SECTION 9A - POWER STEERING

General Description

Power Steering Gear

Hydraulic Pump

Pressure Switch ( 6VE1 Engine)

Power Steering System Test

On-Vehicle Service

Bleeding The Power Steering System

Flushing The Power Steering System

Steering Gear

Power Steering Pump ( 6VE1 Engine)

Power Steering Pump (4JX1 Engine)

Unit Repair

Steering Gear

Power Steering Pump ( 6VE1 Engine)

Power Steering Pump (4JX1 Engine)

GENERAL DESCRIPTION

6VE1 Engine

4JX1 Engine

The hydraulic power steering system consists of a

pump, an oil reservoir, a steering gear, a pressure

hose and a return hose.

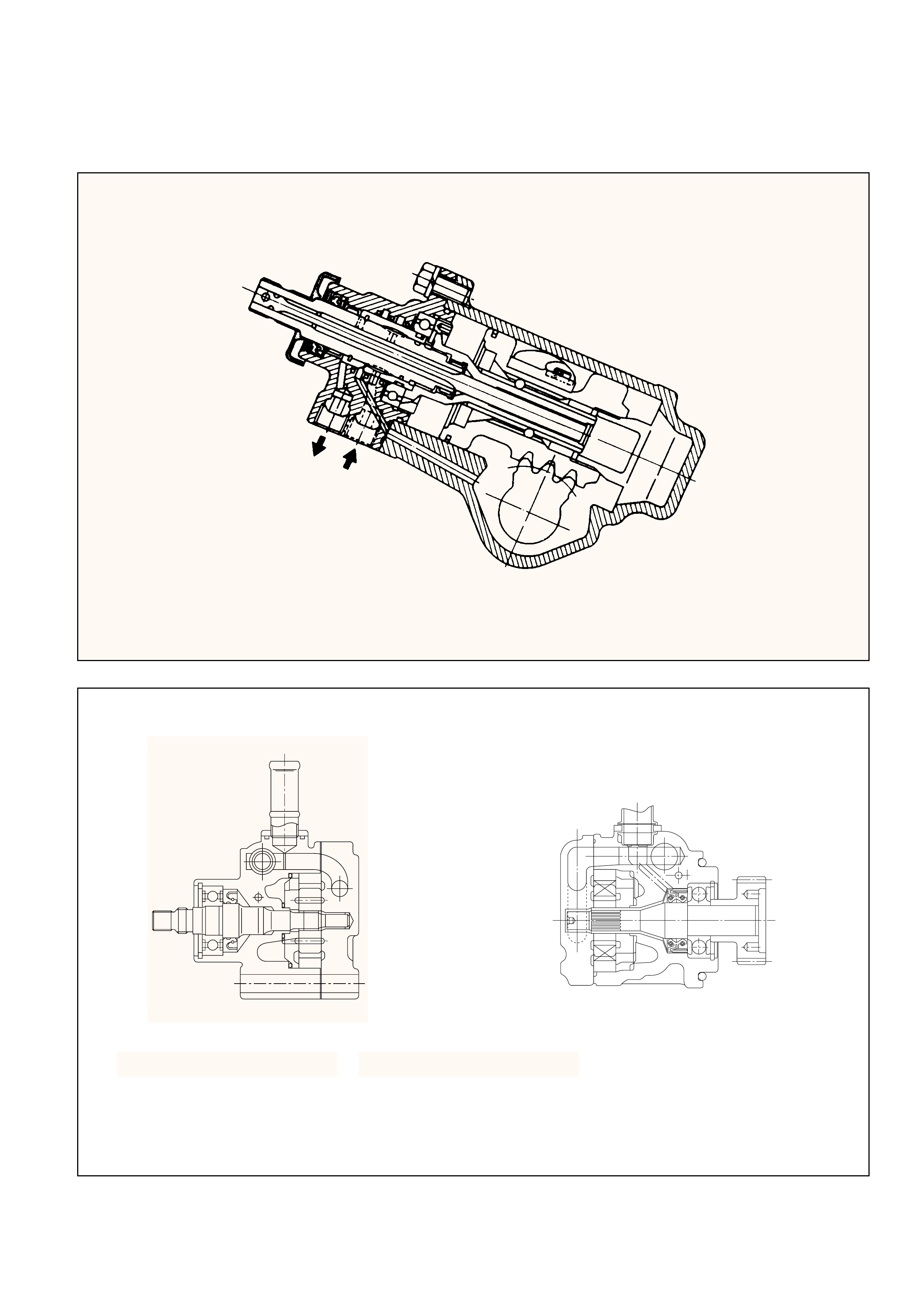

POWER STEERINGGEAR

The power steering gear has a recirculating ball

system which acts as a rolling thread between the

worm shaft and the rack piston. When the worm

shaft is turned right, the rack piston moves up in

gear. Turning the worm shaft left moves the rack

piston down in gear. The rack piston teeth mesh

with the sector, which is part of the sector shaft.

Turning the worm shaft turns the sector shaft,

which turns the wheels through the steering

linkage.

The control valve in the steering gear directs the

power steering fluid to either side of the rack

piston. The rack piston converts the hydraulic

pressure into a mechanical force. If the steering

system becomes damaged and loses hydraulic

pressure, the vehicle can be controlled manually.

HYDRAULICPUMP

The hydraulic pump is vane-type design.

There are two bore openings at the rear of the

pump housing. The smaller opening contains the

pressure line union and flow control valve.

PRESSURESWITCH (6VE1

ENGINE)

When hydraulic pressure reaches 3650 ± 350 kPa

(530 ±50 PSI), the pressure switch closes causing

ECM to actuate the idle air control valve to prevent

the overload-induced engine speed drop. The

switch opens when hydraulic pressure drops to

3150 ± 350 kPa (460 ± 50PSI).

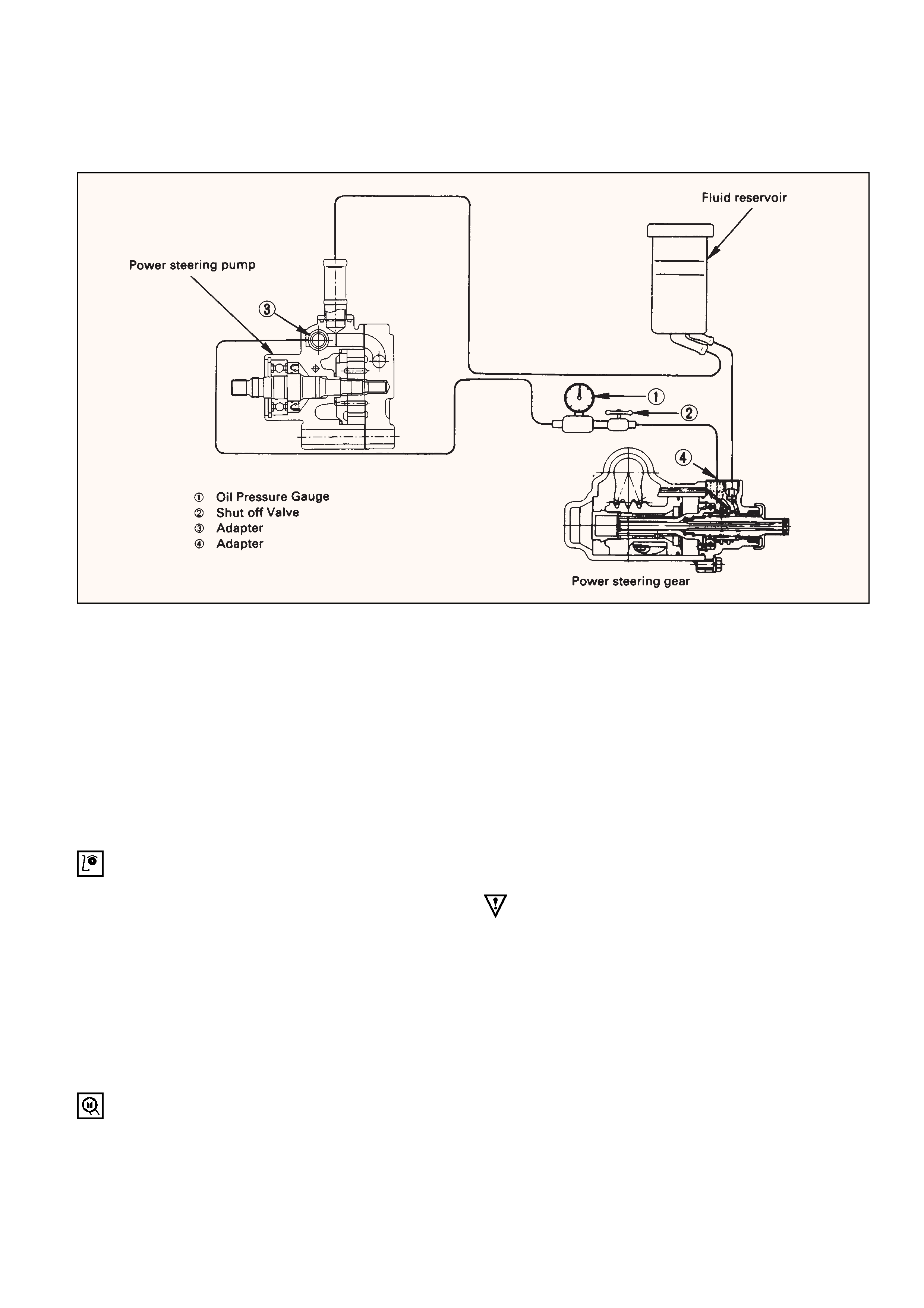

POWER STEERING SYSTEM TEST

TEST PROCEDURE

Test of fluid pressure in the power steering system

is performed to determine whether or not the oil

pump and power steering unit are functioning

normally.

The power steering system test is method used to

identify and isolate hydraulic circuit difficulties.

Prior to performing this test, the following

inspections and corrections, if necessary, must be

made.

INSPECT

•Pump reservoir for proper fluid level.

•Pump belt for proper tension.

•Pump driver pulley condition.

1.Place a container under the pump to catch the

fluid when disconnecting or connecting the

hoses.2. With the engine NOT running , disconnect the

pressure hose at the power steering pump and

install Power Steering tester.

The gage must be between the shutoff valve

and pump. Open the shutoff valve.

Tester: 5-8840-0135-0 (J-29877-A)Adapter: 5-8840-2297-0

3. Check the fluid level. Fill the reservoir with

power steering fluid, to the “Full” mark. Start

the engine then turn the steering wheel andmomentarily hold it against a stop. Turn off

and check the connections at tester for leakage.4. Bleed the system. Refer to “Bleeding the

Power Steering System” in this section.

5. Start the engine and check the pump fluid

level. Add power steering fluid if required.

When the engine is at normal operating

temperature, increase engine speed to 1500

rpm.

CAUTION:

Do not leave shutoff valve fully closed for more

than 5 seconds, as the pump could become

damaged internally.

6. Fully close the shutoff valve. Record the

highest pressures.

•If the pressure recorded is within 9300-9800

kPa (1350-1420 psi) For 6VD1, 6VE1, and

9800-10300 kPa (100-105 kg/cm2/ 1420-1490

psi) For 4JG2, 4JX1, the pump is functioning

within its specifications.

•If the pressure recorded is higher than 9800

kPa (1420 psi) For 6VD1, 6VE1, and 10300

kPa (105 kg/cm2/ 1490 psi) For 4JG2, 4JX1,

the valve in the pump is defective.

· If the pressure recorded is lower than 9300

kPa (1350 psi) For 6VE1, and 9800 kPa

(100 kg/cm 2/ 1420 psi) For 4JX1, the

valve or the rotating group in the pump is

defective.

7. If the pump pressure are within specifications,

leave the valve open and turn (or have

someone else turn) the steering wheel fully in

both directions. Record the highest pressures

and compare with the maximum pump

pressure recorded in step 6. If this pressure

cannot be built in either (or one) side of the

power steering gear, the power steering gear is

leaking internally and must be disassembled

and repaired.

8. Shut the engine off, remove the testing gage,

reconnect the pressure hose, check the fluid

level and make the needed repairs.

9. If the problem still exists, the steering and front

suspension must be thoroughly examined.

BLEEDINGTHEPOWER

STEERING SYSTEM

When a power steering pump or gear has been

installed, or an oil line has been disconnected, the

air that has entered the system must be bled out

before the vehicle is operated. If air is allowed to

remain in the power steering fluid system, noisy

and unsatisfactory operation of the system may

result.

BLEEDING PROCEDURE

When bleeding the system, and any time fluid is

added to the power steering system, be sure to use

only power steering fluid as specified in

“MAINTENANCE ANDLUBRICATION” in section

0B.

1.Fill the pump fluid reservoir to the proper

level and let the fluid settle for at least two

minutes.

2.Start the engine and let it run for a few

seconds.

Do not turn the steering wheel. Then turn the

engine off.

3.Add fluid if necessary.

4.Repeat the above procedure until the fluid

level remains constant after running the

engine.

5.Raise the front end of the vehicle so that the

wheels are off the ground.

6.Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the

wheel stops.

7.Add power steering fluid if necessary.

8.Bring down the vehicle, set the steering wheel

at the straight forward position after turning it

to its full steer positions 2 or 3 times, and stop

the engine.

9.Stop the engine. Check the fluid level and

refill as required.

10.If the fluid is extremely foamy, allow the

vehicle to stand a few minutes and repeat the

above procedure.

INSPECT

•Belt for tightness.

•Pulley for looseness or damage. The pulley

should not wobble with the engine running.

•Make sure that hose and pipes are properly

fitted.

•Fluid level and fill to the proper level.

FLUSHINGTHEPOWER

STEERING SYSTEM

1.Raise the front end of the vehicle off the

ground until the wheels are free to turn.

2.Remove the fluid return line at the reservoir

inlet connector and plug the connector.

Position the line toward a large container to

catch the draining fluid.

3.While running the engine at idle, fill the

reservoir with new power steering fluid. Turn

the steering wheel in both directions. Do not

contact wheel stops or hold the wheel in a

corner, or fluid will stop and the pump will be

in pressure relief mode. A sudden overflow

from the reservoir may develop if the wheel is

held at a stop.

4.While refilling the reservoir, check the

draining fluid for contamination. If foreign

material is still evident, replace all lines,

disassemble and clean or replace the power

steering system components. Do not re-use

any drained power steering fluid.

5.Install all the lines and hoses. Fill the system

with new power steering fluid and bleed the

system as described in “Bleeding The Power

Steering System”. Operate the engine for

about 15 minutes.

ON-VEHICLE SERVICE

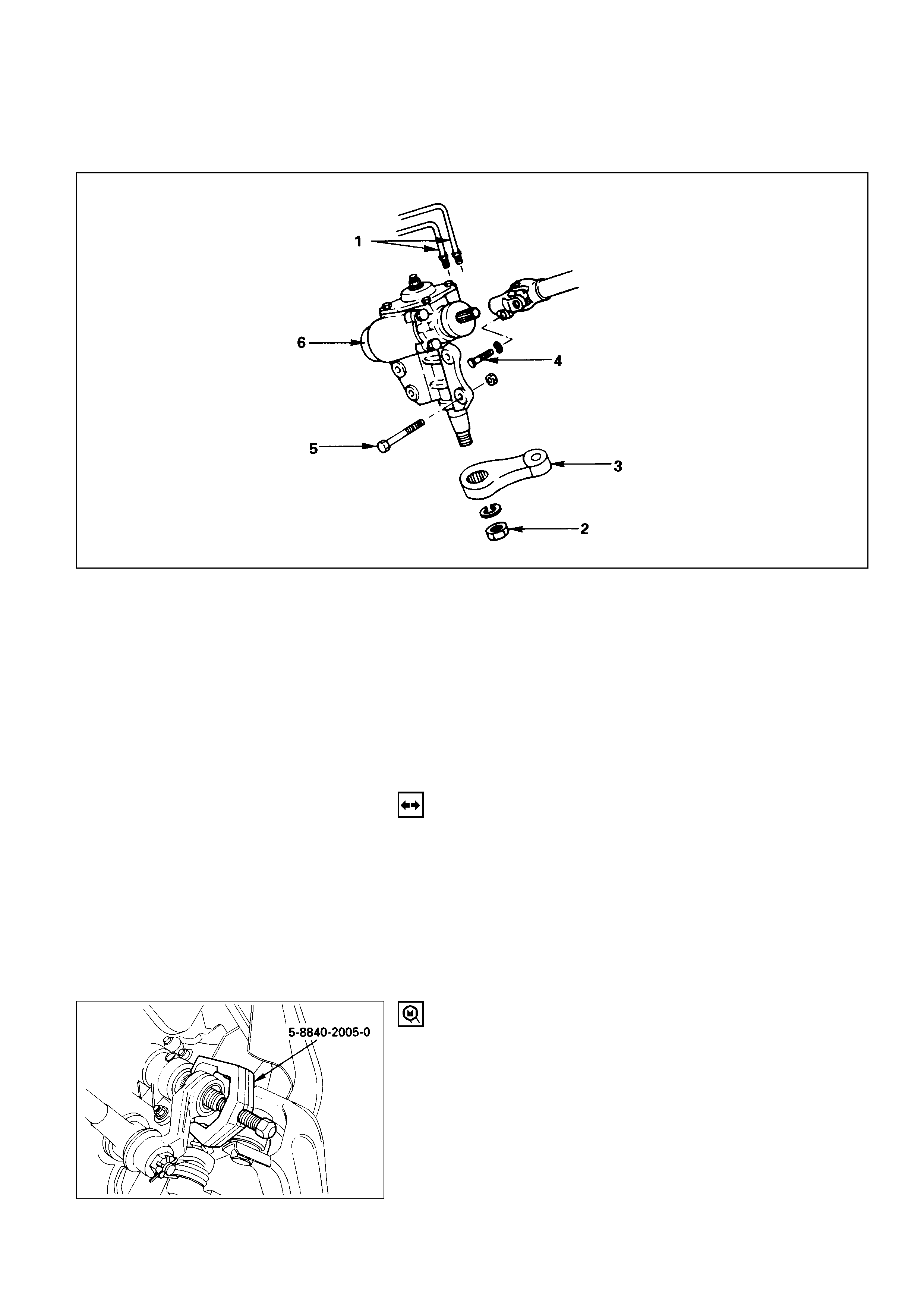

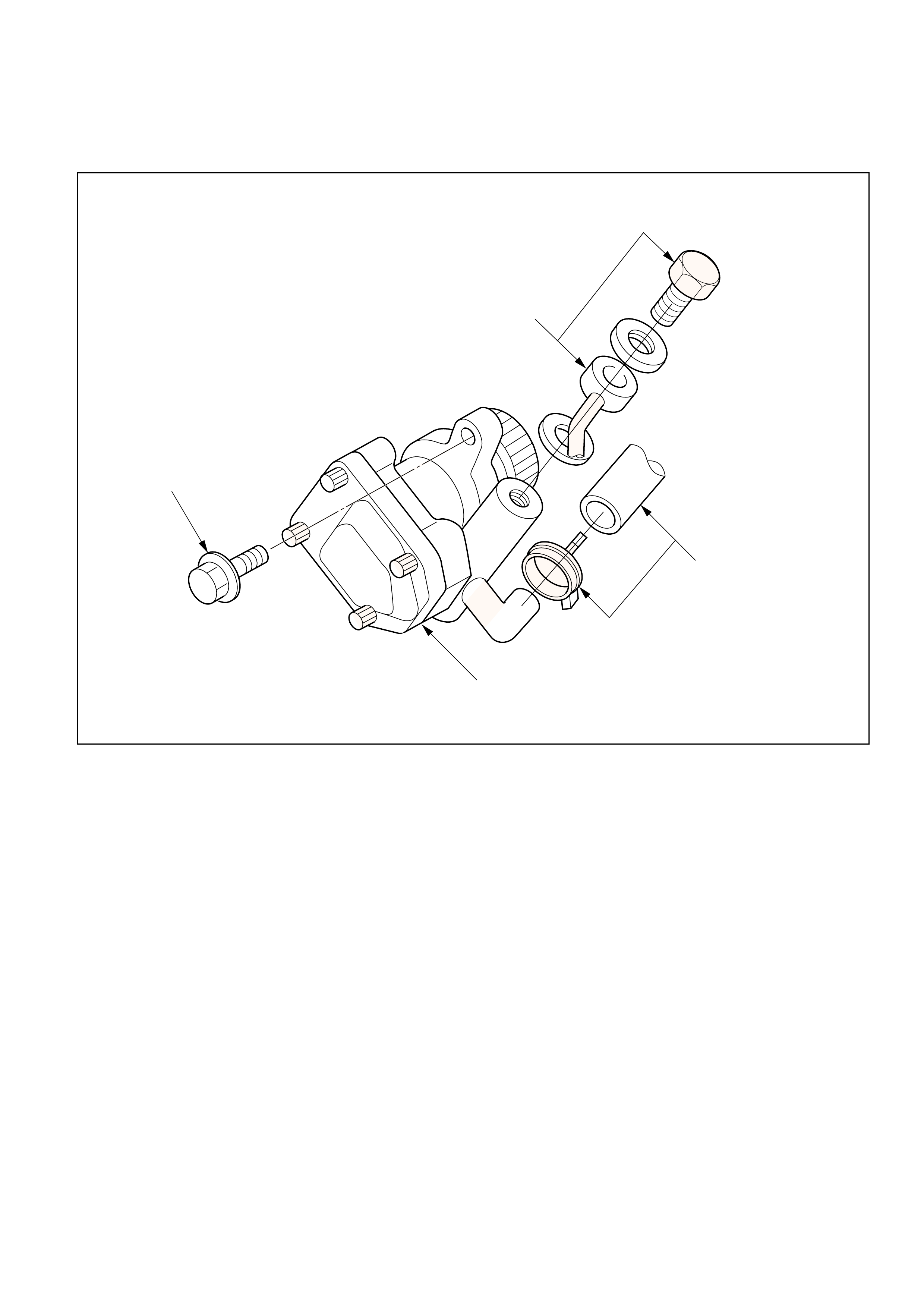

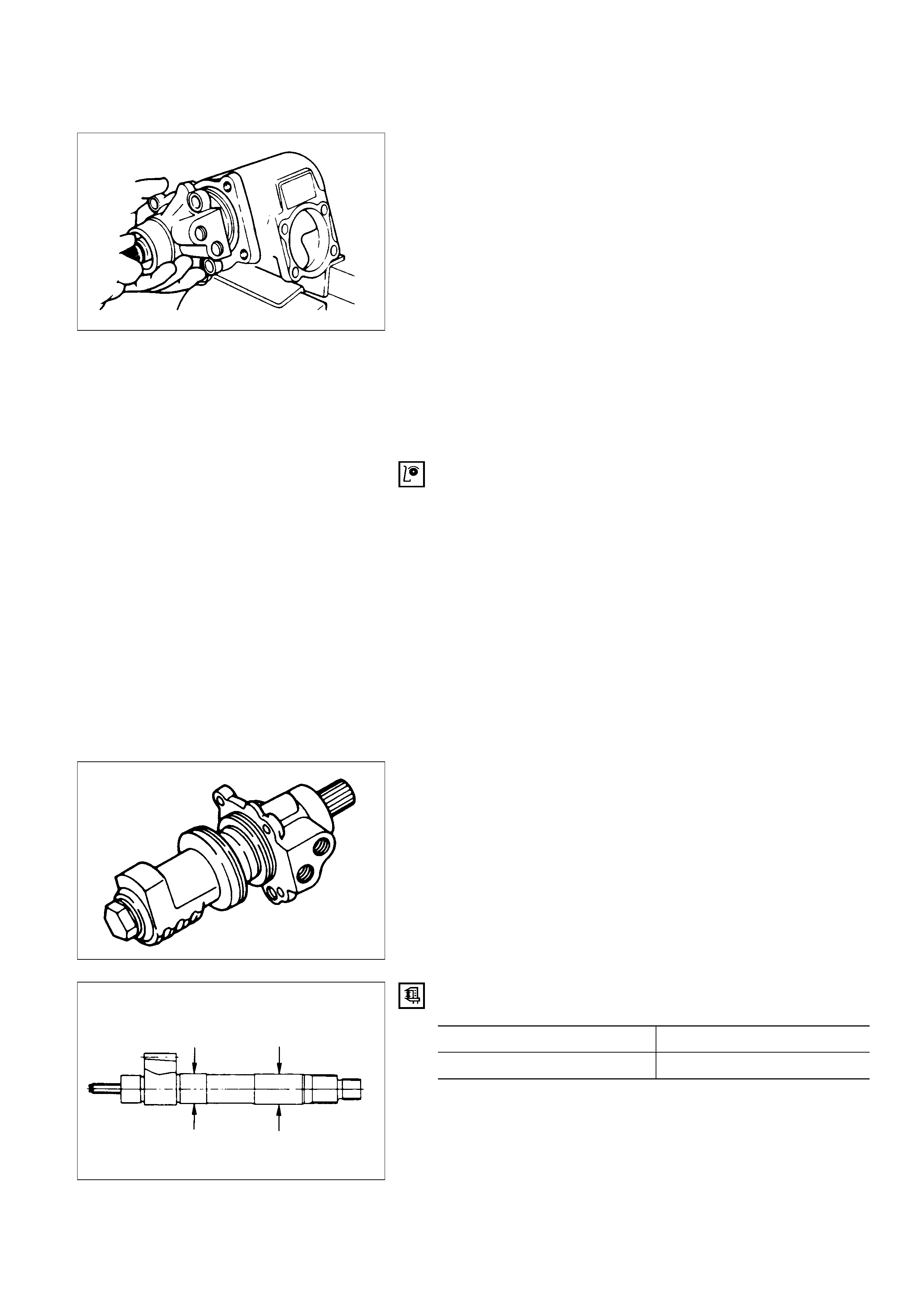

STEERING GEAR

Removal Steps

1. Pipe

2. Nut

3. Pitman arm

4. Universal joint bolt

5. Gear box mounting bolt and nut

6. Gear box

Installation Steps

6. Gear box

5. Gear box mounting bolt and nut

4. Universal joint bolt

3. Pitman arm

2. Nut

1. Pipe

REMOVAL

Preparation:

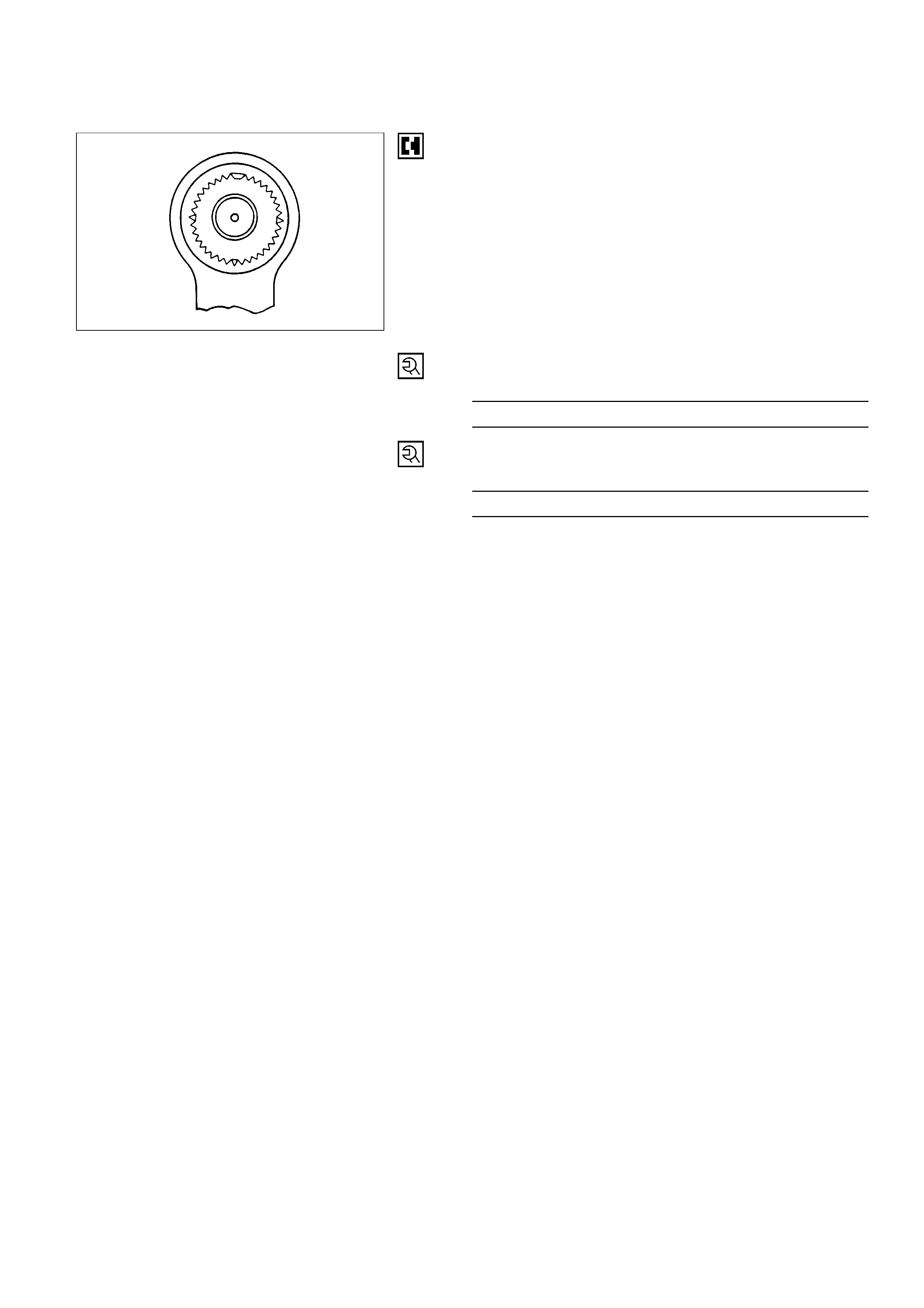

1) Remove the stone guard.

2) Remove the lower fan shroud. Refer to “Engine

cooling” in sections 6B1 and 6B.

3) Disconnect stabilizer bar at the stabilizer links.

Loosen stabilizer bracket fixing nuts.

1. Pipe

2. Nut

3. Pitman Arm

Pitman arm remover: 5-8840-2005-0 (J-29107)

These steps are based on the LHD model.

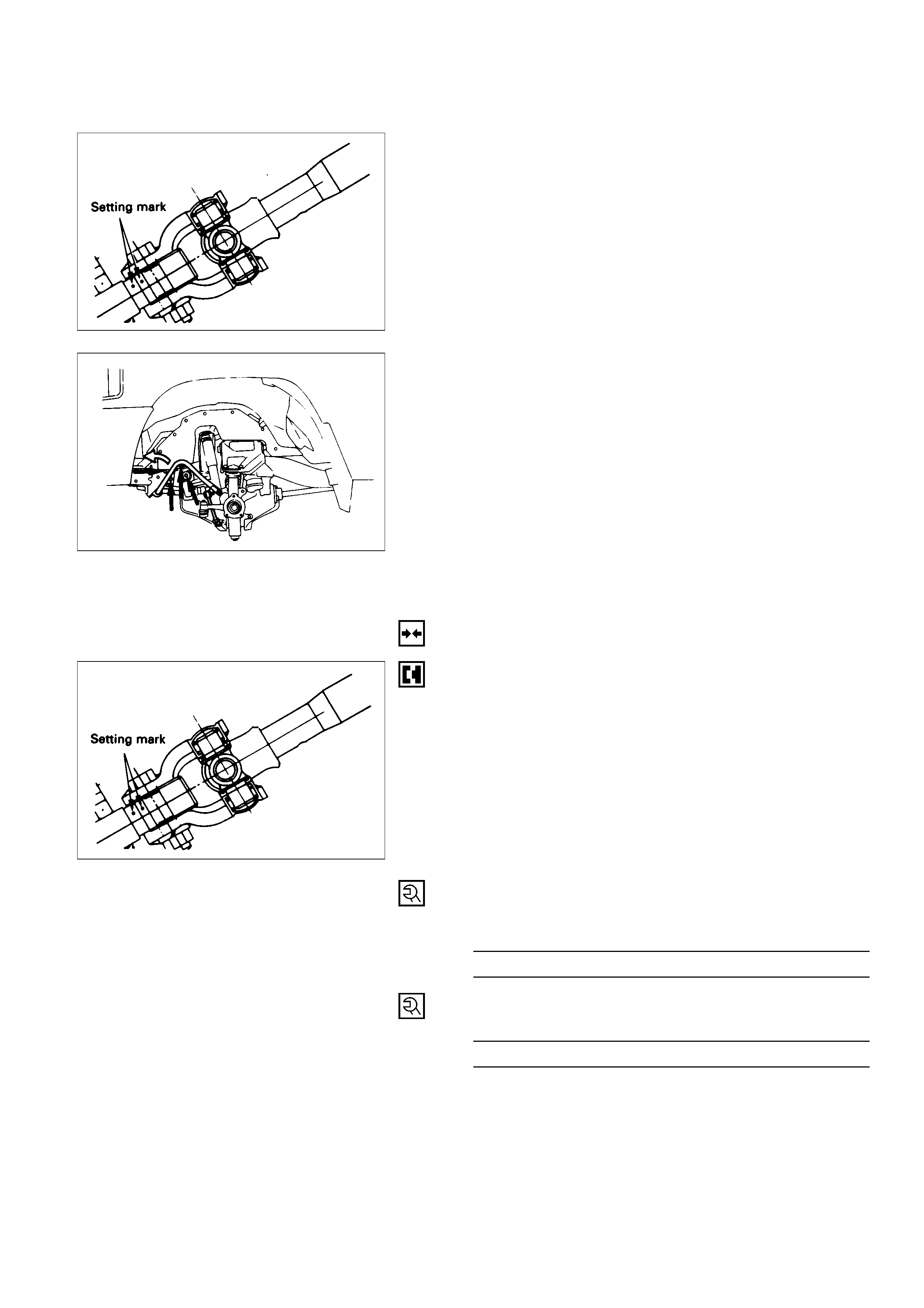

4. Universal Joint Bolt

Make a setting mark across the coupling flange and

worm shaft to ensure reassembly of the parts in the

original position.

5. Gear Box Mounting Bolt and Nut

Push the stabiliser bar aside and remove the bolts

and nuts.

6. Gear Box

INSTALLATION

6. Gear Box

Align the setting marks made at removal.

5. Gear Box Mounting Bolt and Nut

Gear Box Mounting

Bolt and Nut Torque N·m (kg·m/lb·ft)

44 (4.5 / 33)

4. Universal Joint Bolt

Coupling Clamp Bolt Torque N·m (kg·m/lb·ft)

25 (2.5 / 18)

3. Pitman Arm

Align the notched tooth.

2 Nut

Pitman Arm Nut Torque N·m (kg·m/lb·ft)

216 (22.0 / 159)

1. Pipe

Pipe Nut Torque N·m (kg·m/lb·ft)

44 (4.5 / 33)

POWER STEERING PUMP ( 6VE1 ENGINE)

6

5

3

4

5

1

2

Removal Steps

1. Drive belt

2. Pulley

3. Hose, suction

4. Hose, flexible

5. Bolt

6. Pump assembly

Installation Steps

6. Pump assembly

5. Bolt

4. Hose, flexible

3. Hose, suction

2. Pulley

1. Drive belt

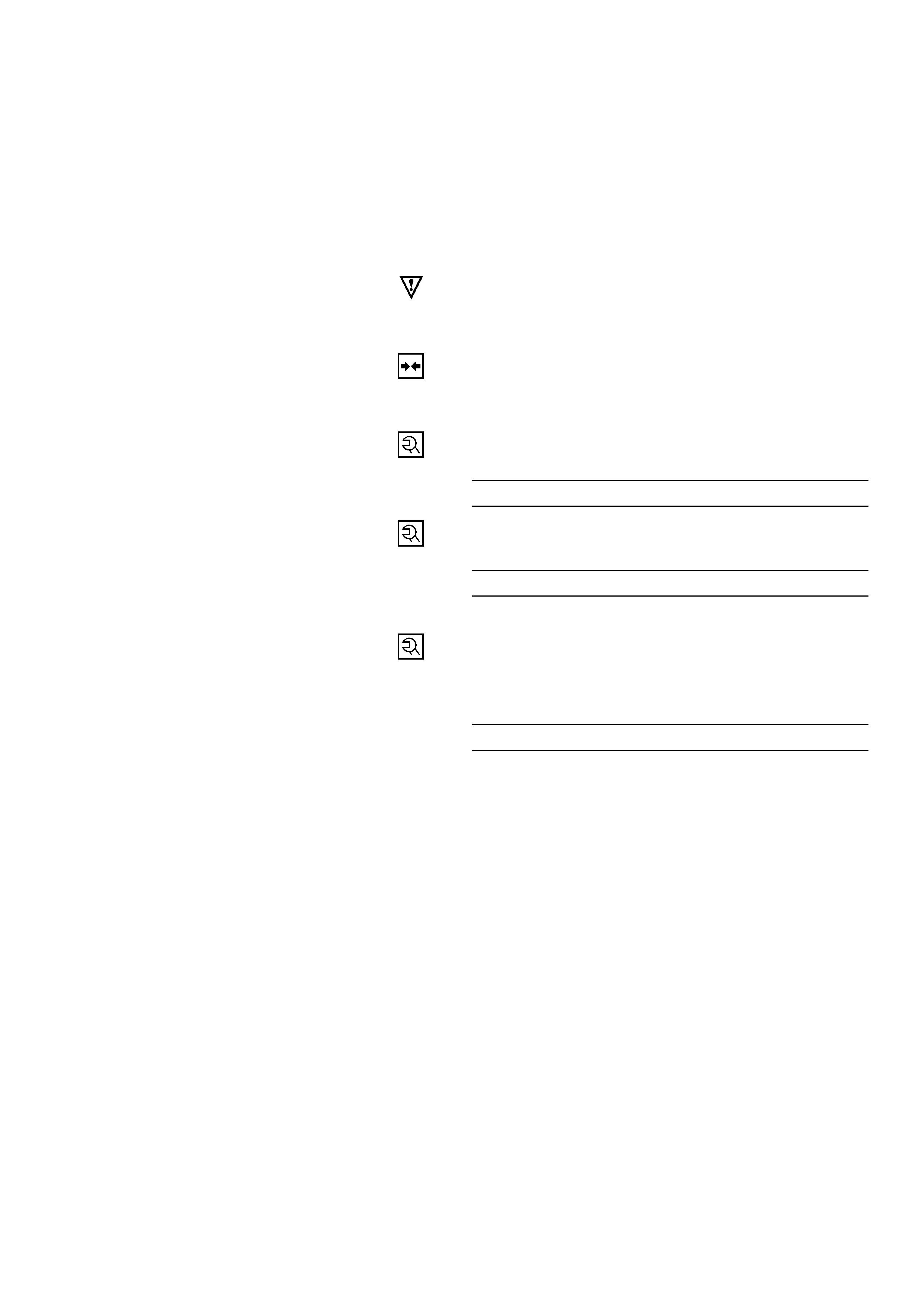

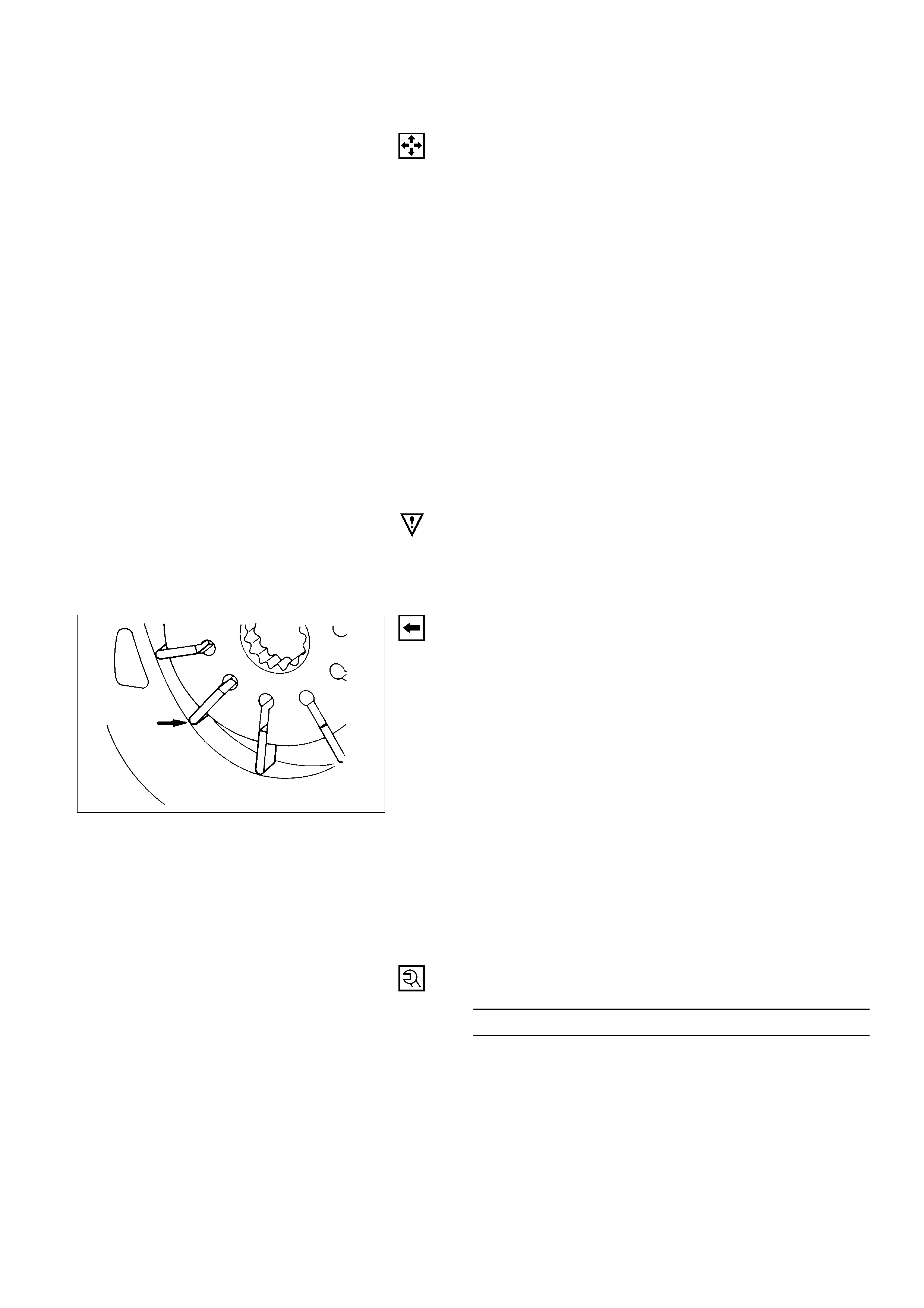

REMOVAL

Preparation:

•Drain the engine coolant.

•Place a drain pan below the pump.

•Remove the air cleaner duct (1) and the radiator

upper hose (2).

436RW006

1

2

436RW005

1.Drive Belt

2.Pulley

3.Hose, Suction

4.Hose, Flexible

5.Bolt

6.Pump Assembly

CAUTION:

When removing the pump assembly, be careful not to

damage the wiring harness under the pump housing.

INSTALLATION

6.Pump Assembly

Connect the harness under the pump housing.

5.Bolt

Pump Bolt TorqueN·m(kg·m/lb·ft)

46 (4.7 / 34)

4.Hose, Flexible

Eye Bolt TorqueN·m (kg·m/lb·ft)

54 (5.5 / 40)

3.Hose, Suction

2.Pulley

Install the pulley onto the power steering pump and

tighten the nut to specified torque.

Pulley Nut TorqueN·m (kg·m/lb·ft)

78 (8.0 / 58)

1.Drive Belt

•Install the air cleaner duct and the radiator upper

hose.

•Refill the engine coolant.

•Fill and bleed the system. Refer to “Bleeding the

Power Steering System” in this section.

POWER STEERING PUMP (4JX1 ENGINE)

3

2

1

4

Removal Steps

1. Hose, suction

2. Hose, flexible

3. Bolt

4. Pump assembly

Installation Steps

4. Pump assembly

3. Bolt

2. Hose, flexible

1. Hose, suction

436RW009

REMOVAL

Preparation:

•Place a drain pan below the pump.

1.Hose, Suction

2.Hose, Flexible

3.Bolt

4.Pump Assembly

INSTALLATION

4.Pump Assembly

3.Bolt

Bolt TorqueN·m (kg·m/lb·ft)

22 (2.2 / 16)

2.Hose, Flexible

Hose, Bolt TorqueN·m (kg·m/lb·ft)

54 (5.5 / 40)

1.Hose, Suction

Fill and bleed the system. Refer to “Bleeding the

Power Steering System” in this section.

UNIT REPAIR

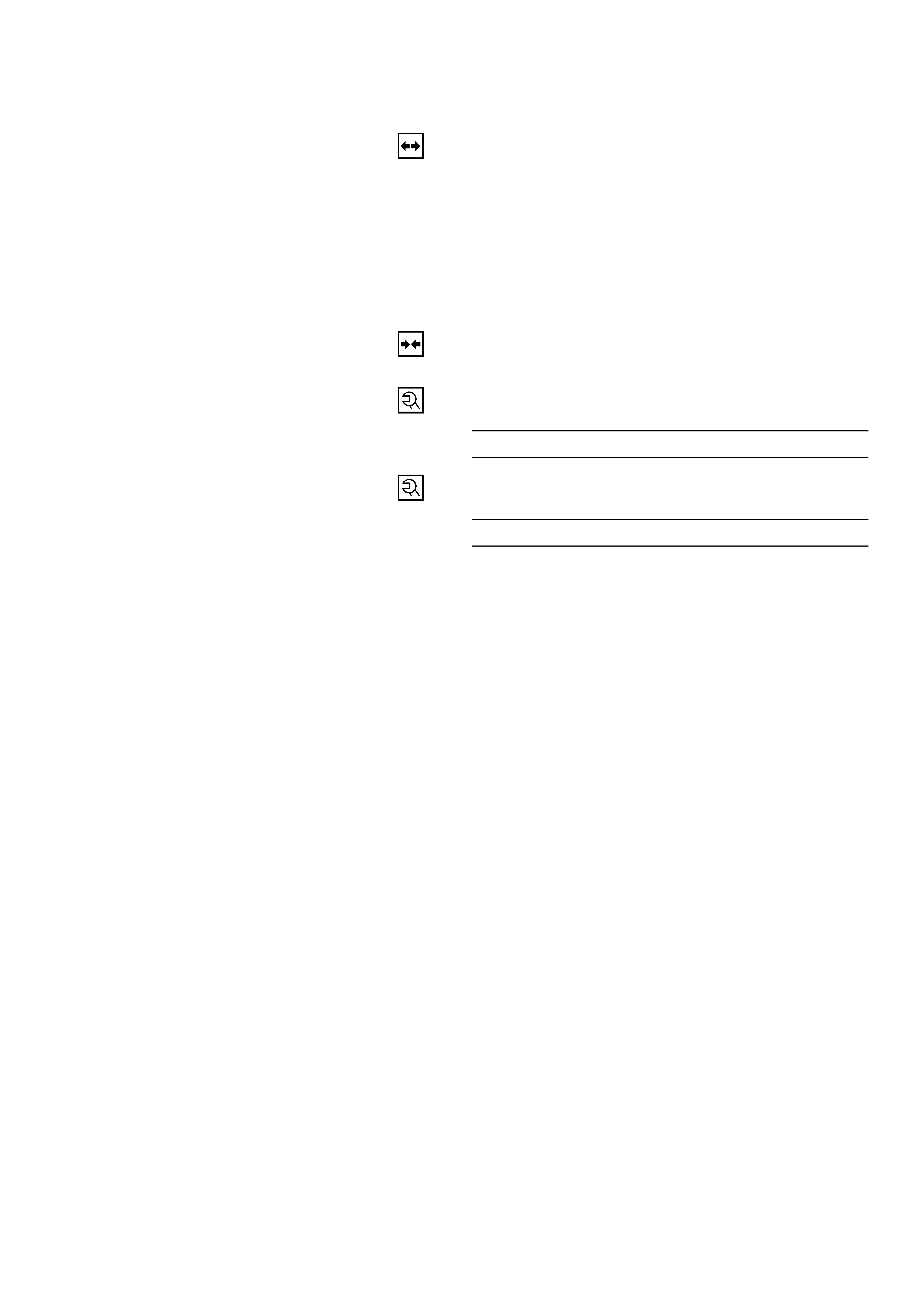

STEERING GEAR

5

These steps are based on the LHD model

6

8

13

1

2

3

4

9

10

11

12

7

Disassembly Steps

1. Dust cover

2. Retaining ring

3. Back up ring

4. Oil seal

5. Lock nut

6. Top cover assembly

7. O-ring

8. Sector shaft

9. Ball-nut and valve housing assembly

10. O-ring

11. Seal ring

12. O-ring

13. Gear box

Reassembly Steps

13. Gear box

12. O-ring

11. Seal ring

10. O-ring

9. Ball-nut and valve housing assembly

8. Sector shaft

7. O-ring

6. Top cover assembly

5. Lock nut

4. Oil seal

3. Back up ring

2. Retaining ring

1. Dust cover

440RW004

DISASSEMBLY

CAUTION:

Do not clamp the steering gear assembly in a vise by the

power cylinder housing.

1. Dust Cover

2. Retaining Ring

3. Back up RIng

4. Oil Seal

1) Clean the faces of the extended stub shaft.

2) Plug the hose fitting on the inlet side.

3) Remove the oil seal by blowing compressed air

through the hole in the outlet side.

5. Lock Nut

Remove the adjusting screw lock nut and turn the

adjusting screw counterclockwise to remove the

preload between the sector gear and the rack piston,

then remove the top cover bolts.

6. Top Cover Assembly

Holding the top cover stationary, turn the adjusting

screw clockwise to raise and free to cover, then

remove the cover.

7. O-ring

8. Sector Shaft

Bring the stub shaft into straight-ahead position. Do

not force the sector shaft off the gear box with a

hammer or other impact tools.

9. Ball-nut and Valve Housing Assembly

It is strongly advisable to always keep the ball nut

and valve housing assembly in a horizontal position,

or the rack piston will fall off onto the end of the

worm, causing the rack piston to slip out of the worm

shaft and the balls to fall out.

10. O-ring

11. Seal Ring

12. O-ring

13. Gear Box

INSPECTION AND REPAIR

Inspect the following parts for wear, damage or any other

abnormal conditions.

•Bearing

•Ball-nut and valve housing

•Sector shaft

•Top cover

•Gear box

•Needle bearing

•Dust seal

•Seal ring

•Gasket

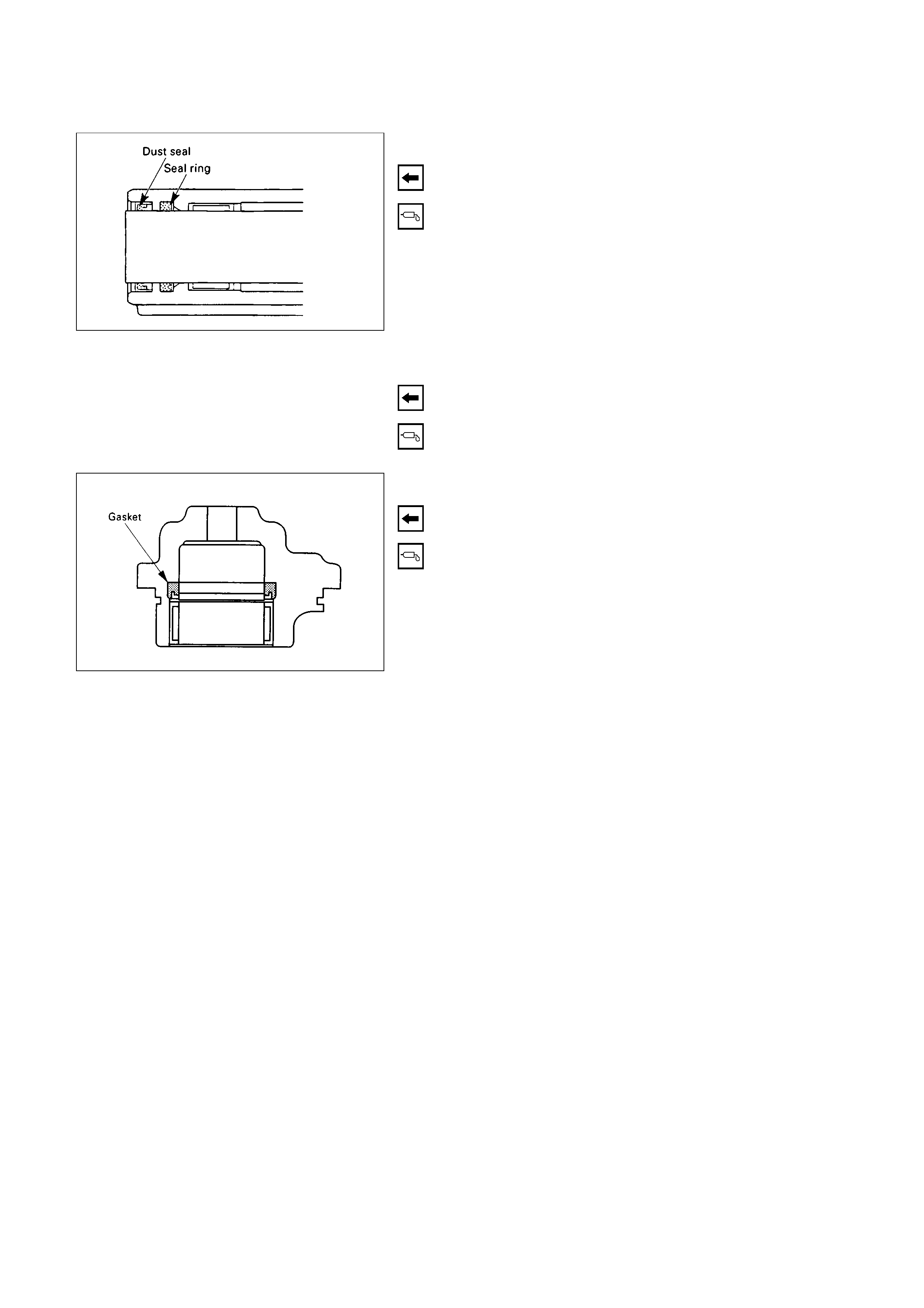

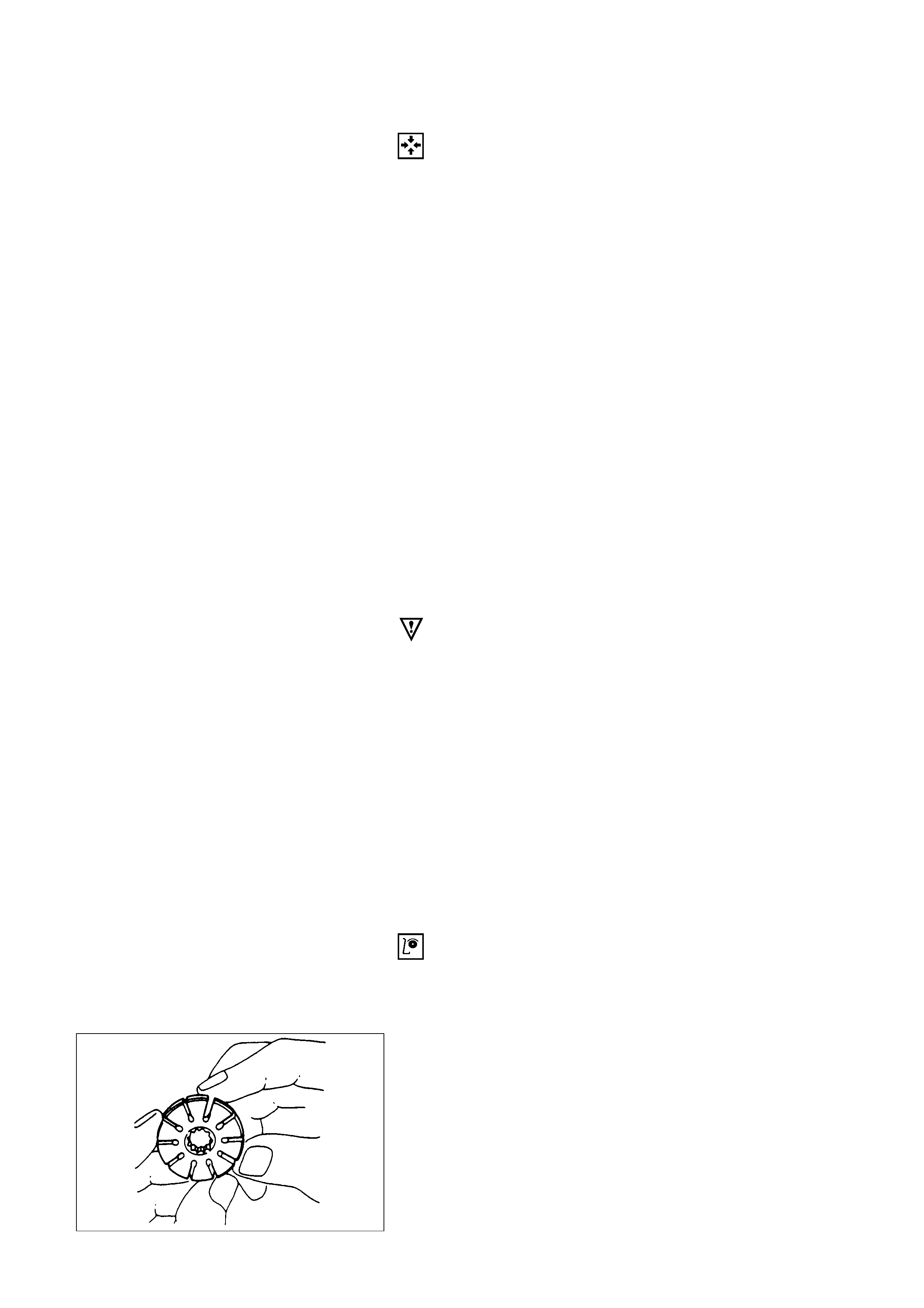

Ball-nut Rotation

Hold the ball nut and valve housing assembly vertically

and see if the ball-nut lower by turning smoothly. If the

ball-nut does not lower smoothly, check the worm shaft

for bending and foreign matter.

NOTE:

When testing the ball nut and valve housing assembly, do

not let it travel all the way to the end of worm shaft, or

damage to the ball tubes will result.

Check sector shaft outside diameter.

Sector Shaft Outside Diameter mm(in)

Standard Limit

32.0 (1.260) 31.7 (1.248)

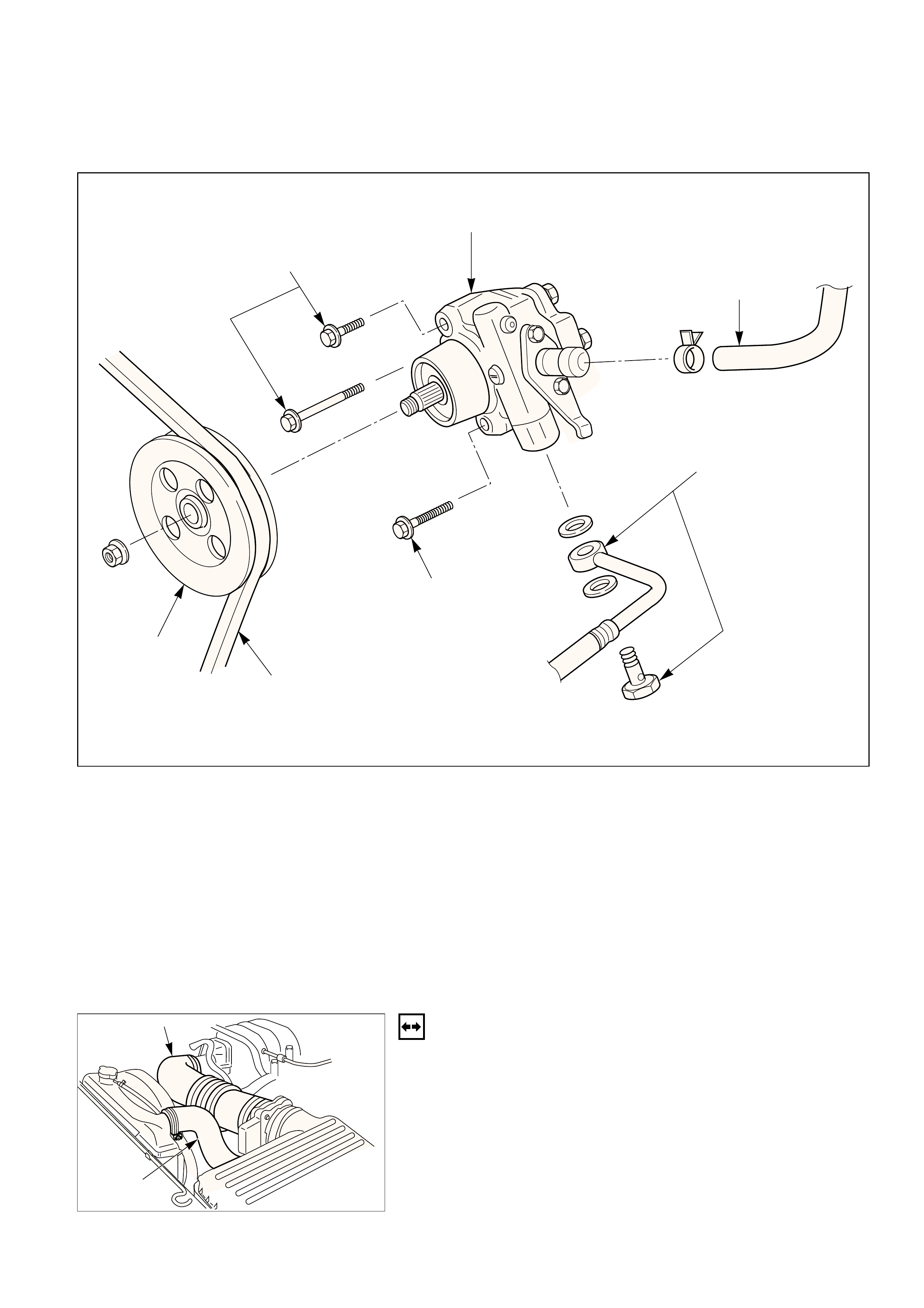

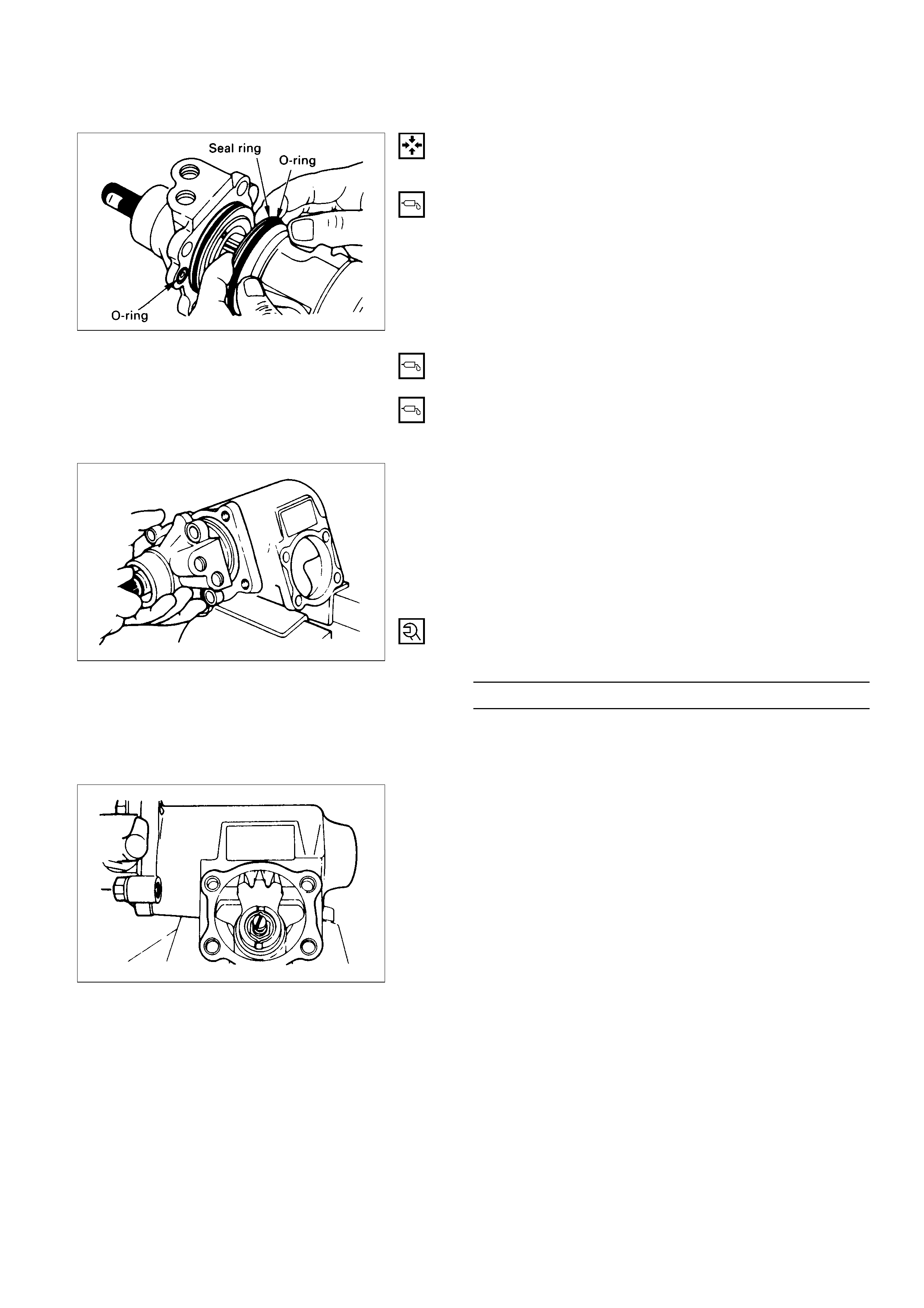

Seal Ring Setting

Note the setting direction. Always install a new part.

Apply a thin coat of power steering fluid to lip of each

part.

Dust Seal Setting

Note the setting direction. Always install a new part.

Apply a thin coat of power steering fluid to lip of each

part.

Gasket Setting

Note the setting direction. Always install a new part.

Apply a thin coat of power steering fluid to lip of each

part.

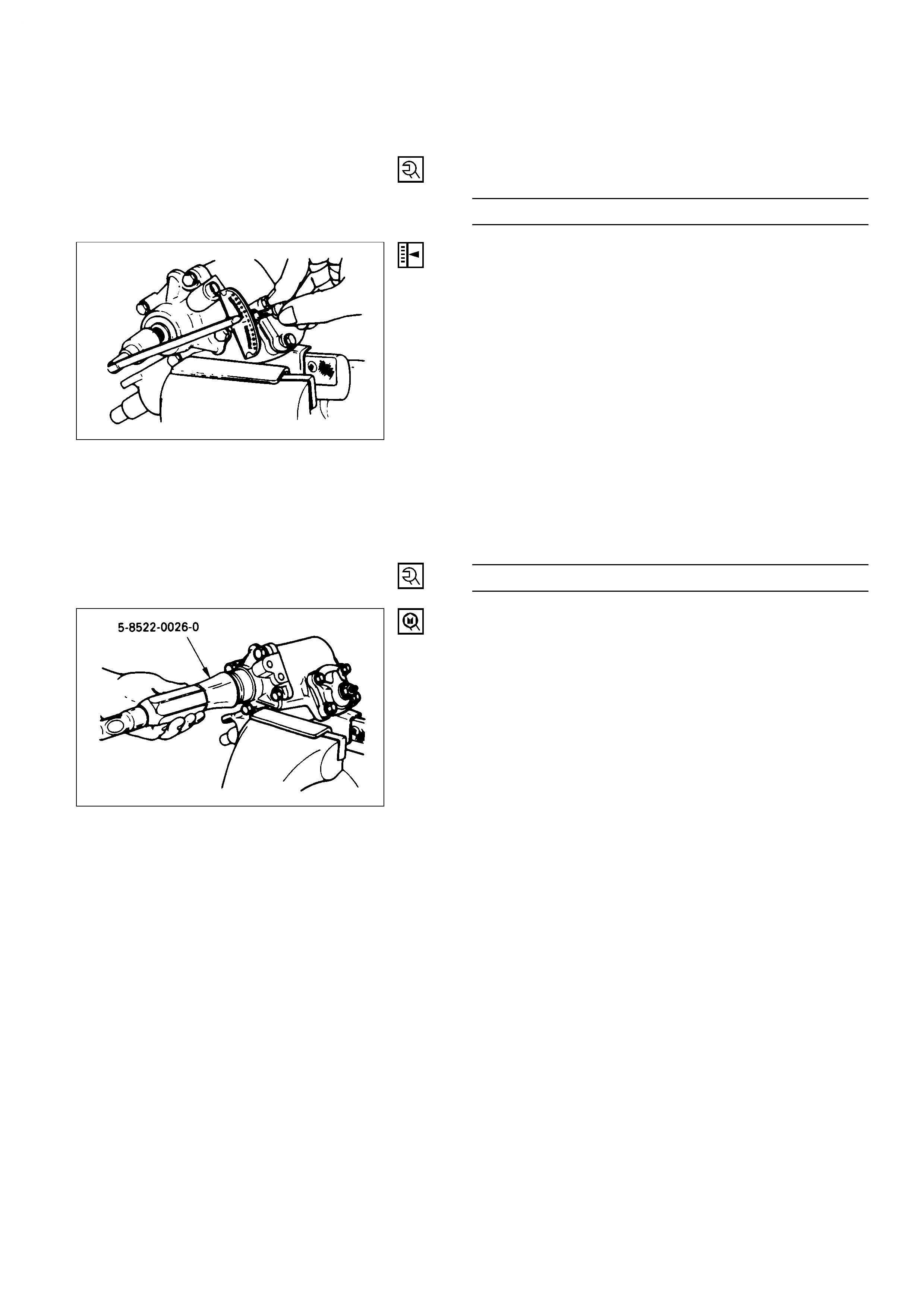

REASSEMBLY

13. Gear Box

12. O-ring

Apply a thin coat of grease.

11. Seal Ring

Apply a thin coat of grease.

10. O-ring

Apply a thin coat of grease.

9. Ball-nut and Valve Housing Assembly

1) It is strongly advisable to always keep the ball

screw and valve housing assembly in a horizontal

position (avoid holding it vertically), or the rack

piston will fall off onto the end of the worm,

causing the rack piston to slip out of the worm

shaft and ball to fall out.

2) Be careful not to drop the O-ring into the valve

housing.

3) Tighten the valve housing bolts to the specified

torque.

Valve Housing Bolt Torque N·m (kg·m/lb·ft)

47 (4.8 / 35)

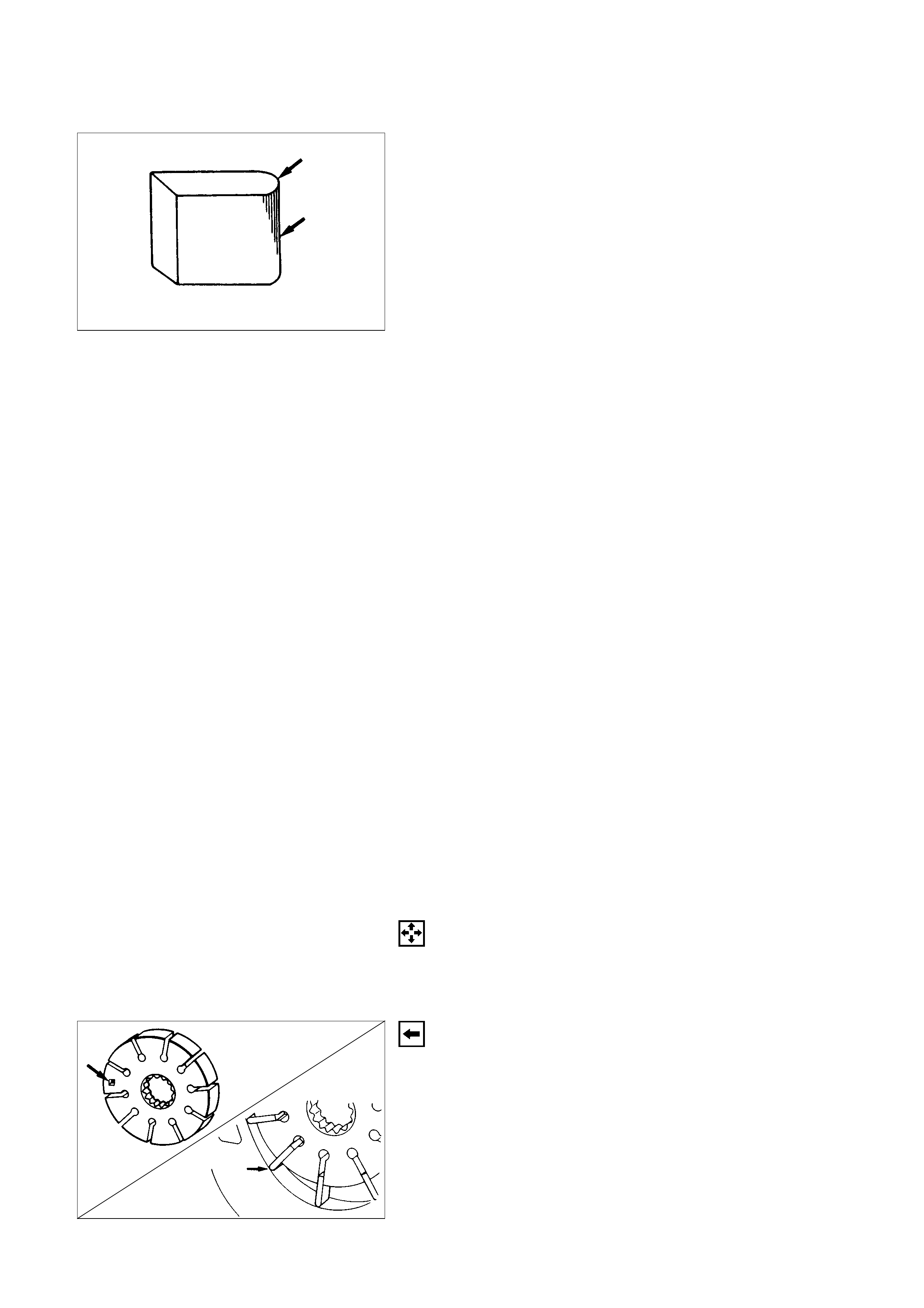

8. Sector Shaft

1) Tape the sector shaft serrations to protect the

seal ring from damage.

2) Align the center tooth of ball nut with that of the

sector shaft.

7. O-ring

6. Top Cover Assembly

Top Cover Bolt Torque N·m (kg·m/lb·ft)

47 (4.8 / 35)

5. Lock Nut

Adjust the backlash between the worm gear and the

ball nut.

1) With the worm gear rotating, set it to the straight

ahead position.

2) Set the worm shaft preload to below 1N·m

(10kg·cm / 9 lb·in) with the sector shaft adjusting

screw.

3) Measure the worm shaft preload with the worm

gear turned 450° both to the right and to the left.

The worm gear preload in these positions should

be 0.4 - 0.6 N·m (4 - 6 kg·cm / 3.5 - 5.2 lb·in) lower

than in the straight ahead position.

4) Lock the sector shaft adjusting screw with the lock

nut.

Lock Nut Torque N·m (kg·m/lb·ft)

41 (4.2 / 30)

4. Oil Seal

Installer: 5-8522-0026-0 (J-26508)

3. Back up Ring

Position the chamfered face (outer circumference)

towards the oil seal.

2. Retaining Ring

position the chamfered face (outer circumference)

toward the oil seal.

1. Dust Cover

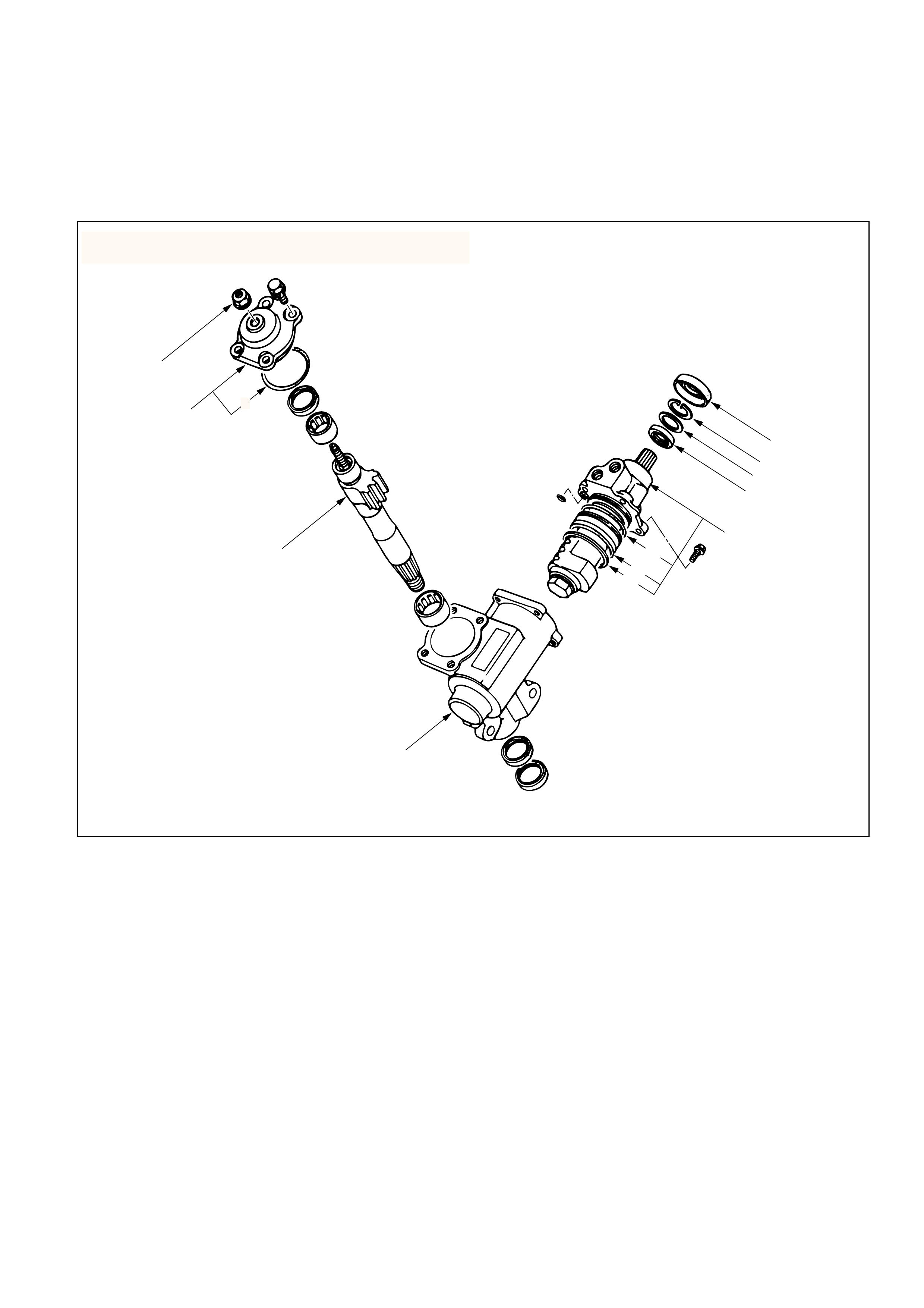

POWER STEERING PUMP ( 6VE1 ENGINE)

2

3

22

1

16

15

12

11

5

6

8

7

9

4

17

18

27

25

26

24

19

20

23

21

14

13

10

Disassembly Steps

1. Bolt

2. Pipe, suction

3. O-ring

4. Connector

5. O-ring

6. Valve

7. Retaining ring

8. Filter

9. Spring

10. Pressure switch

11. Retaining ring

12. Shaft assembly

13. Bearing

14. Shaft

15. Retaining ring

16. Oil seal

17. Bolt

18. Rear housing assembly and pump

cartridge

19. Gasket

20. O-ring

21. O-ring

22. Front housing

23. Pressure plate

24. Rotor and vane

25. Cam

26. Pin

27. Rear housing

Reassembly Steps

27. Rear housing

26. Pin

25. Cam

24. Rotor and vane

23. Pressure plate

22. Front housing

21. O-ring

20. O-ring

19. Gasket

18. Rear housing assembly and pump

cartridge

17. Bolt

16. Oil seal

15. Retaining ring

14. Shaft

13. Bearing

12. Shaft assembly

11. Retaining ring

10. Pressure switch

9. Spring

8. Filter

7. Retaining ring

6. Valve

5. O-ring

4. Connector

3. O-ring

2. Pipe, suction

1. Bolt

412RW055

DISASSEMBLY

Preparation:

Clean oil pump with solvent (plug the discharge and

suction port, to prevent the entry of solvent). Be careful

not to expose the oil seal of shaft assembly to solvent.

1.Bolt

2.Pipe, Suction

3.O-ring

4.Connector

5.O-ring

6.Valve Assembly

7.Retaining Ring

8.Filter

9.Spring

10.Pressure switch

11.Retaining Ring

12.Shaft Assembly

13.Bearing

14.Shaft

15.Retaining Ring

16.Oil Seal

CAUTION:

When removing the oil seal, be careful not to damage the

housing.

17. Bolt

18. Rear Housing Assembly and Pump Cartridge

19. Gasket

20. O-ring

21. O-ring

22. Front Housing

23. Pressure Plate

24. Rotor and Vane

25. Cam

26. Pin

27. Rear Housing

INSPECTION AND REPAIR

Make all necessary adjustments, repairs, and part

replacements if wear, damage, or other problems are

discovered during inspection.

Rotor

Check that the groove in the vane is free from excessive

wear and that the vane slides smoothly.

When part replacement becomes necessary, the pump

cartridge should be replaced as a subassembly.

Vane

Sliding faces of the vane should be free from wear.

(Particularly the curved face at the tip in contact with the

cam should be free from wear and distortion).

When part replacement becomes necessary, the pump

cartridge should be replaced as a subassembly.

Cam

The inner face of the arm should have a uniform contact

pattern without a sign of step wear.

When part replacement becomes necessary, the pump

cartridge should be replaced as a subassembly.

Side plate

The sliding faces of parts must be free from step wear

(more than 0.01 mm), which can be felt by the finger nail.

The parts with minor scores may be reused after lapping

the face.

Valve

The sliding face of the valve must be free from burrs and

damage.

The parts with minor scores may be reused after

smoothing with emery cloth (#800 or finer).

Shaft

Oil seal sliding faces must be free from a step wear which

can be felt by the finger nail.

Bushing face must be free from damage and wear.

O-ring, oil seal, retaining ring

Be sure to discard used parts, and always use new parts

for installation. Prior to installation, lubricate all seals and

rings with power steering fluid.

REASSEMBLY

27. Rear Housing

26. Pin

25. Cam

24. Rotor and Vane

1. Install the rotor with its punch mark facing the front

housing.

2. Install the vanes with curved face in contact with

the inner wall of the cam.

23.Pressure Plate

CAUTION:

When installing side plate, be careful not to damage its

inner surface. Damaged side plate may cause poor pump

performance, pump seizure or oil leakage.

22.Front Housing

21.O-ring

20.O-ring

Be sure to discard used O-rings, and always use new

parts for installation.

19.Gasket

Be sure to discard used parts, and always use new

parts for installation.

18.Rear Housing Assembly and Pump Cartridge

17.Bolt

Rear Housing Bolt TorqueN·m (kg·m/lb·ft)

17.6 (1.8 / 12.8)

16.Oil Seal

Be sure to discard used parts, and always use new

parts for installation.

CAUTION:

When installing the oil seal, be careful not to damage the

oil seal contacting surface of the housing.

15. Retaining Ring

14. Shaft

13. Bearing

12. Shaft Assembly

11. Retaining Ring

10. Pressure switch

Pressure Switch Torque N·m (kg·m/lb·ft)

20 (2.0 / 14)

9. Spring

8. Filter

7. Retaining Ring

6. Valve

5. O-ring

Be sure to discard used parts, and always use new

parts for installation.

4. Connector

Connector Torque N·m (kg·m/lb·ft)

74 (7.5 / 54)

3. O-ring

Be sure to discard used parts, and always use new

parts for installation.

2. Pipe, Suction

1. Bolt

Suction Pipe Bolt Torque N·m (kg·m/lb·ft)

15.7 (1.6 / 11.5)

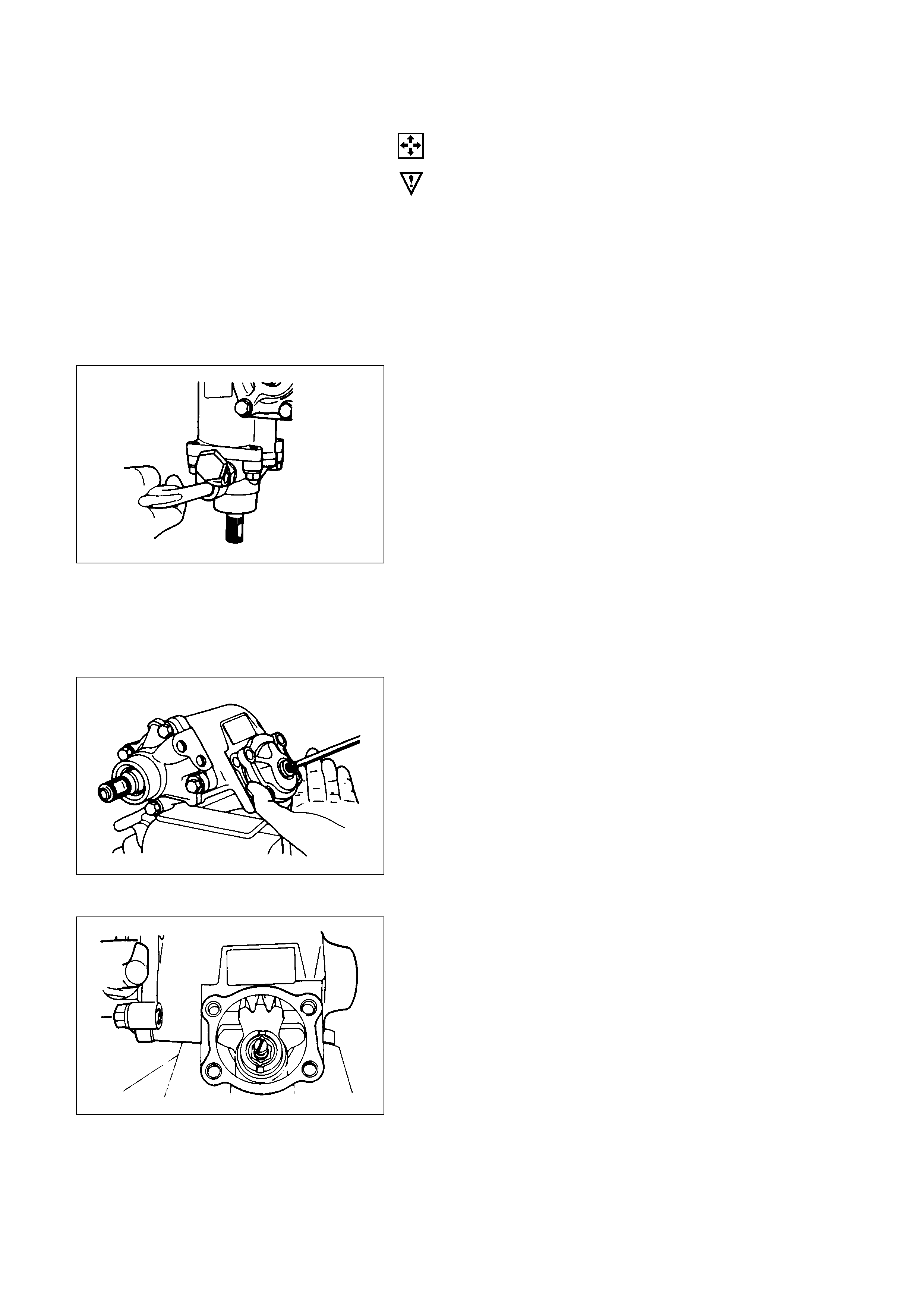

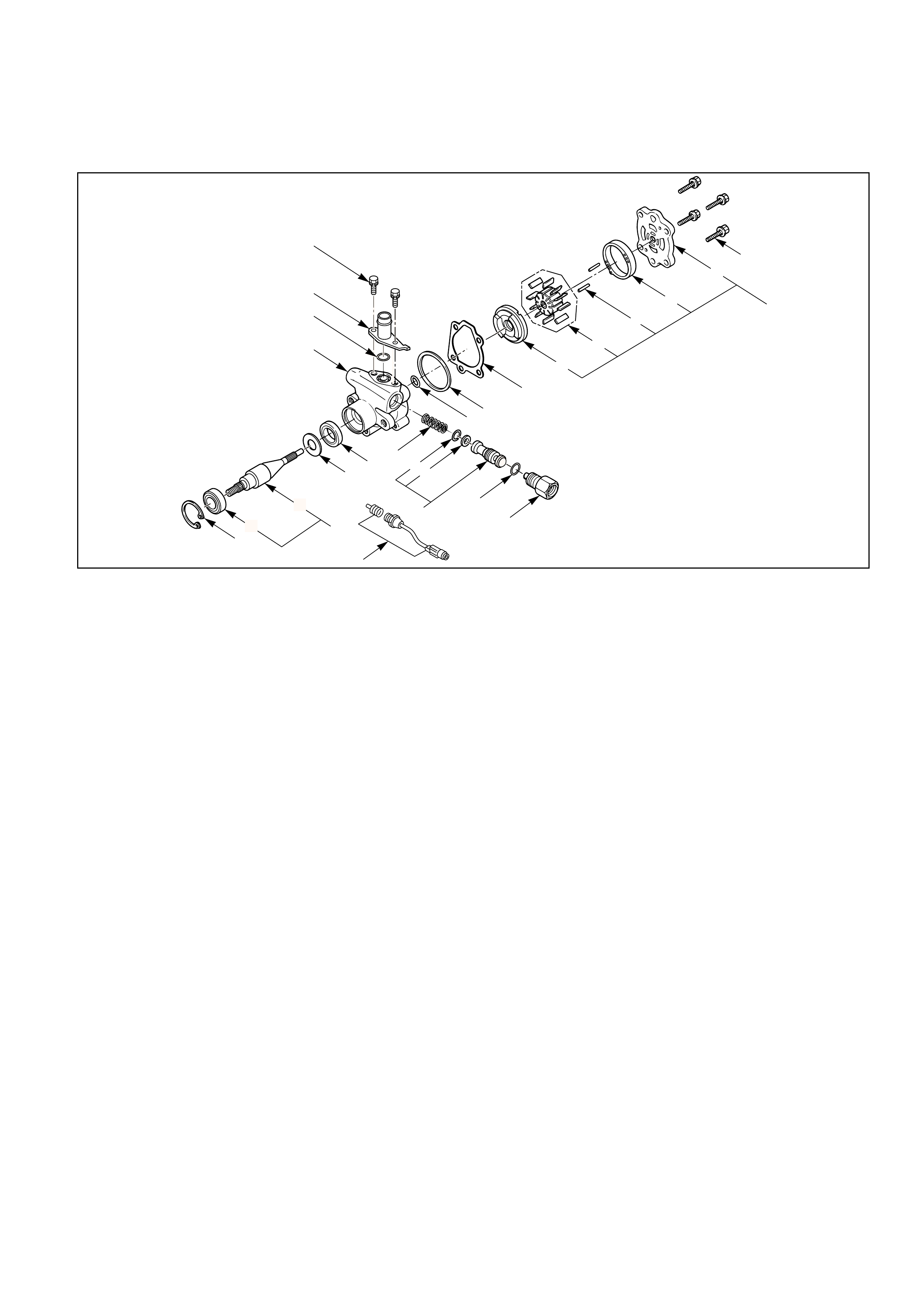

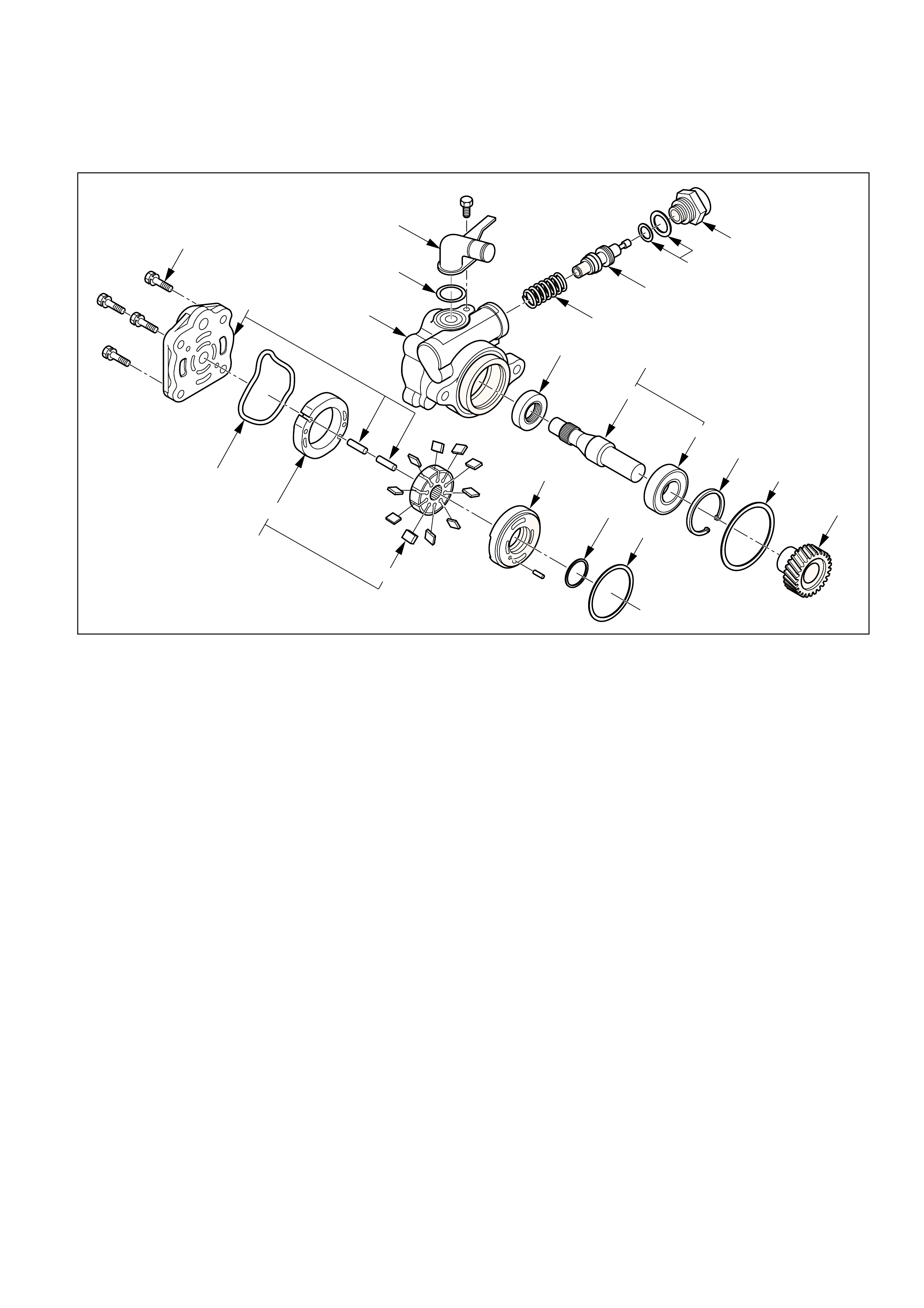

POWER STEERING PUMP (4JX1 ENGINE)

17

1

18

22

7

6

5

4

3

2

19

20

21

15

14

16

8

10

12

11

13

923

Disassembly Steps

1. O-ring

2. Pipe, suction

3. O-ring

4. Connector

5. O-ring

6. Valve

7. Spring

8. Bolt

9. Rear housing assembly

10. O-ring

11. Pump cartridge

12. Cam

13. Rotor and vane

14. Pressure plate

15. O-ring

16. O-ring

17. Gear

18. Retaining ring

19. Shaft assembly

20. Bearing

21. Shaft

22. Oil seal

23. Front housing

Reassembly Steps

23. Front housing

22. Oil seal

21. Shaft

20. Bearing

19. Shaft assembly

18. Retaining ring

17. Gear

16. O-ring

15. O-ring

14. Pressure plate

13. Rotor and vane

12. Cam

11. Pump cartridge

10. O-ring

9. Rear housing assembly

8. Bolt

7. Spring

6. Valve

5. O-ring

4. Connector

3. O-ring

2. Pipe, suction

1. O-ring

412RW048

DISASSEMBLY

Preparation:

Clean oil pump with solvent (plug the discharge and

suction port to prevent the entry of solvent). Be careful not

to expose the oil seal of shaft assembly to solvent.

1.O-ring

2.Pipe, Suction

3.O-ring

4.Connector

5.O-ring

6.Valve

7.Spring

8.Bolt

9.Rear Housing Assembly

10.O-ring

11.Pump Cartridge

12.Cam

13.Rotor and Vane

14.Pressure Plate

15.O-ring

16.O-ring

17.Gear

18.Retaining Ring

19.Shaft Assembly

20.Bearing

21.Shaft

22.Oil seal

CAUTION:

When removing the oil seal, be careful not to damage the

housing.

23. Front Housing

REASSEMBLY

23.Front Housing

22.Oil Seal

Be sure to discard used parts, and always used new

parts for installation.

21.Shaft

20.Bearing

19.Shaft Assembly

18.Retaining Ring

17.Gear

16.O-ring

Be sure to discard used parts, and always used new

parts for installation.

15.O-ring

Be sure to discard used parts, and always used new

parts for installation.

14.Pressure Plate

CAUTION:

When install pressure plate, be careful not to damage its

inner surface. Damaged pressure plate may cause poor

pump performance, pump seizure or oil leakage.

13. Rotor and Vane

Install the vane with curved face in contact with the

inner wall of the cam.

12. Cam

11. Pump Cartridge

10. O-ring

Be sure to discard used parts, and always used new

parts for installation.

9. Rear Housing Assembly

8. Bolt

Rear Housing Bolt Torque N·m (kg·m/lb·ft)

24 (2.4 / 17)

7. Spring

6. Valve

5. O-ring

Be sure to discard used parts, and always used new

parts for installation.

4. Connector

Connector Torque N·m (kg·m/lb·ft)

59 (6.0 / 43)

3. O-ring

Be sure to discard used parts, and always used new

parts for installation.

2. Pipe, Suction

Suction Pipe Bolt Torque N·m (kg·m/lb·ft)

9.8 (1.0 / 7.1)

1. O-ring

Be sure to discard used parts, and always used new

parts for installation.