Rear Propeller Shaft & Universal Joints Page 4C1–1

Page 4C1–1

Section 4C1

Rear Propeller Shaft & Universal Joints

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions And Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

2 Service Operations................................................................................................................................3

2.1 Propeller Shaft........................................................................................................................................................3

Remove ...................................................................................................................................................................3

Reinstall ..................................................................................................................................................................4

2.2 Rubber Coupling....................................................................................................................................................6

Replace ...................................................................................................................................................................6

2.3 Centre Constant Velocity Joint.............................................................................................................................7

Remove ...................................................................................................................................................................7

Disassemble .........................................................................................................................................................10

Inspect...................................................................................................................................................................11

Propeller Shaft and Boot...................................................................................................................................11

Constant Velocity Joint.....................................................................................................................................11

Reassemble ..........................................................................................................................................................12

Method 1...........................................................................................................................................................12

Method 2...........................................................................................................................................................12

Reinstall ................................................................................................................................................................14

2.4 Centre Bearing Assembly....................................................................................................................................16

Remove .................................................................................................................................................................16

Reinstall ................................................................................................................................................................17

2.5 Fixed, Rear Constant Velocity Joint ...................................................................................................................19

Remove .................................................................................................................................................................19

Inspect...................................................................................................................................................................20

Propeller Shaft and Boot...................................................................................................................................20

Constant Velocity Joint.....................................................................................................................................21

Reassemble ..........................................................................................................................................................22

Reinstall ................................................................................................................................................................24

3 Specifications....................................................................................................................................... 25

4 Torque Wrench Specifications........................................................................................................... 26

5 Special Tools........................................................................................................................................ 27

Rear Propeller Shaft & Universal Joints Page 4C1–2

Page 4C1–2

1 General Information

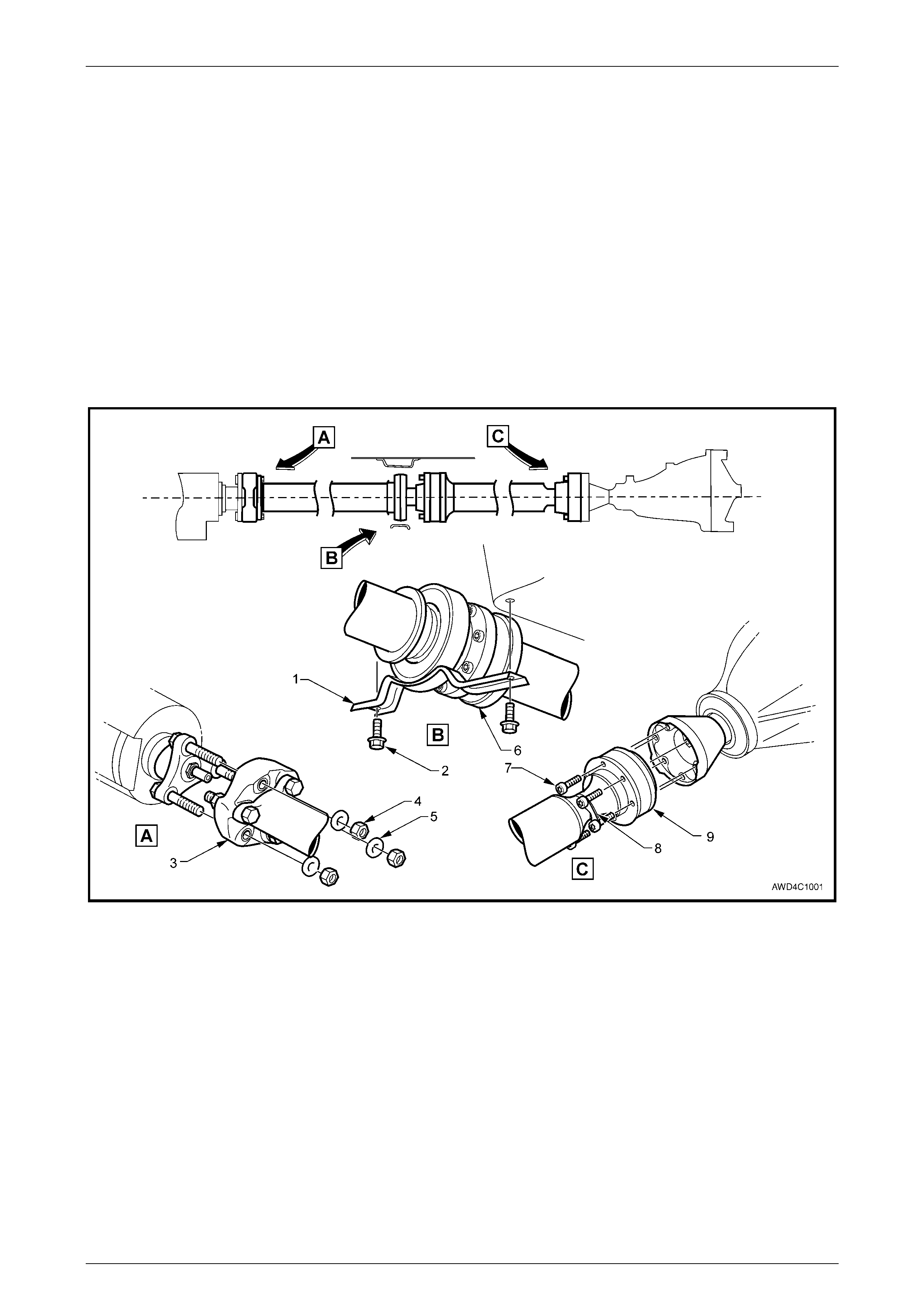

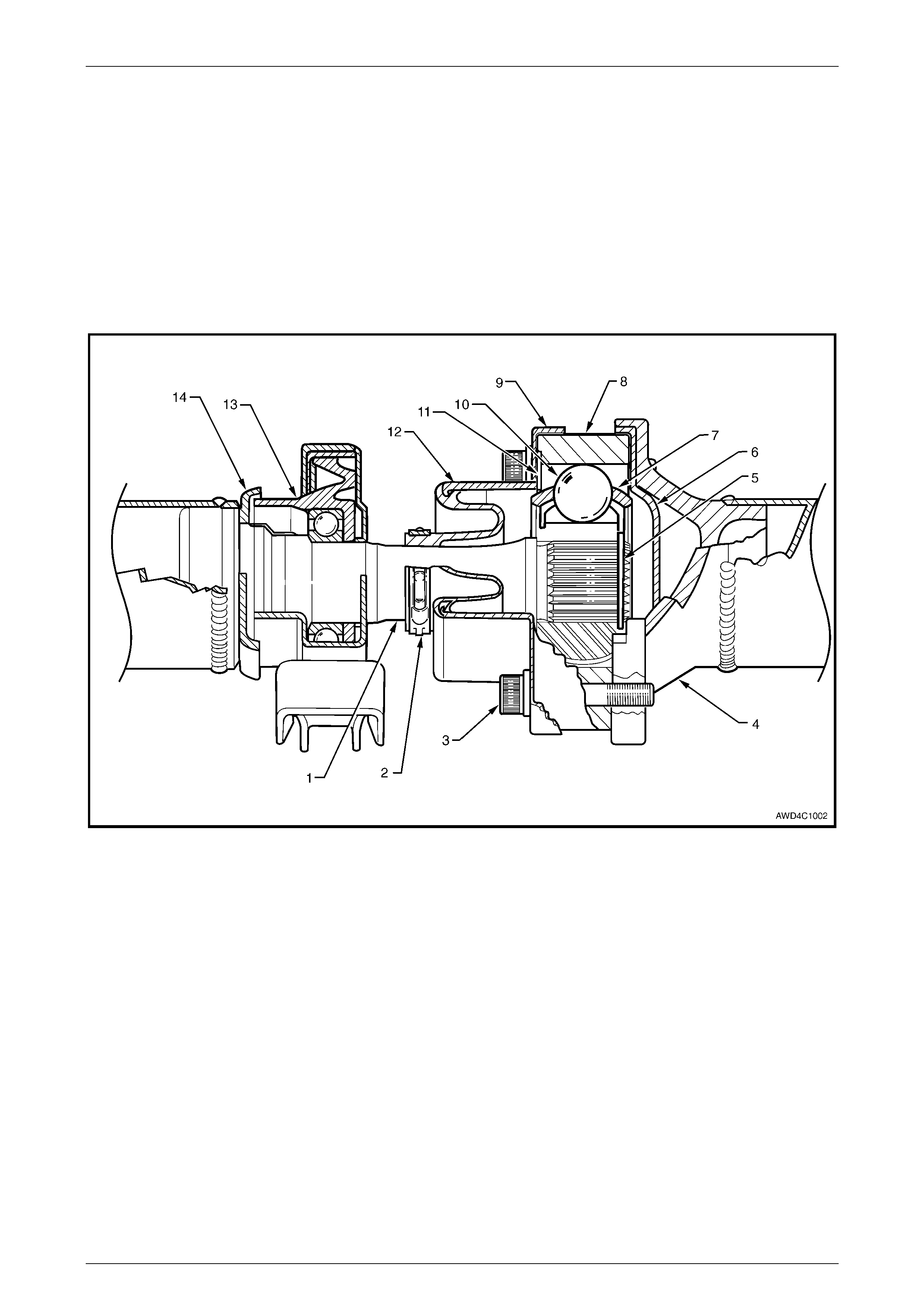

The rear propeller shaft assembly fitted to all variants of the MY 2004 AWD Station Wagon models is a two piece tubular

design that incorporates a centre support bearing, with a rubber coupling at the front of the front propeller shaft and a

constant velocity joint at the front and rear of the rear propeller shaft. The front rubber coupling is bolted to the rear

output flange of the transfer case and the rear constant velocity joint is bolted to the rear final drive pinion flange with six

bolts and three locking plates.

The centre support bearing is a fully sealed ball bearing, mounted in a reinforced rubber cup. This centre bearing rubber

cup is supported in a cup guide and attached to a carrier, which in turn, is bolted to the vehicle underbody brace.

Drive is transmitted between the two halves of the propeller shaft through a centre constant velocity joint directly behind

the centre bearing. To allow for slight changes in propeller shaft length that may occur from body twist and torque

reaction, this centre constant velocity joint is a plunge type.

Provided the service information contained in this Section is followed, both constant velocity joints are fully serviceable,

while the centre bearing assembly and the front rubber coupling can be replaced as assemblies only.

The centre bearing is lubricated for life and does not require any periodic lubrication.

Figure 4C1-1

Legend

1 Centre Bearing Carri er Assem bl y

2 Centre Bearing Carri er Ret ai ning Bolt (2 Places)

3 Front Rubber Coupling

4 Front Coupling Ret aining Nuts (3 Places)

5 Front Coupling Ret aining Nut Washers (3 Plac es)

6 Front Constant Veloci t y Joint (Plunge Type)

7 Rear Constant Vel oci ty Joint Retaining Bolts (6 Places)

8 Locking Plate (3 Places)

9 Rear Constant Vel ocity Joint (Fixed Type)

Rear Propeller Shaft & Universal Joints Page 4C1–3

Page 4C1–3

2 Service Operations

ATTENTION

All fasteners are important attaching parts as they affect the performance of vital components and/or could

result in major repair expense. Where specified in this section, fasteners MUST be replaced w ith parts of the

same part number or an approved equivalent. Do not use fasteners of an inferior quality or substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all components.

Throughout this section, fastener torque wrench specifications may be accompanied with the following

identification marks:

!

!!

! Fasteners must be replaced after loosening.

"

""

" Vehicle must be at curb height before final tightening.

#

##

# Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

2.1 Propeller Shaft

LT Section No. – 05-050

ATTENTION

The following fasteners MUST be replaced when performing these operations:

!

!!

! Rubber coupling to transfer case, rear output flange retaining bolts and nuts.

Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

#

##

# Propeller shaft centre bearing bracket to the vehicle underbody, attaching bolts.

#

##

# Propeller shaft rear constant velocity joint to pinion flange bolts.

Remove

1 Raise the vehicle and support in a safe manner. Refer to Section 0A General Information in the MY 2004 AWD

Wagon Service Information for location of jacking and support points.

2 To provide access to the propeller shaft fasteners, it is recommended that the dual intermediate exhaust pipe,

intermediate and rear muffler assemblies be removed. For information regarding the removal and installation

procedures for these components, refer to Section 8B Exhaust System in the MY 2004 AWD Wagon Service

Information.

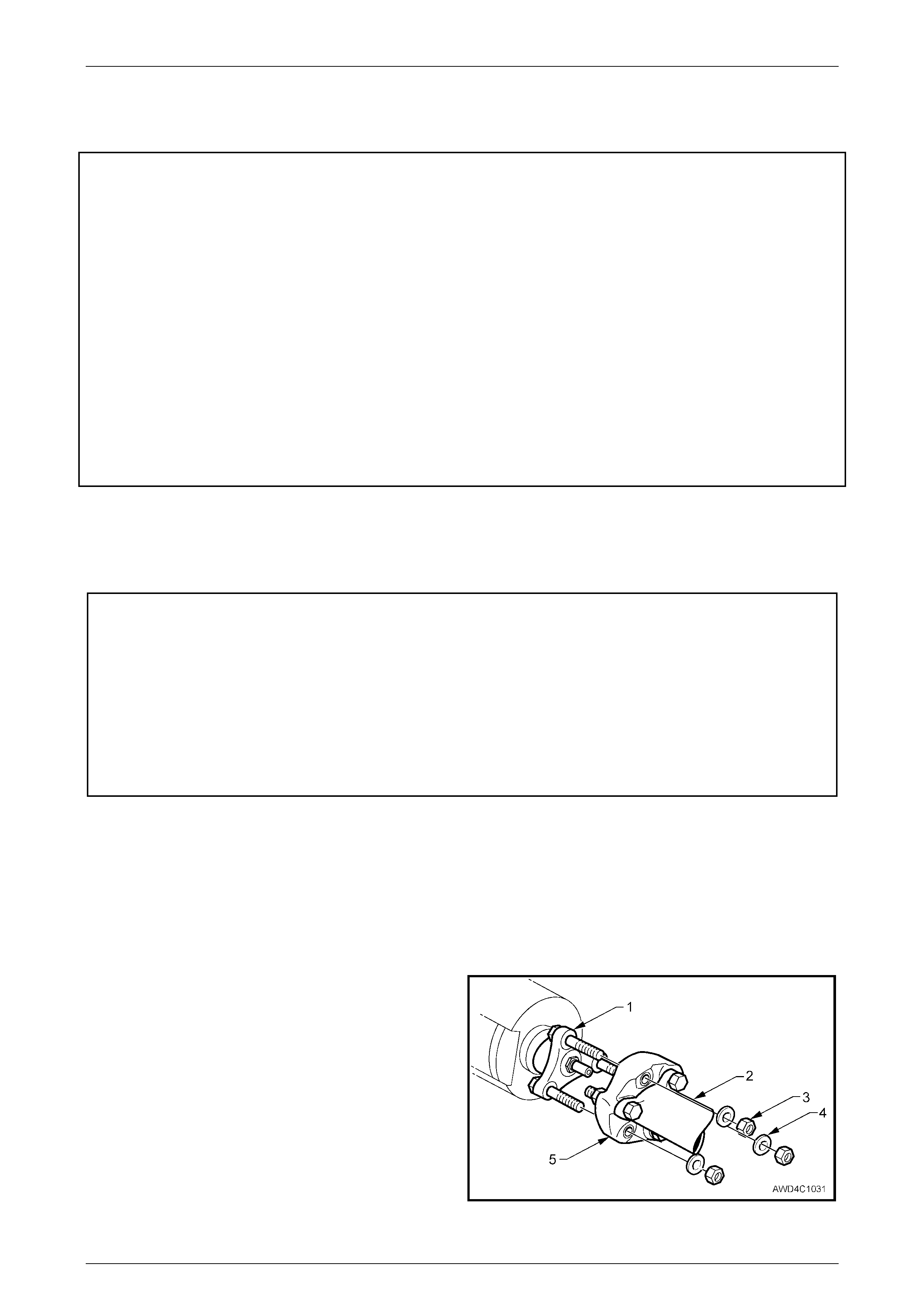

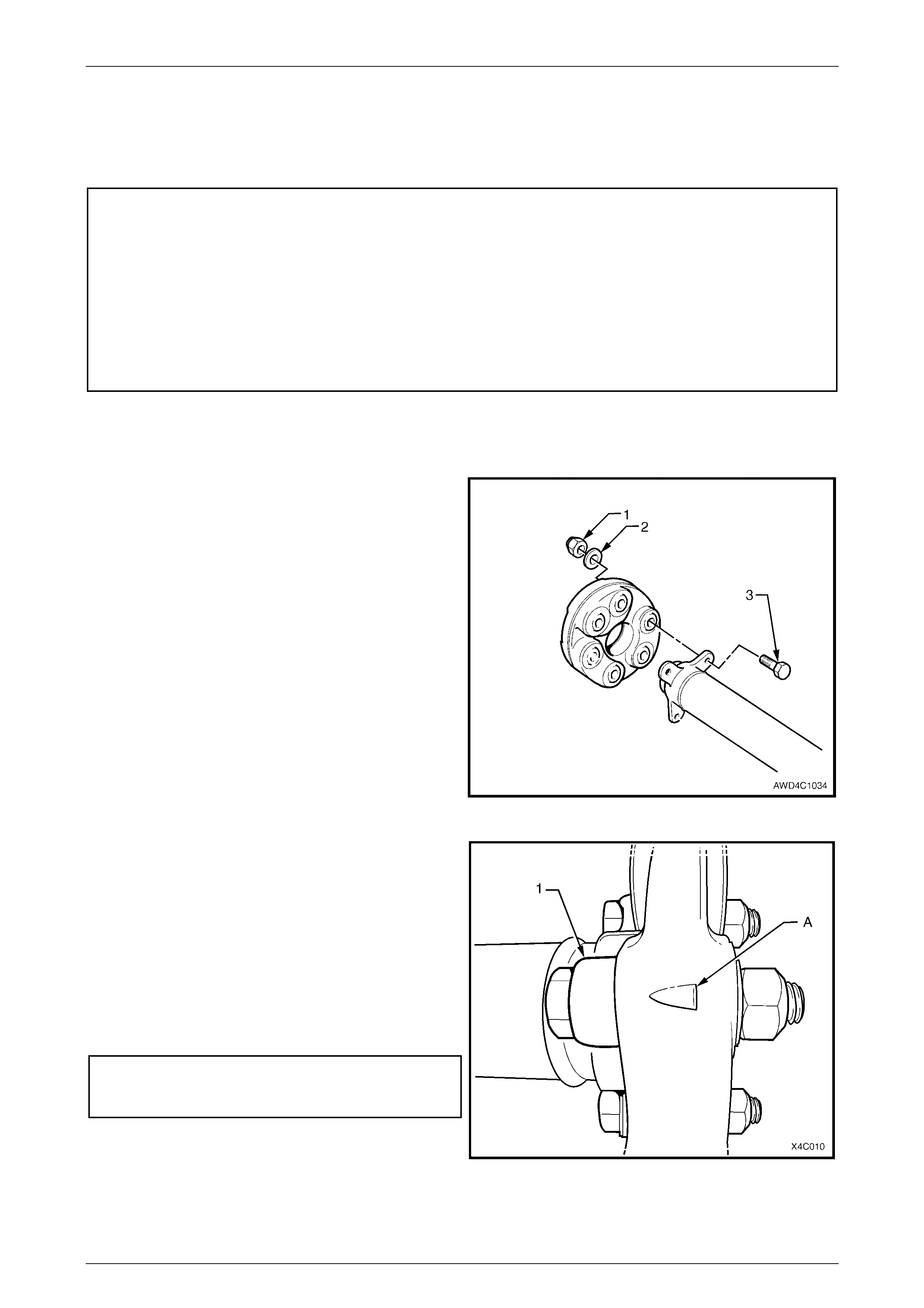

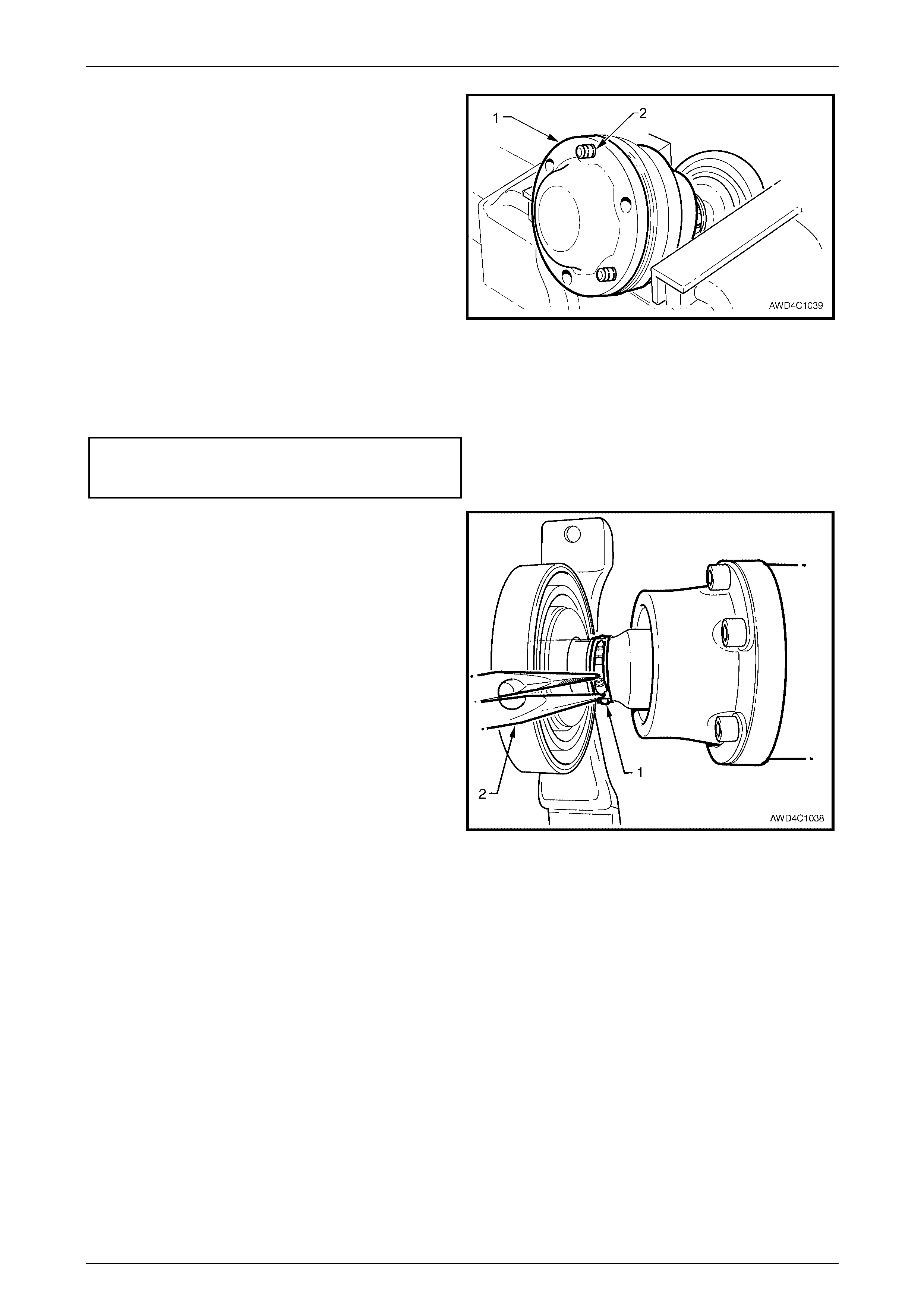

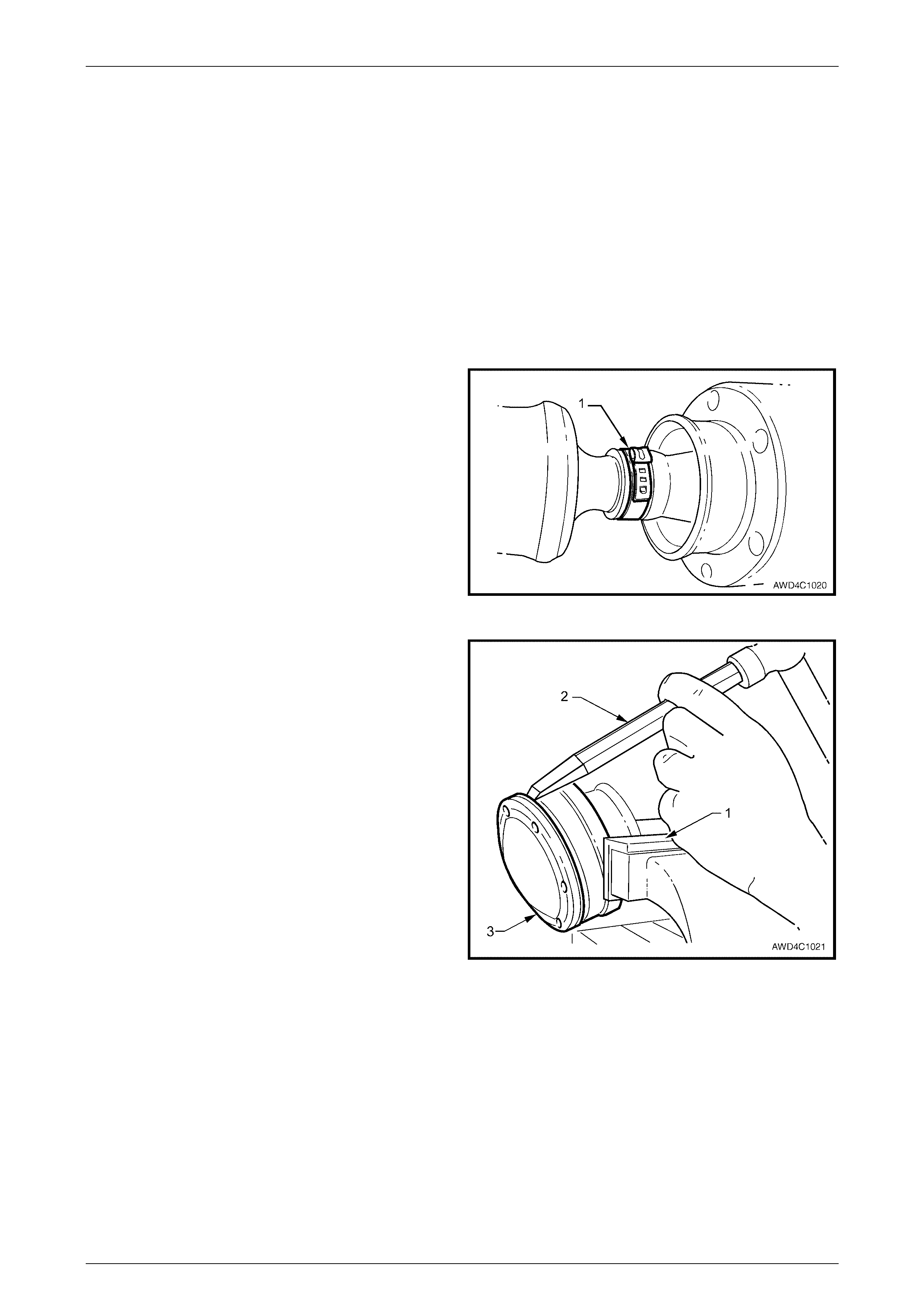

3 Select the Park position with the transmission selector

lever.

4 Loosen then remove the three nuts (3) and washers

(4) securing the front coupling (5) to the transfer case

output flange (1). Discard the removed nuts (3) as they

must be replaced on reassembly.

Figure 4C1 – 2

Rear Propeller Shaft & Universal Joints Page 4C1–4

Page 4C1–4

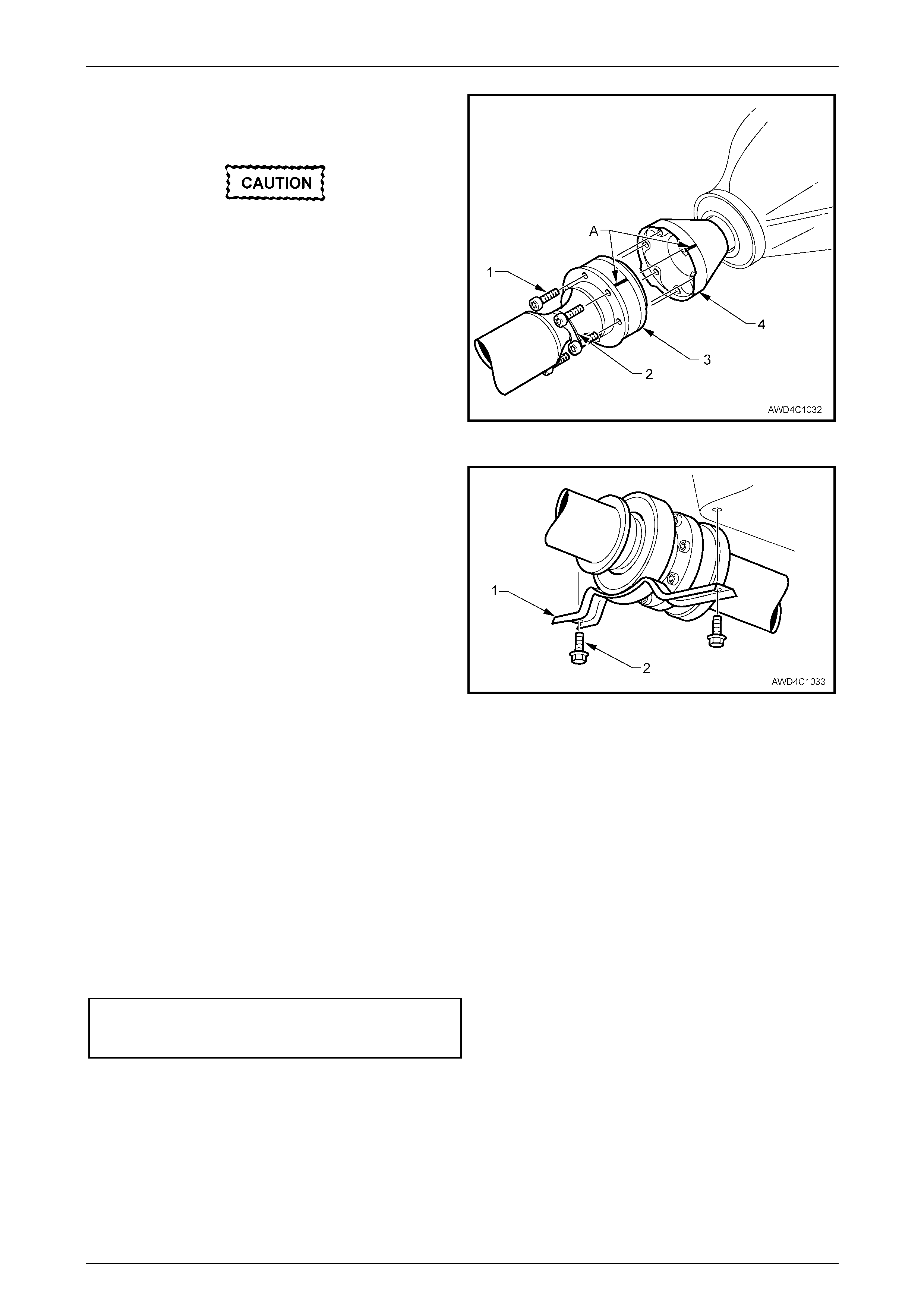

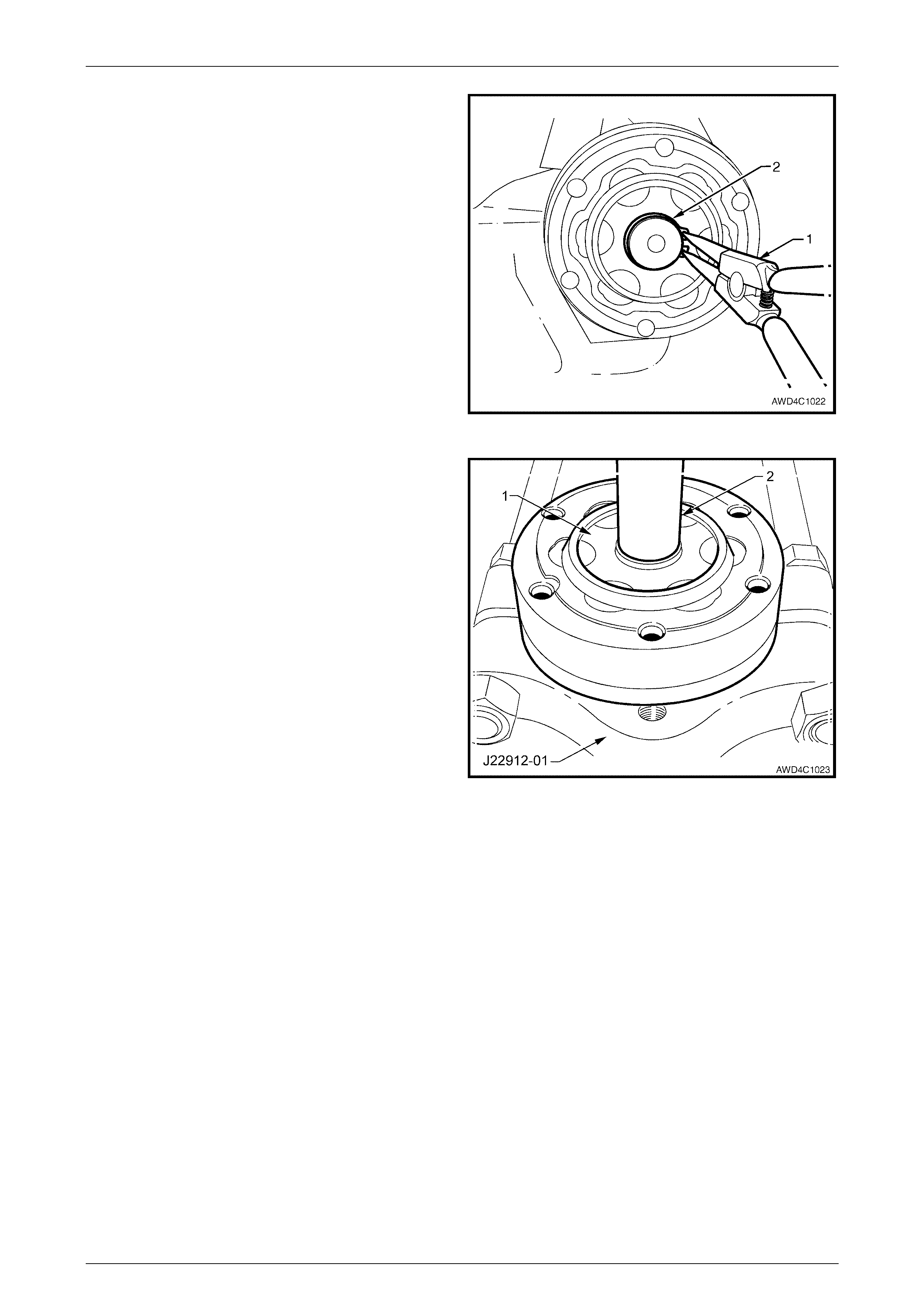

5 To enable the propeller shaft to be installed in the

original position relative to the pinion flange, use a felt

tipped pen or similar (e.g. whiteout) to identify the

relationship of the two components (‘A’).

If all six bolts are removed, the rear of the

propeller shaft must be supported using tie

wire or similar. Do not allow the propeller

shaft to hang, placing undue stress on the

front constant velocity joint.

6 W ith the transmission in the ‘Park’ position and the

park brake firmly applied, loosen the six Torx bit

headed bolts (1), using a T50 Torx bit and suitable

socket equipm ent.

7 Remove five of the six bolts and two locking plates (2)

securing the propeller shaft rear constant velocity joint

(3) to the final drive pinion flange (4). Do not remove

the sixth bolt at this time. Figure 4C1 – 3

8 Remove the two centre bearing carrier (1) to

underbody reinforcement bolts (2), then remove the

heat shield (if fitted) and the centre bearing assembly.

NOTE

The heat shield has not been shown, to clarify

the centre bearing bracket offset.

9 While support ing the cen tre be aring section, remove

the final bolt (and locking plate) from the pinion flange.

10 Slide the propeller shaft assembly forward to

disengage from the final drive pinion flange, then lower

the assembly at the rear, sliding rearward to

disengage the front rubber coupling from the transfer

case output flange studs. Remove the propeller shaft

assembly from the vehicle.

Figure 4C1 – 4

Reinstall

Reinstallation is the reverse of removal procedures, except for the following items:

1 Lubricate the transfer case rear output shaft spigot with a molybdenum disulphide grease such as Molybond GA10

or Shell ML10.

2 Clean the threads of the centre bearing carrier to underbody reinforcement bolts and underbody weld nuts, then

apply a thread sealant such as Loctite 242 or equivalent.

3 Reinstall the front of the propeller shaft assembly first, supporting the centre and rear sections.

4 W hile supporting the rear section, raise the centre bearing assembly and install the bolts and washers to secure to

the underbody reinforcement. Tighten both bolts to the correct torque specification.

( # ) Centre bearing carrier to

underbody reinforcement bolt

torque specific atio n ..............................................22 Nm

5 Slide the propeller shaft assembly forward to allow engagement of the rear constant velocity joint to the final drive

pinion flange, then slide rearward to fully engage.

6 Before reinstalling the attaching bolts and locking plates into the rear constant velocity joint and pinion flange, align

the marks on the pinion flange and rear joint, that were made prior to removal, refer to Figure 4C1-3.

7 Clean the threads of the six, rear constant velocity joint to pinion flange bolts, apply a thread sealant such as

Loctite 242 or equivalent, then reinstall with locking plates and tighten to the correct torque specification, using a

T50 Torx bit and suitable socket equipment.

Rear Propeller Shaft & Universal Joints Page 4C1–5

Page 4C1–5

( # ) Propeller shaft rear constant

velocity joint to pinion flange bolt

torque specific atio n ..............................................35 Nm

8 Reinstall the front rubber coupling to the transfer case rear output flange, using new retaining bolts nuts and

washers, before tightening to the correct torque specification. When reinstalled correctly, the aligning triangular

shapes on the coupling outer surface ‘point’ to the propeller shaft flange. Refer Figure 4C1-6.

( ! ) Rubber coupling to transfer case

output shaft flange retaining nut

torque specific atio n ..............................................78 Nm

9 Reinstall the exhaust system, noting the following;

a. Ensure the catalytic converter flange is clean and free from any gasket material.

b. Install the exhaust system, using a new gasket at the catalytic converter and new hanger retainers for the

muffler supports to the rear crossmember.

c. Tighten all exhaust fasteners to the specified torque.

Intermediate exhaust pipe to

catalytic converter flange bolt

torque specific atio n ..............................................45 Nm

d. Check exhaust clear an ces as detai led in Section 8B EXHAUST SYSTEM in the MY 2004 AWD Wagon

Service Information.

Rear Propeller Shaft & Universal Joints Page 4C1–6

Page 4C1–6

2.2 Rubber Coupling

LT Section No. – 05-050

ATTENTION

The following fasteners MUST be replaced when performing these operations:

!

!!

! Rubber coupling to transfer case, rear output flange retaining bolts and nuts.

Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

#

##

# Propeller shaft centre bearing bracket to the vehicle underbody, attaching bolts.

#

##

# Propeller shaft rear constant velocity joint to pinion flange bolts.

Replace

1 Remove the propeller shaft. Refer to 2.1 Propeller Shaft in this Section.

2 Using a back- up spa nner on each of the three

propeller shaft to coupli ng bolts (3), loosen then

remove the nuts (1) and washers (2). Discard the

removed bolts, nuts and washers. Remove the

coupling from the front of the propeller shaft.

Figure 4C1 – 5

3 Apply 0.5 gm of molybdenum disu lph ide grea se ( su ch

as Molybond GA10 or Shell ML10) to the spigot bush

in the propeller shaft end.

4 Reinstall a replacement rubber coupling onto the end

of the propeller shaft, aligning the holes in such a way

that the triangular shape (‘A’) on the coupling ‘points’

to the propeller shaft flange (1), as shown.

5 Install NEW bolts, washers and nuts to secure the

coupling to the propeller shaft flange and tighten to the

correct torque specification, using a back-up spanner

on the bolt head.

( ! ) Propeller shaft to rubber

coupling nut

torque specific atio n .............18 Nm, then 55 ° Turn Angle

6 Install the propeller shaft, as detailed in 2.1 Propeller

Shaft in this Section.

Figure 4C1 – 6

Rear Propeller Shaft & Universal Joints Page 4C1–7

Page 4C1–7

2.3 Centre Constant Velocity Joint

LT Section No. – 05-050

There are two repair kits available, for this centre, constant velocity joint repairs:

a A DUST SHIELD KIT, which contains dust shield, gasket, strap, and tubes of grease and sealant (or gasket).

b A CONSTANT VELOCITY JOINT KIT, which contains the same items as in the DUST SHIELD KIT, plus the

constant velocity joint and appropriate retaining circlips.

Remove

Figure 4C1 – 7

Legend

1 Propeller Shaft – Front Section

2 Boot Clamp

3 Allen Key Headed Screws - 6 Places

4 Propeller Shaft – Rear Section

5 Circlip

6 Domed End Cover

7 Constant Vel ocity J oi nt Ball Cage

8 Front Constant Velocity Joint Assembly

9 Dust Shield

10 Ball Bearing (6 places)

11 Gasket

12 Dust Boot

13 Centre Bearing and Support Bracket Assembly

14 Slinger

Rear Propeller Shaft & Universal Joints Page 4C1–8

Page 4C1–8

1 Remove propeller shaft. Refer to 2.1 Propeller Shaft in this Section.

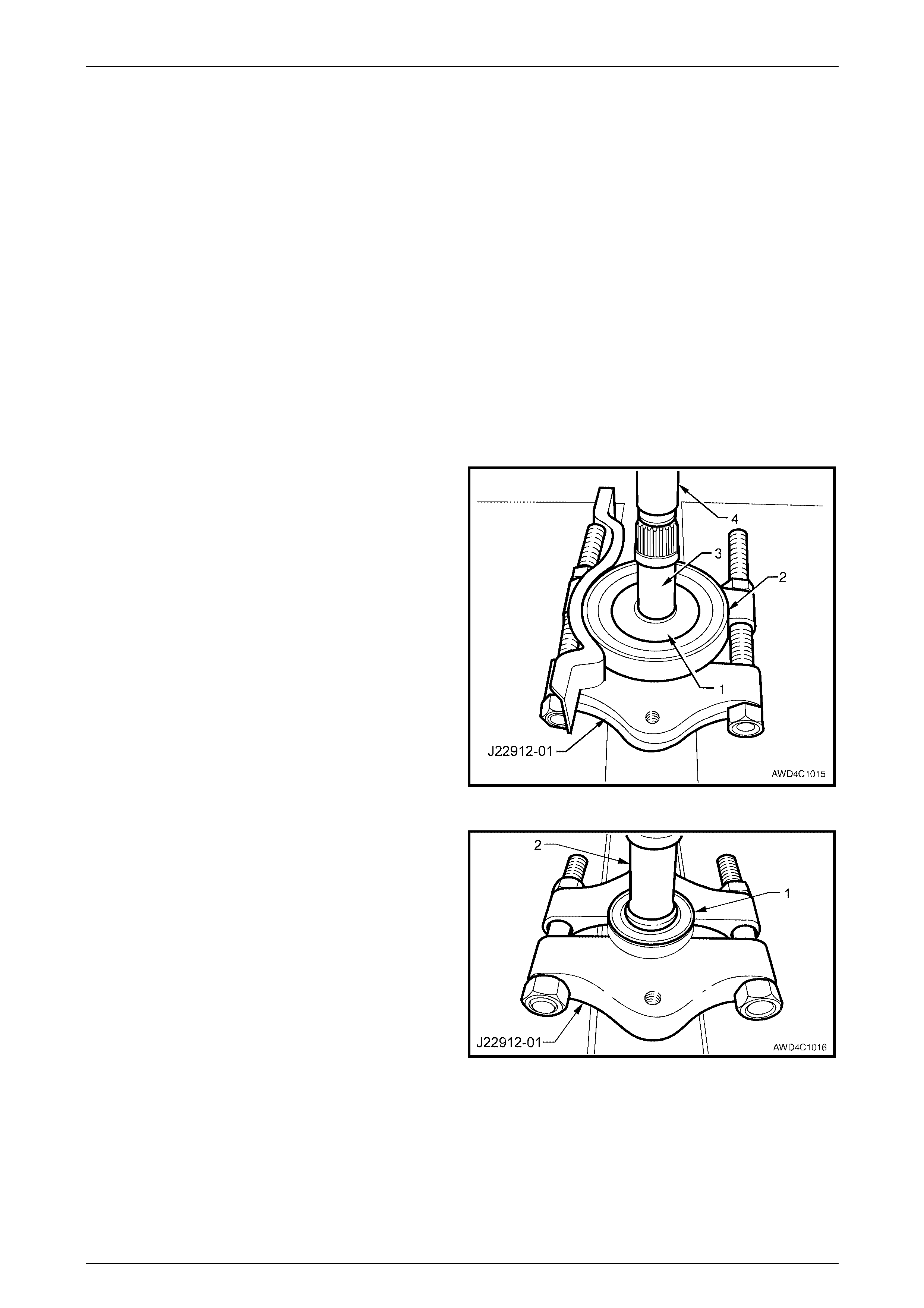

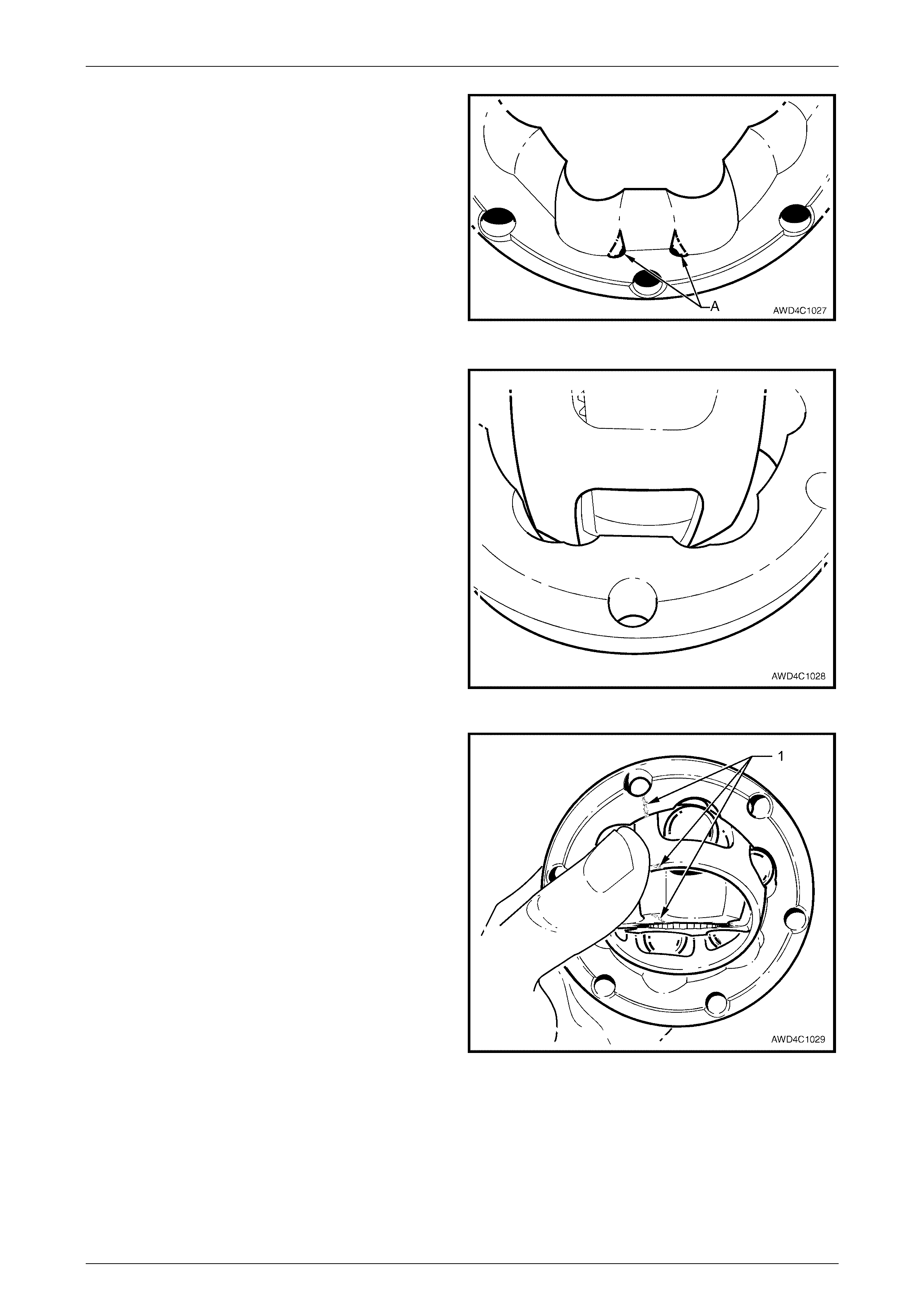

2 To ensure correct alignment of parts at reassembly,

scribe an aligning mark on constant velocity joint (2)

and the rear propeller shaft mounting flange (3).

3 While holding the rear half of the propeller shaft in a

vice fitted with soft jaws, remove the six, 6 mm Allen

key headed screws (1) and three lock plates (4), using

suitable socket equipment.

Figure 4C1 – 8

4 Secure the front constant velocity joint is a vice fitted

with soft jaws (4).

5 Using a hammer and a brass drift, tap the rear

propeller shaft companion flange evenly from constant

velocity joint.

Figure 4C1 – 9

6 W hile still secured in the soft jaws (1) of a vice, use a

brass drift (2) and hammer, dislodge, then remove the

dust shield cap (3) from the end of the constant

velocity joint. Discard the removed cover.

Figure 4C1 – 10

Rear Propeller Shaft & Universal Joints Page 4C1–9

Page 4C1–9

7 Reposition the constant velocity joint in the soft faced

vice jaws, then use a brass drift and hammer to tap

constant velocity joint dust shield (1) to dislodge it from

the constant velocity joint (2).

8 While tensioning the boot clamp (3) with long nosed

pliers (4), use a small bladed screwdriver to lever the

clamp tang (5) releasing it from the clamp barbs.

Remove and discard the clamp.

Figure 4C1 – 11

9 W ipe excess lubricant from the constant velocity joint,

then remove the retaining circlip (1).

Figure 4C1 – 12

10 Pull back constant velocity joint outer race. Install

suitable press plates (approximately 8 mm thick),

between dust shield and constant velocity joint, to

support inner joint race (1). Press the front half of

propeller shaft from constant velocity joint, using a

suitable drift (2).

NOTE

Press plates J22912-01 are too thick to fit

between the constant velocity joint and the dust

shield.

11 Clean old gasket material from dust shield and

constant velocity joint mating surfaces.

Figure 4C1 – 13

Rear Propeller Shaft & Universal Joints Page 4C1–10

Page 4C1–10

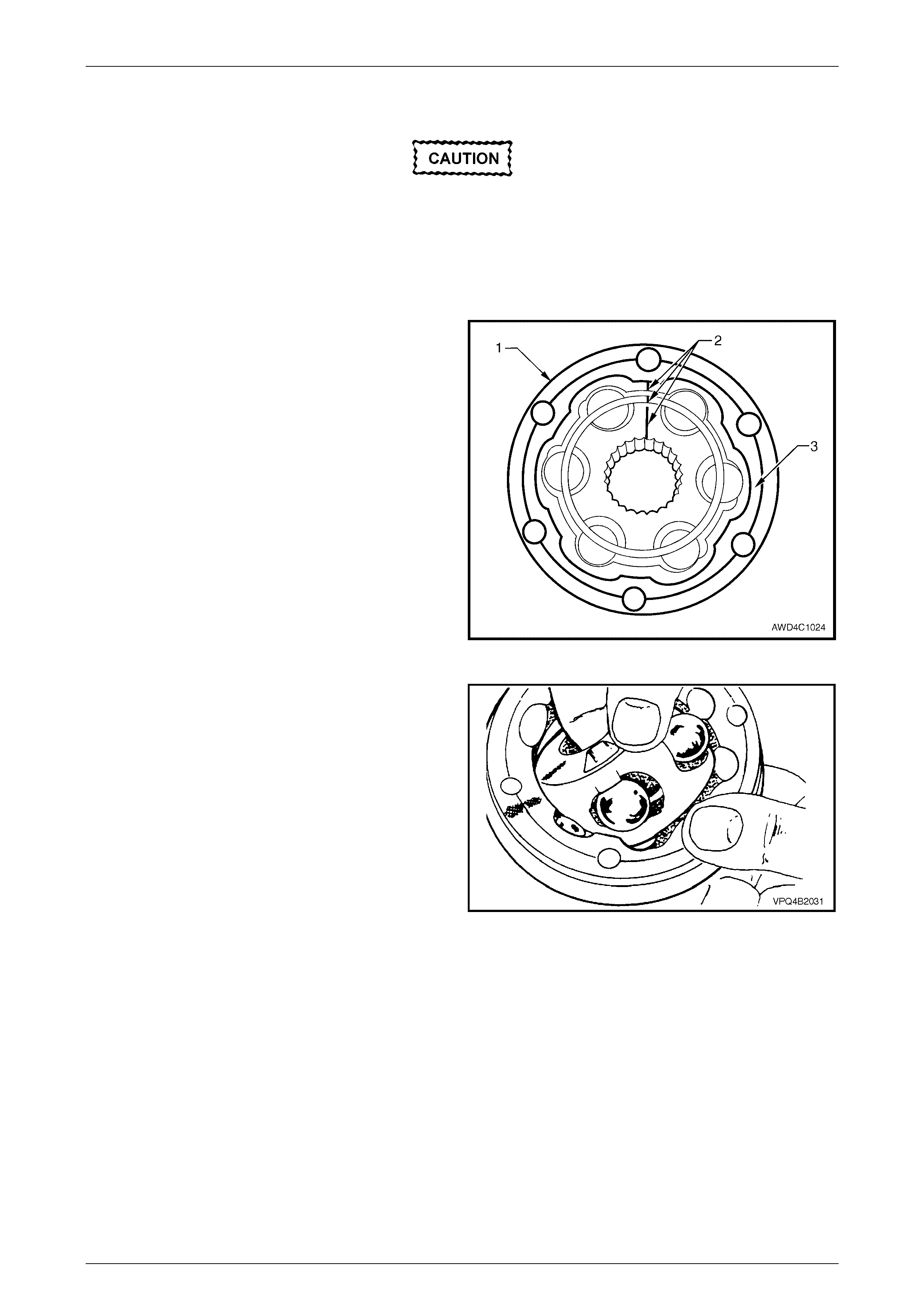

Disassemble

Disassembly of the constant velocity joint is

not recommended. The internal components

are a precision fit and develop their own

characteristic wear patterns. Intermixing

components could result in looseness,

binding and/or subsequent premature failure

of the joint. However, if disassembly must be

attempted, then it is vital that the following

procedure is carefully followed.

1 Remove the excess lubricant from the constant

velocity joint, wipe clean and mark the relationship of

the inner race, ball guide and outer race, using

correction fluid.

Figure 4C1 – 14

2 Pivot inner race and ball guide at 90° to centre line of

outer race as shown, and lift inner race, ball guide and

six balls as an assembly, from outer race.

NOTE

Even with grease surrounding the constant

velocity joint components, be careful not to allow

any balls to slip from the cage. Each ball must

be reinstalled in its original position.

Figure 4C1 – 15

Rear Propeller Shaft & Universal Joints Page 4C1–11

Page 4C1–11

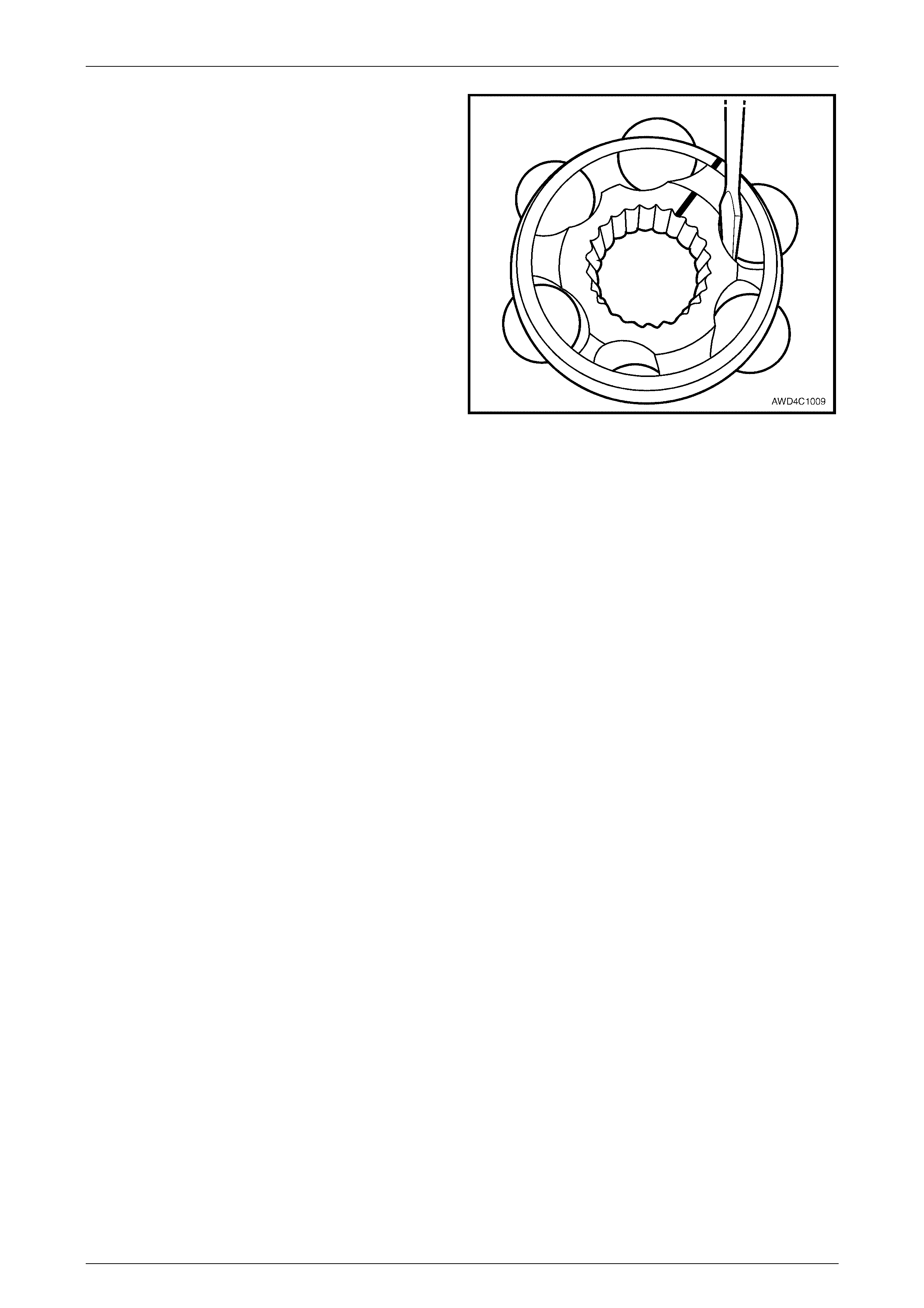

3 Using a small screwdriver, lever balls from guide, as

shown. Keep balls in order, relative to the alignment

marks made in Step 1, for reassembly.

NOTE

Dependent on the length of time the constant

velocity joint has been in service, individual balls

could slip from the cage and not require prising

to release.

4 Lift the inner race from the ball guide.

Figure 4C1 – 16

Inspect

Propeller Shaft and Boot

1 Clean propeller shaft, boot and dust shield in a suitable cleaning solvent.

2 Inspect propeller shaft for visible damage and twisting, cracking or excessive spline wear.

NOTE

If any damage is evident then the propeller shaft

must be replaced.

3 Inspect boot and dust shield, replacing if split, fatigued, cracked or worn.

4 Check that the vent hole in the front flange of the rear propeller shaft half, is clear and not blocked with mud or

other debris.

Constant Velocity Joint

1 Inspect the grease in the joint for contamination and/or dirt ingress. If either of these conditions is evident, then the

constant velocity joint will most probably have suffered damage and should be replaced. If inspection shows that

the joint has not been contaminated, clean the joint by soaking in a suitable cleaning solvent.

2 Clean all components in suitable solvent, ensuring that the part relationships remain undisturbed.

3 Carefully inspect all components for signs of severe pitting, galling, play between balls and the cage windows, any

cracking or damage to cage, pitting or galling or chips in raceways. Replace the constant velocity joint if any of

these conditions are evident.

Rear Propeller Shaft & Universal Joints Page 4C1–12

Page 4C1–12

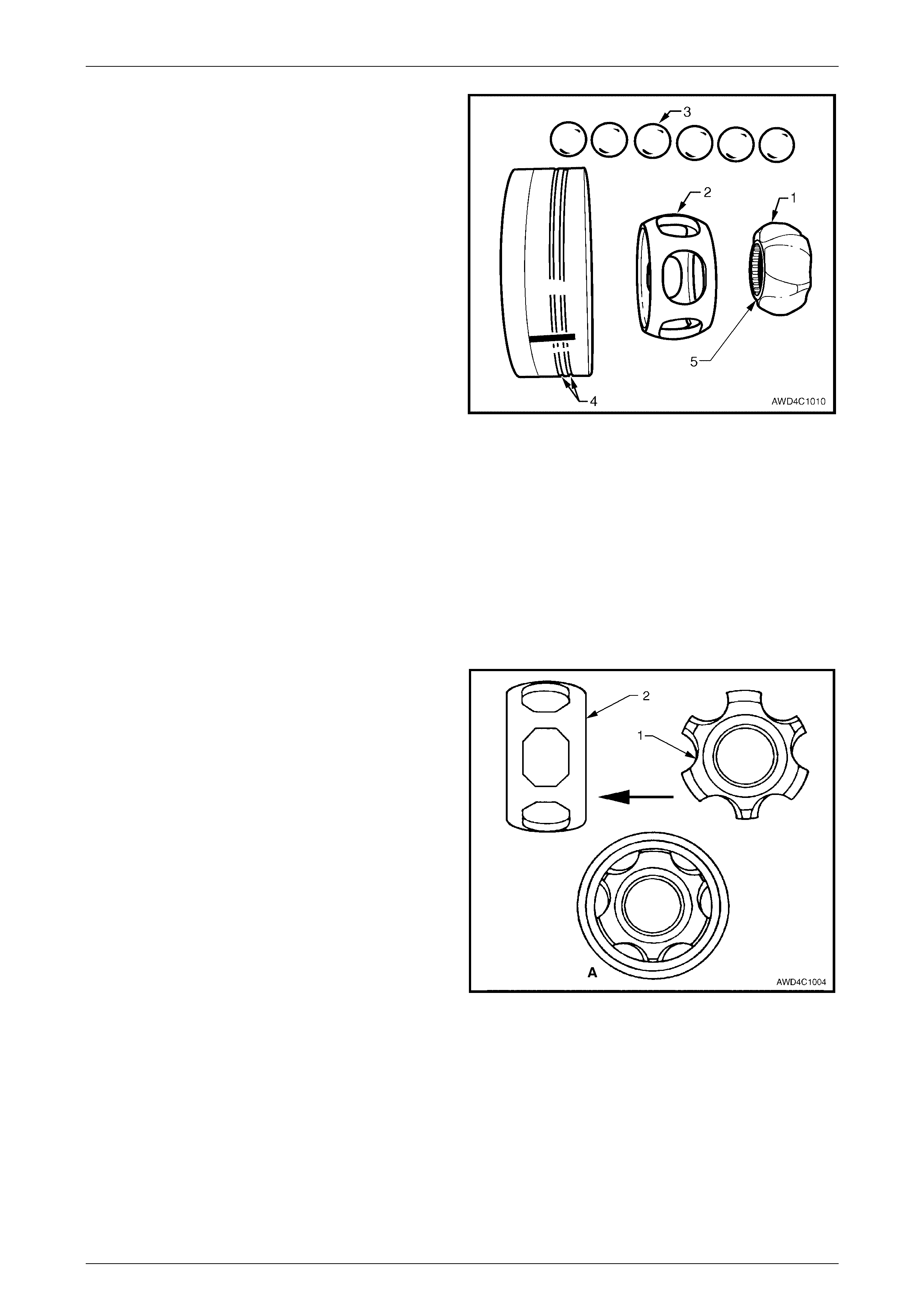

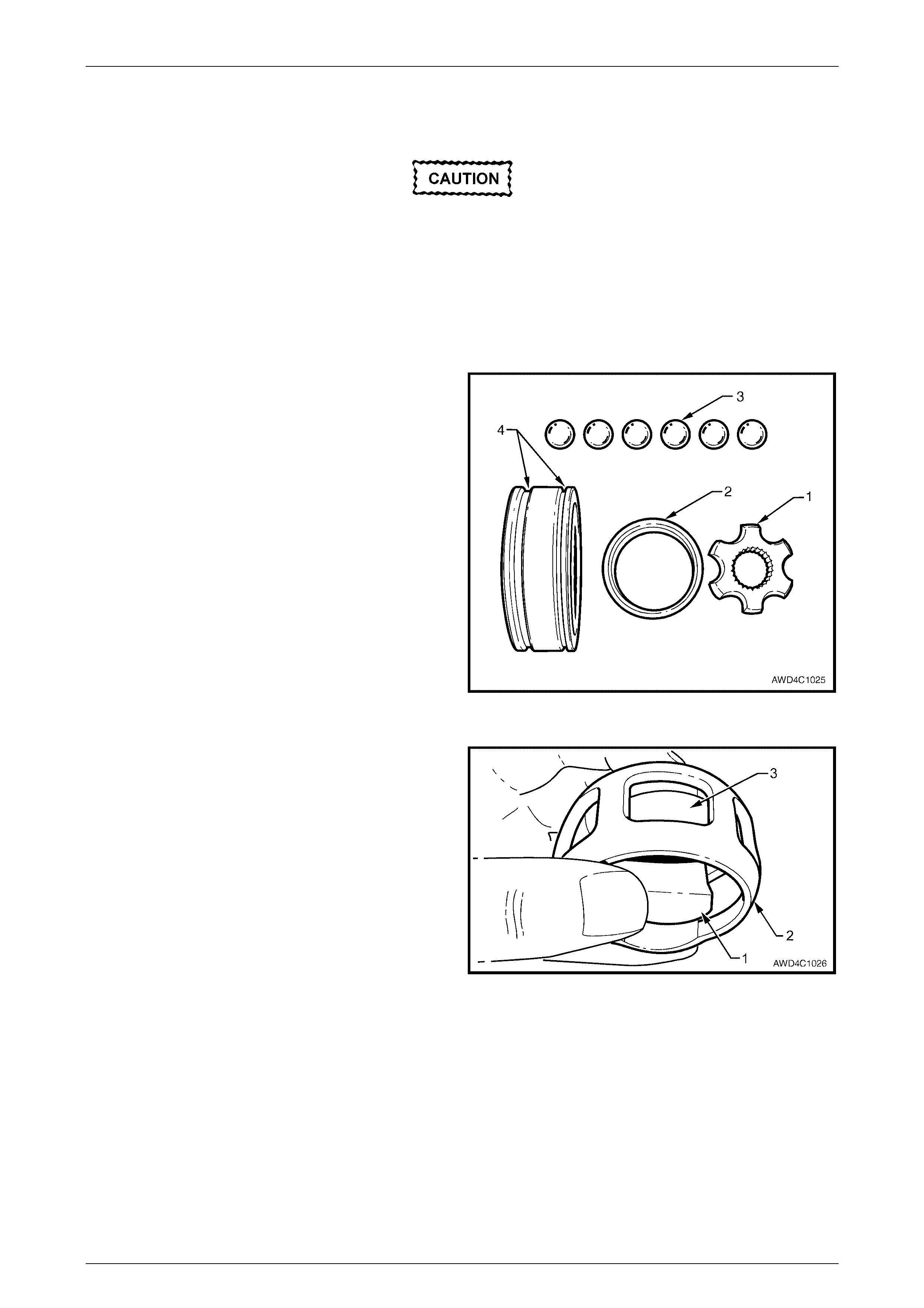

Shown is an exploded view of the centre propeller shaft

constant velocity joint. Note the two identification grooves on

the outer race (4) and the step (5) on the inner race (1).

These features and the angled ball tracks, identify that this

is a ‘plunge’ joint, when assembled.

NOTES

• The inner race (1) and cage (2), together with

the individual balls (3), must be maintained in

their original locations to minimise the

creation of a noisy joint.

• Under no circumstances are components

from one constant velocity joint to be mixed

with components from another constant

velocity joint.

Figure 4C1 – 17

Reassemble

Method 1

1 Provided the balls are held captive in the ball cage when installed, reinstall each in its correct position.

2 While holding the inner race, cage and the six balls in position, reinstall to the outer race by turning the inner

assembly at 90° to the outer race, reinstall the two balls in their raceways, then rotate the inner assembly, to fully

reinstall. Refer to Figure 4C1-14. Check that the relationship marks are aligned, refer to F i gure 4C1-13.

Method 2

1 Place the inner race (1) into the cage (2) and position

centrally within the cage, as shown in view ‘A’. Align

the relationship marks to confirm corr ect insta llation.

NOTE

The flange on the inner diameter of the inner

race should be on the same side as the chamfer

on the inner edge of the ball cage.

Figure 4C1 – 18

Rear Propeller Shaft & Universal Joints Page 4C1–13

Page 4C1–13

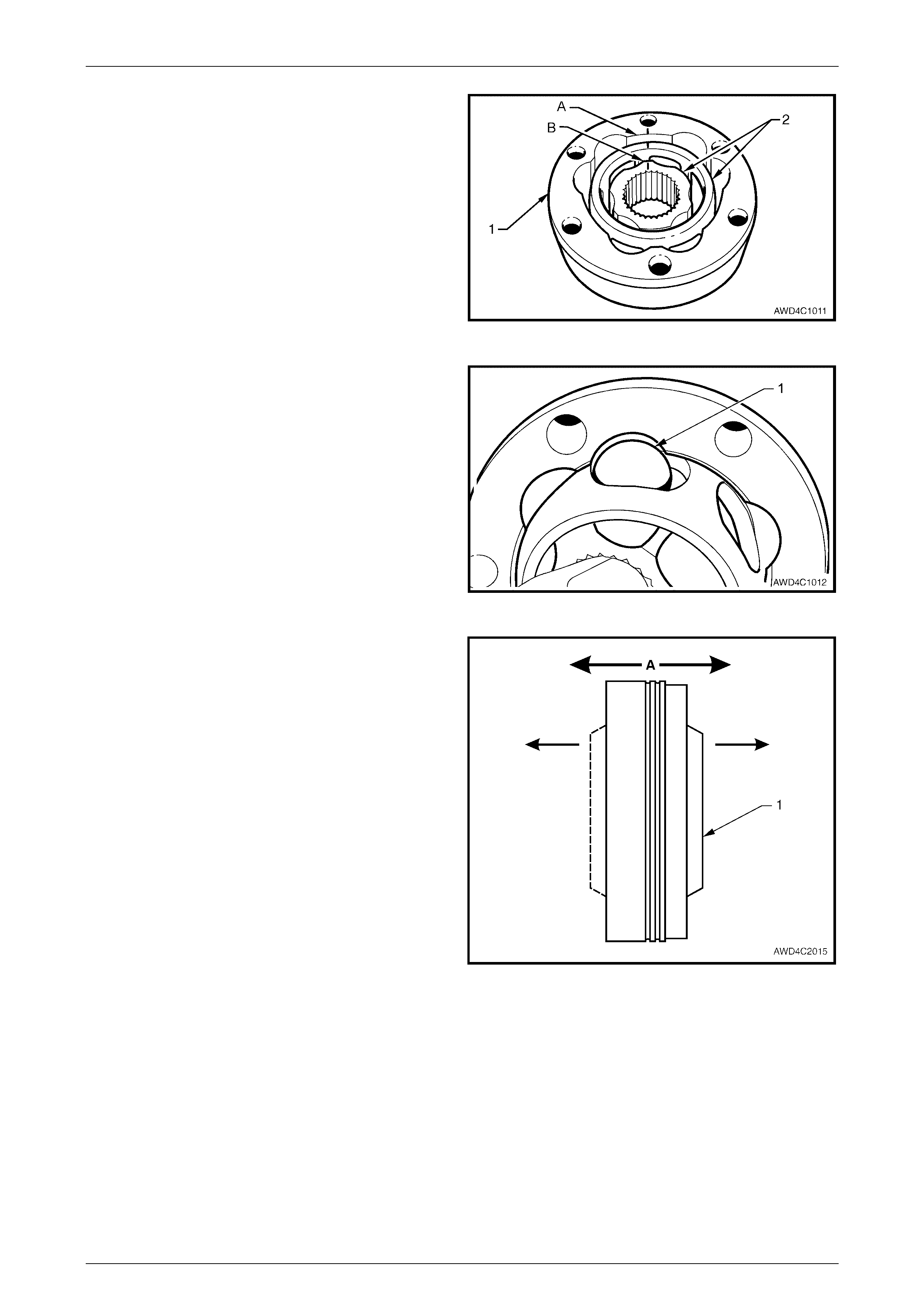

2 Place the inner race and cage (2) into the outer race

(1), as shown.

3 Align a thick section (A) on the outer race, with a

narrow one (B) on the inner race. Note that the

relationship marks are also in alignment.

Figure 4C1 – 19

4 Tilt the cage and inner race as shown, and fit the first

ball (1) in its original location.

Repeat this process for the remaining five balls.

Figure 4C1 – 20

5 W hen assembly of the constant velocity joint is

complete, check for plunge movement of the inner

members (1), indicated by ‘A’. If NO plunge movement

can be achieved, then the constant velocity joint has

NOT been correctly assembled.

If such a situation occurs, the constant velocity joint

must be disassembled and the assembly process

repeated until such time that the required plunge

movement is achieved.

NOTE

The total plunge movement for the centre

constant velocity joint should be approximately

28 mm.

Figure 4C1 – 21

Rear Propeller Shaft & Universal Joints Page 4C1–14

Page 4C1–14

Reinstall

Installation is the reverse of removal procedure, noting the following points:

1 Cleanliness of con stant velo cit y joint and assoc iate d part s is v ital to ensure maximum life.

2 Install a new boot clamp at the small end of the dust boot.

3 Pack the constant velocity joint with the lubricant supplied in either of the two available Repair Kits. Work joint by

hand to distribute grease onto all surfaces inside the joint.

4 Clean mating surfaces of constant velocity joint, dust shield and rear propeller shaft companion flange.

5 Apply a 2 mm bead of Loctite 510 High Temperature

Gasket Eliminator sealant or equivalent to dust shield

mating surface on the constant velocity joint, as shown

(1). Take care not to contaminate the constant velocity

joint grease with sealant.

Figure 4C1 – 22

6 Before pressing the constant velocity joint onto the

splined propeller shaft, support the shaft end (2) with a

suitable length of tube (1) of dimensions 48 mm OD,

32 mm ID and at least 30 mm long.

Figure 4C1 – 23

7 Press constant velocity joint (2) onto shaft using

installer J21426 or a suitable size socket or tube.

Ensure that the press force is applied to the inner race

(1), as shown.

8 Using circlip pliers, install a new circlip to retain the

constant velocity joint. Be careful not to over-expand

the circlip during the installation process.

9 Insert three attaching bolts through the dust boot

flange to align with the constant velocity joint, then tap

the dust boot flange assem bly into pla ce.

10 Clean threads in rear propeller shaft companion flange

and the six Allen head bolts. Apply Loctite 242 or

equivalent thread sealant to the bolt threads.

11

A

pply Loctite 510 High Temperature Gasket Eliminator

sealant or equivalent, to the flanged area of propeller

shaft companion flange, in a similar manner to that

shown in Figure 4C1-22.

Figure 4C1 – 24

Rear Propeller Shaft & Universal Joints Page 4C1–15

Page 4C1–15

12

A

pply Loctite 510 High Temperature Gasket Eliminator

sealant or equivalent, to the flanged area of the

propeller shaft companion flange, in a similar manner

to that shown in Figure 4C1-22.

13 With the three attaching bolts (2) still installed through

the dust boot flange and constant velocity joint, insta ll

then tap a new dust boot cover (1) into place, over the

constant velocity joint.

14 Clean threads in rear propeller shaft companion flange

and the six Allen head bolts. Apply Loctite 242 or

equivalent thread sealant to the bolt threads.

Figure 4C1 – 25

15 Ensure that the relationship marks on the constant velocity joint, dust boot flange and rear propeller shaft flange

(made before disassembly), are all aligned.

16 Reinstall and tighten the six Allen headed screws to the correct torque specification.

( # ) Centre constant velocity joint to

rear propeller shaft flange bolt

torque specific atio n ..............................................35 Nm

17 After locating the boot into the rece ss in the dust boot

groove, tighten the new clamp (1) using long nosed

pliers (2). Ensure that the end of the clamp strap

engages with the last two barbs of the clamp.

18 Reinstall propeller shaft. Refer to 2.1 Propeller Shaft in

this Section.

Figure 4C1 – 26

Rear Propeller Shaft & Universal Joints Page 4C1–16

Page 4C1–16

2.4 Centre Bearing Assembly

LT Section No. – 05-050

NOTES

• This bearing cannot be removed from the

propeller shaft without causing damage to the

rubber ball race carrier and housing

assembly. New parts must be installed when

the propeller shaft is being reassembled.

• The replacement centre bearing kit contains

front and rear dust slingers, centre bearing

and rubber cup assembly.

Remove

1 Remove propeller shaft, refer to 2.1 Propeller Shaft in this Section.

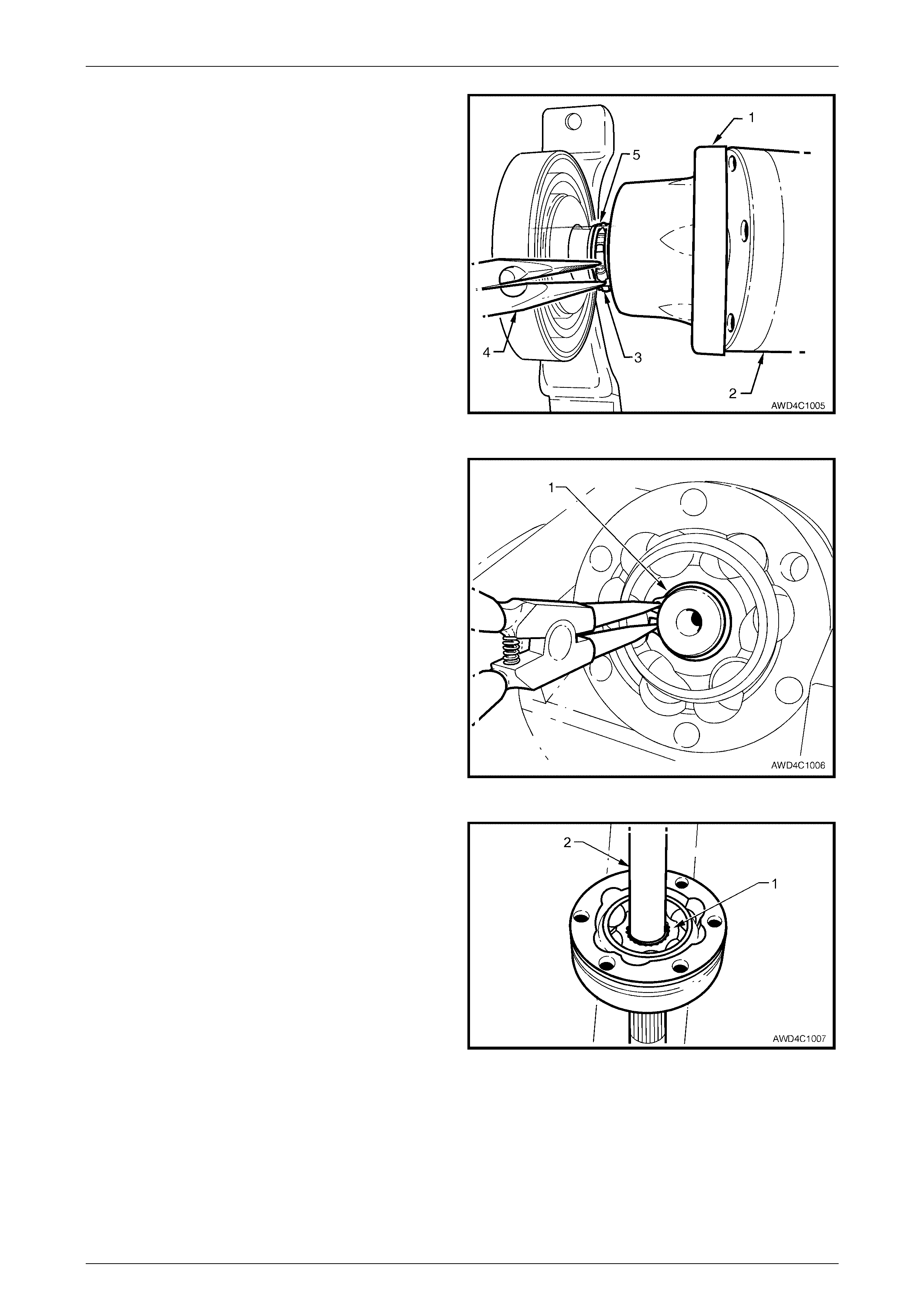

2 Remove constant velocity joint, refer to 2.3 Constant Velocity Joint in this Section.

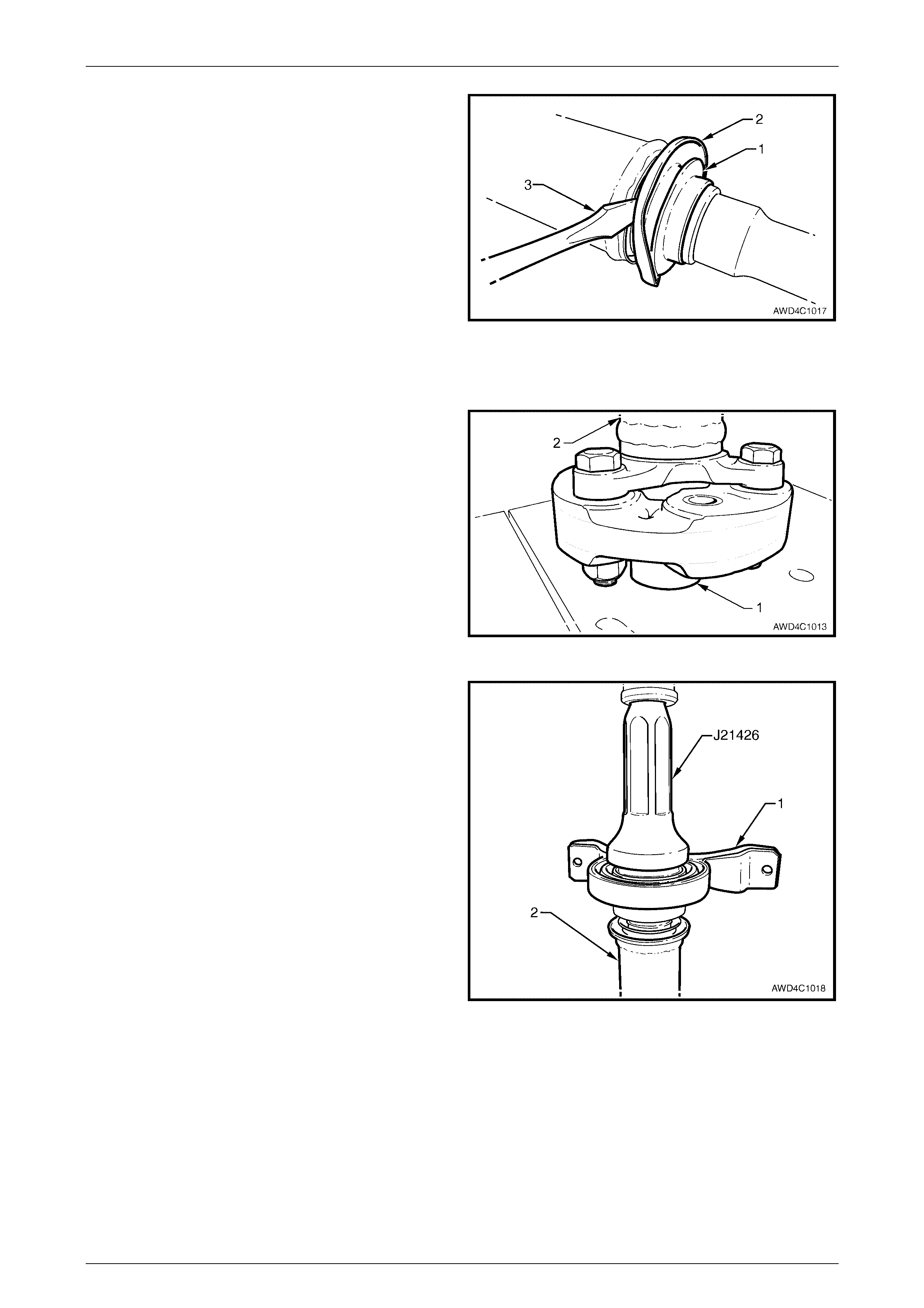

3 Using suitable press plates, such as J22912-01 or

equivalent and a suitable drift (4), support rubber ball

race carrier and housing assembly (2), then press the

propeller shaft (3) from the rear slinger (1) and rubber

ball race carrier and housing assembly (2).

NOTE

This action will separate the bearing from the

rubber support, requiring the replacement of the

complete assembly.

Figure 4C1 – 27

4 Support the centre bearing (1) with suitable press

plates such as J22912-01, then press the propeller

shaft front half (2) from the bearing. Discard the

bearing (1) following removal.

Figure 4C1 – 28

Rear Propeller Shaft & Universal Joints Page 4C1–17

Page 4C1–17

5 If required, remove centre bearing front slingers (1 and

2), using a suitable lever (3), such as a flat bladed

screwdriver.

NOTE

The slingers will be distorted during removal and

must be replaced with new parts on reassembly.

Figure 4C1 – 29

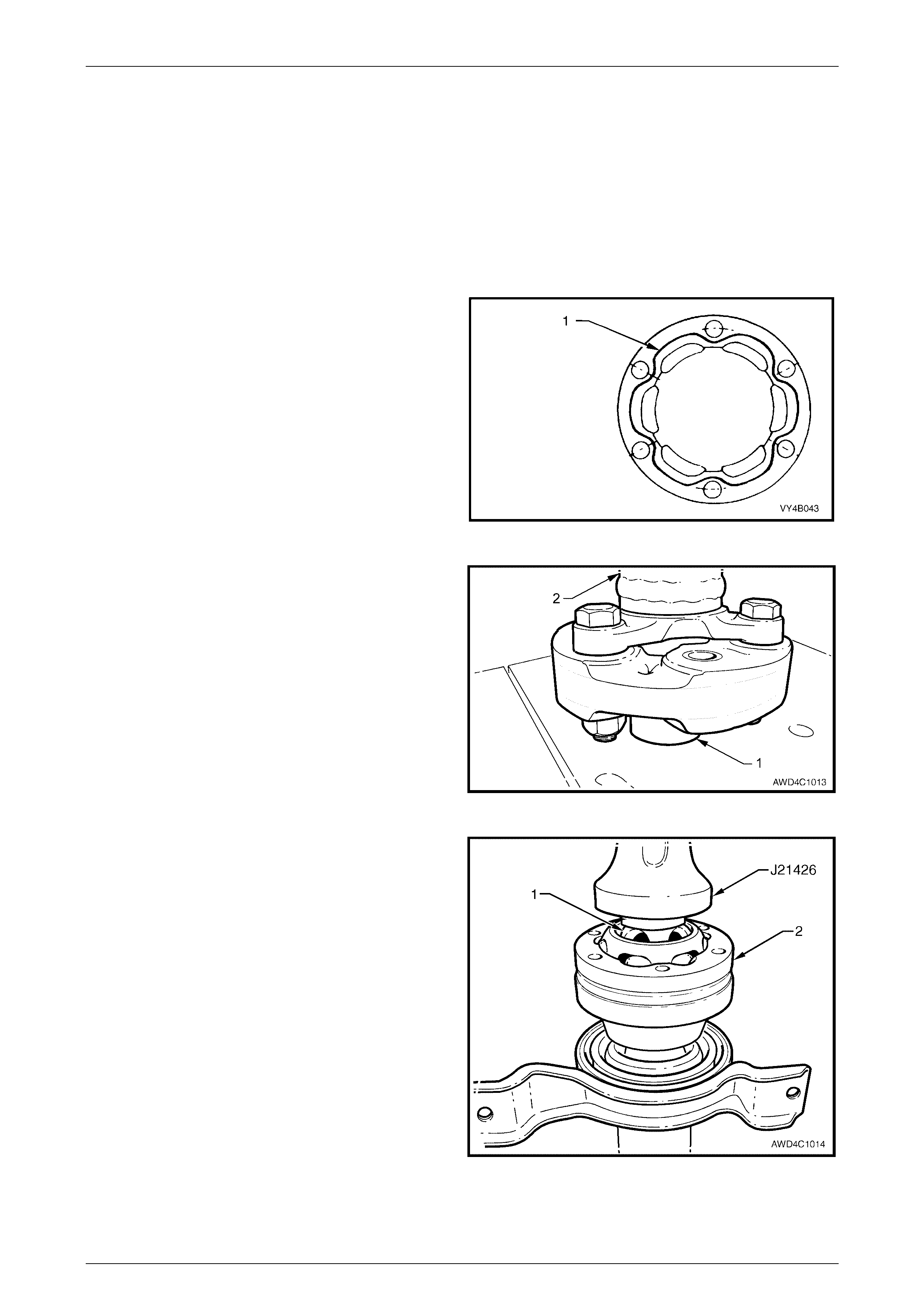

Reinstall

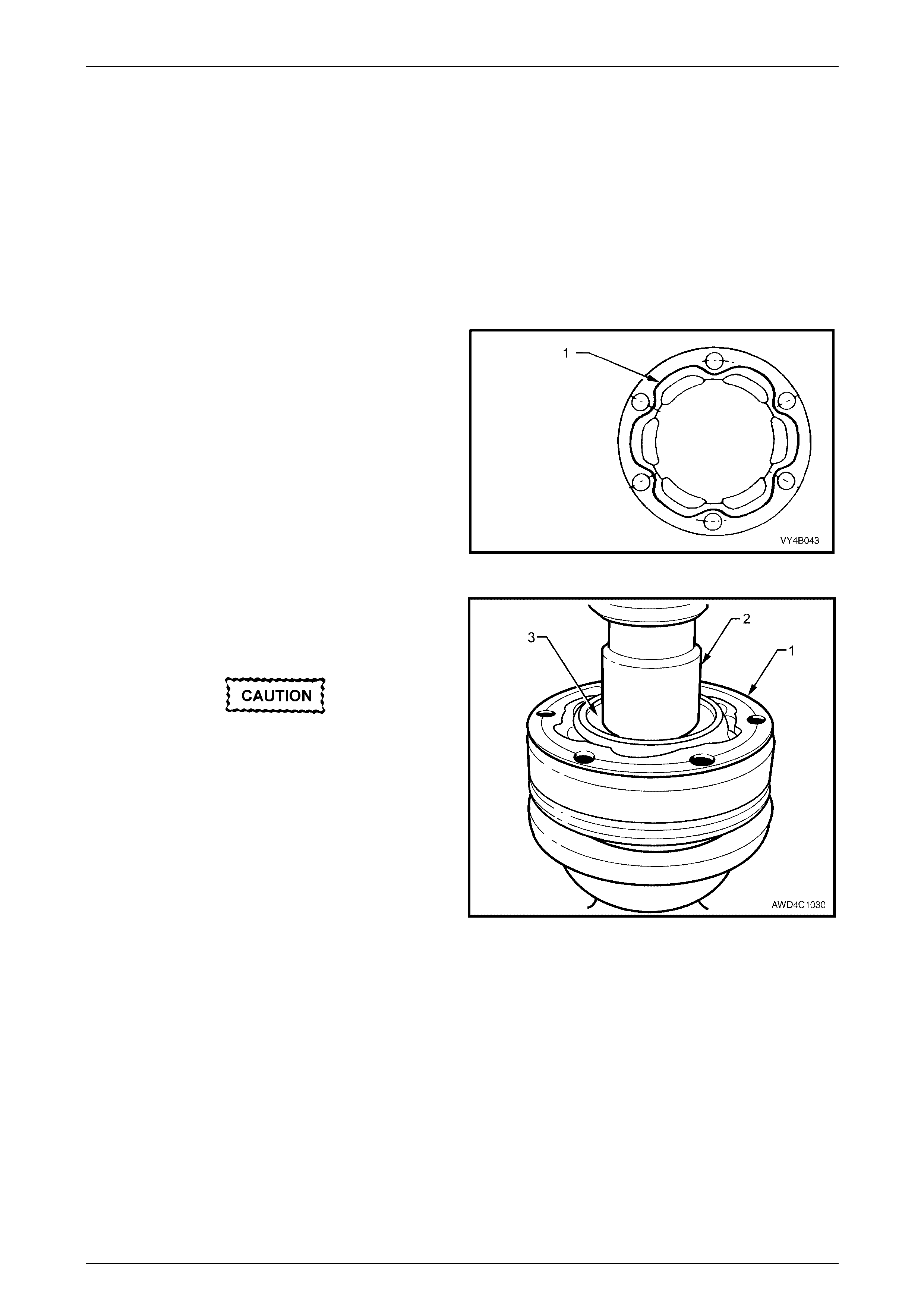

1 Install new front slingers (one at a time), onto front half

of the propeller shaft using J5590 or a suitable sized

tube.

NOTE

During this reinstallation process, ensure that the

front of the propeller shaft (2) is supported on a

suitable length of tube (1) (dimensions; 48 mm

OD, 32 mm ID and at least 30 mm long), as

shown.

Figure 4C1 – 30

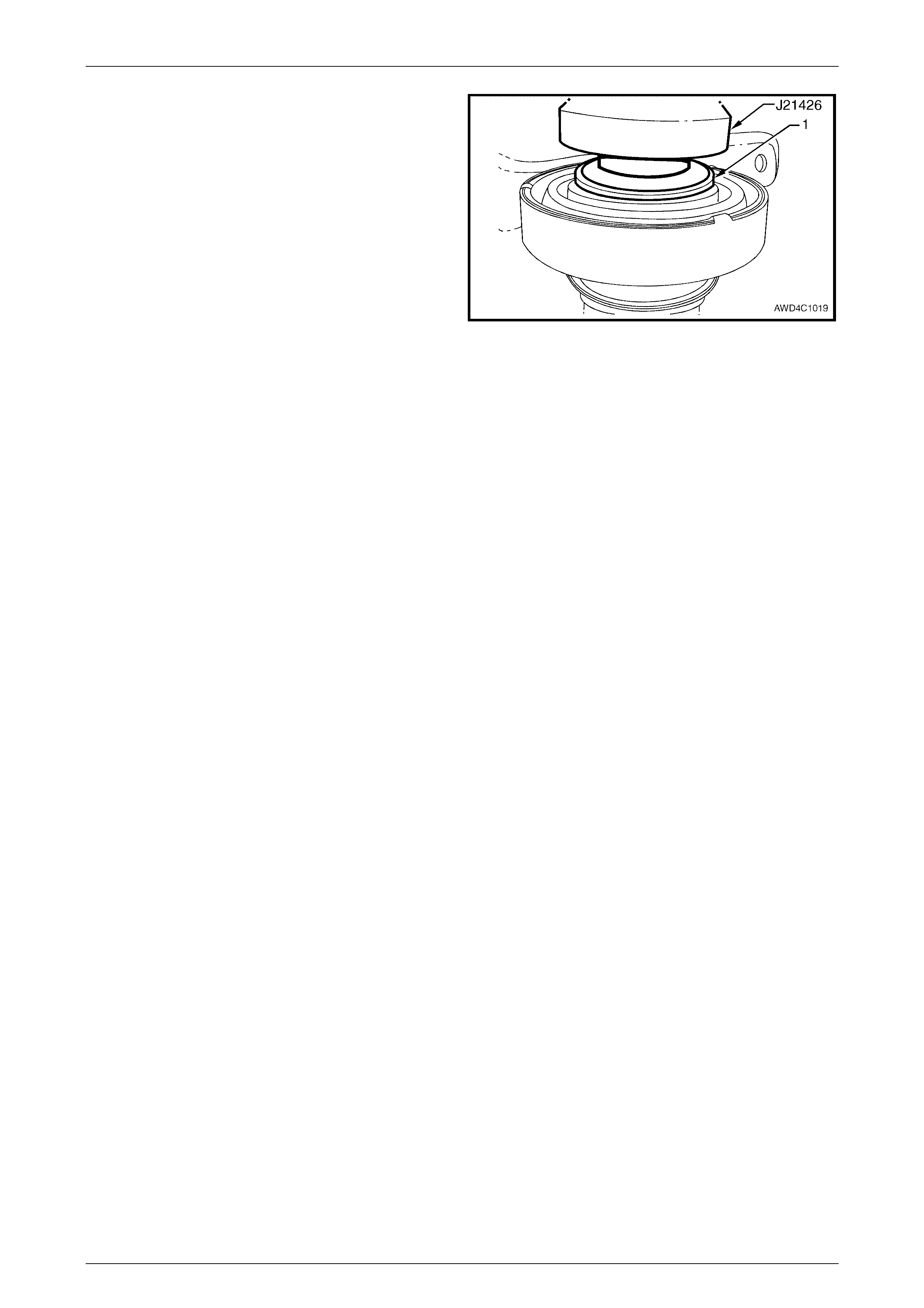

2 Reinstall new centre bearing assembly (1) to propeller

shaft (2) using installer J21426 or a suitable size tube.

NOTE

Only apply press force to the centre ball race.

Figure 4C1 – 31

Rear Propeller Shaft & Universal Joints Page 4C1–18

Page 4C1–18

3 Again using installer J21426 or a suitable size tube,

install a new slinger (1) to the centre bearing, as

shown.

Figure 4C1 – 32

4 Reinstall centre constant velocity joint. Refer to 2.3 Centre Constant Velocity Joint in this Section.

5 Reinstall the rear propeller shaft assembly. Refer 2.1 Propeller Sha ft in this Section.

Rear Propeller Shaft & Universal Joints Page 4C1–19

Page 4C1–19

2.5 Fixed, Rear Constant Velocity Joint

LT Section No. – 05-050

NOTE

The rear propeller shaft, rear constant velocity

joint (constant velocity joint), is a “fixed” joint,

which means that any axial end play is minimal.

Remove

1 Remove rear propeller shaft from the vehicle. Refer to 2.1 Propeller Shaft, in this Section.

2 Using a small bladed screwdriver, lever up the boot

clamp tang to release, then remove and discard the

boot clamp (1).

Figure 4C1 – 33

3 Grip the constant velocity joint in a vice fitted with soft

jaws.

4 Using a suitable cold chisel and hammer, dislodge and

remove the crimped end cap from the end of the

constant velocity joint. Discard the removed end cap.

5 Reposition the constant velocity joint in the vice, to

allow access to the crimped dust boot cap, then

dislodge it, using the same cold chisel and hammer.

NOTE

Assuming that the constant velocity joint is to be

reinstalled, be careful not to damage the outer

race, during the cap removal process.

Figure 4C1 – 34

Rear Propeller Shaft & Universal Joints Page 4C1–20

Page 4C1–20

6 Using suitable circlip pliers (1), remove the circlip (2)

from the end of the propeller shaft and discard.

NOTE

Do not re-use the circlip once it has been

removed. Always fit a new part on reassembly.

Figure 4C1 – 35

7 Push the cap and boot back al ong the propeller shaft,

enough to allow the fitment of press plates such as

J22912-01.

8 Support the constant velocity joint inner race (1) with

the press plates (22912-01) then, using a suitable

mandrel (2), press the propeller shaft from the

constant velocity joint.

9 Remove the boot and dust shield from the propeller

shaft, being careful not to damage the boot on the

propeller shaft spli nes .

Figure 4C1 – 36

Inspect

Propeller Shaft and Boot

1 Clean propeller shaft splines and boot, using suitable cleaning solvent.

2 Inspect the propeller shaft splines for twisting, cracking or excessive wear. If any of these conditions are observed,

then the propeller shaft must be replaced.

3 Carefully inspect the boot and replace if split, fatigued, cracked or worn.

Rear Propeller Shaft & Universal Joints Page 4C1–21

Page 4C1–21

Constant Velocity Joint

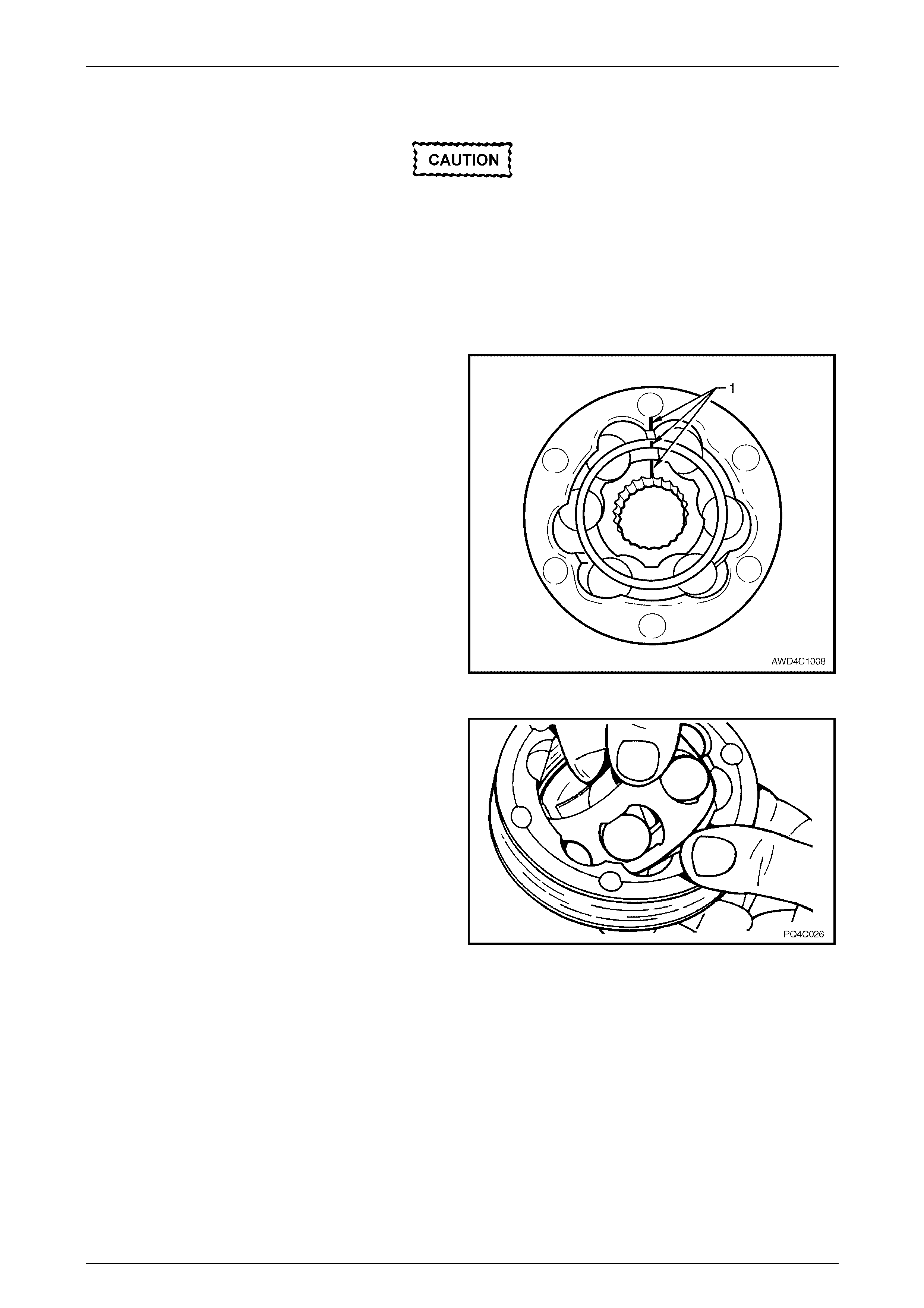

Complete disassembly of the constant

velocity joint is not recommended. The

internal components are a precision fit and

develop their own characteristic wear

patterns. The inter-mixing of components

could result in looseness, binding and/or

premature failure of the joint.

1 Remove the excess lubricant from the constant

velocity joint (1), wipe clean, then use correction fluid

(2), to identify the relationship of the three joint

components.

2 Remove gasket (3) and discard.

Figure 4C1 – 37

3 Inspect grease in joint, and if obviously contaminated

and/or been subjected to dirt ingress, the joint has in

all likelihood suffered damage and should be replaced.

If inspection reveals that the joint has not been

contaminated, clean joint by soaking in a suitable

cleaning solvent.

4 Once grease has been removed, inspect internal

components by tilting inner race to one side to expose

each ball.

NOTE

Take care not to pivot the inner race too sharply,

as the balls can become dislodged. If this does

occur and the original location of the balls is lost,

then the constant velocity joint should be

replaced.

Figure 4C1 – 38

5 Replace joint assembly if there is severe pitting, galling, play between balls and the cage windows, any cracking or

damage to cage, pitting or galling or chips in raceways.

Rear Propeller Shaft & Universal Joints Page 4C1–22

Page 4C1–22

Reassemble

During the removal, cleaning, inspection or

replacement of a constant velocity joint, it is

possible for the joint to become

disassembled. Should an inadvertent

disassembly of a constant velocity joint

occur, and notwithstanding the earlier

recommendation, it is possible to reassemble

the constant velocity joint, provided the

following procedure is followed EXACTLY.

As shown in the exploded view of the fixed constant velocity

joint, two grooves (4) are provided on the outer race for the

crimped dust cov ers – the wide one is to receive the front

cover and boot assembly, while the narrow groove is for the

rea r cover.

The fact that the ball grooves in both the outer and inner

races are equally spaced, identifies this constant velocity

joint as a “fixed” type. Note also the fine groove on the front

edge of the ball cage and the larger, plain chamfer on the

rear.

NOTES

• The inner race (1) and cage (2), together with

the individual balls (3), must be maintained in

their original locations to minimise the

creation of a noisy joint.

• Under no circumstances are components

from one constant velocity joint to be mixed

with components from another constant

velocity joint.

Figure 4C1 – 39

1 With the inner race (1) at 90° to the ball cage (2),

insert one 'leg' (3) of the inner race into one of the ball

holes, then manipu late the inn er race until ins tal led

inside the ball cage. Check that the relationship marks

are both on the same side.

NOTE

The fine groove on the inner edge of the ball

cage and the chamfered spline edge, should

both be opposite the relationship marks.

Figure 4C1 – 40

Rear Propeller Shaft & Universal Joints Page 4C1–23

Page 4C1–23

2 Reinstall the ball cage and inner race into the outer

race, following this next procedure:

a Locate the two reliefs in the ball grooves in the

outer race, indicated by 'A'. There will be similar

reliefs on the opposite side.

Figure 4C1 – 41

b W ith the ball cage and inner race at 90° to the

outer race, install at the relief points (as shown),

then manipulate the bal l cage t o fit inside the

outer race. Ensure that the relationship marks

are all on the same side and aligned.

Figure 4C1 – 42

3 Tilt the ball cage and inner race as shown, and fit the

balls, in their correct order, one at a time.

4 Check that the three relationship marks (1) are in

alignment.

5 Check that axial movement is minimal.

Figure 4C1 – 43

Rear Propeller Shaft & Universal Joints Page 4C1–24

Page 4C1–24

Reinstall

Reinstallation is the reverse of removal procedure, noting the following points:

1 Cleanliness of con stant velo cit y joint and assoc iate d parts is of prime imp ortan ce to ensure maximum life of the

joint assembly.

2 Install a new small boot clamp over the splined propeller shaft splines, then install the boot and dust shield

assembly, taking care not to damage the boot on the propeller shaft splines.

3 Pack the constant velocity joint with the lubricant supplied in either of the two available Repair Kits. Work joint by

hand to distribute grease onto all surfaces inside the joint.

4 Clean mating surfaces of constant velocity joint, dust shield and rear propeller shaft companion flange.

5 Apply a 2 mm bead of Loctite 510 High Temperature

Gasket Eliminator sealant or equivalent, to the dust

shield mating surface on the c onst ant vel oci ty joint, as

shown (1). Take care not to contaminate the constant

velocity joint grease with sealant.

Figure 4C1 – 44

6 Press constant velocity joint onto the rear propeller

shaft splines, using a suitable size socket or tube.

Ensure that socket or tube presses on inner race of

joint.

During this pressing operation, ensure that

the outer surface of the centre constant

velocity joint is supported by press plates

such as J22912-01 or equivalent.

7 Secure the constant velocity joint with a new circlip,

being careful not to over-expand the circlip during the

installation process.

8 Install at least three of the rear constant velocity joint

Allen key headed bolts aligning the dust shield to the

constant velocity joint.

Figure 4C1 – 45

9 Using a plastic faced hammer, install the dust cap to the constant velocity joint.

10 Use keystone clamp pliers such as J22610 or commercial equivalent, to tighten the small boot clamp.

11 Reinstall new gasket to end of constant velocity joint.

12 Press the outer cover into place over the guide bolts, with press plates such as J22910-01 (or equivalent)

supporting the dust shield, with a suitable sized sleeve acting on the outer edges of the end cap.

13 Reinstall propeller shaft. Refer to 2.1 Propeller Shaft, in this Section.

Rear Propeller Shaft & Universal Joints Page 4C1–25

Page 4C1–25

3 Specifications

Propeller Shaft

Length (Mid Position)

Front of Rubber Coupling to Rear Mounting Face of Rear constant velocity Joint........................1490 mm

Propeller Shaft Tube Diameter (Front and Rear Halves) ...............................................................54.1 mm

Centre Bearing

Type...........................................................................................................................Single Row Ball Race

Lubrication ............................................................................................................................Sealed for Life

Constant Velocity Joints

Centre (Plunge Design) – Number of Balls................................................................................................6

Maximum Plunge Distance (from a centralised position) ...............................................................± 14 mm

Rear (Fixed Design) – Number of Balls......................................................................................................6

Lubrication Quantity

Front Plunge Constant Velocity Joint.....................................................................................45 ± 2.5 gram

Rear Fixed Constant Velocity Joint........................................................................................22 ± 2.5 gram

Rear Propeller Shaft & Universal Joints Page 4C1–26

Page 4C1–26

4 Torque Wrench Specifications

ATTENTION

!

!!

! Fasteners must be replaced after loosening.

"

""

" Vehicle must be at curb height before final tightening.

#

##

# Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

# Centre Bearing Carrier to Underbody Reinforcement Bolt ....................22 Nm

# Centre Constant Velocity Joint to Rear Propeller Shaft Flange Bolt......35 Nm

Intermediate Exhaust Pipe to Catalytic Converter Flange Bolt ................45 Nm

# Propeller Shaft Rear Constant Velocity Joint to Pinion Flange Bolt ......35 Nm

! Rubber Coupling to Transfer Case Output Shaft Flange Nut................78 Nm

! Propeller Shaft To Rubber Coupling Nut.......................18 Nm , then 55° turn

Rear Propeller Shaft & Universal Joints Page 4C1–27

Page 4C1–27

5 Special Tools

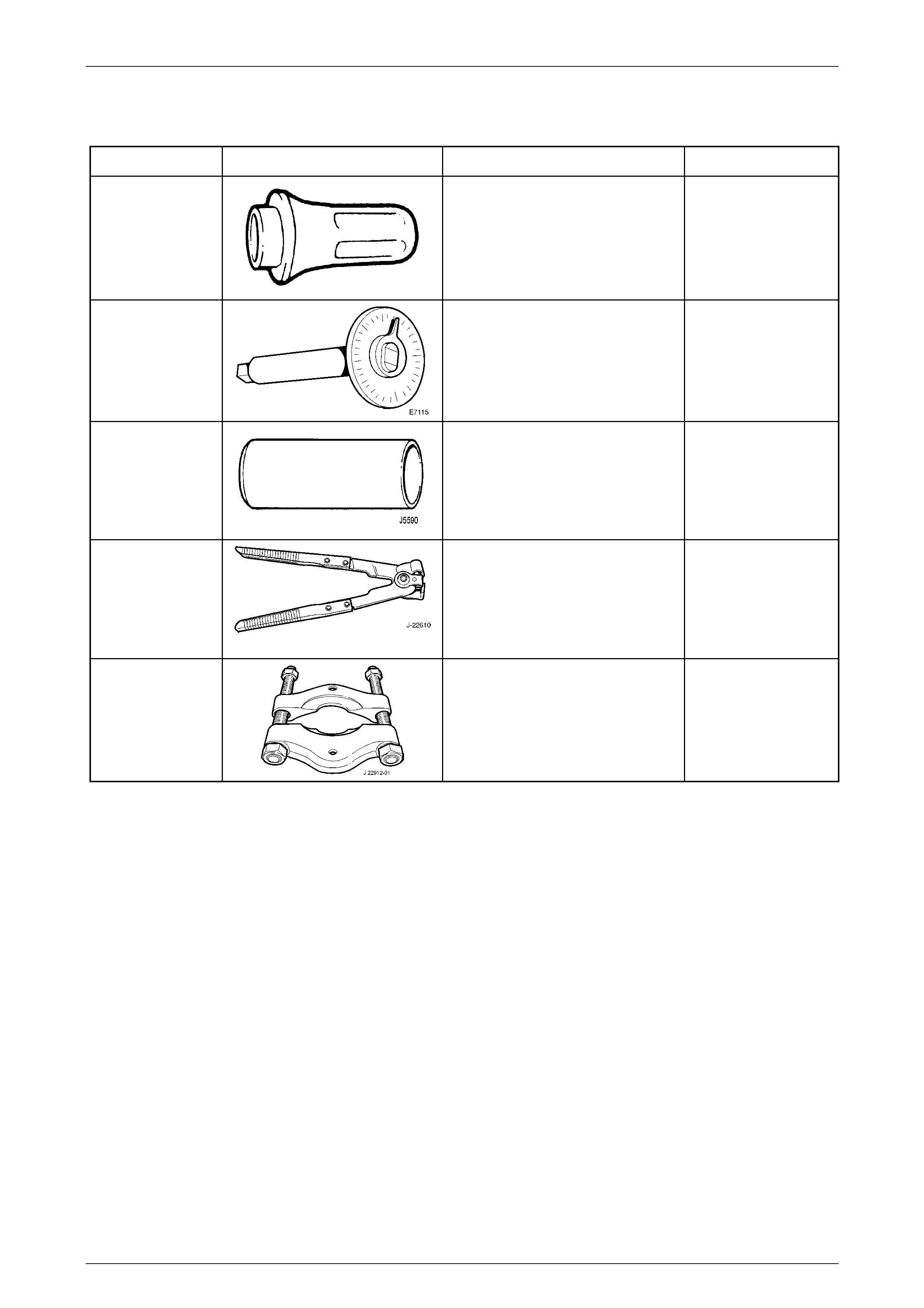

Tool Number Illustration Description Tool Classification

J21426

Installer

Used to install the centre bearing and

outer slinger to the rear propeller

shaft.

Previously released.

Unique

E7115

Angle Wrench

Used to tighten fasteners when an

angle torque is specified. Also

released as BT 8653-A

Previously released.

Unique

J5590

Press Tube

Used to install centre bearing slingers.

Previously released.

Unique

J22610

Ke ystone Clamp Pliers

Used to tighten the constant velocity

joint boot clamps. Also released as

E 1896 and 3A13.

Previously released

Desirable

J22912-01

Press Plates

Also released as E6673

Previously released.

Desirable