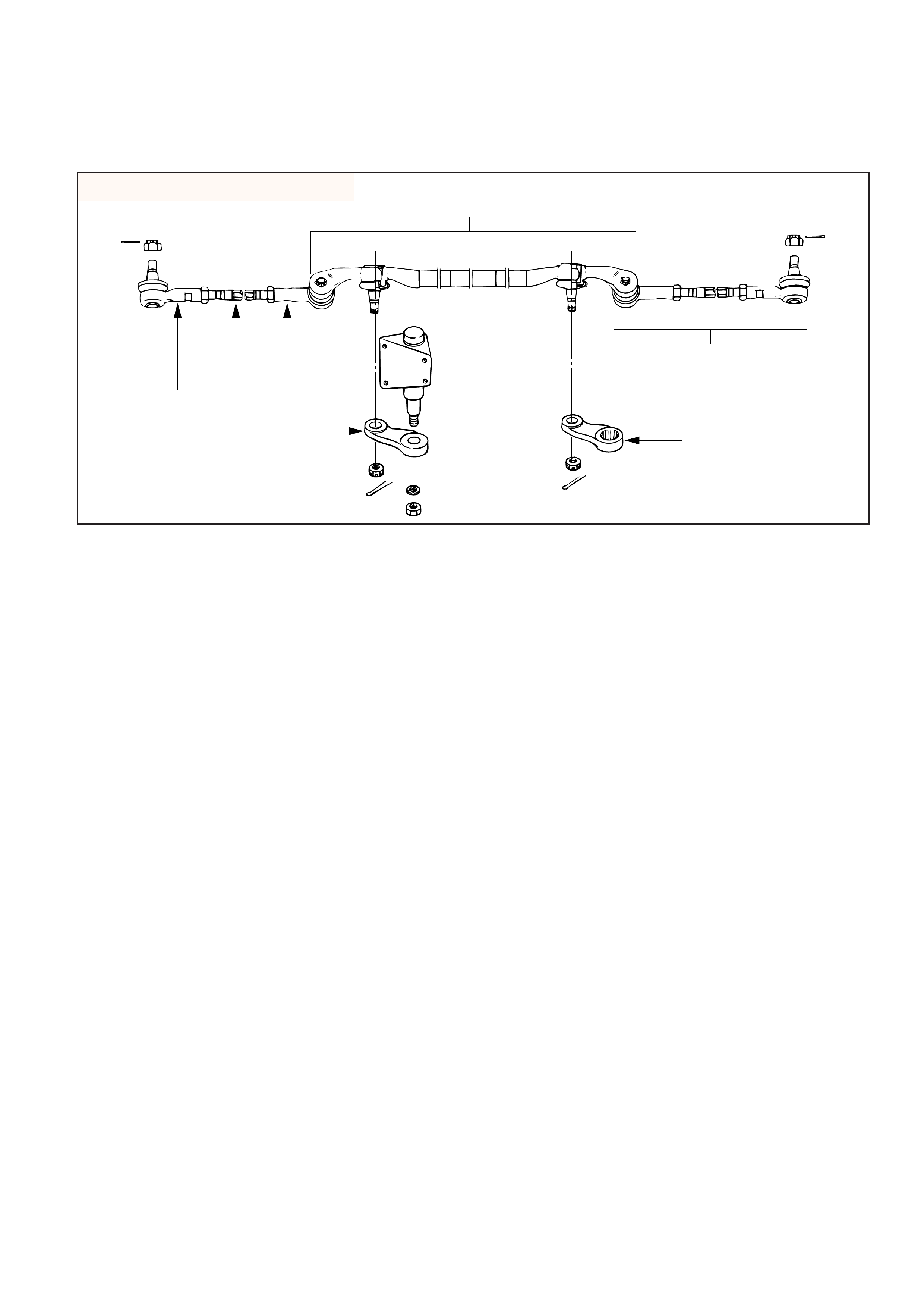

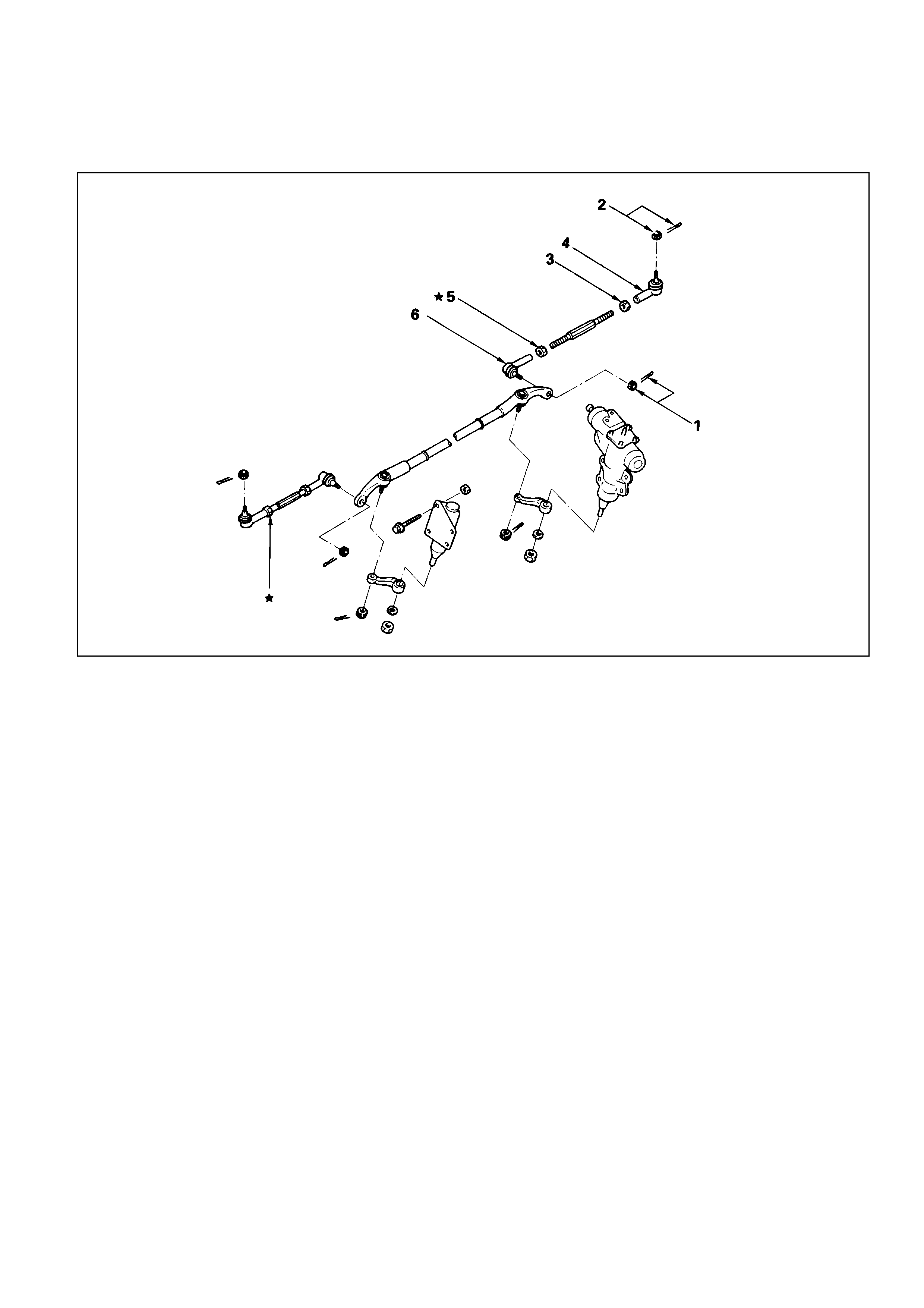

GENERAL DESCRIPTION

Center track rod assembly

Rod end, outer

Track rod

Rod end, inner

Relay lever

These steps are based on the LHD model.

Outer track rod assembly

Pitman arm

The steering linkage consists of a pitman arm,

relay lever, center track rod and two adjustable

outer track rods.

When the steering wheel is turned, the gear rotates

the pitman arm which forces the center track rod to

one side. The outer track rods, connected to the

center track rod by ball studs, transfer the steering

force to the wheels. The outer track rods are

adjustable and are used for toe-in adjustments.

The center track rod is supported by the pitman

arm and relay lever. The relaylever pivots on a

support attached to the frame.

The overall condition of the steering linkage affects

steering performance. If parts are bent, damaged,

worn or poorly lubricated, improper and possibly

dangerous steering action will result.

Whenever any steering linkage components are

repaired or replaced, check the steering geometry

and front end alignment. Refer to Front End

Alignment (Sec. 3A).

433RW004

This illustration is based on the LHD model.

ON-VEHICLE SERVICE

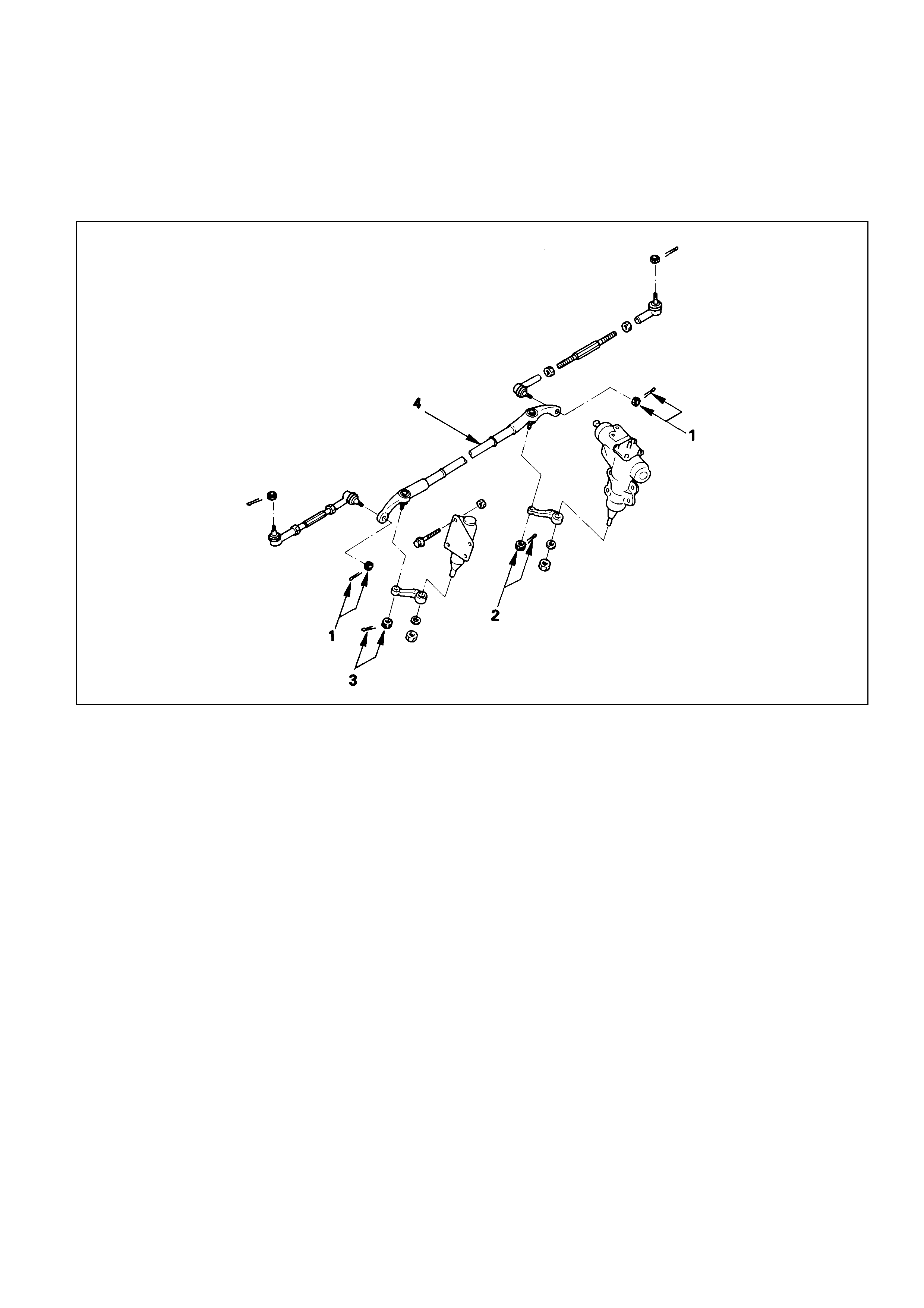

CENTRE TRACK ROD ASSEMBLY

Removal Steps

1. Nut and cotter pin

2. Nut and cotter pin, pitman arm

3. Nut and cotter pin relay lever

4. Center track rod assembly

Installation Steps

4. Center track rod assembly

3. Nut and cotter pin relay lever

2. Nut and cotter pin, pitman arm

1. Nut and cotter pin

REMOVAL

Preparation:

Raise the vehicle and support the frame with suitable

safety stands.

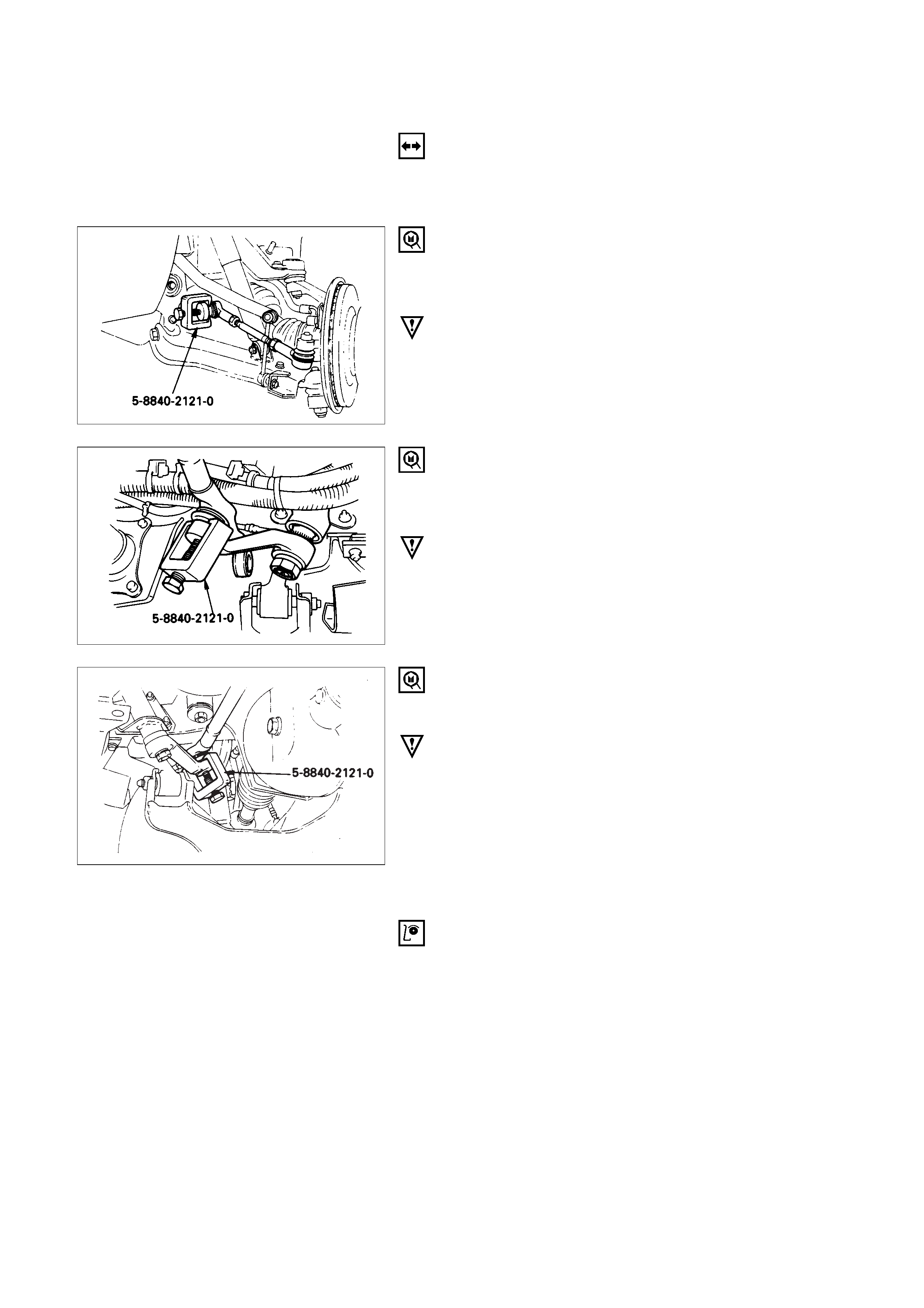

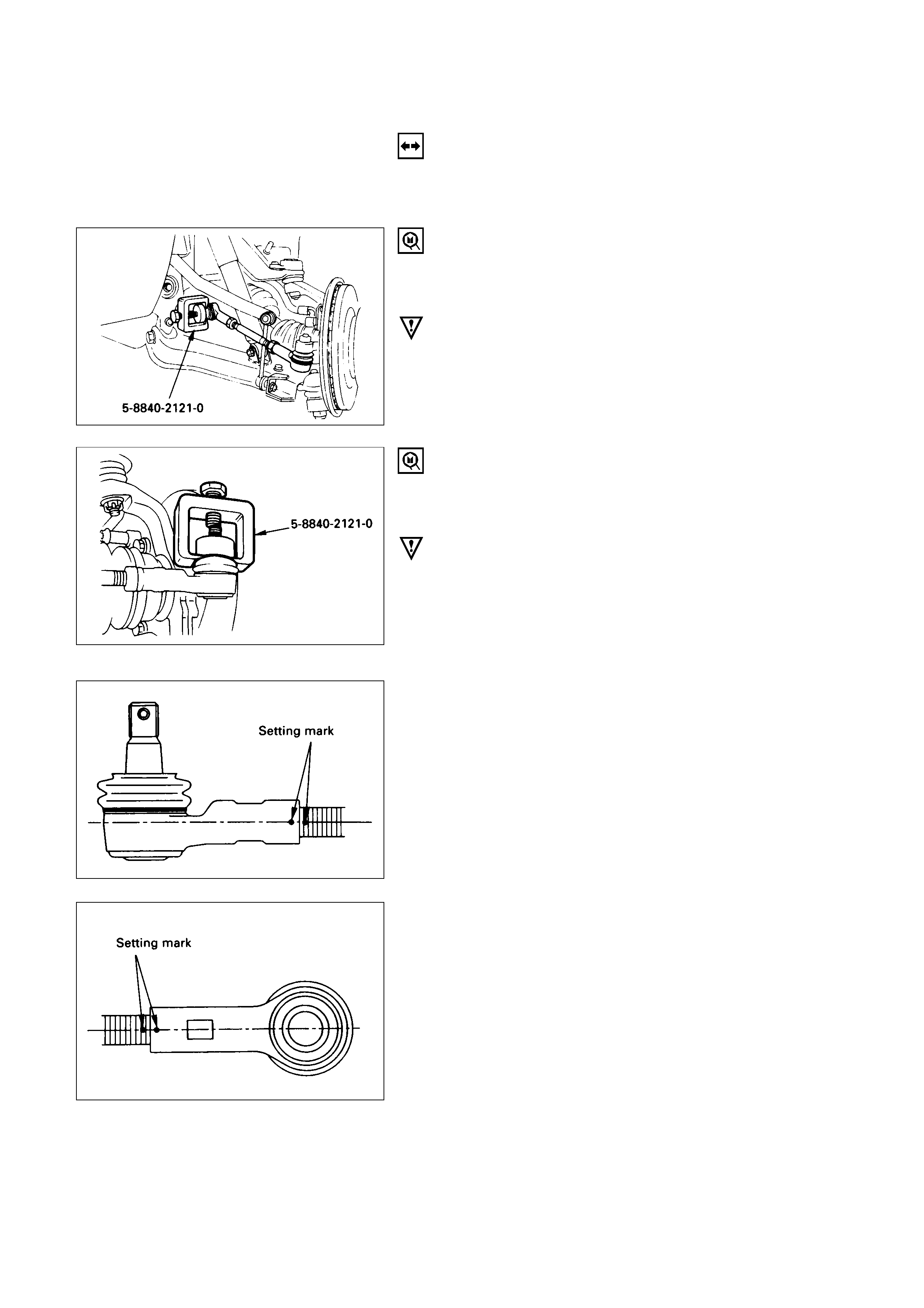

1.Nut and Cotter Pin

Disconnect outer track rod assembly from the center

track rod.

Remover: 5-8840-2121-0 (J-36831)

CAUTION:

Be careful not to break the ball joint boot.

2.Nut and Cotter Pin, Pitman Arm

Remove pitman arm from the center track rod (Fig.

3B3-4)

Remover: 5-8840-2121-0 (J-36831)

CAUTION:

Be careful not to break the ball joint boot.

3.Nut and Cotter Pin, Relay Lever

Remove relay lever from the center track rod.

Remover: 5-8840-2121-0 (J-36831)

CAUTION:

Be careful not to break the ball joint boot.

4. Center Track Rod Assembly

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear,

damage, corrosion, bending, deteriorations or any other

abnormal condition are found through inspection.

Check the following parts.

•Ball joint (Boot, screws and tapered surfaces)

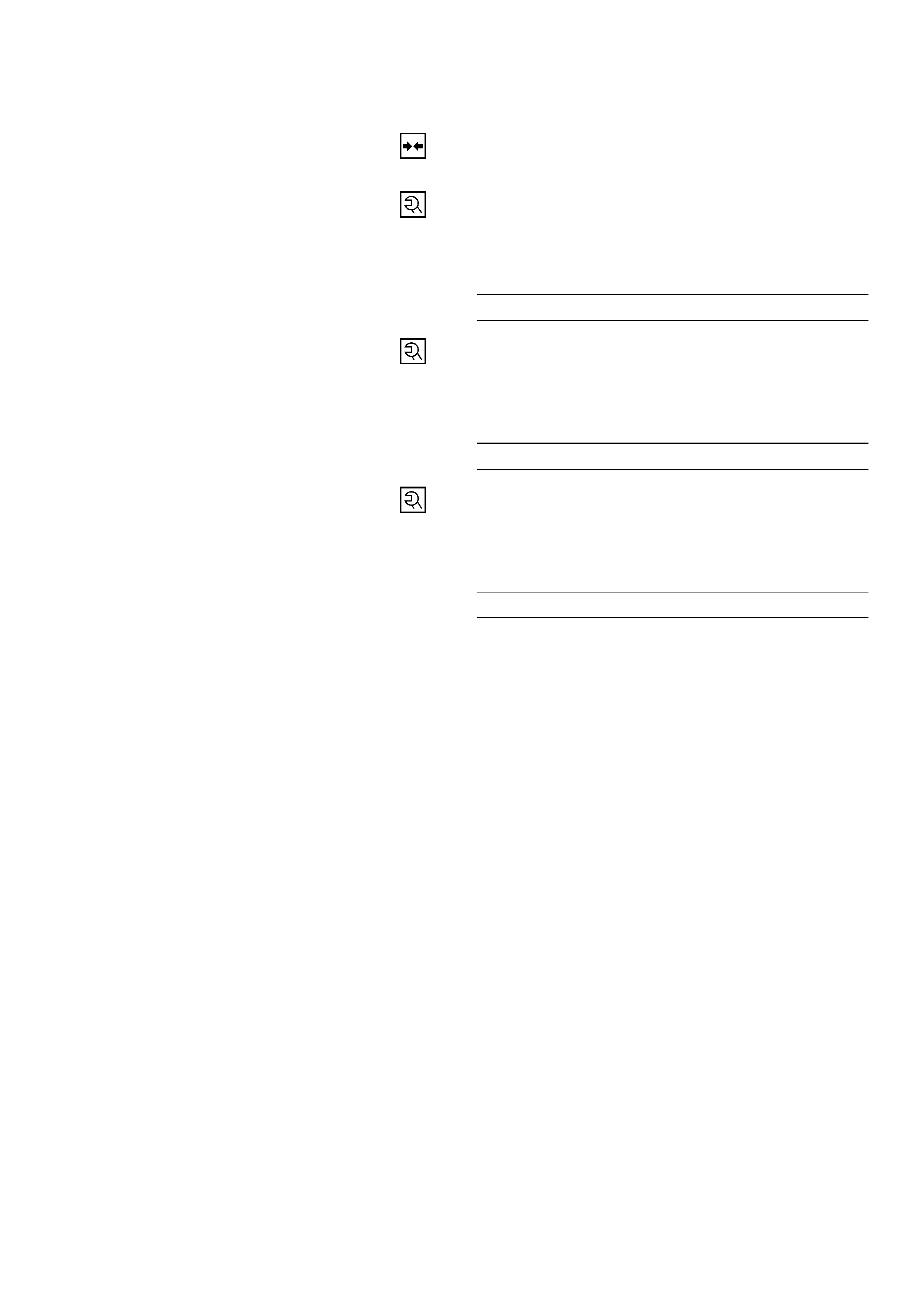

INSTALLATION

4. Center Track Rod Assembly

3. Nut and Cotter Pin, Relay Lever

Tighten the nut to the specified torque, with just

enough additional torque to align cotter pin holes.

Install new cotter pin.

Relay Lever Nut Torque N·m (kg·m/lb·ft)

59 (6.0 / 43)

2. Nut and Cotter Pin, Pitman Arm

Tighten the nut to the specified torque, with just

enough additional torque to align cotter pin hole.

Install new cotter pin.

Pitman Arm Nut Torque N·m (kg·m/lb·ft)

98 (10.0 / 72)

1. Nut and Cotter Pins

Tighten the nut to the specified torque, with just

enough additional torque to align cotter pin holes.

Install new cotter pin.

Center Track Rod Nut Torque N·m (kg·m/lb·ft)

98 (10.0 / 72)

OUTER TRACK ROD ASSEMBLY

Removal Steps

1. Nut and cotter pin, center track rod

2. Nut and cotter pin, knuckle arm

3. Lock nut, outer

4. Rod end assembly outer

5. Lock nut, inner

6. Rod end assembly, inner

★The screw is threaded

counterclockwise.

Installation Steps

6. Rod end assembly, inner

5. Lock nut, inner

4. Rod end assembly outer

3. Lock nut, outer

2. Nut and cotter pin, knuckle arm

1. Nut and cotter pin, center track

rod

These steps are based on the LHD model.

REMOVAL

Preparation:

Remove wheel and tyre assembly.

Refer to “Wheels and Tyres” in section 10.

1.Nut and Cotter Pin, Center Track Rod

Disconnect outer track rod assembly at the center

track rod.

Remover: 5-8840-2121-0 (J-36831)

CAUTION:

Be careful not to break the ball joint boot.

2. Nut and Cotter Pin, Knuckle Arm

Remove outer track rod assembly from the knuckle

arm.

Remover: 5-8840-2121-0 (J-36831)

CAUTION:

Be careful not to break the ball joint boot.

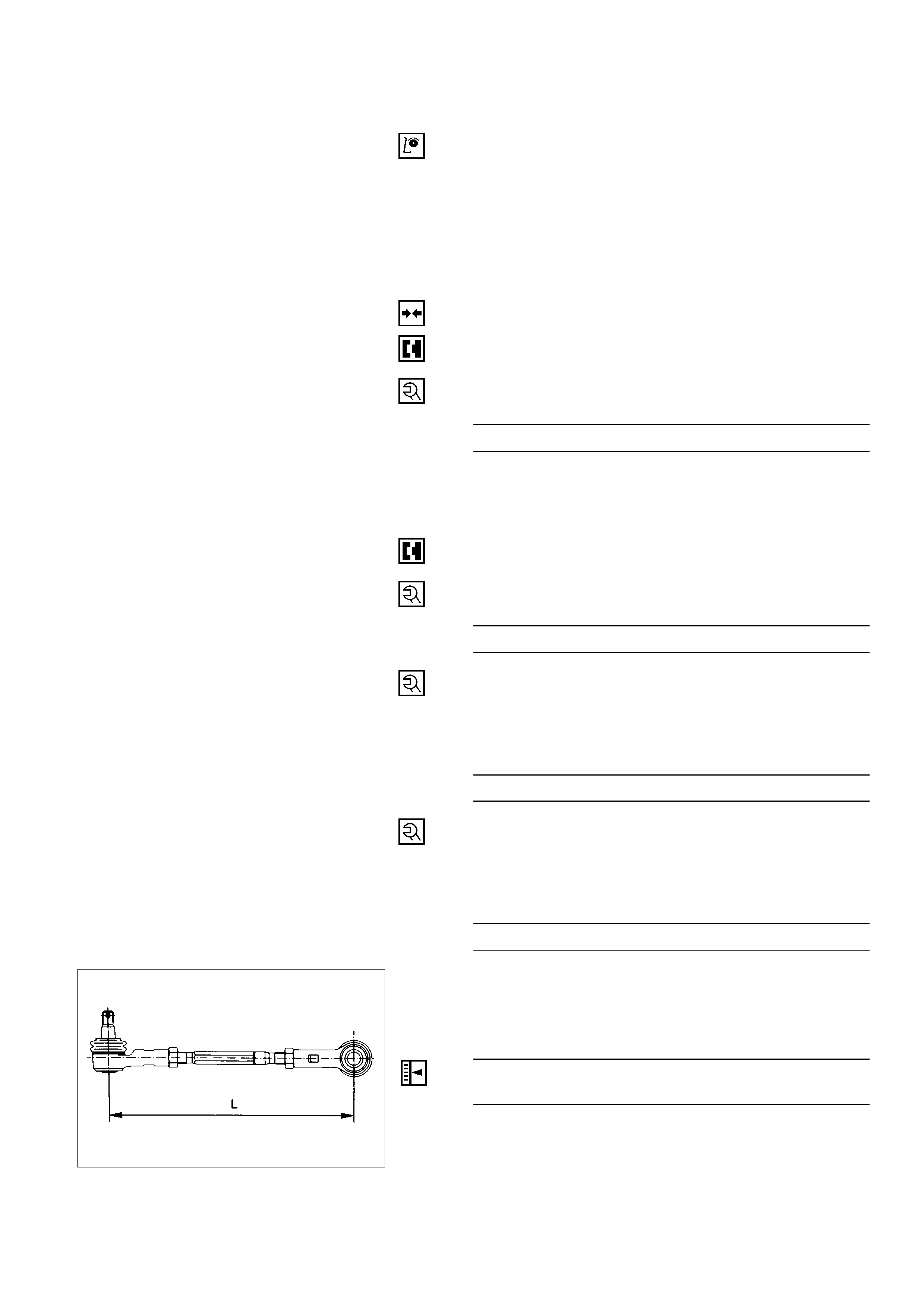

3. Lock Nut, Outer

NOTE:

In either outer rod, the screw on the right side of the

vehicle is threaded counterclockwise.

6. Rod End, Inner

Apply setting marks to ensure reassembly of the

parts in their original position.

4. Rod End Assembly, Outer

Apply setting marks to ensure reassembly of the

parts in their original position.

5. Lock Nut, Inner

NOTE:

In either outer rod, the screw on the right side of the

vehicle is threaded counterclockwise.

INSPECTIONANDREPAIR

Make necessary correction or parts replacement if wear,

damage, corrosion, bending, deteriorations or any other

abnormal condition are found through inspection.

Check the following parts.

•Rod end assembly

•Ball joint (Boot, screws and tapered surfaces)

INSTALLATION

6.Rod End, Inner

Align the setting marks applied during desassembly.

5.Lock Nut, Inner

Lock Nut Torque N·m (kg·m/lb·ft)

118 (12.0 / 87)

NOTE:

In either outer rod, the screw on the right side of the

vehicle is threaded counterclockwise.

4.Rod End Assembly, Outer

Align the setting marks applied during disassembly.

3Lock Nut, Outer

Lock Nut TorqueN·m (kg·m/lb·ft)

118 (12.0 / 87)

2.Nut and Cotter pin, Knuckle Arm

Tighten the nut to the specified torque, with just

enough additional torque to align cotter pin holes.

Install new cotter pin.

Knuckle Arm Nut TorqueN·m (kg·m/lb·ft)

98 (10.0 / 72)

1.Nut and Cotter Pin, Center Track Rod

Tighten the nut to the specified torque, with just

enough additional torque to align cotter pin holes.

Install new cotter pin.

Track Rod Nut TorqueN·m (kg·m/lb·ft)

98 (10.0 / 72)

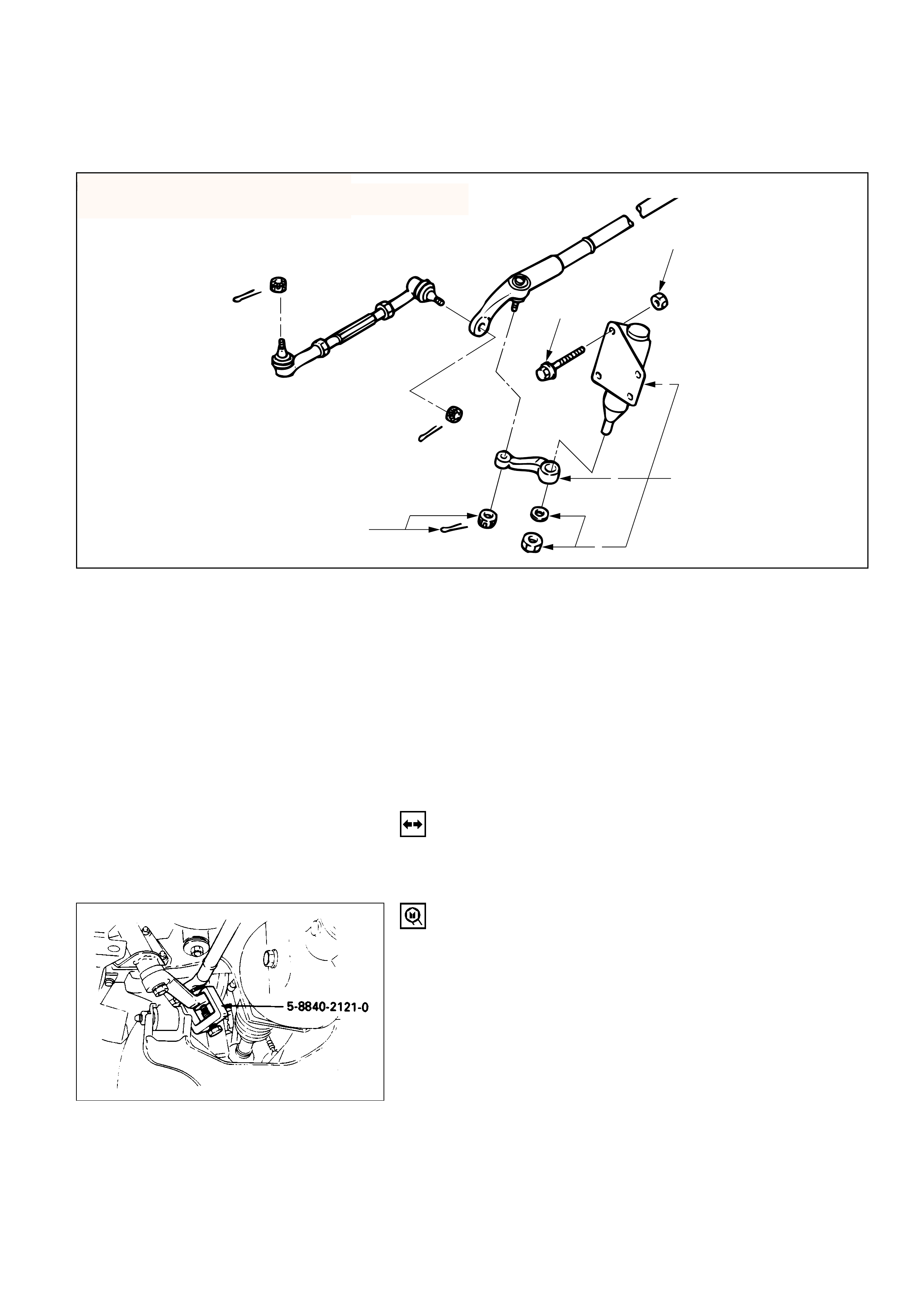

NOTE:

If replacing the track rod, adjust the new track rod

length.

Rod Length (L)mm (in)

328.3 (12.93) : Wide Tread

299 (11.77) : Narrow Tread

NOTE:

Adjust the toe-in. Refer to “Front End Alignment” in

section 3A.

RELAY LEVER

2

2

3

6

5

4

1

hese steps are based on the LHD model.

Removal Steps

1. Nut and cotter pin

2. Bolt and nut

3. Relay lever and Bracket

4. Nut and washer

5. Relay lever

6. Bracket

Installation Steps

6. Bracket

5. Relay lever

4. Nut and washer

3. Relay lever and bracket

2. Bolt and nut

1. Nut and cotter pin

REMOVAL

Preparation:

Raise the vehicle and support the frame with suitable

safety stands.

1. Nut and Cotter pin

Disconnect relay lever at the center track rod.

Remover: 5-8840-2121-0 (J-36831)

433RW005

These steps are based on the LHD model.

2. Bolt and Nut

Remove stabiliser bar bolts and nuts and push the

stabilizer bar aside and remove the bolts and nuts.

3. Relay Lever and Bracket

4. Nut and Washer

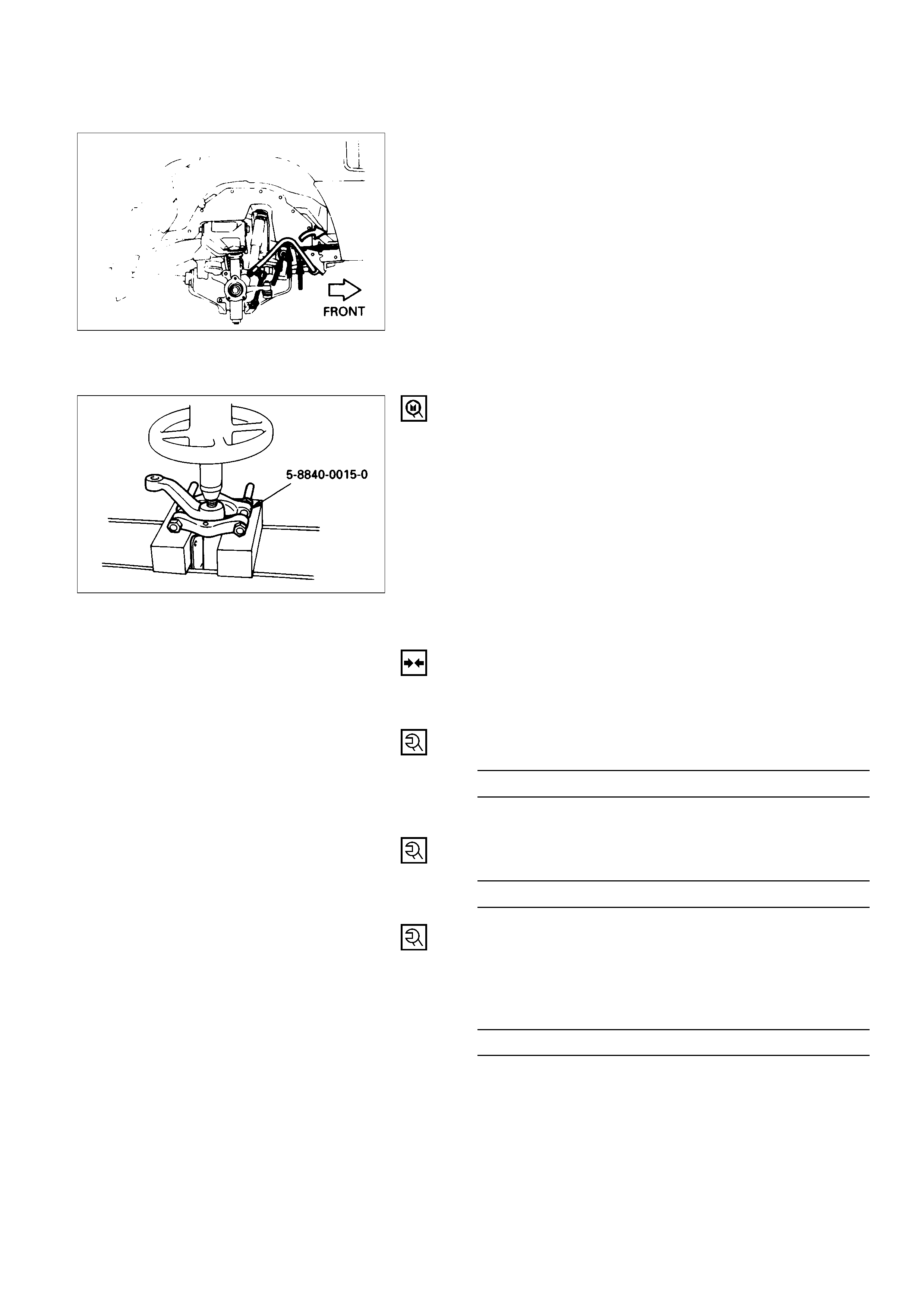

5. Relay Lever

Remove relay lever from the bracket.

Remover: 5-8840-0015-0 (J-22912-01)

6. Bracket

INSTALLATION

6. Bracket

5. Relay Lever

4. Nut and Washer

Relay Lever Nut Torque N·m (kg·m/lb·ft)

118 (12.0 / 87)

3. Relay Lever and Bracket

2. Bolt and Nut

Bracket Nut Torque N·m (kg·m/lb·ft)

44 (4.5 / 33)

1. Nut and Cotter Pin

Tighten the nut to the specified torque, with just

enough additional torque to align cotter pin holes.

Install new cotter pin.

Relay Lever Nut Torque N·m (kg·m/lb·ft)

59 (6.0 / 43)