Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–1

Page 4B2–1

Section 4B2

Front Final Drive, Bearing Housing & Driveshafts

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Description............................................................................................................................... 3

1.1 Final Drive Assembly Identification......................................................................................................................5

1.2 Final Drive Maintenance........................................................................................................................................6

Maintenance............................................................................................................................................................6

Drive Shaft Bearings and Constant Velocity Joints.............................................................................................6

Differential Carrier Assembly..............................................................................................................................6

Final Drive Assembly Breather...........................................................................................................................6

Lubrication..............................................................................................................................................................7

2 Minor Service Operations .....................................................................................................................8

2.1 Checking Final Drive Lubricant Level ..................................................................................................................8

2.2 Changing/Flushing Final Drive Lubricant ............................................................................................................9

2.3 Pinion Oil Seal......................................................................................................................................................10

Replace .................................................................................................................................................................10

2.4 Driveshaft Assembly............................................................................................................................................11

Remove .................................................................................................................................................................11

Reinstall ................................................................................................................................................................13

2.5 Driveshaft Outer Constant Velocity Joint...........................................................................................................16

Remove .................................................................................................................................................................16

Reinstall ................................................................................................................................................................17

2.6 Driveshaft Inner Tripot Joint ...............................................................................................................................19

Disassemble .........................................................................................................................................................19

Inspect...................................................................................................................................................................20

Reassemble ..........................................................................................................................................................21

2.7 Bearing Housing/Final Drive Carrier Outer Oil Seal..........................................................................................23

Replace .................................................................................................................................................................23

2.8 Pinion Oil Seal......................................................................................................................................................25

Replace .................................................................................................................................................................25

2.9 Pinion Flange ........................................................................................................................................................26

Replace .................................................................................................................................................................26

3 Major Service Operations ................................................................................................................... 27

3.1 Bearing Housing Assembly.................................................................................................................................27

Remove .................................................................................................................................................................27

Disassemble .........................................................................................................................................................28

Inspect...................................................................................................................................................................30

Reassemble ..........................................................................................................................................................31

Reinstall ................................................................................................................................................................33

3.2 Front Final Drive Assembly.................................................................................................................................34

Remove .................................................................................................................................................................34

Reinstall ................................................................................................................................................................36

3.3 Removed Final Drive Assembly..........................................................................................................................39

Disassemble .........................................................................................................................................................40

Final Drive Cover..............................................................................................................................................40

Examining Gear Tooth Contact ........................................................................................................................41

Drive Pinion......................................................................................................................................................41

Differential Assembly........................................................................................................................................45

Techline

Techline

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–2

Page 4B2–2

Inspect...................................................................................................................................................................47

General Items...................................................................................................................................................47

Gears................................................................................................................................................................47

Bearing Cups....................................................................................................................................................47

Bearing Cone and Roller Assemblies...............................................................................................................47

Pinion Flange....................................................................................................................................................48

Carrier and Cover Housings.............................................................................................................................48

Differential Case...............................................................................................................................................48

Reassemble ..........................................................................................................................................................48

Differential ........................................................................................................................................................48

Drive Pinion – Shim Selection ..........................................................................................................................50

Differential Assembly – Bearing Preload and Backlash....................................................................................53

Final Drive Unit Assembly.................................................................................................................................56

4 Diagnosis.............................................................................................................................................. 59

5 Specifications....................................................................................................................................... 60

6 Torque Wrench Specifications........................................................................................................... 62

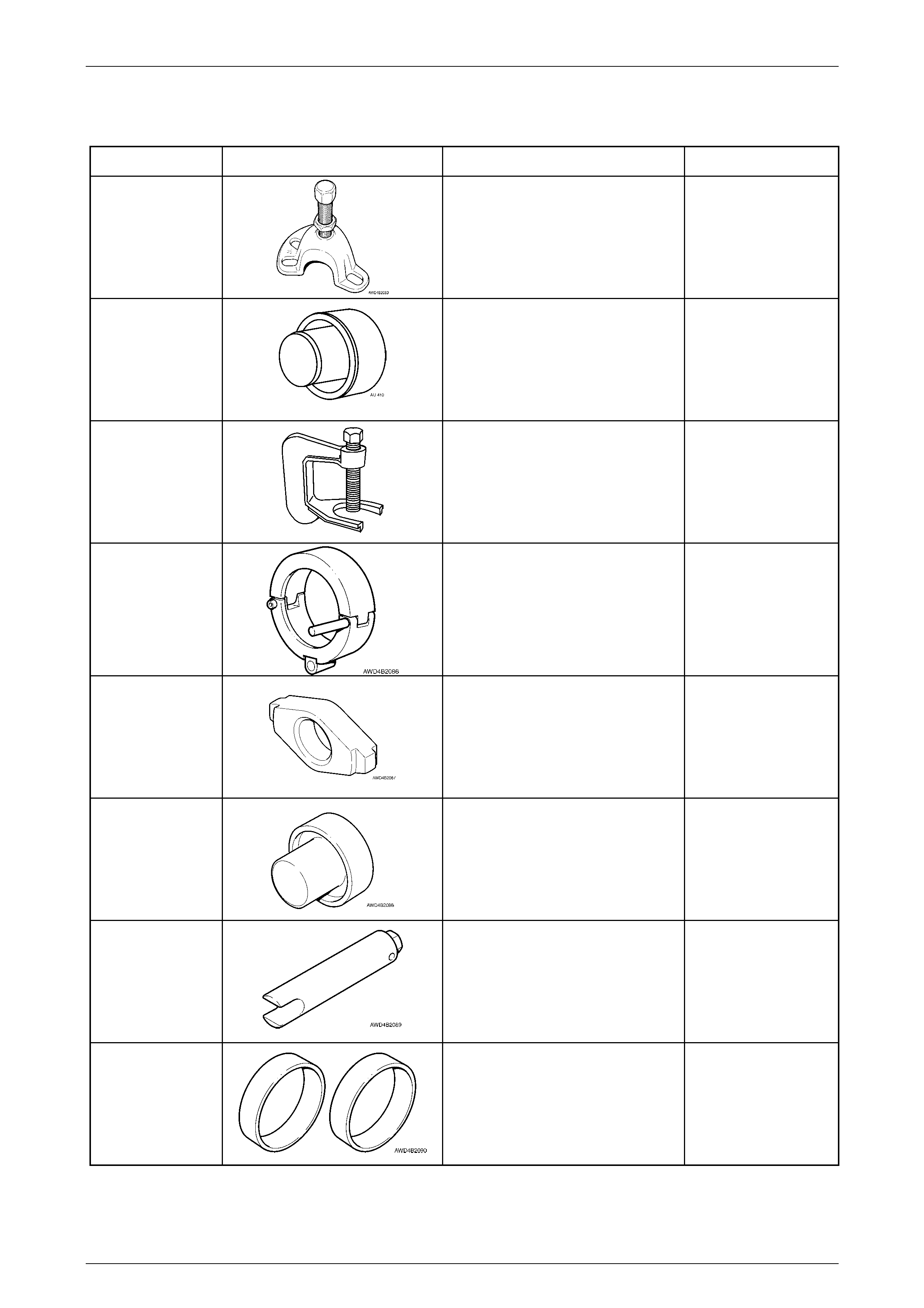

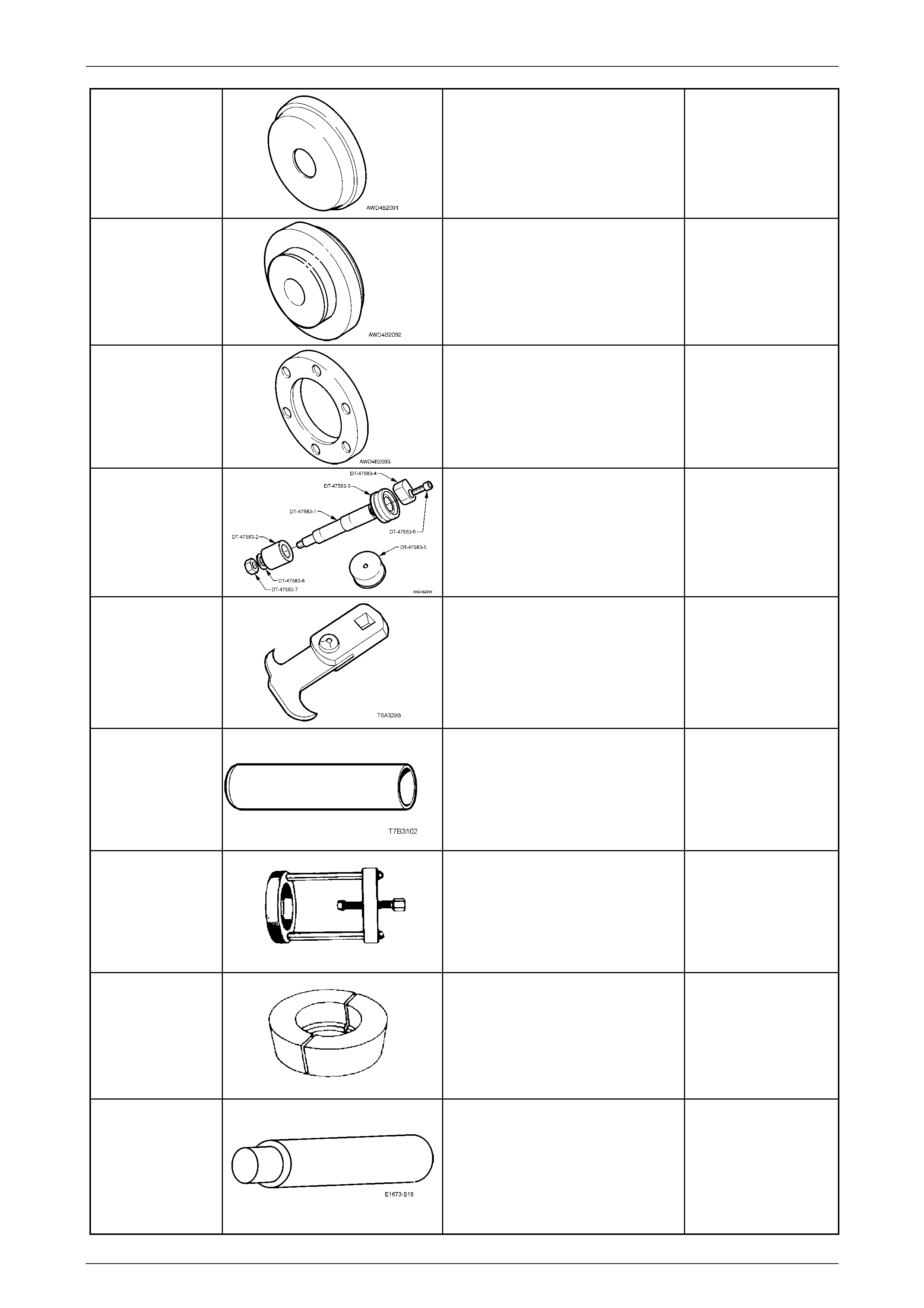

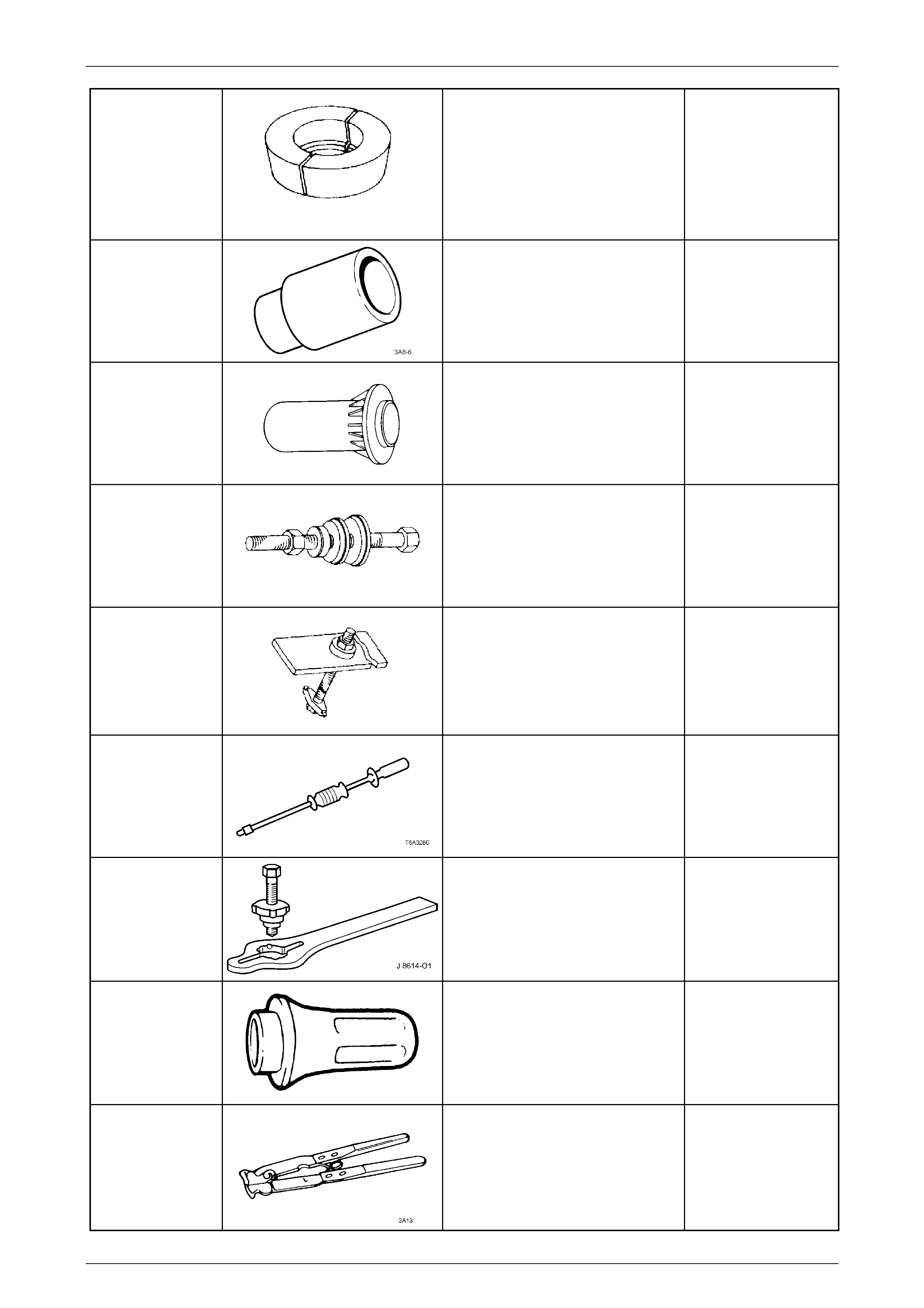

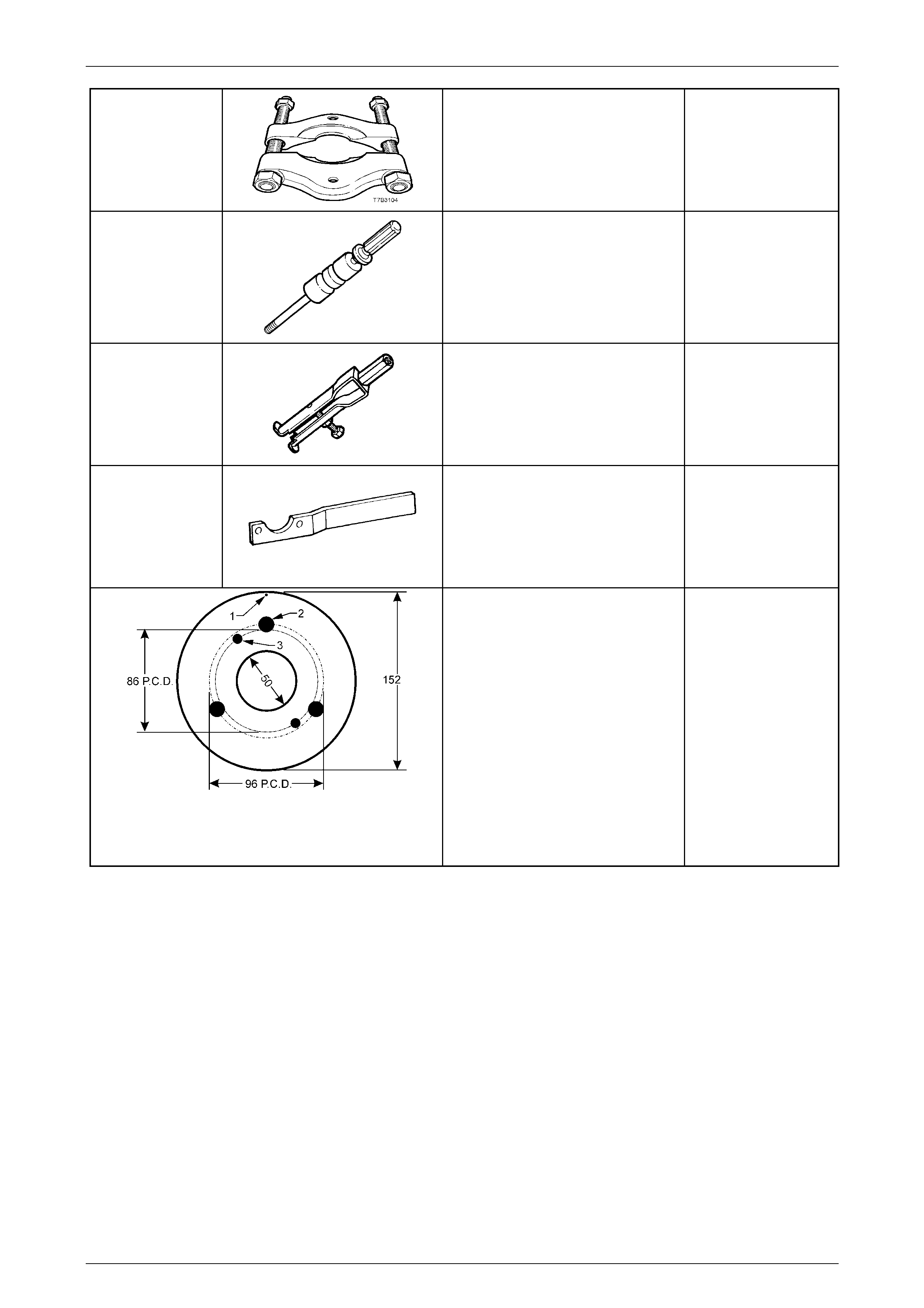

7 Special Tools........................................................................................................................................ 63

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–3

Page 4B2–3

1 General Description

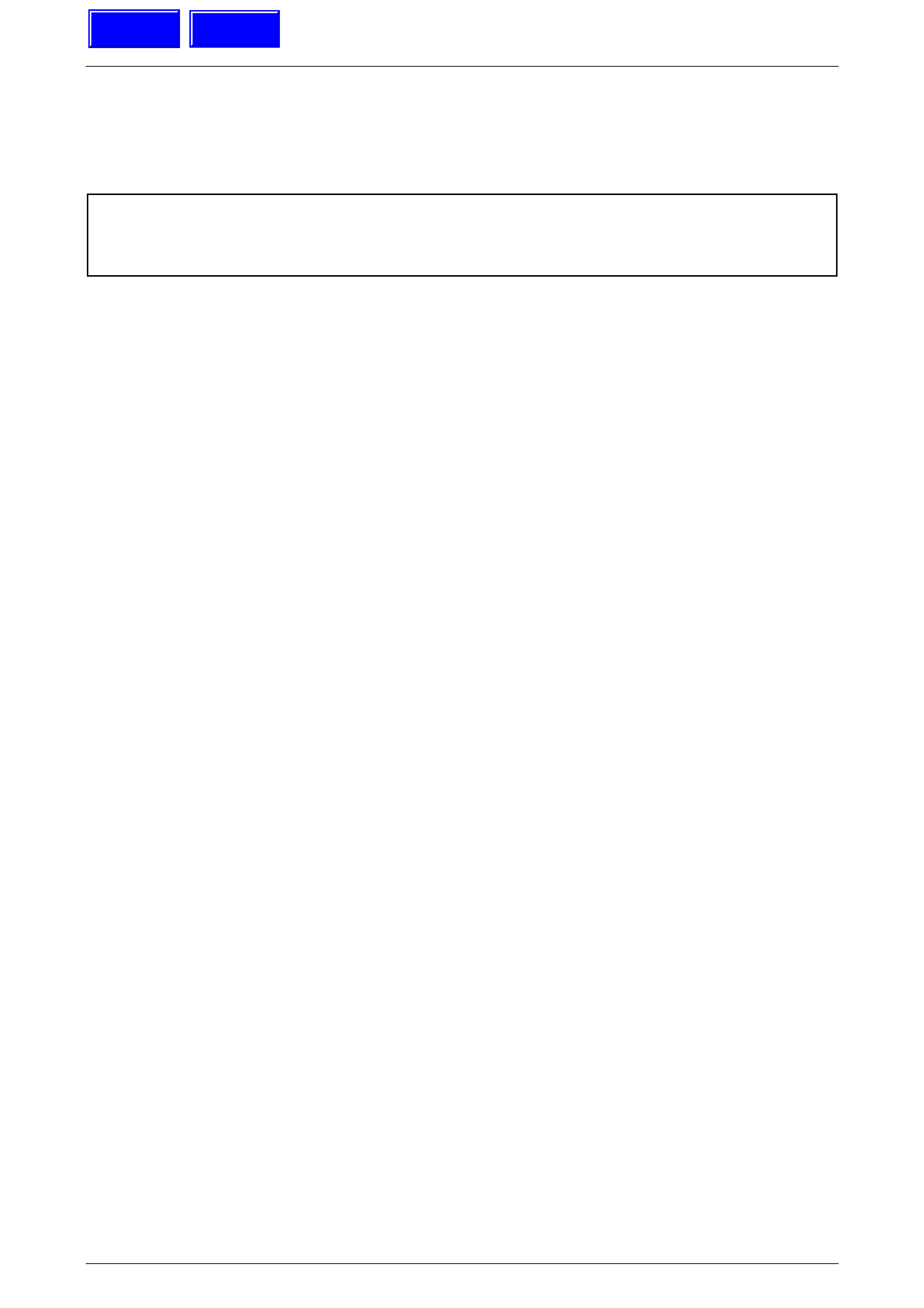

The front final drive assembly (1) is attached to the left side of the engine oil pan and a driveshaft support bearing

assembly (3) is located on the right side of the engine oil pan. An interconnecting shaft (2) passes through an integrally

cast tube in the engine oil pan, from the front drive assembly to the support bearing housing assembly. Refer to Figure

4B2-1. The interconnecting shaft is retained in the right differential axle gear by a snap ring.

The final drive assembly is a “Clam Shell” design, that is split vertically along its length and consists of two housings (1

and 4) made from ductile iron. The major housing (1) is the carrier that houses the hypoid pinion and supports the left

hand crown wheel carrier bearing. The minor half of the unit is called the cover (4), that supports the right hand crown

wheel carrier bearing. This cover is located on the carrier with a large diameter spigot and a hollow dowel to control

bearing to bearing alignment and is secured by ten bolts (6).

The hypoid drive pinion is supported in the carrier on two opposed, preloaded taper roller bearings. A pinion positioning

shim is located under the pinion head bearing cup while the bearing preload is achieved with a collapsible spacer at the

outer (small) pinion bearing. The bearings and the companion flange are retained with the pinion nut.

The differential assembly and ring gear are supported on two opposed and preloaded taper roller bearings; one in the

ca rrier and the second in the cover. The back l ash and the bearin g preload ar e controlled with shims un der the final d rive

carrier bearing cups in the carrier and the cover.

The final drive assembly is indexed to the engine oil pan by the cover seal housing, engaging with a machined recess in

the engine oil pan, while a dowel (5) near the rear mounting bolt controls the pinion nose angle. Four bolts are used to

attach the final drive assembly to the engine pan. The left driveshaft is retained in the left differential axle gear by a snap

ring on the inboard spline of the inner tripot joint.

The final drive ratio is 3.46:1 and the conventional differential assembly has two pinions, with a single, pinned pinion

shaft and two axle side gears.

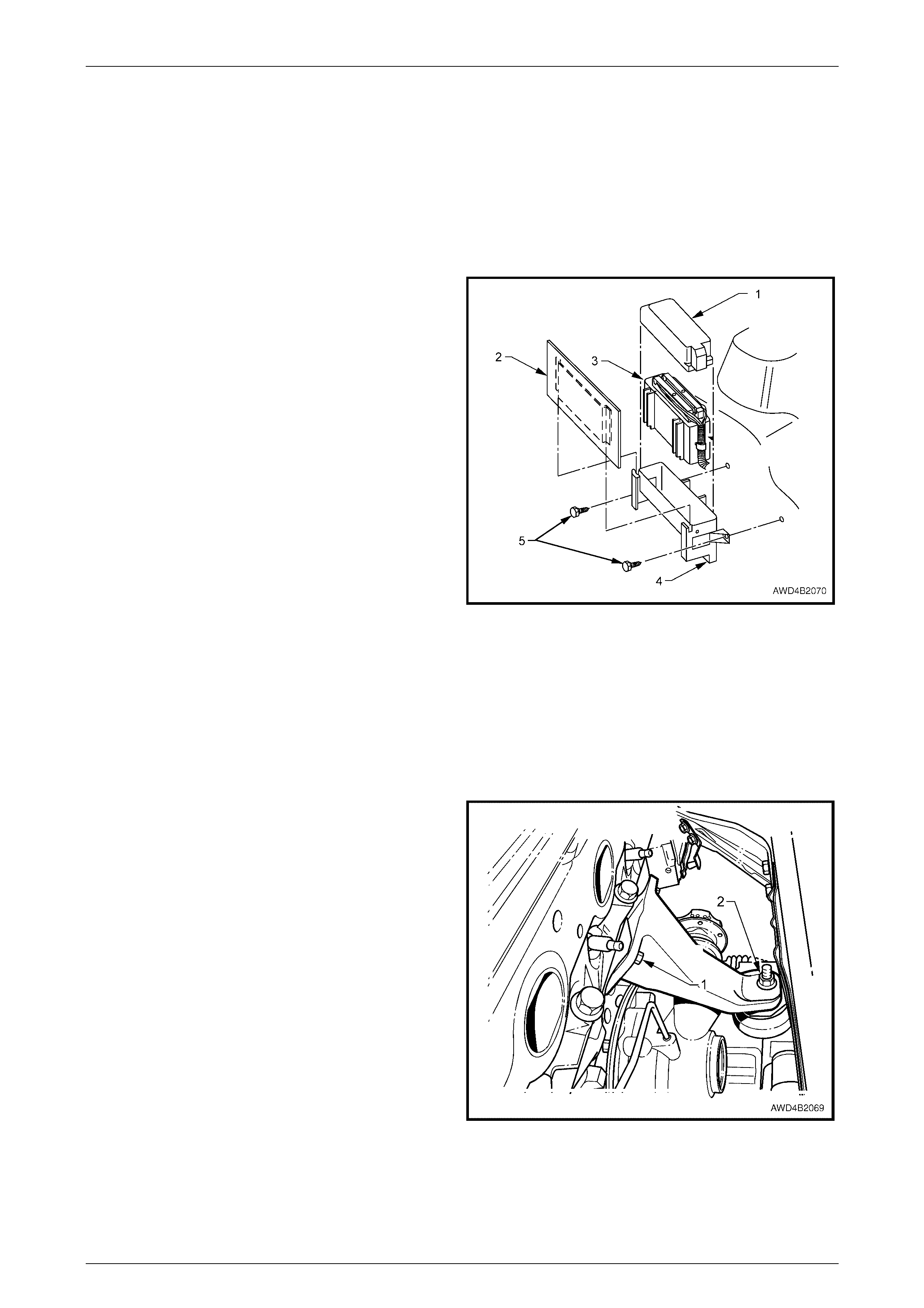

Figure 4B2-1

Legend

1 Final Drive Assembly, Major Housing

2 Final Drive Assembly, Cover

3 Interconnecting Shaft

4 Driveshaft Support Bearing Assembly

5 Carrier to Cover Att aching Bolts (10 places)

6 Pinion Nose Angle Locating Dowel

7 Interc onnect i ng Shaft Snap Ring

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–4

Page 4B2–4

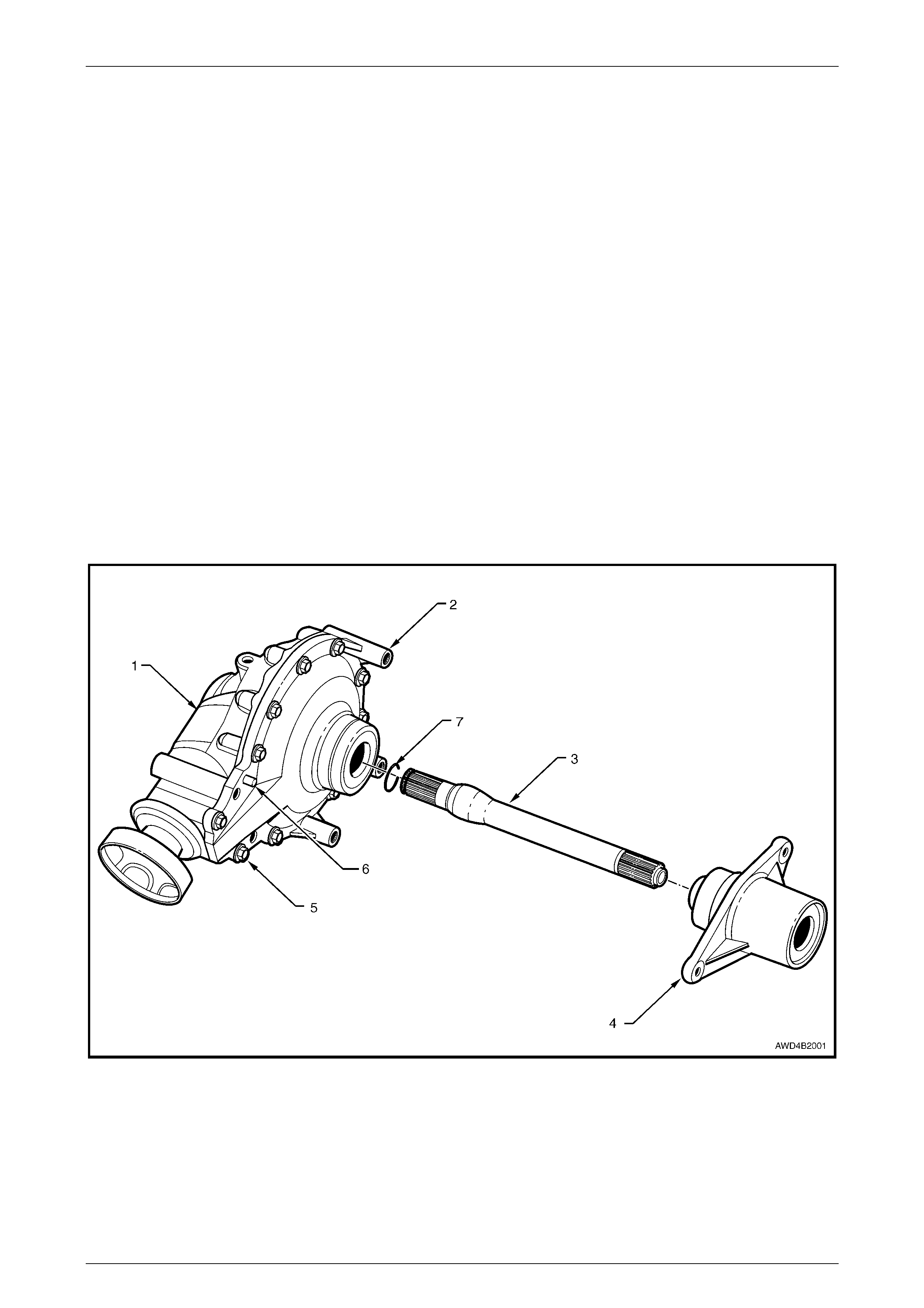

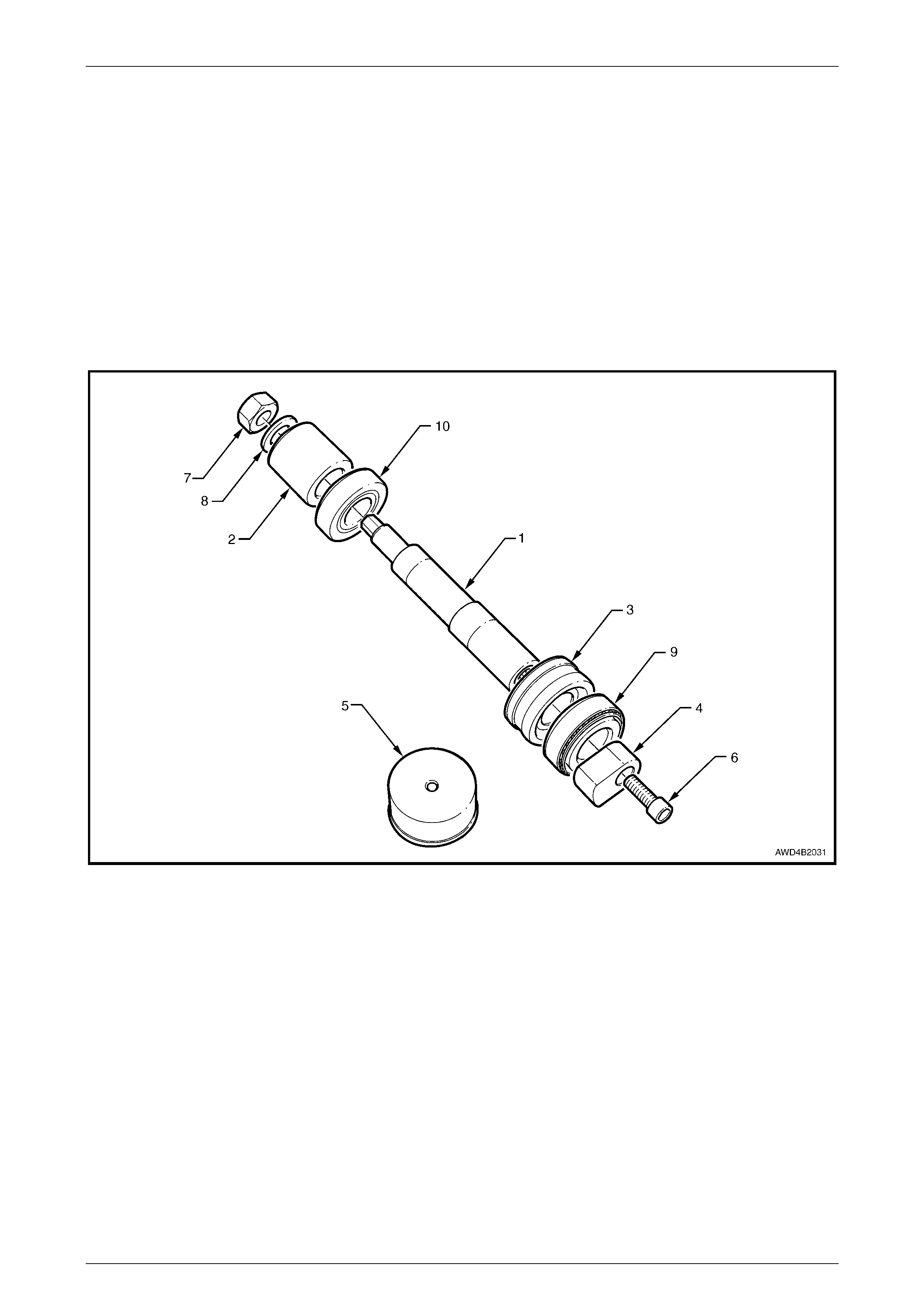

The bearing housing assembly is a one piece aluminium casting attached to the right side of the engine oil pan with three

bolts. The bearing housing assembly is fitted with a needle roller bearing (2) and a ball bearing (6) to support and locate

the connecting sleeve (5). The sleeve supports one end of the interconnecting shaft and retains the right hand driveshaft,

again by a retaining ring on the inner tripot joint spline. Both bearings are lubricated for life and require no periodic

maintenance. An oil seal (1 and 9) at each end of the bearing housing assembly, retain the lubricant.

Figure 4B2-2

Legend

1 Oil Seal – Inner

2 Needle Roller Beari ng

3 Bearing Housing

4 O-Ring Seal

5 Connecting Sleeve

6 Single Row Ball Bearing

7 Circlip – Small

8 Circlip – Large

9 Oil Seal – Outer

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–5

Page 4B2–5

1.1 Final Drive Assembly Identification

There is only one front final drive assembly available for fitment to all MY 2004 All Wheel Drive Wagon models, which

has a final drive ratio of 3.46:1 with a two pinion type, standard differential.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–6

Page 4B2–6

1.2 Final Drive Maintenance

Maintenance

Drive Shaft Bearings and Constant Velocity Joints

The drive shaft outer constant velocity joint and the inner tripot joint are lubricated for life and therefore require no

periodic maintenance.

The constant velocity joint boots are to be inspected at every maintenance service. If there is any evidence of damage to

boots, remove drive shaft and inspect constant velocity joints, refer to 2.4 Driveshaft Assembly in this Section.

Differential Carrier Assembly

Check for lubricant leaks at every maintenance service. If there is evidence of leakage, correct the leak and add lubricant

as necessary. (Refer to 2 Minor Service Operations in this Section).

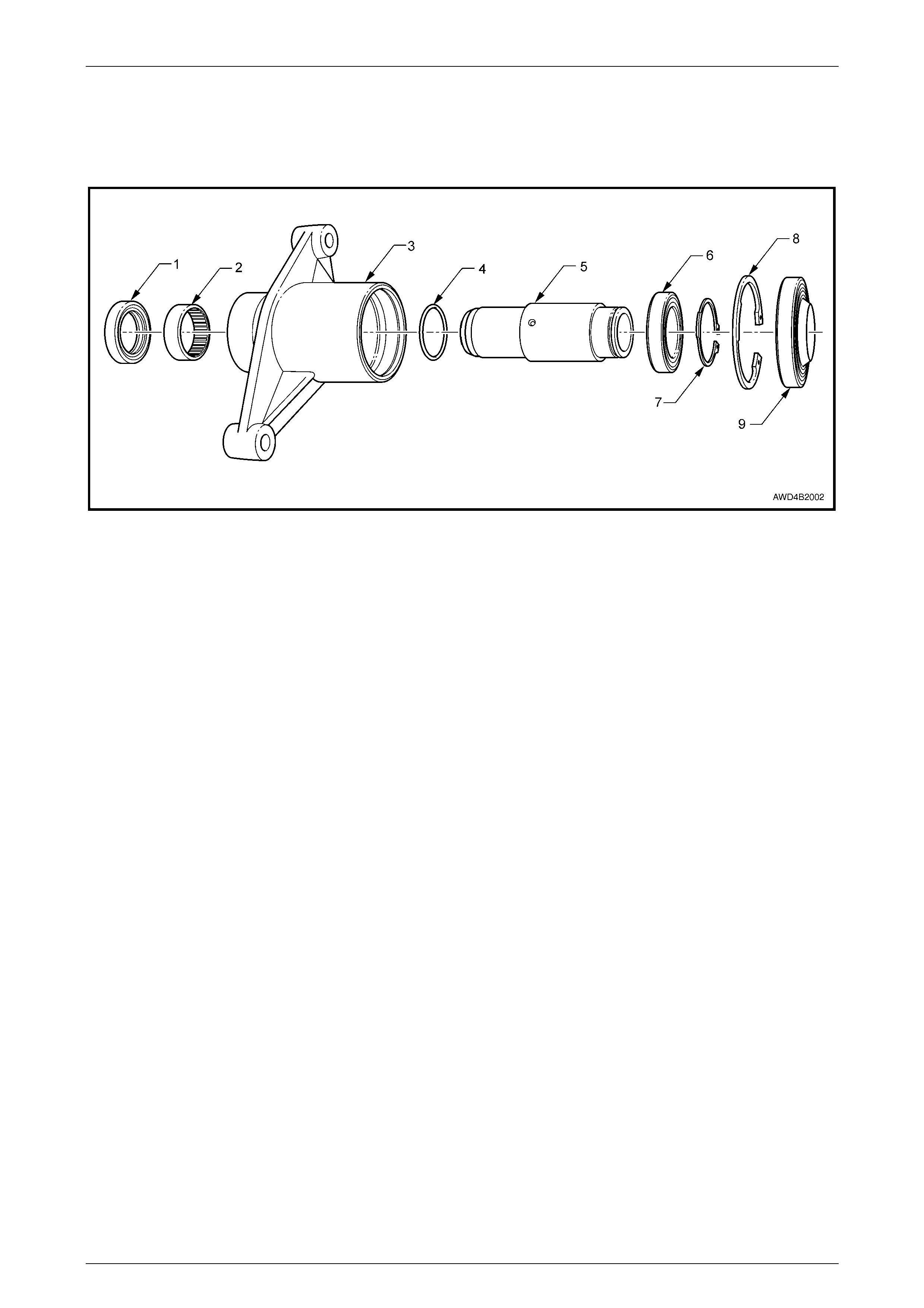

Final Drive Assembly Breather

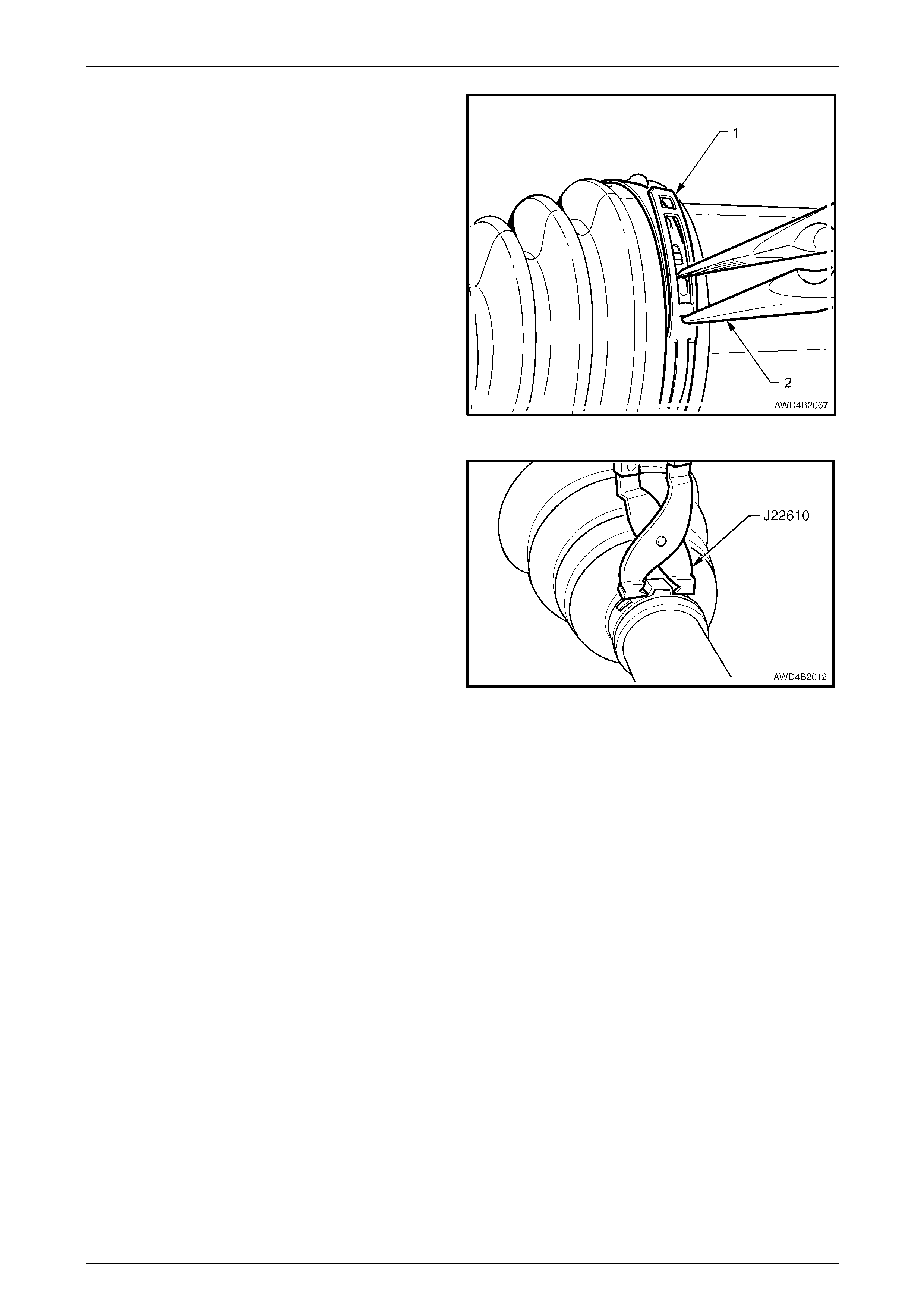

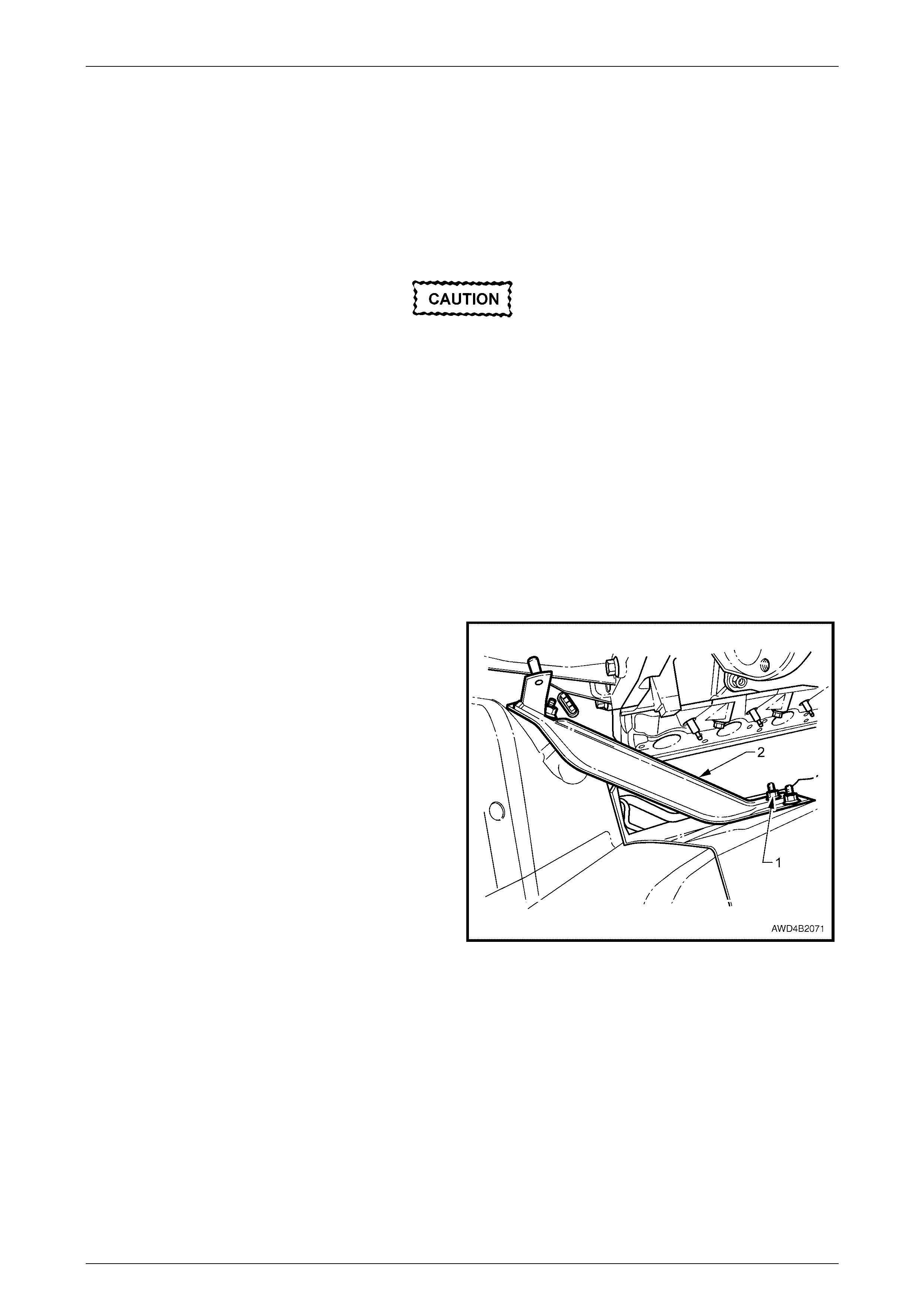

The breather hose and pipe assembly (1) should be

checked regularly to ensure that it is correctly routed, the

hose condition is sound, the end is not blocked and the pipe

bracket fastener (2) is secure.

Figure 4B2 – 3

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–7

Page 4B2–7

Lubrication

Never use any other than the stated and

recommended lubricant.

The lubricant level should be checked and topped up (if required), at the time or distance intervals outlined in the AWD

Wagon Owner's Handbook, with the differential carrier COLD and the vehicle on level ground; refer to 2.1 Checking Final

Drive Lubricant Level in this Section. At this temperature, the lubricant should be within 5 mm of the bottom of the filler

plug hole. Operation 2.1 also details the recommended lubricant for this final drive.

NOTE

The lubricant used in this final drive, is a synthetic

product and the oil seals fitted, have been

specially formulated to tolerate this lubricant. It

must also be noted that, using a mineral type

lubricant in this final drive, may cause gear set

and/or bearing damage under high load driving

conditions.

NOTE

If the incorrect lubricant is accidentally used

in the front final drive of any AWD Wagon vehicle,

then the front final drive must be drained, flushed

(with the recommended lubricant) and then

refilled with the correct lubricant. Refer to

2.2 Changing/Flushing Final Drive Lubricant, in

this Section.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–8

Page 4B2–8

2 Minor Service Operations

ATTENTION

All fasteners are important attaching parts as they affect the performance of vital components and/or could

result in major repair expense. Where specified in this section, fasteners MUST be replaced with parts of the

same part number or an approved equivalent. Do not use fasteners of an inferior quality or substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all components.

Throughout this section, fastener torque wrench specifications may be accompanied with the following

identification marks:

!

!!

! Fasteners must be replaced after loosening.

"

""

" Vehicle must be at curb height before final tightening.

#

##

# Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

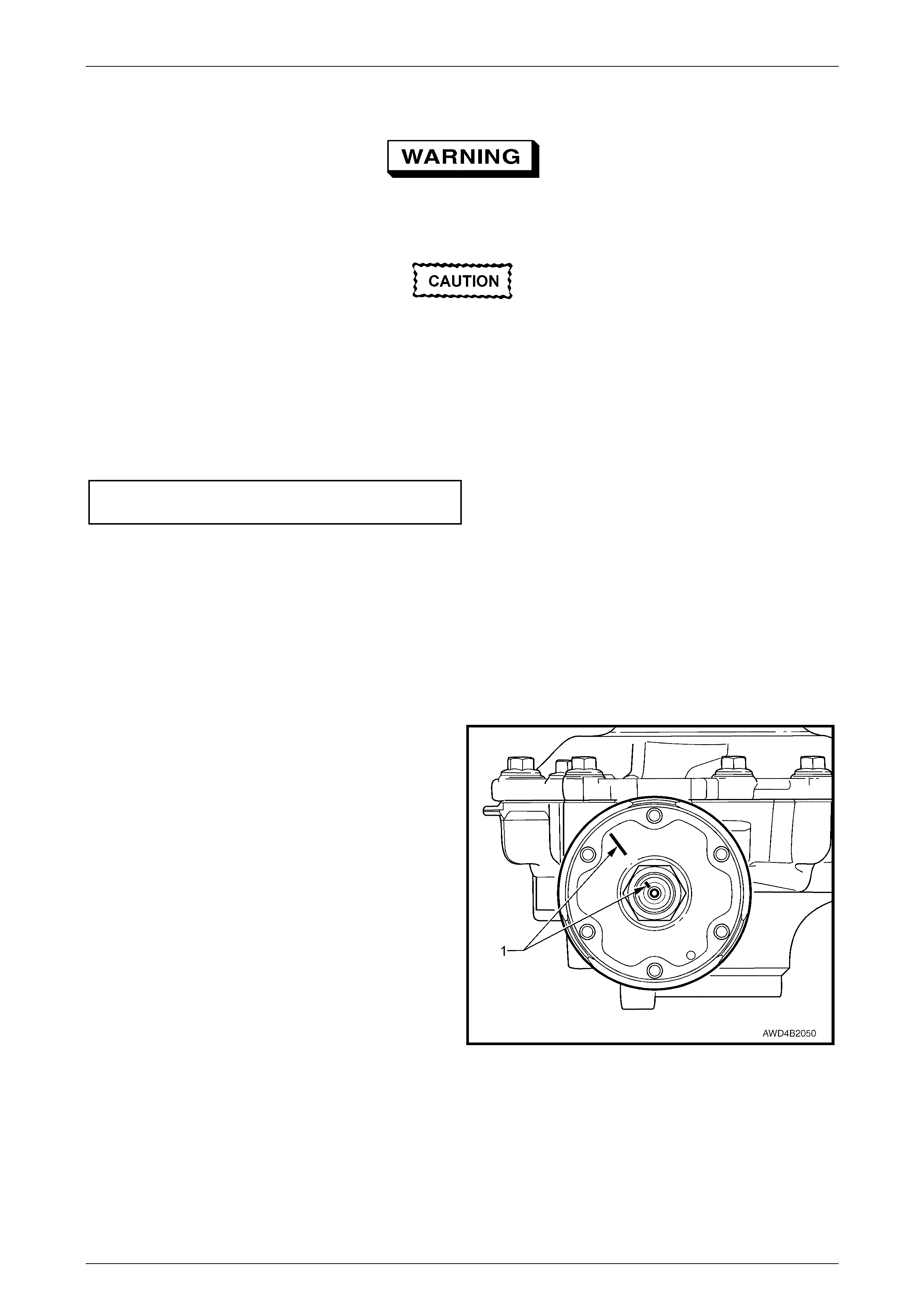

2.1 Checking Final Drive Lubricant Level

1 Ensure vehicle is on level ground.

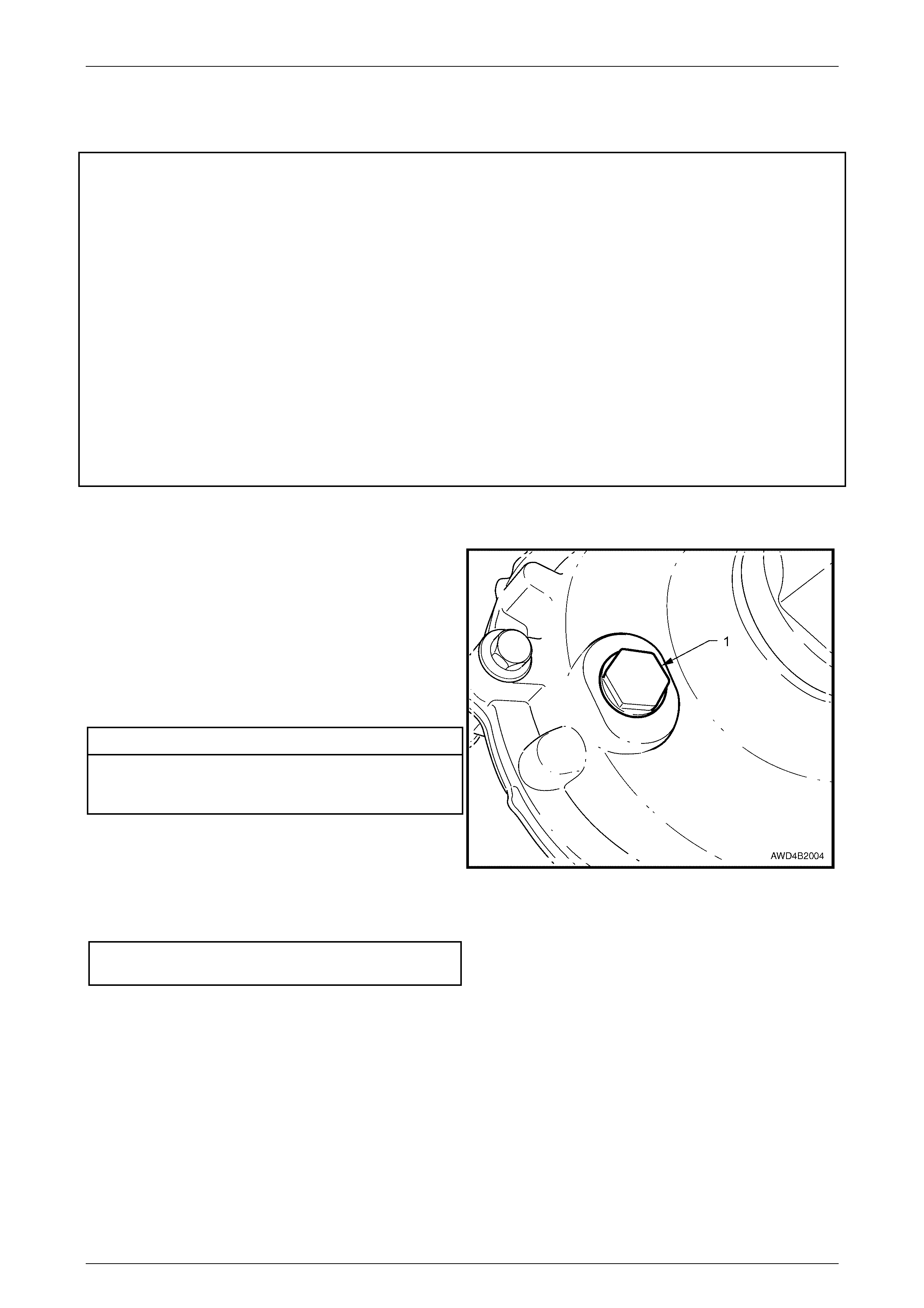

2 Clean area around filler plug (1).

3 Remove the hexagon headed filler plug (1) from the

carrier housing, usi ng suitable socket equ ipm ent.

4 The lubricant level is to be maintained within 5 mm of

the bottom edge of the filler plug hole, when COLD

and the vehicle is on level ground. Use only the

recommended lubricant, detailed as follows:

Front Final Drive Lubricant Specification

Synthetic Hypoid Gear Oil, SAE 80W-140

such as;

Castrol SAF-XA or Mobilube SHC ID

5 Inspect filler plug (1) for damage. If OK, reinstall to the

carrier housing. If damaged, replace plug.

Figure 4B2 – 4

6. Tighten filler plug (1) to the correct torque specification.

Final drive filler plug

torque specific atio n ..............................................28 Nm

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–9

Page 4B2–9

2.2 Changing/Flushing Final Drive Lubricant

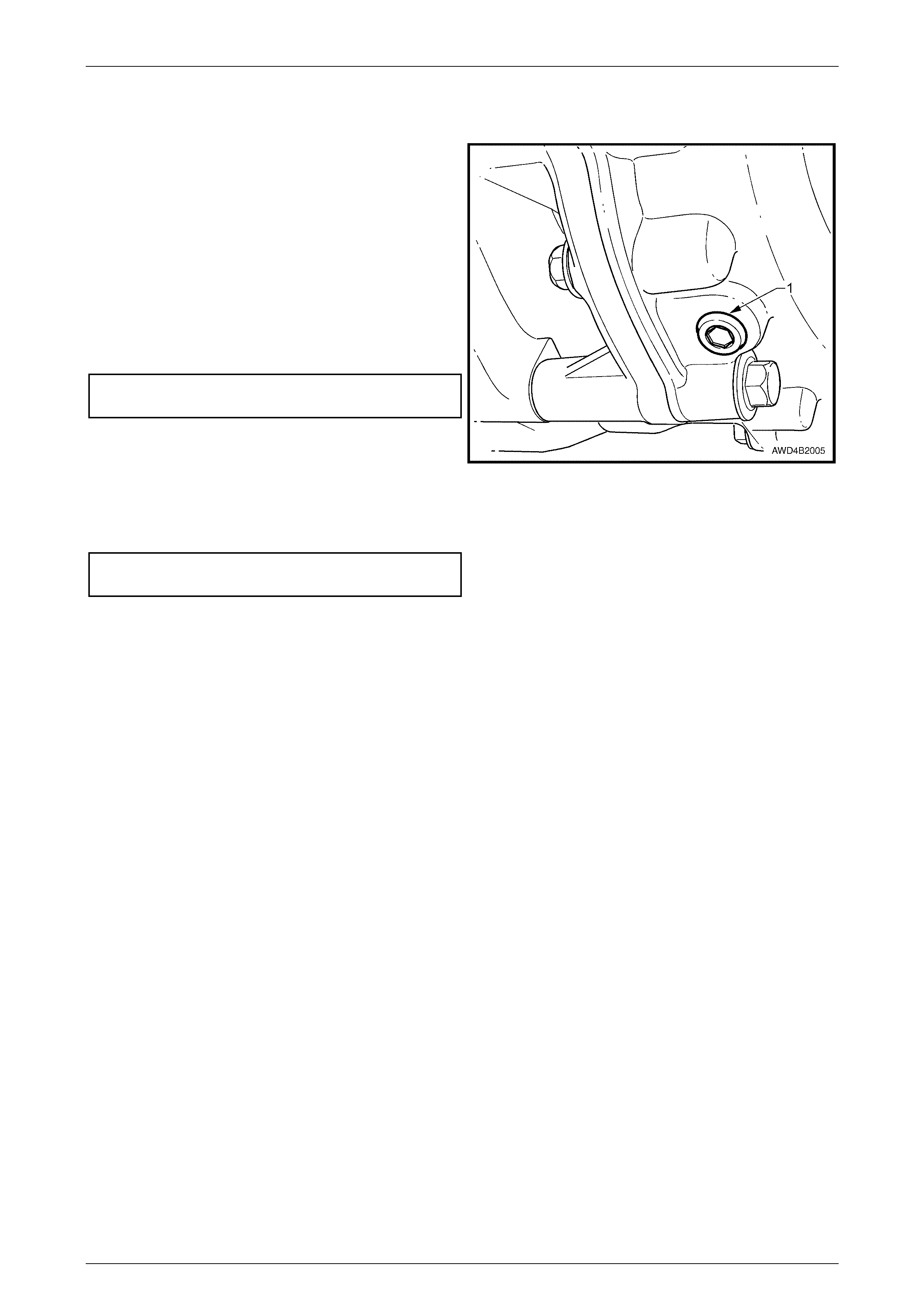

1 To drain lubricant from differential carrier assembly,

remove the hexagon headed filler plug (refer Figure

4B2-4), then the 8 mm Allen key headed drain plug

(1), allowing (preferably warm) lubricant to drain into a

suitable contai ner of at least 1 litre cap aci ty .

2 If flushing is required, use an undiluted quantity of the

recommended lubricant for the operation.

3 When the draining and flushing (if required), operation

is completed, clean the final drive drain plug (1)

threads. If required, Teflon tape may be applied to the

threads. Reinstall and tighten drain plug (1) to the

correct torque specification.

Final drive drain plug

torque specific atio n ..............................................45 Nm

Figure 4B2 – 5

4 Fill the final drive assembly with 0.8 litres of the recommended lubricant. Reinstall the filler plug ('1', in Figure 4B2-

4) and tighten to the correct torque specification.

Final drive filler plug

torque specific atio n ..............................................28 Nm

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–10

Page 4B2–10

2.3 Pinion Oil Seal

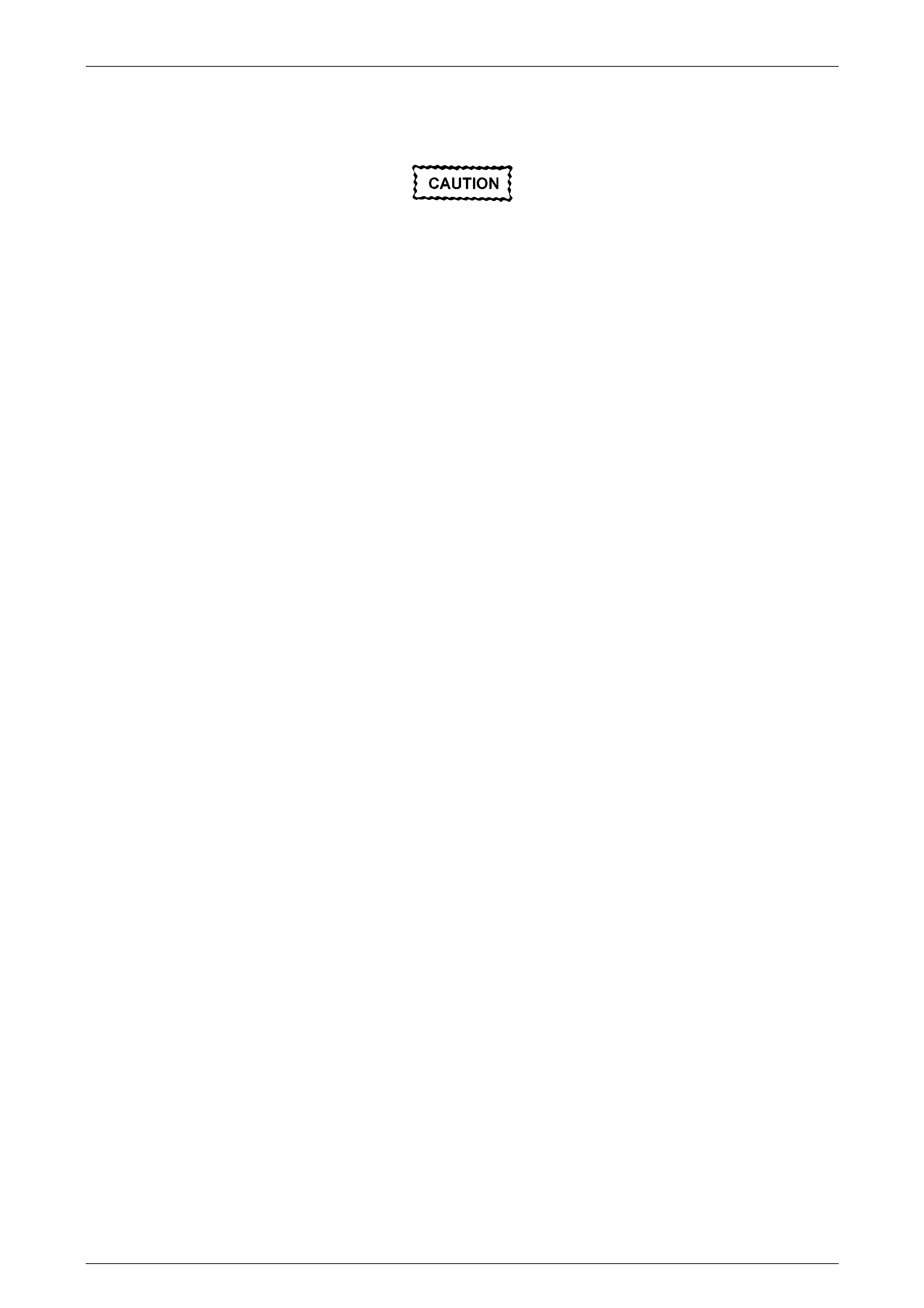

When installing a new pinion oil seal, only

install the seal until it is flush with the

machined face of the final drive housing. If

installed too deeply then a premature oil leak

could occur.

Replace

Apart from the fact that it is the front propeller shaft that needs to be removed (rather than the rear), the procedure for the

front final drive pinion oil seal replacement is the same as that described for the rear final drive assembly. Refer to

Section 4C2 Front Propeller Shaft & Universal Joints and Section 4B1 Rear Final Drive & Driveshafts, in the MY 2004

AWD Wagon Service Information.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–11

Page 4B2–11

2.4 Driveshaft Assembly

LT Section No. – 05-290

Remove

1 Raise the vehicle and secure in a safe manner. Refer to Section 0A General Information in the MY2004 AWD

Wagon Service Information for location of jacking and support points.

2 Remove the decorative wheel nut caps, then mark the relationship of the road wheel to one of the wheel studs.

3 Loosen, then remove the road wheel attaching nuts, working in a 'star' pattern. Refer to Section 10 Wheels and

Tyres, in the MY 2003 VY and V2 Series Service Information, for detailed information. Remove the road wheel.

NOTE

Steps 2 and 3 are necessary to maintain

component relationships and to avoid brake rotor

distortion and the creation of brake shudder, after

the vehicle is placed back in service.

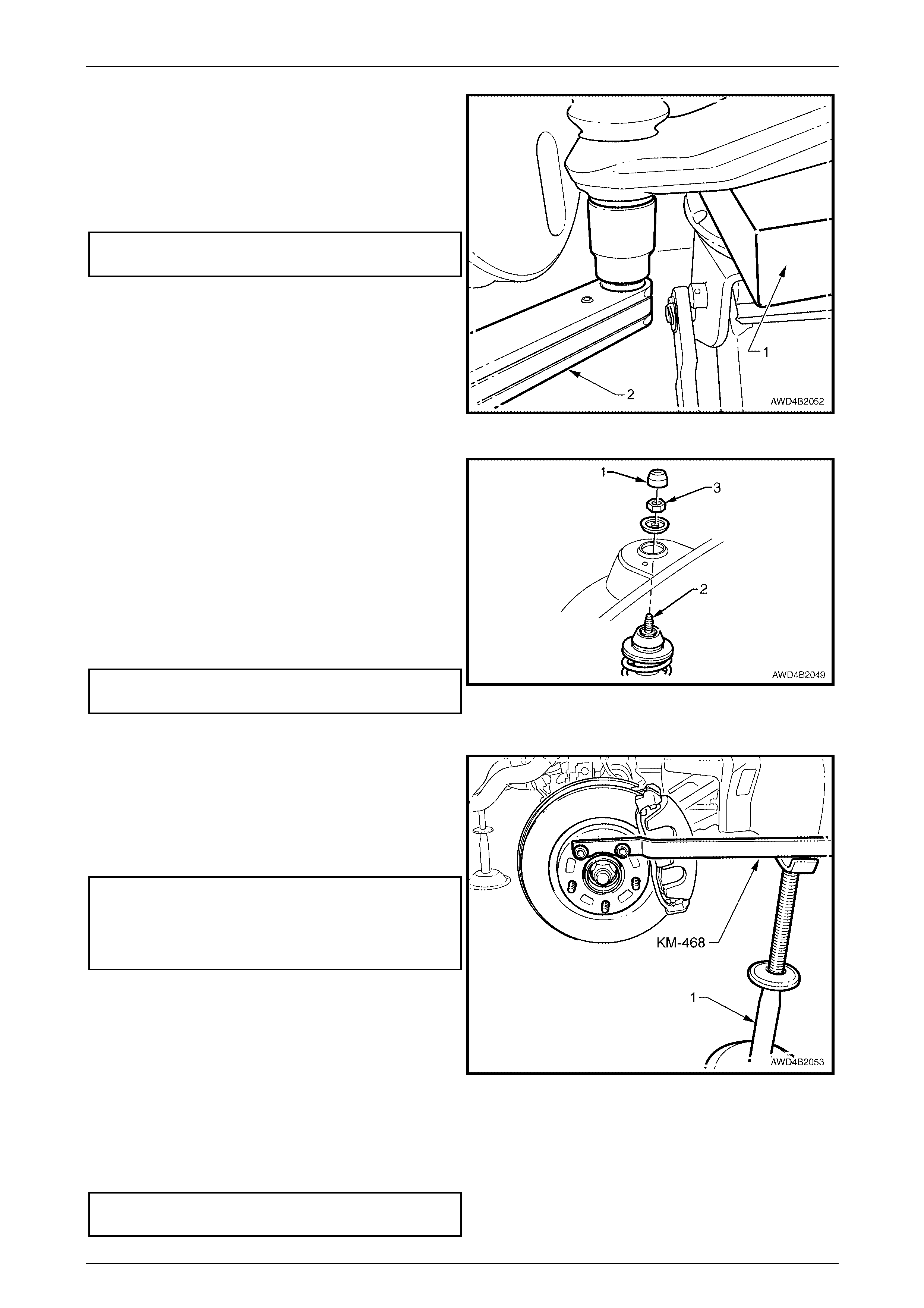

4 Attach holding tool KM-468 to the wheel hub with two

inverted wheel nuts. Support the tool outer end on a

safety stand.

5 Using suitable socket equ ipm e nt, loose n then remov e

the 36 mm driveshaft retaining nut and flat washer.

Discard the removed nut.

Figure 4B2 – 6

6 Remove the dust cover (1) from the upper strut

support, in the engine compartment.

7 While holding the strut rod shaft (2) with a 10 mm

socket, loosen the self-locking nut (3), using a 24 mm

ring spanner. Do not fully remove the nut.

NOTE

This step is necessary to allow the strut to be

moved outward, enabling driveshaft removal.

Figure 4B2 – 7

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–12

Page 4B2–12

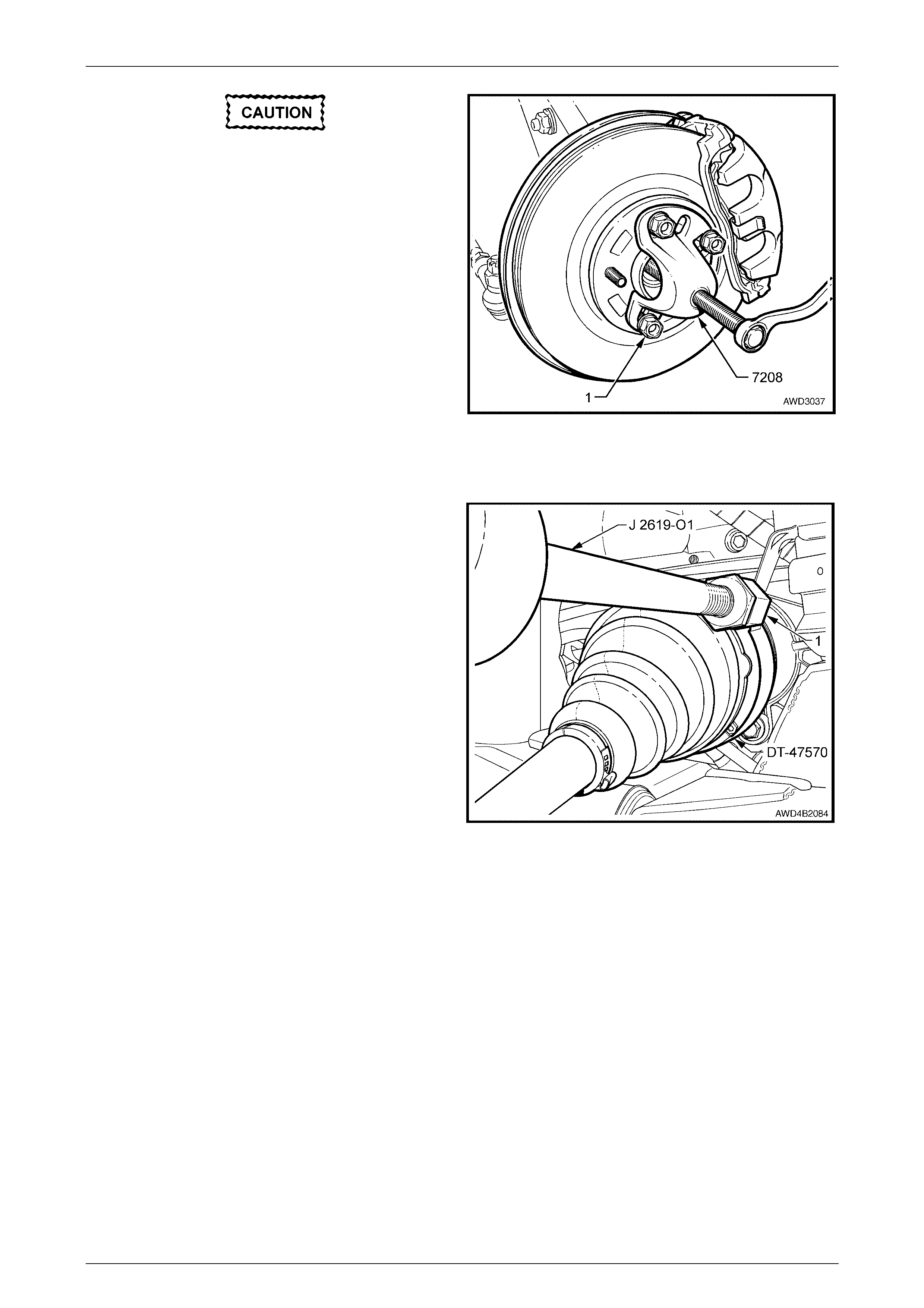

Under no circumstances is the end of the

driveshaft to be struck with a hammer to

dislodge the splines. To do so, will not only

damage the front hub bearing but the

driveshaft to outer constant velocity joint

snap ring can be also be dislodged.

8 Install Tool No. 7208 to the front hub studs and secure

with three of the wheel nuts (1).

NOTE

If not previously modified, it will be necessary to

use a round file to lengthen the slots in Tool No.

7208, to fit over the wheel studs.

9 Tighten the forcing screw to separate the front hub

and outer driveshaft splines. Remove Tool No. 7208.

Figure 4B2 – 8

10 Disconnect the front control arm ball joint stud from the front control arm. Refer to 3.11 Front Control Arm, in

Section 3 Front Suspension, in the MY2004 AWD Wagon Service Information.

11 Install adaptor(1) from sl ide ha mmer J 2619-O1 to the

remover/installer, Tool No. DT-47570, then install DT-

47570 to the groove in the tripot joint housing,

tightening the thumb screw to secure.

12 Screw slide hammer J 2619-O1 into the adaptor until

secure.

13 Using the action of the slide hammer weight against

the handle, dislodge the tripot joint snap ring from the

bearing housing (right side) or the front final drive side

gear (left side).

NOTE

While the right side view is shown, the procedure

is the same for the opposite side.

14 Remove the driveshaft from the vehicle by first

pushing inward to free the outer shaft from the front

hub, then withdraw the driveshaft by pulling on the

tripot housing.

NOTE

If the driveshaft is removed from the final drive

(left) side, lubricant will flow from the oil seal.

Either plug the recess immediately with

a suitable plug or rag, or drain the lubricant into

a suitable, clean container. Refer to

2.2 Changing/Flushing Final Drive Lubricant, in

this Section.

Figure 4B2 – 9

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–13

Page 4B2–13

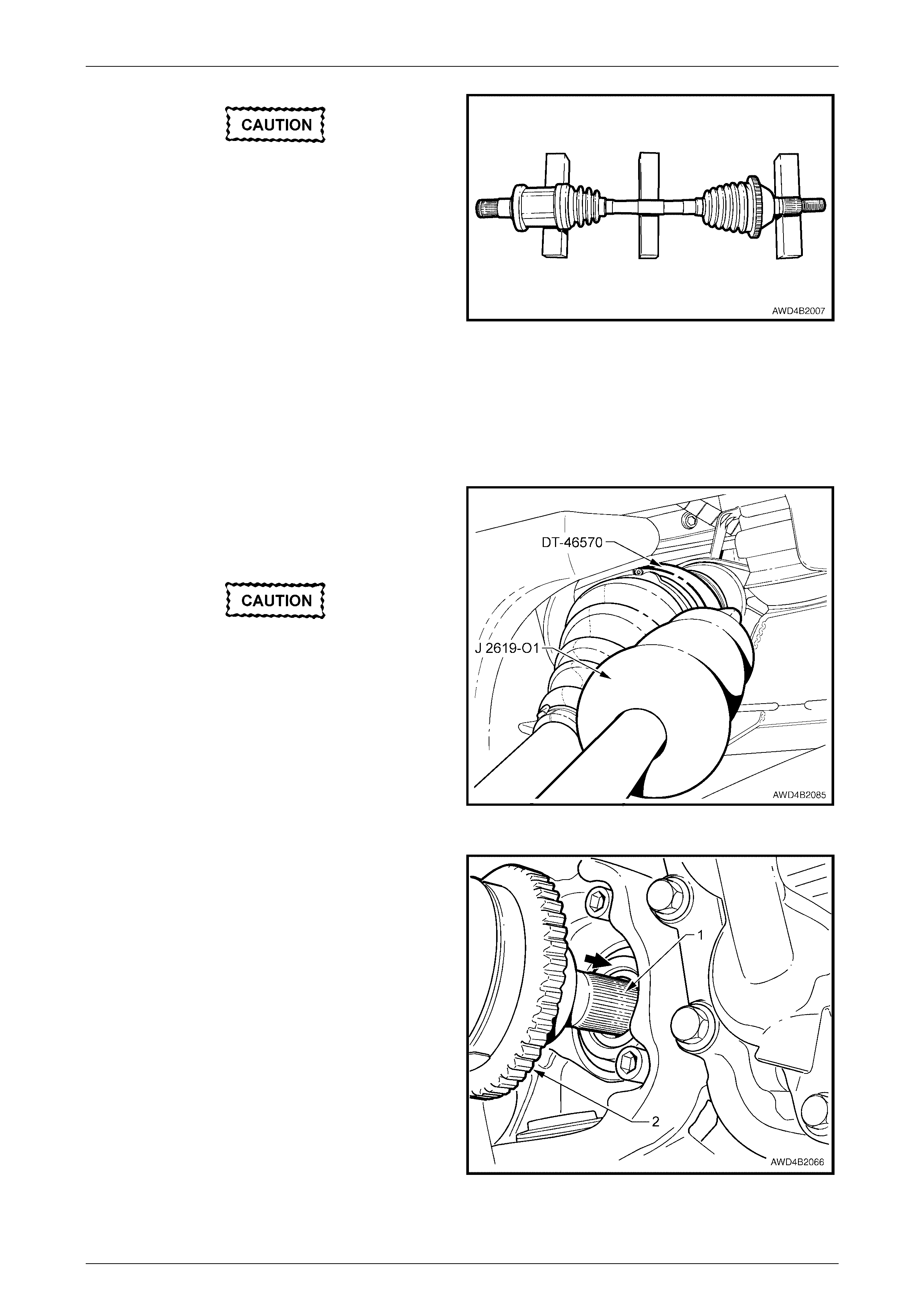

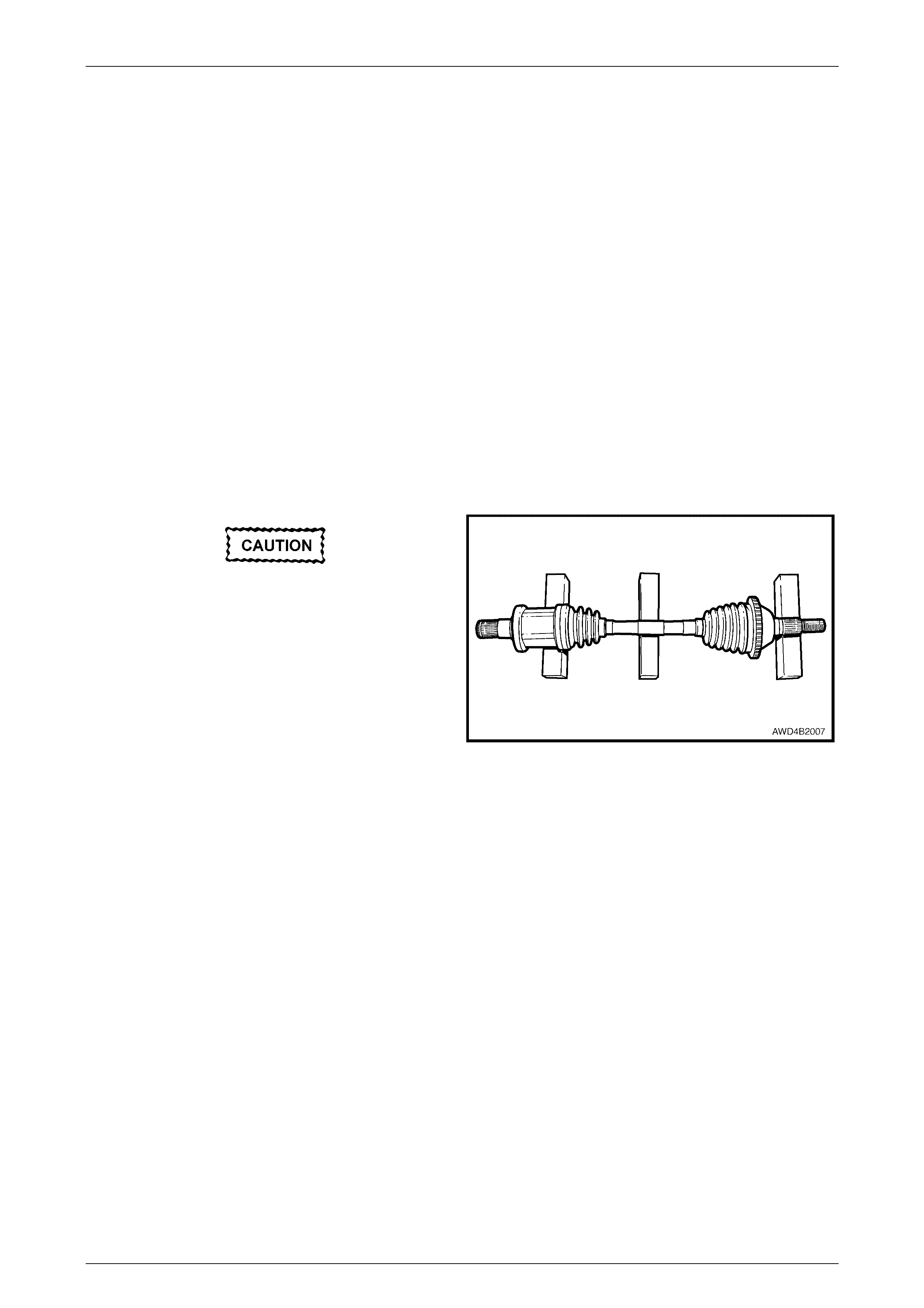

The removed driveshaft must be handled

with care. Do not rest the shaft or bellows for

any longer than necessary. Shaft is not to be

allowed to hang free on one end. Driveshaft

joint deflection should be kept to a minimum

by supporting the driveshaft with wooden

blocks, as shown.

NOTE

If both driveshafts are removed, the left side is

shorter than the right.

Figure 4B2 – 10

Reinstall

1 Install adaptor from slide hammer J 2619-O1 to the driveshaft remover installer, Tool No. DT-47570.

2 Install remover/installer Tool No. DT-47570 to the machined groove in the tripot housing and tighten the thumb

screw to secure.

3 Coat the tripot splines with the recommended final

drive lubricant, then reinstall the shorter driveshaft

tripot joint into the front final drive (left side) or the

longer driveshaft tripot joint into the support bearing

(right side).

Under no circumstances is the driveshaft to

be used as a ram to install the tripot joint. If

this occurs, damage to the needle rollers in

the joint will most likely result.

4 Fully install the tripot joint by using the slide hammer

J 2619-O1, working against its adaptor.

5 Remove the slide hammer J-2619-O1, adaptor and the

remover/installer DT-47570.

6 Check that the retaining ring on the shaft is engaged,

by attempting to pull outwards on the tripot joint

housing. Disengagement should not be possible. Figure 4B2 – 11

7 Lightly lubricate the outer driveshaft splines (1) with

the recommended final drive lubricant, then pull

outward (arrow) by hand, on the wheel speed sensor

pulse ring (2) to allow the splined outer shaft to

engage with the front wheel hub. Take care not to

damage the wheel speed sensor ring in the process.

NOTE

As the splined shaft is designed to be an

interference fit to the hub, use the old retaining

nut and washer to fully install the shaft through

the front wheel hub.

Figure 4B2 – 12

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–14

Page 4B2–14

8 Support the front control arm with a floor jack fitted

with a block of wood (1) on the lifting pad. Raise the

jack until the front control arm i s fully support ed.

9 Reinstall the front control arm ball joi nt stud into the

front control arm, fit a new nut, then use a torque

wrench (2) to tighten to the correct torque

specification.

( # ) Front control arm ball joint

stud nut torque specification.................................55 Nm

Figure 4B2 – 13

10 Raise the floor jack under the front control arm until

the strut is fully raised into the strut tower.

11 Hold the strut rod with a 10 mm socket and suitable

equipment, then fully remove the strut rod retaining nut

and discard.

12 Install a new strut rod retaining nut (3), then use a 10

mm socket to hold the strut rod (2) from turning.

13 Tighten the upper strut rod retaining nut (3) to the

correct torque specification, using a 24 mm ring

spanner with a torque wrench attached.

( ! ) Upper strut locating plate

retaining nut torque specification..........................55 Nm

14 Reinstall the dust cover (1).

Figure 4B2 – 14

15 Install holding tool KM-468 to two of the wheel studs

and secure with two reversed wheel nuts. Support the

outer end of the holding tool on a safety stand (1).

16 Remove the old hub nut and washer. Reinstall the

washer with a new nut and tighten to the correct

torque specif ication.

( ! ) Front driveshaft outer

retaining nut torque

specification.................Stage 1..........................130 Nm

Stage 2....Loosen nut until loose

Stage 3..........................200 Nm

17 If it was the left driveshaft that was removed, check

the final drive lubricant level, topping up as required.

Refer to 2.1 Checking Final Drive Lubricant Level, in

this Section.

18 Reinstall the road wheel, aligning the marks made

prior to removal and secure with attaching nuts.

Figure 4B2 – 15

19 Remove the safety stands and lower vehicle.

20 Tighten road wheel attaching nuts to the correct torque specification, working in a ‘star’ pattern, refer to

Section 10 Wheels and Tyres, in the MY 2003 VY and V2 Series Service Information.

Road wheel attaching

nut torque specification ......................................125 Nm

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–15

Page 4B2–15

21 Install the decorative wheel nut caps.

22 Bounce the vehicle up and down several times to settle the suspension.

23 Check the wheel alignment, refer to 2.2 Wheel Alignment Checking and Adjustment in Section 3 Front Suspension,

in the MY 2004 AWD Wagon Service Information.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–16

Page 4B2–16

2.5 Driveshaft Outer Constant Velocity Joint

LT Section No. – 06-200

NOTE

Disassembly of the outer constant velocity joint is

not recommended. With normal handling, the

constant velocity joint balls will not be dislodged

but, should the joint become disassembled while

handling, then the assembly must be replaced.

NOTE

There are two service kits available for this outer

constant velocity joint:

• A Boot Kit comprising the boot, two boot

clamps and a retaining ring.

• A constant velocity Joint Kit, that includes the

Boot Kit, plus a new constant velocity joint

and lubricant of the correct type and quantity.

• For lubricant quantities, refer to

5 Specifications, in this Section.

Remove

1 Remove the driveshaft. Refer to 2.4 Driveshaft Assembly, in this Section.

2 Clean the outside of the assembly with suitable cleaning solvent before removing.

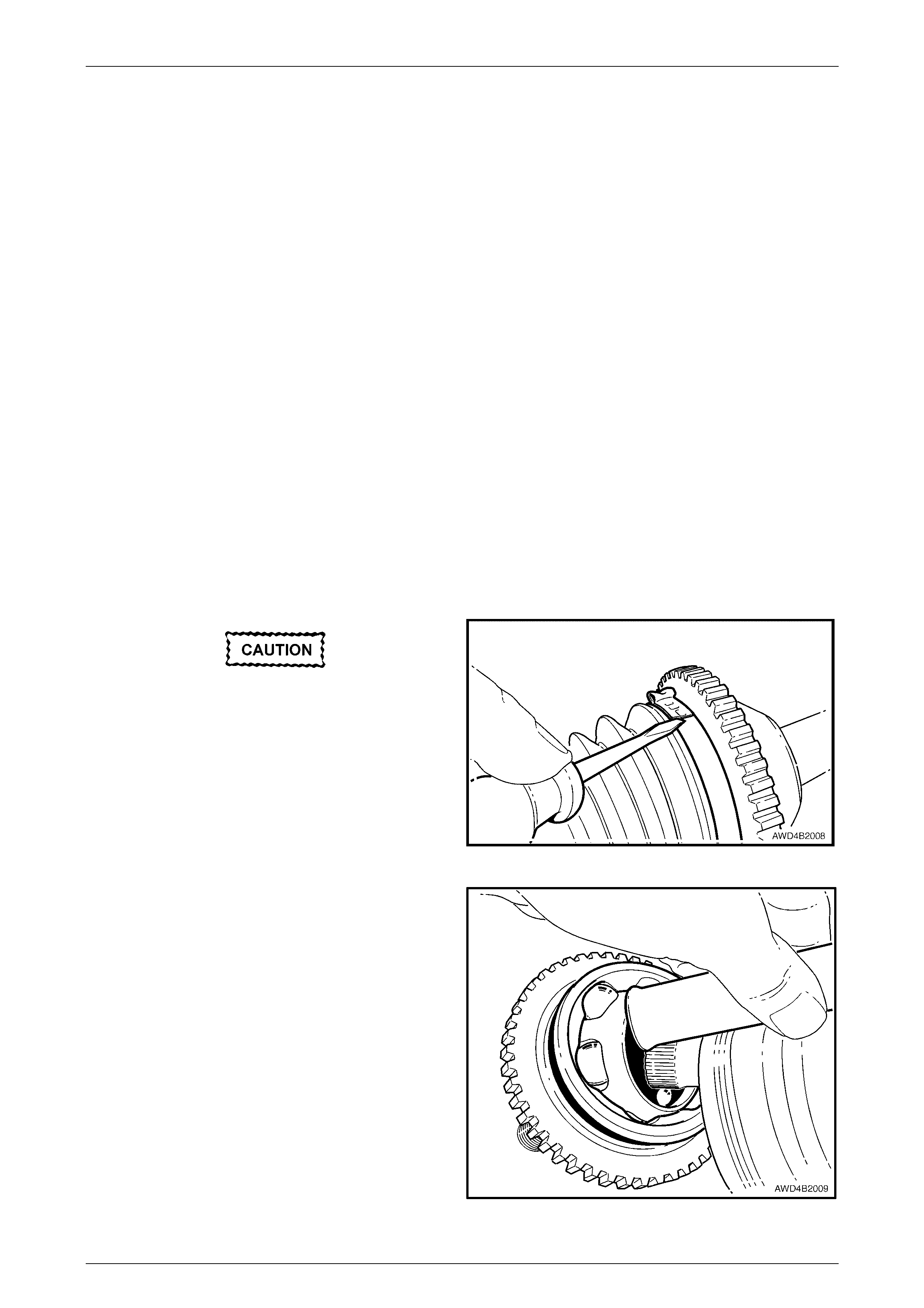

To reduce the possibility of boot damage

during the clamp removal process, it is

recommended that rag be placed over the

boot before using a screwdriver to release

clamp tension.

3 Using a small screwdriver or similar, lever the boot

clamp tang at the constant velocity joint (larger clamp)

sufficient to release the clamp tension. Discard the

removed clamp.

Figure 4B2 – 16

4 Push the boot back from the constant velocity joint and

back over the driveshaft.

5 Turn the constant velocity joint to maximum turn angle

and wipe excess grease from the inner race.

6 With the driveshaft held in a vice fitted with soft jaws,

use a brass drift on the inner race and ham mer to

dislodge the snap ring on the end of the driveshaft and

remove the constant velocity joint.

Figure 4B2 – 17

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–17

Page 4B2–17

7 Remove the snap ring (1) and discard, as it must be

replaced on reassembly of the outer constant velocity

joint to the driveshaft.

8 Clean the driveshaft with suitable cleaning solvent and

inspect the splines for damage.

Figure 4B2 – 18

9 Remove the small boot clamp from the driveshaft end of the boot and discard.

10 Slide the boot from the driveshaft.

NOTE

If a constant velocity joint requires replacement, it

is strongly recommended that a new boot be

fitted.

Reinstall

1 Divide 155 gm of the specified grease into thirds. Apply one third into the new constant velocity joint, working into

the joint. Apply the remainder to the new boot.

2 Slide a new small;l clamp onto the driveshaft, then install the boot over the driveshaft, small end first. Take care not

to damage the boot on the driveshaft splines during the installation process. Do not install any boot clamps at this

time.

3 After checking that a NEW driveshaft snap ring is

installed and undamaged, install the new constant

velocity joint onto the driveshaft, using a plastic faced

hammer. To check for correct installation, try to tug the

driveshaft from the constant velocity joint.

Figure 4B2 – 19

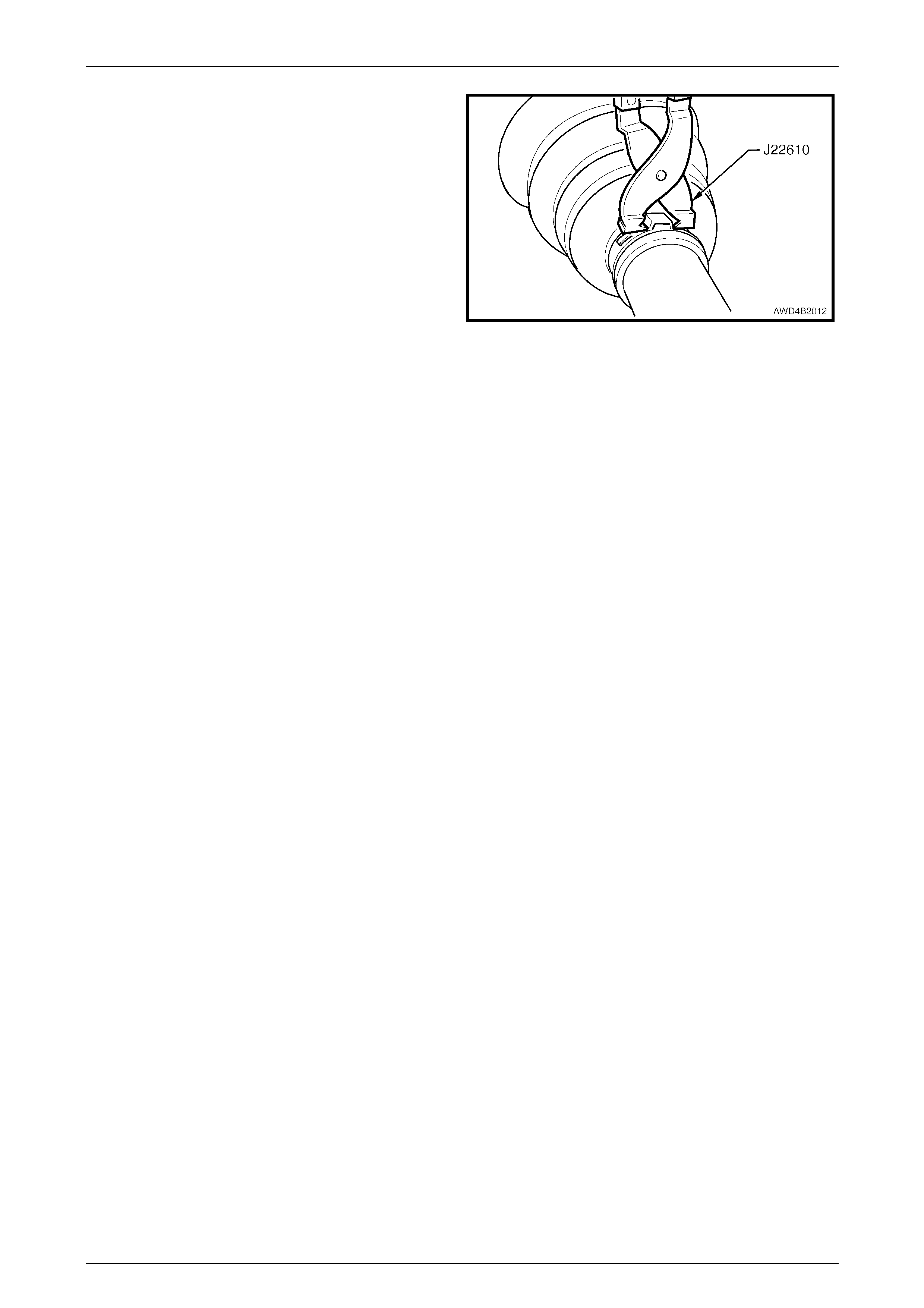

4 Install a new, large boot clamp to secure the boot to the constant velocity joint end, using Tool No. J22610. Load

clamp until the gap between the 'ears' is reduced to 1 – 2 mm.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–18

Page 4B2–18

5 Position the small end of the boot into the groove in

the drivesha ft, then inst all the small cla mp into po siti on

in the boot groove.

6 Use Tool No. J22610 to secure the boot, again until

the gap between the 'ears' is between 1 and 2 mm.

7 Reinstall the driveshaft to the vehicle. Refer to

2.4 Driveshaft Assembly in this Section.

Figure 4B2 – 20

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–19

Page 4B2–19

2.6 Driveshaft Inner Tripot Joint

Disassemble

LT Section No. – 06-200

1 Remove the driveshaft. Refer to 2.4 Driveshaft Assembly, in this Section.

2 Clean the outside of the tripot assembly with suitable cleaning solvent before disassembly.

3 Clamp the driveshaft in a vice fitted with soft jaws.

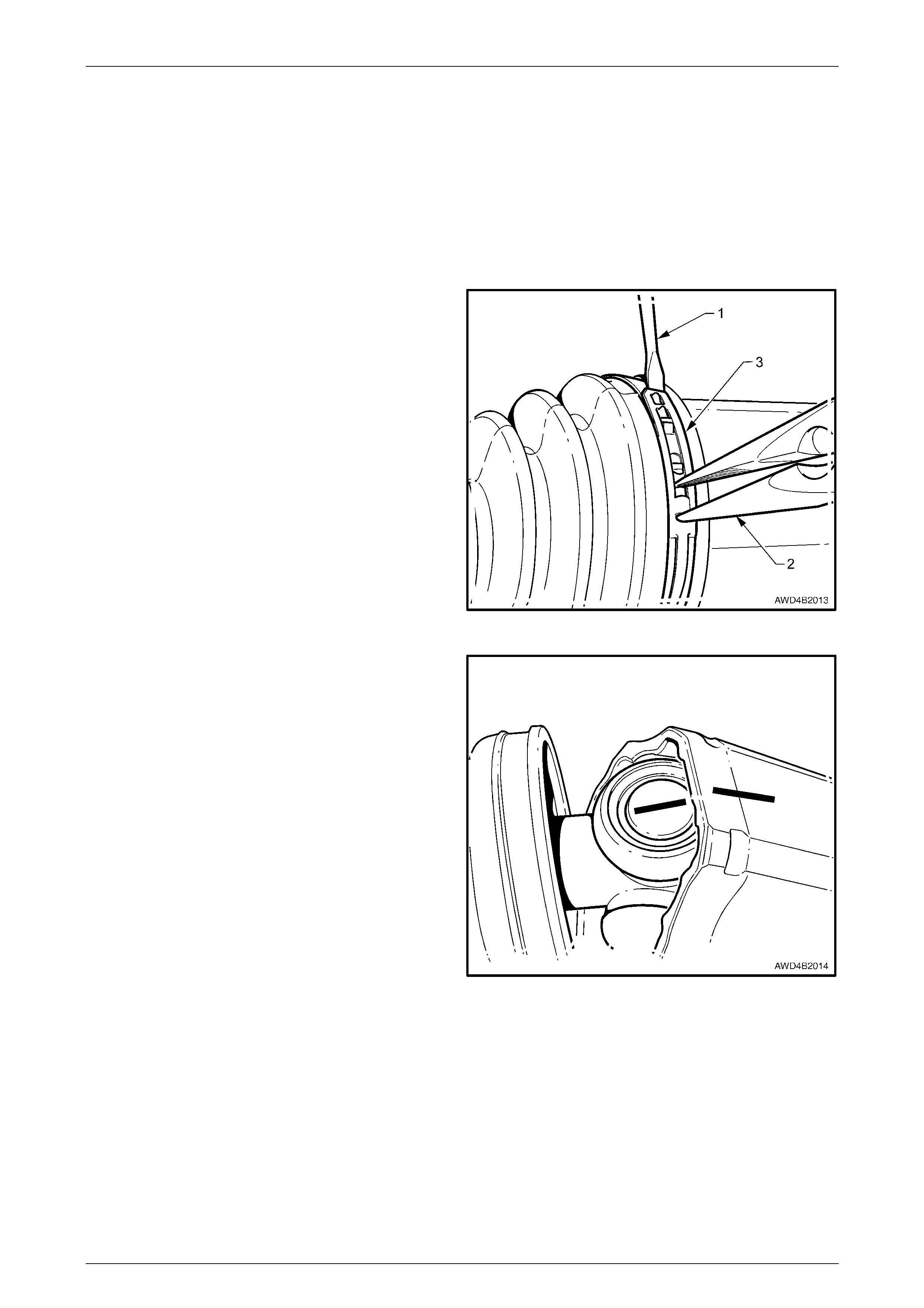

4 Using a small screwdriver (1) or similar, lever the boot

clamp tang at the constant velocity joint (larger clamp),

while using long nosed pliers (2) to tension the clamp

(3). Once released, remove and discard the clamp (3).

5 Push the boot from the tripot joint housing and back

over the driveshaft.

Figure 4B2 – 21

6 If the reason for disassembling the tripot joint is to

replace the boot only, wipe excess lubricant from the

tripot spider and use whiteout or similar, to mark the

relationship of the spider to the tripot housing.

NOTE

This is necessary to ensure that worn parts are

reassembled in their original positions.

Figure 4B2 – 22

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–20

Page 4B2–20

NOTE

There may be some resistance to separating the

trunnions from the outer body because of

distortion (1) created for production purposes.

Removing one trunnion (2) at a time until the

three are released, will overcome the problem.

Figure 4B2 – 23

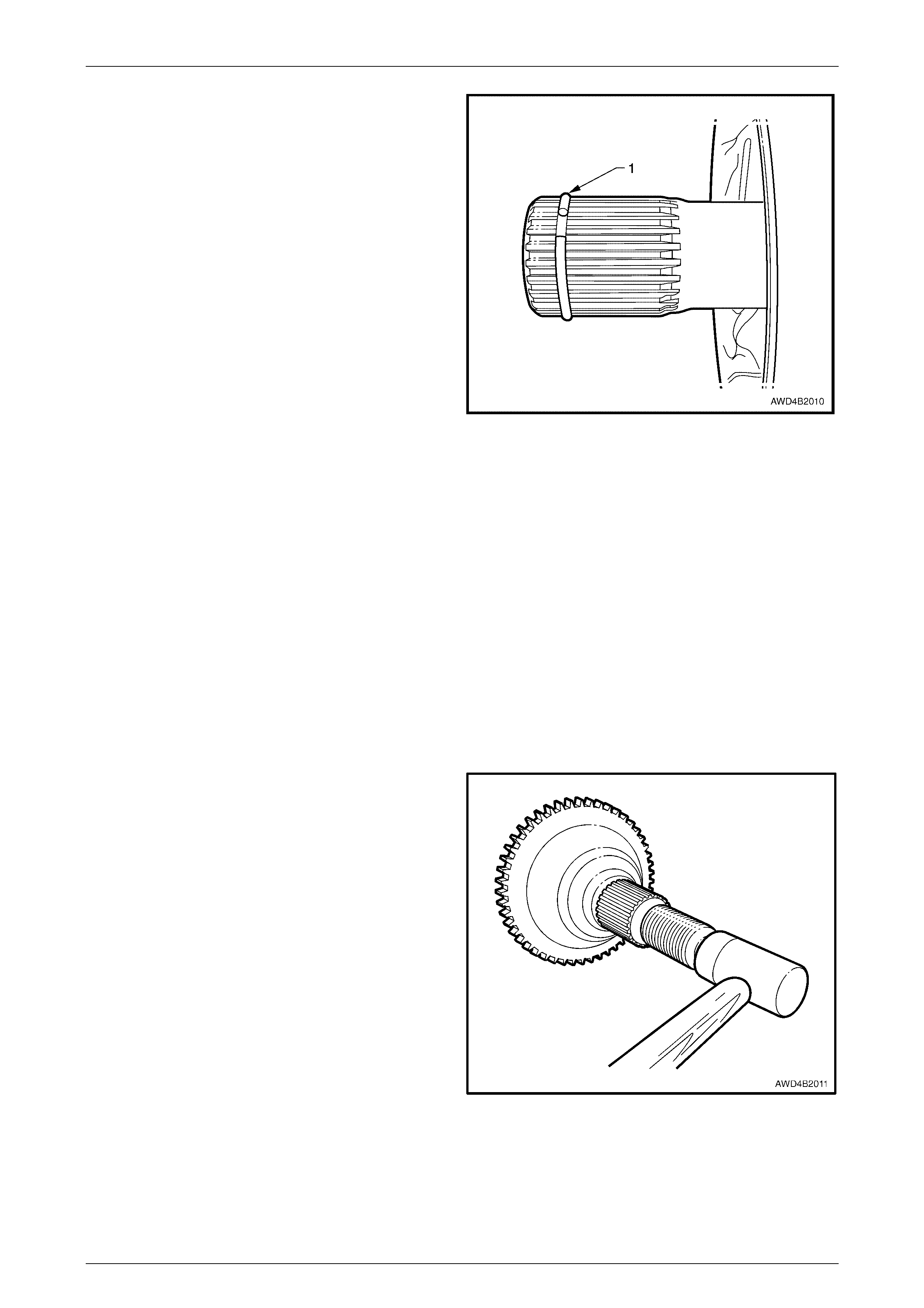

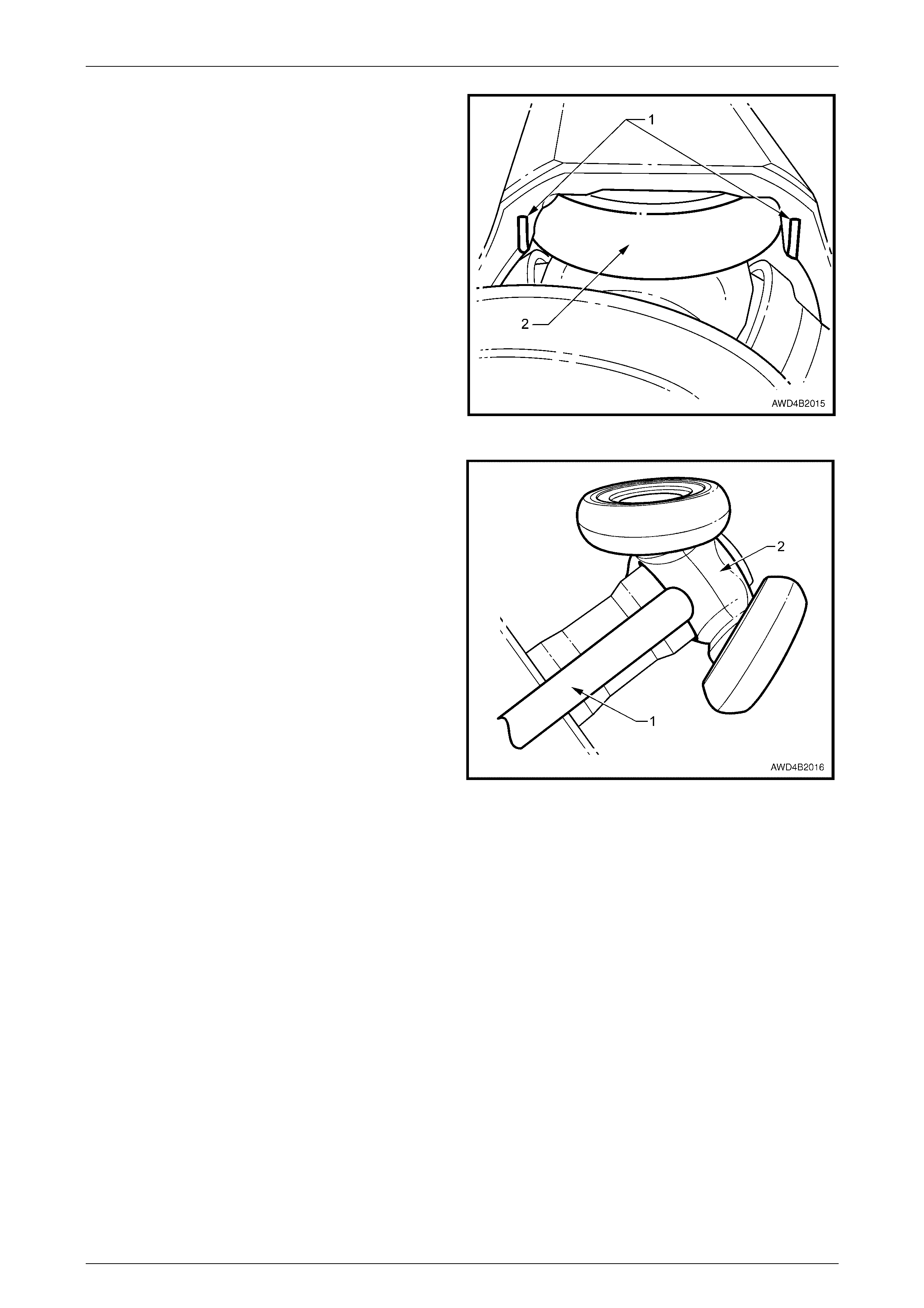

7 Using suitable circlip pliers, remove the circlip securing

the tripot spider to the driveshaft.

8 Remove the tripot spider and trunnion assembly (2)

from the driveshaft, using a brass drift (1) and hammer

on the spider as shown and not on one of the

trunnions.

NOTE

Provided excessive force is not used, the

trunnions will remain on the spider.

9 Remove the small boot clamp, then slide the boot from

the driveshaft. Discard the removed clamp.

Figure 4B2 – 24

Inspect

1 After cleaning components, check:

a. The tripot housing grooves for wear and/or scoring.

b Trunnions for excessive play or binding.

c Boot for cracks or other damage.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–21

Page 4B2–21

d The tripot and driveshaft splines (1) for wear or

damage.

NOTE

The groove (2) in the driveshaft is used to locate

the smaller end of the boot.

2 If any of the above conditions are found, then replace

the tripot assembly or the complete driveshaft.

Figure 4B2 – 25

Reassemble

1 Slide a NEW small clamp over the driveshaft, then slide the boot over the driveshaft splines, taking care not to

damage the boot on any sharp edges. Do not apply any clamps at this stage.

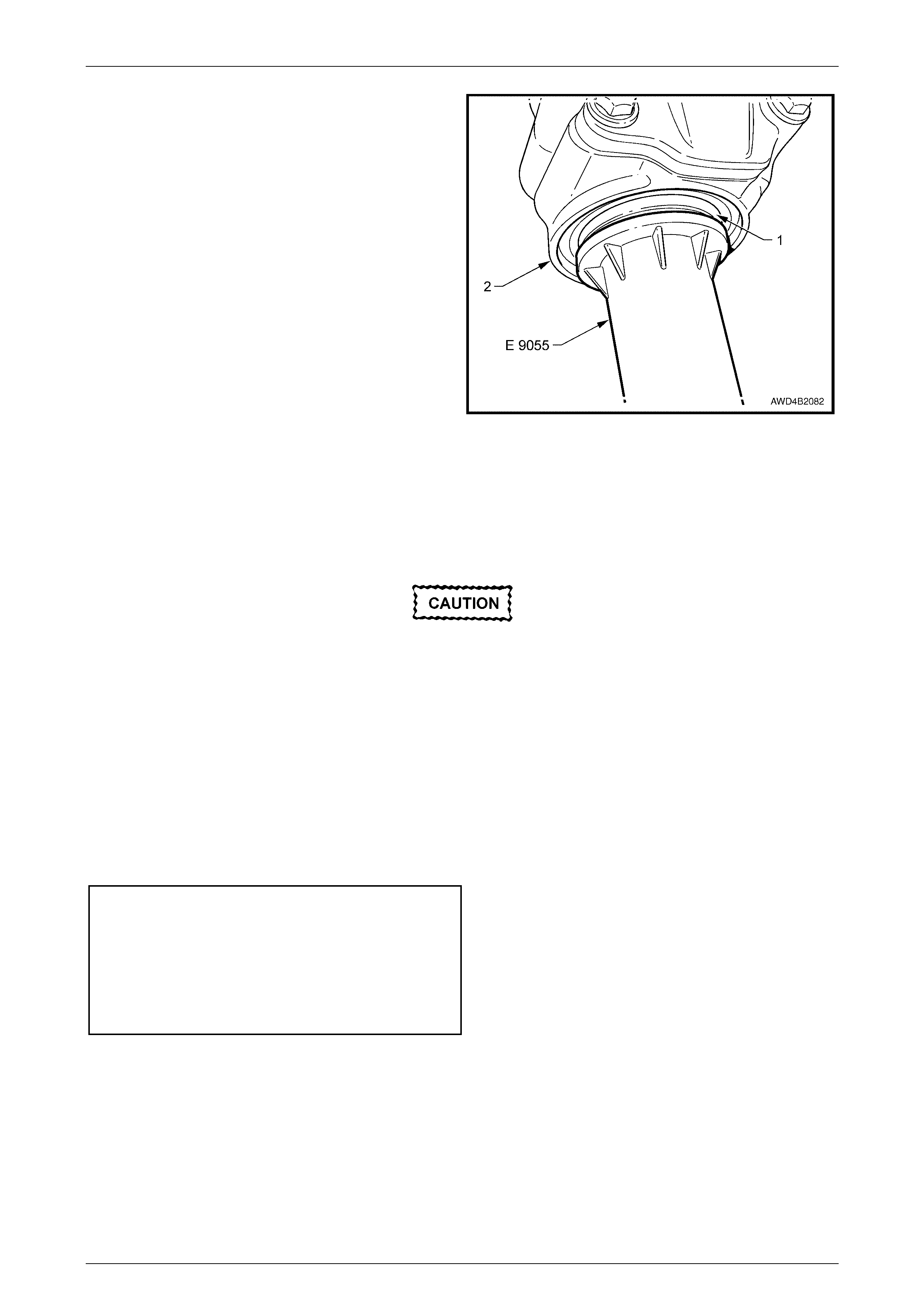

2 Reinstall the tripot spider and trunnions, noting the

following:

a The spider spline chamfer (1) faces inwards.

b Install the spider, using a tube or socket and a

plastic hammer.

c Retain the tripot spider using a NEW circlip. Do

not over-stretch the circlip during installation.

Figure 4B2 – 26

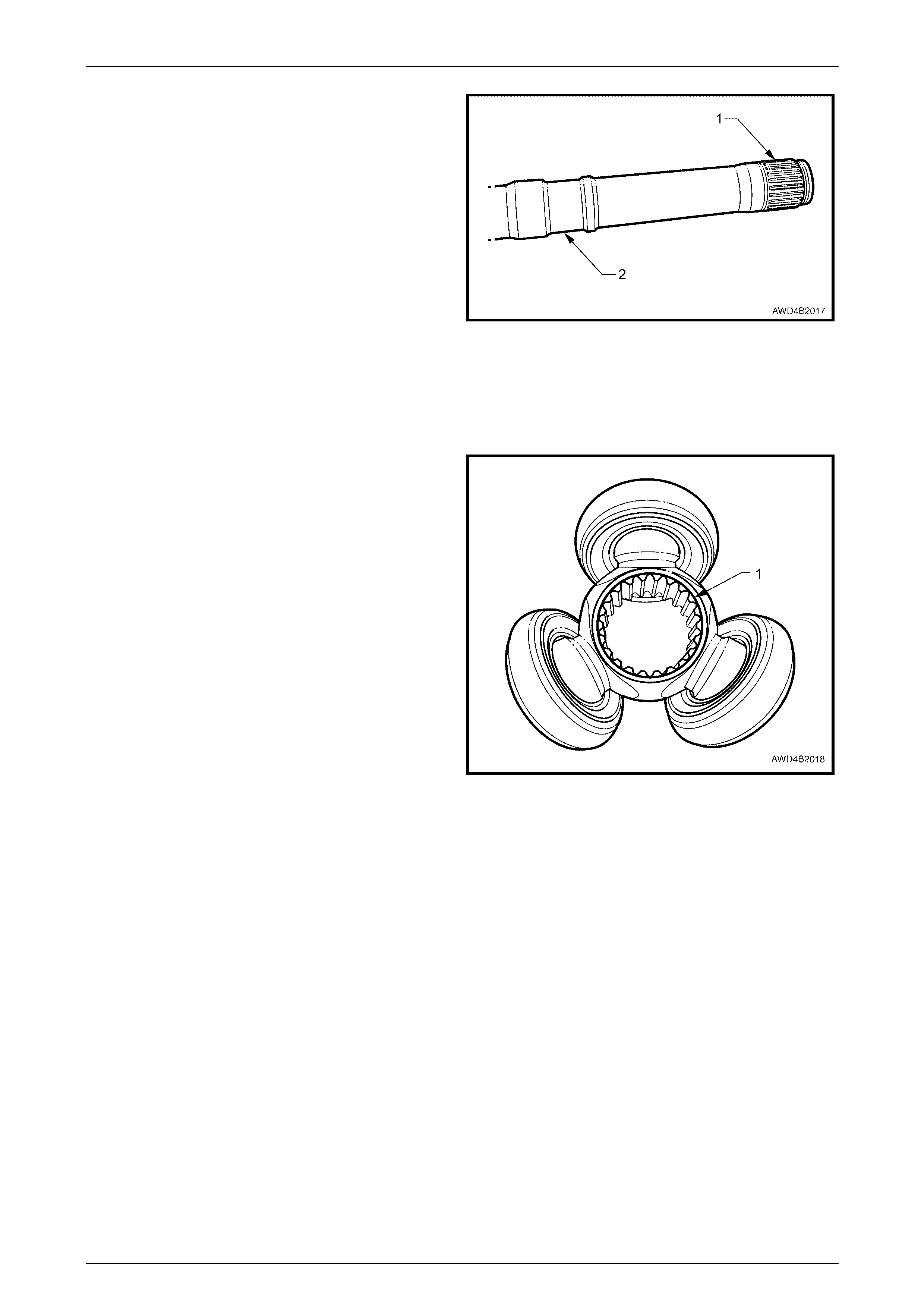

3 Apply approximately 2/3 (140 g ± 5 grams) of the supplied lubricant to the inner half of the tripot housing and the

remainder (appr oximately 60 ± 5 grams) into the boot.

4 If reinstalling the original tripot assembly (e.g. boot damage only), align the marks made before disassembly and

carefully reinstall the trunnions into the tripot housing.

5 Gently stroke the driveshaft to the end of the housing to exude the grease around the trunnions, then return the

spider to the mid-point posi tion.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–22

Page 4B2–22

6 Slide the larger end of the boot over the end of the

tripot joint, then secure with a new clamp (1),

tightening with long nosed pliers (2) until the clamp

engages with the last of the retaining barbs.

Figure 4B2 – 27

7 Locate the small boot end into driveshaft groove, then

install the new , small boot cla mp.

8 After checking that the boot is not twisted, tighten the

small boot clamp, using clamp pliers, Tool No. J22612,

until the distance between the clamp 'ears' is between

1 to 2 mm.

9 Plunge the tripot joint in and out to check that there

are no leaks.

Figure 4B2 – 28

10 Reinstall the driveshaft. Refer to 2.4 Driveshaft Assembly, in this S ect ion.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–23

Page 4B2–23

2.7 Bearing Housing/Final Drive Carrier

Outer Oil Seal

LT Section No. – 06-200

NOTE

If the bearing housing or front final drive

assembly, inner oil seal fails, then the respective

assembly will need to be removed from the

vehicle to effect repairs. Refer to 3.1 Bearing

Housing Assembly, Remove or 3.2 Front Final

Drive, Rem ove in this Section.

Replace

If the seal failure occurred at the outer final

drive location, drain the lubricant into a suitable

container, before proceeding. Refer to

2.2 Changing/Flushing Final Drive Lubricant, in

this Section.

The removed driveshaft must be handled

with care. Do not rest the shaft or bellows for

any longer than necessary. Shaft is not to be

allowed to hang free on one end. Driveshaft

joint deflection should be kept to a minimum

by supporting the driveshaft with wooden

blocks, as shown.

1 Remove the driveshaft on the side where the seal

failure has occurred. Refer to 2.4 Driveshaft Assembly,

in this Section.

Figure 4B2 – 29

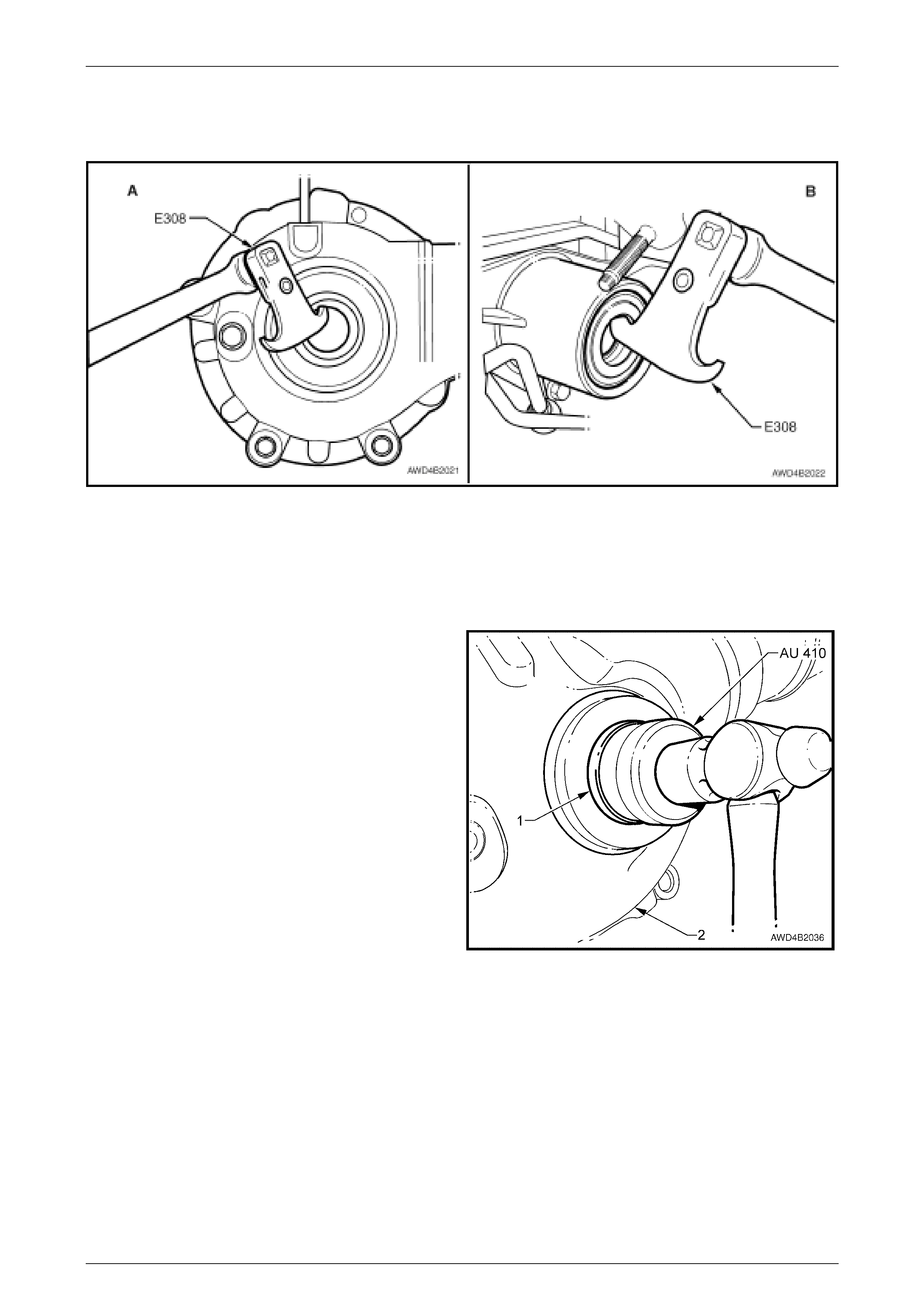

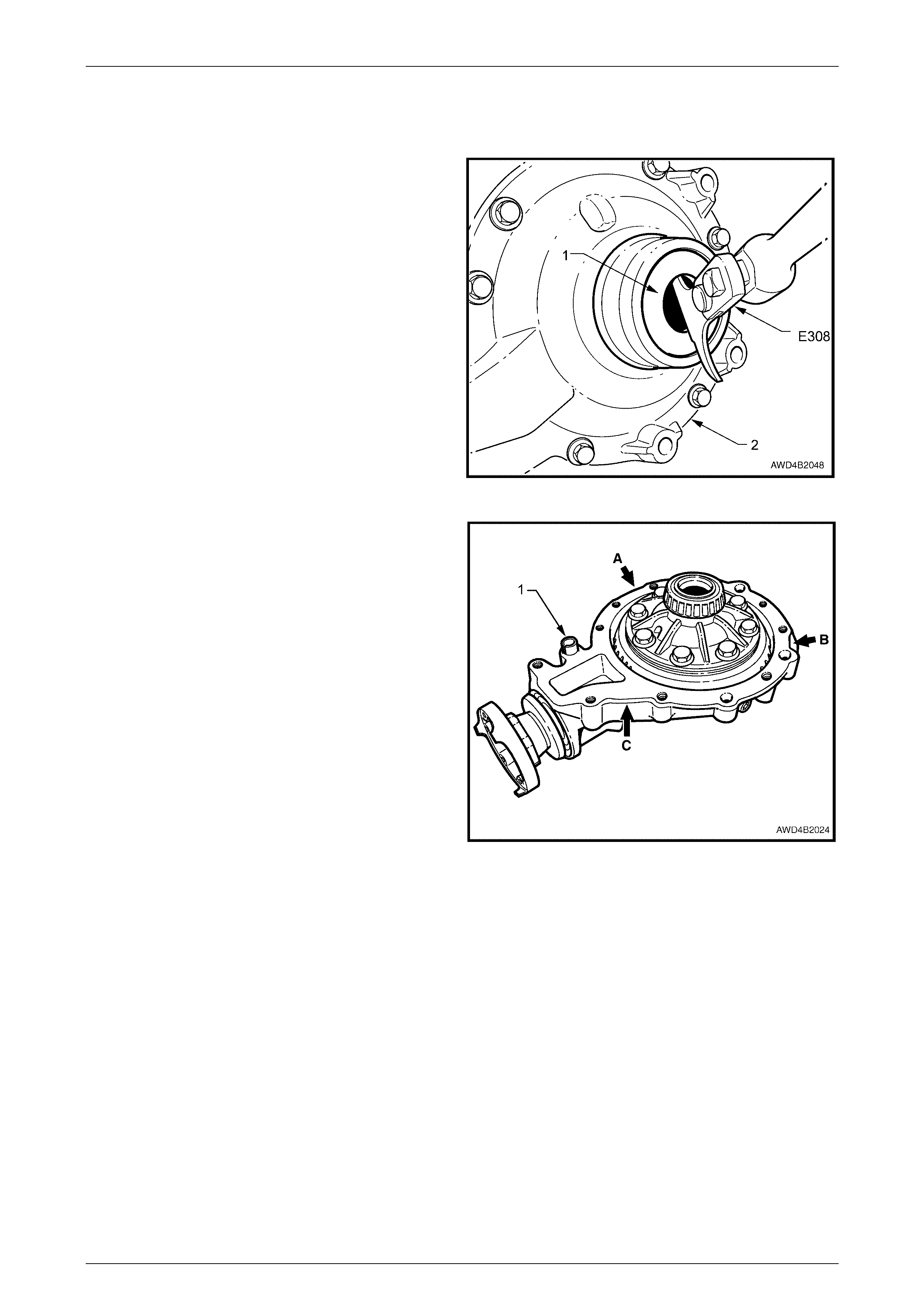

2 Using a seal removal tool such as E308 or commercial equivalent, remove the failed seal from either the front final

drive ('A') or the driveshaft bearing support housing ('B'), refer to Figure 4B2-31.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–24

Page 4B2–24

NOTE

The engine exhaust pipe is shown removed in 'B',

to more clearly show the oil seal removal.

Figure 4B2 – 30

3 Carefully inspect the seal running surface of the driveshaft for evidence of wear, nicks or scratches. If badly worn or

the damage is not repairable, then the particular tripot joint must be replaced. Refer to 2.6 Driveshaft Inner Tripot

Joint, in this Section.

4 Before installing a new oil seal, lightly lubricate with Mobilgrease XHP 222, with the recesses between the seal lips

being filled to approximately 50%.

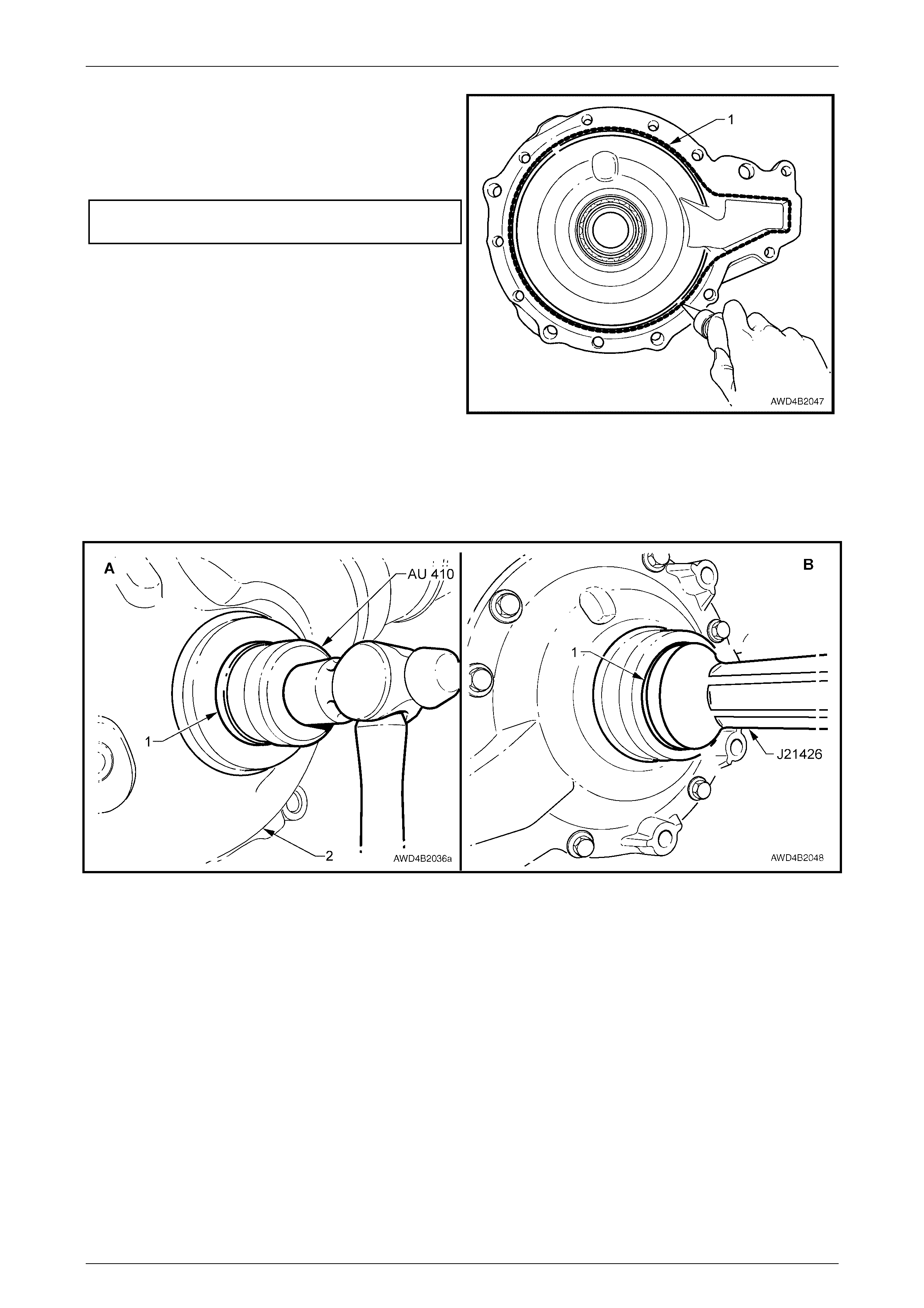

5 Using seal installer AU 410, install the oil seal (1) to

the final drive carrier housing (2) until fully seated.

NOTE

While the final drive is shown, use Tool No.

J 21426 to install the new seal to the support

bearing housing.

6 Reinstall the driveshaft. Refer to 2.4 Driveshaft

Assembly, in this Section.

7 If required, with the vehicle on level ground, fill the

front final drive with the recommended lubricant. Refer

to 2.2 Changing/Flushing Final Drive Lubricant, in this

Section.

Figure 4B2 – 31

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–25

Page 4B2–25

2.8 Pinion Oil Seal

LT Section No. – 05-290

Replace

Apart from the fact that it is the front propeller shaft that needs to be removed (rather than the rear), the procedure for the

front final drive pinion oil seal replacement is the same as that described for the rear final drive assembly. Refer to

Section 4C2 Front Propeller Shaft & Universal Joints and Section 4B1 Rear Final Drive & Driveshafts in the MY 2004

AWD Wagon Service Information.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–26

Page 4B2–26

2.9 Pinion Flange

LT Section No. – 05-290

Replace

Apart from the fact that it is the front propeller shaft that needs to be removed (rather than the rear), the procedure for the

front final drive pinion flange replacement is the same as that described for the rear final drive assembly. Refer to

Section 4C2 Front Propeller Shaft & Universal Joints and Section 4B1 Rear Final Drive & Driveshafts. in the MY 2004

AWD Wagon Service Information.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–27

Page 4B2–27

3 Major Service Operations

ATTENTION

All fasteners are important attaching parts as they affect the performance of vital components and/or could

result in major repair expense. Where specified in this section, fasteners MUST be replaced with parts of the

same part number or an approved equivalent. Do not use fasteners of an inferior quality or substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all components.

Throughout this section, fastener torque wrench specifications may be accompanied with the following

identification marks:

!

!!

! Fasteners must be replaced after loosening.

"

""

" Vehicle must be at curb height before final tightening.

#

##

# Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

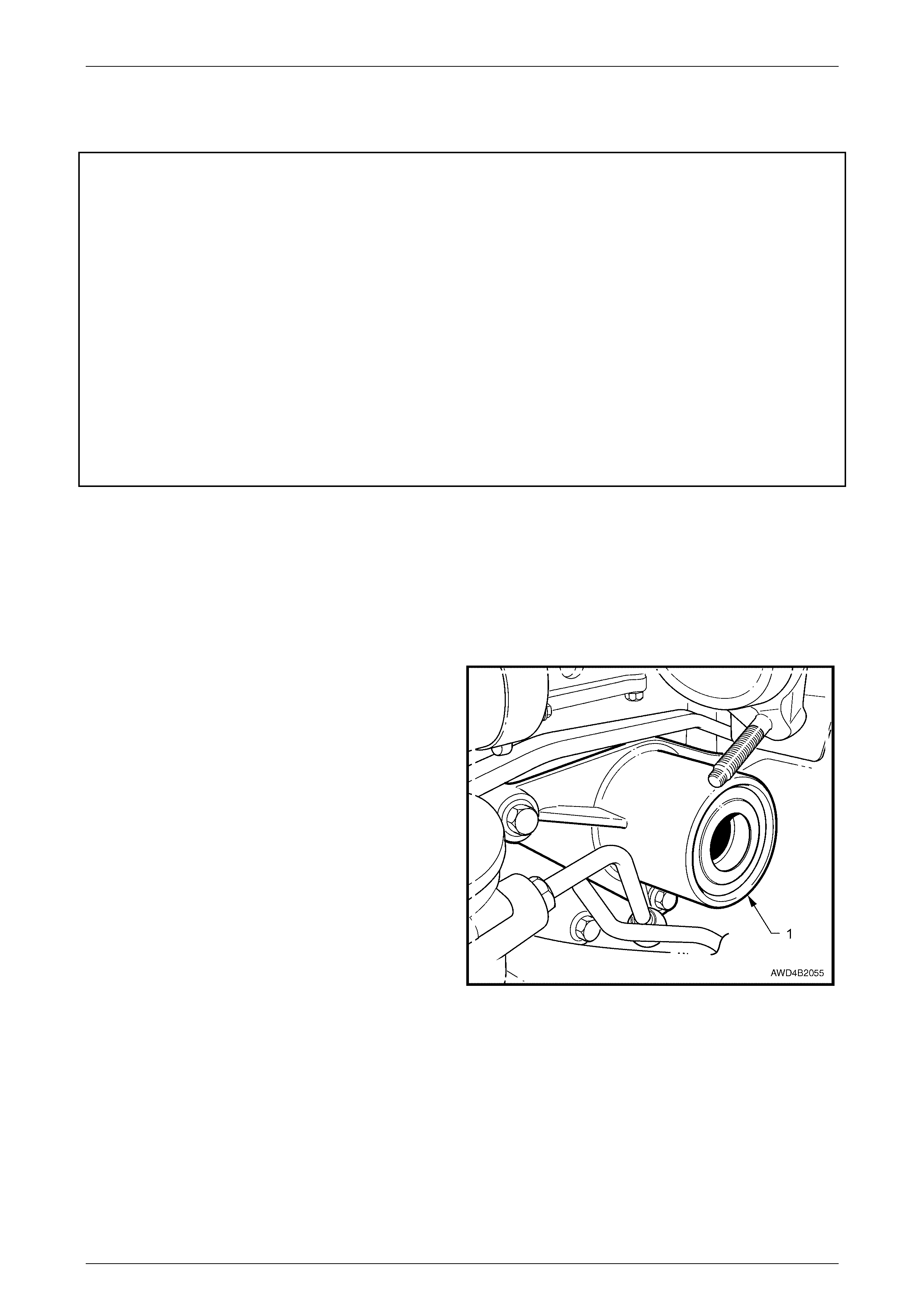

3.1 Bearing Housing Assembly

LT Section No. – 06-200

Remove

1 Remove the right driveshaft. Refer to 2.4 Driveshaft Assembly, Remove, in this Section.

2 Loosen the three bolts securing the bearing housing

assembly (1) to the oil pan. Remove the lower and

rear bolts.

NOTE

The right side exhaust pipe is only shown

removed to more clearly show the support

bearing location and mounting.

3 To fully remove the third bolt, it will be necessary to

raise the engine. Working from under the vehicle,

remove the 18 mm nuts securing both front engine

mounts to the crossmember cradle, using a deep

socket and suitab le soc ket eq uipm ent.

4 Remove cylinder No. 2 spark plug lead by first twisting

the boot to break the seal, then pull on the boot, taking

care not to pull on the lead itself.

Figure 4B2 – 32

5 Using a deep 18 mm socket, universal joint and suitable socket equipment, inserted between the front two exhaust

manifold branches, engage with, then remove the upper, right hand engine mount nut.

6 Raise the engine enough to allow the removal of the third bearing housing assembly retaining bolt. Once removed,

lower the engine back onto the mounts.

NOTE

Lowering the engine is necessary to achieve

optimum clearances for the bearing housing

assembly removal.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–28

Page 4B2–28

7 Remove the bearing housing assembly from the engine oil pan, rotating the assembly to provide sufficient

clearance.

Disassemble

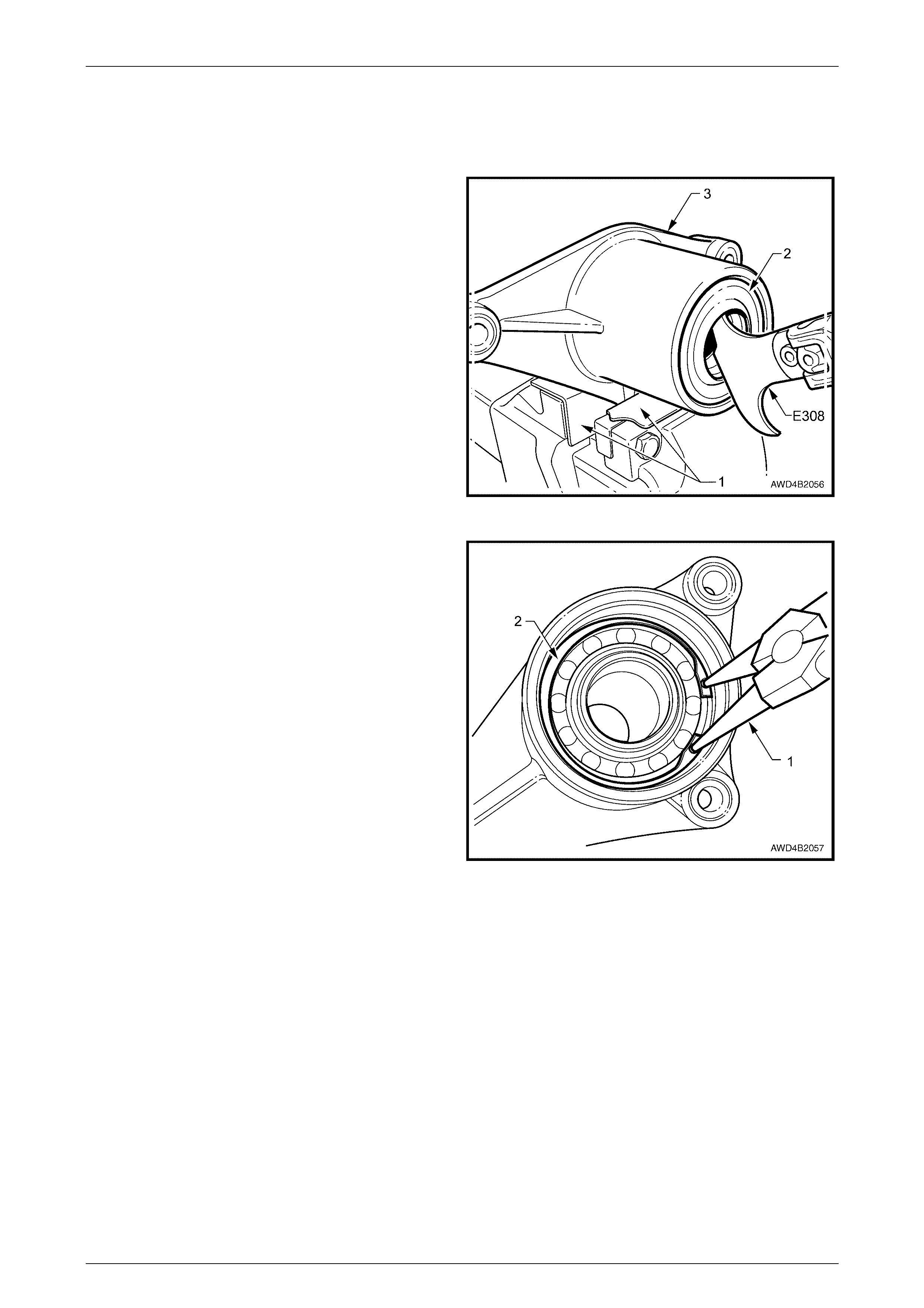

1 With the bearing housing supported in a vice fitted with

soft jaws (1), use seal remover E308 or a commercial

equivalent, to remove the outer oil seal (2) from the

support bearing housing (3).

Figure 4B2 – 33

2 Using suitable circlip pliers (1), remove the outer

bearing retaining circlip (2).

Figure 4B2 – 34

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–29

Page 4B2–29

3 Slide the connecting sleeve and outer ball bearing

race (1) from the housing (2).

NOTE

It may be necessary to bump the housing on a

piece of wood to dislodge the bearing/sleeve

assembly.

4 Remove the O-ring seal from the inner end of the

connecting sleeve and discard.

Figure 4B2 – 35

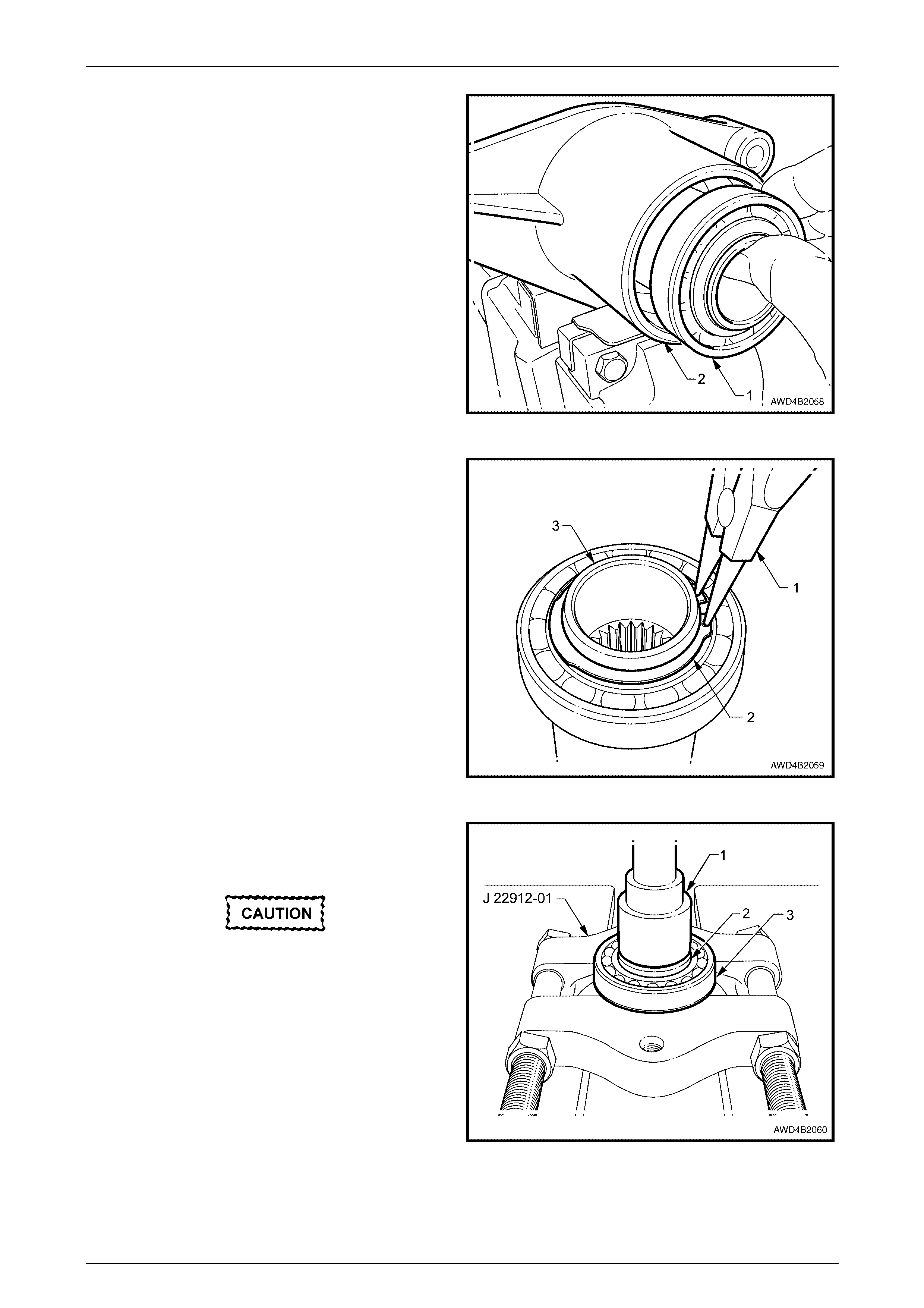

5 Using suitable circlip pliers (1), remove the ball

bearing retaining circlip (2) from the connecting sleeve

(3).

Figure 4B2 – 36

6 Using a drift/tube/socket (1) with an OD of 38 mm and

press plates J22912-01 or equivalent, press the

connecting sleeve (2) from the outer ball bearing (3).

• Do not allow the connecting sleeve to

drop to the floor.

• Discard the bearing after removal as the

ball bearings may have been damaged in

the removal process.

Figure 4B2 – 37

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–30

Page 4B2–30

7 Support the bearing housing over press plates, then

use AU 410 and a drift (1) to press the needle roller

bearing and inner oil seal from the housing. Discard

the removed oil seal and needle roller bearing.

Figure 4B2 – 38

Inspect

Wear eye protection, to avoid personal injury.

1 W ash all components in a suitable solvent and blow dry.

2 Check for spline wear and/or damage in the connecting sleeve and for excess wear at both seal contact or roller

bearing areas. Replace the sleeve if damage/wear is detected.

3 Check the housing for cracks or other damage. Also check that neither bearing is a loose fit in the housing. While

the outer ball bearing is a sliding fit, it should not be loose. If excess clearance or damage is determined, replace

the housing.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–31

Page 4B2–31

Reassemble

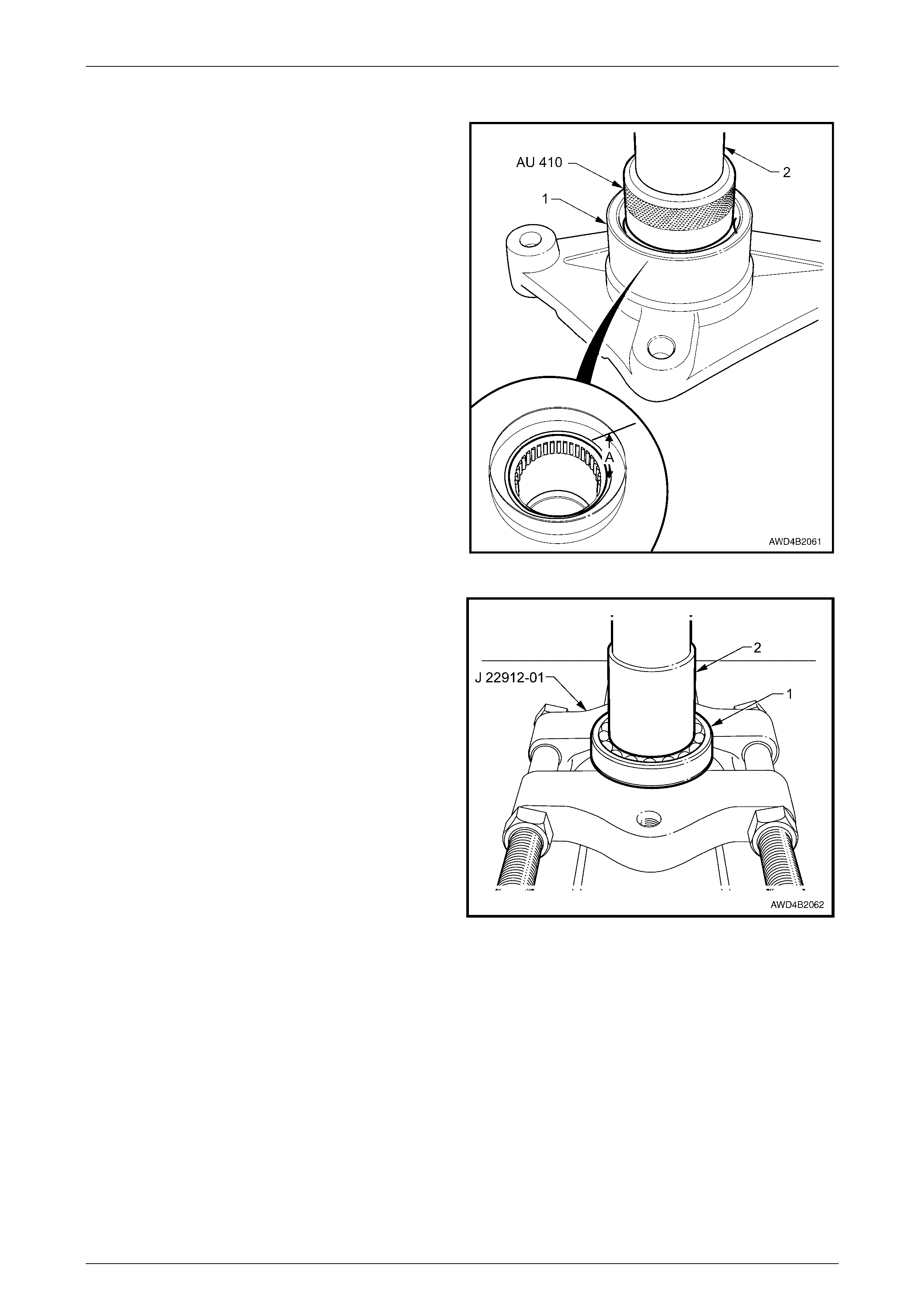

1 Pack a NEW needle roller bearing with Mobilgrease

XHP 222 and press into the housing (1) using Tool AU

410 and a suitable drift (2).

NOTE

There is no machined flange to limit the

installation depth of the needle roller bearing.

Therefore, the needle roller bearing should be

installed to a depth of 15 mm from the end face

of the housing (dimension 'A').

Figure 4B2 – 39

2 Pack the ball bearing (1) with Mobilgrease XHP 222

and press the connecting sleeve (2) into the bearing,

using Tool J22912-01 that has previously been

adjusted to a loose fit over the connecting shaft. With

the flat side of the press plates against the bearing,

the press load will be taken on the inner race.

3 Install a new bearing retaining circlip, using suitable

circlip pliers.

4 Smear a new O-ring with Mobilgrease XHP 222 and

install into the needle roller end of the connecting

sleeve.

5 Pack 30 – 50% of the bearing housing recess volume

with Mobilgrease XHP 222 (approximately 9 grams).

Figure 4B2 – 40

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–32

Page 4B2–32

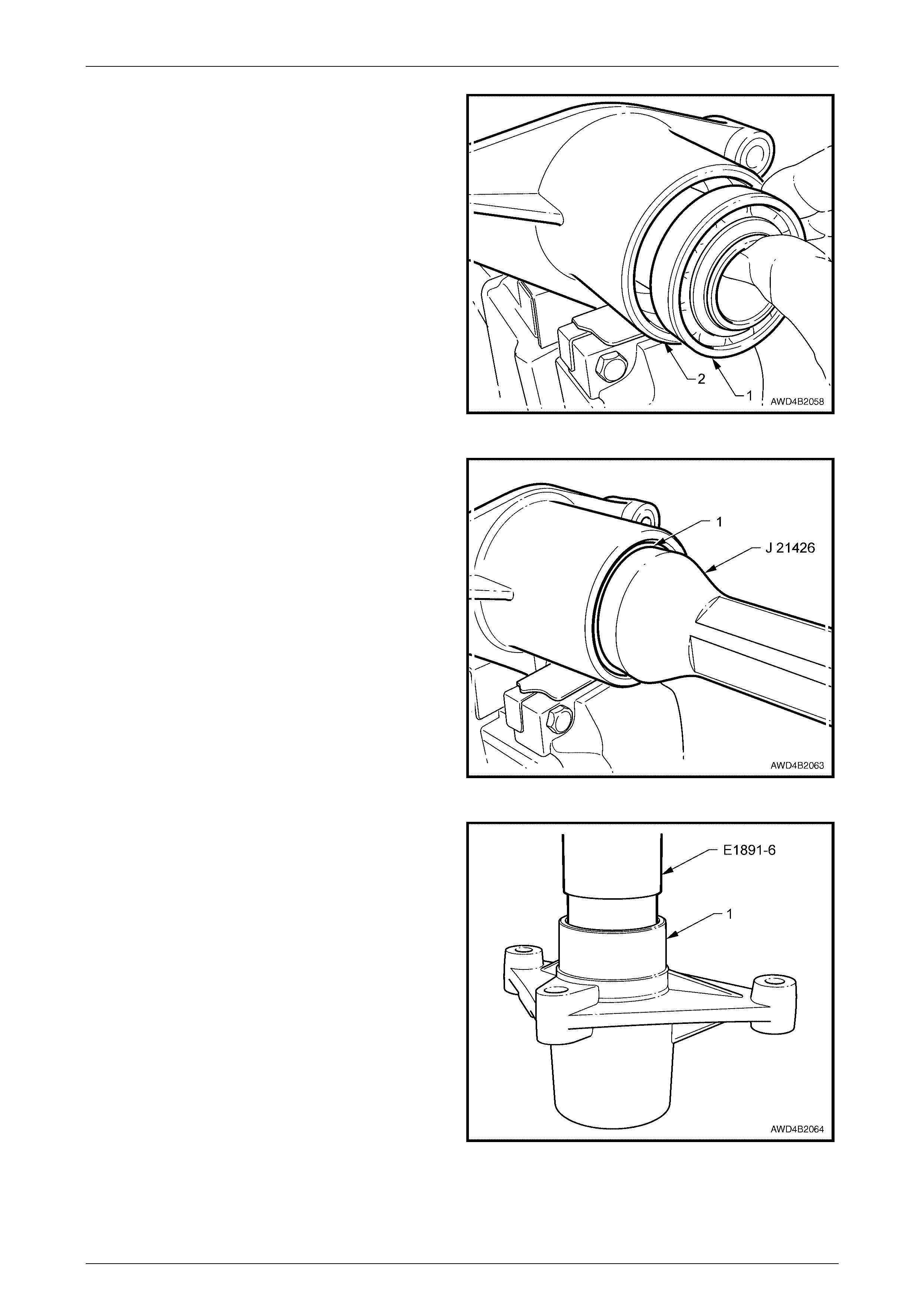

6 Slide the connecting sleeve and ball bearing (1) into

the bearing housing (2), seating with a plastic

hammer.

7 Install a new bearing to housing retaining circlip, using

suitable circlip pliers.

Figure 4B2 – 41

8 Before installing new oil seals, lubricat e with

Mobilgrease XHP 222, with the recesses between the

seal lips being filled to approximately 50%.

9 I ns tall the outer seal (1 ), using seal installer J 21426

until the seal is installed, flush with the end of the

housing.

Figure 4B2 – 42

10 Install the inner seal using sleeve E1891-6 (also

released as 3A8-6), ensuring that the seal is square to

the housing and instal led unti l the outer seal sur fac e is

flush with the housing (1).

Figure 4B2 – 43

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–33

Page 4B2–33

Reinstall

Reinstallation is the reverse of the removal procedure except for the items detailed here.

1 Ensure that the splines of the interconnecting shaft are lubricated with Mobilgrease XHP 222, then engage the

shaft splines with those in the connecting sleeve.

2 Slide the housing assembly into the interconnecting shaft and rotate to install until the housing flanges contact the

engine oil pan.

3 Reinstall the three housing retaining bolts, then tighten to the correct torque specification.

Bearing housing to engine oil pan

retaining bolt torque spe cif icat i on.........................45 Nm

NOTE

Before installation of the front bolt is possible, the

engine must be raised to allow clearance

between the right side engine mount and the

bearing housing.

4 Lower the engine, ensuring that the heat shields are each located correctly on their locating pins.

5 Ensure that the inner splines of the right side driveshaft are lubricated with Mobilgrease XHP 222, then reinstall the

driveshaft. Refer to 2.4 Driveshaft Assembly, Reinstall, in this Section.

6 Install NEW engine mounting nuts to the engine mountings and tighten to the correct torque specification.

Engine mount retaining nut (upper

and lower) torque specification.............................80 Nm

7 Reinstall the spark plug lead to cylinder No. 2.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–34

Page 4B2–34

3.2 Front Final Drive Assembly

LT Section No. – 05-250

Remove

1 Remove the air cleaner assembly. Refer to 5.5 Air Cleaner Assembly, in Section 6C3-3 Service Operations, in the

MY 2003 VY and V2 Series Service Information.

2 Remove the coolant reservoir overflow tube from its

clamp, then remove the heat shield (2) protecting the

Powertrain Control Module (PCM) by pulling up evenly

on each end. Set to one side.

3 Remove the coolant recovery reservoir from the two

mounting pegs, lift up, roll over and disconnect the low

coolant sensor wiring harness connector. Lay the

reservoir forward, leaving all hoses and the cap

installed.

4 Remove the PCM cover (1) and set to one side.

5 Remove the PCM (3) from the engine compartment.

Refer to 2.1 Powertrain Control Module (PCM),

Remove, Section 6C3-3 Service Operations, in the M Y

2003 VY and V2 Series Service Information.

6 Remove the two screws (5) securing the PCM cradle

(4) to the inner fender skirt, then remove the cradle

from the engine compartment.

Figure 4B2 – 44

7 Remove the left side exhaust manifold. Refer to 2.21 Exhaust Manifold, in Section 6A3 Engine Mechanical, in the

MY 2003 VY and V2 Series Service Information.

NOTE

Remove the exhaust manifold from the engine

bay, in the gap left by the removed air cleaner

assembly.

8 Loosen the four 13 mm bolts (1) securing the left side

engine mount bracket to the engine block, then

remove the upper engine mount to bracket nut (2),

using an 18 mm deep socket. Discard the removed

nut.

9 Raise the vehicle, and support in a safe manner. Refer

to Section 0A General Information , for the location of

jacking and support points.

Figure 4B2 – 45

10 Drain the lubricant from the front final drive assembly. Refer to 2.2 Changing/Flushing Final Drive Lubricant, in this

Section.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–35

Page 4B2–35

11 Completely remove the front propeller shaft. Refer to 2.1 Propeller Shaft, Remove, in Section 4C2 Front Propeller

Shaft & Universal Joints, in the MY 2004 AWD Wagon Service Information.

12 Remove both driveshafts. Refer to 2.4 Driveshaft Assembly, Remove, in this Section.

NOTE

This operation will have disconnected the front

control arm ball joints.

Take care not to damage the heated oxygen

sensor during the exhaust pipe removal

procedure.

13 Disconnect the left side exhaust pipe from the exhaust manifold and the flange behind the catalytic converter. Refer

to Section 8B Exhaust System, in the MY 2004 AWD Wagon Service Information.

14 Before the exhaust pipe can be removed from the vehicle, it will be necessary to remove the rear crossmember.

Mark the relationship of the crossmember to the two side rails.

NOTE

Support of the transfer case is not required

unless the rear mount bracket is also removed.

15 Remove the two bolts on each side and the three bolts securing the rear crossmember to the transfer case

mounting bracket.

16 Remove the four flanged nuts (1) securing the left

side, upper underbody front side rail brace (2).

Remove the brace (2) from the vehicle.

Figure 4B2 – 46

17 Remove the bearing housing from the right side of the engine oil pan. Refer to 3.1 Bearing Housing Assembly,

Remove, in this Section.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–36

Page 4B2–36

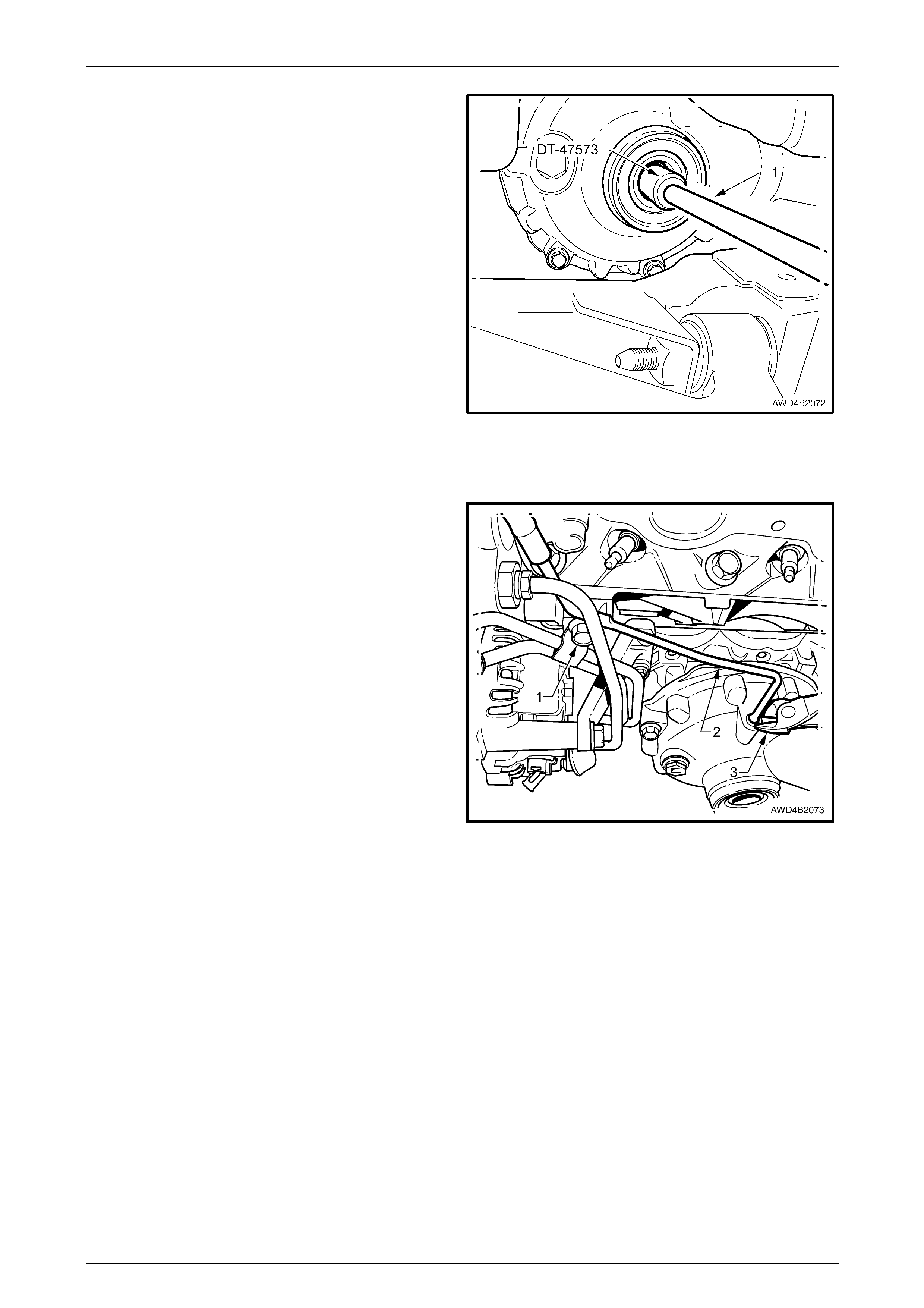

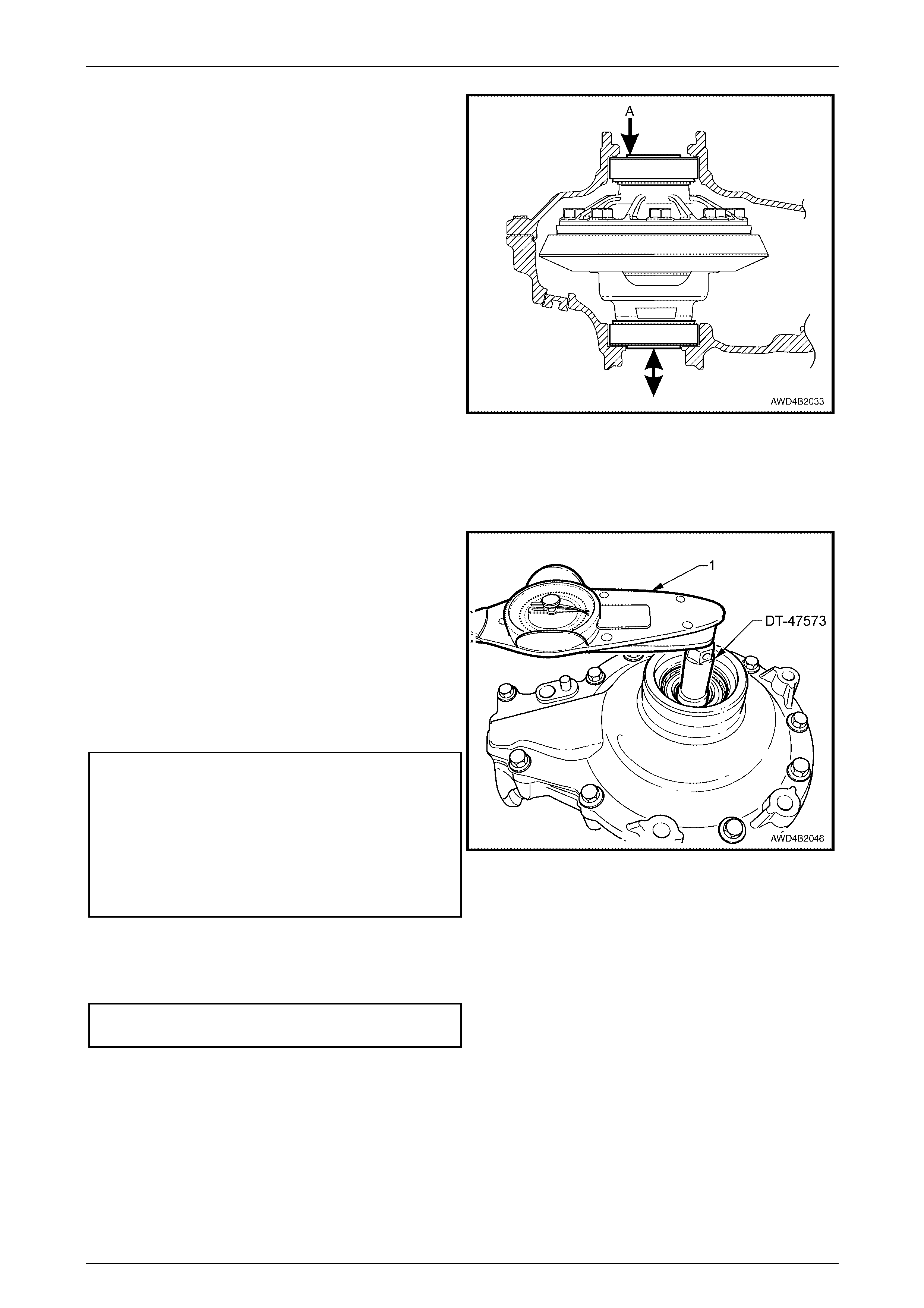

18 Insert final drive ring gear rotation Tool No. DT-47573

into the left side of the final drive and engage the

differential pinion pin.

19 Using a suitable length rod (1) and a plastic hammer,

tap the end of the rotation tool to disengage the

intermediate shaft snap ring from the right side axle

gear in the differential. Remove the interconnecting

shaft from the engine oil pan, on the right side.

Figure 4B2 – 47

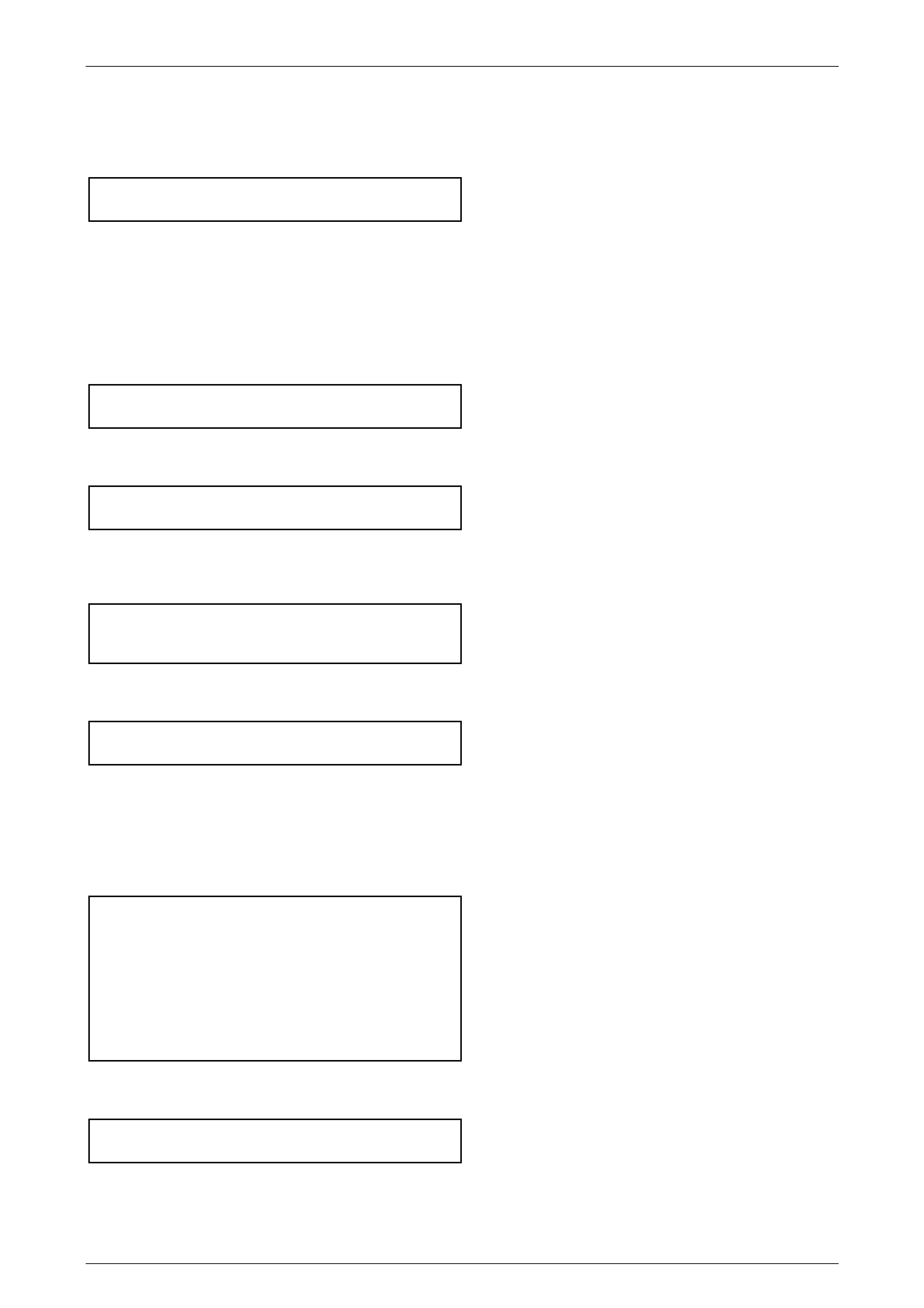

20 Support the engine, then remove the left side engine mount bracket bolts. Lift the bracket from the engine bay, then

the heat shield from the mou nt .

21 Disconnect the final drive breather pipe bracket bolt

(1), then remove the steel breather pipe (2) from the

final drive hous ing, us ing side cutting pliers (3) to prise

the pipe and O-ring free.

Figure 4B2 – 48

22 Remove the four final drive assembly to engine oil pan securing bolts.

NOTE

At this stage, it will not be possible to remove any

of the bolts completely from the final drive

housing.

23 Using a suitable lever, prise the final drive assembly from the engine oil pan, releasing the locating dowel at the

pinion end and the final drive cover boss from the engine oil pan.

24 Remove the final drive assembly from under the vehicle by lowering, pinion end first and out through the space left

by the removed side rail brace.

Reinstall

Reinstallation of the front final drive assembly is the reverse of the removal procedure, except for the following:

1 Apply Loctite 243 or equivalent to the cleaned final drive attaching bolt threads, then insert into the final drive

mounting holes. The longest bolt should be in the pinion nose location.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–37

Page 4B2–37

2 Apply a smear of final drive lubricant to the locating boss on the final drive cover housing, before reinstalling into

place in the side of the engine oil pan. Levering the assembly into place may be required to fully install the pinion

locating dowel.

3 Reinstall the four final drive assembly retaining bolts and tighten to the correct torque specification.

Front final drive assembly to engine

oil pan retaining bolts torque specification............70 Nm

4 Ensure that the splines on the interconnecting shaft are lubricated with the recommended final drive lubricant

before reinstalling into the final drive assembly. Gently tap the shaft snap ring into place in the left side differential

axle gear, using a plastic hammer. Once installed, tug on the shaft to check that the retaining ring is engaged in the

side gear groove.

5 Replace the high temperature O-ring seal to the end of the breather pipe, smear with the recommended final drive

lubricant, then reinstall the pipe into the final drive housing.

6 Secure the pipe with the breather pipe bracket bolt and tighten to the correct torque specification.

Front final drive breather pipe bracket

bolt torque specification........................................22 Nm

7 Reinstall the engine mount heat shield, then manoeuvre the engine mount bracket into position. Reinstall the four

bracket to engine block retaining bolts and tighten to the correct torque specification.

Right side engine mount bracket

bolt torque specification........................................50 Nm

8 Reinstall the exhaust manifold after cleaning the mating surfaces and fitting a new gasket. Refer to Section 6A3

Engine Mechanical – GEN III V8 Engine, in the MY 2003 VY and V2 Series Service Information. Tighten the

retaining bolts to the correct torque specification, working from the centre, outwards.

Engine exhaust manifold bolt

torque specification ..............................Stage 1 – 15 Nm

Stage 2 – 25 Nm

9 Reinstall the upper underbody front side rail brace, then secure with the four retaining nuts, tightening to the correct

torque specif ication.

Underbody front side rail brace

nut torque specification ........................................25 Nm

10 Reinstall the front propeller shaft. Refer to 2.1 Propeller Shaft, Reinstall, in Section 4C2 Front Propeller Shaft &

Universal Joints, in the MY 2004 AWD Wagon Service Information.

11 Reinstall the exhaust pipe. This will require a new gasket being fitted to the cleaned rear mounting flange.

12 Install all exhaust related fasteners and tighten to the correct torque specifications. Refer to Section 8B Exhaust

System, in the MY 2004 AWD Wagon Service Information.

Exhaust pipe to manifol d flang e

nut torque specification ........................................25 Nm

Exhaust pipe to intermediate

exhaust pipe flange bolt

torque specific atio n ..............................................45 Nm

Catalytic converter bracket to

catalytic conv ert er bolt

torque specific atio n ..............................................25 Nm

13 Reinstall the rear crossmember, aligning marks made before removal. Install all fasteners and tighten to the correct

torque specif ication.

Transmission rear crossmember

attaching bolts torque specification – All ..............55 Nm

14 Ensure that the outer splines of the interconnecting shaft are lubricated with Mobilgrease XHP 222, then slide the

housing assembly onto the interconnecting shaft, engaging the splines, until the housing flanges contact the oil

pan. Refer to 3.1 Bearing Housing Assembly, Reinstall.

Front Final Drive, Bearing Housing & Driveshafts Page 4B2–38

Page 4B2–38

15 Reinstall the three bearing housing assembly to engine oil pan retaining bolts and tighten to the correct torque

specification.

Bearing housing to engine oil pan

retaining bolt torque specification......................... 45 Nm

16 Reinstall both driveshafts. Refer to 2.4 Driveshaft Assembly, Reinstall, in this Section.

17 After checking that both engine mount heat shields are in the correct position, lower the engine weight onto the

engine mounts, reinstall and tighten new engine mount to crossmember nuts to the correct torque specification.

Engine mount retaining nut

torque specification – All ...................................... 80 Nm

18 Fill the front final drive with the recommended lubricant. Refer to 2.1 Checking Final Drive Lubricant Level and

2.2 Changing/Flushing Final Drive Lubricant, in this Section.

19 Reinstall the road wheels, aligning marks made on removal but do not tighten at this stage.

20 Lower the vehicle to the ground, bounce the front suspension several times, then push backwards and forwards to

settle the suspension.

21 Tighten the road wheel nuts working in a star pattern to the correct torque specification. Refer to

Section 10 Wheels and Tyres, in the MY 2003 VY and V2 Series Service Information.

Road wheel attaching

nut torque specification ...................................... 125 Nm

22 Check and correct (as required) the front wheel alignment. Refer to 2.2 Wheel Alignment Checking and

Adjustment, in Section 3 Front Suspens ion, in MY 2004 AWD Wagon Service Information.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–39

Page 4B2–39

3.3 Removed Final Drive Assembly

LT Section No. – 05-250

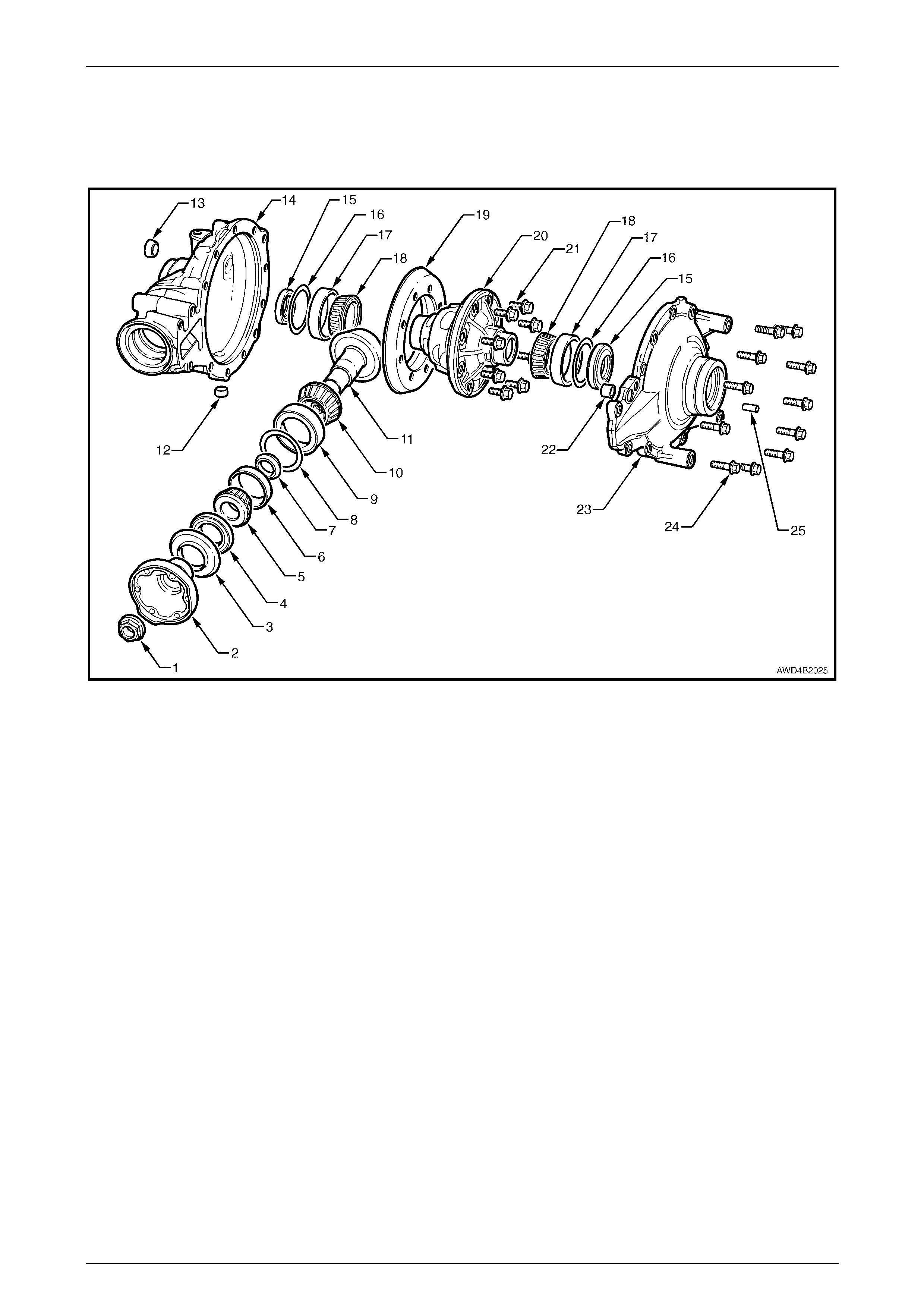

Figure 4B2-49

Legend

1 Pinion Nut

2 Pinion Flange

3 Slinger

4 Pinion Oil Seal

5 Pinion Outer (Tail) Bearing Cone

6 Pinion Outer (Tail) Bearing Cup

7 Collapsible Spacer

8 Pinion Position Shim

9 Pinion Inner (Head) Bearing Cup

10 Pinion Inner (Head) Bearing Cone

11 Hypoid Pinion Gear

12 Drain Plug

13 Filler Plug

14 Carrier Housing

15 Driveshaft Oil Seal

16 Differential Position Shim

17 Different ial Bearing Cup

18 Different i al Beari ng Cone

19 Hypoid Ring Gear

20 Differential Case

21 Ring Gear Retaining Bolts (8 pl aces)

22 Cover Aligning Hol l ow Dowel

23 Cover

24 Cover Retaining B olts (10 pl aces)

25 Pinion Nose Angle Locating Dowel

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–40

Page 4B2–40

Disassemble

Final Drive Cover

1 Using Tool No. E308 or a commercial equivalent,

remove the oil seal (1) from the cover housing (2) and

discard.

Figure 4B2 – 50

2 Support the final drive assembly, with the cover bolts

facing upward.

3 Remove the 10 cover bolts.

4 Use a suitable lever at each of the points provided ('A',

'B' and 'C'), break the sealant seal, then lift the cover

from the carrier housing and the sleeve dowel (1). Set

the cover to one side.

5 Using a suitable scraper, remove the sealant remains

from the cover and carrier housings.

Figure 4B2 – 51

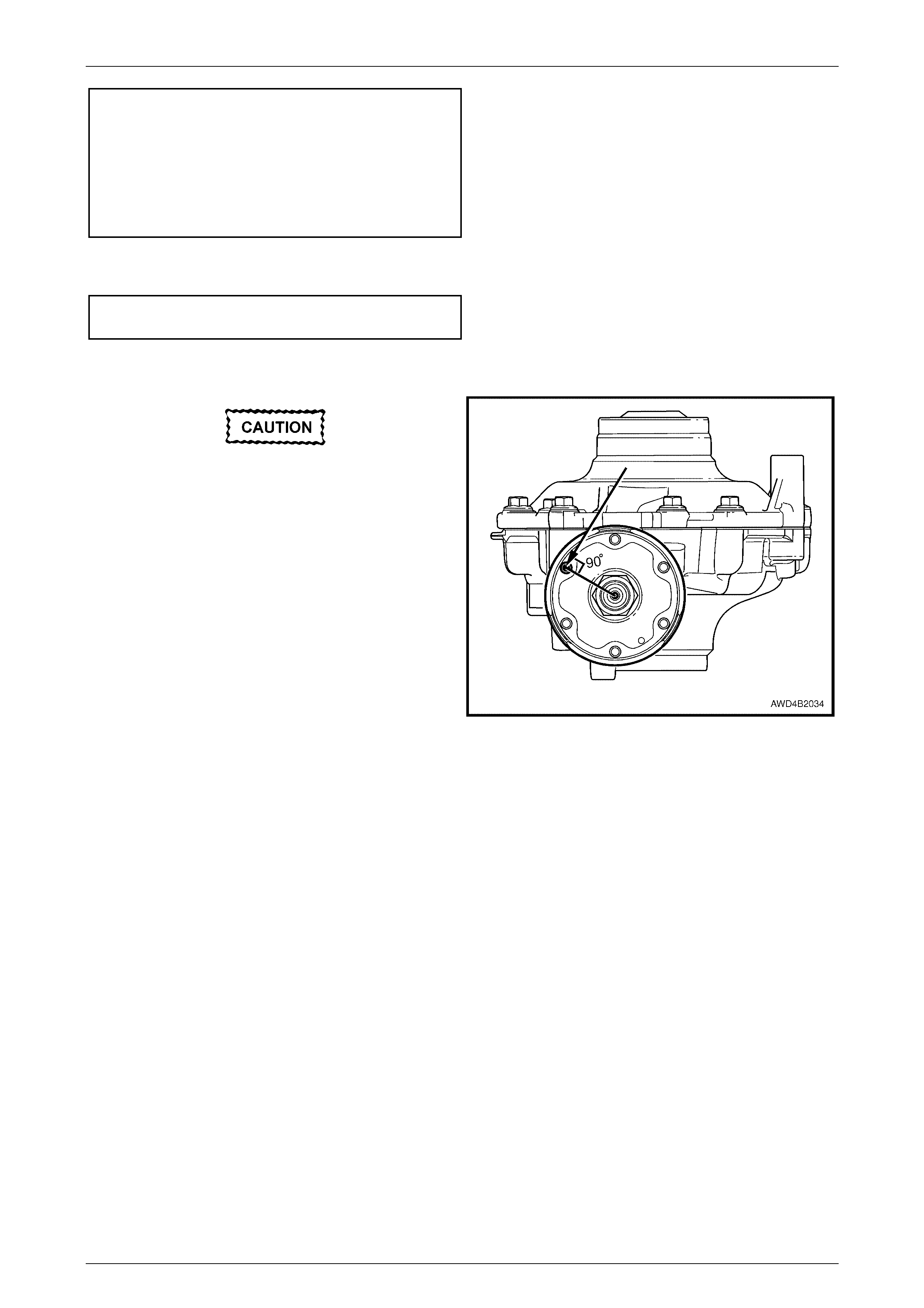

Before proceeding with the disassembly process, the gear tooth contact should be examined and recorded as a

comparison when the reassembly takes place.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–41

Page 4B2–41

Examining Gear Tooth Contact

Wear eye protection when using compressed

air to dry washed components.

Do not allow bearings to spin when applying

compressed air in the drying-off process.

1 Lift the differential and ring gear assembly from the carrier housing, then wash all components in a suitable solvent

and blow dry, using compressed air.

2 Apply light oil to the roller bearings, then apply a thin coating of a gear marking compound to the ring gear teeth.

3 Reinstall the ring gear and differential to the carrier housing, then reinstall the cover and the 10 bolts, tightening

each to the correct torque specification.

Final drive cover bolt

torque specific atio n ..............................................45 Nm

4 Install ring gear rotation tool DT-47573 to engage with the differential pin and grasp the tool to apply a load to the

ring gear while rotating the pinion about 10 times in each direction.

5 Remove the 10 bolts securing the cover to the carrier housing, then remove the cover and the ring gear/differential

assembly.

6 Examine the ring gear tooth marking and record. The most convenient method would be to use a digital camera.

Refer to 'Ring Gear and Pinion Contact Pattern', in 3.3 Removed Final Drive Assembly, Reassemble, Section 4B,

in the MY 2003 VY and V2 Series Service Information, for typical and acceptable tooth contact patterns.

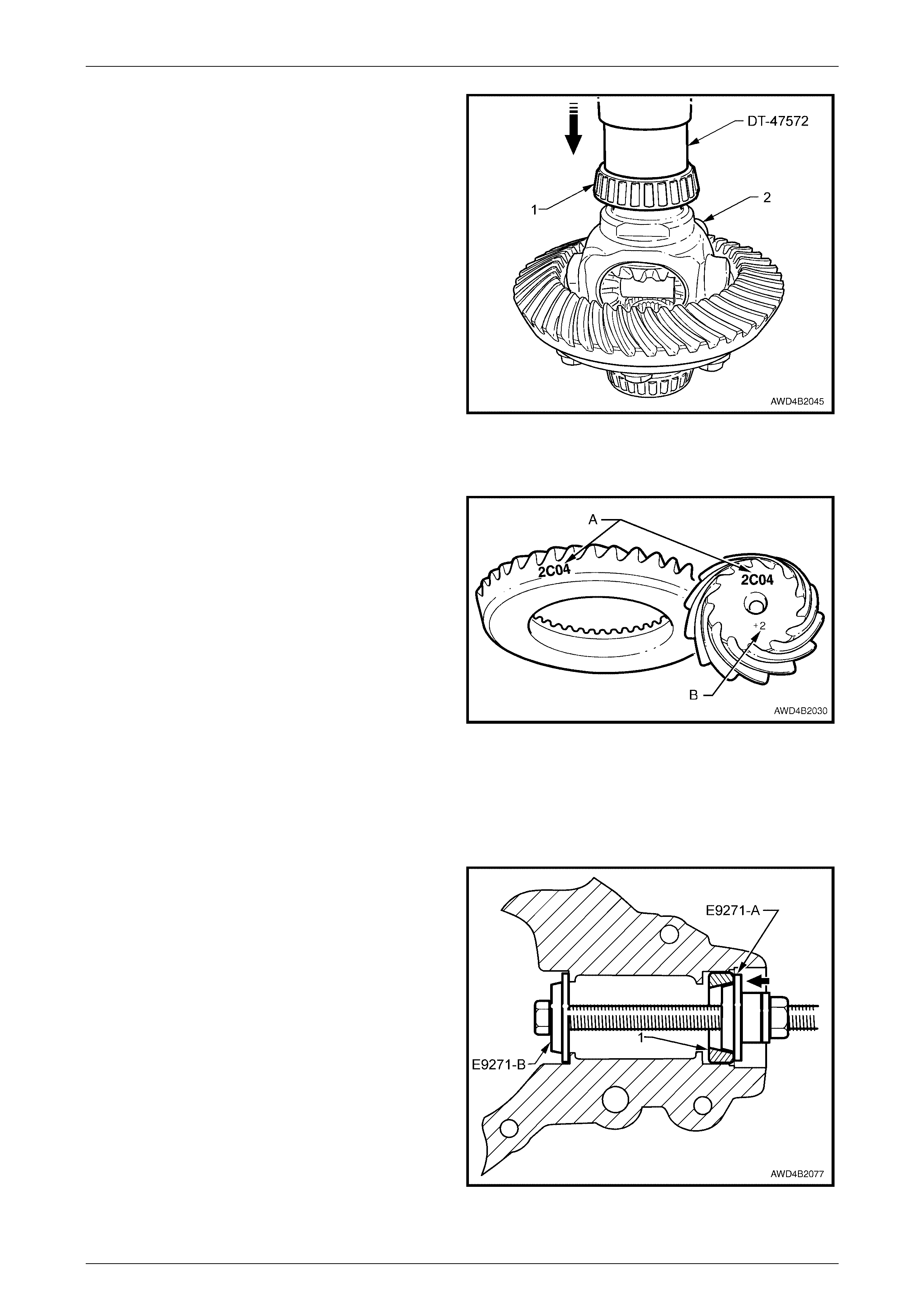

Drive Pinion

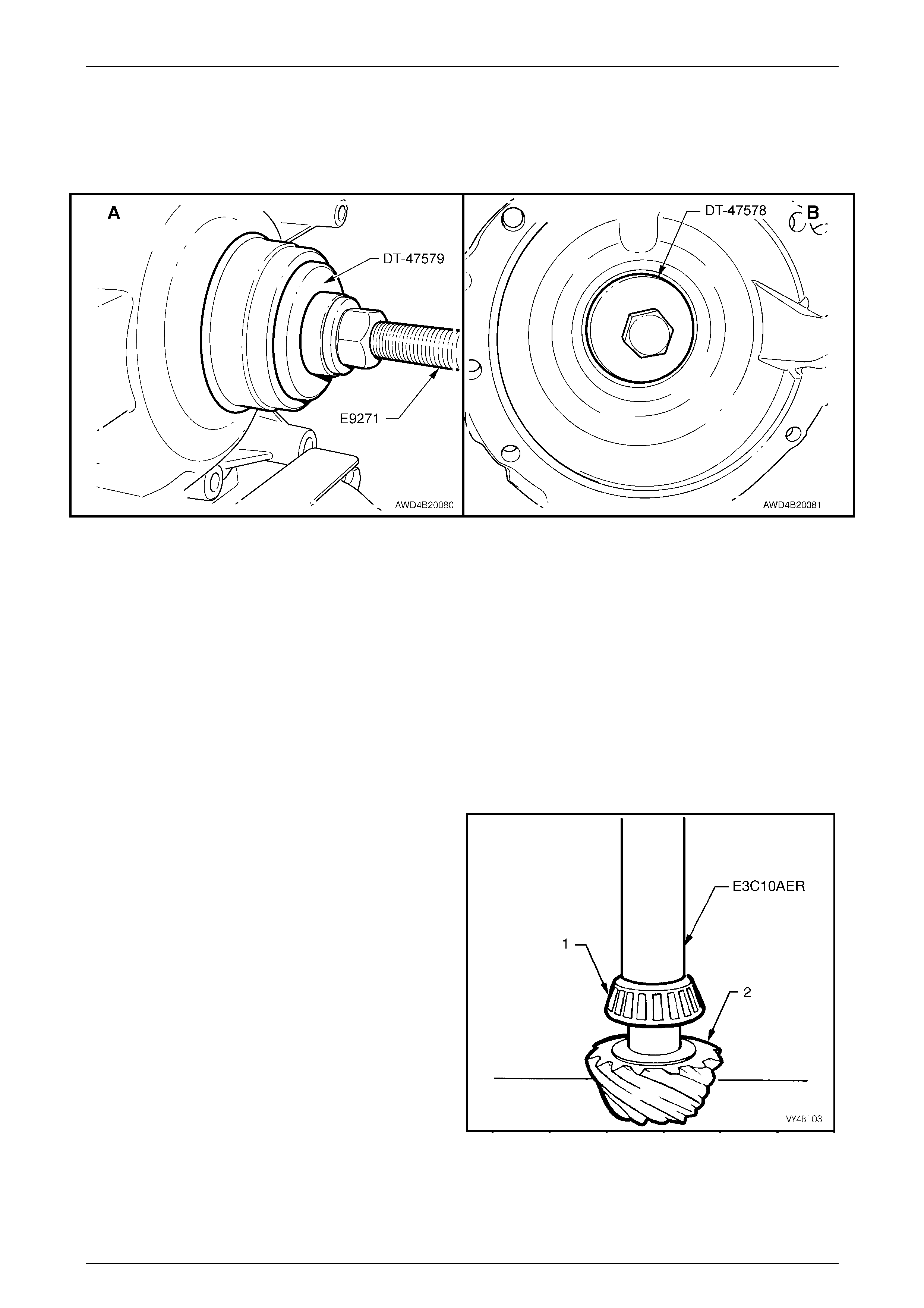

1 Mark the relationship of the pinion flange to the pinion

shaft (1), using correction fluid (e.g. 'whiteout'). This

step will minimise the chance of pinion flange runout,

should the pinion and flange not require replacement.

Figure 4B2 – 52

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–42

Page 4B2–42

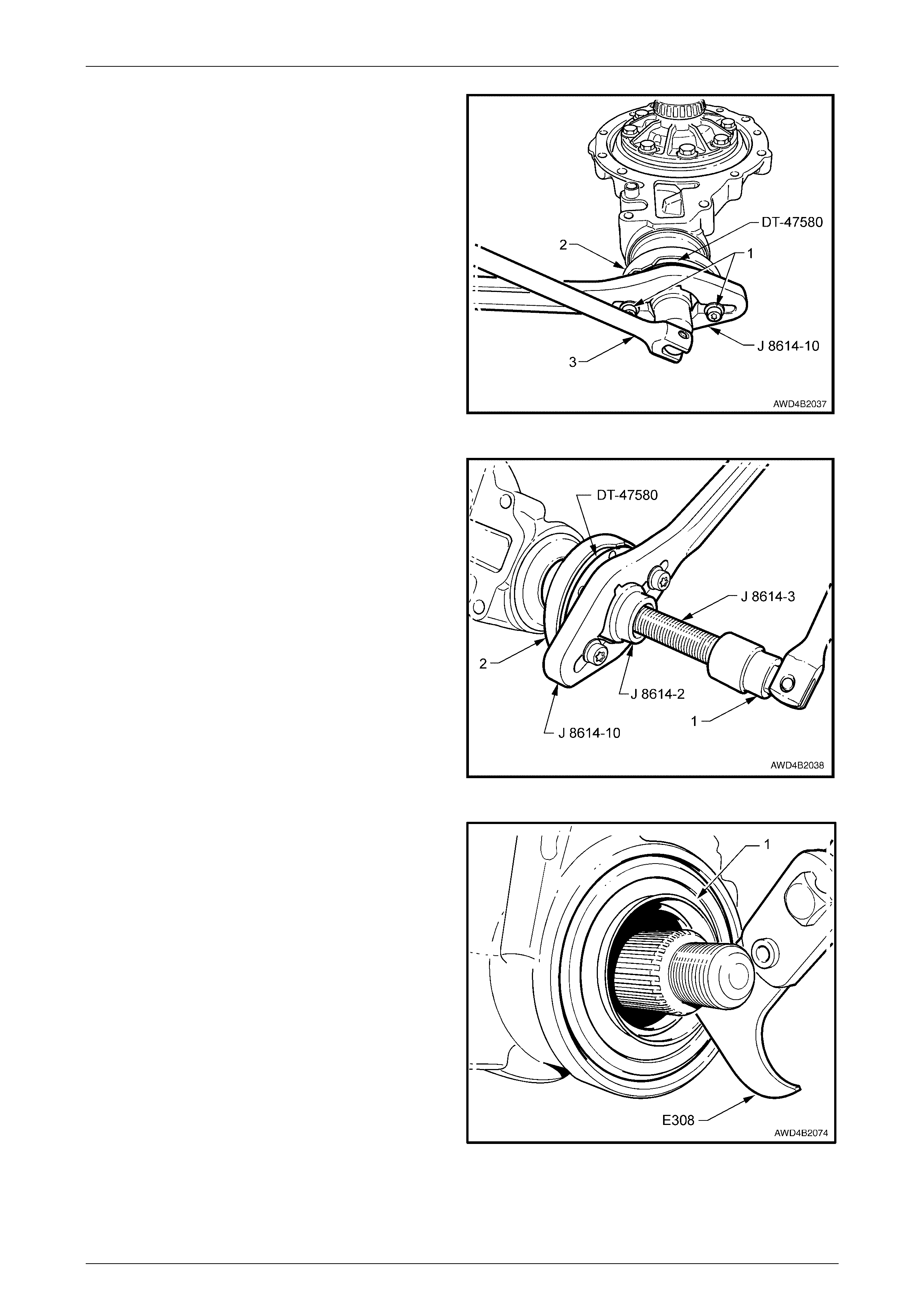

2 Install packing ring, Tool No. DT-47580 into the pinion

flange recess, aligning the holes with those in the

pinion flange.

3 Using two of the propeller shaft constant velocity joint

bolts (1), with flat washers, secure the holding bar,

Tool No. J 8614-10 (part of Tool No. J 8614-O1) to the

pinion flange (2). The central recesses in the holding

tool should face inward.

4 Using a 30 mm deep socket and bar (3), loosen then

remove the pinion flange retaining nut.

NOTE

A suitable length of pipe installed over the end of

the socket bar will reduce the effort required to

loosen the pinion flange nut.

Figure 4B2 – 53

5 W ith Tool No. J 8614-10 and packing ring, Tool No.

DT-47580 still installed, thread the forcing screw, Tool

No. J 8614-3, into the adaptor, Tool No. J 8614-2.

Install this sub-assembly into holder, Tool No. J 8614-

10, then rotate through 45° to locate in the recesses in

J 8614-10.

6 W hile holding J 8614-10, use a socket and bar (1) to

rotate the forcing screw J 8614-3 to remove the pinion

flange (2).

7 Remove the tools from the pinion flange.

Figure 4B2 – 54

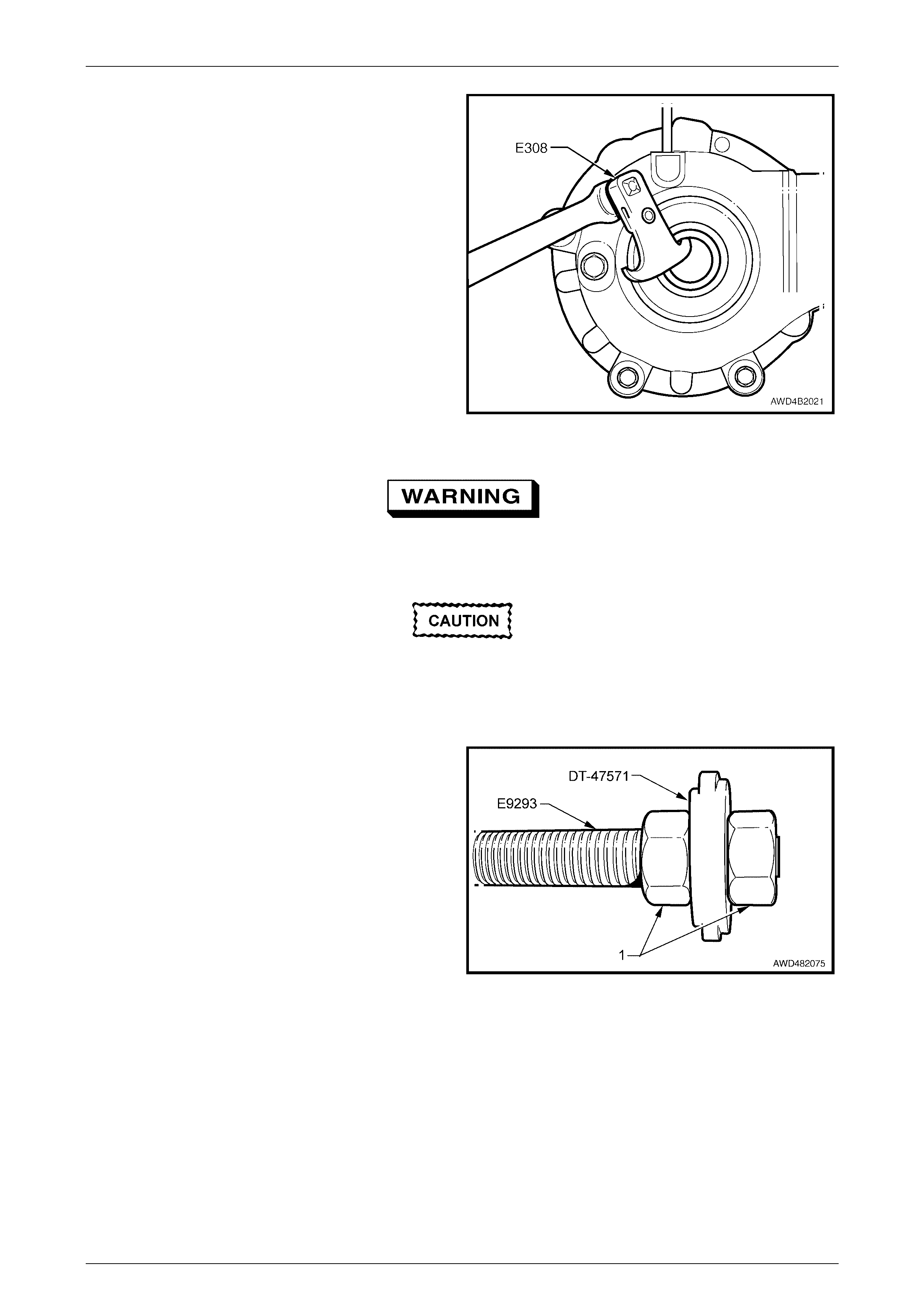

8 Prise the pinion oil seal (1) from the carrie r housing,

using Tool E308 or a commercial equivalent.

9 Use a soft faced hammer, driv e the pinion fr om the

outer (tail) bearing cone.

NOTE

With the offset of the carrier housing, it will be

necessary to hold the pinion to one side, as it is

being driven from the outer bearing. If not, the

pinion head will strike the carrier housing before

being released from the bearing.

10 Remove the outer (tail) pinion bearing and collapsible

spacer from the final drive housing.

Figure 4B2 – 55

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–43

Page 4B2–43

11

A

gain using Tool No. E308, remove the carrier bearing

oil seal from the carrier housing.

Figure 4B2 – 56

Wear eye protection when using compressed

air to dry washed components.

Do not allow bearings to spin when applying

compressed air in the drying off process.

12 Clean all components in a suitable cleaning solvent and blow dry, taking care not to spin any of the roller bearings

with compressed air. Inspect the pinion and the bearings for wear and/or damage.

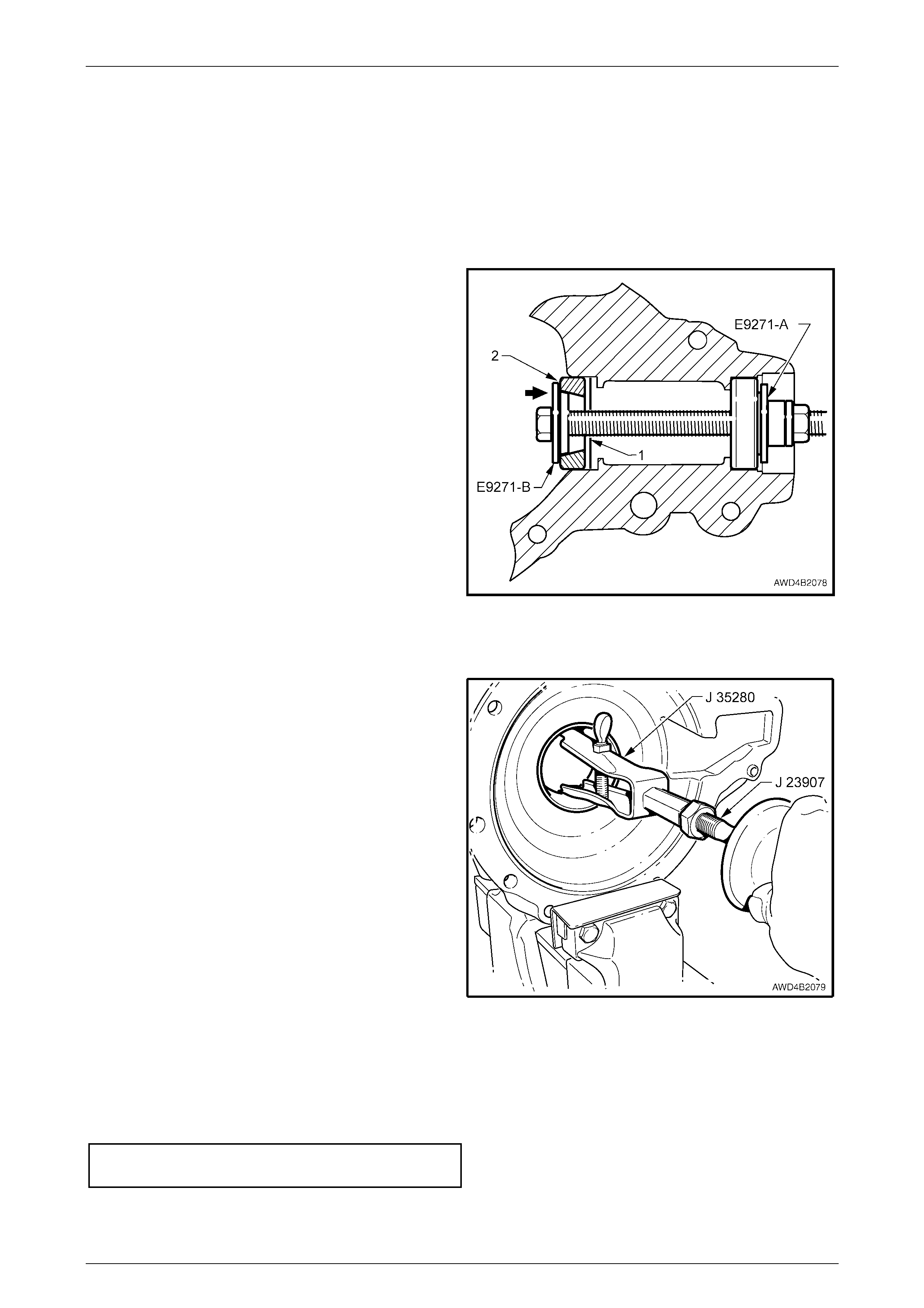

13 To remove the inner pinion bearing cup, first assembl e

the bearing cup remover DT-47571 onto the bolt of

Tool No. E9293 and secure with a nut (1) on each

side.

Figure 4B2 – 57

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–44

Page 4B2–44

14 After clamping the carrier housing in a vice fitted with

soft jaws, insert the bolt and pi nion bear ing cup

removing tool DT-47571 into the pinion cavity, aligning

the tool with the two cut-outs in the housing.

15 Drive the inner pinion bearing cup from the housing

using a hammer.

Figure 4B2 – 58

16 If the pinion bearings are to be replaced, remove the

outer (tail) pinion bear ing cu p, as follows:

a Assemble pinion bearing cup remover, Tool No.

E9293 with the larger land of the remover, Tool

No. DT-47571 into the outer (tail) cup and the

plate (part of Tool No. E9293) over the pinion

opening in the carrier housing.

b Install the bolt through the pinion bearing cup

remover, bearing cup and plat e, then install the

thrust race, washer and nut.

c W hile holding the bolt head, tighten the nut to

remove the bearing cup from the carrier housing.

Figure 4B2 – 59

17 To remove inner bearing cone from the pinion, remove

legs from the ring of Tool No. E1673 MT.

18 Place ring on suitable press plates. Install pinion and

adaptors E 1673-A15 into the ring. Use a press (1) to

remove the pinion (2) from the bearing (3). Discard the

removed bearing ( 3).

NOTE

Do not allow the pinion to drop and hit the floor.

Figure 4B2 – 60

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–45

Page 4B2–45

Differential Assembly

Figure 4B2-61

Legend

1 Differential Case

2 Side Gear Thrust Washer

3 Different i al Side Gear

4 Different i al Pinion Gear

5 Different i al Pinion Gear Thrust Washer

6 Differential Pinion Shaft

7 Locking Roll Pin

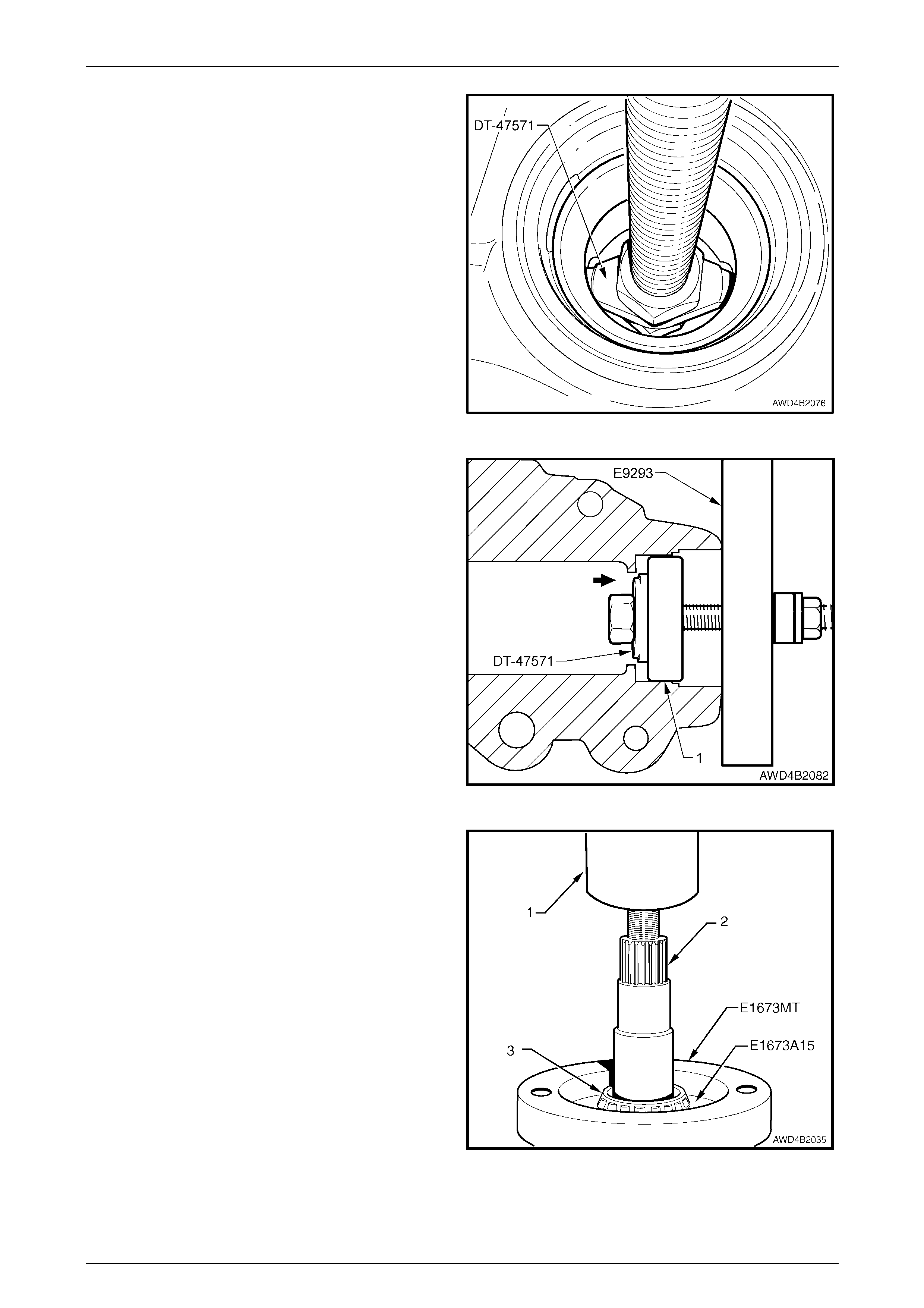

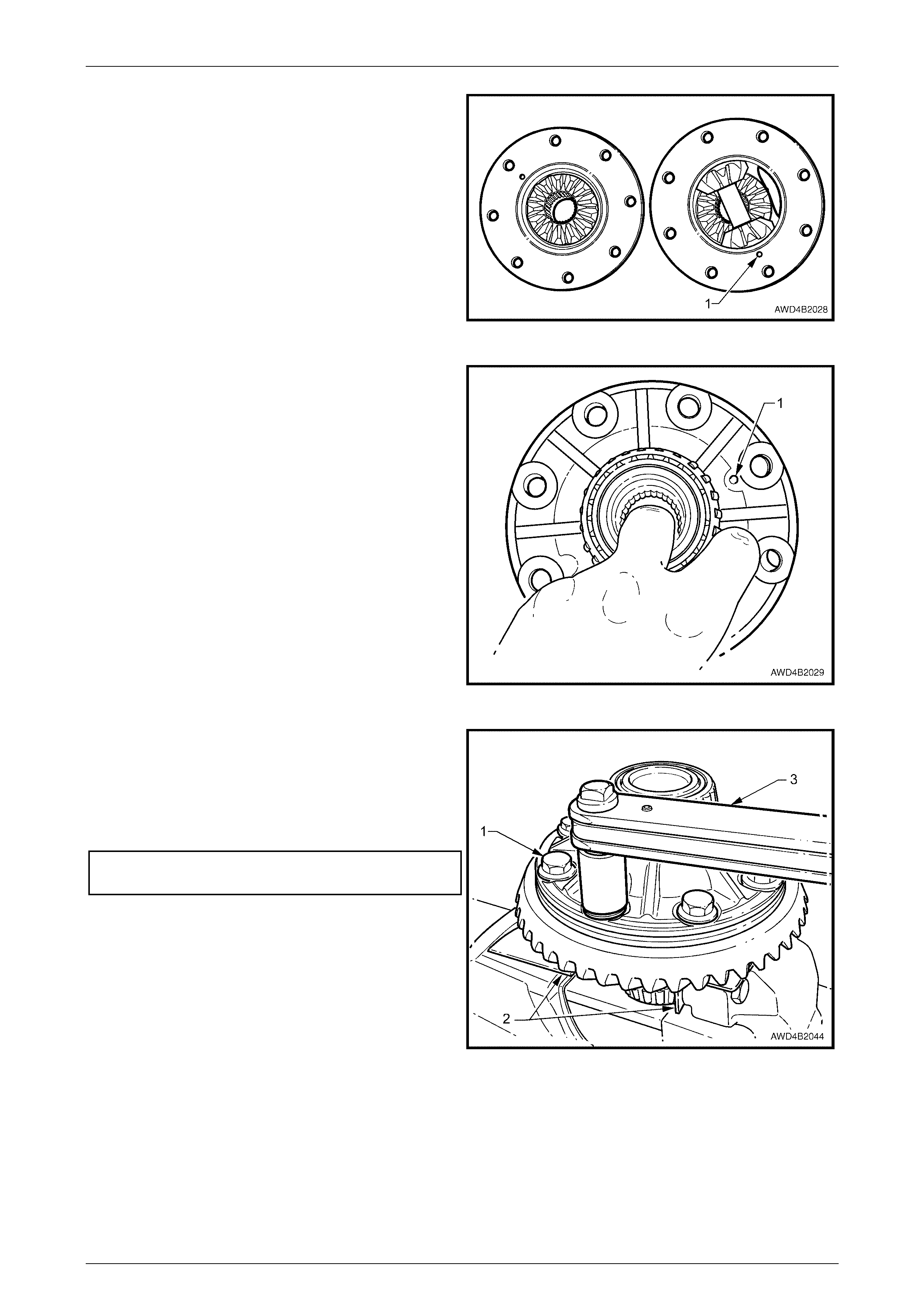

1 Secure the differential housing in a vice fitted with soft

jaws.

2 Using suitable socket equ ipm e nt (1), loosen the ring

gear retaining bolts (2), working from opposite sides

until all bolts are loosened. Remove and discard all

bolts, as they must be renewed on reassembly.

NOTE

The ring gear bolts have a right hand thread.

Do not use a screwdriver to prise between

ring gear and case.

3 Remove the ring gear from the differential case, either

by using a press or a soft faced hammer. Support the

differential case (or ring gear) during this operation to

prevent it from dropping and striking the floor or bench

top.

Figure 4B2 – 62

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–46

Page 4B2–46

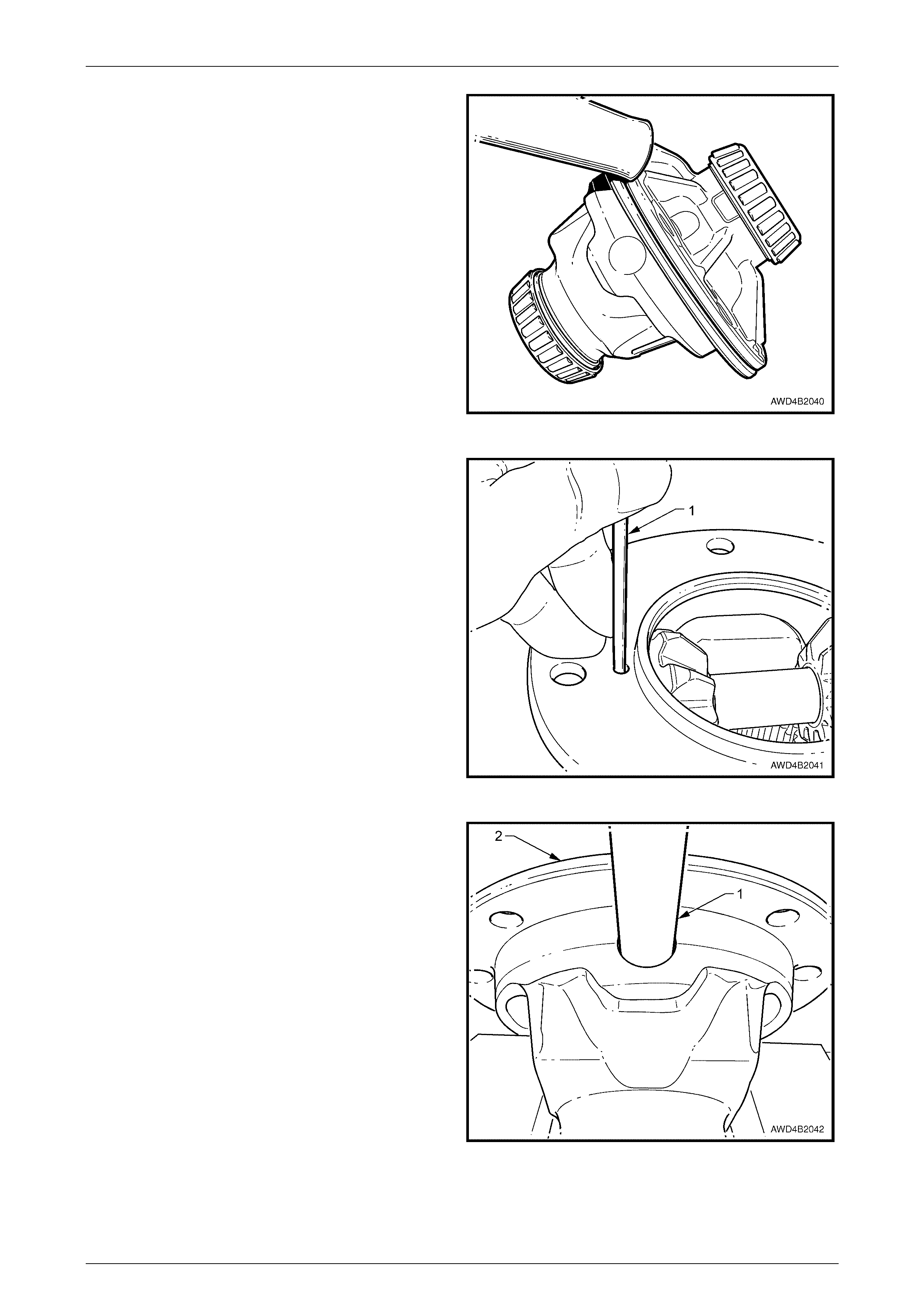

4 Using a suitable sized brass drift, separate the two

piece differential case.

Figure 4B2 – 63

5 Using a suitable sized pin punch (1) and hammer,

remove the differential pinion cross shaft retainer roll

pin.

Figure 4B2 – 64

6 With the differential case (2) held in a vice fitted with

soft jaws, use a suitable sized brass drift (1) and

hammer to drive the differential pinion cross shaft out

from the differential case (2).

7 Lift the pinion gears and thrust washers from the case.

8 Remove the side gears and thrust washers from each

side of the case.

9 If inspection shows that the side bearing cones and

cups are undamaged, the bearing cones may be left

installed on each of the case halves.

NOTE

If the bearing cones are removed, then the

cones and cups must be replaced with new parts

on reassembly.

Figure 4B2 – 65

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–47

Page 4B2–47

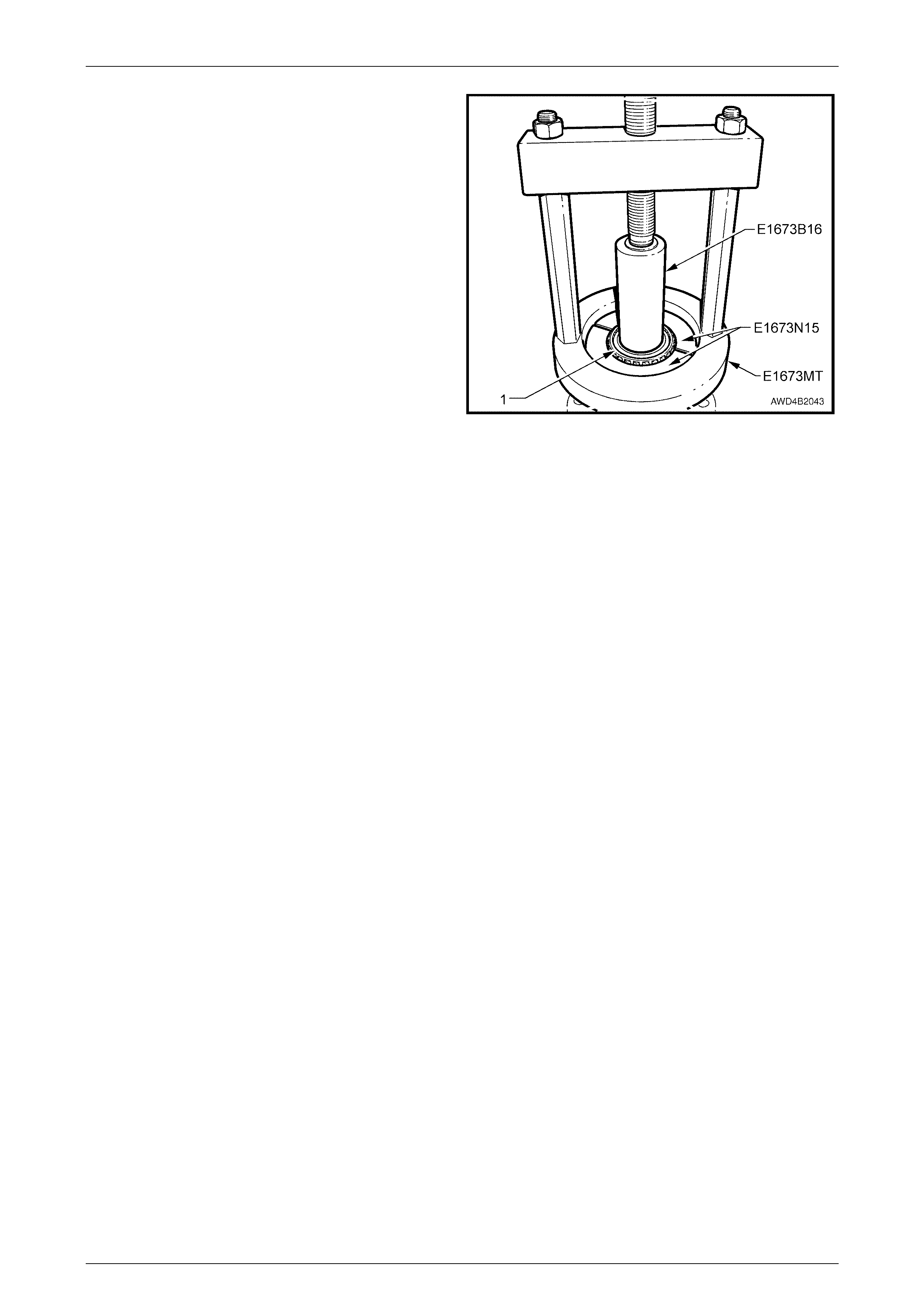

10 If the side bearings are to be replaced, use Tool No.

E1673MT, with E1673N15 adaptors and distance

piece, E1673B16, to remove the bearing cones (1).

Discard the removed bearings.

Figure 4B2 – 66

Inspect

General Items

• Thoroughly clean all parts with a suitable, clean solvent.

• Oil the bearings immediately after cleaning and drying to prevent rust developing.

• Inspect the parts for any major defects.

• Clean the inside of the case before rebuilding and installing the parts, inspect individual parts as detailed next:

Gears

• The pattern taken during the dismantling process should help in judging if the ring gear and pinion can be re-used.

Worn gears cannot be rebuilt to correct a noisy condition. Gear scoring is the result of excessive shock loading or

the use of an incorrect lubricant.

• Scored differential gears must be replaced. Examine the teeth and thrust surface of all differential gears.

• Check the fit of the side gear hubs in the case. Wear on the hub of the side gear can cause a “clunking” noise

when the vehicle is driven at low speeds.

• Check that none of the thrust washers shows signs of wear, cracks or burrs.

• Wear on splines, thrust surfaces, or thrust washers can contribute to excessive driveline backlash.

• Inspect differential pinion gear bores and shaft surfa ce s for scorin g.

Bearing Cups

• Check bearing cups for rings, scores, galling or erratic wear patterns. For various roller bearing abnormal wear

conditions and their causes, refer to 4.4 Bearing Diagnosis, in Section 4B Final Drive & Driveshafts, in the MY 2003

VY and V2 Series Service Information.

• Pinion bearings cups must be solidly seated. Check by attempting to insert a 0.05 mm feeler between these cups

and the bottom of their bores. Ensure that seating surfaces are clean and free from burrs or raised metal.

Bearing Cone and Roller Assemblies

• The bearings in the differential case and the rear (head) pinion should be checked before being removed from the

differential case or pinion. If these bearing cup and cone assemblies are removed, they must be discarded and

replaced with new parts.

• When lightly oiled and rotated in their respective cups, bearing cone rollers must turn without roughness. Examine

the roller ends for wear. Step-wear on the roller ends indicates the bearing preload was incorrect or the rollers were

slightly misaligned. Refer to 4.4 Bearing Diagnosis, in Section 4B Final Drive & Driveshafts, in the MY 2003 VY and

V2 Series Service Information for examples of abnormal bearing wear and their causes.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–48

Page 4B2–48

Pinion Flange

• Check the flange mating face run-out. Refer to 5 Specifications for the maximum Total Indicated Runout (TIR).

• The end of the flange that contacts the bearing cone and the seal surface must be free from imperfections.

• Check that the constant velocity (constant velocity) joint bolt threads are in good condition. Clean out any residual

thread sealant by using an 8 mm tap.

Carrier and Cover Housings

• Check that the differential bearing bores are smooth and the differential carrier bearing preload spacer washer

abutment faces are not dama g ed.

Differential Case

• Carefully examine the case for damage and ensure that bearing seating surfaces are free from dirt and burrs. The

bearing assemblies will fail if they do not seat correctly against the shoulder on the housing.

• The ring gear spigot and mating surfaces for the differential case halves should be clean and free from burrs.

• Check that the differential pinion pin bores in the differential case are not oval.

• Check that the mating surfaces for the two case halves are clean and free from burrs.

• The differential side gear journal bores should be clean and free from scoring. The thrust surfaces for the

differential case halves should be clean and free from burrs.

Reassemble

Differential

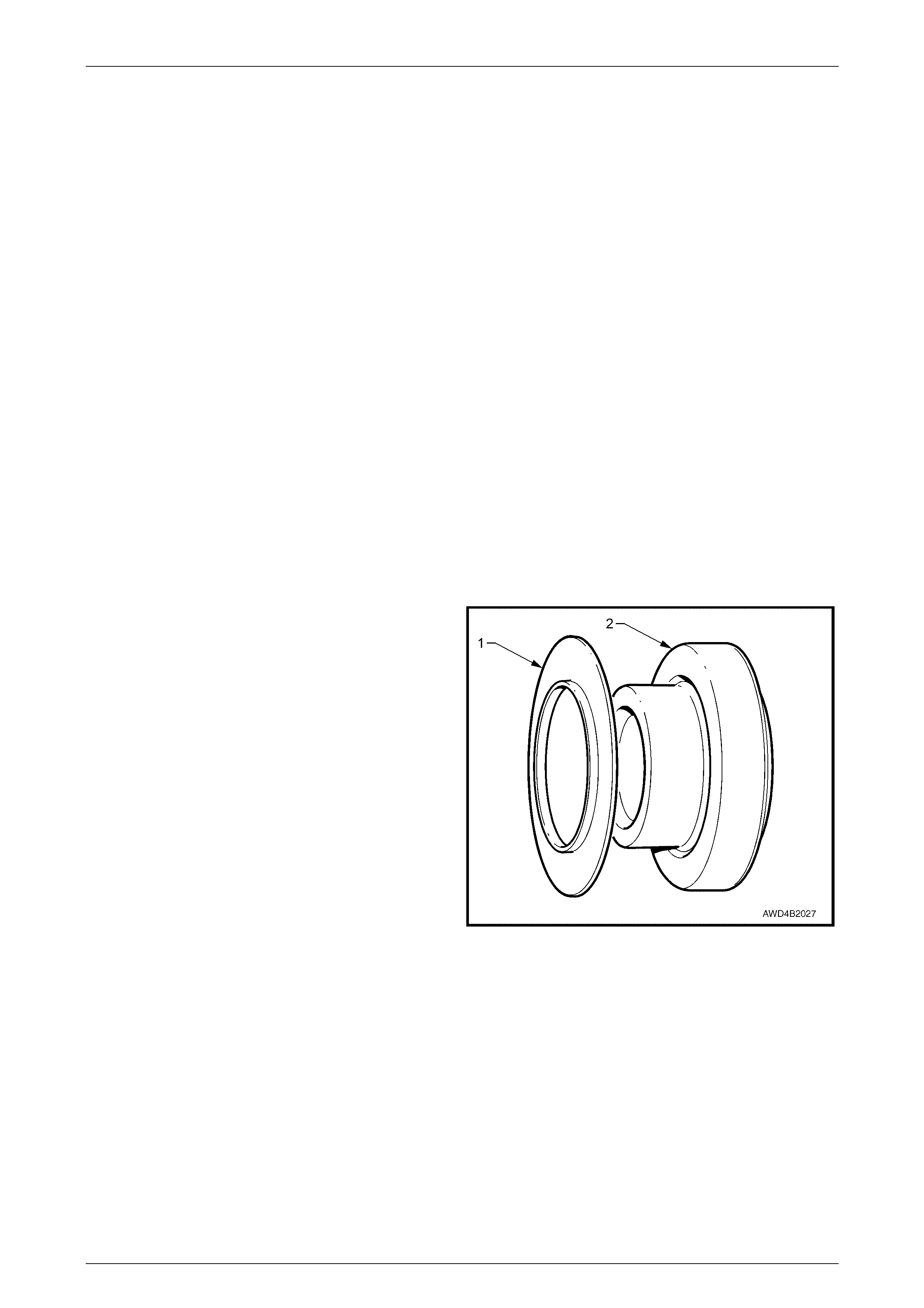

1 Before assembly, lubricate all differential parts with the

recommended front final drive lubricant.

2 Reinstall a side gear thrust washer (1) over each side

gear (2), ensuring that the thrust washer is installed in

the orientation shown.

3 Reinstall one side gear and thrust washer into the

recess in the larger differential case half.

4 Mesh the two pinion gears with the installed side gear

and align with the pinion shaft roll pin hole in the

differenti al cas e.

NOTE

To overcome the risk of damaging the thrust

washers through misalignment, using a

fabricated wooden dowel of 18.5 mm diameter

(100 mm long) can be used to align both pinions

and their thrust washers before installation of the

pinion shaft.

Figure 4B2 – 67

5 Align the roll pin hole by sight, in the differential case with the hole in the differential pinion pin, then use a brass

drift and hammer to drive the pinion pin into position, until the roll pin hole is in alignment.

Front Final Drive, Bearing Housi ng & Driveshafts Page 4B2–49

Page 4B2–49

6 Using a suitable pin punch and hammer install a new

roll pin (1) through the differential case until the pin

protrudes through on the machined case half by about

6 mm. This will ensure a positive location for the case

cover.

7 Reinstall the remaining side gear and thrust washer

into the smaller case half.

Figure 4B2 – 68

8 While holding the side gear and thrust washer in

position with a finger, reinstall the case cover over the

differenti al case, mes hing the differenti al gears and

aligning the roll pin with the accompanying hole in the

case cover (1).

9 Turn the differential assembly over, then Install the

ring gear into position on the differential case, aligning

the bolt holes.

NOTE