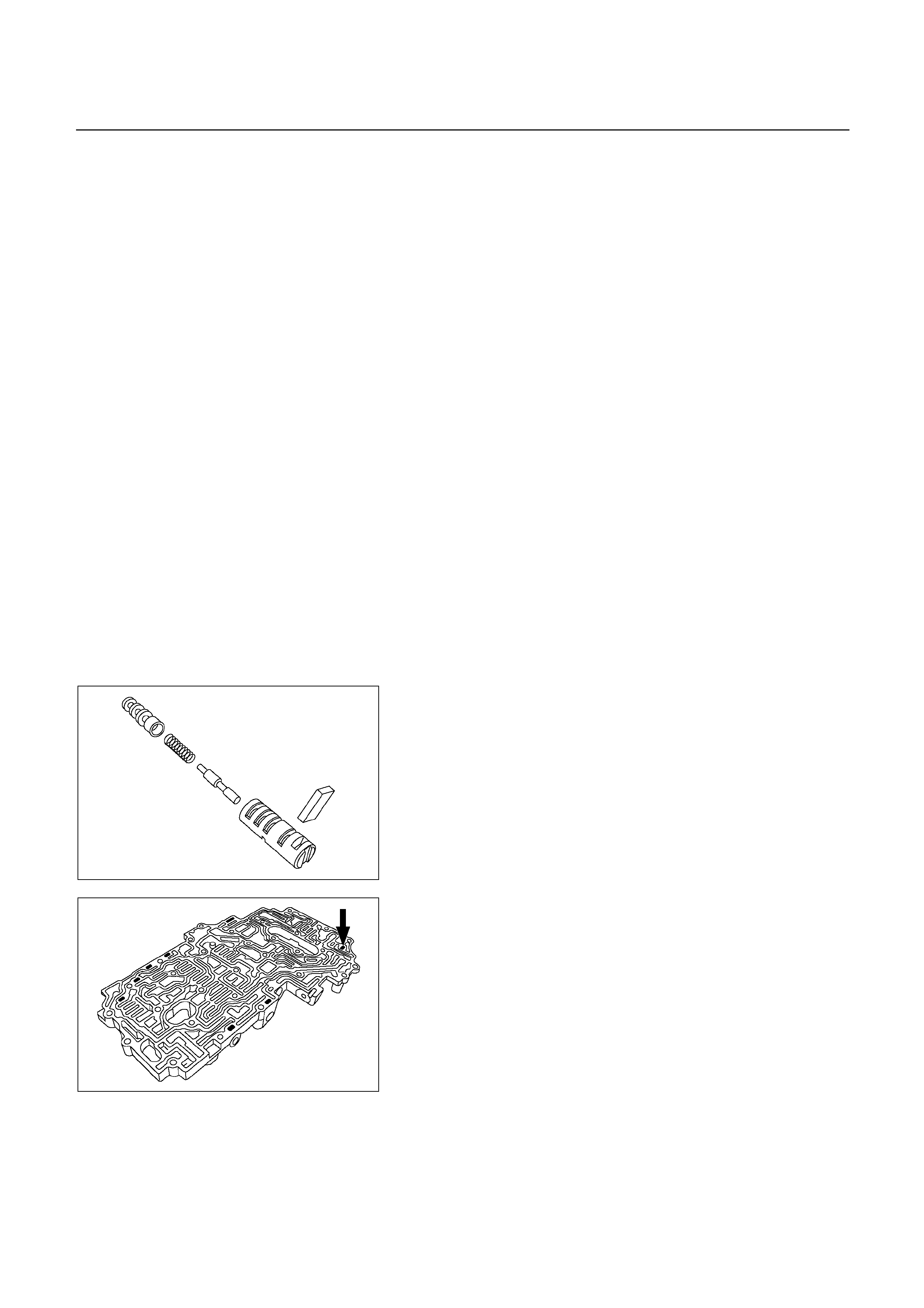

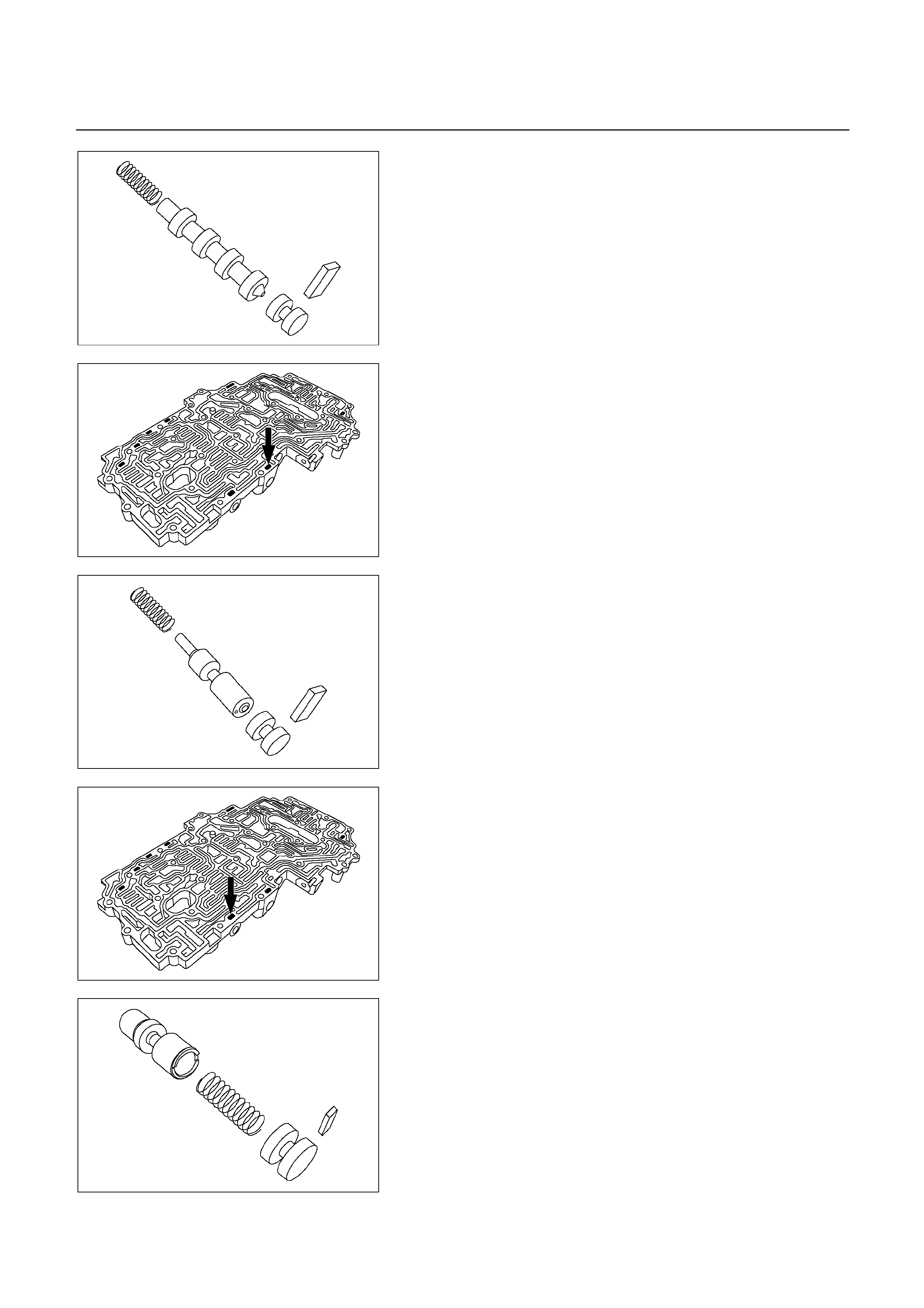

Lower Valve Body

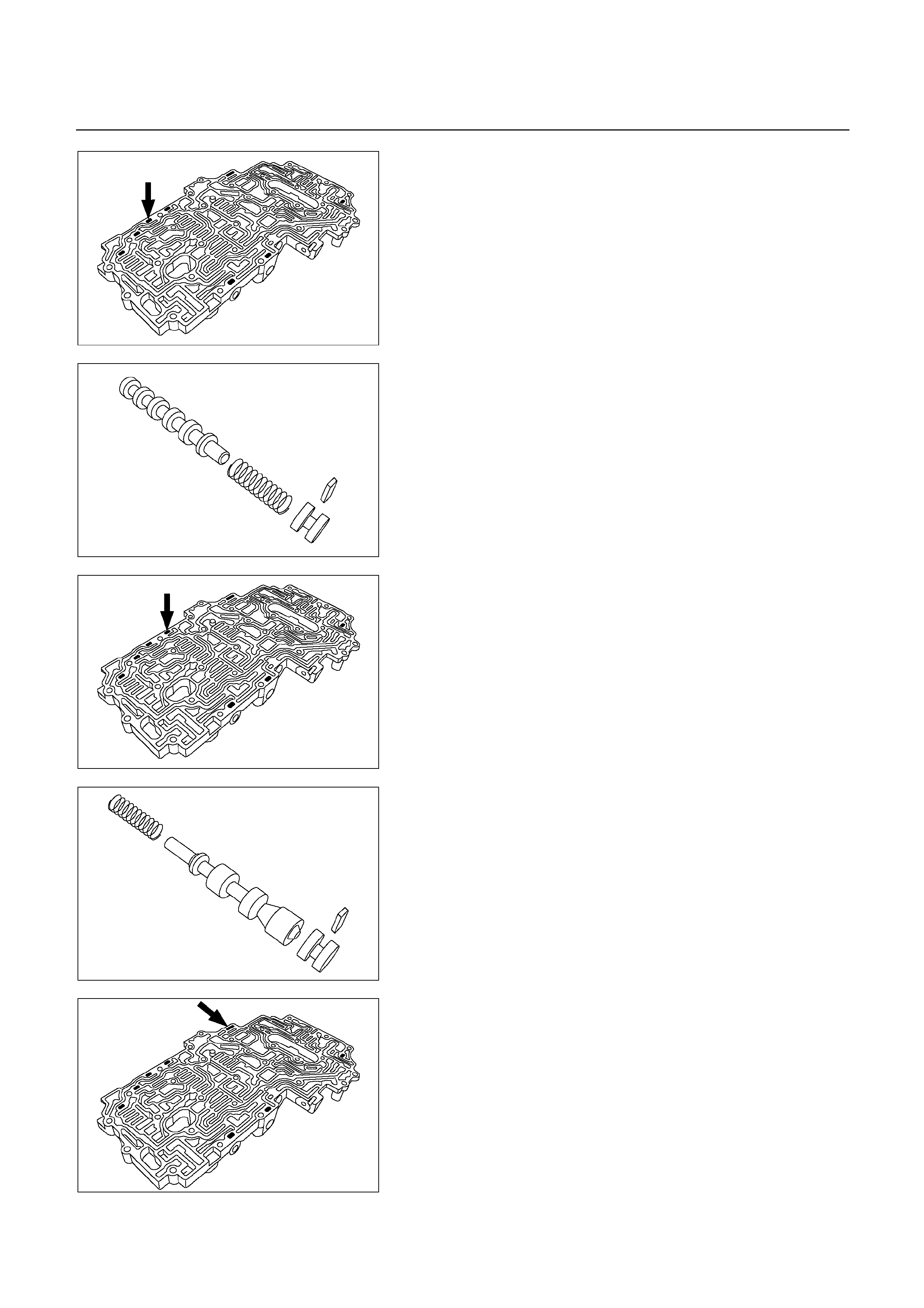

Upper Valve Body

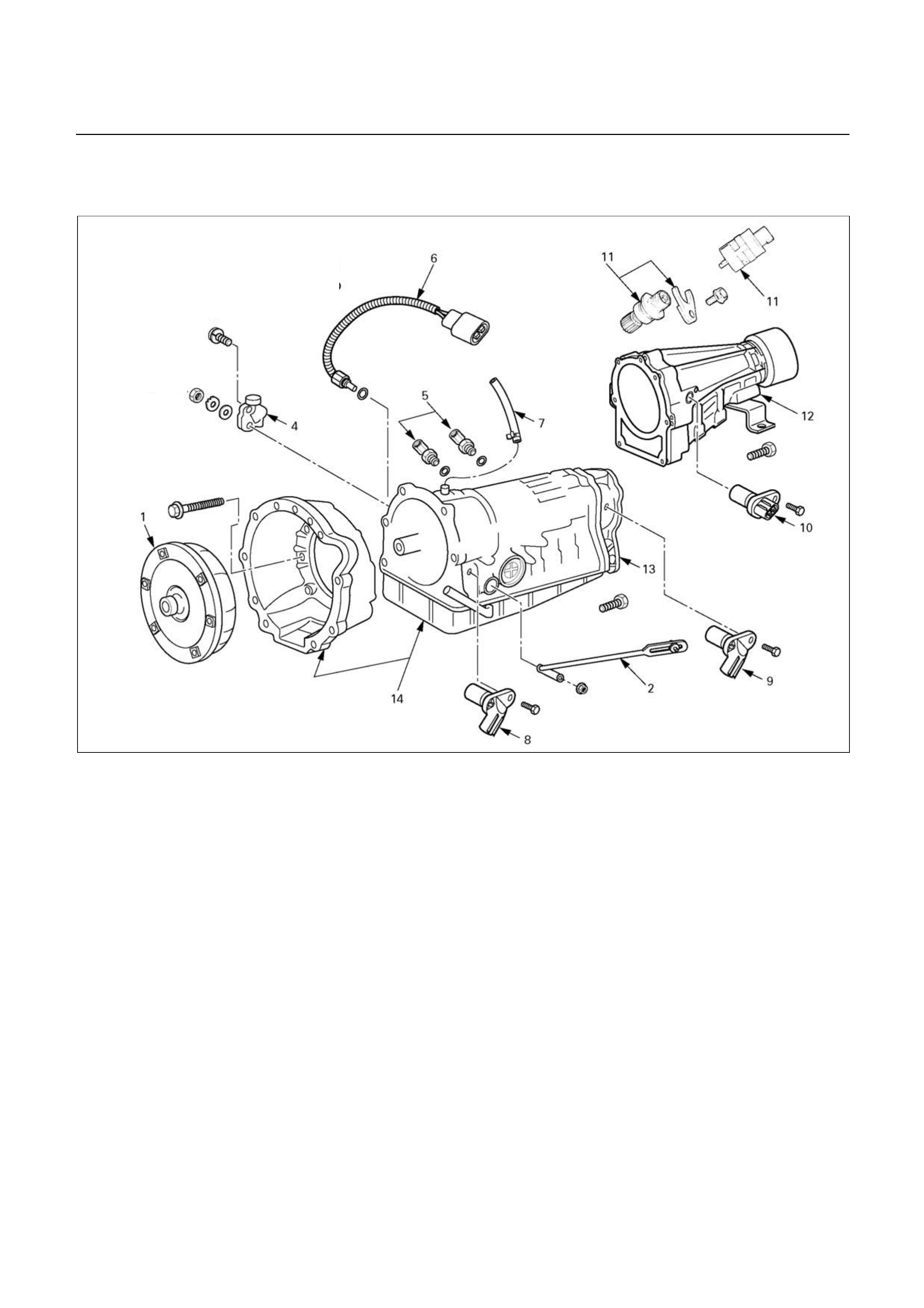

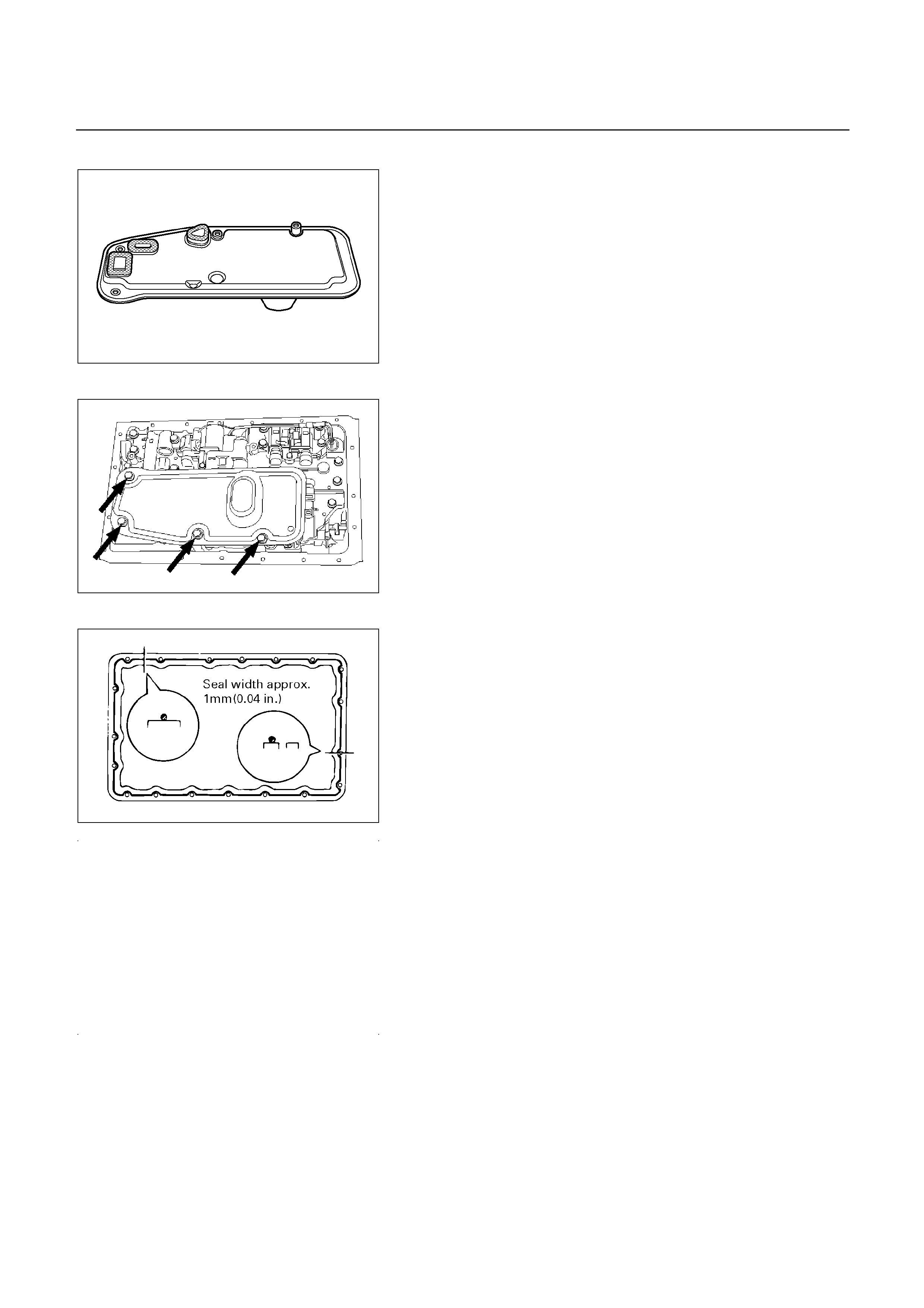

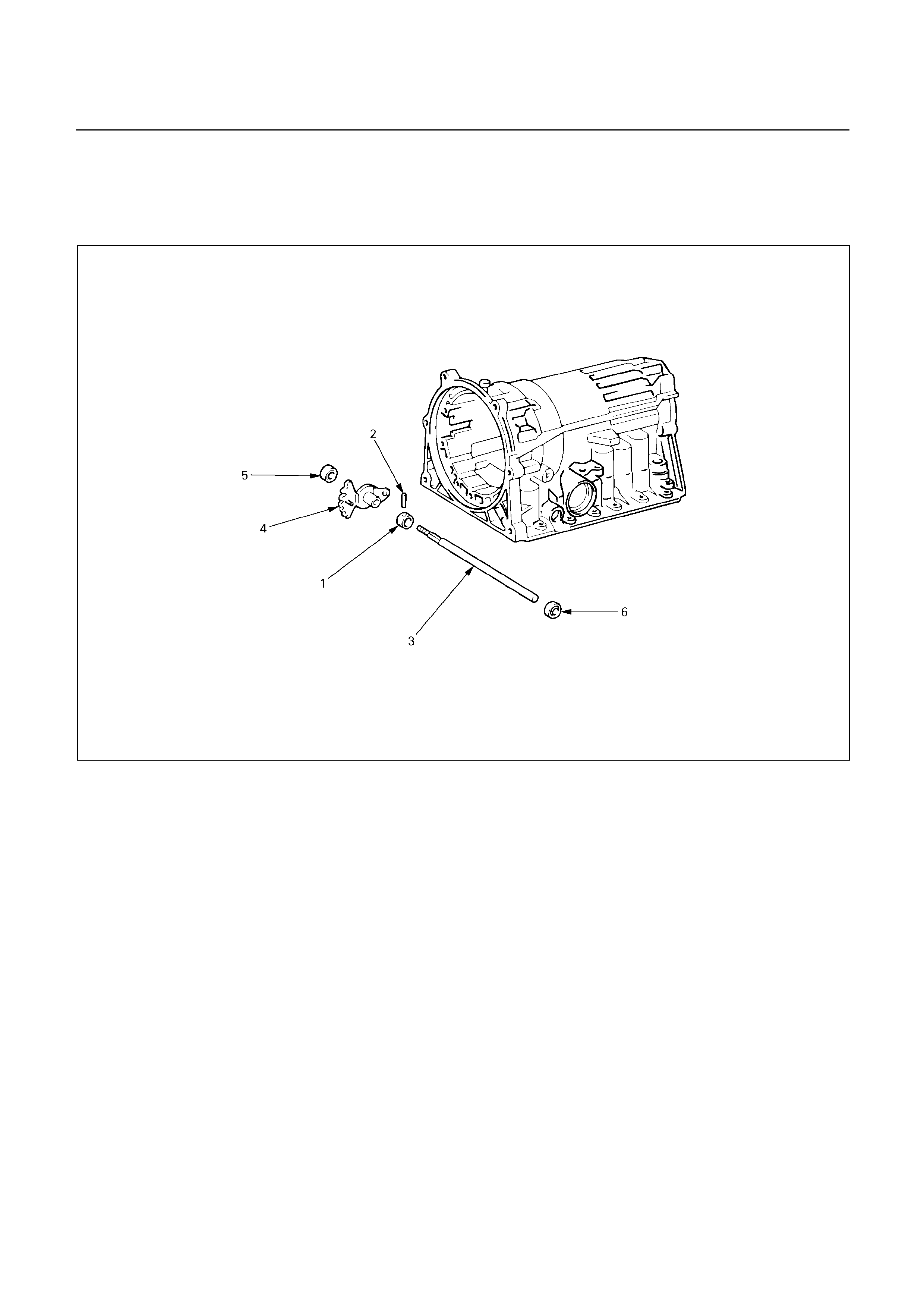

Transmission Case

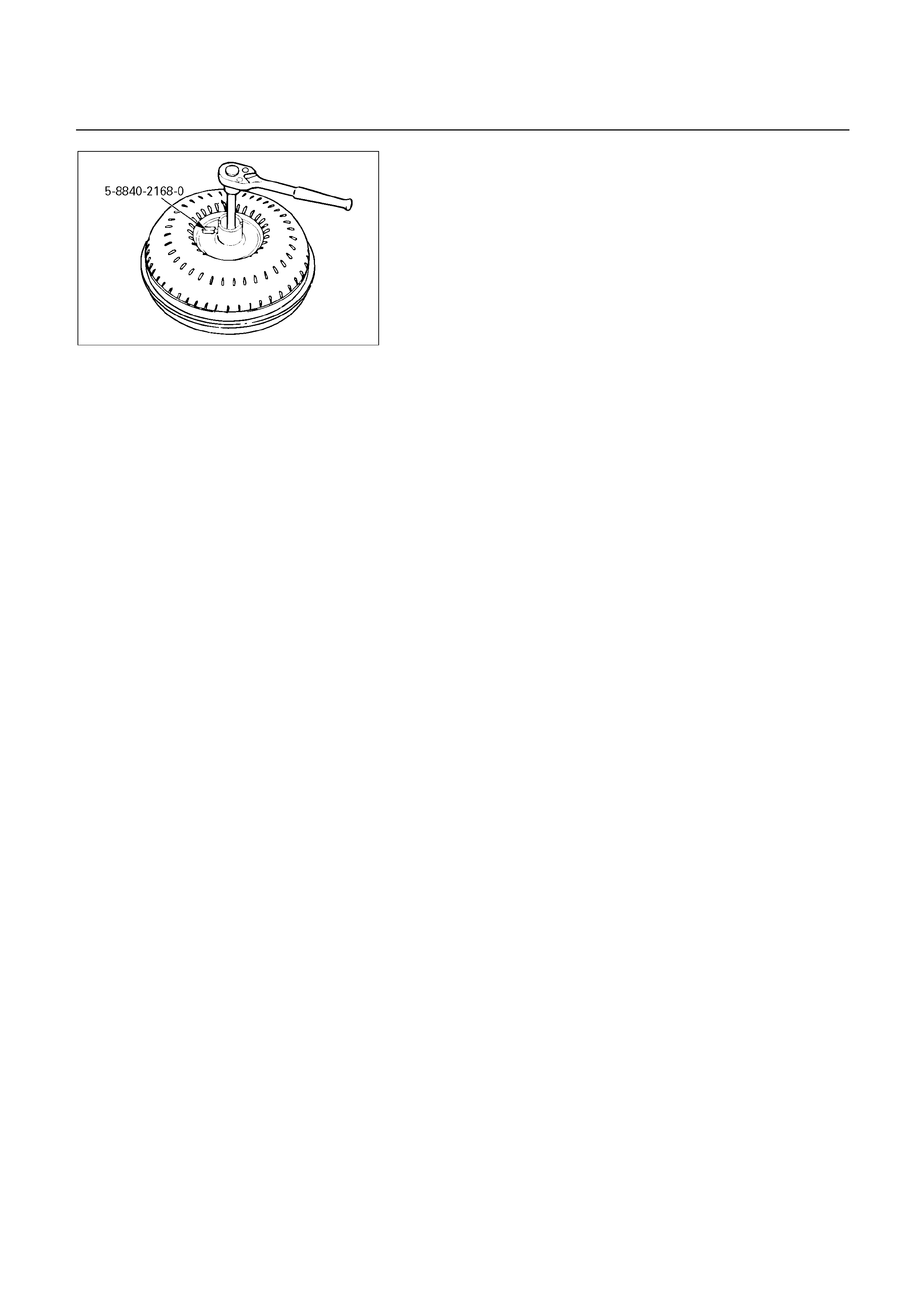

Torque Converter

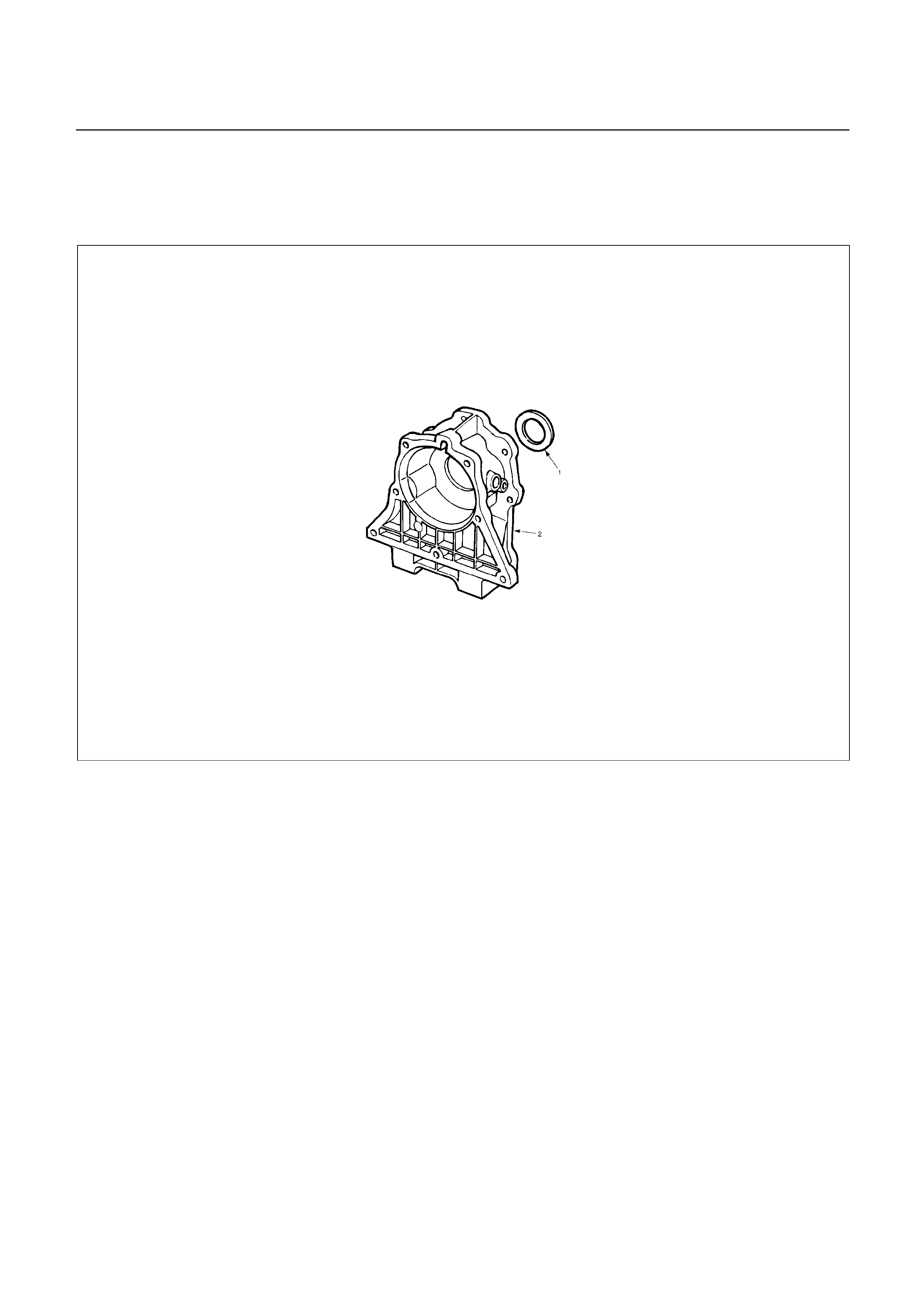

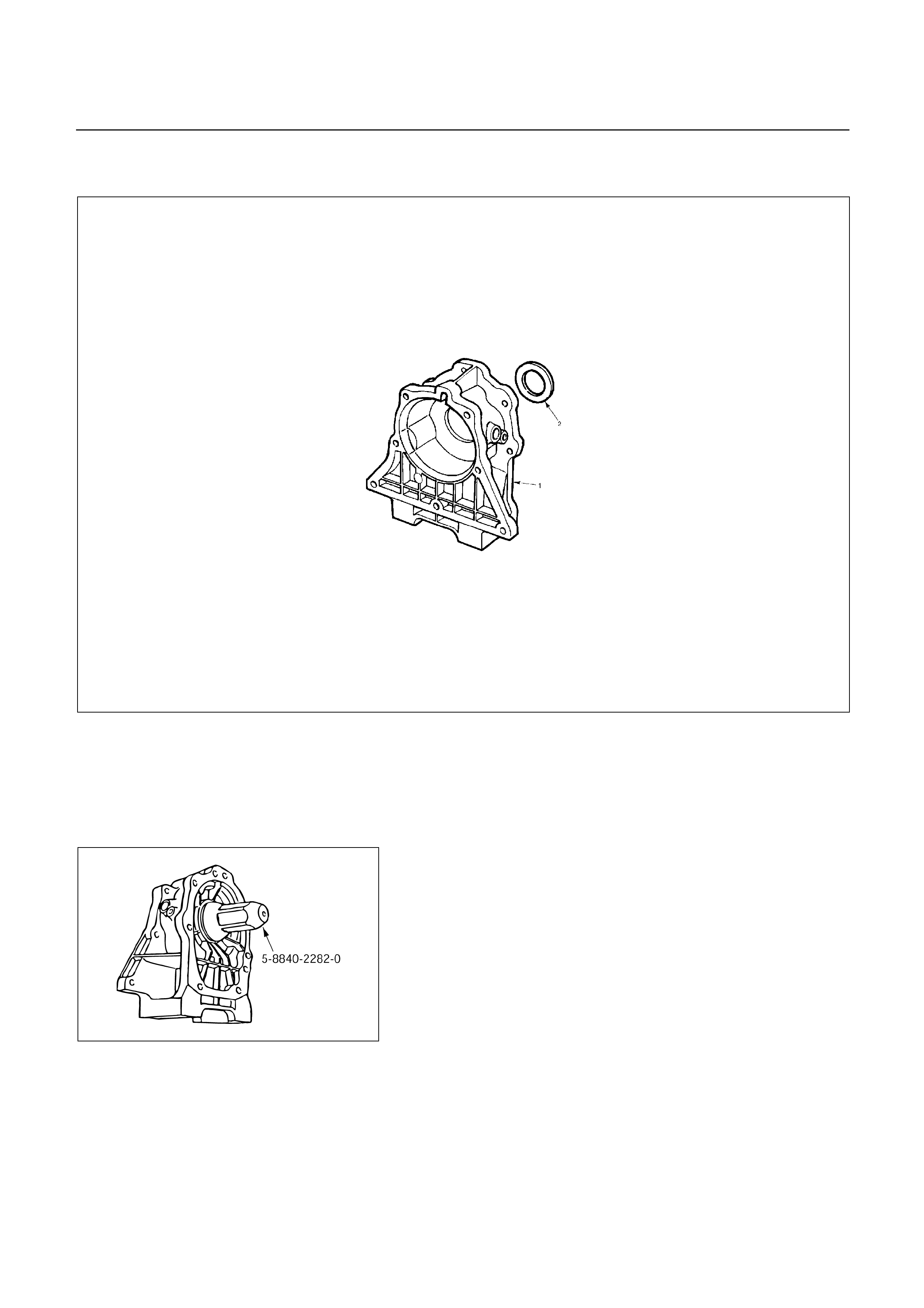

Adapter Housing (44)

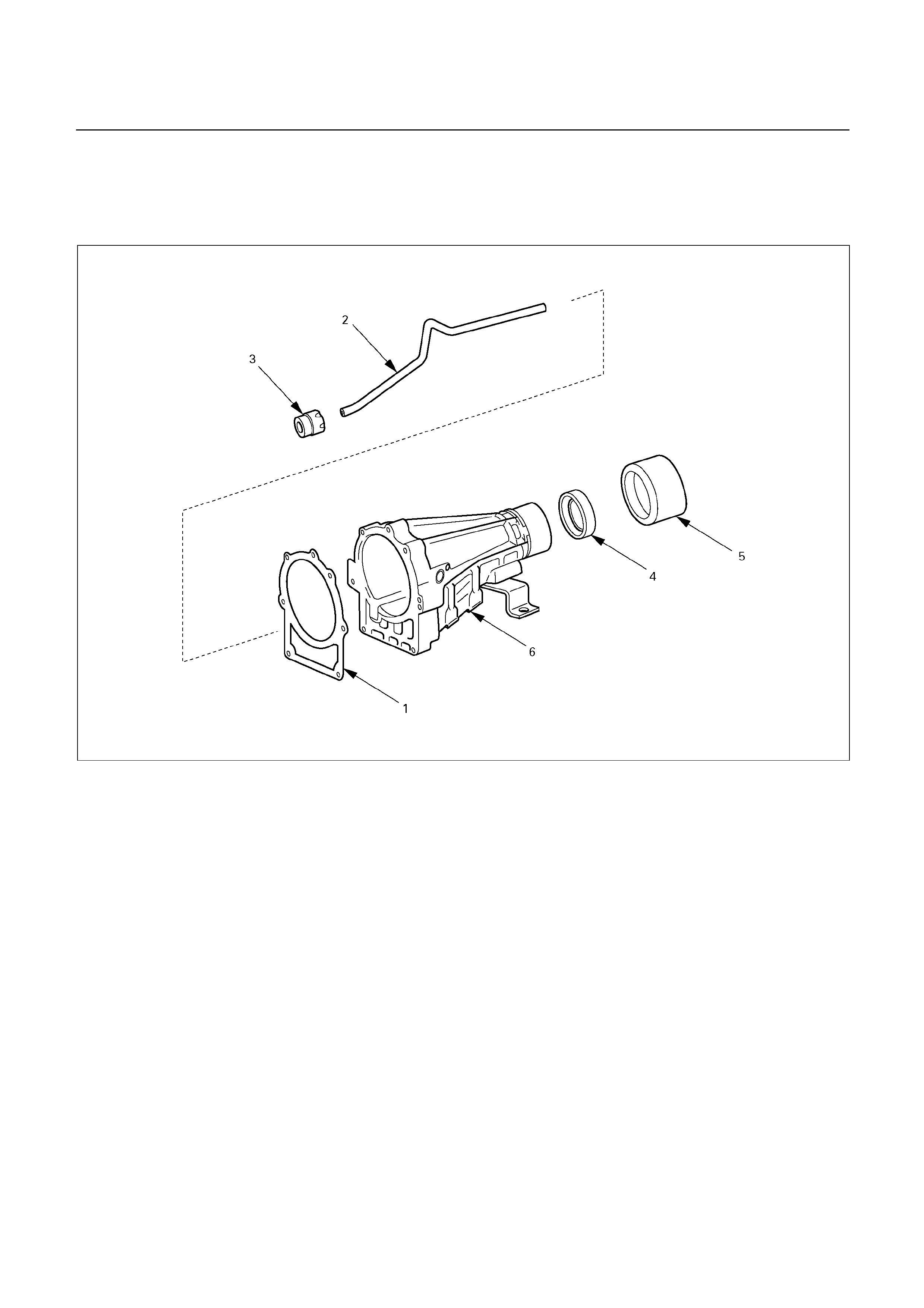

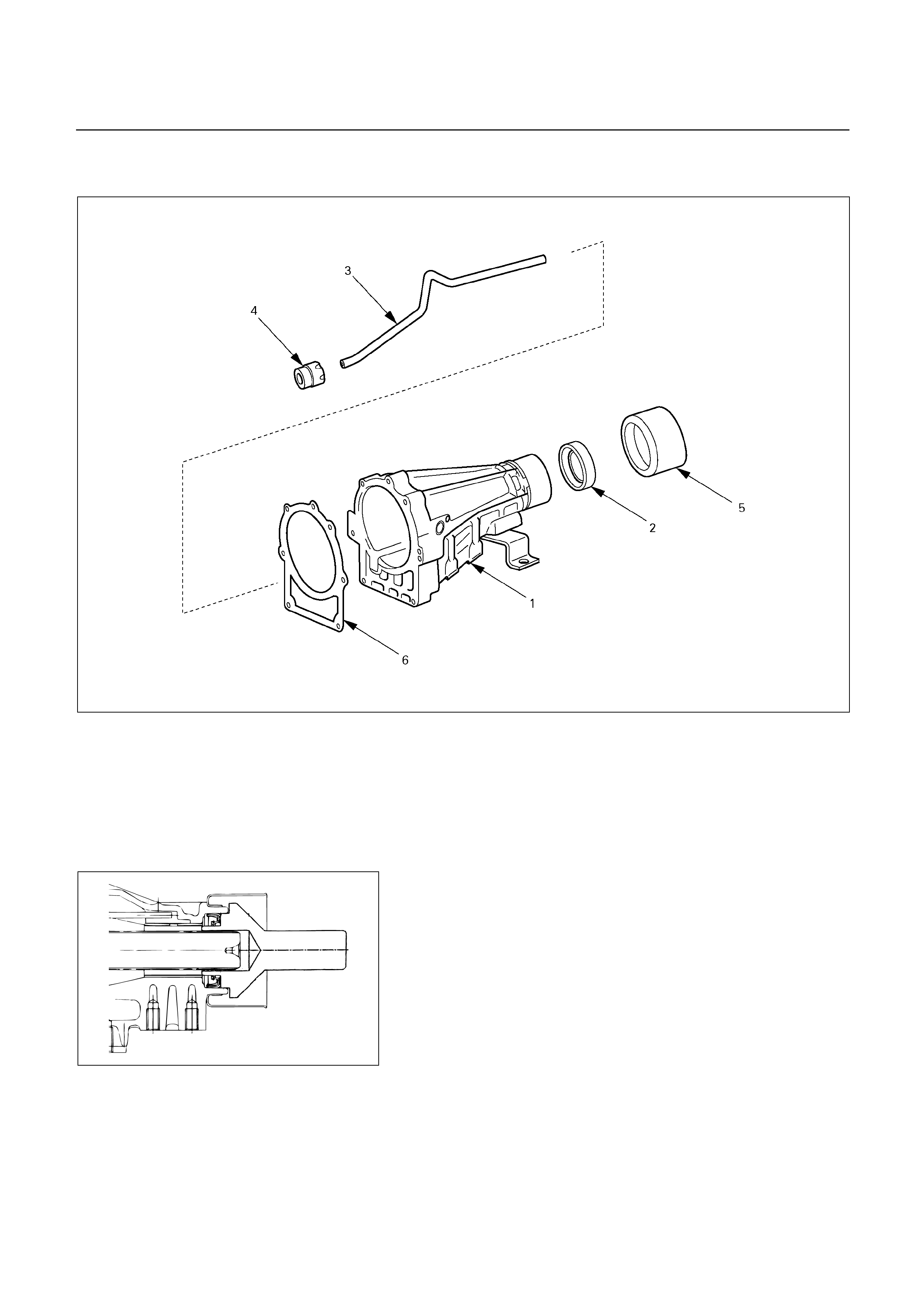

Extension Housing (42)

Main Data and Specifications

General Specifications

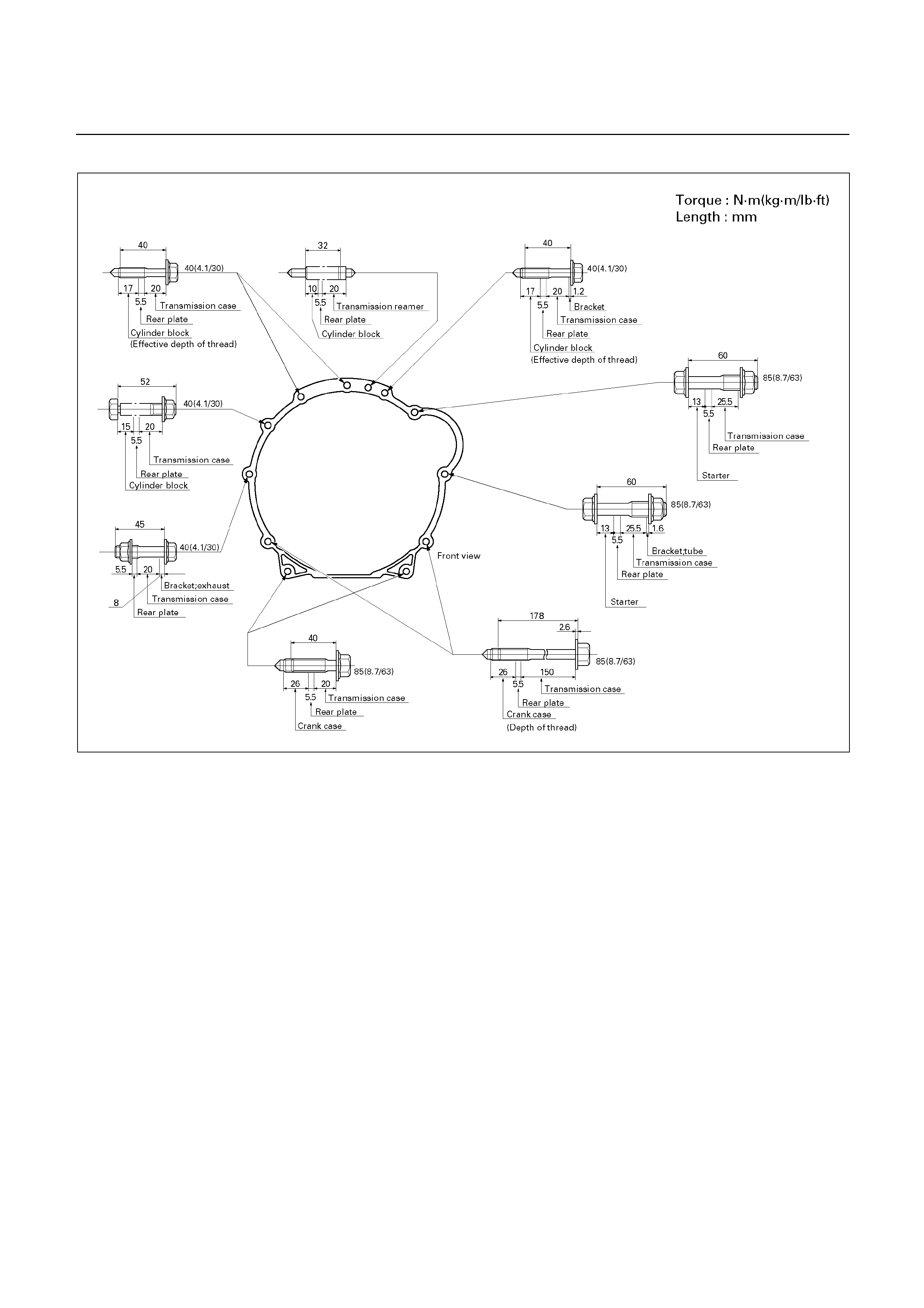

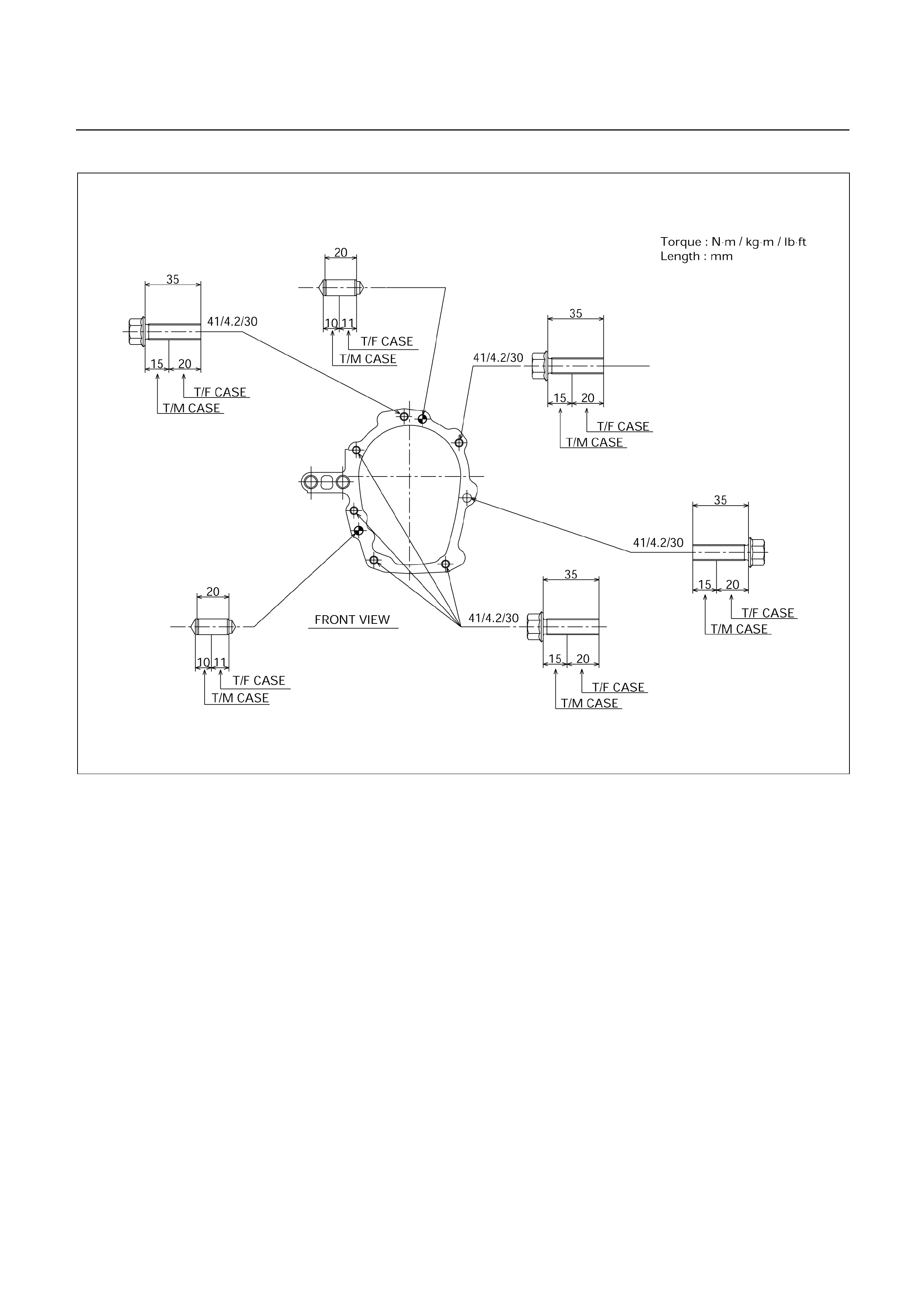

Torque Specifications

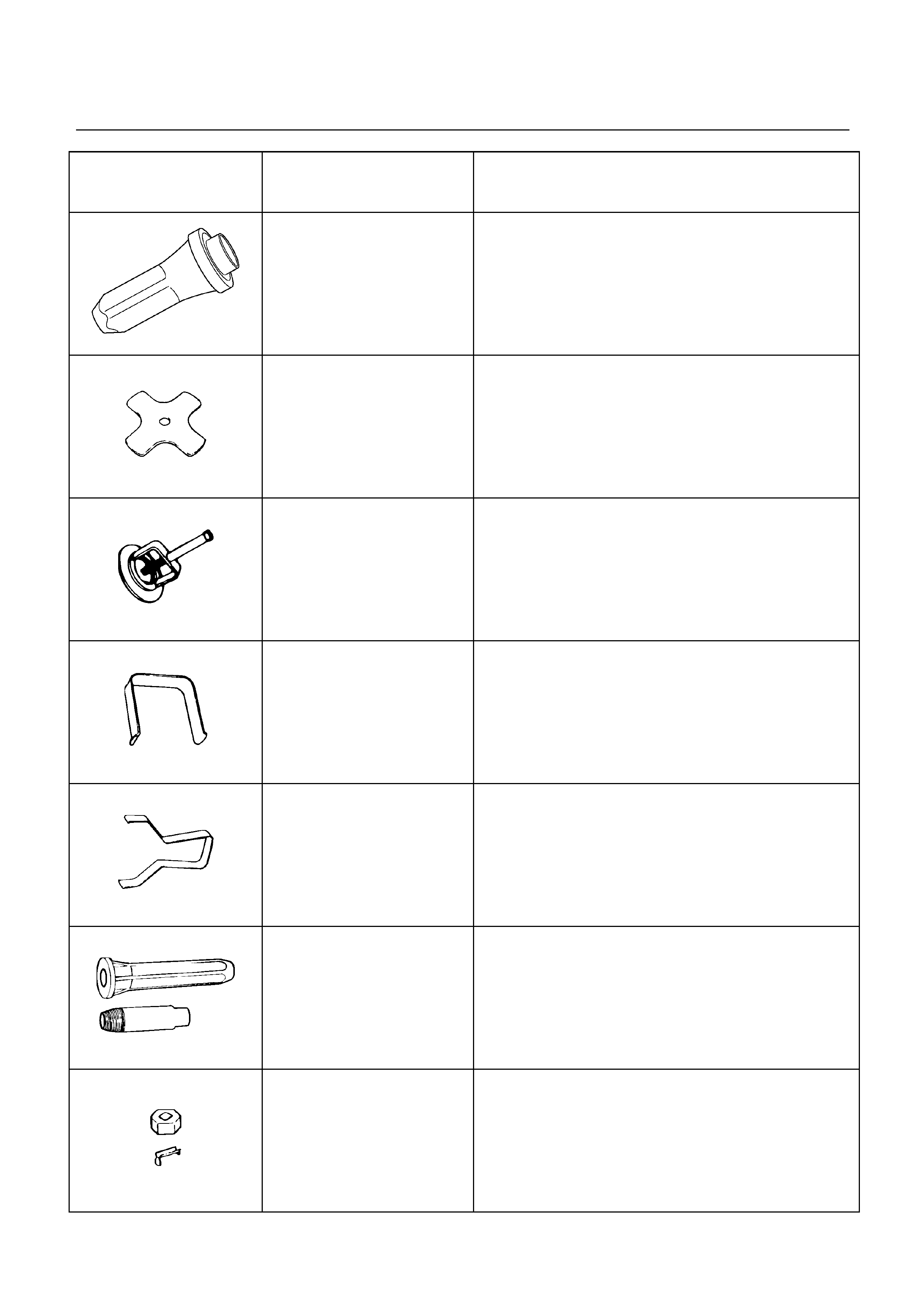

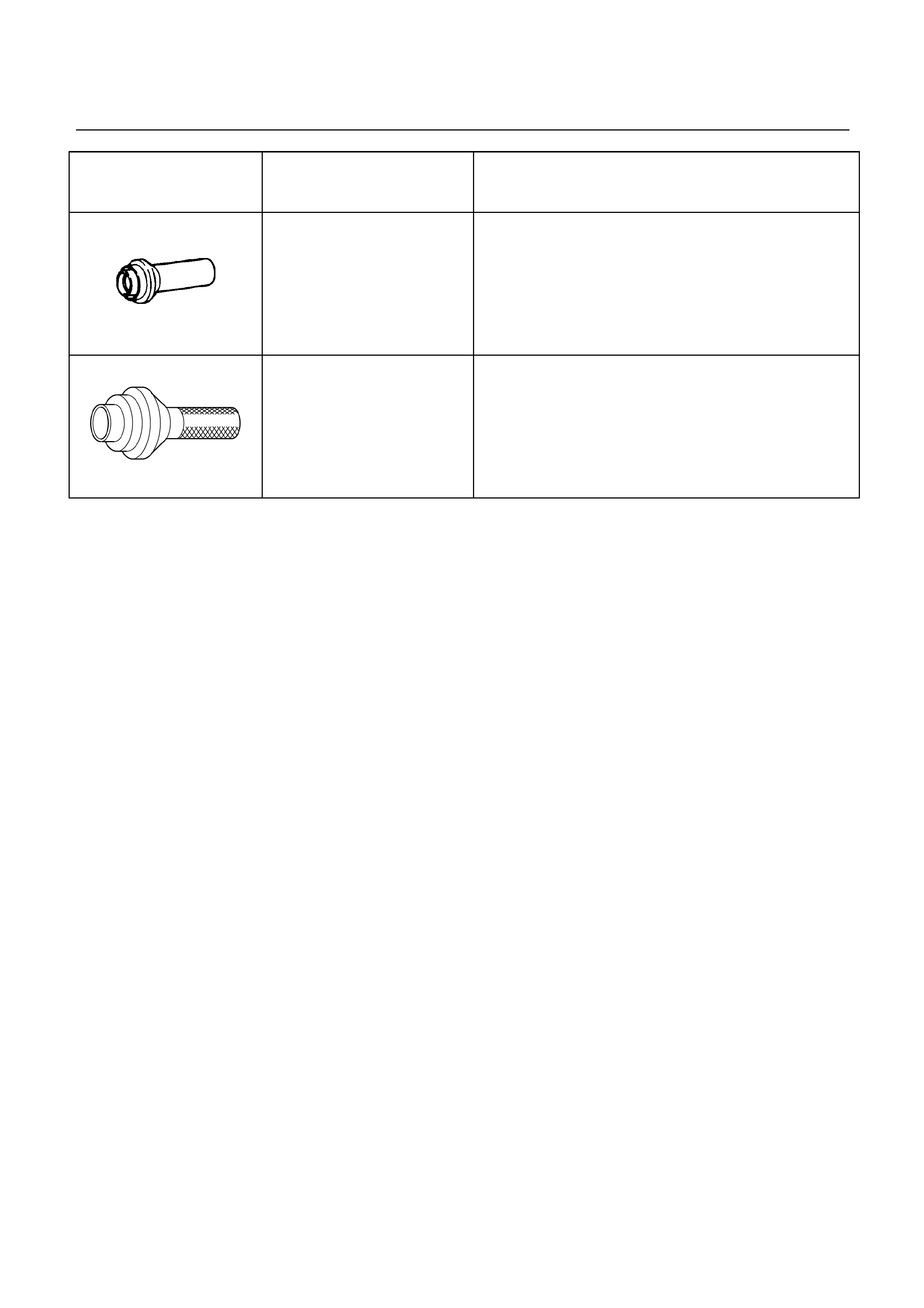

Special Tool

CAUTION:

When fasteners are removed, always reinstall them

at a the same location from which they were

removed. If a fastener needs to be replaced, use

the correct part number fastener for that

application. If the correct part number fastener is

not available, a fastener of equal size and strength

(or stronger) may be used.

Fasteners that are not reused, and those requiring

thread locking compound, will be called out. The

correct torque values must be used when installing

fasteners that require torque. If the above

conditions are not followed, parts or system

damage could result.

GENERAL DESCRIPTION

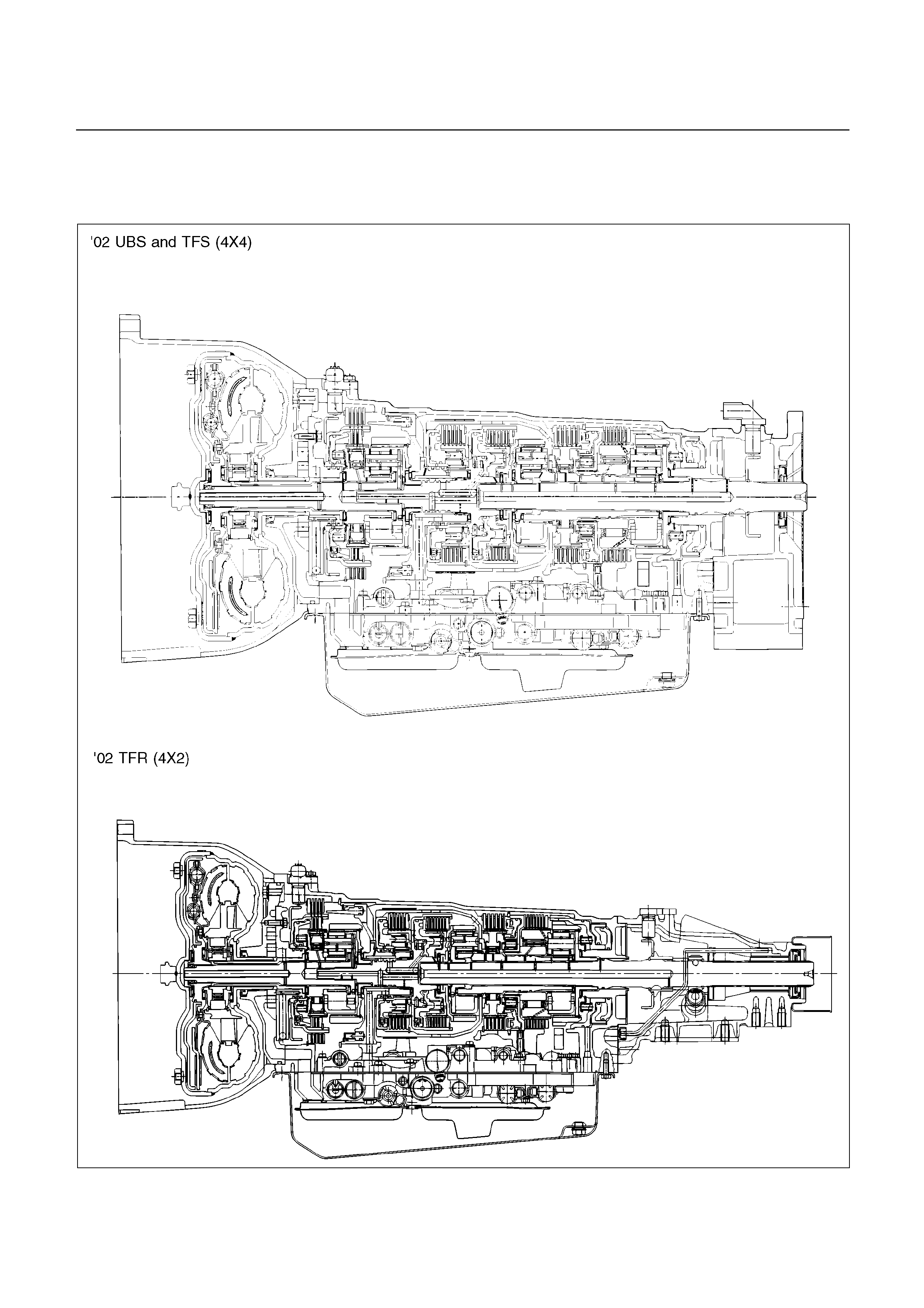

CONSTRUCTION

A07RY00001&A07L200001

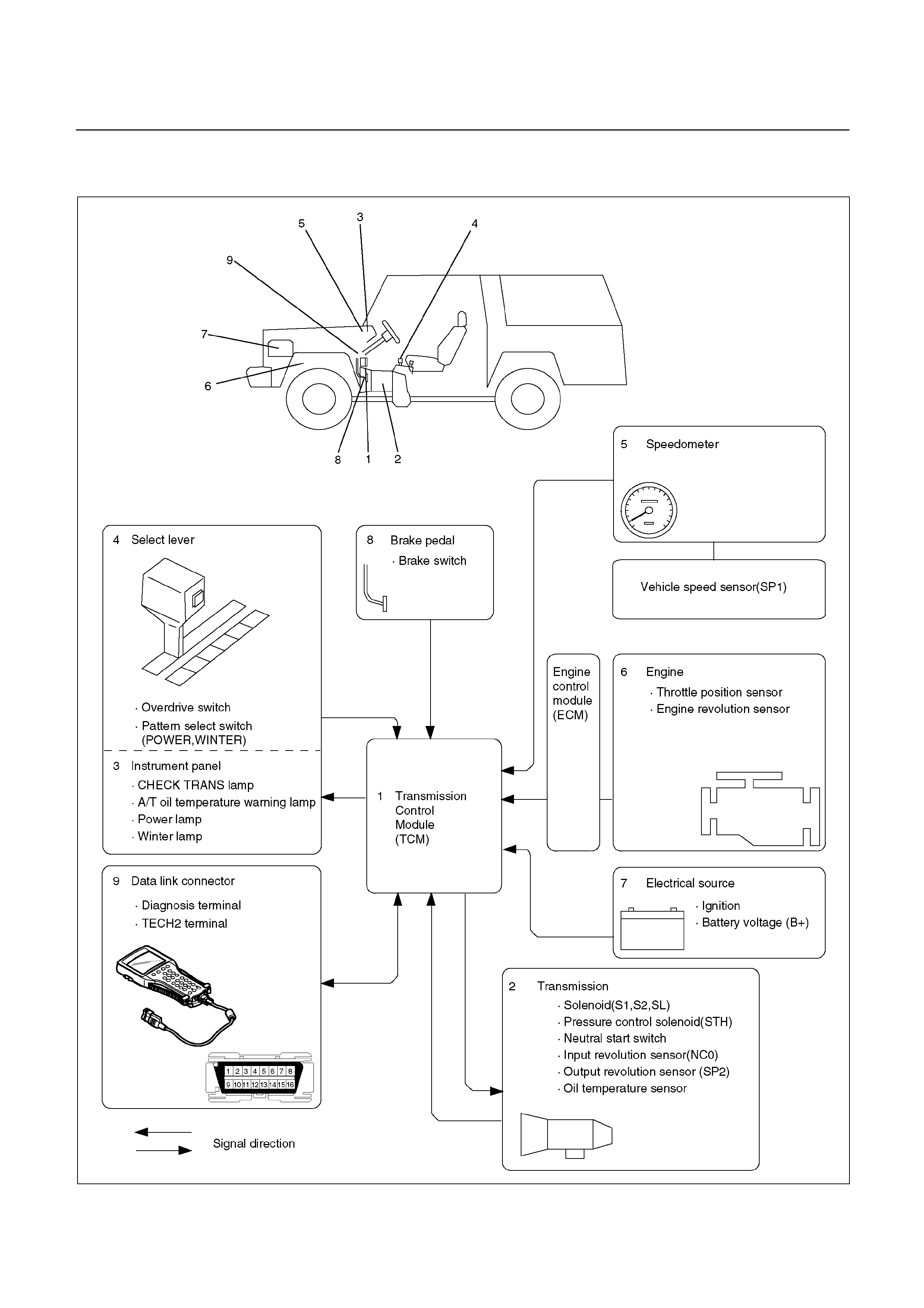

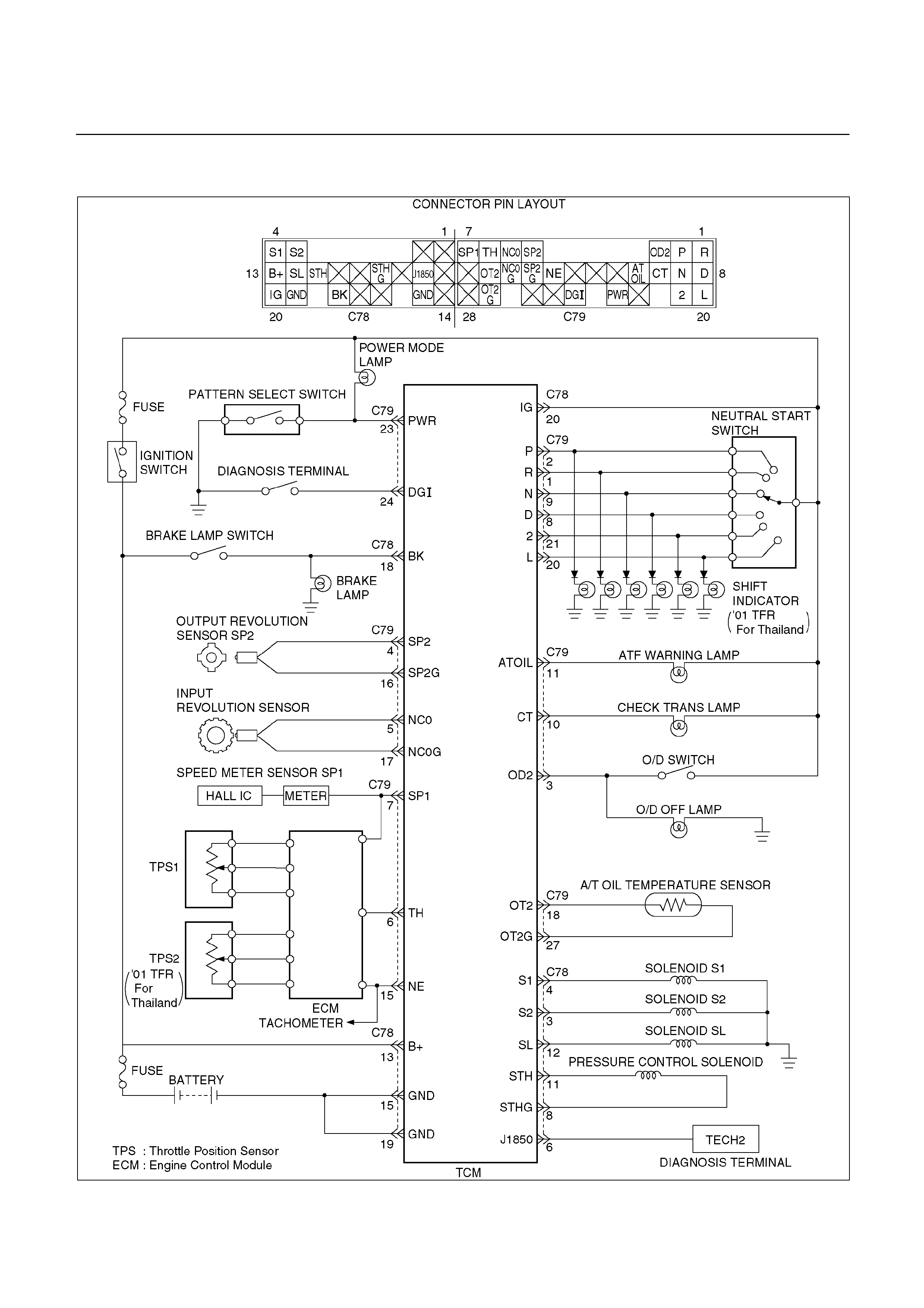

ELECTRONIC CONTROL COMPONENTS - UBS JACKAROO

C07R200019

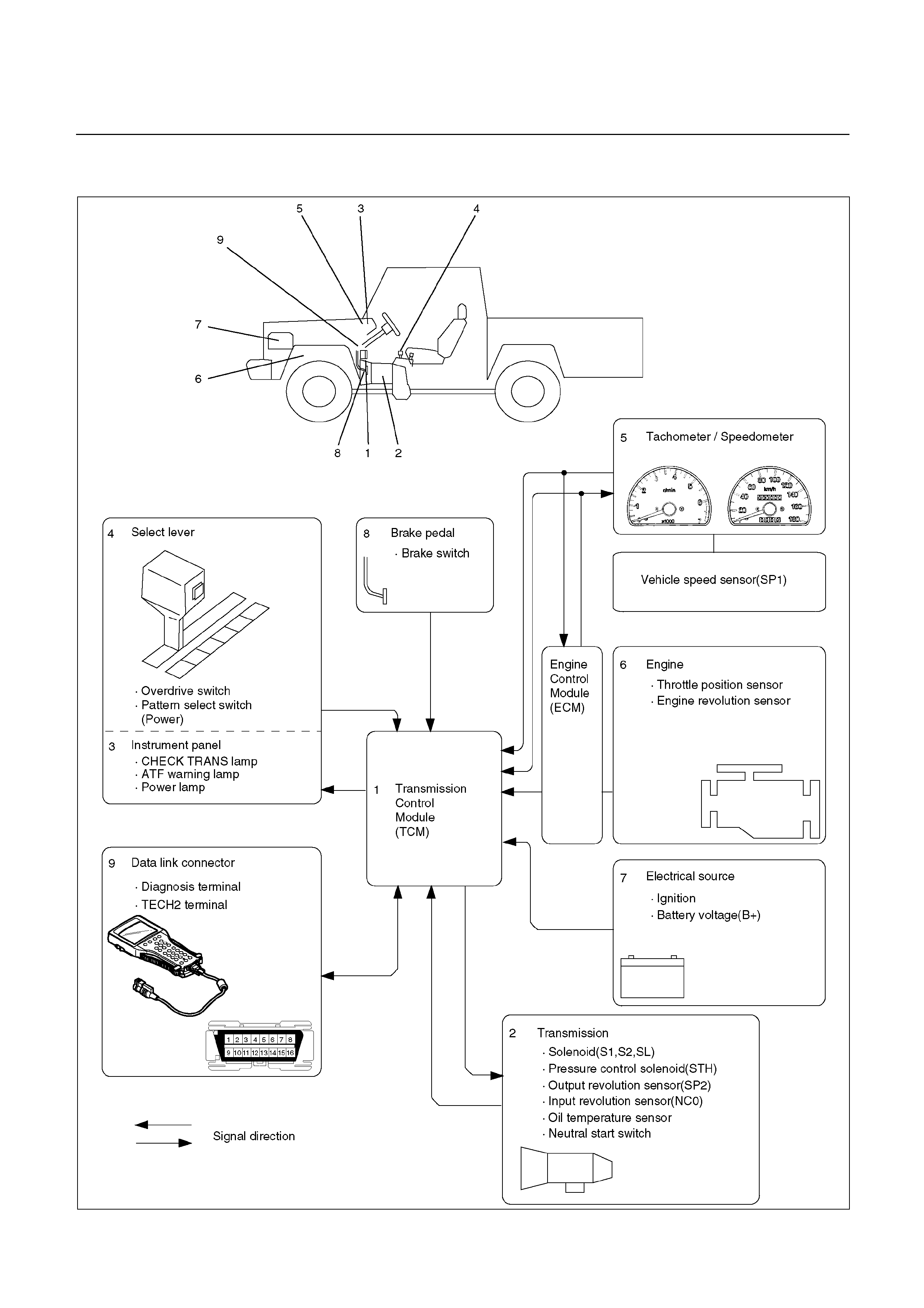

ELECTRONIC CONTROL COMPONENTS - TFR/S RODEO

C07L200001

TRANSMISSION CONTROL MODULE (TCM) - UBS JACKAROO

C07R200020

TRANSMISSION CONTROL MODULE (TCM) - TFR/S RODEO

C07L200002

CONTROL SYSTEM DIAGRAM - UBS JACKAROO

C07R200021

CONTROL SYSTEM DIAGRAM - TFR/S RODEO

C07L200003

CONTROL AND FUNCTIONS

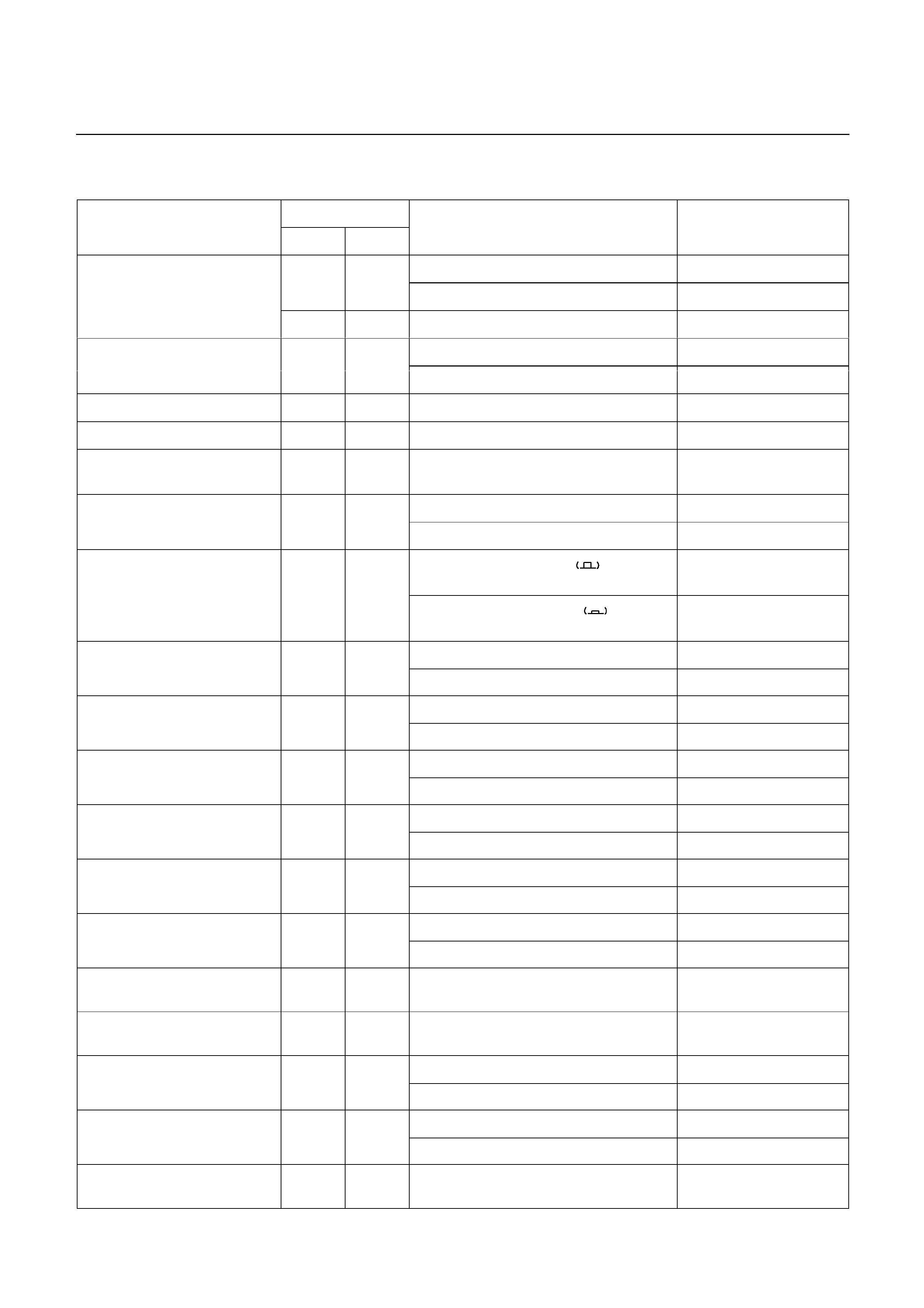

Item Description

Shift and lock-up control • In D range, speed change point and Lock-up point can be

changed by setting pattern selection switch to "POWER",

"NORMAL" or "WINTER (UBS)" mode.

• Gear shift position in the conditions made up of transmission shift

positions (D.2.L) combined with pattern selection switch

(POWER, NORMAL, and WINTER) can be controlled in

accordance with vehicle speed and the opening of throttle valve.

Overdrive cut control • If O/D switch is set on in D range (O/D OFF lamp ON), gear shift

to O/ D is not effected.

• Overdrive is released at O/D switch on and high transmission oil

temperature (More than 130°C).

However, to prevent engine over revolution

• 4

→3 shifting at vehicle speed is less than 118 km/h (UBS) or

117 km/h (TF).

• 3

→4 shifting at vehicle speed is more than 131 km/h (UBS) or

125 km/h (TF).

Lock-up cut control • In D range, 2nd (TF), 3rd or O/D lock-up is conducted in

"POWER" or "NORMAL" mode.

• In 2, L range, lock-up is off in the whole area.

• Lock-up timing is controlled to reduce gear shift shock using kind

of gear shift (shift up, etc.) lock-up status at the time of gear shift

judgement, gear step and throttle opening after gear shift.

• Lock-up is released at brake on or high transmission oil

temperature

(More than 130°C UBS) .

(More than 140°C TF).

• Lock-up is prohibited when idling is defected by throttle position

sensor.

Driving mode select control • The TCM selects a suitable driving mode from the nine kinds for

the variety driving condition.

i) Economy mode ii)Power mode iii)Winter mode(UBS) iv)HOT1

mode v)HOT2 mode vi)L4 mode(4×4) vii)Slope mode(UBS)

(Up slope 1, Up slope 2 and Down slope mode)

• The priority of driving mode:

Economy < Power < Slope(UBS) < L4(4×4) < Winter(UBS) <

HOT1 < HOT2

Squat control • When the TCM detects D signal on, the TCM controls 1–3–1 shift

by setting a timer, in order to improve the shift feel at N→D.

Line pressure control • The TCM output current which corresponds to throttle oil pressure

to pressure control solenoid based on throttle opening.

Indicate oil temperature warning function • If the transmission oil temperature sensor senses that

transmission oil temperature is greater than 146°C, the TCM turn

on A/T OIL TEMP warning lamp. (The warning lamp is turned off,

if oil temperature is less than 126°C.)

Item Description

L4 mode control (4×4) • The TCM judges whether the transfer is engaged in high or low

based on the ratio rpm data from output speed sensor in the

transmission and the rpm data from speed meter sensor to select

the shift map.

Up and down hill control (UBS) • The TCM judges up and down hill, and change shift pattern based

on throttle opening and acceleration.

Correct oil temperature control • If the temperature exceeds a predetermined value, the TCM

selects the high oil temperature shift point for downshifting, thus

preventing the oil temperature from rising. (More than 130°C, D

range)

Winter mode control (UBS) • The TCM controls the vehicle start smoothly on low frictional road

(eg. snow or ice) by executing this control.

Activate condition:

1. Excluding "2", "L" range

2. Vehicle speed is less than 11 km/h

3. Transmission oil temperature is less than 115°C

4. Throttle opening is less than 8%

5. Excluding winter mode

Cancel condition:

1. When winter mode switch is pushed again

2. When either "2" or "L" is detected

3. Ignition switch "OFF"

4. Vehicle speed is more than 34 km/h for 1 second or mode

continuously

5. Transmission oil temperature is more than 130°C

Fail-safe function • When trouble occurs to vehicle sensor and each solenoid, TCM

automatically exerts fail-safe control not to spoil driveability.

• This control is exerted when sensor or actuator is in trouble, while

TCM works normally.

Diagnosis function • If there is an abnormality in vehicle sensors, each solenoid (S1-

S3, STH), or throttle position sensor, "CHECK TRANS" lamp is

actuated to warn the drive. But when the abnormality items have

been restored to normal, the light does not blink.

• Faulty parts are memorized in TCM. If self-diagnosis start signal

is inputted, "CHECK TRANS" lamp is blinked and results of

diagnosis are indicated. A history of faults remains recorded even

when IGN switch is off.

TECH 2 • Output of control data in the TCM

• Actuator (Solenoid) operation check

• Erasure of trouble code

MAJOR INPUT/OUTPUT COMPONENTS

Component Function

Vehicle speed sensor (Speedometer) Detects the vehicle speed (Back-up sensor of output revolution

sensor).

Output revolution sensor (Transmission) Detects the vehicle speed

Input revolution sensor (Transmission) Detects the input revolution (O/D direct clutch drum revolution).

Engine revolution sensor Detects the engine revolution.

Throttle position sensor Detects the throttle opening rate.

Neutral start switch Detects the select lever position.

Pattern select switch Detects whether the driver has selected "NORMAL",

"POWER", or "WINTER" (UBS) mode.

Overdrive switch Detects whether the driver has selected O/D.

Brake lamp switch Detects whether the driver has pressed the brake pedal or not.

Oil temperature sensor Detects the oil temperature.

Input

Diagnostic start switch Starts self-diagnosis and displays a code for faulty part if any.

Input/

Output

Data link connector When connected with Tech2 or tester, can communicate the

data for function check, etc.

Shift solenoid S1, S2 Selects shift point and gear position suited to the vehicle

running condition on the basis of TCM output.

Lock-up control solenoid SL Control the lock-up clutch suited to the vehicle running

condition on the basis of TCM output.

Pressure control solenoid STH Adjusts throttle pressure by energizing current of linear

pressure control solenoid to prevent the shift shock and to

obtain shift smoothly.

"CHECK TRANS" lamp When trouble has occurred to throttle position sensor, vehicle

speed sensor, or solenoid, "CHECK TRANS" lamp is blinked to

warn the driver. If also displays the trouble code.

A/T OIL TEMP warning lamp Lights when ATF oil temperature rises. (Turned on at greater

than 146°C. Turned off at less than 126°C.

Power mode lamp Informs the driver whether the vehicle is in power mode or not.

Output

Winter mode lamp (UBS) Informs the driver whether the vehicle is in winter mode or not.

Computer

Transmission Control Module (TCM) Based on the signal from each switch and sensors, judges

necessary shift point and lock-up operation, and send signal to

each solenoid.

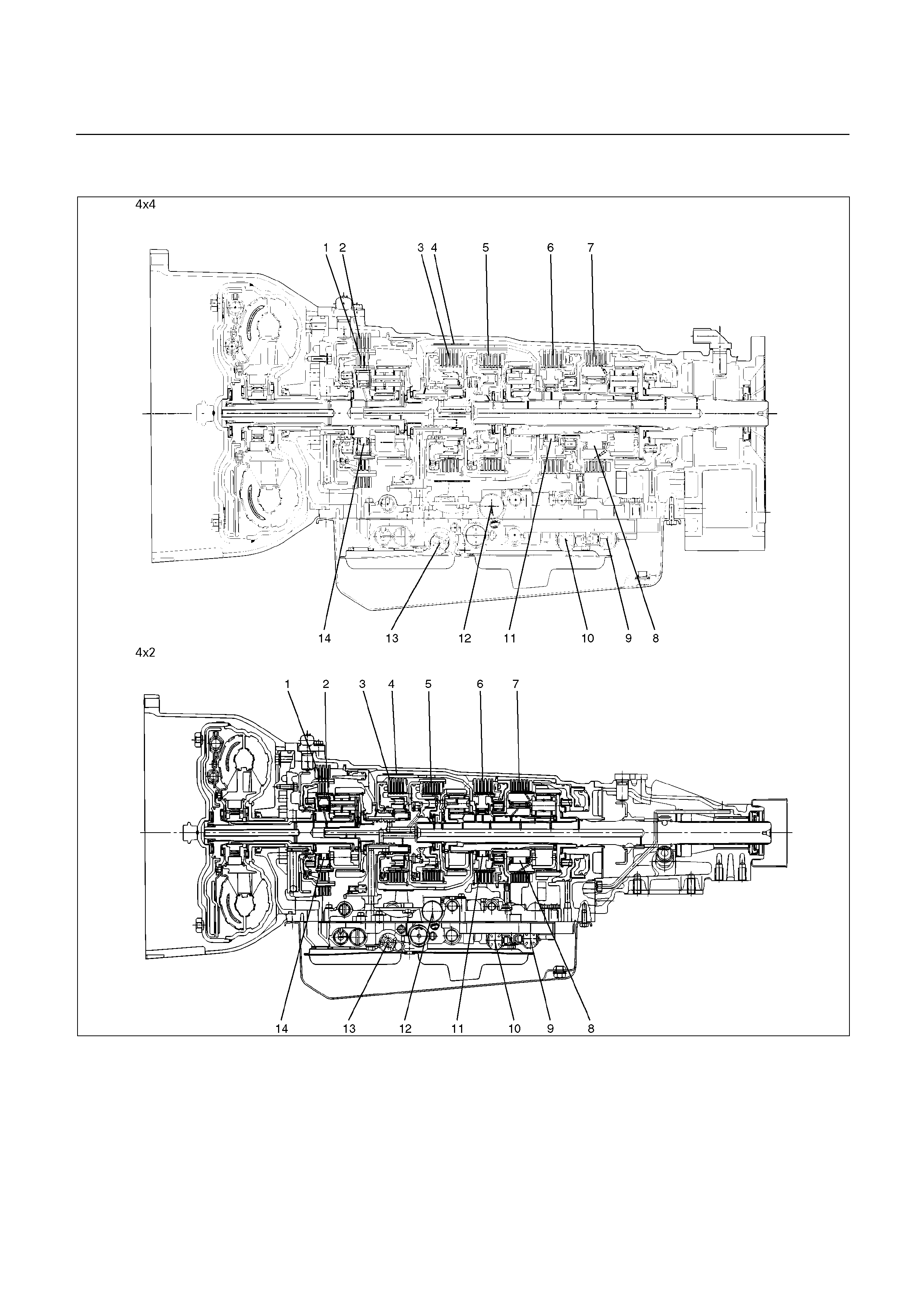

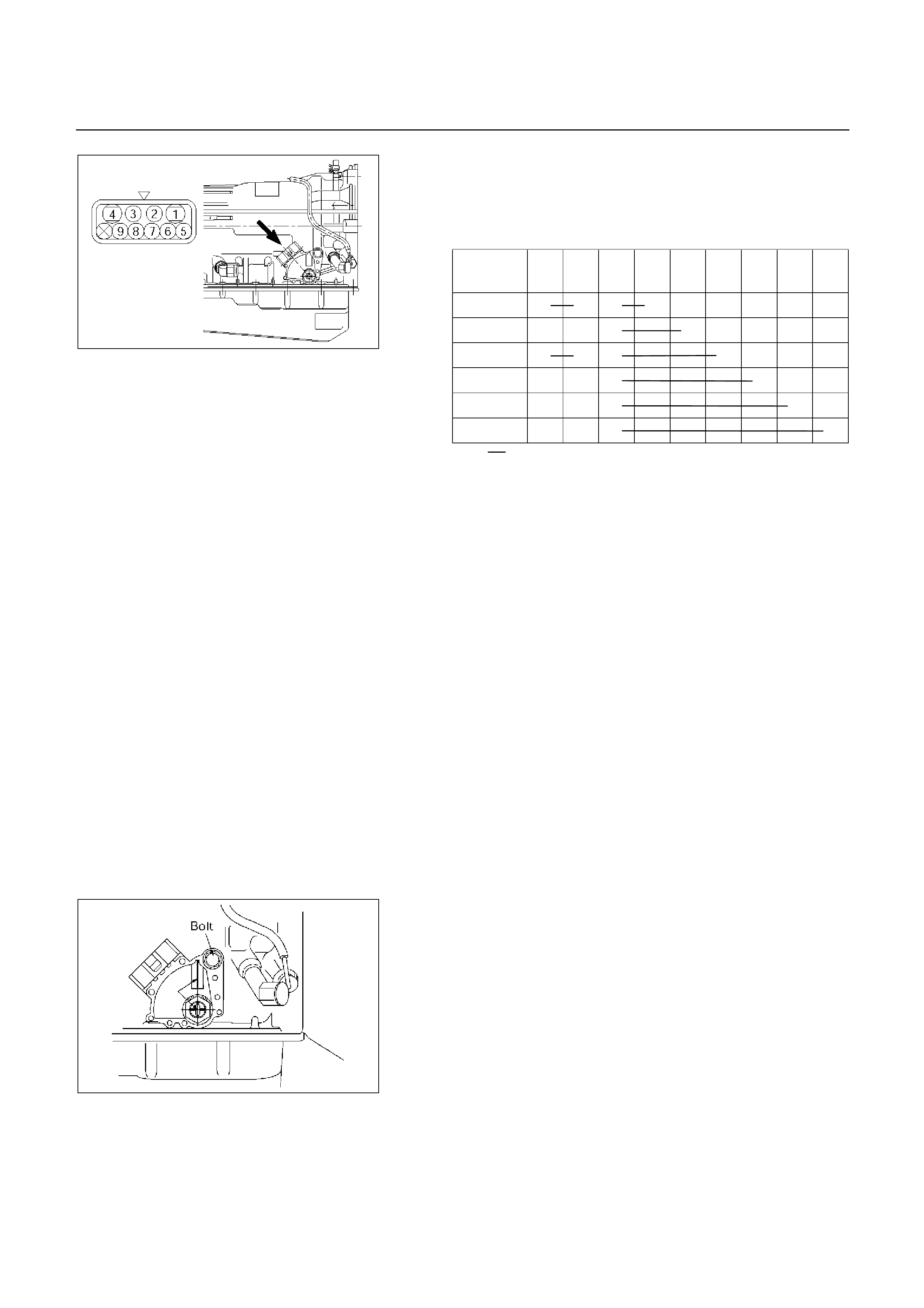

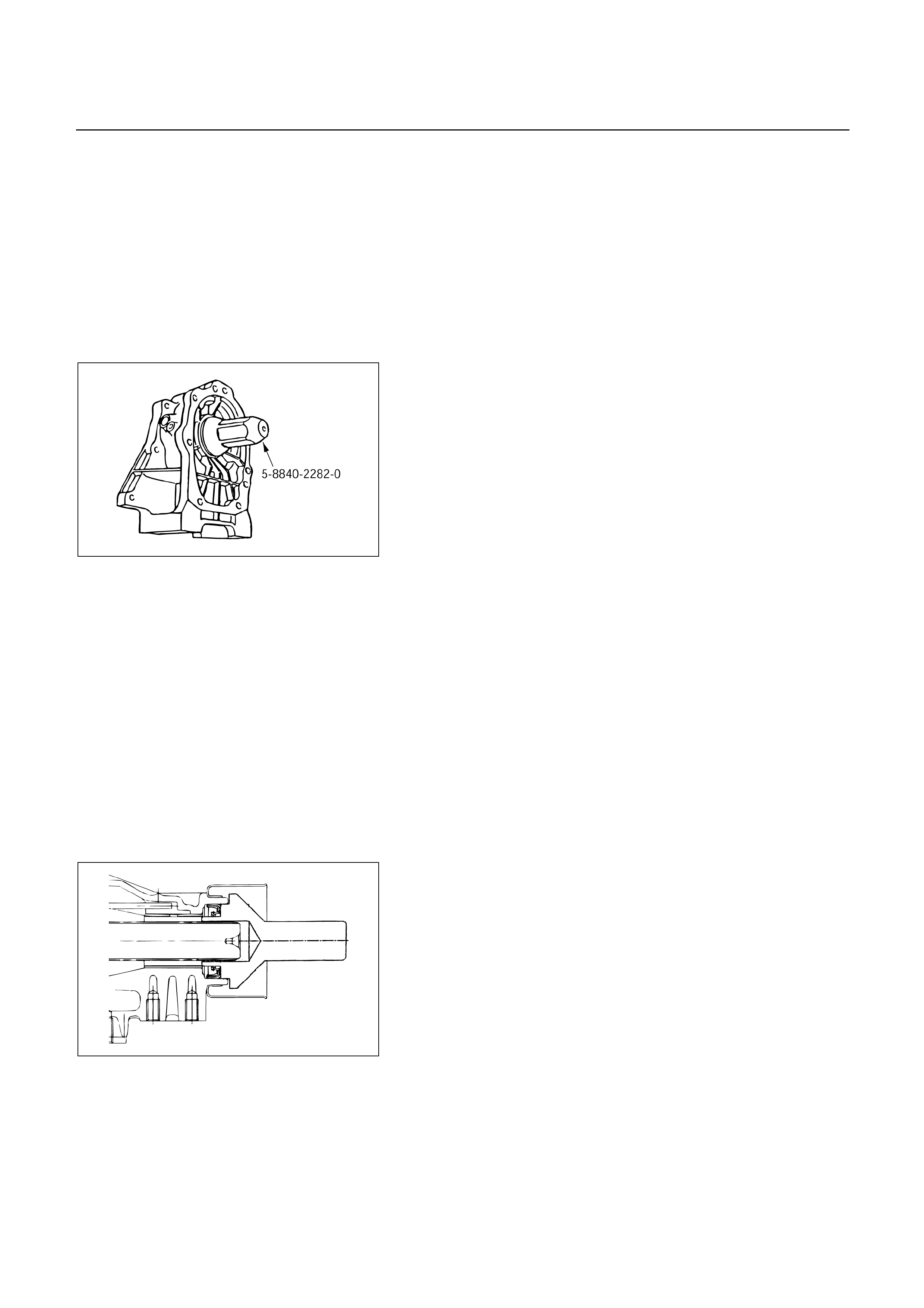

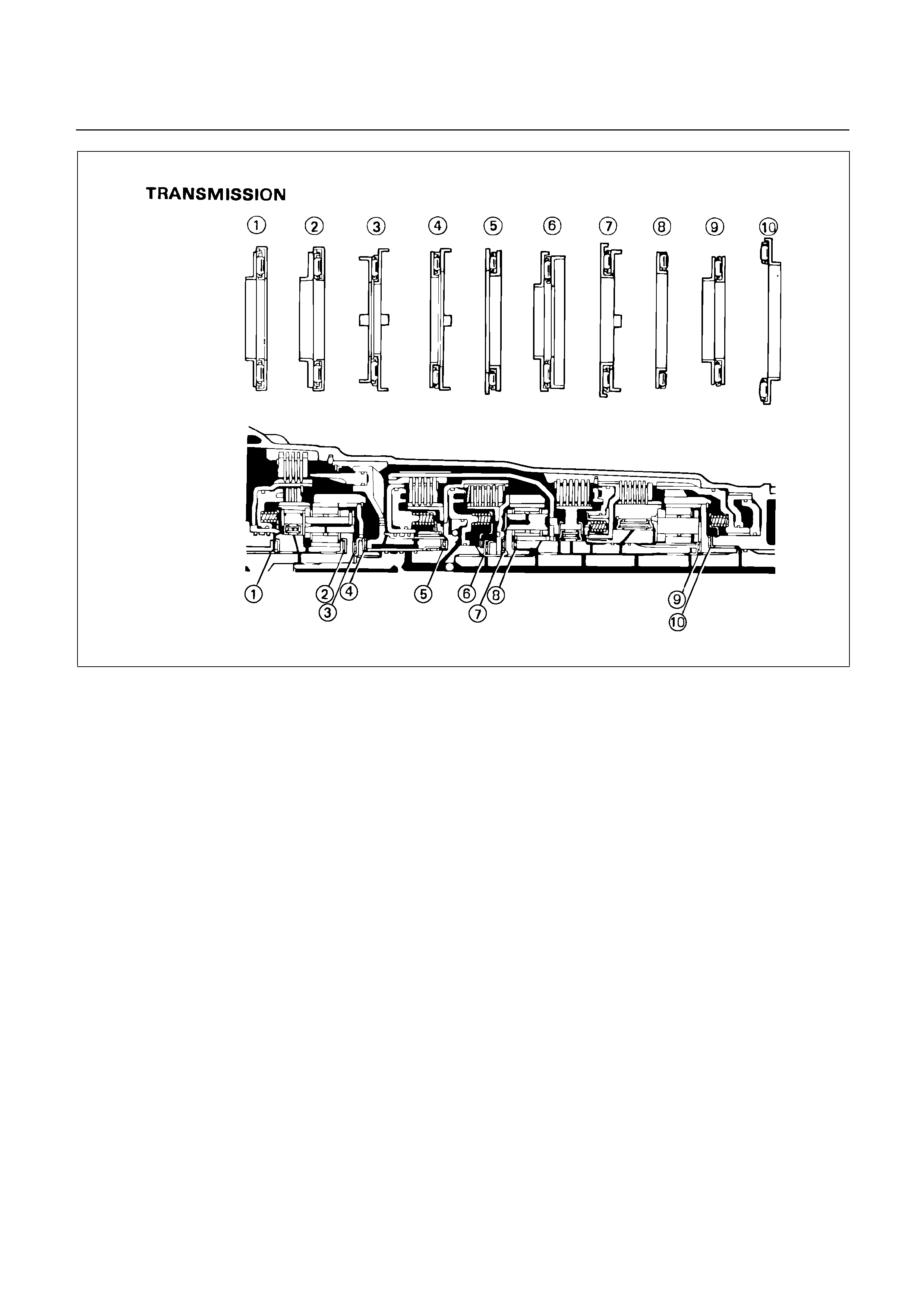

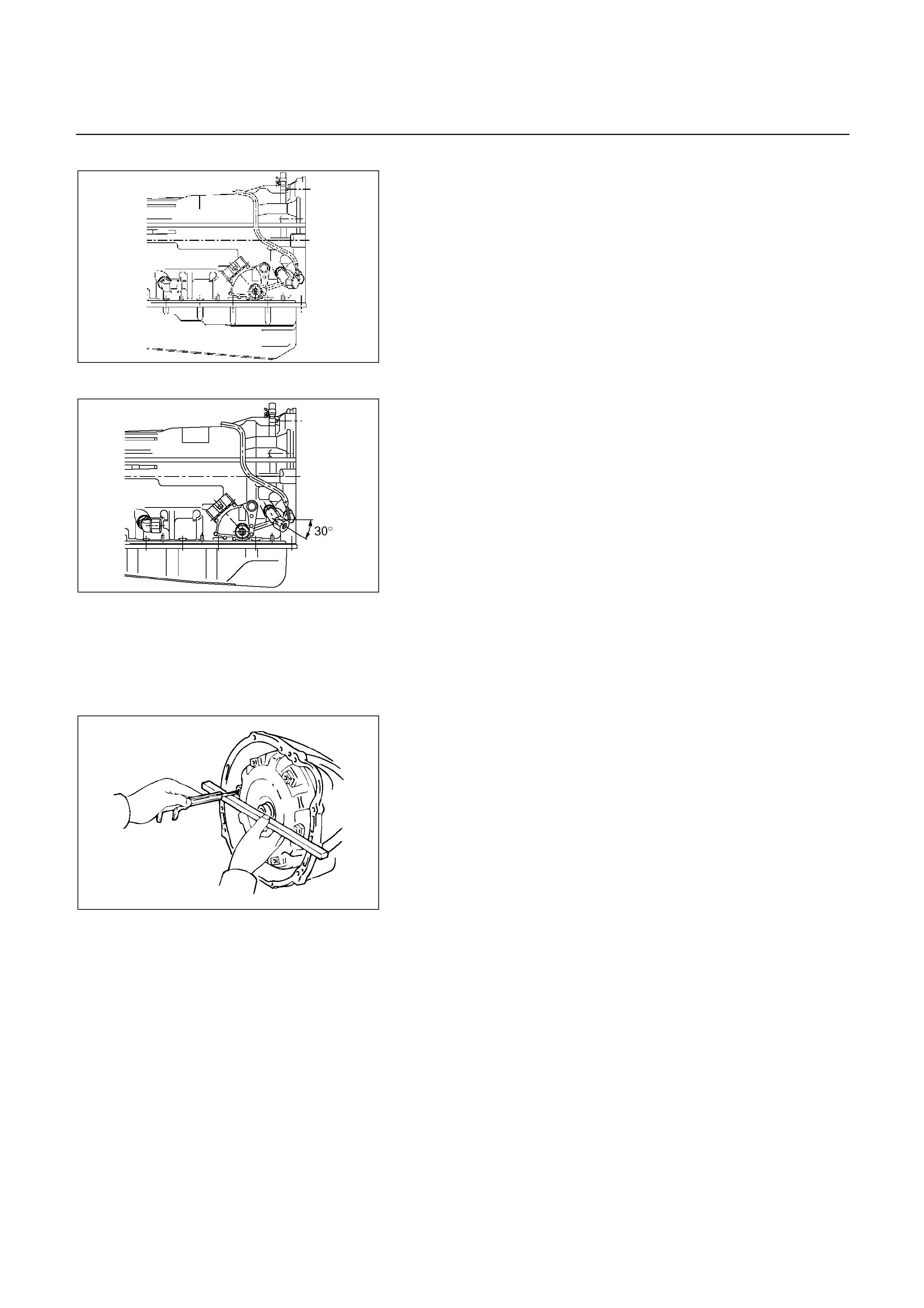

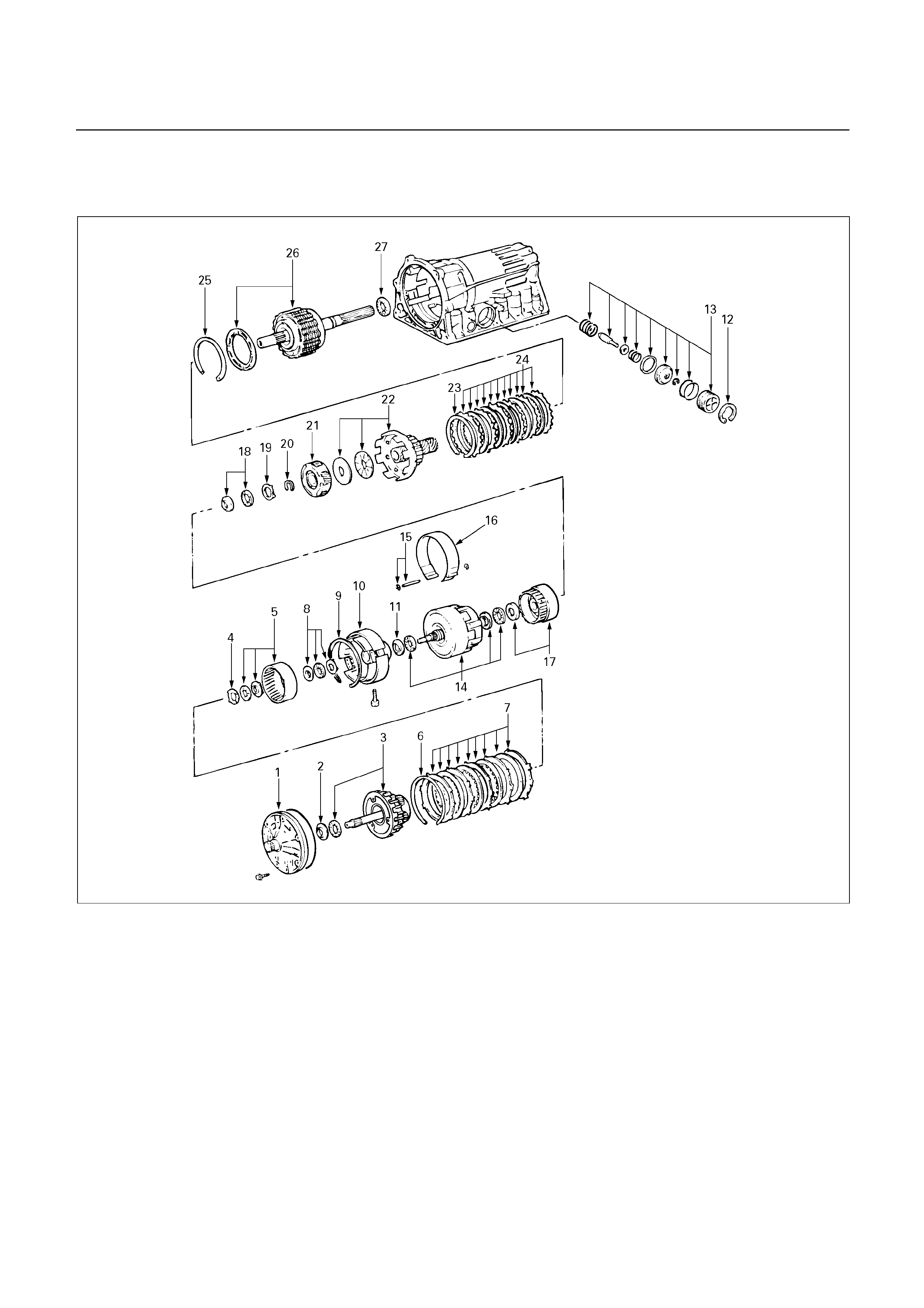

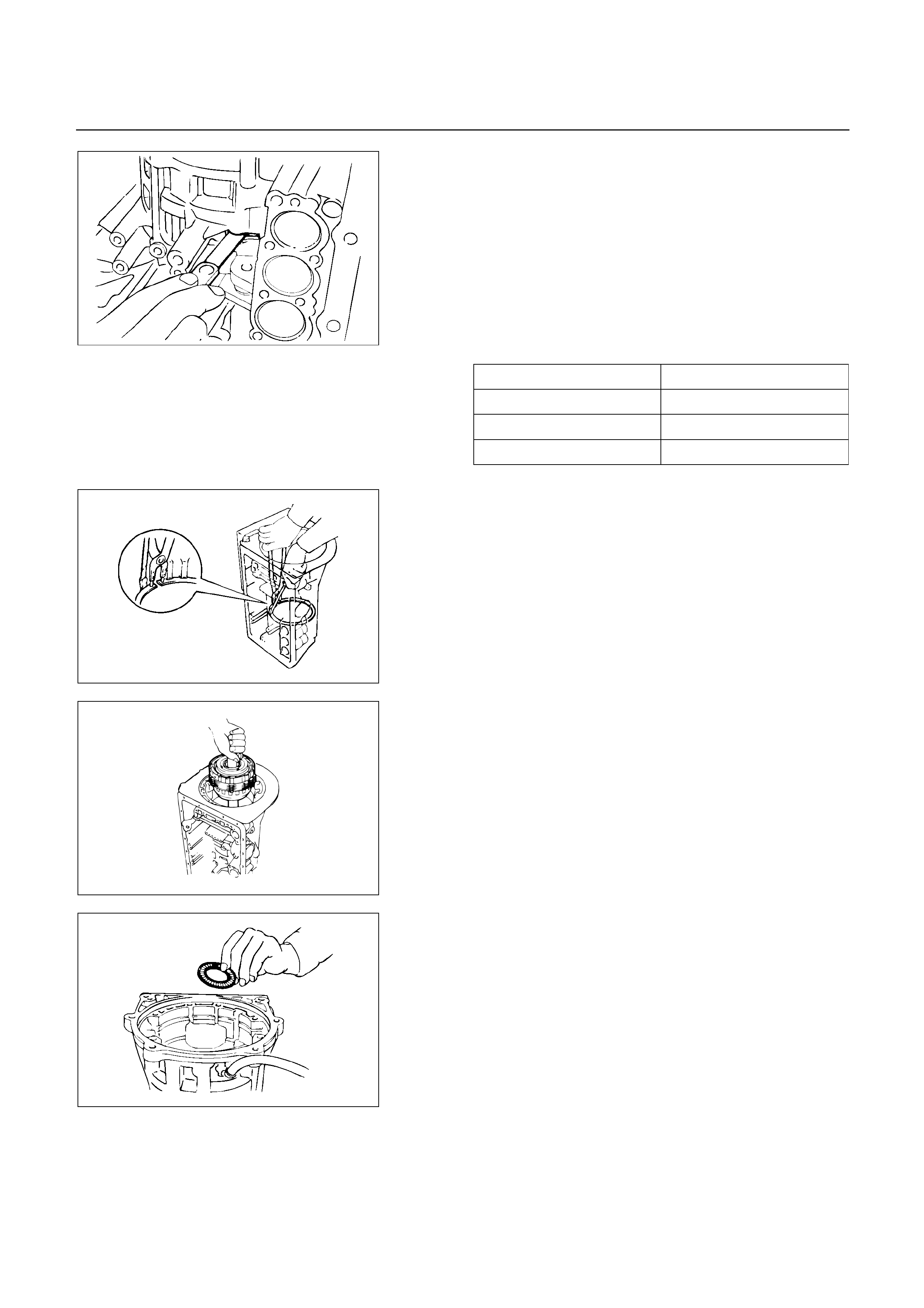

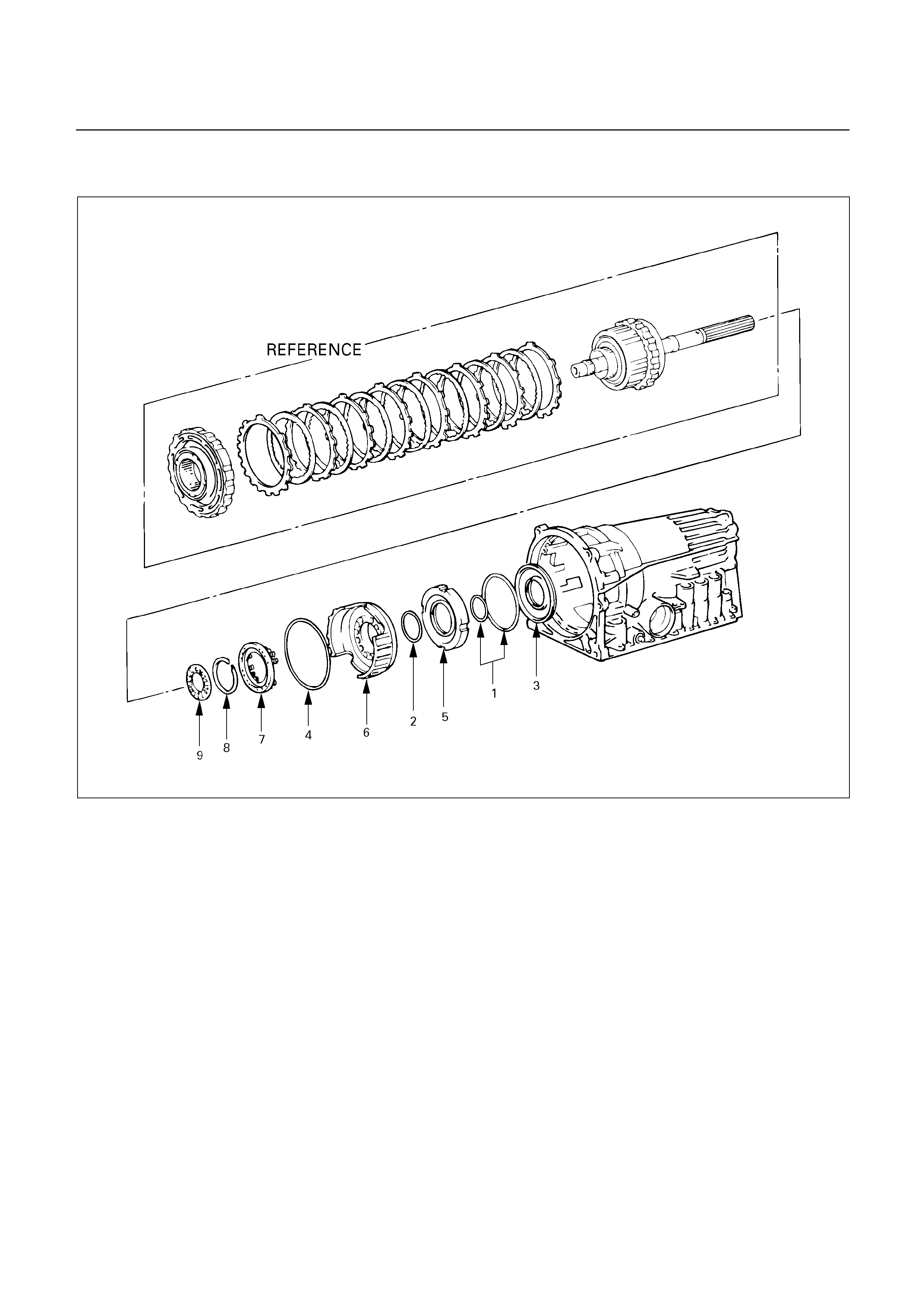

LOCATION OF CLUTCH, BRAKE, ONE-WAY CLUTCH AND SOLENOID

C07R200022

Legend

1. Overdrive direct clutch (C-0)

2. Overdrive brake (B-0)

3. Direct clutch (C-2)

4. Second coast brake (B-1)

5. Forward clutch (C-1)

6. Second brake (B-2)

7. First and reverse brake (B-3)

8. One-way clutch (No.2) (F-2)

9. Shift solenoid (S-1)

10. Shift solenoid (S-2)

11. One-way clutch (No.1) (F-1)

12. Pressure control solenoid (STH)

13. Lock-up solenoid (SL)

14. Overdrive one-way clutch (F-0)

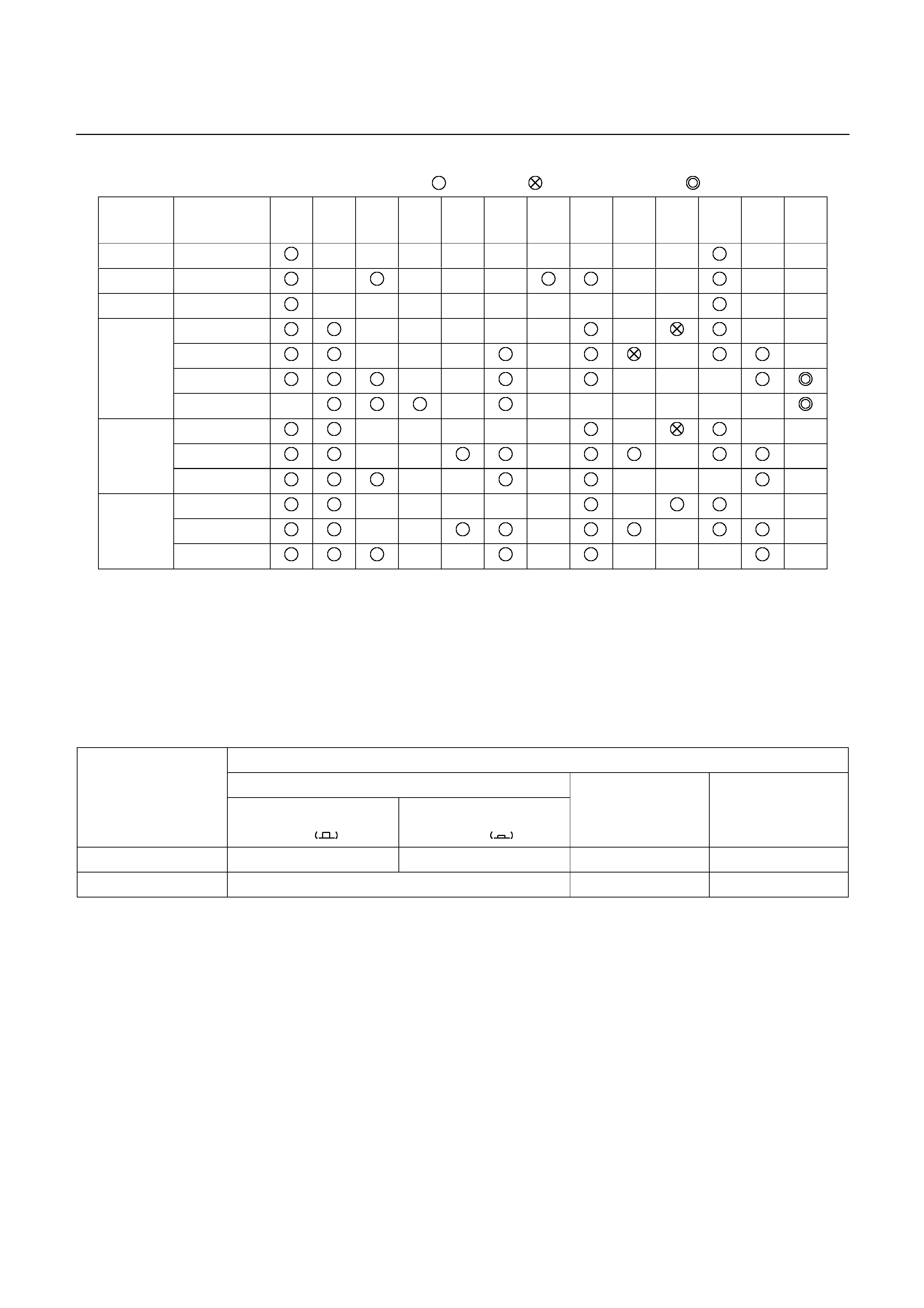

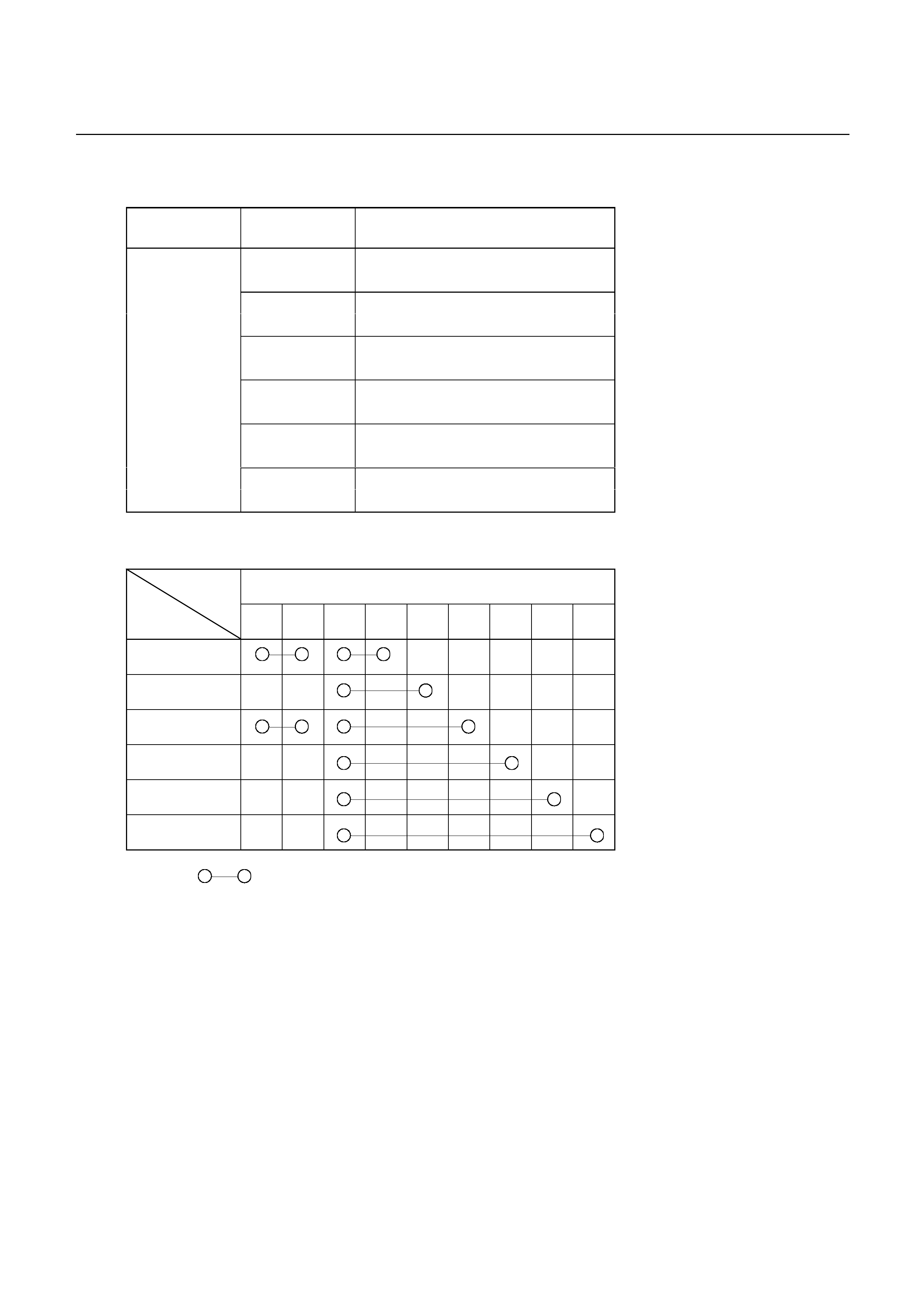

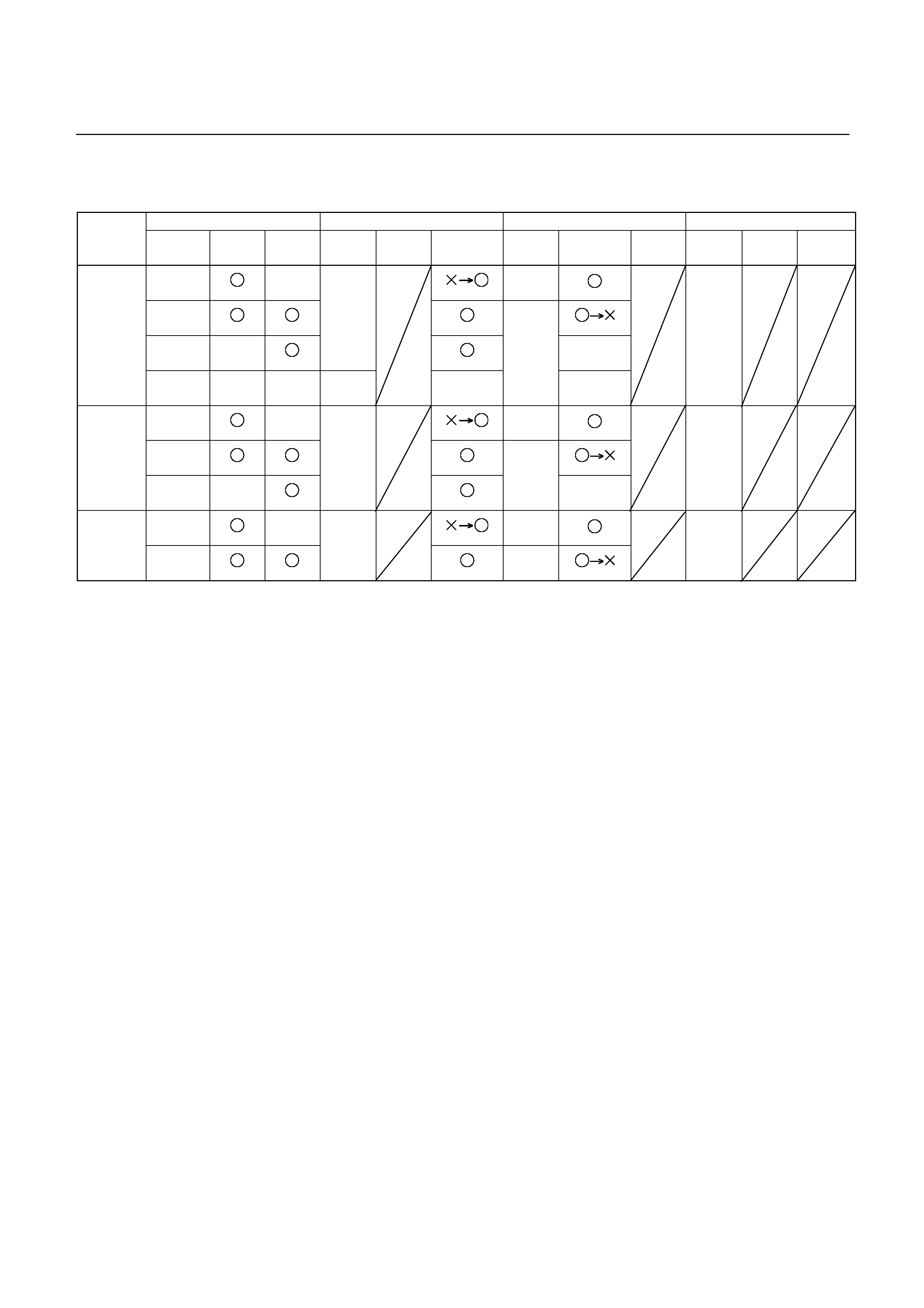

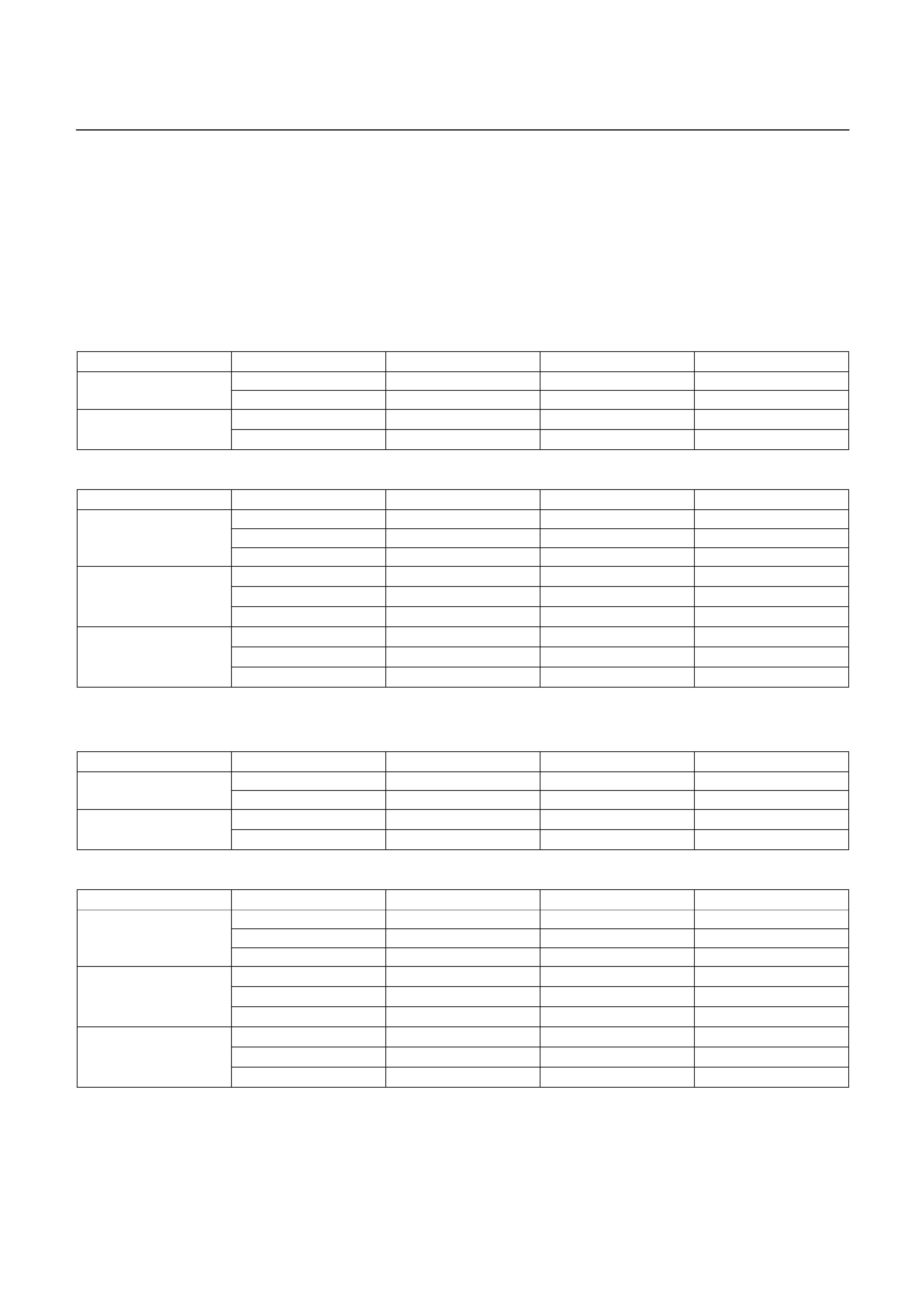

OPERATION OF CLUTCH, BRAKE AND ONE-WAY CLUTCH

: Operating : Free at coast down : Operating at lock-up

Shift lever

position Gear position C-0 C-1 C-2 B-0 B-1 B-2 B-3 F-0 F-1 F-2 S-1 S-2 S-3

P Parking

R Reverse

N Neutral

1st

2nd

3rd

D

O/D

1st

2nd

2

3rd

1st

(1*) 2nd

L

(2*) 3rd

(1*) Down-shift only in the L range and 2nd gear – no up-shift

(2*) Down-shift only in the L range and 3rd gear – no up-shift

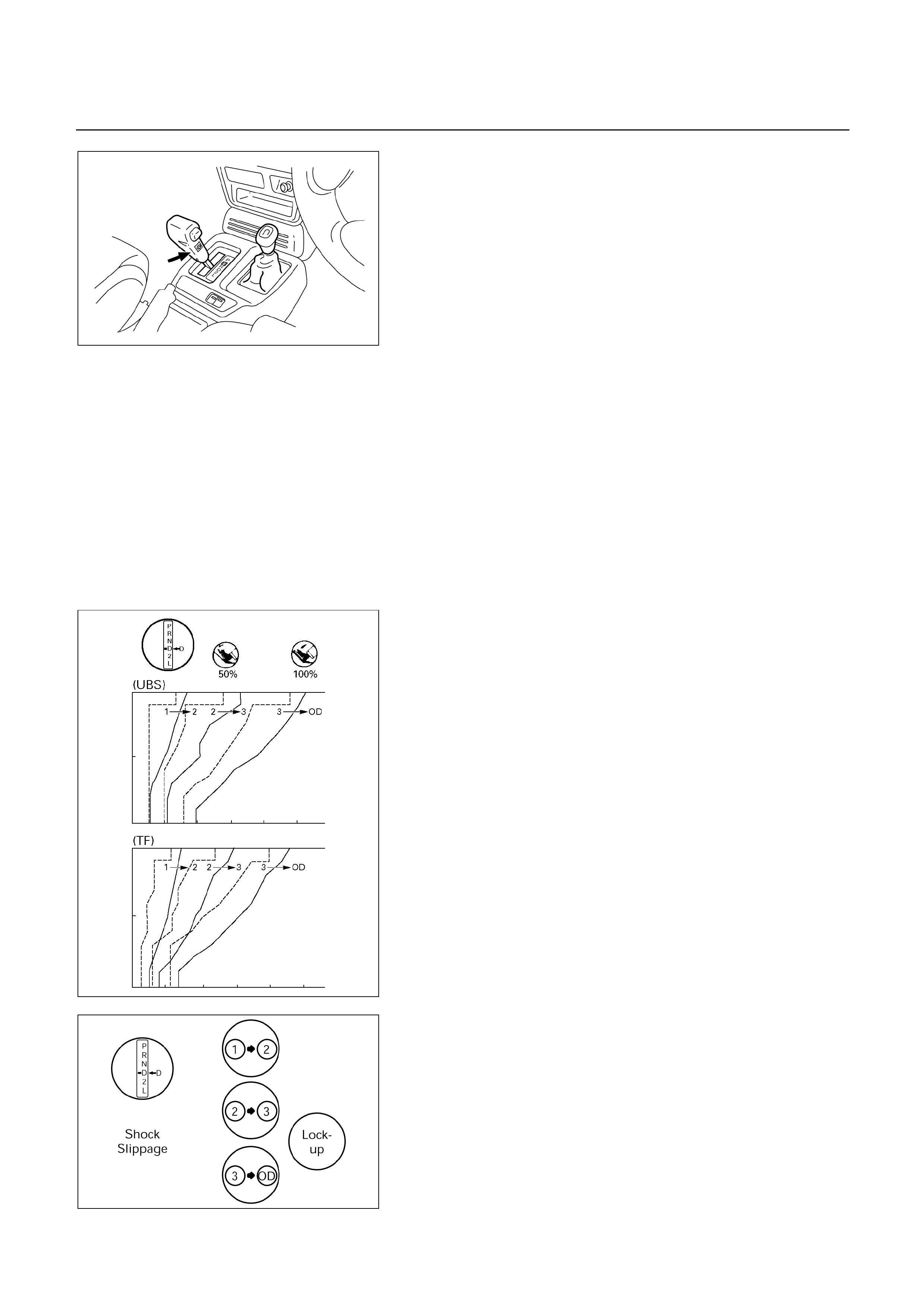

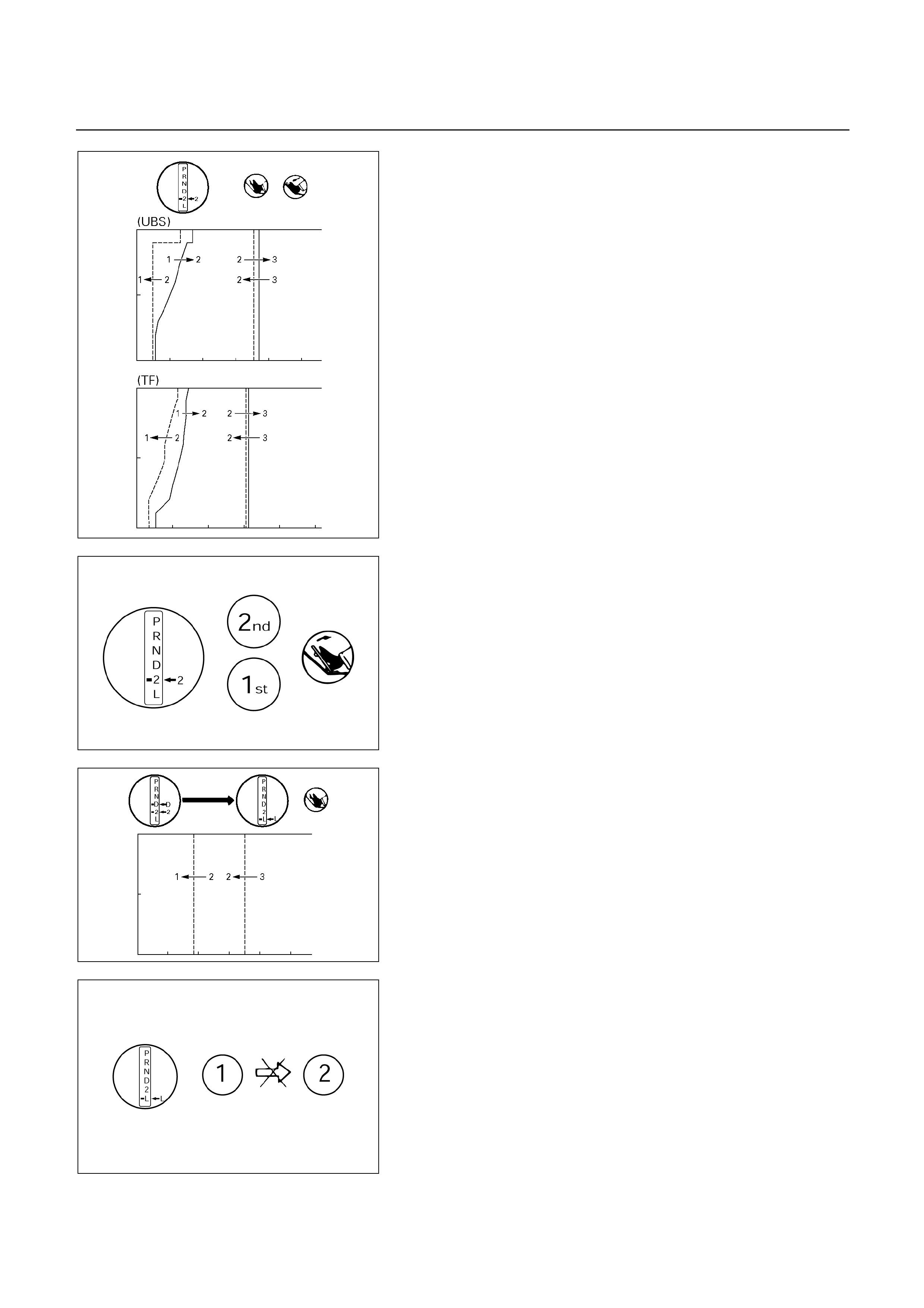

SPEED CHANGE AND LOCK-UP PATTERN

If you select a speed range and a lock-up pattern as shown below by specifying respective positions of transmission

shift lever, transfer shift lever and pattern select switch, the transmission control computer controls speed change

and lock-up operations based on the specified pattern in accordance with the degree of throttle opening and vehicle

speed.

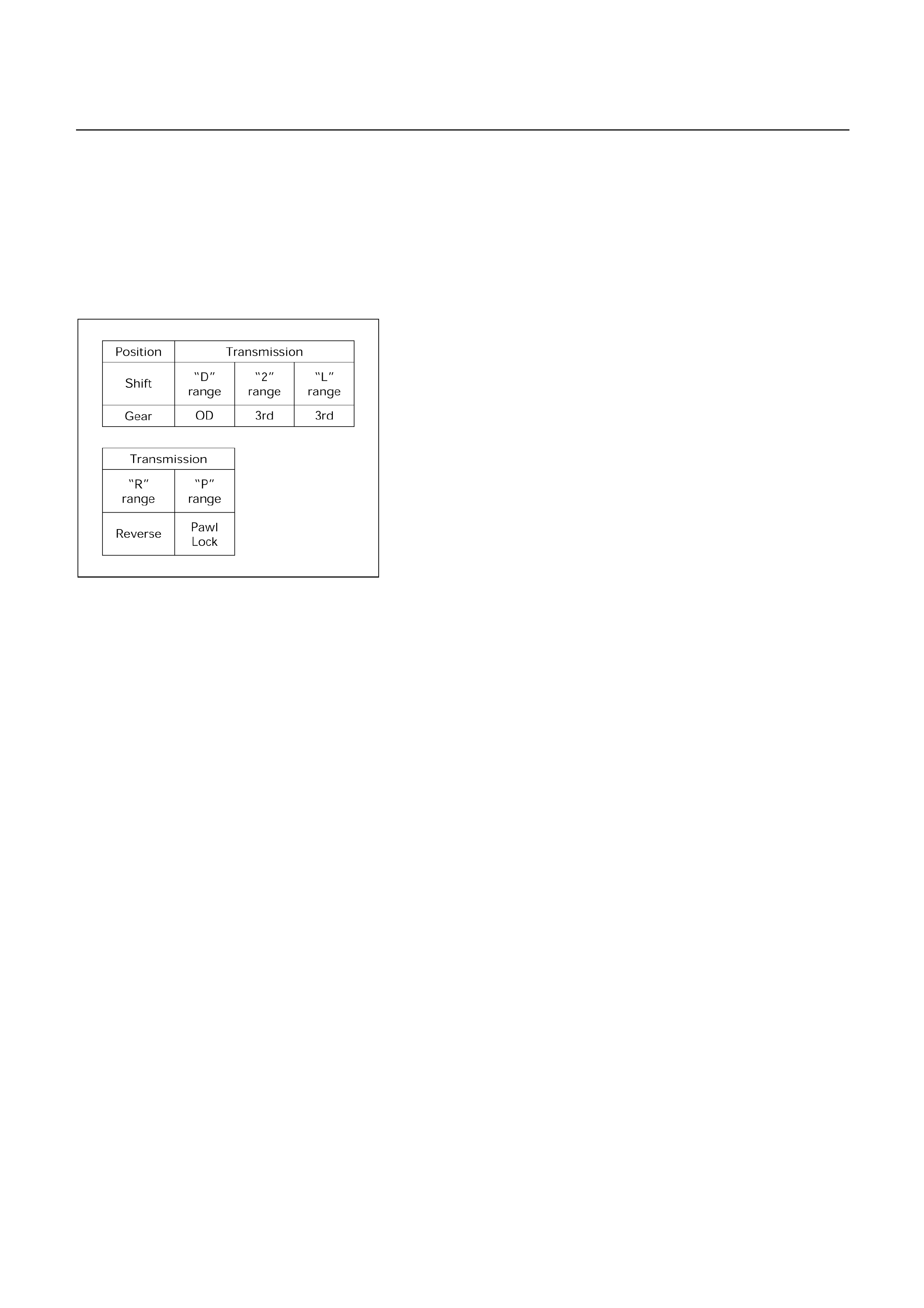

Transmission shift position

D

Pattern select sw.

position Overdrive switch

ON

Overdrive switch

OFF

2 L

NORMAL, POWER 1st [2nd]* [3rd] [O/D] 1st [2nd]* [3rd] [O/D] 1st 2nd (3rd) 1st (2nd) (3rd)

WINTER (UBS) 3rd fixing

[ ]: The lock-up operation is available.

( ): Transmission is shifted at high speed to prevent overrun.

*: TF model

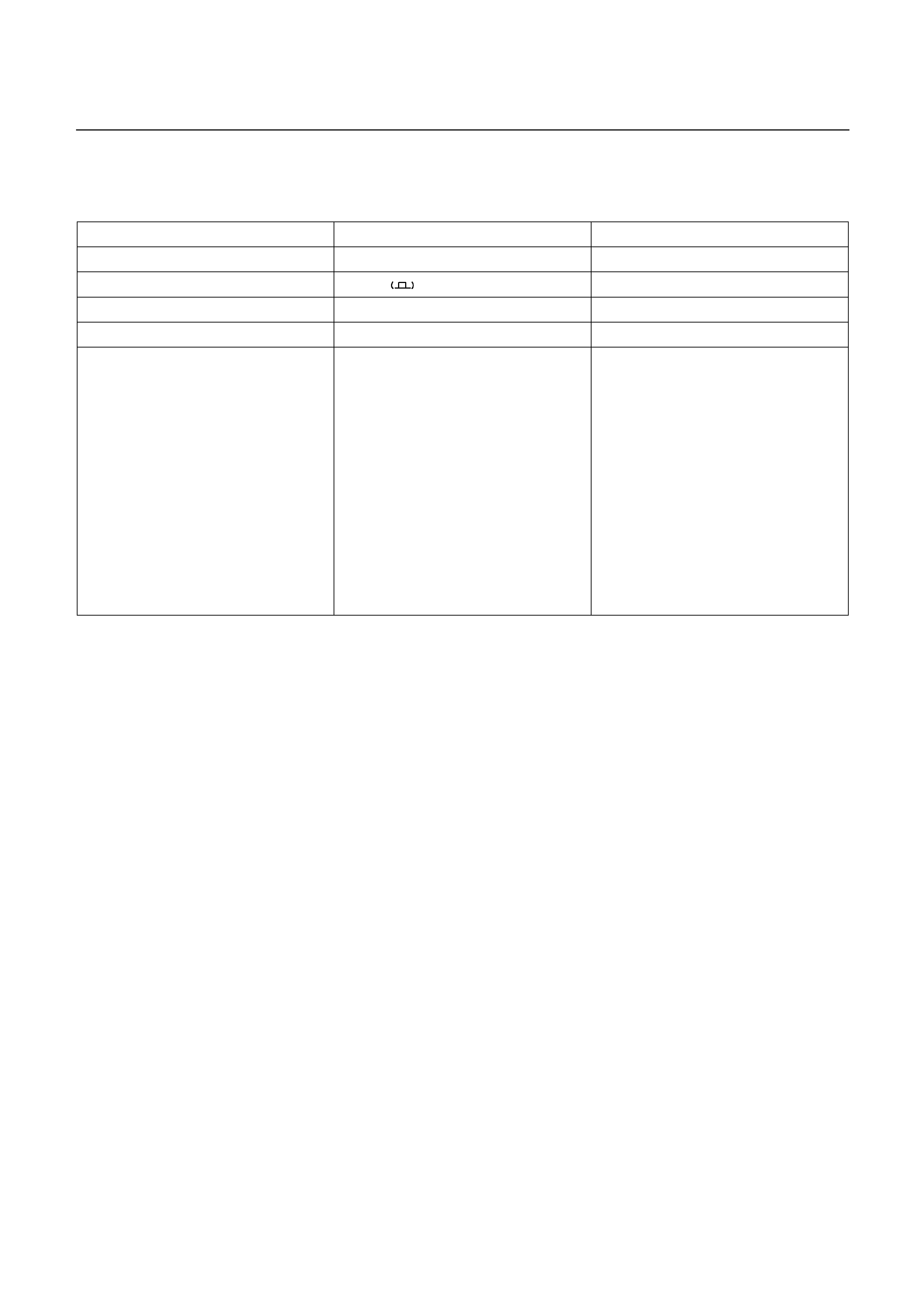

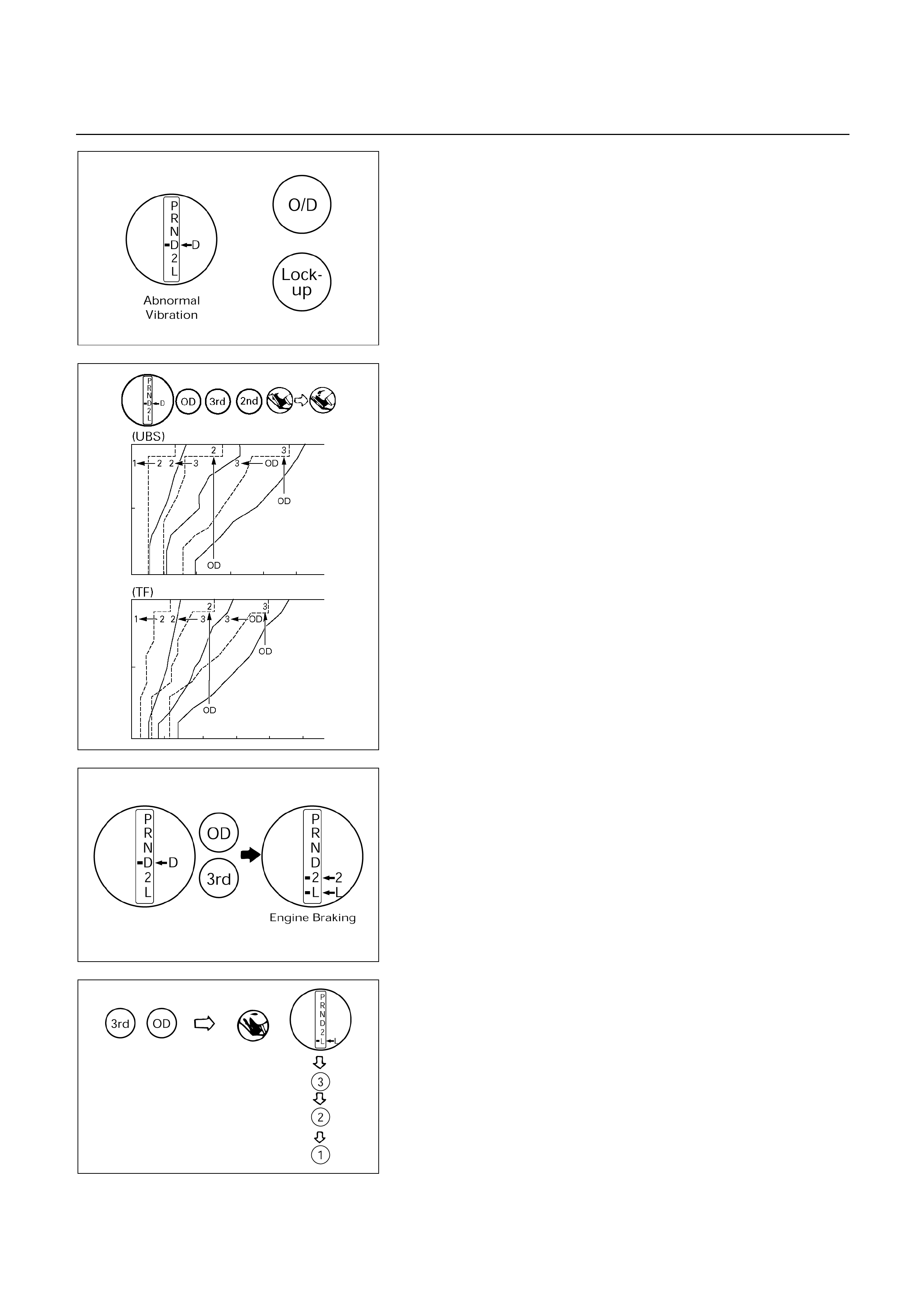

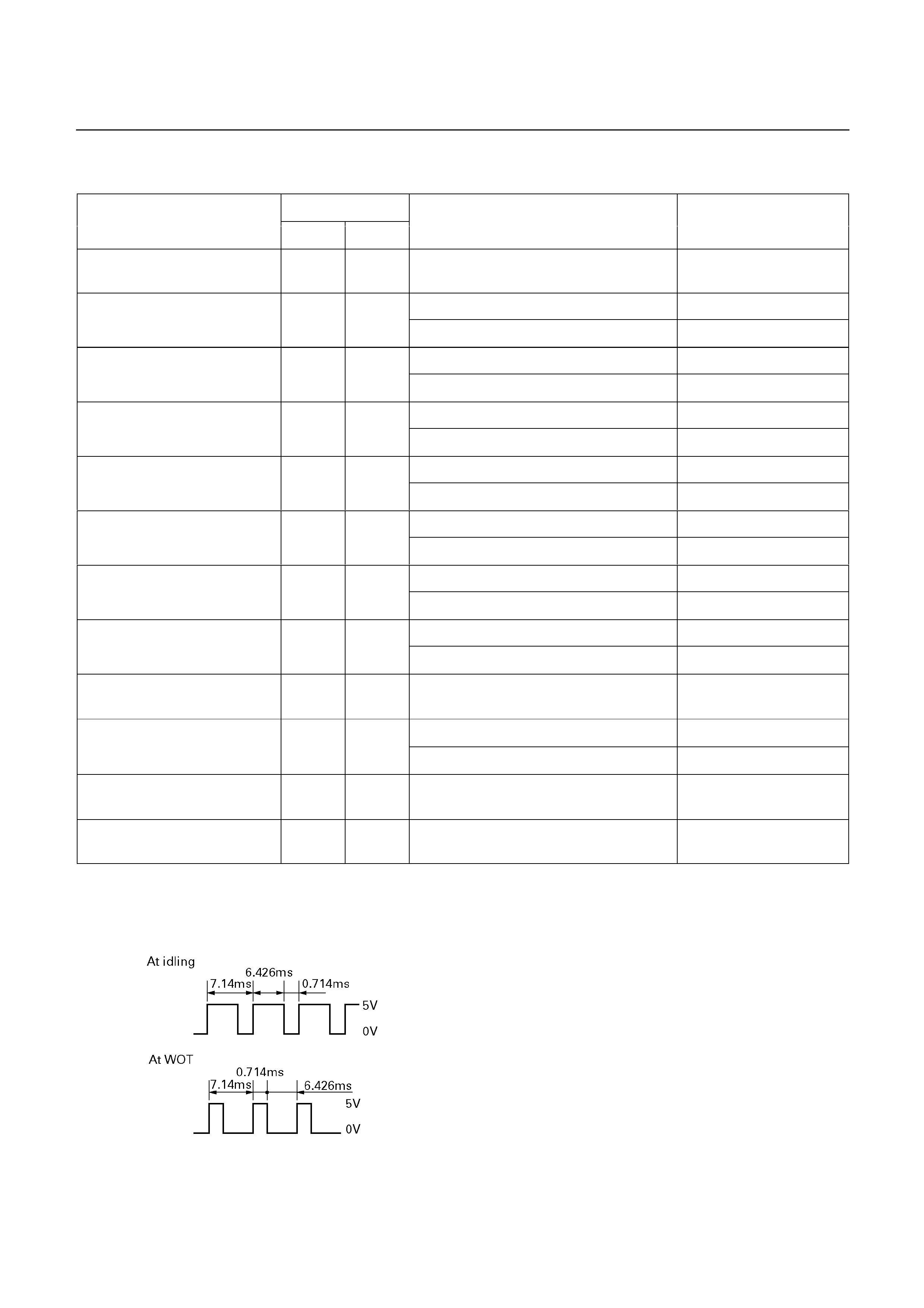

OVERDRIVE AND LOCK-UP OPERATING CONDITIONS

The overdrive and lock-up clutch operate if the following conditions are satisfied.

Overdrive Lock-up clutch

Transmission shift position D range (1*)

O/D switch position ON (O/D OFF lamp OFF)

Brake lamp switch OFF

Throttle opening Except fully closed

Vehicle speed

(UBS)

About 49 km/h or more

(TFR/S)

About 34 km/h or more

(UBS)

3rd: About 50 km/h or more

O/D: About 65 km/h or more

(TFR/S)

2nd: About 35 km/h or more

3rd: About 49 km/h or more

O/D: About 59 km/h or more

(1*): If transmission oil temperature is more than 130°C (UBS and or 140°C (TFR/S), lock-up is

inhibit.

DIAGNOSIS

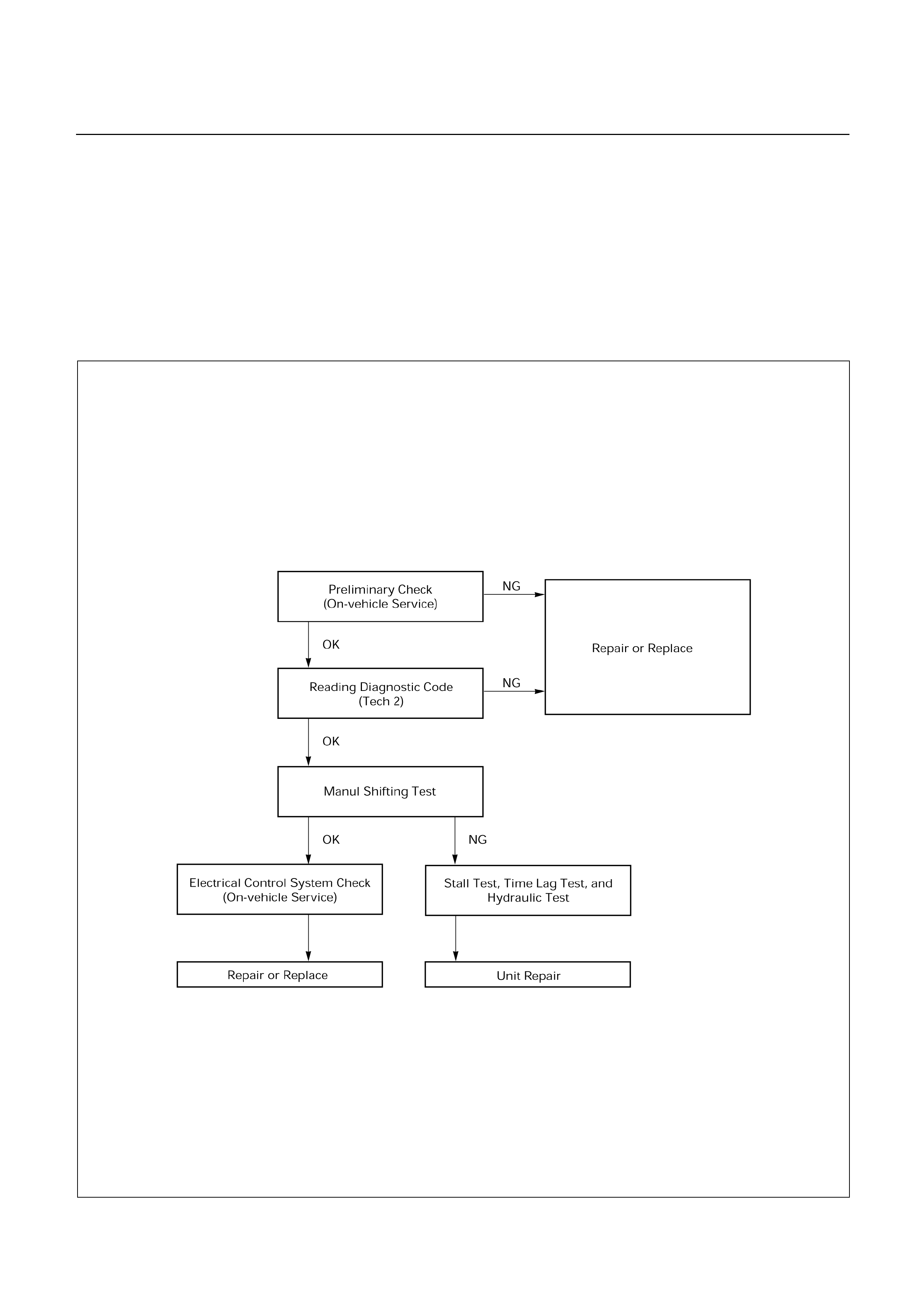

BASIC TROUBLESHOOTING

AW30-40LE transmission, called Electronic Controlled Transmission (ECT), differs from oil pressure control type

transmissions in that it is controlled by a microcomputer. Accordingly, its troubleshooting procedure differs also.

Before troubleshooting an ECT, first determine whether the problem is electrical or mechanical. To do this, just refer

to the basic troubleshooting flowchart provided below.

If the cause is already known, using the basic troubleshooting chart below along with the troubleshooting chart

should speed the procedure.

F07R200005

UBS

825R200084

TFR/S

825R200085

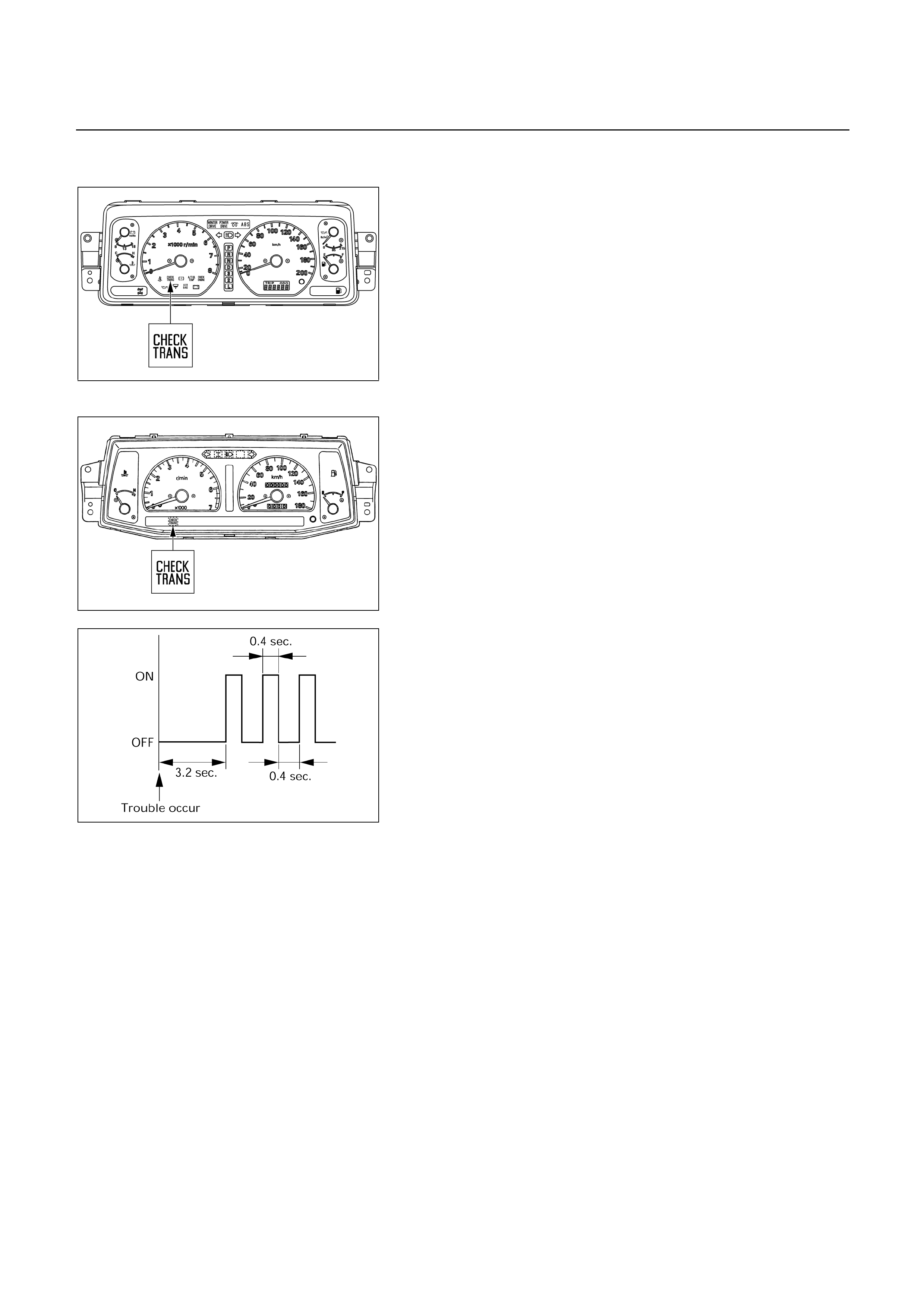

SELF DIAGNOSIS

Warning to the driver

When trouble has occurred to throttle position sensor,

vehicle speed sensor, or solenoid, “CHECK TRANS” lamp

is blinked (1.25 Hz) even during driving to warn the driver.

The trouble is recorded by trouble code is TCM.

When temporary trouble has been shooted, the “CHECK

TRANS” lamp stops blinking. This blinking can be stopped

by setting the ignition key off. But the trouble code remains

memorized in TCM.

F07LV002

UBS

TFR/S

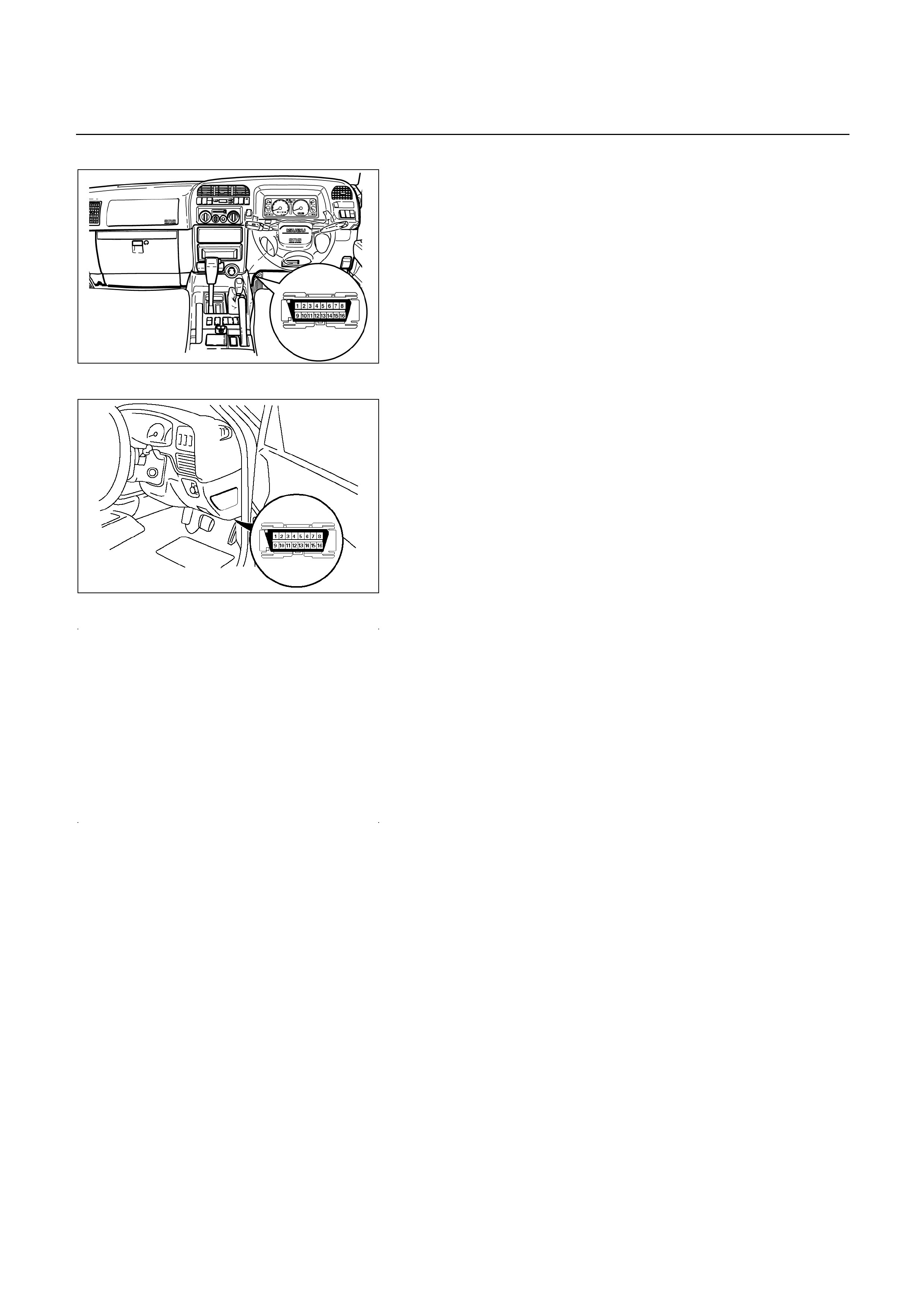

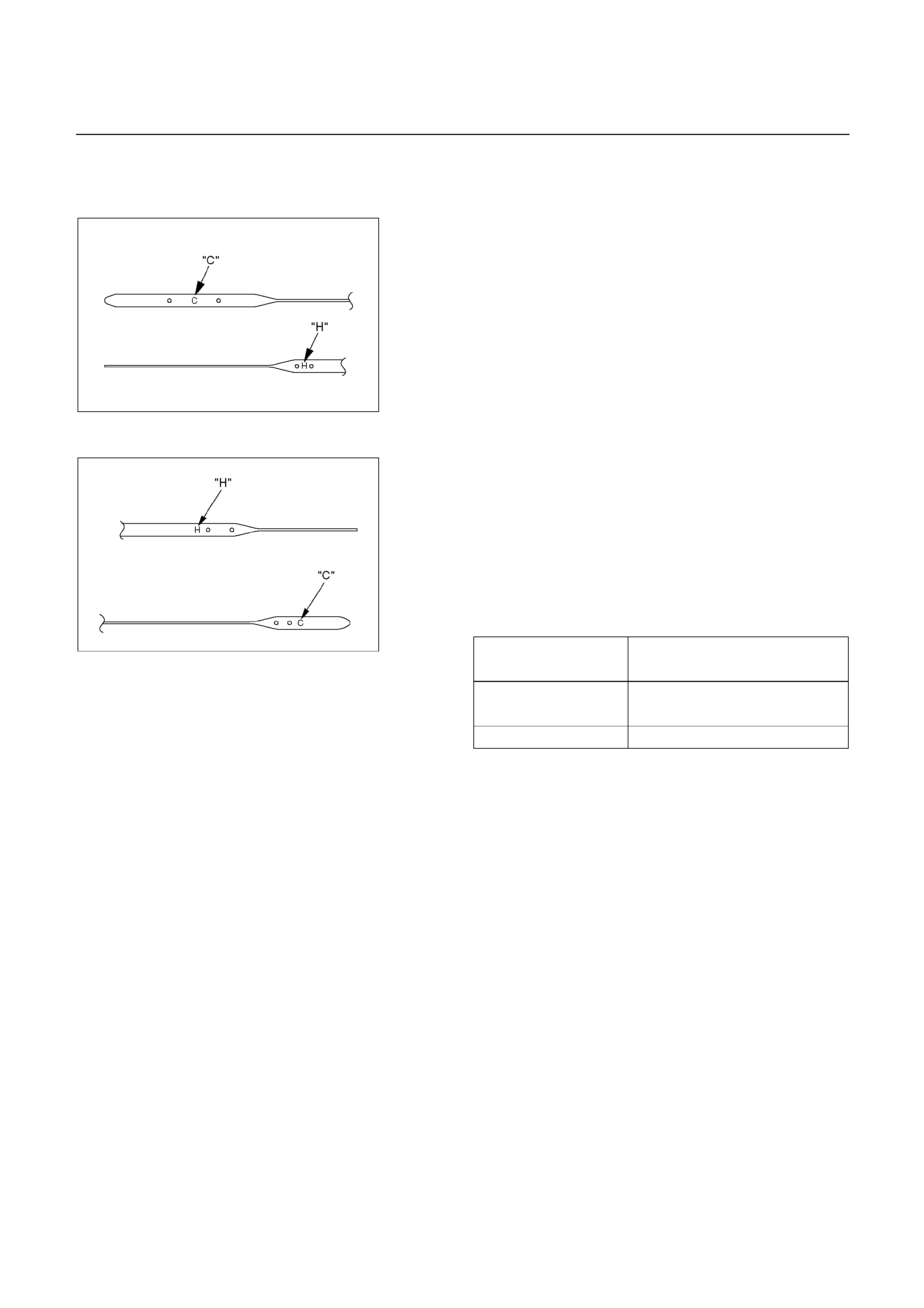

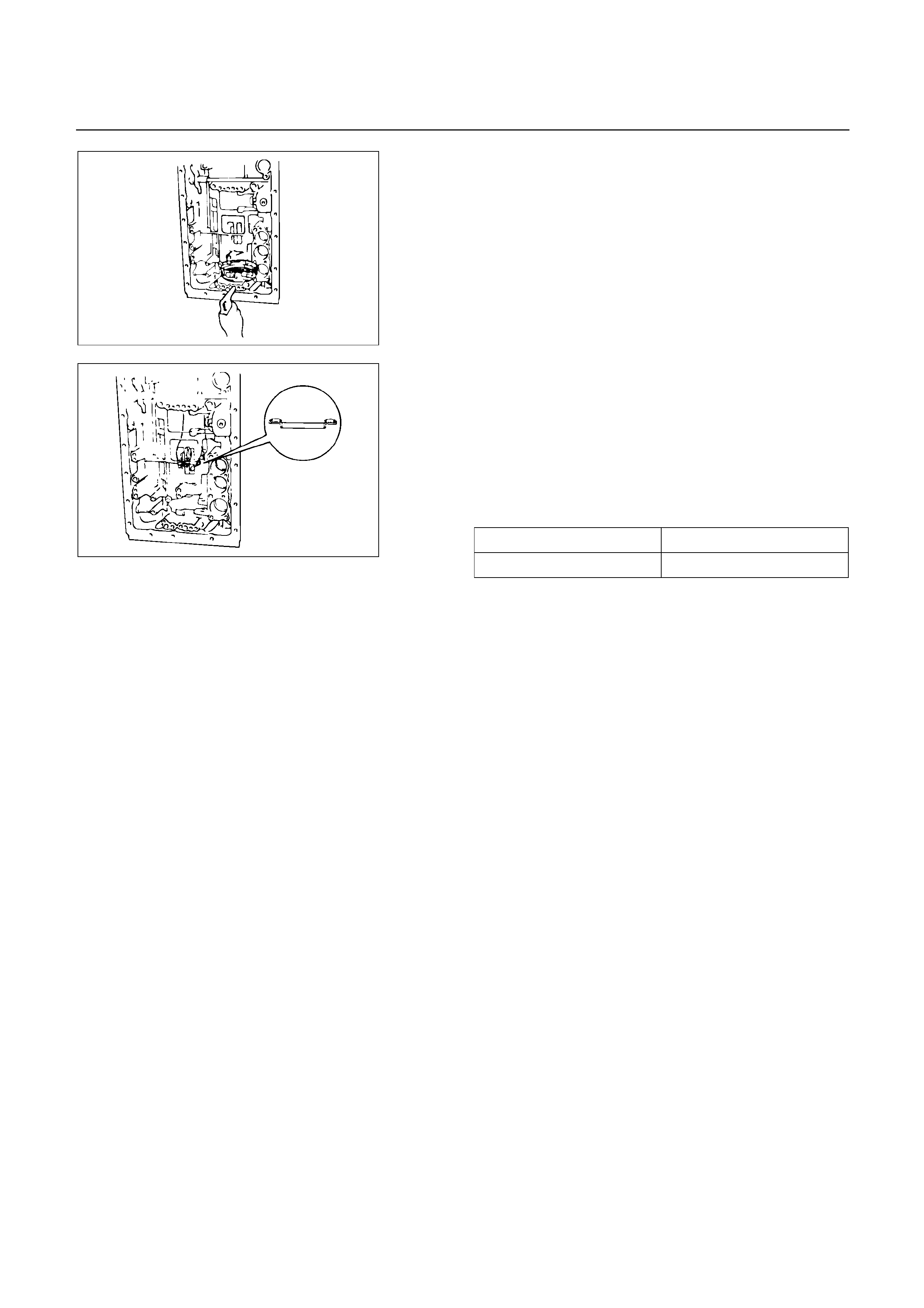

Self-diagnosis code display

For quick search for faulty parts, 11 (TF) or 12 (UBS)

different items of trouble code are indicated by “CHECK

TRANS” lamp blinking.

The storaged trouble codes can be identified by shorting

the terminals No.11 and No.4 or 5 (ground) of diagnosis

connector with a lead wire.

F07LV001

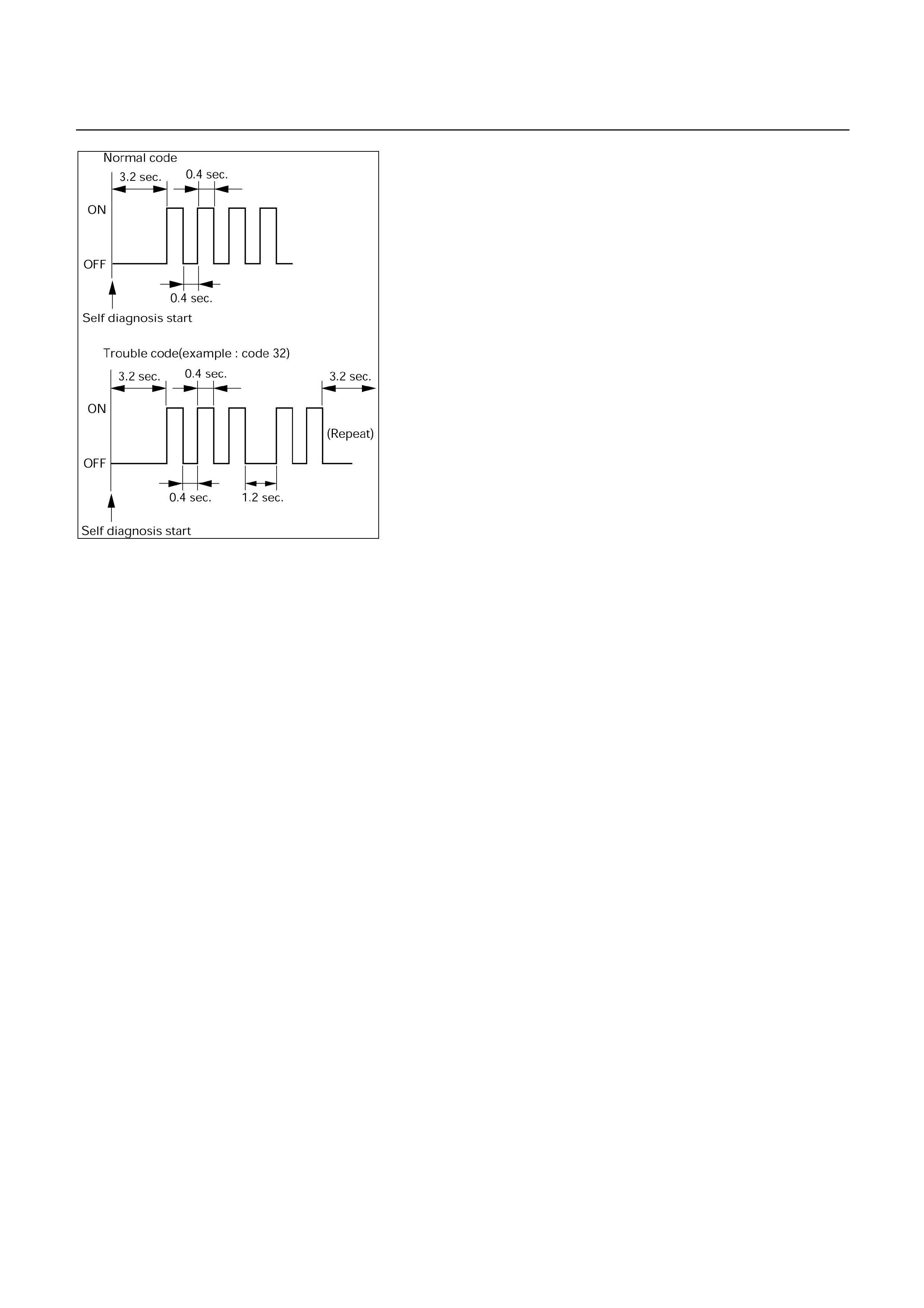

Indication Method:

(1) Terminals No.11 and No.4 or 5 (ground) of diagnosis

connector are short circuited.

(2) Turn the ignition key to the ON position.

(3) In case there no trouble, normal code is indicated.

(4) In case a plurality of trouble codes have occurred at a

time, each code is indicated three times in numerical

order.

NOTE:

Power line runs through diagnosis connector.

Be careful shorting with a lead wire, etc.

(The vehicle side of control module may be damaged.)

For identification of trouble code, connect Tech 2 to

diagnosis connector.

Clear of trouble code memory

1. Clear the trouble code memory using F1: Clear DTC

Information for Tech 2.

2. After more than 1 second has elapsed after the ignition

key has been turned ON, short between NO.11 and No.4

or 5 (ground) of data link connector. Then, after 1 second,

but within 6 seconds, discontinue shorting.

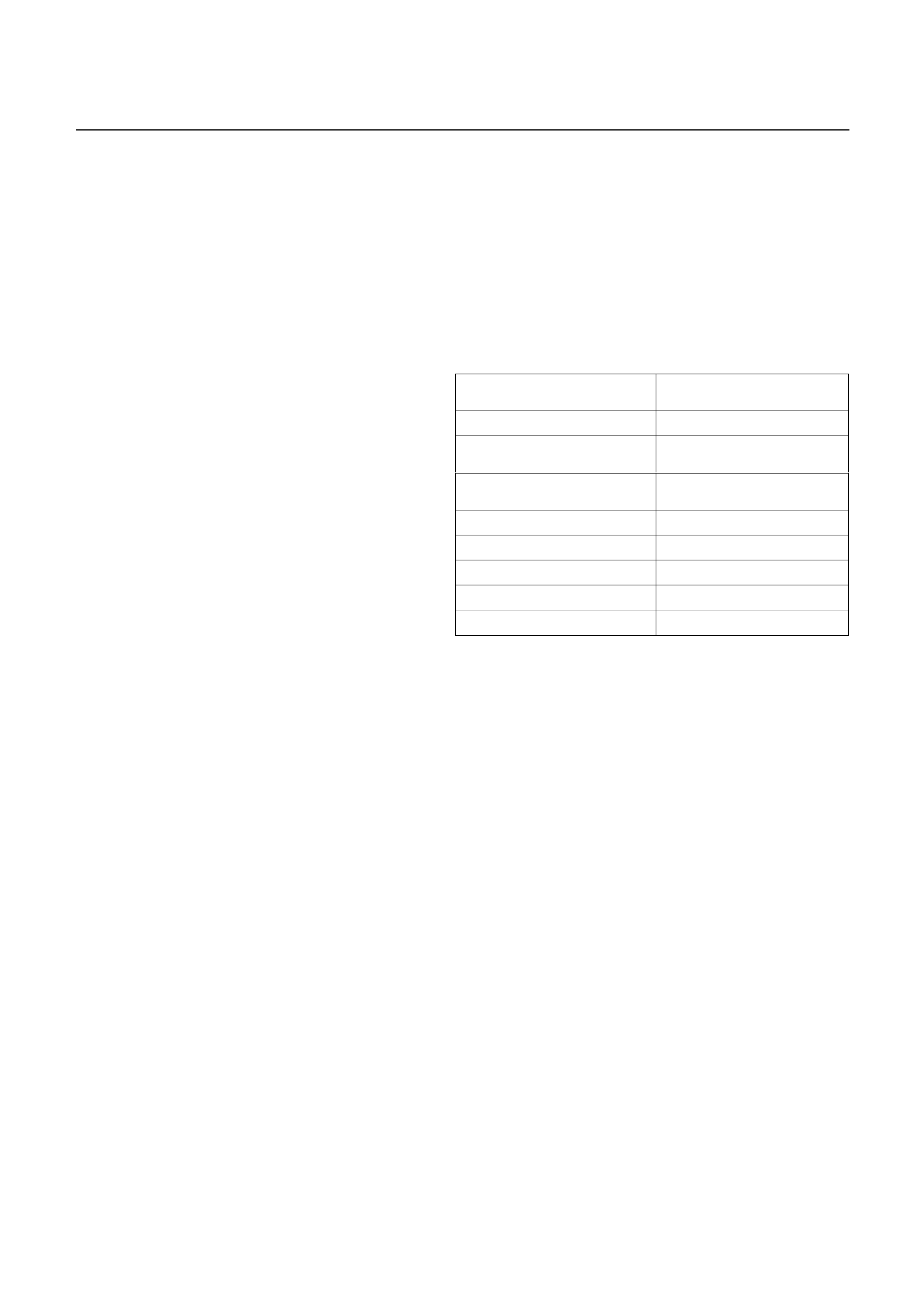

Flashing code

Trouble Code

(P-Code) Mode Diagnostic area and Failure

11

(P0722)

Output revolution sensor failure (SP2)

13

(P0727)

Engine revolution signal failure (NE)

14

(P0717)

Input revolution sensor failure (NC0)

16

(P0710)

Oil temperature sensor failure (OT2)

17

(P0705)

Gear selector failure (PRND2L)

21

(P0120)

Analog throttle signal failure (VTH)

(For UBS)

22

(P1120)

PWM throttle signal failure (TH)

(For TFR/S)

23

(P1121)

Analog throttle signal failure (VREF, VGND)

(For UBS)

24

(P0502)

Speed meter sensor failure (SP1)

31

(P0753)

Solenoid 1 failure (S1)

32

(P0758)

Solenoid 2 failure (S2)

33

(P0743)

Torque converter clutch control lock-up

(ON/OFF) solenoid failure (SL)

35

(P0748)

Pressure control solenoid failure (STH)

F07R200014

DIAGNOSIS WITH TECH 2

In this AW30-40LE transmission, troubleshooting can be

performed for electrical faults using the Tech 2 scan tool.

If the CHECK TRANS lamp blinks, or if an electrical fault in the

transmission may probably exist, check trouble codes using

the Tech 2 scan tool.

In the diagnostic procedures described in this manual, first

repair the faulty positions indicated by trouble code in the orde

r

of numbers and then perform troubleshooting for the fault

y

positions that are not indicated by trouble code. For correct

troubleshooting, it is necessary to first repair the trouble codes

of lower-order numbers, then to repair the trouble codes o

f

higher-order numbers in sequence.

How to Use This Manual:

Check trouble codes using the Tech 2 scan tool.

If no codes are set:

Refer to Data List and identify the electrical faults that are

not indicated by trouble code.

If codes are set:

Record all the codes displayed by the Tech 2 and check i

f

the codes are intermittent (intermittent faults).

Clear the codes.

Drive the vehicle for a test to reproduce the faulty status.

Check trouble codes again using the Tech 2.

If no code is displayed by test driving, the fault is

intermittent. In this case, refer to the cautions on

intermittent conditions.

If a code is present, refer to “DIAGNOSTIC TROUBLE

CODES (DTC) CHECK” for diagnosis.

Because a code of high-order number may be set for the

reason that a code of low-order number has been set afte

r

occurrence of a fault, perform repair work starting with a

lower-order number is ascending order.

USING TECH 2 ON THE VEHICLE

NOTE: Due to the constant evolution of TECH 2

software, the screens shown in this section may

differ slightly from those displayed for the vehicle

being tested.

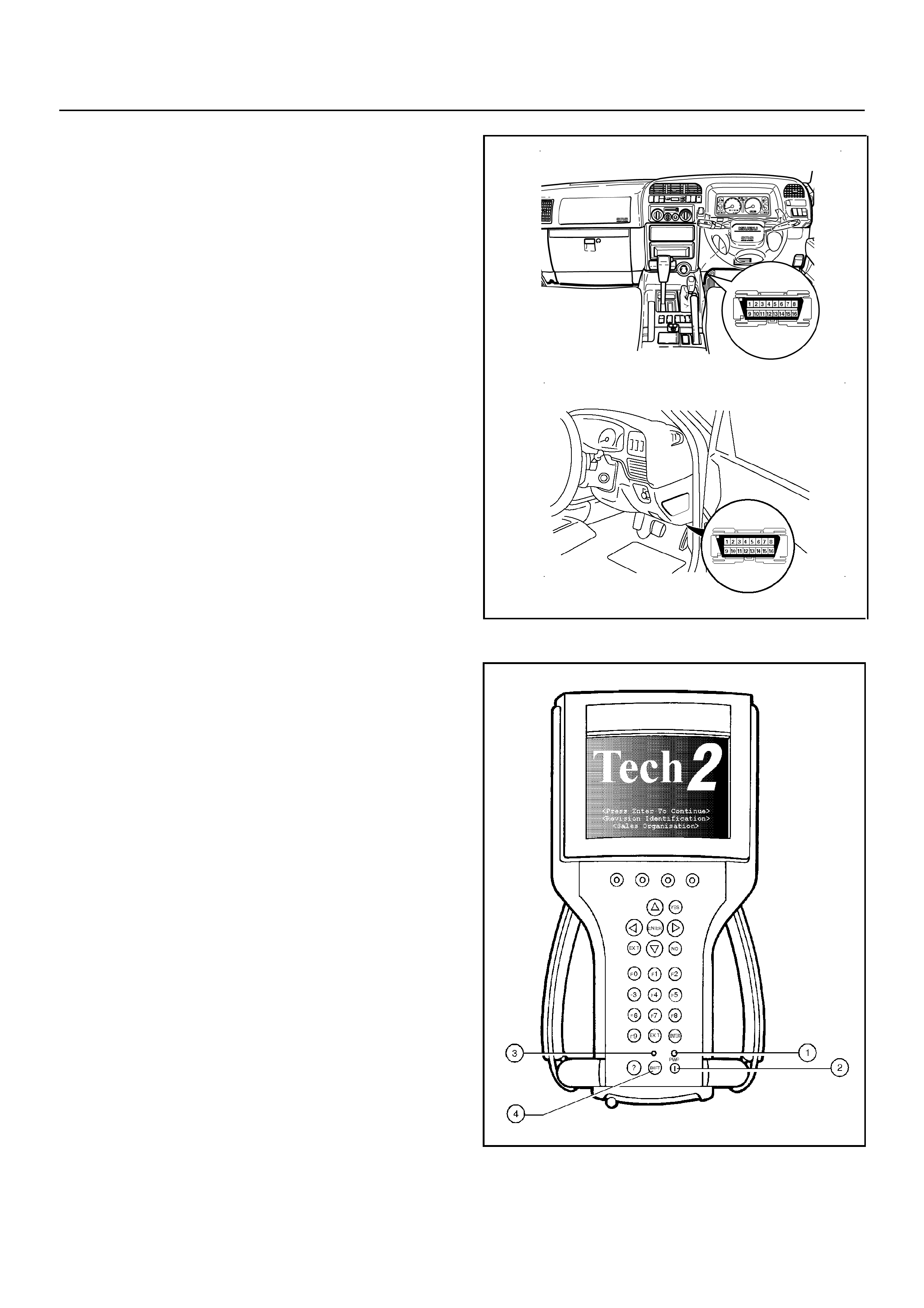

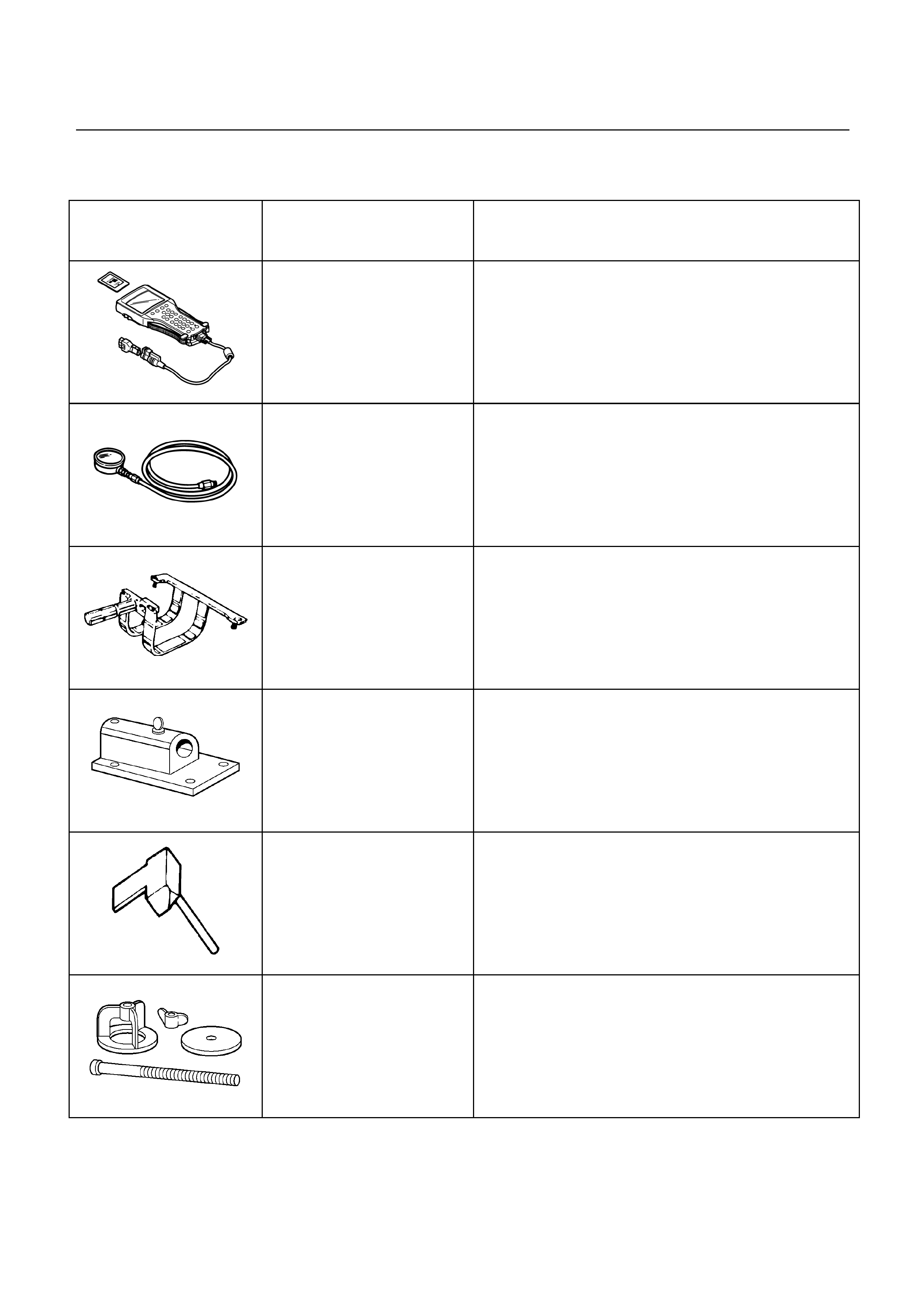

Connecting TECH 2 To The Vehicle

1. Connect Tech 2 to the vehicle DLC, with the DLC

cable and the 16/19 pin adapter.

2. Switch the unit on by pressing the power button (2).

A green light (1) should come on indicating that the

tool is receiving power.

NOTE: At this time the technician should see the Power

On Self Test (POST) run. The POST is a built in

diagnostic self test for the TECH 2 that should find most

common system faults. The POST is run on every

power up to ensure the best operation of the tool. After

the completion of the POST, the TECH 2 unit will briefly

show the POST results. If POST passes, the tool will

continue onto the title screen. If POST fails, results of all

tests will be displayed, and this should show which test

failed. POST failures may be classified as fatal or non-

fatal. A fatal error will not allow the user to continue

using the tool. Failure of the keypad would be an

example of a fatal error. Non-fatal errors found during

the POST will allow continued use of the TECH 2, but

with some limitations. If either a fatal or non-fatal error

occurs, refer to the Troubleshooting section of the

TECH 2 User's Guide.

1. Power Status Indicator Light

2. PWR (Power) Key

3. SHIFT Key Status Indicator Light

4. SHIFT Key

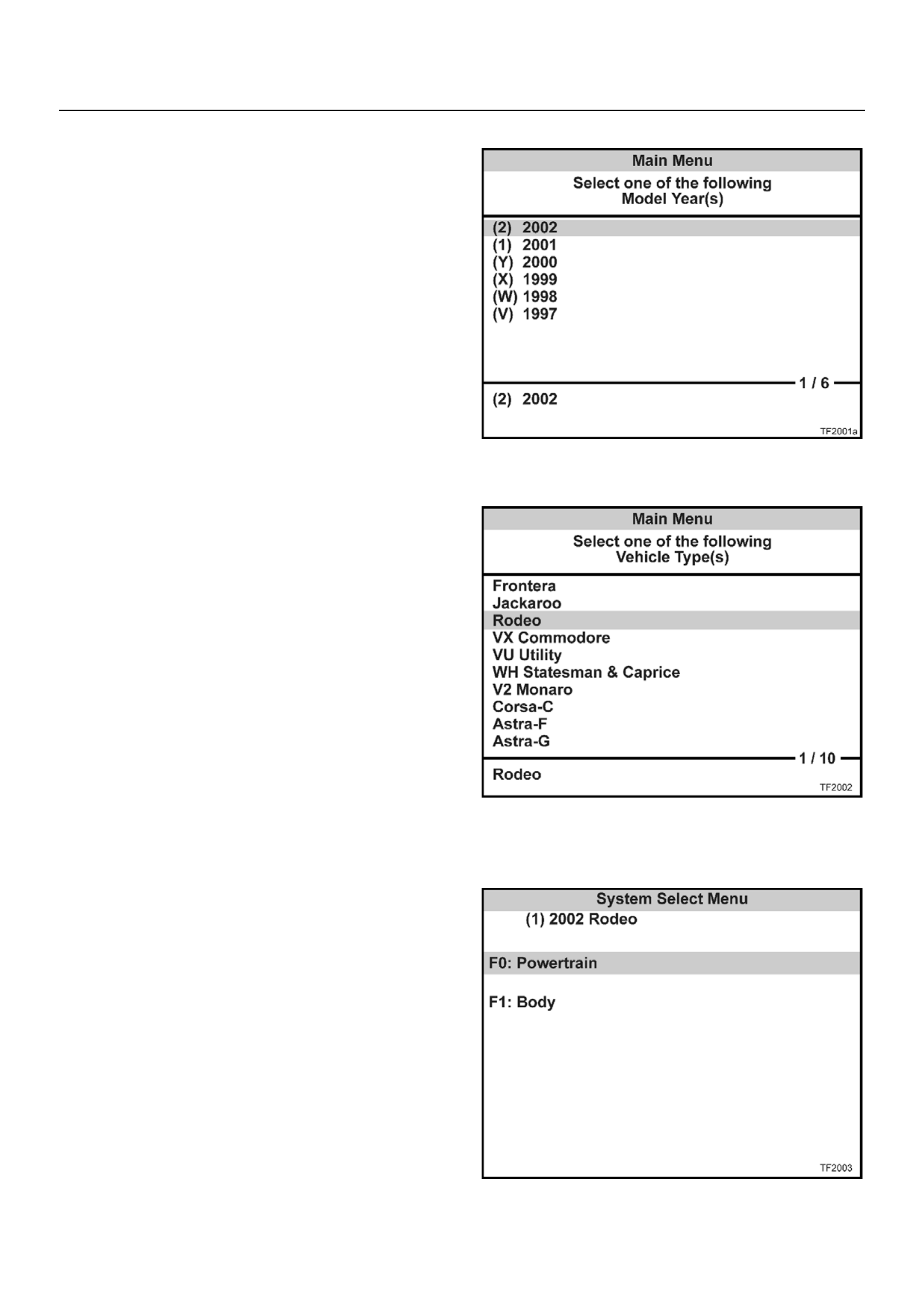

3. At the Tech 2 title screen press the ENTER key to

continue.

UBS

TFR/S

4. A selection can be made from the Main Menu,

either by using a function key or by using the arrow

keys to highlight a menu choice and pressing

ENTER.

•NOTE: You will then need to supply some additional

information to the TECH 2. This requires navigation

through a series of lists (called picklists). On some

menus or picklists, the user can use a function key to

make a menu selection, but most of the picklists

require using the selection and action keys. If a

mistake is made in the selection process, or if a

different application or function is desired, press EXIT

to back up one level. Within an application, there may

be soft keys which are available for use. These soft

keys allow access to additional tool functions without

exiting a current tool function. Soft keys are made up

of sets which will appear together. To see the next set

of soft keys, select the More soft key.

The TECH 2 Main Menu contains the following:

F0: Diagnostics

Contains all functions to test, diagnose, monitor and

program the different vehicle systems.

F1: Service Programming System (SPS)

SPS is used in conjunction with Technical

Information System (TIS) 2000 to program vehicle

control units.

F2: View Capture Data

Contains all functions to work with one or two

previously recorded snapshots on one or two

vehicles. This function is to enable the viewing of

captured data without a vehicle.

F3: Tool Options

Contains the TECH 2 self test, set clock, set units,

set screen contrast and Getting Started.

F4: Download/Upload Help

Contains help information on the downloading and

uploading from the TECH 2 to the TIS 2000 CD-

ROM.

5. Select the correct Model Year with the arrow keys

and the press ENTER. The Vehicle identification

screen will then be displayed.

6. Select the correct Vehicle Type with the arrow keys

and the press ENTER. The System Select Menu

will then be displayed.

7. The desired system can be selected from the

System Select Menu with the function keys or with

arrow keys and then press ENTER.

F0:Powertrain contains all functions to test,

diagnose, and monitor the engine and transmission

systems that communicate with the Tech 2 via the

Powertrain Control Module (PCM).

F1: Chassis contains all functions to test,

diagnose, monitor the vehicles chassis systems;

TOD and ABS modules.

F2: Body contains all functions to test, diagnose,

monitor the instruments and Supplemental

Restraint System.

Once the test vehicle has been identified an

“Application (Powertrain) Menu" screen appears.

Please select the appropriate application.

The following table shows, which functions are used for

the available equipment versions.

F0: Diagnostic Trouble Codes

F0: Read DTC Info Ordered By Priority

F1: Clear DTC Information

F2: DTC Information

F0: History

F1: MIL SVS or Message Requested

F2: Last Test Failed

F3: Test Failed Since Code Cleared

F4: Not Ran Since Code Cleared

F5: Failed This Ignition

F1: Data Display

F0: Transmission Data

F1: TCC Data

F2: Snapshot

F3: Actuator Tests

F0: Lamps

F0: Check Light Test

F1: Power Lamp Test

F2: Winter Lamp Test

F3: AT Oil Temperature Lamp Test

F1: Solenoids

F0: Solenoid 2-3 Test

F1: Solenoid 1-2/3-4 Test

F2: TCC Solenoid Test

F3: Pressure Control Solenoid (PCS)

Diagnostic Trouble Codes

The purpose of the “Diagnostic Trouble Codes" mode

is to display stored TCM trouble codes.

When “Diagnostic Trouble Codes" is selected an

“Application Menu" screen appears.

Clear DTC Information

The purpose of the “Clear DTC Information" mode is to

command the clearing of stored TCM trouble codes.

When “Clear DTC Information" is selected, a “Clear

DTC Information", warning screen appears. This

screen informs you that by cleaning DTC's, “all stored

DTC information in controller will be erased".

Do you want to clear DTC's (Yes/No).

Press either the Yes or No key when answering.

After clearing codes, confirm system operation by test

driving the vehicle.

Allow the vehicle to shift through all four forward gears

in a manner which attempts to repeat the failure

condition.

NOTE: When the trouble has not been repaired and

the trouble code cannot be erased, check the vehicle

again.

DTC Information

When “DTC Information" is selected, an “Application

Menu" appears with a list of DTC information function

keys addressing DTC specifics and their origins.

Function key selections may vary for particular vehicle

and/or system.

Data Display

The purpose of the “Data Display" mode is to

continuously monitor data parameters.

The current actual values of all important sensors and

signals in the system are display through F1 mode.

When “Data Display" is selected an “Application Menu"

appears.

See “TRANSMISSION DATA" and “TCC DATA” on

next page.

Snapshot

When “Snapshot" is selected an “Application Menu"

appears.

When “Transmission Snapshot" application is selected

from the “Application Menu", a “Snapshot Menu"

appears, displaying several options. “Snapshot" options

may vary from one system to another.

“Snapshot" allows a recording of all vehicle

parameters. There parameters may then be replayed

at a future point in time.

This action allows you to focus on making the condition

occur, rather than trying to view all of the data in

anticipation of the fault. The snapshot will collect

parameter information around a trigger point that you

select.

When a snapshot is taken. It is recorded onto the

PCMCIA memory card. When the Tech2 is powered

down. Snapshots are not lost.

Actuator Tests

The purpose of “Actuator Tests" mode is to check for

correct operation of electronic system actuators.

Lamps

You can operate the lamps by pressing the ON and

OFF buttons.

Preconditions: P or N position

Solenoid

Solenoid S1(1-2/3-4), S2(2-3) and TCC Solenoid

(Torque Converter Clutch)

You can operate the solenoids by pressing the ON and

OFF buttons.

Preconditions: P or N position, no vehicle speed, no

engine speed

Pressure Control Solenoid (PCS)

You can operate the PC Solenoid by pressing the ON

and OFF buttons. ON will command a maximum

current of 1000 mA and OFF a minimum of 200 mA.

Preconditions: P or N position, no vehicle speed,

engine running

TRANSMISSION DATA

Item Unit Engine running at idle

Current Gear 1

Lock Up Inactive, Active Inactive

Selector Position Park

AT Output Speed (Automatic Transmission) RPM 0 RPM

Output Speed (Meter Signal Side) RPM 0 RPM

AT Input Speed (Automatic Transmission) RPM 0 RPM

Engine Speed RPM 695 ~ 745 RPM (UBS)

Vehicle Speed (Output Side) km/h 0 km/h

Throttle Position % 0%

Throttle Position Sensor V 0.25 ~ 0.45V

AT Oil Temperature (Automatic Transmission) °C, °F 70 ~ 80°C (158 ~ 176°F)

Shift Pattern

Desired PCS Pressure (Pressure Control

Solenoid) kPa

PCS Desired Current (Pressure Control Solenoid) mA

PCS Actual Current (Pressure Control Solenoid) mA

Overdrive Off Switch Off, On

Brake Switch Open 0V, Closed 12V Closed 12V

Winter Switch Open, Closed 0V Open

Power Switch Open, Closed 0V Open

Diagnostic Request Open, Closed Open

Winter Lamp Inactive 12V, Active 0V Inactive 12V

Power Lamp Inactive 12V, Active 0V Inactive 12V

Check Light Inactive 12V, Active 0V Inactive 12V

AT Oil Temperature Lamp (Automatic

Transmission) Inactive 12V, Active 0V Inactive 12V

Solenoid 2-3 Inactive 0V, Active 12V Inactive 0V

Solenoid 1-2/3-4 Inactive 0V, Active 12V Active 12V

TCC Solenoid (Torque Converter Clutch) Inactive 0V, Active 12V Inactive 0V

TCC DATA

Item Unit Engine running at idle

Current Gear 1

Lock Up Inactive, Active Inactive

AT Output Speed (Automatic Transmission) RPM 0 RPM

Output Speed (Meter Signal Side) RPM 0 RPM

AT Input Speed (Automatic Transmission) RPM 0 RPM

Engine Speed RPM 695 ~ 745 RPM (UBS)

Vehicle Speed (Output Side) km/h 0 km/h

Throttle Position % 0%

Gear Ratio :1 2.804

AT Oil Temperature (Automatic Transmission) °C, °F 70 ~ 80°C (158 ~ 176°F)

TCC Slip Speed RPM 695 ~ 745 RPM

TCC Solenoid Pressure Desired kPa 0 kPa

Desired TCC Solenoid Current mA 0 mA

Actual TCC Solenoid Current mA 0 mA

INTERMITTENT CONDITIONS

If the Tech2 displays a code as intermittent, or if after a test

drive a code does not reappear, the problem is most likely a

faulty electrical connection or loose wiring.

Terminals should always be the prime suspect.

Intermittent rarely occur in sophisticated electronic

components such as the Transmission Control Module (TCM).

When an intermittent problem is encountered, check suspect

circuits for:

Poor terminal to wire connection.

Terminals not fully seated in the connector body (backed

out).

Improperly formed or damaged terminals.

Loose, dirty, or corroded ground connections.

HINT: Any time you have an intermittent in more than one

circuit, check whether the circuits share a common

ground connection.

Pinched or damaged wires.

Electro-Magnetic Interference (EMI)

HINT: Check that all wires are properly routed away from

coil, and generator. Also check for improperl

y

installed electrical options, such as lights, 2-wa

y

radios, etc.

Use the F2: SNAPSHOT mode of the Tech2 to help isolate the

cause of an intermittent fault. The snapshot mode will record

information before and after the problem occurs. Set the

snapshot to "trigger" on the suspect code (or codes) or, if you

notice the reported symptom during test drive, trigger the

snapshot manually.

After the snapshot has been triggered, command the Tech2 to

play back the flow of data recorded from each of the various

sensors. Signs of an intermittent fault in a sensor circuit are a

sudden unexplainable jump in data values out of the normal

range.

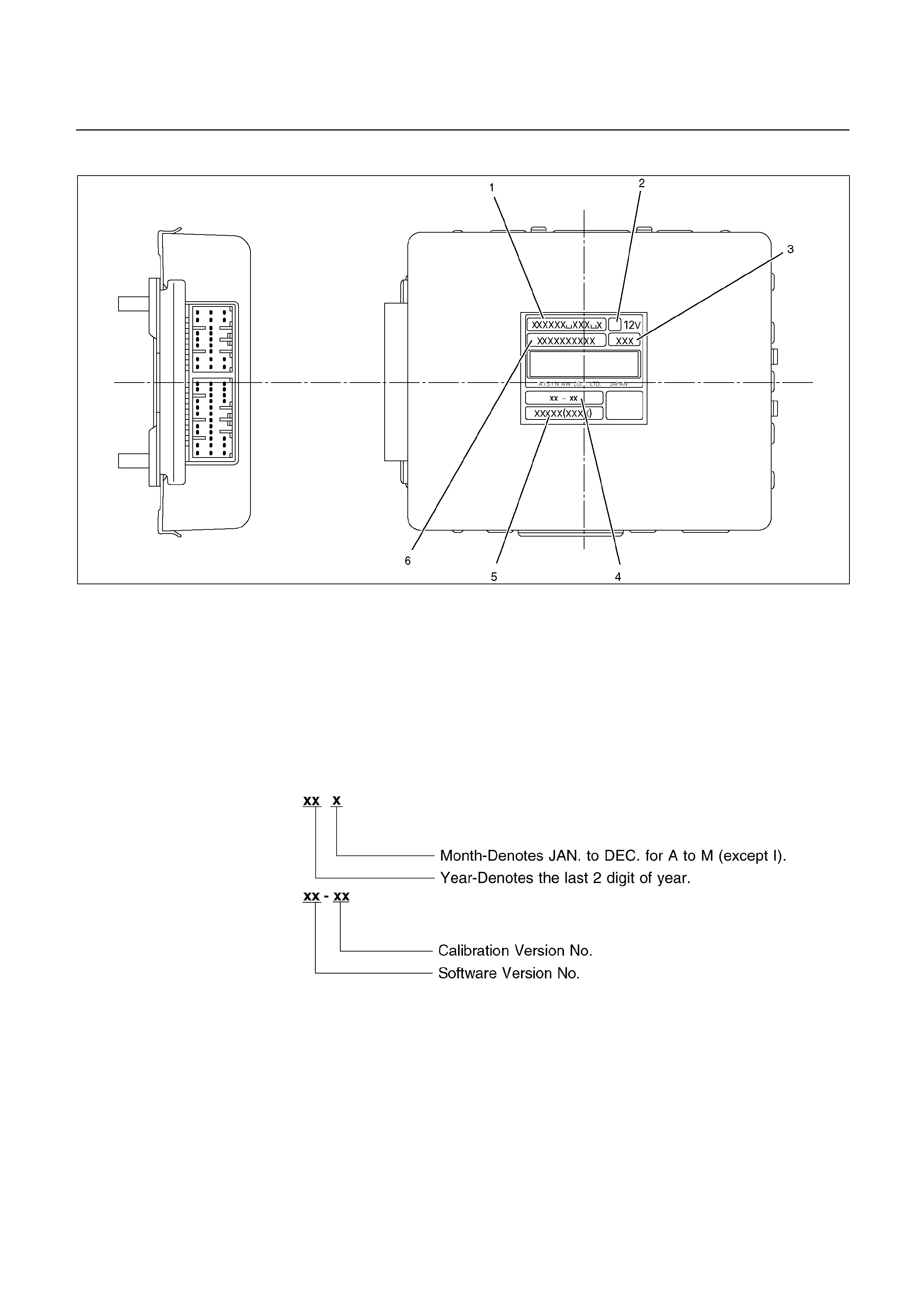

IDENTIFICATION OF TRANSMISSION CONTROL MODULE (TCM)

826R200032

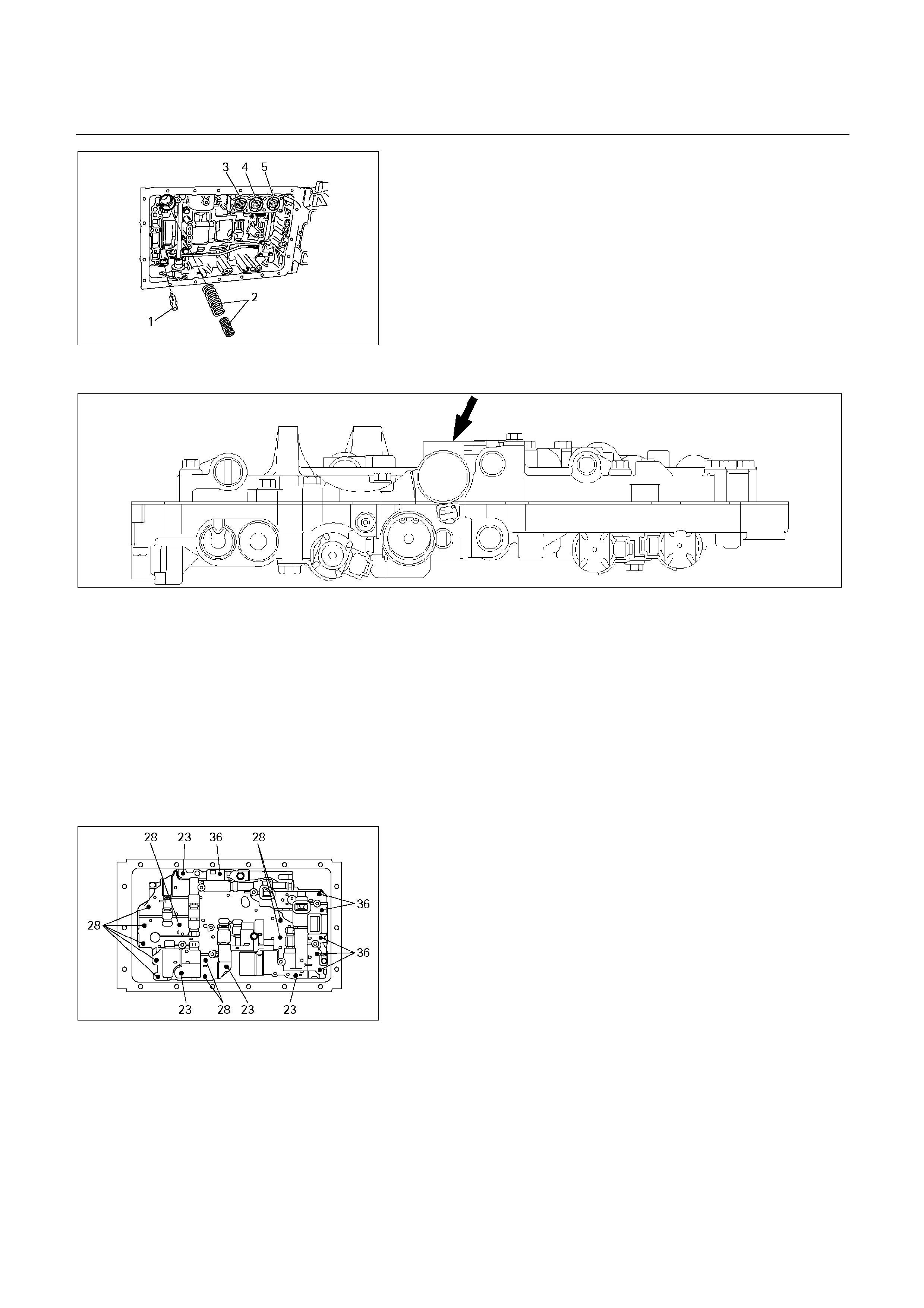

Legend

1. HOLDEN Part No:

‘02UBS 8-97230-821-0

‘02TFS 8-97303-885-0

‘02TFR 8-97303-884-0

2. Calibration Code

3. Production Date:

4. Software Version No.:

5. Model Year, Vehicle Model, Engine Type

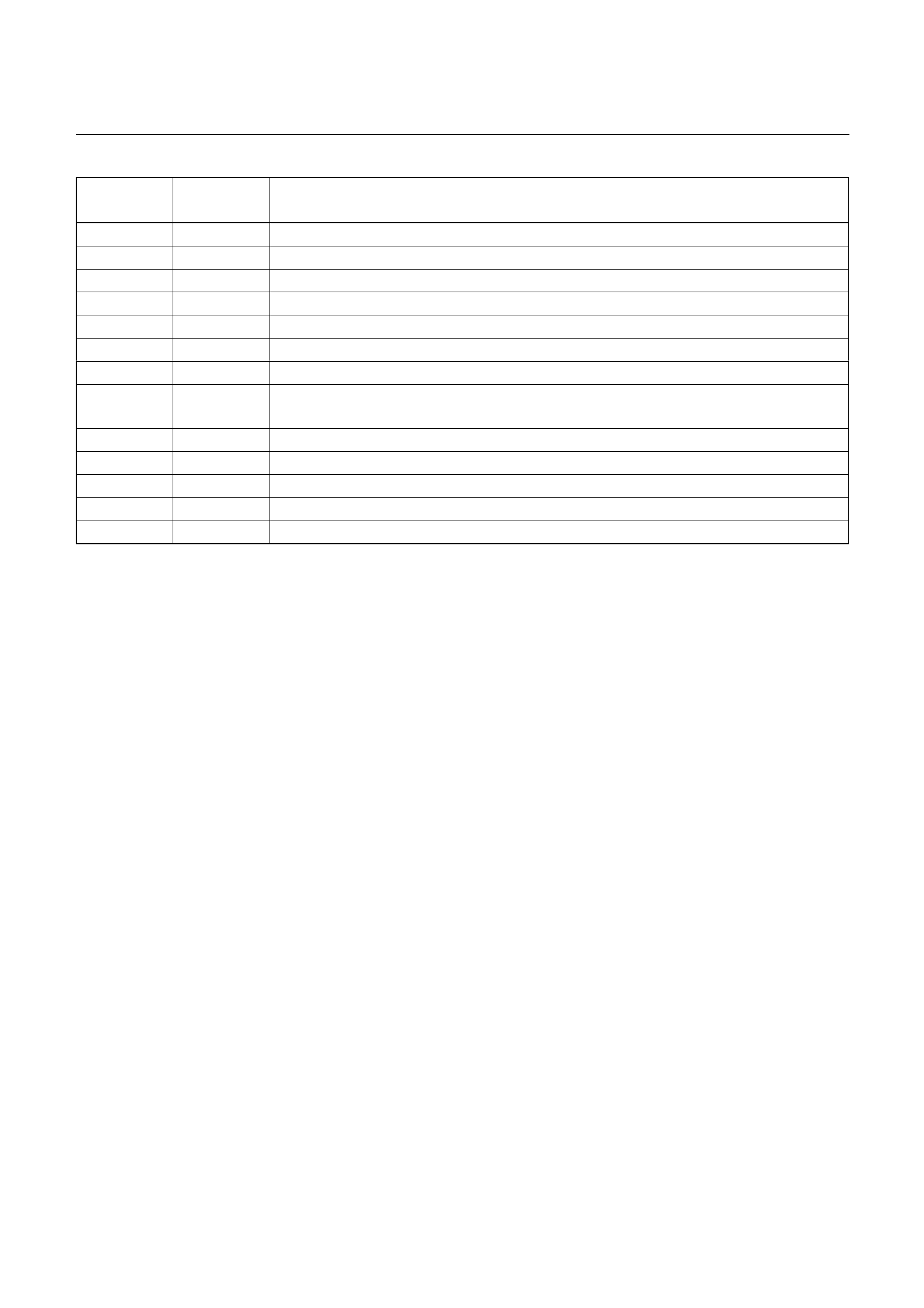

DIAGNOSTIC TROUBLE CODES (DTC) CHECK

DTC

NUMBER

FLASHING

CODE DESCRIPTION

P0120 21 ANALOG THROTTLE SIGNAL FAILURE (VTH) (FOR UBS)

P0502 24 SPEED METER SENSOR FAILURE (SP1)

P0705 17 GEAR SELECTOR FAILURE (PRND2L)

P0710 16 OIL TEMPERATURE SENSOR FAILURE (OT2)

P0717 14 INPUT REVOLUTION SENSOR FAILURE (NC0)

P0722 11 OUTPUT REVOLUTION SENSOR FAILURE (SP2)

P0727 13 ENGINE REVOLUTION SIGNAL FAILURE (NE)

P0743 33 TORQUE CONVERTER CLUTCH CONTROL LOCK-UP (ON/OFF) SOLENOID

FAILURE (SL)

P0748 35 PRESSURE CONTROL SOLENOID FAILURE (STH)

P0753 31 SOLENOID 1 FAILURE (S1)

P0758 32 SOLENOID 2 FAILURE (S2)

P1120 22 PWM THROTTLE SIGNAL FAILURE(TH) (FOR TFR/S)

P1121 23 ANALOG THROTTLE SIGNAL FAILURE (VREF, VGND) (FOR UBS)

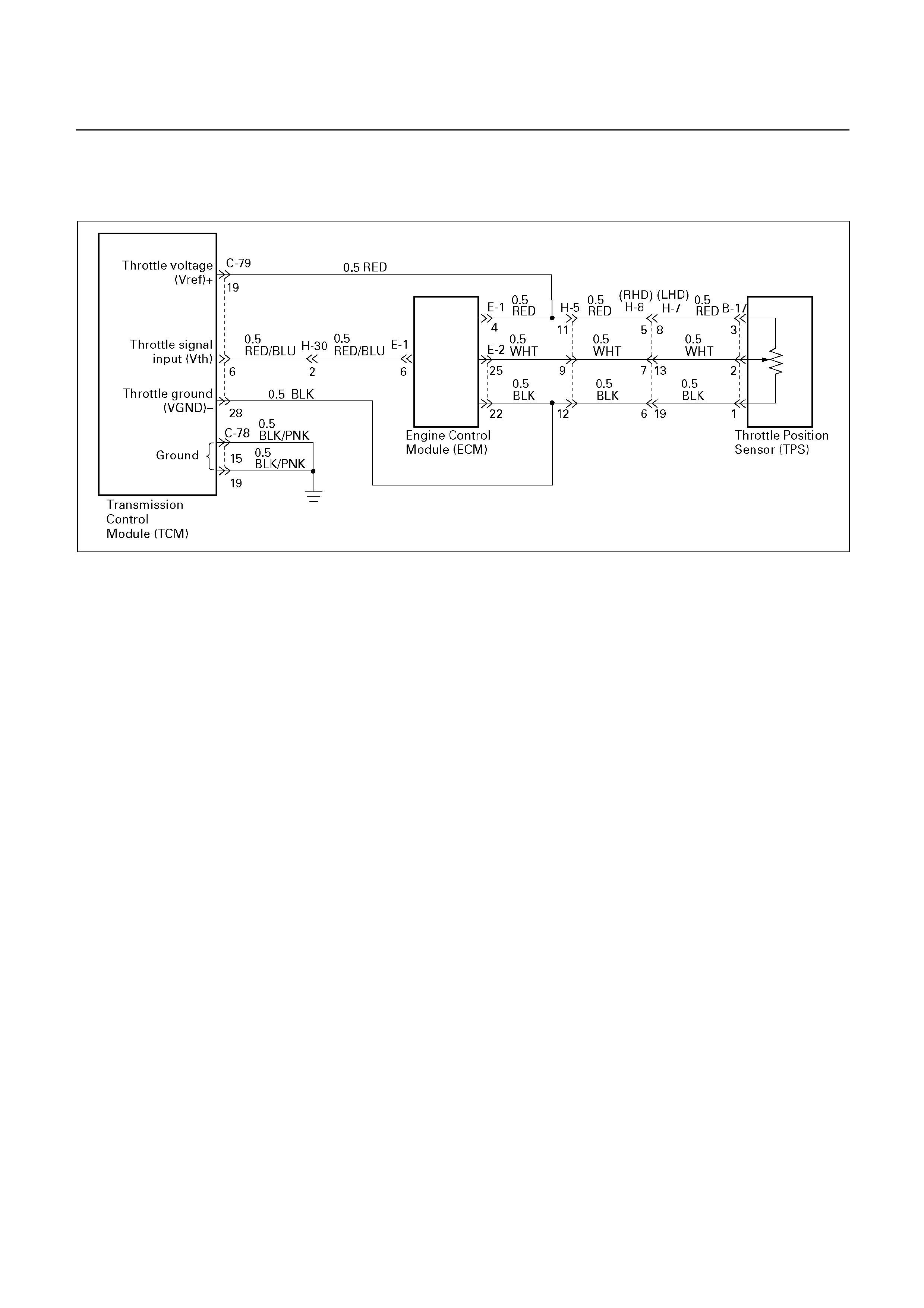

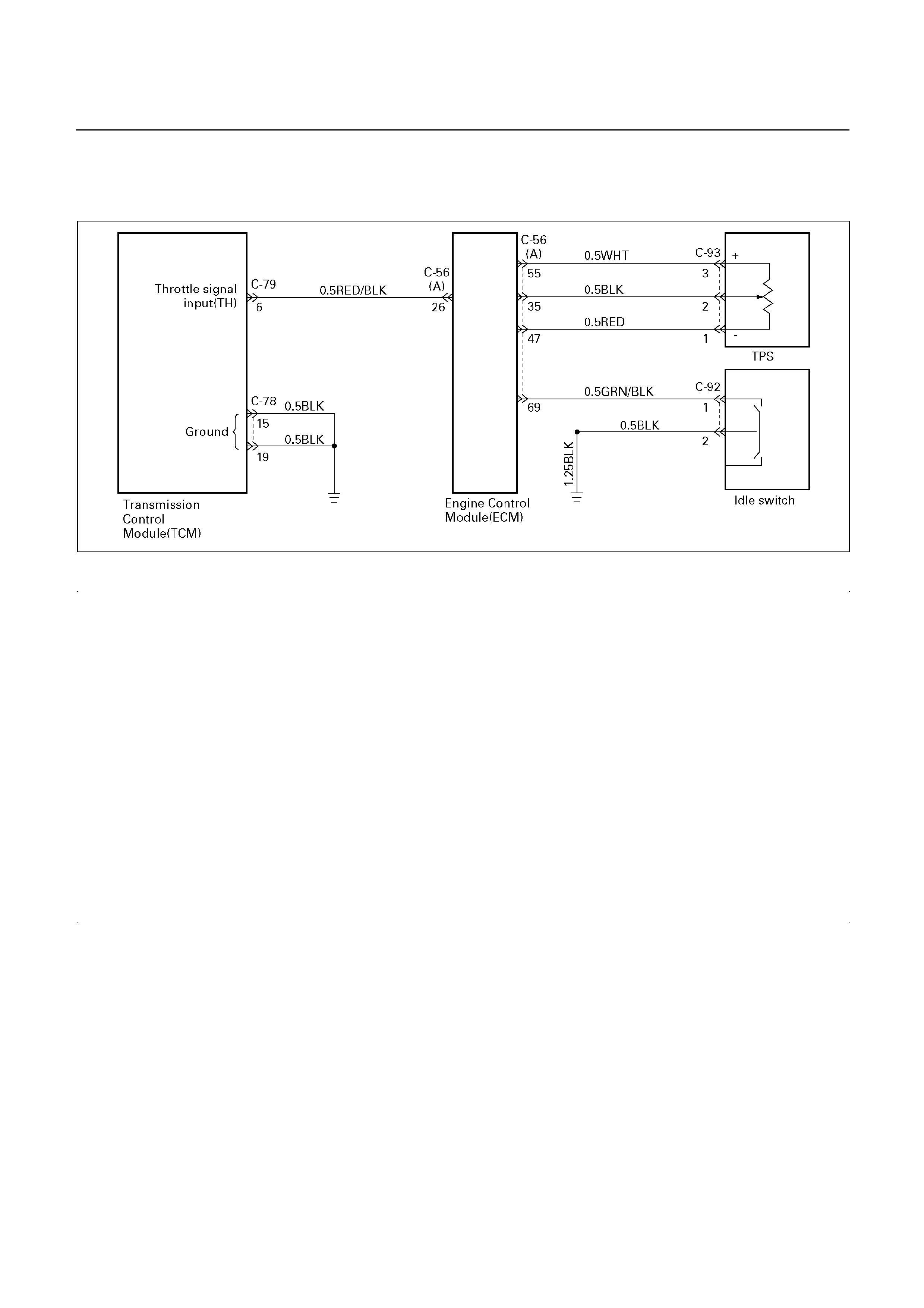

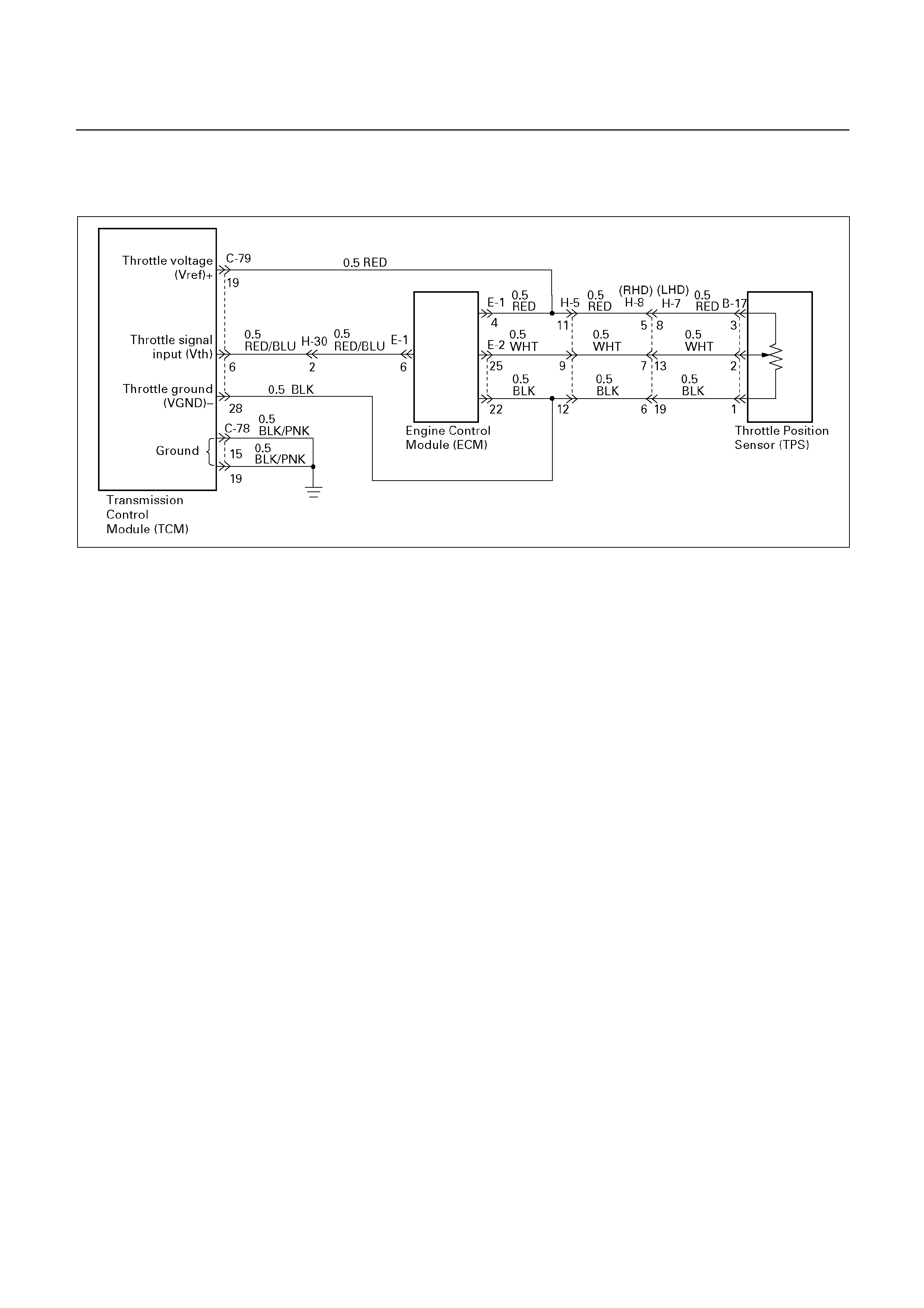

DTC P0120 (FLASHING CODE 21)

ANALOG THROTTLE SIGNAL FAILURE (VTH) (FOR UBS)

D07R200063

Circuit Description:

When the signal of the engine throttle position sensor

located on the accelerator pedal is supplied to the

TCM, the TCM judges the opening condition of the

throttle.

The shift point of the transmission is determined by this

opening condition of the throttle.

Fail-safe control:

The TCM controls fail-safe by detecting analog throttle

signal (VTH) failure.

Failure detection:

• When the throttle input voltage is detected less

than 0.112V or more than 4.417V for 2.0 seconds.

Contents of control:

At failure detection

• Throttle opening for line pressure control ... Throttle

opening 100%

• Throttle opening for shift control ... Throttle opening

0%

• Lock-up control inhibit

• Up hill and down hill control inhibit

• Squat control inhibit

At failure decision

Executes following items in addition to above

control items at failure detection.

• Blinks "CHECK TRANS" lamp

• Stores the failure information in failure-memory

Conditions of turning "CHECK TRANS" lamp

off:

Turns “CHECK TRANS” lamp off when judged 0km/h

by output revolution sensor after throttle signal input

voltage is detected more than 0.112V and less than

4.717V.

(however, uses 0 km/h judgment by back-up vehicle

speed at output revolution failure)

Reversion conditions from fail-safe:

At failure detection

Immediately recovers when the throttle input

voltage is detected more than 0.112V and less than

4.717V.

At failure decision

Recovers at the same time as the conditions of

turning “CHECK TRANS” lamp off are satisfied.

Test description:

The following numbers correspond to the step numbers

on the diagnostic chart.

1. Check that the throttle input voltage is 0.25 to

0.45V.

2. At this test, check that as the throttle opens, the

voltage goes up and that the voltage reaches 3.74

to 4.56V at the full open status.

6. Check the power supply voltage (4.75 – 5.25V) of

the throttle position sensor.

Diagnostic aids:

An intermittent may be caused by a poor connection,

rubbed through wire insulation or a wire broken inside

the insulation. Inspect related harness connector for

backed out terminals, improper mating, broken locks,

improperly formed or damaged terminals, poor terminal

to wire connection and damaged harness.

.

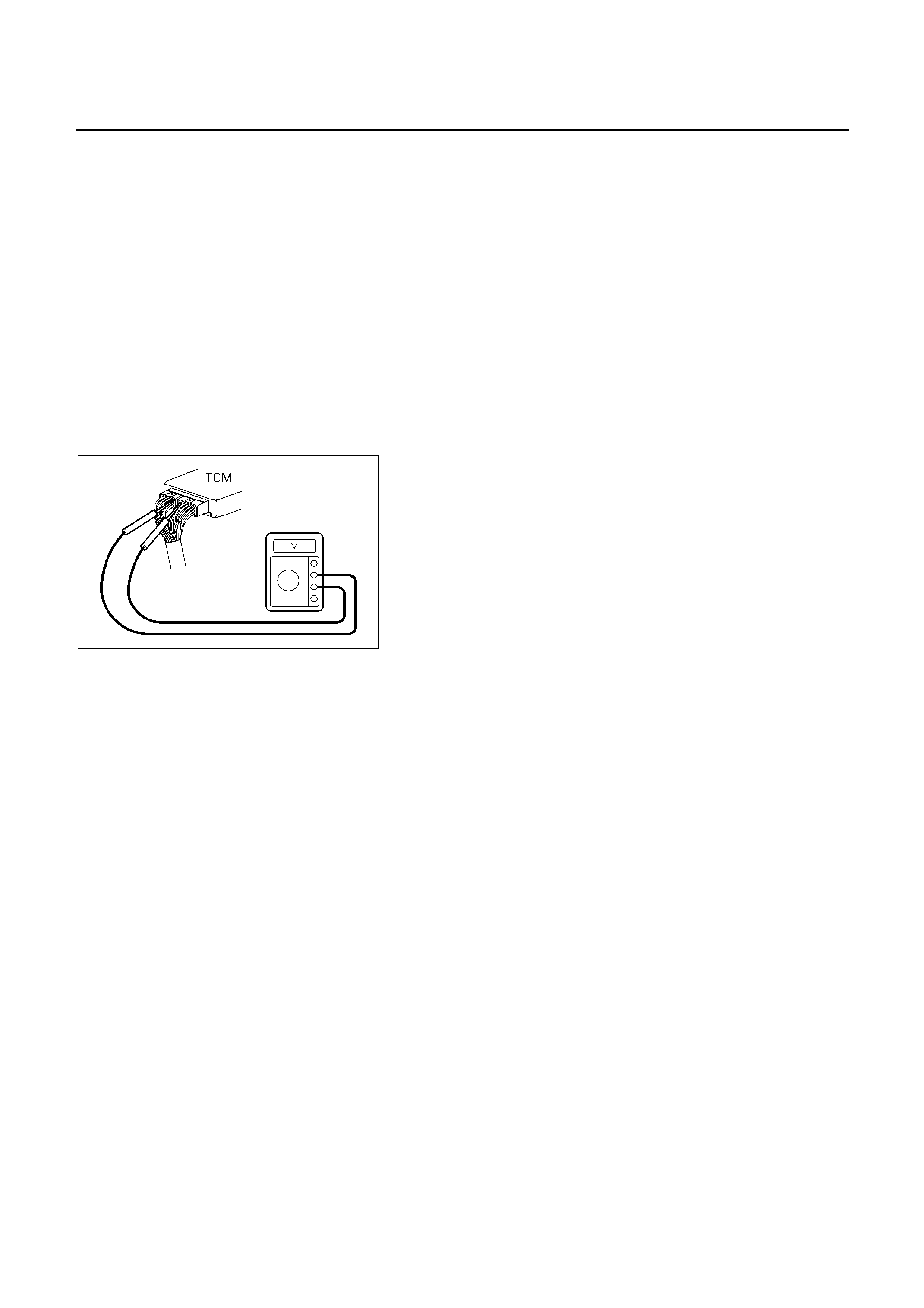

DTC P0120 (FLASHING CODE 21)

ANALOG THROTTLE SIGNAL FAILURE (VTH) (FOR UBS)

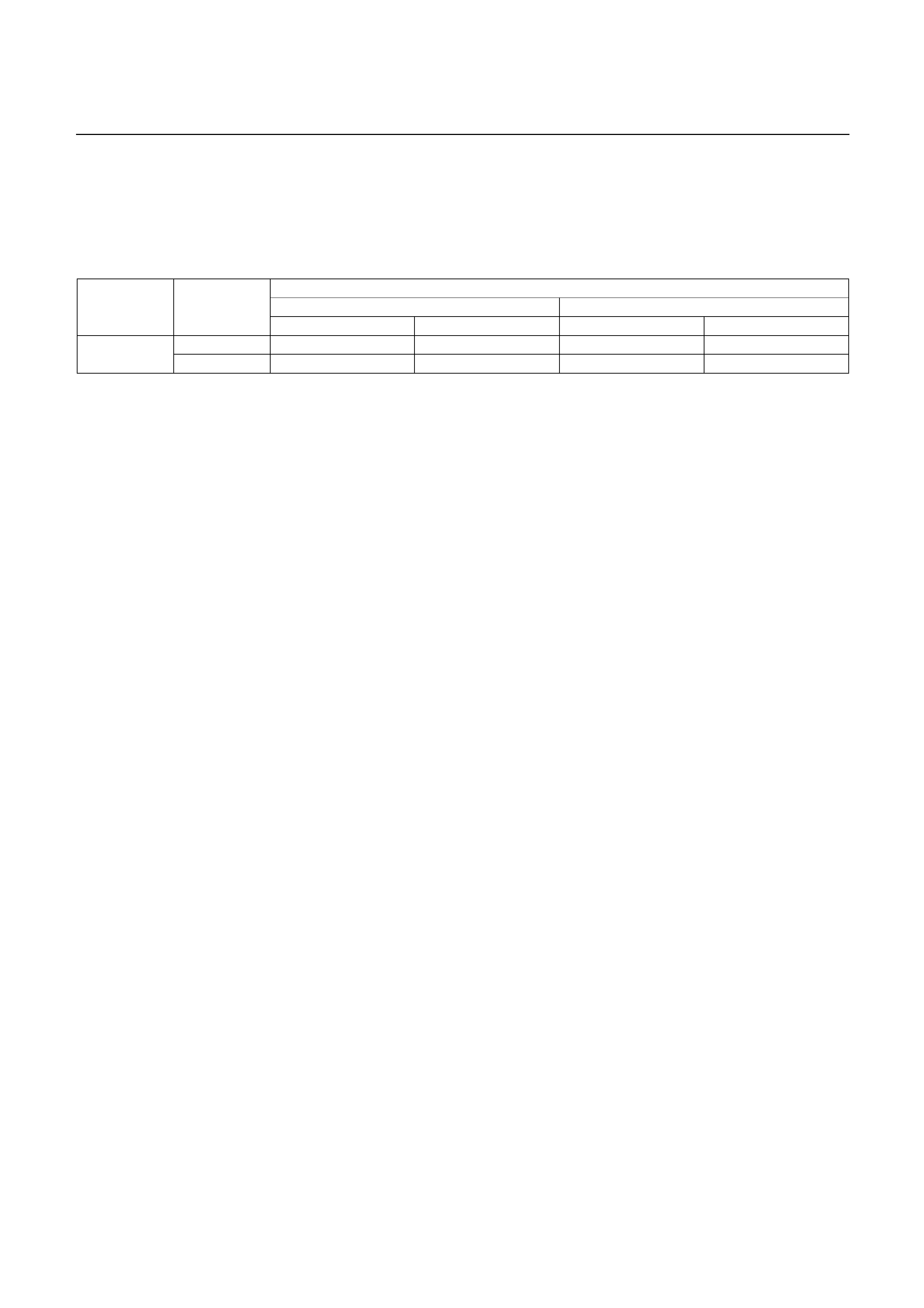

Step Action Value(s) Yes No

1

1. With the engine “OFF”, turn the ignition “ON”.

2. Connect a voltmeter between the TCM 28

pin connector terminal (6) and ground

terminal (28).

Is the voltage within the specified valve?

0.25 0.45 V Go to Step 2 Go to Step 3

2

Open the throttle fully.

Is the voltage within the specified value?

3.74 4.56 V The problem is

intermittent.

Refer to

“Diagnostic

aids”.

Go to Step 3

3

Connect a voltmeter between the ECM 32 pin

connector terminal (E1-6) and (E2-22).

Is the voltage within the specified value?

0.25 0.45 V Go to Step 4 Go to Step 6

4 Open the throttle fully.

Is the voltage within the specified value?

3.74 4.56 V Go to Step 5 Go to Step 6

5

1. Check the wiring harness between the TCM

28 pin connector terminal (6) and ECM 32

pin connector terminal (E1-6).

2. Or TCM is faulty.

Was a problem found and corrected?

Go to Step 9

6

1. Disconnect the TPS 3 pin connecter.

2. Connect a voltmeter between the TPS 3 pin

connector terminal (3) and (1).

Is the voltage within the specified value?

4.75 5.25 V Go to Step 7 Go to Step 8

7

Check the TPS connector. If OK, replace the

TPS.

Is the replacement complete?

Go to Step 9

8

Check the wiring harness between the TPS and

ECM. If OK, replace the ECM.

Is the replacement complete?

Go to Step 9

9

1. After the repair is complete, use the scan tool

to select “DTC”, then “clear Info” function.

2. Make a road running test for the vehicle.

3. Review the scan tool “DTC Info”.

Has the last test failed or is the current DTC

displayed?

Begin the

diagnosis

again.

Go to Step 1

System OK

DTC P0502 (FLASHING CODE 24)

SPEED METER SENSOR FAILURE (SP1)

UBS

D07R200056

TFR/S

D07L200001

Circuit description:

Speed information is provided by the speed meter

sensor to the meter.

In the meter, the pulses of the speed meter sensor are

converted to speed signals (pulses), and these signals

are output to the TCM and ECM(TF). The TCM

converts these pulse voltages to km/h signals.

Fail-safe control:

The TCM controls fail-safe by detecting speed meter

signal failure.

Failure detection:

• When not even 1 pulse is input in the speed meter

signal during the time 100 pulses are input in the

output revolution sensor signal.

• When not even 1 pulse is input in the speed meter

signal during the time 27 pulses are input in the

output revolution sensor signal.

Contents of control:

At failure detection

• Keeps the condition of transfer (High/Low

judgment) just before detection until vehicle speed

is 0km/h, and changes shift map to L4 map (3→4

UP None) at vehicle speed is 0km/h. (For UBS)

• Uses high oil temperature map according to shift

map priority at correct oil temperature control.

• Up hill and down hill control inhibit. (For UBS)

• Stores the failure information in failure -memory.

• The failure detection of oil temperature sensor

inhibit

At failure decision

Executes following items in adition to above control

items at failure detection.

• Blinks "CHECK TRANS" lamp

Conditions of turning "CHECK TRANS" lamp

off:

Turns "CHECK TRANS" lamp off when judged 0km/h

by speed meter sensor after more than 1 pulse are

input in the speed meter signal during the time 27

pulses are input in the output revolution sensor.

Reversion conditions from fail-safe:

At failure detection and decision

Recovers at the same time as the conditions of turning

“CHECK TRANS” lamp off are satisfied.

Test description:

The following numbers correspond to the step numbers

on the diagnostic chart.

2. The cause of DTC P0502 setting is due to the

operation fault of the speed meter.

3. Speed signals are output from the meter. The

sensor power supply is given from the TCM.

Diagnostic aids:

An intermittent may be caused by a poor connection,

rubbed through wire insulation or a wire broken inside

the insulation. Inspect related harness connector for

backed out terminals, improper mating, broken locks,

improperly formed or damaged terminals, poor terminal

to wire connection and damaged harness.

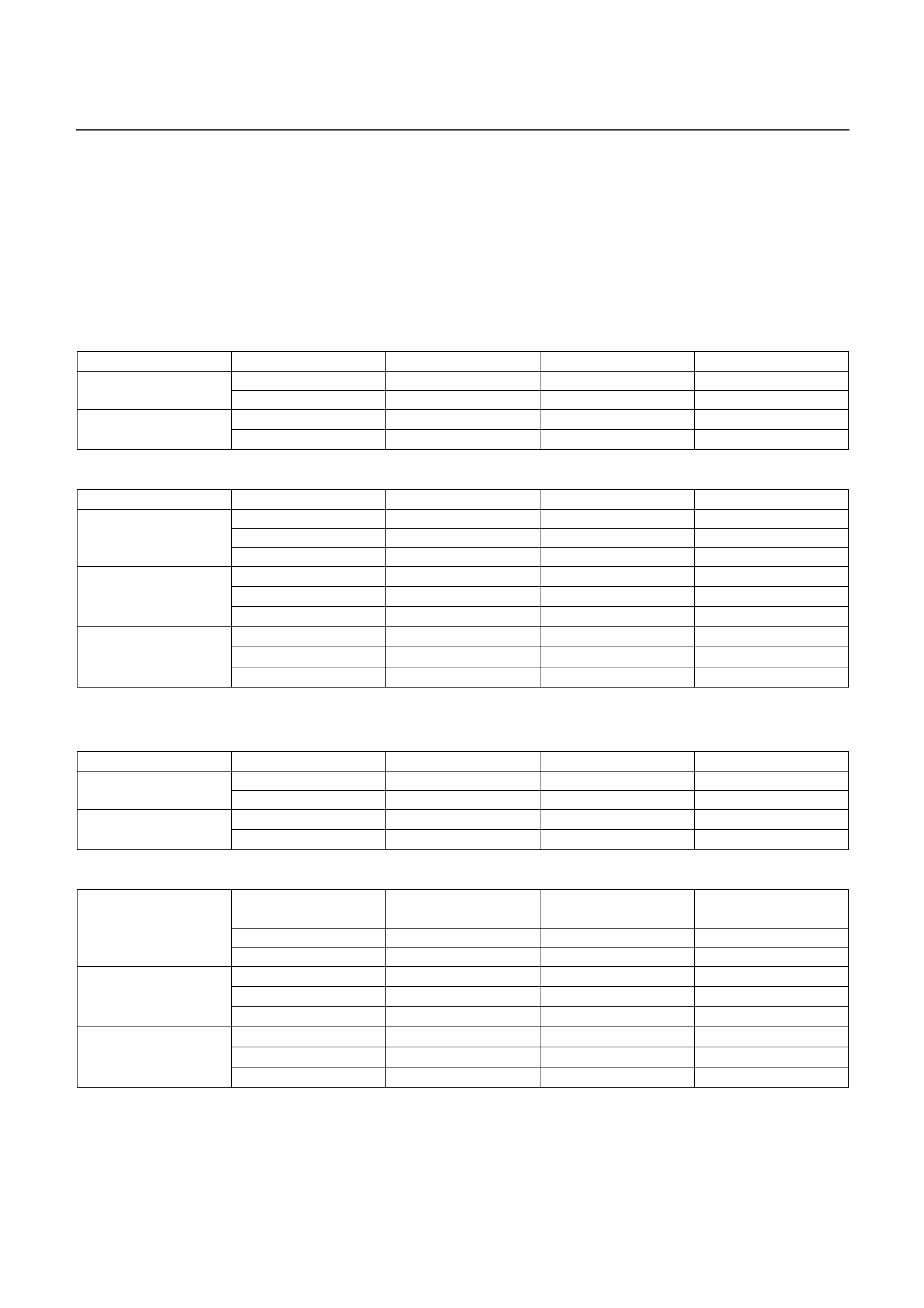

DTC P0502 (FLASHING CODE 24)

SPEED METER SENSOR FAILURE (SP1)

Step Action Value(s) Yes No

1

1. Lift the driving wheels.

2. With the engine idling in gear D range.

Is the Tech 2 displayed speed the specified

value?

0 km/h Go to Step 2 DTC P0502 is

intermittent.

If other DTCs

are not stored

in memory.

Refer to

“Diagnostic

aids”.

2 Does the speed meter operate? Go to Step 3 Go to Step 4

3

1. Open the throttle and increase the revolution

speed of the driving wheels

2. Measure the voltage between the TCM 28

pin connector terminal (7) and TCM 20 pin

connector ground terminal (15 or 19) with a

voltmeter.

Does the voltage vary intermittently in the

specified value?

1.4 about 5V

(AC) (Vehicle

speed 10-20 km/h)

Go to Step 5 Go to Step 6

4

The speed meter or speed meter sensor is

faulty.

Was a problem found and corrected?

Go to Step 7

5 The TCM connect is faulty or the TCM is faulty.

Was a problem found and corrected?

Go to Step 7

6

The wiring harness between the speed meter

and TCM is open or the speed meter sensor is

faulty.

Was a problem found and corrected?

Go to Step 7

7

1. After the repair is complete, use the scan tool

to select “DTC”, then “Clear Info” function.

2. Make the road running test for the vehicle.

3. Review the scan tool “DTC Info”.

Has the last test failed or is the current DTC

displayed?

Begin the

diagnosis

again.

Go to Step 1

System OK

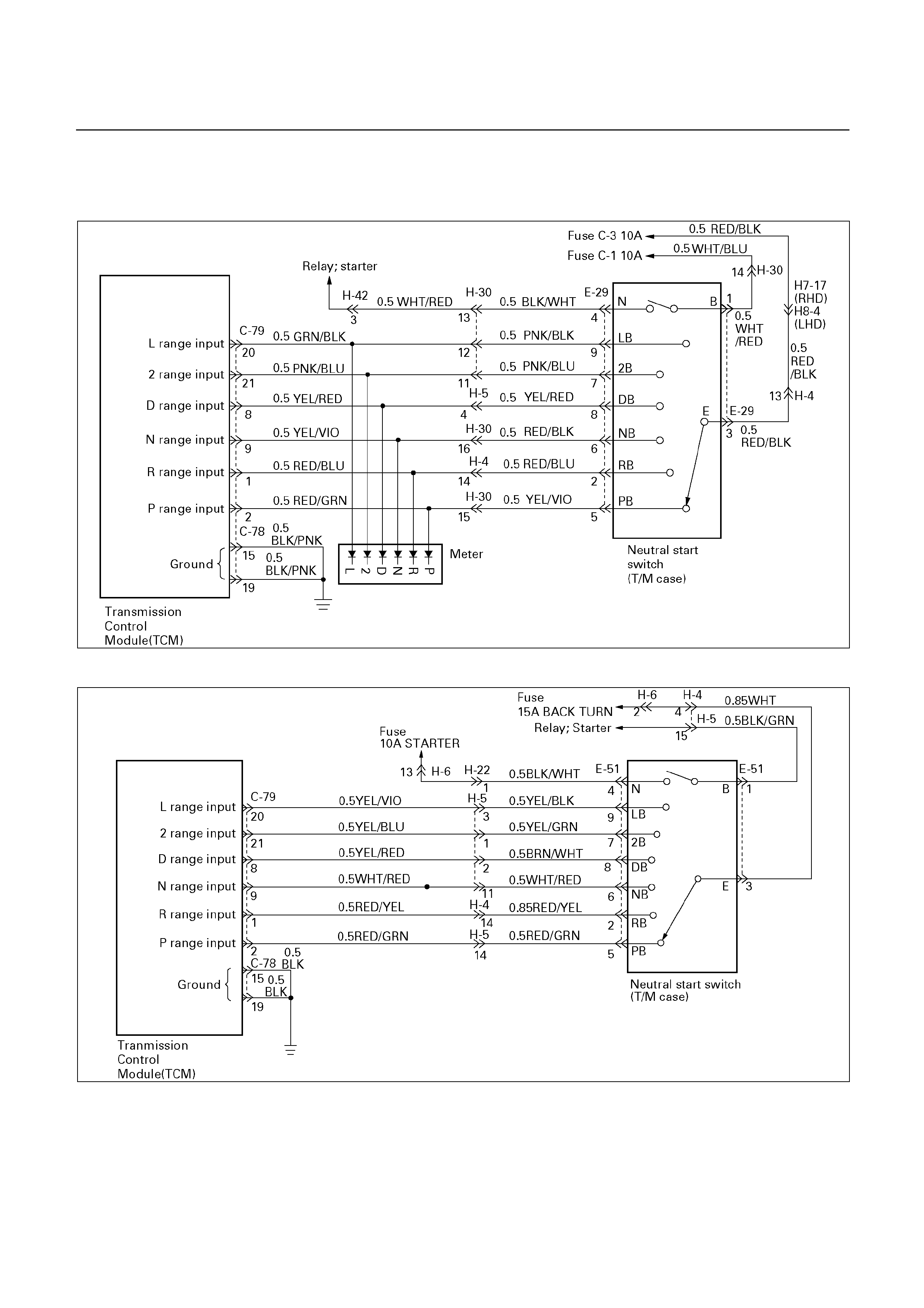

DTC P0705 (FLASHING CODE 17)

GEAR SELECTOR FAILURE (PRND2L)

UBS

D07R200057

TFR/S

D07L200002

Circuit description:

The neutral start switch gives the signals related to the

selector lever position (PRND2L) to the Transmission

Control Module (TCM). The neutral start switch turns

on when the select lever is shifted to the P, R, N, D, 2

or L range. The neutral start switch, which is connected

to the starter switch circuit, is available only when the

select lever is in the P or N range

The neutral start switch is connected to the

transmission manual shaft and installed in the

transmission case.

Fail-safe condition:

The TCM controls fail-safe by detecting selector

position switch failure.

Failure detection:

(1) OPEN:

• When all switches are OFF

• When the failure criteria continues for 30 seconds if

the vehicle speed which is calculated by output

revolution sensor is more than 30 km/h and the

engine revolution is more than 1500 rpm.

(2) SHORT:

• When more than two switches are ON at the same

time.

• When the failure criteria condition for 10 seconds.

Contents of control:

At failure detection

(1) OPEN: D range judgment

(2) SHORT: Judged by priority D>2>L>R>N>P

• Up hill and down hill control inhibit (For UBS)

• Winter mode inhibit (For UBS)

At failure decision

Excutes following items in addition to above control

items at failure detection.

• Blinks "CHECK TRANS" lamp

• Stores the failure information in failure-memory

• Reverse lockout control inhibit

Conditions of turning “CHECK TRANS” off:

Turns “CHECK TRANS” lamp off when only one of all

switches is ON.

Reversion conditions from fail-safe:

Turns “CHECK TRANS” lamp off when only one of all

switches is ON.

Test description:

The following numbers correspond to the step numbers

on the diagnostic chart.

1. It is judged whether the input signal received from

the neutral start switch by the TCM is proper or not.

5. The power status of the neutral start switch is

checked.

6. The continuity between neutral start switch

terminals and the continuity of the wire connected

to the neutral start switch are checked.

Diagnostic aids:

An intermittent may be caused by a poor connection,

rubbed through wire insulation or a wire broken inside

the insulation. Inspect related harness connector for

backed out terminals, improper mating, broken locks,

improperly formed or damaged terminals, poor terminal

to wire connection and damaged harness.

DTC P0705 (FLASHING CODE 17)

GEAR SELECTOR FAILURE (PRND2L)

Step Action Value(s) Yes No

1

1. With the engine "OFF", turn the ignition

"ON".

2. Connect a voltmeter to the each terminals of

the TCM 28 pin connector and TCM 20 pin

connector ground terminal (15 or 19).

3. Measure the voltage shifting the selector

lever to very position.

(Comparison with table 1)

Is the displayed voltage at every position

normal?

See table 1 Go to Step 2 Go to Step 3

2

1. Clear the TCM memory.

2. Make a running test. (Greater than 30

seconds).

Is DTC P0705 displayed by self-diagnosis?

Go to Step 4 The continuity

of wiring is

temporarily

faulty.

Refer to

“Diagnostic

aids”.

3 Is the displayed voltage at every position

abnormal?

Go to Step 5 Go to Step 6

4

The TCM is faulty or the continuity of wiring is

temporarily faulty.

Refer to "Diagnostic aids".

Was a problem found and corrected?

Go to Step 9

5

1. Check if there is any breaking in the fuse and

wire connected to the 10 pin connector

terminal (3) of the neutral start switch.

2. Check the adjusted condition of the neutral

start switch.

3. If no fault is found, replace the neutral start

switch.

Was a problem found and corrected?

Go to Step 9

6

1. Disconnect the 10 pin connector of the

neutral start switch.

2. Make a continuity check between each

terminals of the neutral start switch with an

ohmmeter.

Is the continuity at every position normal?

See table 2 Go to Step 7 Go to Step 8

7

The wiring harness between the TCM and

neutral start switch is open or shorted.

Was a problem found and corrected?

Go to Step 9

8 Replace the neutral start switch.

Is the replacement complete?

Go to Step 9

9

1. After the repair is complete, use the scan tool

to select "DTC", then "Clear Info" function.

2. Make a road running test for the vehicle.

3. Review the scan tool "DTC Info".

Has the last test failed or is the current DTC

displayed?

Begin the

diagnosis

again.

Go to Step 1

System OK

(Table 1)

TCM 20 pin

terminal (-)

TCM 28 pin

terminal (+) Voltage (V)

8-16: P range

2 1 or less: Other than P range

8-16: R range

1 1 or less: Other than R range

8-16: N range

9 1 or less: Other than N range

8-16: D range

8 1 or less: Other than D range

8-16: 2 range

21 1 or less: Other than 2 range

8-16: L range

15 or 19

20 1 or less: Other than L range

(Table 2)

Terminal Neutral start switch 10 pin connector

Range 1 4 3 5 2 6 8 7 9

P

R

N

D

2

L

Continuity

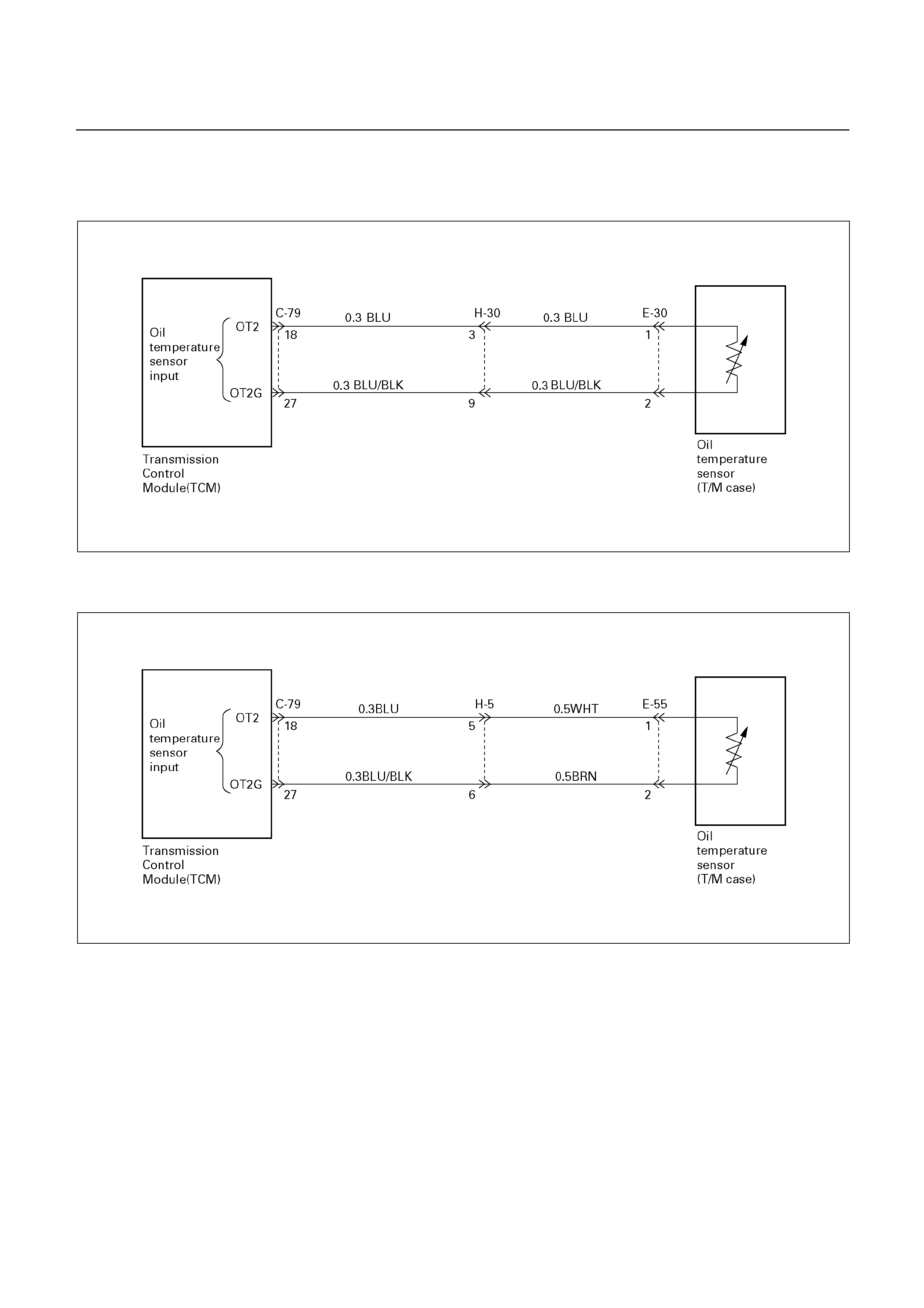

DTC P0710 (FLASHING CODE 16)

OIL TEMPERATURE SENSOR FAILURE (OT2)

UBS

D07R200058

TFR/S

D07L200003

Circuit Description:

The oil temperature sensor is a thermistor sensor that

is installed in the transmission case and converts

temperature changes into continuous electric signals,

then outputs them to the Transmission Control Module

(TCM). When the ATF temperature is low, the

resistance of the sensor (thermistor) goes up, so that

the voltage of the TCM signal becomes high.

As the ATF is gradually warmed, the resistance of the

sensor goes down and the voltage becomes low. At the

normal operating ATF temperature (80°C/176°F) of the

transmission, the voltage of the TCM is about 3.7V.

Fail-safe condition:

The TCM controls fail-safe by detecting oil temperature

sensor failure.

Failure detection:

Short detection

• When the A/D value is detected less than 10

(220°C) for 5 minutes continuously while normal

judgment is not satisfied from ignition on.

Open detection

• After 15 minites passed when the engine revolution

is more than 400 rpm and the selector position

switch is selected on R, D, 2, L range.

• When the change of the A/D value from engine

start is less than 15 and the minnum A/D value is

more than 1000 (-10°C) from engine start.

Contents of control:

At failure detection

• Changes shift map to HOT2 map

• Controls as A/T oil temperature 200°C

• Lock-up control inhibit

• Up hill and down hill control inhibit (For UBS)

• Blinks "CHECK TRANS" lamp

• Stores the failure information in failure-memory

At failure decision

• Same as failure detection.

Conditions of turning "CHECK TRANS" off:

Turns "CHECK TRANS" lamp off when judged 0km/h

by output revolution sensor after the normal area of oil

temperature 40°C – 150°C is detected for 10 sec

continuously.

Reversion conditions from fail-safe:

Recovers at the same time as the conditions of turning

“CHECK TRANS” lamp off are satisfied.

Test description:

The following numbers correspond to the step numbers

on the diagnostic chart.

1. Check that the voltage of the oil temperature

sensor varies with ATF temperatures.

3. Check that the resistance of the oil temperature

sensor varies with ATF temperatures.

Diagnostic aids:

An intermittent may be caused by a poor connection,

rubbed through wire insulation or a wire broken inside

the insulation. Inspect related harness connector for

backed out terminals, improper mating, broken locks,

improperly formed or damaged terminals, poor terminal

to wire connection and damaged harness.

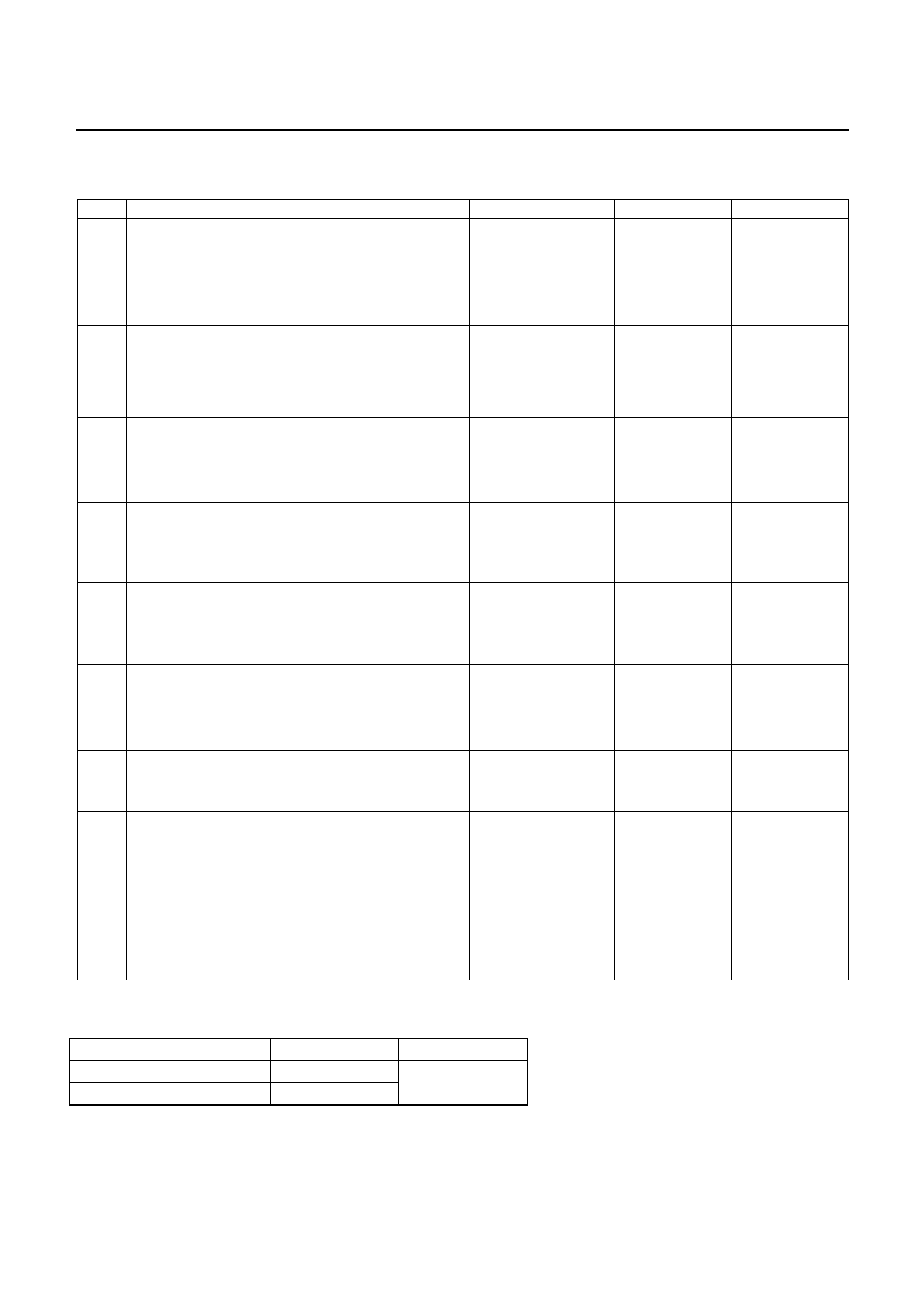

DTC P0710 (FLASHING CODE 16)

OIL TEMPERATURE SENSOR FAILURE (OT2)

Step Action Value(s) Yes No

1

1. With the engine "OFF", turn the ignition

"ON".

2. Connect a voltmeter between the TCM 28

pin connector terminal (18) and (27).

Is the voltage as shown in the table?

See table Go to Step 2 Go to Step 3

2

1. Replace the TCM with a new one.

2. Make a running test.

Is DTC P0710 displayed by self-diagnosis?

Go to Step 4 The TCM is

faulty.

(TCM before

replacement)

Go to Step 9

3

1. Disconnect the TCM 28 pin connector.

2. Measure the resistance between the TCM 28

pin connecter terminal (18) and (27).

Is the resistance as shown in the table?

See table Go to Step 5 Go to Step 6

4

Check the wiring harness or connector

connection between the TCM and oil

temperature sensor.

Was a problem found and corrected?

Go to Step 9

5

The TCM is faulty or the continuity of wiring is

temporarily faulty.

Refer to "Diagnostic aids".

Was a problem found and corrected?

Go to Step 9

6

1. Disconnect the A/T 2 pin connector.

2. Measure the resistance between the A/T 2

pin connector terminal (1) and (2).

Is the resistance as shown in the table?

See table Go to Step 7 Go to Step 8

7

The wiring harness between the TCM and oil

temperature sensor connector is ground-shorted.

Was a problem found and corrected?

Go to Step 9

8 Replace the oil temperature sensor.

Is the replacement complete?

Go to Step 9

9

1. After the repair is complete, use the scan tool

the select "DTC", then "Clear Info" function.

2. Make a road running test for the vehicle.

3. Review the scan tool "DTC Info".

Has the last test failed or is the current DTC

displayed?

Begin the

diagnosis

again.

Go to Step 1

System OK

(Table)

ATF temperature (°C/°F) Voltage (V) Resistance (kΩ)

20/68 Approx. 4.7

80/176 Approx. 3.7

0.5 − 30

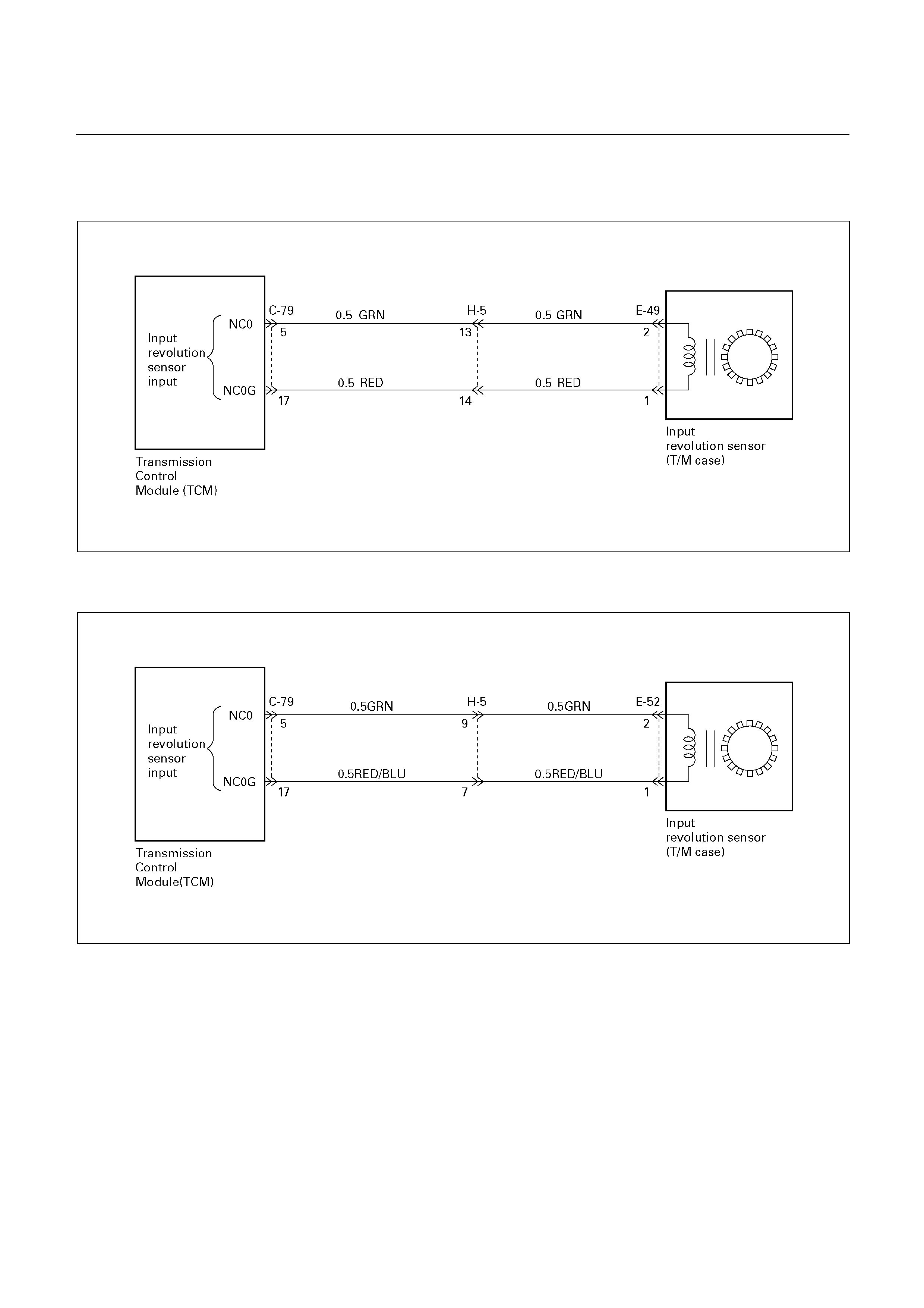

DTC P0717 (FLASHING CODE 14)

INPUT REVOLUTION SENSOR FAILURE (NC0)

UBS

D07R200059

TFR/S

D07L200004

Circuit description:

Input revolution information is provided to TCM by the

input revolution sensor. This sensor is located in the

transmission case.

The input revolution sensor is an electromagnetic pulse

pickup type that generates a speed signal according to

the revolution of the transmission OD direct clutch

drum.

As a result, the sensor sends a sine wave signal (AC)

to the TCM, which converts this sine wave signal (pulse

voltage) to a RPM signal.

Fail-safe control:

The TCM controls fail-safe by detecting input revolution

sensor failure.

Failure detection:

• When not even 1 pulse is input in the input

revolution sensor during the time 4 pulses are input

in the output revolution sensor.

• When the failure criteria is continuously 1000 times

from the time ignition is turned ON until it is turned

OFF.

Prohibits failure detection when at least one among the

following conditions is satisfied.

• When D, 2 and L range signal is not fixed.

• When output revolution is less than 775 rpm.

• When the failure detection timer T1 (*1) is less than

25 seconds.

• Solenoid S1, S2, and selector position switch is on

failure detection or decision.

• At 4th gear.

• When passed less than 10 seconds after shift

command output.

*1: Failure detection inhibit timer T1

Timer starts when D, 2 or L range are detected (fixation

signal).

Contents of control:

At failure detection

• Lock-up control inhibit

• Up hill and down hill control inhibit (For UBS)

At failure decision

Executes following items in addition to above

control items at failure detection.

• Blinks "CHECK TRANS" lamp

• Stores the failure information in failure-memory

Conditions of turning "CHECK TRANS" off:

At D, 2 or L range and not shifting, turns "CHECK

TRANS" lamp off when judged 0km/h by output

revolution sensor after more than 1 pulse input in the

input revolution sensor and finished vehicle speed

calculation during the time 4 pulse are input in the

output revolution sensor.

Reversion conditions from fail-safe:

Recovers at the same time as the conditions of turning

“CHECK TRANS” lamp off are satisfied.

Test description:

The following numbers correspond to the step numbers

on the diagnostic chart.

1. When the engine is running, a revolution signal is

input from the input revolution sensor to the TCM.

2. At this test, the continuity of circuit wiring and the

input revolution sensor is checked.

4. At this test, the continuity of the input revolution

sensor is checked.

Diagnostic aids:

An intermittent may be caused by a poor connection,

rubbed through wire insulation or a wire broken inside

the insulation. Inspect related harness connector for

backed out terminals, improper mating, broken locks,

improperly formed or damaged terminals, poor terminal

to wire connection and damaged harness.

DTC P0717 (FLASHING CODE 14)

INPUT REVOLUTION SENSOR FAILURE (NC0)

Step Action Value(s) Yes No

1

1. Turn the ignition "ON" and the engine "ON".

2. With the engine edling, connect a voltmeter

between the TCM 28 pin connector terminal

(5) and ground terminal (17).

Does the voltage rary in the specified value?

(The voltage increases in proportion to the

speed.)

0-3 V (AC)

or more

DTC P0707 is

intermittent.

If other codes

are not stored,

refer to

“Diagnostic

aids”.

Go to Step 2

2

1. Turn the ignition "OFF".

2. Disconnect the TCM 28 pin connector.

3. Connect an ohmmeter between the TCM 28

pin connector terminal (5) and (17).

Is the resistance within the specified value?

560-680 Ω

(at 20°C, 4×4)

387-473 Ω

(at 20°C, 4×2)

Go to Step 3 Go to Step 4

3

1. Replace the TCM with a new one.

2. Make a road running test for the vehicle.

Is DTC P0717 displayed?

Go to Step 5 Go to Step 7

4

1. Disconnect the 2 pin connector of the input

revolution sensor.

2. Measure the resistance between each

terminals of the input revolution sensor 2 pin

connector with an ohmmeter.

Is the resistance within the specified value?

560-680 Ω

(at 20°C, 4×4)

387-473 Ω

(at 20°C, 4×2)

Go to Step 6 Go to Step 5

5 Replace the input revolution sensor.

Is the replacement complete?

Go to Step 7

6

Check the wiring harness between the TCM and

input revolution sensor for an open or shorted.

Was a problem found and corrected?

Go to Step 7

7

1. After the repair is complete, use the scan tool

to select "DTC", then "Clear Info" function.

2. Make a road running test for the vehicle.

3. Reviews the scan tool "DTC Info".

Has the last test failed or is the current

DTC displayed?

Begin the

diagnosis

again.

Go to Step 1

System OK

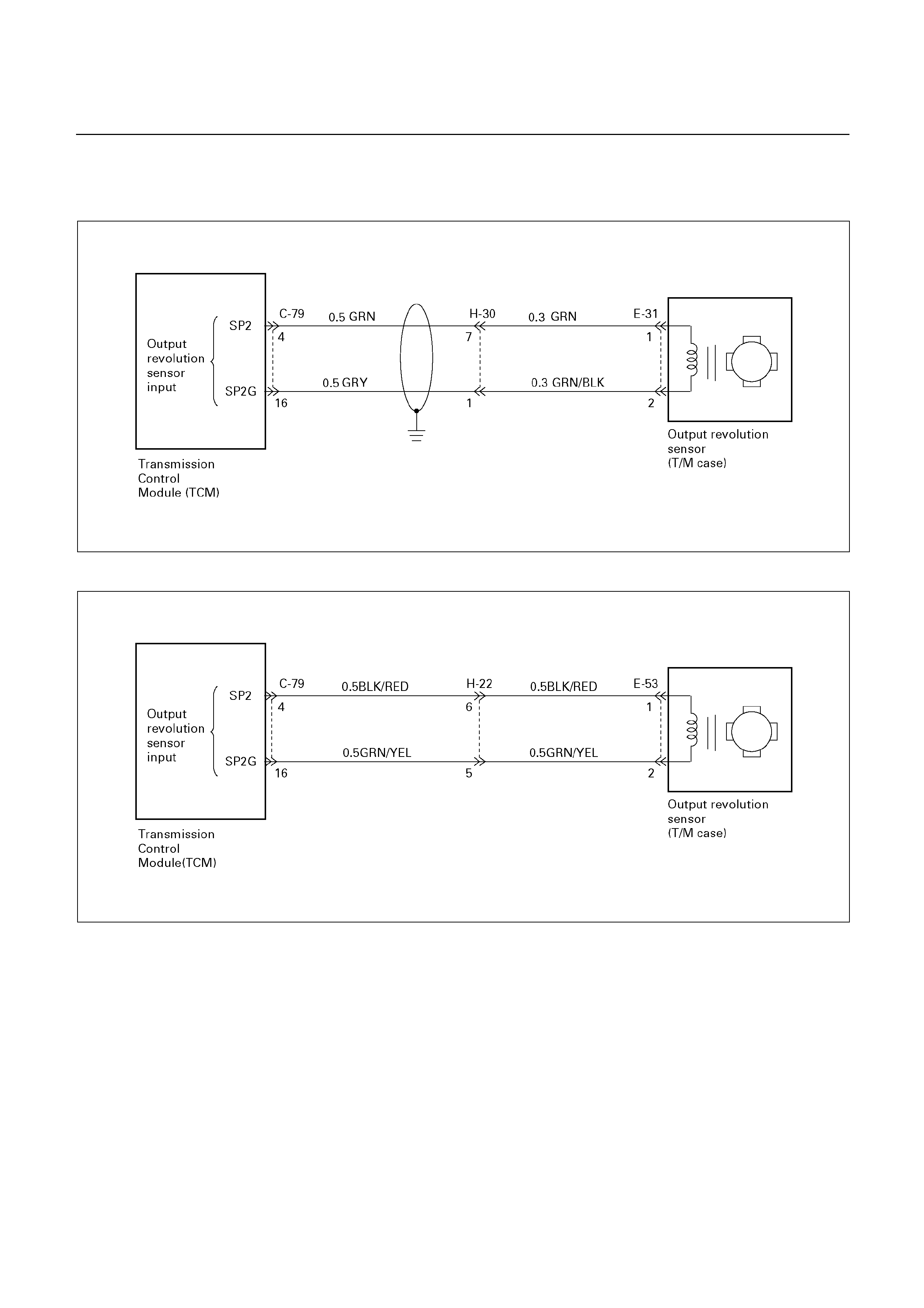

DTC P0722 (FLASHING CODE 11)

OUTPUT REVOLUTION SENSOR FAILURE (SP2)

UBS

D07R200060

TFR/S

D07L200005

Circuit description:

Vehicle speed information is provided to the TCM by

the output revolution sensor. This sensor is located in

the transmission adapter housing (4 4) or extension

housing (4 2). The output revolution sensor is an

electromagnetic pulse pickup type that generates a

speed signal according to the revolution of the

transmission output shaft. As a result, the sensor

sends a sine wave signal (AC) to the TCM, which

converts this sine wave signal (pulse voltage) to a km/h

signal.

Fail-safe control:

The TCM controls fail-safe by detecting output

revolution sensor failure.

Failure detection:

• When not even 1 pulse is input in the output

revolution sensor during the time 4 pulses are input

in the speed meter sensor.

• When the failure criteria is continuously 500 times

from the time ignition is turned ON until it is turned

OFF.

• Detection inhibit condition:

When speed meter sensor revolution is less than

80 rpm.

Contents of control:

At failure detection

• Uses the vehicle speed calculated by speed meter

sensor for shift control

• Keeps the condition of transfer (High/Low

judgment) just before detection until vehicle speed

is 0km/h, and changes shift map to L4 map

(3→4UP None) at vehicle speed 0km/h. (For UBS)

• Use high oil temperature map according to shift

map priority at correct oil temperature control.

• Squat control inhibit

• Up hill and down hill control inhibit (For UBS)

• Reverse lockout control inhibit

• Stores the failure information in failure-memory

At failure decision

Executes following items in addition to above

control items at failure detection.

• Blinks "CHECK TRANS" lamp

Conditions of turning "CHECK TRANS" off:

Turns "CHECK TRANS" lamp off when judged 0km/h

by speed meter sensor after more than 1 pulse input in

the output revolution sensor and finished vehicle speed

calculation during the time 4 pulse are input in the

speed meter sensor.

Reversion conditions from fail-safe:

Recovers at the same time as the conditions of turning

“CHECK TRANS” lamp off are satisfied.

Test description:

The following numbers correspond to the step numbers

on the diagnostic chart.

1. When the vehicle is running, a speed signal is input

from the output revolution sensor to the TCM.

2. At this test, the continuity of circuit wiring and the

output revolution sensor is checked.

4. At this test, the continuity of the output revolution

sensor is checked.

Diagnostic aids:

An intermittent may be caused by a poor connection,

rubbed through wire insulation or a wire broken inside

the insulation. Inspect related harness connector for

backed out terminals, improper mating, broken locks,

improperly formed or damaged terminals, poor terminal

to wire connection and damaged harness.

DTC P0722 (FLASHING CODE 11)

OUTPUT REVOLUTION SENSOR FAILURE (SP2)

Step Action Value(s) Yes No

1

1. Lift the driving wheels.

2. With the engine idling in gear, connect a

voltmeter between the TCM 28 pin connector

terminal (4) and ground terminal (16).

Does the voltage vary in the specified value?

(The voltage increase in proportion to the

speed.)

0-3 V or more DTC P0722 is

intermittent. If

other codes

are not stored,

refer to

"Diagnostic

aids".

Go to Step 2

2

1. Turn the ignition "OFF".

2. Disconnect the TCM 28 pin connector.

3. Connect an ohmmeter between the TCM 28

pin connector terminal (4) and (16).

Is the resistance within the specified value?

560-680

(at 20 )

Go to Step 3 Go to Step 4

3

1. Replace the TCM with a new one.

2. Make a road running test for the vehicle.

Is DTC P0722 displayed?

Go to Step 5 The TCM is

faulty.

(TCM before

replacement)

Go to Step 7

4

1. Disconnect the 2 pin connector of the output

revolution sensor.

2. Measure the resistance between each

terminals of the 2 pin connector with an

ohmmeter.

Is the resistance within the specified value?

560-680

(at 20 )

Go to Step 6 Go to Step 5

5 Replace the output revolution sensor.

Is the replacement complete?

Go to Step 7

6

Check the wiring harness between the TCM and

output revolution sensor for an open or shorted.

Was a problem found and corrected?

Go to Step 7

7

1. After the repair is complete, use the scan tool

to select "DTC", then "Clear Info" function.

2. Make a road running test for the vehicle.

3. Review the scan tool "DTC Info".

Has the last test failed or is the current DTC

displayed?

Begin the

diagnosis

again.

Go to Step 1

System OK

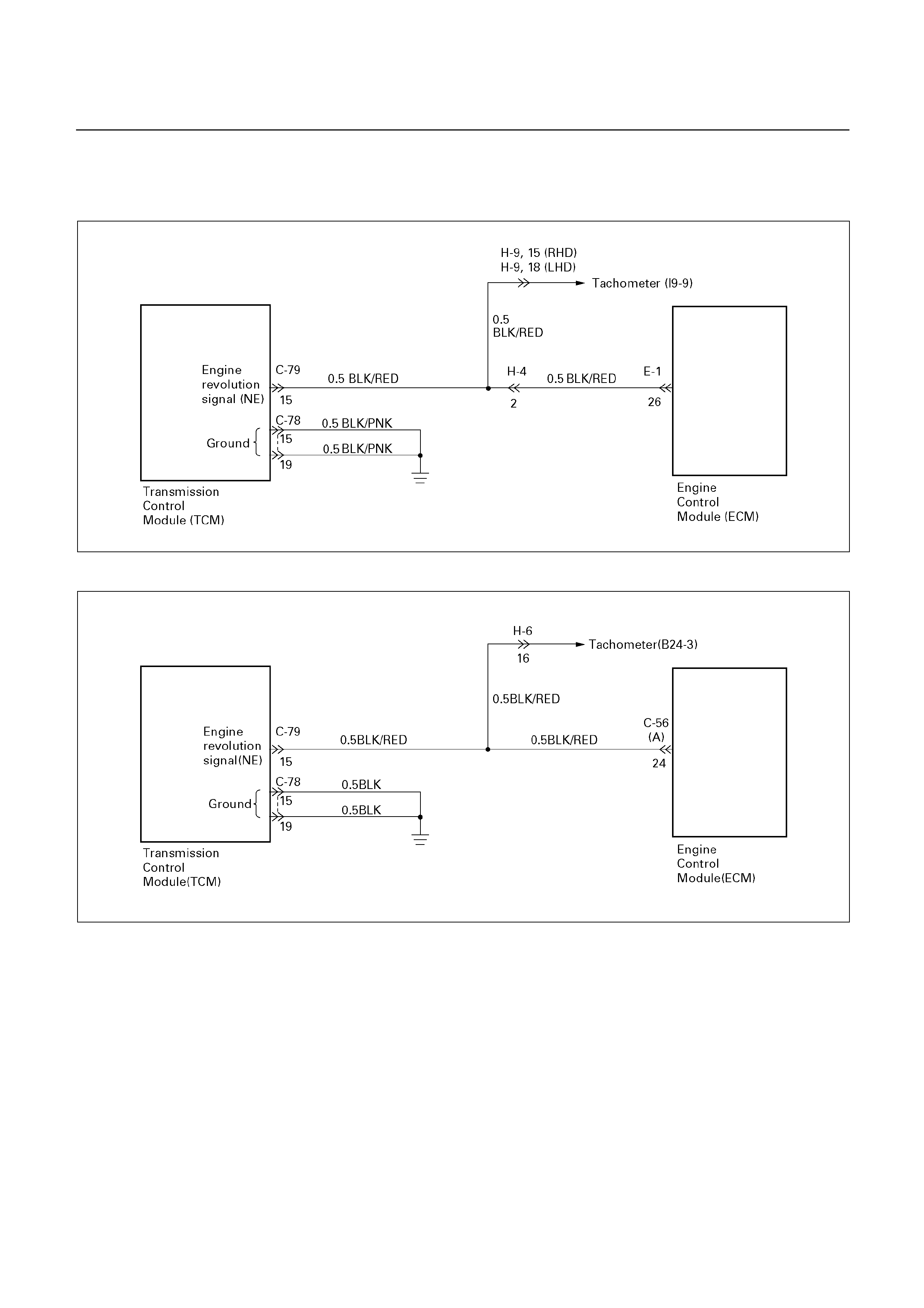

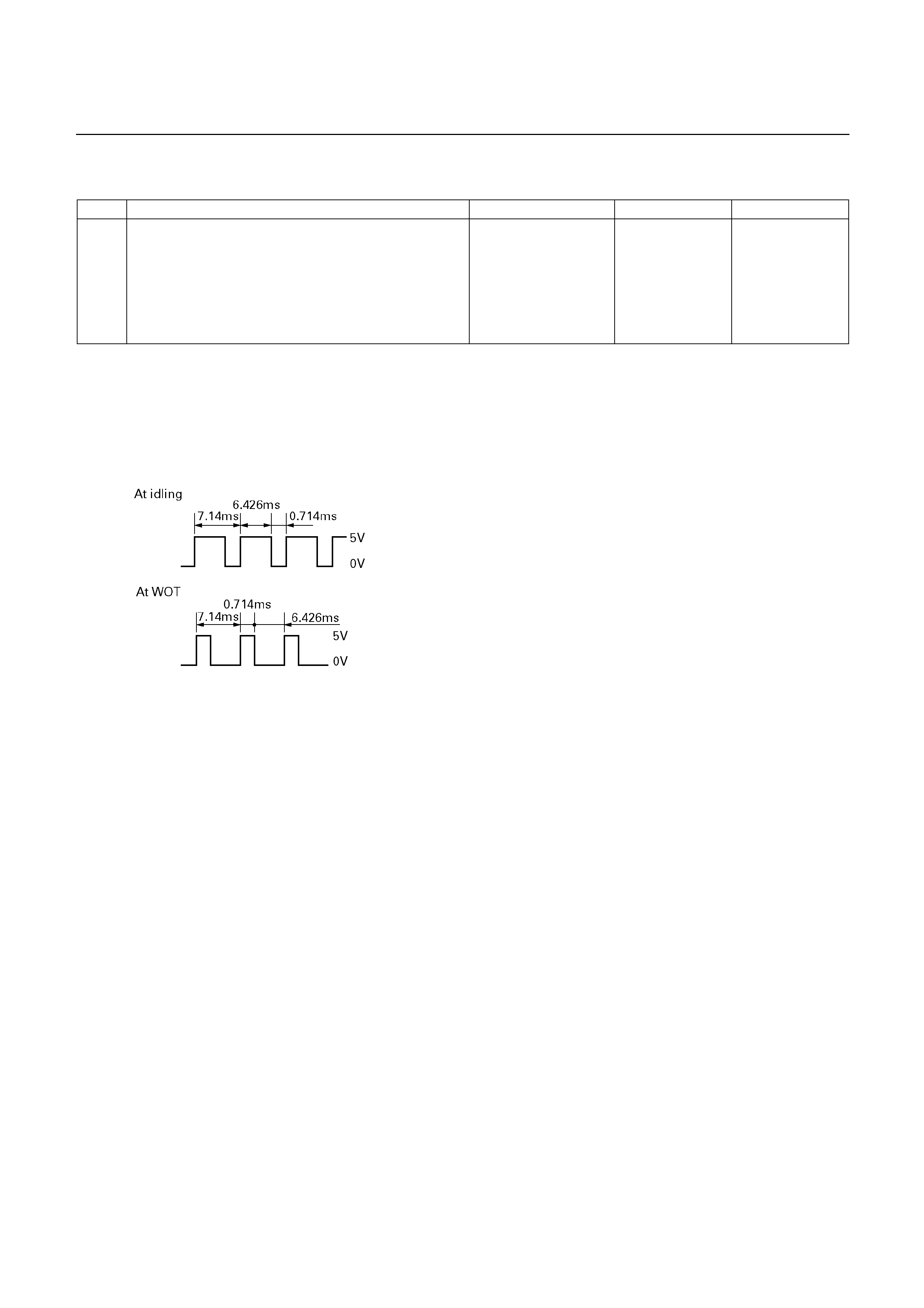

DTC P0727 (FLASHING CODE 13)

ENGINE REVOLUTION SIGNAL FAILURE (NE)

UBS

D07R200061

TFR/S

D07L200006

Circuit description:

Engine revolution (rpm) signals are sent from Engine

Control Module (ECM) to the Transmission Control

Module (TCM).

The engine speed sensor is an electromagnetic pulse

pickup type that generates signals when the flywheel

gear revolves (2 pulses at a single revolution of the

flywheel gear).

The TCM converts these sine wave signals into engine

revolution (RPM) signals.

Fail-safe control:

The TCM controls fail-safe by detecting engine

revolution sensor failure.

Failure detection:

• When input revolution is more than 2000 rpm

• When not even 1 pulse is input in the engine

revolution signal during 5 seconds

• Detection inhibit condition: At 4th gear

Contents of control:

At failure detection

• Up hill and down hill control inhibit (For UBS)

• Oil temperature sensor failure detection inhibit

• Blinks "CHECK TRANS" lamp

• Stores the failure information in failure memory.

At failure decision

Same as failure detection

Conditions of turning "CHECK TRANS" lamp

off:

Turns "CHECK TRANS" lamp off when judged 0km/h

by speed meter sensor after the engine revolution

signal pulses are input 250 pulses normally.

(however, uses 0 km/h judgment by back-up vehicle

speed at output revolution failure)

Reversion conditions from fail-safe:

Recovers at the same time as the conditions of turning

“CHECK TRANS” lamp off are satisfied.

Test description:

The following numbers correspond to the step numbers

on the diagnostic chart.

2. Engine revolution signals are input from the ECM

into the TCM.

3. When the engine idling, voltage fluctuates with (AC

intermittent) range of less than 1.4V ⇔ 9 ∼ 16V.

Diagnostic aids:

An intermittent may be caused by a poor connection,

rubbed through wire insulation or a wire broken inside

the insulation. Inspect related harness connector for

backed out terminals, improper mating, broken locks,

improperly formed or damaged terminals, poor terminal

to wire connection and damaged harness.

DTC P0727 (FLASHING CODE 13)

ENGINE REVOLUTION SIGNAL FAILURE (NE)

Step Action Value(s) Yes No

1

1. Clear the TCM memory.

2. Turn the ignition "ON" and start the engine.

3. With the engine "OFF", turn the ignition

"ON".

Is DTC P0727 displayed by self-diagnosis?

Go to Step 2 DTC P0727

was

temporarily

stored into

TCM memory.

Refer to

"Diagnostic

aids".

2

1. With the engine "OFF", turn the ignition

"ON".

2. Connect a voltmeter to the TCM 28 pin

connector terminal (15) and TCM 20 pin

connector ground terminal (15 or 19).

Is the voltage within the specified value?

9-16V Go to Step 3 Go to Step 4

3

1. With the ignition "ON" and the engine "ON".

2. Connect a voltmeter between the TCM 28

pin connector terminal (15) and TCM 20 pin

connector ground terminal (15 or 19).

Does the voltage vary in the specified value at

the engine idling?

Less than

1.4-9 16 V

(AC intermittently)

Go to Step 5 Go to Step 6

4

Check the wiring harness between the TCM and

ECM for breaking or voltage shorted.

Was a problem found and corrected?

Go to Step 7

5

Check the TCM connection. If OK, replace the

TCM.

Is the replacement complete?

Go to Step 7

6

Check the wiring harness between the TCM and

ECM for ground shorted. If OK, the ECM or the

engine revolution sensor is faulty.

Was a problem found and corrected?

Go to Step 7

7

1. After the repair is complete, use the scan tool

to select "DTC", then "Clear Info" function.

2. Make a road running, test for the vehicle.

3. Review the scan tool "DTC Info".

Has the last test failed or is the current DTC

displayed?

Begin the

diagnosis

again.

Go to Step 1

System OK

DTC P0743 (FLASHING CODE 33) TORQUE CONVERTER CLUTCH

CONTROL LOCK-UP (ON/OFF) SOLENOID FAILURE (SL)

UBS

D07R200062

TFR/S

D07L200007

Circuit description:

The lock-up solenoid SL of the torque converter clutch

(TCC) controls the lock-up clutch by a signal according

to the lock-up range judgement of the TCM when the

vehicle runs.

This function can improve the fuel consumption to

almost the same extent as the manual transmission.

The lock-up solenoid SL is put into B+ by the TCM, so

that the solenoid is actuated with the result of lock-up.

Fail-safe control:

The TCM controls fail-safe by detecting SL solenoid

failure.

Failure detection:

GND SHORT detection

• When SHORT detection continues for 0.3 sec.

• When SHORT failure detection continues 8 times.

Open detection

• When OPEN detection continues for 0.5 sec.

• When OPEN failure detection continues 8 times.

Contents of control:

At failure detection

• Lock-up control inhibit

• If + B short failure is detected, keeps 1st gear when

the vehicle speed calculated by output revolution

sensor is less than 10km/h to prevent stall.

(Canceled at more than 15km/h)

At failure decision

• Executes following items in addition to above

control items at failure detection.

• Stores the failure information in failure-memory.

Conditions of turning “CHECK TRANS” lamp

off:

None

Reversion conditions from fail-safe:

When a normal condition is judged by rechecking on

the state of lock-up ON/OFF

Test description:

The following numbers correspond to the step numbers

on the diagnostic chart.

1. When the key is ON, the voltage between the TCM

20 pin connector terminals (12) and (15 or 19) is

1.0 V or less.

2. When the gear is of the 2nd speed in the D range

and the throttle opening is about 50% at a higher

speed than about 40km/h, the TCM supplies 8 to

16 V, so that the solenoid is actuated with the result

of lock-up.

3.5.7.8. The resistance range of the solenoid is 11 to

15Ω (at 20°C).

Diagnostic aids:

In case of faulty connection, open or shorted circuit. to

the TCM 20 pin connector terminal (12), DTC P0743 is

displayed. A intermittent failure may be caused by a

poor connection, rubbed through wire insulation or a

wire broke inside the insulation.

DTC P0743 (FLASHING CODE 33) TORQUE CONVERTER CLUTCH

CONTROL LOCK-UP (ON/OFF) SOLENOID FAILURE (SL)

Step Action Value(s) Yes No

1

1. With the engine "OFF", turn the ignition "ON"

after warming up.

2. Connect a voltmeter between the TCM 20

pin connector terminal (12) and ground

terminal (15 or 19).

Is the voltage less than the specified value?

1 V Go to Step 2 Go to Step 3

2

1. Lift the driving sheels and support them.

2. At the D range and 2nd speed gear.

3. Make a test at a speed of about 40 km/h or

more with 50% or more opening of the

throttle.

Is the voltage between the TCM 20 pin connector

terminal (12) and ground terminal (15 or 19)

within the specified value?

8-16V Go to Step 4 Go to Step 5

3

1. Turn the ignition "OFF".

2. Disconnect the TCM 20 pin connector.

3. Measure the resistance between the terminal

(12) and ground.

Is the resistance within the specified value?

11-15Ω

(at 20 )

Go to Step 6 Go to Step 7

4

1. Clear the TCM memory.

2. Make a running test.

Is DTC P0743 displayed by self-diagnosis?

Go to Step 6 The continuity

of wiring is

intermittent.

Refer to

"Diagnostic

aids".

5

1. Turn the ignition "OFF".

2. Disconnect the TCM 20 pin connector.

3. Measure the TCM 20 pin connector terminal

(12) and ground.

Is the resistance within the specified value?

11-15Ω

(at 20 )

Go to Step 6 Go to Step 8

6

The TCM is faulty or the continuity of wiring

harness is intermittent.

Was a problem found and corrected?

Go to Step 12

7

Disconnect the A/T 8 pin connector.

Is the resistance between the lock-up solenoid

connector terminal (7) and ground within the

specified value?

11-15Ω

(at 20 )

Go to Step 9 Go to Step 10

8

Disconnect the A/T 8 pin connector.

Is the resistance between the lock-up solenoid

connector terminal (7) and ground within the

specified value?

11-15Ω

(at 20 )

Go to Step 11 Go to Step 10

9

Check the wiring harness between the TCM 20

pin connector terminal (12) and A/T 8 pin

connector terminal (7) for open.

Was a problem found and corrected?

Go to Step 12

Step Action Value(s) Yes No

10 Replace the lock-up solenoid (SL).

Is the replacement complete?

Go to Step 12

11

Check the wiring harness between the TCM 20

pin connector terminal (12) and A/T 8 pin

connector terminal (7) for ground shorted.

Was a problem found and corrected?

Go to Step 12

12

1. After the repair is complete, use the scan tool

to select "DTC", then "Clear Info" function.

2. Make a road running test for the vehicle.

3. Review the scan tool "DTC Info".

Has the last failed or is the current DTC

displayed?

Begin the

diagnosis

again.

Go to Step 1

System OK

DTC P0748 (FLASHING CODE 35)

PRESSURE CONTROL SOLENOID FAILURE (STH)

UBS

D07R200062

TFR/S

D07L200007

Circuit description:

The pressure control solenoid is a PWM duty control

solenoid located in the valve body.

The pressure control solenoid is a TCM-controled

device used to regulate transmission throttle pressure

by energizing current from the TCM.

Fail-safe control:

The TCM controls fail-safe by detecting pressure

control solenoid failure.

Failure detection:

IG short failure

• When the feedback A/D value is more than 1020

for 500 milli-second continuously.

• Detection inhibit condition: Prohibition during 1

second after reversion from open failure, because

the possibility of the mis-detection is high.

Open failure (Including GND Short)

• When the feedback A/D value is less than 15 for

more than 70 milli-second continuously, judges as

faliure, and turns the current of target output off,

after 1.5 second passed turns the current of target

value to normal. The A/D value is checked, and this

operation is repeated during 70 milli-second again.

• When it continues for 12.5 second in total.

Contents of control:

At failure detection

• Lock-up control inhibit

• Up hill and down hill control inhibit (For UBS)

• Squat control inhibit

At failure decision

• Executes following items in addition to above

control items at failure detection.

• Turns Solenoid power supply OFF

• Blinks "CHECK TRANS" lamp

• Stores the failure information in failure memory

*Prohibits failure detection of S1, S2, SL, STH, selector

position switch, and oil temperature sensor.

Conditions of turning "CHECK TRANS" off:

Turns "CHECK TRANS" lamp off after ignition is turned

ON→ OFF→ ON.

Reversion conditions from fail-safe:

At failure detection

When IG short failure···The feedback A/D value is

less than 1020 for 1 second continuously.

When open failure···Detection criteria is not

satisfied or the feedback A/D value is more than 15

for 1 second continuously.

At failure decision

Recovers at the same time as the conditions of

turning “CHECK TRANS” lamp off are satisfied.

Test description:

The following numbers correspond to the step numbers

on the diagnostic chart.

1. The solenoid resistance is within the range of 5 to

5.6Ω. (at 20°C)

2. This test checks for shorted circuit at the TCM.

Diagnostic aids:

An intermittent may be caused by a poor connection,

rubbed through wire insulation or a wire broken inside

the insulation. Inspect related harness connector for

backed out terminals, improper mating, broken locks,

improperly formed or damaged terminals, poor terminal

to wire connection and damaged harness.

DTC P0748 (FLASHING CODE 35)

PRESSURE CONTROL SOLENOID FAILURE (STH)

Step Action Value(s) Yes No

1

1. Turn the ignition "OFF".

2. Disconnect the TCM 20 pin connector.

3. Connect an ohmmeter between the TCM 20

pin connector terminal (11) and (8).

Is the resistance within the specified value?

5-5.6Ω (at 20°C) Go to Step 2 Go to Step 3

2

1. Connect an ohmmeter between the TCM 20

pin connector terminal (11) and ground

terminal (15 or 19).

2. Then, connect between the TCM 20 pin

connector terminal (11) and ignition terminal

(20).

3. Then, connect TCM 20 pin connector

terminal (8) and ground terminal (15 or 19),

then between TCM 20 pin connector

terminal (8) and ignition terminal (20).

Does display a short circuit?

Go to Step 4 The problem is

intermittent.

Refer to

"Diagnostic

aids".

3

1. Disconnect the A/T 8 pin connector.