General Information Page 0A–1

Page 0A–1

Section 0A

General Information

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ...............................................................................................................................2

1.1 Hoist Pad Locations .............................................................................................................................................. 3

2 Model Availability and Equipment........................................................................................................4

3 Major Option Codes ...............................................................................................................................5

4 Powertrain...............................................................................................................................................6

5 Engine Data.............................................................................................................................................7

6 Transmission Data .................................................................................................................................8

7 Transfer Case Data.................................................................................................................................9

8 Exterior Dimensions ............................................................................................................................10

9 Vehicle Weights....................................................................................................................................11

10 Fuel Consumption Label .....................................................................................................................12

11 Serial Numbers.....................................................................................................................................13

11.1 Vehicle Identification Numbering System ......................................................................................................... 13

11.2 Automatic Transmission Serial Number............................................................................................................ 14

11.3 Transfer Case Assembly Serial Numbers.......................................................................................................... 15

11.4 Front Final Drive .................................................................................................................................................. 16

11.5 Rear Final Drive.................................................................................................................................................... 17

12 Special Tools ........................................................................................................................................18

Transfer Case....................................................................................................................................................... 19

Front Suspension ................................................................................................................................................ 20

Front Final Drive .................................................................................................................................................. 21

Rear Suspension.................................................................................................................................................. 22

Techline

Techline

Techline

Techline

Techline

Techline

General Information Page 0A–2

Page 0A–2

1 General Information

The MY 2004 All Wheel Driv e (AWD) Adventra Wagon is a new variant of the five door wagon body style in the Holden

Commodore range. It is a constant AWD vehicle and is available only with the GEN III V8 engine and 4L60-E automatic

transmission.

The CX8 model is Berlina based, but with some sports oriented finishes. The LX8 model variant adopts some MY 2004

VY Calais style interior finishes.

The main features and changes for the MY 2004 AWD Wagon Series are summarised in the following list:

• Constant all wheel drive ‘Cross T rac’ powertrain.

• Heavy duty front and rear sus pension to suit All Wheel Drive applicati on.

• Heavy duty engin e cooling fan system.

• All wheel traction control system (Automatic Brake Differential – ABD) to suit AWD application.

• Front to rear brake proportioning using Electronic Brake-force Distribution (EBD) under heavy braking.

• Climate Control fitted as standard, single zone on CX8 models and dual zone on L X 8 models.

• Visual ice warning via Climate Control display.

• Unique front and rear facia.

• Extension mouldings on front and rear wheelhouses.

• New bodyside mouldings.

• New endgate configuratio n with a separate opening rear window glass.

• 1600 kg capacity tow bar mount.

• New rear roof air deflector including LED high mounte d stop lamp.

• New style roof racks with cross bars option.

• Exterior colour range of eight colo urs, all from MY 2004 VY Series.

• Ochre or Black Anthracite leather interior trims available for LX8 models.

• Neutral Pewter cloth (standard) or leather (optional) for CX8 models.

• SS style front seats for LX8 models.

• Eight way electric seats with memory function and memory mirrors for LX8 models.

• Electric sliding sunroof and roof luggag e carrier – On line fitment for LX8 standard, CX8 optional.

• Interior load tie-down rails and hooks (with stowaway cargo net for LX8 models).

• MY 2004 VY style interior finishes:

• Leather covered, satin chrome gear kn ob and park brake handle.

• Leather covered steering wheel (with sports profile on LX8) and optional a lloy pedals.

• Additional instrumentation (in cli nometer) on top centre of instrument panel area for LX8 mode ls.

• New badging to denote AWD and mo del level.

• Reverse parking aid (first usage on a wagon).

• 17" wheels and tyres.

• Tow points accessed (using towing eye supplied) through port on front and rear fascias.

• Cruise control.

• Steering wheel mounted audio controls (illuminated on LX8).

• Audio system with six disc ‘in dash’ CD player incorporating:

• Six speakers and 60 Watts for CX8 models.

• Premium sound with seven speakers, subwoofer and 200 Watts for LX8 models.

General Information Page 0A–3

Page 0A–3

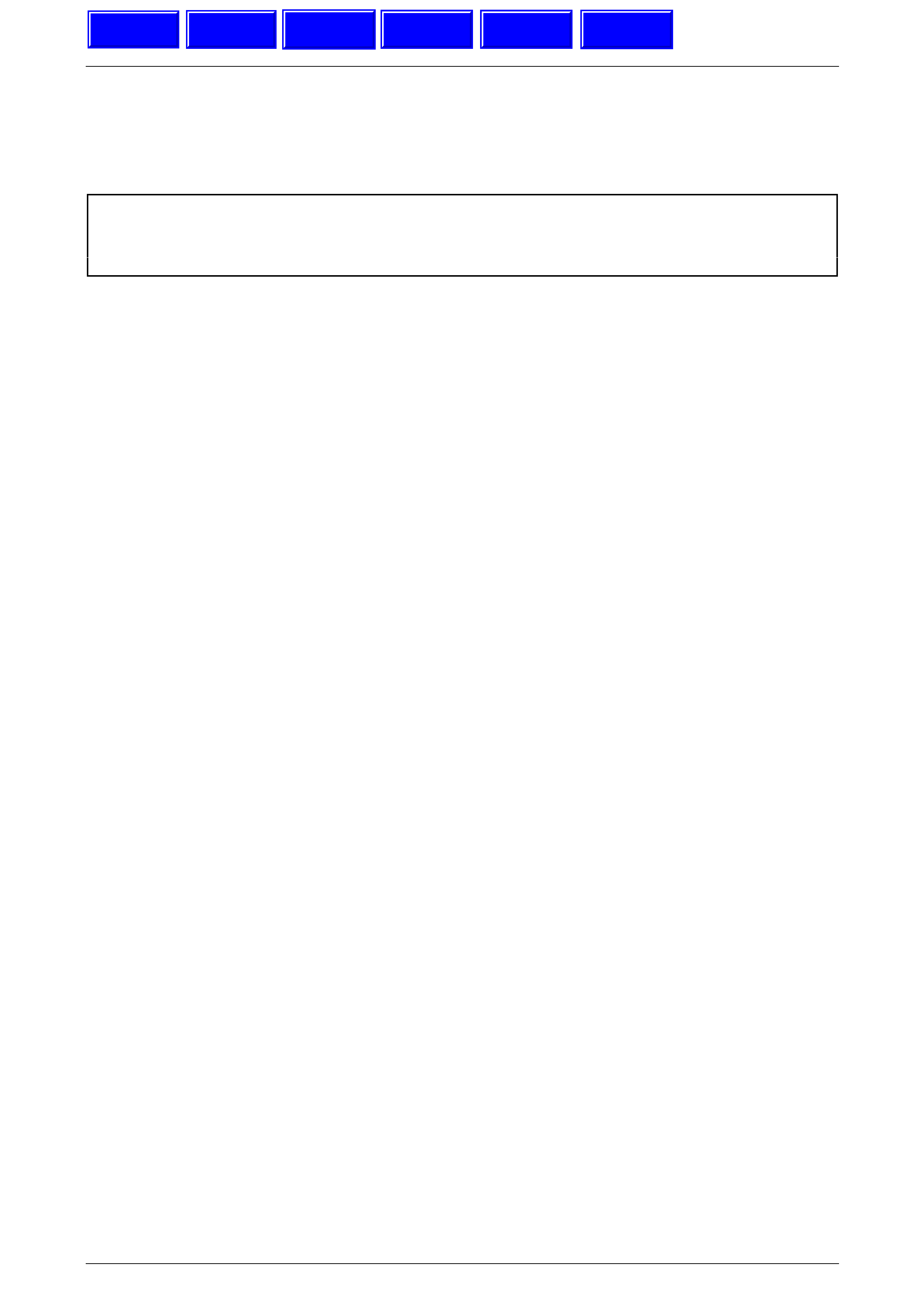

1.1 Hoist Pad Locations

When using a trolle y jack to raise the vehicle, it is important that the jack be positioned un der the suspension cross

member or hoist pad (1) locations. Do not jack under the suspension control arm. The vehicle should always be

supported by jack stands at the hoist pad locations when raised.

Figure 0A – 1

General Information Page 0A–4

Page 0A–4

2 Model Availability and

Equipment

NOTE

For tyre and wheel information, refer to

Section 10 Wheels and Tyres in this Service

Information.

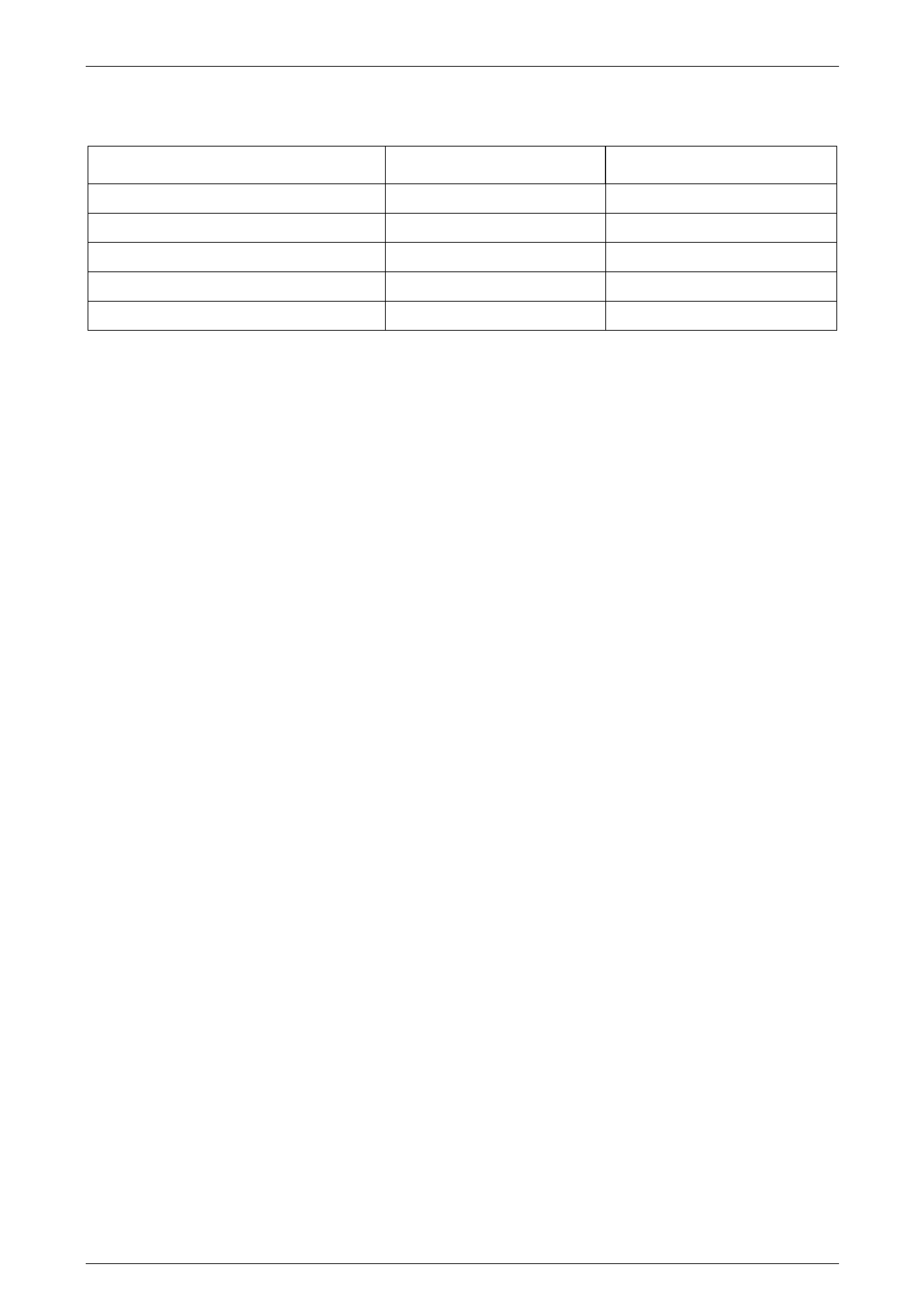

Model Name Luxury Level

(Description) Model Code. Body Style

(Doors) Engine

Adventra CX8 Low Level

(Sport) 8VM35 Wagon (5) V8

Adventra LX8 High Level

(Luxury Sports) 8VM35 & YC3 Wagon (5) V8

General Information Page 0A–5

Page 0A–5

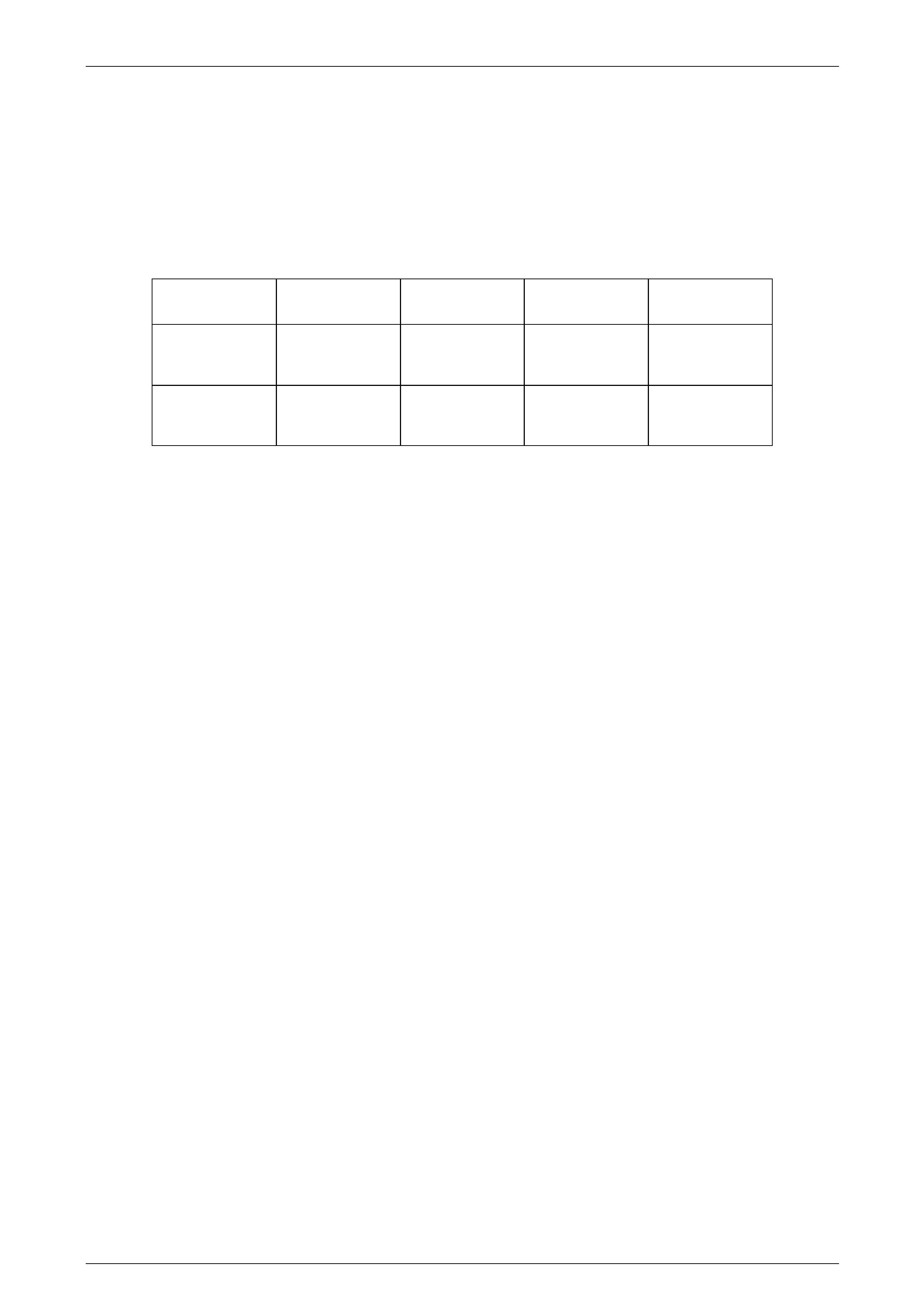

3 Major Option Codes

Option Code Description Option Code Description

A31 Power Windows (Front and Rear) N46 Steering Wheel 4 Spokes

AG3 Memory Driver’s Seat N88 7.5 JJ x17" Alloy wheel (XLS)

AH6 Driver’s Seat, 4 Way N93 7.5 JJ x17" Alloy wheel (XS)

AH8 Passenger Seat, 8 Way NK4 Sports Leather Steering Wheel

AJ7 Side Impact Air Bag NW9 Traction Control (with ABS)

AQ9 Front Seat, Reclining Bucket QBB 225/55 R17 97H Tyre

B58 Mats in anthracite with suede trim R5C Bridgestone Hybrid Tyre Desi gn

C61 Automatic Air Conditioning U08 Dual Note Horns

CC5 Sunroof – Factory Fitted U1V Audio System, 60W 6 Disk CD

CJ2 Dual Zone Air Conditioning U1X Audio System, 260W 6 Disk CD

D42 Retracting Roller Cargo Blin d U75 Antenna, Power

FE1 Suspension – Soft Ride UD7 Reverse Parking Aid

FX3 Suspension – Level Ride UE1 Holden Assist

GS9 Axle, 3.46:1 Ratio Rear UJ8 Instrument Cluster

JL9 Anti-Lock Brake System VDQ Roof Luggage Carrier

K30 Cruise Control W1Y Steering Wheel Radio Controls

K69 Keys, Additional Set XS4 Roo Bar

LS1 235KW, 5.7 V8 EFI Petrol Engine XW6 Paint, Metallic Finish

MK2 Transmission, 4 Speed Automatic YC3 High Series Package

N40 Power Steering

General Information Page 0A–6

Page 0A–6

4 Powertrain

Component Designation / ID Code Type

Engine GEN III V8 V8 5.7 litre OHV PFI

Transmission 4L60-E 4 speed with Overdrive

Transfer Case NV124 Full time AWD, Gear Drive

Final Drive – Front DY Conventional, Ratio – 3.46:1

Final Drive – Rear SB Conventional, Ratio – 3.46:1

General Information Page 0A–7

Page 0A–7

5 Engine Data

Engine Designation GEN III V8

Piston Displacement

Nominal – cm3 5667

Compression Ratio 10.1:1

Number of Cylinders 8

Bore x Stroke – mm 99 X 92

Taxable H.P.

RAC OR SAE 48.6

Power kW

DIN @ RPM 235 kW @ 5200

Torque Nm

DIN @ RPM 465 Nm @ 4400

General Information Page 0A–8

Page 0A–8

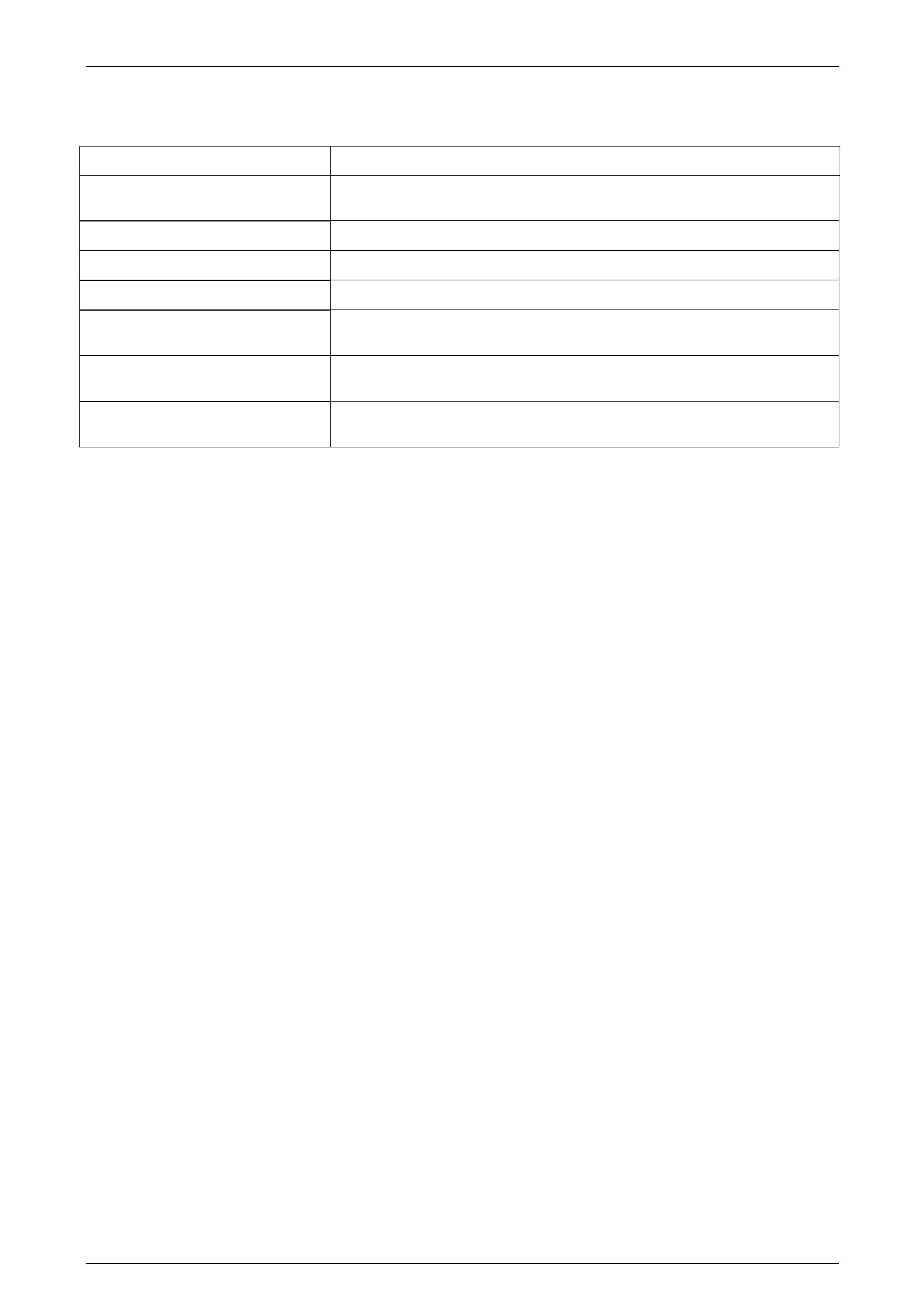

6 Transmission Data

Model 4L60-E

Torque converter 4 element (including lock- up clutch)

Pump 13 Vane, variable displacement

No. of clutch packs 5

No. of bands 1

No. of planetary gear sets 2

No. of solenoids 6

No. of electrical sensors 3

Ratios:

1st

2nd

3rd

4th

Reverse

3.06:1

1.63:1

1.00:1

0.70:1

2.29:1

General Information Page 0A–9

Page 0A–9

7 Transfer Case Data

Manufacturer New Venture Gear (NVG)

Model NV124

Type Full Time AWD

Torque Split 38 / 62 per cent, front to rear

General Information Page 0A–10

Page 0A–10

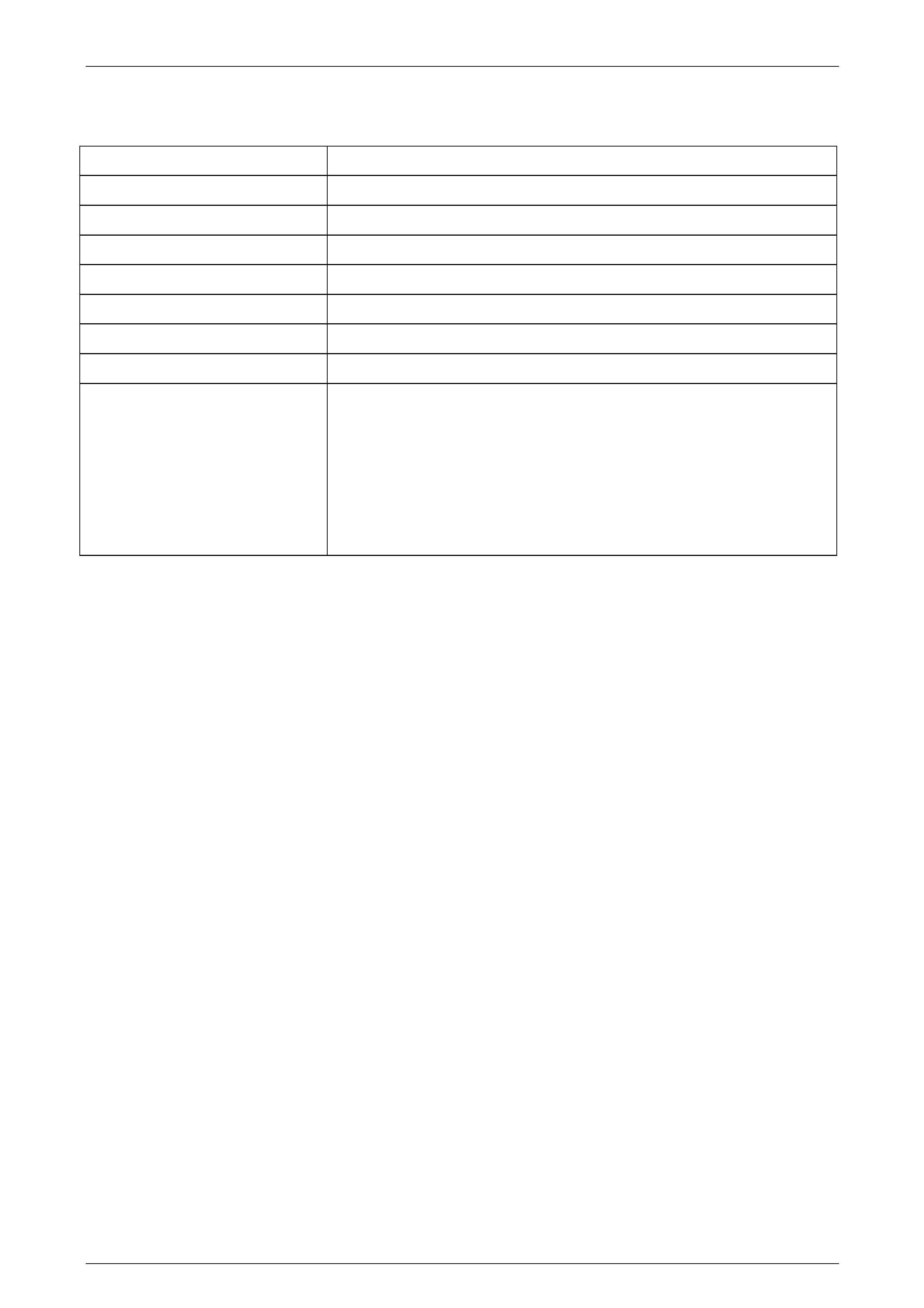

8 Exterior Dimensions

Body Dimensions (mm) CX8 LX8

Vehicle length 5036

Vehicle width (exclu ding moulding) 1934

Vehicle height 1651

Wheelbase 2948

Overhang – front 931

Overhang – rear 1158

Track – front 1617

Track – rear 1623

General Information Page 0A–11

Page 0A–11

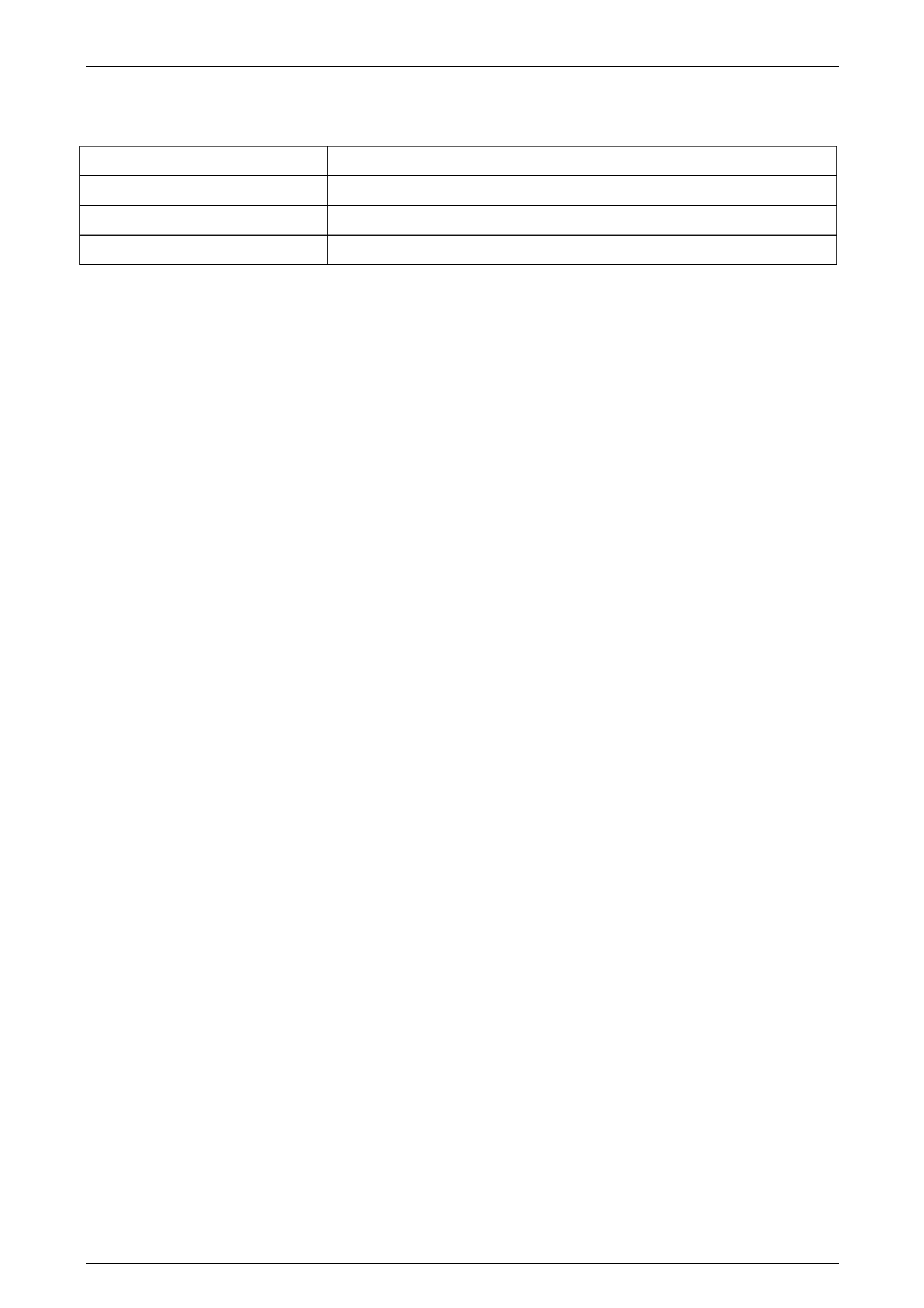

9 Vehicle Weights

Vehicle Weights (kg) CX8 LX8

Kerb mass 1940 1983

Rear axle load 1300

Payload (5 passengers plus cargo) 480

NOTE

Payload figures include luggage, goods,

passengers, roof rack load and a full tank of fuel.

When towing, the weight on the tow bar bal l must

also be included.

NOTE

Maximum rear axle load is the maximum for all

conditions.

General Information Page 0A–12

Page 0A–12

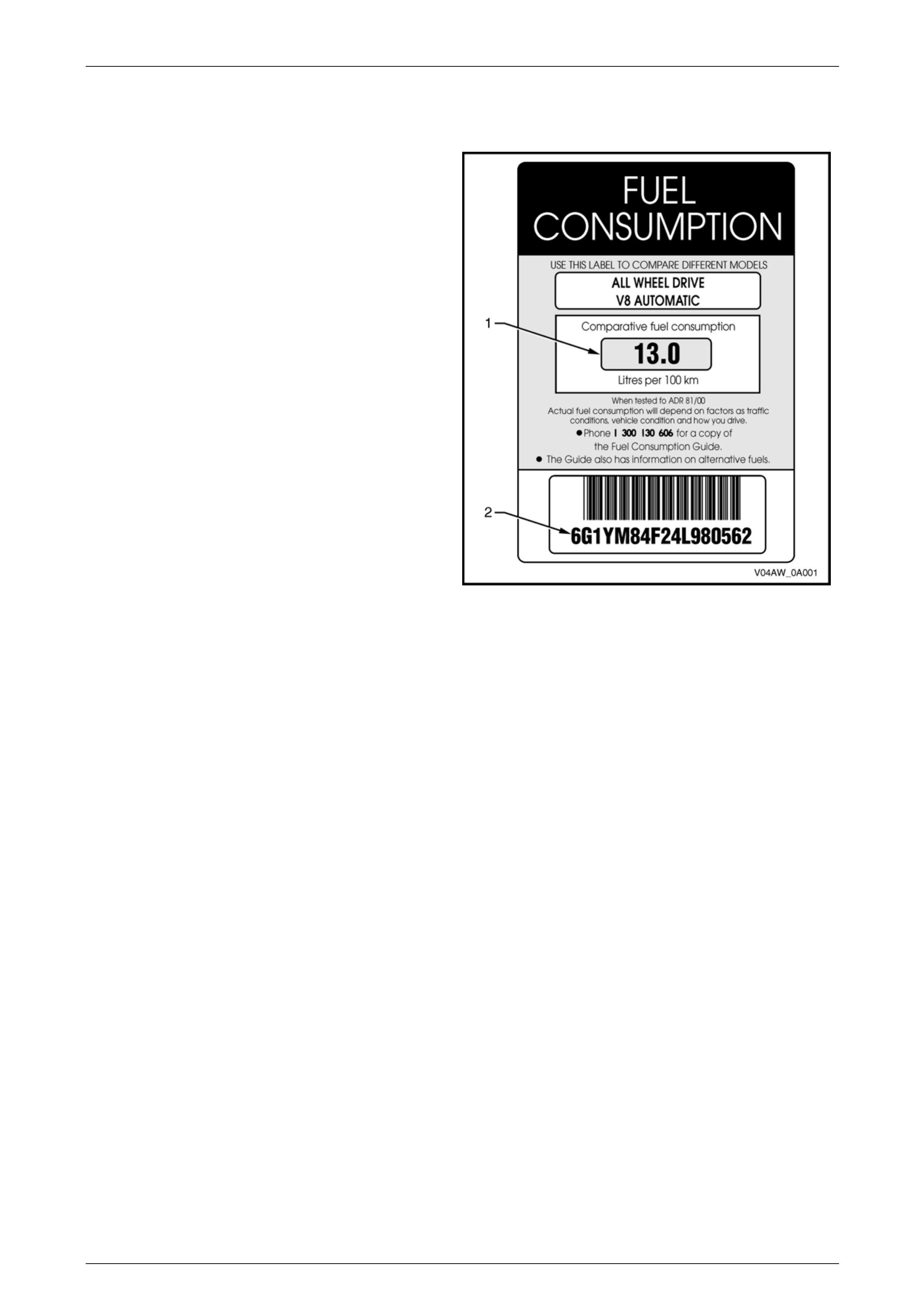

10 Fuel Consumption Label

ADR 81/00 required that from 1 January 2001, a label

similar to that shown in Figure 0A – 2, is attached to the

windscreen of any new domestic vehicle which is displayed

for sale.

The fuel consumption labe l figures (1) quoted are the

results of tests carried out in accordance with the City

Cycle test procedure of AS2877 – 19 86, an Australian

standard for fuel consumption testing. Each vehicle is

tested under identical conditions. T he tests therefore

enable a comparison to be made between vehicles.

The label should be removed from the windscreen

immediately prior to the vehicle being delivered to the

owner.

The number on the lower portion of the label (2) should

match the Vehicle Identification Numb er.

Figure 0A – 2

General Information Page 0A–13

Page 0A–13

11 Serial Numbers

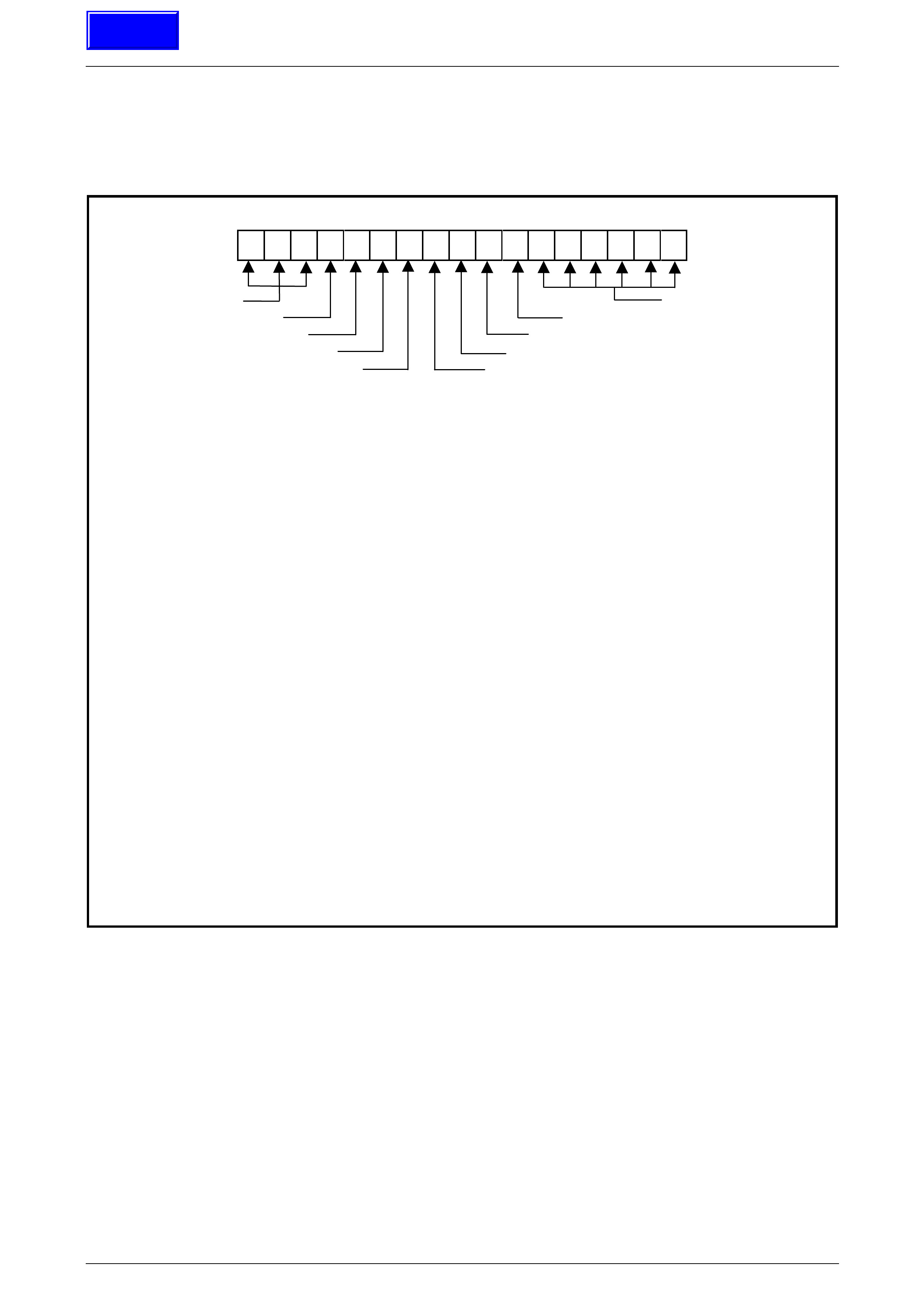

11.1 Vehicle Identification Numbering System

6 G 1 Y M 8 4 F 0 4 L 1 2 3 4 5 6

WMI CODE PRODUCTION

CARLINE PLANT SEQUENCE NUMBER

LUXURY LEVEL MODEL YEAR

BODY STYLE VIN CHECK DIGIT

RESTRAINT CODE ENGINE TYPE

WMI CODE: 6 – Oceania

G – Australia

1 – Holden

CARLINE: Y – VY Series

LUXURY LEVEL: M – CX8

M – LX8

BODY STYLE: 8 – 5 door station wagon (35)

RESTRAINT CODE: 4 – Active (manual) seat belts with driver and passenger inflatable restraint

system – frontal and side

ENGINE TYPE: F – 5.7 litre GEN III V8 engine

VIN CHECK DIGIT: Calculated check digit

MODEL YEAR: 4 – 2004

PLANT: L – Adelaide (Elizabeth) South Australia

PRODUCTION SEQUENCE NUMBER:

123456 – Sequential Production Serial Number

NOTE

The production sequence number is sequentially allocated to each vehicle, regardless of vehicle type.

Figure 0A – 3

Techline

General Information Page 0A–14

Page 0A–14

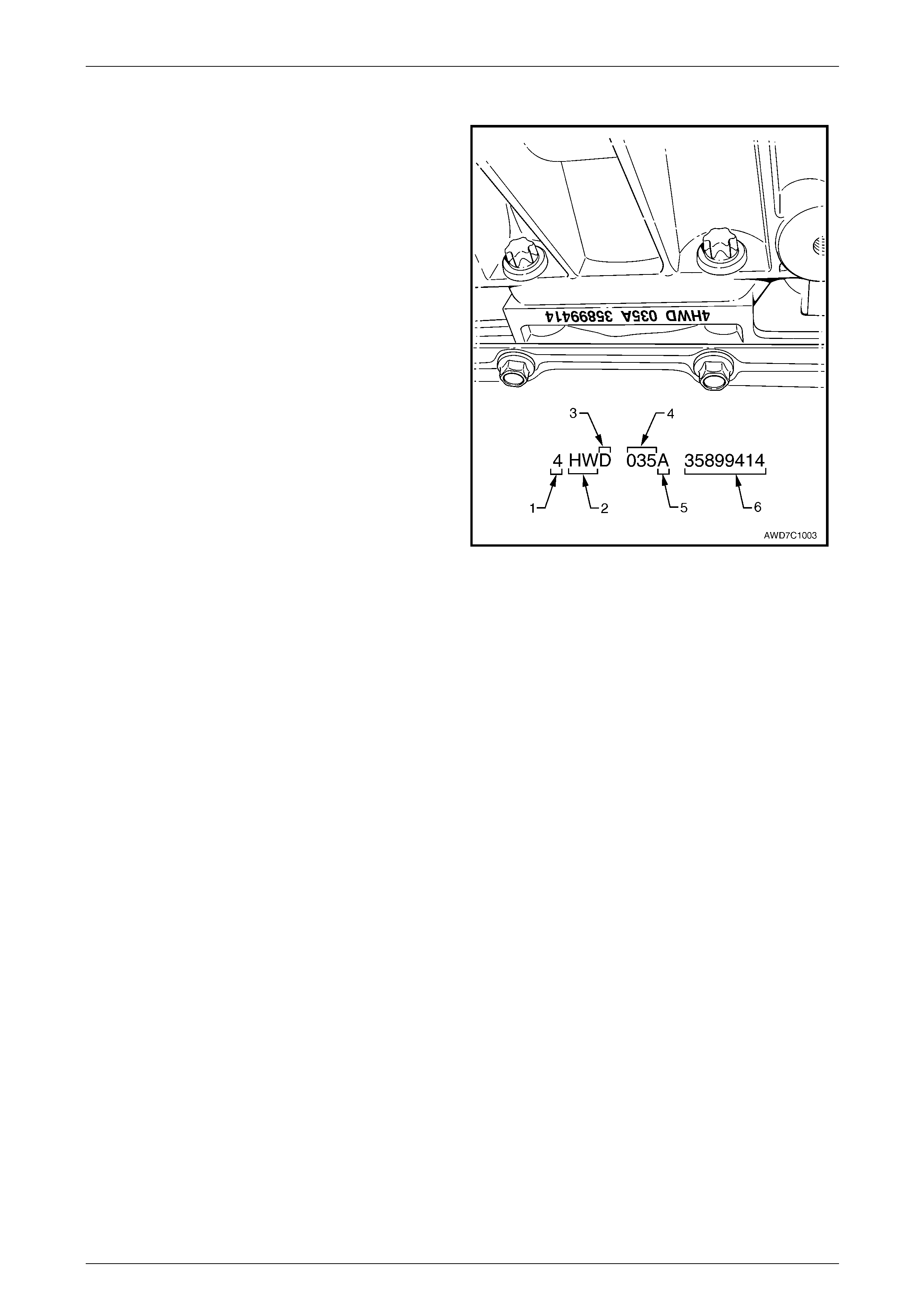

11.2 Automatic Transmission Serial Number

The automatic transmission serial number is stamped into

a machined surface located a t the rear underside of the

transmission centre case, between the rear ext ension

housing and the transmission fluid pan.

Legend

1 Model Year (‘4’ = 2004)

2 Model: AWD Wagon and 5.7 litre GEN III V8 – 'HW'

3 Transmission Model Identifier (‘D’ = 4L60-E)

4 Julian Date (Day of the Year)

5 Shift Build ‘A’, ‘B’, ‘J’ = First Shift;

‘C’, ‘H’, ‘W’ = Second Shift

6 Individual Transmission Serial Number

Figure 0A – 4

General Information Page 0A–15

Page 0A–15

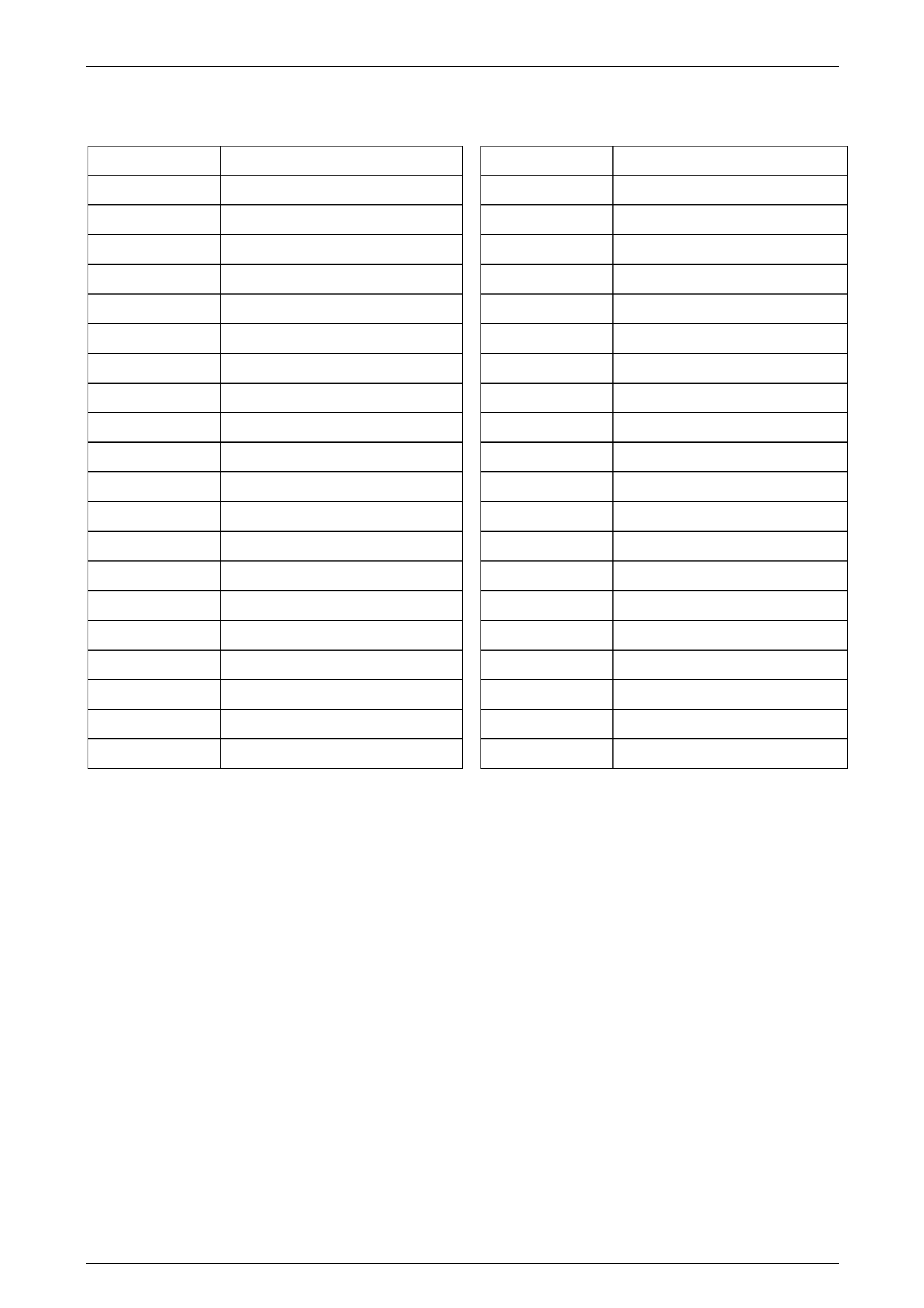

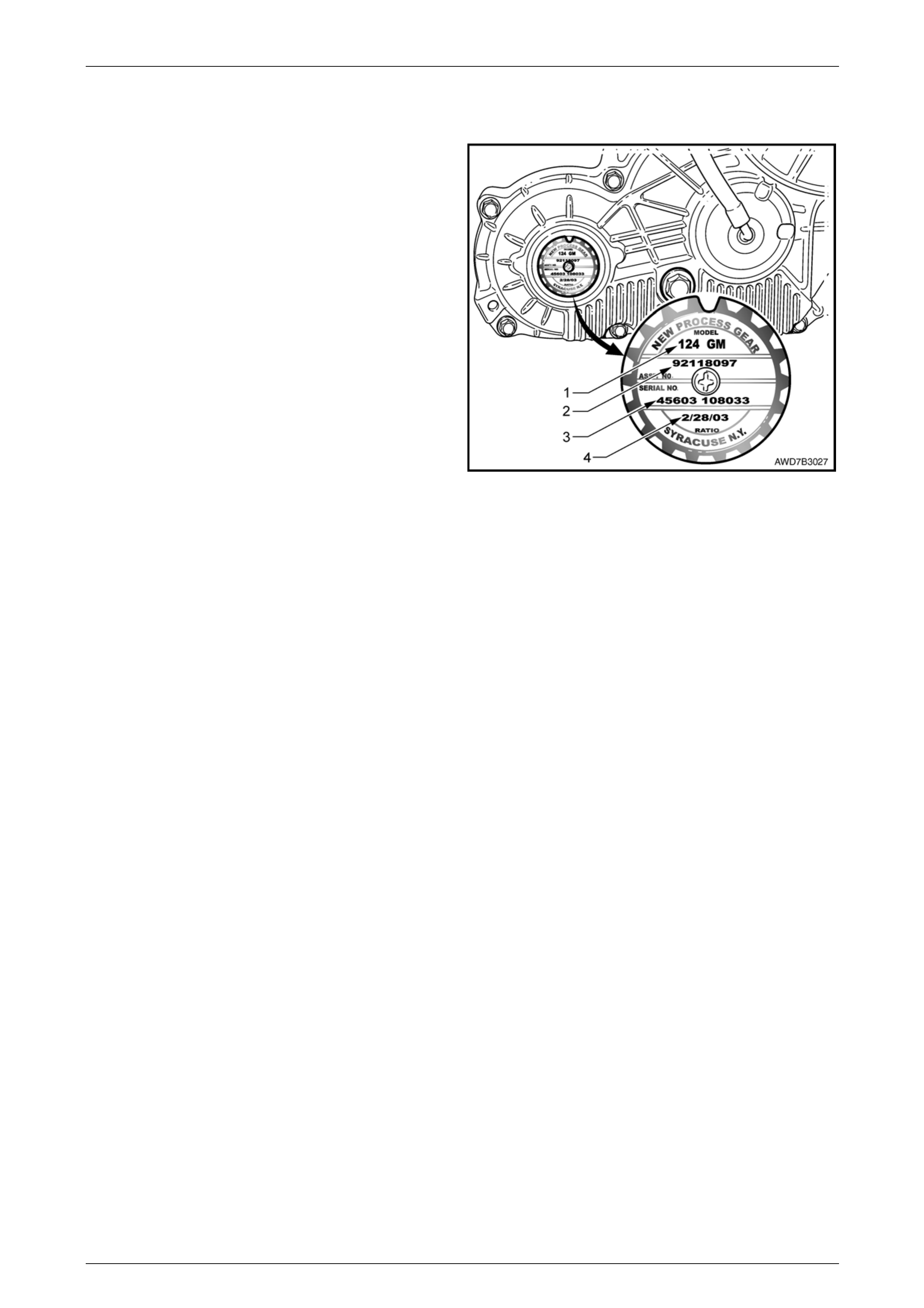

11.3 Transfer Case Assembly Serial Numbers

An identification tag is attached to the rear of the transfer

case housing, refer Figure 0A – 7. The information

contained on the tag provides the transfer case serial

number, build date and other information that may be

required for the correct procurement of service parts.

If the tag is removed or is dislodged during service

operations, the item is to be kept with the assembly.

Legend

1 Model Number ('124')

2 Assembly Part Number

3 Serial Number

4 Build Date

Figure 0A – 5

General Information Page 0A–16

Page 0A–16

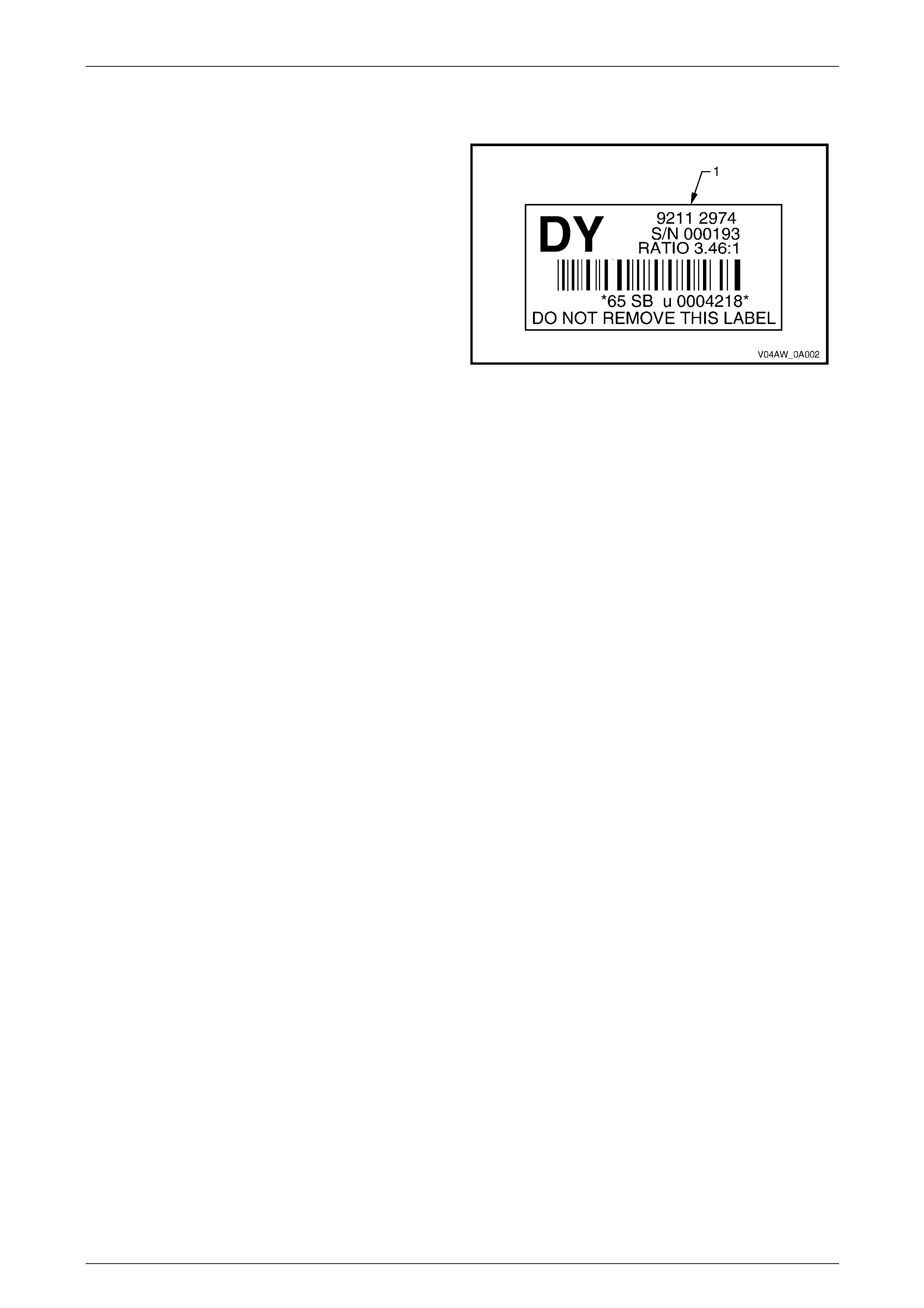

11.4 Front Final Drive

An identification label (1) is adhered to the front final drive

assembly on the left side towards the rear of the housing.

The label contains the Holden Part Number for the

assembly, the serial number of the assembly as well as

the final drive ratio.

The front final drive assembly is attached to the left-hand

side of the engine oil pan.

Figure 0A – 6

General Information Page 0A–17

Page 0A–17

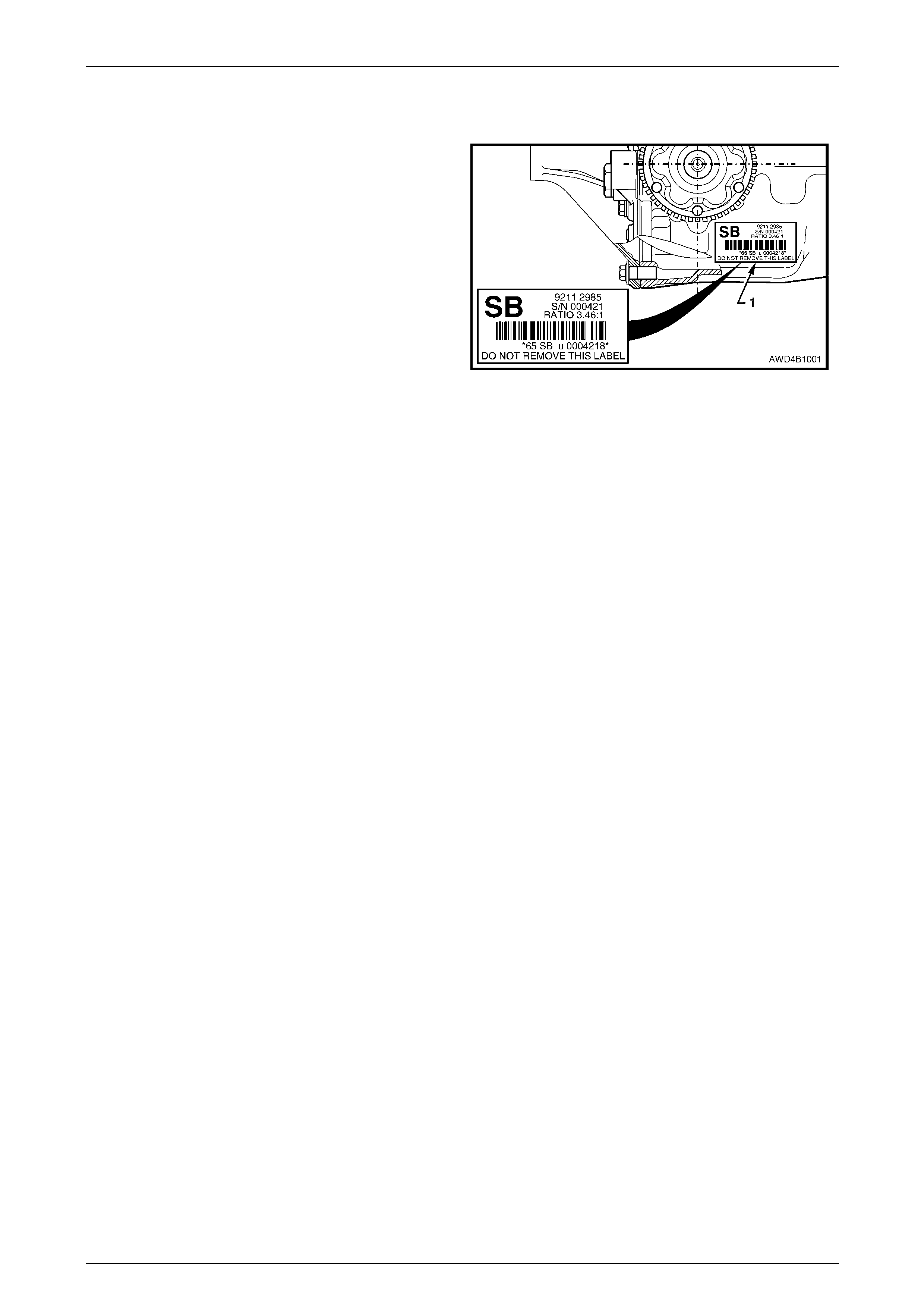

11.5 Rear Final Drive

An identification label is adhered to the rear final drive

assembly to the right-hand side of the carrier housi ng.

The label carries the Holden Part Number for the

assembly, the final drive ratio and the serial number of

the assembly.

Figure 0A – 7

General Information Page 0A–18

Page 0A–18

12 Special Tools

The following information lists the new Special Service Tools required for use on the MY 2004 AWD Wagon. All other

remaining Special Service Tools for use on MY 2004 AWD Wagon carry over from the MY 2003 VY and V2 Series. For

all other Special Service Tools not listed in this Section, refer to Section 0A, 16 Consolidated Tool List in the MY 2003 VY

and V2 Series Service Information.

These new tools are grouped accord ing to their application (transfer case, front suspensio n, front final dri ve and rear

suspension) and within each group, are listed in tool number alphabetical / numerical order. They are also classified into

the following categories:

Mandatory: When required to perform routine maintenance operations and adjustments, or are required to carry out fault

diagnosis procedures.

Desirable: T hese tools shou ld be considered for purchase since the ir use will greatly facilitate performing design ated

tasks and permit achievement of standard times.

Unique: These tools are those that must be employed when overhauling major assemblies or performing relatively large

tasks.

Available: Are those tools that are of general nature for which commercially available equivalents exists, or tools which

have had previous application.

Unless otherwise specified, all Special Service Tools are availabl e from:

SPX Australia Pty. Ltd.

Service Solutions

28 Clayton Road

Notting Hill, Victoria, 3168

Telephone: (03) 9544 6 222

Facsimile: (03) 9544 5222

Email: [email protected]

General Information Page 0A–19

Page 0A–19

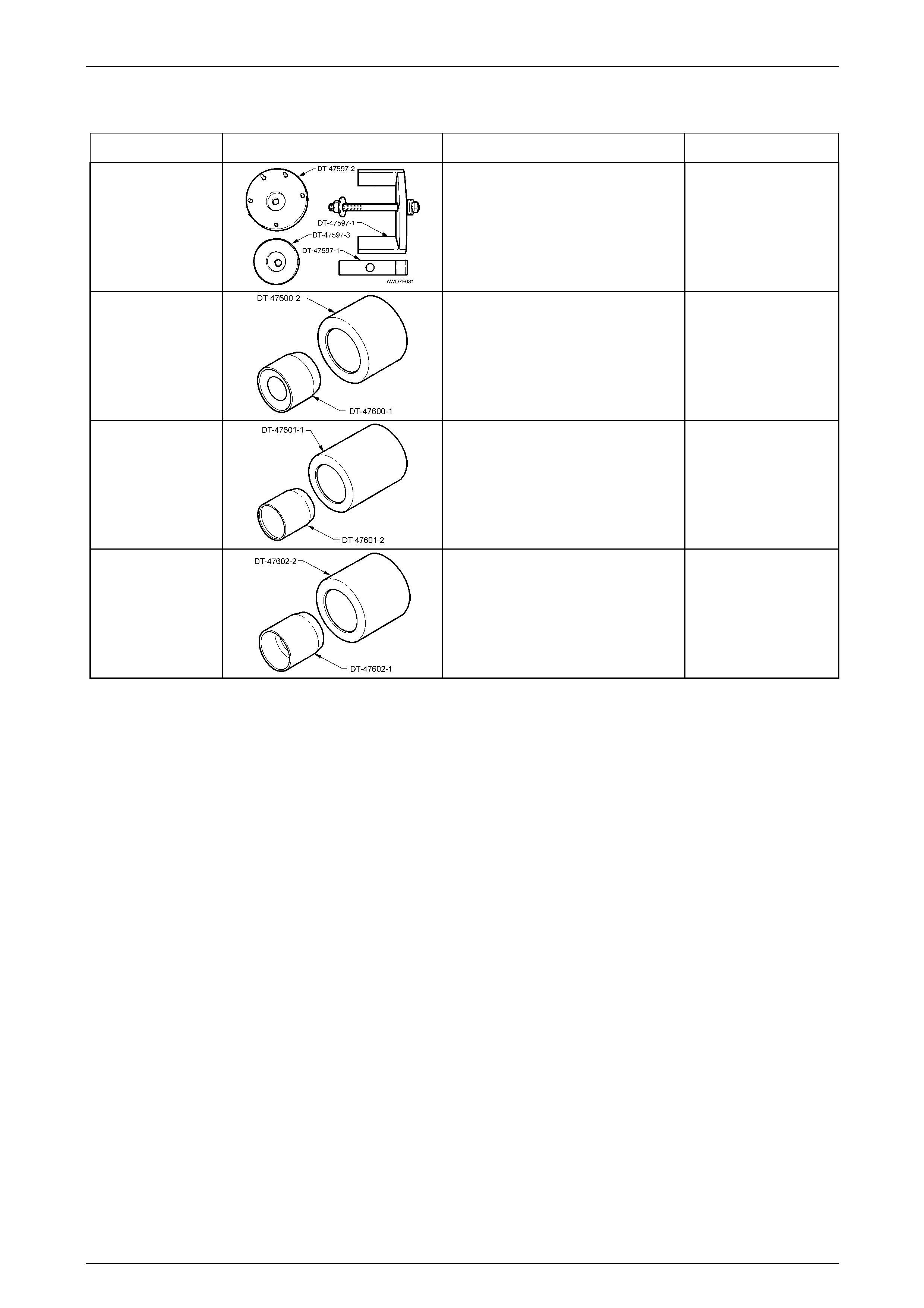

Transfer Case

Tool Number Illustration Description Tool Classification

DT-47597

Rear Mount Remover / Installer

Used to remove and install the rear

support mount from / to the transfer

case.

New release

Available

DT-47600

Seal Protector and Installer

Used to protect and install the front

input shaft oil seal to the transfer

case.

New release

Available

DT-47601

Seal Protector and Installer

Used to protect and install the rear

output shaft oil seal to the transfer

case.

New release

Available

DT-47602

Seal Protector and Installer

Used to protect and install the front

output shaft oil seal to the transfer

case.

New release

Available

General Information Page 0A–20

Page 0A–20

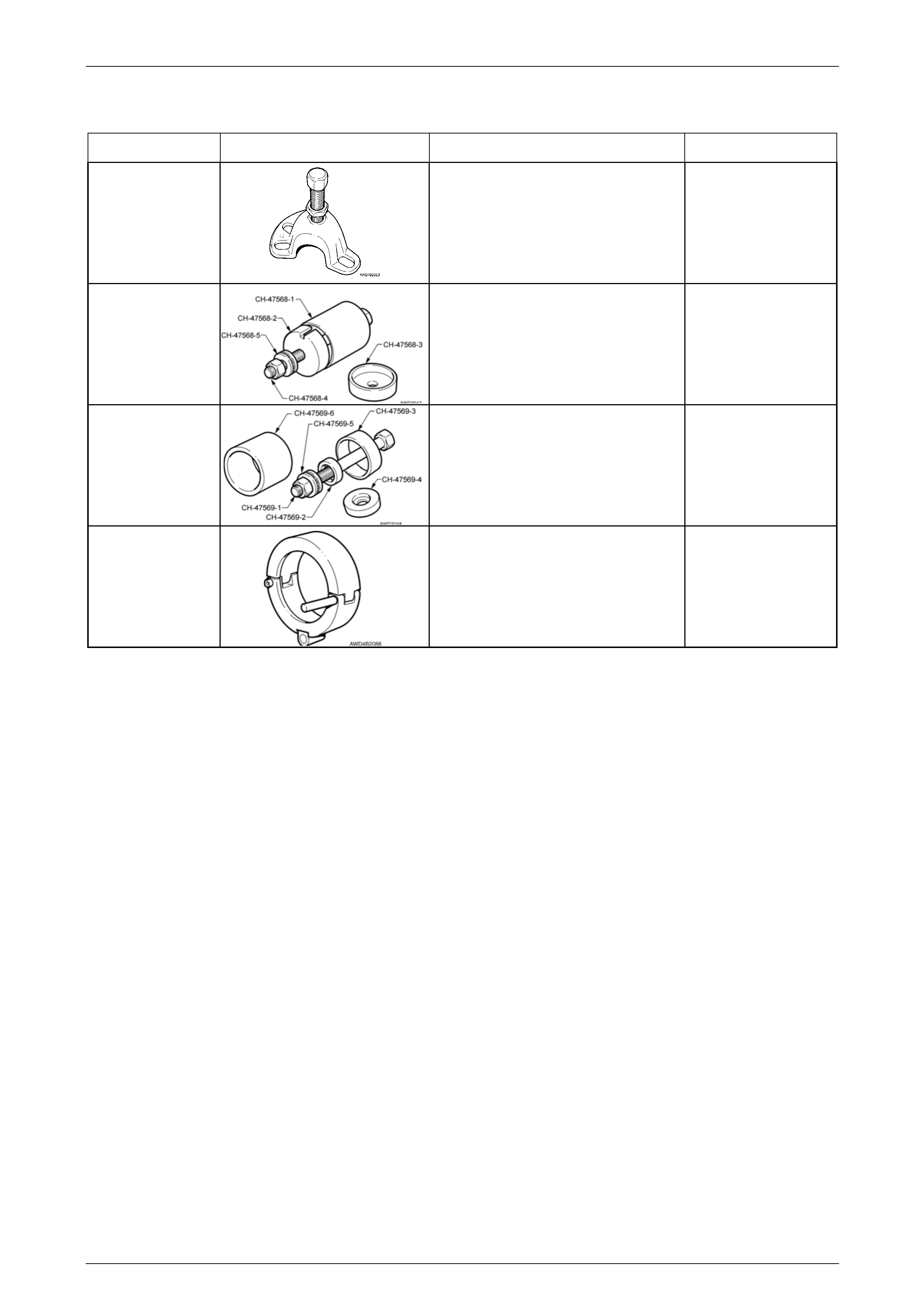

Front Suspension

Tool Number Illustration Description Tool Classification

7208

Hub Puller

Used to press the front driveshaft from

the front hub. Also used to check LSD

breakaway torque on final dri ves so

equipped.

Previously released

Mandatory

CH-47568 Remover / Installer Control Arm,

Front Isolator Bush

Used to remove and install the front

control arm, front hydraulic bushing

from / to the front suspension

crossmember cradle.

New release.

Available

CH-47569 Remover / Installer Control Arm,

Rear Bush

Used to remove and install the rear

bushing, from / to the front control

arm. New release.

Available

DT-47570 Remover / Installer, Front

Driveshafts

Used in conjunction with slide hammer

J 6125-1B (and adaptor), or J 23907

slide hammer to remove and reinstall

the front driveshafts.

New release.

Mandatory

General Information Page 0A–21

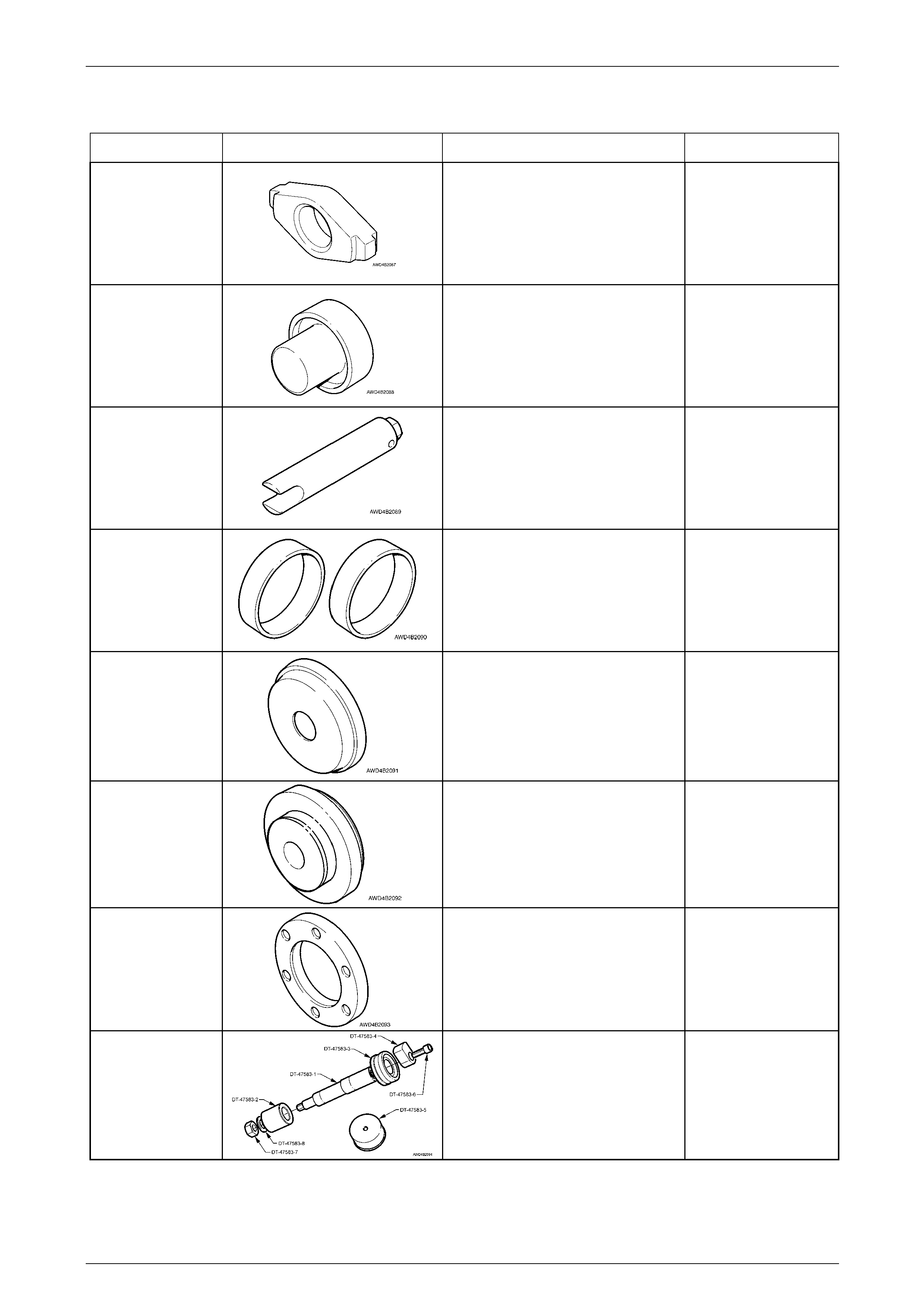

Page 0A–21

Front Final Drive

Tool Number Illustration Description Tool Classification

DT-47571

Cup Removal Adaptor

Used in conjunction with E9293 to

remove both pinion bearing cups from

the carrier housing.

New release

Available

DT-47572

Side Bearing Installer

Used with a hydraulic press to install

the differential carrier bearing cones.

New release

Available

DT-46573

Ring Gear Rotation Tool

Used to rotate differential housing to

measure bearing preload.

New Release

Mandatory

DT-47577

Dummy Bearing Cups

Used when determining the

differential bearing preload and

position.

New release.

Available

DT-47578

Bearing Cup Installer

Used in conjunction with bearing cup

alignment tool, DT-47579, to install

the ring gear carrier bearing cups to

the carrier and cover housings .

New release

Available

DT-47579

Bearing Cup Alignment Tool

Used in conjunction with bearing cup

installer, to ensure that bearing cups

are installed correctly.

New release.

Available

DT-47580

Spacer Ring

Fitted into the pinion flange to act as a

spacer for holding tool J8614-O1.

New Release

Available

DT-47583

Dummy Pinion

Used to determine the pinion bearing

preload and position.

New release

Available

General Information Page 0A–22

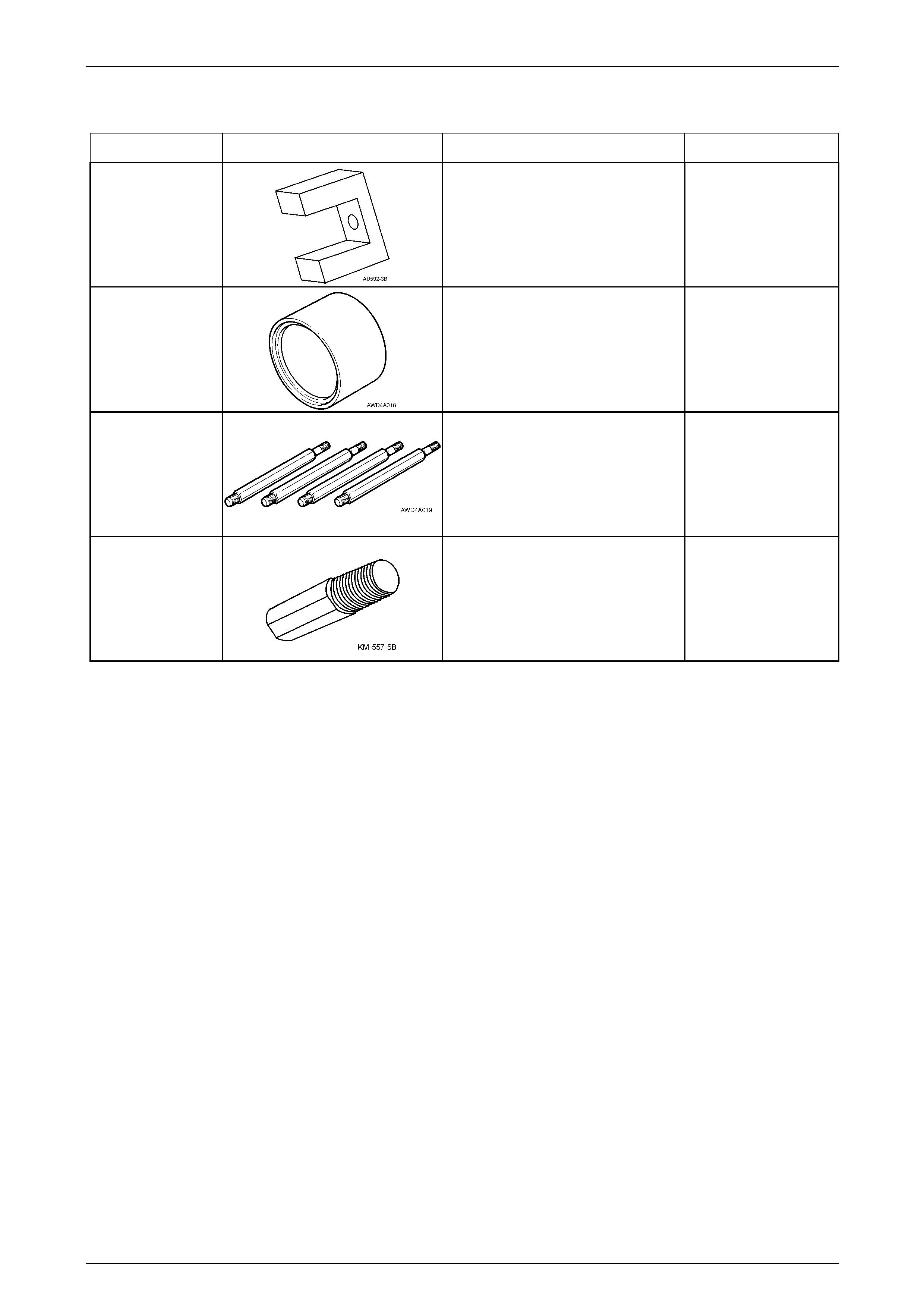

Page 0A–22

Rear Suspension

Tool Number Illustration Description Tool Classification

AU 592-3B

Support Block

Used with the plate, bolt and nut of

AU 592 to install the hydraulic bush

into the front of the rear crossmember.

New release

Available

CH-47575

Rear Wheel Bearing Receiver

Used to support the trailing arm

bearing hub when the bearing is being

removed.

New release

Mandatory

DT-47574 Stand Offs

Used with selected components of

Tool No. KM 620-1A when installin g a

new rear wheel bearing.

New release

Mandatory

KM 557-5B

Adaptor

Used with AU 592-2 and AMKM-557 to

remove the rear crossmember front

hydraulic mount when the crossmember

has been removed from the vehicle.

New release

Available