SECTION 7D - 4L30–E SERVICE & REPAIR

Service Precaution

Construction

Range Reference Chart

Normal Operation Of 2000 4L30–E Transmission

Diagnosis

Driver Information

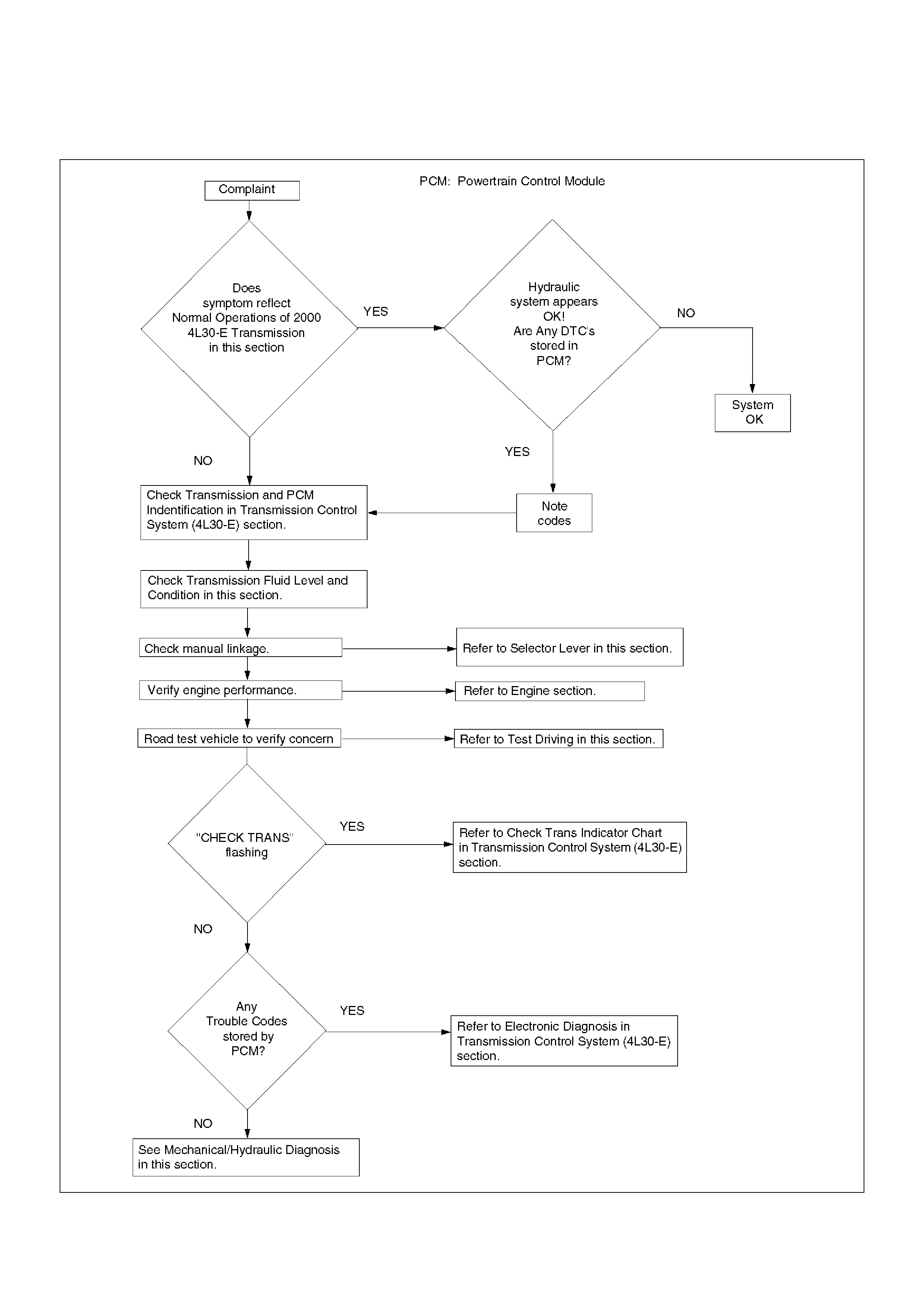

General Diagnosis Procedure

Preliminary Inspection Chart

Checking Transmission Fluid Level and Condition

Test Driving

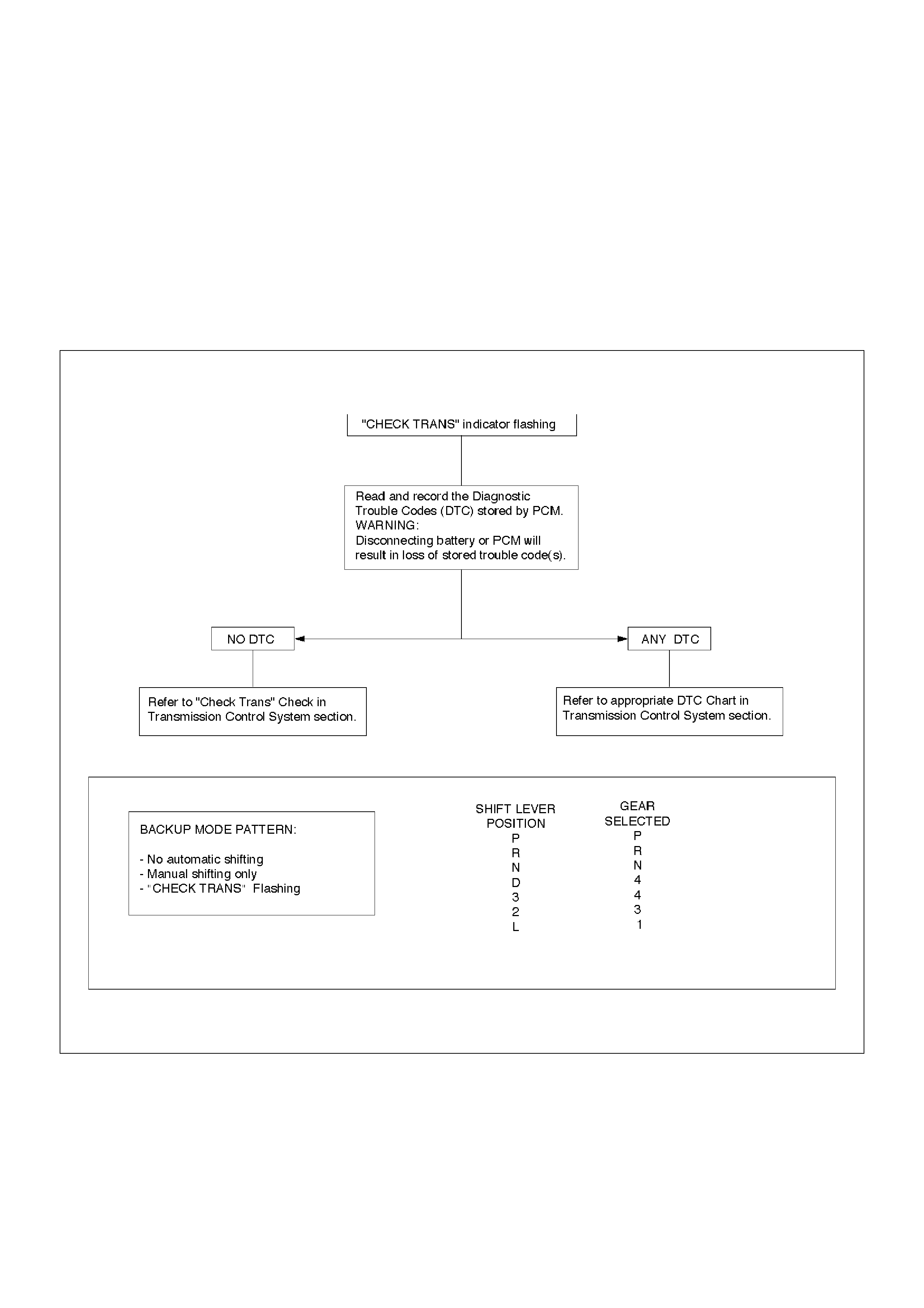

Mechanical / Hydraulic Diagnosis Check Trans

Indicator Chart

Mechanical / Hydraulic Diagnosis Symptoms Index

Chart 1: No Engine Start In Neutral Or Park

Chart 2: No Forward Gears In Any Range/No

Reverse

Chart 3: No Engine Brake In Any Range

Chart 4: Poor Shifting In All Gears (All Harsh Or All

Soft)

Chart 5a: Delays In Drive And Reverse

Chart 5b: Delays In Reverse Only

Chart 6: Diagnostic Trouble Code (DTC) P0730

Chart 7: Harsh 1–2 Shift

Chart 8: Harsh 3–4 Shift

Chart 9a: 3–2 Downshift Complaint

Chart 9b: Harsh Shift When Shifting Into “D” Or

Accelerating From Stop

Chart 9c: Coastdown Harsh Shift Or Clunk At 3–2

Downshift

Chart 10: Intermittent 4TH TO 2ND Gear

Downshift At Steady Speed

Chart 11: Engine Flare At Shifting During Turning

Only (Usually With Warm Engine)

Chart 12: Engine Flare During 1–2 Or 2–3 Shift

Chart 13: Shudder Only During Torque Converter

Clutch (TCC) Applying

Chart 14: Possible Causes Of Transmission Noise

Chart 15a: Possible Causes of Low Line Pressure

Chart 15b: Possible Causes Of High Line Pressure

Chart 16: Possible Causes Of Transmission Fluid

Leaks

Stall Test

Line Pressure Test

Shift Speed Chart (V6 3.2L 6VD1 Model)

Shift Speed Chart (V6 3.5L 6VE1 Model)

Lockup Speed Chart

Changing Transmission Fluid

Selector Lever

Inspection

Removal

Installation

Mode Switch

Removal

Installation

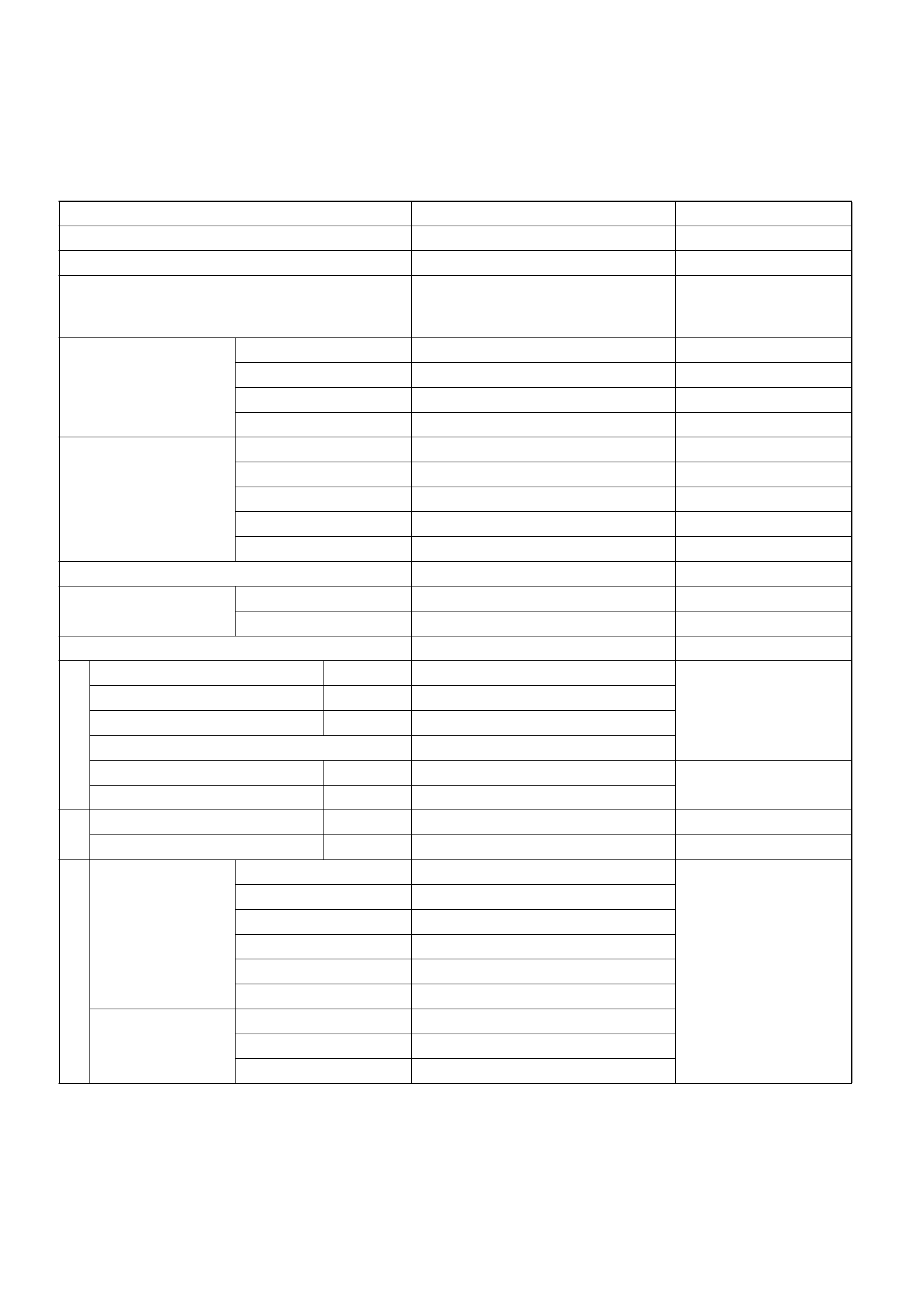

Transmission (With Transfer Case)

Transmission And Associated Parts

Removal

Installation

Solenoid (Main Case Valve Body)

Removal

Installation

Solenoid (Adapter Case Valve Body)

Removal

Installation

Valve Body Assembly (Main Case)

Removal

Installation

Valve Body Assembly (Adapter Case)

Removal

Installation

Powertrain Control Module (PCM)

Removal

Installation

Speed Sensor (Extension Housing)

Removal

Installation

Transmission Oil Temperature Sensor (Adapter Case)

Removal

Installation

Front Oil Seal (Converter Housing)

Removal

Installation

Rear Oil Seal (Extension Housing)

Removal

Installation

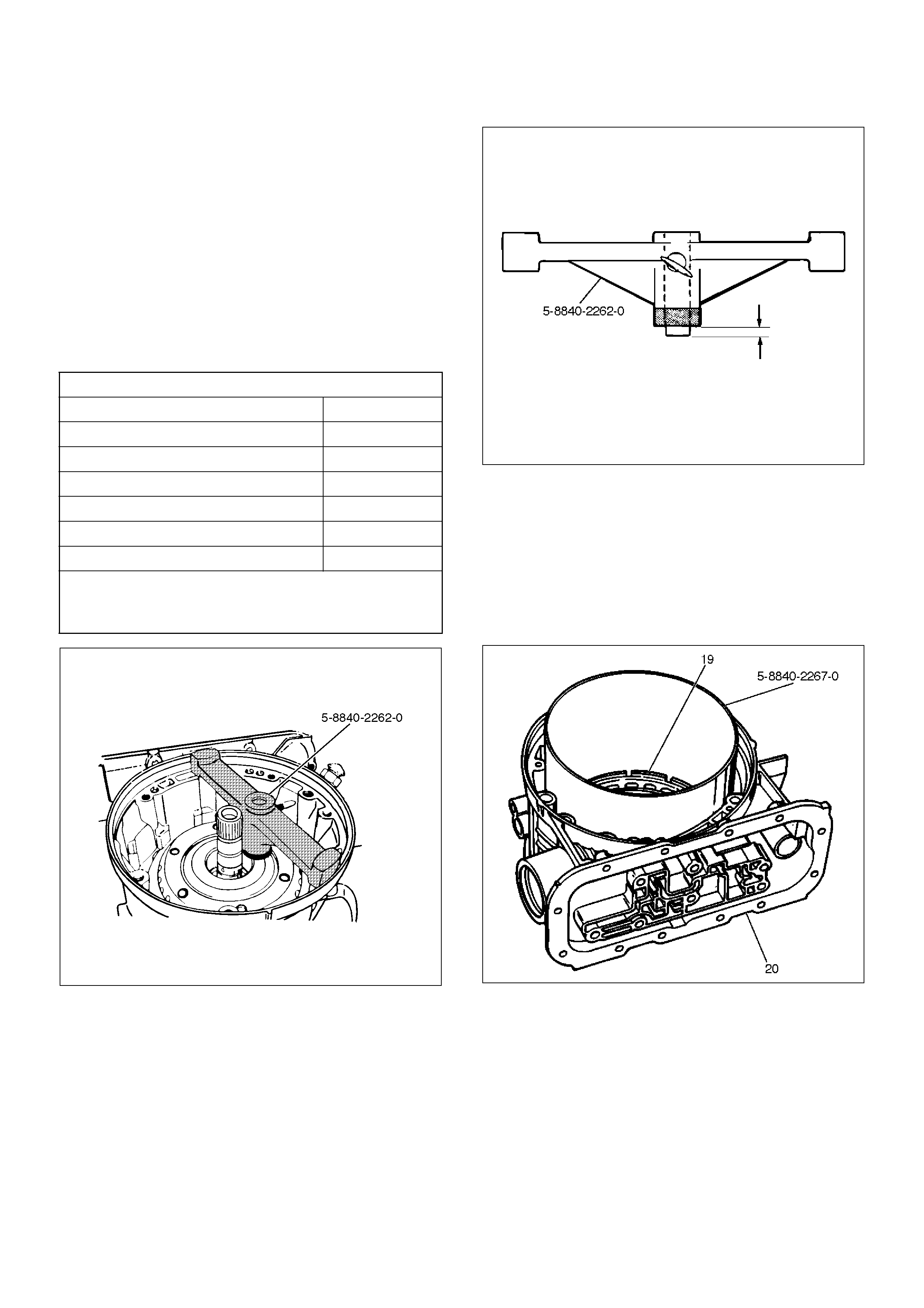

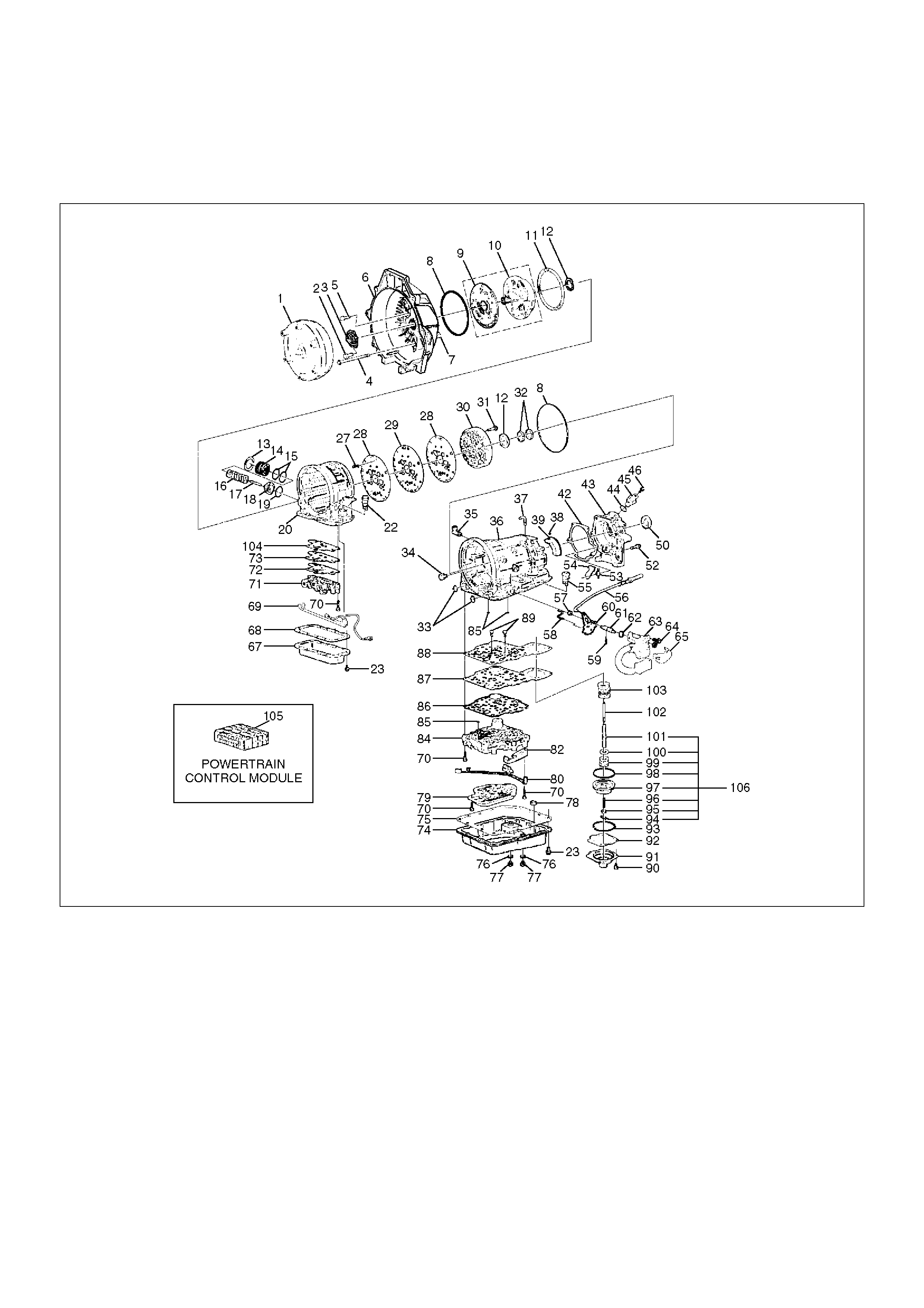

Transmission (4L30–E)

Disassembly

Reassembly

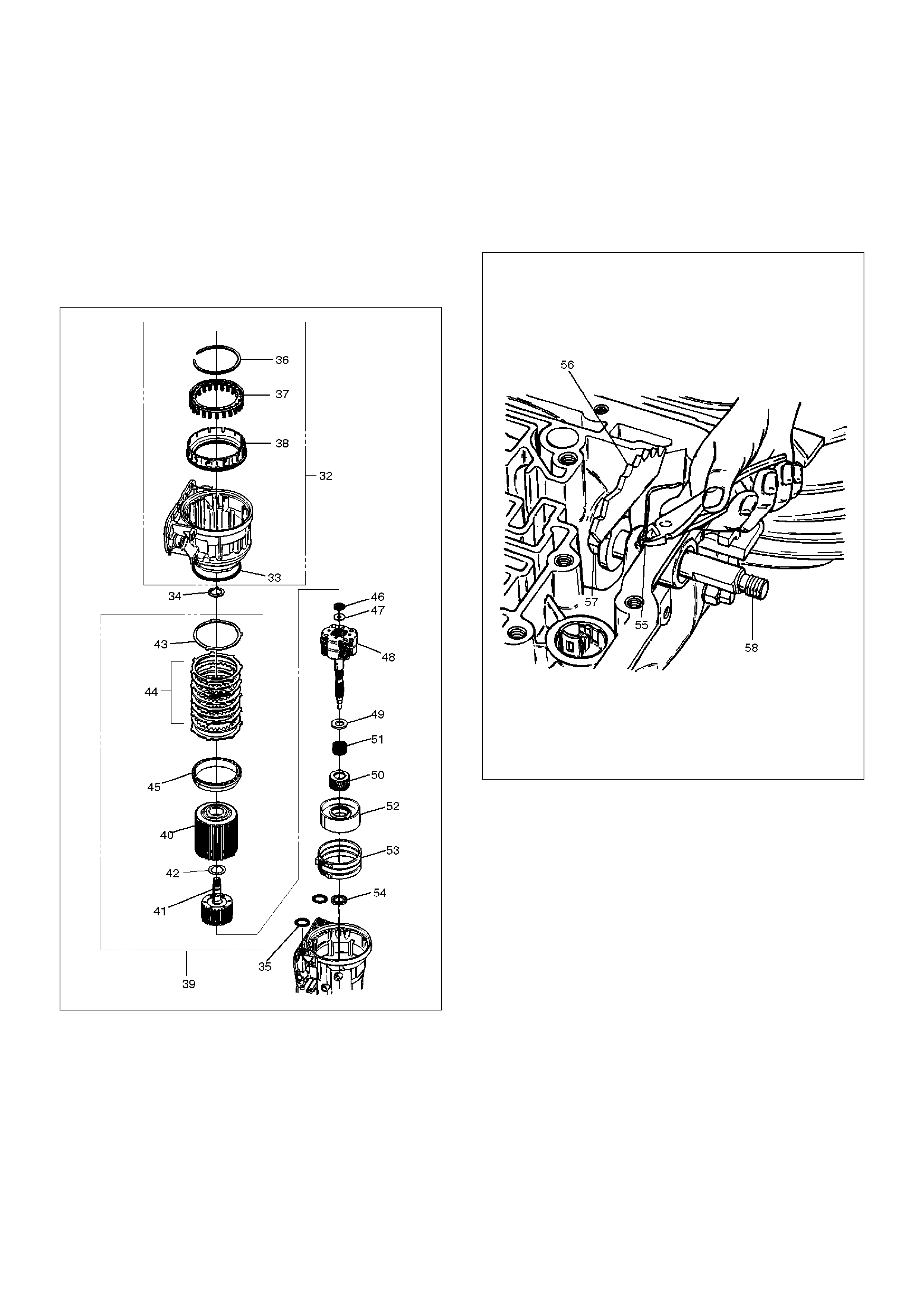

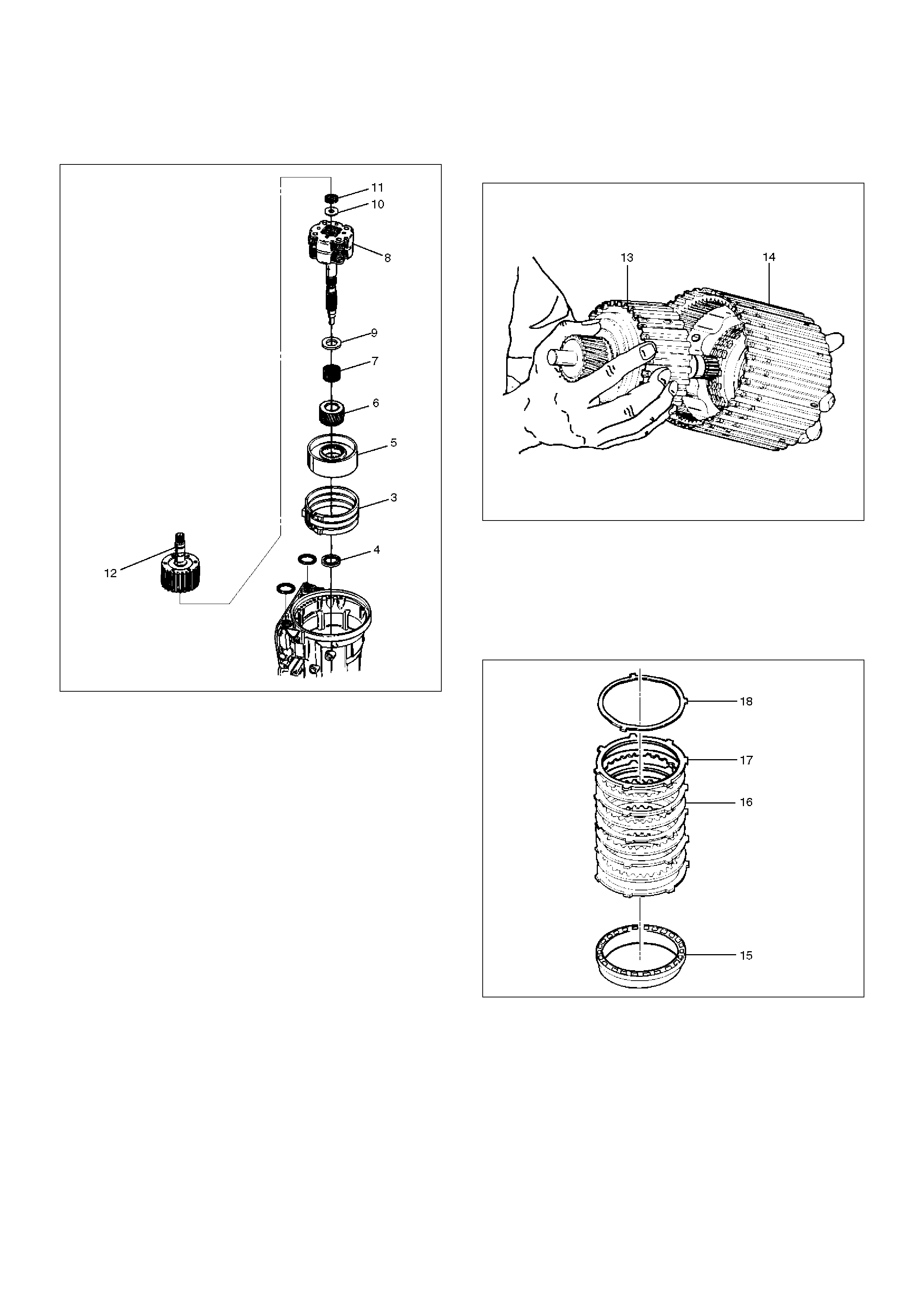

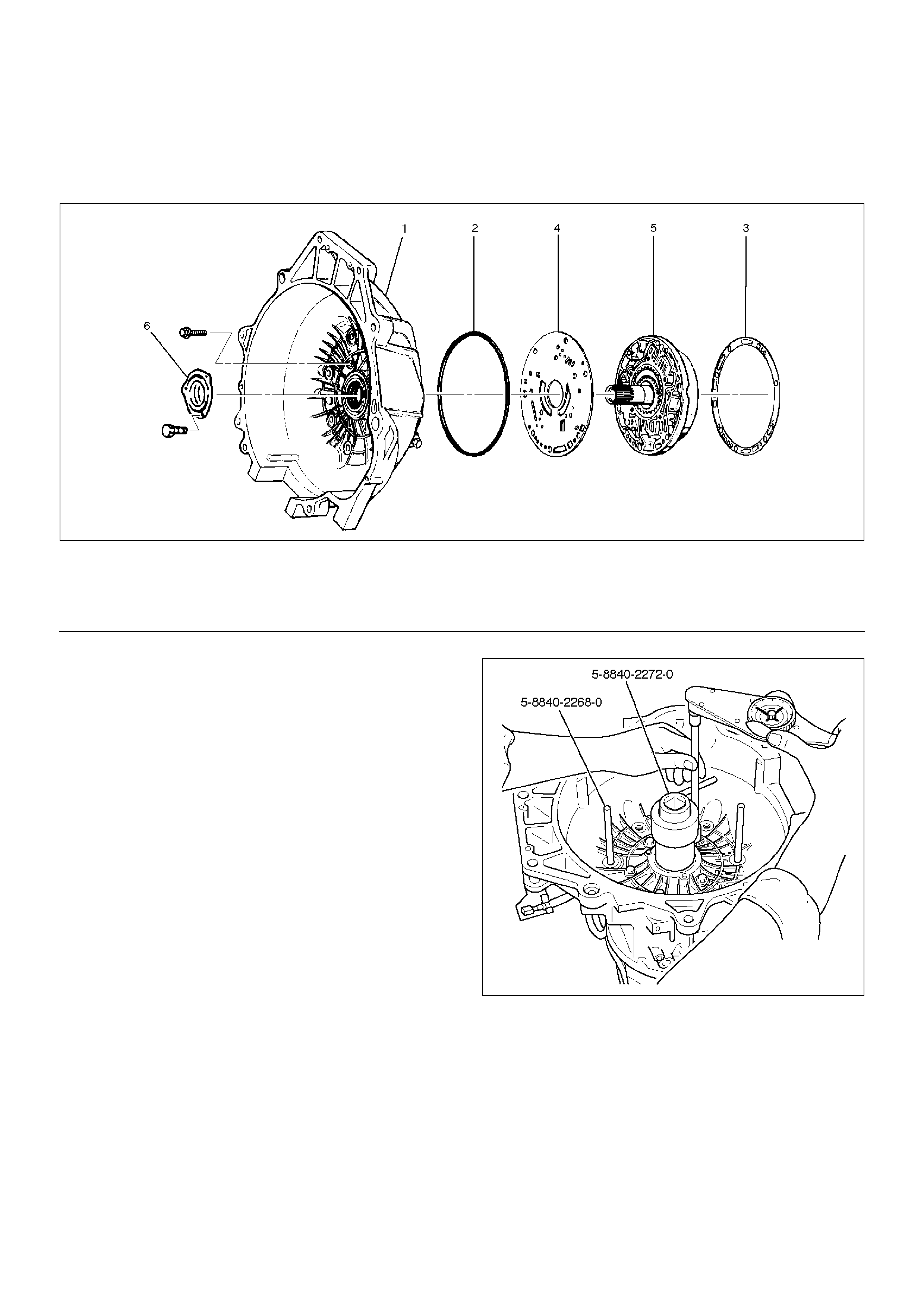

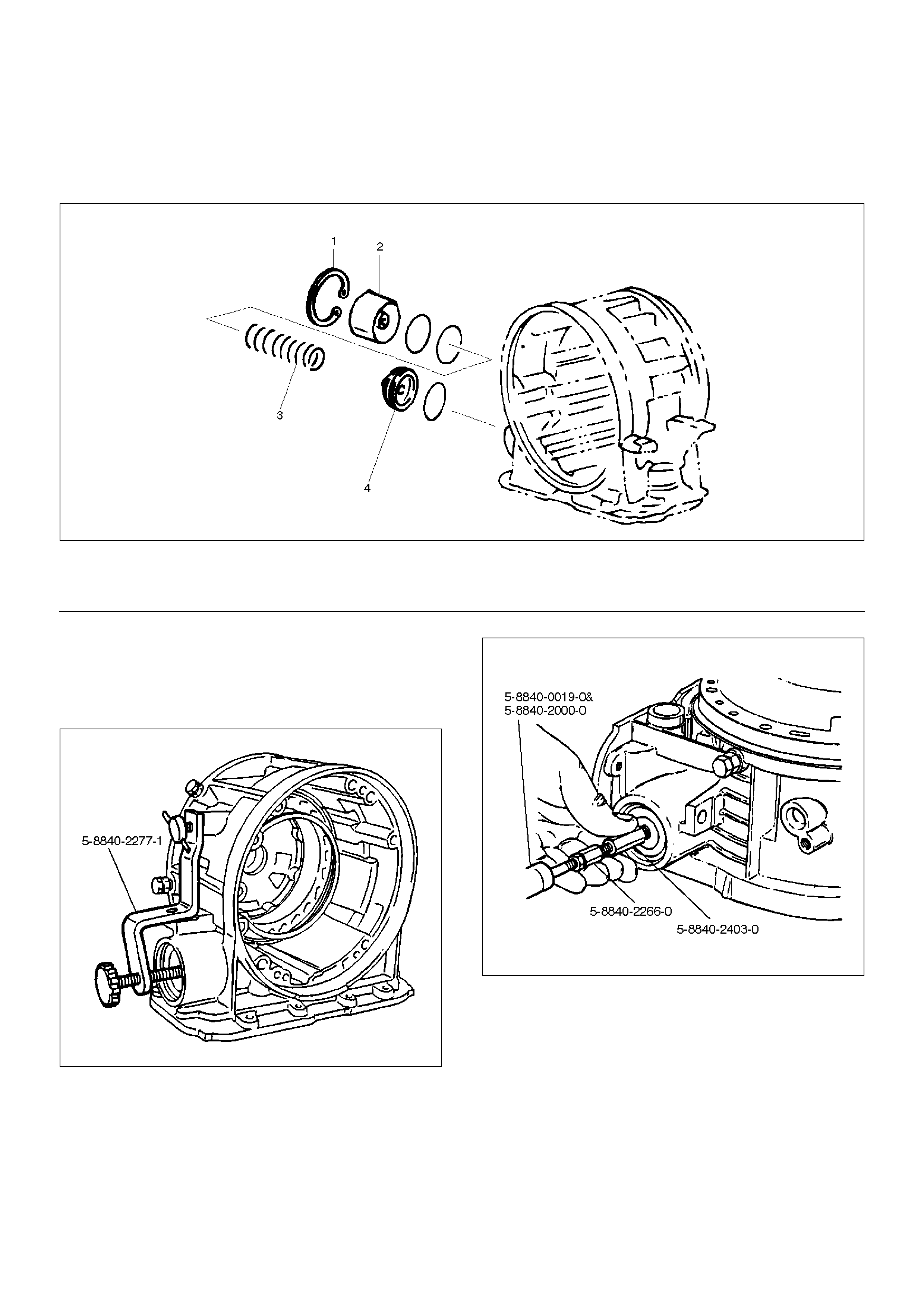

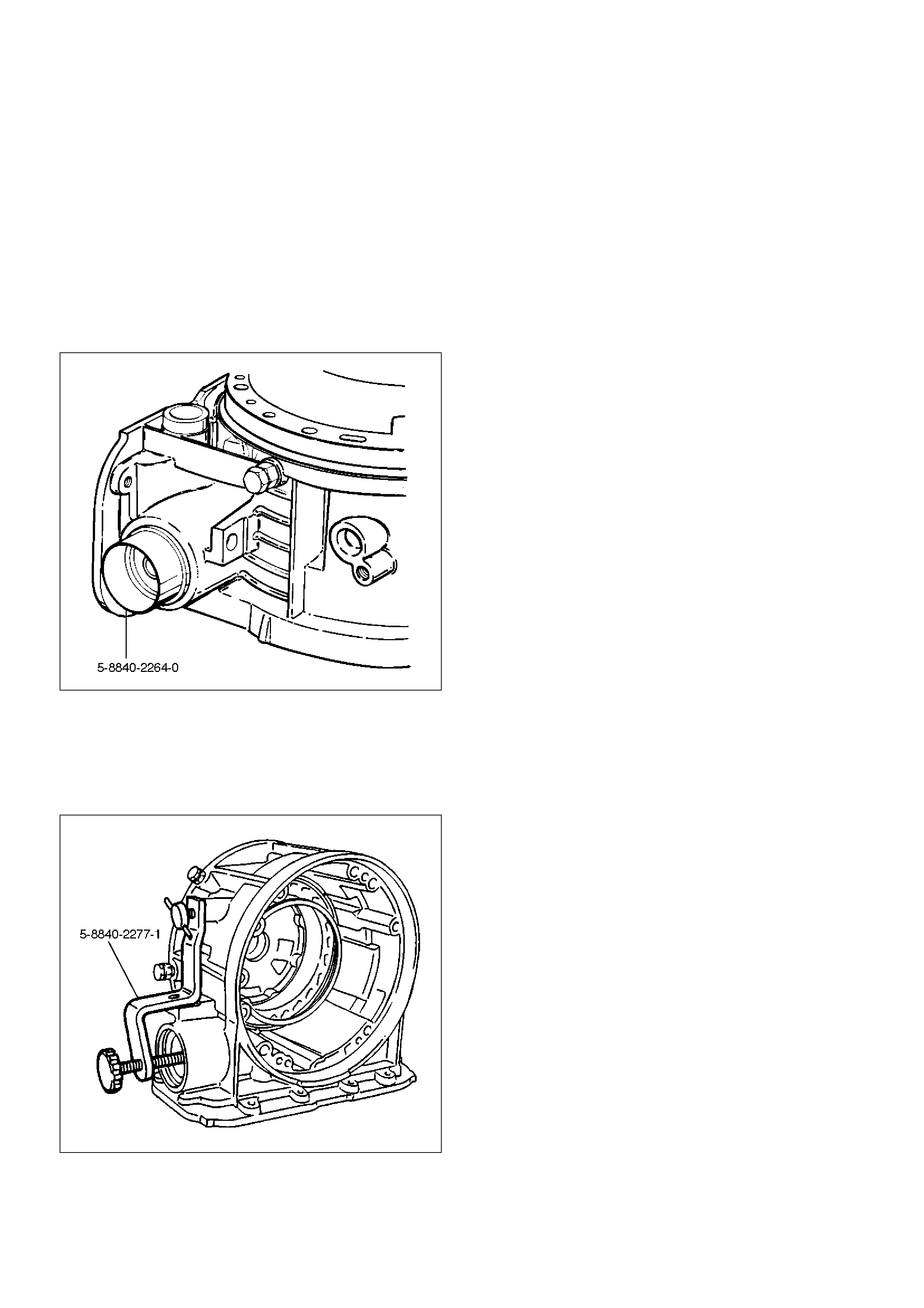

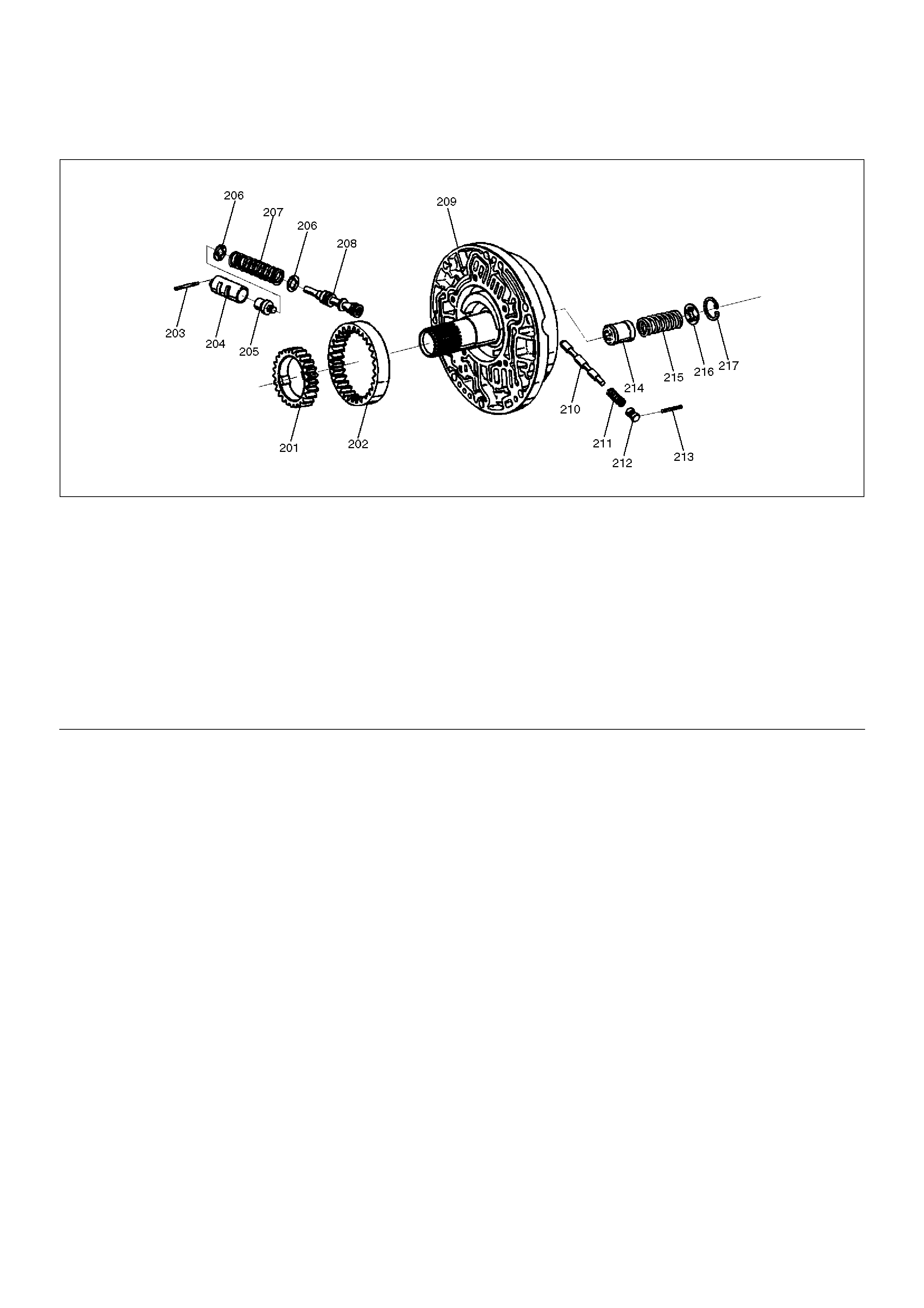

Converter Housing And Oil Pump Assembly

Disassembled View

Disassembly

Inspection And Repair

Reassembly

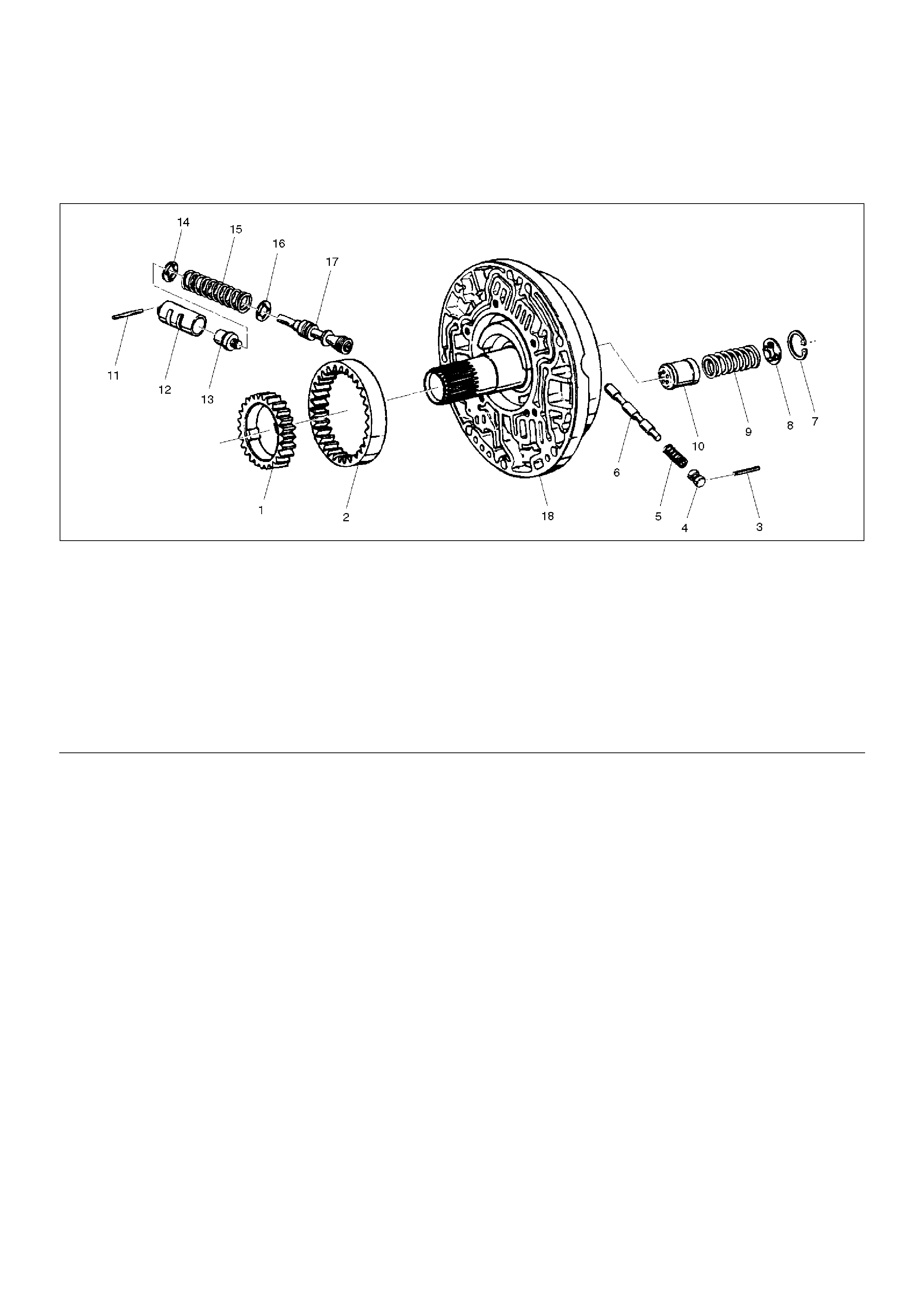

Oil Pump

Disassembled View

Disassembly

Inspection And Repair

Reassembly

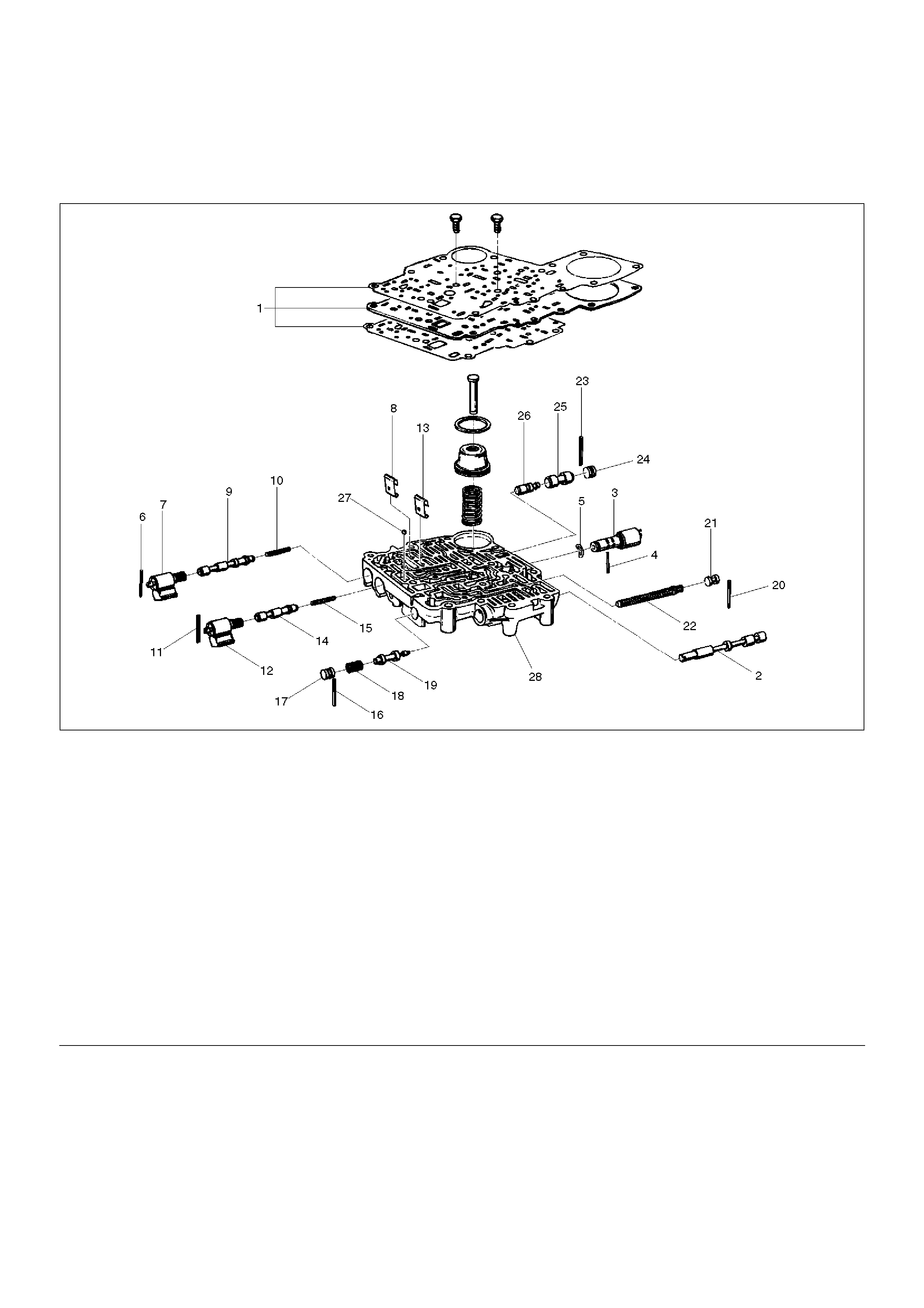

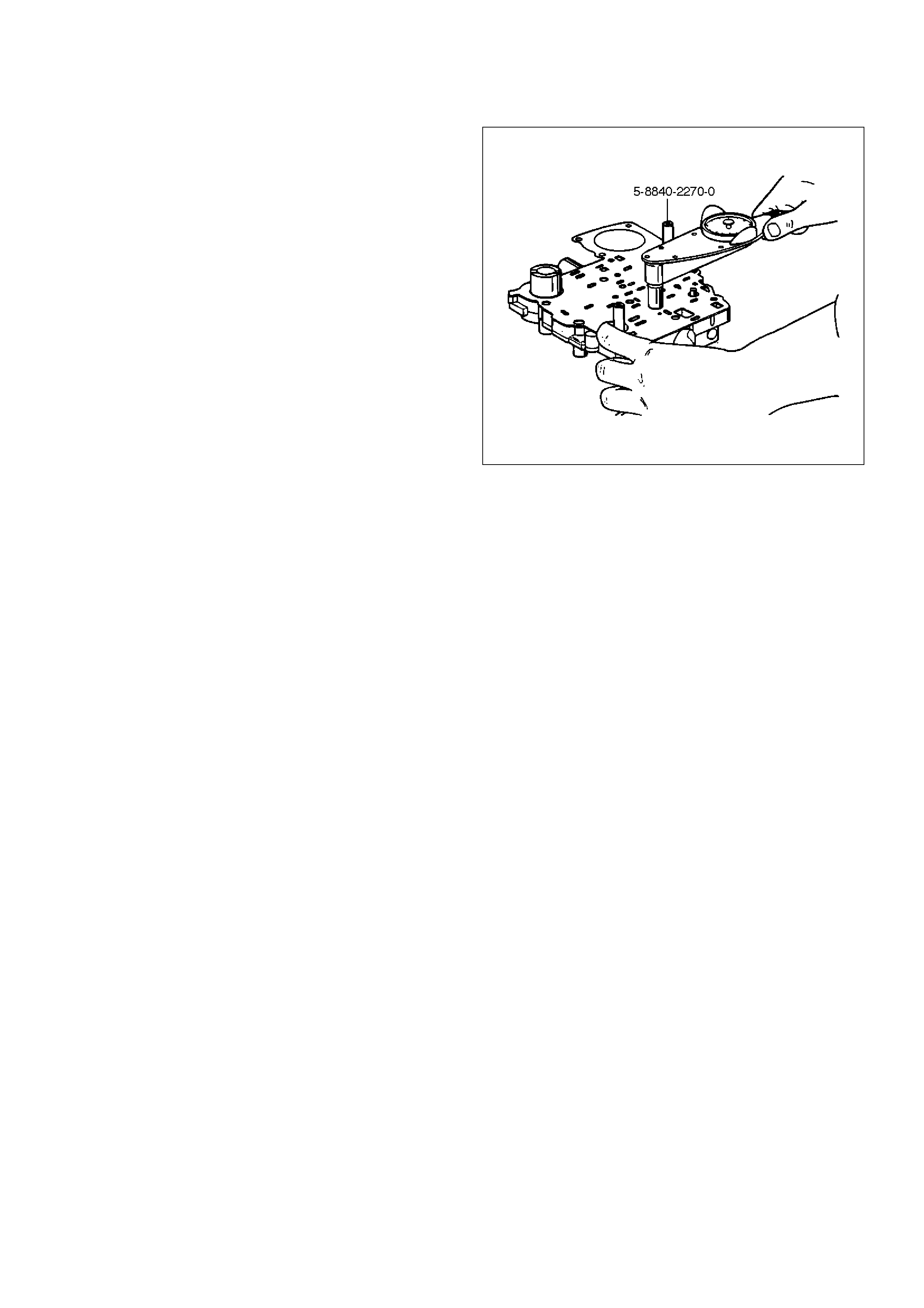

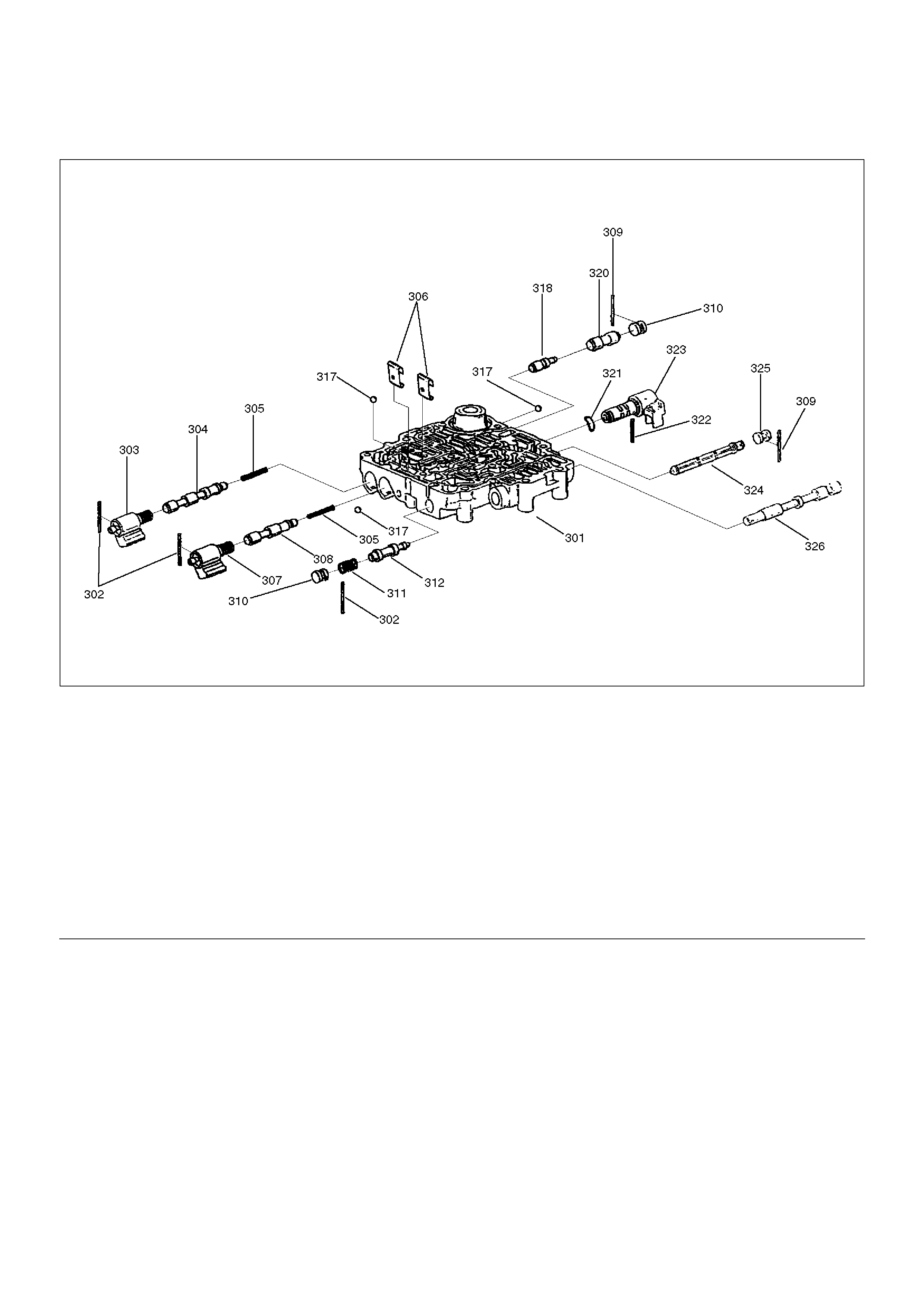

Main Case Valve Body

Disassembled View

Disassembly

Inspection And Repair

Reassembly

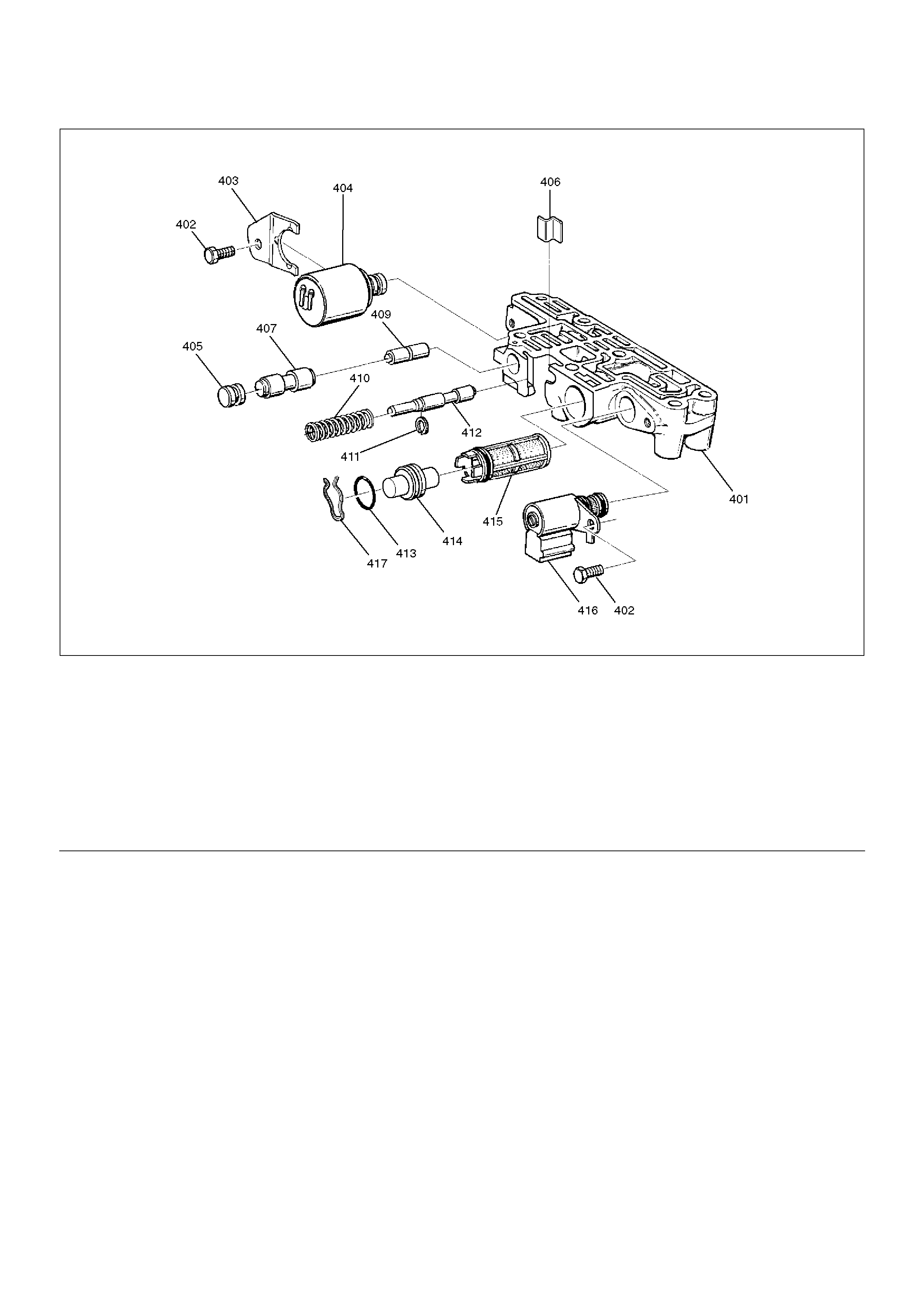

Adapter Case Valve Body

Disassembled View

Disassembly

Inspection And Repair

Reassembly

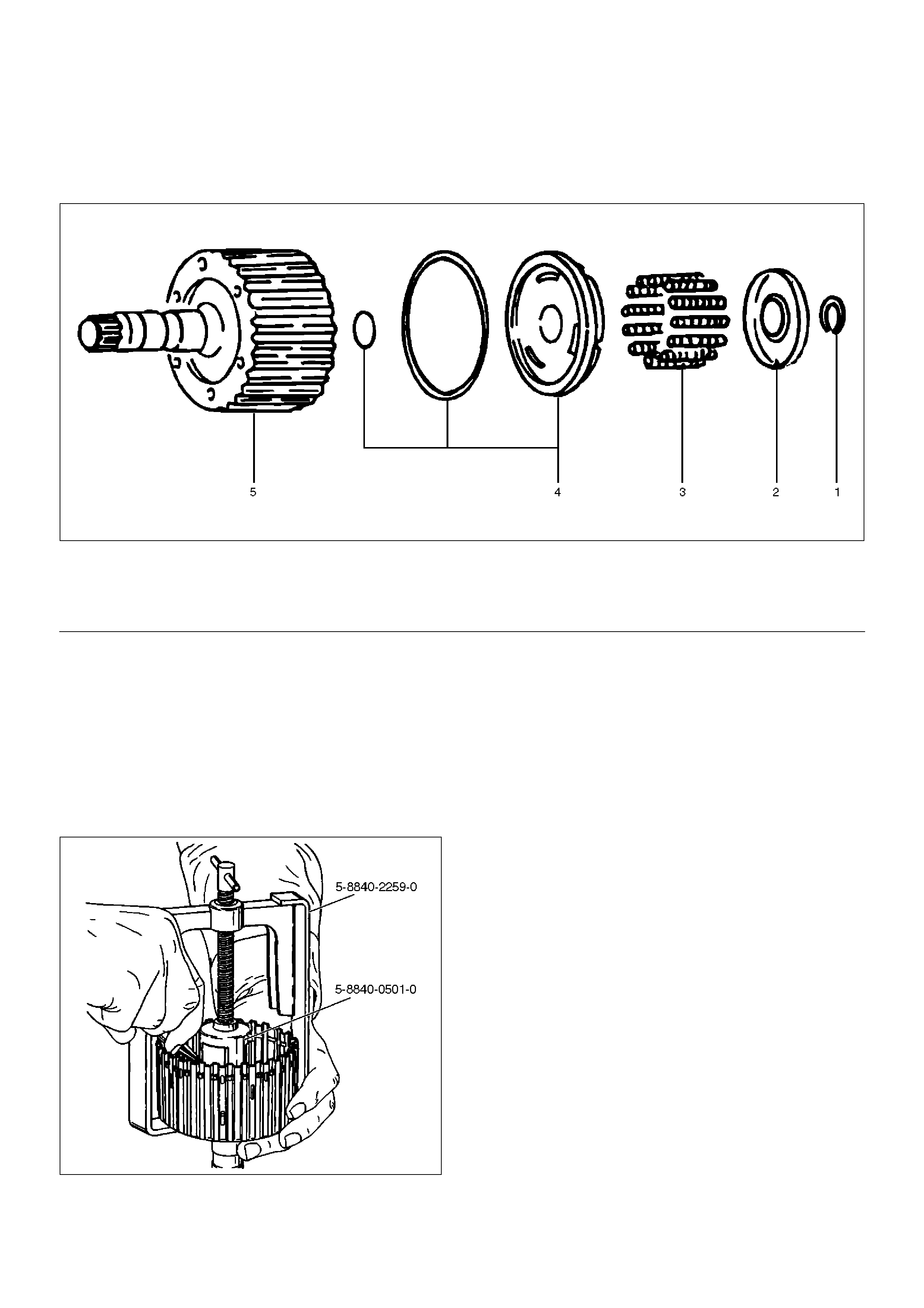

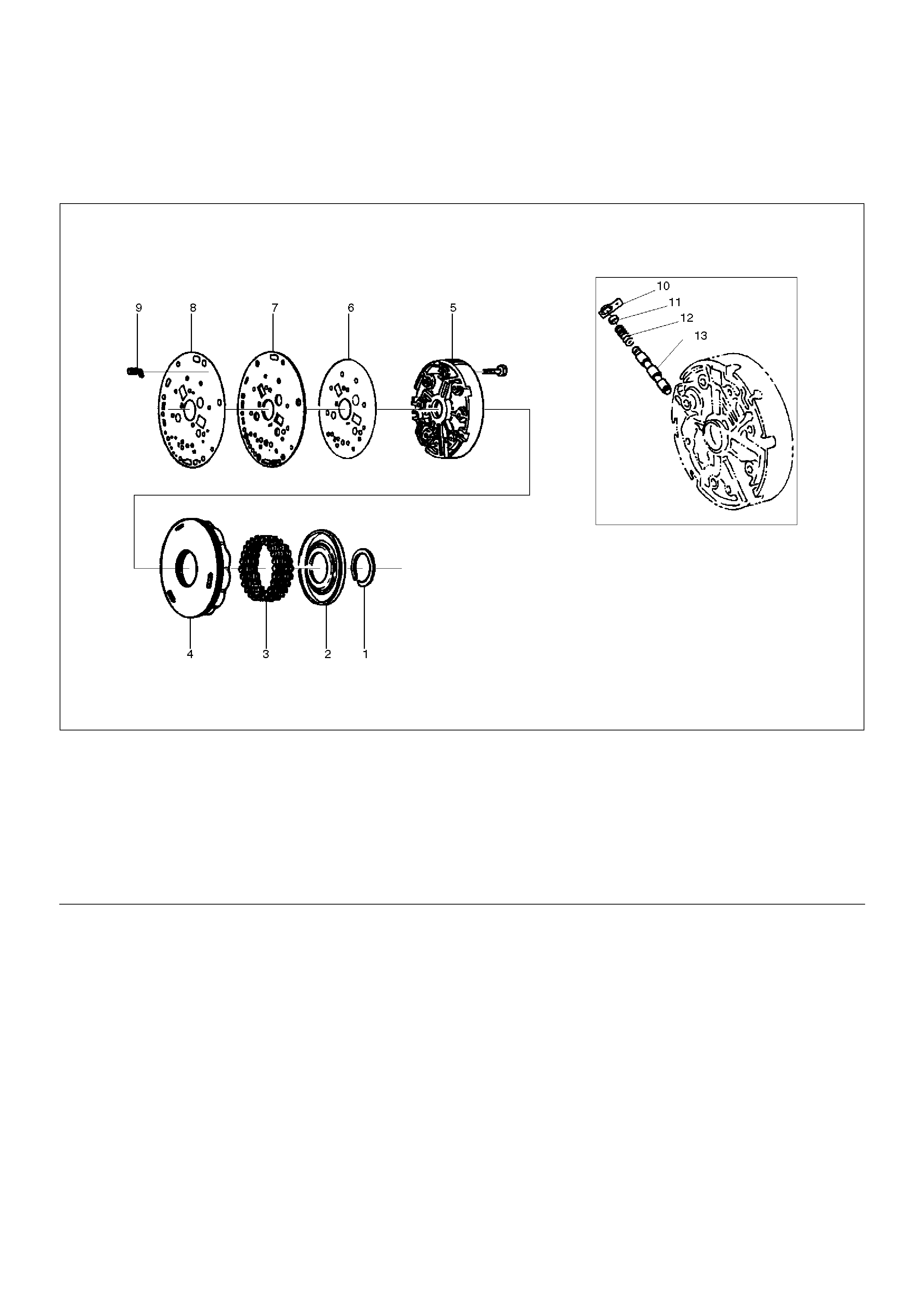

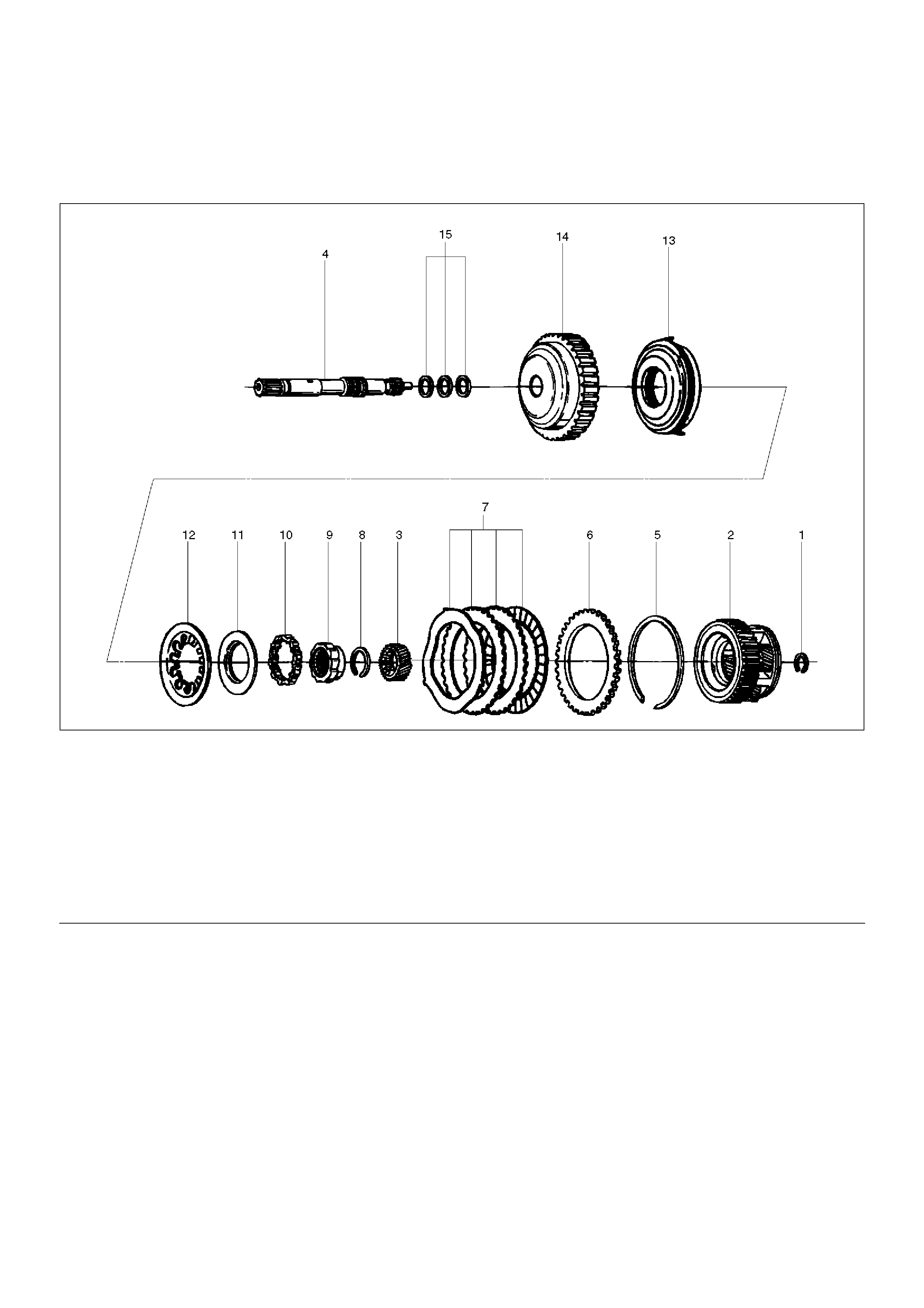

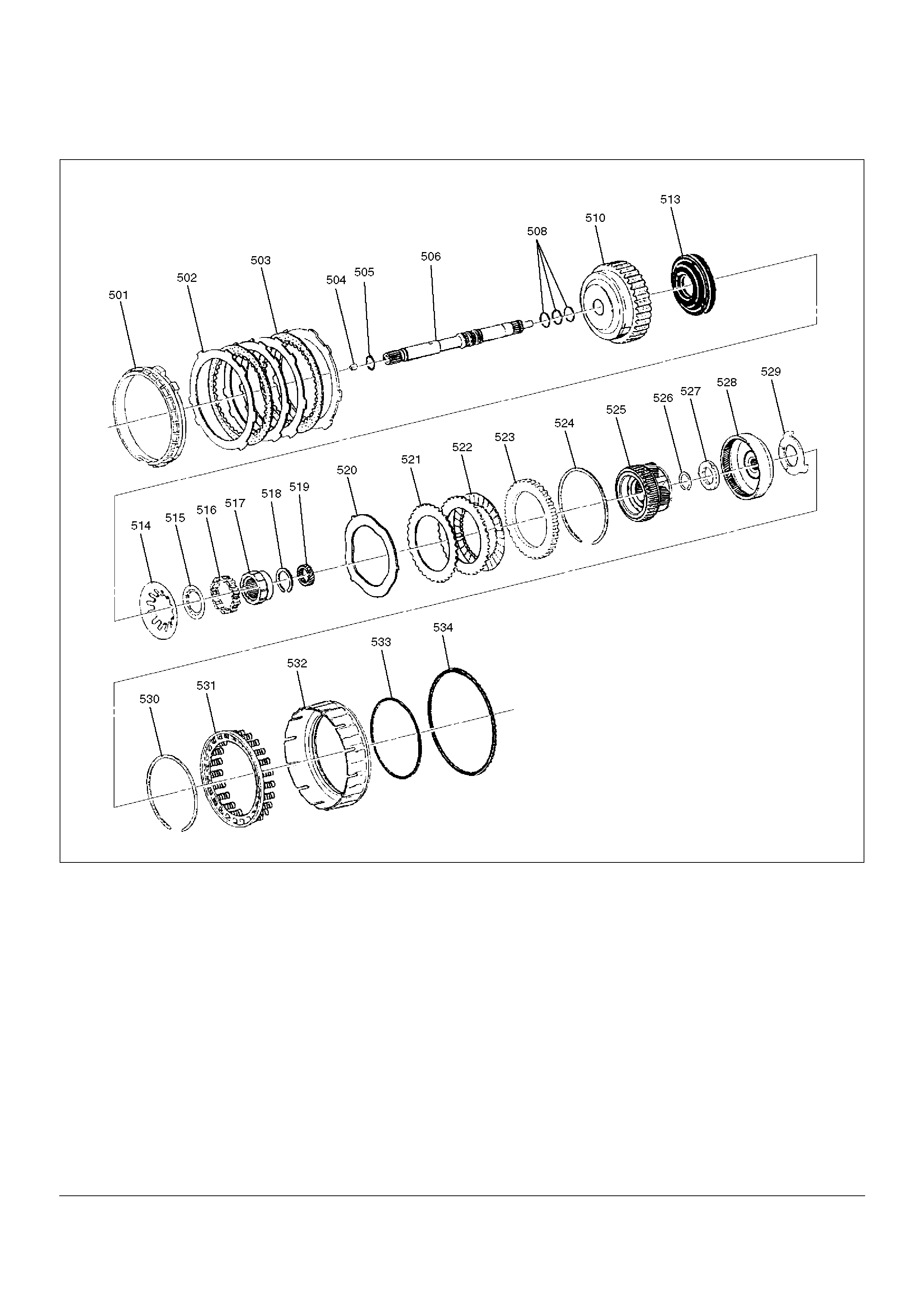

Third Clutch And Sprag Unit

Disassembled View

Disassembly

Inspection And Repair

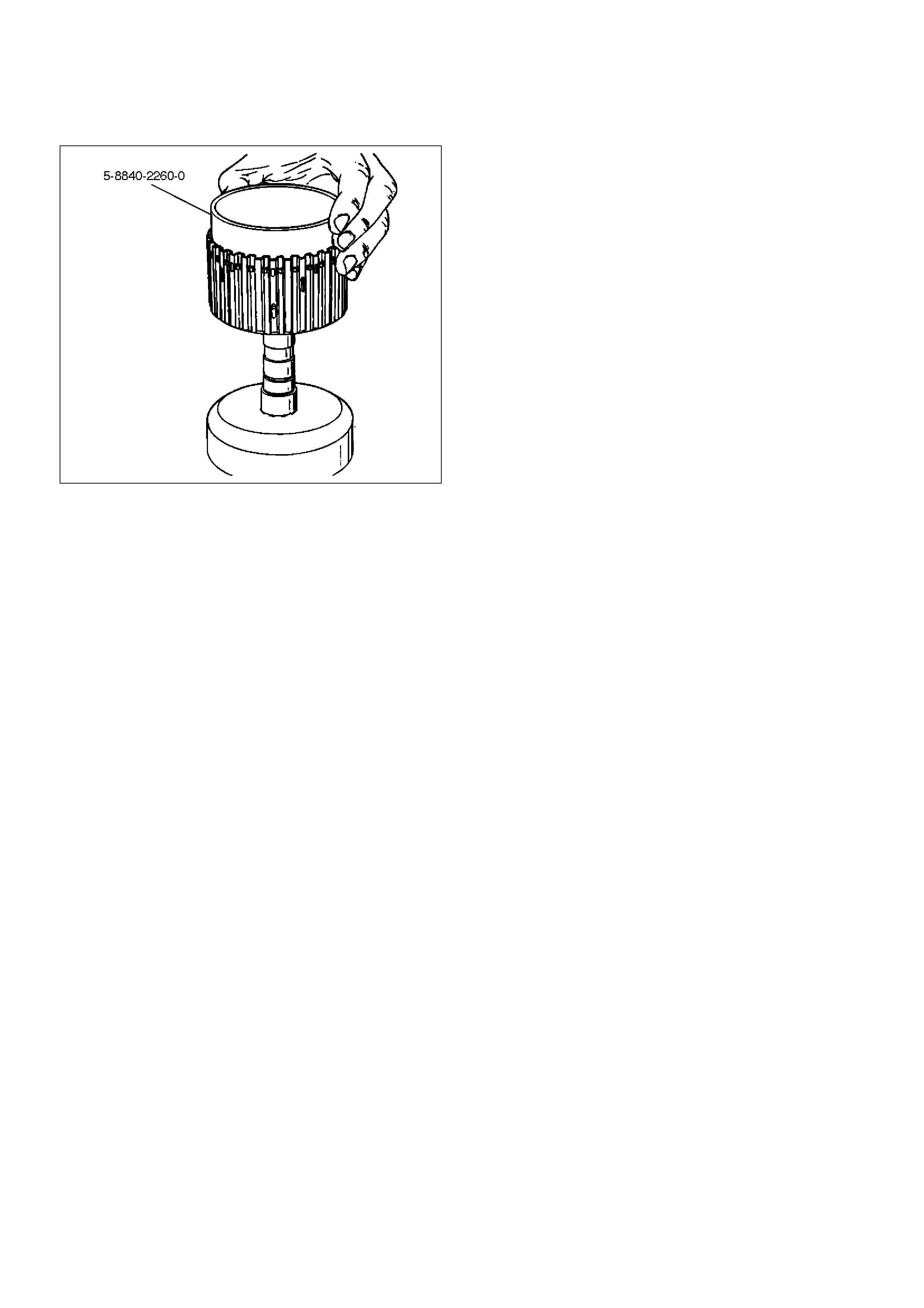

Reassembly

Third Clutch

Disassembled View

Disassemble

Inspection And Repair

Reassembly

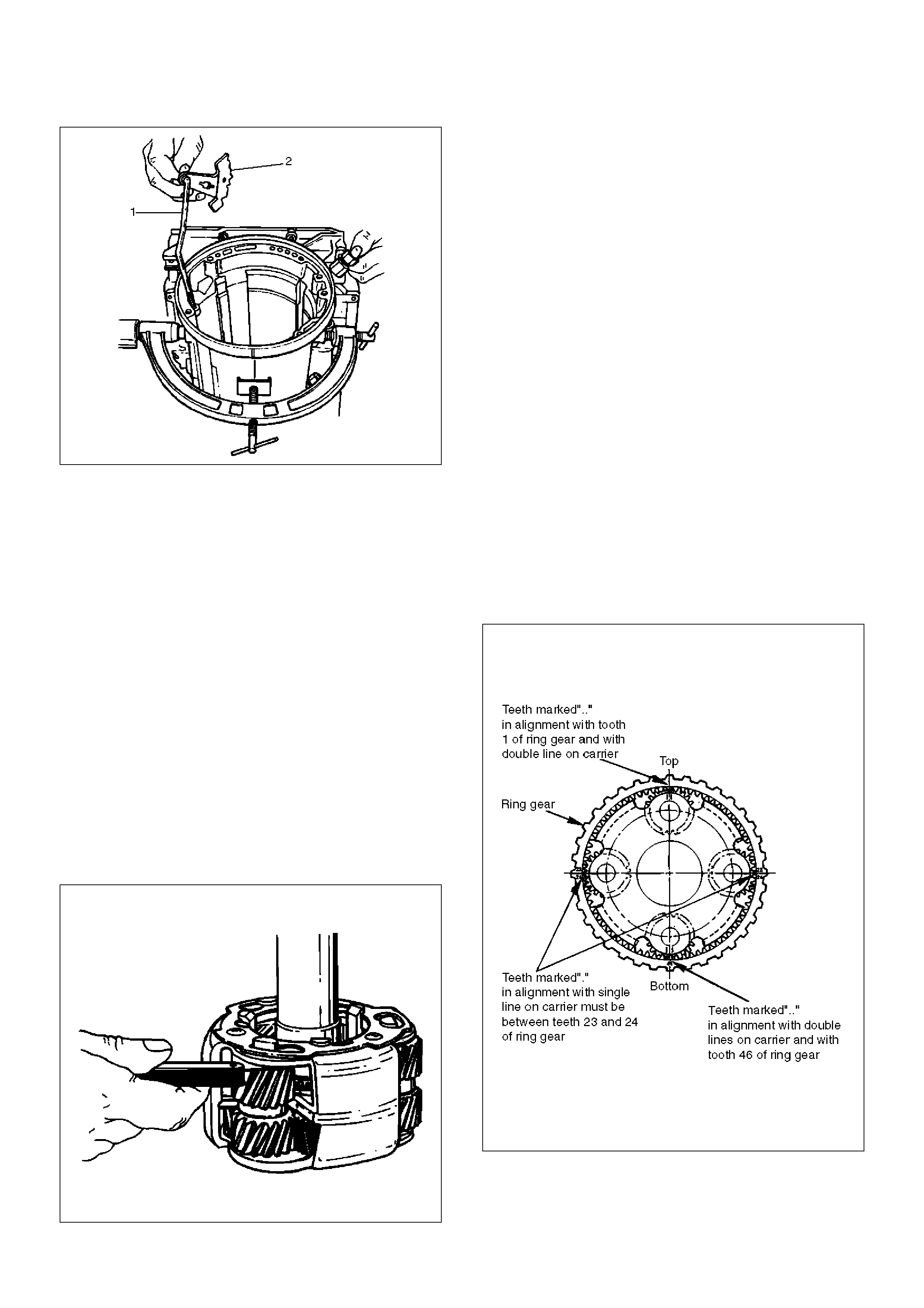

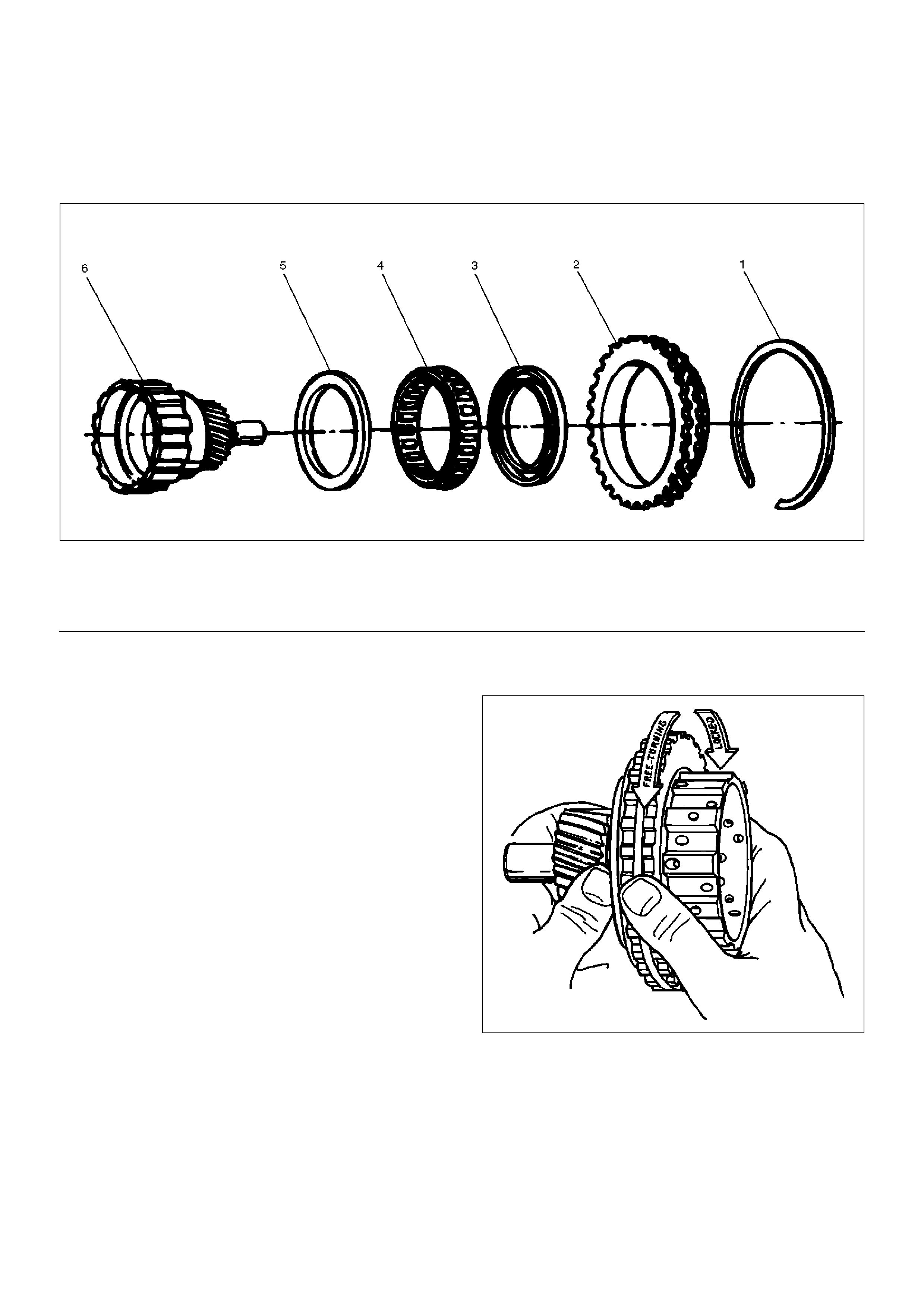

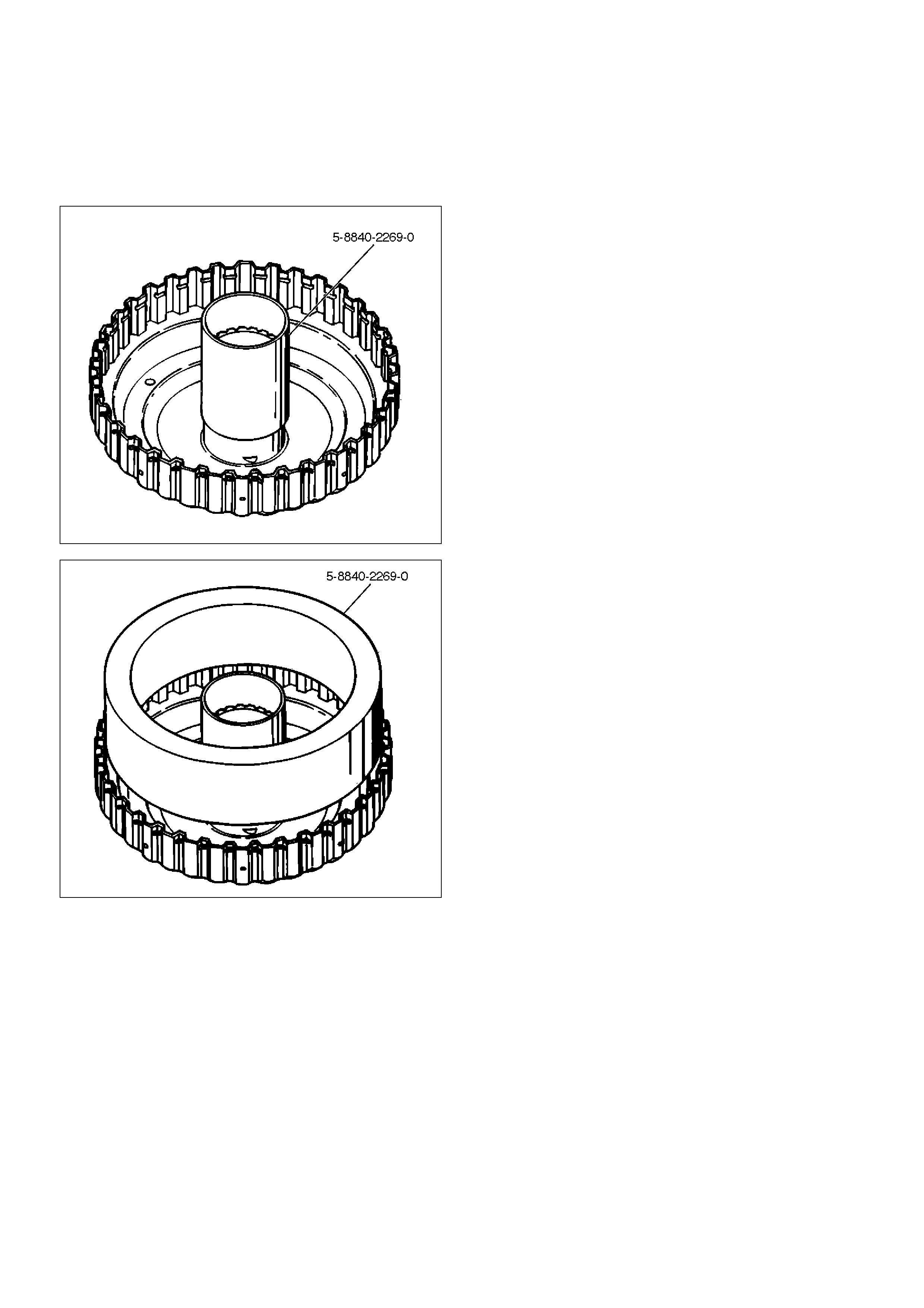

Sprag Unit

Disassembled View

Disassembly

Inspection And Repair

Reassembly

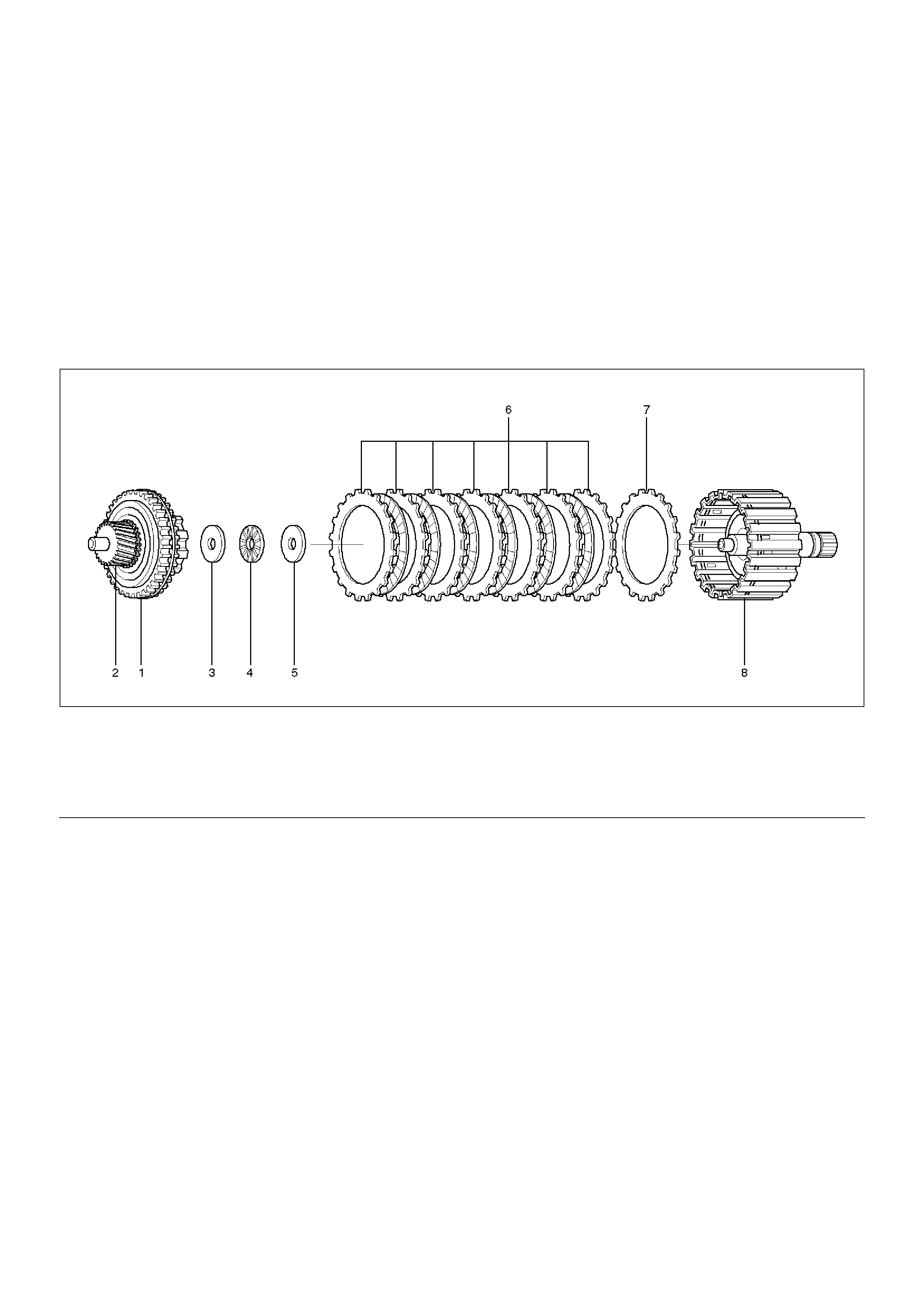

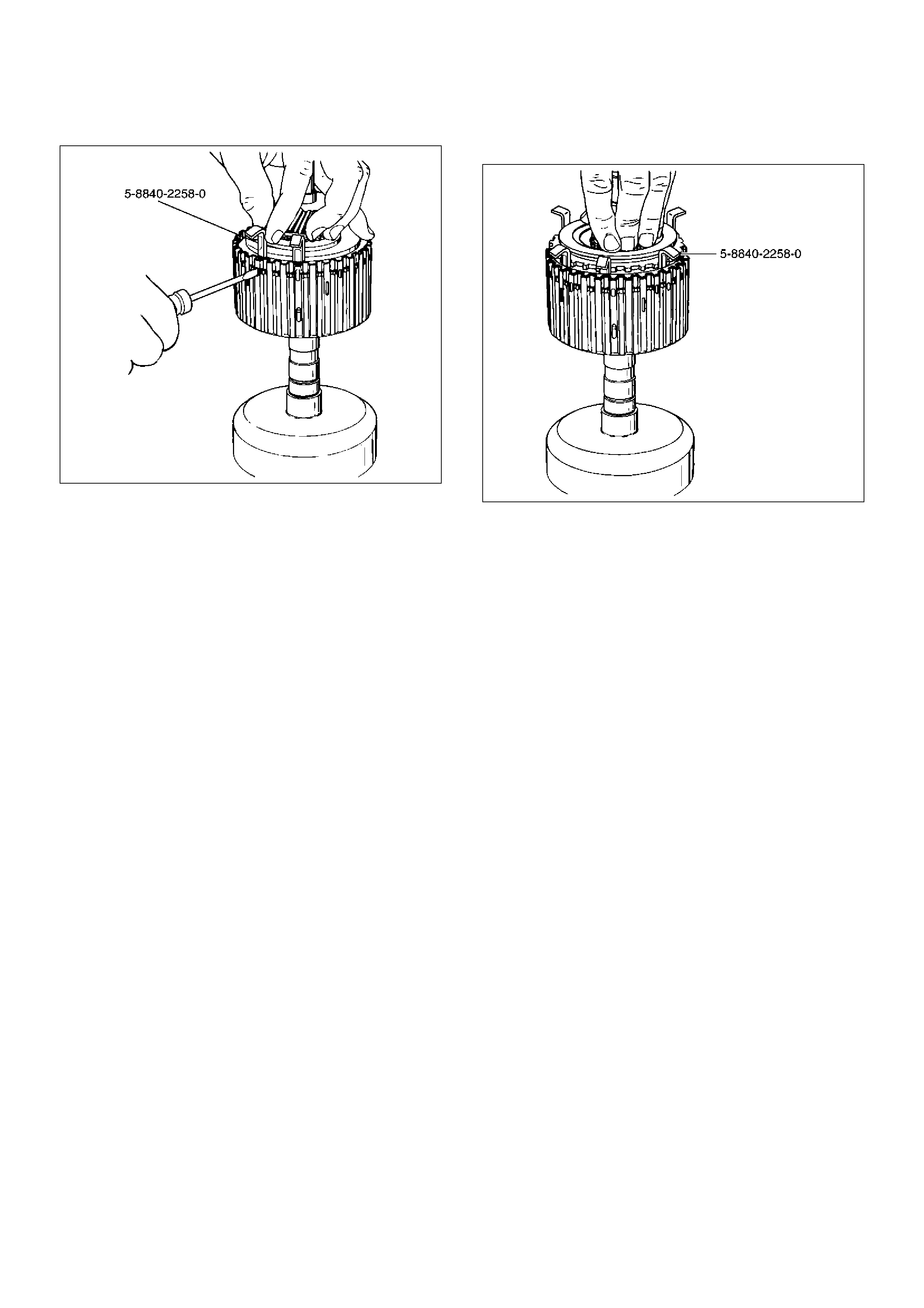

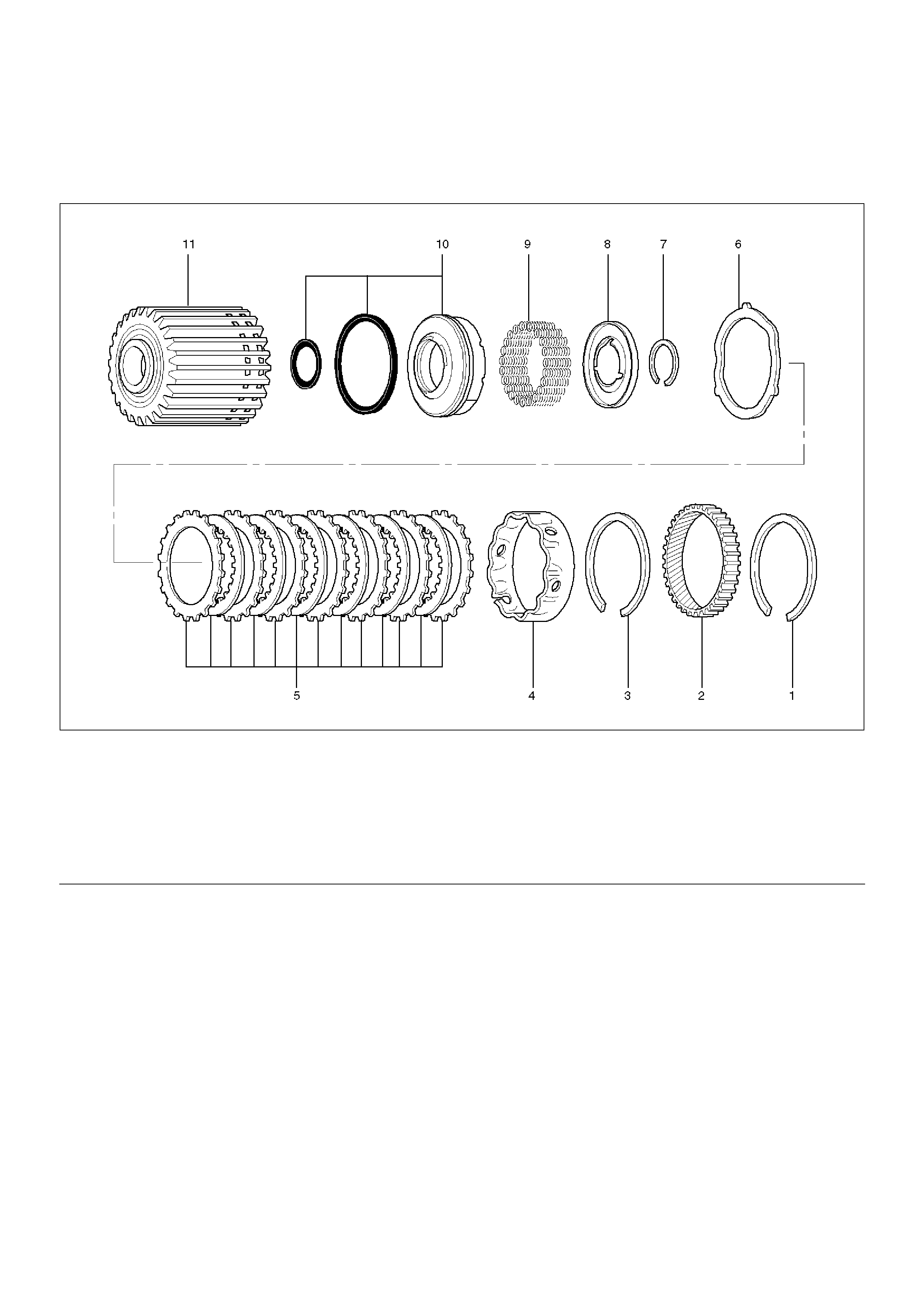

Second Clutch

Disassembled View

Disassembly

Inspection And Repair

Reassembly

3–4 Accumulator Piston

Disassembled View

Disassembly

Inspection And Repair

Reassembly

Reverse Clutch Piston And Center Support

Disassembled View

Disassembly

Inspection And Repair

Reassembly

Overrun Clutch And Turbine Shaft

Disassembled View

Disassembly

Inspection And Repair

Reassembly

Main Data And Specification

General Specifications

Torque Specifications

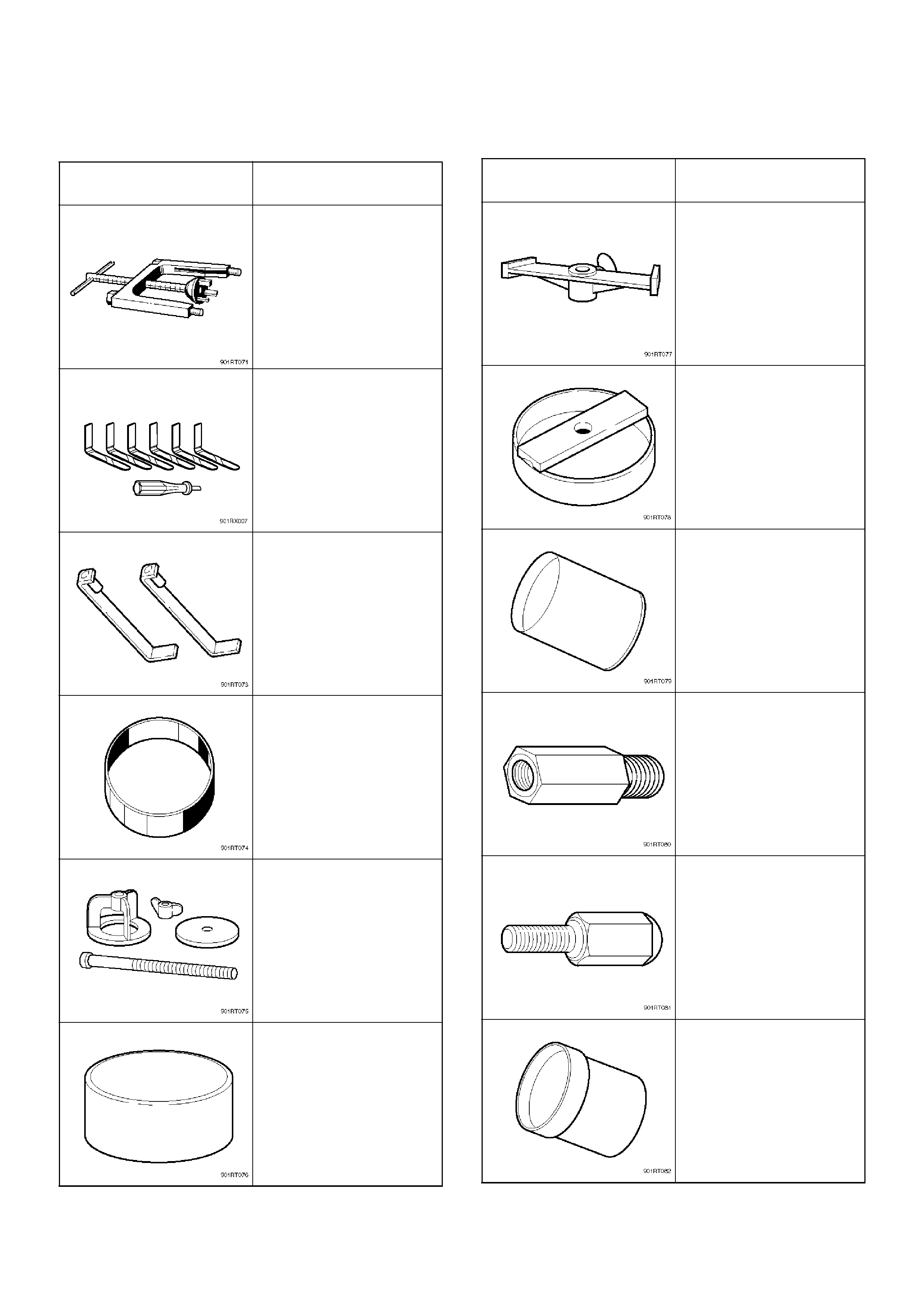

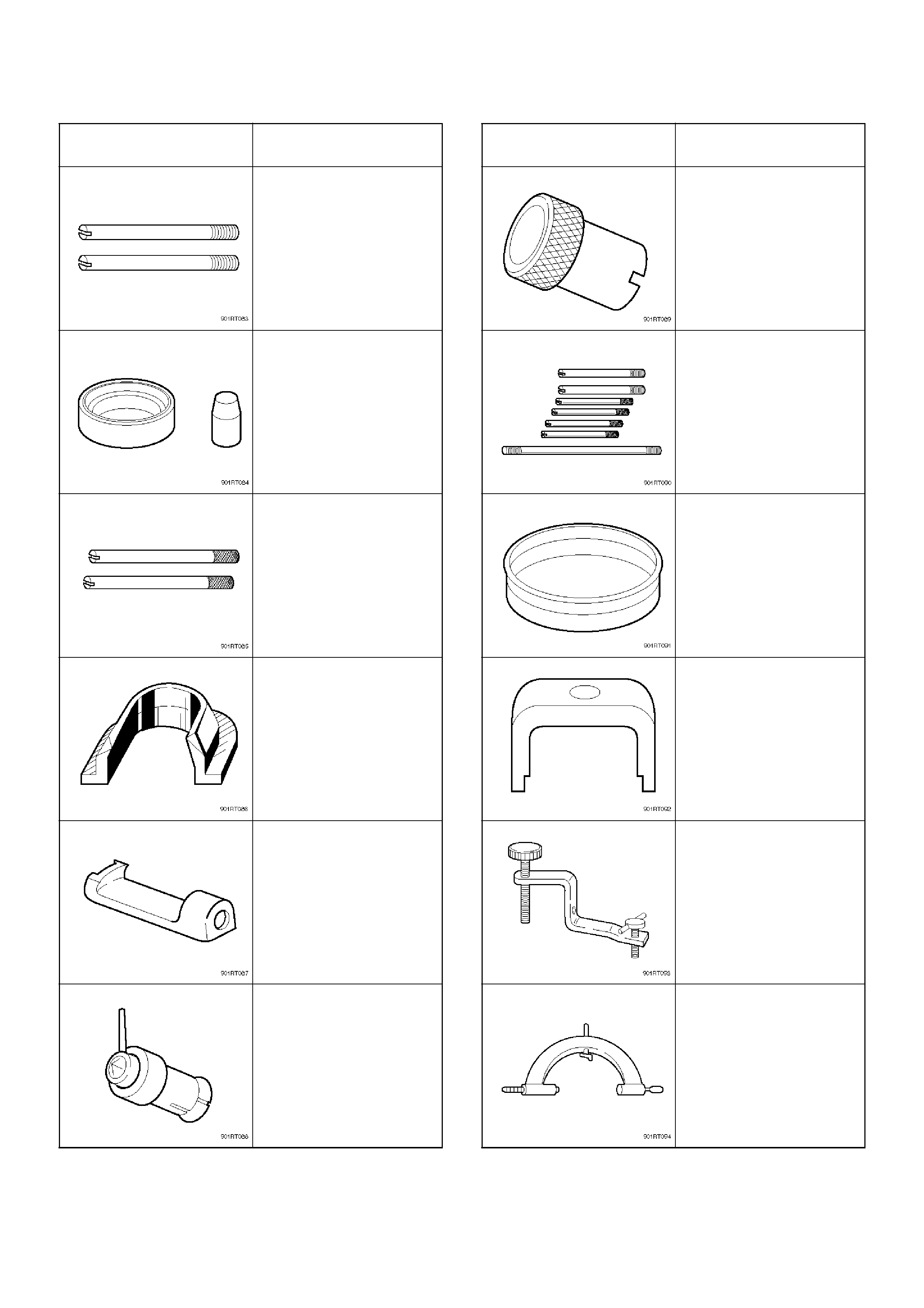

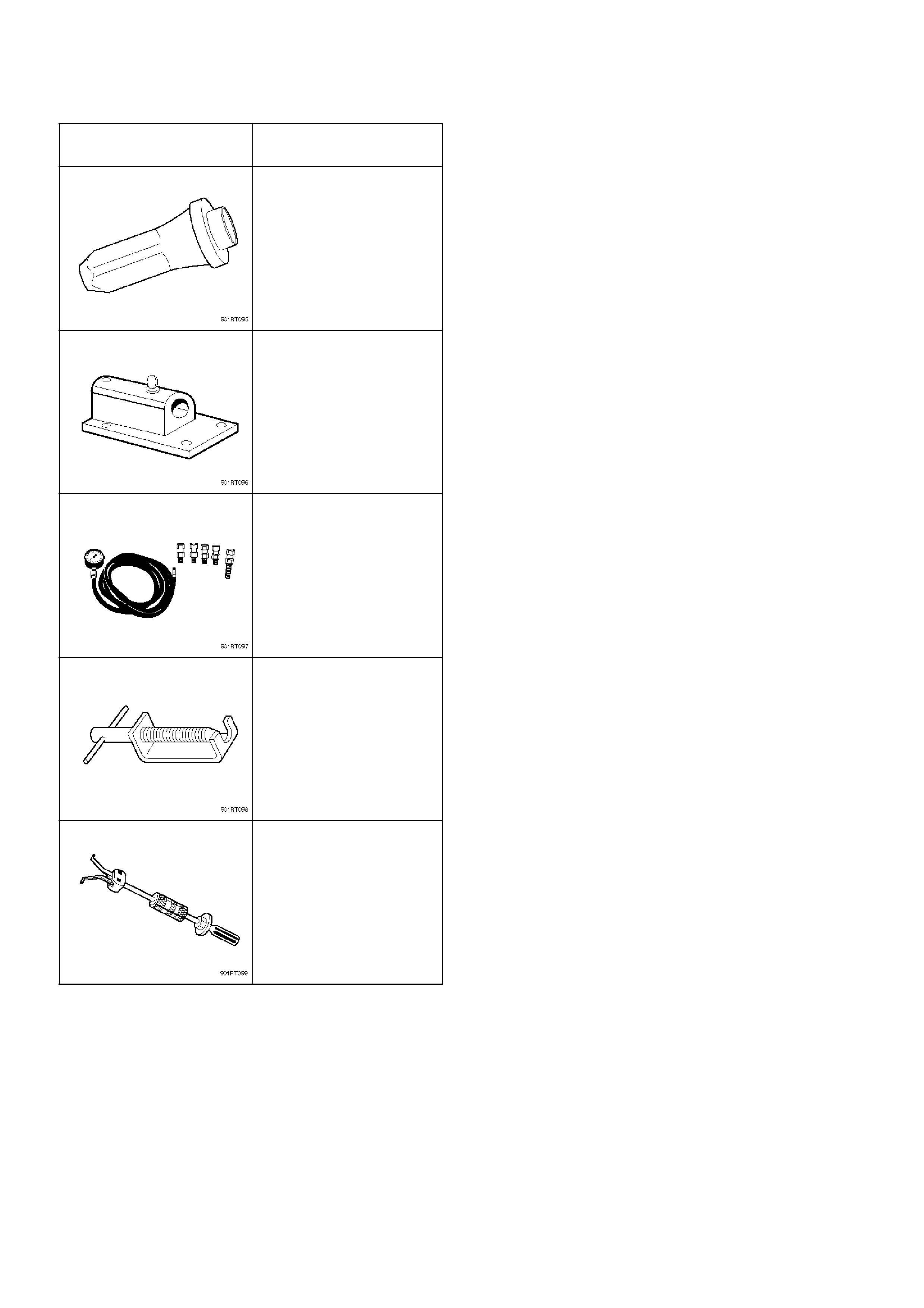

Special Tools

4L30–E Parts List

Case And Associated Parts

Pump Assembly

Valve Body Assemblies

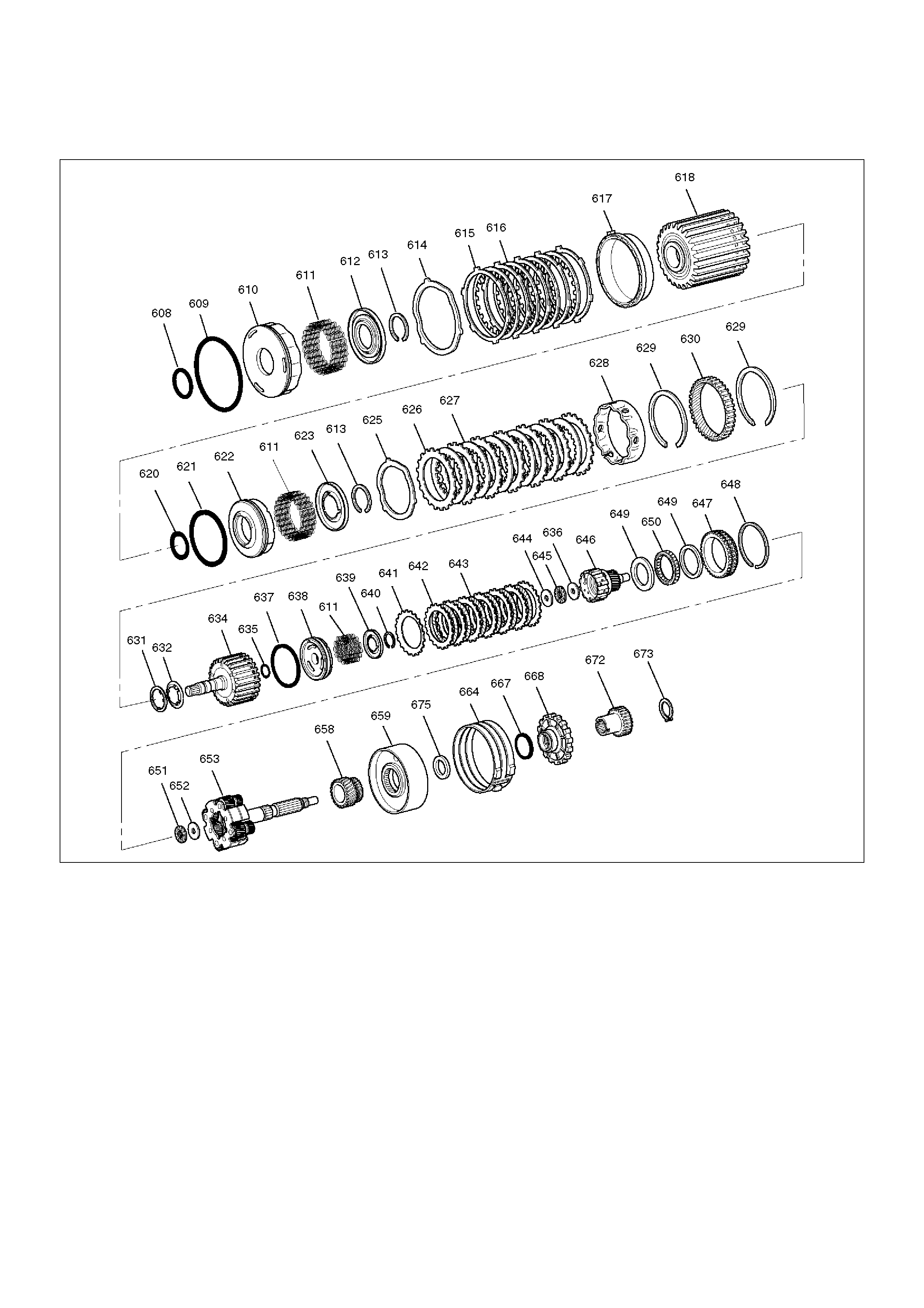

Overdrive Internal Components

Internal Components

Center Support Assembly

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE

SRS WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require a

replacement after removal. HOLDEN will also call

out the fasteners that require thread lockers or

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

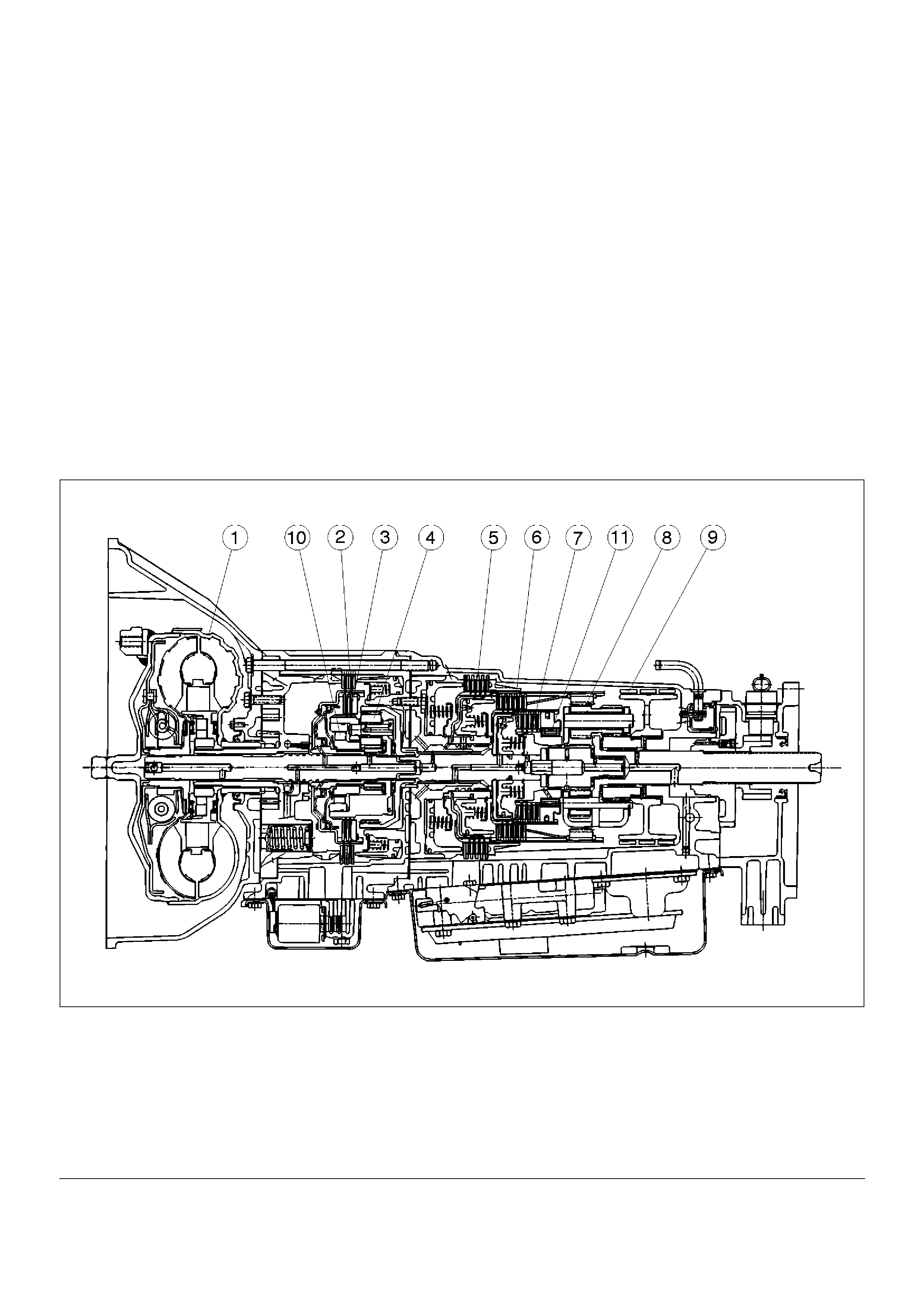

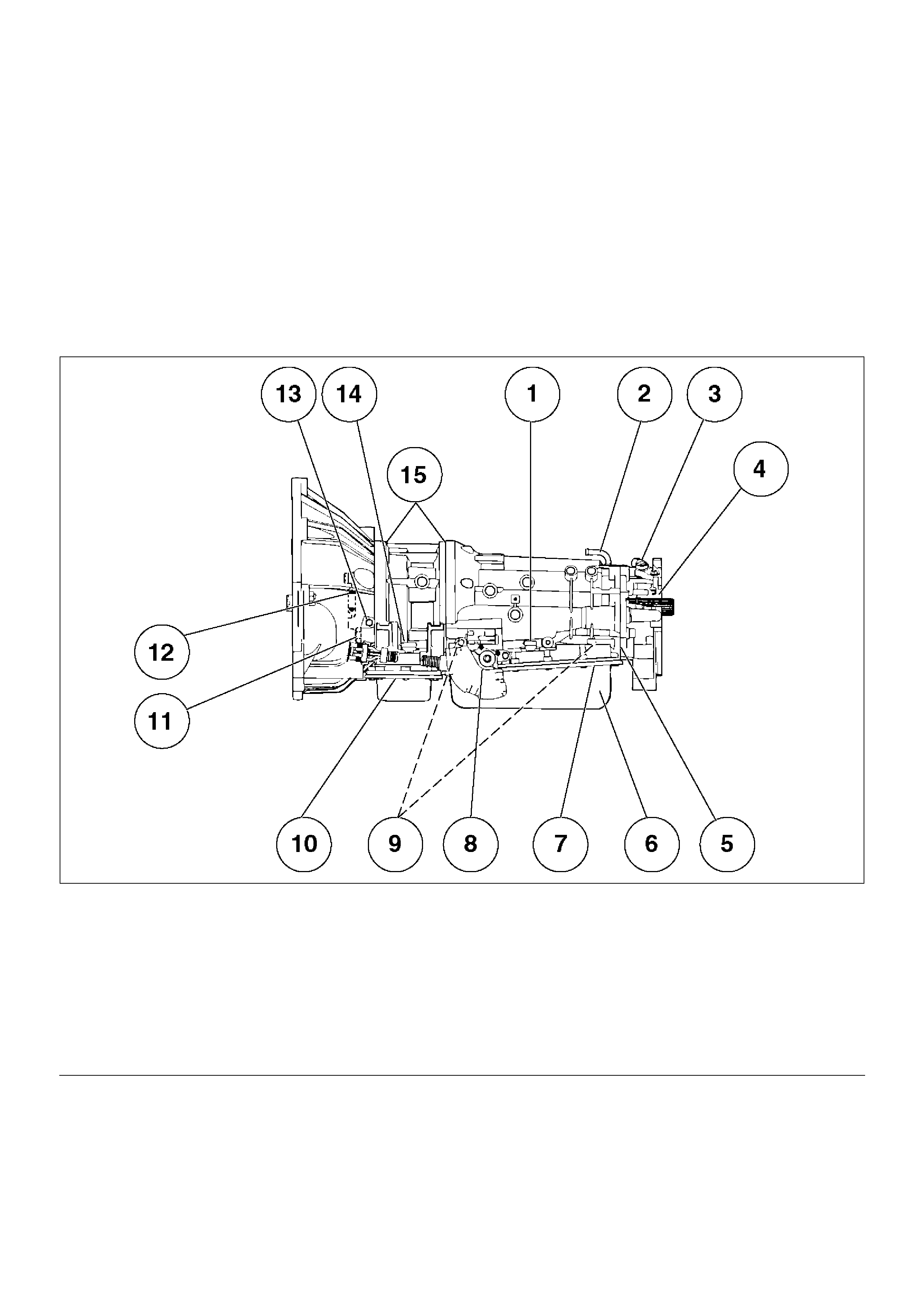

Construction

A07RS001

EndOFCallout

Legend

(1) Torque Converter Clutch (TCC)

(2) Fourth Clutch (C4)

(3) Overrun Clutch (OC)

(4) Overdrive Unit

(5) Reverse Clutch (RC)

(6) Second Clutch (C2)

(7) Third Clutch (C3)

(8) Ravigneaux Planetary Gear Set

(9) Brake Band (B)

(10) Overdrive Free Wheel (One Way Clutch)

(OFW)

(11) Principle Sprag Assembly (One Way Clutch)

(PFW)

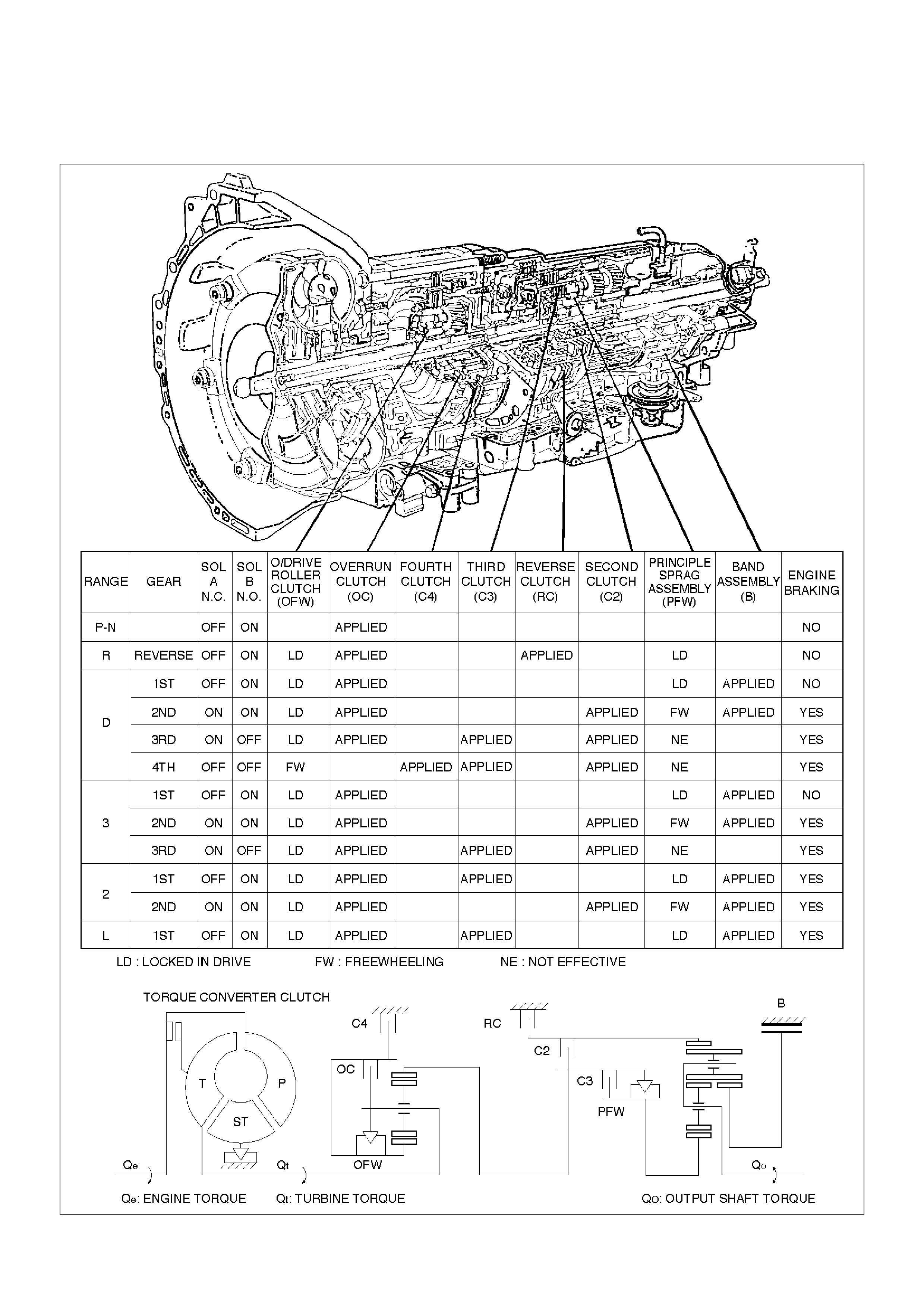

Range Reference Chart

C07RT010

Normal Operation Of 2000 4L30–E

Transmission

Torque Converter Clutch (TCC) Application

Conditions:

The TCC is normally applied in 2nd, 3rd and 4th gears

only when all of the following conditions exist:

– The engine coolant temperature is above 70°C

(158°F).

– The brake pedal is released.

– The shift pattern requests TCC apply.

Moreover, TCC is always applied in 2nd, 3rd and 4th

gears when the transmission oil temperature is above

135°C (275°F).

This mode should be canceled at 125°C (257°F).

ATF Warning Lamp

The ATF warning lamp will be constantly on (not

flashing) if the transmission oil temperature is above

145°C (293°F).

The ATF warning lamp goes off again when the

transmission oil temperature is below 125°C (257°F).

Special Shift Pattern When The Engine Is

Cold:

A special shift pattern is activated when the engine

coolant temperature is below 70°C (158°F). (3–4 shifts,

for example, are delayed for small throttle openings and

will occur a few MPH higher.)

Diagnosis

Introduction

The systematic troubleshooting information covered by

this Section offers a practical and systematic approach

to diagnosing 4L30–E transmission, using information

that can be obtained from road tests, electrical

diagnosis, oil pressure checks or noise evaluation.

The key to correcting a complaint is to make use of all of

the available symptoms and logically letting them

direct you to the cause.

When dealing with automatic transmission complaints, it

is best to gather as many symptoms as possible before

making the decision to remove the transmission from

the vehicle.

Frequently, the correction of the complaint does not

require removal of the transmission from the vehicle.

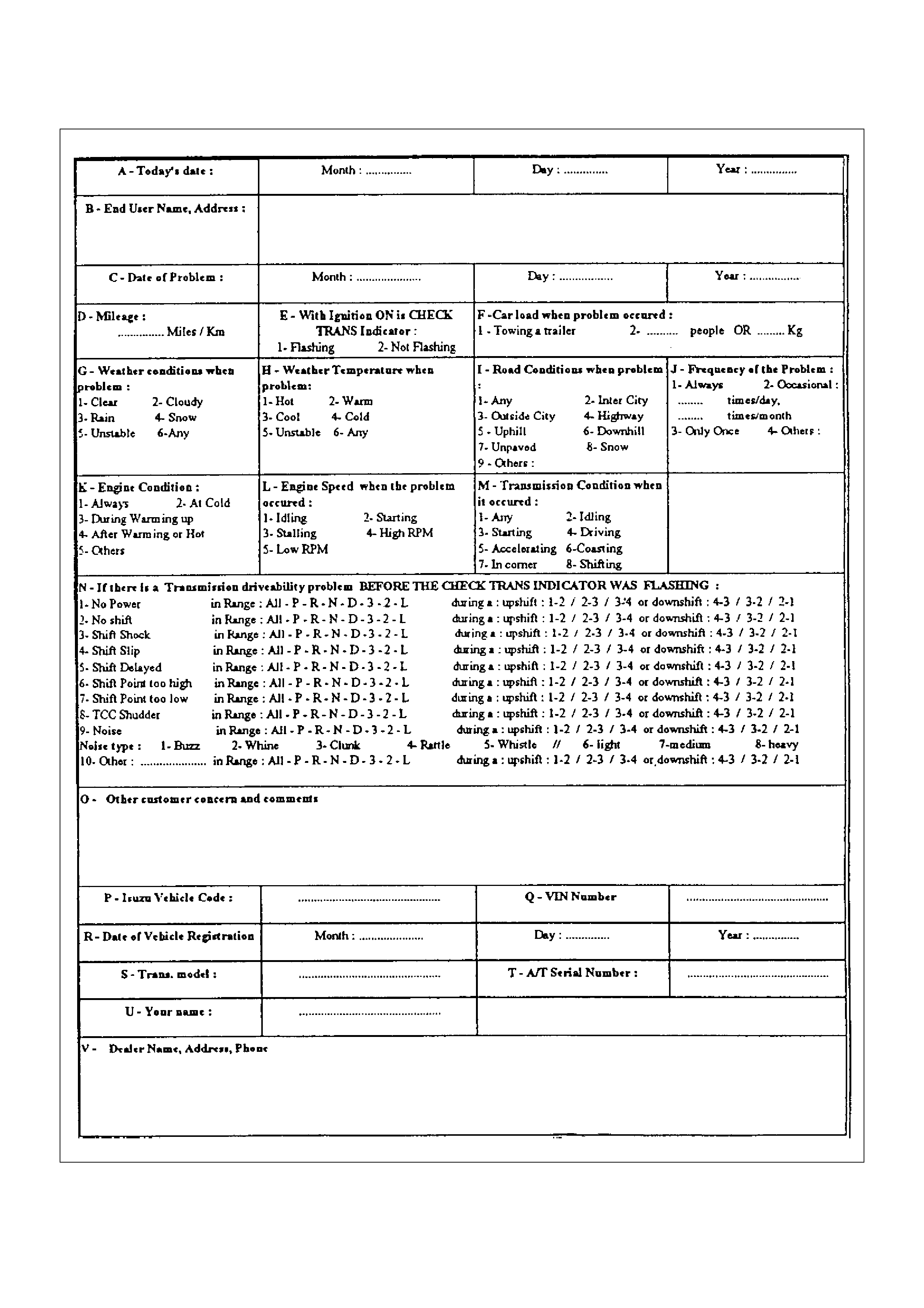

Driver Information

To analyze the problem fill out a complete description of

the owner's complaint.

Please draw a circle around the right information and

complete the following form. (The next page is an

example of a completed form). You can draw a circle

around many numbers if you are not sure.

F07RT036

Example of form completed.

F07RT037

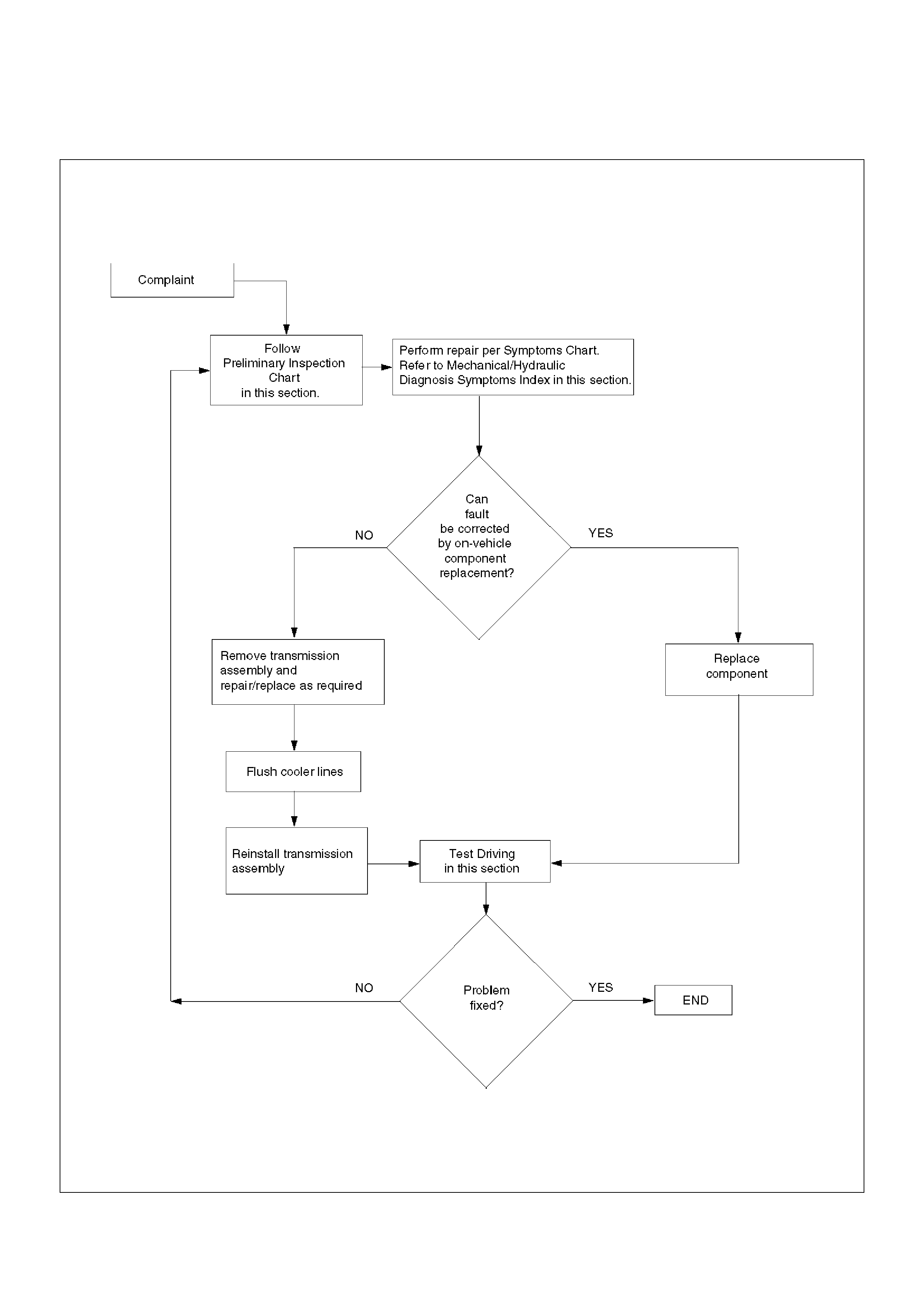

General Diagnosis Procedure

F07RT038

Preliminary Inspection Chart

F07RY00023

Checking Transmission Fluid Level and

Condition

Checking fluid level and condition (color and odor) at

regular intervals will provide early diagnosis

information about the transmission. This information

may be used to correct a condition that, if not detected

early, could result in major transmission repairs.

Important: When new, automatic transmission fluid is

red in color. As the vehicle is driven, the transmission

fluid will begin to look darker in color. The color may

eventually appear light brown.

A dark brown color with burnt odor may indicate

excessive fluid deterioration and signal a need for fluid

change.

Fluid Level

When adding or changing fluid, use only DEXRON ®–

III.

Refer to Maintenance and Lubrication in General

Information section for maintenance information and

servicing interval.

CAUTION: DO NOT OVERFILL.

Overfilling will cause foaming, loss of fluid,

abnormal shifting and possible damage to the

transmission.

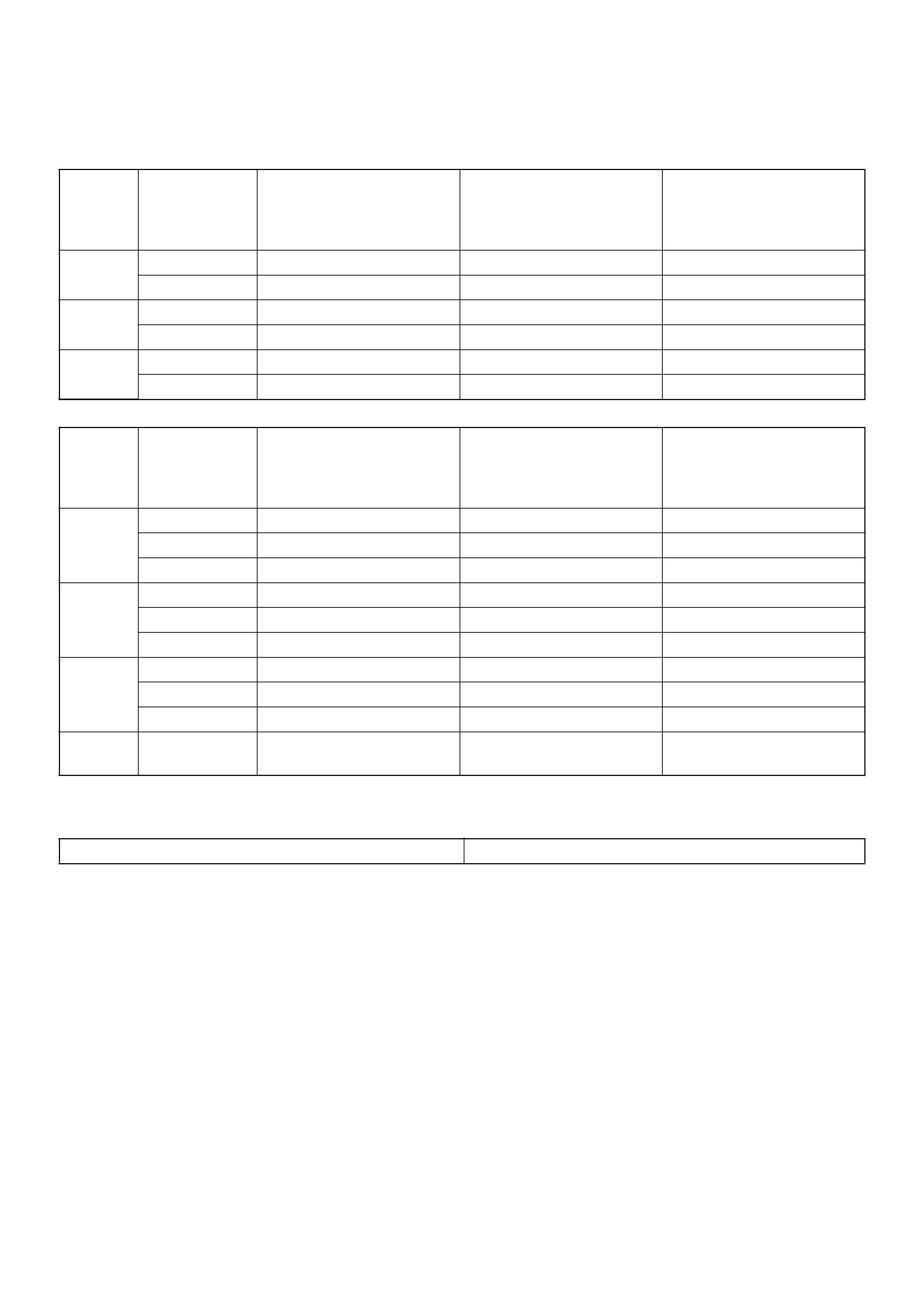

1.Park the vehicle on level ground and apply the

parking brake firmly.

2.Check fluid level with engine running at idle.

NOTE: Be sure that transmission fluid temperature is

below 30°C (86°F).

3.Move the selector lever through all gear ranges.

4.Move the selector lever to“Park”.

5.Let engine idle for 3 minutes and open the overfill

screw (1).

6.Add released transmission fluid until it flows out

over the overfill screw opening.

7.Let engine idle until a fluid temperature between

32°C (90°F) and 57°C (135°F) is reached, then

close the overfill screw (1).

Torque: 38N•m(3.9 kg·m/28lbft)

NOTE: To prevent fluid leaks, the overfill screw and oil

drain screws gasket must be replaced each time these

screws are removed.

NOTE: Check transmission fluid temperature with scan

tool.

Minimum fluid level ® 57°C (135°F)

Maximum fluid level ® 32°C (90°F)

242RW003

CAUTION: Do not open overfill screw with engine

stopped.

CAUTION: DO NOT CHECK FLUID LEVEL UNDER

THESE CONDITIONS:

• Immediately after driving at sustained highway

speeds.

• In heavy city traffic during hot weather.

• If vehicle is towing a trailer.

If the vehicle has been operated under these conditions,

shut the engine off and allow the vehicle to “cool” for

thirty (30) minutes. After the cool down period, restart

the vehicle and continue from step 2 above.

Techline

Fluid Condition

*Fluid should be changed according to maintenance

schedule.

Test Driving

Some 4L30–E automatic transmission complaints will

require a test drive as a part of the diagnostic

procedure. Some codes will not set unless the vehicle is

moving. The purpose of the test drive is to duplicate

the customer's complaint condition and set a current

Powertrain Control Module (PCM) trouble code.

Perform this procedure before each 4L30–E automatic

transmission repair, and again after repairs are made.

Important:

•Duplicate the condition under which the customer's

complaint was observed.

•Depending on the complaint, the line pressure gauge

and the scan tool may be required during the test

drive.

•During the test drive, it is important to record all

necessary data from the areas being monitored, for

use in diagnosis. Also listen for and note any

unusual noises.

The following procedure should be used to test drive

4L30–E automatic transmission complaint vehicles:

1.Turn the ignition ON without starting the engine.

Check that the “CHECK TRANS” lamp comes on for

approximately 2 seconds and then goes out and

remains out.

•If the lamp is flashing, GOTO Check Trans

Indicator in Transmission Control System (4L30–

E) section.

•If no serial data is present, GOTO OBD System

Check. Refer to Driveability and Emissions in

Engine section.

•If the lamp stays ON or stays OFF, GOTO “Check

Trans” Check in Transmission Control System

(4L30–E) section.

2.Drive the vehicle. During the test drive, be sure that

the transmission achieves normal operating

temperature (approx. 20 minutes).

Allow the transmission to go through all of its gear

ranges, checking shift timing and firmness.

Duplicate the owner's complaint condition as

closely as possible during the test drive.

3.If, during the test drive, the “CHECK TRANS” lamp

comes on, use the scan tool to check for trouble

codes.

4.If, during the test drive, a problem is felt, but the

“CHECK TRANS” lamp does not come on and no

trouble codes are present, drive the vehicle with the

PCM disconnected (manually shifting the vehicle).

•In Manual L, the vehicle operates in first gear.

•In Manual 2, the vehicle operates in third gear.

•In Manual 3 or“D”, the vehicle operates in fourth

gear.

If the problem still exists with the PCM

disconnected, refer to Mechanical/Hydraulic

Diagnosis in this section.

FLUID CONDITION

NORMAL* CONTAMINATED

COLOR RED OR LIGHT

BROWN BROWN NON–TRANSPARENT

/ PINK BROWN

DRAIN

REQUIRED? NO YES YES YES

CONTAMINA-

TION

NONE Very small amount of

foreign material in

bottom of pan

Contamination by

coolant or other source

Large pieces of metal

or other foreign

material in bottom of

pan

CORRECT

LEVEL AND

CONDITION

1. LOW LEVEL:

Add fluid to obtain

proper level &

check for

external leaks.

Correct cause of

leak.

2. HIGH LEVEL:

– Remove excess

fluid

– Remove both pans

– Change filter

– Flush cooler

– Add new fluid

– Check level

– Repair/replace

radiator cooler

– Transmission

overhaul required

– Check for:

• Damaged plates

and seals

• Contaminated

solenoids

– Flush cooler

– Add new fluid

– Check level

– Transmission

overhaul required

– Flush cooler and

cooler lines

– Add new fluid

– Check level

5. If no problem has been found at this point, check all

underhood connections that supply power to the

PCM and ignition fuses. Physically and visually

inspect all the PCM harness connectors for loose or

corroded terminals. Inspect the PCM ground

points.

Mechanical / Hydraulic Diagnosis Check Trans Indicator Chart

Perform Preliminary Inspection First!

When the “CHECK TRANS” indicator is flashing, it

indicates that a problem related to the transmission,

the Powertrain Control Module (PCM), or the vehicle

harness has occurred.

The system is now operating in a “BACKUP MODE”

where the risk of further damaging the transmission

has been reduced. The vehicle may be shifted

manually.

If the initial problem is intermittent or seldom, switching

the engine OFF/ON might allow normal operation again

until the problem reoccurs.

F07RT013

Mechanical / Hydraulic Diagnosis Symptoms Index

Perform Preliminary Inspection First!

NOTE: Numbers with parenthesis on the following

charts refer to Parts List at end of this section.

Chart 1: No Engine Start In Neutral Or Park

CHART SYMPTOMS

1 NO ENGINE START IN NEUTRAL OR PARK

2 NO FORWARD GEARS IN ANY RANGE/NO REVERSE

3 NO ENGINE BRAKE IN ANY RANGE

4 POOR SHIFTING IN ALL GEARS (ALL HARSH OR ALL SOFT)

5a DELAYS IN DRIVE AND REVERSE

5b DELAYS IN REVERSE ONLY

6 DIAGNOSTIC TROUBLE CODE (DTC) P0730

7 HARSH 1–2 SHIFT

8 HARSH 3–4 SHIFT

9a 3–2 DOWNSHIFT COMPLAINT

9b HARSH SHIFT WHEN SHIFTING INTO “D” OR ACCELERATING FROM STOP

9c COASTDOWN HARSH SHIFT OR CLUNK AT 3–2 DOWNSHIFT

10 INTERMITTENT 4TH TO 2ND GEAR DOWNSHIFT AT STEADY SPEED

11 ENGINE FLARE AT SHIFTING DURING TURNING ONLY (USUALLY WITH WARM ENGINE)

12 ENGINE FLARE DURING 1–2 OR 2–3 SHIFT

13 SHUDDER ONLY DURING TORQUE CONVERTER CLUTCH (TCC) APPLYING

14 POSSIBLE CAUSES OF TRANSMISSION NOISE

15a POSSIBLE CAUSES OF LOW LINE PRESSURE

15b POSSIBLE CAUSES OF HIGH LINE PRESSURE

16 POSSIBLE CAUSES OF TRANSMISSION FLUID LEAKS

Step Action Yes No

1 Does engine start when shift lever moved from drive to neutral

mostly in hot condition? Go to Step 2 Go to Step 3

2 Does engine start in park at any condition? Re–test vehicle Go to Step 4

3 Does engine also not start in neutral when shift lever moved from

park to neutral? Go to Step 4 Go to Step 5

4 Check mode switch (63) setting. Readjust if necessary.

Problems fixed? Re–test vehicle Go to Step 5

5 Check start circuit of mode switch (63) open in neutral.

Was open found?

Locate and repair

open(s)

Replace mode

switch (63)

Chart 2: No Forward Gears In Any Range/No Reverse

Chart 3: No Engine Brake In Any Range

Step Action Yes No

1 Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15a:

Possible Causes of

Low Line Pressure

in this section

2 1. Check internal linkage:

– Manual linkage (58) not moving manual valve (326).

2. Check for internal mechanical damage:

– Turbine shaft (506) broken loose.

– Overrun roller clutch (516) broken loose.

Was the problem found? Repair or replace —

Step Action Yes No

1 Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15a:

Possible Causes of

Low Line Pressure

in this section

2 1. Check for overrun clutch leaks caused by:

– Damaged piston lip (513)

– Check ball defective (504)

2. Check for overrun lockout valve (705) stuck by foreign

material.

3. Check for leaks at turbine shaft (506) caused by:

– Teflon seal rings damaged (508)

– Excessive wear of turbine shaft bearing surfaces.

Was the problem found? Repair or replace —

Chart 4: Poor Shifting In All Gears (All Harsh Or All Soft)

Chart 5a: Delays In Drive And Reverse

NOTE: A short delay (less than 3 seconds) when first

engaging drive or reverse after allowing vehicle to sit

overnight is normal.

Step Action Yes No

1 Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal? Go to Step 2 Go to Step 3

2 1. Check for these conditions which could affect clutch apply

time:

– Defective band apply solenoid (323).

– Defective servo or/and accumulator piston.

– Excessive clutch piston travel.

2. Check of possible causes of internal leaks:

– Cut or damaged sealing ring(s)

– Damaged sealing gasket(s)

– Check ball missing or out of location in 2nd and 3rd clutch

pistons.

3. Check for caused of burned clutch plates or band.

Was the problem found? Repair or replace —

3 Was the line pressure high?

Go to Step 4

Use Chart 15a:

Possible Causes of

Low Line Pressure

in this section

4 Were DTCs P0560 and P0705 set?

Diagnose those

DTC(s) first

Use Chart 15b:

Possible Causes of

High Line Pressure

in this section

Step Action Yes No

1 Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

More than 3

second delay in

drive and

reverse with

engine off 1

hour or less.

Teflon seals

(508) on turbine

shaft damaged.

Repair

Use Chart 15a:

Possible Causes of

Low Line Pressure

in this section.

Chart 5b: Delays In Reverse Only

Step Action Yes No

1 Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15a:

Possible Causes of

Low Line Pressure

in this section.

2 Main case valve body gasket (88) damaged.

– Reverse check ball (85) in valve body (84) missing or out of

location.

– Check for restrictions at valve body transfer plate orifice.

Was the problem found? Repair —

Chart 6: Diagnostic Trouble Code (DTC) P0730

Step Action Yes No

1 Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15b:

Possible Causes of

High Line Pressure

in this section

2 1. 1st and 2nd gear missing or 3rd and 4th gear missing.

Check appropriate shift valve. If OK replace solenoid.

2. No engine brake in any range (All ranges in Drive and

Reverse are OK).

Check for suspected conditions modifying delays to clutch

apply:

– Overrun clutch seal damaged.

– Excessive overrun clutch piston travel.

– Defective 3-4 accumulator piston.

– Causes of internal leaks.

– Causes of burned clutch plates.

3. 1st and 4th gear missing or 2nd and 3rd gear missing.

Shift solenoid A stuck. Replace shift solenoid A.

4. DTC P0730 is set in D range 1st gear above 3500 rpm.

Go to Step 3.

5. DTC P0730 is set in D range 3rd gear between 55-80 mph.

NOTE: Perform this test within safe and legal limits.

Check for suspected conditions modifying delays to clutch

apply:

– 4th clutch seal damaged.

– Excessive 4th clutch piston travel.

– Defective 3-4 accumulator piston.

– Causes of internal leaks.

– Causes of burned clutch plates.

Was the problem found? Repair or replace —

3 Check 3rd gear in “D” in winter mode.

Does vehicle move?

Shift solenoid A

stuck. Replace

shift solenoid A. Go to Step 4

4 Check for suspected conditions modifying delays to clutch apply:

– 2nd clutch seal damaged.

– Excessive 2nd clutch piston travel.

– Defective accumulator piston.

– Causes of internal leaks.

– Check ball missing or out of location in 2nd clutch.

– Seals cut, damaged or missing.

– Gaskets defective.

– Causes of burned clutch plates.

Was the problem found? Repair or replace —

Chart 7: Harsh 1–2 Shift

Chart 8: Harsh 3–4 Shift

Chart 9a: 3–2 Downshift Complaint

Chart 9b: Harsh Shift When Shifting Into “D” Or Accelerating From Stop

Chart 9c: Coastdown Harsh Shift Or Clunk At 3–2 Downshift

Step Action Yes No

1 Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Check for 1–2

accumulator valve

(320) stuck by

foreign material in

main case valve

body.

Use Chart 15b:

Possible Causes of

High Line Pressure

in this section.

Step Action Yes No

1 Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15b:

Possible Causes of

High Line Pressure

in this section

2 1. Check for 3–4 accumulator valve (407) stuck in adapter case

valve body (401).

2. Check for 3–4 accumulator piston (18) stuck in adapter case

(20).

Was the problem found? Repair or replace —

Step Action Yes No

1 Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15a:

Possible Causes of

Low Line Pressure

in this section

2 Does DTC P1850 set?

Diagnose P1850

first

Replace band

apply solenoid

(PWM) (323)

Step Action Yes No

1 Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15b:

Possible Causes of

High Line Pressure

in this section

2 Does DTC P1850 set?

Diagnose P1850

first

Replace band

apply solenoid

(PWM) (323)

Step Action Yes No

1 Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15b:

Possible Causes of

High Line Pressure

in this section

2 Does DTC P1850 set?

Diagnose P1850

first

Replace band

apply solenoid

(PWM) (323)

Chart 10: Intermittent 4TH TO 2ND Gear Downshift At Steady Speed

Chart 11: Engine Flare At Shifting During Turning Only (Usually With Warm Engine)

Chart 12: Engine Flare During 1–2 Or 2–3 Shift

Step Action Yes No

1 Check for consistent speed sensor reading with scan tool.

Was the reading correct?

Replace mode

switch for

intermittent

contact. Go to Step 2

2 1. Check for wiring harness damage or short to ground. If OK,

go to (2).

2. Check transmission speed sensor connections. If OK, go to

(3).

3. Replace transmission speed sensor.

Was the replacement complete? —

Replace speed

sensor.

Step Action Yes No

1 Check for oil leaks at transmission.

Was the problem found?

Replace

transmission oil

filter and gasket —

Step Action Yes No

1 Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15a:

Possible Causes of

Low Line Pressure

in this section

2 1. Check for a stuck 1–2 accumulator valve (320).

2. Check for servo piston (106) leaks.

3. Check for a stuck band apply solenoid (323).

Was line pressure normal? Repair or replace —

Chart 13: Shudder Only During Torque Converter Clutch (TCC) Applying

Chart 14: Possible Causes Of Transmission Noise

CAUTION: Before checking transmission for what

is believed to be transmission noise, ensure

presence and positioning of insulating plugs, pads

etc. Also make sure that noise does not come from

other drivetrain components.

Step Action Yes No

1 1. TCC shudder is one of the most commonly misdiagnosed

conditions in an automatic transmission. The key to

diagnosing TCC shudder is to note when it happens and

under what conditions. Once the TCC has been fully

applied, it is nearly impossible to make it shudder. TCC

shudder (short burst of noise normally less than 1 second)

will only occur during clutch applying. I t is not a steady state

condition.

2. Drive until whole drivetrain is at normal operating

temperature.

– On 4WD vehicles, the test must be performed with transfer

case selector lever in “2H” position.

– Shudder is a short burst of noise normally less than 1

second in duration, and can be induced by the following

maneuver:

3. From coast condition at 50 mph in “D” range (Normal mode),

depress the throttle to 1/4-1/3 throttle. If present, shudder will

occur within 5 seconds together with TCC application. (The

scan tool may be used to determine the exact time of TCC

applying)

Was the problem found?

1.Replace

transmission

fluid and filter

(remove both

pans) and flush

cooler lines.

Replace

converter

assembly and

O-ring on

turbine shaft

Perform

mechanical

inspection of other

drivetrain

components.

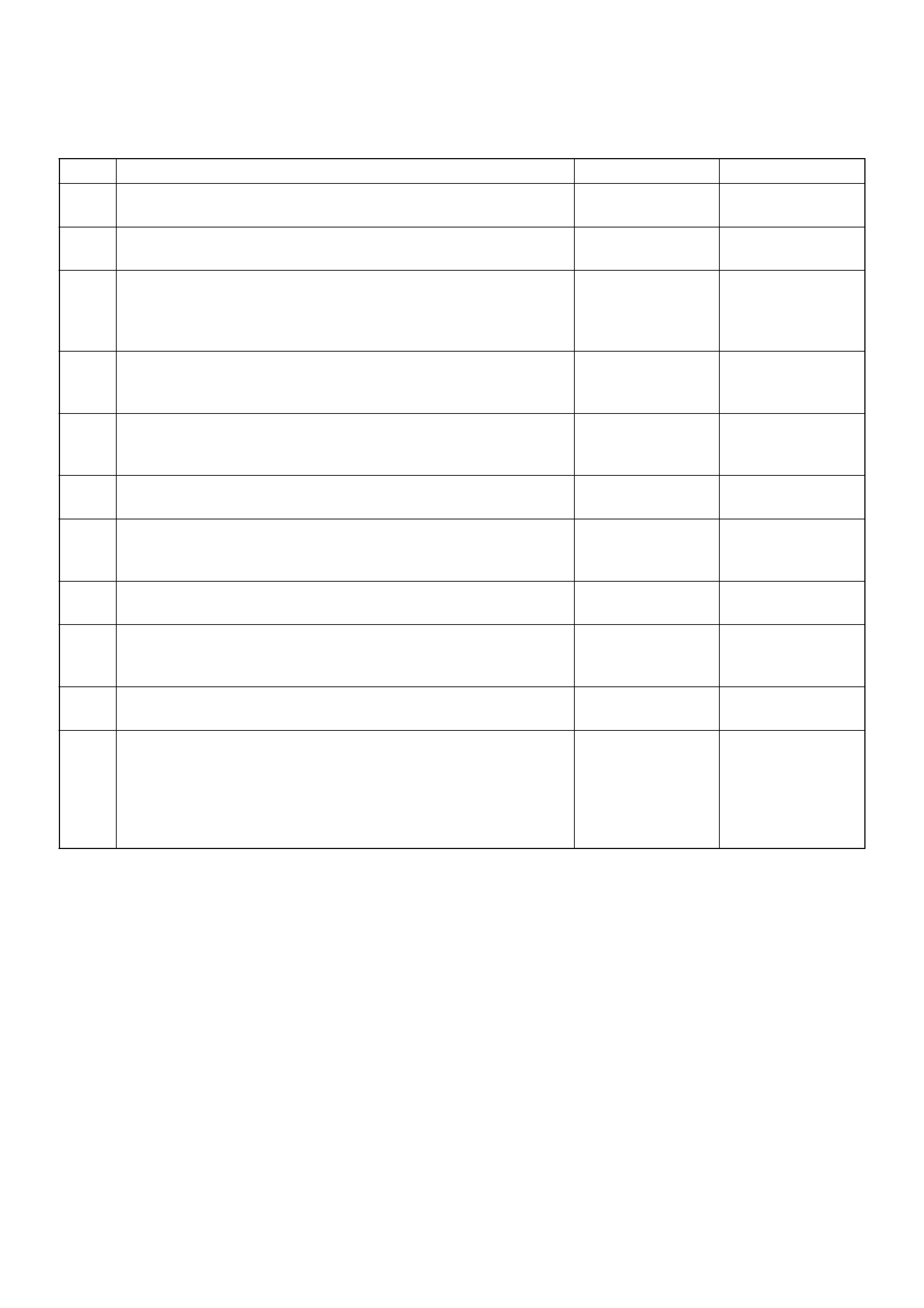

Symptom Possible Cause Action

Whine or Buzz Oil level low Fill with ATF, check for external leaks.

Plugged or restricted oil filter Inspect oil filter.

Replace oil filter or ATF as

necessary.

Damaged oil filter gasket Replace oil filter gasket.

Knocking noise from front of

transmission.

Loose bolts (Converter to flex plate) Tighten to specifications.

Cracked or broken flex plate Replace flex plate.

Converter damaged Replace converter.

Knocking noise while driving, mostly

on acceleration.

Transmission mount loose or broken Tighten mount bolts or replace

transmission mount.

Cooler line mounts loose or broken Tighten or replace cooler line

mounts.

Cooler lines touching body or frame Repair or replace as necessary.

Knocking noise when vehicle is

stationary.

Loose flex plate mounting bolts Tighten to specifications.

Cracked or broken flex plate Replace flex plate.

Damaged converter Replace converter.

Chart 15a: Possible Causes of Low Line Pressure

Step Action Yes No

1 Check oil level.

Was the problem found? Fill with ATF Go to Step 2

2 Check for defective throttle position sensor.

Was the problem found?

Replace throttle

position sensor Go to Step 3

3 Check for plugged, loose, or damaged oil filter (79).

Was the problem found?

Inspect oil filter,

tighten bolts or

replace oil filter

(79) Go to Step 4

4 Check for a stuck force motor plunger (404). (Adapter case valve

body)

Was the problem found?

Replace force

motor plunger

(404) Go to Step 5

5 Check for a stuck feed limit valve (412). (Adapter case valve

body)

Was the problem found?

Replace feed limit

valve (412) Go to Step 6

6 Check for loose converter bolts (4 & 5).

Was the problem found?

Tighten converter

bolts (4 & 5) Go to Step 7

7 Check for a stuck pressure regulator valve (208). (Oil pump)

Was the problem found?

Replace pressure

regulator valve

(208) Go to Step 8

8 Check for a stuck boost valve (205).(Oil pump)

Was the problem found?

Replace boost

valve (205) Go to Step 9

9 Check for blocked intermediate oil passages to pressure

regulator valve. (Oil pump)

Was the problem found? Replace oil pump Go to Step 10

10 Check for defective oil pump (9, 201, 202 & 209).

Was the problem found? Replace oil pump Go to Step 11

11 Check for internal leaks.

– Check balls missing or out of location in valve bodies

– Seals cut or damaged

– Gaskets defective, etc.

Was the problem found?

Install balls, or

correct ball

location

Replace seals

Replace

gaskets —

Chart 15b: Possible Causes Of High Line Pressure

NOTE: If transmission is operating in backup mode,

high line pressure will be present.

Step Action Yes No

1 Check for defective throttle position sensor.

Was the problem found?

Replace throttle

position sensor. Go to Step 2.

2 Check for a stuck force motor plunger (404). (Open circuit/

intermittent) (Adapter case valve body)

Was the problem found?

Replace force

motor plunger

(404) Go to Step 3

3 Check for a stuck feed limit valve (412). (Adapter case valve

body)

Was the problem found?

Replace force

motor plunger

(412) Go to Step 4

4 Check converter bolts (4 & 5).

Was the problem found?

Tighten converter

bolts (4 & 5) Go to Step 5

5 Check for a stuck pressure regulator valve (208). (Oil pump)

Was the problem found?

Replace pressure

regulator valve

(208) Go to Step 6

6 Check for a stuck boost valve (205). (Oil pump)

Was the problem found?

Replace boost

valve (205) Go to Step 7

7 Check for internal leaks.

– Check balls missing or out of location in valve bodies

– Seals cut or missing

– Gaskets defective, etc.

Was the problem found?

Install balls, or

correct ball

location

Replace seals

Replace

gaskets —

Chart 16: Possible Causes Of Transmission Fluid Leaks

Before attempting to correct an oil leak, the actual

source of the leak must be determined. In many cases,

the source of the leak may be difficult to determine due

to “wind flow” around the engine and transmission.

The suspected area should be wiped clean before

inspecting for the source of the leak.

Oil leaks around the engine and transmission are

generally carried toward the rear of the vehicle by the

air stream. In determining the source of an leak, the

following two checks should be made:

1. With the engine running, check for external line

pressure leaks.

2. With the engine off, check for oil leaks due to the

raised oil level caused by drainback of converter oil

into the transmission.

Possible Causes Of Fluid Leaks Due To Sealing Malfunction

240RX008

EndOFCallout

Legend

(1) Electrical Connector (Main Case) Seal

(2) Transmission Vent (Breather)

(3) Speed Sensor O–Ring

(4) Extension (Adapter) Lip Seal

(5) Extension (Adapter) to Main Case Gasket

(6) Overfill and Oil Drain Screws Gasket

(7) Oil Pan Gasket (Main Case)

(8) Selector Shaft Seal

(9) Oil Cooler Connectors (2)

(10) Oil Pan Gasket (Adapter Case)

(11) Converter housing attaching bolts not correctly

torqued

(12) Converter Housing Lip Seal

(13) Line Pressure Tap Plug

(14) Electrical Connector (Adapter Case) Seal

(15) Adapter Case Seal Rings (2)

Stall Test

The stall test allows you to check the transmission for

internal abrasion and the one way clutch for slippage.

Torque converter performance can also be evaluated.

The stall test results together with the road test results

will identify transmission components requiring

servicing or adjustment.

Stall Test Procedure:

1. Check the level of the engine coolant, the engine oil,

and the automatic transmission fluid. Replenish if

necessary.

2. Block the wheels and set the parking brake.

3. Connect a tachometer to the engine.

4. Start the engine and allow it to idle until the engine

coolant temperature reaches 70 – 80°C (158 –

176°F).

5. Hold the brake pedal down as far as it will go.

6. Place the selector in the “D” range.

7. Gradually push the accelerator pedal to the floor.

The throttle valve will be fully open.

Note the engine speed at which the tachometer

needle stabilizes.

Stall Speed : 2,100 ±150 rpm

NOTE: Do not continuously run this test longer than 5

seconds.

8. Release the accelerator pedal.

9. Place the selector in the “N” range.

10. Run the engine at 1,200 rpm for one minute.

This will cool the transmission fluid.

11. Repeat Steps 7 – 10 for the“3”, “2”, “L”and “R”

ranges.

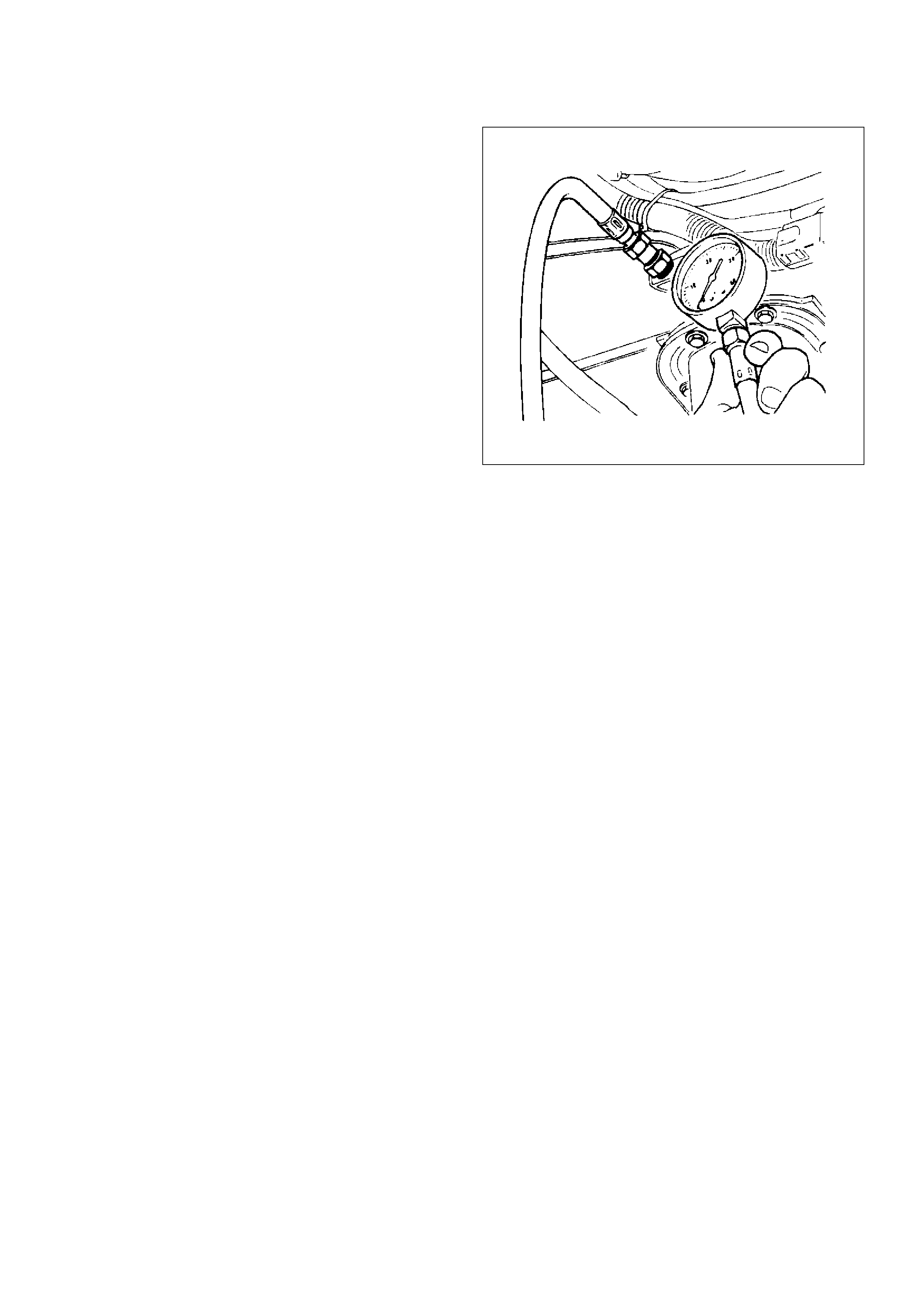

Line Pressure Test

The line pressure test checks oil pump and control valve

pressure regulator valve function. It will also detect oil

leakage.

Line Pressure Test Procedure:

1. Check the level of the engine coolant, the engine oil,

and the automatic transmission fluid.

Replenish if required.

2. Block the wheels and set the parking brake.

3. Remove the pressure detection plug at the left side

of the transmission case.

Set 5–8840–0004–0 pressure gauge and adapter to

the pressure detection plug hole.

241RS001

4. Start the engine and allow it to idle until the engine

coolant temperature reaches 70 – 80°C (158 –

176°F).

5. Hold the brake pedal down as far as it will go.

6. Place the selector in the “D” range.

7. Note the pressure gauge reading with the engine

idling.

8. Gradually push the accelerator pedal to the floor.

The throttle valve will be fully open.

Note the pressure gauge reading with the

accelerator pedal fully depressed.

NOTE: Do not continuously run this test longer than 5

seconds.

9. Release the accelerator pedal.

10. Place the selector in the “N” range.

11. Run the engine at 1,200 rpm for one minute.

This will cool the transmission fluid.

12. Repeat Steps 7 – 11 for the“3”, “2”, “L”, and “R”

ranges.

13. Install a pressure detection plug to the transmission

case, applying recommended thread locking agent

(LOCTITE 242) or its equivalent to thread of plug.

Make sure that thread is cleaned before applying

locking agents.

14. Tighten the pressure detection plug to the specified

torque.

Torque:9–14N·m(0.9–1.4kg·m/7–10lbft)

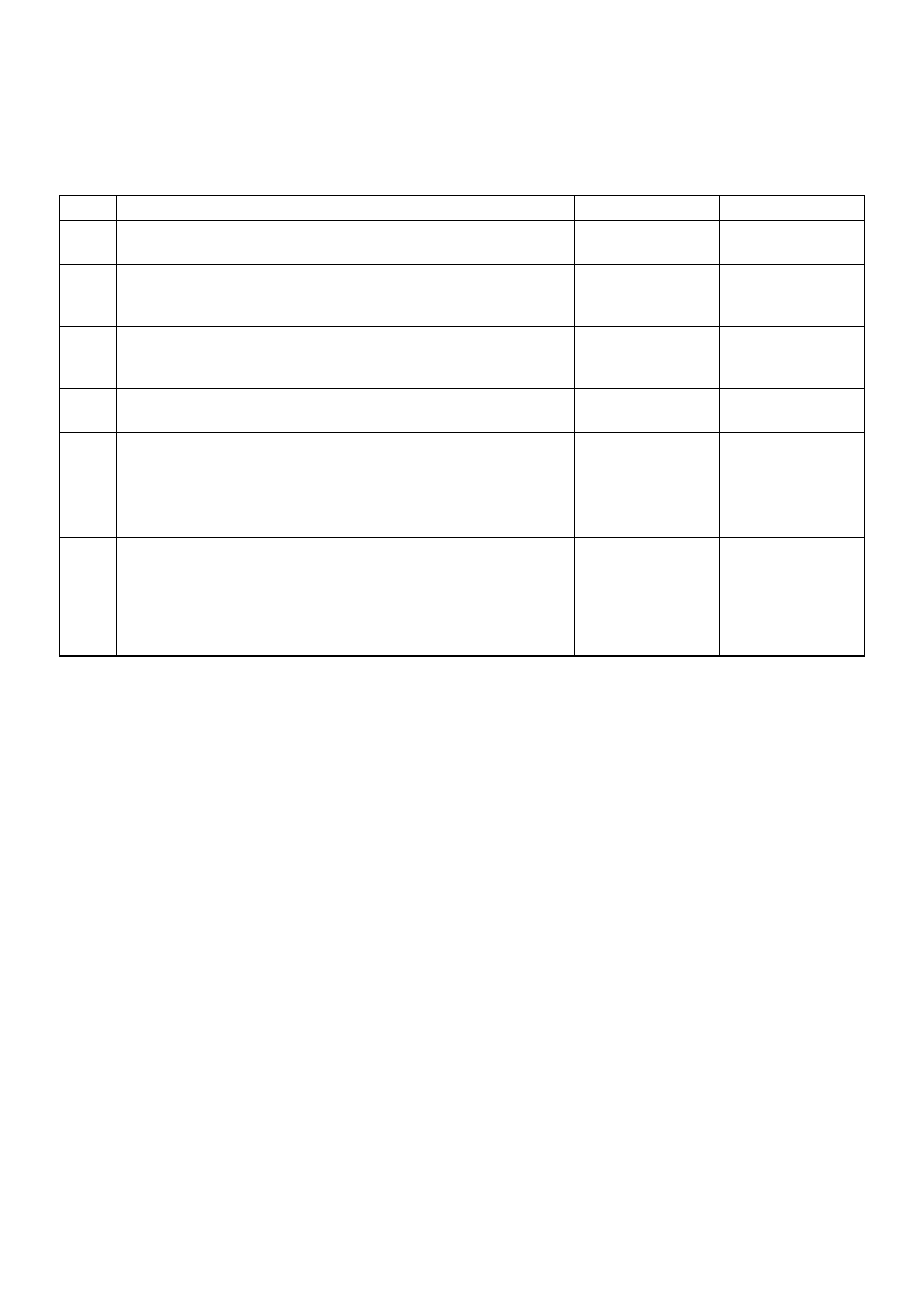

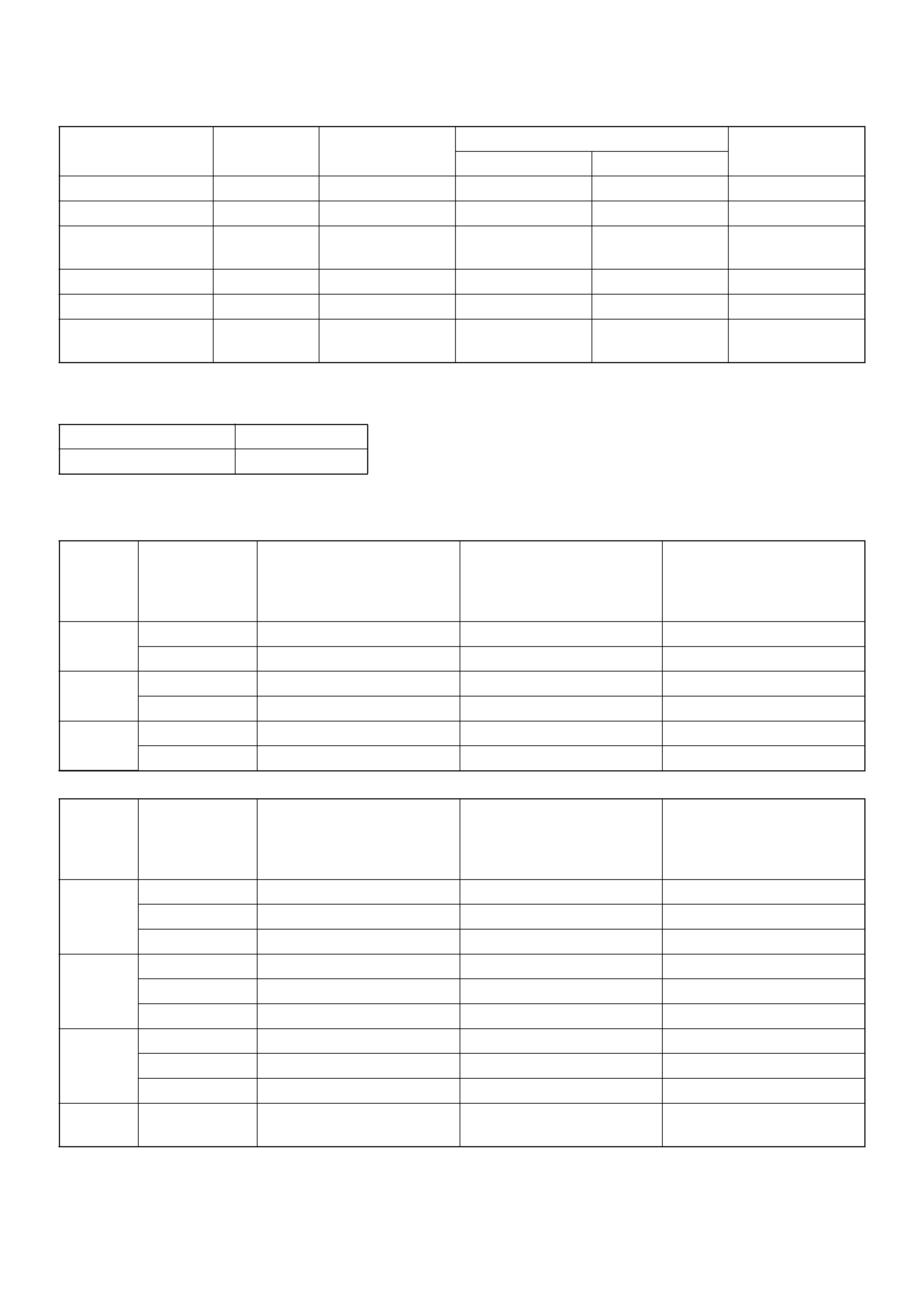

Shift Speed Chart (V6 3.2L 6VD1 Model)

“Normal mode”

Upshift

Downshift

MODE LEVER

POSITION ENGINE SPEED LINE PRESSURE FORCE MOTOR

CURRENT

kPa PSI

NORMAL/POWER D,3,2,L IDLE 312–363 45.2–52.6 VARIABLE

WINTER D IDLE 312 – 363 45.2 – 52.6 0.9 – 1.0A

NORMAL/POWER

WINTER REVERSE IDLE 419 – 486 60.7 – 70.5 0.9 – 1.0A

NORMAL/POWER D, 3, 2, L STALL SPEED 1,236 – 1,320 179.3 – 191.4 0.1 – 0.2A

WINTER D STALL SPEED 1,236 – 1,320 179.3 – 191.4 0.1 – 0.2A

NORMAL/POWER

WINTER REVERSE STALL SPEED 1,634 – 1,743 236.9 – 252.8 0.1 – 0.2A

Transfer gear ratio: High: 1.000

Rear axle ratio: 4.555

Range Throttle

opening

1 ® 2

(First Gear) (Second

Gear)

Km/h (mph)

2 ® 3

(Second Gear) (Third

Gear)

Km/h (mph)

3 ® 4

(Third Gear) (Fourth

Gear)

Km/h (mph)

D

(Drive)

Fully opened 37 ~ 43 (23 ~ 27) 76 ~ 82 (47 ~ 51) 125 ~ 131 (78 ~ 81)

Half throttle 29 ~ 35 (18 ~ 22) 54 ~ 60 (34 ~ 37) 107 ~ 113 (66 ~ 70)

3

(Third)

Fully opened 37 ~ 43 (23 ~ 27) 76 ~ 82 (47 ~ 51) —

Half throttle 29 ~ 35 (18 ~ 22) 54 ~ 60 (34 ~ 37) —

2

(Second)

Fully opened 37 ~ 43 (23 ~ 27) — —

Half throttle 29 ~ 35 (18 ~ 22) — —

Range Throttle

opening

1 ¬ 2

(First Gear) (Second

Gear)

Km/h (mph)

2 ¬ 3

(Second Gear) (Third

Gear)

Km/h (mph)

3 ¬ 4

(Third Gear) (Fourth

Gear)

Km/h (mph)

D

(Drive)

Fully opened 14 ~ 20 (9 ~ 12) 69 ~ 75 (43 ~ 47) 107 ~ 113 (66 ~ 70)

Half throttle 13 ~ 19 (8 ~ 12) 30 ~ 36 (19 ~ 22) 61 ~ 67 (38 ~ 42)

Fully closed 12 ~ 18 (7 ~ 11) 20 ~ 26 (12 ~ 16) 27 ~ 33 (17 ~ 20)

3

(Third)

Fully opened 14 ~ 20 (9 ~ 12) 69 ~ 75 (43 ~ 47) —

Half throttle 13 ~ 19 (8 ~ 12) 30 ~ 36 (19 ~ 22) —

Fully closed 12 ~ 18 (7 ~ 11) 20 ~ 26 (12 ~ 16) —

2

(Second)

Fully opened 14 ~ 20 (9 ~ 12) 82 ~ 88 (51 ~ 55) —

Half throttle 13 ~ 19 (8 ~ 12) 82 ~ 88 (51 ~ 55) —

Fully closed 12 ~ 18 (7 ~ 11) 82 ~ 88 (51 ~ 55) —

L

(First) — 36 ~ 42 (22 ~ 26) — —

“Power mode”

Upshift

Downshift]

“Winter mode”

Range Throttle

opening

1 ® 2

(First Gear) (Second

Gear)

Km/h (mph)

2 ® 3

(Second Gear) (Third

Gear)

Km/h (mph)

3 ® 4

(Third Gear) (Fourth

Gear)

Km/h (mph)

D

(Drive)

Fully opened 41 ~ 47 (25 ~ 29) 79 ~ 85 (49 ~ 53) 125 ~ 131 (78 ~ 81)

Half throttle 36 ~ 42 (22 ~ 26) 69 ~ 75 (43 ~ 47) 119 ~ 125 (74 ~ 78)

3

(Third)

Fully opened 41 ~ 47 (25 ~ 29) 79 ~ 85 (49 ~ 53) —

Half throttle 36 ~ 42 (22 ~ 26) 69 ~ 75 (43 ~ 47) —

2

(Second)

Fully opened 41 ~ 47 (25 ~ 29) — —

Half throttle 36 ~ 42 (22 ~ 26) — —

Range Throttle

opening

1 ¬ 2

(First Gear) (Second

Gear)

Km/h (mph)

2 ¬ 3

(Second Gear) (Third

Gear)

Km/h (mph)

3 ¬ 4

(Third Gear) (Fourth

Gear)

Km/h (mph)

D

(Drive)

Fully opened 28 ~ 34 (17 ~ 21) 70 ~ 76 (43 ~ 47) 115 ~ 121 (71 ~ 75)

Half throttle 20 ~ 26 (12 ~ 16) 46 ~ 52 (29 ~ 32) 90 ~ 96 (56 ~ 60)

Fully closed 12 ~ 18 (7 ~ 11) 22 ~ 28 (14 ~ 17) 43 ~ 50 (27 ~ 31)

3

(Third)

Fully opened 28 ~ 34 (17 ~ 21) 70 ~ 76 (43 ~ 47) —

Half throttle 20 ~ 26 (12 ~ 16) 46 ~ 52 (29 ~ 32) —

Fully closed 12 ~ 18 (7 ~ 11) 22 ~ 28 (14 ~ 17) —

2

(Second)

Fully opened 28 ~ 34 (17 ~ 21) 82 ~ 88 (51 ~ 55) —

Half throttle 20 ~ 26 (12 ~ 16) 82 ~ 88 (51 ~ 55) —

Fully closed 12 ~ 18 (7 ~ 11) 82 ~ 88 (51 ~ 55) —

L

(First) — 36 ~ 42 (22 ~ 26) — —

D range, winter mode ON ® OFF 27 ~ 33 Km/h (17 ~ 20 mph)

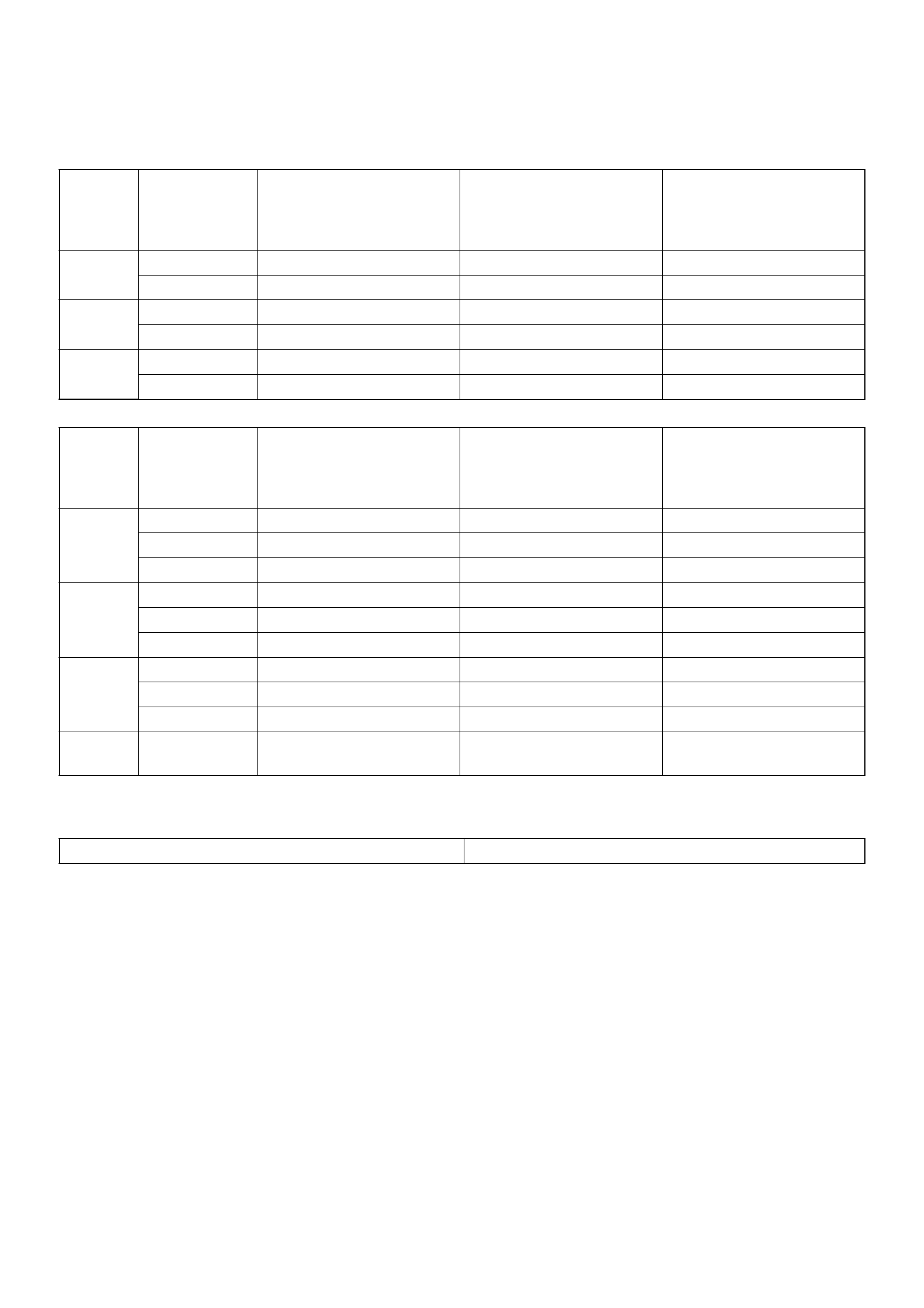

Shift Speed Chart (V6 3.5L 6VE1 Model)

“Normal mode”

Upshift

Downshift

Transfer gear ratio: High: 1.000

Rear axle ratio: 4.300

Range Throttle

opening

1 ® 2

(First Gear) (Second

Gear)

Km/h (mph)

2 ® 3

(Second Gear) (Third

Gear)

Km/h (mph)

3 ® 4

(Third Gear) (Fourth

Gear)

Km/h (mph)

D

(Drive)

Fully opened 42 ~ 48 (26 ~ 30) 86 ~ 92 (54 ~ 58) 139 ~ 145 (87 ~ 91)

Half throttle 29 ~ 35 (18 ~ 22) 58 ~ 64 (36 ~ 40) 113 ~ 118 (70 ~ 74)

3

(Third)

Fully opened 52 ~ 58 (33 ~ 36) 105 ~ 111 (66 ~ 69) —

Half throttle 32 ~ 38 (20 ~ 24) 58 ~ 64 (36 ~ 40) —

2

(Second)

Fully opened 52 ~ 58 (33 ~ 36) — —

Half throttle 32 ~ 38 (20 ~ 24) — —

Range Throttle

opening

1 ¬ 2

(First Gear) (Second

Gear)

Km/h (mph)

2 ¬ 3

(Second Gear) (Third

Gear)

Km/h (mph)

3 ¬ 4

(Third Gear) (Fourth

Gear)

Km/h (mph)

D

(Drive)

Fully opened 17 ~ 23 (11 ~ 14) 75 ~ 81 (47 ~ 51) 118 ~ 124 (74 ~ 78)

Half throttle 23 ~ 29 (14 ~ 18) 32 ~ 38 (20 ~ 24) 65 ~ 71 (40 ~ 44)

Fully closed 13 ~ 19 (8 ~ 12) 20 ~ 26 (12 ~ 16) 28 ~ 34 (17 ~ 21)

3

(Third)

Fully opened 42 ~ 48 (26 ~ 30) 92 ~ 98 (58 ~ 61) —

Half throttle 15 ~ 21 (9 ~ 13) 34 ~ 40 (21 ~ 25) —

Fully closed 13 ~ 19 (8 ~ 12) 15 ~ 21 (9 ~ 13) —

2

(Second)

Fully opened 43 ~ 49 (27 ~ 31) 100 ~ 106 (63 ~ 66) —

Half throttle 15 ~ 21 (9 ~ 13) 94 ~ 100 (59 ~ 63) —

Fully closed 13 ~ 19 (8 ~ 12) 82 ~ 88 (51 ~ 55) —

L

(First) — 50 ~ 56 (31 ~ 35) — —

“Power mode”

Upshift

Downshift

“Winter mode”

Range Throttle

opening

1 ® 2

(First Gear) (Second

Gear)

Km/h (mph)

2 ® 3

(Second Gear) (Third

Gear)

Km/h (mph)

3 ® 4

(Third Gear) (Fourth

Gear)

Km/h (mph)

D

(Drive)

Fully opened 47 ~ 53 (29 ~ 33) 89 ~ 95 (56 ~ 59) 140 ~ 146 (88 ~ 91)

Half throttle 37 ~ 43 (23 ~ 27) 73 ~ 79 (45 ~ 49) 126 ~ 132 (78 ~ 82)

3

(Third)

Fully opened 52 ~ 58 (33 ~ 36) 105 ~ 111 (66 ~ 69) —

Half throttle 37 ~ 43 (23 ~ 27) 74 ~ 80 (46 ~ 50) —

2

(Second)

Fully opened 52 ~ 58 (33 ~ 36) — —

Half throttle 37 ~ 43 (23 ~ 27) — —

Range Throttle

opening

1 ¬ 2

(First Gear) (Second

Gear)

Km/h (mph)

2 ¬ 3

(Second Gear) (Third

Gear)

Km/h (mph)

3 ¬ 4

(Third Gear) (Fourth

Gear)

Km/h (mph)

D

(Drive)

Fully opened 33 ~ 39 (21 ~ 24) 79 ~ 85 (49 ~ 52) 126 ~ 132 (79 ~ 82)

Half throttle 21 ~ 27 (13 ~ 17) 50 ~ 56 (31 ~ 35) 94 ~ 100 (58 ~ 62)

Fully closed 13 ~ 19 (8 ~ 12) 23 ~ 29 (14 ~ 18) 45 ~ 51 (28 ~ 32)

3

(Third)

Fully opened 43 ~ 49 (27 ~ 30) 96 ~ 102 (60 ~ 63) —

Half throttle 21 ~ 27 (13 ~ 17) 53 ~ 59 (33 ~ 37) —

Fully closed 13 ~ 19 (8 ~ 12) 24 ~ 30 (15 ~ 19) —

2

(Second)

Fully opened 43 ~ 49 (27 ~ 30) 100 ~ 106 (63 ~ 66) —

Half throttle 21 ~ 27 (13 ~ 17) 94 ~ 100 (59 ~ 63) —

Fully closed 13 ~ 19 (8 ~ 12) 82 ~ 88 (51 ~ 55) —

L

(First) — 53 ~ 59 (33 ~ 36) — —

D range, winter mode ON ® OFF 31 ~ 37 Km/h (19 ~ 23 mph)

Lockup Speed Chart

Transfer gear ratio: High: 1.000

Rear axle ratio: 4.300

D range Throttle

opening 6%

Mode

Lockup ON Lockup OFF

2nd

Km/h

(mph)

3rd

Km/h

(mph)

4th

Km/h

(mph)

2nd

Km/h

(mph)

3rd

Km/h

(mph)

4th

Km/h

(mph)

Normal 72 ~ 78 (45

~ 48)

53 ~ 59 (33

~ 37)

78 ~ 84 (48

~ 52)

67 ~ 73 (42

~ 45)

45 ~ 51 (28

~ 32)

73 ~ 79 (45

~ 49)

Power 72 ~ 78 (45

~ 48)

77 ~ 83 (48

~ 52)

77 ~ 83 (48

~ 52)

67 ~ 73 (42

~ 45)

68 ~ 74 (42

~ 46)

72 ~ 78 (45

~ 48)

Changing Transmission Fluid

There is no need to change the transmission fluid

unless the transmission is used under one or more of

the following heavy duty conditions.

ARepeated short trips

BDriving on rough roads

CDriving on dusty roads

DTowing a trailer

If the vehicle is used under these conditions, change the

fluid every 20,000 miles (32,000 km).

More over, the remaining life percentage of ATF can be

estimated by using Tech 2 as an auxiliary tool to judge

the right time for ATF replacement.

The remaining life percentage is calculated from ATF'S

heat history. When it is close to 0%, ATF replacement is

recommended.

1.Place a large drain pan under the oil pan.

2.Remove the transmission oil drain screw (2) and

drain fluid.

3.Tighten drain screw (2).

Torque: 38N•m (3.9kg·m/28lbft)

4.Remove the transmission overfill screw (1) and fill

transmission through overfill screw opening, using

DEXRON®-III ATF.

NOTE: Add transmission fluid until it flows out over the

overfill screw opening.

5.Let engine idle until a fluid temperature between

32°C (90°F) and 57°C (135°F) is reached.

6.Add transmission fluid until it flows out over the

overfill screw opening, then close the overfill screw

(1).

Torque: 38N•m (3.9kg·m/28lbft)

NOTE: To prevent fluid leaks, the overfill screw and oil

drain screws gasket must be replaced each time these

screws are removed.

NOTE: Check transmission fluid temperature with

service scan tool.

7.Reset “Oil Life Monitor” data by using Tech2.

Refer to Tech2 OBD II Connector in Transmission

Control System (4L30-E) Section.

242RW003

Selector Lever

Inspection

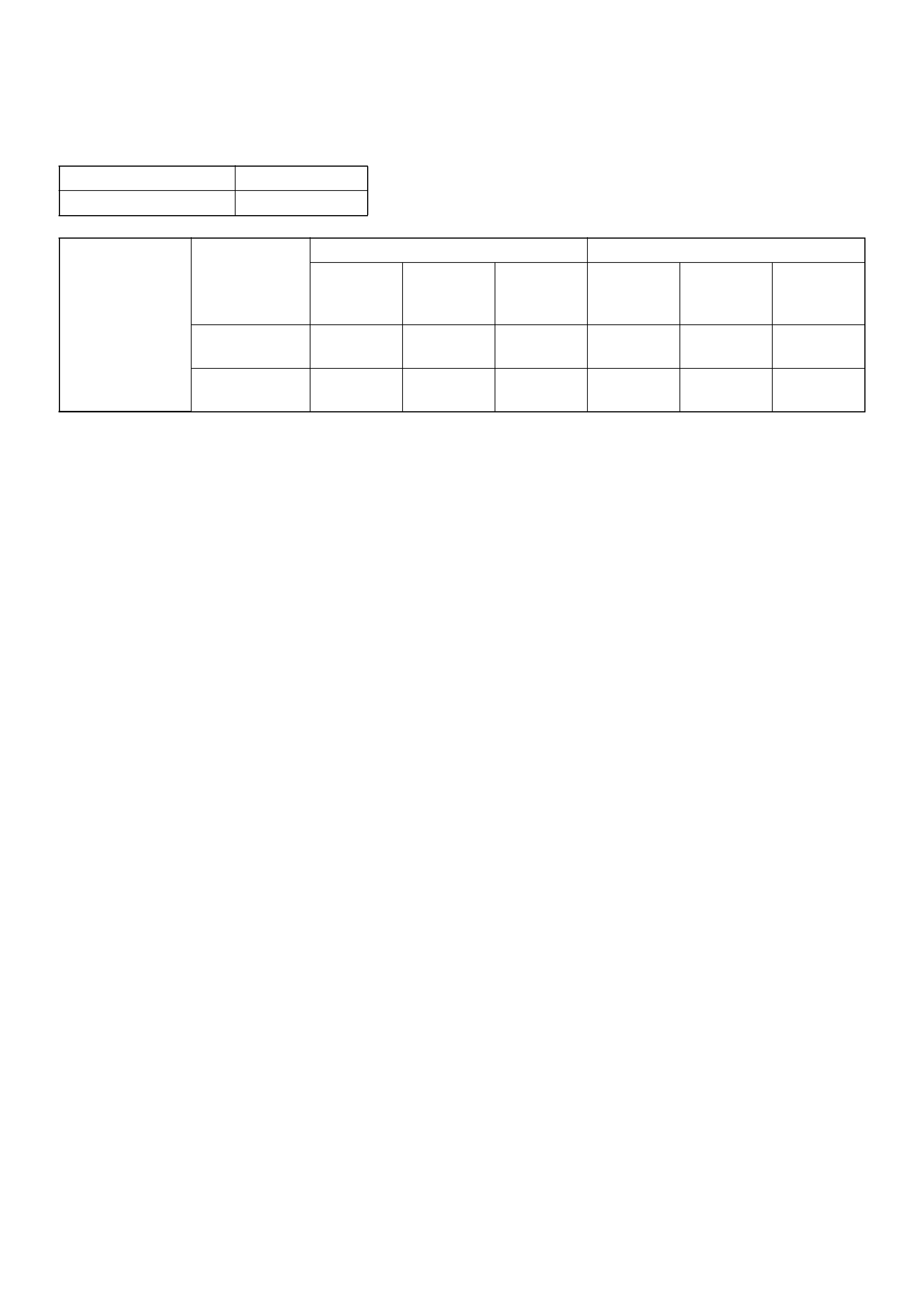

1. Make sure that when the selector lever is shifted

from “P” to“L”, a “clicking” can be felt at each shift

position. Make sure that the gear corresponds to

that of the position plate indicator.

2. Check to see if the selector lever can be shifted as

shown in illustration.

C07RW009

Removal

1. Disconnect battery ground cable.

2. Remove transfer control lever knob.

3. Remove front console.

• Disconnect wiring harness connectors from front

console.

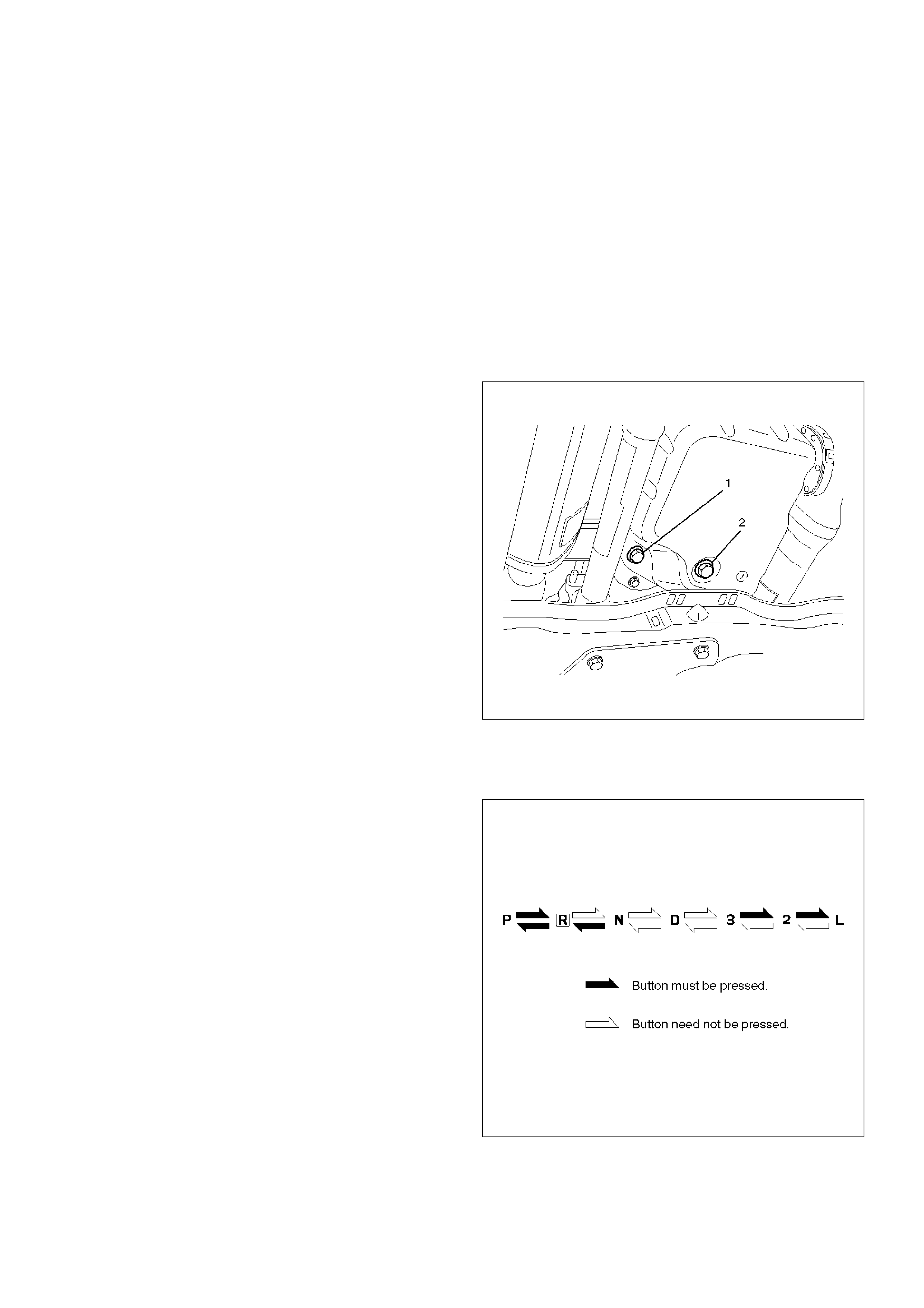

4. Disconnect shift lock cable (1) from the selector

lever assembly side.

256RW012

5. Disconnect shift control rod (2) from the selector

lever assembly side.

256RW013

6. Disconnect wiring harness connectors from the

selector lever assembly.

7. Remove selector lever assembly.

Installation

To install, follow the removal steps in the reverse order,

noting the following points:

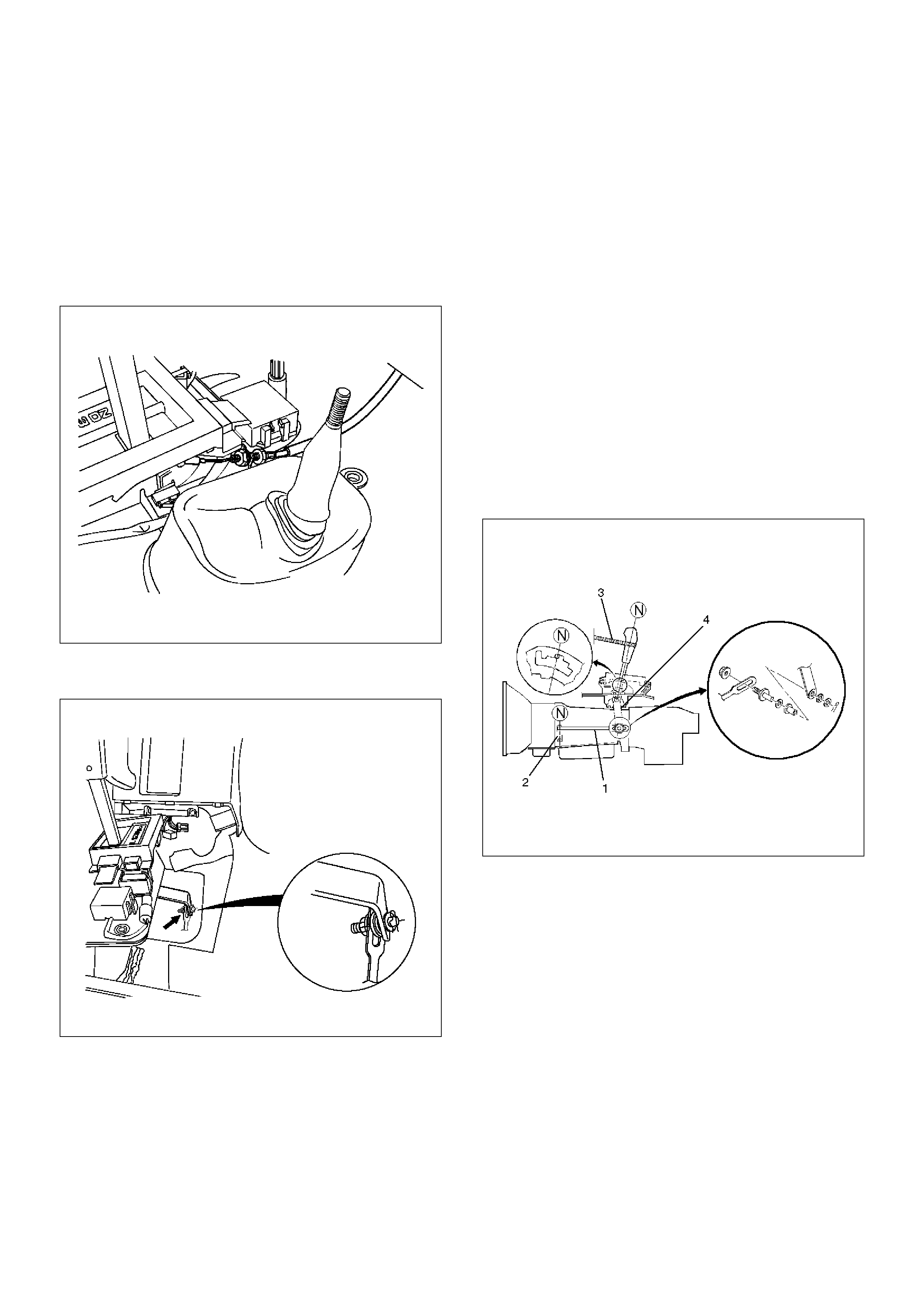

Adjustment of select lever and control rod

1. Place the vehicle on a level surface.

NOTE: If the vehicle is not on level surface, the shift

select cable set positions will vary with the movement of

engine. To prevent possible misadjustment of the cable,

the vehicle must be placed on a level surface.

2. Install the shift control rod (1) to the transmission

select lever (2), and then place the lever in the “N”

position.

3. Set select lever in the “N” position.

4. Push select lever forward (“R”position side) and

secure it (using a rubber band (3), etc.) so that the

pin comes into contact with the wall of the detent

plate.

5. Install the shift control rod (1) to the selector lever

arm (4).

Torque: 32N•m (3.3kg·m/24lbft)

NOTE: Do not apply oil to the threaded portions.

256RW014

6. After adjustment, make sure that the selector lever

operates normally, and that each selector position is

properly indicated. (The red mark shows through

the window.)

Adjustment of shift lock cable

1. Set ignition key in “LOCK” position and selector

lever in “P” position.

2. Adjust cable screw cap on selector lever side to

provide a gap (slack for cable) of 1 – 2 mm between

rod on steering lock side and stopper.

Adjust cap as follows:

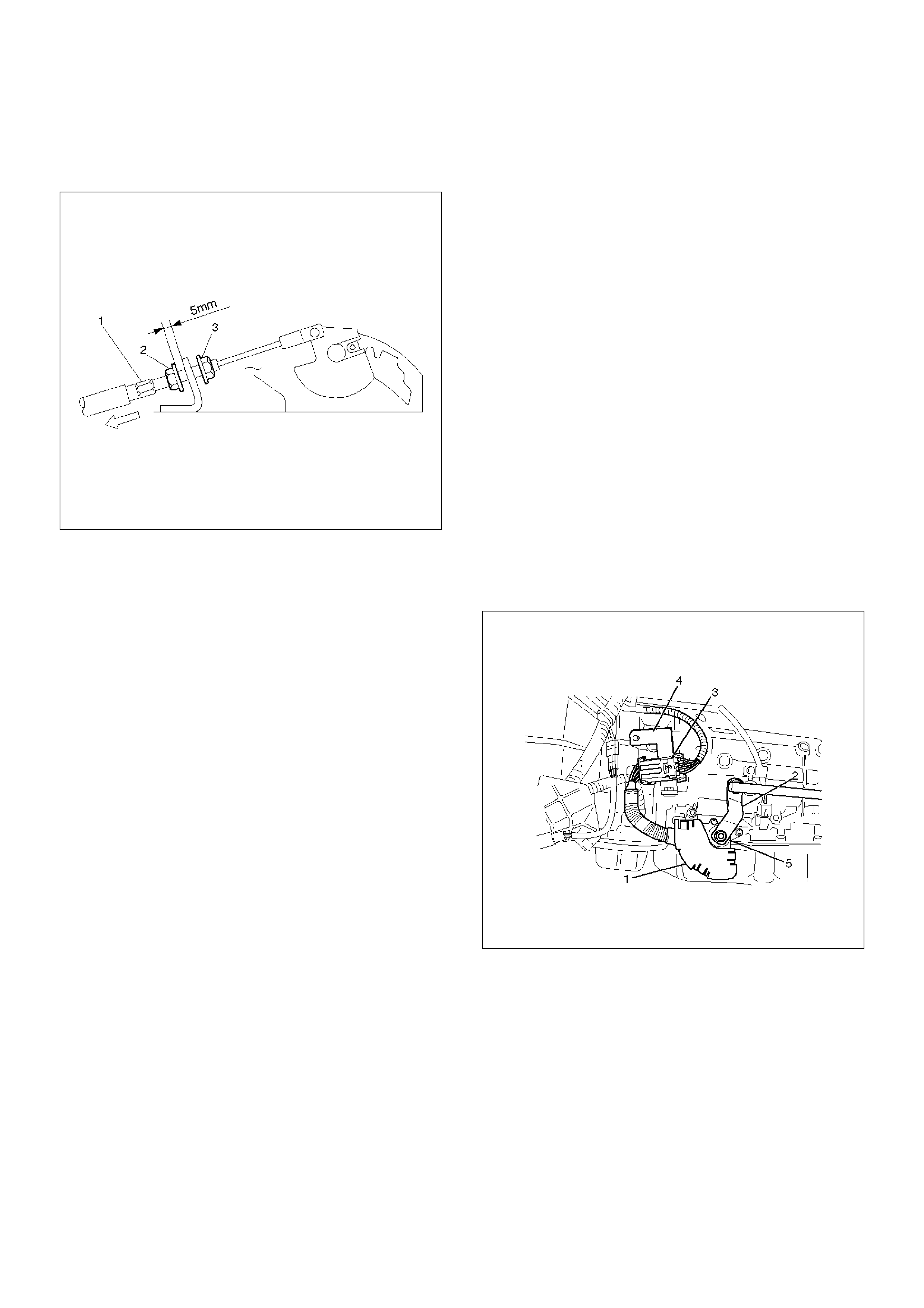

a Pull screw cap (1) in arrow direction to remove

inner cable slack.

b With cable kept as (a), adjust gap between nut

(2) and bracket to 5 mm (0.2 in).

c Lock inner cable by turning nut (3) while holding

nut (2) in place.

Torque : 3.7N•m(38kg·cm/33lbin)

NOTE: Clean the cable threads, and do not apply oil to

them.

256RW015

3. Check the shift lock operation:

a Selector lever should not move out of “P”

position with ignition key in “Lock” position.

b Selector lever can be moved out of “P” position

with ignition key in “ON” position only when

brake pedal is depressed.

c Ignition key can be turned to “LOCK” position

only when selector lever is in “P” position (key

can be pulled out).

If (a) and (c) fail, readjust cable. If (b) fails, readjust

connector wiring and brake pedal switch.

Mode Switch

Removal

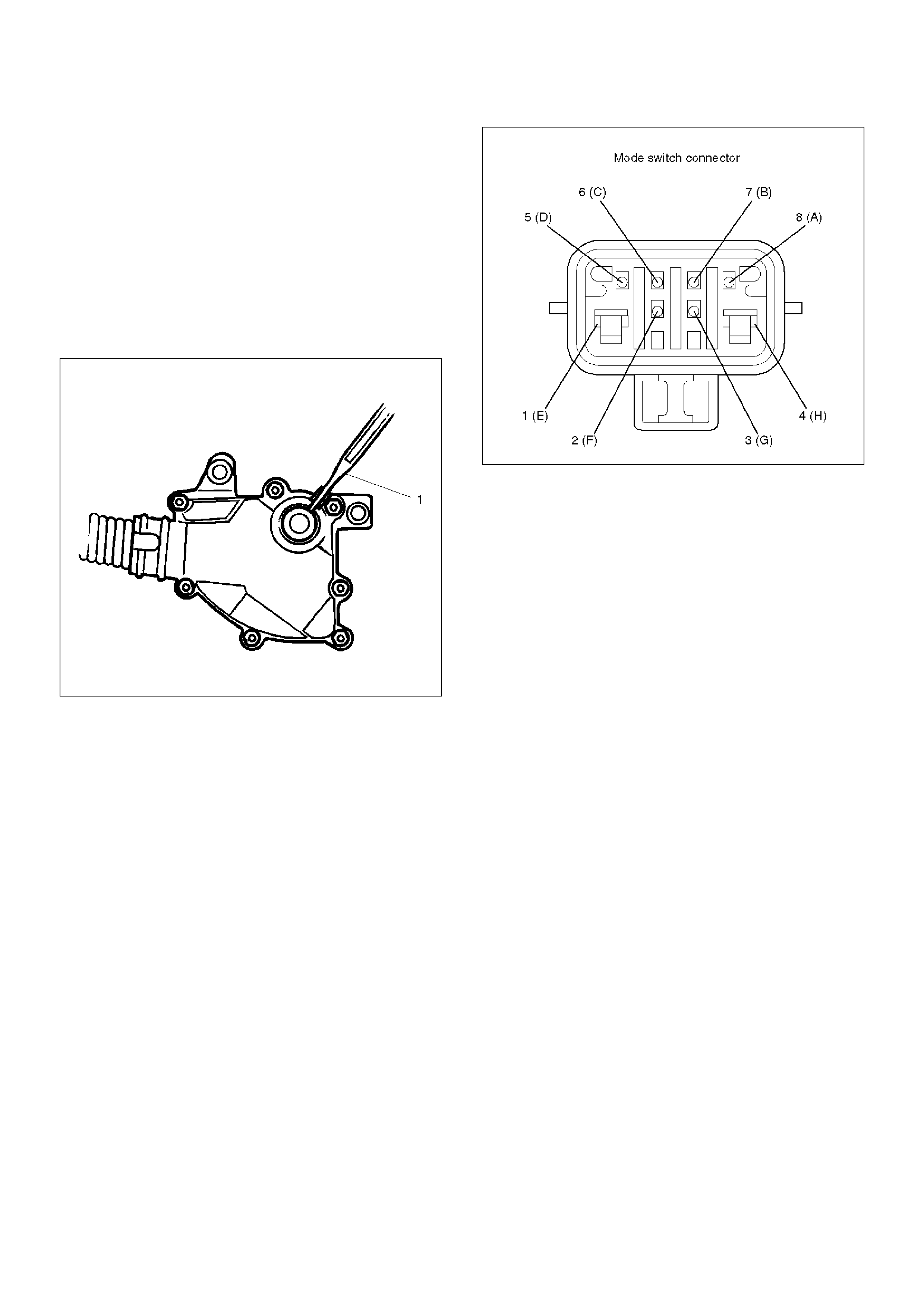

1. Place selector lever in neutral.

2. Disconnect battery ground cable.

3. Remove mode switch cover (1) .

4. Disconnect selector lever (2) from the mode switch.

5. Disconnect transmission harness from the mode

switch connector (3).

6. Remove bracket with mode switch connector from

the transmission case.

7. Remove mode switch connector (3) from the

bracket (4).

8. Remove two mode switch bolts and nut then

remove mode switch (5).

210RW008

Installation

To install, follow the removal steps in the reverse order,

noting the following points;

1. Torque

Mode switch bolt: 13N•m(1.3kg·m/113lbin)

Selector lever nut: 23N•m(2.3kg·m/17lbft)

2. Mode switch setting procedure

Perform either of the following adjustment

procedures:

Procedure 1

a Place selector lever in neutral.

b Remove selector lever from the mode switch.

c Remove the mode switch cover.

d Loosen the two 10 mm screws.

e Rotate the mode switch until the slot in the

mode switch housing aligns with the selector

shaft bushing, and insert a 3/32 in. (2.4 mm) drill

bit or punch (1) into the slot.

f Tighten the screws to 13 N·m (1.3kg·m/113lbin).

g After completing adjustment, snap the mode

switch cover into place.

h Reinstall the selector lever.

249RW001

Procedure 2

a Place selector lever in neutral.

b Disconnect transmission harness connector

from mode switch connector.

c Remove mode switch connector with bracket

from the transmission case.

d Connect multimeter (resistance mode) to

terminals 1(E) and 4(H) on mode switch

connector.

e Loosen two mounting screws.

f Rotate mode switch slightly in both directions to

determine the range (approx. 5 degrees) of

electrical contact.

g Position mode switch in middle of contact range.

h Tighten two mounting screws.

i Remove multimeter and install mode switch

harness connector with bracket to the

transmission case.

j Connect transmission harness connector to

mode switch connector.

F07RW003

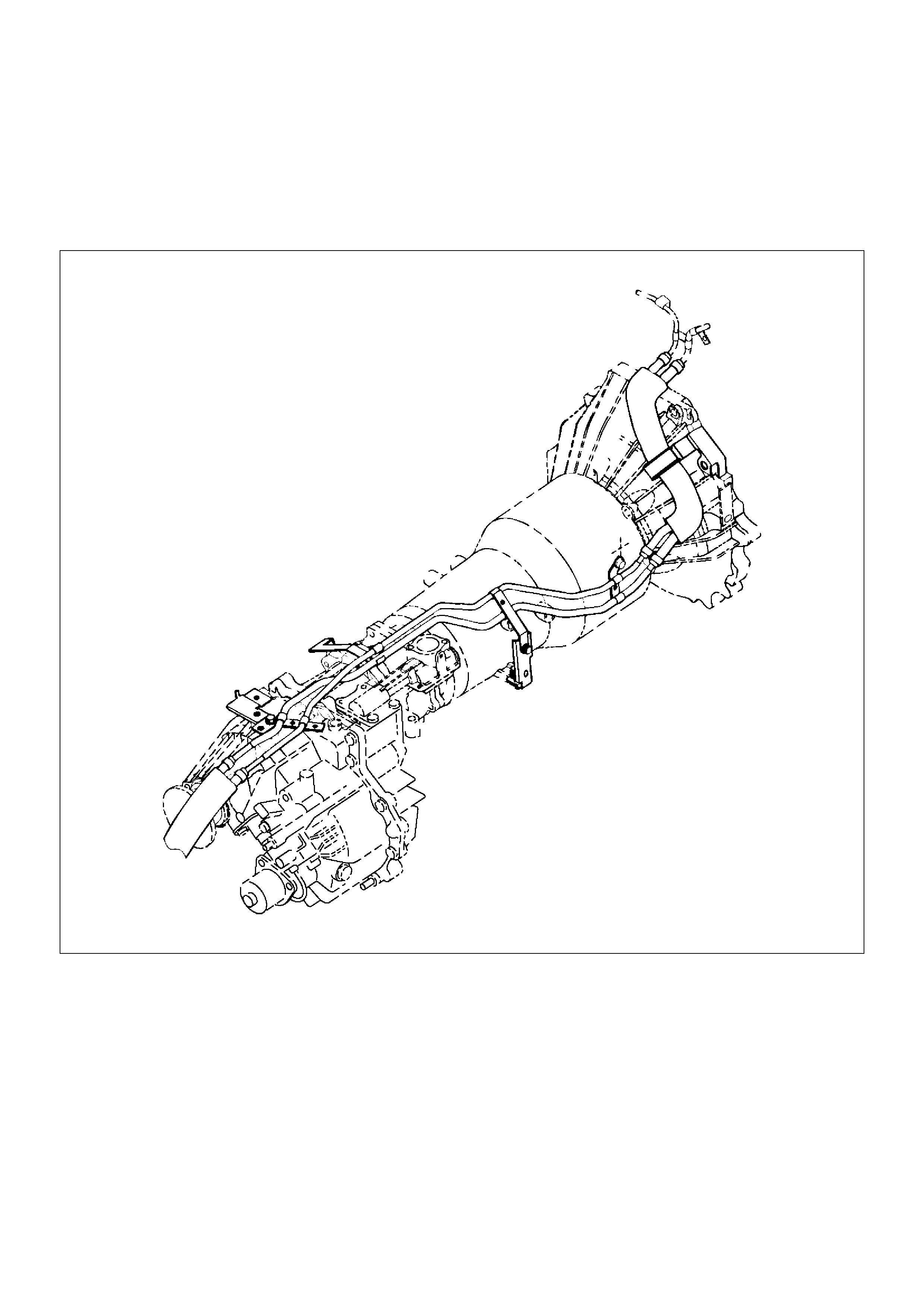

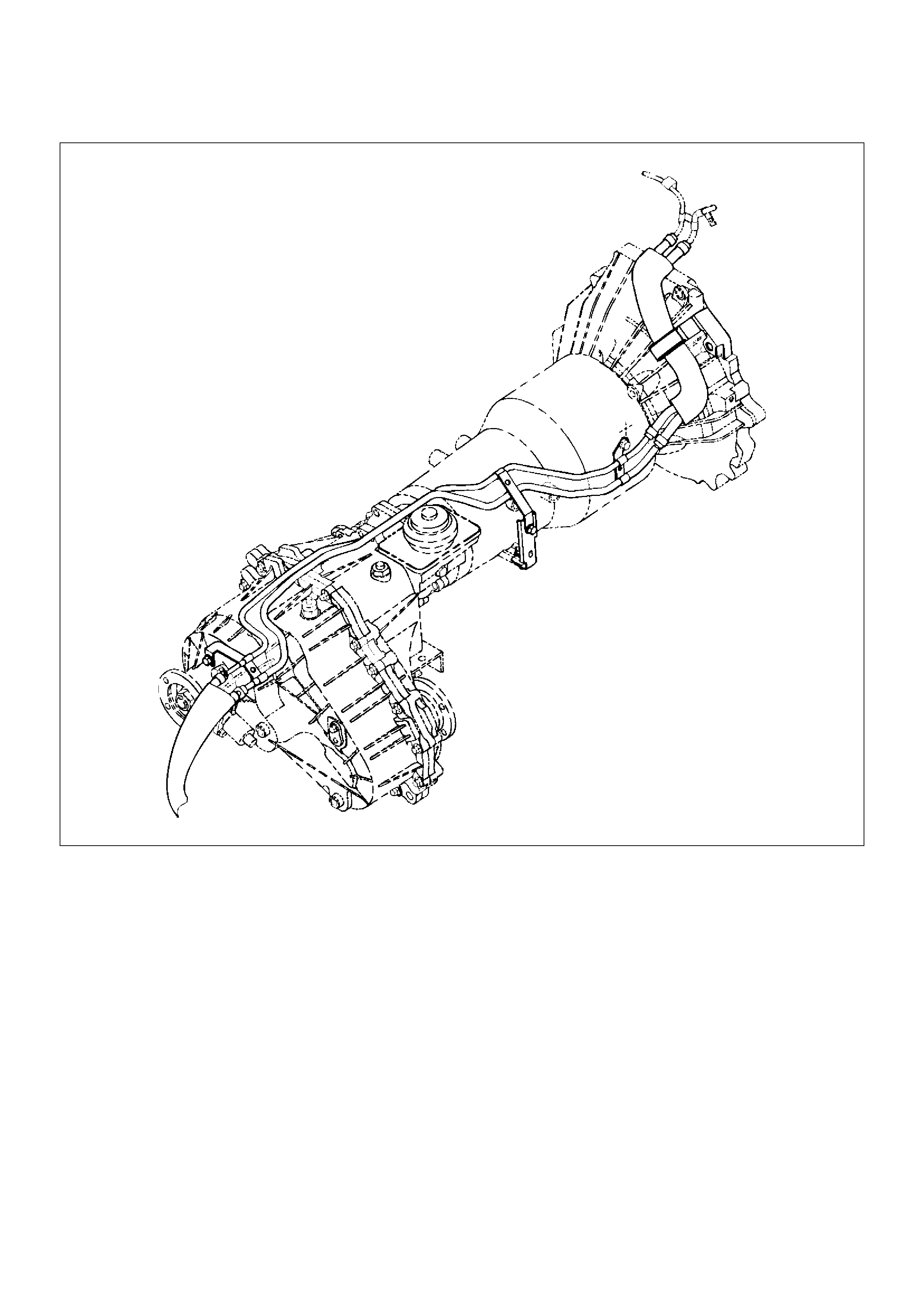

Transmission (With Transfer Case)

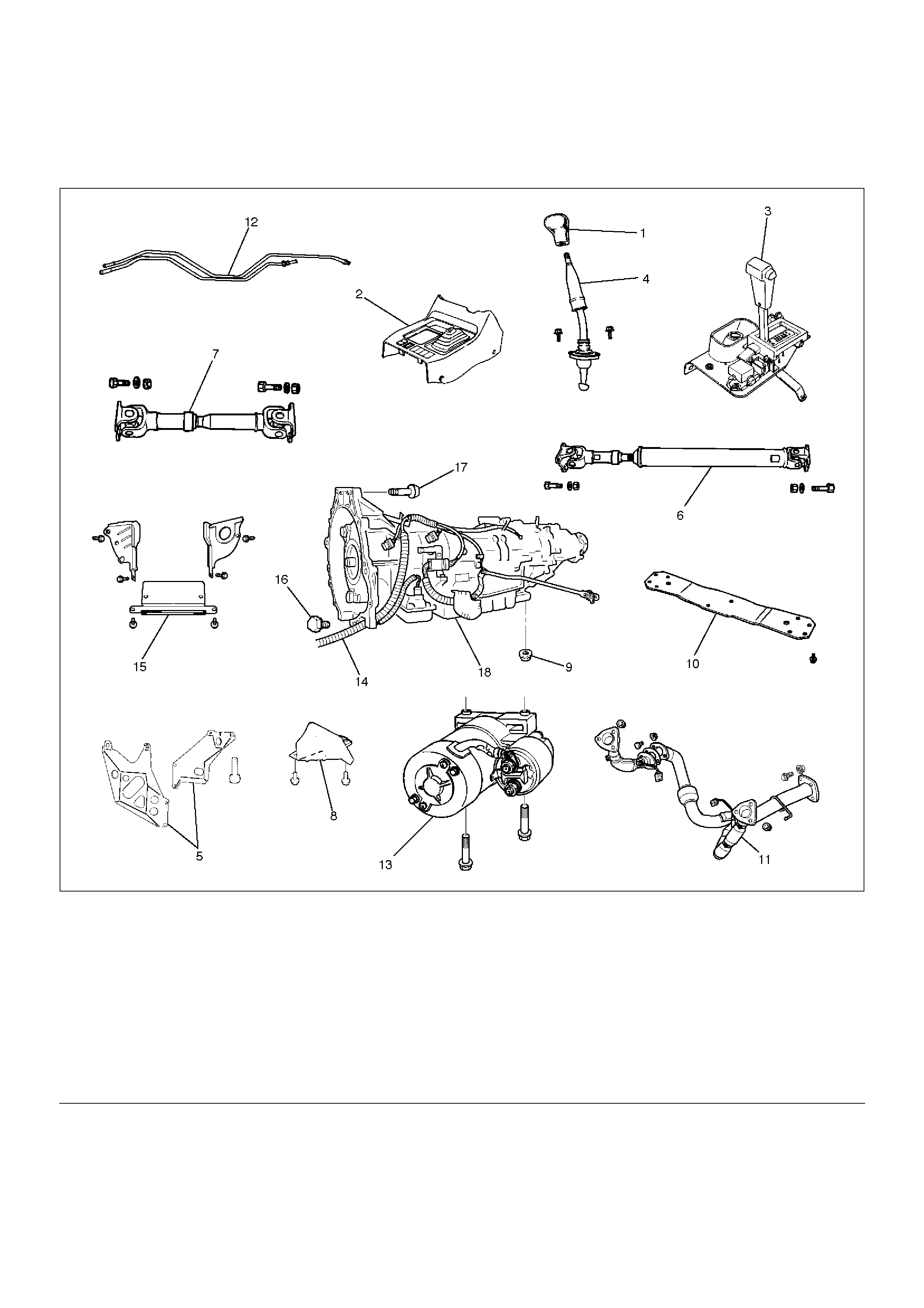

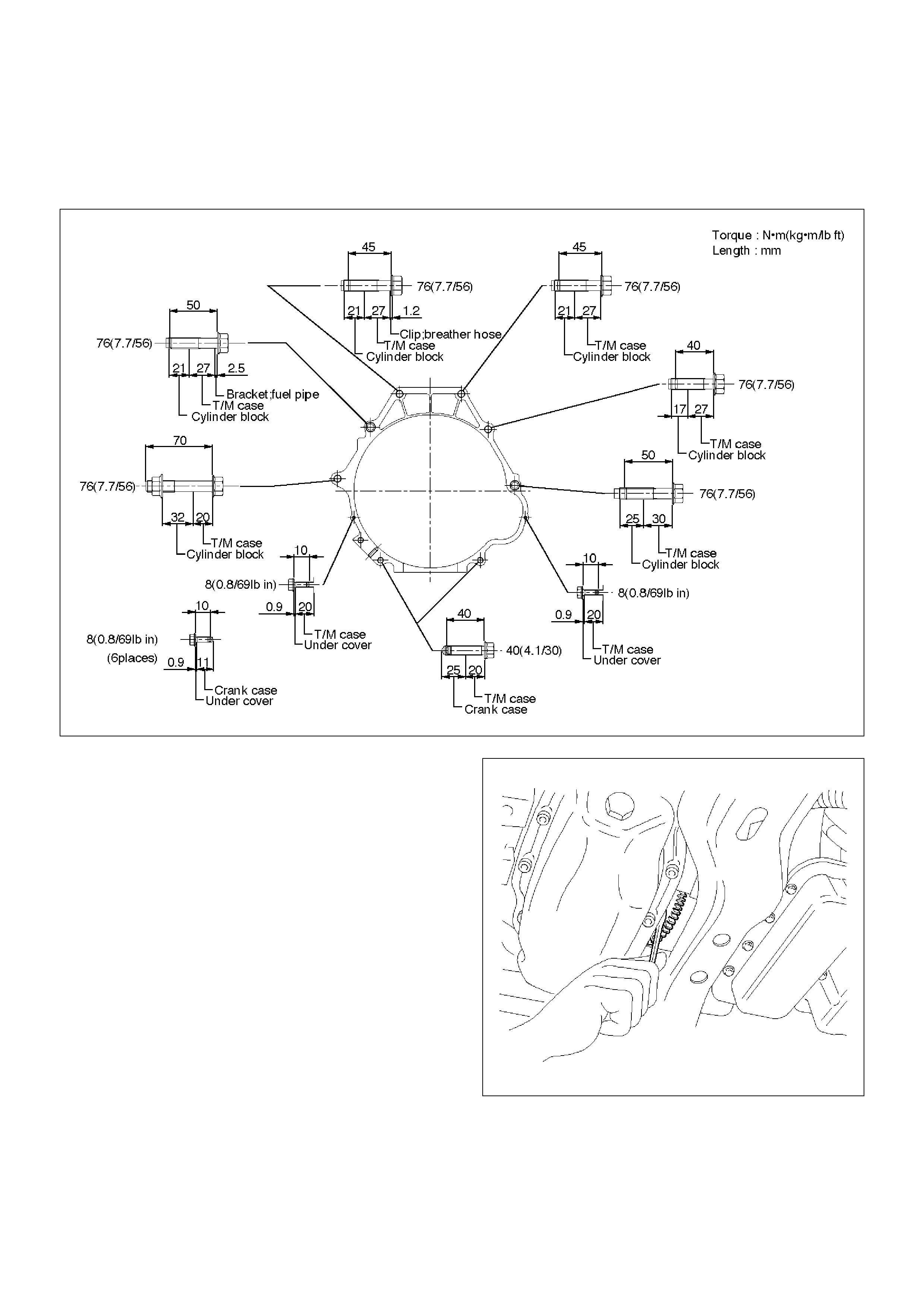

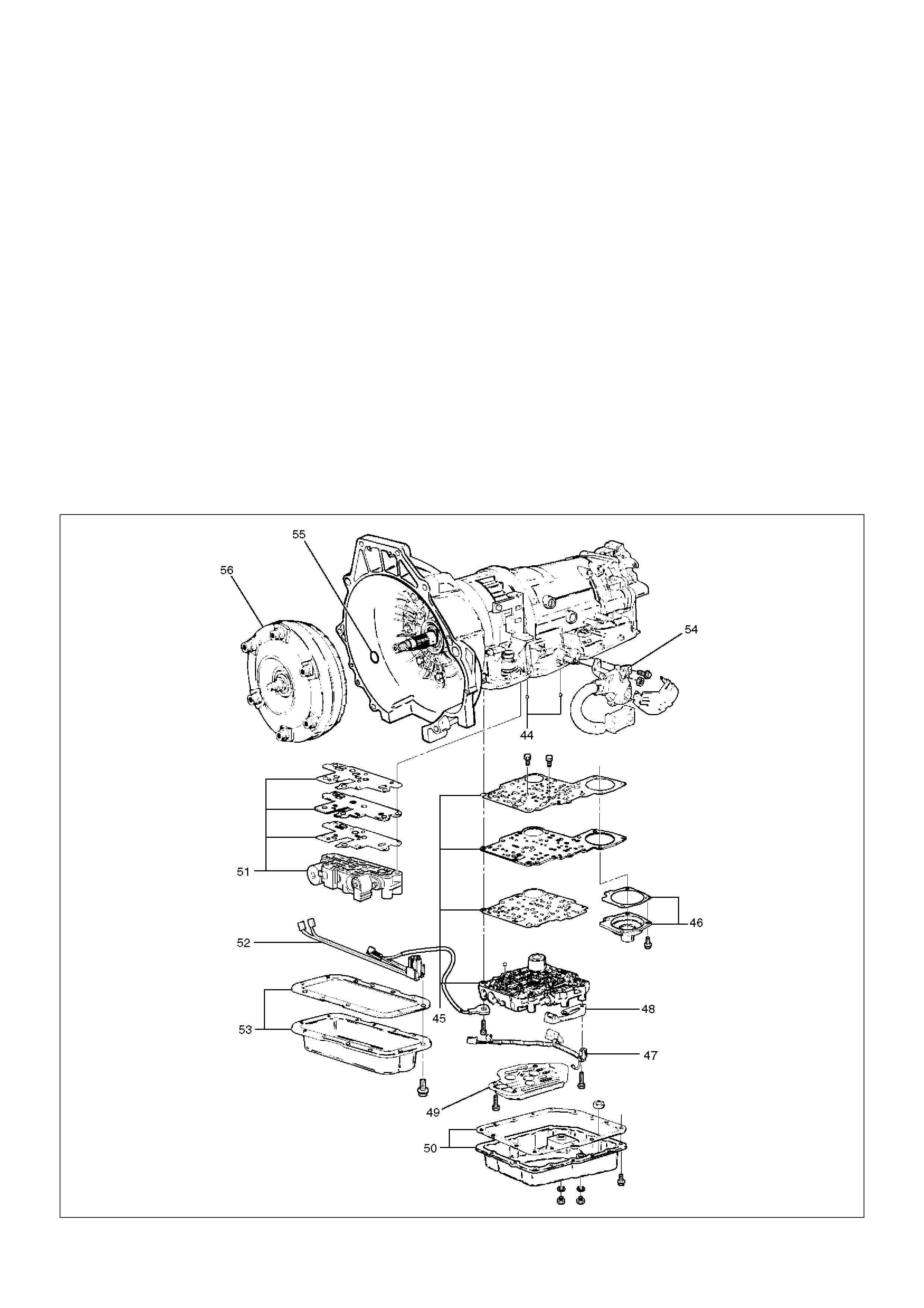

Transmission And Associated Parts

240RW027

EndOFCallout

Removal

NOTE: Before remove transmission and transfer

assembly from vehicle, change the tansfer mode to

2WD using push button on dash panel.

1. Remove engine hood.

2. Disconnect battery ground cable.

3. Remove transfer control lever knob (1) and

disconnect wiring harness connectors, then remove

front console (2).

Legend

(1) Transfer Control Lever Knob

(2) Front Console

(3) Selector Lever Assembly

(4) Transfer Control Lever

(5) Transfer and Exhaust Protector

(6) Rear Propeller Shaft

(7) Front Propeller Shaft

(8) Harness Protector

(9) Rear Mount Nut

(10) Third Crossmember

(11) Exhaust Pipe

(12) Transmission Oil Cooler Pipe

(13) Starter

(14) Transmission Harness Connector

(15) Under Cover

(16) Torque Converter Bolt

(17) Engine Transmission Bolt

(18) Transmission Assembly

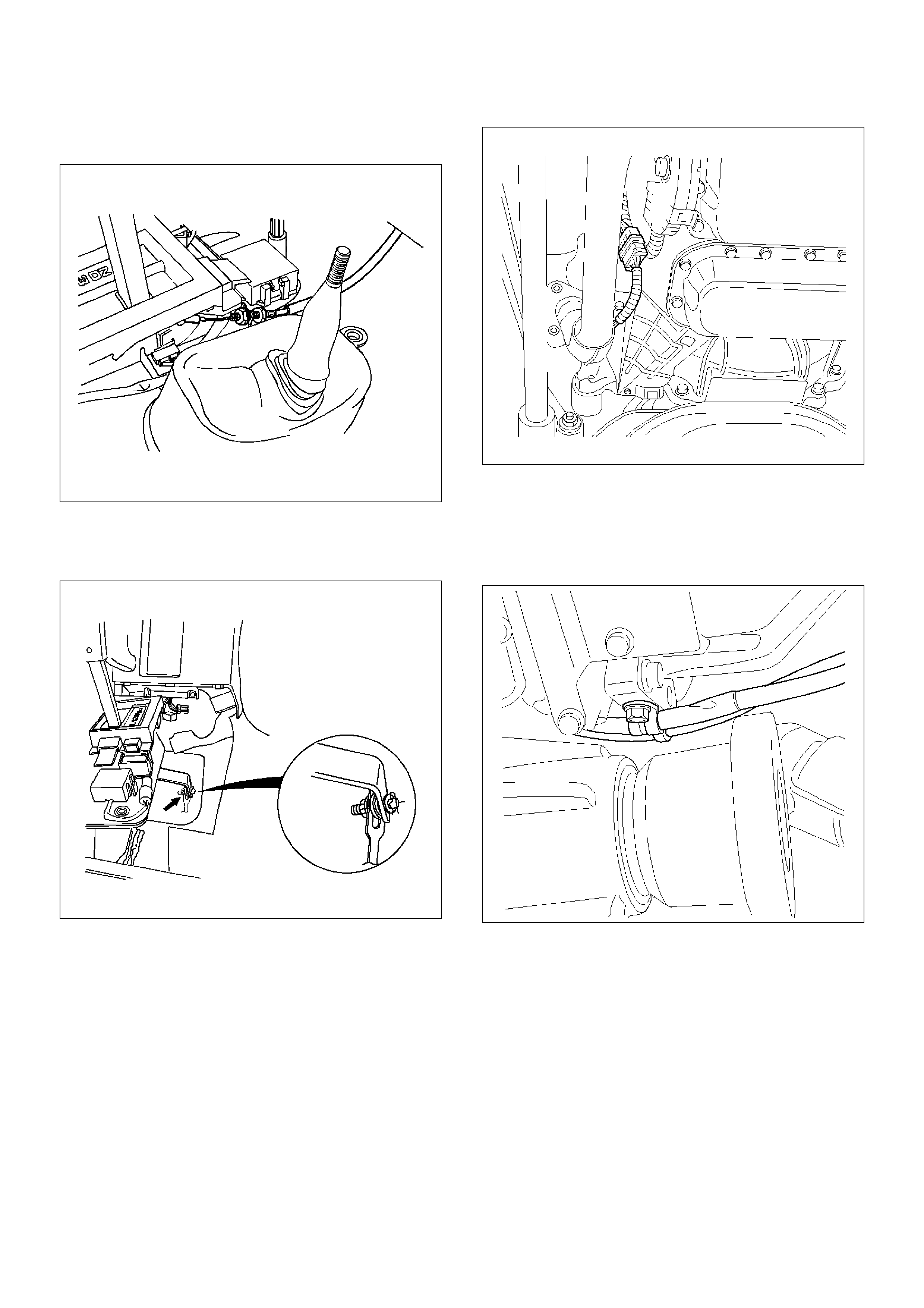

4. Disconnect shift lock cable from the selector lever

assembly side.

256RW012

5. Disconnect wiring harness connectors.

6. Disconnect shift control rod from the selector lever

assembly side.

256RW013

7. Remove selector lever assembly (3).

8. Remove transfer control lever (4).

9. Remove transfer and exhaust protector (5).

10. Remove rear propeller shaft (6).

11. Remove front propeller shaft (7).

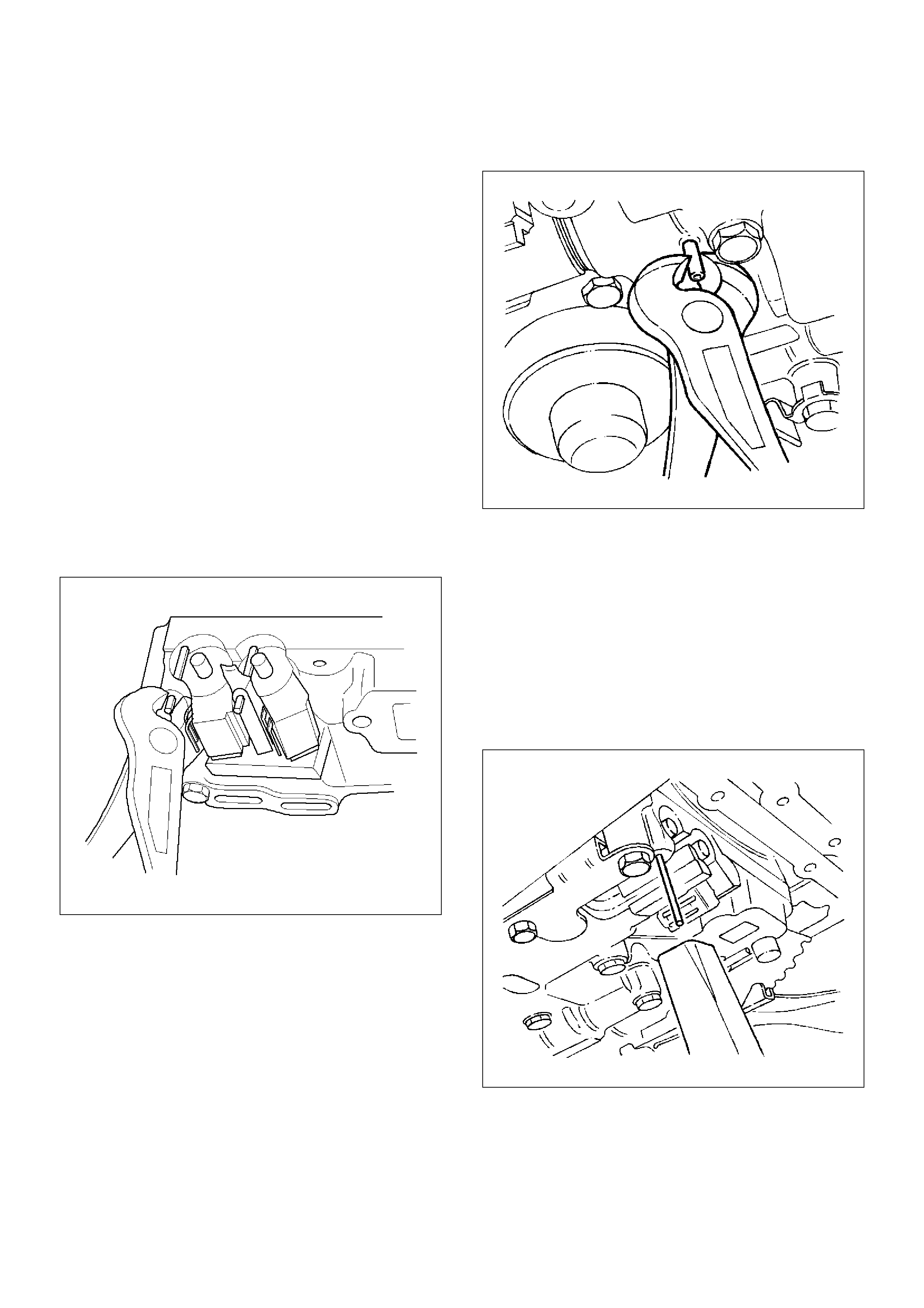

12. Remove harness protector (8).

13. Support transfer case with a jack and remove two

rear mount nuts (9) from the 3rd crossmember side.

14. Remove eight third crossmember bolts and third

crossmember (10).

15. Disconnect one oxygen sensor connector from the

transmission harness.

150RW002

16. Remove exhaust pipe (11).

17. Disconnect transmission oil cooler pipe (12) from A/

T side.

18. Remove oil pipe clamp from torque converter

housing bracket.

253RY001

19. Loosen oil pipe clamp bolt at the engine mount side.

20. Remove starter (13).

21. Disconnect fuel pipe clamp bracket from

transmission side.

22. Disconnect transmission harness connectors (14)

from transmission, and transfer.

23. Remove under covers (3 pieces) (15) from

transmission case.

24. Lower the front of the transmission a little, then

remove flex plate torque converter fixing bolts (6

pieces) (16) by turning crankshaft.

25. Support the transmission with a transmission jack,

and hoist engine with a chain block.

26. Remove engine transmission fixing bolts (17).

27. Remove transmission assembly (18).

Installation

1. Slowly raise transmission jack until front of the

transmission is aligned with rear of the engine, then

install transmission assembly.

2. Tighten engine transmission bolts to the specified

torque.

F07RW041

3. Support transfer case with a jack, and remove the

transmission jack.

4. Install flex plate torque converter bolts (6 pieces) by

turning crankshaft.

Torque: 54N•m(5.5kg·m/40lbft)

NOTE: Do not reuse the flex plate torque converter

bolt.

240RW005

5. Install the under cover (3 pieces), and tighten the

bolts to the specified torque.

Torque: 8 N•m (0.8 kg·m/69 lb in)

6. Install the starter, and tighten the bolts to the

specified torque.

Torque: 40N•m(4.1kg·m/30lbft)

7. Connect transmission harness connectors to

transmission, and transfer.

8. Connect fuel pipe bracket to transmission side.

For 4´4

141RW027

For 4´4 (TOD)

141RW001

9. Install transmission oil cooler pipe to transmission.

Torque: 44N•m(4.5kg·m/33lbft)

10. Install oil pipe clamp to torque converter housing

bracket.

11. Tighten oil pipe clamp bolt at engine mount side.

12. Install exhaust pipe, and tighten the bolts to the

specified torque.

Exh. pipe to exh. manifold 67N•m (6.8kg·m/

49lbft)

Exh. pipe flange bolt 43N•m (4.4kg·m/32lbft)

13. Connect one oxygen sensor connector to the

transmission harness.

14. Install third crossmember, and tighten the bolts to

the specified torque.

Torque: 76N•m (7.8kg·m/56lbft)

15. Install rear mount nuts, and tighten the nuts to the

specified torque.

Torque: 50N•m (5.1kg·m/37lbft)

16. Remove the jack from the transfer case.

17.Install harness protector.

815RW002

18.Install the front propeller shaft, and tighten the bolts

to the specified torque.

Torque: 63N•m (6.4kg·m/46lbft)

19.Install the rear propeller shaft, and tighten the bolts

to the specified torque.

Torque: 63N•m (6.4kg·m/46lbft)

20.Install the transfer and exhaust protectors, and

tighten the bolts to the specified torque.

Torque: 37N•m (3.8kg·m/27lbft)

21.Install the transfer control lever.

22.Install the selector lever assembly.

23.Connect the shift control rod to selector lever

assembly.

24.Connect the wiring harness connectors.

25.Connect the shift lock cable to selector lever

assembly. Refer to Selector Lever in this section.

26. Connect the wiring harness connectors to front

console.

27. Install the front console.

28. Install the transfer control lever knob.

29. Connect the battery ground cable.

30. Install the engine hood.

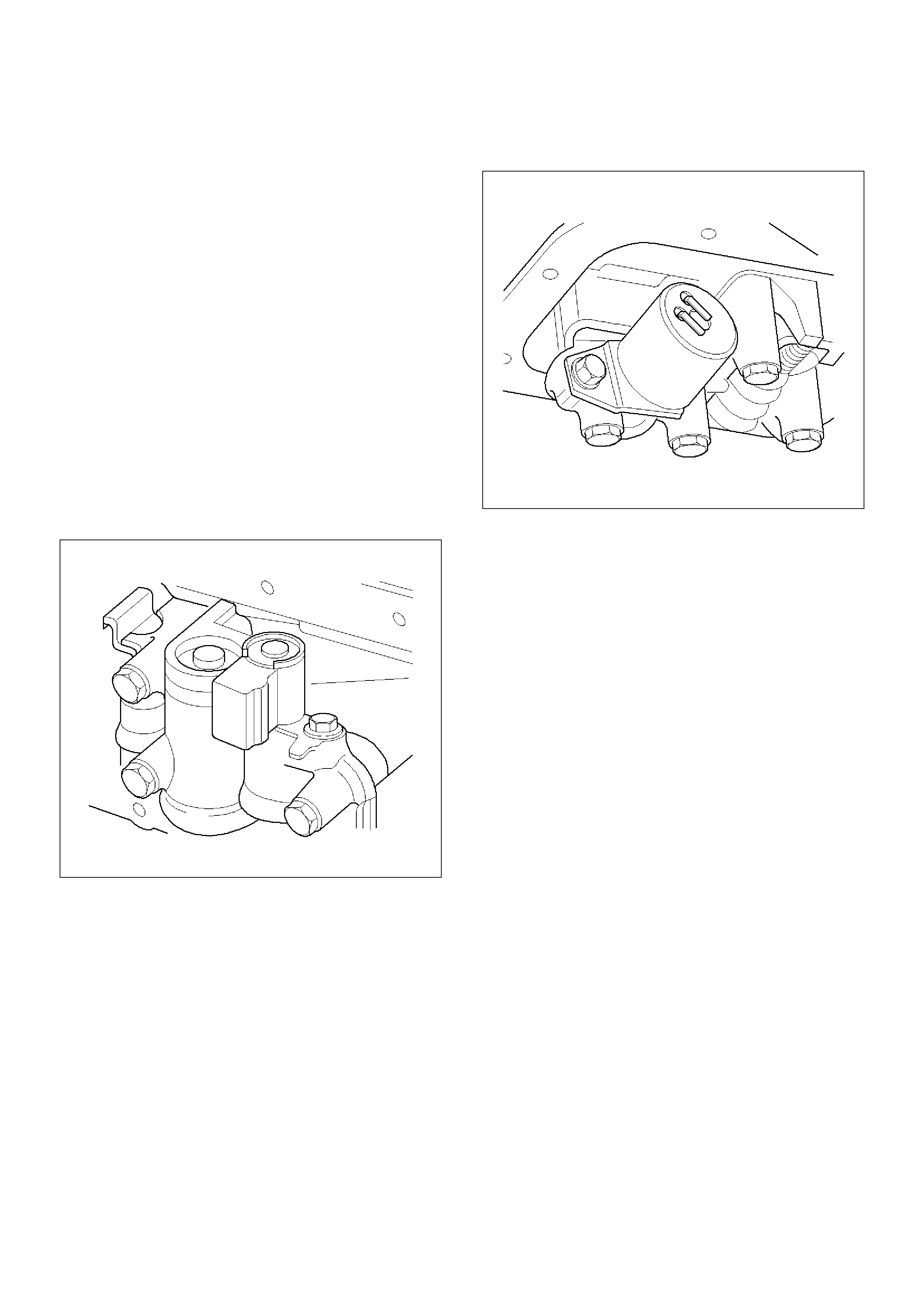

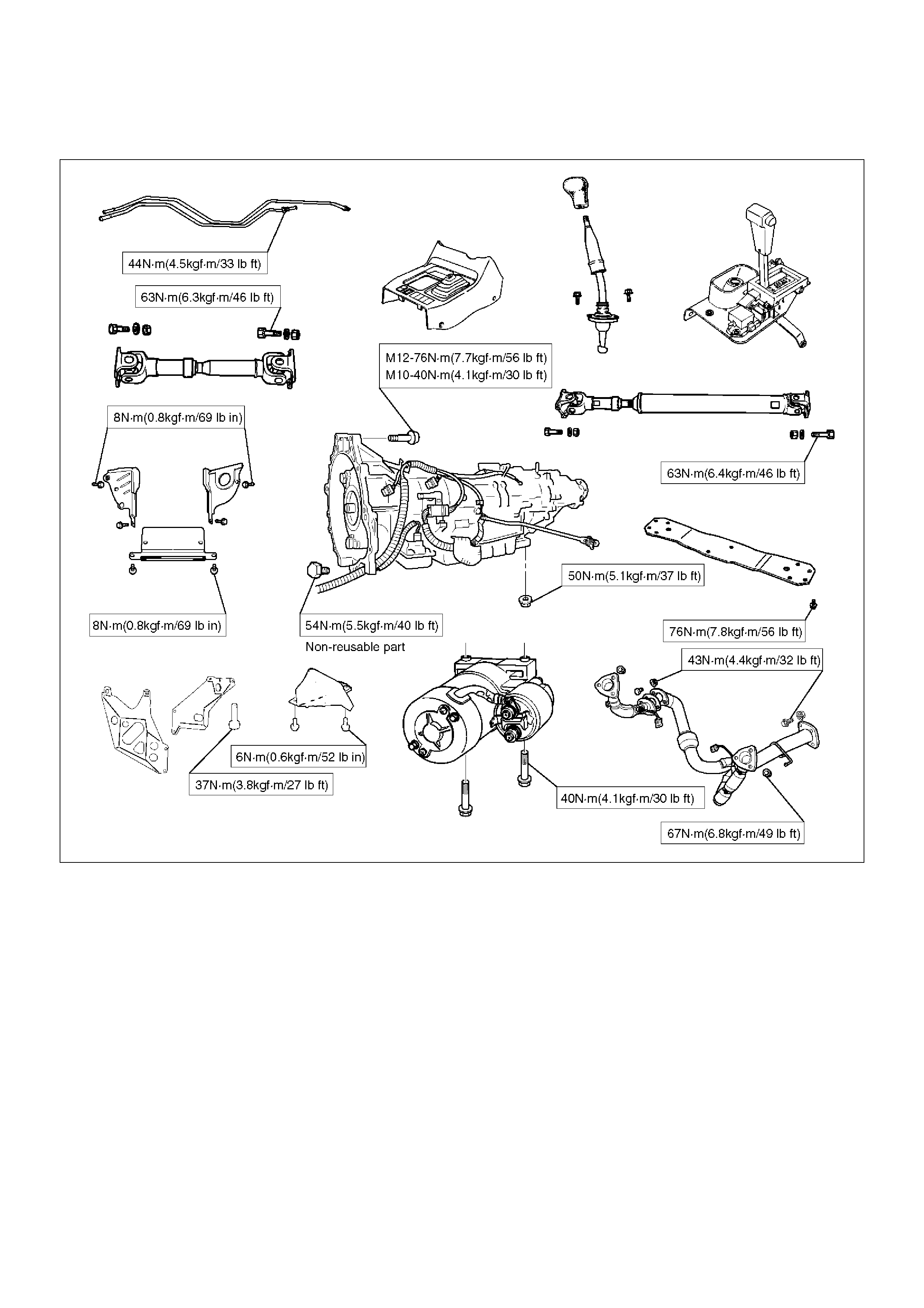

Solenoid (Main Case Valve Body)

Removal

1. Raise the vehicle and support it on jack stands.

2. Disconnect battery ground cable.

3. Remove transfer and exhaust protectors.

4. Drain fluid.

5. Remove exhaust pipe and disconnect oxygen

sensor connector.

6. Support transfer case with a jack and remove third

crossmember.

7. Remove sixteen 10 mm screws, main case oil pan,

magnet, and gasket.

8. Remove three 13 mm screws, oil filter.

9. Disconnect wiring harness from band control

solenoid and shift solenoids. Pull only on

connectors, not on wiring harness.

10. Remove spring pin for shift solenoid A, shift

solenoid B, and band control solenoid respectively,

using suitable pliers taking care not to damage

solenoids.

210RW010

244RW003

11. Remove shift solenoid A, shift solenoid B, band

control solenoid, and gaskets from main case valve

body. Do not pull on wiring harness. Remove

solenoids by grasping the metal tip.

Installation

1. Install shift solenoid A, shift solenoid B, band control

solenoid with new gaskets to main case valve body

respectively.

2. Carefully install spring pin with hammer to avoid

damage to valve body, etc.

243RW004

3. Connect wiring harness to solenoids.

4. Install oil filter with a new gasket and the three 13

mm screws. Tighten the screws to the specified

torque.

Torque: 20N•m (2.0kg·m/15lbft)

5.Install magnet, main case oil pan with new gasket,

sixteen 10 mm screws. Tighten the screws to the

specified torque.

Torque: 11N•m (1.1kg·m/96lbin)

6.Install third crossmember and rear mount nuts.

Tighten the nuts and bolts to the specified torque.

Third crossmember bolt: 76N•m (7.8kg·m/56lbft)

Rear mount nut: 50N•m (5.1kg·m/37lbft)

7.Install exhaust pipe and connect oxygen sensor

connector. Tighten the bolts to the specified torque.

Exhaust pipe flange bolt torque: 43N•m(4.4kg·m/

32lbft)

8.Install the transfer and exhaust protectors. Tighten

the bolts to the specified torque.

Torque: 37N•m (3.8kg·m/27lbft)

9.Fill transmission through the overfill screw hole of oil

pan, using ATF DEXRON®-III. Refer to Changing

Transmission Fluid in this section.

10. Connect the battery ground cable.

Solenoid (Adapter Case Valve Body)

Removal

1.Raise the vehicle and support it on jack stands.

2.Disconnect battery ground cable.

3.Drain fluid.

4.Remove transfer and exhaust protectors.

5.Remove exhaust pipe and disconnect oxygen

sesnor connector.

6.Remove adapter case oil pan twelve fixing 10 mm

screws, adapter case oil pan, and gasket.

NOTE: Oil pan still contains transmission fluid. Place a

large drain container under the oil pan and drain the

fluid carefully.

7.Disconnect wiring harness from force motor

solenoid and converter clutch solenoid. Pull only on

connectors, not on wiring harness.

8.Remove 11 mm bolt and converter clutch solenoid

with two O–rings.

210RW011

9.Remove 11 mm bolt, retainer, and force motor

solenoid.

210RW009

Installation

1.Install force motor solenoid, retainer, and 11 mm bolt

to adapter case valve body. Tighten the bolt to the

specified torque.

Torque: 10 N•m (1.0kg·m/87lbin)

2.Install converter clutch solenoid with two O– rings,

and 11 mm bolt to adapter case valve body. Tighten

the bolt to the specified torque.

Torque : 10N•m (1.0kg·m/87lbin)

3.Connect wiring harness assembly to solenoids.

4.Install adapter case oil pan, new gasket, and twelve

10 mm screws. Tighten the screws to the specified

torque.

Torque : 11N•m (1.1kg·m/96lbin)

5.Install exhaust pipe and connect oxygen sensor

connector. Tighten the bolt to the specified torque.

Exhaust pipe flange bolt torque : 43N•m(4.4kg·m/

32lbft)

6.Install transfer and exhaust protectors. Tighten the

bolt to the specified torque.

Torque : 37N•m(3.8kg·m/27lbft)

7.Fill transmission through overfill screw hole oil pan,

using ATF DEXRON®-III. Refer to Changing

Transmission Fluid in this section.

8. Connect battery ground cable.

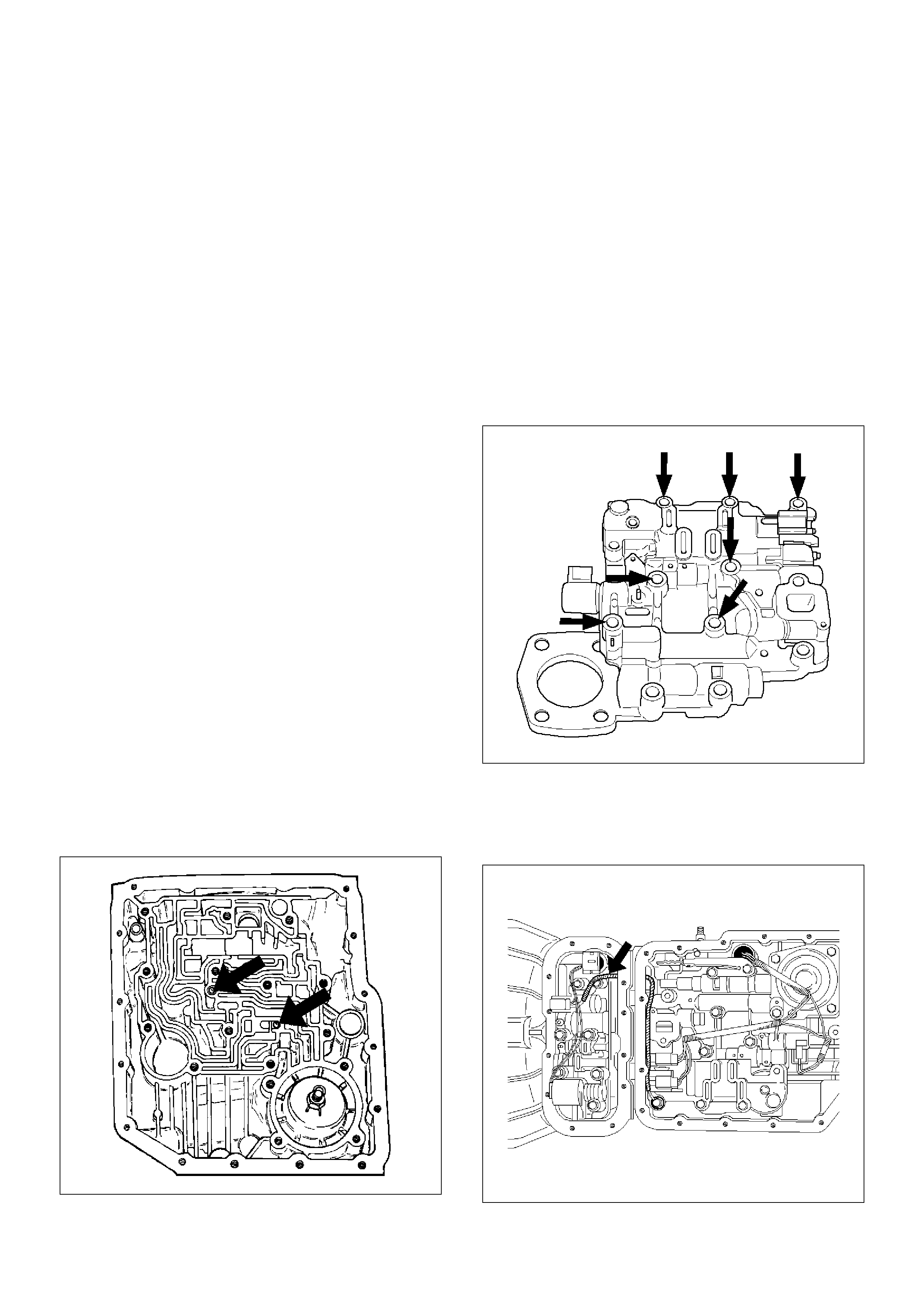

Valve Body Assembly (Main Case)

Removal

1. Raise the vehicle and support it on jack stands.

2. Disconnect battery ground cable.

3. Remove transfer and exhaust protectors.

4. Drain fluid.

5. Remove exhaust pipe and disconnect oxygen

sensor connector.

6. Support transfer case with a jack and remove third

crossmember.

7. Remove sixteen 10 mm screws, main case oil pan,

magnet and gasket.

8. Remove three 13 mm oil filter fixing screws, then

remove oil filter.

9. Remove two 13 mm manual detent fixing screws,

then remove roller and spring assembly.

10. Disconnect wiring harness from band control

solenoid and shift solenoids. Pull only on

connectors, not on wiring harness.

11. Remove four 13 mm servo cover fixing screws, then

remove servo cover and gasket.

12. Remove seven 13 mm valve body fixing screws.

• Disconnect the ground wire from the main case

valve body.

13. Remove main case valve body with manual valve

link and transfer plate. Note the position of the link

(long end into valve, short end into range selector

lever).

14. Remove transfer plate gasket from main case.

15. Remove two check balls from main case.

Installation

1. Install two check balls to main case.

244RW002

2. Inspect electrical 4 pin connector and seal of main

case. Replace if necessary.

3. Use two 5–8840–0022–0 (J–25025–B) guide pin to

install main case.

• Install valve body assembly and manual valve

link.

NOTE: Valve must be extended as the short end of

manual valve link is connected to the range selector

lever. Long end of link goes into valve.

4. Install seven 13 mm screws, and tighten them to the

specified torque.

Torque: 20N•m (2.0kg·m/15lbft)

243RS008

5. Install 8.5 mm connector of ground wire the head of

this valve body bolt and reinstall it. Tighten the bolt

to the specified torque.

Torque: 20N•m (2.0kg·m/15lbft)

244RW001

6. Remove two guide pins from main case.

7.Install servo cover gasket, cover, and four 13 mm

screws. Tighten the screws to the specified torque.

Torque: 25N•m (2.6kg·m/18lbft)

8.Connect wiring harness to band control and shift

solenoids.

9.Install roller and spring assembly to manual detent.

•Install two 13 mm screws, and tighten them to the

specified torque.

Torque: 20N•m (2.0kg·m/15lbft)

10.Install oil filter and three 13 mm screws. Tighten the

screws to the specified torque.

Torque : 20N•m (2.0kg·m/15lbft)

11.Install oil pan gasket, magnet, oil pan and sixteen 10

mm screws. Tighten the screws to the specified

torque.

Torque: 11N•m (1.1kg·m/96lbin)

12.Install third crossmember and rear mount. Tighten

the bolts and nuts to the specified torque.

Torque

Third crossmember bolt: 76N•m(7.8kg·m/56lbft)

Rear mount nut: 50N•m(5.1kg·m/37lbft)

13.Install exhaust pipe and connect oxygen sensor

connector. Tighten the bolts to the specified torque.

Exhaust pipe flange bolt torque: 43N•m(4.4kg·m/

32lbft)

14.Install transfer and exhaust protectors. Tighten the

bolts to the specified torque.

Torque: 37N•m (3.8kg·m/27lbft)

15.Fill transmission through overfill screw hole of oil

pan, using ATF DEXRON®-III, refer to Changing

Transmission Fluid in this section.

16. Connect battery ground cable.

Valve Body Assembly (Adapter Case)

Removal

1.Raise the vehicle and support it on jack stands.

2.Disconnect battery ground cable.

3.Drain fluid.

4.Remove transfer and exhaust protectors.

5.Remove exhaust pipe and disconnect oxygen

sensor connector.

6.Remove twelve 10 mm adapter case oil pan fixing

screws, adapter case oil pan, and gasket.

NOTE: Oil pan still contains transmission fluid. Place a

large drain container under the oil pan.

Drain the fluid carefully.

7.Disconnect wiring harness from force motor

solenoid and converter clutch solenoid. Pull only on

connectors, not on wiring harness.

8.Remove seven 13 mm screws from adapter case

valve body assembly, then remove transfer plate,

two gaskets, and adapter case valve body.

Installation

1.Inspect electrical 5 pin connector and seal of

adapter case. Replace if necessary.

2.Install gasket, transfer plate, and gasket.

3.Install adapter case valve body and seven 13 mm

screws. Tighten the screws to the specified torque.

Torque: 20N•m (2.0kg·m/15lbft)

4.Connect wiring harness assembly to converter

clutch solenoid and force motor.

5.Install oil pan gasket, oil pan, and twelve 10 mm

screws. Tighten the screws to the specified torque.

Torque: 11N•m (1.1kg·m/96lbin)

6.Install exhaust pipe and connect oxygen sensor

connector. Tighten the bolts to the specified torque.

Exhaust pipe flange bolt torque: 43N•m(4.4kg·m/

32lbft)

7.Install transfer and exhaust protectors. Tighten the

bolts to the specified torque.

Torque: 37N•m(3.8kg·m/27lbft)

8.Fill transmission through the overfill screw hole of oil

pan, using ATF DEXRON®-III. Refer to Changing

Transmission Fluid in this section.

9. Connect battery ground cable.

Powertrain Control Module (PCM)

Removal

1. Disconnect battery ground cable.

2. Remove front console.

3. Disconnect PCM wiring harness connectors from

PCM.

4. Remove three PCM retaining screws.

5. Remove two brackets from PCM.

826RV006

Installation

1. Install two brackets to PCM.

2. Install three PCM retaining screws.

3. Connect PCM wiring harness connectors to PCM.

4. Install front console.

5. Connect battery ground cable.

Speed Sensor (Extension Housing)

Removal

1.Disconnect battery ground cable.

2.Remove front console.

3.Remove selector lever assembly.

4.Disconnect speed sensor harness connector from

speed sensor.

5.Remove one 10 mm screw and speed sensor with

O–ring.

241RW007

Installation

1.Inspect the speed sensor O–ring, and replace it if

necessary.

2.Install speed sensor assembly and 10 mm screw.

Torque: 9N•m (0.9kg·m/78lbin)

3.Connect speed sensor harness connector to speed

sensor.

4.Install selector lever assembly.

•Adjust shift lock cable. Refer to Selector Lever in

this section.

5. Install front console.

6. Connect battery ground cable.

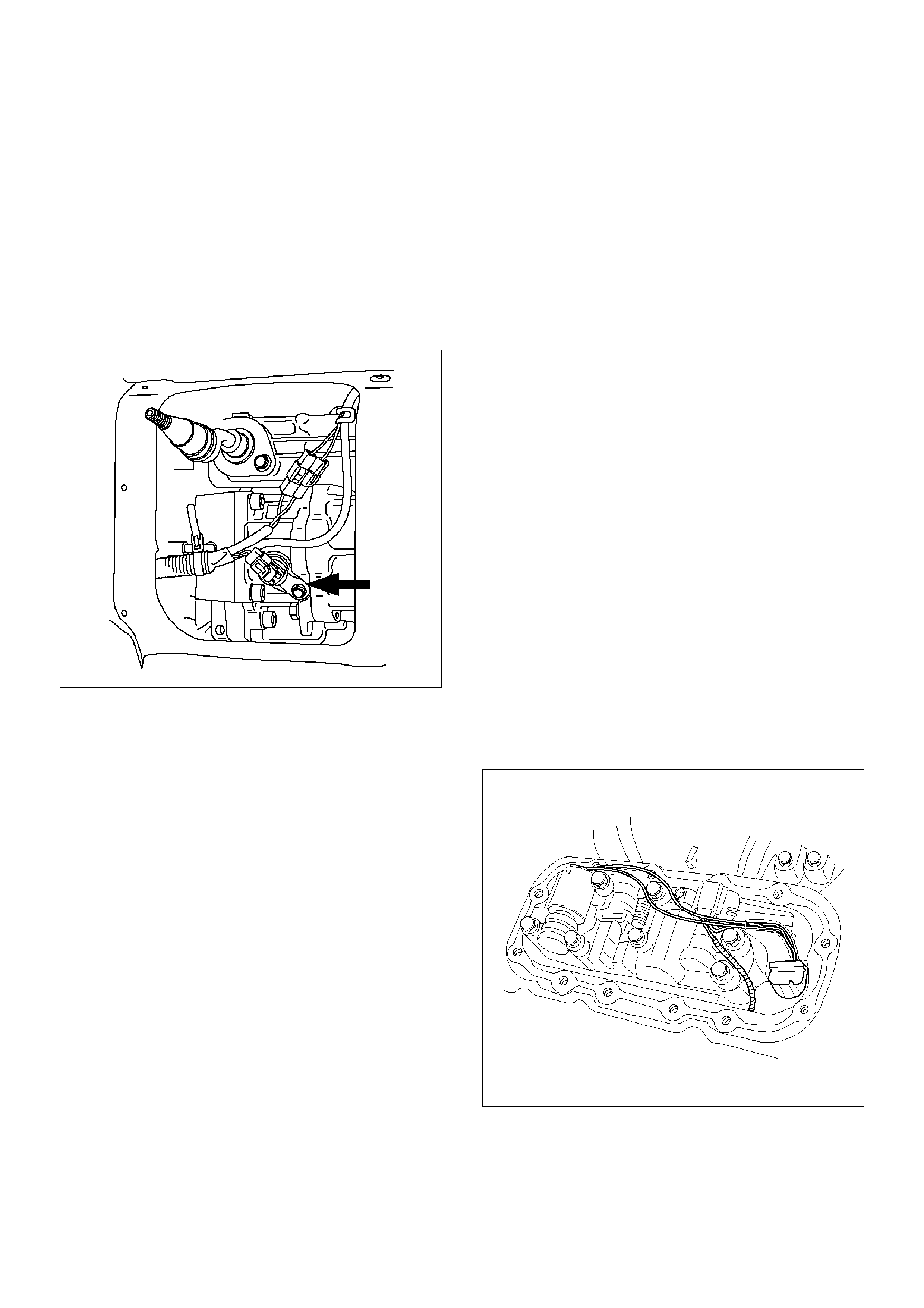

Transmission Oil Temperature Sensor (Adapter Case)

Removal

1. Raise the vehicle and support it on jack stands.

2. Disconnect battery ground cable.

3. Drain fluid.

4. Remove transfer and exhaust protectors.

5. Remove exhaust pipe and disconnect oxygen

sensor connector.

6. Remove twelve 10 mm adapter case oil pan fixing

screws, adapter case oil pan, and gasket.

NOTE: Oil pan still contains transmission fluid. Place a

large drain container under the oil pan, and drain the

fluid carefully.

7. Disconnect wiring harness from force motor

solenoid, converter clutch solenoid, and 5 pin

connector of adapter case. Pull only on connectors,

not on wiring harness.

8. Disconnect ground wire from converter clutch

solenoid wiring harness connector.

9. Remove wiring harness assembly (transmission oil

temperature sensor).

243RW002

Installation

1. Connect ground wire to converter clutch solenoid

wiring harness connector of the wiring harness

assembly.

2.Install wiring harness assembly to converter clutch

solenoid, force motor, and 5 pin connector of

adapter case.

3.Install oil pan gasket, oil pan, and twelve 10 mm

fixing screws. Tighten the screws to the specified

torque.

Torque: 11N•m (1.1kg·m/96lbin)

4.Install exhaust pipe and connect oxygen sensor

connector. Tighten the bolts to the specified torque.

Exhaust pipe flange bolt torque: 43N•m(4.4kg·m/

32lbft)

5.Install transfer and exhaust protectors. Tighten the

bolts to the specified torque.

Torque: 37N•m (3.8kg·m/27lbft)

6.Fill transmission through the overfill screw hole of oil

pan, using ATF DEXRON®-III.

Refer to Changing Transmission Fluid in this

section.

7.Connect battery ground cable.

8.

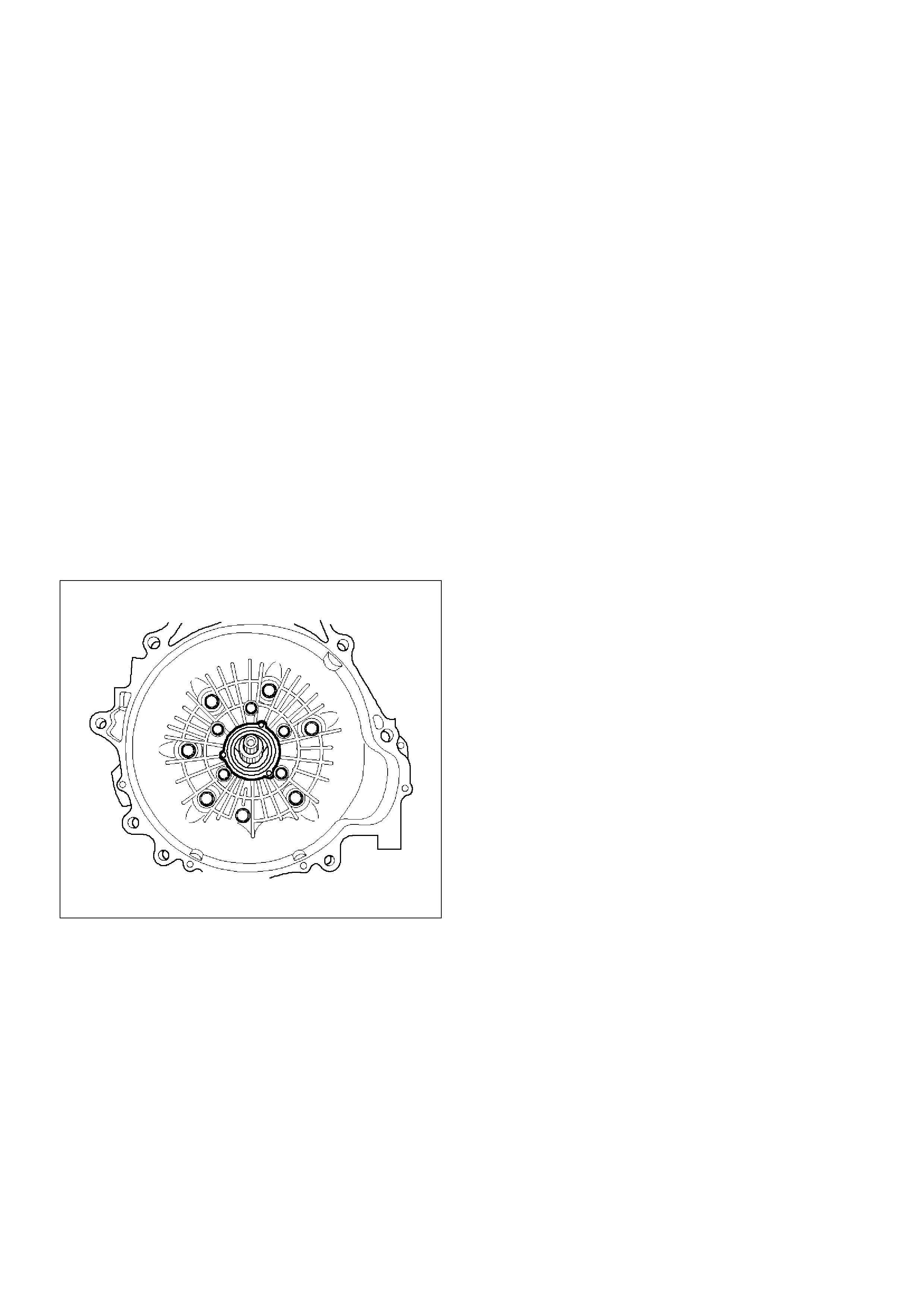

Front Oil Seal (Converter Housing)

Removal

1.Remove transmission assembly with transfer case

from the vehicle. Refer to Transmission (with

Transfer Case) in this section.

2.Remove torque converter from converter housing.

3.Remove three screws and oil seal ring from

converter housing.

241RW008

Installation

1.Apply clean ATF to the new oil seal ring lip.

•Install oil seal ring to converter housing. Tighten

the screws to the specified torque.

Torque: 3N•m (0.3kg·m/26lbin)

2.Install torque converter to converter housing.

3.Install transmission assembly with transfer case to

the vehicle. Refer to Transmission (with Transfer

Case) in this section.

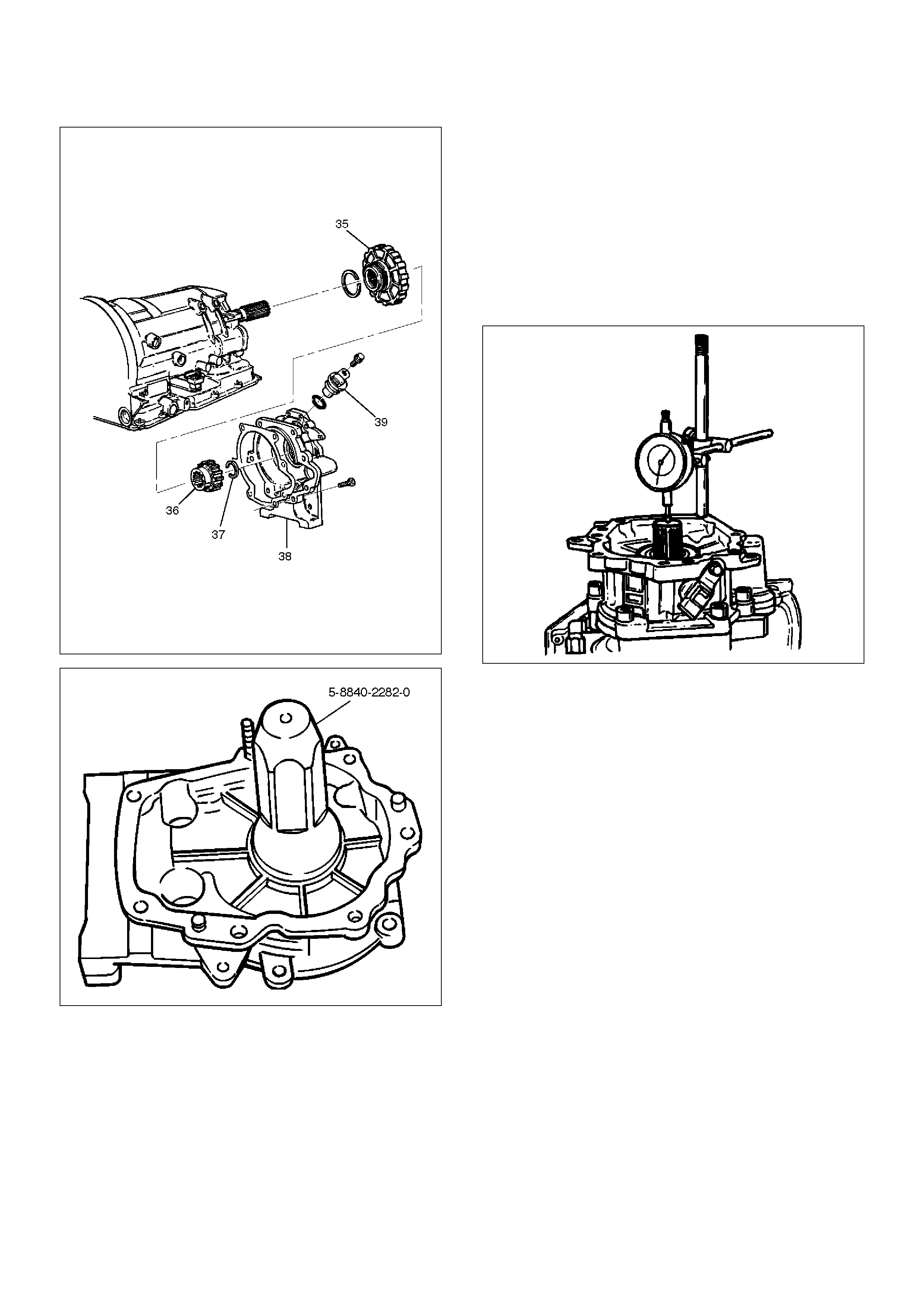

Rear Oil Seal (Extension Housing)

Removal

1.Remove transfer case assembly from the vehicle.

Refer to Transfer Case in Drive Line/Axle section.

2.Remove rear oil seal from transmission extension

housing.

241RW005

Installation

1.Use 5–8840–2282–0 (J–36797) extension housing

oil seal installer, and install the rear oil seal to the

transmission extension housing.

2.Install the transfer case assembly to the vehicle.

Refer to Transfer Case in Drive Line/Axle section.

Transmission (4L30–E)

Disassembly

NOTE: During the disassembly and reassembly,

perform the following:

• Wash each part thoroughly, and blow air through

each oil passage and groove to eliminate blockage.

• Seal rings, roll pins, and gaskets should be replaced.

• When assembling the components, apply

DEXRON®-III Automatic Transmission Fluid (ATF) to

each seal, rotating part, and sliding part.

• Do not dip part facings, such as clutch or brake drive

plates, in cleaner when washing it.

Also, always coat parts with new ATF two or three

times after cleaning with solvent.

1. Remove torque converter (1).

• Drain fluid from torque converter.

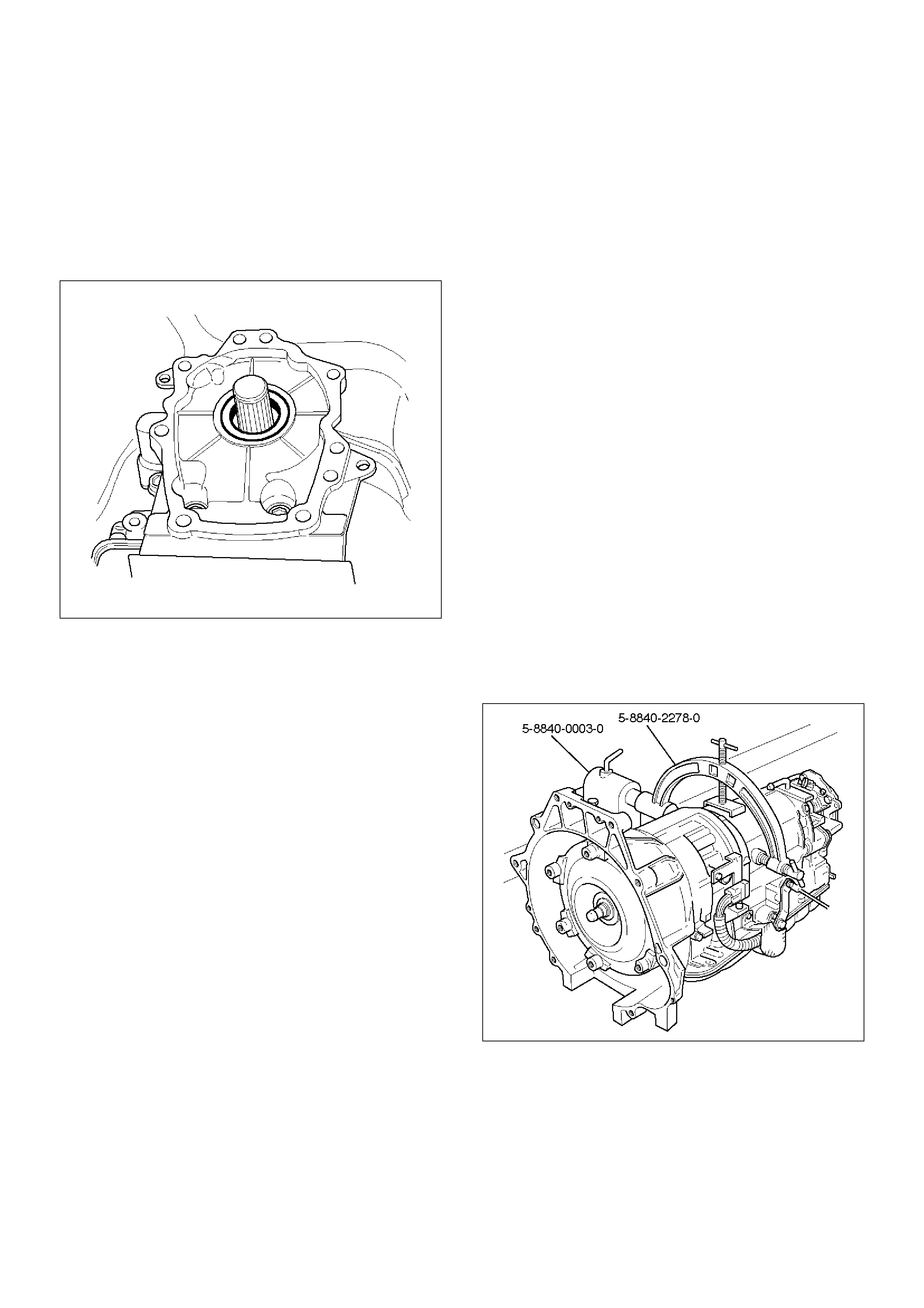

• Attach 5–8840–2278–0 (J–8763–02) holding

fixture to the transmission and set it on 5–8840–

0003–0 (J–3289–20) holding fixture base.

NOTE: Do not overtighten the tool, as case damage

may result.

420RW019

2. Remove O–ring (2) from turbine shaft.

3. Remove two 10mm mode switch screws, selector

lever nut, cover, and mode switch (3).

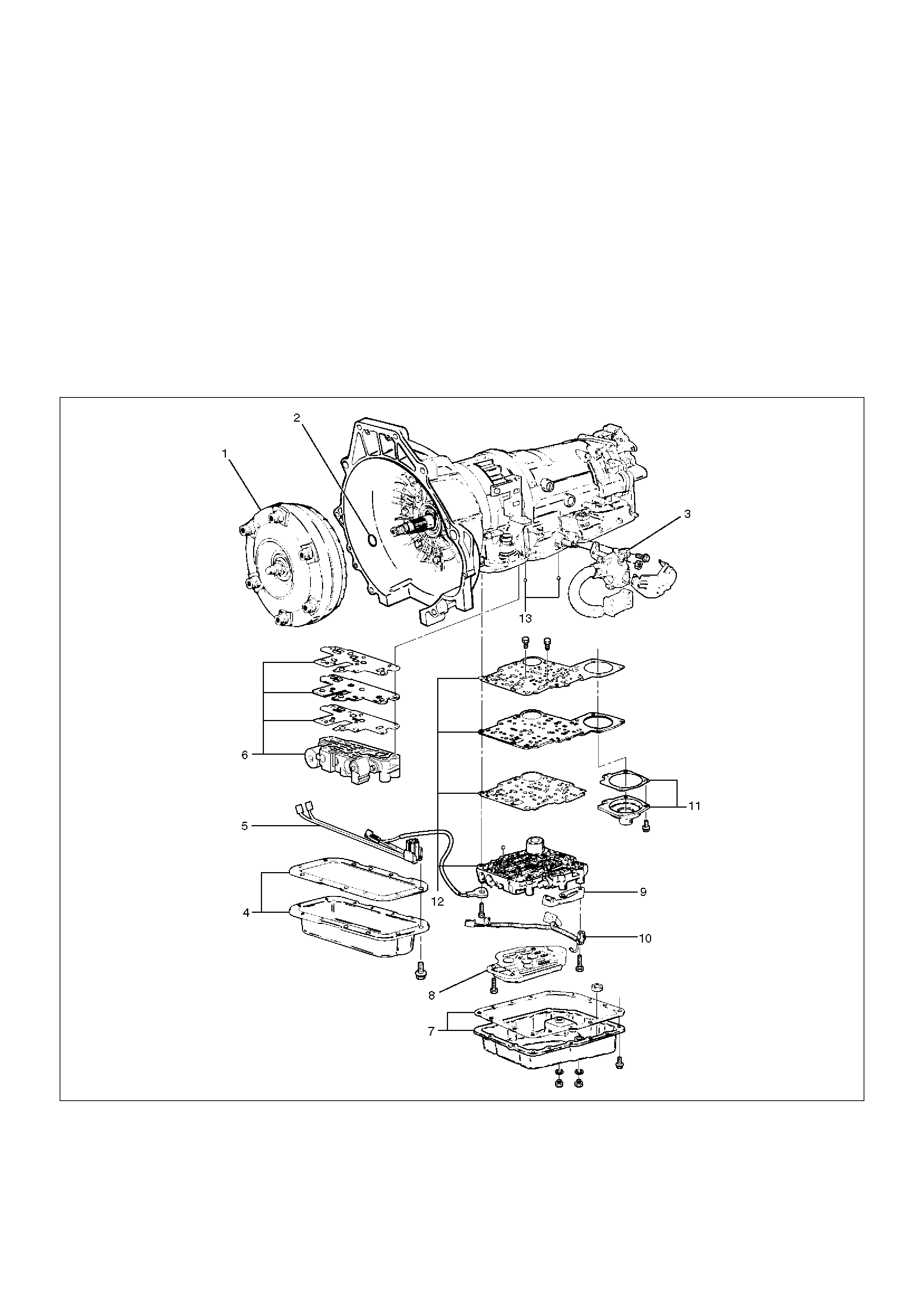

4. Remove twelve 10mm adapter case oil pan (4)

fixing screws, adapter oil pan, and gasket.

5. Disconnect electrical wiring connections (5) from

solenoids and 5 pin connector of adapter case. Pull

on connectors only, not on wiring harness.

6. Remove seven 13mm adapter case valve body (6)

fixing screws, adapter case valve body assembly,

transfer plate, and two gaskets.

• Remove wiring harness and 5 pin connector.

7. Remove sixteen 10mm main case oil pan (7) fixing

screws, main oil pan, magnet, and gasket.

8. Remove three 13mm oil filter (8) fixing screws and

oil filter.

9. Remove two 13mm manual detent (9) fixing screws,

roller and spring, and manual detent.

10. Disconnect wiring harness assembly (10) from band

apply solenoid, shift solenoids, and main case 4 pin

connector.

Pull on connectors only, not on wiring harness.

11. Remove four 13mm servo cover (11) fixing screws,

servo cover, and gasket.

12. Remove seven 13mm valve body screws and

ground wire from main case.

• Remove wiring harness assembly (5) from the

adapter case side.

• Remove main valve body assembly (12) with

manual valve link and transfer plate. Note the

position of the link (long end into valve, short end

into range selector lever).

• Remove 4 pin connector.

• Remove gasket transfer plate from main case.

13. Remove two check balls (13) from main case.

240RW022

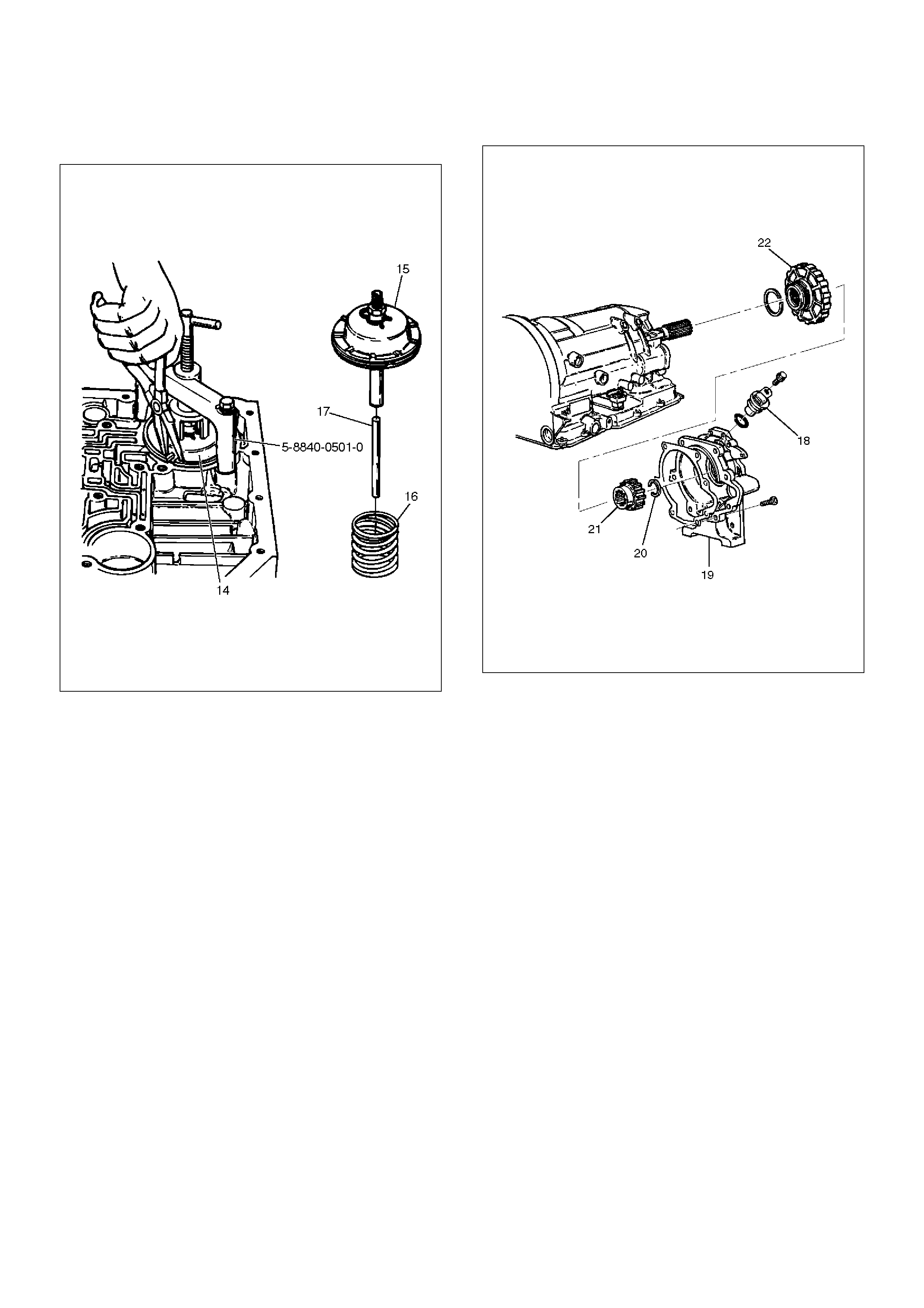

14. Turn transmission to vertical position to drain fluid.

Return back to horizontal position when drained.

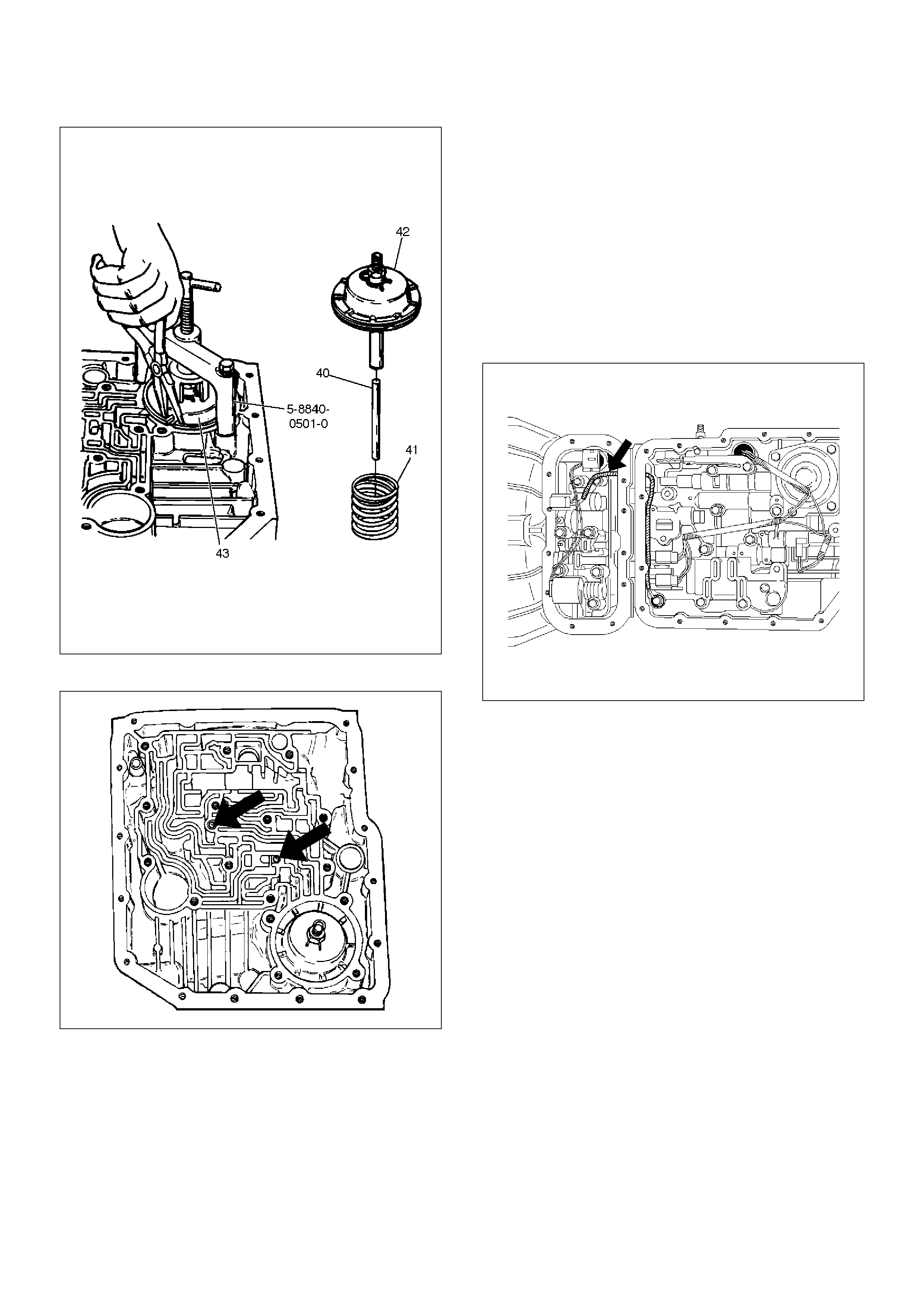

• Install 5–8840–0501–0 (J–23075) servo piston

spring compressor with offset to the rear of case.

• Compress servo piston assembly.

• Remove servo piston retaining ring (14).

• Slowly release servo piston assembly (15).

• Remove tool.

15. Remove servo piston assembly (15), return spring

(16), and servo apply rod (17).

242RW006

16. Rotate transmission to horizontal position, pan side

down.

• Remove one 10mm screw, and speed sensor

(18) with “O” ring.

17. Remove seven 8mm extension housing hexagon

socket head screws, extension housing assembly

(19), and gasket.

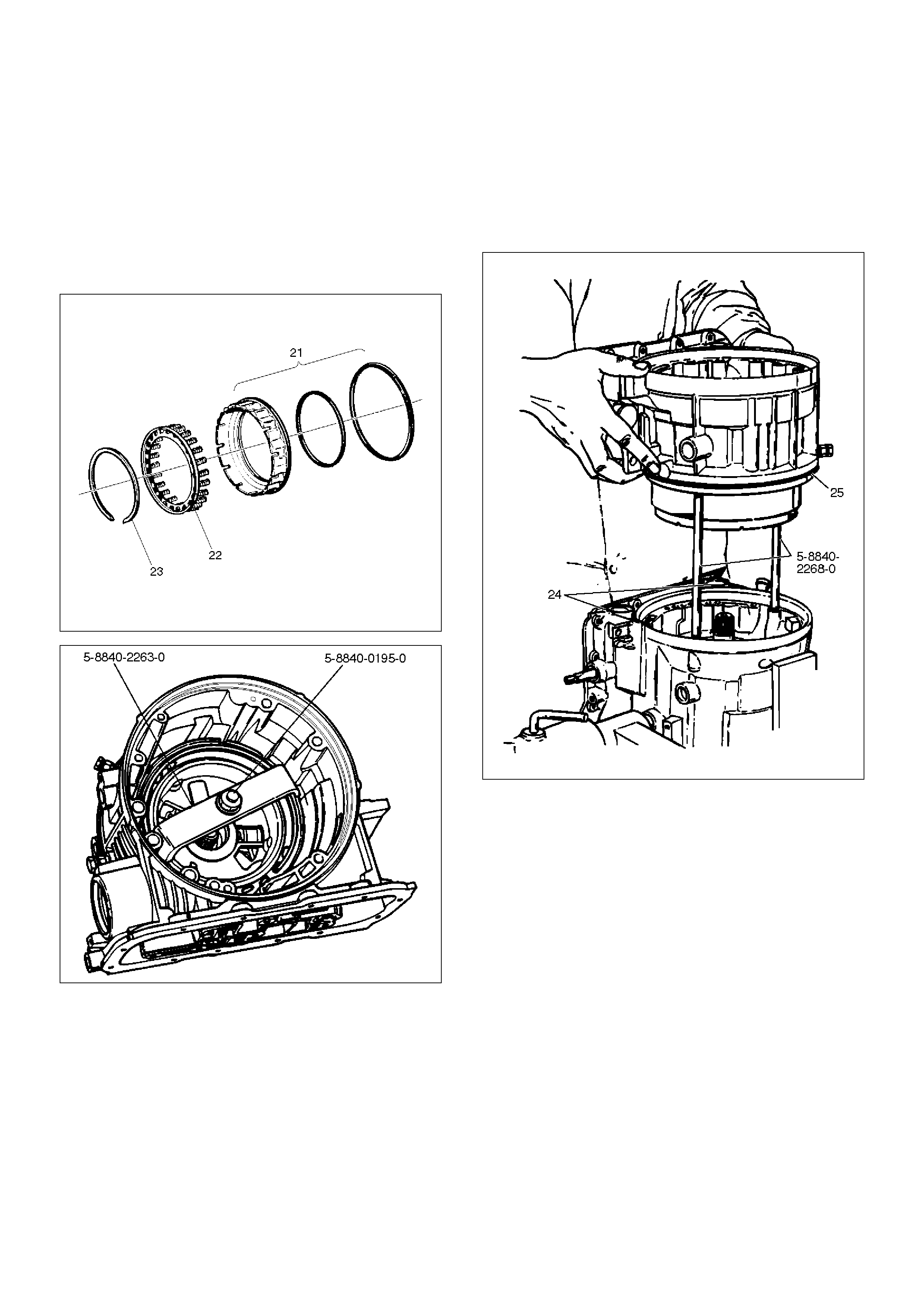

18. Remove retaining ring (20).

NOTE: Use extra long, needle- nose pliers.

19. Remove speed wheel (21).

20. Remove wheel parking lock (with seal ring) (22).

241RS002

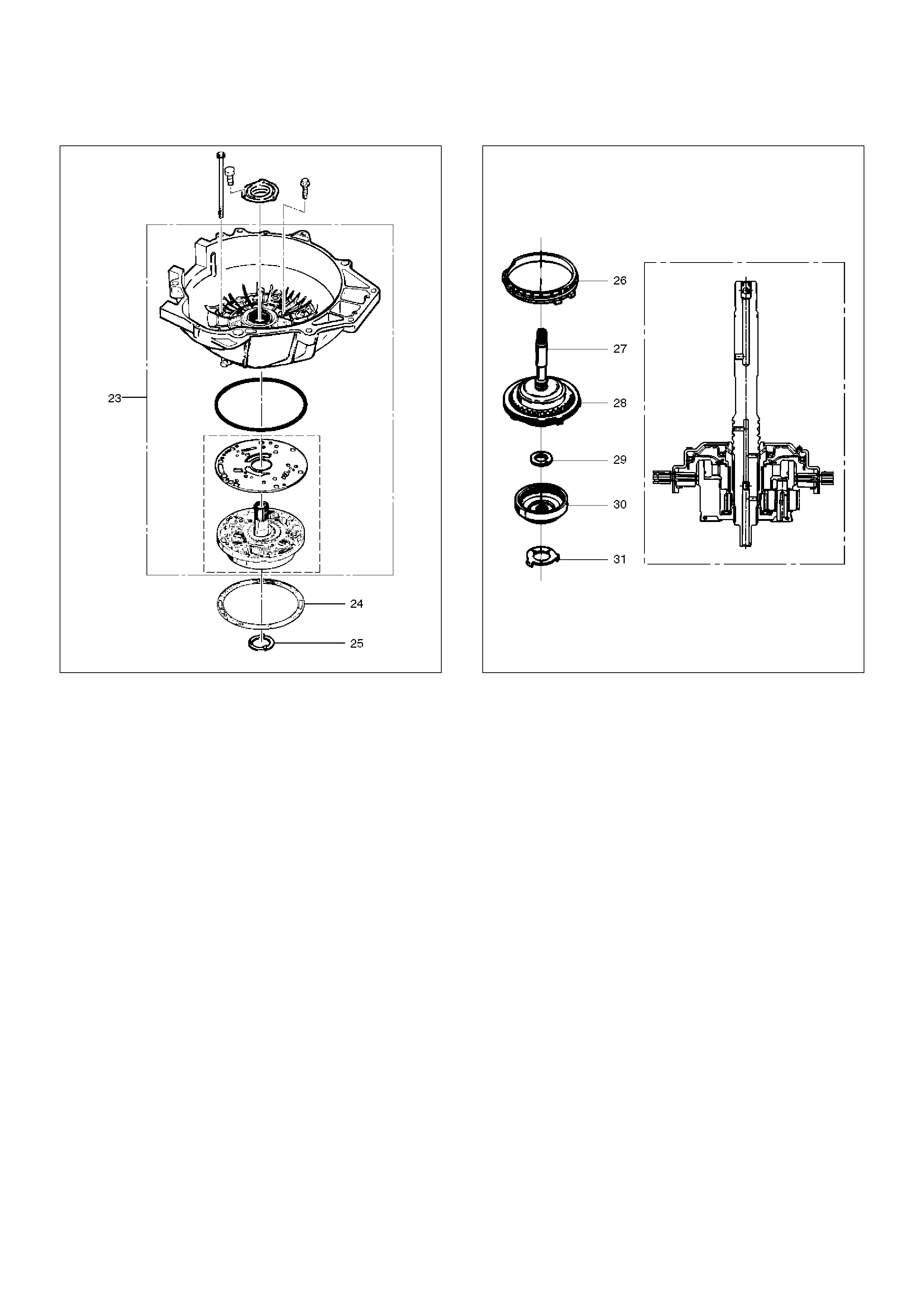

21. Rotate transmission to vertical position, converter

housing up.

• Loosen the converter housing and oil pump

assembly fixing screws, but do not remove the

five 13 mm inner screws if oil pump disassembly

is required.

• Remove seven outer screws.

• Remove converter housing and oil pump

assembly (23).

22. Remove gasket (24).

23. Remove selective thrust washer (25).

241RW004

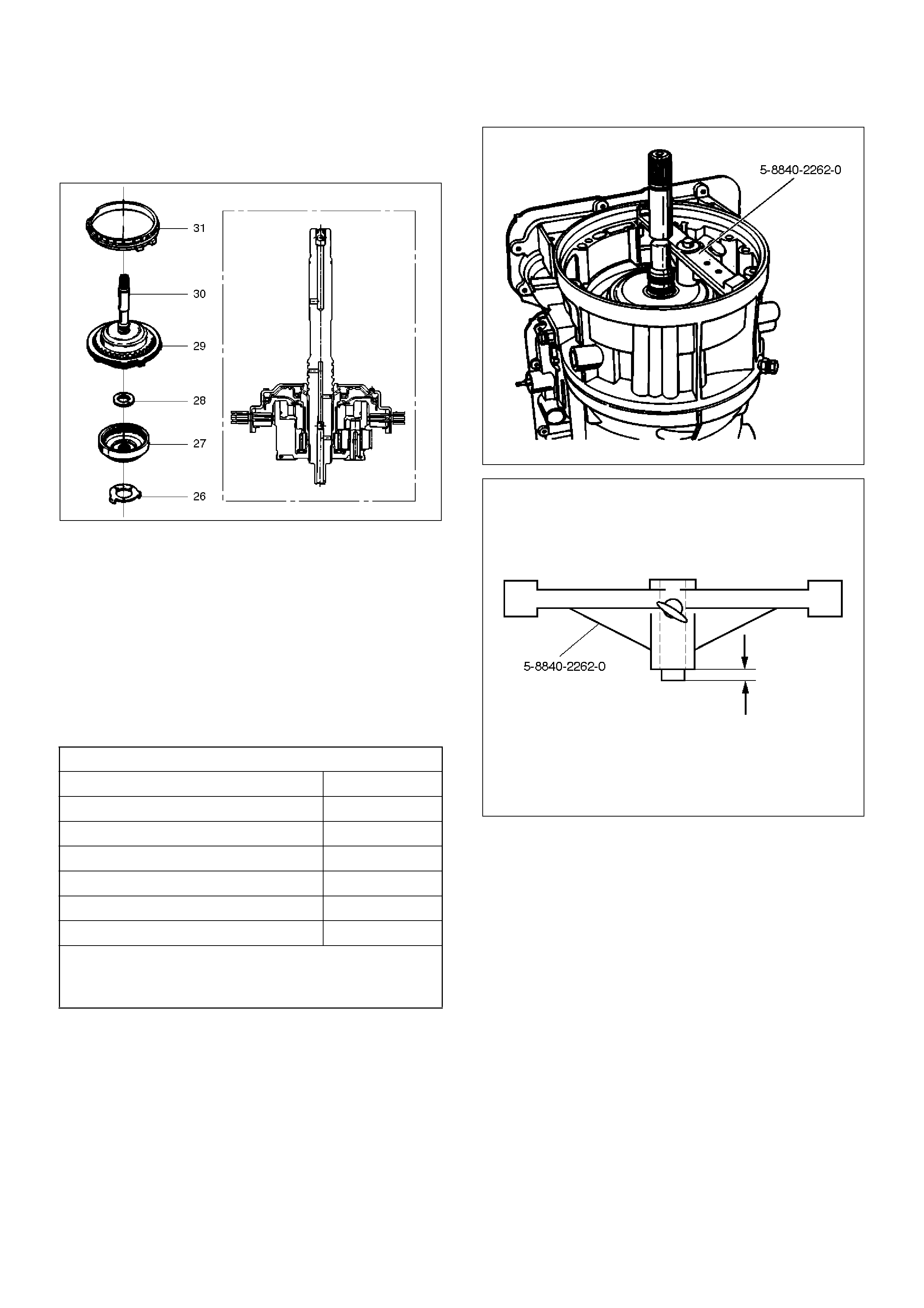

24. Remove fourth clutch retainer (26).

25. Grasp turbine shaft and lift out the overrun clutch

housing assembly (27) and fourth clutch plates (28).

26. Remove thrust bearing assembly (29).

27. Remove overdrive internal gear (30).

28. Remove thrust washer (31).

252RS001

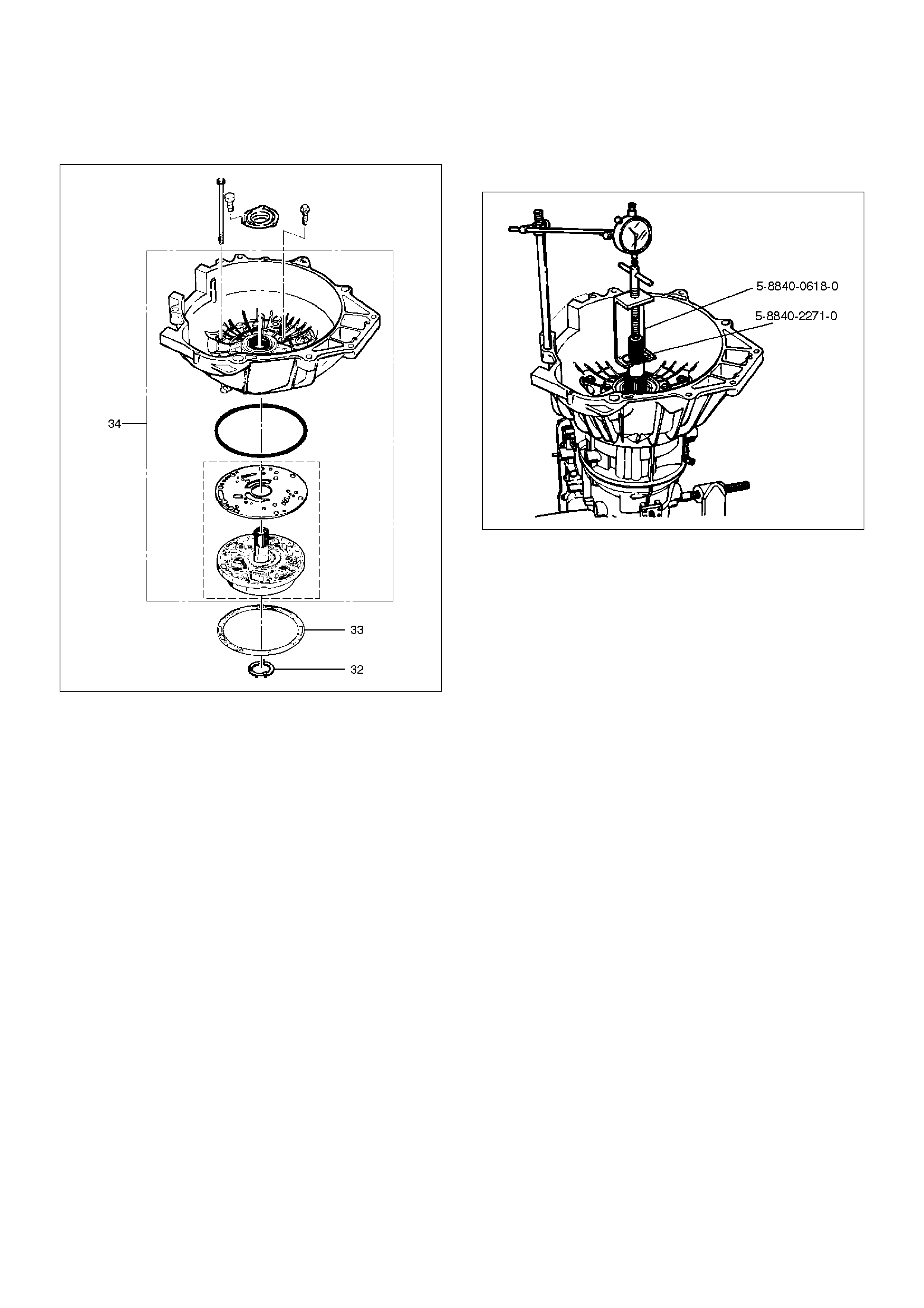

29. Remove adapter case and center support assembly

(with fourth clutch piston) (32).

30. Remove seal ring (33).

31. Remove selective thrust washer (34) and two O–

ring seals (35) from main case.

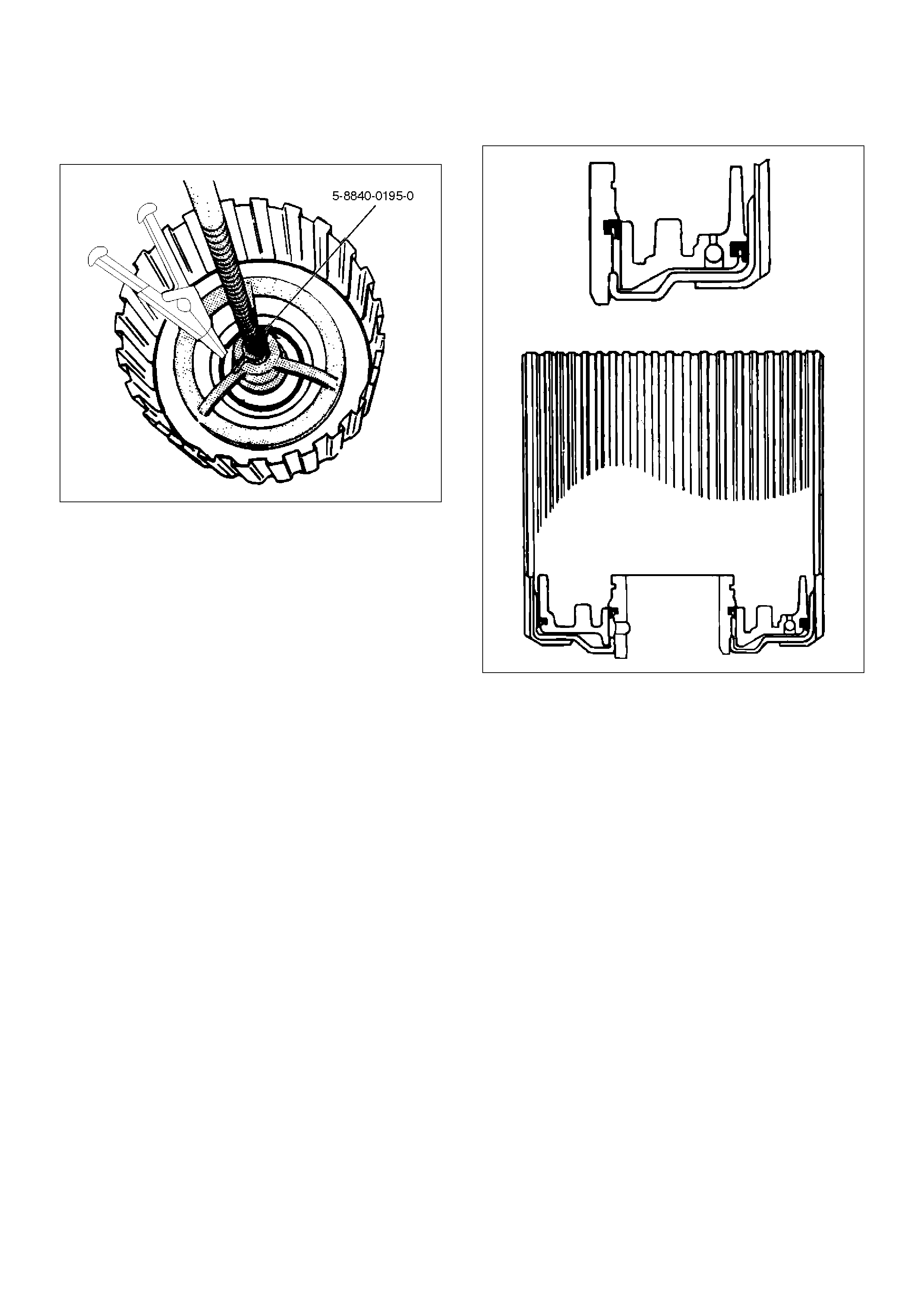

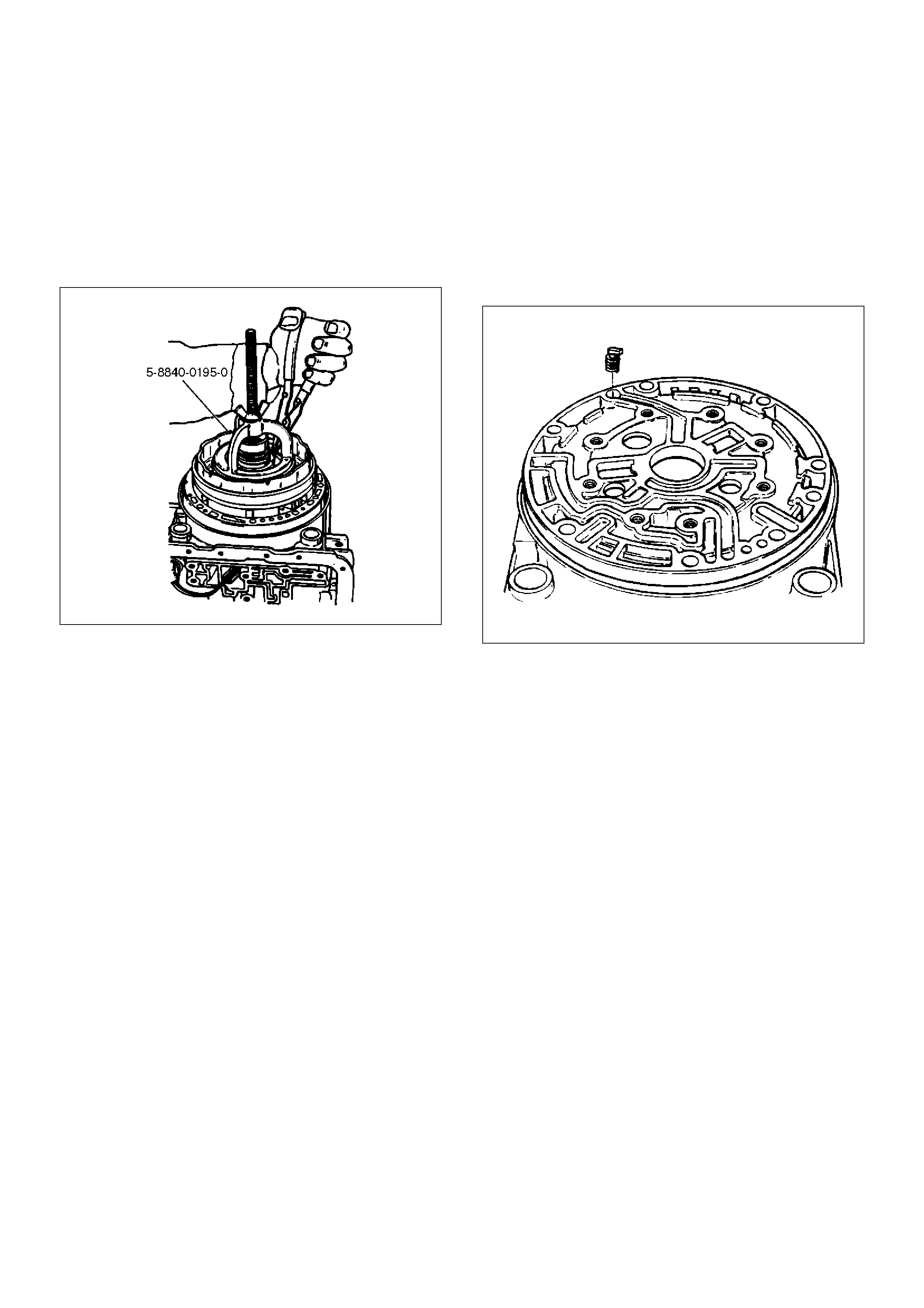

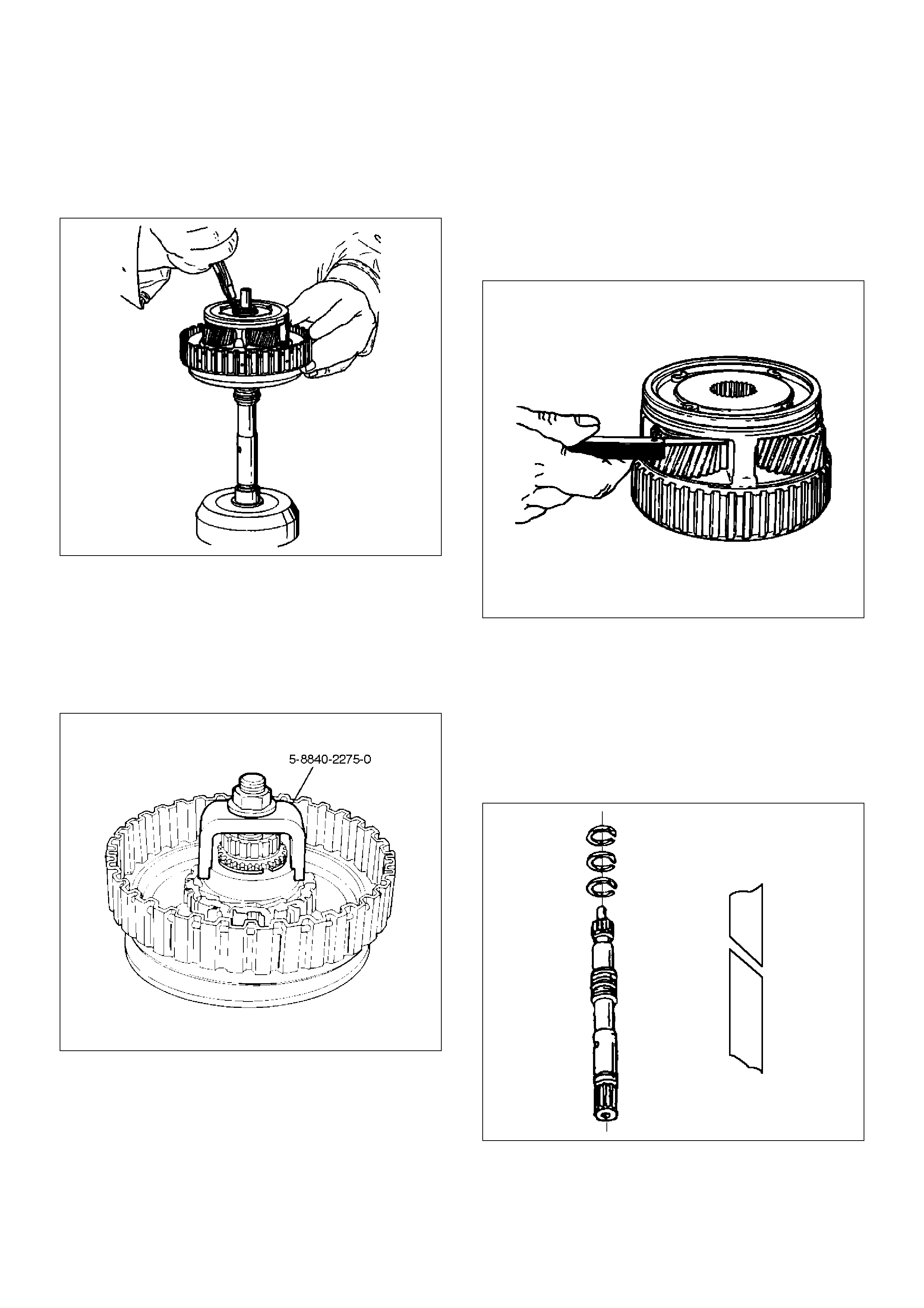

32. Use 5–8840–0195–0 (J–23327) and 5–8840–2263–

0 (J–23327–90) compressor to compress the fourth

clutch spring retainer and springs (37).

• Release snap ring (36) from groove.

• Remove clutch compressor and snap ring (36).

33. Remove retainer and spring assembly (37).

34. Insert two converter housing/main case screws to

hold adapter case while pulling out fourth clutch

piston (38).

• Remove fourth clutch piston assembly (38) from

the adapter case.

• Remove converter housing/main case screws.

35. Grasp intermediate shaft, twist and pull out the

second and third clutch drum assemblies with