Rear Final Drive & Driveshafts Page 4B1–1

Page 4B1–1

Section 4B1

Rear Final Drive & Driveshafts

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Cautions And Notes for correct workshop practices with regard to safety and/or property damage.

1. General Description............................................................................................................................... 2

1.1 Final Drive Assembly Identification......................................................................................................................5

1.2 Final Drive Lubricant..............................................................................................................................................6

2. Minor Service Operations.....................................................................................................................7

2.1 General Information ...............................................................................................................................................7

Road Wheel Requirements....................................................................................................................................7

2.2 Driveshaft Assembly..............................................................................................................................................8

Remove ...................................................................................................................................................................8

Reinstall ..................................................................................................................................................................8

2.3 Driveshaft and/or Constant Velocity Joints.........................................................................................................9

Disassemble ...........................................................................................................................................................9

Inspect...................................................................................................................................................................10

Driveshaft and Boots ........................................................................................................................................10

Constant Velocity Joints ...................................................................................................................................11

Reassemble ..........................................................................................................................................................12

Constant Velocity Joints ...................................................................................................................................12

Driveshaft and Boots ........................................................................................................................................14

2.4 Pinion Oil Seal......................................................................................................................................................16

Replace .................................................................................................................................................................16

2.5 Pinion Flange ........................................................................................................................................................19

Replace .................................................................................................................................................................19

Using Old Seal..................................................................................................................................................19

Using New Oil Seal...........................................................................................................................................21

3 Major Service Operations ................................................................................................................... 25

3.1 Trailing Arm Trunnion Flange, Trunnion Assembly and/or Wheel Bearing....................................................25

3.2 Rear Final Drive Assembly..................................................................................................................................26

Remove .................................................................................................................................................................26

Reinstall ................................................................................................................................................................31

3.3 Removed Final Drive Assembly..........................................................................................................................36

4 Specifications....................................................................................................................................... 37

6 Torque Wrench Specifications........................................................................................................... 38

7 Special Tools........................................................................................................................................ 39

Techline

Techline

Techline

Techline

Techline

Techline

Rear Final Drive & Driveshafts Page 4B1–2

Page 4B1–2

1. General Description

Independent rear suspension is fitted as standard equipment on all MY 2004 AWD Wagon models and all are fitted with

a final drive assembly that has a four pinion type rear differential assembly. The final drive ratio is 3.46:1.

As the standard fitment Traction Control System requires independent control of each rear wheel, the Limited Slip

Differential (LSD) option is not available, in this vehicle.

The final drive assembly is mounted directly to a crossmember which is rubber mounted to the vehicle underbody. The

differential case and drive pinion are mounted in opposed taper roller bearings in the carrier. Differential case side

bearing pre-load adjustment is provided by screw adjusters in the sides of the case. Pinion bearing pre-load is provided

by a collapsible spacer. Torque is transferred from the propeller shaft to the final drive assembly via the pinion flange

which is splined to the hypoid pinion. The torque is then transferred from the pinion through the ring gear, differential

case, differential pinion cross shafts, differential pinions, side gears and then via splines, to the inner axle shafts and

driveshafts.

The final drive assembly should be removed from the vehicle for all service operations other than the removal of the

inner axle shafts, inner axle shaft oil seals, pinion oil seal or the rear cover.

Two driveshaft assemblies are fitted, each consisting of a shaft which is splined at each end into ball type constant

velocity joints. The inner constant velocity joint is bolted to the inner axle shaft flange at the differential carrier, with the

outer joint bolted to the trunnion flange at the rear trailing arm. Both joints are of the ‘plunge’ type design.

With the following exceptions, MY 2004 AWD Wagon Series Final Drive and Driveshafts Service Information carries over

from MY 2003 VY Series vehicles:

• Final Drive Pinion Flange and/or Seal.

• Driveshafts.

For information not contained within this Section, (including all Final Drive Assembly Maintenance items), refer to

MY 2003 VY and V2 Series Service Information, Section 4B Final Drive and Driveshafts.

Rear Final Drive & Driveshafts Page 4B1–3

Page 4B1–3

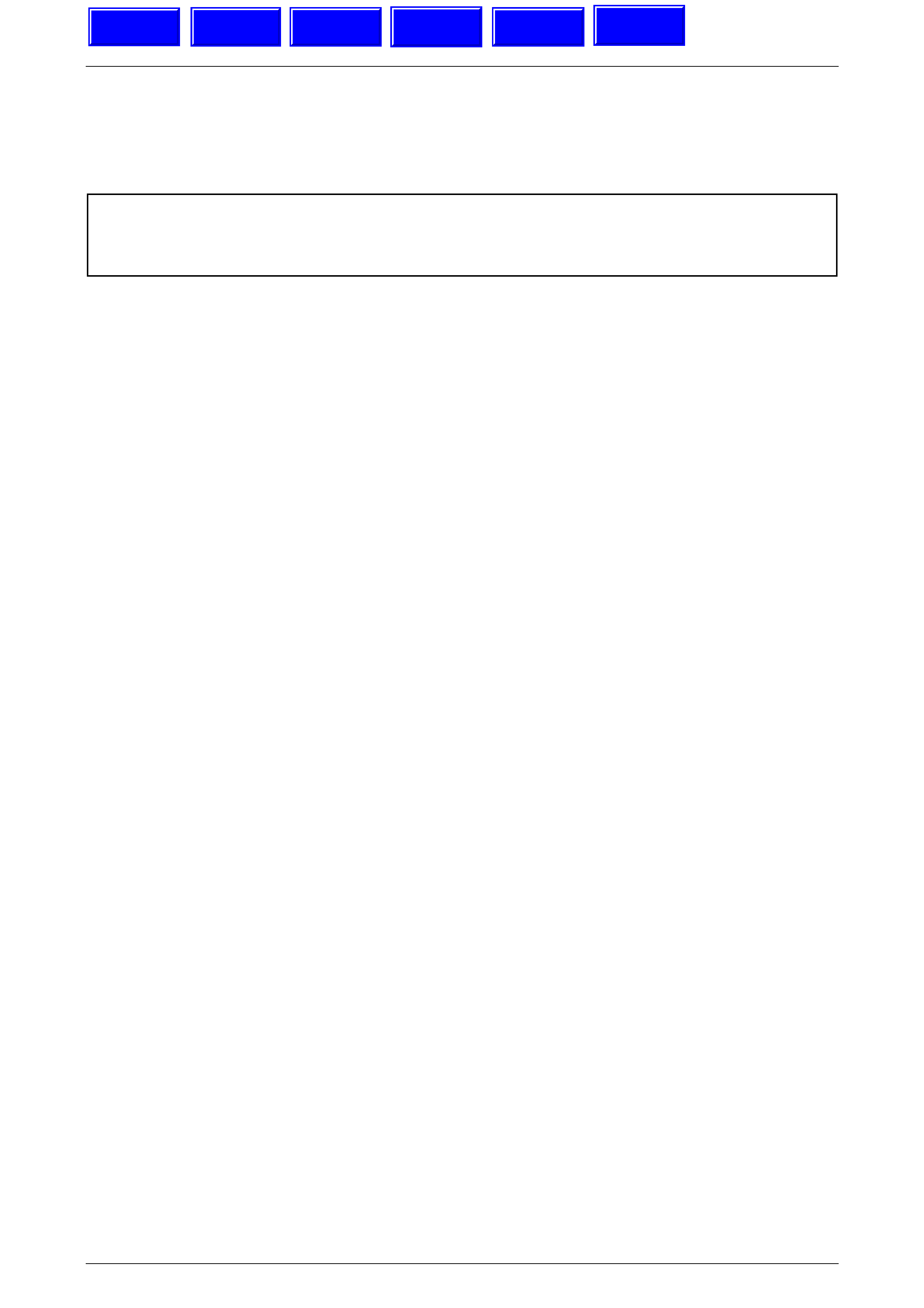

Figure 4B1 – 1

Legend

1 Driveshaft

2 Rear Suspension Stabiliser Bar

3 Final Drive Assembly

4 Constant Velocity Joints

5 Trailing Arm

6 Rear Suspension Crossm ember

7 Rear Stabiliser Bar to Trailing Arm Link

Rear Final Drive & Driveshafts Page 4B1–4

Page 4B1–4

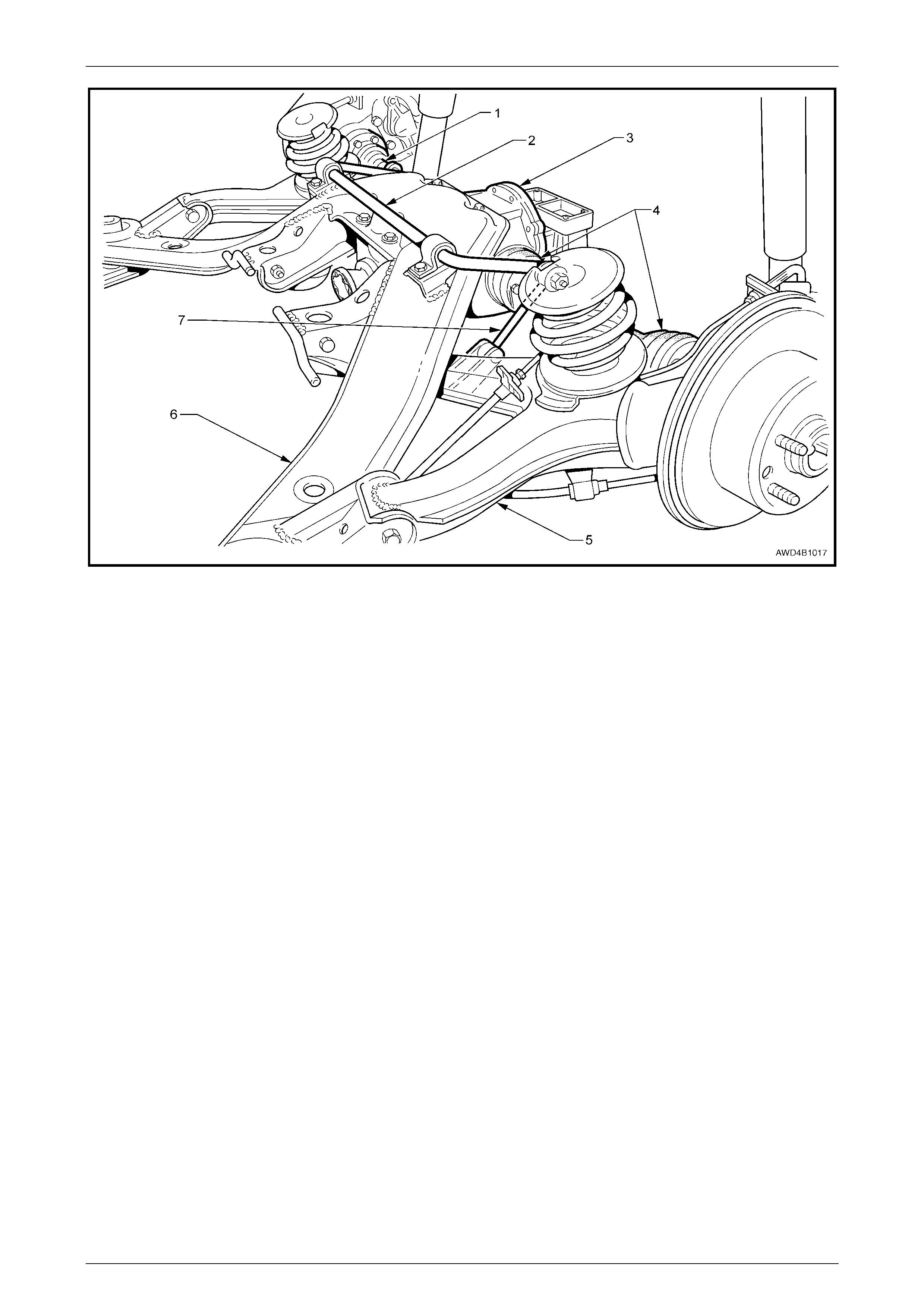

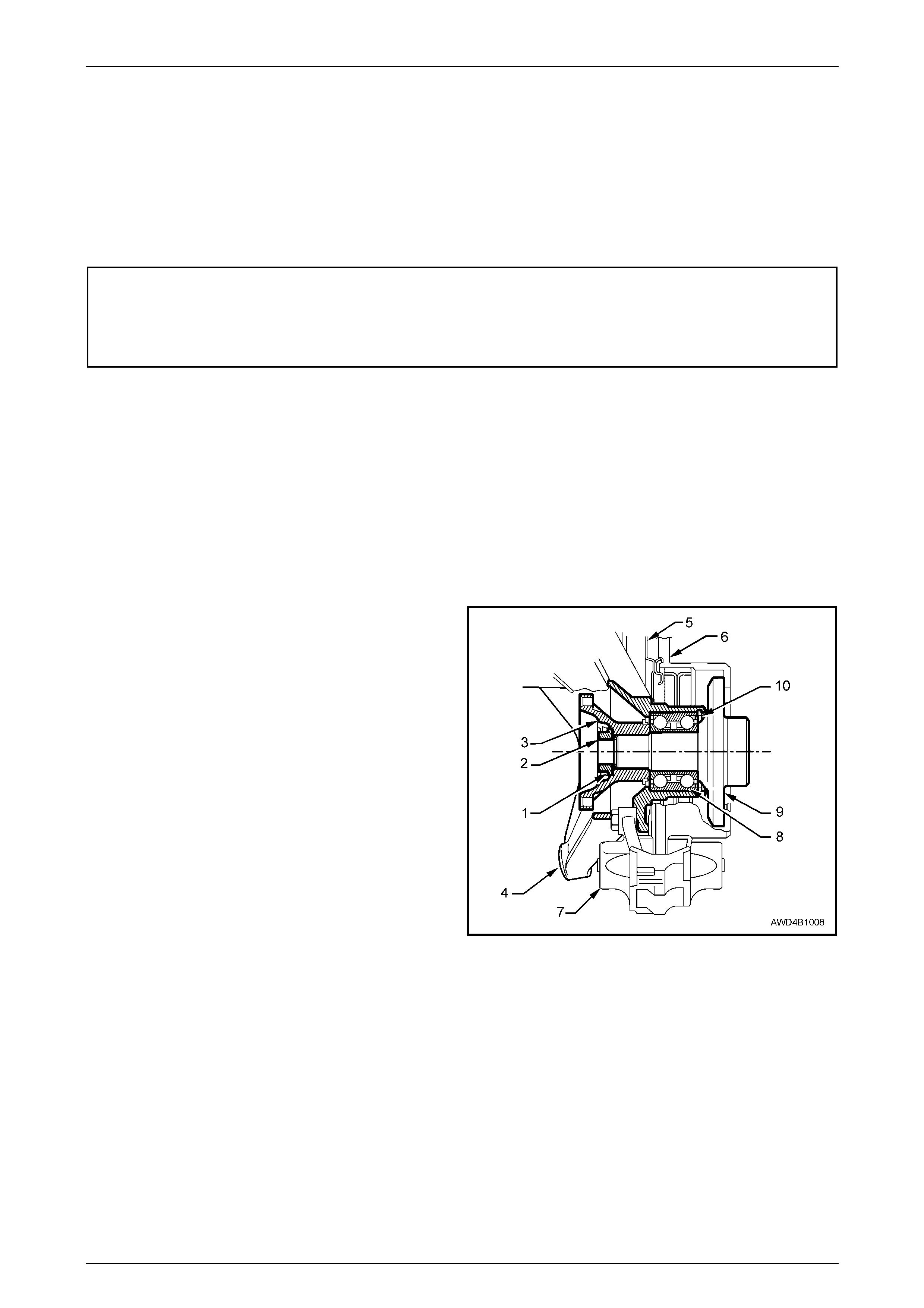

Figure 4B1 – 2

Legend

1 LH Inner Axle Shaft

2 Pinion Flange

3 RH Inner Axle Shaft

4 Identification Label

5 Drain Plug

6 Rear Cover

7 Breather

8 Filler Plug

9 Lubrication Tag

Rear Final Drive & Driveshafts Page 4B1–5

Page 4B1–5

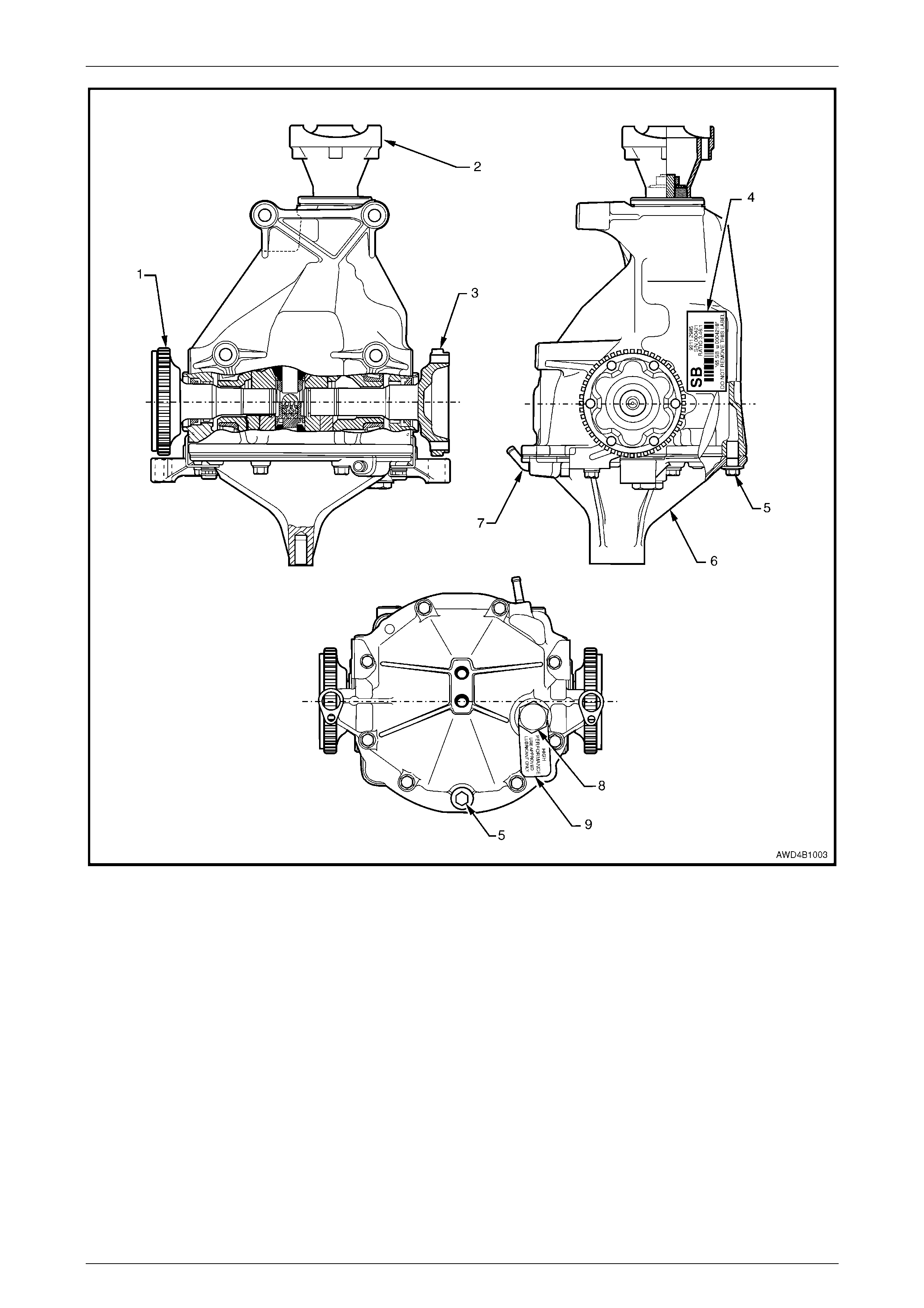

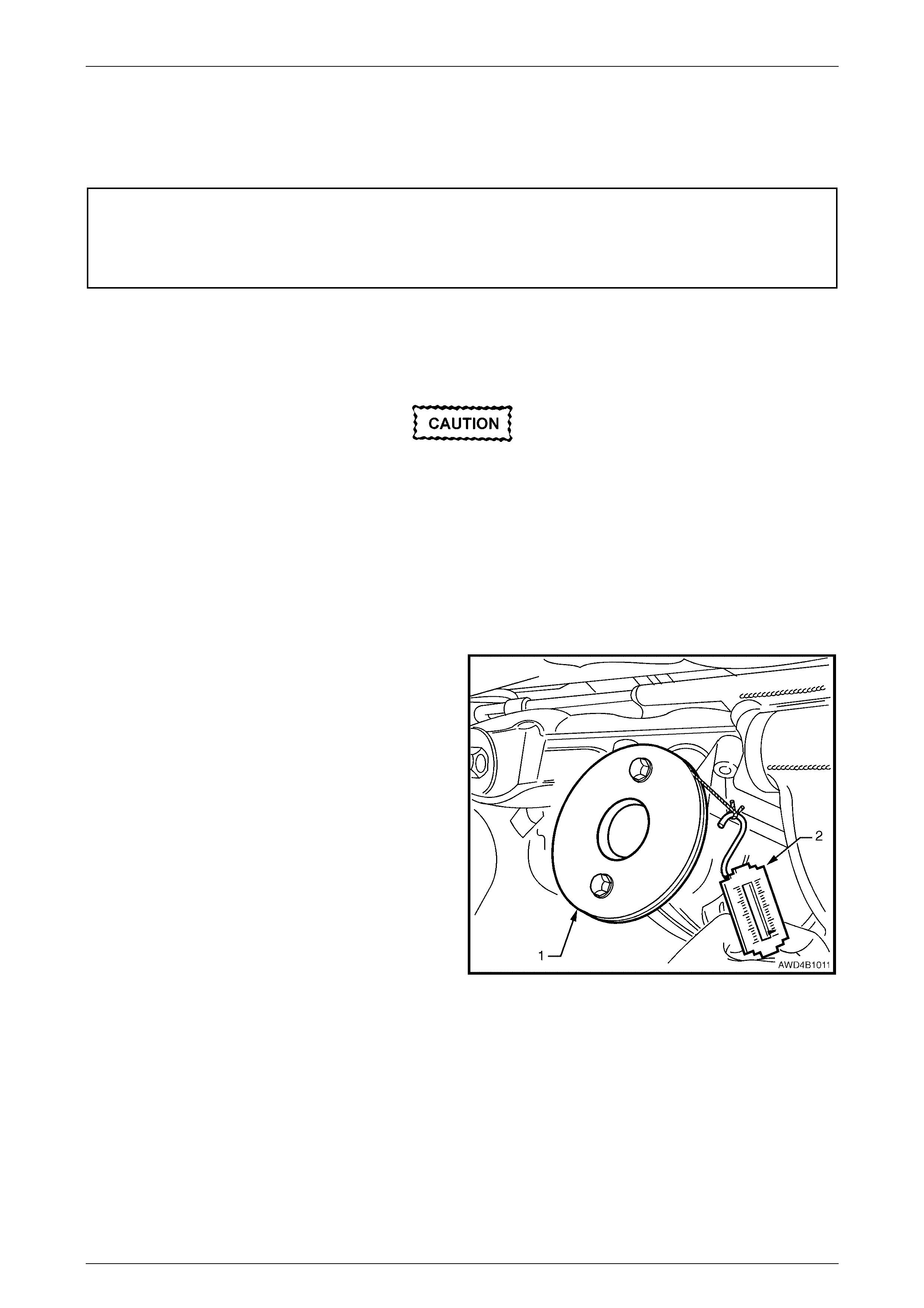

1.1 Final Drive Assembly Identification

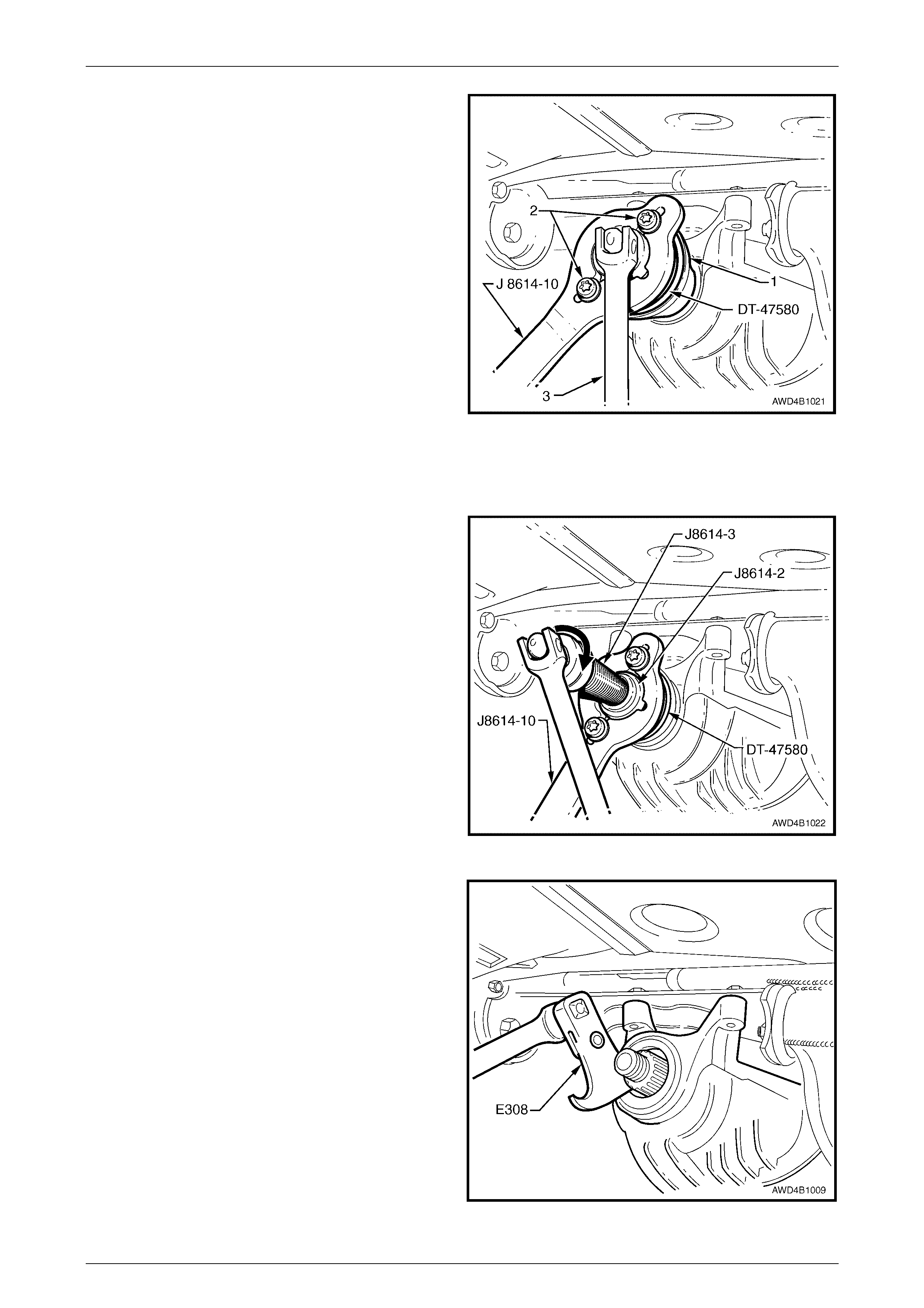

The type of differential fitted to this final drive assembly can

be identified by referring to the identification label (1)

attached to the RHS of the carrier housing.

The identification label (1) carries the final drive assembly

part number for the final drive ratio and the serial number of

the assembly.

The inform ation on the lubrication tag (2) under the filler

plug (3), will be:

HIGH

PERFORMANCE

USE APPROVED

LUBRICANT ONLY

Figure 4B1 – 3

Rear Final Drive & Driveshafts Page 4B1–6

Page 4B1–6

1.2 Final Drive Lubricant

Should the final drive assembly require the lubricant to be replaced, then the only lubricant that is to be used, is a

Synthetic Hypoid Gear Oil, with a viscosity, SAE 80W -140, such as; MOBIL Mobilube SHC ID or CASTROL SAF-XA.

Rear Final Drive & Driveshafts Page 4B1–7

Page 4B1–7

2. Minor Service Operations

2.1 General Information

ATTENTION

All fasteners are important attaching parts as they affect the performance of vital components and/or could

result in major repair expense. Where specified in this section, fasteners MUST be replaced with parts of the

same part number or an approved equivalent. Do not use fasteners of an inferior quality or substitute design.

Torque values must be used as specified during reassembly or reinstallation of all components, to ensure

correct retention.

Throughout this section, fastener torque wrench specifications may be accompanied with the following

identification marks:

!

!!

! Fasteners must be replaced after loosening.

"

""

" Vehicle must be at curb height before final tightening.

#

##

# Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

Road Wheel Requirements

1 Whenever a road wheel and/or brake disc is removed from the vehicle, the relationship of the road wheel and the

disc to the hub MUST be marked with a felt tipped pen or similar, in order for those parts to be reinstalled in their

original positions. This is critical to maintain the brake disc and road wheel runout dimension to a minimum.

2 When reinstalling road wheels, do not use an impact

gun to tighten wheel nuts unless the impact gun is

fitted with a torque limiter socket (Tool No. AU 534 or

a commercial equivalent). Failure to correctly tighten

wheel nuts to the correct torque specification and in

the correct order, may result in a distorted brake disc,

leading to the development of brake shudder.

Road Wheel Attaching Nut

Torque Specification....................................... 125 Nm

NOTE:

For a complete description of the method used

to measure both brake disc and trunnion

assembly runout and correction, refer to

3.5 Rear Brake Disc, Brake Disc and Hub

Indexing Procedure in Section 5A Service and

Park Braking Systems, in the MY 2003 VY and

V2 Series Servic e Information. Figure 4B1 – 4

Rear Final Drive & Driveshafts Page 4B1–8

Page 4B1–8

2.2 Driveshaft Assembly

LT Section No: 05-290

ATTENTION

The following fasteners MUST be replaced when performing these operations:

!

!!

! All removed driveshaft constant velocity joint attaching bolts.

Remove

1 Raise the rear of vehicle and support in a safe mann er. Ref er to Section 0A General Information, in the MY 2003

VY and V2 Series Service Information, for the location of jacking points.

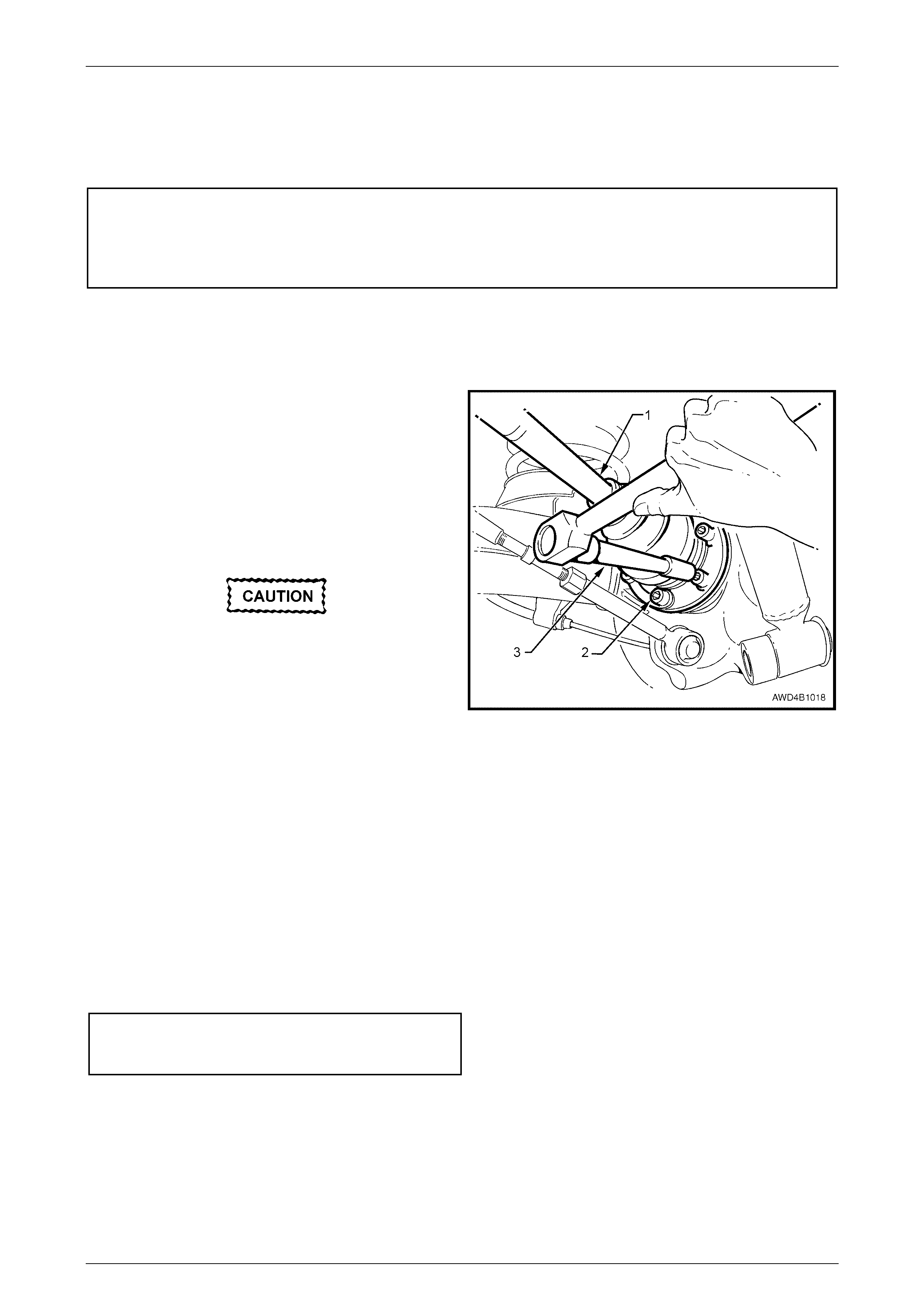

2 Use a felt tipped pen or similar, to identify the

driveshaft as being either right or left and also, which

constant velocity joint is the outer.

NOTE

Even though both inner and outer constant velocity

j

oints are of the plunge design, it is important that the

driveshaft orientation is marked, to maintain the shaft

‘wind-up’ direction when reinstalled.

During driveshaft removal and reinstallation,

the driveshaft 'free' end MUST be supported

to keep constant velocity joint angles to a

minimum. Excessive angles and/or dropping

the 'free' end will cause damage to the boot

cap and the joint itself.

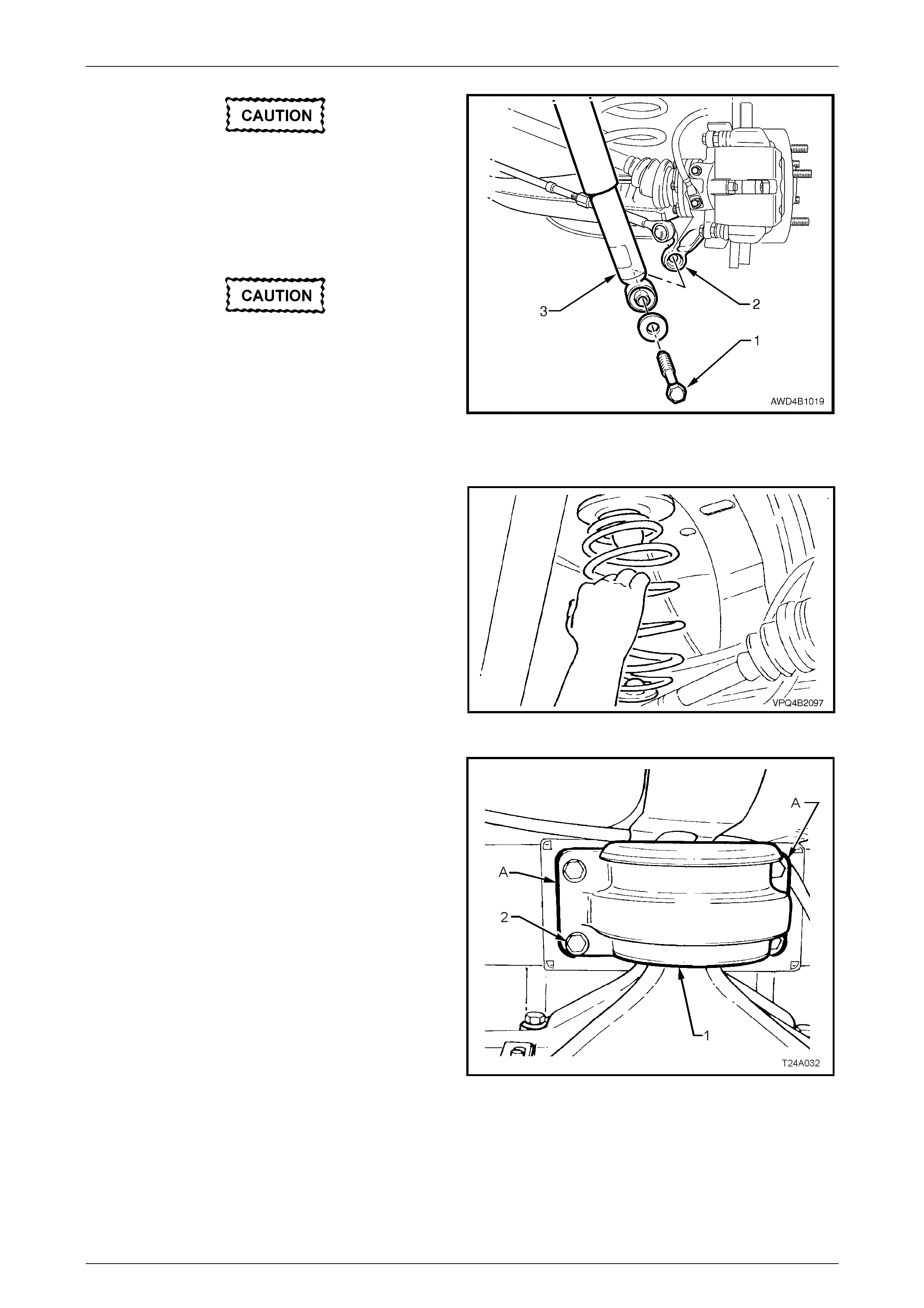

3 With the park brake firmly applied, use an 8 mm Allen

key socket and suitable socket equipment (3) to

remove the driveshaft, inner constant velocity joint to

inner axle shaft and outer constant velocity joint to

trunnion flange attaching bolts (2) (six places) and

plates, remove driveshaft (1).

Figure 4B1 – 5

Reinstall

Reinstallation of the driveshaft is reversal of the removal procedure, noting the following points.

1 When reinstalling the driveshaft, ensure that either constant velocity joint is not deflected excessively and that the

orientation is the same as before removal, using the identification marks previously applied.

2 Reinstall the driveshaft, then six NEW bolts and three plates at each end, tightening to the correct torque

specification.

( ! ) Driveshaft constant velocity joint

attaching bolt torque specification........................50 Nm

then 70° turn angle

Rear Final Drive & Driveshafts Page 4B1–9

Page 4B1–9

2.3 Driveshaft and/or Constant Velocity

Joints

LT Section No: 05-290

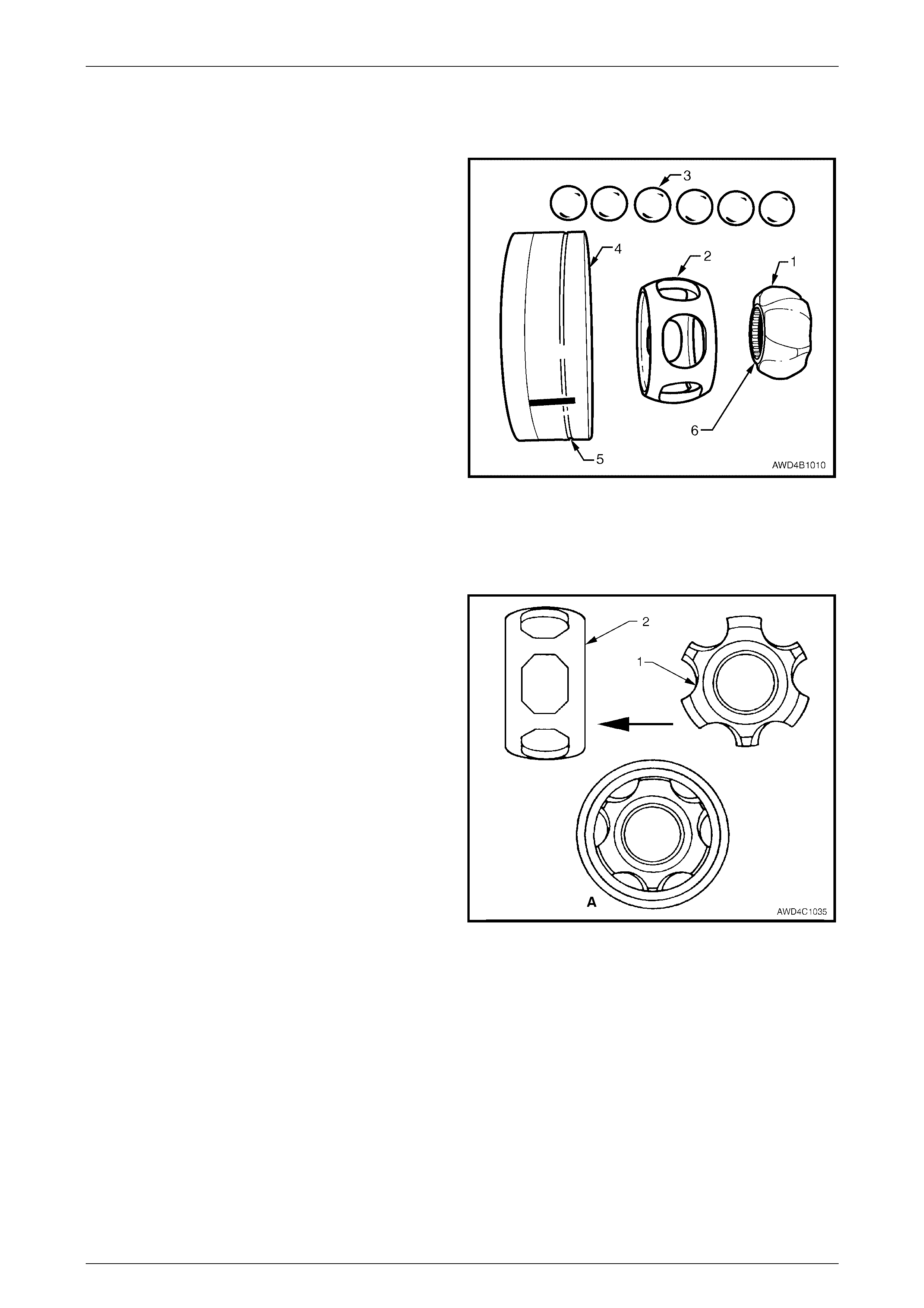

There are two repair kits available for driveshaft constant velocity joint repairs:

a A ‘Boot Kit’, which consists of a boot, boot clamps and retaining circlip.

b A ‘Constant Velocity Joint Kit’, which contains the same items as the Boot Kit plus the constant velocity joint and

lubricant of the correct type and quantity.

NOTE

Sealant for the constant velocity joint covers is

not supplied. Refer to 4 Specifications, in this

Section for the recommended type.

Disassemble

1 Remove driveshaft assembly, refer to 2.2 Driveshaft

Assembly in this Section.

2 Clean outside of assembly with a suitable solvent

before disasse mbl ing.

3 Using metal shears or other suitable cutting tool, cut

boot clamps (1) in the raised crimped area, then

remove the clamps and discard.

4 Clamp assembly, by the constant velocity joint (2), in a

vice fitted with soft metal jaws.

Figure 4B1 – 6

5 Using a suitable drift (1) and hammer, tap end dust

shield cap (3) from the outer end of the constant

velocity joint.

6 After changing the clamping, use a similar procedure

to dislodge the inner dust shield (2) from the constant

velocity joint.

Figure 4B1 – 7

Rear Final Drive & Driveshafts Page 4B1–10

Page 4B1–10

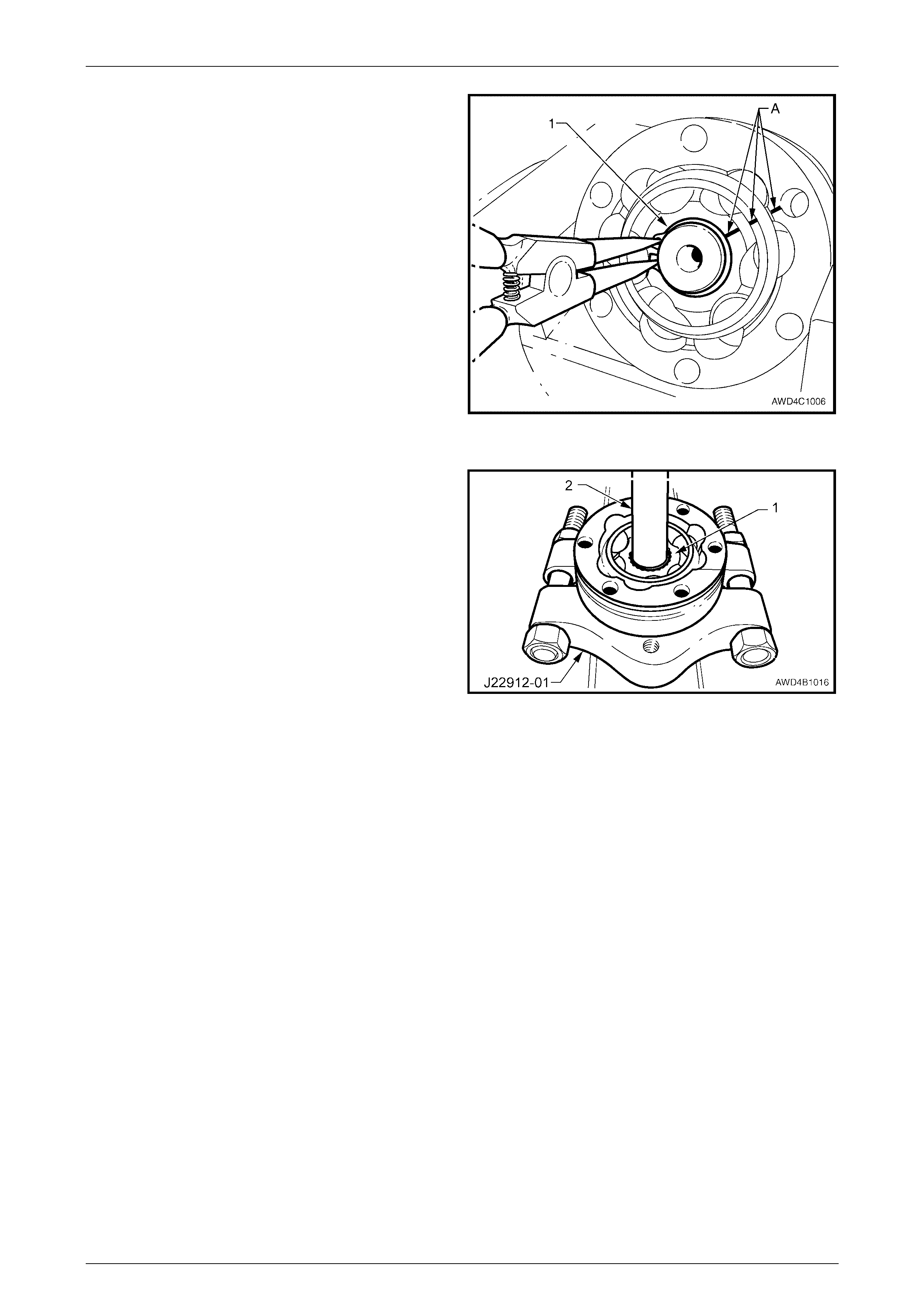

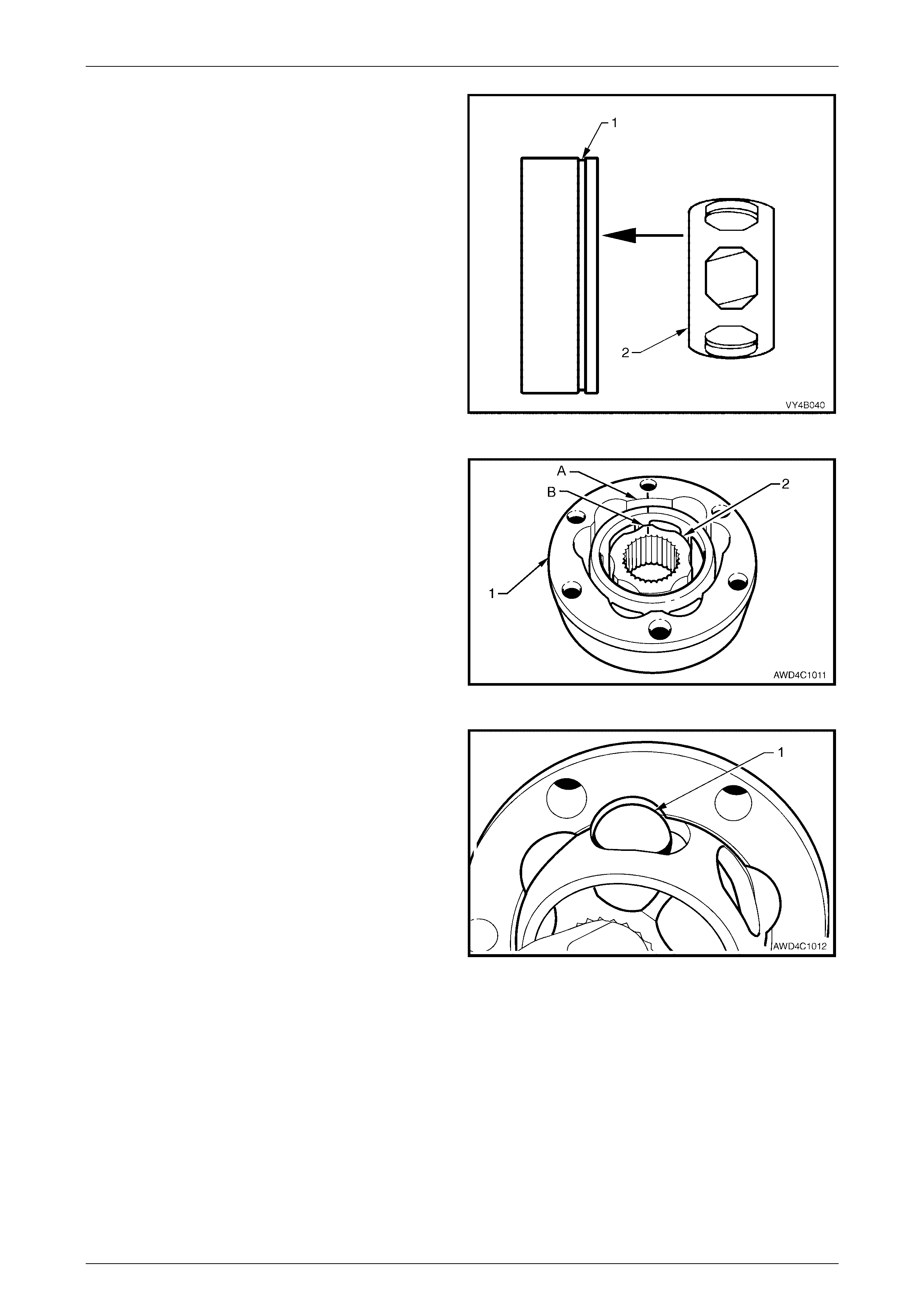

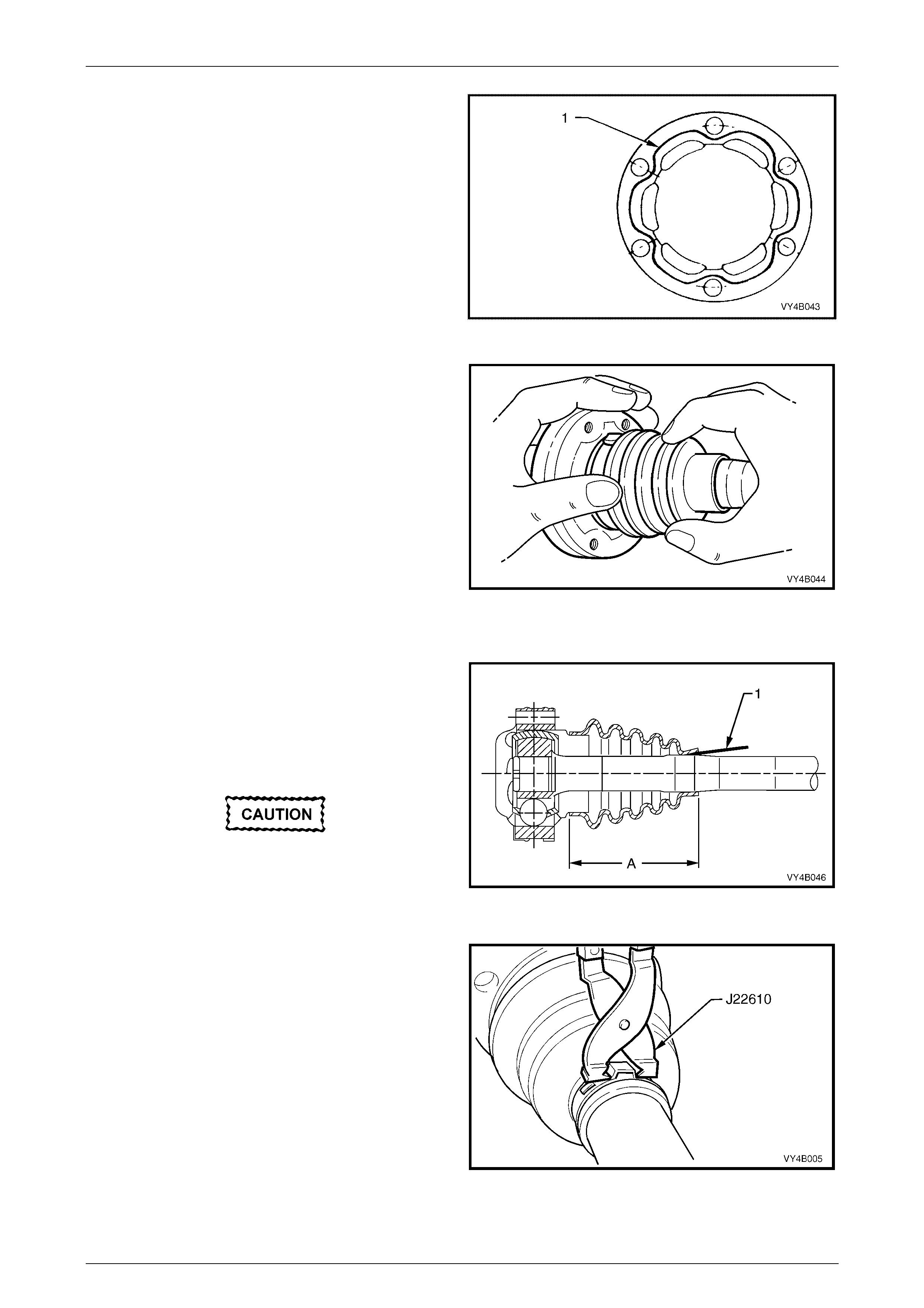

7 Using suitable circlip pliers, remove the circlip (1) from

the end of driveshaft where the constant velocity joint

is to be removed. Discard the removed circlip.

NOTE

Do not re-use circlips once they have been

removed. Always use new snap rings on

reassembly.

8 Wipe the excess lubricant from the outer joint surfaces

then apply correction fluid across the inner race, ball

carrier and outer race as indicated by 'A'.

NOTE

This step is necessary to maintain the original

relationship of these three components.

9 Remove assembly from vice. Slide inner dust shield

and boot towards the centre of the driveshaft.

Figure 4B1 – 8

10 Using suitable press plates (such as Tool No. J22912-

01), supporting inner race (1), press driveshaft from

constant velocity joint, using a suitable drift (2).

NOTE

While the press plates must support the inner

race, if clamped too tight to the driveshaft, then

the splines will foul against the press plates.

11 Repeat process to remove remaining constant velocity

joint, as required.

12 Remove boots and dust shields from driveshaft,

ensuring boots are not damaged on edges of shaft

splines. Figure 4B1 – 9

Inspect

Driveshaft and Boots

1 Clean shaft and boot/s in a suitable cleaning solvent.

2 Inspect driveshaft for tw isti ng, cracking or excessive spline wear.

NOTE

As the interconnecting shaft is not serviced

separately, if found to be defective, then the

complete driveshaft must be replaced.

3 Inspect boots and replace if split, fatigued, cracked or worn.

Rear Final Drive & Driveshafts Page 4B1–11

Page 4B1–11

Constant Velocity Joints

Complete disassembly of the constant

velocity joints is not recommended. The

internal components are a precision fit and

develop their own characteristic wear

patterns. Intermixing components could

result in looseness, binding and/or premature

failure of the joint.

1 Inspect grease in joint and, if obviously contaminated

with and/or has been subjected to dirt/water ingress,

the joint has in all likelihood suffered damage and

sh ould be replaced.

2 If inspection reveals that the joint has not been

contaminated, clean joint by soaking in a suitable

cleaning solvent.

3 Once grease has been removed, inspect internal

components by tilting inner race to one side to expose

each ball.

NOTE

Take care not to pivot the inner race too sharply,

as the balls can become dislodged. If this does

occur and the original location of the balls is lost,

then the constant velocity joint should be

replaced.

Figure 4B1 – 10

4 Replace joint assembly if there is severe pitting, galling, play between balls and the cage windows, any cracking or

damage to cage, outer race, pitting or galling or chips in raceways.

Rear Final Drive & Driveshafts Page 4B1–12

Page 4B1–12

Reassemble

Constant Velocity Joints

NOTES

• During the removal, cleaning, inspection or

replacement of a constant velocity joint, it is

possible for the joint to become

disassembled. Should an inadvertent

disassembly of a constant velocity joint

occur, and notwithstanding the earlier

recommendation, it is possible to reassemble

the constant velocity joint, provided the

following procedure is followed EXACTLY.

• The inner race (1) and cage (2), together with

the individual balls (3), should be maintained

in their original locations to minimise the

creation of a noisy joint.

• Under no circumstances are components

from one constant velocity joint to be mixed

with components from another constant

velocity joint.

Shown in Figure 4B1-11 is an exploded view of one

constant velocity joint. As each are of the plunge design,

this view is suitable for either joint. Note the single

identification groove (5) on the outer race (4) and the

identification step (6) on the inner race.

Figure 4B1 – 11

1 Place the inner race (1) into the cage (2) and position

centrally.

Figure 4B1 – 12

Rear Final Drive & Driveshafts Page 4B1–13

Page 4B1–13

2 Place the inner race and cage assembly (2) into the

outer race (1). Make sure that the identification groove

(1) and step (2) are on opposite sides of the assembly,

as shown.

Figure 4B1 – 13

3 Align the thick sections (A) on the outer race (1) , with

the narrow ones (B) on the inner race (2), aligning the

three marks mad e bef ore dis assembly.

Figure 4B1 – 14

4 Tilt the cage and inner race, as shown and fit one ball

(1).

Repeat this process for the remaining five balls.

Figure 4B1 – 15

Rear Final Drive & Driveshafts Page 4B1–14

Page 4B1–14

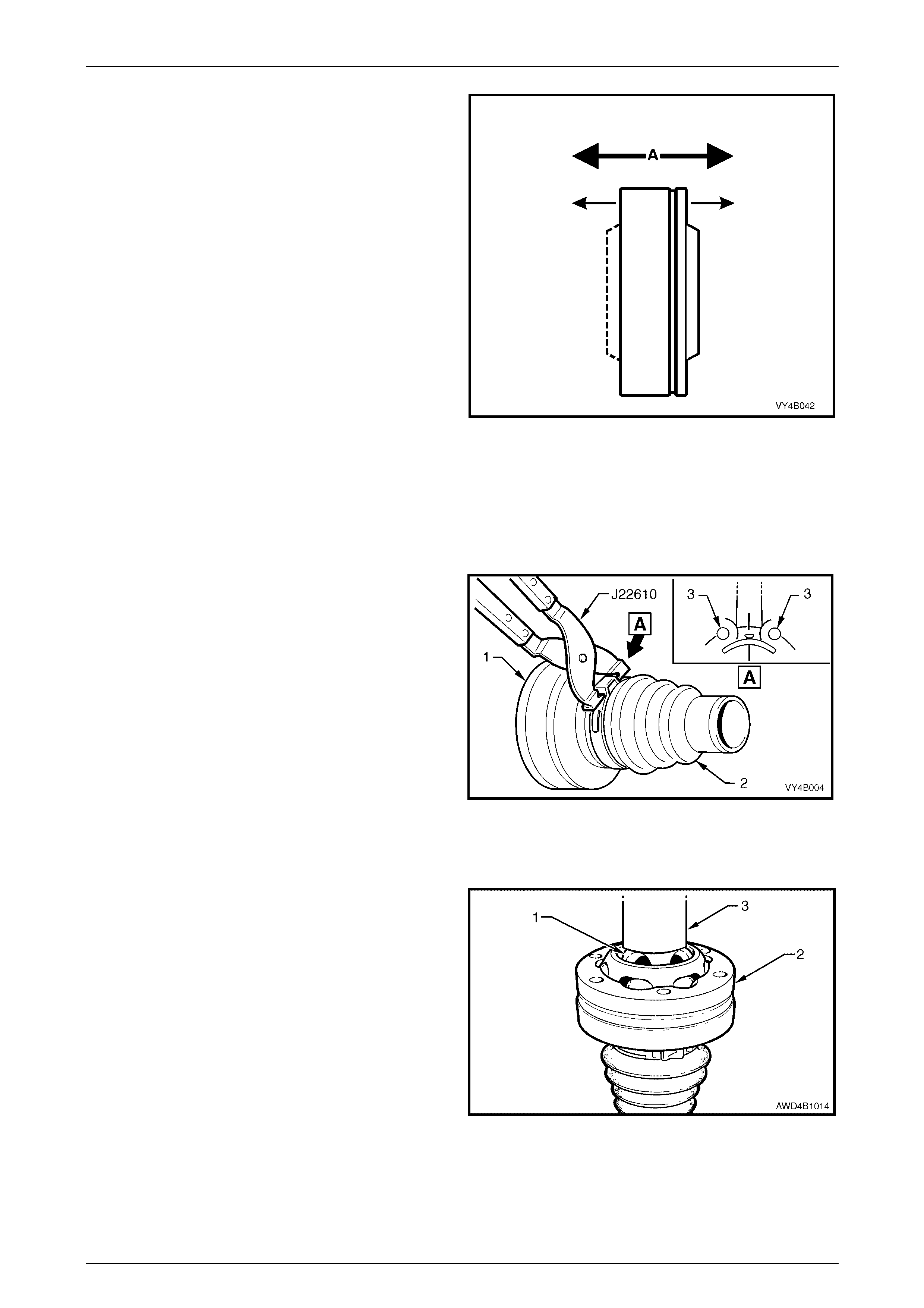

5 When assembly of the constant velocity joint is

complete, check for plunge movement of the inner

members, as indicated by ‘A’. If NO plunge movement

can be achieved, then the constant velocity joint has

been incorrectly asse mbl ed.

If such a situation occurs, the constant velocity joint

must be disassembled and the assembly process

repeated until such time that the required plunge

movement is achieved.

NOTE

This check applies to both constant velocity

joints fitted to the rear driveshafts on the

MY2004 AWD Wagon.

Figure 4B1 – 16

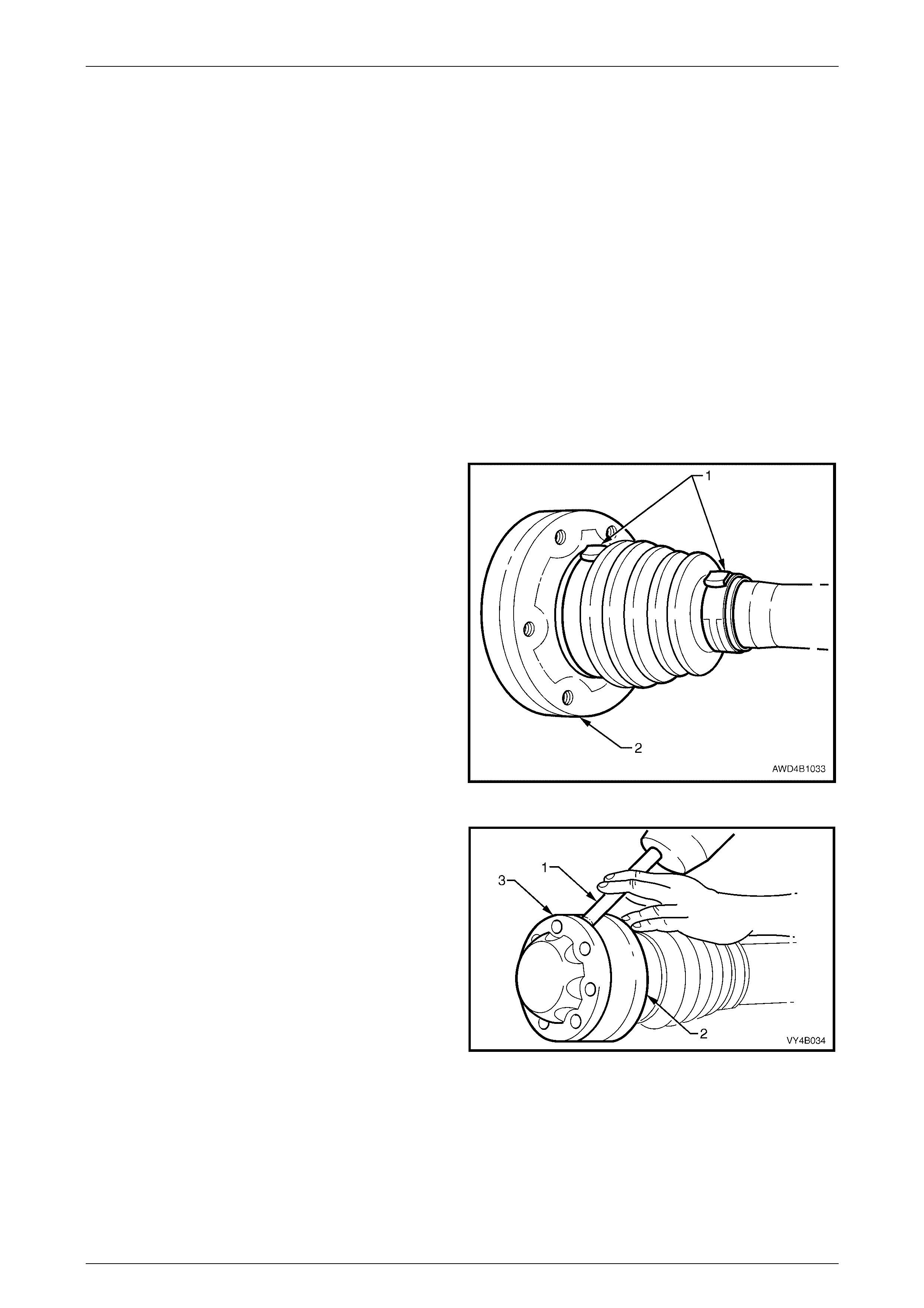

Driveshaft and Boots

1 Remove old sealing bead of silicon from dust shields, dust caps and constant velocity joints.

2 Slide a NEW sma ll boot cla mp over the driveshaft, then insta ll both dust shield and boot assembl ie s onto

driveshafts, ensuring that boots are not damaged by sharp edges on each end by the shaft splines.

3 Position NEW large boot clamp over boot (2) and

place boot over dust shield (1). Using Tool No.

J22610, se curely crimp b oot cl amp, ens urin g the crimp

is positioned mid-way between two bolt holes (3, in

view ‘A’).

Figure 4B1 – 17

4 Pack inside section of joint and boot with one tube of grease (40 grams) and pack half tube (20 grams) to outside

section of joint. Work the joint by hand to distribute grease onto all surfaces, inside the joint.

5 Using a suitable size tube (3), press the constant

velocity joint (2) onto the driveshaft, ensuring that the

press load is taken by the inner race (1).

6 Install a NEW circlip to secure the constant velocity

joint, at each end.

Figure 4B1 – 18

Rear Final Drive & Driveshafts Page 4B1–15

Page 4B1–15

7 Apply a 2 mm diameter bead (4) of commercially

available RTV 732 sealant to dust caps/shields. Take

care not to contaminate the constant velocity joint

grease with sealant.

Figure 4B1 – 19

8 Position dust caps and du st sh ield s onto con stan t

velocity joints, ensuring that all bolt holes align.

NOTE

Temporarily install three of the retaining bolts to

assist with the alignment.

9 Using a suitable punch and ha mmer , tap caps and

shields into place.

Figure 4B1 – 20

10 Place new small boot clamps onto driveshaft. Do not crimp the small boot at this time.

11 Locate sm all ends of boots into boot grooves on

driveshafts, ensuring that boots are not twisted.

With each joint, pry up the small ends of boots from

the shaft (1) to equalise air pressure inside and

outside of boots and work out any dimples before

crimping the small clamp/s.

The location distance ’A’, applies to both the

inner and outer joints, as both are the plunge

type (MY 2004 AWD Wagon only) and should

be set at 81 mm before applying the small

clamp.

Figure 4B1 – 21

12 Position small clamps over en ds of boots and usi ng

Tool No. J22610, crimp ends of clamps until a gap

between the clamp 'ears' of 1 to 2 mm is achieved.

13 Reinstall driveshaft, refer to 2.2 Driveshaft Assembly –

Reinstall in this Section.

Figure 4B1 – 22

Rear Final Drive & Driveshafts Page 4B1–16

Page 4B1–16

2.4 Pinion Oil Seal

LT Section No: 05-290

Replace

1 Using a floor jack under centre of differential carrier, jack up rear of vehicle, then place safety stands under trailing

arms.

2 Mark the position of the propeller shaft rear coupling to pinion flange, using a felt tipped pen or similar.

3 Remove propeller shaft, refer to Section 4C1 Propeller Shaft and Universal Joints, in the MY 2004 AWD Wagon

Service Information. This operation may also require partial exhaust system removal.

4 Lightly centre-punch alignment marks (A) on the pinion

flange, flange nut and pinion end as an aid for

reassembly.

By reassembling to the original position, the flange

run-out will be minimised and the pinion bearing

preload will be maintained.

Figure 4B1 – 23

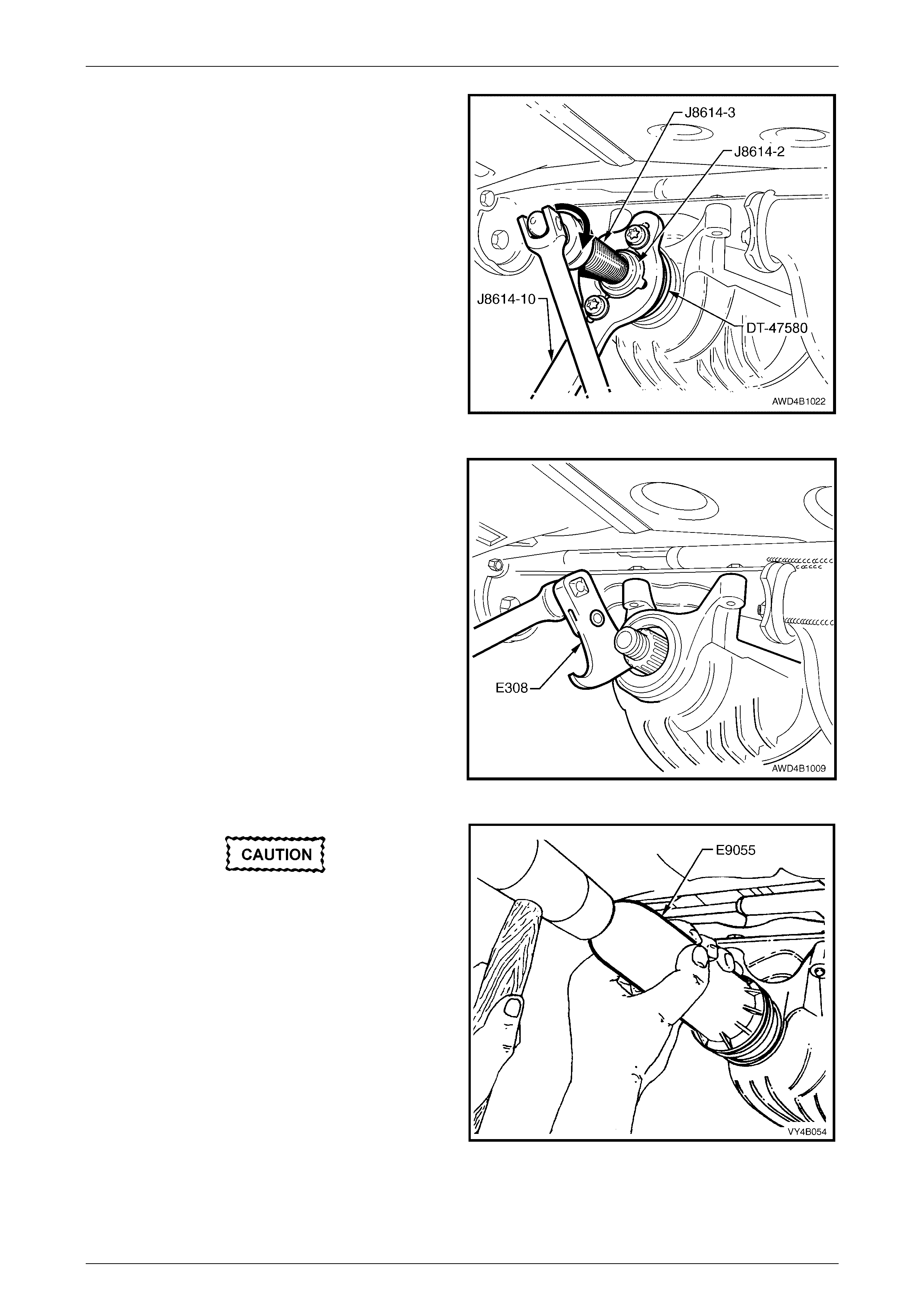

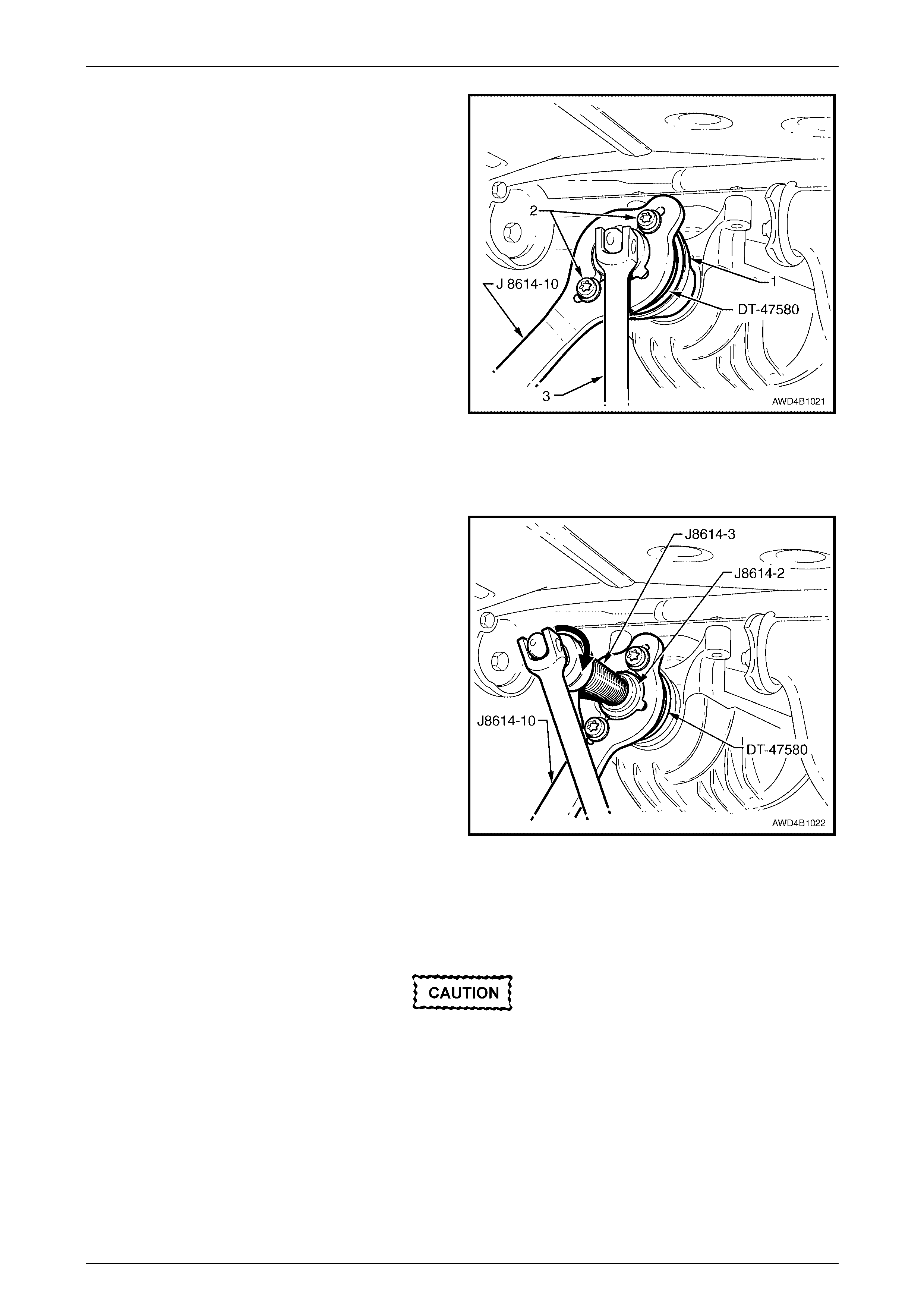

5 Install packing flange DT-47580 into the pinion flange

recess, aligning the holes with those in the pinion

flange.

6 Using two of the propeller shaft constant velocity joint

bolts (2) with flat washers, secure the holding bar, Tool

No. J8614-10 (part of Tool No. J 8614-O1) to the

pinion flange (1). The central recesses in the holding

tool should face inw ard.

7 While anchoring Tool No. J8614-10, loosen then

remove the pinion flange retaining nut, using a

commercially available, 30 mm deep socket and

socket bar (3).

NOTE

A suitable length of pipe installed over the end of

the socket bar will reduce the effort required to

loosen the pinion flange nut.

Figure 4B1 – 24

Rear Final Drive & Driveshafts Page 4B1–17

Page 4B1–17

8 Place drain tray beneath differential carrier.

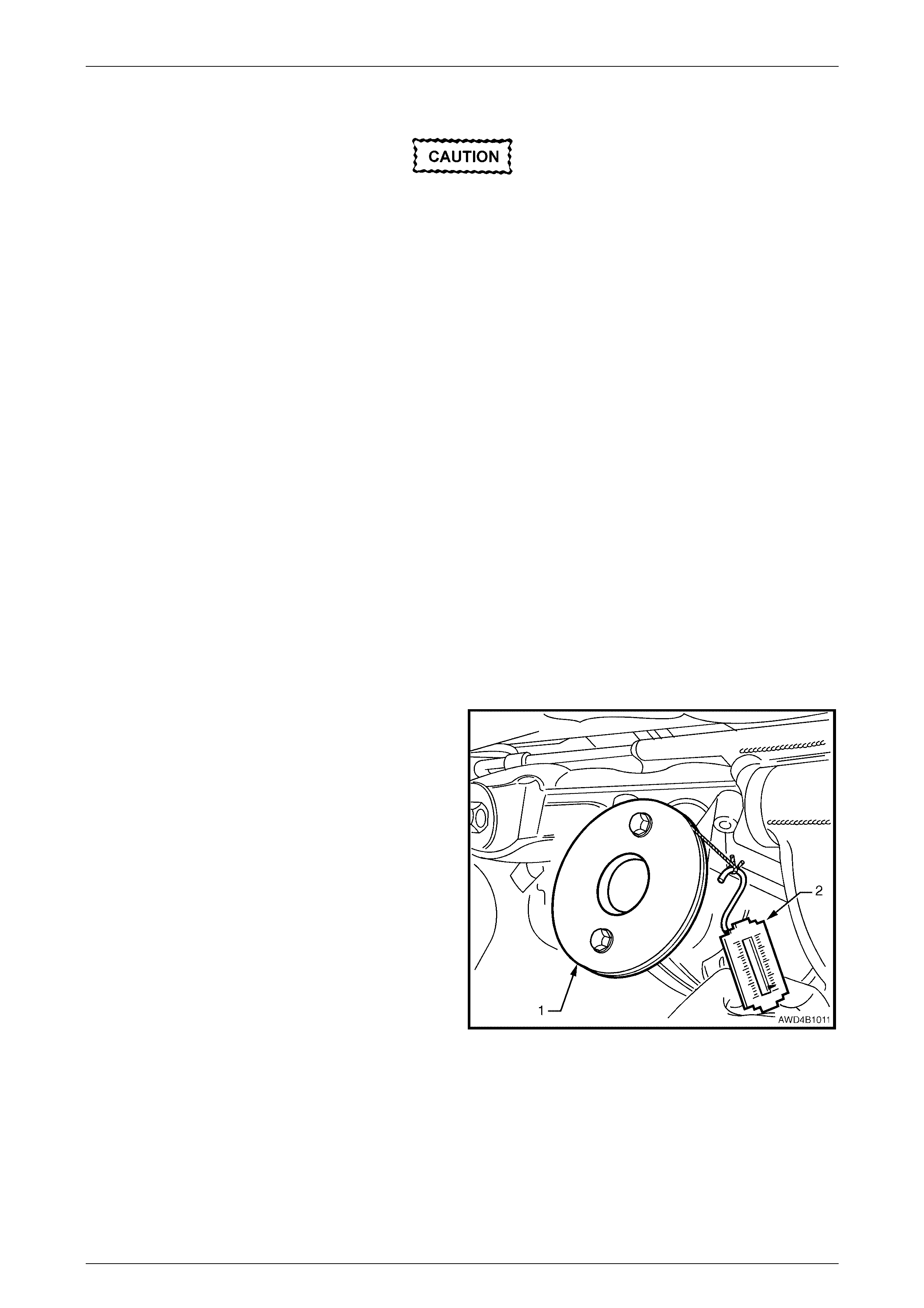

9 With Tool Nos J8614-10 and DT-47580 still installed,

thread the forcing screw, Tool No. J8614-3, into the

adaptor, Tool No. J8614-2. Install this sub-assembly

into holder, Tool No. J8614-10, then rotate through 45°

to locate in the recesses in J8614-10.

10 While holding J8614-10, use a socket and bar to rotate

the forcing screw J8614-3 in the direction shown, to

remove the pinion flange.

11 Remove the tools from the pinion flange, then carefully

set the pinion flange to one side to avoid damage to

the flanged seal surface.

Figure 4B1 – 25

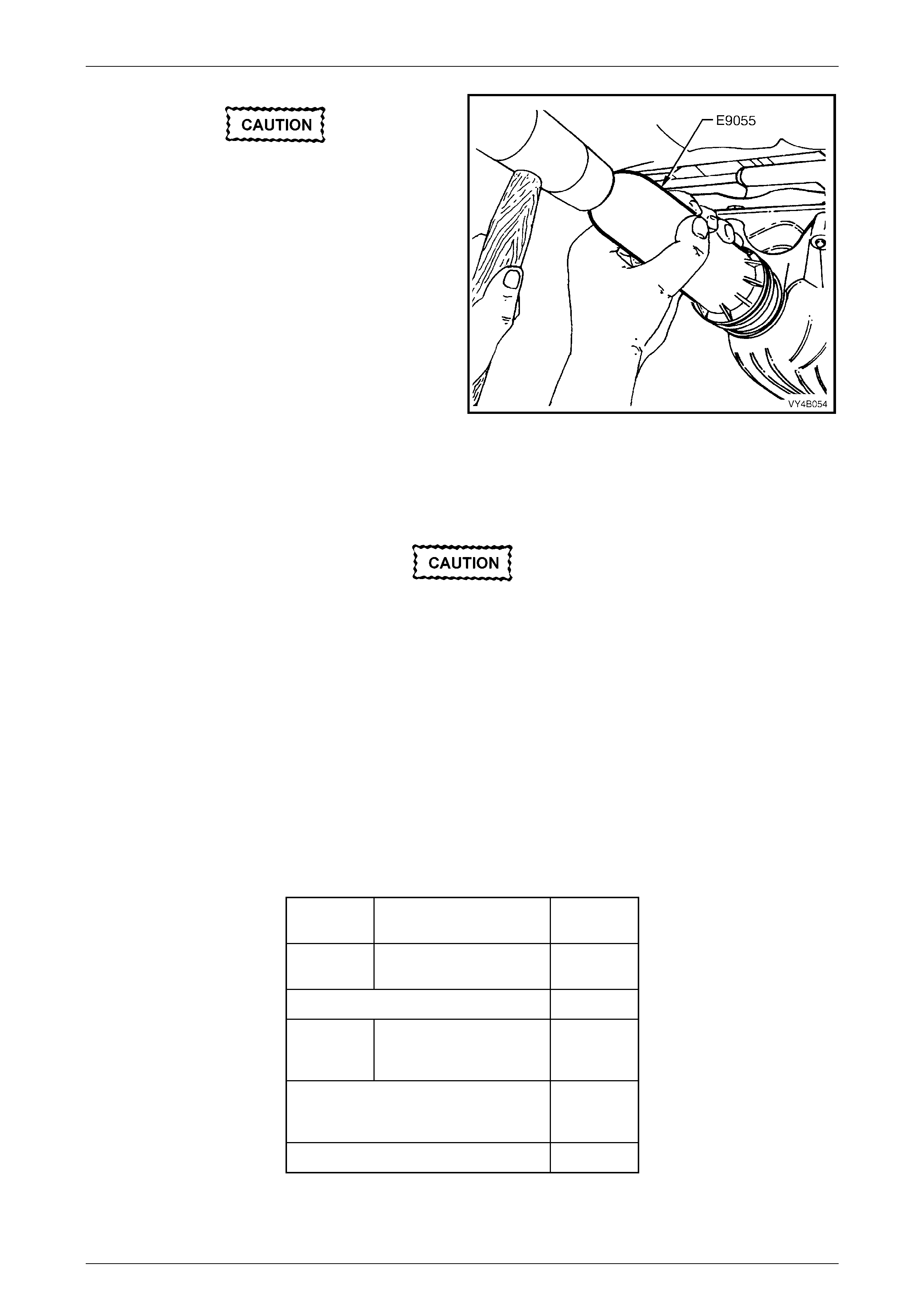

12 Prise pinion oil seal from carrier bore using Tool No.

E308 or a universal seal removing tool.

Figure 4B1 – 26

When installing a new pinion oil seal, only

install the seal until it is square and flush

with the machined face of the final drive

housing. If installed too deeply then a

premature oil leak could occur.

13 Lubricate the lips and outside diameter of a new pinion

oil seal with the Mobilgrease XHP 222. The recess

between the lips should be approximately 50% filled

with grease. A light coating of grease is also to be

applied to the dirt lip that contacts the pinion flange

slinger.

14 Start oil seal into differential carrier housing and drive

seal squarely into position using Tool No. E9055.

15 Ensure that pinion shaft is free from burrs and that

flange oil seal surface is free from damage. Figure 4B1 – 27

16 Clean the threads of the pinion shaft and the flange retaining nut, removing any oil, dirt or grease.

Rear Final Drive & Driveshafts Page 4B1–18

Page 4B1–18

17 Coat splines and seal surface of pinion flange with the recommended final drive lubricant, and install flange onto

pinion shaft splines. Ensure that centre-punch marks made at Step 4, are aligned.

18 Reinstall the packing flange Tool No. DT-47580 and holding tool J 8614-10 to the pinion flange, as detailed in

Steps 5 and 6.

19 Apply a thread locking compound such as Loctite 262 or equivalent, to the cleaned threads of the pinion flange

retaining nut, then reinstall the nut.

20 Tighten the flange retaining nut until all centre-punch marks align. Then carefully tighten the nut to a position not

more than 5° past the aligned setting.

• The pinion flange is an interference fit on

pinion shaft splines and should only be

pulled into place by tightening the

retaining nut. During installation, do not,

under any circumstances, use force or

hammer the flange onto the pinion splines.

• Should the retaining nut be over-tightened

and pre-load exceeded, it will be

necessary to remove the pinion from the

carrier and install a new collapsible

spacer. Under no circumstances must the

retaining nut be backed off to decrease the

pre-load setting.

21 Reinstall propeller shaft, refer to Section 4C1 Propeller Shaft and Universal Joints, in the MY 2004 AWD Wagon

Service Information.

22 If removed previously, reconnect exhaust system, in the reverse to the removal procedure. Refer to

Section 8B Exhaust System, in the MY 2004 AWD Wagon Service Information, for details.

23 Remove safety stands and lower vehicle.

24 Check lubricant level and top up as necessary. Refer to 2.2 Checking Differential Carrier Lubricant Level, in

Section 4B Final Drive and Driveshafts, in the MY 2003 VY and V2 Series Service Information.

25 Start vehicle and check for exhaust leak s.

Rear Final Drive & Driveshafts Page 4B1–19

Page 4B1–19

2.5 Pinion Flange

LT Section No: 05-290

ATTENTION

The following fasteners MUST be replaced when performing these operations:

!

!!

! All removed driveshaft constant velocity joint attaching bolts.

Replace

Using Old Seal

Due to production tolerances in the length of

the pinion flange, it is essential that the

following method be used when installing a

new pinion flange.

1 Using a floor jack under centre of differential carrier, jack up rear of vehicle then place safety stands under trailing

arms.

2 Remove propeller shaft, refer 2.1 Propeller Shaft, in Section 4C1 Rear Propeller Shaft & Universal Joints, in the MY

2004 AWD Wagon Service Information.

3 Remove both driveshafts, refer 2.2 Driveshafts in this Section.

4 Check and record pre-load at pinion flange as follows:

a Fit a pulley (1) to pinion flange, using two

M8 x 1.25 bolts and attach a cord around pulley

and to a spring scale (2).

NOTE

For details of the fabricated pulley, refer

7 Special Tools at end of this Section.

b Start rotation of pulley and whilst in motion

(approximately 50-60 rpm) note and record

reading of spring balance.

NOTE

• This pre-load reading includes pinion

bearings, side bearings, meshing effect of

gear set and pinion oil seal.

• To determine pre-load, multiply reading on

spring balance by radius of pulley.

Example: With a pulley diameter of 152 mm, the radius is

76 mm, = 0.076 m. With a spring balance reading of 25 N,

the pre-load = 0.076 m x 25 N = 1.9 Nm.

5 Remove pulley from pinion flange.

Figure 4B1 – 28

Rear Final Drive & Driveshafts Page 4B1–20

Page 4B1–20

6 Install packing flange, Tool No. DT-47580 into the

pinion flange recess, aligning the holes with those in

the pinion flange.

7 Using two of the propeller shaft constant velocity joint

bolts (2), with flat washers, secure the holding bar,

Tool No. J8614-10 (part of Tool No. J 8614-O1) to the

pinion flange (1). The central recesses in the holding

tool should face inw ard.

8 While anchoring Tool No. J8614-10, loosen the pinion

flange retaining nut, using a commercially available,

30 mm deep socket and socket bar (3), until end play

can be felt in the pinion shaft.

NOTE

A suitable length of pipe installed over the end of

the socket bar will reduce the effort required to

loosen the pinion flange nut.

9 Check the oil seal and differential side bearing pre-

load using the spring scale and pulley, as detailed in

steps 4a and 4b. Record oil seal and side bearing pre-

load for later use.

Figure 4B1 – 29

10 Place drain tray beneath differential carrier.

11 With Tool Nos J8614-10 and DT-47580 still installed,

thread the forcing screw, Tool No. J8614-3, into the

adaptor, Tool No. J8614-2. Install this sub-assembly

into holding bar, Tool No. J8614-10, then rotate

through 45° to locate in the recesses in J8614-10.

12 While holding J8614-10, use a socket and bar to rotate

the forcing screw J8614-3 in the direction shown, to

remove the pinion flange.

13 Remove the tools from the pinion flange, then carefully

set the pinion flange to one side to avoid damage to

the flanged seal surface.

Figure 4B1 – 30

14 Ensure that pinion shaft thread is free from thread sealant, burrs, oil, dirt or grease, then coat splines and seal

surface of a new pinion flange with the recommended final drive lubricant.

15 Install the new pinion flange and a new retaining nut.

The new pinion flange will be an interference

fit on the pinion shaft splines and should only

be pulled into place by tightening the

retaining nut. During installation, do not,

under any circumstances use force or

hammer the flange onto the pinion splines.

16 Tighten flange retaining nut gradually until pinion shaft end play is reduced to approximately 0.50 mm.

17 Attach pulley to the new pinion flange and using spring balance, check pre-load. Continue tightening nut while

alternatively turning pinion to seat bearings, until the pre-load figure recorded previously (Step 4b) is reached.

Further increase this original pre-load reading by 0.5 Nm.

Rear Final Drive & Driveshafts Page 4B1–21

Page 4B1–21

18 Rotate the pinion an extra 30 – 40 turns and re-check the preload to ensure that no change has occurred.

Should the retaining nut be over-tightened

and the pre-load exceeded, it will be

necessary to remove the differential carrier

assembly and install a new collapsible

spacer. Under no circumstances must the

retaining nut be backed off to decrease the

pre-load setting.

19 Reinstall driveshafts, refer to 2.2 Driveshaft Assembly in this Section.

20 Reinstall propeller shaft, refer to Section 4C1 Rear Propeller Shaft & Universal Joints, in the MY 2004 AWD Wagon

Service Information.

21 If removed previously, reconnect exhaust system, in reverse to the removal procedure. Refer to

Section 8B Exhaust System, in the MY 2004 AWD Wagon Service Information, Section , for details.

22 Remove safety stands and lower vehicle to the ground.

23 Check lubricant level and top up as necessary with the recommended lubricant, refer to 2.2 Checking Differential

Carrier Lubric ant Level, in Section 4B Final Drive and Driveshafts, in the MY 2003 VY and V2 Series Service

Information.

24 Start vehicle and check for exhaust leak s.

Using New Oil Seal

1 Using a floor jack under centre of differential carrier, raise the rear of vehicle then place safety stands under trailing

arms.

2 Remove propeller shaft, refer to Section 4C1 Rear Propeller Shaft & Universal Joints, in the MY 2004 AWD Wagon

Service Information.

3 Remove both driveshafts, refer to 2.2 Driveshaft Assembly in this Section.

4 Check and record pre-load at pinion flange as follows:

a Fit a pulley (1) to pinion flange, using two

M8 x 1.25 bolts and attach a cord around pulley

and to a spring balance (2).

NOTE

For fabricated pulley details, refer to 7 Special

Tools at end of this Section.

b Start rotation of pulley and whilst in motion

(approximately 50-60 rpm), note and record the

spring balance reading.

NOTES

• This pre-load reading includes pinion

bearings, side bearings, meshing effect of

gear set and pinion oil seal.

• To determine pre-load, multiply reading on

spring balance by radius of pulley.

Figure 4B1 – 31

Example: With a pulley diameter of 152 mm, the radius is 76 mm which equals 0.076 m. With a spring balance reading

of 25 N, the pre-load equals 0.076 m x 26 N = 1.9 Nm.

5 Remove pulley from pinion flange.

Rear Final Drive & Driveshafts Page 4B1–22

Page 4B1–22

6 Install packing flange, Tool No. DT-47580 into the

pinion flange recess, aligning the holes with those in

the pinion flange.

7 Using two of the propeller shaft constant velocity joint

bolts (2), with flat washers, secure the holding bar,

Tool No. J8614-10 (part of Tool No. J 8614-O1) to the

pinion flange (1). The central recesses in the holding

tool should face inw ard.

8 While anchoring Tool No. J8614-10, loosen the pinion

flange retaining nut, using a commercially available,

30 mm deep socket and socket bar (3), until end play

can be felt in the pinion shaft.

NOTE

A suitable length of pipe installed over the end of

the socket bar will reduce the effort required to

loosen the pinion flange nut.

9 Check the oil seal and differential side bearing pre-

load using the spring scale and pulley, as detailed in

steps 4a and 4b. Record oil seal and side bearing pre-

load for later use.

Figure 4B1 – 32

10 Place drain tray beneath differential carrier.

11 With Tool Nos J8614-10 and DT-47580 still installed,

thread the forcing screw, Tool No. J8614-3, into the

adaptor, Tool No. J8614-2. Install this sub-assembly

into holder, Tool No. J8614-10, then rotate through 45°

to locate in the recesses in J8614-10.

12 While holding J8614-10, use a socket and bar to rotate

the forcing screw J8614-3 in the direction shown, to

remove the pinion flange.

13 Remove the tools from the pinion flange, then carefully

set the pinion flange to one side.

Figure 4B1 – 33

14 Prise pinion oil seal from carrier bore using Tool No.

E308 or a commercially available, universal seal

removing tool.

Figure 4B1 – 34

Rear Final Drive & Driveshafts Page 4B1–23

Page 4B1–23

When installing a new pinion oil seal, only

install the seal until it is flush with the

machined face of the final drive housing. If

installed too deeply then a premature oil leak

could occur.

15 Lubricate the lips and outside diameter of a new pinion

oil seal with the Mobilgrease XHP 222. The recess

between the lips should be approximately 50% filled

with grease. A light coating of grease is also to be

applied to the dirt lip that contacts the pinion flange

slinger.

16 Start oil seal into differential carrier housing and drive

seal squarely into position using Tool No. E9055.

17 Ensure that pinion shaft is free from burrs, then clean

the threads of the pinion shaft, removing any thread

sealant, oil, dirt or grease. Figure 4B1 – 35

18 Coat splines and seal surface of pinion flange with the recommended final drive lubricant, then reinstall flange to

the pinion shaft splines.

19 Install a new flange retaining nut, then tighten to draw the pinion flange onto the pinion shaft splines.

The new pinion flange will be an interference

fit on the pinion shaft splines and should only

be pulled into place by tightening the

retaining nut. During installation Do not,

under any circumstances use force or

hammer the flange onto the pinion splines.

20 Continue to tighten the flange retaining nut gradually until pinion shaft end play is reduced to approximately

0.5 mm.

21 Check new oil seal and differential assembly pre-load using spring balance as previously outlined in steps 4a and

4b. Record pre-load for reassembly reference.

22 The pre-load reading for the final drive assembly obtained in step 9, is subtracted from the pre-load reading

obtained in step 21. The difference between these figures represents extra lip tension of new seal expressed as a

Nm pre-load figure. The difference between the pre-load readings obtained in steps 9 and 21 must be added to

pre-load reading obtained in step 4b to obtain a total pre-load reading.

Theoretical Example

Step 21 New oil seal and side

bearing pre-load setting 1.47 Nm

Step 9 Old seal and side bearing

pre-load reading 1.02 Nm

Subtract Step 9 from Step 21 0.45 Nm

Step 4b Complete differential

assembly pre-load

reading 1.47 Nm

The pre-load reading combination will

be the s um of: -

1.47 Nm

plus

0.45 Nm

Which gives a total pre-load reading of:- 1.92 Nm

23 Continue tightening retaining nut while alternately turning pinion to seat bearings until total pre-load figure obtained

in step 22 is achieved, then increase this pre-load reading by 0.11 – 0.34 Nm. Further rotate pinion an extra 30-40

turns and recheck pre-load to ensure that no change has occurred.

Rear Final Drive & Driveshafts Page 4B1–24

Page 4B1–24

Should the retaining nut be over-tightened

and the pre-load exceeded, it will be

necessary to remove the differential carrier

assembly and install a new collapsible

spacer. Under no circumstances must the

retaining nut be backed off to decrease the

pre-load setting.

NOTE

It must be realised that the pre-load readings in

the example are only theoretical. In practice, the

figures could differ greatly, so the readings

obtained when performing the actual operations,

are the ones to use.

24 Reinstall driveshafts, refer to 2.2 Driveshaft Assembly in this Section.

25 Reinstall propeller shaft, refer to Section 4C1 Rear Propeller Shaft & Universal Joints, in the MY 2004 AWD Wagon

Service Information,.

26 If removed previously, reconnect exhaust system, in the reverse to the removal procedure. Refer to

Section 8B Exhaust System, in the MY 2004 AWD Wagon Service Information, for details.

27 Remove safety stands and lower vehicle.

28 Check lubricant level and top up as necessary, refer to 2.2 Checking Differential Carrier Lubricant Level,

Section 4B Final Drive and Driveshafts, in the MY 2003 VY and V2 Series Service Information.

29 Start vehicle and check for exhaust leak s.

Rear Final Drive & Driveshafts Page 4B1–25

Page 4B1–25

3 Major Service Operations

3.1 Trailing Arm Trunnion Flange, Trunnion

Assembly and/or Wheel Bearing

LT Section No: 05-290

ATTENTION

The following fasteners MUST be replaced when performing these operations:

!

!!

! Collar nut to trunnion assembly.

NOTES

• With the revised design of the trailing arm for

this vehicle, to replace any of the subject

items, removal of the trailing arm assembly

from the vehicle is necessary. Refer to

Section 4A Rear Suspension in the MY 2004

AWD Wagon Service Information for the

removal and disassembly processes, with the

trailing arm rem oved from the vehicle.

• The rear wheel bearing should only be

removed if it is faulty, or if the trunnion

assembly is to be removed.

Legend

1 Collar Nut Lock Plate

2 Collar Nut

3 Trunnion Flange

4 Trailing Arm

5 Brake Backing Plate

6 Brake Disc

7 Brake Caliper

8 Rear Wheel Bearing

9 Trunnion Assembly

10 Rear Wheel Bearing Retaining Ring

Figure 4B1 – 36

Rear Final Drive & Driveshafts Page 4B1–26

Page 4B1–26

3.2 Rear Final Drive Assembly

LT Section No: 05-290-1

ATTENTION

The following fasteners MUST be replaced when performing these operations:

!

!!

! Final drive assembly to crossmember attaching bolts.

!

!!

! Rear mount to differential carrier rear cover attaching bolts.

!

!!

! Rear mount to vehicle underbody attaching bolts.

!

!!

! Rear driveshaft constant velocity joint attaching bolts.

!

!!

! Rear crossmember front mounting bolt

!

!!

! Rear crossmember front mounting brace to underbody bolt.

The following fasteners MUST be at curb height before final tightening:

"

""

" Rear shock absorber to trailing arm bolt.

Whenever any component that forms part of

the ABS is disturbed during Service

Operations, it is vital that the complete ABS

system be checked, using the recommended

procedure. Refer to Section 5B ABS-TC, in

DIAGNOSIS, ABS FUNCTION CHECK in the

MY 2004 AWD Wagon Service Information.

Before disturbing the rear suspension

crossmember mounting bolts, an alignment

procedure is required on reinstallation and a

special tool is required for this purpose. If this

tool is not available, then the crossmember

cannot be correctly aligned and steering

and/or handling abnormalities will result.

NOTE

For this service operation, new intermediate

muffler support retainers must be used on

reassembly.

Remove

1 Raise the vehicle and support in a safe manner. Refer to Section 0A General Information, in the MY 2004 AWD

Wagon Service In formation, for loca tion of jacking and s upport points.

2 Remove the decorative wheel nut caps and mark relationship of the wheels to the hub, using a felt tipped pen or

similar.

3 Loosen, then remove the road wheel attaching nuts, working in a 'star' pattern. Refer to Road Wheel Requirements,

in 2.1 General Information, in this Section. Remove the road wheel.

Rear Final Drive & Driveshafts Page 4B1–27

Page 4B1–27

NOTE

Steps 2 and 3 are necessary to maintain part

relationships and to avoid brake rotor distortion

and the creation of brake shudder, after the

vehicle is placed back in service.

4 To provide access to the propeller shaft fasteners, it is recommended that the exhaust system is removed, from the

rear of the catalytic conv erters , rearward. Refer to Section 8B Exhaust System in the MY 2004 AWD Wagon

Service Information.

5 Remove propeller shaft, refer to Section 4C1 Rear Propeller Shaft & Universal Joints, in the MY 2004 AWD Wagon

Service Information.

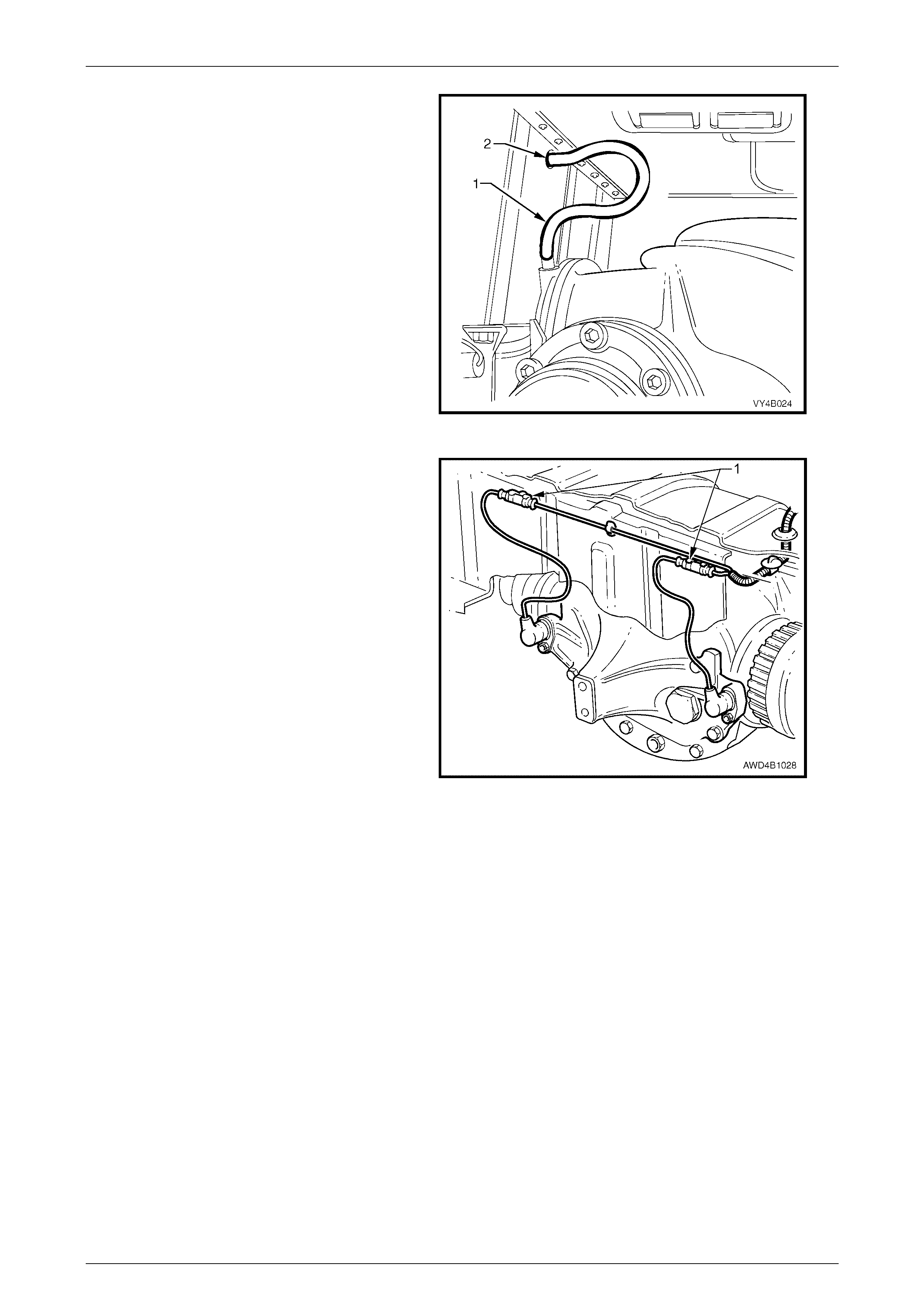

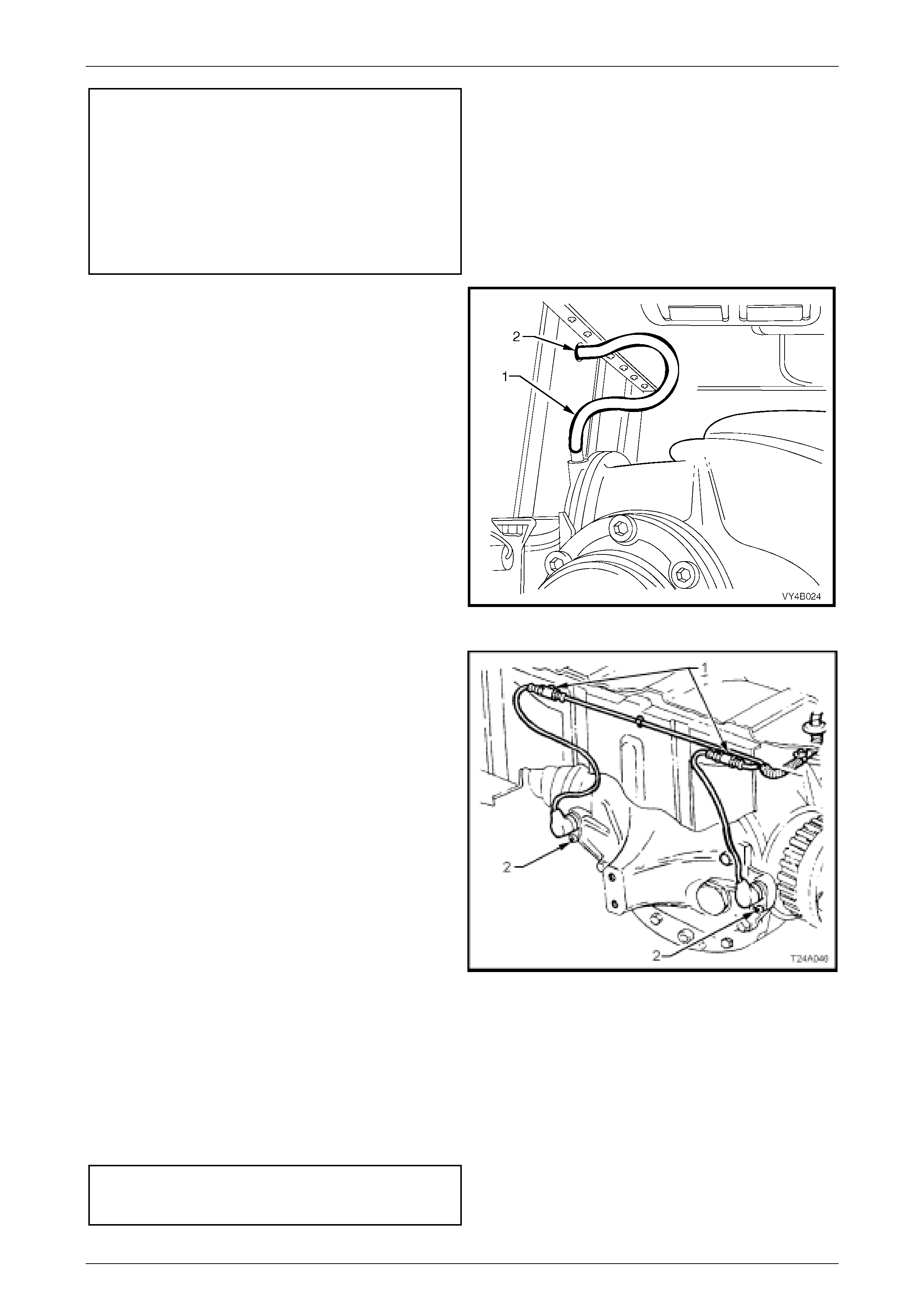

6 Set park brake in fully released position, then release

each of the underbody to park brake cable retaining

clips (1) and free cables (2).

Figure 4B1 – 37

7 Remove park brake outer cable retaining bracket bolt

(underbody bracket and bolt are not shown) from the

vehicle underbody.

8 Pull each park brake inner cable forward and up, (1)

out of the cable retainer to release each cable.

9 Pull the outer cable rearward (2) to remo ve from the

underbody retainer.

Figure 4B1 – 38

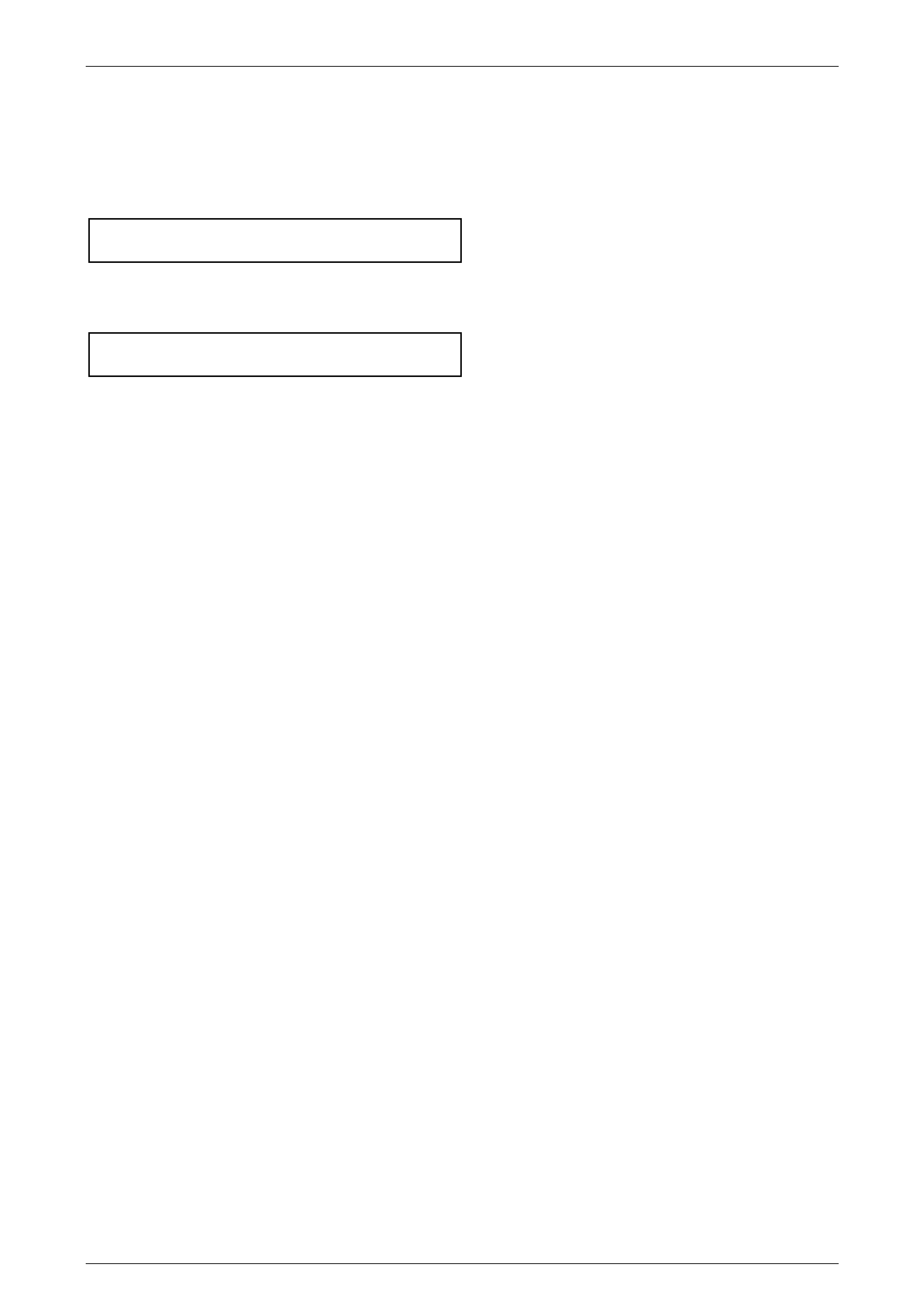

10 Disconnect brake pipe (3) from brake hose (4) at

trailing arm bracket (2) and remove the brake hose

retaining clip (1) .

Plug the open ends of both pipes and hoses to prevent

unnecessary fluid lo ss and/ or dirt entry .

11 Repeat for the other side.

Figure 4B1 – 39

Rear Final Drive & Driveshafts Page 4B1–28

Page 4B1–28

12 Pull out differential carrier breather hose (1) from

vehicle underbody crossmember hole (2).

Figure 4B1 – 40

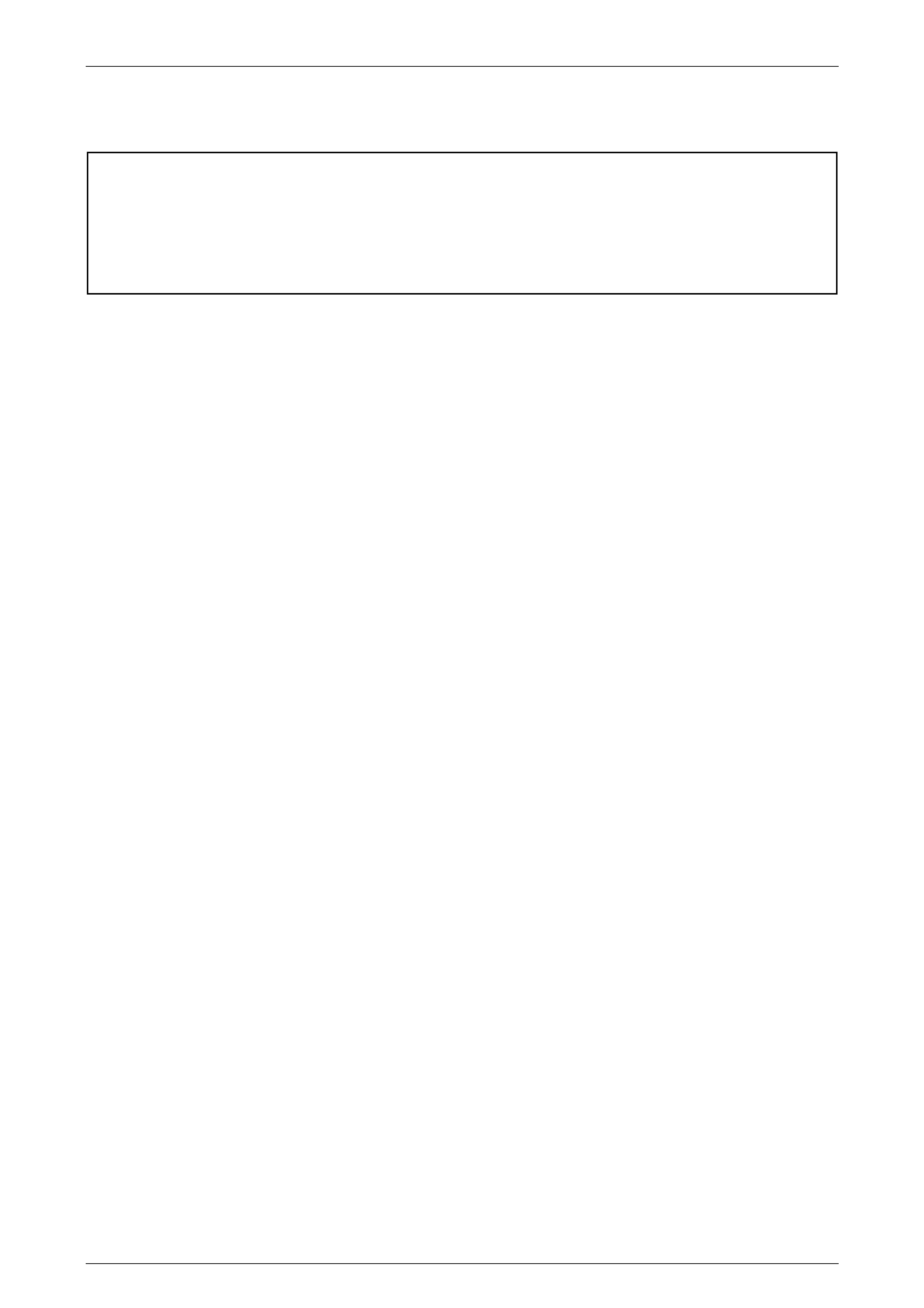

13 Pull both ABS-TC wheel speed sensor lead

connect ors from the under body retaining clips (1).

Separate the sensor connectors from the body

harness connectors by levering with a

screwdriver.

Figure 4B1 – 41

Rear Final Drive & Driveshafts Page 4B1–29

Page 4B1–29

Damage to the driveshaft constant velocity

joint boot caps will occur if the shock

absorber is disconnected from the trailing

arm before the trailing arm is raised.

14 Position floor jack with a block of wood under trailing

arm. Raise jack slightly to take spring load off trailing

arm.

If automatic level ride suspension is fitted to

the vehicle, there are specific procedures

relating to the system pressure and the

removal of the rear shock absorbers. Refer to

Section 4A Rear Suspension, in the MY 2004

AWD Wagon Service Information.

15 Disconnect rear shock absorber lower mounting bolt

(1) from trailing arm (2), and pull lower end of shock

absorber (3) from trailing arm (2).

Figure 4B1 – 42

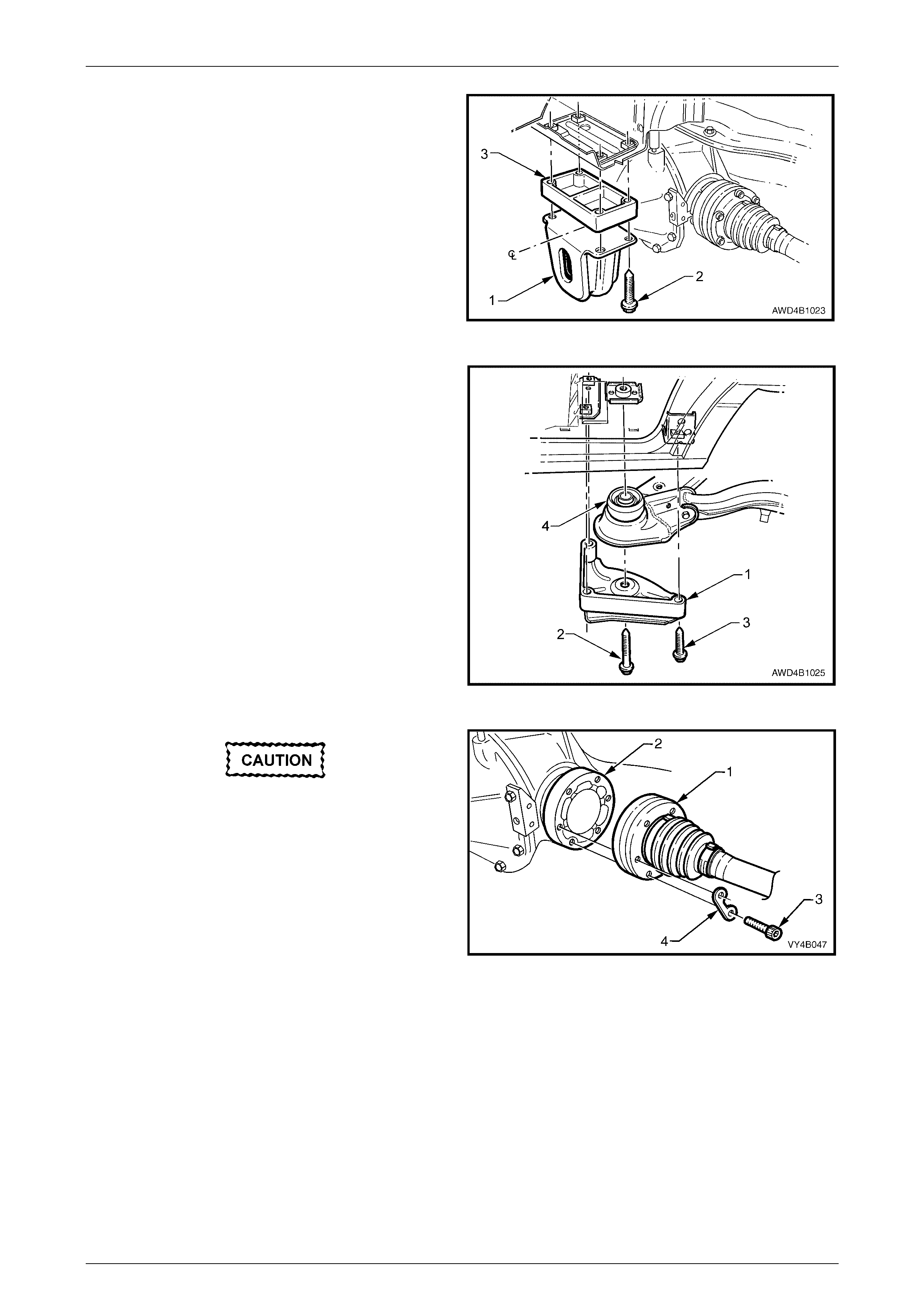

16 Remove rear springs and insulators from vehicle

underbody and trailing arms.

17 Raise differential carrier and rear crossmember on

floor jack until rear mount cont acts underbo dy .

Figure 4B1 – 43

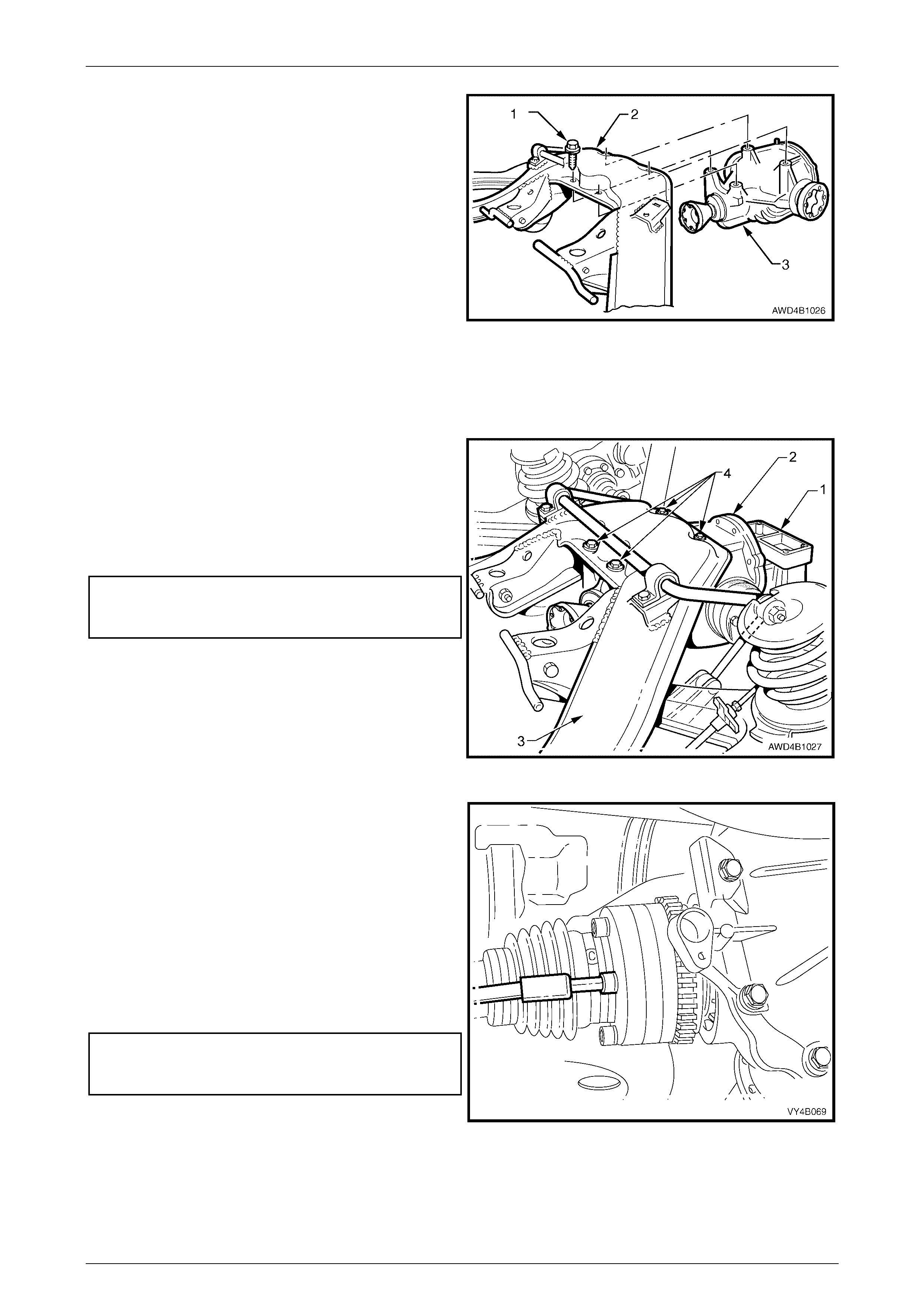

18 Using a scriber, mark rear mount (1) to vehicle under

body location (A). This will assist in rear crossmember

alignment on reinstallation.

19 Support weight of differential carrier with floor jack.

Figure 4B1 – 44

Rear Final Drive & Driveshafts Page 4B1–30

Page 4B1–30

20 Remove rear mount (1) to vehicle underbody attaching

bolts (2) and discard removed bolts. Lower differential

carrier, spacer (3) and rear crossmember assembly by

at least 60 mm.

Figure 4B1 – 45

21 Use a floor jack and block of wood to support

differential carrier and crossmember assembly.

22 Remove brace to underbody bolts (3) (3 places ) and

crossmember to vehicle underbody attaching bolt (2)

from each side.

23 Remove the braces (1) from the vehicle.

24 With an assistant supporting front end of rear

crossmember, lower assembly on jack and remove

from beneath vehicle.

NOTE

Do not dislodge the snubber bushes (4) fitted to

the centre spigot of each crossmember bushing.

Figure 4B1 – 46

The disconnected driveshaft 'free' end MUST

be supported with tie wire or similar, to keep

constant velocity joint angles to a minimum.

Excessive angles and/or dropping the 'free'

end will cause damage to the boot cap and

the joint itself.

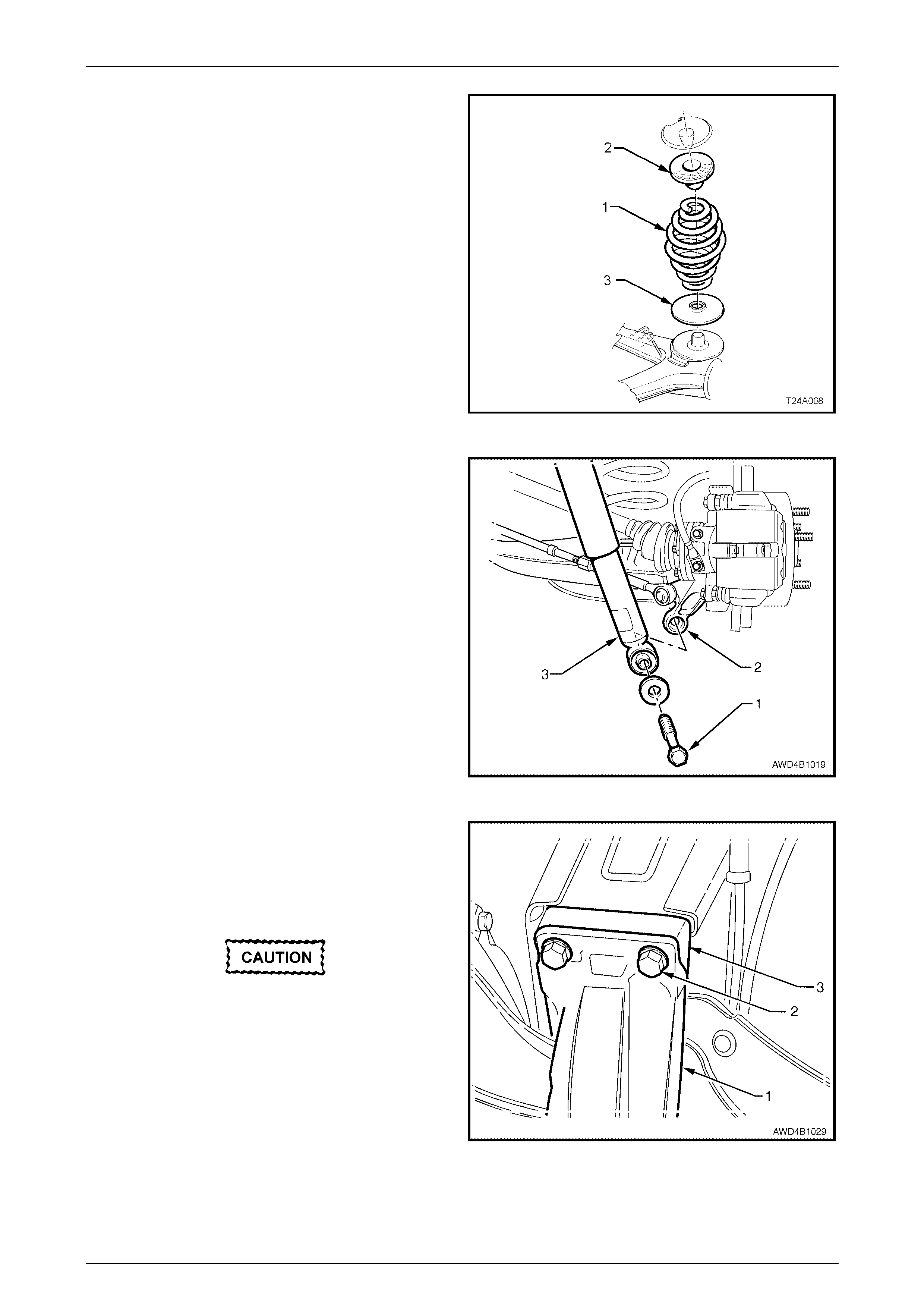

25 Using an 8 mm Allen key socket, remove driveshaft

inner constant velocity joint (1) to inner axle shaft (2)

attaching bolts (3) and plates (4).

Disconnect joints from inner axle shafts.

Figure 4B1 – 47

Rear Final Drive & Driveshafts Page 4B1–31

Page 4B1–31

26 Remove rear crossmember assembly (3) to rear

crossmember (2) attaching bolts (1), remove rear

crossmember assembly from rear final drive assembly

(3) and discard attaching bolts(1).

27 If not carried out in step 20, remove rear mount to rear

cover attaching bolts, remove mount and discard

attaching bolts.

Figure 4B1 – 48

Reinstall

Installation is the reverse of removal procedure except for the following items:

1 If necessary, reinstall rear mount (1) to rear cover

using NEW bolts but leave bolts finger tight at this

stage.

2 Line up mounting holes in rear final drive assembly (2)

and rear crossmember (3). Install NEW attaching bolts

(4) (four places) and tighten to the correct torque

specification.

( ! ) Rear final drive assembly to rear

crossmember attaching bolt

torque specific atio n ..................... 90 Nm, then 40° turn

Figure 4B1 – 49

3 Inspect driveshaft constant velocity joint boots and

covers for damage, replace as necessary. Refer to

2.3 Driveshaft and/or Constant Velocity Joints, in this

Section.

4 To reduce the working angle of the constant velocity

joint the rear trailing arms should still be raised and

supported with a floor jack with a block of wood under

each trailing arm (refer Step 14 of the 'Remove'

procedures).

5 Install NEW driveshaft inner constant velocity joint to

inner axle shaft attaching bolts and tighten to the

correct torque specification.

( ! ) Driveshaft constant velocity

joint attaching bolt

torque specific atio n ..................... 50 Nm, then 70° turn

Figure 4B1 – 50

6 With the aid of two assistants, place the differential carrier and rear crossm ember assembly onto a floor jack.

7 Position assembly under vehicle, raise with the jack and, with the aid of the assistants, guide the crossmember

front mounting points into position.

Rear Final Drive & Driveshafts Page 4B1–32

Page 4B1–32

NOTES

"$ When raising the assembly, take care that the

rear mount does not foul on the fuel tank or

fuel hoses.

"$ During this operation, ensure that trailing

arms are also supported on safety stands, to

keep the driveshafts as near to horizontal as

possible. Otherwise, bruising to the insides of

the constant velocity joint boots will result,

leading to boots splitting and eventually joint

failure, if left unchecked.

8 Reinstall crossmember front mounting braces (1),

attaching bolts (‘3’ – three places) and rear

crossmember, front mounting bolt (2) but do not fully

tighten any of these bolts at this stage.

NOTE

Ensure that each snubber bush (4) is in a

serviceable condition and fitted to the centre

spigot of each crossmember bushing.

Figure 4B1 – 51

9 Lower rear of the final drive assembly to gain access

to the rear mount to cover attaching bolts. Tighten

attaching bolts to the correct torque specification.

At the same time, ensure that mount does not

twist, as the mount to vehicle underbody

mating surface should be parallel to the rear

crossmember, to within 1 mm (distance ‘X’).

( ! ) Rear mount to rear final drive

cover attaching bolt torque specification ............95 Nm

NOTE

Use a spirit level on rear mount to underbody

surface and top surface of crossmember to

ensure that both surfaces are parallel.

Dimension ‘A’ is to be 56.7 mm, measured from

the top of the spacer block.

Figure 4B1 – 52

Rear Final Drive & Driveshafts Page 4B1–33

Page 4B1–33

10 Lower differential carrier and rear crossmember

assembly on floor jack and safety stands. Install rear

springs (1) and the two insulators, (2 and 3).

NOTE

During this operation, the differential carrier and

rear crossmember assembly rear mount must be

lowered at least 60 mm from the vehicle

underbody. Otherwise damage to the driveshaft

constant velocity joint boots will occur.

Figure 4B1 – 53

11 Reinstall shock absorber (3) to the trailing arm (2), fit

washer to the lower mounting bolt, install bolt (1) but

do not fully tighten at this time, as the vehicle must be

at curb weight before final tightening is undertaken.

Figure 4B1 – 54

12 Raise assembly until the spacer (3) and rear mount (1)

contact the vehicle underbody.

13 Align the spacer (3) with marks on underbody, made

on disassembly, then loosely install new attaching

bolts (2) but do not fully tighten at this stage.

Failure to correctly align the rear

crossmember to the centreline of the vehicle

will result in steering problems and uneven

tyre wear!

14 The rear crossmember MUST now be aligned to

the vehicle centreline, using the special tool and

procedure as detailed in Section 1A2 Body

Dimensions, in the MY2003 VY and V2 Series

Service Information.

Figure 4B1 – 55

15 Tighten all crossmember mounting fasteners to the correct torque specification.

Rear Final Drive & Driveshafts Page 4B1–34

Page 4B1–34

( ! ) Rear mount to vehicle

underbody attaching bolt

torque specific atio n ........................35 Nm, plus 60° turn

( ! ) Rear crossmember front

mounting bolt

torque specification ......................125 Nm, then 35° turn

( ! ) Rear crossmember front

mounting brace bolt

torque specific atio n ..............................................75 Nm

16 Install different ial carri er breather hose into vehicle

underbody crossmember hole. Ensure that end of

hose is pushed into hole approximately 25 mm.

Figure 4B1 – 56

17 Reconnect wheel sensor wiring harness connectors.

Reinstall into the retaining clips (1).

18 Reinstall park brake inner cables to the front retainer,

install and secure outer cables in the underbody

retainers, then install the outer cable retaining bracket

bolt to the vehicle underbody.

19 Check and fill differential carrier to correct level with

specified lubricant, refer to 2.2 Checking Differential

Carrier Lubric ant Level, in Section 4B Rear Final Drive

and Driveshafts, in the MY 2003 VY and V2 Series

Service Information.

20 Check park brake adjustment and bleed brake

hydraulic system, refer to Section 5A Service and Park

Braking Systems, in the MY 2 003 VY and V2 Series

Service Information.

21 Reinstall propeller shaft. Refer to Section 4C1 Rear

Propeller Shaft & Universal Joints, in the MY 2004

AWD Wagon Service Information.

22 Reinstall exhaust system, by first installing the front of

the intermediate pipe to the catalytic converters. Use

new gaskets at the converter flanges.

Figure 4B1 – 57

23 While supporting the exhaust system, install the exhaust hanger rubbers to the rear of the intermediate muffler/s

and secure with new retainers.

24 Install rear muffler support rings to the rear of the rear muffler and secure with new retainers.

25 Tighten intermediate exhaust pipe to catalytic converter bolts to the correct torque specification.

Intermediate exhaust pipe to

catalytic conv ert er bolt

torque specific atio n ..............................................45 Nm

Rear Final Drive & Driveshafts Page 4B1–35

Page 4B1–35

26 Check exhaust clearances, Refer to Section 8B Exhaust System, in the MY 2004 AWD Wagon Service Information.

27 Reinstall road wheel/s, aligning the marks made prior to removal and secure with attaching nuts.

28 Remove safety stands and lower vehicle.

29 Bounce the rear of the vehicle several times to settle suspension then, tighten road wheel attaching nuts to correct

torque specification, working in a ‘star’ pattern, refer to Figure 4B1-5, in this Section.

Road wheel attaching nut

torque specific atio n ............................................125 Nm

30 Reinstall wheel nut decorative caps.

31 Tighten lower shock absorber lower mounting bolts to the correct toque specification.

( ! ) Shock absorber lower mounting

bolt torque specification......................................115 Nm

32 Start vehicle and check for exhaust leaks. Repair as necessary.

Rear Final Drive & Driveshafts Page 4B1–36

Page 4B1–36

3.3 Removed Final Drive Assembly

Apart from the fact that the appearance of the pinion flange and the drive pinion is different, the unit repair for the

removed final drive assembly is the same as described for the 3.46:1 ratio assembly without LSD. Refer to 3.3 Removed

Final Drive Assembly, in Section 4B Final Drive and Driveshafts, in the MY 2003 VY and V2 Series Service Information,

for the required procedures.

Rear Final Drive & Driveshafts Page 4B1–37

Page 4B1–37

4 Specifications

NOTE

Only those specifications referred to within this

Section are stated here. For all remaining

specifications, refer to Section 4B Final Drive and

Driveshafts, in the MY2003 VY and V2 Series

Service Information.

GENERAL

Final Drive Assembly............................................................................................... DANA – 80 Series

Drive Type............................................................................................................... Independent Housing

Gear Type ............................................................................................................... Hypoid

Gear Ratio (See ID tag attached to the carrier)....................................................... 3.46:1

No. of Teeth:

Ring Gear.......................................................................................................... 45

Drive Pinion Gear.............................................................................................. 13

LUBRICANT

Final Drive Assembly:

Capacity............................................................................................................. 1.6 litres

Type – Synthetic Hypoid Gear Oil ................................................................... 1.5 litres SAE 80W-140

Plus 'Sturaco' Additive......................................................................... 0.1 litre

FINAL DRIVE PINION GEAR BEARINGS

Bearing Type........................................................................................................... Adjustable Tapered Roller

Bearing Adjustment................................................................................................. Collapsible Spacer

Bearing Pre-Load: Timken Koyo

Dummy pinion - New bearings........................................................................... 1.4 – 2.0 1.5 – 1.9 Nm

Dummy pinion - Used bearings ......................................................................... 0.7 – 1.2 0.7 – 1.2 Nm

New with oil seal................................................................................................ 1.4 – 2.4 1.5 – 2.1 Nm

New without oil seal........................................................................................... 1.4 – 2.0 1.5 – 1.9 Nm

Used with oil seal............................................................................................... 0.7 – 1.2 0.7 – 1.2 Nm

Used without oil seal.......................................................................................... 0.7 – 1.2 0.7 – 1.2 Nm

RUN-OUT SPECIFICATIONS

Trunnion Assembly Hub.......................................................................................... 0.06 mm Total Indicated

Run-out

ABS-TC SENSOR

Air Gap (non-adjustable)......................................................................................... 0.4 – 1.5 mm

SEALANTS

Driveshaft Dust Caps/Shield.................................................................................... RTV 732 Sealant, or

commercial equivalent

Thread Sealant – As Required................................................................................ Loctite 262 or equivalent

Rear Final Drive & Driveshafts Page 4B1–38

Page 4B1–38

6 Torque Wrench Specifications

ATTENTION

!

!!

! Fasteners must be replaced after loosening.

"

""

" Vehicle must be at curb height before final tightening.

#

##

# Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

NOTE

Only those torque wrench specifications referred

to within this Section are stated here. For all

remaining torque wrench specifications, refer to

Section 4B Final Drive and Driveshafts, in the

MY2003 VY and V2 Series Service Information.

Nm

Brake caliper anchor plat e to traili ng ar m bolt................................................85

" Collar nut to trunnion assembly................................................................300

Drain plug ......................................................................................................28

" Driveshaft constant velocity joint attaching bolt............. 50 Nm, plus 70° turn

Filler plug.......................................................................................................28

" Final drive assembly to crossmember attaching bolt..... 90 Nm, plus 40° turn

Intermediate exhaust pipe to catalytic converter attaching bolt......................45

" Rear crossmember front mounting bolt....................... 125 Nm, plus 35° turn

" Rear crossmember front mounting brace to underbody bolt......................75

Rear disc brake shield to trailing arm. Upper bolt ........................................75

Lower bolt ........................................88

" Rear mount to vehicle underbody attaching bolt........... 35 Nm, plus 60° turn

" Rear mount to differential carrier rear cover attaching bolt ........................95

Road wheel attaching nut............................................................................125

! Shock absorber lower mounting bolt........................................................115

Rear Final Drive & Driveshafts Page 4B1–39

Page 4B1–39

7 Special Tools

NOTE

Only those Special Tools referred to within this

Section are stated here. For all remaining Special

Tools, refer to Section 4B Final Drive and

Driveshafts, in the MY2003 VY and V2 Series

Service Information,

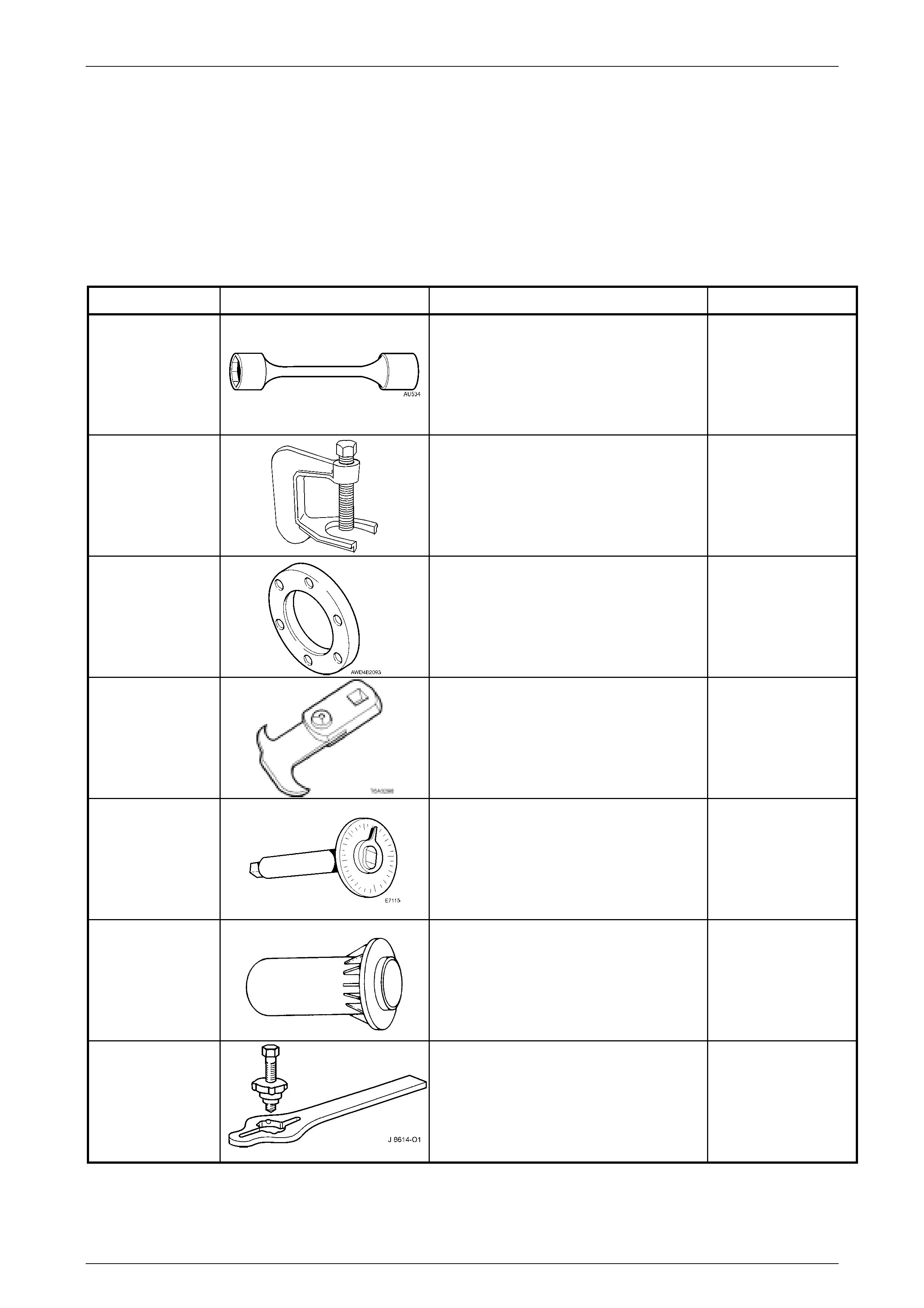

TOOL NUMBER ILLUSTRATION DESCRIPTION CLASSIFICATION

AU 534

Torque Limiting Socket

Used in conjunction with an impact gun to

tighten wheel nuts.

Previously released.

Unique

C4150-C

Press Tool

Used to remove rear wheel studs from the

trunnion flange.

Previously released.

Unique

DT-47580

Packing Flange

Fitted into the pinion flange to act as a

spacer for holding tool J8614-O1

New release

Available

E308 Seal Remover

Used as a universal seal remover. Also

released as 56750.

Previously released.

Available

E7115

Angle Wrench

Used to tighten fasteners when an angle

torque is specif ied .

Also released as BT 8653-A

Previously released.

Unique

E9055

Pinion Oil Seal Installer

Used to install the pinion oil seal.

Also releas ed as 17-010A.

Previously released.

Unique

J 8614-O1 Flange/Pulle y Holding Tool

Includes J 8614-2, J 8614-3 and

J 8614-10

Previously released.

Unique

Rear Final Drive & Driveshafts Page 4B1–40

Page 4B1–40

TOOL NUMBER ILLUSTRATION DESCRIPTION CLASSIFICATION

J22610

Clamp Pliers

Used to crimp the drives haft b oot cla mps.

Also releas ed as E1896.

Previously released.

Available

J22912-01

Press Plates

Used in a number of different applications

in removing bearings and other

transmission components when pressing

operations are required.

Previously released.

Unique

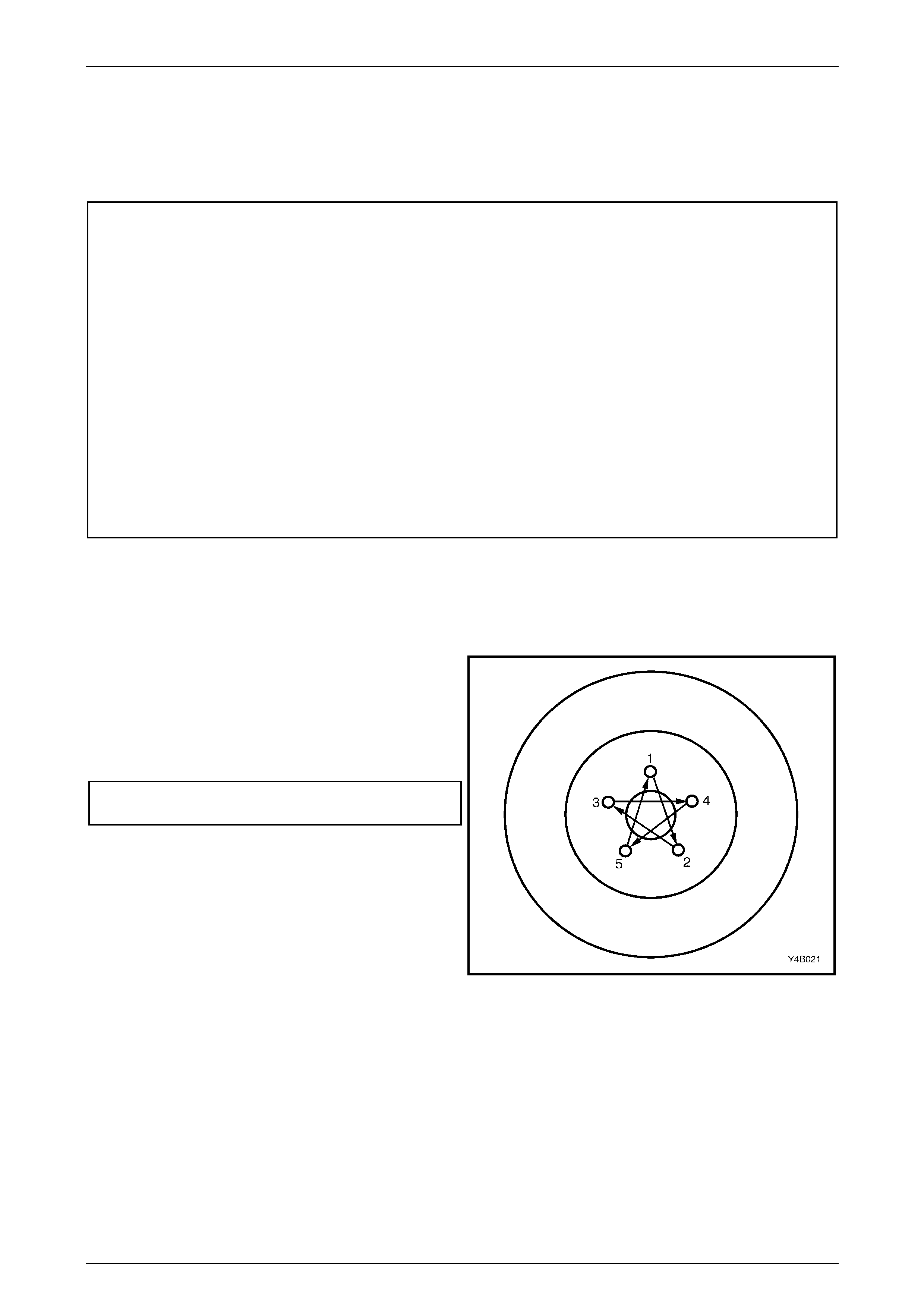

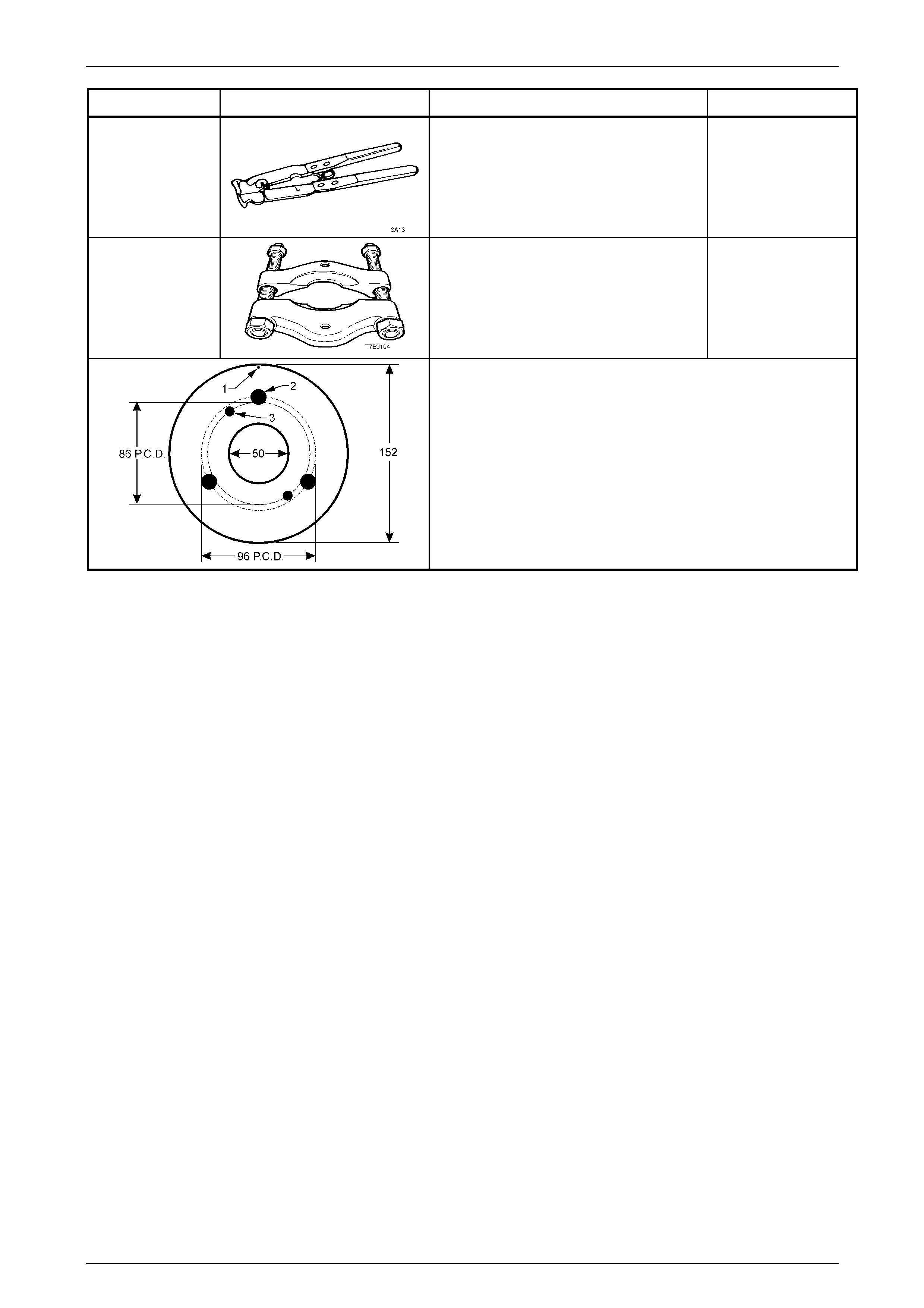

Pinion Flange Pulley

Modify the fabricated pulley made up for VY Series vehicles:

1. Made from a 13 mm thick piece of wood.

2. Drill a small hole at '1' and attach a one metre length of

string at this point.

3. Drill two, 8.5 mm holes (3) opposite to each other on a pitch

ci rcle diameter of 86 mm .

4. For application to VY Series final drive pinion flange, drill

three, 13 mm holes (2) on a pitch circle diameter of 96 mm,

120 mm apart.