AW D ABS-TCS Page 5B–1

Page 5B–1

Section 5B

AWD ABS-TCS

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices w ith regard to safety and/or property damage.

1 General Information............................................................................................................................... 4

1.1 Component Location .............................................................................................................................................6

1.2 AWD ABS-TCS Hydraulic Circuit ..........................................................................................................................8

2 System Operation................................................................................................................................ 10

2.1 Non-ABS Braking.................................................................................................................................................10

Non-ABS Braking Operation ...............................................................................................................................10

2.2 Antilock Braking System (ABS)..........................................................................................................................12

ABS-TCS Normal Operating Conditions ............................................................................................................12

ABS Phase – Maintaining Pressure....................................................................................................................12

ABS Phase – Reducing Pressure .......................................................................................................................14

ABS Phase – Increasing Pressure......................................................................................................................16

2.3 Automatic Brake Distribution (ABD) System.....................................................................................................18

ABD System – Brake Intervention ......................................................................................................................18

2.4 Electronic Brake-force Distribution (EBD) System ...........................................................................................20

EBD System Keep Alive Function.......................................................................................................................20

EBD – Maintaining Pressure ...............................................................................................................................20

EBD Phase – Reducing Pressure .......................................................................................................................22

EBD Phase – Increasing Pressure......................................................................................................................24

3 Component Description and Operation.............................................................................................25

3.1 Electronic Control Unit (ECU) .............................................................................................................................25

ECU Self-test Initialisation Sequence.................................................................................................................25

ECU Inputs............................................................................................................................................................26

ECU Outputs.........................................................................................................................................................26

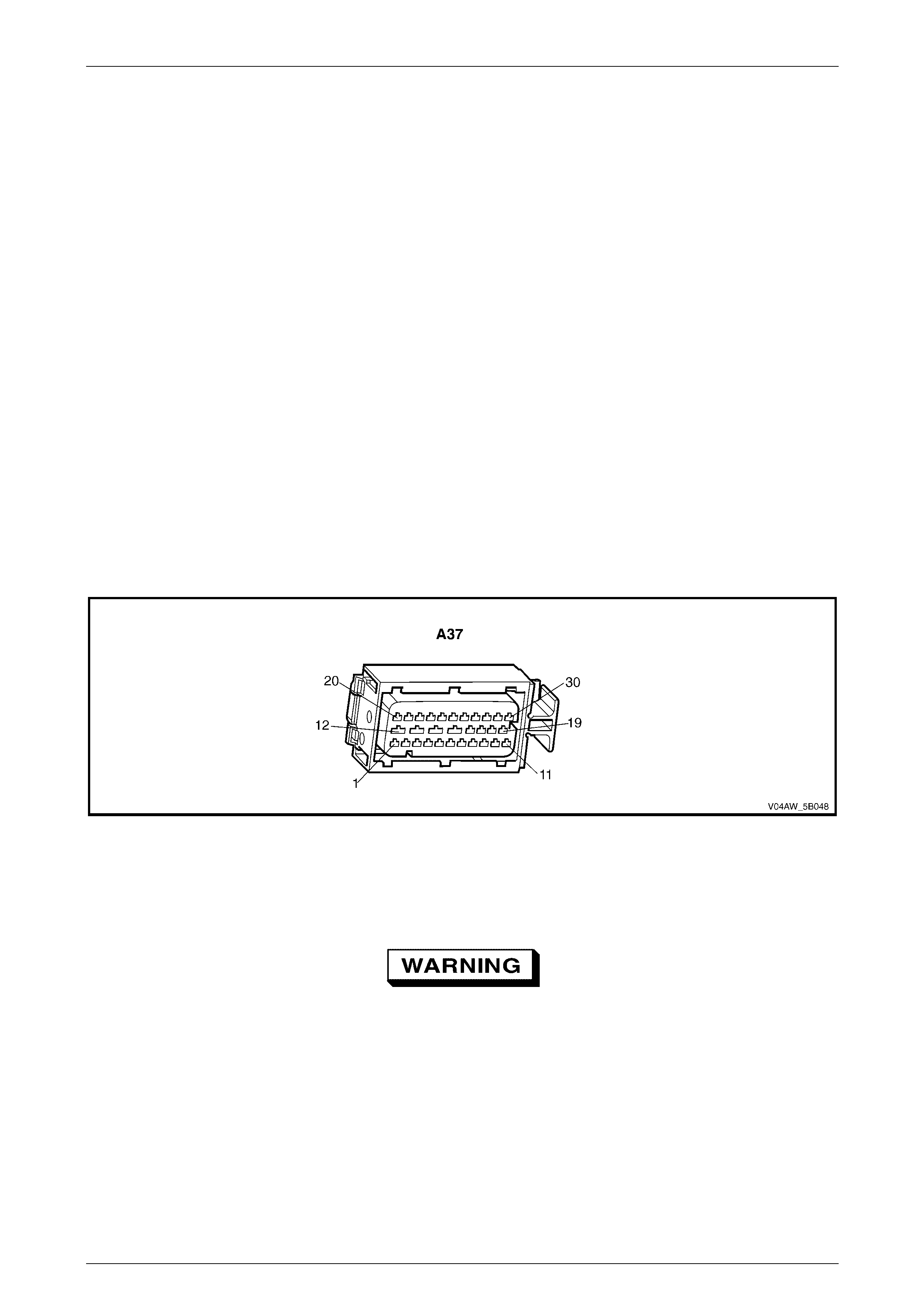

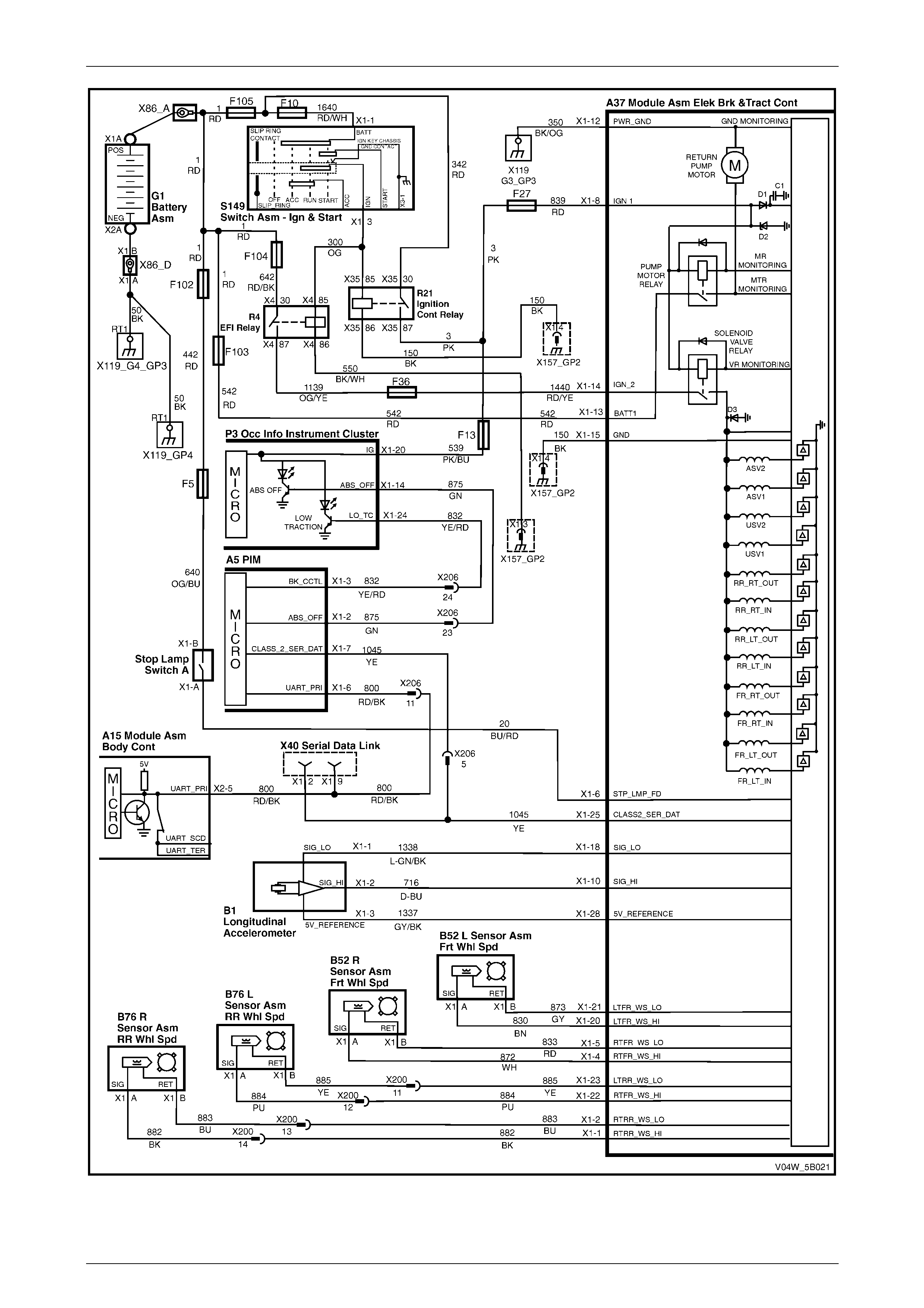

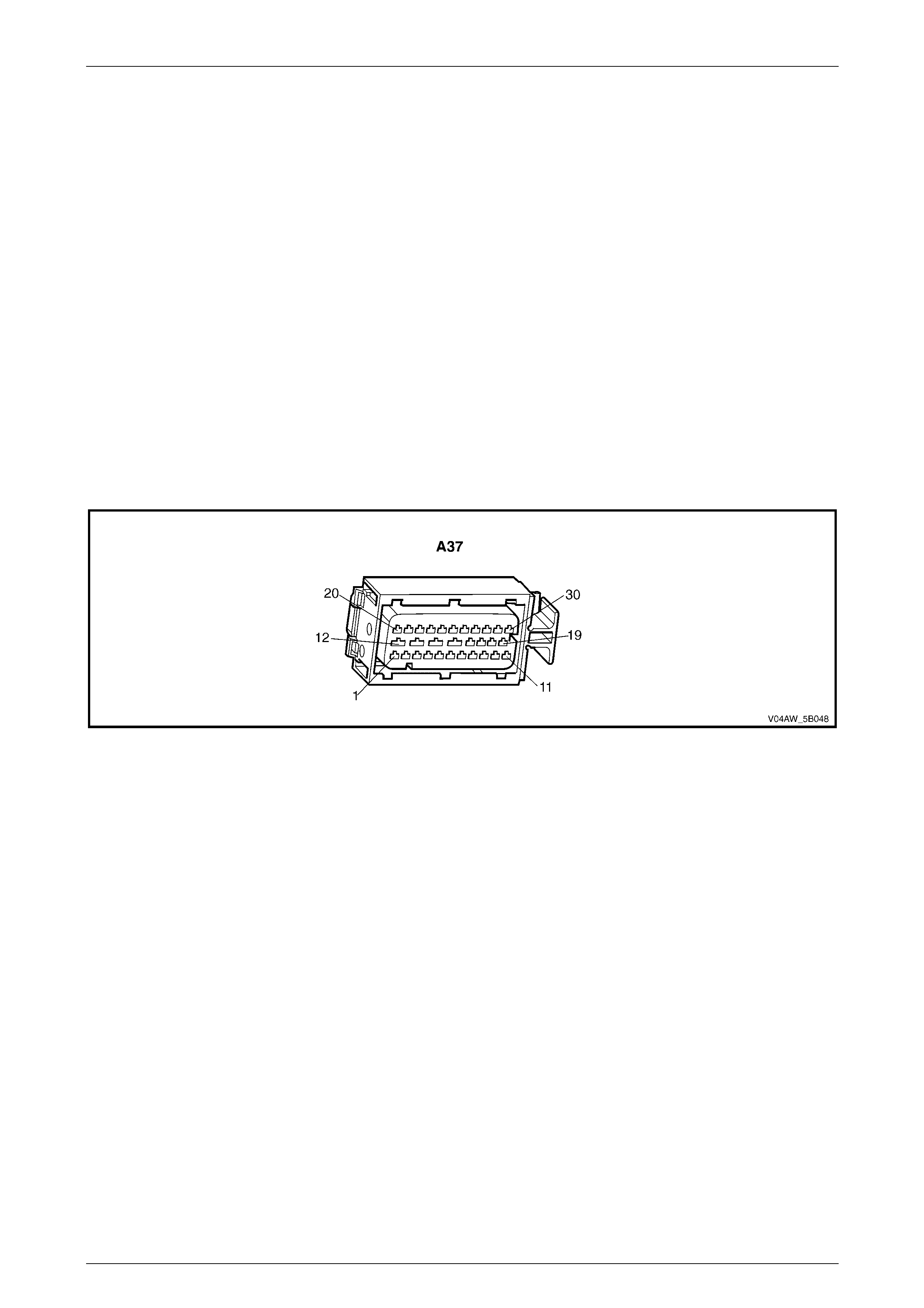

ECU Wiring Connector Terminal Assignment...................................................................................................27

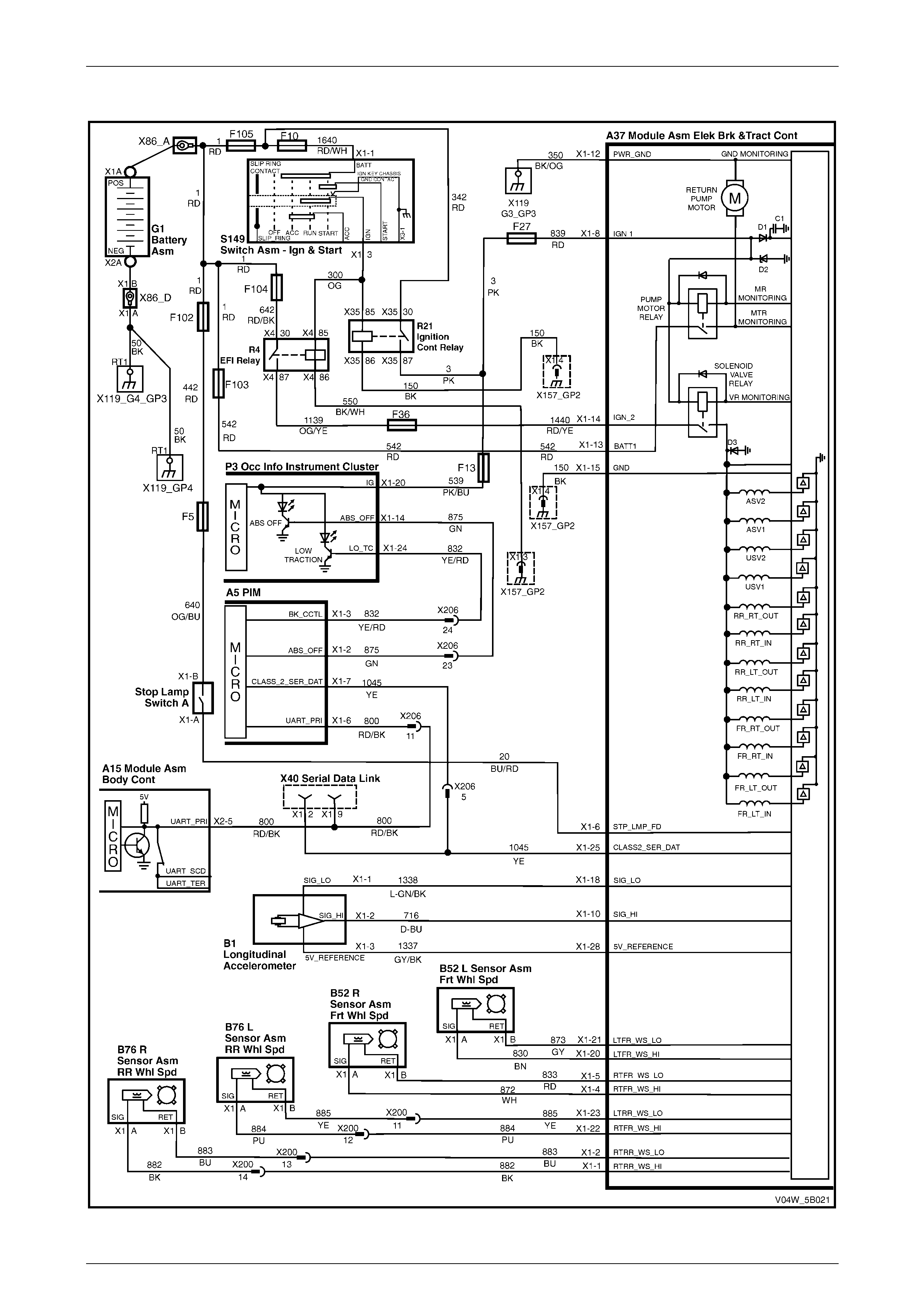

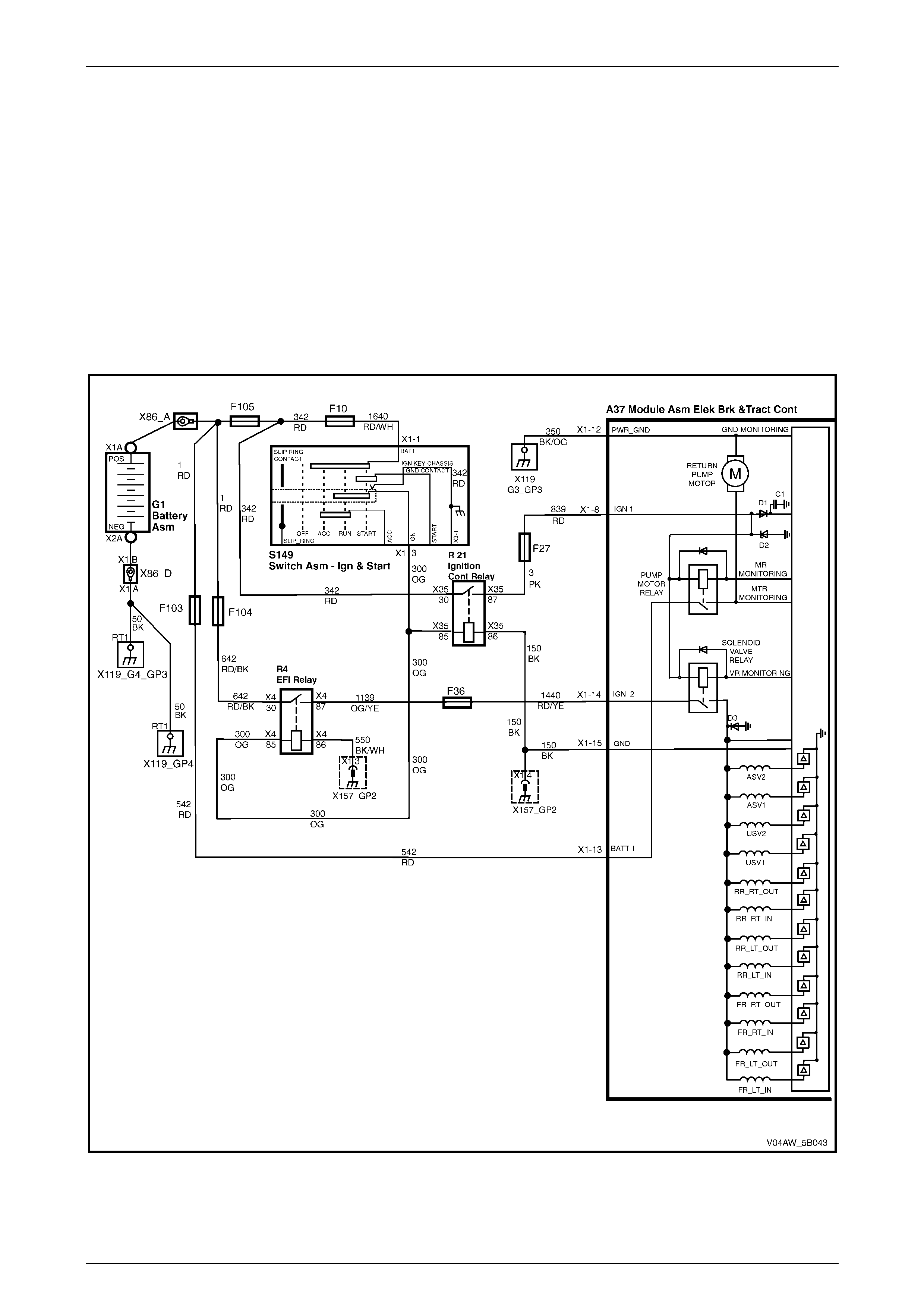

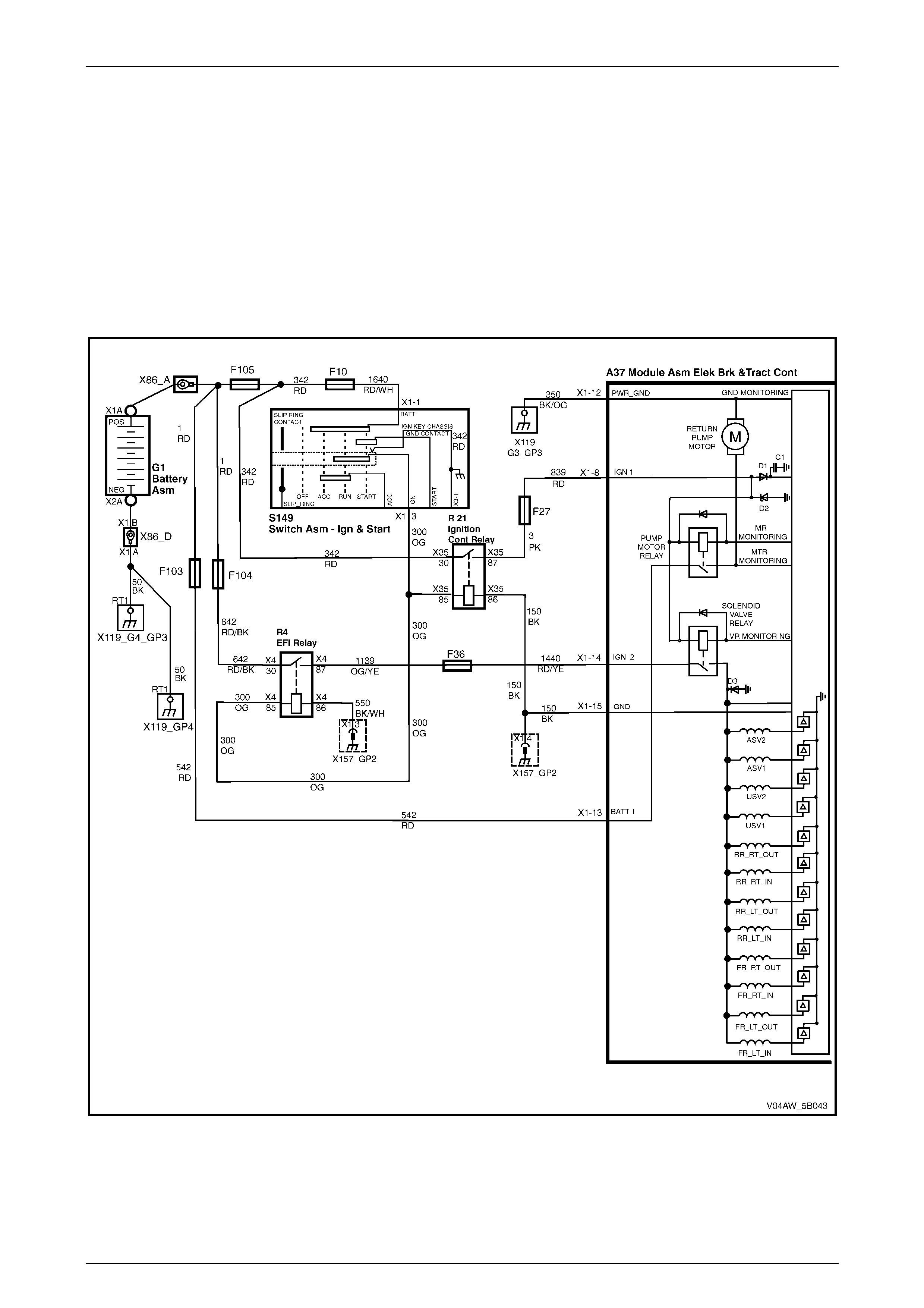

ECU Wiring Diagram............................................................................................................................................28

3.2 Hydraulic Modulator.............................................................................................................................................29

3.3 Wheel Speed Sensors..........................................................................................................................................30

Testing Wheel Speed Sensor Using an Oscilloscope ......................................................................................30

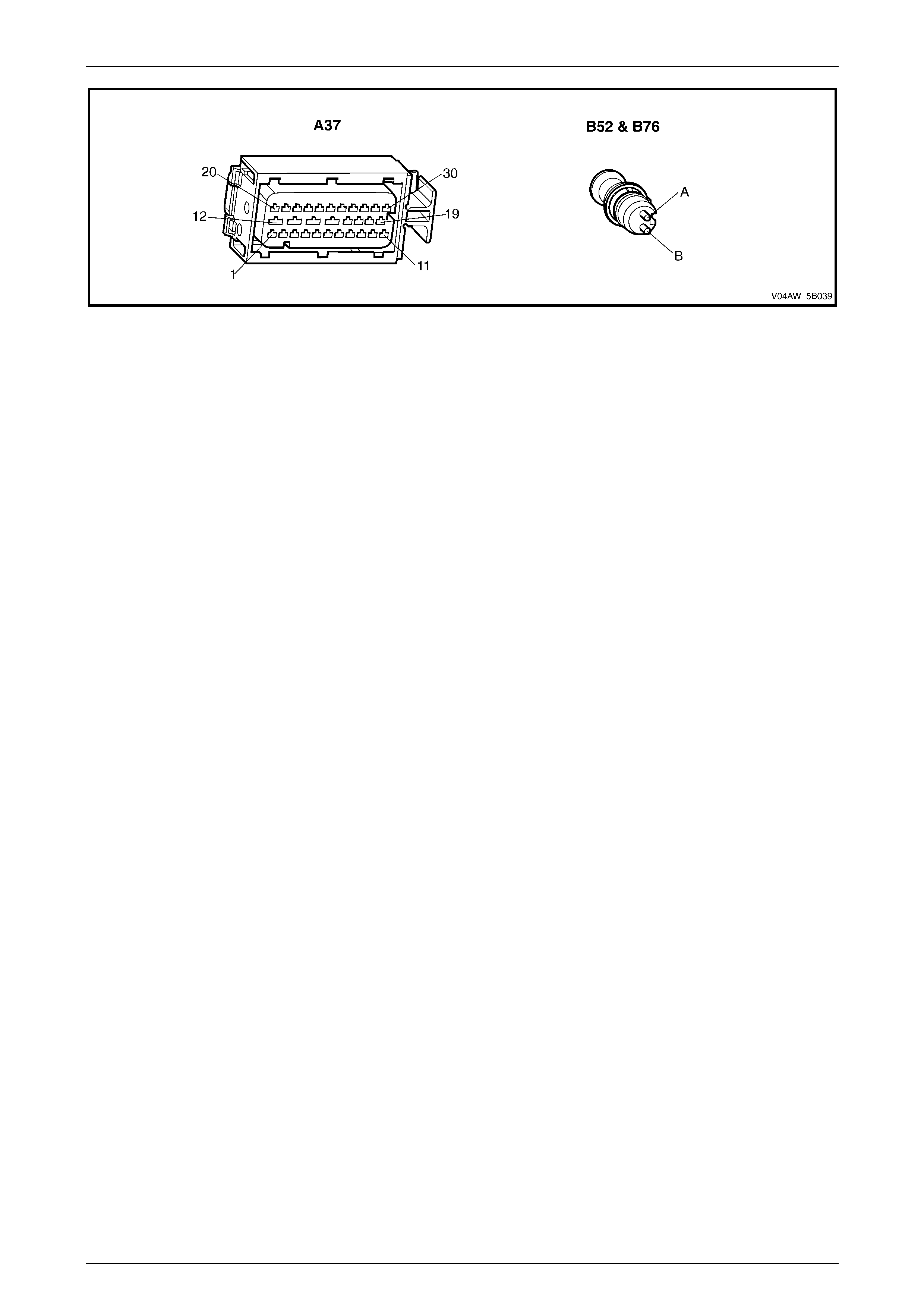

Wheel Speed Sensor Wiring Connector.............................................................................................................31

Front Wheel Speed Sensor..................................................................................................................................31

Rear Wheel Speed Sensors.................................................................................................................................31

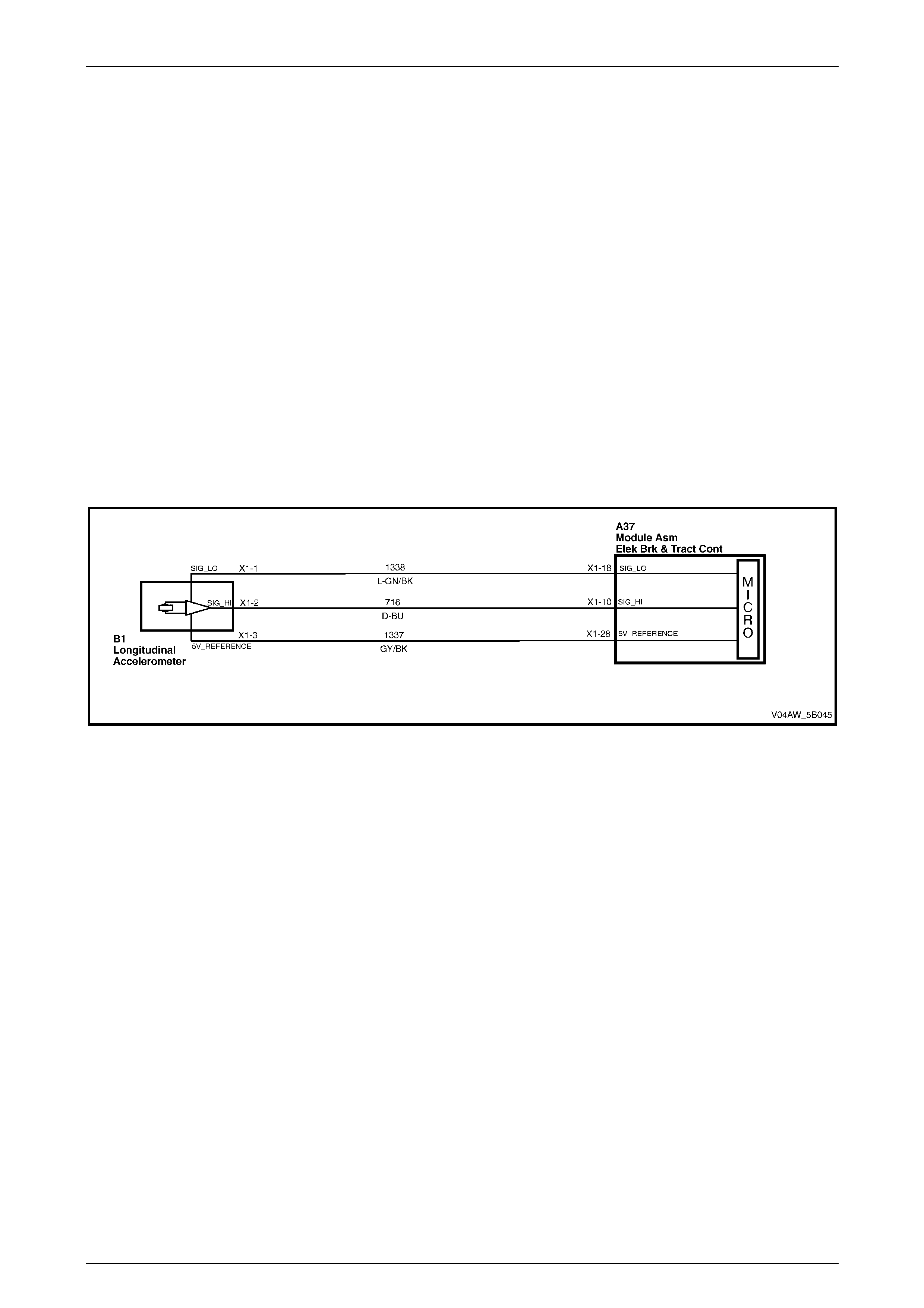

3.4 Longitudinal Accelerometer................................................................................................................................32

Longitudinal Accelerometer Wiring Connector.................................................................................................32

3.5 Stop Lamp Switch-A ............................................................................................................................................33

Stop Lamp Switch-A Wiring Connector.............................................................................................................33

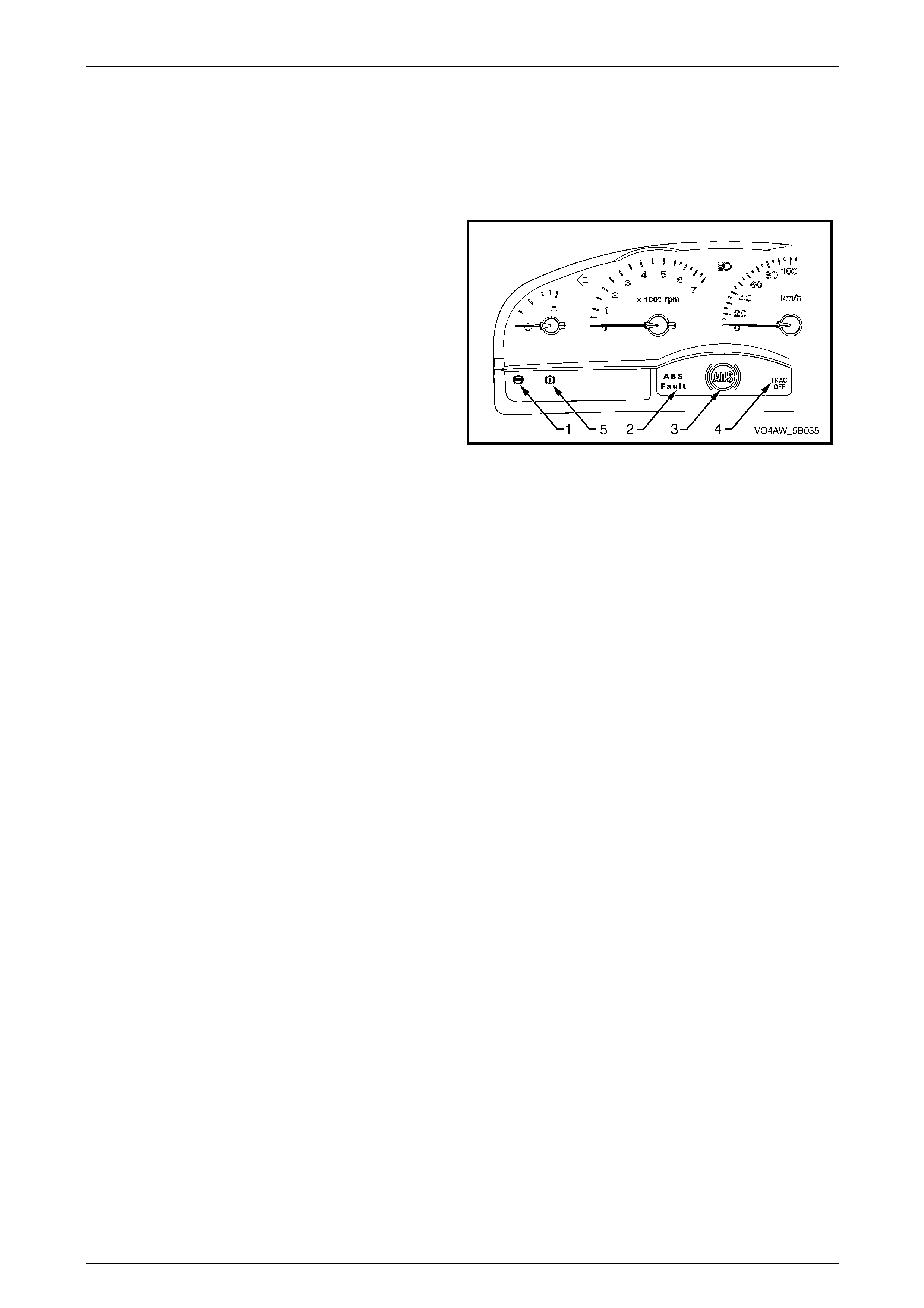

3.6 AWD ABS – TCS Warning Display......................................................................................................................34

ABS Warning Lamp..............................................................................................................................................34

ABS Fault / Trac Off Warning Display ................................................................................................................34

Low Traction Warning Display............................................................................................................................34

3.7 ABS-TCS Fuse Locations....................................................................................................................................35

Techline

Techline

Techline

Techline

AW D ABS-TCS Page 5B–2

Page 5B–2

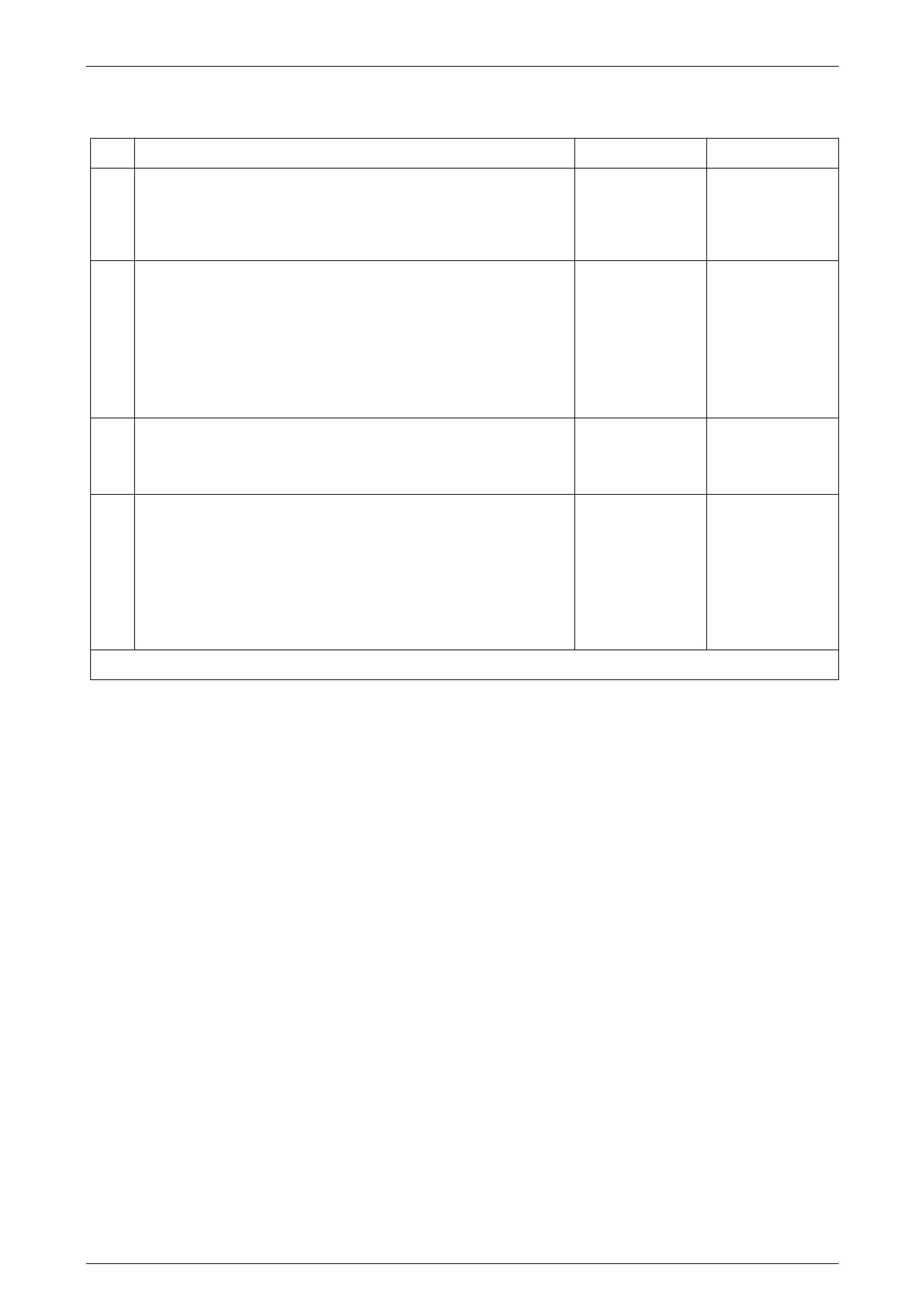

4 AWD ABS-TCS Diagnostics General Information............................................................................. 36

4.1 Diagnostic Trouble Code (DTC) Tables ..............................................................................................................36

4.2 Diagnostic Trouble Codes (DTCs)......................................................................................................................37

Status of DTCs .....................................................................................................................................................37

Conditions for Clearing DTCs.............................................................................................................................37

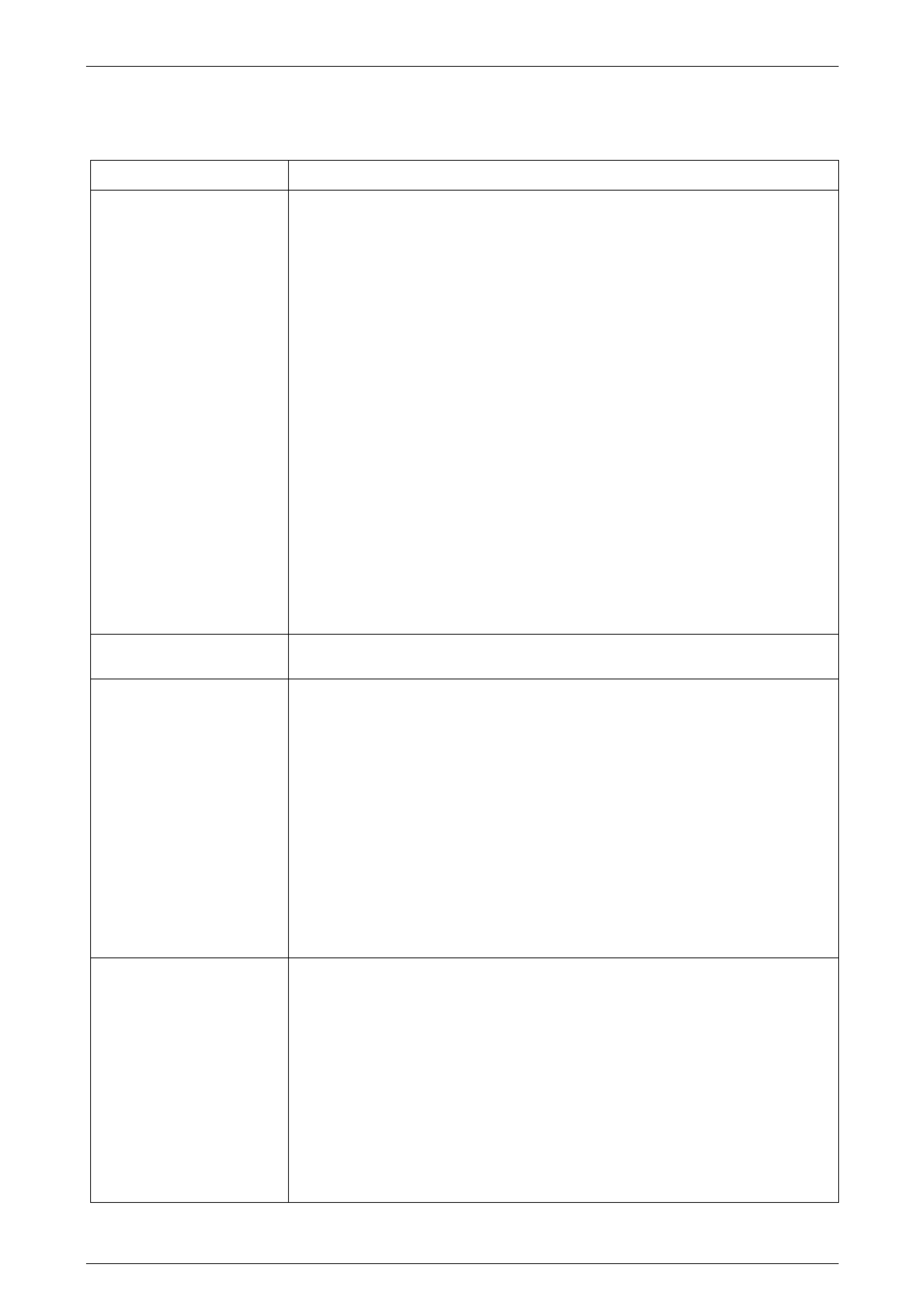

4.3 Tech 2 ECU Diagnostic Tests..............................................................................................................................38

Tech 2 Limitations ................................................................................................................................................38

Tech 2 Intermittent Fault Tests...........................................................................................................................38

Tech 2 Data List....................................................................................................................................................39

5 AWD ABS-TCS Diagnostic Starting Point ......................................................................................... 40

5.1 Diagnostic Requirements, Precautions and Preliminary Checks....................................................................40

Basic Knowledge Required.................................................................................................................................40

Basic Diagnostic Tools Required.......................................................................................................................40

Diagnostic Precautions .......................................................................................................................................41

Preliminary Checks..............................................................................................................................................42

5.2 AWD ABS-TCS Main Diagnostic Table...............................................................................................................43

6 AWD ABS-TCS Intermittent Conditions.............................................................................................44

6.1 Description ...........................................................................................................................................................44

6.2 AWD ABS-TCS Intermittent Conditions Diagnostic Table................................................................................45

7 AWD ABS-TCS DTC Tables................................................................................................................. 47

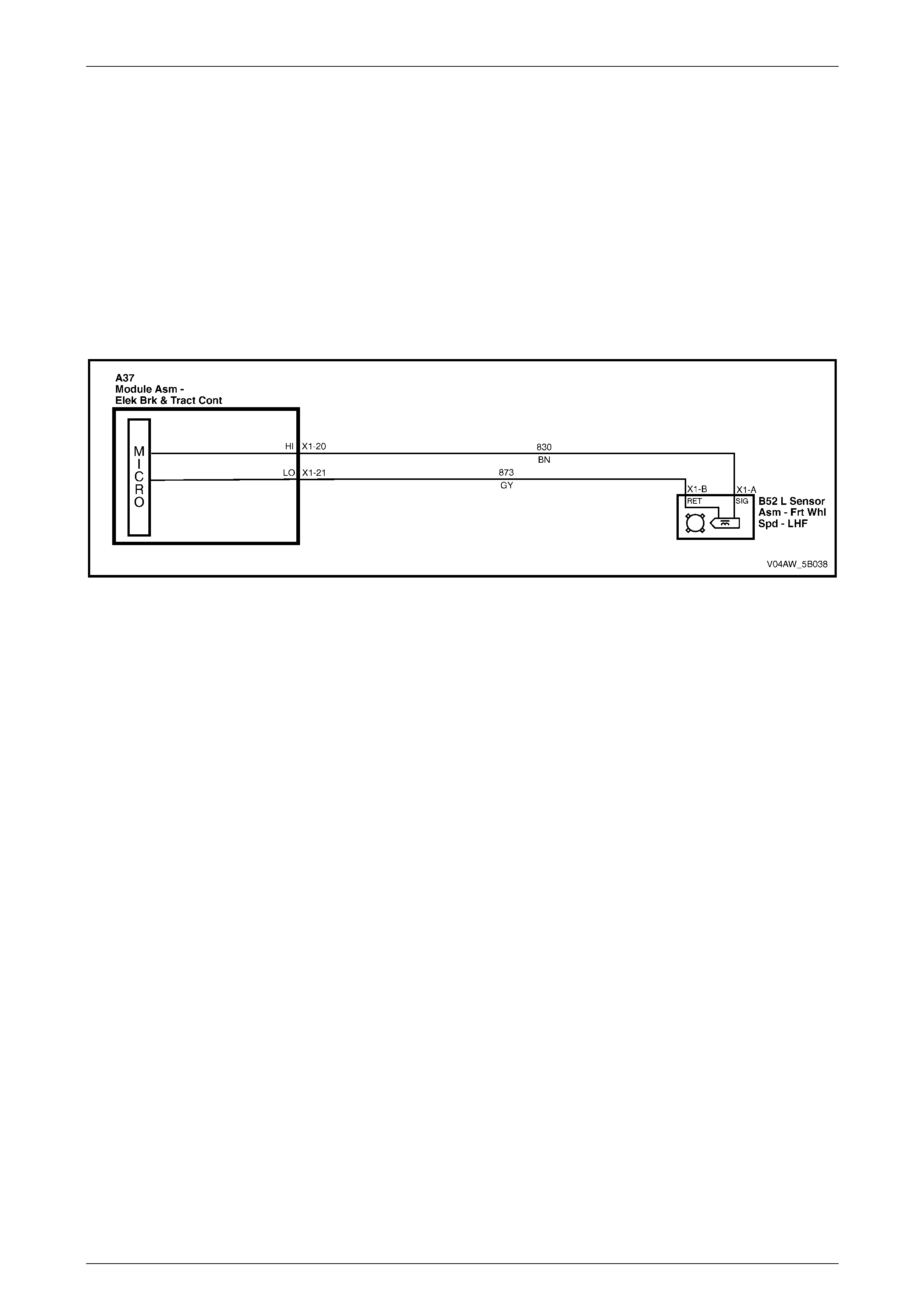

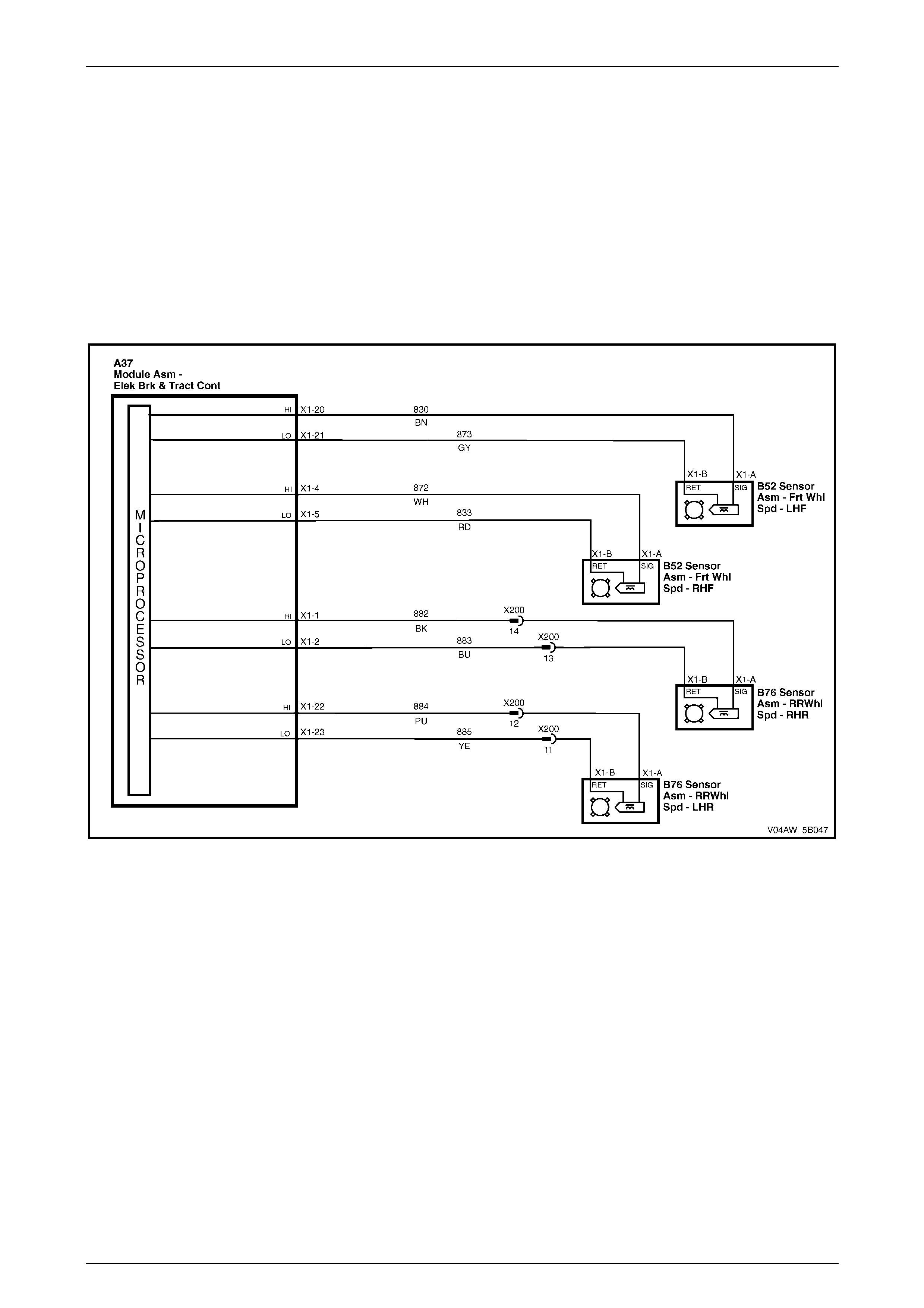

7.1 DTC C0035 – Front Left Wheel Speed Sensor Short or Open Circuit..............................................................47

Circuit Description...............................................................................................................................................47

Diagnostic Aids....................................................................................................................................................47

7.2 DTC C0036 – Front Left Wheel Speed Sensor Signal Correlation...................................................................51

Circuit Description...............................................................................................................................................51

Diagnostic Aids....................................................................................................................................................51

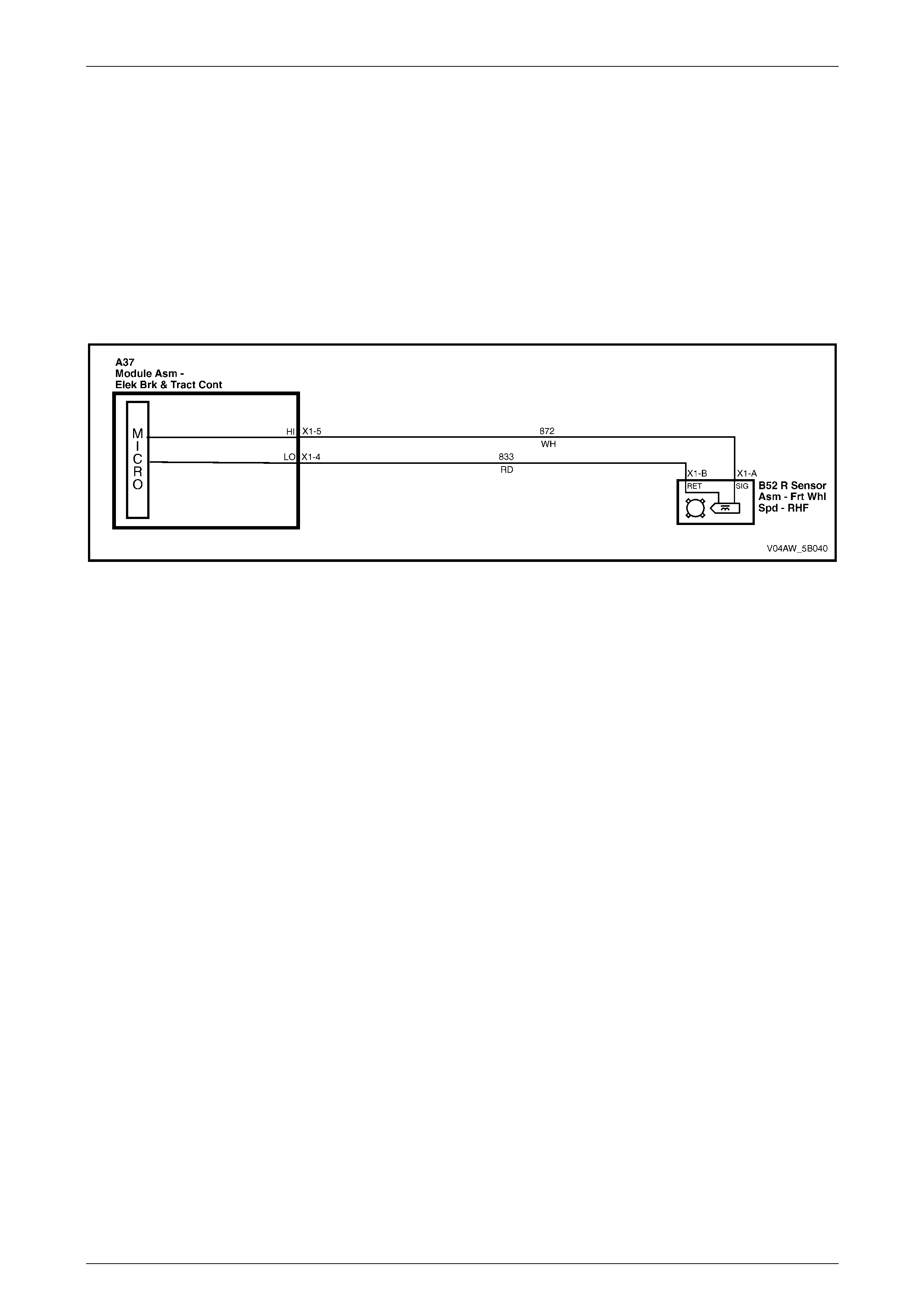

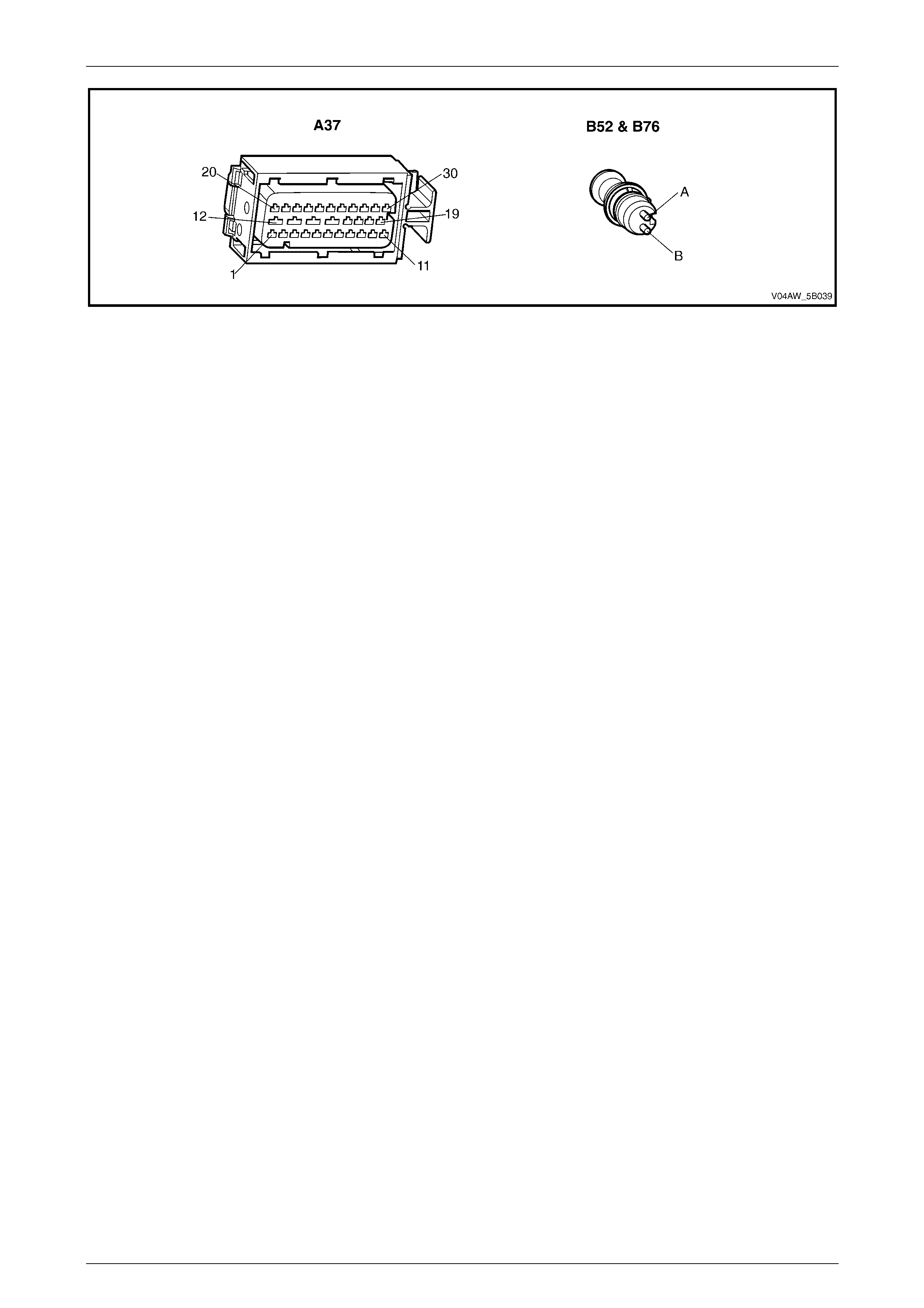

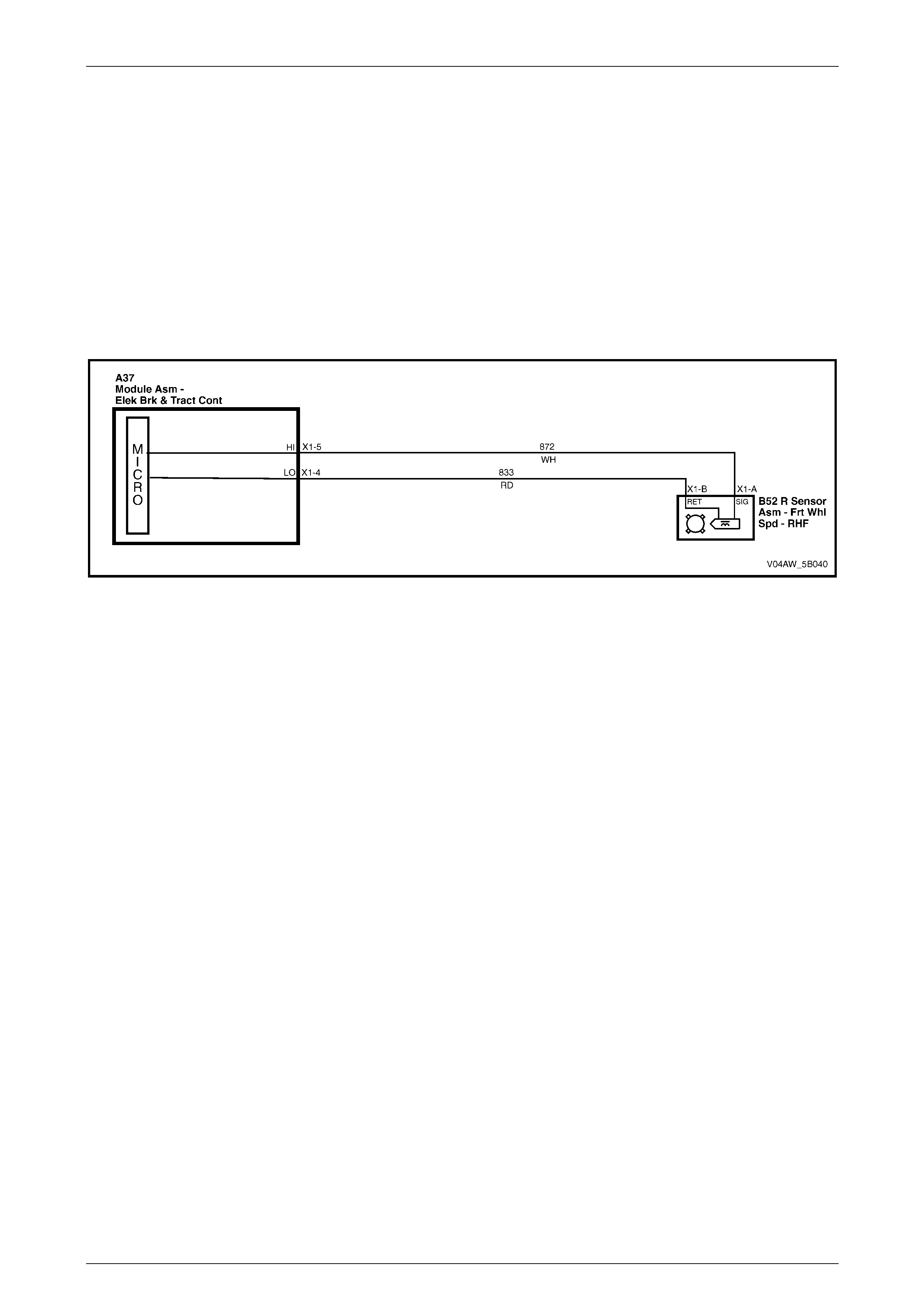

7.3 DTC C0040 – Front Right Wheel Speed Sensor Short or Open Circuit...........................................................55

Circuit Description...............................................................................................................................................55

Diagnostic Aids....................................................................................................................................................55

7.4 DTC C0041 – Front Right Wheel Speed Sensor Signal Correlation.................................................................59

Circuit Description...............................................................................................................................................59

Diagnostic Aids....................................................................................................................................................59

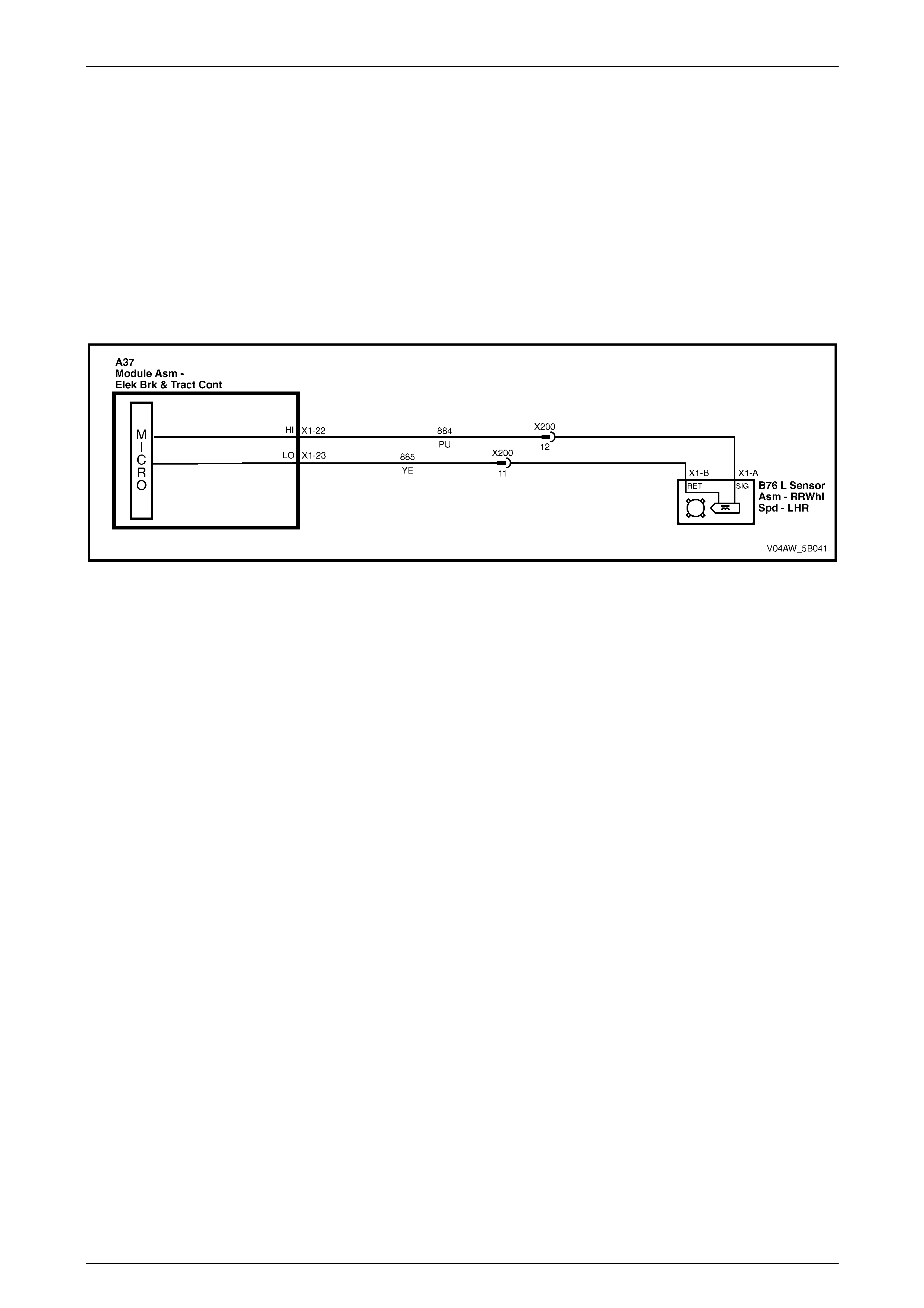

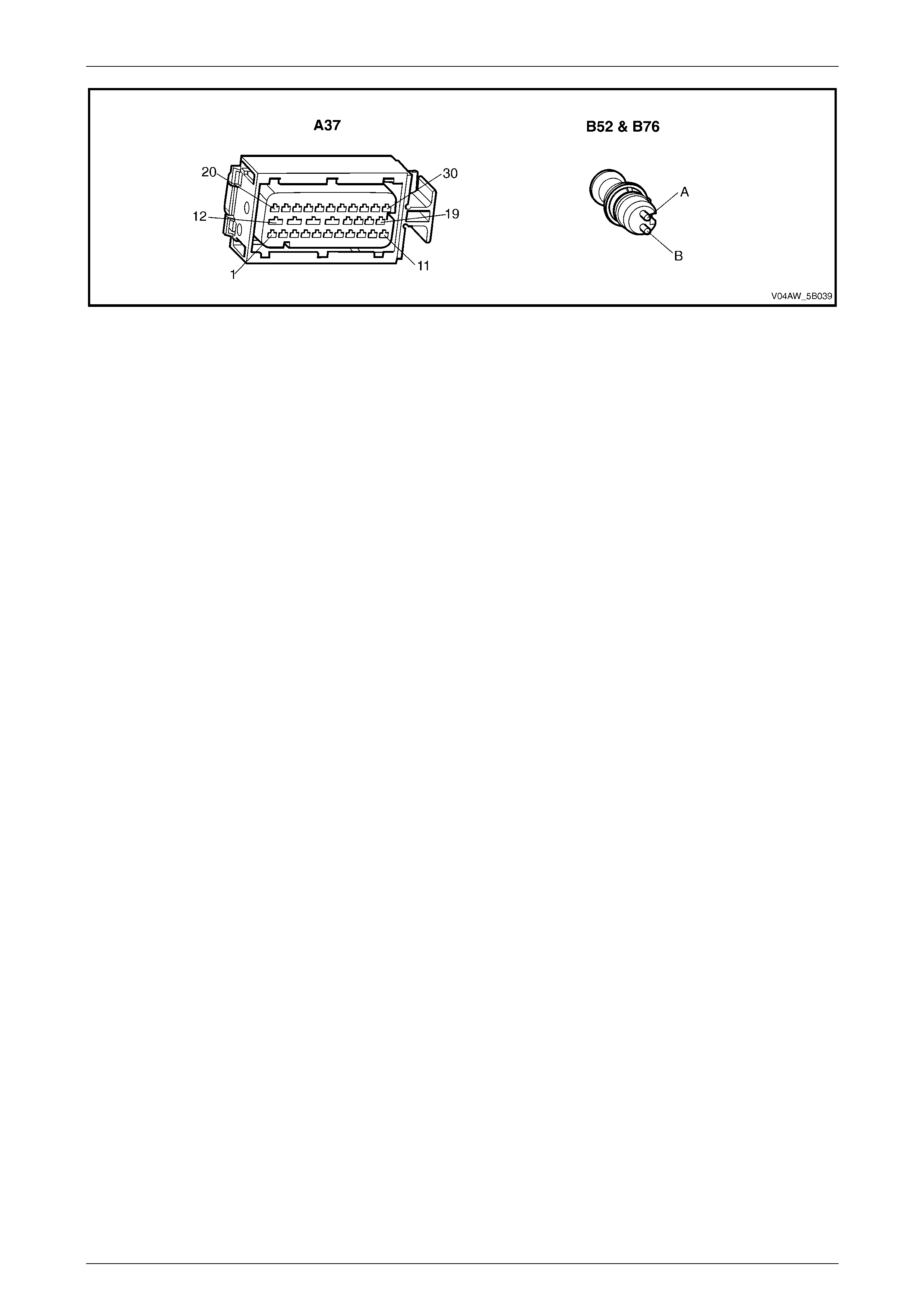

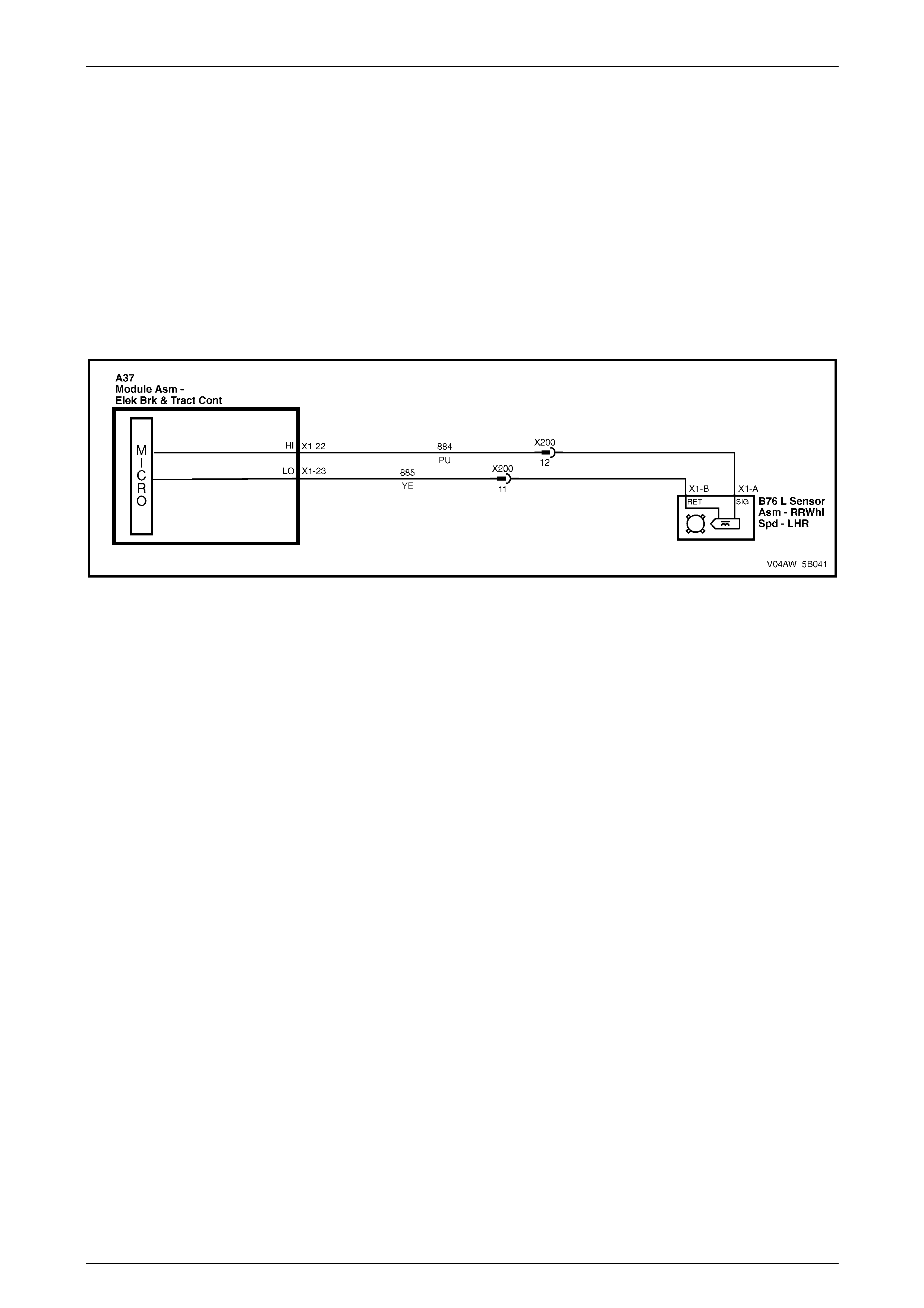

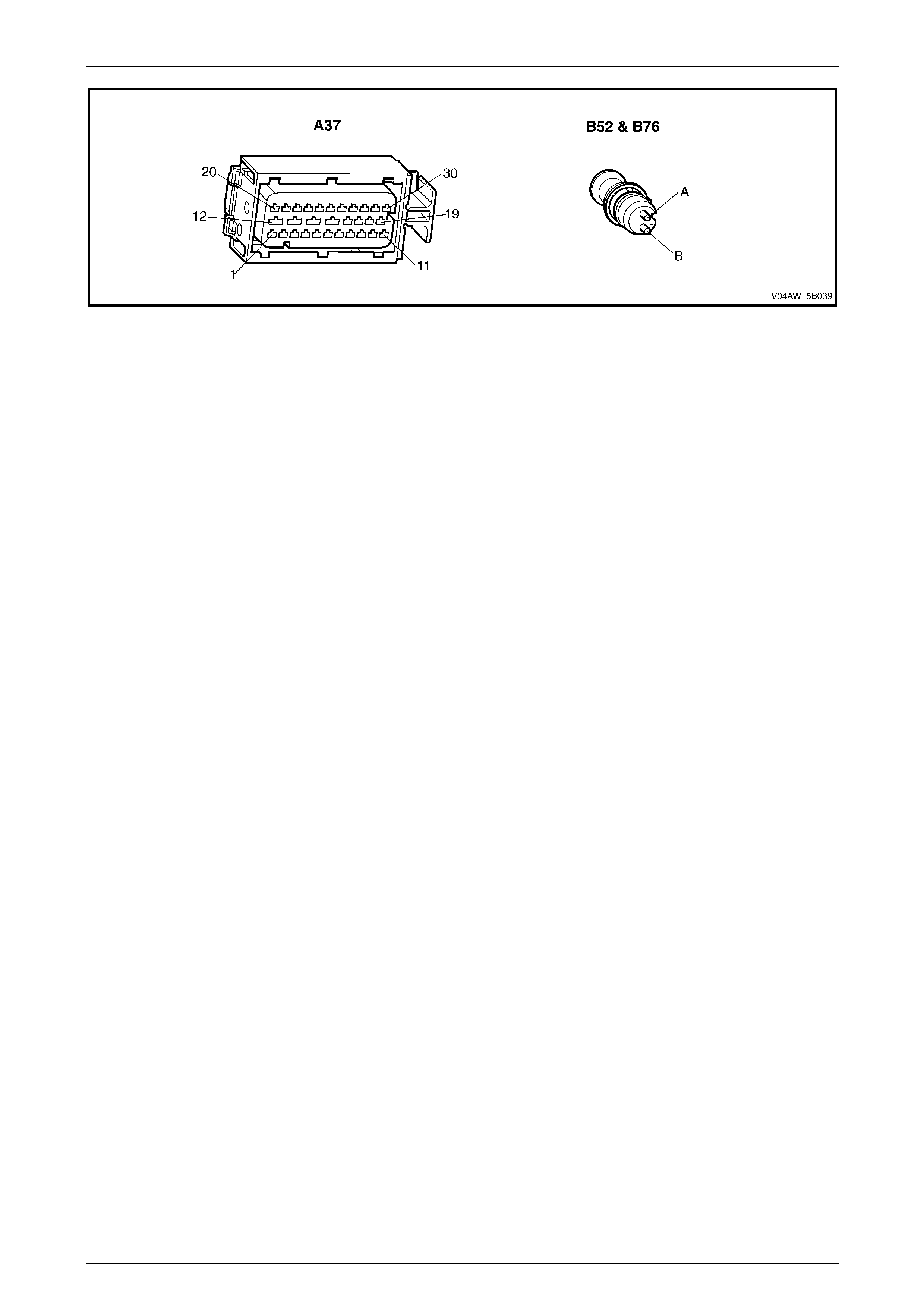

7.5 DTC C0045 – Rear Left Wheel Speed Sensor Short or Open Circuit...............................................................63

Circuit Description...............................................................................................................................................63

Diagnostic Aids....................................................................................................................................................63

7.6 DTC C0046 – Rear Left Wheel Speed Sensor Signal Correlation ....................................................................67

Circuit Description...............................................................................................................................................67

Diagnostic Aids....................................................................................................................................................67

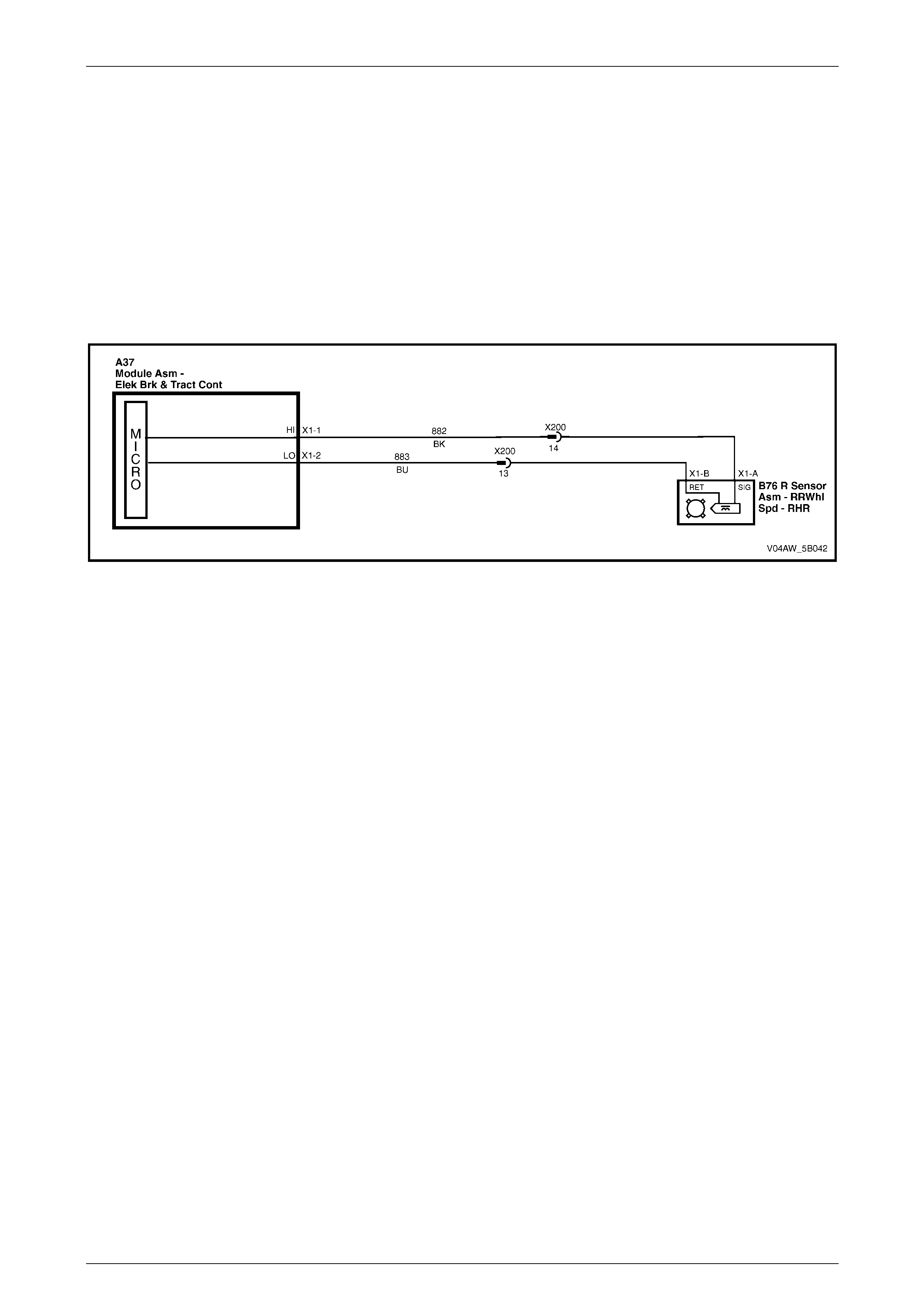

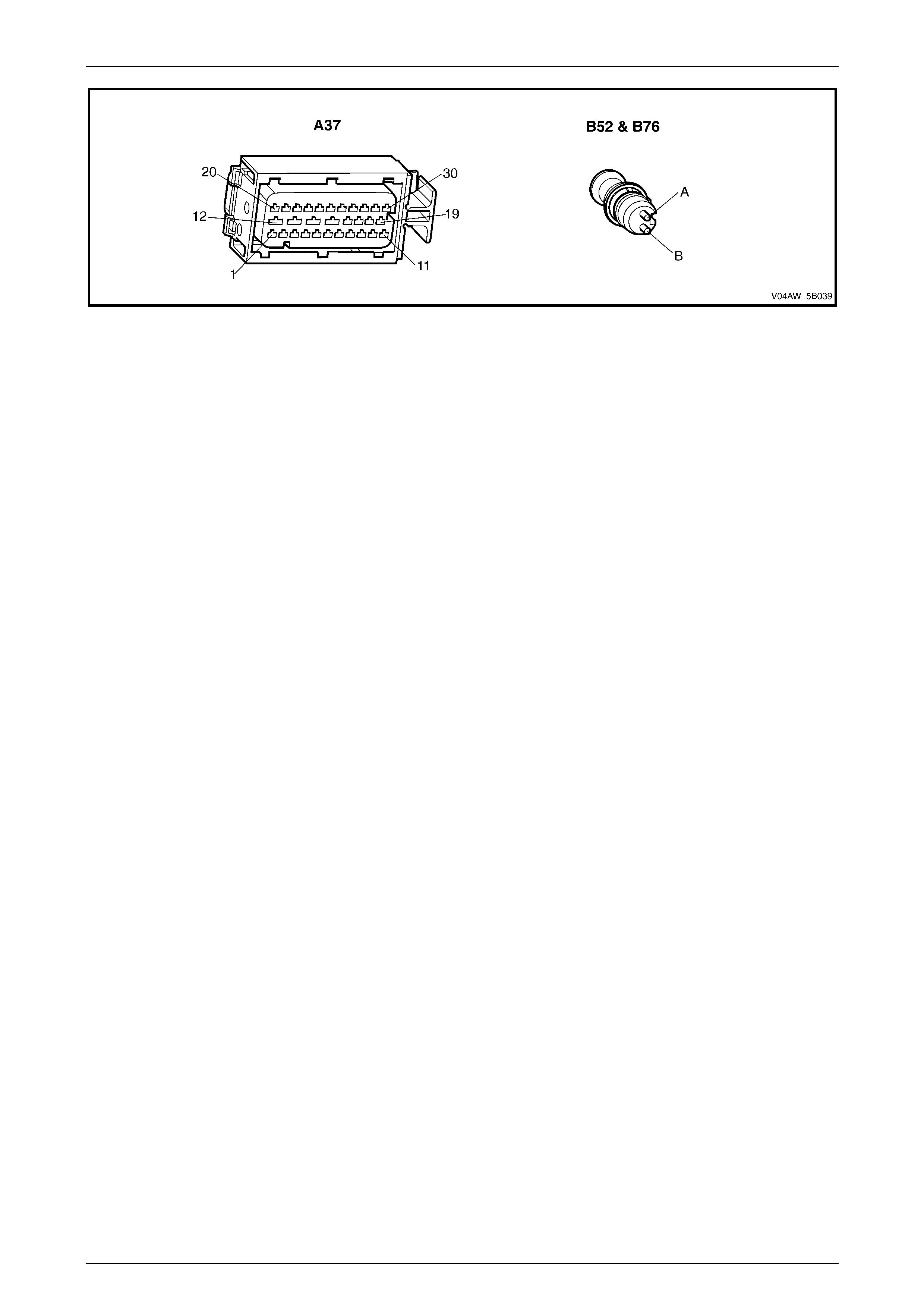

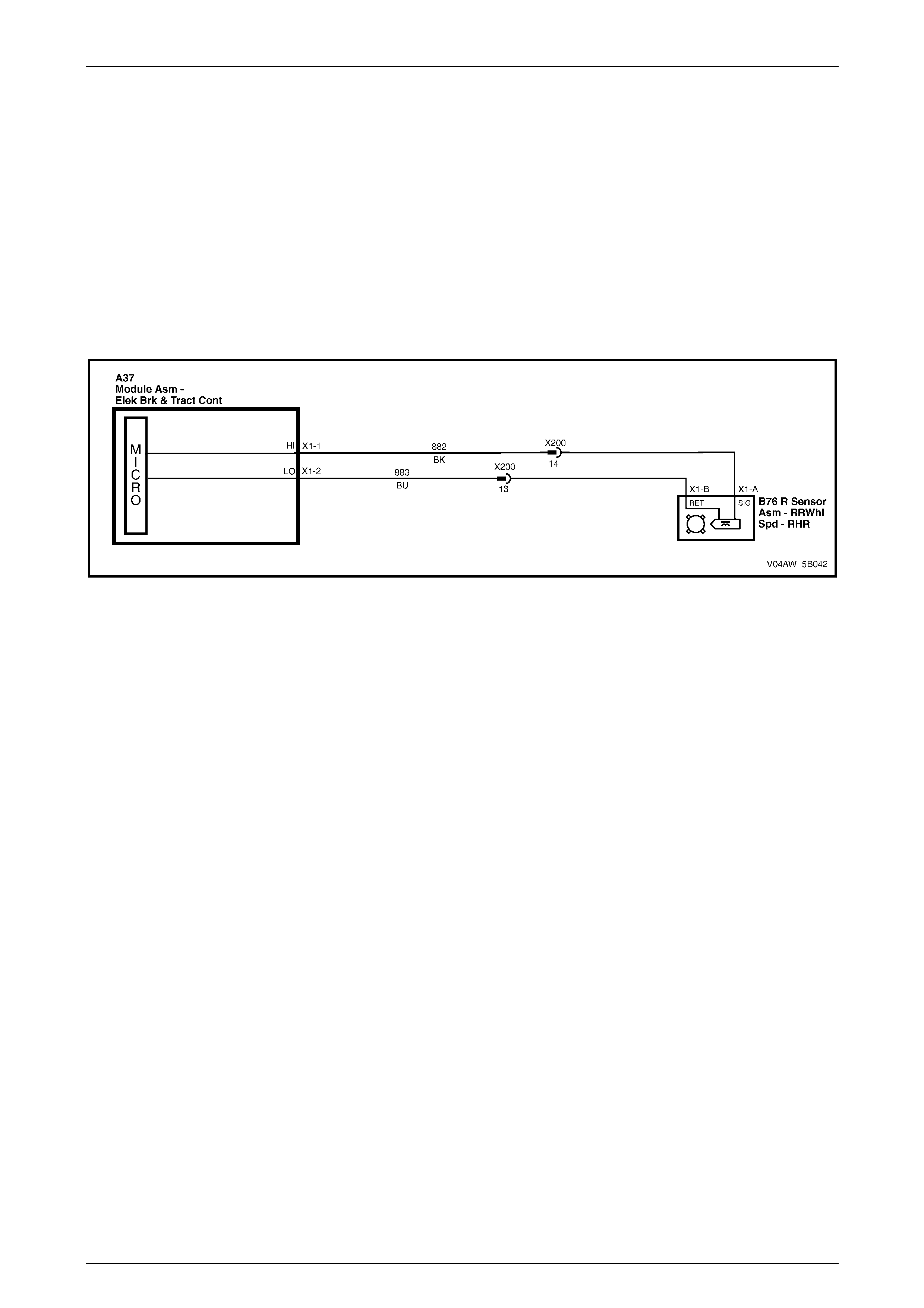

7.7 DTC C0050 – Rear Right Wheel Speed Sensor Short or Open Circuit ............................................................71

Circuit Description...............................................................................................................................................71

Diagnostic Aids....................................................................................................................................................71

7.8 DTC C0051 – Rear Right Wheel Speed Sensor Signal Correlation..................................................................75

Circuit Description...............................................................................................................................................75

Diagnostic Aids....................................................................................................................................................75

7.9 DTC C0110 – Pump Motor or Relay Fault...........................................................................................................79

Circuit Description...............................................................................................................................................79

Diagnostic Aids....................................................................................................................................................80

7.10 DTC C0121 – Valve Solenoid Relay Fault...........................................................................................................82

Circuit Description...............................................................................................................................................82

Diagnostic Aids....................................................................................................................................................83

7.11 DTC C0161 – Brake Switch Circuit Malfunction................................................................................................85

Circuit Description...............................................................................................................................................85

Diagnostic Aids....................................................................................................................................................85

AW D ABS-TCS Page 5B–3

Page 5B–3

7.12 DTC C0191 – Longitudinal Acceleration Sensor Incorrect Signal...................................................................88

Circuit Description...............................................................................................................................................88

Diagnostic Aids....................................................................................................................................................88

7.13 DTC C0192 – Longitudinal Acceleration Sensor Circuit Malfunction..............................................................92

Circuit Description...............................................................................................................................................92

Diagnostic Aids....................................................................................................................................................92

7.14 DTC C0245 – Wheel Speed Signal Malfunction.................................................................................................96

Circuit Description...............................................................................................................................................96

Diagnostic Aids....................................................................................................................................................96

7.15 DTC C0550 – Electronic Control Unit (ECU) Internal Fault.............................................................................100

Circuit Description.............................................................................................................................................100

Diagnostic Aids..................................................................................................................................................102

7.16 DTC C0896 – Battery Voltage Out of Range.....................................................................................................104

Circuit Description.............................................................................................................................................104

Diagnostic Aids..................................................................................................................................................105

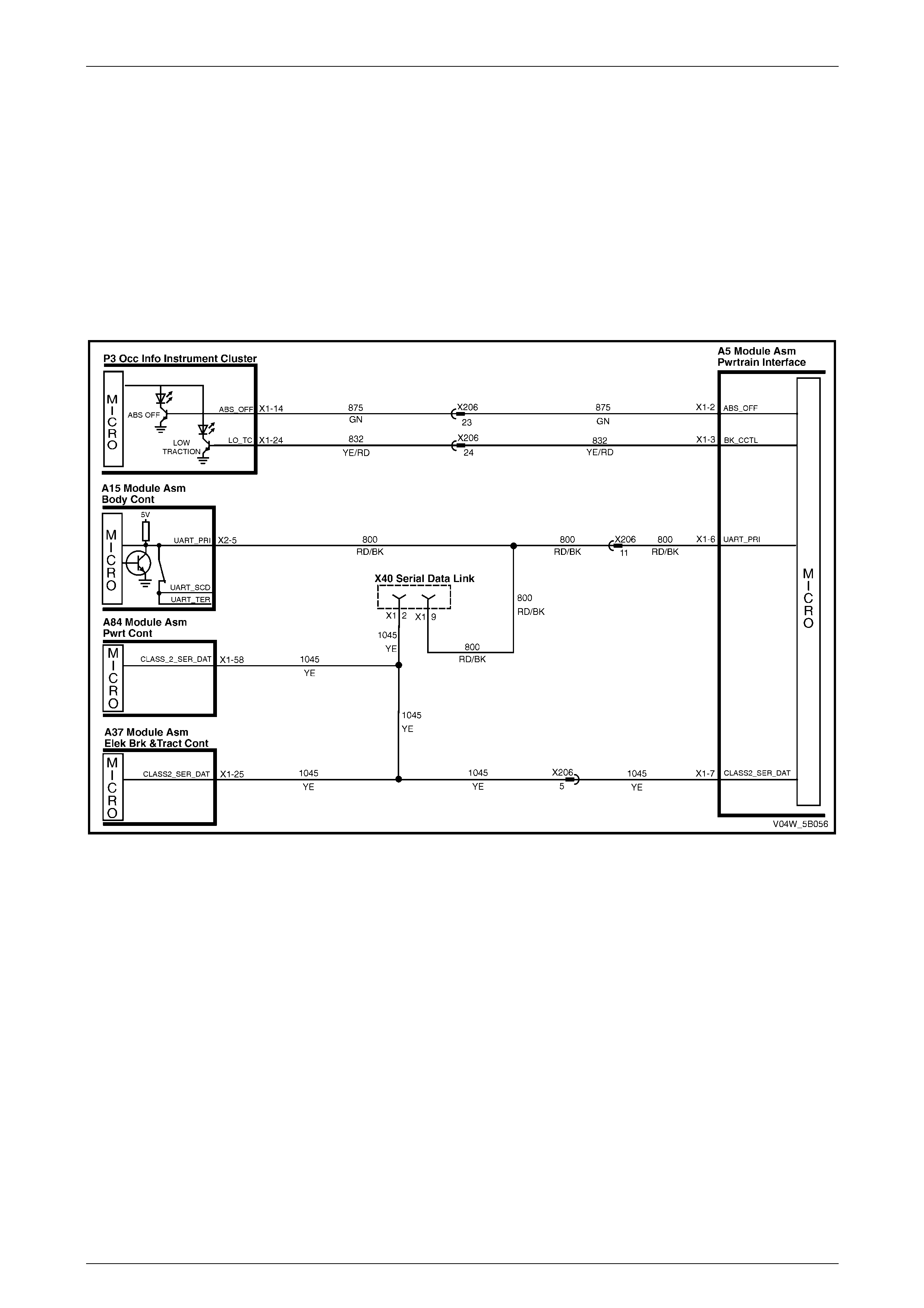

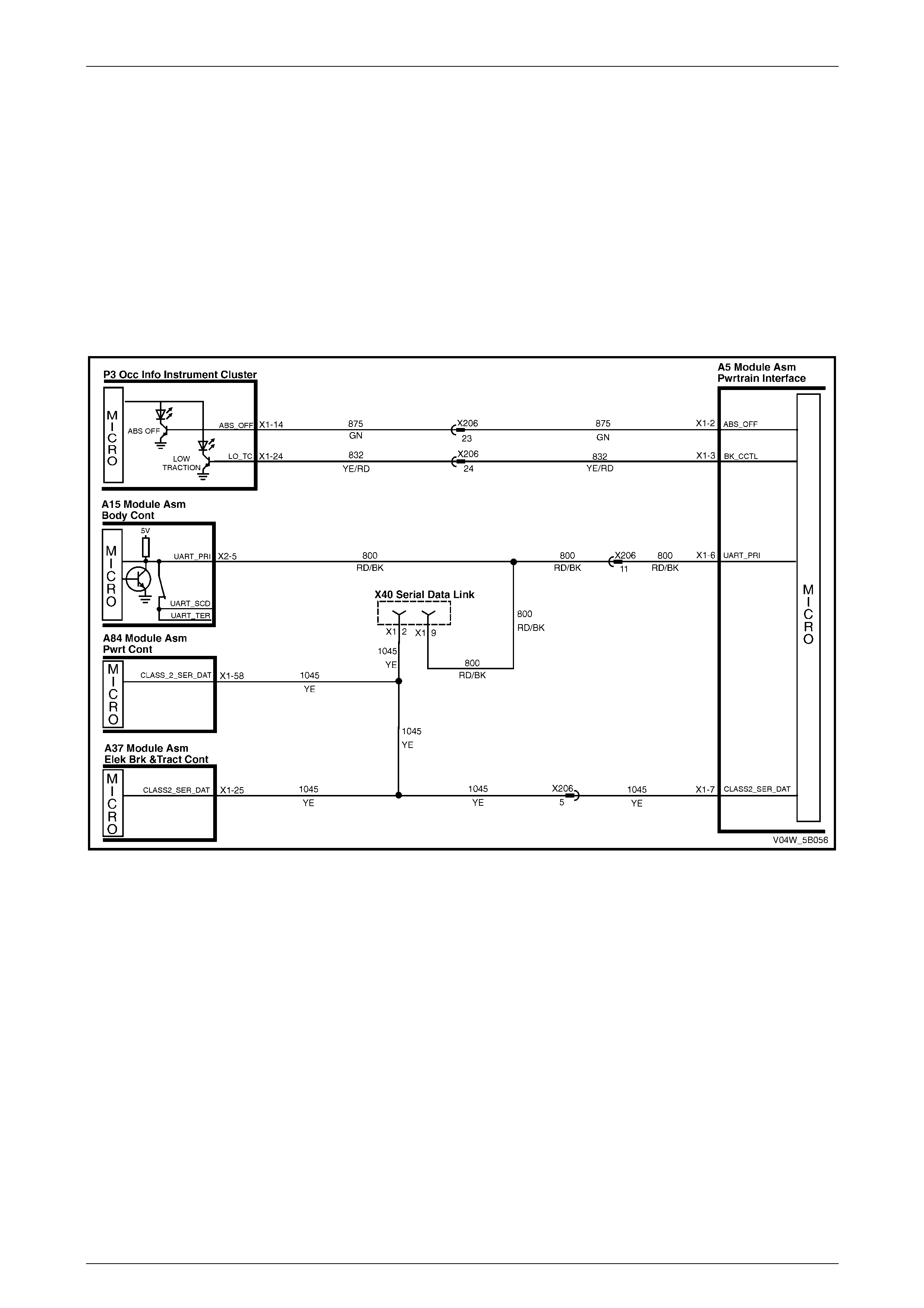

8 AWD ABS-TCS Serial Data Communication Diagnostics.............................................................. 107

8.1 Serial Data Communication Preliminary Diagnostic Table ............................................................................107

Circuit Description.............................................................................................................................................107

Diagnostic Aids..................................................................................................................................................108

8.2 DTC U1000–No Serial Data................................................................................................................................110

Circuit Description.............................................................................................................................................110

Diagnostic Aids..................................................................................................................................................110

8.3 DTC U1016–No Serial Data from PCM..............................................................................................................112

Circuit Description.............................................................................................................................................112

Diagnostic Aids..................................................................................................................................................112

8.4 DTC U1300 or U1301 Class 2 Communication Data Link Input Too Low or Too High.................................114

Circuit Description.............................................................................................................................................114

Diagnostic Aids..................................................................................................................................................114

9 Service Operations............................................................................................................................ 116

9.1 Safety and Precautionary Measures.................................................................................................................116

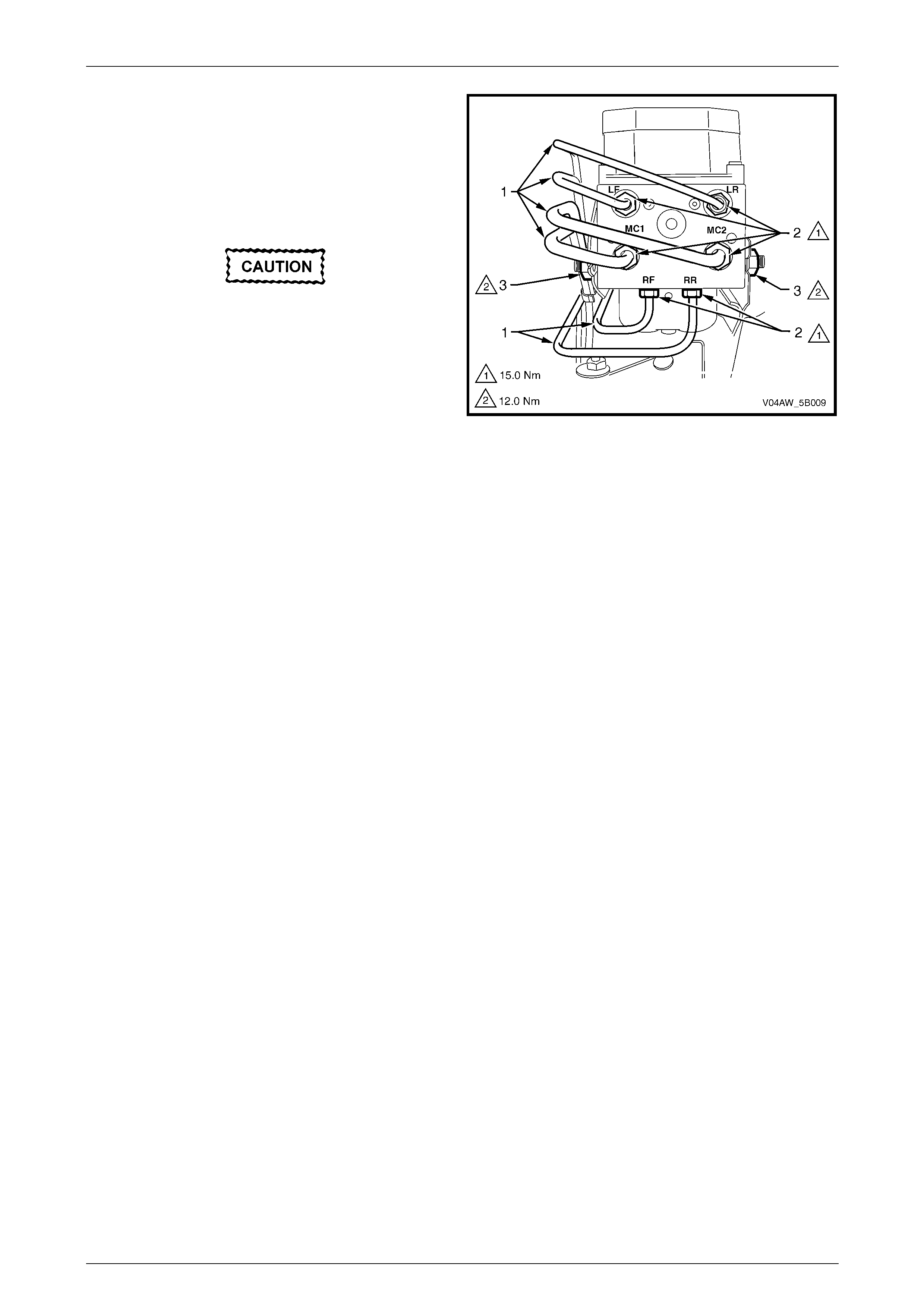

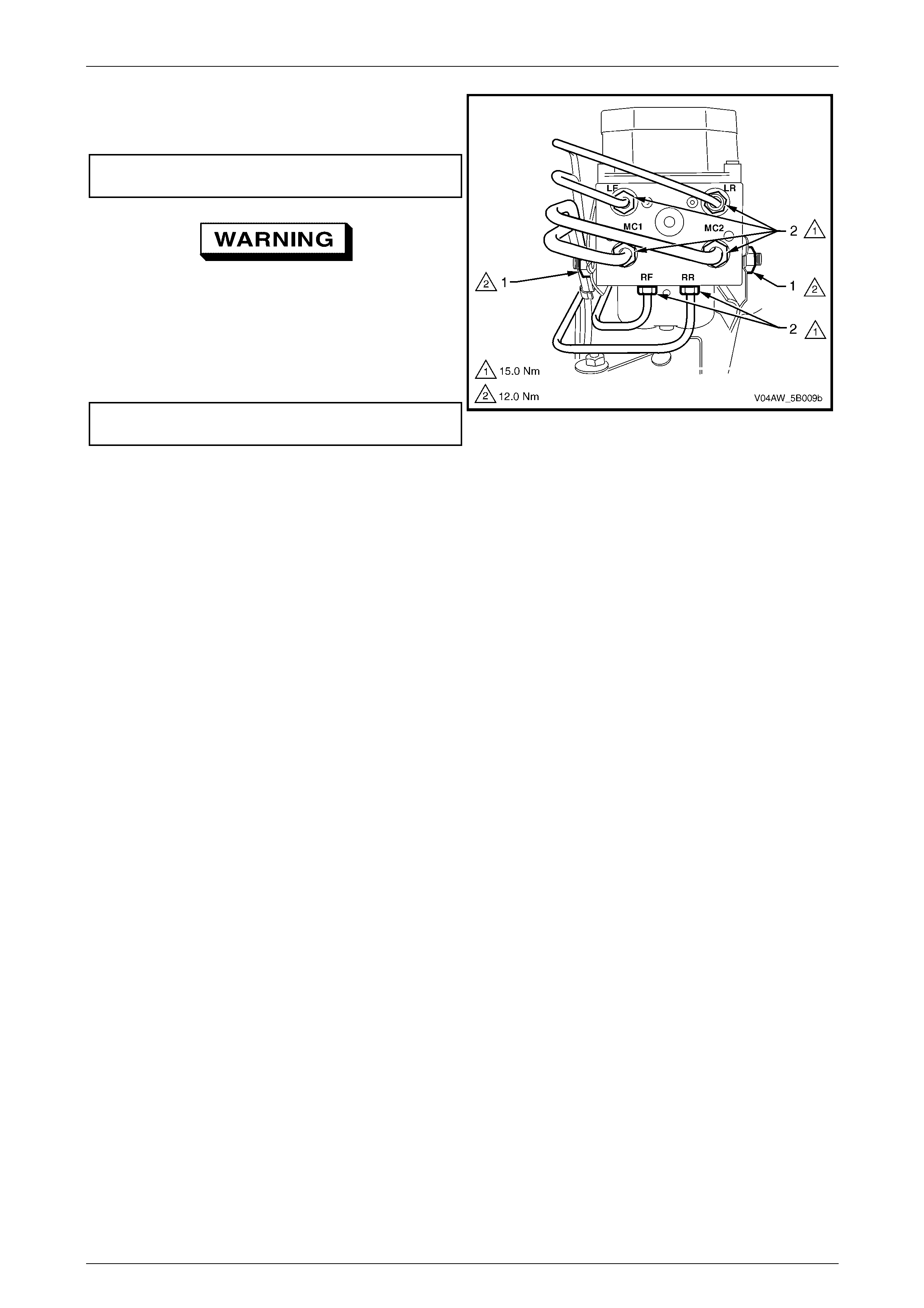

9.2 ABS-TCS Brake Bleeding Procedure................................................................................................................118

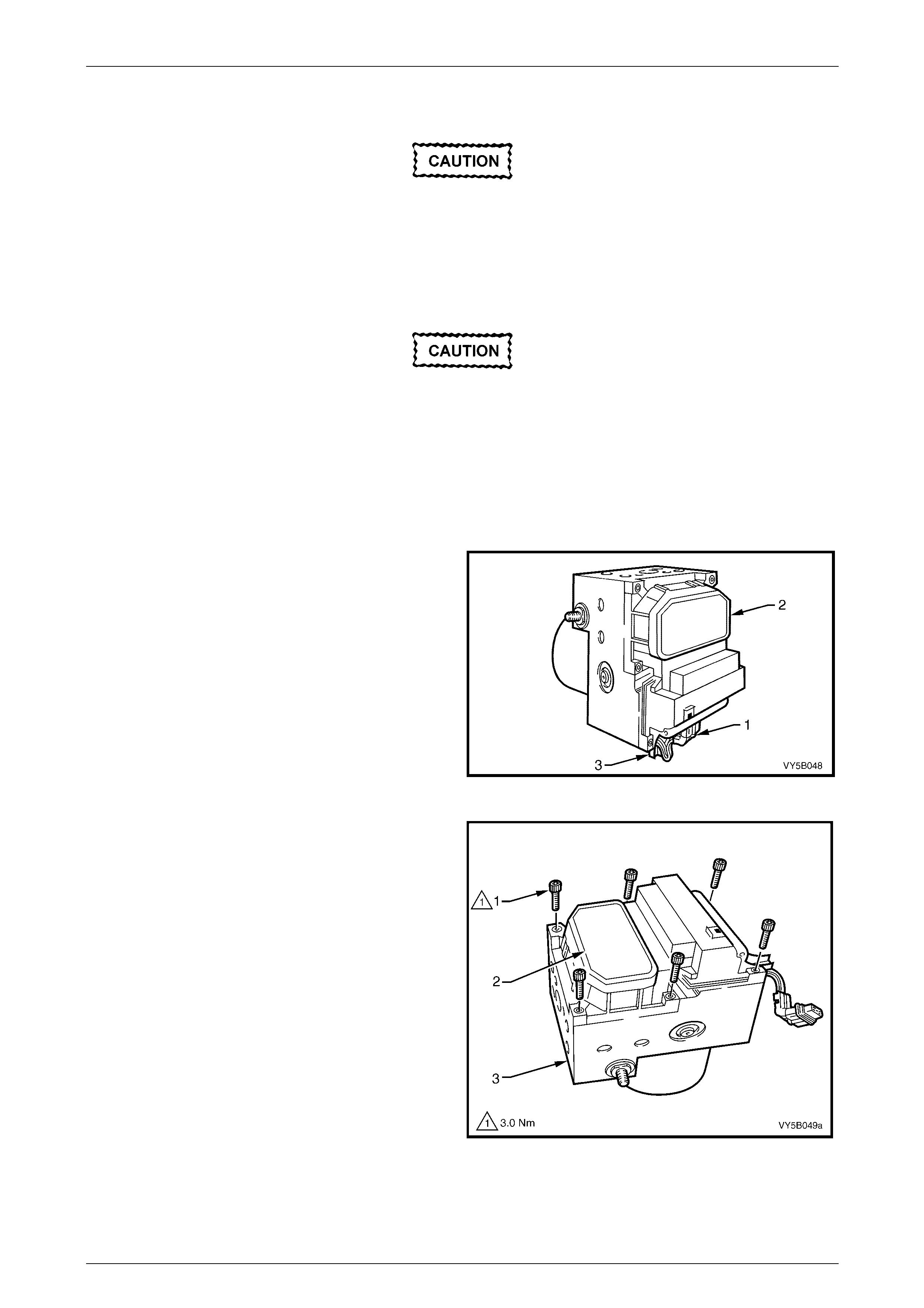

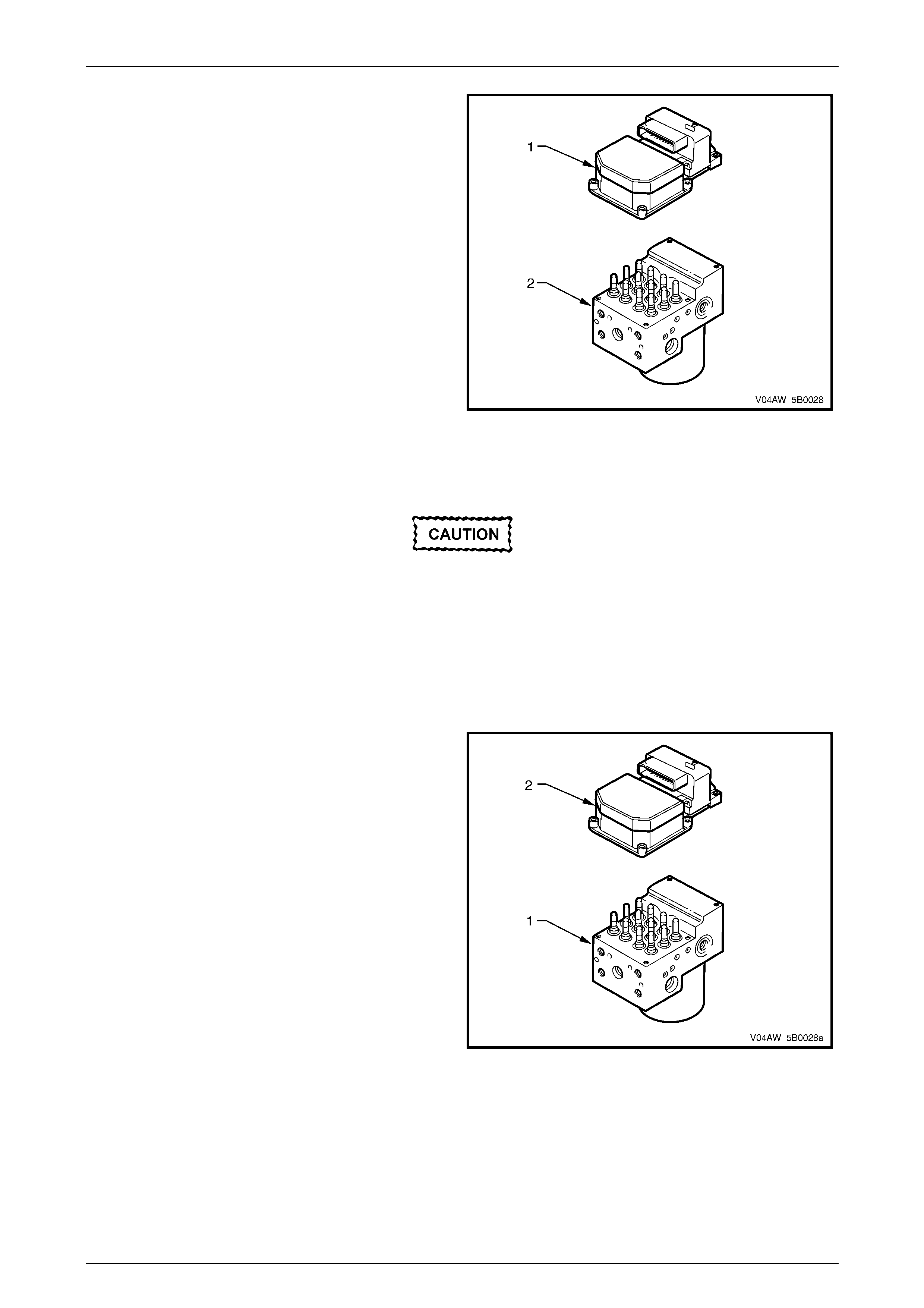

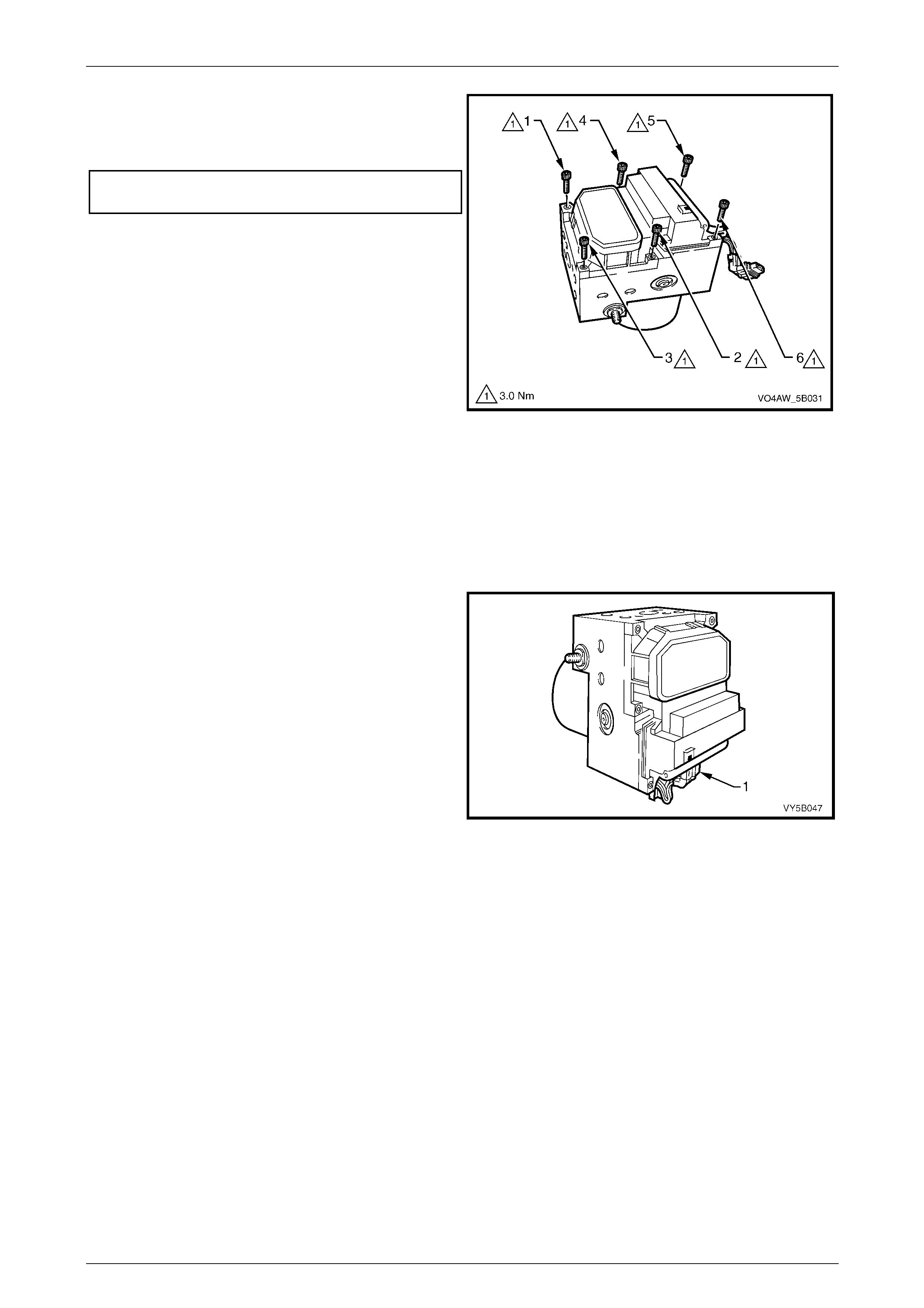

9.3 Electronic Control Unit (ECU) / Hydraulic Modulator Assembly....................................................................119

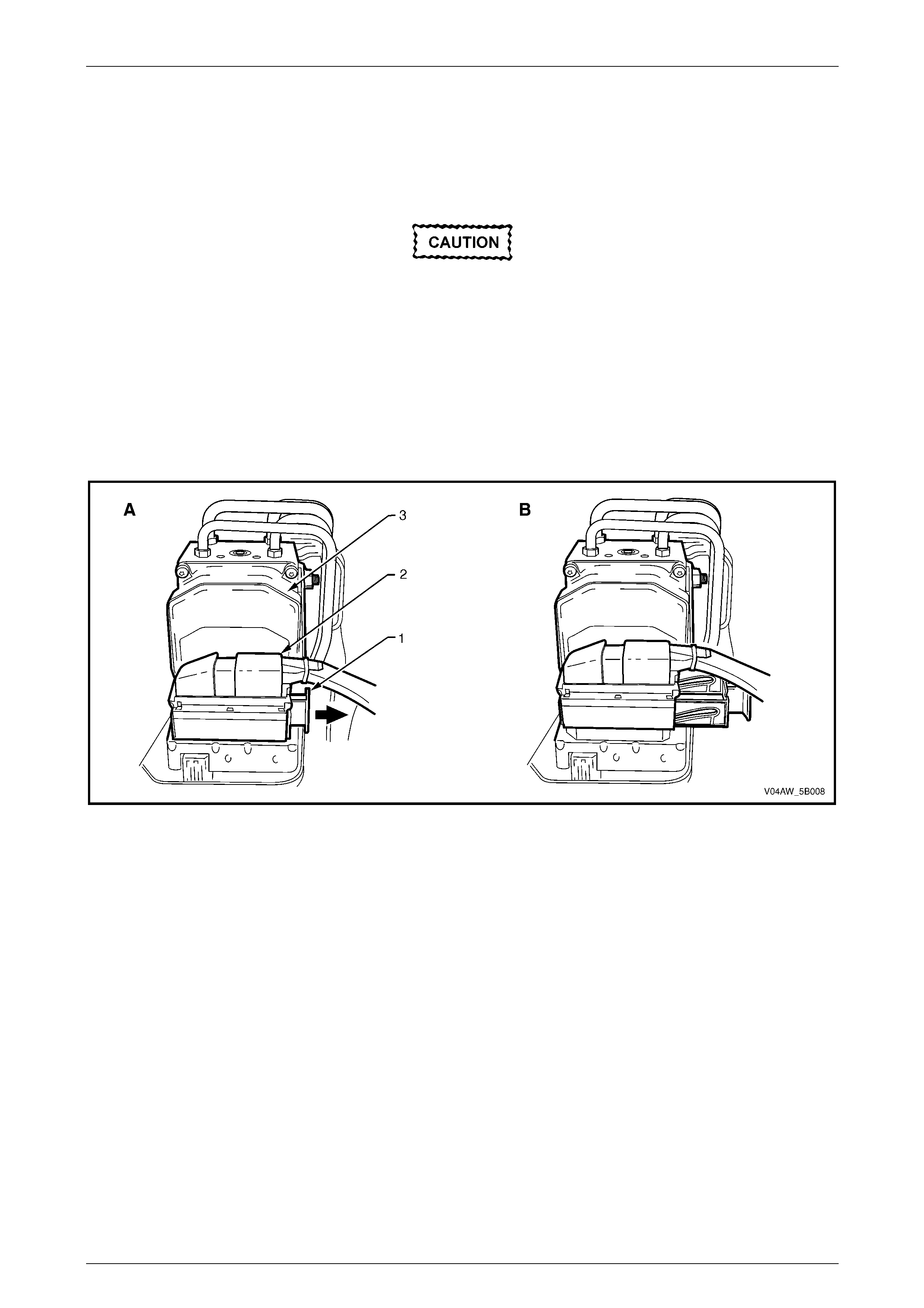

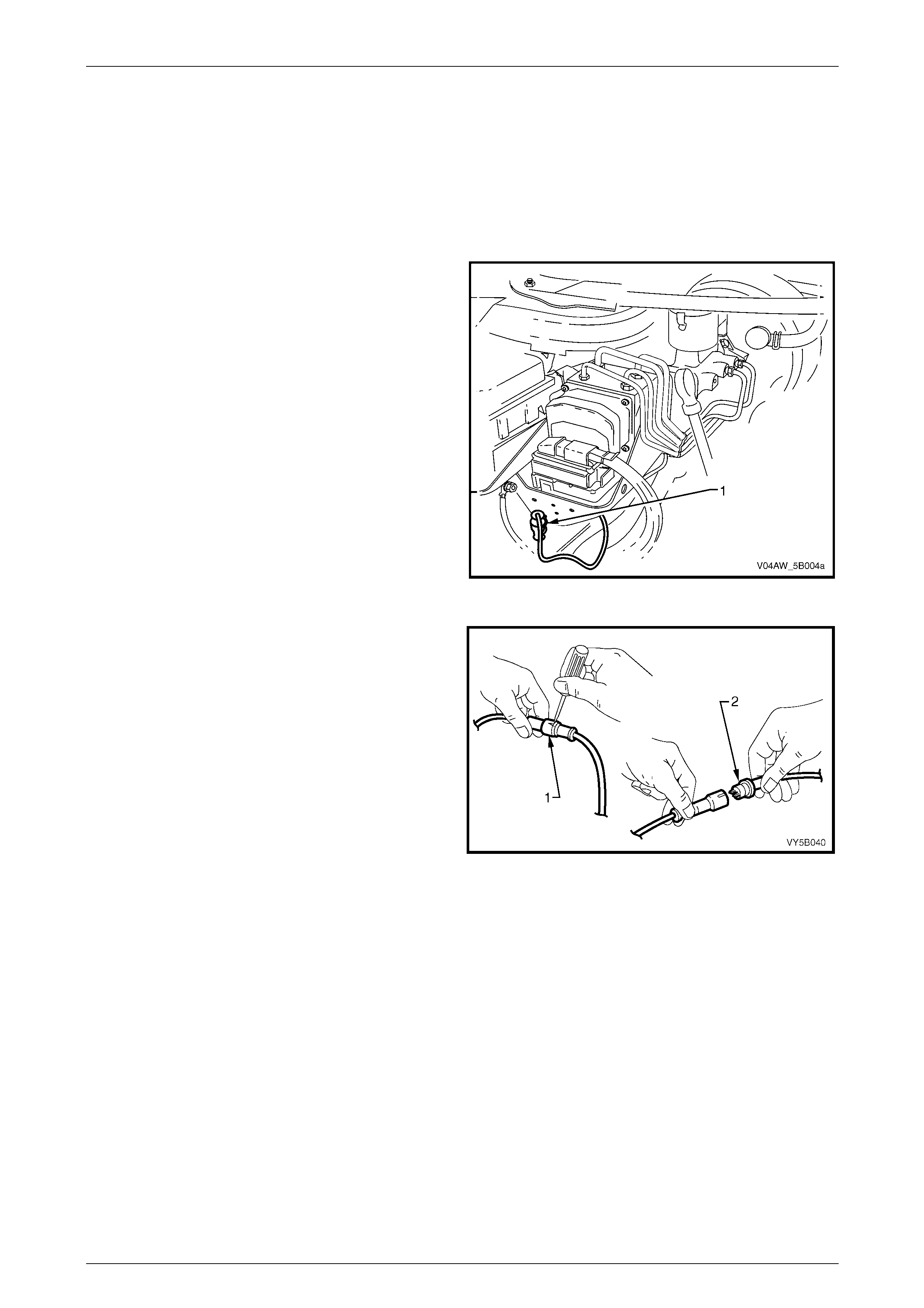

Remove ...............................................................................................................................................................119

Disassemble.......................................................................................................................................................121

Reinstall..............................................................................................................................................................123

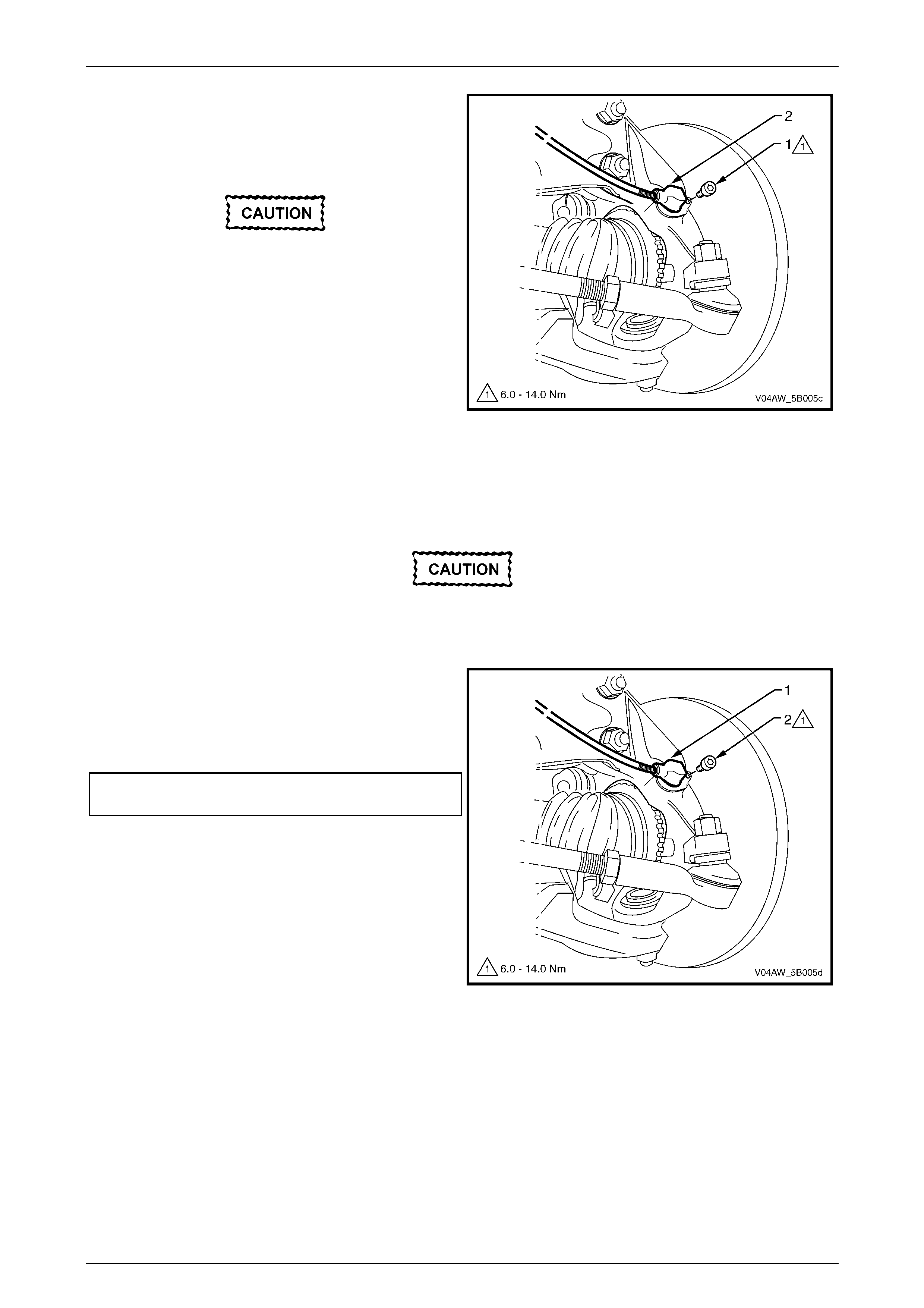

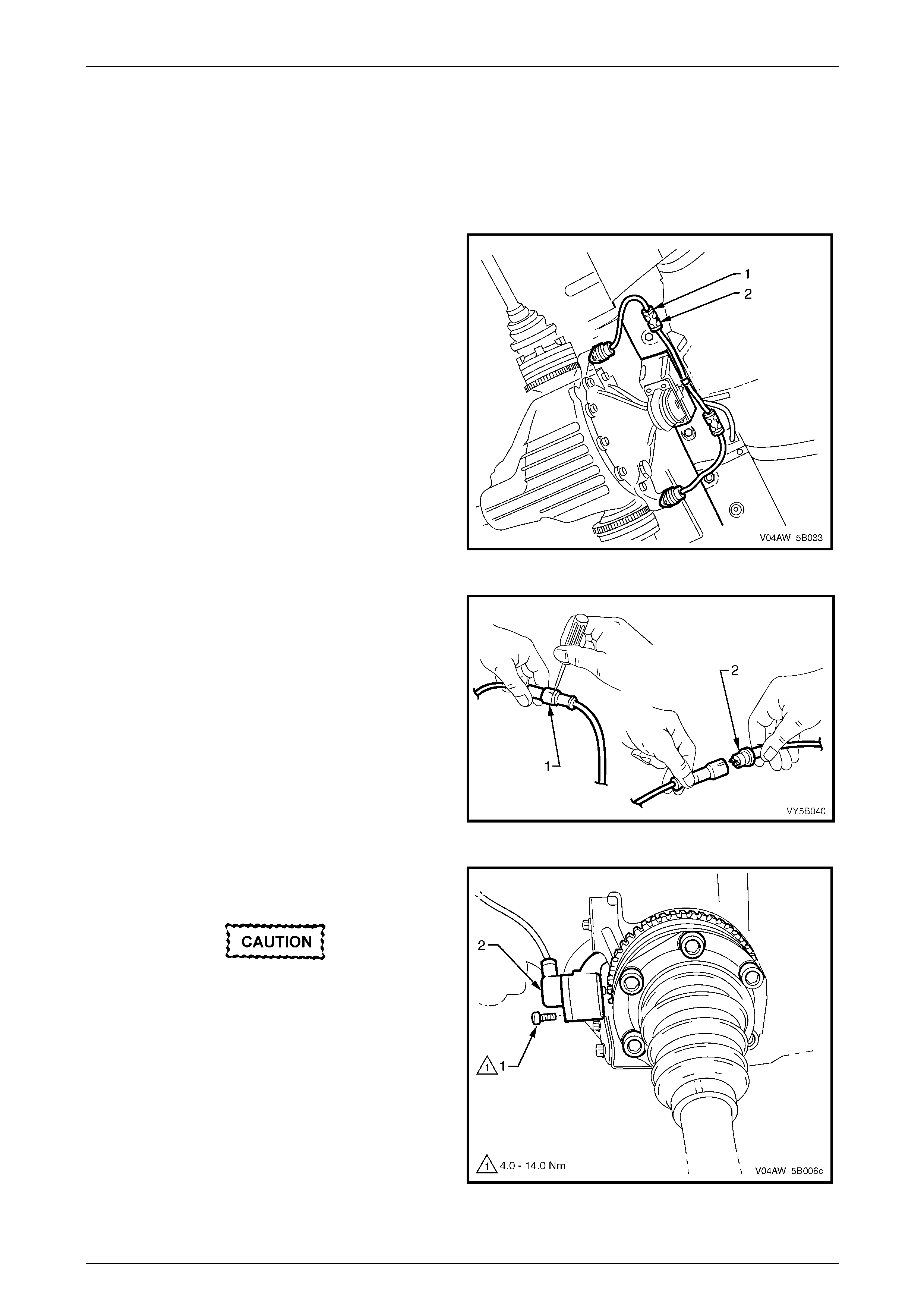

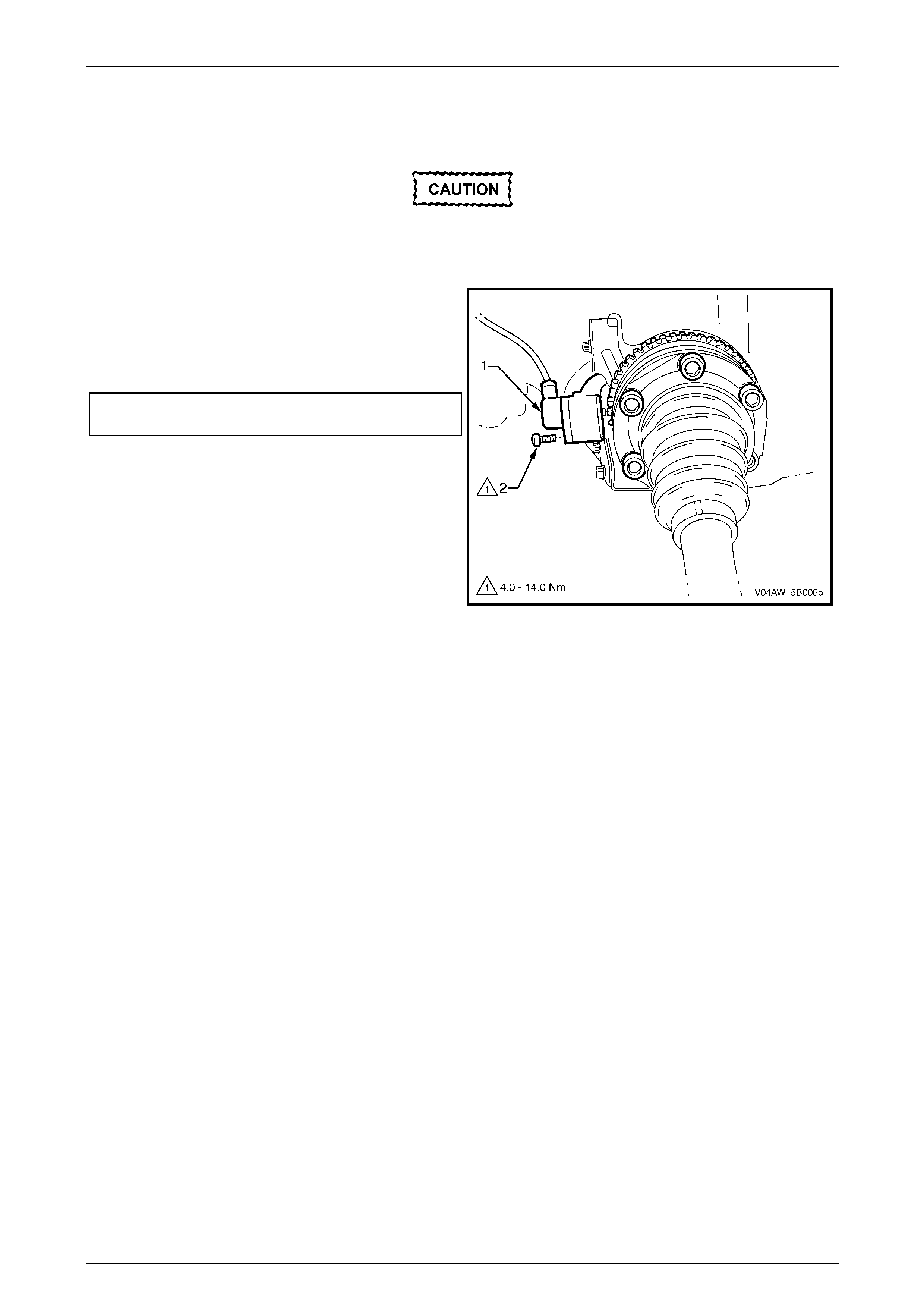

9.4 Front Right Wheel Speed Sensor .....................................................................................................................125

Remove ...............................................................................................................................................................125

Reinstall..............................................................................................................................................................126

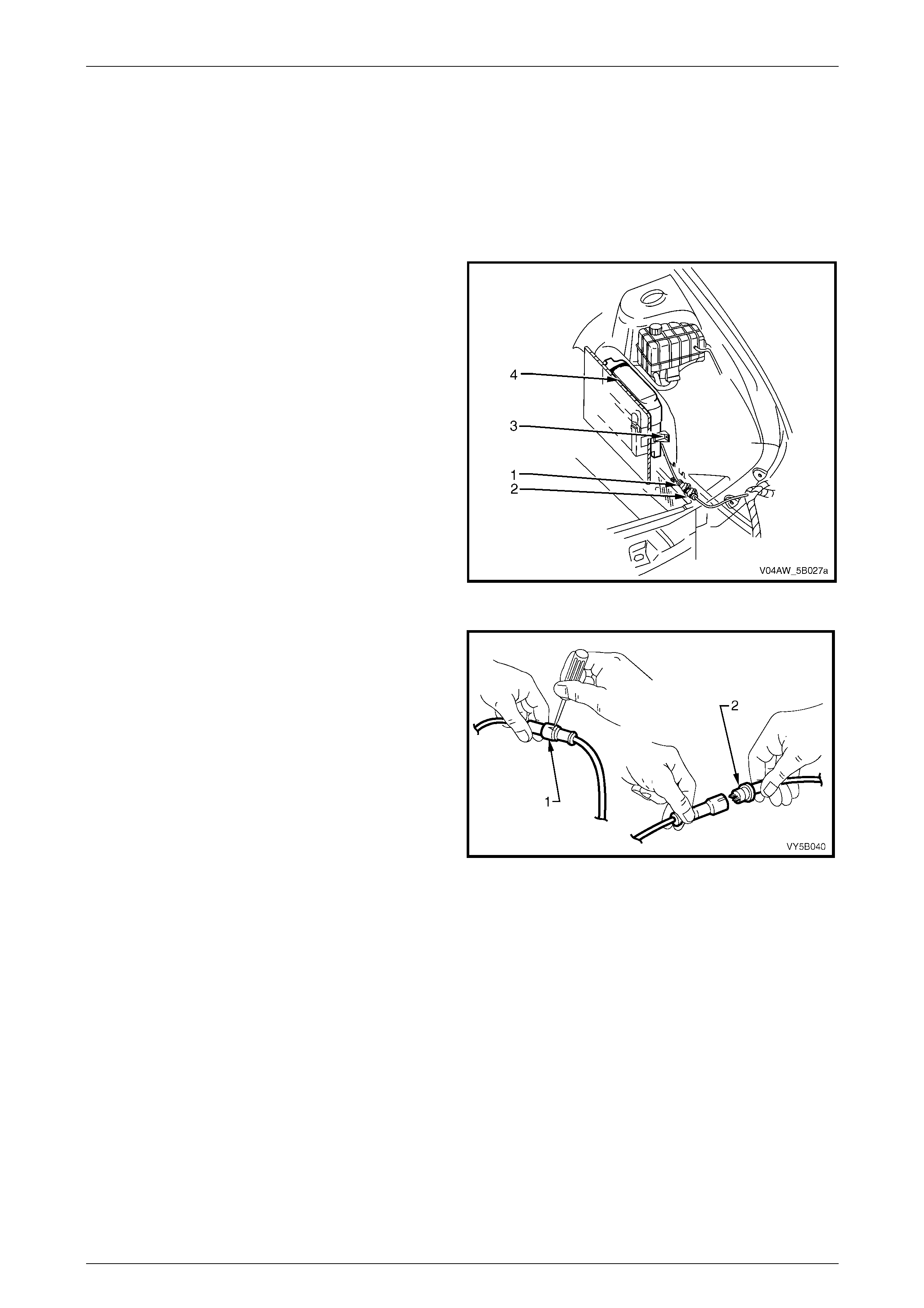

9.5 Front Left Wheel Speed Sensor........................................................................................................................127

Remove ...............................................................................................................................................................127

Reinstallation......................................................................................................................................................128

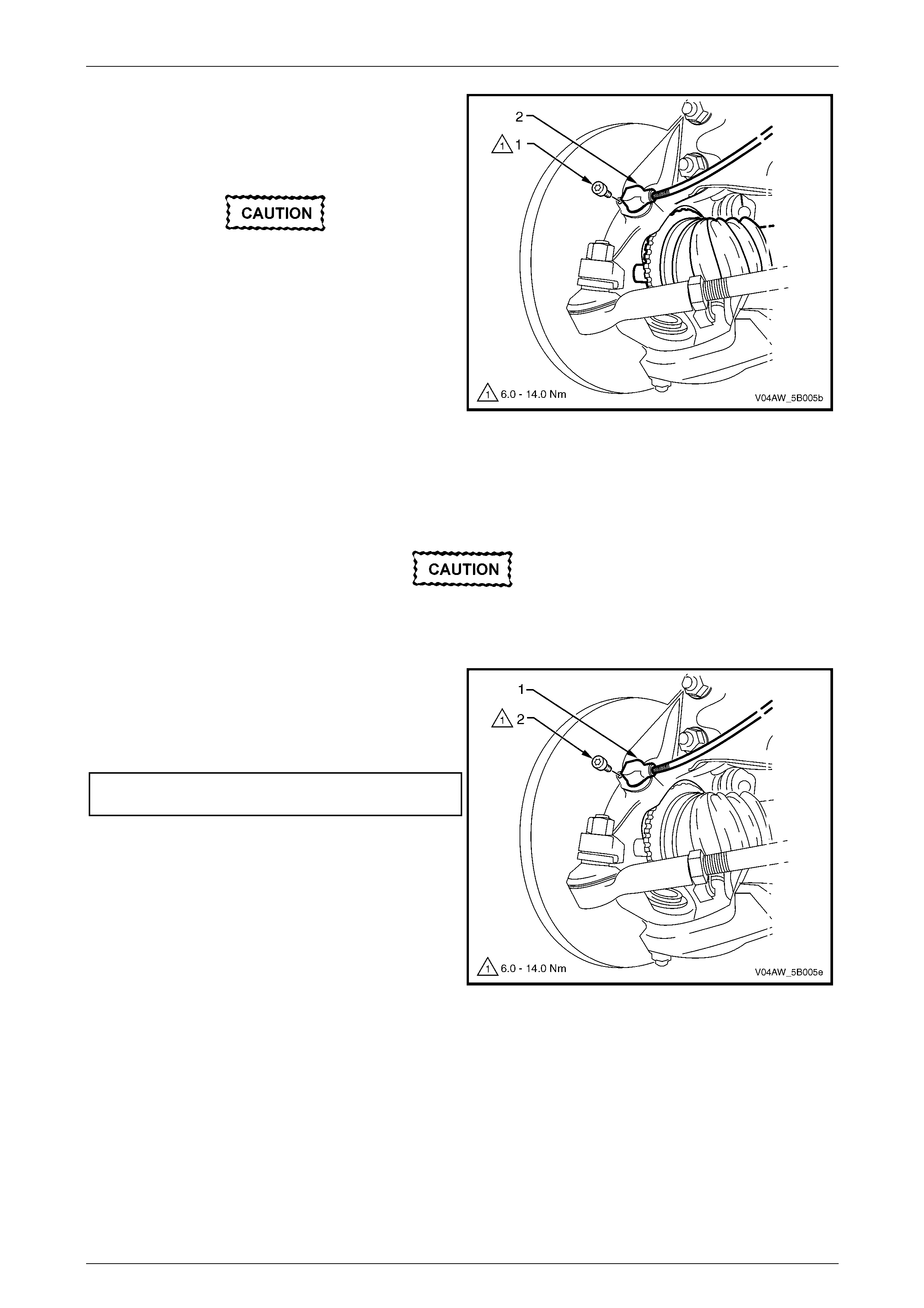

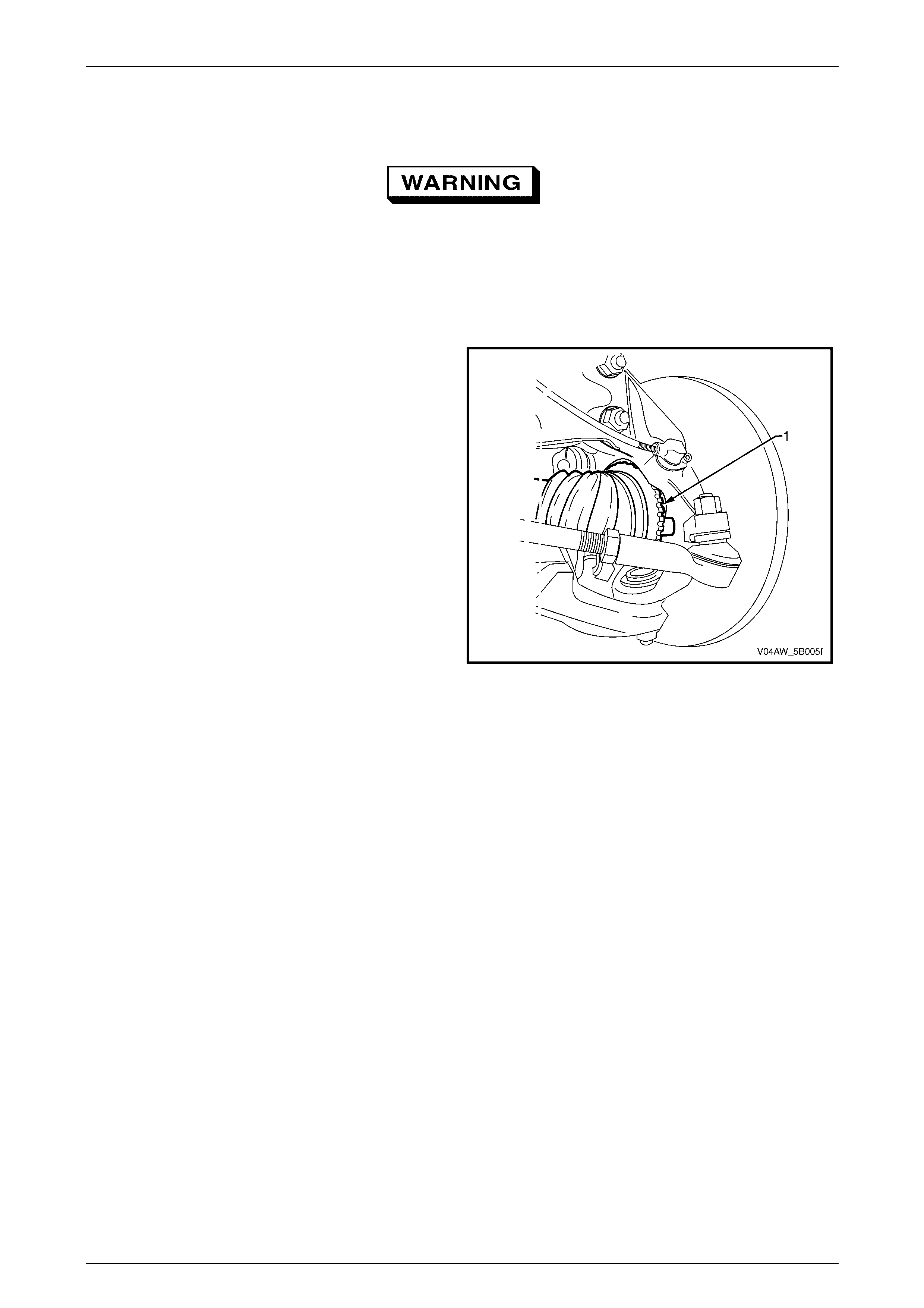

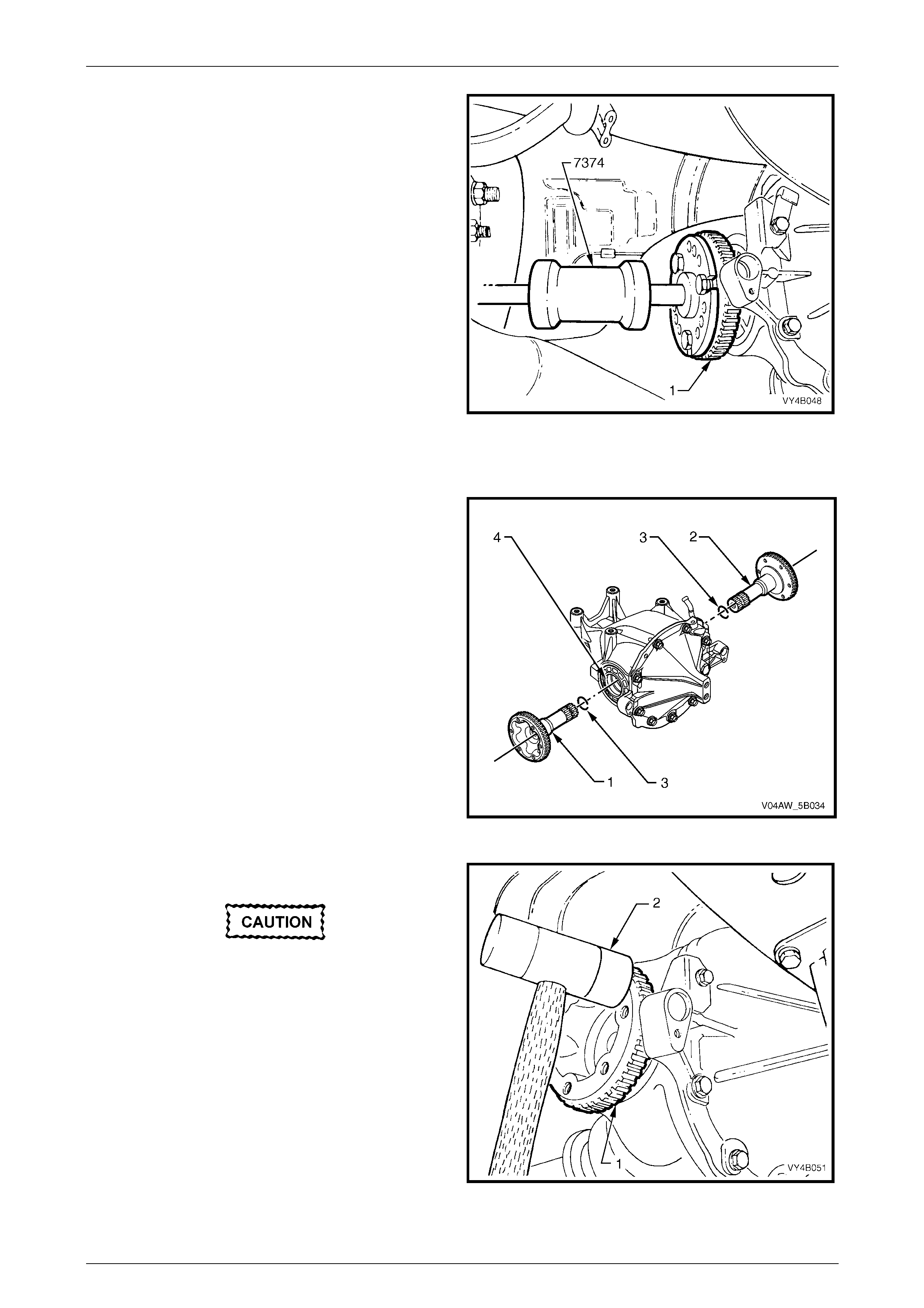

9.6 Rear Wheel Speed Sensor.................................................................................................................................130

Remove ...............................................................................................................................................................130

Reinstall..............................................................................................................................................................131

9.7 Pulse Rings .........................................................................................................................................................132

Front Wheel Speed Sensor Pulse Ring............................................................................................................132

Rear Wheel Speed Sensor Pulse Ring.............................................................................................................132

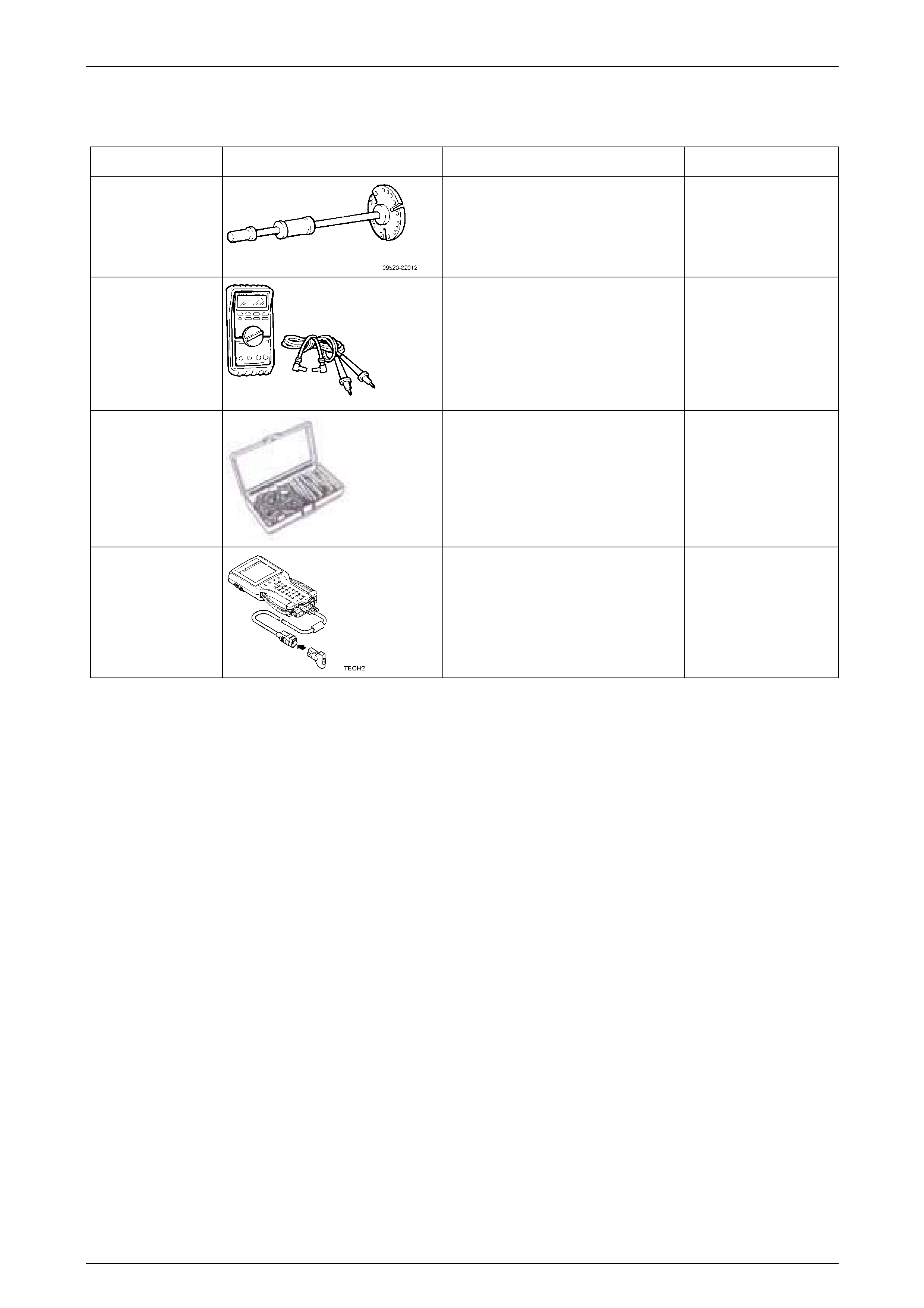

9.8 Longitudinal Accelerometer..............................................................................................................................135

Remove ...............................................................................................................................................................135

Reinstall..............................................................................................................................................................135

10 Specifications..................................................................................................................................... 136

11 Torque Wrench Specifications......................................................................................................... 137

12 Special Tools...................................................................................................................................... 138

AW D ABS-TCS Page 5B–4

Page 5B–4

1 General Information

MY 2004 VY AWD Wagon vehicles are equipped with an Antilock Braking System (ABS) that incorporates a Traction

Control System (TCS). This AWD ABS-TCS is calibrated for off-road driving conditions and comprises of the following:

• Antilock Braking System (ABS), refer to 2.2 Antilock Braking System for information on ABS.

• Automatic Brake Distribution (ABD) System, refer to 2.3 Automatic Brake Distribution System for information on

ABD System.

• Electronic Brake-force Distribution (EBD) System, refer to 2.4 Electronic Brake-force Distribution for information on

EBD System.

The ABS-TCS modulates the brake fluid pressure at each wheel during hard driving or an emergency braking situation,

to provide the following safety factors for safe and stable driving under various vehicle load and road surface conditions:

• Reduced vehicle stopping distance,

• Optimum vehicle stability and steering control,

• Improved vehicle traction control, and

• Dynamic front to rear wheel brake proportioning.

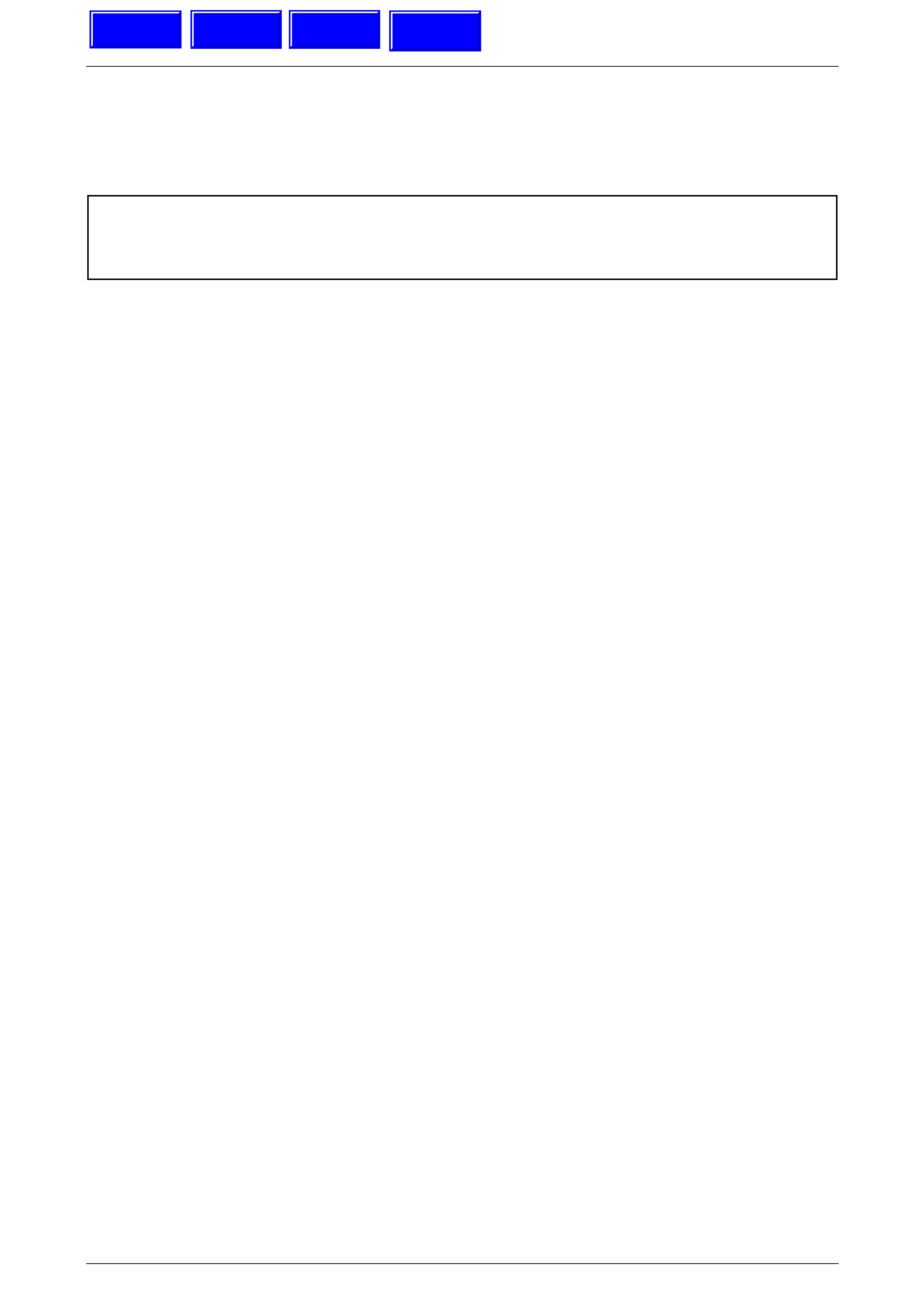

The vehicle braking system is dependent upon tyre traction to the road surface to achieve maximum braking efficiency.

The braking action converts the vehicle's forward motion into heat energy. Maximum braking efficiency is achieved when

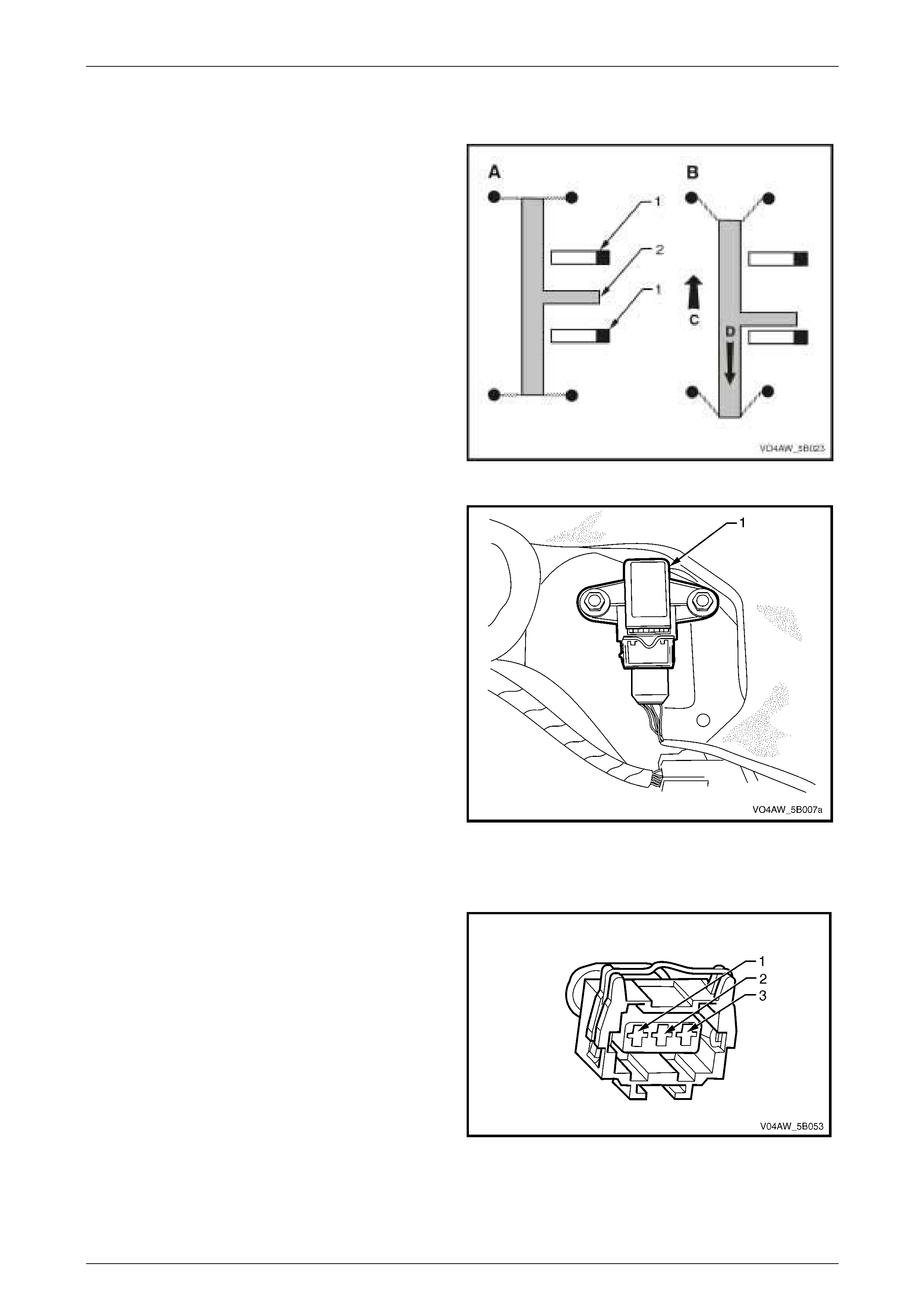

a wheel lock-up is prevented and the wheel slip is approximately 12%. Refer to Figure 5B – 1 for the illustration of the

following:

• At 0% slip, the tyre rolls freely (A).

• At 100% slip, the tyre locks-up (B) as the weight of the vehicle (C) pushes the non-rotating tyre along the road

surface (1). The force involved in stopping an 1800 kg vehicle from 100 km/h requires the braking system to

generate approximately 8,100 kilojoule (kJ) of braking energy.

When the tyres are locked-up, the vehicle's forward energy is converted into braking energy (friction) between the

tyre and the road surface. This will result in an unstable and inefficient braking due to the effect of the following

factors:

• Asphalt, cement, gravel or dirt road surfaces provide different degree of tyre traction.

• Oil puddles, ice spots or other contaminants that cause a sudden change in the road surface condition.

• Wet, dry, smooth, rough road surface condition affect tyre traction.

Figure 5B – 1

When none of the wheels are locked during braking, the heat energy produced by the braking action is transferred to

the brake pads and the brake disc. As the friction surfaces between the brake pads and the brake disc are designed to

provide a stable and controlled braking action, a vehicle that is stopped without locking the wheels will stop in a shorter

distance while maintaining directional stability and steering capability.

AW D ABS-TCS Page 5B–5

Page 5B–5

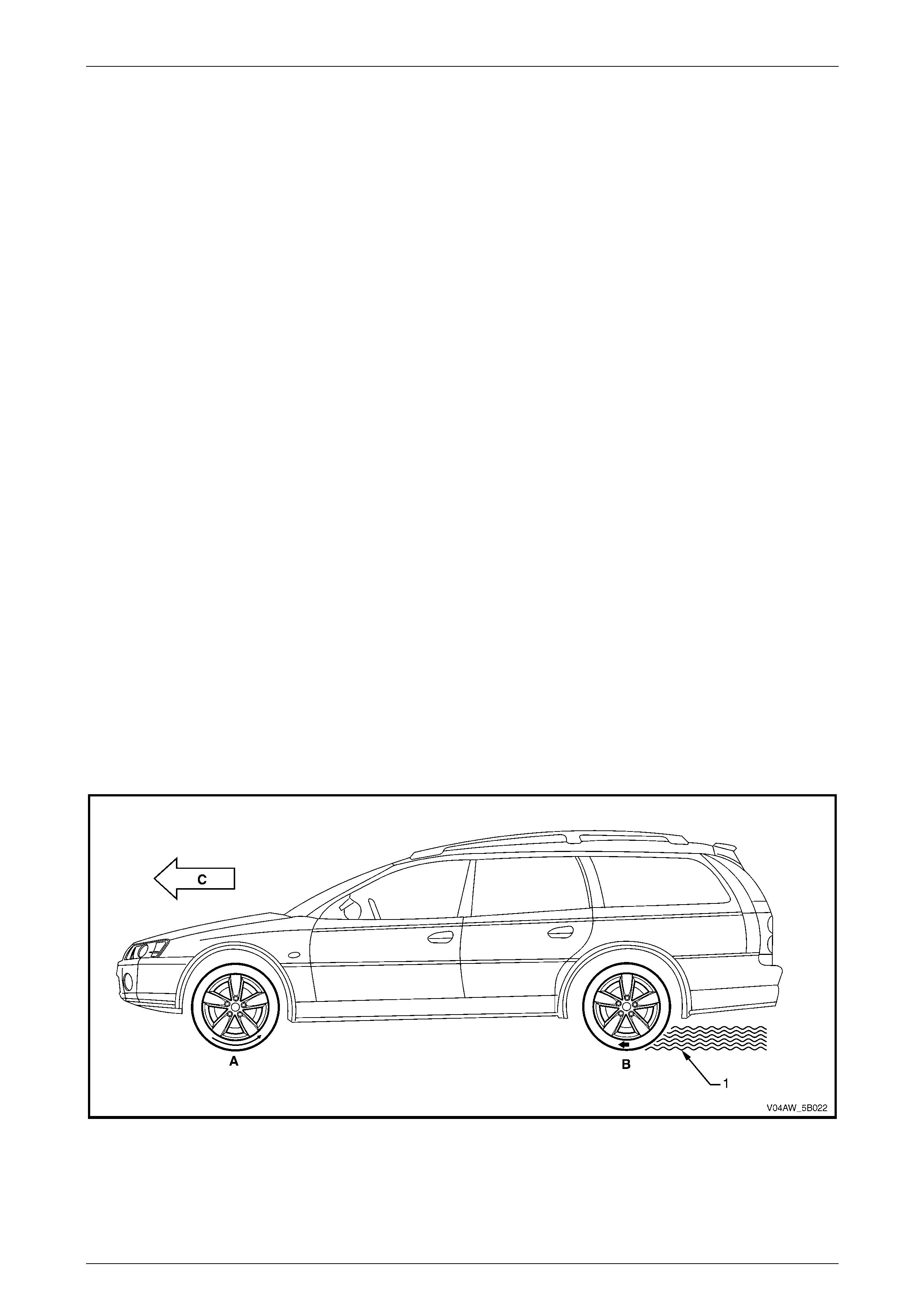

In addition, steering control also depends upon tyre traction.

A locked wheel in a 100% slip condition delivers poor

braking and directional control.

In this example, the front tyre direction (A) has minimal

steering effect while the vehicle slides in direction (B). The

tyres must regain their traction before steering control is

restored to the vehicle.

Figure 5B – 2

Skilled drivers carefully control wheel lock-up by limiting brake pressure, but wheel lock-up on wet roads or in other

reduced traction conditions are difficult to prevent through non-ABS braking.

In theory, the skilled driver limits brake application just short of lock-up. In practice, the driver rapidly pumps the brake

pedal to prevent wheel lock-up. The driver applies, releases, reapplies and releases the brakes until the vehicle stops.

However, the most skilled drivers cannot pump the brakes rapidly or precisely enough for the best braking under all road

surface conditions. In addition, if only one wheel is locking-up, pumping of the brake pedal applies and releases the

brakes at all four wheels at the same time.

The MY 2004 VY AWD Wagon ABS-TCS is designed to provide automatic wheel braking control to each wheel for

optimum vehicle braking, traction and stability under any road surface condition.

AW D ABS-TCS Page 5B–6

Page 5B–6

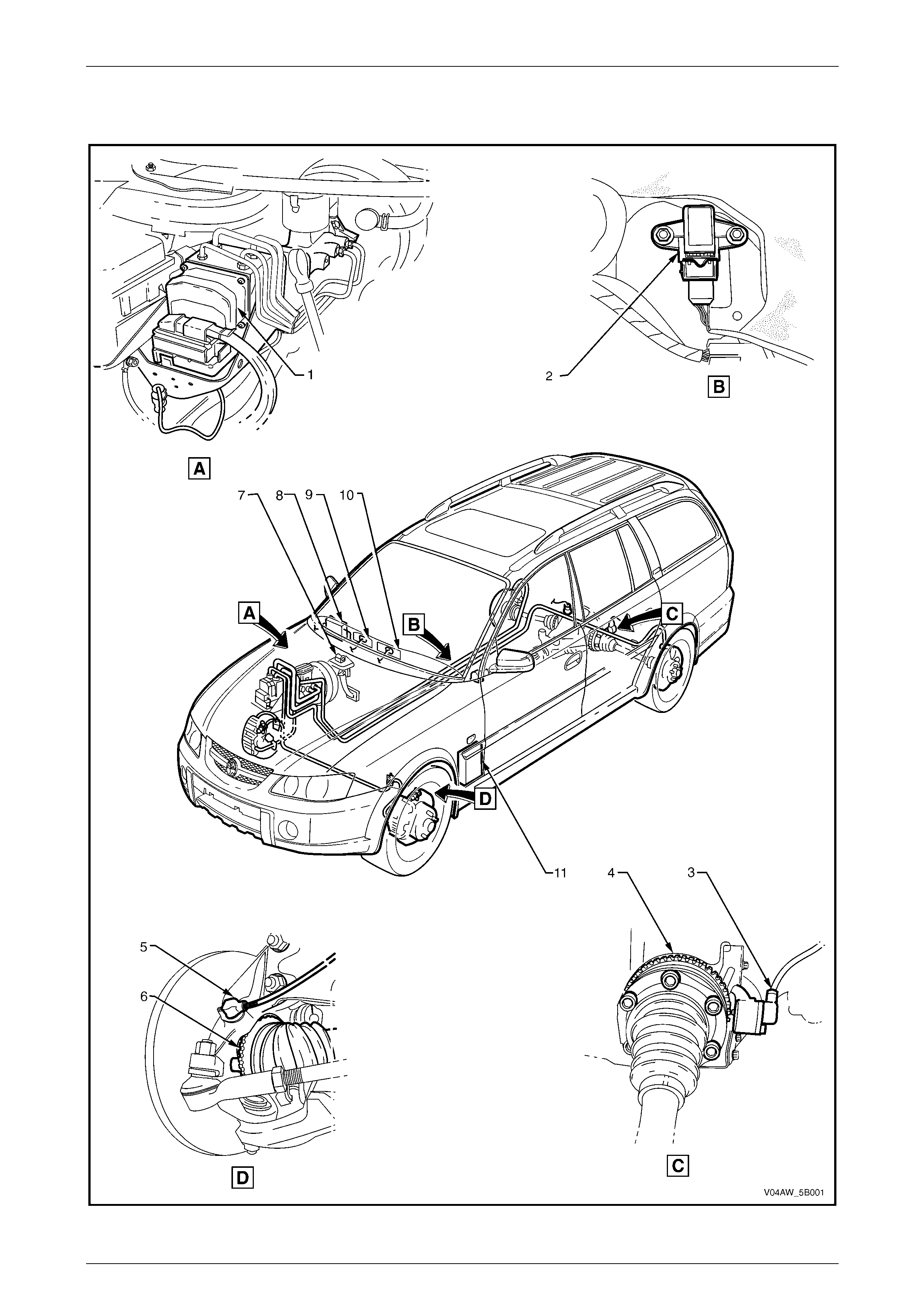

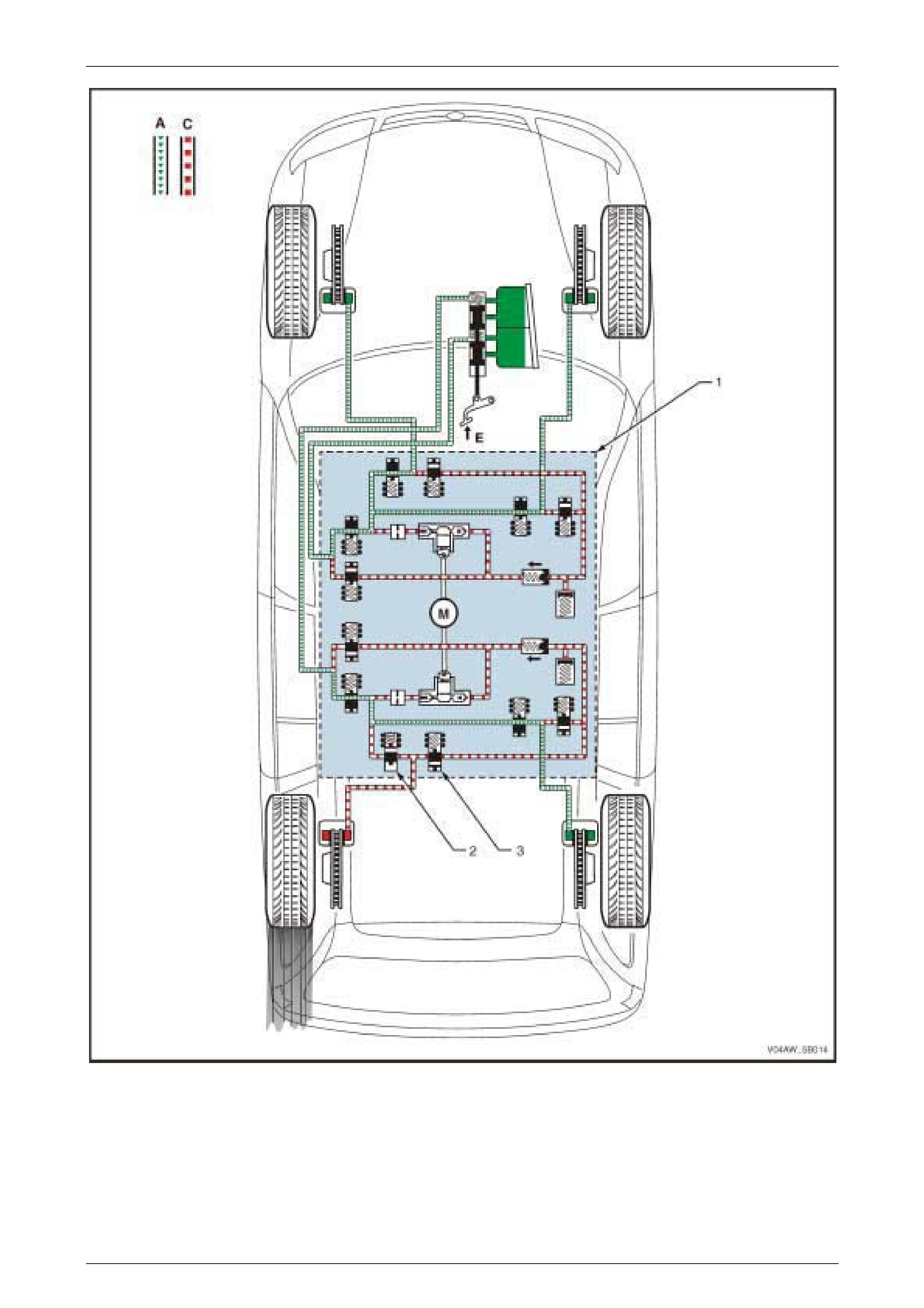

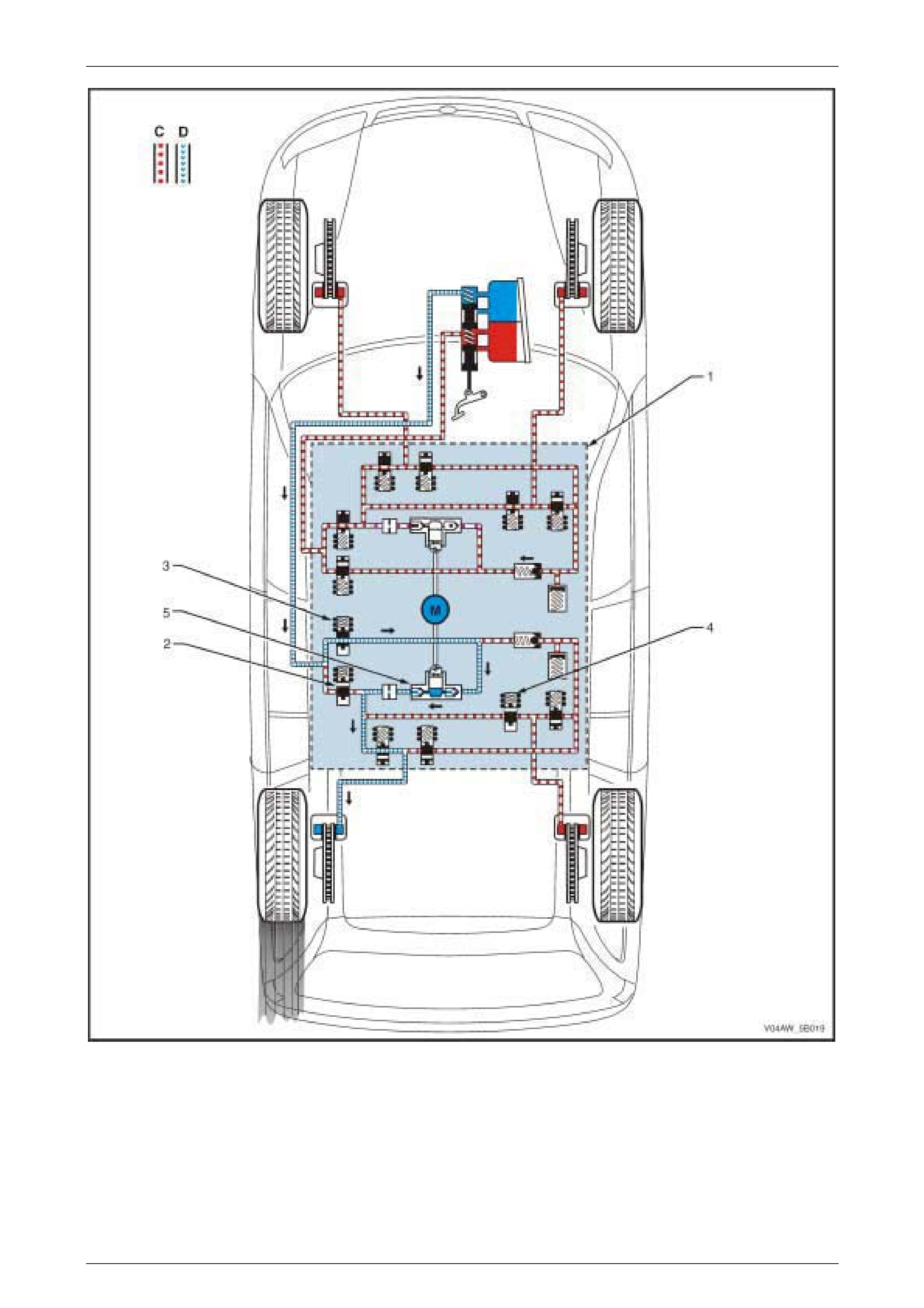

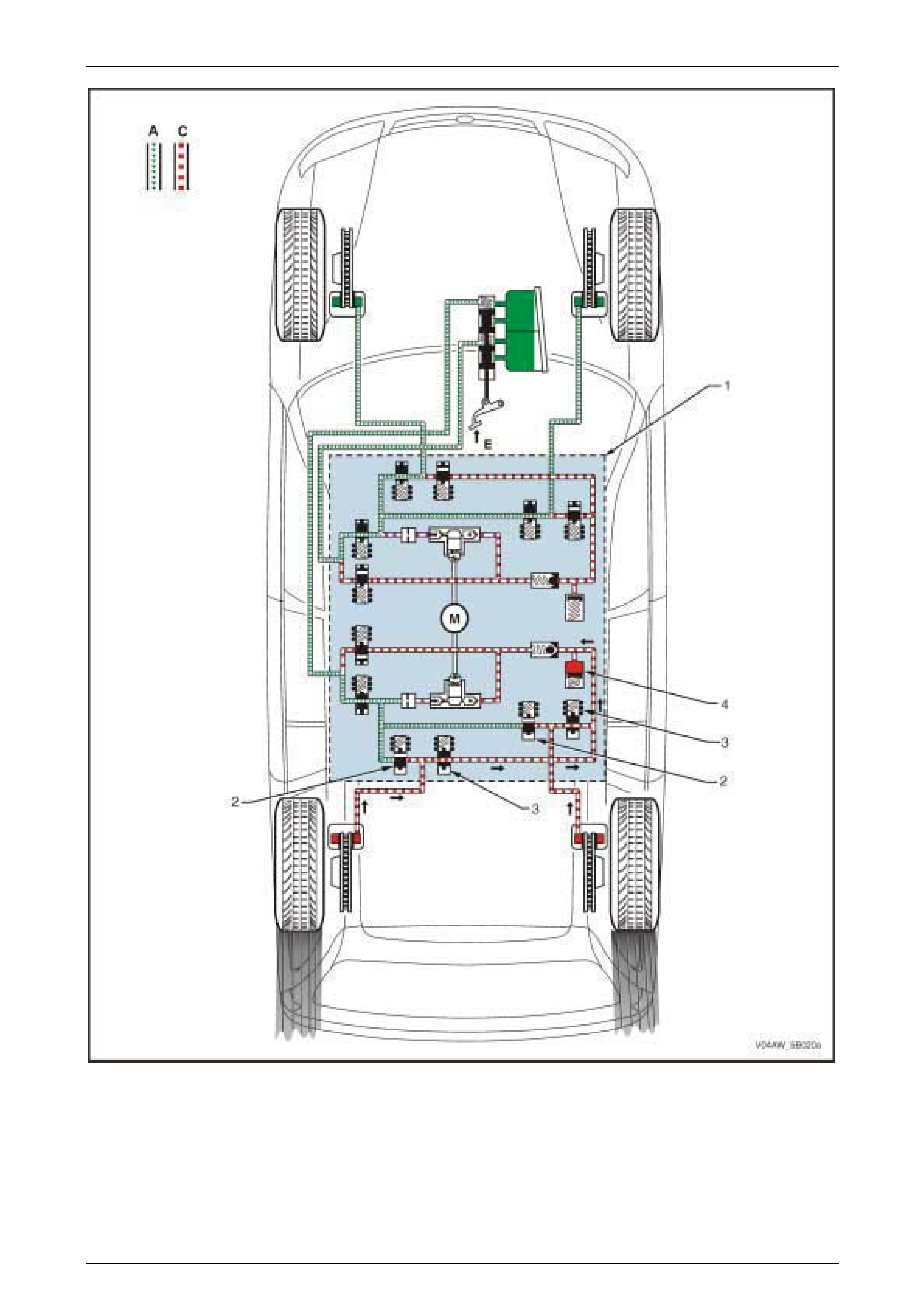

1.1 Component Location

Figure 5B – 3

AW D ABS-TCS Page 5B–7

Page 5B–7

Component Location Legend

1 Elect roni c Control Uni t and

Hydraulic Modulat or A ssembly

2 Longitudinal Accelerometer

3 Rear Wheel Speed Sensor

4 Rear Wheel Speed Sensor Pul se Ring

5 Front Wheel S peed Sensor

6 Front Wheel Speed Sensor P ul se Ring

7 Stop Lamp Switch

8 Body Control Module

9 ABS Icon, ABS Fault and Traction Control Warning Display

10 ABS Warning Lamp

11 Powertrain Interface Module

AW D ABS-TCS Page 5B–8

Page 5B–8

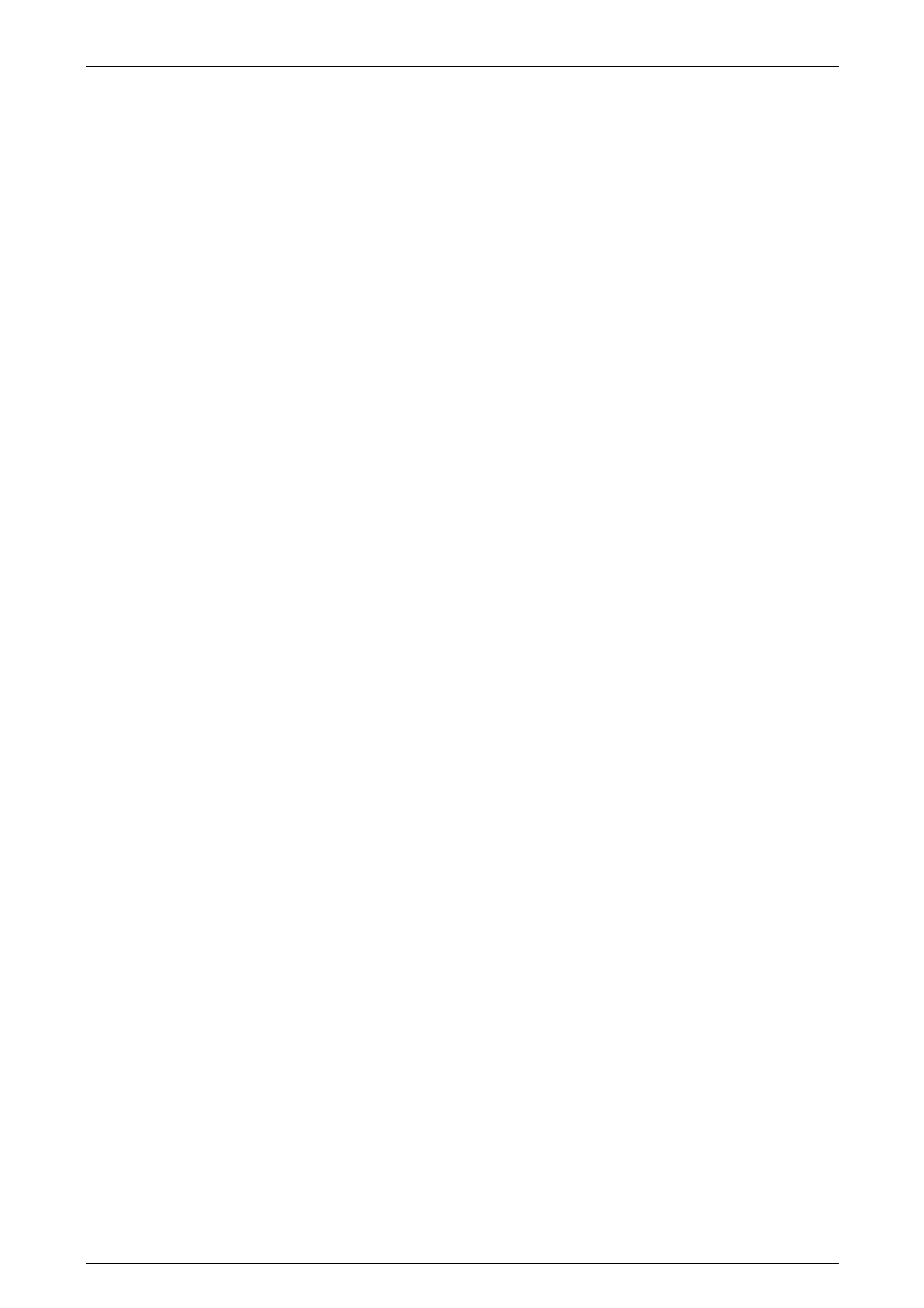

1.2 AWD ABS-TCS Hydraulic Circuit

Figure 5B – 4

AW D ABS-TCS Page 5B–9

Page 5B–9

Hydraulic Circuit Legend

1 Brake Caliper

2 Brake Mast er Cyl i nder

3 Inlet Valve

4 Outlet Valve

5 Pump Motor

6 Accumulator

7 One-way Valve

8 Priming Valve

9 Isolating Valve

10 Hydraulic Damper

11 Hydraulic Pump

A Normal (conventional) B rake Fluid Pressure

B Modulated Brake Flui d P ressure

C St opped B rake Fluid Pressure Flow (Solenoid V al ve Closed)

D hydraulic modul ator Pum p Generated Brake Fl ui d P ressure

Flow

E Brake Pedal A ppl i ed

AW D ABS-TCS Page 5B–10

Page 5B–10

2 System Operation

2.1 Non-ABS Braking

Under normal braking and driving conditions, the ABS-TCS functions like a conventional braking system. Refer to

Section 5A Service and Park Braking System for further information on the conventional braking system.

Non-ABS Braki ng O perat ion

When the brakes are applied (E), the brake booster assists the brake master cylinder (1) in providing brake fluid

pressure (A) to the brake calipers (2) without any intervention from the hydraulic modulator (3). Refer to Figure 5B-5.

However, the Electronic Control Unit (ECU) constantly monitors each wheel for wheel slip. If the ECU detects a wheel

slip, it switches to the appropriate Mode:

• ABS Mode – If any of the wheels begin to lock-up.

• EBD Mode – If the front-to-rear wheel speed is not balanced during braking.

Condition Description

At normal braking, all the valves in the hydraulic modulator are in their normal rest positions allowing for uninterrupted

flow of brake fluid from the master cylinder to the brake calipers. The hydraulic modulator provides conventional non-

ABS braking by allowing the brake fluid to flow between the brake master cylinder and the brake caliper in either

direction.

AW D ABS-TCS Page 5B–11

Page 5B–11

Figure 5B – 5

Legend – Normal Braking Hydraulic Circuit

1 Brake Mast er Cyl i nder

2 Brake Caliper

3 Hydraulic Modulat or A ssembly

A Normal (conventional) B rake Fluid Pressure

C St opped B rake Fluid Pressure Flow (Solenoid V al ve Closed)

E Brake Pedal A ppl i ed

AW D ABS-TCS Page 5B–12

Page 5B–12

2.2 Antilock Braking System (ABS)

The ABS is designed to prevent wheel loc k -up during hard or emergency braking. When the ABS detec ts that a wheel is

beginning to lock-up, the hydraulic modulator reduces the braking force applied by modulating the brake fluid supply

pressure of the locking wheel. The following are conditions that may occur under various ABS-TCS Phases:

ABS-TCS Normal Operating Conditi ons

The following are conditions that may be experienced when the ABS-TCS is activated and are considered normal:

• During ABS-controlled braking, the braking pressure of the affected wheel is automatically adjusted to prevent

wheel lock-up, regardless of brake pedal force.

• During some ABS-TCS operation, the following conditions may be experienced and are considered normal:

• A series of rapid pulsations are felt through the brake pedal – these pulsations occur as solenoid valves

within the hydraulic modulator change position to modulate the brake hydraulic pressure.

• A ticking or popping noise in the hydraulic modulator – this noise occurs as the hydraulic modulator solenoid

valves cycle rapidly to modulate the hydraulic brake pressure.

• Intermittent chirping noises – this noise may be heard as the tyres approach slipping on dry pavement.

• Electric motor and pump noise and rapid brake pedal pulsation – these are caused by the operation of the

hydraulic modulator pump during the ABS/EBD Reducing or Increasing Pressure Phase, ABD Brake

Intervention or the ECU self-test.

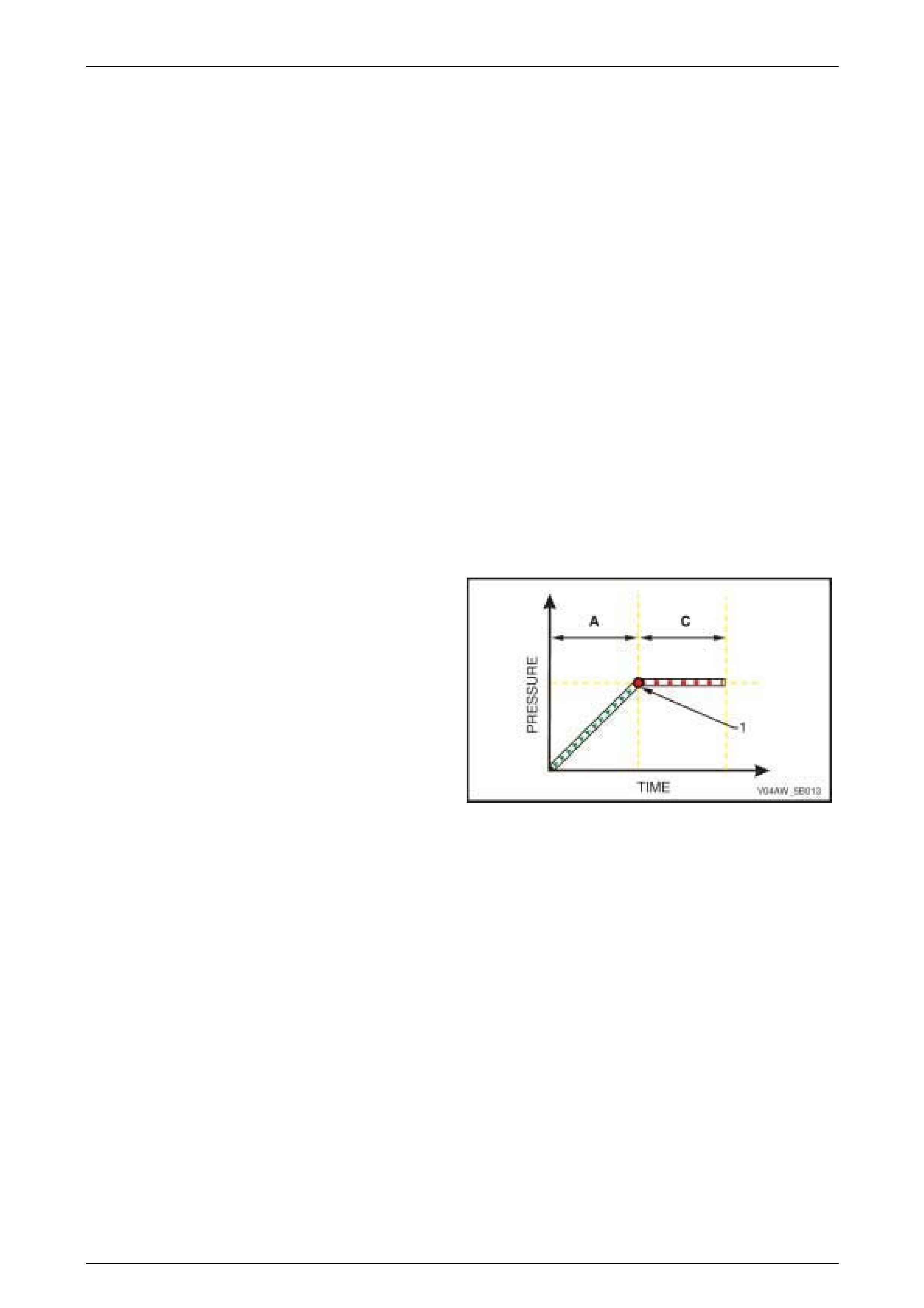

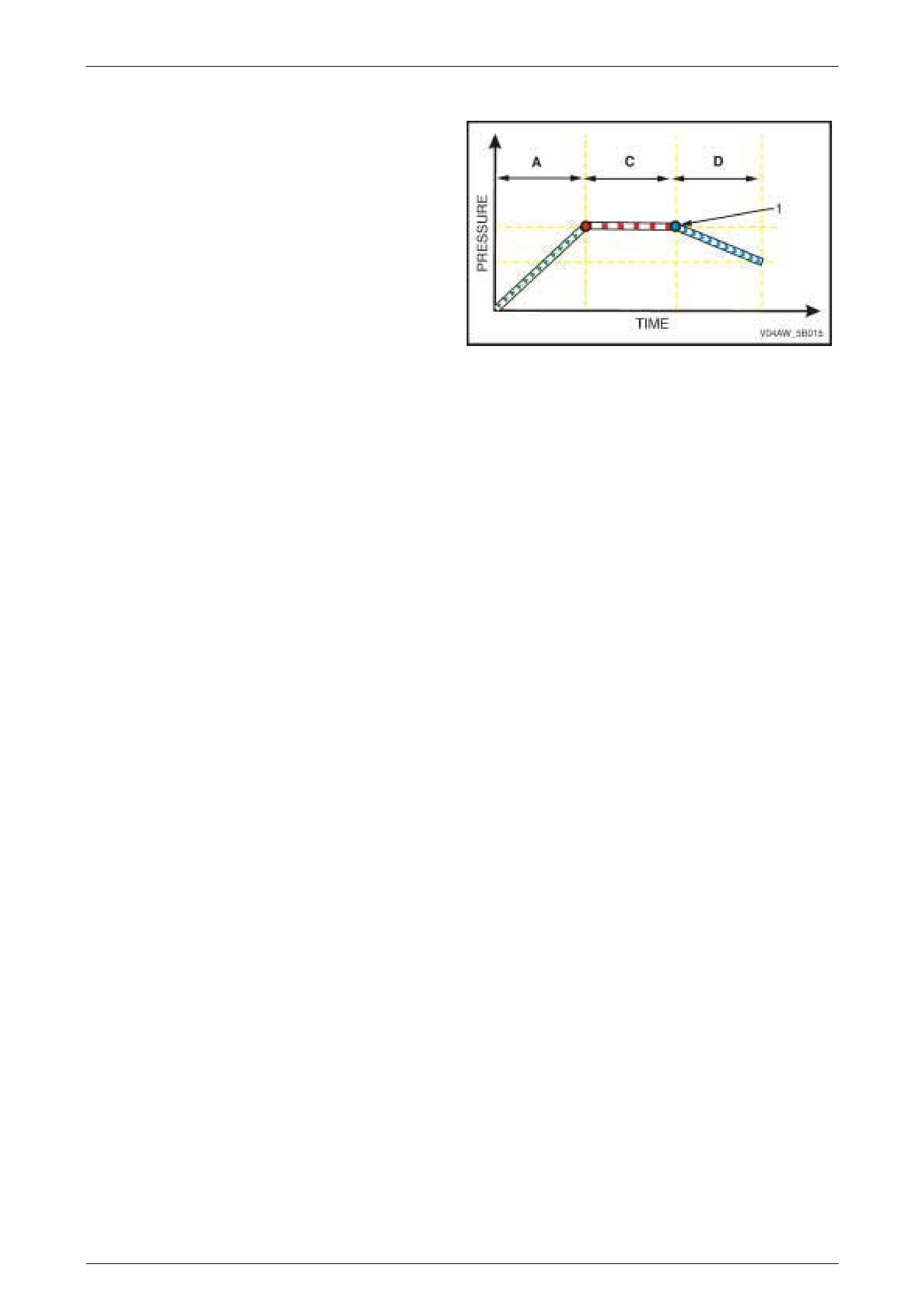

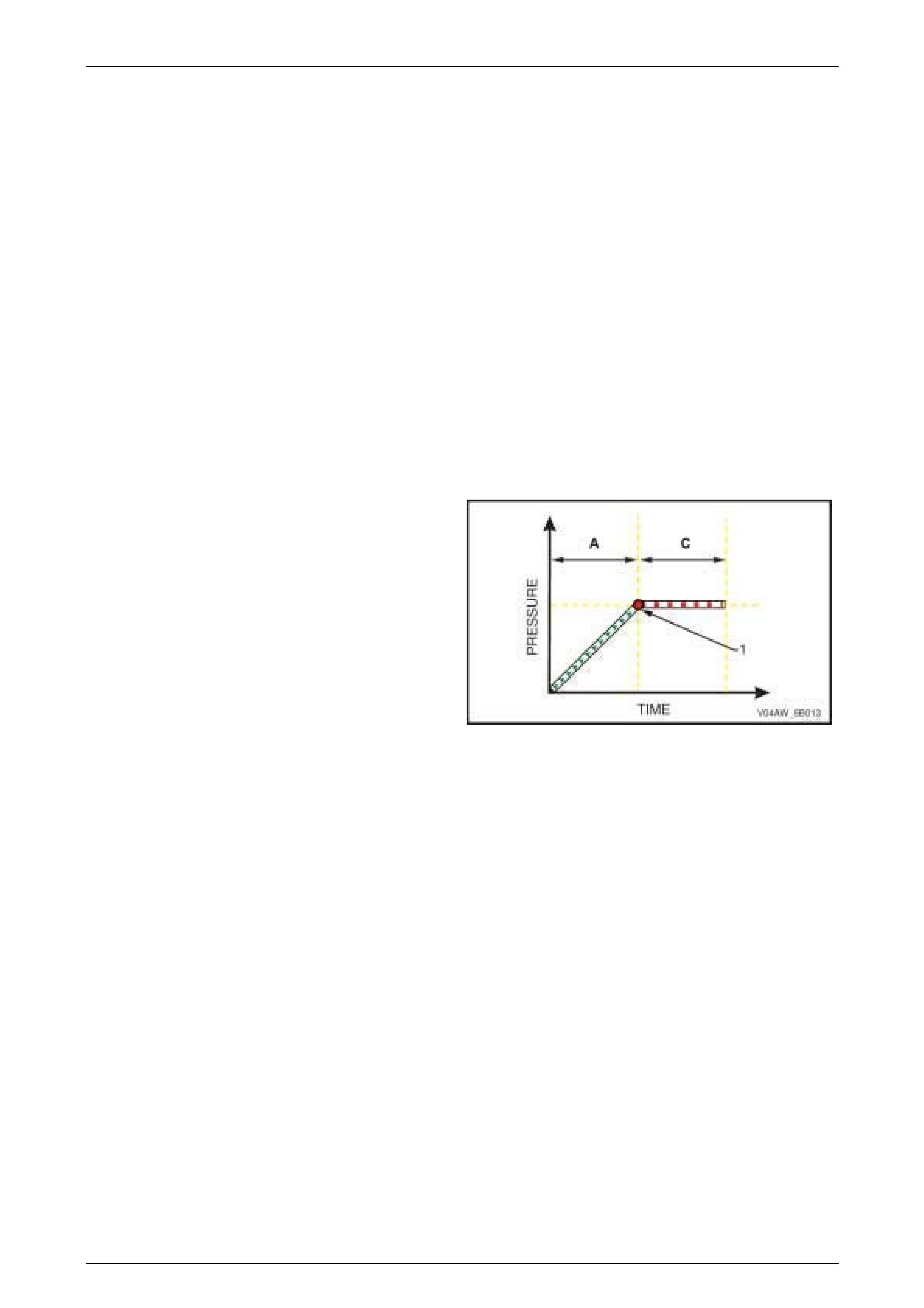

ABS Phase – Mai nt ai ning Pressure

Condition Description

When the brakes are applied (A) and the Electronic Control

Unit (ECU) detects that a wheel reaches a point (1) where it

is beginning to lock-up, the hydraulic modulator controls the

brake fluid pressure of the affected wheel to maintain its

brake fluid pressure (C) and prevent a wheel lock-up.

Figure 5B – 6

Control Action

NOTE

The following ABS situation assumes that the

rear left wheel is beginning to lock-up. Refer to

Figure 5B – 7 for the illustration of the ABS

Phase – Maintaining Pressure Hydraulic Circuit.

The ECU monitors and compares signals from each wheel speed sensor to determine wheel lock-up or wheel spin. If a

wheel lock-up is detected during braking, the ECU switches to the Maintaining Pressure Phase and sends a control

signal to the hydraulic modulator (1) to close the rear left inlet valve (2).

With both the rear left inlet valve and outlet valve (3) closed, the rear left brake fluid circuit is isolated and the rear left

brake fluid pressure (C) is kept constant regardless of the brake fluid pressure (A) exerted by the brake pedal (E).

AW D ABS-TCS Page 5B–13

Page 5B–13

Figure 5B – 7

Legend – ABS Maintaining Pressure Phase Hydraulic Circuit

1 Hydraulic Modulator

2 Inlet Valve

3 Outlet Valve

A Normal (conventional) B rake Fluid Pressure

C St opped B rake Fluid Pressure Flow (Solenoid V al ve Closed)

E Brake Pedal A ppl i ed

AW D ABS-TCS Page 5B–14

Page 5B–14

ABS Phase – Reducing Pressure

Condition Description

If maintaining the brake fluid pressure in the Maintaining

Pressure Phase (C) did not prevent the affected wheel from

locking-up (1), the ABS switches from Maintaining Pressure

Phase to Reducing Pressure Phase.

The hydraulic modulator modulates the brake fluid circuit of

the affected wheel to reduce its brake fluid pressure (D) and

prevent wheel lock-up.

Figure 5B – 8

Control Action

NOTE

The following ABS situation assumes that the

rear left wheel is still locking-up while the ABS is

already in Maintaining Pressure Phase. Refer to

Figure 5B – 9 for the illustration of the ABS –

Reducing Pressure Hydraulic Circuit.

The ECU monitors and compares signals from each wheel speed sensor to determine wheel lock-up and wheel spin. If

the rear left wheel lock-up is still detected when the ABS is already in the Maintaining Pressure Phase, the ECU

switches to the ABS Reducing Pressure Phase. The ECU sends a control signal to the hydraulic modulator (1) to:

• Open the rear left outlet valve (2).

• Close rear left inlet valve (3).

• Operate the hydraulic modulator pump (4). The hydraulic modulator pump will remain operational for the duration

of the ABS Phase.

The ABS performs the following actions during the Reducing Pressure Phase:

1 The rear left brake fluid is initially directed towards the accumulator (5) to guarantee instant pressure reduction

when the rear left outlet valve is opened.

2 The accumulator stores the excess rear left brake fluid.

3 The hydraulic modulator pump builds-up the rear left brake fluid return flow pressure that will allow the brake fluid

released from rear left brake caliper (6) to be returned back to the brake master cylinder (7) against brake pedal

pressure (D). Because the brake pedal is still being depressed during this phase, the released pressure from the

brake caliper has to be greater than the brake fluid pressure applied by the master cylinder.

AW D ABS-TCS Page 5B–15

Page 5B–15

Figure 5B – 9

Legend – ABS Reducing Pressure Phase Hydraulic Circuit

1 Hydraulic Modulator

2 Outlet Valve

3 Inlet Valve

4 Hydraulic Pump

5 Accumulator

6 Brake Caliper

7 Brake Mast er Cyl i nder

A Normal (conventional) B rake Fluid Pressure

C St opped B rake Fluid Pressure Flow (Solenoid V al ve Closed)

D hydraulic modul ator Pum p Generated Brake Fl ui d P ressure

Flow

E Conventional Brake Pres sure combined with Releas ed

Brake Fluid P ressure

AW D ABS-TCS Page 5B–16

Page 5B–16

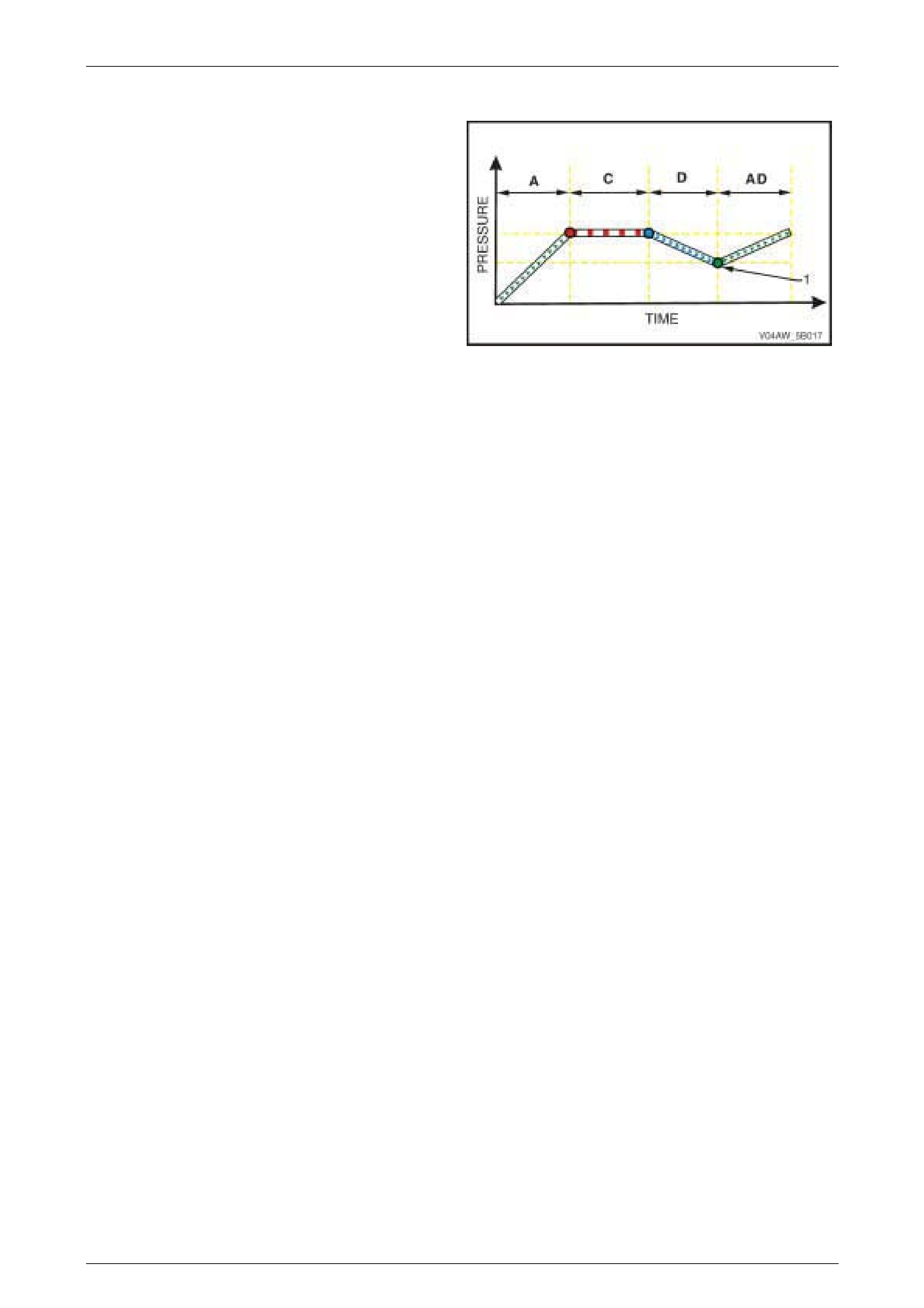

ABS Phase – Increasing Pressure

Condition Description

If reducing the brake fluid pressure in the Reducing

Pressure Phase (D) results in the following:

• The brake fluid pressure reaches a point (1) where

insufficient braking force is applied to the affected

wheel,

• The ECU determines that the affected wheel is now

underbraked.

The ABS switches from Reducing Pressure Phase to

Increasing Pressure Phase (AD). In this phase, the

hydraulic modulator modulates the affected wheel brake

fluid circuit to increase its brake fluid pressure, which

increases braking force and balances wheel speed during

braking.

Figure 5B – 10

Control Action

NOTE

The following ABS situation assumes that the

rear left wheel speed is under braked as a result

of the reduced braking force applied during the

ABS Reducing Pressure Phase. Refer to Figure

5B – 11 for the illustration of the ABS –

Increasing Pressure Hydraulic Circuit.

The ECU monitors and compares signals from each wheel speed sensor to determine wheel lock-up and wheel spin. If

the ECU detects that the rear left wheel speed is higher than the other three wheels as a result of the reduced braking

force applied during the Reducing Pressure Phase, the ECU switches to the Increasing Pressure Phase. The ECU

sends a control signal to the hydraulic modulator (1) to:

• Close (normal position) the rear left outlet valve (2).

• Open (normal position) the rear left inlet valve (3).

• Continue operation of the hydraulic modulator pump (4) for the duration of the ABS Phase.

The master cylinder (5) brake fluid pressure (A) is again directed to the rear left brake caliper (6) as in normal brake

operation. The previously reduced rear left brake fluid pressure is now increased to reduce the rear left wheel speed.

These ABS Phases are repeated until the ECU detects that the wheel speeds are balanced or the brake pedal pressure

removed. There are approximately four to six control cycles per second depending on the road surface condition.

AW D ABS-TCS Page 5B–17

Page 5B–17

Figure 5B – 11

Legend – ABS Increasing Phase Pressure Hydraulic Circuit

1 Hydraulic Modulat or

2 Outlet Valve

3 Inlet Valve

4 Hydraulic P ump Assembly

5 Brake Mast er Cyl i nder

6 Brake Caliper

A Normal (conventional) B rake Fluid Pressure

C St opped B rake Fluid Pressure Flow (Solenoid V al ve Closed)

D hydraulic modul ator Pum p Generated Brake Fl ui d P ressure

Flow

E Brake Pedal A ppl i ed

AW D ABS-TCS Page 5B–18

Page 5B–18

2.3 Automatic Brake Distribution (ABD)

System

The Automatic Brake Distribution (ABD) System is designed to prevent wheel spin during a standing start, acceleration

or cornering. When the ECU is in the ABD Mode, the hydraulic modulator modulates the brake hydraulic circuit of the

spinning wheel and applies appropriate brake fluid pressure, which enables the ABD System to automatically apply

braking force and prevent wheel spin.

A wheel spin causes the following vehicle conditions:

• The rear of the vehicle swerves and the vehicle becomes unstable.

• Increased tyre tread wear.

• High drivetrain stress that may result in premature drivetrain failure when a spinning wheel suddenly finds traction

on a high adhesive surface.

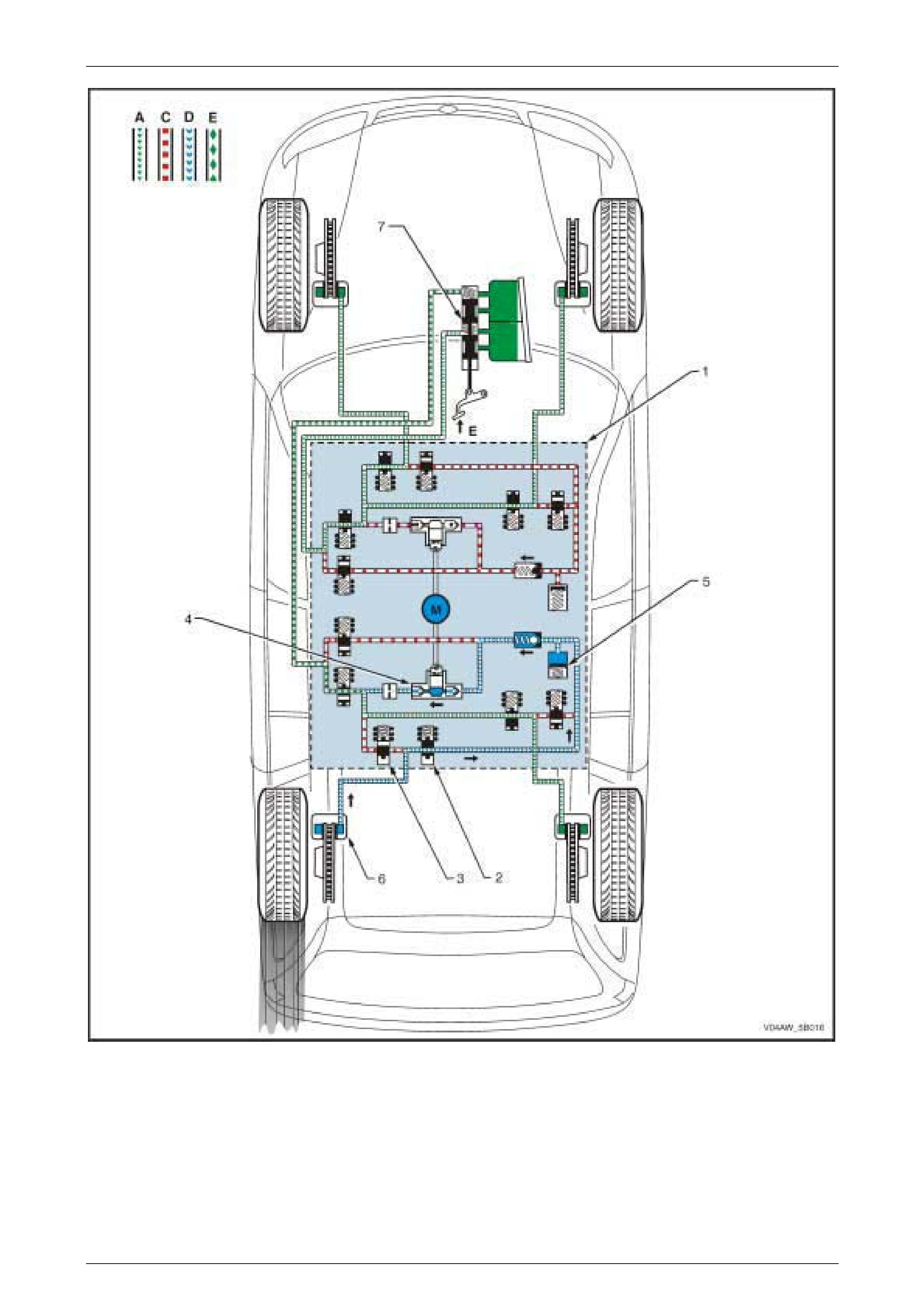

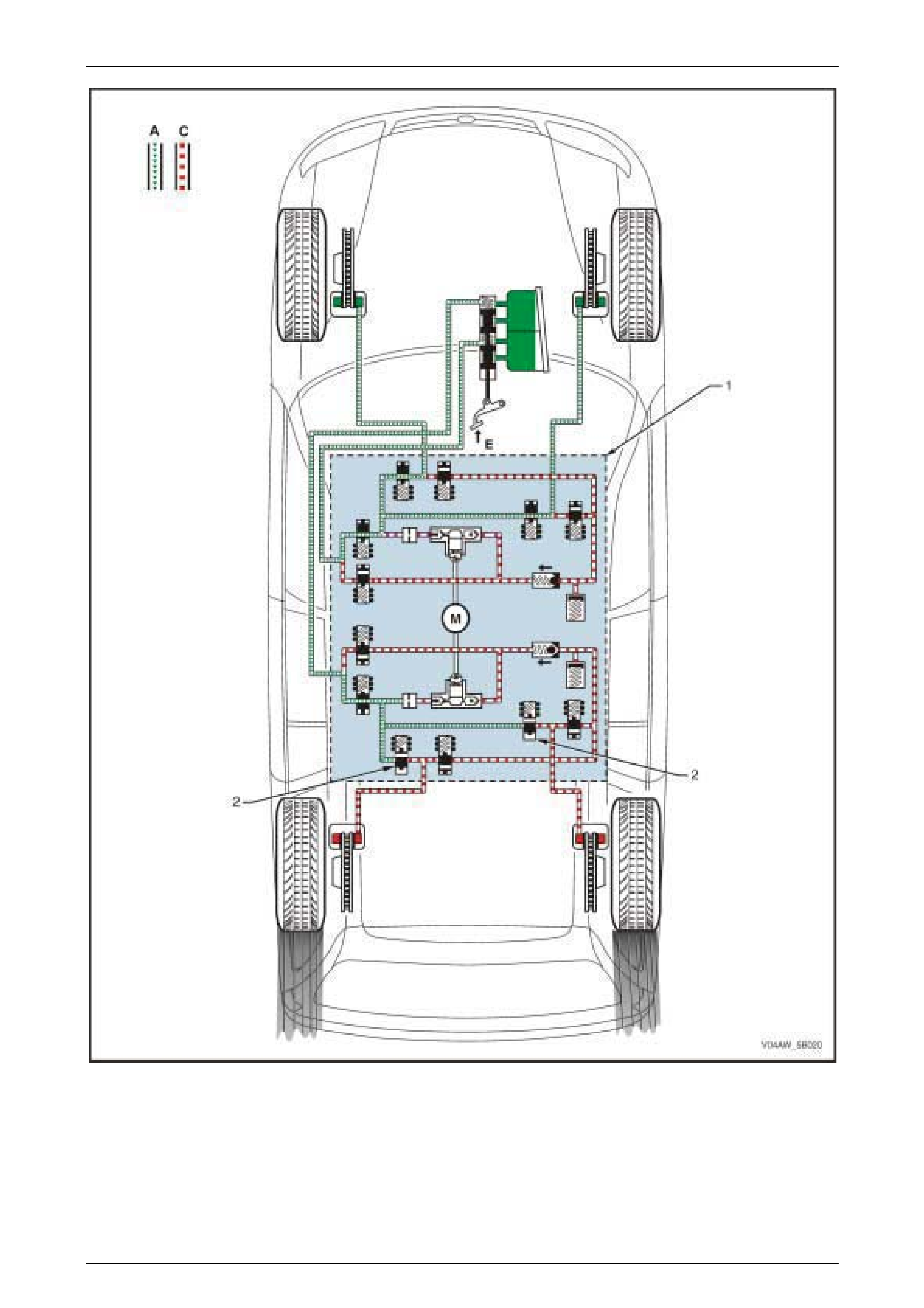

ABD System – Brake Intervention

NOTE

The following ABD System situation assumes

that the rear left wheel is beginning to slip. Refer

to Figure 5B – 12 for the illustration of the

ABD System – Hydraulic System Circuit.

The ECU monitors and compares signals from each wheel speed sensor to determine wheel lock-up and wheel spin. In

addition, the ECU monitors and evaluates signals from the longitudinal accelerometer the rate of vehicle acceleration.

In addition, if the vehicle is travelling on a slippery road condition or on a slope, which causes all four wheels to loose

traction, the ECU uses the longitudinal wheel speed sensor signal voltage to support the calculation of the actual vehicle

speed. Refer to 3.4 Longitudinal Accelerometer for further information on the longitudinal accelerometer.

If the ECU detects that the rear left wheel is beginning to slip due to a slippery road surface or excessive engine torque

and the brakes are not applied, the ECU switches to the ABD Mode. During this Mode, the ECU sends the following

signal to the hydraulic modulator (1) to:

• Close the rear isolating valve (2).

• Open the rear prime valve (3).

• Close the rear right inlet valve (4)

• Operate the hydraulic modulator pump (5).

The hydraulic modulator performs the following operations during the ABD Mode. These operations can be applied

approximately four to six times a second and can function on one or more driven wheels:

• The rear isolation valve is closed to isolate the rear brake fluid circuits from the master cylinder and prevent the

brake fluid returning to the brake master cylinder when the hydraulic pump builds-up the brake fluid pressure.

• The rear right inlet valve is closed to isolate the rear right wheel hydraulic circuit (C) allowing the hydraulic

modulator to supply brake fluid pressure only to the rear left wheel.

• The rear priming valve is open to allow brake fluid to be drawn from the master cylinder into the hydraulic pump

• The hydraulic pump supplies brake fluid pressure (D) to the rear left brake caliper. Applying brake force to the

spinning wheel allows torque to be transferred to the wheel with good traction.

• The rear left wheel inlet and outlet valves cycle open and close to provide sufficient braking force to the rear left

wheel to stop it from spinning. The inlet and outlet valve cycle assists in obtaining maximum road surface traction

in the same manner as the ABS Mode. The difference between ABS and ABD mode is that during ABD Mode, the

brake fluid pressure is increased to reduce wheel spin. In contrast, during the ABS Mode, the brake fluid pressure

is decreased to avoid wheel lock-up.

NOTE

If at any time during ABD Mode the brakes are

manually applied, the brake switch sends a

signal to the ECU to exit the ABD Brake

Intervention Mode and allow for manual braking.

AW D ABS-TCS Page 5B–19

Page 5B–19

Figure 5B – 12

Legend – ABD Mode, Brake Intervention Hydraulic Circuit

1 Hydraulic Modulator

2 Isolating Valve

3 Prime Valve

4 Inlet Valve

5 Hydraulic P ump

C St opped B rake Fluid Pressure Flow (Solenoid V al ve Closed)

D hydraulic modul ator Pum p Generated Brake Fl ui d P ressure

Flow

M Pump Motor

AW D ABS-TCS Page 5B–20

Page 5B–20

2.4 Electronic Brake-force Distribution

(EBD) System

The Electronic Brake-force Distribution (EBD) System is part of the ABS-TCS software programmed into the Electronic

Control Unit (ECU) and is designed to replace the rear brake proportioning valve in preventing rear wheel lock-up during

moderate braking. The EBD System utilises the existing ABS System active controls to regulate the vehicle's rear brake

fluid pressure. This enables the EBD System to provide dynamic front to rear brake proportioning under various vehicle

loads, driving manoeuvres, or road conditions.

In some situations, when the EBD System is activated, a brake pedal height drop of approximately 10 mm will be

experienced when the driver varies the brake pedal pressure while performing brake stops. This is caused by the

hydraulic modulator performing an adjustment on the rear brake fluid pressure and is considered normal. The following

are conditions that may occur under various EBD System Phases:

EBD System Keep Alive Function

The EBD System plays an important role in vehicle stability during braking. For this reason, the EBD System has a Keep

Alive Function integrated in its software. When the ECU detects a fault in the ABS-TCS, depending on the type of

failure, certain parts of the system are kept alive. This allows the EBD System to apply some rear wheel brake

proportioning even under certain ABS-TCS fault conditions.

EBD – Maintai n i ng Pressure

Condition Description

When the brakes are applied (A) and the ECU determines

that the rear wheels reach a point (1) where their rotational

speed is decelerating faster than the front wheels, the

hydraulic modulator individually modulates the rear wheel

brake fluid pressure (C) to maintain the rear braking force

and prevent a wheel lock-up.

NOTE

The EBD System operation takes effect before

the increased slip rate required for an ABS

brake intervention.

Figure 5B – 13

Control Action

NOTE

The following EBD situation assumes that the

rear wheels are beginning to slip. Refer to Figure

5B – 14 for the illustration of the EBD Hydraulic

Circuit.

The ECU monitors and evaluates signals from each wheel speed sensor to determine wheel lock-up or wheel spin.

When the ECU determines that the rear wheels are decelerating faster than the front wheels but the rate of deceleration

doesn't reach a point where it requires ABS intervention, the ECU switches to EBD Maintaining Pressure Phase.

As a first step during the EBD Maintaining Pressure Phase, the ECU sends a control signal to the hydraulic modulator

(1) to close the rear inlet valves (2) and isolate the rear brake fluid circuit from the brake master cylinder. This maintains

the rear brake fluid pressure (C) regardless of the brake fluid pressure (A) exerted by the brake pedal (E).

AW D ABS-TCS Page 5B–21

Page 5B–21

Figure 5B – 14

Legend – EBD Maintaining Pressure Phase Hydraulic Circuit

1 Hydraulic Modulator

2 Rear Inlet V al ve

A Normal (conventional) B rake Fluid Pressure

C St opped B rake Fluid Pressure Flow (Solenoid V al ve Closed)

E Brake Pedal A ppl i ed

AW D ABS-TCS Page 5B–22

Page 5B–22

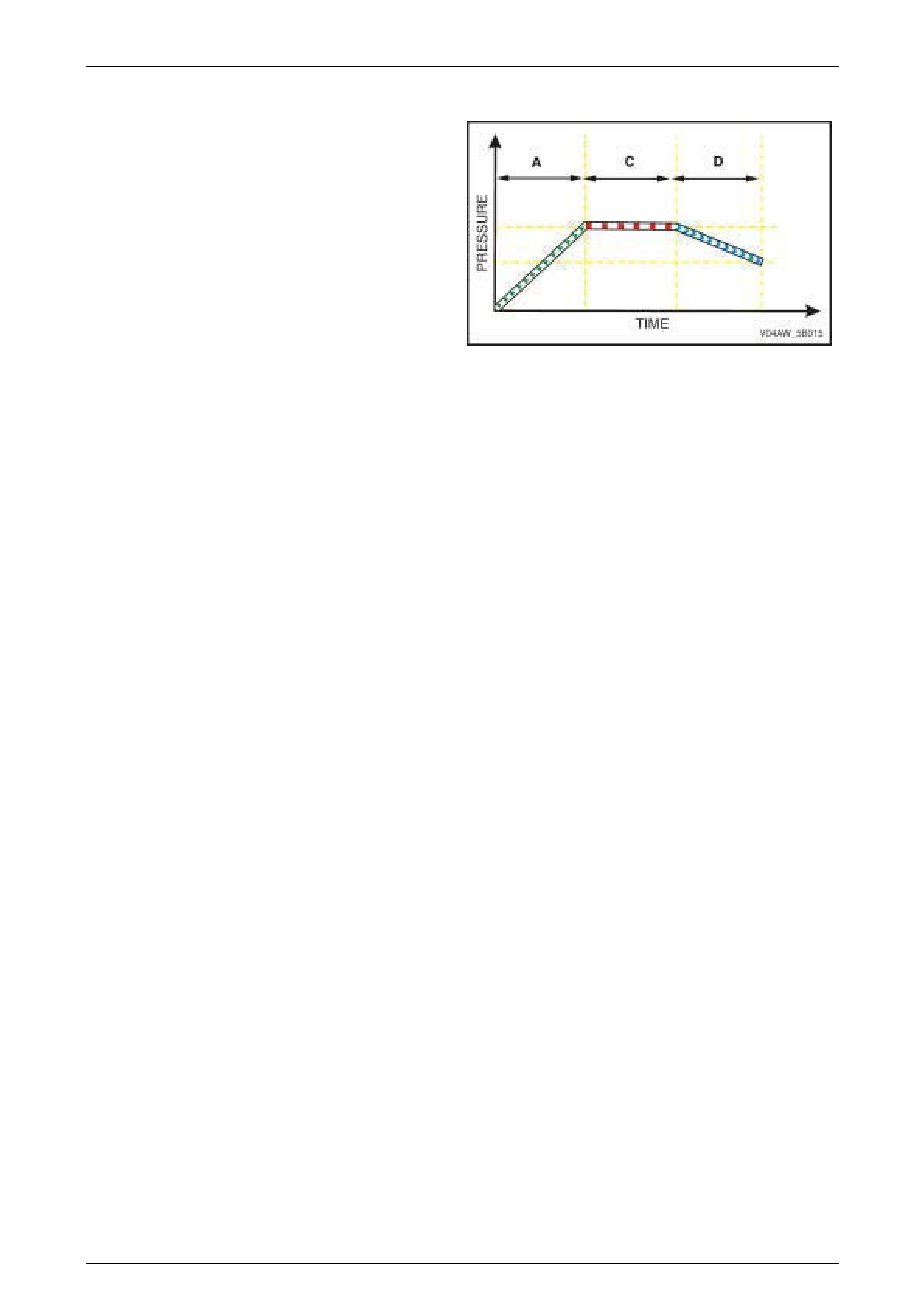

EBD Phase – Reducing Pressure

Condition Description

If maintaining the brake fluid pressure in the EBD System

Maintaining Pressure Phase (C) did not prevent the rear

wheels from decelerating faster than the front wheels, the

EBD System switches from Maintaining Pressure Phase to

Reducing Pressure Phase (D).

The hydraulic modulator modulates the rear wheel brake

fluid circuits to reduce its brake fluid pressure and prevent

wheel lock-up.

NOTE

The EBD System operation takes effect before the

increased slip rate required for an ABS brake intervention.

Figure 5B – 15

Control Action

NOTE

The following EBD System situation assumes

that the rear wheels are still decelerating faster

than the front wheels while the EBD System is

already in Maintaining Pressure Phase. Refer to

Figure 5B – 16 for the illustration of the EBD –

Reducing Pressure Hydraulic Circuit.

If the ECU detects that the rear wheels are still decelerating faster than the front wheels while the EBD System is

already in Maintaining Pressure Phase, the ECU switches to the Reducing Pressure Phase. The ECU sends a control

signal to the hydraulic modulator (1) to:

• Close the rear inlet valves (2).

• Open the rear outlet valves (3).

The EBD performs the following actions during the Reducing Pressure Phase:

1 The rear brake fluid is directed towards the accumulator (4) to allow brake fluid pressure reduction.

2 The accumulator stores the excess rear brake fluid. It is capable of storing all the excess brake fluid during an

EBD System operation. However, if the accumulator has been filled to its limit and the ECU still determines that

the rear wheels are decelerating faster than the front wheels, the ECU activates the hydraulic modulator pump and

returns the excess brake fluid to the brake master cylinder.

AW D ABS-TCS Page 5B–23

Page 5B–23

Figure 5B – 16

Legend – EBD Reducing Pressure Phase Hydraulic Circuit

1 Hydraulic Modulator

2 Rear Inlet V al ve

3 Rear Outlet V al ve

4 Accumulator

A Normal (conventional) B rake Fluid Pressure

C St opped B rake Fluid Pressure Flow (Solenoid V al ve Closed)

E Brake Pedal A ppl i ed

AW D ABS-TCS Page 5B–24

Page 5B–24

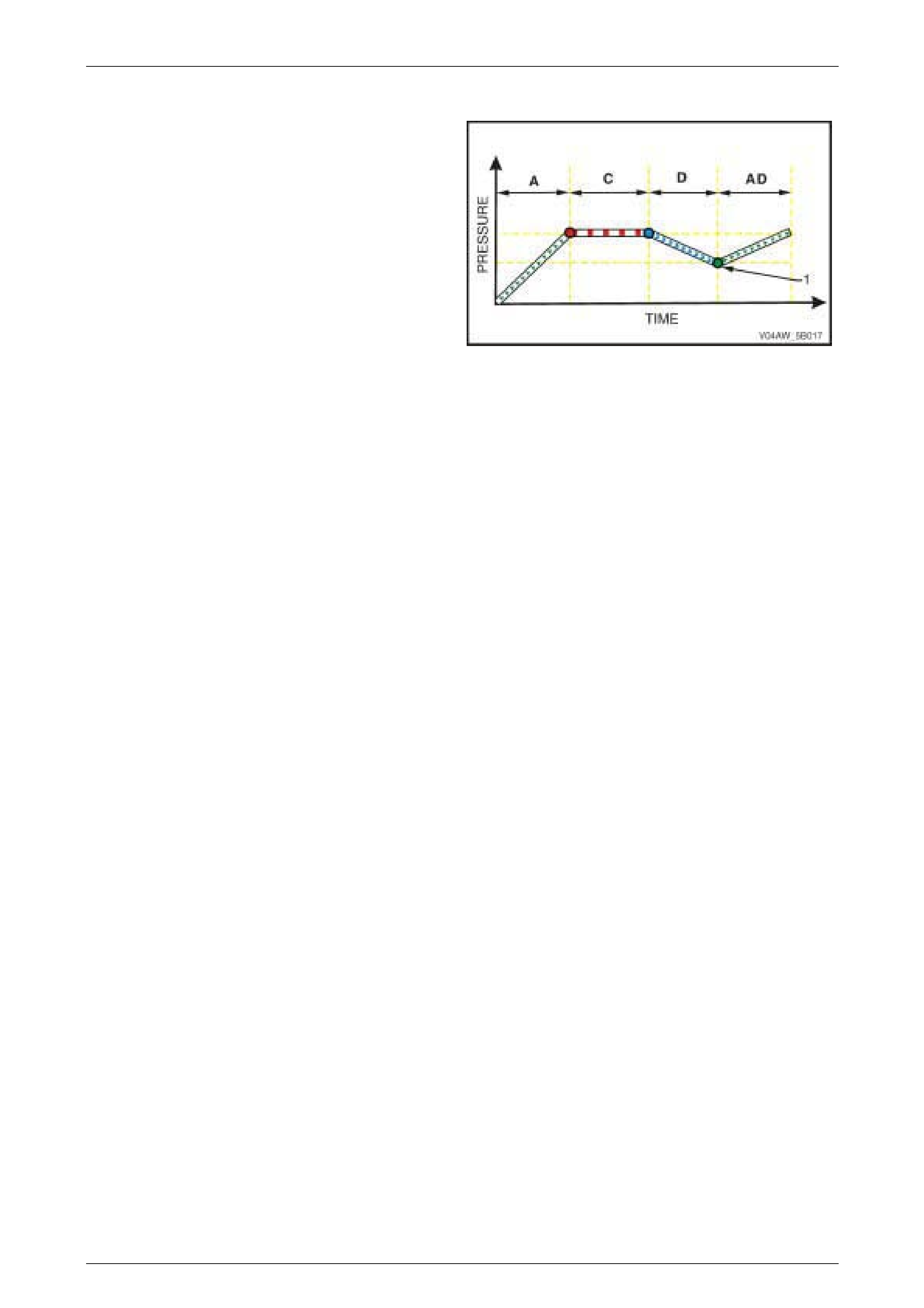

EBD Phase – Increasing Pressure

Condition Description

If reducing the rear brake fluid pressure in the EBD

Reducing Pressure Phase (D) causes the brake fluid

pressure to drop to a point (1) where the front and rear

wheels are now rotating at the same speed or almost at the

same speed, the EBD System switches from Reducing

Pressure Phase to Increasing Pressure Phase (AD).

In this phase, the ECU sends a signal to the hydraulic

modulator to allow normal brake master cylinder pressure to

be applied to the rear wheels as in normal brake operation.

Figure 5B – 17

Control Action

NOTE

The following EBD System operation assumes

that the front and rear wheels are now rotating at

the same speed or almost at the same speed, as

a result of the reduced braking force applied

during the EBD Reducing Pressure Phase.

The ECU monitors and compares signals from each wheel speed sensor to determine wheel lock-up and wheel spin. If

the ECU detects that the front and rear wheels are now rotating at the same speed or almost at the same speed as a

result of the reduced braking force applied during the EBD Reducing Pressure Phase, the EBD System switches from

Reducing Pressure Phase to Increasing Pressure Phase.

The ECU sends a control signal to the hydraulic modulator to return the rear outlet valve and the rear inlet valve to their

normal rest position.

The master cylinder brake fluid pressure is directed to the rear brake calipers as in normal brake operation. The

previously reduced rear brake fluid pressure is now increased to normal brake master cylinder pressure and the front

and rear wheels brake fluid pressures are again equal.

These EBD Phases are repeated until the ECU detects that the wheel speeds are balanced or the brake pedal pressure

removed. There are approximately four to six control cycles per second depending on the road surface condition.

AW D ABS-TCS Page 5B–25

Page 5B–25

3 Component Description and

Operation

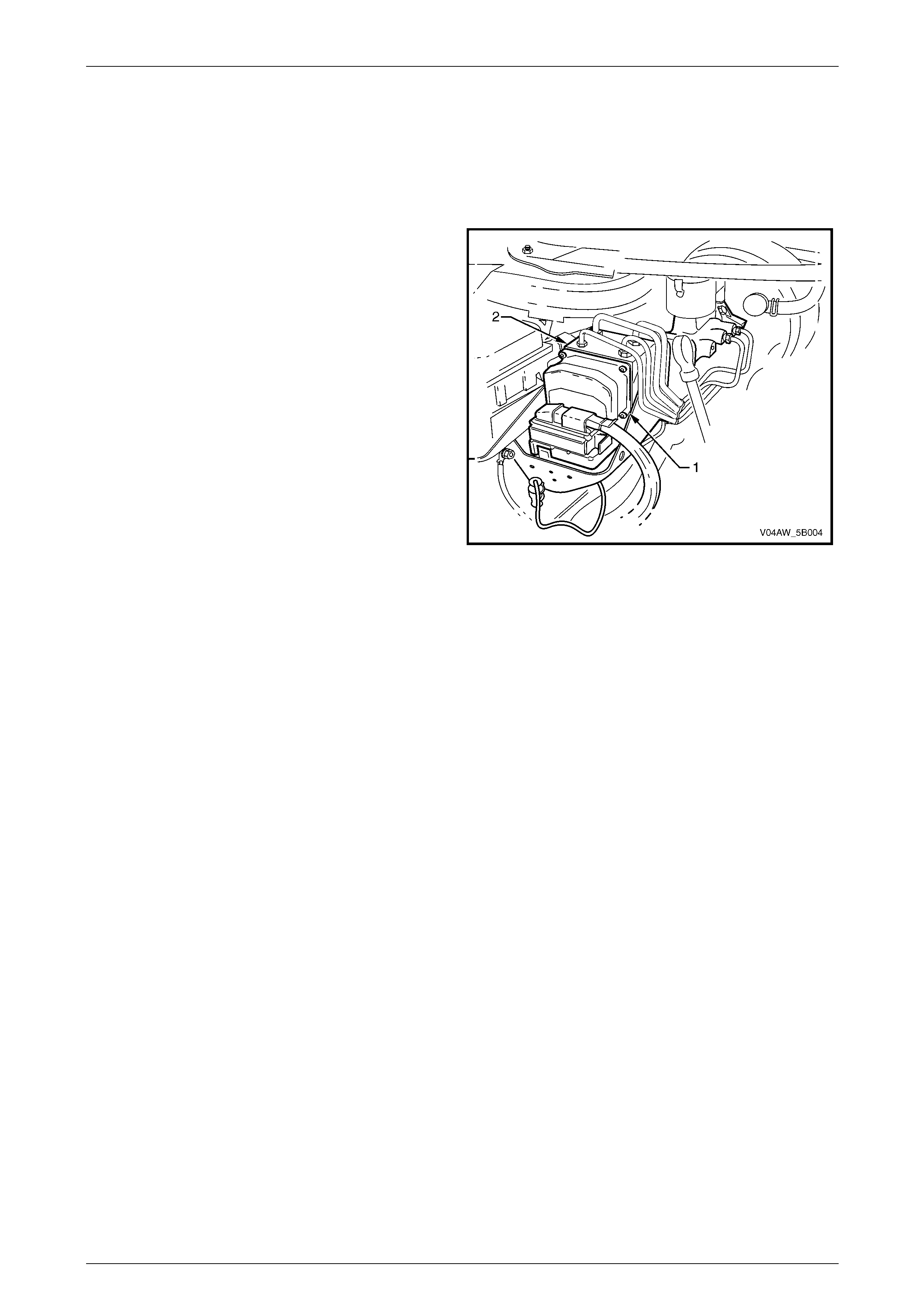

3.1 Electronic Control Unit (ECU)

The Electronic Control Unit (ECU) (1) is the control centre of

the ABS-TCS Braking System. It is integrated with the

hydraulic modulator (2) to form one assembly.

The ECU constantly monitors and evaluates input signals

from various sensors and switches. If it detects a wheel spin

or a wheel slip condition, the ECU switches to the following

Mode:

• ABS Mode – Refer to

2.2 Antilock Braking System (ABS).

• ABD Mode – Refer to

2.3 Automatic Brake Distribution (EBD) System.

• EBD Mode – Refer to

2.4 Electronic Brake-force Distribution (EBD) System.

Figure 5B – 18

ECU Self-test Initialisation Sequence

NOTE

If the ECU detects a fault in the ABS-TCS

Braking System, it takes the following action:

• The ECU will disable the ABS-TCS Braking

System.

• The ABS-TCS remains disabled until the next

ignition cycle.

• Illuminate the warning lamps.

• Sets a DTC.

NOTE

Conventional braking system is available while

the ABS-TCS is disabled.

The ECU performs one Self-test Initialisation Sequence for each ignition cycle. This Initialisation Sequence commences

when the vehicle reaches approximately 6 km/h.

During the Initialisation Sequence, the ECU sends a control signal to the hydraulic modulator to cycle each of the

solenoid valve as well as the pump motor for approximately 1.5 seconds to check for correct component operation. If the

pump or any solenoid valves fail to operate, the ECU will disable the ABS-TCS Braking System, illuminate the warning

lamp and sets a DTC.

NOTE

The Initialisation Sequence may be heard and

felt while it is taking place, which is considered

part of the normal system operation. Refer to,

2.2 Antilock Braking System (ABS).

In addition, as soon as the ECU receives a signal from any of the wheel speed sensors, it checks all the wheel speed

sensor outputs. If any of the wheel speed sensor signals are not detected, or are incorrect, the ECU will disable the

ABS-TCS Braking System, illuminate the warning lamps and sets a DTC.

AW D ABS-TCS Page 5B–26

Page 5B–26

Once the vehicle speed exceeds 6 km/h, the ECU continuously monitors the ABS-TCS by comparing the logical

sequence of input and output signals with the normal operating parameter stored in the ECU . If any of the input or

output signals are outside the normal operating parameters, the ECU will disable the ABS-TCS Braking System,

illuminate the warning lamps and set a DTC.

ECU Inputs

The ECU constantly monitors and evaluates the input signals from the following components:

• Wheel speed sensors.

• Stop lamp switch.

• Longitudinal accelerometer sensor.

• Ignition ON input.

• Battery voltage.

• Engine speed signal.

• Serial data (input and output).

ECU Output s

Based on the inputs received, the ECU sends output signals to the following ABS-TCS components:

• ABS warning lamp.

• Multifunction Display (MFD) ABS icon, ABS fault, low traction and trac off display.

• Class 2 serial data.

• Diagnostic link.

• hydraulic modulator solenoid valves.

• hydraulic modulator pump motor.

AW D ABS-TCS Page 5B–27

Page 5B–27

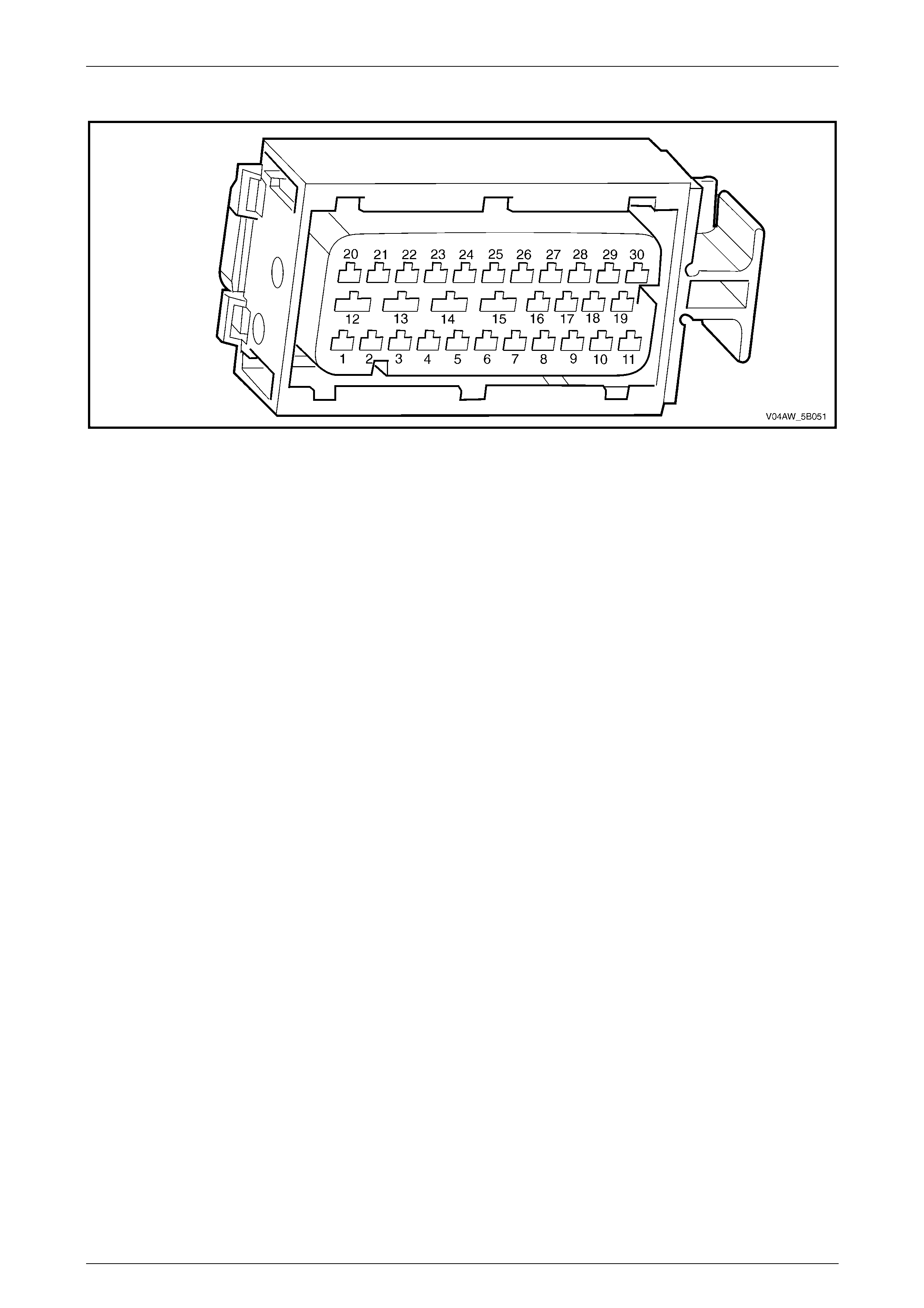

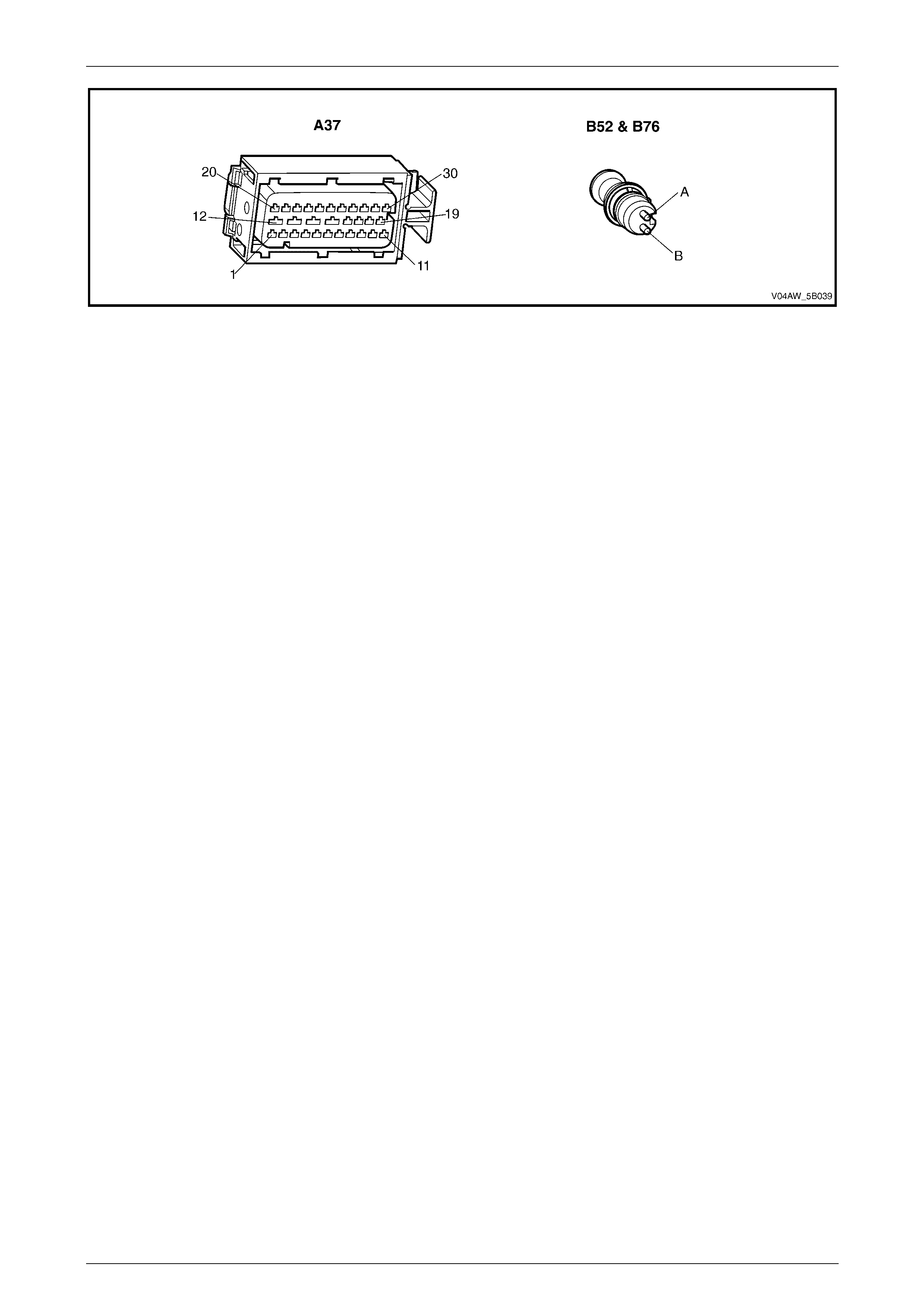

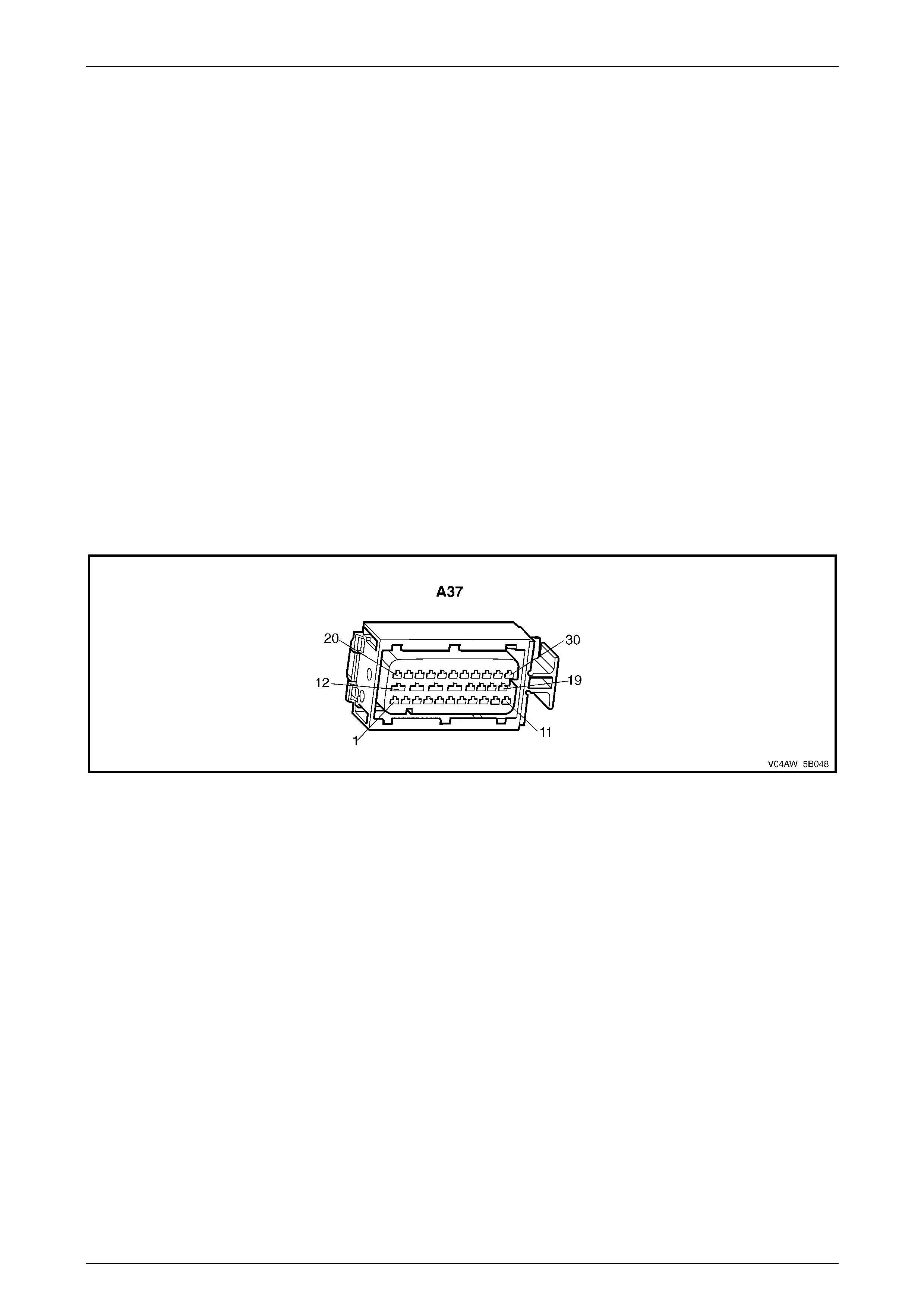

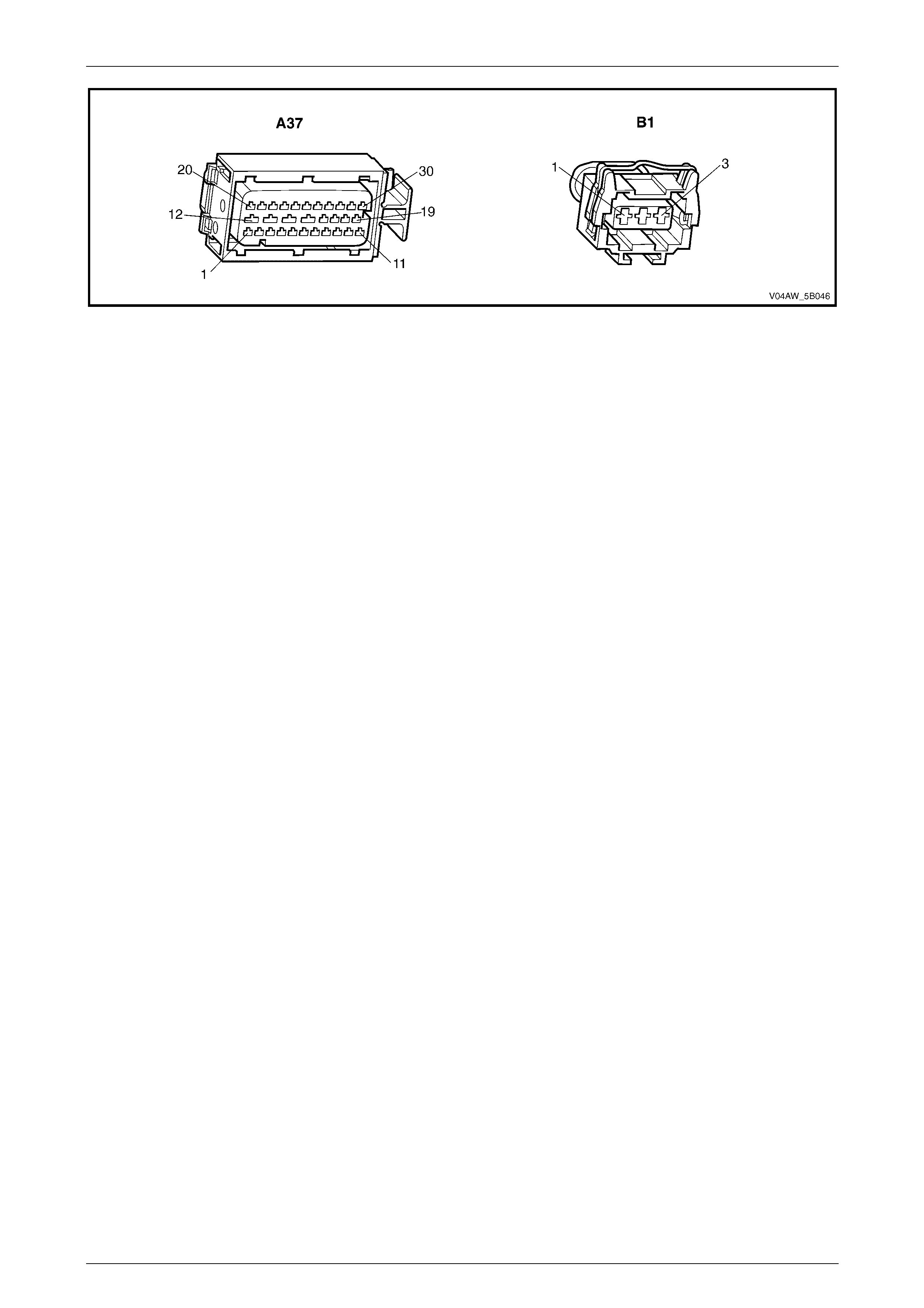

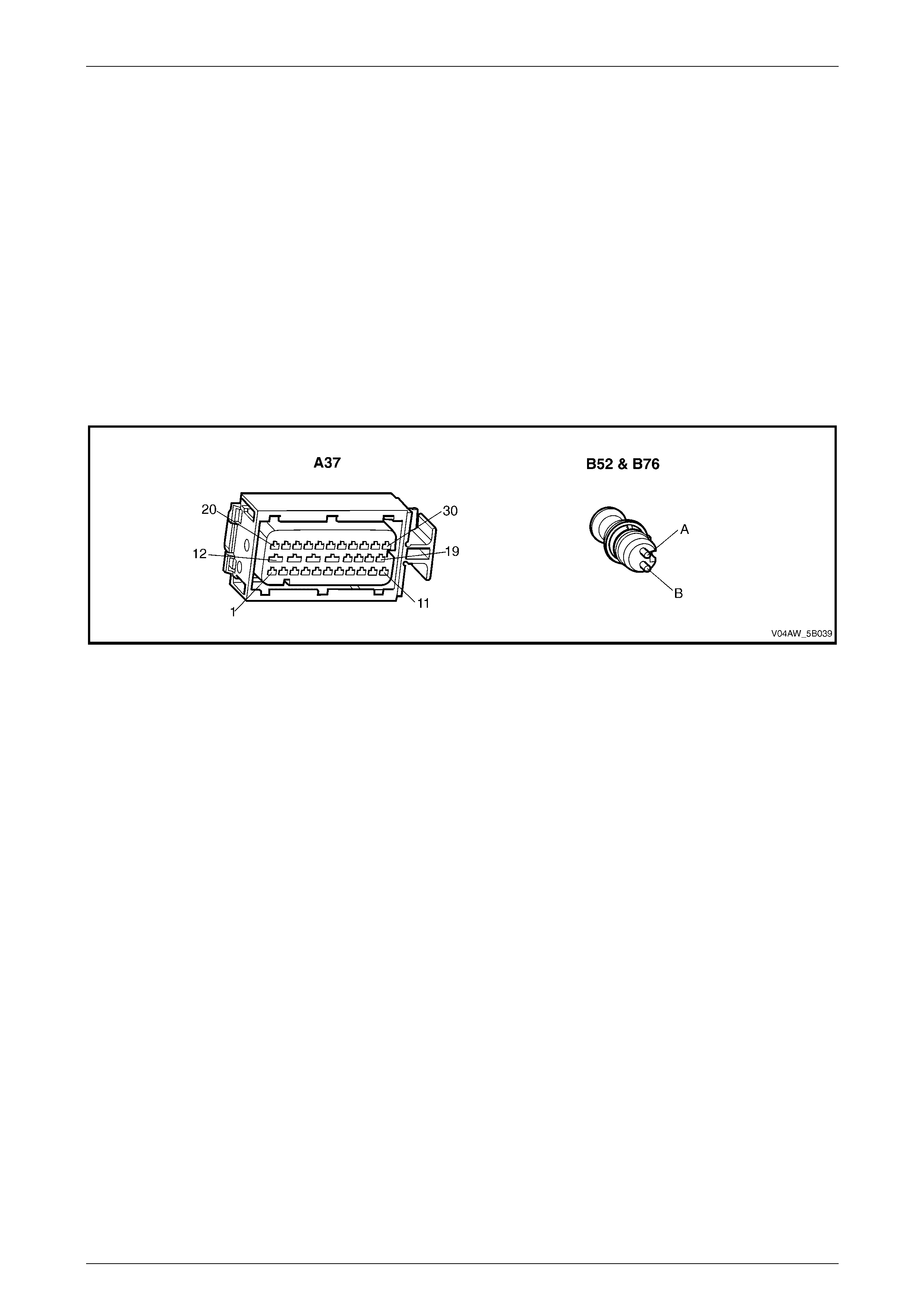

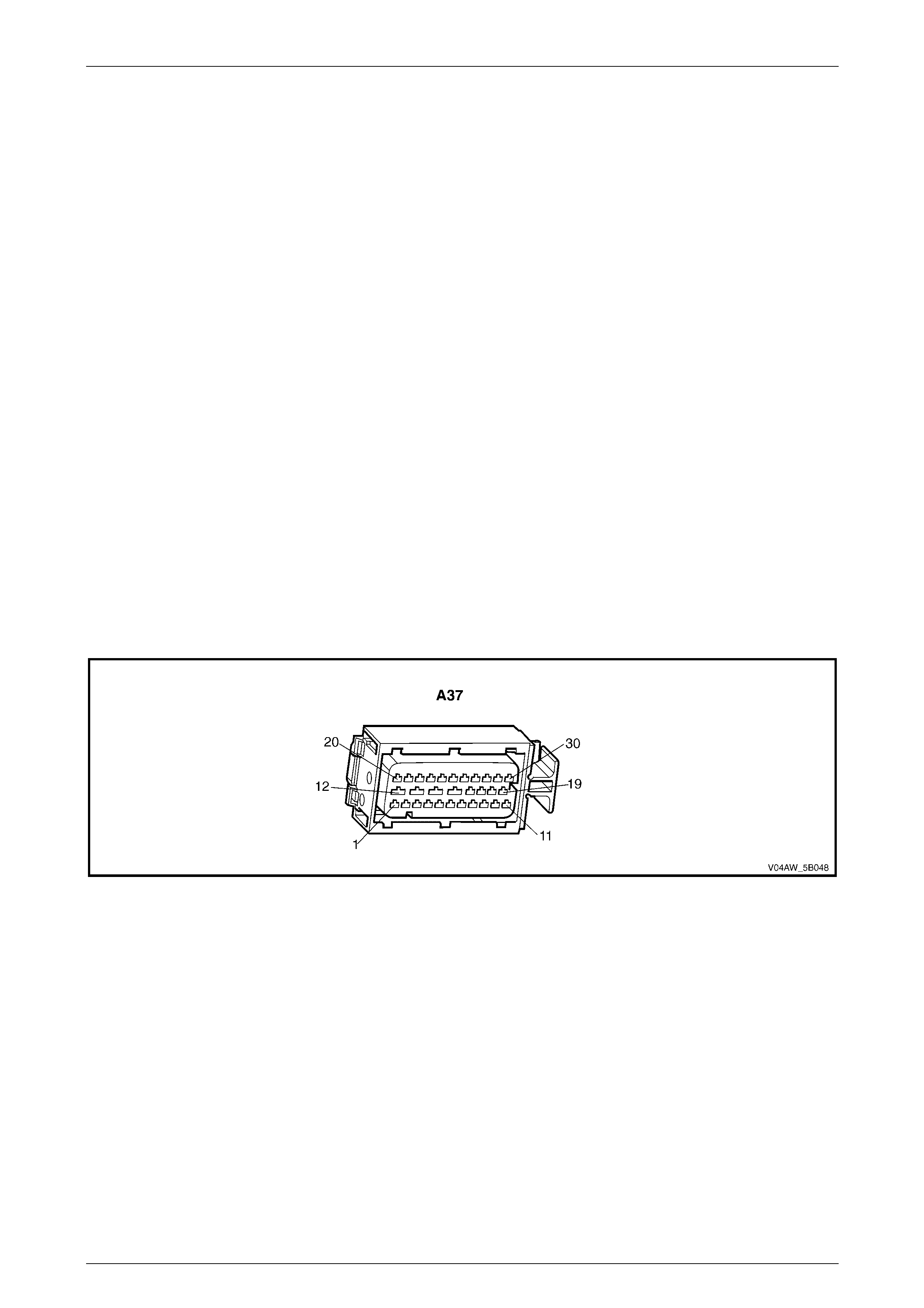

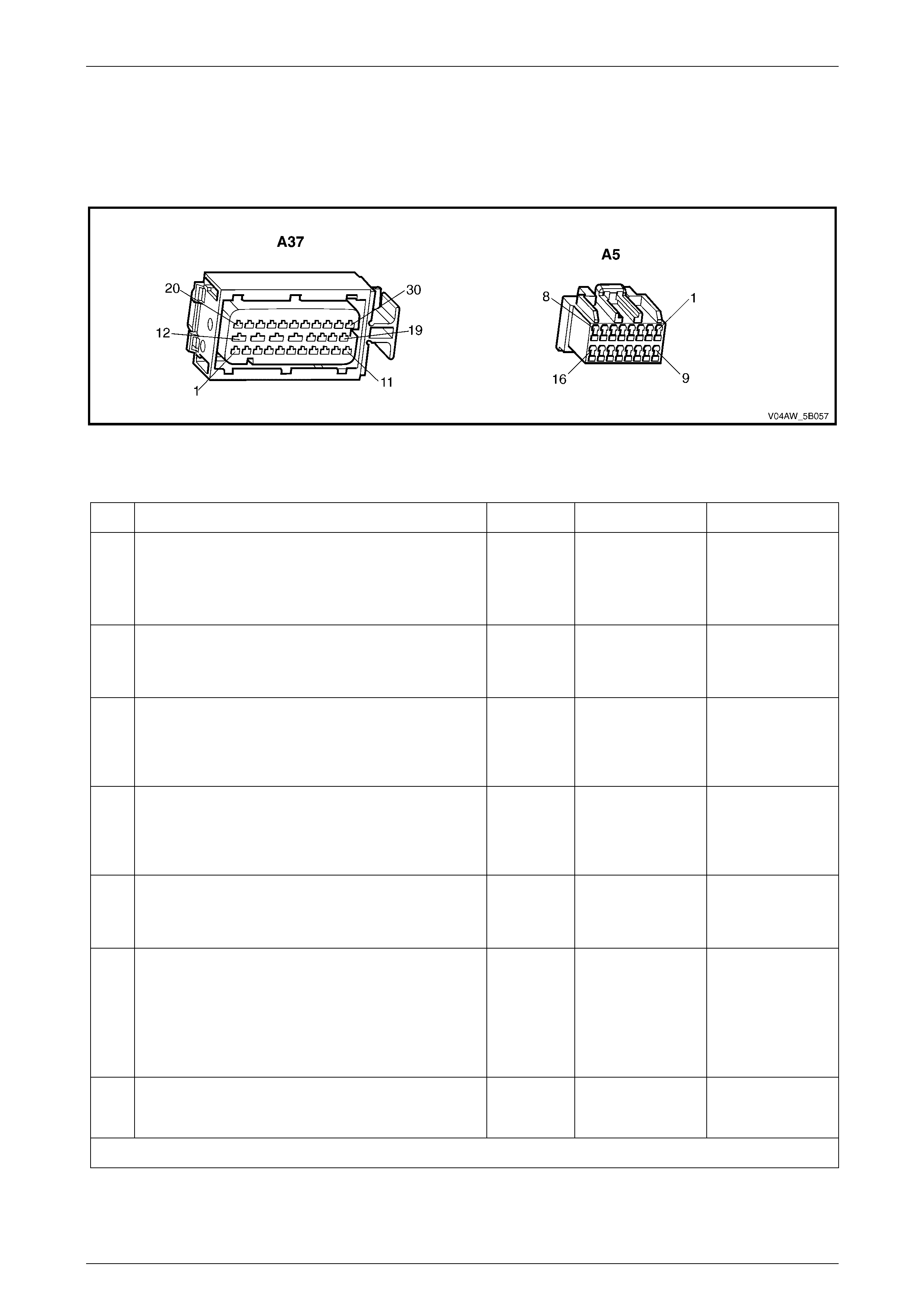

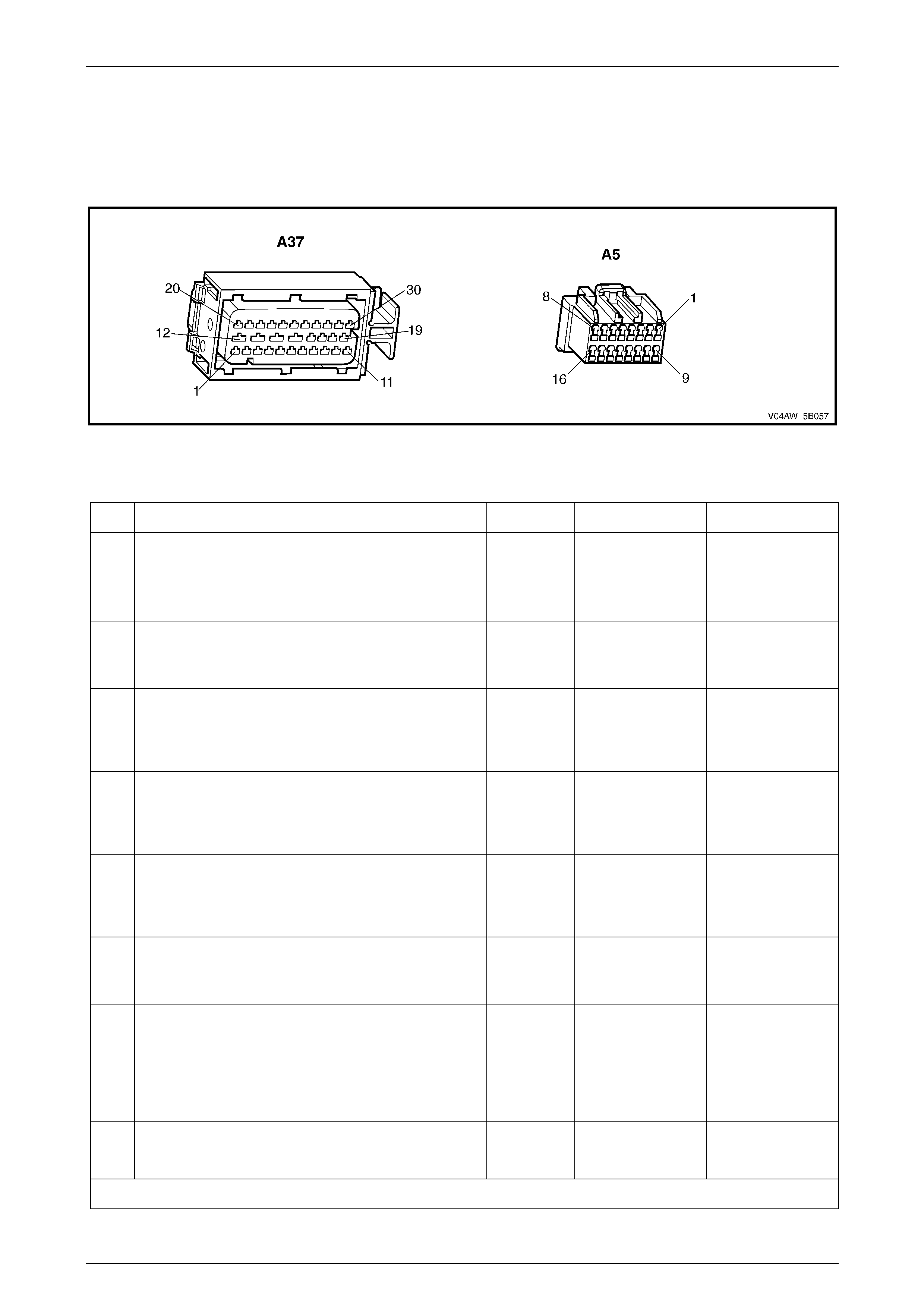

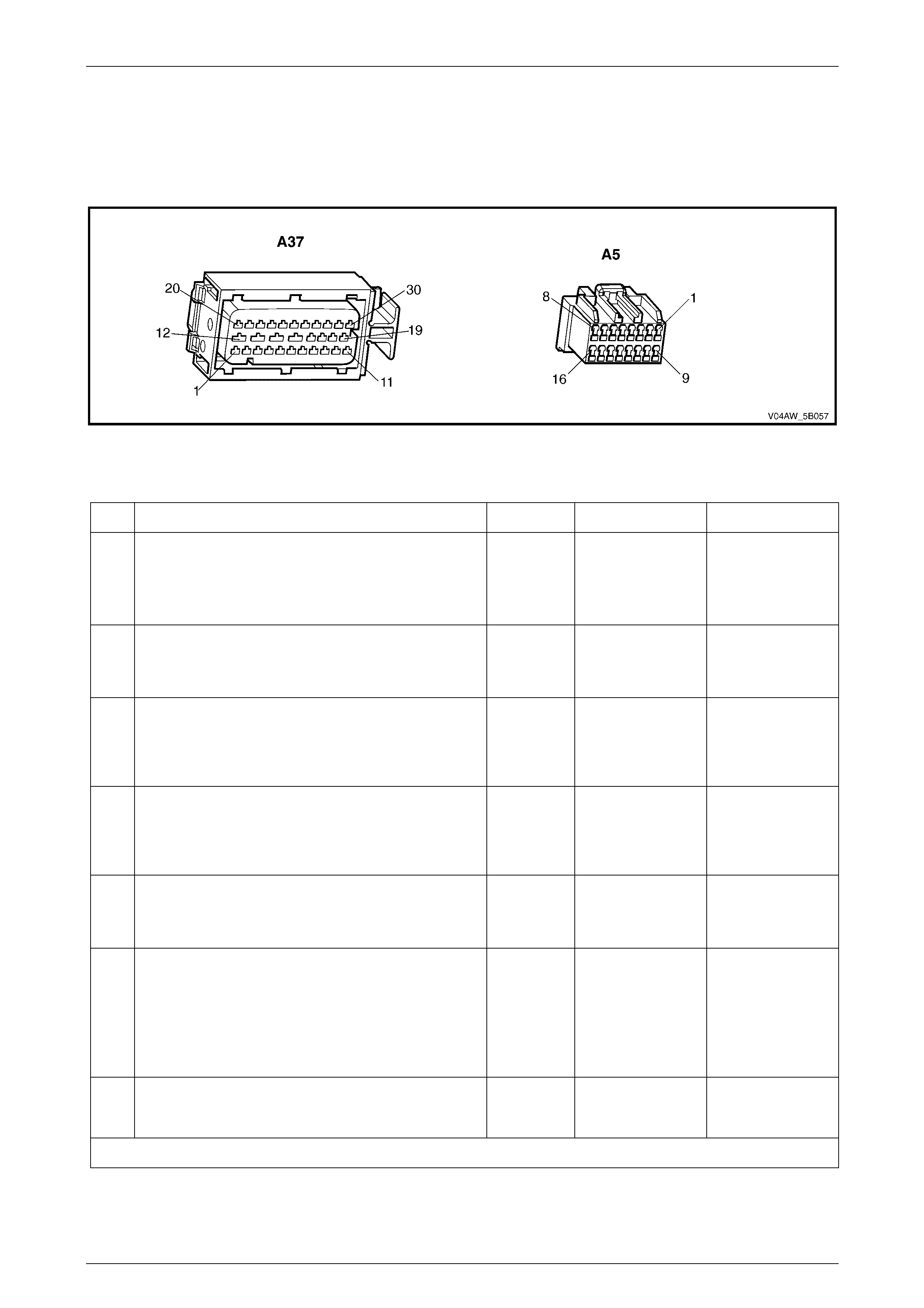

ECU Wiring Connector Terminal Assignment

Figure 5B – 19

ECU Wiring Connector Terminal Assignment Legend

1 Rear Right Wheel Speed Sensor – Signal Circ ui t 882 16 Not Used

2 Rear Right Wheel Speed Sensor – Low Ref. Ci rcuit 883 17 Not Used

3 Not Used 18 Longitudinal A ccelerometer – Low Referenc e Ci rcuit 1337

4 Front Right Wheel Speed Sensor – Signal Ci rcuit 872 19 Not Used

5 Front Right Wheel Speed Sensor – Low Ref. Circui t 833 20 Front Left Wheel Speed Sensor – Signal Ci rcuit 830

6 Stop Light Switch – 12 volt s Signal Ci rcuit 20 21 Front Left Wheel Speed Sensor – Low Ref. Circ ui t 873

7 Not Used 22 Rear Left Wheel Speed Sens or – S i gnal Ci rcuit 884

8 12 volts Ignition Supply Volt age – Igniti on Ci rcuit 839 23 Rear Left Wheel Speed Sens or – Low Ref. Ci rcuit 885

9 Not Used 24 Not Used

10 Longitudinal A ccelerometer – Signal Circuit 716 25 Class 2 Serial Data Bus Circ ui t 1045

11 Not Used 26 Not Used

12 Relays, Valves and Pu mp Motor – Main Ground Circuit 350 27 Not Used

13 12 volts Uni nterrupted Suppl y V ol tage – Fuse 103 Circuit

542 28 Longitudinal A ccelerometer – 5 vol ts Ref erence Circuit 1337

14 12 volts Uni nterrupted Suppl y V ol tage – Fuse 36 Circuit

1440 29 Not Used

15 Ground – ECU Ground Circui t 150 30 Not Used

AW D ABS-TCS Page 5B–28

Page 5B–28

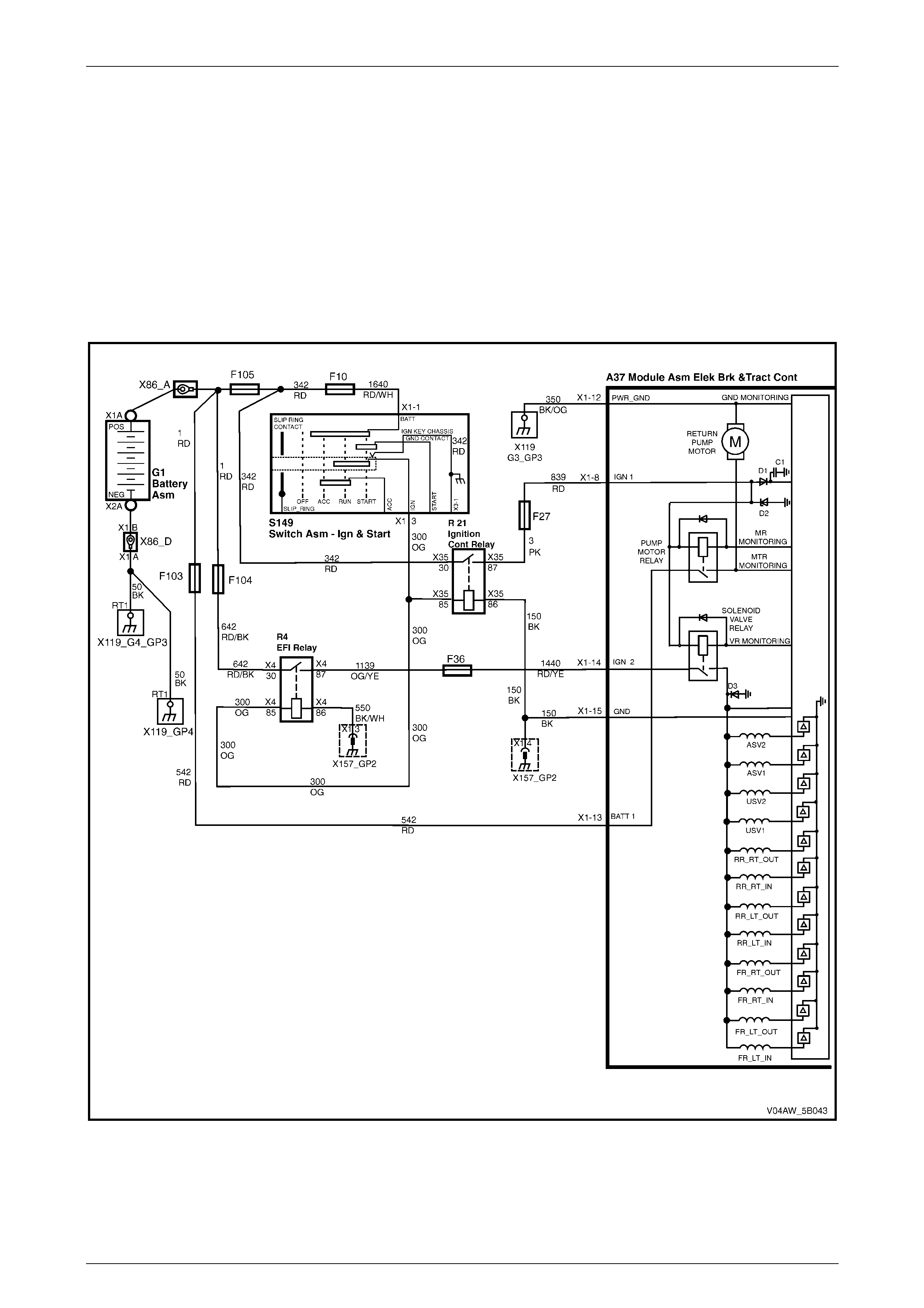

ECU Wiring Diagram

Figure 5B – 20

AW D ABS-TCS Page 5B–29

Page 5B–29

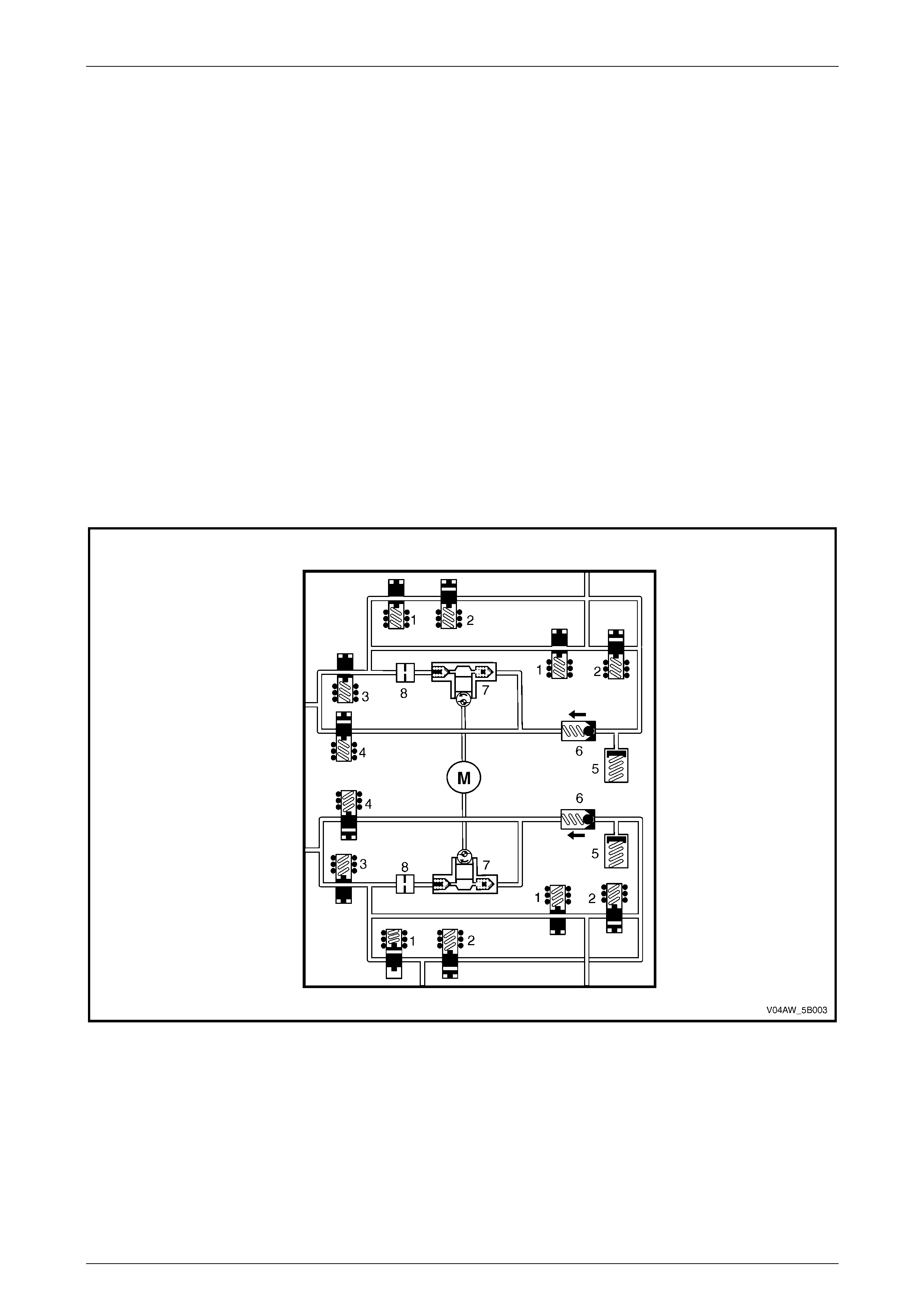

3.2 Hydraulic Modulator

The Hydraulic Modulator modulates the brake fluid pressure based on the control signal sent by the Electronic Control

Unit (ECU).

To allow individual control of each wheel brake fluid circuit, a four-channel circuit configuration with a front/rear split has

been used. Each of the brake fluid circuits is hydraulically isolated, which enables continued braking ability if a leak

develops in any of the brake fluid circuits. The internal components of the hydraulic modulator consist of the following:

(refer to Figure 5B – 21)

• Four inlet solenoid valves (1).

• Four outlet solenoid valves (2).

• Two isolating solenoid valves (3).

• Two priming solenoid valves (4).

• Two accumulators (5).

• Two one-way valves (6).

• Two hydraulic pumps (7).

• Two dampers (8).

• Pump motor (M)

Figure 5B – 21

AW D ABS-TCS Page 5B–30

Page 5B–30

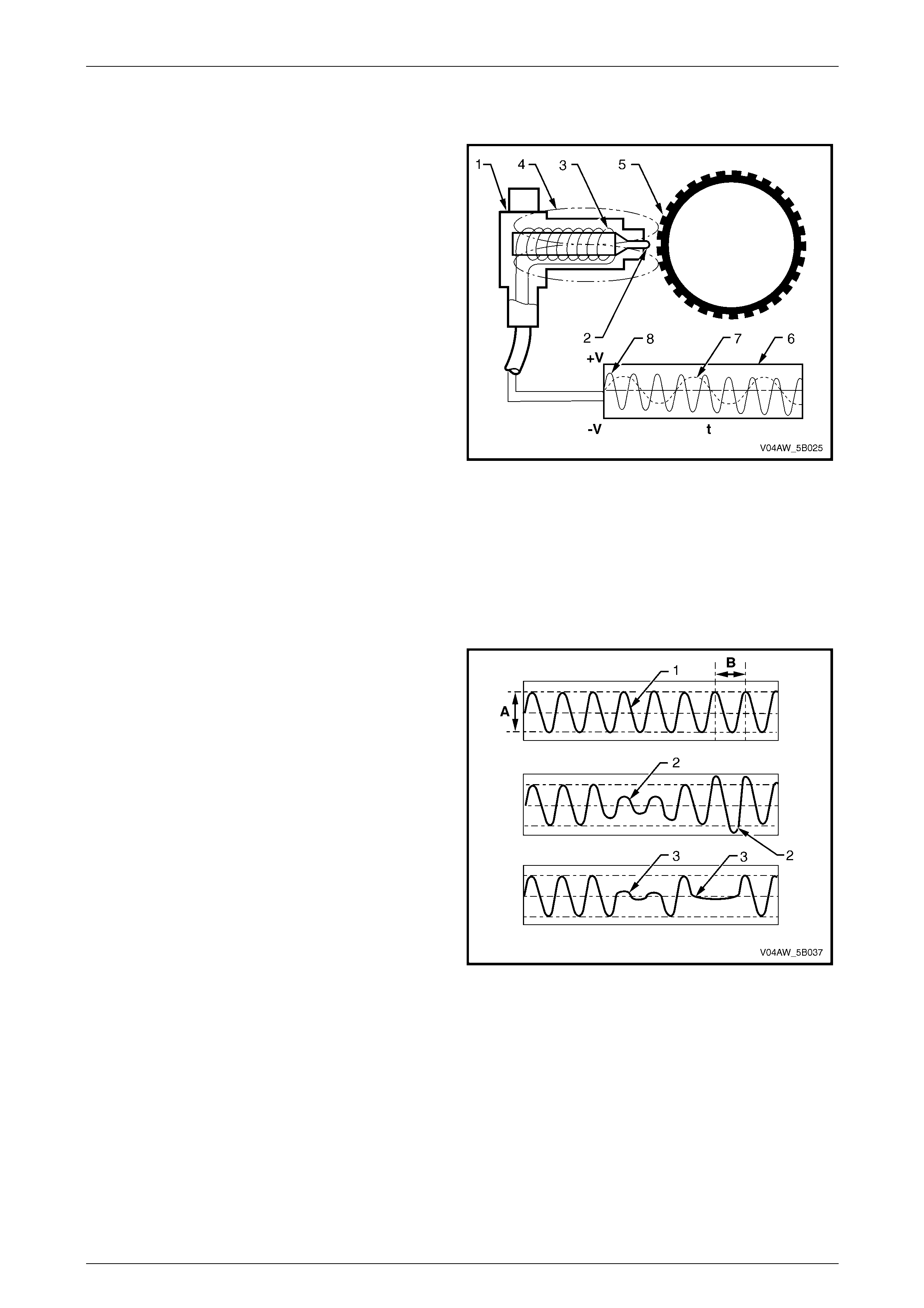

3.3 Wheel Speed Sensors

The front and rear wheel speed sensors (1) consist of a

pole pin (2) surrounded with a coil winding (3). The pole pin

tip is positioned pointing to the pulse ring (5) and is

attached to a permanent magnet that projects a magnetic

field (4) towards the pulse ring.

As the wheel turns, the teeth of the pulse ring induces

changes in the magnetic field of the pole pin and the coil

winding. The magnetic flux thereby changes and an

alternating voltage (6) is induced in the coil of the wheel

speed sensor.

The number of turns of the coil, the magnetisation level of

the pole pin and the number of pulse ring teeth are constant

and the only variable is the wheel RPM. Therefore, the

frequency and amplitude of the output signal depend on the

speed of wheel rotation.

The dotted line (7) represents the voltage generated by the

wheel speed sensor versus time (t) at low wheel speed.

The continuous line (8) represents the voltage generated by

the wheel speed sensor versus time (t) at high wheel

speed.

Figure 5B – 22

Testing Wheel Speed Sensor Using an Oscilloscope

Using an oscilloscope to display the output signal voltage of a suspected wheel speed sensor will enable the service

technician to graphically view a pulse ring related wheel speed sensor fault condition that may be difficult to detect

otherwise.

A normal wheel speed sensor signal produces a sine wave

with the height of the amplitude (A) and the width of the

frequency (B) proportional to the wheel speed.

If the pulse ring is out of round or if it is incorrectly aligned

with the wheel speed sensor, the air gap between the wheel

speed sensor and the pulse ring will vary as the wheel

rotates. This fault condition will produce a wheel speed

sensor signal with varying amplitude (2).

If the pulse ring teeth are missing or damaged, the

oscilloscope sine wave pattern will display flat spots (3) that

represent the missing or damaged pulse ring teeth.

Figure 5B – 23

AW D ABS-TCS Page 5B–31

Page 5B–31

Wheel Speed Sensor Wiring Connect or

Legend

1 Wheel Sensor Wiri ng Connector

A Wheel Sensor Signal Ci rcuit

B Wheel Sensor Low Reference Circ ui t

Figure 5B – 24

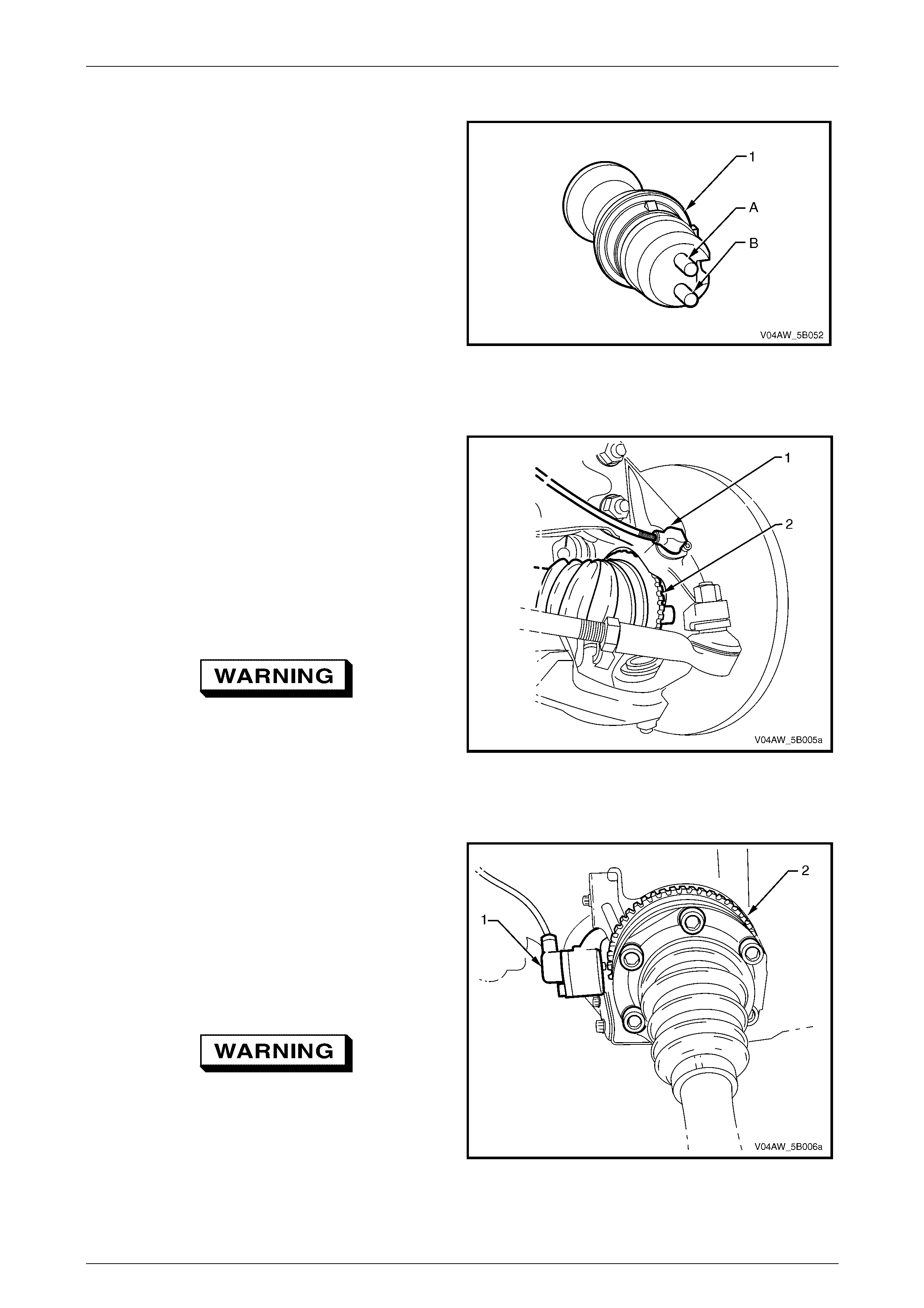

Front Wheel Speed Sensor

The front wheel speed sensor (1) in conjunction with a

pulse ring (2) generates an AC signal voltage. The

amplitude and frequency of the signal generated is

proportional to the wheel speed.

Signals generated by the front wheel speed sensor are

transmitted to the Electronic Control Unit (ECU). The ECU

uses this signal voltage to determine the rotational speed of

the front wheels.

The front wheel speed sensor pulse ring is a part of the

front driveshaft constant velocity joint assembly and is not

serviced separately. Refer to Section 4B2 Final Drive.

If the front constant velocity joint requires

replacement, the correct replacement part

must be installed. Otherwise, ABS-TCS

malfunction will occur. Figure 5B – 25

Rear Wheel Speed Sensors

The rear wheel speed sensor (1) in conjunction with a pulse

ring (2) generates an AC signal voltage. The amplitude and

frequency of the signal generated is proportional to the

wheel speed.

Signals generated by the rear wheel speed sensor are

transmitted to the ECU. The ECU uses this signal voltage to

determine the rotational speed of the front wheels.

The rear wheel speed sensor pulse ring is part of the final

drive inner axle flanges and is not serviced separately.

If the final drive inner axle flange requires

replacement, the correct replacement part

must be installed. Otherwise, ABS-TCS

malfunction will occur.

Figure 5B – 26

AW D ABS-TCS Page 5B–32

Page 5B–32

3.4 Longitudinal Accelerometer

The longitudinal accelerometer consists of differential

capacitors connected to the fixed side plates (1) and a

sprung mass (2) that moves in response to vehicle

acceleration (C).

When the vehicle is stationary (A), the distance between

the sprung mass and the two side plates are equal.

Therefore, the capacitance between the two capacitors are

the same and the longitudinal accelerometer signal voltage

is zero.

As the vehicle accelerates (B), the sprung mass moves

rearward (D). The capacitance between the two capacitors

changes causing the longitudinal accelerometer to produce

a signal voltage with an amplitude proportional to the

movement of the sprung mass.

The signal voltage from the accelerometer is proportional to

the vehicle level of acceleration or deceleration.

Figure 5B – 27

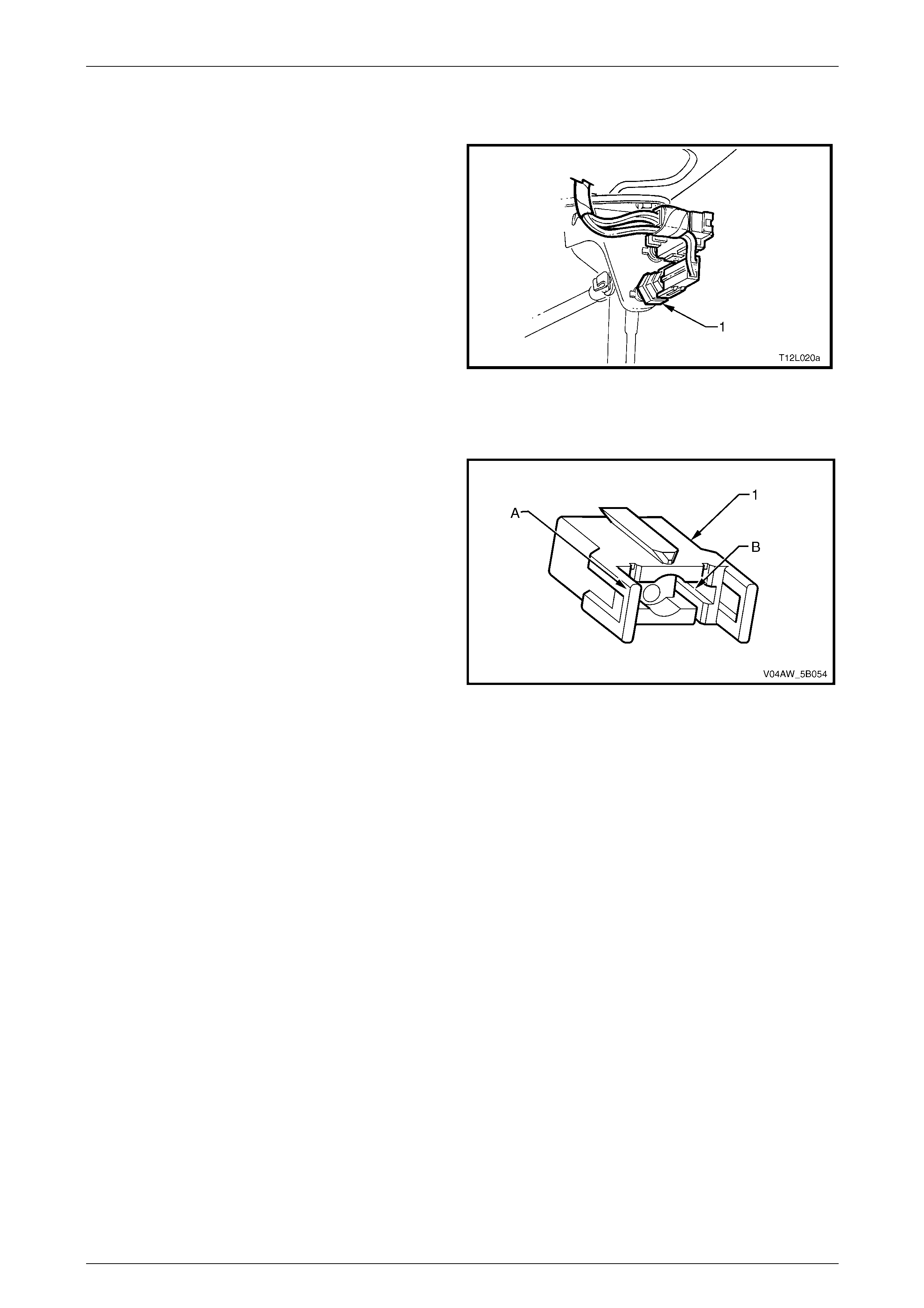

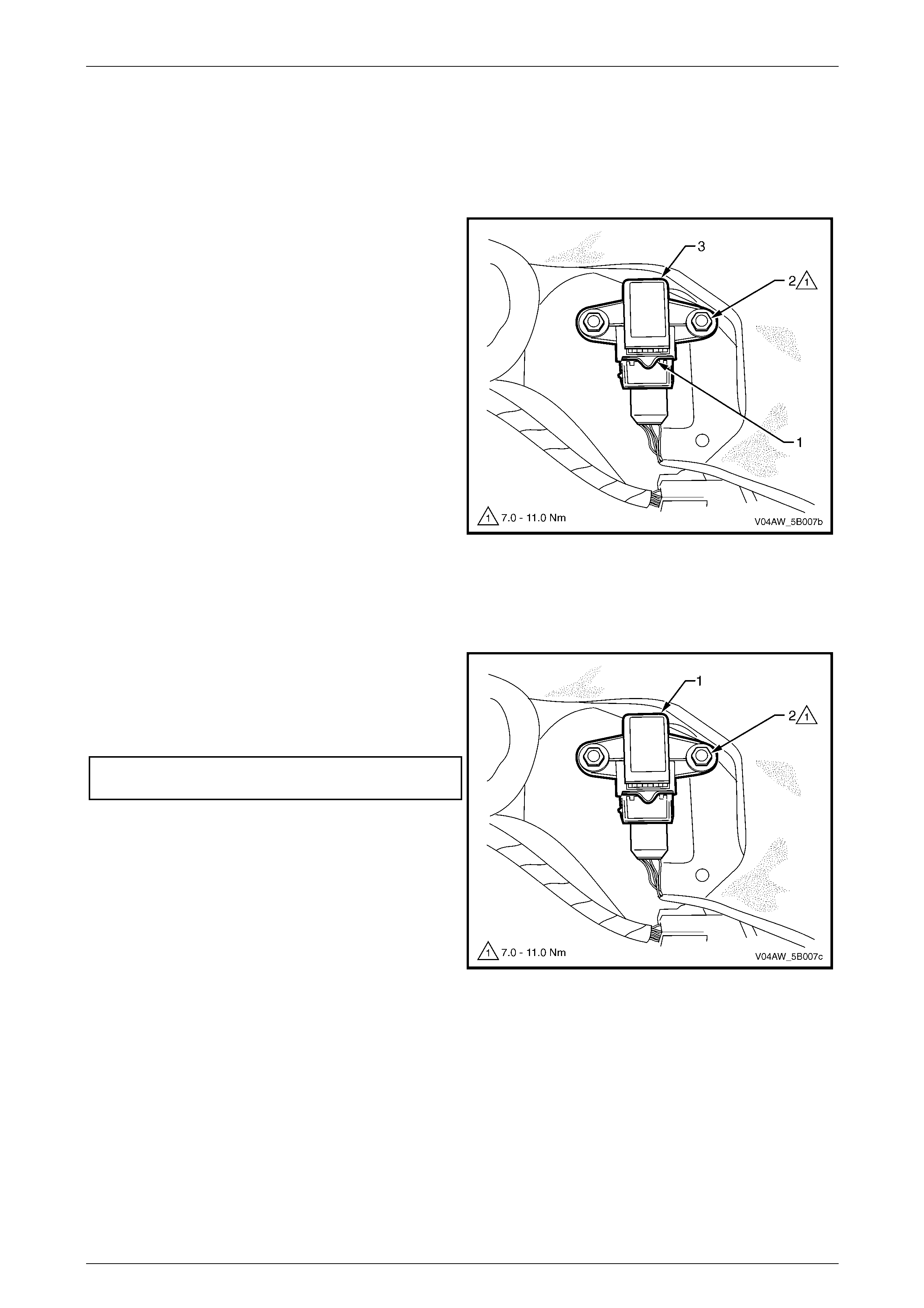

The Longitudinal Accelerometer (1) sends signal voltage,

which the ECU uses to determine the rate of vehicle

acceleration or deceleration. In addition, the longitudinal

accelerometer supports the calculation of the actual vehicle

speed when all four wheels are slipping.

In addition, the ECU monitors and evaluates the longitudinal

accelerometer signal voltage along with the wheel speed

sensor signal voltage to determine the uphill or downhill

gradient.

The longitudinal accelerometer aids the ECU to correctly

identify different driving situations and conditions to

enhance the vehicle's stability, steering control and traction

control.

Figure 5B – 28

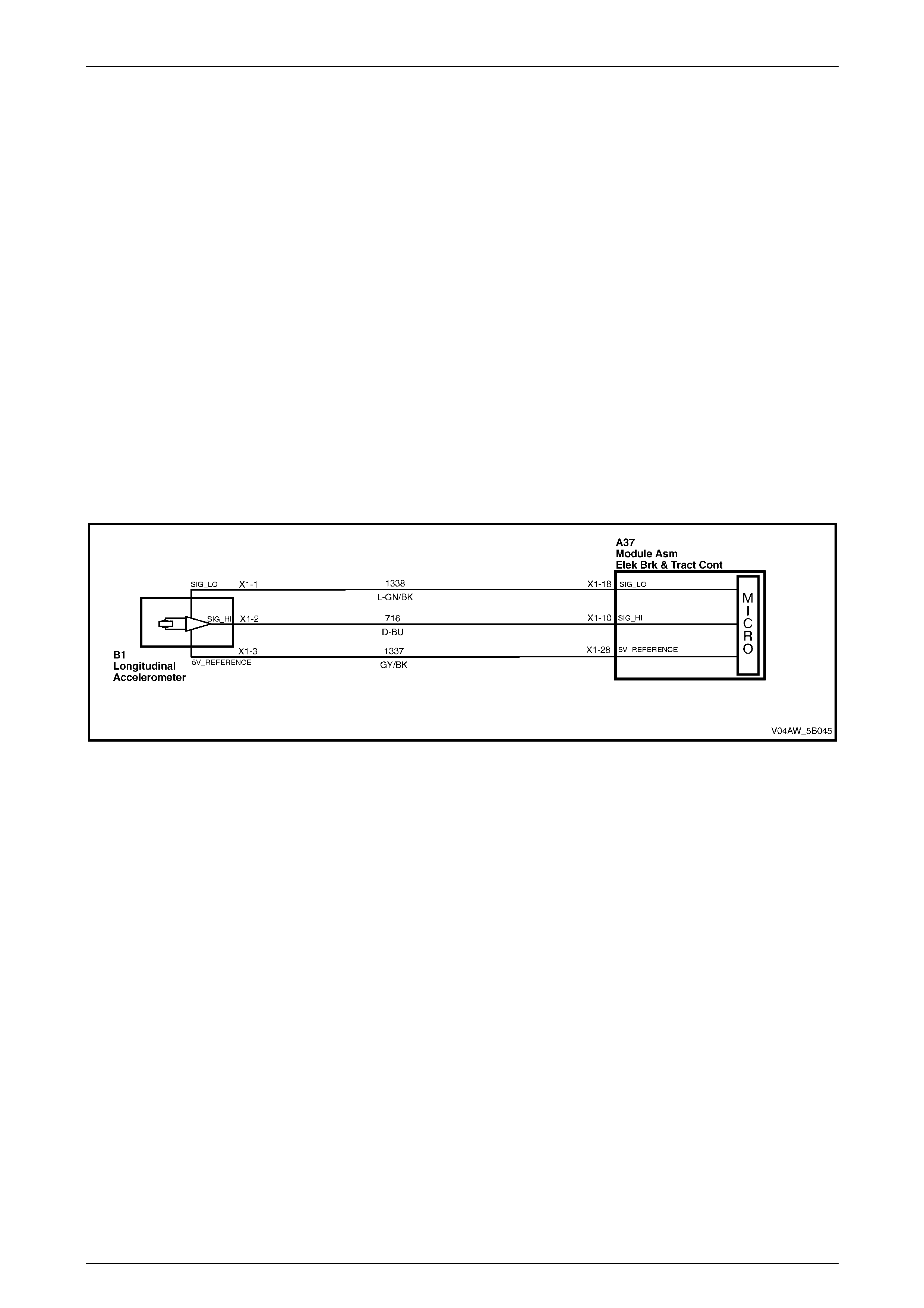

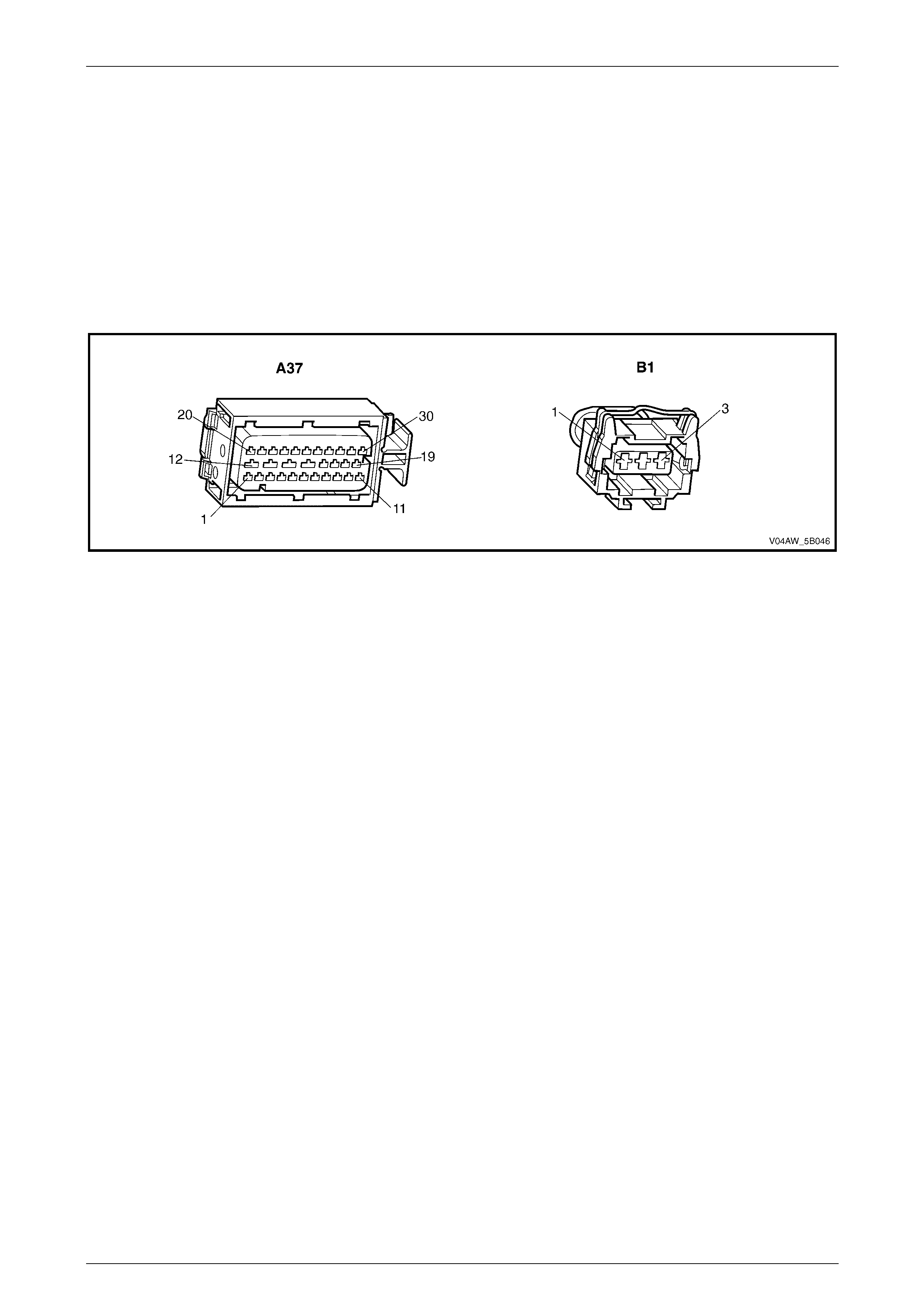

Longitudinal Accelerometer Wiring Connector

Legend

1 Longitudinal A ccelerometer Low Referenc e Ci rcuit 1338

2 Longitudinal A ccelerometer Signal Circ ui t 716

3 Longitudinal A ccelerometer 5 Volts Reference Circuit 1337

Figure 5B – 29

AW D ABS-TCS Page 5B–33

Page 5B–33

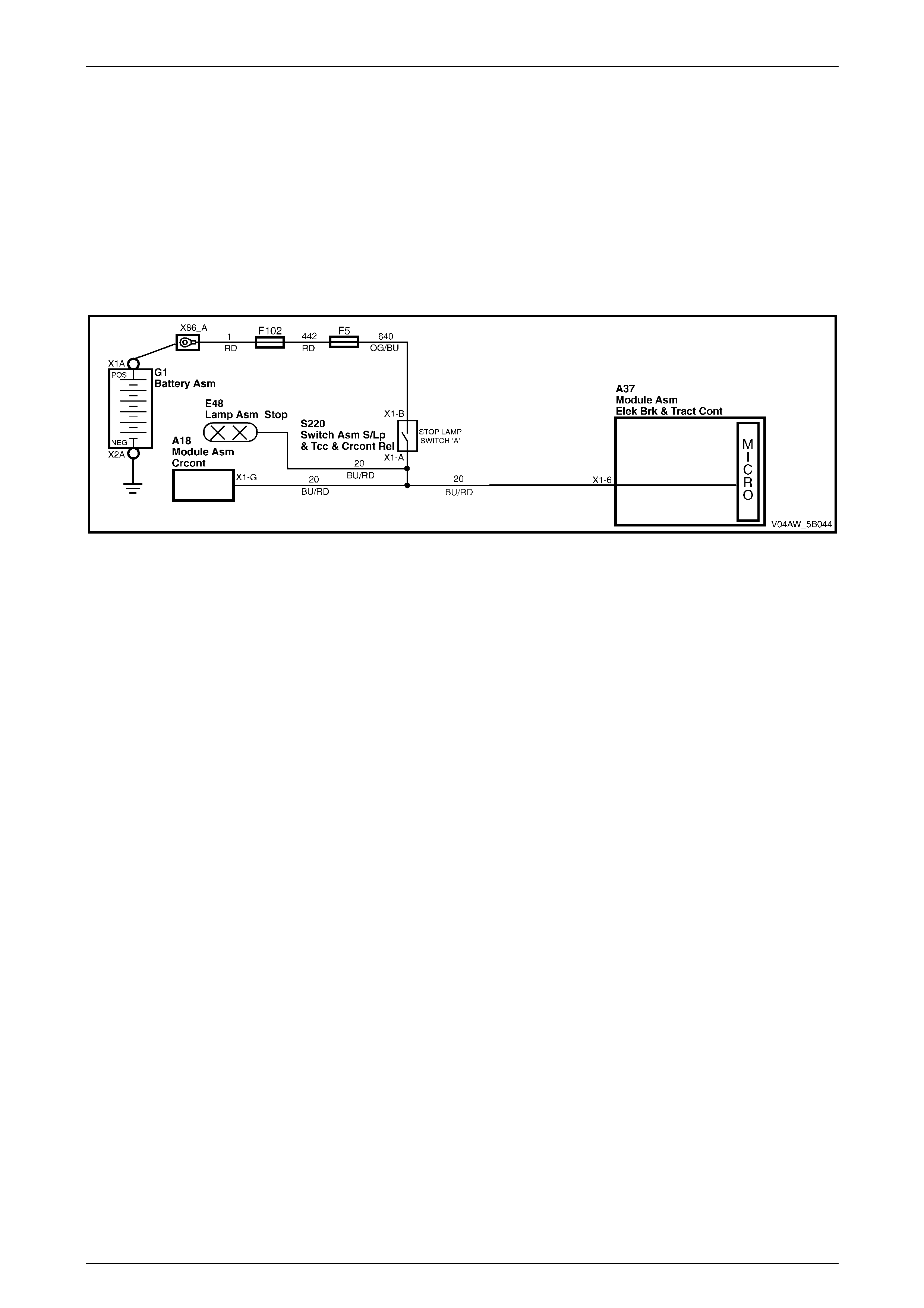

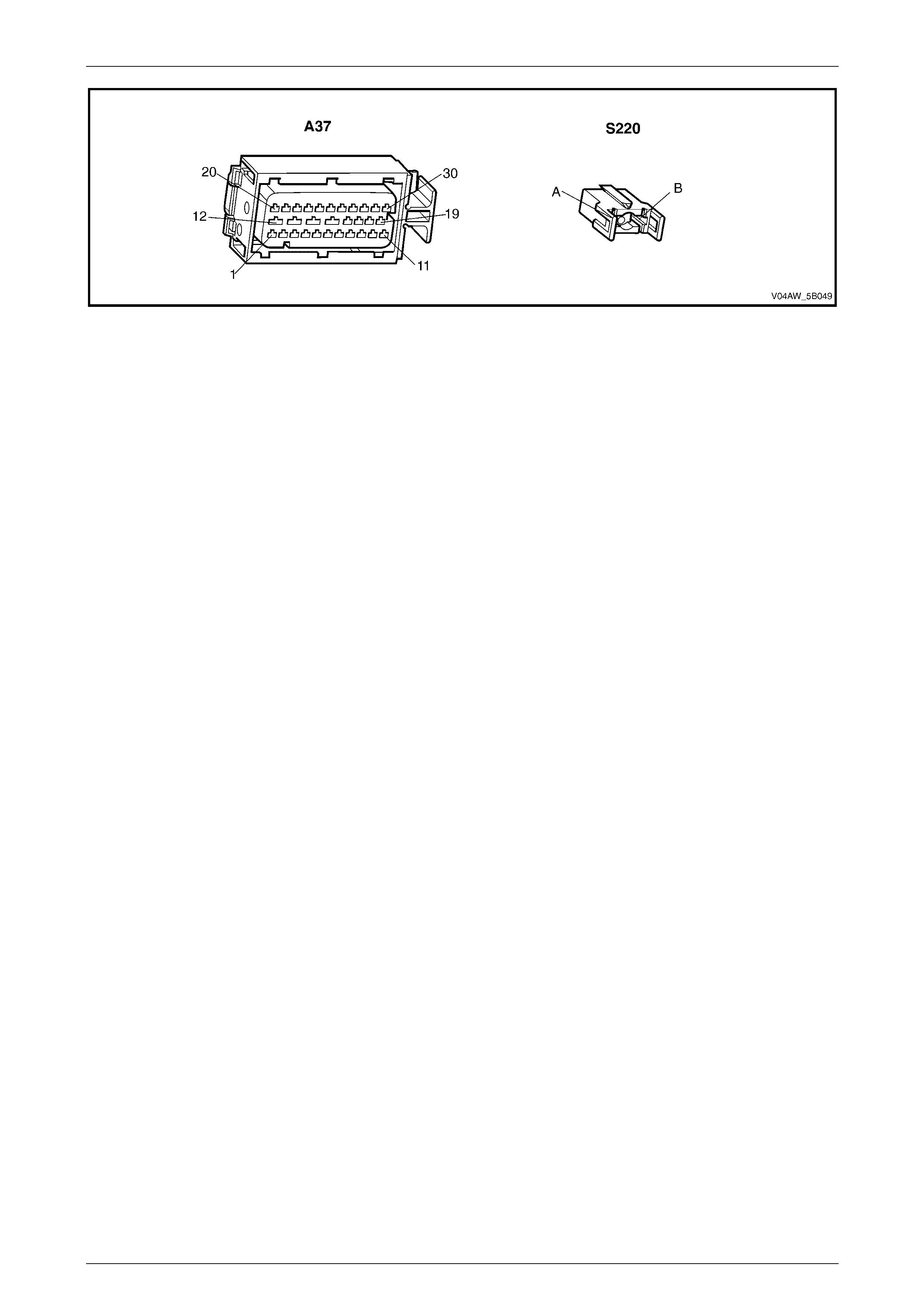

3.5 Stop Lamp Switch-A

The stop lamp switch A (1) is a normally open switch that

closes when the brake pedal is depressed.

The ECU uses the stop lamp switch signal voltage to

determine when the brakes pedal is depressed.

For stop lamp switch service operations, refer to

Section 12B Lighting System.

Figure 5B – 30

Stop Lamp Switch-A Wi ri ng Connect or

Legend

1 Stop Lamp Switch-A Wiri ng Connector

A Stop Lamp Switch Signal Vol tage Circuit 20

B Stop Lamp Switch Supply – Fuse F5 Circuit 640

Figure 5B – 31

AW D ABS-TCS Page 5B–34

Page 5B–34

3.6 AWD ABS – TCS Warning Display

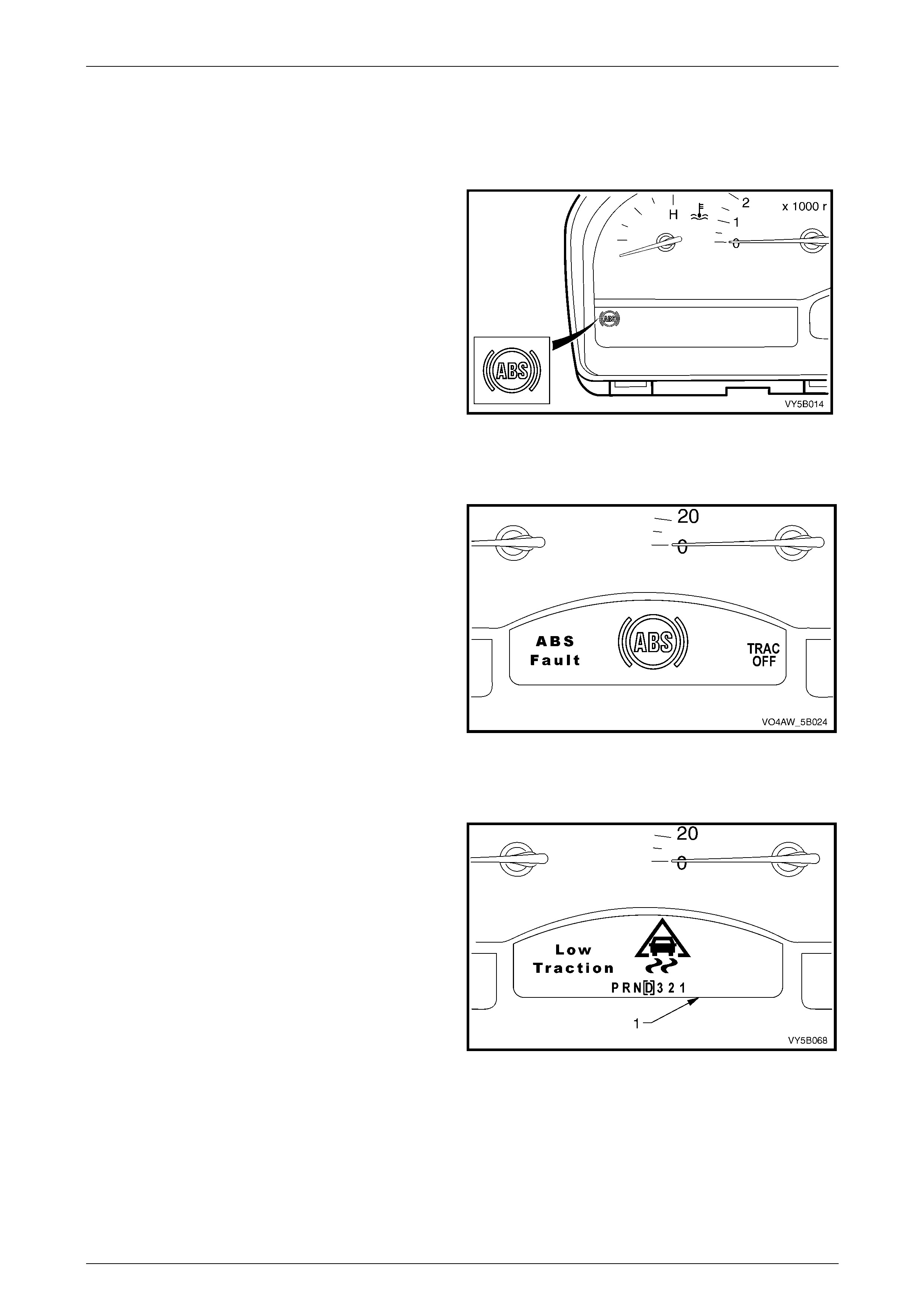

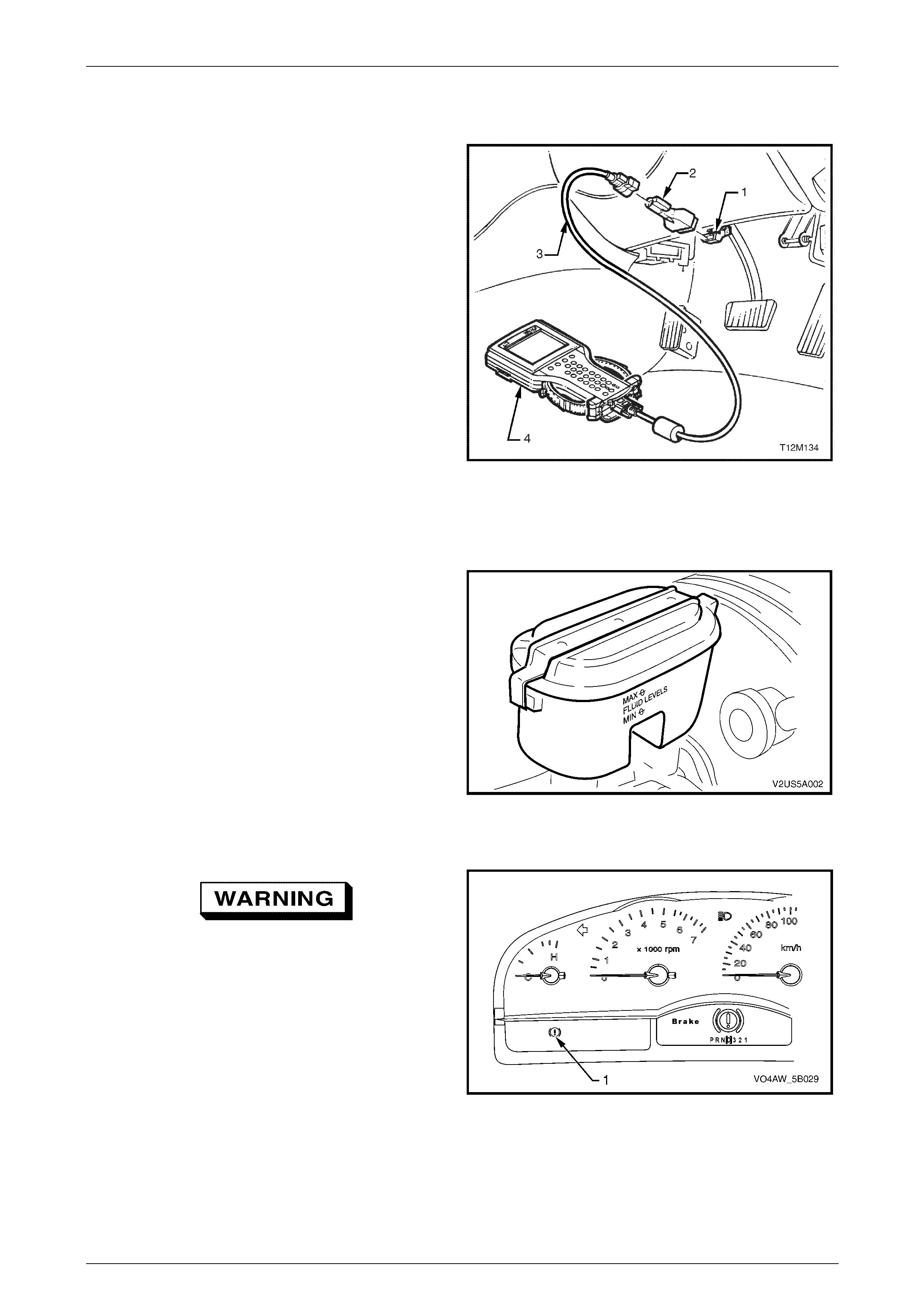

ABS Warning Lamp

The ABS wa rning lamp is located in the instrument cluster

and is a part of the driver warning system.

When the ignition is switched on, the ECU performs self-

test and the ABS warning lamp illuminates. The ABS lamp

should go out after the self-test or approximately 2 seconds.

If the ECU detects a fault in the ABS, the ABS lamp will stay

illuminated to warn the driver of the ABS fault.

Refer to Section 12C Instruments for further information on

the ABS warning lamp operation and diagnostic procedure.

Figure 5B – 32

ABS Fault / Trac Of f Warning Displ ay

If the ECU detects a fault in ABS, ABD or EBD System, the

ABS Fault, ABS Icon and TRAC OFF warning display

activates to warn the driver that ABS, ABD and EBD System

have been disabled. Refer to Section 12C, Instruments for

further information on the ABS Fault / Trac Off warning

display operation and diagnostic procedure.

Figure 5B – 33

Low Traction Warning Di spl ay

If the ECU detects a wheel spin condition and the brakes

are not applied, it switches to ABD Mode and activates the

LOW TRAC warning display to warn the driver of the

situation. Refer to Section 12C Instruments for further

information on the Low Traction warning display operation

and diagnostic procedure.

Figure 5B – 34

AW D ABS-TCS Page 5B–35

Page 5B–35

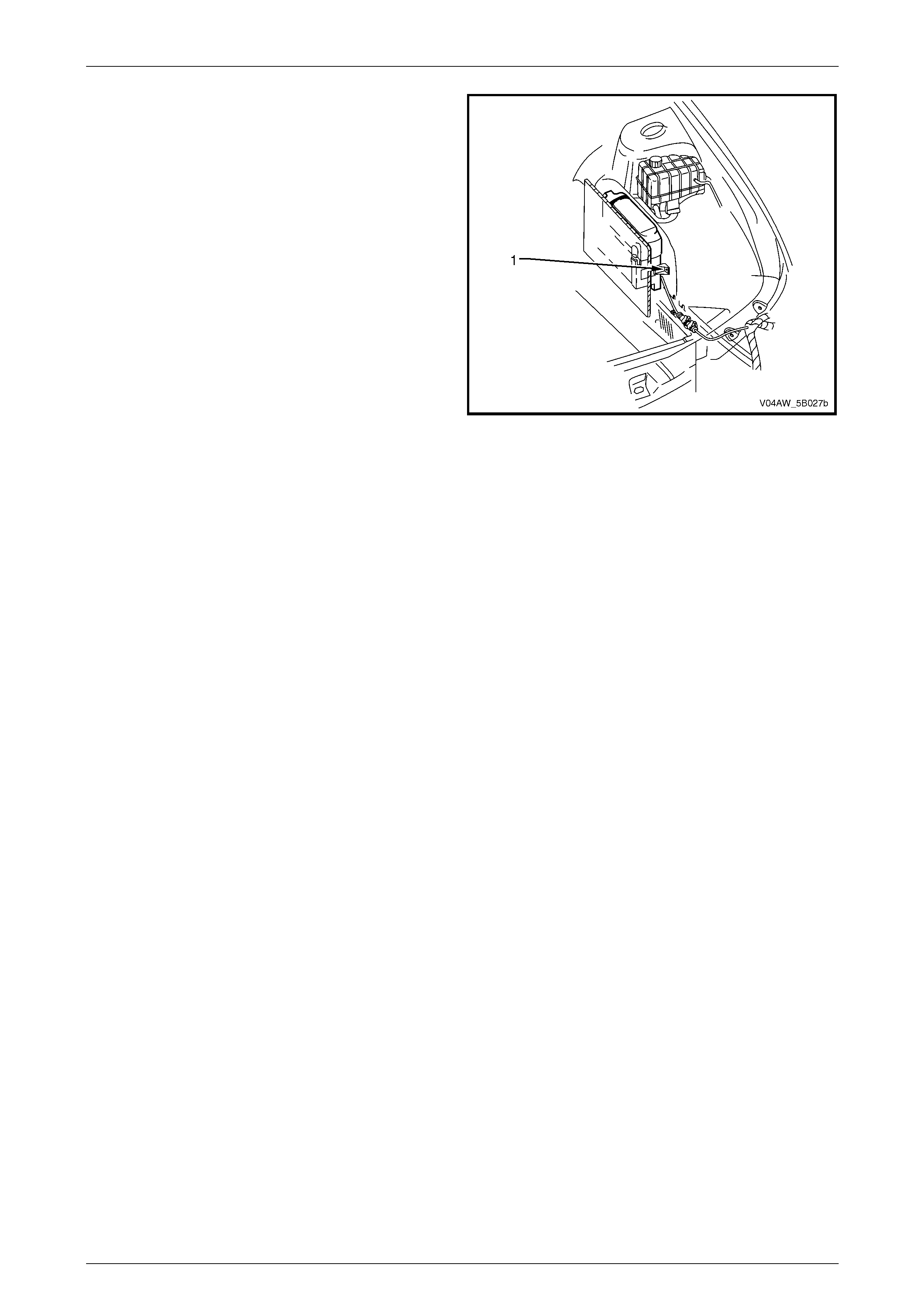

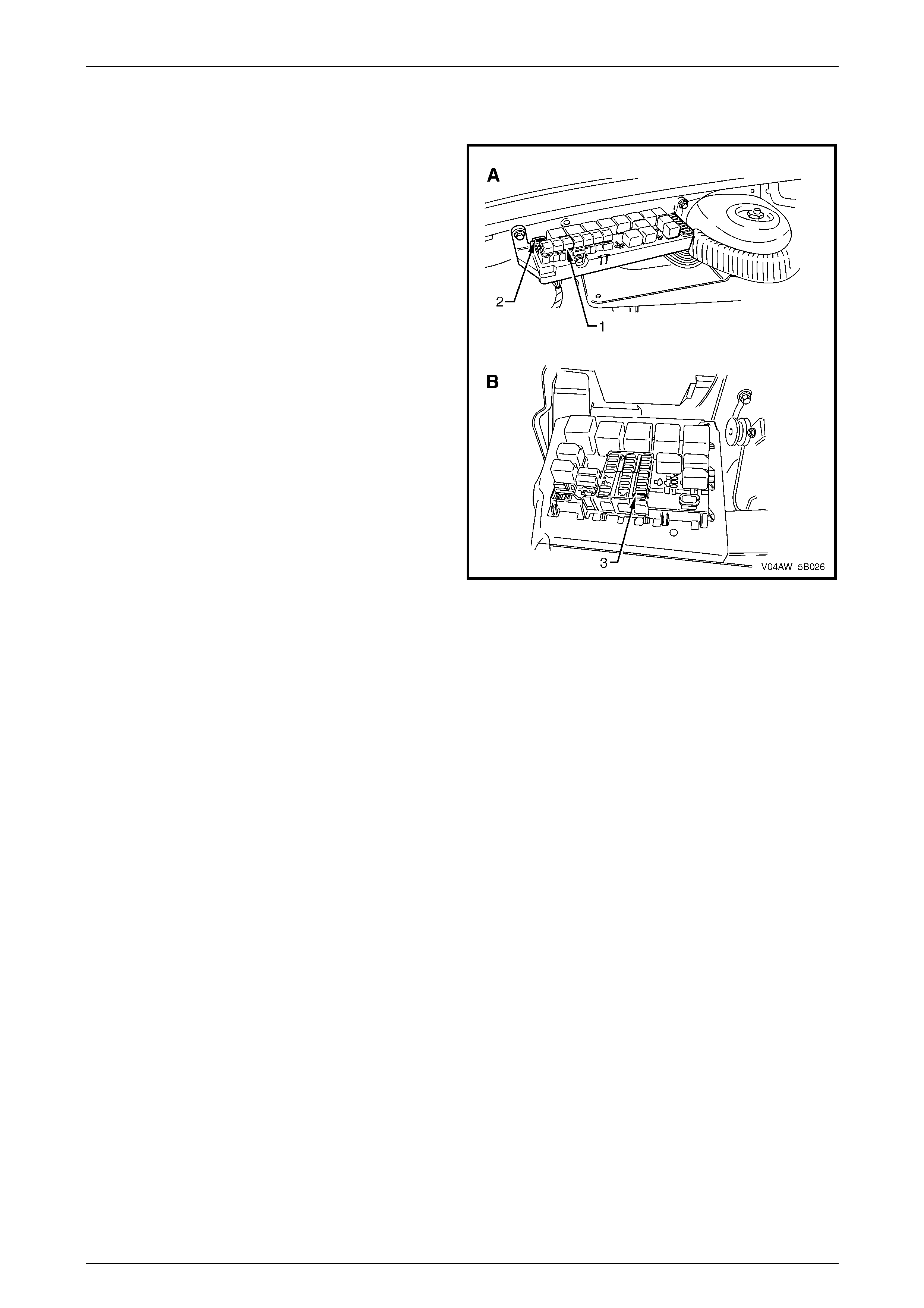

3.7 ABS-TCS Fuse Locations

The ABS-TCS fuse location are as follows:

• 50 Amp fusible link (1), F103 is located on the engine

compartment fuse and relay panel assembly (A).

• 25 Amp fuse (2), F36 is located on the engine

compartment fuse and relay panel assembly (A).

• 10 Amp fuse (3), F27 is located on the passenger

compartment fuse and relay panel assembly (B).

Figure 5B – 35

AW D ABS-TCS Page 5B–36

Page 5B–36

4 AWD ABS-TCS Diagnostics

General Information

The ABS-TCS diagnostic procedure is organised in a logical structure that begins with the ABS-TCS Main Diagnostic

Table. The Main Diagnostic Table provides the following information:

• Identification of the ECU ,

• Condition of the diagnostic circuit,

• Identification and status of the DTCs if present.

In addition, the Main Diagnostic Table will direct the service technician to the next logical step or diagnostic table, which

may again refer the service technician to the next logical step or diagnostic table. This process will continue until the

fault is located and rectified.

However, the diagnostic information covered in this Section covers fault conditions only in the ABS-TCS. If there are

fault conditions with the conventional braking system such as the following; these fault conditions must be corrected

before attempting to rectify any suspected ABS-TCS fault.

• Brake noise,

• Spongy brake pedal feel,

• Brake pedal or vehicle vibration during normal brake application,

• Brake pulling to one side,

• Parking brake problem.

Refer to Section 5A Service and Park Braking Systems for the diagnosis and repair procedure of the conventional

braking system.

4.1 Diagnostic Trouble Code (DTC) Tables

The diagnostic procedure is directed to the Diagnostic Trouble Code (DTC) Tables if there are DTCs currently stored in

the ECU.

The diagnostic tables are designed to locate a faulty circuit or component through a logic based on the process of

elimination. The tables are prepared with the understanding that the vehicle:

• Functioned correctly at the time of assembly,

• There are no multiple faults,

• The problem currently exists.

If there are multiple DTCs stored in the ECU, the diagnostic process must begin with the most likely DTC that may

trigger other DTCs. The following situation is an example of a DTC that may trigger other DTCs to set.

• If there is a battery supply voltage fault condition in the ECU, DTC C0896 Battery Voltage Out of Range may set.

• Insufficient battery supply voltage to an ABS-TCS component such as a solenoid valve coil may cause

incorrect hydraulic modulator operation. This condition will cause incorrect ABS-TCS operation and may

trigger DTC C0121 to set.

• A battery supply voltage to the ECU that is too high may cause damage to other ABS-TCS components. If

this charging system fault condition is not rectified and an ABS-TCS component is replaced, premature

failure of the replacement component may occur.

Therefore, knowledge of the ABS-TCS and Tech 2 Limitations are important to reduce diagnostic time and to prevent

misdiagnosis. Refer to 5.1 Diagnostic Requirements, Precautions and Preliminary Checks and 4.3 Tech 2 ECU

Diagnostic Tests.

AW D ABS-TCS Page 5B–37

Page 5B–37

4.2 Diagnostic Trouble Codes (DTCs)

The ECU performs a self-test that detects and isolates ABS-TCS faults (refer to 3.1 ECU Self-test Initialisation

Sequence). When a fault is detected, the ECU will log a Diagnostic Trouble Code (DTC) that represents the fault

detected. The DTCs stored in the ECU may be accessed using Tech 2, refer to Section 0C Tech 2 for information on

Tech 2.

NOTE

To warn the driver that there is a fault in the ABS

and/or TCS System and that the ABS and/or

TCS is currently disabled, the ECU sends a

signal to the following instrument cluster warning

lamps or icons to activate:

• ABS warning lamp (1)

• ABS fault (2)

• ABS icon (3)

• TRAC OFF (4)

• Parking brake/brake fail warning lamp (5)

Refer to Section 12C, for further information on

the braking system warning lamps and icon.

Figure 5B – 36

Status of DTCs

The ECU designates the DTCs logged into a Current or History DTC.

Current DTCs

If the fault condition that triggers the DTC is present during the last ECU self-diagnostics, that DTC will be designated as

a current DTC.

History DTCs

If the fault condition that triggers the DTC is not present during the last ECU self-test, that DTC will be designated as a

Histo r y DTC.

Conditions f or Clearing DTCs

• If there is no DTC logged in the current ECU self-test, the current DTC will be cleared.

• If there is no DTC logged after the last ECU self-diagnostics, the ECU deactivates the MFD ABS warning display.

• If there is no DTC logged after 100 consecutive drive cycles, the history DTC will be cleared.

• Use Tech 2 to clear the DTC.

AW D ABS-TCS Page 5B–38

Page 5B–38

4.3 Tech 2 ECU Diagnostic Tests

NOTE

Refer to Section 0C TECH 2 and the Tech 2

Users Manual for detailed information and

instruction regarding the use of Tech 2.

Tech 2 Limitations

Some DTCs trigger other DTCs to set, which cause Tech 2 to display multiple DTCs. Therefore, in those situations,

Tech 2 may display more DTCs than what is needed to rectify a fault.

In addition, when Tech 2 is displaying an ECU Output Function, it displays only the command given by the ECU. If a

connector is disconnected or if a solenoid valve is faulty, that fault will not be registered in the ECU Output Function.

Tech 2 does not verify if the command action took place.

The service technician must understand the system being diagnosed as well as the correct use and limitations of Tech 2

to be able to perform diagnostic procedures efficiently and successfully.

Tech 2 Intermittent Faul t Tests

The following are lists of Tech 2 diagnostic tests that may be used to diagnose intermittent faults:

• Wiggle test the suspected ABS-TCS component wiring harness and connectors while observing the Tech 2

operating parameters of the circuit being tested. If the Tech 2 read-out fluctuates during this procedure, check the

wiring harness circuit for loose connection.

• Road test the vehicle in the conditions that triggers the intermittent fault while an assistant observes the suspected

Tech 2 operating parameter data.

• Capture and store data in the Snapshot mode when the fault occurs. The stored data may be played back at a

slower rate to aid in diagnostics. Refer to the Tech 2 User Instructions for more information on the Snapshot

function.

• Operate suspected ABS-TCS components to test their operation using the Tech 2 Output Control Data.

AW D ABS-TCS Page 5B–39

Page 5B–39

Tech 2 Data List

The Tech 2 ABS-TCS Data List contains the ABS-TCS operating parameters that may be used to analyse the ABS-TCS

operating parameters of the vehicle being diagnosed.

This enables the technician to compare the operating parameter of the vehicle being diagnosed to the typical data value

of a known good vehicle.

NOTE

The Tech 2 Data List Typical Data Values are

obtained from a properly operating vehicle under

the following conditions;

• Ignition switched on.

• Engine not running,

• Vehicle is stationary.

Tech 2 Data List Table

Tech 2 Parameter Units Displayed Typical Data Value

Battery Voltage Volts B+

ABS Active Yes / No No

EBD Active (Electronic Brake-force Distribution) Yes / No No

EBD Disabled (Electronic Brake-force Distribution) Yes / No No

Valve Relay Inactive / Active Active

Motor Relay Inactive / Active Inactive

Brake Switch Inactive / Active Inactive

Front Left Wheel Speed km/h 0

Front Right Wheel Speed km/h 0

Rear Left Wheel Speed km/h 0

Rear Right Wheel Speed km/h 0

Front Left Inlet Valve Inactive / Active Inactive

Front Left Outlet Valve Inactive / Active Inactive

Front Right Inlet Valve Inactive / Active Inactive

Front Right Outlet Valve Inactive / Active Inactive

Rear Left Inlet Valve Inactive / Active Inactive

Rear Left Outlet Valve Inactive / Active Inactive

Rear Right Inlet Valve Inactive / Active Inactive

Rear Right Outlet Valve Inactive / Active Inactive

FL/FR TC Priming Valve (Front Left/Front Right) Inactive / Active Inactive

FL/FR TC Switch Over Valve (Front Left/Front Right) Inactive / Active Inactive

RL/RR TC Priming Valve (Rear Left/ Rear Right) Inactive / Active Inactive

RL/RR TC Switch Over Valve (Rear Left/ Rear Right) Inactive / Active Inactive

AW D ABS-TCS Page 5B–40

Page 5B–40

5 AWD ABS-TCS Diagnostic

Starting Point

5.1 Diagnostic Requirements, Precautions

and Preliminary Checks

Basic Knowledge Requi red

A lack of basic understanding regarding

electronics, electrical wiring circuits and use

of electrical circuit testing tools when

performing the ABS-TCS diagnostic

procedures could result in incorrect

diagnostic results or damage to components.

A general understanding of basic electronics, electrical wiring circuits and the correct use of the basic ABS-TCS System

electrical circuit testing tools is required to perform the diagnostic procedures detailed in this Section. Refer to

Section 12P Wiring Diagrams .

In addition, a general understanding of the ABS-TCS and its component operation is essential to prevent misdiagnosis

and component damage.

Basic Diagnosti c Tools Required

Use of incorrect electrical circuit diagnostic

tools when performing the ABS-TCS

diagnostic procedures could result in

incorrect diagnostic results or damage to

components.

The following electrical circuit testing tools are required to perform the diagnostic procedures detailed in this Section.

• Tech 2, refer to Section 0C Tech 2.

• Test light, refer to Section 12P Wiring Diagrams.

• Digital multimeter with 10 mega ohms impedance, refer to Section 12P Wiring Diagrams.

• Connector test adapter kit Tool No. J35616-A.

AW D ABS-TCS Page 5B–41

Page 5B–41

Diagnostic Precaut ions

In addition to the safety and precautionary

measures listed in the Service Operation

Safety and Precautionary Measures, (refer to

9.1 Safety and Precautionary Measures) the

following Diagnostic Precautions must be

observed when performing any ABS-TCS

diagnostic procedure:

1 If there is a fault condition in the conventional braking system, rectify that fault condition before proceeding with

the ABS-TCS diagnostics.

2 Use only the test equipment specified in the diagnostic tables, other test equipment may either give incorrect

results or may damage good components.

3 The vehicle drive wheels must be chocked and the parking brake firmly applied while checking any system.

4 Do not clear any DTCs unless instructed.

5 The fault must be present when using the Diagnostic Trouble Code (DTC) Diagnostic Tables. Otherwise,

misdiagnosis or replacement of good parts may occur.

6 Always use connector adaptors such as those contained in Connector test adapter kit Tool No. J35616-A to

prevent connector terminal damage.

7 Thorough inspection of the wiring circuits and connectors that are part of diagnostic procedure must be performed,

otherwise misdiagnosis may occur.

8 Inspect the electrical circuitry or connector terminals that are suspected to be causing the complaint for the

following conditions:

• Backed-out connector terminals,

• Improper wiring connector mating,

• Broken wiring connector locks,

• Damaged connector terminals, and

• Physical damage to the wiring harness.

9 Before replacing a component, inspect its connector terminal for corrosion or deformation that may cause the fault

condition.

10 If Tech 2 was used for diagnosis, disconnect it from the DLC and switch the ignition off for at least 10 seconds

before road testing. This is necessary to reset the ABS/TCS control module as it is disabled during most Tech 2

diagnostic procedures.

11 After completing the required diagnostic and repair operations, road test the vehicle to ensure proper ABS/TCS

operation.

AW D ABS-TCS Page 5B–42

Page 5B–42

Prelimi nary Checks

The ABS-TCS Preliminary Checks is an examination of easily accessible components that could cause problems with