SECTION 9C - STEERING WHEEL & COLUMN

CAUTION:

When fasteners are removed, always reinstall them at the same location from which

they were removed. If a fastener needs to be replaced, use the correct part number

fastener for that application. If the correct part number fastener is not available, a

fastener of equal size and strength (or stronger) may be used. Fasteners that are not

reused, and those requiring thread locking compound, will be called out. The correct

torque value must be used when installing fasteners that require it. If the above

conditions are not followed, parts or system damage could result.

General Description

On-Vehicle Service

SRS Connectors

Inflator Module Replacement

Steering Wheel Replacement

Combination Switch Replacement

Lock Cylinder Replacement

Steering Column Replacement

This steering wheel and column repair section

covers the Supplemental Restraint System (SRS)

steering column. The following repair procedures

are specific to SRS Components. When servicing a

vehicle equipped with Supplemental Restraint

System, pay close attention to all WARNINGS and

CAUTIONS.

For detailed explanation about SRS, refer to Section

12M "SUPPLEMENTAL RESTRAINT SYSTEM (SRS)"

of manual.

The steering column has three important features in

addition to the steering function:

1. The column is energy absorbing, designed to

compress in a front-end collision to minimize

the possibility of injury to the driver of the

vehicle.

2. The ignition switch and lock are mounted

conveniently on the column.

3. With the column mounted lock, the ignition

and steering operation can be locked to

prevent theft of the vehicle.

The column may be disassembled and

reassembled. To insure the energy absorbing

action, it is important that the specified screws,

bolts and nuts be used only as designated and that

they are tightened to the specified torque.

When the column is removed from the vehicle, a

sharp blow on the end of steering shaft or shift

lever, leaning on the column assembly, or dropping

the assembly could shear or loosen the fasteners

that maintain column rigidity.

WARNING

THIS VEHICLE HAS A SUPPLEMENTAL RE-

STRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW

IN ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN

YOU ARE PERFORMING SERVICE ON OR NEAR

THE SRS COMPONENTS OR THE SRS WIRING,

REFER TO THE SRS SERVICE INFORMATION.

FAILURE TO FOLLOW WARNINGS COULD RE-

SULT IN POSSIBLE AIR BAG DEPLOYMENT,

PERSONAL INJURY, OR OTHERWISE UN-

NEEDED SRS SYSTEM REPAIRS.

SAFE HANDLING OF INFLATOR MODULES

REQUIRES FOLLOWING THE PROCEDURES

DESCRIBED BELOW FOR BOTH LIVE AND

DEPLOYED MODULES.

SAFETY PRECAUTIONS MUST BE FOLLOWED

WHEN HANDLING A DEPLOYED AIR BAG AS-

SEMBLY (AIR BAG). AFTER DEPLOYMENT,

THE AIR BAG ASSEMBLY (AIR BAG) SURFACE

MAY CONTAIN A SMALL AMOUNT OF SODIUM

HYDROXIDE, A BY-PRODUCT OF THE DEPLOY-

MENT REACTION, THAT IS IRRITATING TO THE

SKIN AND EYES. MOST OF THE POWDER ON

THE AIR BAG ASSEMBLY (AIR BAG) IS HARM-

LESS. AS A PRECAUTION, WEAR GLOVES

AND SAFETY GLASSES WHEN HANDLING A

DEPLOYED AIR BAG ASSEMBLY, AND WASH

YOUR HANDS WITH MILD SOAP AND WATER

AFTERWARDS.

WHEN CARRYING A LIVE AIR BAG ASSEMBLY,

MAKE SURE THE BAG AND TRIM COVER ARE

POINTED AWAY FROM YOU. NEVER CARRY

AN AIR BAG ASSEMBLY BY THE WIRES OR

CONNECTOR ON THE UNDERSIDE OF MODULE.

IN THE CASE OF AN ACCIDENTAL DEPLOY-

MENT, THE BAG WILL THEN DEPLOY WITH

MINIMAL CHANCE OF INJURY. WHEN PLACING

A LIVE AIR BAG ASSEMBLY ON A BENCH OR

OTHER SURFACE, ALWAYS FACE THE BAG AND

TRIM COVER UP, AWAY FROM THE SURFACE.

NEVER REST A STEERING COLUMN ASSEMBLY

ON THE STEERING WHEEL WITH THE AIR

BAG ASSEMBLY FACE DOWN AND COLUMN

VERTICAL. THIS IS NECESSARY SO THAT A

FREE SPACE IS PROVIDED TO ALLOW THE AIR

BAG ASSEMBLY TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT. OTHER-

WISE, PERSONAL INJURY COULD RESULT.

TO AVOID DEPLOYMENT WHEN TROUBLE

SHOOTING THE SRS SYSTEM, DO NOT USE

ELECTRICAL TEST EQUIPMENT, SUCH AS

BATTERY-POWERED OR A/C-POWERED VOLT-

METER, OHMMETER, ETC., OR ANY TYPE OF

ELECTRICAL EQUIPMENT OTHER THAN SPECI-

FIED IN THIS MANUAL. DO NOT USE A NON-

POWERED PROBE-TYPE TESTER.

INSTRUCTIONS IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PER-

SONAL INJURY MAY RESULT.

GENERAL DESCRIPTION

ON-VEHICLE SERVICE

21

827RW035

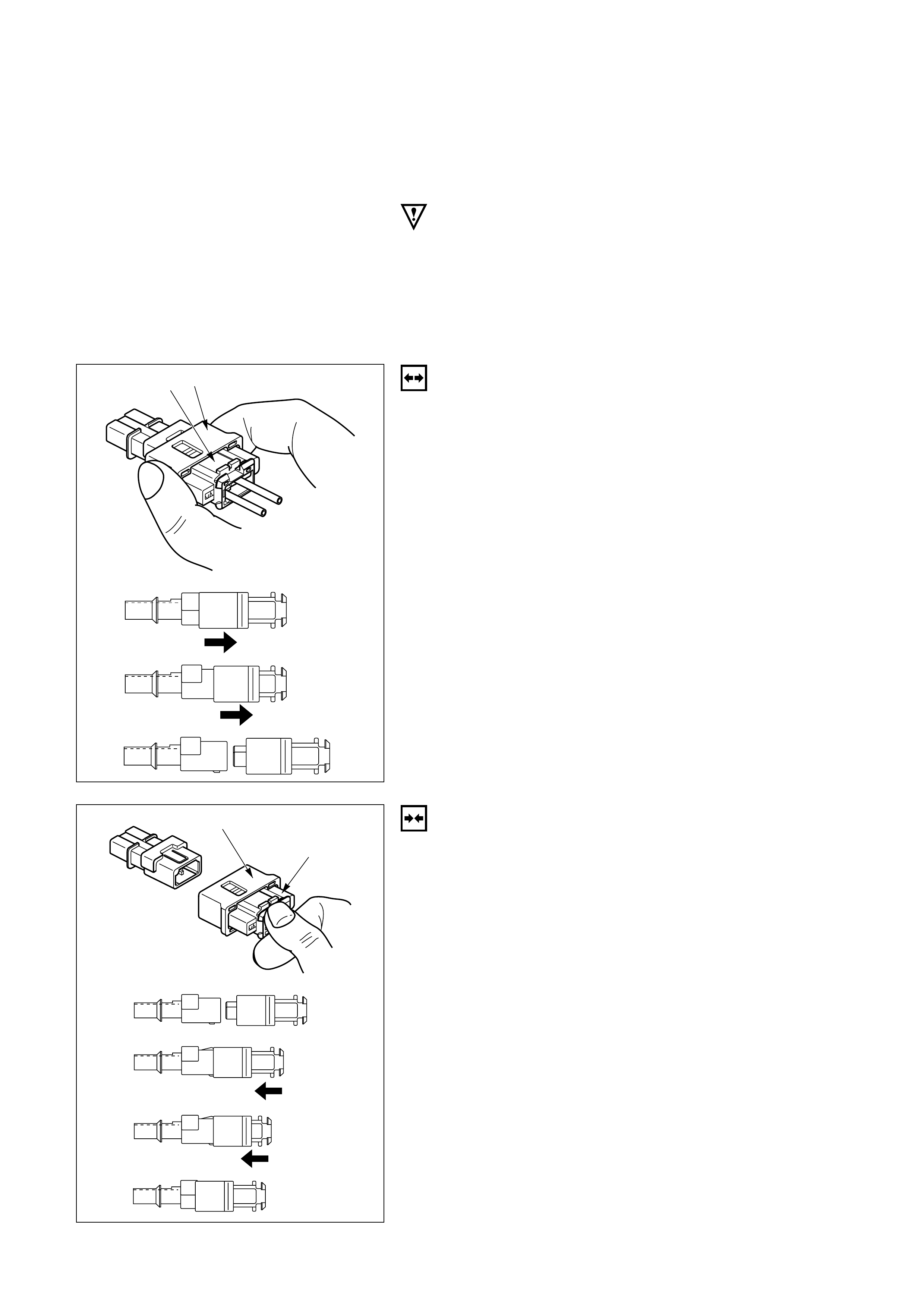

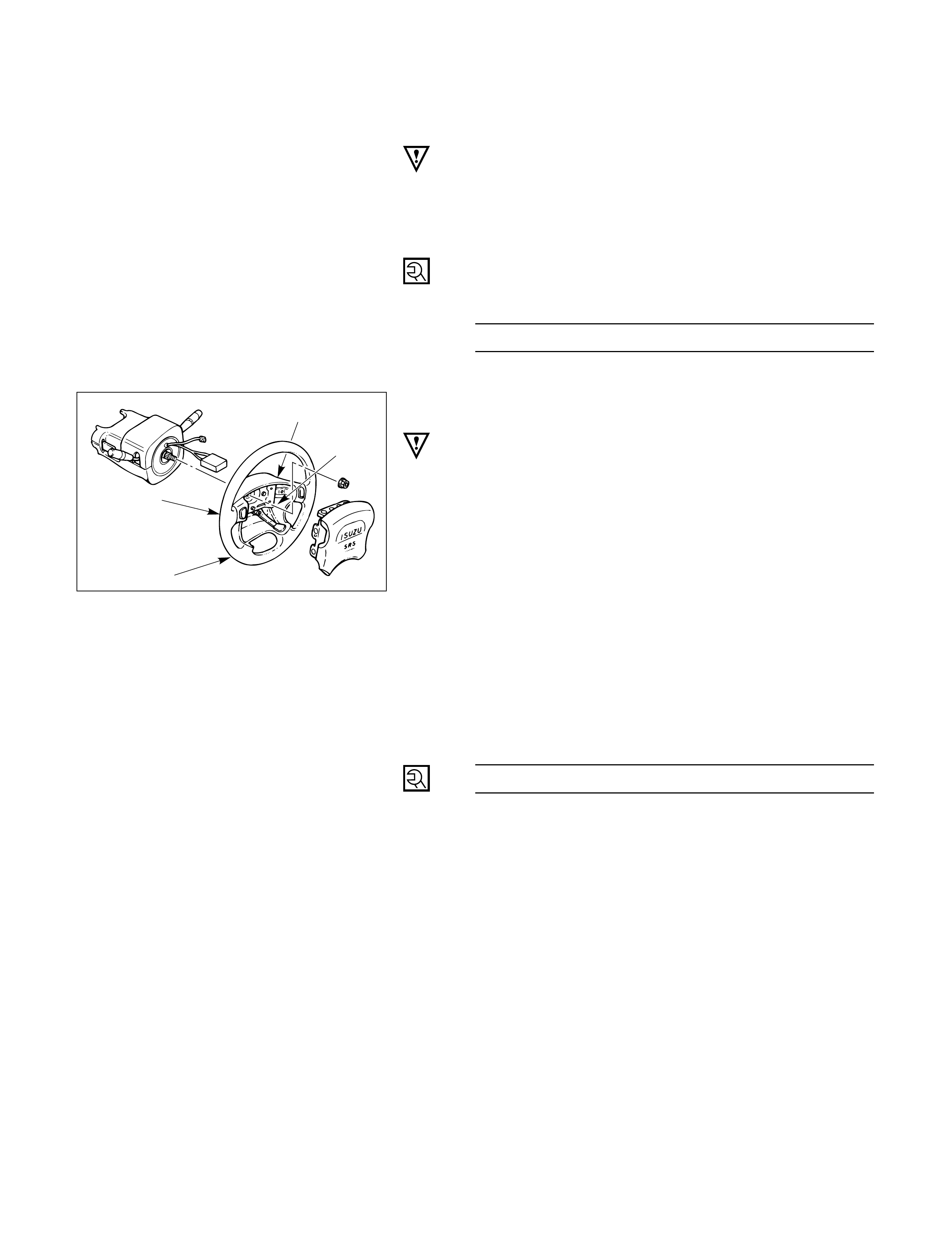

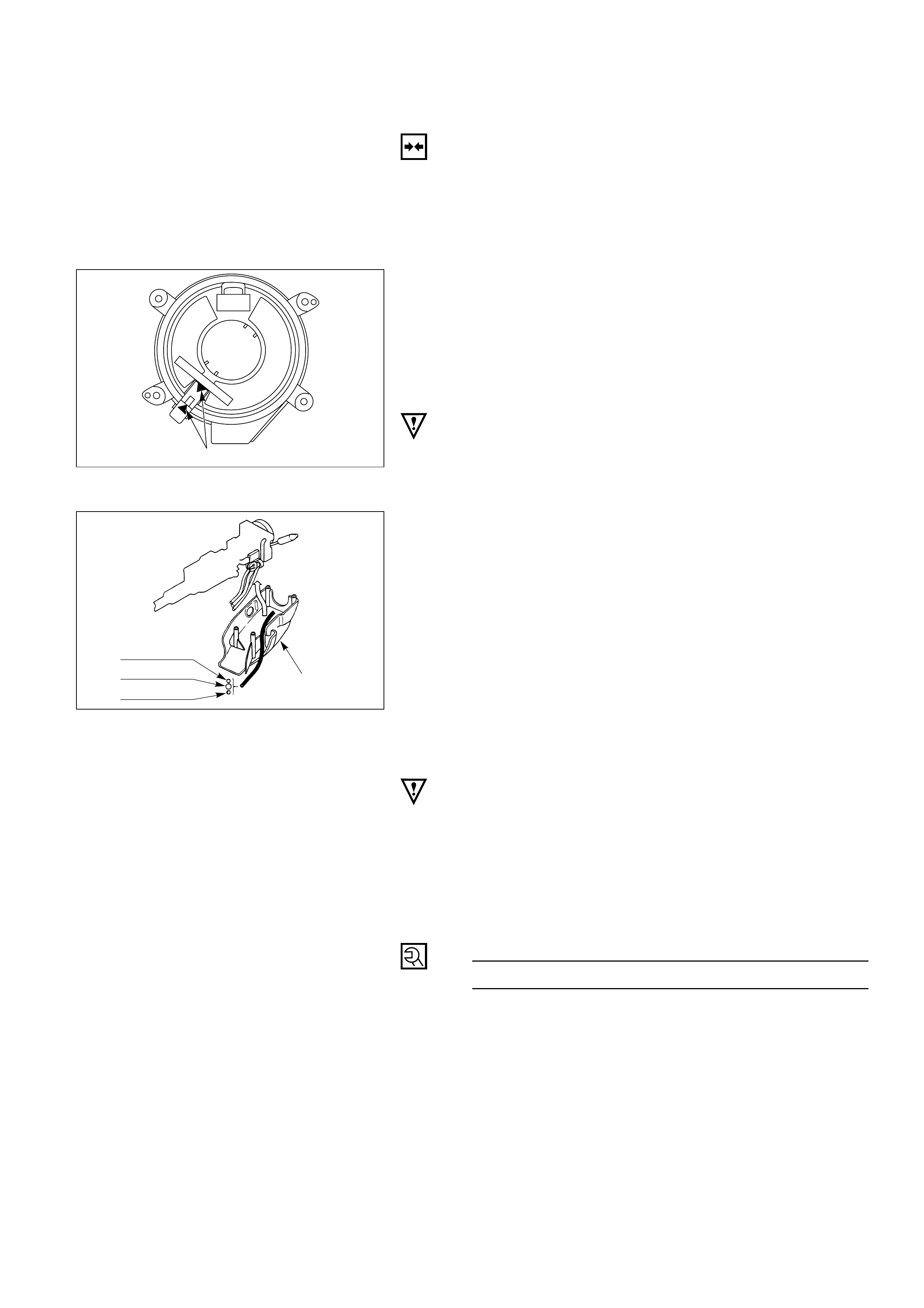

SRS CONNECTORS

CAUTION:

The special yellow color connectors are used for

supplemental restraint system-air bag circuit.

When removing the cable harness, do not pull the cables.

Otherwise, cable disconnection may occur.

When connect the SRS connector, insert the connector

completely. Imperfect locking may cause malfunction of

SRS circuit.

REMOVAL

To remove the connector, hold the cover insulator(1) and

pull it. The cover insulator slides and lock will be released.

Do not hold the socket insulator(2).

INSTALLATION

To install the connector, hold the socket insulator(1) and

insert it. The cover insulator slides and connector will be

locked.

Do not hold the cover insulator(2).

2

1

827RW034

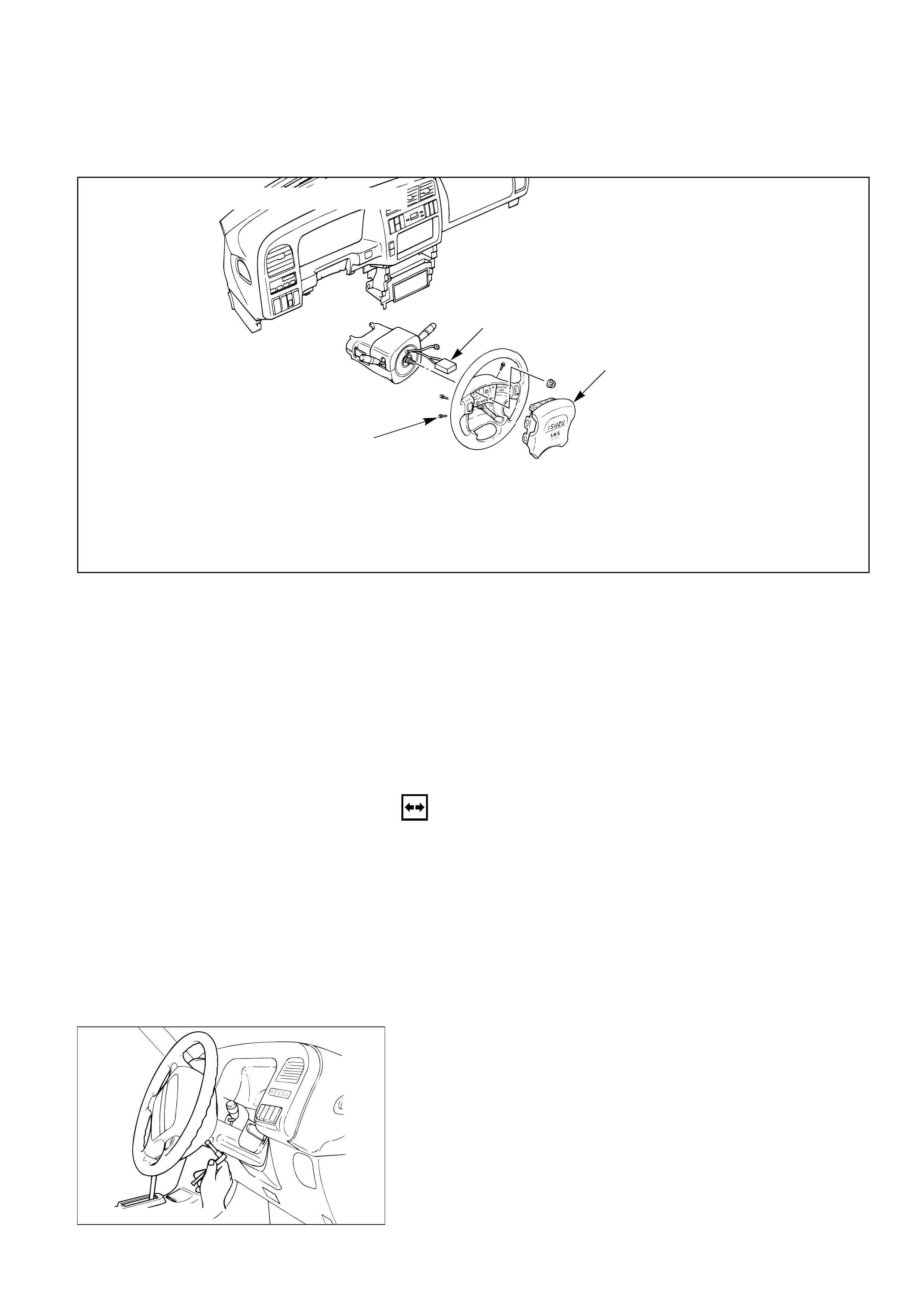

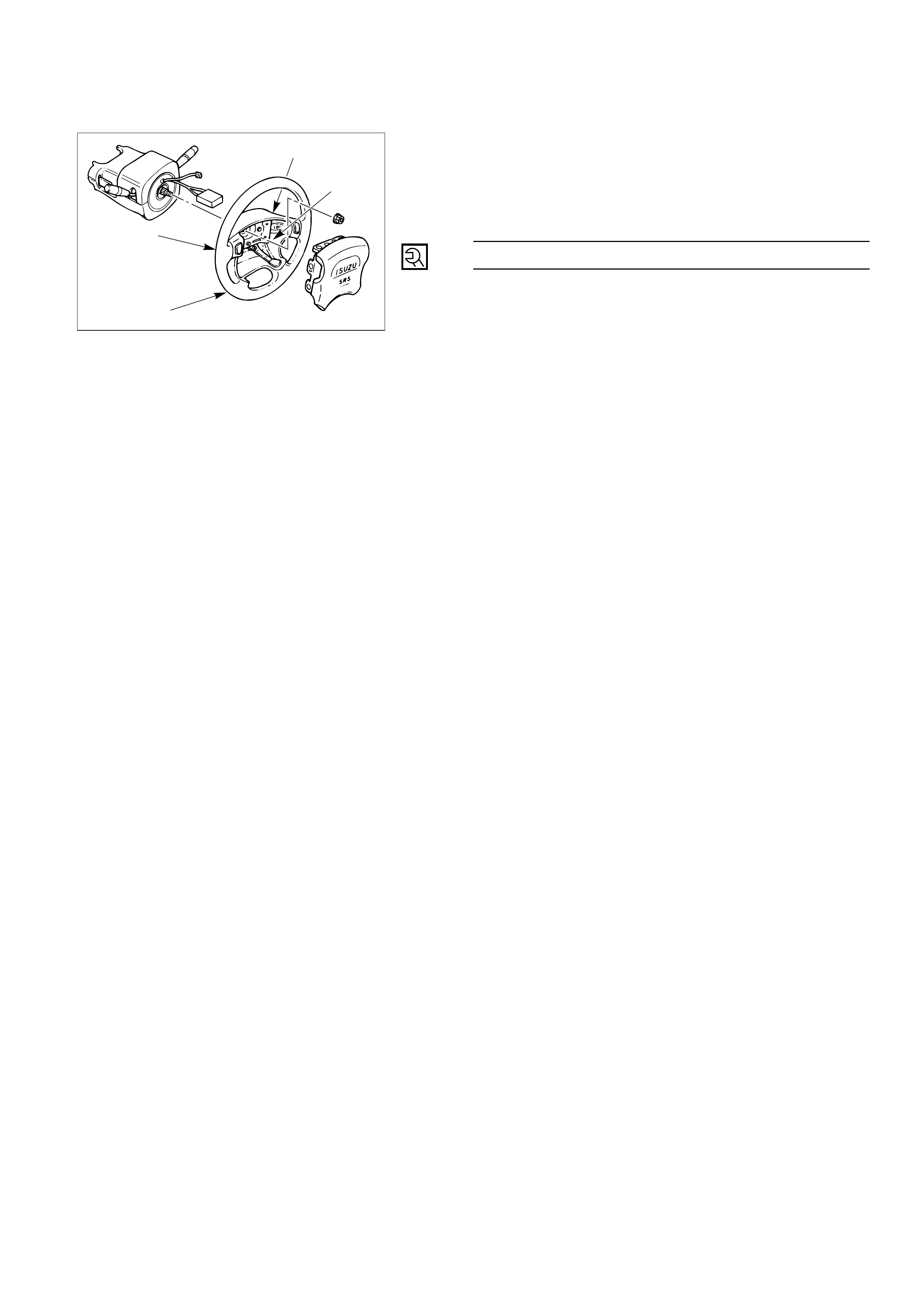

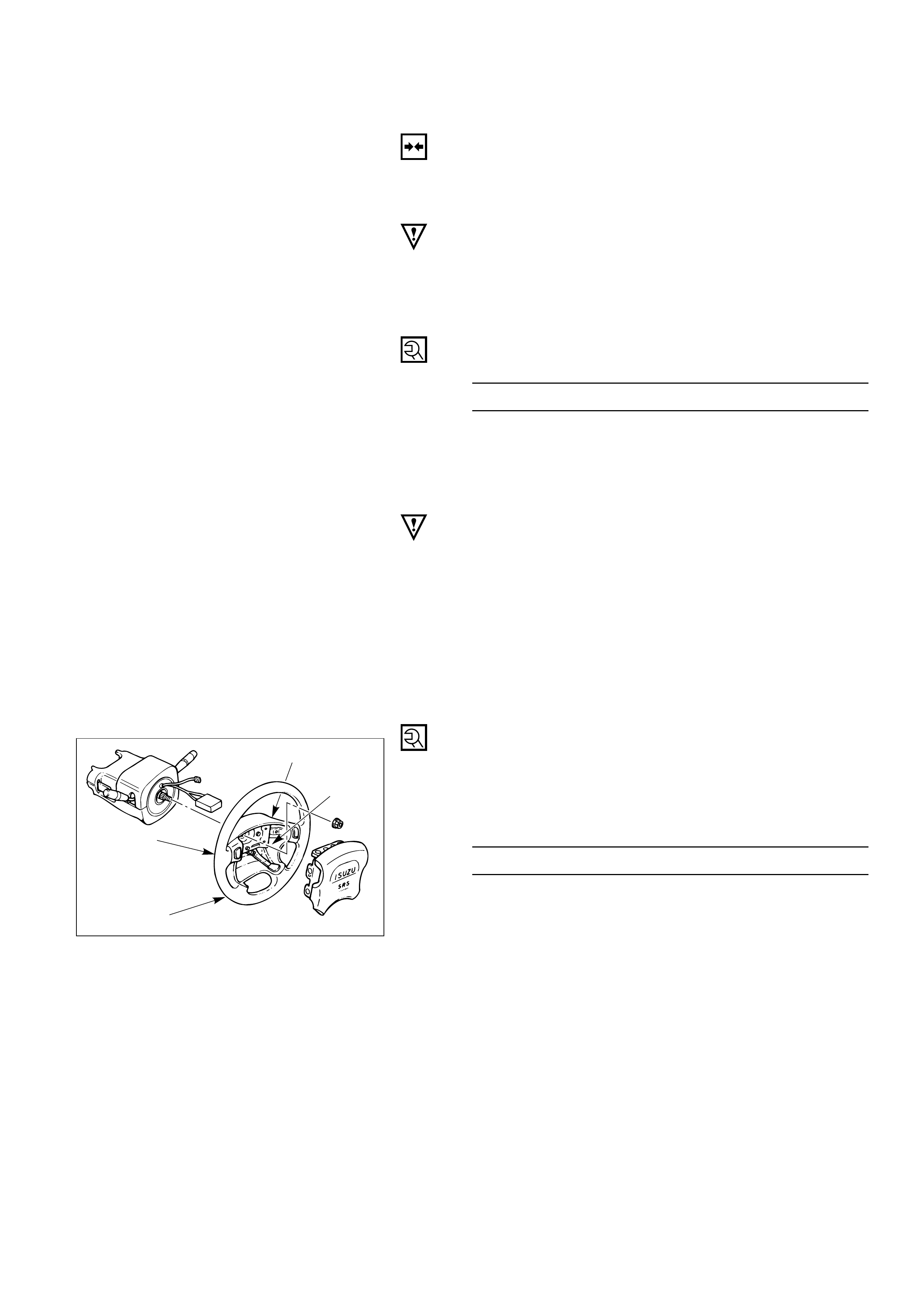

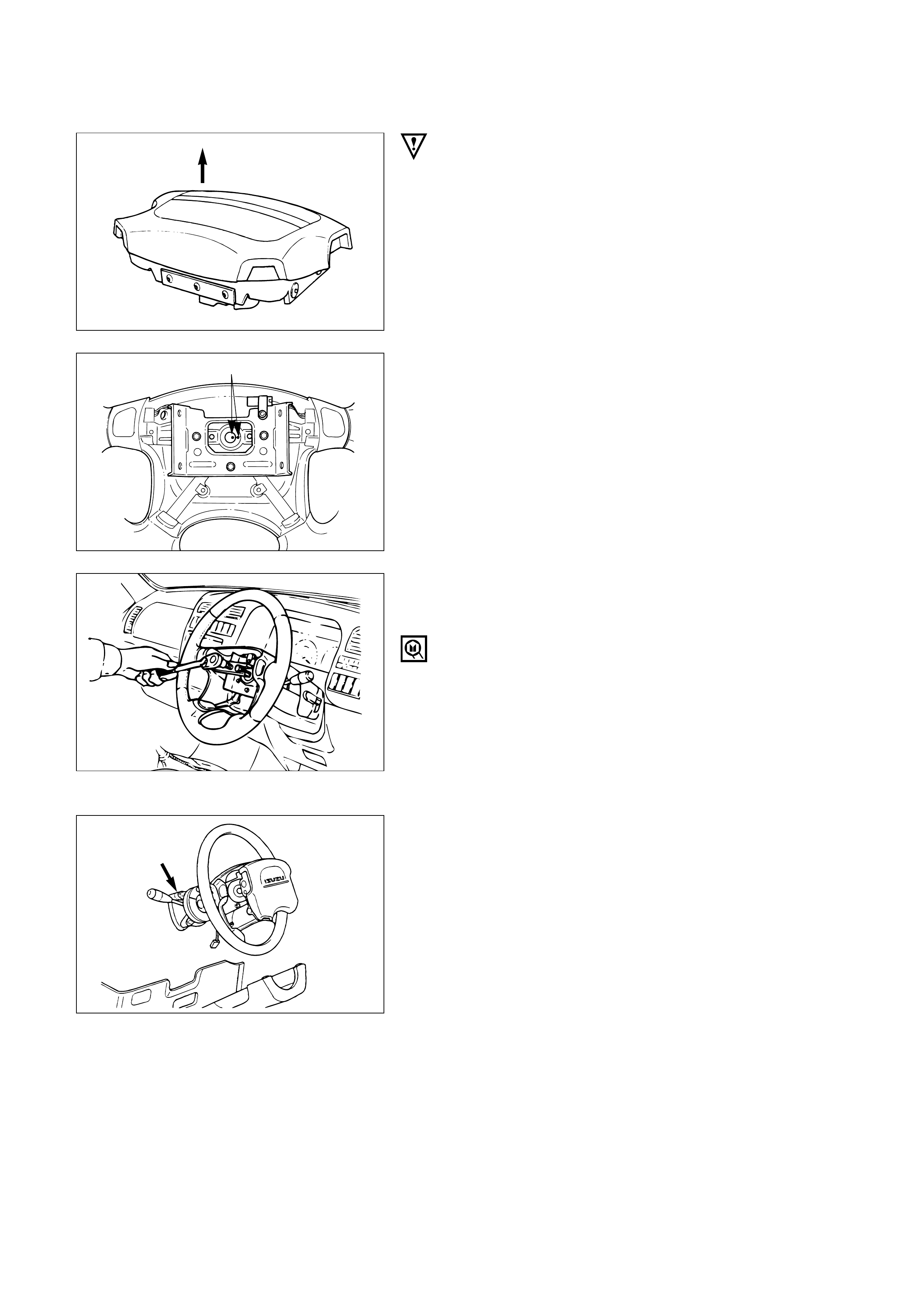

INFLATOR MODULE REPLACEMENT

1

3

2

Removal Steps

1. Fixing bolt

2. Module connector

3. Inflator module

Installation Steps

3. Inflator module

2. Module connector

1. Fixing bolt

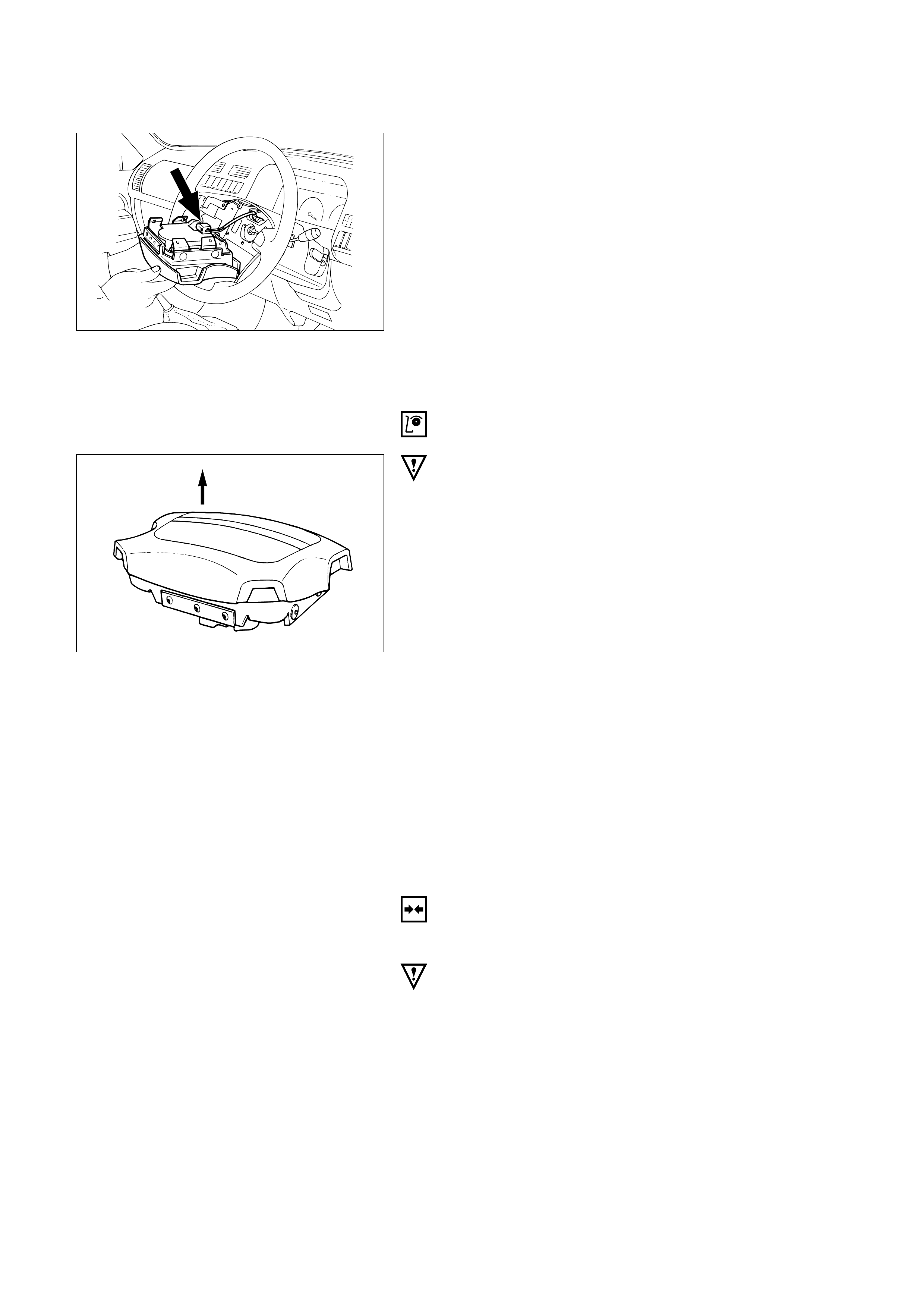

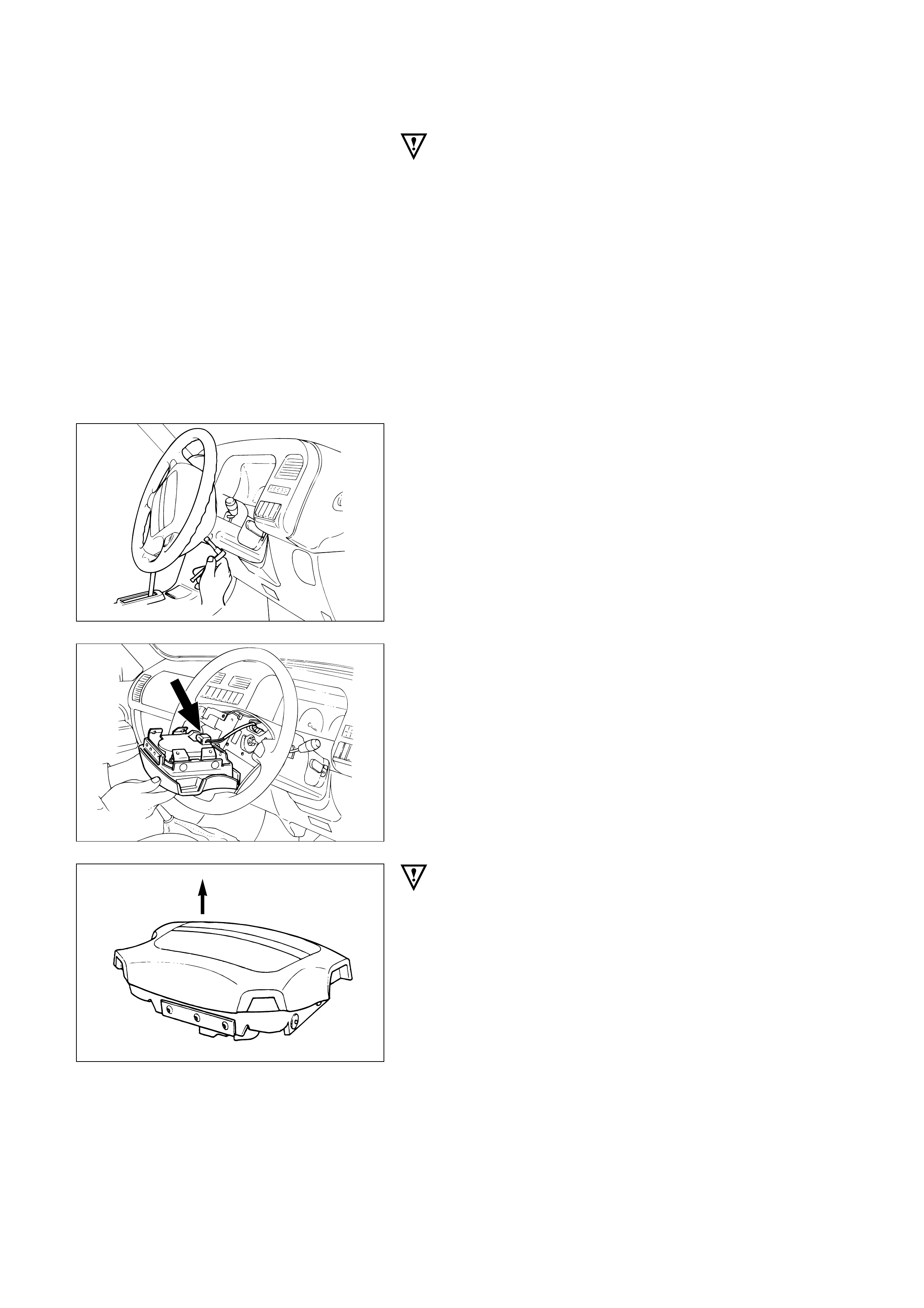

REMOVAL

Preparation:

1) Turn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2) Turn the ignition switch to "LOCK".

3) Disconnect the battery ground cable, and wait at least

5 minutes.

4) Disconnect the yellow 2way SRS connector located

under the steering column.

1. Fixing Bolt

Loosen the inflator module fixing bolt from behind

the steering wheel assembly using a TORX‚ driver or

equivalent until the inflator module can be released

from steering assembly.

827RT914

2. Module Connector

Disconnect the yellow 2way SRS connector located

behind the inflator module.

3. Inflator Module

827RW037

827RS016

INSPECTION AND REPAIR

WARNING

THE INFLATOR MODULE SHOULD ALWAYS BE CARRIED

WITH THE URETHANE COVER AWAY FROM YOUR BODY

AND SHOULD ALWAYS BE LAID ON A FLAT SURFACE

WITH THE URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW THE

AIR CUSHION TO EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. OTHERWISE, PERSONAL

INJURY MAY BE RESULT.

The Inflator module consists of a cover, air bag,

inflator, and retainer. Inspect the Inflator module

mainly for the following:

1) Check for holes, cracks, severe blemishes and

deformation on the cover.

2) Check that the retainer is not deformed.

3) Check for defects such as damage and breakage

in the lead wire of the squib.

If an abnormality is found as the result of the

inspection, replace the Inflator module with a new

one.

Up

INSTALLATION

3.Inflator Module

CAUTION:

•Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

•When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

2. Module Connector

Support the module and carefully connect the

module connector.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinched.

3

4

1

2

1. Fixing Bolt

1) Secure the module with one bolt to relieve

weight on the connector wire.

2) Tighten bolts to specified sequence as figure.

N·m (kg·m/lb·in)

8 (0.8 / 69)

3) Connect the yellow 2way SRS connector located

under the steering column.

4) Connect the battery ground cable.

5) Set ignition to "ON" while watching warning

light. Light should flash 7 times and then go off.

If lamp does not operate correctly, refer to

Section 12M.

827RS017

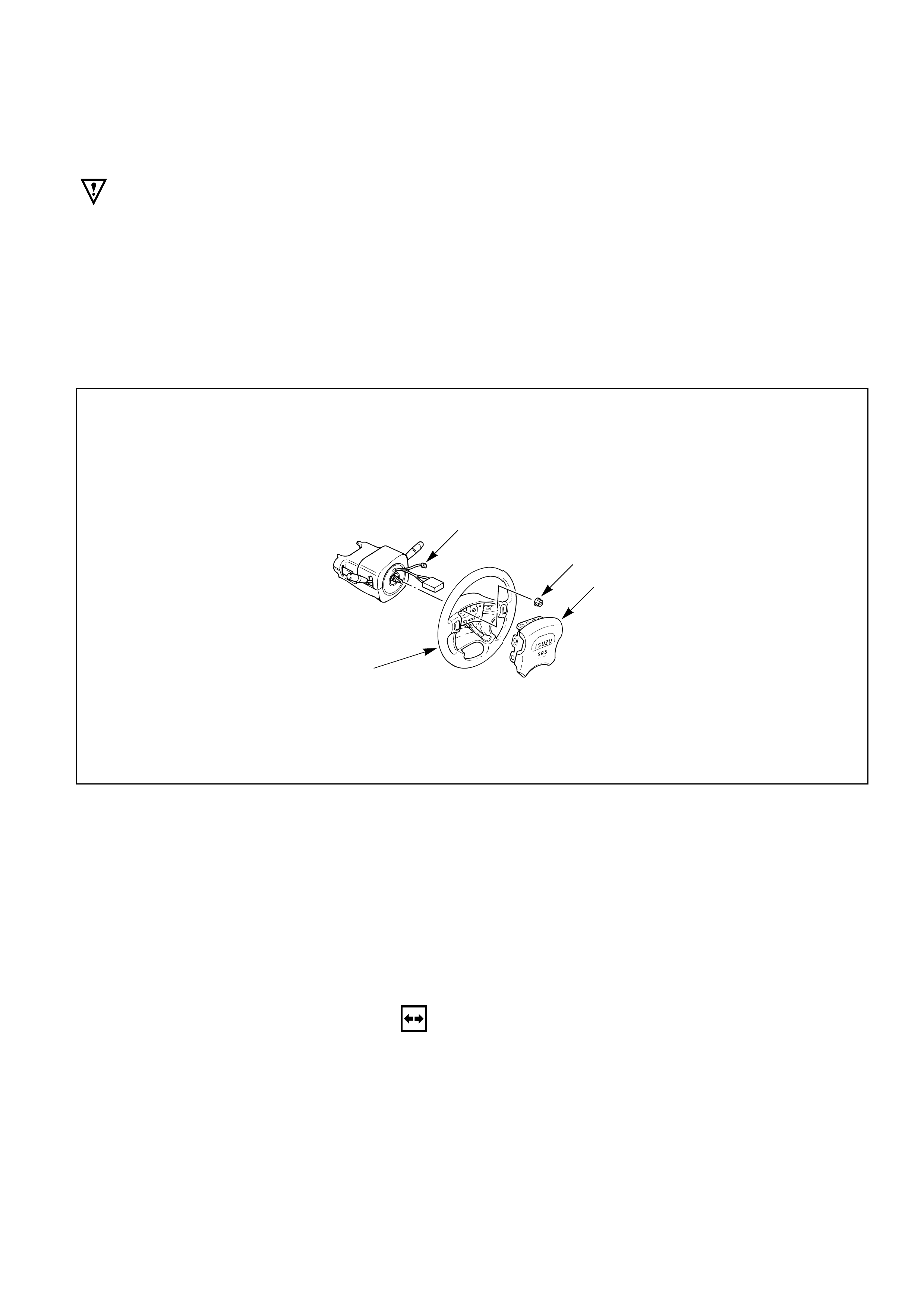

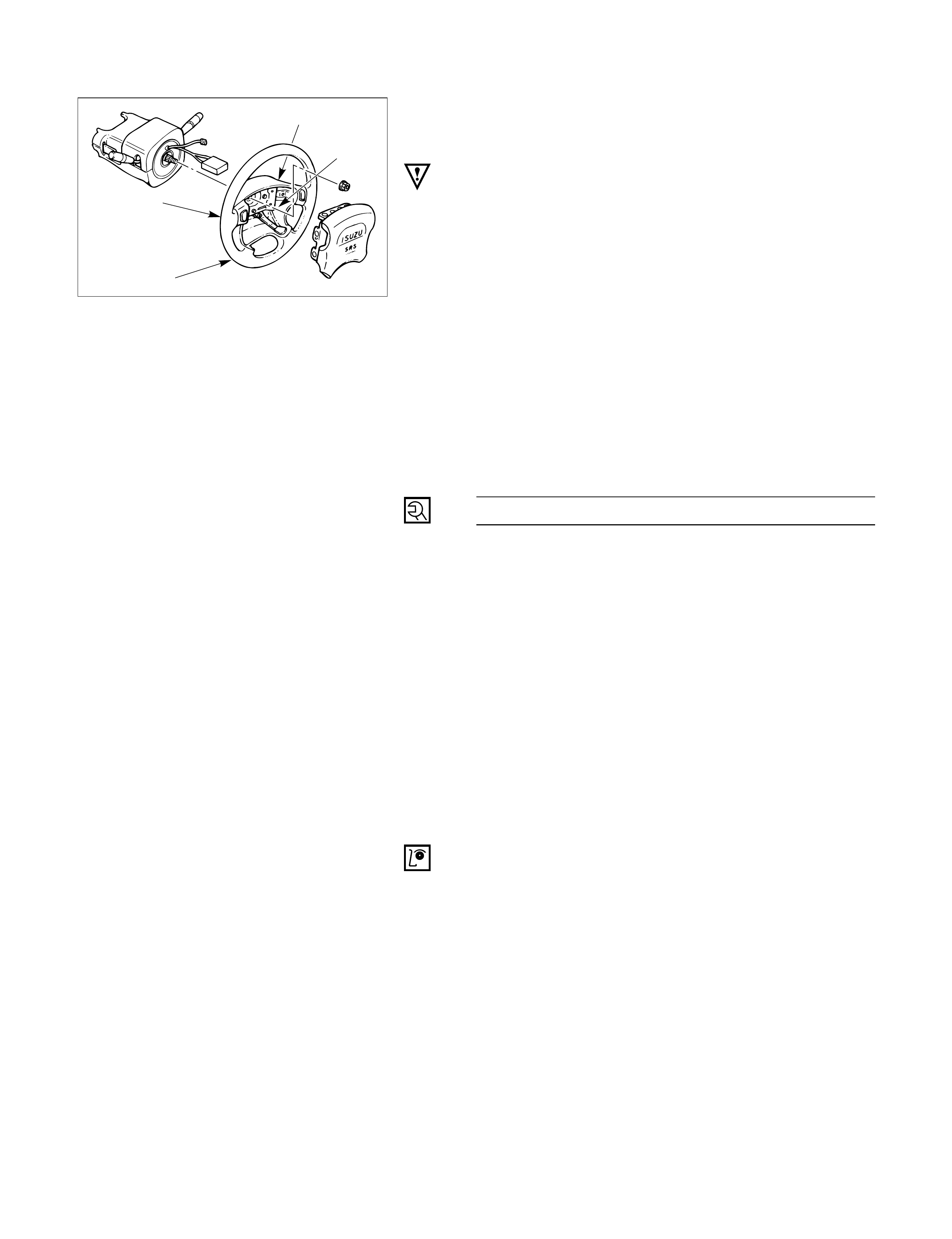

STEERING WHEEL REPLACEMENT

1

3

2

4

Removal Steps

1. Inflator module

2. Horn lead

3. Steering wheel fixing nut

4. Steering wheel

Installation Steps

4. Steering wheel

3. Steering wheel fixing nut

2. Horn lead

1. Inflator module

REMOVAL

Preparation:

1) Turn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2) Turn the ignition switch to "LOCK".

3) Disconnect the battery ground cable, and wait at least

5 minutes.

4) Disconnect the yellow 2way SRS connector located

under the steering column.

CAUTION:

Once the steering column is removed from the vehicle, the column is extremely suspectible to

damage. Dropping the column assembly on its end could collapse the steering shaft or loosen the

slide block which maintains column rigidity. Leaning on the column assembly could cause the jacket

to bend or deform. Any of the above damage could impair the column's collapsible design. If it is

necessary to remove the steering wheel, use only the specified steering wheel puller. Under no

conditions should the end of the shaft be hammered upon, as hammering could loosen slide block

which maintains column rigidity.

1. Inflator Module

1) Loosen the inflator module fixing bolt from

behind the steering wheel assembly using a

TORXdriver or equivalent until the inflator

module can be released from steering assembly.

2) Disconnect the yellow 2way SRS connector

located behind the inflator module.

WARNING

THE INFLATOR MODULE SHOULD ALWAYS BE CARRIED

WITH THE URETHANE COVER AWAY FROM YOUR BODY

AND SHOULD ALWAYS BE LAID ON A FLAT SURFACE

WITH THE URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW THE

AIR CUSHION TO EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. OTHERWISE, PERSONAL

INJURY MAY RESULT.

2. Horn Lead

3. Steering Wheel Fixing Nut

4. Steering Wheel

1) Apply a setting mark across the steering wheel

and shaft so parts can be reassembled in their

original position.

2) Move the front wheels to the straight ahead

position and use special tool.

Steering wheel remover: 5-8840-0016-0 (J-29752)

NOTE:

Never apply force to the steering wheel in direction

of the shaft by using a hammer or other impact tools

in an attempt to remove the steering wheel. The

steering shaft is designed as an energy absorbing

unit.

827RT914

827RS016

430RS004

Up

Setting mark

430RW014

INSTALLATION

4. Steering Wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the setting wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to install the steering wheel. The setting shaft is

designed as an energy absorbing unit.

3. Steering Wheel Fixing Nut

Steering Wheel Nut Torque N·m (kg·m/lb·ft)

8 (0.8 / 69)

4) Connect the yellow 2way SRS connector located

under the steering column.

5) Connect the battery ground cable.

6) Set ignition to "ON" while watching warning

light. Light should flash 7 times and then go off.

If lamp does not operate correctly, refer to

Section 12M.

3

4

1

2

827RS017

34 (3.5 / 25)

2. Horn Lead

1. Inflator Module

1) Support the module and carefully connect the

module connector.

CAUTION:

•Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

•When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinches.

2) Secure the module with one bolt to relieve

weight on the connector wire.

3) Tighten bolts to specified sequence as figure.

Inflator module Bolt Torque N·m (kg·m/lb·in)

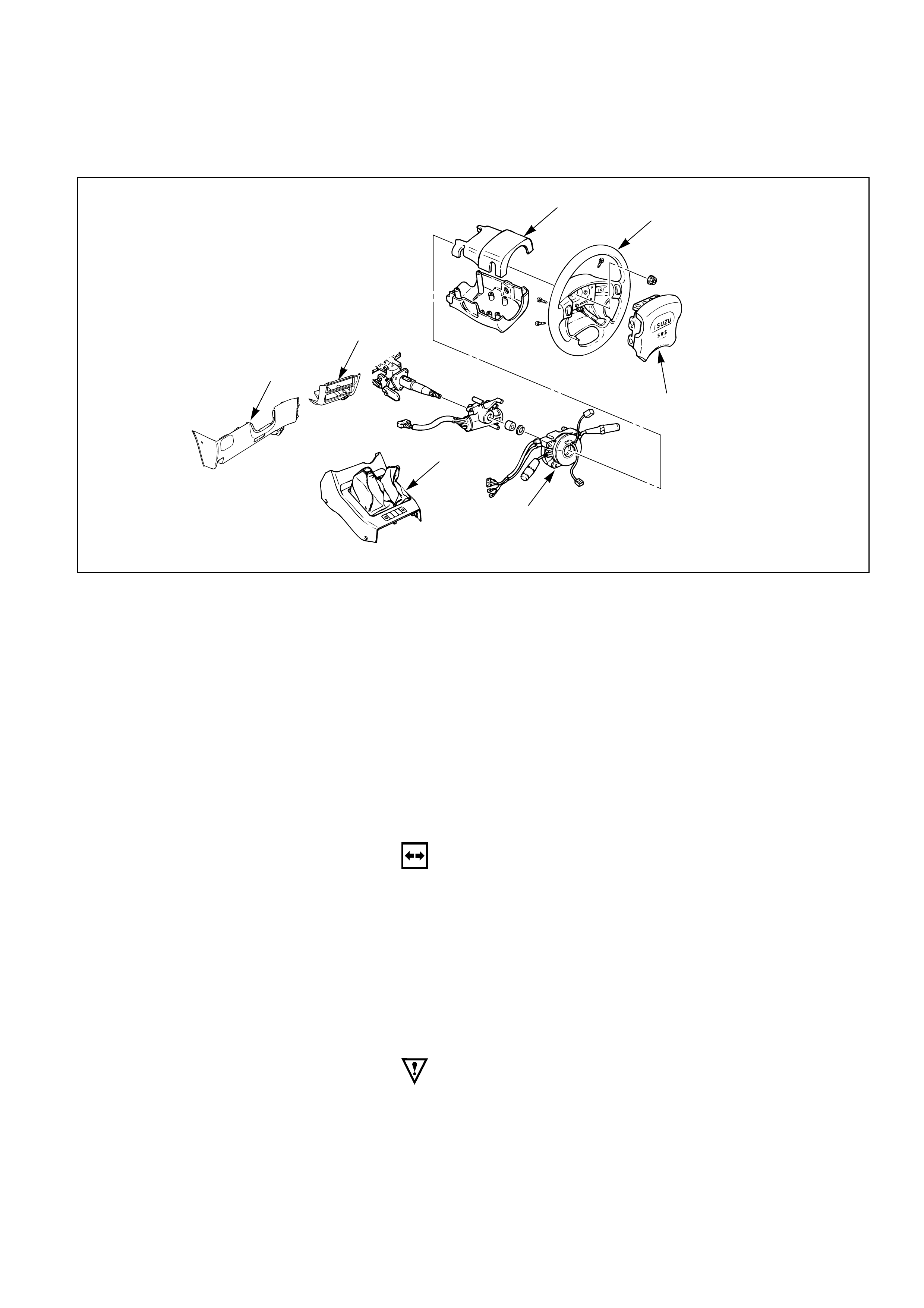

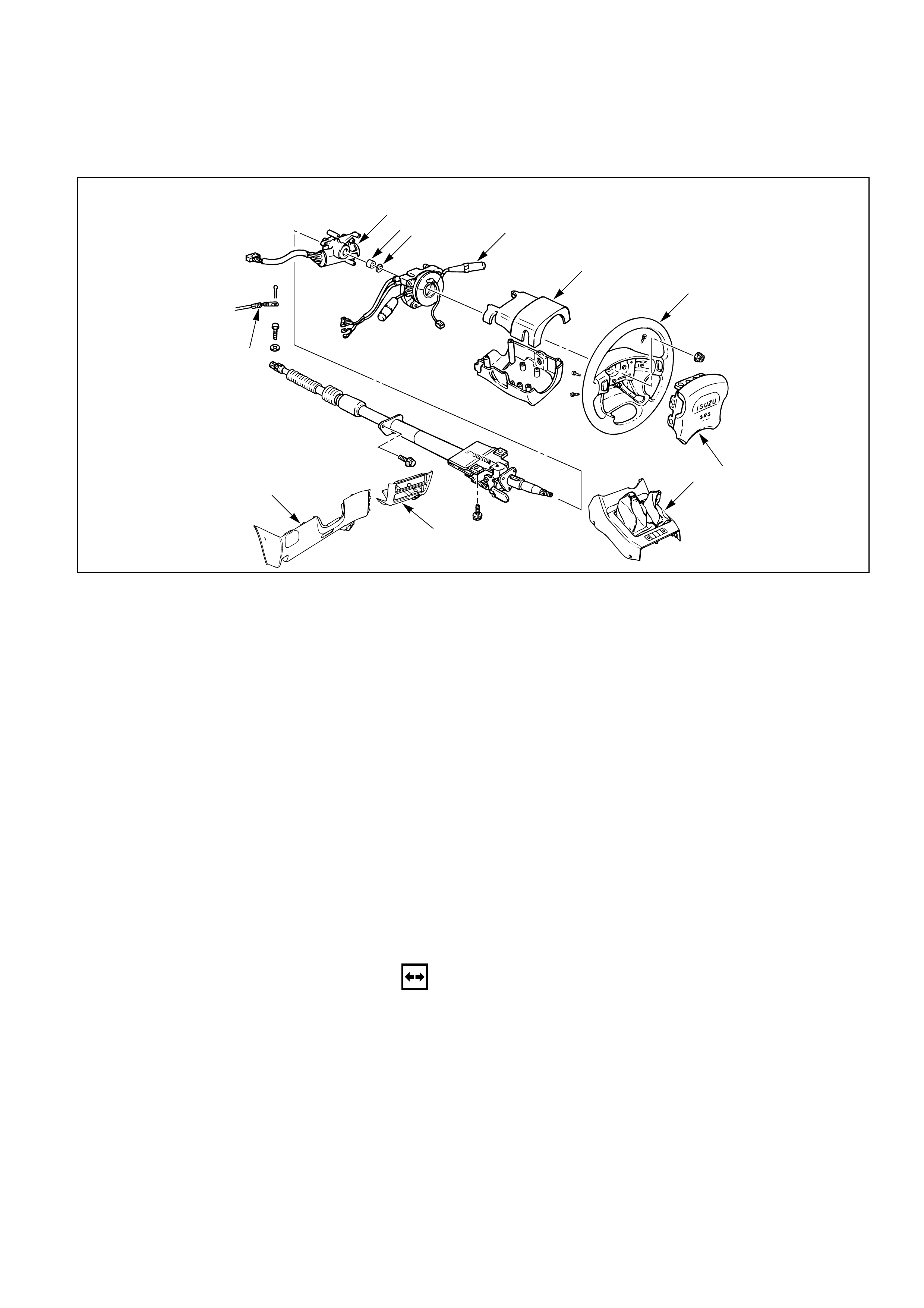

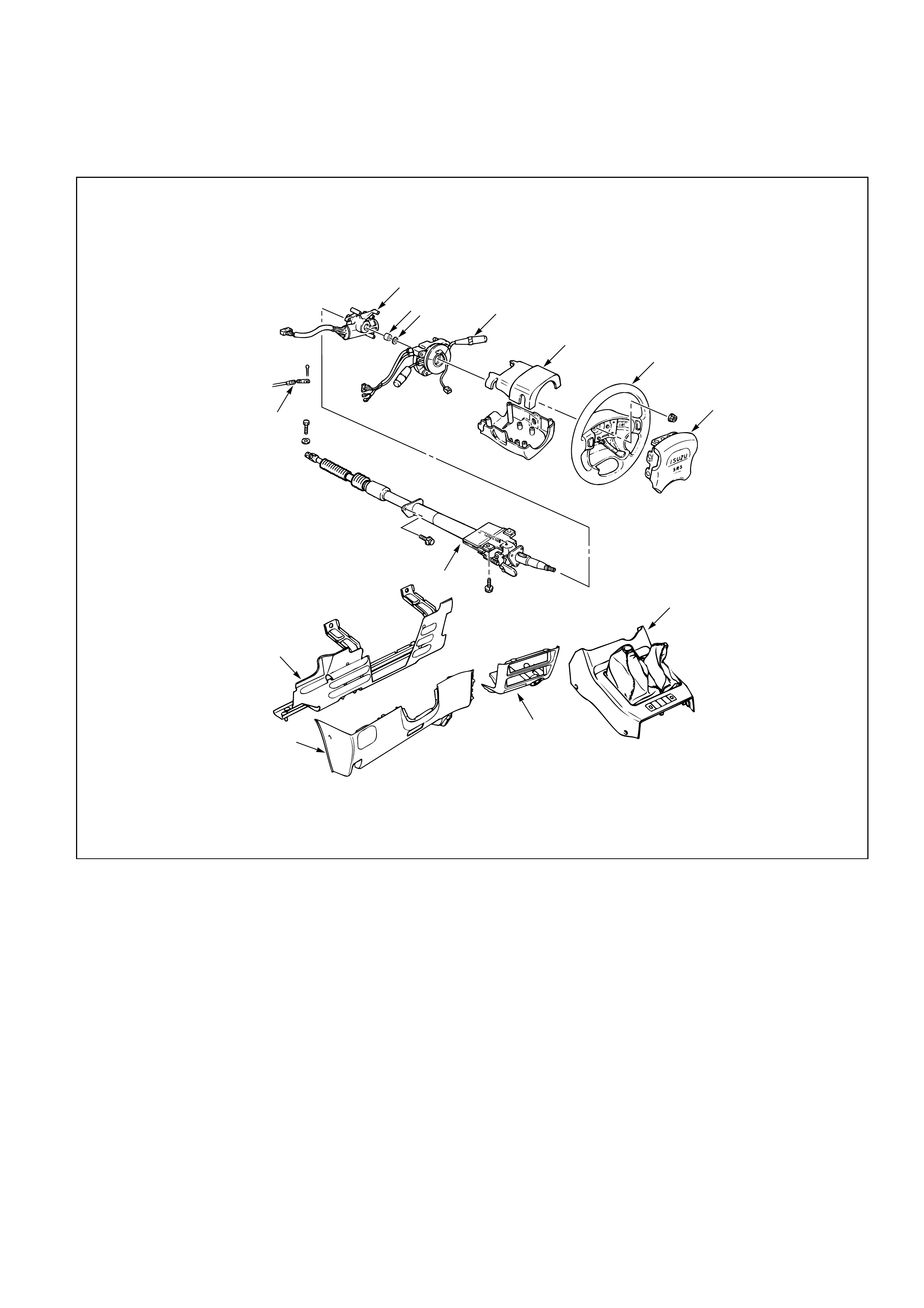

COMBINATION SWITCH REPLACEMENT

3

2

1

7

4

5

6

Removal Steps

1. Front console assembly

2. Lower cluster assembly

3. Steering lower cover

4. Inflator module

5. Steering wheel

6. Steering column cover

7. Combination switch and

SRS coil assembly

Installation Steps

7. Combination switch and

SRS coil assembly

6. Steering column cover

5. Steering wheel

4. Inflator module

3. Steering lower cover

2. Lower cluster assembly

1. Front console assembly

REMOVAL

Preparation:

1) Turn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2) Turn the ignition switch to "LOCK".

3) Disconnect the battery ground cable, and wait at least

5 minutes.

4) Disconnect the yellow 2way SRS connector located

under the steering column.

CAUTION:

The wheels of the vehicle must be straight ahead and the

steering column in the "LOCK" position before

disconnecting the steering wheel. Failure to do so will

cause the coil assembly to become uncentered which will

cause damage to the coil assembly.

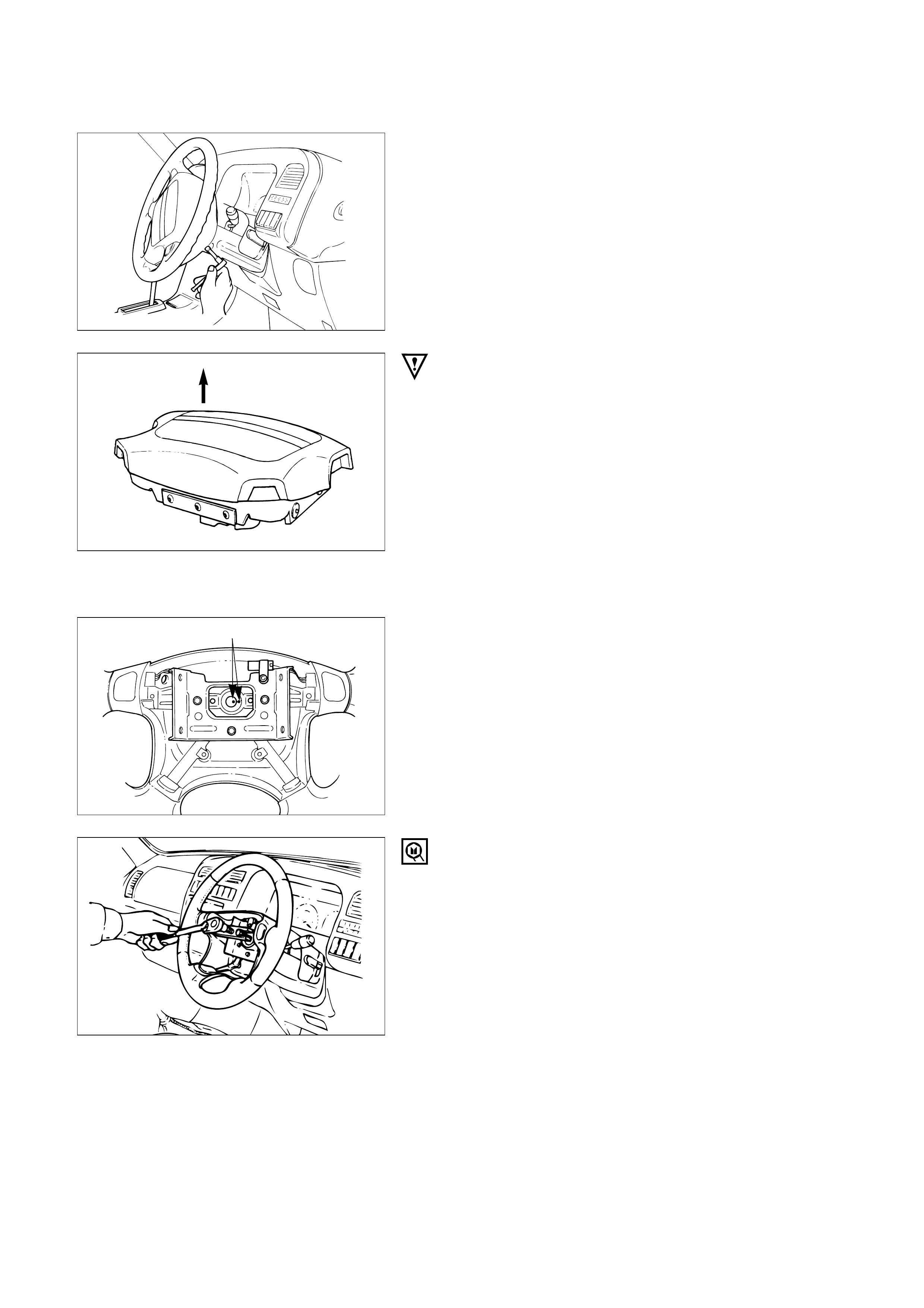

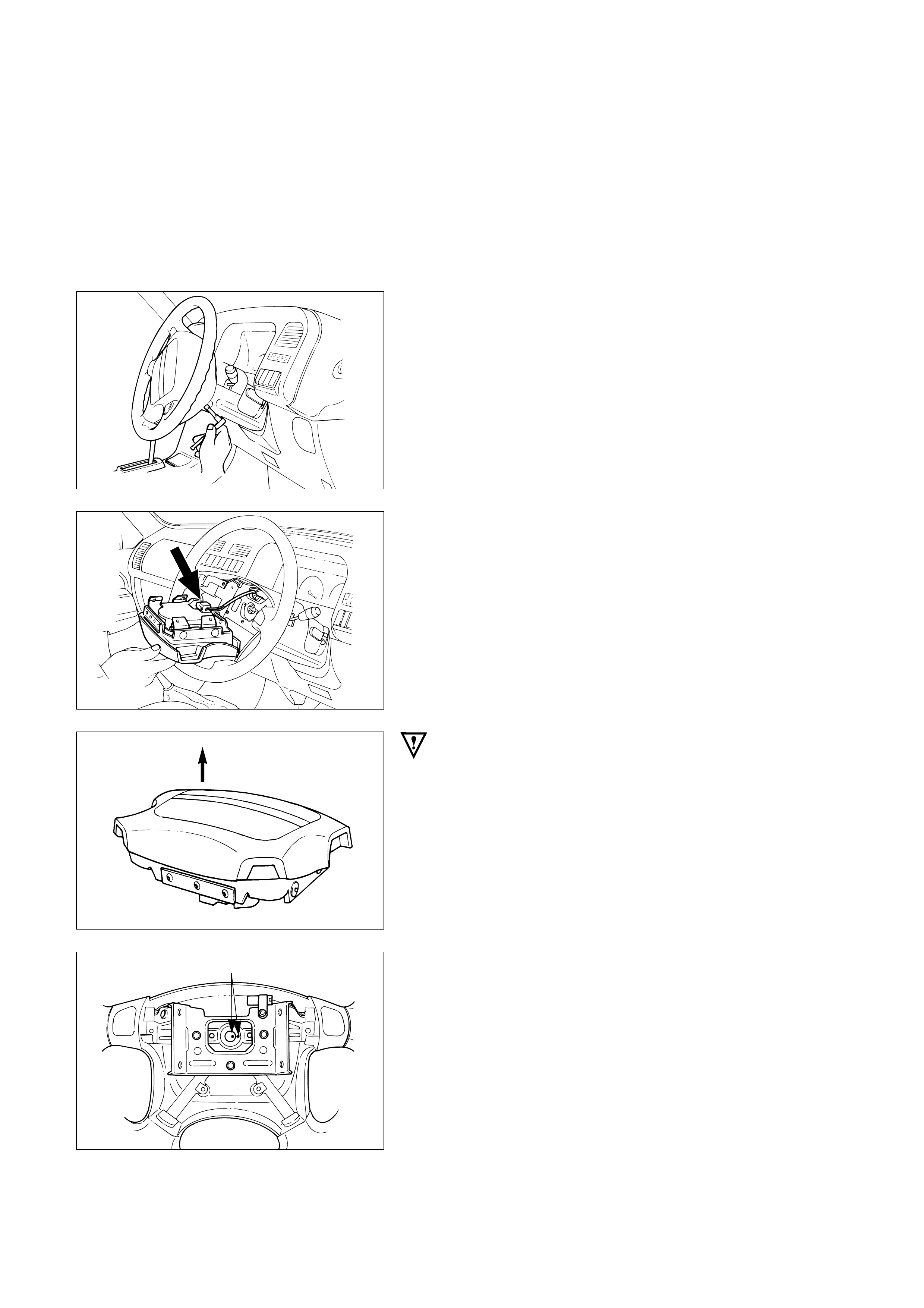

1. Front Console Assembly

1) Remove the transmission (for M/T) and transfer

control lever knob.

2) Disconnect the wiring harness connectors.

2. Lower Cluster Assembly

3. Steering Lower Cover

Remove the engine hood opening lever.

4. Inflator Module

1) Loosen the inflator module fixing bolt from

behind the steering wheel assembly using a

TORXdriver or equivalent until the inflator

module can be released from steering assembly.

2) Disconnect the yellow 2way SRS connector

located behind the inflator module.

WARNING

THE INFLATOR MODULE SHOULD ALWAYS BE CARRIED

WITH THE URETHANE COVER AWAY FROM YOUR BODY

AND SHOULD ALWAYS BE LAID ON A FLAT SURFACE

WITH THE URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW THE

AIR CUSHION TO EXPAND IN THE UNLIKELY EVENT OF A

ACCIDENTAL DEPLOYMENT. OTHERWISE, PERSONAL

INJURY MAY RESULT.

5. Steering Wheel

Apply a setting mark across the steering wheel and

shaft so parts can be reassembled in their original

position.

827RT914

827RW037

827RS016

Up

430RS004

Setting mark

Use special tool. Remove the steering wheel.

Move the tires to the straight ahead position before

removing the steering wheel.

Steering wheel remover: 5-8840-0016-0 (J-29752)

CAUTION:

Never apply force to the steering wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

is designed as an energy absorbing unit.

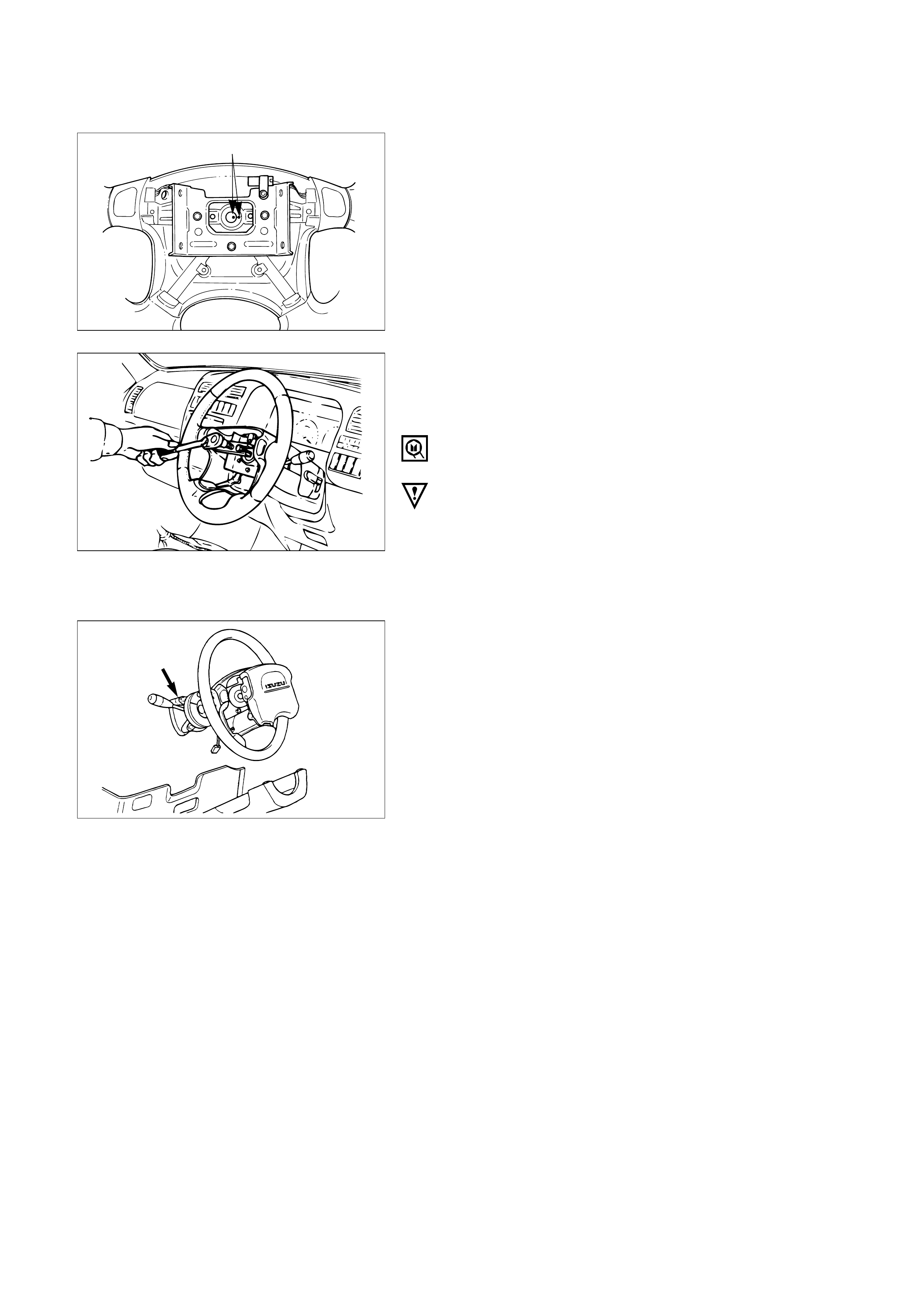

6. Steering Column Cover

7. Combination Switch and SRS Coil Assembly

1) Disconnect the wiring harness connectors

located under the steering column.

2) Remove the combination switch assembly with

SRS coil.

NOTE:

The SRS coil is a part of the combination switch

assembly, which can not be replaced separately.

Therefore, be sure not to remove the SRS coil from

the combination switch assembly.

825RS046

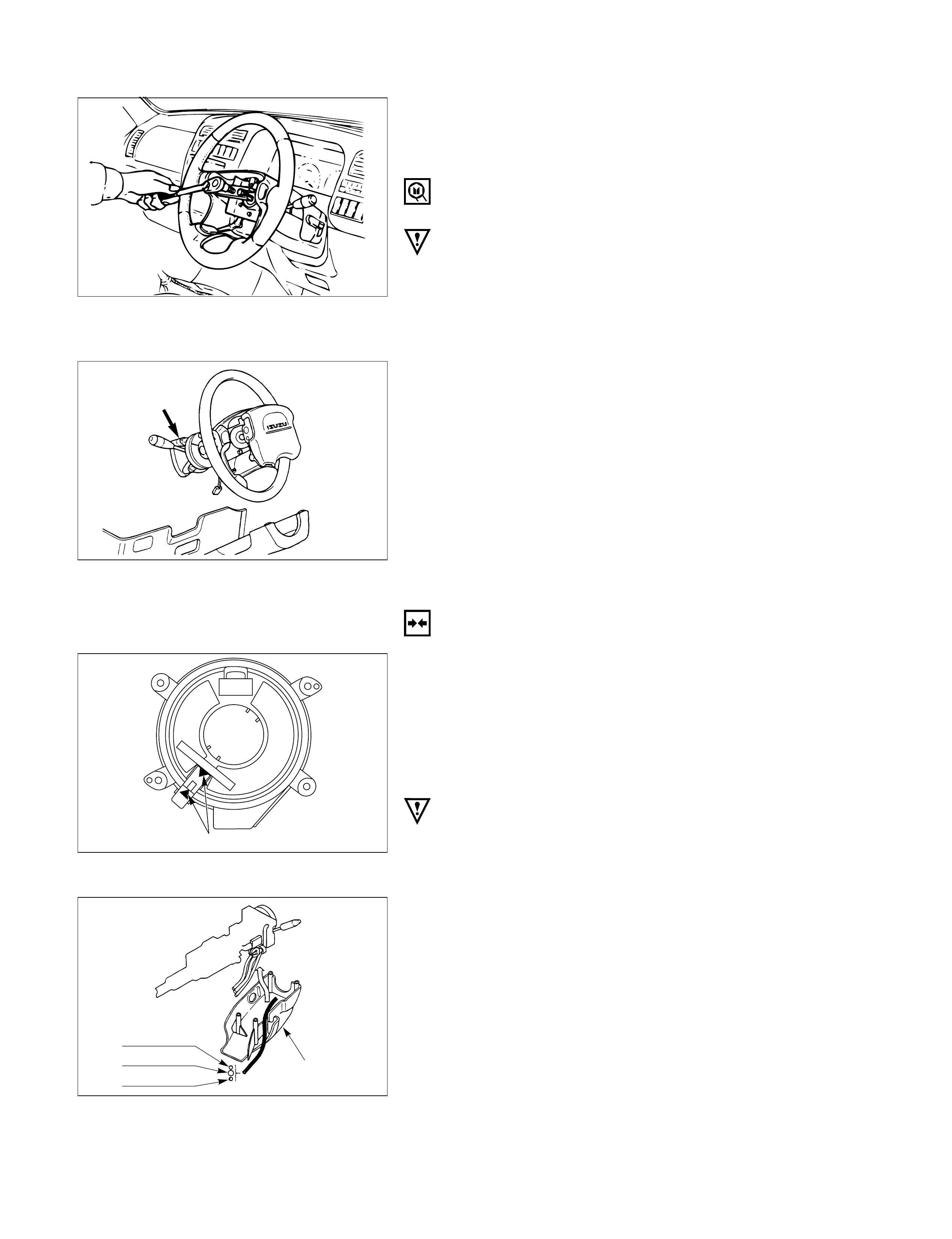

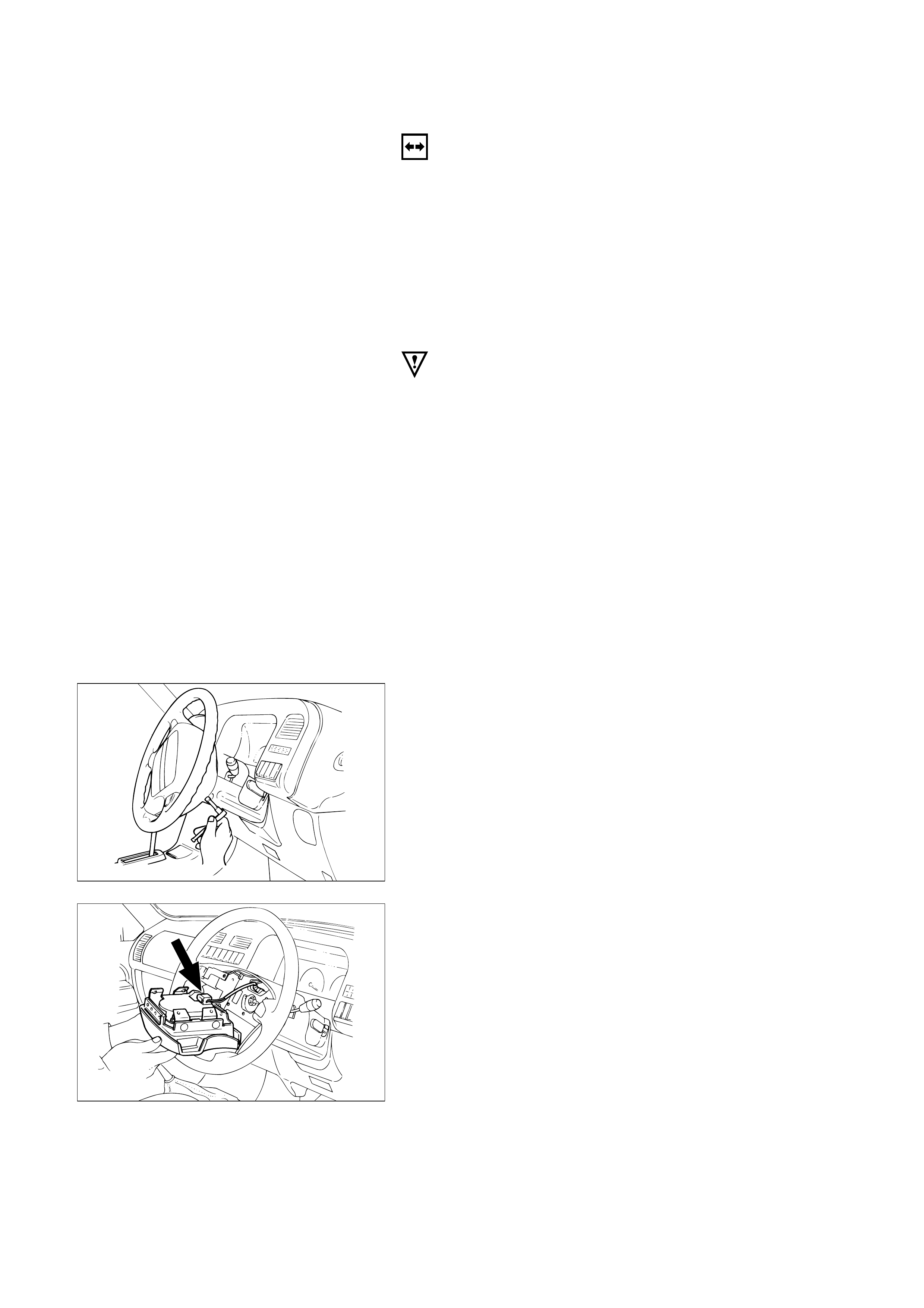

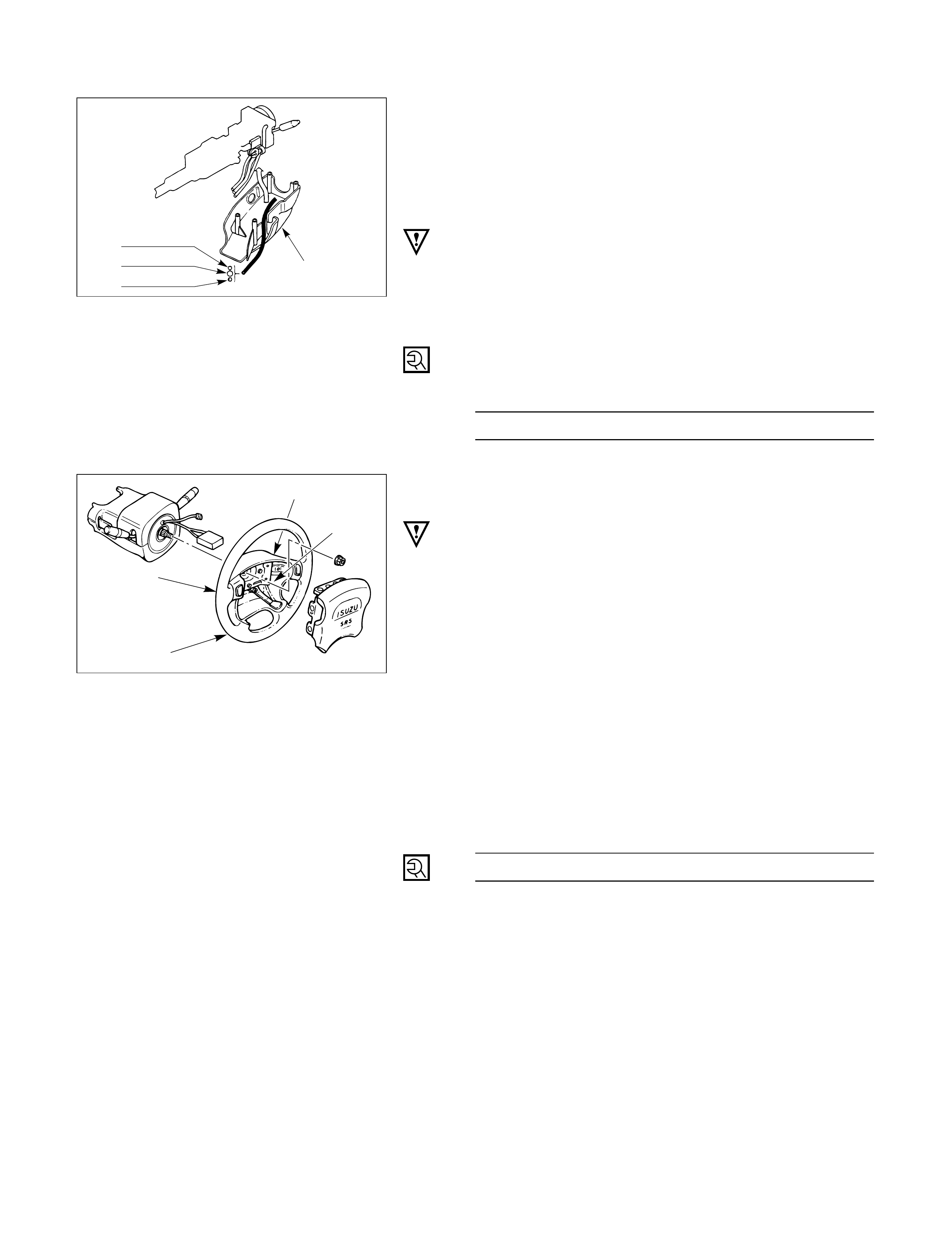

INSTALLATION

Alignment mark

7. Combination Switch and SRS Coil Assembly

1) After installation of combination switch

assembly, connect the combination switch

wiring harness connector and the SRS 2way

connector located under the steering column.

2) Turn the SRS coil counterclockwise to full, return

about 3 turns and align the neutral mark.

CAUTION:

When turning the SRS coil counterclockwise to full, stop

turning if resistance is felt. Forced further turning may

damage to the cable in the SRS coil.

826RW027

Starter switch

harness

Combination

switch harness

Inflator module

harness

Setting cowl

(Lower)

6. Steering Column Cover

When installing the steering column cover, be sure to

route each wire harness as illustrated so that the

harnesses do not catch on any moving parts.

825RS048

5.Steering Wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the steering wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

is designed as an energy absorbing unit.

Tighten the steering wheel fixing nut to the specified

torque.

Steering Wheel Nut TorqueN·m (kg·m/lb·ft)

34 (3.5 / 25)

4.Inflator Module

1)Support the module and carefully connect the

module connector.

CAUTION:

•Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

•When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinched.

2)Secure the module with one bolt to relieve

weight on the connector wire.

3)Tighten bolts to specified sequence as figure.

Inflator Module Bolt TorqueN·m (kg·m/lb·in)

8 (0.8 / 69)

3.Steering Lower Cover

Install the engine hood opening lever.

2.Lower Cluster Assembly

1.Front Console Assembly

1)Install the transmission (for M/T) and transfer

control lever knob.

2)Install the wiring harness connectors.

Connect the battery ground cable.

Turn the ignition to "ON" while watching warning light.

Light should flash 7 times and then go off. If lamp

does not operate correctly, refer to Section 12M.

3

4

1

2

827RS017

LOCK CYLINDER REPLACEMENT

1

5

4

6

7

8

9

11

10

3

2

Removal Steps

1. Front console assembly

2. Lower cluster assembly

3. Steering lower cover

4. Inflator module

5. Steering wheel

6. Steering column cover

7. Combination switch and

SRS coil assembly

8. Snap ring

9. Cushion rubber

10. Shift lock cable (for A/T)

11. Lock cylinder assembly

Installation Steps

11. Lock cylinder assembly

10. Shift lock cable (for A/T)

9. Cushion rubber

8. Snap ring

7. Combination switch and

SRS coil assembly

6. Steering column cover

5. Steering wheel

4. Inflator module

3. Steering lower cover

2. Lower cluster assembly

1. Front console assembly

431RT003

REMOVAL

Preparation:

1) Turn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2) Turn the ignition switch to "LOCK".

3) Disconnect the battery ground cable, and wait at least

5 minutes.

4) Disconnect the yellow 2way SRS connector located

under the steering column.

CAUTION:

The wheels of the vehicle must be straight ahead and the

steering column in the "LOCK" position before

disconnecting the steering wheel. Failure to do so will

cause the coil assembly to become uncentered which will

cause damage to the coil assembly.

1. Front Console Assembly

1) Remove the transmission (for M/T) and transfer

control lever knob.

2) Disconnect the wiring harness connectors.

2. Lower Cluster Assembly

3. Steering Lower Cover

Remove the engine hood opening lever.

4. Inflator Module

1) Loosen the inflator module fixing bolt from

behind the steering wheel assembly using a

TORXdriver or equivalent until the inflator

module can be released from steering assembly.

2) Disconnect the yellow 2way SRS connector

located behind the inflator module.

WARNING

THE INFLATOR MODULE SHOULD ALWAYS BE CARRIED

WITH THE URETHANE COVER AWAY FROM YOUR BODY

AND SHOULD ALWAYS BE LAID ON A FLAT SURFACE

WITH THE URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW THE

AIR CUSHION TO EXPAND IN THE UNLIKELY EVENT OF A

ACCIDENTAL DEPLOYMENT. OTHERWISE, PERSONAL

INJURY MAY RESULT.

827RT914

827RW037

827RS016

Up

5. Steering Wheel

Apply a setting mark across the steering wheel and

shaft so parts can be reassembled in their original

position.

Use special tool. Remove the steering wheel.

Move the tires to the straight ahead position before

removing the steering wheel.

Steering wheel remover: 5-8840-0016-0 (J-29752)

CAUTION:

Never apply force to the steering wheel in direction of

the shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering

shaft is designed as an energy absorbing unit.

6. Steering Column Cover

7. Combination Switch and SRS Coil Assembly

1) Disconnect the wiring harness connectors

located under the steering column.

2) Remove the combination switch assembly with

SRS coil.

NOTE:

The SRS coil is a part of the combination switch

assembly, which can not be replaced separately.

Therefore, be sure not to remove the SRS coil from

the combination switch assembly.

8. Snap Ring

9. Cushion Rubber

10. Shift Lock Cable (for A/T)

11. Lock Cylinder Assembly

Disconnect the starter switch harness connector

located under the steering column.

825RS046

430RS004

430RW014

Setting mark

INSTALLATION

11. Lock Cylinder Assembly

10. Shift Lock Cable (for A/T)

9. Cushion rubber

8. Snap ring

7. Combination Switch and SRS Coil Assembly

1) After installation of combination switch

assembly, connect the combination switch

wiring harness connector and the SRS 2way

connector located under the steering column.

2) Turn the SRS coil counterclockwise to full, return

about 3 turns and align the neutral mark.

CAUTION:

When turning the SRS coil counterclockwise to full, stop

turning if resistance is felt. Forced further turning may

damage to the cable in the SRS coil.

6. Steering Column Cover

When installing the steering column cover, be sure to

route each wire harness as illustrated so that the

harnesses do not catch on any moving parts.

5. Steering Wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the setting wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

is designed as an energy absorbing unit.

Tighten the steering wheel fixing nut to the specified

torque.

Steering Wheel Nut Torque N·m (kg·m/lb·ft)

34 (3.5 / 25)

Alignment mark

826RW027

Starter switch

harness

Combination

switch harness

Inflator module

harness

Setting cowl

(Lower)

825RS048

3

4

1

2

4.Inflator Module

1)Support the module and carefully connect the

module connector.

CAUTION:

•Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

•When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinched.

2)Secure the module with one bolt to relieve

weight on the connector wire.

3)Tighten bolts to specified sequence as figure.

Inflator Module Bolt TorqueN·m (kg·m/lb·in)

8 (0.8 / 69)

3.Steering Lower Cover

Install the engine hood opening lever.

2.Lower Cluster Assembly

1.Front Console Assembly

Connect the wiring harness connectors.

Install the transmission (for M/T) and transfer control

lever knob.

Connect the yellow 2way SRS connector located

under the steering column.

Connect the battery ground cable.

827RS017

SYSTEM INSPECTION

•Turn the ignition to "ON" while watching

warning light.

•Light should flash 7 times and then go off. If

lamp does not operate correctly, refer to Section 12M.

STEERING COLUMN REPLACEMENT

12

10 98

7

5

6

11

2

13

4

3

1

Removal Steps

1. Front console assembly

2. Lower cluster assembly

3. Steering lower cover

4. Driver knee bolster (rein-

forcement)

5. Inflator module

6. Steering wheel

7. Steering column cover

8. Combination switch and

SRS coil assembly

9. Snap ring

10. Cushion rubber

11. Shift lock cable (for A/T)

12. Lock cylinder assembly

13. Steering column assembly

Installation Steps

13. Steering column assembly

12. Lock cylinder assembly

11. Shift lock cable (for A/T)

10. Cushion rubber

9. Snap ring

8. Combination switch and

SRS coil assembly

7. Steering column cover

6. Steering wheel

5. Inflator module

4. Driver knee bolster (reinforcement)

3. Steering lower cover

2. Lower cluster assembly

1. Front console assembly

REMOVAL

Preparation:

1) Turn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2) Turn the ignition switch to "LOCK".

3) Disconnect the battery ground cable, and wait at least

5 minutes.

4) Disconnect the yellow 2way SRS connector located

under the steering column.

CAUTION:

The wheels of the vehicle must be straight ahead and the

steering column in the "LOCK" position before

disconnecting the steering wheel.

Failure to do so will cause the SRS coil assembly to

become uncentered which will cause damage to the SRS

coil assembly.

1. Front Console Assembly

Disconnect the transmission (for M/T) and transfer

control lever knob.

Disconnect the wiring harness connectors.

2. Lower Cluster Assembly

3. Steering Lower Cover

Remove the engine hood opening lever.

4. Driver Knee Bolster (Reinforcement)

5. Inflator Module

1) Loosen the inflator module fixing bolt from

behind the steering wheel assembly using a

TORXdriver or equivalent until the inflator

module can be released from steering assembly.

2) Disconnect the yellow 2way SRS connector

located behind the inflator module.

827RT914

827RW037

WARNING

THE INFLATOR MODULE SHOULD ALWAYS BE CARRIED

WITH THE URETHANE COVER AWAY FROM YOUR BODY

AND SHOULD ALWAYS BE LAID ON A FLAT SURFACE

WITH THE URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW THE

AIR CUSHION TO EXPAND IN THE UNLIKELY EVENT OF A

ACCIDENTAL DEPLOYMENT. OTHERWISE, PERSONAL

INJURY MAY RESULT.

6. Steering Wheel

Apply a setting mark across the steering wheel and

shaft so parts can be reassembled in their original

position.

Use special tool. Remove the steering wheel.

Move the tires to the straight ahead position before

removing the steering wheel.

Steering wheel remover: 5-8840-0016-0 (J-29752)

7. Steering Column Cover

8. Combination Switch and SRS Coil Assembly

1) Disconnect the wiring harness connectors

located under the steering column.

2) Remove the combination switch assembly with

SRS coil.

NOTE:

The SRS coil is a part of the combination switch

assembly, which can not be replaced separately.

Therefore, be sure not to remove the SRS coil from

the combination switch assembly.

9. Snap Ring

10. Cushion Rubber

11. Shift Lock Cable (for A/T)

12. Lock Cylinder Assembly

Disconnect the starter switch harness connector

located under the steering column.

827RS016

825RS046

Up

430RS004

430RW014

Setting mark

Setting mark

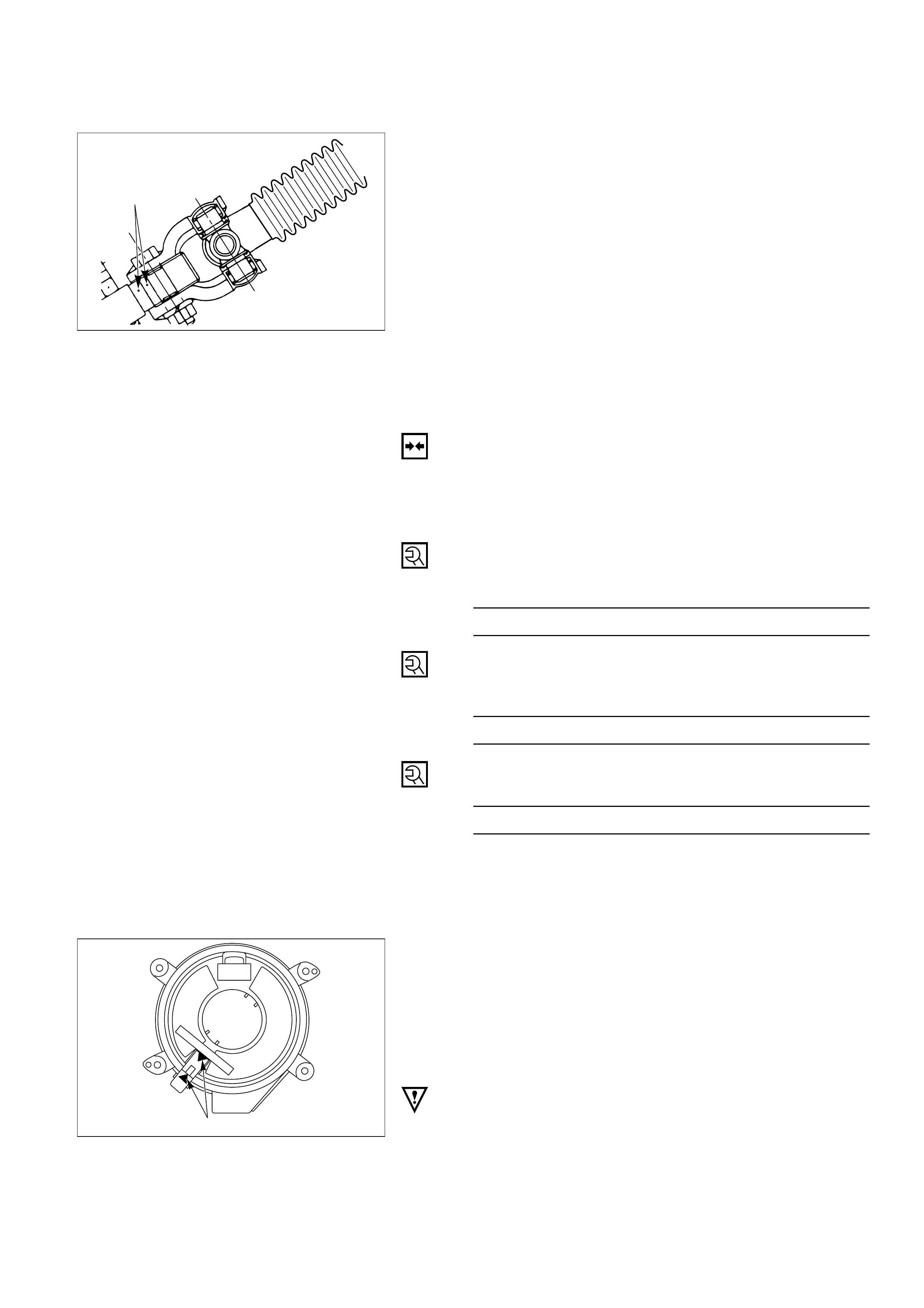

13. Steering Column Assembly

Apply a setting mark across the universal joint and

steering shaft to reassemble the parts in their original

position.

NOTE:

A setting mark can be easily made if the shaft is

withdrawn a little by loosening the steering shaft

universal joint.

431RV003

INSTALLATION

13. Steering Column Assembly

Align the setting marks on the universal joint and

steering shaft made during removal.

Tighten the steering column fixing bolt (dash panel)

to the specified torque.

Steering Column Bolt Torque N·m (kg·m/lb·ft)

19 (1.9 / 14)

Tighten the steering column fixing bolt (pedal

bracket) to the specified torque.

Steering Column Bolt Torque N·m (kg·m/lb·ft)

17 (1.7 / 13)

Tighten the universal joint to the specified torque.

Universal Joint Torque N·m (kg·m/lb·ft)

25 (2.5 / 18)

12. Lock Cylinder Assembly

11. Shift Lock Cable (for A/T)

10. Cushion Rubber

9. Snap Ring

8. Combination Switch

1) After installation of combination switch

assembly, connect the combination switch

wiring harness connector and the SRS 2way

connector located under the steering column.

2) Turn the SRS coil counterclockwise to full, return

about 3 turns and align the neutral mark.

CAUTION:

When turning the SRS coil counterclockwise to full, stop

turning if resistance is felt. Forced further turning may

damage to the cable in the SRS coil.

Alignment mark

826RW027

Starter switch

harness

Combination

switch harness

Inflator module

harness

Setting cowl

(Lower)

7. Steering Column Cover

When installing the steering column cover, be sure to

route each wire harness as illustrated so that the

harnesses do not catch on any moving parts.

6. Steering Wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the steering wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

if designed as an energy absorbing unit.

Tighten the steering wheel fixing nut to the specified

torque.

Steering Wheel Nut Torque N·m (kg·m/lb·ft)

34 (3.5 / 25)

5. Inflator Module

1) Support the module and carefully connect the

module connector.

CAUTION:

•Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

•When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinched.

2) Secure the module with one bolt to relieve

weight on the connector wire.

3) Tighten bolts to specified sequence as figure.

Inflator Module Bolt Torque N·m (kg·m/lb·in)

8 (0.8 / 69)

4 Driver Knee Bolster (Reinforcement)

3. Steering Lower Cover

Install the engine hood opening lever.

2. Lower Cluster Assembly

1. Front Console Assembly

Connect the wiring harness connectors.

Install the transmission (for M/T) and transfer control

lever knob.

Connect the yellow 2way SRS connector located

under the steering column.

Connect the battery ground cable.

825RS048

3

4

1

2

827RS017