Body Dimensi ons Page 1A2–1

Page 1A2–1

Section 1A2

Body Dimensions

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

1.1 Front Suspension Frame Assembly.....................................................................................................................2

1.2 Transmission Rear Crossmember and Transfer Case Rear Mounting Bracket................................................3

2 Service Procedures ............................................................................................................................... 4

2.1 Rear Suspension Frame Assembly ......................................................................................................................4

Rear Suspension Frame Assembly Alignment....................................................................................................4

3 Torque Wrench Specifications............................................................................................................. 8

4 Special Tools.......................................................................................................................................... 9

Body Dimensi ons Page 1A2–2

Page 1A2–2

1 General Information

With the following exceptions, MY 2004 VY AWD Wagon Body Dimension Information carries over from MY 2003 VY

Wagon vehicles.

• Front suspensio n frame as se mbly .

• Transmission rear crossmember and transfer case rear mounting bracket.

• Rear suspension frame assembly.

While there are minor differences in the body structure between the AWD Wagon and the conventional Wagon, the

dimensional measuring points are the same.

For all body dimension information, refer to Section 1A2 Body Dimensions in the MY 2003 VY Series and V2 Series

Service Information.

1.1 Front Suspension Frame Assembly

A new front suspension frame assembly is fitted to suit the AWD application.

While there are minor differences in the construction of the front suspension frame assembly, the installation and

alignment procedures carry over from MY 2003 VY Series vehicles, refer to Section 1A2 Body Dimensions in the

MY 2003 VY and V2 Series Service Information.

Body Dimensi ons Page 1A2–3

Page 1A2–3

1.2 Transmission Rear Crossmember and

Transfer Case Rear Mounting Bracket

A new transmission rear crossmember and transfer case rear mounting bracket is fitted to MY 2004 VY AWD Wagon

vehicles to accommodate the transfer case.

While no specific alignment procedures are required, it is important to either mark the position of the bolts before

removal, or ensure that the holes are centralised before re-assembly. For further information, refer to Section 7F,

3.1 Transfer Case.

Body Dimensi ons Page 1A2–4

Page 1A2–4

2 Service Procedures

ATTENTION

All rear suspension fasteners are important attaching parts as they affect the performance of vital

components and/or could result in major repair expense. Where specified in this section, fasteners must be

replaced with parts of the same part number or a Holden approved equivalent. Do not use fasteners of an

inferior quality or substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all suspension

components.

Through out this section, fastener torque wrench specifications may be accompanied with the following

Identification marks:

!

!!

! Fasteners must be replaced after loosening.

"

""

" Vehicle must be at curb height before final tightening.

#

##

# Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

2.1 Rear Suspension Frame Assembly

Rear Suspension Frame Assembly Alignment

LT Section No. 07-150A

NOTE

The rear suspension frame assembly centering

tool needs to be held in position during the

alignment procedure. Therefore, assistance will

be required to complete this operation.

Body Dimensi ons Page 1A2–5

Page 1A2–5

1 Using chassis stands (1) support the vehicle at hoist

pad locations.

2 Remove the rear wheels, refer to Section 10 Wheels

and Tyres.

3 Remove the intermediate muffler and pipe assembly

together with the rear muffler and pipe assembly, refer

to Section 8B Exhaust System.

4 From underneath the vehicle, support the final drive

assembly with a trolley jack. Raise the jack slightly to

take some of the weight off the final drive mount.

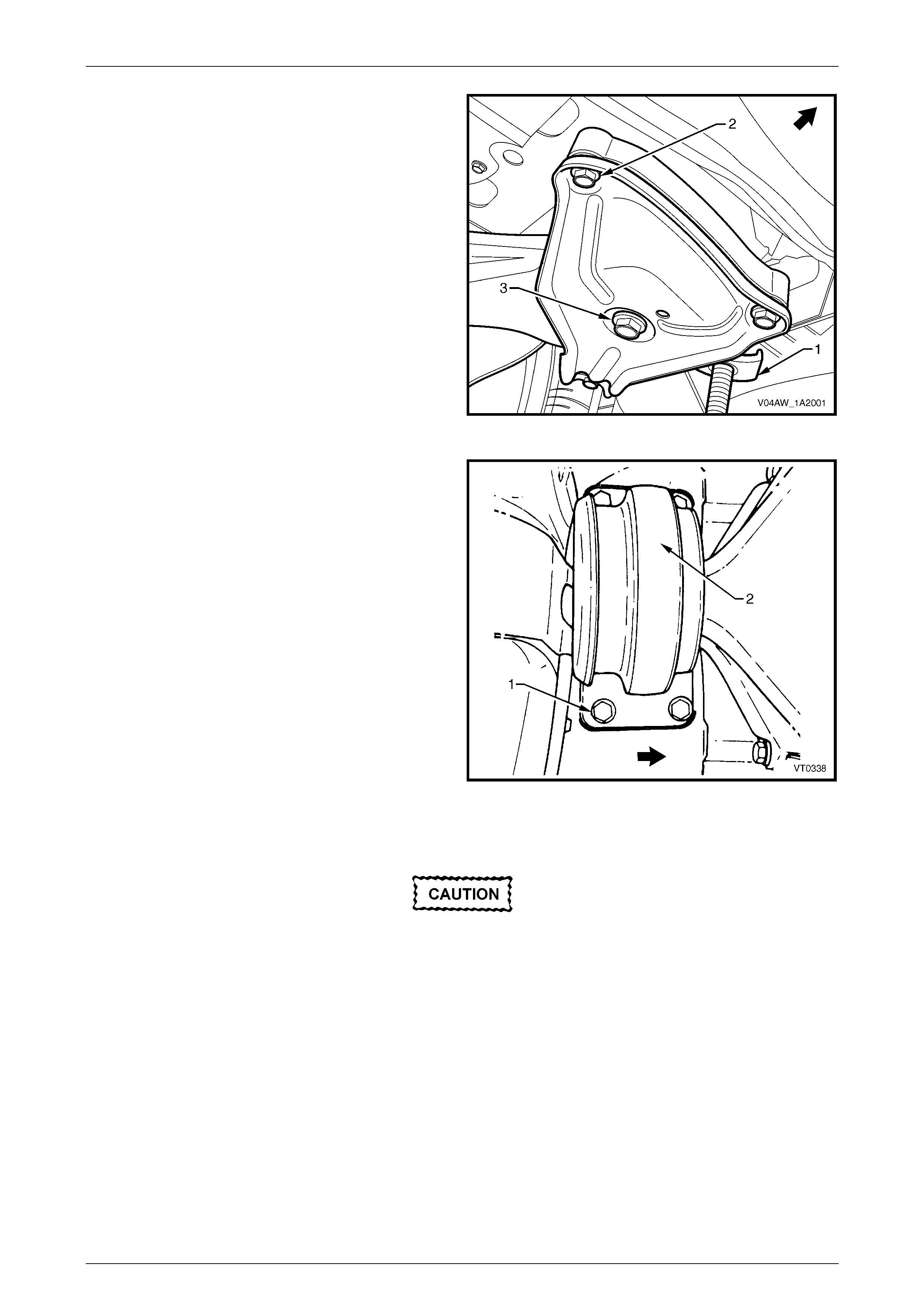

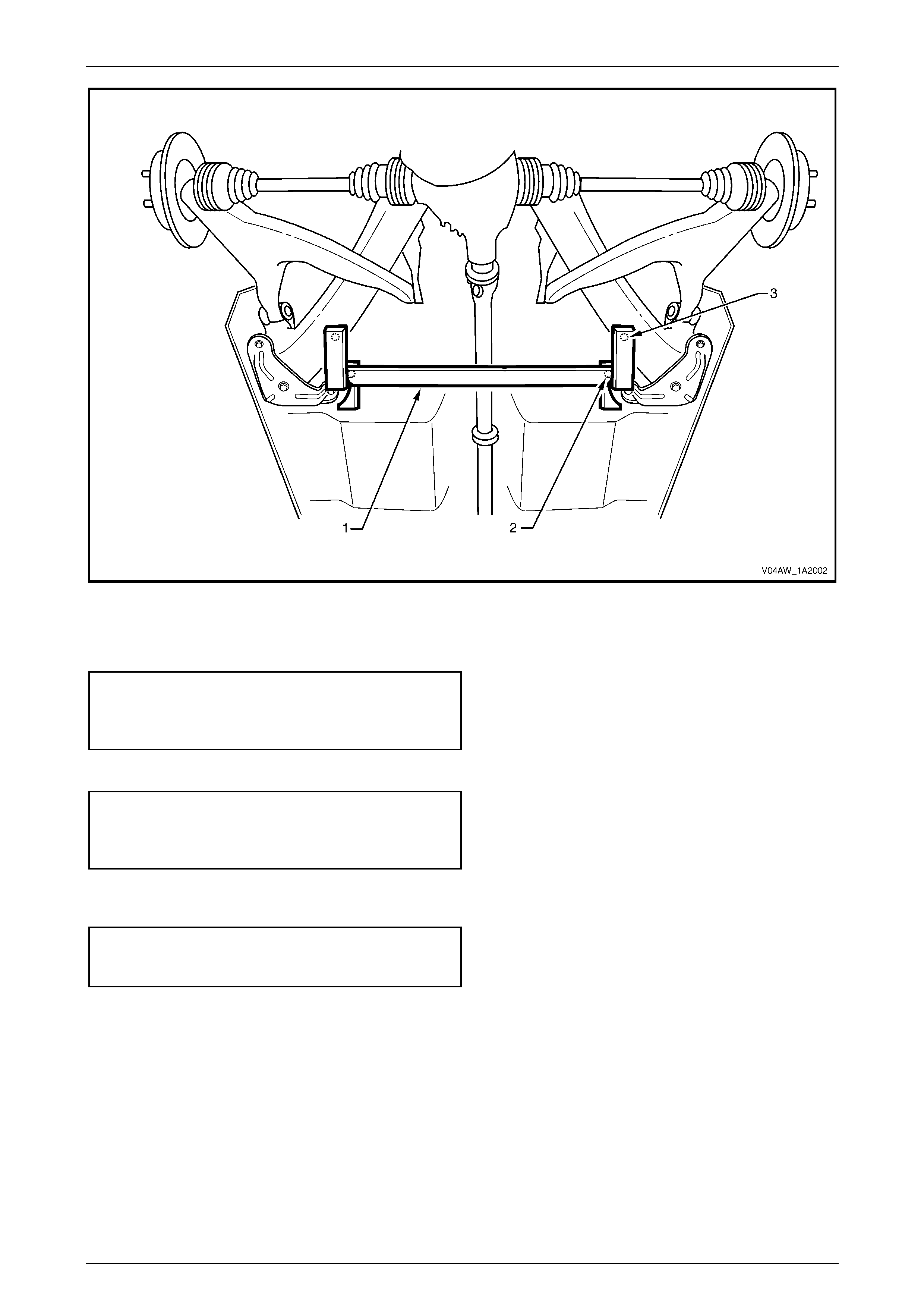

5 Loosen the M10 bolt (2), three places, attaching the

rear suspension support insulator bracket to the

vehicle, left-hand and right-hand side.

6 Loosen the rear suspension frame assembly M14

attaching bolt (3) left-hand and right-hand side.

Figure 1A2 – 1

7 Loosen the bolt (1), four places, attaching the final

drive rear mount (2).

Figure 1A2 – 2

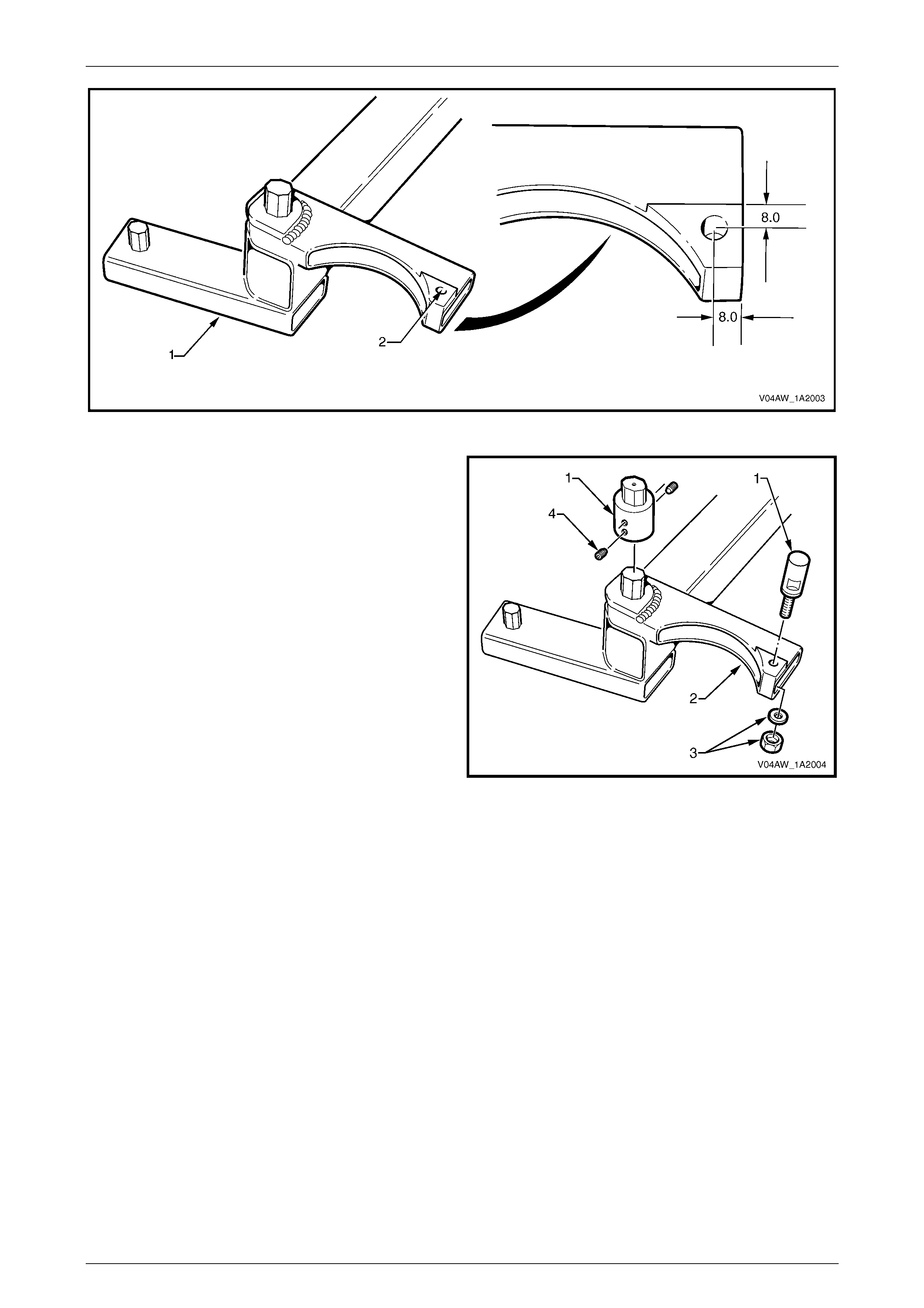

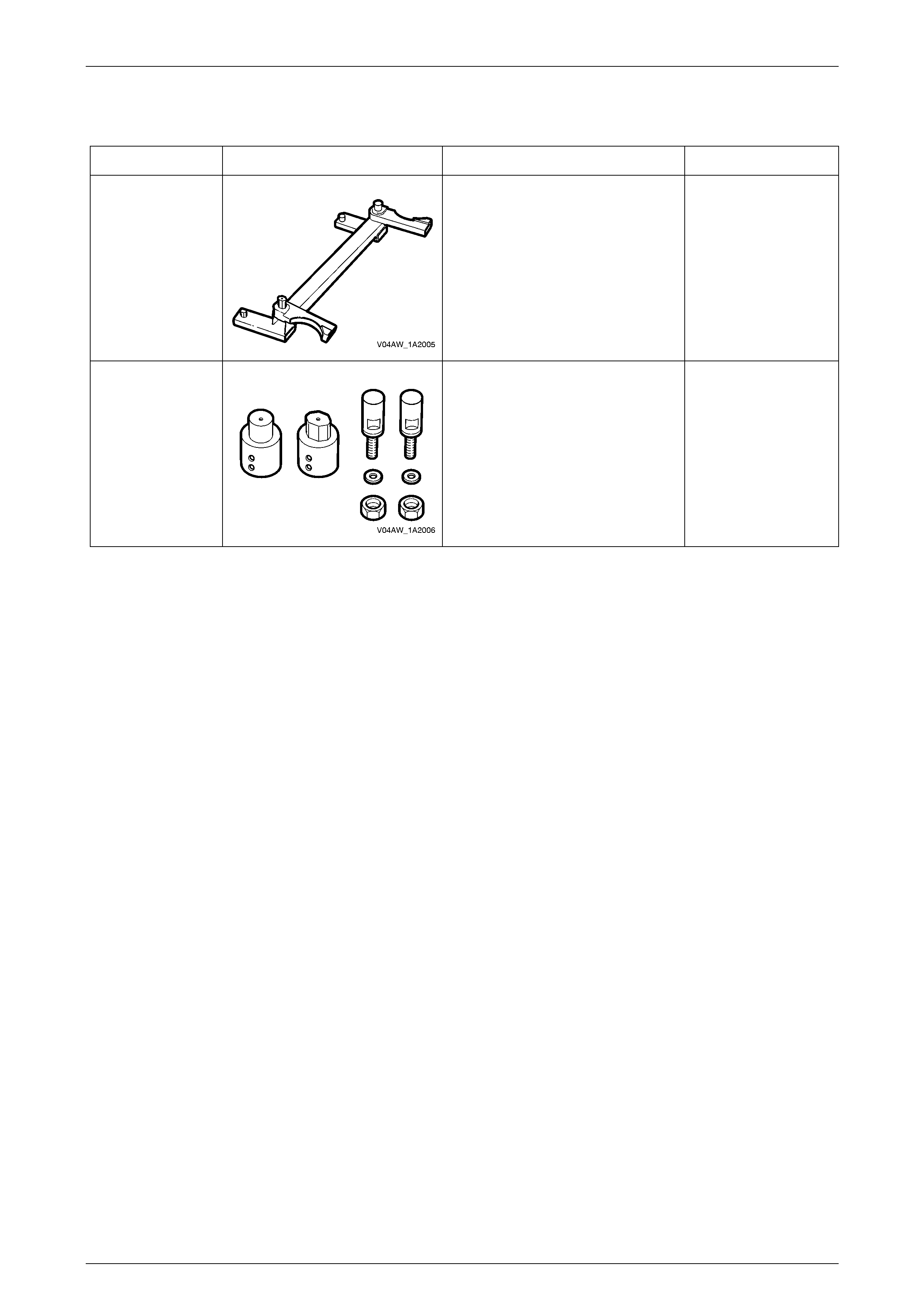

8 If required, modify the rear crossmember centering tool No CH-46839 (AU458) (1), refer to Figure 1A2 – 3:

Do not attempt to drill the hole in the rear

crossmember centering tool without a drill

press, as the tool will be rendered inaccurate

if the hole is not drilled square to the surface

of the tool.

a) Mount the rear crossmember centering tool in a drill press.

b) Drill a 6 mm hole (2) through the landing on the top surface of the tool, 8.0 mm from the edges as shown.

c) Repeat steps a) and b) for the other end of the tool.

Body Dimensi ons Page 1A2–6

Page 1A2–6

Figure 1A2 – 3

9 Fit the rear crossmember centering tool adaptor pins

No CH47621 (1) to the rear crossmember centering

tool (2). Fit and tighten the nut and washer (3). Tighten

the grub screws (4).

NOTE

Ensure that the adaptor pins with the hexagonal

heads are fitted on to the side of the tool with the

hexagonal pins.

Figure 1A2 – 4

10 Fit rear crossmember centering tool (1) to the vehicle, refer to Figure 1A2 – 5.

NOTE

The rear crossmember centering tool locates into

19 mm diameter body datum holes (2) positioned

forward of the rear suspension frame assembly.

11 With the help of an assistant, manoeuvre the rear suspension assembly until the location pins of the rear

crossmember centering tool engage the alignment holes (3) on the rear frame assembly.

Body Dimensi ons Page 1A2–7

Page 1A2–7

Figure 1A2 – 5

12 Tighten the rear frame assembly M14 attaching bolt (3) right-hand and left-hand side to the specified torque, refer

to Figure 1A2 – 1.

! Rear suspension frame

assembly attaching bolt

torque specification ......................Stage 1 125.0 Nm

.............. Stage 2 Turn 30° – 40°

13 Tighten the bolt (1), four places, attaching the final drive rear mount (2), refer to Figure 1A2 – 2.

! Final drive rear mount

attaching bolt torque

specification .............Stage 1 30.0 – 40.0 Nm

.............. Stage 2 Turn 55° – 65°

14 Tighten to the specified torque, the M10 bolt (2), three places, attaching the rear suspension support insulator

bracket to the vehicle, right-hand and left-hand side, refer to Figure 1A2 – 1.

Rear suspens ion sup port ins ul ator

bracket attaching bolt torque

specification............................................60.0 – 85.0 Nm

15 Remove the rear crossmember centering tool.

16 Gently lower the trolley jack and remove from under the vehicle.

17 Refit the rear wheels, refer to Section 10 Wheels and Tyres.

18 Remove the vehicle from the chassis stands.

Body Dimensi ons Page 1A2–8

Page 1A2–8

3 Torque Wrench Specifications

ATTENTION

All rear suspension fasteners are important attaching parts as they affect the performance of vital

components and/or could result in major repair expense. Where specified in this section, fasteners MUST be

replaced with parts of the same part number or a Holden approved equivalent. Do not use fasteners of an

inferior quality or substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all suspension

components.

Through out this section, fastener torque wrench specifications may be accompanied with the following

Identification marks:

!

!!

! Fasteners must be replaced after loosening.

"

""

" Vehicle must be at curb height before final tightening.

#

##

# Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

! Rear Suspension Frame Assembly Attaching Bolt............. Stage 1 125.0 Nm

.......................................................................................Stage 2 Turn 30° – 40°

! Final Drive Rear Mount Attaching Bolt...................... Stage 1 30.0 – 40.0 Nm

.......................................................................................Stage 2 Turn 55° – 65°

Rear Suspension Support Insulator Bracket Attaching Bolt.......60.0 – 85.0 Nm

Body Dimensi ons Page 1A2–9

Page 1A2–9

4 Special Tools

Tool Number Illustration Description Tool Classification

CH46839

(AU458)

Rear Crossmember Centering Tool.

Previously released. Mandatory.

CH47621

Rear Crossmember Centering Tool

Adaptor Pins. Mandatory.